Patents

Literature

14008results about "Fluid heaters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

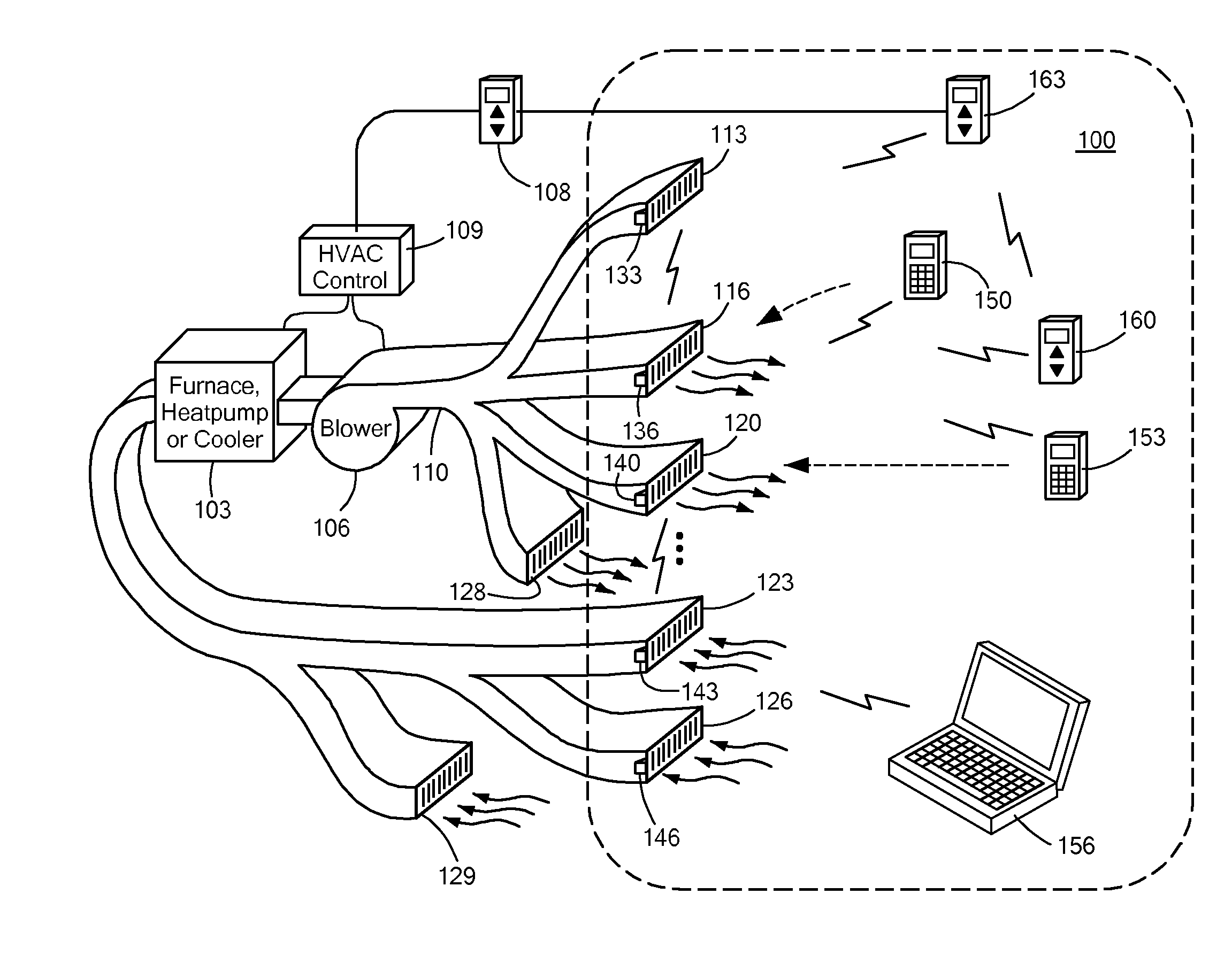

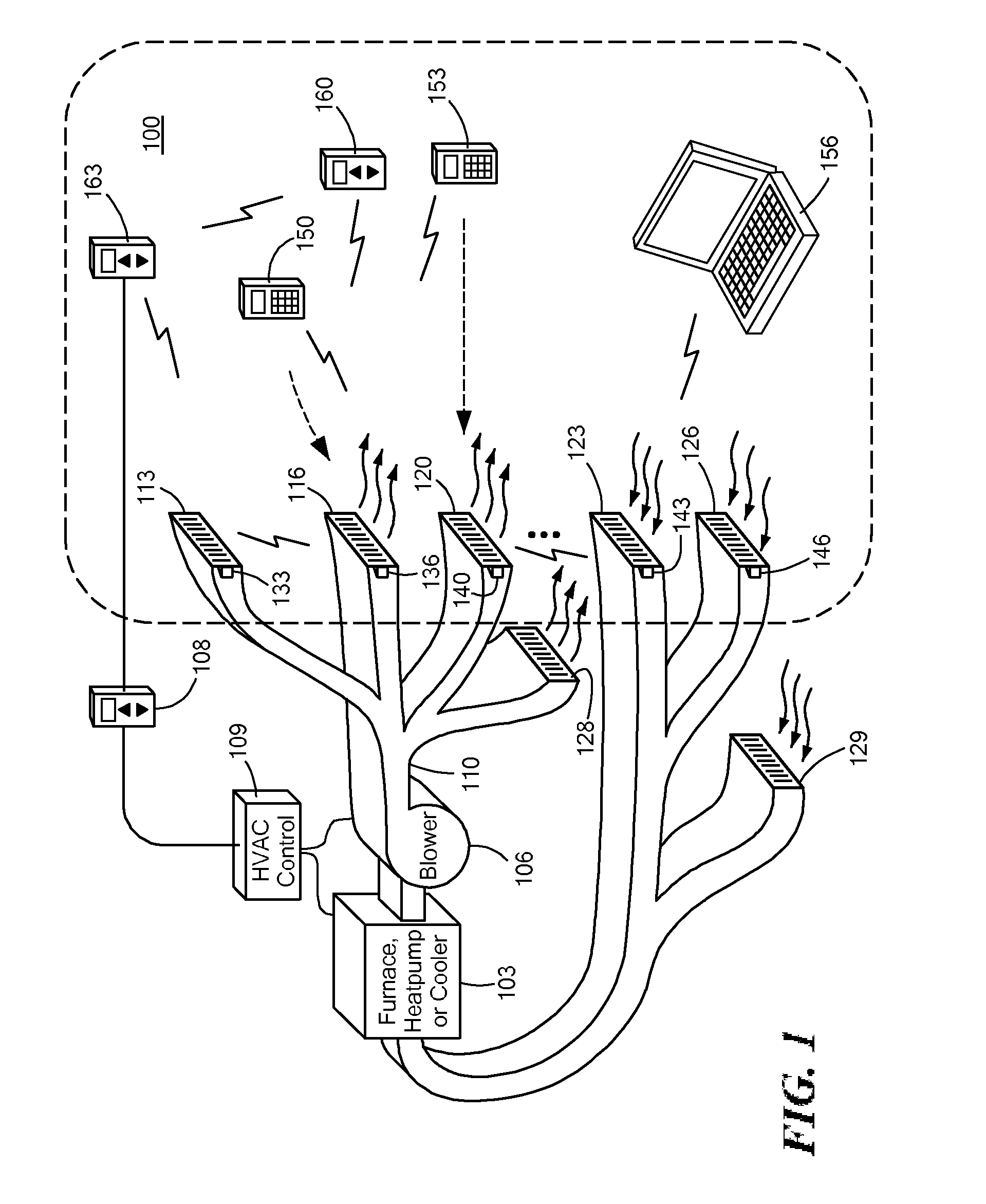

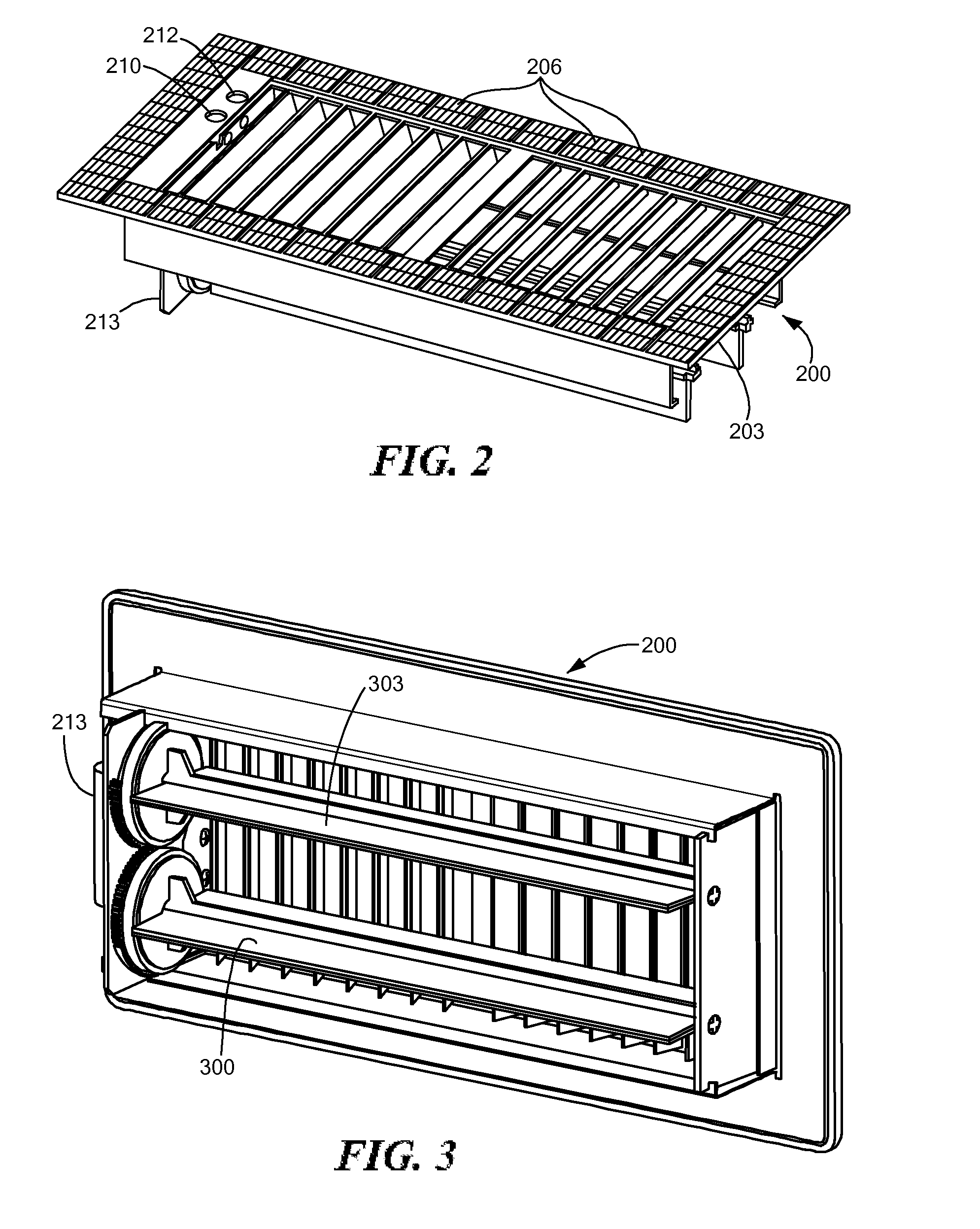

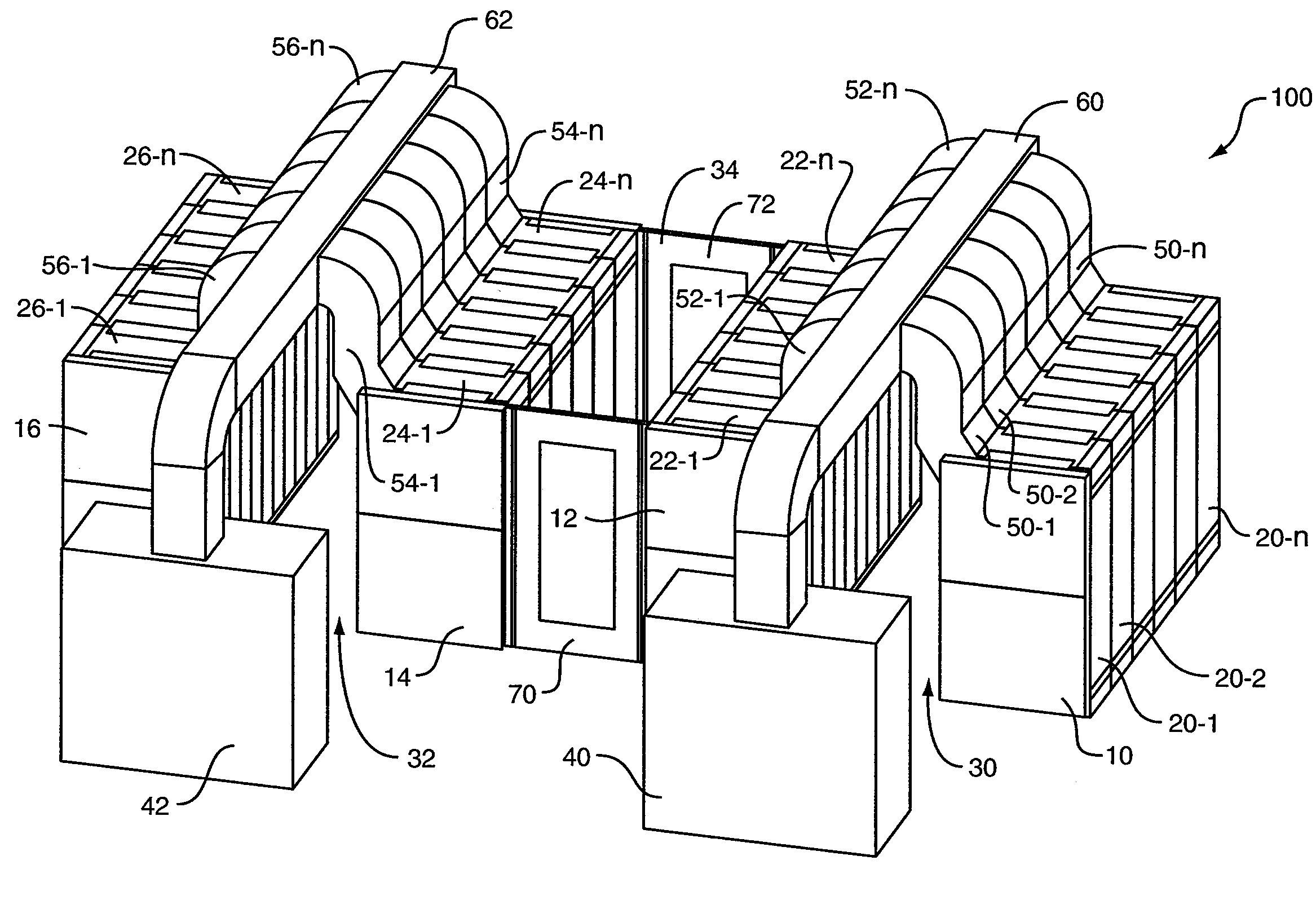

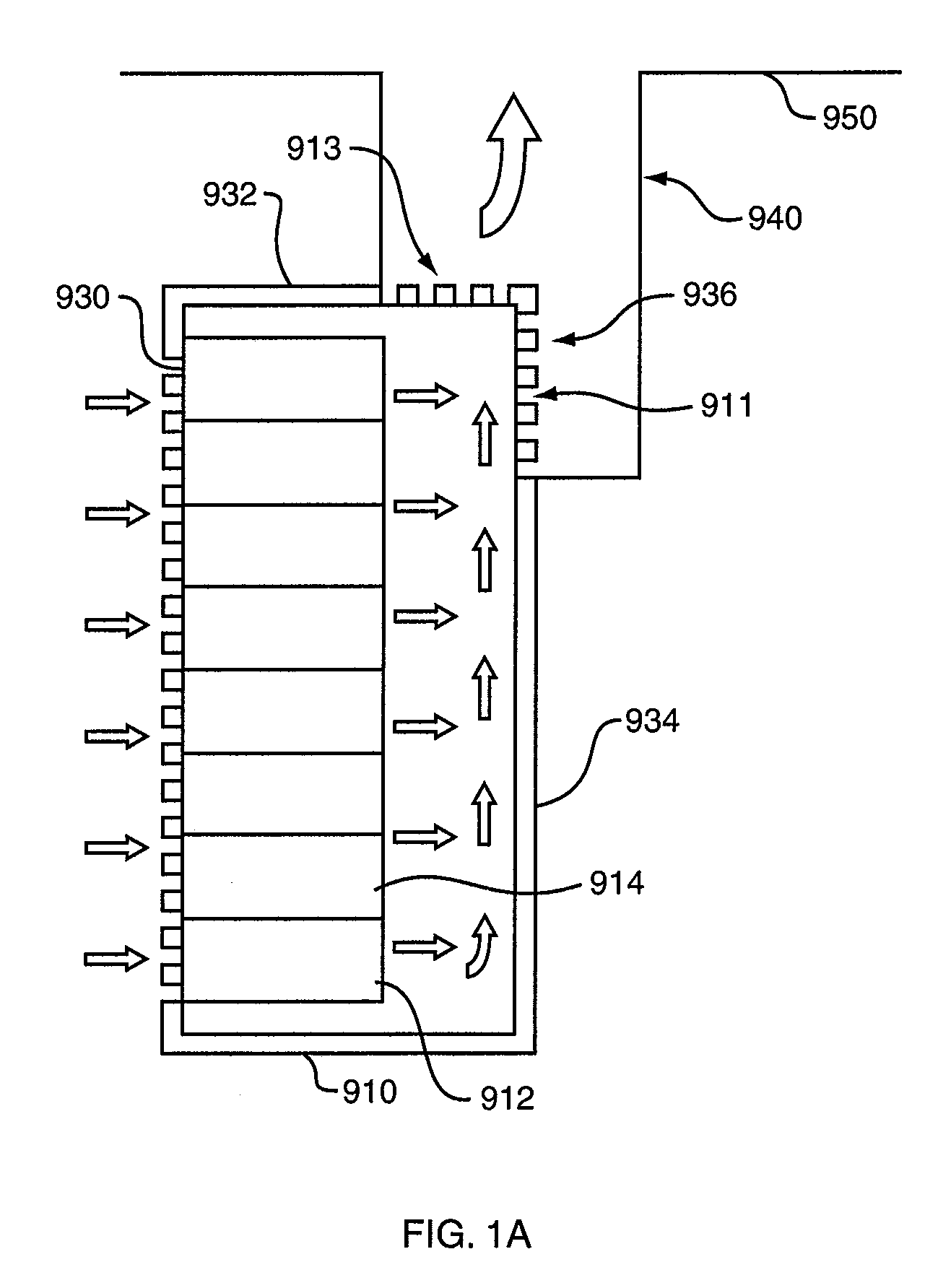

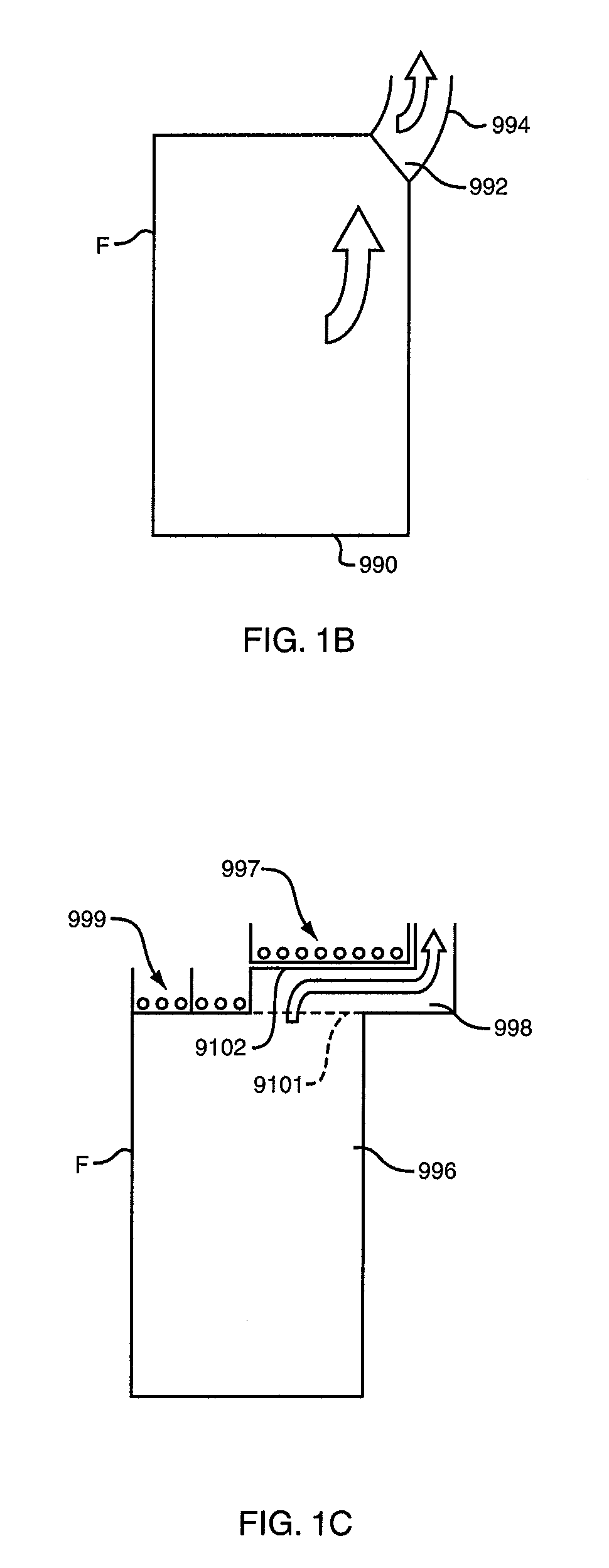

Automatically Balancing Register for HVAC Systems

Distributed nodes, such as intelligent register controllers, of a heating, ventilating and / or air conditioning (HVAC) system wirelessly communicate with each other on a peer-to-peer basis, forming a network, and collectively control the HVAC system, without a central controller. The intelligent register controllers collectively control the amount of conditioned air introduced into each region. Each node may base its operation at least in part on information about one or more (ideally all) of the other nodes. Each intelligent register controller automatically determines how much conditioned air to allow into its region, or how much return air to allow to be withdrawn from its region, based on information collected by the register controller, such as: current temperature of the region; desired temperature of the region; calculated amount of conditioned air required to change the region's temperature to the desired temperature; temperature of conditioned air begin supplied by a duct to the register; current time, day of week, vacation or other schedule data; temperatures of other regions and their respective desired temperatures; calculated amounts of air required to be supplied or withdrawn by the other controlled registers to change their respective regions' temperatures to their desired temperatures; or combinations thereof. Each register controller automatically determines when and to what extent to operate its respective controllable damper.

Owner:ZONER

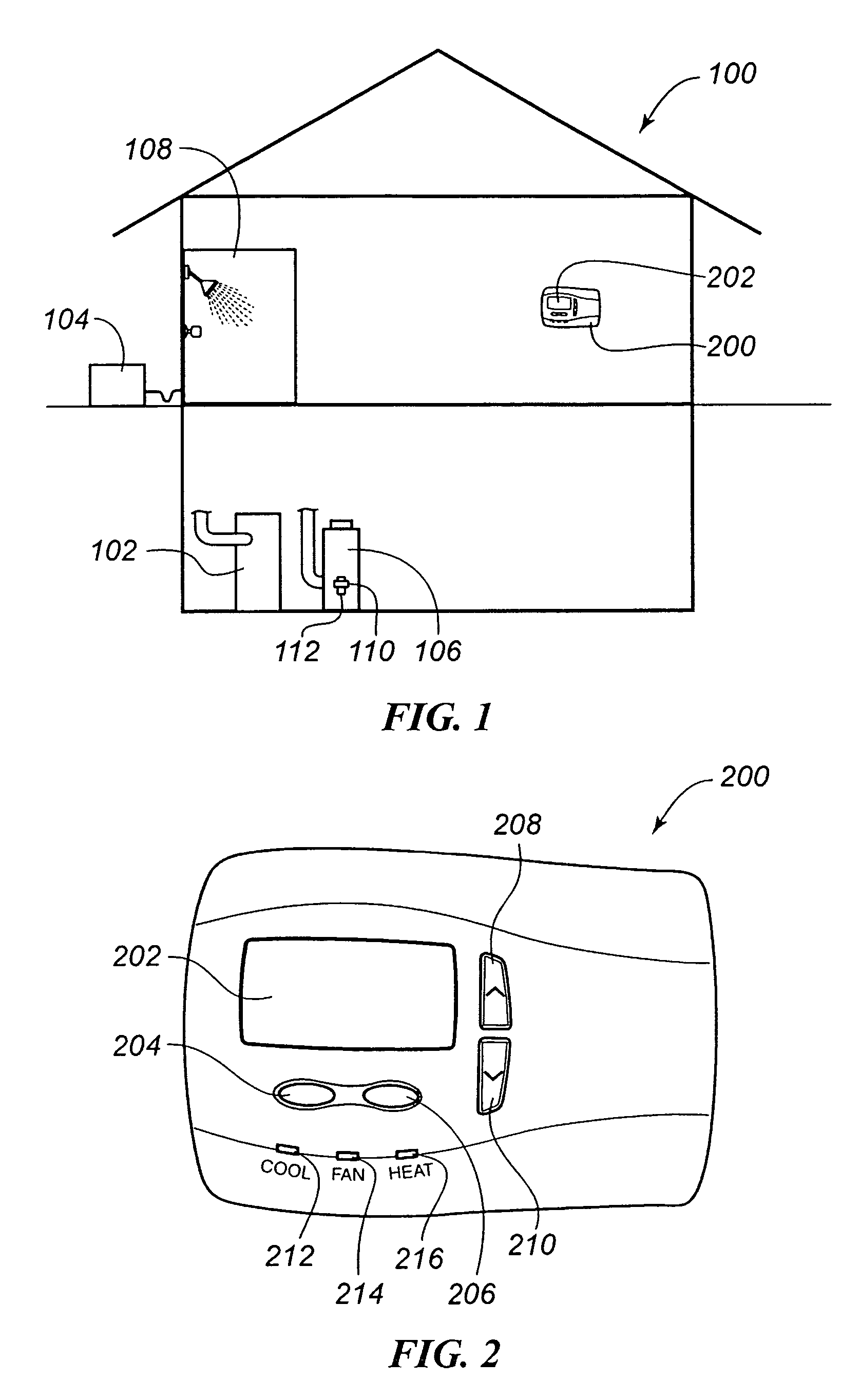

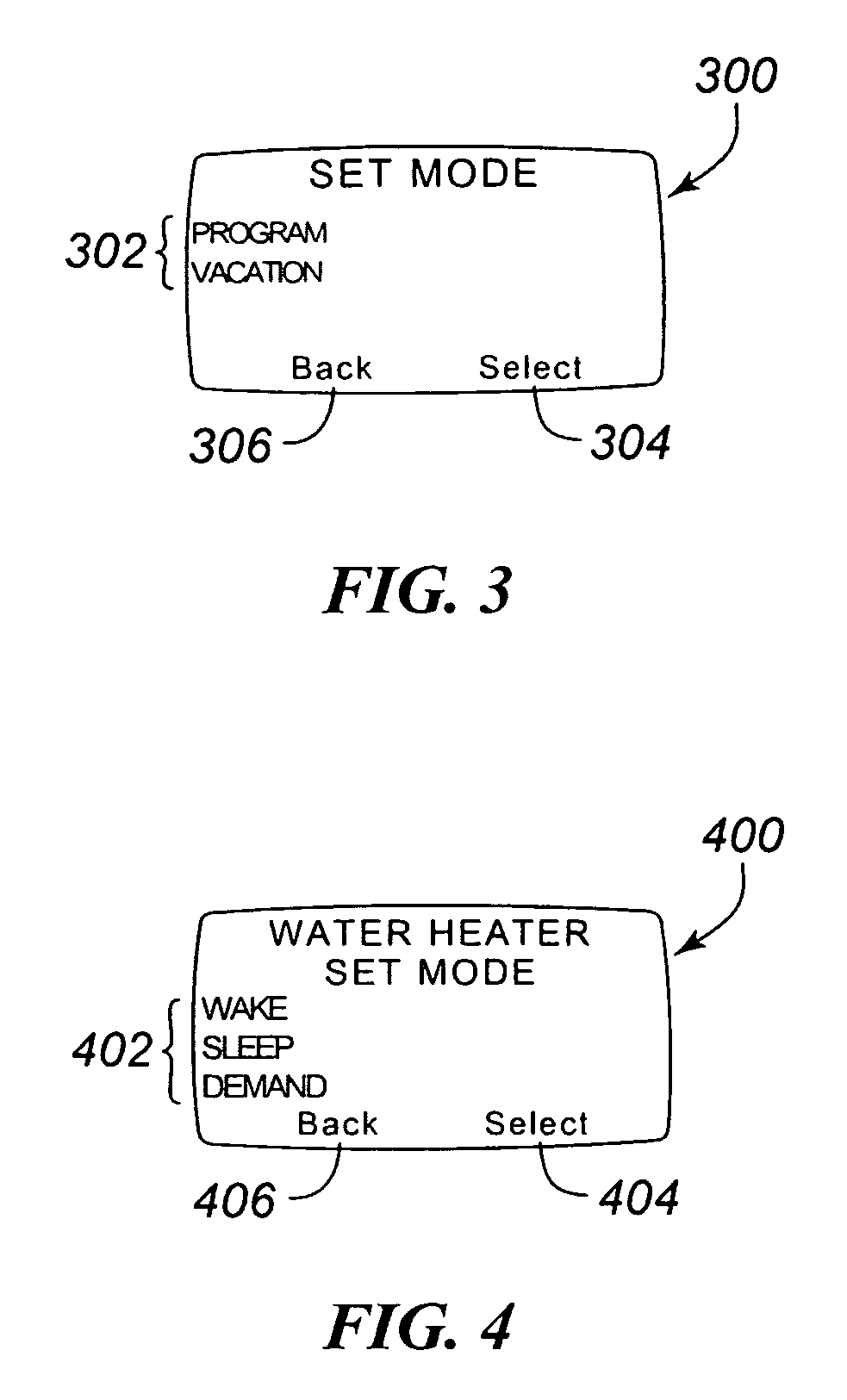

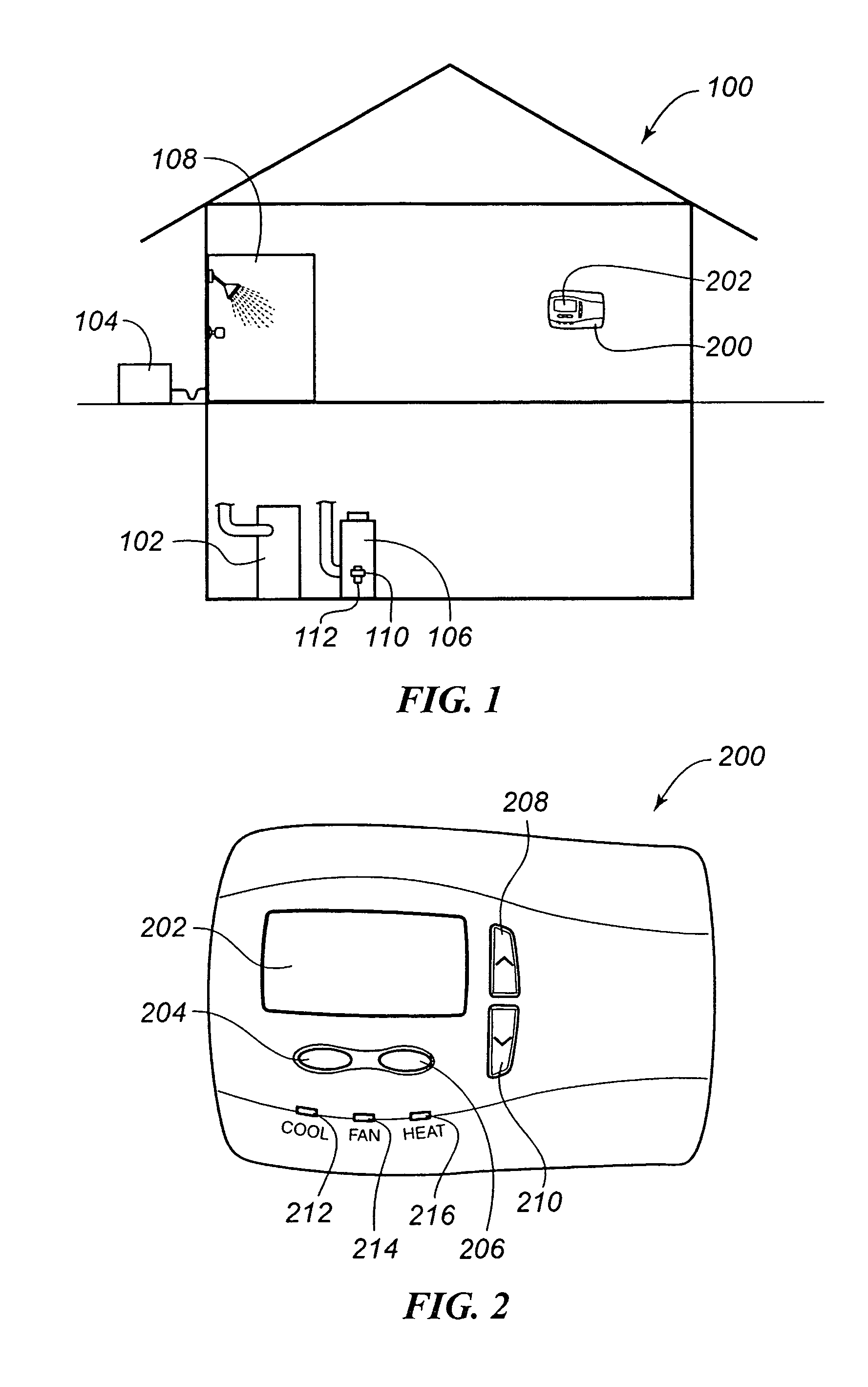

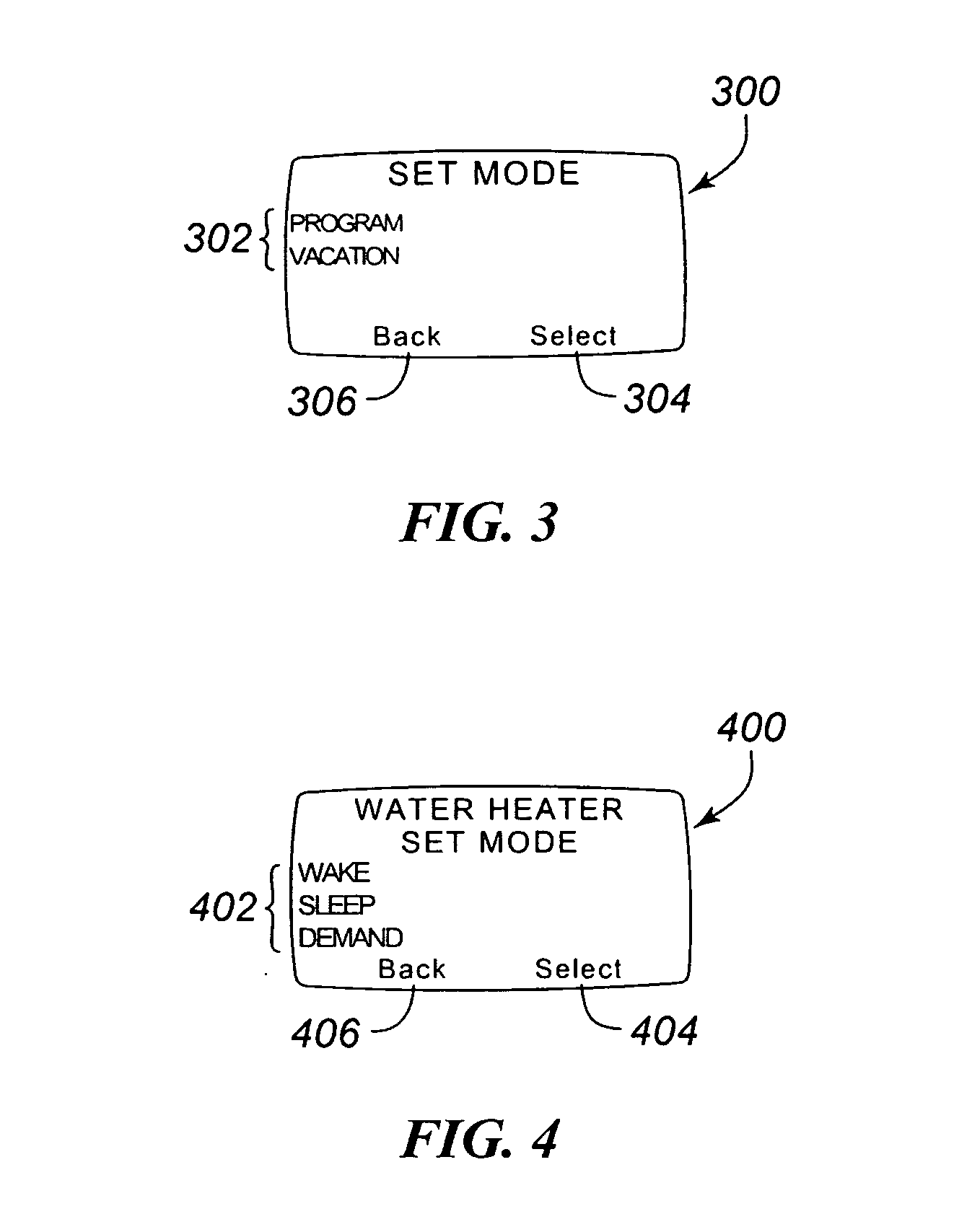

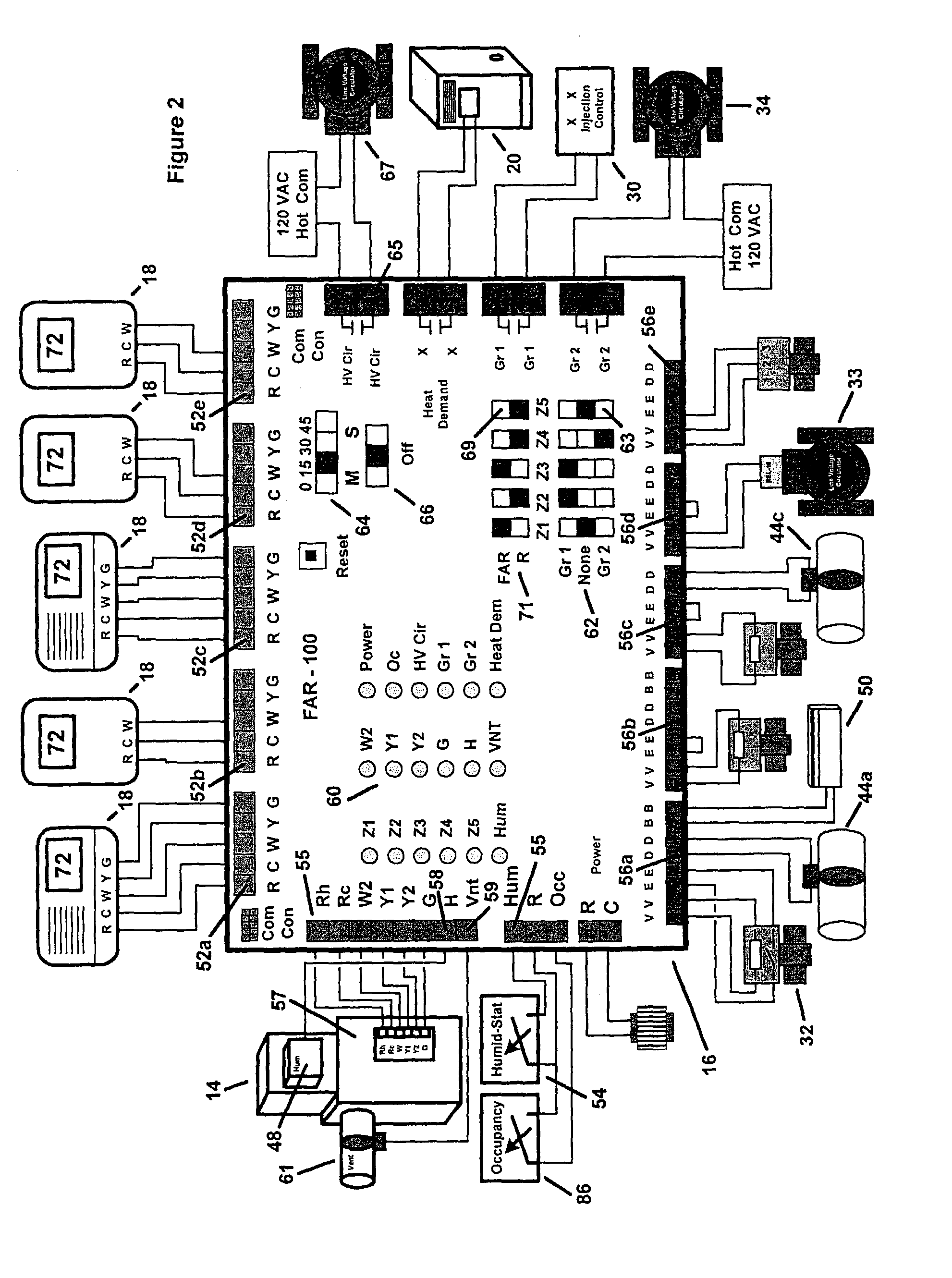

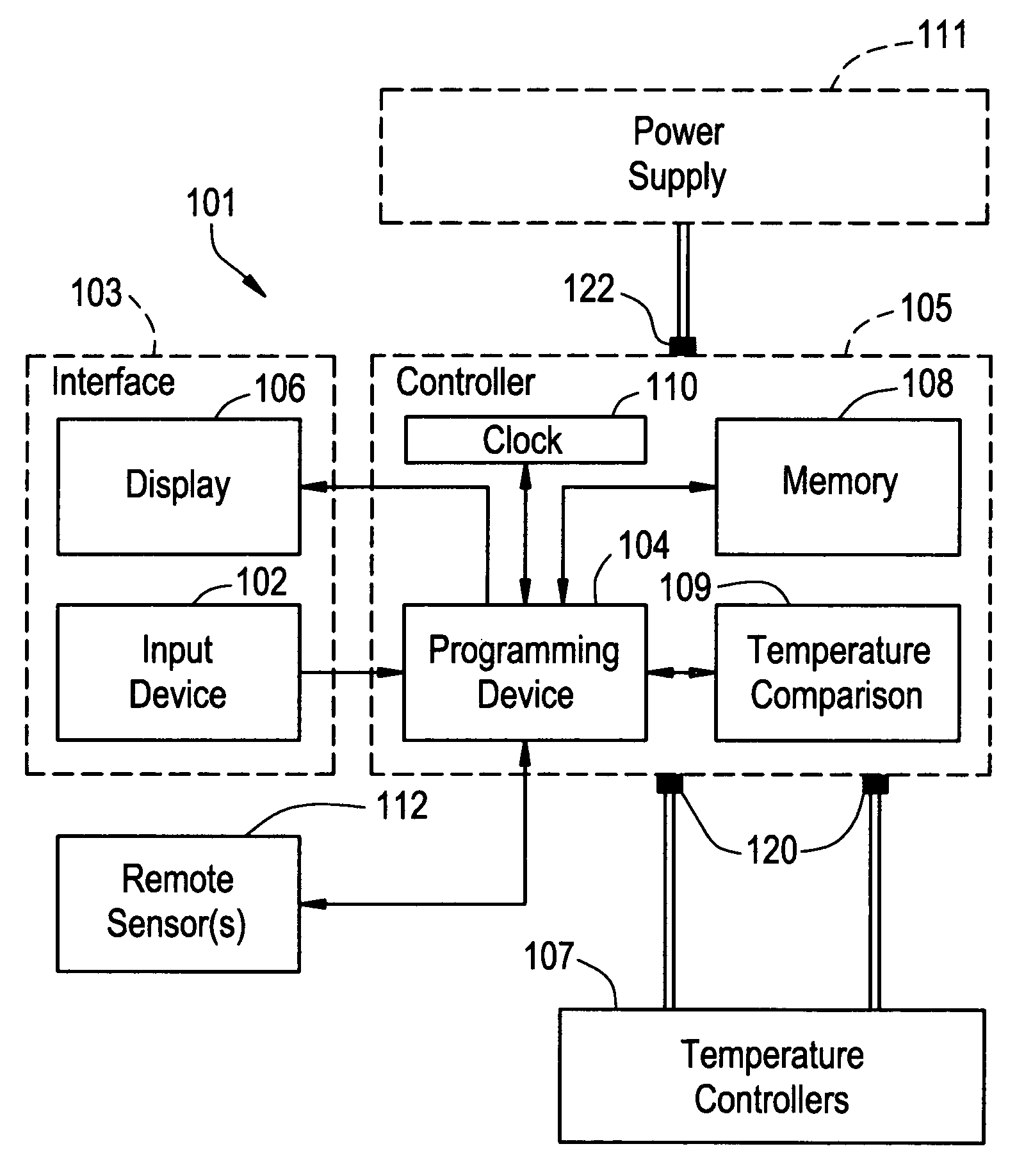

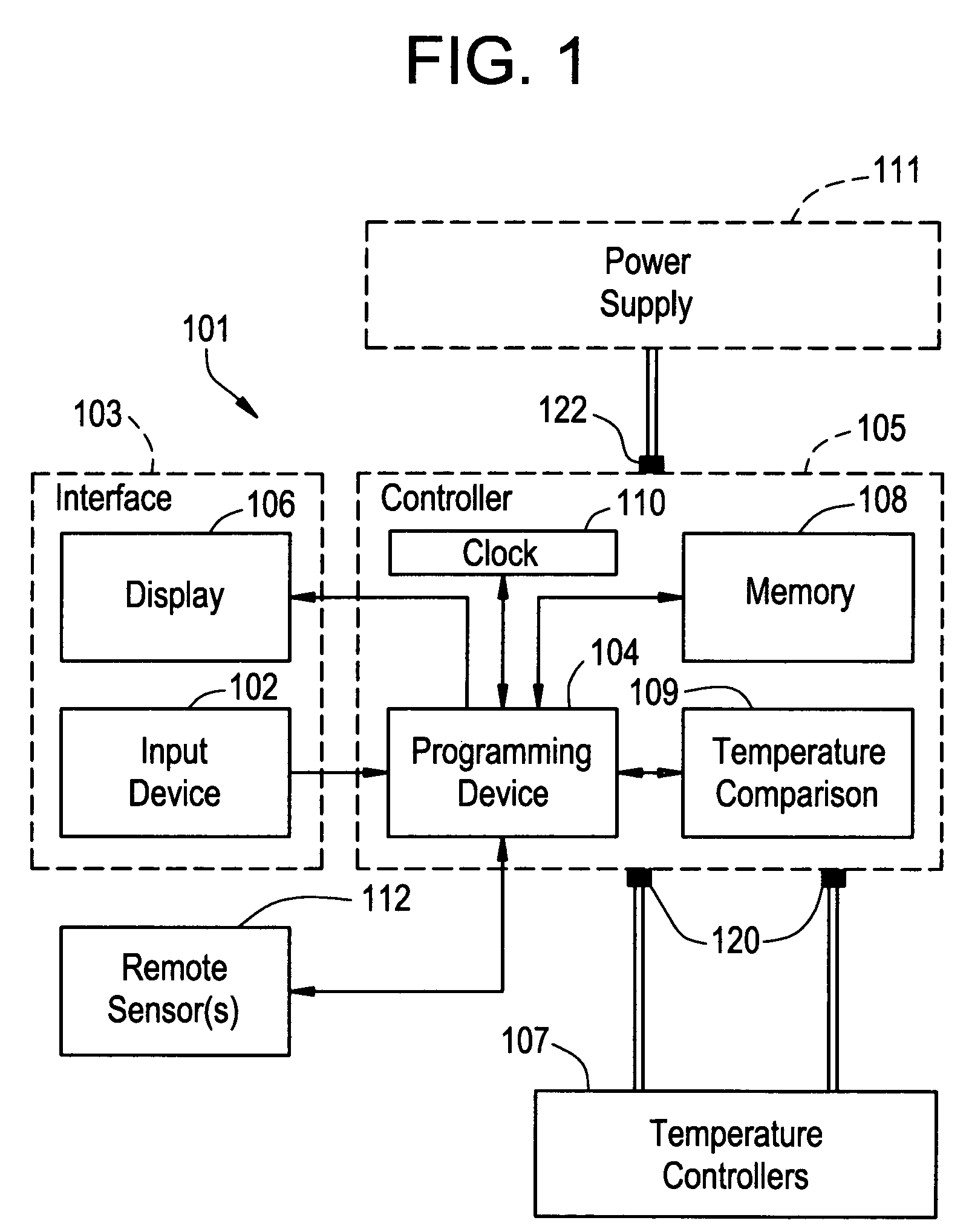

System and method for controlling appliances and thermostat for use therewith

InactiveUS7469550B2Save energySaving of operationTemperature control without auxillary powerMechanical apparatusThermostatEngineering

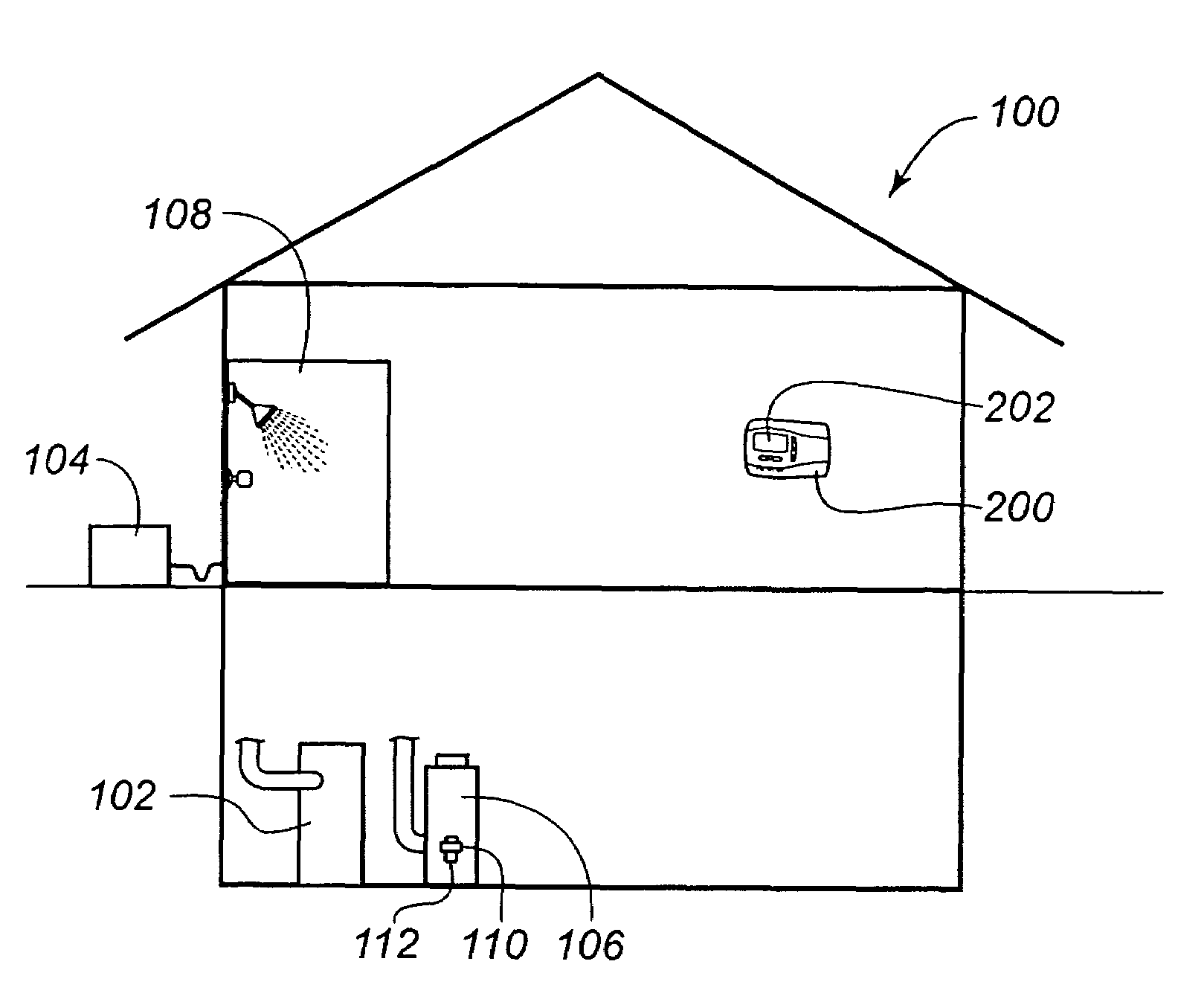

An energy saving control for appliances via an intelligent thermostat is provided. This intelligent thermostat provides programmatic control over the HVAC system, and provides coordinated control over the appliances. This control over the appliances is accomplished via a communications network between the intelligent thermostat and the appliances. The appliances include occupancy sensors and transmit usage and occupancy information to the intelligent thermostat. The intelligent thermostat processes this information to determine the occupancy of the dwelling. The thermostat controls the HVAC system and the appliances according to the determined occupancy of the dwelling.

Owner:ROBERTSHAW CONTROLS CO

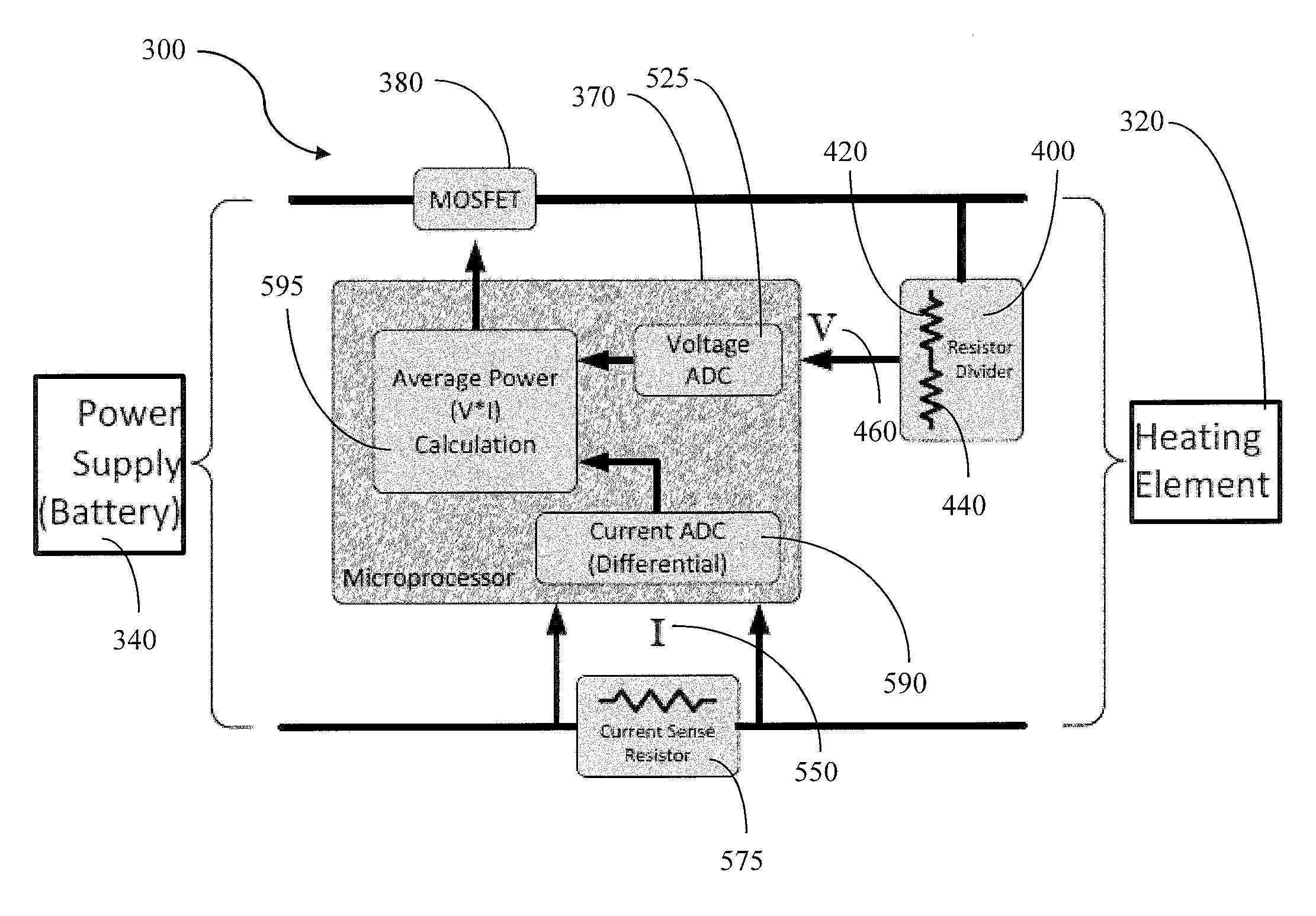

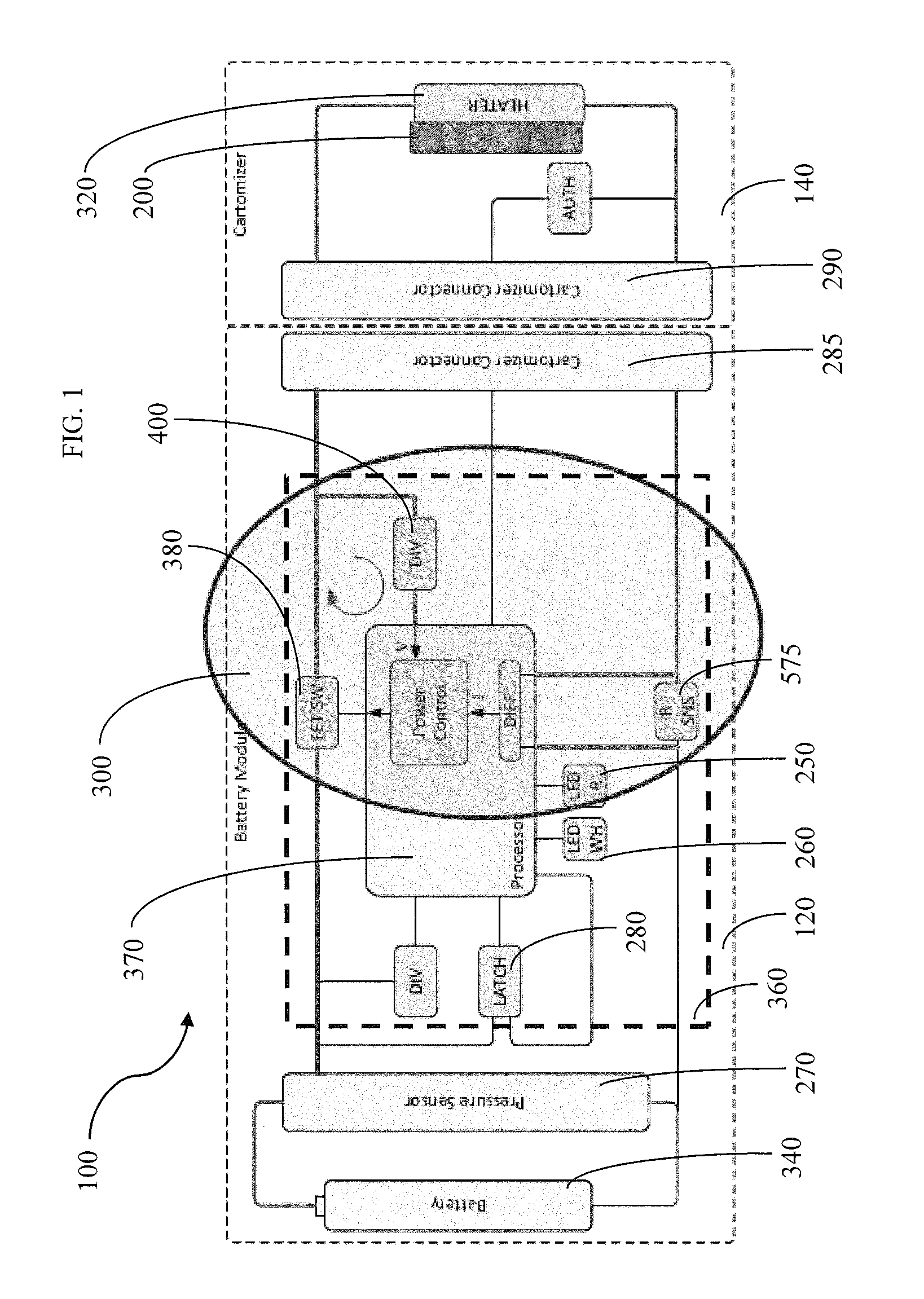

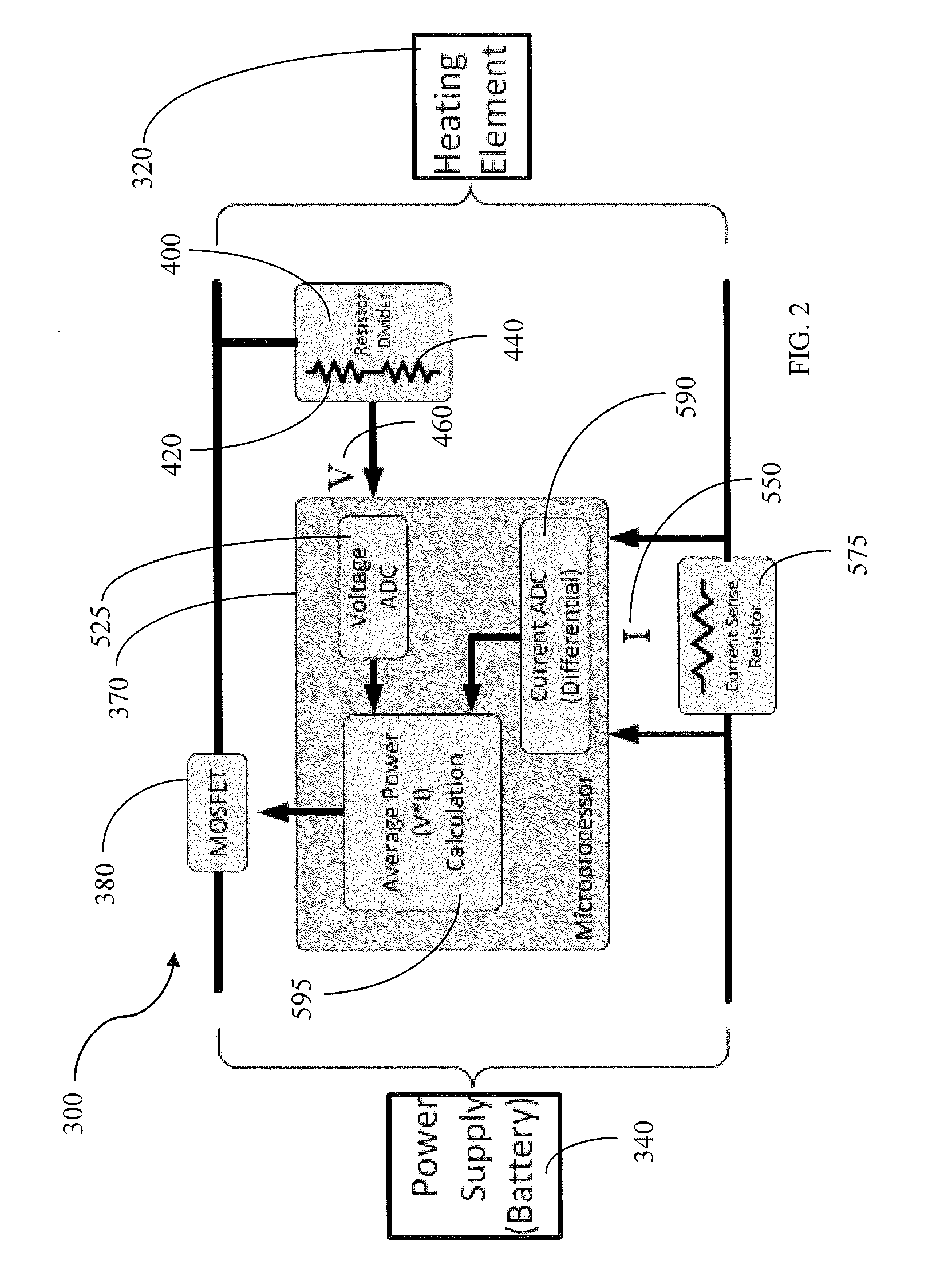

Heating control arrangement for an electronic smoking article and associated system and method

Owner:RAI STRATEGIC HLDG INC

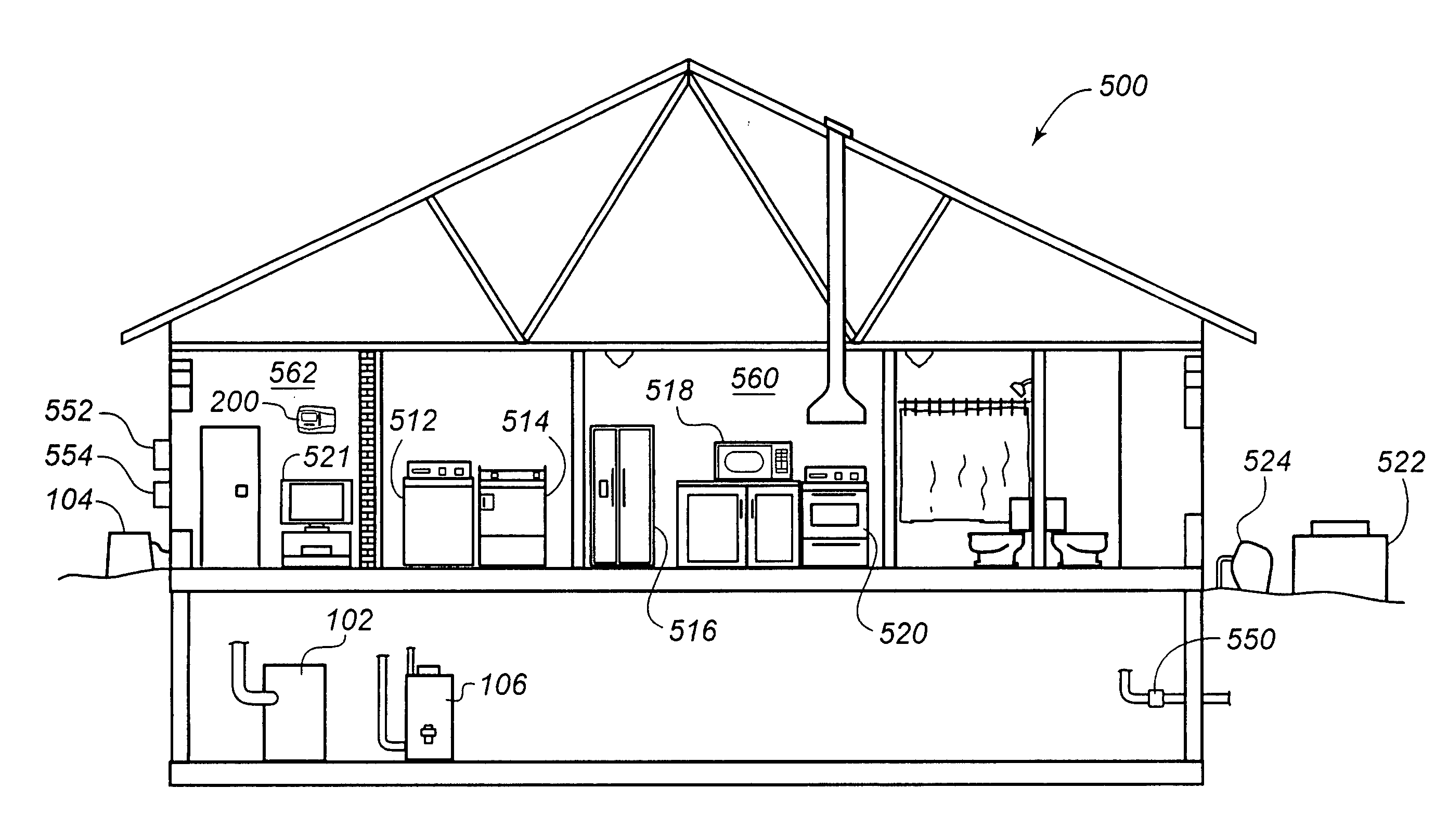

System and method for controlling appliances and thermostat for use therewith

InactiveUS20060208099A1Reduce energy consumptionSave energyFluid heatersMechanical apparatusControl systemEngineering

An energy saving control for appliances via an intelligent thermostat is provided. This intelligent thermostat provides programmatic control over the HVAC system, and provides coordinated control over the appliances. This control over the appliances is accomplished via a communications network between the intelligent thermostat and the appliances. The appliances include occupancy sensors and transmit usage and occupancy information to the intelligent thermostat. The intelligent thermostat processes this information to determine the occupancy of the dwelling. The thermostat controls the HVAC system and the appliances according to the determined occupancy of the dwelling.

Owner:ROBERTSHAW CONTROLS CO

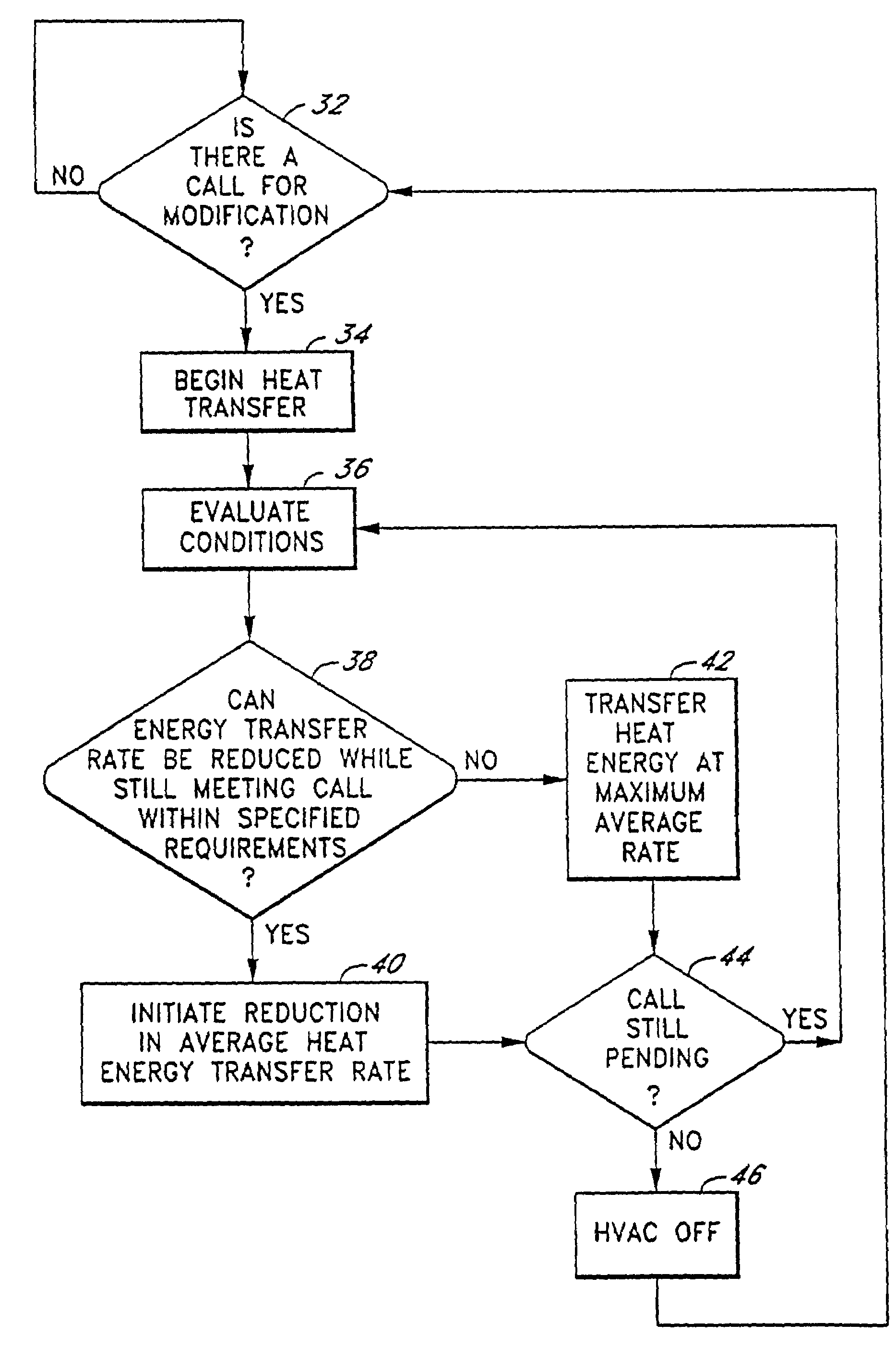

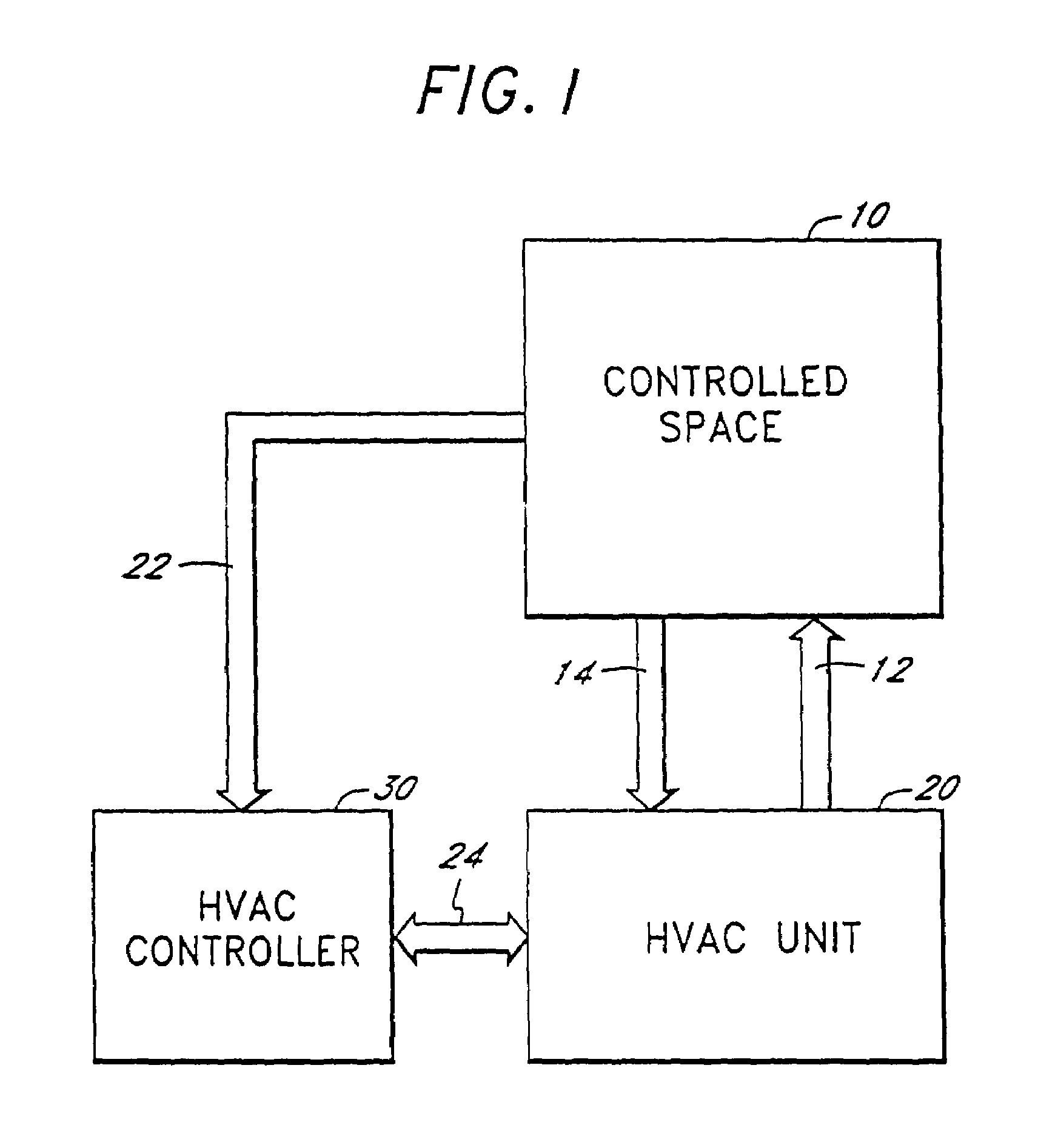

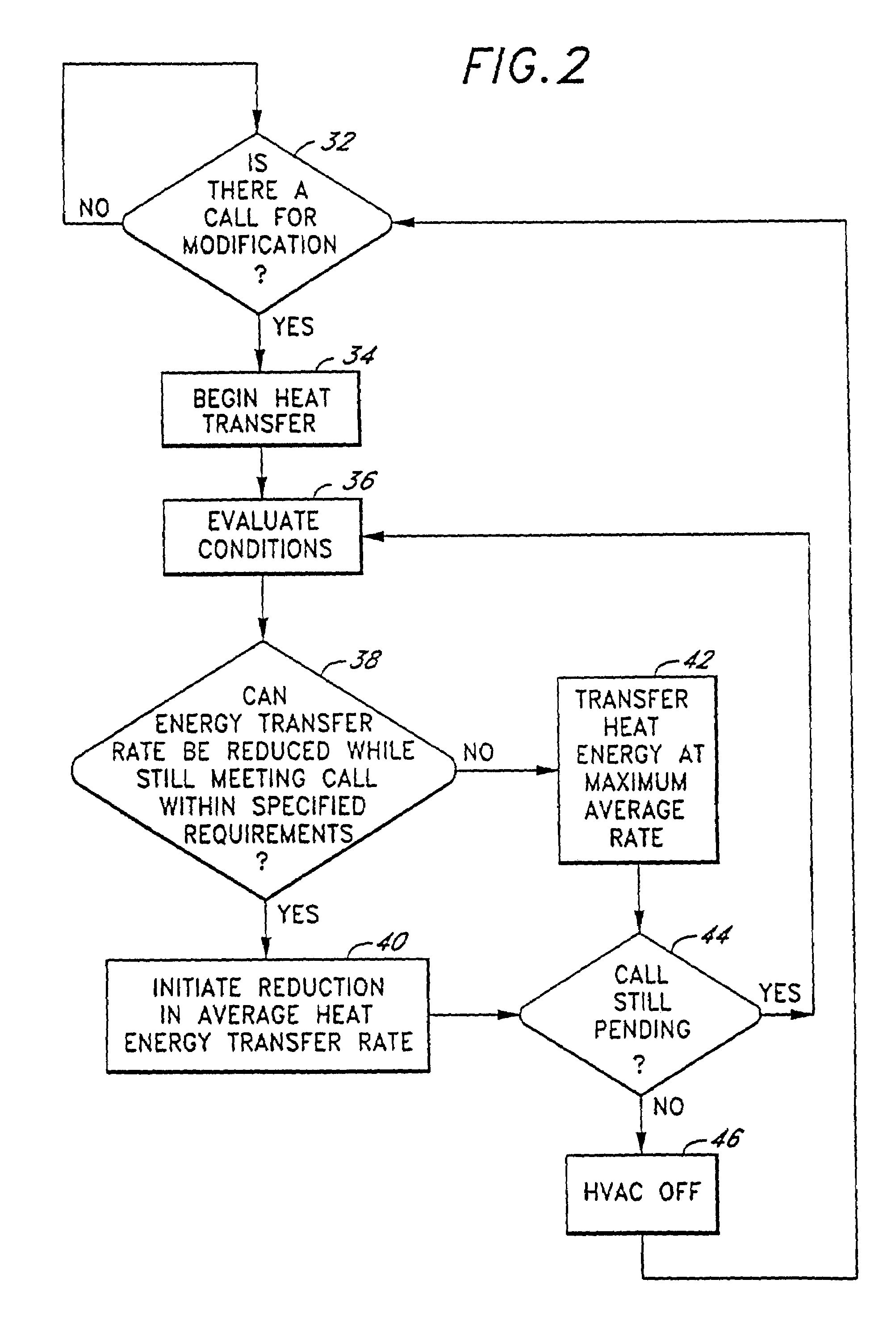

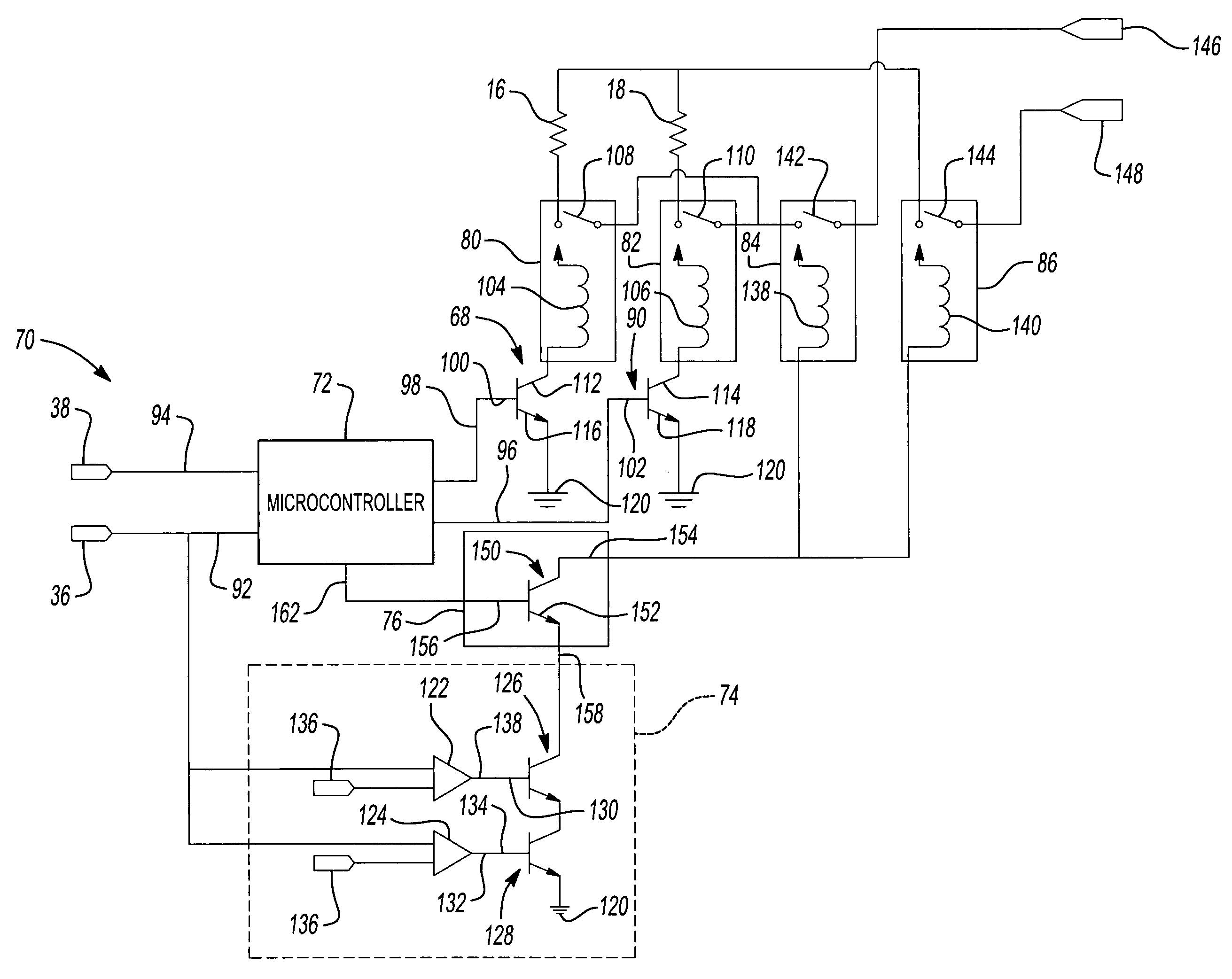

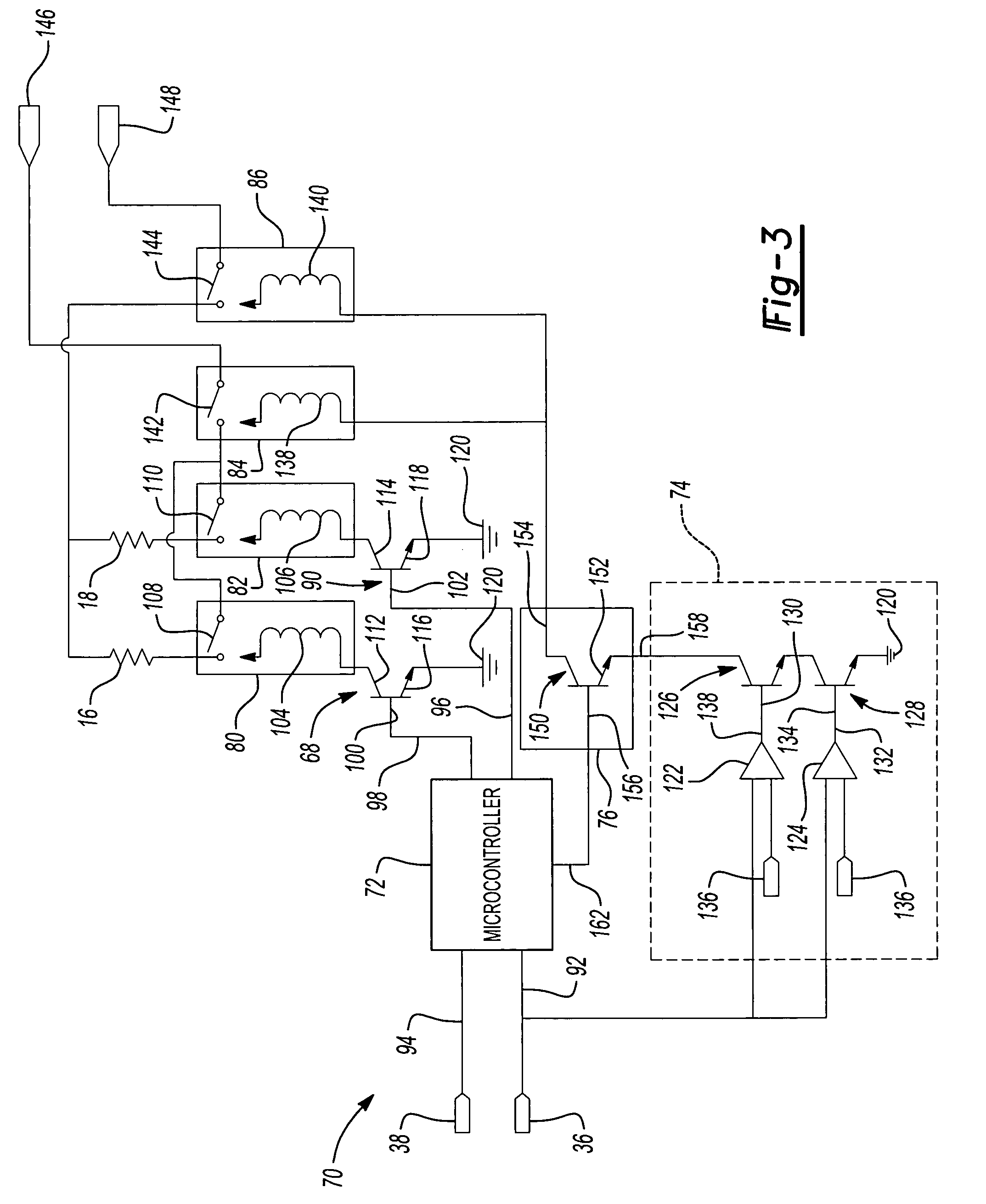

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

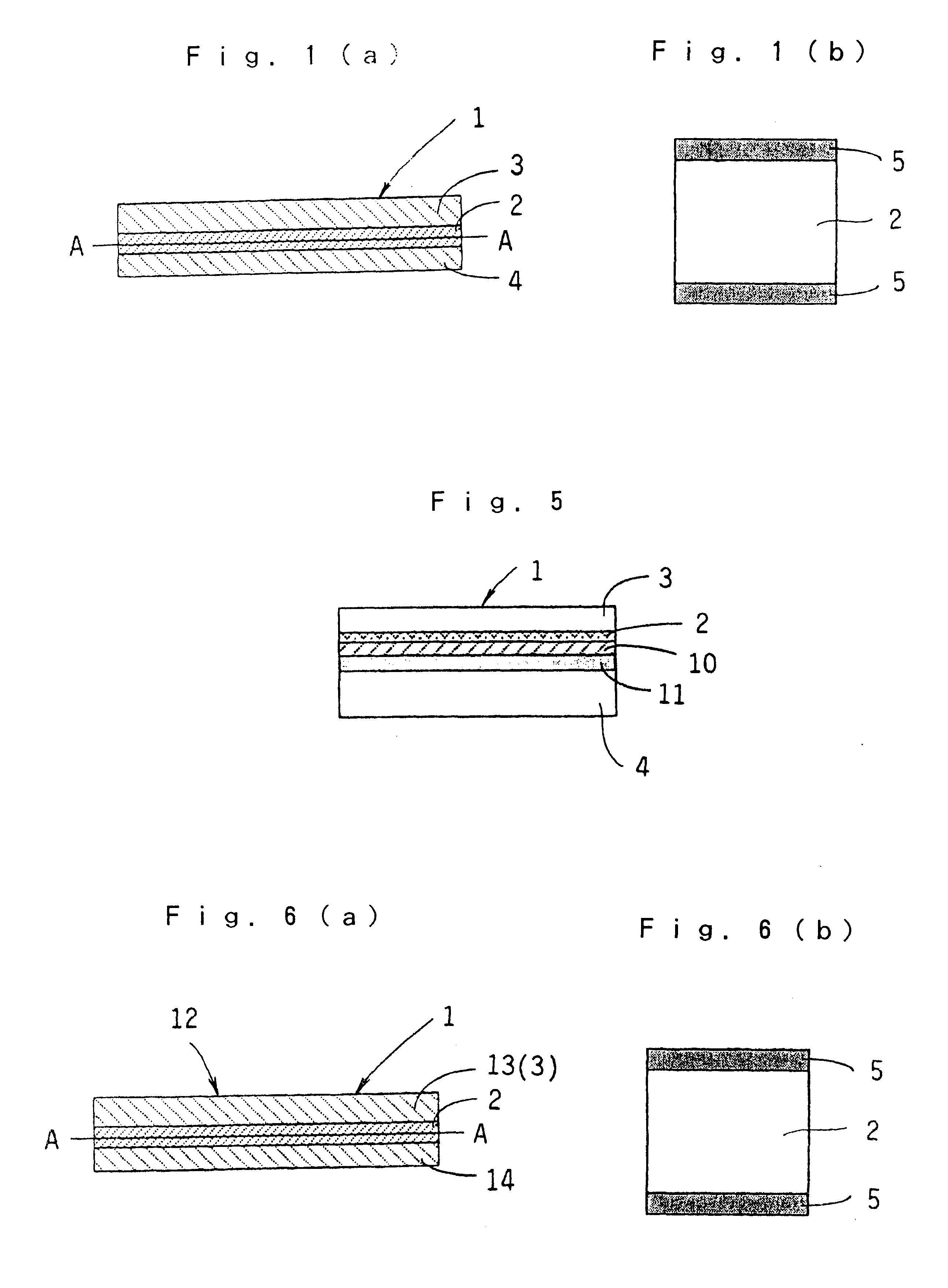

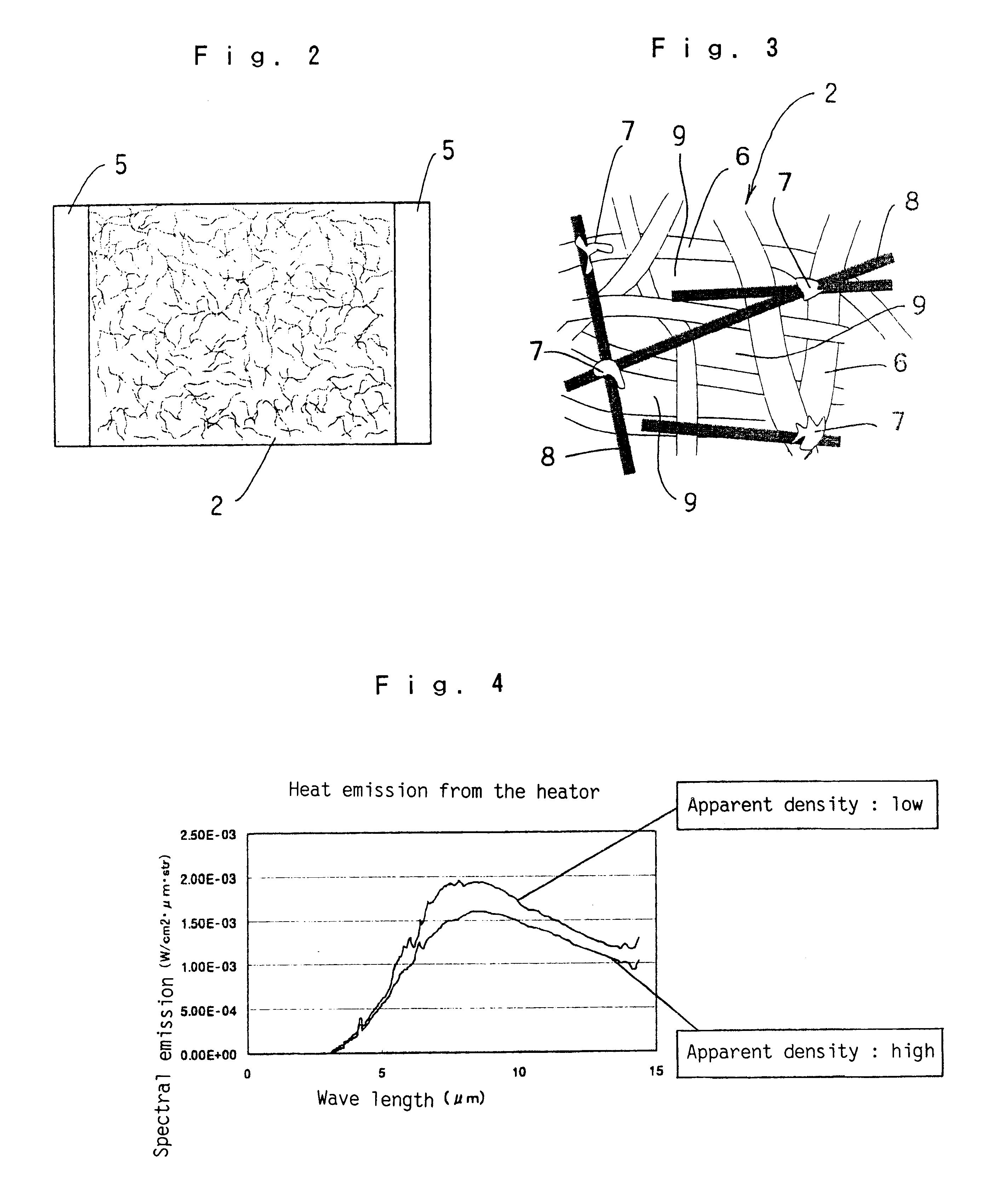

Heat radiator

InactiveUS6294758B1Excellent in quick heating capabilityReduce power supplyFluid heatersHeater elementsHuman bodyEngineering

A heat radiator for emitting infrared radiation to the human body has a heat source which is energized to emit infrared radiation, whose penetration depth into the human body is to near warmth sensing points of the human body, and an insulator for covering the surface of the heat source to be directed toward the human body. The free surface of the insulator forms a surface for contacting with the human body and the thickness of the insulator is less than the penetration depth of the infrared radiation into the insulator.

Owner:TOTO LTD

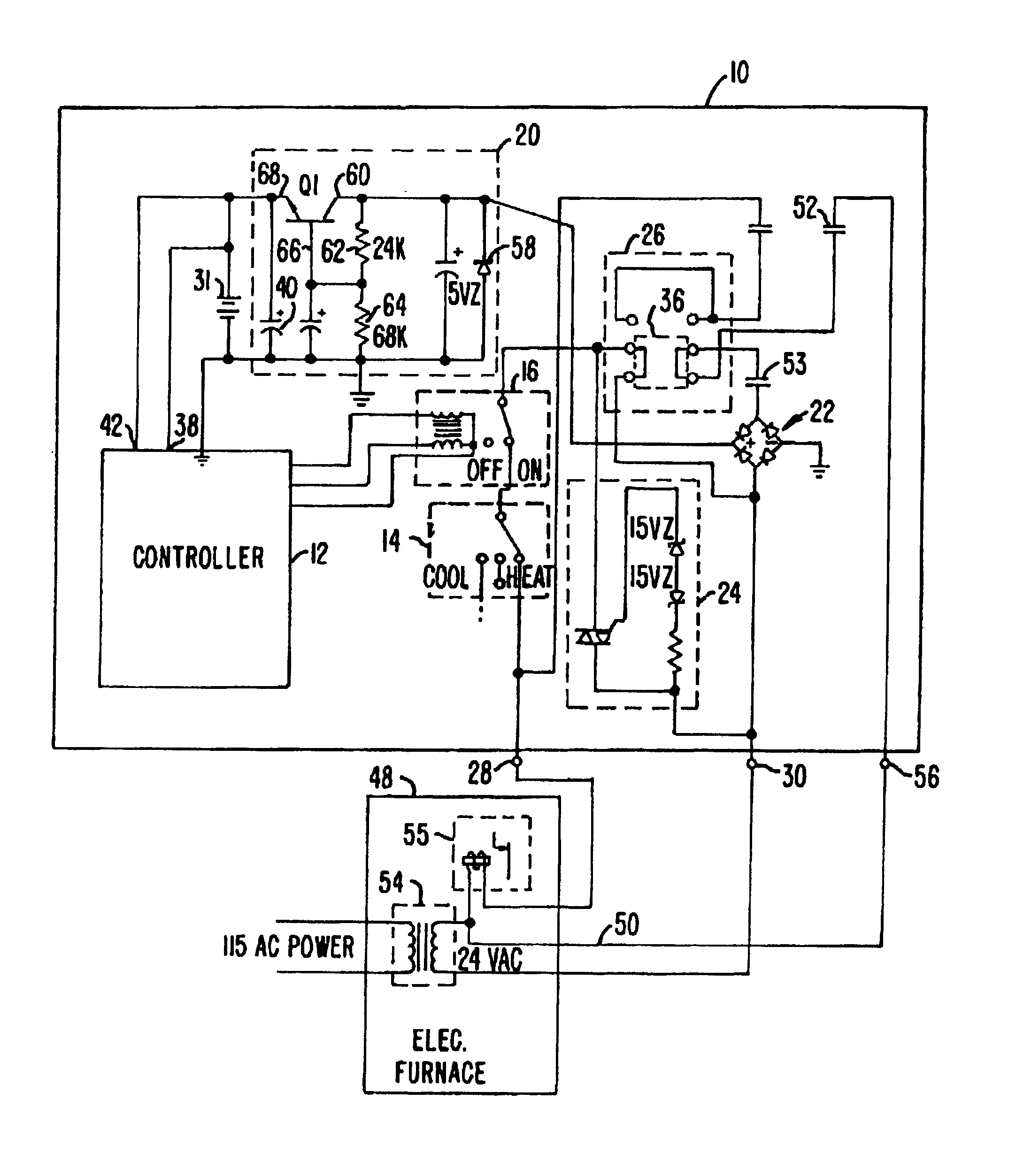

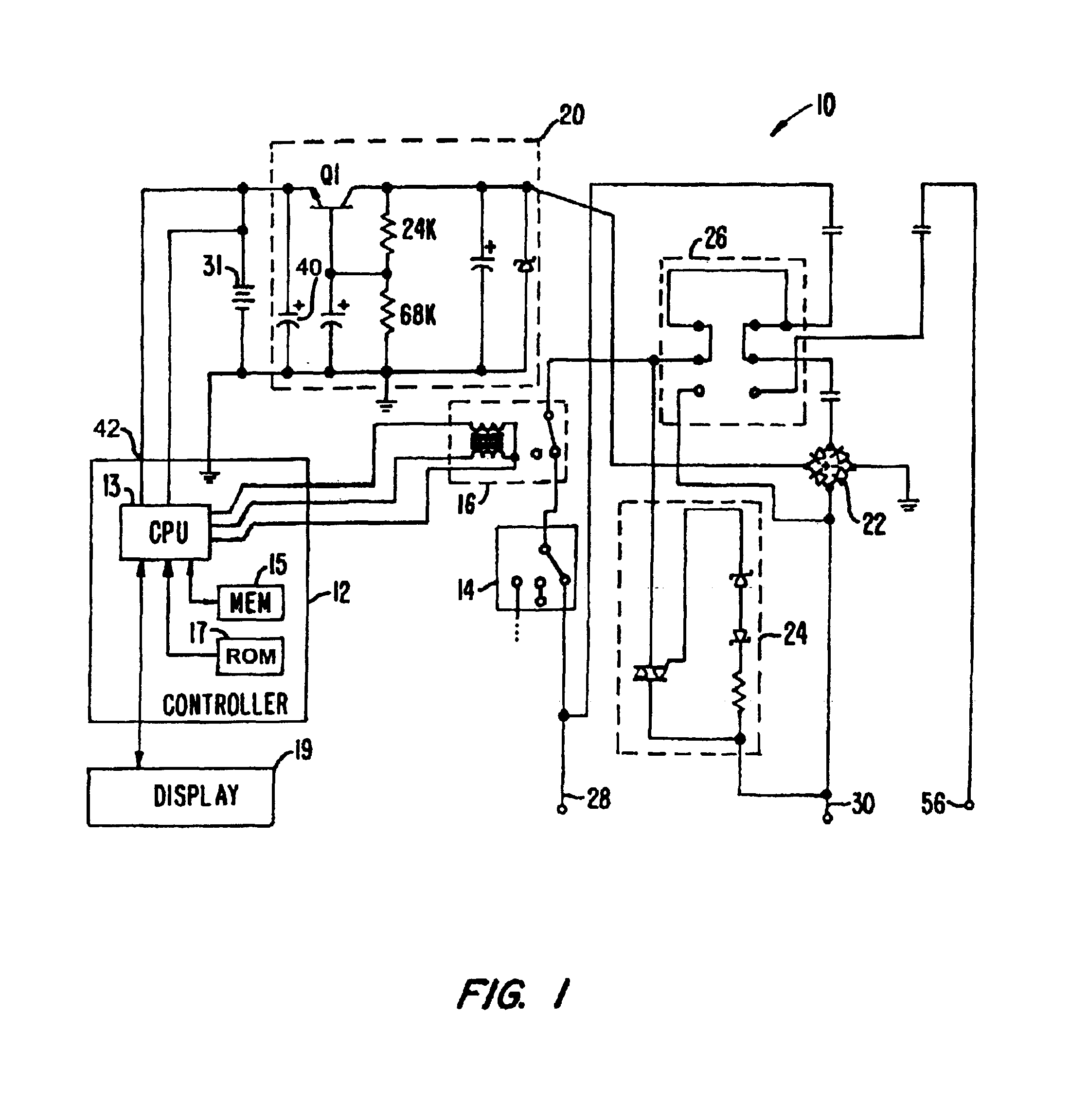

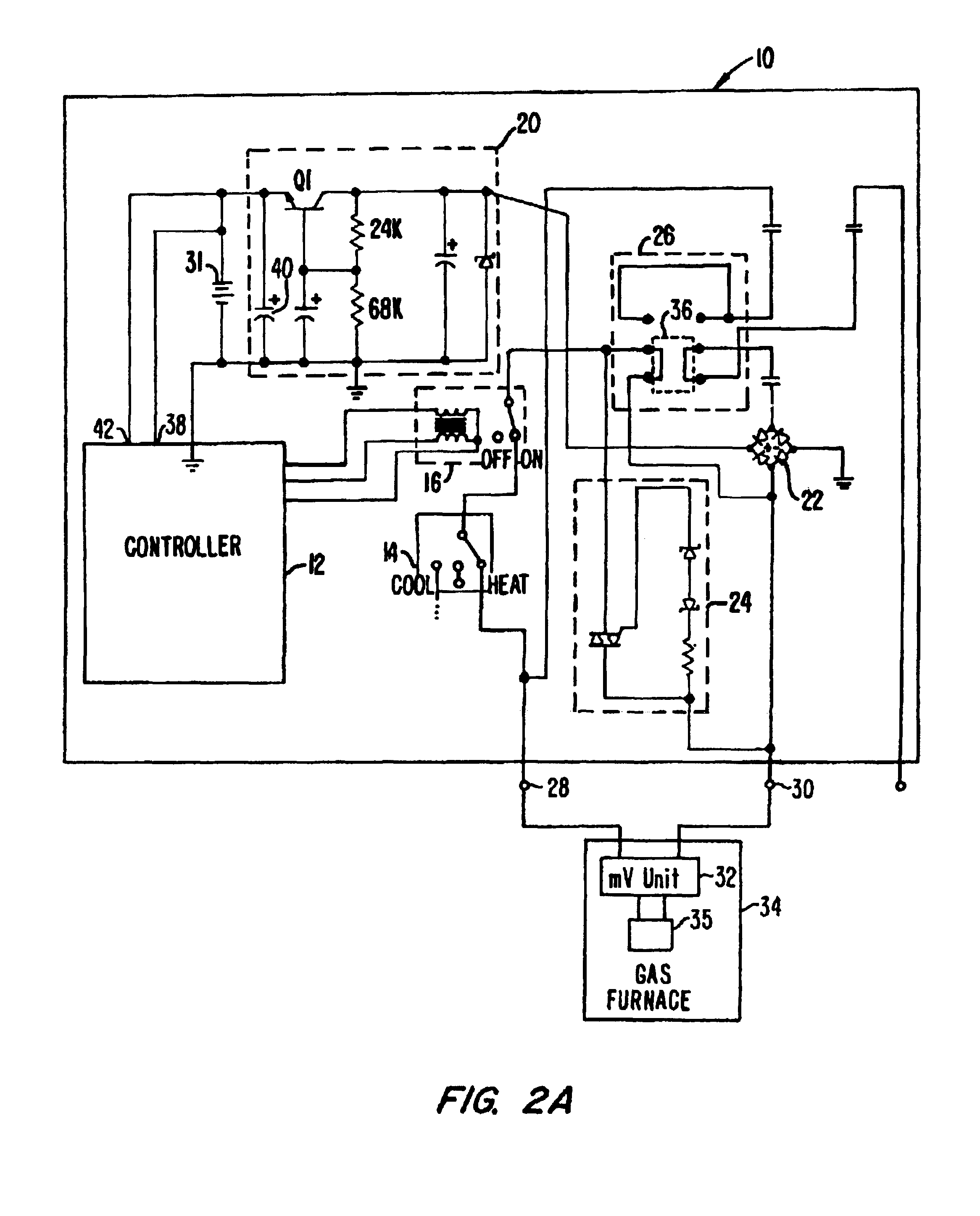

Thermostat operable from various power sources

InactiveUS6886754B2Fluid heatersTemperature control using electric meansVoltage spikeOperating point

A thermostat is operable from battery, common-wire (“C-wire”), or furnace relay power. The thermostat includes a power source selector, such as a jumper wire, that is set when the thermostat is installed in a heating system. In a gas millivolt heating system, the thermostat operates off of battery power. In heating systems having a C-wire, a diode bridge converter converts alternating-current voltage to direct-current voltage to provide operating power to the thermostat. In heating systems without a C-wire and having sufficient furnace relay current, a triac converter in series with the furnace relay provides voltage spikes to the diode bridge converter to provide operating power to the thermostat when the furnace is on, and the diode bridge converts AC to DC voltage when the furnace is not on. The thermostat can also be used in cooling systems and heating, ventilation, and air-conditioning systems. Thus, the thermostat can be used in a wide variety of applications.

Owner:TIM SIMON

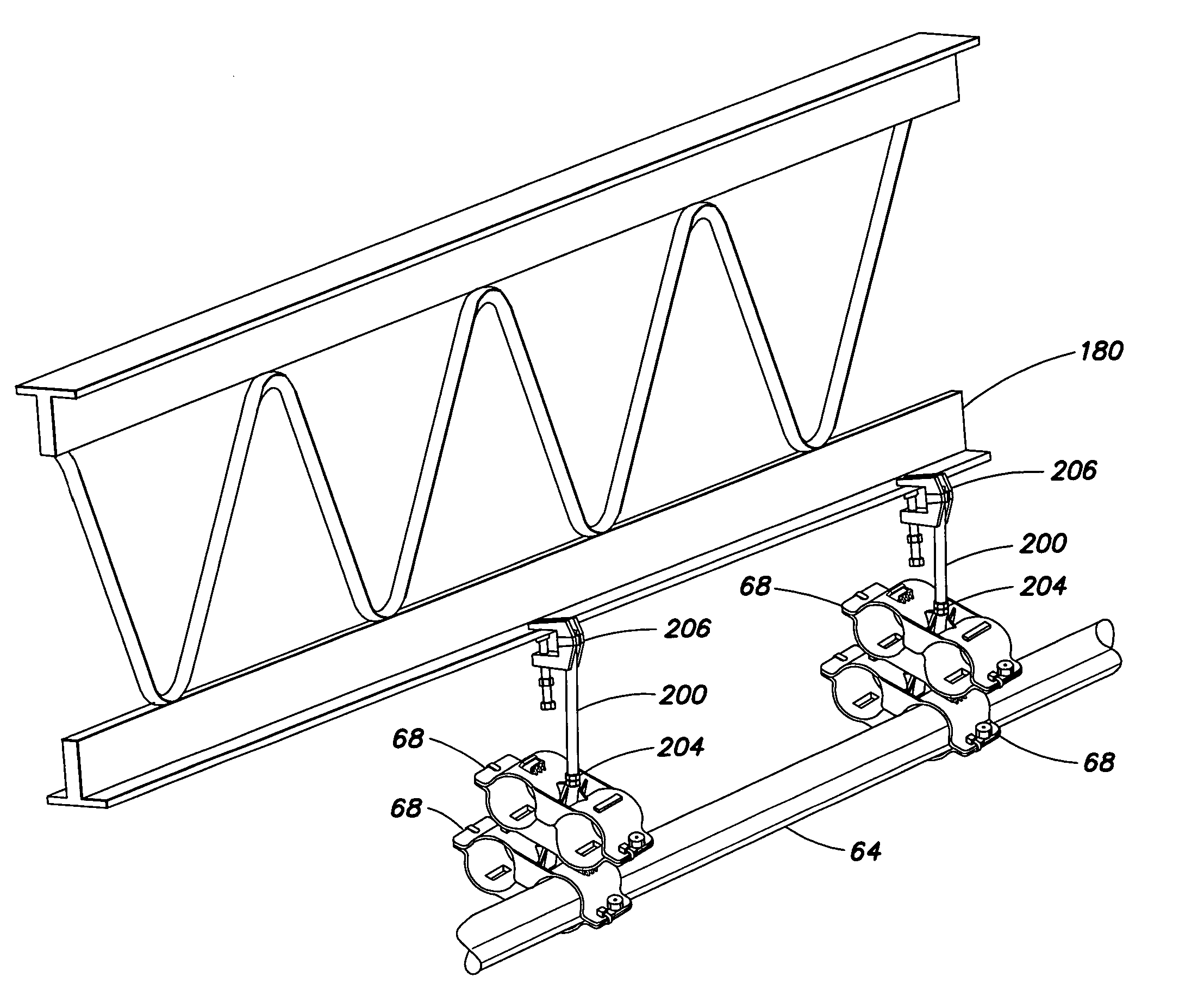

Cooling system and method

A fluid communication system for providing coolant to and exhausting coolant from a cooling unit includes flexible tubing and a plurality of support members. Each support member is configured to be secured to a support structure and to be releasably secured to the flexible tubing. Each support member includes a first part and a mating second part, with the first and second parts being configured to be secured to one another with the flexible tubing disposed in between. A method of installing a fluid communication system of a cooling system is further disclosed.

Owner:AMERICA POWER CONVERSION CORP

Thermostat with gfci

InactiveUS20100163635A1Quick checkFast handlingFluid heatersMechanical apparatusComputer moduleThermostat

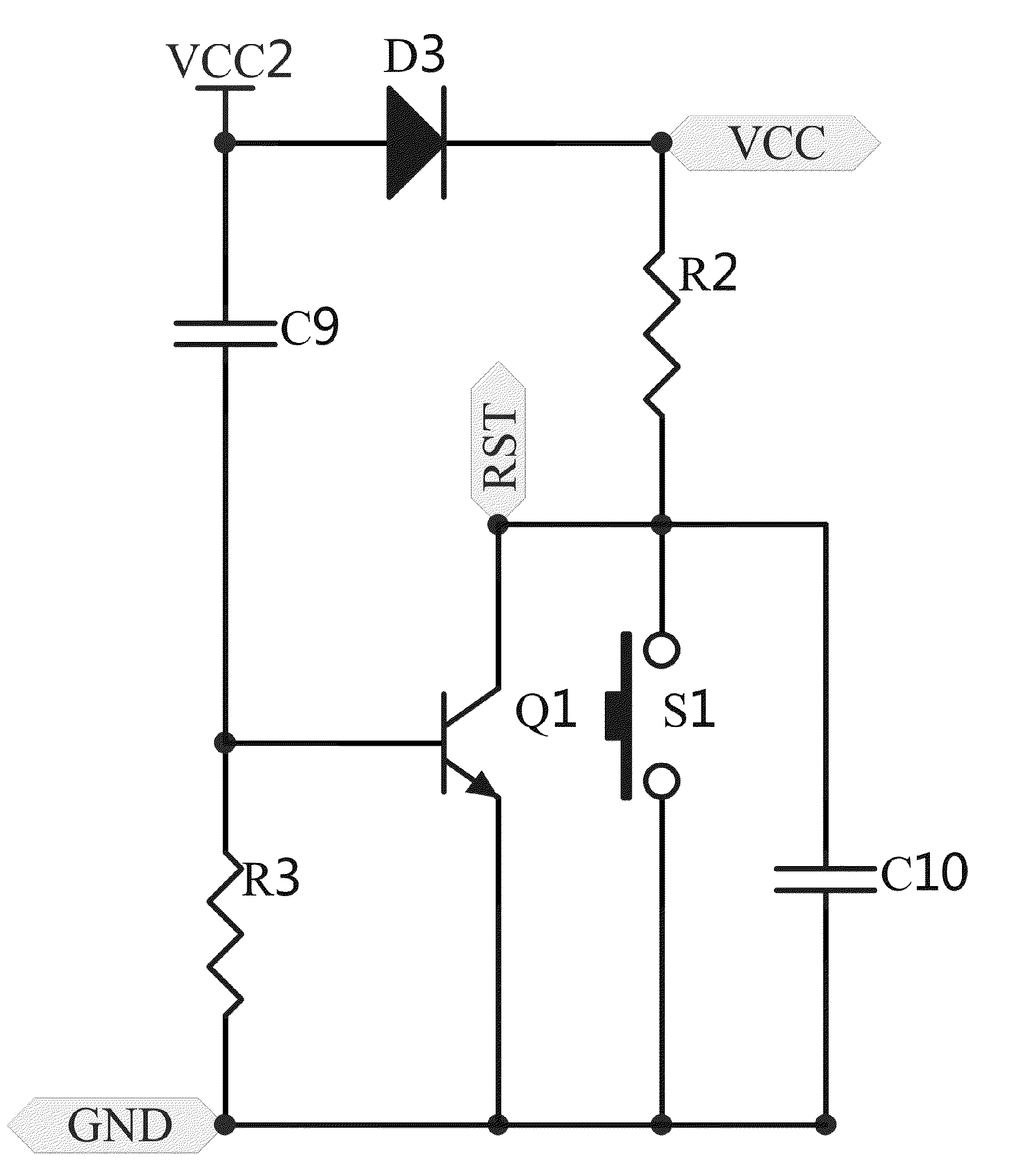

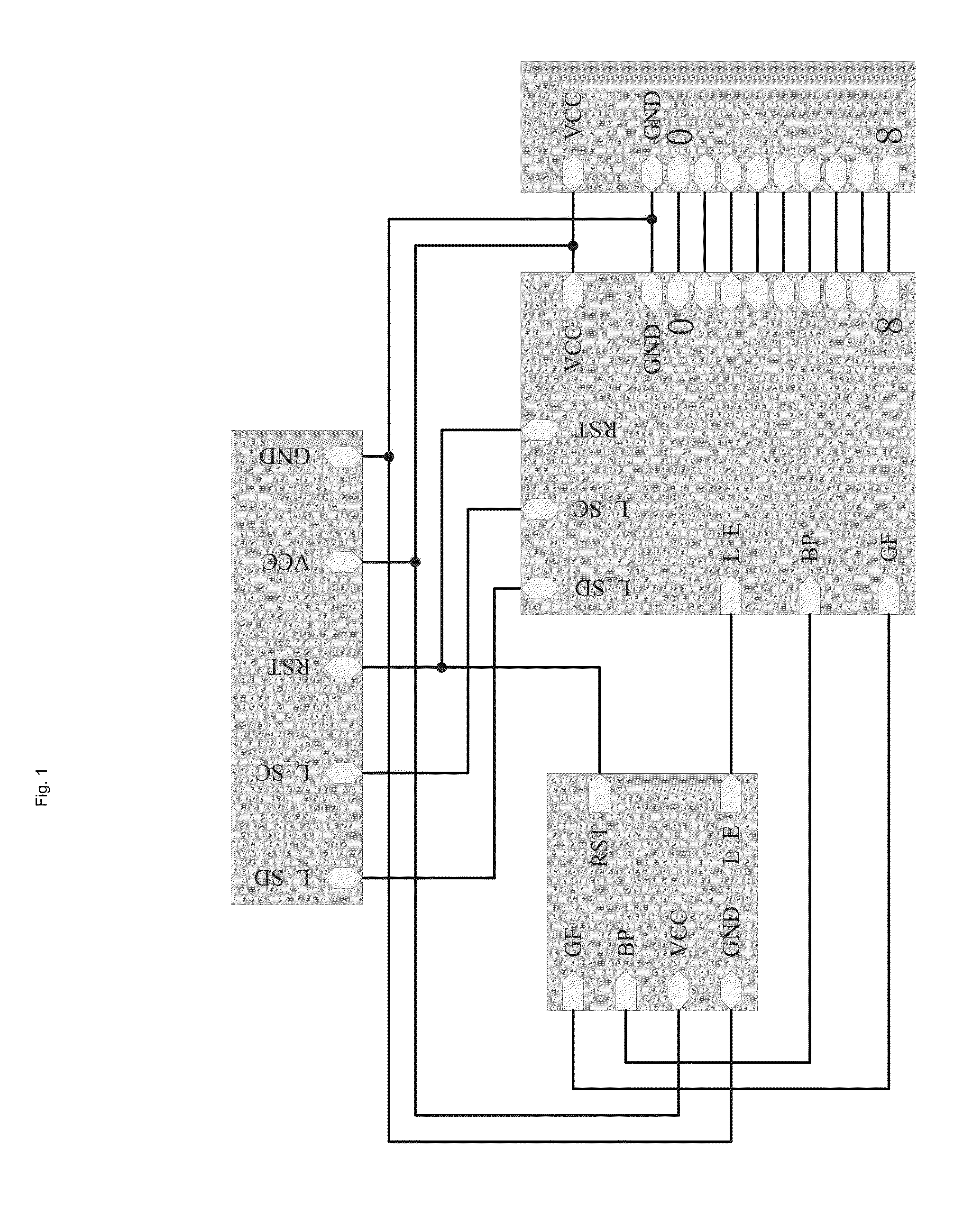

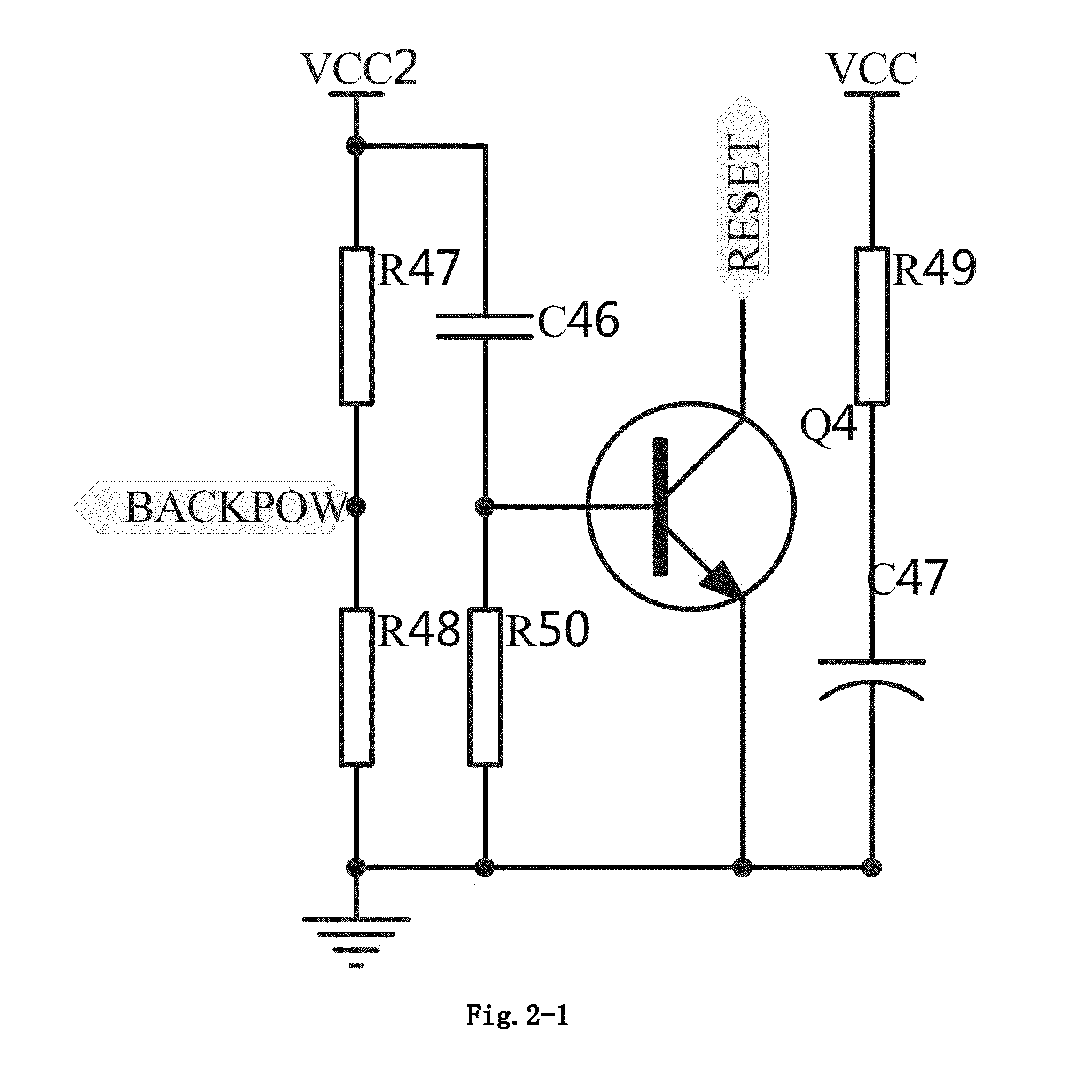

The present invention provides a thermostat with GFCI which includes control module, keyboard module, communication module and display module, and it further includes a leakage detection module, and the control module includes the temperature sensor, and the leakage detection module is connected with the control module, keyboard module and display module respectively. The control module is connected with the controlled device by the leakage detection module. The thermostat monitors current status of output circuit while adjusting the temperature of room, so that it can ensure the safety of the output circuit in use. If leakage occurs to the controlled device, the thermostat can cut off the power and stop power supplying at once, and the alarm light illuminates in the meantime. After manual reset, the alarm light goes out. It works with a wide input voltage range and makes the thermostat normally work at multistage voltage, and it can detect the leakage current accurately, and cut off power in time and report to the system.

Owner:SHANGHAI OKONOFF ELECTRIC

Power distribution/generation system

A power distribution / generation system is disclosed for supplying electrical power to a number of sites (32, 33, 34), one or more of which has a generator (53, 1) such as a Stirling engine (1) which is capable of generating electrical power. The generators (53, 1) are linked together on a local network that is connectable to an external power grid (31). A controller (35) can hold the distribution of power so that a site is supplied with electrical power from the local network if its power demand exceeds the power generated by the generators in that network. However, if the total power demand of all the sites in the network exceeds the total power available from the generators in that network, then the controller (35) causes power to be drawn from the grid (31) instead.

Owner:MICROGEN ENERGY

Cooking apparatus and methods of employing such apparatus

ActiveUS7154069B1Reducing and bleeding off pressureReduce pressureFluid heatersBoiling over preventionEngineeringGasket

A cooking apparatus includes a cooking vessel and a lid for covering the cooking vessel. The cooking apparatus also may include an exhaust tube for bleeding off pressure within the cooking vessel, in which a portion of the exhaust tube is positioned above the lid when said lid covers said cooking vessel. In another embodiment, the cooking apparatus includes a first O-ring gaskets for forming a first seal between the cooking vessel and the lid, and a second O-ring gasket for forming a second seal between the cooking vessel and the lid. A method for reducing pressure includes the steps of providing a vessel and covering the vessel with a lid. The method also includes the steps of positioning a portion of an exhaust tube above the lid when the lid covers the vessel and bleeding off at least a portion of the pressure inside the vessel through the exhaust tube.

Owner:HENNY PENNY

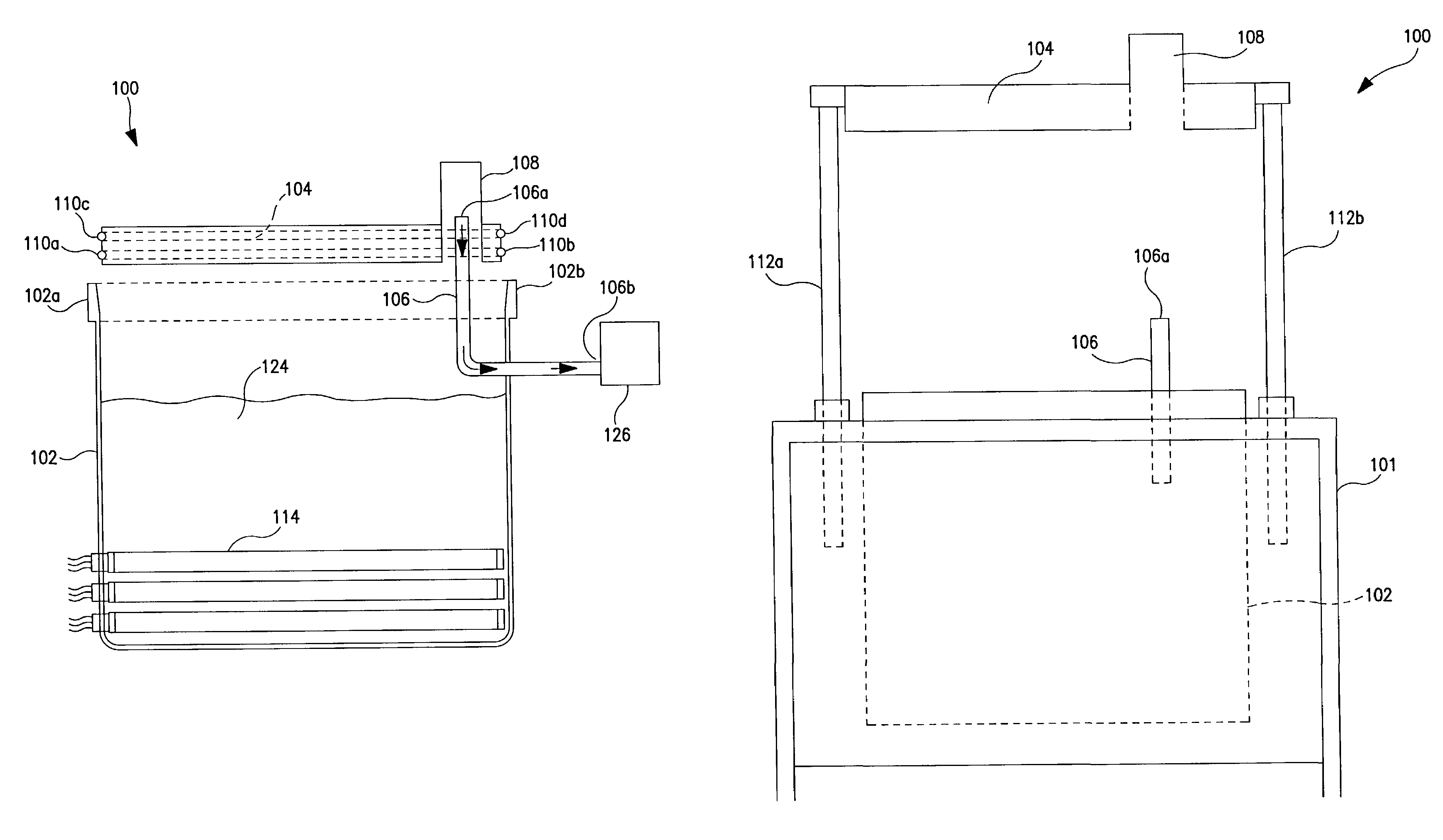

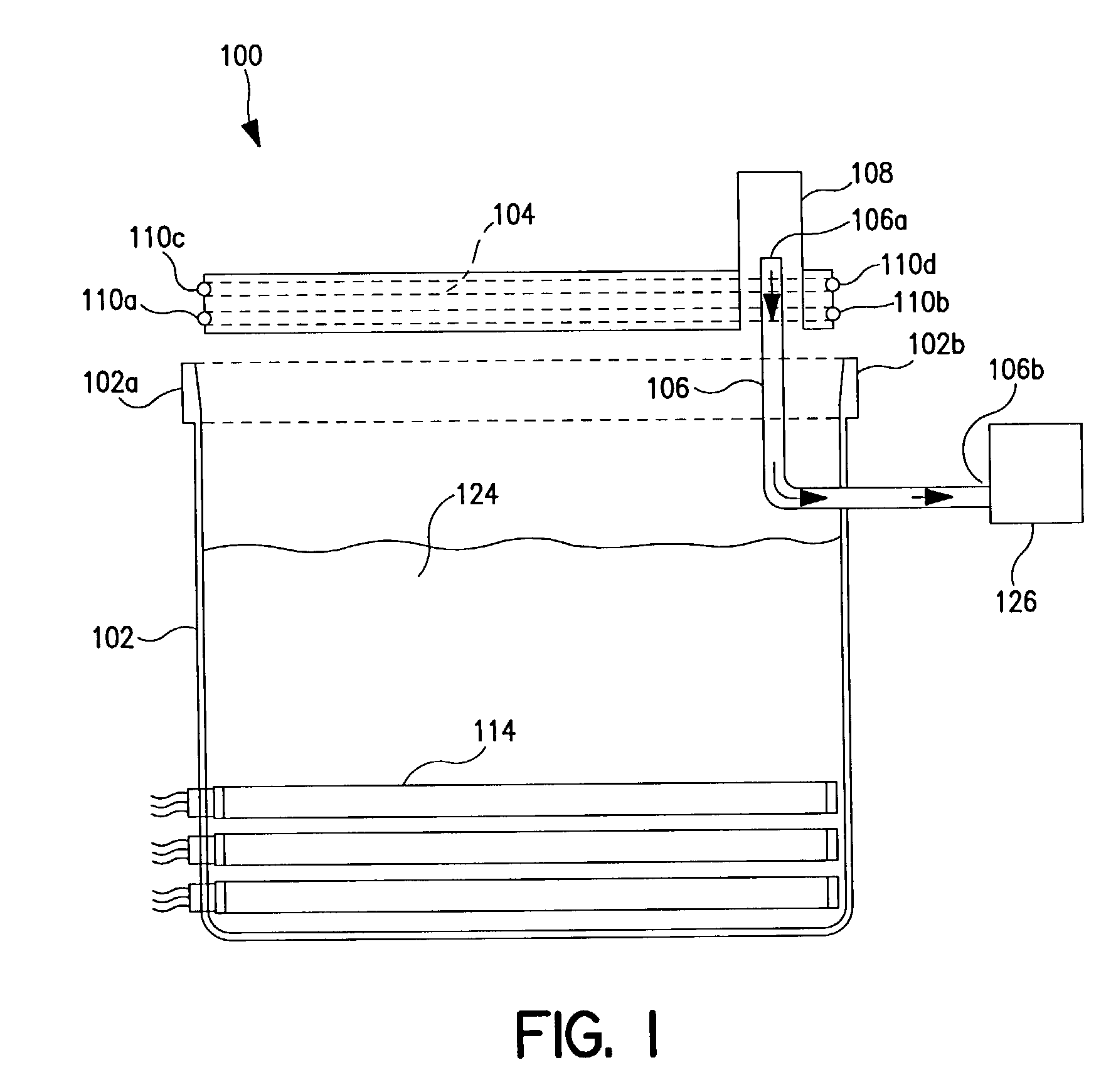

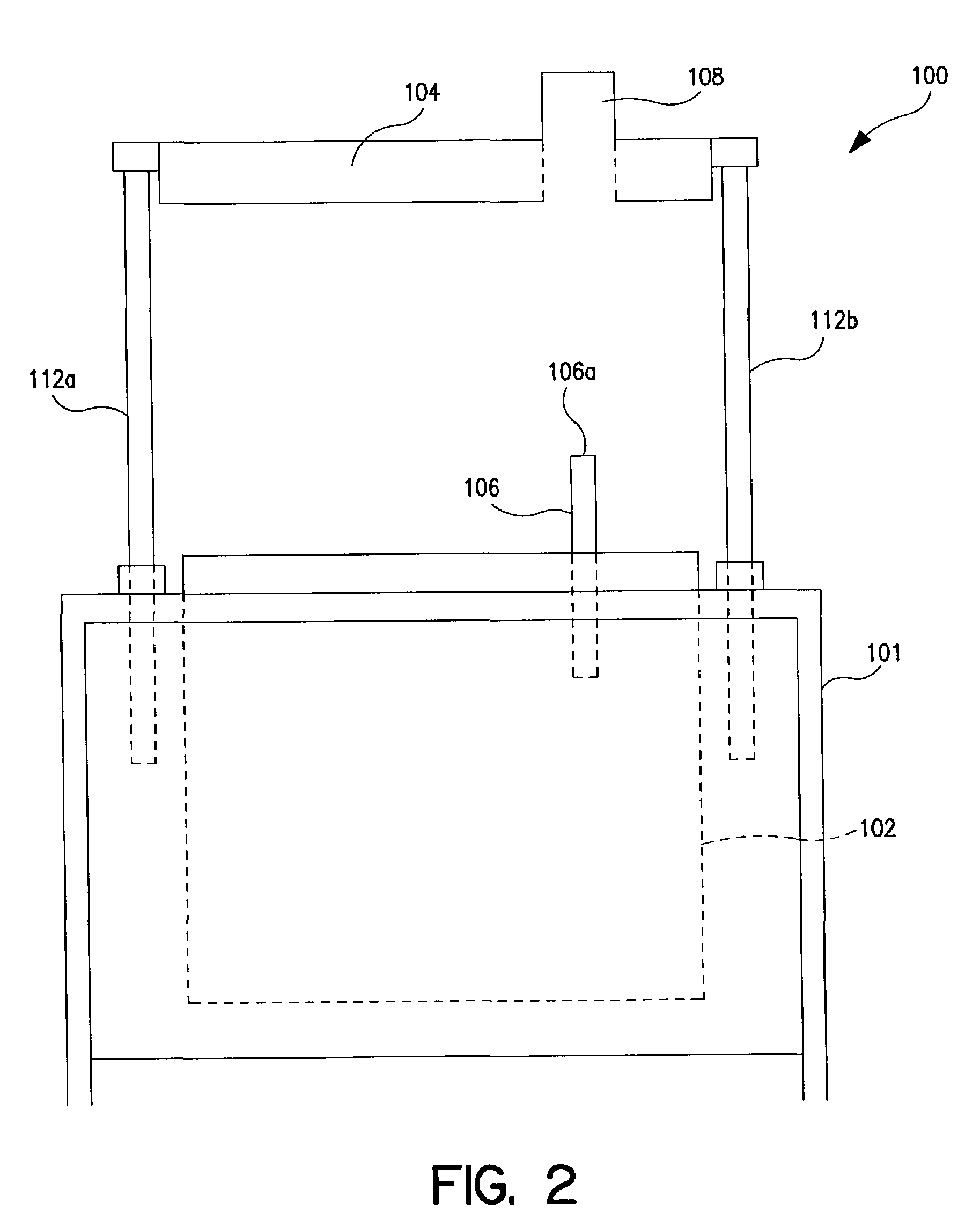

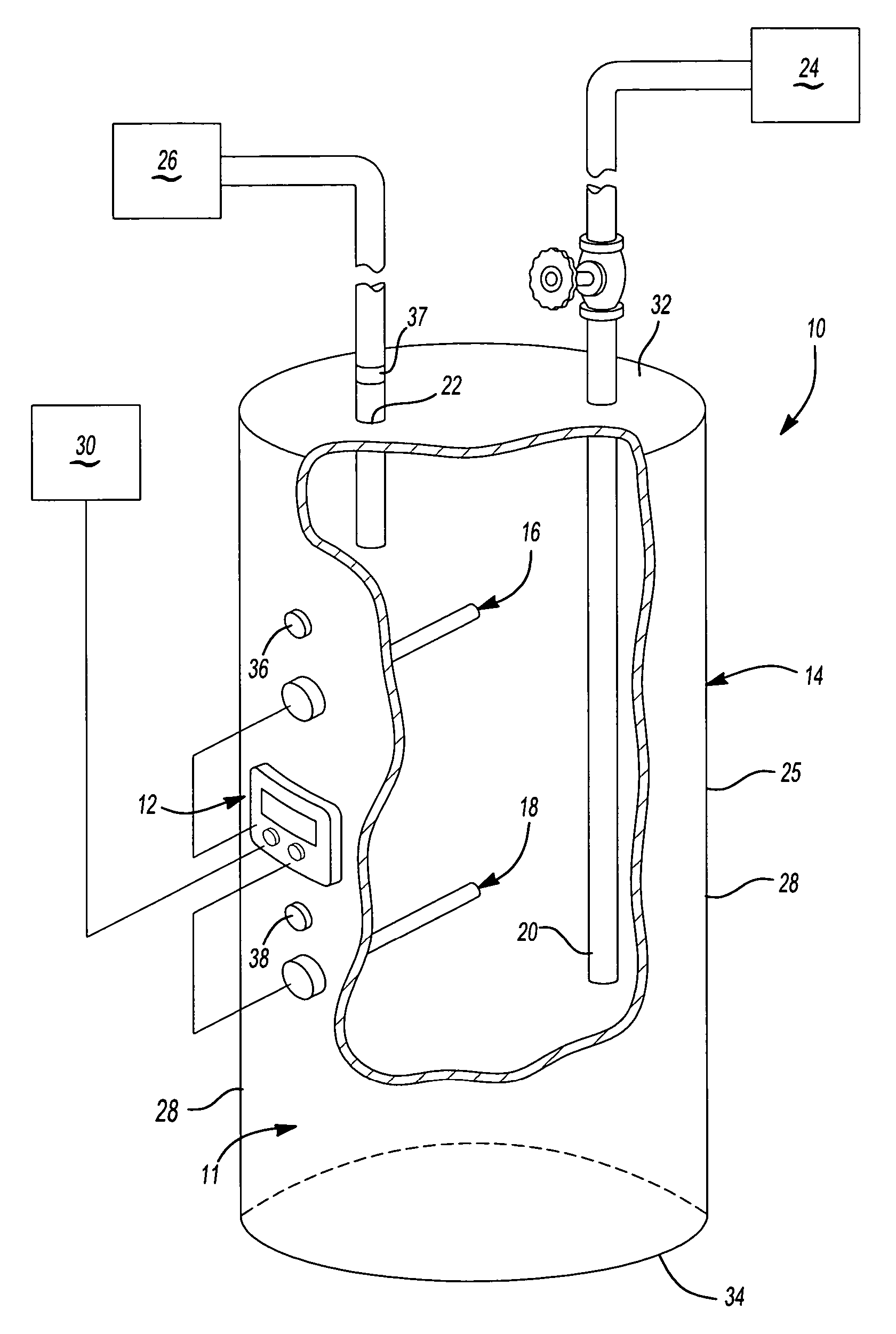

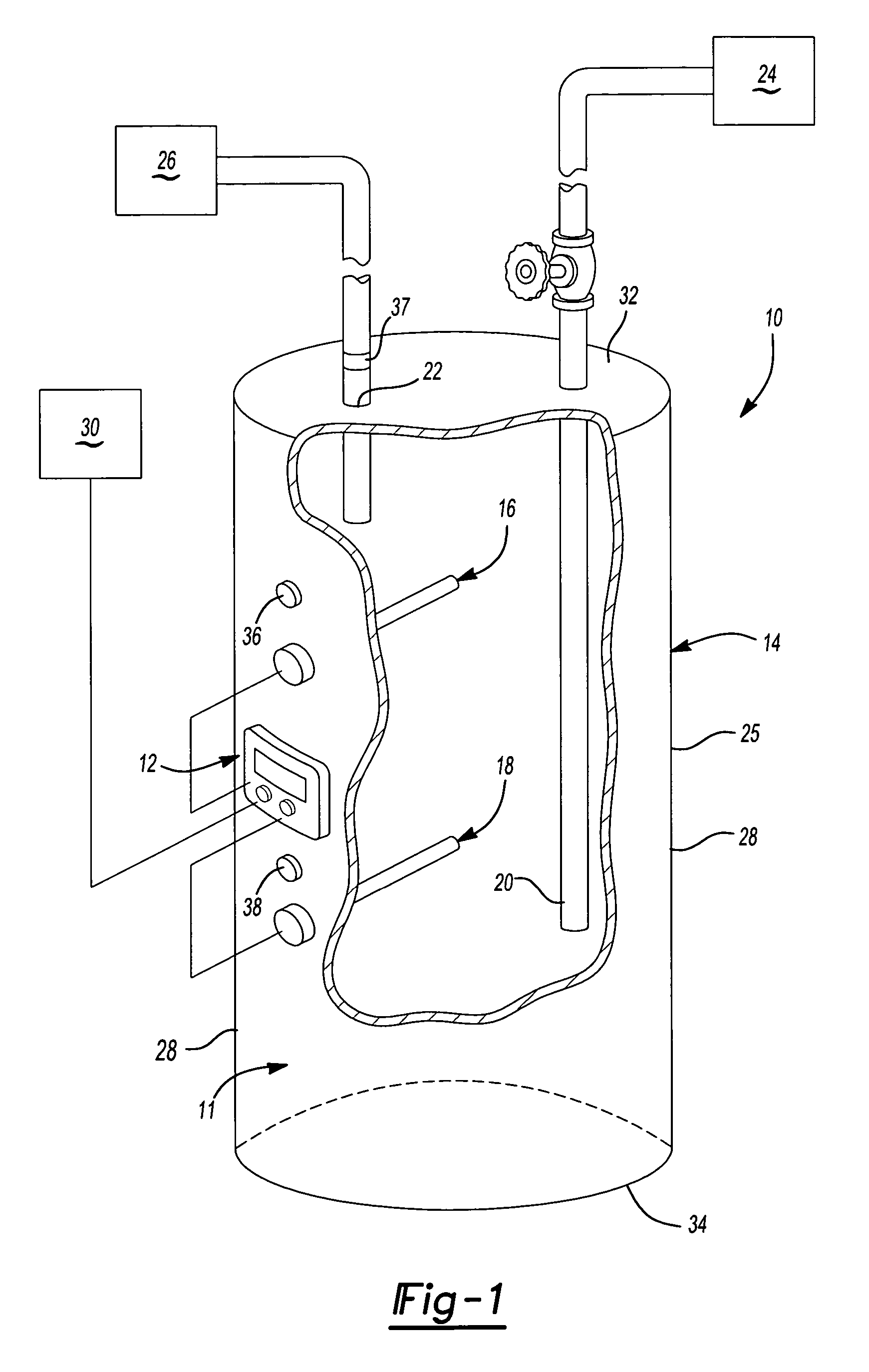

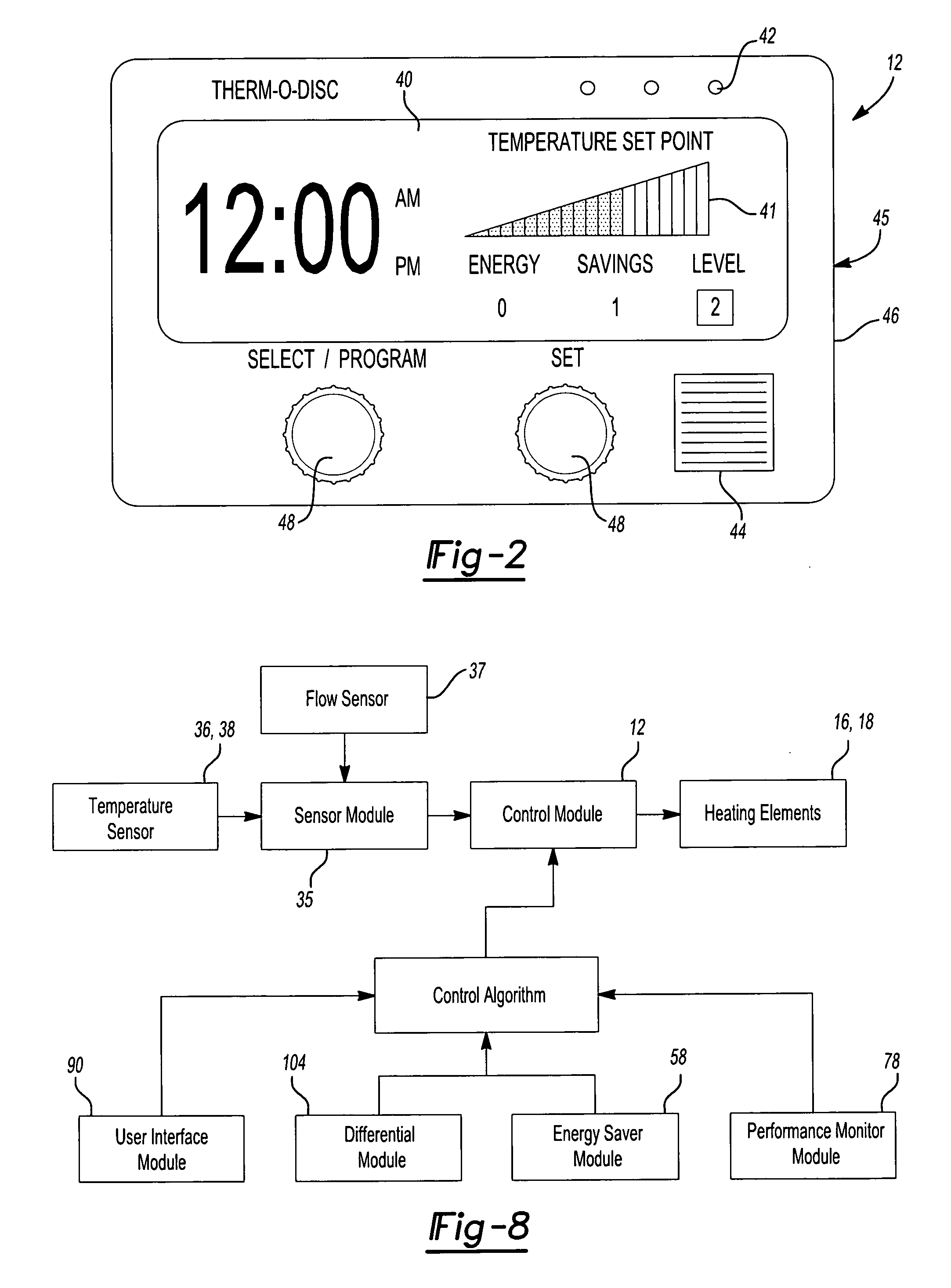

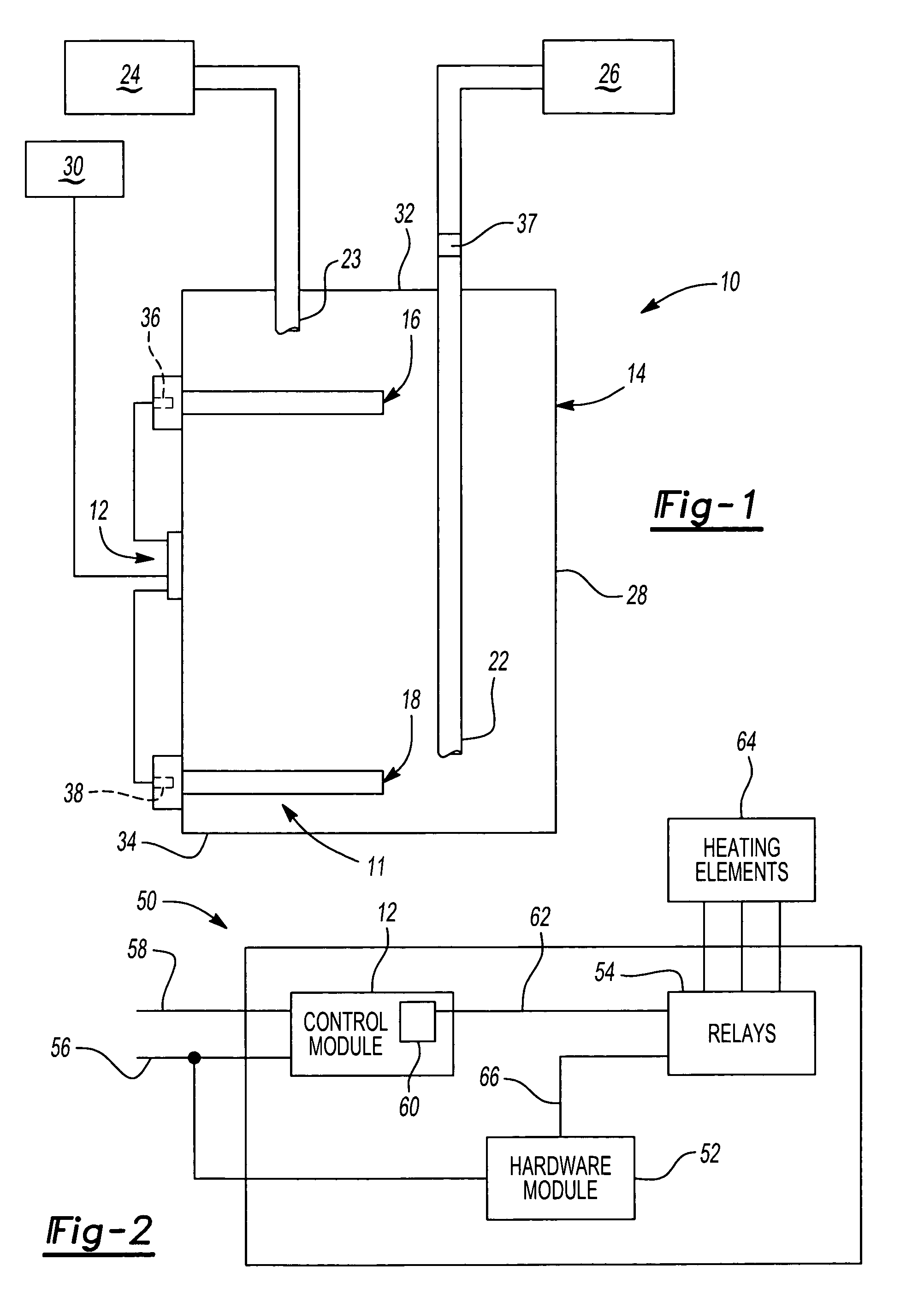

Method and apparatus for operating an electric water heater

A control system for an electric water heater having an upper heating element and a lower heating element is disclosed. The control system includes a control module that controls operation of the electric water heater by selectively toggling the upper and lower heating elements between an ON state and an OFF state and a consumer interface module that allows a consumer to input a set point temperature and select an energy savings mode for the electric water heater. The control module regularly monitors hot water usage and adjusts the set point temperature by a predetermined setback amount until a capacity of the water heater matches consumer usage.

Owner:EMERSON ELECTRIC CO

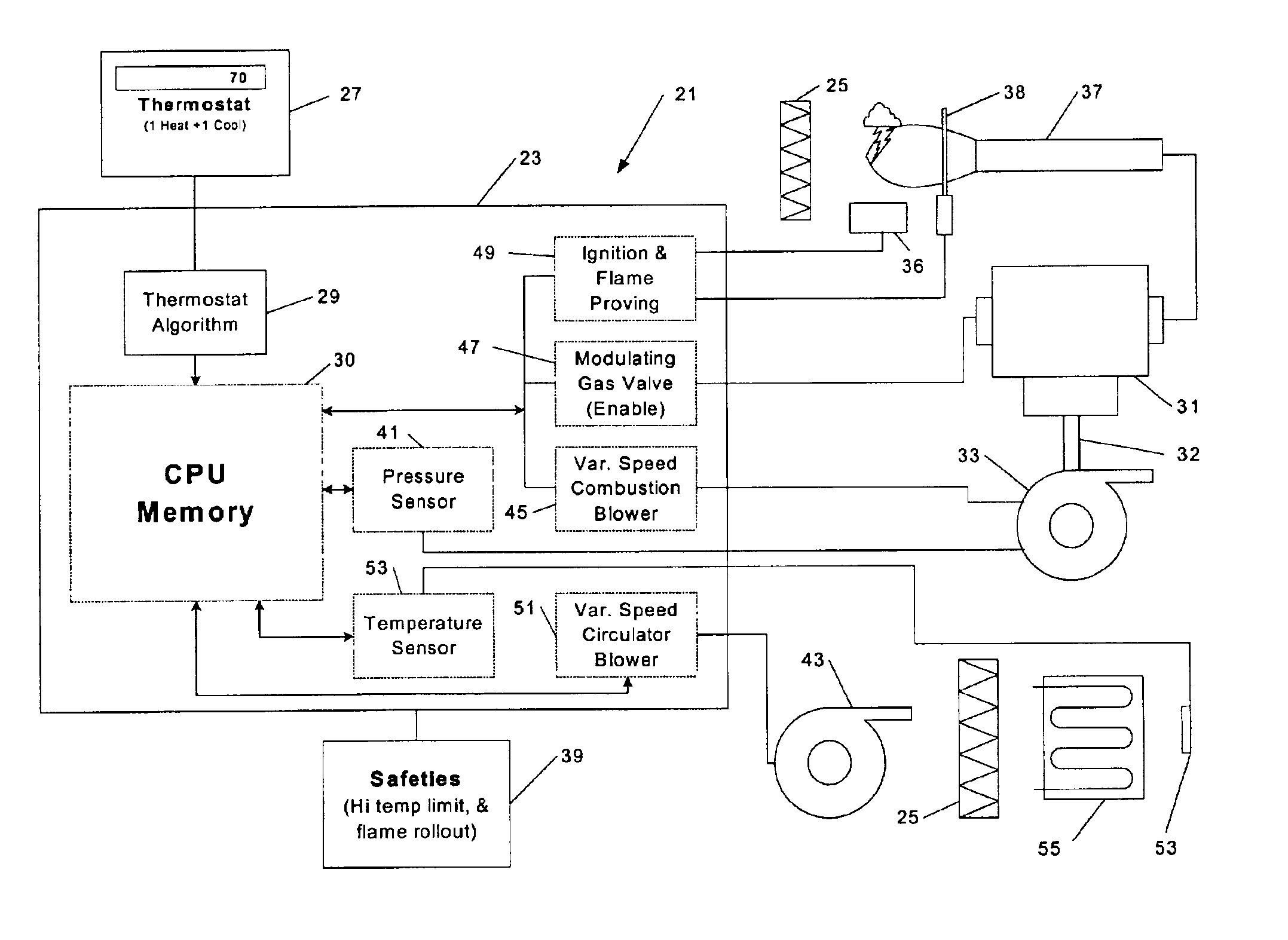

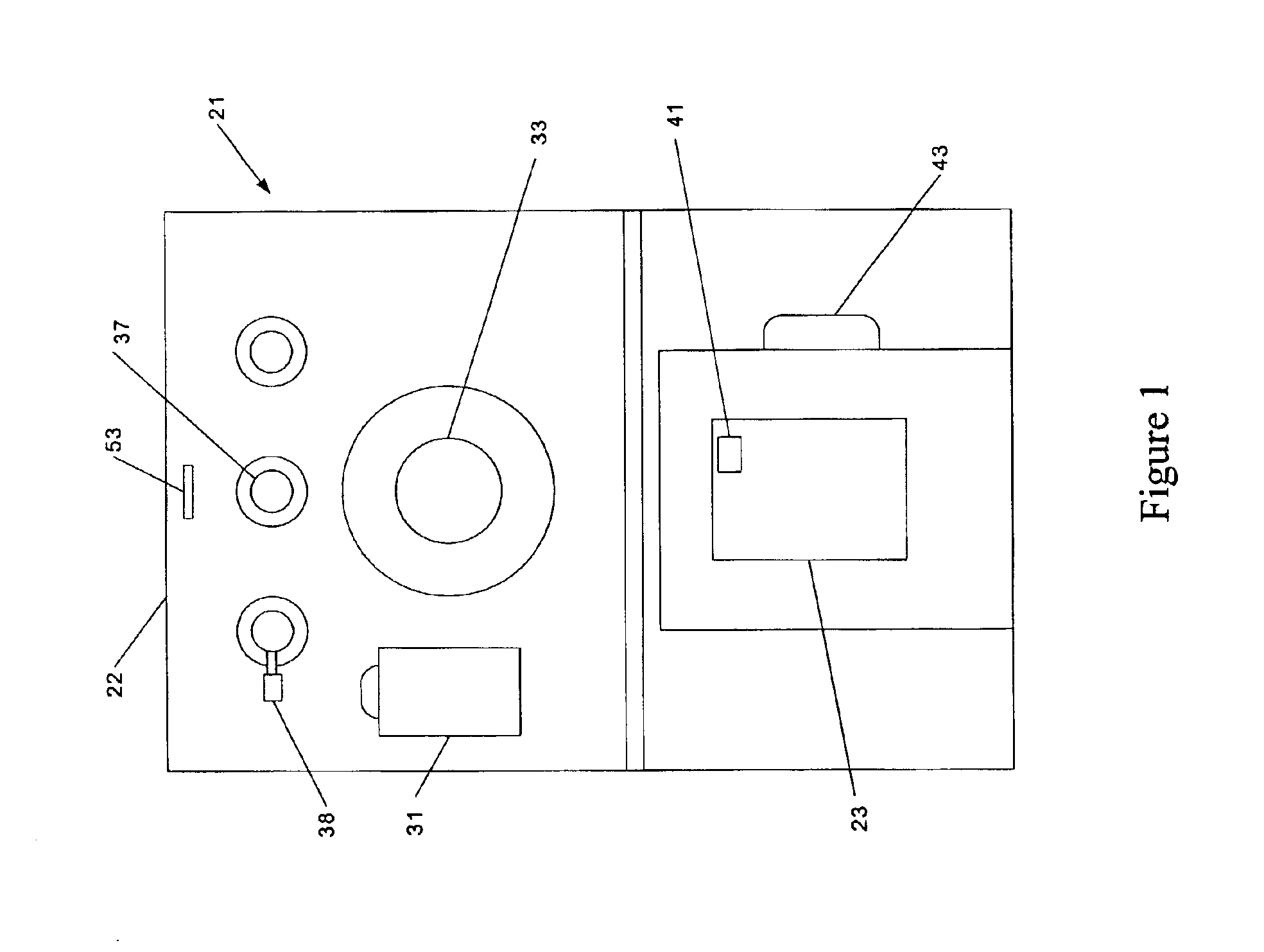

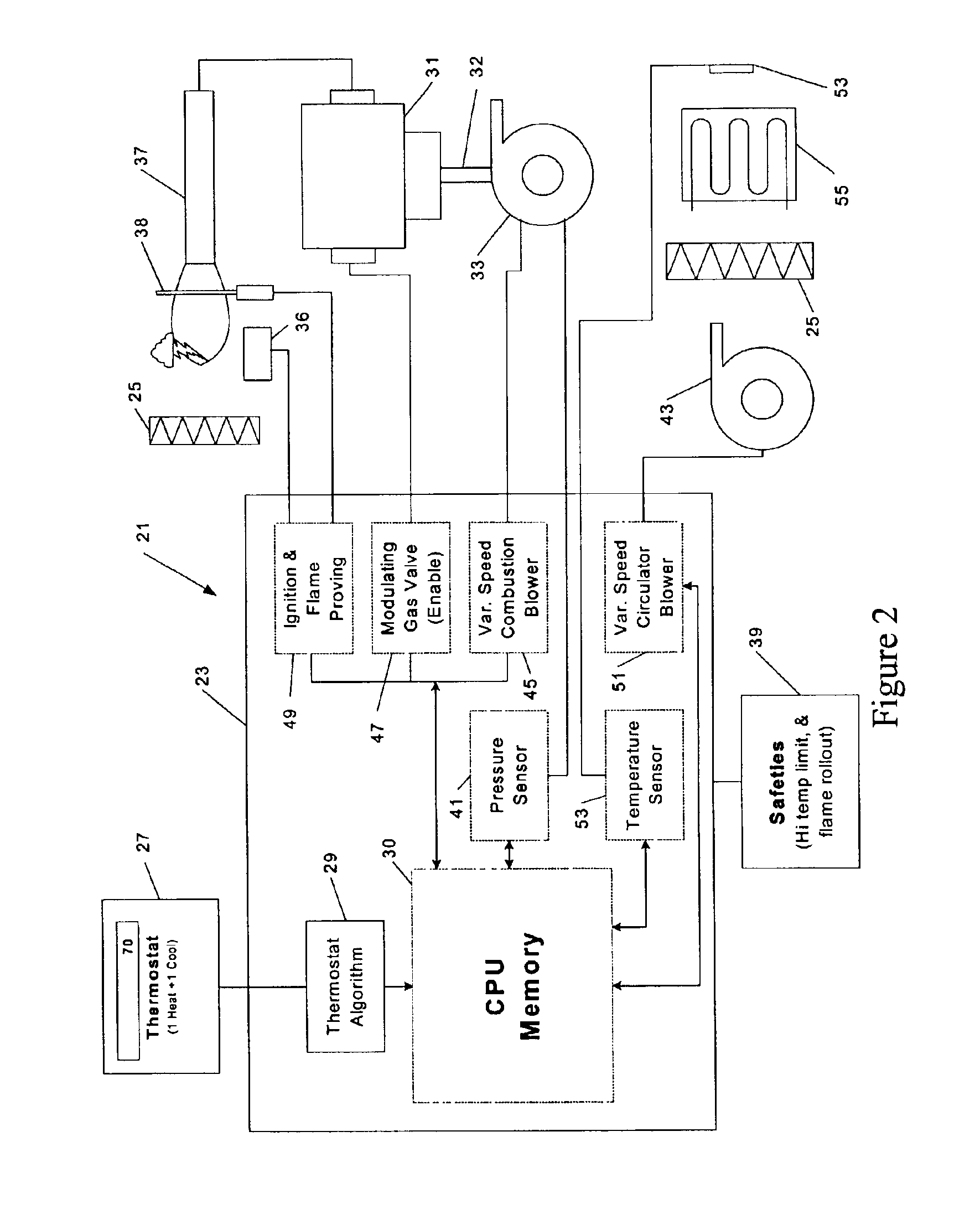

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

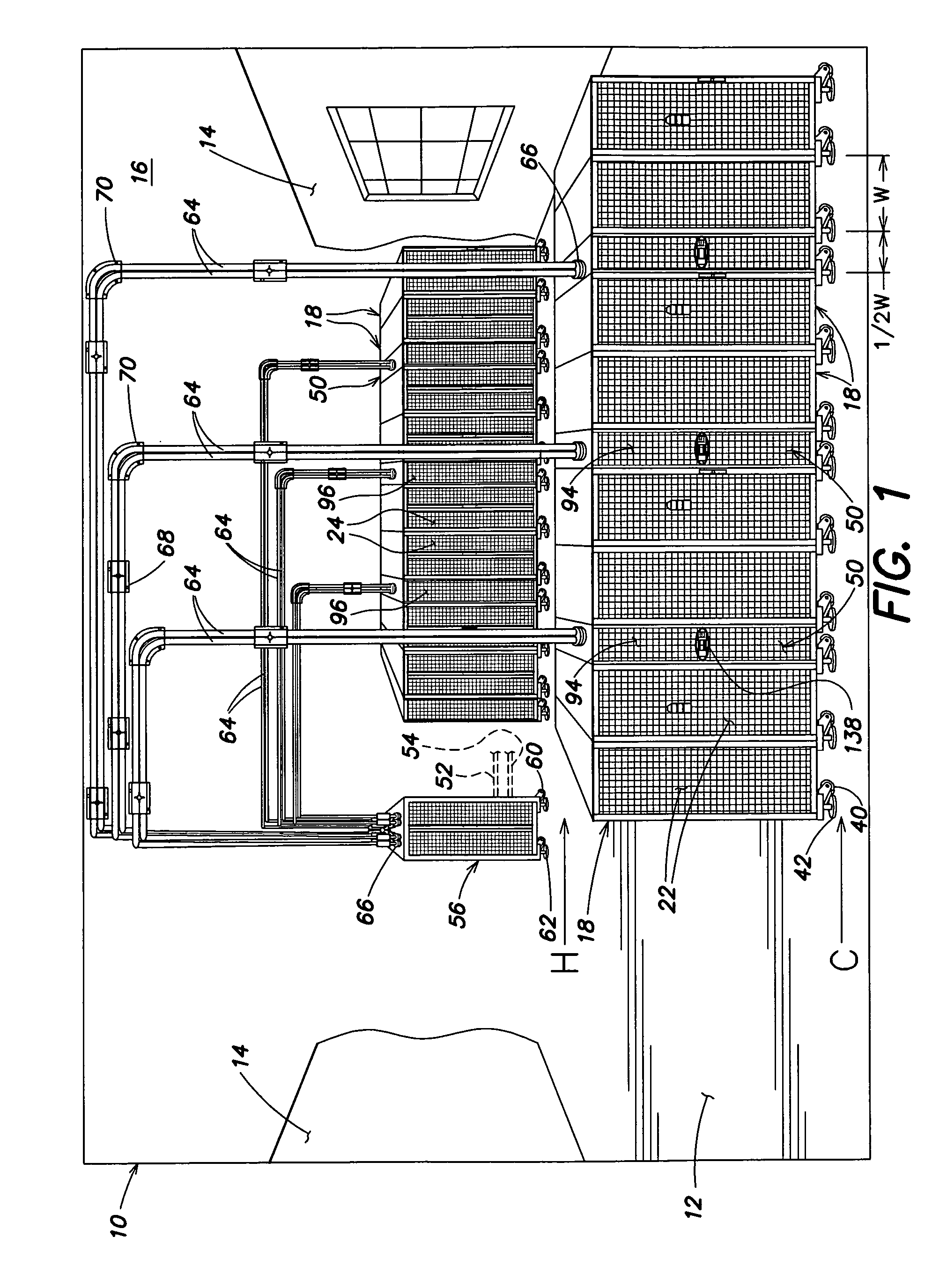

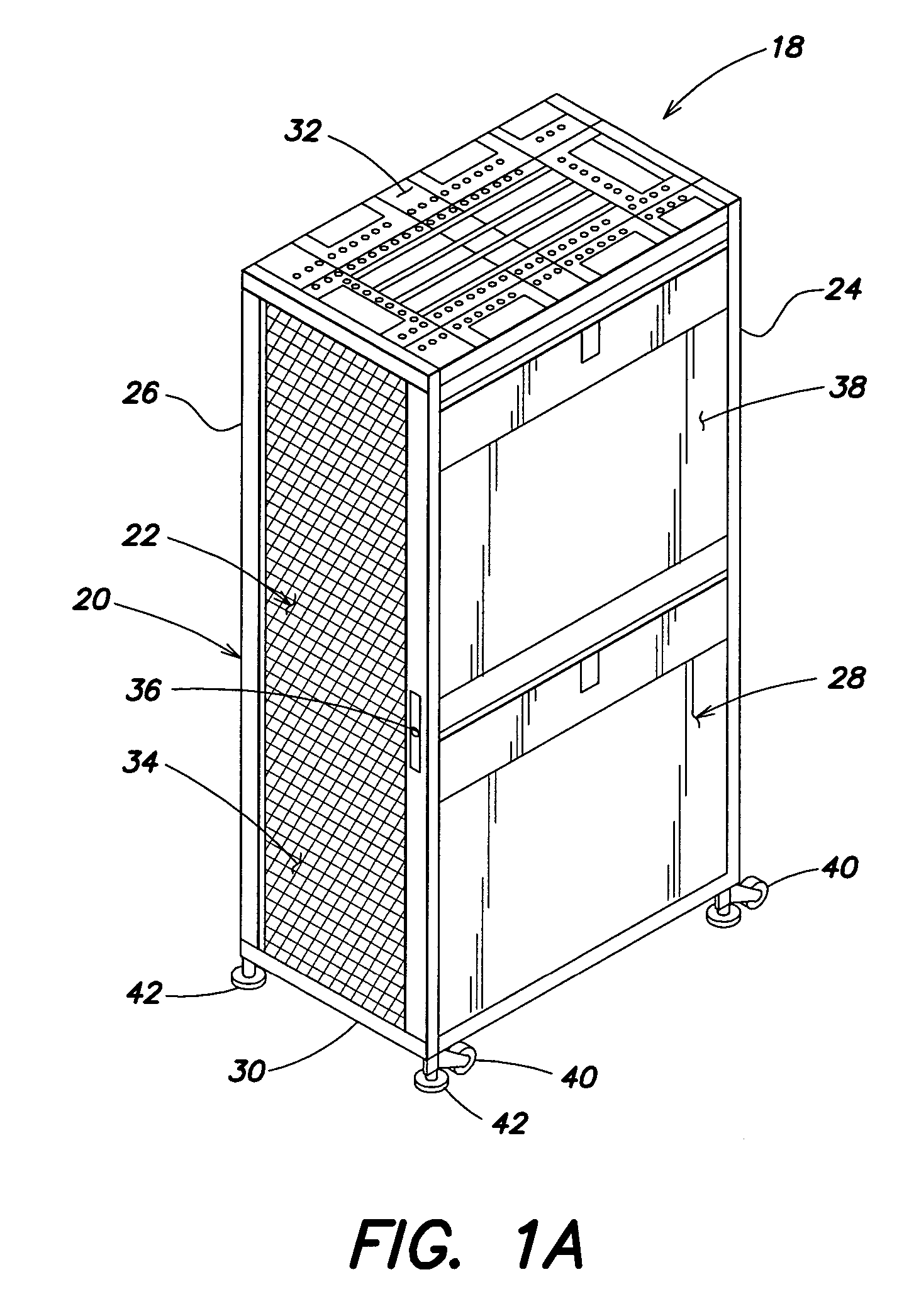

Assembly For Providing A Downflow Return Air Supply

InactiveUS20100248609A1Maximize capacityMaintain depthFluid heatersHot-air central heatingEngineeringAir conditioning

An assembly for supplying heated air to a housing with an interior that is adapted to hold air conditioning equipment. The housing has a top portion and a back portion, where the top portion defines a first opening that leads to the interior of the housing, and where the first opening is proximate the back of the top portion of the housing. The back portion of the housing defines a second opening that leads to the housing interior, where the second opening is proximate the top of the back portion. The assembly includes a flue external to the housing and adapted to be coupled to the housing such that the flue encompasses and is in fluid communication with the first and second openings, the flue defining an inlet for conducting heated air into the flue and an outlet for conducting heated air out of the flue and into the housing through the first and second openings. The air cooled by the air conditioning equipment in the housing is used to cool electronic equipment.

Owner:WRIGHT LINE

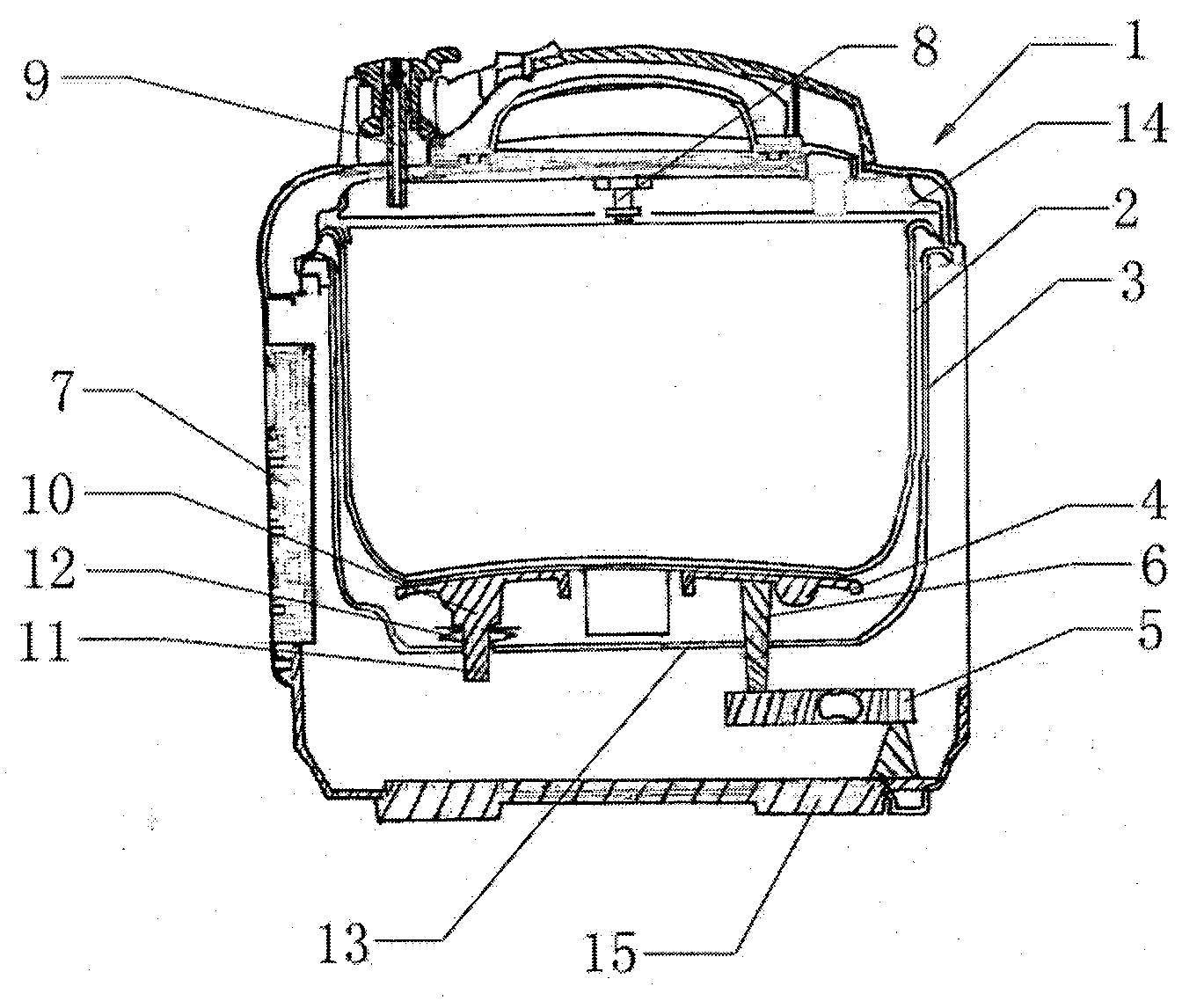

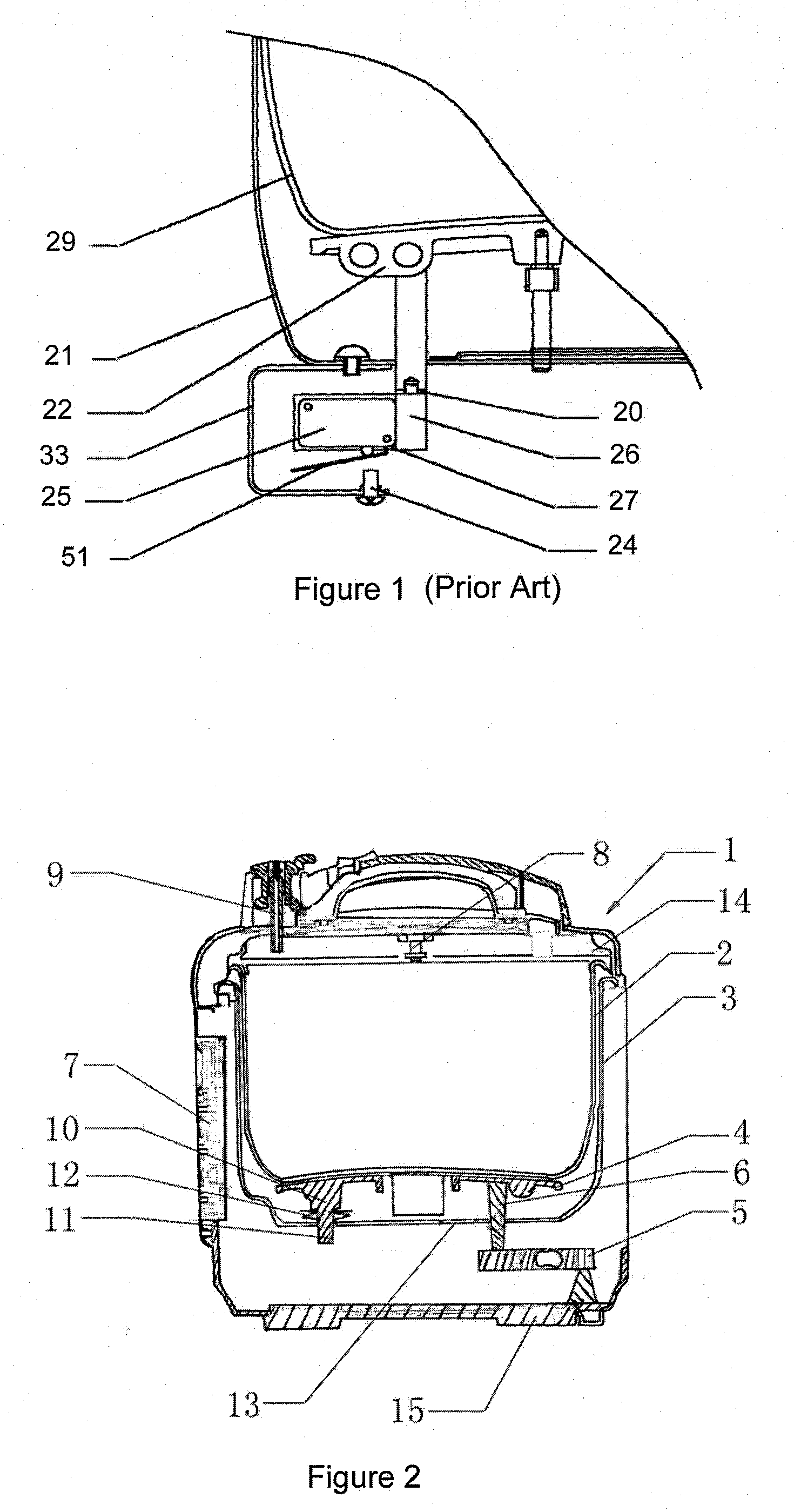

Pressure-detection method and a detection device for an electric pressure cooker

InactiveUS20090095166A1Detect and controlEasy to detectFluid heatersBoiling over preventionElectricityElastomer

A pressure-detection method and detection device for electric pressure cooker is used for detecting continuously and accurately to control the pressure in the electric pressure cooker. The method comprises that a strainometer is provided on the periphery of a cooking pot of the electric pressure cooker, and a transmission arm is utilized to sense the expanding amount of the cooking pot and converts the expanding amount into a displacement, then makes the elastomer of the strainometer distorting; the distorting elastomer generates subsequently a controllable electric signal due to the electric characteristic of a sensitive foil, and the controllable electric signal is delivered to a central control unit, then control signals and display signals are outputted by the central control unit. The detection device comprises a strainometer, a transmission arm, a central control unit and the like. The strainometer is provided on the periphery of the cooking pot of the electric pressure cooker and is fixed by a proper way. The present invention can be used not only to detect and control the pressure of the electric pressure cooker and can be used for the household appliances also, such as electric iron, electric water heater and the like, the temperature and pressure of which need to be detected.

Owner:JIAN WEI WEN

Method and apparatus for energy recovery in an environmental control system

Control apparatus for an environmental control system comprises input circuitry receiving environmental information and output circuitry for controlling an HVAC system. Processing circuitry in the controller configures the output circuitry based at least in part on the signals received on the input circuitry. Information about the status of the HVAC system may be transferred to system administrators using a wireless link.

Owner:ELUTIONS

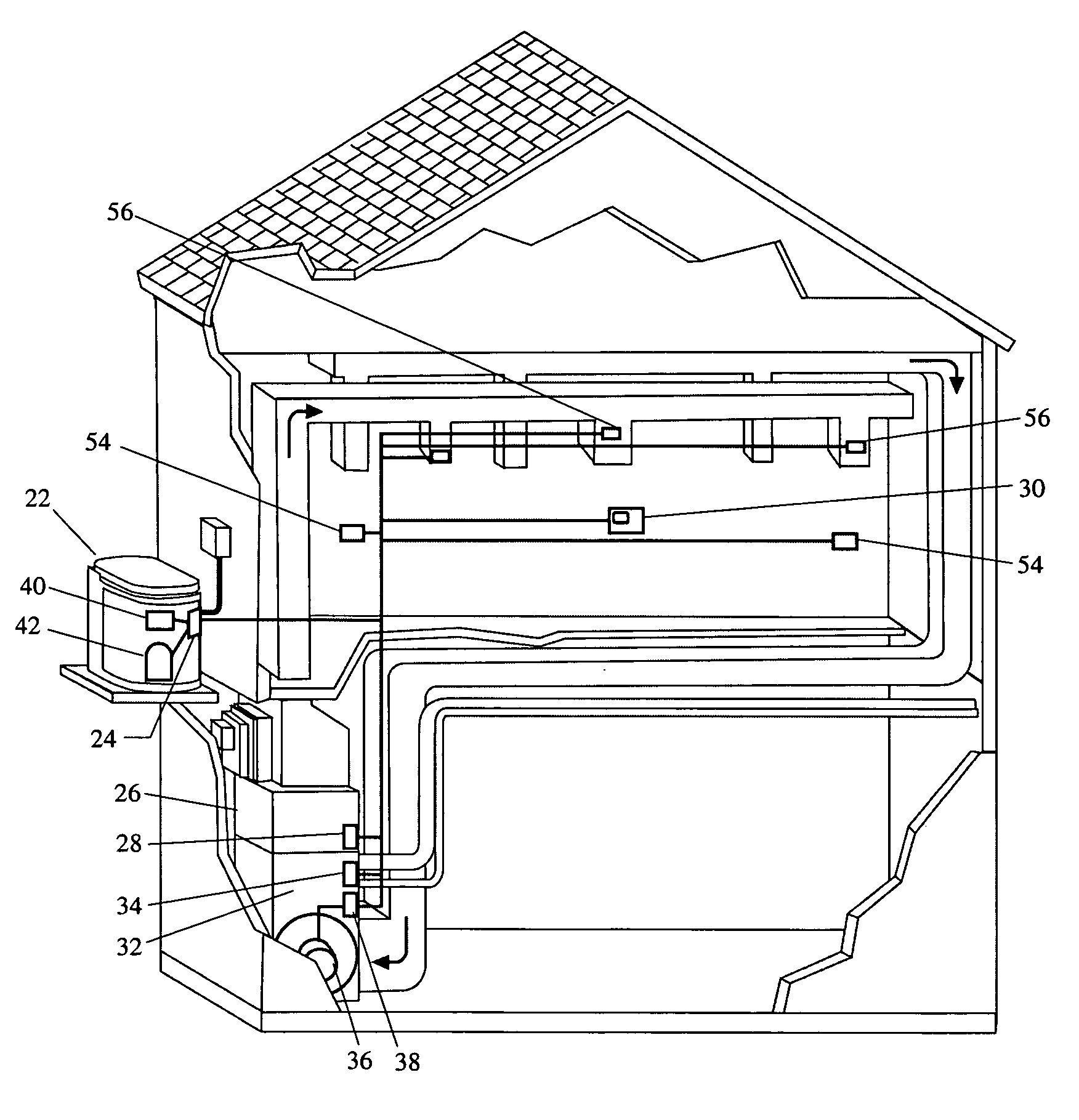

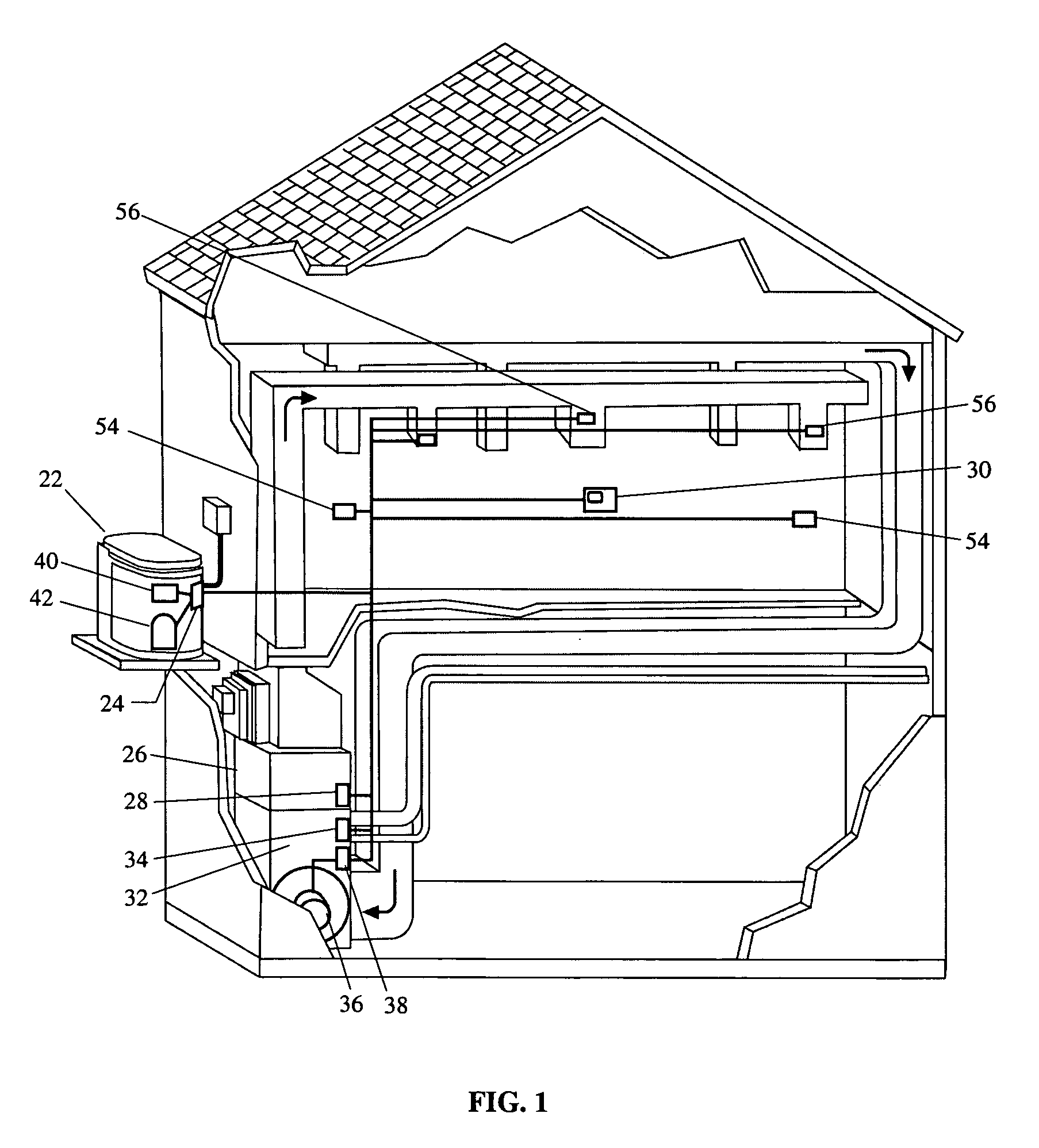

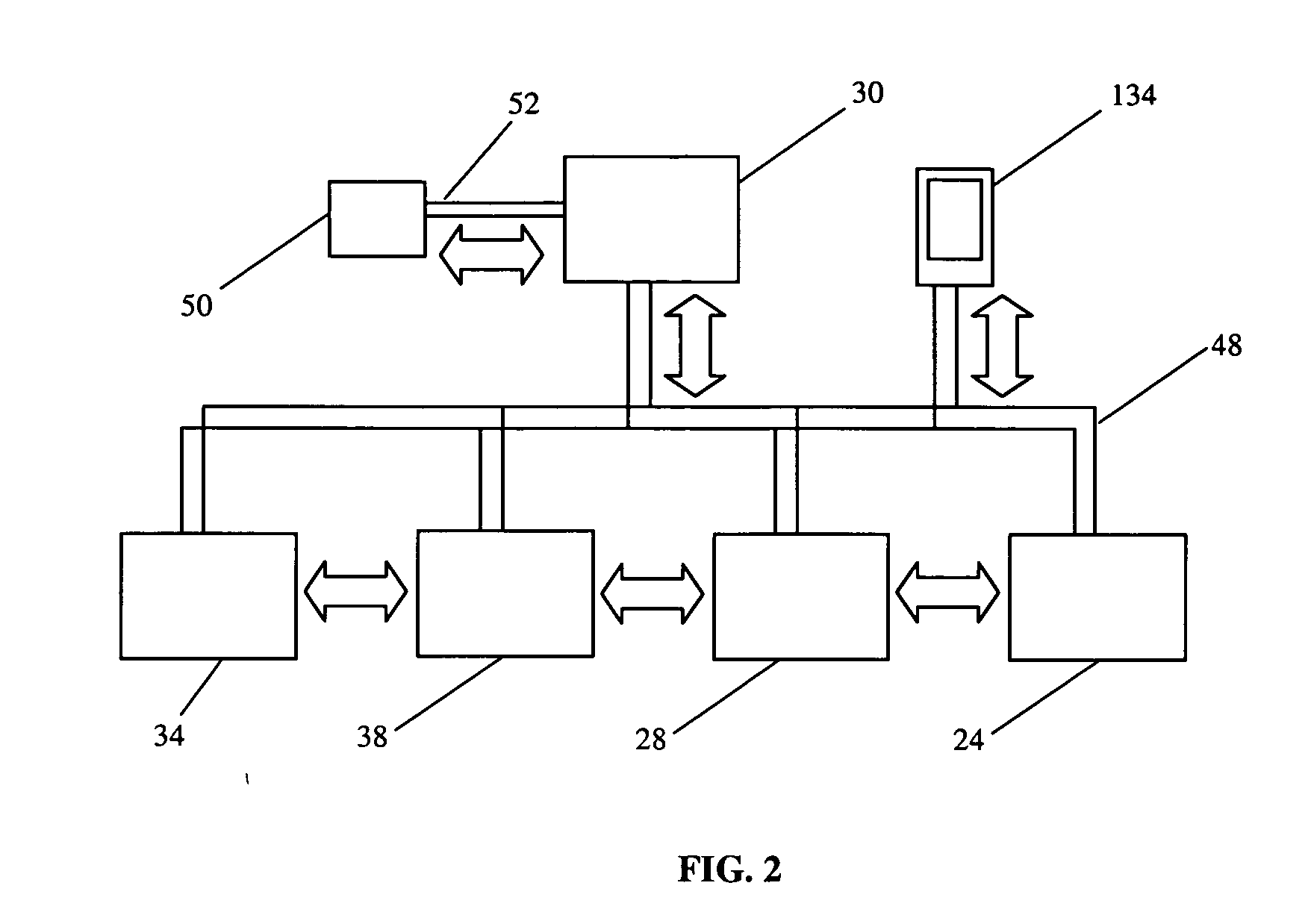

Combination radiant and forced air climate control system

InactiveUS6957696B1Easy to operateInhibition of activationTemperature control without auxillary powerDucting arrangementsResidenceControl system

A method and controller for controlling the operation of a zoned climate control system including a primary heat source, a secondary heat source, a cooling unit, and a humidifier unit. The controller is configured to receive both heating demand signals and cooling demand signals from a plurality of zone thermostats positioned throughout the residence. Upon receiving a heating demand signal, the controller operates the primary heat source to provide heat to the zone issuing the heating demand signal. The controller determines whether the primary heat source satisfies the heating demand signal within a maximum heating period. If the heating demand is not satisfied within this period, the controller activates the secondary heat source to supplement the heat being supplied by the primary heat source.

Owner:KRUMNOW MARK J

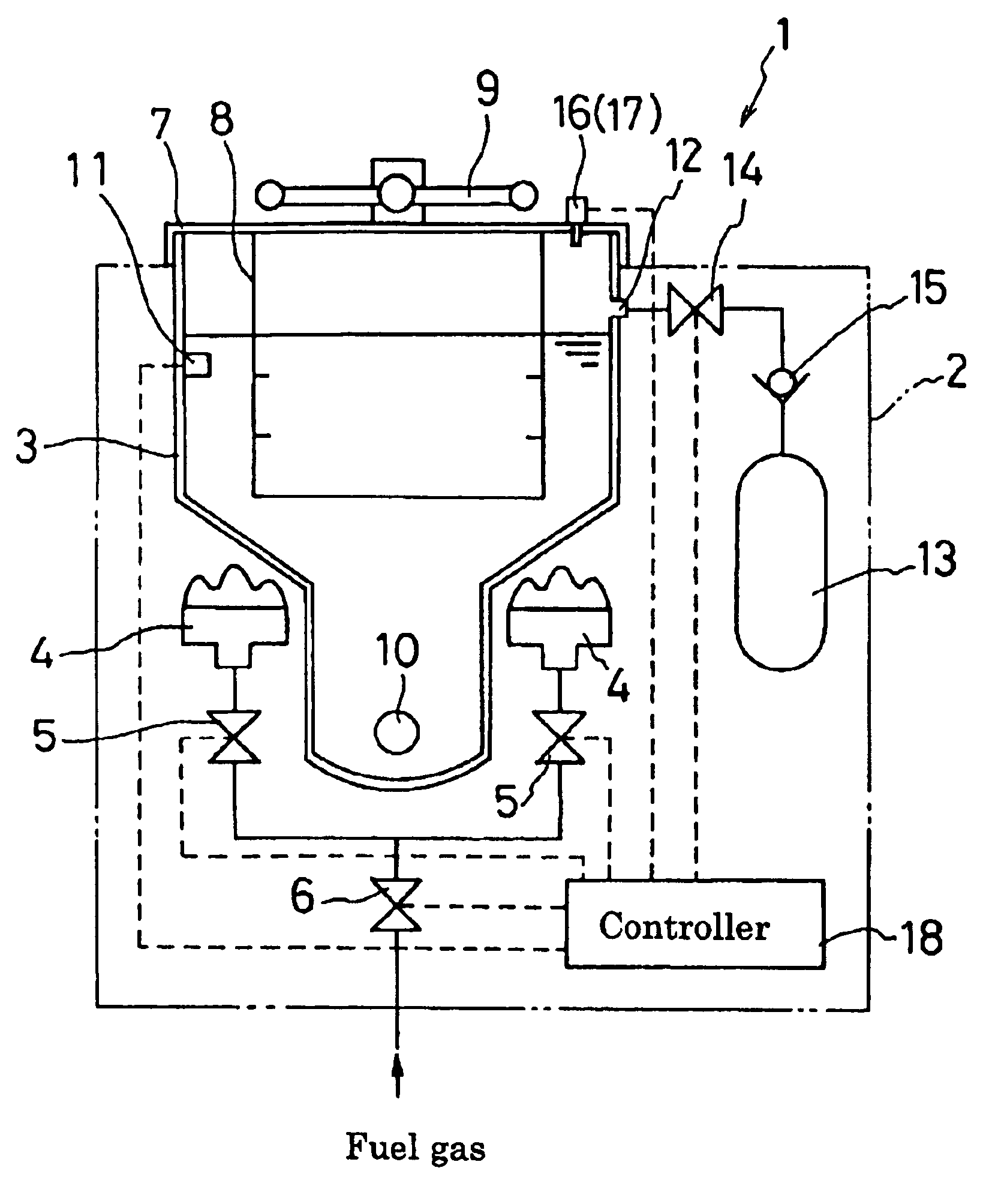

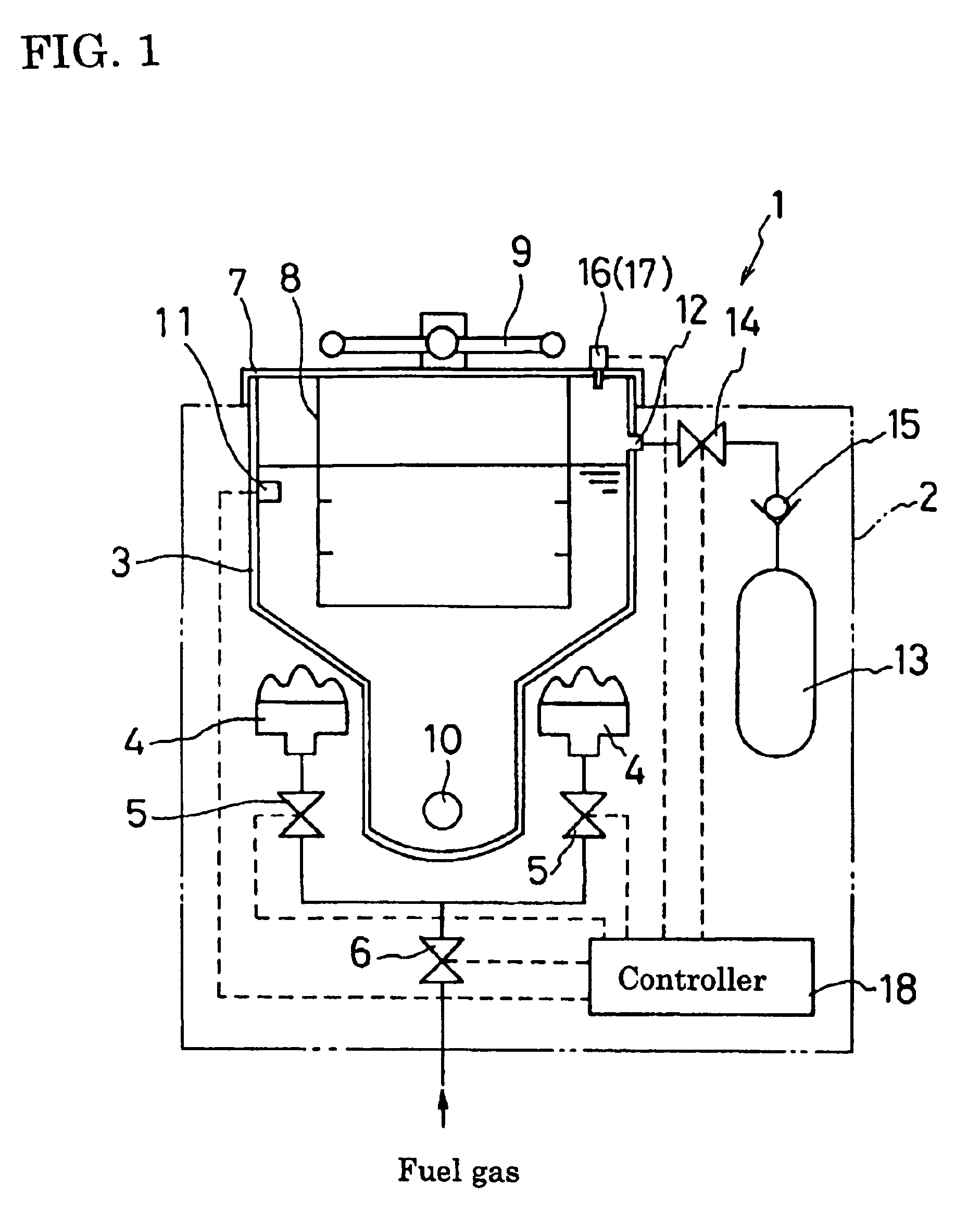

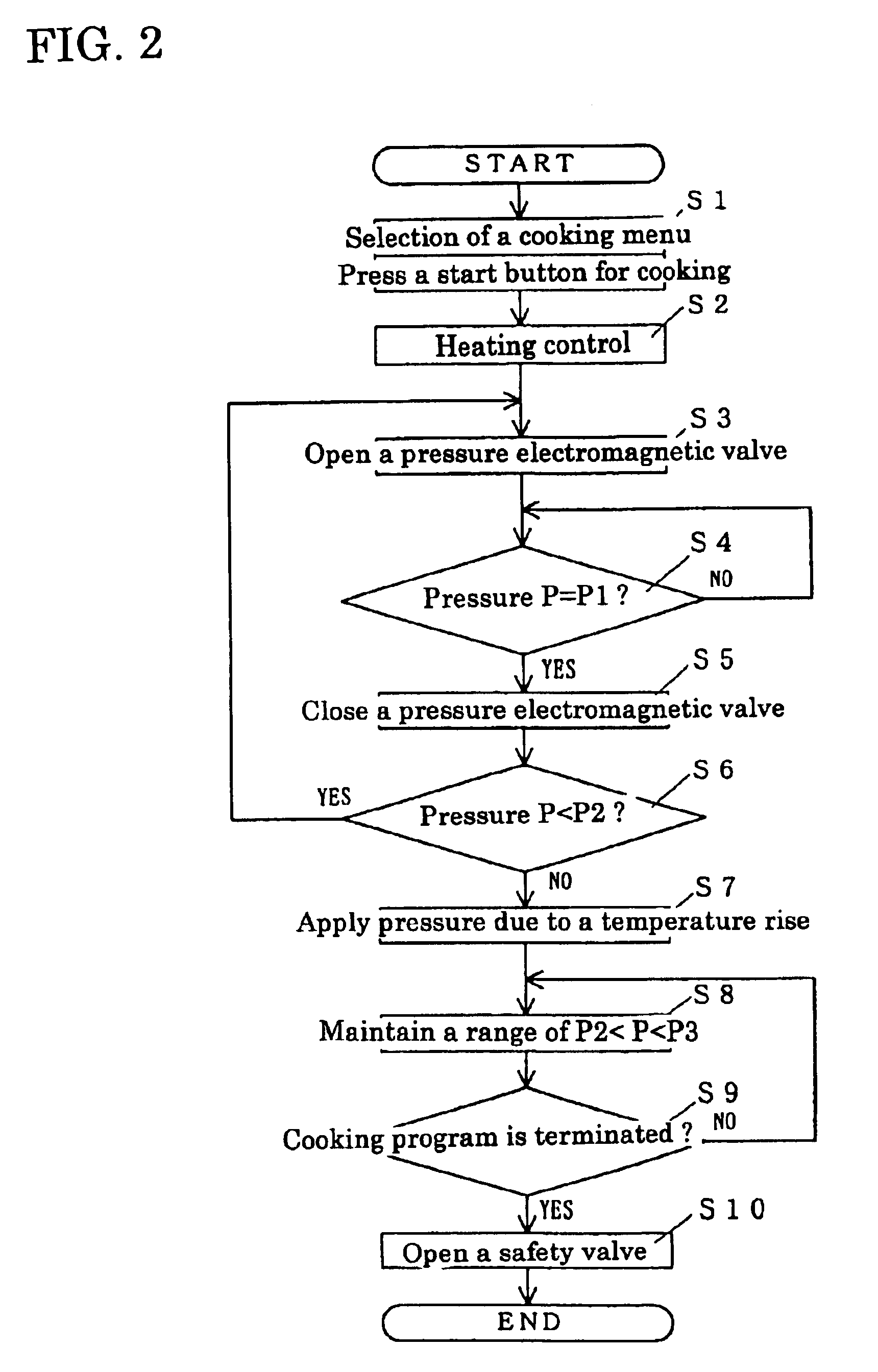

Pressure fryer

ActiveUS6935223B2Easy to obtainEasy maintenanceFluid heatersBoiling over preventionEngineeringHigh pressure

A pressure fryer is provided including a cooking container having a pressure vent which is connected to a high pressure cylinder filled with carbon dioxide. An electromagnetic valve and a check valve are provided on the connecting tube between the pressure vent and the high pressure cylinder. A lid includes a safety valve and a pressure sensor. A controller opens and closes the safety valve and the pressure for the electromagnetic valve for supplying carbon dioxide into the cooking container based on the pressure therein which is obtained from the pressure sensor, such that the pressure in the cooking container can be maintained within a predetermined value.

Owner:PALOMA

Control and method for operating an electric water heater

A water heater control for an electric water heater operates according to at least one fixed hardware and / or software temperature limit and a variable software temperature limit. The control monitors a temperature of water in a tank of the electric water heater to determine if the temperature exceeds the fixed hardware and / or software temperature limit. If the temperature exceeds the fixed temperature limit, the control turns off one or more heating elements of the electric water heater. The variable software temperature limit is indicative of a desired user temperature and an offset temperature. If the temperature exceeds the variable software temperature limit, the control turns off the one or more heating elements.

Owner:EMERSON ELECTRIC CO

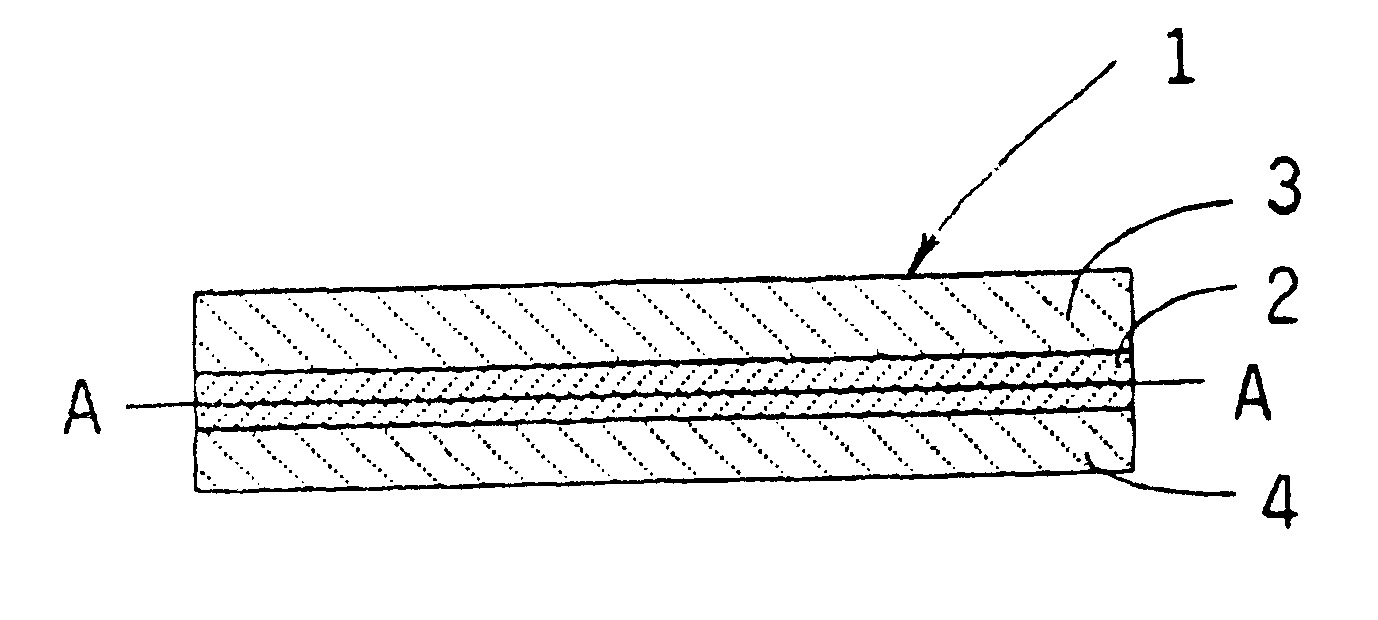

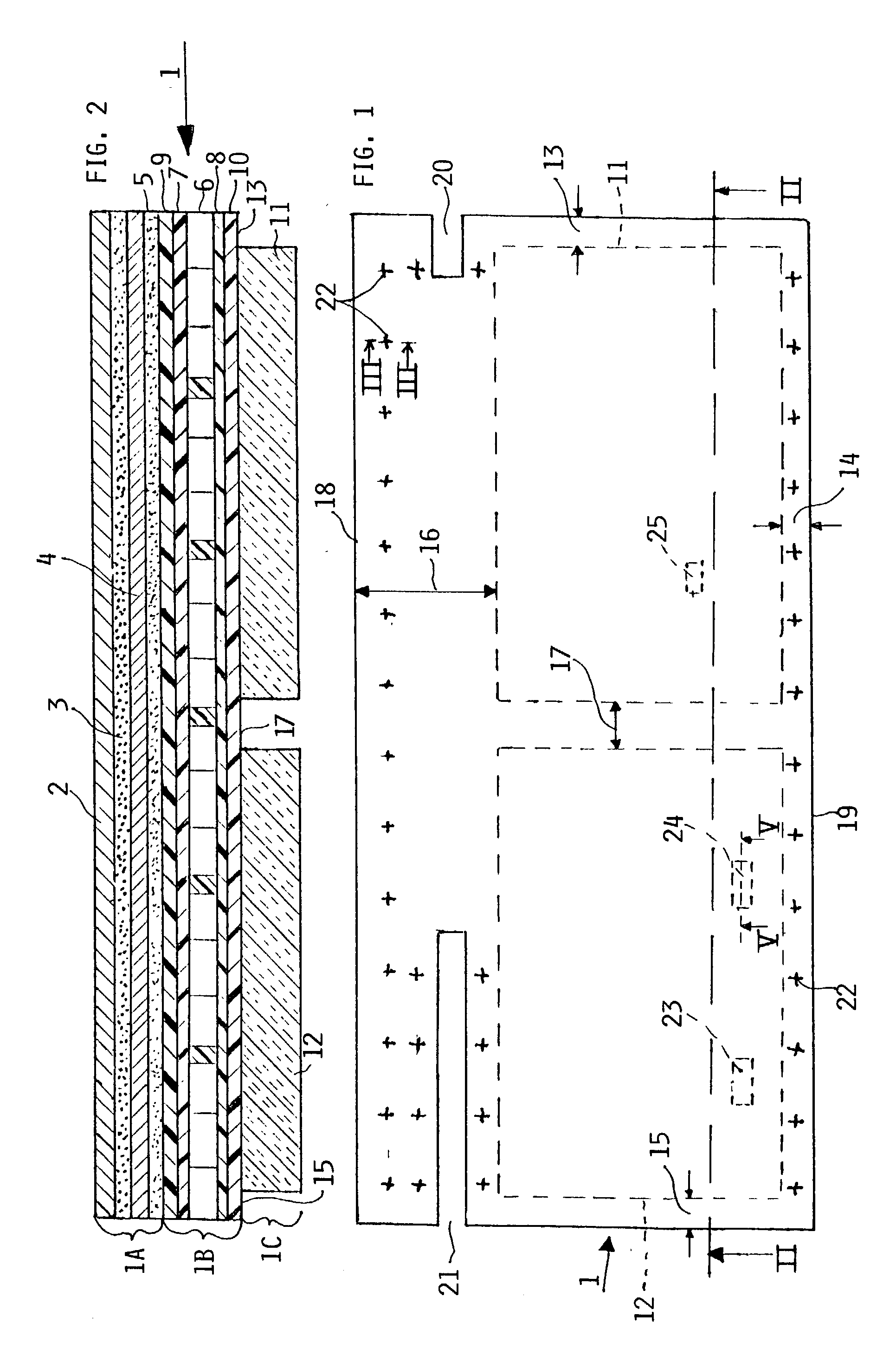

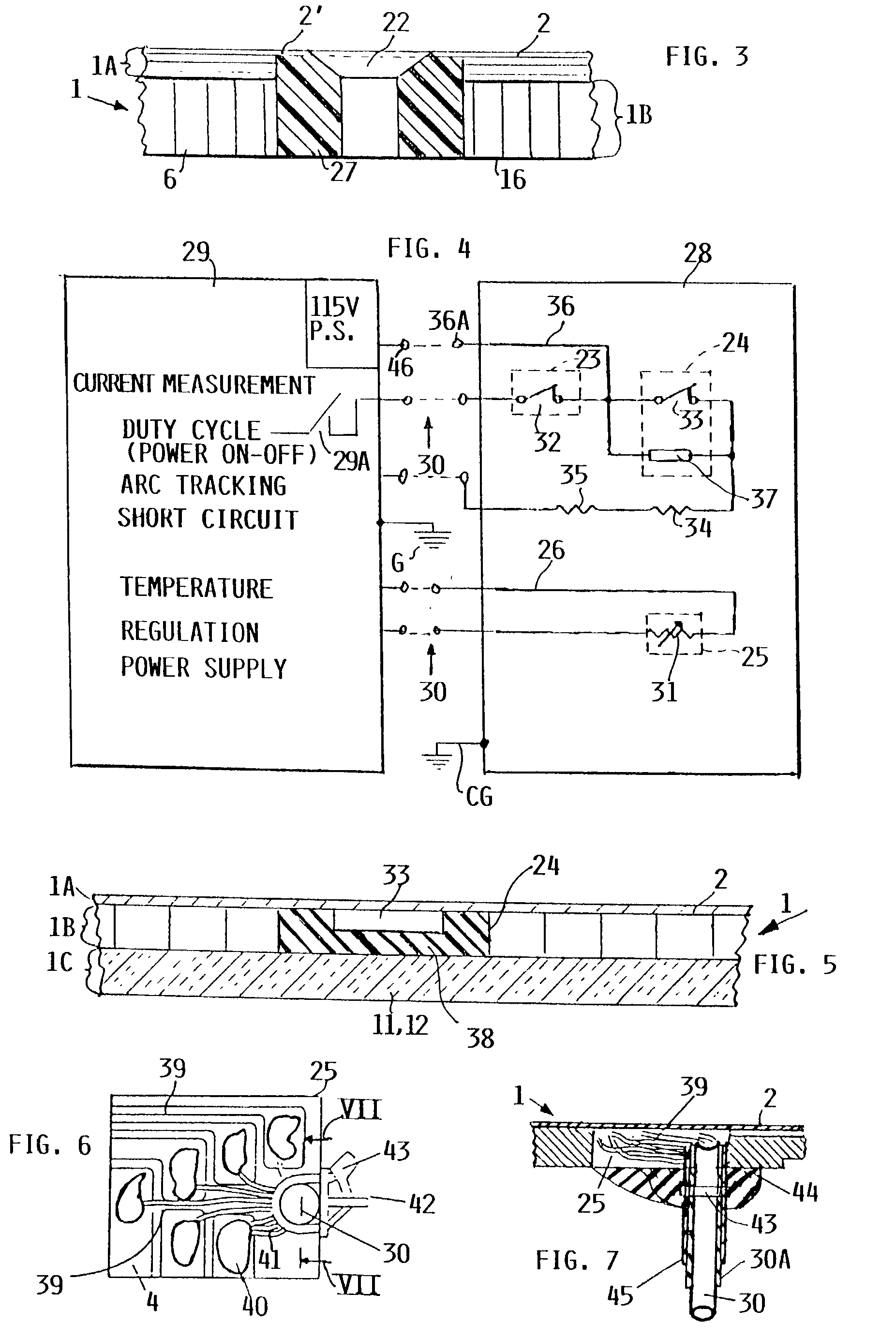

Electrically heated aircraft composite floor panel

InactiveUS20020168184A1Avoid temperature riseReduce consumptionFluid heatersElectric heating systemGlass fiberFiber-reinforced composite

An aircraft floor heating panel is constructed for mechanical strength and to meet special heating requirements next to a door in an aircraft. The panel has a lightweight core. Each surface of the core is first covered with at least one carbon-fiber reinforced composite layer for protection against deterioration. Each carbon fiber layer in turn is covered by a glass fiber reinforced composite layer for mechanical strength. A foil heater is arranged inside the composite panel coextensive with at least a portion of the panel area. A heat distributing metal plate covers the panel as an upper step-on surface. A heat insulating layer is bonded to the panel opposite the heat distributing metal plate. A triple heat control is provided for an increased safety against fire hazards.

Owner:AIRBUS OPERATIONS GMBH

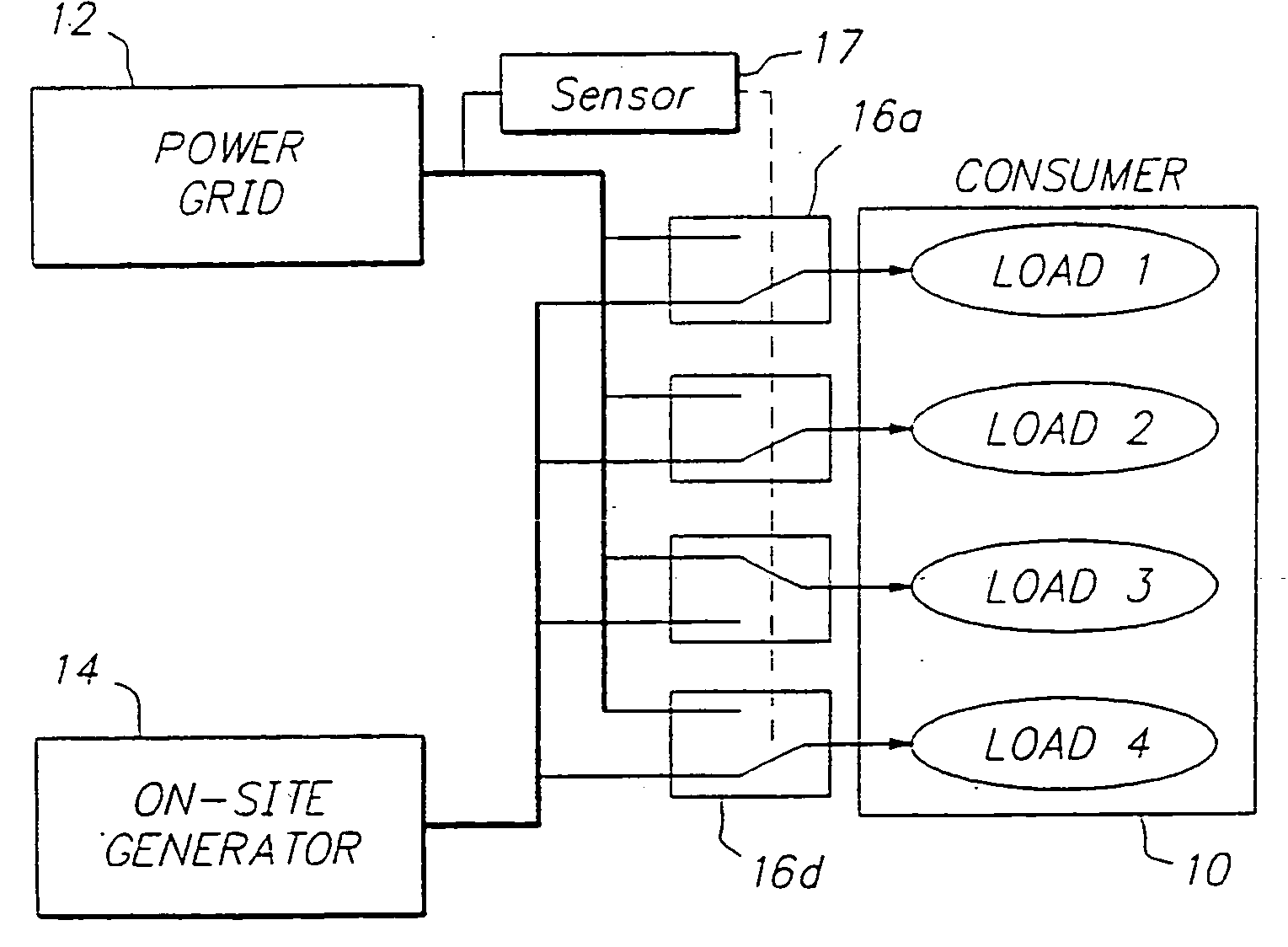

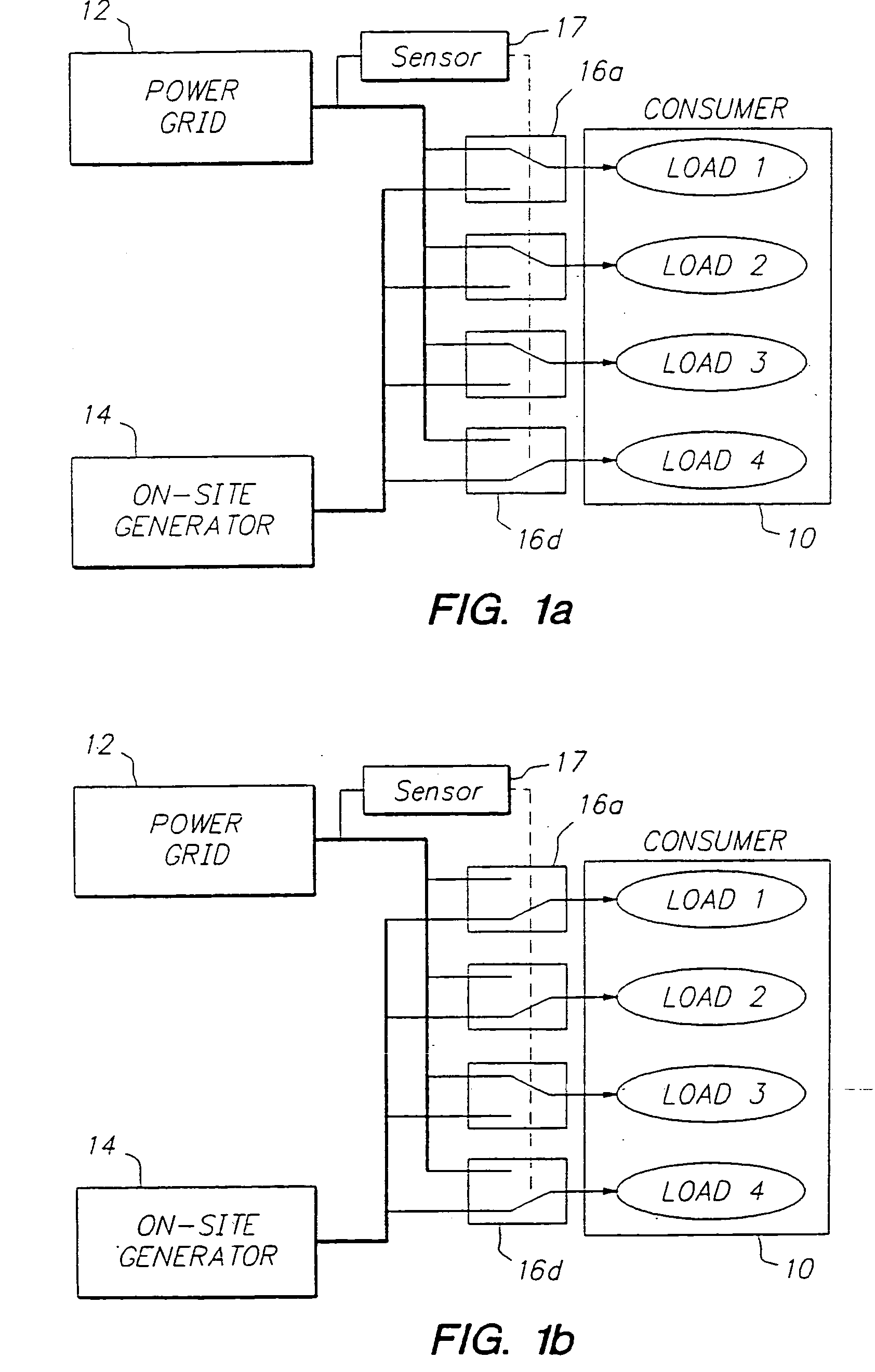

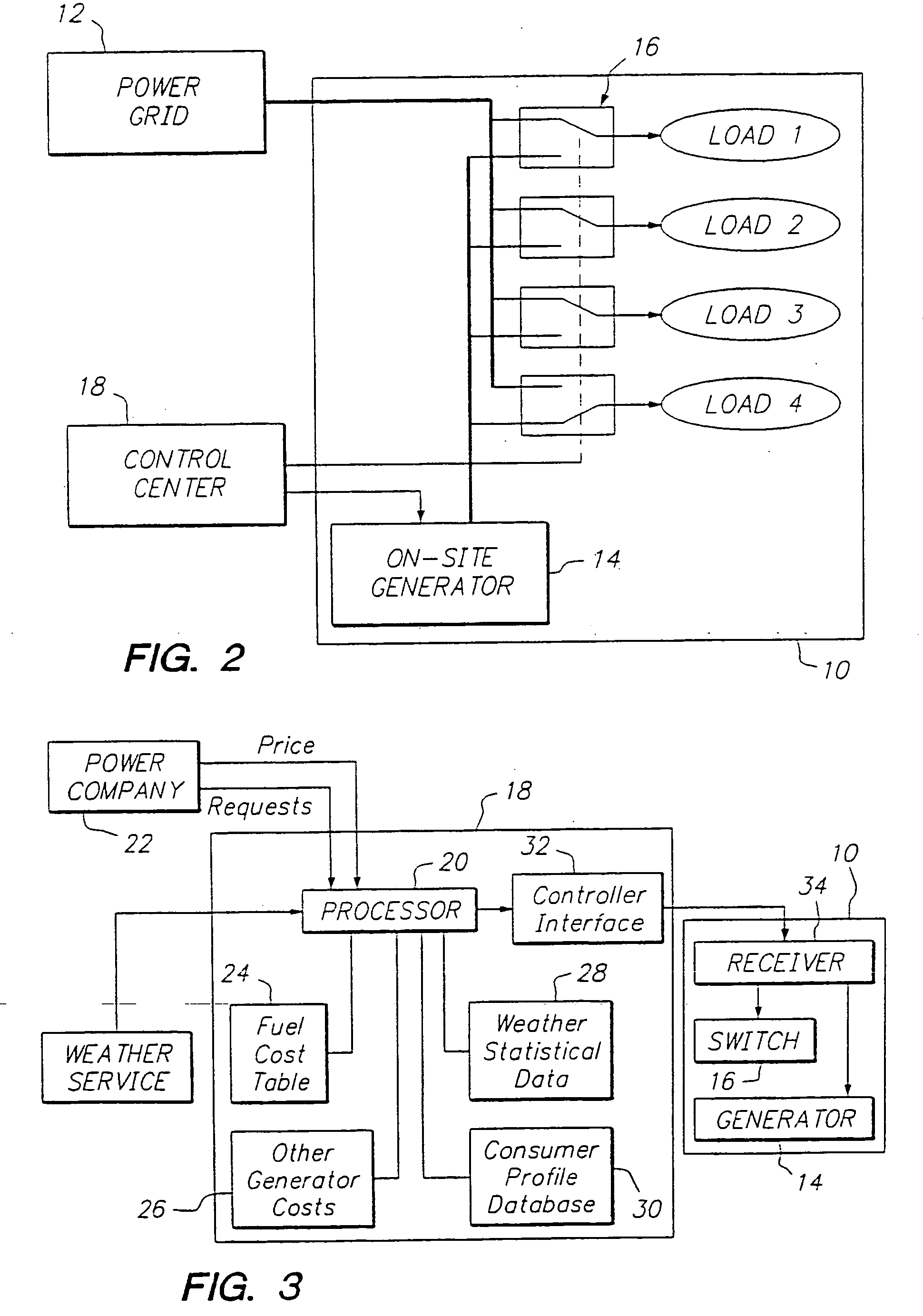

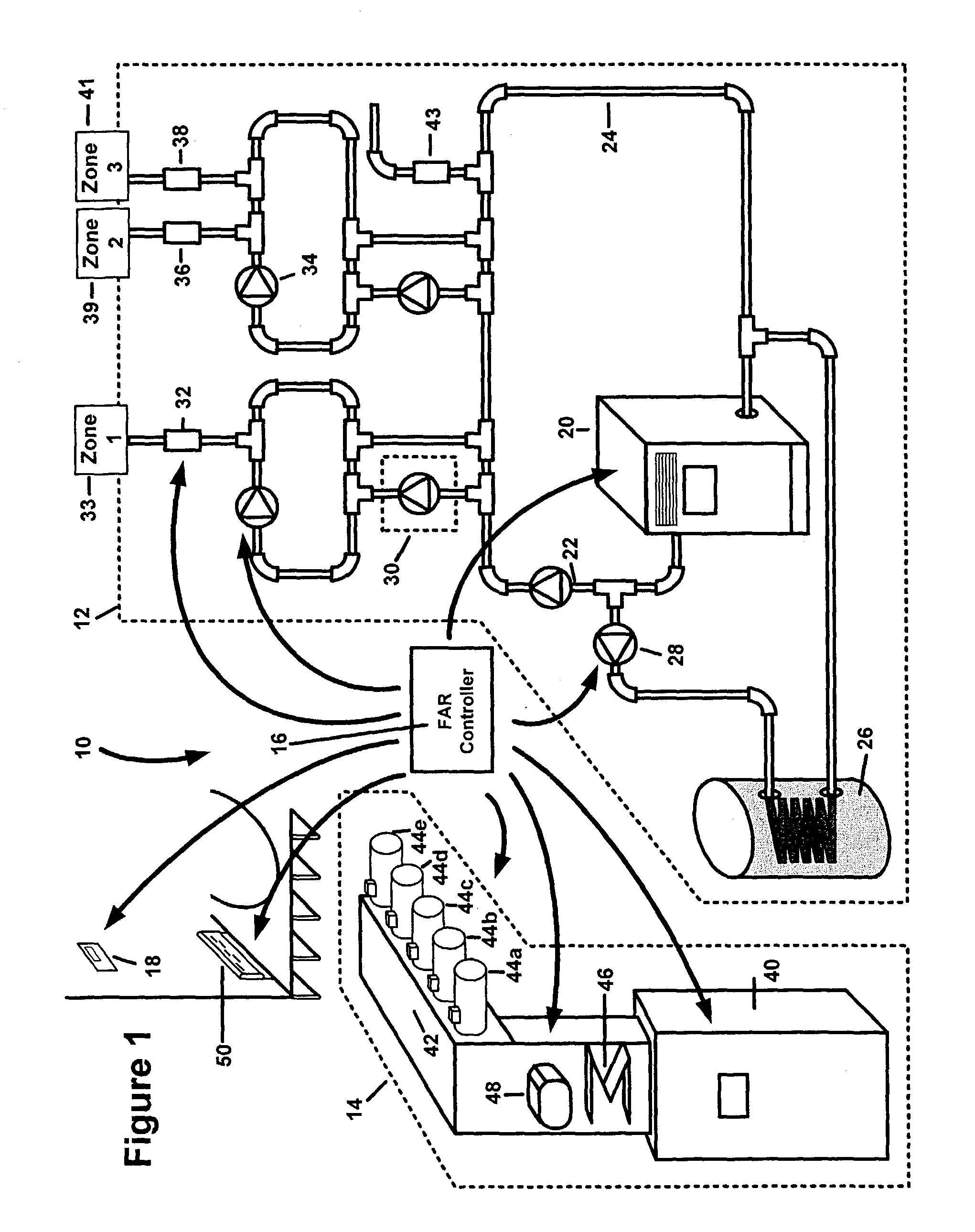

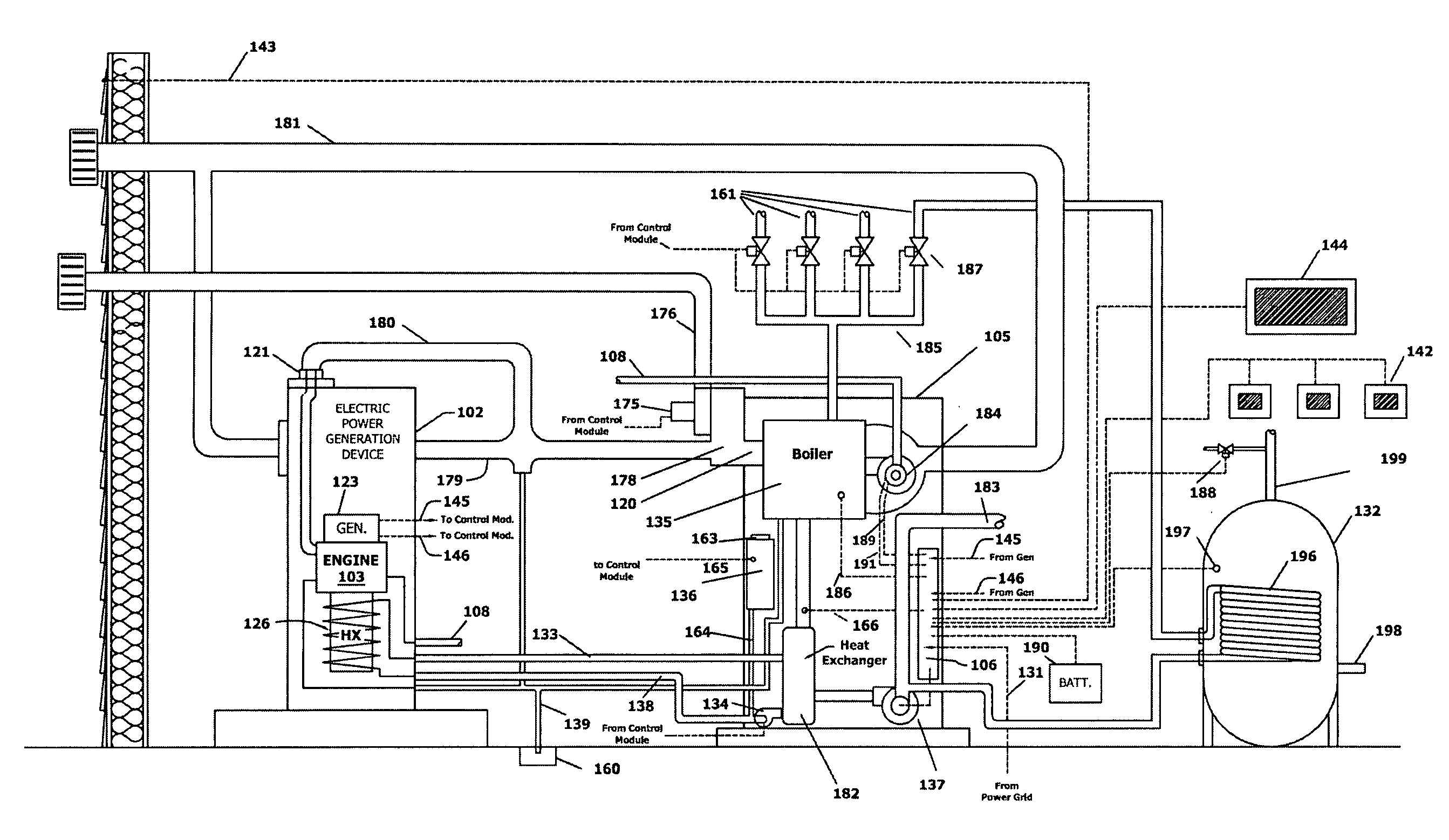

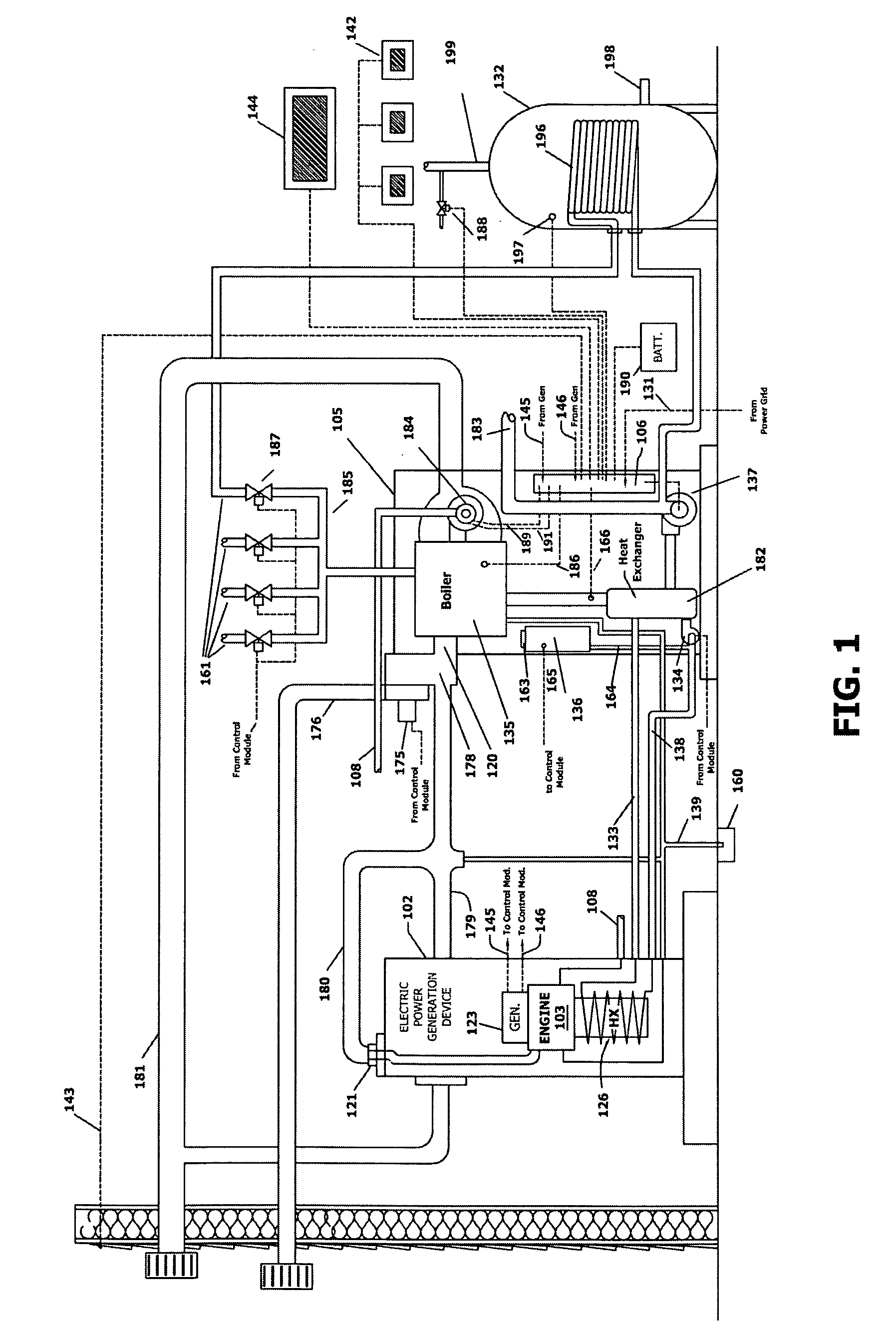

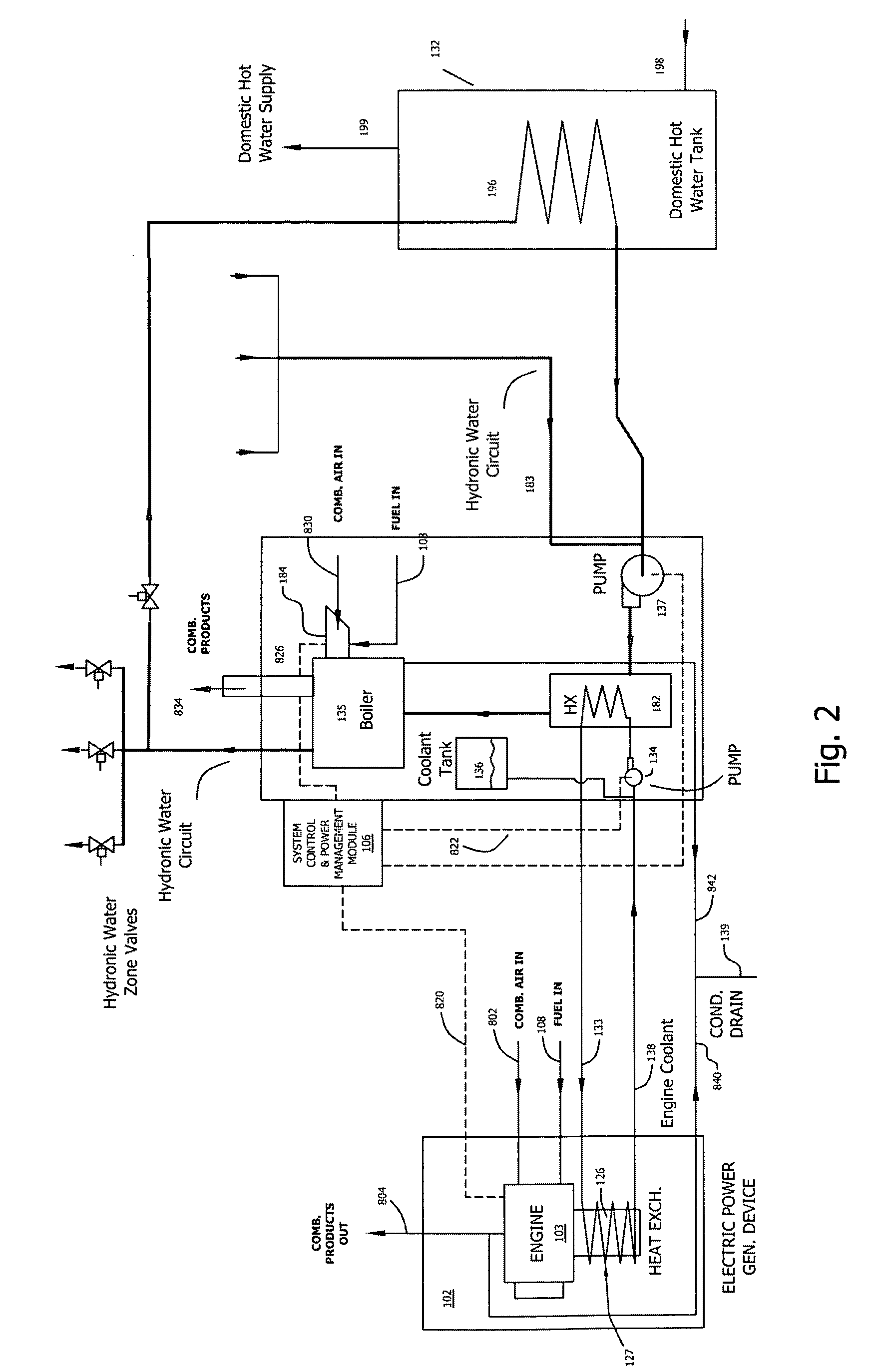

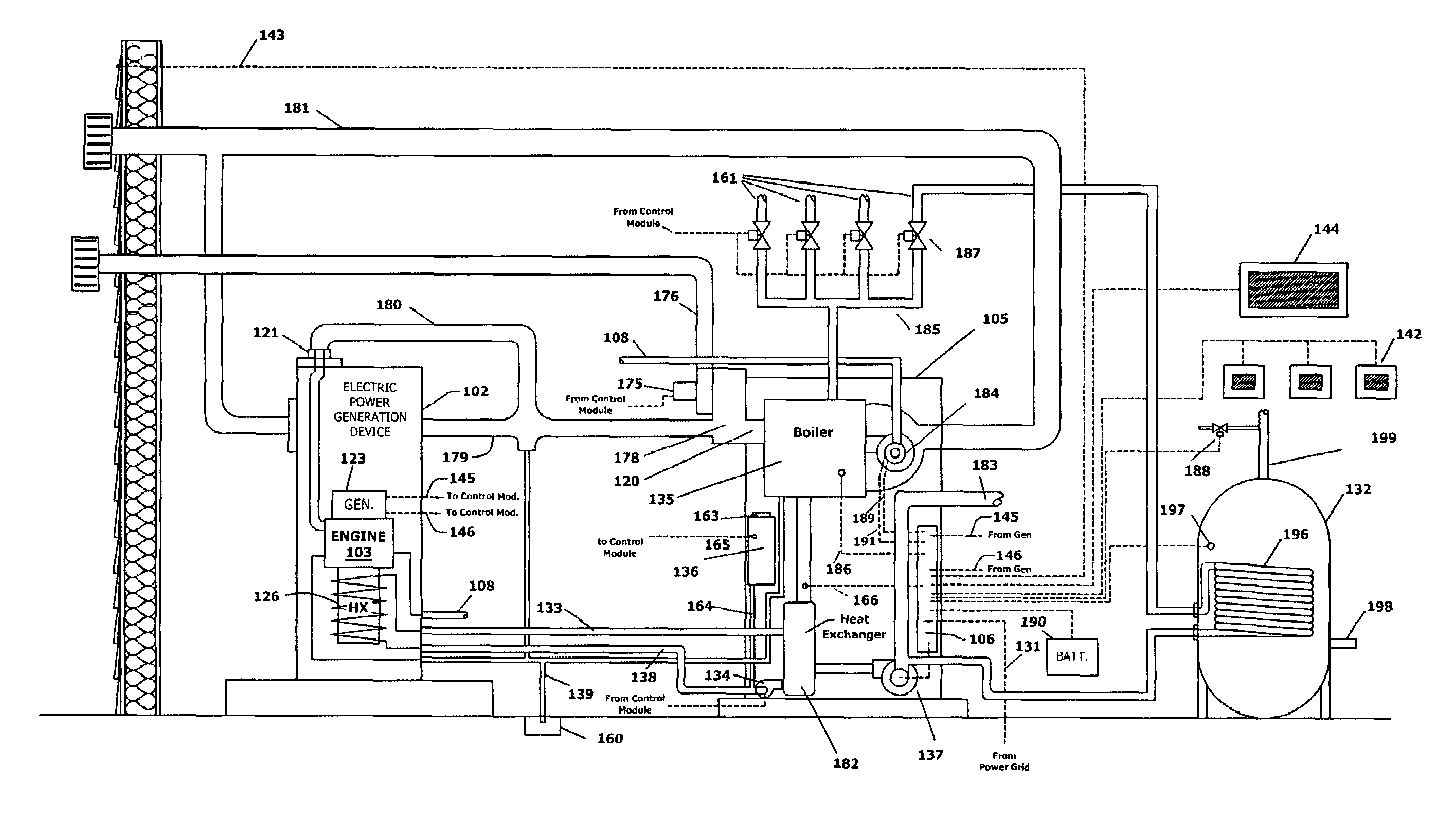

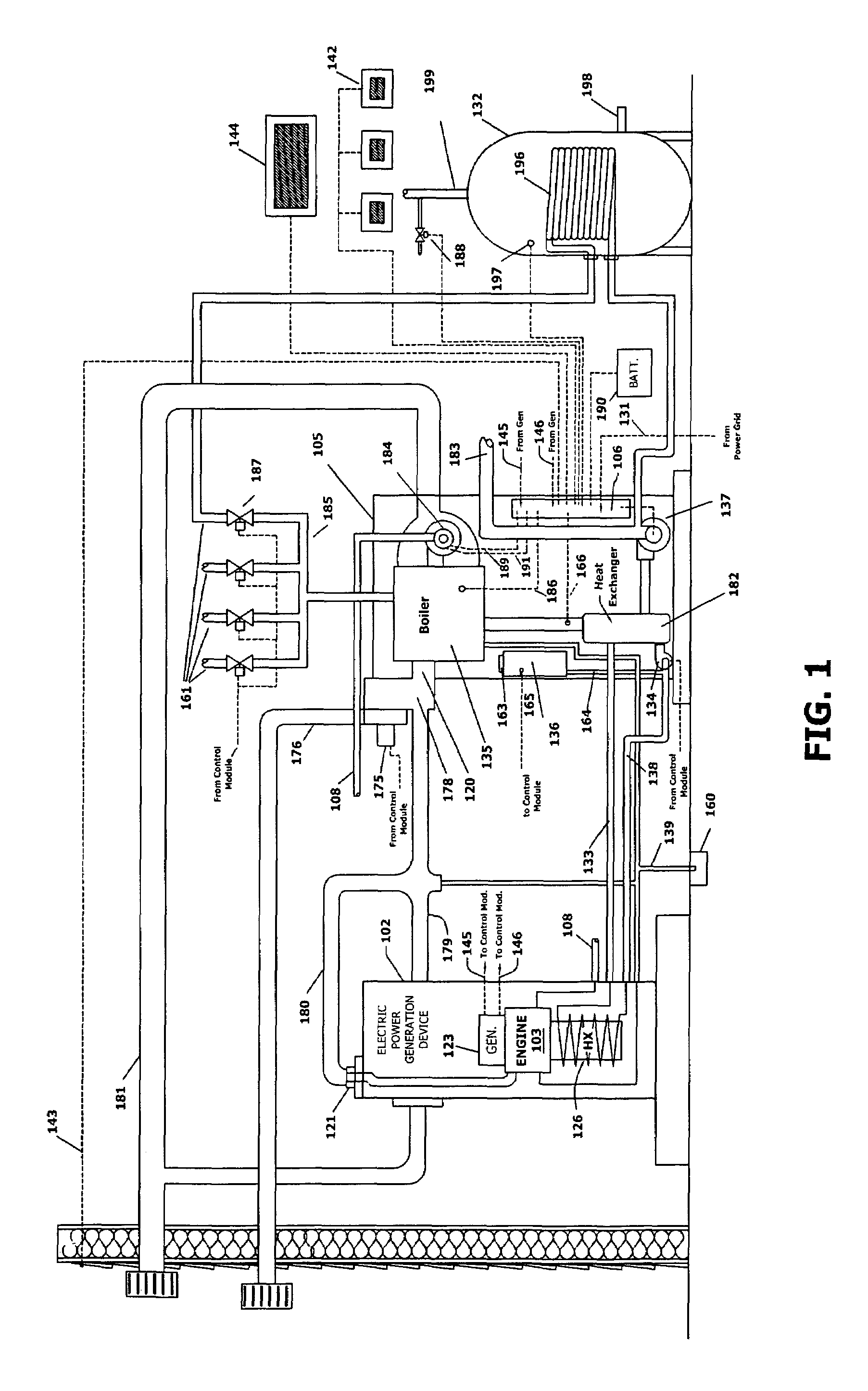

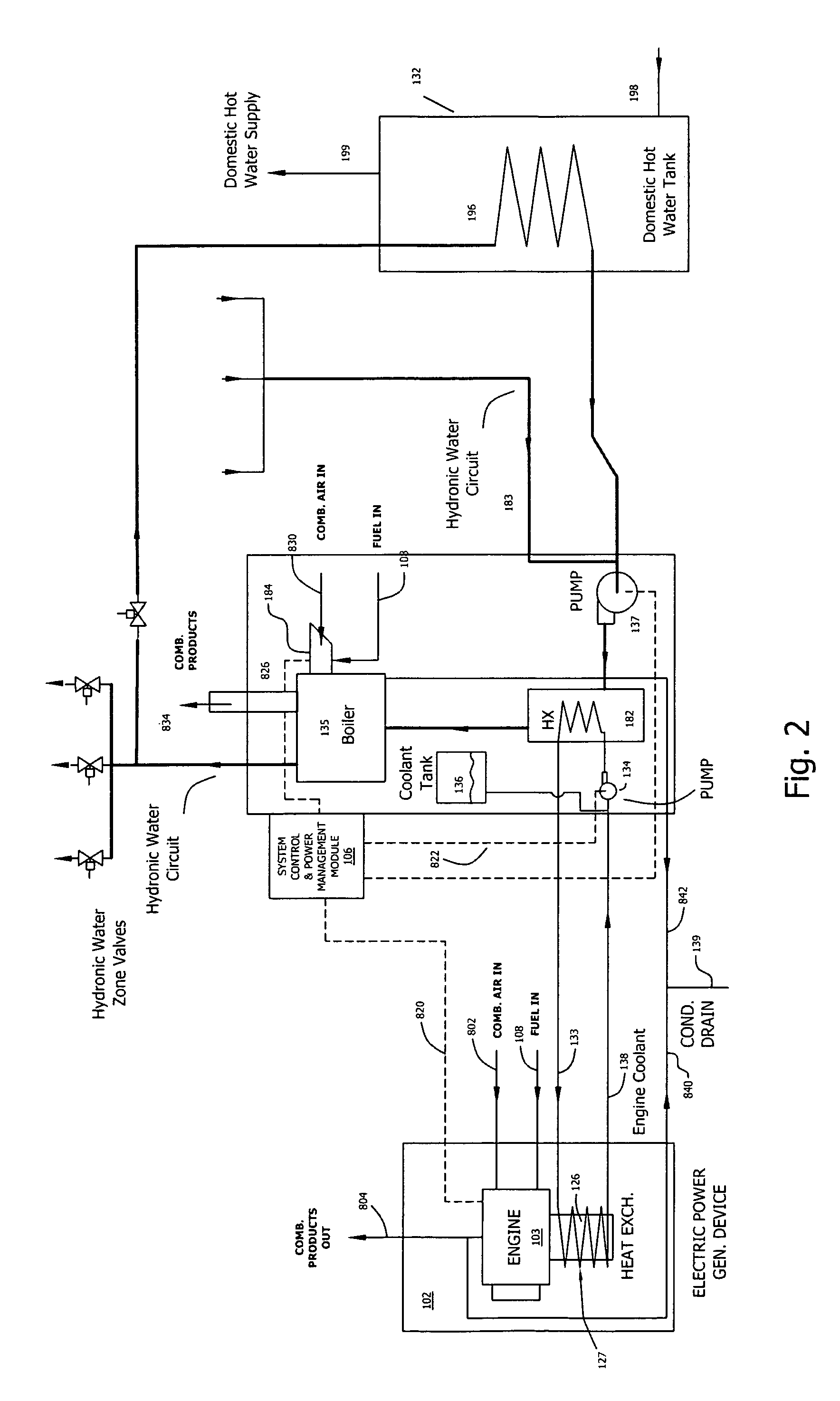

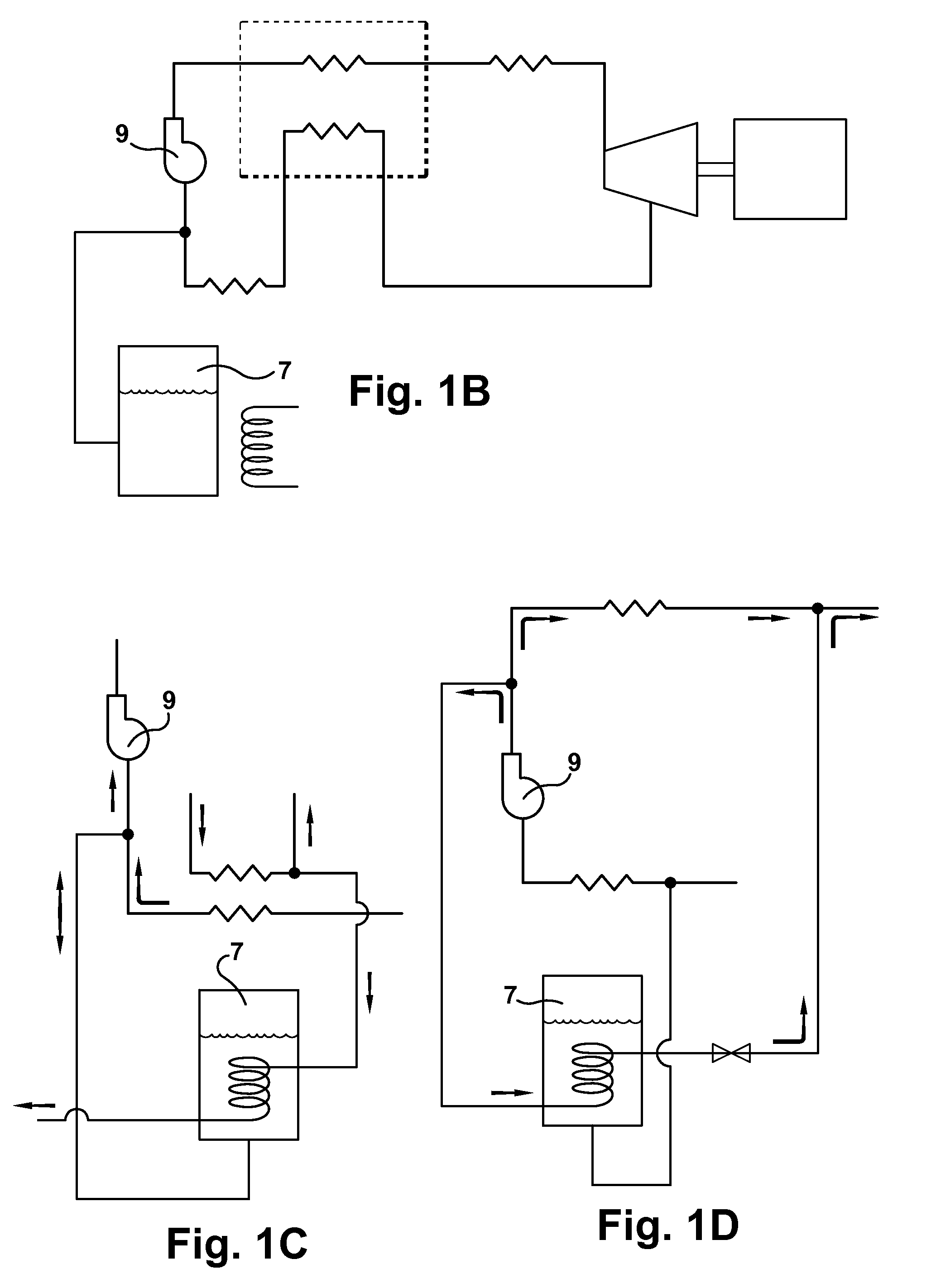

System and method for hydronic space heating with electrical power generation

ActiveUS20050161521A1Easy to useMaximizing run timeInternal combustion piston enginesWaste gas energyCogenerationEngineering

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

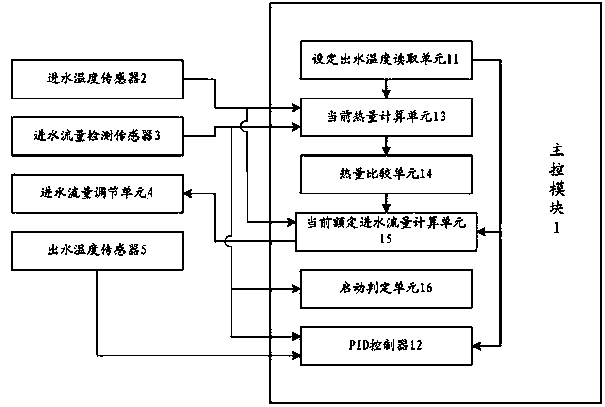

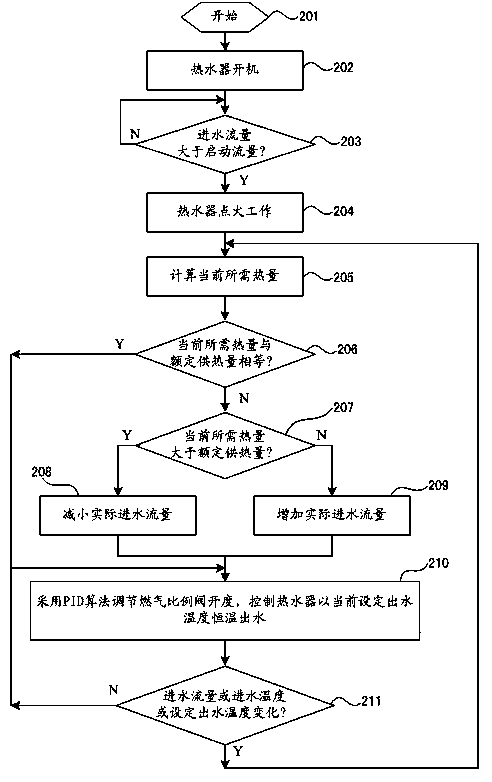

Control method and control device of constant-temperature gas water heater

ActiveCN104236109AImprove use comfort performanceRaise the water temperatureFluid heatersProportion integration differentiationEngineering

The invention discloses a control method and a control device of a constant-temperature gas water heater. The control method includes steps of detecting current water inlet temperature, current water inlet flow and current set water outlet temperature of the water heater and calculating current required heat; comparing the current required heat with rated heat supply of the heater; when the current required heat is higher than the rated heat supply, reducing practical water inlet flow of the heater, and when the current required heat is lower than the rated heat supply, increasing practical water inlet flow of the heater; adjusting opening of a gas proportion valve of the water heater by an PID (proportion integration differentiation) algorithm, and controlling the water heater so as to supply water at constant temperature by the current set water outlet temperature. By the control method and the control device of the constant-temperature gas water heater, the water heater is controlled, water outlet temperature reaches the set temperature, water outlet temperature can be quickly and stably adjusted, and service performance of the water heater is improved.

Owner:HAIER GRP CORP +1

System and method for hydronic space heating with electrical power generation

ActiveUS7284709B2Minimizing starting and stoppingMaximizing run timeInternal combustion piston enginesGas turbine plantsCogenerationElectric generator

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

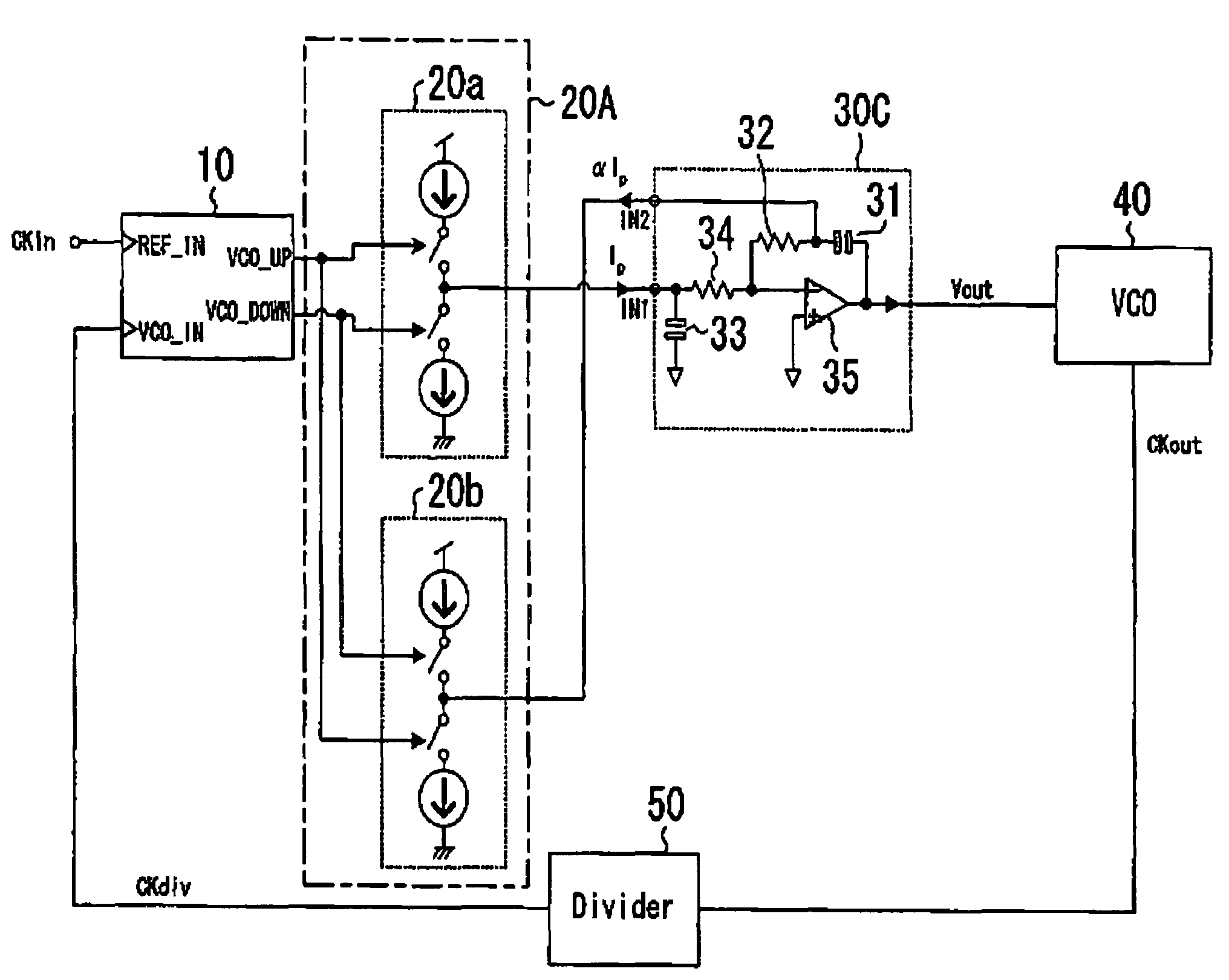

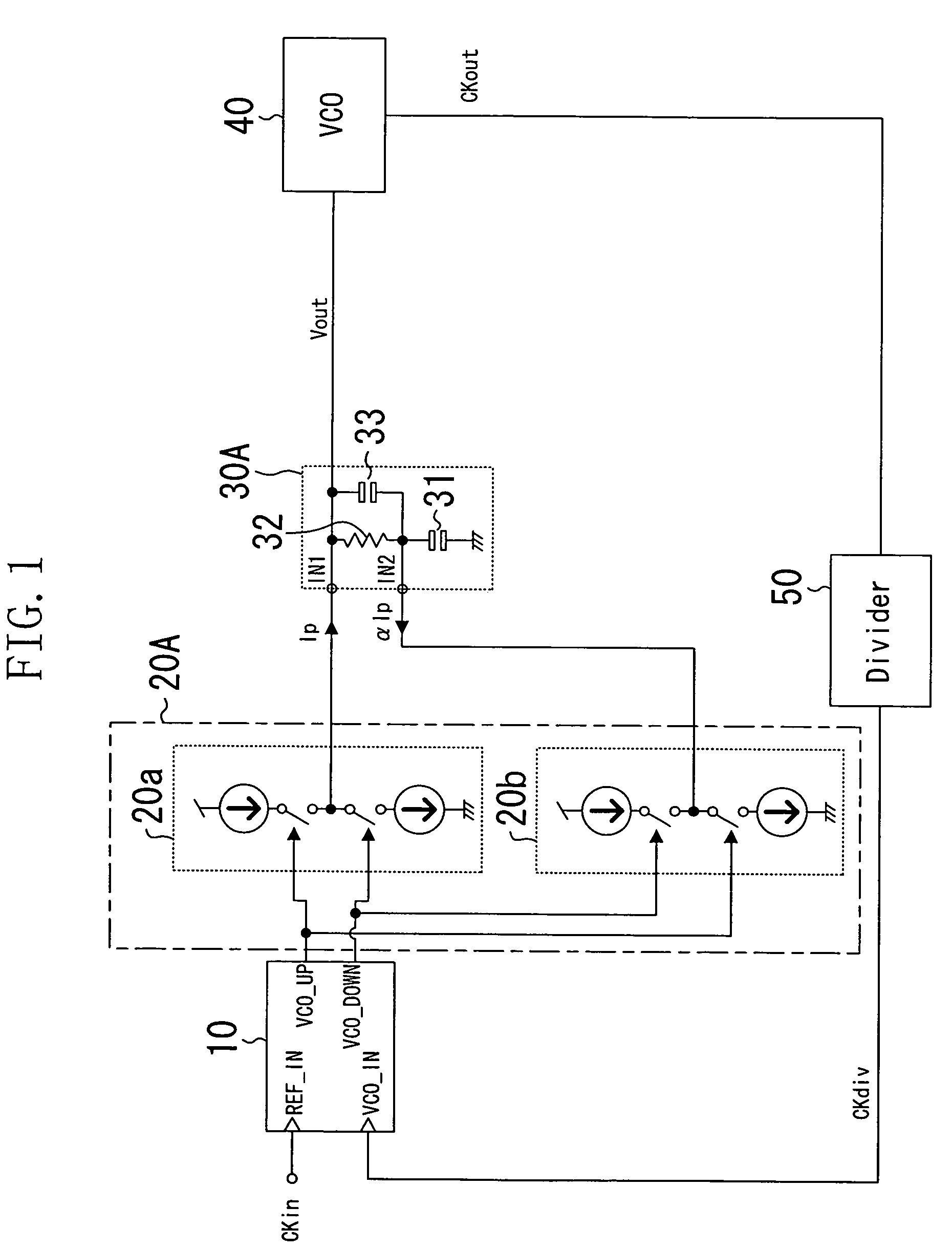

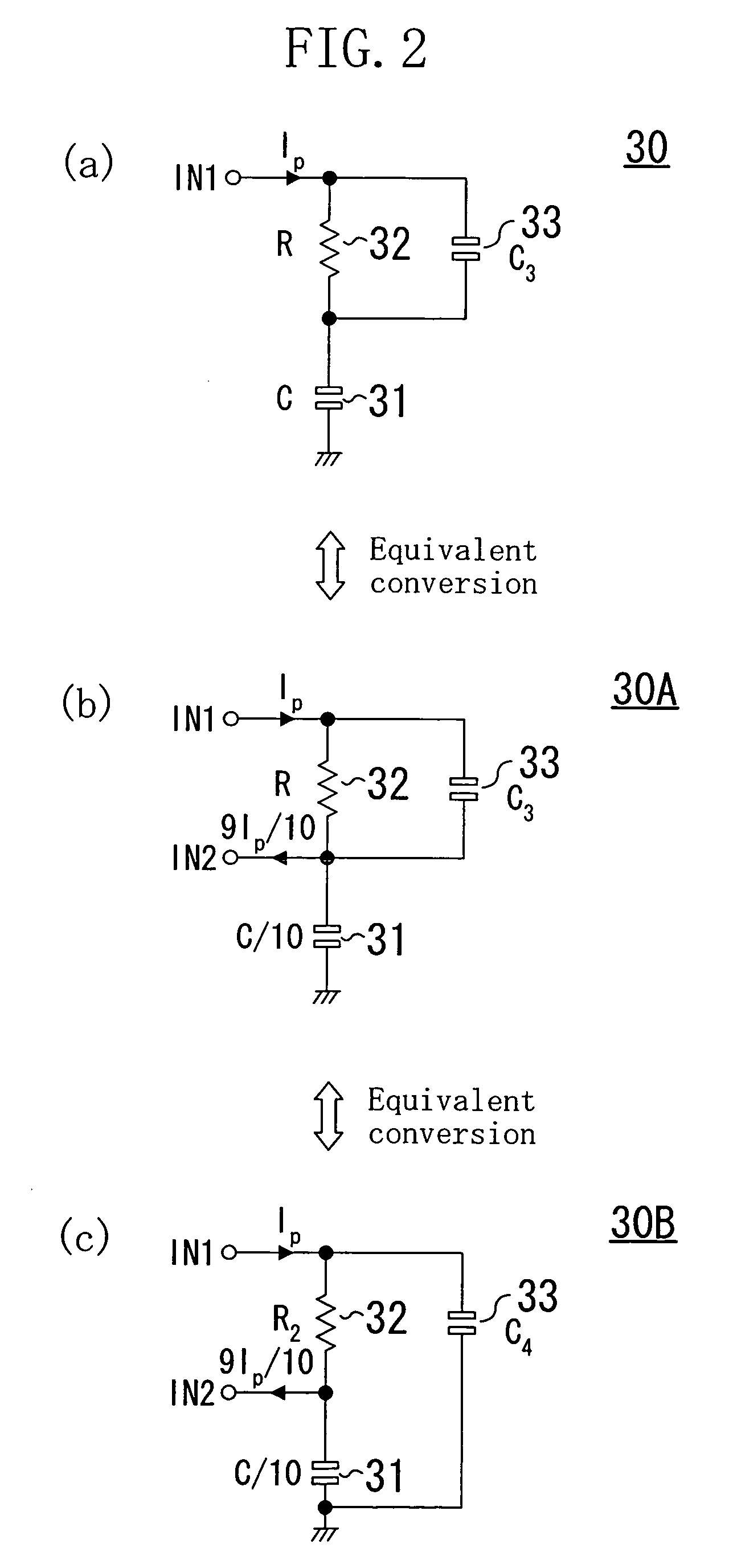

Low-pass filter, feedback system, and semiconductor integrated circuit

InactiveUS7078948B2Reduce circuit areaSmall sizeFluid heatersMultiple-port networksCircuit complexityCapacitance

In a low-pass filter which is preferably used as a loop filter in a PLL or DLL, filter characteristics which are the same as those of a conventional low-pass filter are realized without causing collateral problems, such as an increase in the circuit area, the circuit complexity, or the resistance value, which may be caused due to size reduction of a capacitive element in the conventional low-pass filter. Thus, in a loop filter including a capacitive element and a resistive element which are connected in series, the first input terminal is provided at the side including the resistive element, and the second input terminal is provided at a connection point of the capacitive element and the resistive element. The first input terminal is supplied with the first electric current. On the other hand, the second electric current, which is a part of the first electric current supplied to the first input terminal, is extracted from the second input terminal, so that the electric current flowing into the capacitive element is smaller than the electric current flowing through the resistive element.

Owner:PANASONIC CORP

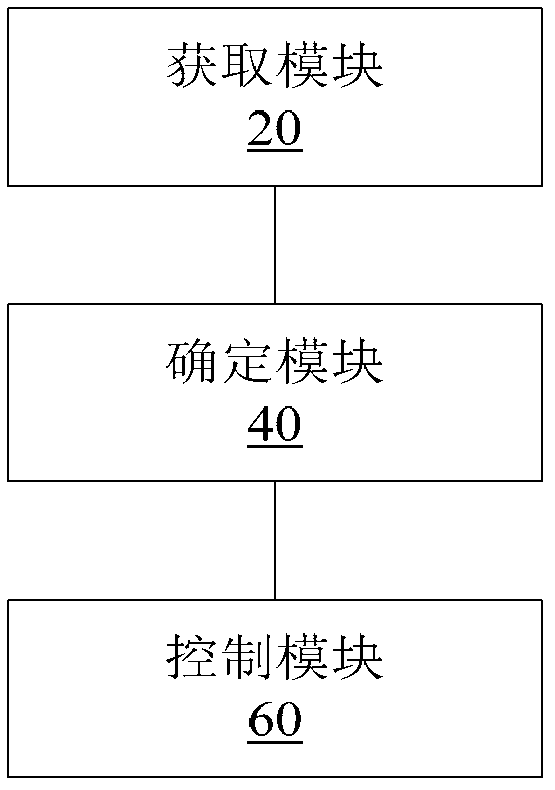

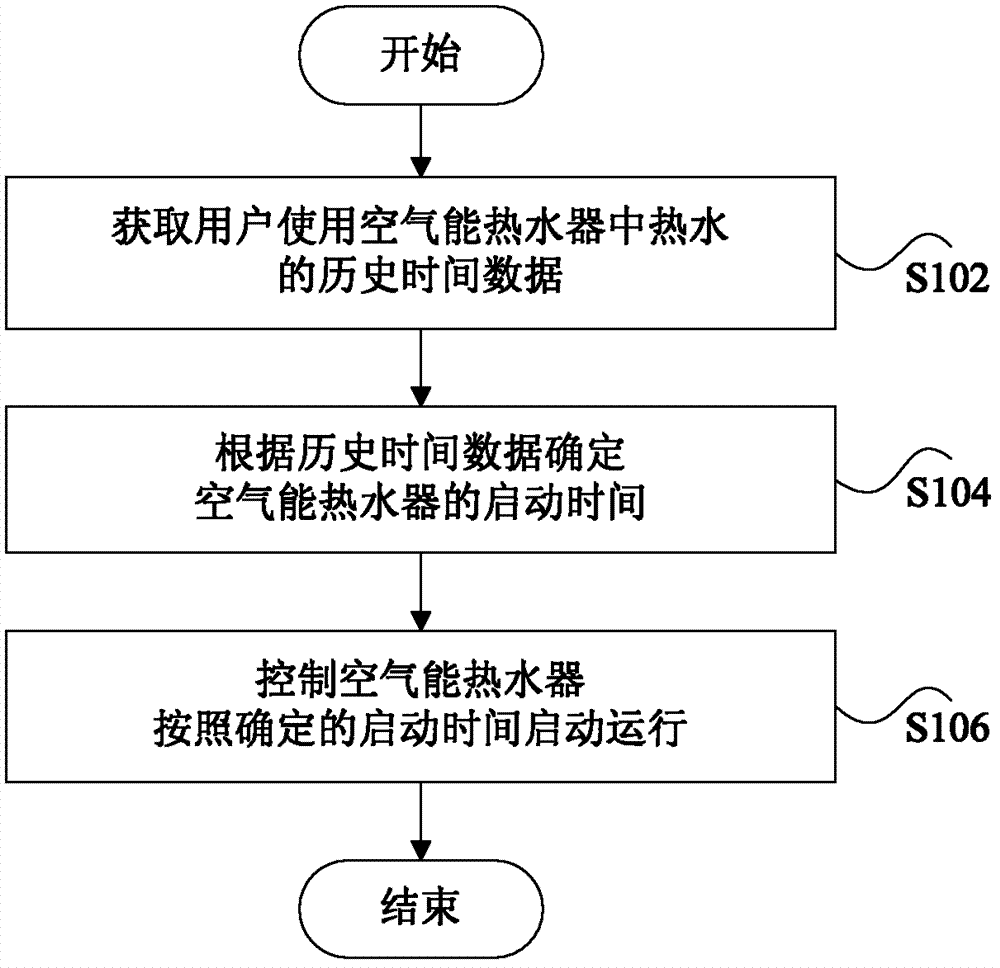

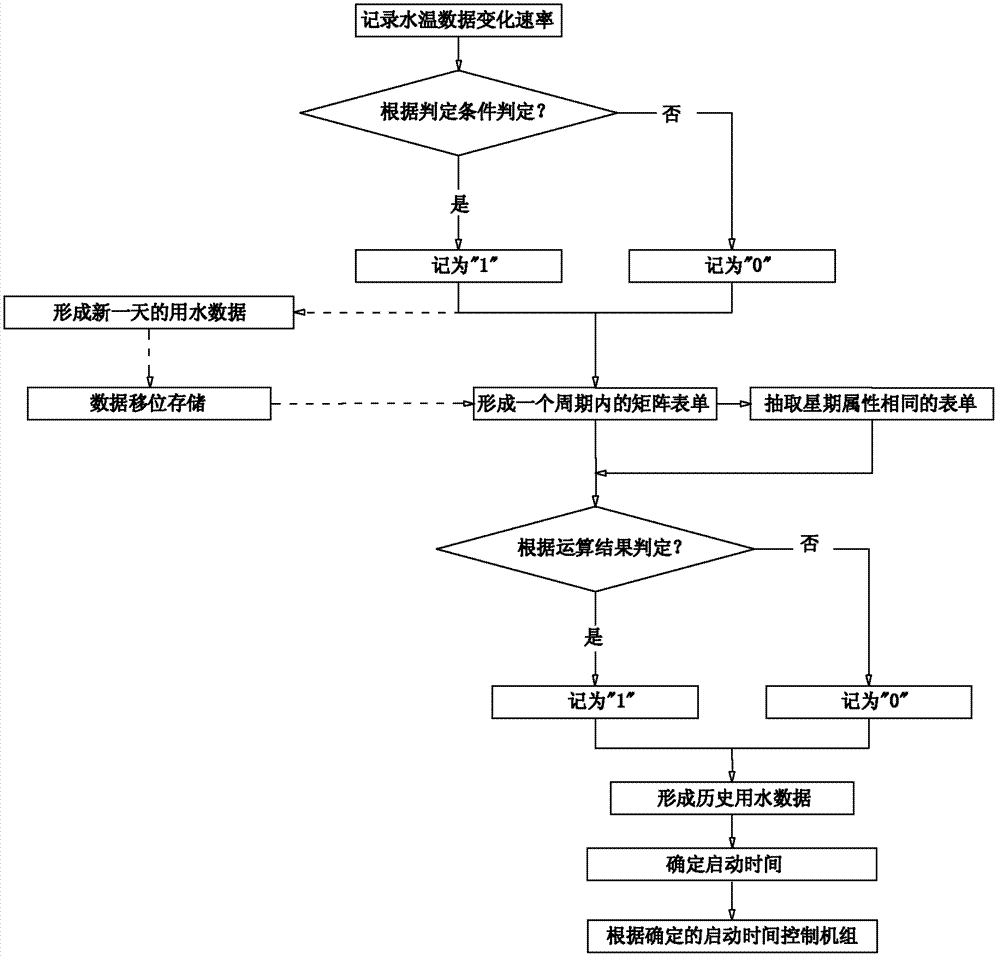

Air energy water heater and control method and device for same

ActiveCN103363670ASolve the problem of high energy consumptionRealize energy-saving controlFluid heatersStart timeEngineering

The invention provides an air energy water heater and a control method and device for the same. The control method comprises obtaining historical time data of utilization of hot water in the air energy water heater by users; determining starting time of the air energy water heater according to the historical time data; controlling the air energy water heater to be started to operate according to the determined starting time. By means of the air energy water heater and the control method and device for the same, the air energy water heater can be controlled to be started to operate according to user own water consumption habits, so that hot water can be provided as user required, frequent heating is not required, and energy-saving control is effectively achieved.

Owner:GREE ELECTRIC APPLIANCES INC

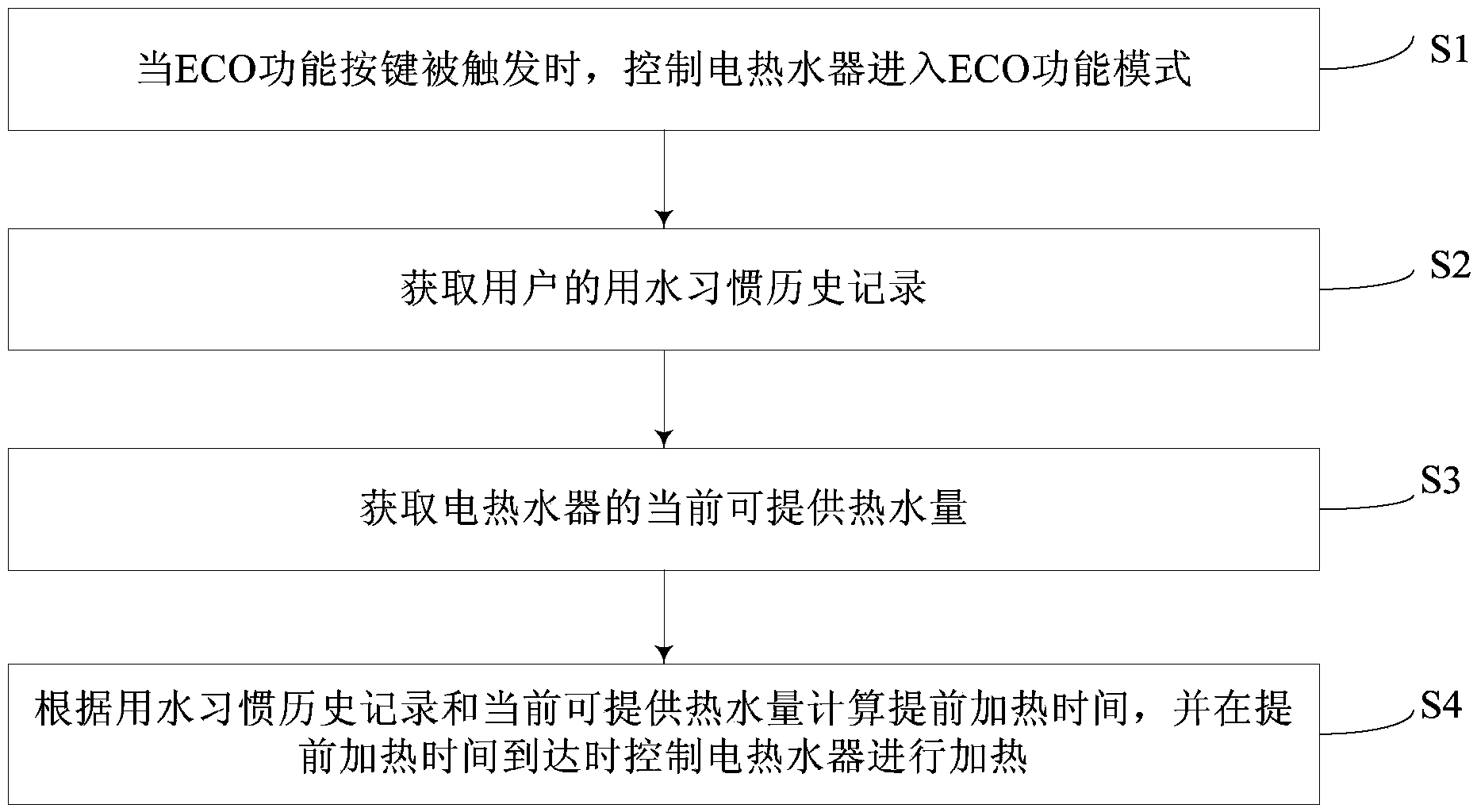

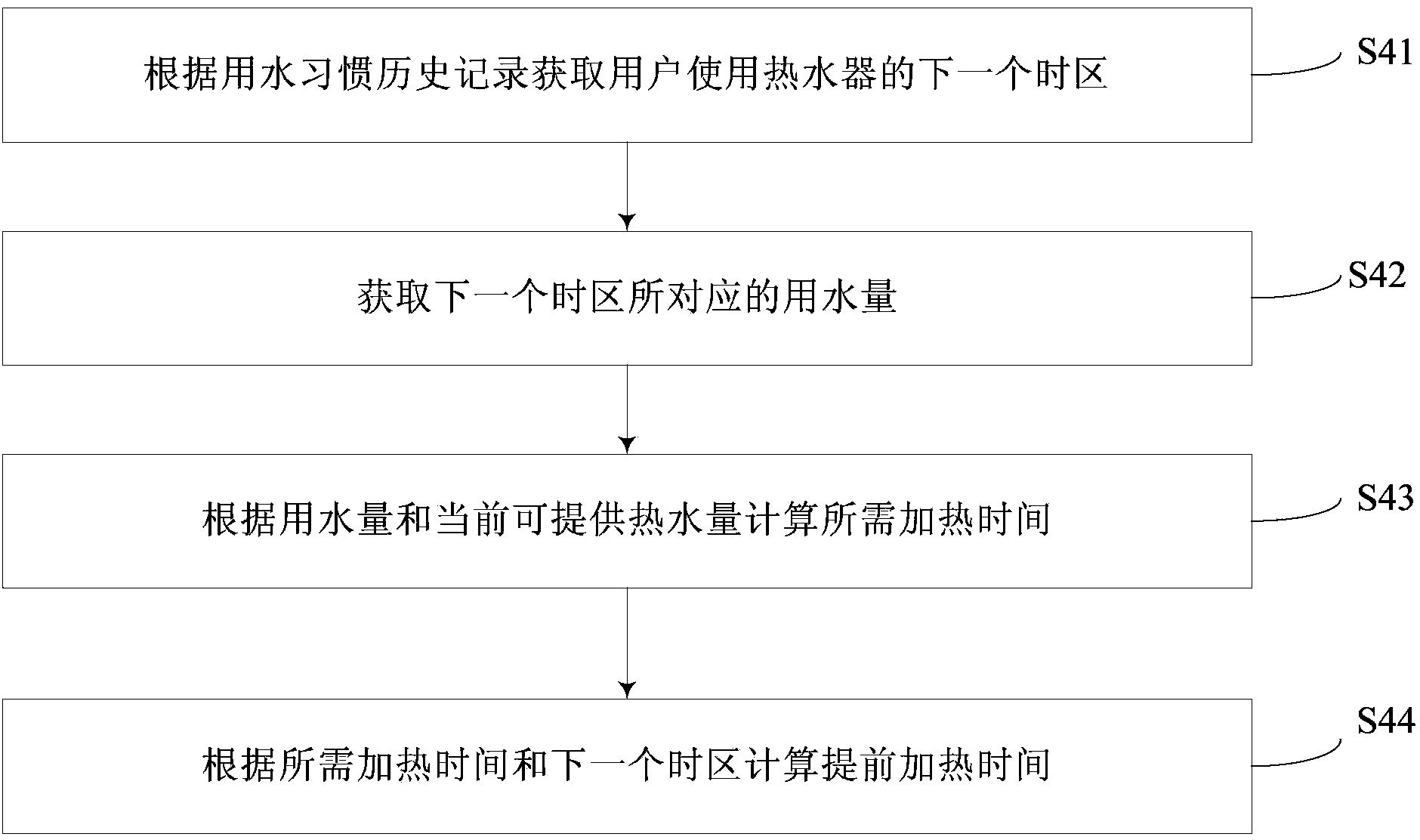

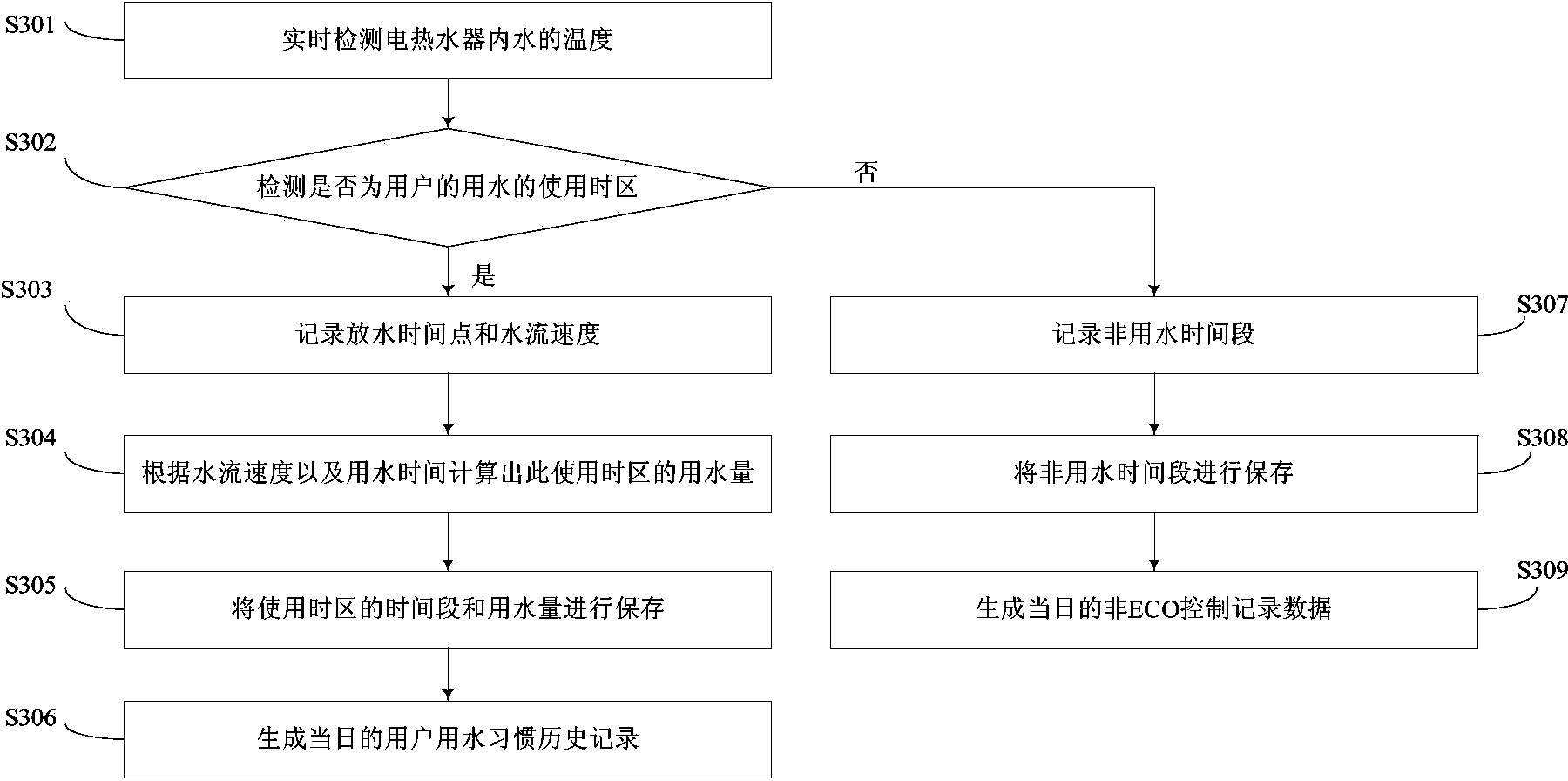

Electric water heater with ECO (ecology, conservation and optimization) function mode and controlling method thereof

The invention provides an electric water heater with an ECO (ecology, conservation and optimization) function mode and a controlling method thereof. The electric water heater comprises an operation interface having an ECO function key. The controlling method includes the steps of controlling the electric water heater to enter the ECO function mode after the ECO function key is triggered; acquiring history of water habits of a user; acquiring currently provided hot water quantity of the electric water heater; calculating pre-heating time according to the history of water habits and the currently provided hot water quantity, and subjecting the electric water heater to heating when the pre-heating time is out. Once the ECO function key is triggered, the energy-saving mode runs. The electric water heater is simple and convenient and capable of heating in advance, meeting bath requirements of the user in using water and reducing energy waste caused by excess heating. The electric water heater is controlled to be free of heating when the user does not use water, thus energy is greatly saved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

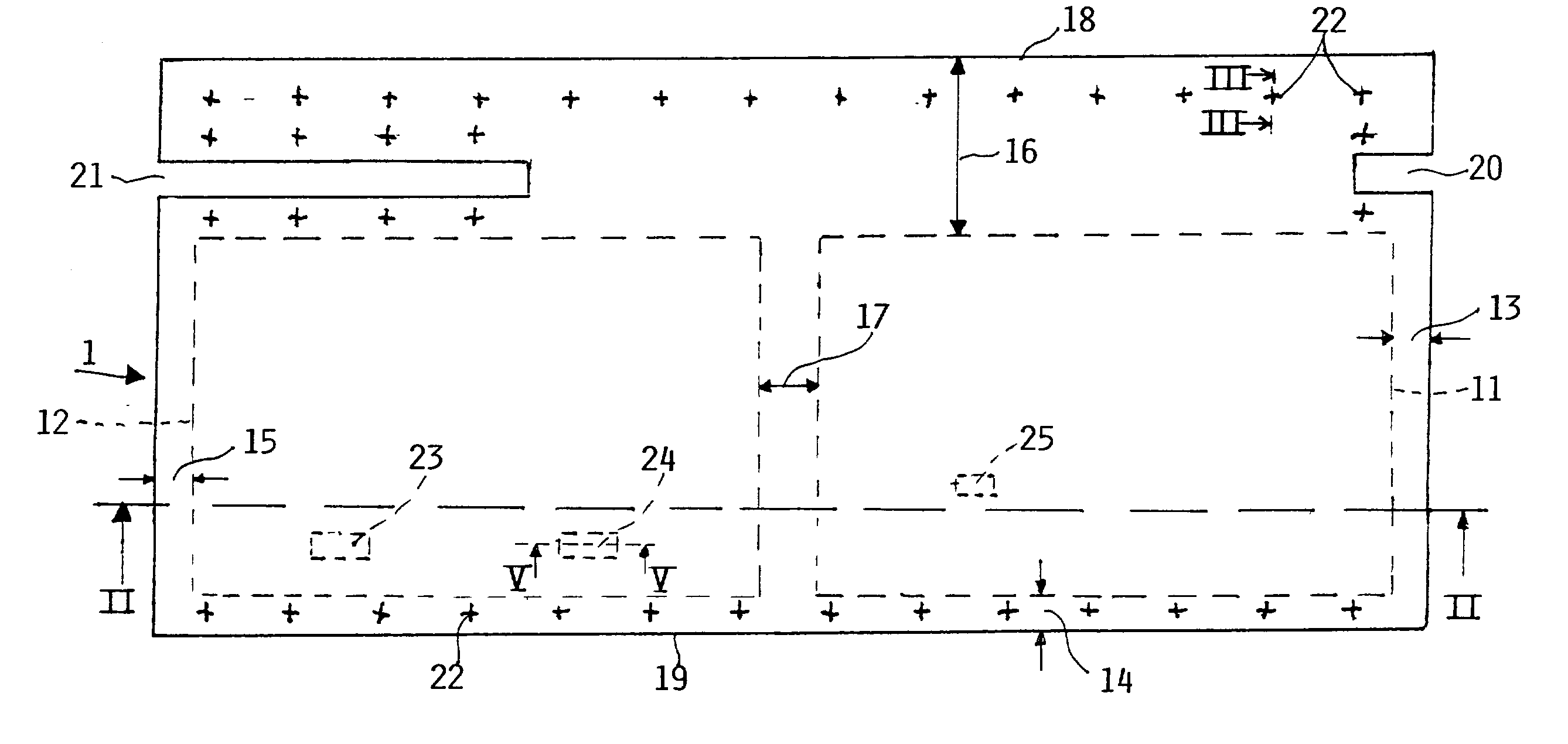

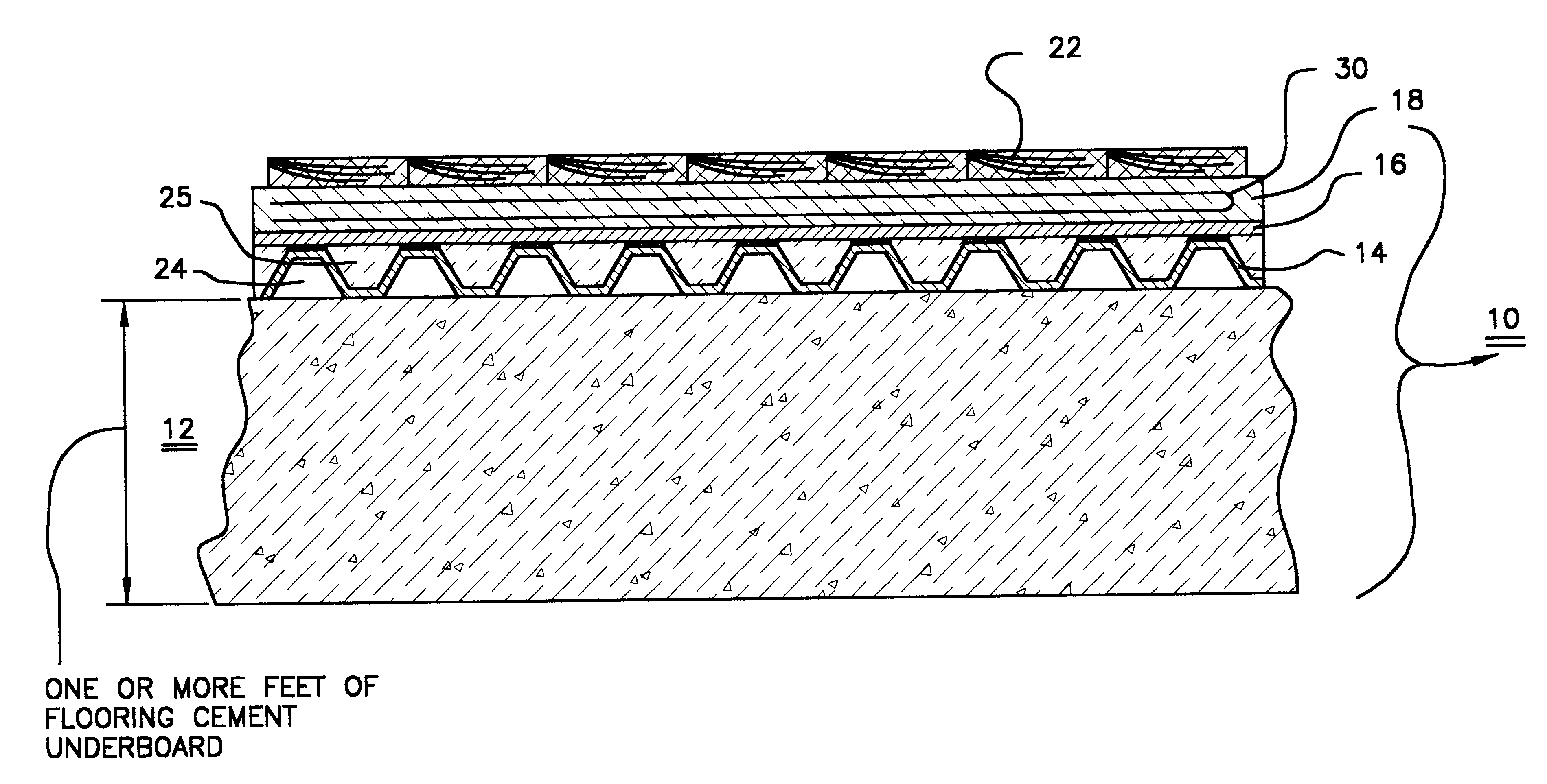

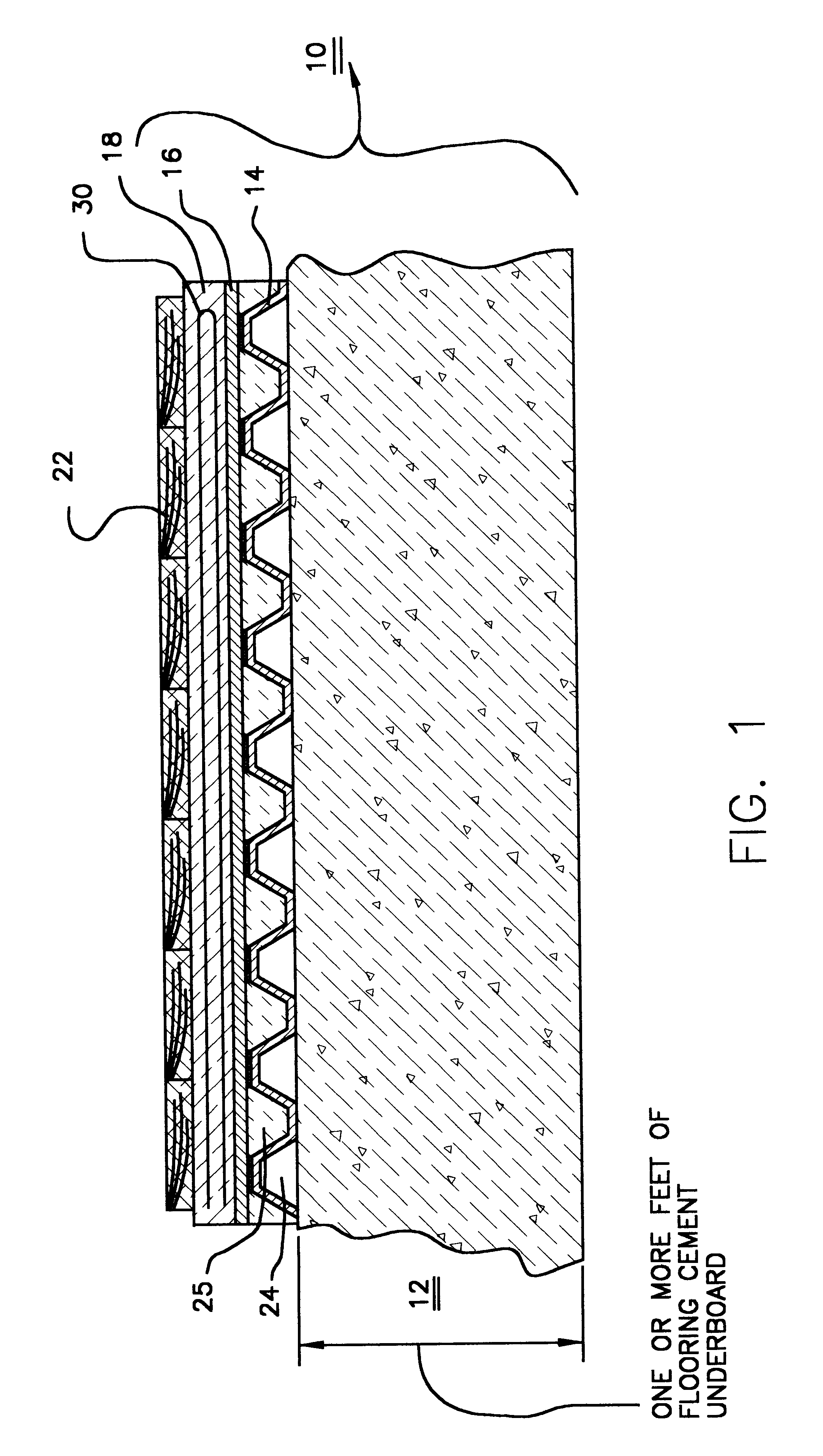

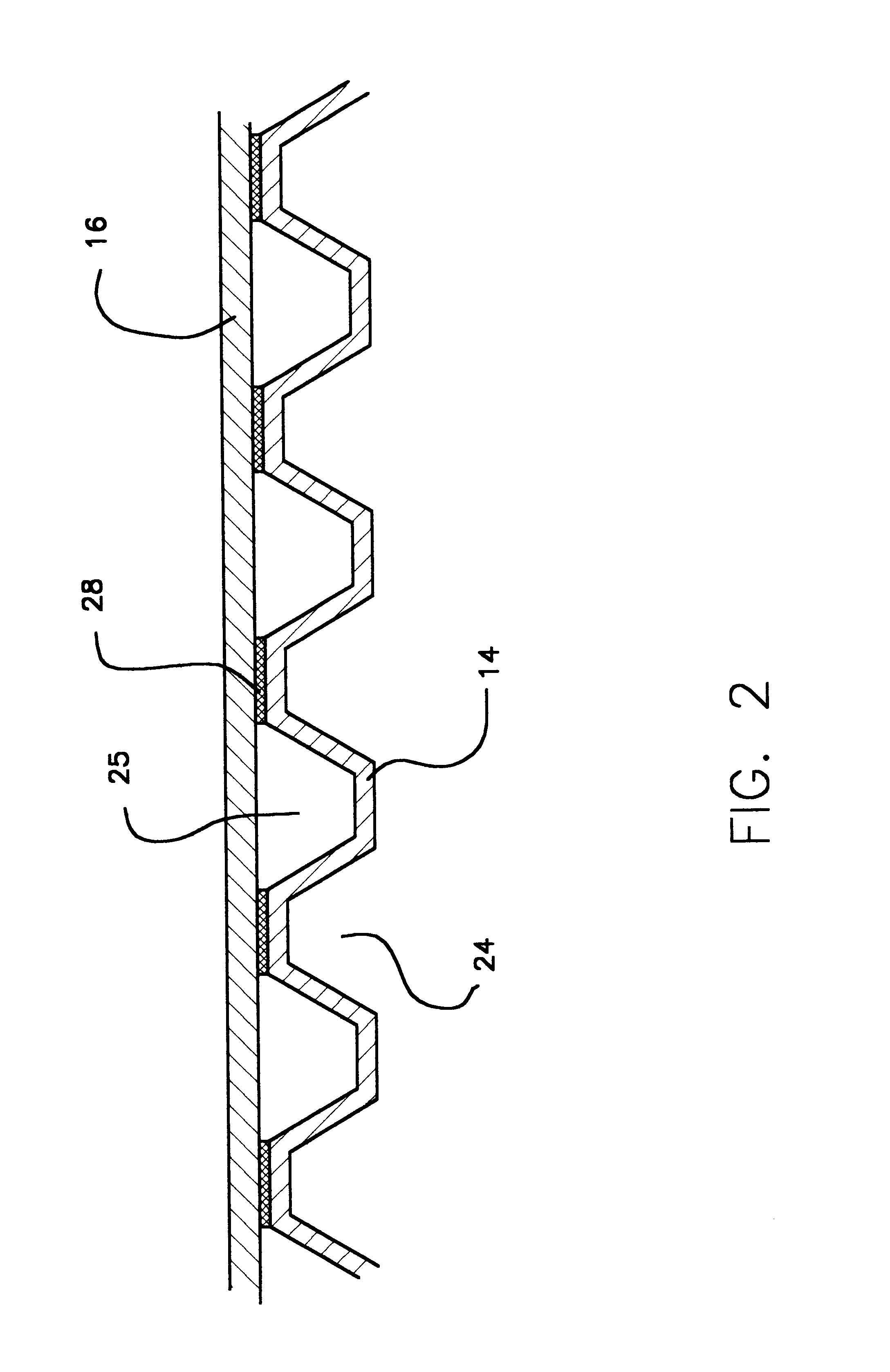

Radiant floor heating system with reflective layer and honeycomb panel

InactiveUS6188839B1Prevent heat lossPrevents dispersal (and hence waste)Fluid heatersLayered productsThermal breakHoneycomb

A radiant floor heating system and method of installation is provided, the system of the present invention being disposed within a solidified cement or under board. A panel member having a laminated reflective material which serves as a thermal break is placed upon the hardened cement or under board. The panel member may be comprised of any substance to which the reflective material may be secured such as a honeycombed plastic panel to which the reflective material layer is laminated. A heating element is disposed on the reflective material. Thereafter, both the heating element and the reflective layer are coated with a layer of thin set or cement. The heating element may include a heated wire element which is unwound off a roll, or the heating element may be meshed within a web of material which is cut to match the dimensions of the floor and then disposed on top of the reflective layer. After the thin set or cement dries with the heating element embedded within, marble or other types of tiles may be laid as flooring.

Owner:PENNELLA RONALD J

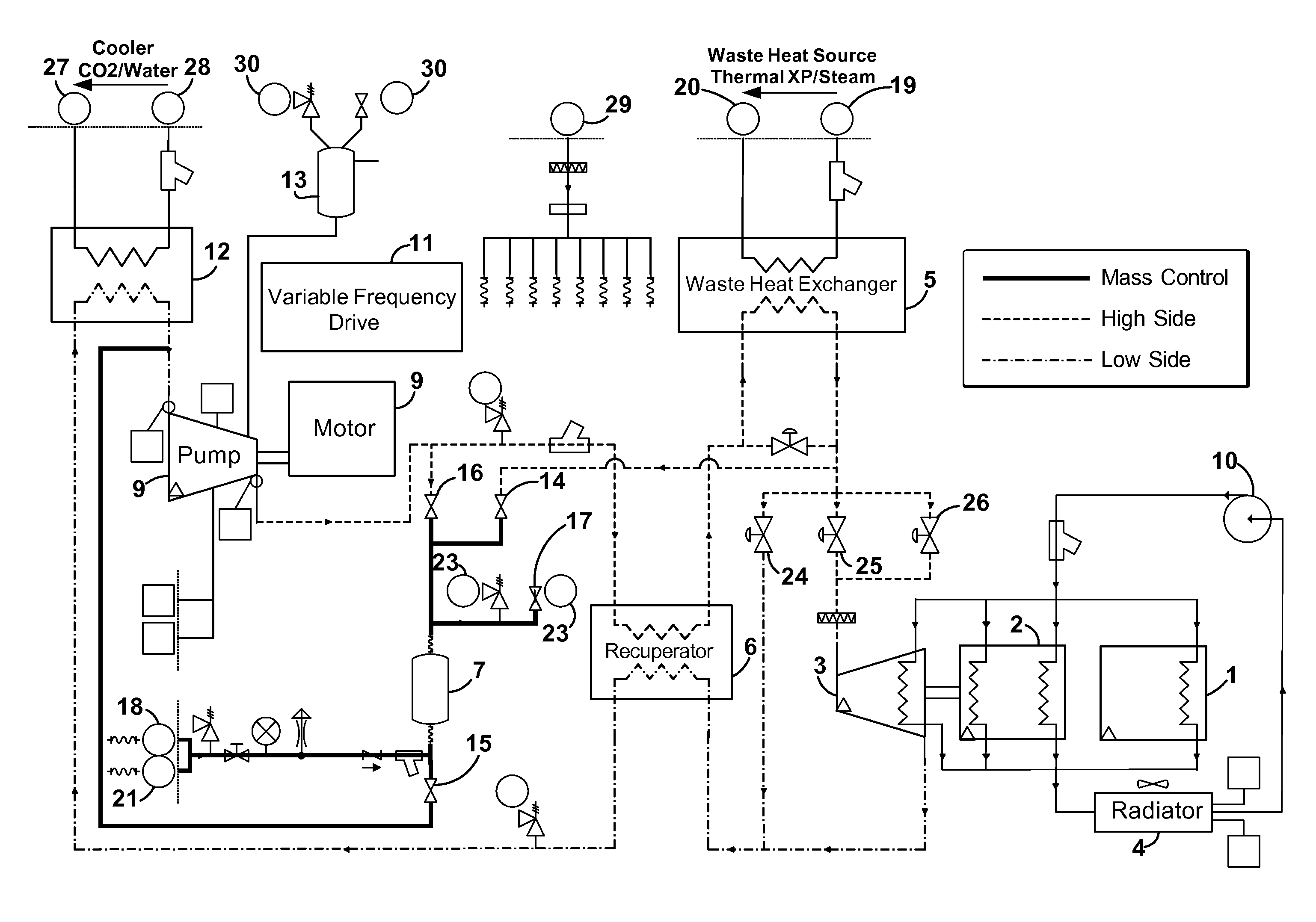

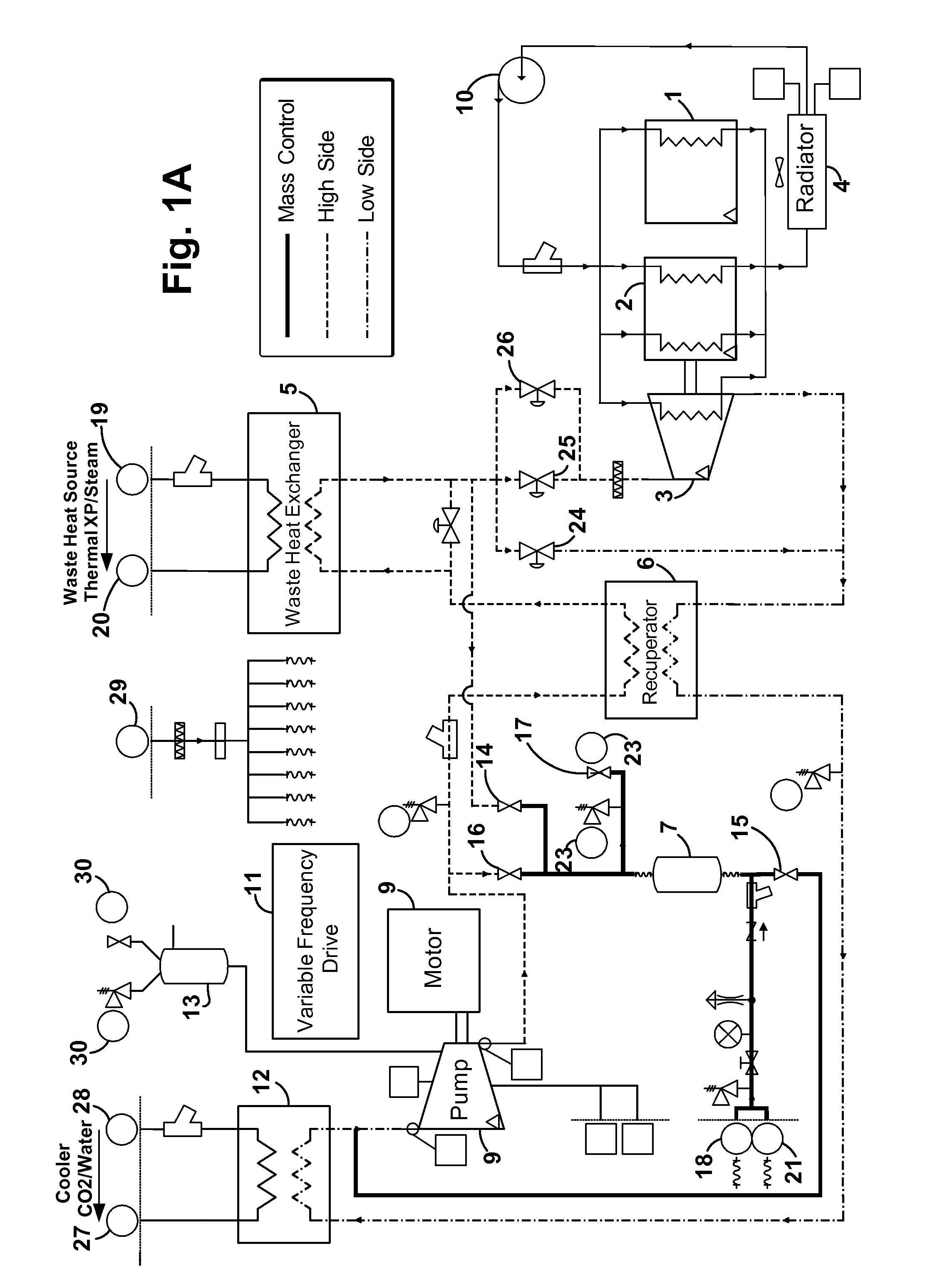

Heat engine and heat to electricity systems and methods

ActiveUS20100156112A1Efficiently and effectively produce powerFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:REXORCE THERMIONICS INC +1

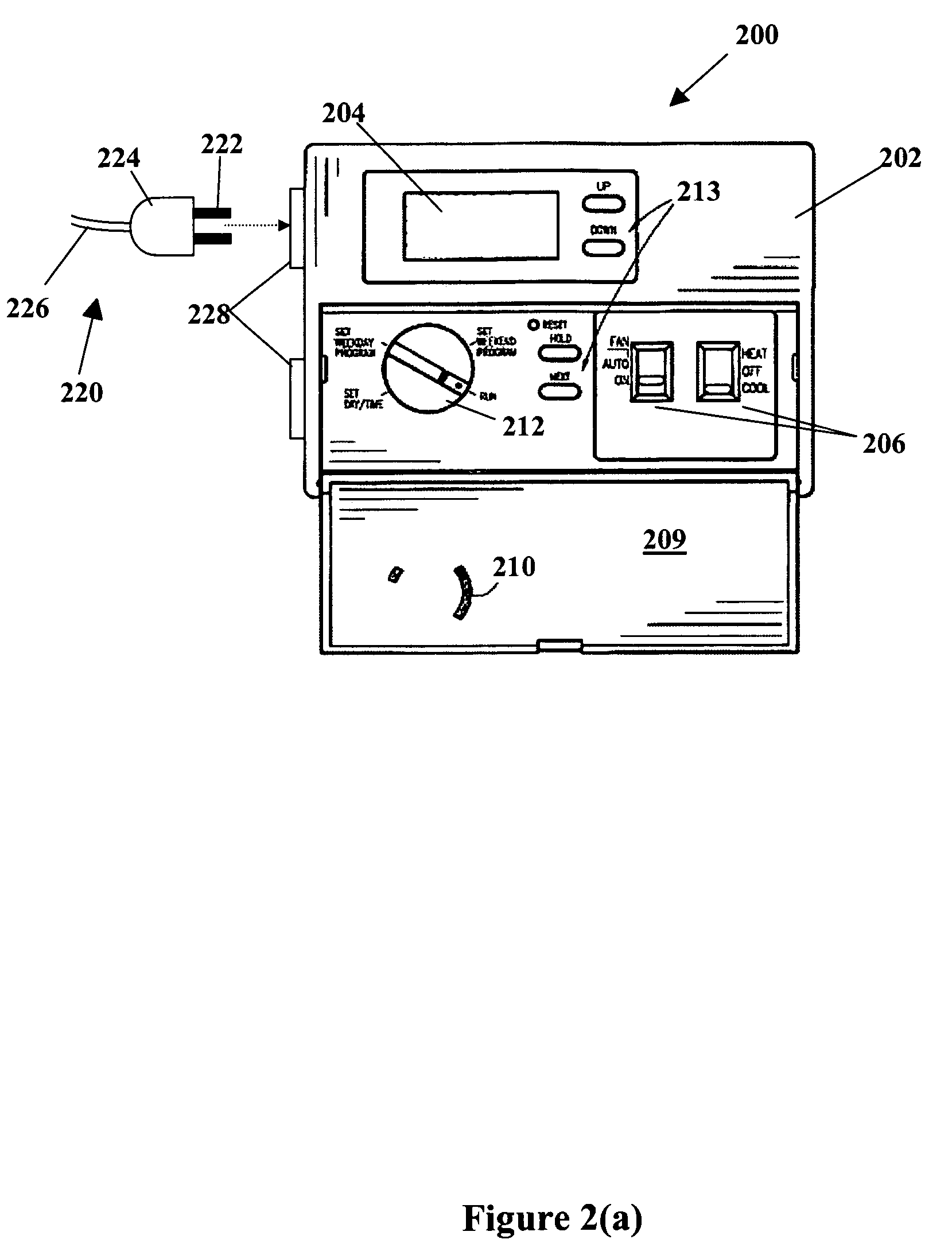

Removable programmable thermostat for air conditioning and heating systems

ActiveUS7175098B2Temperature control without auxillary powerMechanical apparatusTemperature controlPower controller

Owner:JOHNSON CONTROLS INC

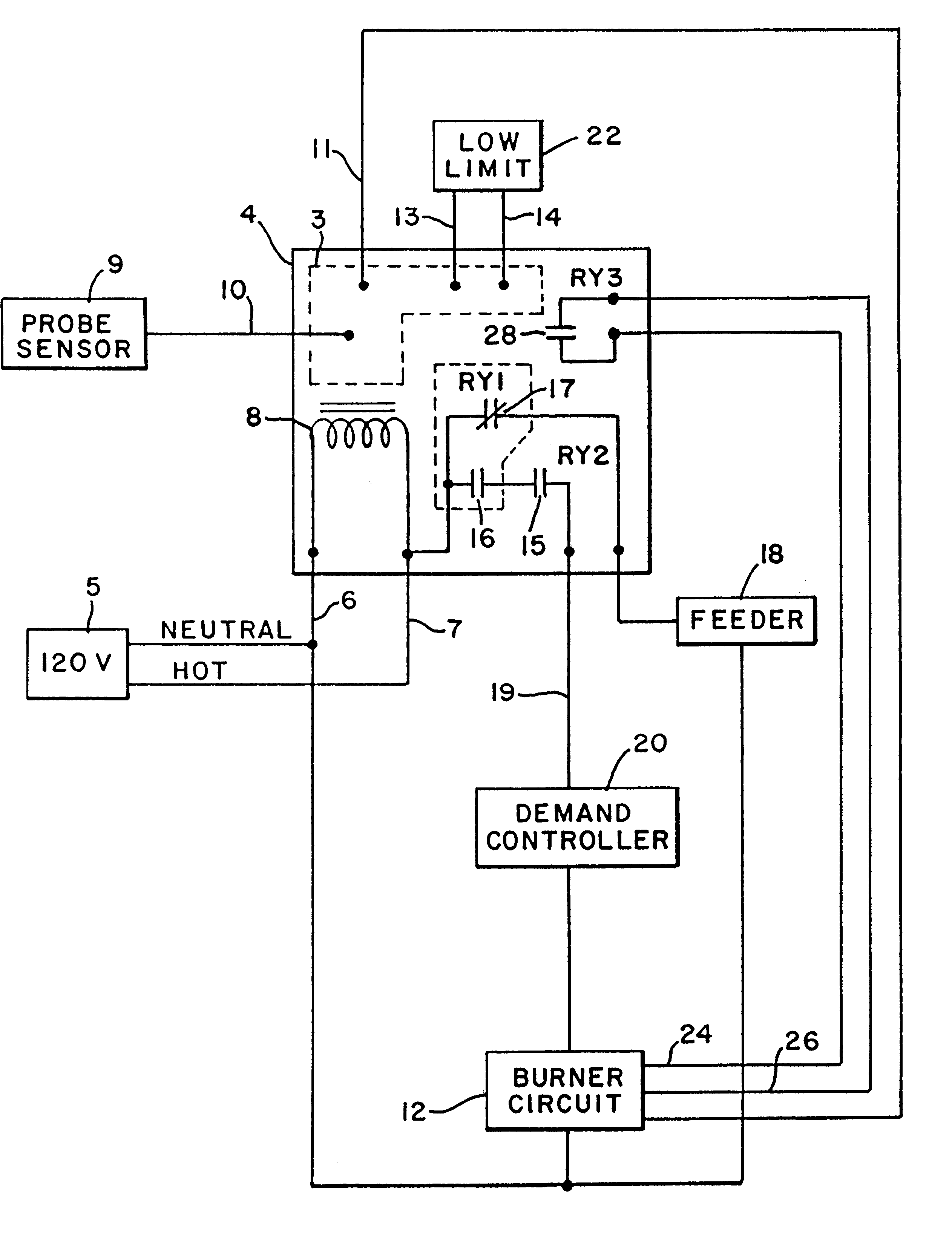

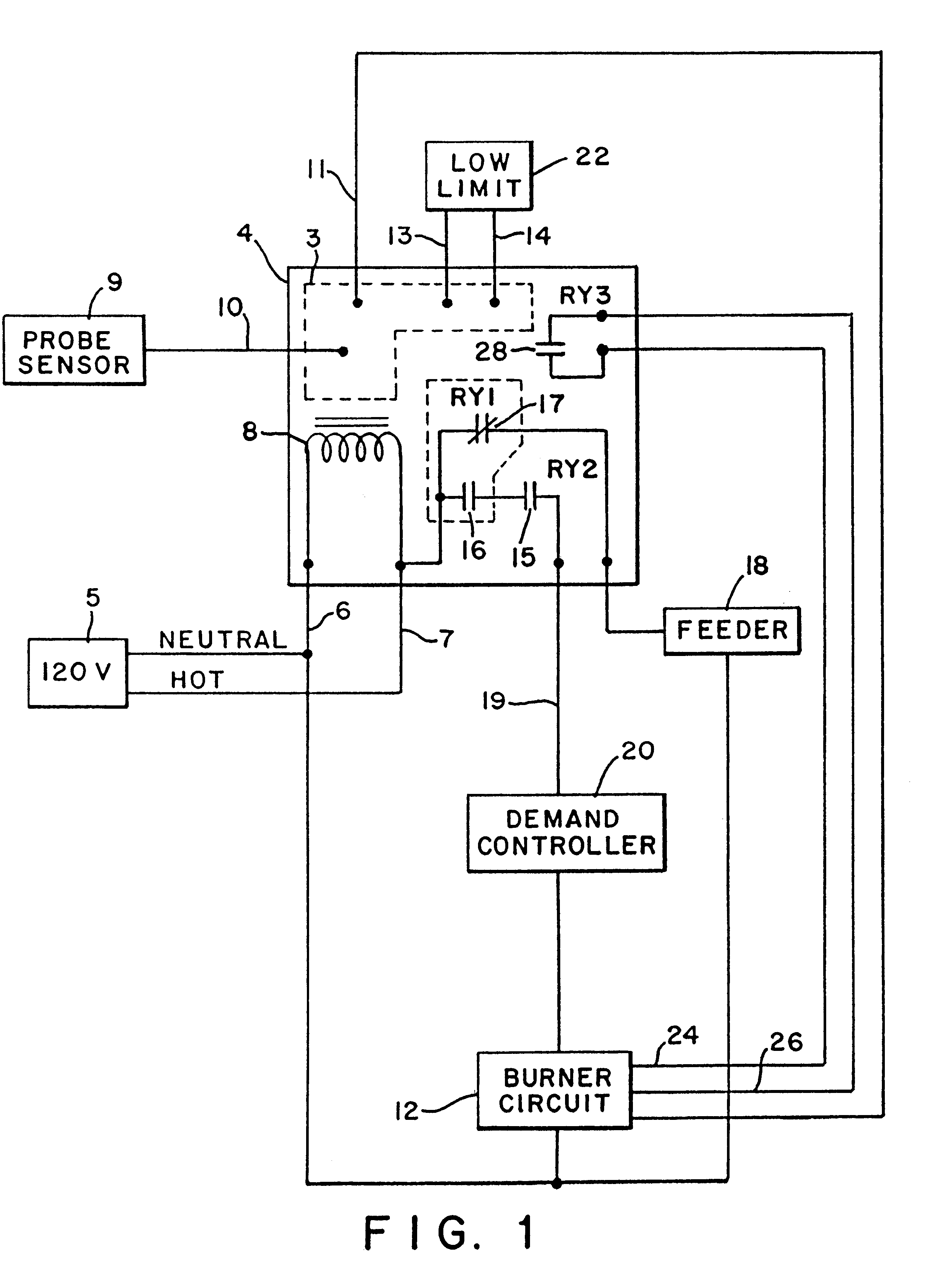

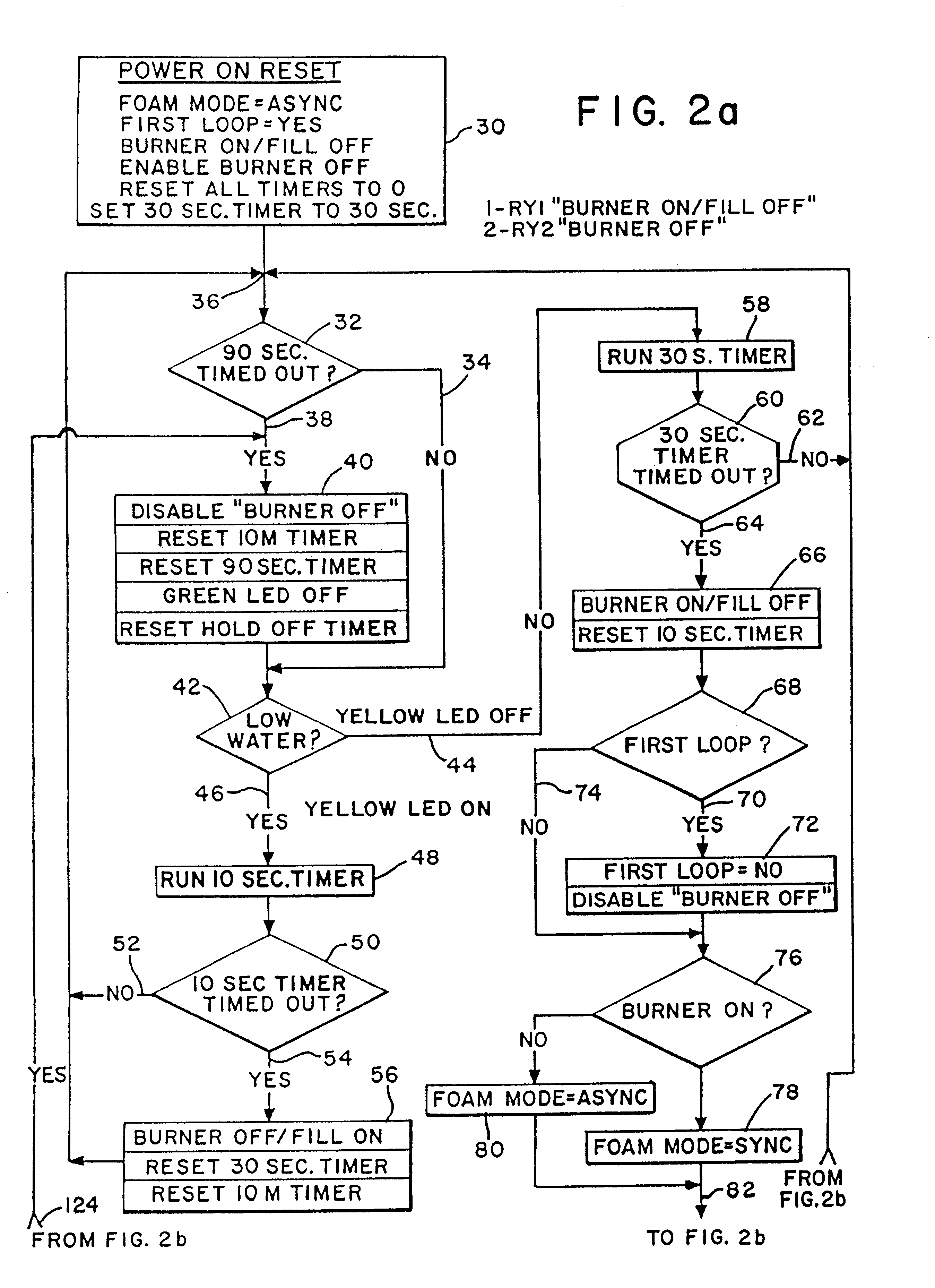

Cycle control system for boiler and associated burner

A cycle control system for use with a boiler having a fluid therein and a method of monitoring a boiler to determine the presence of an adequate level of fluid therein. The cycle control system includes a timing circuit producing a burner control signal having alternating on and off states corresponding to on and off period timers to allow foam to settle so that a probe can accurately check the fluid level in the boiler. A burner monitor circuit monitors when a demand controller turns the burner on and off responsive to demand. The on-period timer is reset whenever the burner monitor circuit indicates the demand control circuit has turned off the burner for a length of time sufficient for the probe to accurately check the fluid level.

Owner:COWLES OPERATING CO

Popular searches

Space heating and ventilation safety systems Temperature control using plurality of sensors Computer control Space heating and ventilation control systems Static/dynamic balance measurement Space heating and ventilation details Air conditioning systems Adaptive control Ventilation systems Machines using refrigerant evaporation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com