Patents

Literature

39results about How to "Low tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-flaming non-woven paper and preparation method thereof

The invention relates to an anti-flaming non-woven paper and a preparation method thereof. The anti-flaming non-woven paper comprises the following raw materials by weight part: 70-99 parts of fiber slurry and 1-30 parts of adhesives, wherein the fiber slurry comprises a wood pulp fiber and a functional fiber; the quantity of the wood pulp fiber is 0%-95%; the quantity of the functional fiber is 5%-100%; and the anti-flaming non-woven paper is prepared by processing the functional fiber, the wood pulp fiber and the adhesives or mixing and processing the functional fiber and the wood pulp fiber and then using an adhesive machine for coating inside. A natural stripe appears on the surface of the anti-flaming non-woven paper provided by the invention; the appearance is beautiful; no additional treatment is required; and meanwhile, the anti-flaming non-woven paper product does not contract during a processing process and is free from moist feel; paper uncovering is complete; the flexibility of the paper is excellent; the paper is not burned under the flame and is free from flame; and the paper is only carbonized at the temperature above 400 DEG C, so that the product has excellent anti-flaming property.

Owner:SHANDONG LUNAN NEW MATERIALS

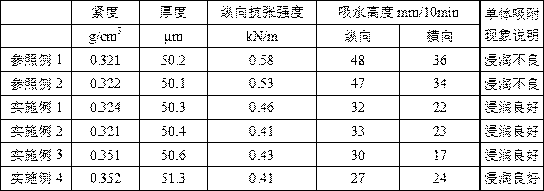

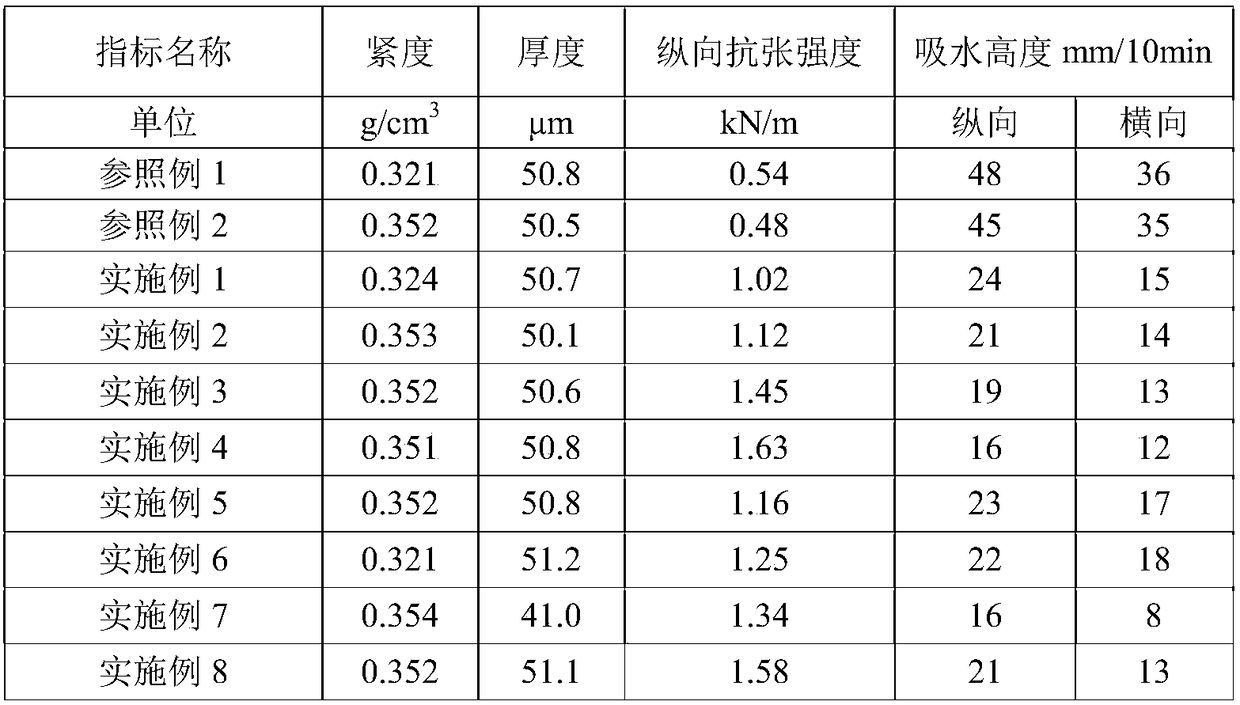

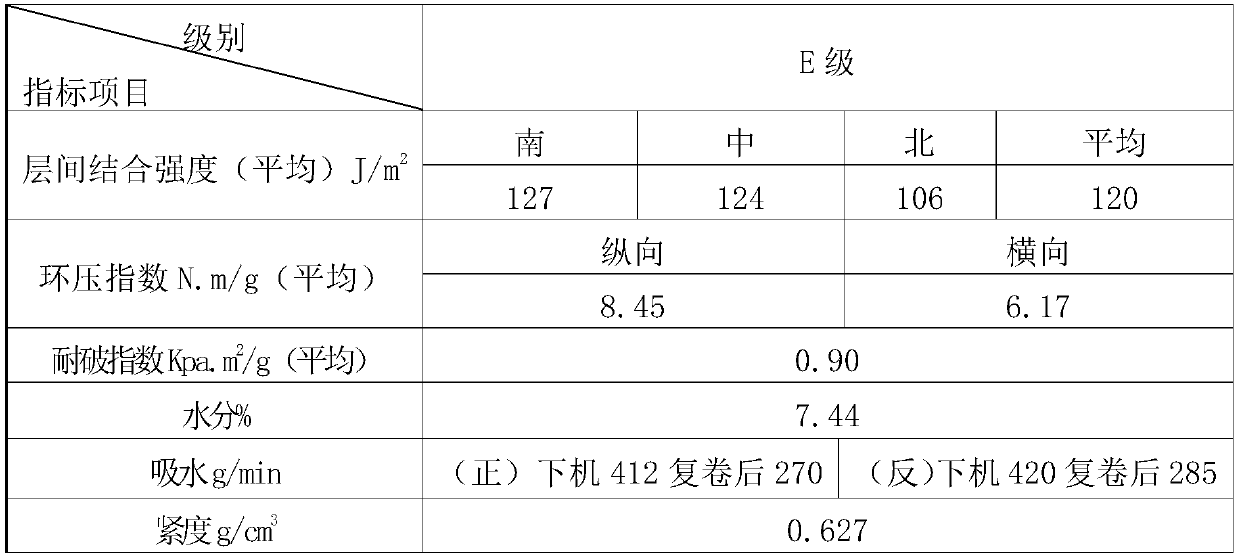

Low-tightness non-carbonization solid electrolytic capacitor paper and preparation method thereof

InactiveCN109208375AImprove adsorption capacityEvenly distributedSpecial paperPaper/cardboardElectrolysisConductive polymer

The invention belongs to the field of electrolytic capacitor paper, and particularly relates to low-tightness non-carbonization solid electrolytic capacitor paper and a preparation method thereof. Theelectrolytic capacitor paper comprises the following raw materials by dry mass: 10-80% of jute pulp and 20-90% of chemical fiber, the pulping degree of the jute pulp is 10-30 degrees SR, the wet weight of the jute pulp is 10-40g, the length of the chemical fiber is 1.5-15 mm, and the fineness of the chemical fiber is 0.1-3 dtex. The low-tightness non-carbonization solid electrolytic capacitor paper provided by the invention has good adsorbability to conductive polymer monomers, and can reduce side reactions during polymerization of the conductive polymer monomers, and the low-tightness non-carbonization solid electrolytic capacitor paper has low tightness, so that the monomers can be uniformly distributed in the paper. Therefore, the capacitor paper does not need to be subjected to carbonization treatment in the production process of capacitors.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL +1

Watermark high-definition copperplate paper and manufacture technique thereof

InactiveCN101015969AImprove technical indicatorsLow costMechanical working/deformationCoatingsPolymer scienceAdhesive

The invention relates to a method for producing watermark high-resolution copper plate paper, wherein the copper plate paper is made by uniformly coating the high-solid-content paint of mixed white paint and adhesive on the base paper, to be dried and composed with watermark paper. The invention comprises following steps that 1, selecting glazed printing paper as base paper, using coating machine to mix white paint and adhesive into ink adsorption paint to be coated, 2, uniformly coating the highlight layer made fro mixing silicon gel or aluminum gel and adhesive via casting machine on the ink-adsorption paint. And the step 3 has a process synchronous with the step 2 comprises that using auxiliary press roller of casting machine to compose the watermark paper with back adhesive and the base paper not coated with paint into single-face watermark high-resolution copper plate paper, 4, using the mirror cylinder of casting machine to dry and dewater the base paper with secondary coating to complete rolling and polishing, 5, furnishing, cutting and coiling.

Owner:石家庄中康纸业有限公司

Coating-enhanced low-density carbonization-free solid-state electrolytic capacitor paper and preparation method thereof

InactiveCN109137593AIncrease production capacityLow tightnessPulp beating methodsDry weightElectrolysis

The invention belongs to the field of electrolytic capacitor papers, in particular to a coating-enhanced low-density carbonization-free solid-state electrolytic capacitor paper and a preparation method thereof. The raw materials of the electrolytic capacitor paper comprise hemp pulp and chemical fibers; a beating degree of the hemp pulp is 10-30 degree SR, and a wet weight is 10-40 g; the length of the chemical fibers is 1.5-15 mm, and the fineness of the chemical fibers is 0.1-3 dtex; according to a dry weight percentage, the hemp pulp is 10-80% and the chemical fibers are 20-90%; and the surface of the electrolytic capacitor paper is coated with an enhancement layer through spraying or dipping, and the coating amount after coating is 1-10% of an absolute dry weight of the paper. The paper is coated, so that the paper strength can be further enhanced, and a smooth production of capacitors can be ensured.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL +1

Bulked paper and its production process

InactiveCN1641101ALow tightnessNo wavy deformationNon-fibrous pulp additionNatural cellulose pulp/paperAluminum sulphateNewsprint

This invention relates to the manufacturing method of a kind of paper, in a specific is a kind of bulked paper. The invention uses the spruce APMP pulp, old newspaper, old book write papers, the yellow card wastepaper as raw material, then go together with de-inking, the bleacher, cation starch, bulking agent, SPN-1colophony mucus ,liquid sulfuric acid aluminum, produced pass by to have the pulp preparation, transcribe, the dry craft process system. The invention mainly is light, cheap, as the bottom paper or core paper of the adornment material; the stationery series product (the document clip, cover, the packing thing); the handicraft colorful bulking paper. This invention contain low the tight degree of the paper, neat good, level up, slice pare good; 30% above of the economical unit of physical volume cost is saved.

Owner:谭加仔

Preparation method of sound-absorbing flame-retardant fiber composite material

PendingCN110318287AImprove ease of settlementGuaranteed appearance and performancePaper coatingPaper/cardboardPlasticizerHardwood

The invention relates to a preparation method of a sound-absorbing flame-retardant fiber composite material. The method comprises the following steps of pulp selection, pulping, pulp preparation, papermaking, drying and impregnation. Pulp of the sound-absorbing flame-retardant fiber composite material comprises 30-70% of bleached softwood pulp, 20-40% of glass fibers and 10-30% of hardwood pulp, wherein the beating degree of the softwood is 18-30 degrees SR, and the beating degree of the hardwood pulp is 13-25 degrees SR. Then, 0.5-2% of a plasticizer, 1-3% of an adhesive and 3-5% of a flame retardant are adopted for impregnation. According to the method, various measures are combined to prepare the fiber composite material which is light in texture, good in air permeability and excellentin sound absorption performance and flame retardance performance, the application field of the glass fibers is widened, and the method has important significance in the development and cost reductionof novel building decoration materials.

Owner:SHAANXI UNIV OF SCI & TECH

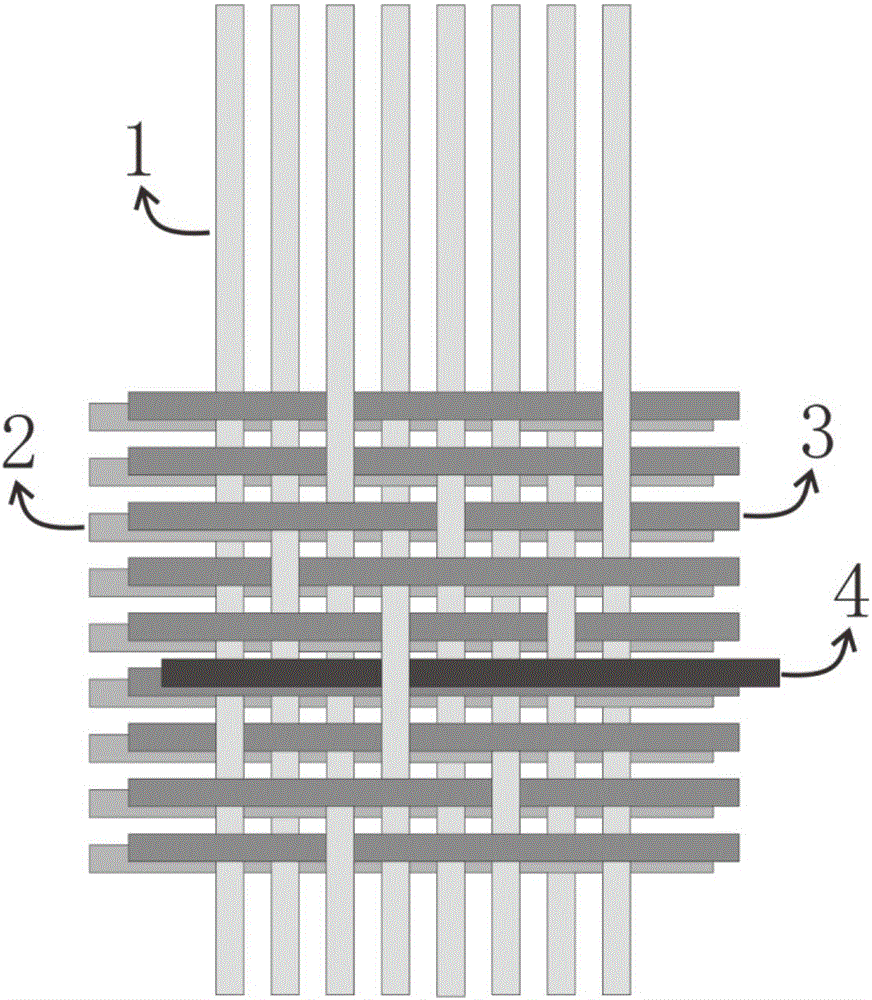

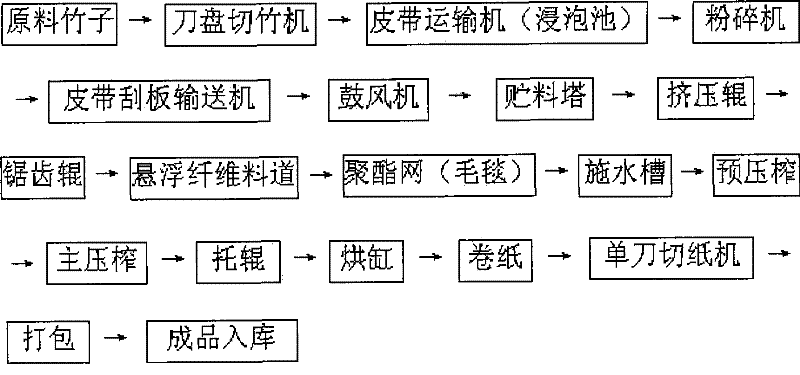

Translucent-color-reduced eight-harness double-brocade woven label and knitting method thereof

ActiveCN105970402ALow tightnessReduce bit transparencyMulti-ply fabricsSwivel-woven fabricsEngineering

The invention discloses a translucent-color-reduced eight-harness double-brocade woven label and a knitting method thereof. The woven label is a light-colored 'ground' and a deep-colored pattern and composed of one warp system and 3-12 weft systems; the weft system is based on the 'ground' and comprises a 'ground' organization layer, a lining organization layer and a netting shuttle organization layer. The 'ground' organization layer is an 8 / 5 or 8 / 3 weft face organization; the netting shuttle organization layer is an amplified organization of the 'ground' organization layer; a novel lining organization is adopted for the lining organization layer, and point loosening processing is conducted on netting shuttle points. The translucent color phenomenon of the eight-harness double-cotton multi-color woven label is reduced through a series of methods of selection of the lining shuttle, improvement of the lining shuttle organization, arrangement of the color shuttle from the light color to the deep color, selection of the netting shuttle mode, control over tension of warp and weft in the knitting process and the like.

Owner:广东康派环创科技有限公司

Coating-enhanced carbonization-free solid electrolytic capacitor paper and preparation method thereof

PendingCN109235137AIncrease production capacityGuaranteed smooth productionSpecial paperPaper/cardboardFiberElectrolysis

The invention belongs to the field of electrolytic capacitor paper and specifically relates to coating-enhanced carbonization-free solid electrolytic capacitor paper and a preparation method thereof.Raw materials of the electrolytic capacitor paper are composed of wood pulp and chemical fibers; the wood pulp has the pulping degree of 5-25degree SR and the wet weight of 10-30 g; the chemical fibers have the length of 1.5-15 mm and the fiber number of 0.1-3 dtex; the raw materials are in drying mass percentage: 10-80% of wood pulp and 20-90% of chemical fibers; and the surface of the electrolytic capacitor paper is coated with a reinforced layer in a spraying or dipping way, and the coating quantity accounts for 1-10% of absolute dry mass of paper sheets after coating. By coating the papersheets, the strength of the paper sheets can be further improved, and the smooth production of a capacitor is more favorably guaranteed.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL +1

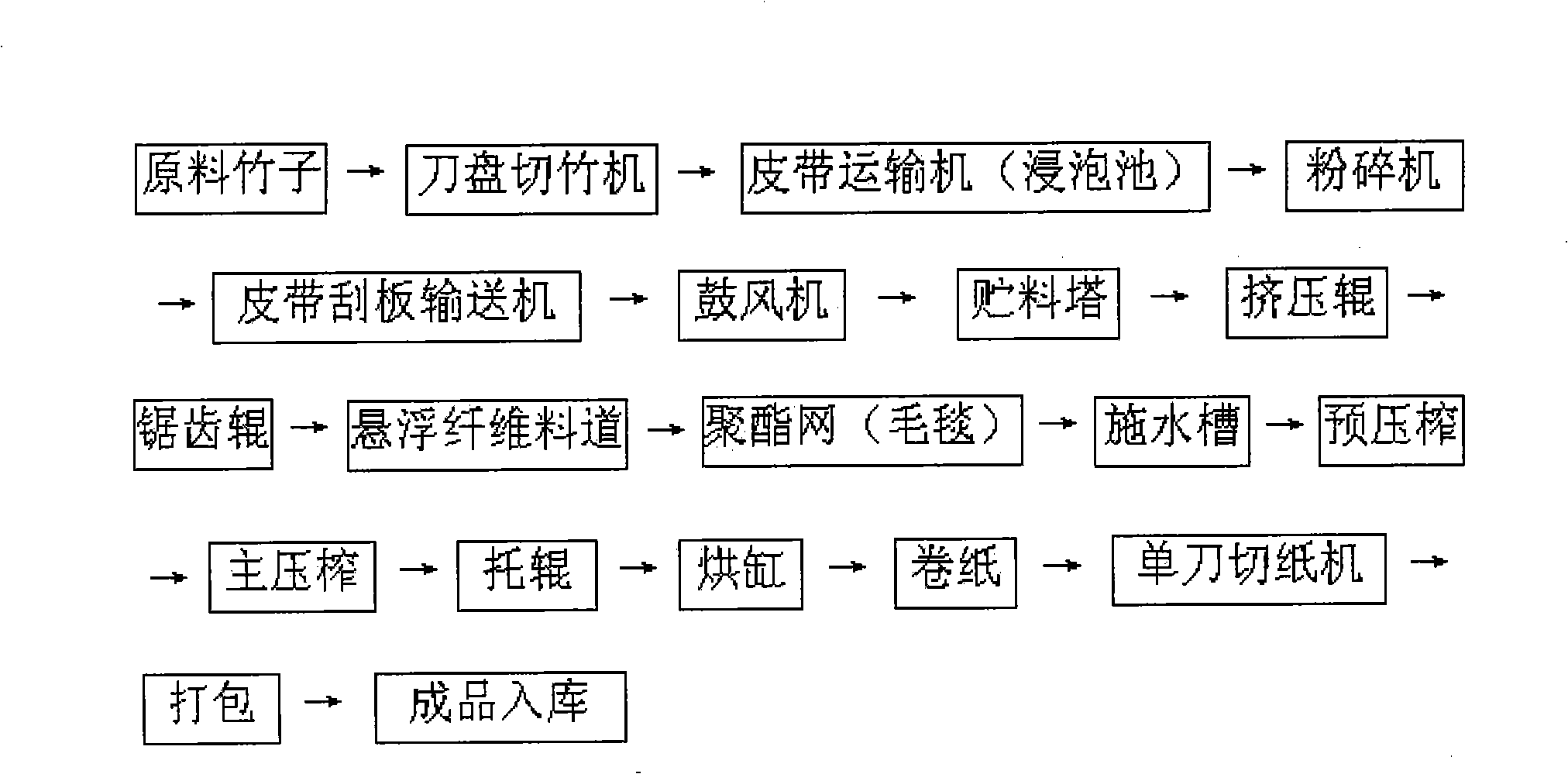

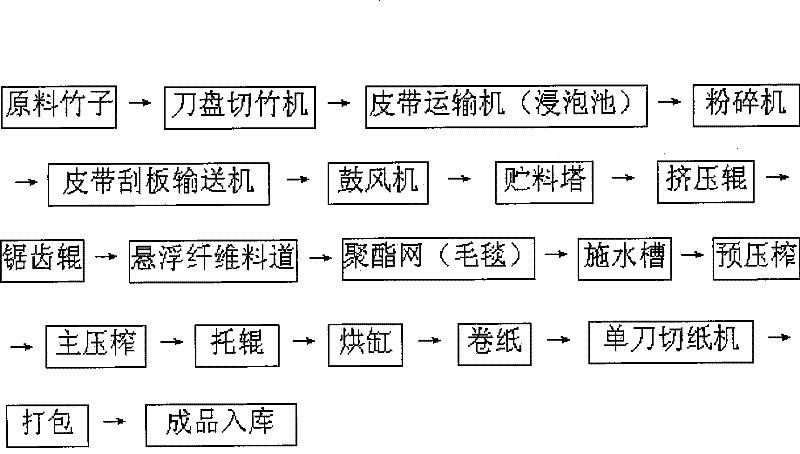

Method for making hand-made paper by dry method

InactiveCN101408010ANo pollution in the processSave energyDryer sectionRaw material divisionPolyesterFiber

The invention relates to a method for making handmade paper by a dry method, wherein, bamboo is adopted as raw material, dry paper pulp is obtained after the bamboo is crashed, a dry paper pulp sheet can be obtained from the dry paper pulp by extrusion, the dry paper pulp sheet is further dispersed into fiber, and the dry paper pulp fiber enters an air channel in the suspension form under the action of an airflow generated by an induced draft fan and is intercepted by a polyester net to form a uniform dry paper pulp layer which is covered with a fixed layer; under the holding of the upper fixed layer and the lower polyester net, wet paper is formed by the dry paper pulp layer treated with water absorption by a water supplying tank, the wet paper is separated from the fixed layer and the polyester net after being extruded, and the handmade paper can be obtained form the separated wet paper by drying. The method for making the handmade paper has only one harmful chemical, i.e., alkali liquor which is added in the production process, and gas and liquid are not discharged in the production process to pollute the environment; in the pulping process, the pulp outcome rate of the raw material reaches more than 95 percent, the sizing agent does not need washing and can not be lost, thus utilizing the bamboo resources maximally and saving the raw material.

Owner:HUIBEI ZIGUIHENGKANG FURNITURE

Preparation method for improving waterproof performance of paper cup

InactiveCN109252424AGood flexibilityImprove plasticityBag making operationsPaper/cardboardSodium BentonitePotato starch

The invention discloses a preparation method for improving the waterproof performance of a paper cup. The preparation method includes the following steps of mixing locust bean gum and sweet potato starch with water for pregelatinization, adding polyethylene glycol 4000 for uniform mixing, adding polyether amine D230 and tri-(dimethylamino methyl)phenol for uniform mixing, conducting vacuum degassing, adjusting the temperature for stirring, and conducting cooling, drying and smashing to obtain a first material; mixing straw stalks with locust tree bark, conducting disc grinding to obtain pulp,adjusting the concentration of the pulp, adding the first material, and stirring the mixture to obtain a second material; adding methyl silicone oil, paraffin and cocamidopropyl betaine into the second material for uniform mixing, then adding montmorillonite, trimethylethoxysilane, organic-silicone polymerized emulsion, bentonite and silicon carbide powder for uniform mixing, pumping the mixture into a die for paper pulp molding, making the mixture subjected to adsorption forming and then dried into raw paper, and conducting rolling, hot press, cropping and bonding forming to obtain the waterproof paper cup.

Owner:安庆市双龙纸业有限公司

Low closeness paper for electrolytic capacitor

InactiveCN100373002CImprove electrical performanceReduce energy consumptionNon-fibrous pulp additionPaper/cardboardState of artElectrolysis

This invention provides a kind of paper with special use, especially in low-tightness electrolytic capacitor and diaphragm cells, which at least comprises two fibers: one is aromatic polyamide fiber, other is bio-cellulose fiber, the former used as frame of paper, weighing 20%-65% of amount, the latter filled among aromatic polyamide fibers, weighing 35%-80%. The invention has advantages of low-tightness, absorbent quality, and improves electric property of electrolytic capacitor and cells and increases service life.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL

Preparation method of plant fiber/glass fiber-based special thin-sheet substrate

ActiveCN109629320AReduce performanceEvenly dispersedPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberGlass fiber

The invention discloses a preparation method of a plant fiber / glass fiber-based special thin-sheet substrate. The method comprises the steps that a commercial chemical pulp board is pretreated, fiberis dispersed, base paper is manufactured with pulp, a maceration extract is prepared, and the base paper is macerated and dried. The plant fiber / glass fiber-based special thin-sheet substrate preparedby combining various measures has the advantages that through maceration with different plasticizers, the compactness of the plant fiber / glass fiber-based special thin-sheet substrate is reduced, thebulk of the material is improved, the absorbing quality is better, and the brittleness of the material is ameliorated, so that the plant fiber / glass fiber-based special thin-sheet substrate is difficult to break during construction and better meets the needs for production and life.

Owner:SHAANXI UNIV OF SCI & TECH

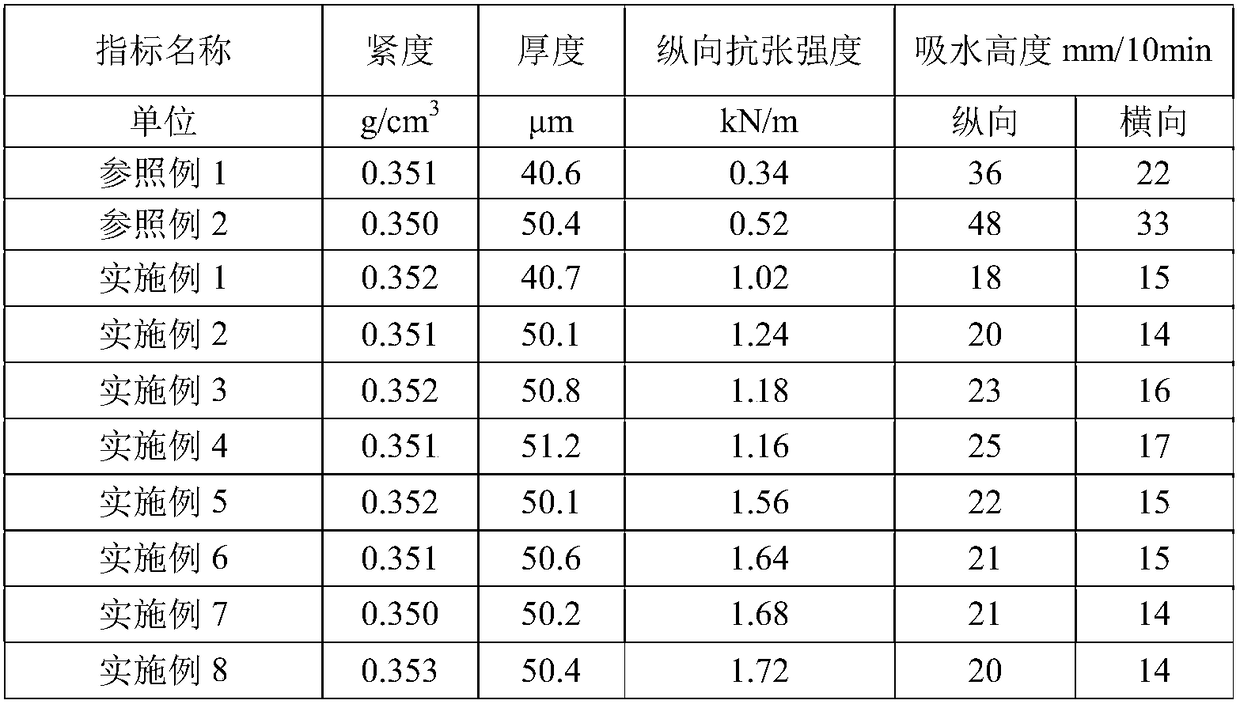

E-grade paper tube base paper and preparation process thereof

InactiveCN111395049AReduce churnIncrease profitSpecial paperPulp beating methodsProcess engineeringIndustrial engineering

The invention discloses E-grade paper tube base paper. Quantification of the paper tube base paper is 420 g / m < 2 >, 500 g / m < 2 > or 520 g / m < 2 >, a transverse quantification allowable error range is + / -3%, and a longitudinal quantification allowable error range is 1.5%. The tightness is 0.60-0.62 g / cm < 3 >, and the moisture of the finished paper is 6.0-8.0%; the longitudinal ring crush index is 7.5 + / -0.5 N.m / g, and the interlayer bonding strength is 100 + / -20J / m < 2 >. Meanwhile, the invention discloses a process for preparing the base paper by adopting the steps of pulping, spraying starch preparation, paper forming, rewinding and packaging, pulping is carried out separately during pulping, and spraying starch is sprayed among all layers during paper forming. The finished paper disclosed by the invention is high in strength index, low in tightness and good in appearance quality, can effectively solve the problem of cracking during production of paper angle beads, and is free of scrap and powder falling; the preparation process mainly adopts a production process of adding the spraying starch between layers without pulp grinding to prepare a finished product.

Owner:ZHONGTIAN PAPER

Environmentally-friendly ecologic paper and making method thereof

InactiveCN107268335ALoose structureImprove water absorptionVegetable material additionPaper/cardboardFiberPolyester

The invention discloses an environmentally-friendly ecologic paper and a making method thereof. The environmentally-friendly ecologic paper comprises, by mass, 15-20% of bleached softwood pulp, 40% of chemi-mechanical wood pulp, 30-35% of poplar wood powder and 10% of polyester fibers. The finished paper has the advantages of loose structure, high water absorption rate, great reduction of the production cost, high surface flatness (smooth paper surface), increase of the interweaving force among fibers, improvement of the bonding force of the fibers, and enhanced tensile strength.

Owner:杭州先进特种纸业有限公司

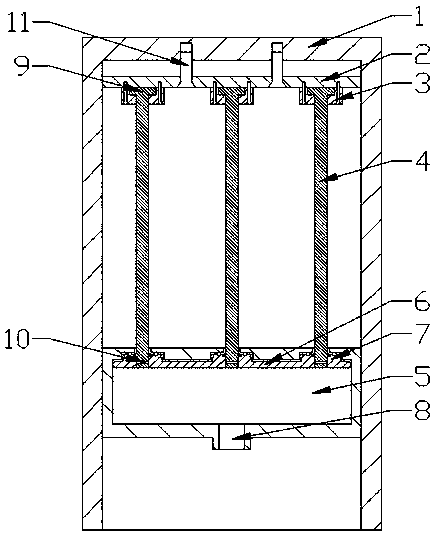

A fireproof component of an electrical cabinet

ActiveCN106785958BEasy maintenanceImprove stabilitySubstation/switching arrangement casingsEngineeringMechanical engineering

The invention relates to a fire-proof assembly of an electric appliance cabinet. The fire-proof assembly comprises a flame-retardant gas storage box and a flame-retardant gas storage box closing assembly. The flame-retardant gas storage box is an enclosed box body fixed inside an electric appliance cabinet and is filled with flame-retardant gas; a plurality of vent holes are formed in the positions, corresponding to a sealing cover, of the top of the flame-retardant gas storage box; a sealing cover is arranged inside the flame-retardant gas storage box; and a plurality of plugging blocks corresponding to the vent holes are arranged at the sealing cover. The flame-retardant gas storage box closing assembly consists of a support rod fixed inside the electric appliance cabinet; a plurality of tensioning bars are fixed at the support rod; one end of each tensioning bar is fixed at one plugging block; and the tensioning bars are made of elastic materials. The sealing cover is in close contact with the top of the flame-retardant gas storage box under tensioning of the tensioning bars, so that the plugging blocks can be embedded into the vent holes.

Owner:JIANGSU TENGEN ELECTRIC

Fuel oil filter paper and preparation method thereof

PendingCN113931010ALow tightnessImprove filtration efficiencyPaper/cardboardPress sectionFiberGlass fiber

The invention relates to the technical field of filtering materials, and discloses fuel oil filter paper which comprises a high-permeability low-resistance supporting material on the outer side and filter paper body paper on the inner side. The supporting material comprises, by weight, 10-20 parts of mercerized wood pulp; 20-40 parts of polyester resin; 10-20 parts of alkali-free glass fiber chopped strands; and 1-10 parts of polyester long fiber. The filter paper body paper comprises the following components in parts by weight: 40-80 parts of softwood bleached wood pulp; 0.2-8 parts of modified starch light fat calcium carbonate, 10-20 parts of alkali-free glass fiber chopped strands, and 1-15 parts of fibrous binding element. The fuel oil filter paper and the preparation method thereof disclosed by the invention have the beneficial effects of low tightness, high filtering efficiency, long service life, high filtering precision, good strength and toughness and convenience and safety in use.

Owner:杭州特种纸业有限公司

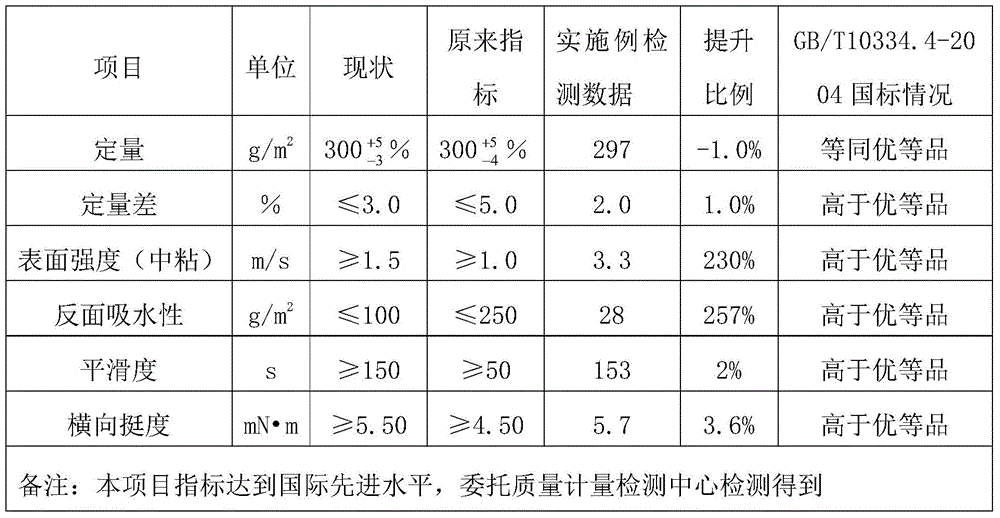

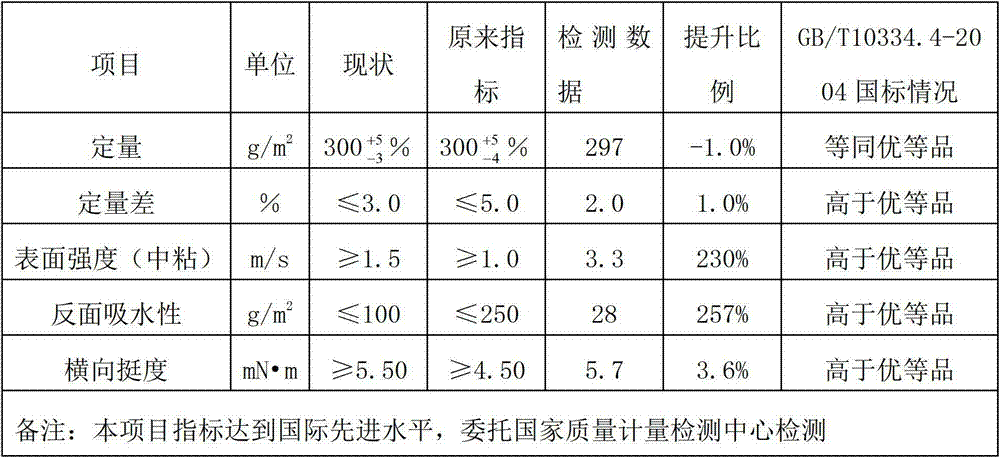

A production process of advanced coated white paperboard

InactiveCN103437232BEmission reductionHigh removal rateFats/resins/pitch/waxes removal in pulpWater-repelling agents additionControl systemQuality control system

The invention belongs to the technical field of a coating white paper board production method. A high-grade coating white paper board production process comprises the steps of pulping and paper making, wherein the pulping step adopts the separated and segmented beating modes including surface pulp beating, lining pulp beating, core pulp beating and bottom pulp beating, the paper making step comprises a net part, a squeezing part, a drying part and a coating and QCS (quality control system) control system, and in addition, a film transfer sizing machine is added in the middle of the drying part. Modes completely different from the traditional mode are adopted in the coating white paper board beating process and the paper making process, the process improvement is carried out on several key control points, the technical indexes are correspondingly regulated, the energy consumption is reduced, and the subsequent paper making quality is also improved, so the quality of finished product paper is always controlled to be higher than the nationally specified A grade (high grade) index.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

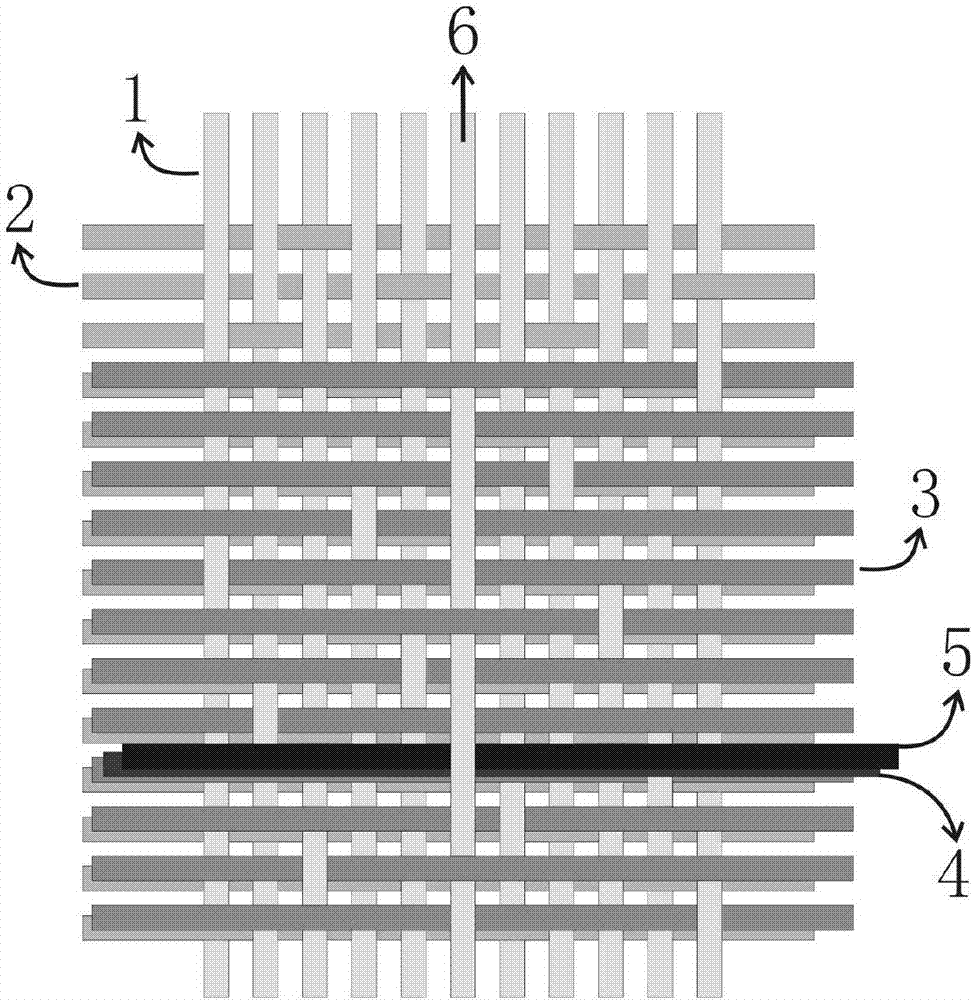

Membrane-electrode unit for direct methanol fuel cells (DMFC)

ActiveUS8512912B2Improve power densityReduce metal consumptionFuel cell auxillariesActive material electrodesReformed methanol fuel cellElectrochemistry

The invention relates to a membrane electrode unit (MEU) for electrochemical apparatuses, in particular for direct methanol fuel cells (DMFC). The membrane electrode unit contains backings (i.e. gas diffusion layers) on the anode side and cathode side, which have a different water tightness (WT). The anode backing must have a lower water tightness (i.e. a higher water permeability) than the cathode backing, where WTAnode<WTCathode. The anode backing preferably has no compensating layer (microlayer), has a lower content of water repellent (from 2 to 10 wt.-%, based on the total weight) and has a higher total pore volume (VTot) than the cathode backing. The membrane electrode units produced have a substantially improved performance in DMFC fuel cells which are operated with aqueous methanol solution.

Owner:UMICORE AG & CO KG

Coated white board pulping process low in energy consumption

InactiveCN103046417BReduce energy consumptionImprove paper qualityPulp beating methodsPulp de-wateringProduction lineCardboard

The invention belongs to the technical field of coated white board pulping methods. A coated white board pulping process low in energy consumption is in separated and segmented pulping mode and comprises surface pulp pulping, lining pulp pulping, core pulp pulping and bottom pulp pulping. Bottom pulp and core pulp respectively undergo intermediate-concentration continuous disintegration, and the concentration is 4-5%; lining pulp undergoes high-concentration disintegration, and the concentration is 13-18%; when the beating degree of surface pulp reaches or exceeds 45 degree SR at any production stage, knife-adding pulping is not performed, and pulp is only defibered to pass through a production line; and when the beating degree of the lining pulp, the beating degree of the core pulp and the beating degree of the bottom pulp reach 35 degree SR at any production stage, knife-adding pulping is not performed, and the pulp is only defibered to pass through the production line. A mode completely different from the tradition is adopted in the coated white board pulping process, corresponding adjustment is performed on several key control indexes, and not only is energy consumption reduced, but also follow-up papermaking quality is improved.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

Method for making hand-made paper by dry method

InactiveCN101408010BNo pollution in the processSave energyDryer sectionRaw material divisionPolyesterPulp fibre

The invention relates to a method for making handmade paper by a dry method, wherein, bamboo is adopted as raw material, dry paper pulp is obtained after the bamboo is crashed, a dry paper pulp sheet can be obtained from the dry paper pulp by extrusion, the dry paper pulp sheet is further dispersed into fiber, and the dry paper pulp fiber enters an air channel in the suspension form under the action of an airflow generated by an induced draft fan and is intercepted by a polyester net to form a uniform dry paper pulp layer which is covered with a fixed layer; under the holding of the upper fixed layer and the lower polyester net, wet paper is formed by the dry paper pulp layer treated with water absorption by a water supplying tank, the wet paper is separated from the fixed layer and the polyester net after being extruded, and the handmade paper can be obtained form the separated wet paper by drying. The method for making the handmade paper has only one harmful chemical, i.e., alkali liquor which is added in the production process, and gas and liquid are not discharged in the production process to pollute the environment; in the pulping process, the pulp outcome rate of the raw material reaches more than 95 percent, the sizing agent does not need washing and can not be lost, thus utilizing the bamboo resources maximally and saving the raw material.

Owner:HUIBEI ZIGUIHENGKANG FURNITURE

A kind of preparation method of firecracker paper

ActiveCN104372709BLow tightnessIncrease measurement rednessNon-fibrous pulp additionPaper/cardboardFiberFirecracker

Owner:GUANGXI UNIV +1

Double brocade woven label with warp net shuttle and its weaving method

ActiveCN106283328BLow tightnessNo translucent phenomenonMulti-ply fabricsSwivel-woven fabricsYarnEngineering

The invention discloses a double brocade weaving label and a weaving method thereof. The double brocade weaving label is composed of a warp system and 3 to 12 weft systems, and the weft system is based on "ground" , including the ground tissue layer, the lining ground tissue layer and the net shuttle tissue layer in turn; the fabric structure of the ground tissue layer is to combine the warp yarns with fixed interval value with the weft surface structure of the common woven label ground structure, and make the ground shuttle weft yarns in the The warp yarns are all up and formed; the fabric structure of the mesh shuttle weave layer is formed by carrying out mesh shuttle interweaving only on the independent layers formed by the warp yarns drawn at a fixed interval value; the fabric structure of the lining fabric layer is After interweaving the lining weave corresponding to the ordinary double-brocade label with warp yarns drawn at fixed intervals, and combining the fabric weave of the mesh shuttle weave layer, the weft yarn of the lining shuttle is stretched at the mesh shuttle weave point and its warp direction. And formed. The warp-drawing mesh shuttle method of the present invention avoids the color see-through phenomenon of the multi-color shuttle double-brocade label with light-colored ground and dark-colored flowers.

Owner:广东康派环创科技有限公司

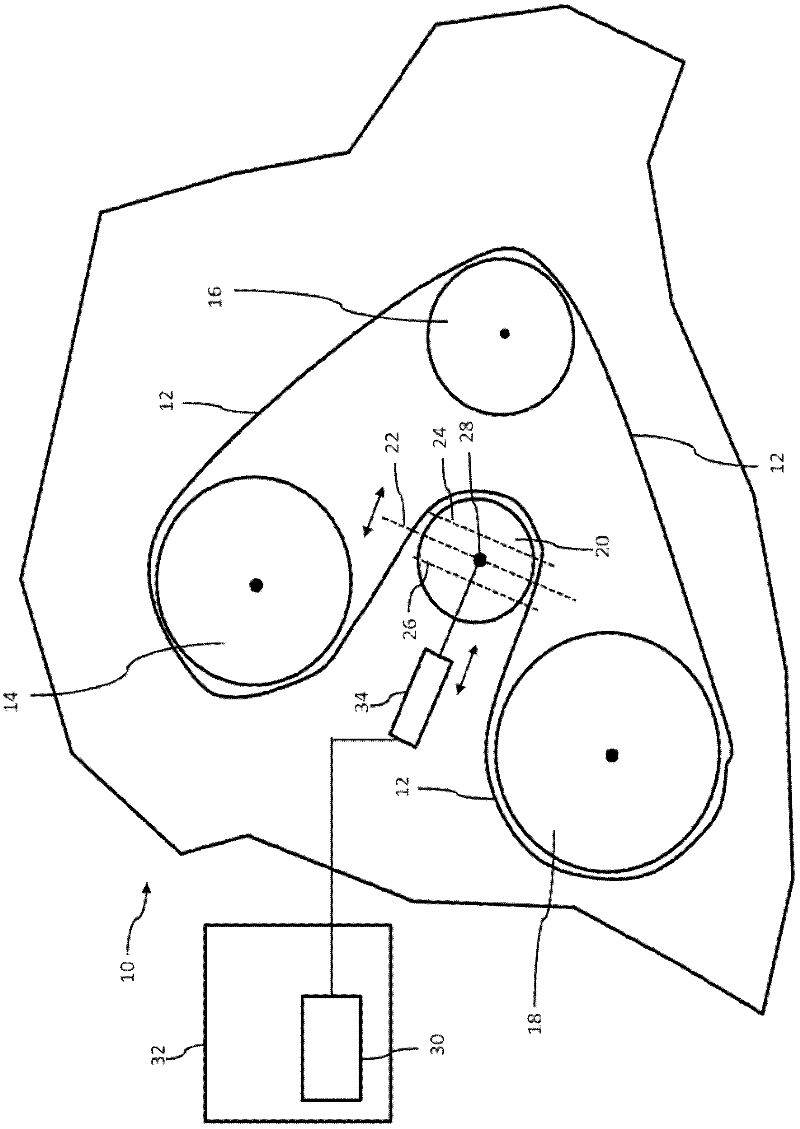

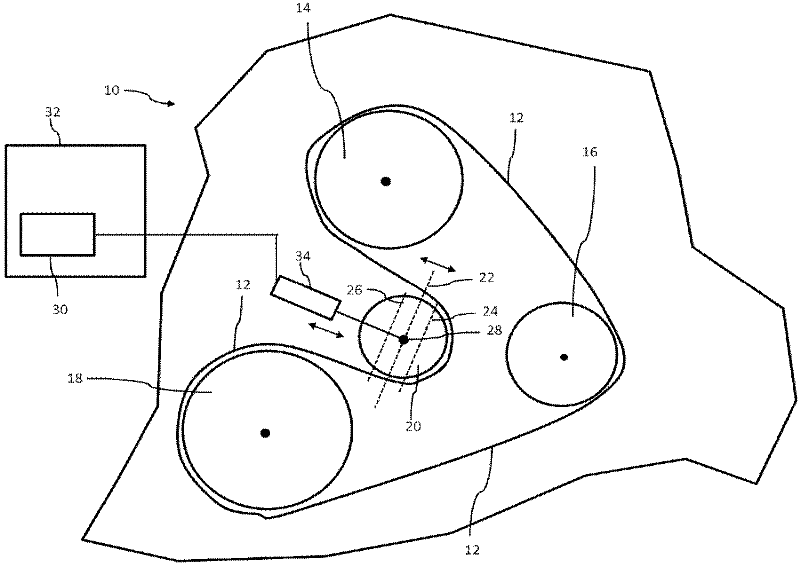

Control for a variable tensioning device for a ribbedv-belt of a motor vehicle drive

InactiveCN102401097AImprove tightnessLower base tightnessGearingMachines/enginesEngineeringControl theory

A tensioning device is provided for a ribbed V-belt (12) of a motor vehicle with at least one tensioning pulley (20) that is directly and functionally connected to the ribbed V-belt (12) and with a controller (30) designed for varying the position and / or configuration of the tensioning pulley (20) in dependence on the instantaneous operating state of at least one belt pulley (14, 16, 18) on a driven side and / or a driving side that is connected to the ribbed V-belt (12) in order to operationally adapt the tension of the ribbed V-belt (12).

Owner:GM GLOBAL TECH OPERATIONS LLC

Low-voltage low-loss electrolytic capacitor paper and preparation method and application thereof

ActiveCN114263069ALow tightnessGood absorbencySpecial paperElectrolytic capacitorsPulp (paper)Polyolefin

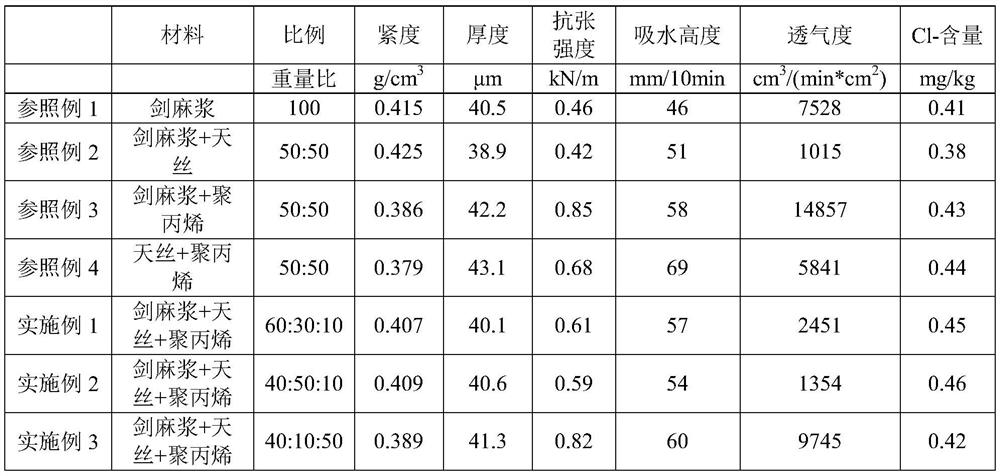

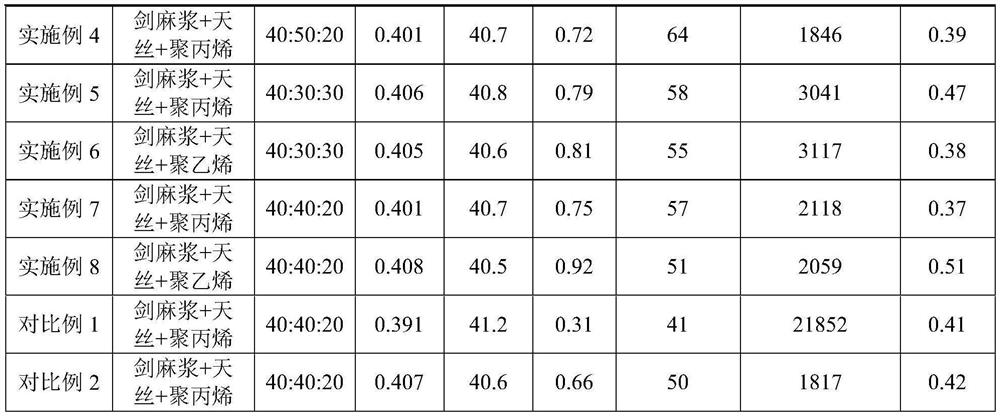

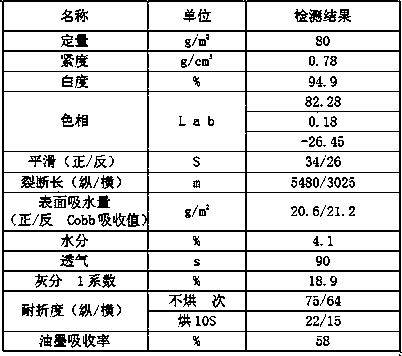

The invention relates to the technical field of aluminum electrolytic capacitor paper new materials, in particular to low-voltage low-loss electrolytic capacitor paper and a preparation method and application thereof. The invention relates to low-voltage low-loss electrolytic capacitor paper, which is prepared from the following fiber raw materials in percentage by mass: 30 to 60 percent of hemp pulp, 20 to 50 percent of tencel pulp and 10 to 50 percent of polyolefin short fiber, the beating degree of the hemp pulp is 15-50 degrees SR; the beating degree of the hemp pulp is 40-70 degrees SR, the beating degree of the tencel pulp is 40-70 degrees SR, the hemp pulp, the tencel pulp and the polyolefin short fibers are uniformly mixed and then fed into a paper machine drifting system, then wet-process papermaking forming is performed to obtain raw paper, and the raw paper is shaped by adopting a shaping drying cylinder to obtain a finished product of the low-voltage and low-loss electrolytic capacitor paper. The product has good absorptivity, relatively low aperture and relatively high strength, the used raw materials are high in purity, the high purity of the electrolytic paper can be effectively ensured, and the risk of aluminum foil corrosion is avoided.

Owner:浙江凯恩新材料有限公司 +2

Process for preparing silver fiber blend-weaving fencing metal clothes fabric

InactiveCN107268145AGood flexibilityLow tightnessSucessive textile treatmentsWoven fabricsMetalFineness

The invention discloses a process for preparing a silver fiber blend-weaving fencing metal clothes fabric and relates to the technical field of textile materials. The process comprises the steps of mixing: silver fiber with the fineness of 80 D, high-strength polyester filament yarn with the fineness of 80 D and high-strength polyester filament yarn with the fineness of 150 D are selected for standby application: weaving: the fabric is woven by the plain weave structure of warp yarn and weft yarn, the warp yarn is formed by the silver fiber with the fineness of 80 D and the high-strength polyester filament yarn with the fineness of 80 D according to a certain proportion, and the weft yarn is formed by silver fiber with the fineness of 80 D and the high-strength polyester filament yarn with the fineness of 150 D; aftertreatment: the woven fabric undergoes bleaching, drying, treatment through softening liquid and drying and formation. The tightness of the fabric manufactured by adoption of the process descends, and the silver fiber blend-weaving fencing metal clothes fabric is soft in touch and good in conductivity.

Owner:丹阳市斯鲍特体育用品有限公司

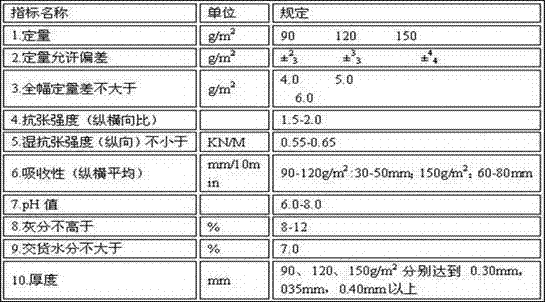

A papermaking process of single-sided blue engineering paper

ActiveCN106676942BImprove absorption rateImprove uniformityCoatings with pigmentsReinforcing agents additionIsothiazolinoneSolid content

The invention provides a coating process of single-sided blue engineering paper. The coating process comprises a paint preparation step, and according to the paint preparation, solid content of paintis 2%-3%, viscosity of the paint is 3-5 mpa.s, and pH value of the paint is 8.2-8.4. The paint is prepared from components in percentage by mass as follows: 0.2% of a color toner, 1.5% of latex, 0.1%of CMC and 0.08% of isothiazolinone. According to single-sided blue engineering paper prepared with the process, deviation of basis weight in cross direction is smaller than or equal to 3 g / m<2>, dustcontent is lower than or equal to 40 / m<2>, and water content is 4.2%-4.7%.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Paper making process of single-side blue engineering raw paper

ActiveCN108755237AImprove absorption rateImprove uniformityCoatings with pigmentsReinforcing agents additionFiberSulfate

The invention provides a paper making process of single-side blue engineering raw paper. The process comprises a pulp preparation step; the pulp preparation includes the preparation of long fiber pulpand the preparation of poplar pulp. For the preparation of long fiber pulp, bleached sulfate needle leaf long fiber wood pulp with the fiber length being 2.5 to 2.7mm is used; the pulping concentration is 4.0 to 4.3 percent; the pulping degree is 38 to 40 degrees SR. For the preparation of poplar pulp, the pulping concentration is 4.0 to 4.3 percent; the pulping degree is 36 to 38 degrees SR. Theink absorption rate of the prepared single-side blue engineering raw paper is 42 to 45 percent.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

High definition enamelled paper possessing safety line and its making process

InactiveCN101260632BLow costMeet high standardsNon-fibrous pulp additionCoatings with pigmentsPulp and paper industryCopper

The invention relates to a high definition copper paper board with a secure line and a manufacturing technique thereof. The copper paper board is formed by coating a high solid content dope combined by a white pigment and a cementing compound evenly on a base paper and being dried as well as rewound. The manufacturing technique comprises the following steps that: 1. a common offset paper is selected as a base paper, a coating machine is adopted to coat an ink absorbing layer dope formed by mixing the white pigment and the cementing compound; 2. a cast coater is adopted to coat a specular layer dope mixed by a silicasol or a colloidal alumina and the cementing compound on the surface of the ink absorbing layer dope after dried; 3. the process the same as the step 2 is performed, the secureline with the back surface applied by the glue is arranged at the designed position on the ink absorbing layer dope layer and below the specular layer dope by means of the match of a small-sized compression roller which is arranged for matching the cast coater; 4. a mirror cylinder of the cast coater is adopted to perform the pressing and glazing processes on the paper surface after the secondary coating after the paper is dried and dewatered; 5. the post sorting, cutting and rewinding processes are performed to form finished products.

Owner:石家庄中康纸业有限公司

A kind of midsole plate for shoes and its preparation method

ActiveCN107059458BReduce manufacturing costAchieve recyclingReinforcing agents additionPress sectionFiberSlurry

Owner:温州川新鞋材有限公司

A kind of tipping paper base paper with heat-clearing and alcohol-relieving functions and preparation method thereof

ActiveCN104005254BHas health benefitsLarge adsorption capacityCoatings with pigmentsPulp beating methodsFiberAlcohol poisonings

The invention discloses a tipping paper base paper with functions of clearing away heat and relieving alcohol, which is characterized in that it is prepared from the following raw materials in parts by weight: 3-4 parts by weight of ashweed, 1-2 parts of nigella seed oil, and 41 parts by weight of pomegranate pulp -46, cork pulp 52-55, pterygium 2-4, mannitol 1-1.5, Hovenia dulcis 1-2, taurine 0.5-0.7, activated clay 3-4, iron oxide yellow 1-2, Carboresin 2-3, Ammonium Bicarbonate 1-1.6, Calcium Peroxide 2-2.5, Calcium Propionate 1-2, Auxiliary 1-2, appropriate amount of water; the present invention adds Pterocephala clearing heat and detoxifying, Hovenia dulcis Alcohol poisoning, the production of tipping paper base paper has certain health effects, suitable for social use, adding additives, not only can increase the amount of tar adsorption, but also has a natural fragrance, fresh and pleasant, reducing bad breath, and the fiber distribution of the product of the present invention Uniform, small fluctuations in thickness, tightness, air permeability and other indicators, easy to print.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com