Patents

Literature

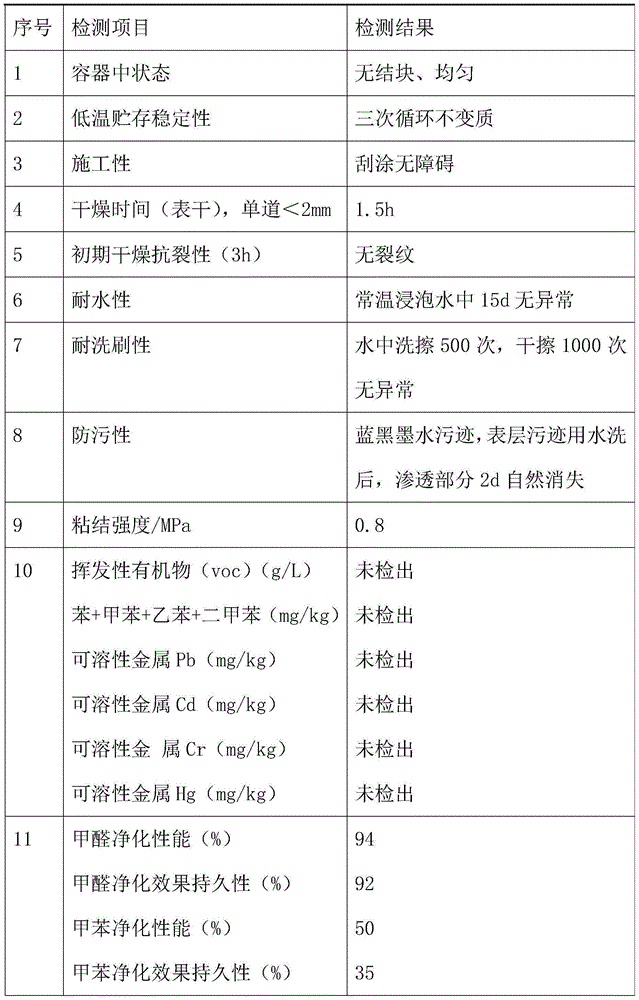

606 results about "Lithopone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

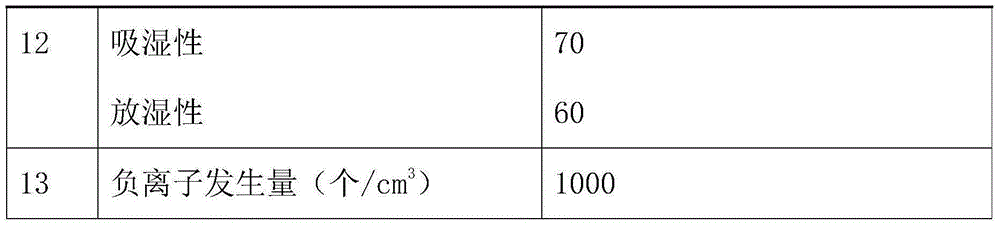

Patent Status

Application Year

Inventor

Lithopone, C.I. Pigment White 5, is a mixture of inorganic compounds, widely used as a white pigment powder. It is composed of a mixture of barium sulfate and zinc sulfide. These insoluble compounds blend well with organic compounds and confer opacity. It was made popular by the cheap production costs, greater coverage. Related white pigments include titanium dioxide, zinc oxide ("zinc white"), and zinc sulfide.

High-temperature resistant fiber filter paper for engine oil filter and preparation method of high-temperature resistant fiber filter paper

ActiveCN102912680AImprove high temperature resistanceImprove toughnessNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses high-temperature resistant fiber filter paper for an engine oil filter and a preparation method of the high-temperature resistant fiber filter paper. The high-temperature resistant fiber filter paper comprises, by weight, 60-70 parts of coniferous wood pulp, 20-30 parts of cotton pulp, 20-30 parts of modified polyimide fiber, 2-5 parts of kaoline, 1-3 parts of lithopone, 2-4 parts of silica gel, 1-2 parts of nanometer titania, 0.5-0.8 part of ammonium polyphosphate, 1-2 parts of modified acrylic emulsion, 2-4 parts of acetic styrene-acrylic emulsion, 0.5-1 part of stearic acid monoglyceride, 0.5-1 part of silane coupling agent KH590, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of urea resin. The high-temperature resistant fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the high-temperature resistant fiber filter paper can reach 99.97%.

Owner:ANHUI PHOENIX INT CO LTD

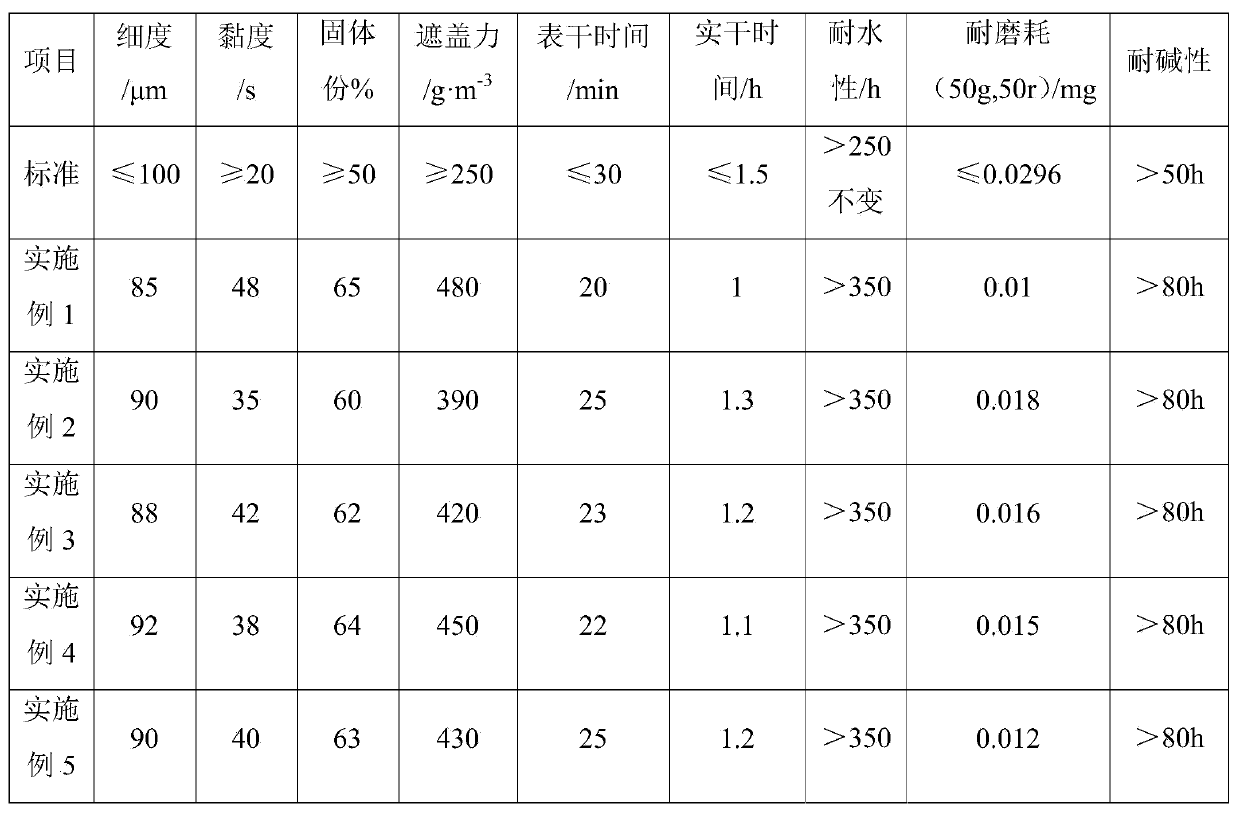

Nano modified paint used for inner and outer wall

The main structure of said invented internal and external wall coating material respectively includes film-forming substance, dispersion medium, pigment filler and adjuvant, and its raw material formula is formed from (wt%) 35-55% of acrylic resin emulsion, 0.1-0.3% of dispersion moistening agent, 4-8% of titanium white powder, 4-8% of lithopone, 2-6% of talcum powder, 1.5-4.5% of nano SiO2, 1.5-4.5% of nano Tio2, 0.1-0.3% of pH regulating agent and 20-30% of water. The above-mentioned materials are stirred, ground and filtered so as to obtain the invented coating material with improved water-proofing property, contamination resistance, ageing resistance, UV ray resistance and bacteria-resisting property. Said coating material can be washed for above 11000 times, and its service life can be up to above 10 years.

Owner:刘尚文 +1

Multifuntional green environmental protection nanometer titania coating and preparing method thereof

InactiveCN1583907ASolve technical problems that are easy to reuniteGood weather resistanceCoatingsSilicic acidTalc

This invention is that a kind of multi-functional green nanometer two of environmental protection is oxidized Titanium coating and method of preparing, this coating can not merely be solved now. There is coating that is able to bear staining difference, is able to bear waiting difference, not the skills, such as environmental protection, etc. Skill question, it is clean to give the coating at the same time, disinfect and disinfect, Purify new functions, such as air, etc., it is the green environmental protection of more than one kind of kinetic energy Coating. Coating this by titanium white powder, exceed detailed silicic acid aluminium, nanometer Oxidize the titanium and disperse the liquid two times, the calcium carbonate of light quality, the calcium carbonate of heavy quality, Silicon lime powder, lithopone, talc powder, dispersant is moist. It is the dispersant, thickener, disappear and steep and pharmaceutical, become membrane auxiliary, flow flat pharmaceuticla, water, the cream base material, etc. make up, it is simple to prepare the craft. The cost performance is high, have very good economic benefits and social result Benefit.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

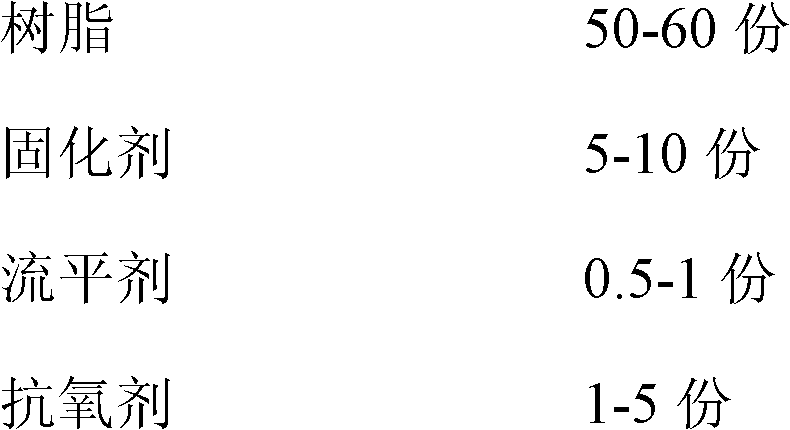

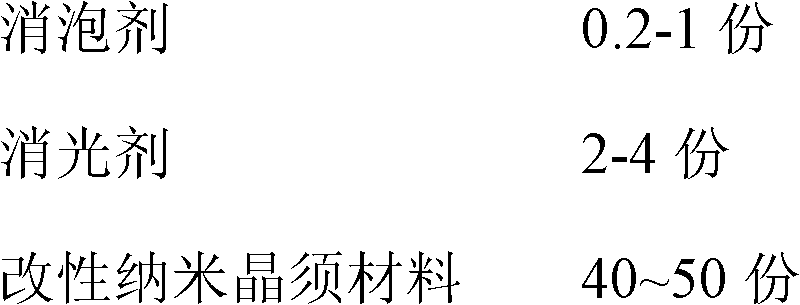

Powder coating containing nano whisker material and preparation method thereof

InactiveCN102277061AImprove performanceReduce manufacturing costPowdery paintsEpoxy resin coatingsWhiskersOxygen

The invention discloses a powder coating containing nano-whisker materials and a preparation method thereof. The parts by weight of each component are: 50-60 parts of resin, 5-10 parts of curing agent, 0.5-1 part of leveling agent, anti- 1-5 parts of oxygen agent, 0.2-1 part of defoamer, 2-4 parts of matting agent, 40-50 parts of modified nano whisker material. The invention adopts the nano-whisker material as the filler in the powder coating to replace the commonly used titanium dioxide and lithopone, and can reduce the production cost while obtaining the high-performance powder coating. The preparation method is simple and efficient, not only the powder coating with excellent performance can be obtained, but also the production cost can be greatly reduced, and the application range of the powder coating can be expanded.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of exterior wall coating for adsorbing CO2 by using magnesium slag

InactiveCN103613975ASolve the pollution of the environmentReduce manufacturing costAlkali metal silicate coatingsEpoxy resin coatingsEpoxySlag

The invention discloses a preparation method of an exterior wall coating for adsorbing CO2 by using magnesium slag, and in particular relates to a preparation method of an exterior wall coating. The preparation method comprises the steps of screening the magnesium slag through a screen of 200 meshes, taking the magnesium slag as a filler of the coating, and uniformly mixing the magnesium slag with other components of the coating to prepare the exterior wall coating for adsorbing CO2, wherein the magnesium slag powder can be used as the filler of the exterior wall coating singly or one or a combination of more of the magnesium slag powder, quartz powder, talc powder, mica powder and lithopone is used as the filler of the coating. The preparation method can be used for preparing exterior wall coatings such as a styrene-acrylic emulsion-magnesium slag exterior wall coating, a silicone-acrylic emulsion-magnesium slag exterior wall coating, an epoxy resin-magnesium slag exterior wall coating, a water glass-magnesium slag exterior wall coating, a hydrosol inorganic polymer-magnesium slag exterior wall coating, a silica sol-magnesium slag exterior wall coating and a potassium silicate-magnesium slag exterior wall coating. By adopting the preparation method disclosed by the invention, the problems that the stack of the magnesium slag occupies a lot of farmlands, an enterprise pays a large number of slag discharge fees and the magnesium slag causes environmental pollution are solved. By using the magnesium slag to prepare a coating, a large number of production cost can be saved, CO2 can be fixed, and huge environmental and social benefits are brought.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Multifunctional inner wall paint

InactiveCN105131774AGood scrub resistanceImprove rheologyCoatingsAcrylic resinHydroxyethyl cellulose

The invention discloses a multifunctional inner wall paint. The multifunctional inner wall paint comprises raw materials: modified acrylic resin emulsion, pure acrylic emulsion, light calcium carbonate, diatomite, lithopone, ultrafine talcum powder, water absorption composite materials, negative ion-anti-microbial additives, hydroxyethyl cellulose, a dispersant SN-5040, a wetting agent AP-680, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, propylene glycol monomethyl ether, an antifoaming agent TSP-01, sodium hexametaphosphate, a leveling agent L-150, a stain-resistant agent JZM-1, glycol, a multifunctional auxiliary agent AMP-95, mildew inhibitors and deionized water. The multifunctional inner wall paint has good scrubbing resistance, rheological property and brushing performance, can absorb harmful components in air indoors, adsorbs moisture, releases moisture, refreshes air, releases negative ions and is environmentally friendly and is helpful for health.

Owner:TIANCHANG YINHU PAINT

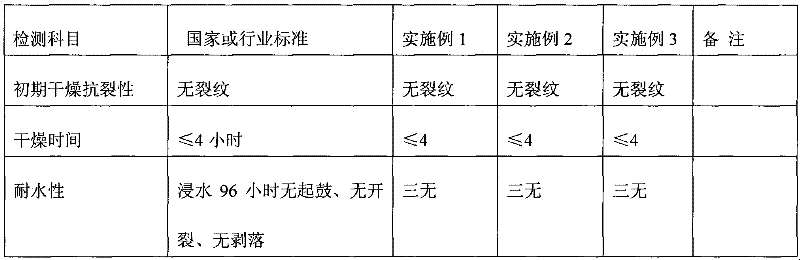

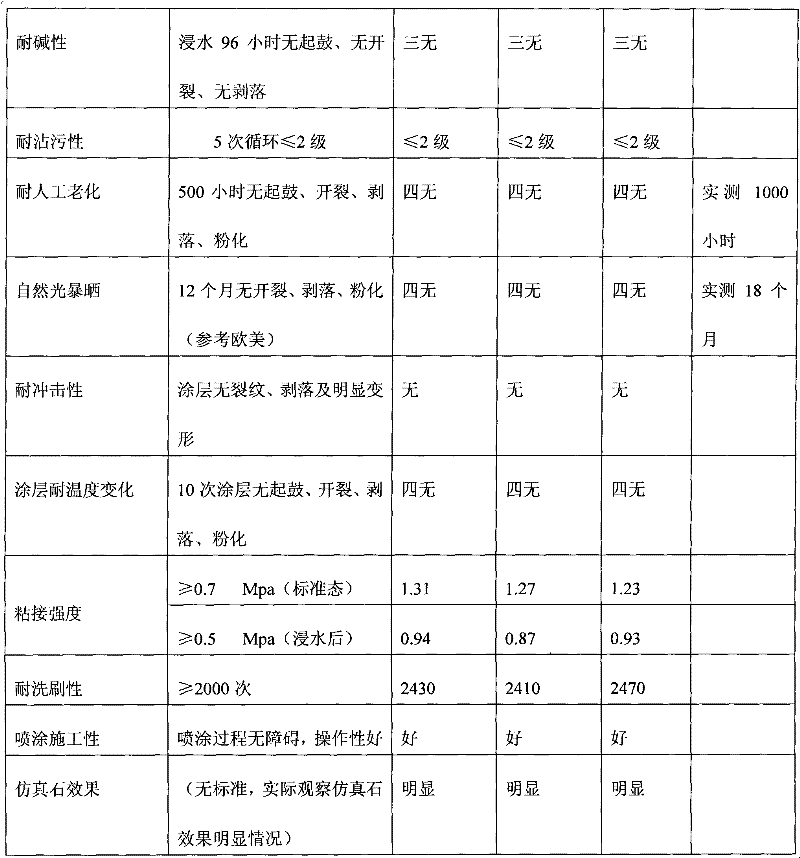

Sand textured two-component plaster mortar composition

The invention provides a sand textured two-component plaster mortar composition. The composition consists of the following components in parts by weight: 20 to 30 parts of white cement, 40 to 60 parts of silicon carbide, 0.5 to 1.5 parts of gelatin powder, 0.1 to 0.3 part of xanthan gum, 0.1 to 0.2 part of cellulose ether, 3 to 7 parts of lithopone, 1.5 to 3 parts of fire retardant, 0.1 to 0.5 part of sodium tripolyphosphate, 0.1 to 0.5 part of hardening agent, 0.1 to 0.3 part of defoaming agent, 40 to 50 parts of modified polyurethane emulsion, and 1 to 3 parts of dipropylene glycol methyl ether. A filmed polyurethane adhesive film has hydrophobic nature better than an adhesive film copolymerized from pure acrylic acid, styrene-acrylate or vinyl acetate, so that the mortar spraying effect is excellent, and the effect of simulating stones rivals that of stones; and the composition has good effects in adhesive strength, water resistance, stain resistance, light and weather resistance.

Owner:苏州盛泽科技创业园发展有限公司

Negative oxygen ion dry powder paint and preparation method thereof

InactiveCN106189393AHigh tensile strengthGood dispersionAntifouling/underwater paintsPaints with biocidesWollastoniteUltimate tensile strength

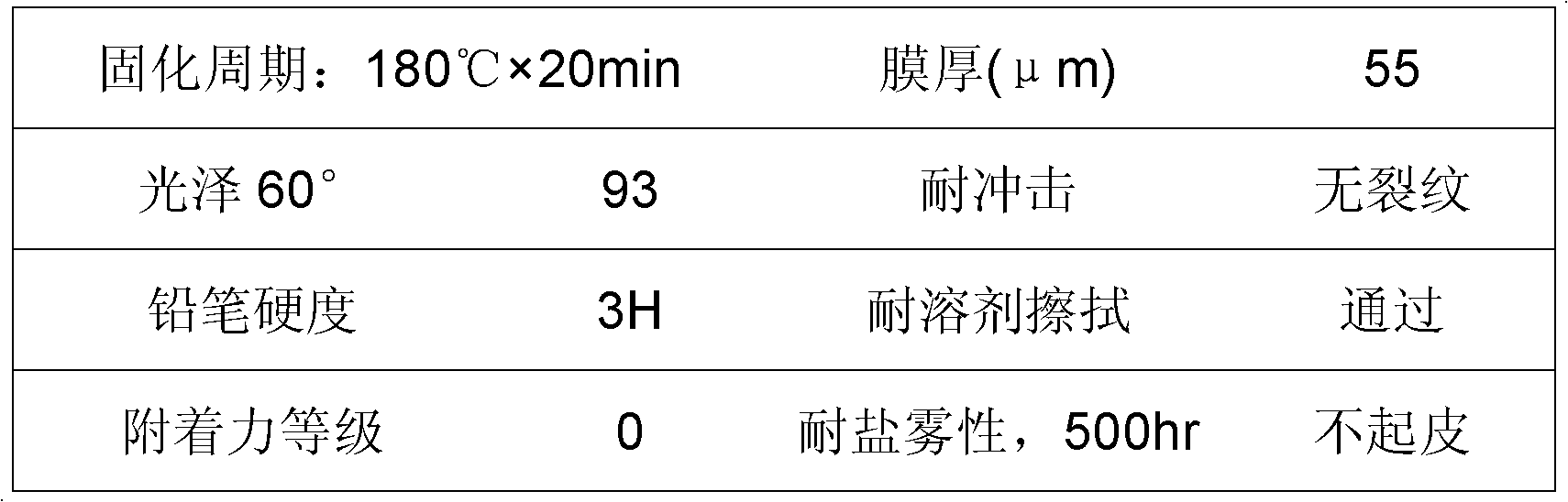

The invention discloses a negative oxygen ion dry powder paint, belonging to the technical field of paints. The paint comprises the following components in percentage by mass: 25-35% of ash calcium powder, 6.2-8.0% of diatomite, 4.5-6.5% of negative ion additive, 1.5-5.0% of antimicrobial agent, 0.15-0.80% of talcum powder, 0.15-0.80% of kaolin, 0.15-0.50% of wollastonite, 0.05-0.15% of surfactant, 0.55-1.5% of redispersible latex powder, 1.2-1.8% of light calcium carbonate powder, 0.15-0.50% of lithopone and the balance of heavy calcium carbonate powder. The paint is capable of efficiently absorbing formaldehyde and other harmful gases and naturally and enduringly releasing negative ions, has the characteristics of high mildew resistance, high bactericidal capacity and favorable air permeability, and can adjust the humidity of indoor air. The coating has the characteristics of favorable strength, favorable toughness, favorable scrubbing resistance and the like.

Owner:深圳锦家安科技有限公司

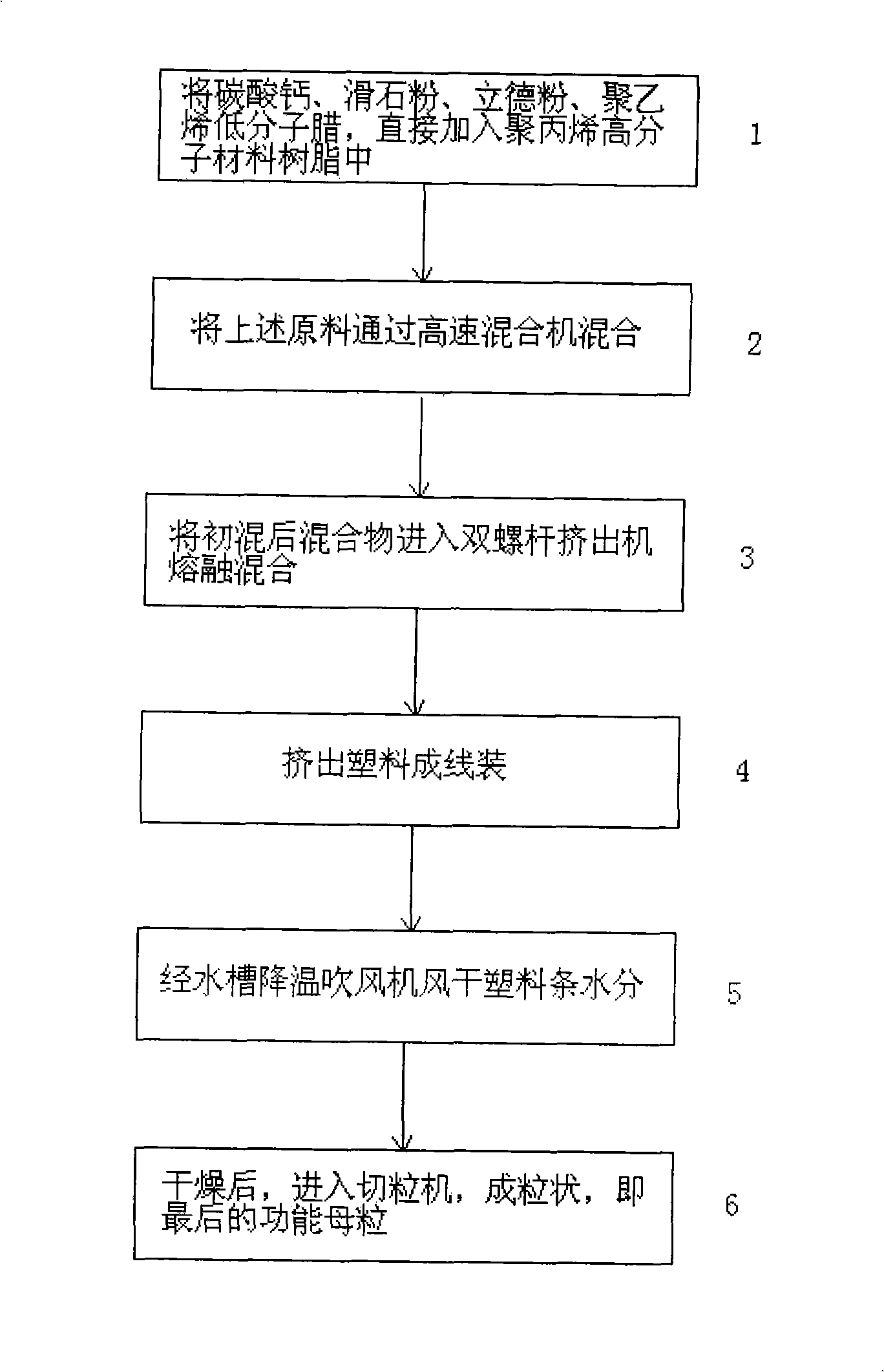

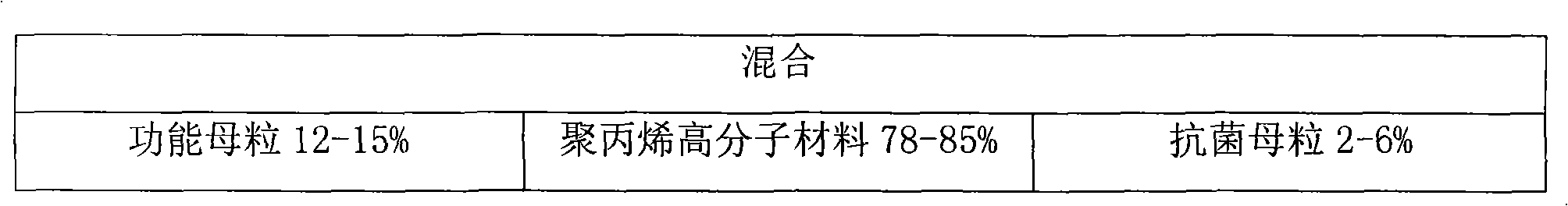

Antibacterial plastic sheet-like chopping board and manufacturing method thereof

The invention discloses an antibacterial plastic sheet cutting board and a preparation method thereof. The cutting board is prepared by functional master batch, polypropylene high molecular material and antibacterial master batch according to a certain proportion. The method comprises the following steps: firstly inorganic filling calcium carbonate, French chalk, lithopone and polyethylene low molecular wax are directly added into polypropylene high molecular material resin, mixed in a mixer and granulated; secondly inorganic silicate antibacterial agent and the polyethylene low molecular wax are added directly in the polypropylene high molecular material resin, mixed and granulated; thirdly the functional master batch, polypropylene high molecular material and inorganic silicate antibacterial master batch containing silver ions are mixed according to proportion; fourthly the mixture is poured into a plastic injection machine provided with the cutting board, heated, stirred, dissolved, molded, formed and cooled; and fifthly the prepared antibacterial master batch and the thermoplastic rubber are stirred, placed in a mold and formed so as to obtain antibacterial and antisliding cutting board. The method is easy to be carried out, has simple operation, strong practicability and good antisliding and antibacterial effect.

Owner:PURE SHANGHAI NEW MATERIAL TECH CO LTD

Inner wall paint

InactiveCN101245207ANo pollution in the processSave resourcesAntifouling/underwater paintsPaints with biocidesGreen environmentCarrageenan

The invention relates to an interior wall coating which takes green renewable substance as a film former and is processed and prepared by the extracting solution of natural interior wall decoration mineral composition and bactericidal and virus-killing Chinese herbal tea, and is characterized by taking konjaku flour as film-forming substance with the matching of the powder material of titanium dioxide, lithopone, heavy calcium carbonate, light calcium carbonate, kaolin powder, talc, and pengrun soil, and with the further matching of gelatin, xanthan gum, carrageenan, DK2 and CA-1, and calculated according to the component weight, konjaku flour takes up 0.10 to 5 percent, the total amount of other substance materials takes up 25 to 45 percent, and water as solution takes up 54 to 70 percent. The interior wall coating has no harm to human health no matter in construction or in using, and is a green environment protective natural interior wall coating.

Owner:朱庆成

Full effect negative ion interior wall paint

InactiveCN101575471AStrong covering powerEasy constructionAntifouling/underwater paintsPaints with biocidesMaterials scienceDefoamer

The invention discloses a full effect negative ion interior wall paint, comprising the following raw materials according to parts by weight: 100 to 500 parts of water, 0.05 to 25 parts of composite nano sterilizing powder, 1 to 2 parts of preservative, 1.5 to 4.5 parts of droxyethylcellulose, 1 to 2 parts of pH modifier, 2 to 5 parts of dispersant A, 1 to 3 parts of dispersant B, 15 to 35 parts of glycol, 1 to 2 parts of wetting dispersant, 1 to 3 parts of antifoaming agent A, 2 to 3 parts of antifoaming agent B, 40 to 70 parts of French chalk, 30 to 150 parts of heavy calcium carbonate, 2 to 7 parts of film forming agent, 4 to 6 parts of thickening agent A, 40 to 240 parts of titanium dioxide; one or more of light calcium carbonate, acetic acid emulsion, styrene-acrylic emulsion, Lithopone, calcined kaolin, elastic emulsion, rheology modifier are added to the mixture to obtain various full effect negative ion interior wall paint which can be widely applied to interior walls in dwelling houses and hospitals; the full effect negative ion interior wall paint in the invention has no toxicity, no smell, and has strong sterilization and antimeldow effects.

Owner:ZHANG ZHOU SAN PAINTS

Leather cup rubber material for brake of automobile and preparation method thereof

Owner:WUHU HENGKUN AUTO PARTS

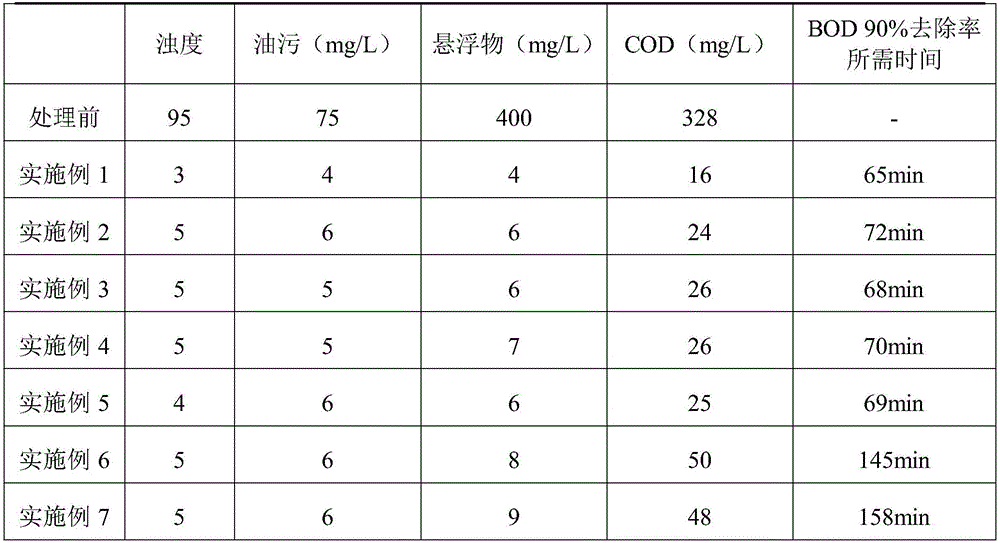

Sewage processing agent and preparation method thereof

InactiveCN105936533AHigh clarityGood flocculation effectWater treatment parameter controlWater/sewage treatment by flocculation/precipitationSodium acetateStain

The invention discloses a sewage processing agent and a preparation method thereof. The sewage processing agent is prepared from the following raw materials in parts by weight: 30 to 40 parts of cationic flocculant, 30 to 40 parts of sodium chloride, 10 to 15 parts of lithopone, 5 to 10 parts of polyethylene imine, 5 to 10 parts of critic acid, 8 to 10 parts of zinc oxide, 4 to 6 parts of active carbon, 5 to 10 parts of polymeric silicate aluminum sulfate, 5 to 10 parts of polyacrylamide, 20 to 30 parts of composite synergist, 8 to 10 parts of corn starch, and 50 to 100 parts of deionized water, wherein the composite synergist is one or more of ferric chloride, sodium lignosulfonate, polymeric aluminum chloride, and sodium acetate. The provided sewage processing agent can effectively remove oil stain, suspensions, COD and BOD of sewage, and prominently improve the clarity of water.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Seam crack-resisting putty

The invention discloses a seam crack-resisting putty and aims at solving the problems that the existing similar seam crack-resisting putties have complex process, high cost, poor surface flatness after filling, repairing or finishing, and difficult polishing and finishing, and can not be applicable to wood or metal wall surfaces, table surfaces, furniture and other objects. The seam crack-resisting putty is characterized by being formed by the uniform mixing of a paste-shaped main agent and an auxiliary agent with the weight ratio of 1:0.5 to 2, wherein the main agent contains 63 to 84 percent of epoxy resin and 16 to 37 percent of plant powder with the particle size of less than 1 mm in percentage by weight. The auxiliary agent contains 63 to 84 percent of epoxy resin curing agent and 16 to 37 percent of plant powder with the particle size less than 1 mm in percentage by weight. 0.8 to 17 percent of toner can also be added to the main agent and the auxiliary agent in percentage by weight; and in percentage by weight the toner can be formed by uniform mixing of 1 to 99 percent of pigment powder and 1 to 99 percent of lithopone, titanium dioxide, talc powder, kaolin or bentonite, and the like.

Owner:张彬菊

Coatings capable of protecting metal and enhancing heat transfer during metallic object heating process

The invention relates to a coating to reinforce the metal heat transfer in the metal heating process, which is characterized in that the weight component of the coating comprises 100 to 400 SiC, 0 to 400 ferrochromium ore, 100 to 200 bentonite, 0 to 100 black carbons, 5 to 20 titanium dioxide, 5 to 20 lithopone, 5 to 20 zinc powder, 30 to 100 Al2O3, and 200 to 600 glue PA80s, which are solid state component grain with below 320 meshes, and the balance is water. When in use, the coating is applied on the surface of the heating workpiece, the coated workpiece is positioned inside the furnace to heat up, that is to dress a piece of clothes for the workpiece, protecting the metal and reinforcing heat transfer. The coating to reinforce the metal heat transfer in the metal heating process has the advantages of being particularly applicable to the heating process in the subsequent machining process for a metal casting blank which is between after casting blank and before heating process, and between after the casting blank segmentation and before positioning inside the furnace, and enabling to be coated on the metal surface by the means of brush coating, immerse coating, roller coating or spray coating.

Owner:BAOSTEEL ENG & TECH GRP

Low-specific-gravity stone paper

ActiveCN102154932AIncrease coverageReduce weightCoatings with pigmentsCoated paper substrateManufacturing cost reductionGlass ball

The invention discloses low-specific-gravity stone paper relating to synthetic paper. The low-specific-gravity stone paper comprises a base paper layer and a coating layer, wherein the coating layer is coated on the base paper layer; the base paper layer comprises 15-30 parts by weight of synthetic resin and 70-85 parts by weight of mixing material, wherein the synthetic resin is polylactic acid, EVA (ethylene vinyl acetate copolymer), PP (polypropylene), PE (poly ehtylene) or a mixture of any two of the polylactic acid, the EVA, the PP and the PE; the mixing material is a hollow glass ball, coal ash or the mixture of the hollow glass ball and the coal ash; and the coating layer comprises 20-40 parts by weight of acrylic resin, 20-40 parts by weight of lithopone and 30-50 parts by weight of deionized water. The low-specific-gravity stone paper has the following benefits: the mixing material is the hollow glass ball or coal ash so that the mixing material has low specific gravity and good dispersity; the lithopone has good covering power, thus the weight of the paper is convenient to reduce, the paper quality is improved, and the manufacturing cost is reduced.

Owner:大正新型材料(肇庆)有限公司

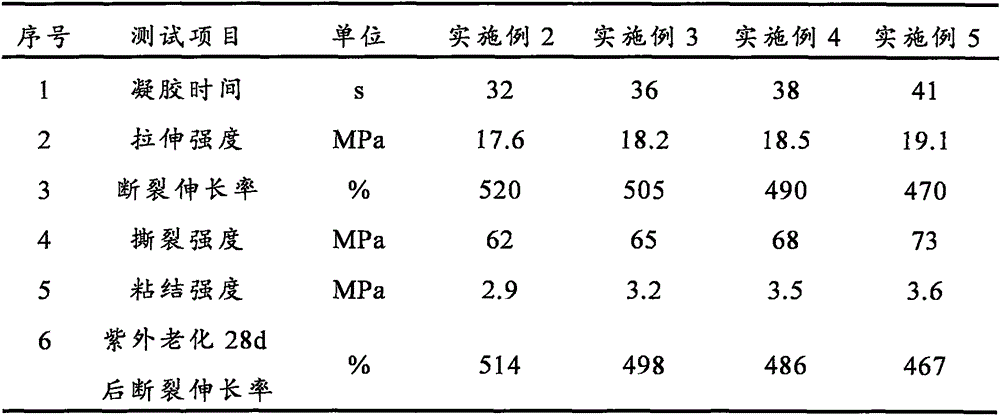

Waterproof polyurea coating and preparation method thereof

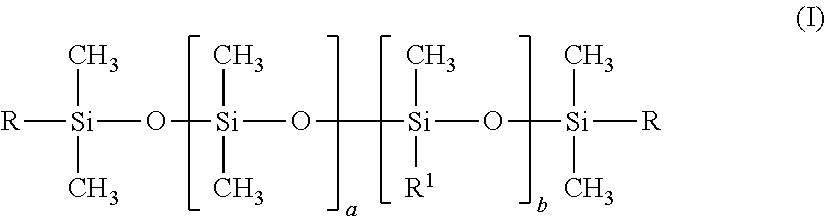

ActiveCN105176343AImprove photostabilityGood weather resistanceAntifouling/underwater paintsPaints with biocidesPhotocatalytic reactionSilanes

The invention provides a waterproof polyurea coating and a preparation method thereof. The waterproof polyurea coating comprises a component A and a component B, wherein the component A comprises 3,3-dimethyl- 4,4-diisocyanatodicyclohexylmethane, polyether glycol and a solvent; and the component B comprises aminopolyether, an amine chain extender, a plasticizer and silane-modified nanometer lithopone. According to the waterproof polyurea coating, 3,3-dimethyl-4,4-diisocyanatodicyclohexylmethane is used as the raw material, so that the light stability and weather resistance of the waterproof polyurea coating are improved, the problem that a coating prepared by taking an aromatic compound as a raw material is easily aged is solved, the coating is kept to have long enough gelling time and curing time, and the coating is relatively good in permeation and combination with a substrate. The silane-modified nanometer lithopone is adopted, so that the corrosion resistance and ageing resistance of the coating are improved; and ultraviolet is effectively absorbed, and a photocatalytic reaction is carried out, so that the coating has antibacterial property, and the pollution resistibility of the coating is improved.

Owner:上海恩缔实业有限公司

Spring grinding abrasive wheel

The invention relates to a spring-grinding grinding wheel. The invention is characterized in that the grinding wheel consists of raw material and fine material; wherein, each group of the raw material comprises ZA16<#>, WA16<#>, WA30<#>, resin liquids, resin powders, lithopone, light calcium carbonates, cryolites and ferric oxides and each group of the fine material comprises A24<#>, A30<#>, A36<#>, resin liquids, resin powders, light calcium carbonates, cryolites and carbon black. Each group of the raw material and fine material are mixed to make finished materials. The finished materials can be divided into two kinds: the raw material is used for grinding with lower hardness and the fine material is a non-grinding part with higher hardness. When in shaping, the raw material is casted first, and the fine material is casted by three times respectively. Two web pieces are arranged in the middle for pressing, mould-disassembling and hardening. After a qualified inspection the product is the eligible product. The invention integrates two specifications and materials into a whole, with both high strength and low hardness. The invention is characterized in that the strength is high; crash can be avoided; burn to work pieces can be avoided and grinding accuracy is high.

Owner:沈阳市盛世磨料磨具有限公司

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

Water polyurethane latex composite compounding color coat art canvas and producing technique thereof

InactiveCN101215787AOvercoming sticky flawsImprove performancePretreated surfacesPolyurea/polyurethane coatingsWater basedSlurry

The invention relates to a water-based polyurethane emulsion compounded colored coating art canvas and a manufacturing technique, in particular to a canvas for painting artist and hobbies to paint, which belongs to the technical field of painting articles. And the process for manufacturing comprises getting hydroxypropyl cellulose to swell, heat up, stir and dissolve with half purified water of the total amount, and mixing and evenly stirring water-based polyurethane emulsion, styrene monomer- acrylate copolymer emulsion, graining paste, glycerin, alcohol and sodium benzoate, getting lithopone powder and calcium carbonate to mix with the upper glue solution after wetting with the residual water of the total purified water, evenly stirring to be coating slurry in normal temperature, and then applying coating slurry on primary backing, drying and baking to be end products. The service performance of the art canvas of the invention is greatly improved, since aqueous polyurethane emulsion (APU) is utilized in the formula, therefore the thermoplasticity polyurethane emulsion has the advantages of easy filming, low temperature resistance, excellent elasticity, flexibility and the like.

Owner:宋健

Antiskid paint for bicycle court tracks and preparation method thereof

InactiveCN104194601AImprove skid resistanceImprove water resistancePolyurea/polyurethane coatingsEmulsionTitanium

The invention discloses an antiskid paint for bicycle court tracks, which comprises the following components in parts by weight: 25-40 parts of emulsion, 5-8 parts of light calcium carbonate, 3-8 parts of titanium white, 2-5 parts of film formation assistant, 5-8 parts of talcum powder, 10-25 parts of antiskid agent, 0.5-1 part of anti-aging agent, 8-12 parts of lithopone, 0.2-0.3 part of defoaming agent and 35-45 parts of water. The invention also discloses a preparation method of the antiskid paint. By selecting the emulsion, film formation assistant, antiskid agent and the like according to the proper formula and proportion and combining the film formation assistant, talcum powder, lithopone and defoaming agent, all the components interact and are coordinated, so that the prepared antiskid paint has the characteristics of favorable antiskid effect, excellent water resistance and favorable wear resistance, and is especially suitable for bicycle court tracks.

Owner:句容市石狮冲压件厂

Assembling modification and integration process for preparing functional white dye

InactiveCN1887973ASimple processReduce manufacturing costChemical industryPigment treatment with macromolecular organic compoundsWhite powderPapermaking

The assembling modification and integration process for preparing functional white pigment belongs to the field of inorganic material technology. The functional white pigment is prepared through mixing white lithopone in 15-25 wt% with heavy calcium carbonate, wollastonite, kaolin or barium sulfate in 75-85 wt%; adding dispersant and deionized water in 0.2-0.8 wt% through stirring to form the core material; adding titanium white powder as filming material and assembling modification in an improved peeling machine to obtain slurry; and direct drying to obtain the white pigment. The present invention has simple preparation process, low cost and use performance similar to that of titanium white powder, and may be used to replace titanium white powder in plastic, papermaking, paint and other field to improve product performance and lower product cost.

Owner:UNIV OF SCI & TECH BEIJING +1

Stone paper and processing method thereof

ActiveCN102154931ANo smellNo risk of releaseNon-fibrous pulp additionCoatings with pigmentsManufacturing technologyInorganic compound

The invention provides a stone paper and a processing method thereof, and relates to synthetic papers and a manufacture technology thereof. The stone paper consists of a base paper layer and a coating layer, wherein the coating layer is coated on the base paper layer; the base paper layer consists of 15-30 parts by weight of organic component and 70-85 parts by weight of inorganic component, the organic component is polylactic acid; and the inorganic component comprises light calcium carbonate and lithopone. The processing method of the stone paper comprises the steps of: thermally drying the light calcium carbonate and the lithopone and evenly stirring, mixing with the organic component and evenly stirring, treating by means of banburying and kneading, and pelleting in pelleting equipment; extruding by a calendar to obtain a base paper layer, and treating by corona; and coating a coating material on the surface of the base paper layer. The stone paper is environment-friendly, good in flexibility, good in folding resistance and tearing resistance, and suitable for the common ink, thereby being capable of being used as the paper for the culture, the food, the sanitation, the notebook, the textbook and the printing.

Owner:大正新型材料(肇庆)有限公司

Sewage treating agent

InactiveCN1344688AImprove precipitation effectImprove water qualitySedimentation separationWater/sewage treatment by flocculation/precipitationWater qualityTreated water

The present invention relates to environment protection technology. The sewage treating agent contains Al iron, Fe ion, Mg iron, Mn ion and lithopone, and is compounded by mixing water, aluminium sulfate, ferric sulfate, magnesium sulfate, manganese sulfate and lithopone through stirring for complete dissolving. It has the advantages of wide use range, high deposit rate, good quality of treated water, low cost, no corrosion to steel structure, no toxicity, no pollution and relatively high safety, and it may be widely used for effluent treatment in oil field, coal mine, textile mill, printing and dyeing mill, etc. and city sewage treatment.

Owner:SHENYANG ZHONGLU WATER BUSINESS

Surface treatment of particles and their use

ActiveUS20170002181A1Reduced susceptibility to dustingReduce dust emissionsOther chemical processesPigment treatment with organosilicon compoundsZinc sulfideBarium sulfate

Owner:HUNTSMAN P&A GERMANY GMBH +1

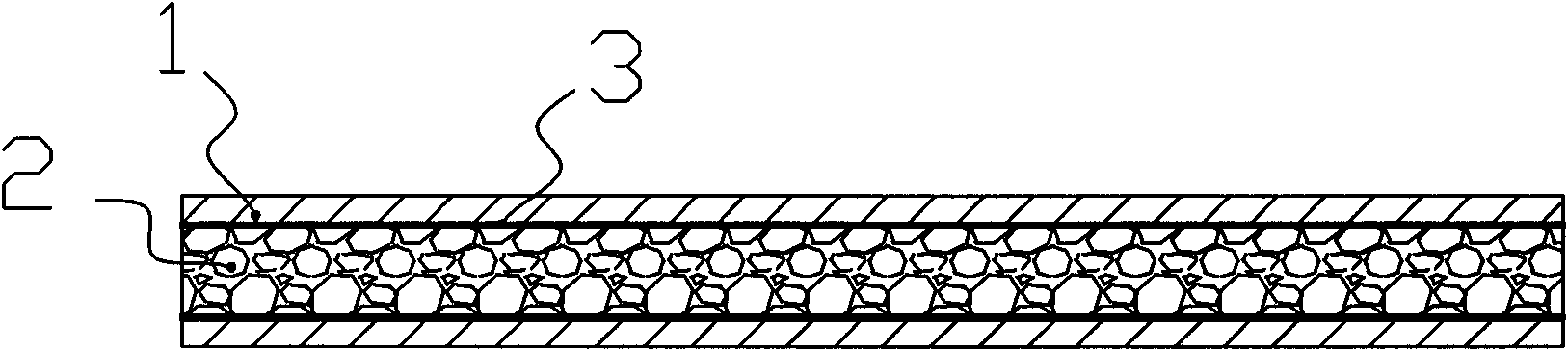

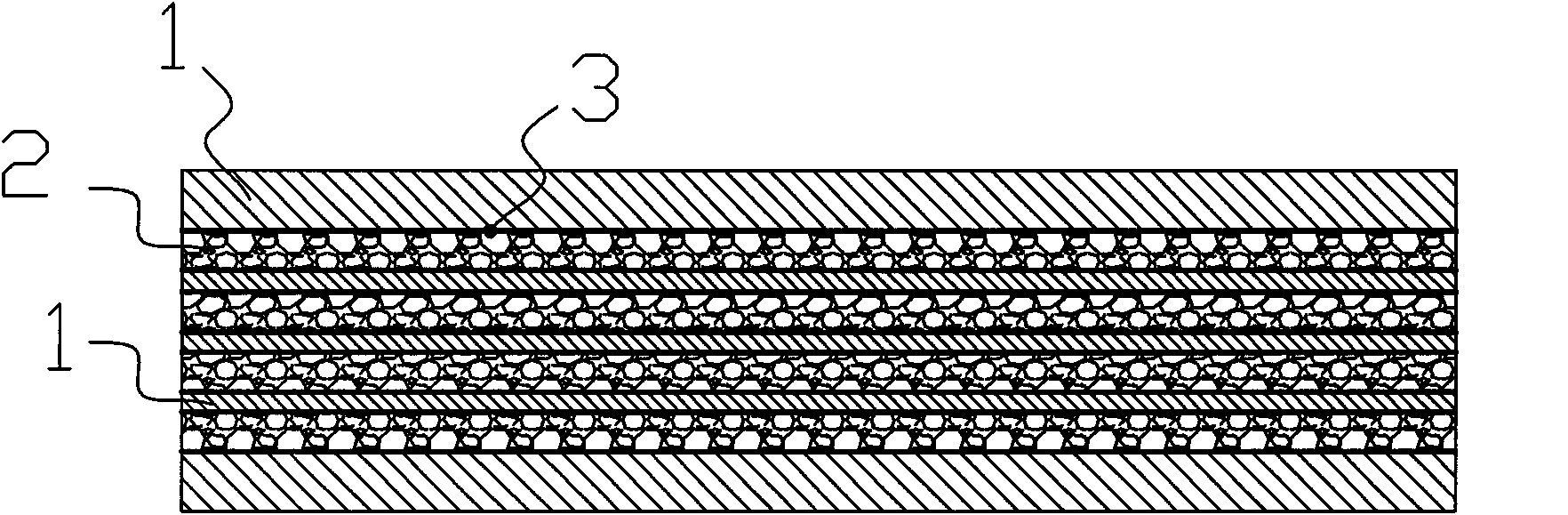

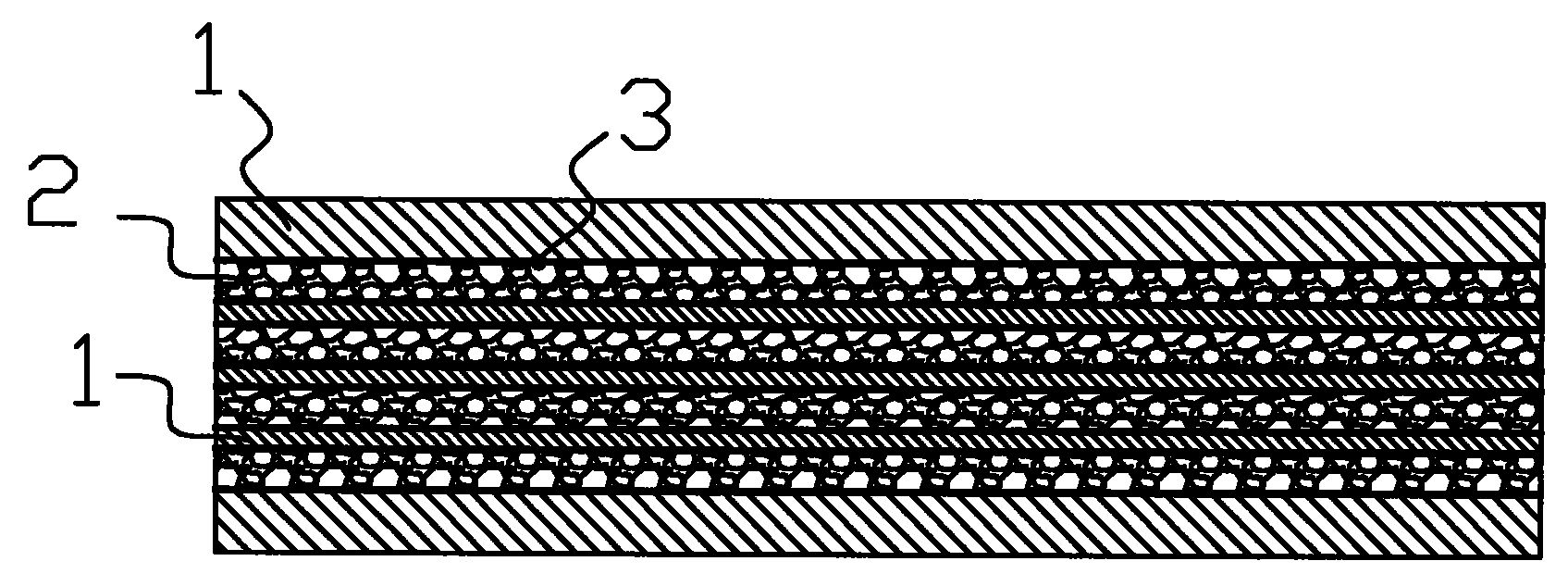

Multilayer perlite composite flame-retardant sheet and preparation method thereof

InactiveCN101793063ASave woodSave moistureWater-setting substance layered productFire proofingFiberSodium phosphates

The invention relates to a multilayer perlite composite flame-retardant sheet. The flame-retardant sheet has a laminated structure containing at least three layers, wherein the surface layer is a wooden layer, a middle wooden layer is separated from a flame-retardant layer, adhesive is used between the layers; the wooden layers are processed through conventional flame-retardant treatment, the thickness is 1-5mm; the thickness of the flame-retardant layer is 1-120cm and comprises the following components by weight: 10-25kg of expanded perlite with 1.5-3mm of particle diameter, 25-40kg of magnesium chloride, 10-25kg of magnesium oxide, 100-300kg of sodium phosphate, 150-350kg of lithopone, 0.1-2.0kg of emulsifier and 50-200kg of adhesive, wherein magnesium chloride, magnesium oxide, sodium phosphate, lithopone, emulsifier and adhesive are used as auxiliary material and filler. As flame-retardant treatment is preformed to the wooden layers and the flame-retardant layer is prepared by mixing expanded perlite and adhesive, the flame-retardant sheet is fire-retardant, wood is saved, no pollution is caused, and the flame-retardant sheet is free from any insect and is the best replacement of the existing shaving board, fiber-board, core-board, solid wood board and other materials.

Owner:杨光伟

Butyl acetate-polyvinyl alcohol copolymer emulsion color coating canvas and its producing process

InactiveCN1858337ANo crackingNo peelingSpecial artistic techniquesTextiles and paperPolymer scienceSlurry

The present invention belongs to the field of drawing article technology, and is especially one kind of artists' canvas with color coating of butyl acetate-vinyl alcohol copolymer and its production process. The artists' canvas producing process includes compounding the coating materials with butyl acetate-vinyl alcohol copolymer as main material, styrene-ethylene copolymer emulsion, pigment slurry, titanium white powder, etc. for the bottom layer, the middle layer and facing layer; painting the bottom coating and stoving; painting 1-3 middle coating and stoving; and painting 1 or 2 facing coating and stoving to obtain the product. The artists' canvas has stable and high strength coating, improved use performance, no oil permeation, and other advantages.

Owner:无锡龙腾画材有限公司

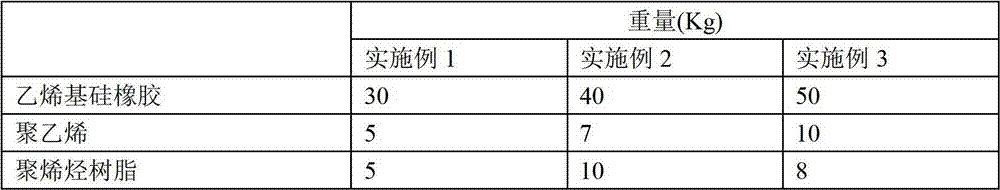

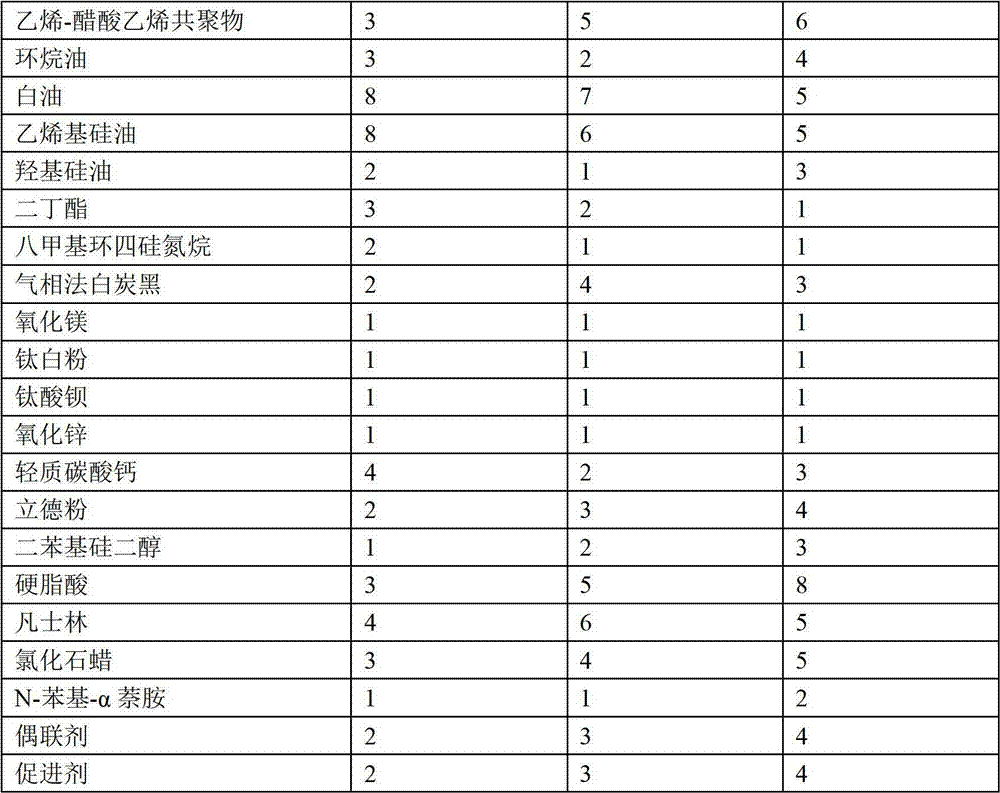

Tearing-resistant silicone rubber composition

The invention discloses a tearing-resistant silicone rubber composition, falling into the technical field of polymer material. The composition comprises the following materials by weight: 30-50 parts of vinyl silicone rubber, 5-10 parts of polyethylene, 5-10 parts of polyolefin resin, 3-6 parts of ethylene-vinyl acetate (EVA) copolymer, 2-4 parts of naphthene oil, 5-8 parts of white oil, 5-8 parts of vinyl silicone oil, 1-3 parts of hydroxyl silicone oil, 1-3 parts of dibutyl ester, 1-2 parts of octamethylcyclotetrasilazane, 2-4 parts of fumed silica, 1 part of magnesia, 1 part of titanium dioxide, 1 part of barium titanate, 1 part of zinc oxide, 2-4 parts of light calcium carbonate, 2-4 parts of lithopone powder, 1-3 parts of diphenylsilanediol, 3-8 parts of stearic acid, 4-6 parts of vaseline, 3-5 parts of chlorinated paraffin, 1-2 parts of N-phenyl-alpha-naphthylamine, 2-4 parts of a coupling agent, and 2-4 parts of accelerator. The silicone rubber composition has excellent mechanical properties, especially tearing-resistant property.

Owner:汕头市科源有机硅材料有限公司

Modified ABS high temperature resistant high polymer material

The invention discloses a modified ABS (acrylonitrile butadiene styrene) high temperature resistant high polymer material, which comprises the following substances by weight: 30-80 parts of ABS resin, 20-25 parts of a glass fiber, 2-9 parts of a compatilizer, 10-20 parts of an organic solvent, 10-30 parts of concentrated hydrochloric acid, 20-23 parts of a curing agent, 10-20 parts of methylphenyl siloxane branched chain prepolymer, 10-15 parts of a modifier, 10-19 parts of a pigment, 10-25 parts of a diluent, 10-25 parts of a toughening agent, 10-35 parts of active calcium, 20-35 parts of stearic acid, 21-23 parts of lithopone, 1-3 parts of carbon black, 1-9 parts of nano-calcium carbonate, 1-9 parts of stearic acid, 1-8 parts of talcum powder, 2-9 parts of ethylene-propylene-diene monomer rubber, and 3-6 parts of an anti-impact agent. The modified ABS high temperature resistant high polymer material disclosed in the invention has superior comprehensive performance and a wide application range, thus having very good economic benefits.

Owner:青岛永卓真塑料制品有限公司

Sewage processing agent

InactiveCN105439217AImprove processing efficiencyLow running costSpecific water treatment objectivesRadioactive contaminantsSodium BentoniteOrganic polymer

The invention relates to a sewage processing agent, which comprises the following raw materials in parts by weight: 4 to 7 parts of bentonite, 2 to 4 parts of alum, 1 to 2 parts of aluminum sulfate, 5 to 10 parts of lithopone, 10 to 15 parts of sodium chloride, 0.3 to 1 part of lime, 10 to 20 parts of adsorbate, 0.5 to 1 part of sodium carbonate, 6 to 10 parts of iron chloride, and 40 to 50 parts of water. By controlling and changing the addition sequence of inorganic polymer and organic polymer with different functional groups and the conditions, under which reactions will or will not happen during the compounding process, the components can maintain good morphology distribution and stability before addition; after addition, the morphology of the components quickly changes, and the components carry out flocculation efficiently.

Owner:WUXI JIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com