Moisture-cured polyurethane hot melt adhesive for car lamp and preparation method thereof

A polyurethane hot-melt adhesive, moisture-curing technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of reduced strength, poor initial adhesion of one-component silicone adhesives, and long standing time and other problems, to achieve the effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation method of the moisture-curing polyurethane hot-melt adhesive for car lights is as follows in terms of weight fraction: 40 parts of polyester polyol adipate-1,4-butanediol PBA, 1020 parts of polycarbonate diol JSB, and Put 20 parts of 1,4-butanediol phthalate in a reaction kettle, heat to 120°C, vacuum dehydrate under stirring for 2 hours, then cool down to 70°C; take 15 parts of polyisocyanate MDI, preheat to 60°C , added to the reaction kettle, and slowly stirred, the temperature was raised to 90°C. The prepolymerization reaction was carried out under stirring at 90° C. for 2 h. After the prepolymerization is completed, add 0.0001 parts of catalyst dimorpholino diethyl ether and 5 parts of carbon black, heat up to 120°C and vacuumize to remove air bubbles for 30 minutes (vacuum degree ≥ 0.095MPa), pour out the product under the condition of nitrogen protection , sealed and packaged to obtain a moisture-curing polyurethane hot-melt adhesive for car ligh...

Embodiment 2

[0017] The preparation method of the moisture-curing polyurethane hot-melt adhesive for car lights is as follows in terms of weight fraction: 40 parts of polyester polyol adipate-1,6-hexanediol ester PHA, polycarbonate diol G-467230 20 parts of polyisocyanate TDI-800, preheated to 60 ℃, added to the reaction kettle, and slowly stirred, the temperature was raised to 90°C. The prepolymerization reaction was carried out under stirring at 90° C. for 2 h. After the prepolymerization is completed, add 0.0005 parts of dibutyltin dilaurate and 10 parts of carbon black as catalysts, raise the temperature to 120°C and vacuumize to remove air bubbles for 30 minutes (vacuum degree ≥ 0.095MPa), pour out the product under the condition of nitrogen protection, and seal the package , to obtain a moisture-curing polyurethane hot-melt adhesive for lamps.

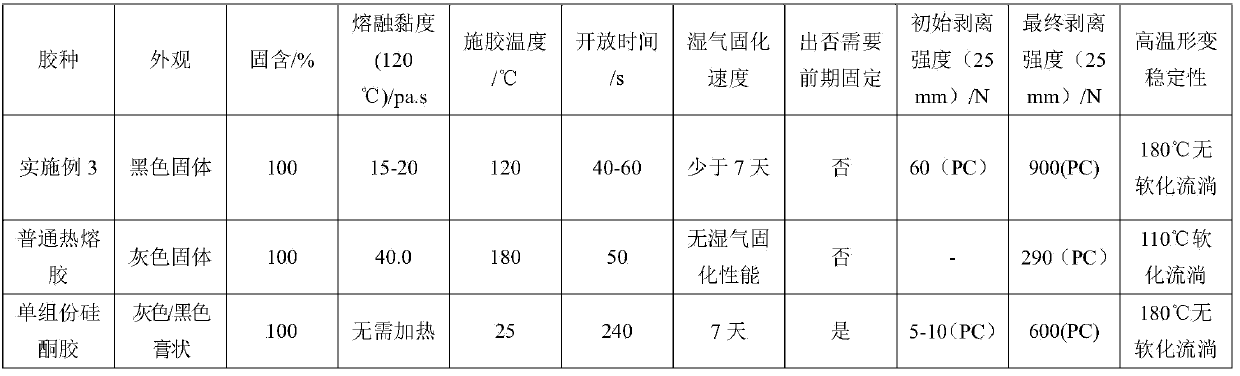

Embodiment 3

[0019] The preparation method of the moisture-curing polyurethane hot-melt adhesive for car lights is as follows in terms of weight fraction: polyester polyol sebacic acid-1,4-butylene glycol ester 35, polycarbonate diol G-467 220 parts , 17 parts of -1,4-butanediol phthalate were placed in a reaction kettle, heated to 120°C, vacuum dehydrated for 2 hours under stirring, and then cooled to 70°C; 18 parts of polyisocyanate MDI were taken and preheated to 60°C, add to the reaction kettle, stir slowly, and raise the temperature to 90°C. The prepolymerization reaction was carried out under stirring at 90° C. for 2 h. After the prepolymerization is completed, add 0.001 parts of dibutyltin dilaurate catalyst and 10 parts of carbon black, heat up to 120°C and vacuumize to remove air bubbles for 30 minutes (vacuum degree ≥ 0.095MPa), pour out the product under the condition of nitrogen protection, and seal the package , to obtain a moisture-curing polyurethane hot-melt adhesive for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com