Coating nano antimicrobial material surface layer self-adhering edge-trimming plate material and its making method

A nano-antibacterial material and manufacturing method technology, applied in coatings, wood layered products, chemical instruments and methods, etc., can solve the problems of destroying the surface, not having surface antibacterial, deodorizing functions, and unable to achieve long-term antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

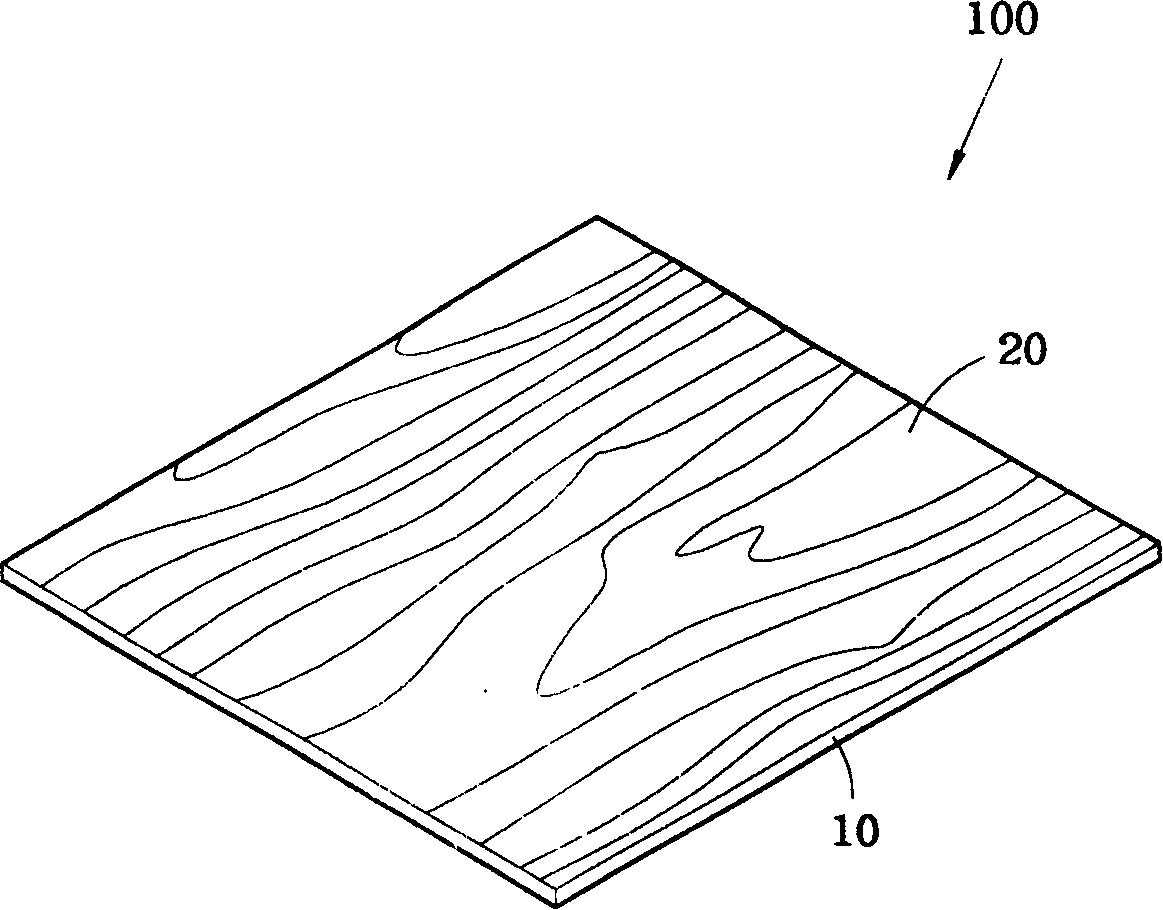

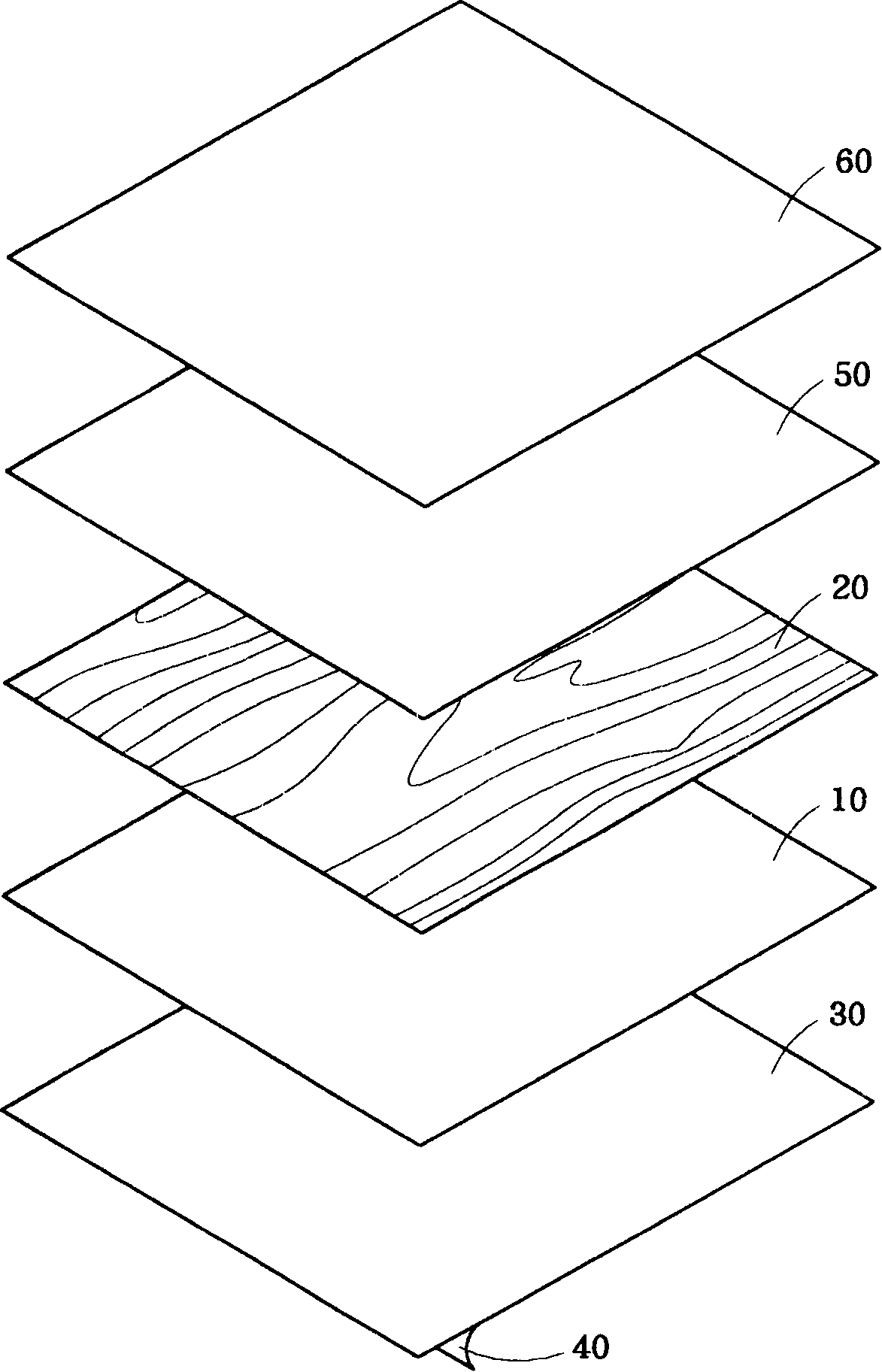

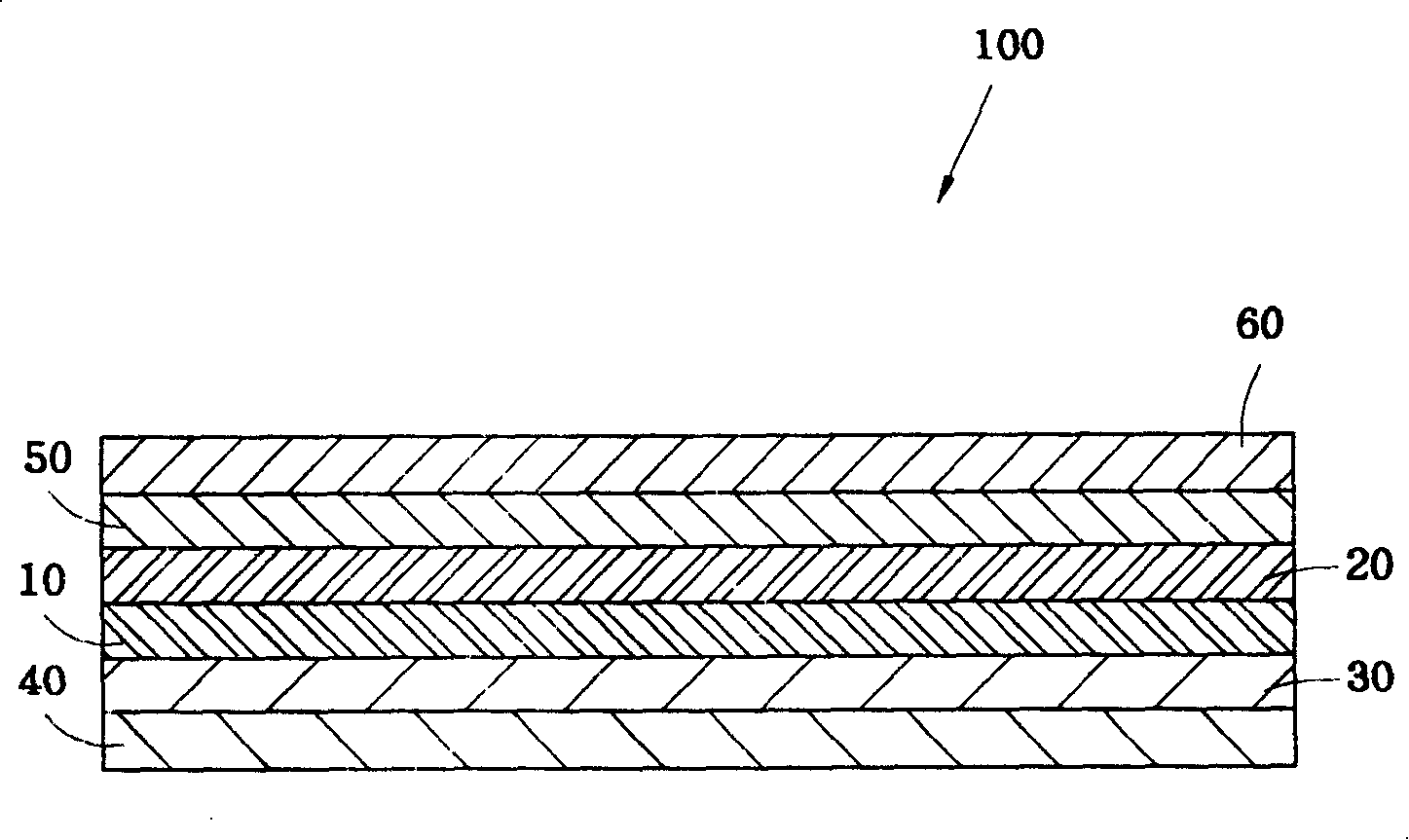

[0040] refer to figure 1 , figure 2 and image 3 Shown, be the first embodiment of the self-adhesive trimming plate 100 of the coating nano-antibacterial material surface layer of the present invention, wherein, the self-adhesive trimming plate 100 of this coating nano-antibacterial material surface layer comprises a chemical fiber paper 10, decorative veneer 20 , self-adhesive adhesive layer 30, release paper 40, at least one layer of UV interface paint interlayer 50 and nano antibacterial material surface layer 60; the chemical fiber paper 10 is a plain synthetic paper, and the surface of the decorative veneer 20 has natural or artificial synthetic wood decorations, And the decorative veneer 20 is combined on the top surface of the chemical fiber paper 10 . Above-mentioned self-adhesive adhesive layer 30 is combined on chemical fiber paper 10 backside, and the form of this self-adhesive adhesive layer 30 is not limited, and in the present invention, take self-adhesive adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com