Patents

Literature

328results about How to "Good high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

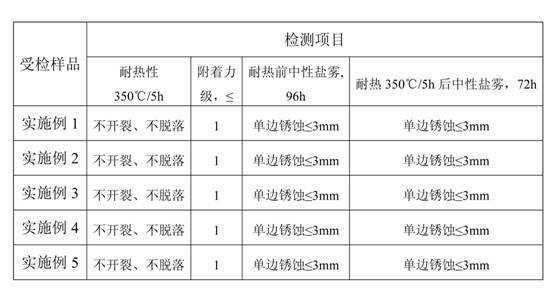

Heat-resisting organic silicon antiseptic inner tank coating

InactiveCN101935498AGood high temperature resistanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsSolventFilling materials

The invention discloses a heat-resisting organic silicon antiseptic inner tank coating which comprises the following components in part by mass: 5-30 parts of organic silicon resin, 5-15 parts of modified organic silicon resin, 1-5 parts of amino resin, 0-18 parts of epoxy resin, 0-8 parts of phenolic resin, 11-43 parts of antiseptic pigment, 8-20 parts of filling material and 4-22 parts of solvent. The heat-resisting organic silicon antiseptic inner tank coating has good heat resistance and can work for long term at the high temperature of 350 DEG C; the coating has good adhesion force, good corrosion resistance and excellent performance; and a coating film still has good corrosion resistance after working at high temperature.

Owner:JIANGMEN PAINT FACTORY

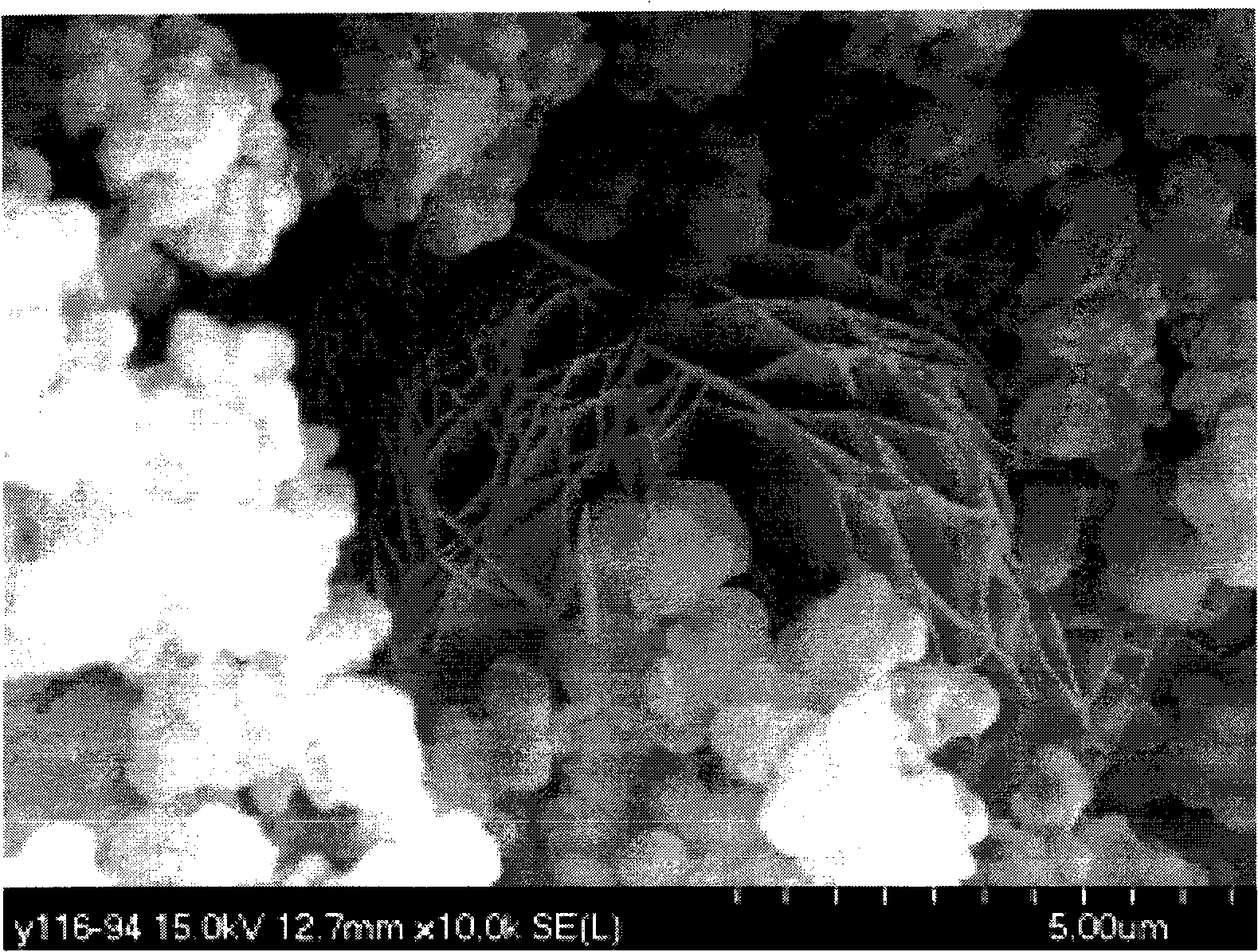

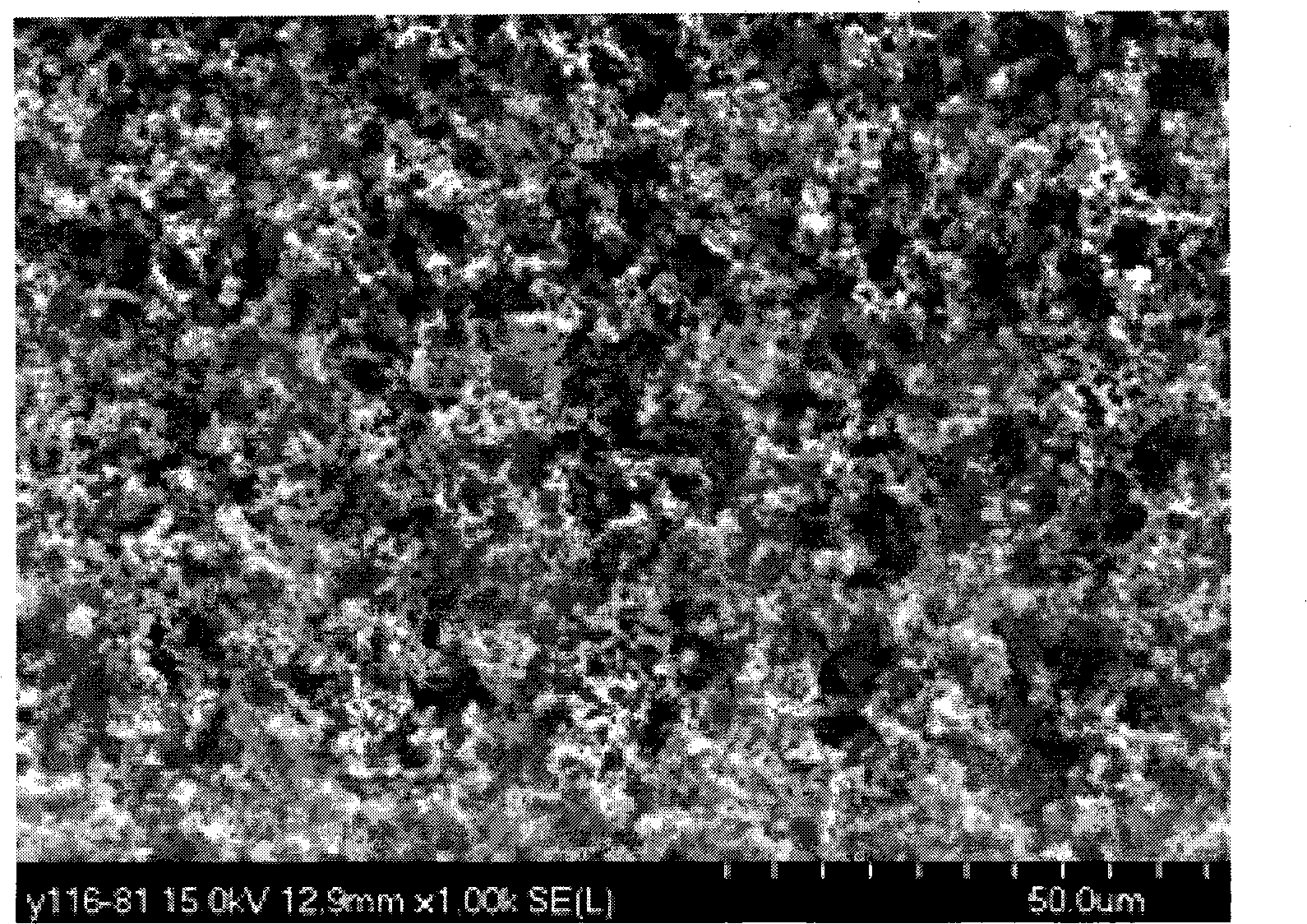

Ceramic aerogel and method for preparing the ceramic aerogel by gel injection moulding

ActiveCN101525248AGood high temperature resistanceGood insulation performanceClay processing apparatusCeramicwareSolid phasesThermal insulation

A ceramic aerogel and a method for preparing the ceramic aerogel by gel injection moulding belong to the field of porous materials. The invention solves the problem that the prior aerogel has easily broken and damaged air holes under the action of external force and low heat resistant temperature, and that the porous material prepared by prior gel injection moulding has bad heat-insulating property. The ceramic aerogel forms a three-dimensional skeleton structure by mutually jointing ceramic particles, porosity thereof is 50-90%, the aperture is micrometre-sized, and the most probable aperture can be below 3 microns. The ceramic aerogel is prepared by the gel injection moulding technology under the conditions of low solid phase content and no any foaming agent and pore forming agent. The product of the method has uniform aperture size distribution, heat resistance, thermal insulation and high intensity, is light, and can be used as heat-proof material of high-temperature structure. The heat-resistant temperature thereof is 1000-3000 DEG C and the compressive strength is 1-50 MPa. The method of the invention has a simple technology and short flow, can prepare finished pieces with complex shapes, and is suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

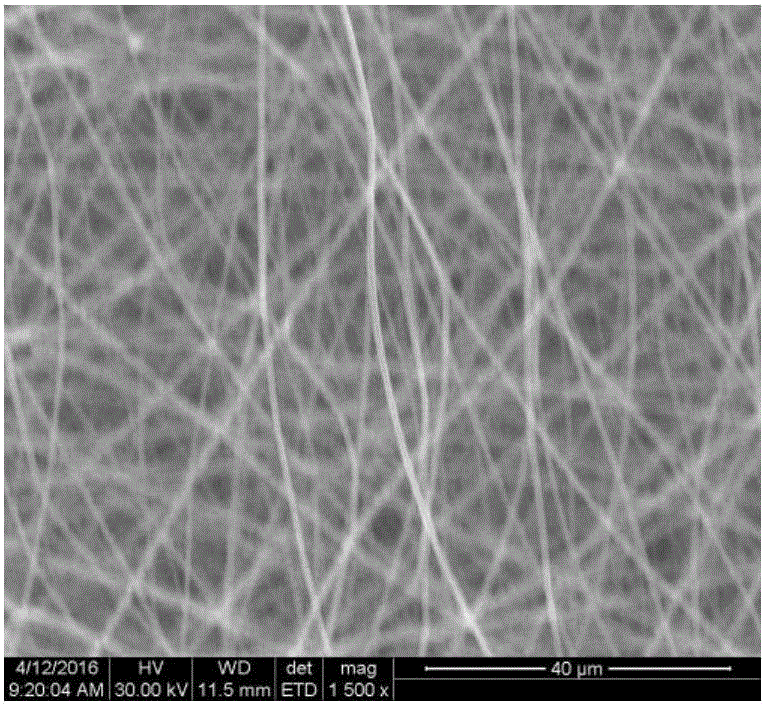

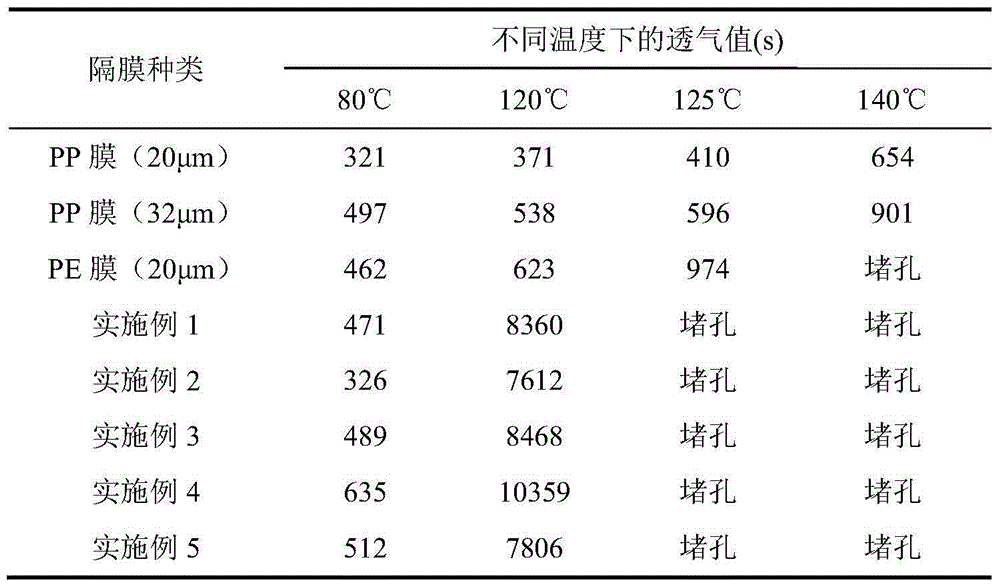

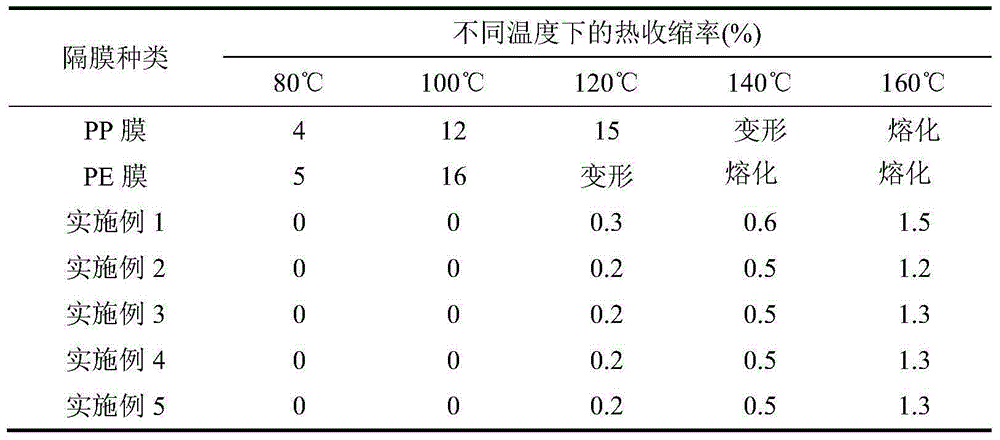

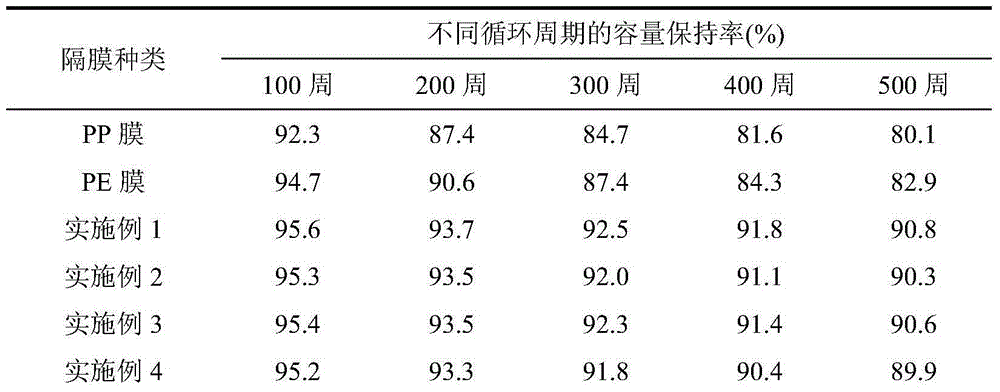

Method for preparing novel lithium battery diaphragm by coaxial electrostatic spinning

ActiveCN106450101AGood high temperature resistanceImproved high temperature thermal stabilityElectro-spinningCell component detailsPolyvinylidene fluorideElectrospinning

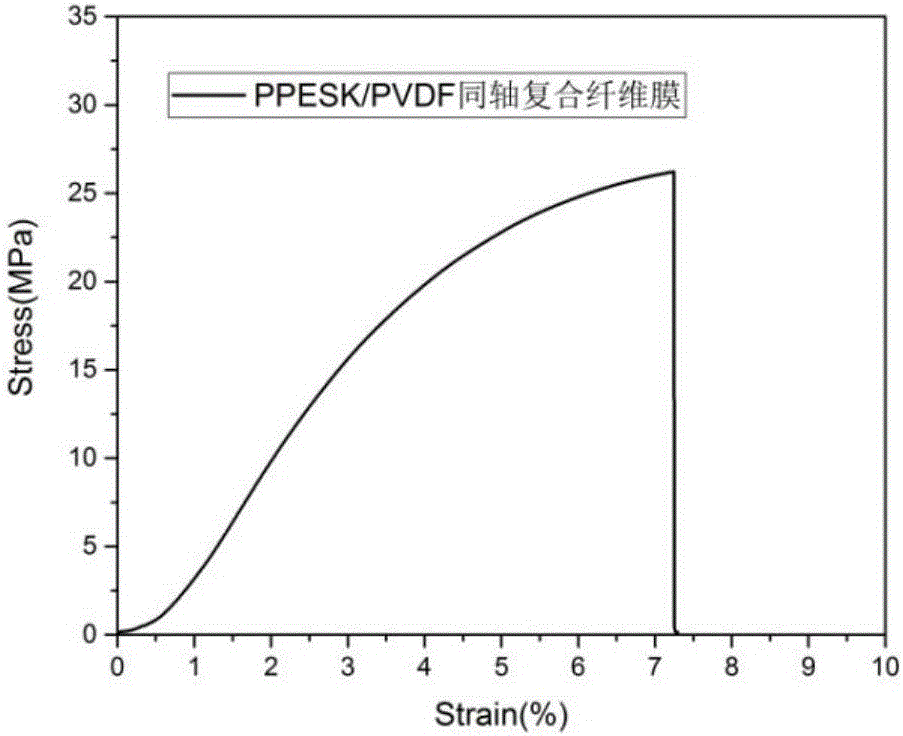

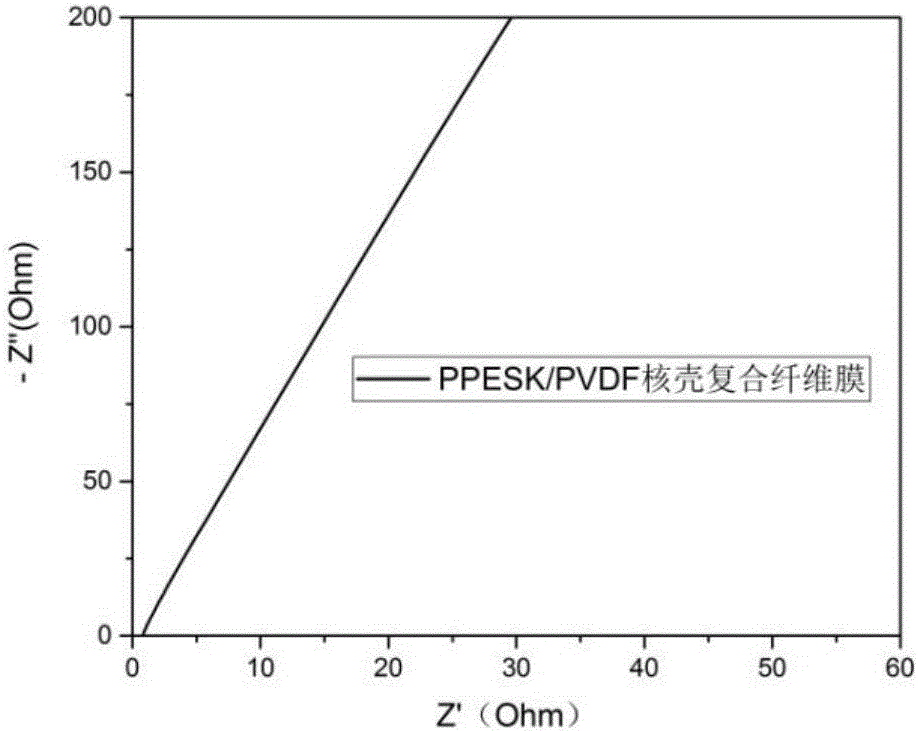

The invention provides a method for preparing a novel lithium battery diaphragm by coaxial electrostatic spinning, and belongs to the technical field of the lithium battery diaphragm. The novel lithium battery diaphragm is a composite fiber membrane prepared by a coaxial electrostatic spinning technology and having a core / shell structure; the core and shell layers of the composite fiber membrane are concentric-coaxial-shaped; the core layer consists of high-melting-point polyarylether sulfone ketone nanofibers; the shell layer consists of low-melting-point polyvinylidene fluoride nanofibers; particularly, the coaxial composite diaphragm is subjected to hot-press treatment at certain temperature and pressure; and the shell layer fibers generate micro melting or melting to enhance the binding power between fibers, so that the tensile strength of the composite diaphragm in each direction is greatly improved. The porosity of the novel lithium battery diaphragm reaches greater than 75%; and the electrolyte absorption rate reaches greater than 550%; the diaphragm can withstand a temperature of 180 DEG C, so that the diaphragm prepared by the method has good electrochemical property, thermal performance and mechanical performance, which has high application value in the fields of aviation, spaceflight, electric vehicle and the like.

Owner:DALIAN UNIV OF TECH

High temperature resistant, high strength modified epoxy resin adhesive and preparation thereof

InactiveCN101407708AGood high temperature resistanceImprove flexibilityEpoxy resin adhesivesChemistryDiol

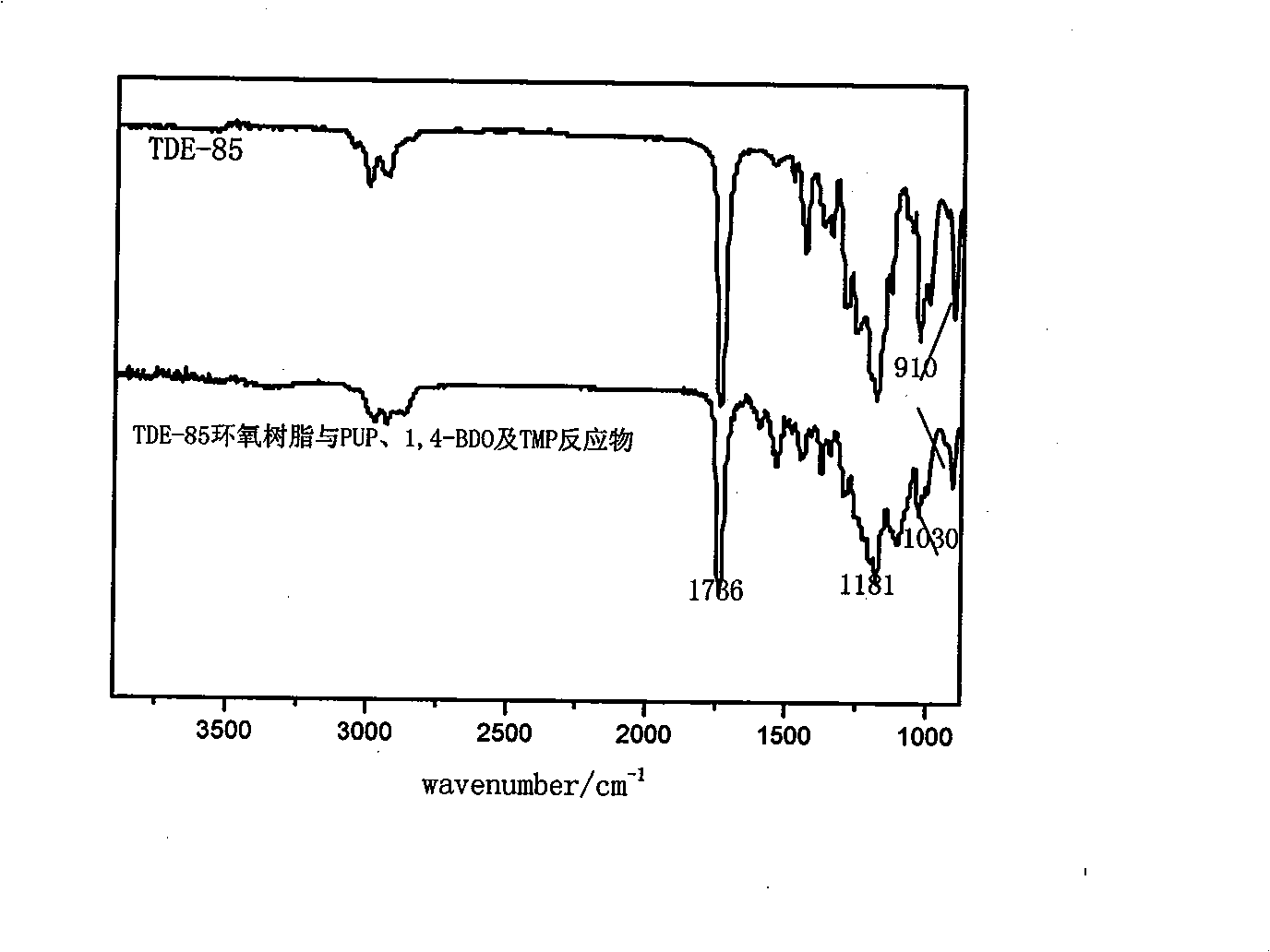

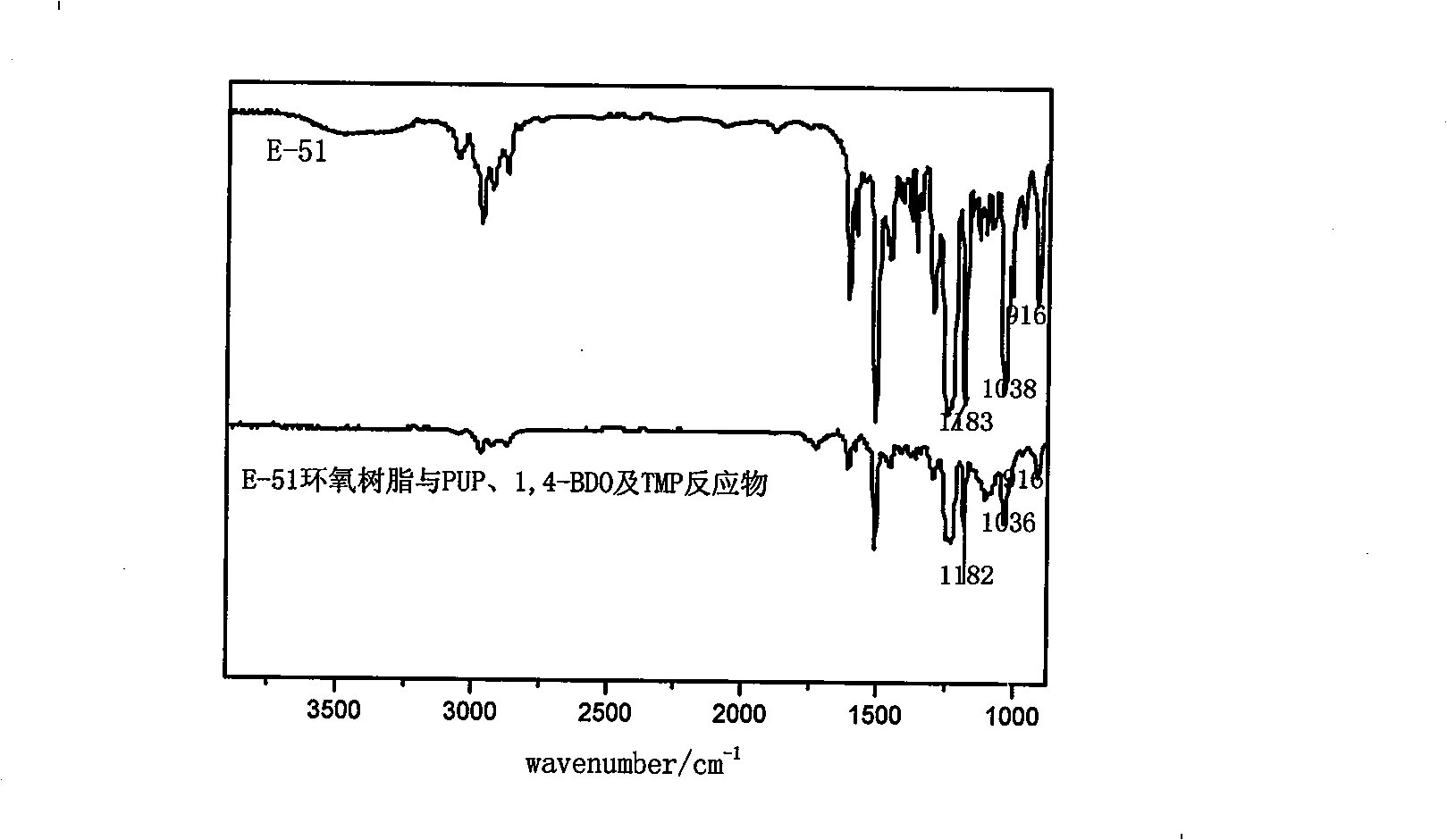

The invention discloses a high-temperature-resistant and high-strength modified epoxy resin structured adhesive. First, polyether diols and 2, 4-tolylene diisocyanate are reacted to prepare polyurethane prepolymer (PUP); 1, 4-butanediol and trimethylolpropane are added into the prepared PUP and, after agitation, the mixture is added into TDE-85 / E-51 epoxy resin; then, a curing agent is added into the TDE-85 / E-51 epoxy resin and, and finally, a curing accelerator is added. The prepared adhesive has high tenacity, excellent high-temperature resistance and high reaction activity. After curing, the tensile and shear strength of the adhesive reach 22.81MPa at room temperature and 12.85MPa at high temperature of 160 DEG C, and the peel strength reaches 51.68N / cm, therefore, the adhesive can be widely applied to the adhesion of metals, porcelain, plastics and wood and the like.

Owner:CENT SOUTH UNIV

Adhesive combination, covering film and flexible circuit board

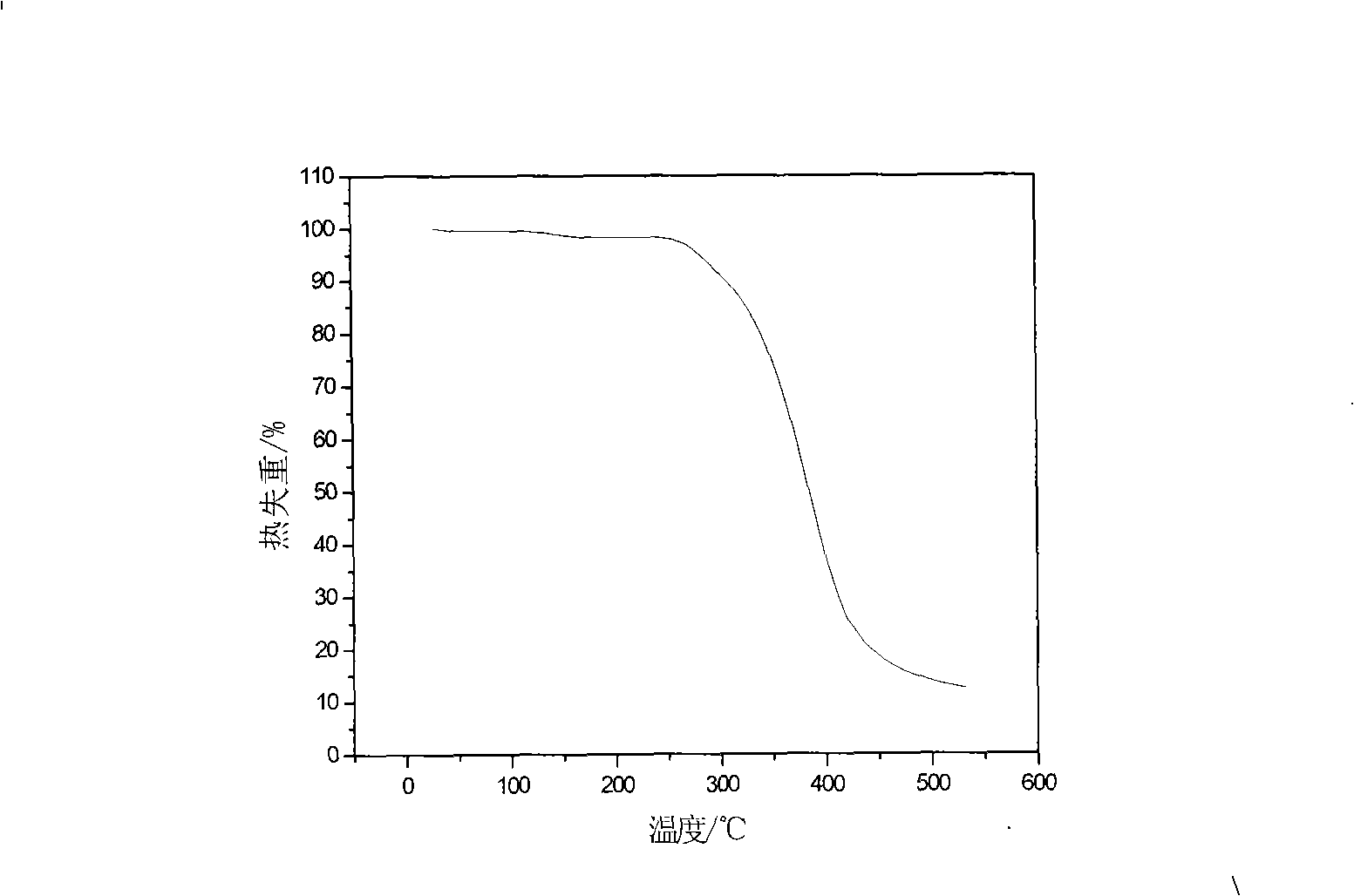

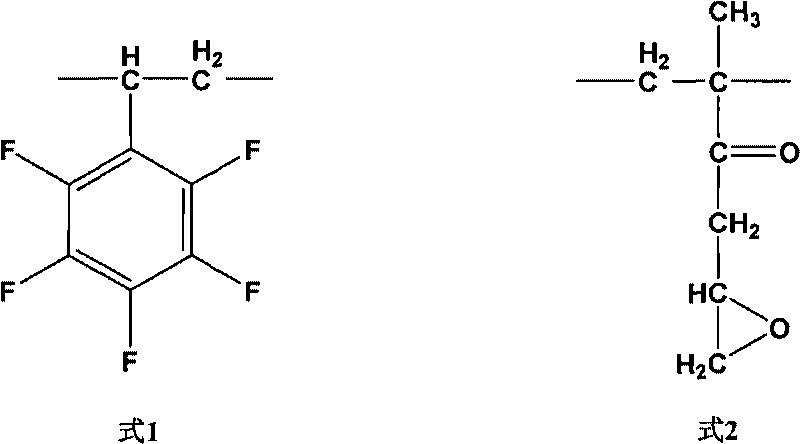

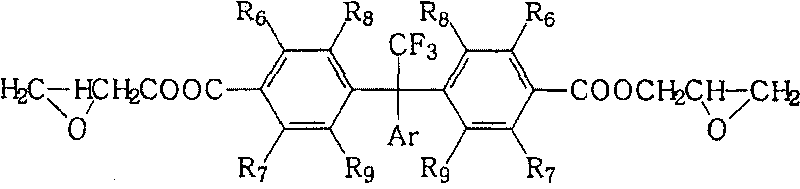

ActiveCN101747854AGood high temperature resistanceLow dielectric lossEpoxynovolac adhesivesNon-metallic protective coating applicationChemistryFirming agent

The invention provides an adhesive combination. The adhesive combination contains thermoplastic resin, thermosetting resin and a firming agent, wherein the thermosetting resin contains polyphenyl ether with epoxy functional groups at the end, perfluor styrene-methacrylic acid epoxy propyl ester copolymer, bisphenol A epoxy resin and phenolic aldehyde epoxy resin. The invention further provides a flexible circuit board and a covering film which comprises the adhesive combination. The peeling strength of the provided flexible circuit board is from 12 to 16N / cm, the dielectric constant is from 1.4 to 1.8, the dielectric loss is from 0.0013 to 0.0017, the rotating speed is 300 r / m under the working environment (50 DEG C), the flexibility is 180 DEG, the flexible circuit board can be bent more than 12 million number of times, the flame retardance reaches UL to 94V0, and the GTT (glass-transition temperature) of an adhesive is from 200 to 220 DEG C.

Owner:BYD CO LTD

High-temperature-resistance pork paste essence and preparation method thereof

The invention discloses a high-temperature-resistance pork paste essence. The pork paste essence comprises the following components in parts by weight: 90-98 parts of thermal reaction pork paste and 2-10 parts of pork flavoring base, wherein, the thermal reaction pork paste is prepared from the following raw materials according to a certain mass ratio: a pork thermal reactant, edible salt, white granulated sugar, sodium glutamate, disodium 5'-ribonucleotide, disodium succinate, corn starch, hydroxypropyl distarch phosphate, beta-cyclodextrine and glycerin monostearate; and the pork thermal reactant is prepared from the following raw materials according to a certain mass ratio: a pork zymolyte, a yeast extract, glucose, xylose, dark soy sauce, animal fat, sodium glutamate, amino acid, ginger powder, cinnamon powder and water. After high-temperature treatment, the pork paste essence disclosed by the invention still has the characteristics of rich and durable flavor and strong high temperature resistance. Meanwhile, the invention further discloses a preparation method of the high-temperature-resistance pork paste essence.

Owner:广东江大和风香精香料有限公司

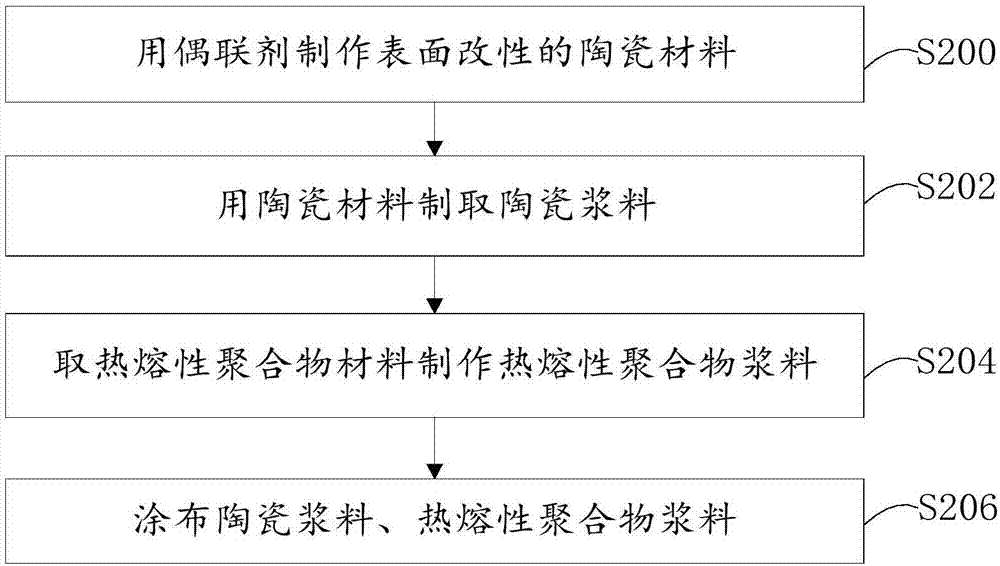

Lithium ion battery composite separator, preparation method thereof, and lithium ion battery

InactiveCN105140450APrevent internal short circuitGood high temperature resistanceCell seperators/membranes/diaphragms/spacersFinal product manufactureLithium electrodeElectrochemistry

The invention relates to a lithium ion battery composite separator, a preparation method thereof, and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery composite separator comprises a base film; one side of the base film is coated with a hot-melting polymer coating; the other side of the base film is coated with a heat-proof coating; the melting temperature of the hot-melting polymer coating is lower than the hot-melting temperature of the base film; the melting temperature of the heat-proof coating is higher than the hot-melting temperature of the base film; the hot-melting polymer coating comprises the following ingredients by weight: 50 to 98 parts of one or more hot-melt polymer materials, and 2 to 50 parts of one or more agglomerants; the heat-proof coating comprises the following ingredients by weight: 50 to 92 parts of one or more heat-proof polymer materials, and 3 to 20 parts of one or more agglomerants. The lithium ion battery composite separator is favorable in liquid sucking and retention properties, low in heat blocking hole temperature, and high in separator breaking temperature, thereby being capable of obviously improving the safety and the electrochemical property of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

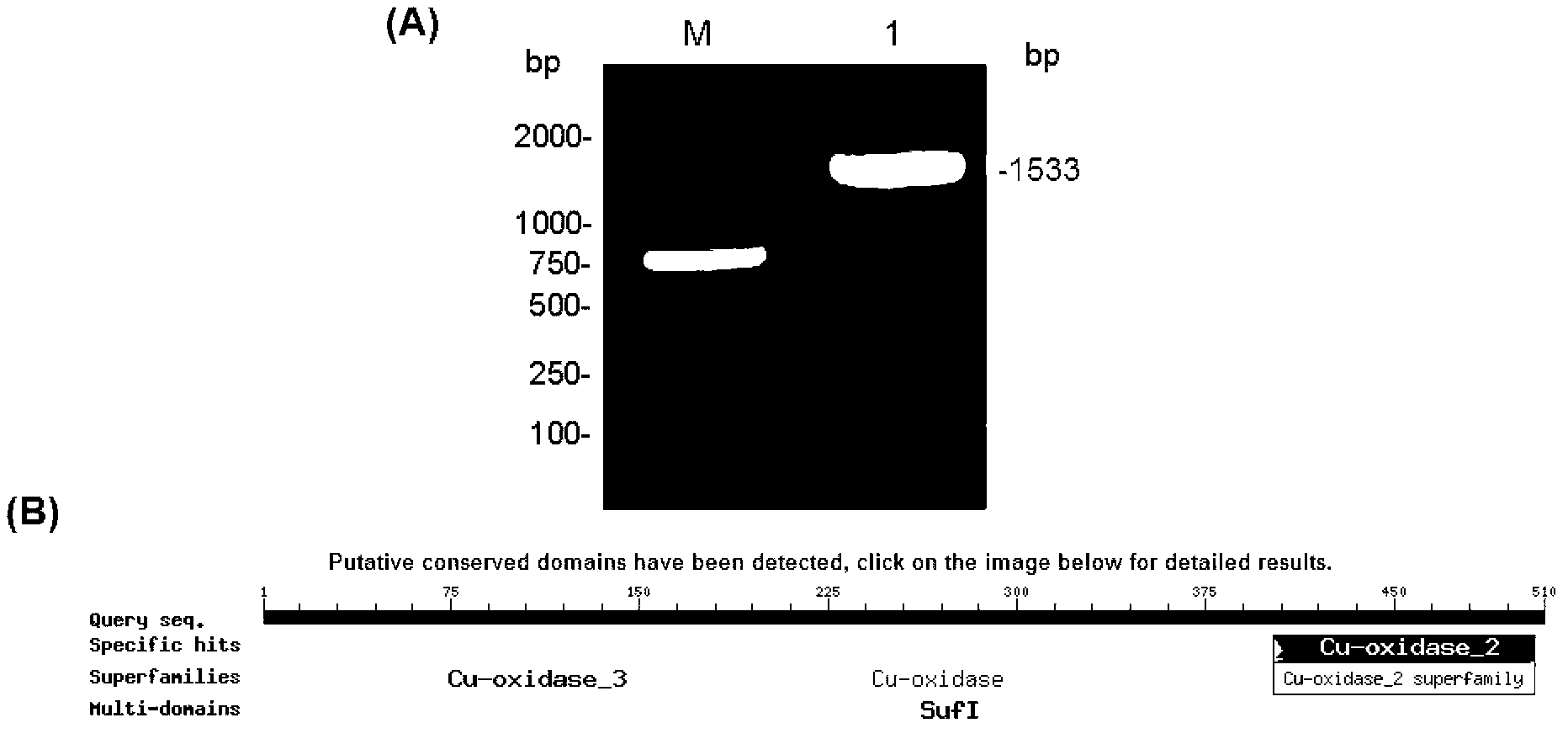

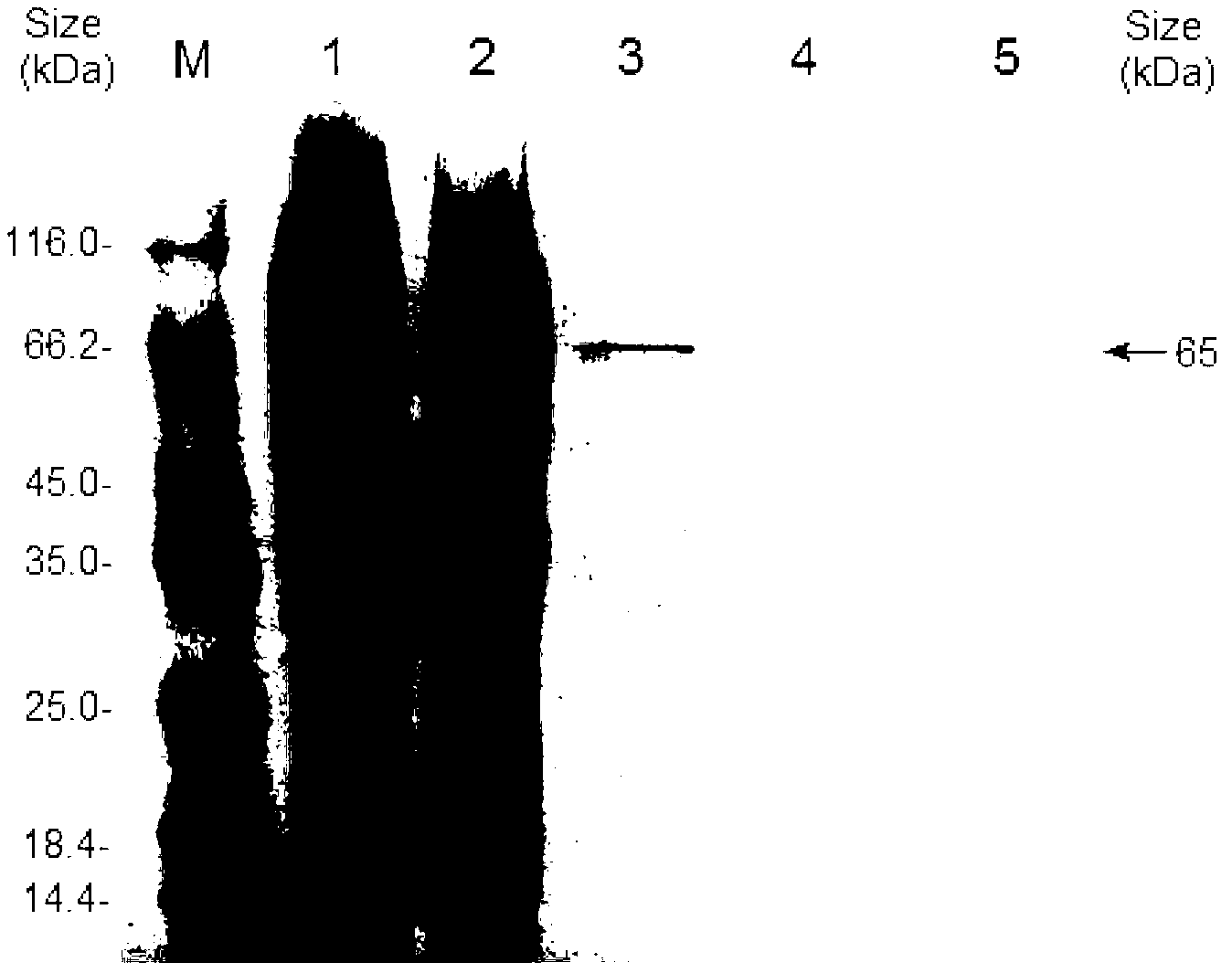

Bacillus pumilus laccase gene as well as expression and application thereof

InactiveCN103320453AIncrease productionEasy to meet industrial application requirementsBacteriaMicroorganism based processesEscherichia coliBacillus pumilus

The invention relates to a bacillus pumilus (Bacillus pumilus) L-9 laccase gene cotA as well as recombinant expression and application thereof, belonging to the field of bioengineering. The cotA is separated from the bacillus pumilus (Bacillus pumilus) L-9, an expression vector pColdII-cotA is constructed, and an escherichia coli expression strain BL21(DE3) is transformed to realize high-efficiency expression. The obtained recombinase laccase has the advantages of high alkaline environment resistance and high high-temperature resistance, has a good effect of discoloring azo dyes and anthraquinone dyes and has high application potential.

Owner:JIANGNAN UNIV

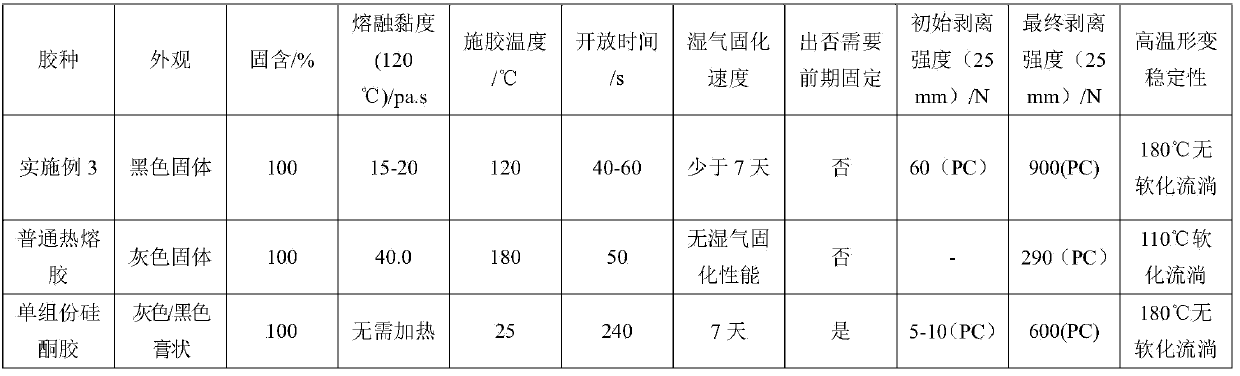

Moisture-cured polyurethane hot melt adhesive for car lamp and preparation method thereof

InactiveCN103740316AGood high temperature resistanceExcellent initial peel strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterSizing

The invention provides a moisture-cured polyurethane hot melt adhesive for a car lamp and a preparation method of the hot melt adhesive. The preparation method comprises the following steps: placing polyester polyol into a reaction kettle and heating; agitating and dehydrating in vacuum; then cooling; pre-heating diphenylmethane diisocyanate and adding into the reaction kettle; agitating in vacuum to carry out a pre-polymerization reaction; after the reaction, introducing nitrogen and pouring out a product under a protection condition; and sealing and packaging to obtain the moisture-cured polyurethane hot melt adhesive for the car lamp. The hot melt adhesive obtained by the invention has high initial and final bonding strength; the initial 180-degree stripping strength is more than or equal to 60N / 25mm and the final 180-degree stripping strength is more than or equal to 900N / 25mm; the surface drying time is less than 60 seconds; the moisture-cured polyurethane hot melt adhesive is not softened to flow at 180 DEG C and has a good sizing temperature (120 DEG C).

Owner:NANJING FORESTRY UNIV +1

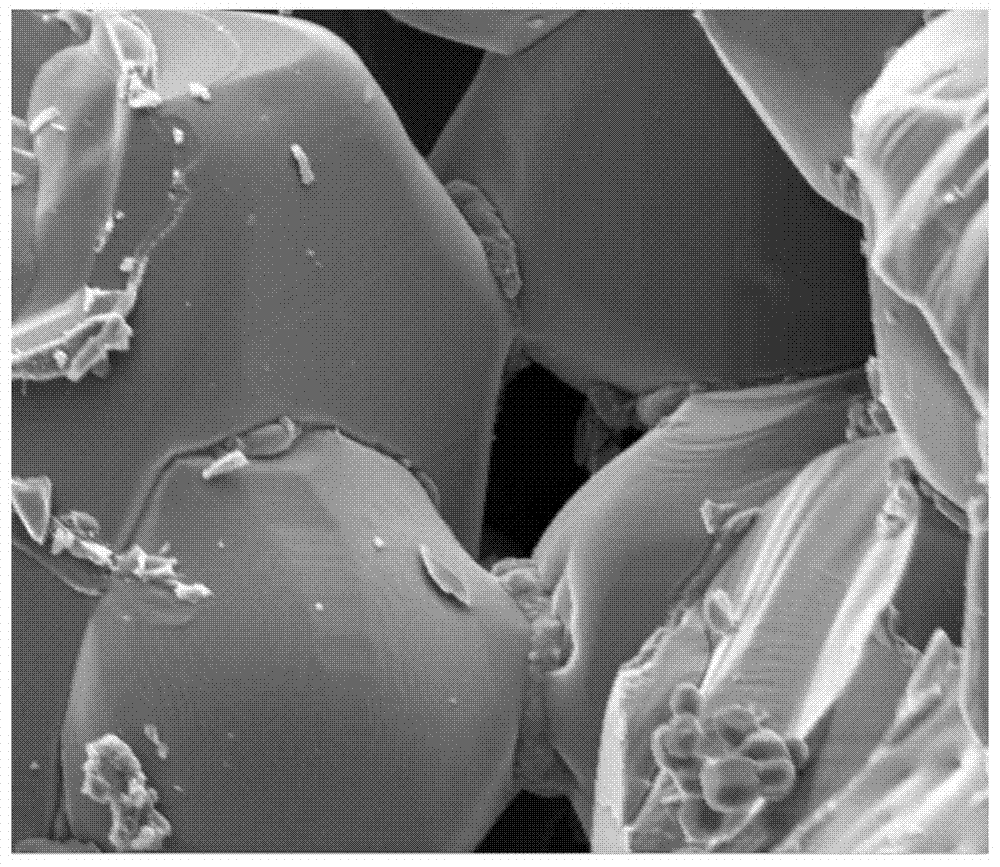

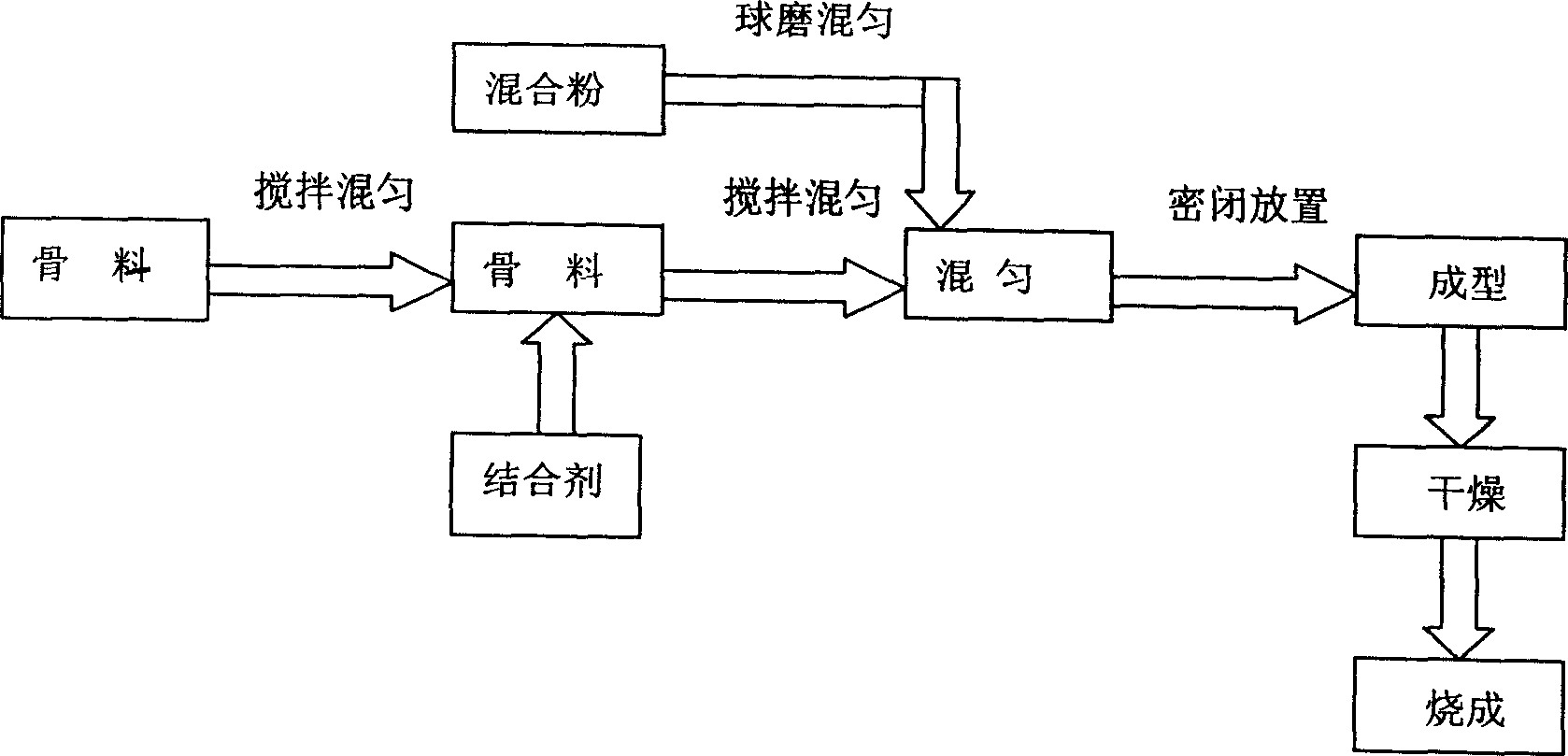

Preparation method of pure silicon carbide porous ceramic membrane

ActiveCN104261867AGood high temperature resistanceImprove high temperature resistanceCeramicwareCordieriteTemperature resistance

The invention relates to a preparation method of a pure silicon carbide porous ceramic membrane, which comprises the following steps: 1) forming a silicon carbide biscuit; 2) applying a silicon carbide membranous layer; and 3) sintering the pure silicon carbide porous ceramic. Since the silicon carbide has better high temperature resistance, corrosion resistance and thermal shock resistance than the alumina, cordierite, mullite and the like, the pure silicon carbide porous ceramic membrane material, which is prepared by using the fine-particle silicon carbide as the adhesive and large-particle silicon carbide as the aggregate as well as a composite pore forming agent and other materials, has greatly better high temperature resistance, corrosion resistance and thermal shock resistance, greatly widens the application range of the inorganic ceramic membrane, prolongs the service life under severe conditions, and has wide application prospects.

Owner:湖北迪洁膜科技有限责任公司

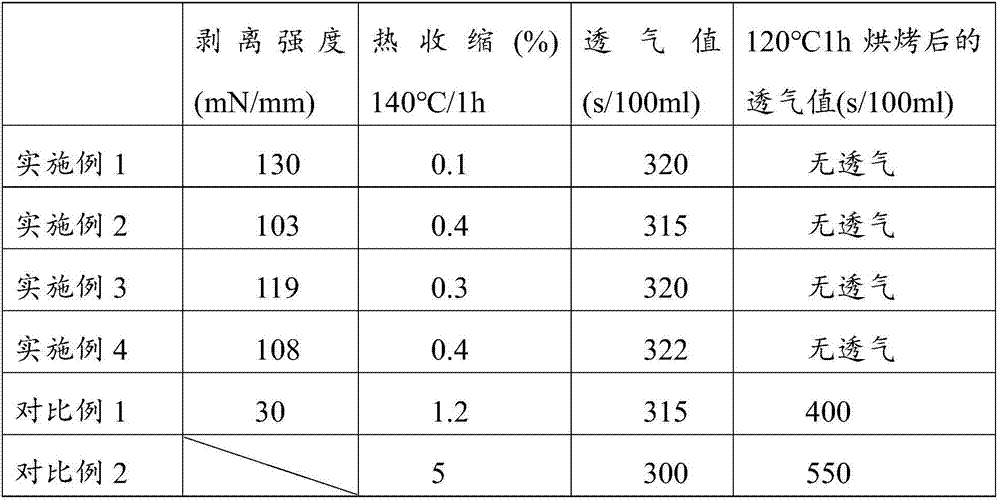

Diaphragm of lithium battery and preparation method thereof

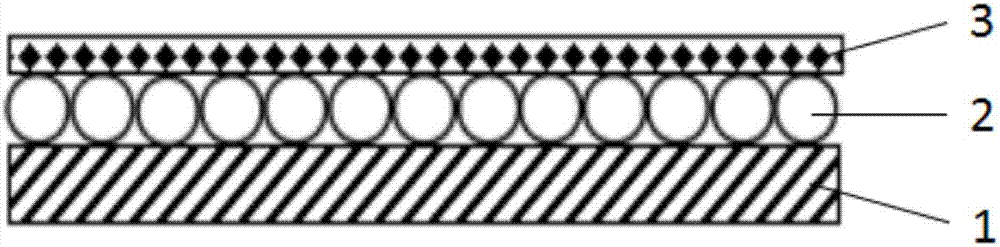

InactiveCN106887559AGood high temperature resistancePrevent heat shrinkageCell seperators/membranes/diaphragms/spacersCeramic coatingCeramic particle

The invention provides a diaphragm of a lithium battery and a preparation method thereof. The diaphragm of the lithium battery comprises a base diaphragm, a ceramic coating and a hot melted polymer coating. The ceramic coating and the hot melted polymer coating are located on the same side of the base diaphragm, and the ceramic coating comprises a ceramic particle material and a first adhesive; the hot melted polymer coating comprises hot melted polymer material particles and a second adhesive. The problem of thermal closing and thermal contraction of the diaphragm is solved.

Owner:XUCHENG FUJIAN SCI & TECH

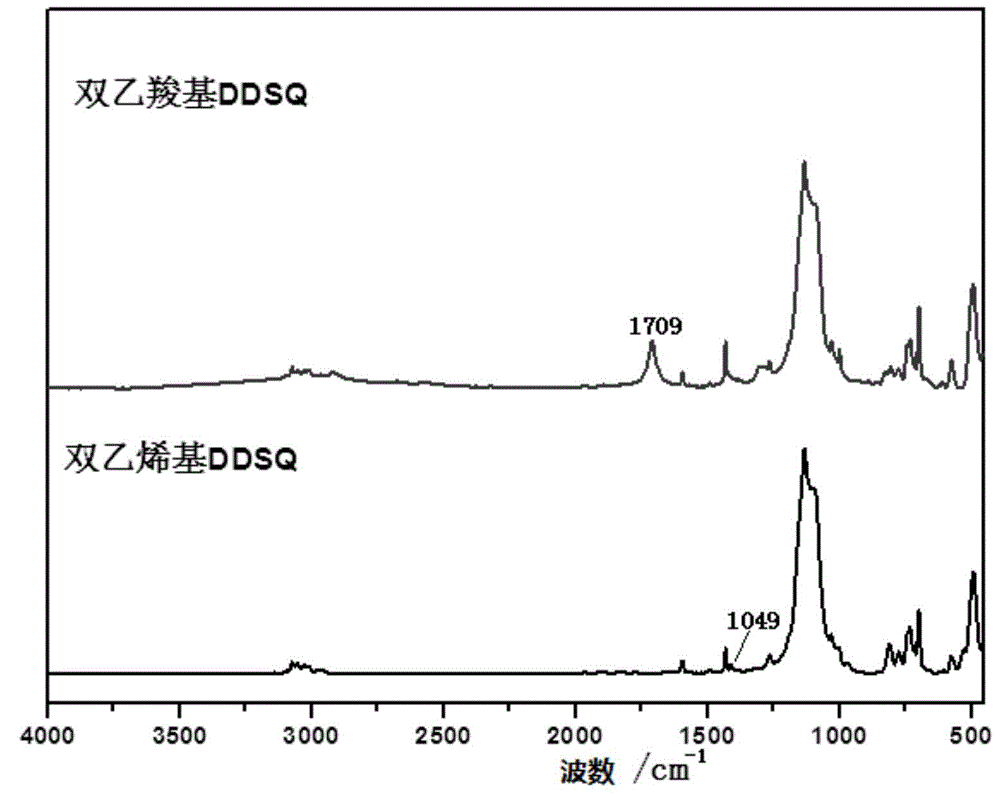

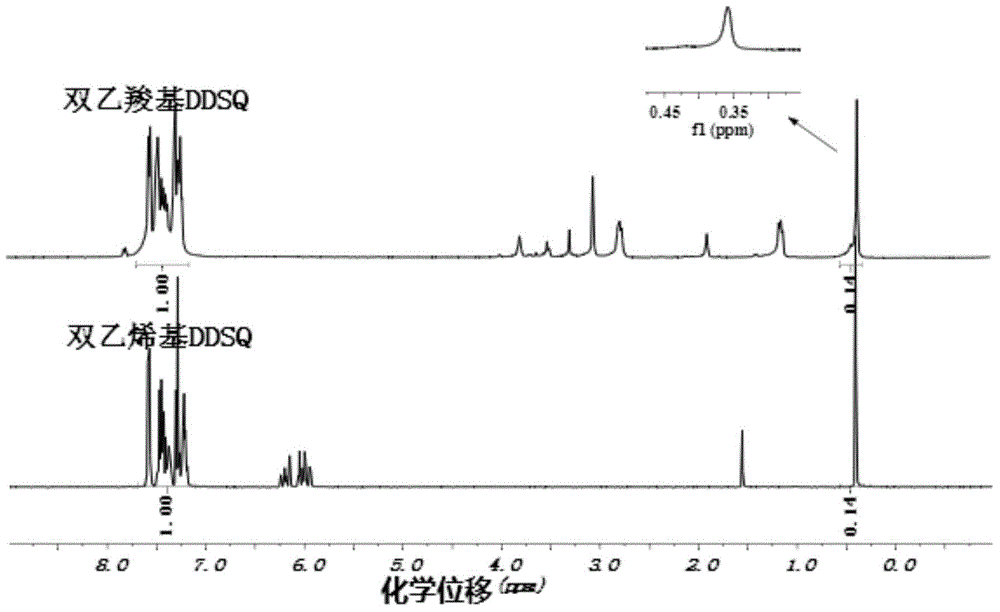

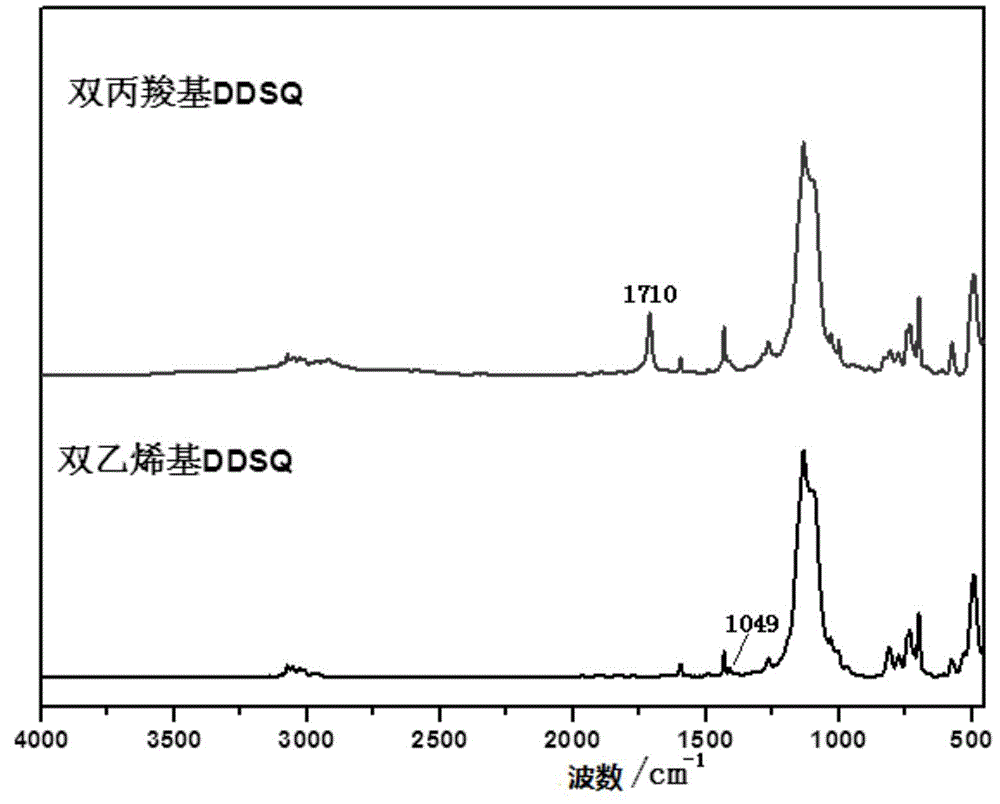

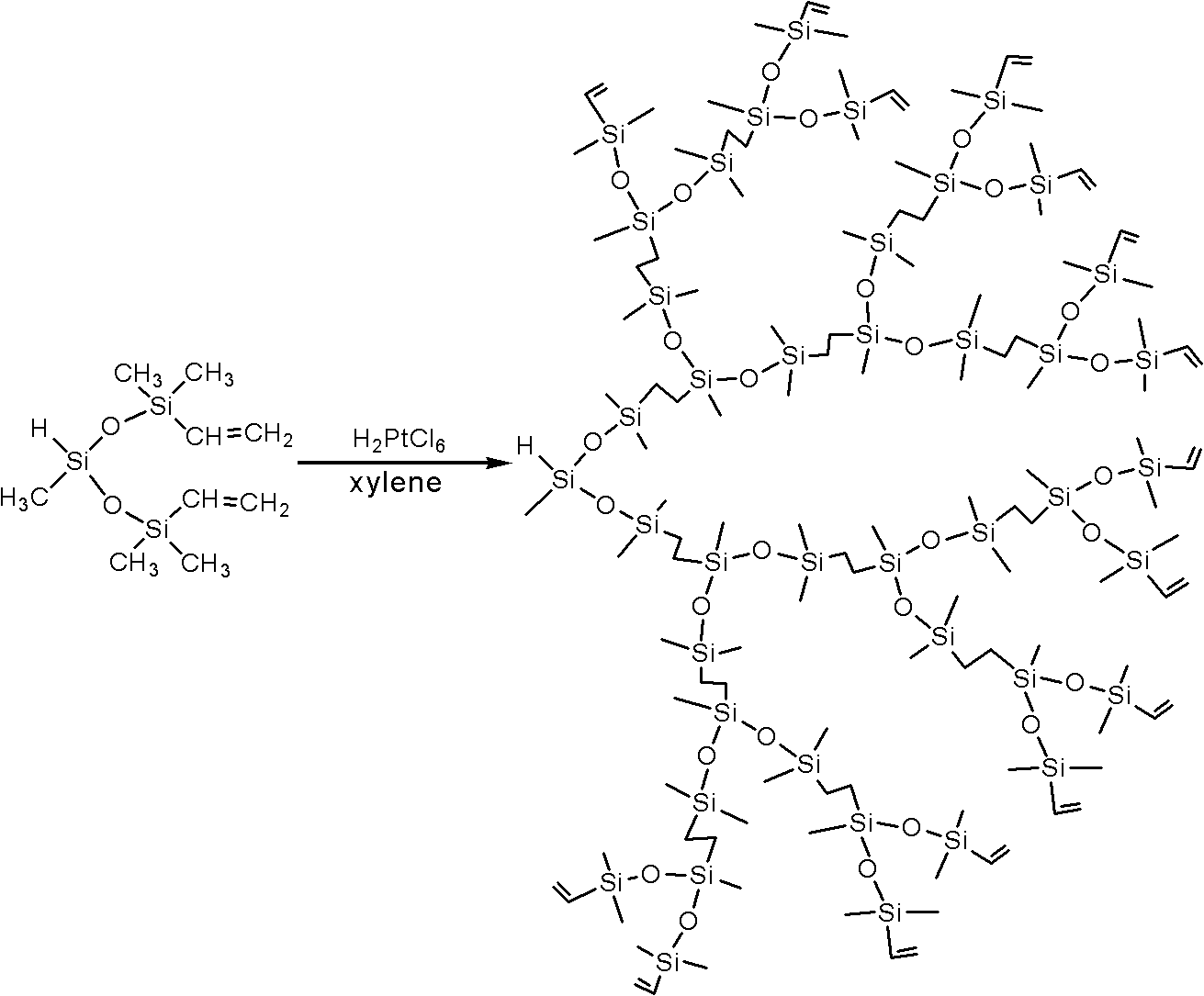

Functionalized double tower-type polyhedron oligomeric silsesquioxane and preparation method thereof

ActiveCN105198916AGood high temperature resistanceGood flame retardant performanceSilicon organic compoundsChemistryAddition reaction

The invention discloses functionalized double tower-type polyhedron oligomeric silsesquioxane. The functionalized double tower-type polyhedron oligomeric silsesquioxane can be widely used in special structure double tower-type polyhedron polysilsesquioxane preparation, polymer modification and polymer synthesis, and can be used in biomedical and photoelectric functional materials. The oligomeric silsesquioxane is obtained by a mercapto-olefin addition reaction of divinyl-containing double tower-type polyhedron oligomeric silsesquioxane, mercapto-terminated carboxylic acid, alcohol and amine. The preparation method has the advantages of control and operation easiness, short reaction time, high yield and purification easiness.

Owner:BEIJING UNIV OF CHEM TECH

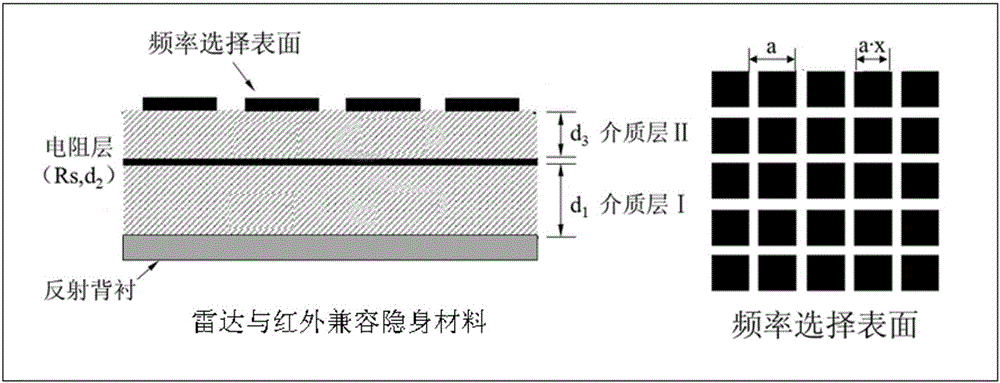

High-temperature-resistant radar and infrared compatible stealth material based on frequency selective surface and preparation method of high-temperature-resistant radar and infrared compatible stealth material

ActiveCN106003864AGood high temperature resistanceStrong antioxidantLamination ancillary operationsVacuum evaporation coatingOxideMetal coating

The invention discloses a high-temperature-resistant radar and infrared compatible stealth material based on a frequency selective surface. The high-temperature-resistant radar and infrared compatible stealth material comprises a dielectric layer I, a resistance layer, a dielectric layer II and the frequency selective surface from inside to outside sequentially, wherein the dielectric layer I and the dielectric layer II are made of oxide fiber reinforced oxide based composite materials; the resistance layer mainly comprises a high-temperature-resistant resistance coating; the frequency selective surface mainly comprises an anti-oxidative metal coating with periodical patterns, high temperature resistance and low infrared emittance. The preparation method comprises steps as follows: the dielectric layer I is prepared firstly, and the resistance layer is prepared on the dielectric layer I with a silk-screen printing technology; then the dielectric layer II is prepared on the resistance layer; finally, the frequency selective surface is prepared on the dielectric layer II with a physical deposition technology and a laser etching technology, and the stealth material is prepared. The radar and infrared compatible stealth material can be resistant to high temperature of 1,000 DEG C or higher, and has better high temperature resistance and excellent oxidation resistance.

Owner:NAT UNIV OF DEFENSE TECH

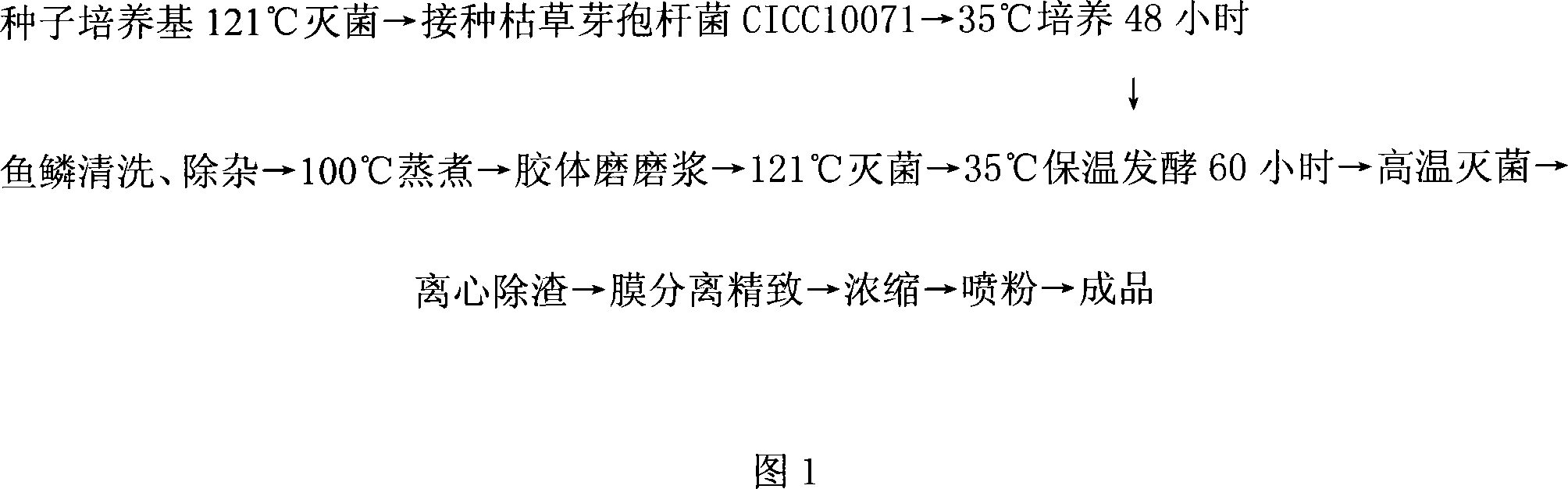

Method for preparing collagen peptide

InactiveCN101240313AGood acid resistanceGood high temperature resistanceMicroorganism based processesFermentationPeptideChemistry

The invention provides a method for preparing fish scale collagen protein peptides comprising the following steps (1) preparing fermentation seeds culture medium, (2) preparing fermentation seeds, (3) processing fish scale, (4) fermenting with constant temperature, (5) separating, (6) delicacy, (7) drying to obtain fish scale collagen protein peptides powder. The preparing process incorporating the invention comparing with other methods is simple, prepared collagen protein peptides can be solved into water complete, its solution in water is low viscosity and also has good flow property in high concentration, has good acid resistant and has no precipitating in acid or alkaline circumference, also has good high temperature resistant which has no precipitating even it is heated up to 100 DEG C.

Owner:湖北瑞邦生物科技有限公司

Refractory ceramic tile and preparation method thereof

The invention discloses a refractory ceramic tile and a preparation method thereof. The refractory ceramic tile is prepared from the following raw materials in parts by weight: 50-60 parts of cobblestone, 10-20 parts of cullet, 15-25 parts of apatite, 20-30 parts of bauxite, 10-15 parts of datolite, 16-22 parts of perlite, 9-16 parts of serpentine, 3-6 parts of floating bead, 12-18 parts of dickite, 5-10 parts of asbestos powder, 4-8 parts of mica powder, 10-15 parts of nanometer aluminum hydroxide, 4-6 parts of nanometer zirconia and 15-20 parts of modified clay. The ceramic tile has excellent high temperature resistance, has the refractoriness of over 1200 DEG C, is high in strength, low in shrinkage rate and wide in market prospect, has acid and alkali corrosion resistance and ageing resistance and can be applied to special occasions at relatively high temperature.

Owner:安徽省亚欧陶瓷有限责任公司

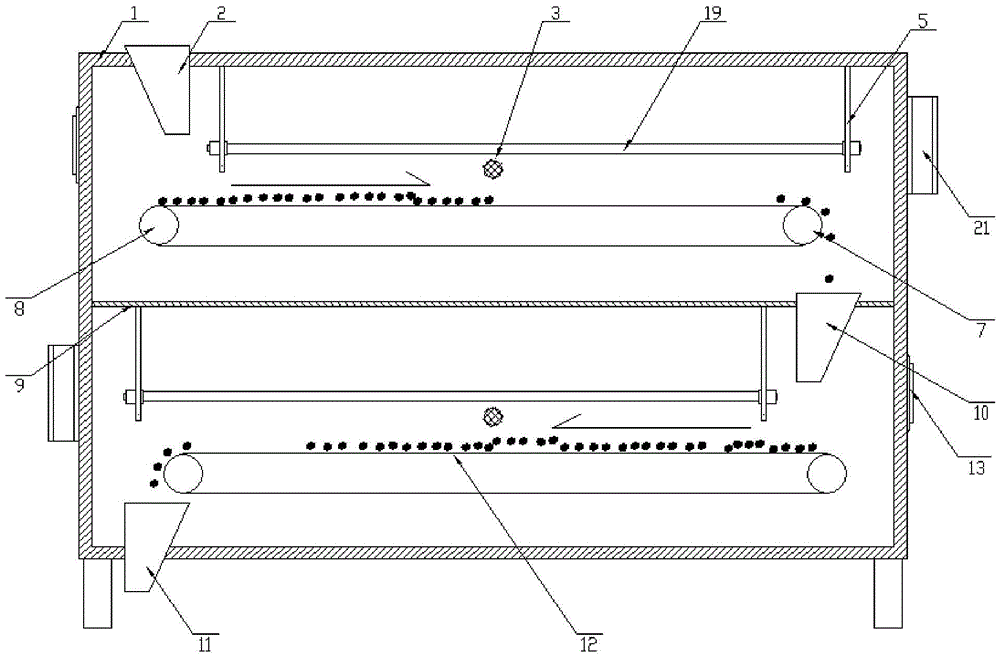

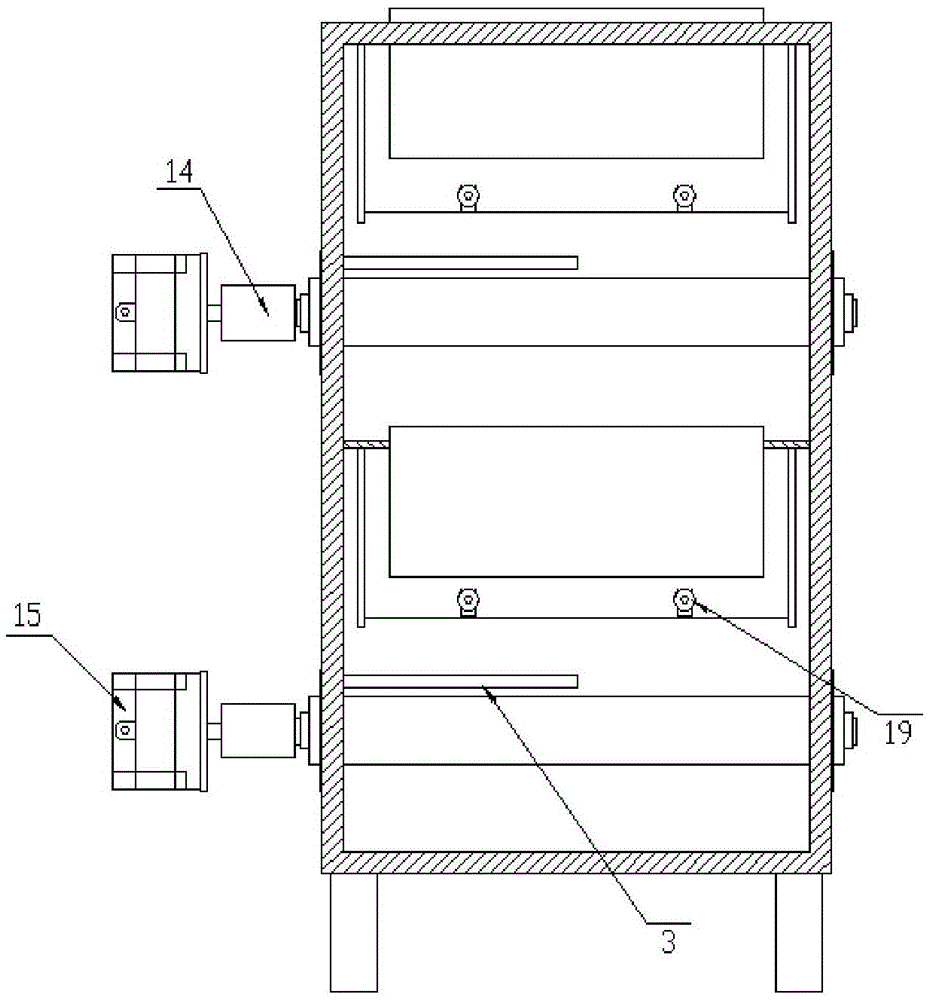

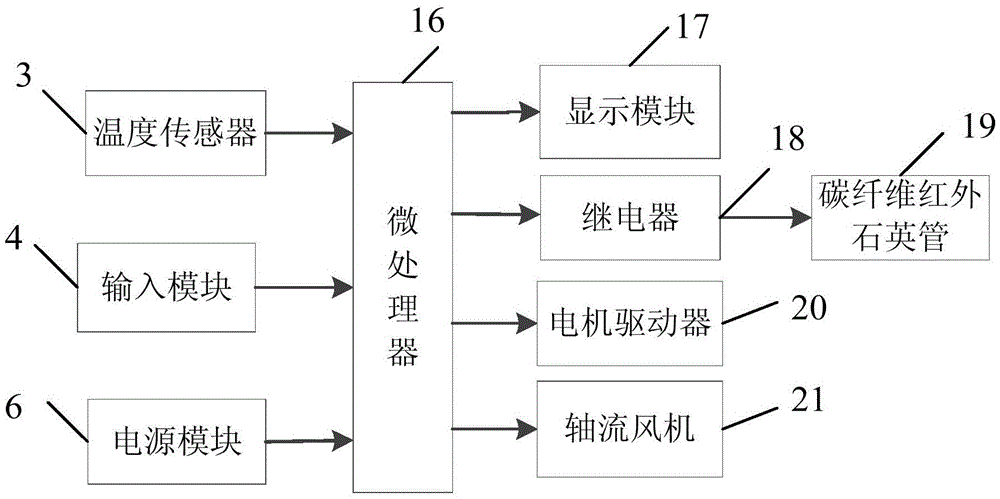

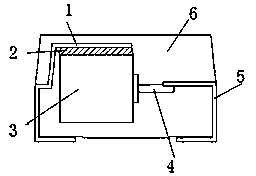

Granular crop grain drying device and method

InactiveCN105605906AImprove efficiencyGood high temperature resistanceDrying gas arrangementsDrying solid materialsEngineeringMoisture

The invention discloses a granular crop grain drying device and method. The drying device comprises a drying box, a conveying mechanism, a drying mechanism, a moisture removal mechanism, a temperature sensor, an input module and a microprocessor, wherein the top of the drying box is provided with a feed port; the bottom of the drying box is provided with a discharge port; the conveying mechanism is used for supporting and conveying crop grains, a feed end of the conveying mechanism is positioned below the feed port, and a discharge end of the conveying mechanism is positioned above the discharge port; the drying mechanism is horizontally arranged above or below the conveying mechanism, and used for emitting infrared rays and irradiating the infrared rays onto the crop grains; the moisture removal mechanism comprises a vent hole arranged in the drying box, and an axial fan installed on the drying box; the temperature sensor is used for detecting the temperature in the drying box; the input module is used for inputting a command by a user; and the microprocessor is respectively connected with the input module, drying mechanism, moisture removal mechanism and temperature sensor. The drying device has the advantages of high stability, high drying efficiency, high drying quality, high automation degree and low energy consumption.

Owner:SOUTHWEST UNIVERSITY

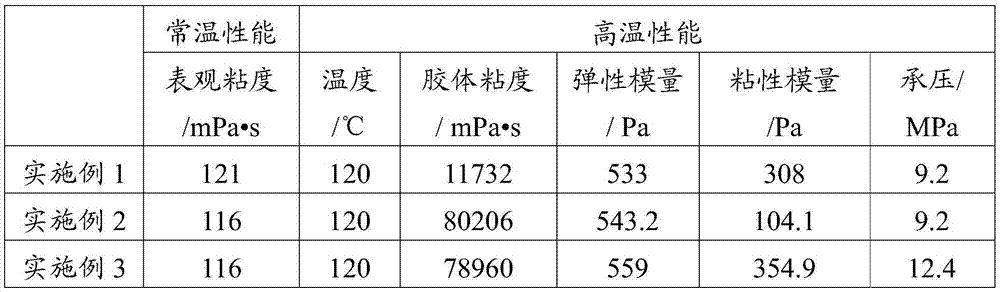

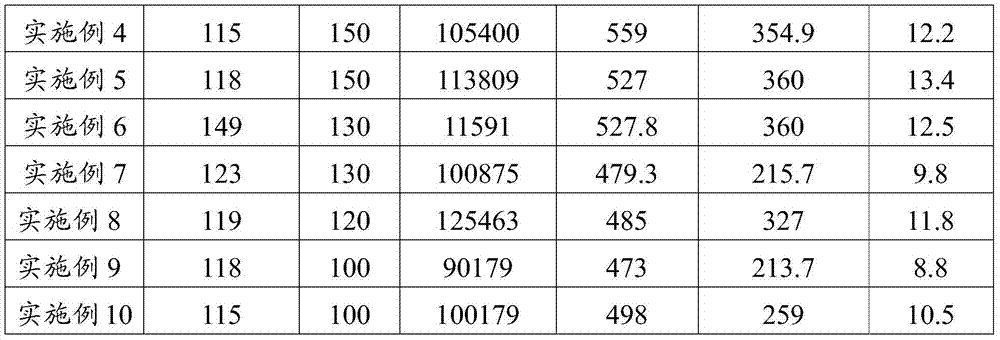

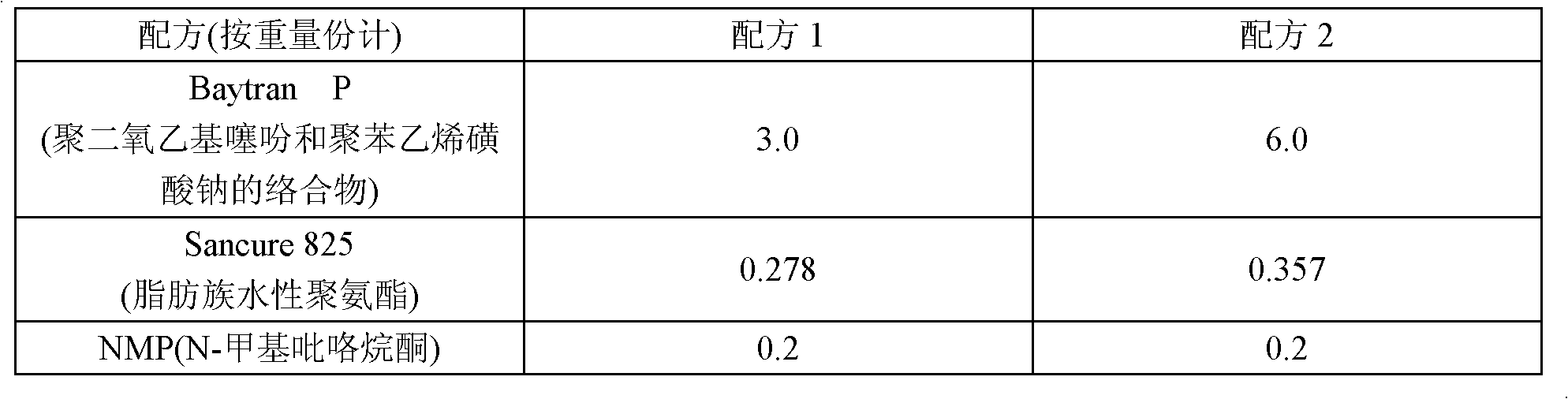

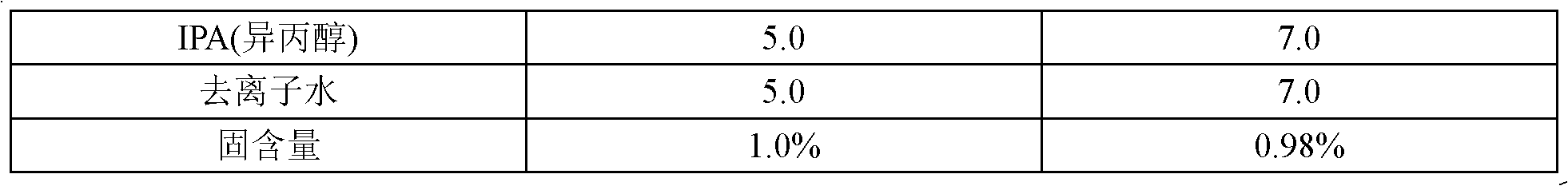

High temperature-resistant leakage stopping agent, and preparation method and application thereof

ActiveCN106867485AImprove high temperature resistanceGood high temperature resistanceDrilling compositionTemperature resistancePolyacrylamide

The invention discloses a high temperature-resistant leakage stopping agent, and a preparation method and an application thereof, and belongs to the technical field of petroleum drilling leakage stopping. The high temperature-resistant leakage stopping agent comprises, by mass, 2-3% of polyacrylamide, 1-2% of sulfonated phenolic resin, 0.9-2% of hexamethylenetetramine, 3-5% of a water swelling type granular plugging agent, 2-6% of a unidirectional pressure blocking agent, 0-3% of an alkaline pH regulator, and the balance of water. The leakage stopping agent has good high temperature resistance, and can meet leakage stopping needs of 80-150 DEG C drilling. The leakage stopping agent has low viscosity and low fluidity before forming gel, and is convenient for leakage stopping construction; and the leakage stopping agent has high strength and high stability after forming the gel, and has good plugging performance.

Owner:PETROCHINA CO LTD

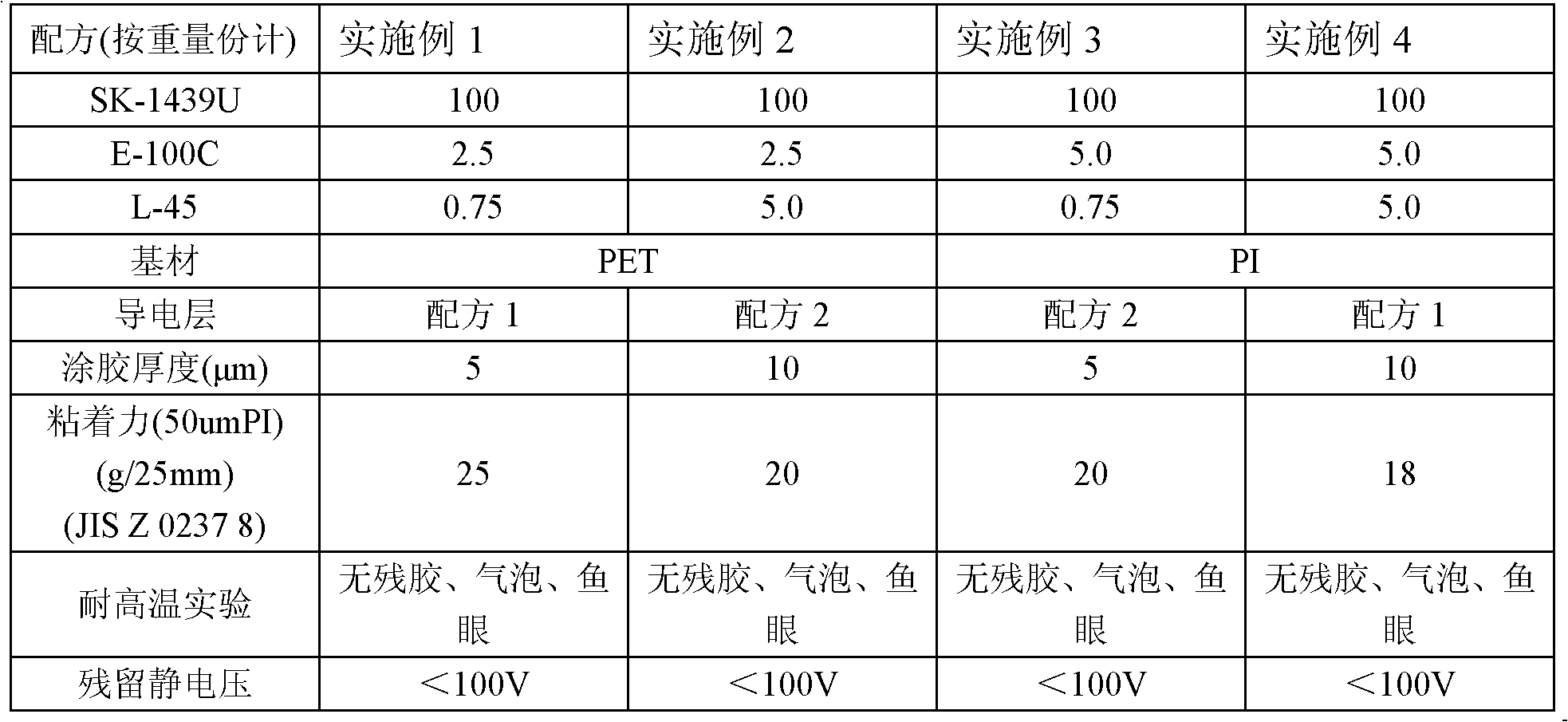

High-temperature-resistant antistatic adhesive tape and preparation method thereof

InactiveCN102352197AGood high temperature resistanceNot easy to residue glueFilm/foil adhesivesChemistryAcrylate

The invention relates to a high-temperature-resistant antistatic adhesive tape which comprises a substrate layer and an adhesive layer, wherein a conducting layer is arranged between the substrate layer and the adhesive layer; the adhesive layer adopts an acrylate adhesive; and the hardener adopts an epoxy hardener / isocyanate hardener mixed hardener. The invention also relates to a preparation method of the adhesive tape. Compared with the prior art, the invention has favorable high-temperature-resistant and antistatic functions; and the conducting layer is positioned between the adhesive layer and the substrate, thereby preventing the ionic additive from transferring to the PI surface to cause pollution.

Owner:NINGBO SOKEN CHEM

Block alumina aerogel with high temperature resistance and high specific surface area and preparation method thereof

InactiveCN102145994ALarge specific surface areaGood high temperature resistanceCeramicwareSolventTemperature resistance

The invention relates to a block alumina aerogel with high temperature resistance and high specific surface area, which comprises the following components in percentage by weight: 5 to 26.0 percent of yttrium oxide serving as an additive and the balance of alumina. The invention also relates to a method for preparing the block alumina aerogel with high temperature resistance and high specific surface area. In the method, inorganic aluminum salt is used as a precursor, YC13 is used as an additive, mixed solution of absolute ethyl alcohol and water is used as a solvent, and epoxide is used as a gel network inductive agent. The method comprises the following steps of: preparing sol by a sol-gel method; and preparing the transparent block alumina aerogel by supercritical drying. The block alumina aerogel prepared by the method has the characteristics of large specific surface area and good high temperature resistance performance and has an adjustable density in the range of 0.05g / cm3 to 0.1g / cm3. In the invention, sintering and phase variation of the alumina aerogel are inhibited by adding the additive when the alumina aerogel is used at high temperature, and the high specific surface area is kept.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

UV-curable organosilicon pressure-sensitive adhesive composition

ActiveCN102220106AImprove crosslink density and cohesionGood high temperature resistanceAdhesivesPressure sensitiveSolvent

The invention discloses a UV-curable organosilicon pressure-sensitive adhesive composition, mainly comprising the following ingredients: 2-60wt% of nonsaturated hyperbranched organosilicon polymer and 40-98wt% of MQ tackifying silicone resin, radical photoinitiator and catalyst, wherein, and the summation of nonsaturated hyperbranched organosilicon polymer and MQ tackifying silicone resin is 100wt%. The nonsaturated hyperbranched organosilicon polymer is at least one of polysiloxane, carbosilane, silazane or organosilicon polymer containing boron. The UV-curable organosilicon pressure-sensitive adhesive composition prepared by using nonsaturated hyperbranched organosilicon polymer as main ingredient, can significantly improve the crosslinking density and cohesion of the pressure-sensitive adhesive, and allows the organosilicon pressure-sensitive adhesive to have excellent properties of high temperature resistance, solvent resistance and radiation resistance.

Owner:广东宏昌新材料科技有限公司

High-temperature sheet-type tantalum capacitor and manufacturing method thereof

ActiveCN103366963AGood high temperature resistanceReduce volumeCapacitor dielectric layersCapacitor housing/encapsulationGlycol synthesisO-Phosphoric Acid

The invention discloses a high-temperature sheet-type tantalum capacitor and a manufacturing method of the high-temperature sheet-type tantalum capacitor. The manufacturing method of the high-temperature sheet-type tantalum capacitor comprises the steps that an anode is designed, namely, the weight of tantalum powder is calculated according to formation voltage which is 2-6 times of the nominal voltage, and a porous matrix anode tantalum core is formed through sintering; dielectric film is formed, namely, aqueous solution with electrolyte being boric acid or nitric acid or phosphoric acid or ammonium dihydrogen phosphate or ethylene glycol is selected as formation solution, and tantalum pentoxide dielectric film which is uniform in thickness and good in uniformity is formed on the surface of the anode tantalum core; a manganese dioxide cathode is manufactured, namely, the anode tantalum core is put into manganous nitrate with different proportions, repeated operation is conducted, and a manganese dioxide cathode layer is formed; the high-temperature sheet-type tantalum capacitor is assembled. The high-temperature sheet-type tantalum capacitor can resist high temperature of 200 DEG C, has good high-temperature-resisting capacity, and is small in size, good and stable in performance, and capable of being widely applied to the fields of power supply control parts of airplane noses or guided missiles or the like and the fields of petroleum drilling electronic circuits and the like.

Owner:ZHUZHOU HONGDA ELECTRONICS

Lost foam casting method for heavy casting

ActiveCN102825215AHigh strengthGood high temperature resistanceFoundry mouldsFoundry coresStationary modelLost-foam casting

The invention discloses a lost foam casting method for a heavy casting. The method comprises the following steps of: a. manufacturing a foam model; b. mounting a counter-deformation bracket: manufacturing the steel-structured counter-deformation bracket according to the size and the length of a workpiece and placing the counter-deformation bracket on the bottom of the foam model; c. painting: the thickness of the paint is not less than 4mm; d. drying: placing the painted foam model in a drying room for drying at the constant temperature of 50 DEG C; e. fixing core: placing the steel-structured bracket in an inner cavity of the foam model so as to fix the model, and putting the whole foam model into a sandbox together; f. boxing: enabling the sandbox containing the foam model to drop sand evenly, vibrating the sandbox during sand dropping, gradually enhancing the vibration amplitude with the increasing of added sand quantity, mounting a main runner and a branch runner of a ceramic tube, and placing a pouring cup; g. pouring: opening a vacuum pump for vacuum pumping before pouring; h. releasing negative pressure: after pouring, keeping the negative pressure for 8 to 15 minutes until solidification of an iron liquid, and then releasing the negative pressure; and i. cleaning.

Owner:东莞市巨高机床有限公司

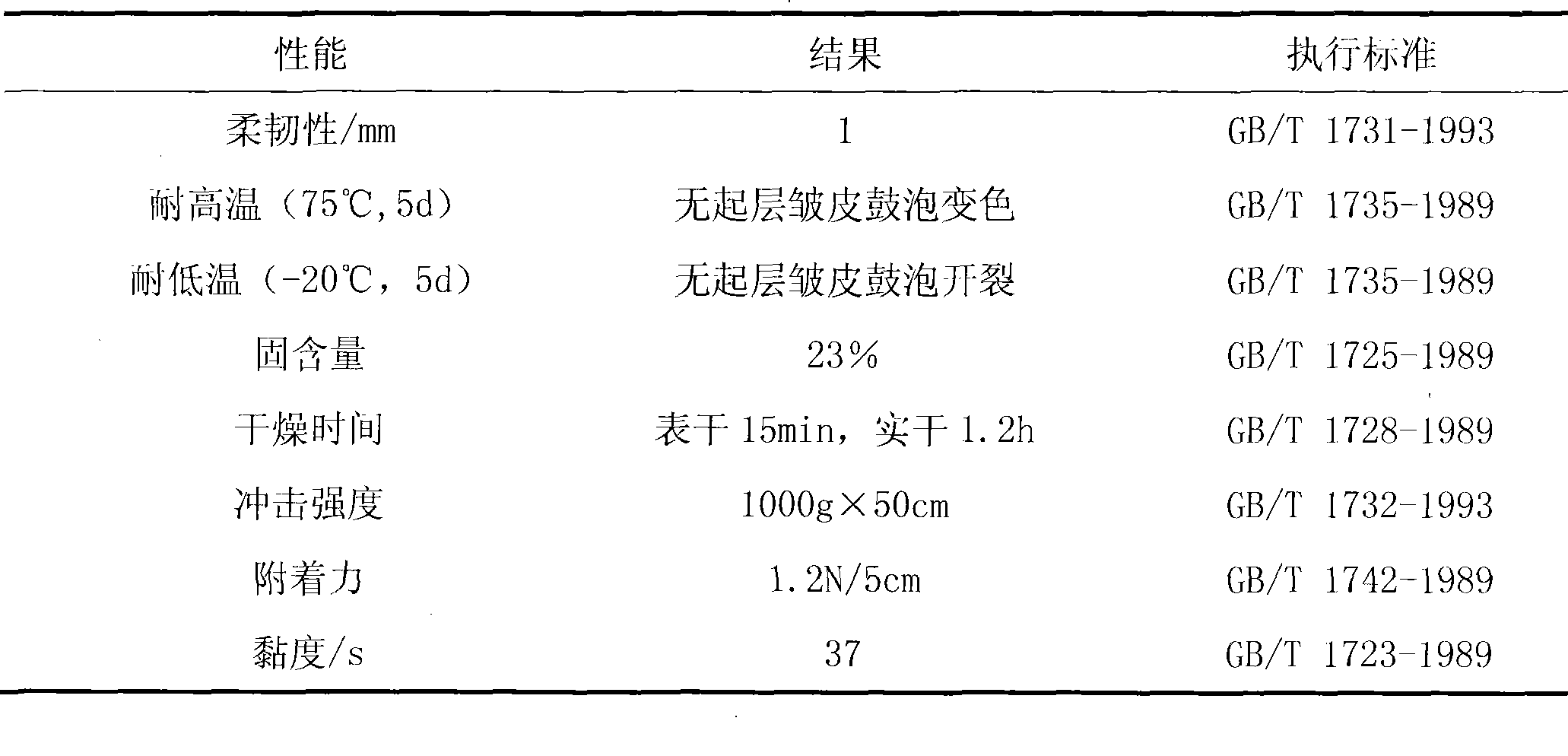

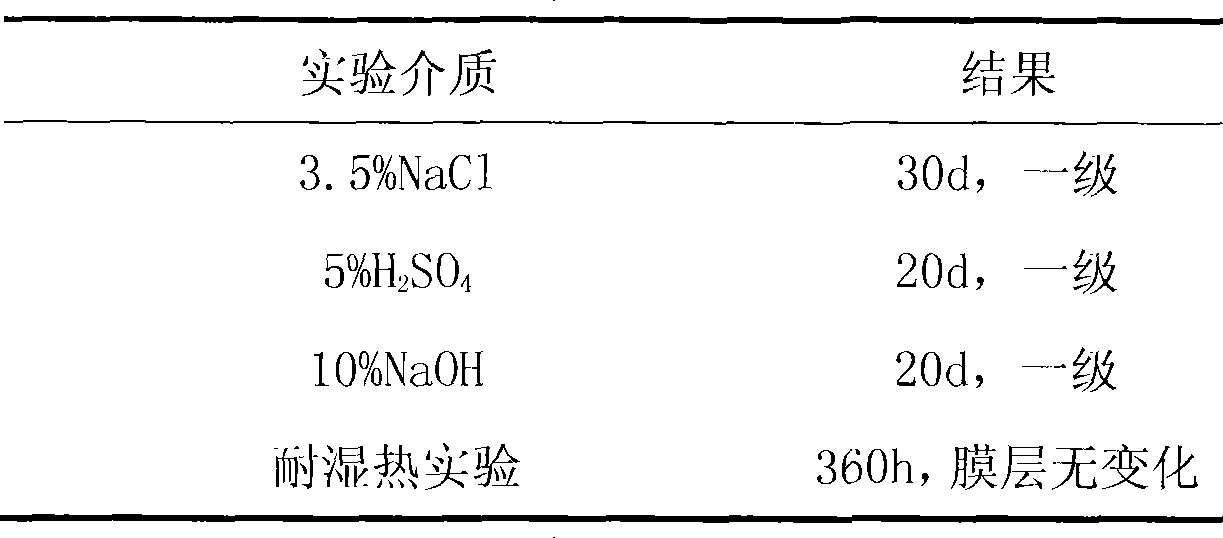

High temperature resistant strippable anti-corrosive paint and preparation method thereof

InactiveCN101386763AGood high temperature resistanceEasy to applyAnti-corrosive paintsSolventTemperature resistance

The invention relates to a special coating, in particular to a high temperature resistant strippable anti-corrosion coating and a preparation method thereof. The coating consists of a film forming agent, an auxiliary agent and a solvent, and the compositions in percentage by weight are as follows: 12 to 17 percent of the film forming agent, 5 to 10 percent of the auxiliary agent, and 73 to 83 percent of the solvent. The concrete preparation method comprises the following steps: the film forming agent, the auxiliary agent and the solvent are mixed according to the weight ratio, and then are stirred at normal temperature in a closed container to dissolve for 30 minutes to obtain a product. The coating takes a high molecular polymer as a film forming material, has the advantages of good acid, base and salt resistances, excellent toughness, remarkable high temperature resistance, easiness for coating, convenient unsealing, and no pollution to the surface of metal after a solidified coating film is stripped; in addition, the stripped coating film can be repeatedly used after the treatment.

Owner:DALIAN MARITIME UNIVERSITY

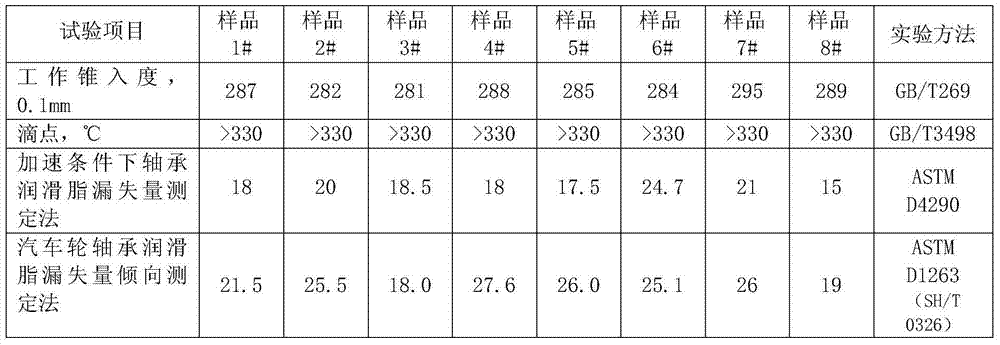

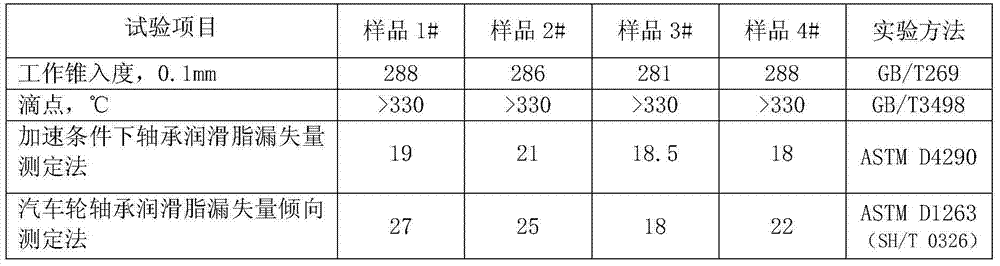

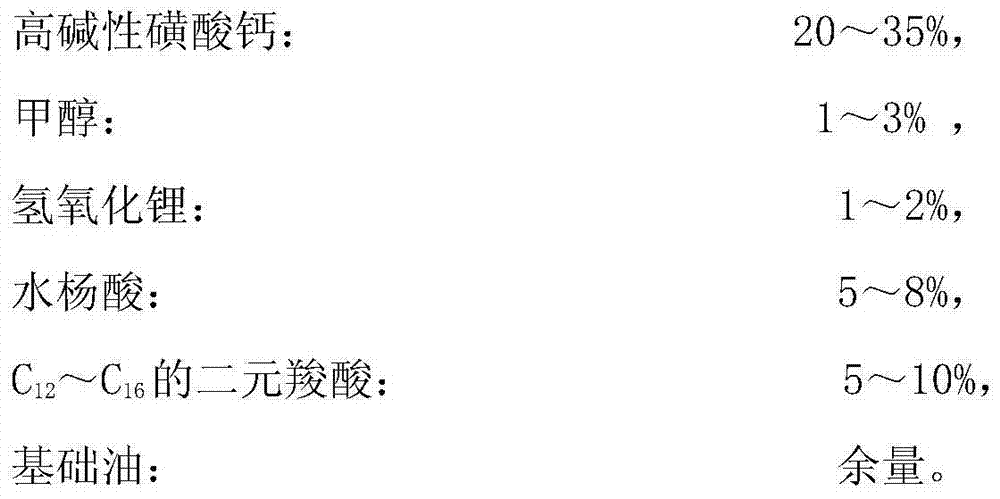

Composition of compound calcium sulfonate-based lubricating grease for improving high-temperature performance and preparation method thereof

InactiveCN104327906AGood high temperature resistanceImprove retentionThickenersTemperature resistanceSalicylic acid

The invention relates to a composition of compound calcium sulfonate-based lubricating grease for improving high-temperature performance and a preparation method thereof. The composition is prepared from a high-alkalinity calcium sulfonate cleaner, methanol, lithium hydroxide, salicylic acid, C12-C16 salicylic acid and base oil. The lubricating grease provided by the invention has relatively good high-temperature resistance and meets the seepage loss of ASTM D4290 and ASTM D1263 (industrial standard is SH / T0326). Experiments show that the seepage loss ranges from 5 to 10 which is obviously better than that (15-35g) of marketed products. The improving method provided by the invention can be used for prolonging the retentivity of the lubricating grease in a friction pair so as to ensure the operating reliability of equipment. The high-temperature performance of the prepared sample is obviously better than that of the marketed products.

Owner:CHINA PETROLEUM & CHEM CORP

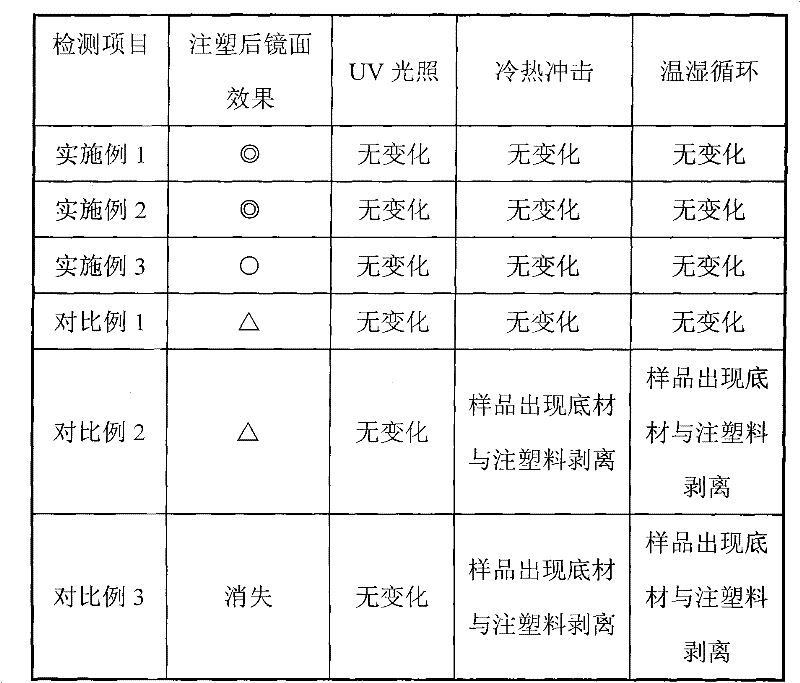

Mirror-like silver ink and preparation method thereof, and printed matter

InactiveCN102453380AGood high temperature resistanceWide range of applicationsOther printing matterInksSolventInjection molding process

The invention relates to a mirror-like silver ink and a preparation method thereof, and a printed matter. The components of the mirror-like silver ink include aluminum paste, a matrix resin, a first solvent and an auxiliary, wherein the matrix resin is composed of an ether modified polyurethane resin and a cellulose acetate butyrate modified acrylic resin. The mirror-like silver ink disclosed in the invention has excellent resistance to high temperature and has wider application range; the ink can be combined with the in-mold labeling injection molding process to show new decoration effect and even to replace the appearance effect that generally only a metal can achieve; therefore, the process is simplified and the cost is reduced. The printed matter obtained through printing using the mirror-like silver ink disclosed in the invention has excellent mirror-like effect.

Owner:BYD CO LTD

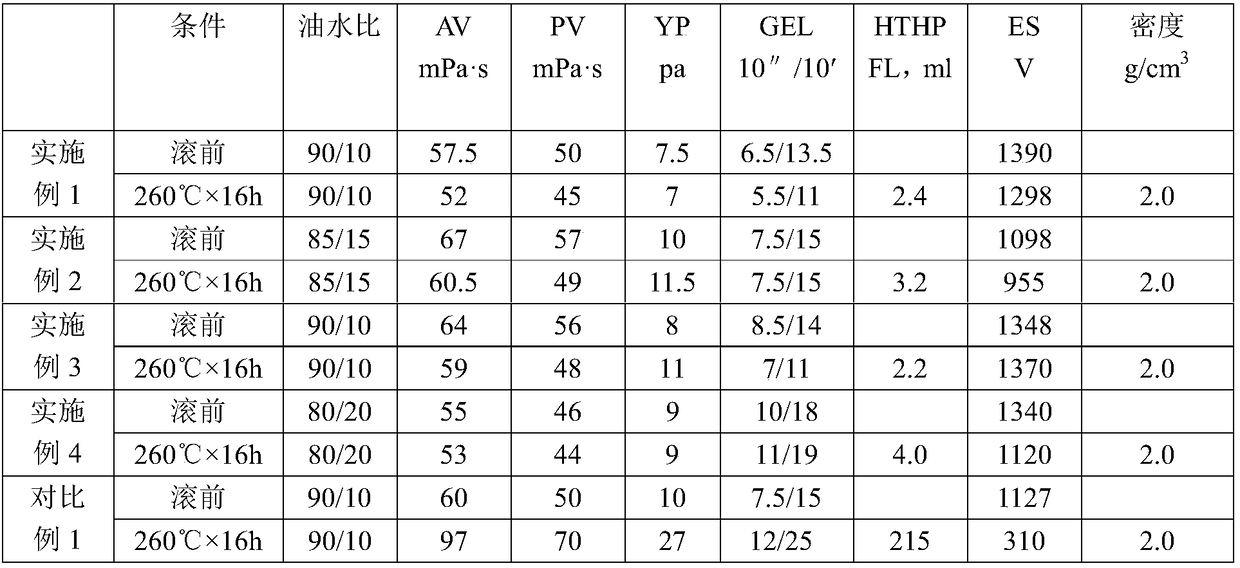

High-temperature resistant oil-based drilling fluid and preparation method thereof

InactiveCN109337659ASystem performance is stableGood high temperature resistanceDrilling compositionWater in oilChemistry

The invention discloses high-temperature resistant oil-based drilling fluid, wherein the drilling fluid comprises water-in-oil base liquid, a primary emulsifier, a co-emulsifier, a filtrate reducer, an alkalinity adjuster, organic soil, a wetting agent and weighting agent powder; the water-in-oil base liquid comprises base oil and brine in a volume ratio of 65:35-95:5; rest components including 0.5 to 2.5g of the organic soil, 0.5 to 2g of the primary emulsifier, 1 to 2g of the co-emulsifier, 1 to 2g of the wetting agent, 1 to 3g of the alkalinity adjuster, 5 to 8g of the filtrate reducer, and0 to 230g of a weighting agent are added calculated in per 100mL of the water-in-oil base liquid; the drilling fluid prepared with the method is subjected to hot rolling at the temperature of 260 DEGC, system performances are stable, the demulsification voltage is above 1000V, the filtration loss is below 8ml, and the preparation process is simple and convenient to operate.

Owner:北京石大胡杨石油科技发展有限公司

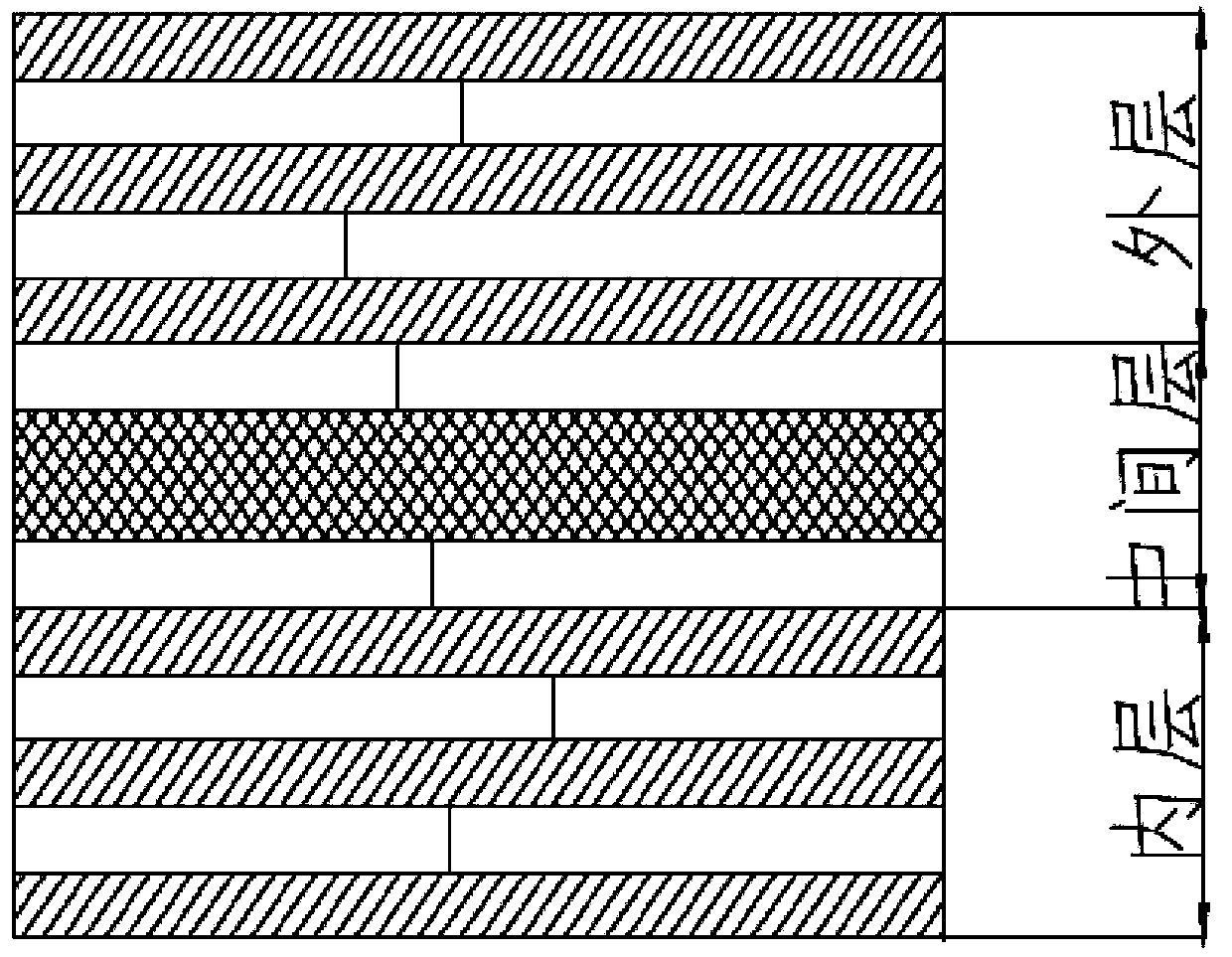

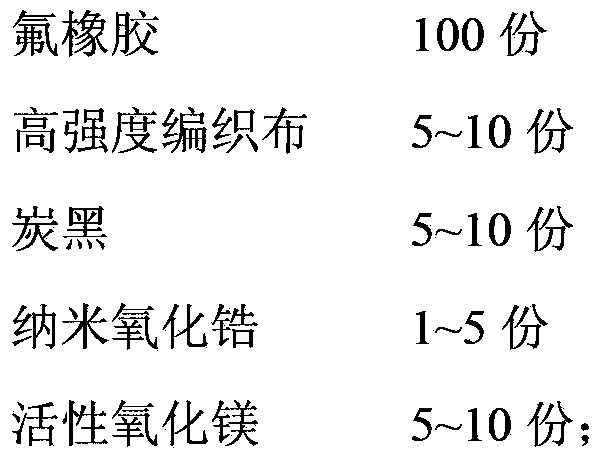

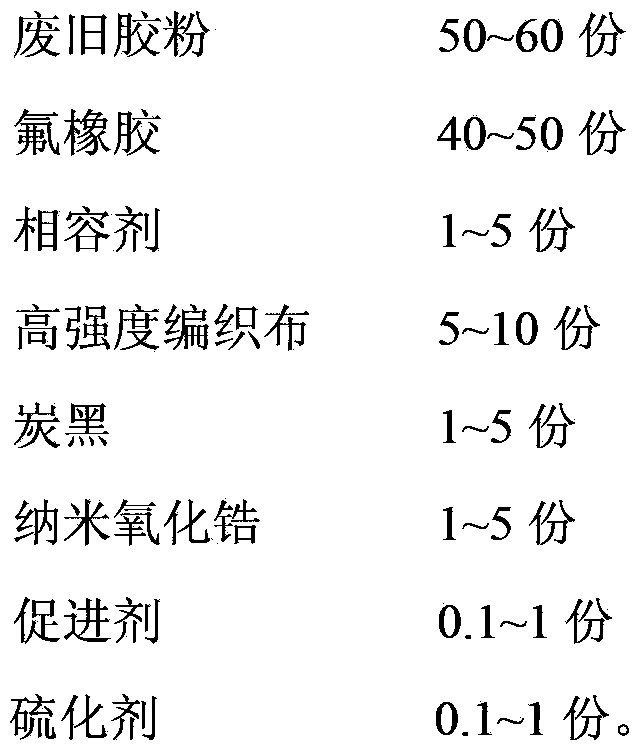

High-temperature resistant oil well rubber sealing ring material and preparation method thereof

ActiveCN103496229AGood high temperature resistanceReduce raw material costsEngine sealsLaminationFilling materialsCarbon black

The invention provides a high-temperature resistant oil well rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is composed of three parts: the inner layer and the outer layer are both composed of high-strength knitted cloth added with inorganic materials such as carbon black, nano zirconia, and the like; the middle layer is prepared through following steps: compounding rubber powder, which has been desulfurated through thermal mechanical shearing, with fluoro-rubber, adding a compatilizer to increase the compatibility between the rubber powder and the fluoro-rubber; then adopting high-strength knitted cloth, which has been subjected to a surface treatment, as the support body, adding inorganic filling materials such as carbon black, nano zirconia, and the like, and subjecting the knitted cloth added with inorganic filling materials to a high-temperature sulfide cross-linked forming so as to obtain the middle layer. The sealing ring knitted cloth and the rubber base material are subjected to processes of multi-layer compounding and sulfide forming. The sealing ring prepared by the invention has a good high-temperature resistant performance, and is capable of being used in areas with a large temperature difference for a long period.

Owner:CHANGZHOU UNIV

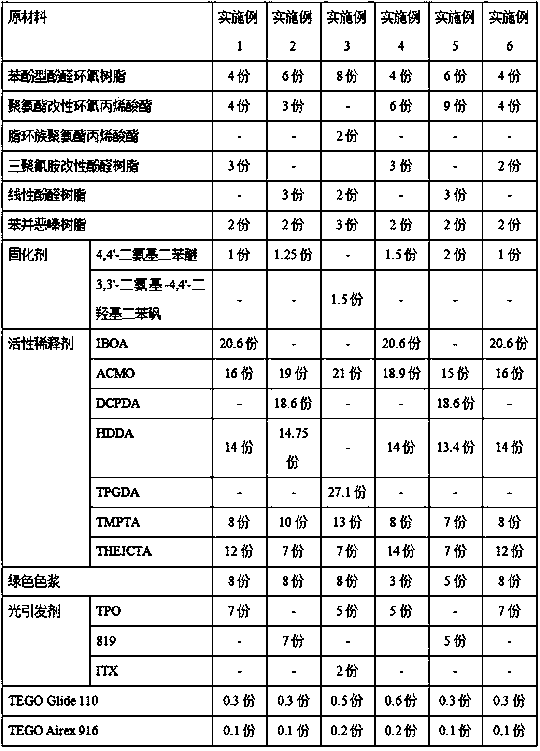

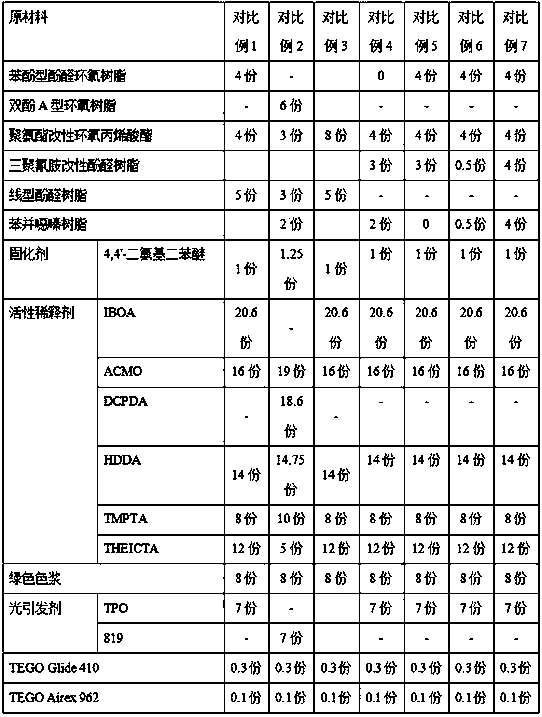

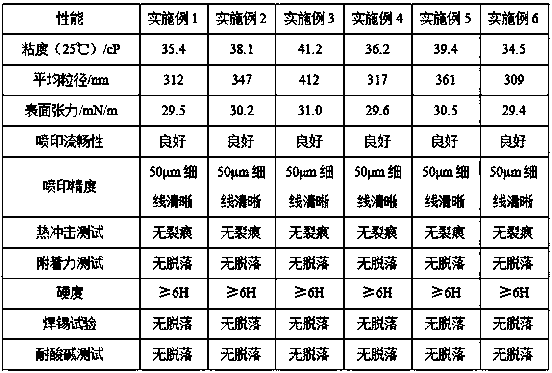

High-temperature-resisting type UV-LED (Ultraviolet-Light Emitting Diode) inkjet printing solder-resisting ink as well as preparation method and application thereof

The invention discloses high-temperature-resisting type UV-LED (Ultraviolet-Light Emitting Diode) inkjet printing solder-resisting ink as well as a preparation method and application thereof. The high-temperature-resisting type UV-LED inkjet printing solder-resisting ink is prepared from the following components in parts by mass: 2 to 10 parts of phenolic epoxy resin, 2 to 10 parts of photo-curingacrylic resin, 1 to 5 parts of first phenolic resin, 1 to 5 parts of second phenolic resin, 1 to 4 parts of curing agent, 40 to 80 parts of active diluting agent, 3 to 10 parts of nano color paste, 3to 10 parts of photoinitiator and 0.1 to 1 part of auxiliary agent; the second phenolic resin is benzoxazine resin; the first phenolic resin is other phenolic resin except the benzoxazine resin; themass ratio of the phenolic epoxy resin to the first phenolic resin to the second phenolic resin is 2 to (0.5 to 1.5) to (0.5 to 1.5). The high-temperature-resisting type UV-LED inkjet printing solder-resisting ink provided by the invention has good high-temperature-resisting performance, good adhesive force, good acid and alkali resistance, good heat impact resistance, high rigidity and the like.

Owner:江门市阪桥电子材料有限公司

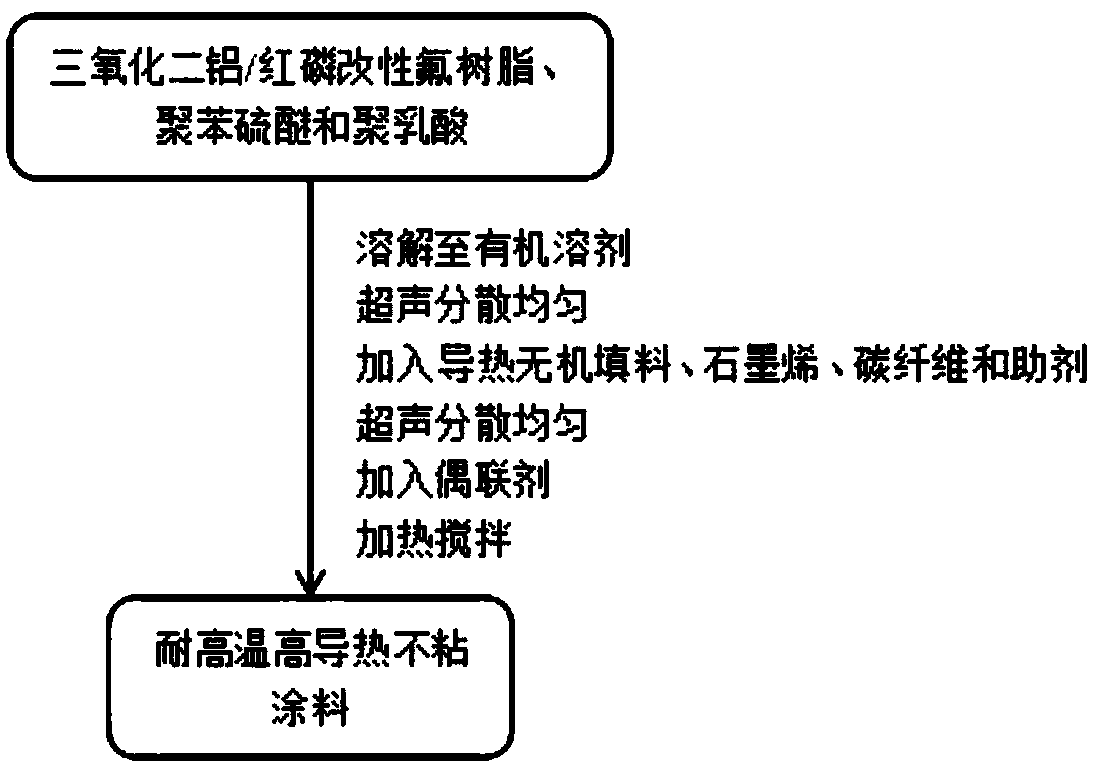

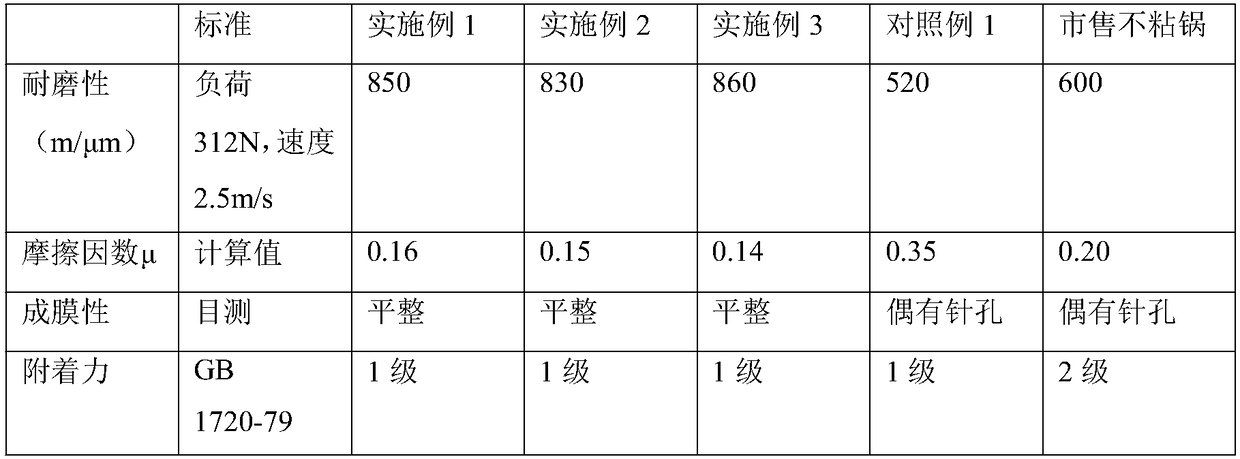

High-temperature-resistant and high-thermal-conductivity non-stick coating, method for preparing same and application of high-temperature-resistant and high-thermal-conductivity non-stick coating

ActiveCN108893009AGood high temperature resistanceGood thermal conductivityFireproof paintsPolyester coatingsAluminiumSulfide

The invention provides high-temperature-resistant and high-thermal-conductivity non-stick coating. The high-temperature-resistant and high-thermal-conductivity non-stick coating is prepared from raw materials including, by weight, 100-120 parts of aluminium sesquioxide / red phosphorus modified fluorine resin, 50-70 parts of polyphenylene sulfide, 50-70 parts of graphene, 30-50 parts of carbon fibers, 40-70 parts of polylactic acid, 20-30 parts of thermal conduction inorganic fillers, 10-20 parts of coupling agents and 20-30 parts of auxiliaries. The auxiliaries comprise leveling agents, defoaming agents, film-forming agents, antioxidants, preservatives and ceramic powder. The high-temperature-resistant and high-thermal-conductivity non-stick coating has the advantages that the raw materialsfor the prepared high-temperature-resistant and high-thermal-conductivity non-stick coating can come from wide sources, a method for manufacturing the high-temperature-resistant and high-thermal-conductivity non-stick coating is simple and controllable, coatings prepared from the high-temperature-resistant and high-thermal-conductivity non-stick coating can be used at the high temperatures of 400-500 DEG C for a long term without influence on the performance, and accordingly the high-temperature-resistant and high-thermal-conductivity non-stick coating has a broad application prospect.

Owner:ZHEJIANG COOKER KING COOKER

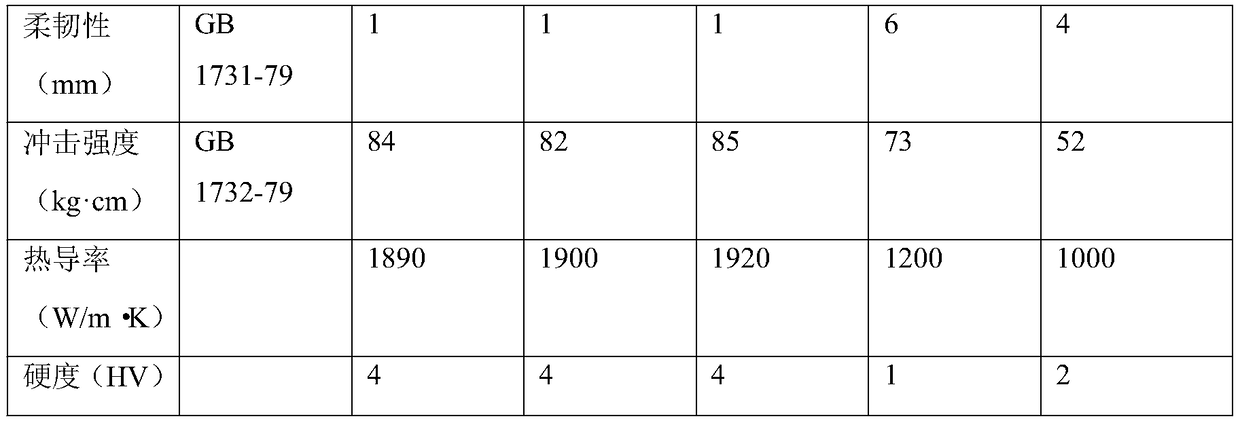

Thermal-knock resisting diamond spar-spinele refractory materials and its production

A diamond spar-spinele refractory material with high-thermal shock resistance and its production are disclosed. The process is carried out by taking spinel grain and electric-melting diamond spar grain as aggregate, taking diamond spar powder, aluminum oxide powder, electric-melting magnesium powder and titanium pigment as substrates, taking industrial citrine as binder and sintering at 1000-1650 degree in industrial furnace and metallurgical kiln lining. It has excellent thermal stability and high-temperature resistance, better mechanical strength and alkali resistance and abrasion resistance. It can be used for various non-ferrous metal metallurgical kilns, cement rotary kiln, high-temperature tunnel kiln and glass kiln.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com