Antibacterial plastic sheet-like chopping board and manufacturing method thereof

An antibacterial plastic and sheet technology, applied in the field of kitchen supplies, can solve the problems of high processing cost, affecting the appearance of plastic products, reducing antibacterial efficiency, etc., achieving the effects of easy processing and manufacturing, reducing cross infection and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

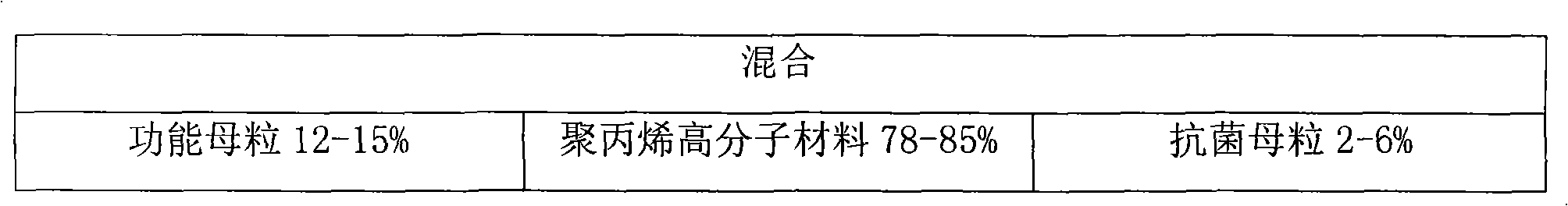

[0078] An antibacterial plastic sheet-like cutting board is made of the following raw materials in percentage by weight:

[0079] The composition ratio of the present invention is:

[0080] Example

Functional masterbatch%

Antibacterial Masterbatch%

Polypropylene polymer material%

1

13

2

85

2

14

3

83

3

15

4

81

4

16

5

79

5

17

6

77

6

18

3

79

[0081] The proportion of intermediate product functional masterbatch is as follows

[0082] Example

CaCO3%

Talc%

Polyethylene low molecular weight wax%

Polypropylene polymer material resin%

1

38

7

12

3

40

2

39

6

11

6

38

3

40

5

10

5

40

4

38

4

9

7

42

5 ...

specific Embodiment approach

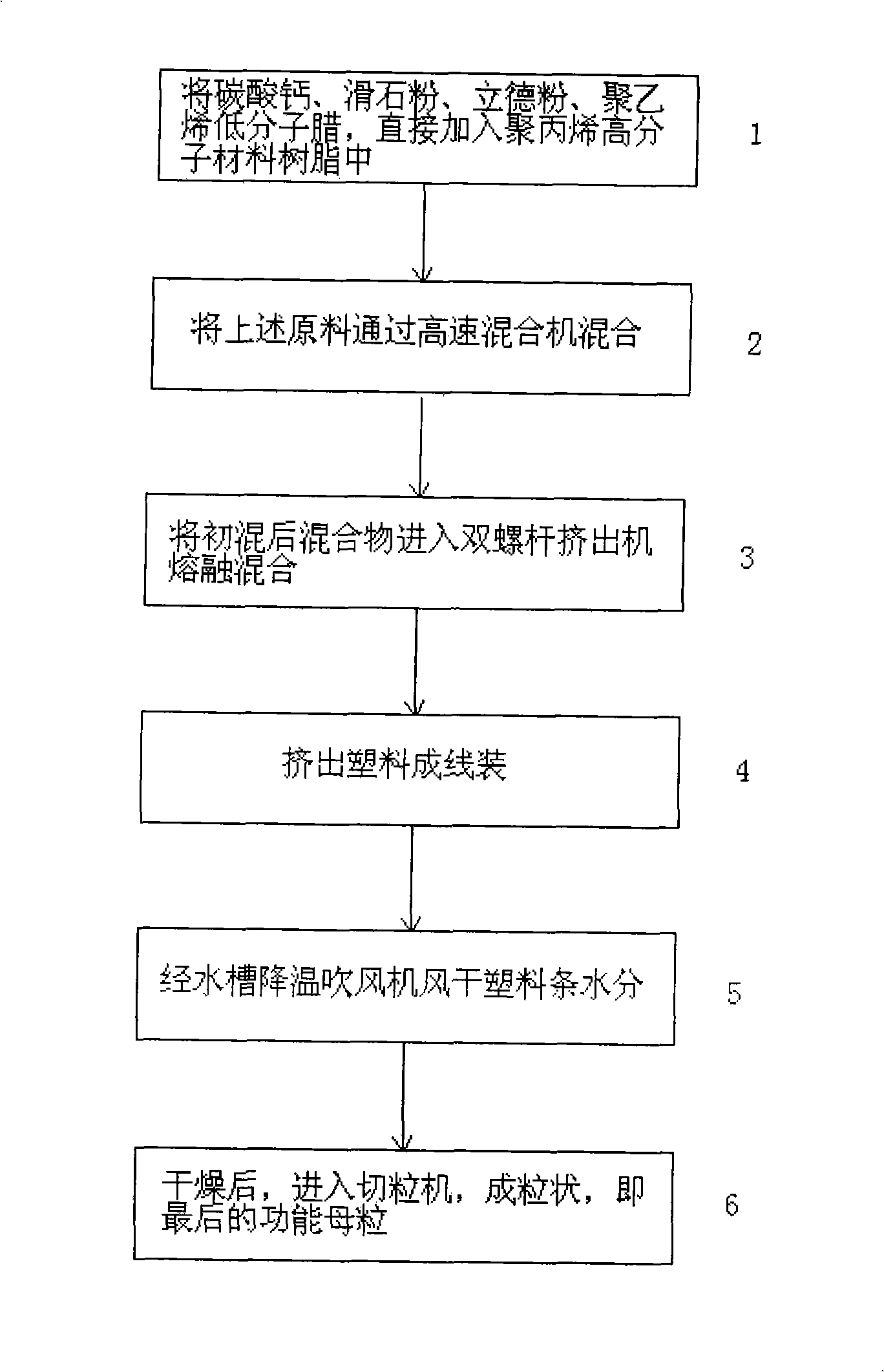

[0086] A kind of preparation method steps of antibacterial non-slip plastic sheet cutting board is as follows:

[0087] A. Add inorganic fillers such as calcium carbonate, talcum powder, lithopone, and polyethylene low-molecular wax directly into the polypropylene polymer material resin 1, mix through a high-speed mixer 2, and put the mixture into the twin-screw extrusion after initial mixing Machine melt mixing 3;

[0088] The process is as follows: first pour the above-mentioned raw materials mixed in proportion into the mixing chamber of the high-speed mixer, first run at low speed for 30 seconds and then switch to high-speed rotation, when the temperature of the material rises to 70 degrees, the mixing is completed, and after the material is slightly cooled, it will be rotated under the action of the impeller Discharged from the discharge port;

[0089] After the temperature reaches the requirement, pour the mixture into the hopper of the twin-screw extruder, turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com