Patents

Literature

2657 results about "Enthalpy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enthalpy /ˈɛnθəlpi/ , a property of a thermodynamic system, is equal to the system's internal energy plus the product of its pressure and volume. In a system enclosed so as to prevent mass transfer, for processes at constant pressure, the heat absorbed or released equals the change in enthalpy.

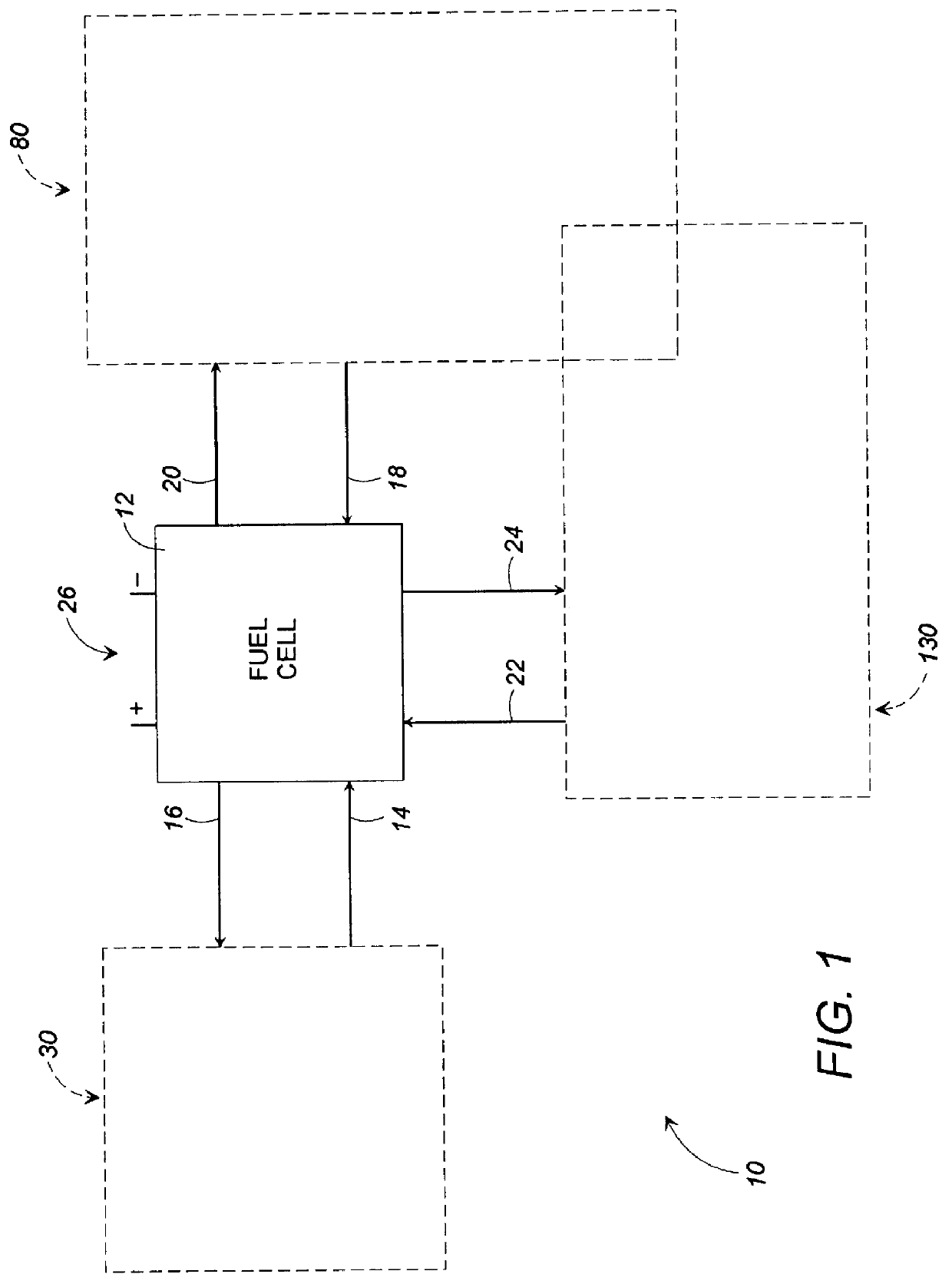

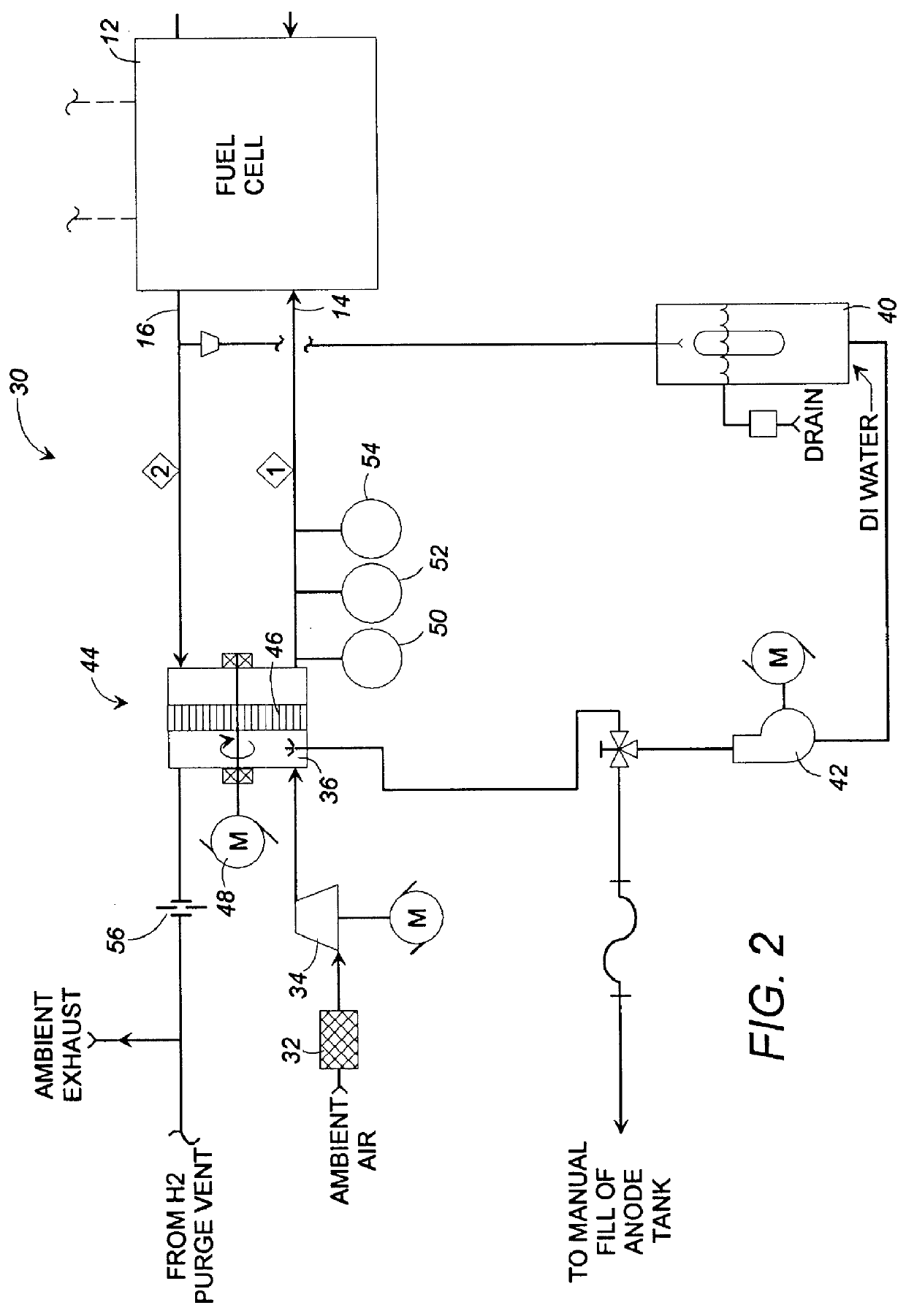

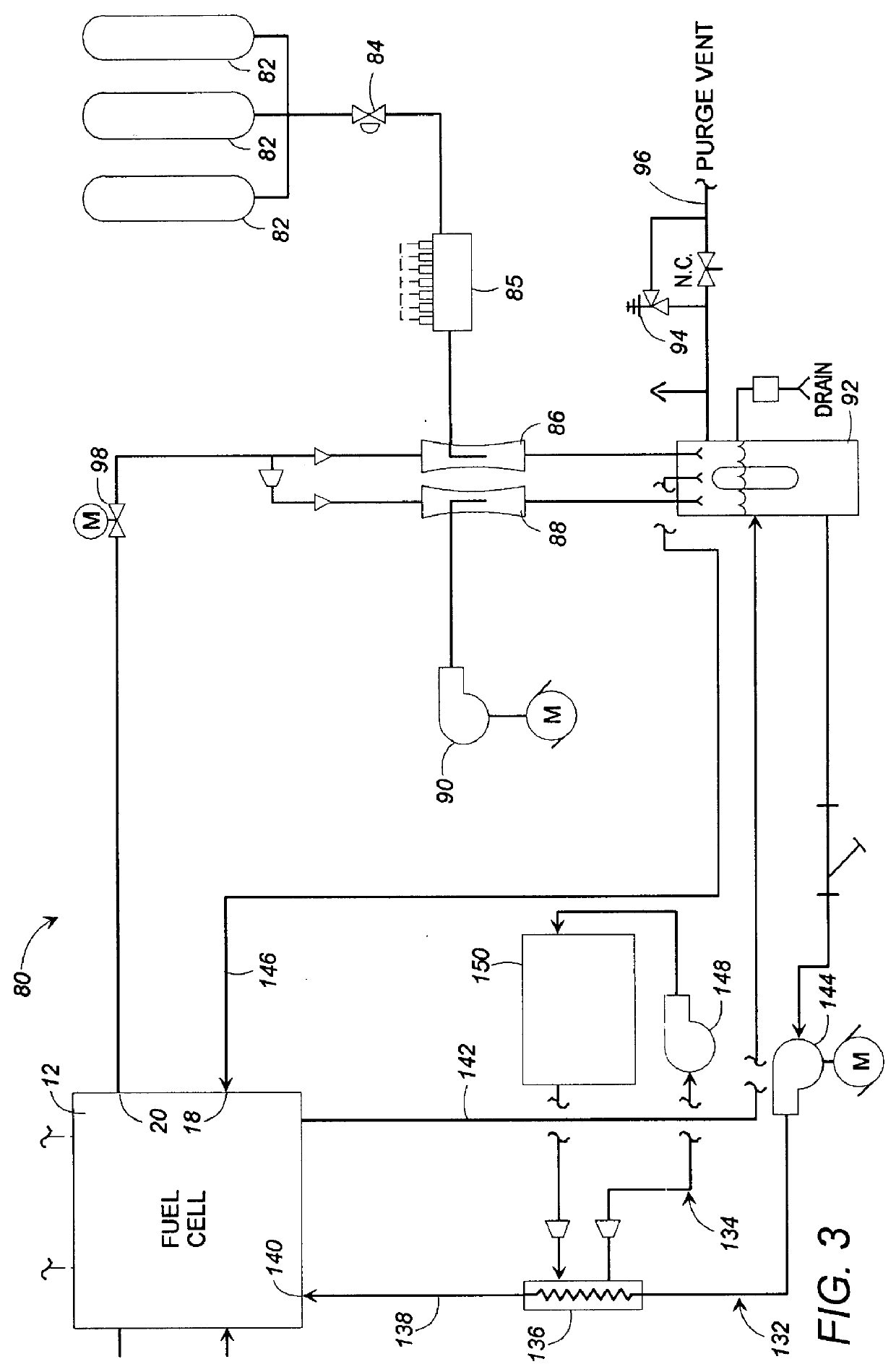

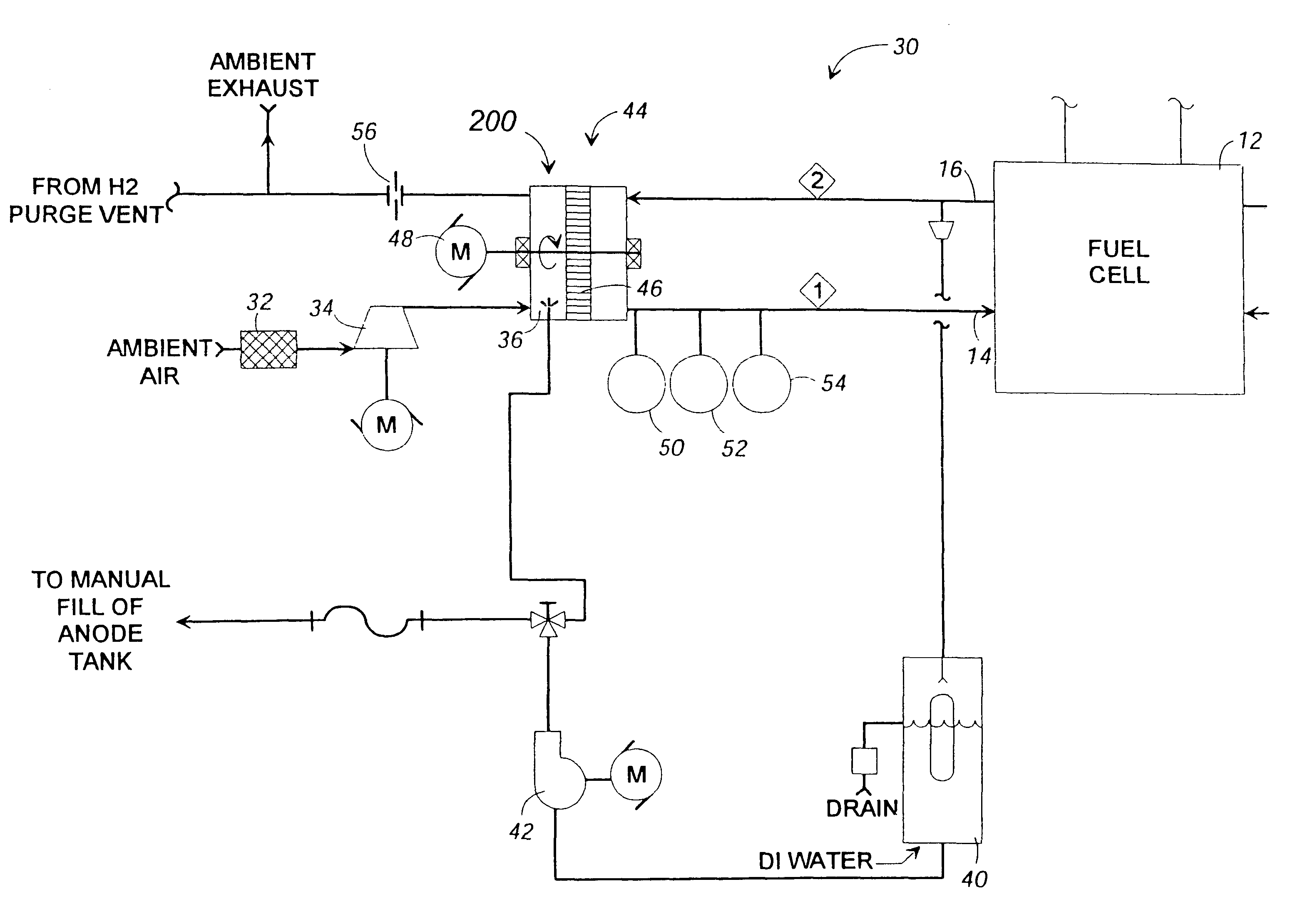

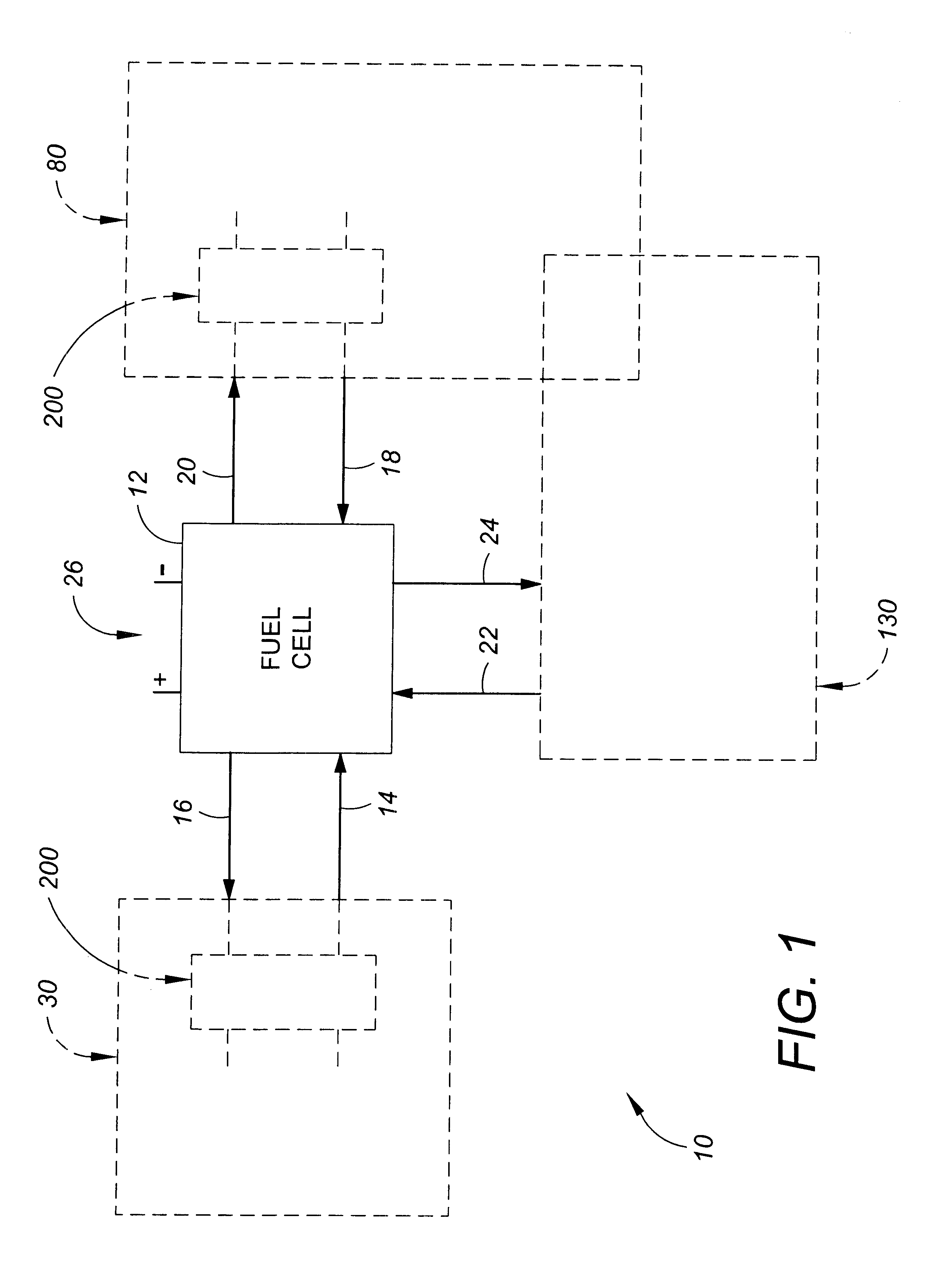

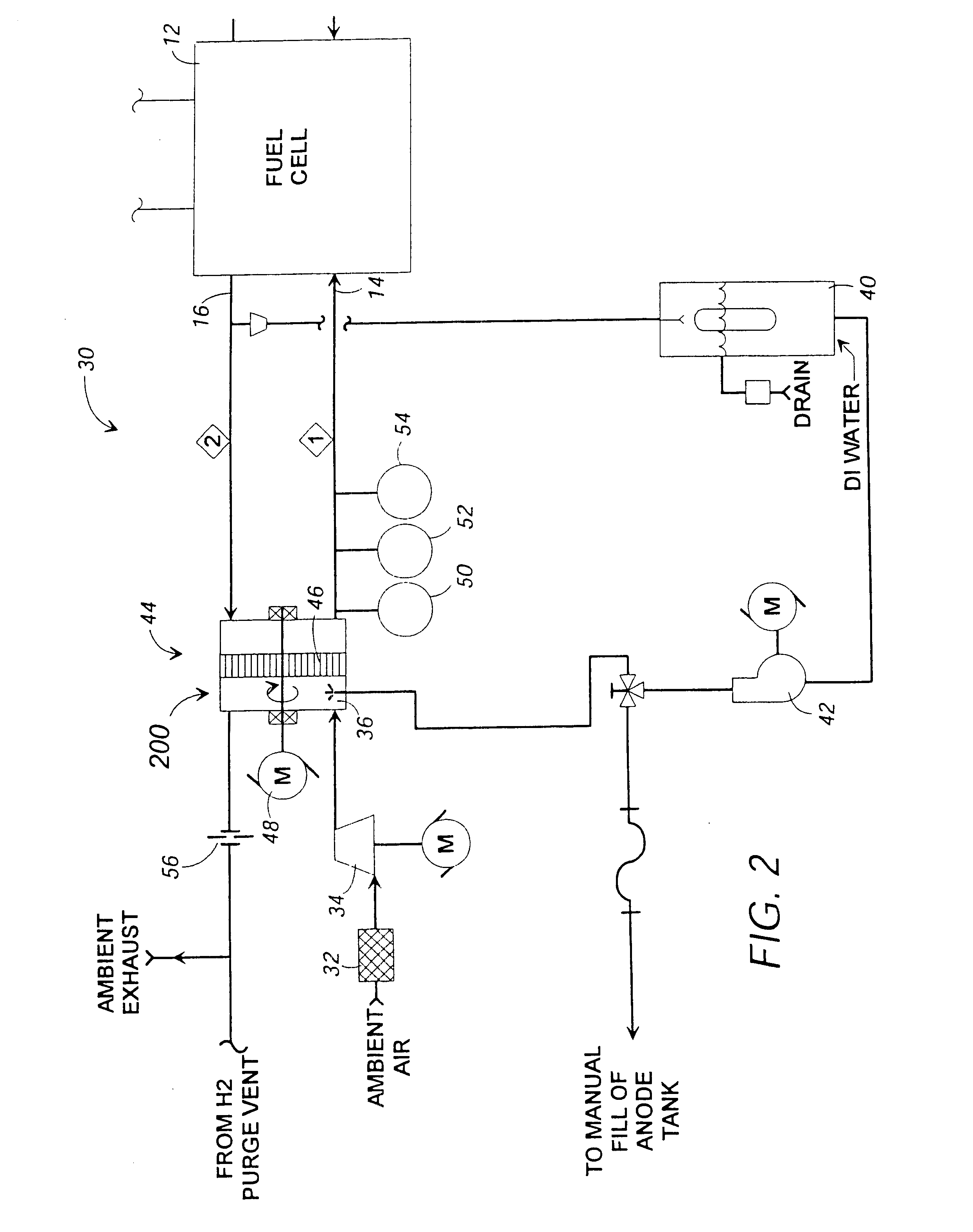

Fuel cell gas management system

InactiveUS6013385AImprove battery efficiencyMinimize the possibilityFuel cell heat exchangeFuel cell controlIonEnthalpy

A fuel cell gas management system including a cathode humidification system for transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell equal to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

Fuel-cell engine stream conditioning system

A stream conditioning system for a fuel cell gas management system or fuel cell engine. The stream conditioning system manages species potential in at least one fuel cell reactant stream. A species transfer device is located in the path of at least one reactant stream of a fuel cell's inlet or outlet, which transfer device conditions that stream to improve the efficiency of the fuel cell. The species transfer device incorporates an exchange media and a sorbent. The fuel cell gas management system can include a cathode loop with the stream conditioning system transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell related to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

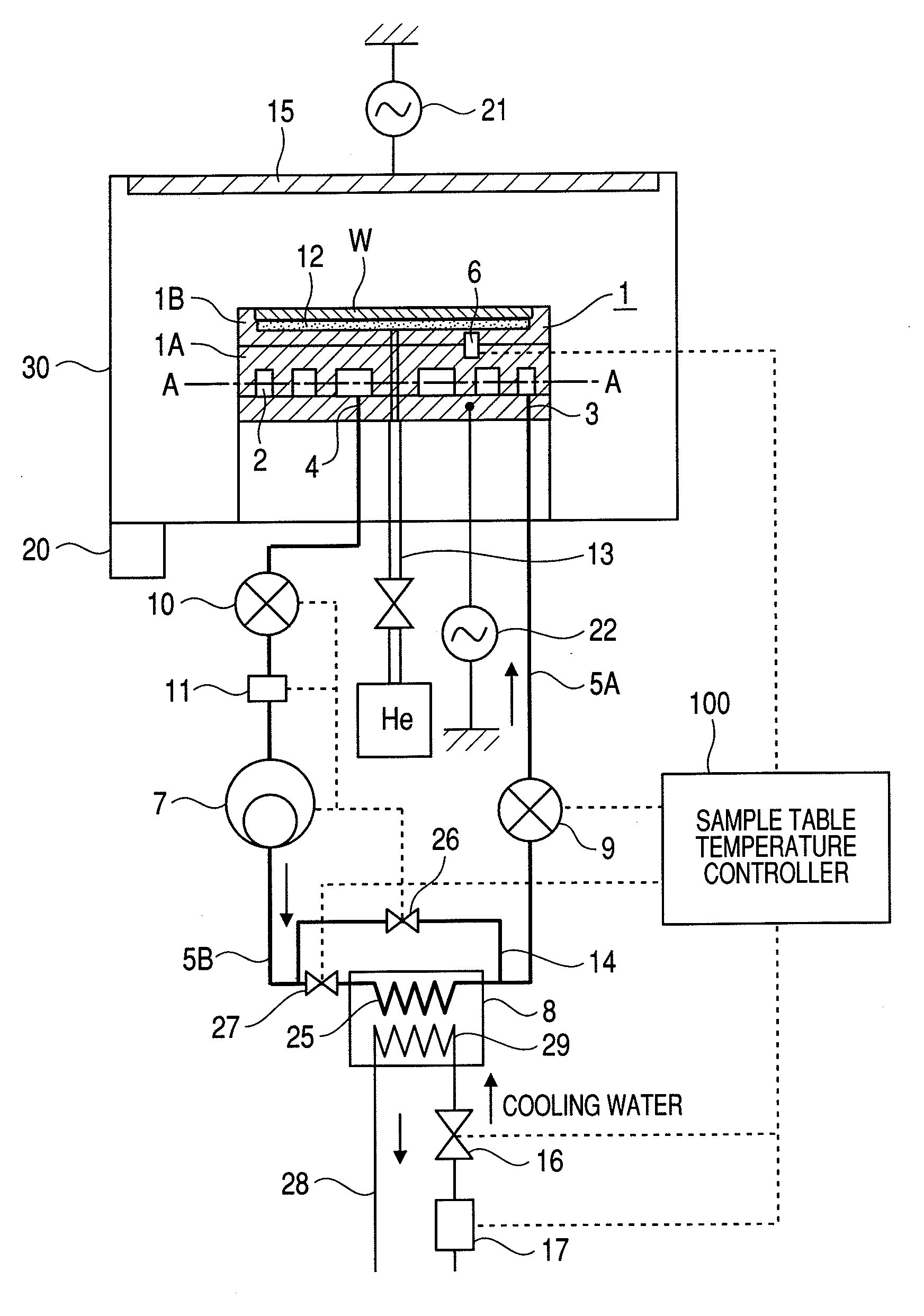

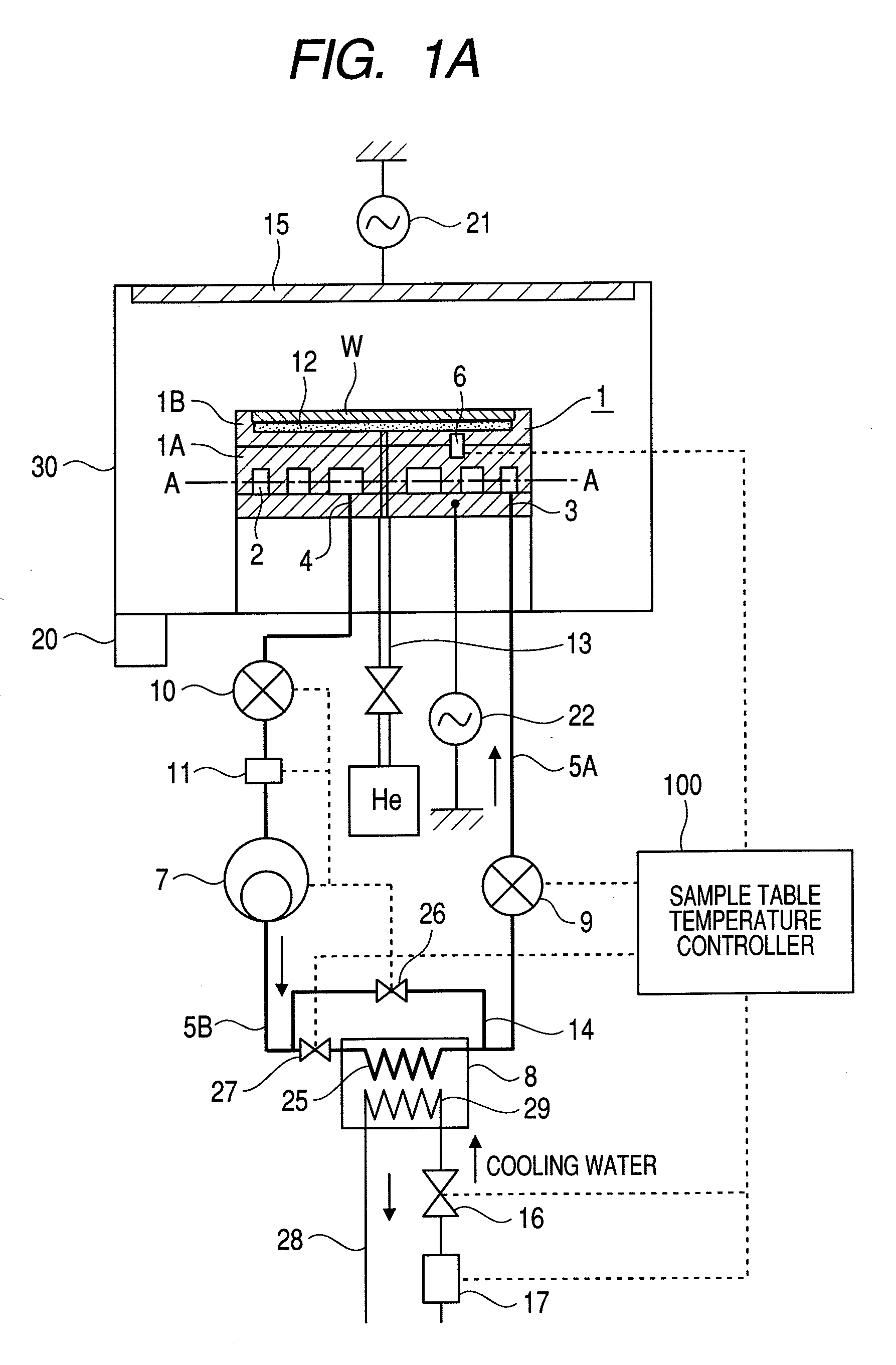

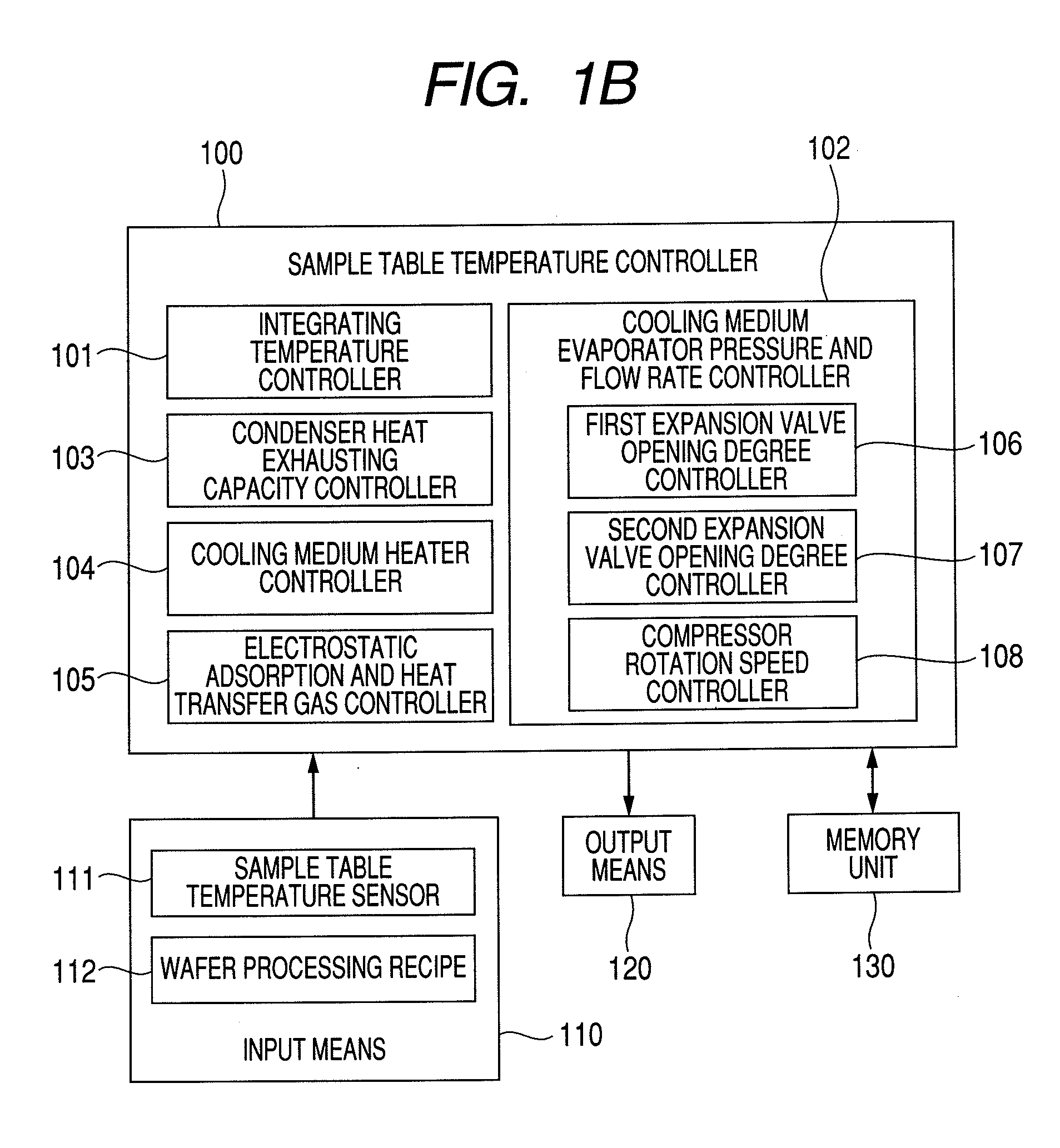

Plasma processing apparatus

InactiveUS20100126666A1Uniform processingUnified controlElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeEngineering

In a plasma processing apparatus; a refrigerant flow passage being formed in the sample table and constituting an evaporator of a cooling cycle and the in-plane temperature of the sample to be processed is controlled uniformly by controlling the enthalpy of the refrigerant supplied to the refrigerant flow passage and thereby keeping the flow mode in the refrigerant flow passage, namely in the sample table, in the state of a gas-liquid two-phase. If by any chance dry out of the refrigerant occurs in the refrigerant flow passage because the heat input of plasma increases with time or by another reason, it is possible to increase speed of a compressor and inhibit the dry out from occurring in the refrigerant flow passage. Further, if the refrigerant supplied to the refrigerant flow passage is liquefied, it is kept in the gas-liquid two-phase state.

Owner:HITACHI HIGH-TECH CORP

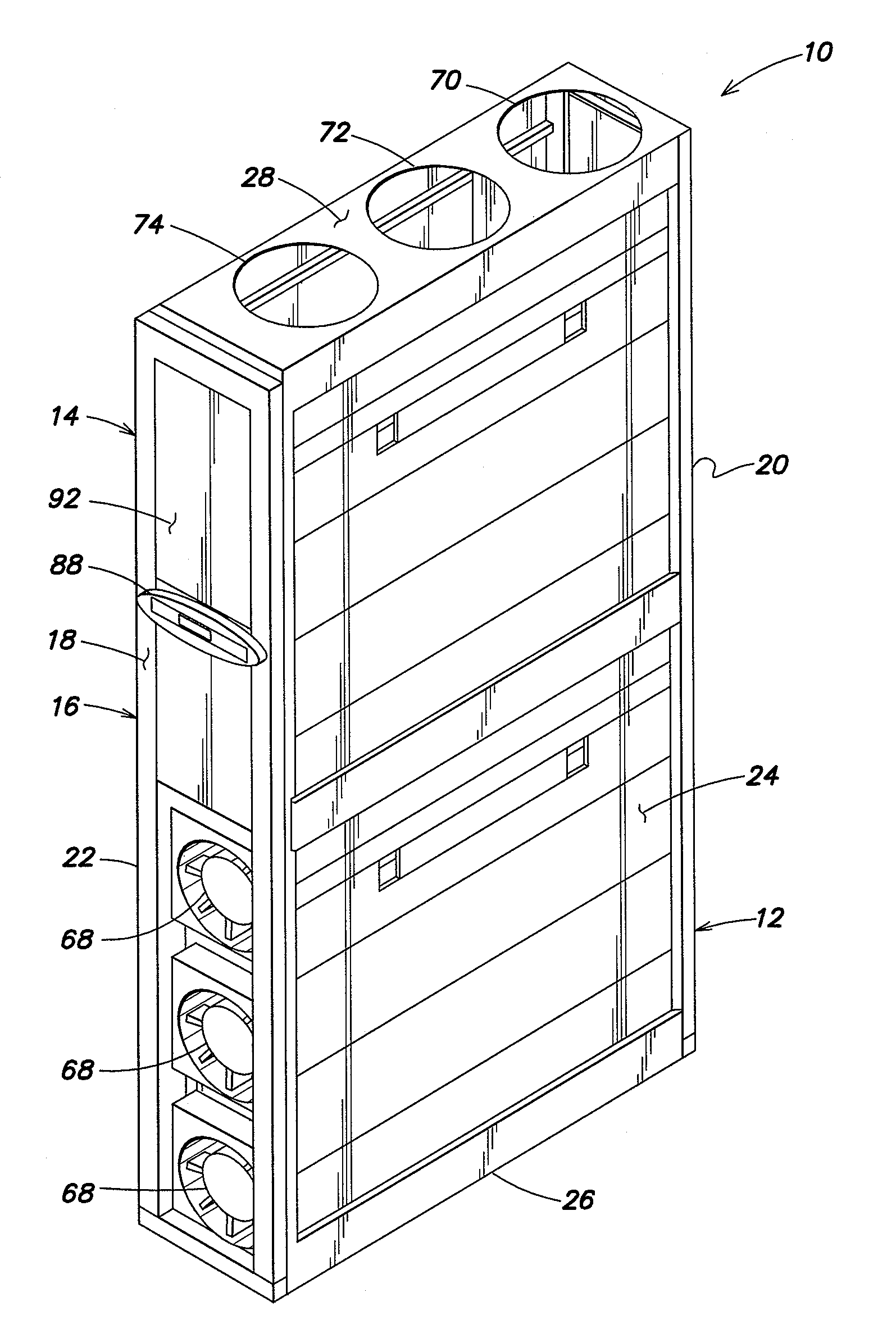

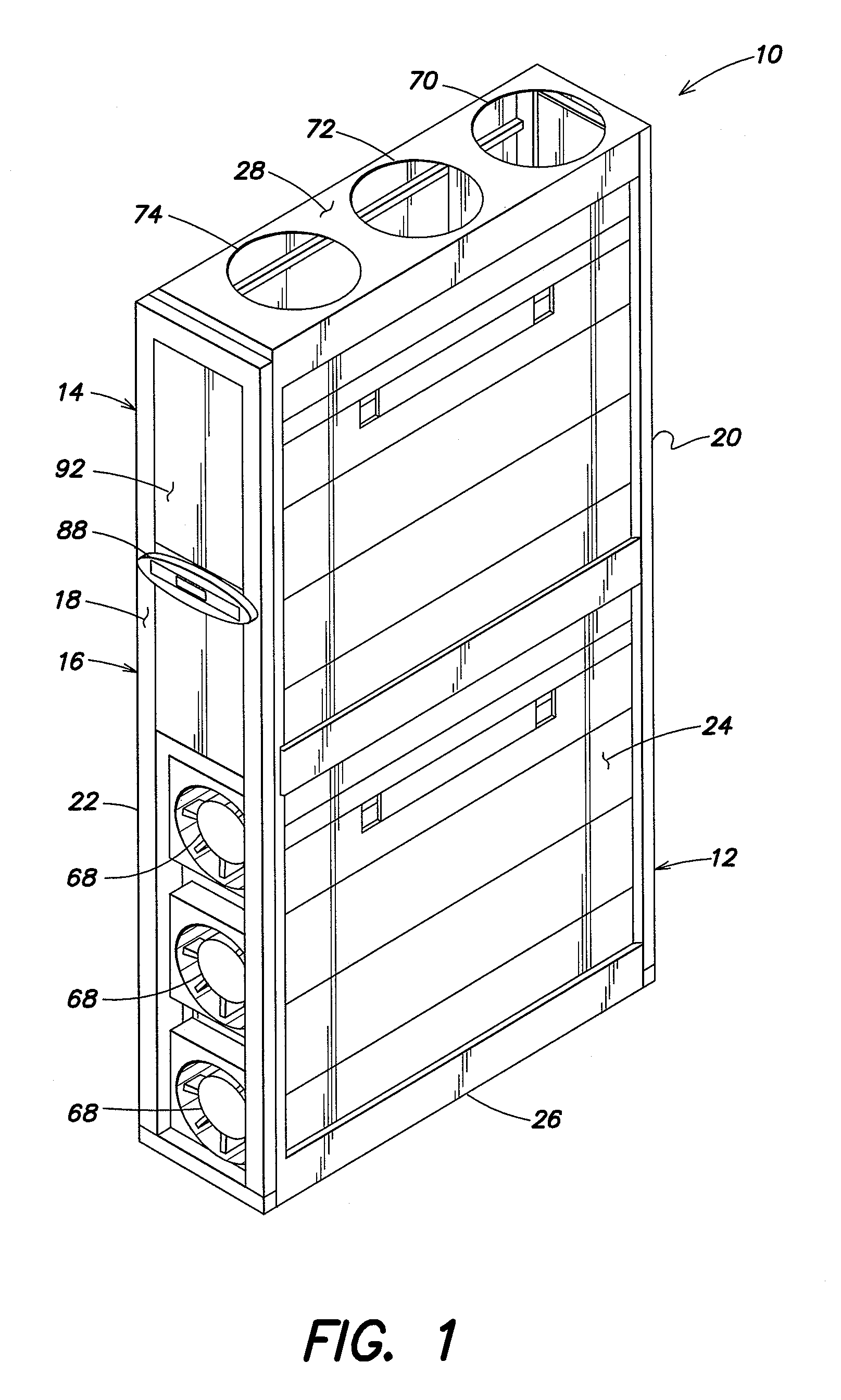

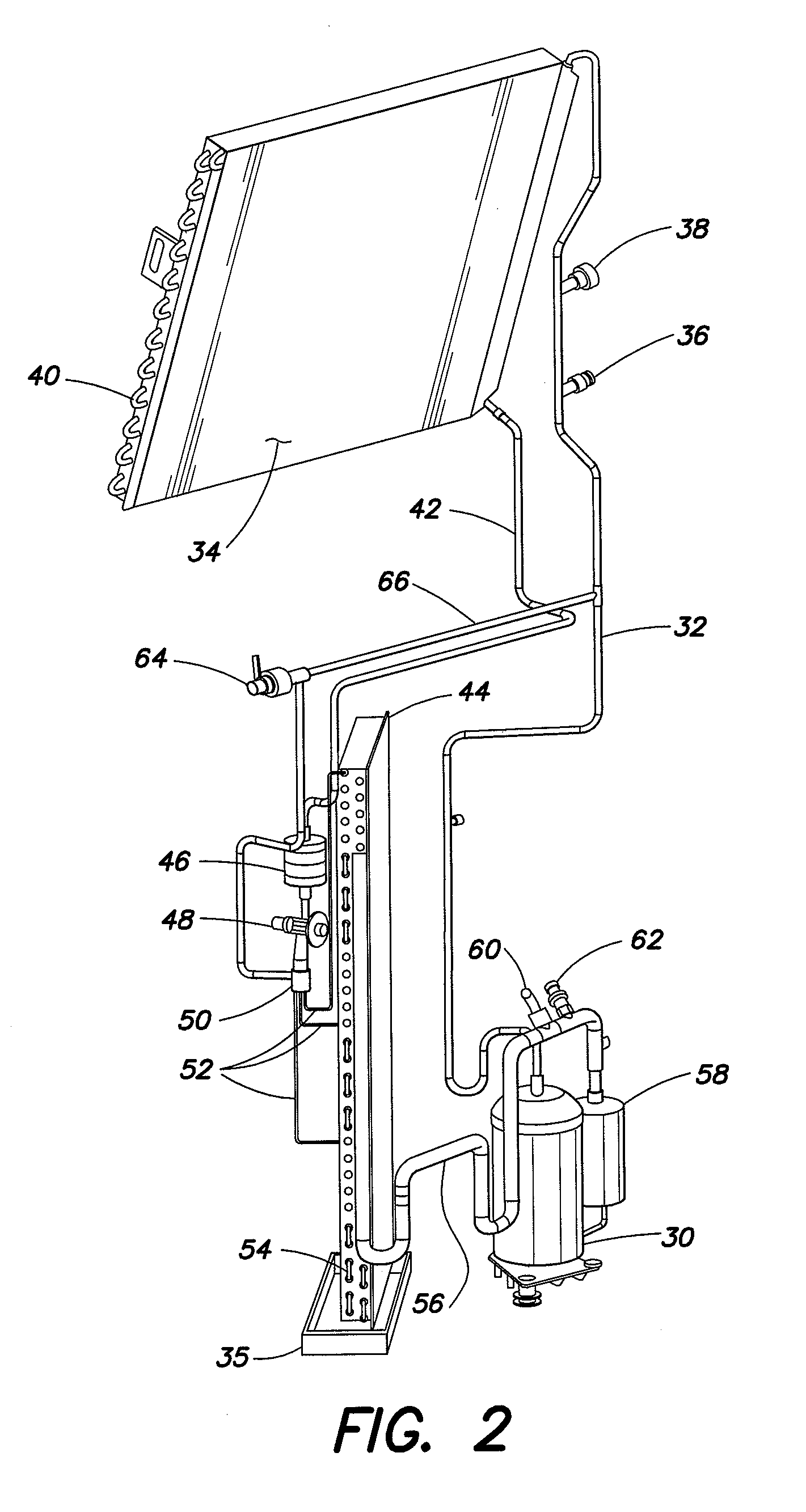

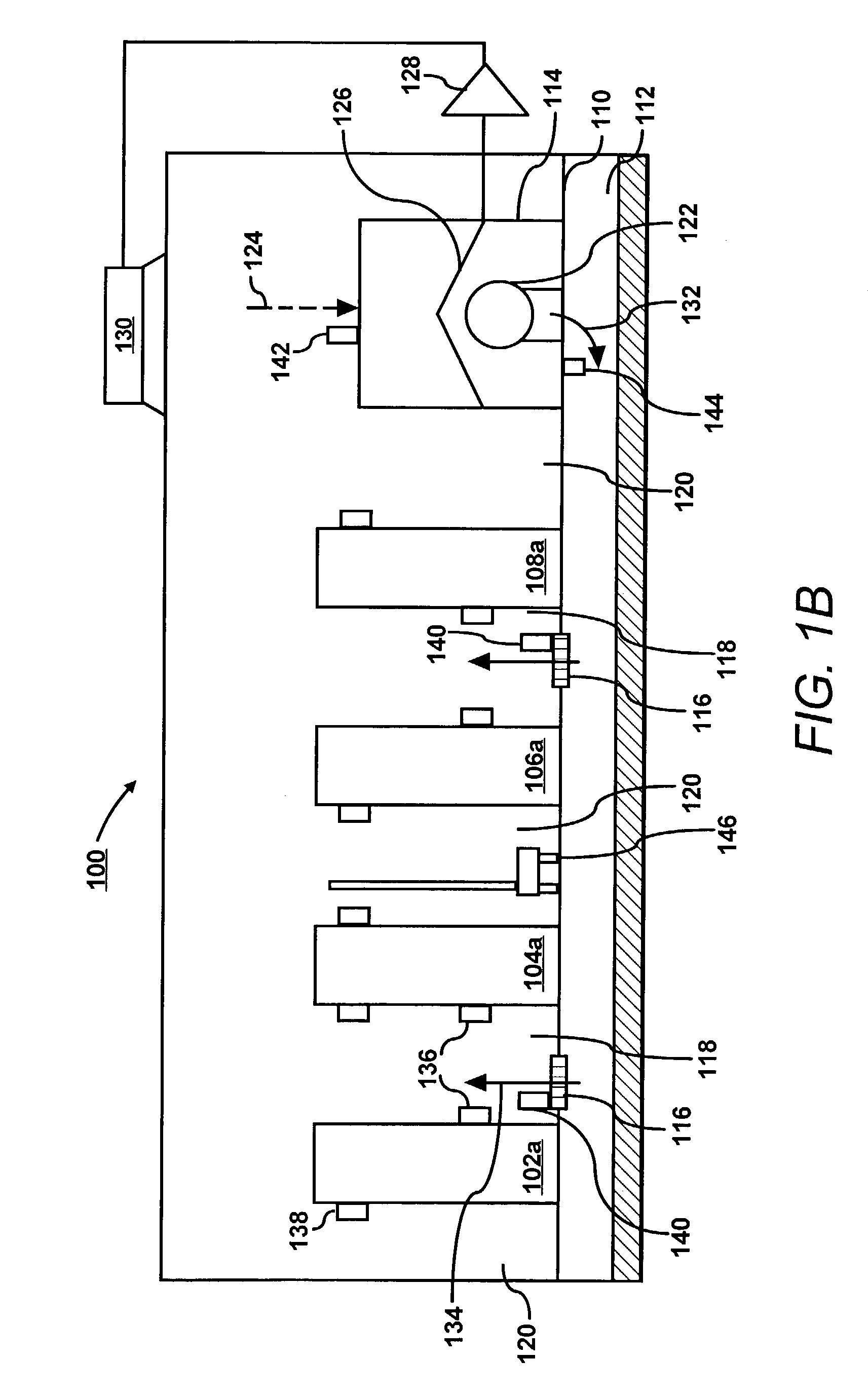

Method and apparatus for cooling

ActiveUS20080245083A1Increase loopHigh trafficMechanical apparatusTemperatue controlEngineeringCooling capacity

A method of calculating net sensible cooling capacity of a cooling unit includes measuring a discharge pressure from of fluid from a compressor and a suction pressure from an evaporator, calculating a condensing temperature of fluid flowing from the compressor and an evaporating temperature of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing from the compressor, calculating enthalpy of fluid flowing from the compressor, of fluid flowing from the thermal expansion valve, and of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing through the hot gas bypass valve, and calculating net sensible cooling capacity. Embodiments of cooling units and other methods are further disclosed.

Owner:AMERICA POWER CONVERSION CORP

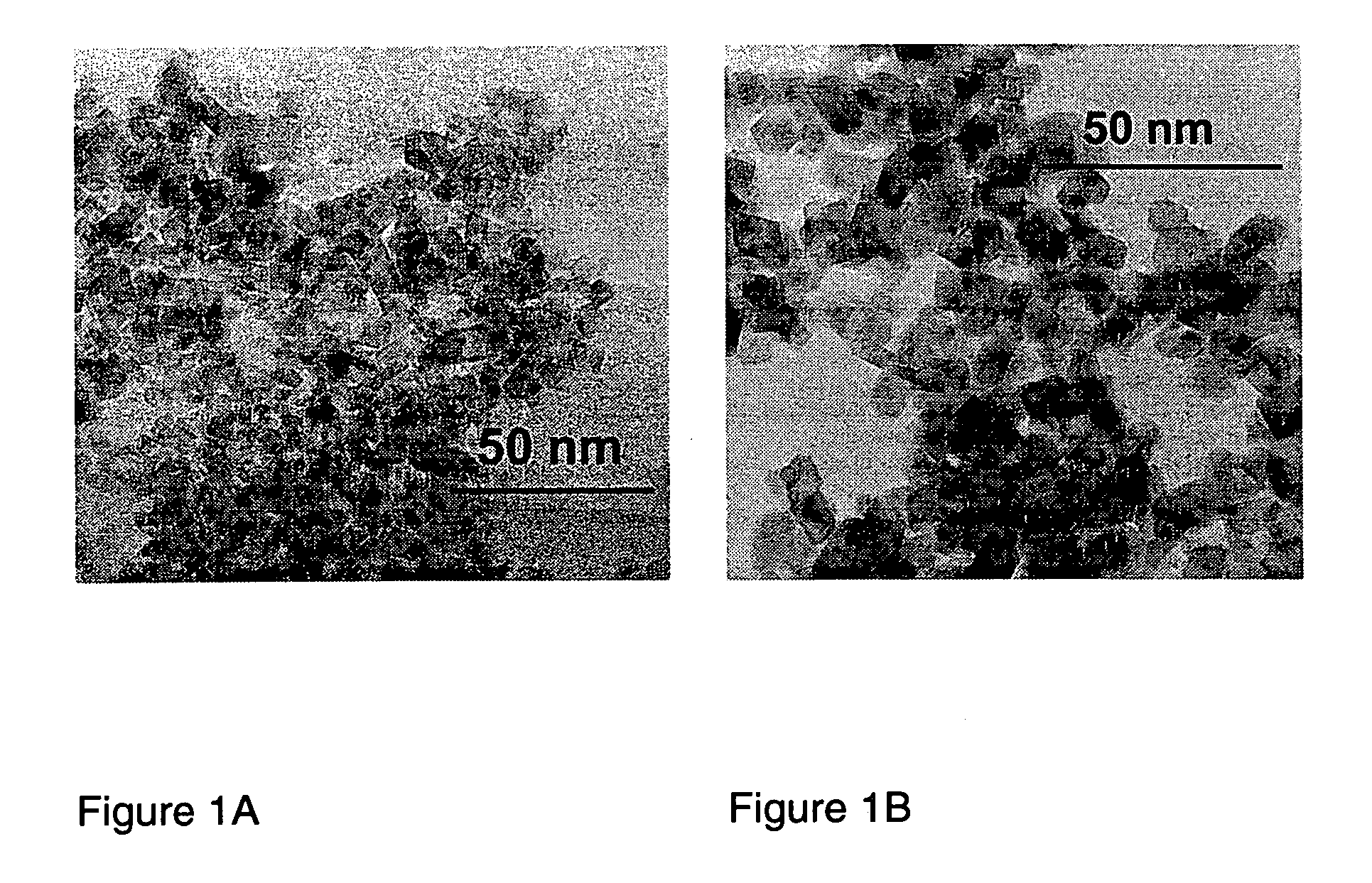

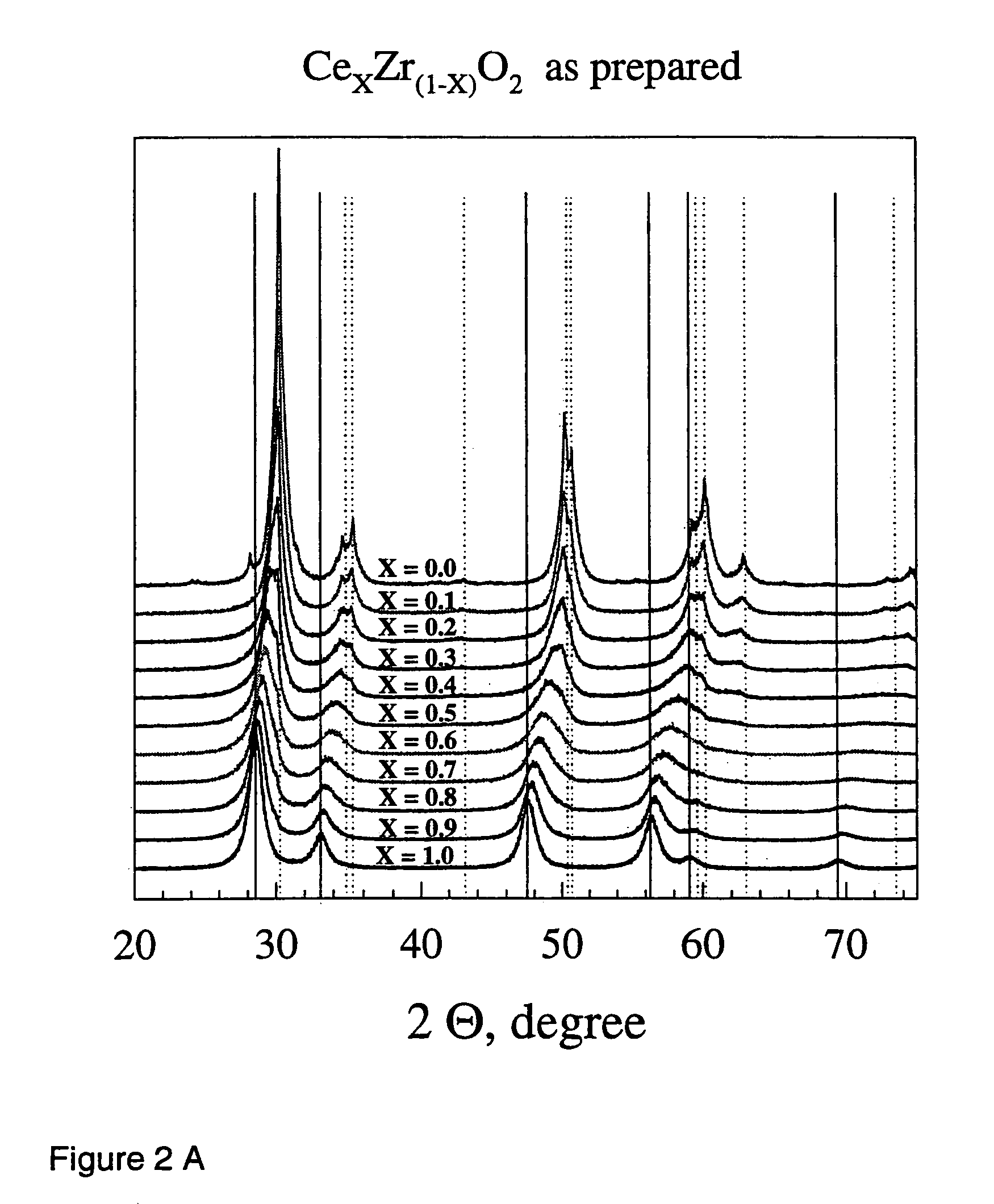

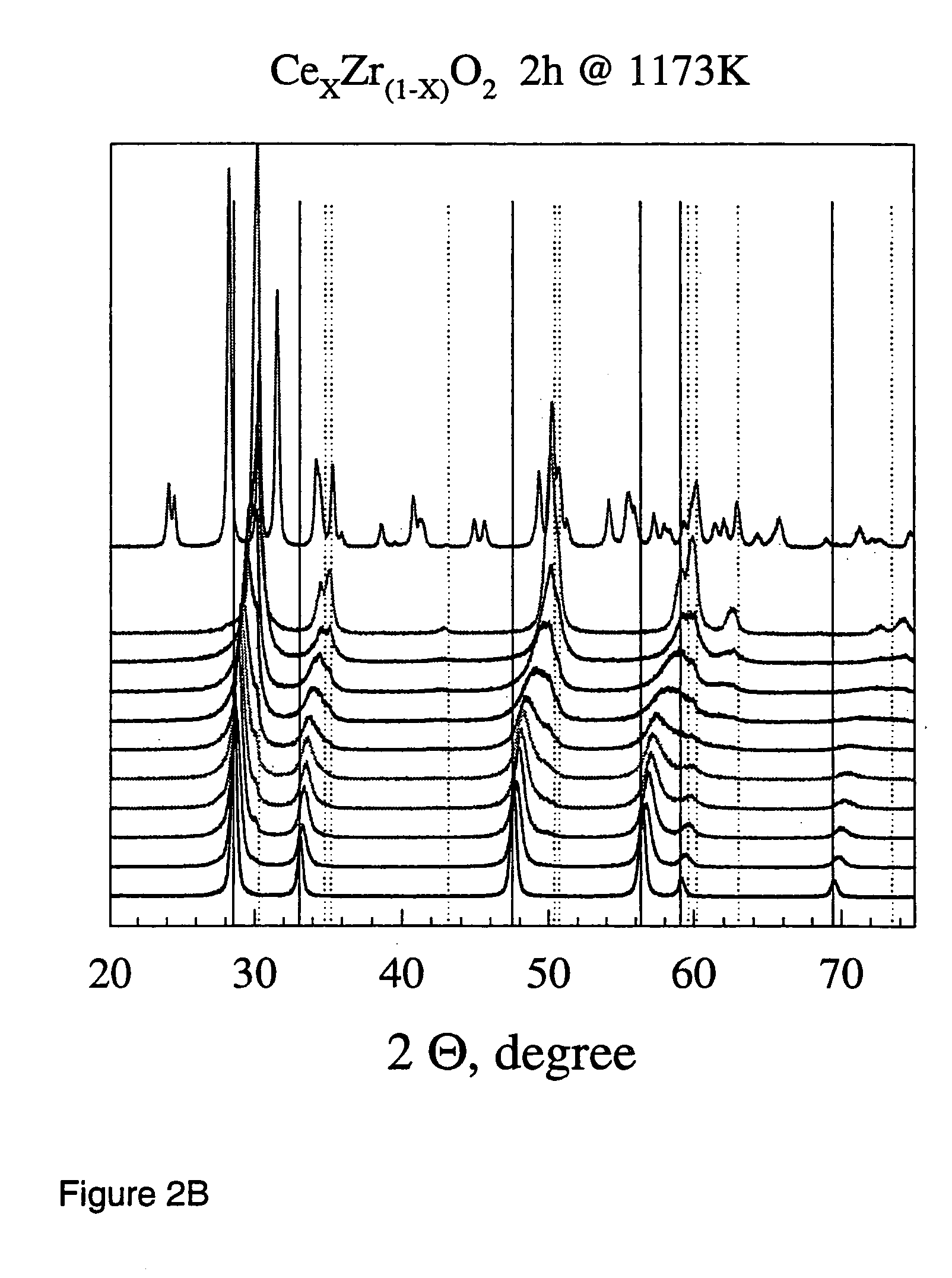

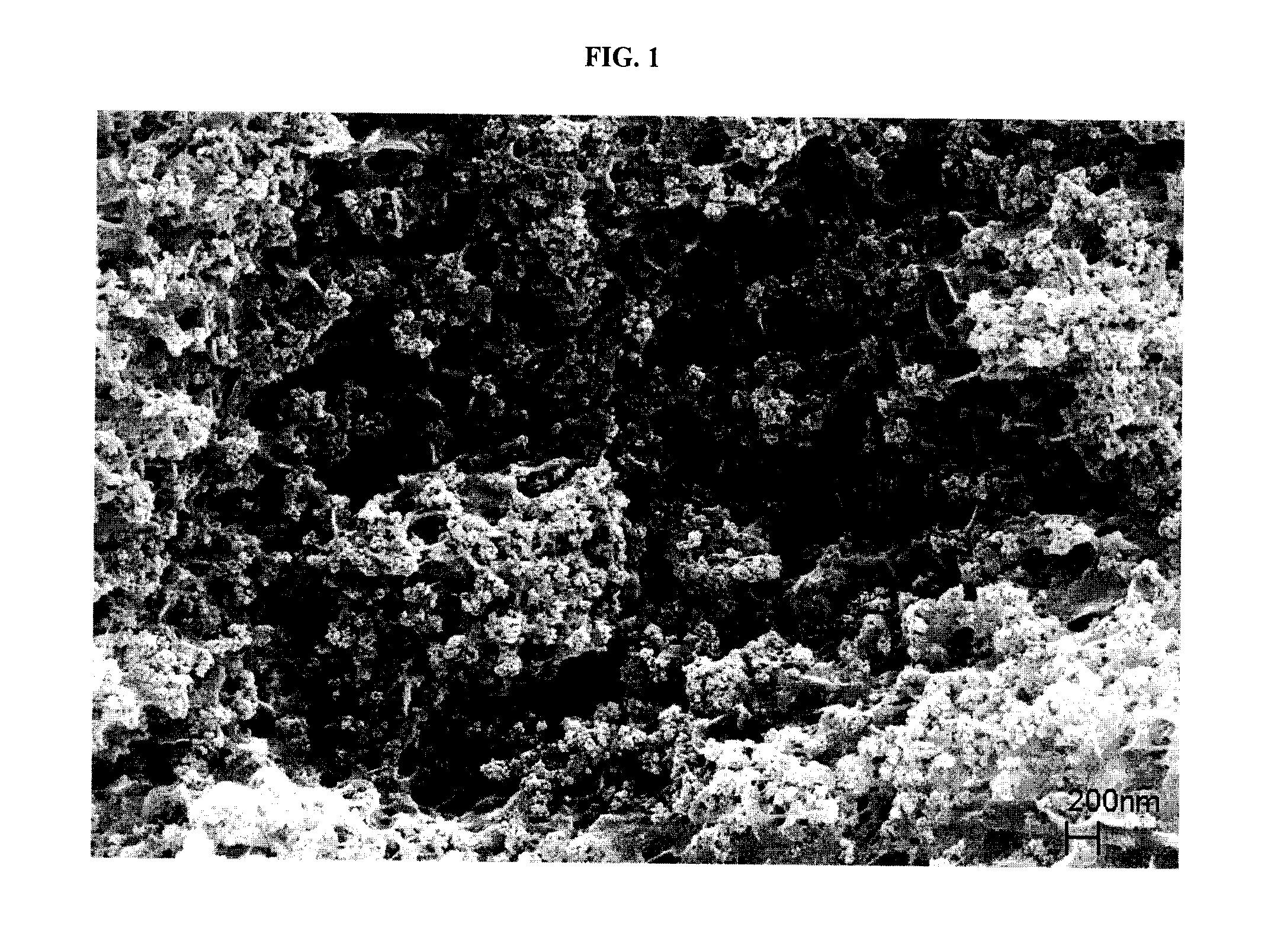

Flame made metal oxides

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

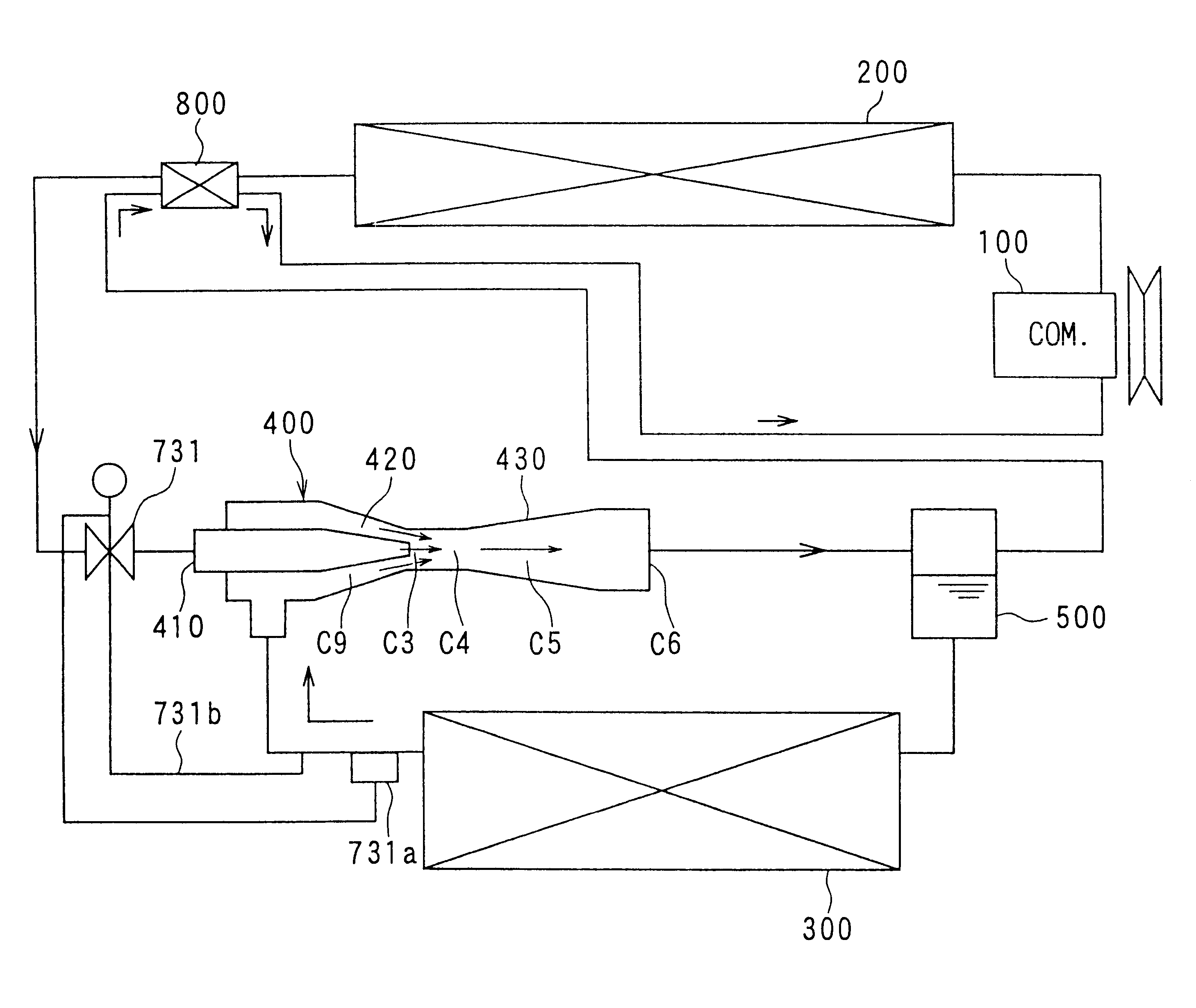

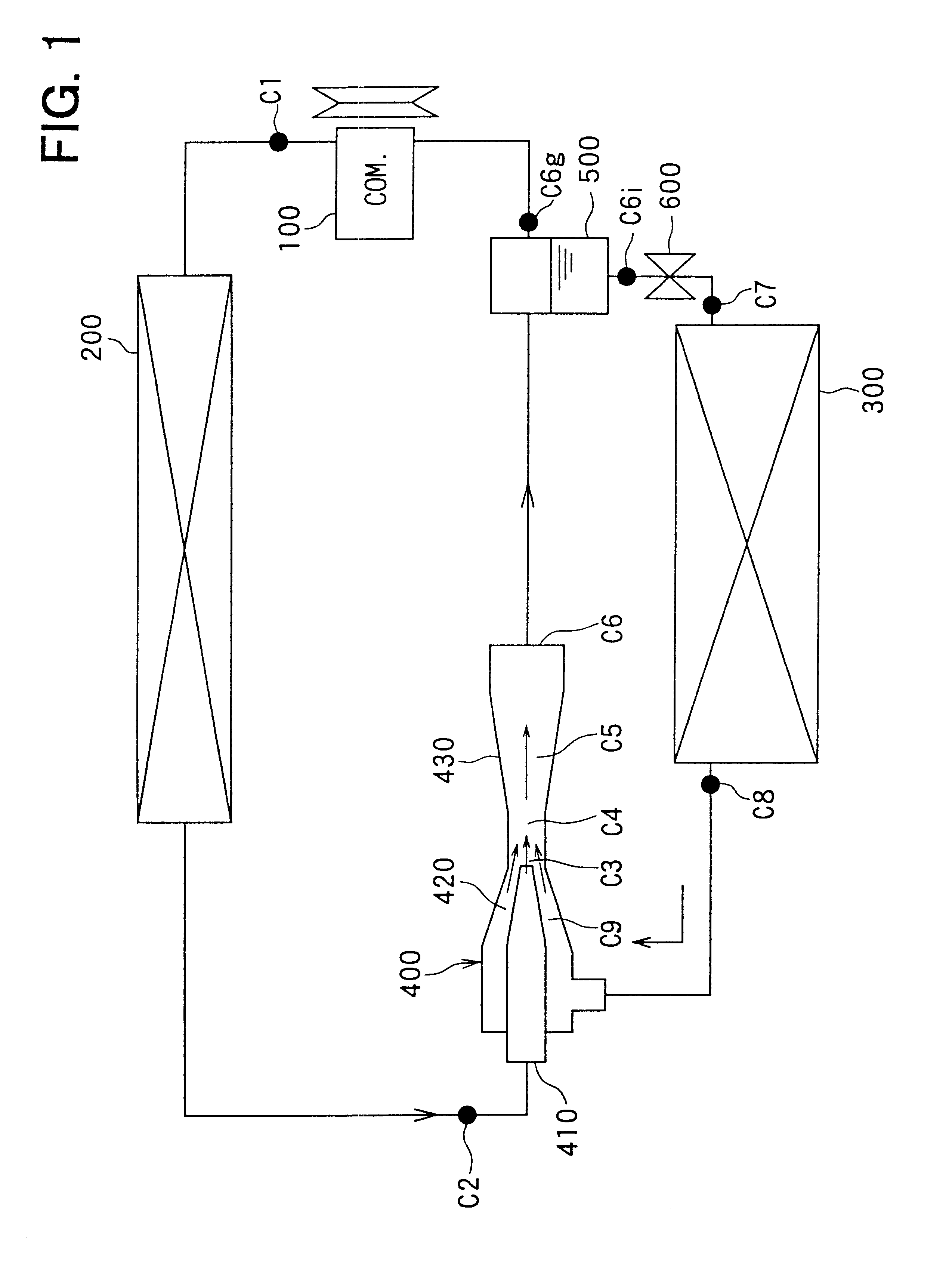

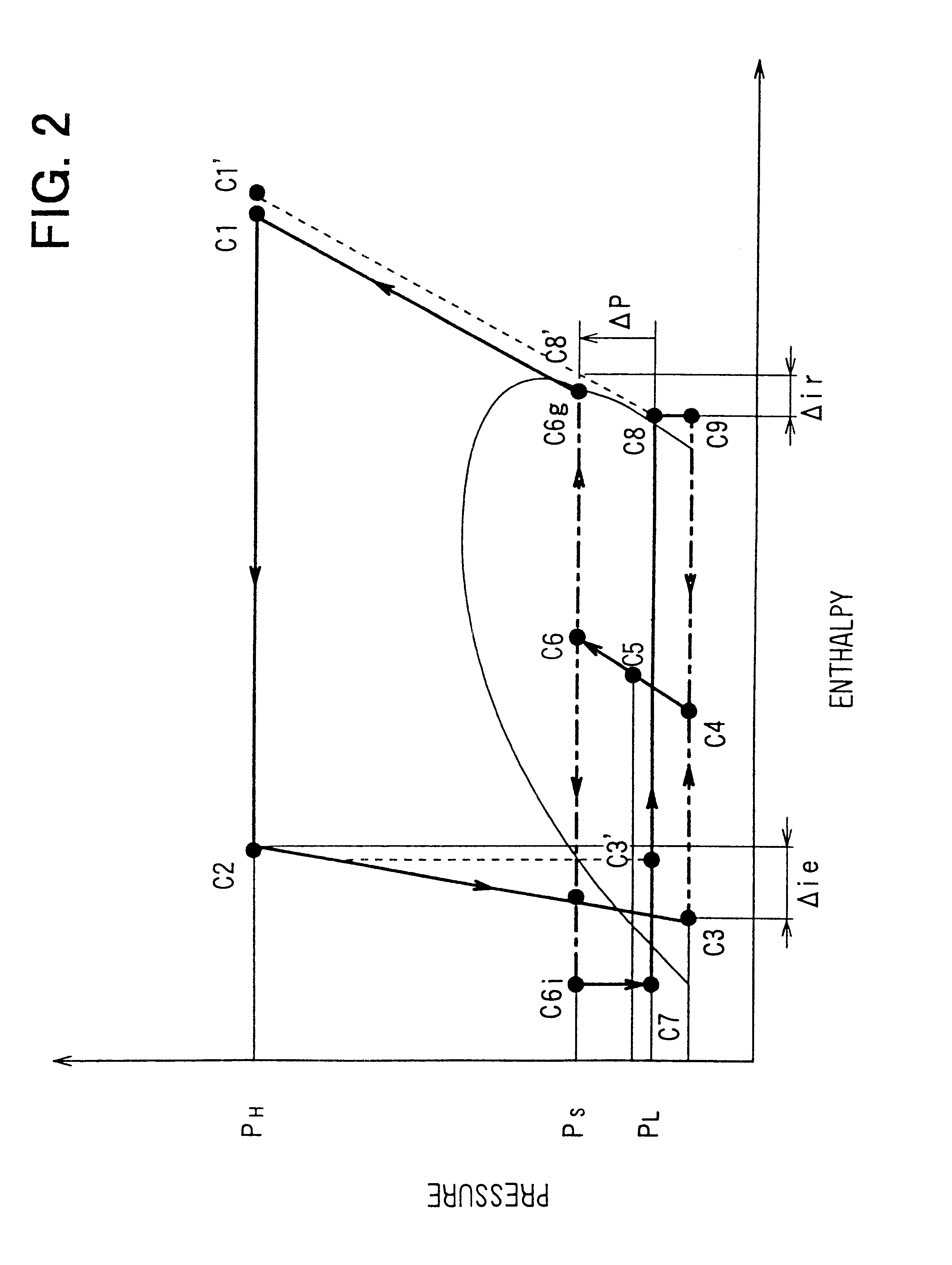

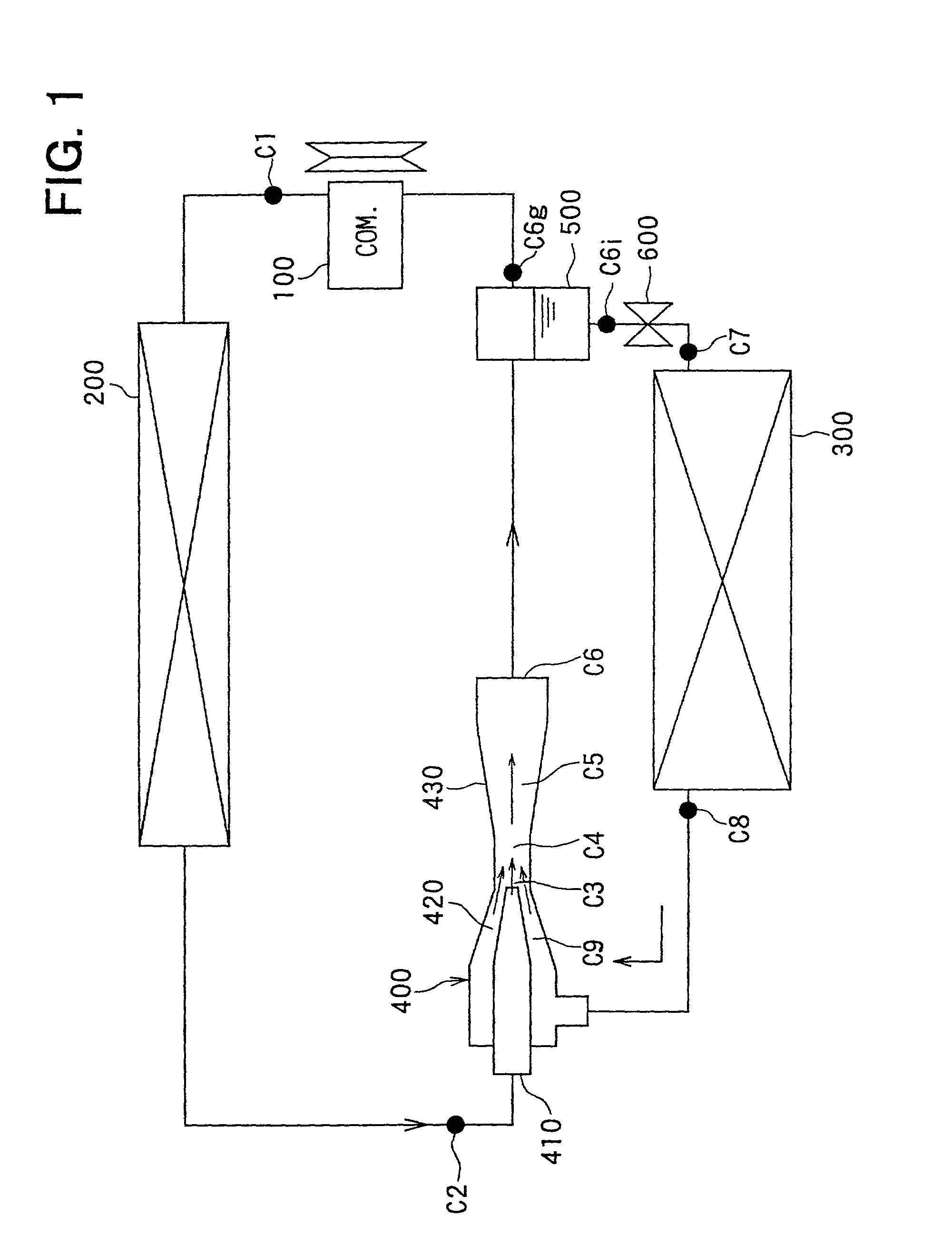

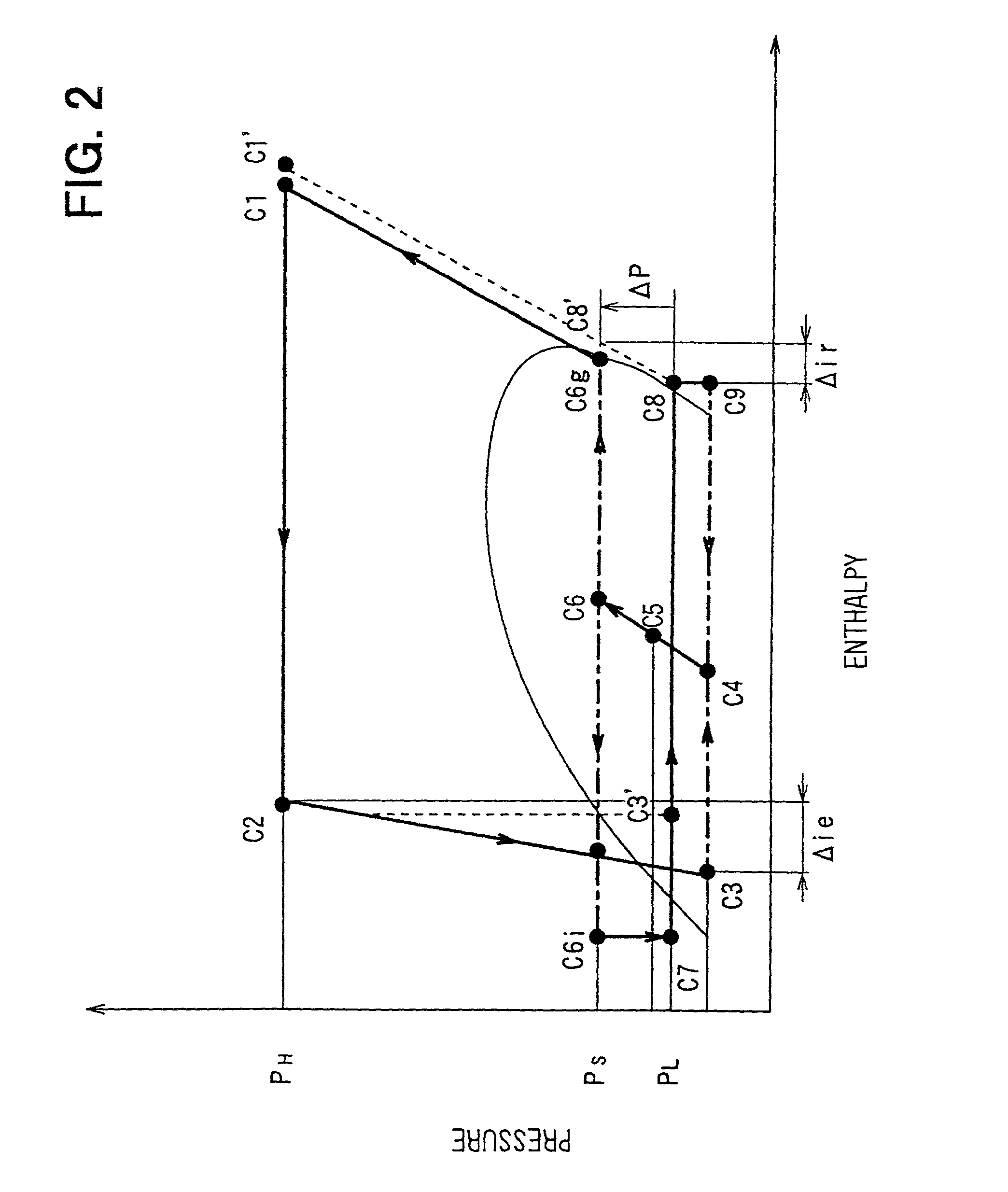

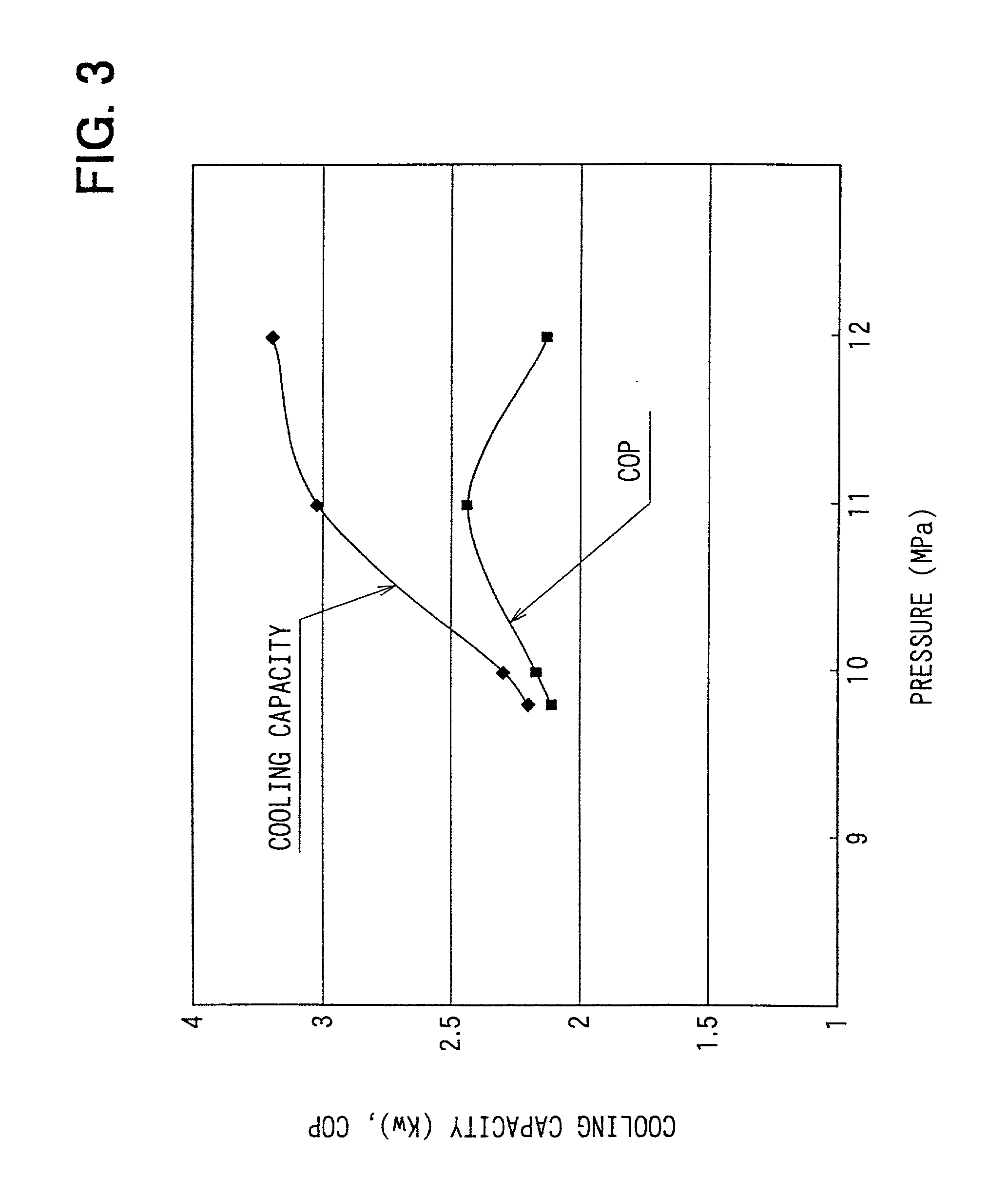

Ejector cycle system with critical refrigerant pressure

InactiveUS6477857B2Recover energyReduce power consumptionCompression machines with non-reversible cycleEvaporators/condensersEngineeringPressure difference

Owner:DENSO CORP

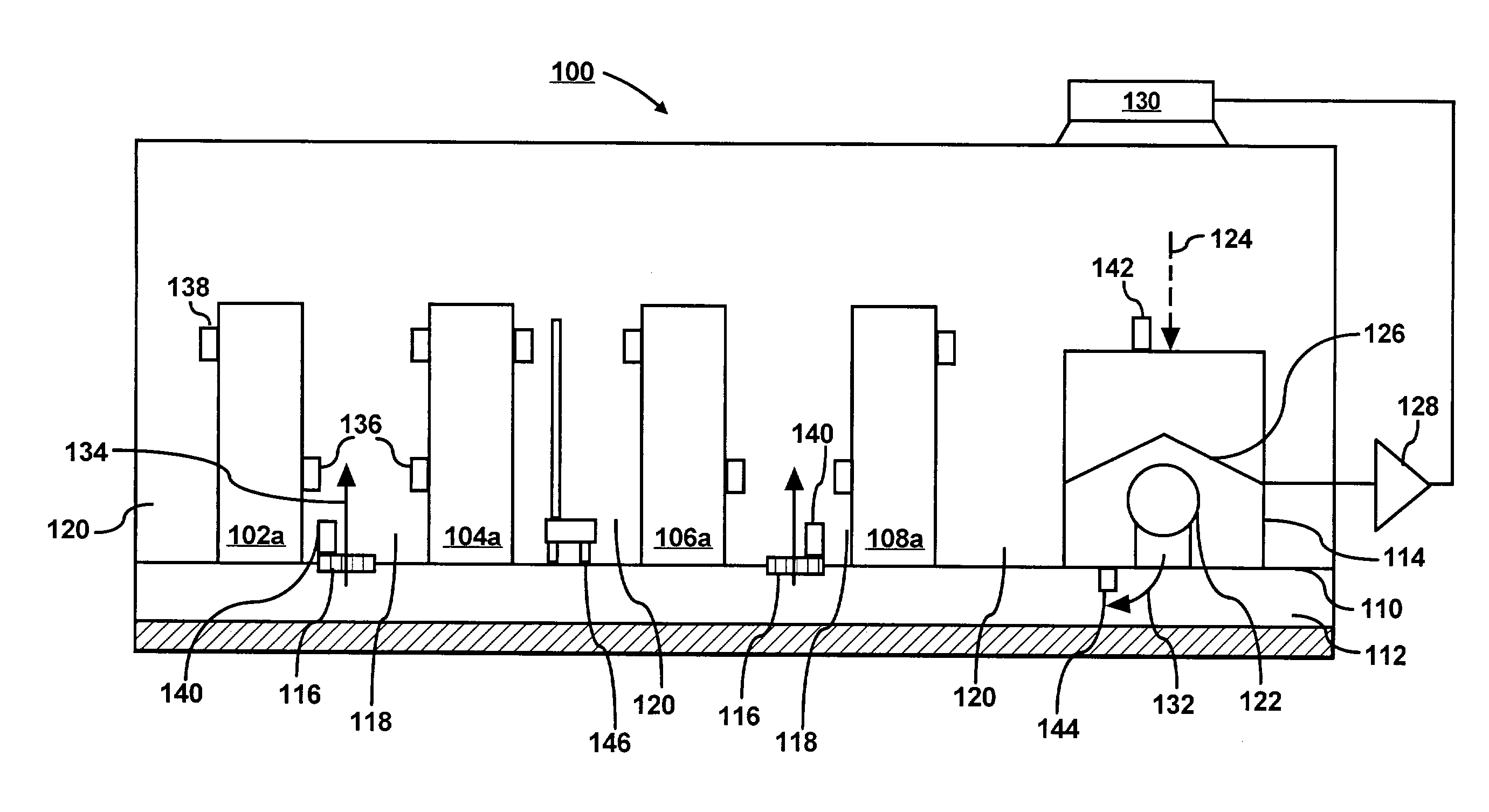

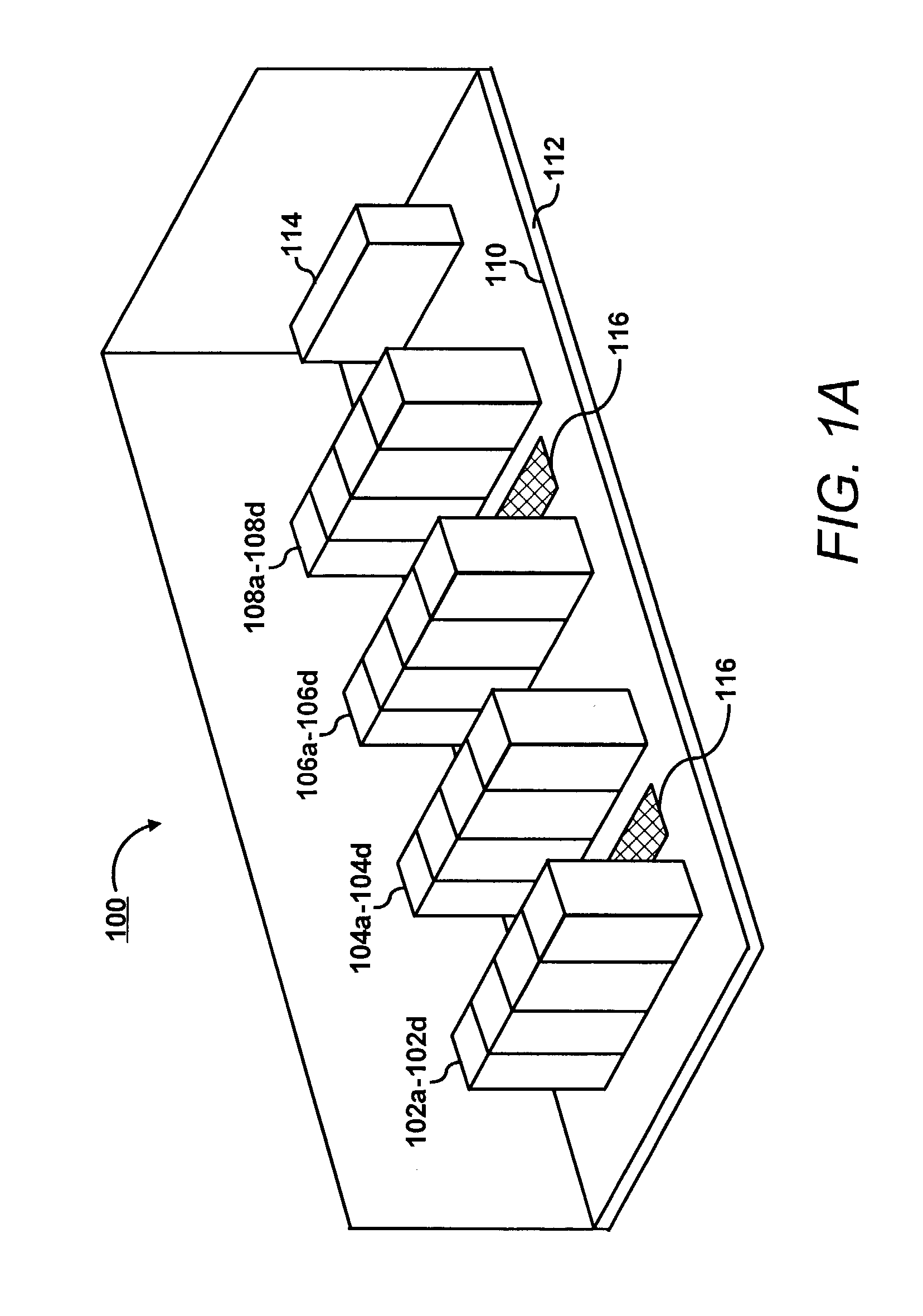

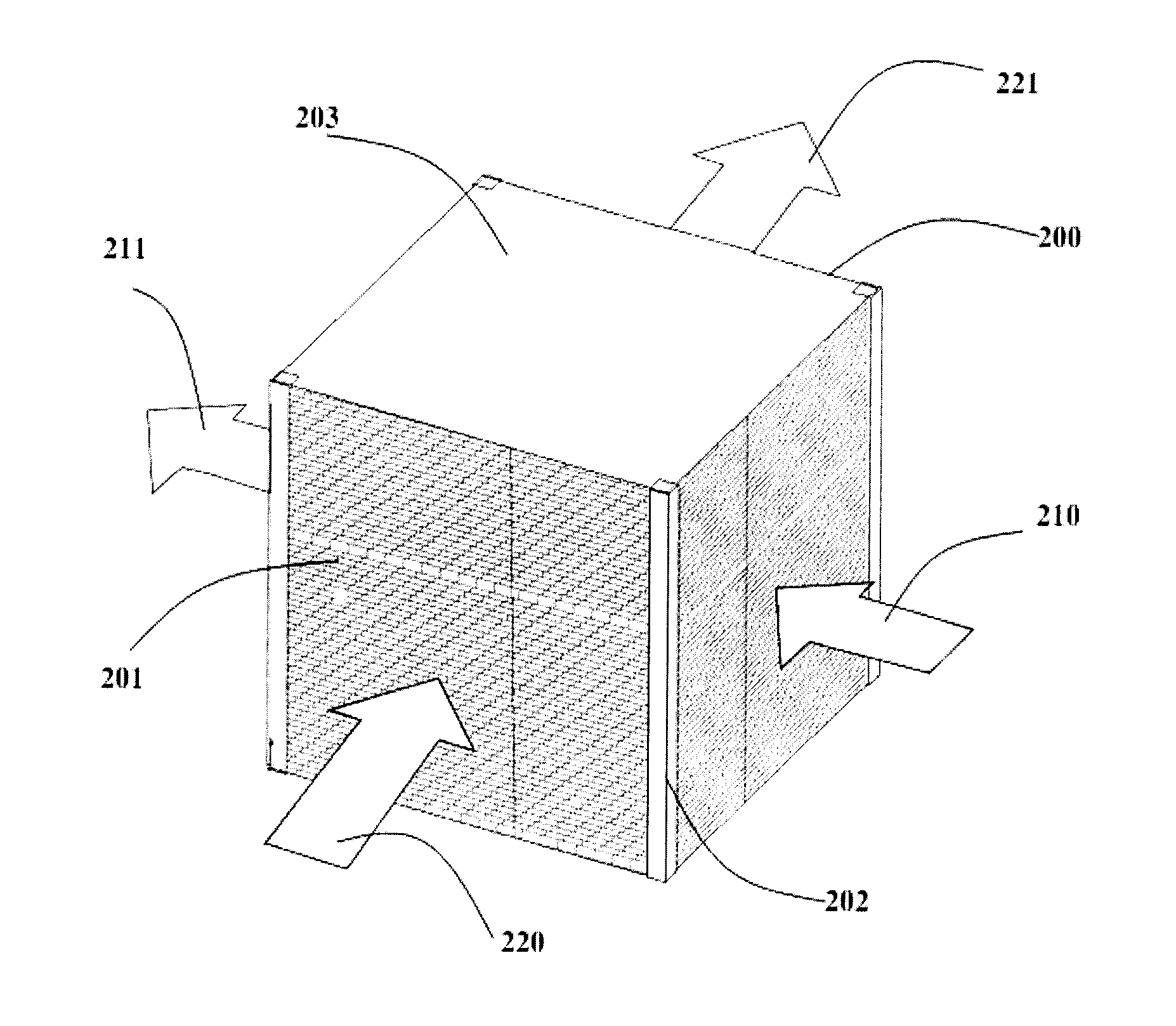

Air re-circulation index

InactiveUS7051946B2Reducing air re-circulationMechanical apparatusDomestic cooling apparatusData centerEngineering

An index of air re-circulation in a data center having one or more racks is determined to identify the level of heated air re-circulation into cooling fluid delivered to the one or more racks. The one or more racks comprise inlets and outlets and are positioned along a cool aisle and a hot aisle. The index is calculated by dividing the enthalpy rise due to infiltration of heated air into the cool aisle and the total enthalpy rise of the heated air from the outlets of the one or more racks.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

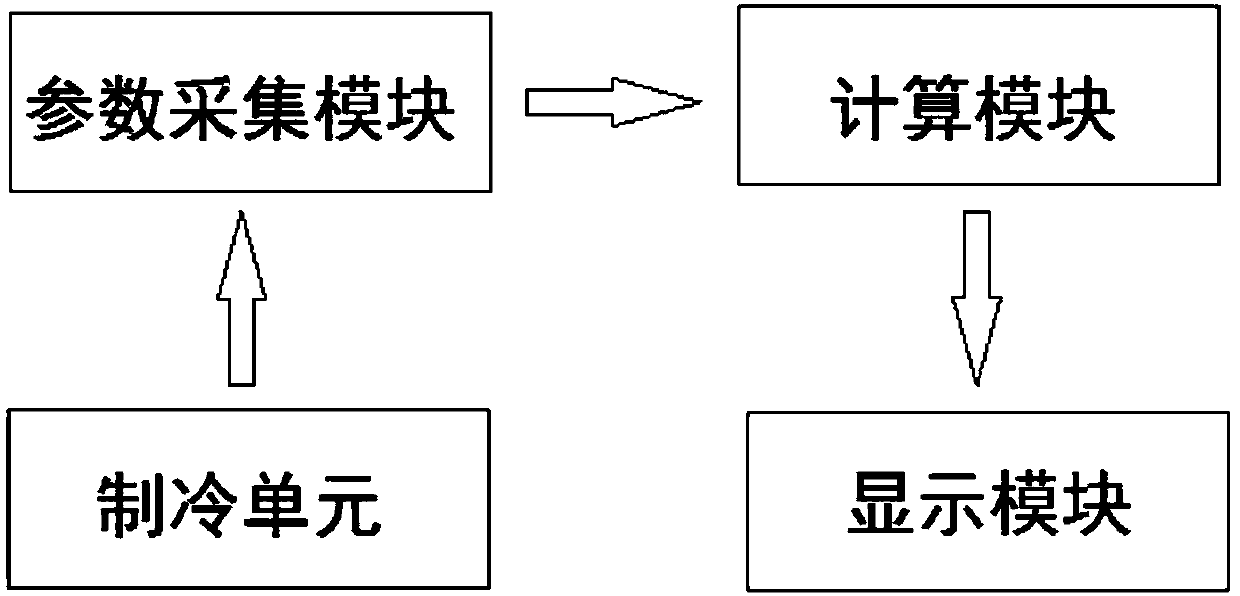

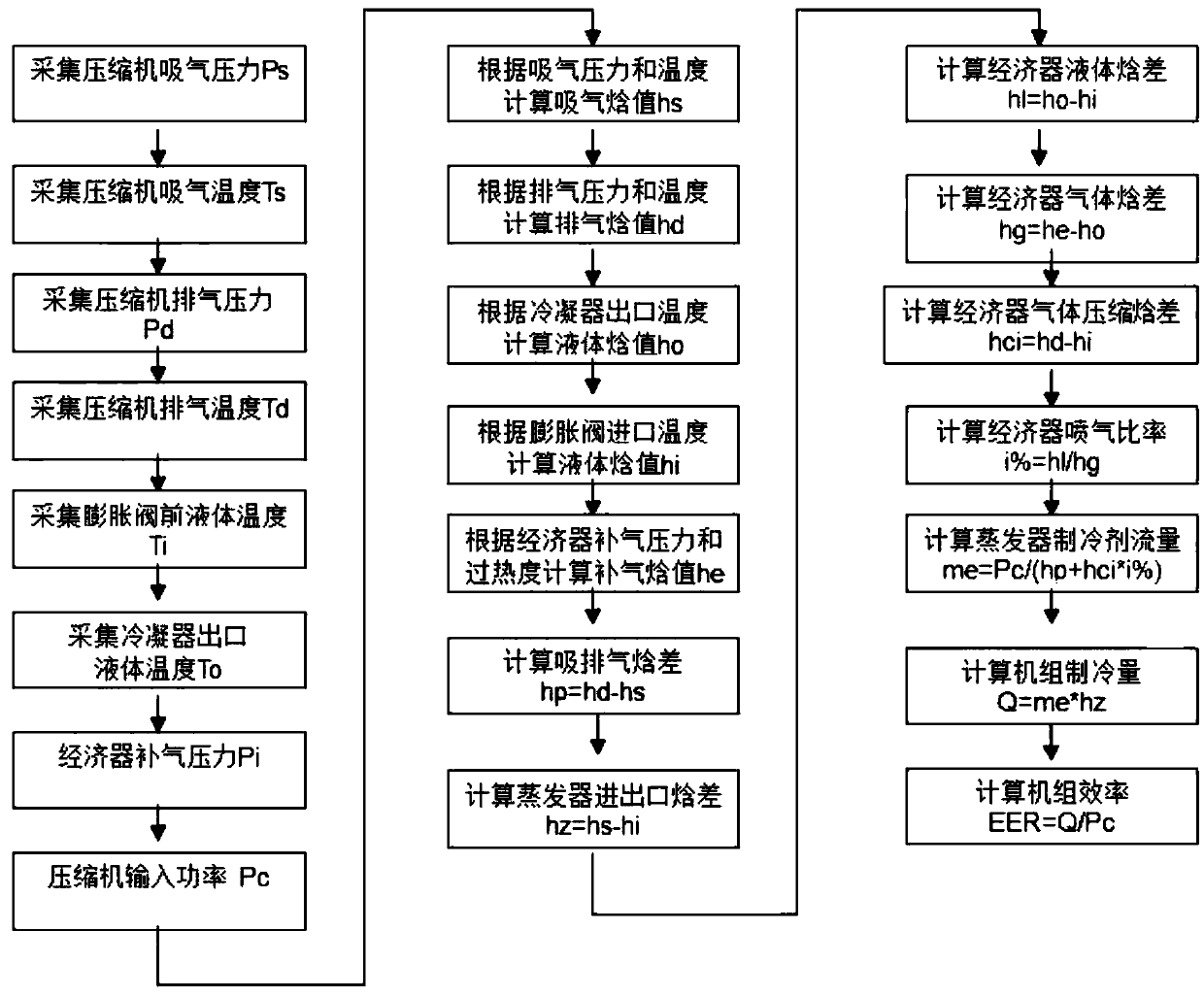

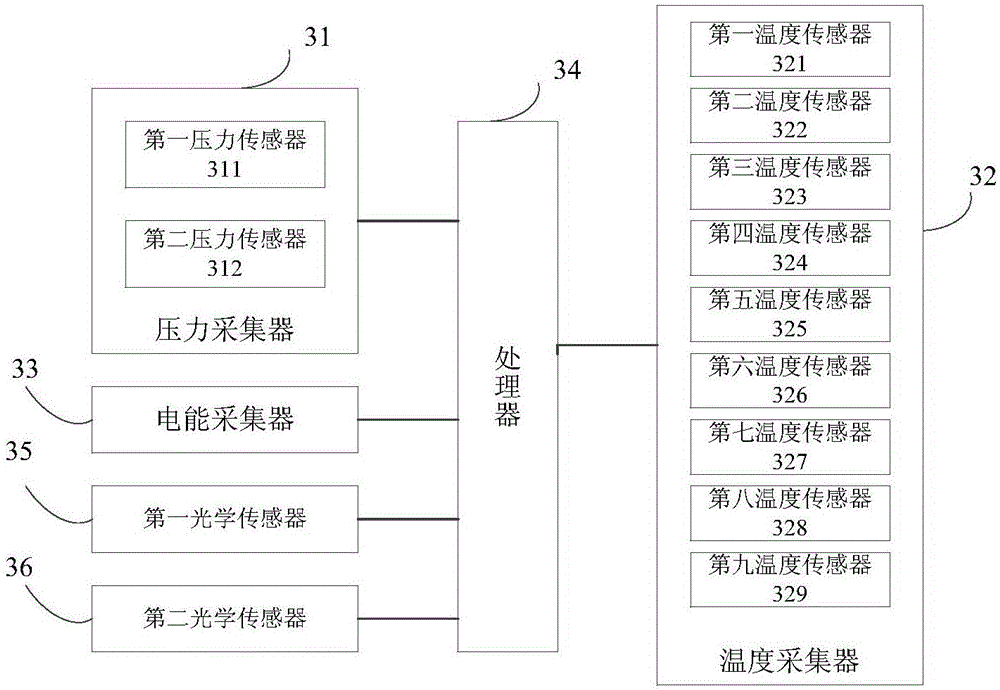

Computing method of refrigerating capacity and refrigerating efficiency of oil-free refrigerating system and refrigerating system

ActiveCN105091439AMaster the running status in real timeNot complexRefrigeration safety arrangementElectricityOil free

The invention discloses a computing method of the refrigerating capacity and the refrigerating efficiency of an oil-free refrigerating system and the refrigerating system. The computing method comprises the following steps of (1) collecting parameters; (2) looking up and obtaining an enthalpy value; (3) computing the enthalpy value; (4) computing the refrigerating capacity and the refrigerating efficiency of the refrigerating system. The refrigerating system comprises a refrigerating unit, a computing module and a display module, wherein the display module is electrically connected with the computing module and is used for displaying the computed refrigerating capacity Q and the computed refrigerating efficiency EER. According to the computing method of the refrigerating capacity and the refrigerating efficiency of the oil-free refrigerating system and the refrigerating system disclosed by the invention, a flow meter of which the cost is expensive is not required to be additionally arranged, the computing method is simple and effective, and the cost is lower; the display module can be used for displaying the refrigerating capacity and the refrigerating efficiency to a user for reference through a display panel, so that an operating state of the refrigerating system can be conveniently controlled by the user in real time.

Owner:SUZHOU BSE AIR CONDITIONER

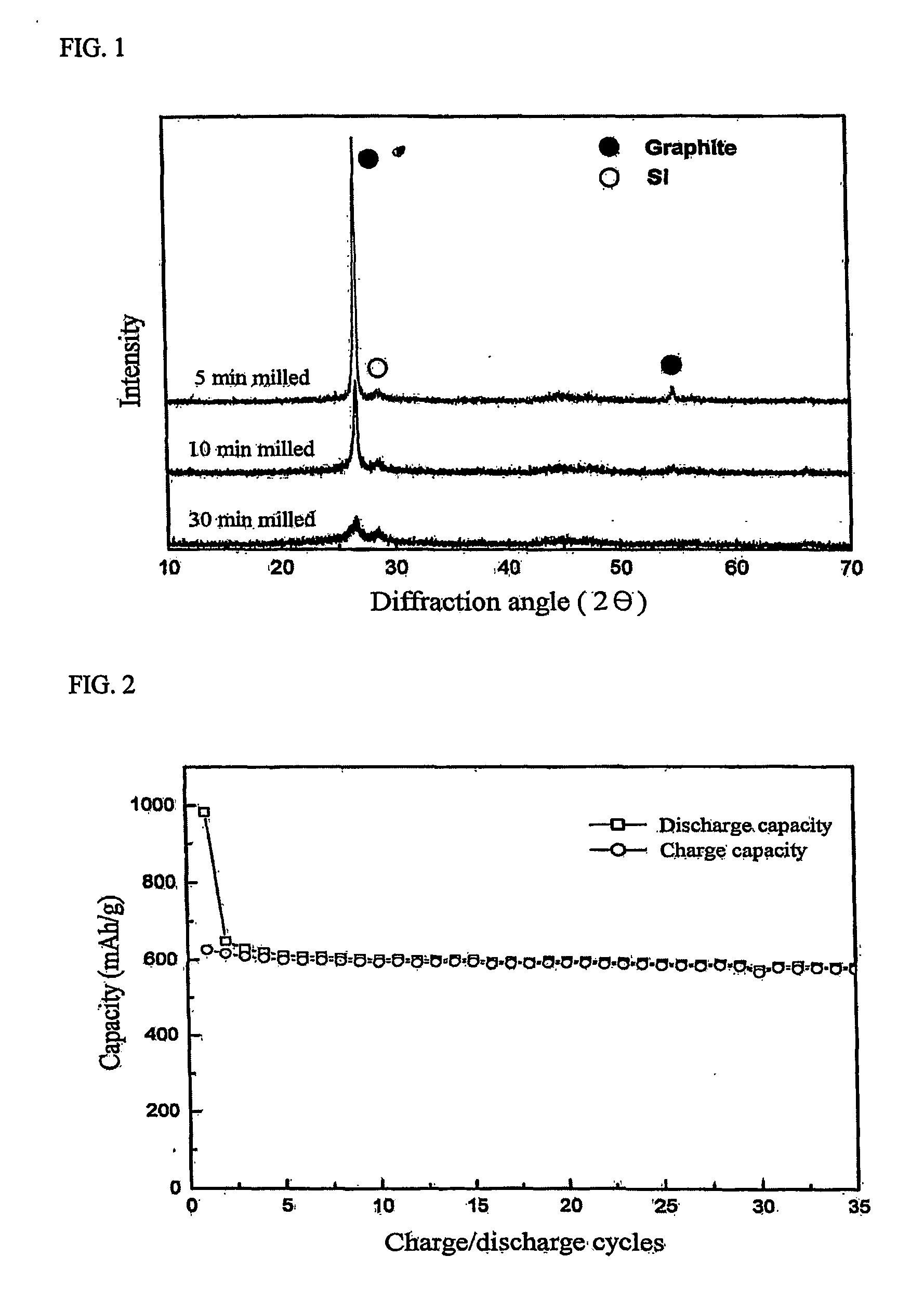

Negative active material for lithium secondary battery and method for preparating same

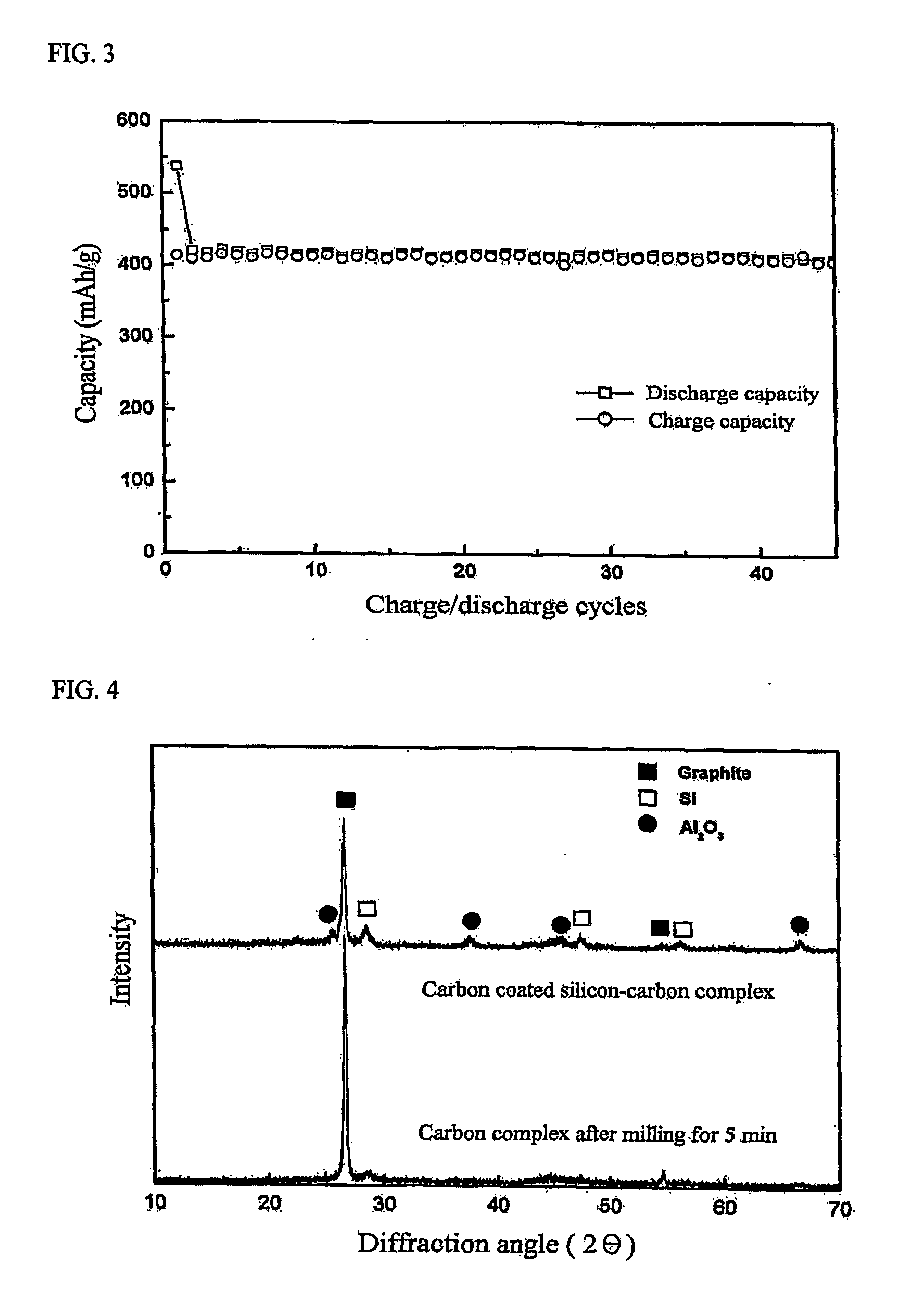

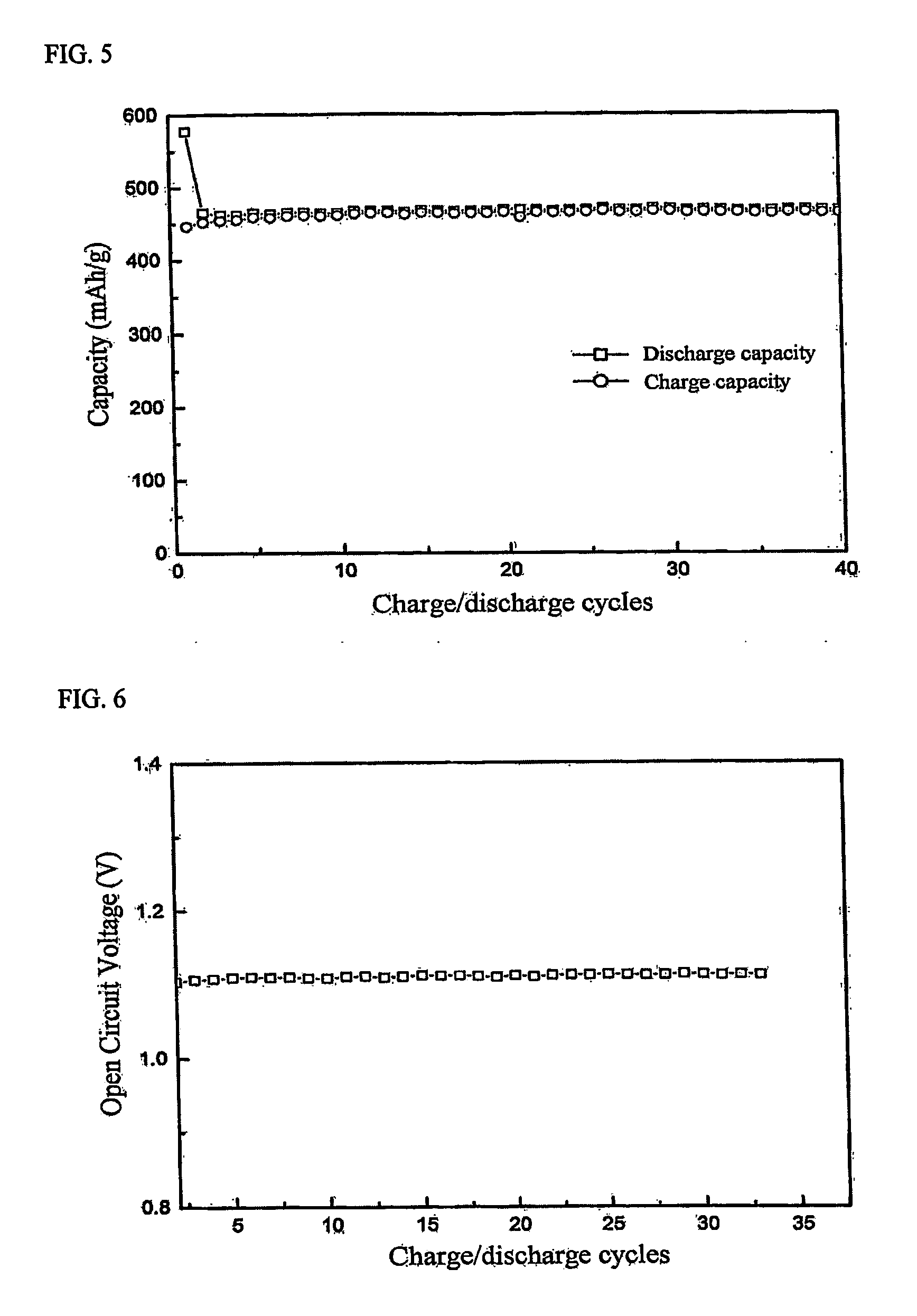

ActiveUS20070190413A1Reduce the amount of solutionImprove charge and discharge cycle lifeElectrode thermal treatmentActive material electrodesLithiumDischarge efficiency

Provided are an anode active material for a lithium secondary battery having high reversible capacity and excellent charge / discharge efficiency, comprising a complex composed of ultra-fine Si phase particles and an oxide surrounding the ultra-fine Si phase particles, and a carbon material; and a method for preparing the same. The present invention also provides a method for preparing an anode active material for a lithium secondary battery comprising producing a complex composed of ultra-fine Si particles and an oxide surrounding the ultra-fine Si particles by mixing a silicon oxide and a material having an absolute value of oxide formation enthalpy (ΔHfor) greater than that of the silicon oxide and negative oxide formation enthalpy by a mechanochemical process or subjecting them to a thermochemical reaction to reduce the silicon oxide; and mixing the Si phase-containing oxide complex and carbon material.

Owner:LG ENERGY SOLUTION LTD

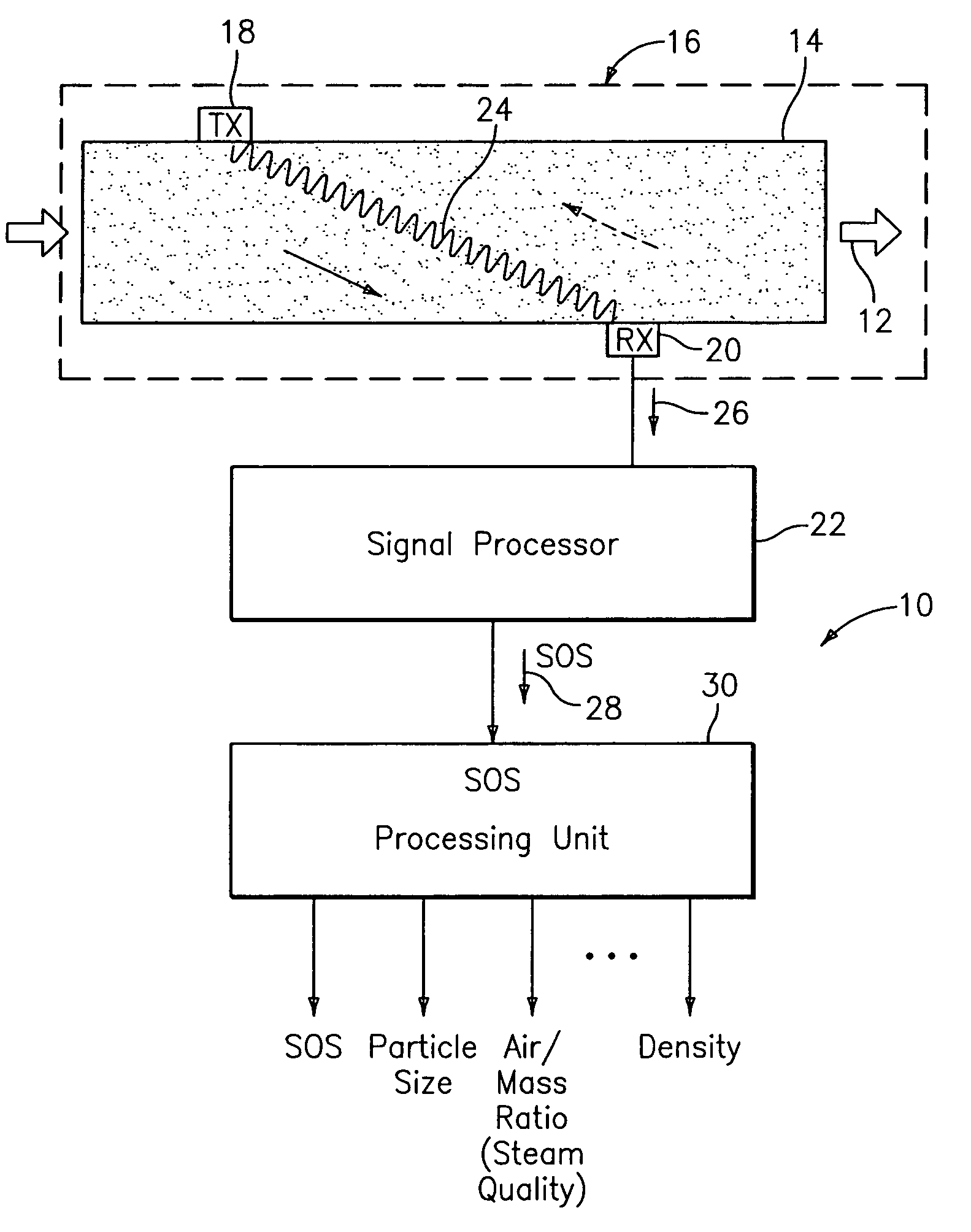

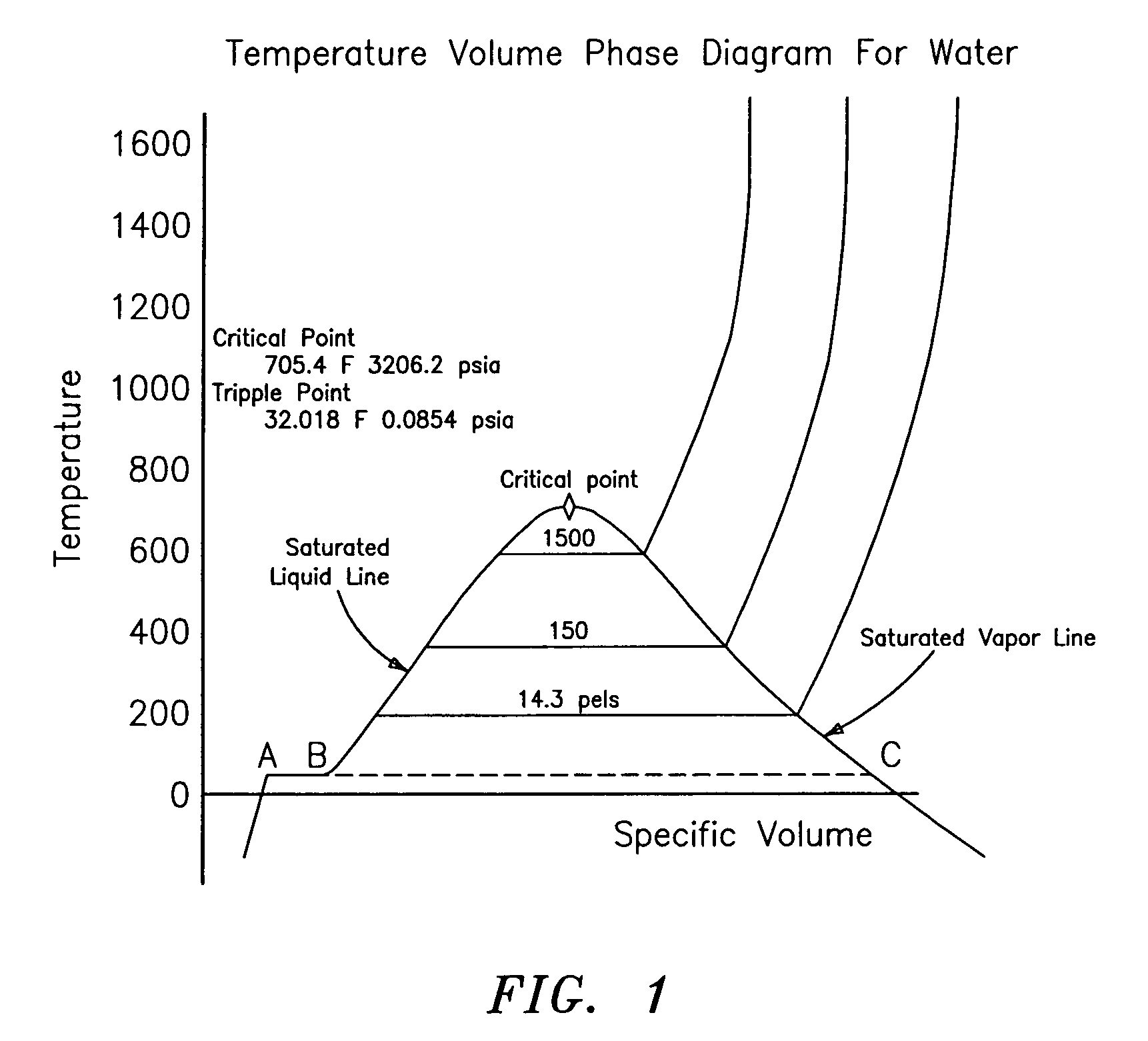

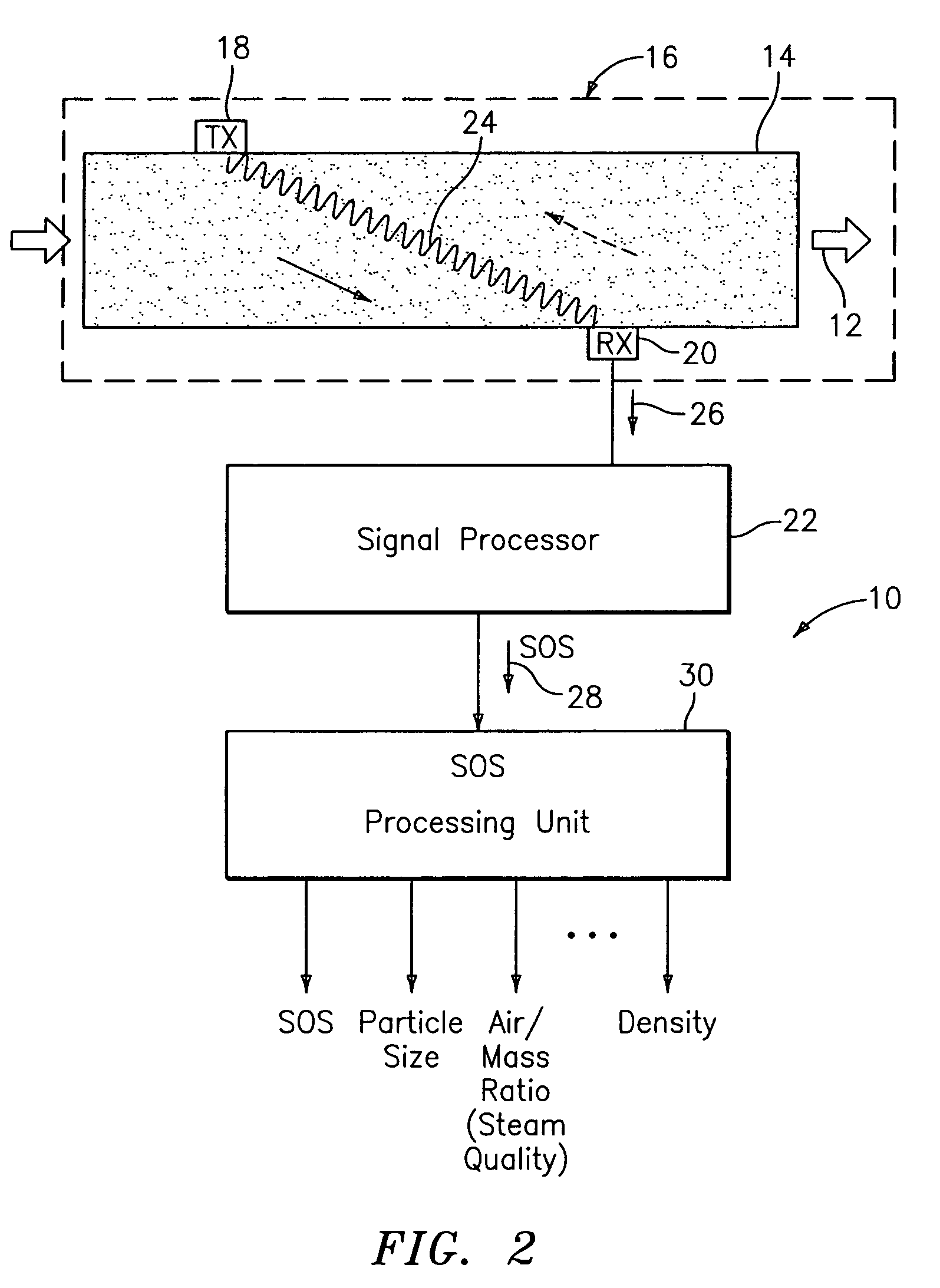

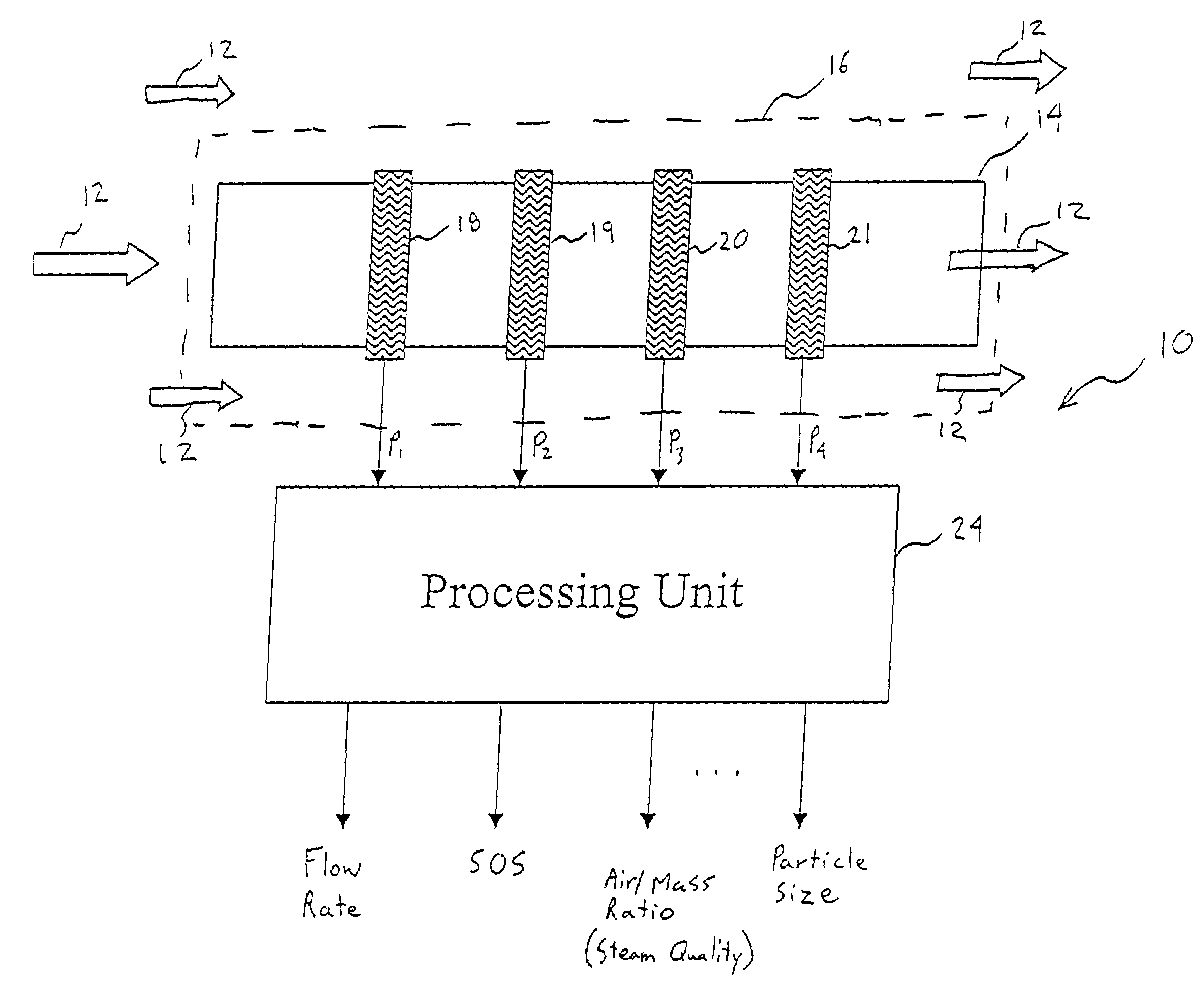

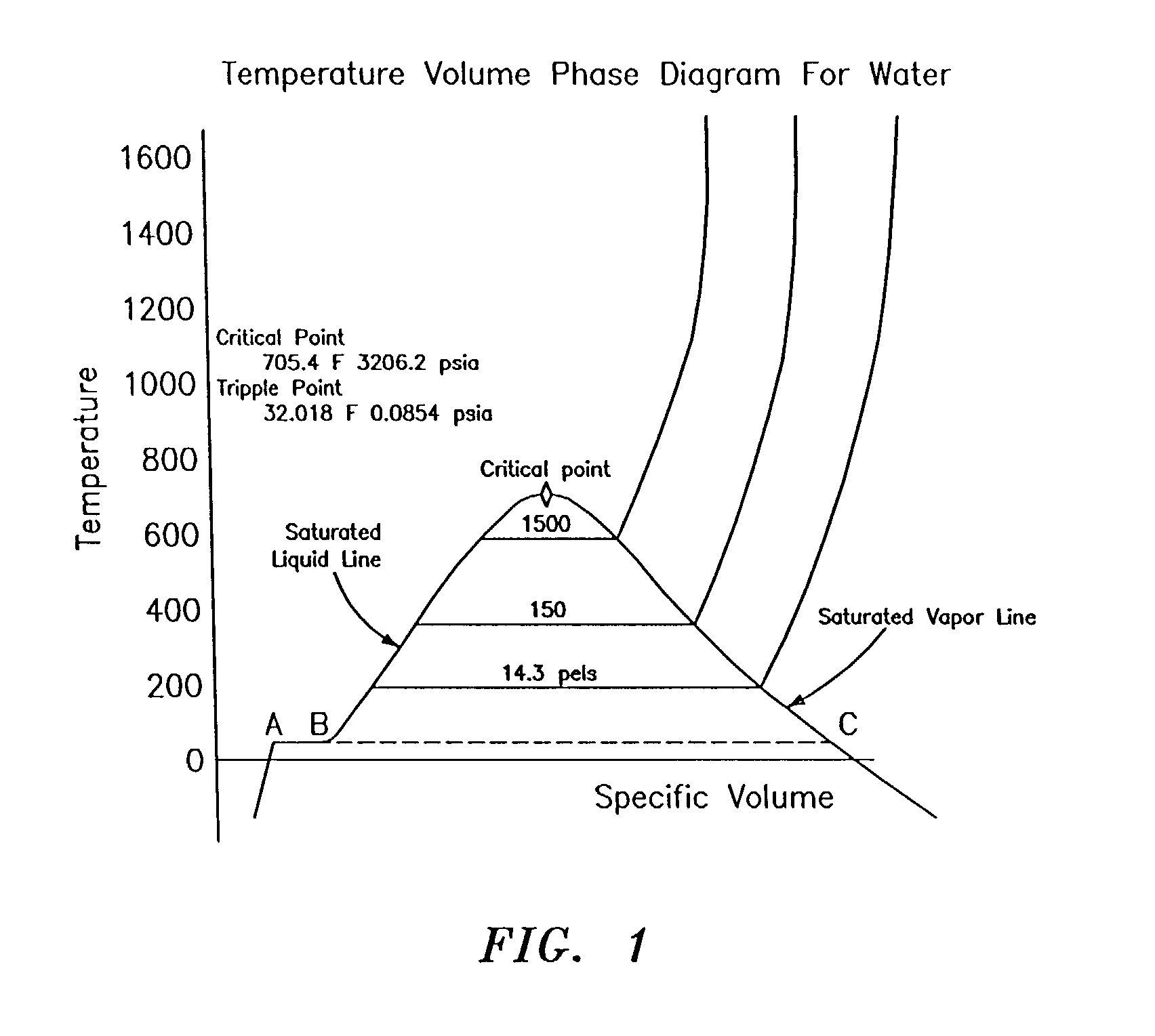

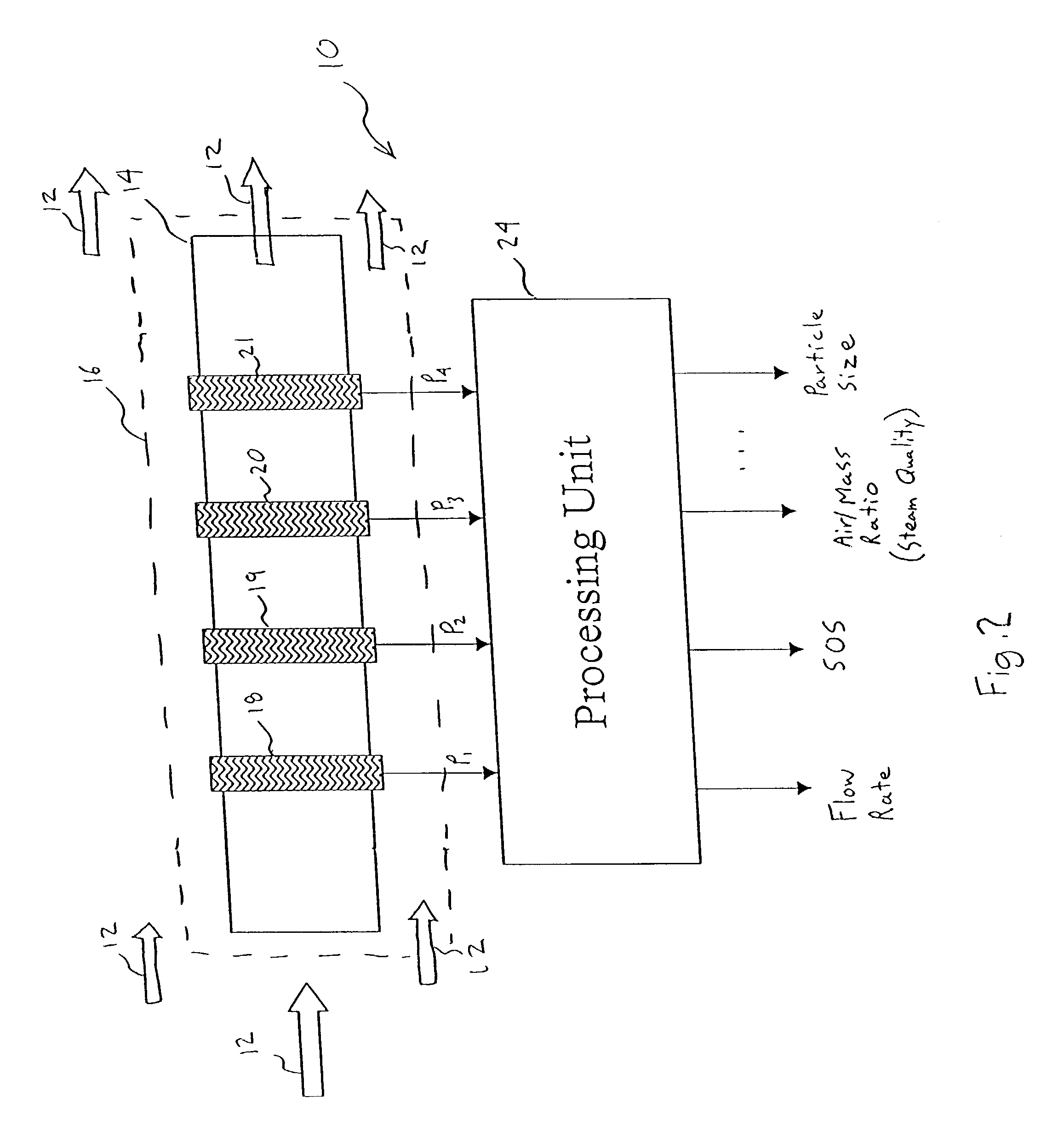

Apparatus for measuring parameters of a flowing multiphase mixture

ActiveUS7096719B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorMass ratio

An apparatus 10 is provided that measures the speed of sound propagating in a multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The apparatus includes a pair of ultrasonic transducers disposed axially along the pipe for measuring the transit time of an ultrasonic signal to propagate from one ultrasonic transducer to the other ultrasonic transducer. A signal process, responsive to said transit time signal, provides a signal representative of the speed of sound of the mixture. An SOS processing unit then provides an output signal indicative of at least one parameter of the mixture flowing through the pipe. The frequency of the ultrasonic signal is sufficiently low to minimize scatter from particle / liquid within the mixture. The frequency based sound speed is determined utilizing a dispersion model to determine the at least one parameter of the fluid flow and / or mixture.

Owner:CIDRA CORP SERVICES

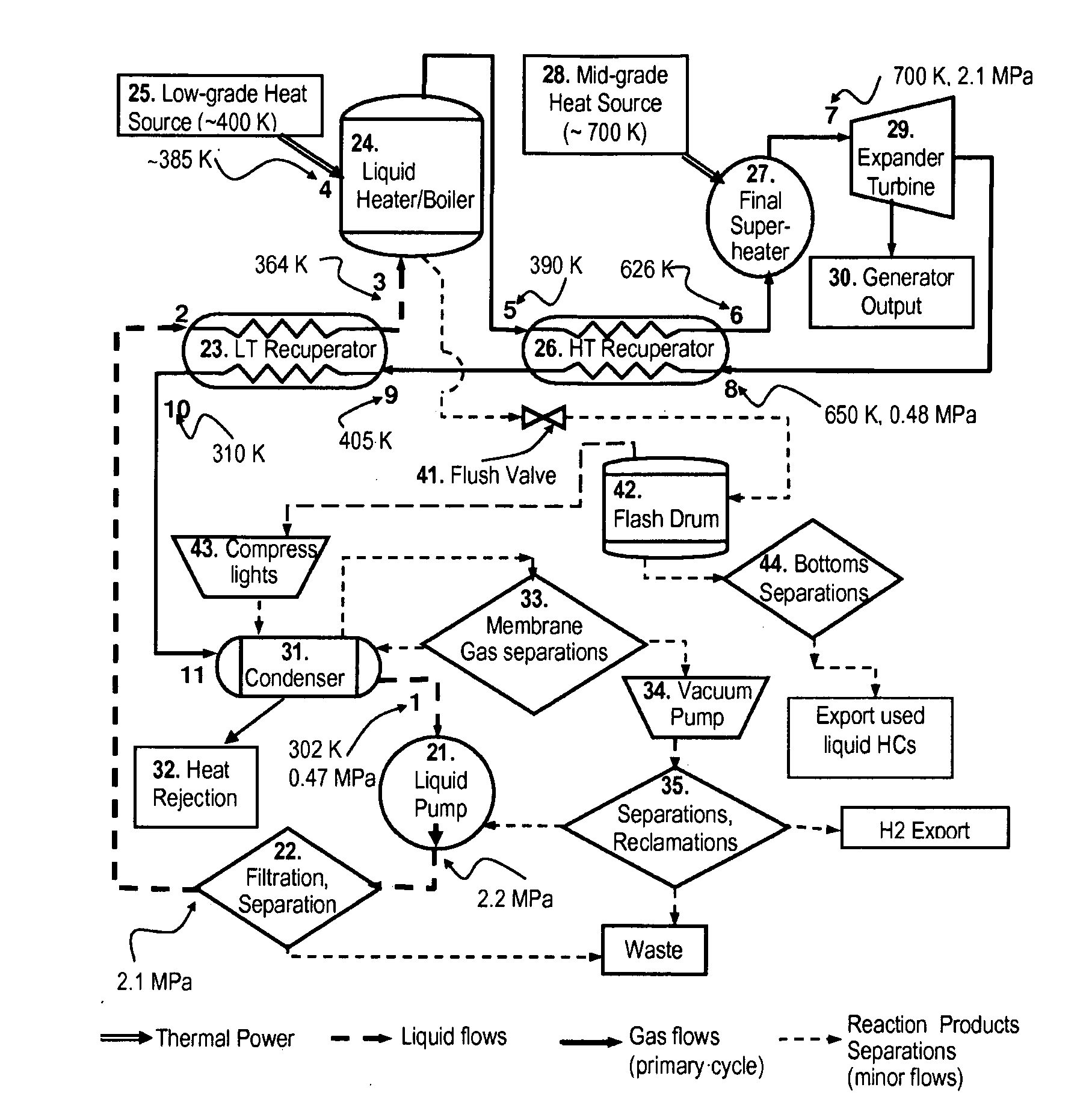

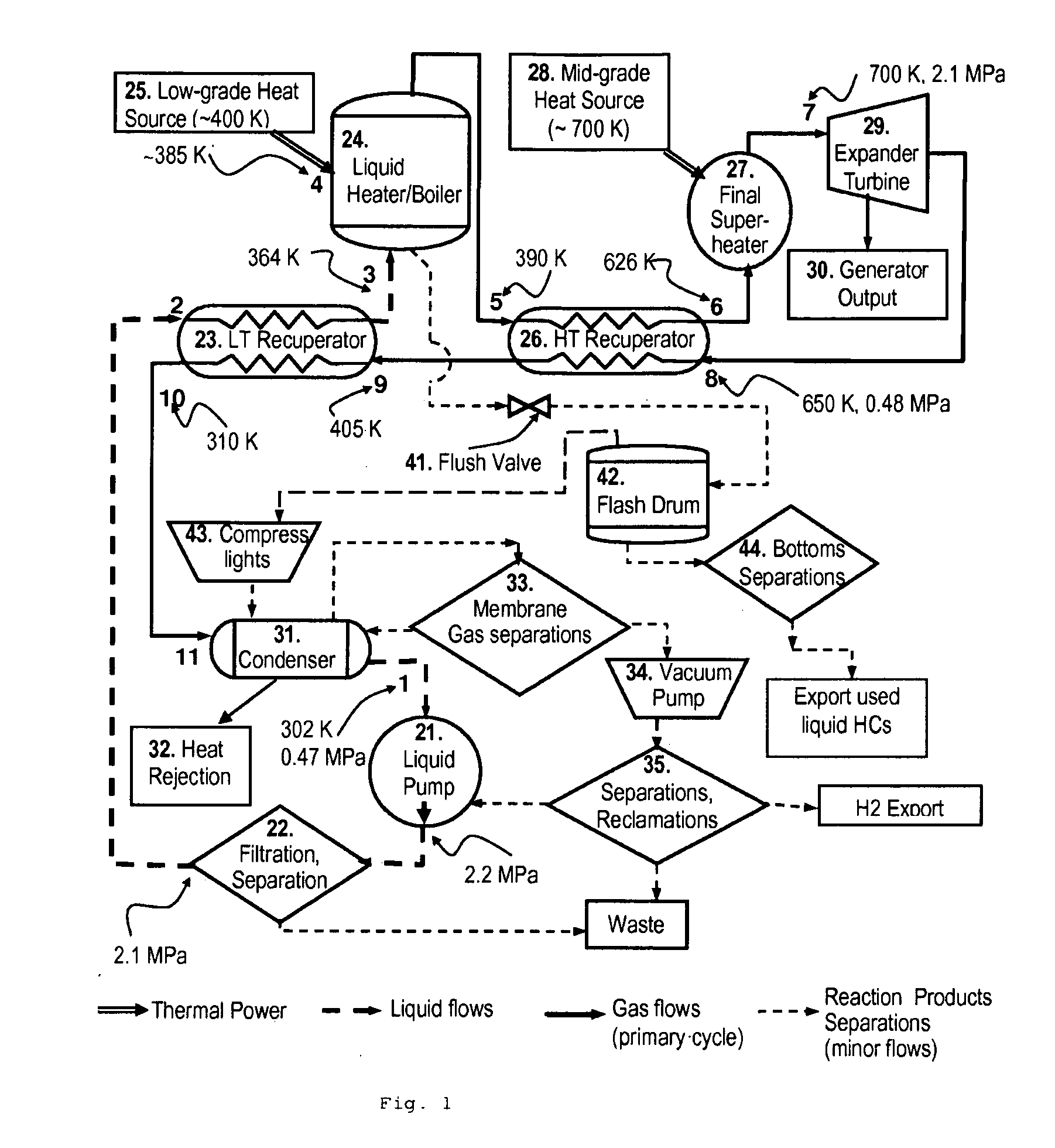

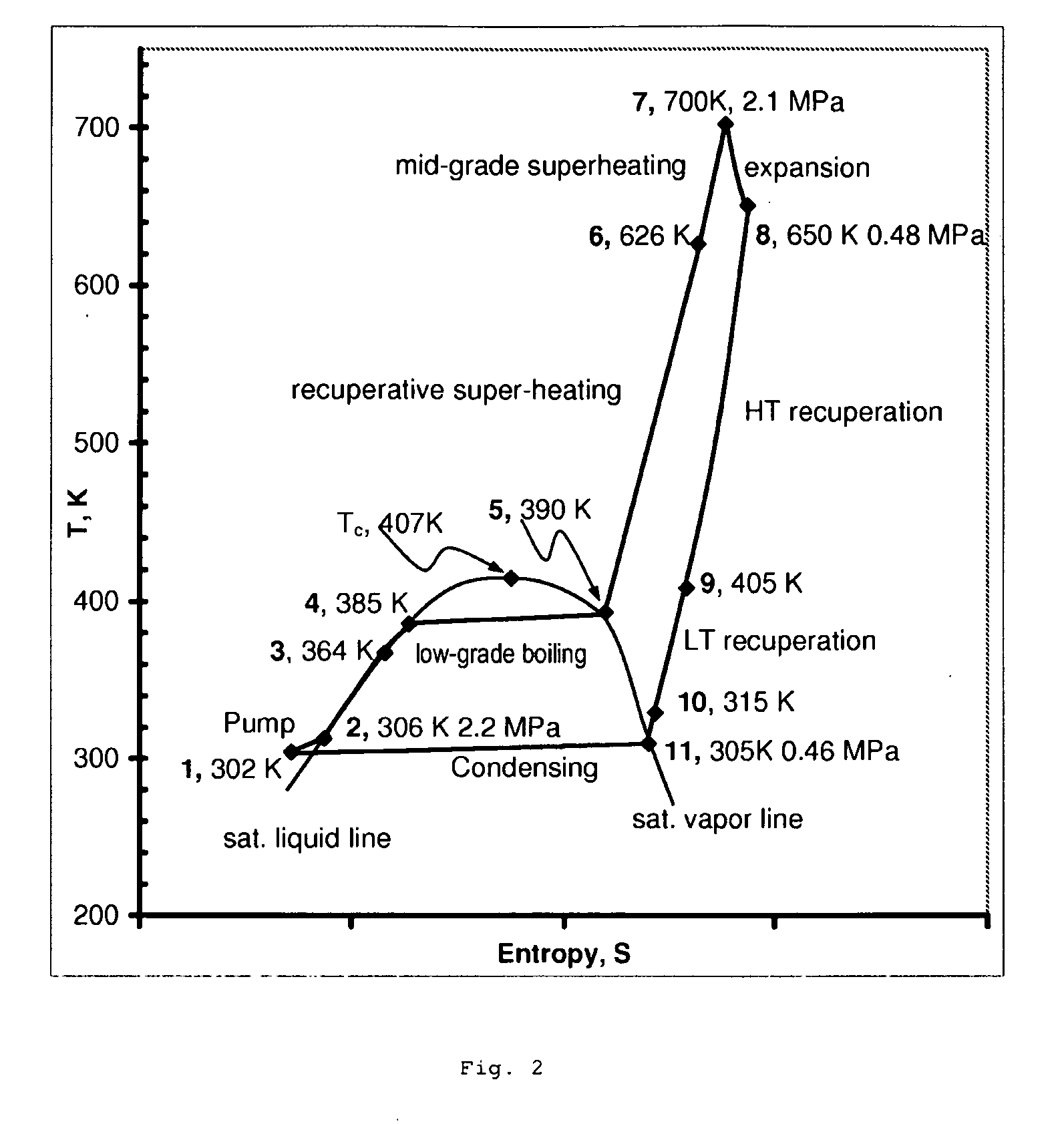

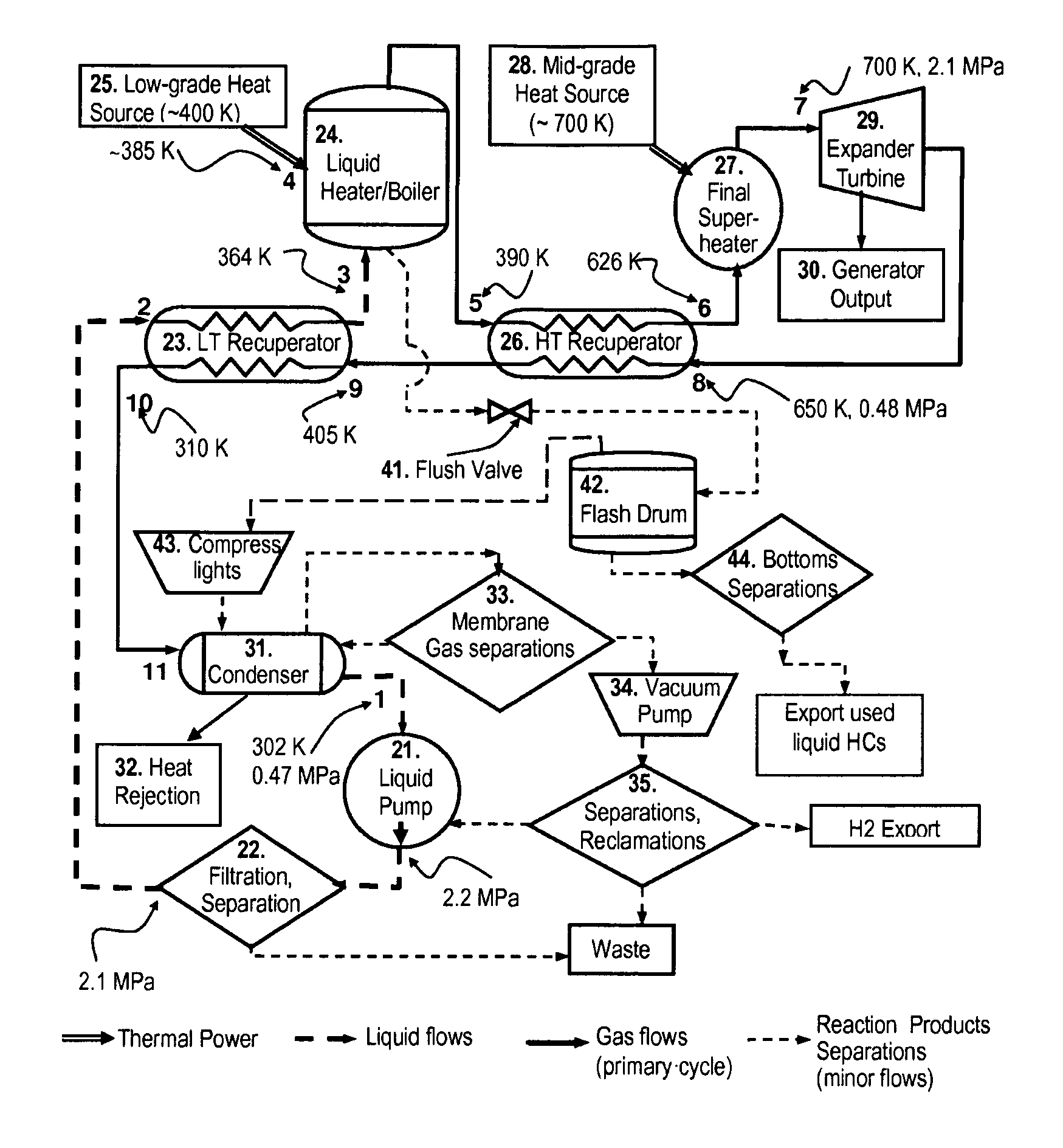

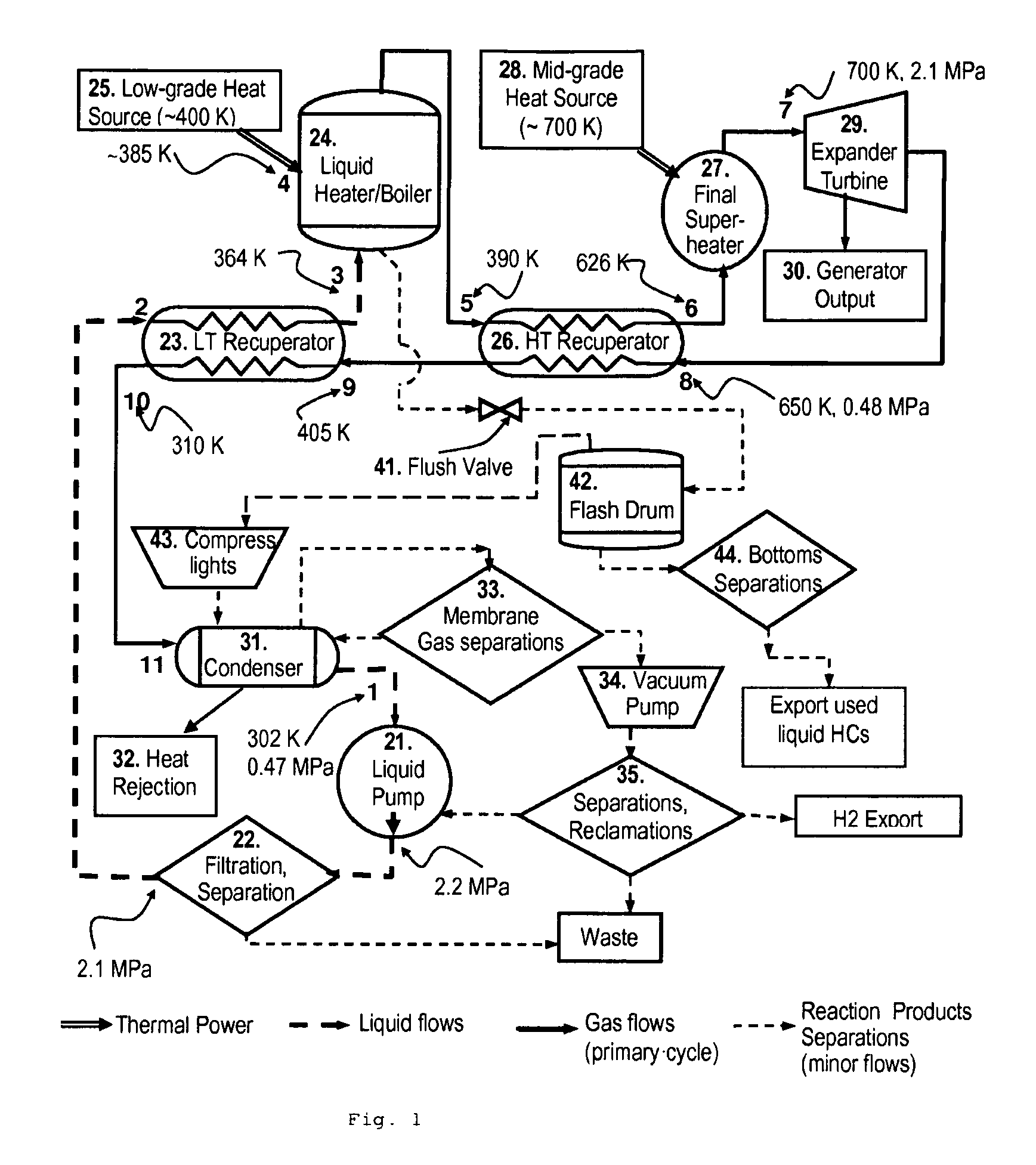

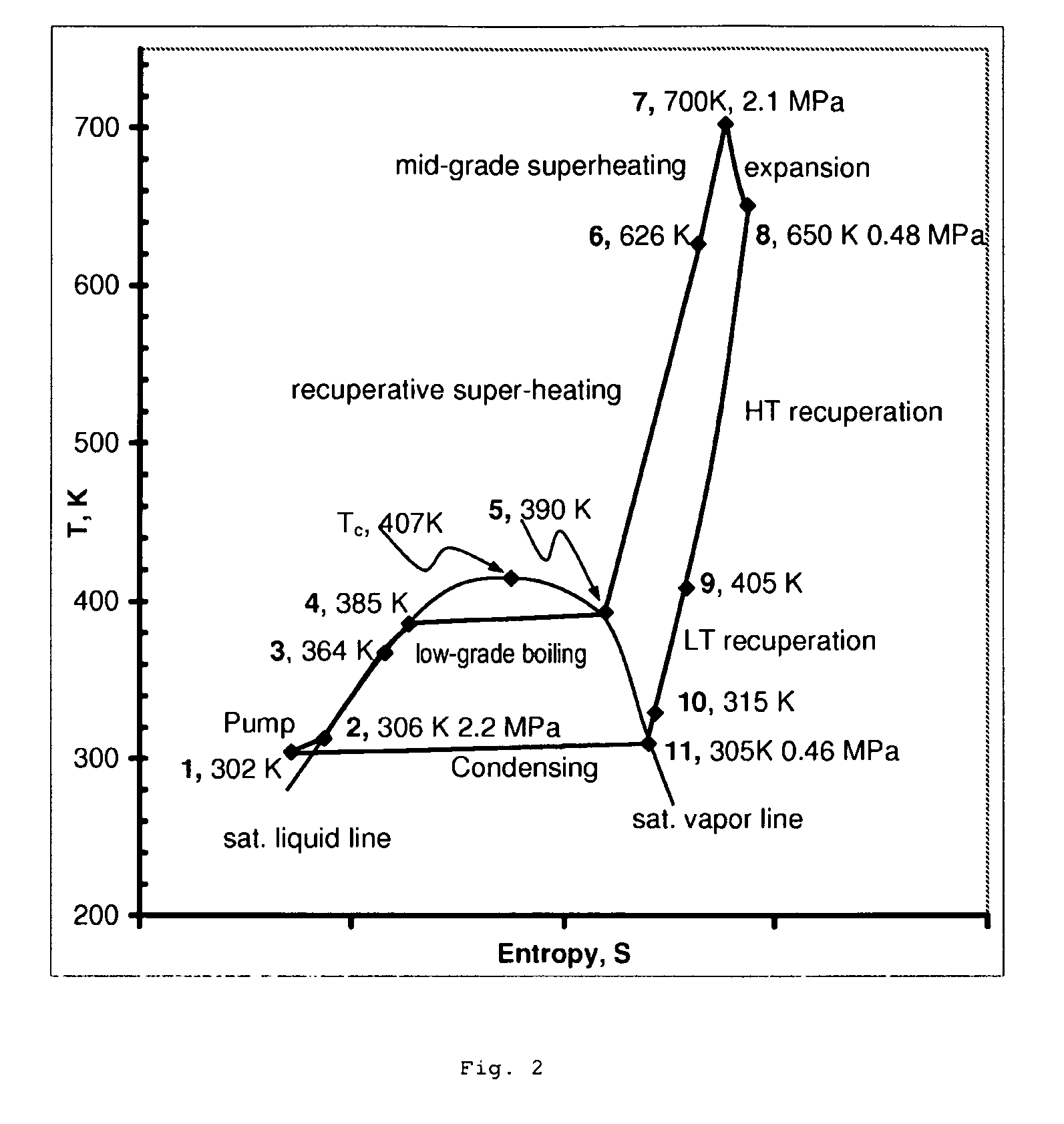

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

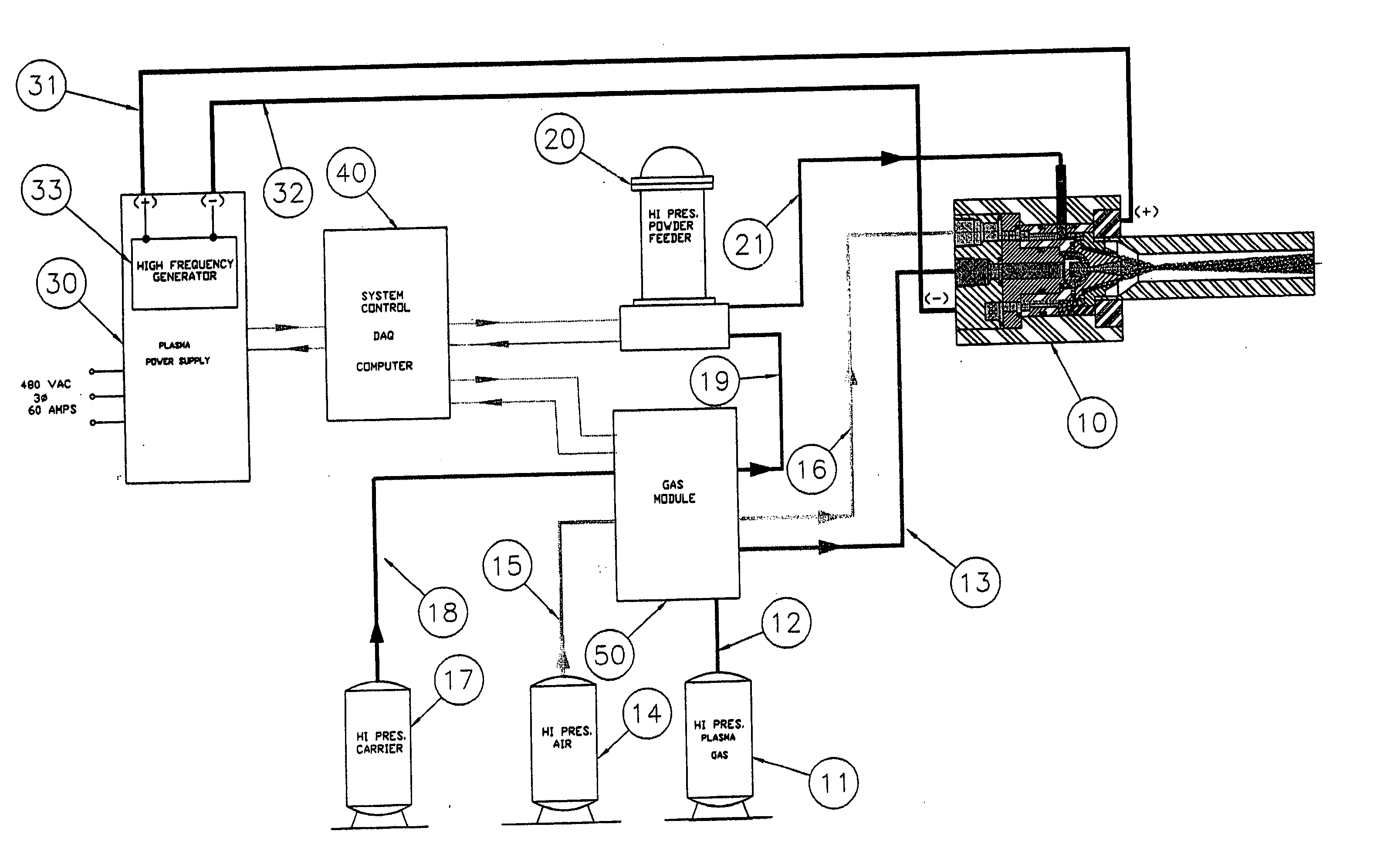

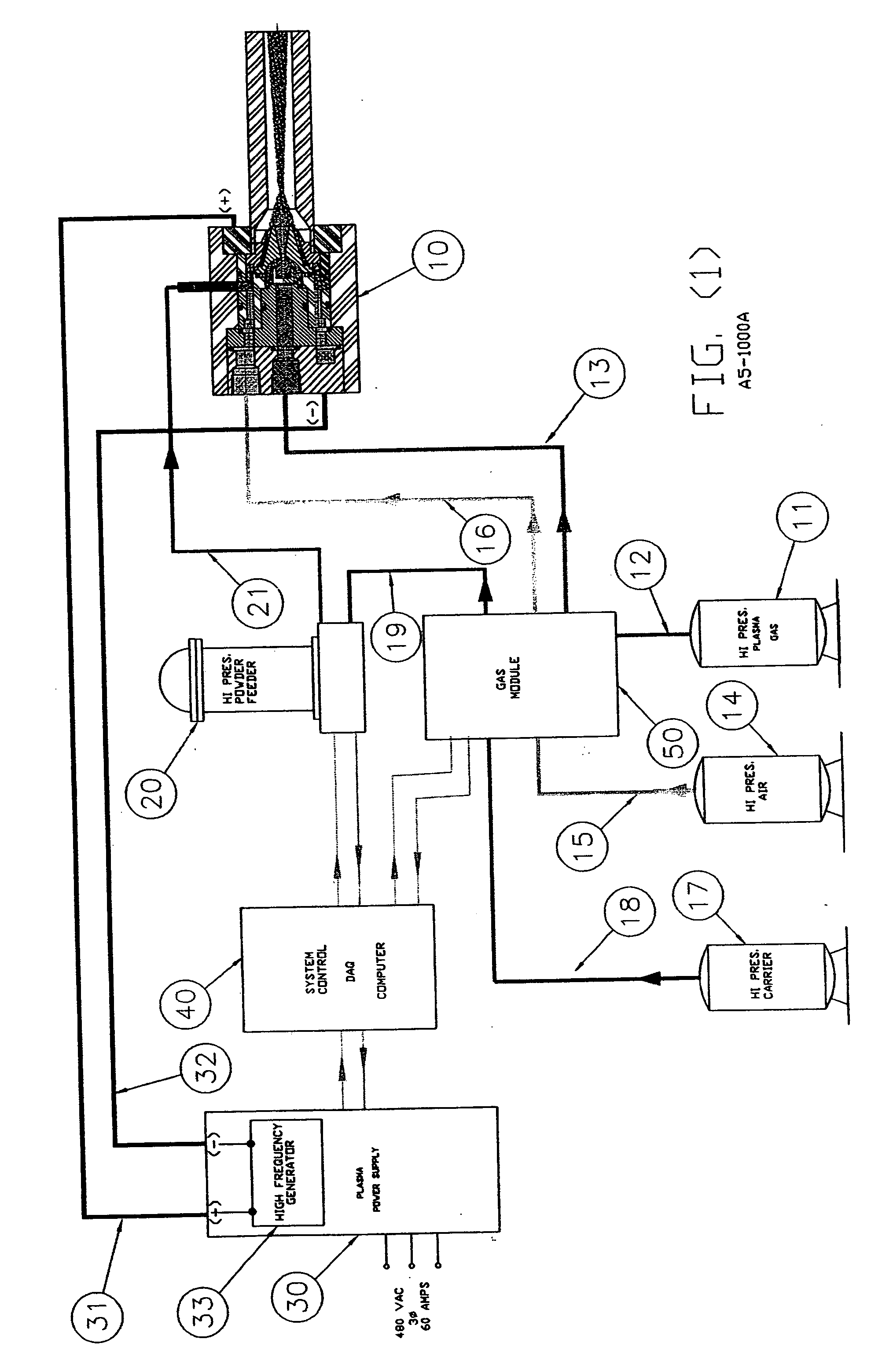

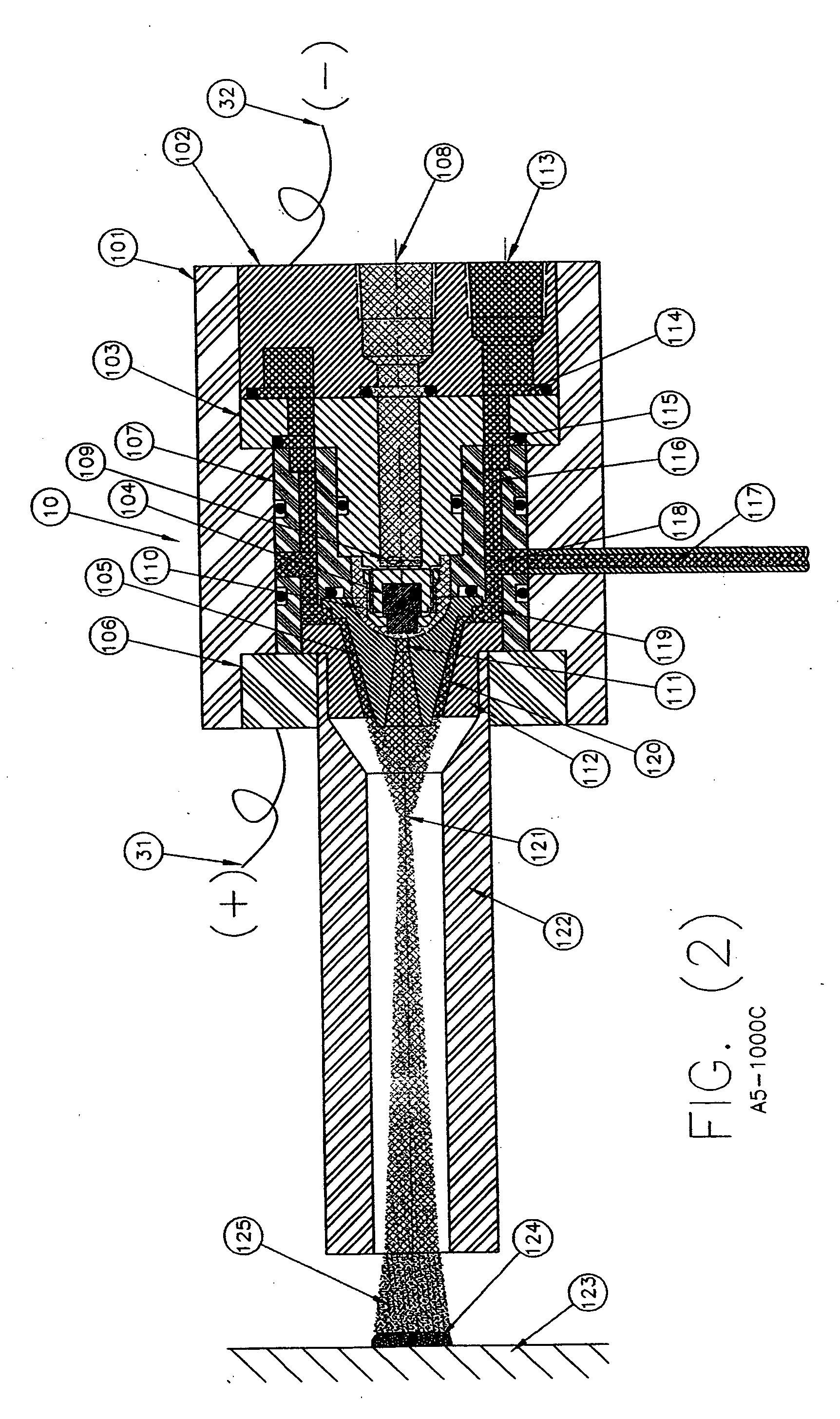

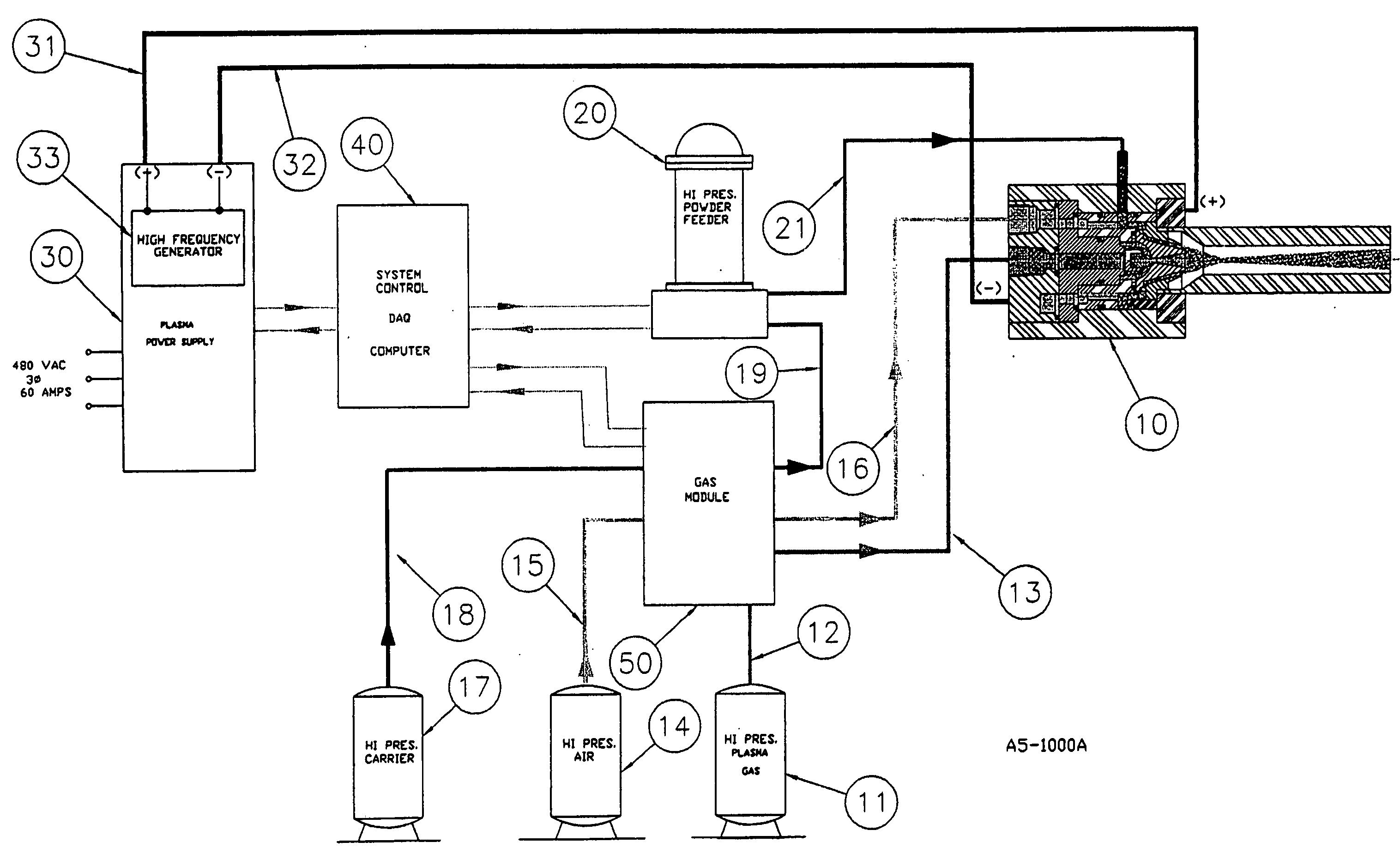

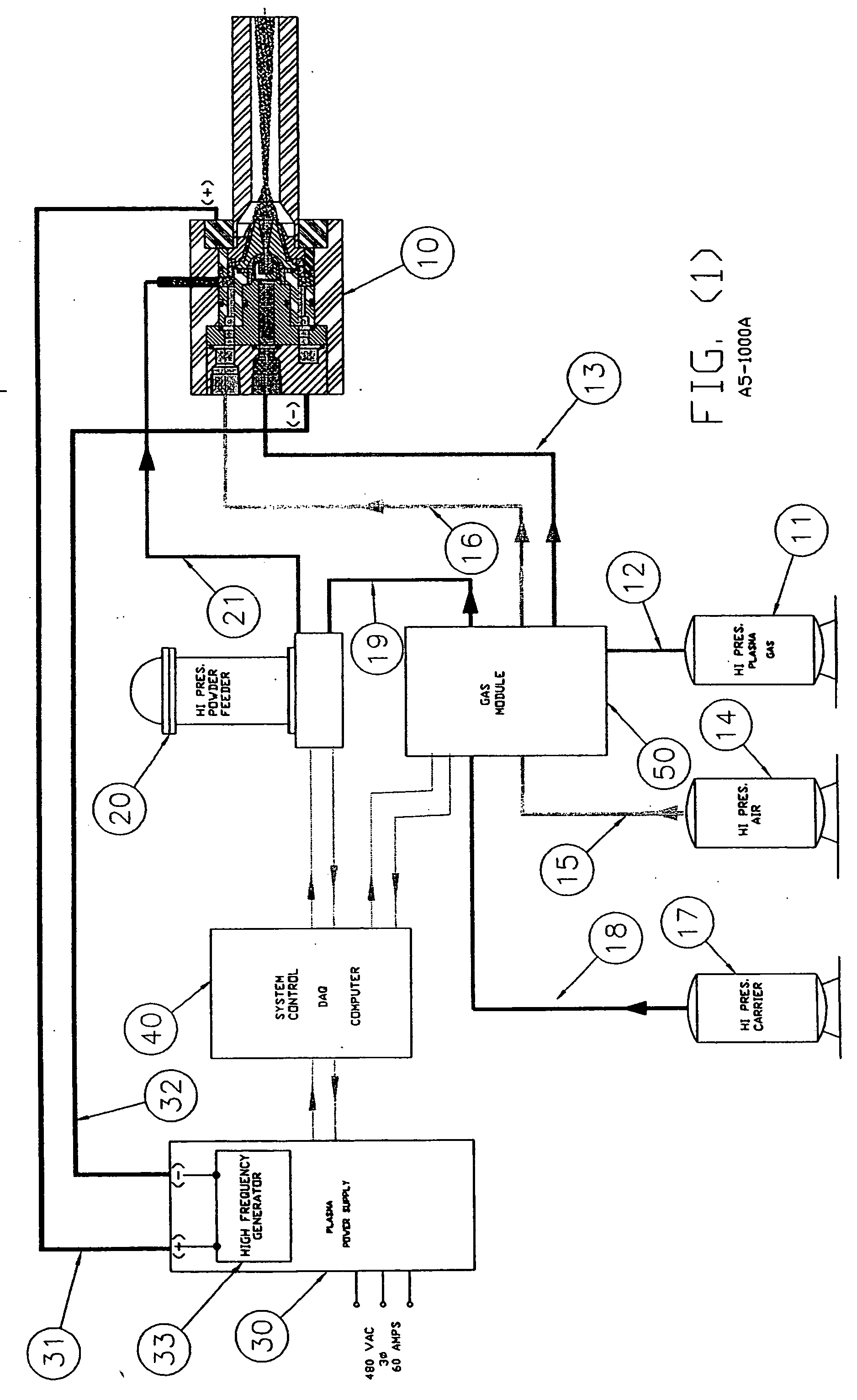

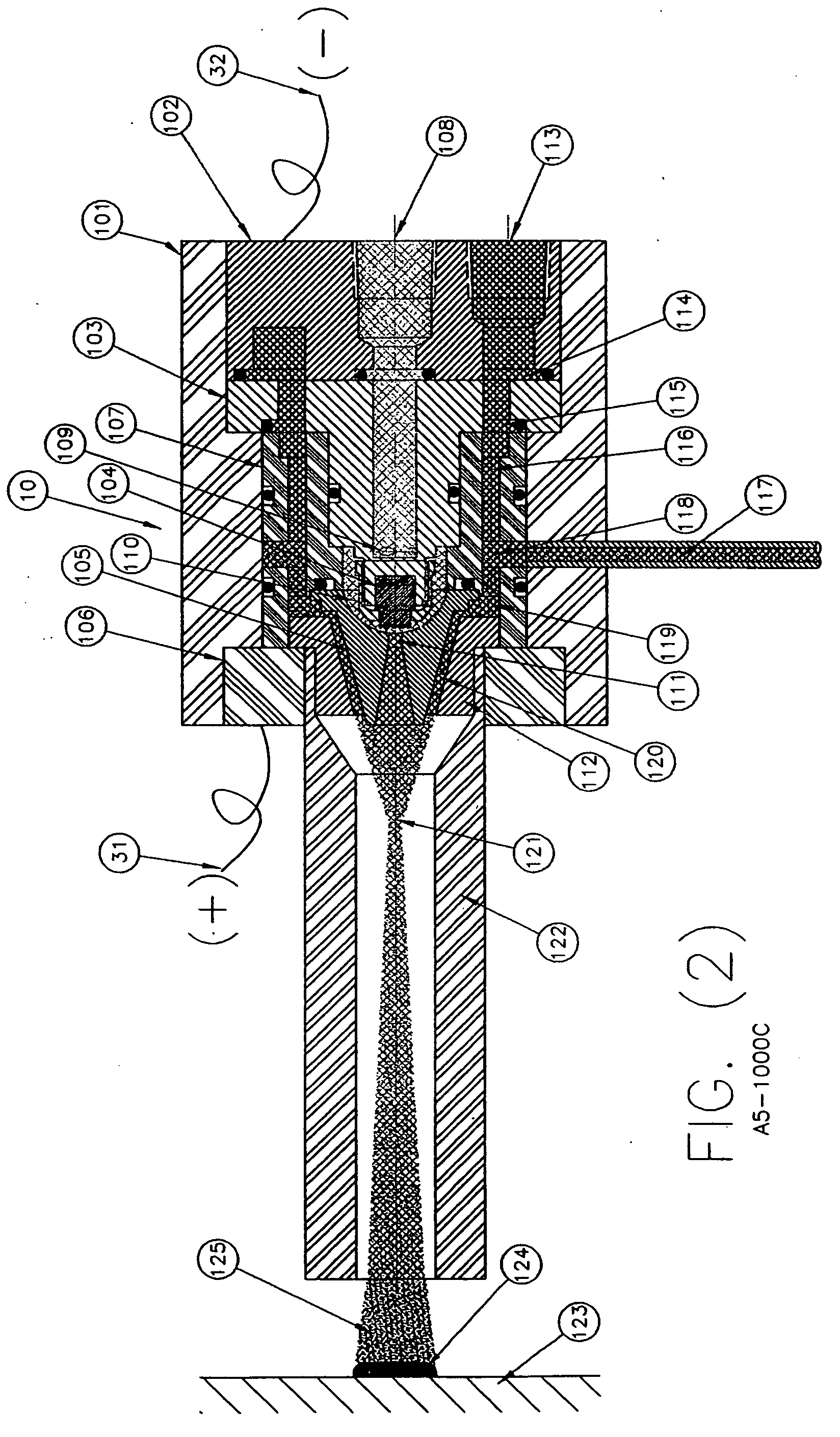

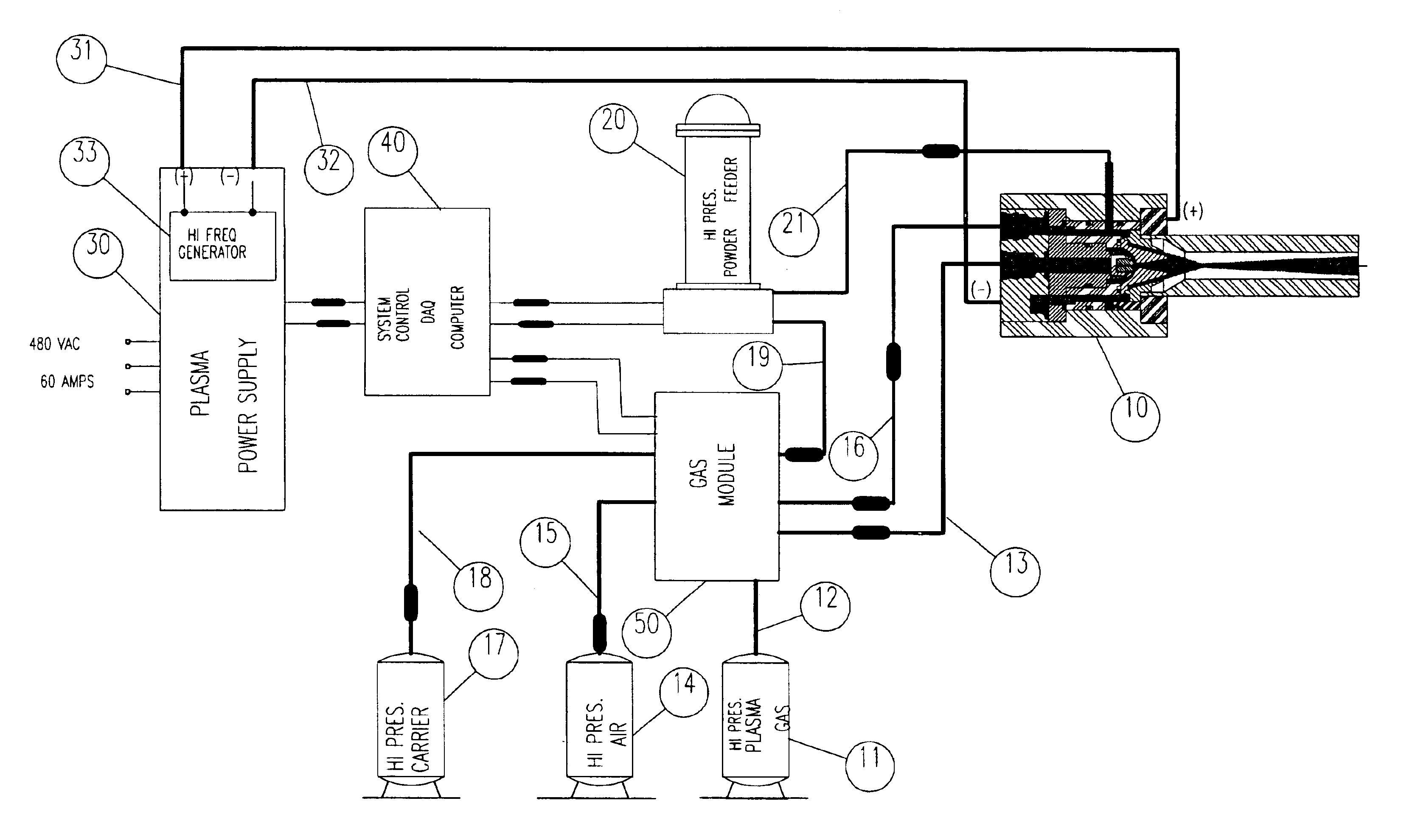

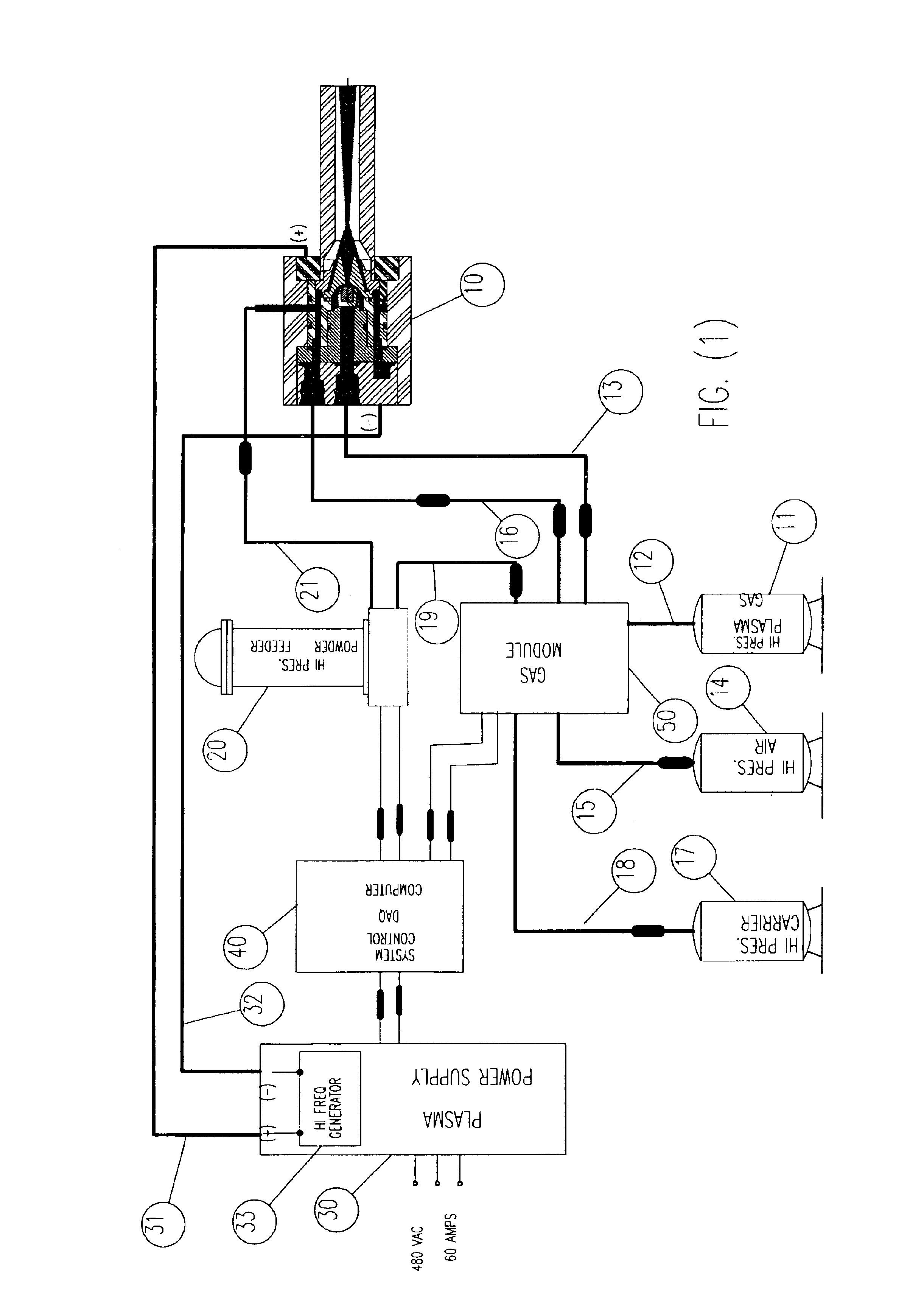

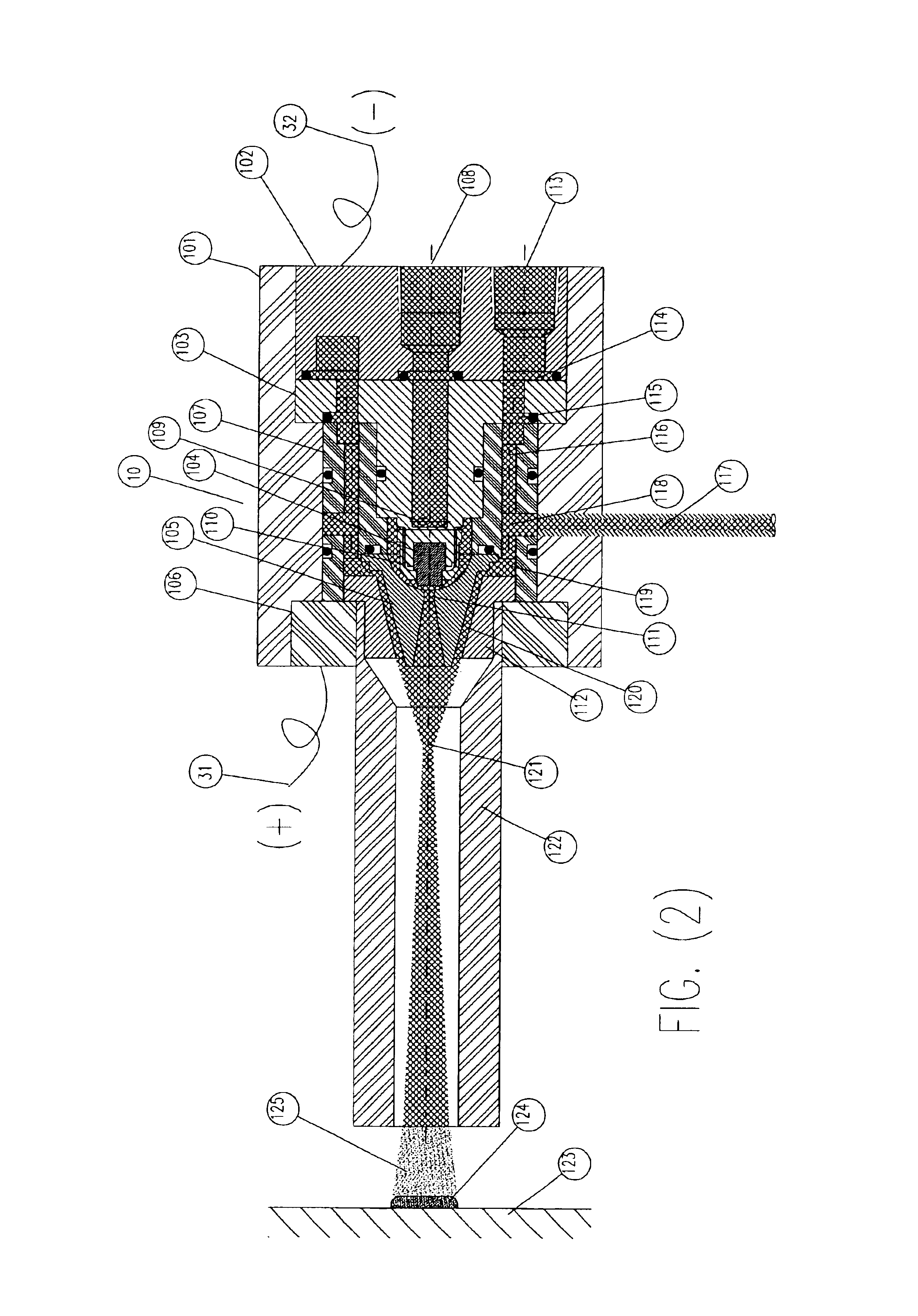

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

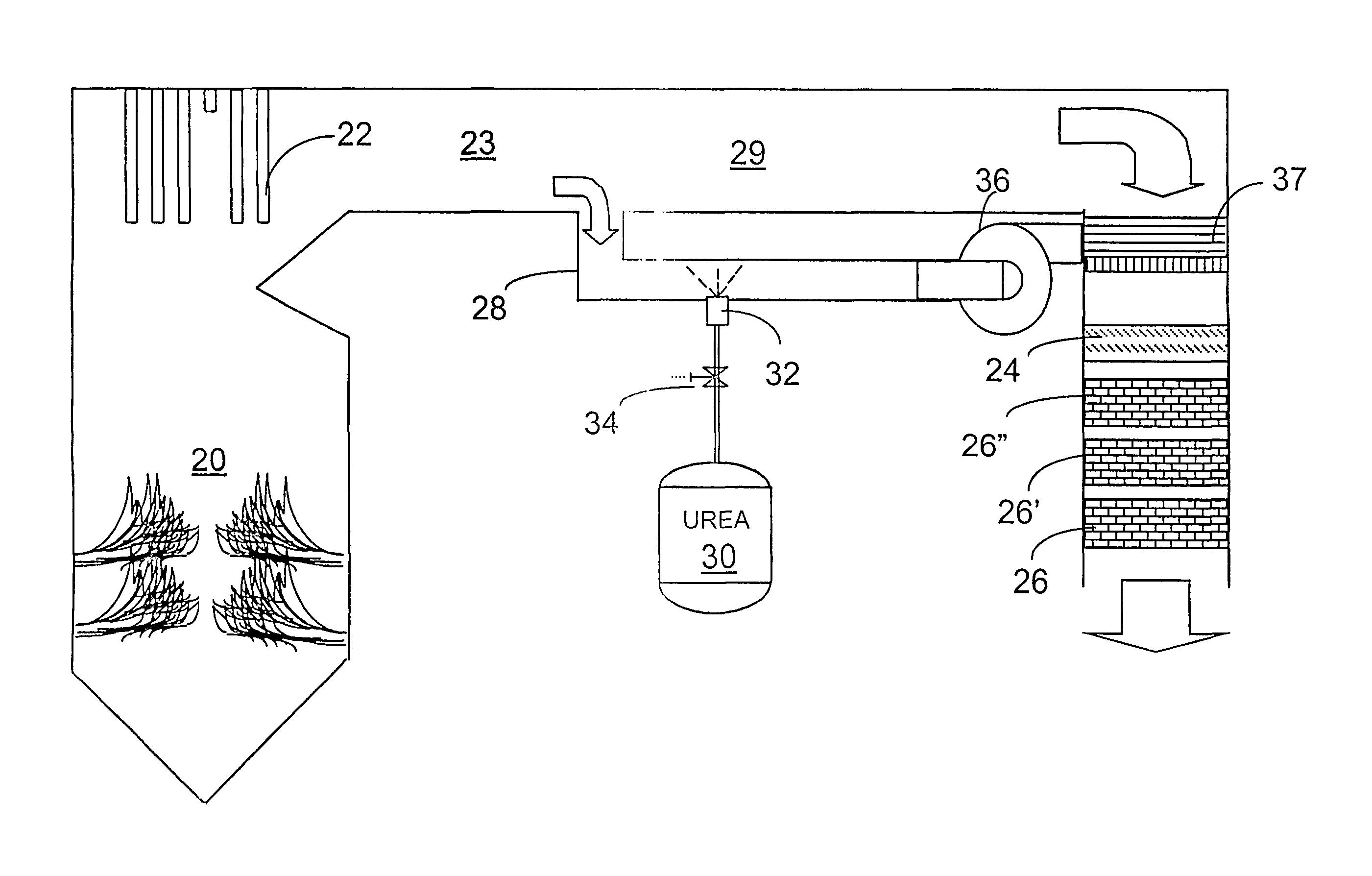

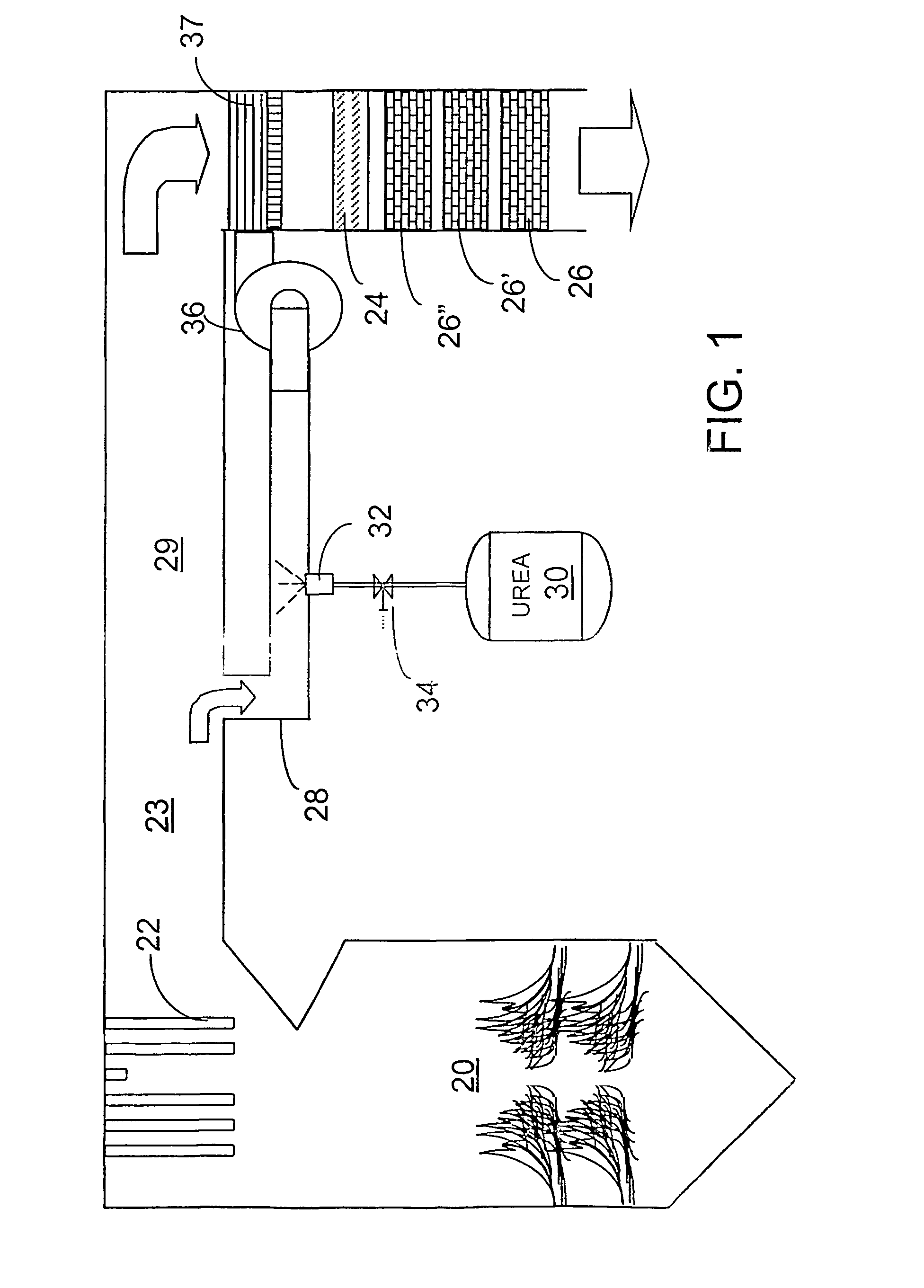

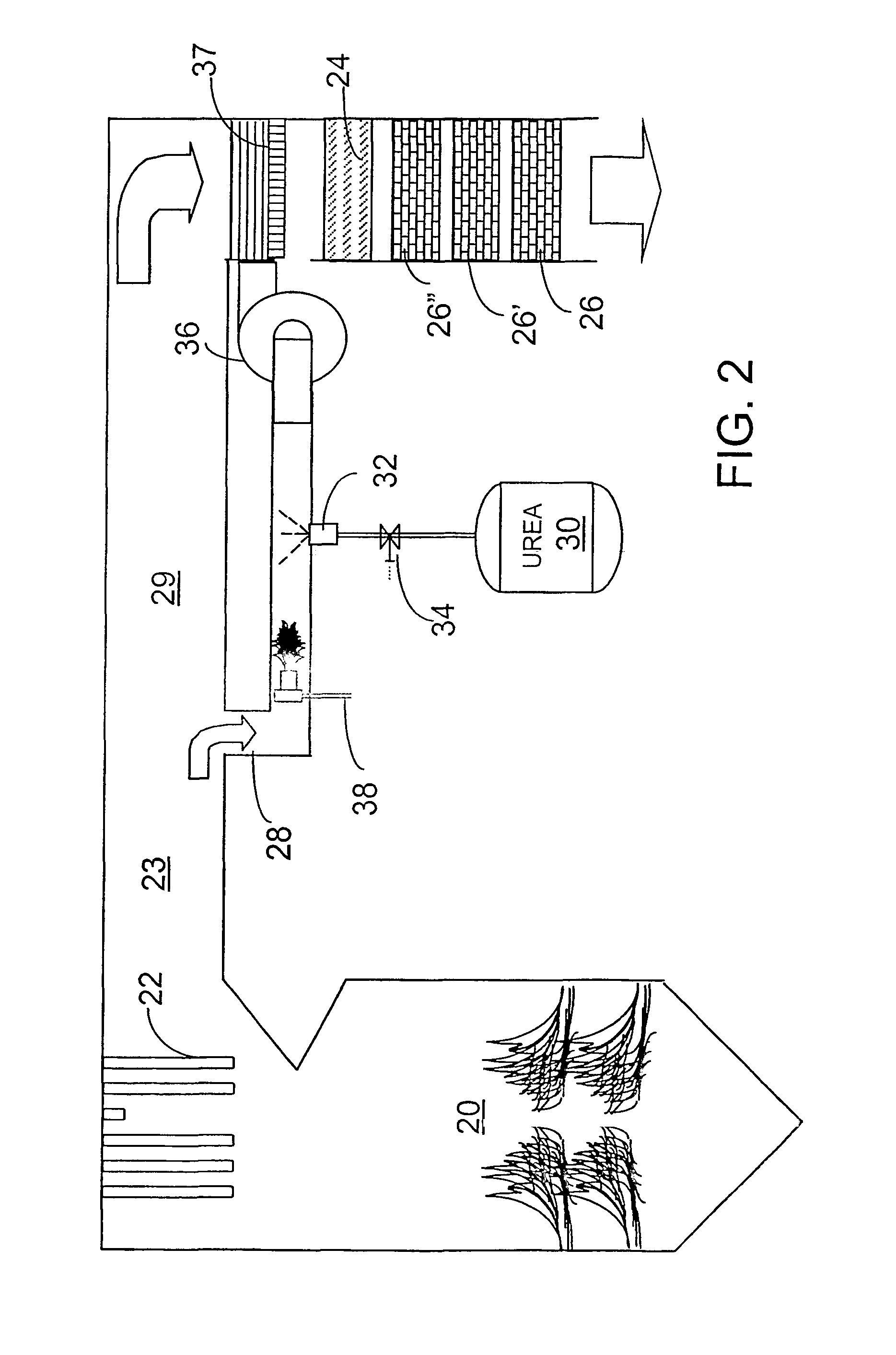

Selective catalytic reduction of nox enabled by sidestream urea decomposition

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

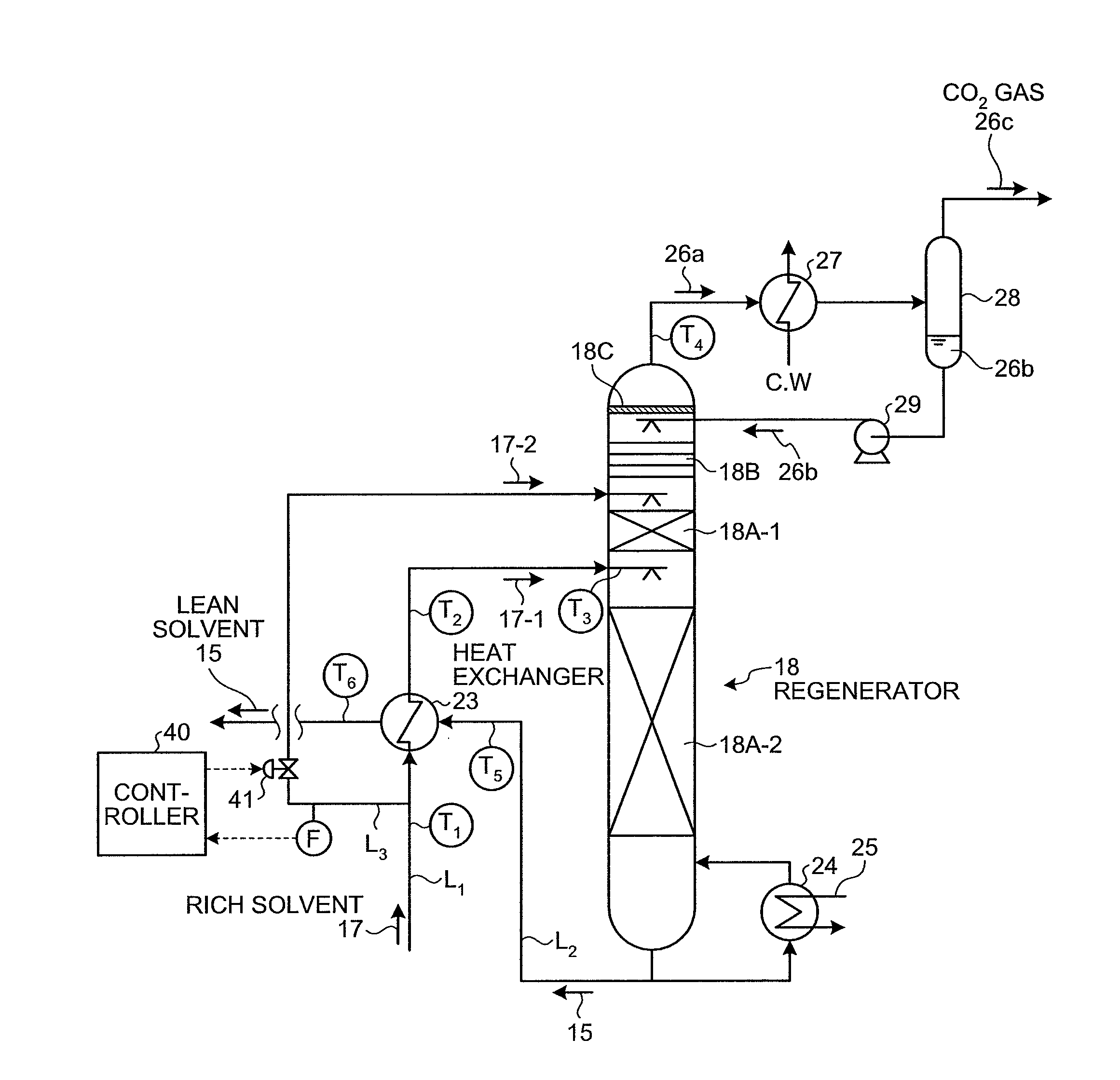

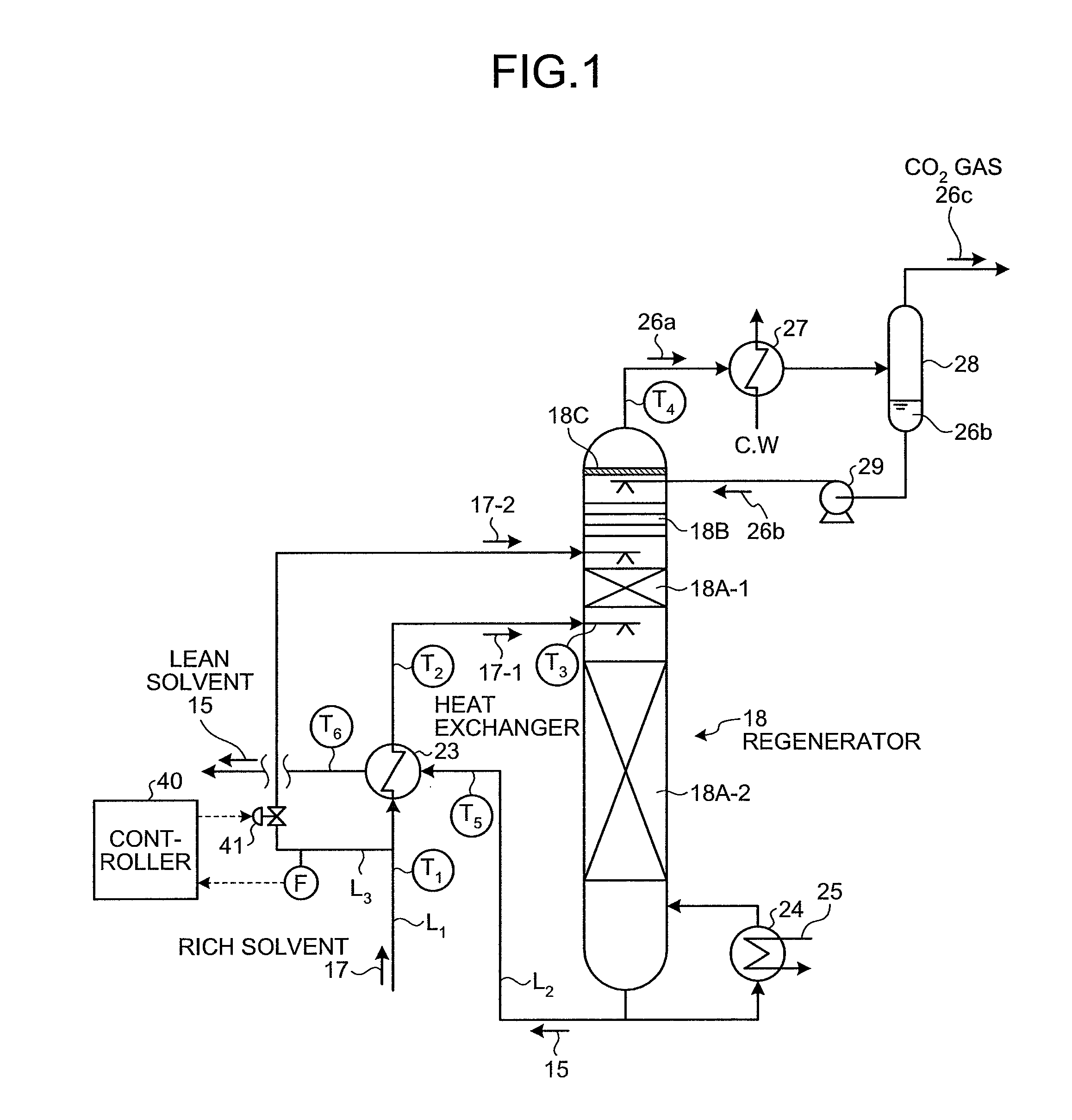

CO2 recovery apparatus and CO2 recovery method

ActiveUS8414694B2Reduce the amount requiredGas treatmentLiquid degasificationRecovery methodFlue gas

Provided are a CO2 absorber that reduces CO2 contained in flue gas; a regenerator that reduces CO2 contained in rich solvent absorbing CO2 to regenerate the rich solvent, so that lean solvent having the CO2 reduced in the regenerator is reused in the CO2 absorber; a heat exchanger that allows the rich solvent to exchange heat with the lean solvent; and a controller that controls to extract rich solvent portion that is part of the rich solvent, to allow the rich solvent portion to by pass the heat exchanger, and to be supplied into the top of the regenerator without exchanging heat so as to minimize a sum of an enthalpy that is taken out of the regenerator as CO2 gas accompanying steam and an enthalpy of the lean solvent after heat exchange with the rich solvent in the heat exchanger.

Owner:THE KANSAI ELECTRIC POWER CO +1

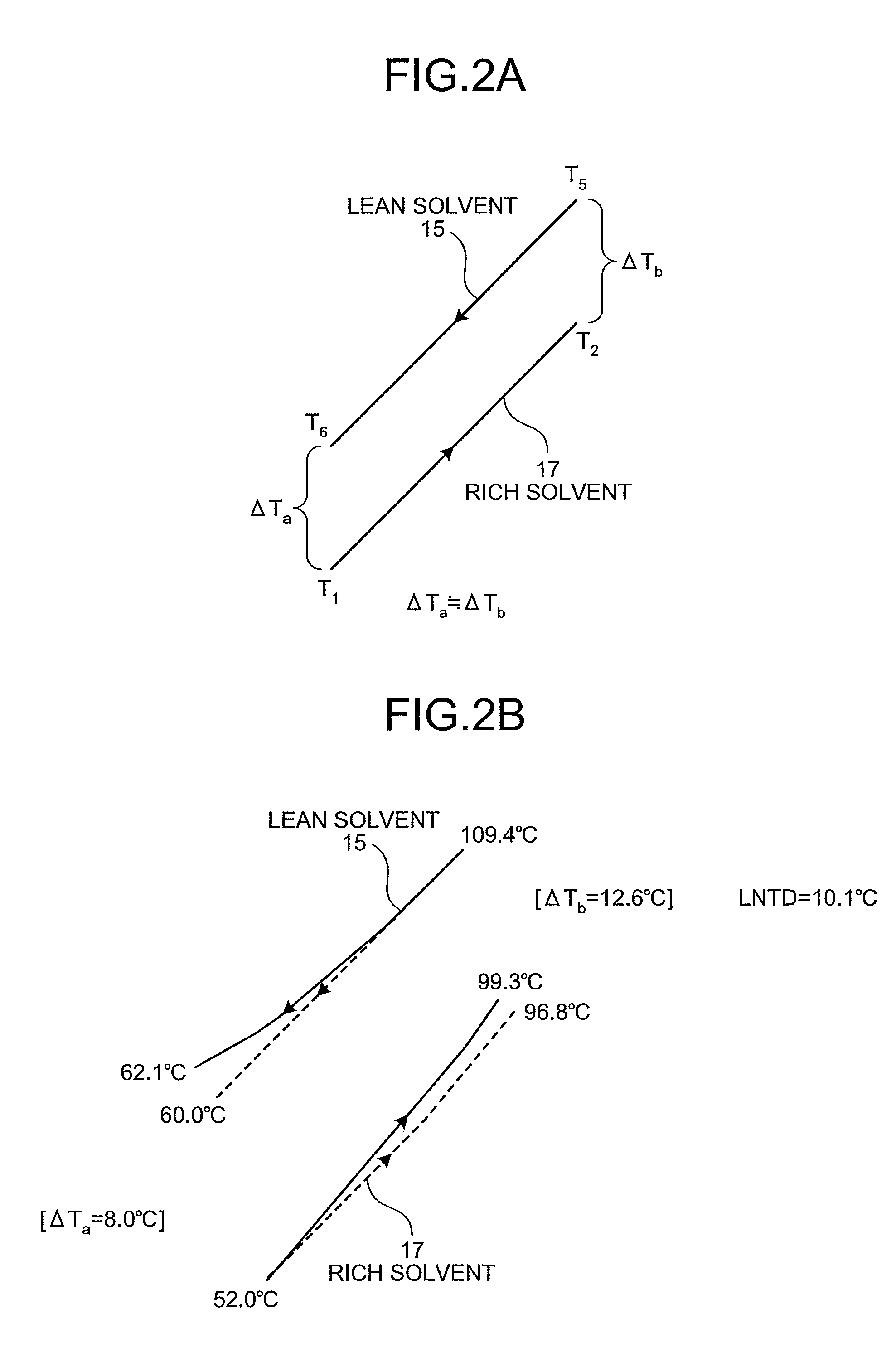

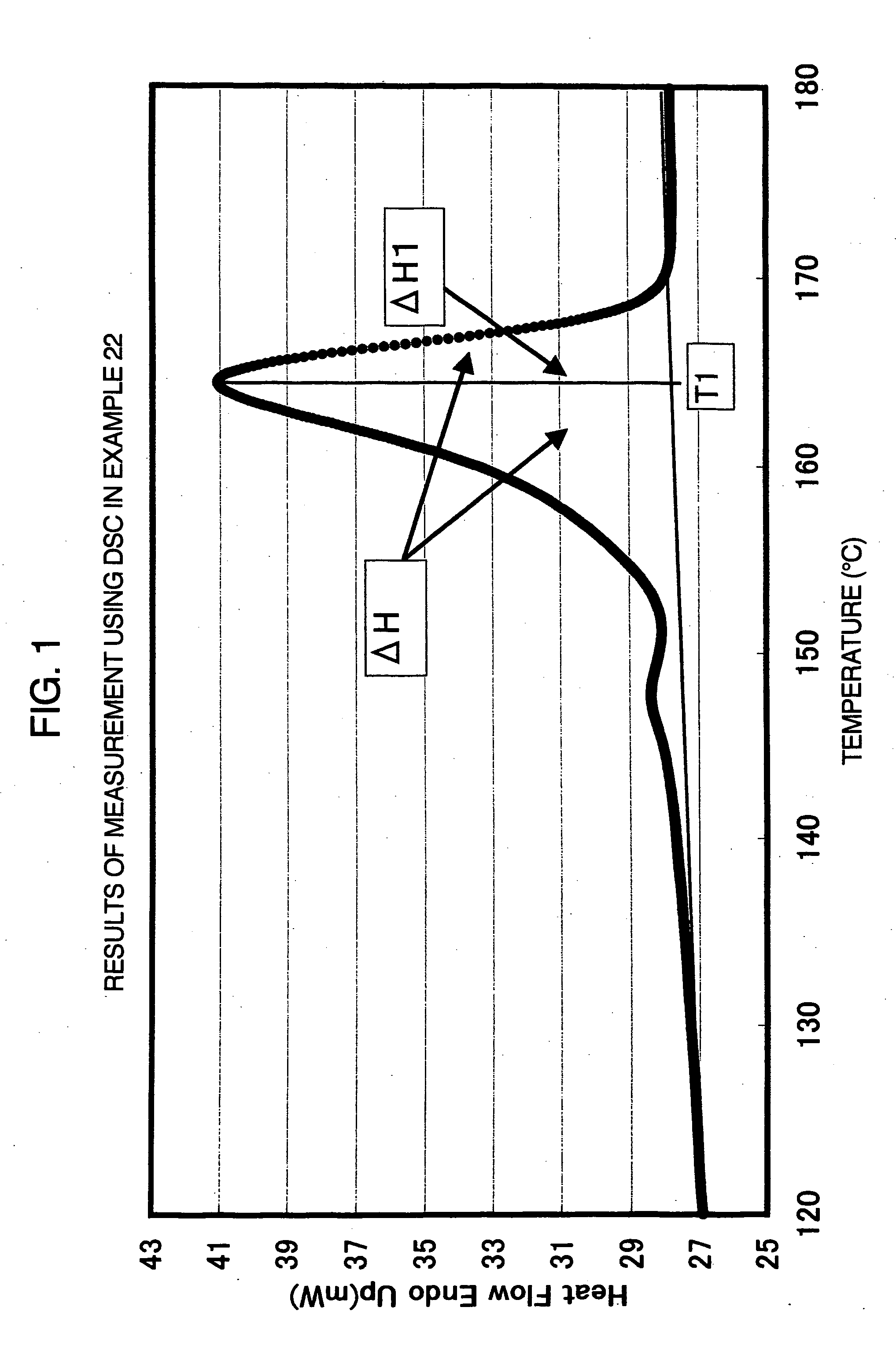

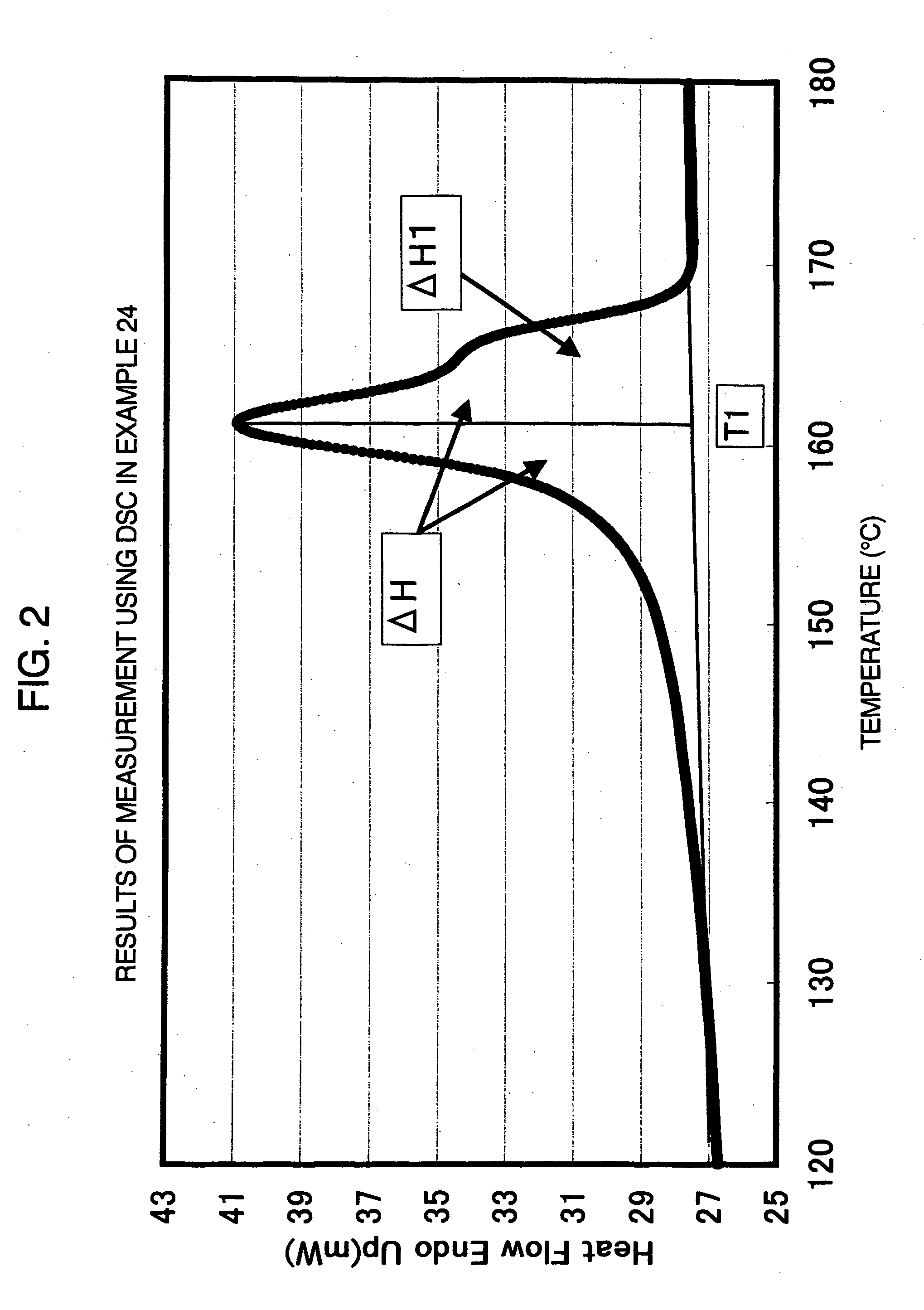

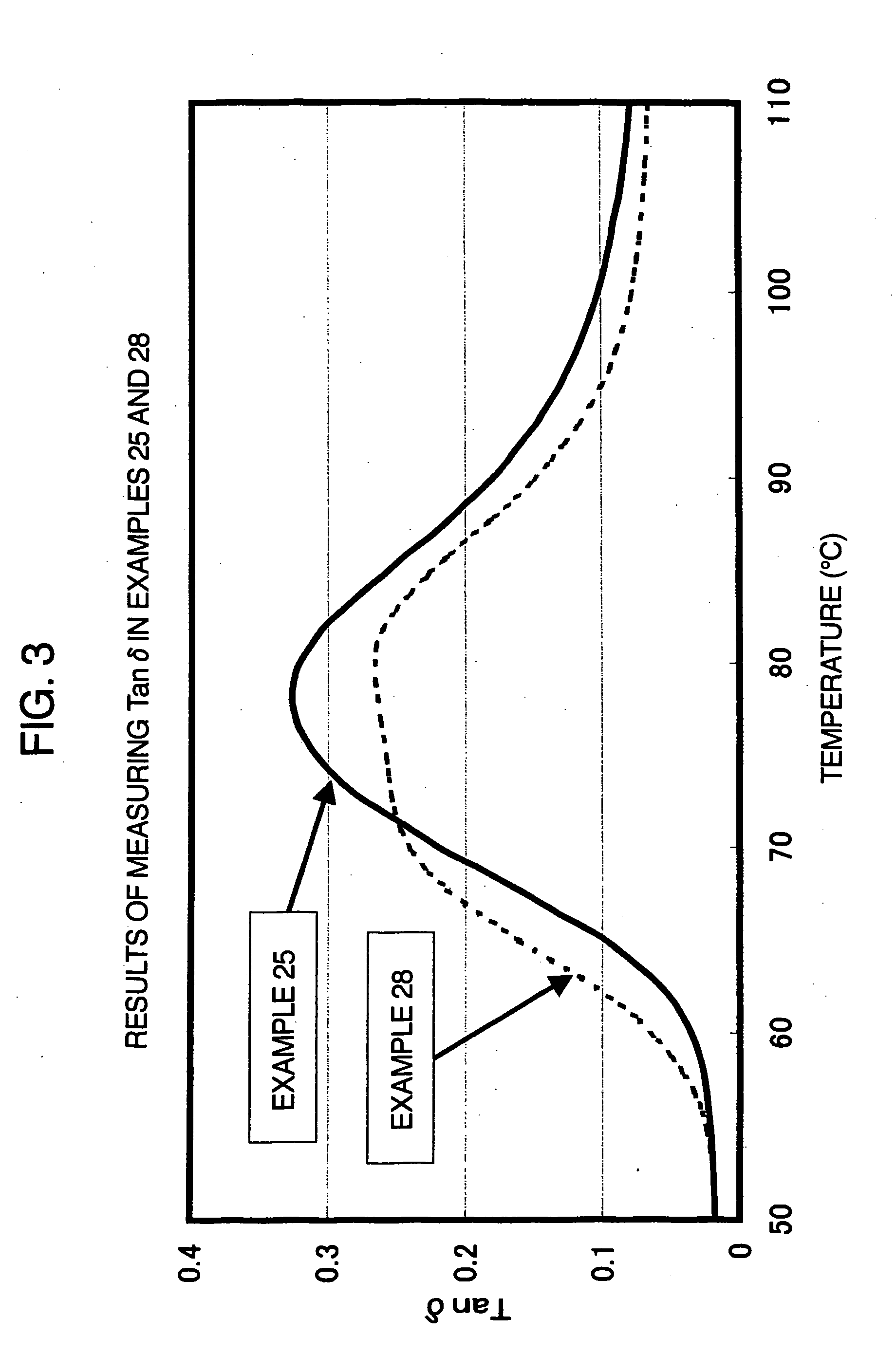

Molded article produced from aliphatic polyester resin composition

ActiveUS20050154148A1DistanceDeterioration of mechanical propertiesPlastic/resin/waxes insulatorsDyeing processShell moldingPolyester resin

The present invention provides a molded article obtained from an aliphatic polyester resin composition comprising 60 to 99.9 parts by weight of at least one aliphatic polyester (A) and 0.1 to 40 parts by weight of at least one elastic polymer (B), provided that the total amount of the components (A) and (B) is 100 parts by weight, wherein the aliphatic polyester component in the molded article has an enthalpy of crystal fusion ΔH determined using a differential scanning calorimeter of 5 J / g or more, the molded article has a continuous phase composed of the aliphatic polyester (A) and dispersed phases composed of the elastic polymer (B), and the distance T between the walls of the dispersed phases is less than 5.0 μm.

Owner:ASAHI KASEI CHEM CORP

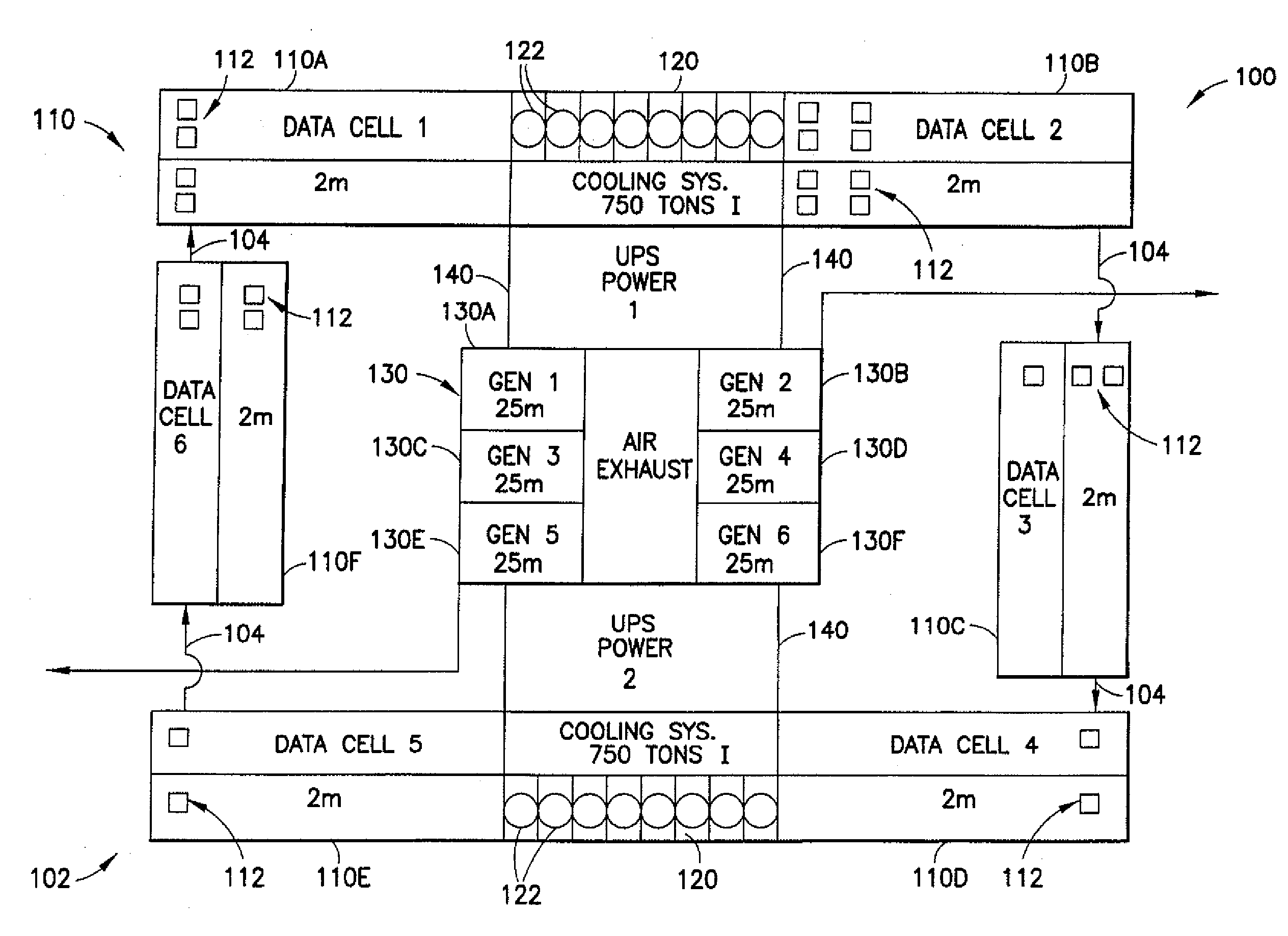

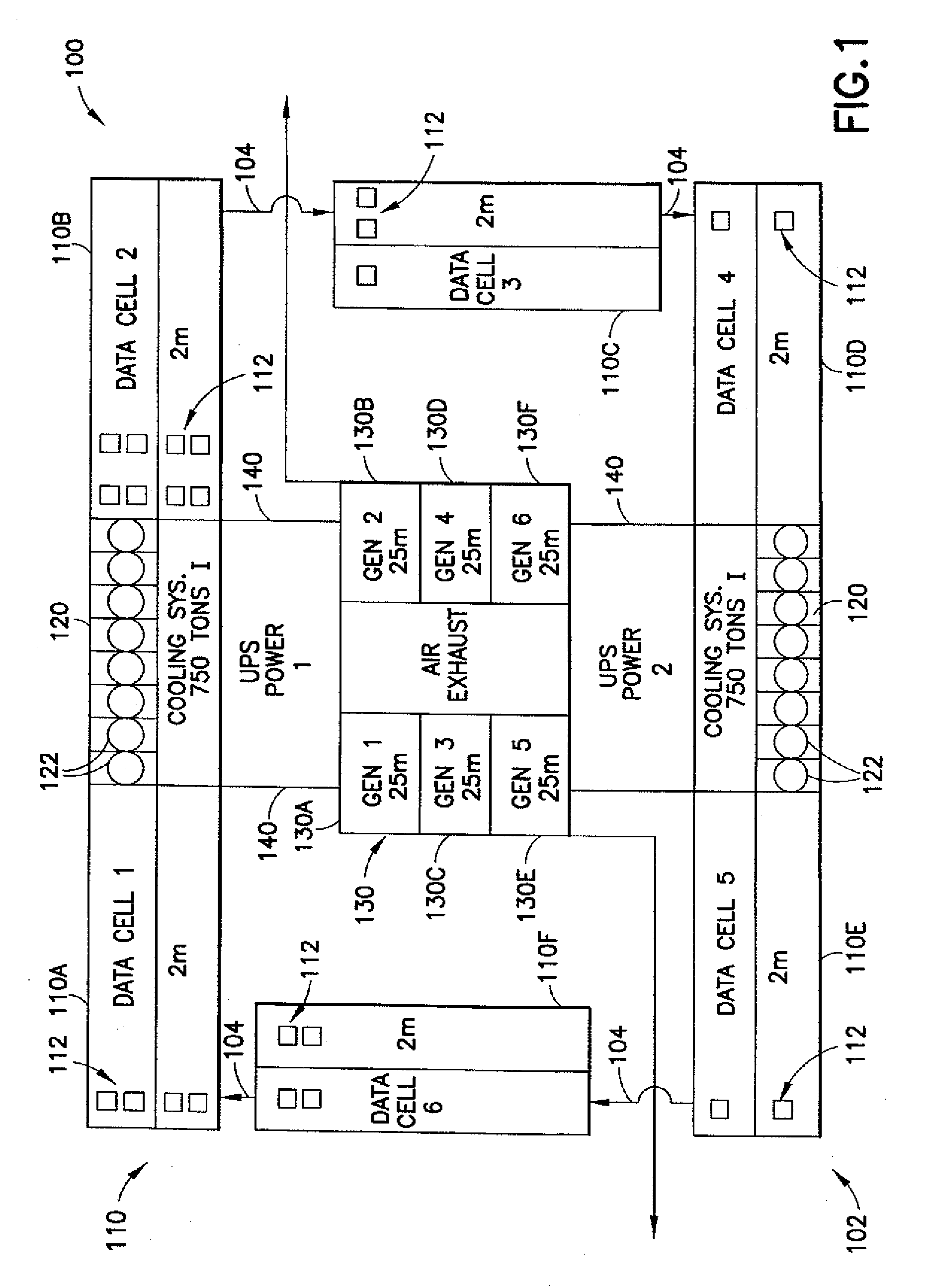

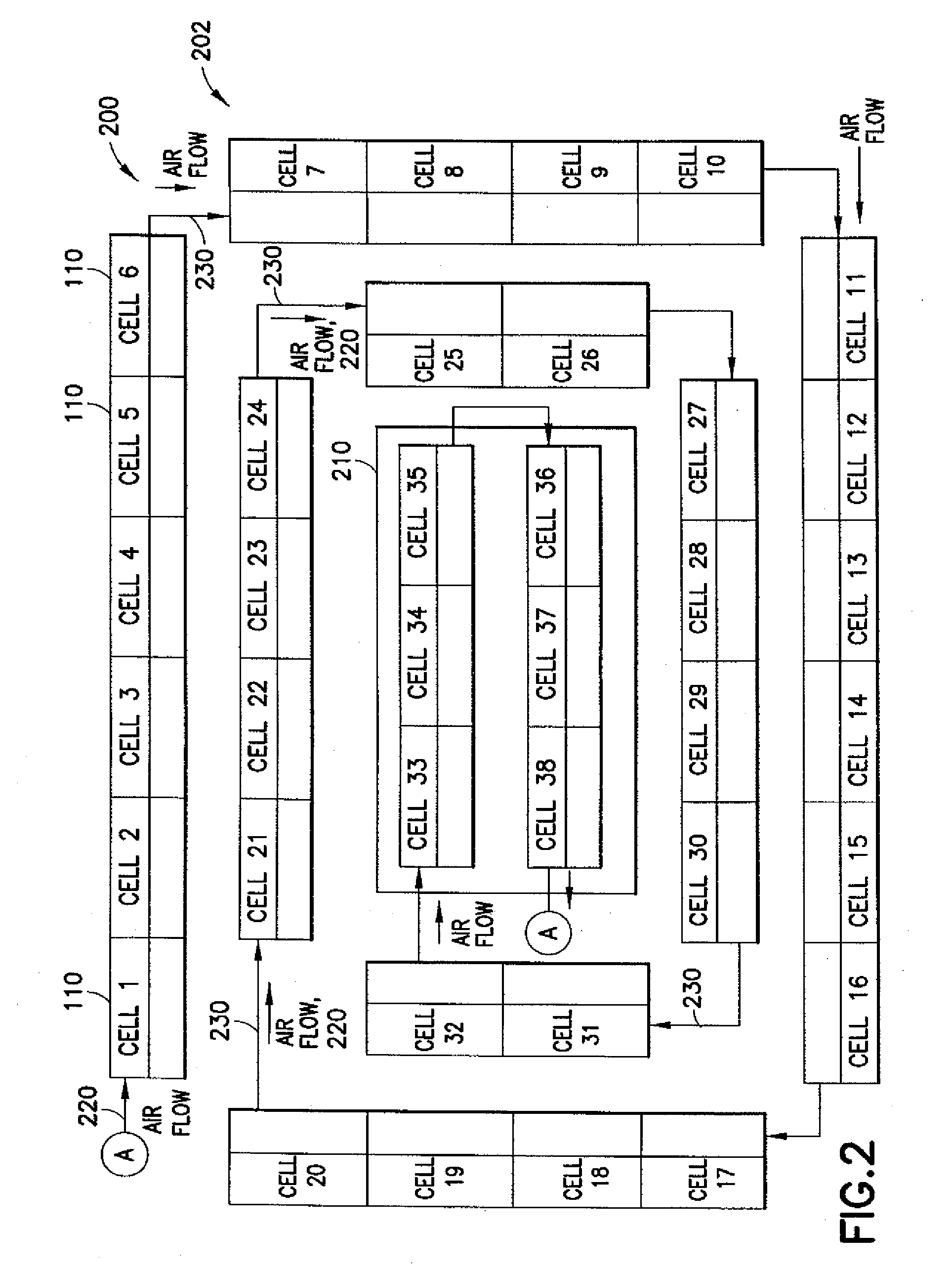

Data center and methods for cooling thereof

InactiveUS20100136895A1Improve cooling efficiencyImprove performance efficiencyCasings/cabinets/drawers detailsIndirect heat exchangersData centerClosed loop

Disclosed is a data center and methods for cooling thereof. The data center includes a plurality of data cells. Each data cell included a first heat exchanger, a first set of equipment racks, a second heat exchanger, a second set of equipment racks, and a plurality of fans operable to establish a substantially horizontal and vertical air flow through the heat exchangers and the equipment racks. The data center includes a plurality of mixed air chambers. One air chamber is located between two data cells to form a substantially continuous, closed-loop air flow through the cells and chambers. The air chambers include an outside air intake for drawing ambient air into the closed loop air flow based on a comparison of enthalpy of the closed loop air and the ambient air.

Owner:TURNER LOGISTICS

Probe for measuring parameters of a flowing fluid and/or multiphase mixture

A probe 10,170 is provided that measures the speed of sound and / or vortical disturbances propagating in a single phase fluid flow and / or multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The probe includes a spatial array of unsteady pressure sensors 15-18 placed at predetermined axial locations x1-xN disposed axially along a tube 14. For measuring at least one parameter of a saturated vapor / liquid mixture 12, such as steam, flowing in the tube 14. The pressure sensors 15-18 provide acoustic pressure signals P1(t)-PN(t) to a signal processing unit 30 which determines the speed of sound amix propagating through of the saturated vapor / liquid mixture 12 in the tube 14 using acoustic spatial array signal processing techniques. Frequency based sound speed is determined utilizing a dispersion model to determine the parameters of interest.

Owner:EXPRO METERS

Nano cellulose solid-solid phase transition material and its preparing method

InactiveCN1710012ASimple manufacturing processNo phase separationHeat-exchange elementsPolyethylene glycolFunction group

The invention relates to a kind of nano cellulose solid - solid phrase change material and its producing method. Its characteristics are: in non-homogeneous phase system, according to the reactants proportions as polyethylene glycol containing active group at one end or both ends 19.8% - 82.0%, crosslinking agent 0% - 55.1% and nanometer cellulose or its ramification 4.0% - 69.5%, ingraft the polyethylene glycol containing active group at one end or both ends as energy storing function group onto nanometer cellulose or its ramification framework material. The biggest enthalpy of phase change of the nanometer cellulose solid - solid phrase change material of the invention can get to over 110 J / g, the phrase change temperature is 0 - 60 Deg. C, and can keep good solid state before and after the phrase change. It won't occur phrase separation, besides it is non-toxic and harmless, low cost, simple producing technics.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

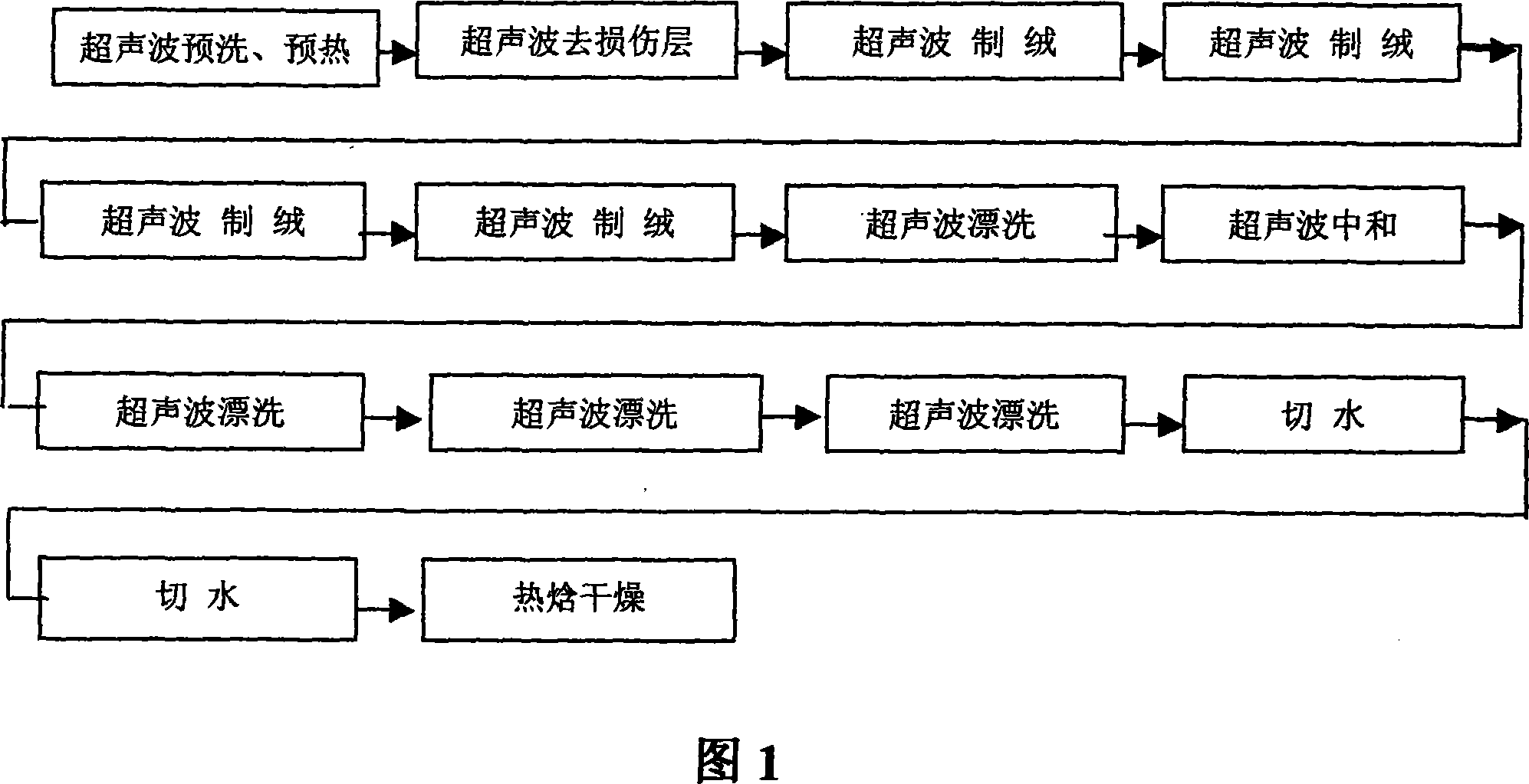

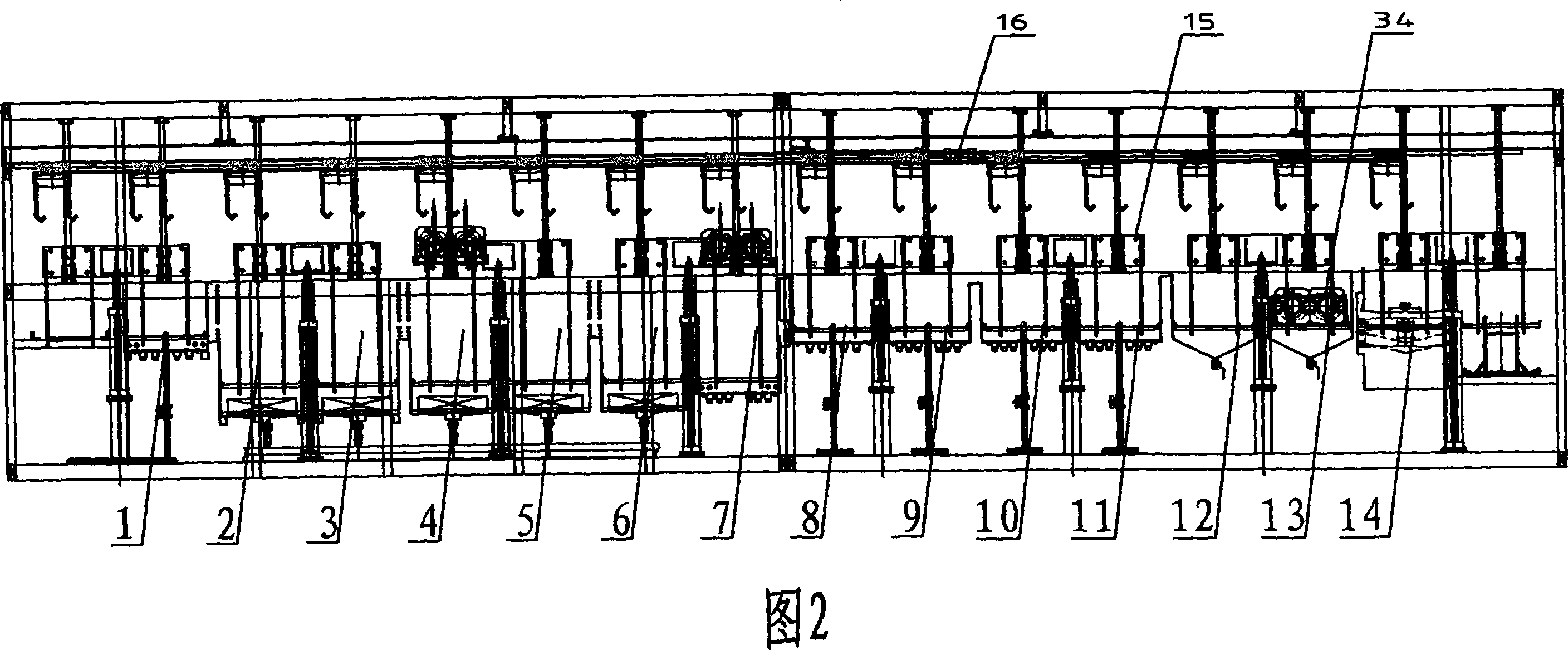

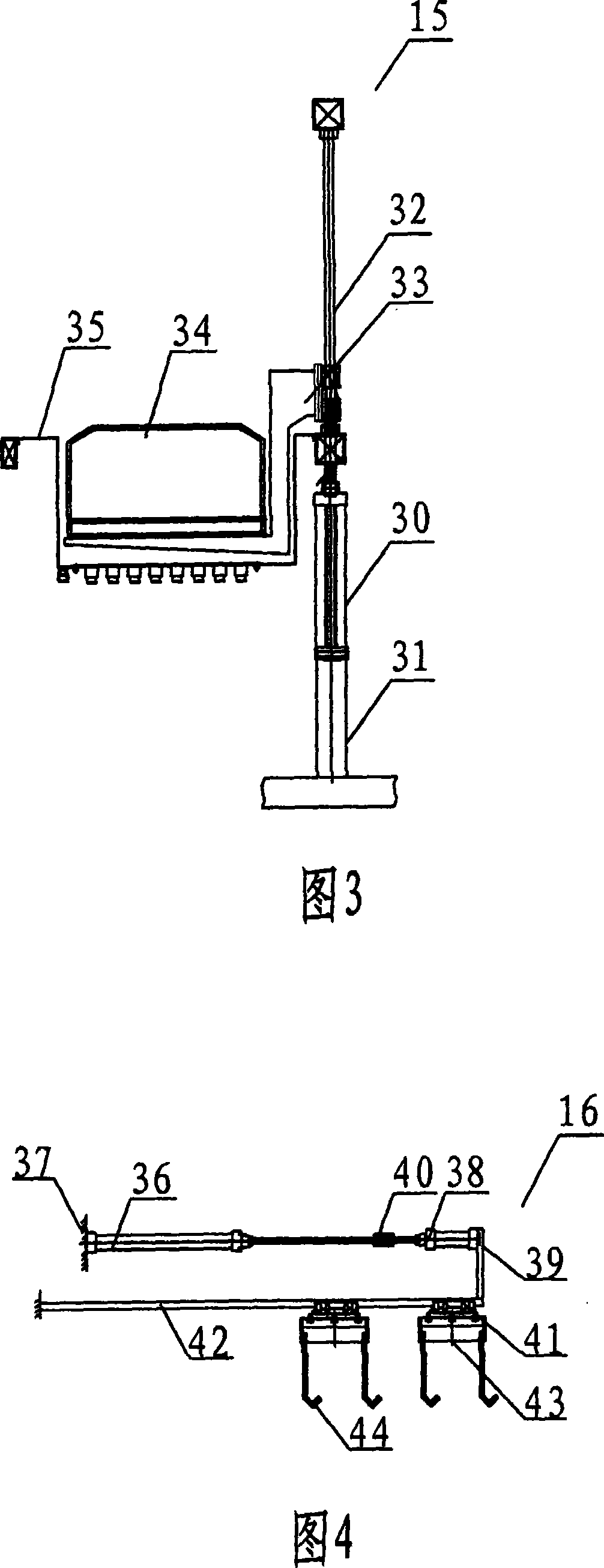

Chemical etching, cleaning and drying method of single-crystal silicon solar battery and integrated processing machine

InactiveCN101087007AImprove reflective effectAvoid secondary pollutionFinal product manufactureSemiconductor devicesEtchingWater source

Monocrystalline silicon solaode chemical etching, washing, drying method and integral processor belong to technique field of chemical etching technique and washing. It characterized in that it not only includes water, acid, alkali, but also ultrasonic participates in etching and washing course: it includes following steps: (1) ultrasonic washes and heats in advance, (2) ultrasonic removes damnification layer, (3) ultrasonic makes herbs into wool, (4) ultrasonic rinses, (5) washing with acid to counteract, (6) ultrasonic rinses, (7) cutting water, (8) hot enthalpy to dry. Positive effects of the invention are: adopting ultrasonic to etch and wash, liquid of making wool can be acted with silicon piece, similar coarseness degree can be generated on surface, perfect pyramid pattern can be obtained; it also eliminates kalium, natrium ion from alkalescent solution, and extends service life of silicon piece; pollution can be decreased, energy consumption and water source can be saved greatly, it is a practical invention.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH +2

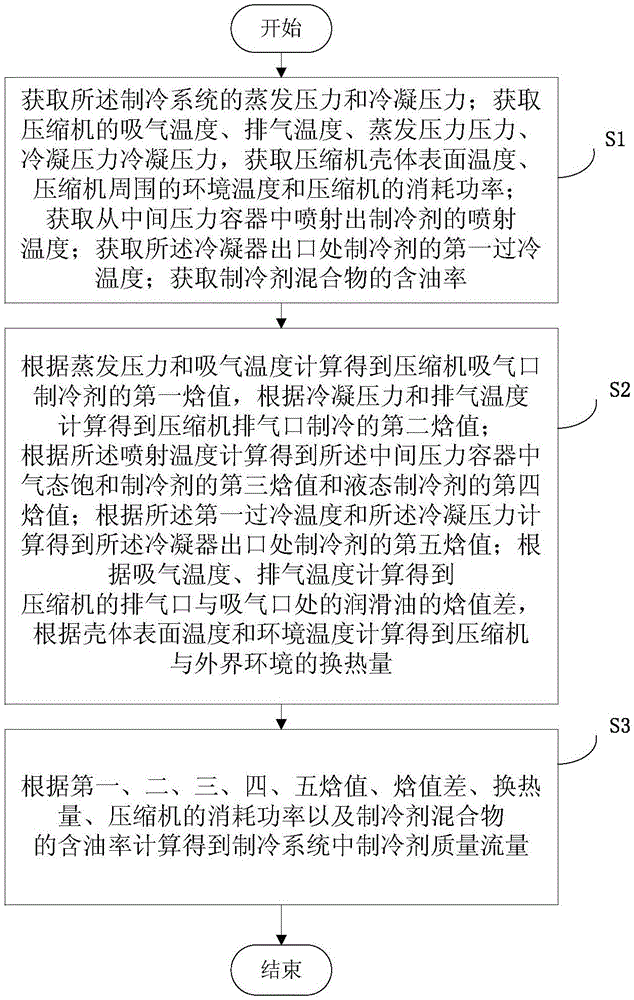

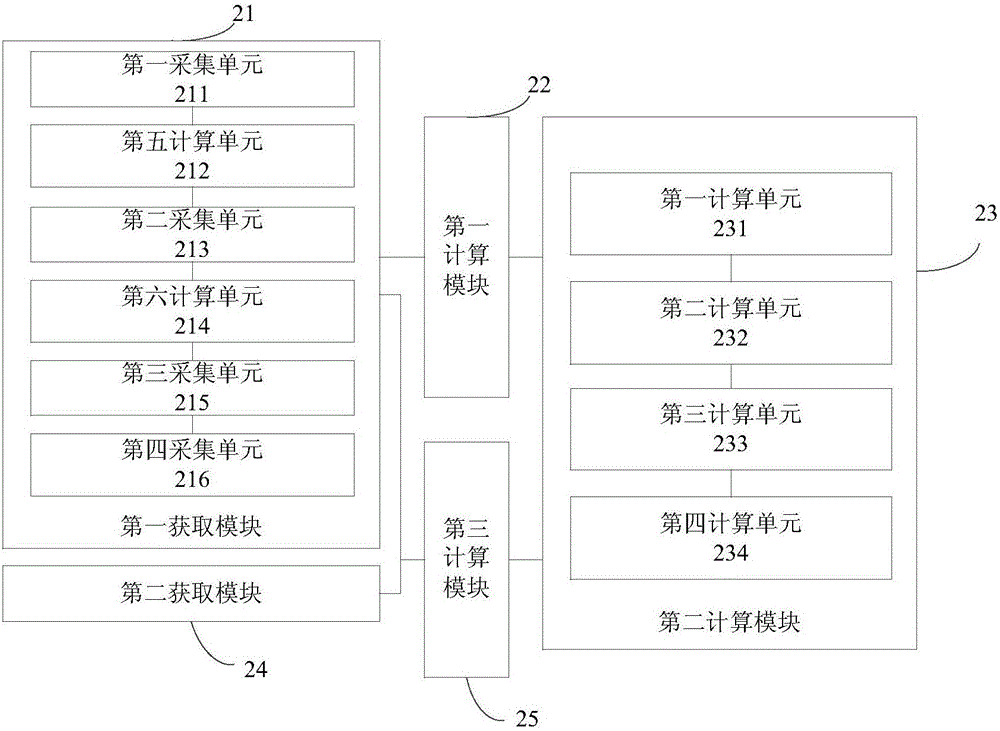

Refrigerant mass and flow measuring method and device and measuring instrument

InactiveCN106524548AAvoid adverse effects from normal operationImprove experienceCompression machines with non-reversible cycleRefrigeration safety arrangementMeasuring instrumentEvaporation

The invention provides a refrigerant mass and flow measuring method and device and a measuring instrument. The method is used in a refrigerating system and comprises the steps that the evaporation pressure and the condensation pressure are obtained; the air suction temperature and the exhaust temperature of a compressor are obtained, and the compressor shell surface temperature, the environment temperature around the compressor and the compressor consumption power are obtained; the jetting temperature of an intermediate pressure container is obtained, and the oil content of a refrigerant mixture is obtained; a corresponding first enthalpy value, a corresponding second enthalpy value, a corresponding third enthalpy value, a corresponding fourth enthalpy value, a corresponding fifth enthalpy value, an enthalpy value difference and the heat exchange amount of the compressor and the outside environment are obtained through calculation according to the obtained various parameters; and according to the first enthalpy value, the second enthalpy value, the third enthalpy value, the fourth enthalpy value, the fifth enthalpy value, the enthalpy value difference, the heat exchange amount, the consumption power of the compressor and the oil content of the refrigerant mixture, the mass and flow of the refrigerant in the refrigerating system are obtained through calculation. According to the scheme, non-intrusive and high-precision measurement on the mass and flow of the refrigerant is achieved, bad influences brought to the refrigerating system in the measurement process are avoided, and the user experience is improved.

Owner:TSINGHUA UNIV

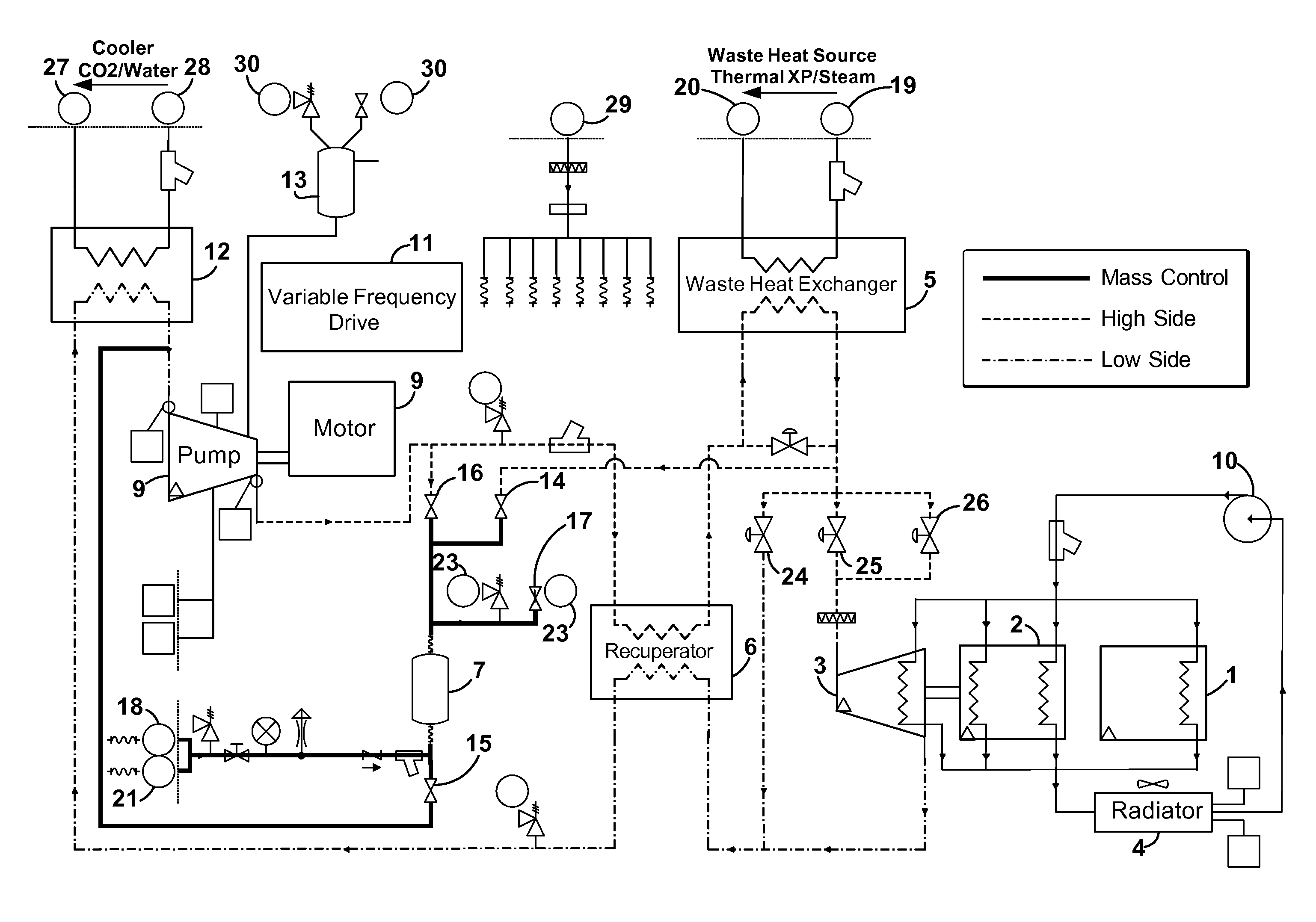

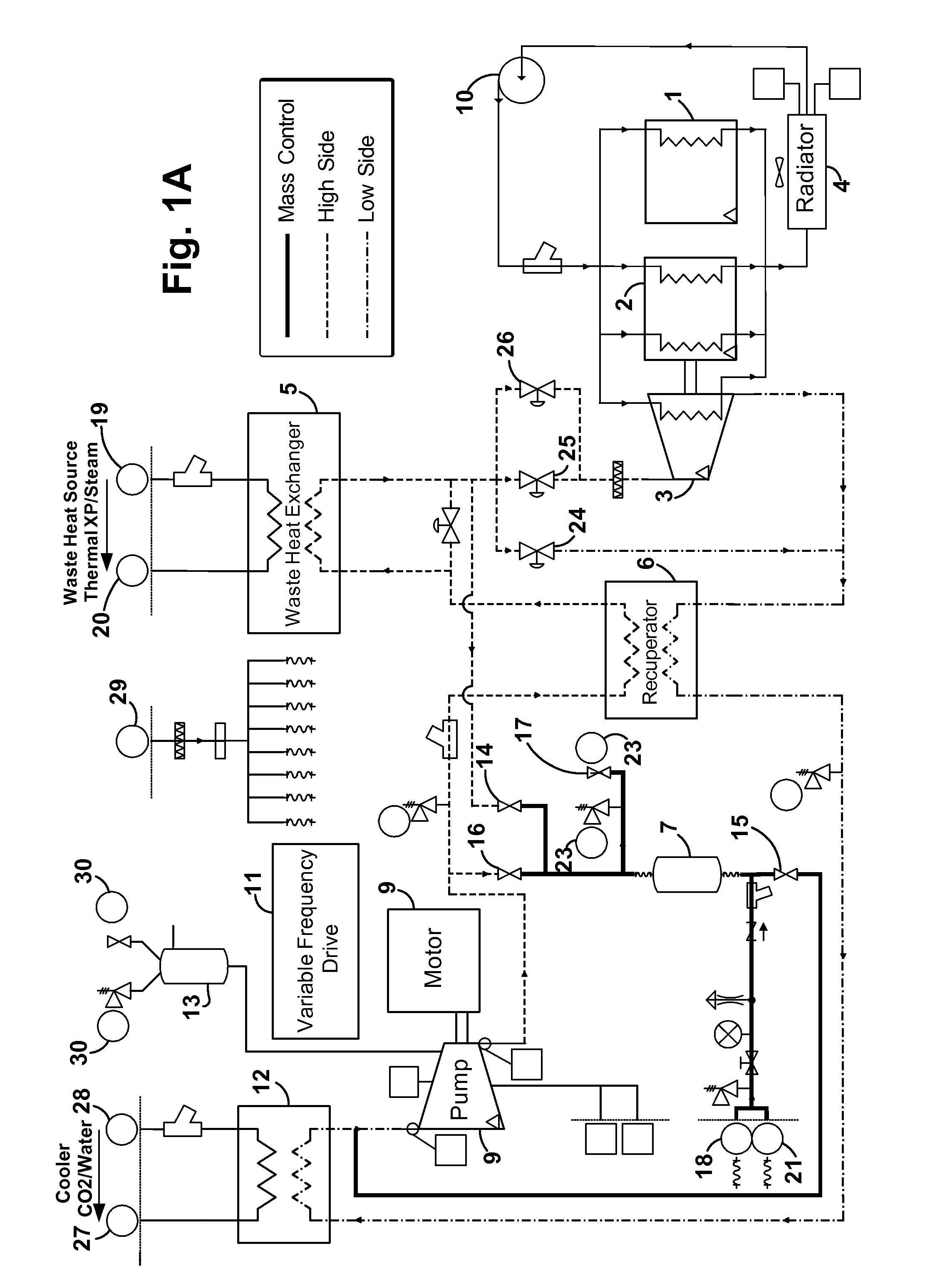

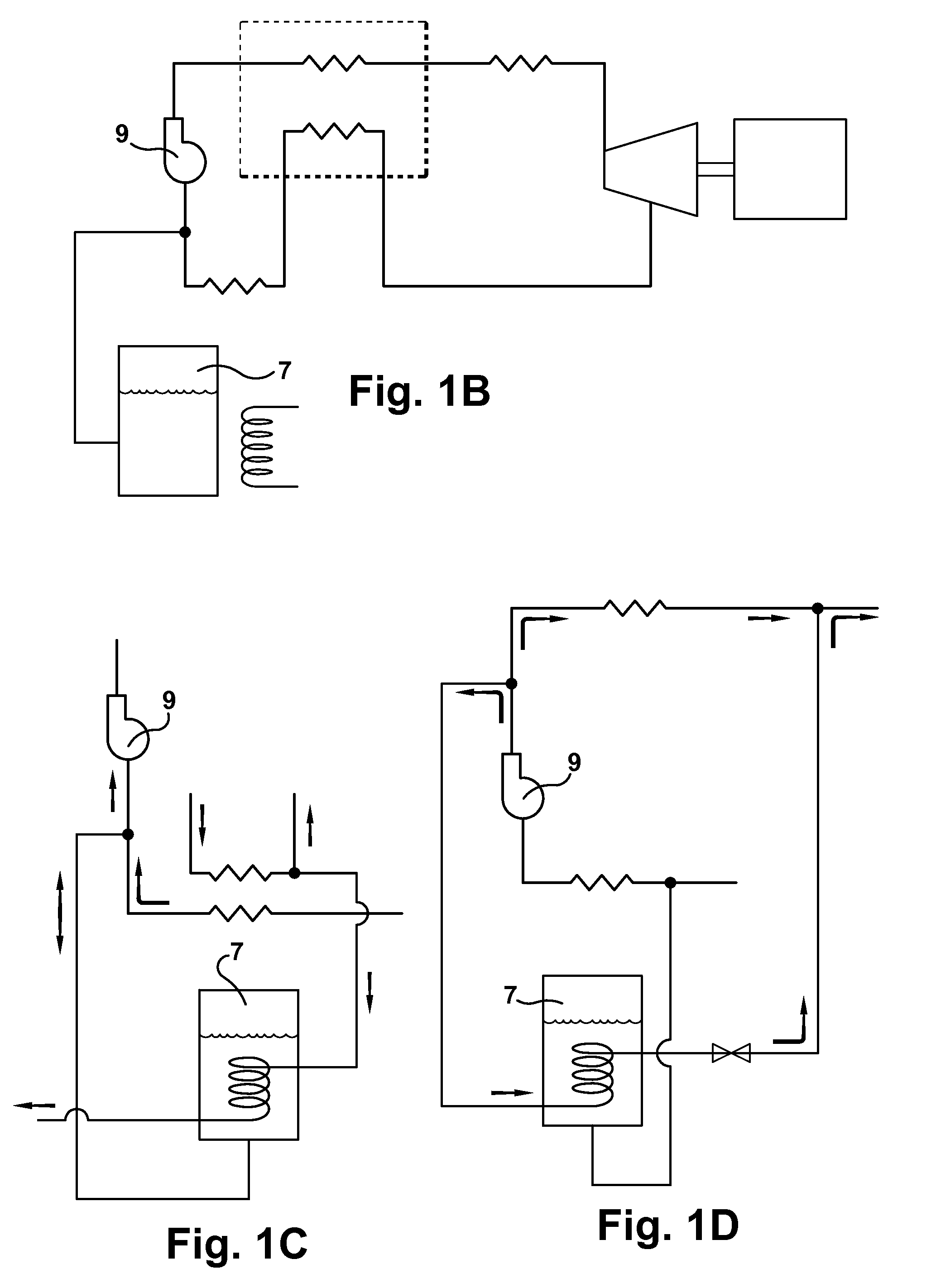

Heat engine and heat to electricity systems and methods

ActiveUS20100156112A1Efficiently and effectively produce powerFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:REXORCE THERMIONICS INC +1

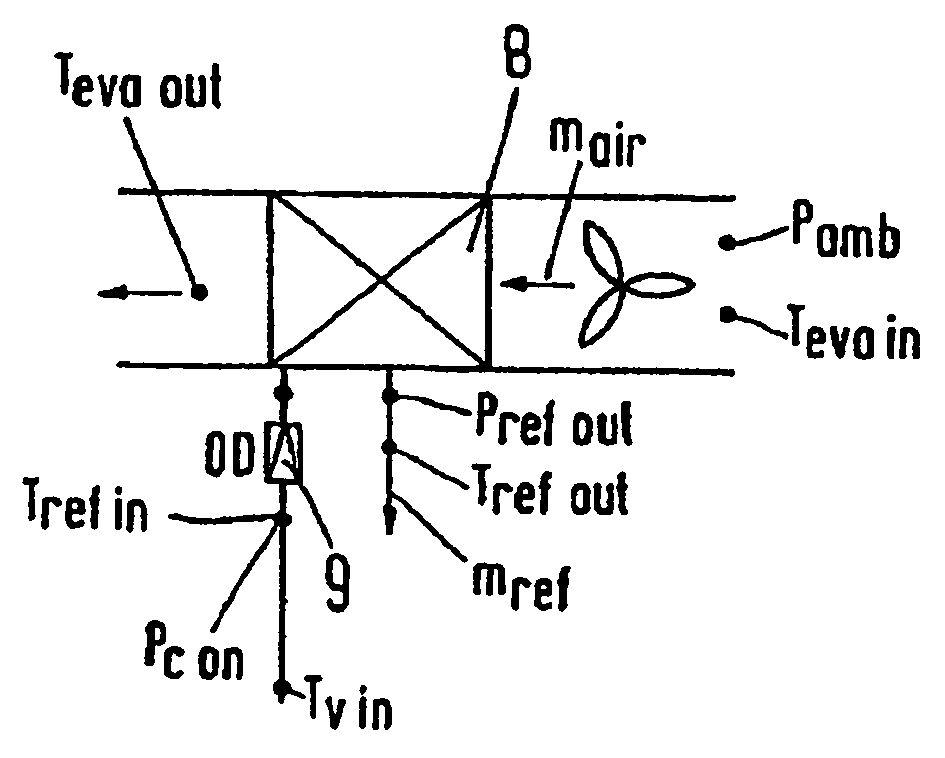

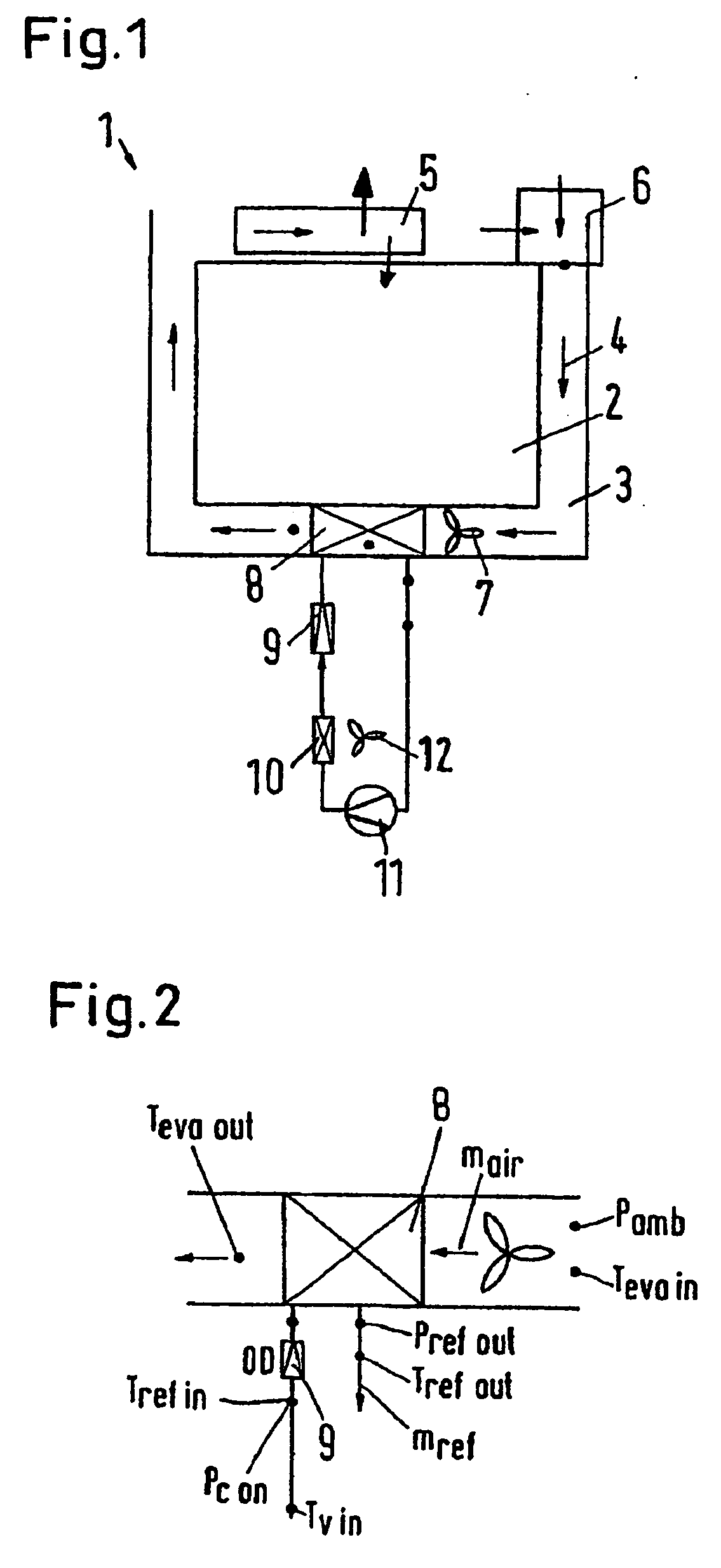

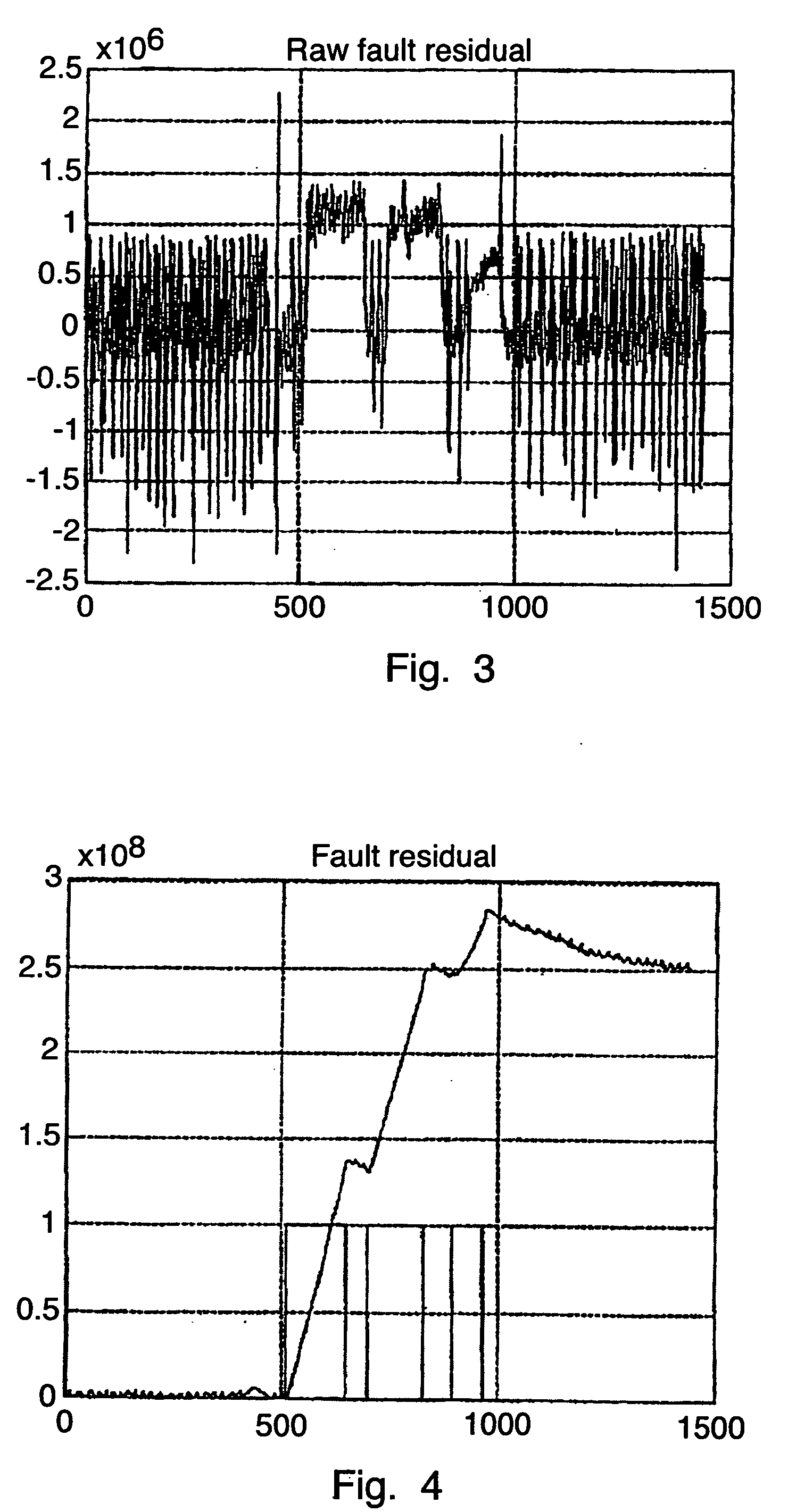

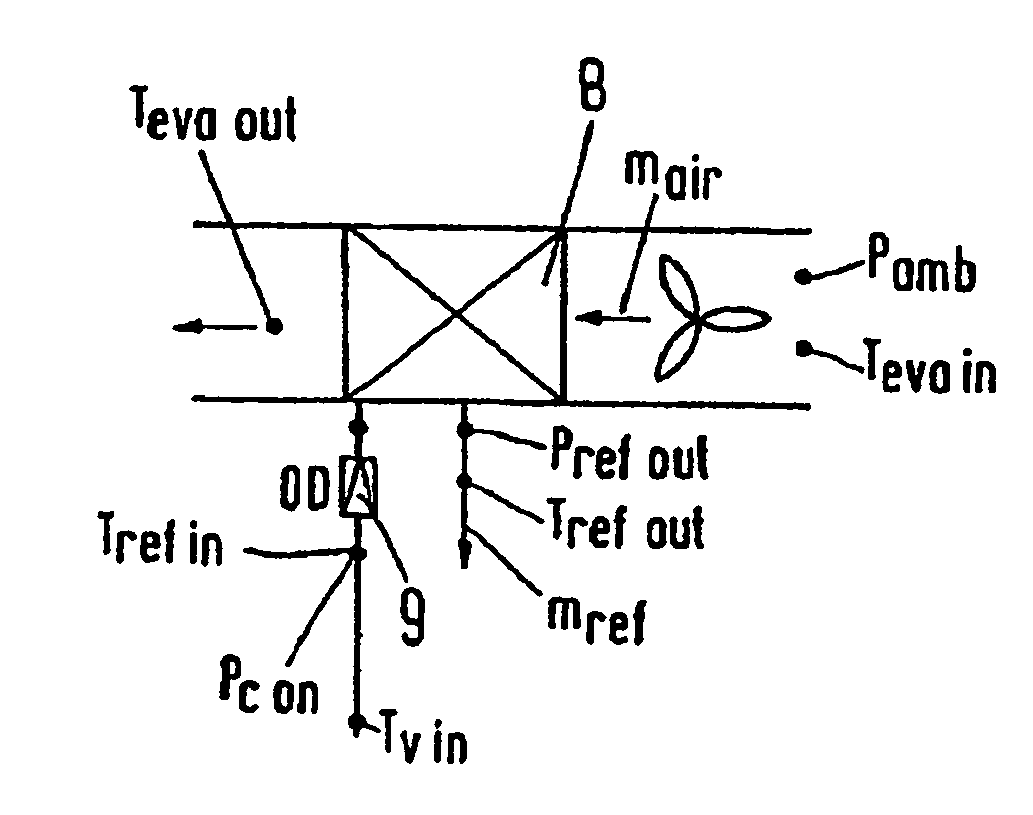

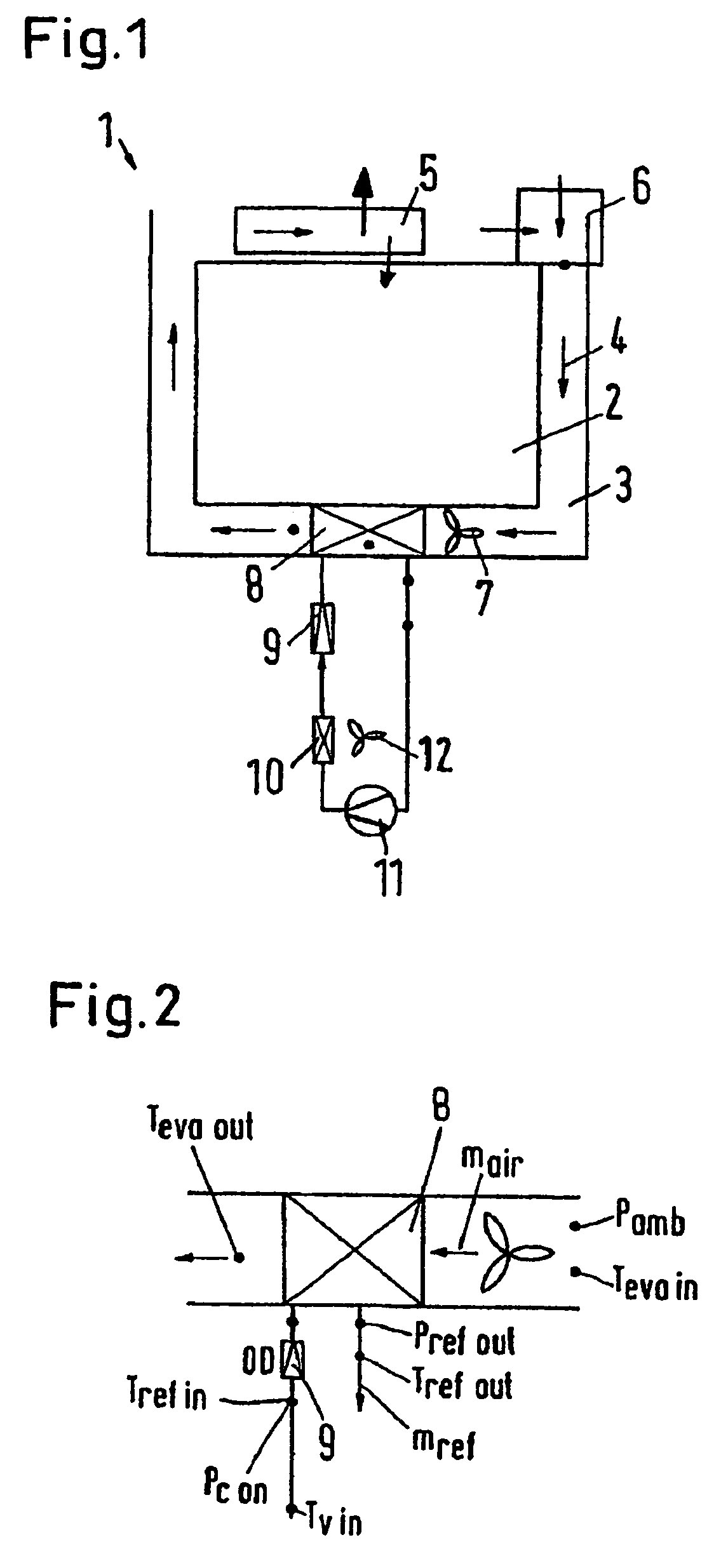

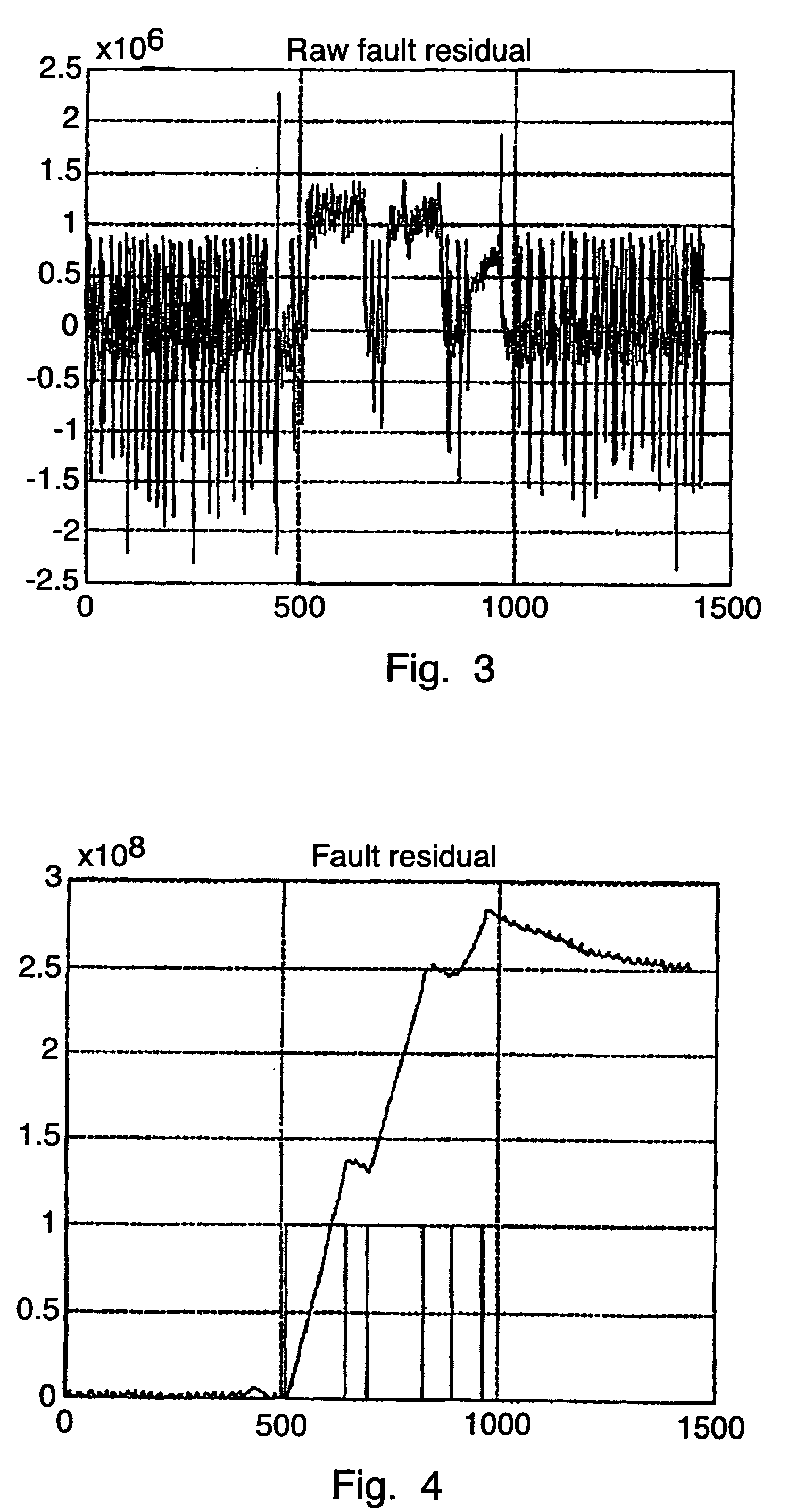

Method for detecting changes in a first flux of a heat or cold transport medium in a refrigeration system

InactiveUS20050172647A1Ease of evaluationEasy to monitorSpace heating and ventilation safety systemsSpace heating and ventilation control systemsTransport mediumEngineering

The invention concerns a method for detecting changes in a first flow of a heating or cooling medium in a refrigeration system whereby the first flow is conveyed through a heat exchanger wherein occurs heat transfer from the first flow to a second flow of a heating or cooling medium. The earliest possible detection of the changes is desired. For this it is provided that for the supervision of the first media flow moving through the heat exchanger a change in the enthalpy of the second media stream or a value derived therefrom is determined.

Owner:DANFOSS AS

Stretch blow molded container and production process thereof

InactiveUS6159416AImprove barrier propertiesHigh mechanical strengthBottlesRefuse receptaclesShear rateVolumetric Mass Density

The invention provides a stretch blow molded container formed from a thermoplastic resin material which comprises polyglycolic acid having (a) a repeating unit represented by the following formula (1): (b) a melt viscosity, eta * [as measured at a temperature of (the melting point, Tm of the polymer+20 DEG C.) and a shear rate of 100 / sec] of 500-100,000 Pa.s; (c) a melting point, Tm of at least 180 DEG C.; (d) a melt enthalpy, DELTA Hm of at least 20 J / g; and (e) a density of at least 1.50 g / cm3 as measured in an unoriented, crystallized form, wherein the stretch blow molded container has tensile strength (in a circumferential direction) of at least 100 MPa and a carbon dioxide permeability (as measured at a temperature of 23 DEG C. and 80% relative humidity; in terms of the thickness of 50 mu m) of 300 cc / m2.day.atm or smaller at the body sidewall thereof, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

Method for detecting changes in a first media flow of a heat or cooling medium in a refrigeration system

InactiveUS7685830B2Sure easyEase of evaluationSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringRefrigeration

The invention concerns a method for detecting changes in a first flow of a heating or cooling medium in a refrigeration system whereby the first flow is conveyed through a heat exchanger wherein occurs heat transfer from the first flow to a second flow of a heating or cooling medium. The earliest possible detection of the changes is desired. For this it is provided that for the supervision of the first media flow moving through the heat exchanger a change in the enthalpy of the second media stream or a value derived therefrom is determined.

Owner:DANFOSS AS

Ejector cycle system with critical refrigerant pressure

InactiveUS20010025499A1Recover energyReduce power consumptionCompression machines with non-reversible cycleEvaporators/condensersEngineeringPressure difference

In an ejector cycle system using carbon dioxide as refrigerant, an ejector decompresses and expands refrigerant from a radiator to suck gas refrigerant evaporated in an evaporator, and converts an expansion energy to a pressure energy to increase a refrigerant pressure to be sucked into a compressor. Because refrigerant is decompressed and expanded in a super-critical area, a pressure difference during the decompression operation becomes larger, and a specific enthalpy difference becomes larger. Accordingly, energy converting efficiency in the ejector becomes higher, and efficiency of the ejector cycle system is improved.

Owner:DENSO CORP

Encapsulated phase change materials in seed coatings

InactiveUS20090227451A1Good flexibilityIncrease productionBiocideFertilising methodsSeed dormancyPhase change

The present invention is directed to improved seed coatings which facilitate fall or early spring planting while maintaining seed dormancy until soil temperatures are appropriate for successful germination. The improved seed coatings contain encapsulated phase change materials within a polymeric shell which preserve the dormancy of the seed during early planting by slowing the rate at which the seed temperature rises in the event of a temperature spike thus preventing premature germination. The encapsulated phase change material is a material characterized by a solid / liquid or liquid / solid phase change which occurs at a temperature which ranges from about −5 to about 20° C., preferably between about 0 to about 19° C., most preferably between about 5 to about 15° C. The solid / liquid or liquid / solid phase change is further characterized by an effective enthalpy of fusion / crystallization for the solid-liquid / liquid-solid phase change equal to or greater than 20 J / g when determined by Differential Scanning Calorimetry.

Owner:CIBA CORP

Coated membranes for enthalpy exchange and other applications

ActiveUS20120061045A1Energy recovery in ventilation and heatingSemi-permeable membranesCoated membranePolymer science

Coated membranes comprise a porous desiccant-loaded polymer substrate that is coated on one surface with a thin layer of water permeable polymer. Such membranes are particularly suitable for use in enthalpy exchangers and other applications involving exchange of moisture and optionally heat between gas streams with little or no mixing of the gas streams through the membrane. Such membranes have favorable heat and humidity transfer properties, have suitable mechanical properties, are resistant to the crossover of gases when the membranes are either wet or dry, and are generally low cost.

Owner:CORE ENERGY RECOVERY SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com