Method and system for purification and concentration of lithium-containing desorbed solution in alumina plant

A technology of alumina and analysis solution, which is applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the deterioration of the working condition of the electrolytic cell, the unreasonable utilization of lithium resources, and the absence of purified concentrated alumina containing lithium Analytical liquid reporting and other issues, to achieve the effect of simple process flow, reduce energy consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

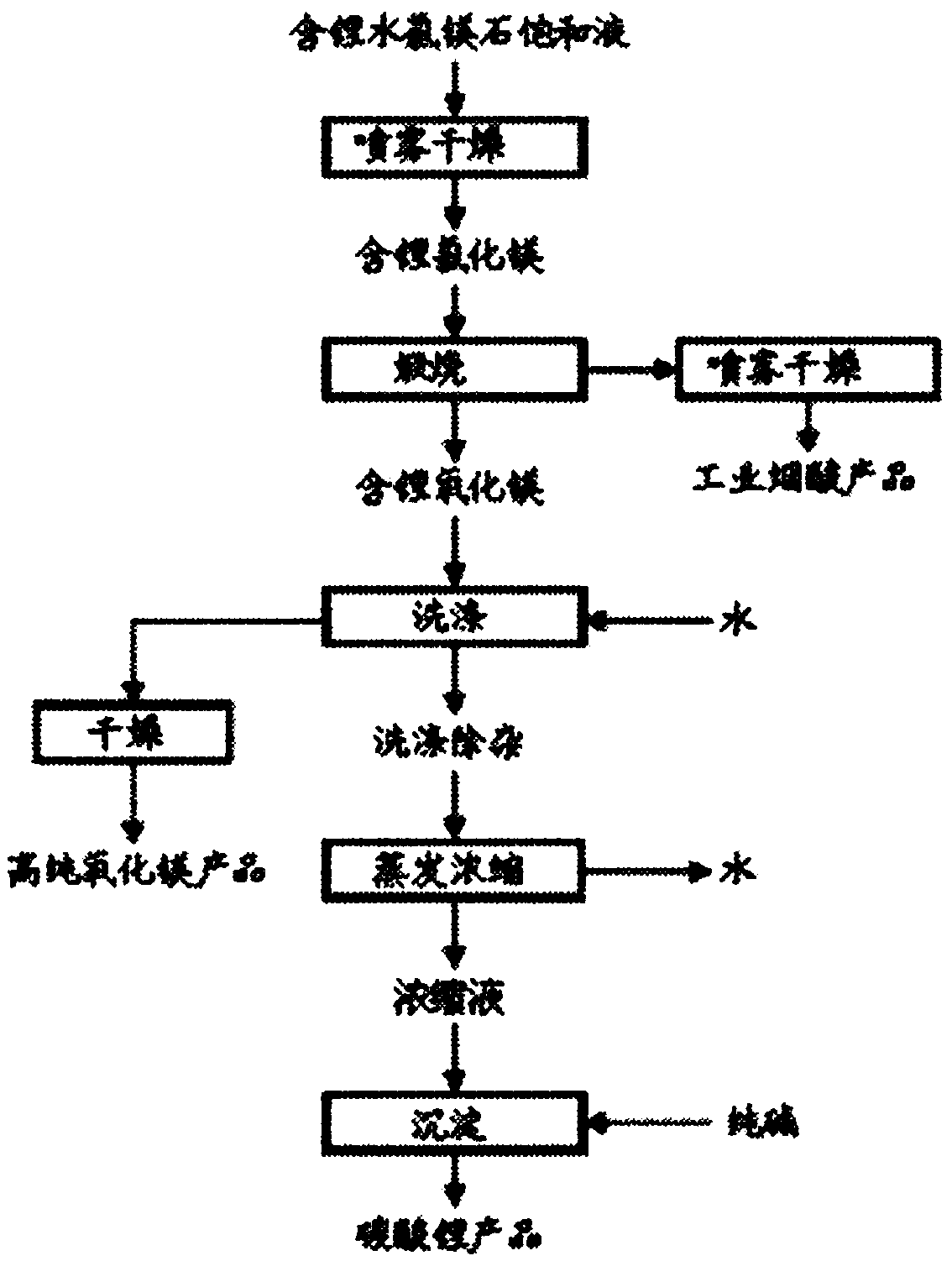

[0052] Such as Figure 5 As shown, the embodiment of the present invention provides a system for purifying lithium-containing desorption solution in a concentrated alumina factory, including a neutralization tank 1 , a clarification overflow assembly 2 , a heat exchanger 4 and a membrane separation assembly 6 connected in sequence.

[0053] In detail, the neutralization tank 1 is used for neutralizing the lithium-containing desorption solution, and it is specifically a normal-pressure stirring tank made of conventional carbon steel.

[0054] After the neutralization treatment, the mixed liquor is subjected to static overflow treatment in the clarification overflow assembly 2, and the clarification overflow assembly 2 includes a clarification tank 21 and an overflow tank 22, and the feed end of the clarification tank 21 passes through the first The centrifugal pump 3 is connected to the discharge end of the neutralization tank 1, the supernatant outlet of the clarification tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com