Patents

Literature

84results about How to "Increased fiber length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing fibrillated fibers

ActiveUS7566014B2Inhibit productionIncreased fiber lengthFilament/thread formingGrain treatmentsFiberShear rate

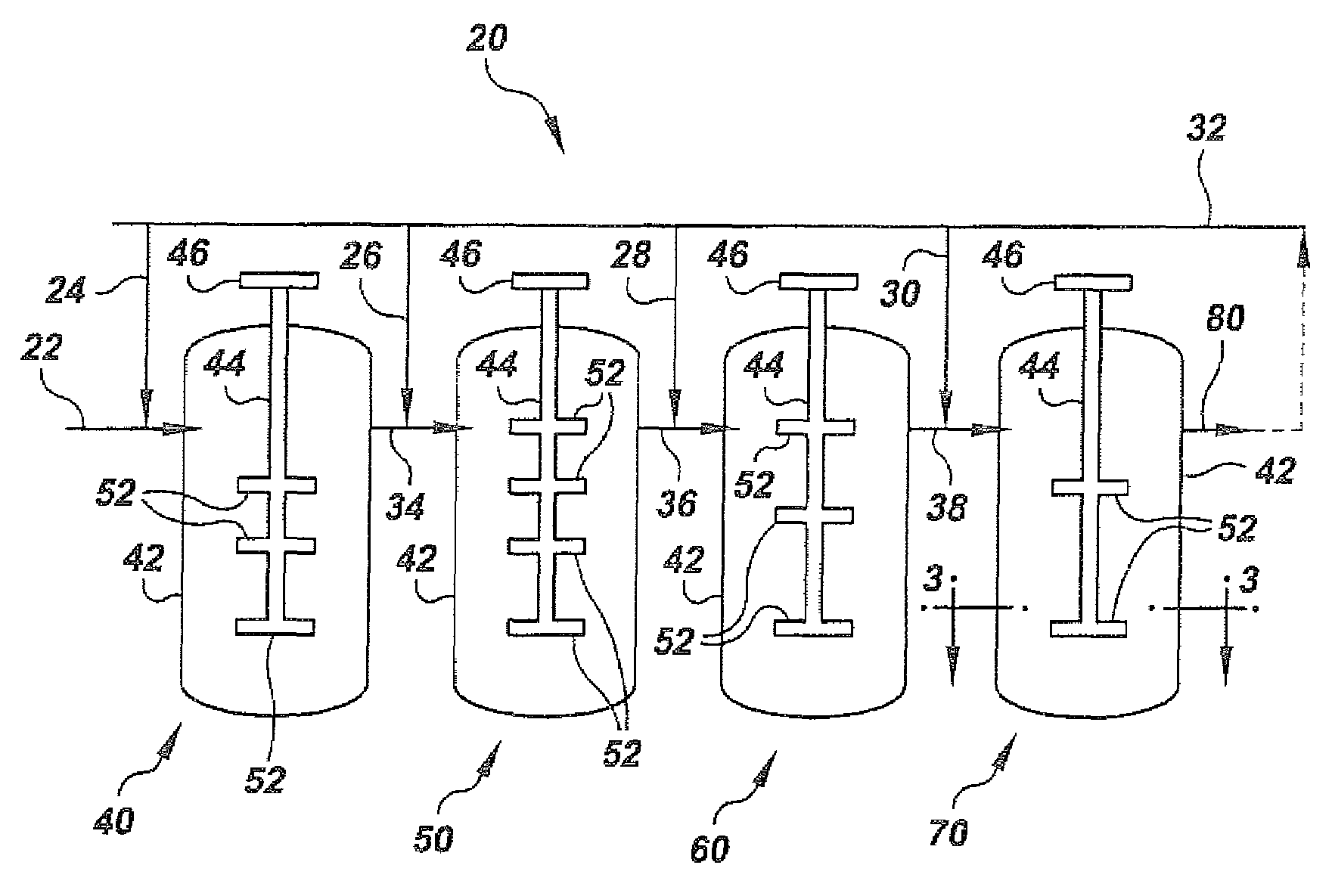

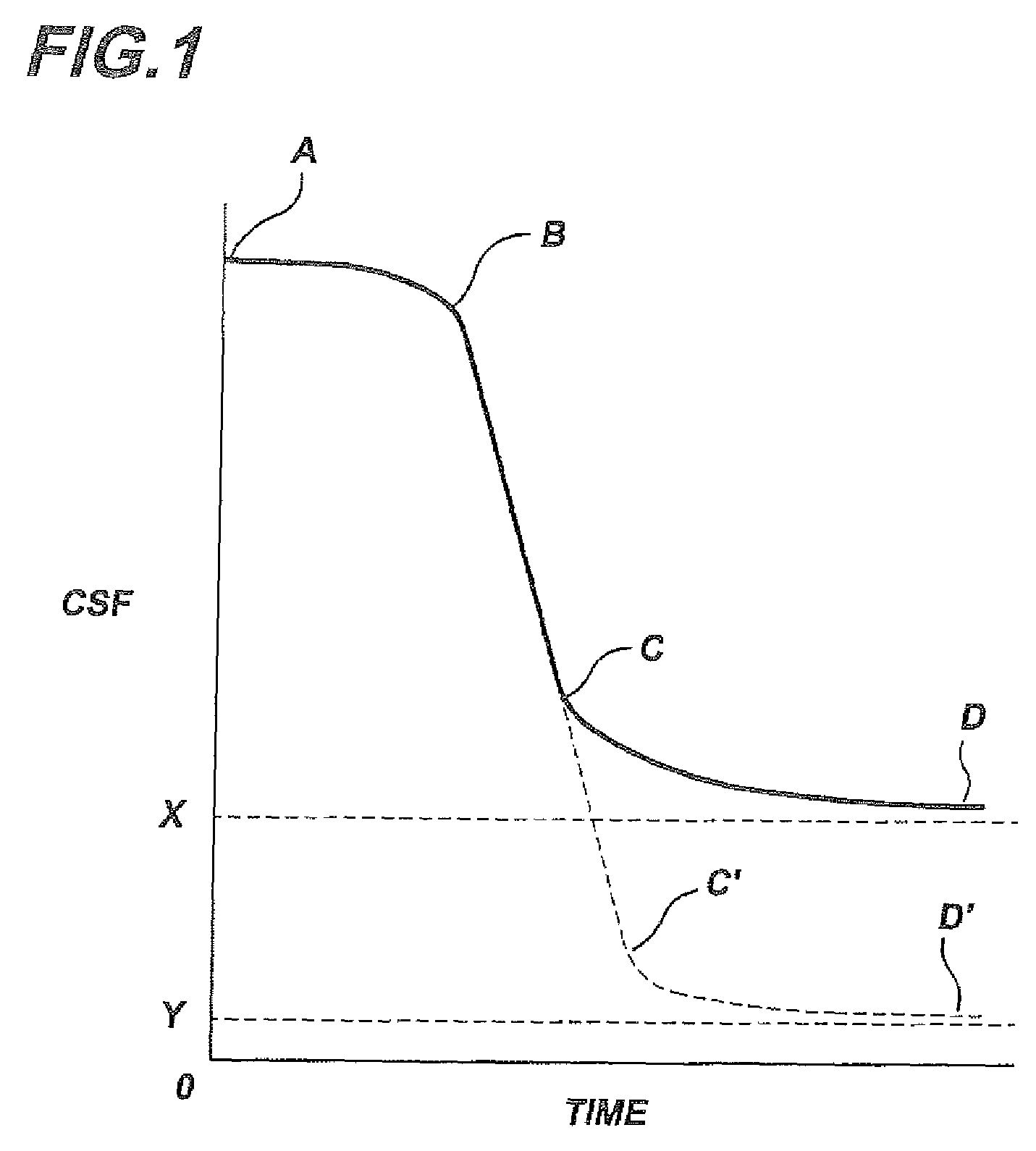

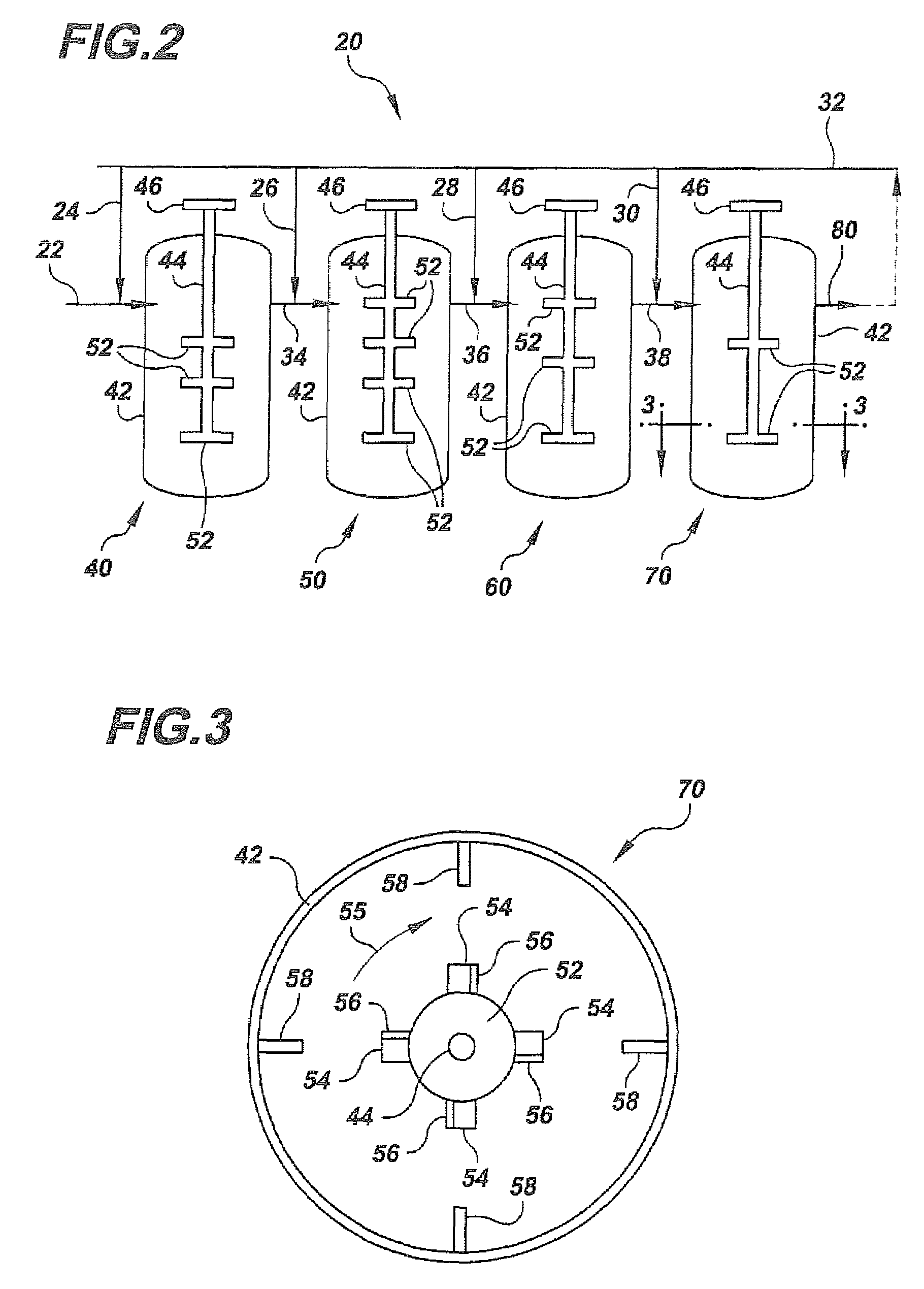

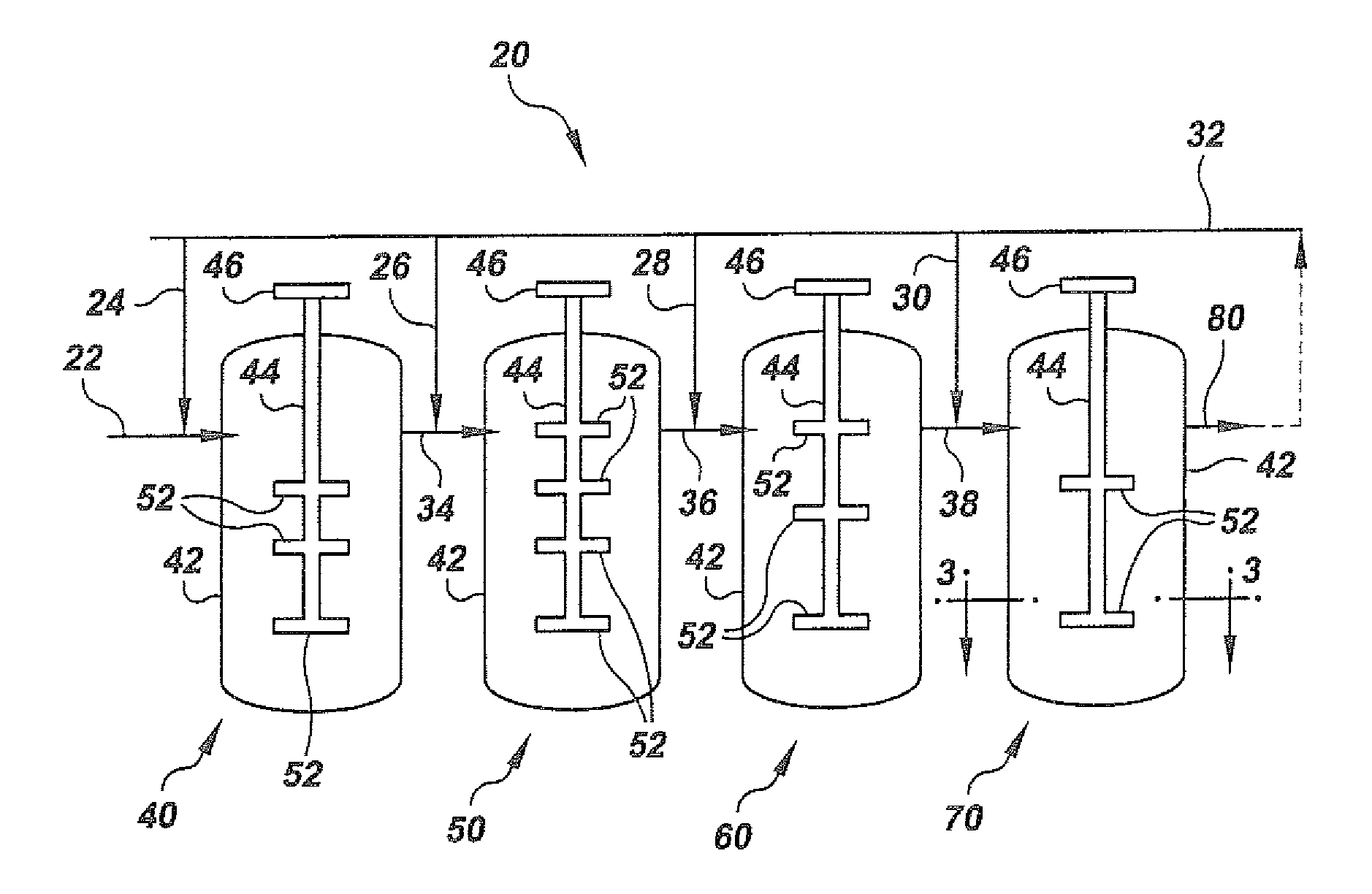

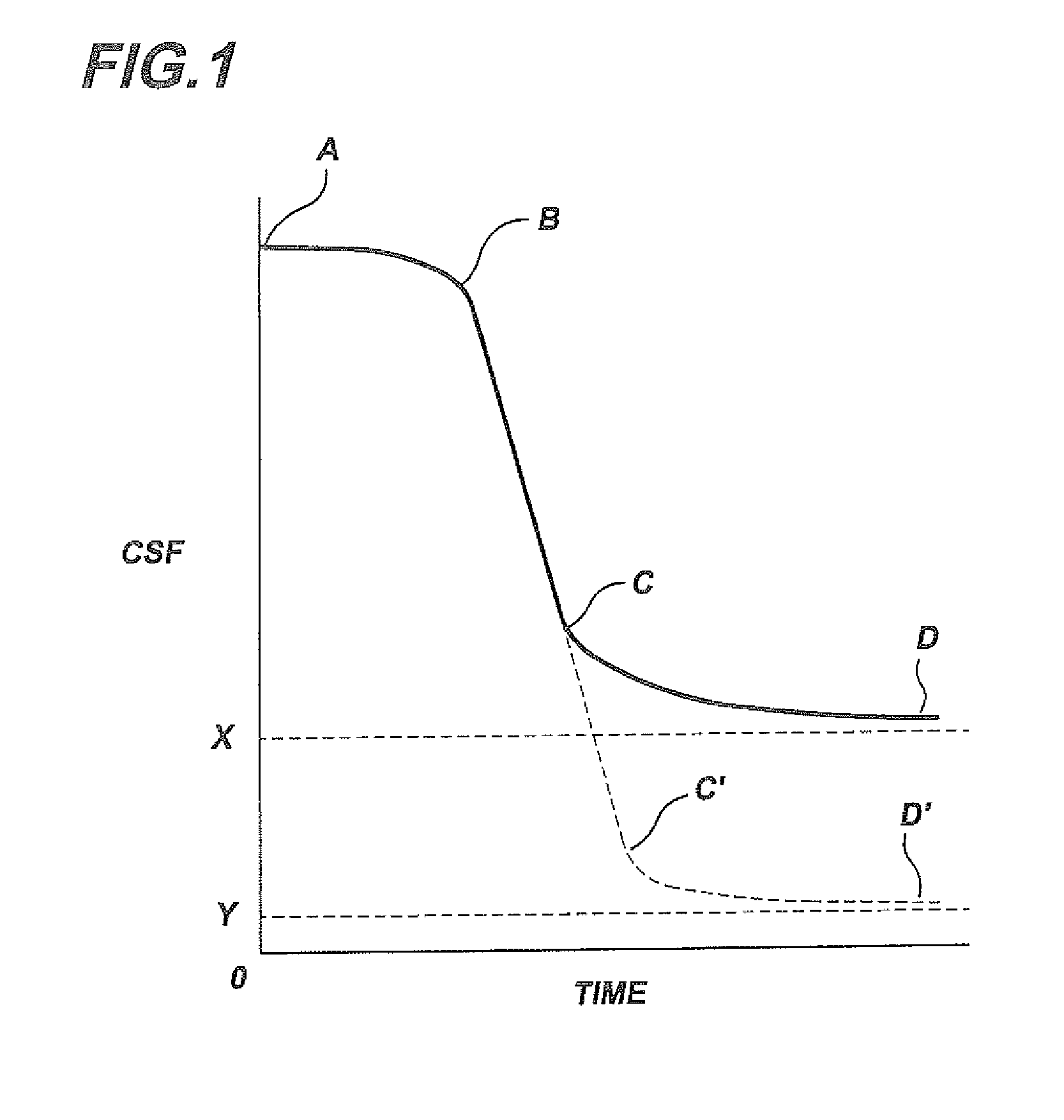

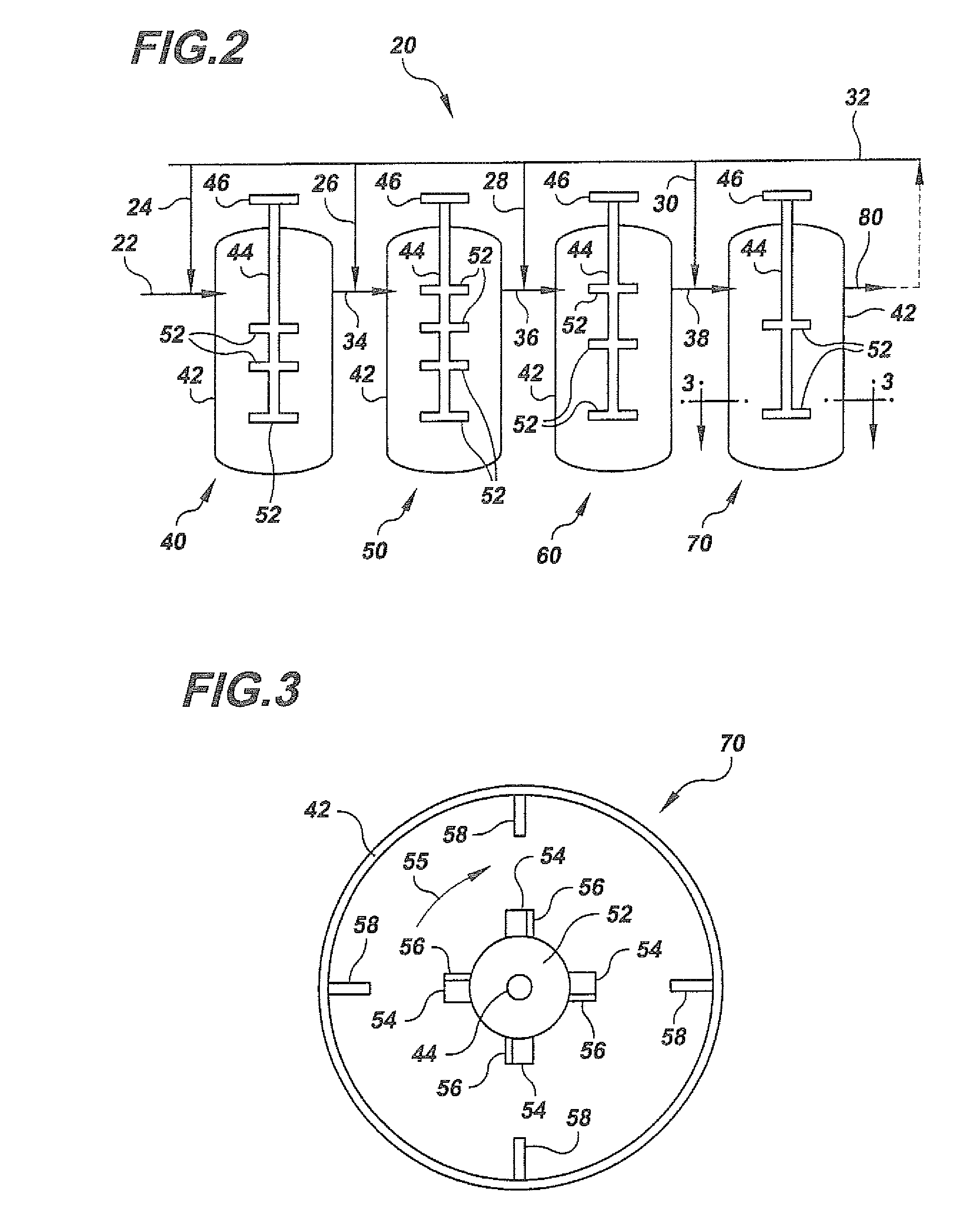

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

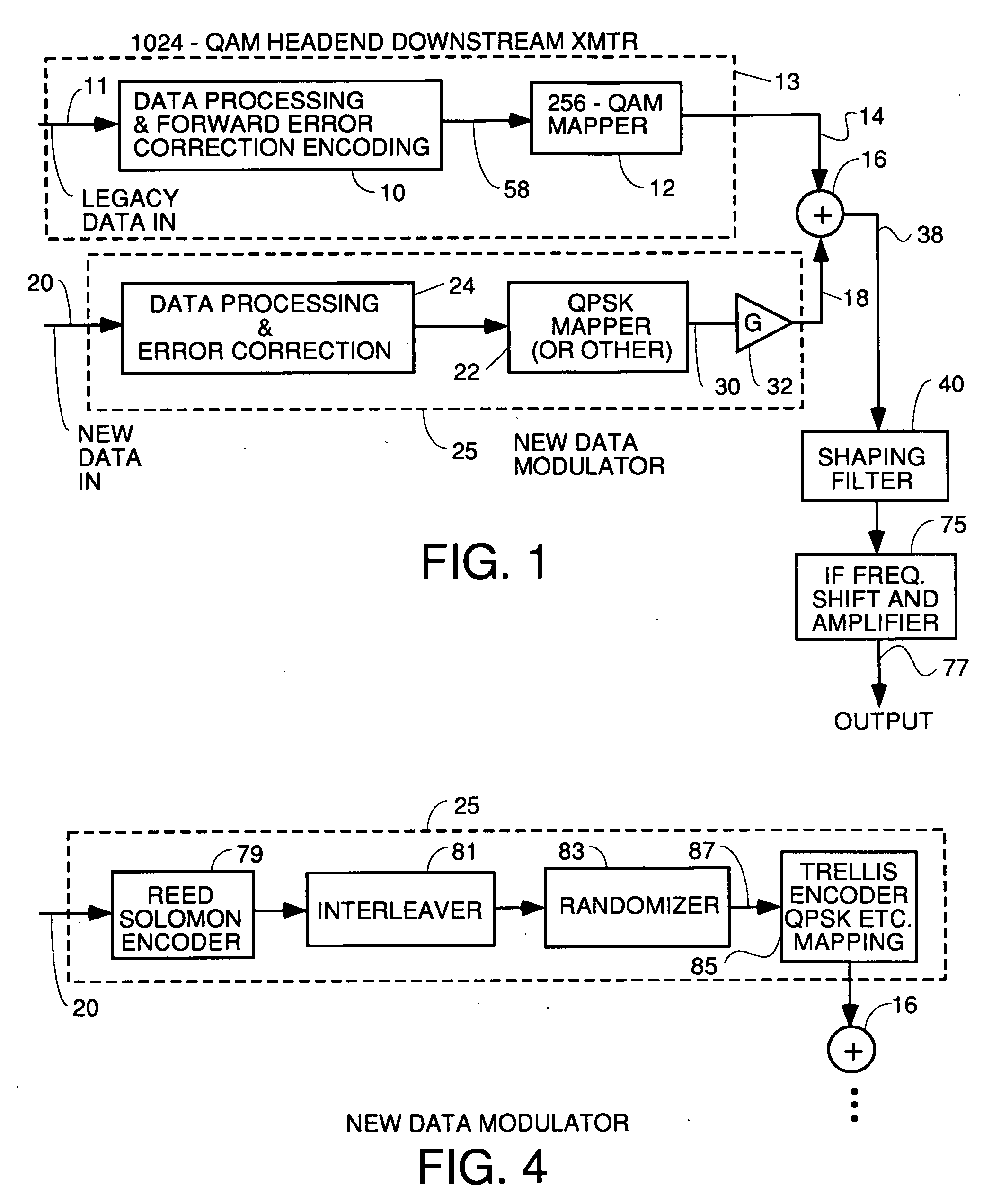

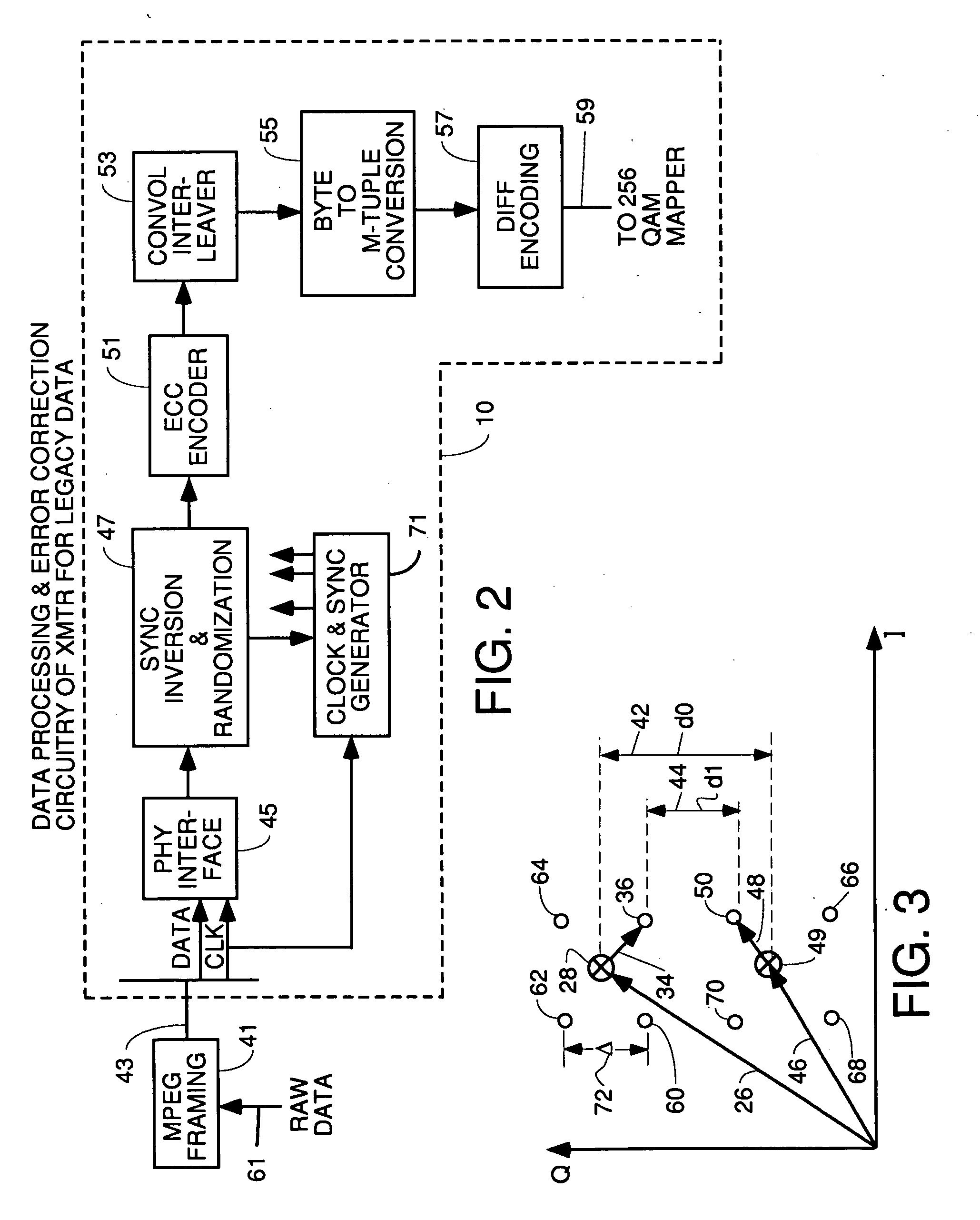

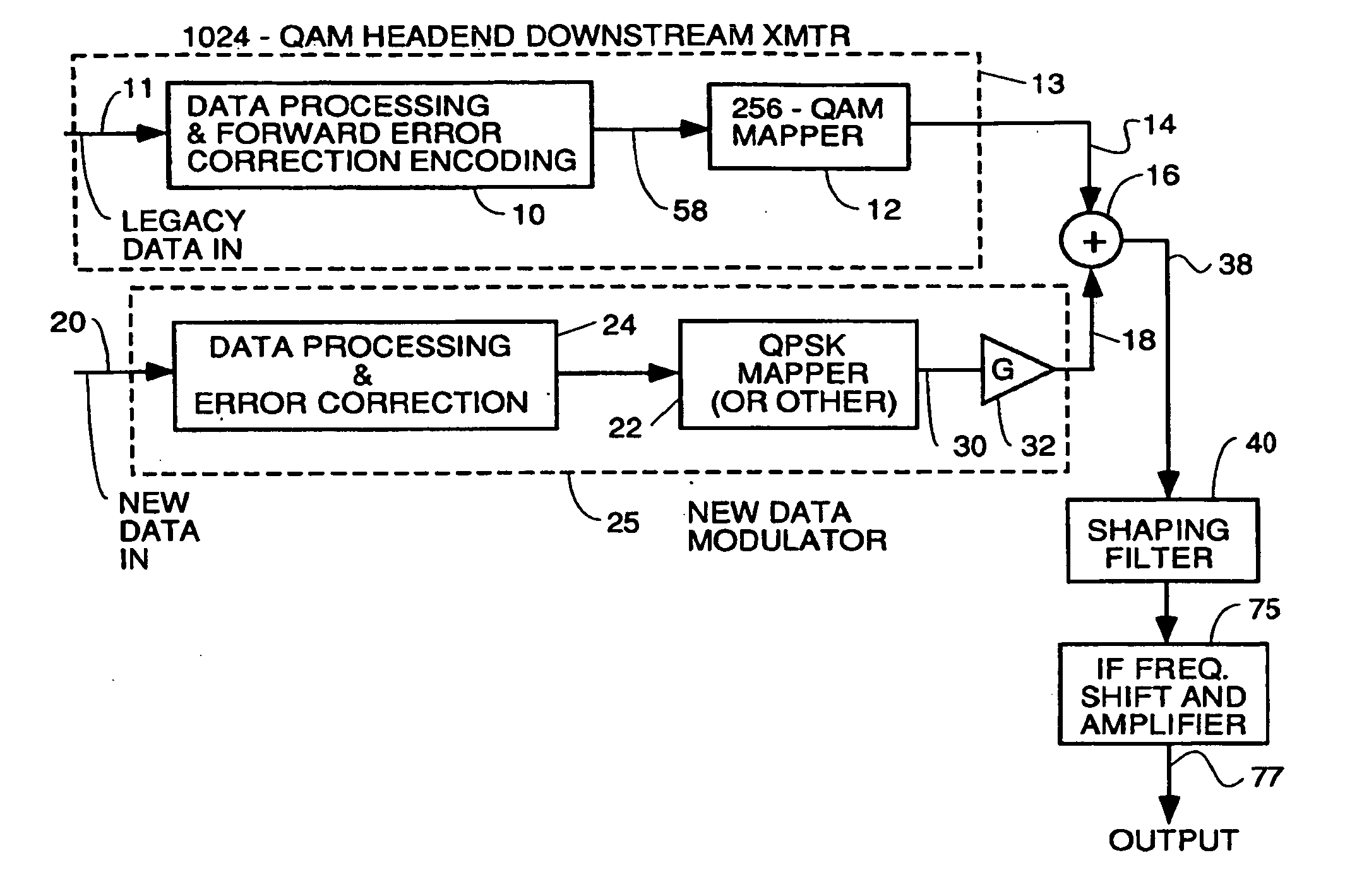

Downstream transmitter and cable modem receiver for 1024 QAM

InactiveUS20060085727A1Shortening HFC lengthMinimize reflectionSimultaneous amplitude and angle modulationData representation error detection/correctionModem deviceAudio power amplifier

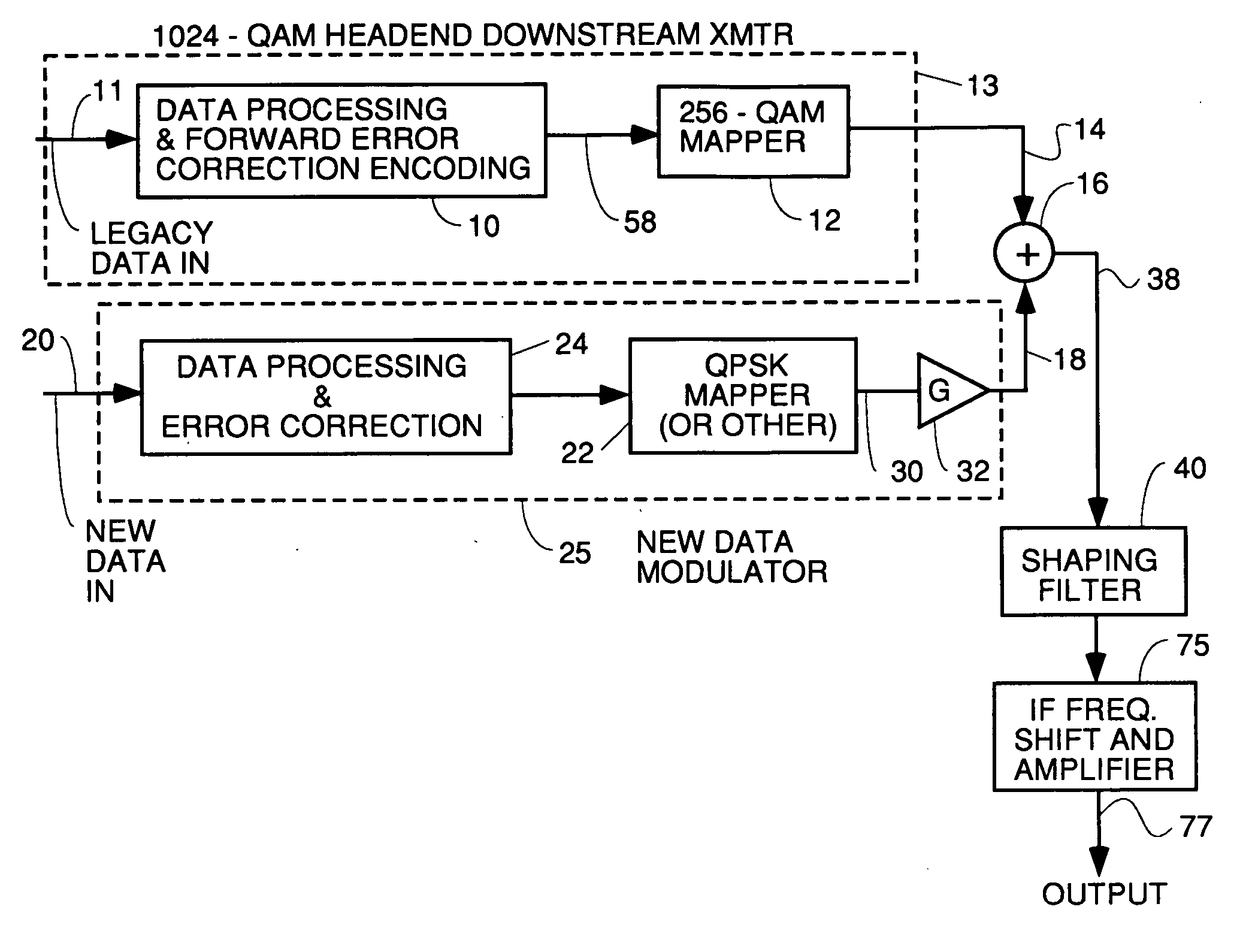

A headend transmitter that transmits 1024 QAM including a 256 QAM modulator which has been modified to have more aggressive forward error correction processing. The 256 QAM modulator outputs 256 QAM points to a summer. Another data modulator receives additional data to be transmitted in a separate, substantially less complex constellation. This modulator processes the additional data to do forward error correction thereon and then maps the encoded data into a less complex constellation such as QPSK, 16 QAM etc. The additional data constellation points are then amplified in a variable gain amplifier and fed to a summer where each additional data point is added by vector summation to one 256 QAM point. The output 1024 QAM point is filtered and shifted to the desired transmission frequency. Legacy cable modem receivers can still receive the 256 QAM point since the addition of the new data just appears to be noise which they can overcome using the parity bits encoded in the transmitted symbols. 1024 QAM cable modem receivers receive both the 256 QAM points and the new data points and output both.

Owner:AVAGO TECH INT SALES PTE LTD

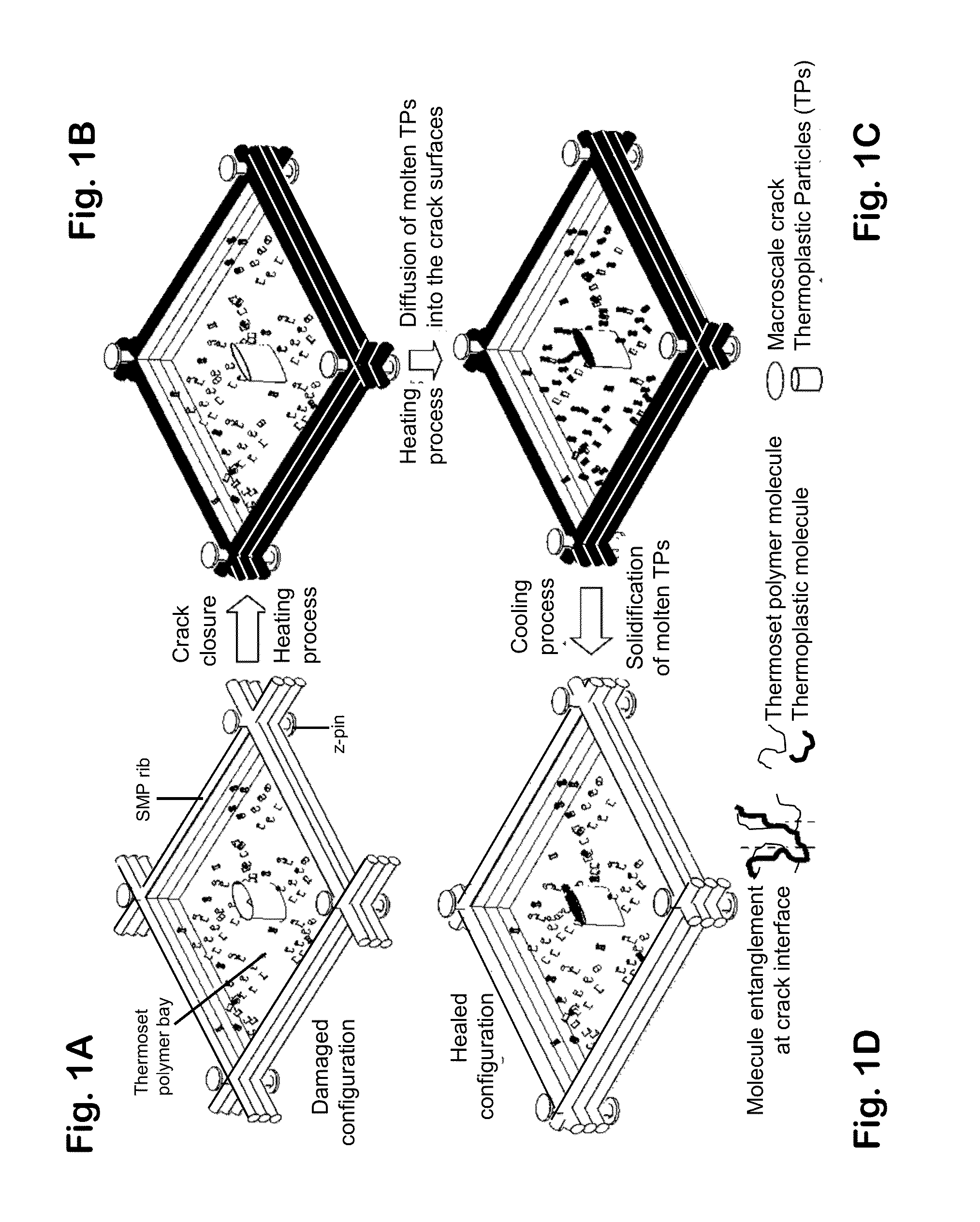

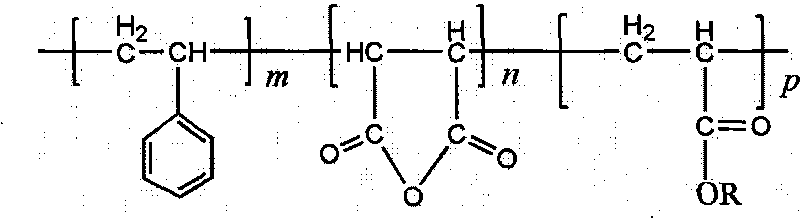

Self-Healing Composite of Thermoset Polymer and Programmed Super Contraction Fibers

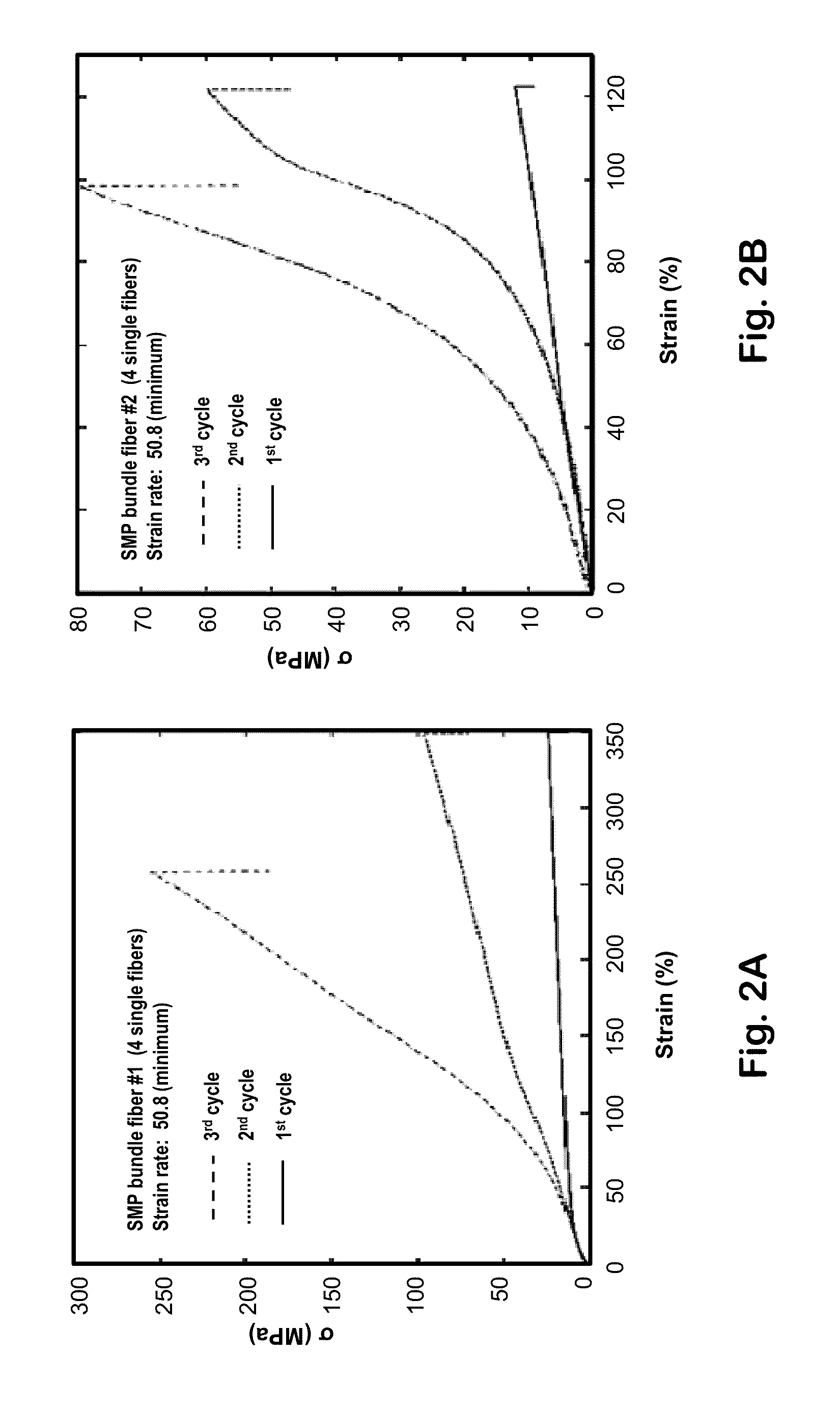

ActiveUS20140303287A1Light weightReduce vibrationMonocomponent polyurethanes artificial filamentPretreated surfacesFiberThermoplastic

A composition comprising thermoset polymer, shape memory polymer to facilitate macro scale damage closure, and a means for molecular scale healing is disclosed; the composition has the ability to resolve structural defects by a bio-mimetic close-then heal process. In use, the shape memory polymer serves to bring surfaces of a structural defect into approximation, whereafter use of the means for molecular scale healing allowed for movement of the healing means into the defect and thus obtain molecular scale healing. The means for molecular scale healing can be a thermoplastic such as fibers, particles or spheres which are used by heating to a level at or above the thermoplastic's melting point, then cooling of the composition below the melting temperature of the thermoplastic. Compositions of the invention have the ability to not only close macroscopic defects, but also to do so repeatedly even if another wound / damage occurs in a previously healed / repaired area.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Process for producing fibrillated fibers

ActiveUS20080054107A1Reduce flow rateIncrease degree of fibrillationFilament/thread formingPulp beating/refining methodsFiberShear rate

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

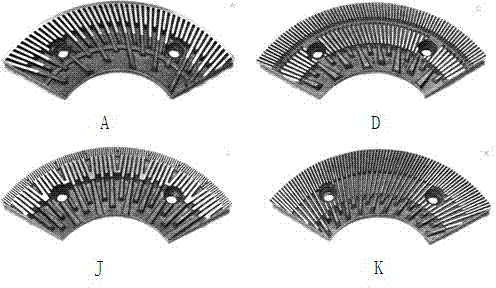

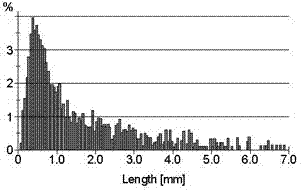

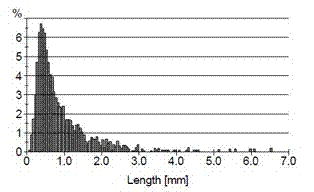

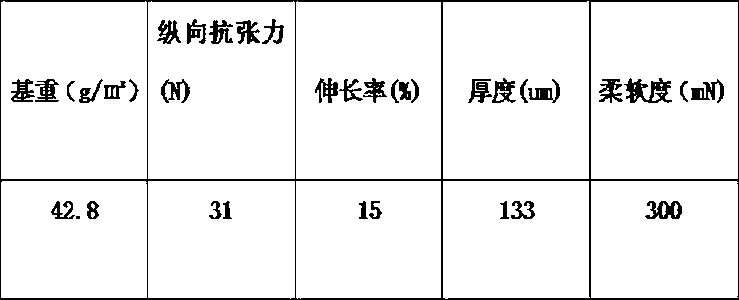

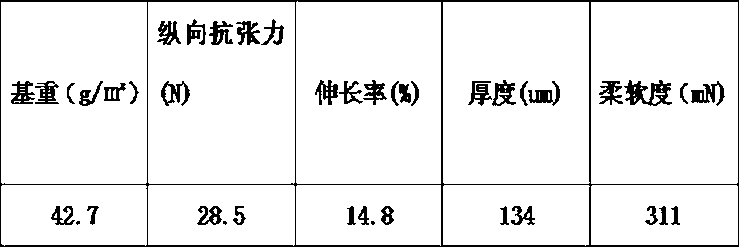

Method for preparing reconstituted tobacco paper base made from tobacco stems

The invention discloses a method for preparing reconstituted tobacco paper base made from tobacco stems, wherein the reconstituted tobacco paper base is prepared through taking the tobacco stems as a raw material and adopting a papermaking method and the preparing method comprises the steps of impregnation, defibrination, pulping, sheet making and drying of the tobacco stems. According to the invention, a technical scheme capable of optimizing the comprehensive property of the reconstituted tobacco paper base made from the tobacco stems is provided, which comprises treatment conditions of key processes of the impregnation, the defibrination, the pulping and the like; and a technical mean capable of improving the fiber morphology of the tobacco stems and the physical property of paper pulp is obtained. Showed by results, contents of water-soluble sugar, total plant alkaloid, chlorine and total nitrogen in the tobacco stems are decreased to varying degrees and the holocellulose content is relatively increased by 12.4% after the impregnation and extraction in the technical scheme provided by the invention are adopted; the fiber length of the obtained tobacco stem pulp is longest and the bulk of the finished paper is highest through selecting different types of refining plates and different defibrination gaps; and the tensile index, the tear index, the bulk, the air permeability and the burst index of a paper base product are appropriate and the good quality of reconstituted tobacco is guaranteed through combining the design of the beating degree of the tobacco stem pulp and the technical condition of the sheet making.

Owner:CHINA TOBACCO GUANGDONG IND +1

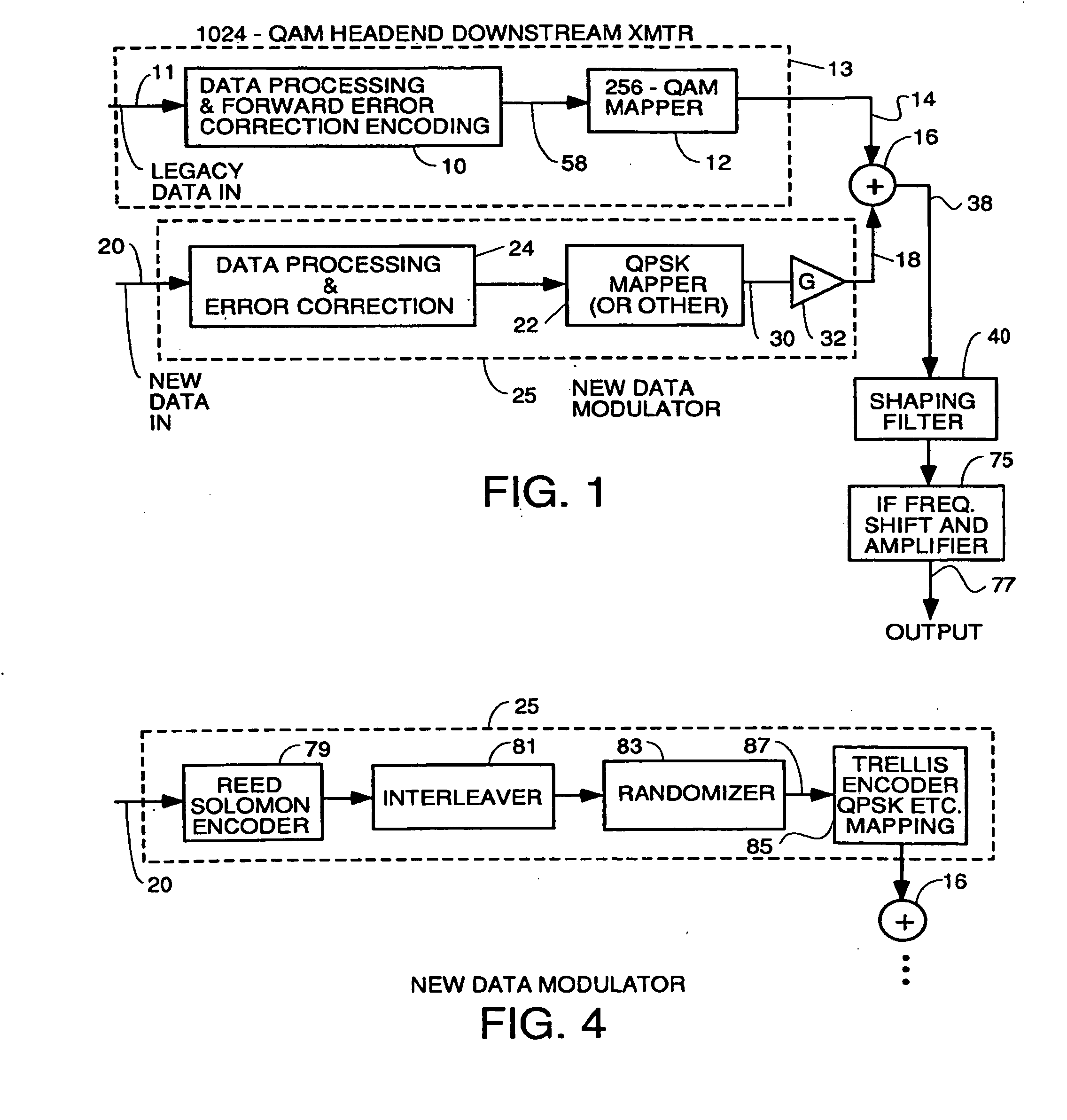

Downstream transmitter and cable modem receiver for 1024 QAM

ActiveUS20090044083A1Quality improvementAdditional circuitryData representation error detection/correctionCode conversionModem deviceAudio power amplifier

A headend transmitter that transmits 1024 QAM including a 256 QAM modulator which has been modified to have more aggressive forward error correction processing. The 256 QAM modulator outputs 256 QAM points to a summer. Another data modulator receives additional data to be transmitted in a separate, substantially less complex constellation. This modulator processes the additional data to do forward error correction thereon and then maps the encoded data into a less complex constellation such as QPSK, 16 QAM etc. The additional data constellation points are then amplified in a variable gain amplifier and fed to a summer where each additional data point is added by vector summation to one 256 QAM point. The output 1024 QAM point is filtered and shifted to the desired transmission frequency. Legacy cable modem receivers can still receive the 256 QAM point since the addition of the new data just appears to be noise which they can overcome using the parity bits encoded in the transmitted symbols. 1024 QAM cable modem receivers receive both the 256 QAM points and the new data points and output both.

Owner:AVAGO TECH INT SALES PTE LTD

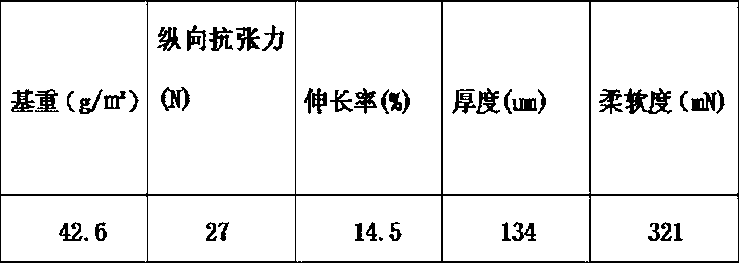

Method for preparing tobacco sheet paper base from tobacco stems

The invention discloses a method for preparing tobacco sheet paper base from tobacco stems as raw materials by adopting the paper making process. The method comprises the following steps: impregnating, pulping and making sheets. The invention changes the traditional technological prejudice and custom of controlling the pulping by controlling the current of a pulping machine and innovatively realizes the pulping by controlling the pulping disc, the pulping gaps, the pulping segments and the pulping concentration. The condition of the pulping process is optimized systematically, two or three segments of pulping are adopted, the pulping concentration is controlled at 20%, and the pulping gaps for the first and second segments of pulping are respectively 0.4mm and 0.20mm. Through studying and analyzing the relation between the pulping process and the performance of the tobacco stem fiber integrally, the controllable optimum pulping condition is summarized, the longest fiber of the tobacco stem pulp, the highest bulk of the formed paper and the good quality of the reconstituted tobacco are guaranteed, the performance of the tobacco sheet paper base is improved comprehensively, and finally the technological basis is provided for improving the quality of the tobacco sheets and the cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

Writing paper and preparation method thereof

InactiveCN101787660AIncreased fiber lengthIncrease dosagePulp de-wateringReinforcing agents additionPollutant emissionsPulp and paper industry

The invention provides writing paper made of slurry comprising the following components by percentage: 20% to 100% of unbleached straw pulp and 0% to 80% of wood pulp. According to the ISO (International Standardization Organization), the whiteness of the writing paper is 35% to 75%; the opacity thereof is higher than or equal to 75%; and the basis weight thereof is 45.0g / m<2> to 80.0g / m<2>. The production process of the writing paper is energy-saving and cost-saving; and the pollutant emission can be greatly reduced.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

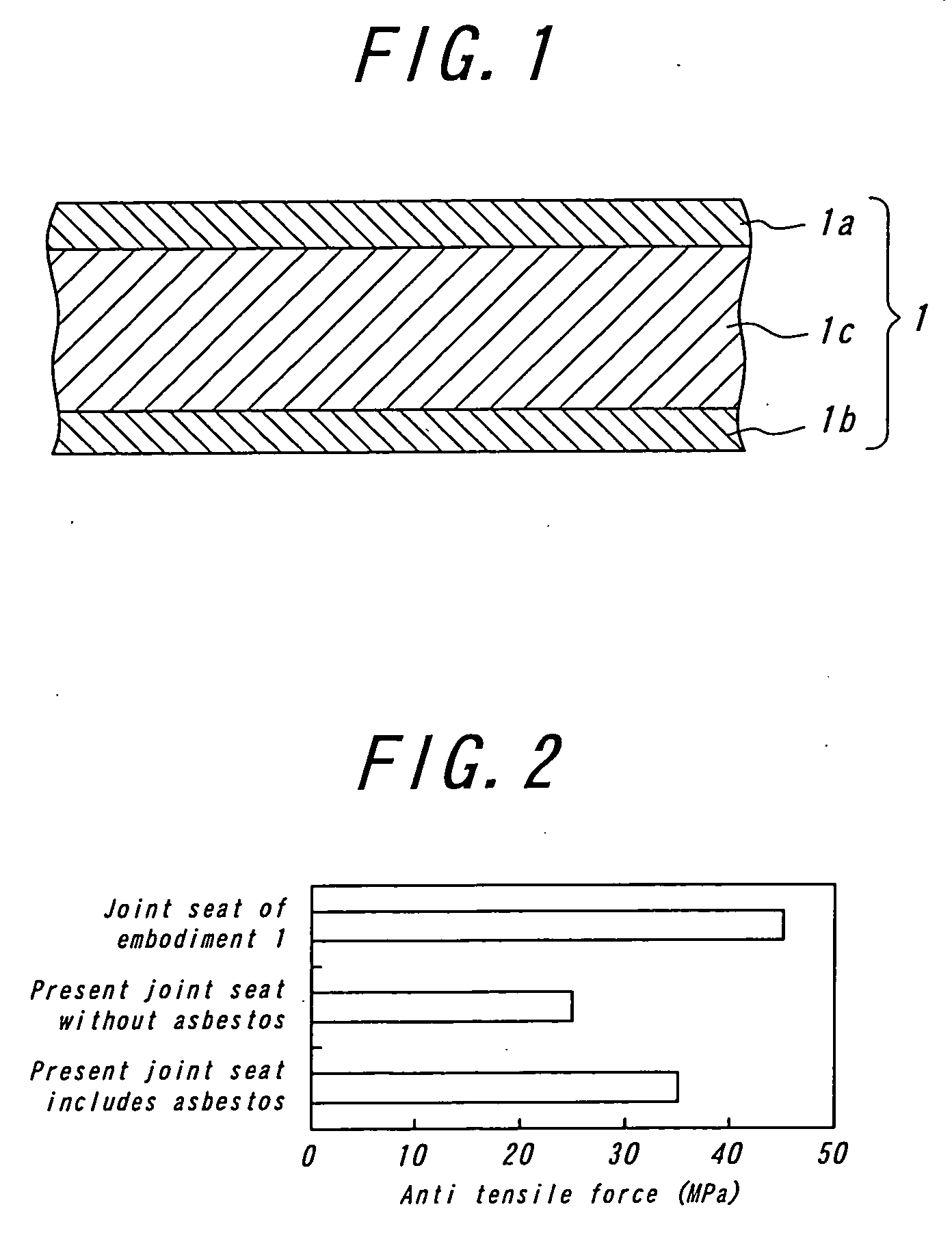

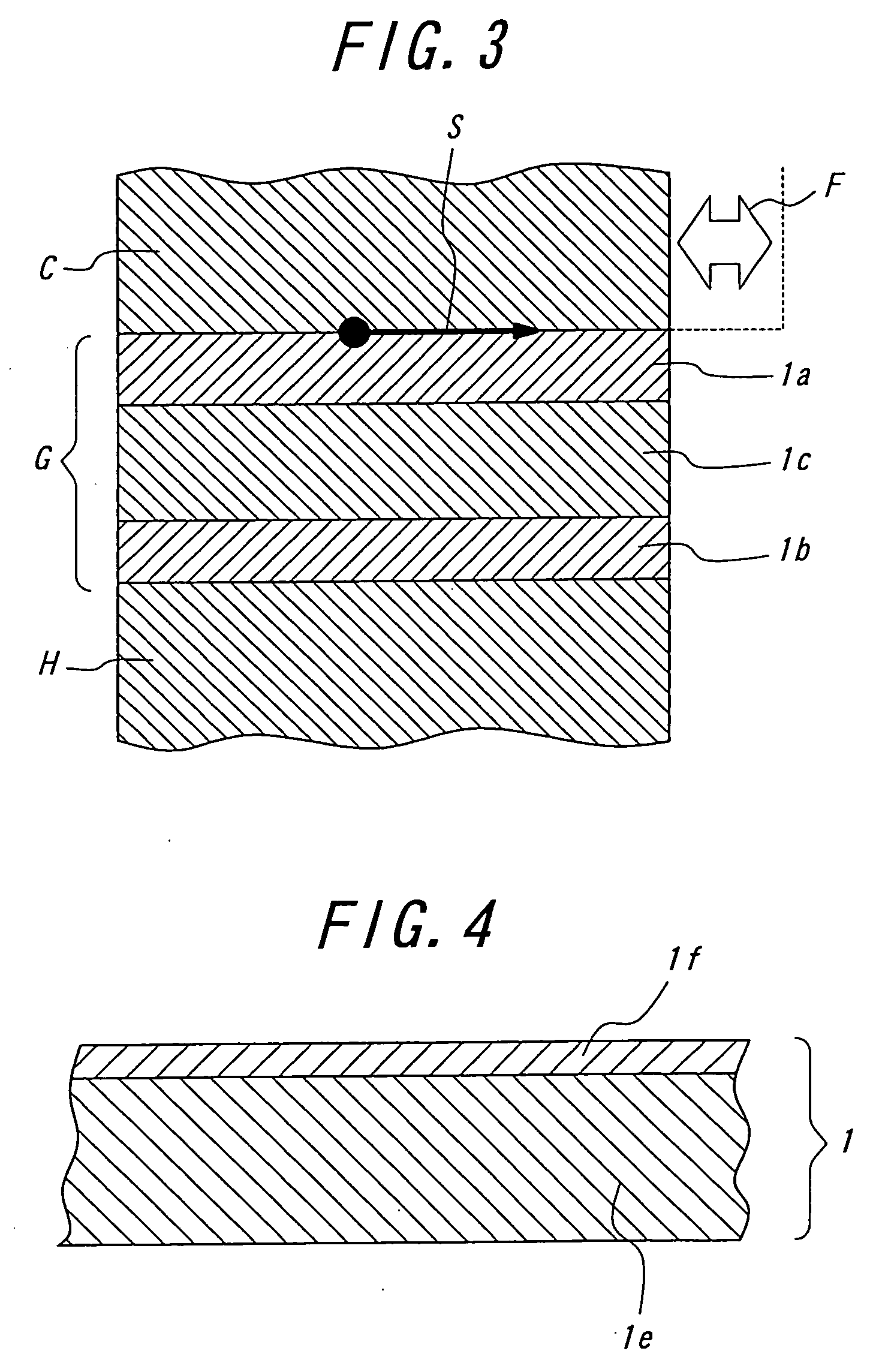

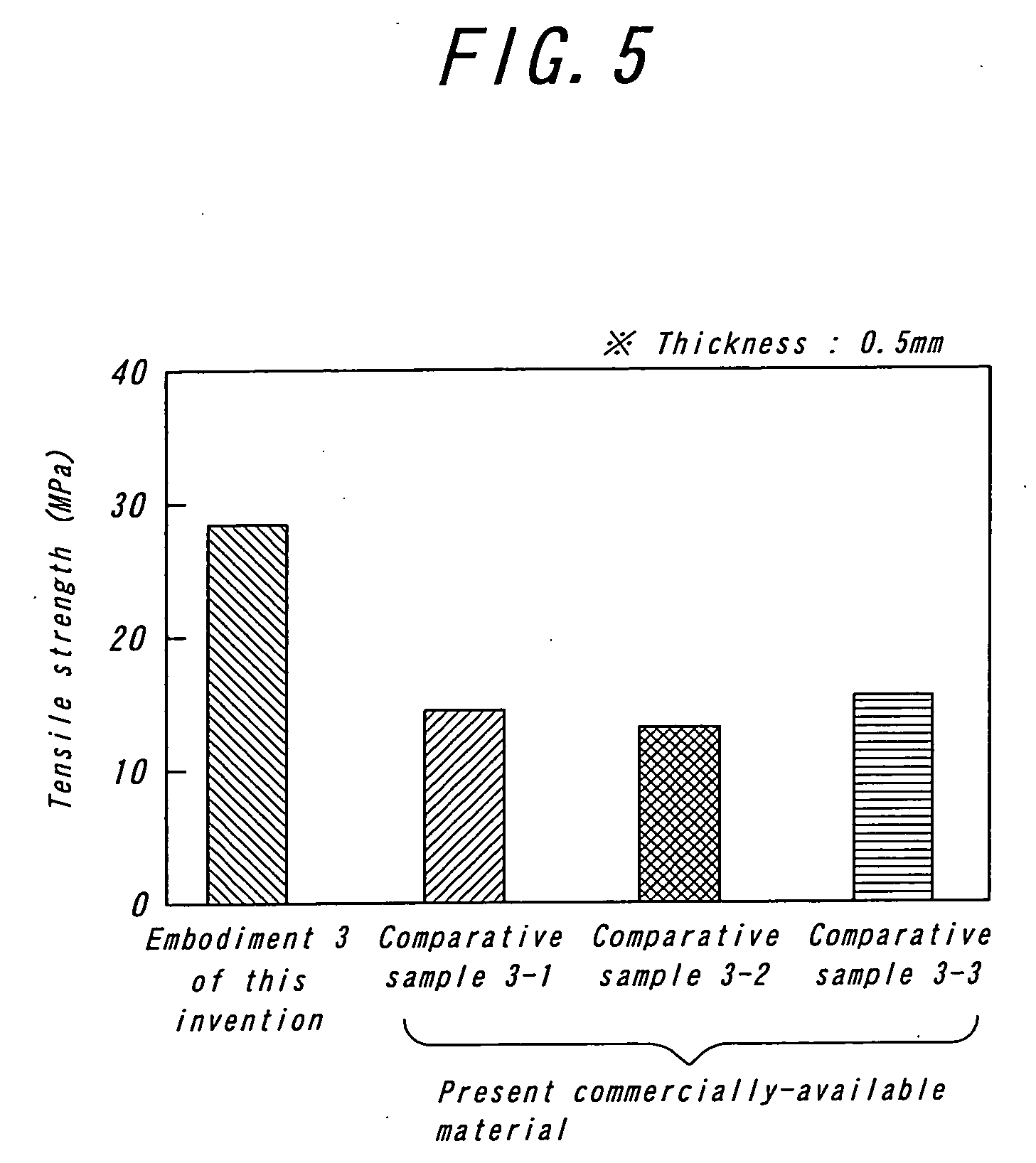

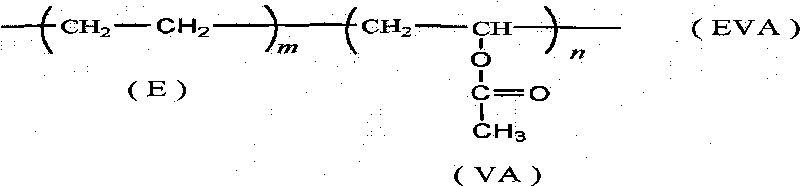

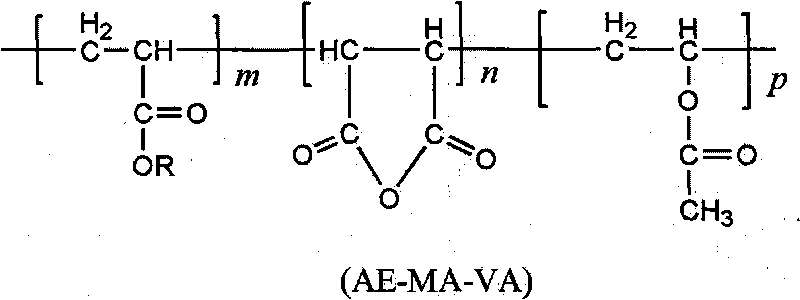

Gasket material

The gasket material that is manufactured from a joint seat which includes three layers, that is, a front surface layer (1a), a back surface layer (1b) and the middle layer (1c), and these layers have different composition of reinforced fiber and filler respectively, and this joint seat is made from an ingredient made by mixing and kneading rubber, reinforced fiber and filler, then pressurized laminating and vulcanizing the ingredient, this joint seat is characterized in that the reinforced fiber is as a sort of fibril which is composed from one or both of organic fiber and non-asbestos type inorganic fiber, and at least a part of the filler is spicular inorganic fiber and its composition is 10 wt %-45 wt %. According to this joint seat (1), a crack breakage of the gasket that the ingredient material is the joint seat (1) due to fretting is prevented.

Owner:NIPPON LEAKLESS IND CO LTD +1

Andalusite fiber size and preparation method thereof

The invention provides a multifunctional size for andalusite fibers, which uses an organic compound containing flexible chains in molecules as a main body and compounds a plurality of auxiliary agents. The size comprises the following components in percentage by weight: 0.5-1.5 percent of film forming agent, 1-10 percent of softening agent (penetrating agent), 0.05-0.3 percent of antistatic agent(antiseptic), 0.01-0.2 percent of dispersant, 0.01-0.07 percent of coupling agent, 0.05-0.1 percent of catalyst and the balance of tap water. The size has good convergence, lubricating property, filmforming property, antistatic property and antiseptic characteristic. Not only fibers processed through the size have flexible, anti-bending and anti-stretching characteristics, but also the fibers sprayed with the size have good dispersive property in water and can be used for the surface soakage treatment of multiple silicate fibers.

Owner:甘肃紫鑫矿业煤化工有限公司

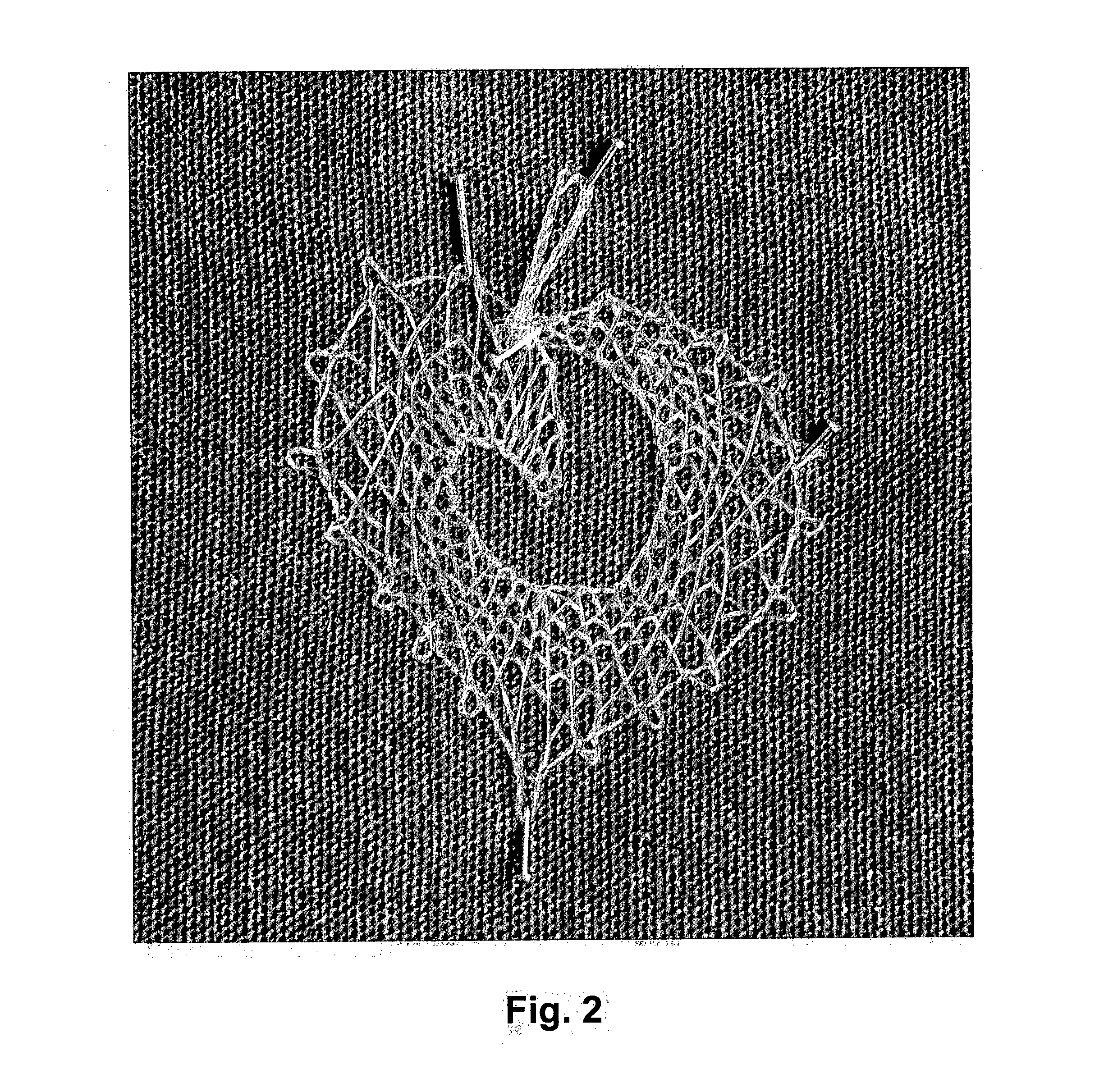

Hyaluronan fibres, method of preparation thereof and use thereof

InactiveUS20130309494A1Low viscosityHigh molecular weightArtificial filament washing/dryingWet spinning methodsIonFiber

The invention relates to the method of preparation of hyaluronic acid-based fibres, where first the spinning solution of hyaluronic acid and / or a metal compound thereof, optionally containing a metal salt or a hyaluronic acid compound and metal ions, is prepared, then the spinning solution is introduced into the coagulation bath comprising an acid, an alcohol and not more than 10% wt. of water, and optionally a metal salt, resulting in forming a fibre which is preferably left in the coagulation bath and / or is drawn, then the fibre is washed with alcohol and dried. After washing of the fibre, metal ions may be introduced in the fibre by means of the metalization bath. Further, the invention relates to the fibres based on hyaluronic acid and / or a metal compound thereof, having the fibre (monofilament) diameter 4 μm to 1 mm, linear weight 0.1 to 30 g / 1000 m (0.1 to 30 tex), tensile strength 0.5 to 3 cN·dtex−1 and loop strength 20 to 80% of the tensile strength. The invention also relates to a silk tow that contains 2 to 50 primary fibres. Moreover, the invention relates to the use of the fibres for the production of woven and non-swoven fabrics.

Owner:CONTIPRO BIOTECH

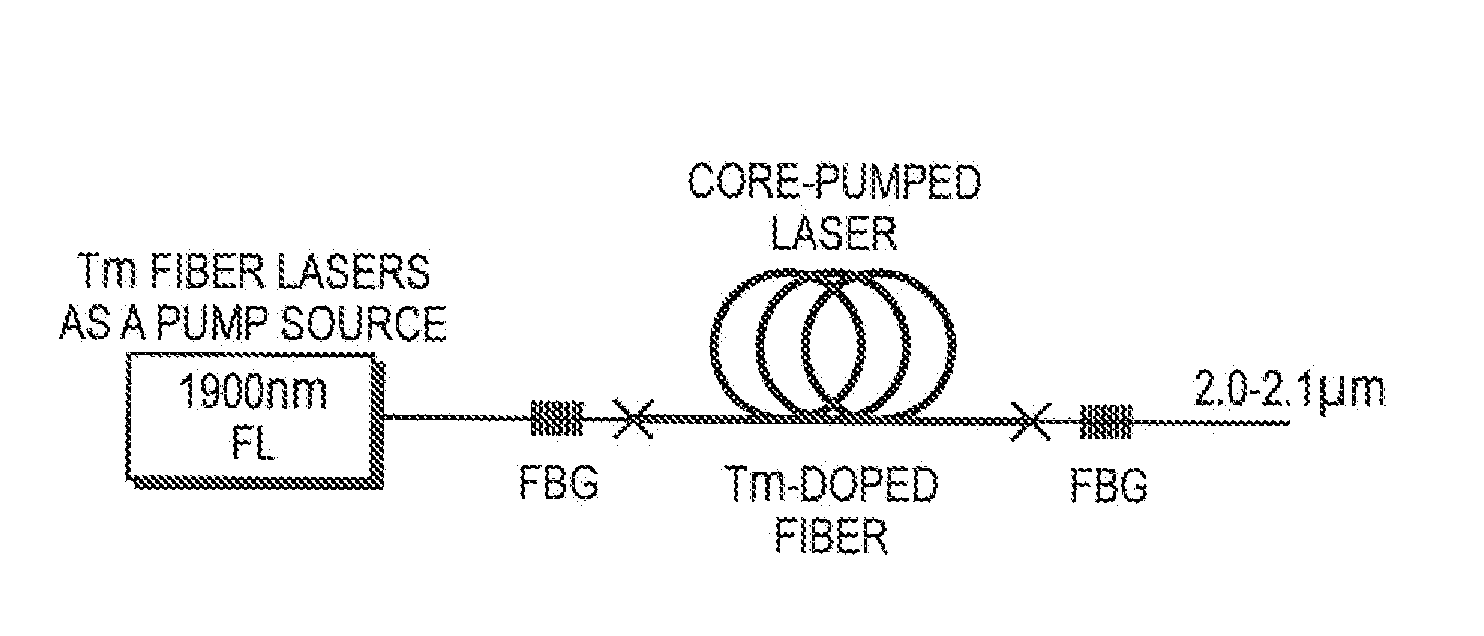

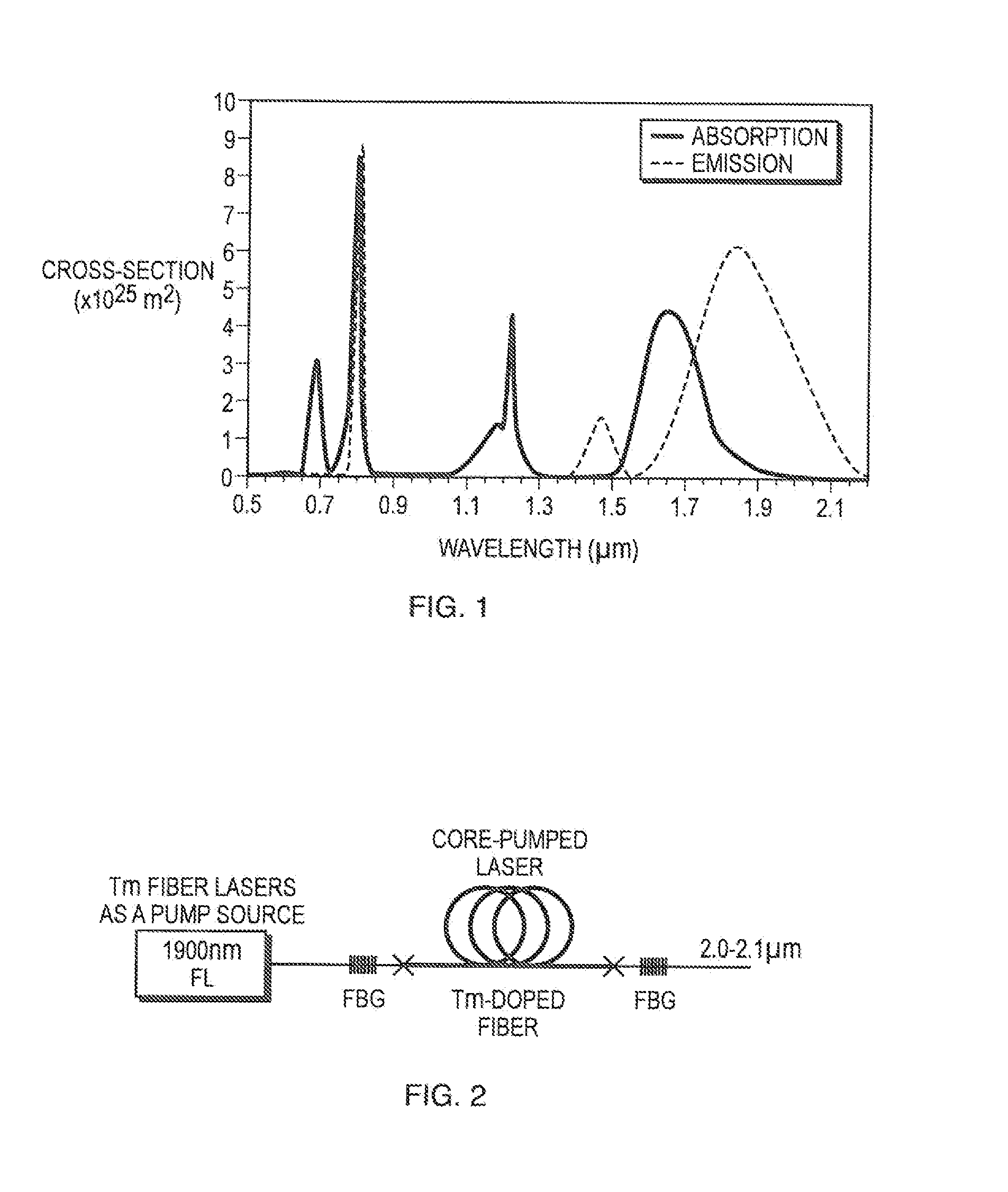

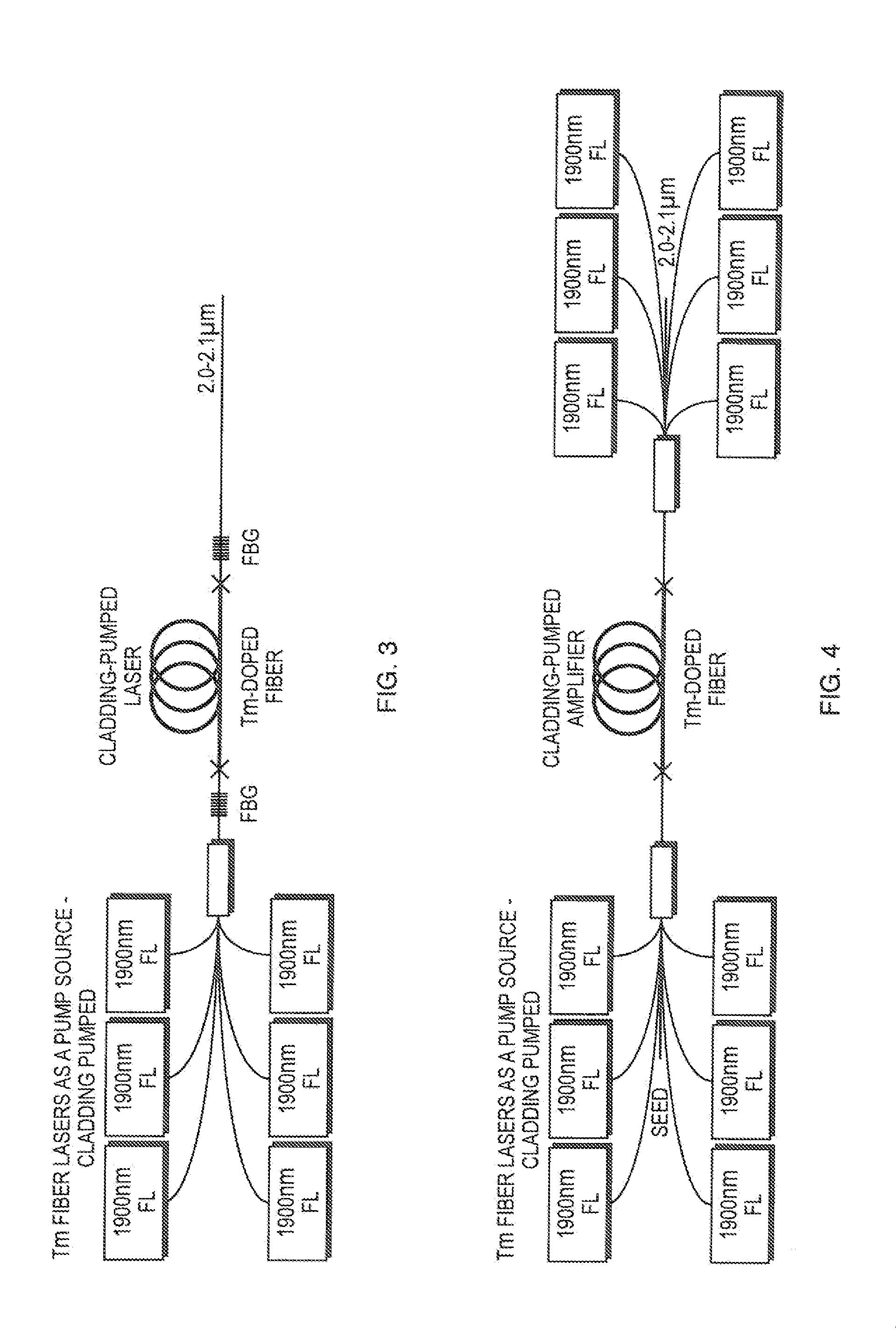

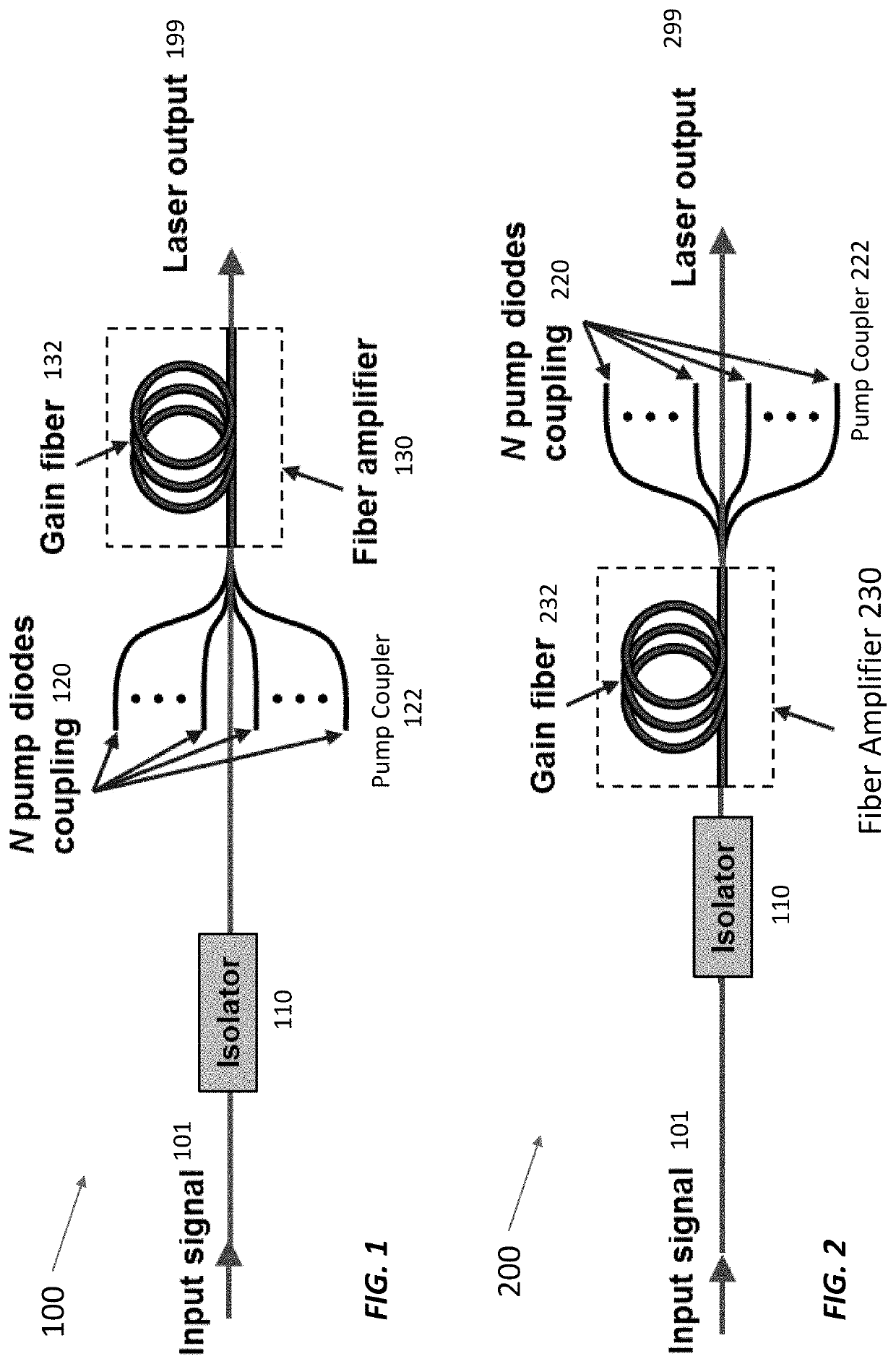

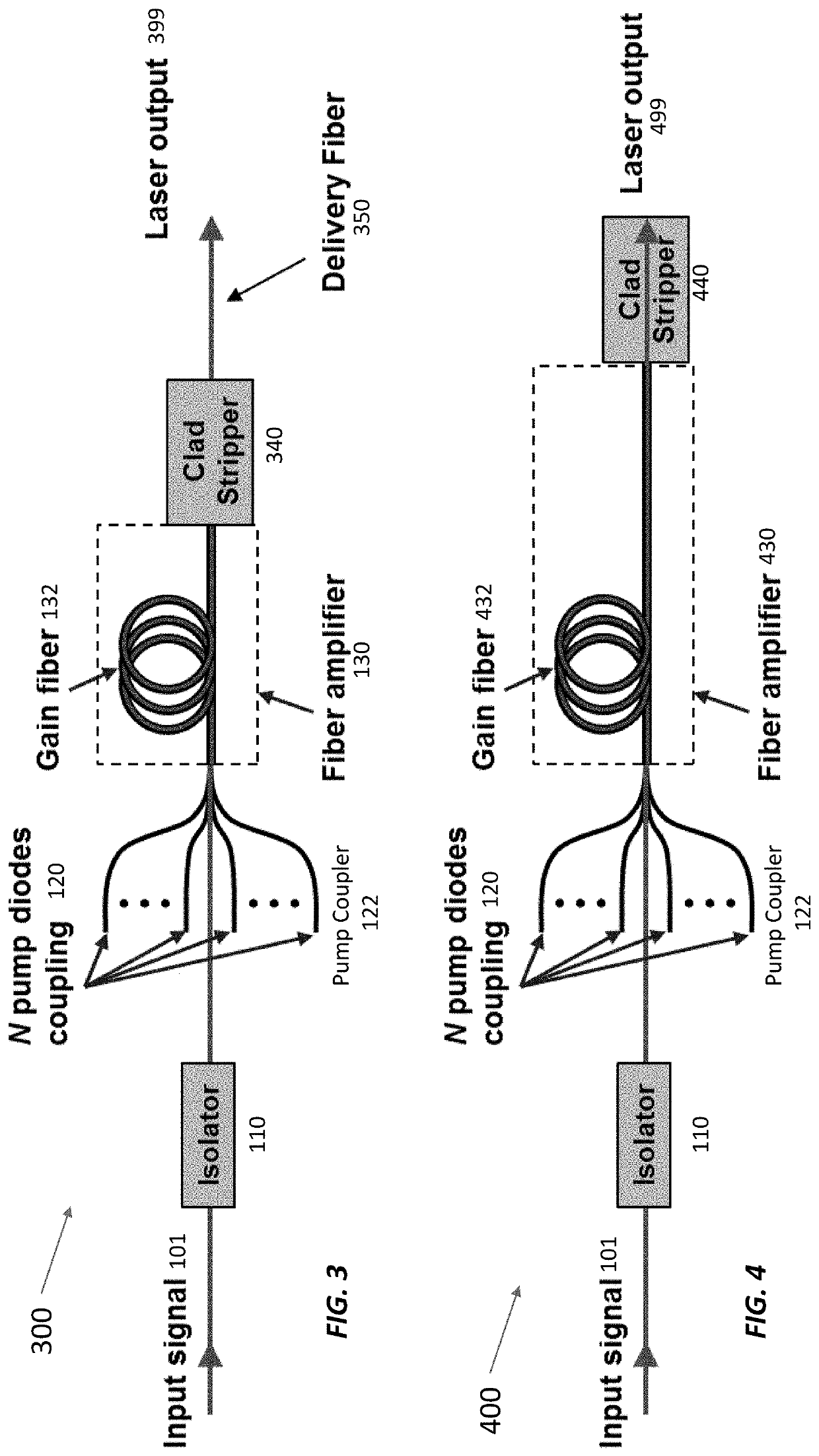

Highly efficient thulium doped fiber laser

ActiveUS20130322470A1Reduce heat loadHigh power scalingLaser using scattering effectsActive medium shape and constructionThuliumWavelength

In the method of generating high power light with high efficiency and low thermal loading, the improvement comprising the steps of resonantly pumping a first thulium-doped fiber laser with a second thulium-doped fiber last, said second thulium-doped fiber laser having a shorter wavelength than said first thulium-doped fiber laser.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Production technology of kraft vermicelli case board paper

InactiveCN105696395AHigh strengthIncrease the lengthPulp beating methodsPaper recyclingEnvironmental resistanceSurface layer

The invention discloses a production technology of kraft vermicelli case board paper. The production technology comprises the steps that recycled waste paper materials are screened, the recycled waste paper with low ash content is selected for pulping with softwood pulp, preliminary pulping is conducted through the processes of repulping, purifying, screening and the like, the fiber strength is emphatically improving in the grading and beating processes, longer fibers are screened to serve as surface layer pulp, the fiber beating degree is improved on the condition that the fiber strength is not damaged, and the fiber bonding strength is improved through the fiber arrangement mode on a net portion so as to improve the surface strength, toughness and folding strength of finished paper; by means of the measures of surface sizing, after-drying moisture precise control and finished paper coating, the product has the better explosion-proof line quality advantage and is more environmentally friendly, and the market share of the product is bound to be increased.

Owner:JIANGSU LEE & MAN PAPER MFG

Manufacturing process for macerative masking tape

InactiveCN103015258AHigh strengthHigh bonding strengthReinforcing agents additionPaper/cardboardMasking tapeHigh intensity

The invention relates to a masking tape making and macerating process for manufacturing a masking tape, in particular to a manufacturing process for macerative masking tape. The process comprises two parts including a masking tape making part and a macerating part, wherein the masking tape making part comprises the steps as following: wood pulp untwining; pulp milling, that is, wood pulp is pulped via a double-disc refiner, wherein the beating degree is 40-70 degrees SR, the wet weight is 6-11 g, and the beating intensity is 3.5-5.0 percent; pulp preparation means that a softening agent and a wet strength agent are added into milled pulp, the use level of the softening agent is 3-8 kg / T and the use level of the wet strength agent is 30-45 kg / T; purification; screening; shaping on a net; grinding and cockling, wherein the grinding dryness degree is controlled within a range of 36-45 percent; drying; and winding and cutting. The macerating part comprises the steps of unwinding, macerating processing, drying, winding, cutting, winding, packing and warehousing. The macerative masking tape has good flexibility, high intensity and large thickness.

Owner:浙江晶鑫特种纸业有限公司

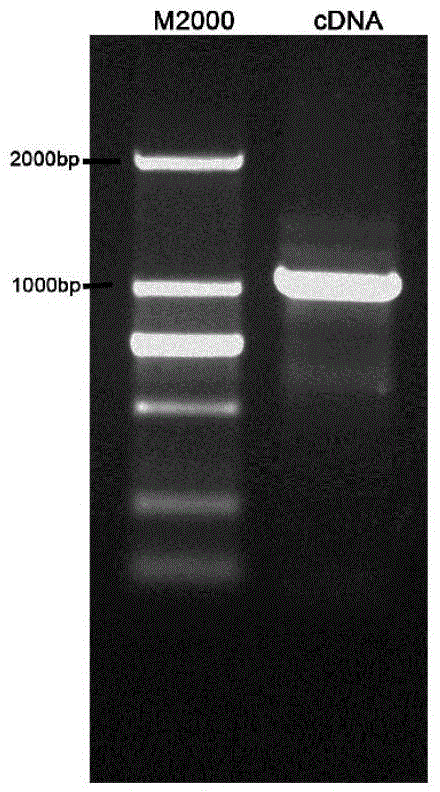

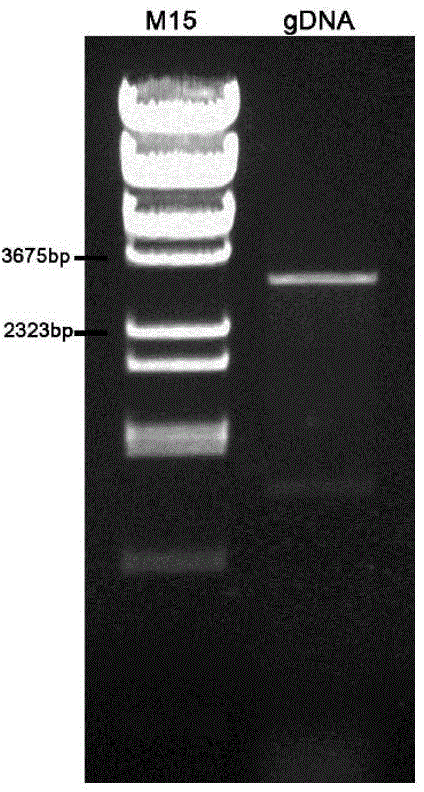

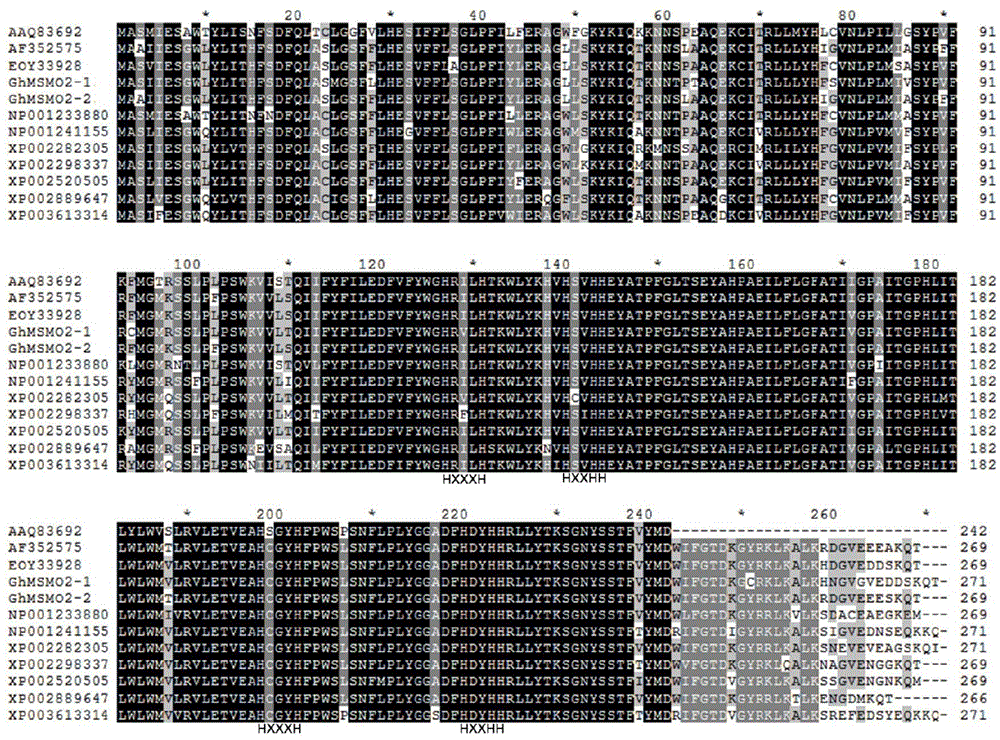

Cotton fiber predominantly-expressed gene, expression vector and applications thereof, and preparation method of transgenic cotton containing gene

InactiveCN104611348AObvious fiber expression advantageHigh expressionOxidoreductasesGenetic engineeringFiberGrowth plant

The invention discloses a cotton fiber predominantly-expressed gene GhMSMO2-2, which has one of the following nucleotide sequences: a cDNA sequence shown in SEQ ID NO.1, a gDNA sequence shown in SEQ ID NO.2, and a nucleotide sequence which has over 85% homology with the DNA sequences above and encodes functional proteins same as those encoded by the DNA sequences above, or a nucleotide sequence hybridized with the nucleotide sequences above under high-preciseness conditions; a protein encoded by the gene has an amino acid sequence shown in SEQ ID NO.3; the invention also provides a plant expression vector of the gene which at least contains a promoter sequence and the nucleotide sequences of the gene; the invention further provides a preparation method of a transgenic cotton containing the gene, which is implemented by transforming a host by using the vector, so that a transformant is obtained; and transforming a cotton by using the transformant, so that the transgenic cotton is obtained. The GhMSMO2-2 gene can be applied to the promotion of the plant growth of the transgenic cotton, the increasing of fiber length, and the improvement of fiber quality and yield.

Owner:SOUTHWEST UNIV

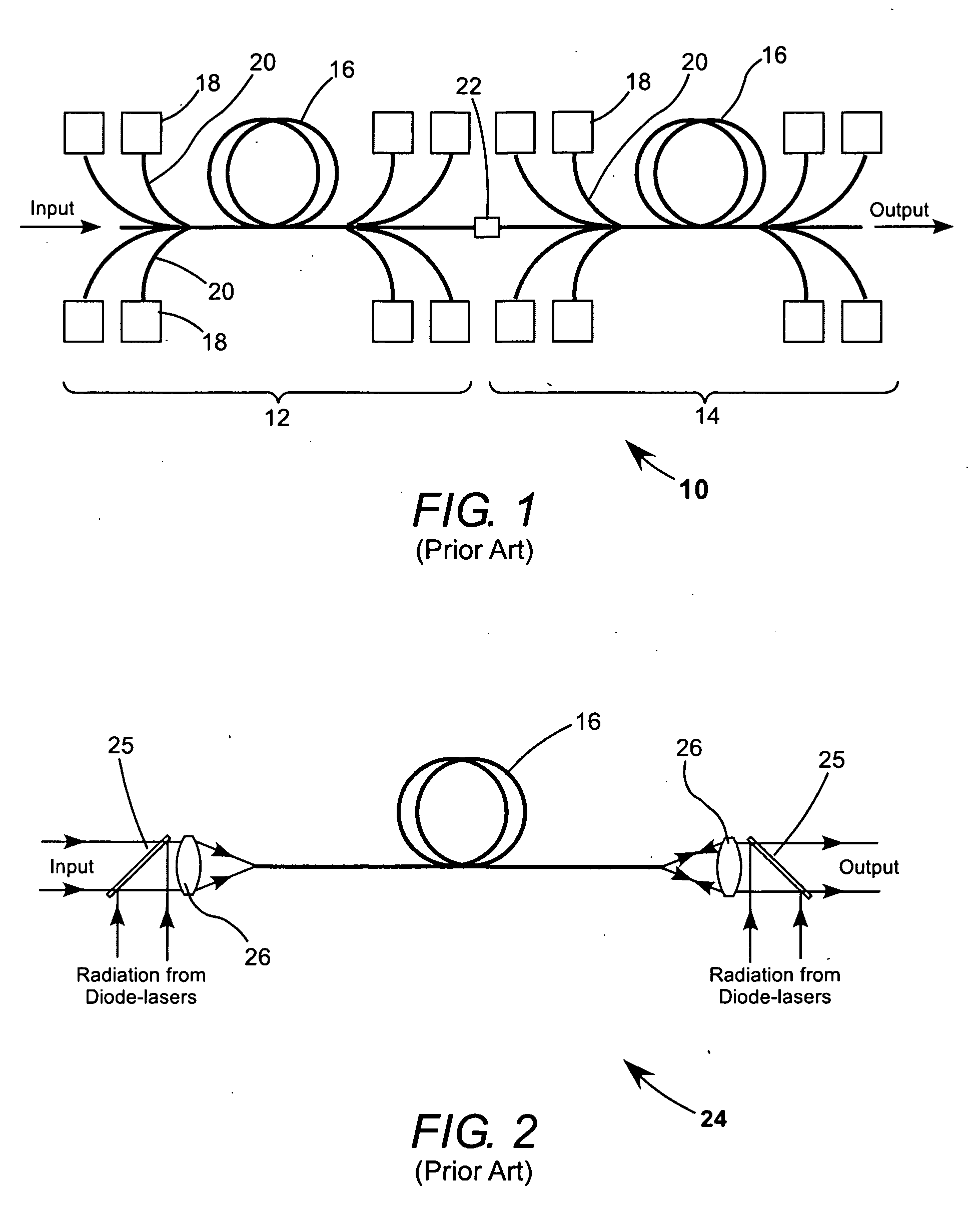

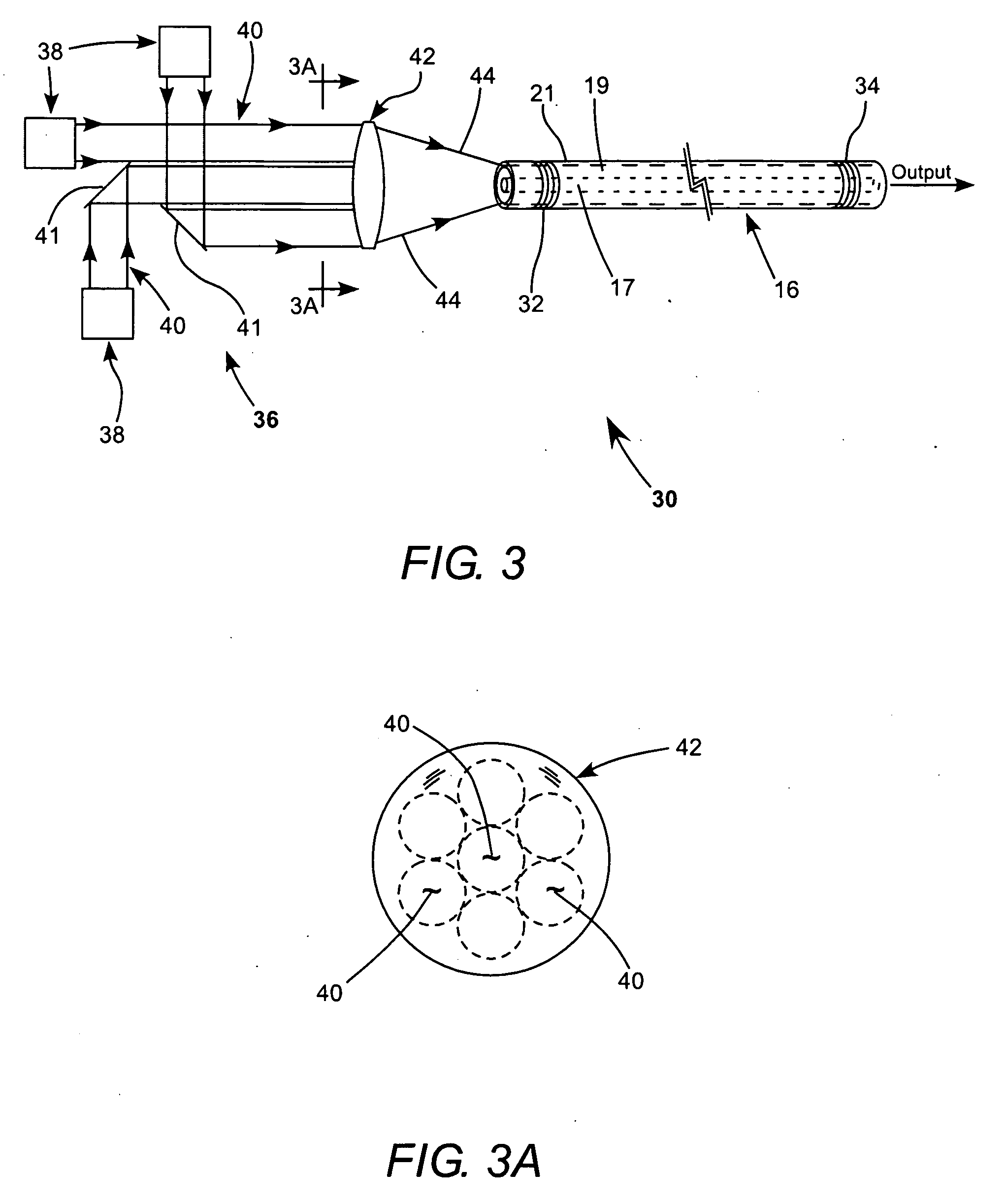

Ops-laser pumped fiber-laser

InactiveUS20100260210A1Reduce brightnessImprove fill factorLaser optical resonator constructionLaser using scattering effectsFiber amplifierSemiconductor

An optical gain-fiber of a fiber-laser or a fiber-amplifier is optically pumped by radiation from a plurality of external cavity, optically pumped, surface-emitting semiconductor lasers (OPS-lasers). In one example, radiation from the OPS-lasers is focused by a lens into cladding of the gain-fiber at one end of the fiber. In another example radiation from the diode-lasers is focused into the core of a delivery fiber at one end of the delivery fiber. The other end of the delivery fiber is coupled to the cladding of the gain-fiber.

Owner:COHERENT INC

High strength impregnation textured paper production process

InactiveCN104499371AImprove acceleration performanceWell mixedReinforcing agents additionPaper/cardboardPaper productionPulp and paper industry

The invention relates to a high strength impregnation textured paper production process including the parts of paper making and impregnation processing, paper making part comprises wood pulp defibering, grinding, pulp mixing, purification, screening, forming on a net, squeezing and wrinkling, drying, coiling and cutting, the pulp mixing is as follows: ground pulp is added with a softening agent, a wet strength agent and cationic starch, the softening agent dosage is 3-8kg / T pulp, the wet strength agent dosage is 30-45kg / T pulp; the addition of the wet strength agent and the cationic starch comprises the steps of: the wet strength agent to be added into the paper making pulp is divided into two parts of a first wet strength agent and a second wet strength agent; the first wet strength agent and the cationic starch to be added into the paper making pulp are mixed evenly to obtain a mixture; the mixture is added into the paper making pulp and mixed evenly; the paper making pulp added with the evenly mixed mixture is added with the second wet strength agent, and is evenly mixed.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

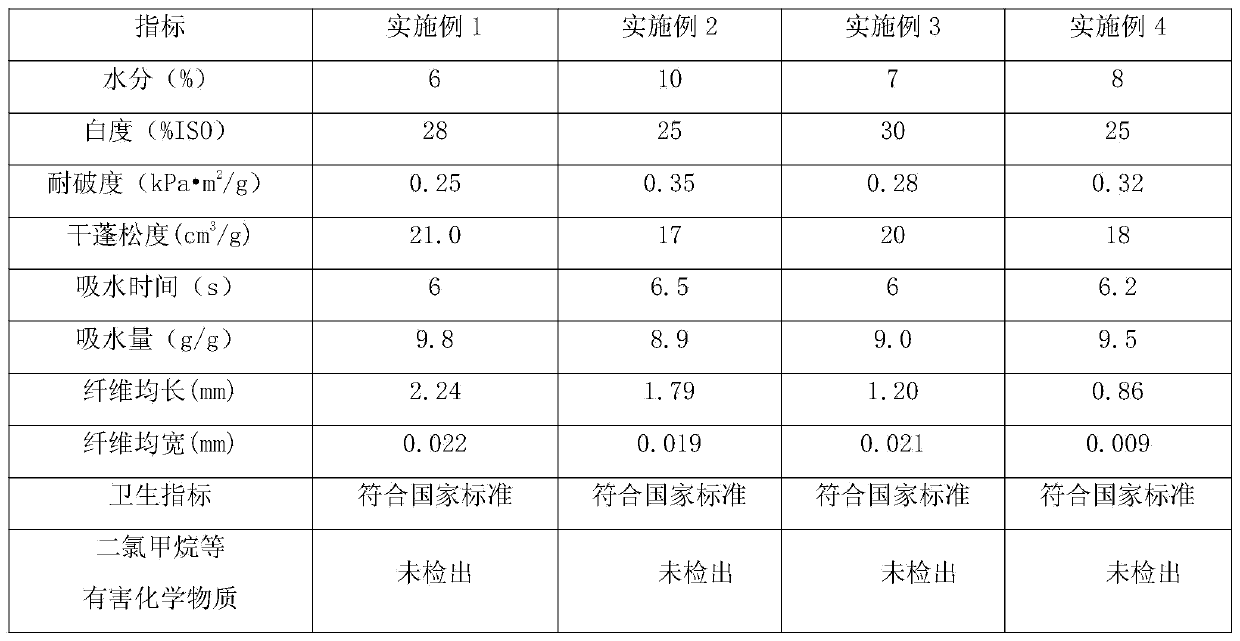

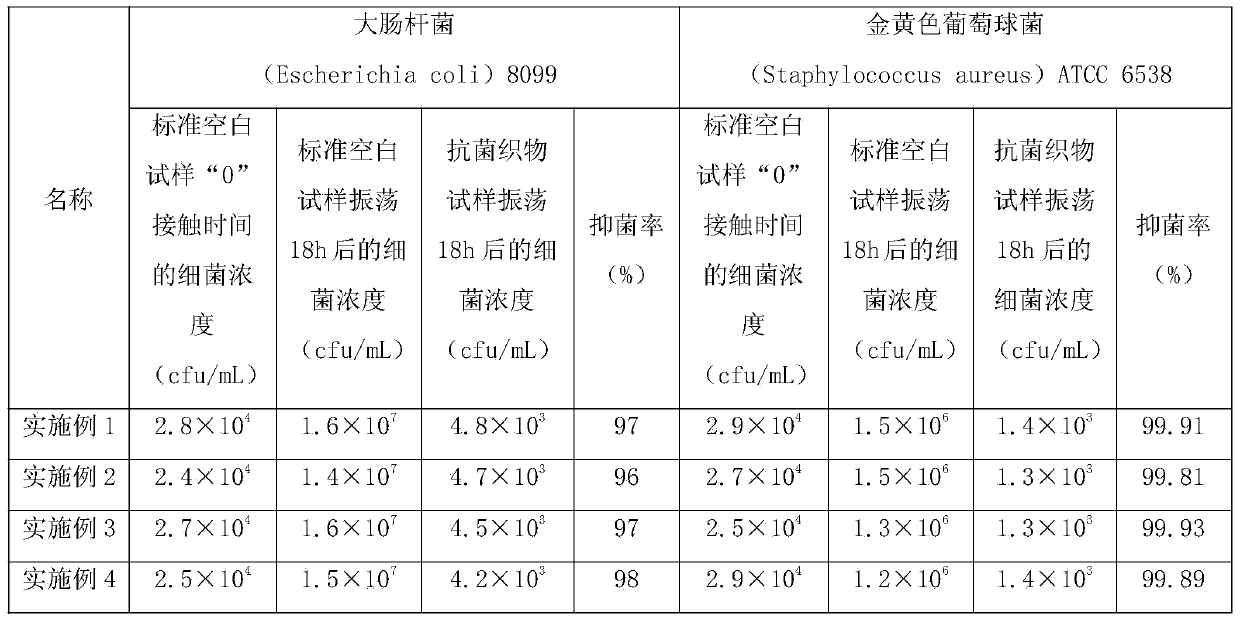

Natural-color fuzzy bamboo pulp with high bacteriostatic activity and preparation method thereof

ActiveCN104195868AReduce usageAvoid residual contaminationPaper/cardboardPulping with inorganic basesBursting strengthFiber

The invention discloses natural-color fuzzy bamboo pulp with high bacteriostatic activity. The natural-color fuzzy bamboo pulp is 25-30%ISO (International Standardization Organization) in whiteness degree, is 0.25-0.35kPa m<2> / g in bursting strength, is 17-21cm<3> / g in dry filling power, is 6-6.5s in water absorption time, is 8.9-9.8g / g in water absorption capacity, is 0.86-3.79mm in average fiber length and is 0.009-0.022mm in average fiber width. A preparation method of the natural-color fuzzy bamboo pulp comprises the steps of pulping raw materials, cooking, washing, modifying and drying, wherein the washing step comprises coarse selection by a vibrating screen, black liquid extraction by a vacuum pulp washer, fine selection by a pressure screen, dedusting by a residue removal and pulp washing by a vacuum pulp washing machine. The natural-color fuzzy bamboo pulp has long fiber length, high flexibility and good water-absorbing ability and water-retaining property, has soft and fluffy texture and strong antibacterial property, can keep the 100% natural color of the bamboo fiber and can remarkably improve the quality of the down-stream products; and the preparation method has the characteristics of simplicity in operation, convenience in production, low cost and environment protection.

Owner:SICHUAN HUANLONG NEW MATERIAL

Textured base paper dipping production technology

InactiveCN104499355AMelting fastPrevent leakageReinforcing agents additionPaper/cardboardPolyvinyl alcoholPulp and paper industry

The invention relates to a textured base paper dipping production technology including paper making and dipping processing parts, the paper making part comprises wood pulp defibering, grinding, pulp mixing, purification, screening, forming on a net, squeezing and wrinkling, drying, coiling and cutting, the pulp mixing step is as follows: adding water into polyvinyl alcohol powder for fully wetting and swelling the polyvinyl alcohol, and adding the wetted and swollen polyvinyl alcohol into ground pulp, wherein the absolute dry mass of the added polyvinyl alcohol is 0.1% to 3% of the absolute dry mass of pulp fiber; in the drying step, at least one section of a drying cylinder is used for drying a wet paper web to obtain a paper sheet, and the temperature of the initial section of the drying cylinder is set at 58 to 60 DEG C. The PVA powder is wetted and swollen, then the wetted and swollen polyvinyl alcohol powder is added into the pulp, and the wetted and swollen PVA (polyvinyl alcohol) can effectively be self trapped in gaps of paper fiber network structures.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

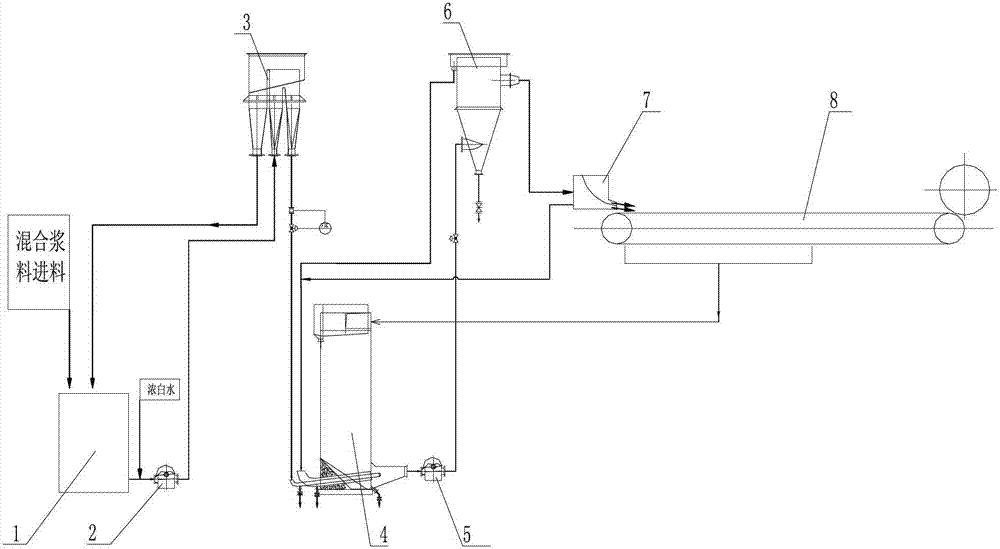

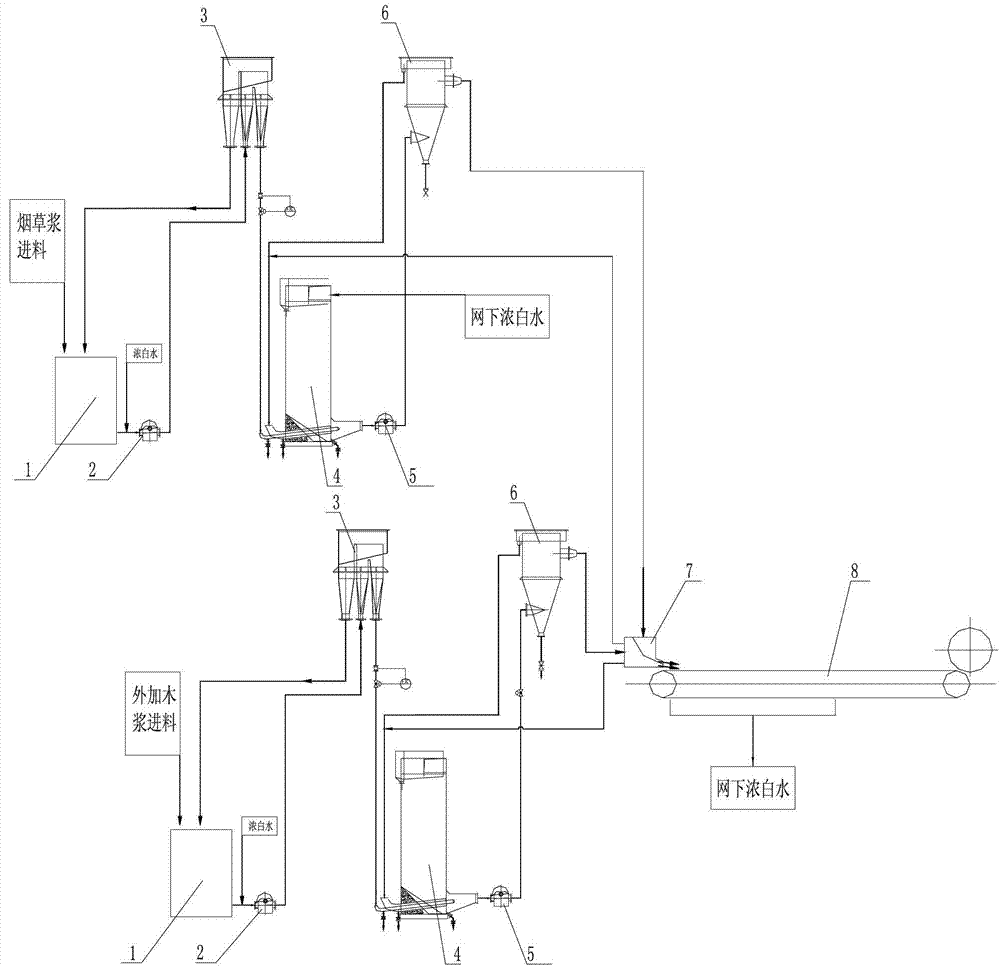

Double-layer papermaking process for paper-making reconstituted tobacco and equipment for double-layer papermaking process

The invention relates to a double-layer papermaking process for paper-making reconstituted tobacco and equipment for the double-layer papermaking process. The double-layer papermaking process can reduce the waste of raw materials, particularly the waste of tobacco pulp. The double-layer papermaking process comprises the step of allowing pulp to enter a molding net for papermaking; and the double-layer papermaking process also comprises the steps of independently mixing the pulp and feeding the pulp before the papermaking step. The equipment comprises two sets of pulp mixing systems which are independent respectively, and a pre-net flowing delivery system, wherein a double-layer headbox comprises a headbox body; the top of the headbox body is provided with a feed port; a discharge port is formed below a side wall of the headbox; a partition plate is also arranged in the headbox body, and partitions the headbox body into two independent headboxes; the two headboxes are provided with homogenating rollers with power devices respectively; a baffle divides the discharge port into upper and lower layers; the headbox of which the discharge port is positioned on the upper layer is a tobacco pulp headbox; and the headbox of which the discharge port is positioned on the lower layer is an external fiber headbox. The double-layer papermaking process and the equipment have the advantages that the utilization rate of the tobacco pulp is improved, and the adhesion of substrates of reconstituted tobacco and the cylinder surface of a drying cylinder during drying is effectively prevented.

Owner:黄申元

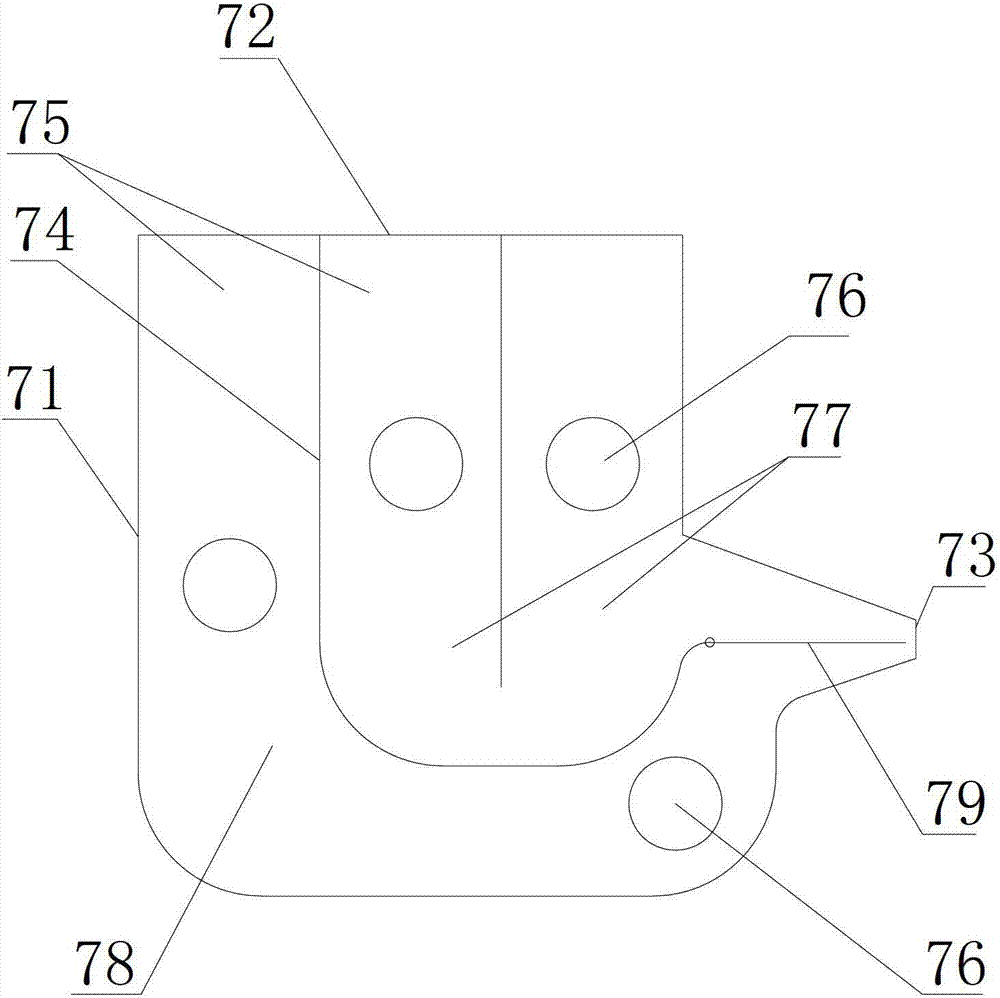

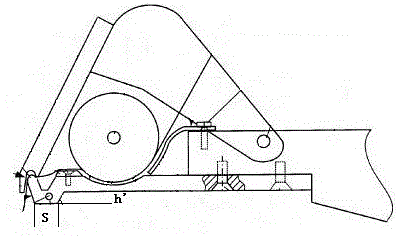

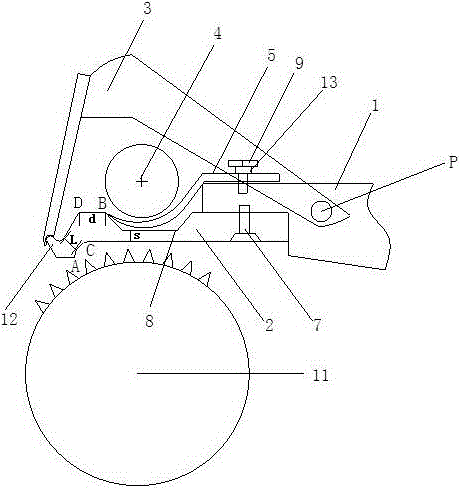

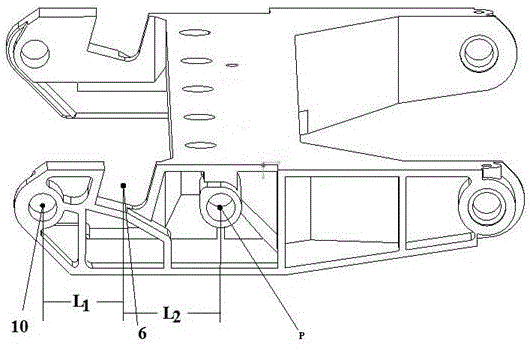

Novel combing-machine nipper mechanism

The invention discloses a novel combing-machine nipper mechanism which comprises a lower nipper seat. A lower nipper plate is fixed in front of the lower nipper seat, a trapezoidal groove is formed in the middle of the top surface of the lower nipper plate, a cotton guide plate is arranged in the trapezoidal groove, the cotton guide plate is arc-shaped on the front portion and horizontal at the tail, the tail portion of the cotton guide plate is fixed on the lower nipper plate, a feed roller is arranged above the cotton guide plate, and grooves for holding the feed roller are arranged at two ends of the lower nipper seat; the front end of the bottom surface of the lower nipper plate is provided with a plane, the rear of the plane is gradually raised through circular arc transition, and the lower nipper seat is connected with an upper nipper plate connector in a hinge joint manner. By the arrangement, a cotton feed channel can be flexibly adjusted according to thickness of a small roll, distance of the center of the front end of each nipper plate, the center of each groove and hinge point of each nipper plate can be reasonably arranged, and large quantitative of small rolls and long fibers 35mm above in length are assured to be processed smoothly through a combing machine; due to the arc-raised surface, collision against the lower nipper plate by cylinder needle teeth is avoided, compressive strength of the nipper lip of the lower nipper plate is guaranteed, the nipper plates and a cylinder of the combing machine are prevented from being damaged, and production cost is obviously reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

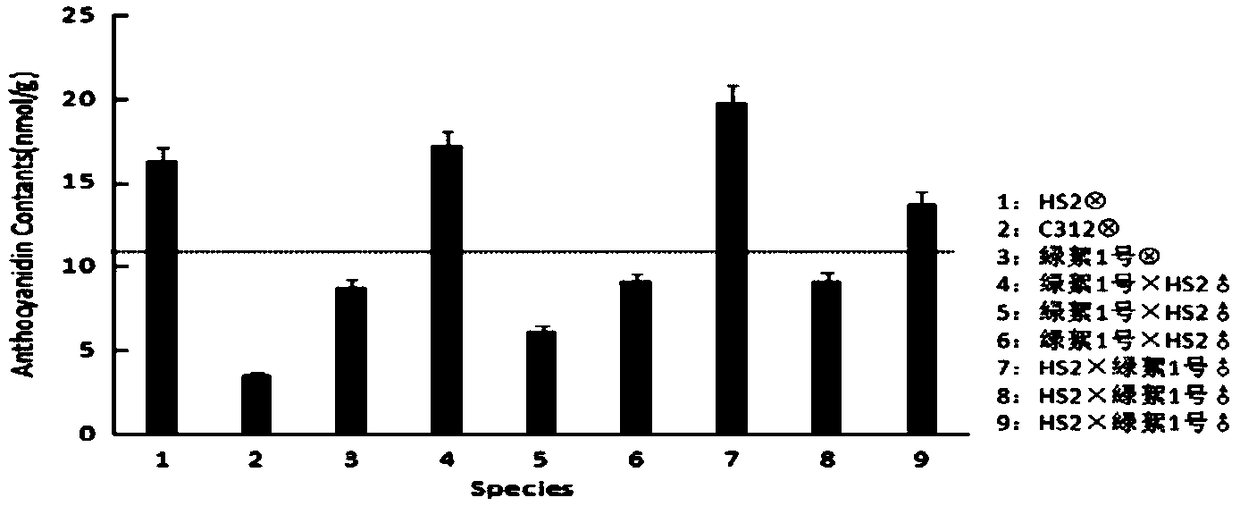

Method for cultivating colored cotton

ActiveCN109234304AIncreased fiber lengthHigh strengthVector-based foreign material introductionPlant genotype modificationMutantAgricultural science

The invention discloses a method for cultivating colored cotton, which comprises the following steps: (1) crossing cotton purple mutant HS2 as parent with different varieties of cotton to obtain colored cotton; (2) knocking out, editing, interfering with or overexpressing the key enzyme genes in the anthocyanin biosynthetic metabolic pathway of cotton to obtain colored cotton; The key enzyme genesinclude PAL, C4H, 4CL-8, CHS, CHI, F3H, F3 'H, F3' 5 'H, DFR, LAR, LDOX, ANR, OMT or GST.

Owner:孙玉强

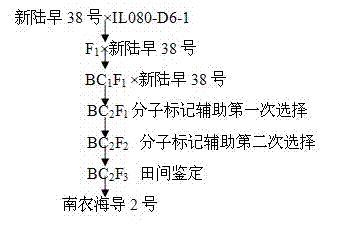

Molecular breeding method for improving cotton fiber length, fiber strength, and micronaire value

InactiveCN102229982BImproved fiber lengthHigh fiber strengthMicrobiological testing/measurementPlant genotype modificationAgricultural scienceMolecular breeding

The invention relates to a molecular breeding method for improving cotton fiber lengths, fiber strengths, and micronaire values. The method is applied in oriented improving of crop (cotton) agronomic properties, and in selective breeding of novel breeds. According to the invention, cotton fiber quality detection is carried out upon gossypium barbadense chromosome segment introgression lines (CSIL), and an introgression line IL080-D6-1 with substantially increased fiber length and fiber strength, and substantially reduced micronaire value is selected. The introgression line is regarded as a non-backcross parent, and Xinluzao No.38, which is a breed from Xinjiang cotton region, is regarded as a backcross parent. Crossing is carried out between the two. The resulting breeds are backcrossed for 2 generations and self for 3 generations. With molecular marker auxiliary selection, a novel cotton line with good fiber length, fiber strength, and micronaire value is obtained. With the method, anovel high-quality and high-yield cotton line, which is Nannong gossypium barbadense No.2, is obtained.

Owner:NANJING AGRICULTURAL UNIVERSITY

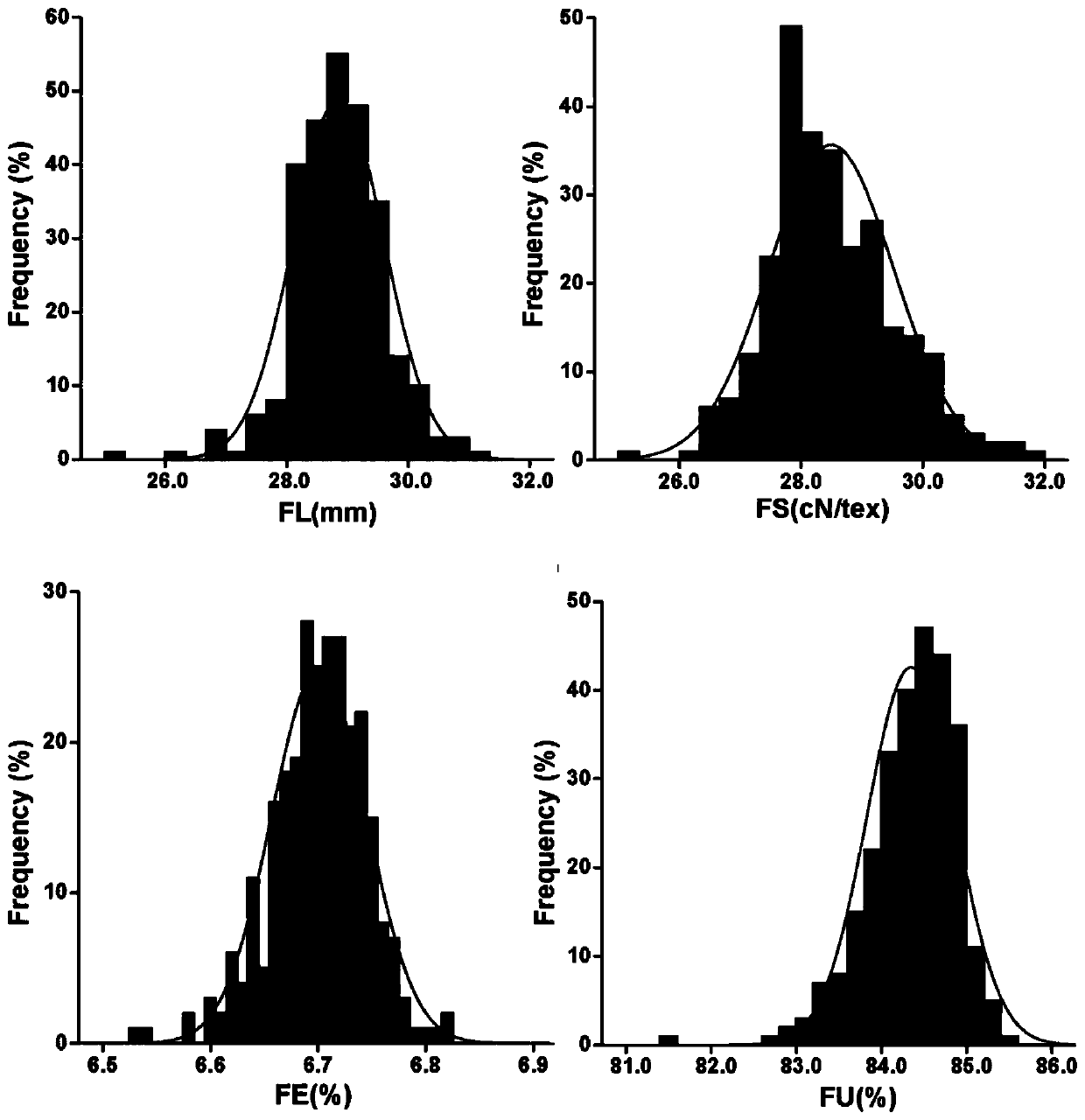

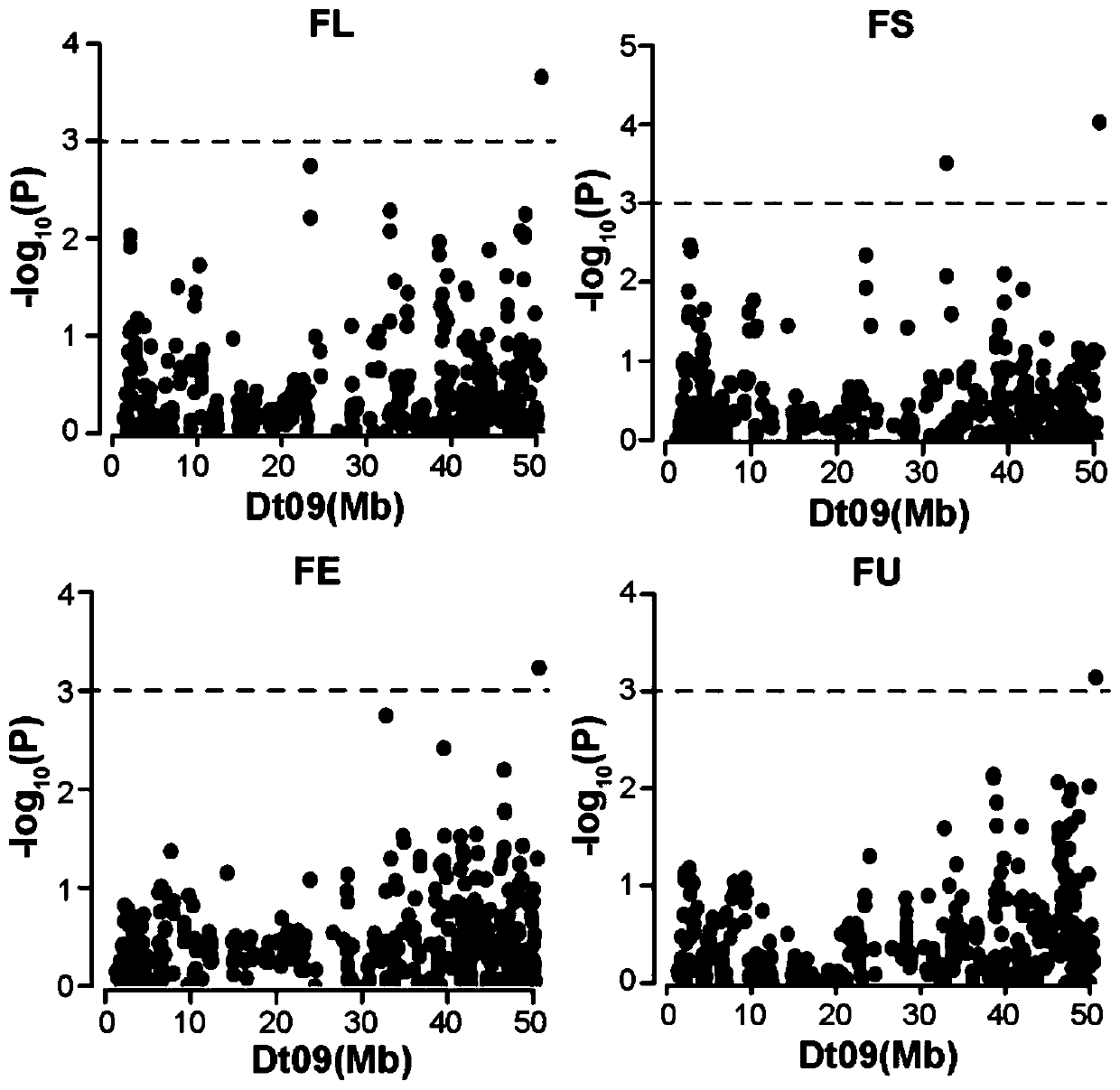

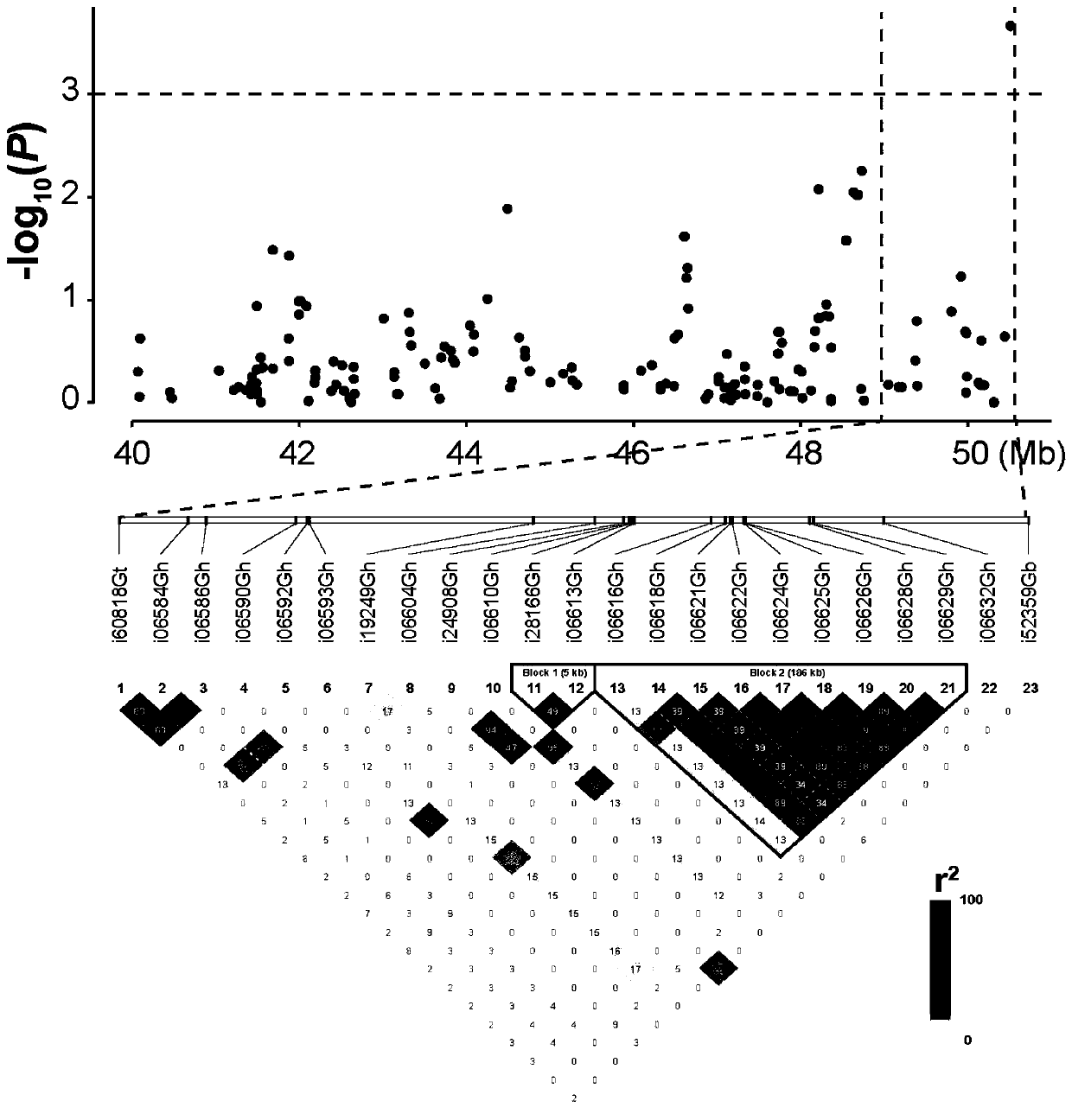

GhJMJ12 gene SNP marker related to cotton fiber quality, and application of same

ActiveCN111218524AEfficient prediction of fiber qualityEarly screeningMicrobiological testing/measurementPlant genotype modificationBiotechnologyFiber

The invention relates to the technical field of quality breeding of cotton fibers and specifically relates to a GhJMJ12 gene SNP marker related to cotton fiber quality and application of the same. TheGhJMJ12 gene SNP marker related to cotton fiber quality is located at the 7215bp locus of a GhJMJ12 gene of a Dt09 chromosome of cotton, the SNP marker is a base A or C, and the GhJMJ12 gene has a nucleotide sequence shown by SEQ ID NO:1. According to the invention, 10660 SNP markers are used for whole genome association study of quality characters of the cotton fibers, and the study indicates one SNP locus on the GhJMJ12 is significantly correlated with fiber quality characters such as the fiber length, the fiber specific strength, the fiber elongation and the fiber uniformity.

Owner:HENAN AGRICULTURAL UNIVERSITY

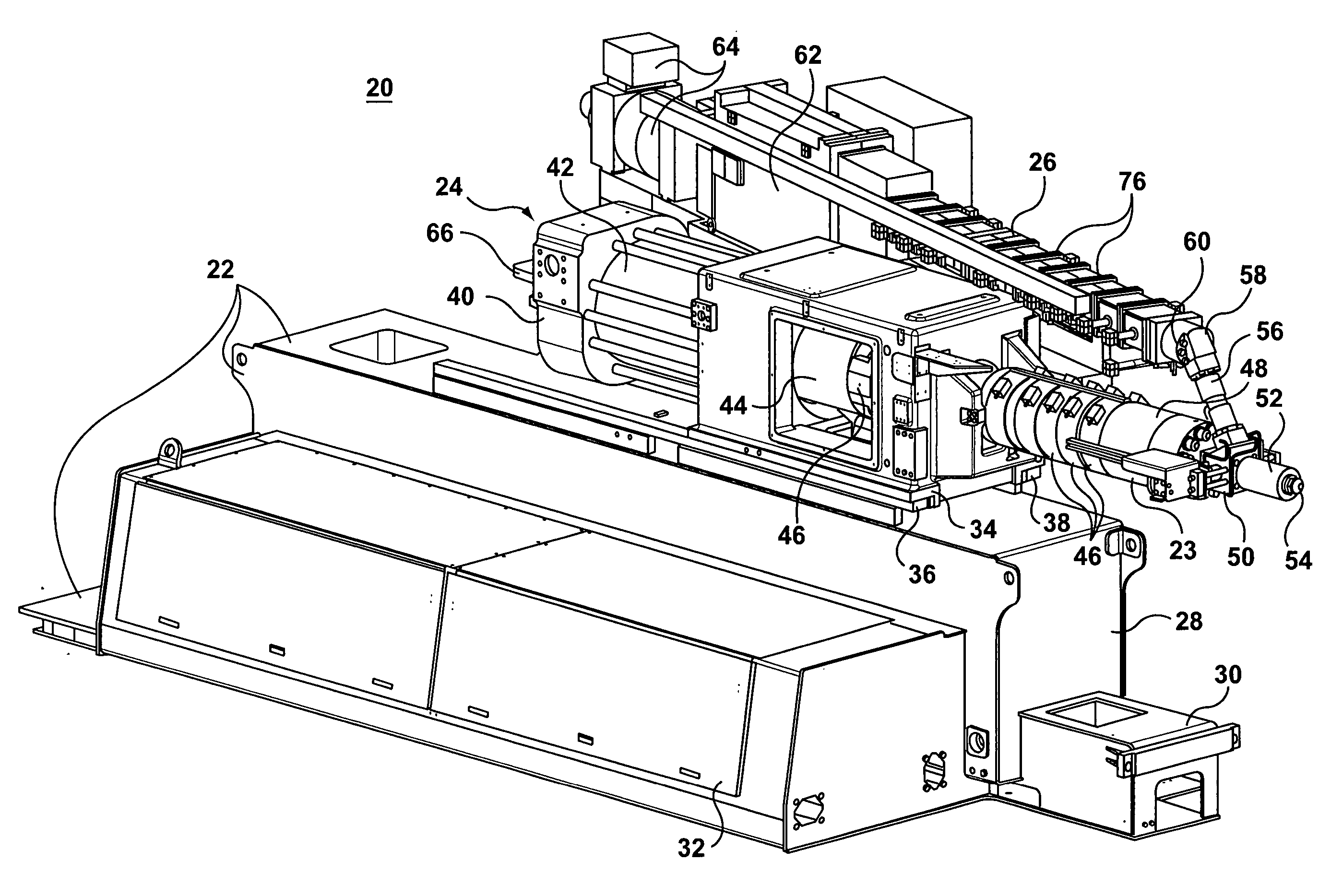

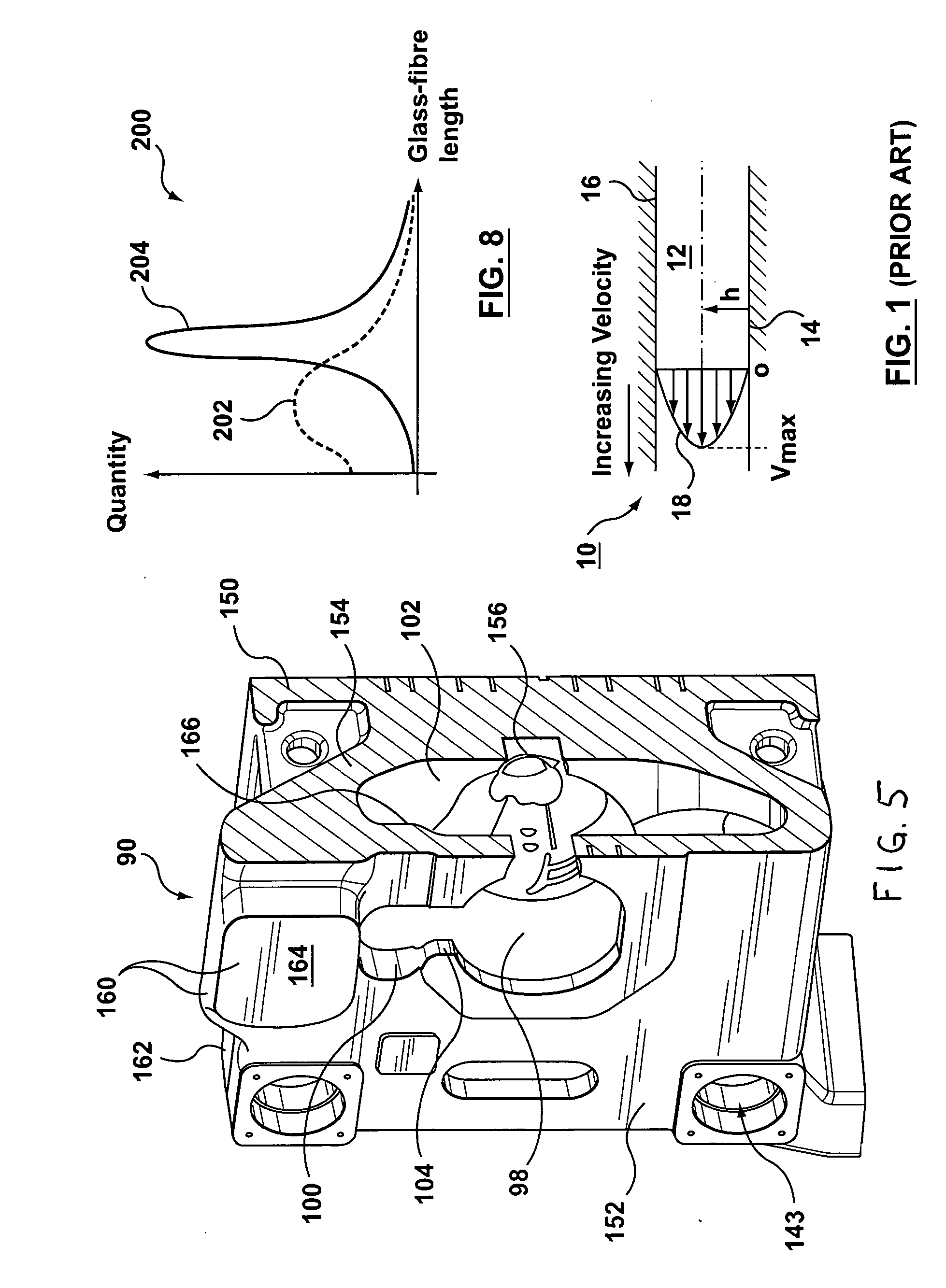

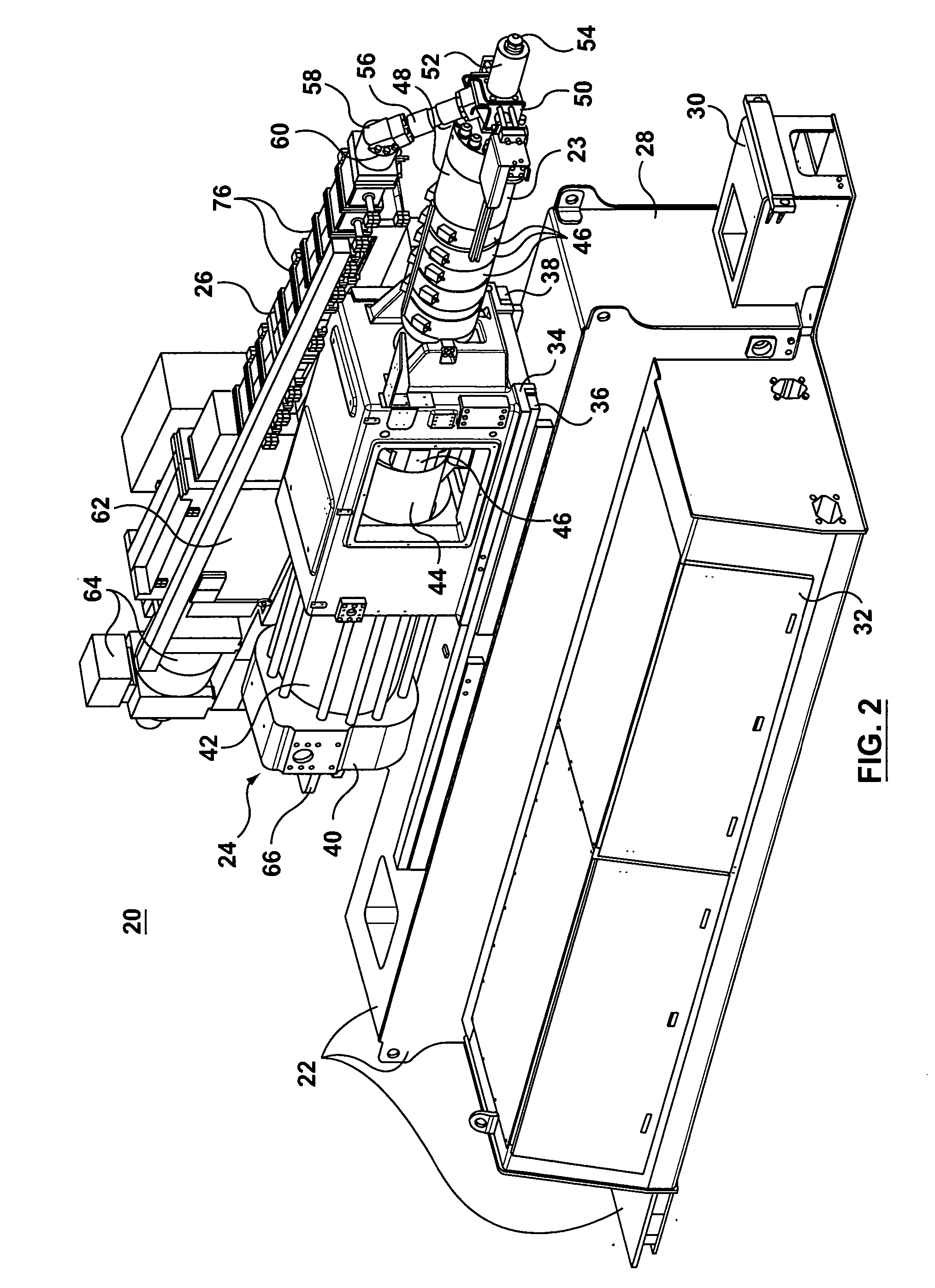

Molding machine plasticizing unit sub-assembly and a method of reducing shearing effects in the manufacture of plastic parts

In a molding machine (130), exemplified in FIG. 4, lateral and angled offsetting of a twin screw extruder (26) from a shooting pot assembly (24) permits shortening of a transfer channel (56). To additionally reduce shear effects arising from melt residence time a nozzle adaptor (52), the transfer channel (56) is located within a hollow cone (102) of a platen (90), the hollow cone (102) typically formed by an arch-shaped intermediate support structure (154) coupling together front (150) and rear (152) walls of the platen (90). To address bulk material removal brought about by the introduction of a barrel head, transfer channel (56) and extruder barrel tip within the hollow cone (102), reinforcement of an upper region of the rear wall (152) of the platen (90) is accomplished using a cross-member (160, 164). In an in-line compounding application, decreased lengths for the transfer channel (56) and nozzle adaptor (52) both reduce shear effects on the melt (by decreasing melt residence time) and thus an increased average fibre length in a molded part is achieved.

Owner:HUSKY INJECTION MOLDING SYST LTD

News printing paper and preparation method thereof

InactiveCN101787659AIncreased fiber lengthIncrease dosagePulp de-wateringReinforcing agents additionPulp and paper industryEnergy conservation

The invention provides a news printing paper. Pulp materials of the news printing paper comprise 20-100 percent of unbleached straw pulp and 80-0 percent of wood pulp, the definite quantity is 42-51g / m2, the opacity is more than or equal to 88 percent, the fracture length is more than or equal to 3.5km, and the whiteness is 35-75 percent of ISO. The production of the news printing paper not only can save the energy and cost, but also can significantly reduce the emission of pollutants.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Rock wool production method

InactiveCN104057621AIncreased fiber lengthAvoid breakingGlass making apparatusFiberEnergy consumption

The invention discloses a rock wool production method. The rock wool production method is characterized by comprising the following steps of first, obtaining a melt, second, obtaining fibers, third, obtaining rock wool felt, fourth, manufacturing structural rock wool, and fifth carrying out pressurization shaping. The rock wool produced through the rock wool production method has the advantages of being large in fiber length, resistant to water, not prone to breakage and resistant to fire; moreover, loss in the production process is greatly reduced, energy consumption is reduced, yield is increased, cost is further reduced, and product quality is ensured.

Owner:王力虎

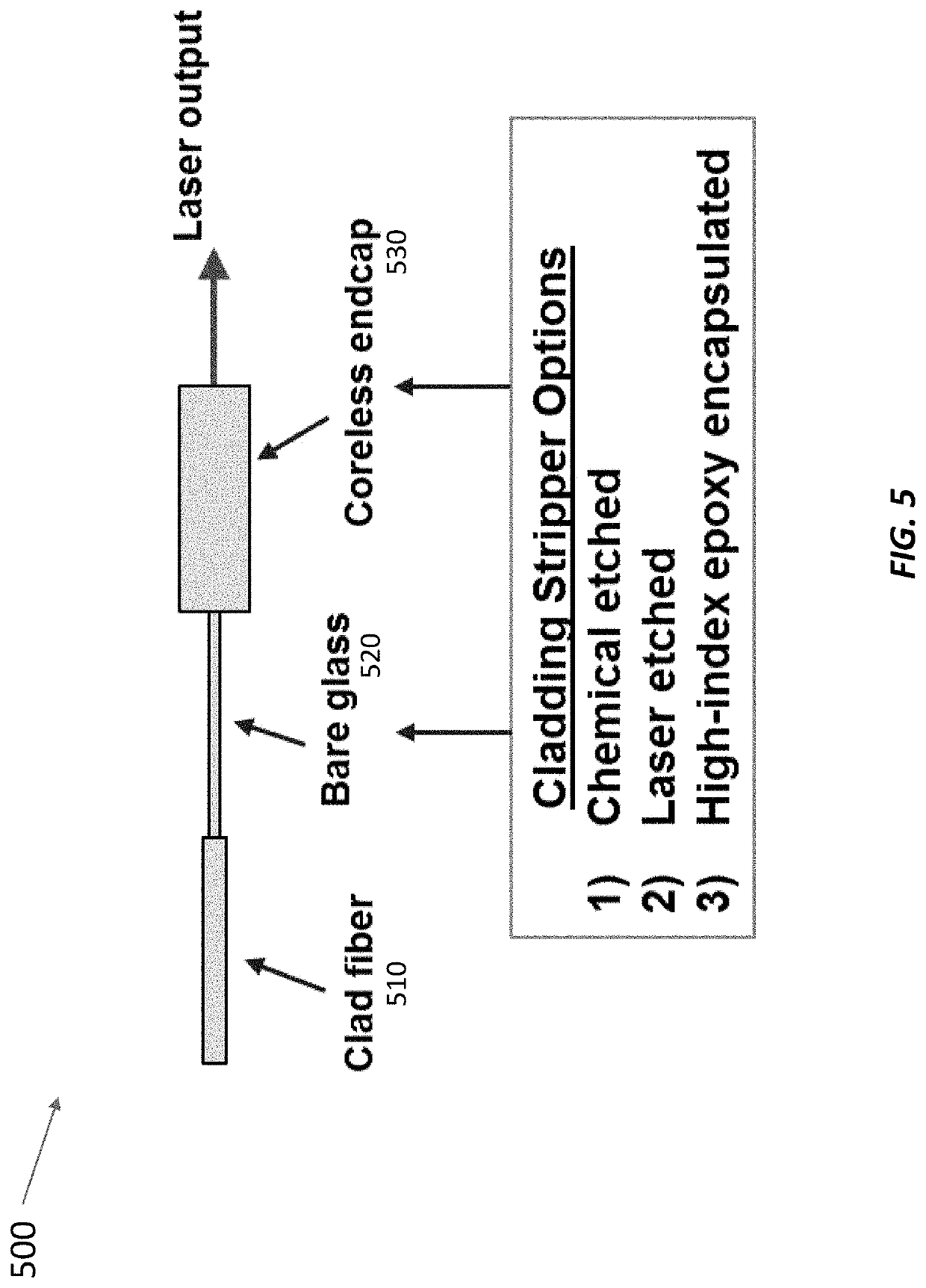

Single-Frequency Fiber Amplifier with Distal Cladding Stripper

ActiveUS20210006029A1Linewidth also decreaseReducing power thresholdLaser using scattering effectsActive medium shape and constructionLine widthEngineering

Stimulated Brillouin scattering (SBS) limits the maximum power in fiber lasers with narrow linewidths. SBS occurs when the power exceeds a threshold proportional to the beam area divided by the effective fiber length. The fiber lasers disclosed here operate with higher SBS power thresholds (and hence higher maximum powers at kilohertz-class linewidths) than other fiber lasers thanks to several techniques. These techniques include using high-absorption gain fibers, operating the laser with low pump absorption (e.g., ≤80%), reducing the length of un-pumped gain fiber at the fiber output, foregoing a delivery fiber at the output, foregoing a cladding light stripper at the output, using free-space dichroic mirrors to separate signal light from unabsorbed pump light, and using cascaded gain fibers with non-overlapping Stokes shifts. The upstream gain fiber has high absorption and a larger diameter for high gain, and subsequent gain fiber has a smaller diameter to improve beam quality.

Owner:MASSACHUSETTS INST OF TECH

Low-voltage low-loss electrolytic capacitor paper and preparation method and application thereof

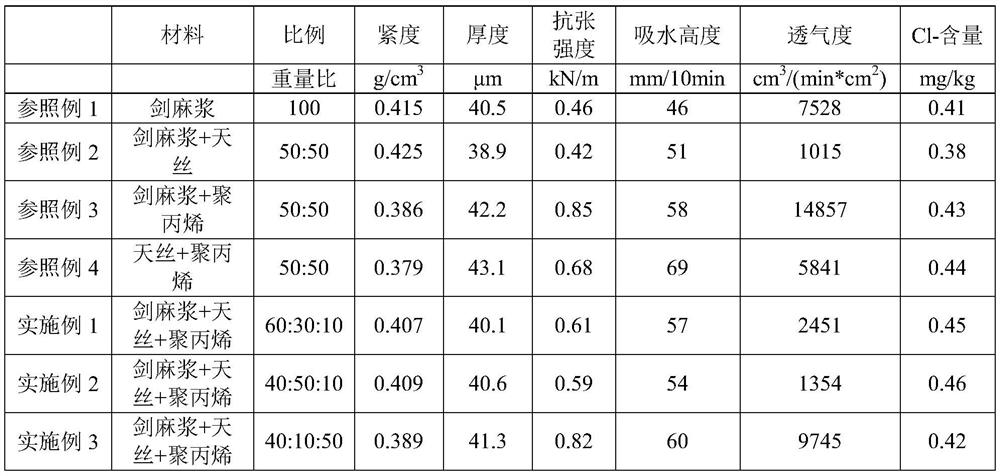

ActiveCN114263069ALow tightnessGood absorbencySpecial paperElectrolytic capacitorsPulp (paper)Polyolefin

The invention relates to the technical field of aluminum electrolytic capacitor paper new materials, in particular to low-voltage low-loss electrolytic capacitor paper and a preparation method and application thereof. The invention relates to low-voltage low-loss electrolytic capacitor paper, which is prepared from the following fiber raw materials in percentage by mass: 30 to 60 percent of hemp pulp, 20 to 50 percent of tencel pulp and 10 to 50 percent of polyolefin short fiber, the beating degree of the hemp pulp is 15-50 degrees SR; the beating degree of the hemp pulp is 40-70 degrees SR, the beating degree of the tencel pulp is 40-70 degrees SR, the hemp pulp, the tencel pulp and the polyolefin short fibers are uniformly mixed and then fed into a paper machine drifting system, then wet-process papermaking forming is performed to obtain raw paper, and the raw paper is shaped by adopting a shaping drying cylinder to obtain a finished product of the low-voltage and low-loss electrolytic capacitor paper. The product has good absorptivity, relatively low aperture and relatively high strength, the used raw materials are high in purity, the high purity of the electrolytic paper can be effectively ensured, and the risk of aluminum foil corrosion is avoided.

Owner:浙江凯恩新材料有限公司 +2

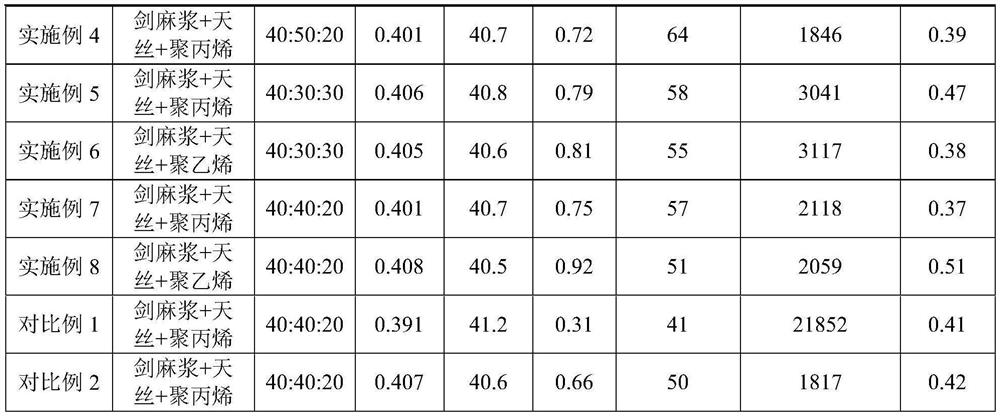

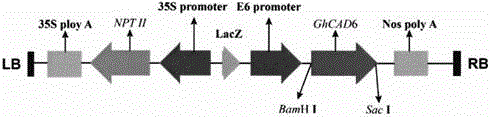

Method for improving quality of cotton fibers by overexpressing GhCAD6 gene

InactiveCN105039397AHigh specific strengthIncreased fiber lengthMicrobiological testing/measurementFermentationFiberAgricultural science

The invention relates to a method for improving quality of cotton fibers by overexpressing GhCAD6 gene, belonging to the technical field of biology. The method comprises the following steps: constructing a plant overexpression vector pCAMINBIA-2300-GhCAD6 from styrone dehydrogenase gene GhCAD6 in cotton fibers, transforming the vector into agrobacterium LB4404 by agrobacterium mediation, and integrating into cotton to obtain the trans-styrone dehydrogenase gene cotton plant. The field and molecular detection analysis detects that the lignin content in cotton fibers obviously increases in different development periods, the fibrocyte wall thickness obviously decreases in the cotton secondary wall rapid deposition stage, and the ripe cotton fiber surface becomes more compact and smooth. The method can maximally enhance the length of the cotton fibers by 16.935%, enhance the specific strength by 25.10% and enhance the fiber yield by 3.80%, thereby greatly improving the quality of the cotton fibers.

Owner:新疆农业科学院核技术生物技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com