Patents

Literature

179results about How to "Antibacterial has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

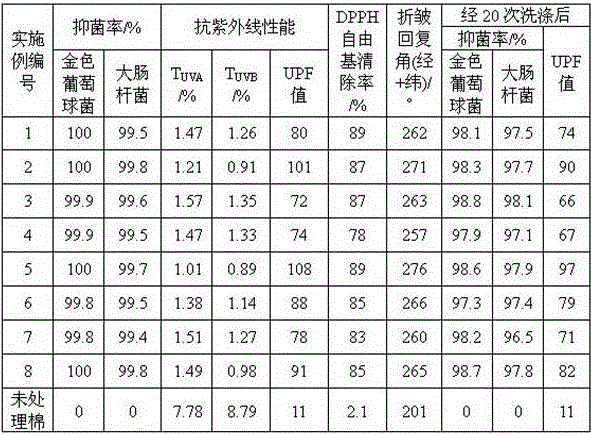

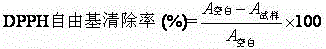

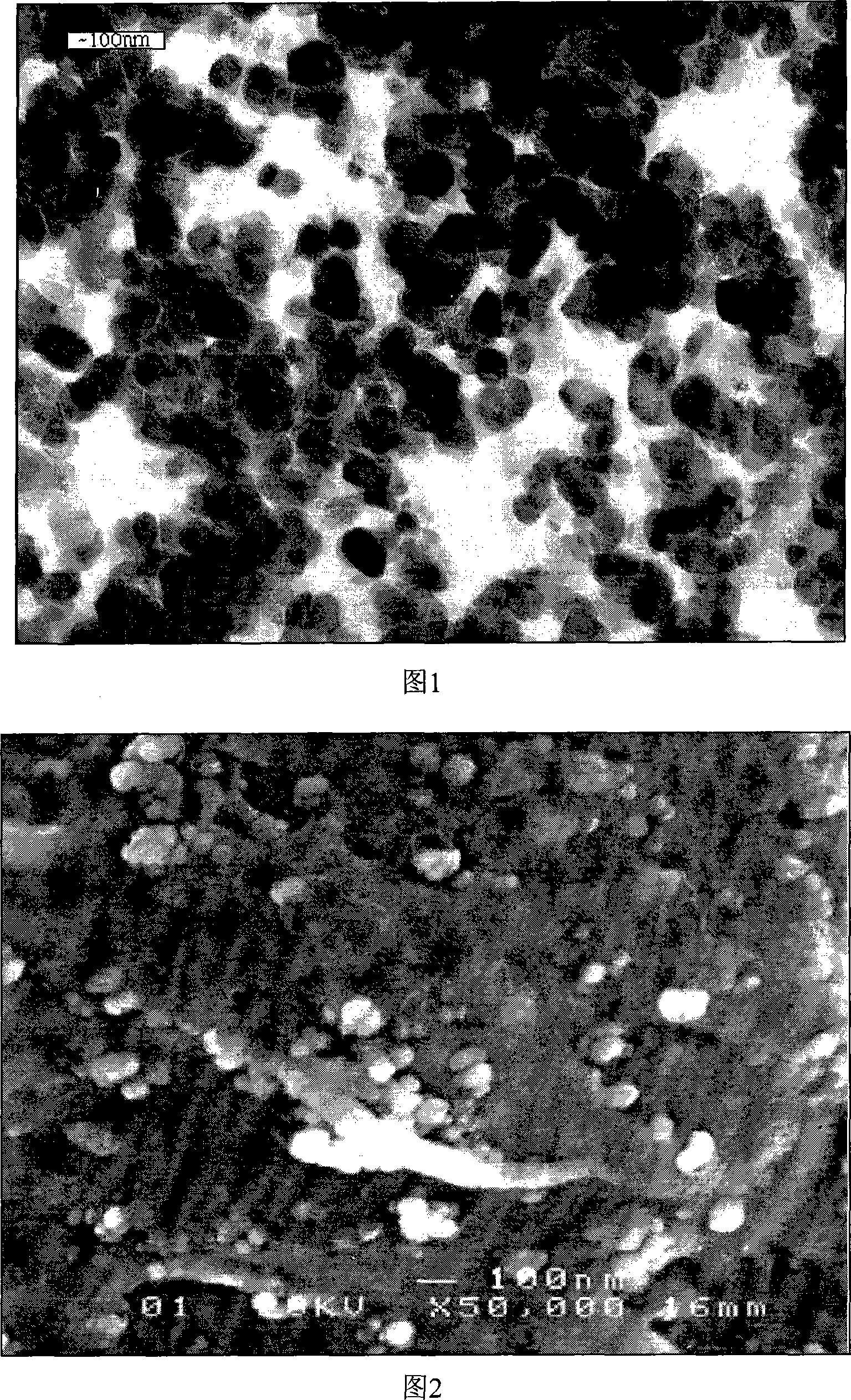

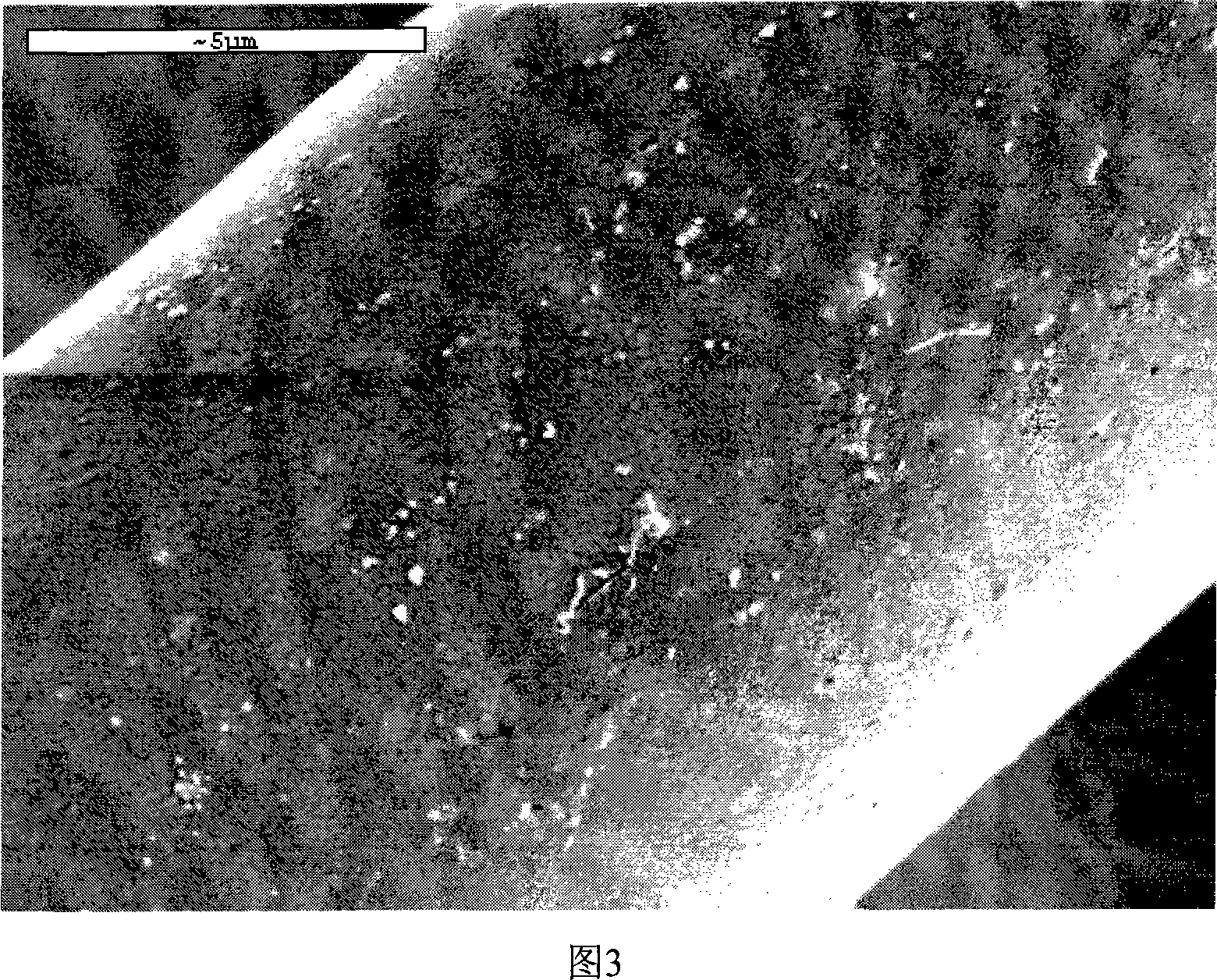

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

Nano ceramic composite thin polypropylene multifunction fiber and preparing method

ActiveCN101070635AFunctionalImprove economyMonocomponent polyolefin artificial filamentProtective garmentCeramic compositeThermal insulation

The invention discloses nano-ceramic composite fine polypropylene fiber and the processing method. The fiber contains nano-ceramic powder with 12-45 of 300, polypropylene with 250-270 of 300, polyethylene wax with 2-18 of 300 by weight. The denier of the fiber monofilament is 0.5-1.5D, the breaking strength is more than 2.5cN / dtex. We can get the fiber by the step of nano-ceramic powder aqueous dispersion, pre-dispersed precursor, composite masterbatch, composite sections, and high-speed spinning. The nano-ceramic powder is made up of ZrO2, or ZrO2 and ZrC, or TiO2 and Ag+. This type of fiber can be made of various type of textiles, such as sports apparel, underwear, bedding, shirt, socks and so on. The textiles with the function of launch biological waves of energy, anti-UV, anti-bacterial, absorption and barrier the near-infrared. So that to make the textiles have the function of anti-bacterial, energy health, insulation sunscreen, regenerative thermal insulation, dry and comfortable and so on.

Owner:吴进前

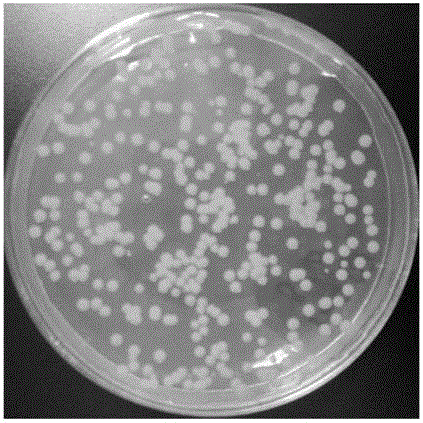

Preparation method of tea polyphenols/chitosan nanofiber membrane

InactiveCN101665985APromote healingAntibacterial hasFilament/thread formingNon-woven fabricsEscherichia coliFiber

The invention relates to a preparation method of tea polyphenols / chitosan nanofiber membrane, wherein, a tea polyphenols / chitosan nanofiber membrane is made from tea polyphenols / chitosan nanofibers with the diameter of 300 to 500 nm, and the preparation process of the tea polyphenols / chitosan nanofibers comprises the following processing steps: preparing a chitosan acid solution with the mass concentration of 40 g / L to 70 g / L; preparing a tea polyphenols solution; preparing a solution for spinning; filling the solution for spinning into a syringe of an electrostatic spinning device for carrying out electrostatic spinning, and obtaining the tea polyphenols / chitosan nanofibers. The invention has the advantages that the preparation process is simple, and the prepared membrane has broad-spectrum sterilization and higher bacteriostasis effect on escherichia coli and staphylococcus aureus within 24 hours. The invention can be used in the filed of medical treatment and health, food packagingand the like.

Owner:JIANGNAN UNIV +1

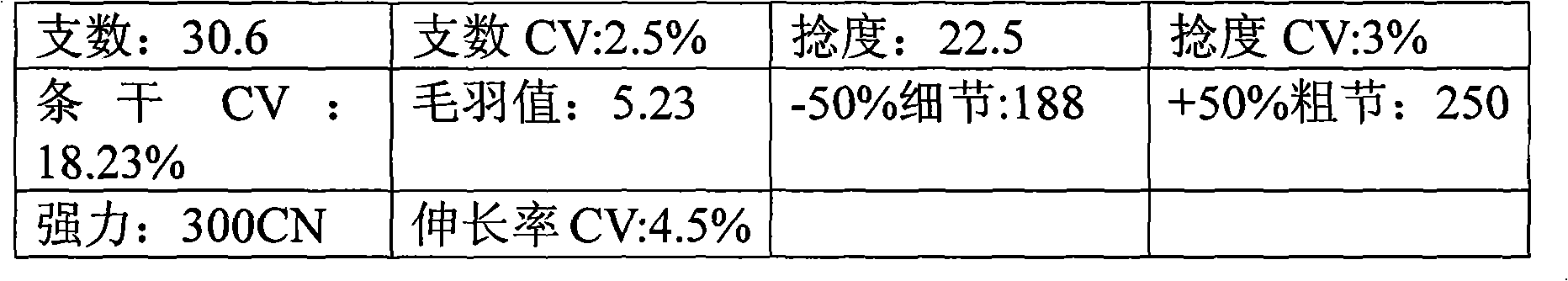

Semi-worsted emerald pearl fiber blended healthcare yarn and production method and application thereof

InactiveCN103603109ASuitable for processingGood moisture absorption and heat dissipationMonocomponent cellulose artificial filamentYarnYarnMedicine

The invention discloses semi-worsted emerald pearl fiber blended health care yarn and a production method and application thereof. The weight percent of an emerald pearl fiber in the blended yarn is 20-40%, the weight percent of a flax fiber in the blended yarn is 15-30%, the weight percent of a wool fiber in the blended yarn is 30-50%, and the weight percent of a cashmere fiber in the blended yarn is 10-35%. According to performance indexes of the blended yarn, the single yarn breaking strength is 11.4-20.3cN / tex, the single yarn breaking strength variation coefficient Cv value is 10.3-17.9%, and the yarn evenness variation coefficient Cv value is 13.6-20.8%. Not only do the semi-worsted blended health care yarn made of the emerald pearl fiber, the flax fiber, the wool fiber and the cashmere fiber and a manufactured fabric have healthcare functions of antibacterium, deodorization, inflammation diminishing, odor removal, skin care, fitness, beauty and skin moistening and the like, but also the fabric is good in skin friendliness, comfort, moisture absorption, air permeability and dyeing property, soft in touch, attractive and elegant in product appearance, bright in color, full of gloss, good in ultraviolet resistance, unique in appearance and wide in product purpose, and high-quality healthcare fabrics can be produced in the fields of knitting or weaving.

Owner:ZHONGYUAN ENGINEERING COLLEGE

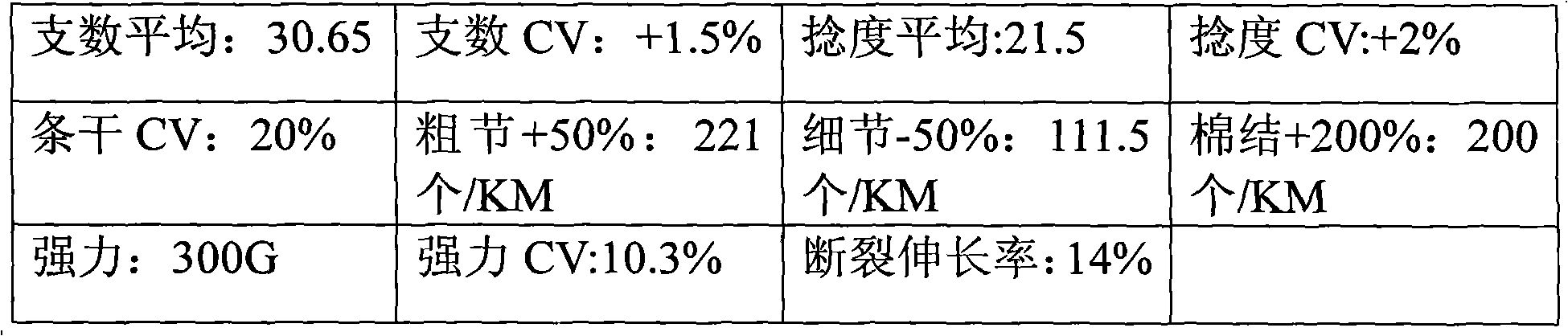

Jade fiber and flax fiber blended yarn and preparation method thereof

The invention provides a jade fiber and flax fiber blended yarn and a preparation method thereof. The blended yarn comprises the components in percentage by weight: 20%-22% of jade fiber and 78%-80% of flax fiber, the twist degree of the blended yarn is 22.5-23T / inch, the strength is 280-300CN, and the elongation is 4.5%-6%. The jade fiber and flax fiber blended yarn has the advantages of strong moisture absorption, softness and elegance, strong comfortableness and bacterium resistance and odor elimination, and can be applied to cotton, fur and hemp products and be used for producing high-grade and good-quality products in knitting and weaving fields.

Owner:SHANGHAI FEILONG TEXTILE

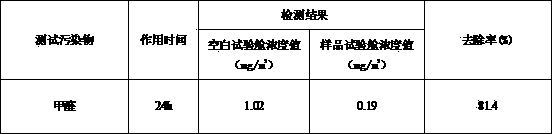

Antibacterial formaldehyde scavenger used in automobile

InactiveCN103463952APrevent degradationStop agingBiocideDispersed particle separationBiotechnologyOrganic acid

The invention relates to an antibacterial formaldehyde scavenger used in an automobile. The scavenger is prepared from the following components in parts by weight: 10-50 parts of hawthorn seed extracting solution, 10-20 parts of radix angelicae extracting solution, 5-15 parts of pomegranate peel extracting solution, 1-5 parts of cananga odorata essential oil, 1-5 parts of lavender essential oil, 1-5 parts of clove essential oil, 10-20 parts of absolute ethyl alcohol, and 30-50 parts of water. The antibacterial formaldehyde scavenger has no chemical substances harmful to human bodies such as chlorine, but has multiple components beneficial to human bodies such as plant flavones, organic acid, amino acid, bio-enzyme and the like, thus being capable of well eliminating the formaldehyde in the automobile; the scavenger is used through spraying and is simple to use; the scavenger is not harmful to human health but is beneficial to human bodies after being inhaled; the cananga odorata essential oil and the absolute ethyl alcohol have good sterilizing and antibacterial effects, can improve the quality of the air in the automobile, and can purify the air, so that the scavenger has the advantages of having no toxicity and pollution, having good effect in eliminating the formaldehyde, having no stimulation to human bodies, being suitable for long-term use, having no secondary pollution, and being capable of resisting bacterium and eliminating peculiar smell.

Owner:杨振生

Flax fiber and tencel fiber blended yarn and preparation method thereof

The invention provides a flax fiber and tencel fiber blended yarn and a preparation method thereof. The flax fiber and tencel fiber blended yarn comprises 35 to 40 weight percent of flax fiber and 60 to 65 weight percent of tencel fiber, wherein the twist degree of the blended yarn is 21.32 to 23 T / inch; the average strength of the blended yarn is 300 g; and the elongation percentage of the blended yarn is 14.1 percent. The flax fiber and tencel fiber blended yarn combines moisture absorption, perspiration, antibacterial effect and the like of the flax fiber and the healthy environmentally-friendly characteristic of the tencel fiber, has the advantages of natural environmental friendliness, cooling performance and antibacterium, and can be applied to clothing fabrics and other industries.

Owner:SHANGHAI FEILONG TEXTILE

Anti-haze green mouth mask based on oxidized graphene and manufacturing method

ActiveCN105266238AEasy to prepareSimple preparation processProtective garmentSpecial outerwear garmentsMarket potentialWoven fabric

The invention discloses an antibiotic anti-haze green mouth mask based on oxidized graphene and a manufacturing method and belongs to the medical health and medical protection field. The antibiotic anti-haze green mouth mask comprises multiple layers of non-woven fabrics, one layer of the non-woven fabrics contains a compound antibiotic green material of oxidized graphene-tannic acid-nanometer silver, and the antibiotic green compound material has filtering and anti-microbic effects and has great inhibition and killing effects on bacteria and fungi microbes. The mouth mask has antibiotic and peculiar smell removing functions, the compound antibiotic material layer is nontoxic and has no pollution, the manufacturing technology is simple, and excellent ventilation performance is further realized. The manufacturing method is simple, breathing resistance of a high-efficiency anti-influenza face mask is not only reduced, but also cross infection caused the mouth mask itself can be avoided, relatively good market potential is realized.

Owner:CHANGZHOU NANOMEDIA INC LTD

Chitosan derivative based clean makeup-removing wet tissue with effects of bacterial inhibition and moisture preservation and preparation method of chitosan derivative based clean makeup-removing wet tissue

InactiveCN106309200AWide range of raw materialsLow costCosmetic preparationsMake-upFacial skinGlyceryl Caprate

The invention discloses chitosan derivative based clean makeup-removing wet tissue with effects of bacterial inhibition and moisture preservation. The chitosan derivative based clean makeup-removing wet tissue with the effects of bacterial inhibition and moisture preservation is prepared from raw materials in percentage by weight as follows: 2%-5% of chitosan derivatives, 5%-10% of PEG-8 caprylic / capric glycerides, 3%-8% of butanediol, 2%-5% of glycerin, 1%-3% of trehalose, 1%-5% of olive oil PEG-6 esters, 0.5%-3% of a skin conditioner, 0.15%-0.3% of phenoxyethanol, 0.15%-0.3% of ethylhexylglycerin, 0.1%-0.2% of methylparaben, 0.05%-0.2% of sodium hyaluronate, 0.01%-0.05% of essence and the balance of deionized water. According to the chitosan derivative based clean makeup-removing wet tissue with the effects of bacterial inhibition and moisture preservation and a preparation method, the makeup-removing wet tissue prepared with the preparation method is low in production cost, high in stability and good in cleansing power and realizes deep cleaning, besides, the makeup-removing wet tissue further has the effects of bacterial inhibition and moisture preservation, the facial skin after application of the makeup-removing wet tissue is smooth and tender, and makeup residues on the facial skin are removed.

Owner:湖北立天生物工程有限公司

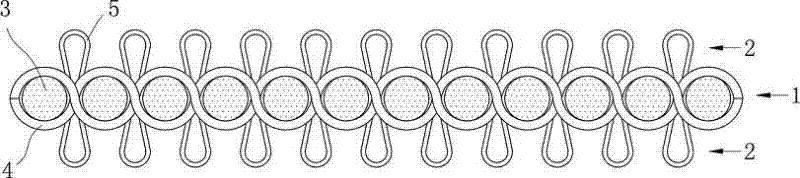

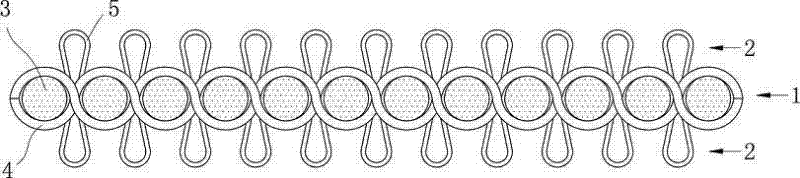

Bamboo fiber and mulberry silk blended yarn towel and production process thereof

InactiveCN102493100AHigh strengthImprove breathabilityFibre treatmentBleaching apparatusFiberPolymer science

Provided are a bamboo fiber and mulberry silk blended yarn towel and a production process thereof. The bamboo fiber and mulberry silk blended yarn towel comprises a base cloth layer and wool warps, wherein the base cloth layer is formed by body warps and weft yarns, and the wool warps penetrate through interweaving holes formed by the body warps and the weft yarns to form terry layers on one surface or two surfaces of the base cloth layer. The wool warps are blended yarns formed by bamboo fibers and the mulberry silk, and the body warps and the weft yarns of the base cloth layer are pure cotton yarns or pure mulberry silk yarns or blended yarns formed by cotton and the mulberry silk. The production process comprises the steps of yarn warping, warp sizing, machine weaving, dyeing treatment, cutting, sewing and finishing and the like. The towel not only integrates soft and smooth features, good air permeability, moisture absorption and moisture releasability of the bamboo fibers and the mulberry silk and outstanding antibacterial and health-care effects, but also has the advantages of being high in abrasion resistance and strength, long in service life, low in price and the like. The novel product with high quality and price benefits and the appropriate production process of the novel product are provided for towel textile fabrics.

Owner:HUZHOU SICHOUFU TEXTILE

Wear-resisting anti-microbial sweat-absorbing fabric and preparation method thereof

ActiveCN109501400AHigh strengthIncrease elasticityLamination ancillary operationsWeft knittingPolyesterUltimate tensile strength

The invention discloses a wear-resisting anti-microbial sweat-absorbing fabric and a preparation method thereof. The wear-resisting anti-microbial sweat-absorbing fabric comprises a wearing layer andan anti-microbial layer; the wearing layer is weaved by blending the following fibers in parts by weight: 30-60 parts of nylon fiber, 20-40 parts of polyester fiber and 5-15 parts of bamboo fiber; theanti-microbial layer is weaved by blending the following fibers in parts by weight: 40-60 parts of cotton fiber and 15-45 parts of linen fiber. The wear-resisting anti-microbial sweat-absorbing fabric prepared according to the invention has high strength, high abrasive resistance, excellent antibacterial property and capability of keeping anti-microbial effect after repeated washing; the preparation method is simple; the production process is easy for operation; the wear-resisting anti-microbial sweat-absorbing fabric is suitable for large-scale promotion.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Graphene antimicrobial air conditioner filtering cloth

InactiveCN108673970ARemove PM2.5Avoid bacterial contaminationDispersed particle filtrationTransportation and packagingActive carbonWoven fabric

The invention provides graphene antimicrobial air conditioner filtering cloth, which comprises graphene composite non-woven fabric and buckles, wherein the graphene composite non-woven fabric comprises two graphene non-woven fabric layers; a graphene active carbon power filtering layer is clamped and arranged between the two graphene non-woven fabric layers. The graphene antimicrobial air conditioner filtering cloth has the advantages that 1, the multifunctional antimicrobial graphene air conditioner filtering cloth uses the graphene composite non-woven fabric, so that the functions of realizing an antimicrobial effect, removing PM2.5, formaldehyde and TVOC gas and the like are realized; the generation of secondary pollution caused by bacteria contamination in the long-period use process is avoided; 2, the graphene air conditioner filtering cloth uses the four-layer graphene composite non-woven fabric and buckle form; simplicity is realized; the operation is easy; the use efficiency ofan air conditioner is improved.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Production method of dirt repelling and felting resisting wool fabric

ActiveCN105568665AFeel goodIncreased cross-linking sitesUltrasonic/sonic fibre treatmentGrip property fibresCross-linkFiber

The invention discloses a production method of a dirt repelling and felting resisting wool fabric. The method comprises the following steps: preprocessing a wool fabric, preparing a chitosan silica sol finishing liquid, finishing the obtained wool, and drying the finished wool. Hydrogen peroxide pretreatment and chitosan solution are adopted to protect the wool fabric, so damages to the surfaces of fibers obtained after plasma treatment in low temperature atmosphere are small; the chitosan silica sol finishing liquid is finished to the surface of one side of the wool fabric, and components in the finishing liquid undergo a condensation reaction, and are cross-linked on the surface of the wool fabric to form a film with certain rigidity, so the wool fabric has single side dirt repelling and felting resisting performances; the film formed on the surface of the wool fabric also has flexibility adapting to the fabric, the bonding area between the film and the fabric is large, the bonding strength is good, and the service life of the film bonded wool fabric is long; and chitosan has bacterium prevention and moisture absorption characteristics, so the finished wool fabric has the advantages of good handle, bacterium prevention, moisture absorption and breathability.

Owner:常熟市易美纺织品有限公司

Method for treating thermal inductance non-ironing all-cotton shirt

InactiveCN105040410AEndothermicAntibacterial hasSucessive textile treatmentsPhysical treatmentMicrowaveFreeze-drying

The invention relates to a method for treating a thermal inductance non-ironing all-cotton shirt. The method comprises the steps of conducting liquefied ammonia treatment on all-cotton fabric; using a pre-shrinking machine for conducting pre-shrinking treatment on the fabric, and using antibacterial, heat-emitting, hydrophilic and non-ironing liquid for conducting electrostatic spraying on the all-cotton fabric which is preshrunk; conducting microwave treatment on the all-cotton fabric after the electrostatic spraying is finished; conducting vacuum treatment on the all-cotton fabric after the microwave treatment is finished; continuing to conduct cooking treatment on the all-cotton fabric with wood pulp after the vacuum treatment is finished, and the wood pulp is treated by the microwave treatment; Spin-drying the all-cotton fabric which is cooked with the wood pulp, and then placing the fabric in a freezing chamber for conducting freeze-drying treatment; putting the all-cotton fabric which is treated through the free-drying into impregnation liquid which contains warm-keeping finishing agents for conducting padding treatment, and conducting drying, cutting and clothing fabrication on the all-cotton fabric after the padding treatment is finished; using a baking shaping machine for conducting ironing and shaping on ready-made clothes, then conducting the trimming and packing, and finally putting the clothes in storage. The all-cotton shirt treated by the method has the heat-emitting, anti-bacterial and non-ironing effect.

Owner:JIANGSU SUNSHINE

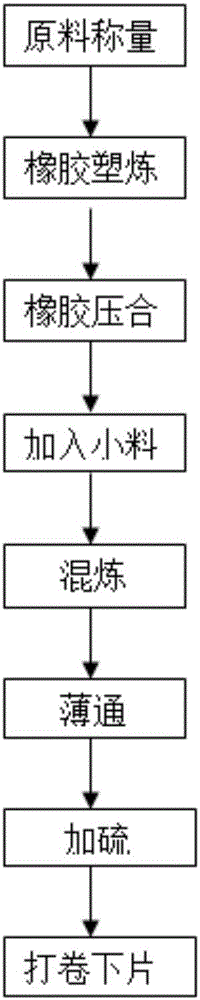

EPDM series environment-friendly type rubber floor sizing material and preparing method thereof

The invention discloses an EPDM series environment-friendly type rubber floor sizing material. The EPDM series environment-friendly type rubber floor sizing material is prepared from, by weight, 29%-32% of EPDM rubber, 1.4-1.6% of zinc oxide, 1.1-1.3% of active magnesium oxide, 0.2-0.35% of stearic acid, 0.4-0.5% of an anti-aging agent 445, 1.4-3.2% of titanium dioxide, 0-6.5% of pottery clay, 12-18.5% of a fire retardant FR-880, 18-23.5% of aluminum hydroxide, 4-6.5% of zinc borate, 0-4.6% of a fire retardant BN-18C, 4-6.5% of white carbon black, 0-7.6% of nanometer kaolin, 0-6.5% of calcium carbonate superfine powder, 0.5-0.65% of an antistatic agent, 0.5-0.65% of a dispersing agent, 0.5-0.65% of a flow promoter, 0.4-0.5% of an anti-ultraviolet agent, 0.4-0.5% of an antibacterial agent, 0.5-0.7% of a deodorant, 0.7-0.85% of DCP, 0.4-0.5% of a vulcanizing agent and 0-0.2% of pigment, wherein the total content percentage of the components is 100%. The invention further discloses a preparing method of the sizing material. The problems that in the prior art, a floor material is poor in skid resistance, nonelastic, not waterproof or wearproof or fireproof or antibacterial and high in price, and releases harmful gas or radioactive elements are solved.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Preparation method of edible antibacterial membrane

InactiveCN107245155AFood safetyReduce environmental problemsFlexible coversWrappersGlycerolPlasticizer

The invention relates to a preparation method of an edible antibacterial membrane, and belongs to the field of green degradable packaging materials. More specifically, the invention relates to the preparation method of the edible antibacterial membrane. The edible antibacterial membrane is prepared by taking chitosan as a base material, glycerinum as a plasticizer, and beta-acidic hydrogenation derivative hexahydro beta-acid in lupulus barras as a bacteriostat, mixing and cross-linking the chitosan and the glycerinum, uniformly dispersing the hexahydro beta-acid to a film-forming solution, coating a film through a flow casting method or a spraying method, and drying at a specific temperature. The used raw materials of the edible antibacterial membrane obtained by the method are all from biologically degradable environment-friendly materials of natural animals and plants, the obtained antibacterial membrane can effectively inhibit common food spoilage bacteria, such as staphylococcus aureus and escherichia coli, and a packaging material with biological activity is provided to food industry.

Owner:XINJIANG UNIVERSITY

Environmentally-friendly multi-effect nanometer water-based paint

InactiveCN105176221AHigh strengthImprove the finishAntifouling/underwater paintsPaints with biocidesWater basedSurface-active agents

The invention discloses environmentally-friendly multi-effect nanometer water-based paint. The water-based paint is prepared from, by weight, 40-60 parts of macromolecular synthesis resin emulsion, 3-6 parts of nanometer scale silicon dioxide, 0.5-2 parts of nanometer titanium dioxide, 1-2 parts of water-based paint thickening agents, 0.5-2 parts of polyether type surface active agents, 0.4-1 part of preservative, 1-3 parts of anti-freezing agents, 1-2 parts of solidifying agents, 0.4-1.2 parts of dispersing agents, 25-45 parts of filling and 10-30 parts of water. The environmentally-friendly multi-effect nanometer water-based paint is waterproof, high in hardness, resistant to washing, high in adhesive force, smoothness and cleanness and resistant to oil stains, ageing and bacteria, meanwhile the content of VOC and formaldehyde is low, and the water-based paint is safe, environmentally friendly, excellent in performance and wide in application range.

Owner:ZIBO KUAKE MEDICINE TECH

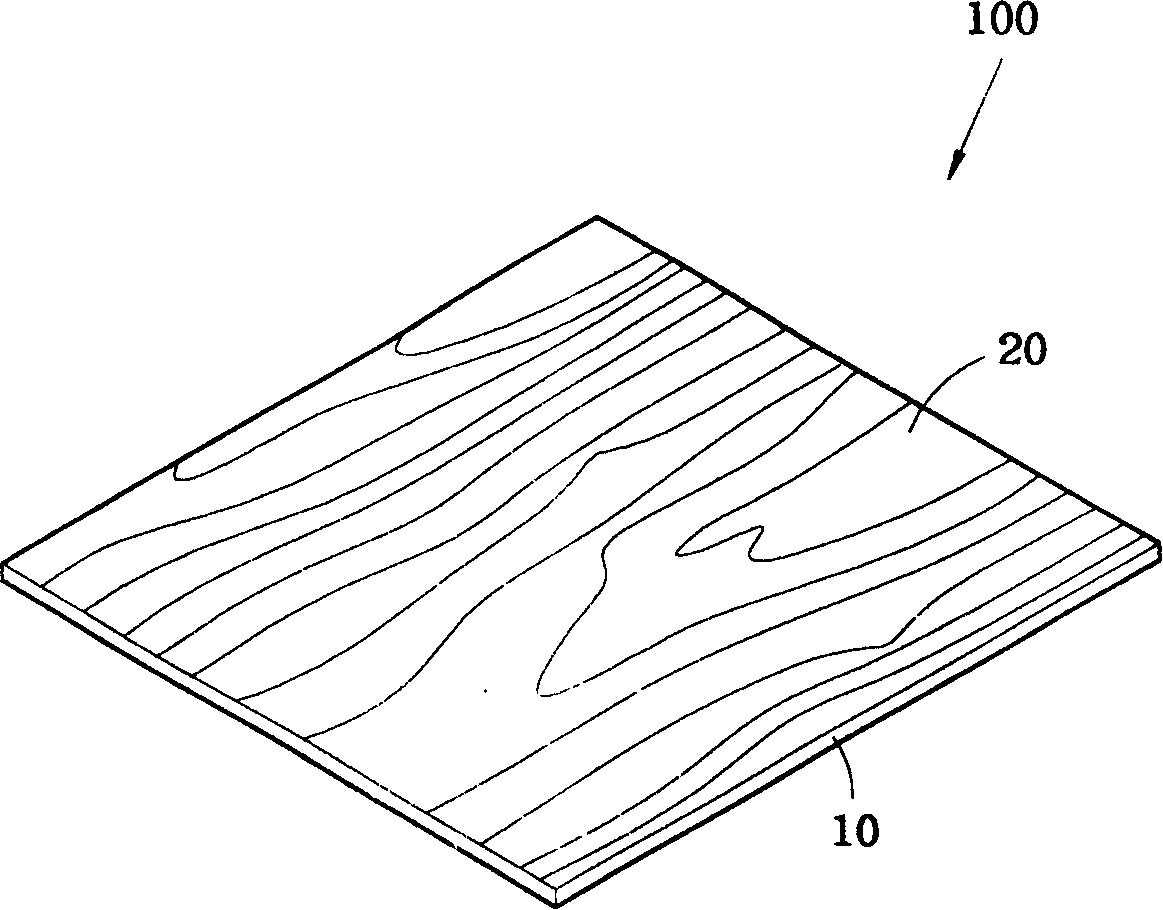

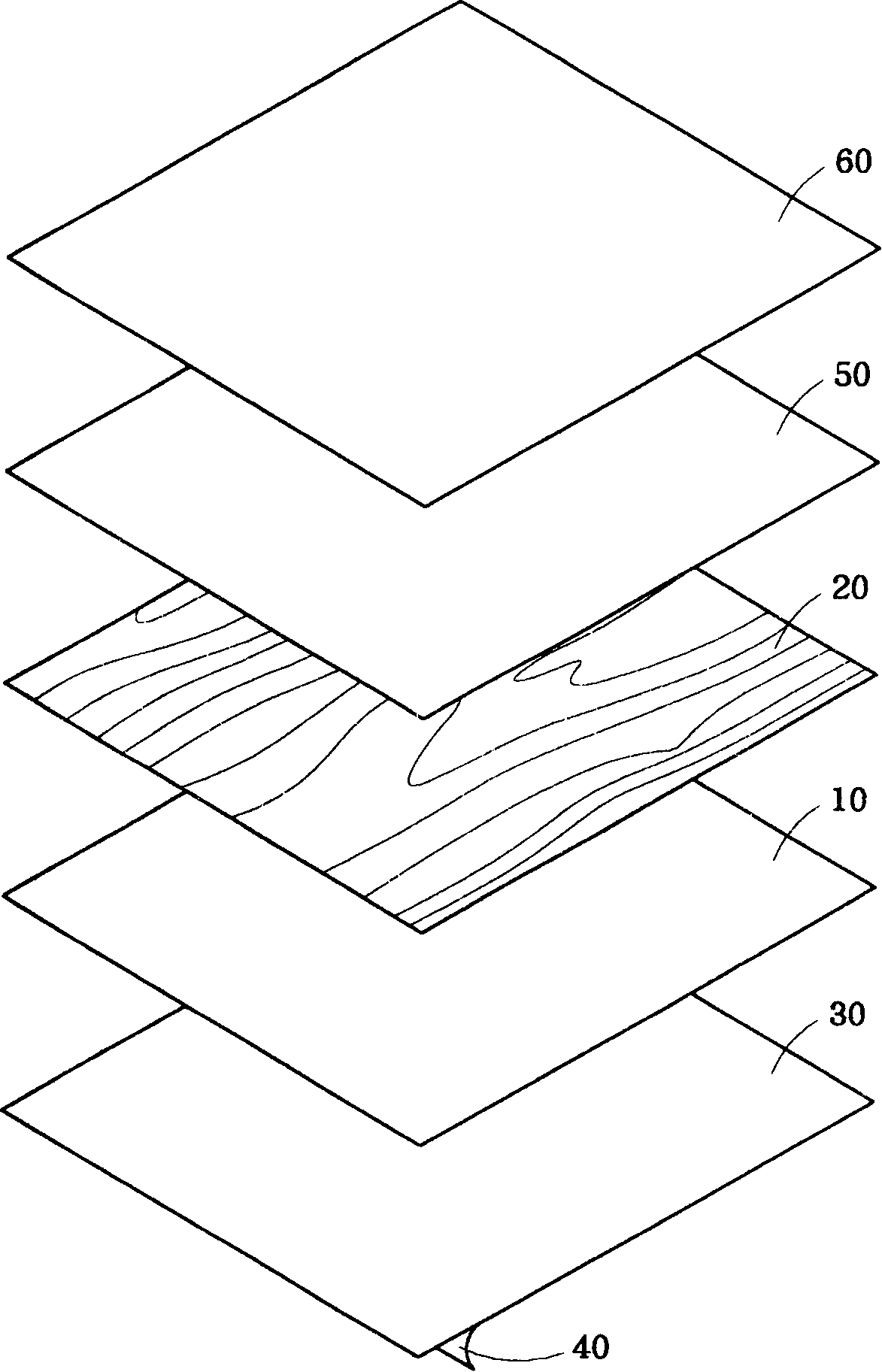

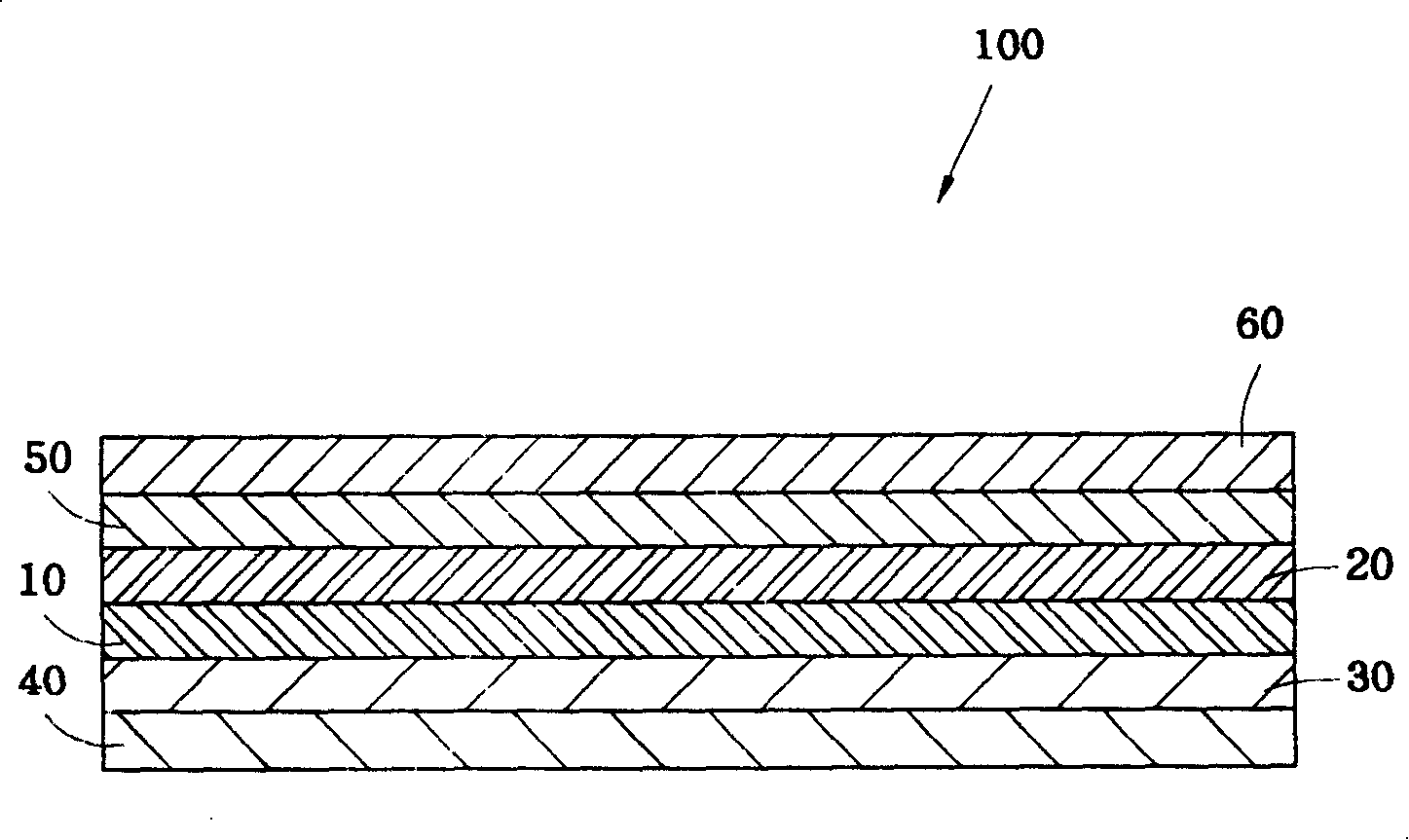

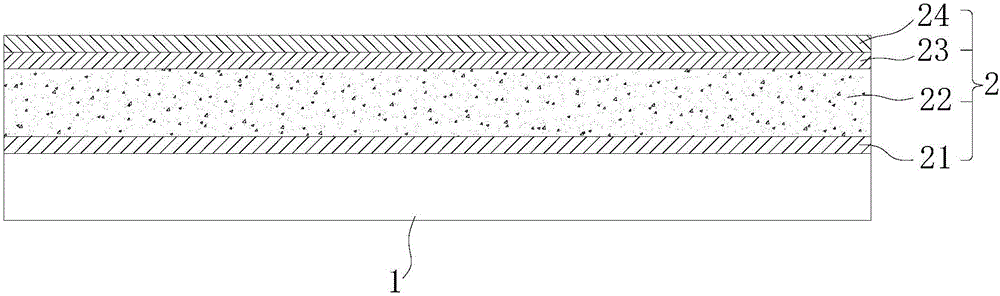

Coating nano antimicrobial material surface layer self-adhering edge-trimming plate material and its making method

InactiveCN101190581AAntibacterial hasThe self-adhesive surface layer of the antibacterial material hasLamination plant layoutLamination ancillary operationsNanometreLacquer

The invention relates to a self-adhesive trimming board used for painting the surface layer of nanometer antibacterial materials and a manufacturing method thereof, wherein, the board comprises: chemical fiber paper, which is plain synthetic paper wood; a decoration veneer with a woody shiver on the surface, combined to the top surface of the chemical fiber paper; a self-adhesive glue layer, combined to the back of the chemical fiber paper; release paper, combined to the surface of the self-adhesive layer; at least a UV interface painting interlayer, combined to the top surface of the decoration veneer; at least a surface layer of the nanometer antibacterial materials, combined to the top surface of the UV interface painting interlayer; the manufacturing method comprises the following steps of gluing and veneer pasting, heat pressing and sealing, cold pressing and leveling, sanding processing with the cold pressing and leveling of the chemical fiber paper and the surface of the decoration veneer, coating the self-adhesive glue layer in the back, gluing of the release paper, coating of at least a layer of UV interface painting, ultraviolet ray drying of the UV interface painting of the coating, sanding processing of the UV interface painting interlayer surface, coating of the nanometer antibacterial surface layer and ultraviolet ray drying of the painting of the nanometer antibacterial surface layer and the self-adhesive trimming board products used for painting the nanometer antibacterial materials on the surface layer are obtained. The invention is convenient for applying in the trimming construction of furniture and decoration.

Owner:科彰有限公司

Water-based natural biological composite antibacterial coating and preparation method thereof

ActiveCN102757702AReduce manufacturing costSimple preparation processAntifouling/underwater paintsPaints with biocidesWater basedMaterials science

The invention relates to a building interior wall decorative coating, in particular to a water-based natural biological composite antibacterial coating and a preparation method thereof. The water-based natural biological composite antibacterial coating comprises the following materials in percentage by weight: 0.8-1.2% of natural chitosan-inorganic metal ion complex, 38.0-42.0% of low-VOC (Volatile Organic Compounds) pure-taste core-shell acrylic elastic emulsion, 0.4-0.6% of dispersing agent, 20.0-23.0% of titanium dioxide, 5.0-8.0% of ground calcium carbonate, 6.0-8.0% of kaolin, 0.8-1.0% of thickener and 18.0-20.0% of water. The water-based natural biological composite antibacterial coating provided by the invention has the advantages of simple preparation process and low production cost. After a finished product is used in construction, the water-based natural biological composite antibacterial coating provided by the invention has a composite antibacterial efficacy integrated with antibacterial, bacteriostasis, mildew proof and air purification properties and can be widely applied to building interior wall coating; and it is tested that the antibacterial ratio of the water-based natural biological composite antibacterial coating provided by the invention is more than 95%.

Owner:广西亚多漆业有限责任公司

Method of preparing moss prevention nano titanium ceramic paint

InactiveCN108659585AAntibacterial hasHas anti-moss propertiesFireproof paintsAntifouling/underwater paintsPotassium permanganateOxide

The invention discloses a method of preparing moss prevention nano titanium ceramic paint. The method comprises the following steps of: step I, performing hydrophobization treatment on nano silicon oxide and nano titanium oxide through silicane under a catalyst condition to form nano titanium ceramic resin, and step II, adding at least one compound of nano titanium dioxide, copper sulfate, potassium permanganate, potassium ferrate and sodium ferrate, and other filling and pigments into the nano titanium ceramic resin, and performing dispersion in a high-speed dispersion machine to form a finished product. A major film former and an adhesive agent of the prepared moss prevention nano titanium ceramic paint are the nano titanium ceramic resin; the nano titanium ceramic resin comprises nano silicon oxide and titanium dioxide as principal ingredients; and the paint has the characteristics of moss prevention, high hardness, fouling prevention, fire prevention, water resistance, static prevention, ageing resistance and the like and is particularly suitable for external walls of public buildings and various outdoors equipment and facilities.

Owner:成都今天化工有限公司 +1

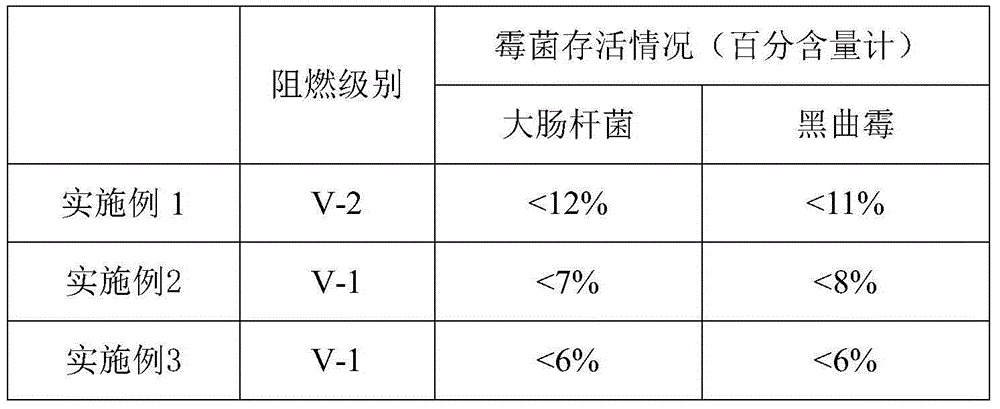

Antibacterial flame-retardant paint and preparation method thereof

InactiveCN104962148AImprove antibacterial propertiesImprove the bactericidal effectEpoxy resin coatingsPolyvinyl butyralZinc borate

The invention relates to antibacterial flame-retardant paint. The antibacterial flame-retardant paint consists of the following substances in parts by weight: 6 to 10 parts of glycidyl acrylate, 15 to 30 parts of trumpet shell powder, 8 to 16 parts of aluminium triphosphate, 10 to 25 parts of antibacterial nano titanium dioxide, 8 to 10 parts of coconut oil fatty acid diethanol amide, 4 to 10 parts of precipitated barium sulfate, 12 to 20 parts of polyvinyl butyral, 0.5 to 1 part of superfine acrylate rubber powder, 0.1 to 0.5 part of isophorone diisocyanate, 5 to 15 parts of epoxy acrylic resin and 1 to 3 parts of zinc borate. The antibacterial flame-retardant paint preparation process is carried out under the normal temperature and normal pressure, no novel device is needed, the process is simple, and the production cost is low. After the antibacterial flame-retardant paint is used, not only is the surface antibacterial performance of the material effectively improved, but also the flame-retardant performance is relatively good.

Owner:饶烨

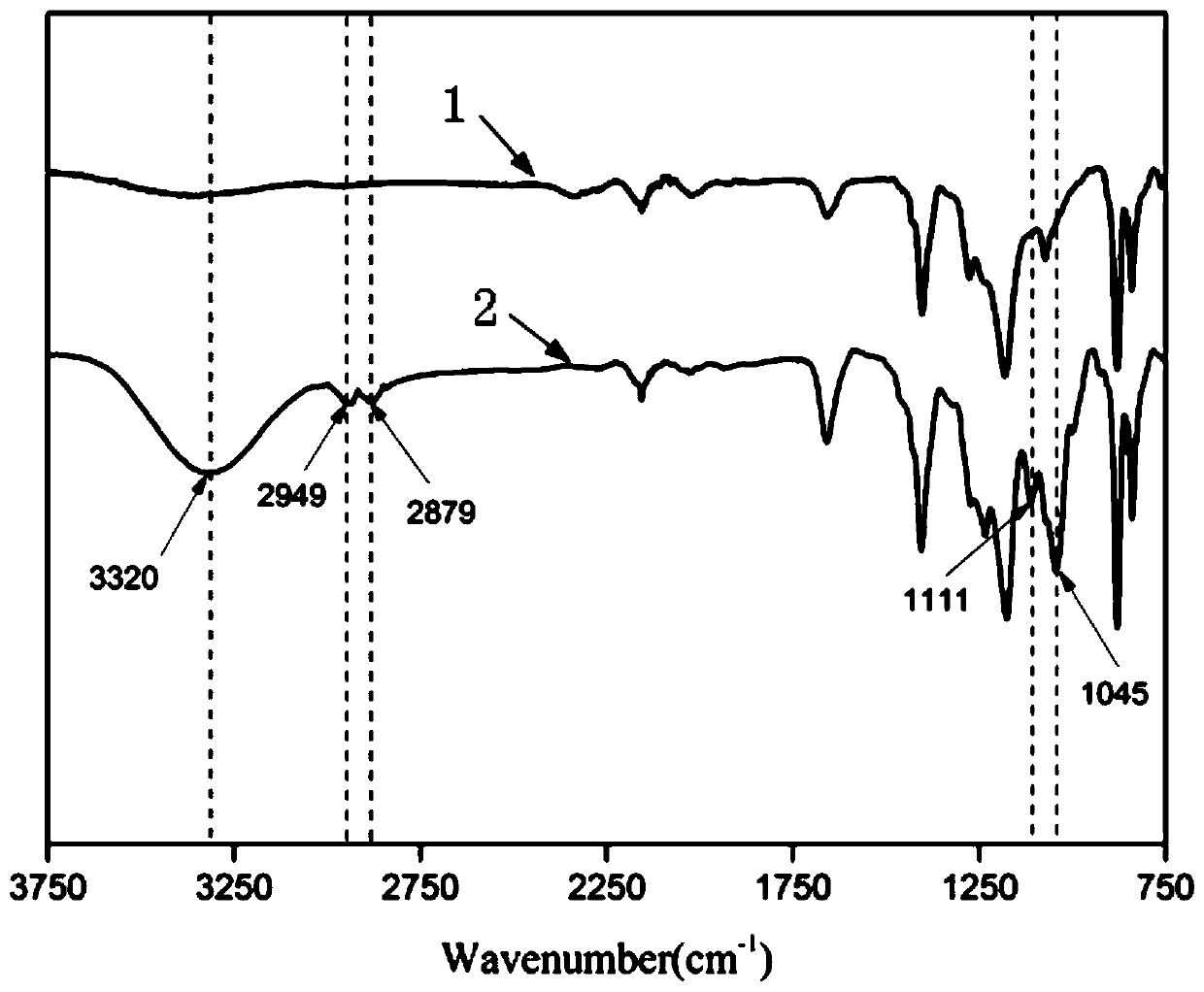

Preparation method and application of hydrophilic and antibacterial dual-modified ultrafiltration membrane

ActiveCN110559877AImprove hydrophilicityHigh throughputSemi-permeable membranesMembranesAlkaneGraphite oxide

The invention discloses a preparation method and application of a hydrophilic and antibacterial dual-modified ultrafiltration membrane, belonging to the technical field of ultrafiltration membranes. The invention aims to solve the problem that conventional ultrafiltration membrane materials are difficult to realize hydrophilic and antibacterial dual modification at the same time. The preparation method comprises the following steps: adding a condensing agent and 3-dimethylaminopropylamine into a graphene oxide suspension for a reaction, adding a cleaned reactant and long-chain halogenated alkane into an organic solvent, and carrying out a sufficient reaction at 20-80 DEG C for 8-24 hours to obtain a quaternized graphene oxide modifier; and 2, adding the quaternized graphene oxide modifierinto an organic solvent, carrying out ultrasonic dispersion to obtain a GO-Q suspension, dissolving a polymeric membrane matrix material and a membrane modifier into the GO-Q suspension to obtain a uniform membrane casting solution, and carrying out casting molding. The ultrafiltration membrane with the double functions of hydrophilicity and antibacterial performance is prepared by an immersion precipitation phase inversion method; and the modified ultrafiltration membrane shows better mechanical properties, water treatment performance, hydrophilicity and antibacterial performance.

Owner:HARBIN ENG UNIV

Graphene antibacterial master batch, fiber and preparation method of master batch

ActiveCN108047709AEvenly dispersedIncreasing interlamellar spacingArtifical filament manufactureMonocomponent polyamides artificial filamentFiberNylon 6

A preparation method of graphene antibacterial master batch comprises the following steps of first powder preparation, second powder preparation and master batch preparation. According to the technical scheme, water-soluble polyquaternary ammonium salt serves as an intercalation agent and an antibacterial agent, gaps between layers of a graphene oxide sheet are increased, then the water-soluble polyquaternary ammonium salt and nylon 6 are prepared into a microcapsule, and a core-shell structure is formed. According to the antibacterial master batch prepared through the method, polyquaternary ammonium salt and graphene oxide are used for preventing bacteria together, so that the master batch is good in antibacterial property; meanwhile, graphene is uniform in dispersion, and the physical and mechanical properties are enhanced; the graphene and nylon 6 can be fused and blended for preparing antibacterial textile silk.

Owner:福建烯石新材料科技有限公司

Lotus fiber semi-worsted blended skin-care health-care yarn, and preparation method and application thereof

The invention discloses a lotus fiber semi-worsted blended skin-care health-care yarn, which comprises lotus fiber, Amicor fiber, anti-bacferial polyester fiber, wool fiber and cashmere fiber with the content by weight as below: 12-30 percent of the lotus fiber, 12-32 percent of the Amicor fiber, 12-30 percent of the anti-bacferial polyester fiber, 15-35 percent of the wool fiber and 15-35 percent of the cashmere fiber, wherein the blended yarn property indexes are that the single yarn breaking strength is 11.6-19.0cN / tex, the single yarn breaking strength variable coefficient Cv value is 7.5-16.8 percent, and the yarn evenness variable coefficient Cv value is 14.2-21.5 percent. The blended yarn prepared by the invention and fabric prepared by the blended yarns have the health-care functions of antibiosis, bacteriostat, antiphlogosis, deodorization, skin care and body health, beauty, skin moisten and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Anti-mosquito environment-friendly wallpaper

InactiveCN106283789AImprove moisture resistanceImprove anti-agingAgeing prevention agents additionCovering/liningsEnvironmental resistanceFiber

The invention discloses anti-mosquito environment-friendly wallpaper, made from, by weight, 20-30 parts of used clothes, 10-20 parts of waste wood, 10-20 parts of straws, 2-5 parts of nano zinc oxide, 1-2 parts of chitosan, 2-8 parts of sodium sulfate, 10-25 parts of sodium hydroxide, 5-10 parts of cassava starch, 2-5 parts of butyl acetate, 1-2 parts of titanate coupling agent, 1-3 parts of cationic polyacrylamide, 1-2 parts of sodium cocoyl glycinate, 1-2 parts of azodiisobutyronitrile, 60-100 parts of deionized water, 20-30 parts of ethyl acetate, and 5-10 parts of Chinese herbal powder; the anti-mosquito environment-friendly wallpaper employs the used clothes, waste wood and straws as fiber bases, resources are effectively utilized, resource waste is avoided, and environment protection is achieved; the anti-mosquito environment-friendly wallpaper using the Chinese herbal powder as a plant material can dispel mosquitoes but is harmless to human bodies, and can soothe body and mind and calm the mind since containing nerve-soothing ingredients.

Owner:南宁东印时代广告有限公司

Thick automobile inner chamber leather with pressure resistance and friction-resistant color fastness

InactiveCN106087458AReasonable structureGood high temperature resistanceTextiles and paperEmulsionHollow form

The invention discloses thick automobile inner chamber leather with pressure resistance and friction-resistant color fastness. The thick automobile inner chamber comprises a base cloth layer and a surface layer coating one surface of the base cloth layer, wherein the surface layer is a four-layer structure and comprises a water-base PU bottom layer, a water-base PU foamed layer, a water-base PU reinforcing layer and a water-base PU surface layer which are sequentially connected. According to the thick automobile inner chamber leather, the base cloth layer has the effects of resisting bacteria and ultraviolet light and retarding combustion; the surface layer is a four-layer structure and has strong leather sensation, and the four layers are made of a water-base polyurethane emulsion, so that the environmental protection property is good, the strength is high, and the water repellency and the gas permeability are strong; the PU foamed layer is of a hollow formed structure and is light, so that the automobile inner chamber leather is endowed with relatively rebound resilience and compression strength; nano-TiO2 powder, nano-ZnO powder and polyol fatty acid ester are further added into the water-base PU surface layer, so that the automobile inner chamber leather has relatively strong light aging resistance and static electricity resistance; by utilizing a Dow Corning DC-57 organosilicon polyether copolymer, the automobile inner chamber leather is smooth and wearable and has strong friction-resistant color fastness.

Owner:浙江嘉科新材料科技有限公司

Food plastic packaging bag and preparation method thereof

The invention discloses a food plastic packaging bag and a preparation method thereof, and belongs to the field of packaging, wherein the food plastic packaging comprises the following raw materials by weight: 25-30 parts of polyethylene, 44-48 parts of polylactic acid, 15-20 parts of polycarbonate resin, 10-20 parts of polyethylene terephthalate, 23-25 parts of castor bean fiber, 6-8 parts of jute fiber, 12-14 parts of sisal fiber, 5-7 parts of natural zeolite powder, 7 to 9 parts of diatomite, 3 to 5 parts of calcium carbonate, 2 to 4 parts of an antibacterial agent, and 2 to 4 parts of a degradation promoter. The food plastic packaging bag has excellent degradation performance, and has the advantages of high mechanical strength, tensile strength, light weight and good tear resistance.

Owner:桐城市强峰包装有限公司

Natural plant type formaldehyde elimination agent and preparation method thereof

InactiveCN110523258AAntibacterial hasGood formaldehyde removal effectDispersed particle separationTanninPropylene glycol

The invention relates to the technical field of formaldehyde and in particular to a natural plant type formaldehyde elimination agent and a preparation method thereof. The natural plant type formaldehyde elimination agent is prepared from the following raw materials in percentage by weight: 3-5% of persimmon tannin, 0.2-0.3% of a plant amino acid antibacterial agent, 1-4% of propylene glycol and the balance of water. The invention provides the natural plant type formaldehyde elimination agent and the preparation method thereof, and due to interactions of the persimmon tannin, the plant amino acid antibacterial agent, the propylene glycol, a polyphenolic substance with one amino acid at least, a stabilizer and a smell neutralizer substance, the prepared natural plant type formaldehyde elimination agent not only is good in formaldehyde removal effect and good in stability, but also has effects of bacterium inhibition and deodorization, and in addition is green and environment-friendly inthe formaldehyde removal process and free of secondary pollution in the formaldehyde removal process.

Owner:杭州施维康控股有限公司 +1

Novel antibacterial thermal-insulation brick, and preparation method thereof

The invention discloses a novel antibacterial thermal-insulation brick. The novel antibacterial thermal-insulation brick comprises, by weight, 10 to 20 parts of industrial coal slag, 8 to 17 parts ofbuilding garbage, 5 to 12 parts of waste circuit board, 15 to 25 parts of Portland cement, 7 to 13 parts of expanded perlite, 5 to 10 parts of nut shell, 6 to 14 parts of glass bead, 13 to 21 parts offly ash, 9 to 18 parts of bentonite, 12 to 19 parts of modified diatomite, 5 to 11 parts of wood chip, 4 to 8 parts of kaolin, 5 to 10 parts of borax, 6 to 12 parts of tourmalinite powder, 1 to 4 parts of lignocelluloses, 2 to 6 parts of polyvinyl alcohol fiber, 1 to 3 part of a water reducer, and 2 to 3 parts of a foaming agent. The novel antibacterial thermal-insulation brick possesses excellent thermal insulation properties, is light in weight, is high in compression strength, and possesses antibacterial performance, and air purification performance.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Medicine for treating non-gonococcal vaginitis and preparation method

InactiveCN1438016AAct quicklyGood effectUnknown materialsUrinary disorderDiuresisNon-gonococcal urethritis

The present invention discloses a Chinese medicine for curing nongonococcal urethritis and its preparation method. Said medicine is made up by using 6 Chinese medicinal materials of gardenia fruit, astragalus root, hedyotis, ophiopogon tuber, mallow seed and picrasma quassioides as raw material through a certain preparation process. Said medicine has the functions of clearing heat, disinhibiting dampness, boosting qi, nourishing yin and inducing diuresis for treating stranguria, and possesses the action of resisting inflammation, resisting bacteria, raising immunity and stopping pain.

Owner:贵州远程制药有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com