Patents

Literature

2632 results about "White powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

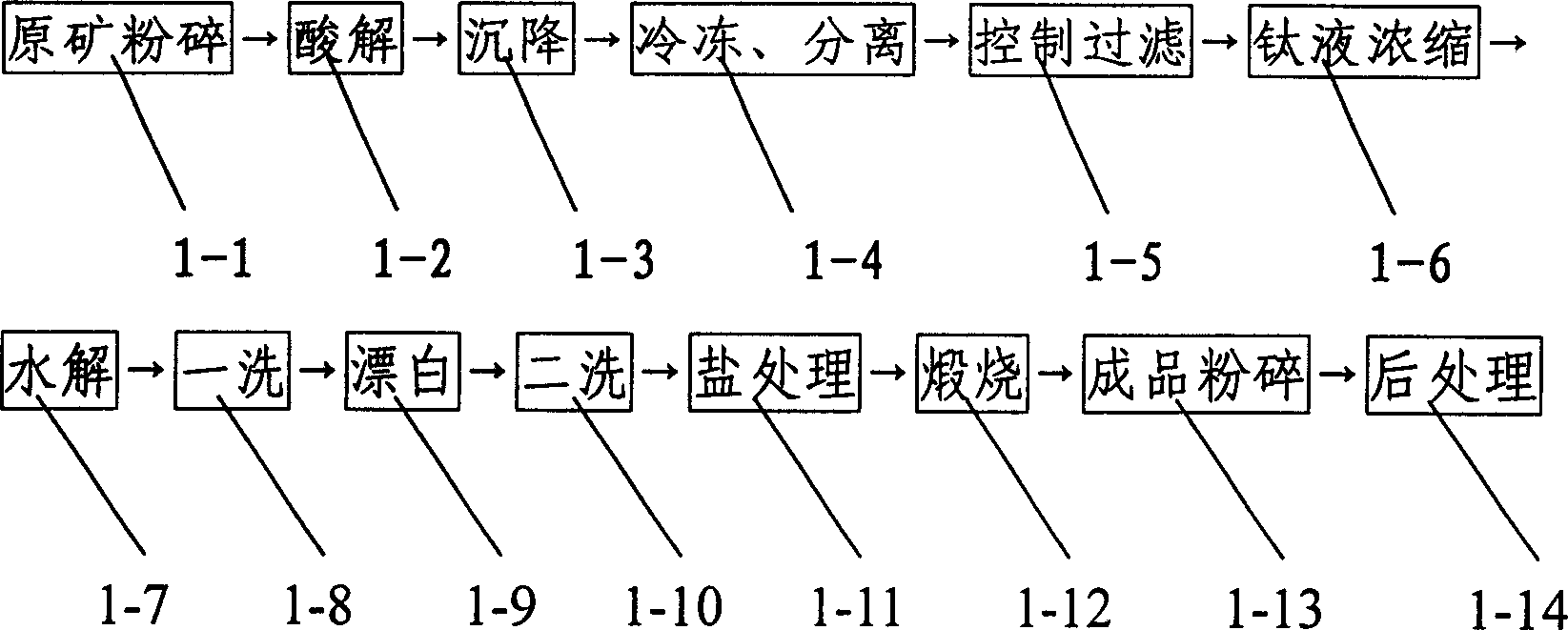

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

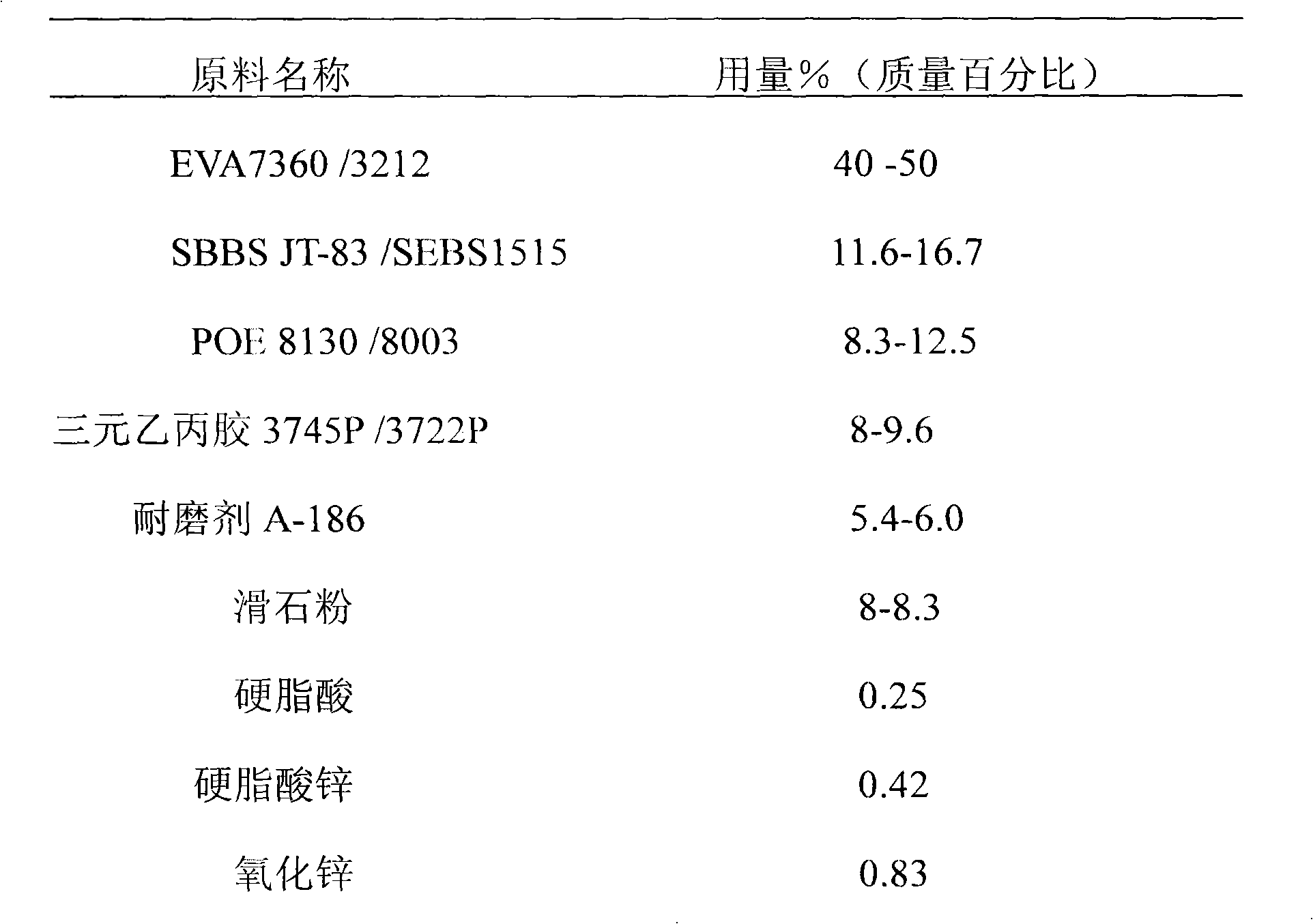

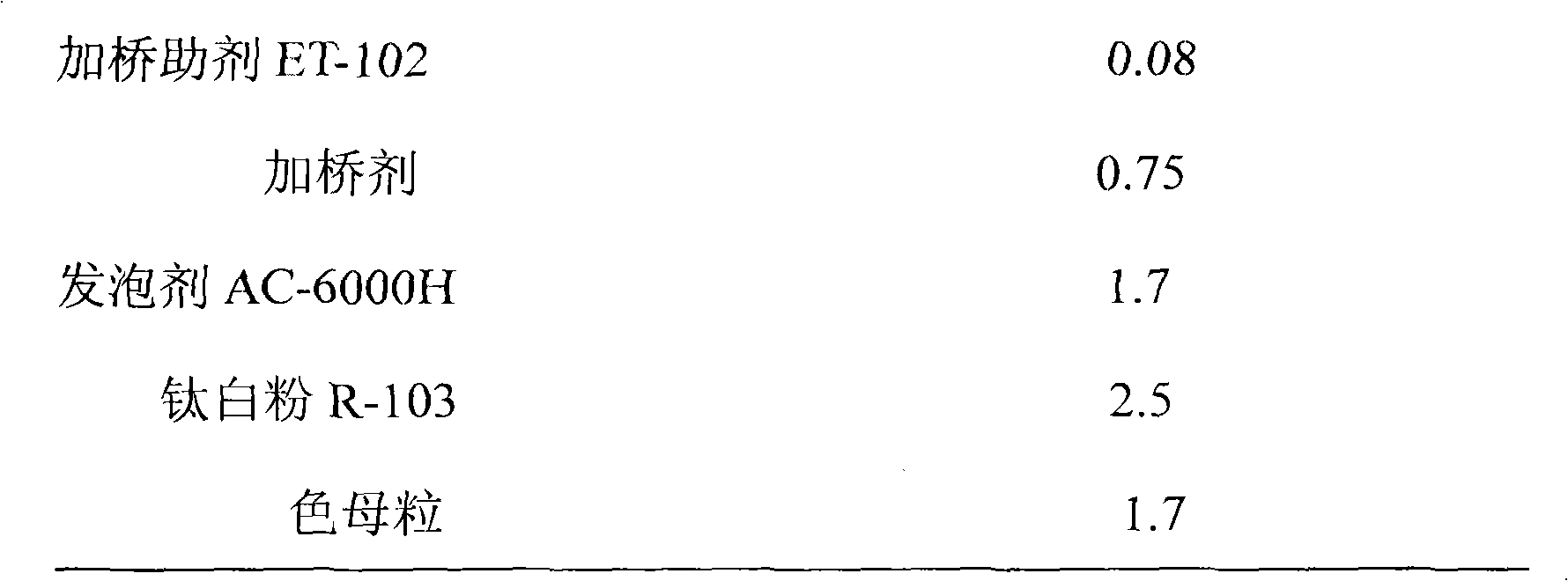

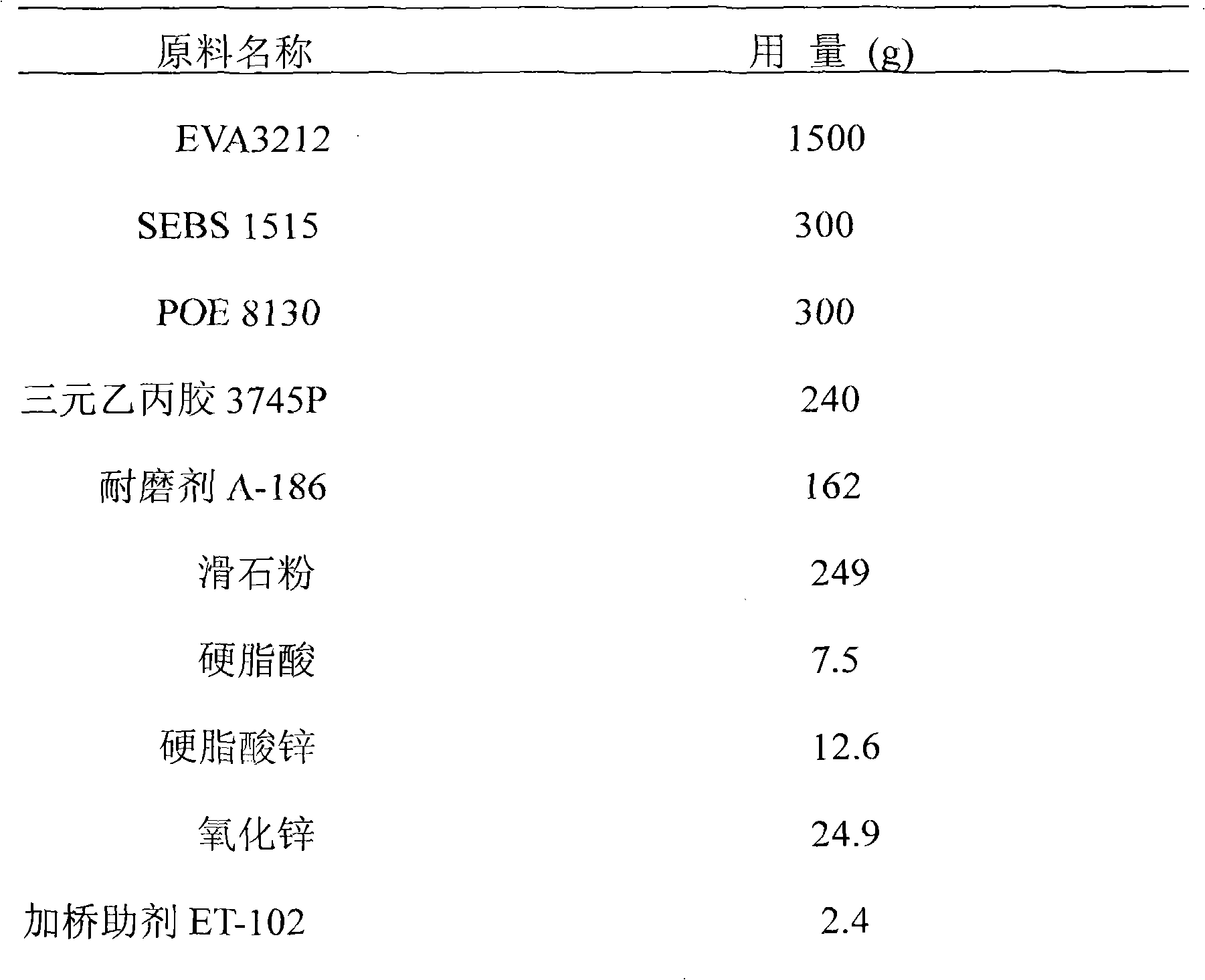

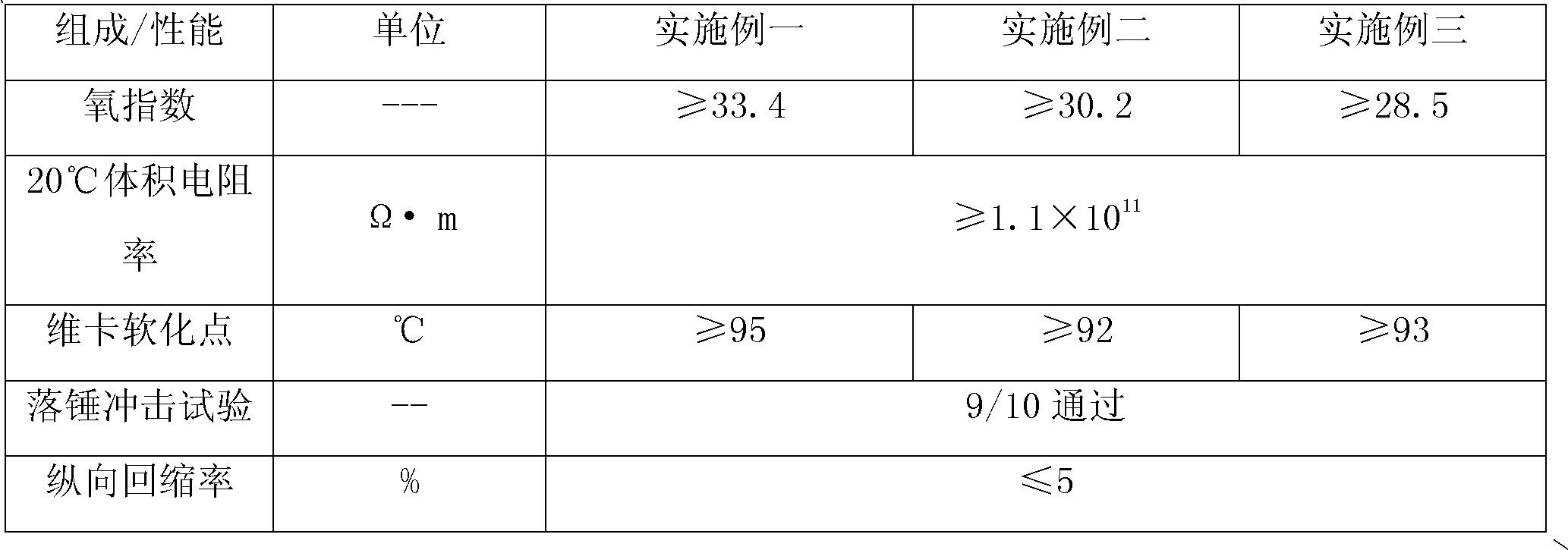

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

Interior wall paint composition

The invention relates to an interior wall decorating material, in particular to a building material composition consisting of natural source materials and containing diatomite. The composition comprises the following components in percentage by weight: 20 to 40 percent of diatomite, 20 to 58 percent of shell powder, 8 to 32 percent of dolomite sand, 2 to 10 percent of casein, 5 to 12 percent of 4A zeolite powder, 3 to 8 percent of seaweed gelatine powder, 0.5 to 1.5 percent of jute fiber and 2 to 5 percent of titanium white powder. The composition fully consists of natural source materials, does not contain chemical substances of synthetic resins, and really has no volatilization, emission and pollution. Because the composition does not contain the hydraulic materials such as white cement and the like, the construction opening time is long, the stirred material can be used for long term, the construction is convenient, and the material waste is avoided. The composition can be stored for long term by packing with moisture-proof paper bags, brings convenience to producers, can be mass-produced, and enables dealers not to worry about the problem of material invalidation.

Owner:深圳市汇益德环保材料有限公司

Fire-retardant insulating polyvinyl chloride material and electrical sleeve

InactiveCN102093652AImprove flame retardant performanceImprove insulation performanceInsulating bodiesLow voltagePolyvinyl chloride

The invention discloses a fire-retardant insulating polyvinyl chloride material and an electrical sleeve made from the material. The fire-retardant insulating polyvinyl chloride material comprises the following raw materials in part by weight: 100 to 150 parts of polyvinyl chloride, 0.2 to 5 parts of heat stabilizer, 5 to 20 parts of compatibilizer, 20 to 60 parts of fire retardant master batch, 0.3 to 1 part of lubricant, 1 to 3 parts of titanium white powder, 10 to 20 parts of impact modifier, 2 to 4 parts of processing aid and 5 to 20 parts of calcium carbonate. The fire-retardant insulating polyvinyl chloride material provided by the invention has excellent flame retardant property and insulating property; the oxygen index can be over 33.4; the test is up to V-0 level according to the measurement standard of GB / T2048-2008 plastic combustibility; and the resistivity can be up to 1.1*1,011 Omega.m. Therefore, the material can meet the requirement on insulation and fire retardance of a low-voltage wire cable.

Owner:KANGTAI PLASTIC SCI & TECH GRP

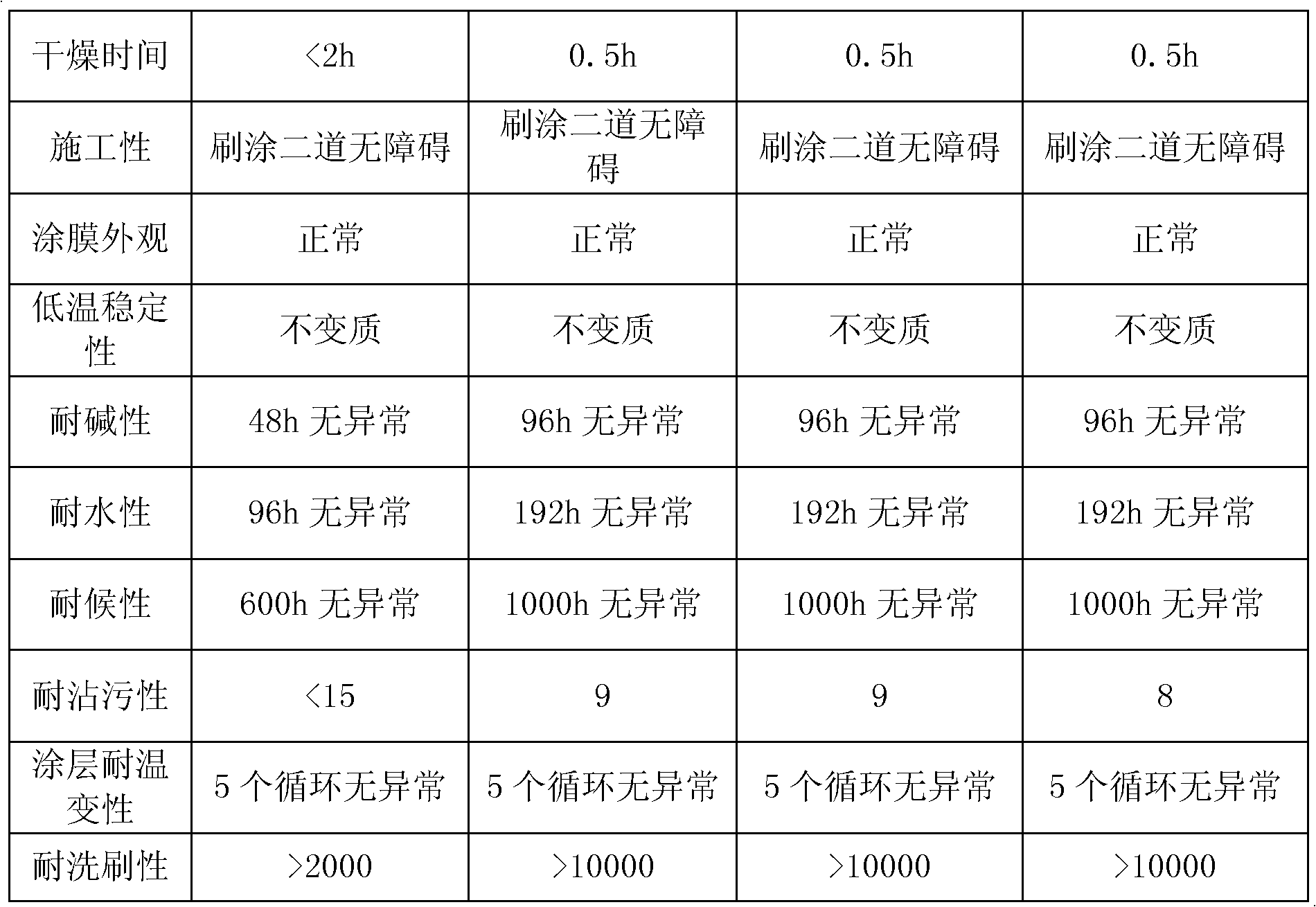

A nano-modified highly stain-resistant elastic coating and its preparation method

InactiveCN102286233AOvercome sticking backImprove stain resistanceCoatingsPigment treatment with organosilicon compoundsColloidal silicaAluminum Carbonate

The invention provides a nano-modified highly stain-resistant elastic paint and a preparation method thereof, belonging to the technical field of building paint preparation. The composition and mass percent of the elastic coating provided by the present invention are: emulsion 40-50; water-based nano-colloidal silicon; 2-5; ultrafine aluminum carbonate; 15-25; modified nano-calcium carbonate 5-10; rutile titanium White powder; 8~15; pH regulator; 0.30~35; film-forming aid 0.50~0.65; elastic defoamer; 0.35~0.40; wetting agent 0.20~0.30; ; Leveling agent; 0.30~0.45; Bactericidal preservative; 0.10~0.15; Thickener; 0.10~0.20; Water; Balance. The nano-modified highly stain-resistant elastic paint provided by the present invention well achieves a balance among elasticity, stain resistance, water resistance, adhesion and practicability.

Owner:CHINA MCC17 GRP

Composite envelope titanium white powder and preparation method thereof

InactiveCN101143978AImprove performanceThe characteristic value of the blue phase spectrum is excellentPigment treatment with non-polymer organic compoundsChemical industryCerium

The invention relates to a composite coated titanium dioxide and a method for preparing the same, which belongs to chemical industry, wherein the surface of the composite coated titanium dioxide concludes at least one ingredient of silicon, aluminum and zirconium and cerium. The preparation method of the composite coated titanium dioxide of the invention includes 6 steps as follows: beating and dispersion, fine grinding and screening, inorganic coating, washing and filtering, dry and grinding, which is simple without any special equipment needed. The composite coated titanium dioxide of the invention has good comprehensive pigment performance, blue phase spectrum characteristic parameter, dispersion and brightness which are superior to international advanced levels, so the invention has wide application prospect.

Owner:PANZHIHUA UNIV

Low-irritation and high-foaminess fancy soap formula

The invention discloses a low-irritation and high-foaminess fancy soap formula, which is composed of the following components by mass percentage: 2%-10% of alpha-lauryl betaine ampholytic surfactant, 20%-30% of coconut oil sodium salt, 50%-70% of sodium palmitate, 2%-5% of sorbic alcohol, 0.1%-1.5% of antioxidant, 0.05%-0.15% of Kathon, 0.05%-0.2% of chelant, 0.5%-1% of titanium white powder, 0.5%-1.0% of essence and water (the rest). In the fancy soap, the alpha-lauryl betaine ampholytic surfactant is used as additive, which can reduce the irritation of the fancy soap taking the normal sodium soap as the soap base and improve the foaminess of the fancy soap.

Owner:JIANGNAN UNIV +1

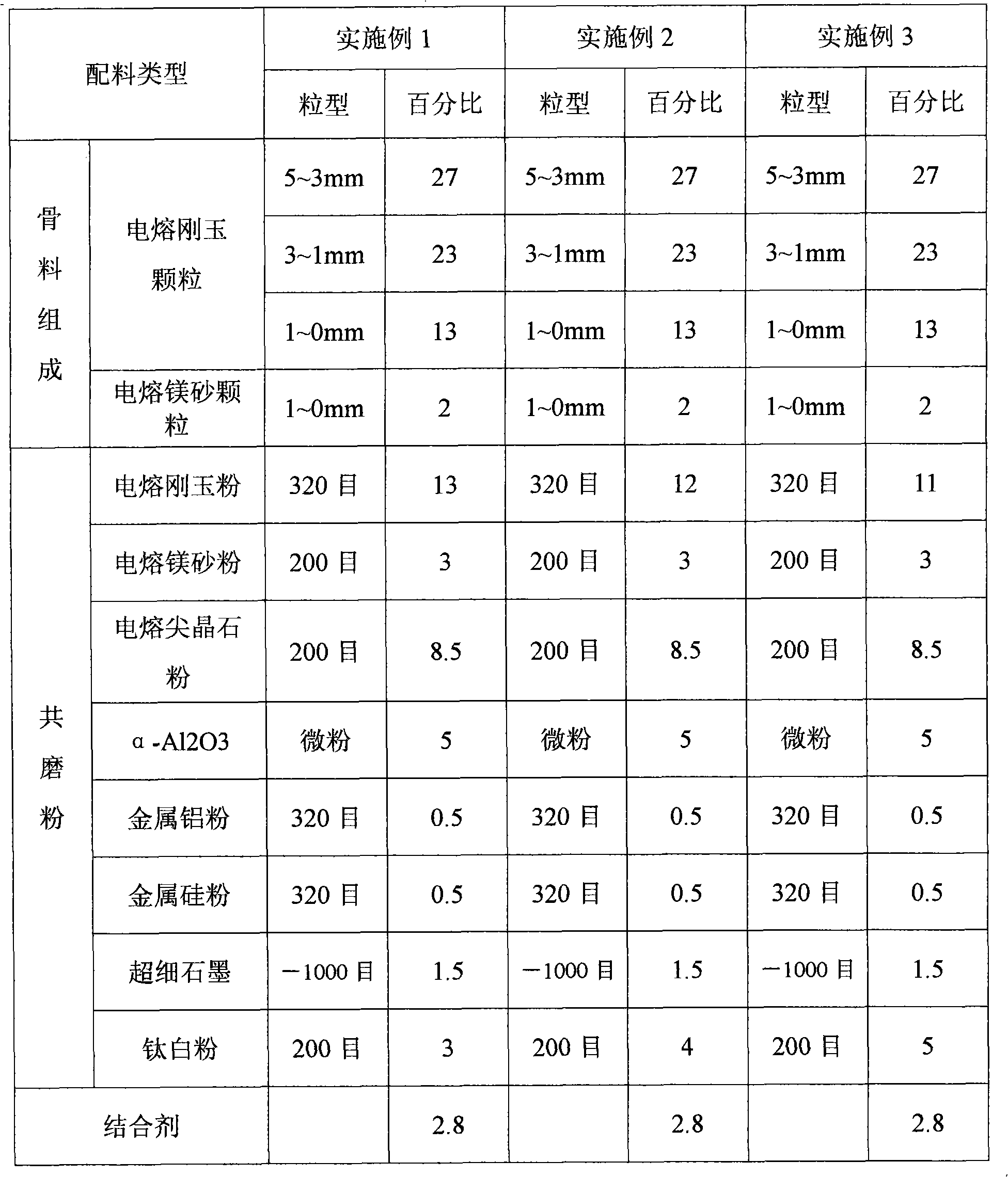

Low-carbon corundum spinelle brick for refined steel ladles and preparation method thereof

The invention relates to a low-carbon corundum spinelle brick for refined steel ladles and a preparation method thereof for overcoming the defect of overhigh carbon content in the prior carbon-contained fireproof material technology. The low-carbon corundum spinelle brick for refined steel ladles comprises the following components in percentage by weight: 60-70 fused corundum particles, 2-6 fused magnesite particles, 10-20 fused corundum fine powder, 2-10 fused magnesite fine powder, 5-15 fused spinelle fine powder, 3-6 alpha-Al2O3 micro powder, 0-2.0 metal aluminum fine powder, 0-2.0 metal silicon fine powder, 2-6 bond, 1-2 superfine graphite and 2-6 titanium white powder. The invention has good thermal stability at high temperature, resists high temperature and the erosion of molten steel and slag and has high mechanical strength, good thermal shock stability and high under-load softening point, thereby being widely applied to various steel ladles, in particular to steel ladles of refined low-carbon steel and ultra-low-carbon steel.

Owner:海城利尔麦格西塔材料有限公司 +2

Titanium white for dry acrylic spinning delustering its preparing method

InactiveCN1858309ADry spinning methodsPigment treatment with organosilicon compoundsWeather resistanceWhite powder

The present invention discloses a kind of titanium white powder for extinction in dry spinning acrylic fiber and its preparation process. The titanium white powder is prepared with anatase type titanium white as material and through pulping, sanding milling, grading, purifying and other steps to eliminate coarse grains and impurity ions, coating with compact Al2O3 to obtain high weather resistance, water washing and coating with organic material. It has excellent dispersivity in spinning solution for dry spinning acrylic fiber and is used for extinction. It can result in excellent filtering performance and spinnability, low end breakage, high tow strength, high whiteness and high dyeability.

Owner:EAST CHINA UNIV OF SCI & TECH

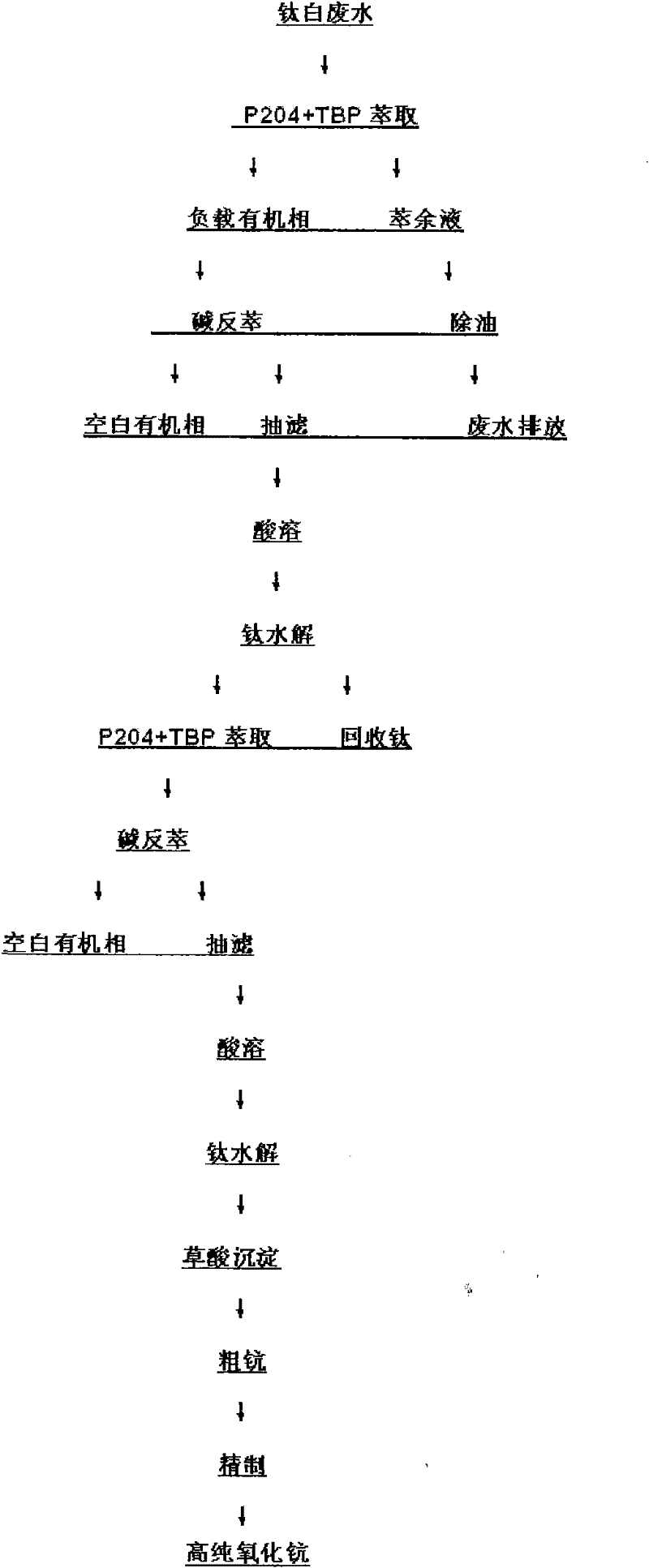

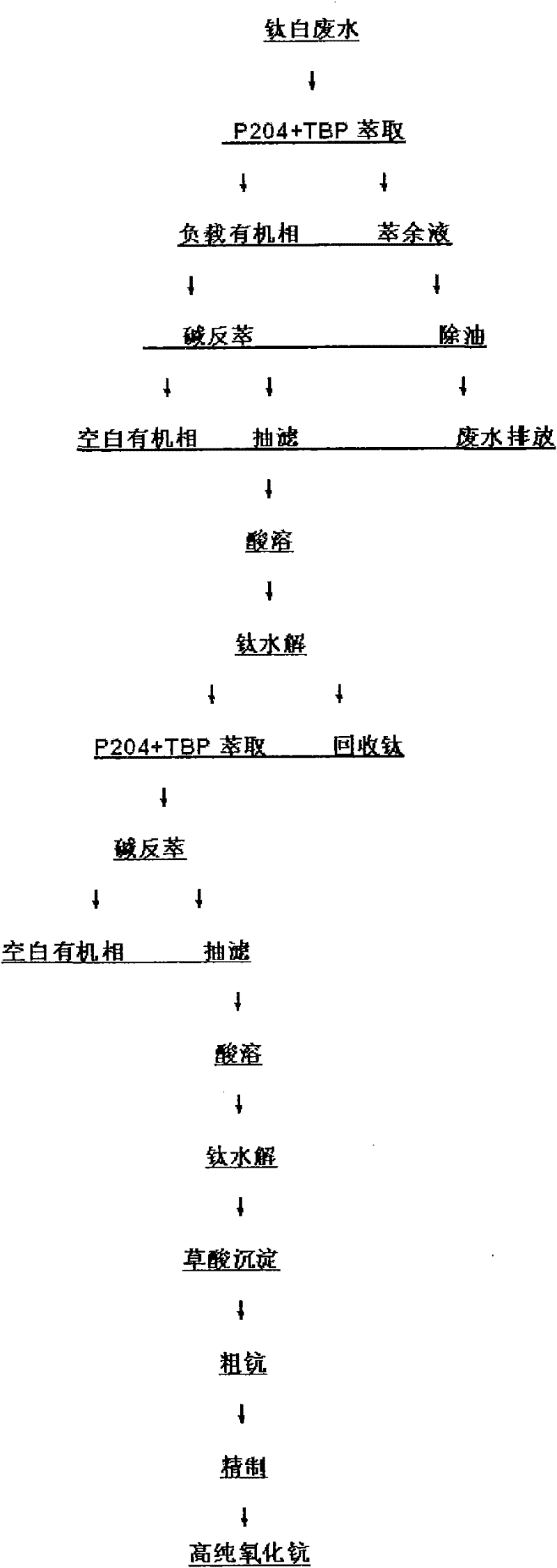

Method for recovering scandium and titanium in titanium white wastewater

ActiveCN102127641AOrganic phase content is smallReduce pollutionProcess efficiency improvementKeroseneEmission standard

The invention discloses a method for recovering scandium and titanium from wastewater in the production of titanium white powder. The method comprises the following steps of: carrying out single stage extraction in titanium white wastewater with P2O4, TBP and kerosene, wherein a phase ratio O / A is 1:50 to 1:10, and balance time is 10-20 min; then, stripping with alkali, filtering and dissolving a stripped substance with acid; heating a solution in a reaction kettle, adjusting a pH value, hydrolyzing titanium, filtering and recovering titanium, repeating the above process to process supernatant fluid, secondarily extracting and dissolving a stripped substance alkali cake with acid; precipitating scandium with oxalic acid and burning to obtain scandium oxide with the purity of 95 percent; and further refining to obtain high-pure scandium oxide. In the invention, titanium is recovered under the condition of ensuring scandium recovery without adopting a titanium washing process of sulfuric acid and hydrogen peroxide, and a hydrolysis mode is adopted to recover titanium, and the recovery cost of scandium is decreased. In addition, a degreasing device and oil-absorbing felt are adopted in waste liquid generated after extraction. The invention has the advantages of environmental protection and simple process, the wastewater contains the organic phase of less than 50 mg / l and reaches an emission standard.

Owner:河南荣佳钪钒科技有限公司

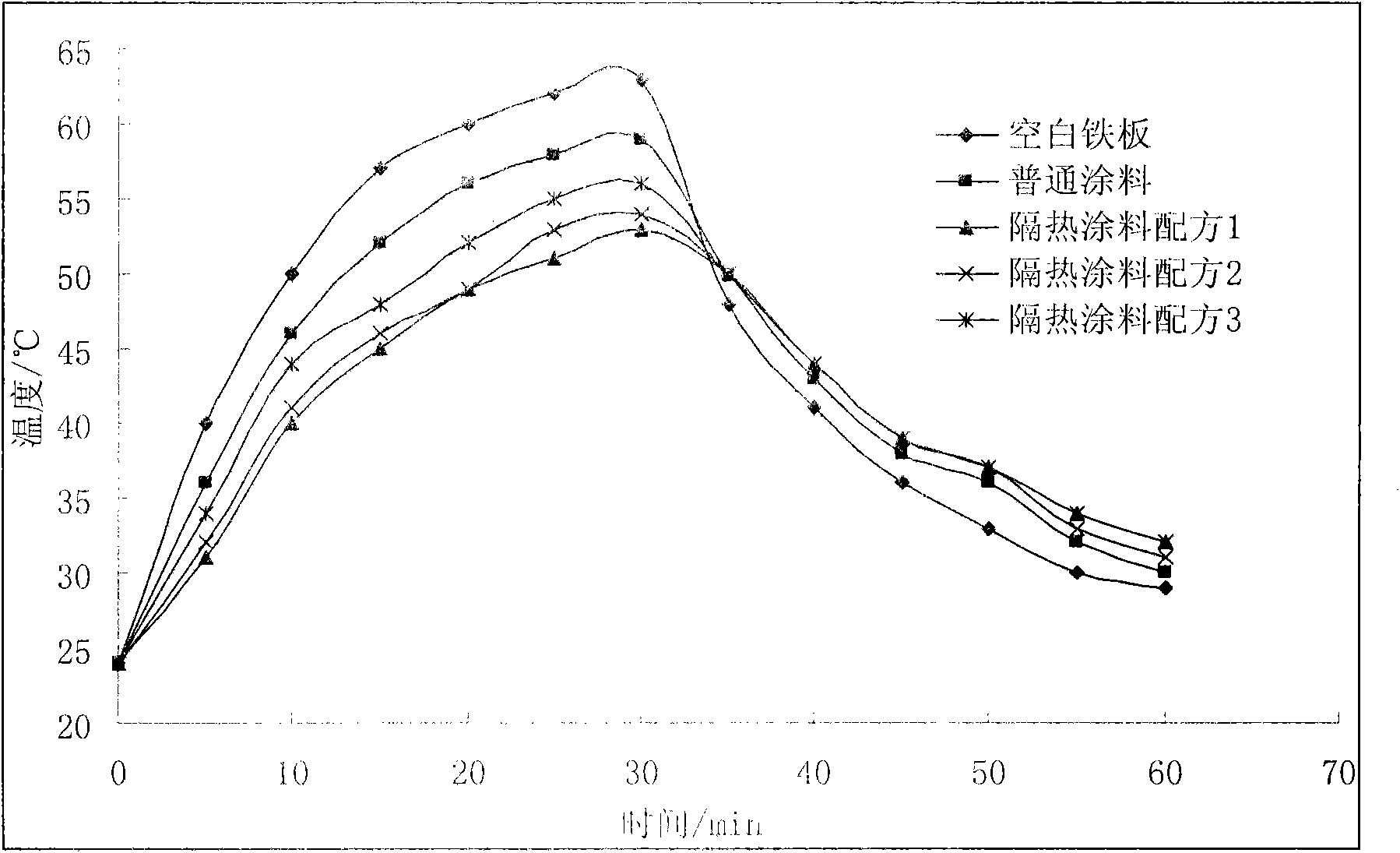

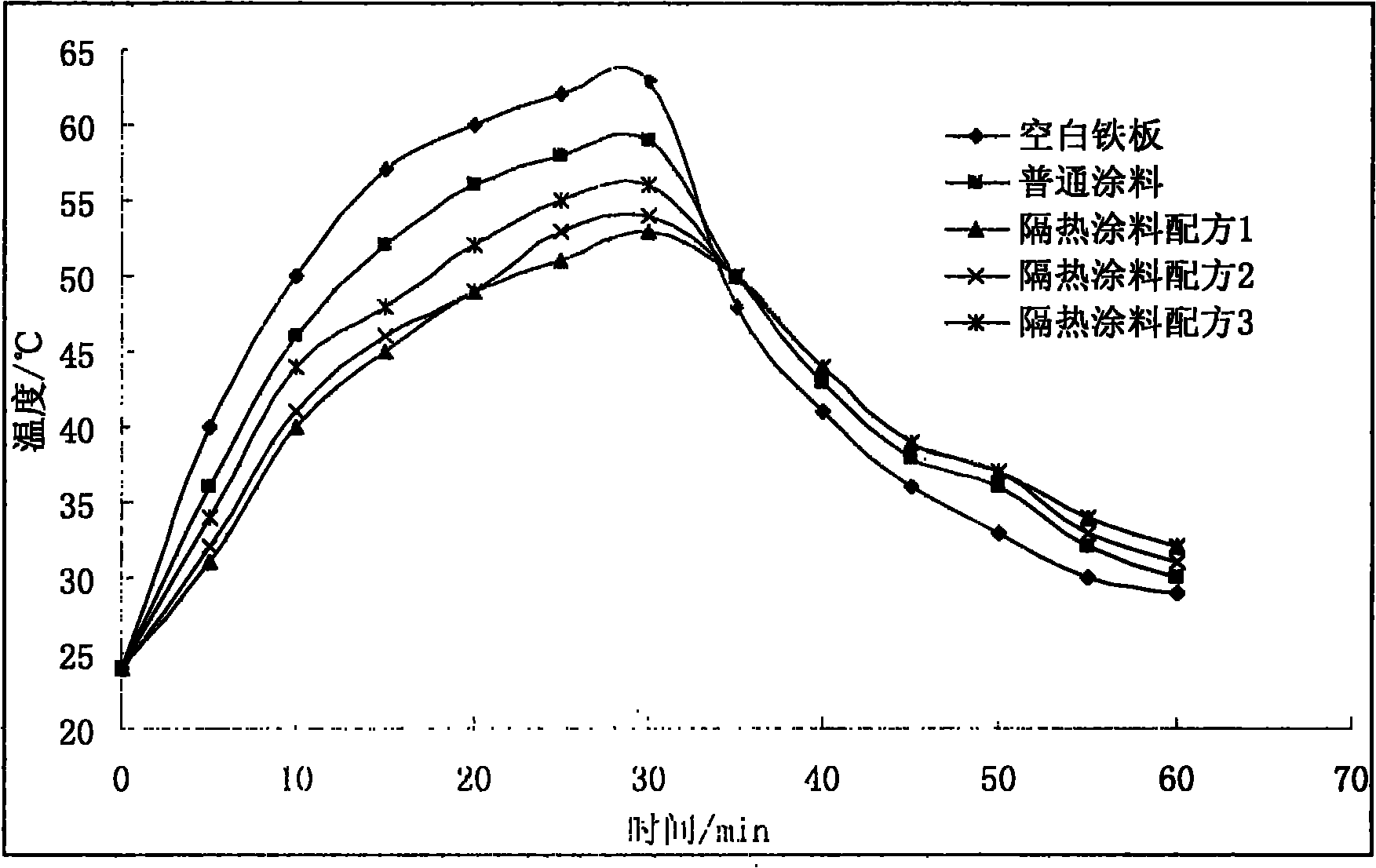

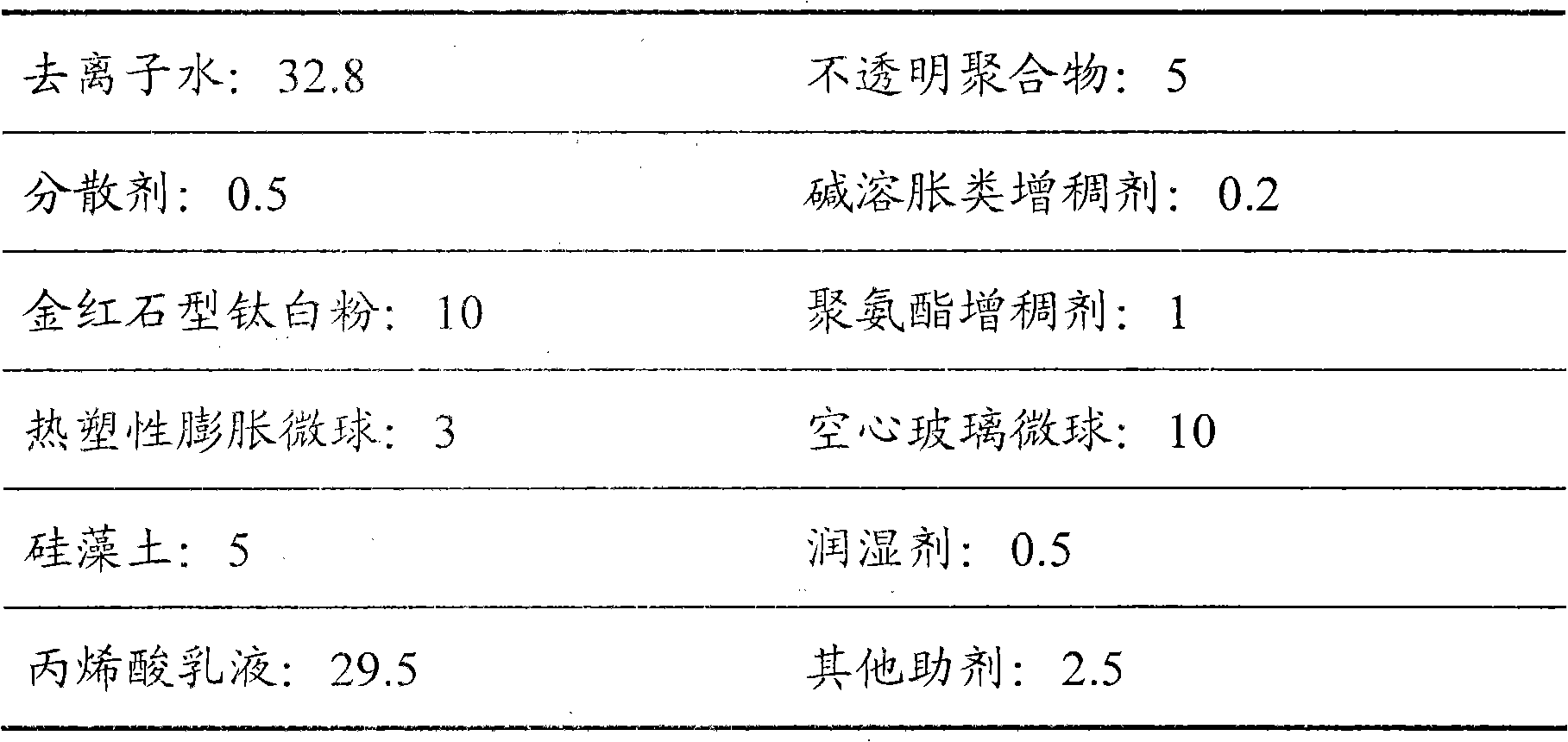

Heat-insulating coating for inner wall

The invention discloses a heat-insulating coating for an inner wall. The heat-insulating coating comprises the following components in percentage by weight: 20 to 40 percent of acrylic acid latex, 0.1 to 5 percent of moistening agent, 0.1 to 5 percent of dispersing agent, 5 to 20 percent of diatomite, 5 to 10 percent of hollow glass microsphere, 5 to 25 percent of titanium white powder, 0.1 to 5 percent of thickening agent, 1 to 10 percent of swelling microsphere, 3 to 10 percent of opaque polymer and 20 to 40 percent of water. The novel heat-insulating coating for the inner wall has the characteristics of slow temperature rise during heating and slow temperature drop during heat emission, and can properly adjust the indoor temperature and make the housing environment more comfortable; and, the aqueous latex is used, so that the heat-insulating coating is safe to the human body and the environment, and belongs to green environmentally-friendly product.

Owner:CHINA PAINT MFG CO SHENZHEN

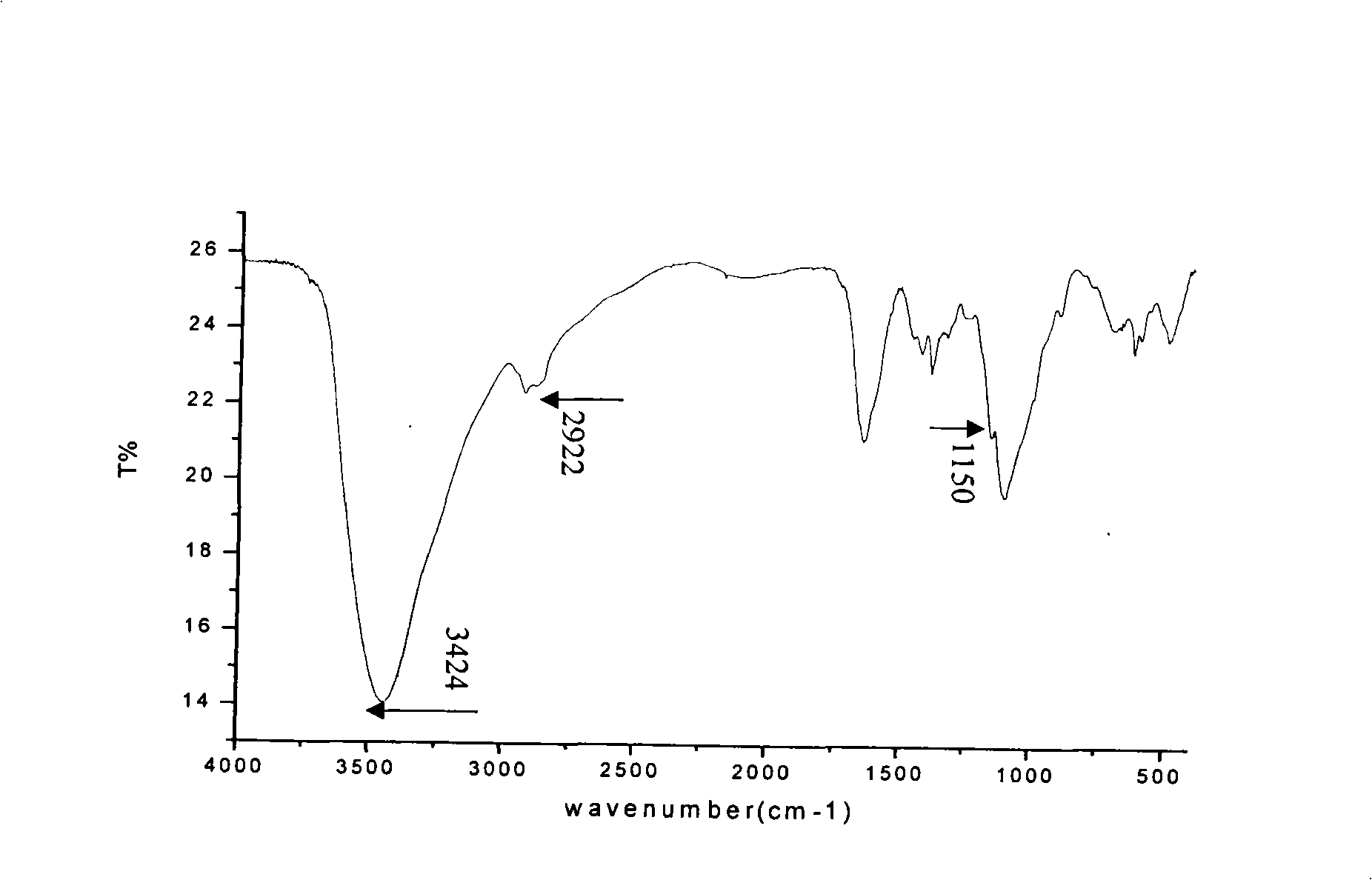

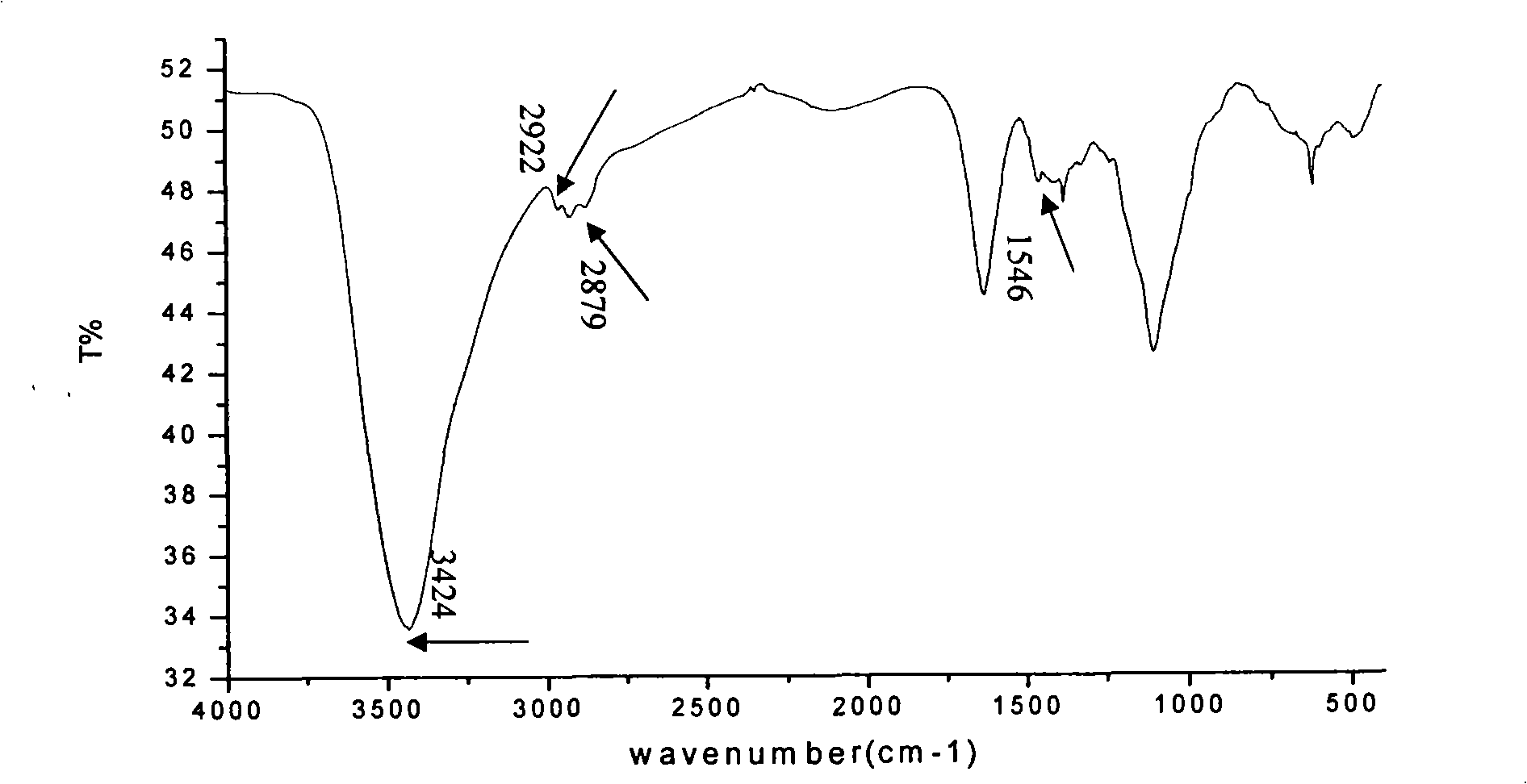

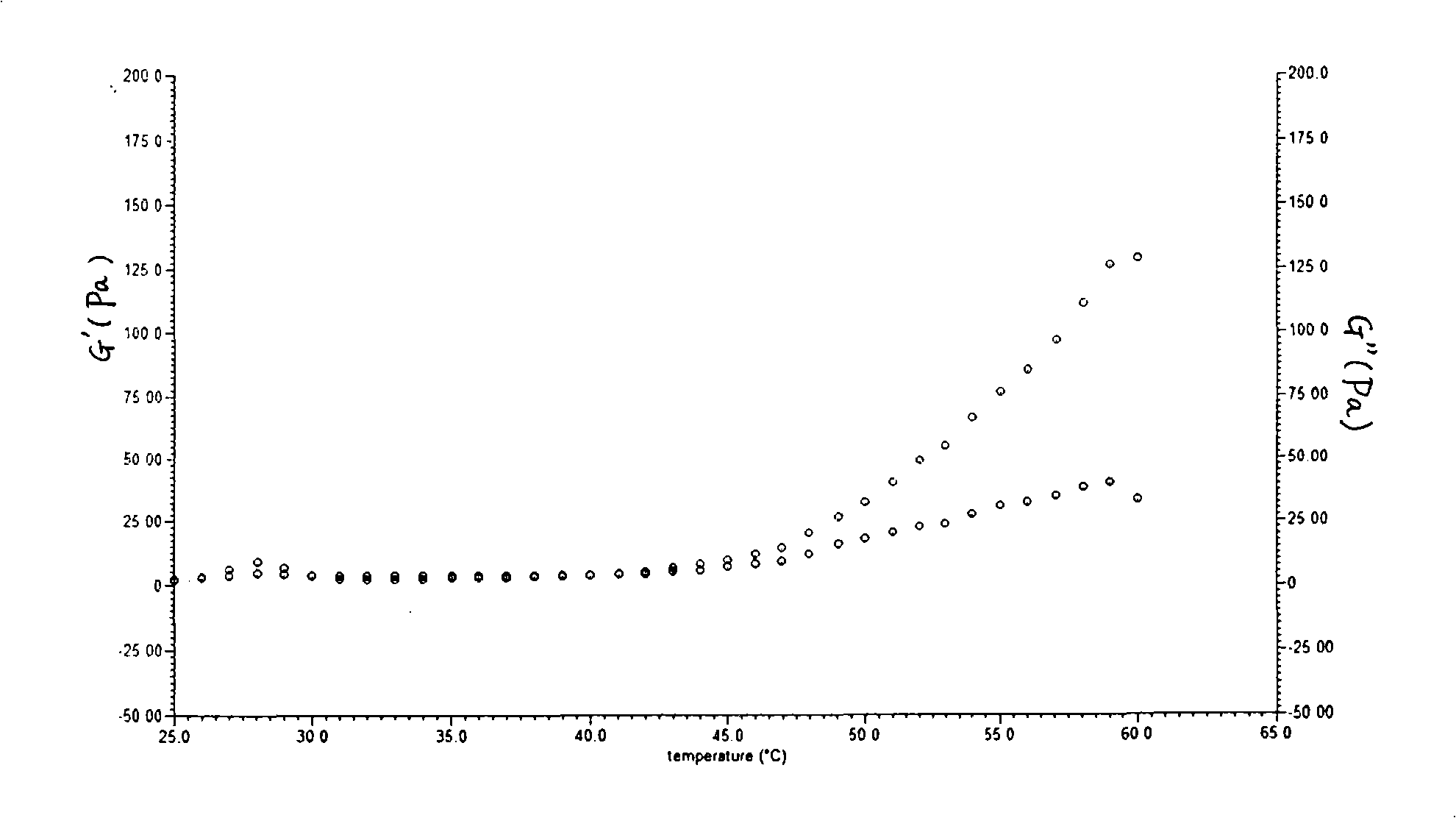

Preparation method of temperature sensitivity chitosan derivate-hydroxybutyl chitosan

The invention relates to a method for making a chitosan derivative. The method is characterized in that: firstly, the purified chitosan is activated by a strong base to form a hydroxyl-K type chitosan; secondly, a 1, 2-butyl oxide linkage is taken as an etherifying agent, an isopropanol is taken as a disperse phase, the reaction lasts 2 to 4 days moderately at room temperature; after the reaction is finished, 8 to 10 times volume of acetone is precipitated and washed to be neutral as well as is dried in vacuum at a temperature of 50 DEG C to obtain the white powder. The hydroxybutyl chitosan with different degrees of substitution is obtained by controlling the proportion of the chitosan and the 1, 2-butyl oxide linkage and the reaction time. The method has the advantages of good water-solubility and the existence of the temperature sensitivity at a physiological temperature.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

Decolored and debitterized Momordica grosvenori extract and preparation method thereof

InactiveCN101327244AAvoid Yield ProblemsAvoid the disadvantages of multiple column chromatography proceduresMetabolism disorderDigestive systemFruit juiceMomordica

The invention discloses an extractive of discoloring, debitterizing corsvenor momordica fruit and a preparation method thereof, the method is as follows: the corsvenor momordica fruit is cleaned, crushed and extracted to juice, the fruit juice is centrifugated, the supernatant fluid enters into the macroporous absorption resin, the resin is washed by water, alkali solvent and water in order, till the effluent liquid is neutral; and then is eluted by 30 percent -65 percent ethanol, the ethanol eluent is collected, ethanol is recovered and dried, and then the extractive is obtained. The technology is simple, the production cost is low, and the production is easy to control; the traditional heating extracting method is replaced by extracting the juice, so the energy consumption is reduced, the color of the obtained extractive is light, the impurity is little, and the product quality is better; the adopted absorption resin achieves better discoloring, debitterizing effects at the same time of enriching the active components completely, the content of momordica glycosides is improved, the pigment and the impurity in the extractive are removed completely through eluting; the obtained product is white powder, the taste is sweet and pure, without traditional bitter taste, wherein, the gypenosides weight content of momordica glycosides can reach over 90 percent, and the V weight content of momordica glycosides can reach over 60 percent.

Owner:卢照凯 +1

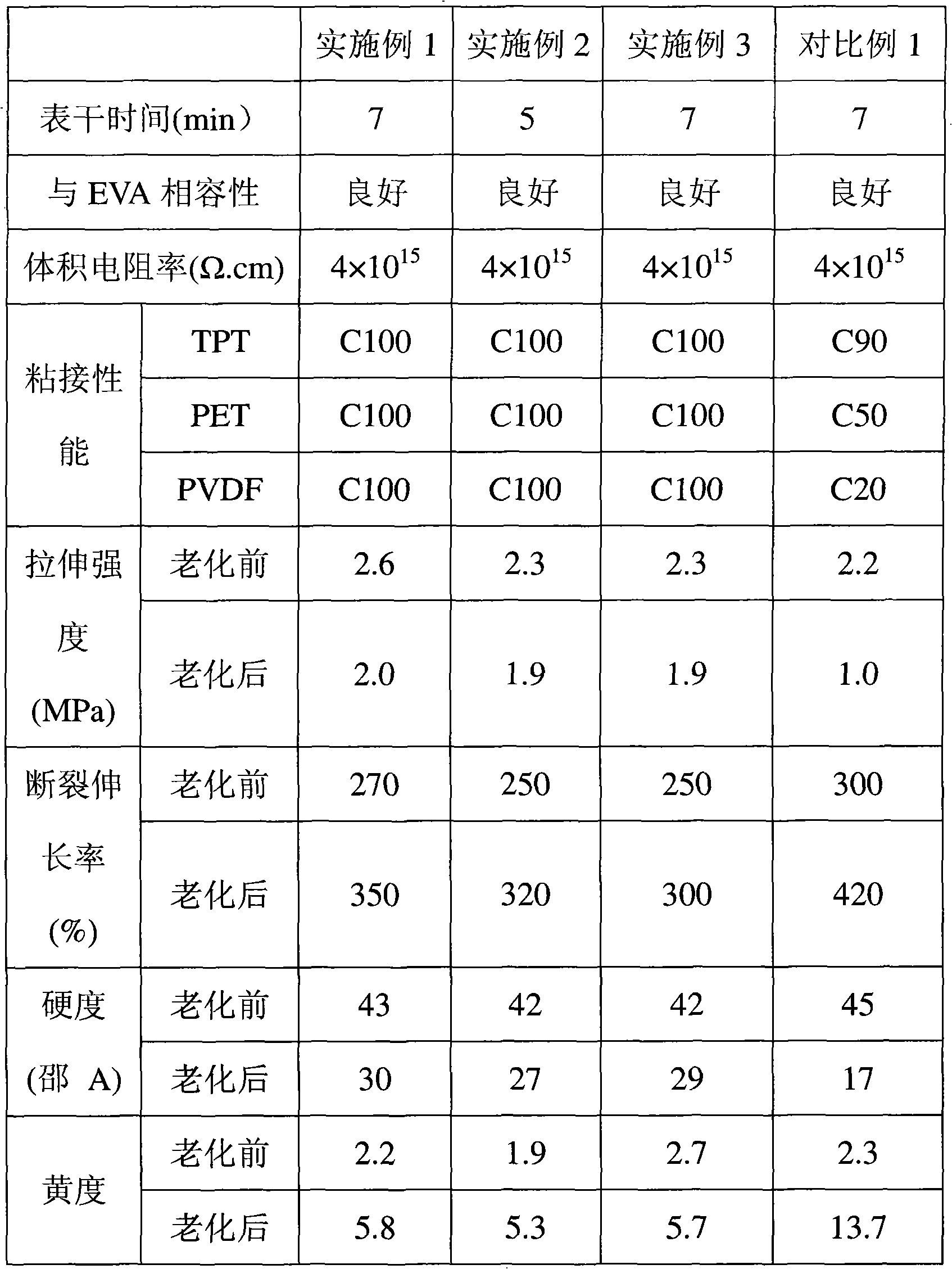

Room-temperature vulcanized organic polyorganosiloxane composition and preparation method

ActiveCN101775217AImproved high temperature and high humidity aging resistanceGood adhesionRoom temperatureWhite powder

The invention discloses a room-temperature vulcanized organic polyorganosiloxane composition and a preparation method thereof. The composition comprises 100 parts of hydroxy-terminated polydimethylsiloxane with viscosity of 3,000 to 100,000mPa.s, 10 to 30 parts of dimethicone with viscosity of 50 to 5,000mPa.s, 50 to 250 parts of filler, 5 to 20 parts of rutile titanium white powder paint, 0.5 to 2 parts of water absorbent, 0.1 to 1 part of ultraviolet absorbent, 5 to 15 parts of cross linker, 2 to 5 parts of coupling agent, and 0.1 to 1 part of catalyst. The composition is prepared by adding 100 parts of the hydroxy-terminated polydimethylsiloxane with viscosity of 3,000 to 100,000mPa.s, 10 to 30 parts of the dimethicone with viscosity of 50 to 5,000mPa.s and 50 to 250 parts of the filler into a stirring kettle, stirring the mixture for 2 to 4 hours at the temperature of between 110 DEG C and 130 DEG C under the vacuum condition of 0.09 to 0.1MPa, then cooling the mixture to below 40 DEG C, adding the water absorbent, the ultraviolet absorbent, the cross linker, the coupling agent and the catalyst in part into the stirring kettle and stirring the mixture uniformly.

Owner:富乐(苏州)新材料有限公司

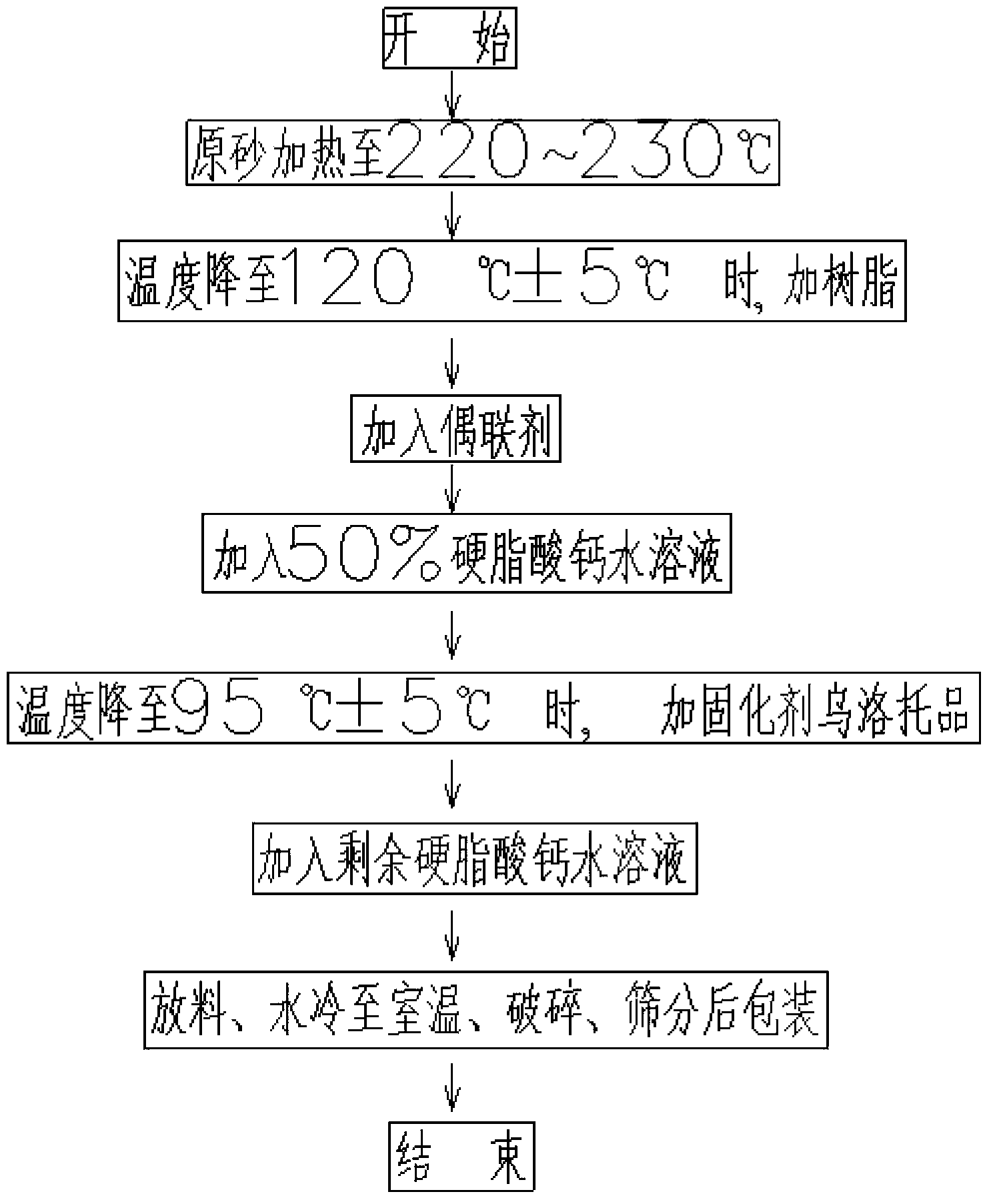

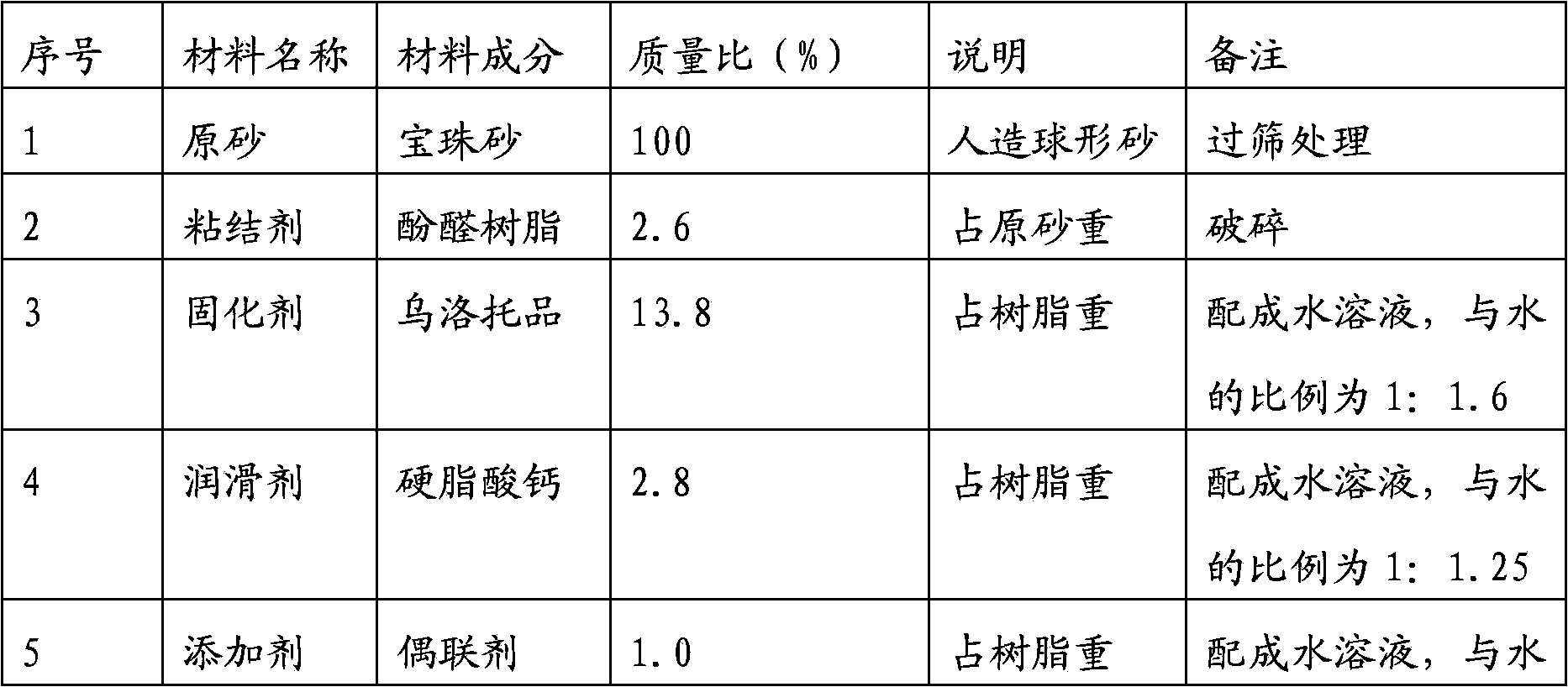

Production technology of precoated sand for selective laser sintering and quick molding technology

InactiveCN103567352AReduce intensityHigh strengthFoundry mouldsFoundry coresThermoplasticSelective laser sintering

The invention discloses a production technology of a precoated sand for a selective laser sintering and quick molding technology. The formula of the precoated sand comprises the following components: crude sands, a binding agent, a curing agent, a lubricant, and an addictive; wherein the crude sands are selected from a foundry sand with a particle size of 100 to 200 meshes, the binding agent is selected from a PF-1904 thermoplastic solid phenolic resin whose melting point is from 80 to 90 DEG C, the curing agent is selected from white or colorless crystal urotropine powder, the lubricant is selected from white calcium stearate powder, and the addictive is selected from silane colorless transparent liquid coupling agent KH-550. The production technology of the precoated sand for the selective laser sintering and quick molding technology adopts a fine and round foundry sand, selects a resin with a low melting point, reduces the addition amount of the resin, strictly controls the temperature when the binding agent and the curing agent are added, and adds a proper amount of addictive so as to manufacture a high strength and low gas evolution precoated sand, which is suitable for the selective laser sintering and quick molding technology.

Owner:GUANGXI YUCHAI MASCH CO LTD

Synthetic method of salt tolerant quadripolymer superabsorbent resin

The invention relates to a synthetic method of a salt tolerant quadripolymer superabsorbent resin, comprising the following steps of: adding cyclohexane and a dispersant Span-80 into a 3-mouth flask, stirring and heating up to the temperature of 60-68 DEG C, dropwisely adding a hydrophilic cross-linking agent, an initiator and a comonomer by a constant-voltage titration tunnel, staying at constant temperature for 1 hour after the addition, heating up to the temperature of 70-75 DEG C and reacting for 2-3 hours, cooling to room temperature, pouring the obtained product into a beaker with enough methanol, fully depositing, followed by pumping filtration by a vacuum pump, repeatedly washing by the use of methanol, and drying in a vacuum chamber at the temperature of 80-90 DEG C to obtain a white powder, namely the salt tolerant quadripolymer superabsorbent resin. The invention has the following beneficial effects: the technology is simple; the requirement on equipment is low; the resin prepared by the synthetic method has strong water absorption, fast water absorption rate, excellent water retention, high strength in the superabsorbent state, good light and thermal stability as well as salt tolerance which is remarkably improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

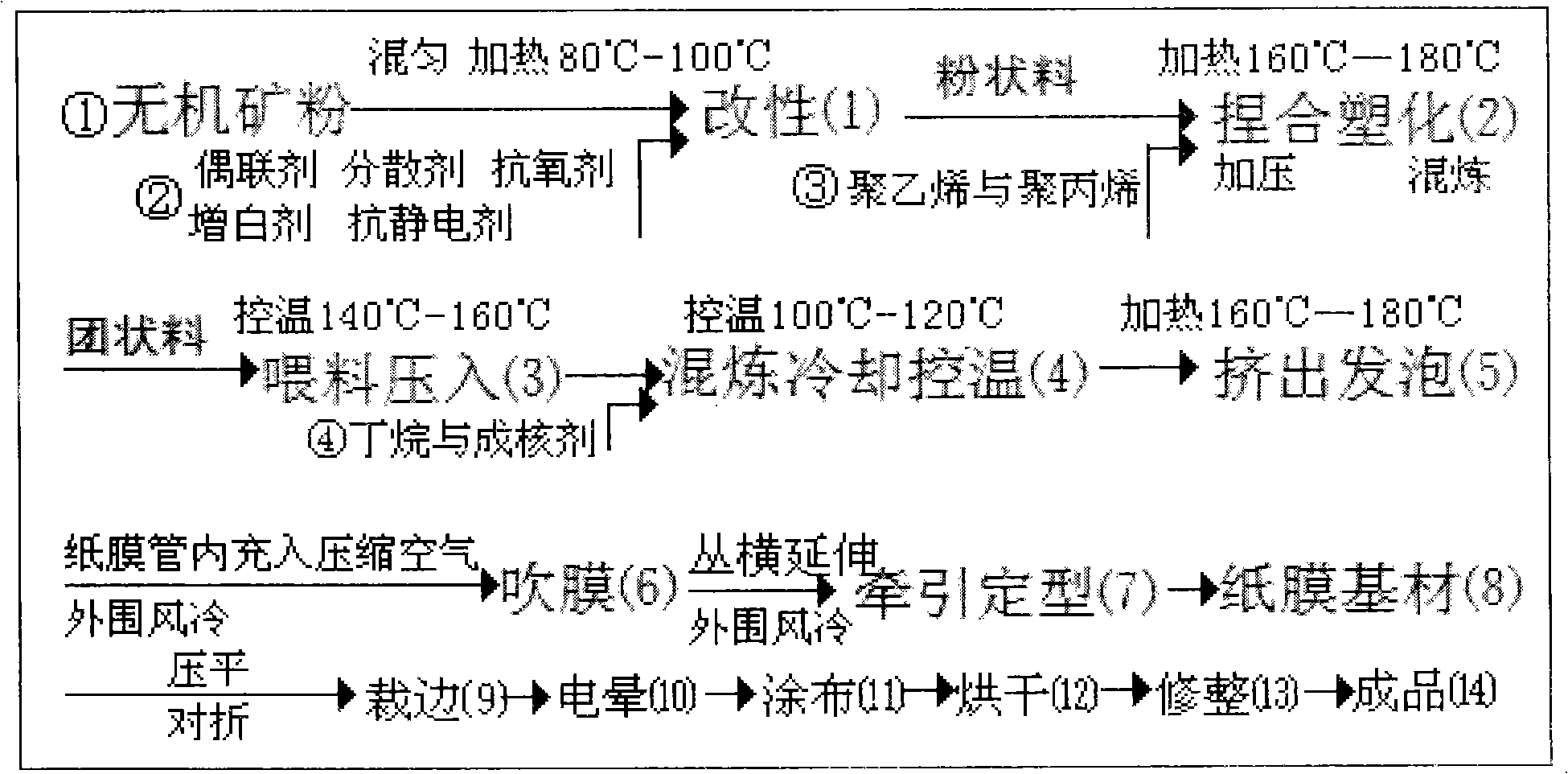

Stone papermaking method

InactiveCN101831835AControl the amount of inflationLight weightInorganic fibres/flakesSpecial paperFilm baseWhite powder

The invention discloses a stone papermaking method, which is characterized by comprising the following steps: adding 2 to 2.5 weight percent of auxiliary agent such as stearic acid and the like into 70 to 80 percent of natural inorganic ore powder such as heavy calcium, light calcium, talcpowder, titanium white powder and the like serving as main raw materials to modify the raw materials, adding 18 to 11.5 weight percent of polyethylene and 9 to 5 weight percent of polypropylene into the raw materials, and mixing, plasticizing and kneading the mixture to form a bulk material; and performing double-fold feed on the bulk material, pressing the bulk material into a paper film extruder, injecting 0.5 weight percent of butane and 0.5 weight percent of nucleating agent into the extruder, mixing and heating the mixture, extruding a paper film, then foaming, blowing, drawing, cooling and shaping the paper film to form a paper film base material, and forming a stone paper finished product through corona, coating, drying and finishing. The gram weight of stone paper is reduced by physical micro-foaming technology. The method has the advantages of simple manufacturing process, low cost, dry production, use of few water circulating cooling machines, no three-waste discharge and pollution avoidance.

Owner:山西典石晨晶科技有限公司

Water-based epoxy anti-corrosive coating and preparation method thereof

ActiveCN102311695AHas neutral salt spray resistanceLimit the spreadFireproof paintsAnti-corrosive paintsWater basedEpoxy

The invention discloses a water-based epoxy anti-corrosive coating and a preparation method thereof, and relates to a ship antirust and cabin inside and outside antirust fireproof paint. The invention provides a water-based epoxy coating with the VOC lower than 10g / l, and the coating belongs to an environment-friendly coating, which not only has the antirust performance of anti-corrosive coating,but also has low flame propagation of cabin inside finish paint, meets the requirement of cabin inside smoke and toxin, resists aging, and is a multifunctional water-based coating, and the bottom andthe surface are combined. Zhejiang Ampang AB-EP-20 is used as the epoxy resin, Zhejiang Ampang AD-HGF is used as the curing agent, and fluorocarbon emulsion (the model of which is Beijing Baowei PF-1) is used as the base material. Wetting dispersant, defoamer I, defoamer II, flash rust inhibitor, thickener, defoamer and substrate wetting agent are used as additives, rutile titanium white powder, compound zinc phosphate, ferrotitanium powder, talcum powder, ultra-fine aluminum hydroxide, precipitated barium sulfate, mica powder and aluminum tripolyphosphate are used as pigment fillers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Elastic anti-fouling outer wall paint with acid rain resistance and preparation method thereof

ActiveCN101948650AStrong adhesionImprove stain resistanceAntifouling/underwater paintsPaints with biocidesAnti freezingWhite powder

The invention discloses elastic anti-fouling outer wall paint with acid rain resistance. The outer wall paint comprises the following components in percentage by weight: 10 to 20 percent of water, 0.5 to 0.8 percent of acrylic ammonium salt dispersant, 20 to 26 percent of rutile type titanium white powder, 2 to 3 percent of kieselguhr, 8 to 15 percent of superfine barium sulfate, 1 to 2 percent of sericite powder, 40 to 50 percent of self-crosslinked elastic acrylic polymer latex, 3 to 5 percent of opaque covering polymer, 1 to 2 percent of anti-freezing agent, 1 to 2 percent of film-forming aid, 0.5 to 0.8 percent of mold-proof anti-algae agent, 1 to 3 percent of organic silicon waterproof agent and 0.5 to 1.5 percent of polyurethane associated thickener. The paint has the advantages of acid rain resistance, good anti-fouling performance, excellent elasticity, mold injury resistance, good storage stability and capability of repeatedly coating a paint film.

Owner:紫荆花制漆(成都)有限公司

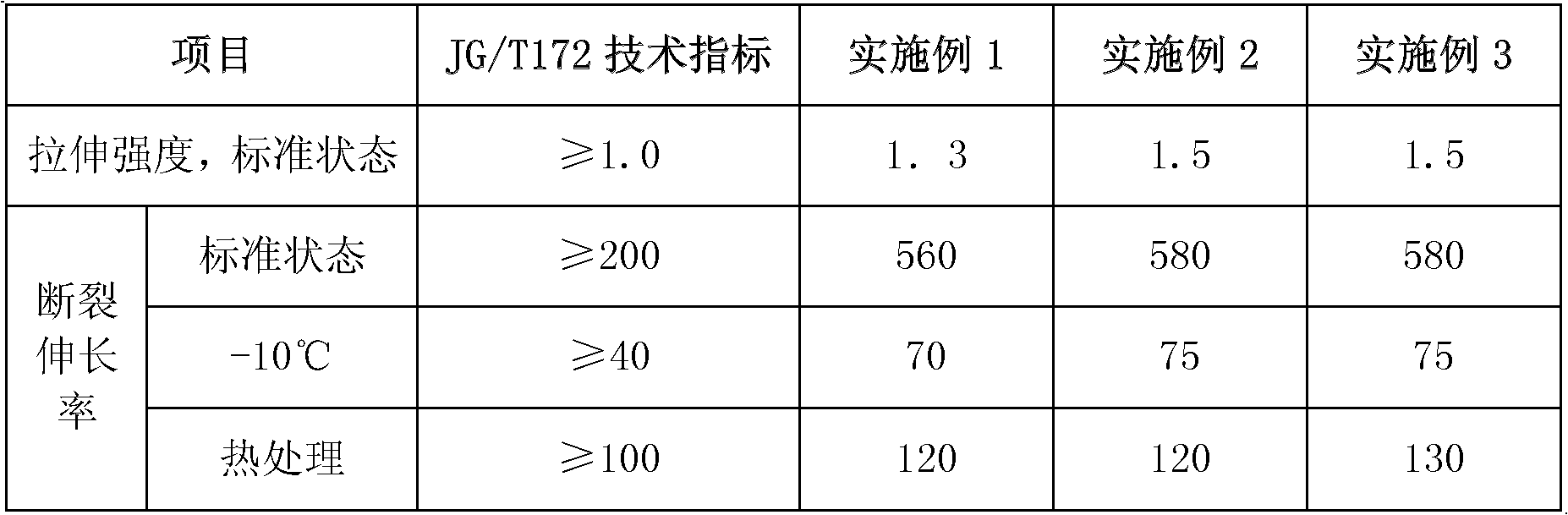

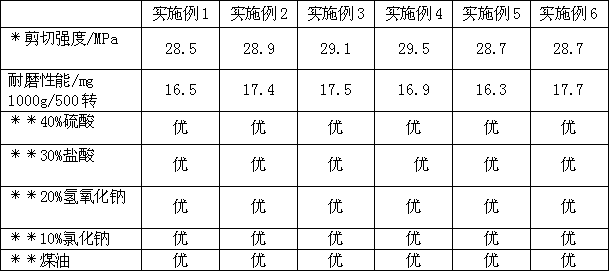

Brushed high-strength abrasion-resistant anticorrosive coating and preparation method

InactiveCN102838921AReduce harmImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCavitation

The invention relates to a brushed high-strength abrasion-resistant anticorrosive coating. The component A of the coating comprises 80 to 100 parts of mixed epoxy resin, 10 to 15 parts of toughening agent, 5 to 10 parts of diluent, 60 to 100 parts of ceramic powder, 5 to 10 parts of quartz powder, 20 to 30 parts of titanium white powder, 5 to 10 parts of fumed silica, 0.1 to 0.5 part of de-foaming agent, 0.1 to 0.5 part of flatting agent, and 0.1 to 0.5 part of wetting dispersant. The component B comprises 40 to 50 parts of mixed amine curing agent, 2 to 5 parts of epoxy accelerant, and 2 to 5 parts of silane coupling agent. The coating is easy to construct and easy to operate, and the coating does not contain volatile solvents and has low smell and low harm to a human body; the coating has extremely high adhesion after being cured, and can resist erosion of different media such as 40 percent sulfuric acid, 30 percent hydrochloric acid, 20 percent sodium hydroxide, 10 percent sodium chloride and engine oil and abrasion and cavitation of different mines such as drifting sand, gas dust and mud.

Owner:TONSAN ADHESIVES INC

Preparation process for titanium white of golden red stone type

InactiveCN1559913AQuality improvementGood application effectTitanium dioxideTitanium nitrideWhite powder

The invention discloses a method of making high-quality rutile titanium white powder by a method of improving sulphuric acid by crystal phase control, and its characteristic: after bleaching, adding rutile to burn crystal seeds, using deionized water to make metatitantic acid qualified by potching into metatitantic acid pulp, then adding in salt processing agent composed of K, P and Al compound crystal phase control preparations, burning and transforming the metatitantic acid at 800-1050 deg.C, so as to make primary product of rutile titanium white powder; it remarkably improves the quality of rutile titanium white powder, largely enhances application property of finished pigment, unitedly harmonizes the contradictory relations between decoloring force, conversion and whiteness, and makes the conversion quality of burnt products more stable, the particle size distribution more uniform, especially applied to after-processing.

Owner:SICHUAN LOMON CORP

Decorative brick with diatomite as main component

The invention discloses a decorative brick with diatomite as a main component. The decorative brick with the diatomite as the main component comprises the following components: 20-40 percent of refined diatomite, 50-70 percent of gypsum powder, 1-3 percent of plant fiber, 3-8 percent of titanium white powder, 0.5-2 percent of nano titanium dioxide and 1-3 percent of negative ion material. The decorative brick with the diatomite as the main component is made by adding a proper amount of plant pigment and water, uniformly stirring the mixture into paste, pouring the paste into a mould, solidifying and demoulding, putting into a drying box, and drying for 11-13 hours at the temperature of 70-90 DEG C. The diatomite brick has the characteristics that: the diatomite material with an air purifying function does not contain any harmful substance, has the functions of adsorbing and decomposing harmful gas, has a strong air humidity regulating function, and can be made into decorative bricks and mosaic tiles with different shapes; the transportation and the construction are simple; and the decorative bricks can be bonded onto a wall surface on site by using a special bonding agent.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

Method for preparing superfine nano-silicon by taking silicon-containing biomass as raw material as well as prepared superfine nano-silicon and application thereof

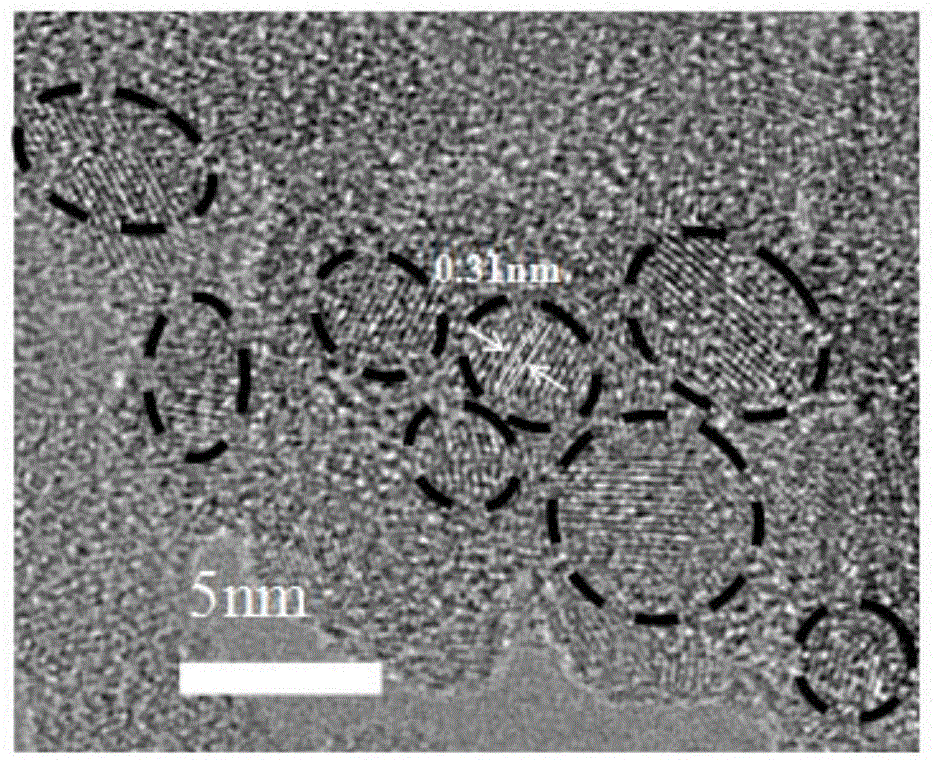

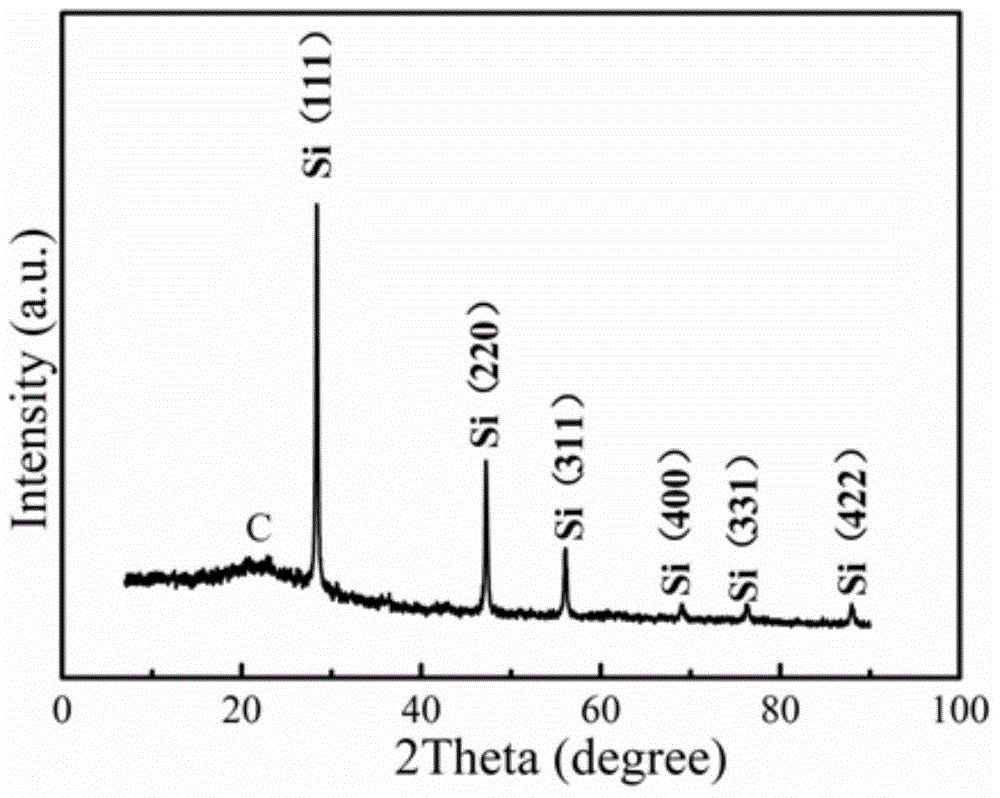

InactiveCN104671247AWide variety of sourcesNot easy to reuniteMaterial nanotechnologyCell electrodesSemiconductor materialsReaction temperature

The invention discloses a method for preparing superfine nano-silicon by taking a silicon-containing biomass as the raw material. The method comprises the following steps: eliminating an inorganic salt ion impurity by performing acid boiling on the silicon-containing biomass, grinding and smashing the white powders processed by air annealing to obtain a nano-silicon dioxide granule, uniformly mixing the white product, the magnesium powder and the fused salt, putting into a tube furnace, reacting under an inert atmosphere to obtain the silicon and the magnesium oxide, and removing the magnesium oxide by performing acid dipping on the reaction product to obtain the superfine nano-silicon granule. The reaction step is simple and practicable, the sources of the raw materials are extensive, most importantly the reaction temperature is controlled by adding the fused salt to melt and absorb heat, the reactant is hard to agglomerate, the specific surface area of the prepared nano-silicon is 302.13m<2> / g, the purity is greater than 98%, the granules are uniform with mesopores and the nano-silicon can be used in the fields such as the lithium ion battery, the semiconducting material and the medicine.

Owner:WUHAN UNIV OF SCI & TECH

Nano modified paint used for inner and outer wall

The main structure of said invented internal and external wall coating material respectively includes film-forming substance, dispersion medium, pigment filler and adjuvant, and its raw material formula is formed from (wt%) 35-55% of acrylic resin emulsion, 0.1-0.3% of dispersion moistening agent, 4-8% of titanium white powder, 4-8% of lithopone, 2-6% of talcum powder, 1.5-4.5% of nano SiO2, 1.5-4.5% of nano Tio2, 0.1-0.3% of pH regulating agent and 20-30% of water. The above-mentioned materials are stirred, ground and filtered so as to obtain the invented coating material with improved water-proofing property, contamination resistance, ageing resistance, UV ray resistance and bacteria-resisting property. Said coating material can be washed for above 11000 times, and its service life can be up to above 10 years.

Owner:刘尚文 +1

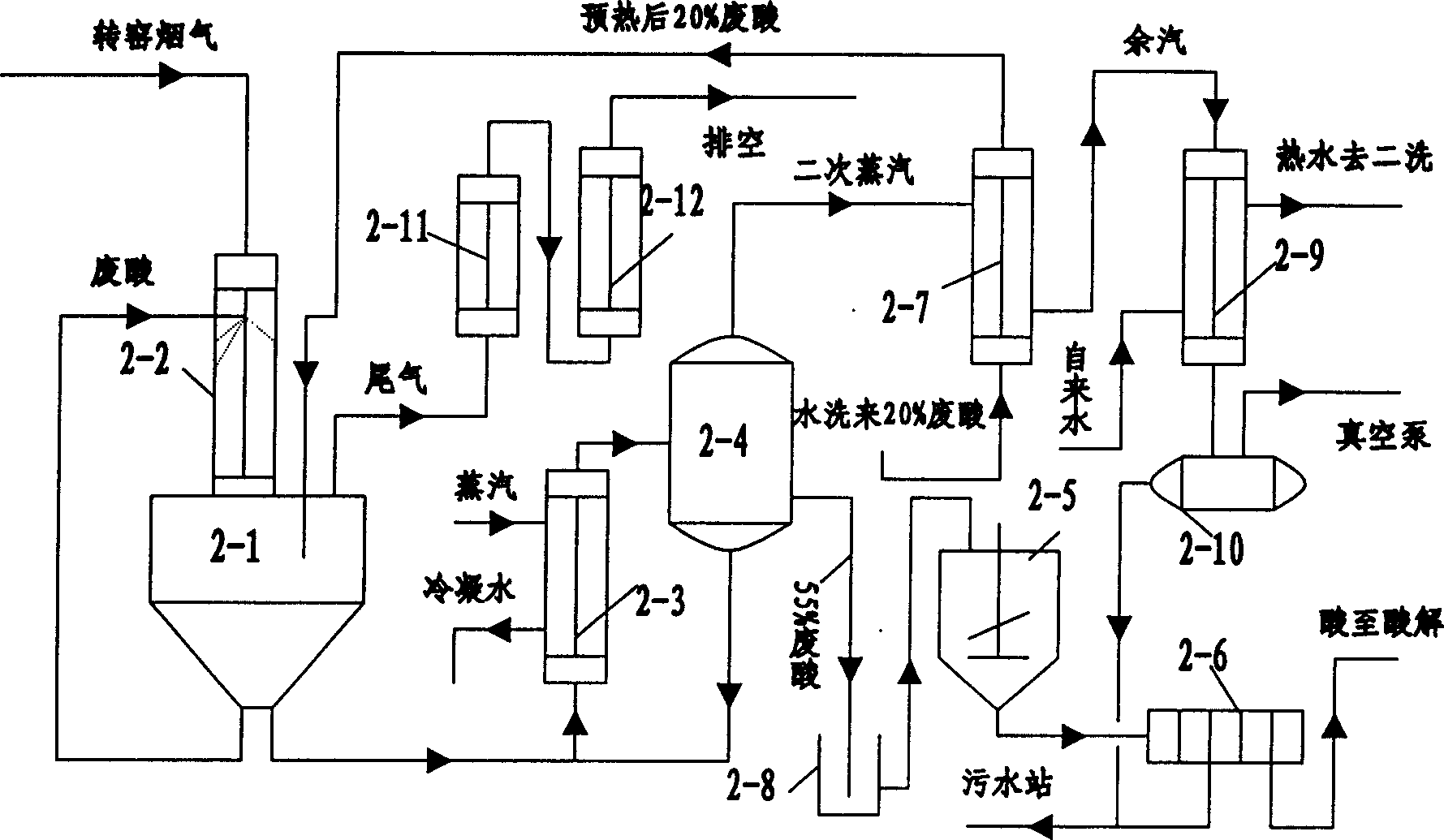

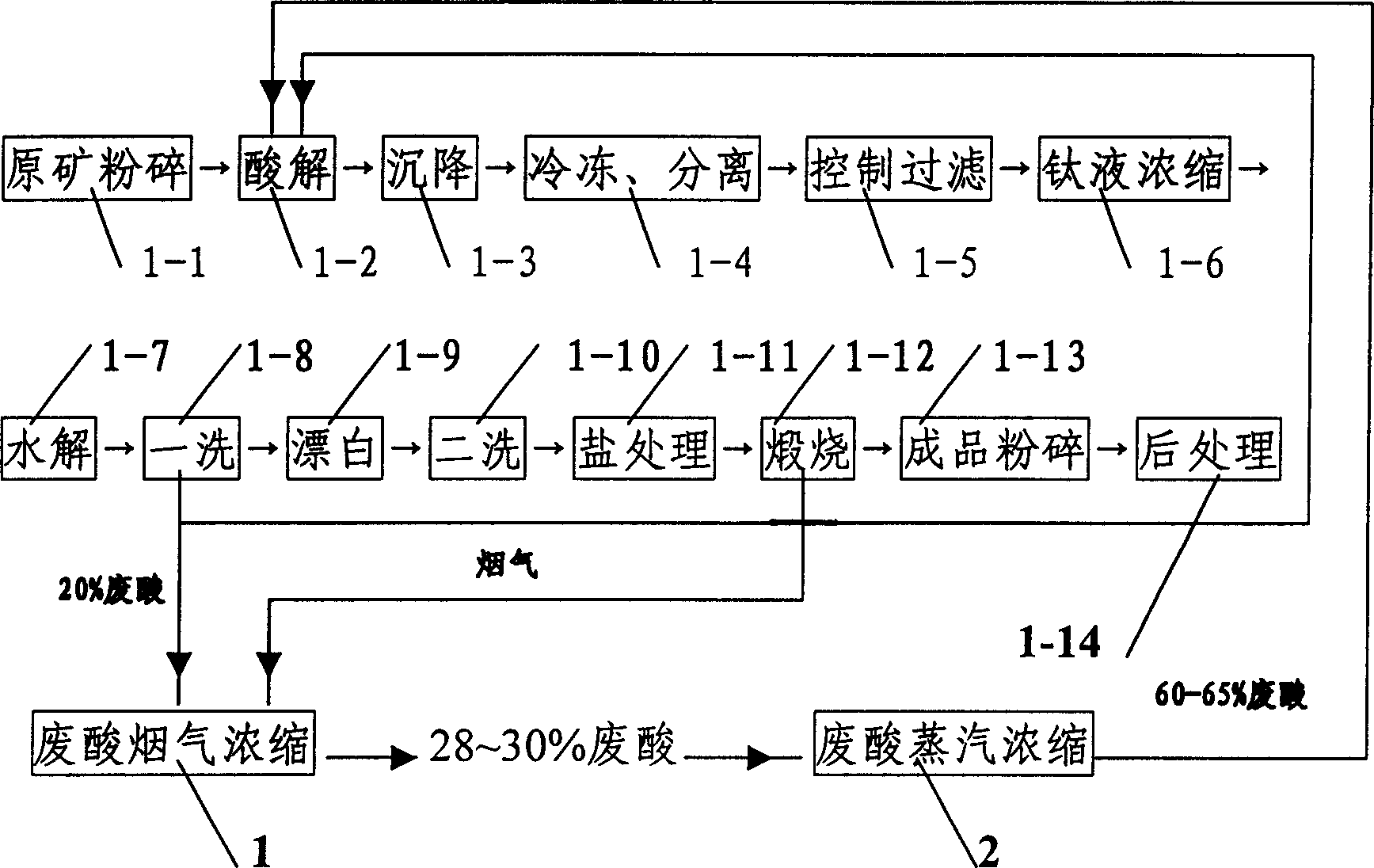

Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

ActiveCN1724339AReduce energy consumptionReduce dosageSulfur-trioxide/sulfuric-acidTitanium dioxideWhite powderTitanium

An industrial process for reclaiming the waste acid in the production of titanium white powder by sulfuric acid method features that the waste acid is concentrated by fume and then by steam. Its advantages are high efficiency, low cost, and no environmental pollution.

Owner:潜江方圆钛白有限公司

Process for preparing fucoidan by enzymatic hydrolysis of brown algae

The enzymically hydrolysis process of preparing fucan sulfate with brown algae includes the following steps: compounding composite cellulase with cellulase and pectase; enzymolyzing brown algae material via adding the composite water and cellulase at pH 6.0-8.0 for 50-80 min; heating at 90-100 deg.c in water bath for 3-4 hr, cooling to room temperature and centrifuging to obtain supernatant; adding alcohol to the supernatant to produce precipitate and centrifuging to obtain the second supernatant; adding alcohol to the second supernatant to produce precipitate and collecting the precipitate; washing the precipitate and vacuum freeze drying to obtain white powder. The said process has high extraction rate, low product cost, and less environmental pollution.

Owner:DALIAN FISHERIES UNIVERSITY

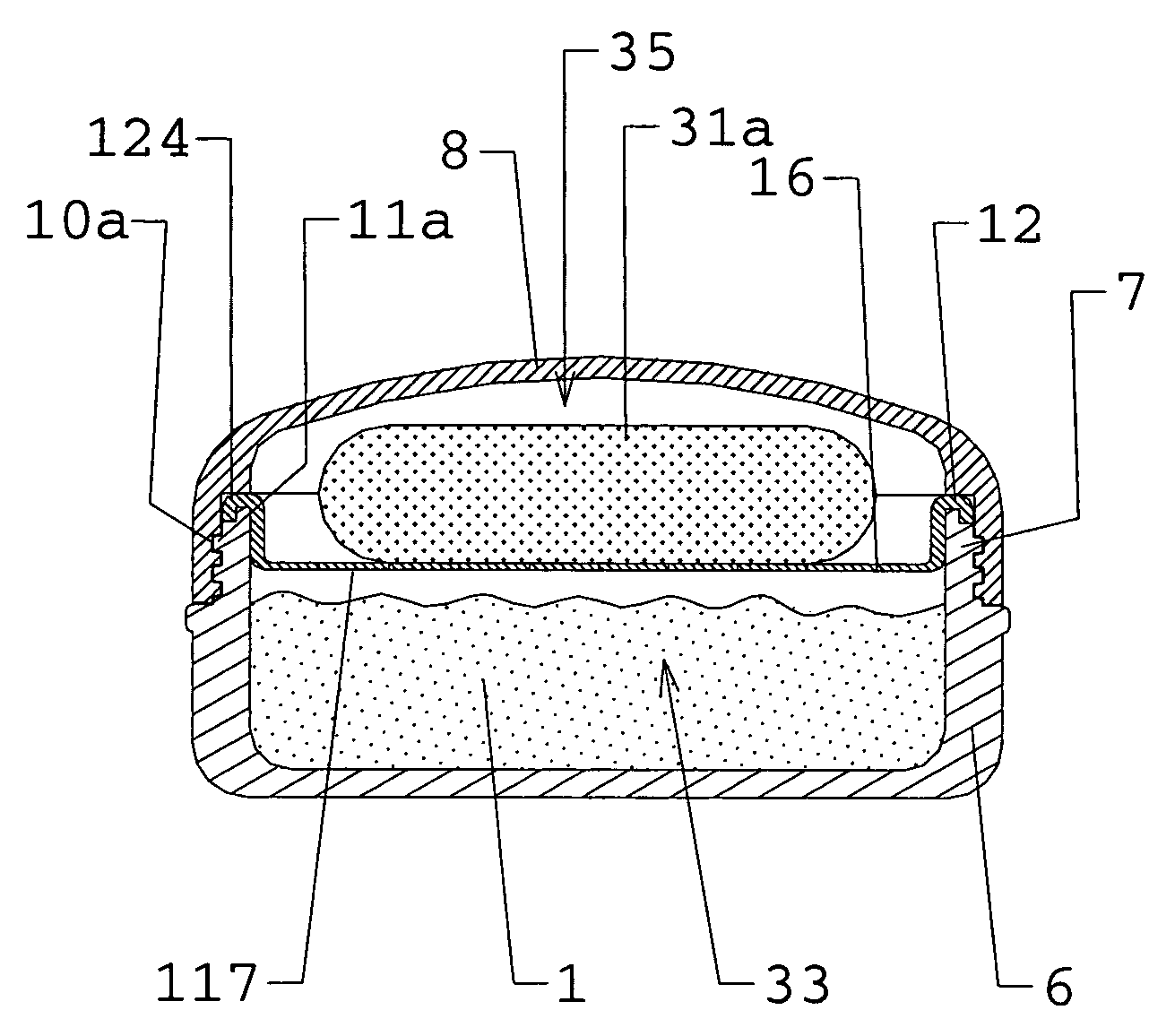

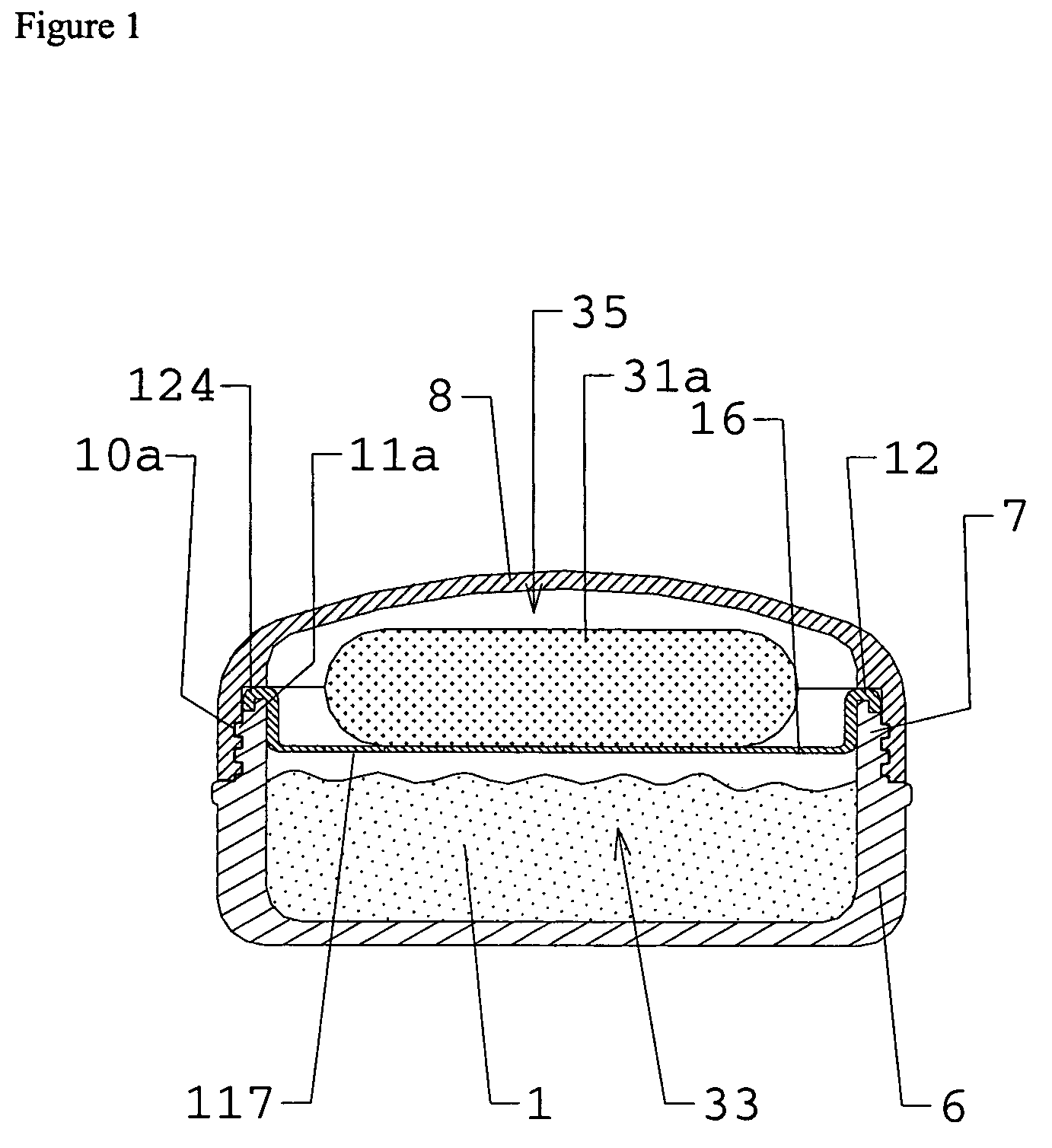

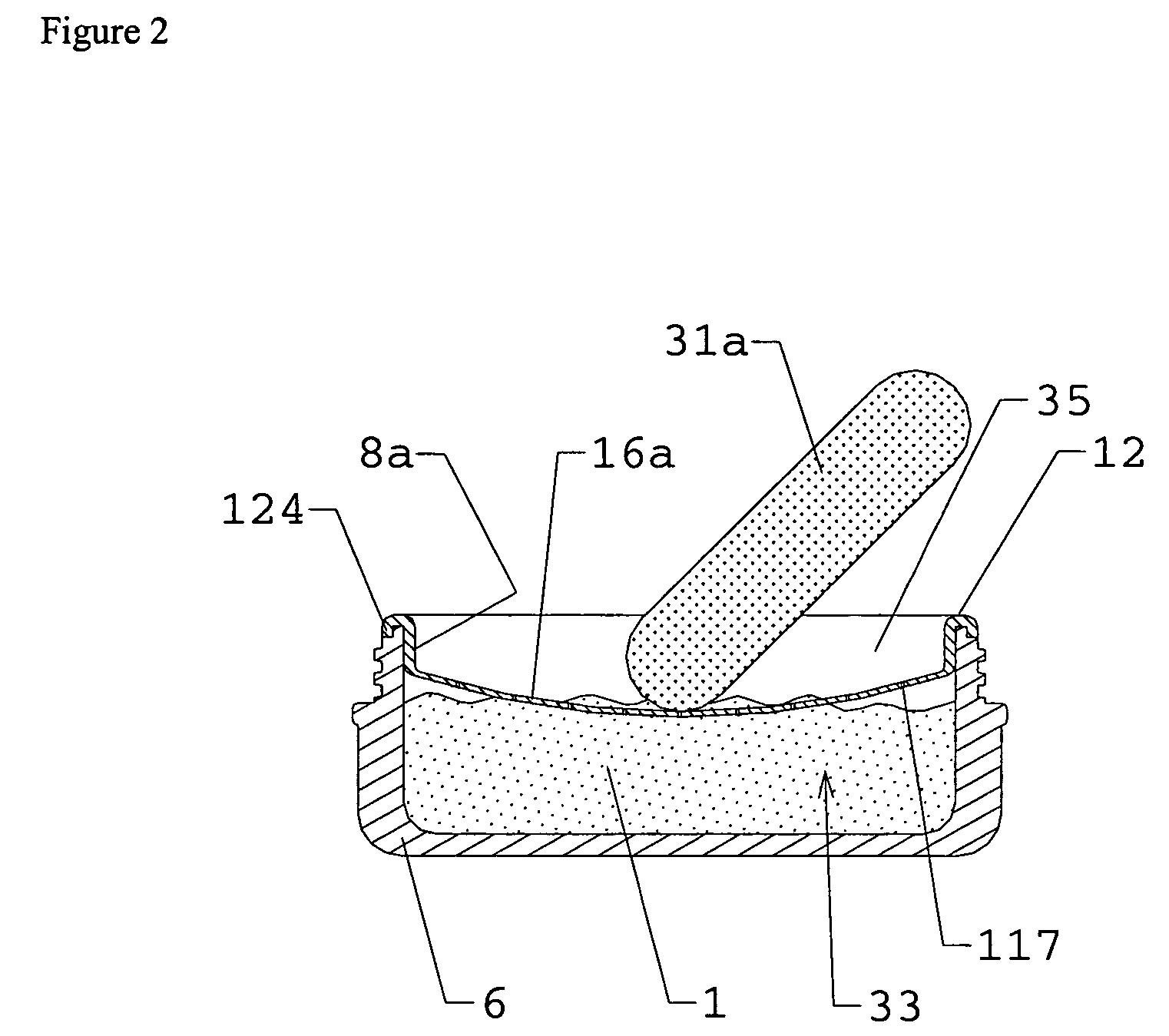

Container for make-up powder

A container for storing make-up powder, such as white powder or powder foundation and an application member such as a powder puff includes a structure wherein a make-up material-storing compartment for storing make-up powder has an intermediate lid which is engaged with a container. At least a part of a partition portion of the intermediate lid is formed with an elastic material, with numerous small cuts vertically formed through the partition portion, thereby enabling make-up powder to pass through the small cuts opened by extending the partition portion. The small cuts are arranged in a direction crossing a direction of extension of the partition portion under a normal use condition.

Owner:KATSUSHIKA

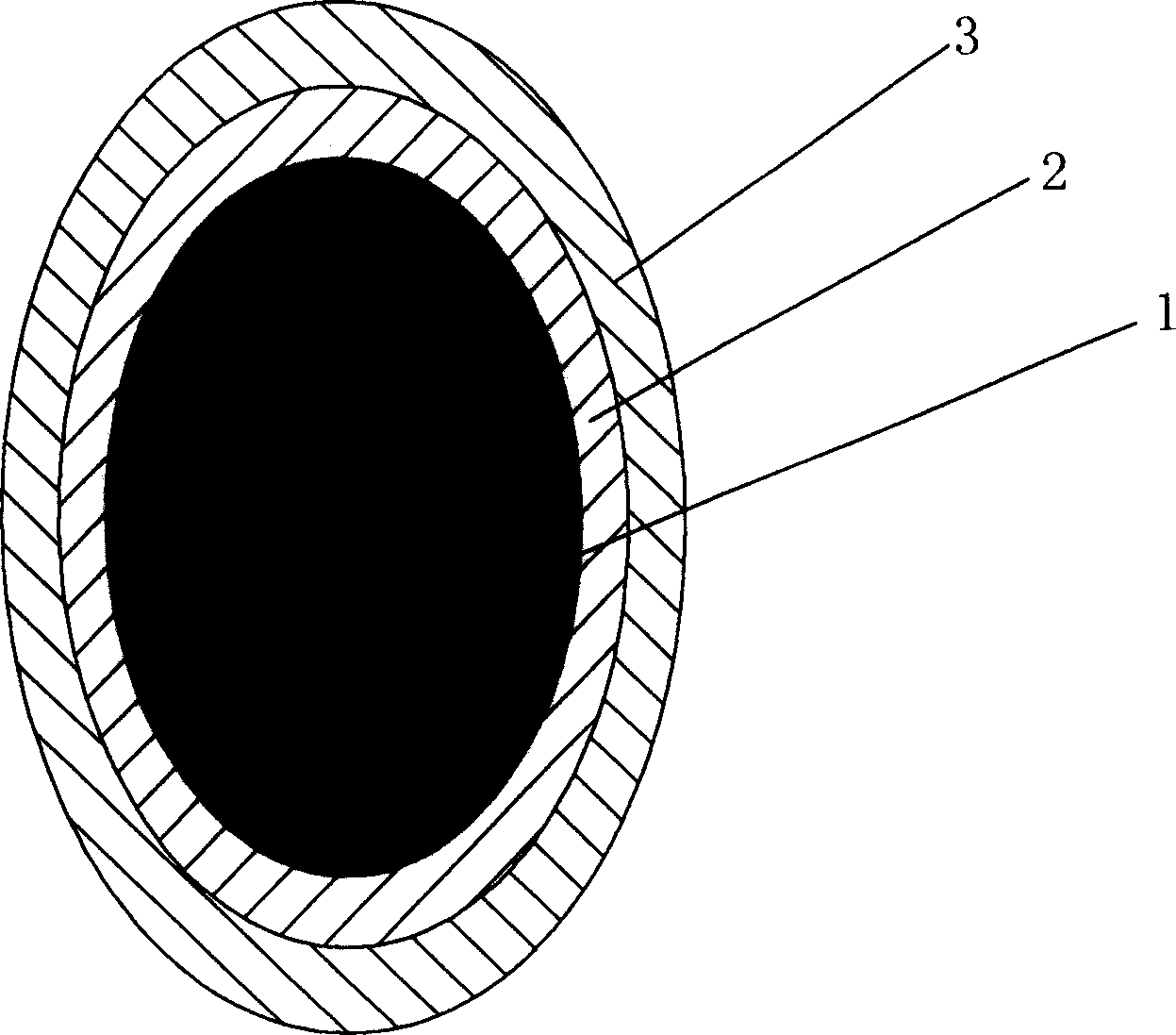

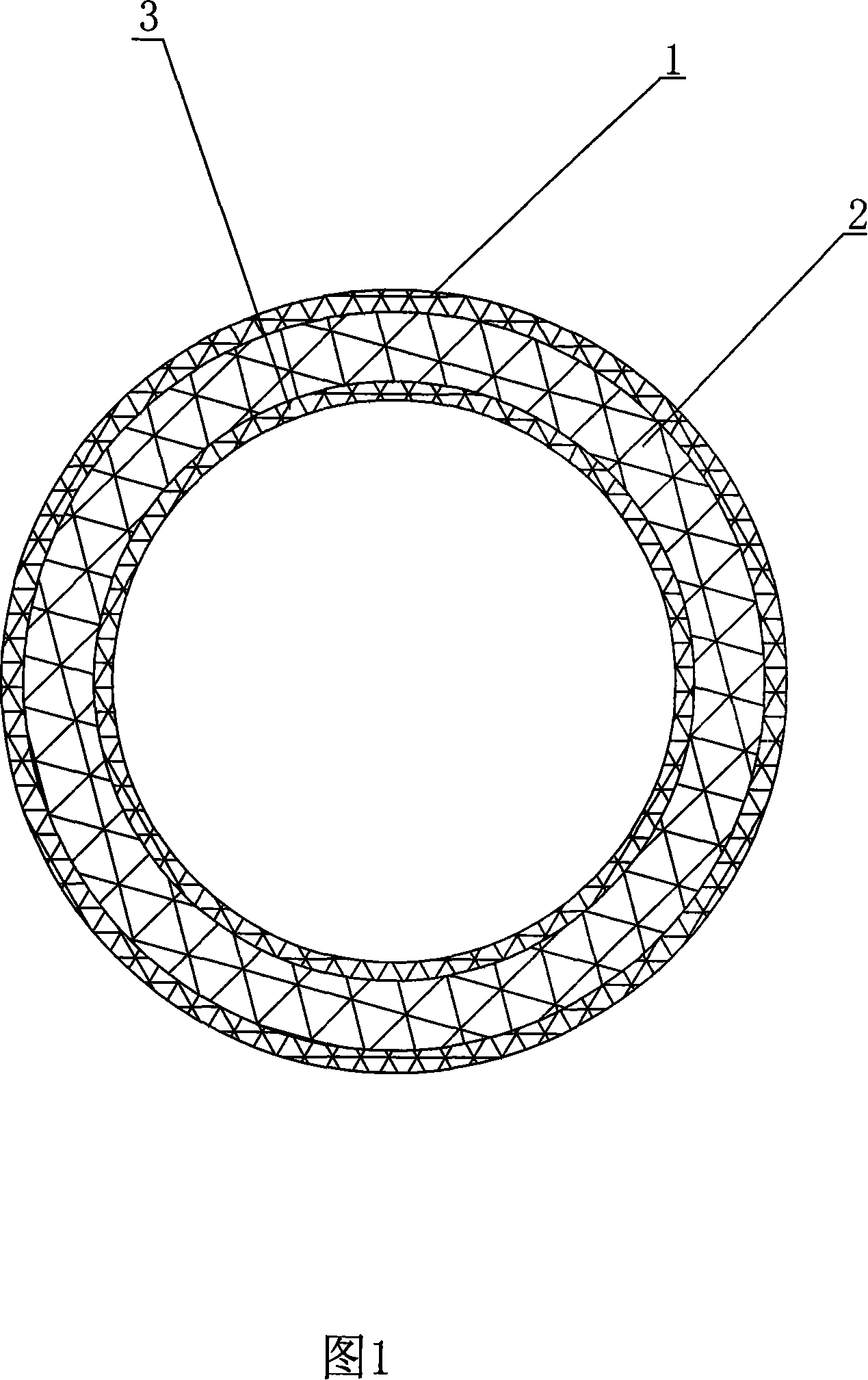

PVC-U composite nano drainpipe manufacturing method

The present invention discloses a production method for a PVC-U nanocomposites drainpipe. The pipe wall of the drainpipe consists of an inner layer (3), a sandwich layer (2) and an outer layer (1). The present invention is characterized in that each layer is formed by feed preparation, high speed mixing, low speed mixing, high speed mixed squeezing out, then molding by the same complex mould, and the finished product is got by cooling size, hauling, fixed length cutting; the inner and the outer layer materials consist of PVC resin, plain calcium carbonate, nano-size calcium carbonate, PVC composite stabilizer, PE wax, stearic acid, titanium white powder, and ACR, the core material compared with the outer layer material adopts the reclpurposeed PVC reclpurposeed material to replace the PVC resin, and the other materials are fixed. The present invention greatly enhances the solidity, toughness, stain resistance, and heat resistance etc. of the physical and chemical properties of the pipe material, when the solidity and the service property of the pipe material are ensured, the production cost of the pipe material is reduced, the color and luster of the pipe material is whiter, and the figure is more beautiful.

Owner:李子清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com