Patents

Literature

93results about How to "Reduce raw material costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

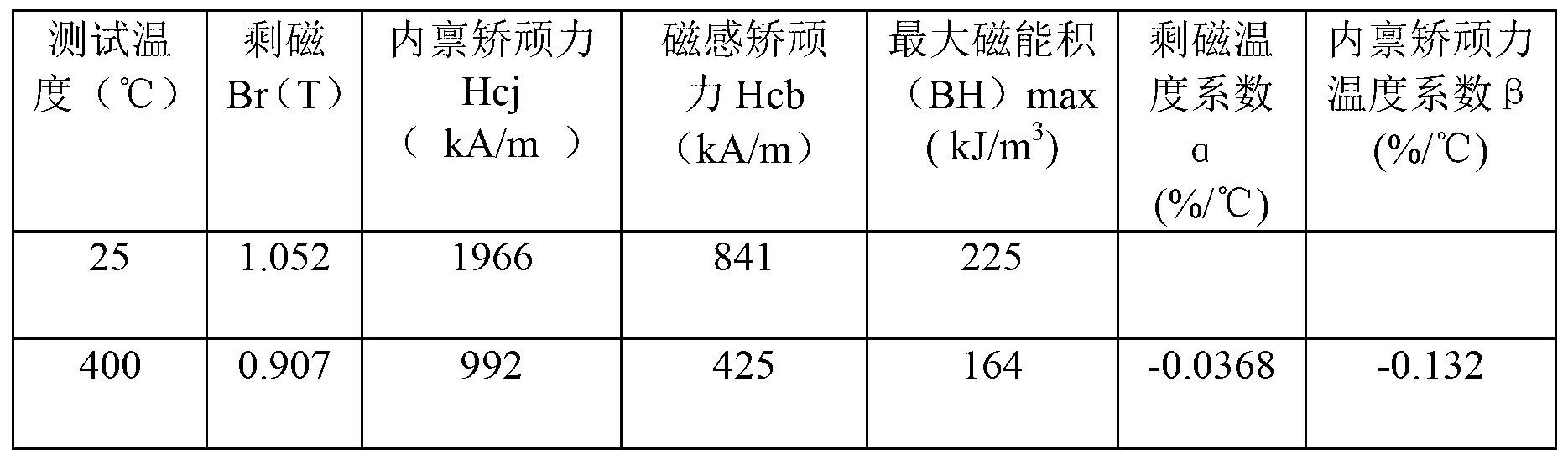

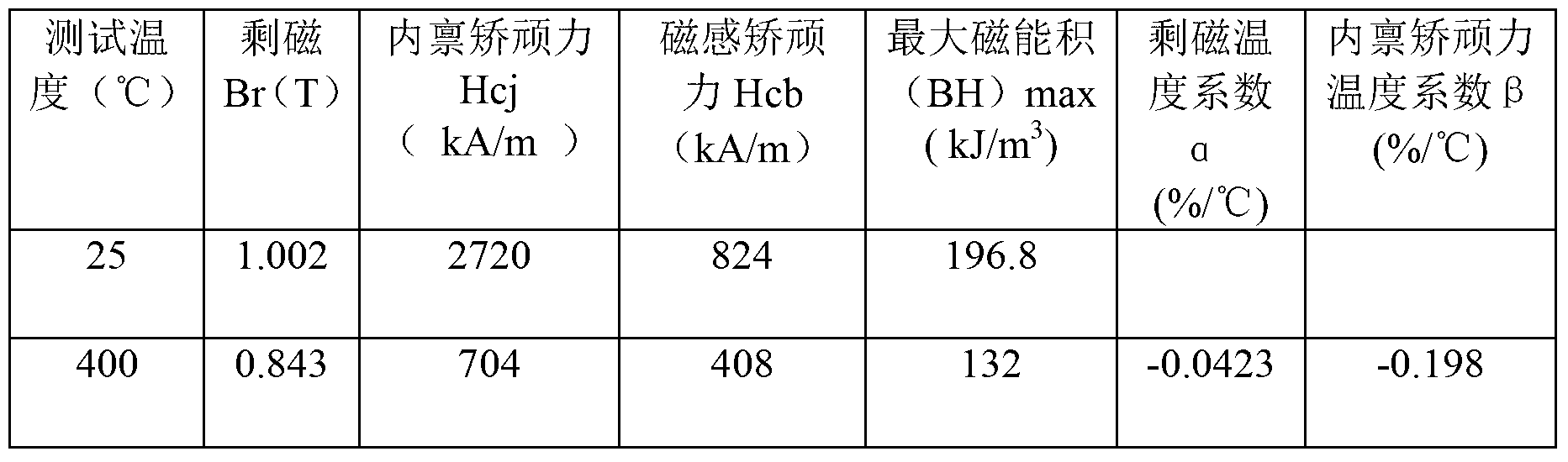

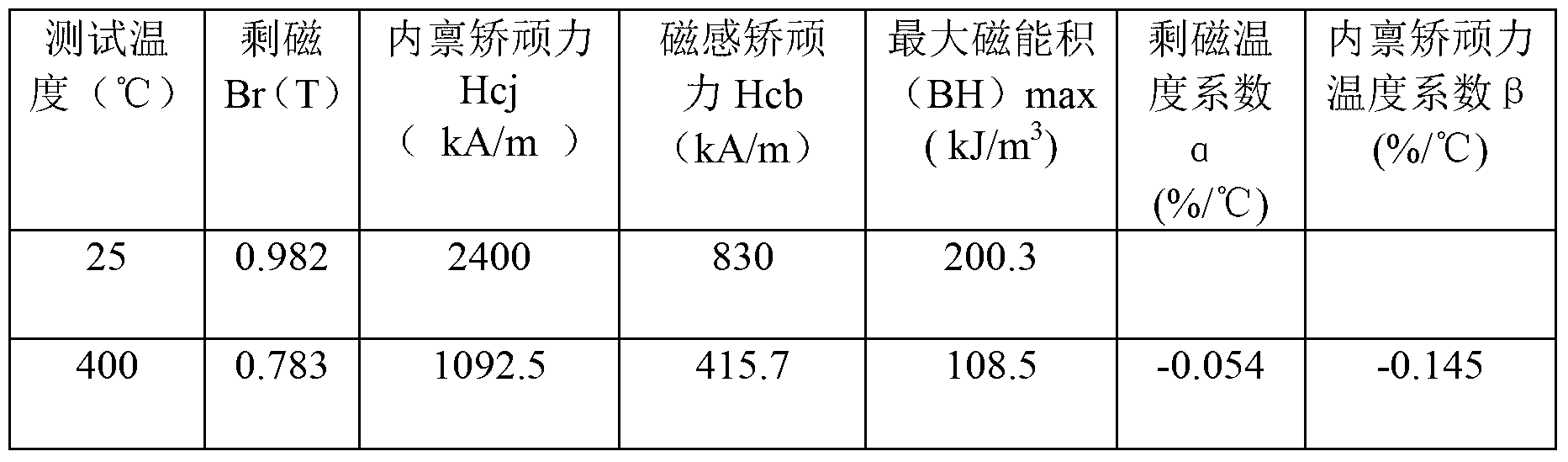

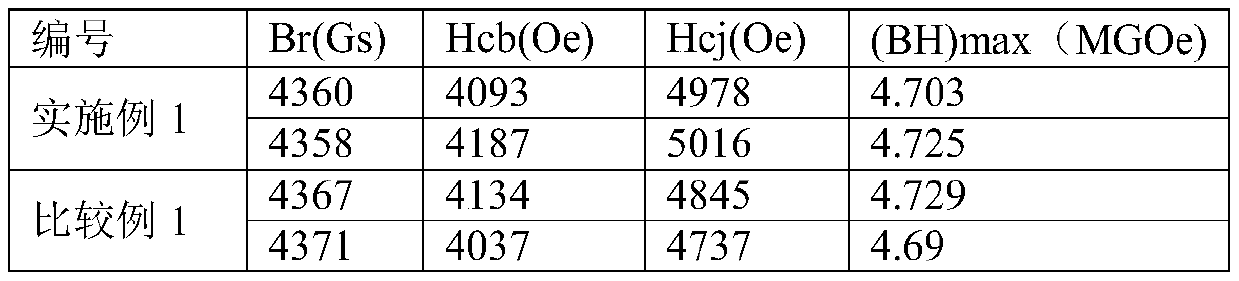

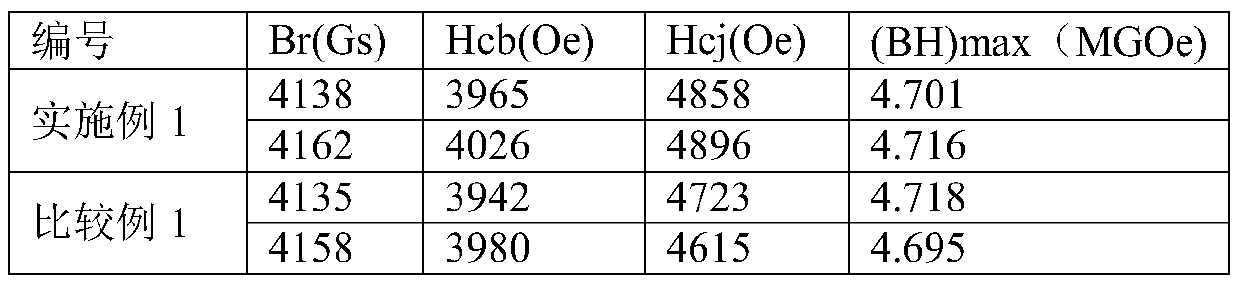

Samarium cobalt permanent magnetic material and preparation method thereof

InactiveCN103325513AHigh cost of preparationReduce raw material costsMagnetic materialsTemperature coefficientChemical Ingredients

The invention discloses a samarium cobalt permanent magnetic material and a preparation method thereof. The samarium cobalt permanent magnetic material is prepared from the following chemical ingredients by mass percent: 24.5-26% of samarium, 52-56% of cobalt, 7.5-12% of iron, 6.5-8% of copper, and 2-4% of zirconium. The samarium cobalt permanent magnet disclosed by the invention has high coercivity and low temperature coefficient; the magnetic performance at the temperature of 400-450 DEG C is that the residual magnetism Br is 0.783-0.907 T; the intrinsic coercivity Hcj is 704-1092.5 kA / m; the maximal magnetic level (BH)max is 108.5-164 kJ / m<3>; the temperature coefficient alpha of the residual magnetism is -0.0368% / DEG C to -0.054% / DEG C; and the temperature coefficient beta of the intrinsic coercivity is -0.132% / DEG C to -0.198% / DEG C. Thus, the samarium cobalt permanent magnetic material is simple in process and low in manufacturing cost.

Owner:湖南航天有限责任公司

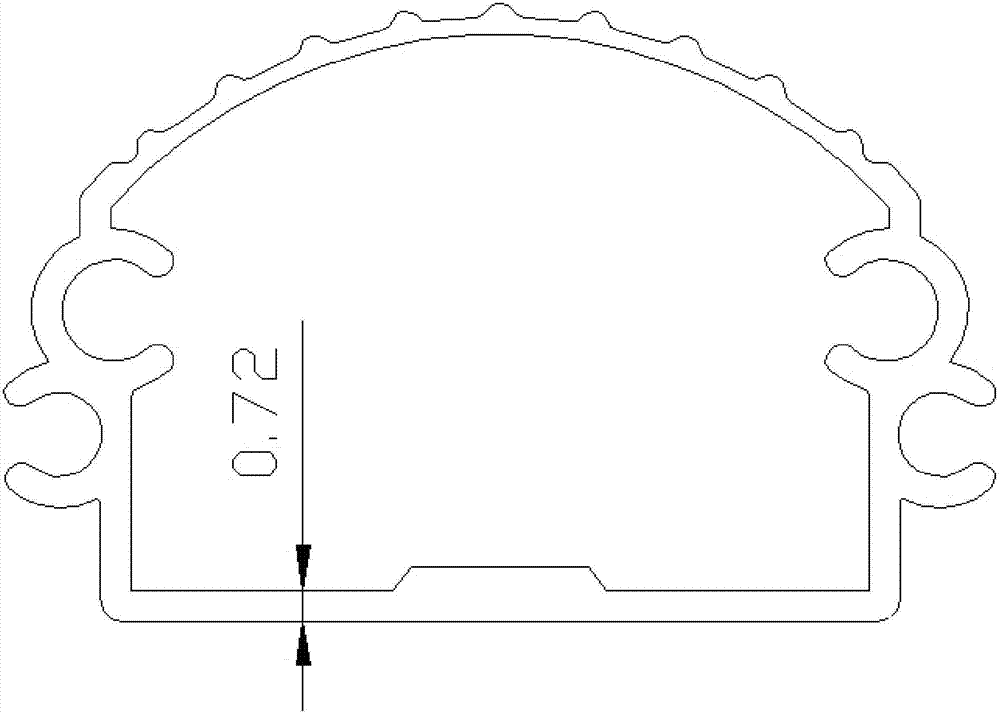

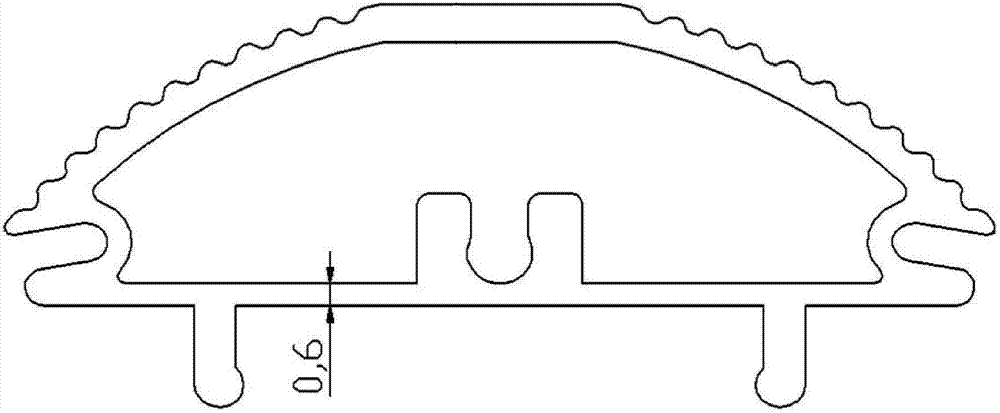

Magnesium alloy LED (Light Emitting Diode) tube profile and extrusion molding process thereof

The invention discloses a magnesium alloy LED (Light Emitting Diode) tube profile and an extrusion molding process thereof. The extrusion molding process comprises the following steps of: (1). according to the component proportioning requirements, smelting a magnesium alloy raw material; (2). preparing a magnesium alloy casting rod with the obtained magnesium alloy raw material; (3). heating the magnesium alloy casting rod to 400 DEG C to carry out heat preservation for 6 hours, and slowly cooling to room temperature along with a furnace after homogenization treatment; (4). heating the magnesium alloy casting rod subjected to homogenization treatment to 350 DEG C to carry out heat preservation for 2 hours, then slowly heating to 410 DEG C to carry out heat preservation for 2 hours, afterwards cooling to 380 DEG C to carry out heat preservation for 1 hour, and simultaneously heating an extrusion mould to 400 DEG C to carry out heat preservation; and (5). finally taking out the extrusion mould, assembling the extrusion mould on an extrusion machine, filling the magnesium alloy casting rod into the extrusion container of the extrusion mould for extrusion molding, so as to obtain the magnesium alloy LED tube profile by extrusion molding. The magnesium alloy LED tube profile and the extrusion molding process thereof have the advantages that the production efficiency and yield are improved and the machining cost is reduced on the premise that the size precision is ensured to meet the design requirements.

Owner:WUXI FUMEI LIGHT ALLOY TECH

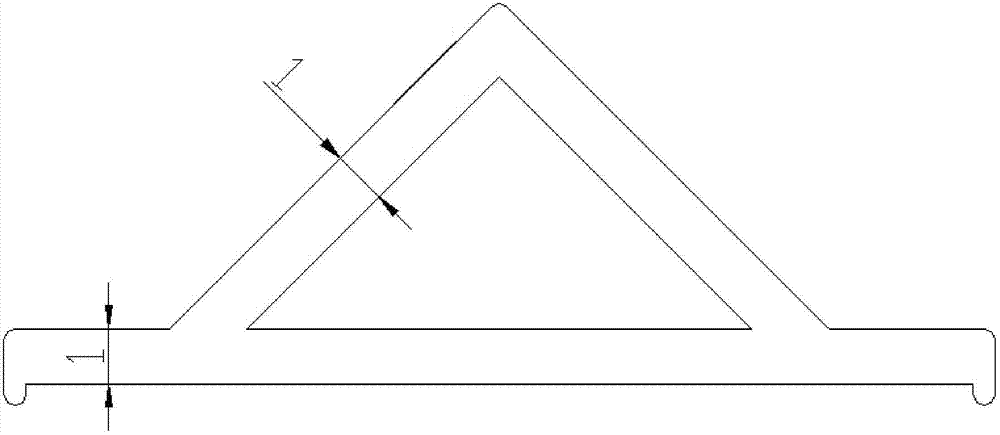

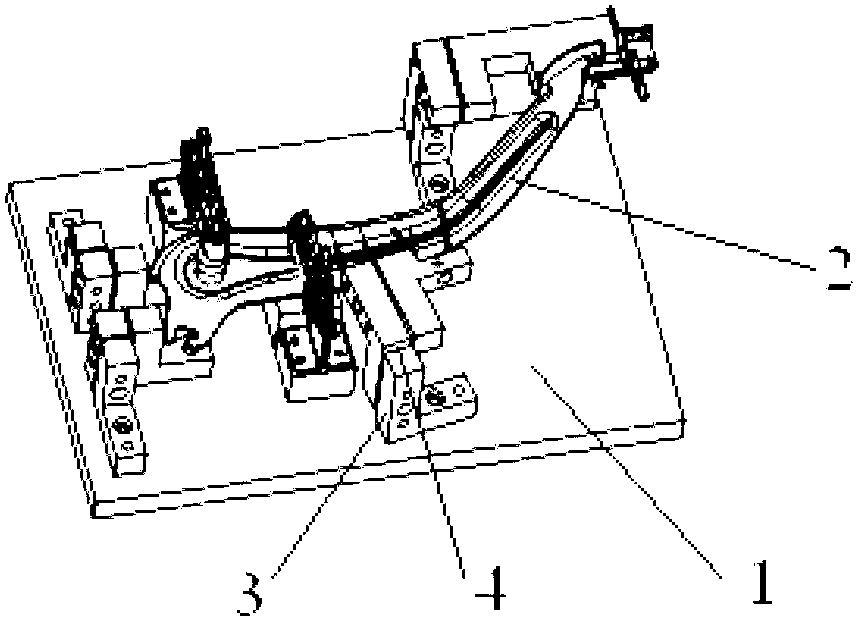

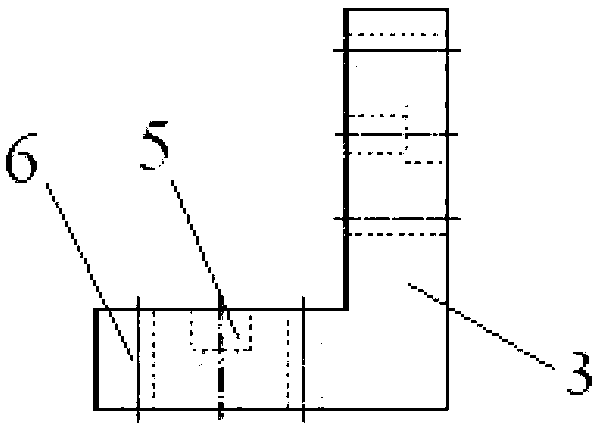

Automobile pedal welding fixture

InactiveCN102935566AReduce material consumptionReduce raw material costsWelding/cutting auxillary devicesAuxillary welding devicesMaterial consumptionEngineering

The invention discloses an automobile pedal welding fixture which comprises a fixture bottom plate (1) and is provided with an adjusting block (3) and an adjusting shim (4), wherein a connection bolt hole (5) and a positioning pin hole (6) are arranged on the adjusting bock (3); and slots (7) corresponding to the connection bolt hole (5) and the positioning pin hole (6) in position are arranged on the adjusting shim (4). Through the invention, the fixture can be quickly adjusted according to the field welding condition; the welding fixture can be standardized and is suitable for the production and manufacturing of multiple types of welding fixtures; the material consumption is low, and the raw material cost is saved; the welding quality of the product is improved; the maintenance is facilitated, and the interchangeability is high; and the welding fixture has beautiful appearance and looks more beautiful.

Owner:ANHUI DACHANG TECH

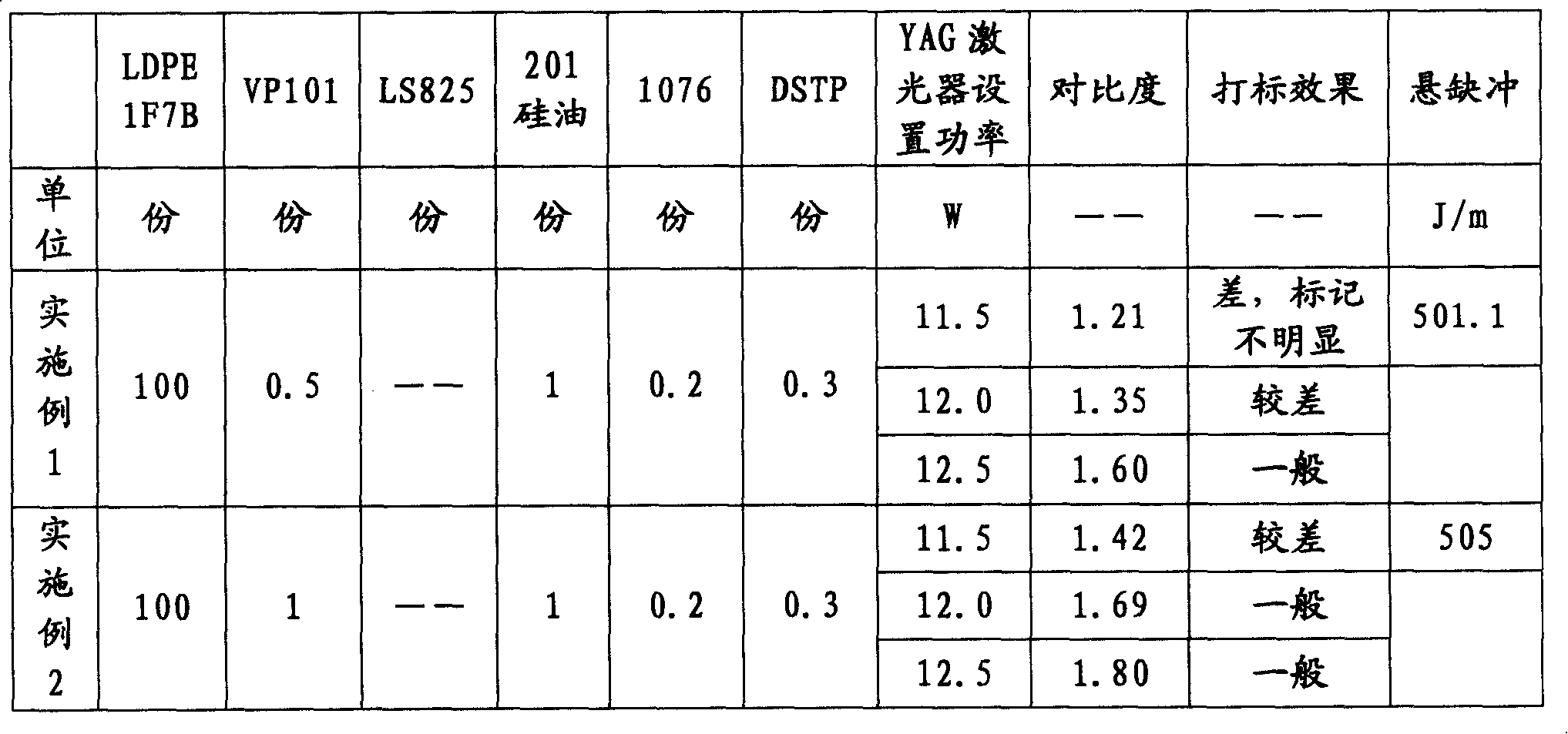

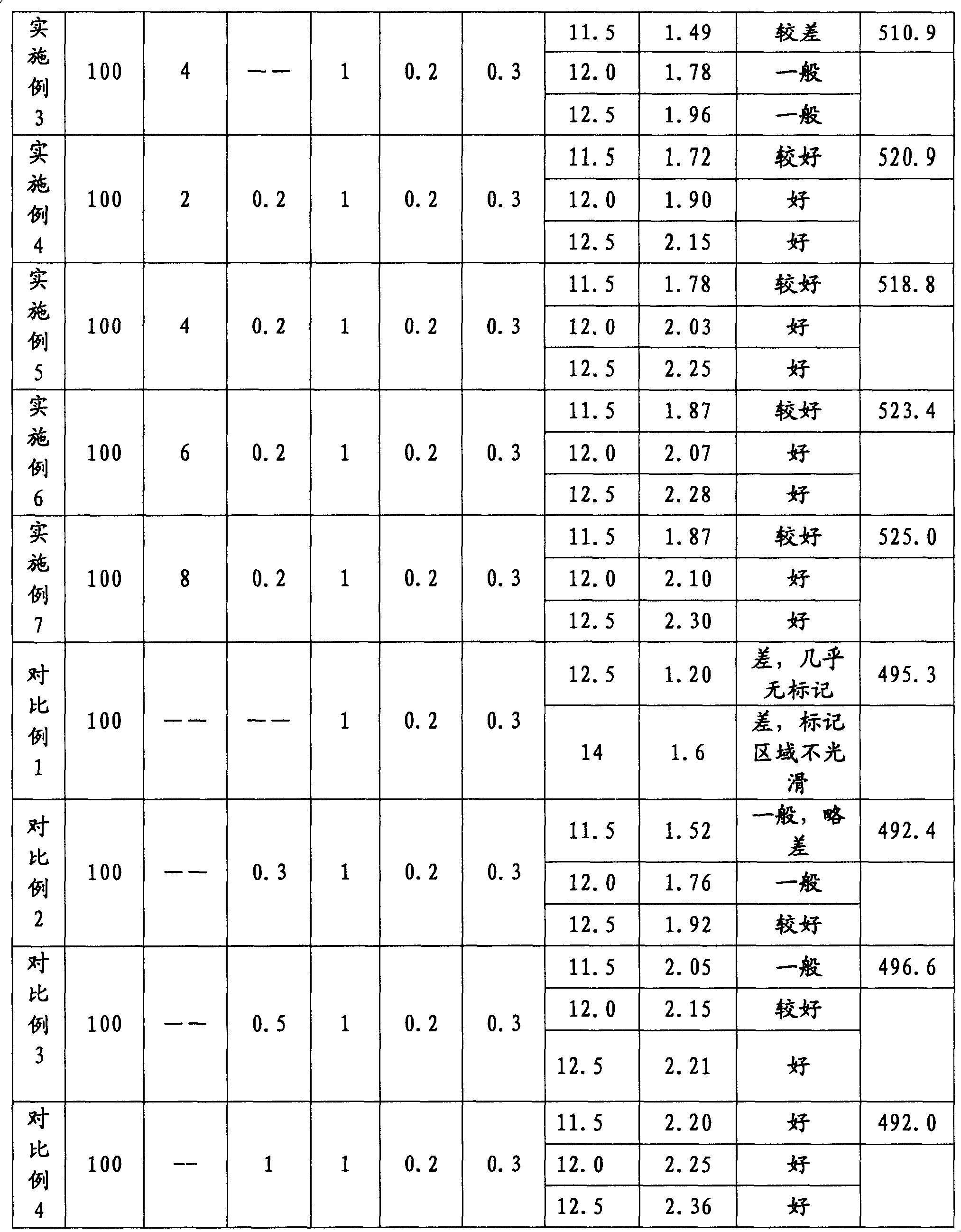

Laser markable polyethylene composition and preparation method thereof

ActiveCN101230164AReliable workmanshipReduce raw material costsButadiene-styrene rubberStyrene-butadiene

The invention relates to polyethylene composition which can be marked with laser and the preparation method thereof. The composition includes the following blended components: 100 parts of polyethylene by weight, 0.1-15 parts of powdered rubber by weight, 0-2 parts of laser additive by weight, wherein, the powdered rubber comprises butylbenzene powdered rubber or / and carboxyl styrene butadiene powdered rubber. The preparation method comprises the step that the components including the polyethylene and the powdered rubber is melted and blended according to the compounding ratio of the components. The composition of the invention can overcome the problems that the polyethylene is difficult to be marked with laser, and the material physical performance is decreased and the cost is high caused by overabundant addition amount of the prior laser additive. In the preparation method of the invention, the process is simple and reliable. The polyethylene composition which can be marked with laser in the invention can be widely applied to the polyethylene products which are needed to be marked with laser.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-lithium-matrix heat resisting ceramic materials

InactiveCN101337809AReduce raw material costsImprove heat resistanceLoss on ignitionChemical composition

The invention relates to the field of a ceramic material, in particular to a low-lithium heat resisting ceramic material. The ceramic blank primarily contains the chemical compositions of SiO2, Al2O3, Fe2O3, Ti2O, CaO, MgO, K2O, Na2O and Li2O. The low-lithium heat resisting ceramic material is characterized in that SiO2 accounts for 50 to 65 percent by mass; Al2O3 accounts for 22 to 32 percent by mass; Fe2O3 accounts for 0.80 to 1.2 percent; Ti2O accounts for 0.05 to 0.15 percent; CaO accounts for 1.60 to 2.50 percent; MgO accounts for 0.60 to 1.2 percent; K2O accounts for 0.40 to 0.80 percent; Na2O accounts for 0.15 to 0.05 percent; and Li2O accounts for 1.20 to 2.20 percent; and other components account for 0.20 to 0.60 percent in the balancing amount, and the loss on ignition accounts for 7.00 to 10.00 percent. The dosage of spodumene in the ceramic blank is reduced to 20 to 30 percent; Li2O accounts for just 1.20 to 2.20 percent; the heat resistance can be improved to the extent that the low-lithium heat resisting ceramic material does not crack when cooled quickly after the ceramic material is burnt in dry state at the temperature of 420 to 440 DEG C. Accordingly, the raw material cost is reduced; and the heat resistance is improved.

Owner:鄢爱奎

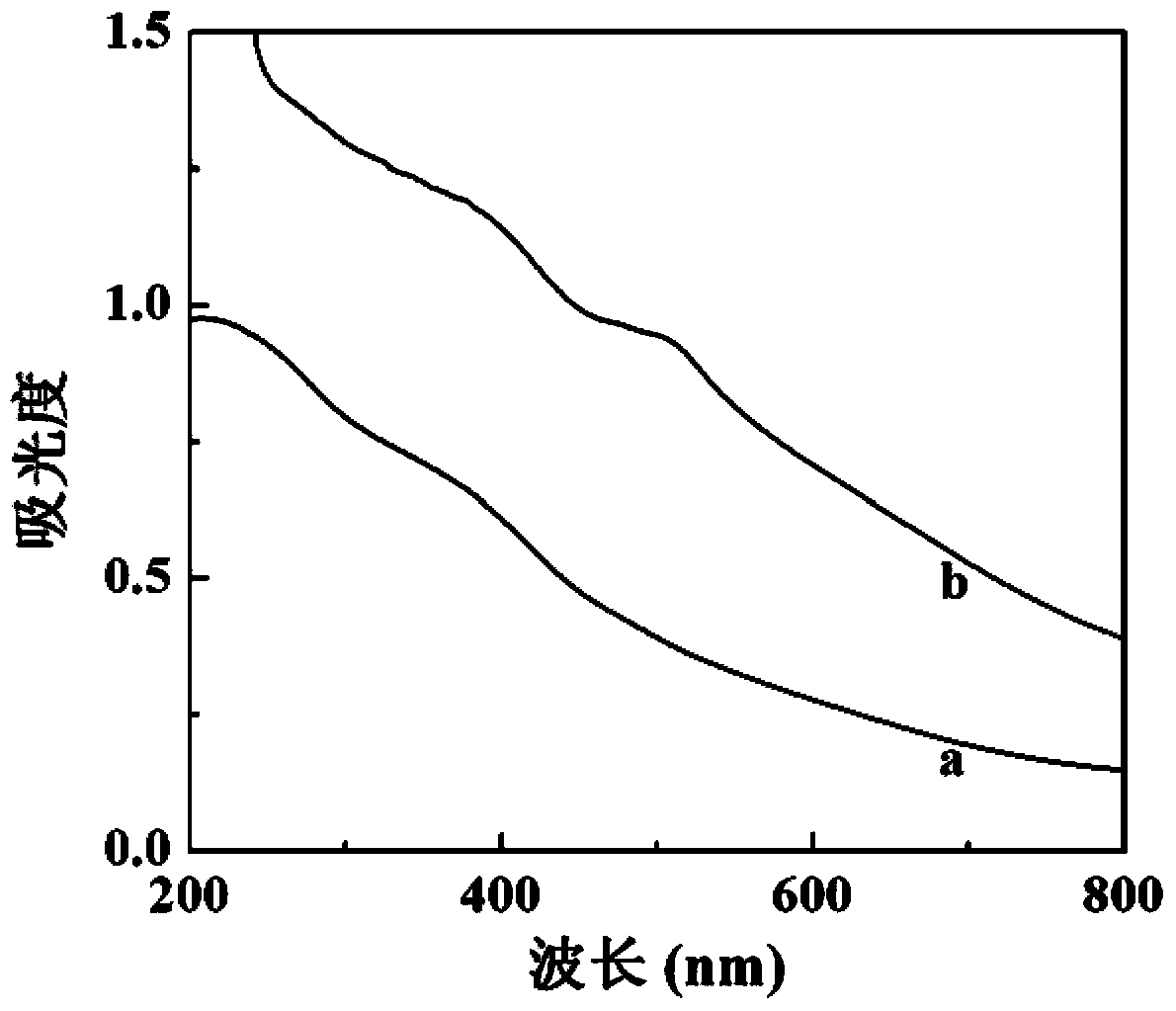

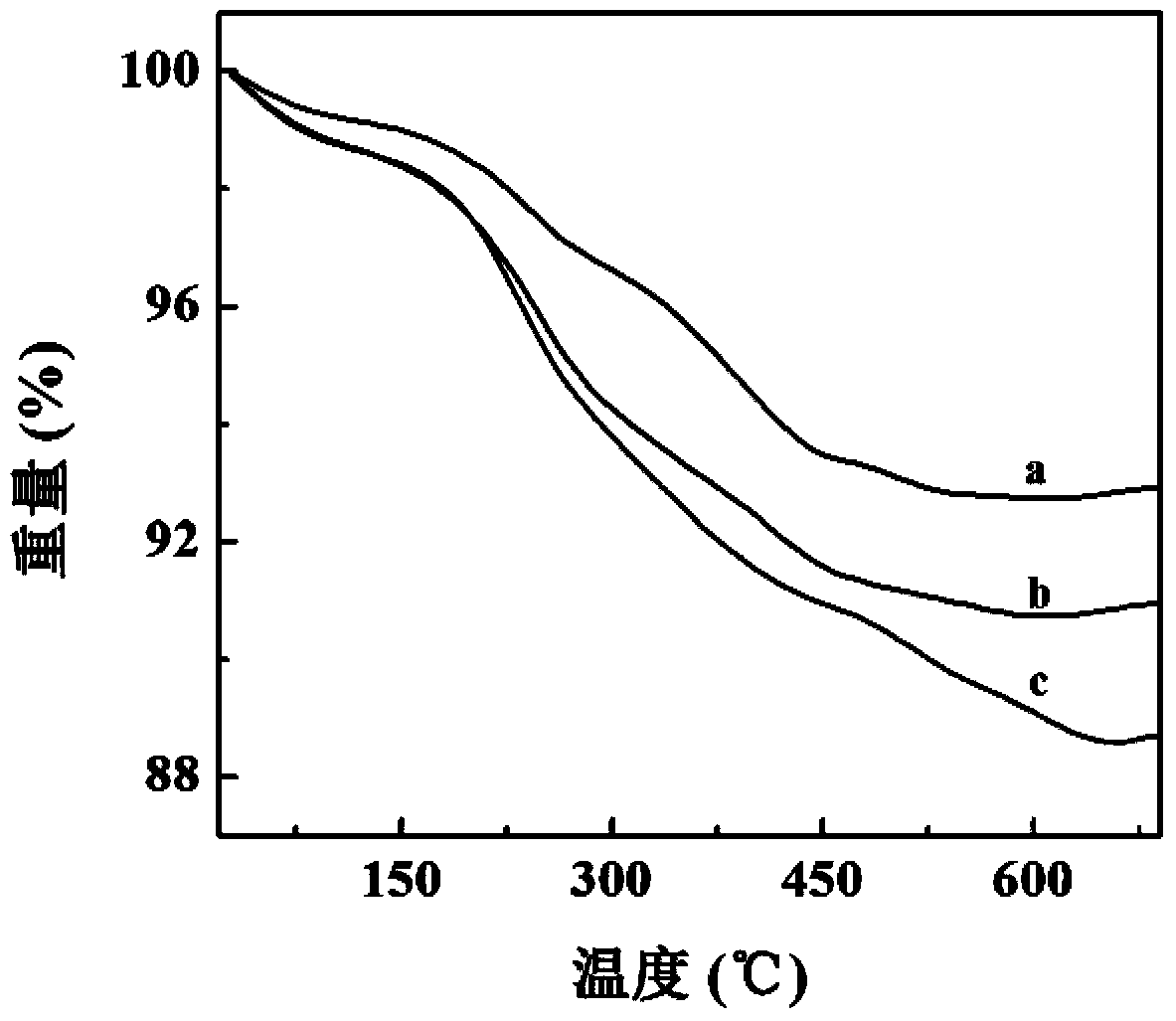

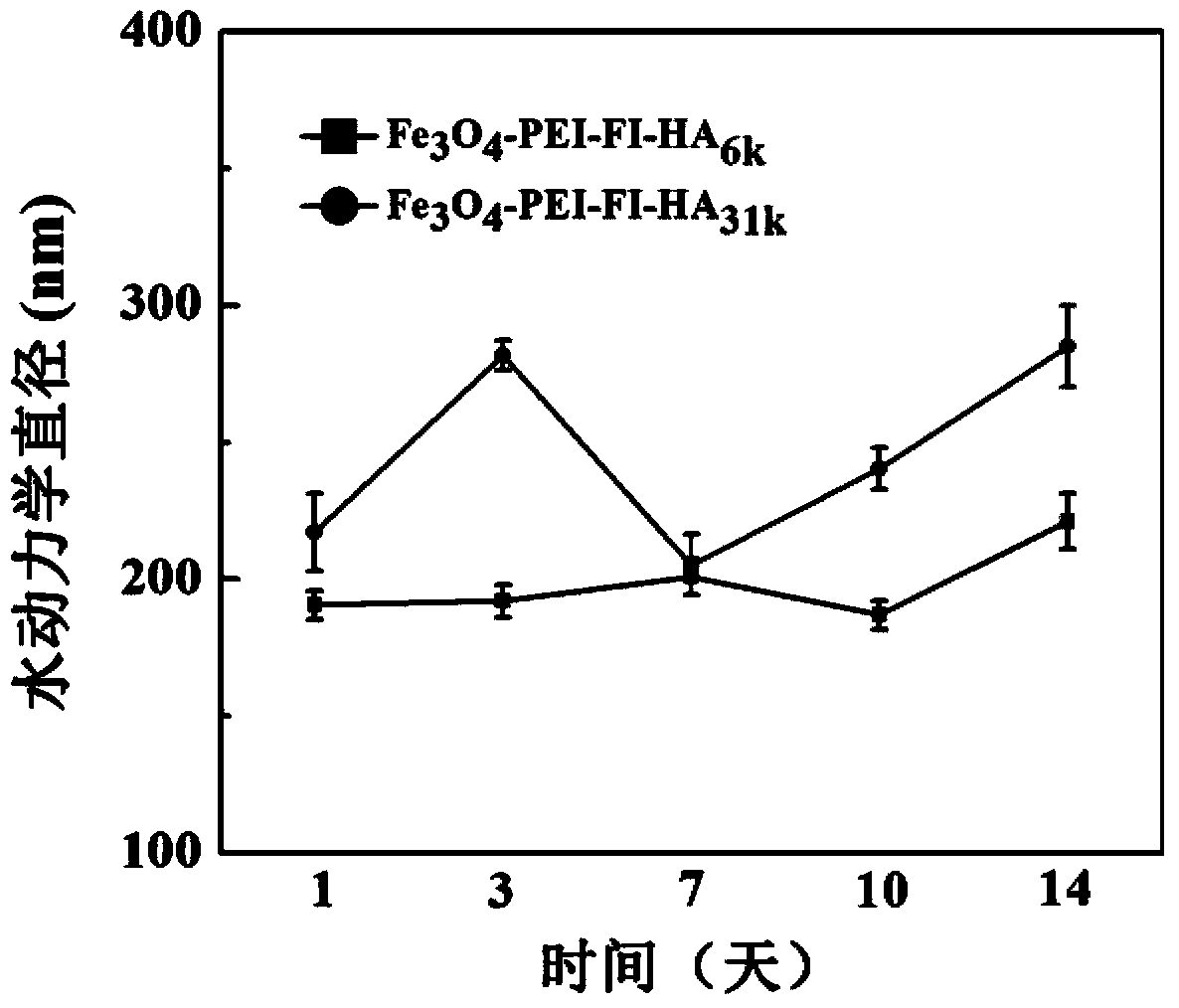

Preparation method for ferroferric oxide nano particle targeted MRI contrast agent

InactiveCN103417992AEasy to operateReduce raw material costsIn-vivo testing preparationsTumor targetFluorescein isothiocyanate

The invention relates to a preparation method for a ferroferric oxide nano particle targeted MRI contrast agent. The method comprises the following steps: 1, utilizing a hydrothermal method to synthesize PEI coated Fe3O4 nano particles Fe3O4-PE1; 2, conducting surface modification on fluorescein isothiocyanate FI by the Fe3O4-PE1 nano particles; 3, connecting hyaluronic acids of different molecular weights with surfaces of the nano particles to obtain the ferroferric oxide nano particle targeted MRI contrast agent. The method has the advantages of mild reaction conditions, simple operation process, and easiness in separating and purification. The prepared Fe3O4 magnetic nano particles have good colloid stability, biocompatibility and tumor targeting, and underlying application value in the field of in-vivo tumor targeted MRI diagnoses.

Owner:DONGHUA UNIV

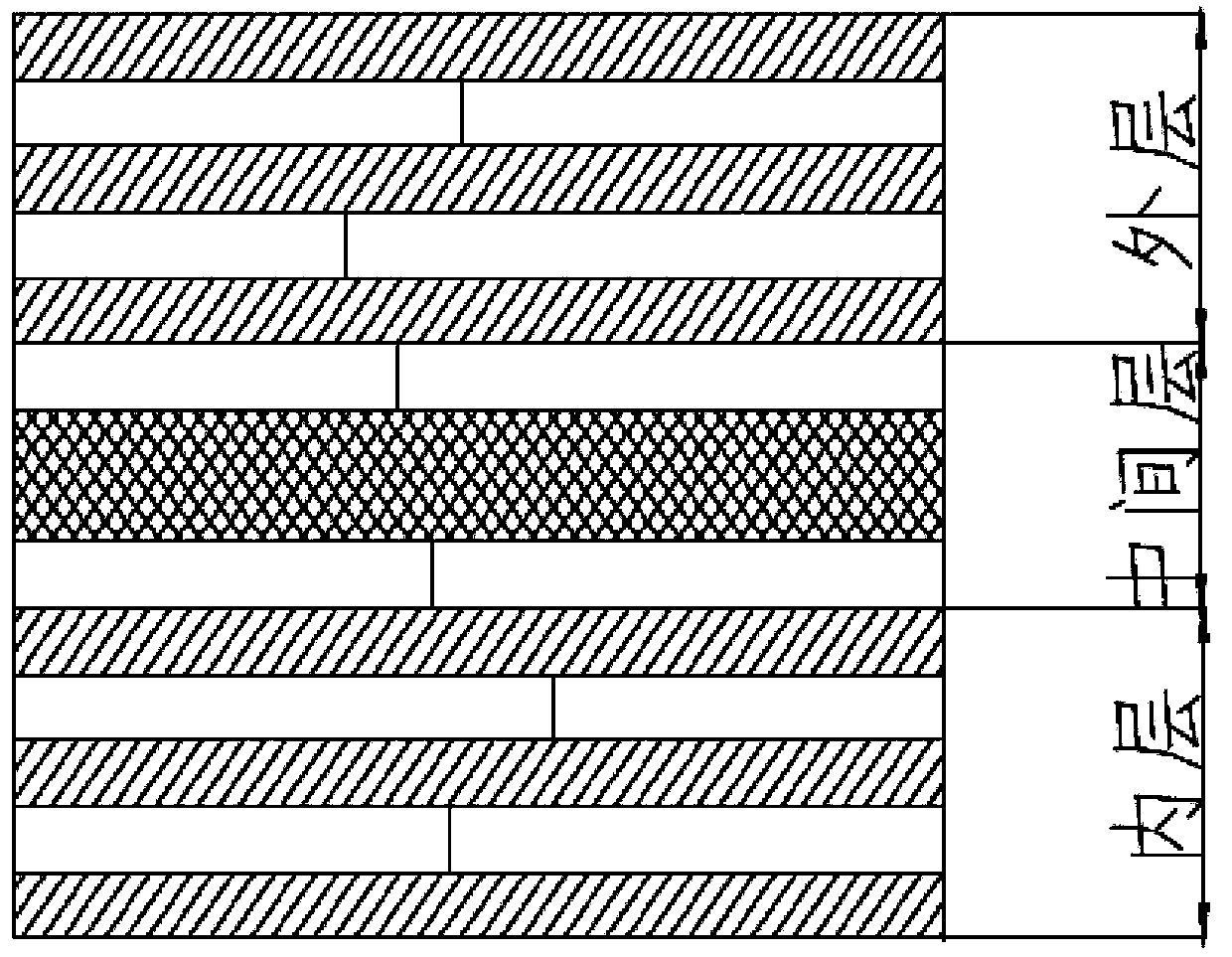

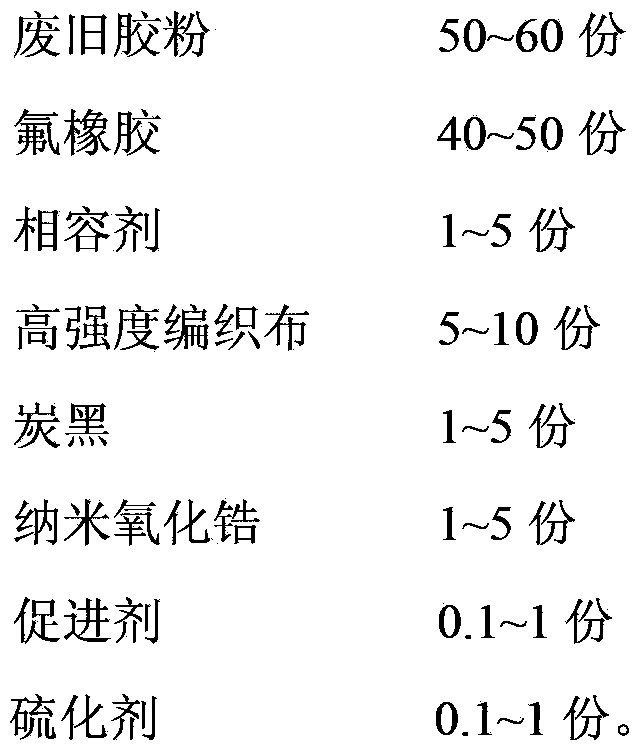

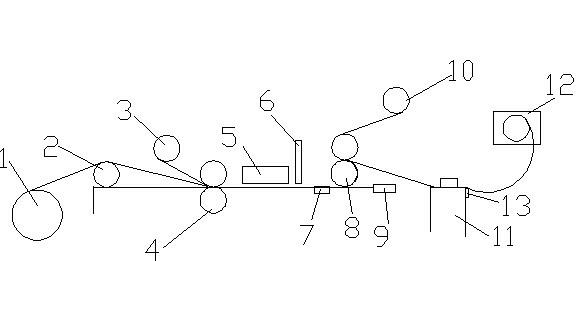

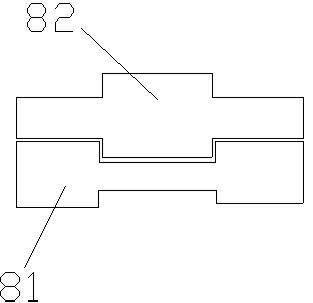

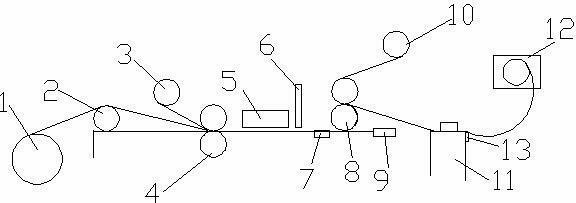

High-temperature resistant oil well rubber sealing ring material and preparation method thereof

ActiveCN103496229AGood high temperature resistanceReduce raw material costsEngine sealsLaminationFilling materialsCarbon black

The invention provides a high-temperature resistant oil well rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is composed of three parts: the inner layer and the outer layer are both composed of high-strength knitted cloth added with inorganic materials such as carbon black, nano zirconia, and the like; the middle layer is prepared through following steps: compounding rubber powder, which has been desulfurated through thermal mechanical shearing, with fluoro-rubber, adding a compatilizer to increase the compatibility between the rubber powder and the fluoro-rubber; then adopting high-strength knitted cloth, which has been subjected to a surface treatment, as the support body, adding inorganic filling materials such as carbon black, nano zirconia, and the like, and subjecting the knitted cloth added with inorganic filling materials to a high-temperature sulfide cross-linked forming so as to obtain the middle layer. The sealing ring knitted cloth and the rubber base material are subjected to processes of multi-layer compounding and sulfide forming. The sealing ring prepared by the invention has a good high-temperature resistant performance, and is capable of being used in areas with a large temperature difference for a long period.

Owner:CHANGZHOU UNIV

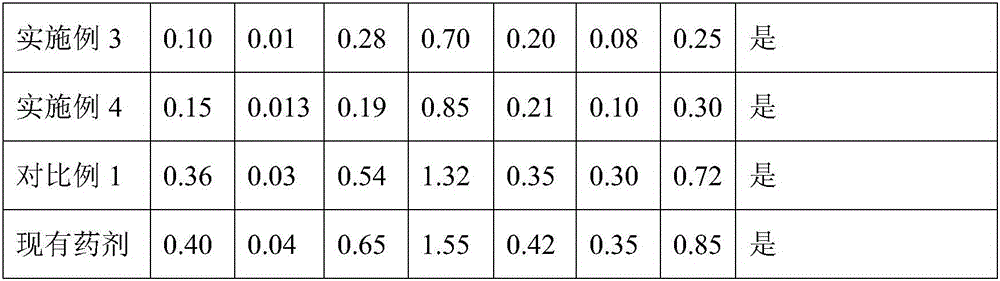

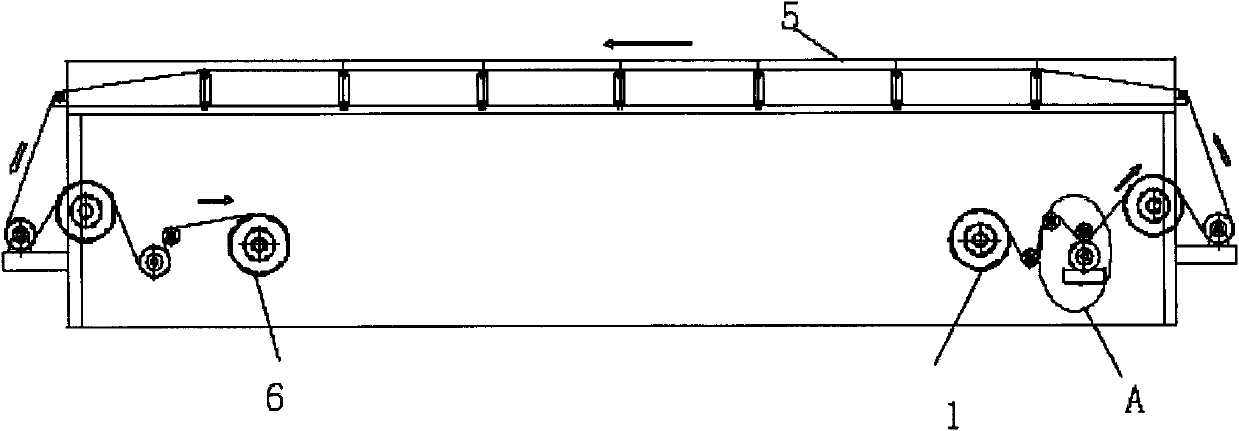

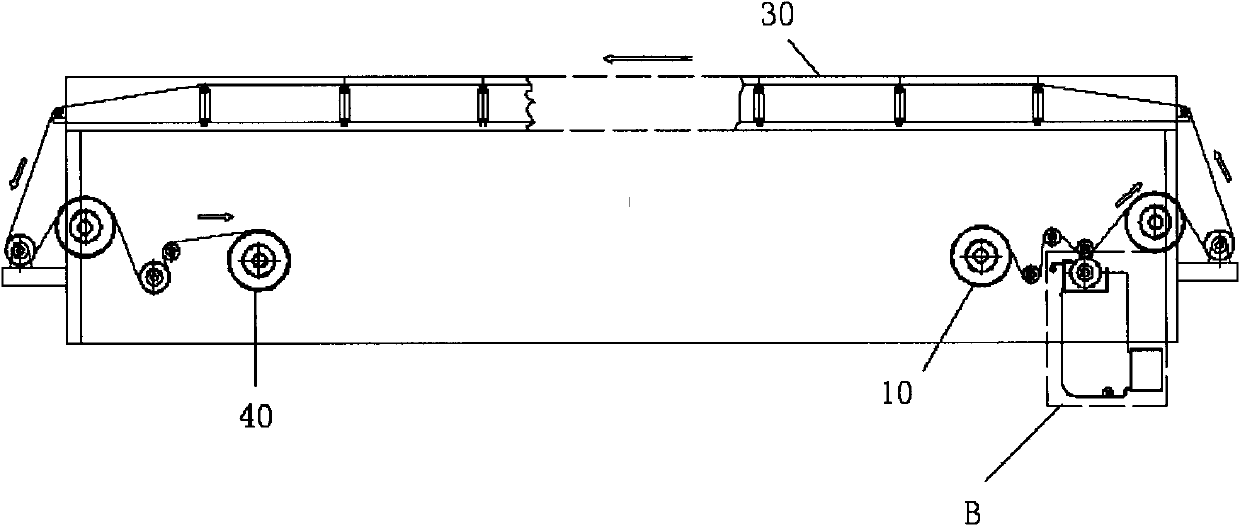

Die-cutting machine with waste recovering function

The invention discloses a die-cutting machine with a waste recovering function. The die-cutting machine is sequentially provided with a feeding device, a splitting device, an adhesive mounting bracket, a film roller, a die-cutting base, a double-electric eye device, a waste coiling device and a rewinding and cutting device. A composite material rubber roller is mounted between the double-electric eye device and the waste coiling device; and a release paper feeding device is mounted behind the composite material rubber roller. With the adoption of the die-cutting machine provided by the invention, the problem that the production cost is greatly increased as the die-cutting machine in the prior art cannot recover a wasted raw material for reusing can be solved. The waste recovering function is added on basis of the former functions of the conventional die-cutting machine, so that the use ratio of the material is improved. The skip distance for the recovered material is accurately set through a sensing cam and a puncher, so that the later-stage production of the recovered material is convenient. Furthermore, the recovered material and release paper can be well adhered together after passing through a convex rubber roller and a concave rubber roller in a manner that the convex rubber roller and the concave rubber roller are embedded mutually, and the convenience for later-stage use is achieved.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

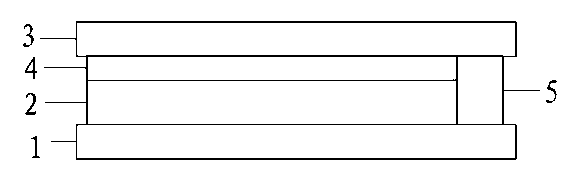

Capacity touch panel employing copper-plated conductive substrate

InactiveCN103279250AReduce raw material costsImprove production efficiency and production yieldInput/output processes for data processingTouch panelCopper foil

The invention provides a capacity touch panel employing a copper-plated conductive substrate, and belongs to the field of capacity touch panels. The capacity touch panel comprises a cover lens arranged outmost, a sensor bonded with the cover lens and an LCM (liquid crystal module) attached on the inner side of the capacity touch panel. The sensor is manufactured by processes of firstly, sputtering copper foil on the conductive substrate through a film coating process; secondly, forming a copper film signal line graph on the conductive substrate by performing operations of exposure, development and etching on a copper plated film by the aid of a dry film photoresist; thirdly, forming a transparent conductive film graph with the copper film signal line graph on the conductive substrate with the copper film signal line graph by operations of exposure, development and etching; and fourthly, cutting to obtain the sensor. The capacity touch panel employing the copper plated conductive substrate has the advantages that raw materials and processing cost can be reduced, production efficiency can be increased, and productivity can be improved.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

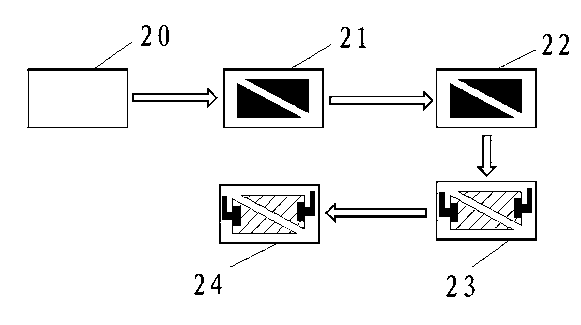

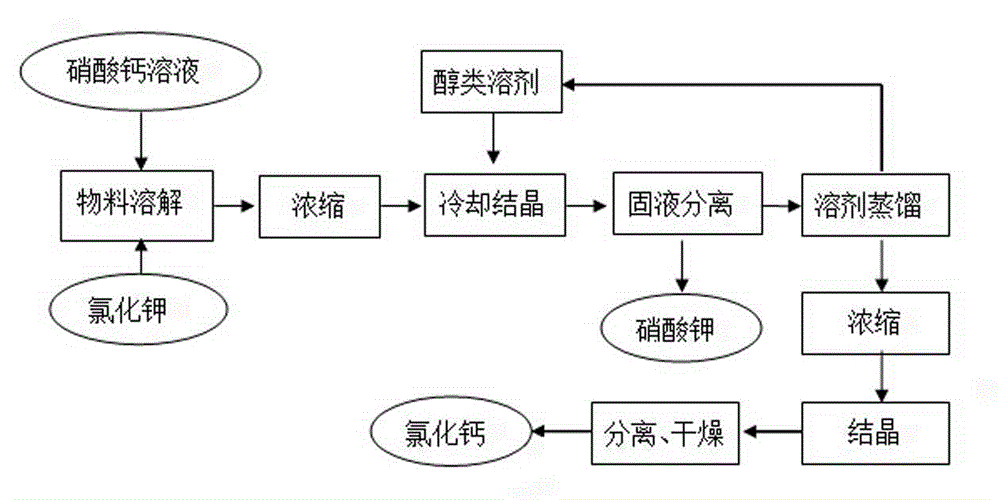

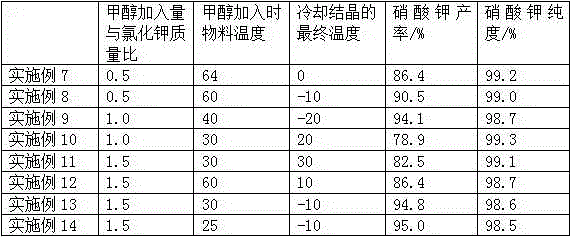

Method for simultaneously preparing potassium nitrate and calcium chloride from calcium nitrate solution and potassium chloride

ActiveCN104445292AReduce raw material costsImproved separationCalcium/strontium/barium chloridesAlkali metal nitrate preparationChloride potassiumSide product

The invention relates to a method for simultaneously preparing potassium nitrate and calcium chloride from a calcium nitrate solution and potassium chloride. According to the method, the problems that the product yield is low and the purities of side products are low in an existing preparation process are solved. According to the main principle of the method, alcohol solvents are added in a cooling crystallization process of potassium nitrate according to the characteristic that a stable complex can be generated by calcium chloride and the alcohol solvents, so that calcium chloride cannot be separated out in a solid form; meanwhile, by adding the alcohol solvents, the solubility of potassium nitrate in the solution is reduced, so that the number of crystals of potassium nitrate can be substantially increased, and the yield of potassium nitrate is increased. The method has the beneficial effects that the cost of raw materials is low; by introducing the organic alcohol solvents, the separation effect between potassium nitrate and calcium chloride is remarkably improved; compared with a traditional double decomposition process, the purity of the obtained product is relatively high, and the yield is high; by virtue of closed circulation of the alcohol solvents, the environmental pollution is avoided.

Owner:JIAOCHENG KNLAN CHEM

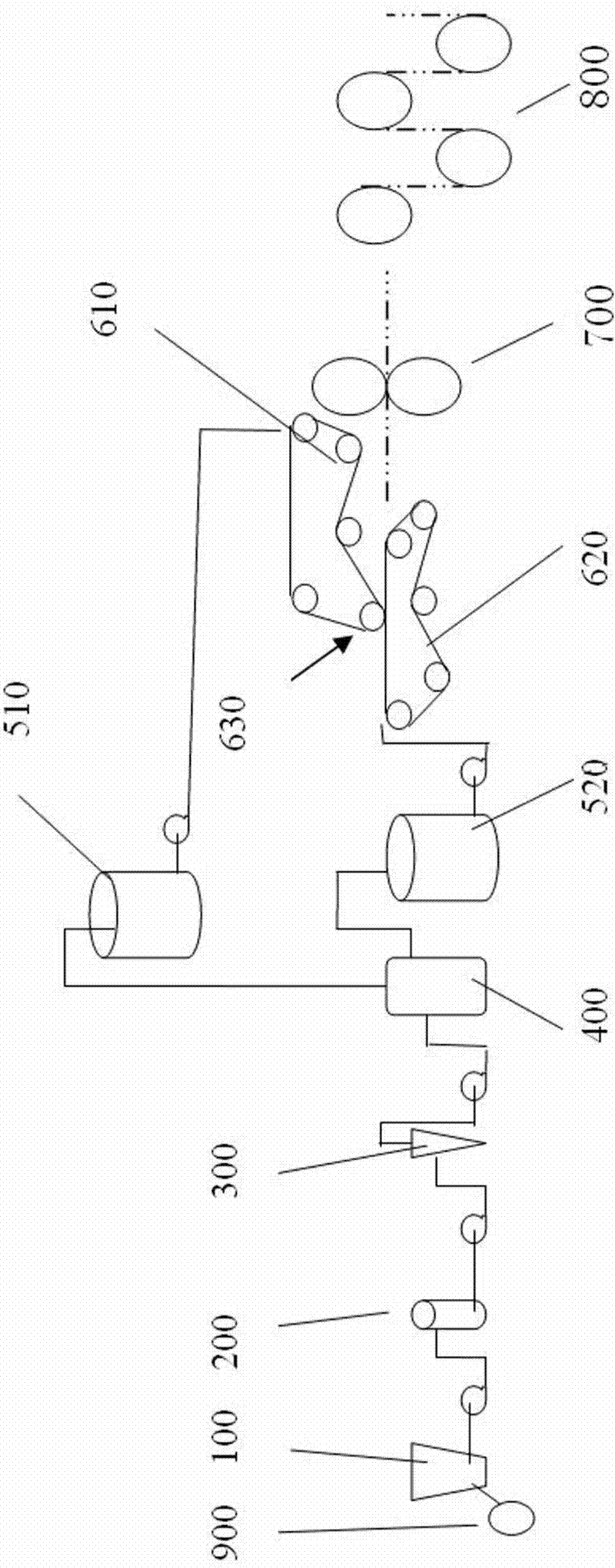

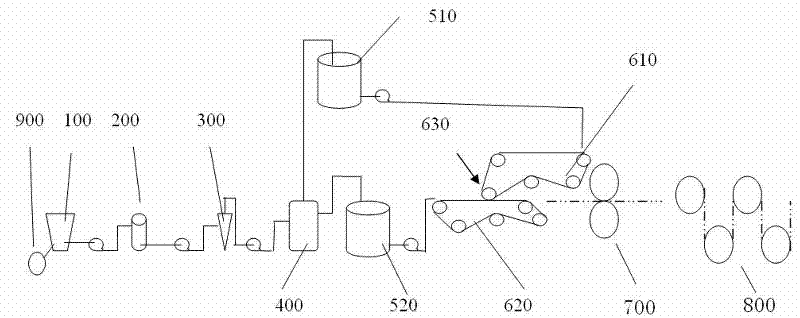

Preparation process of environmental protection liner paper

The invention relates to a preparation process of an environmental protection liner paper, comprising the steps of: a. adding domestic waste paper and European waste paper into a pulper to break them into paper pulp; b. removing impurities from the paper pulp through a scalping screen and a slag separator in sequence; c. inputting the slurry into a grading sieve, separating long fibers and short fibers, and then conveying the long fibers and short fibers respectively to a long fiber slurry pond and a short fiber slurry pond; d. adding adjuvants composed of 10-20kg reinforcing agent per ton of slurry, 10-15kg sizing agent per ton of slurry and 10-18kg pearl alum per ton of slurry into the long fiber slurry pond and the short fiber slurry pond respectively; e. pumping the long fiber slurry into a first bed at a wire section for shaping up and dehydrating to a dryness of 10%-30%, and pumping the short fiber slurry into a second bed for shaping up and dehydrating to a dryness of 10%-30%, then conveying the shaped and dehydrated slurries into a composite roll to compound a piece of paper; f. pressing and dehydrating the paper to a dryness of 35%-50%; g. drying the paper so as to obtain a finished product of liner paper. The preparation process of the invention is characterized by low cost, low power consumption, outstanding energy conservation and better environmental protection.

Owner:LEE & MAN PAPER MFG

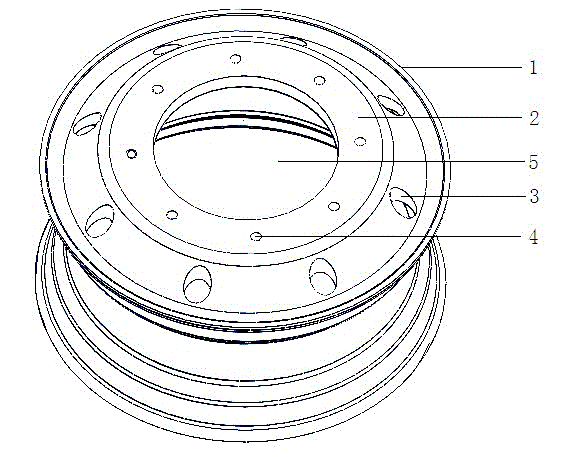

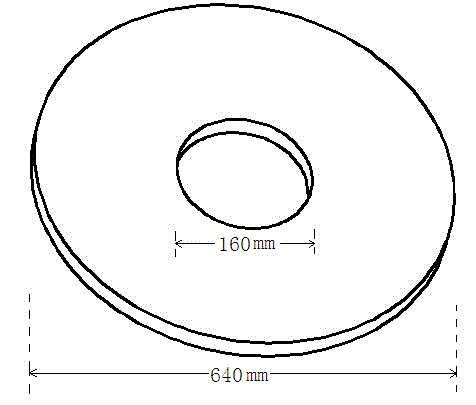

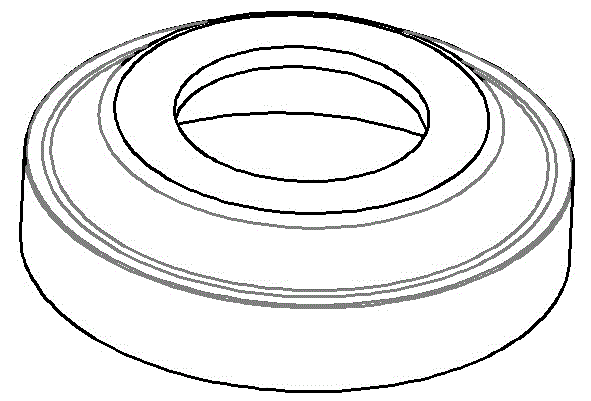

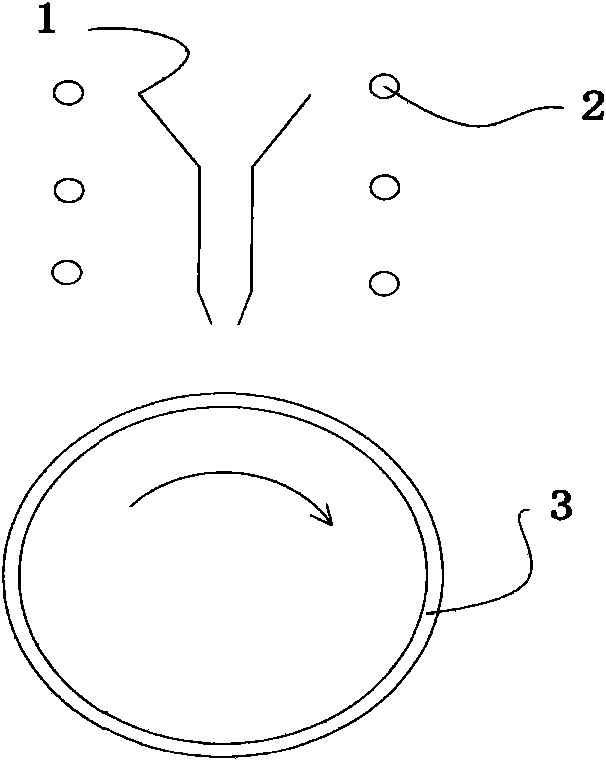

Integral aluminum alloy spinning hub and manufacturing method thereof

The invention discloses an integral aluminum alloy spinning hub and a manufacturing method thereof. The method mainly comprises the steps of (1) selecting an aluminum alloy medium-thickness panel as an initial blank; (2), forming the middle material of the aluminum alloy panel to be a hub and pre-forming the edge material of the aluminum alloy panel to be a rim by adopting strong bending spinning; (3) splitting the preformed rim to be a rim front piece blank and a rim rear piece blank by adopting splitting spinning; (4) respectively forming the front piece blank and the rear piece blank to a rim front piece and a rim rear piece by adopting strong thinning spinning. The spinning hub produced by the process is high in material use rate, and the material is subjected to plastic deformation for multiple times and is high in strength; a workblank does not need to be precast, forged or cast, the process is simple, the machining cost is low and the production efficiency is high. The front piece and the rear piece do not need welding and screw connection and have stable mechanical performance and high safety performance.

Owner:SHANGHAI HUIRU MACHINERY MFG

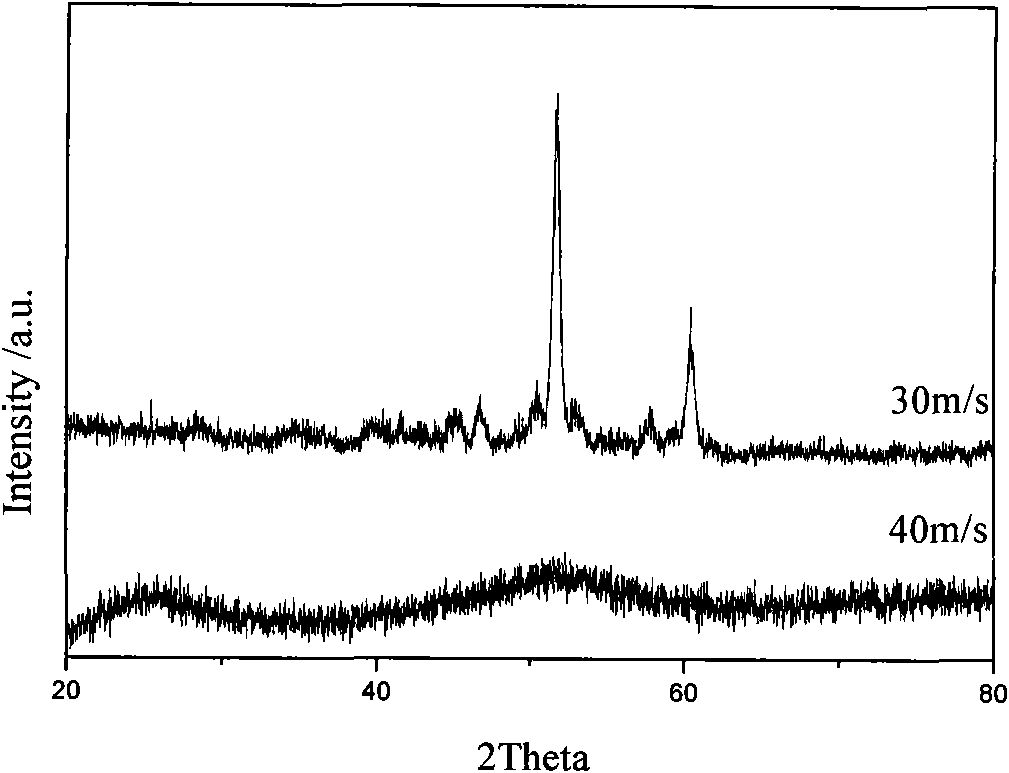

Method for preparing manganese-aluminium hard-magnetic alloy

ActiveCN101684527AReduce raw material costsImprove magnetic propertiesMagnetic materialsRare-earth elementQuenching

The invention provides a method for preparing manganese-aluminium hard-magnetic alloy, which is characterized by: (1) heating the raw material alloy comprising transition metal elements, rare earth elements and non-metallic elements to obtain melting alloy; (2) rapidly quenching in a speed of 1*10<5>-1*10<6> DEG C / s to obtain an alloy band; and (3) hot working the alloy powder under the protectionof vacuum / inert atmosphere. The method has advantages of low cost increase on raw material compared with the initial prescription, comprehensive utilization of rapid quenching and hot working, greatincrease of magnetic property of the products and easy operation and production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Micro-alloyed copper magnesium alloy

The invention relates to a micro-alloyed copper magnesium alloy. The micro-alloyed copper magnesium alloy comprises the following components in percentage by weight: 0.05-0.15% of magnesium, 0.001-0.005% of phosphor, 0.005-0.1% of CuY15 alloy, not larger than 0.15% of other elements serving as impurities, and the balance of copper. The micro-alloyed copper magnesium alloy is smelted in a vacuum furnace. The micro-alloyed copper magnesium alloy provided by the invention is low in manufacturing cost, high in conductivity, high in strength, high in ductility and capable of replacing a copper based silver alloy in practical application.

Owner:北京金鹏振兴铜业有限公司

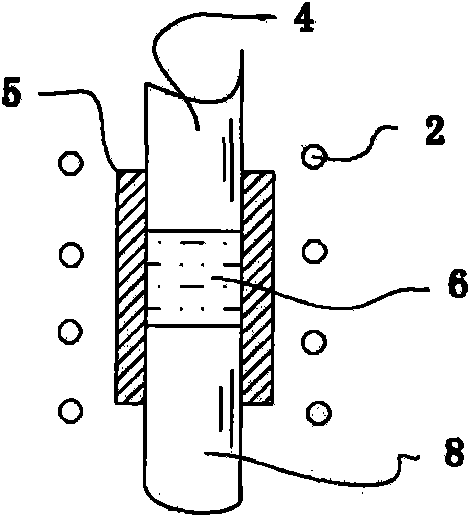

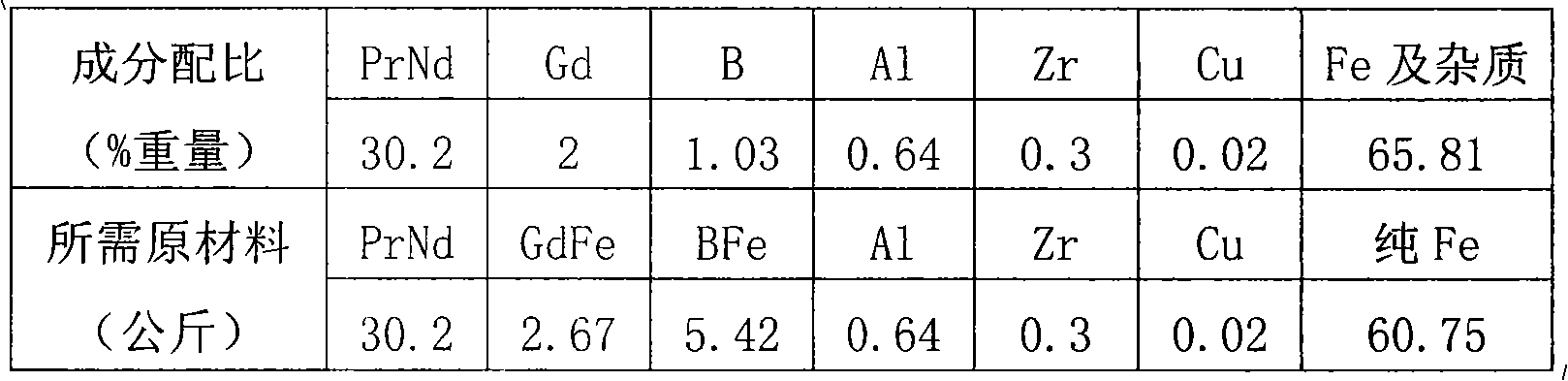

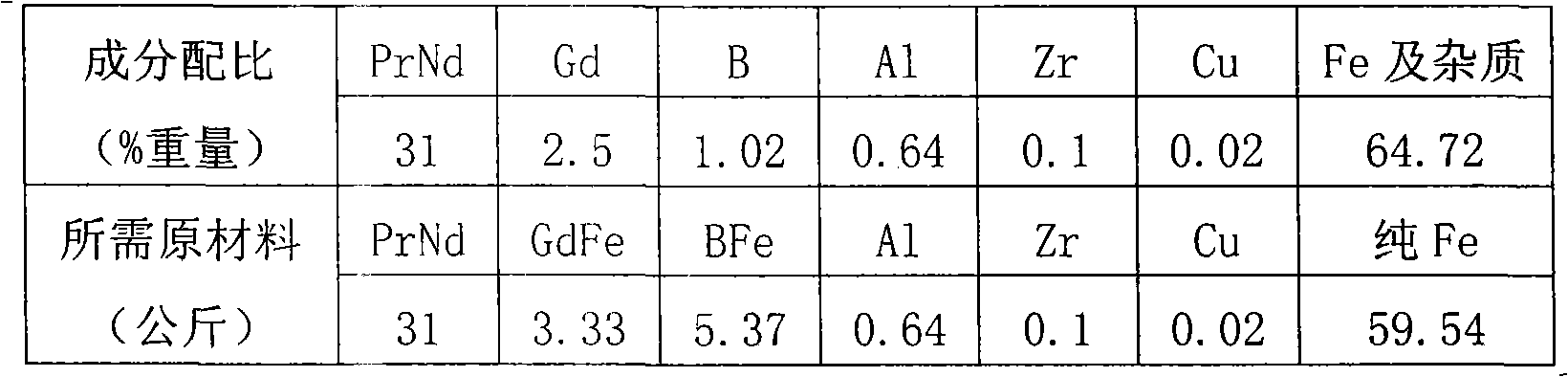

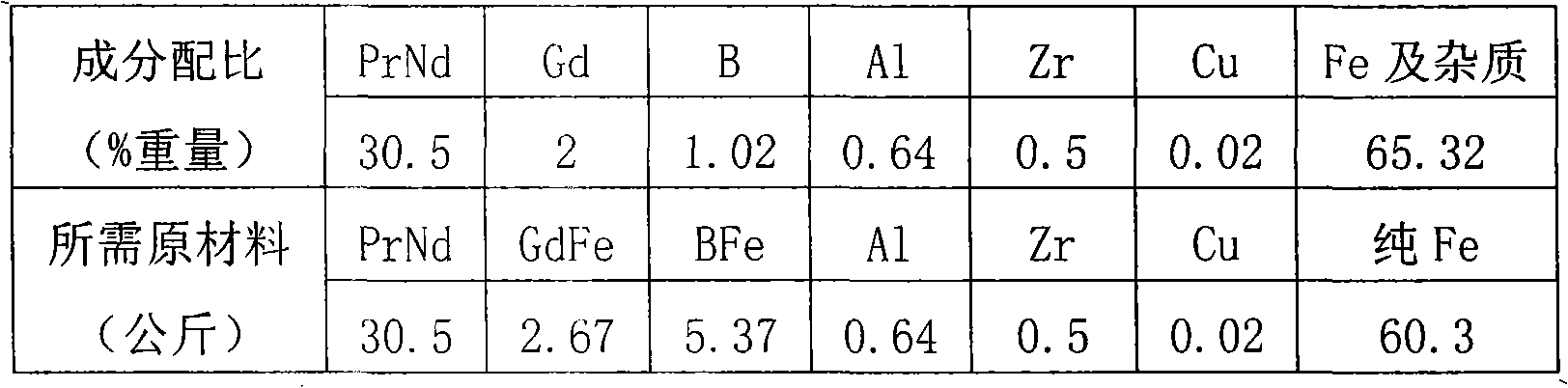

Neodymium iron boron permanent magnetic material using zirconium to substitute niobium

The invention relates to a NdFeB permanent material whose Nb is replaced by Zr, and constituents are: (28-35)% Pr-Nd alloy, (1-10)% Gd, (0.1-0.5)% Zr, (0.95- 1.3)% B, (0.1-1.5)% Al, (0.01-0.3)% Cu, Fe and inevitable impurities which are the rest, wherein, the percentages below are weight percentages. The metal element Zr is added so as to replace the Nb in the NdFeB alloy by adjusting the constituents of the alloy. The invention uses Zr which is a plentiful resource in our country to replace the rare metal Nb with high melting point, so that the cost of material is reduced under the condition of that the magnetic performance is not reduced, and the addition of Zr is significantly less than that of Nb, but the NdFeB alloy material with the same magnetic performance can also be obtained.

Owner:NINGBO KETIAN MAGNET

Multifunctional dura mater repairing material based on biomimetic design and preparation method thereof

ActiveCN109260520AReduce raw material costsReduce manufacturing costElectro-spinningNon-woven fabricsElectrospinningChemistry

The invention discloses a multifunctional dura mater repairing material based on biomimetic design and a preparation method thereof. The dura mater repairing material comprises a polylactic acid layerwith hydrophobic and leakproof properties, a hydrogel layer with hydrophilic and repairing functions, and a chitosan with antibacterial, joining and anti-adhesion properties. Polylactide layer. By electrospinning polylactic acid film, electrospinning chitosan- Poly (lactic acid) (PLA) films, gelatin prepared on bilayer electrospun films- SIS pow hydrogel. The dura mater repairing material of theinvention has low cost, and can simultaneously realize the effects of leakproof liquid and induced regeneration, anti-adhesion, anti-immunity and anti-bacterial.

Owner:BEIHANG UNIV

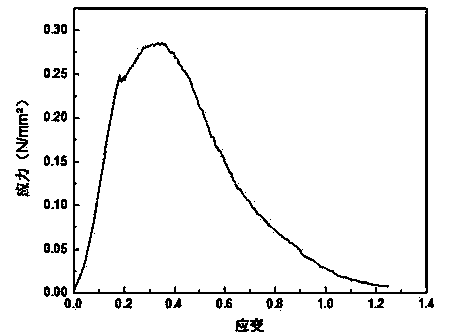

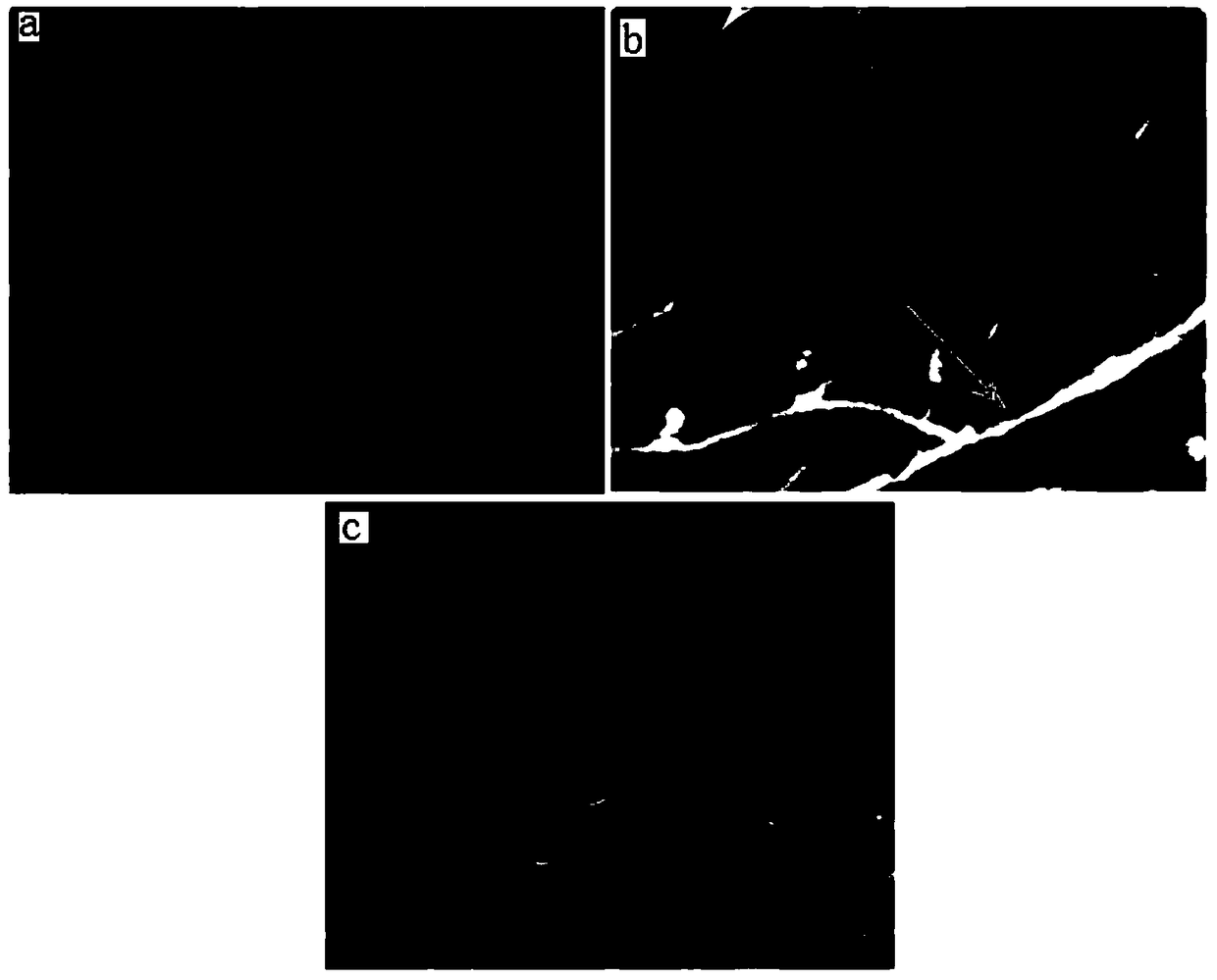

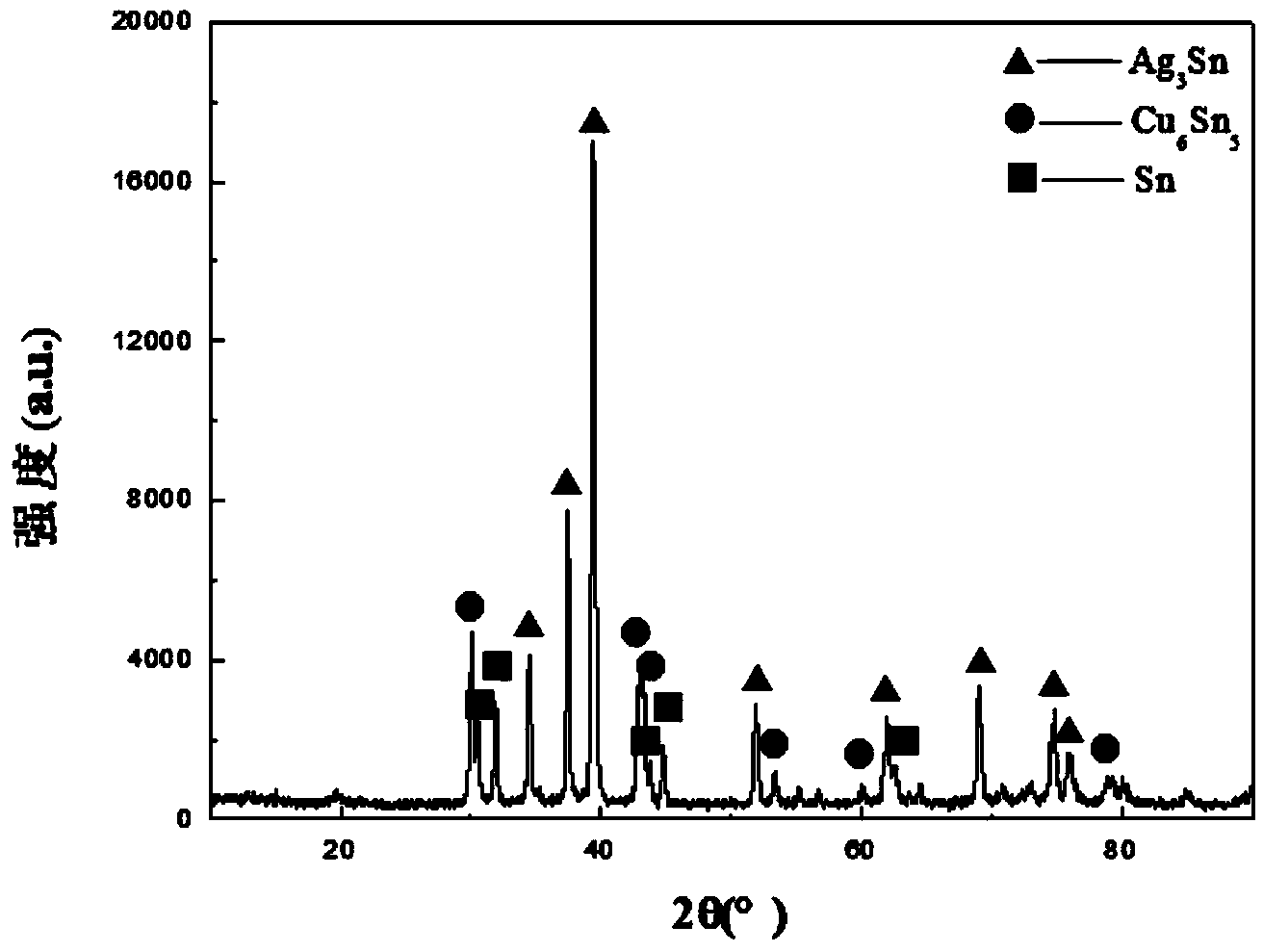

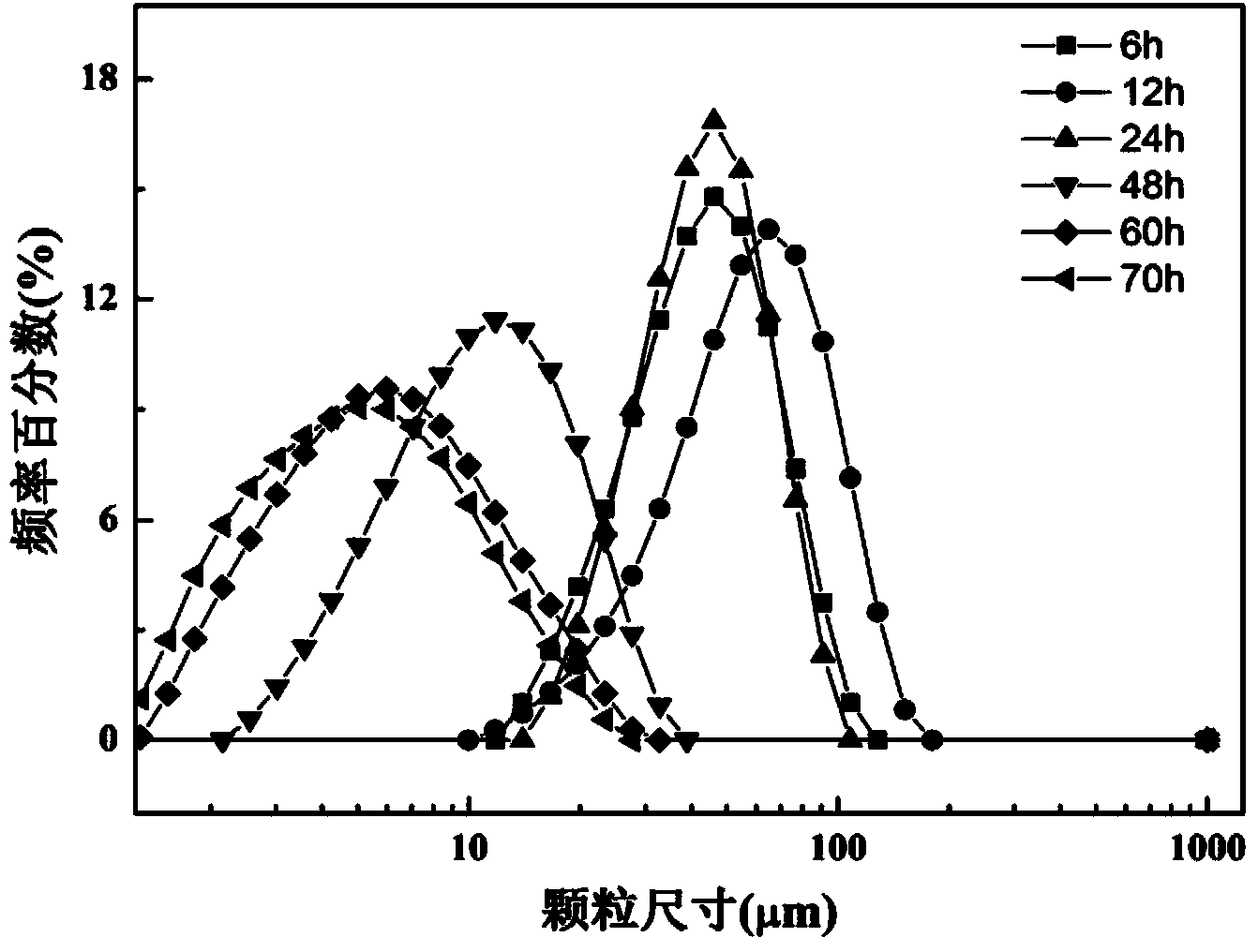

Method for preparing annular moderate-temperature Ag-Cu-Sn brazing filler metal piece

InactiveCN103659059AReduce raw material costsWell formedWelding/cutting media/materialsSoldering mediaBall millWetting

The invention belongs to the technical field of electronic packaging brazing, and discloses a method for preparing an annular moderate-temperature Ag-Cu-Sn brazing filler metal piece in a pressing and thermal processing mode through Ag-Cu-Sn alloy powder which is prepared through a mechanical alloying method. The method includes the steps of placing simple-substance Ag powder, simple-substance Cu powder and simple-substance Sn powder which are weighed according to a certain mass ratio and are within a certain particle size range into a ball grinding machine container so that mechanical alloying can be conducted, then, placing the prepared alloy powder into a specific die so that pressing forming can be conducted, and finally, conducting thermal processing on a formed green body to obtain a brazing filler metal piece. The method is simple in process and low in cost, components are easy to control, the shape of the prepared Ag-Cu-Sn brazing filler metal piece is easy to control, the melting range is from 450 DEG C to 500 DEG C, wettability of a base body plated with Ni is good, and the wetting angle of the base body is smaller than 5 degrees.

Owner:UNIV OF SCI & TECH BEIJING

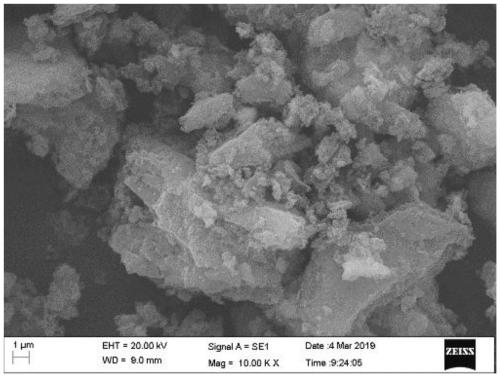

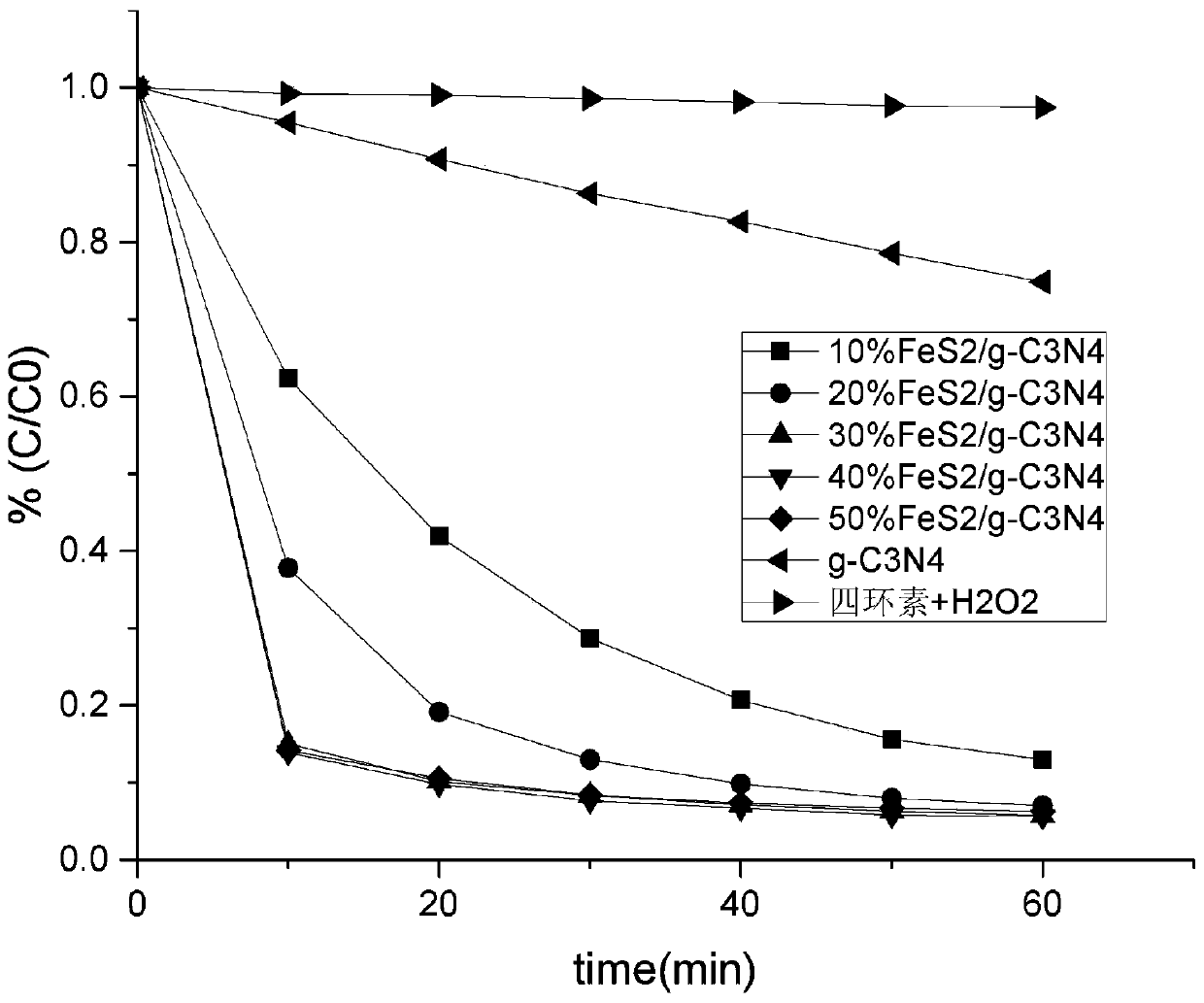

Preparation method and application of FeS2/g-C3N4 heterojunction material

ActiveCN110075896AReduce raw material costsThe preparation process is environmentally friendly and pollution-freePhysical/chemical process catalystsWater/sewage treatment by irradiationCarbon disulfideMuffle furnace

The invention discloses a preparation method and an application of a FeS2 / g-C3N4 heterojunction material. The preparation method comprises steps as follows: melamine is added to a tubular furnace andcalcined, and g-C3N4 is prepared; besides, FeSO4.7H2O, Na2S2O3.5H2O, powdered sulfur and deionized water are added to a reaction kettle and subjected to a hydrothermal reaction, FeS2 is prepared, theproduct is repeatedly washed with dilute sulfuric acid, carbon disulfide and deionized water, finally, g-C3N4 and FeS2 in a certain ratio are dissolved in a methanol solution, the mixed solution is subjected to ultrasonic bath, water-bath heating is performed to volatilize methanol, an obtained product is calcined in a muffle furnace, and the FeS2 / g-C3N4 heterojunction material can be prepared. The preparation method has a simple process and is pollution-free, low in manufacturing cost and environmentally friendly, and a prepared composite catalyst has a good treatment effect.

Owner:CHONGQING UNIV

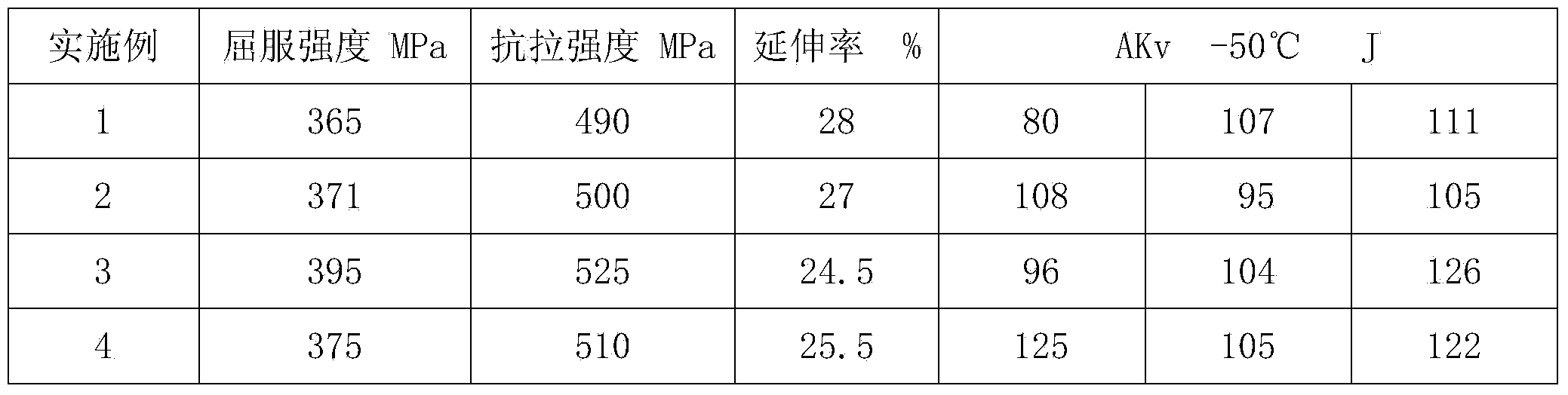

355MPa-class thick plate and production method thereof

The invention provides a 355MPa-class thick plate and a production method thereof. The 355MPa-class thick plate contains the following chemical ingredients: 0.12-0.16% of C, 0.1-0.4% of Si, 1.3-1.7% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.01-0.05% of V, 0.01-0.04% of Cr, 0.005-0.011% of Ti, 0.01-0.015% of N and 0.01-0.04% of Als, wherein Als is not more than 1.7N + 0.0037%. A converter-LF-RH or VD (vacuum degassing) smelting technology is used, and nitrogen-containing alloy is added during converter nitrogen blowing and refining process so as to add nitrogen; heating temperature is 1150-1180 DEG C, in-furnace time is 100-300min, and soaking time is 60-90min; first-stage rolling is carried out, the start rolling temperature is 1050-1170 DEG C, single pass deformation rate is 15%-25%, and final rolling temperature is 930-1050 DEG C; the rolled thick plates are independently placed flatly and cooled to 500-700 DEG C by air, and then, the thick plates are stacked for slow cooling. According to the invention, production efficiency is improved, production cost is reduced greatly, yield strength of the thick plate is up to 388MPa, tensile strength of the thick plate is 521MPa, ductility of the thick plate is 26.75%, and AKv of the thick plate at -50 DEG C is 143J.

Owner:ANGANG STEEL CO LTD

High-capacity hydrogen storage alloy electrode material and production method thereof

ActiveCN103361517AHigh rate discharge performance is goodReduce raw material costsHigh rateLarge capacity

The invention discloses a high-capacity hydrogen storage alloy electrode material which comprises the following chemical components in percentage by weight of 42-45 percent of La, 29-35 percent of Nd, 2-5 percent of Ce and 8-11 percent of Pr. The high-capacity hydrogen storage alloy electrode material has a chemical formula of ML1-x-ySmxMgyNizAlwCouMnv, wherein x is more than 0 and less than 6.7, y is more than 0 and less than 0.4, z is more than 3 and less than 4, w is more than 0.03 and less than 0.15, u is more than 0.03 and less than 0.15, v is more than 0.03 and less than 0.15, z+w+u+v is more than 3.1 and less than 4.2, and ML is a lanthanum-rich mixed rare earth metal. The invention also discloses a production method of the high-capacity hydrogen storage alloy electrode material. The high-capacity hydrogen storage alloy electrode material related in the invention has the advantages that the discharge specific capacity is 20-30 percent higher than that of a conventional AB5 type hydrogen storage alloy, and a good high-rate discharge property is achieved.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD

High water absorbing and retaining composite containing rectorite clay mineral and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, rectorite-clay mineral in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding rectorite-clay mineral into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

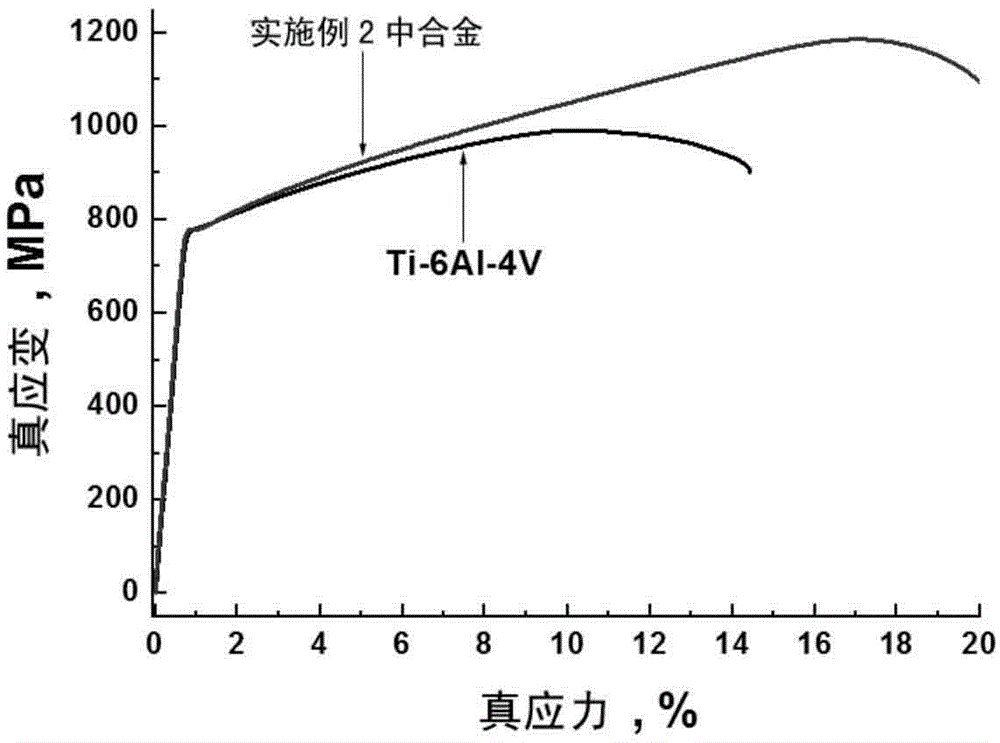

Novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy

The invention discloses a novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy, belonging to the technical field of a new titanium alloy. The novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy comprises the following elements by weight: 3.0-4.5% of Al, 2.0-3.0% of V, 0.5-1.5% of Fe, 0.5-2.0% of Cu and balance of Ti and impurity elements. Compared with Ti-6Al-4V alloy, the characteristics of the new alloy are as follows: (1) the raw materials are low in cost, hot workability plasticity is good, yield is high, and low is significantly reduced; (2) room temperature tensile strength of the new alloy after annealing is equal to that of the Ti-6Al-4V alloy, room temperature plasticity is higher, and the new titanium alloy is suitable for cold processing and warm processing forming of plates and pipes; and (3) corrosion resistance in seawater of the alloy is further improved. The titanium alloy is suitable for producing titanium alloy products such as rods, wires, plates, pipes,and the like, and can be widely used in the technical fields of aviation, spaceflight, ocean, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

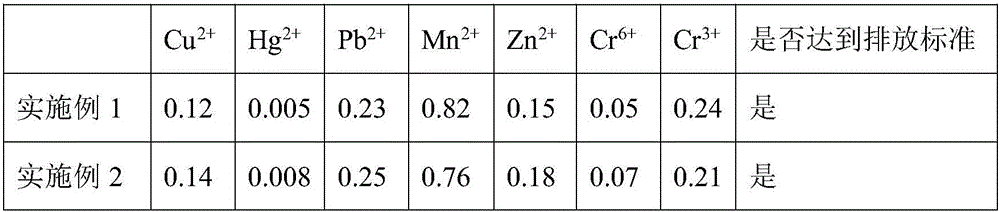

Wastewater treating agent for wastewater containing heavy metal and preparing method of wastewater treating agent

InactiveCN105776375AEasy to makeReduce raw material costsWater/sewage treatment by sorptionChemistryActivated carbon

The invention discloses a wastewater treating agent for wastewater containing heavy metal. The wastewater treating agent is prepared from, by weight, 10-18 parts of nano-titania, 10-21 parts of dendrobium leaves, 45-73 parts of attapulgite, 10-17 parts of hydrochloric acid, 8-15 parts of ferric trichloride, 5-21 parts of polyacrylamide, 5-13 parts of dimethyl diallyl ammonium chloride, 1-5 parts of activated carbon powder, 3-14 parts of ethylenediamine tetraacetic acid disodium salt, 4-8 parts of tert-butylamine, 3-8 parts of hydroxymethyl starch, 1-5 parts of sodium silicate, 2-7 parts of sodium hydrosulfite, 4-16 parts of sodium hydroxide and 16-34 parts of water. The invention further discloses a preparing method of the wastewater treating agent. According to the prepared wastewater treating agent, the preparing process is simple, the raw material cost is low, and the raw material source is wide; the agent contains various active groups, the active groups and heavy metal can be subjected to a complexation reaction, a chelation reaction, an adsorption reaction, an exchange reaction and the like, and therefore heavy metal ions in wastewater can be removed. Thus, wastewater discharge can reach the standard, and remarkable economic benefits can be achieved.

Owner:许婷

Release agent coating process method

ActiveCN102019250AReduce raw material costsGuaranteed qualityLiquid surface applicatorsCoatingsSolventWater circulation

The invention relates to a release agent coating process method. The invention has good compatibility with a solvent by adopting octadeca-carbamic acid esters, good release effect and capability of recycling the solvent, adopts a preparation method of child-mother liquor and a manufacturing method of a sandwiching heat-preservation reaction kettle and is easy to disperse after dissolution without generating sediments and more uniform for coating; a hot-water circulation sandwiching silicon groove is adopted, and a silicon solution is ensured to be more than 40 DEG C so as to not sediment, therefore nonuniform coating quantity caused by the sediments is precluded in the coating process. The coating method changing an original plain guide roller into a 350 mesh reticulated mottle guide roller matched with a scraper reduces the coating quantity of a release agent from original 7-9g / m<2> to current 2-4g / m<2> and uniformly scrapes an extremely thick release solvent positioned on a smooth roller, thereby not only saving the release agent more than doubling, but also enabling the coating to be more uniform; and in addition, the invention develops the release effect into optimal effect, greatly reduces the cost of raw materials and also ensures the quality.

Owner:SHANGHAI YONGGUAN ADHESIVE PROD CORP LTD

Six-element brass alloy with high strength and corrosion resistance

The invention relates to a six-element brass alloy with high strength and corrosion resistance, and the objective of the invention is to provide a high strength corrosion-resisting six-element brass alloy with high intensity and high elongation percentage. The six-element brass alloy comprises the following components by weight percentage: 55.00-95.00% of Cu, 0.05-19.00% of Mn, 0.05-1.50% of Fe, 0.01-6.50% of Ni, 0.01-0.5% of Ag and 3-42.00% of Zn; the elements are smelted according to present technology, and the six-element brass alloy with high strength and corrosion resistance is obtained.

Owner:北京金鹏宝志科技有限公司

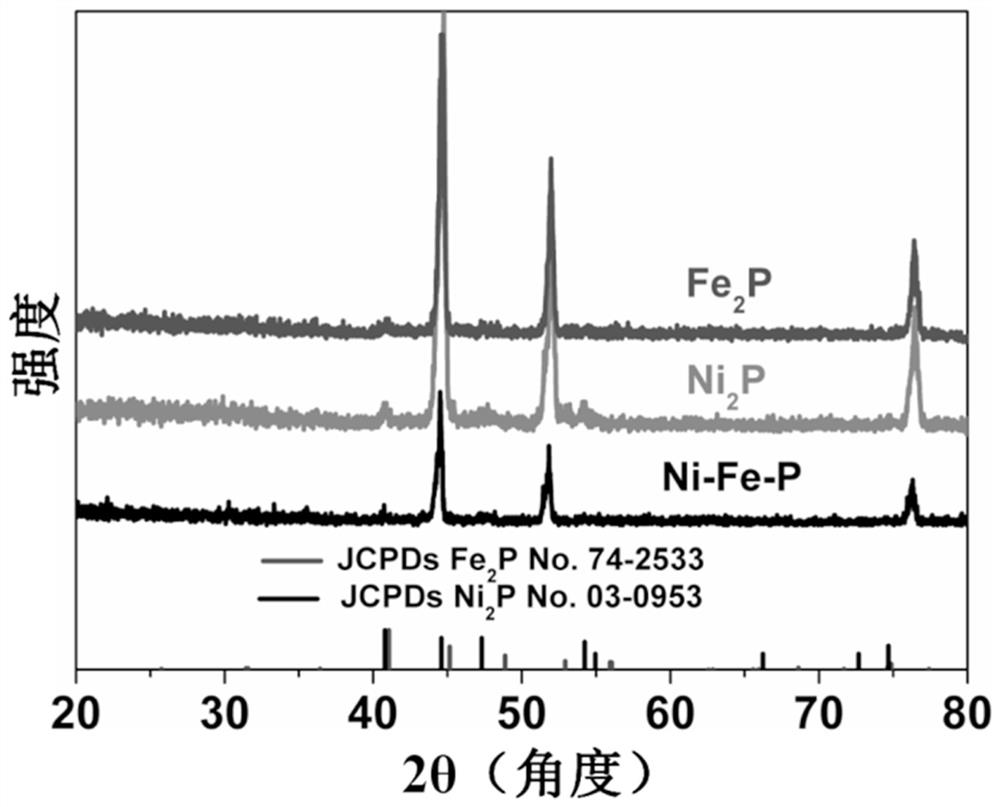

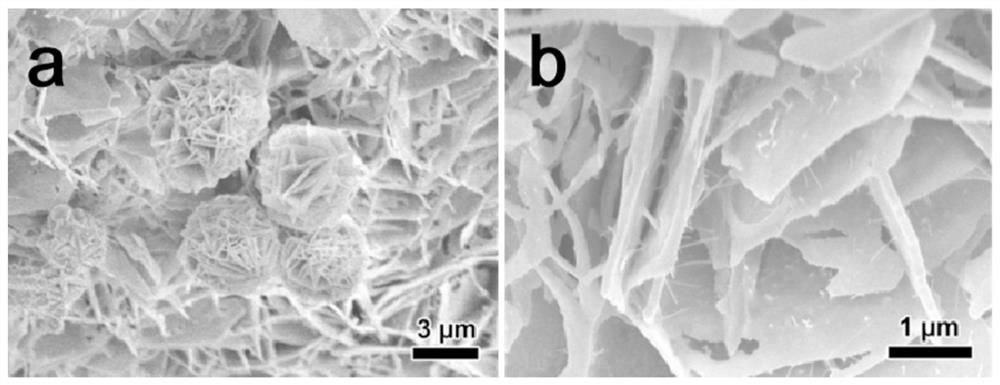

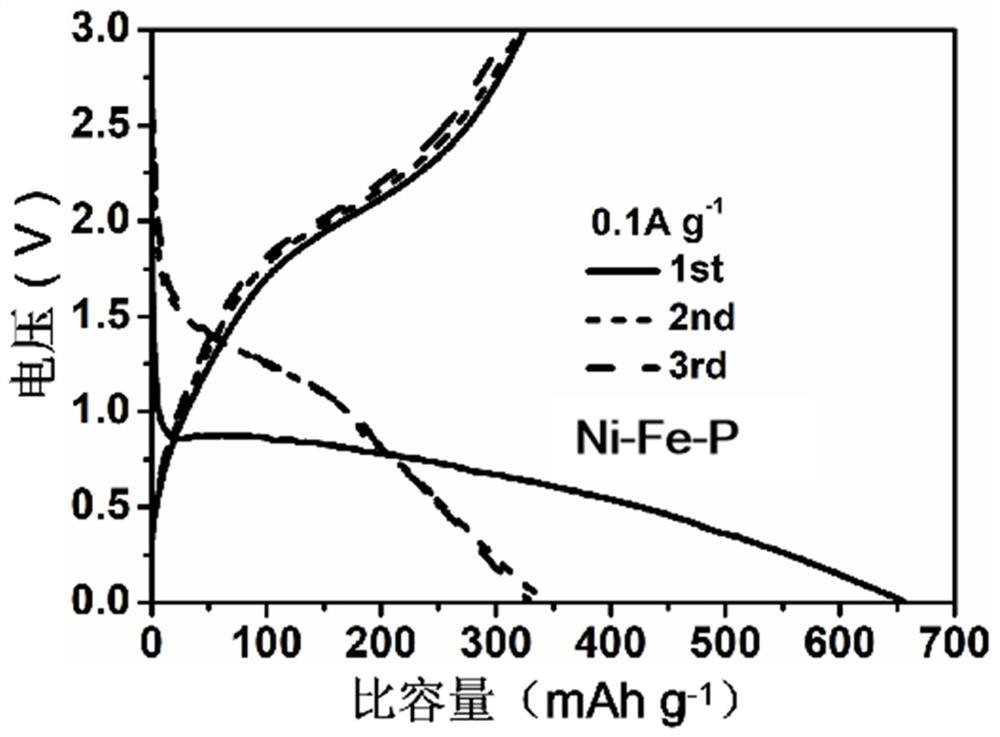

Preparation method of self-supporting ferronickel phosphide composite nanosheet

PendingCN111747388AReduce raw material costsIron richMaterial nanotechnologyNegative electrodesPotassium ionsAmmonium fluoride

The invention provides a preparation method of a self-supporting nickel-iron-phosphorus (Ni-Fe-P) composite nanosheet. The preparation method comprises the following specific steps: preparing a mixedsolution from nickel nitrate, ferric nitrate, ammonium fluoride and urea in proportion, uniformly stirring, transferring into a reaction kettle, adding clean foamed nickel (3 * 5cm < 2 >, the purity is 99%), synthesizing a ferronickel composite precursor by using a hydrothermal reaction, and carrying out a phosphating reaction to obtain the ferronickel-phosphorus composite nanosheet. Compared witha single material of nickel phosphide and iron phosphide, the nickel-iron-phosphorus composite nanosheet serving as the negative electrode material of the sodium-ion battery has the advantages that the capacity and the stability of the battery during testing are improved, and relatively good electrochemical performance is shown. The nanosheet also shows good electrochemical performance as a potassium ion battery negative electrode material, and has potential application value in the field of potassium ion batteries.

Owner:CHINA THREE GORGES UNIV

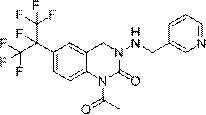

Preparation method of pyridylquinazoline

InactiveCN109705094AHigh yieldReduce raw material costsOrganic chemistryCatalytic hydrogenationPhenylcarbamic acid

The invention discloses a preparation method of pyridylquinazoline. The method uses 2-methyl-4-(perfluoropropan-2-yl)phenylcarbamate as a raw material, acetylation is performed, chlorination is performed, hydration hydrate ring formation is performed, and finally reaction is performed on the ring-formed compound and 3-halomethylpyridine to obtain the pyridylquinazoline with a content of 97.5%-98.5%, wherein the total yield is 59.0-63.0% (calculated based on the 2-methyl-4-(perfluoropropan-2-yl)phenylcarbamate). The method provided by the invention avoids dangerous processes such as catalytic hydrogenation and shortens reaction steps; and the preparation method of the pyridylquinazoline provided by the invention has low costs and simple and safe process operation.

Owner:湖南速博生物技术有限公司

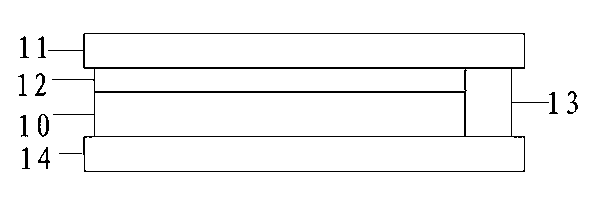

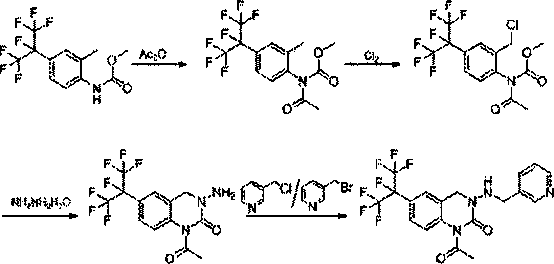

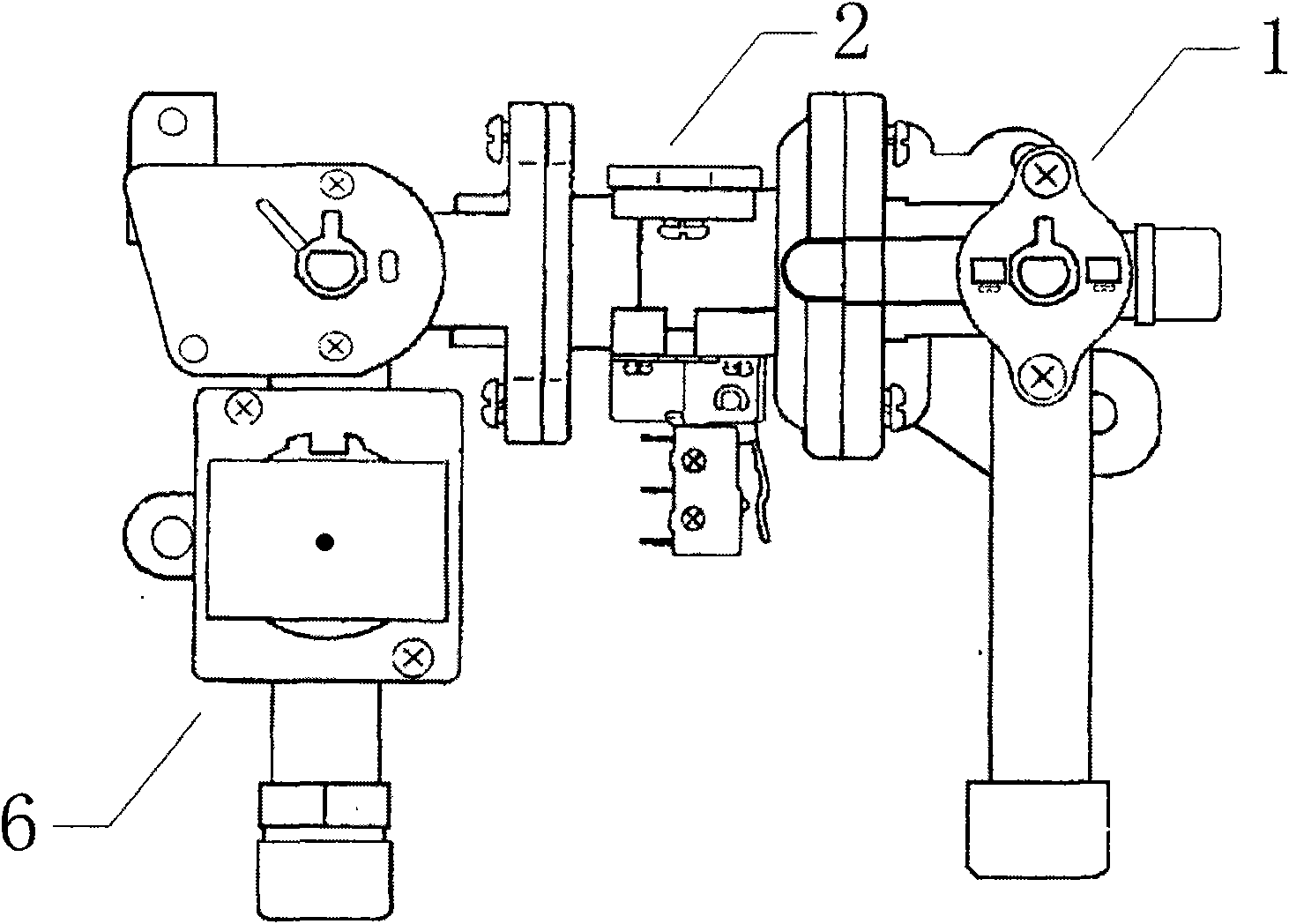

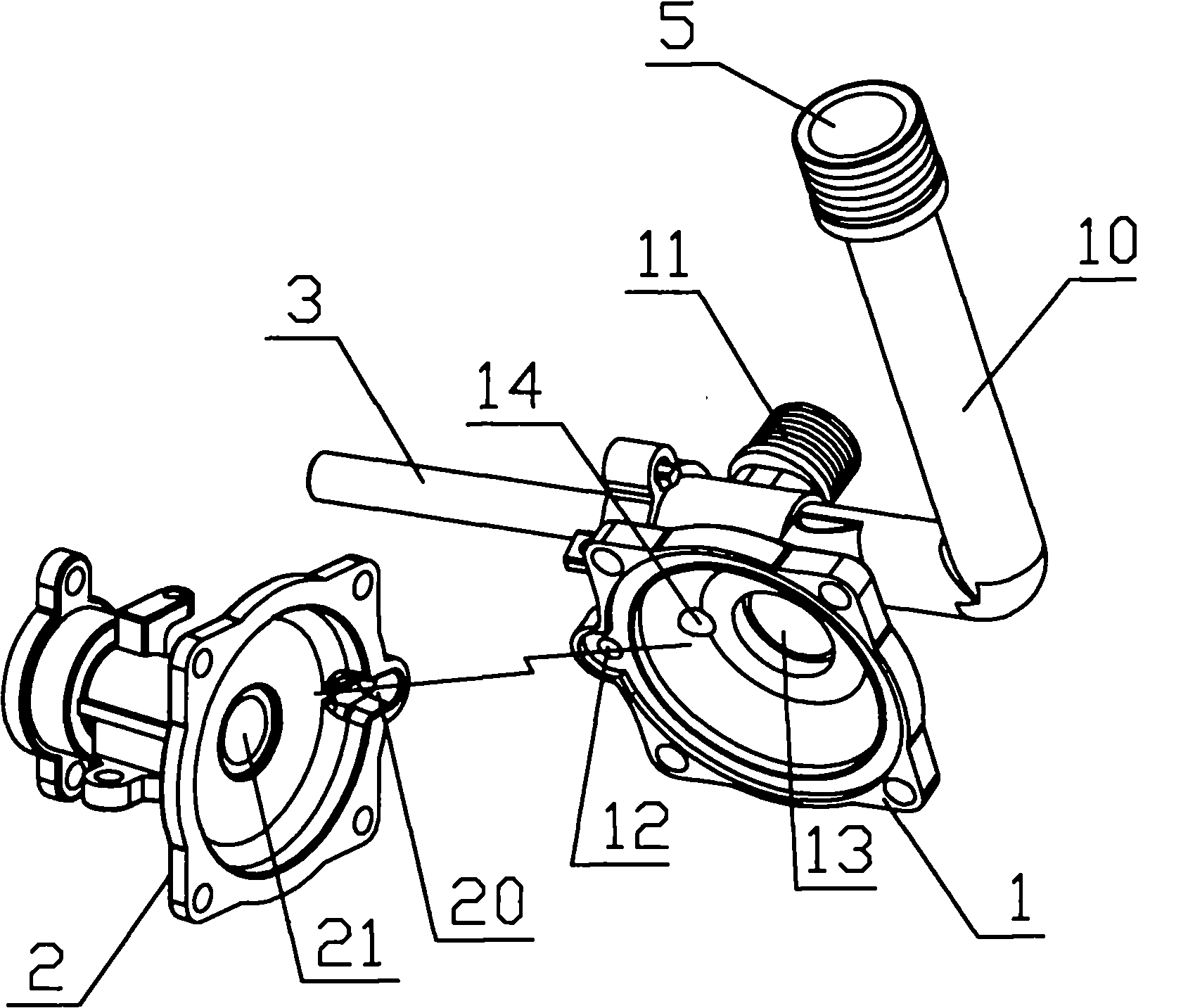

Water and gas coupled valve of gas water heater

InactiveCN101865531AReduce raw material costsPrevent burstFluid heatersOperating means/releasing devices for valvesPolyamideEngineering

The invention belongs to the technical field of gas water heaters and particularly relates to a water and gas coupled valve of the gas water heater. The water and gas coupled valve of the gas water heater comprises a gas valve, a water valve and a middle water and gas linkage, wherein guide channels which are communicated with one another are positioned between a shell (1) of the water valve and the shell (2) of the water and gas linkage. The water and gas coupled valve of the gas water heater is characterized in that: the shell (1) of the water valve is made of plastics and has a water inlet (10), a water outlet (11) and an adjusting opening for adjusting water flow; and a valve rod (3) is arranged on the adjusting opening. The lower end of the valve rod (3) is circumferentially provided with a water flow channel (30) which has a grooved structure for adjusting the volume of water amount; the distance from a front end groove of the water flow channel (30) to a circle centre is not equal to that from a rear end groove of the water flow channel (30) to the circle centre; and the water flow channel has smooth transition from the front end to the rear end. The shell (1) of the water valve is made of a polyamide (nylon PA) PA66 material. The water and gas coupled valve which adopts the structure has simple and rational structural design and reduces production cost.

Owner:黎晚滔

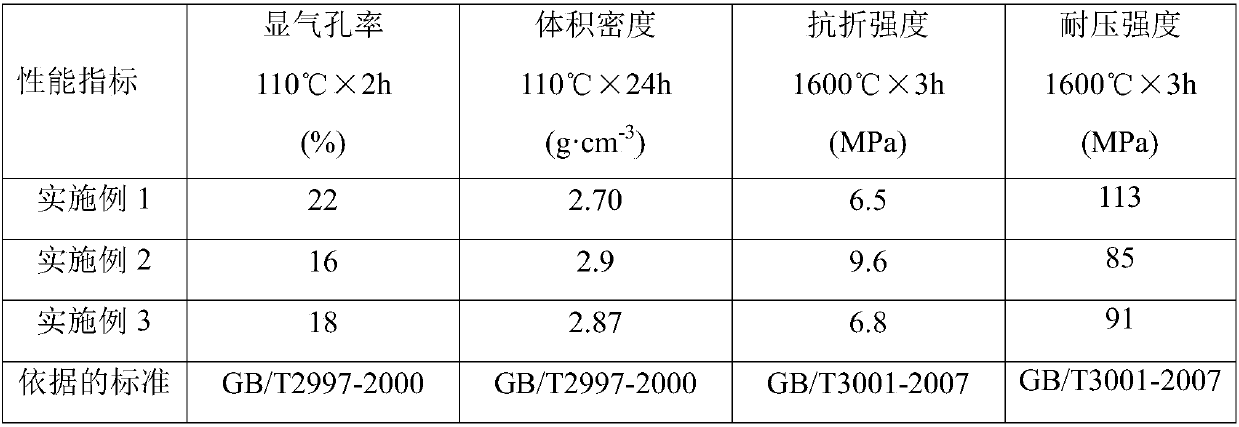

Ladle lining repair material as well as preparation method and application thereof

The invention relates to a ladle lining repair material. The ladle lining repair material is prepared from 5 to 3 mm recycled corundum aggregate, 3 to 1 mm recycled corundum aggregate, 1 to 0 mm recycled corundum aggregate, less than 88 [mu]m corundum fine powder, less than 88 [mu]m magnesia powder, less than 88 [mu]m soft clay fine powder, less than 88 [mu]m calcium aluminate cement, less than 5[mu]m silica powder, and less than 5 [mu]m alpha-Al2O3 micro powder, as well as a water reducing agent and explosion-proof fibers; the raw materials are uniformly stirred to obtain the ladle lining repair material. 9 to 12 percent of water is added into the ladle lining repair material to obtain repair pug; the repair pug is uniformly smeared on the surface of a ladle lining refractory material atthe smearing thickness of 1 to 3 cm; the ladle lining refractory material can be used after curing and baking. The ladle lining repair material has the advantages of being low in price, environment friendly, high in strength, high in corrosion resistance, long in service life, simple and quick; the service life of a ladle can be effectively prolonged by 20 to 30 percent, the cost of the refractory material is reduced and the production efficiency of the ladle is improved.

Owner:河南竹林庆州耐火材料有限公司

Preparation method of permanent ferrite material

InactiveCN110372365AReduce raw material costsGood for the environmentInorganic material magnetismHeat treatedRaw material

The invention relates to the field of permanent ferrite, in particular to a preparation method of a permanent ferrite material. The preparation method includes the steps that (1), a pre-burned material is prepared, specifically, the ferrite raw material is weighed according to the proportion, ball milling is carried out with a wet method at one time, the ferrite raw material is pre-pressed after being dried, and then pre-burned to obtain a block pre-burned material, and then the block pre-burned material is crushed to obtain pre-burned material powder; (2), crushing through the wet method is carried out, specifically, the pre-burned material powder and additives are ground under the condition of deionized water as a ball milling medium to obtain slurry for forming; (3), forming is carriedout, specifically, the forming slurry is subjected to centrifugal dehydration, and then pressed for forming under the condition of applying a forming magnetic field; and (4) sintering is carried out,specifically, a forming body is subjected to heat treatment to completely remove water and then sintered in the air to obtain the sintered body. According to the preparation method of the permanent ferrite material, the defects of high cost, low compactness and poor performance of the permanent ferrite material in the prior art are overcome, and the preparation method of the permanent ferrite material has the advantages of reducing the cost and even better performance of the ferrite material.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com