Preparation method and application of FeS2/g-C3N4 heterojunction material

A g-c3n4, heterojunction technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve carcinogenic secondary pollutants, cannot be effectively degraded, not easy to degrade and easily Accumulation and other problems, to achieve the effect of low cost of raw materials, environmental protection and pollution-free preparation process, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] FeS 2 / g -C 3 N 4 A method for preparing a heterojunction material, comprising the steps of:

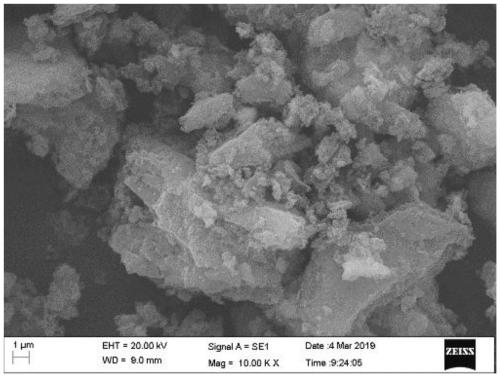

[0024] Step 1: Weigh 1g of melamine and place it in a tube furnace, blow it with nitrogen, and fire it at 550°C for 2 hours (the heating rate is 10°C / min) to form a block g-C 3 N 4 . Then it was fired at 500°C for 2 hours (the heating rate was 5°C / min) to make flake g-C 3 N 4 .

[0025] Step 2: Add 0.025mol FeSO to the 50mL reactor 4 ·7H 2 O, 0.025mol Na 2 S 2 o 3 ·5H 2O and 0.0125mol sulfur powder, mix well and add 25mL deionized water. Hydrothermal reaction was carried out at 180° C. for 24 hours in a blast drying oven. After the reaction, cool to room temperature, put the obtained black precipitate into a centrifuge tube, wash it with deionized water, dilute sulfuric acid and carbon disulfide, and finally dry it in vacuum at 80°C for 6 hours, which is FeS 2 .

[0026] Step 3: Add 50mL methanol to the beaker, then add 0.05g FeS 2 , ultrasonic bath for 15 min...

Embodiment 2

[0028] FeS 2 / g -C 3 N 4 A method for preparing a heterojunction material, comprising the steps of:

[0029] Step 1: Weigh 1g of melamine and place it in a tube furnace, blow it with nitrogen, and fire it at 560°C for 1.8 hours (the heating rate is 10°C / min) to form a block g-C 3 N 4 . Then it was fired at 490°C for 1.8 hours (the heating rate was 5°C / min) to make flake g-C 3 N 4 .

[0030] Step 2: Add 0.025mol FeSO to the 50mL reactor 4 ·7H 2 O, 0.025mol Na 2 S 2 o 3 ·5H 2 O and 0.0125mol sulfur powder, after mixing evenly, add 25mL deionized water. Hydrothermal reaction at 170°C for 24 hours in a blast drying oven. After the reaction, cool to room temperature, put the obtained black precipitate into a centrifuge tube, wash it with deionized water, dilute sulfuric acid and carbon disulfide, and finally dry it in vacuum at 70°C for 7 hours, which is FeS 2 .

[0031] Step 3: Add 50mL of methanol to the beaker, then add 0.1g of FeS 2 , ultrasonic bath for 20 min...

Embodiment 3

[0033] FeS 2 / g -C 3 N 4 A method for preparing a heterojunction material, comprising the steps of:

[0034] Step 1: Weigh 1g of melamine and place it in a tube furnace, blow it with nitrogen, and fire it at 550°C for 2 hours (the heating rate is 10°C / min) to form a block g-C 3 N 4 . Then it was fired at 500°C for 2 hours (the heating rate was 5°C / min) to make flake g-C 3 N 4 .

[0035] Step 2: Add 0.025mol FeSO to the 50mL reactor 4 ·7H 2 O, 0.025mol Na 2 S 2 o 3 ·5H 2 O and 0.0125mol sulfur powder, mix well and add 25mL deionized water. Hydrothermal reaction was carried out at 180° C. for 24 hours in a blast drying oven. After the reaction, cool to room temperature, put the obtained black precipitate into a centrifuge tube, wash it with deionized water, dilute sulfuric acid and carbon disulfide, and finally dry it in vacuum at 80°C for 6 hours, which is FeS 2 .

[0036] Step 3: Add 50mL of methanol to the beaker, then add 0.15g of FeS 2 , ultrasonic bath for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com