Patents

Literature

1055 results about "Shear rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shear rate is the rate at which a progressive shearing deformation is applied to some material.

Compositions and methods for treating a posterior segment of an eye

InactiveUS20050101582A1Improve abilitiesIncrease viscosity of compositionAntibacterial agentsOrganic active ingredientsShear ratePharmacology

Compositions, and methods of using such compositions, useful for injection into the posterior segments of human or animal eyes are provided. Such compositions include corticosteroid component-containing particles present in a therapeutically effective amount, a viscosity inducing component, and an aqueous carrier component. The compositions have viscosities of at least about 10 cps or about 100 cps at a shear rate of 0.1 / second. In a preferred embodiment, the viscosity is in the range of from about 140,000 cps to about 300,000 cps. The compositions advantageously suspend the particles for prolonged periods of time.

Owner:ALLERGAN INC

Method of releasing stuck pipe or tools and spotting fluids therefor

Aphron-containing spotting fluids and their use in releasing pipe or tools stuck in the filter cake on the sides of a borehole are disclosed. The spotting fluids comprise a liquid, either aqueous, oleaginous, or mixtures thereof, a viscosifier which imparts a low shear rate viscosity to the fluids of at least 10,000 centipoise, an aphron-generating surfactant, and aphrons. The spotting fluids are used in a conventional method of releasing pipes or tools stuck in the filter cake on the sides of a borehole during conventional drilling or well servicing operations.

Owner:ENVENTIVES LLC

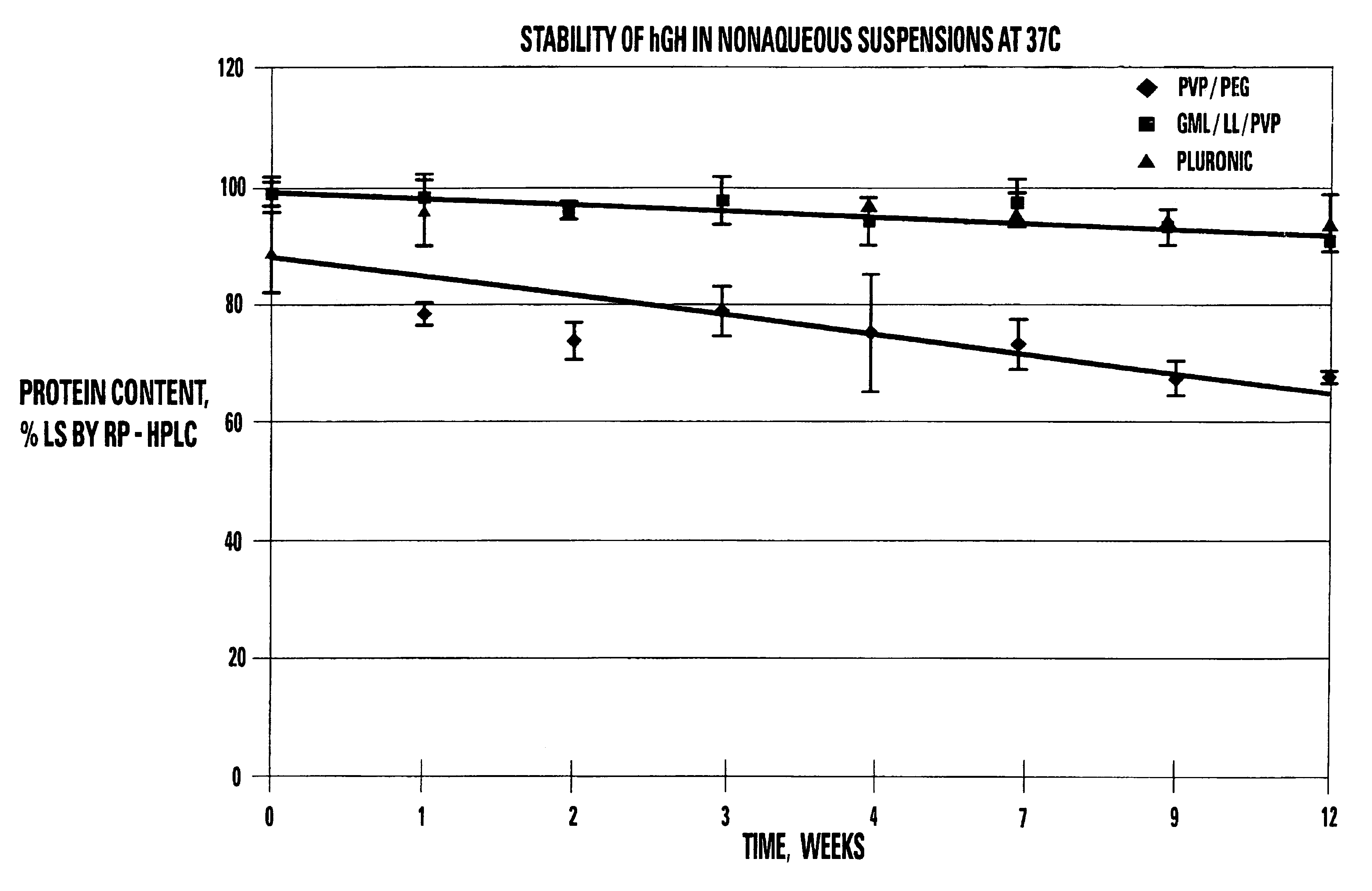

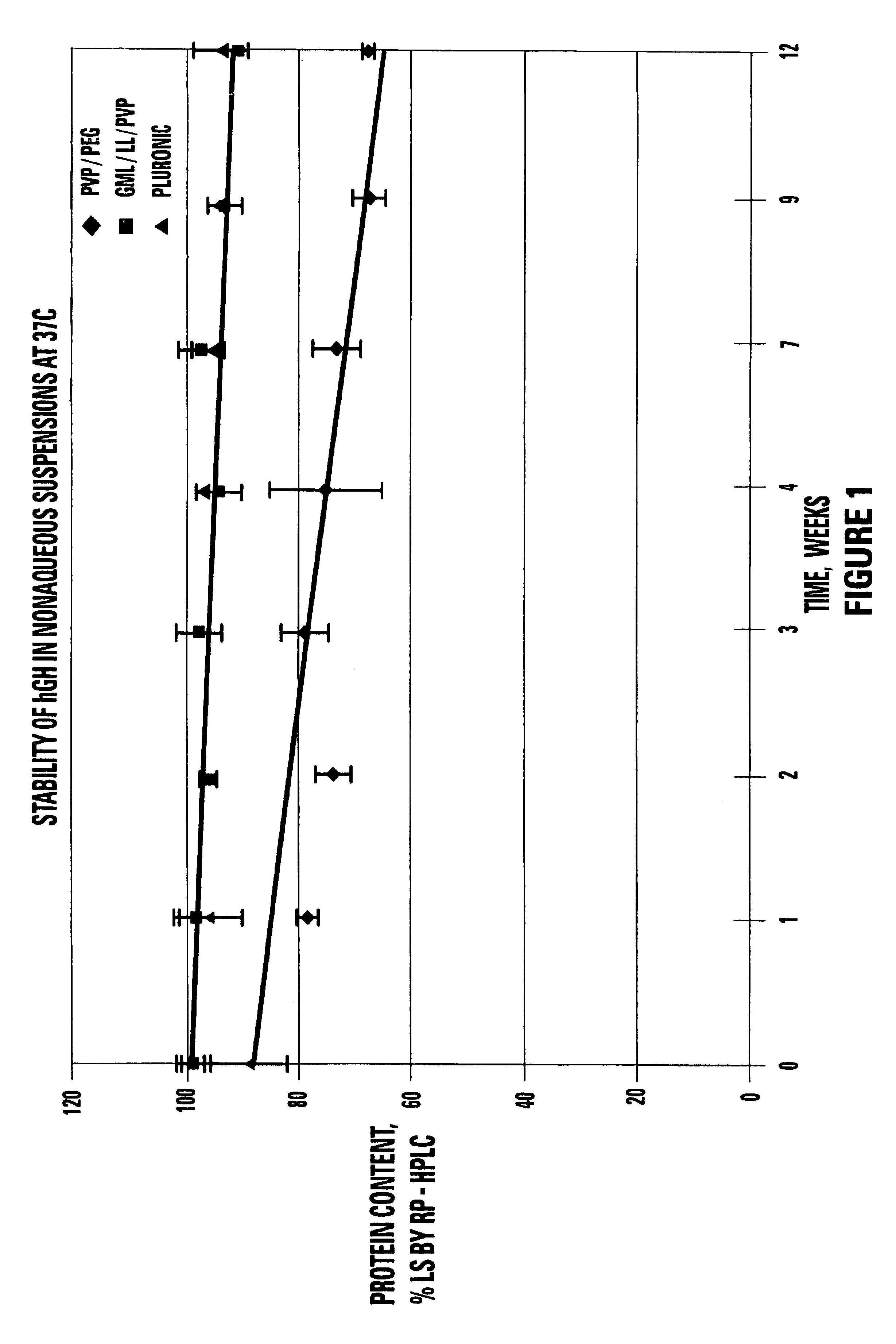

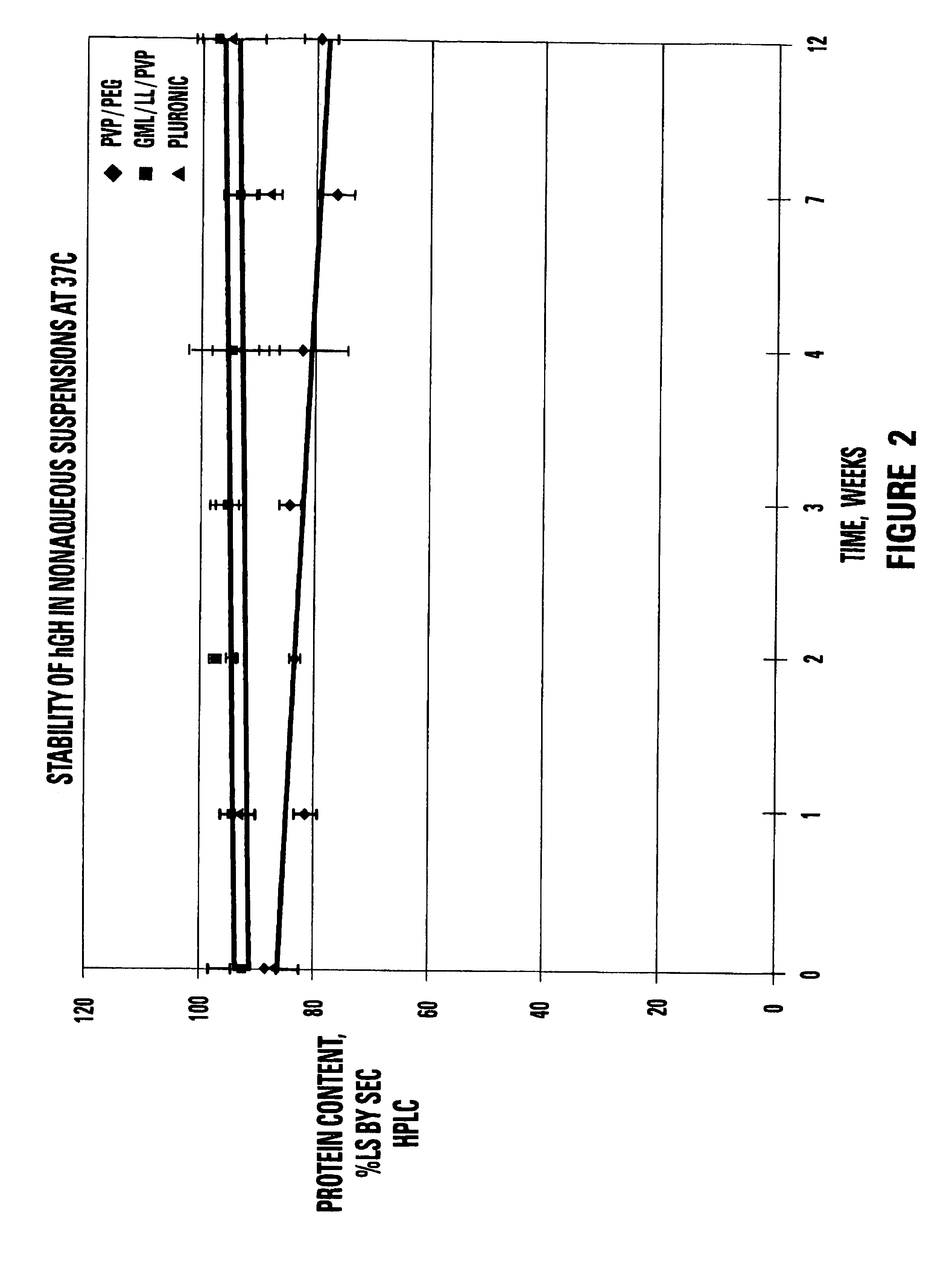

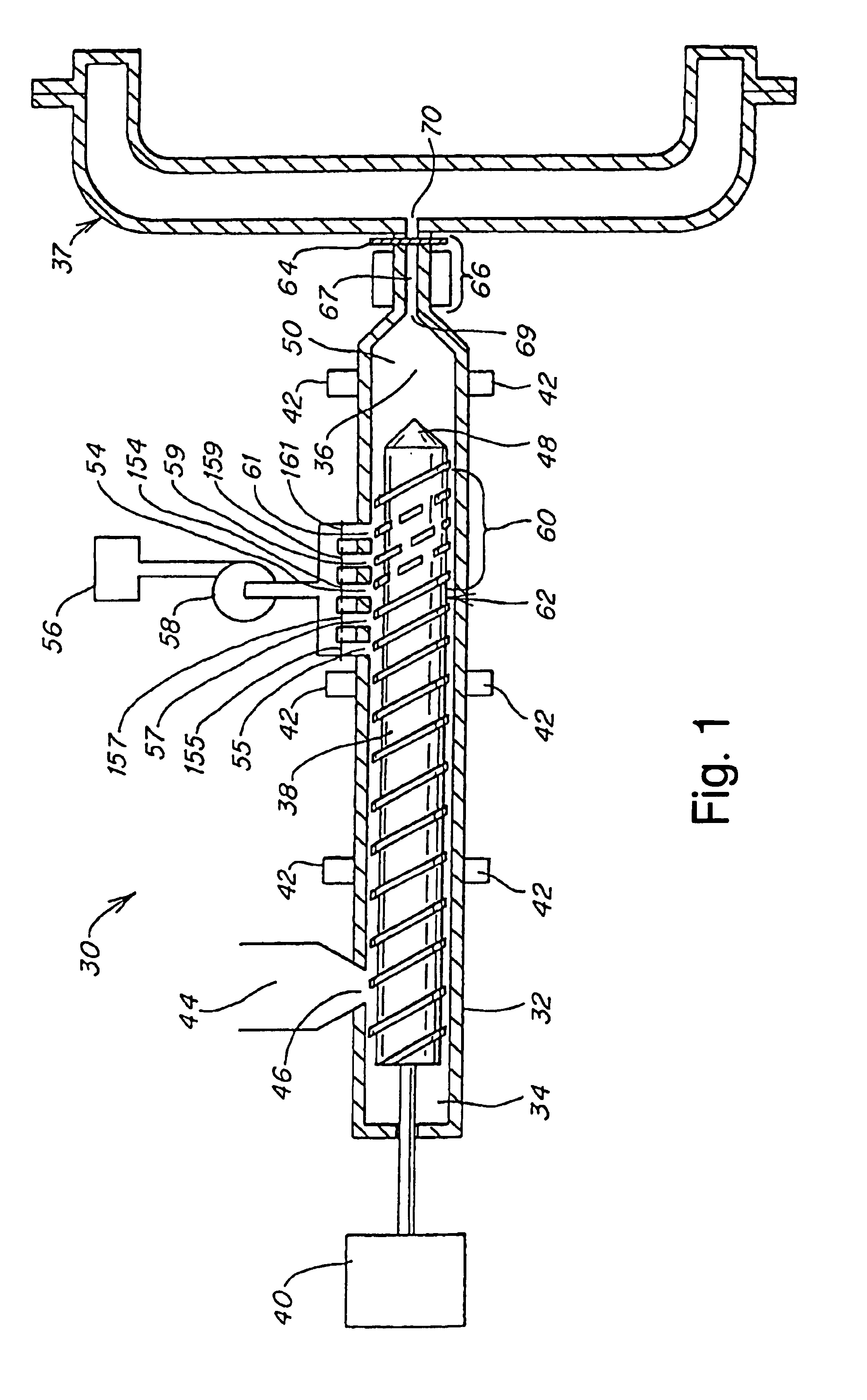

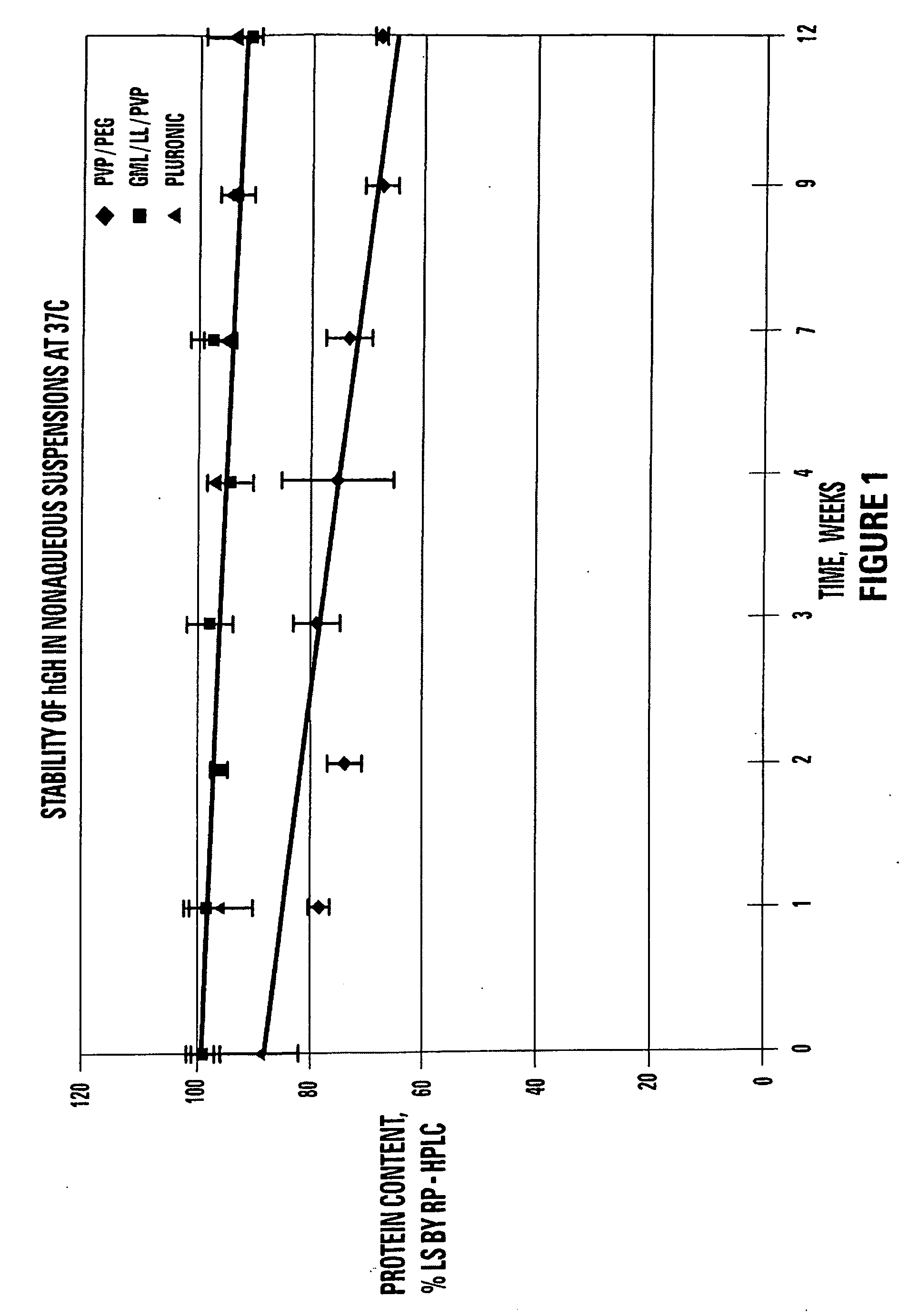

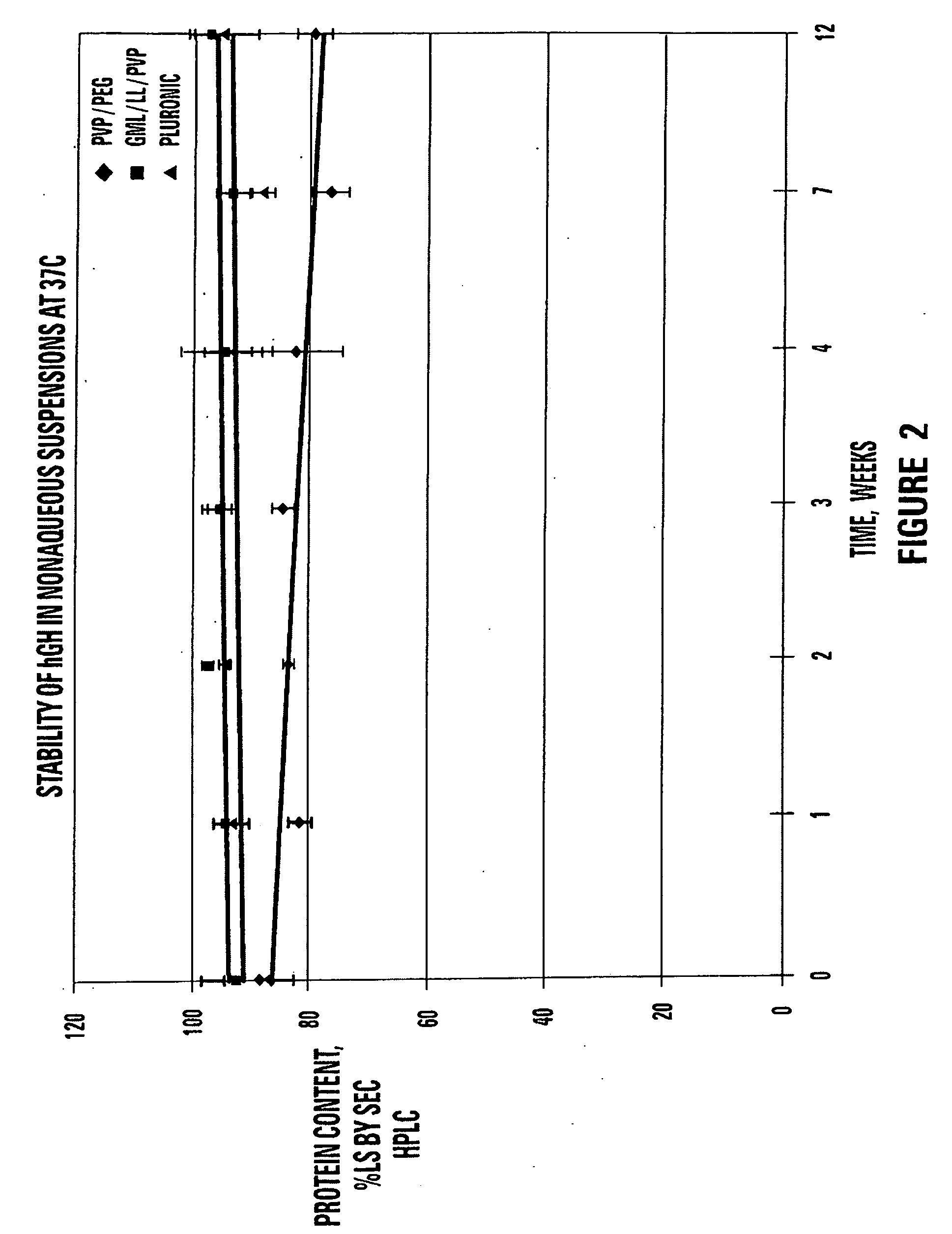

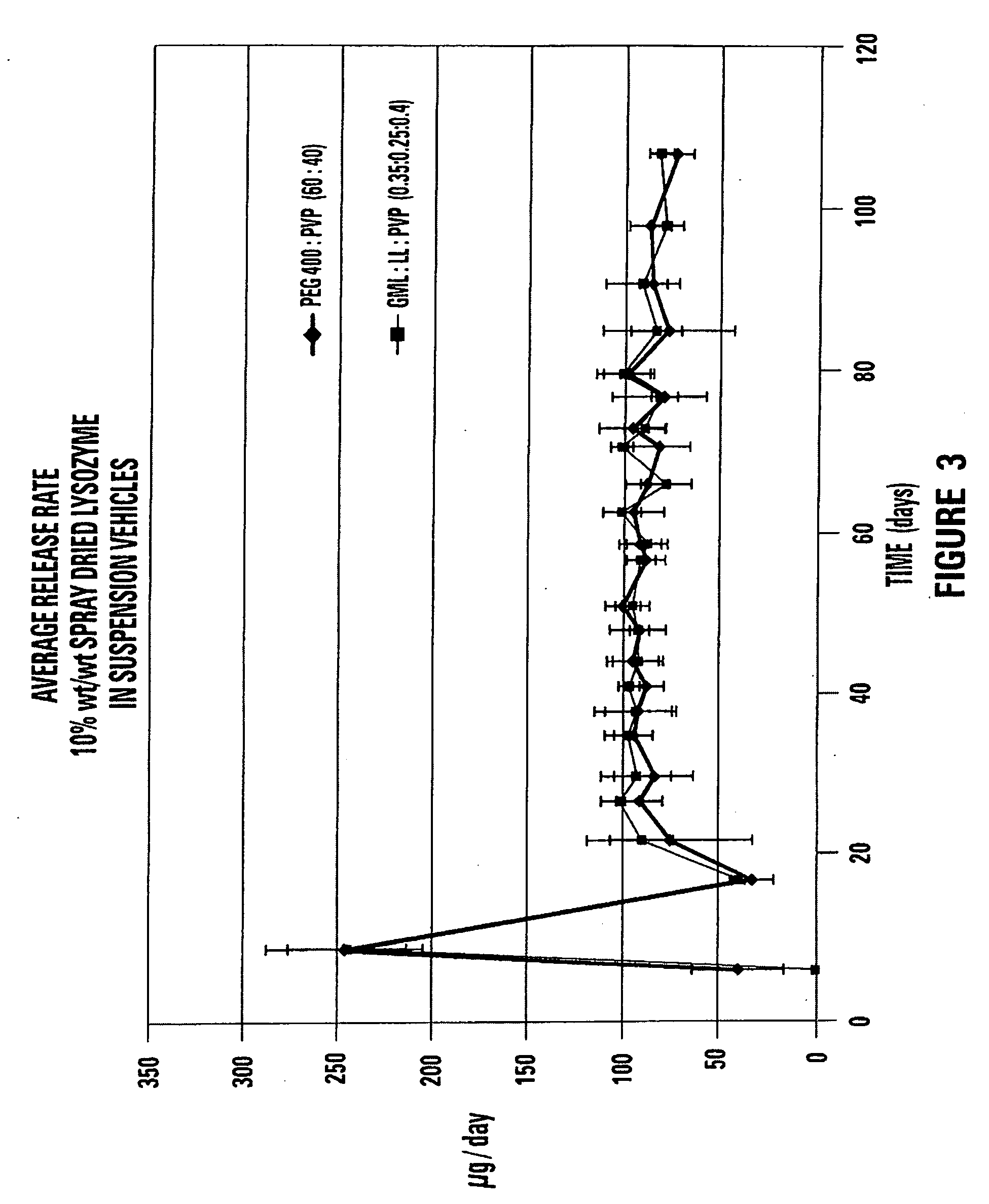

Stable non-aqueous single phase viscous vehicles and formulations utilizing such vehicle

InactiveUS7258869B1Zero order release rateReduce flow rateBiocidePeptide/protein ingredientsMedicineShear rate

This invention relates to stable non-aqueous single phase viscous vehicles and to formulations utilizing such vehicles. The formulations comprise at least one beneficial agent uniformly suspended in the vehicle. The formulation is capable of being stored at temperatures ranging from cold to body temperature for long periods of time. The formulations are capable of being uniformly delivered from drug delivery systems at an exit shear rate of between about 1 to 1×10−7 reciprocal second.

Owner:INTARCIA THERAPEUTICS INC

Injection molding of polymeric material

Injection molding systems and methods useful for making microcellular foamed materials are provided as well as microcellular articles. Pressure drop rate and shear rate are important features in some embodiments, and the invention provides systems for controlling these parameters in an injection molding system. Another aspect involves an injection molding system including a nucleator that is upstream of a pressurized mold. Another aspect involves an extrusion system with the reciprocating screw for forming a single phase solution of non-nucleated blowing agent and polymeric material. Another aspect involves very thin walled microcellular material and very thin walled polymeric material. Another aspect provides a method for producing high weight reductions in very thin-walled parts with surfaces that have no noticeable differences from non-foamed parts.

Owner:TREXEL

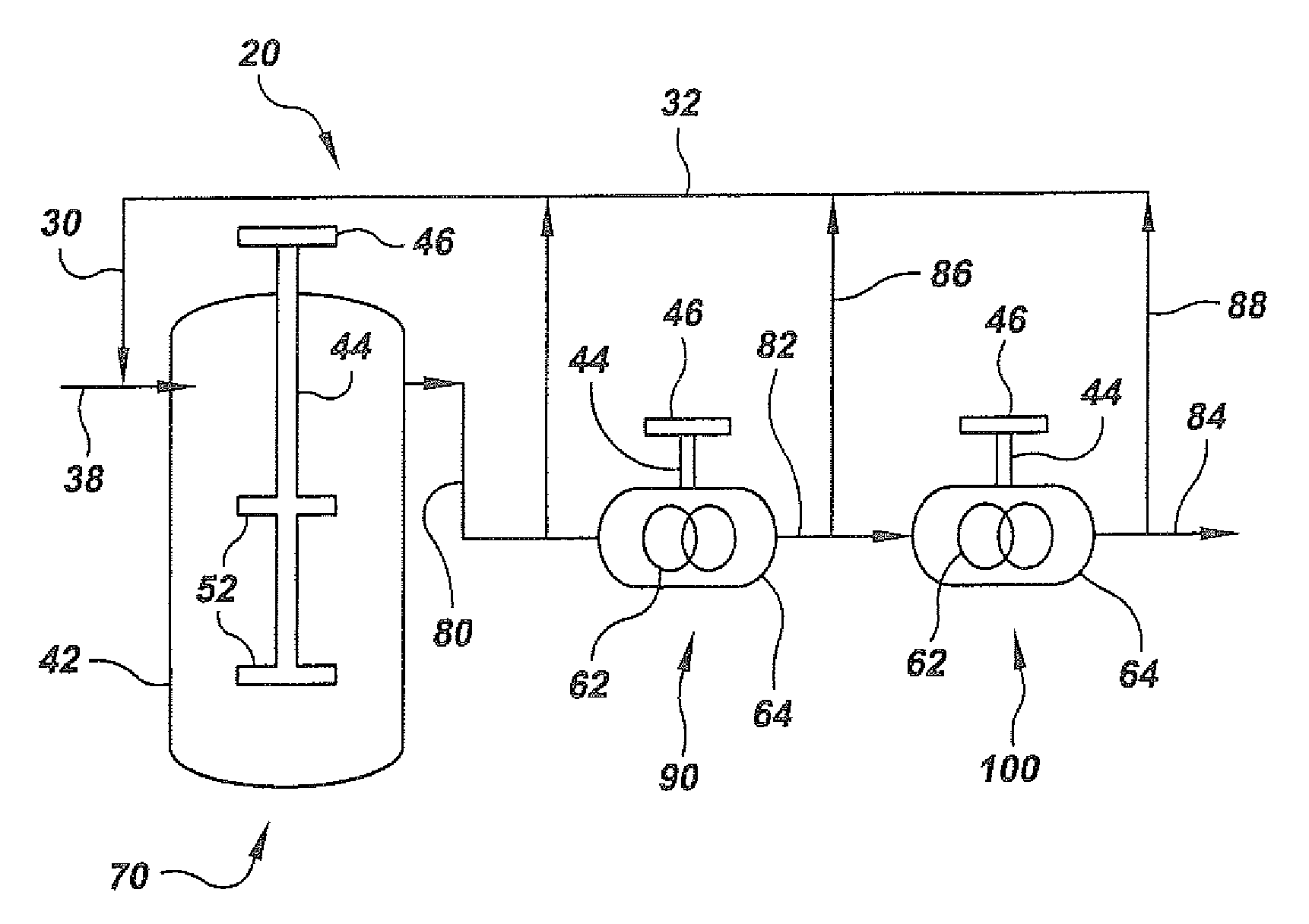

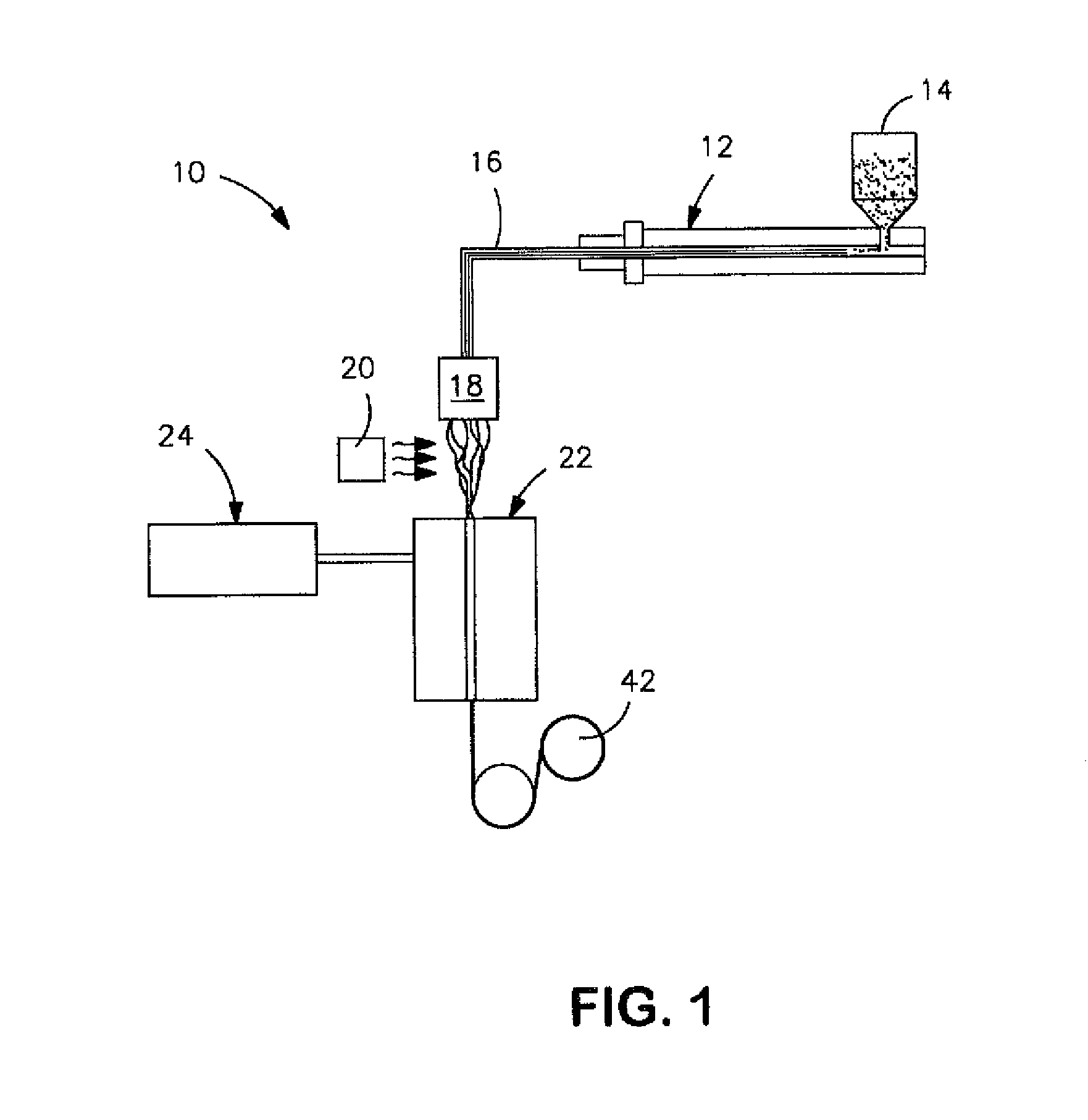

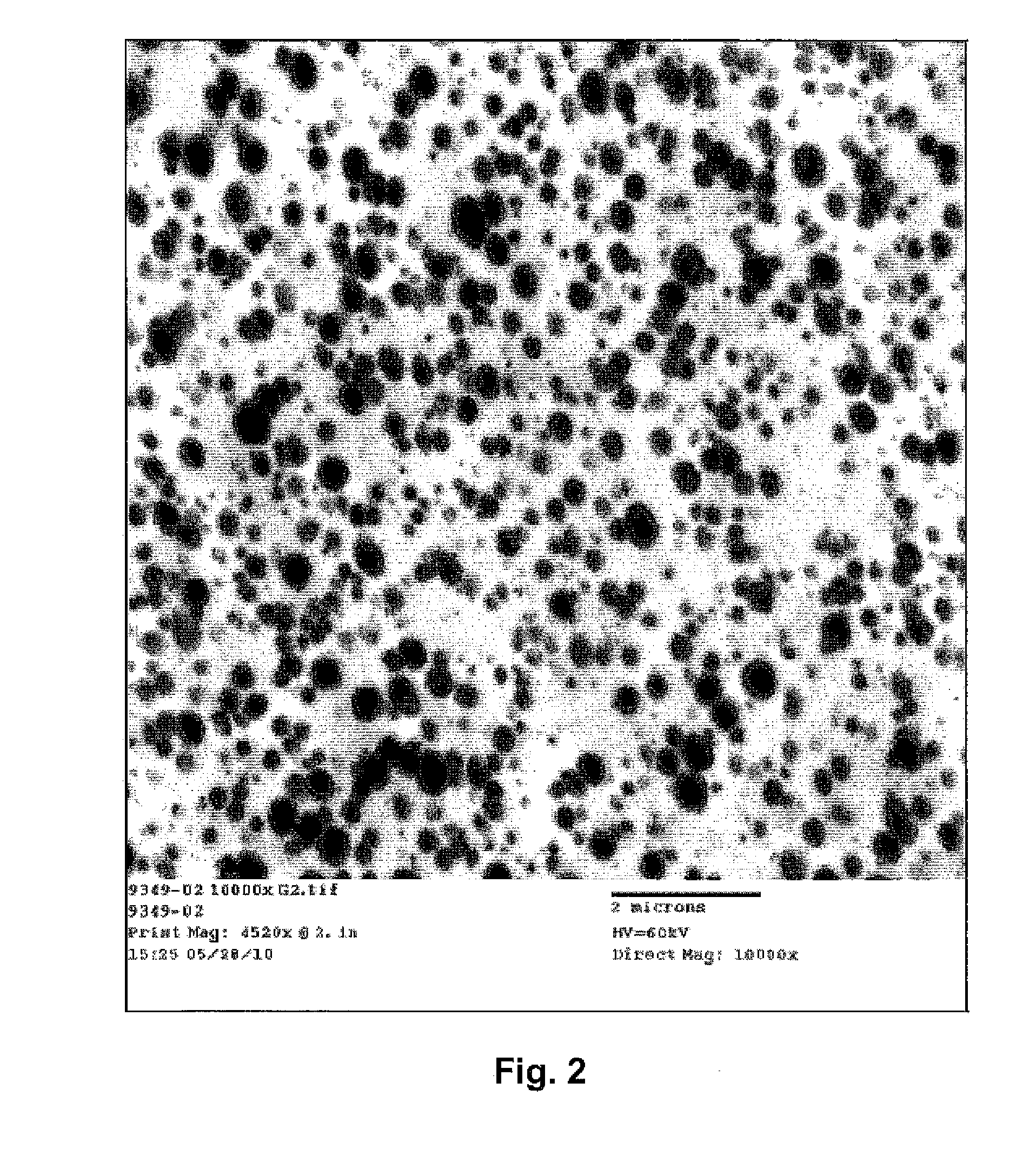

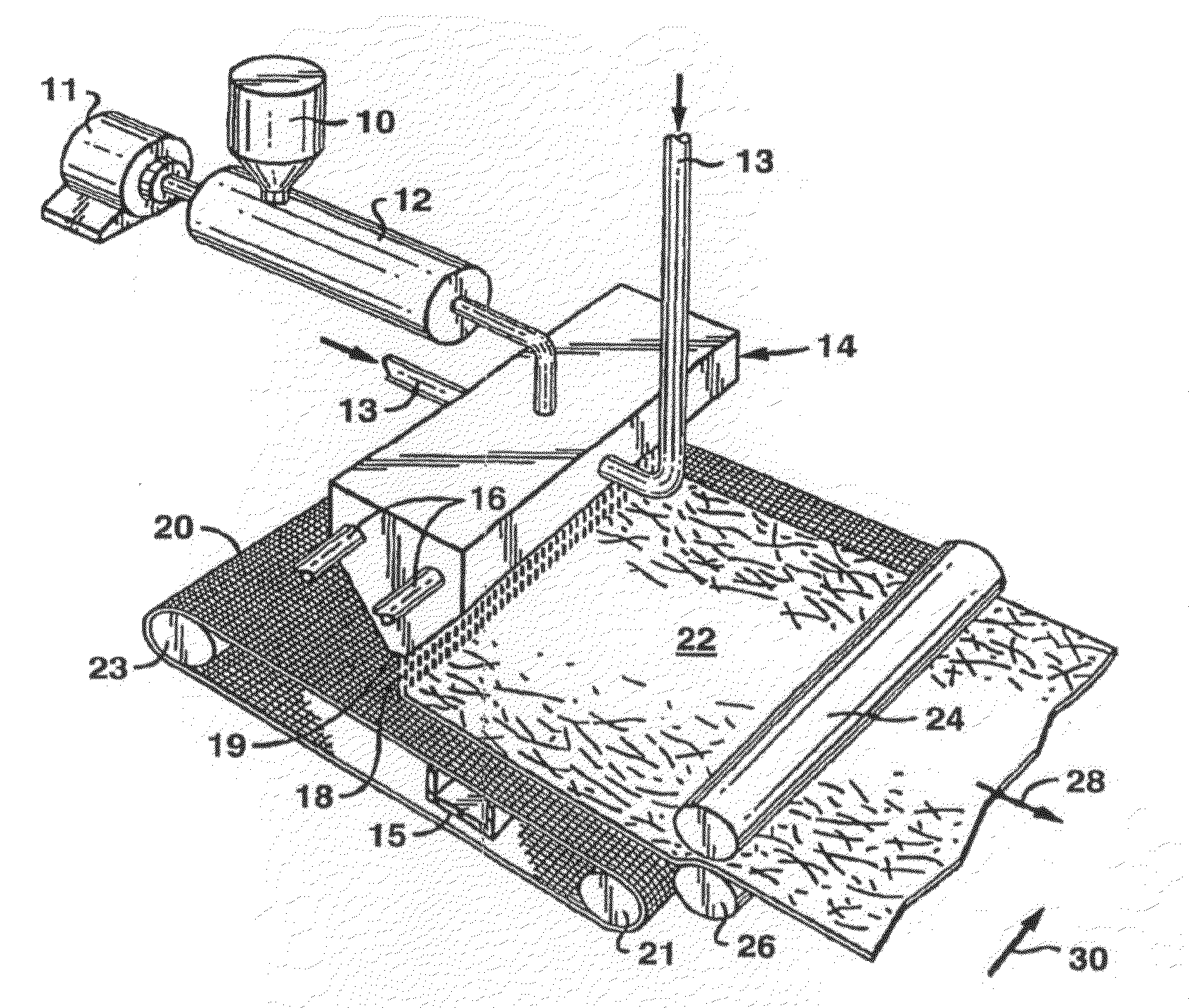

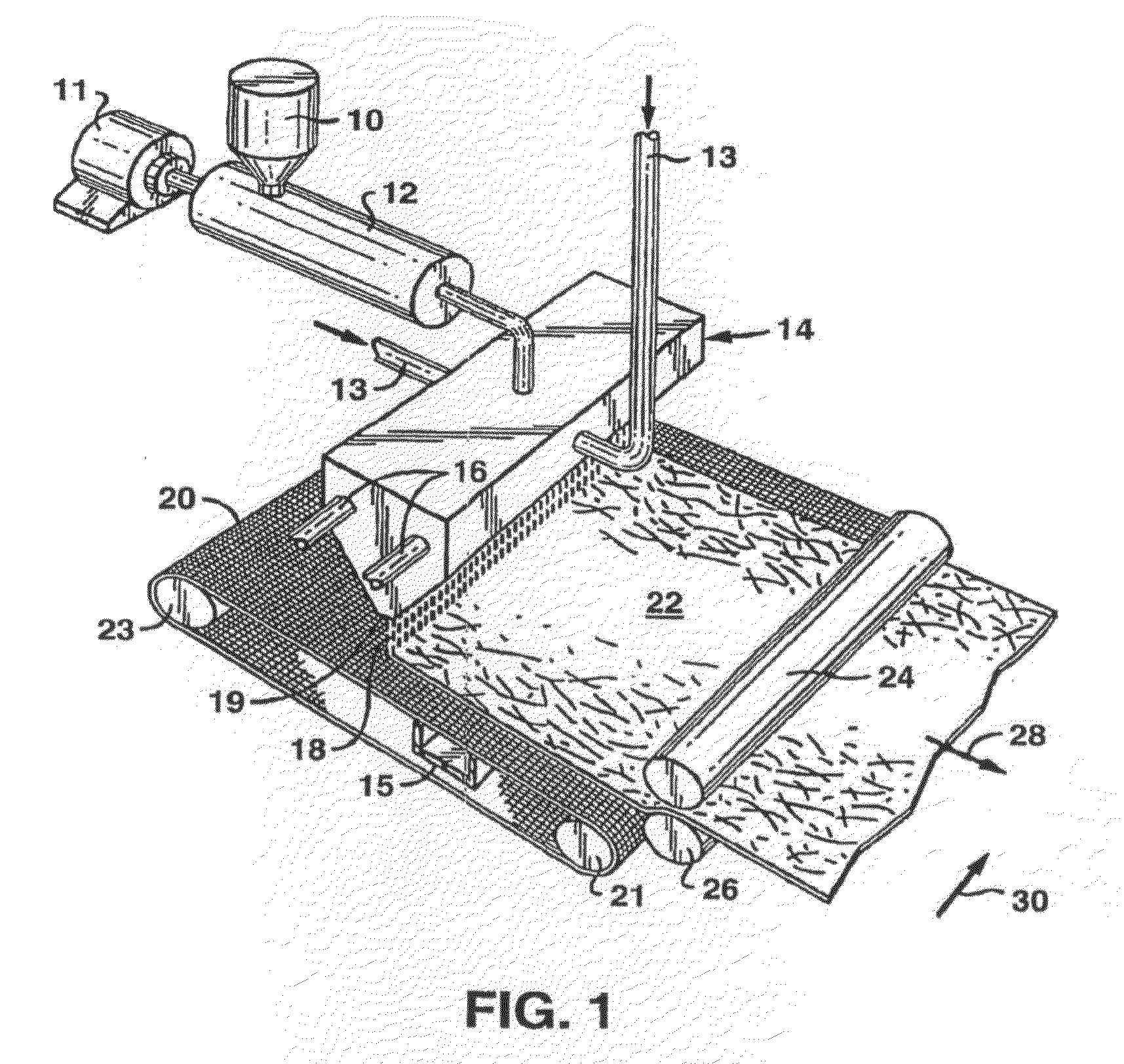

Process for producing nanofibers

ActiveUS20080057307A1Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberNanofiber

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

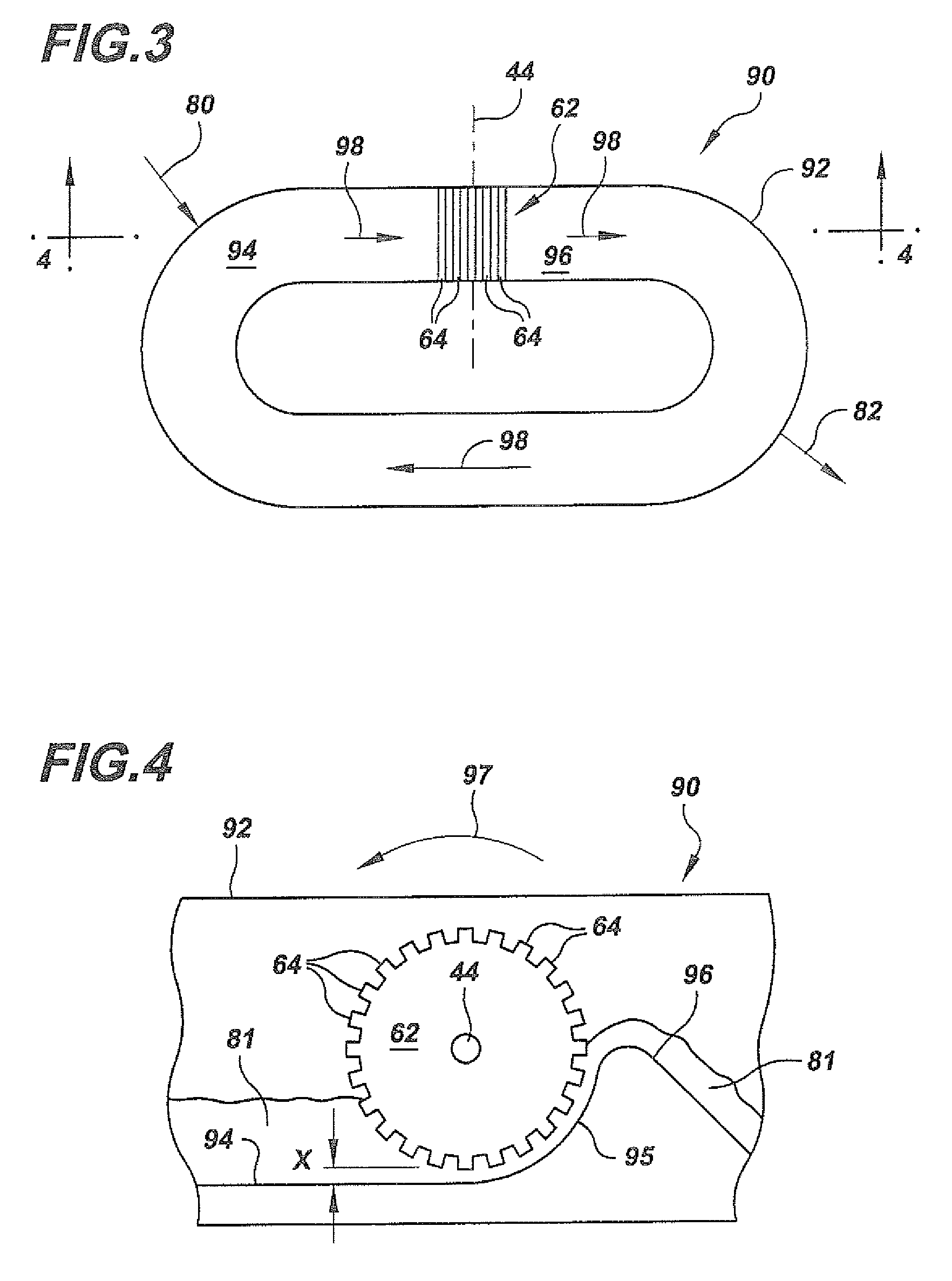

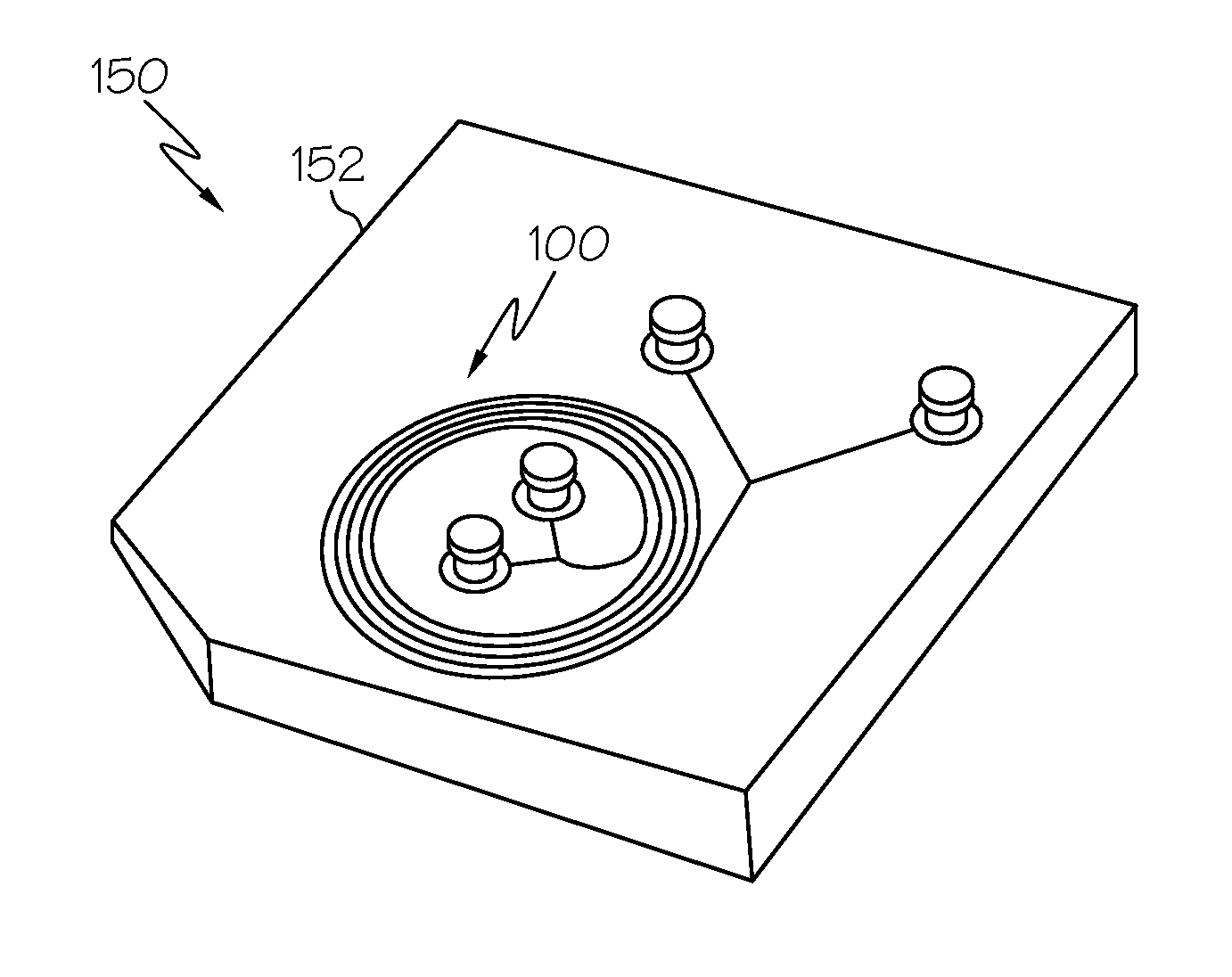

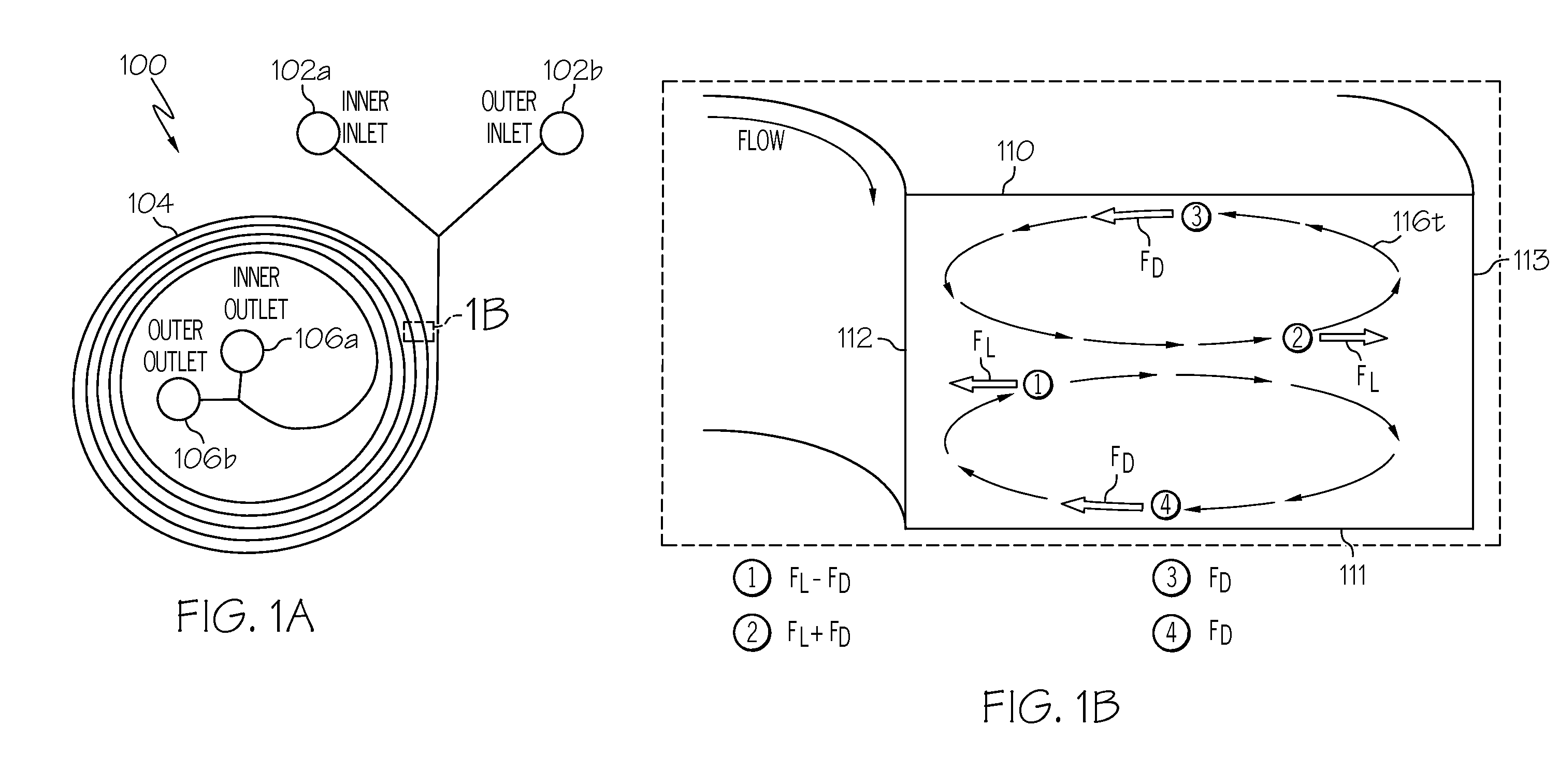

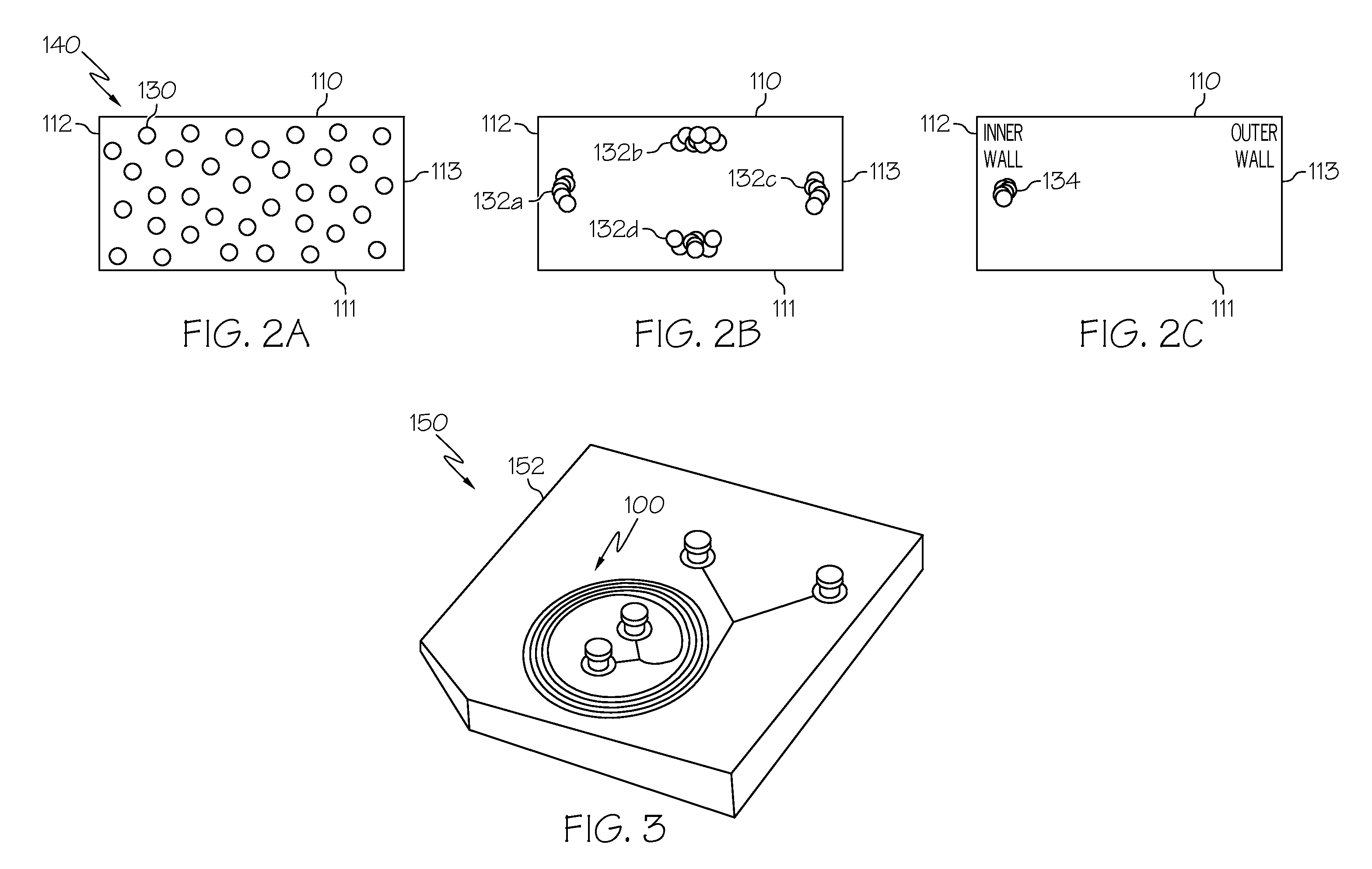

Spiral Microchannel Particle Separators, Straight Microchannel Particle Separators, and Continuous Particle Separator and Detector Systems

A spiral microchannel particle separator includes an inlet for receiving a solution containing particles, at least two outlets, and a microchannel arranged in a plurality of loops. Particles within a solution flowing through the spiral microchannel experience a lift force FL and a Dean drag force FD. The spiral radius of curvature R and the hydraulic diameter Dh of the spiral microchannel are such that for a flow rate U of the solution, the lift force FL and a Dean drag force FD are approximately equal and act in opposite directions for particles of a first size. The particles of the first size are focused in a single stream located at an equilibrium position near an inner wall of the microchannel. In another embodiment, a straight microchannel particle separator separates particles by modulating shear rates via high aspect ratios that focuses particles of a first size along two first walls.

Owner:UNIVERSITY OF CINCINNATI

Stable non-aqueous single phase viscous vehicles and formulations utilizing such vehicles

InactiveUS20080226689A1Zero order release rateReduce flow rateBiocidePharmaceutical delivery mechanismMedicineShear rate

This invention relates to stable non-aqueous single phase viscous vehicles and to formulations utilizing such vehicles. The formulations comprise at least one beneficial agent uniformly suspended in the vehicle. The formulation is capable of being stored at temperatures ranging from cold to body temperature for long periods of time. The formulations are capable of being uniformly delivered from drug delivery systems at an exit shear rate of between about 1 to 1×10−7 reciprocal second.

Owner:ALZA CORP

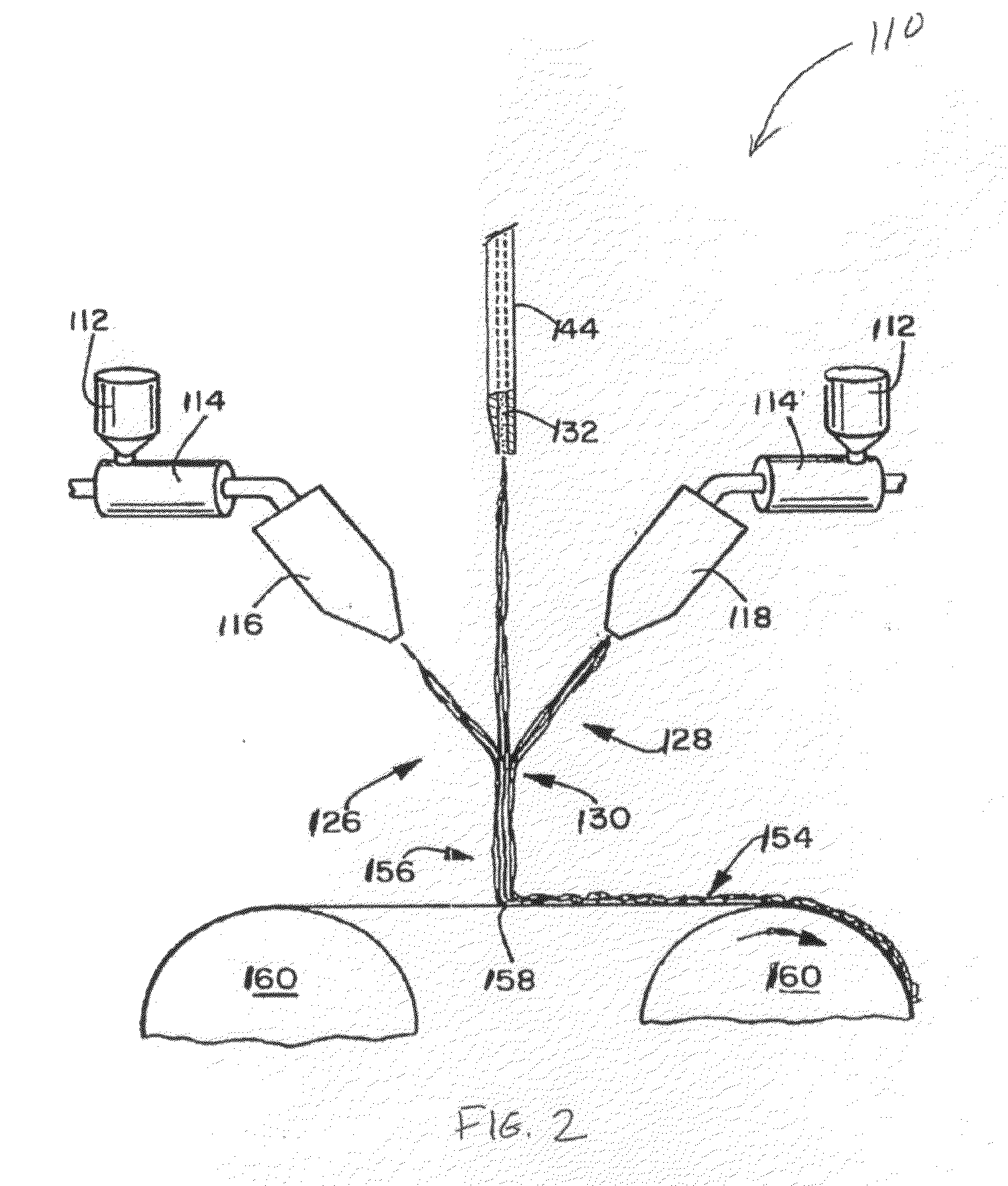

Modified Polylactic Acid Fibers

ActiveUS20120040582A1Improve responseMelt spinning methodsWoven fabricsChain scissionGlass transition

A method for forming biodegradable fibers is provided. The method includes blending polylactic acid with a polyepoxide modifier to form a thermoplastic composition, extruding the thermoplastic composition through a die, and thereafter passing the extruded composition through a die to form a fiber. Without intending to be limited by theory, it is believed that the polyepoxide modifier reacts with the polylactic acid and results in branching of its polymer backbone, thereby improving its melt strength and stability during fiber spinning without significantly reducing glass transition temperature. The reaction-induced branching can also increase molecular weight, which may lead to improved fiber ductility and the ability to better dissipate energy when subjected to an elongation force. To minimize premature reaction, the polylactic acid and polyepoxide modifier are first blended together at a relatively low temperature(s). Nevertheless, a relatively high shear rate may be employed during blending to induce chain scission of the polylactic acid backbone, thereby making more hydroxyl and / or carboxyl groups available for subsequent reaction with the polyepoxide modifier. Once blended, the temperature(s) employed during extrusion of the blended composition can be selected to both melt the composition and initiate a reaction of the polyepoxide modifier with hydroxyl and / or carboxyl groups of the polylactic acid. Through selective control over this method, the present inventors have discovered that the resulting fibers may exhibit good mechanical properties, both during and after melt spinning.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Molding composition with good capability for blow molding

InactiveUS6677015B2Reduce concentrationIncrease stiffnessSynthetic resin layered productsThin material handlingBlow moldingPolymer science

A molding composition of at least 50% by weight of a polyamine-polyamide copolymer obtained from 0.05 to 2.5% by weight of a polyamine having at least 4 nitrogen atoms and having a viscosity of at least 5 000 Pa.s at 250° C. and at a shear rate of 0.1 l / s, and having a viscosity ratio of at least 7 at 250° C., when the melt viscosities at shear rates of 0.1 l / s and 100 l / s are compared with one another, has high melt stiffness and is easy to cut, and performs well in blow molding.

Owner:EVONIK DEGUSSA GMBH

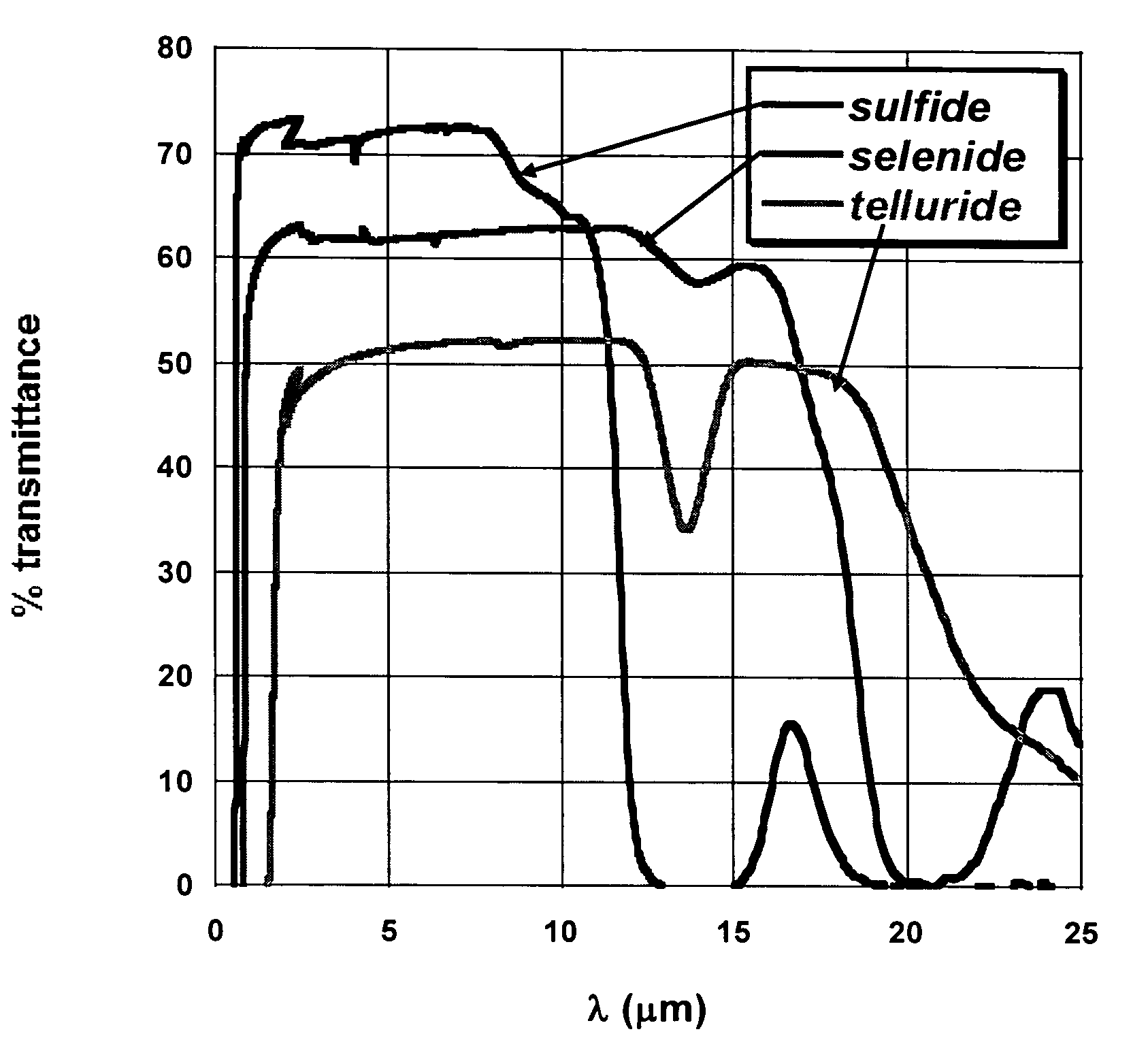

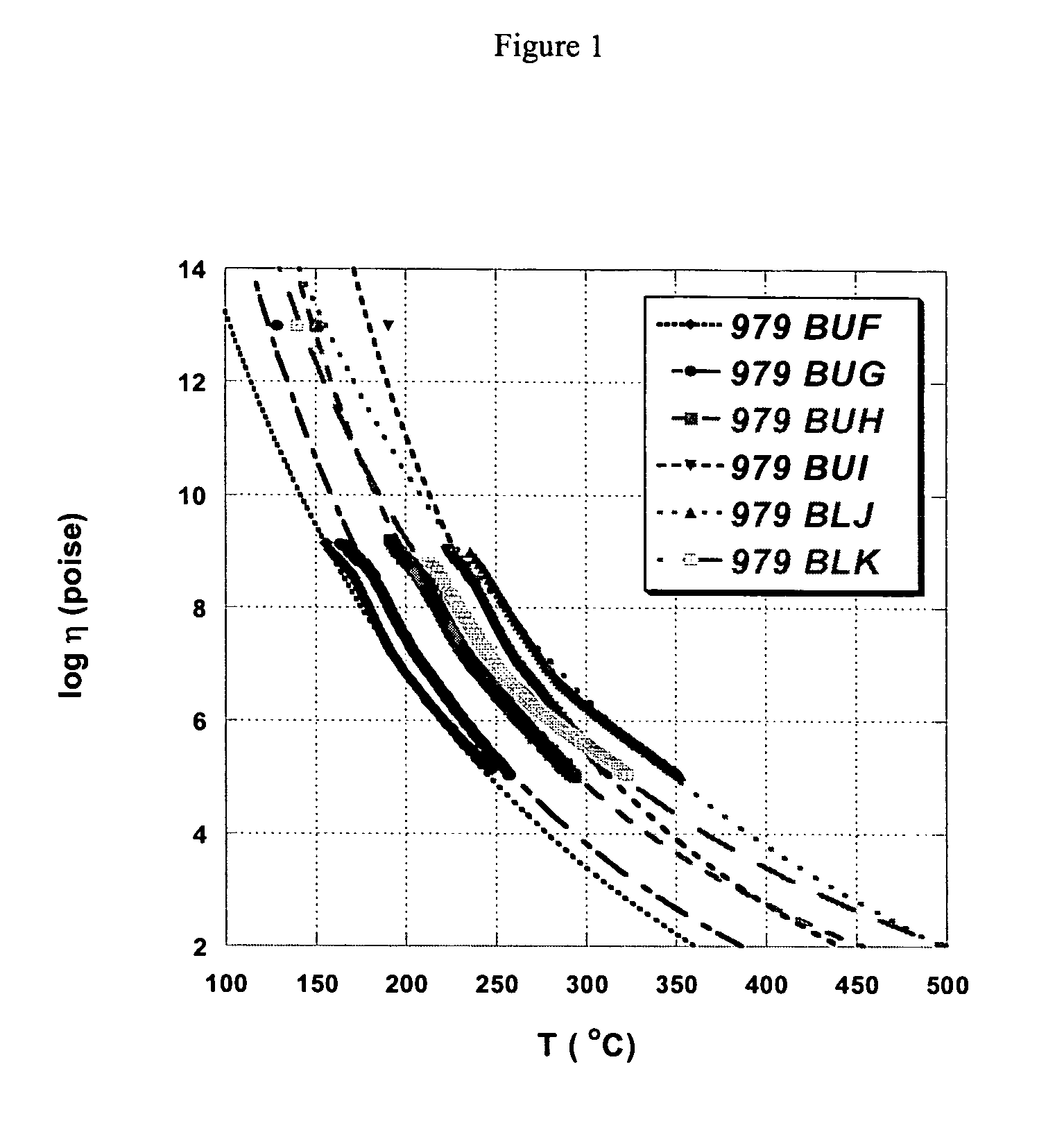

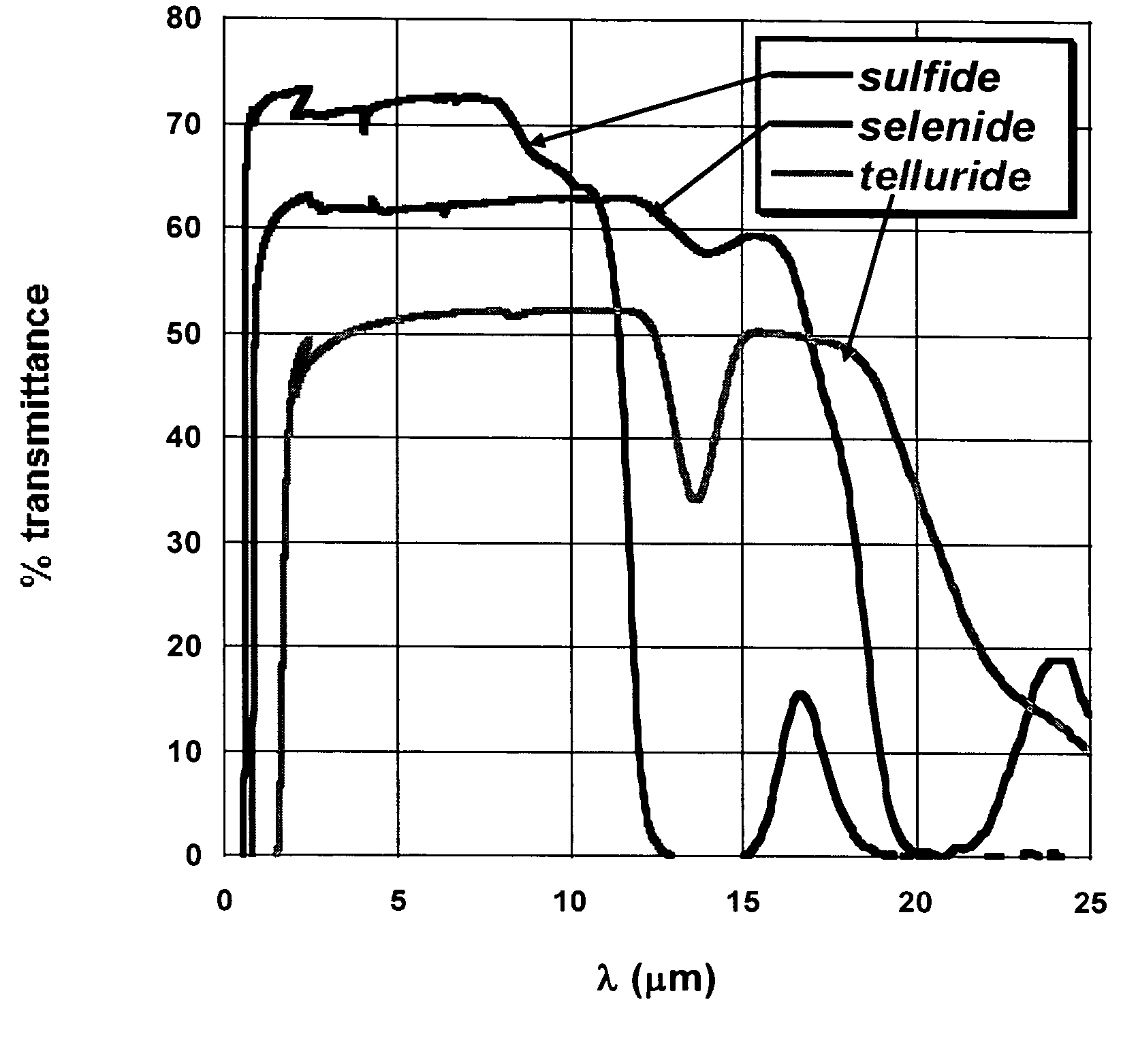

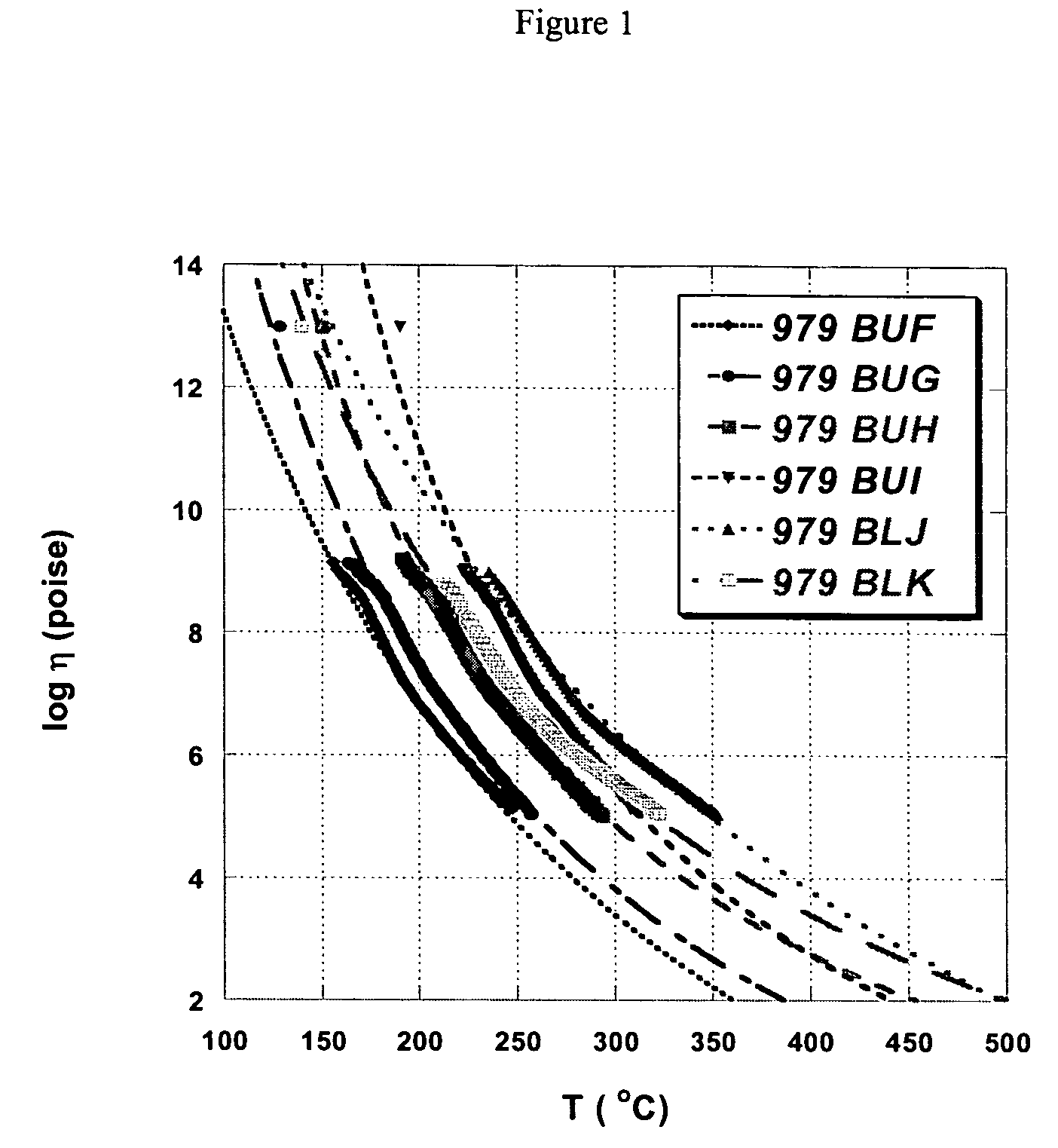

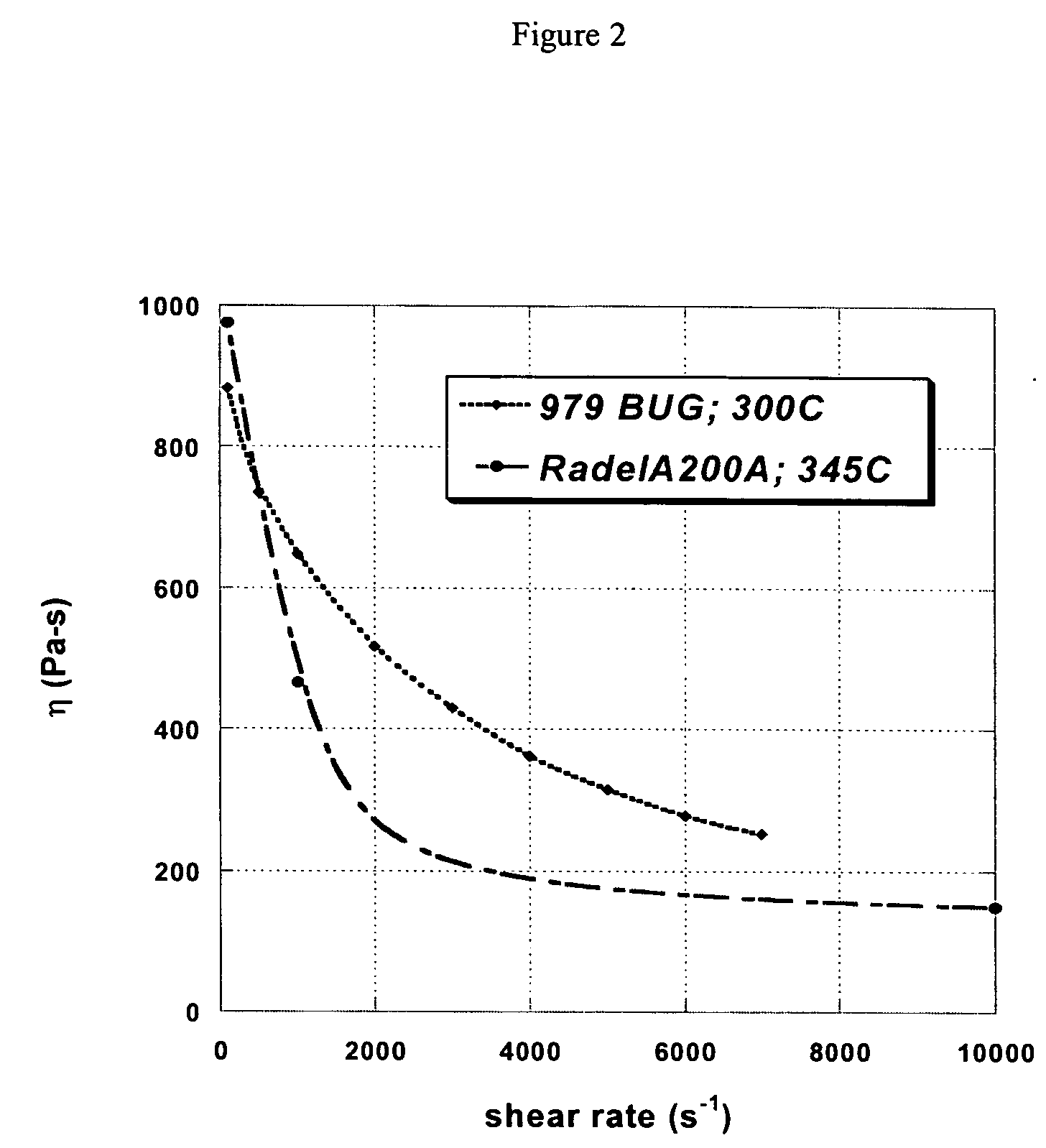

Chalcogenide glass for low viscosity extrusion and injection molding

The invention is directed to chalcogenide glasses suitable for use in plastics forming processes. The glasses have the general formula YZ, where Y is Ge, As, Sb or a mixture of two or more of the same; Z is S, Se, Te, or a mixture of two or more of the same; and Y and Z are present in amounts (in atomic / element percent) in the range of Y=15–70% and Z=30–85%. The chalcogenide glasses of the invention have a 10,000 poise temperature of 400° C. and are resistant to crystallization when processed at high shear rates at their 10,000 poise temperature. The glasses can be used to make, among other items, molded telecommunication elements, lenses and infrared sensing devices.

Owner:CORNING INC

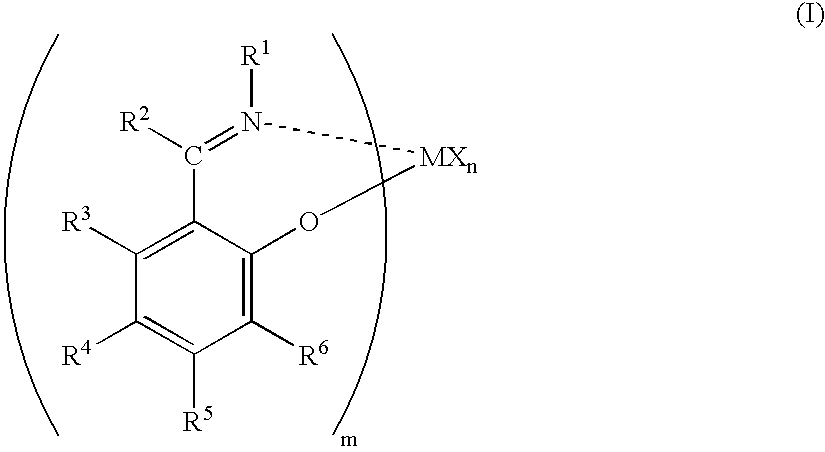

Catalyst support and method of producing the same

ActiveUS7618919B2Improve adhesionImprove reforming performanceHydrogenCatalyst activation/preparationRare-earth elementAlkali metal oxide

A method of producing a catalyst support comprising a substrate, and coating formed on the surface of the substrate and including powder of a first metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, wherein the coating is obtained by heat treating the substrate after applied with a coating composition obtained by mixing the first metal oxide powder together with a fluid raw material composition containing raw material of a second metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, at a shear rate of 1000 sec−1 or higher.

Owner:TOYOTA CENT RES & DEV LAB INC

Method of exfoliating skin

InactiveUS6294179B1Avoid excessive abrasion of and damageInorganic/elemental detergent compounding agentsCosmetic preparationsMean diameterViscous liquid

A viscous, liquid, skin washing composition comprising water, at least one surface active agent, abrasive particles and a viscosifier, CHARACTERISED IN THAT the viscosity of the composition is typically that of a shower gel, i.e. in the range 4000-8000 mPas measured at a shear rate of 10 s-1, the particles, preferably calcite, have a mean diameter of 40-400 micrometres and a bulk density of 1-4.

Owner:LEVER BROTHERS

Process for preparing bead polymers with an average particle size in the range from 1 to 40 muM, moulding compositions comprising bead polymer, and mouldings and PAMA plastisols

The present invention provides a process for preparing bead polymers having an average particle size of 1 to 40 mum, which includes:contacting:at least one polymerizable mix which includes at least 50% by weight of at least one (meth)acrylate monomer,at least one aluminum compound, andan aqueous phase,to prepare a mixture;dispersing the mixture at a shear rate>=10<3 >s<-1 >to form a dispersion, wherein the dispersion is stabilized by the aluminum compound; andpolymerizing to produce bead polymers having an average particle size of 1 to 40 mum.

Owner:MAGVENTION (SUZHOU) LTD +1

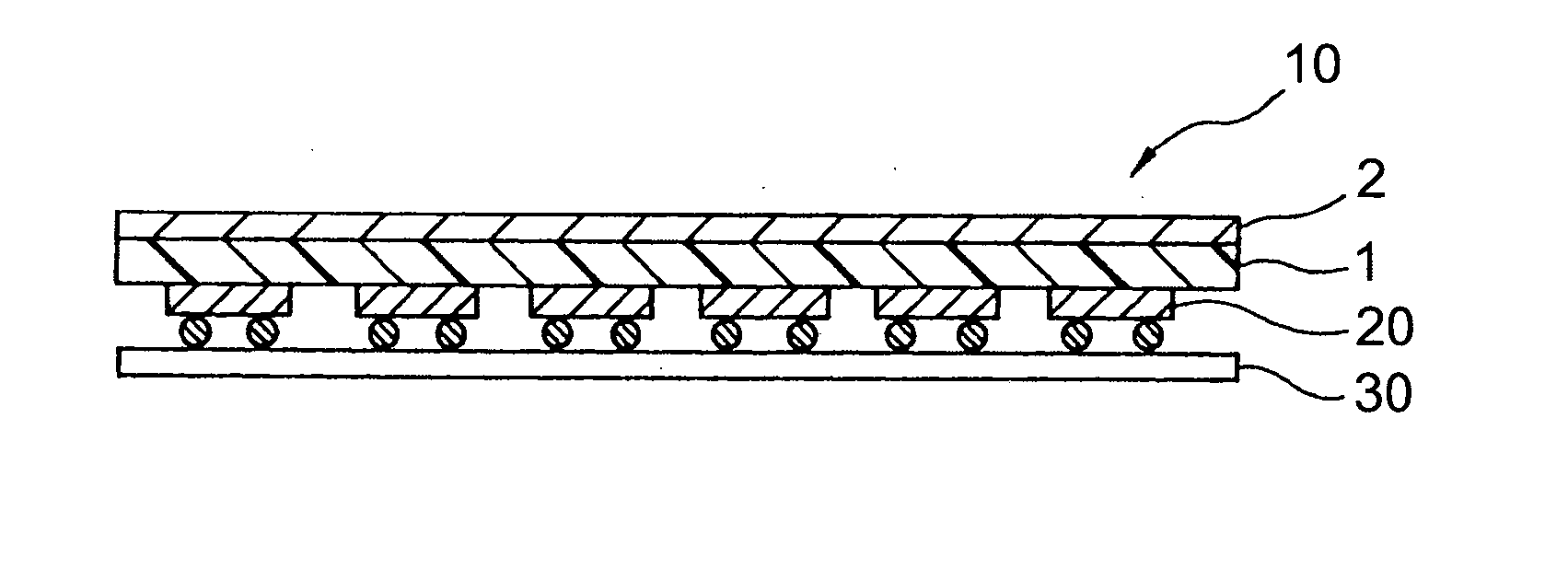

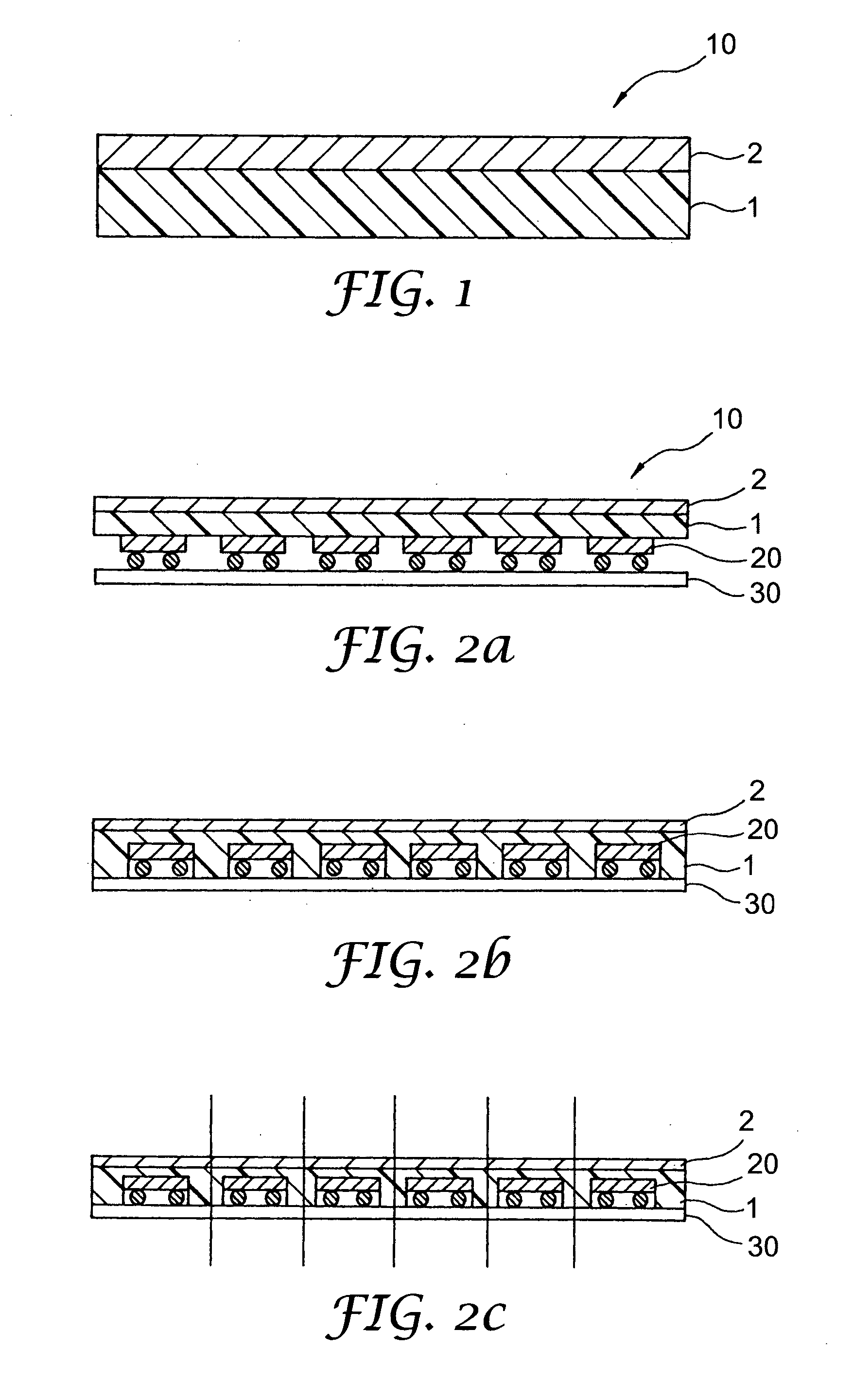

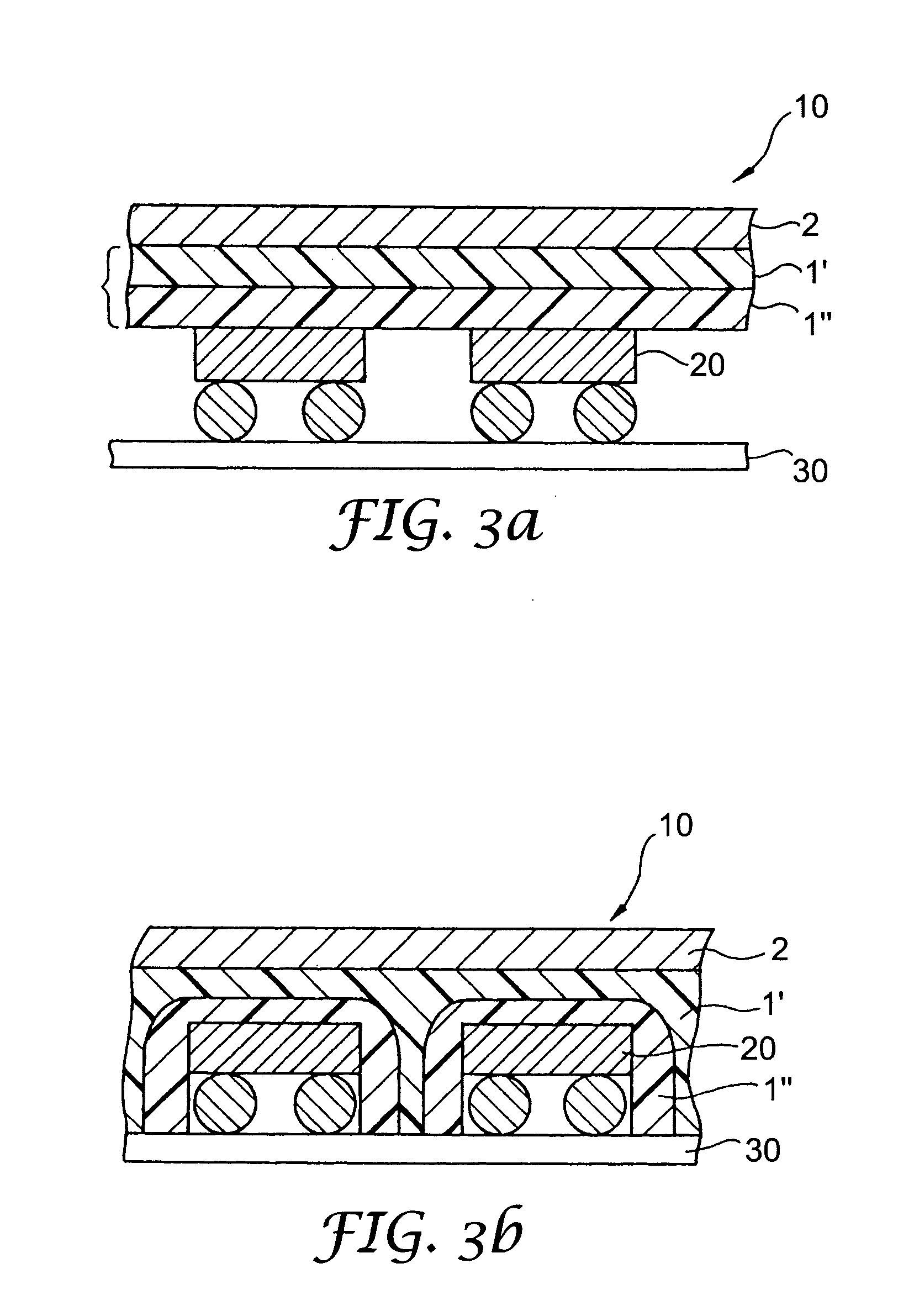

Film adhesive for sealing, film laminate for sealing and sealing method

InactiveUS20040213973A1Poor compatibilityReduce adhesionImpedence networksSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

A film adhesive for sealing a plurality of chip-type devices on a substrate at one time, including an adhesive layer of an adhesive composition which exhibits a minimum value of a storage modulus of elasticity before curing from 1x10<3 >to 5x10<5 >Pa measured by using a dynamic visco-elasticity measuring apparatus while elevating the temperature from 80° C. to 150° C. at an elevating temperature rate of 2.4° C. / min and at a shearing rate of 6.28 rad / sec and a storage modulus of elasticity after curing from 5x10<5 >to 5x10<7 >Pa measured by using a dynamic visco-elasticity measuring apparatus at a sample temperature of 150° C. in a tensile mode at a measuring frequency of 6.28 rad / sec.

Owner:3M INNOVATIVE PROPERTIES CO

Drug delivery systems and methods for treating neovascularization

InactiveUS20100098772A1Effective treatmentImprove clarityOrganic active ingredientsBiocideShear rateNeovascularization

Anti-angiogenesis compositions, and methods of using such compositions, useful for intraocular to treat neovascularization. The compositions can have viscosities at about 25° C. of at least about 10 cps or about 100 cps at a shear rate of 0.1 / second. In a preferred embodiment, the viscosity at 25° C. is in the range of from about 80,000 cps to about 300,000 cps.

Owner:ALLERGAN INC

Chalcogenide glass for low viscosity extrusion and injection molding

ActiveUS20060233512A1Low cost manufacturingGlass making apparatusCladded optical fibreSulfurChalcogenide glass

Owner:CORNING INC

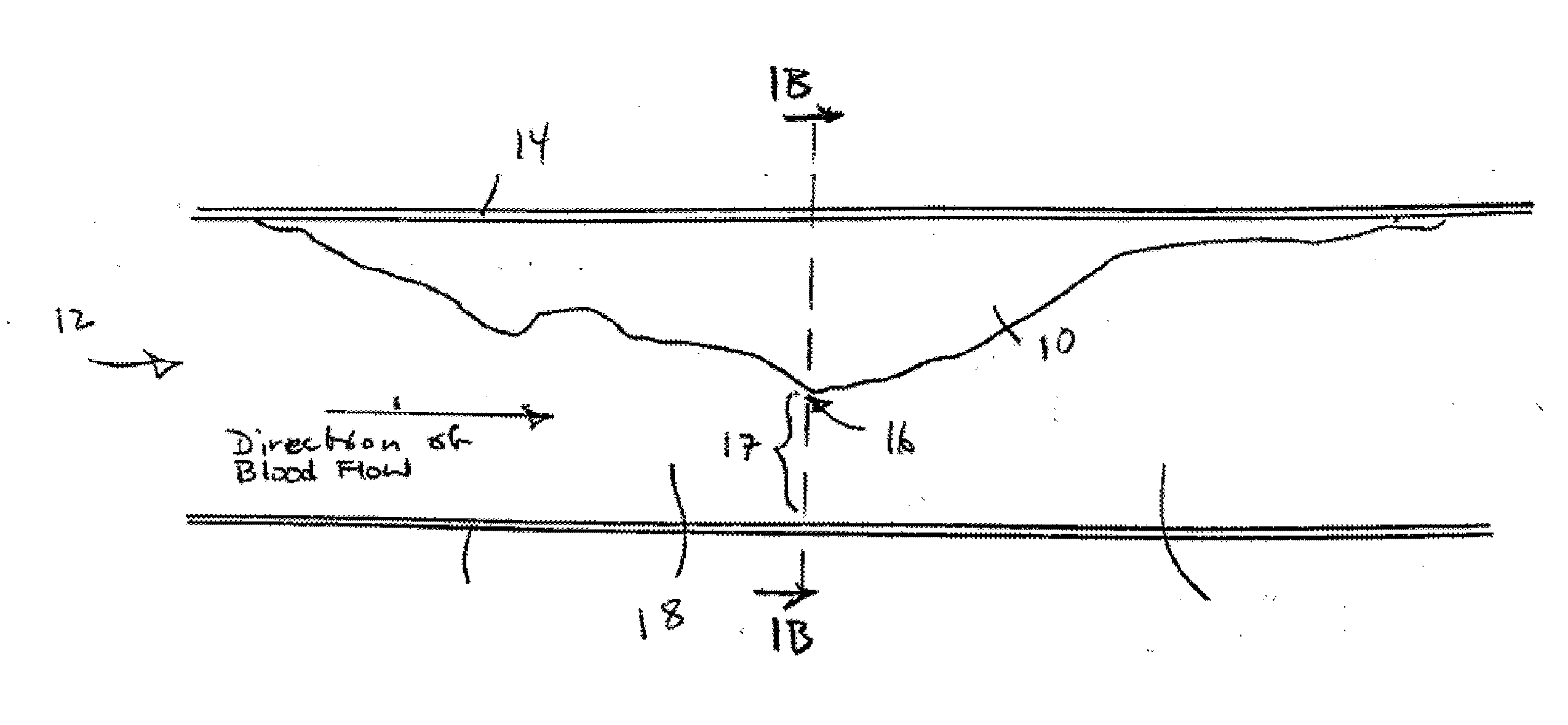

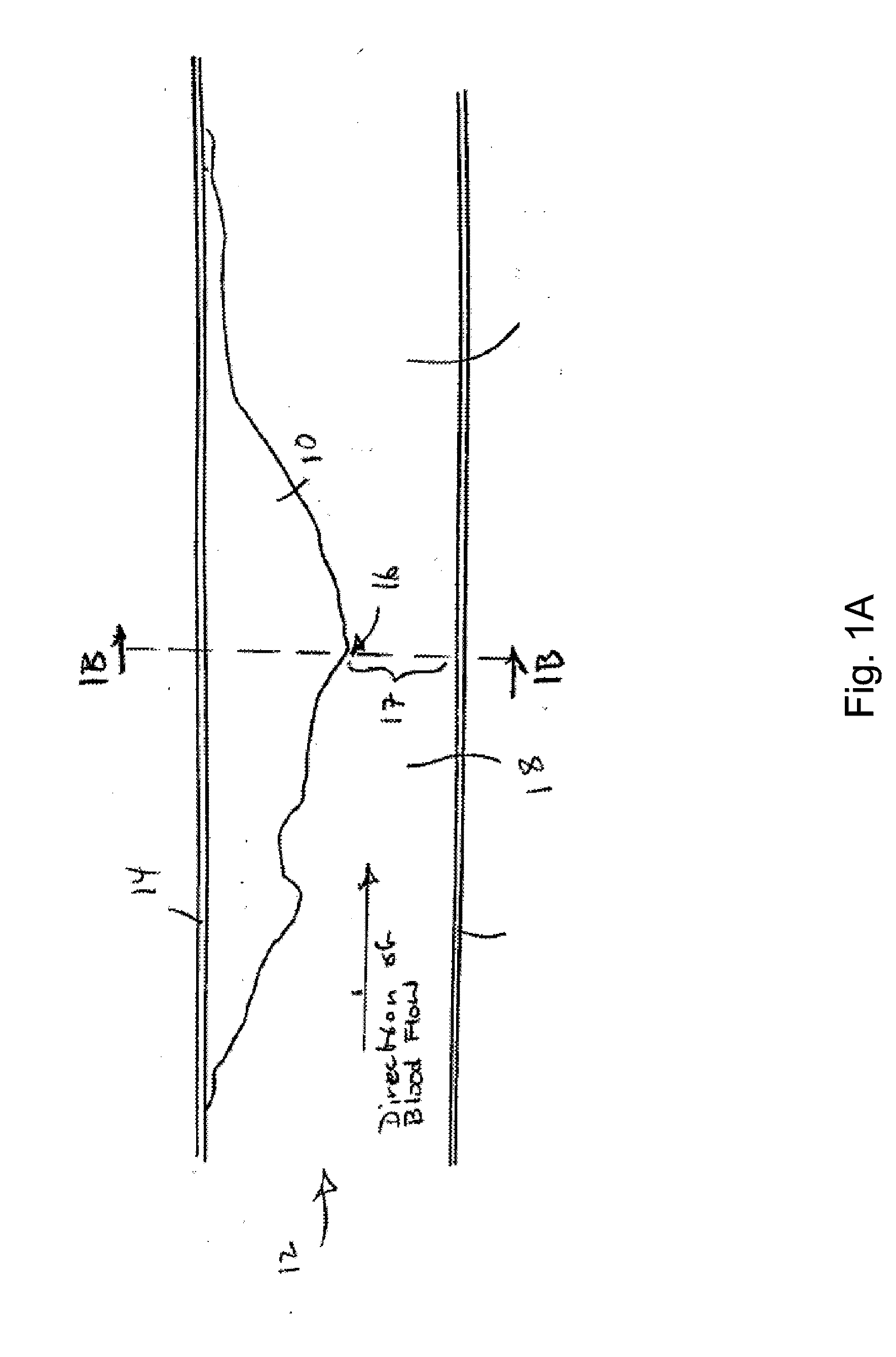

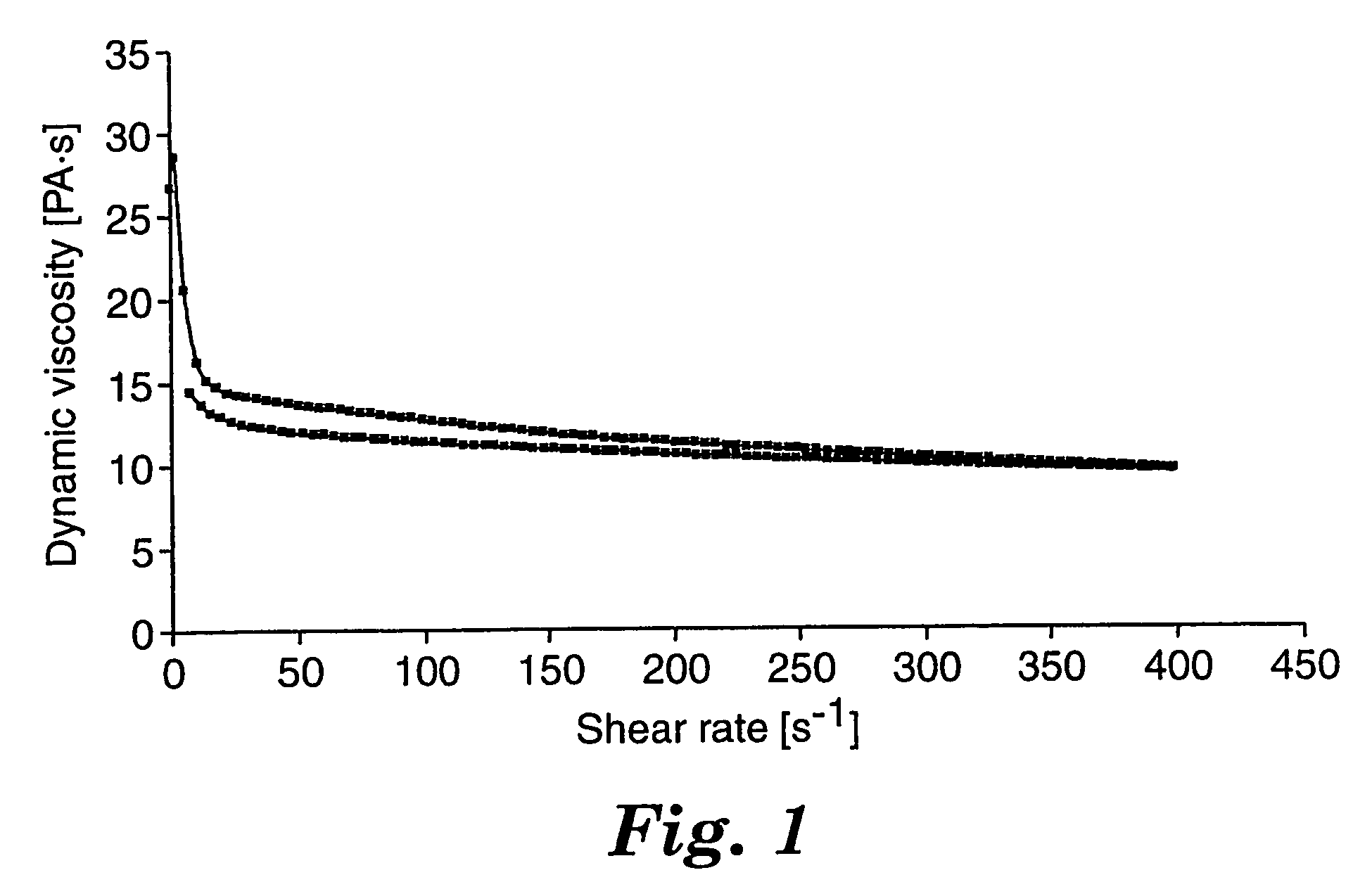

Method for determining shear stress and viscosity distribution in a blood vessel

InactiveUS20110275936A1Blood flow measurement devicesOrgan movement/changes detectionShear stressShear rate

A method for computing patient specific blood viscosity and patient specific shear stress on a location of interest in the interior of a blood vessel that includes calculating shear rate of blood in the vessel, using imaging techniques and calculating the shear rate related blood viscosity.

Owner:RHEOVECTOR

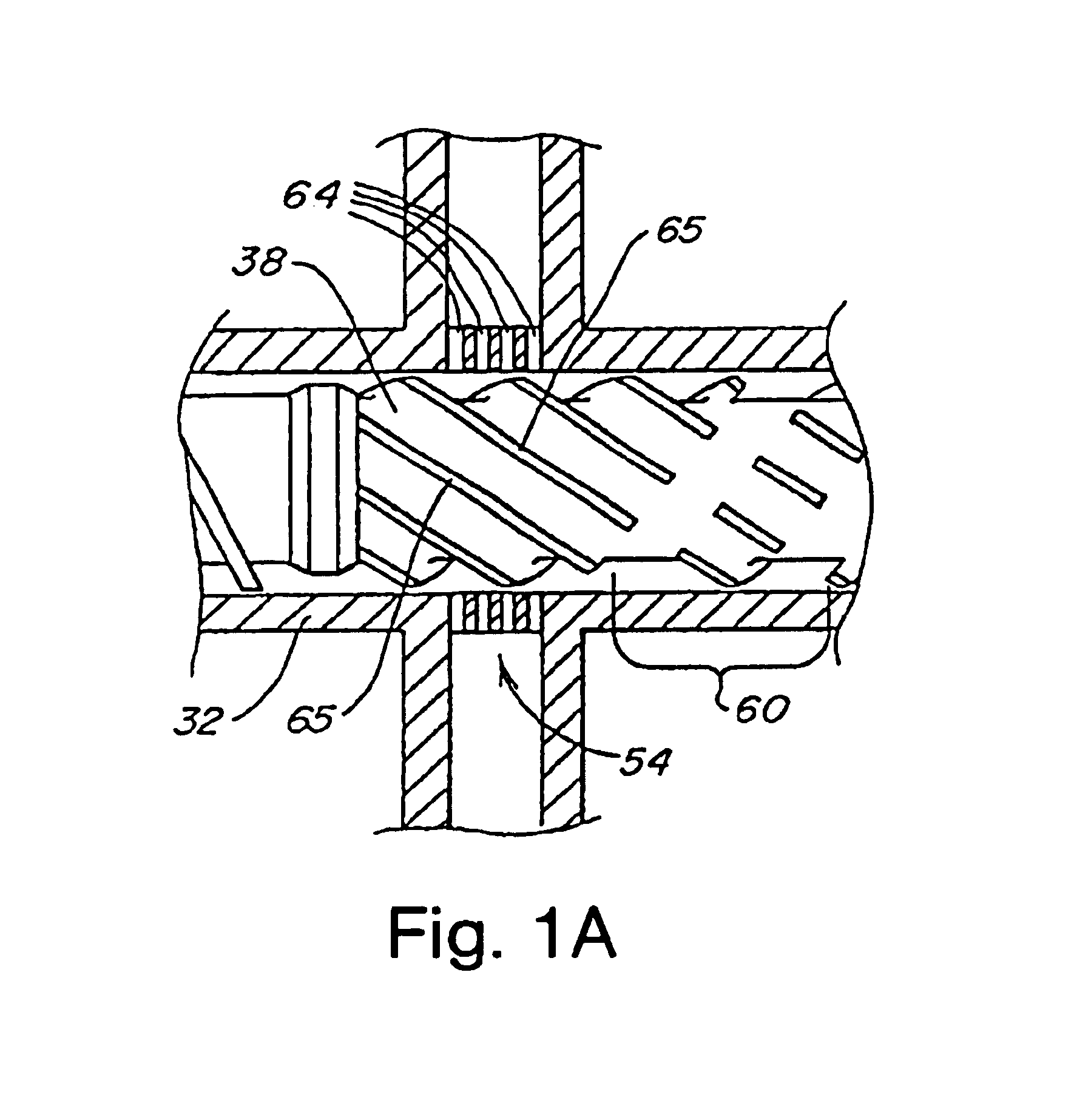

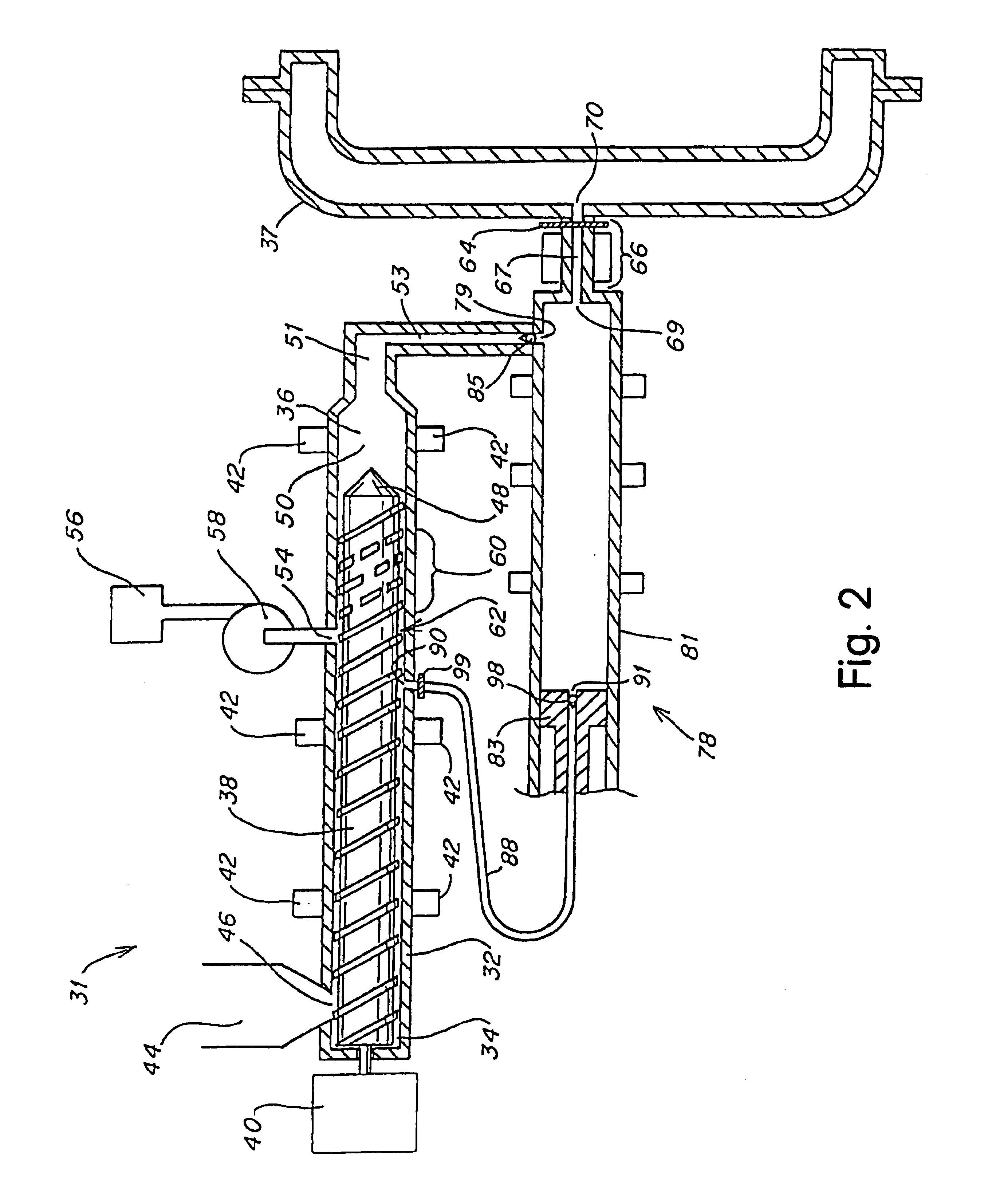

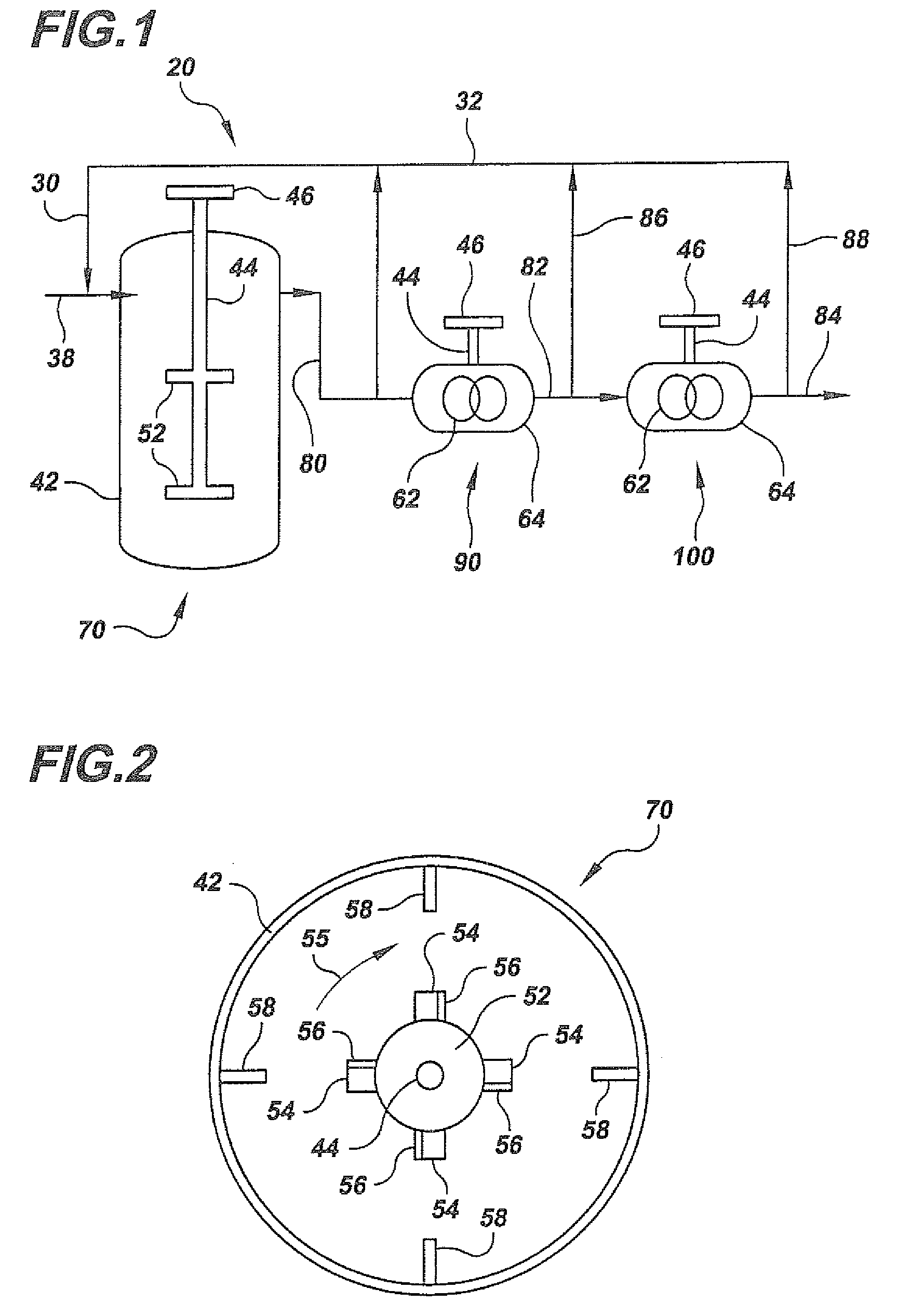

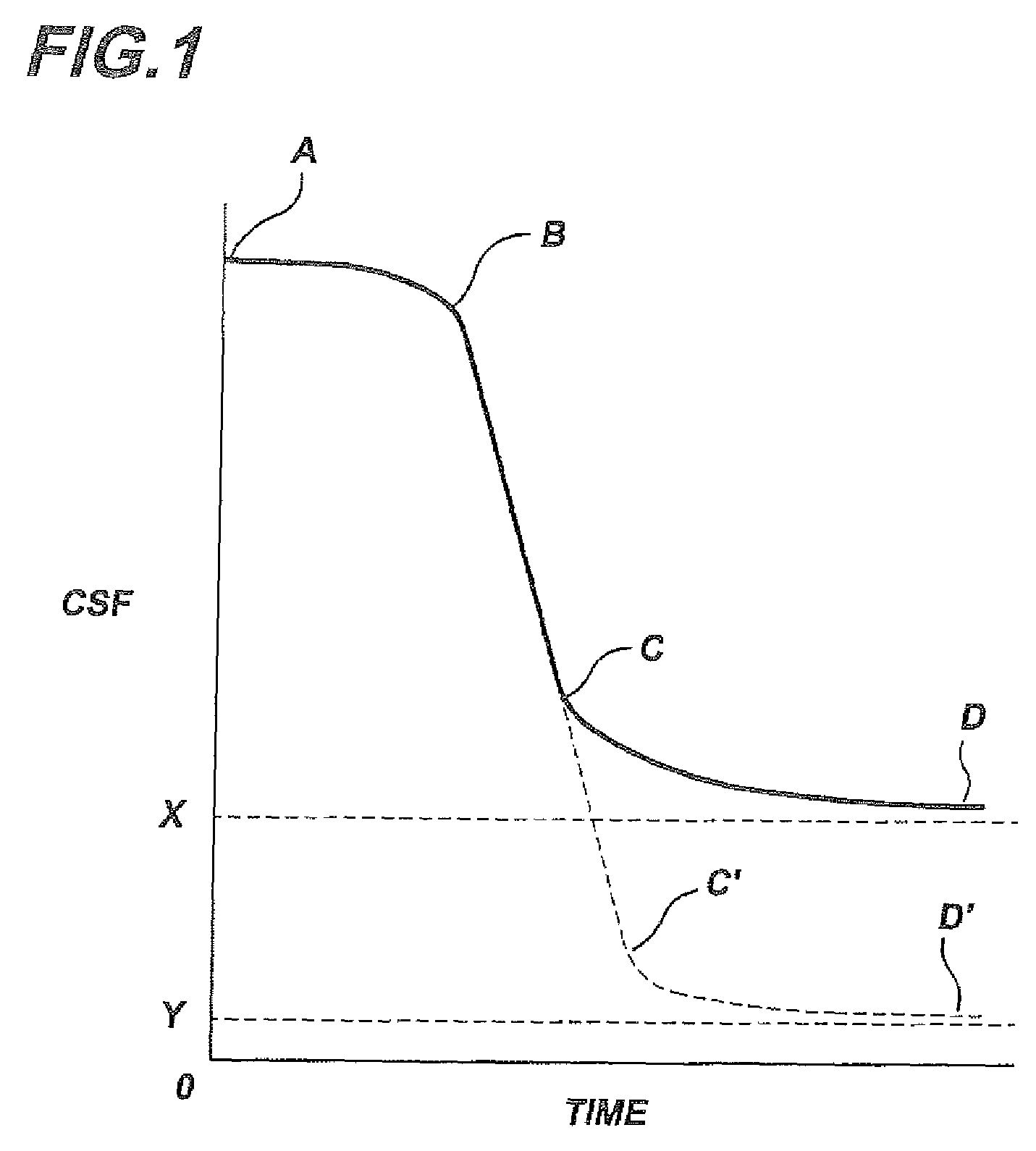

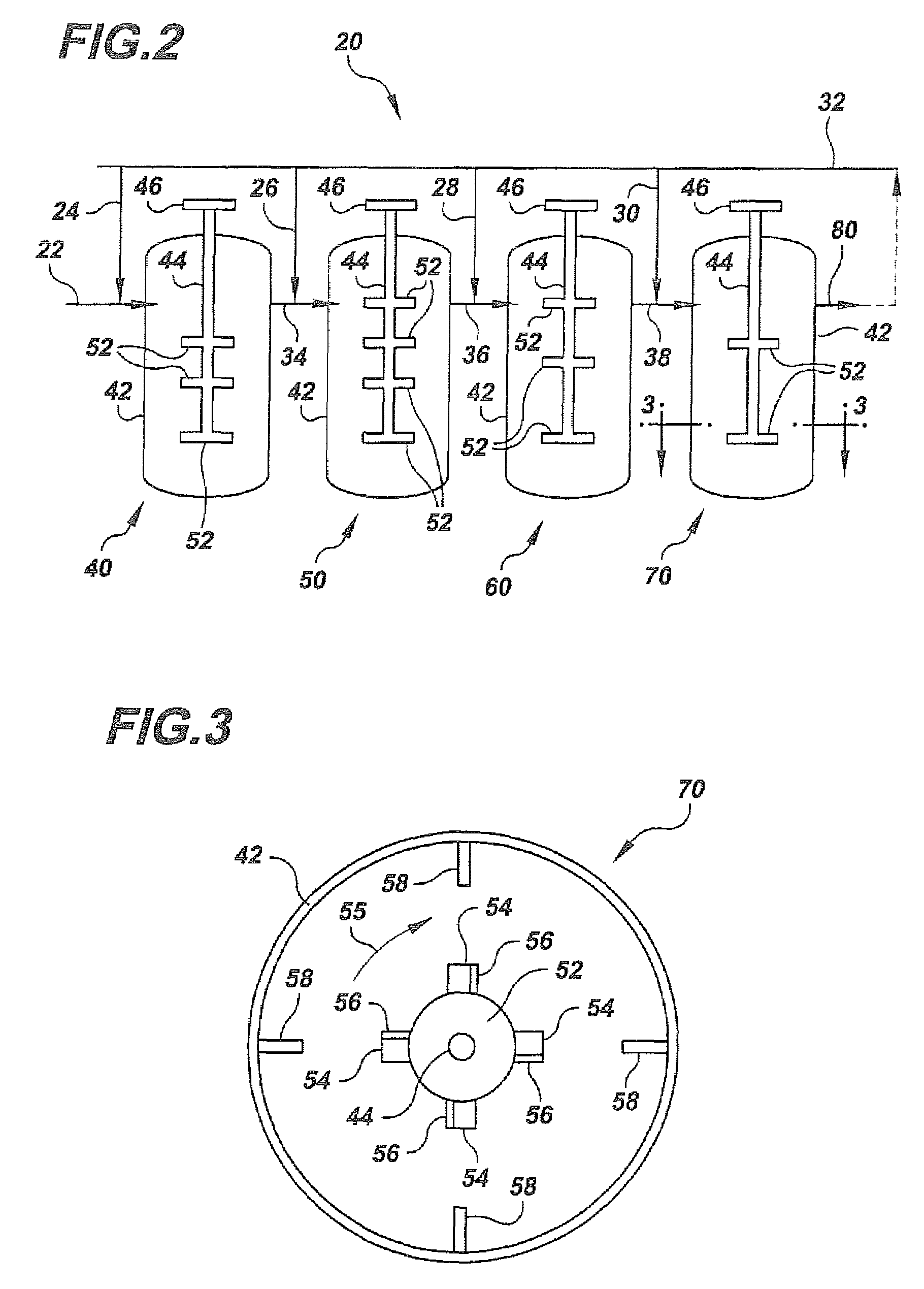

Process for producing fibrillated fibers

ActiveUS7566014B2Inhibit productionIncreased fiber lengthFilament/thread formingGrain treatmentsFiberShear rate

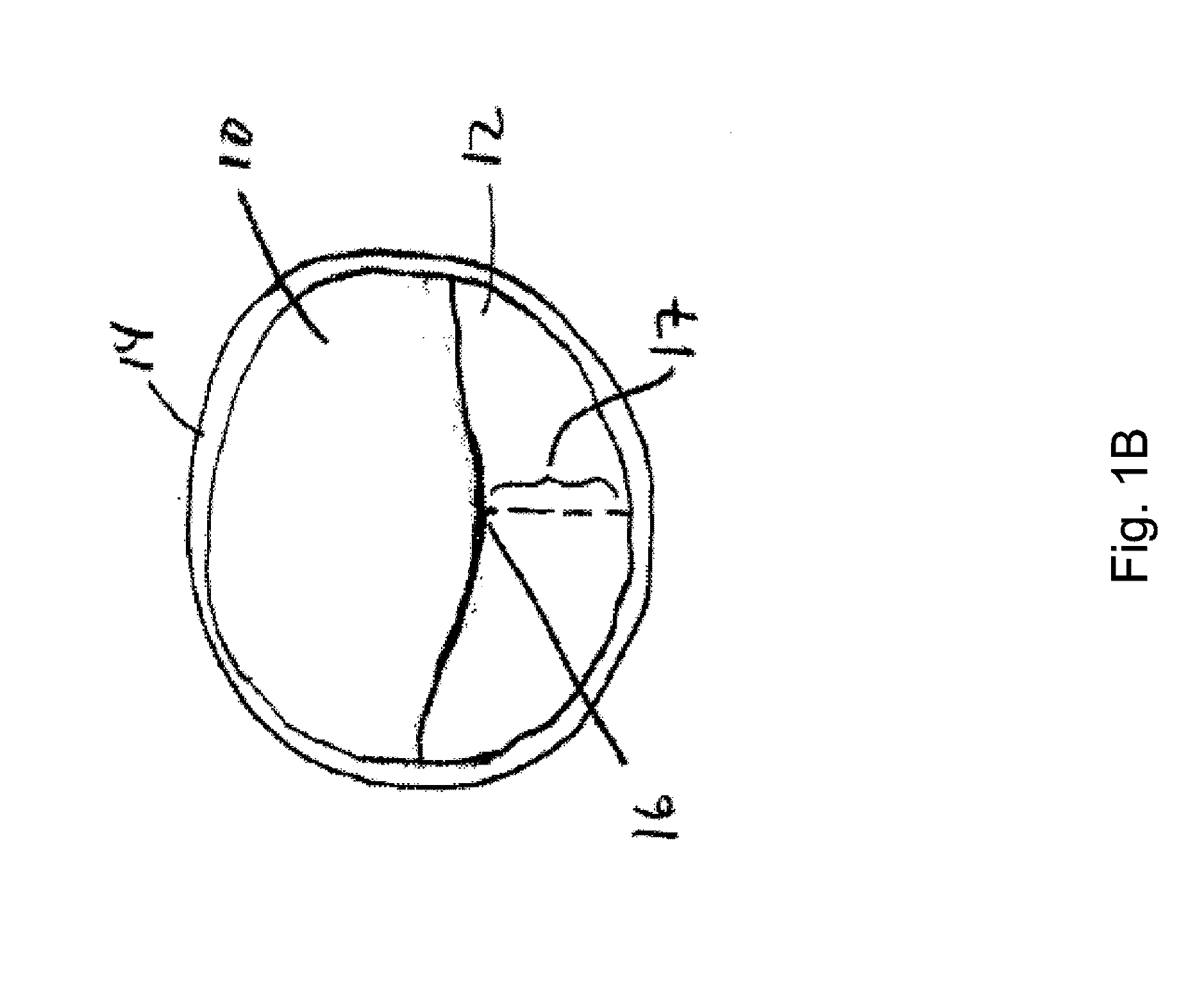

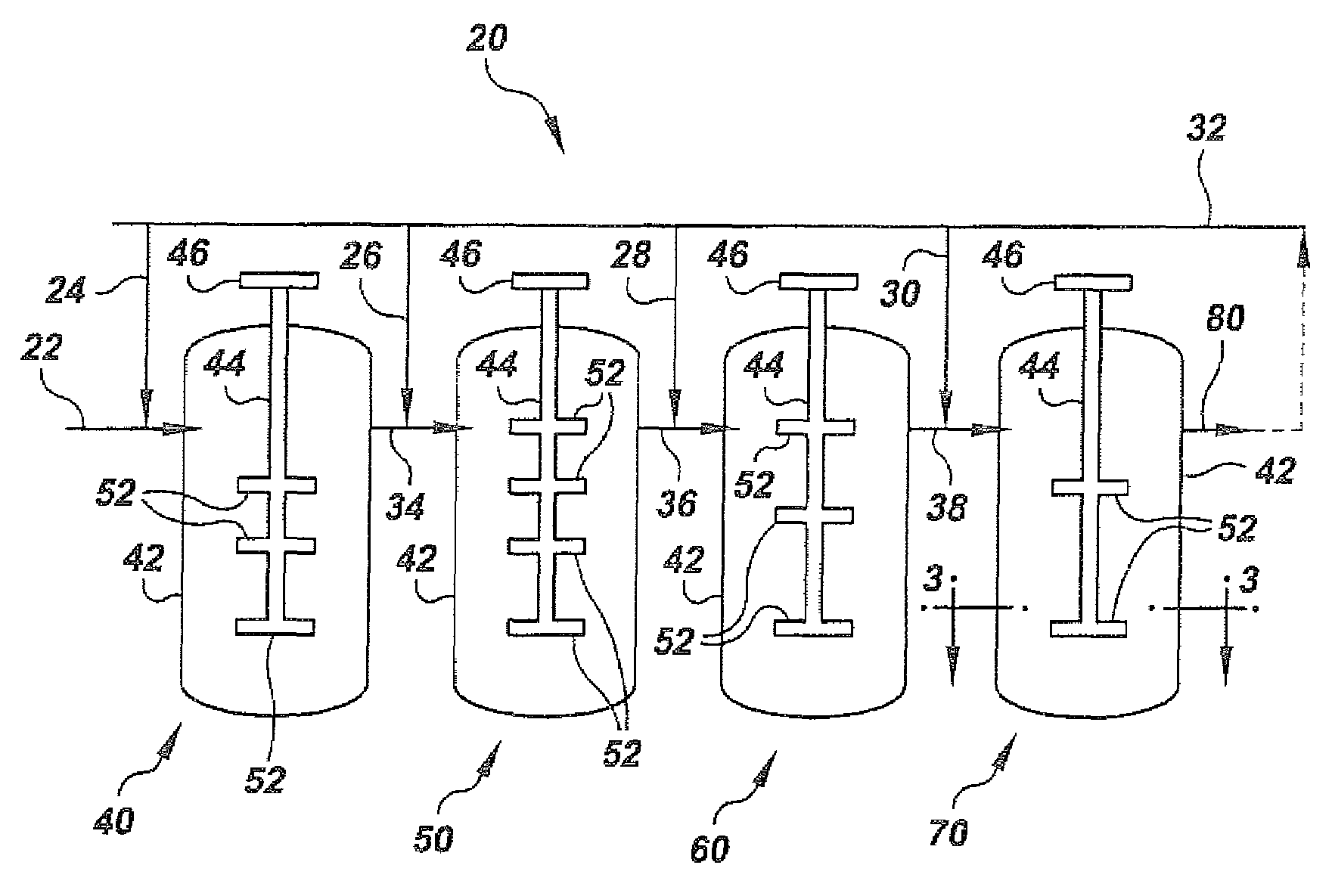

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

Resin composition and jig for use in transportation

InactiveUS6344513B1Excellent static charge dissipating performanceLittle changeSemiconductor/solid-state device manufacturingSpecial tyresFiberCarbon fibers

Owner:TEIJIN LTD

Stretch blow molded container and production process thereof

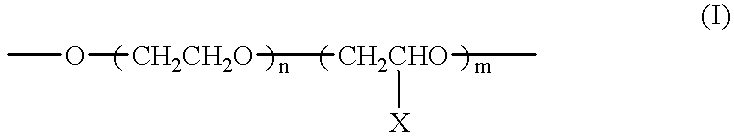

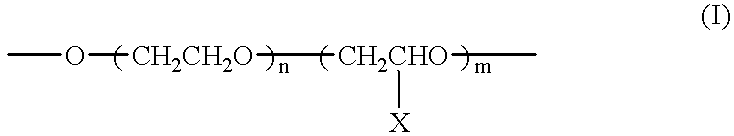

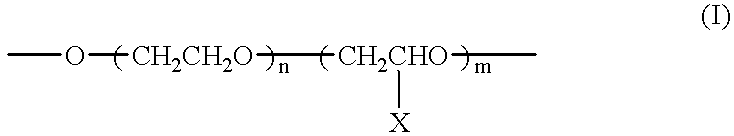

InactiveUS6159416AImprove barrier propertiesHigh mechanical strengthBottlesRefuse receptaclesShear rateVolumetric Mass Density

The invention provides a stretch blow molded container formed from a thermoplastic resin material which comprises polyglycolic acid having (a) a repeating unit represented by the following formula (1): (b) a melt viscosity, eta * [as measured at a temperature of (the melting point, Tm of the polymer+20 DEG C.) and a shear rate of 100 / sec] of 500-100,000 Pa.s; (c) a melting point, Tm of at least 180 DEG C.; (d) a melt enthalpy, DELTA Hm of at least 20 J / g; and (e) a density of at least 1.50 g / cm3 as measured in an unoriented, crystallized form, wherein the stretch blow molded container has tensile strength (in a circumferential direction) of at least 100 MPa and a carbon dioxide permeability (as measured at a temperature of 23 DEG C. and 80% relative humidity; in terms of the thickness of 50 mu m) of 300 cc / m2.day.atm or smaller at the body sidewall thereof, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

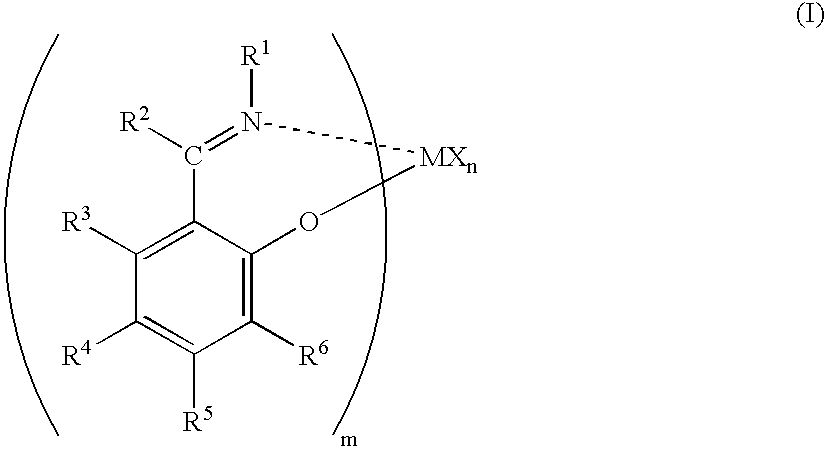

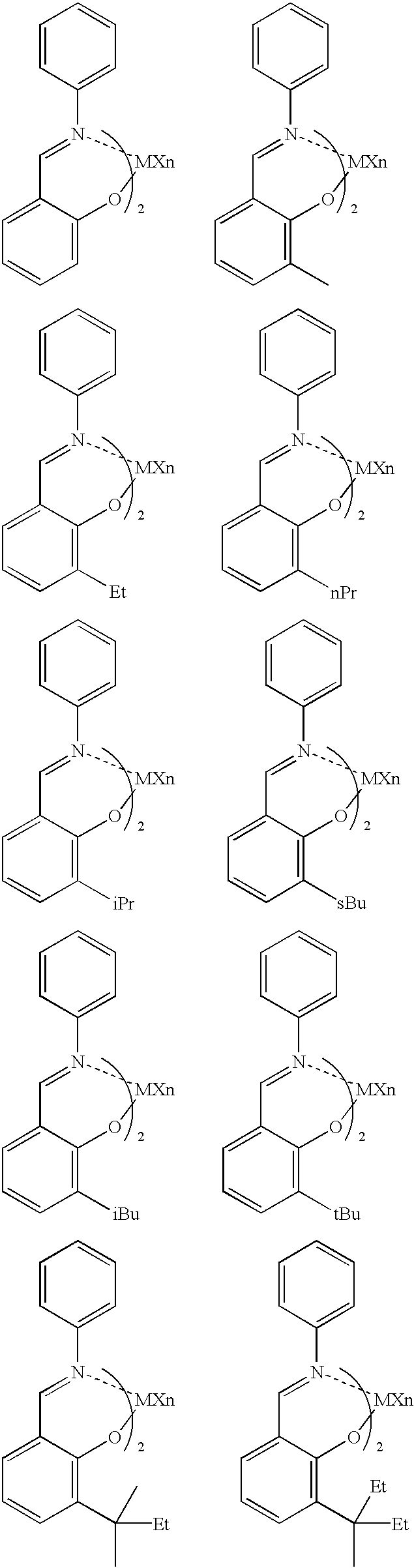

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

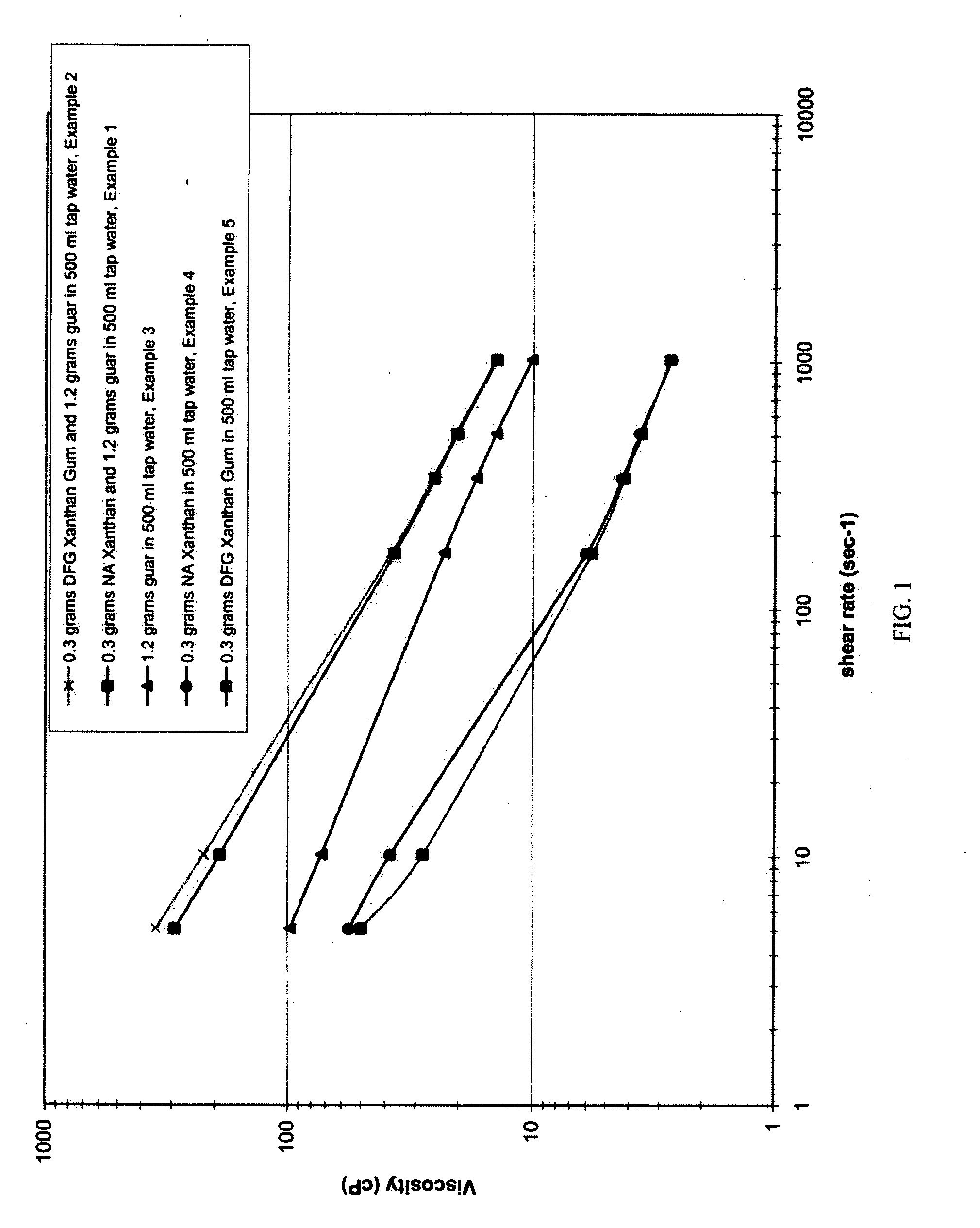

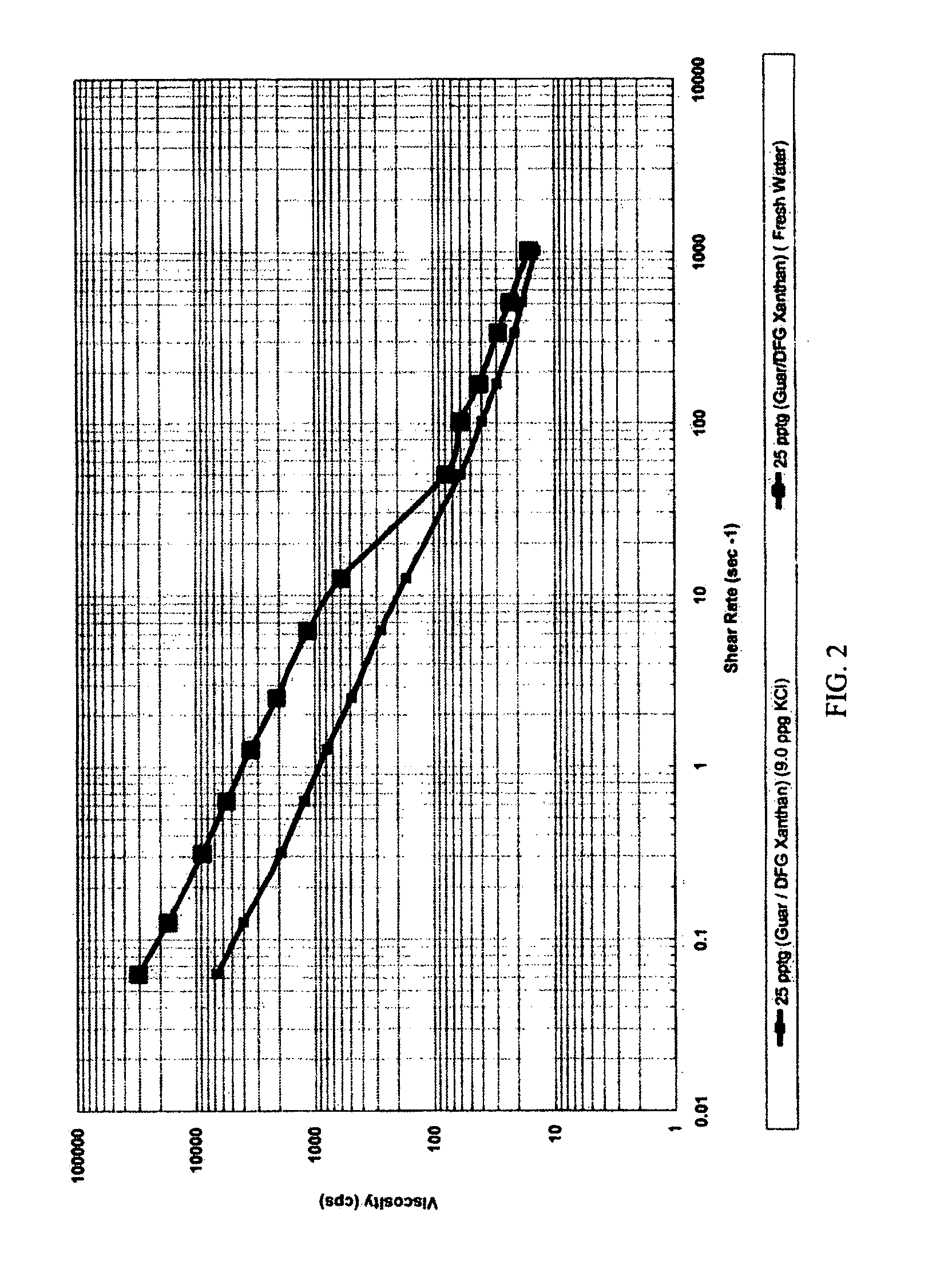

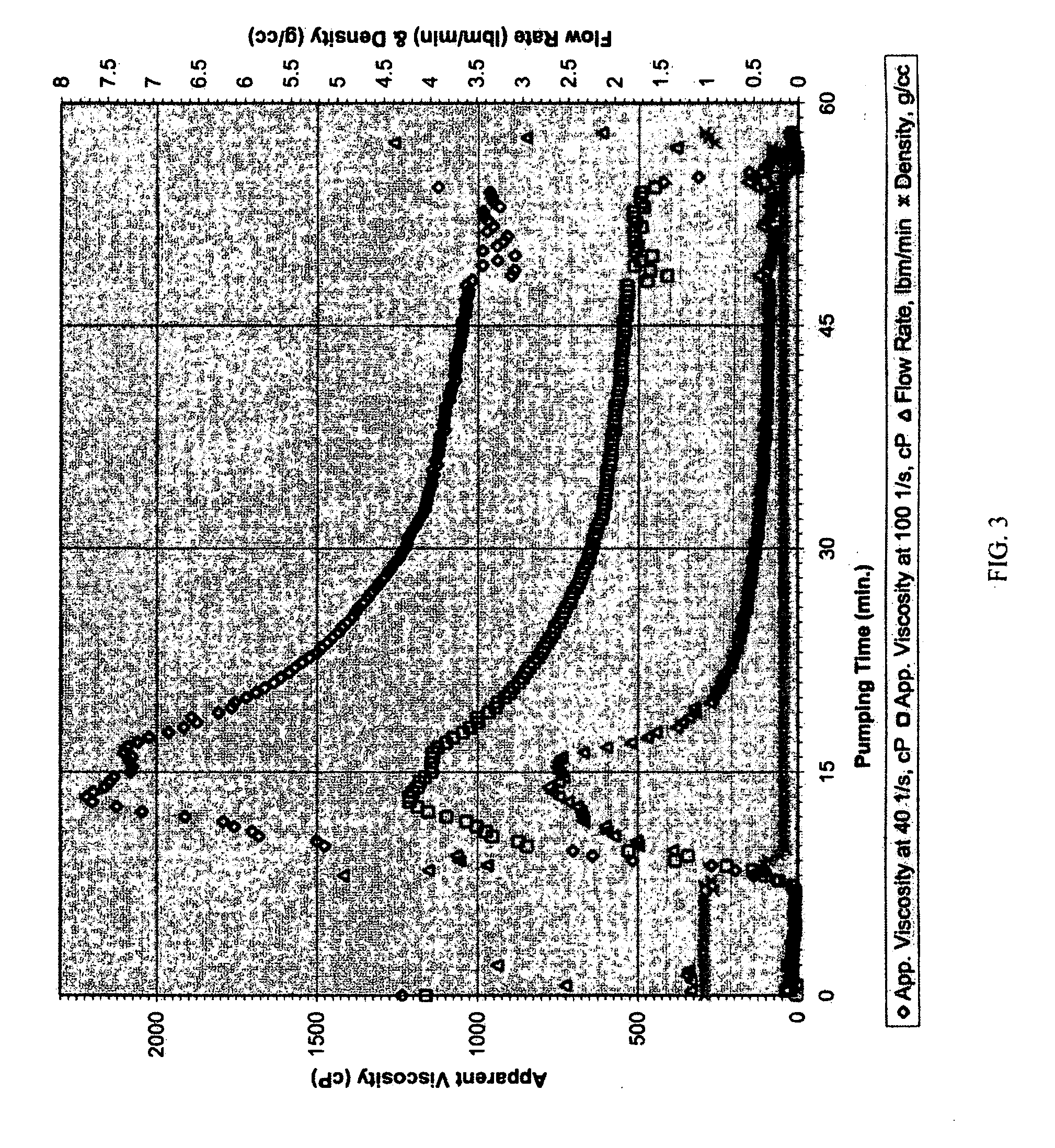

Storable fracturing suspensions containing ultra lightweight proppants in xanthan based carriers and methods of using the same

A storable suspension for the treatment of a subterranean formation contains an ultra lightweight (ULW) particulate and a carrier fluid of xanthan gum or a xanthan variant, a polysaccharide and water. The suspension exhibits a high viscosity at low shear rates and does not appear to separate for at least one week. The weight ratio of polysaccharide:xanthan in the storable suspension is between from about 8:1 to about 1:8. Prior to introducing the suspension into the formation, a foaming agent may be added, preferably in an amount sufficient to render a foam quality between from about 30 to about 98.

Owner:BAKER HUGHES INC

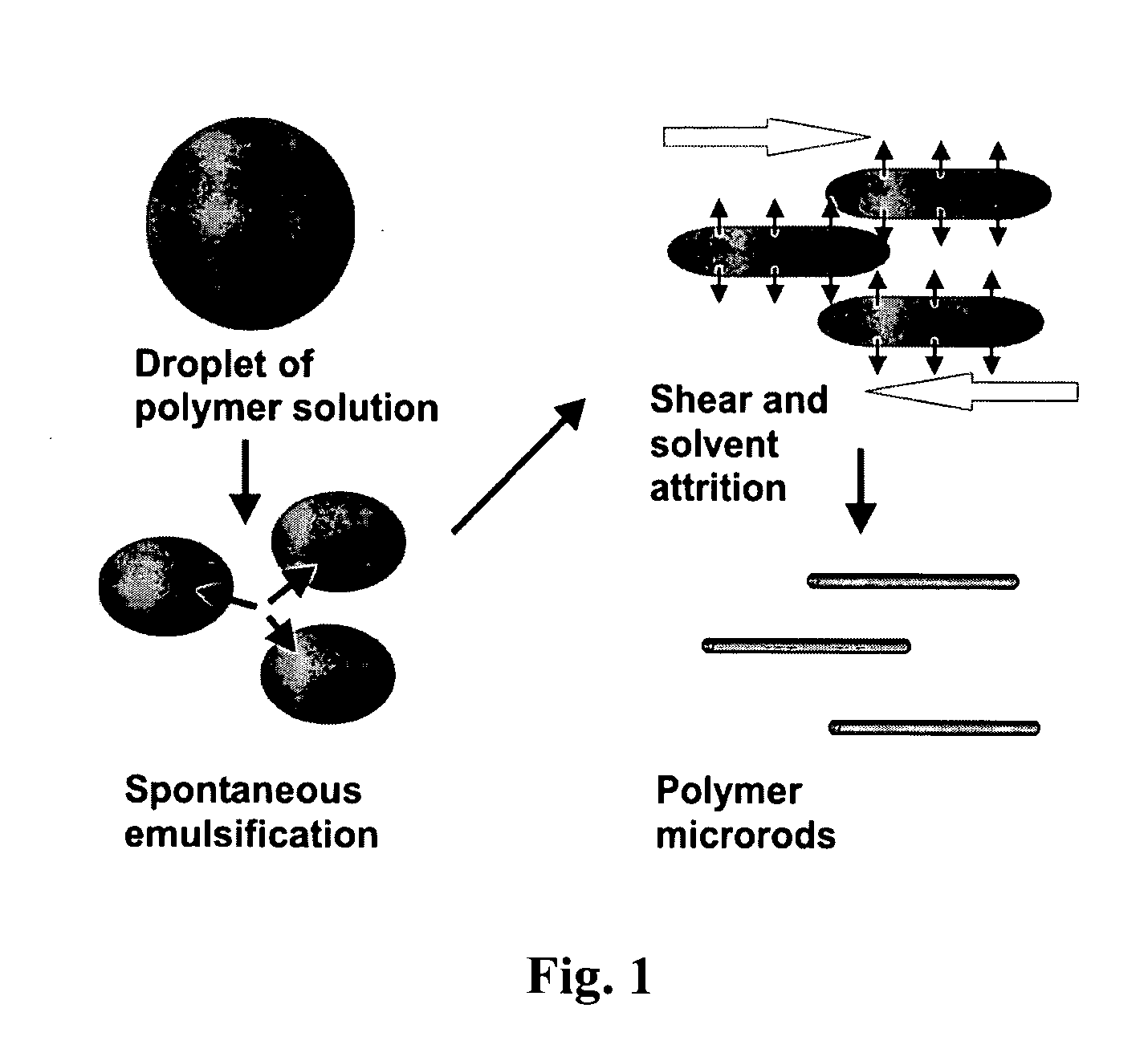

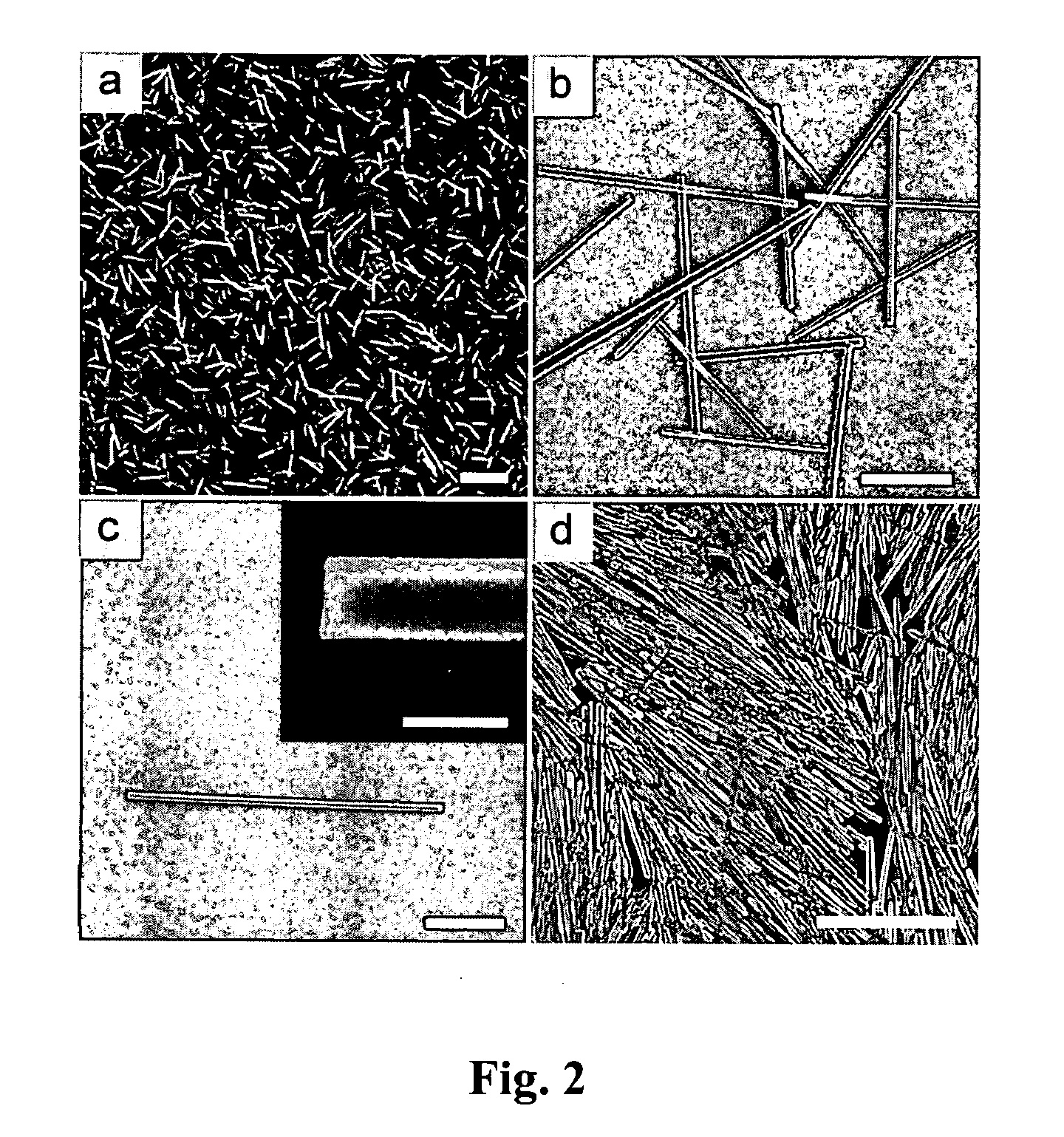

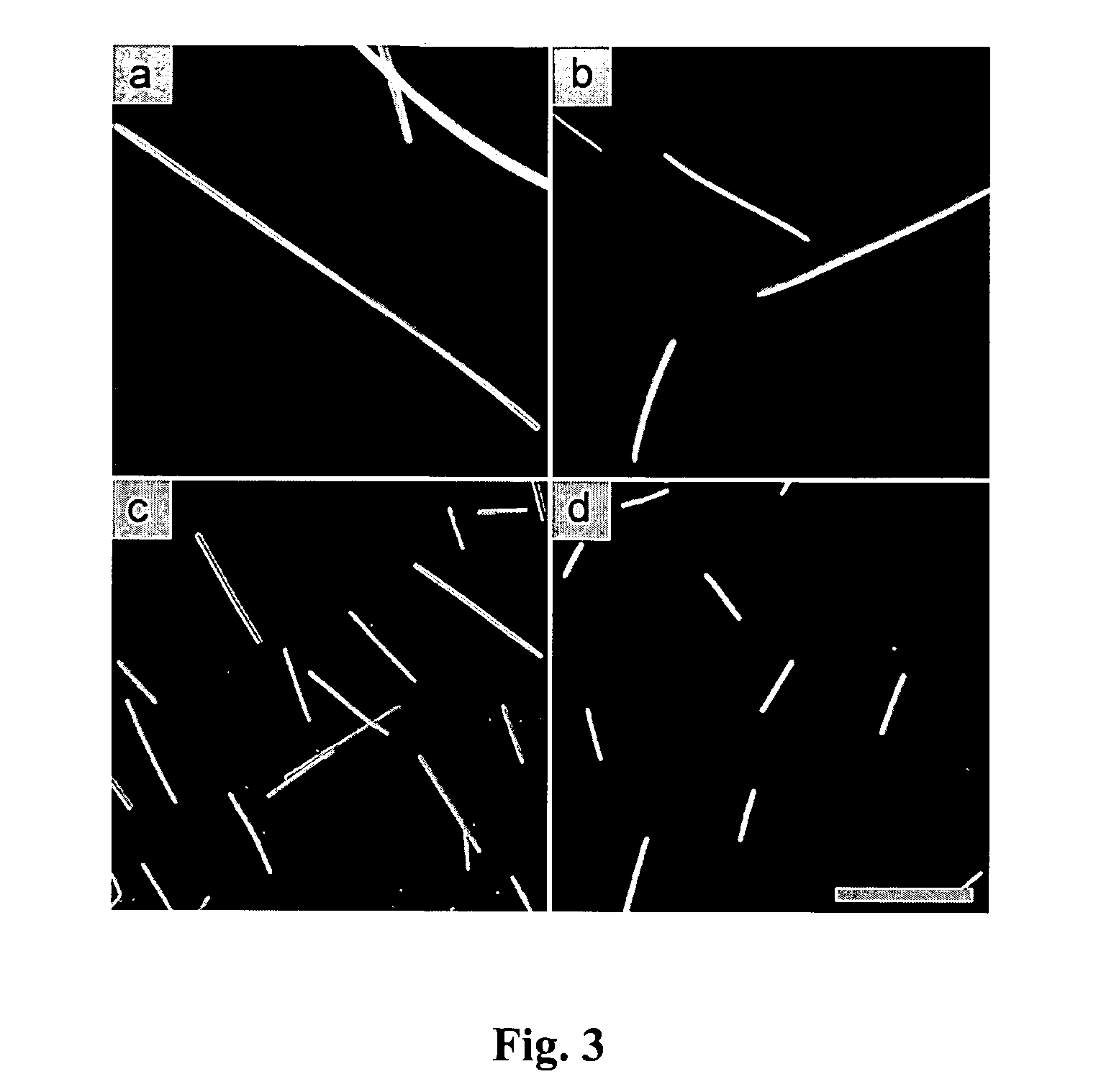

Process for preparing microrods using liquid-liquid dispersion

ActiveUS20060063882A1Large aspect ratioSimple methodBiocideOrganic active ingredientsPolymer scienceDispersed media

The invention provides a method for forming polymer microrods, the method including the steps of providing a polymer solution comprising a polymer dissolved in a first solvent; providing a dispersion medium comprising a second solvent, wherein the first solvent and the second solvent are miscible or partially soluble in each other, and wherein the polymer is insoluble in the second solvent; adding the polymer solution to the dispersion medium to form a dispersed phase of polymer solution droplets within the dispersion medium; and introducing a shear stress to the dispersion medium and dispersed polymer solution droplets for a time and at a shear rate sufficient to elongate the polymer solution droplets to form microrods and solidify the microrods by attrition of the polymer solvent into the dispersion medium.

Owner:NORTH CAROLINA STATE UNIV

Biodegradable polylactic acids for use in forming fibers

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. Specifically, a polylactic acid is melt processed at a controlled water content to initiate a hydrolysis reaction. Without intending to be limited by theory, it is believed that the hydroxyl groups present in water are capable of attacking the ester linkage of polylactic acids, thereby leading to chain scission or “depolymerization” of the polylactic acid molecule into one or more shorter ester chains. The shorter chains may include polylactic acids, as well as minor portions of lactic acid monomers or oligomers, and combinations of any of the foregoing. By selectively controlling the hydrolysis conditions (e.g., moisture and polymer concentrations, temperature, shear rate, etc.), a hydrolytically degraded polylactic acid may be achieved that has a molecular weight lower than the starting polymer. Such lower molecular weight polymers have a higher melt flow rate and lower apparent viscosity, which are useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

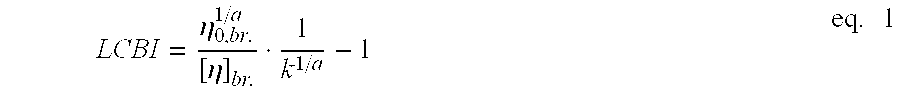

Melt-processible polymer composition comprising fluoropolymer having long chain branches

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 107 Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycaprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

Soft drink replacer

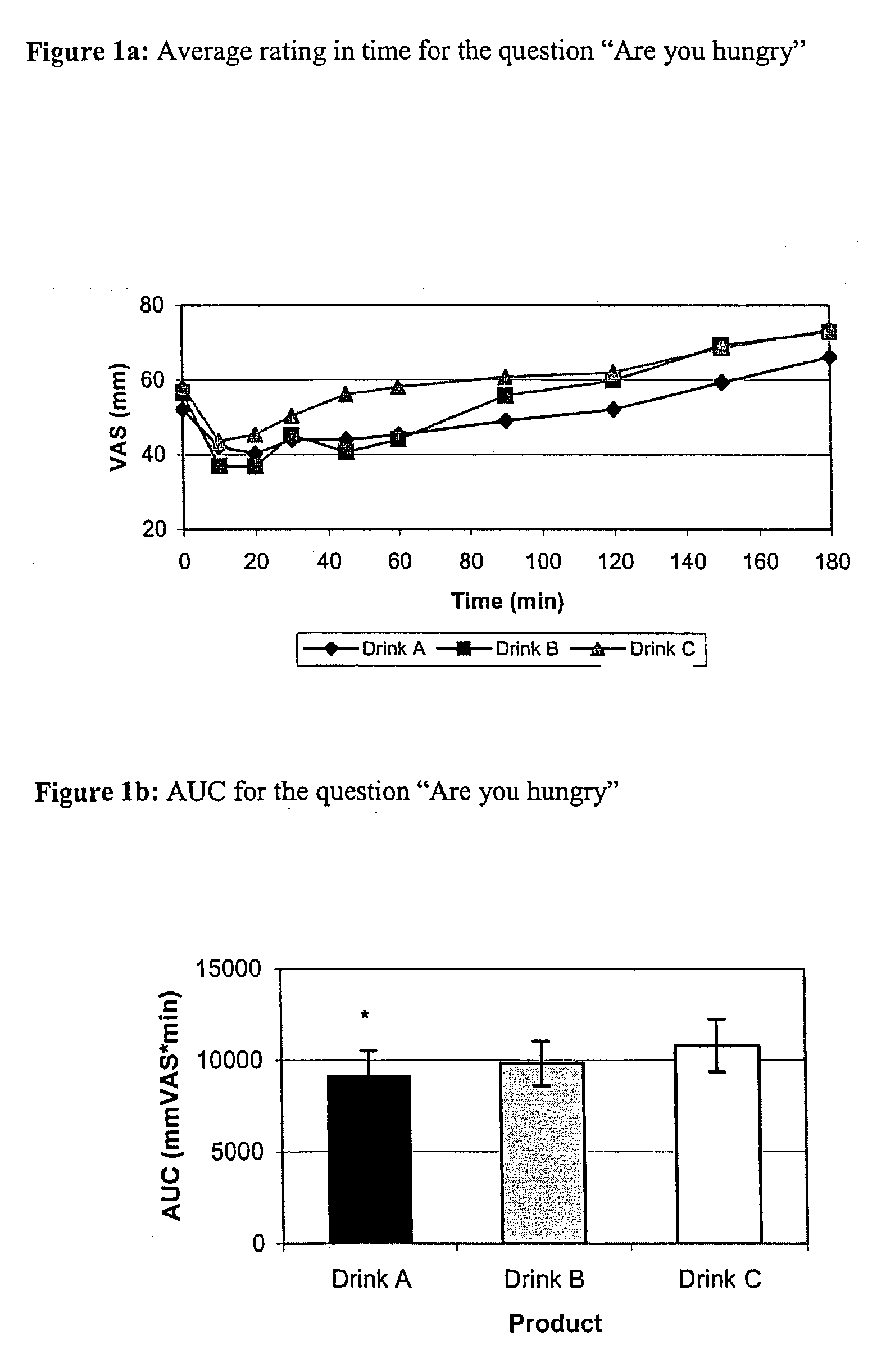

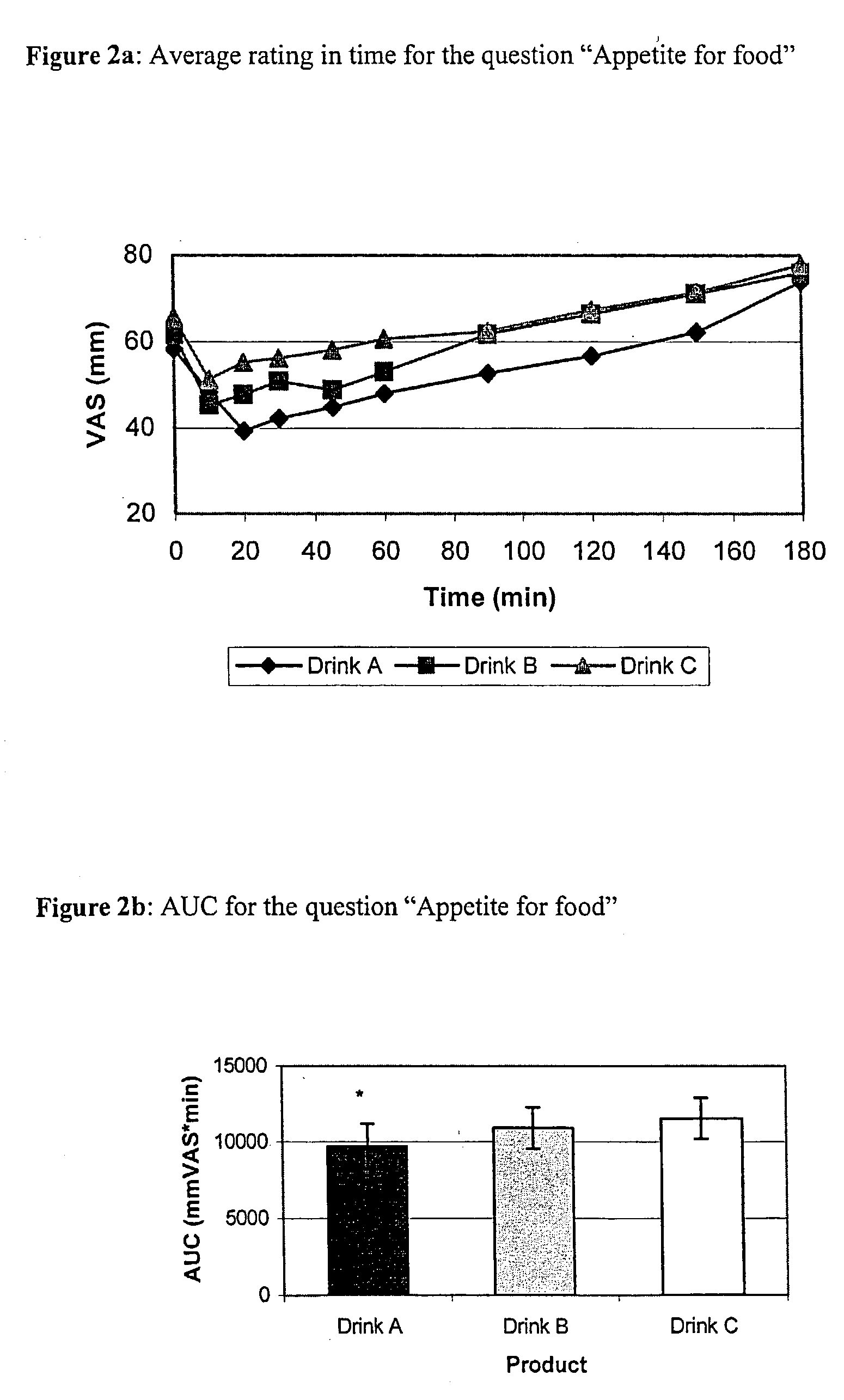

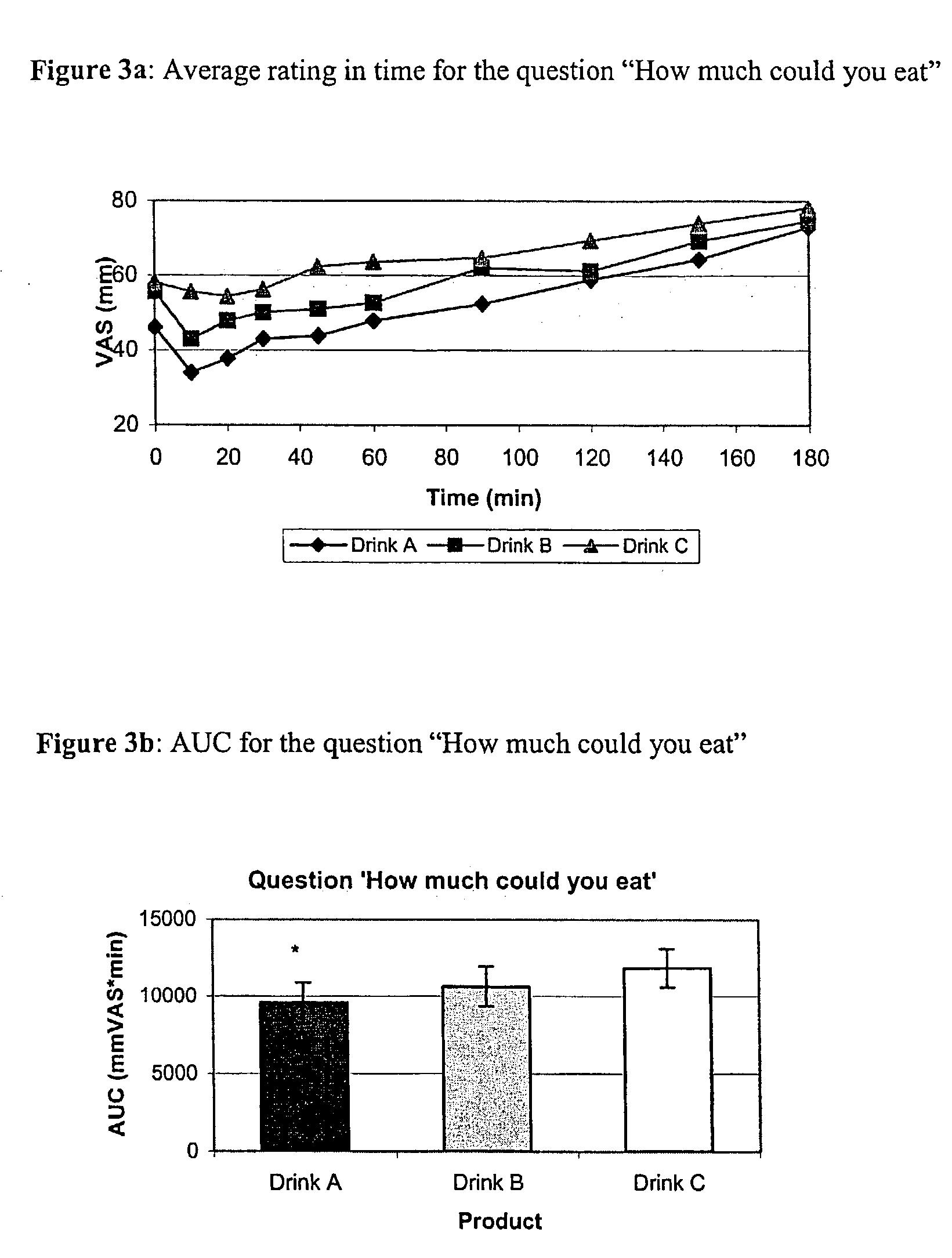

InactiveUS20030134027A1Reduced palatabilityEasy to handleBiocideOrganic active ingredientsShear rateOverweight

The present invention relates to a method for the treatment and / or prevention of overweight in a monogastric mammal. More particularly, the invention is concerned with such a method comprising administering to the mammal a liquid edible composition with a pH of more than 5, a viscosity below 50 mPas at a shear rate of 100 s-1 and 20° C., and a viscosity of at least 125% of the aforementioned viscosity at a pH 3 and a temperature of 37° C.; and with a caloric density between 0 and 500 kcal per liter, the composition comprising: c. between 0.01 and 5 wt. % of one or more polysaccharides selected from the group consisting of pectin and alginate; and between 0.01 and 3 wt. % calcium

Owner:NUTRICIA

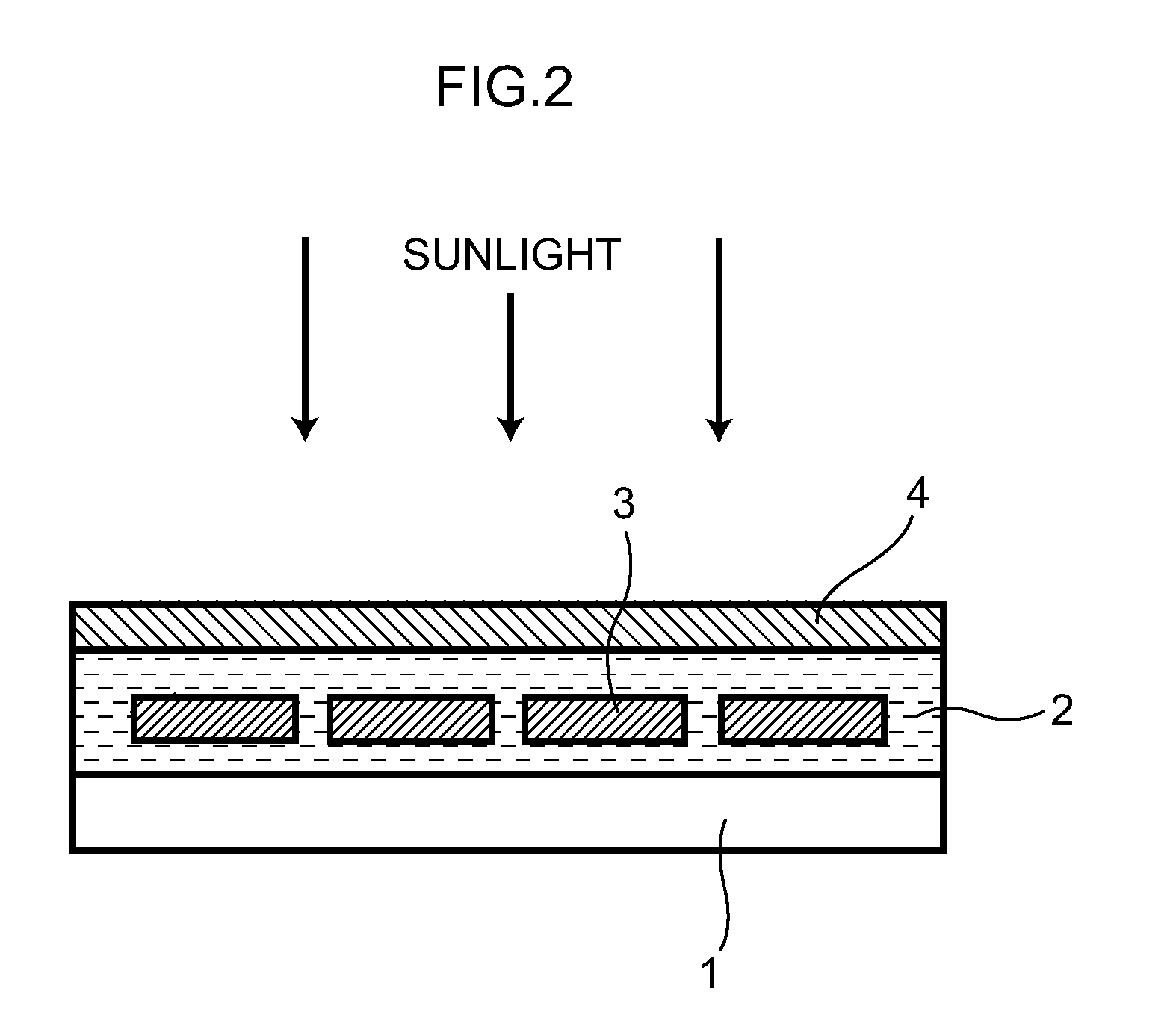

Polyester film, method for producing the same, back sheet for solar cells, and solar cell module

InactiveUS20120070615A1Not impairing effectImprove productivityLayered productsTraffic signalsShear rateEngineering

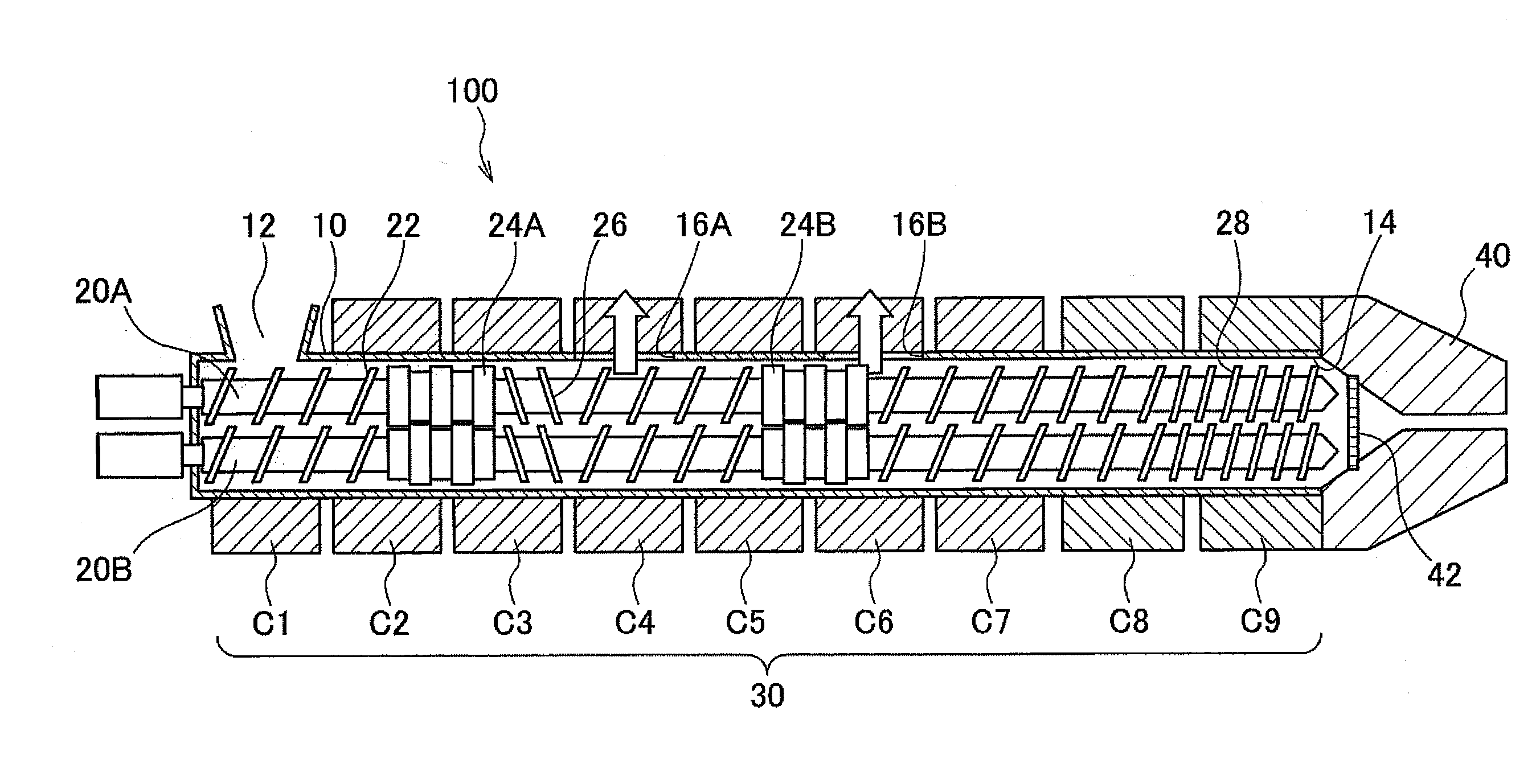

Provided is a method for producing a polyester film, including: subjecting a polyester raw material resin, which contains a titanium compound and has an intrinsic viscosity of from 0.71 to 1.00, to melt extrusion using a twin-screw extruder which includes a cylinder; two screws disposed inside the cylinder; and a kneading disk unit disposed in at least a portion of a region extending from a 10%-position to a 65%-position of screw length with respect to an upstream end of the screws in a resin extrusion direction as a starting point, at a maximum shear rate generated inside the twin-screw extruder of from 10 sec−1 to 2000 sec−1;forming an unstretched film by cooling and solidifying the melt extruded polyester resin on a cast roll; subjecting the unstretched film to biaxial stretching in a longitudinal direction and a lateral direction; and heat fixing the stretched film formed by biaxial stretching.

Owner:FUJIFILM CORP

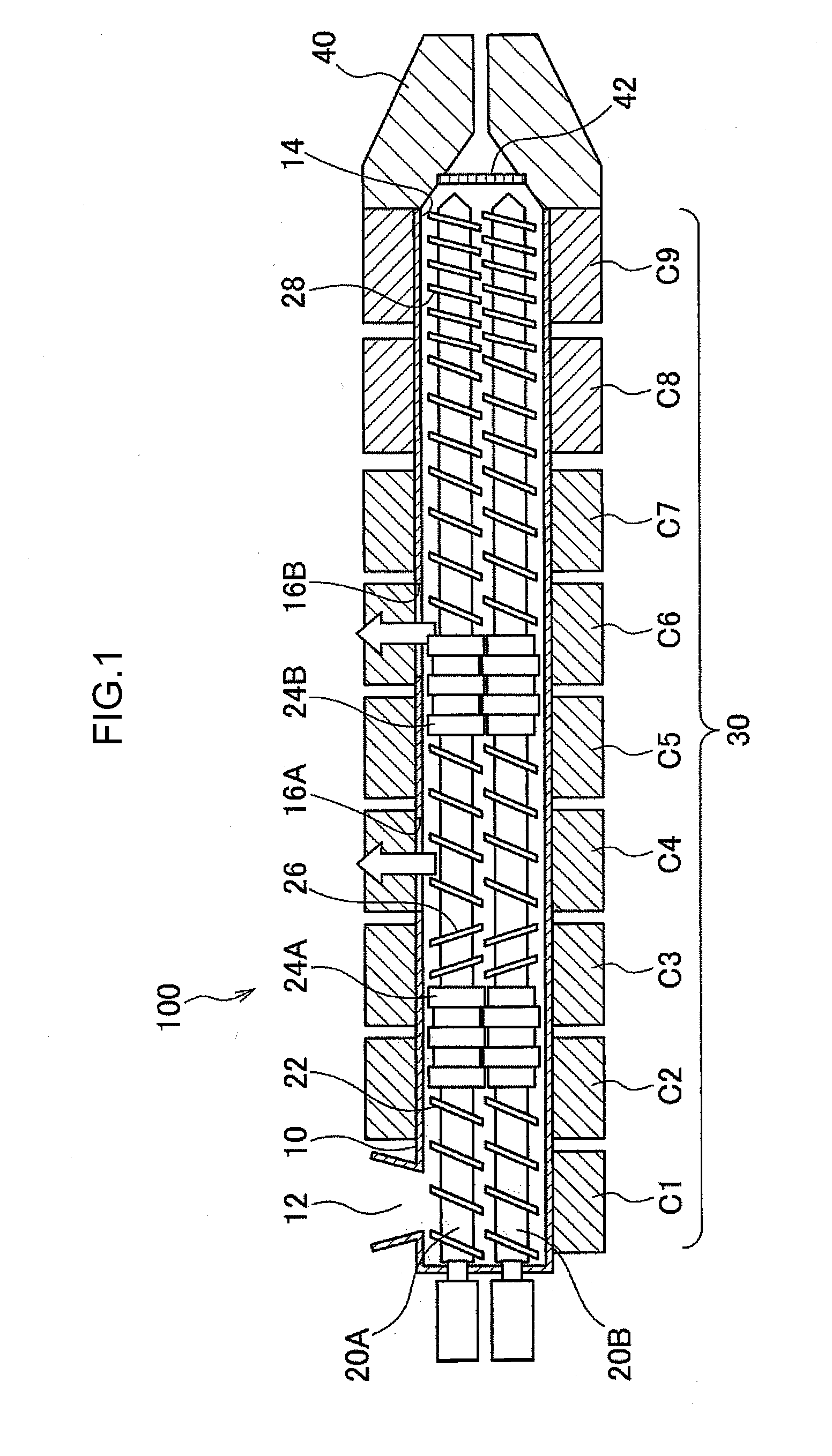

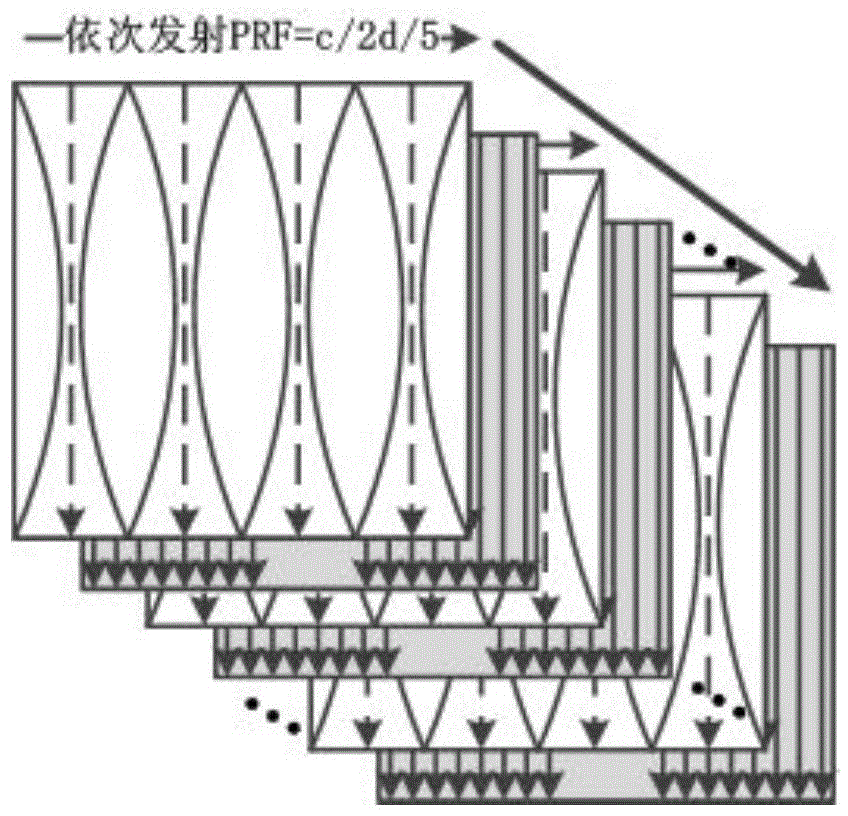

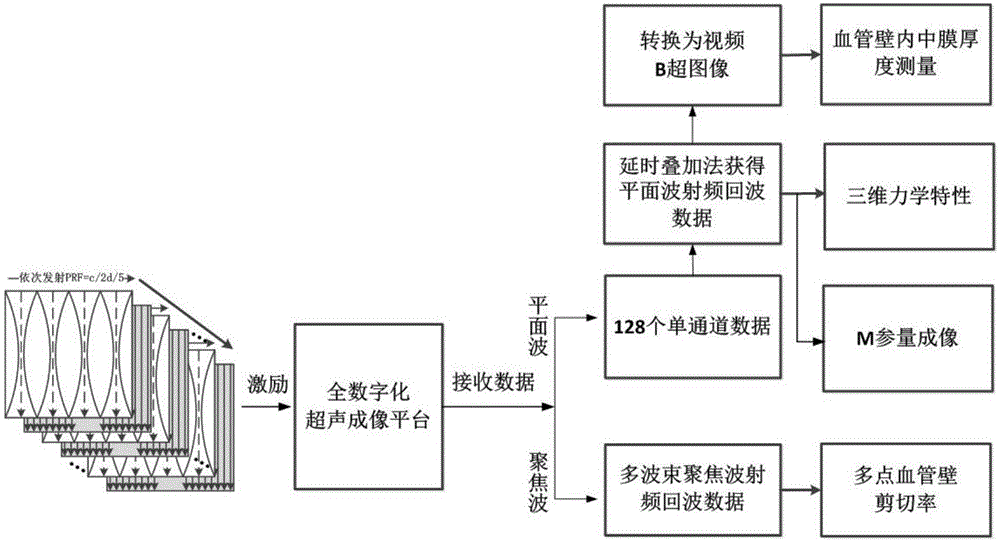

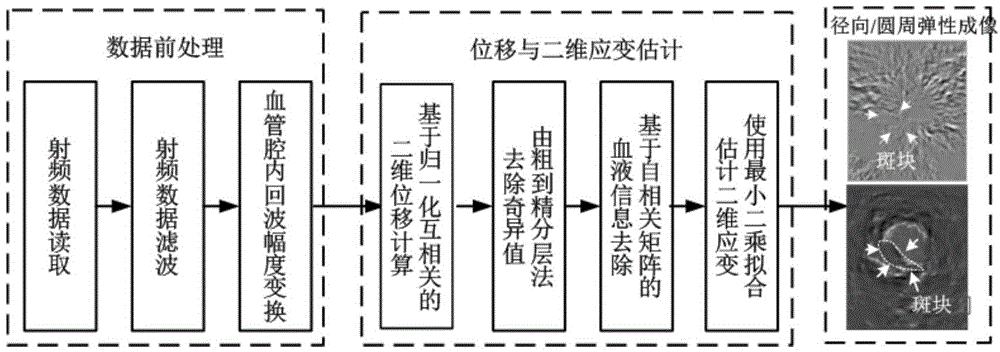

Method using three-dimensional mechanics and tissue specific imaging of blood vessels and plaques for detection

InactiveCN104398271ARealize three-dimensional mechanical property detectionRealize simultaneous measurementOrgan movement/changes detectionInfrasonic diagnosticsVulnerable plaqueShear rate

The invention relates to a method using three-dimensional mechanics characteristics and tissue specific imaging of blood vessels and plaques for detection. The method is on the basis of a multi-beam focus wave and superfast plane wave alternative transmitting sequence and can also be extended to a line-by-line scan imaging manner; the forms and the functions of the blood vessels and the plaques are evaluated and imaged respectively from the aspects of the radial-direction, circumferential and axial-direction three-dimensional mechanics characteristics, blood vessel wall shear rate, plaque form and tissue characterization, and the like; the new method which is provided for detection of the vulnerable plaques of a carotid artery is regarded as the improvement of the existing method.

Owner:XI AN JIAOTONG UNIV

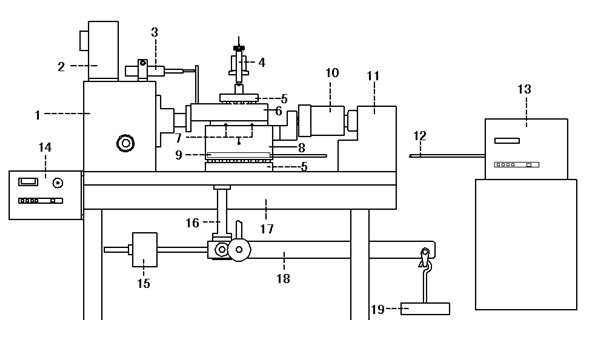

Frozen soil-structure direct shear apparatus and use method thereof

ActiveCN102252919AApplicable Mechanical PropertiesPreparing sample for investigationMaterial strength using steady shearing forcesEngineeringStrain rate

The invention discloses a frozen soil-structure direct shear apparatus and a use method thereof. The frozen soil-structure direct shear apparatus comprises a horizontal thruster, a stepping motor, a displacement sensor, a vertical pressure dowel bar, a horizontal ball guide rail, an upper shearing box, a thermocouple, a lower shearing box, a semiconductor refrigeration block, a load sensor, a horizontal end fixing device, a cooling liquid delivery pipe, a low temperature thermostatic bath, a strain rate controller, counterbalance weights, a lever end fixing device, a horizontal bearing platform, a lever and weights. The frozen soil-structure direct shear apparatus has the advantage of being suitable for the research on the mechanical characteristics of the contact surface of different materials at a low temperature. The apparatus can provide different normal stress and temperatures for the contact surface of the materials according to test requirements; and when the freeze condition of the contact surface of the different materials meets the corresponding requirements, a shear force is applied on the contact surface at a selected shear rate until the contact surface of the sample is subjected to damage, and the relation curve of the shear stress of the frozen soil-structure contact surface and the shear displacement is determined.

Owner:JIANGSU JIANKE PROJECT MANAGEMENT

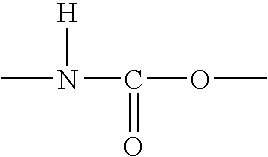

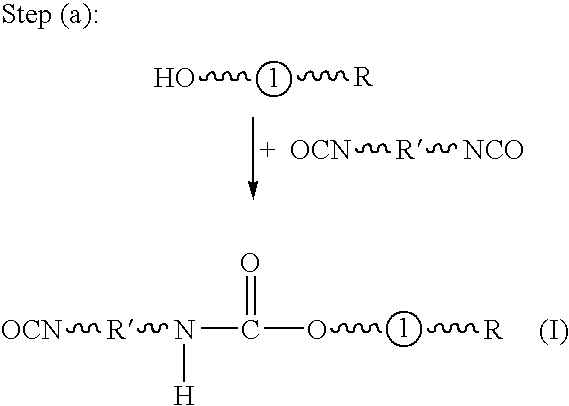

Free-radically radiation-curable, solvent-free and printable precursor of a pressure-sensitive adhesive

The present invention relates to a free-radically radiation-curable, solvent-free and printable precursor of a pressure-sensitive adhesive, the precursor comprising: (i) 30-75 wt. % of one or more mono(meth)acrylate functional oligomer compounds at least one of said oligomer compounds comprising at least one urethane bond, (ii) 0-15 wt % of one or more poly(meth)acrylate functional oligomer compounds, (iii) 5-45 wt. % of one or more monomer compounds comprising one ethylenically unsaturated group, (iv) 0-5 wt. % of one or more monomer compounds comprising two or more ethylenically unsaturated groups, and (v) an effective amount of one or more free radical photoinitiators, wherein the percentages which are percentages by weight with respect to the mass of the precursor, are selected so that the precursor has a dynamic viscosity at 20° C. and at a shear rate of 100 s−1 of between 300 to 15,000 mPa·s.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com