Patents

Literature

139results about How to "Meet high standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

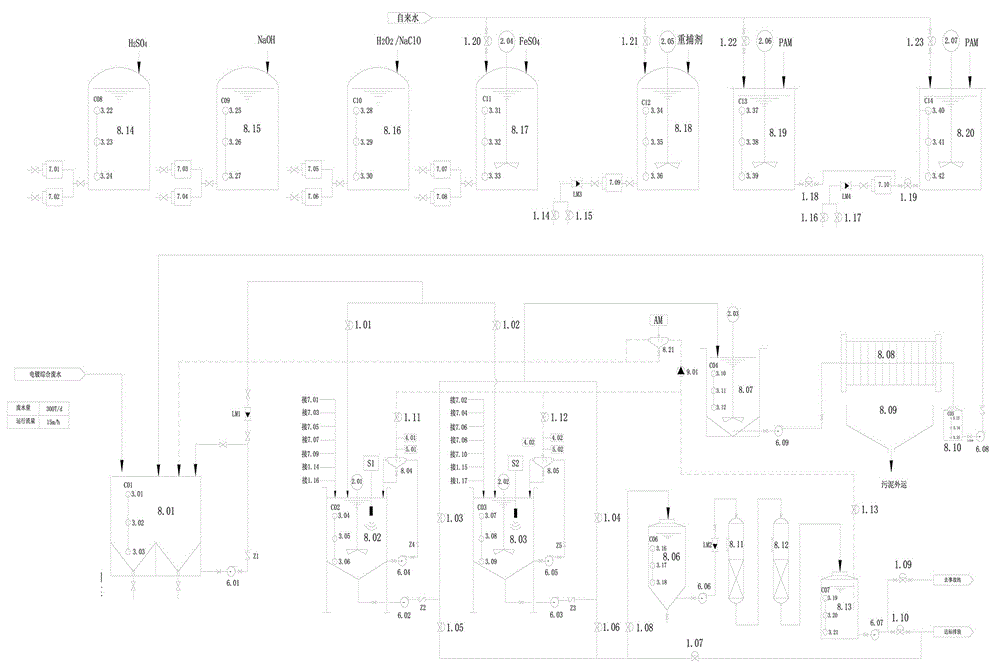

Intelligent treatment device for electroplating synthetical wastewater and control method thereof

ActiveCN106277427AEnter in time automaticallyShorten water intake timeWater treatment parameter controlWater contaminantsTreatment effectPh regulation

The invention relates to an intelligent control technology for electroplating synthetical wastewater, wherein through the steps of pH regulation of wastewater, oxidation, reduction, Cr<6+> filtering, heavy metal capture, settling of suspended solids, ion exchange and sludge treatment, the intelligent synthetical treatment of electroplating wastewater is realized, and the technology has the characteristics of high automation degree and good treatment effect. In the invention, the treatment process is finished by a sequencing bath method in a reactor, two or more reactors alternate to realize timely accurate dosing in the wastewater treatment process as well as real-time detection and control before discharge, the stability, reliability and economy of the wastewater treatment quality are guaranteed, and the wastewater treatment stably meets the requirements of the Discharge Standard for Electroplating Pollutants (GB21900-2008); furthermore, the intelligent unmanned operation can accurately control the wastewater treatment time, the drug adding amount and the wastewater treatment quality, so that the volume of the wastewater treatment equipment is reduced, and the treatment cost is lowered.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

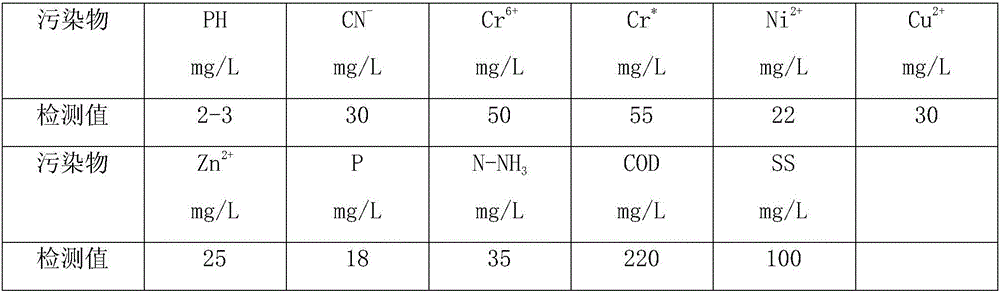

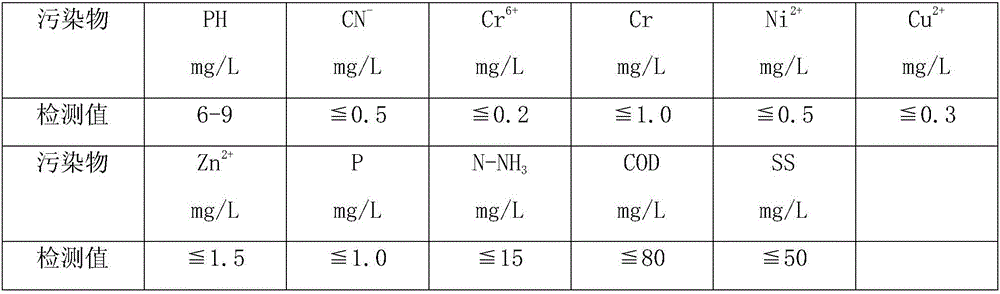

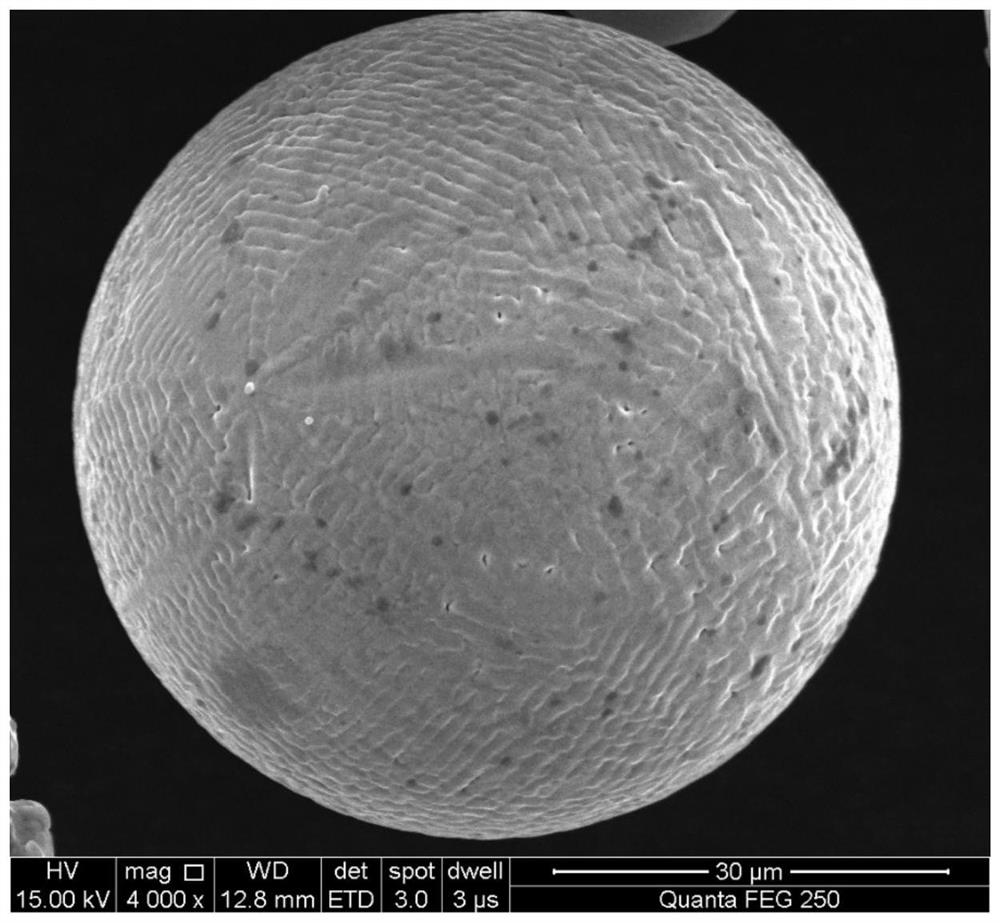

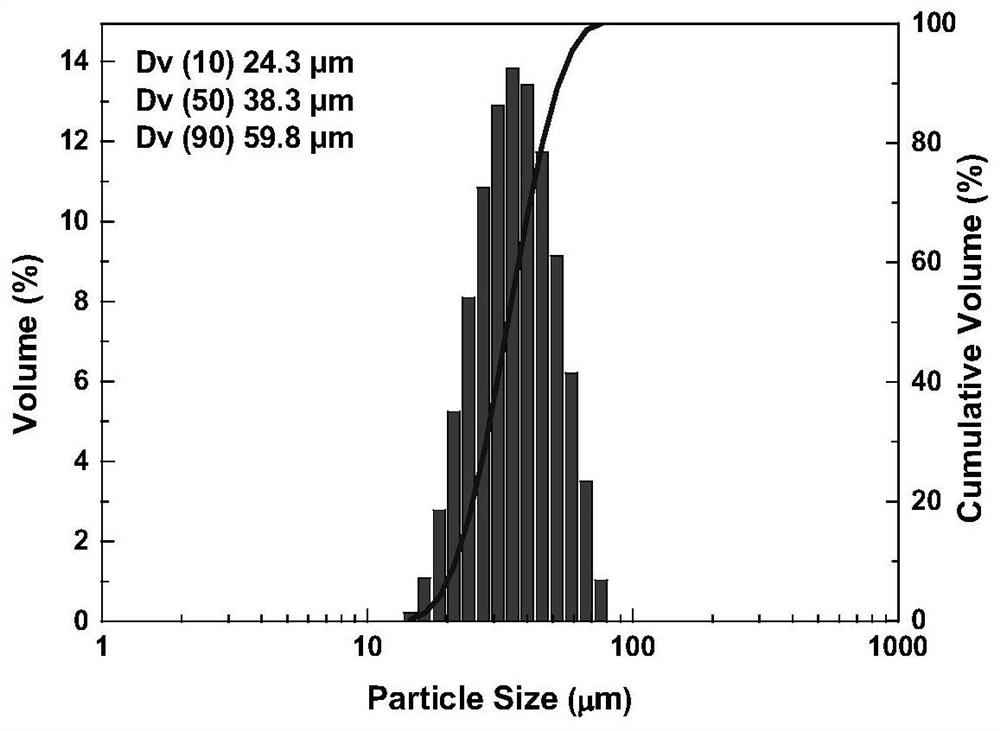

Nickel-based superalloy for 3D printing and method for preparing nickel-based superalloy powder

ActiveCN111996414AGood sphericityLow oxygen sulfur contentAdditive manufacturing apparatusTransportation and packaging3D printingFine powder

The invention provides a nickel-based superalloy for 3D printing and a method for preparing nickel-based superalloy powder and belongs to the technical field of superalloys and additive manufacturing.The nickel-based superalloy for 3D printing and the method for preparing the nickel-based superalloy powder aim at the problem that an unweldable powder nickel-based superalloy is likely to crack inthe 3D printing process. By means of rare earth microalloying, in combination with a vacuum melting, degassing, refining, reasonable parameter atomizing and screening process, the nickel-based superalloy meeting 3D printing needs and the powder thereof are prepared. According to the nickel-based superalloy for 3D printing and the method for preparing the nickel-based superalloy powder, the cracking sensitivity of the unweldable powder nickel-based superalloy is remarkably reduced, a 3D printing process window is widened, and a printed workpiece is free of cracks and excellent in mechanical property; meanwhile, the prepared powder is high in degree of sphericity, good in mobility and small in amount of special-shaped powder, and the yield of the fine powder with the grain size of 15-35 micrometers and the median-grain-size powder with the grain size of 53-106 micrometers is increased; and the need for the high-quality low-cost nickel-based superalloy powder for 3D printing is met

Owner:CENT SOUTH UNIV

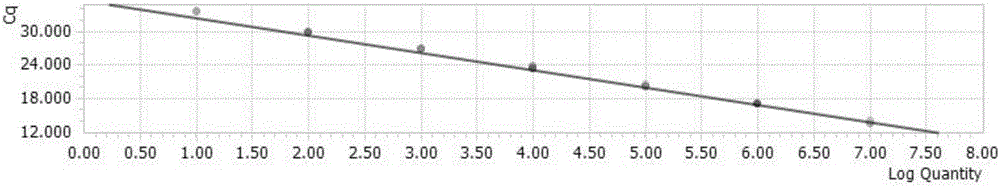

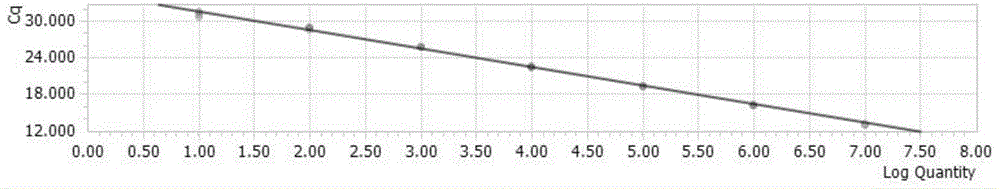

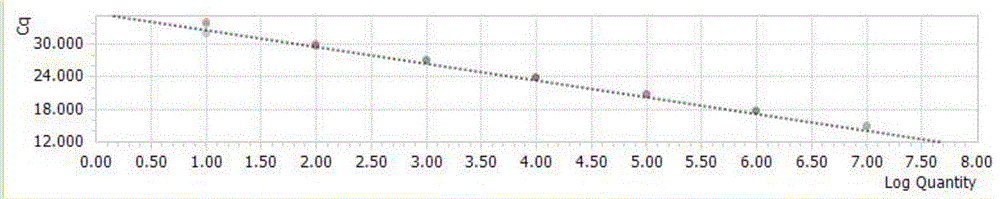

Fluorescent quantitative PCR primer, probe, kit and detection method for detecting avian influenza subtype

ActiveCN106435024AHigh detection sensitivityHigh sensitivityMicrobiological testing/measurementAvian influenza virusRepeatability

The invention provides a multiplex fluorescent quantitative PCR primer and a probe for detecting H5, H7 and H9 subtype avian influenza viruses. With adoption of the primer and the probe, multiplex fluorescent quantitative PCR can be adopted to simultaneously detect which subtypes the H5, H7 and H9 subtype avian influenza viruses concretely are, no influences exist among the primers of different subtypes, the specificity is strong, the detection sensitivity is 10-50 copy numbers, a target sequence can be accurately detected quantitatively and qualitatively, the repeatability is good, and the reliability is high. The invention provides a multiplex fluorescent quantitative PCR kit for simultaneously detecting the H5, H7 and H9 subtype avian influenza viruses. The kit has the detection sensitivity being 10-50 copy numbers and is high in sensitivity and strong in specificity. The invention also provides a detection method which is good in stability. With adoption of plasmids with gene fusion as a positive standard substance, tedious operation of changing the positive standard substance for multiple times is avoided, the detection time is greatly shortened, the detection times are greatly reduced, and detection of a sample can be finished within 2h.

Owner:NANJING AGRICULTURAL UNIVERSITY

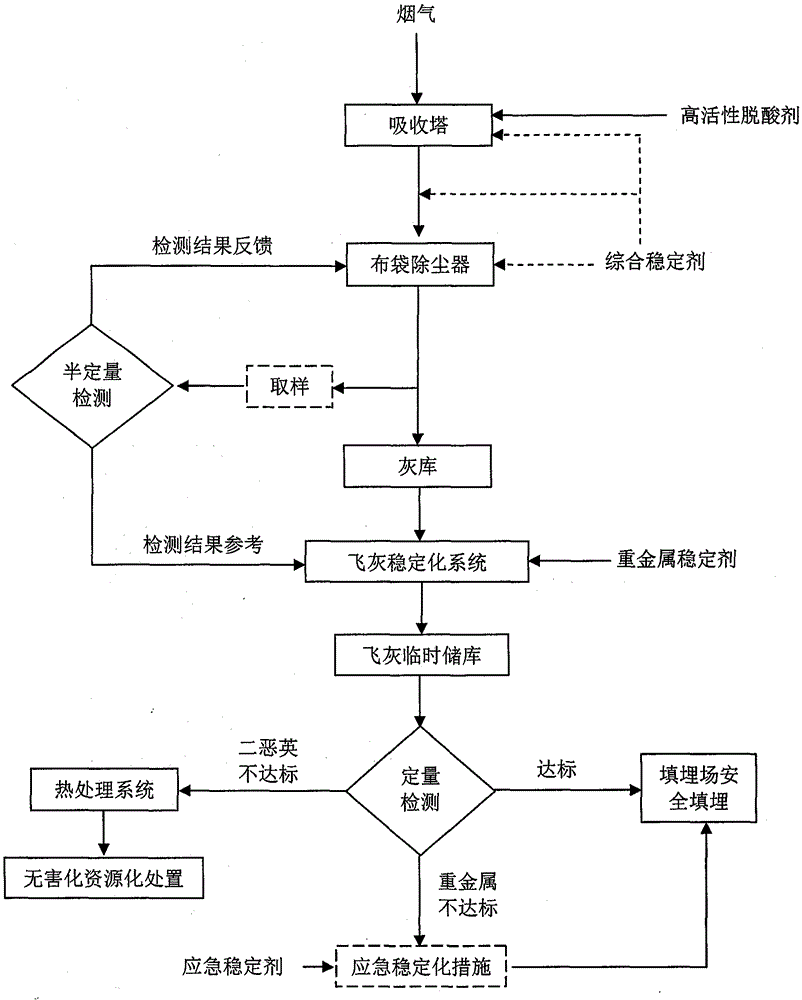

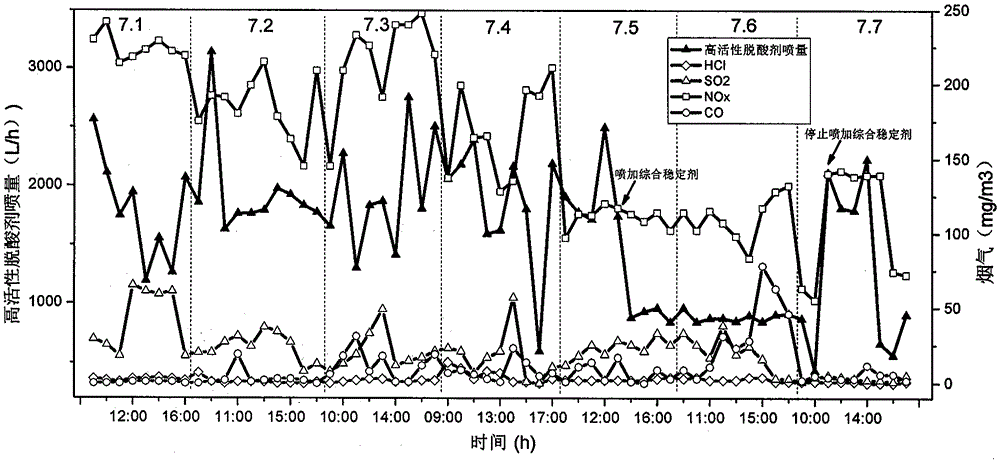

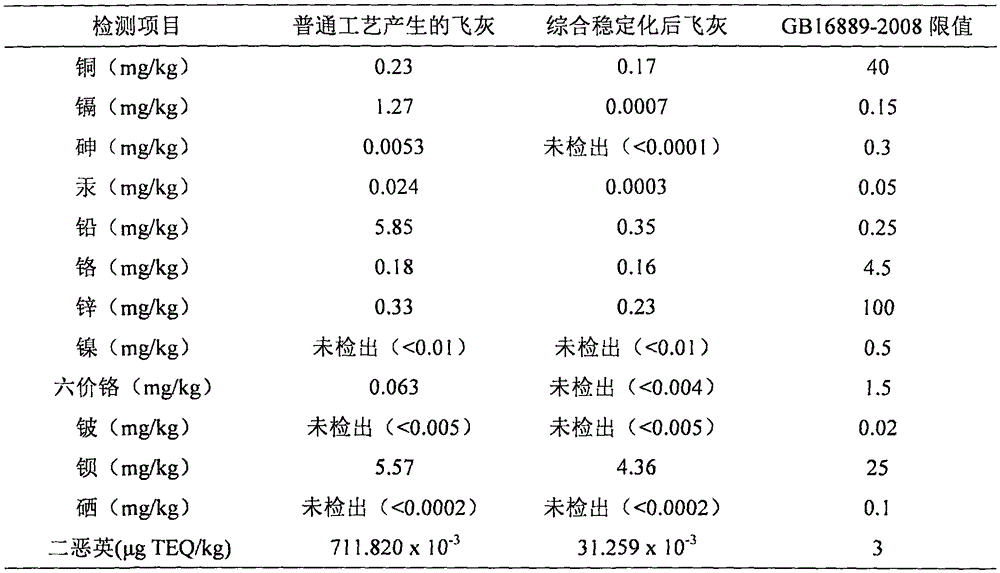

Comprehensive stabilization treatment technology of waste incineration fly ash

The invention relates to a comprehensive stabilization treatment technology of waste incineration fly ash, aims at the problems of high consumption of lime slurry, large generation amount of fly ash and high treatment difficulty in the smoke treatment process of the waste incineration plant in the prior art and the problems of high chemical adding ratio and low qualified rate of the fly ash in the ordinary stabilization technology, and combines four core technologies of modifying a smoke deacidification agent through a semi-dry process, reinforcing deacidification of smoke through a dry process and pre-stabilizing fly ash, carrying out chemical stable rapid field detection, reinforcing stabilization effect of fly ash and emergently remedying. Through adoption of high-activity, high-efficiency, high-stability and low-dosage chemicals, the comprehensive stabilization purposes of reducing fly ash source, degrading dioxin source, stabilizing components of smoke and fly ash and stabilizing heavy metals in the fly ash are achieved; the fly ash treatment difficulty is greatly reduced; the generation of fly ash is changed into production of fly ash; the purpose of ensuring that the safe treatment rate of the fly ash reaches up to 100% on the premise of controllable cost can be finally achieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

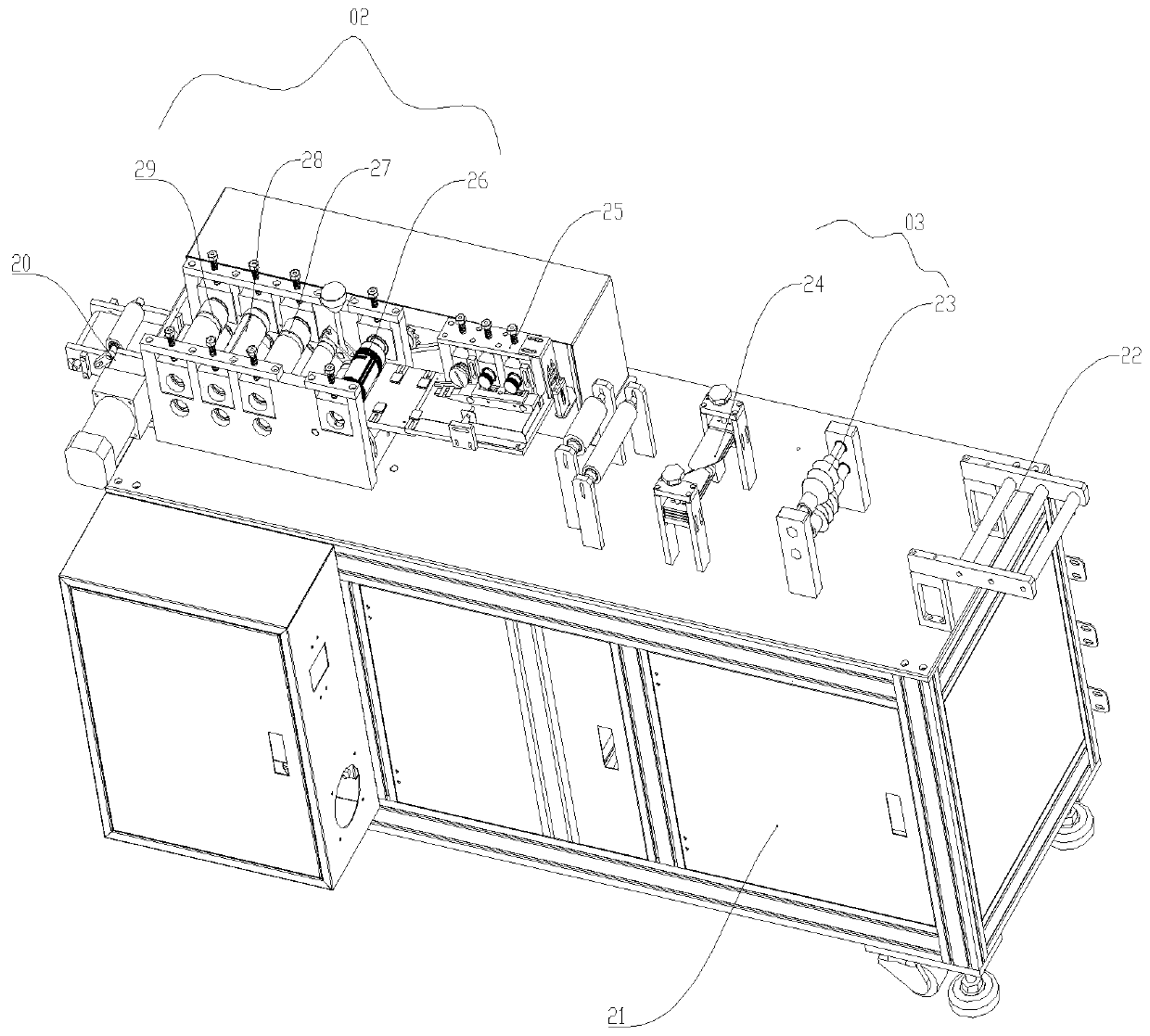

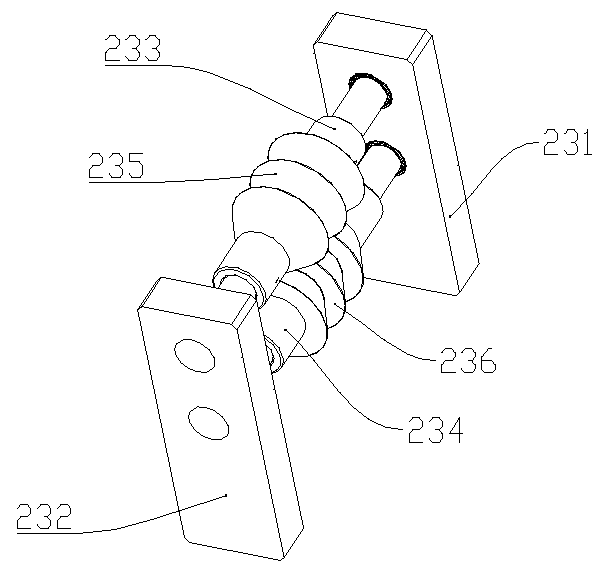

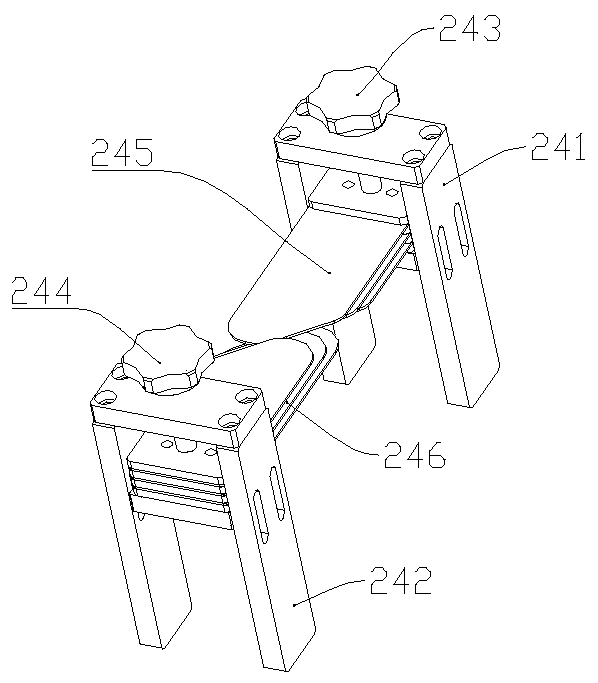

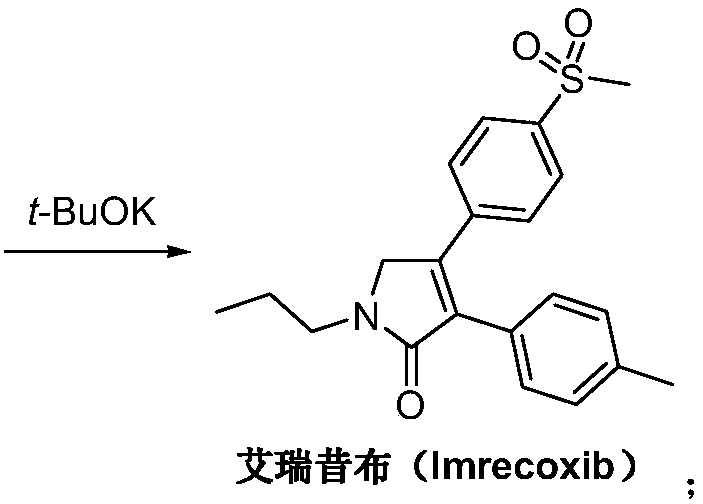

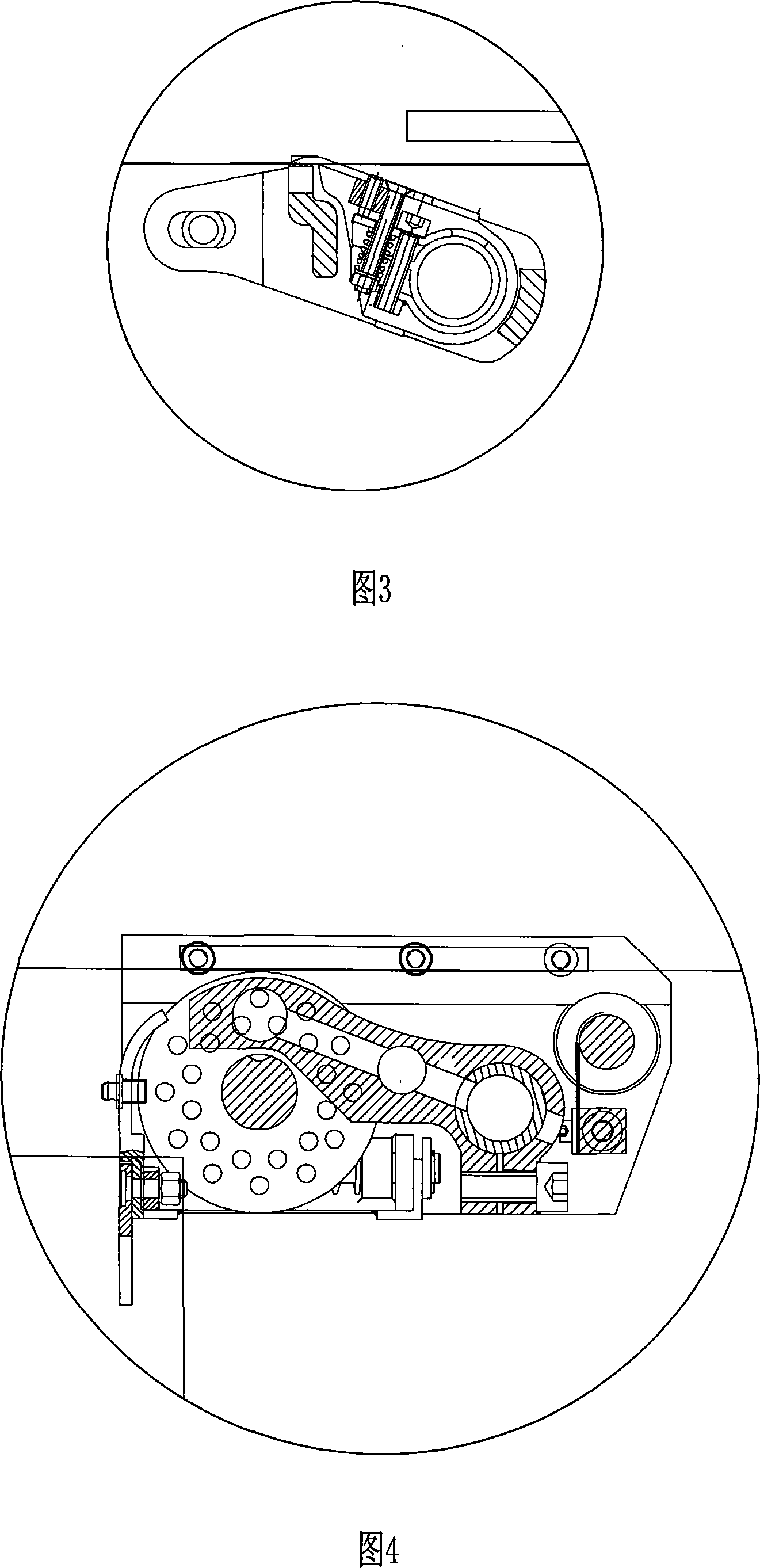

Mask body forming mechanism

PendingCN111452367AImprove molding qualitySimple structureDomestic articlesClothes making applicancesMolding machineEngineering

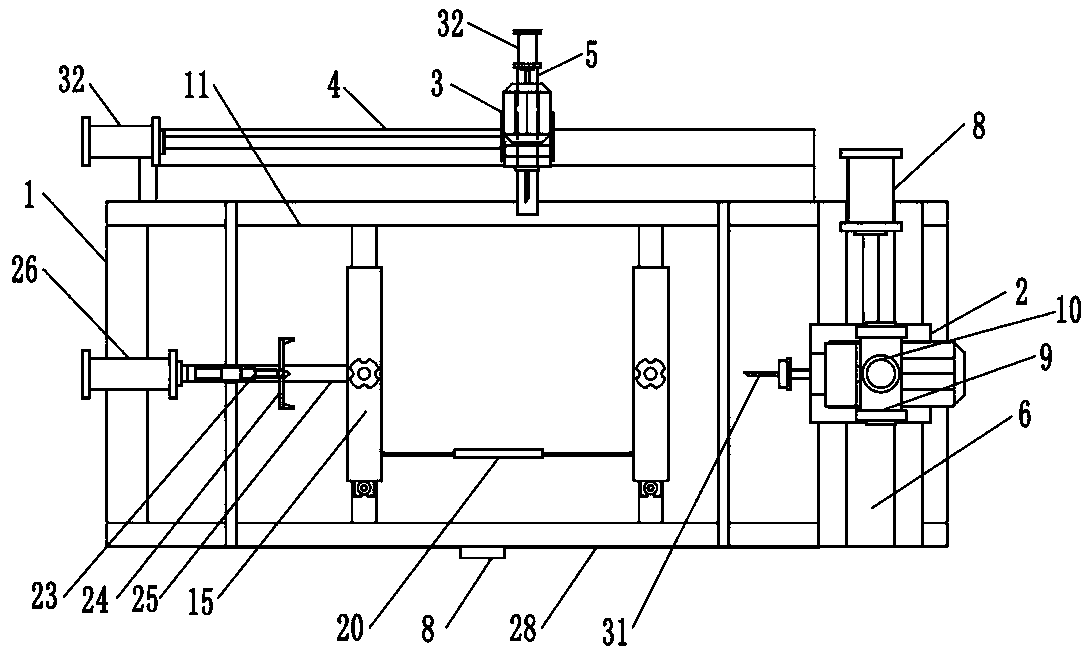

The invention discloses a mask body forming mechanism. The mask body forming mechanism comprises a machine cabinet and further comprises a guiding mechanism, a folding mechanism, a nose bridge strip mechanism and a fusion welding forming mechanism which are arranged on the machine cabinet and sequentially distributed. The guiding mechanism is used for tightening and guiding incoming materials froma previous station to the folding mechanism according to the preset stacking sequence, the folding mechanism is used for folding the middle portions of the stacked incoming materials, the nose bridgestrip mechanism is used for conducting conveying and tailoring a nose bridge strip into the preset length, the fusion welding forming mechanism is used for conducting fusion welding on the folded formed incoming materials containing the nose bridge strip and cutting the incoming materials into mask bodies with the set size. Compared with the prior art, according to the mask body forming mechanism, through redesign of the nose bridge strip mechanism and the fusion welding forming mechanism, the integral structure is more simple, meanwhile, the mask body forming quality is improved, and higherstandard requirements are met.

Owner:SHENZHEN PREVAIL TECH

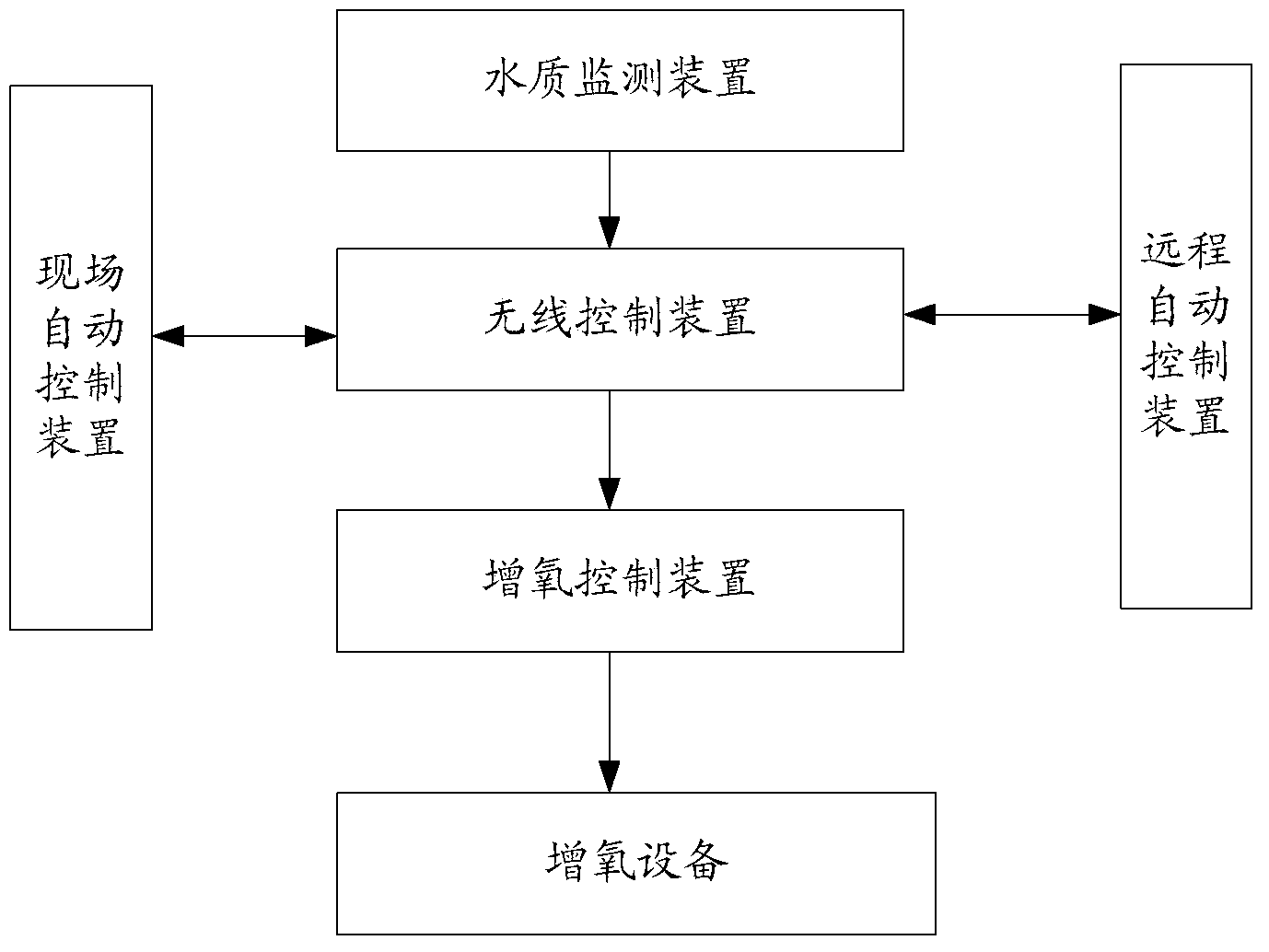

Aquaculture intelligent monitoring system

InactiveCN103576634AMeet high standardsSave human effortTotal factory controlProgramme total factory controlWireless controlAutomatic control

The invention discloses an aquaculture intelligent monitoring system. The aquaculture intelligent monitoring system comprises a water quality monitoring device, a site automatic control device, an oxygen enrichment control device and a wireless control device, wherein the water quality monitoring device is used for collecting dissolved oxygen, the PH value, the water level, the salinity and turbid water quality environment parameter data of an aquaculture field, the site automatic control device is used for receiving the turbid water quality environment parameter data collected by a water quality monitoring station through the wireless control device and sending wireless control instructions to the oxygen enrichment control device through the wireless control device, and the oxygen enrichment control device is used for controlling oxygen enrichment equipment to operate according to the wireless control instructions. The water quality environment is automatically monitored in real time, the oxygen enrichment equipment is controlled to enrich oxygen in real time in a wireless mode through the control device, and therefore manpower is largely saved, meanwhile, the control over the water quality for aquaculture meets standard requirements, and the high-standard need for the aquaculture is met.

Owner:TIANJIN SHENGYI CULTURE

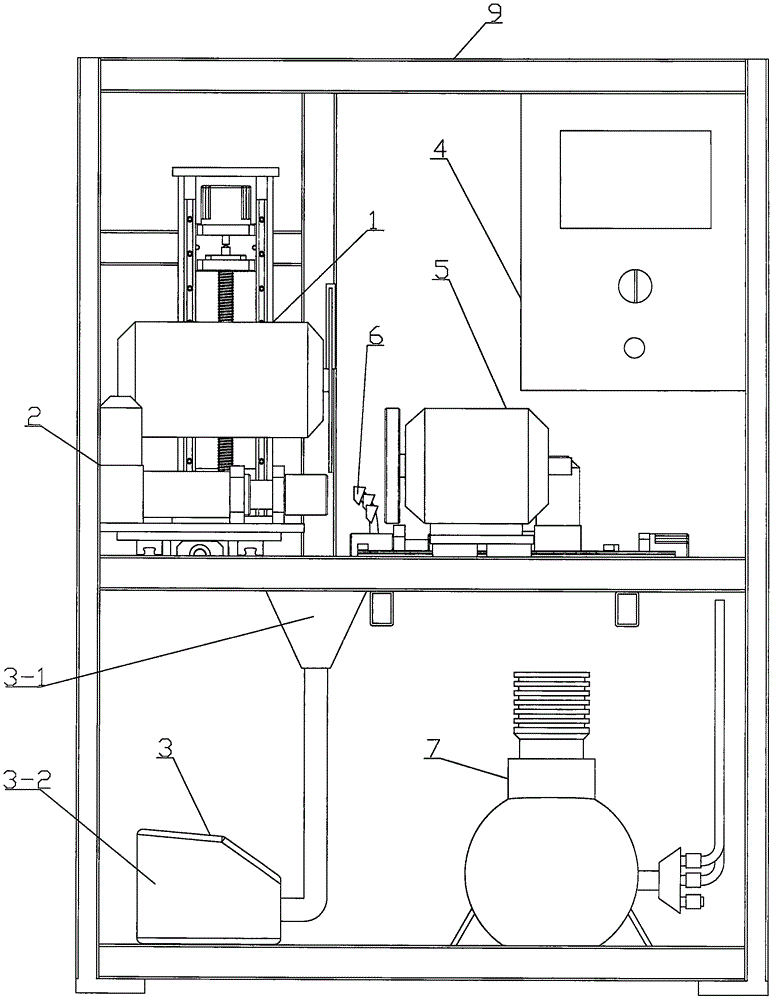

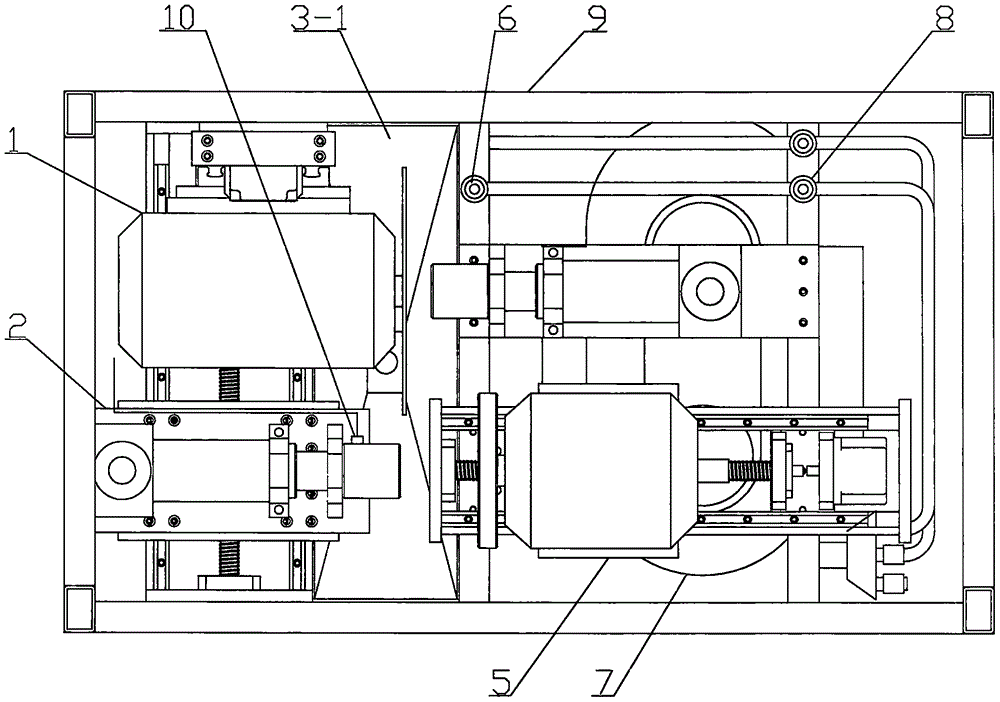

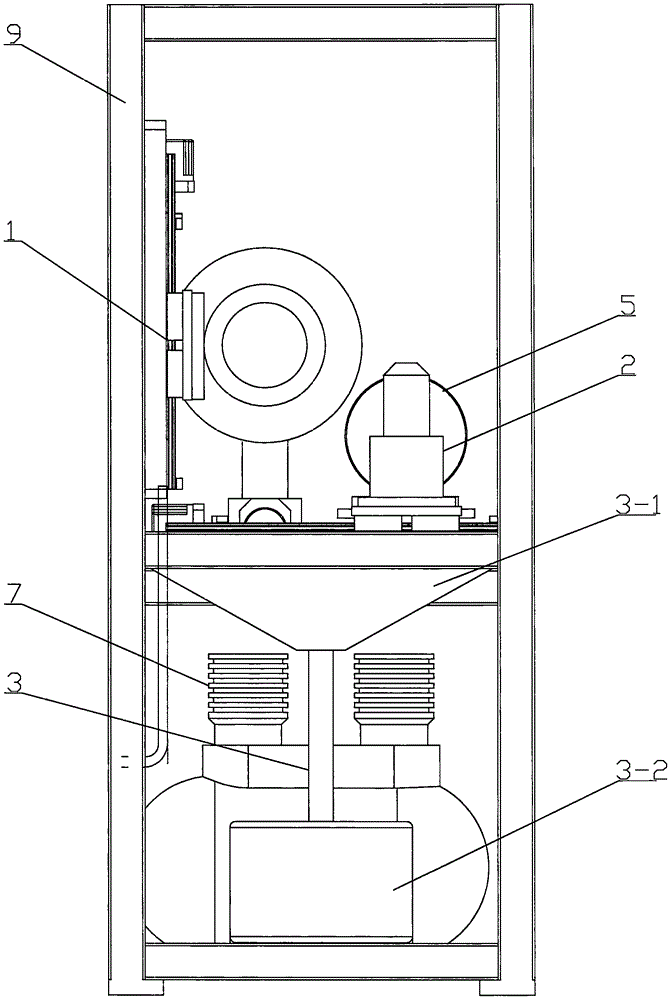

Automatic cutting and grinding all-in-one machine

InactiveCN105690097ASmooth transmissionSimple transmission structureOther manufacturing equipments/toolsAir cooling systemElectromagnetic valve

The invention relates to an automatic cutting and grinding all-in-one machine. The automatic cutting and grinding all-in-one machine comprises a rack, an automatic cutting device, an automatic rod piece clamping device, an automatic grinding device, a dust collection device, an air cooling system, an air cooling device, an electromagnetic valve and a control cabinet. The automatic cutting device, the automatic rod piece clamping device and the automatic grinding device are each provided with a linear walking device. The cutting work end of the automatic cutting device longitudinally corresponds to a rod piece on the automatic rod piece clamping device, and the grinding work end of the automatic grinding device transversely corresponds to the rod piece on the automatic rod piece clamping device. The automatic cutting device, the automatic rod piece clamping device, the automatic grinding device, the linear walking devices, the dust collection device, the air cooling system and the air cooling device are all connected to the control cabinet, and the starting and shut-down action is controlled by the control cabinet. Cutting and grinding functions are integrated, through control of the control cabinet, cutting and grinding work of the rod piece can be completed in a one-stop manner, and automatic machining of cutting and grinding is achieved; and meanwhile, linear walking structures are adopted, transmission is stable, and plane thickness uniformity of the ground rod piece is good.

Owner:ZHUZHOU TANPU TECH CO LTD

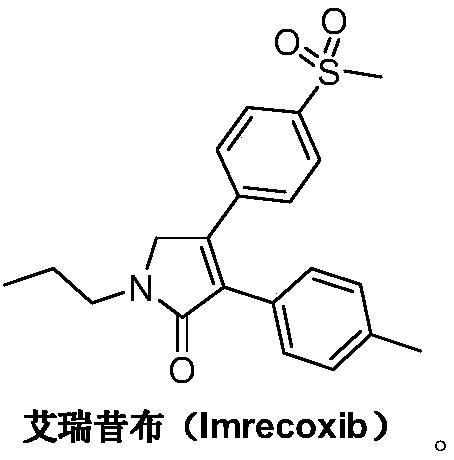

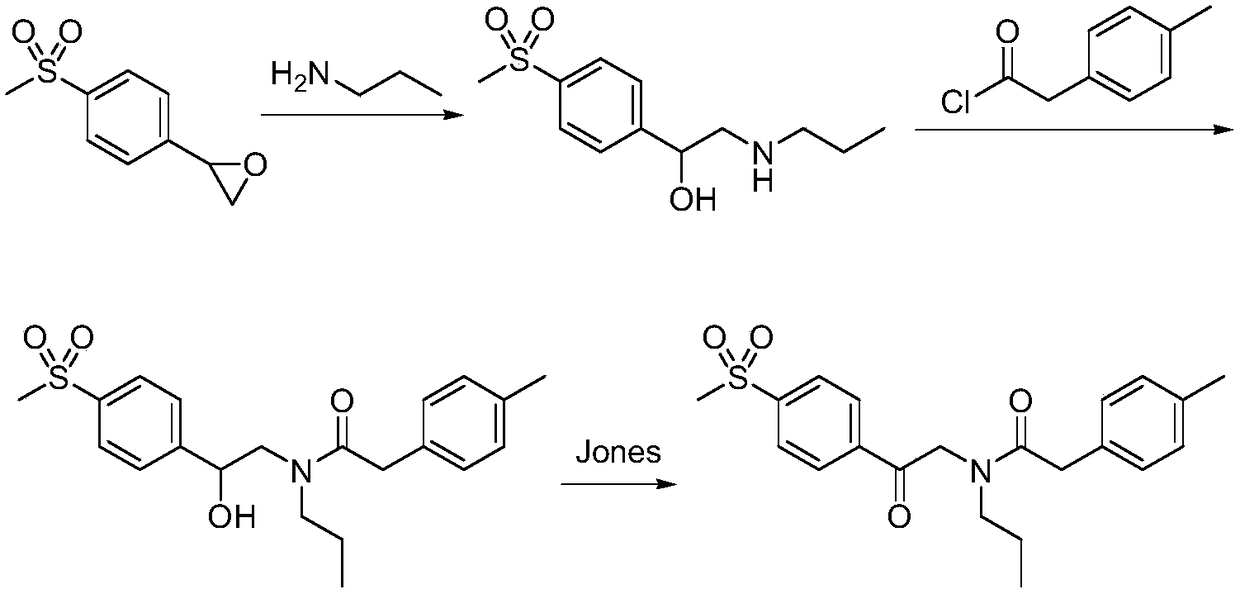

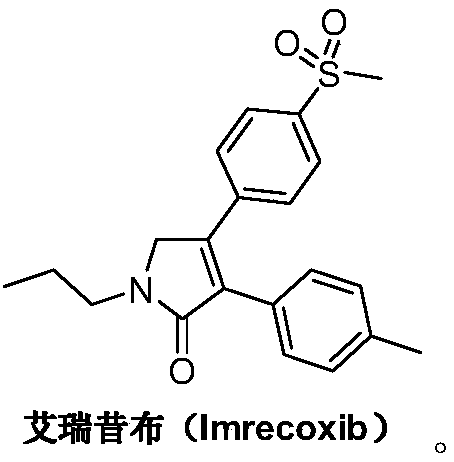

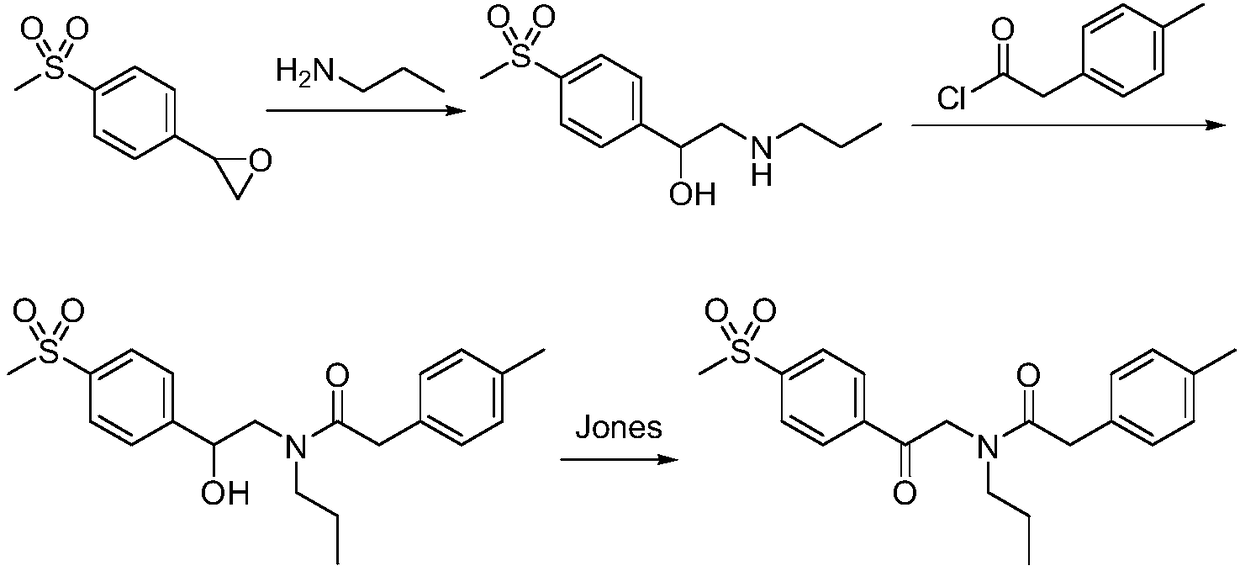

Preparation method of imrecoxib and intermediate thereof

The invention discloses a preparation method of imrecoxib and an intermediate thereof. the preparation methoc comprises the following steps: 1) carrying out an amidation reaction between 2-amino-1-p-methylsulfonyl acetophenone and p-methylphenylacetyl halide so as to obtain N-[2-oxo-2-(4-methylsulfonylphenyl)]ethyl-4-methyl phenylacetamide; 2) carrying out a condensation and cyclization reaction on N-[2-oxo-2-(4-methylsulfonylphenyl)]ethyl-4-methyl phenylacetamide so as to obtain 3-p-methyl phenyl-4-p-methylsulfonylphenyl-3-pyrrolidine-2-ketone; and 3) carrying out a substitution reaction between 3-p-methyl phenyl-4-p-methylsulfonylphenyl-3-pyrrolidine-2-ketone and 1-halopropane or hydrocarbon sulfoacid propyl ester derivative so as to obtain imrecoxib; and preparing the intermediate of imrecoxib: N-[2-oxo-2-(4-methylsulfonylphenyl)]ethyl-4-methyl phenylacetamide or 3-p-methylphenyl-4-p-methylsulfonylphenyl-3-pyrrolidine-2-ketone. The reaction process is optimized by the synthetic route. Separation in each step is simpler, purity is higher, and ideal yield of the product also can be achieved.

Owner:江苏美迪克化学品有限公司

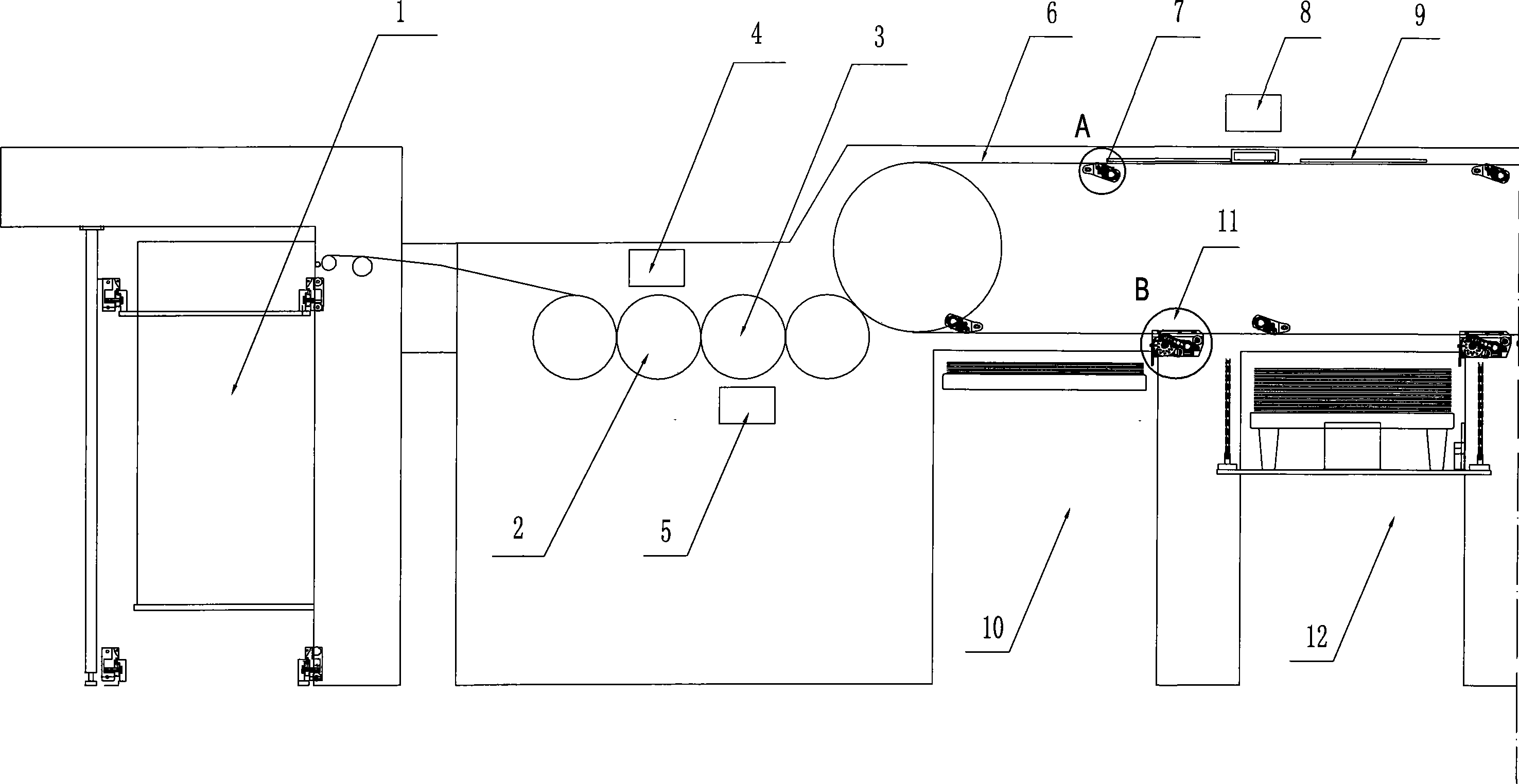

A method for automatically tidying and selecting papers

The invention discloses a method for automatically sorting and classifying paper, and belongs to a quality detection and sorting method of a paper making process. The purpose is to provide the method that paper is decomposed into a single piece of paper to detect the appearance quality, and the single piece of detected paper is classified and respectively counted by adopting a linking automatic equipment, and then sorted the ream output or the quire output. The method mainly comprises the following steps: quires of flat paper are outputted by utilizing a paper conveying machine in the form of a single piece of flat paper; at the outlet end of the paper conveying machine, the appearance quality of the paper is detected by utilizing a computer visual processing system; the appearance quality of the paper is detected by utilizing a computer visual processing system; the paper is counted and selected; the ream and the quire are sorted to qualified paper; reams or quires of paper are outputted. The invention can be suitable for the quality detection and the sorting and the classifying of various pieces of paper in the paper making production.

Owner:CHINA BANKNOTE PRINTING & MINTING

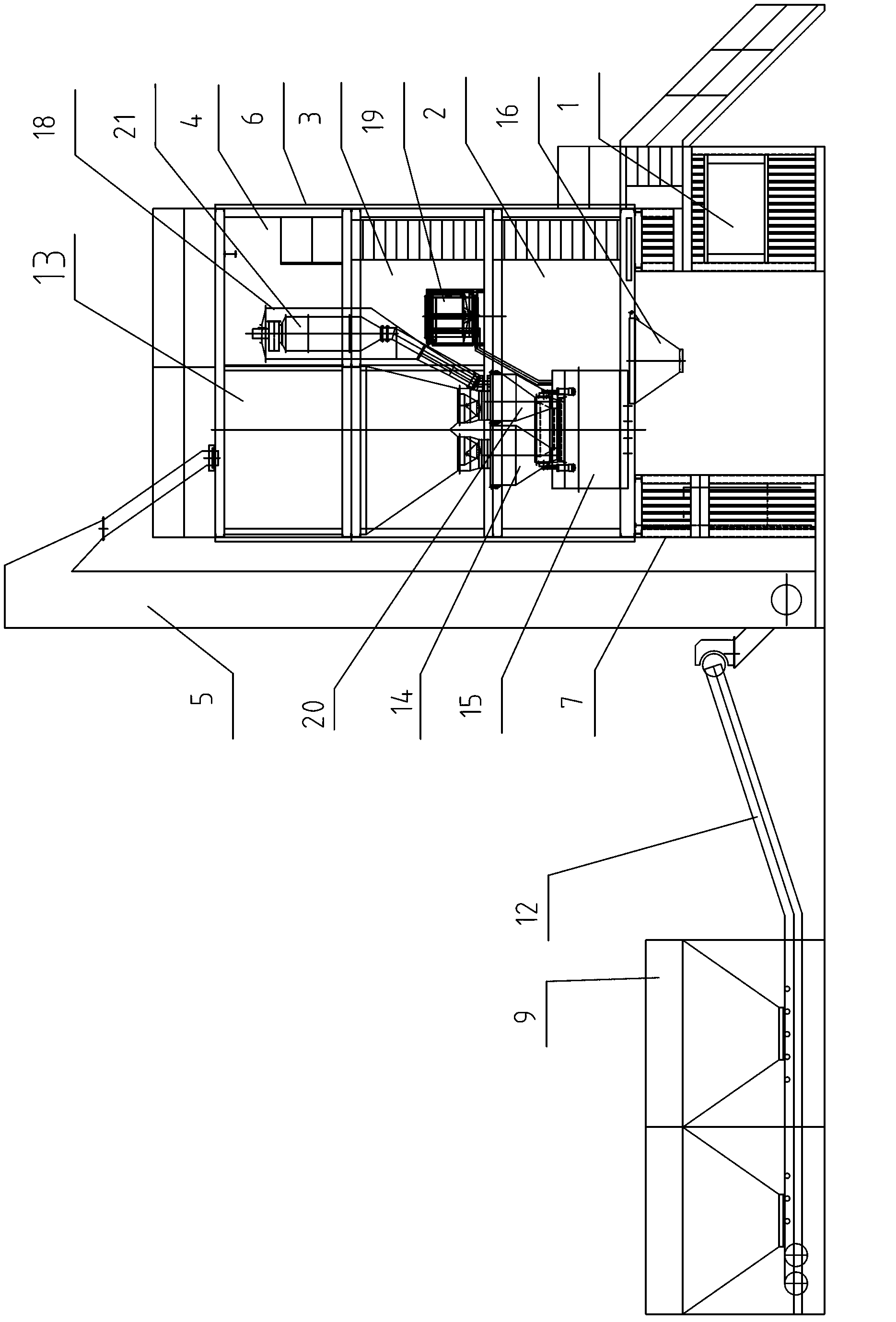

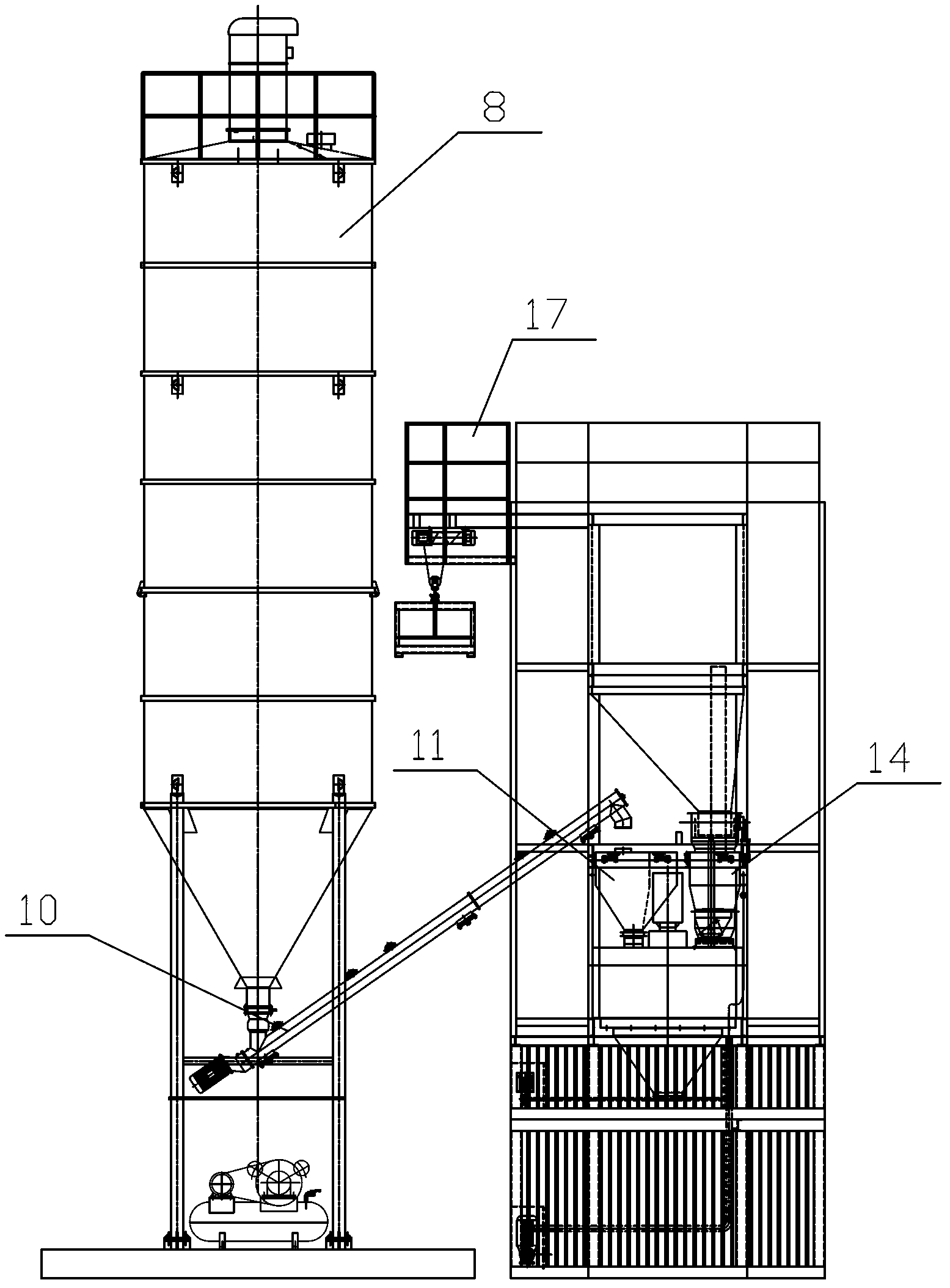

Stirring equipment specially for metro mortar

InactiveCN103213199ASimple solutionSmall footprintMixing operation control apparatusMixing operation plantWater tanksConstruction aggregate

The invention discloses stirring equipment specially for metro mortar, and belongs to stirring equipment. The stirring equipment comprises a control chamber, a water tank, an additive tank, a stirring unit, a metering unit, an aggregate storage unit, an aggregate burdening system and a powder storage system, wherein the control chamber, the water tank and the additive tank are arranged at the bottommost layer; the stirring unit, the metering unit and the aggregate storage unit are sequentially arranged from bottom to top; the aggregate burdening system is connected with the lower part of a bucket elevator through a burdening belt conveyer; the upper part of the bucket elevator is connected with the aggregate storage unit; the aggregate storage unit comprises an aggregate storehouse and a bentonite storehouse; the metering unit comprises a liquid metering system; the stirring unit comprises a sand metering hopper, a left-side powder metering hopper, a right-side powder metering hopper and a stirring system; and a bentonite lifting system is arranged on one side of a building body at the upper part of the bentonite storehouse. The stirring equipment can meter stirring raw materials at high precision and guarantee the quality of mortar, is convenient to dismount and mount and extremely high in environment friendliness and can fully meet a requirement of stirring urban mortar.

Owner:SHANTUI JANEOO MACHINERY

Watermark high-definition copperplate paper and manufacture technique thereof

InactiveCN101015969AImprove technical indicatorsLow costMechanical working/deformationCoatingsPolymer scienceAdhesive

The invention relates to a method for producing watermark high-resolution copper plate paper, wherein the copper plate paper is made by uniformly coating the high-solid-content paint of mixed white paint and adhesive on the base paper, to be dried and composed with watermark paper. The invention comprises following steps that 1, selecting glazed printing paper as base paper, using coating machine to mix white paint and adhesive into ink adsorption paint to be coated, 2, uniformly coating the highlight layer made fro mixing silicon gel or aluminum gel and adhesive via casting machine on the ink-adsorption paint. And the step 3 has a process synchronous with the step 2 comprises that using auxiliary press roller of casting machine to compose the watermark paper with back adhesive and the base paper not coated with paint into single-face watermark high-resolution copper plate paper, 4, using the mirror cylinder of casting machine to dry and dewater the base paper with secondary coating to complete rolling and polishing, 5, furnishing, cutting and coiling.

Owner:石家庄中康纸业有限公司

Preparation methods of imrecoxib intermediate and imrecoxib

ActiveCN108707100AReduce usageMeet high standardsOrganic chemistryOrganic compound preparationAcetophenoneSolvent

The invention discloses preparation methods of an imrecoxib intermediate and imrecoxib. The preparation method of N-propyl-N-[2-oxo-2-(4-mesylphenyl)]ethyl-4-methyl phenyl acetamide as the imrecoxib intermediate comprises the following steps of performing substitution reaction on 2-amino-1-p-methylsulfonyl acetophenone and 1-halopropane in a system of an acid binding agent and a solvent to obtain2-propylamino-1-p-methylsulfonyl acetophenone; and enabling 2-propylamino-1-p-methylsulfonyl acetophenone and p-methyl phenylacetyl halide to perform amidation in the system of the acid binding agentand the solvent to obtain N-propyl-N-[2-oxo-2-(4-mesylphenyl)] ethyl-4-methyl phenyl acetamide. The preparation method of the imrecoxib comprises the following step of performing condensation and cyclization reaction on N-propyl-N-[2-oxo-2-(4-mesylphenyl)] ethyl-4-methyl phenyl acetamide in a system of an alkaline matter and a solvent on the basis. The synthetic route provided by the invention enables the reaction process to be more simple and post-treatment separation to be easier and is capable of acquiring ideal yield.

Owner:江苏美迪克化学品有限公司

Multi-layer efficient waterproof rolled material and its manufacturing method

InactiveCN1814439AExtended service lifeMeet high standardsRoof covering using flexible materialsSynthetic resin layered productsWork in processMono layer

The invention relates to a multilayer high effective water proof coiled material and the manufacture method. The main feature is that it is constructed by upper coating layer, water proof base layer, water proof base plies, 1-3 sets water proof unit layer constructed by single water proof base layer, single layer water proof plies, water proof base layer, water proof plies, water proof base layer and down coating layer. Taking draught to the two layers or 3-5 layers basal plies, superposing and cutting the brim, separating the basal plies to 15-30cm until finishing the dipping mixture process, razing the rest mixture to from 0.2-0.5mm water proof basal layer, adhering coating material, the multiplayer high effective water proof coiled material would be formed. It is mainly used in construction.

Owner:邓世超

Production method of high straightness super-strength steel

The invention discloses a production method of high straightness super-strength steel. A steel production process route comprises the following steps: pretreatment of molten iron, converter smelting,LF external refining, VD vacuum treatment, continuous casting, heating, rolling, straightening, quenching, tempering, finishing, performance inspection, and flaw detection. The high straightness super-strength steel is characterized by being prepared from the following chemical components in percentage: 0.15 to 0.20 percent of C, 0.15 to 0.35 percent of Si, 1.0 to 1.50 percent of Mn, smaller thanor equal to 0.012 percent of P, smaller than or equal to 0.003 percent of S, 0.010 to 0.030 percent of Nb, 0.015 to 0.040 percent of V, 0.010 to 0.025 percent of Ti, 0.020 to 0.045 percent of Als, 0.040 to 0.60 percent of Cr, 0.10 to 0.30 percent of Mo, 0.20 to 0.50 percent of Ni, 0.0008 to 0.0025 percent of B, smaller than or equal to 0.60 percent of CEV and the balance of Fe and inevitable impurities. The super-strength steel has the characteristics that the production thickness is 6 to 25 mm, the width is 1,500 to 3,800 mm, the yield strength of a steel plate is greater than or equal to 1,100 MPa, the tensile strength is greater than or equal to 1,200 MPa, the elongation percentage is greater than or equal to 11 percent, the impact work at -40 DEG C below zero is greater than or equal to 50 J and the straightness in any direction of the steel plate is smaller than or equal to 3 mm / m.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Alclad casting ingot rolling method

InactiveCN104525563AImprove surface qualityConsistent surface quality levelsRoll mill control devicesMetal rolling arrangementsIngot castingAlclad

The invention provides an alclad casting ingot rolling method. The alclad casting ingot rolling method comprises the following steps of firstly feeding a casting ingot and a alclad plate after milling into a rolling gap to enable a casting ingot welding central line and a rolling gap to be coincided, performing static pressure welding rolling and obtaining an alclad casting ingot after first-time rolling; performing second-time rolling on the first-time rolled alclad casting ingot after heating and obtaining a rolled alclad casting ingot, wherein the alclad casting ingot is obtained from the above step; wherein the second-time rolling comprises a structure welding process, a structure improvement process, a depress deformation process and a plate shape control process. According to the alclad casting ingot rolling method, rolling is performed in twice, process parameters are controlled, and the temperature for second-time rolling is fit, so that the surface quality of plates after rolling is stable and surface 11# defects generated during the rolling process are eliminated.

Owner:SOUTHWEST ALUMINUM GRP

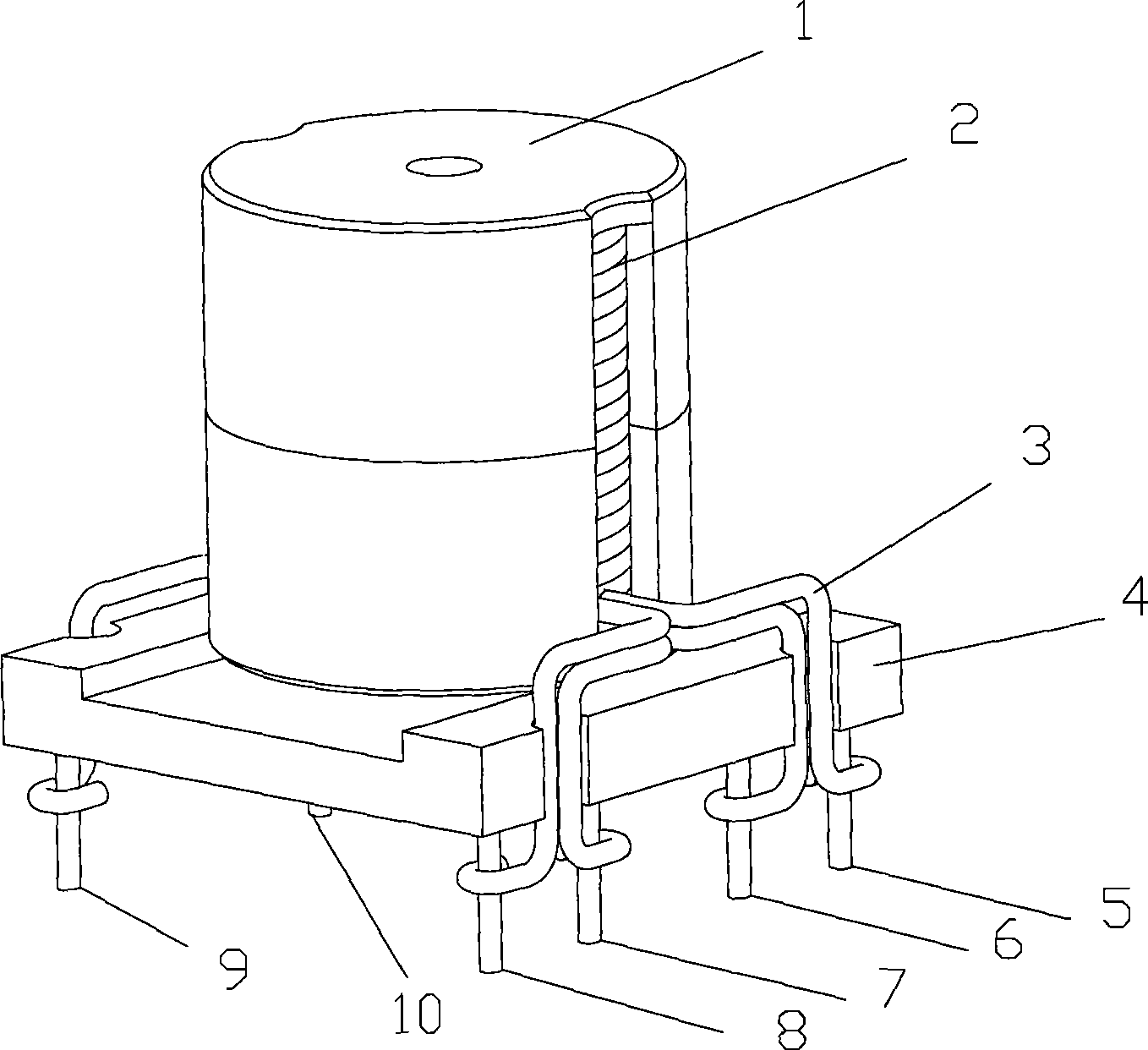

Pulse transformer for driving isolated gate double-base transistor

InactiveCN101447321AImprove the performance index of electromagnetic compatibilityImprove performance indicatorsTransformers/inductances coils/windings/connectionsCouplingPerformance index

The pulse transformer for a driving an isolated gate double-base transistor in the invention changes layering and grouping coiling into mixing layer coiling, thus strengthening and deepening coupling degree, so that the parameters and functions such as impedance, inductance, coupling degree, waveform and the like of various secondary levels and windings are basically consistent, thus providing identical driving waveform and conditions for a bridge arm which needs to open and close simultaneously in the working process of IGBT, improving the working reliability of IGBT, reducing noise wave and spike, improving efficiency and reducing loss. The adoption of high-temperature lead can satisfy high-standard requirements, and the selection of a can-shaped magnetic core ensures excellent shielding effect and improves performance index of electromagnetic compatibility of the pulse transformer. Summarizing all the advantages, the IGBT driving transformer is an ideal transformer for driving IGBT.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

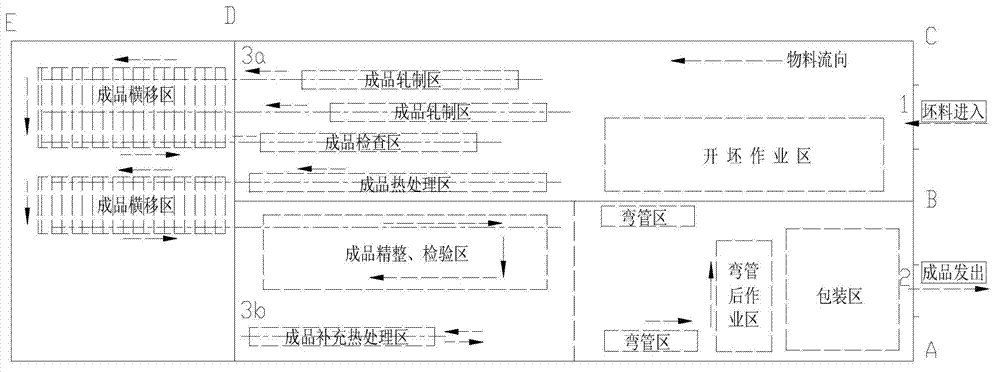

690 alloy U-shaped heat transfer pipe production line for nuclear power evaporator

The invention discloses a 690 alloy U-shaped heat transfer pipe production line for a nuclear power evaporator. The 690 alloy U-shaped heat transfer tube production line comprises two adjacent longitudinal spans and a transverse span which is arranged at the ends of the two adjacent longitudinal spans and is adjacent to and perpendicular to the two adjacent longitudinal spans; the whole production line has an n shape; a cogging area, a finished product area, a blend area and other production operation areas are respectively arranged in two adjacent longitudinal span plants (AB and BC spans), and the transverse plant (DE span) is mainly used for span transfer for finished product elongated pipes. The pipe blank enters into the n-shaped factory from one end of the longitudinal plant and is gradually pushed in the communicating area according to the process flow, and the finished products are discharged from the other end of the adjacent longitudinal plant; and the whole process is smooth, and the technical problem that the super-long pipes (28m) need to be repeatedly transferred in multiple production spans can be solved, so that the non-grounded production of the 690 alloy U-shaped pipes is realized, and the continuous and stable operation of the whole production process is guaranteed.

Owner:BAOYIN SPECIAL STEEL TUBE CO LTD

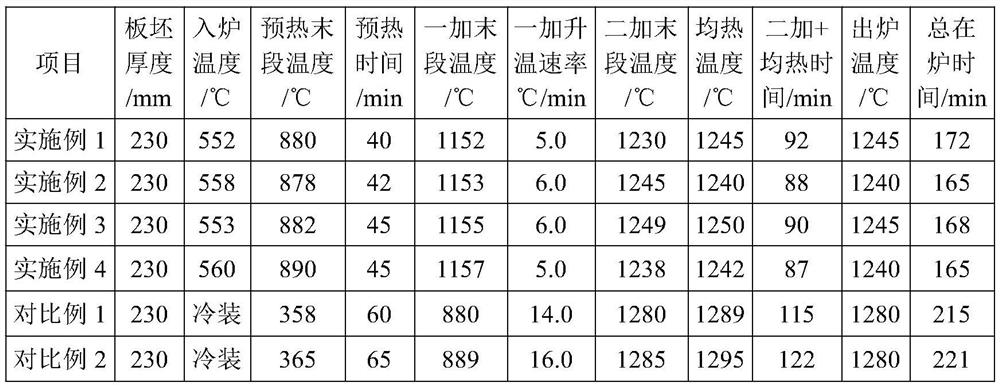

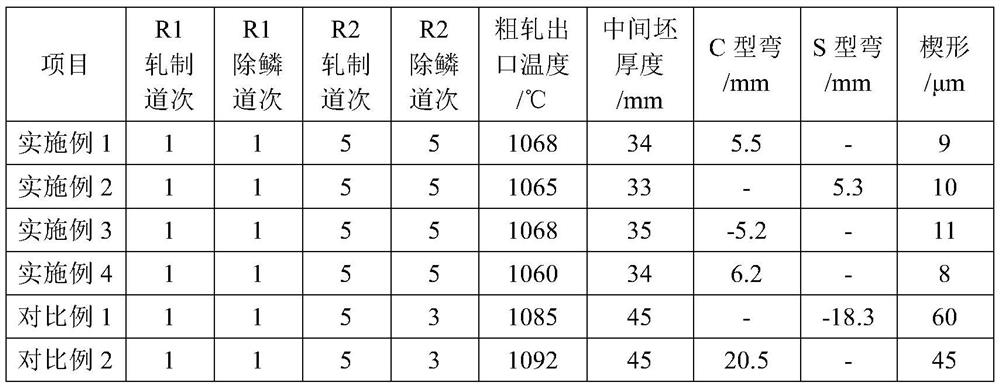

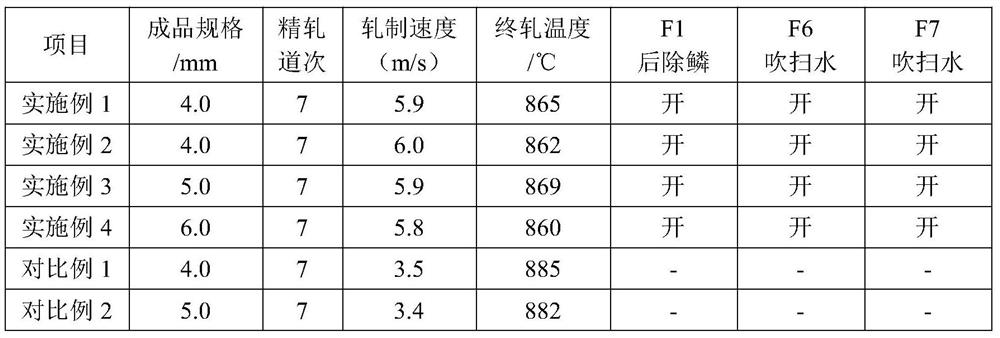

Plate shape control method for steel for hot-rolled high-strength stirring tank body

ActiveCN112108527AReduce cooling-heating historySmall footprintTemperature control deviceRollsProduction lineTemperature control

Owner:武汉钢铁有限公司

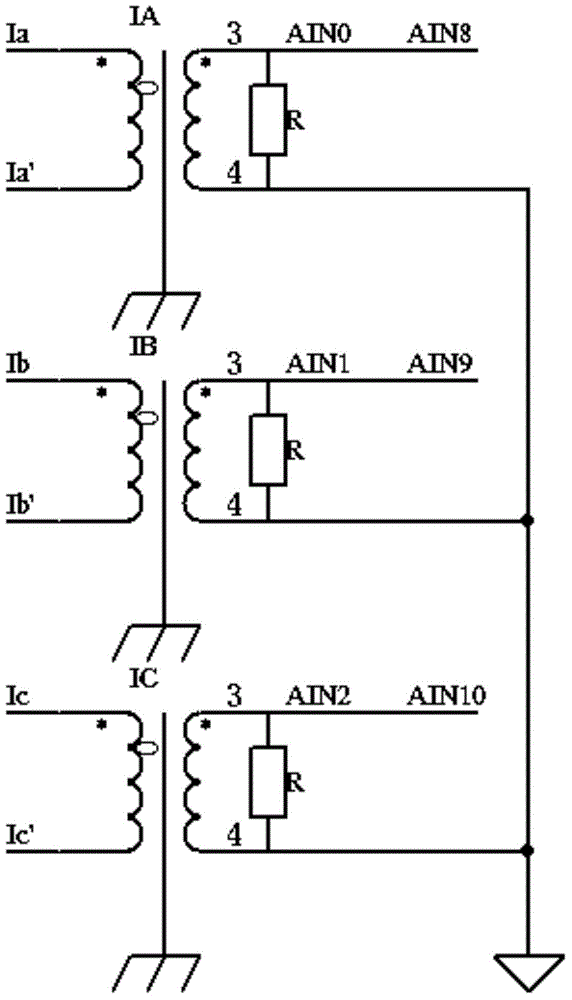

Digitalized protection and measuring/control device integrated with metering function

InactiveCN103337905AMeet high standardsImprove reliabilityCircuit arrangementsSmart substationTransformer

The invention discloses a digitalized protection and measuring / control device integrated with a metering function. The device comprises a protection and measuring / control CPU module, an input / output module, and a sampling module. The device is characterized in that: a metering module is also included in the device; the metering module uses a built-in metering mutual inductor to receive analog quantity sampling data; or the metering module receives IEC61850-9-2 format sampling data through an optical port of the protection and measuring / control CPU module to carry out an electric energy calculation. The device can meet application demands of the conventional transformer station and the intelligent transformer station; and the alternating current sampling can support the conventional analog quantity acquisition and can receive the sampling data of the IEC61850-9-2 or IEC60044-8 output format from a merging unit. The trip-out mode can support the conventional contact mode output, and can also support outputting a trip-out signal in a GOOSE network message mode. The original installation devices are reduced; the integrated level of the device is increased reasonably; and the device can realize the protection, measuring and metering function.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

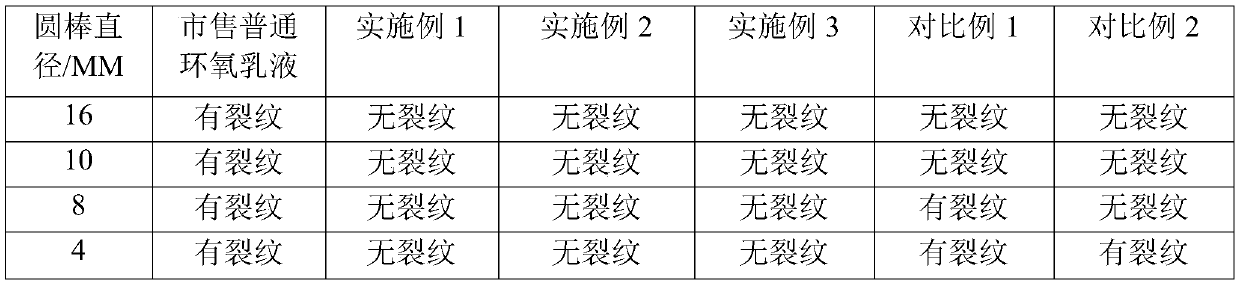

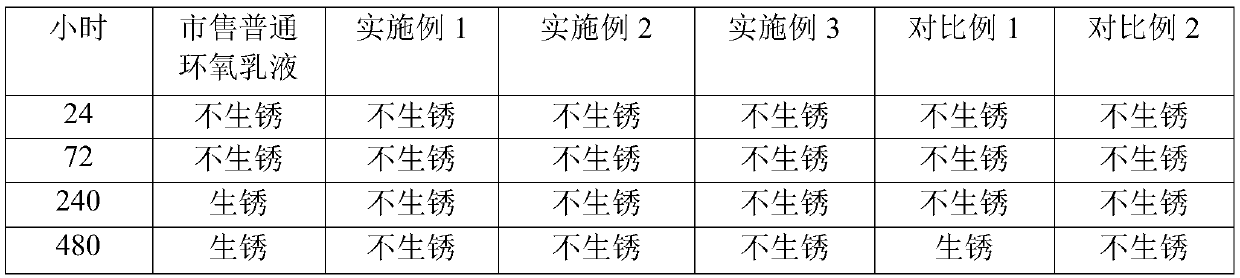

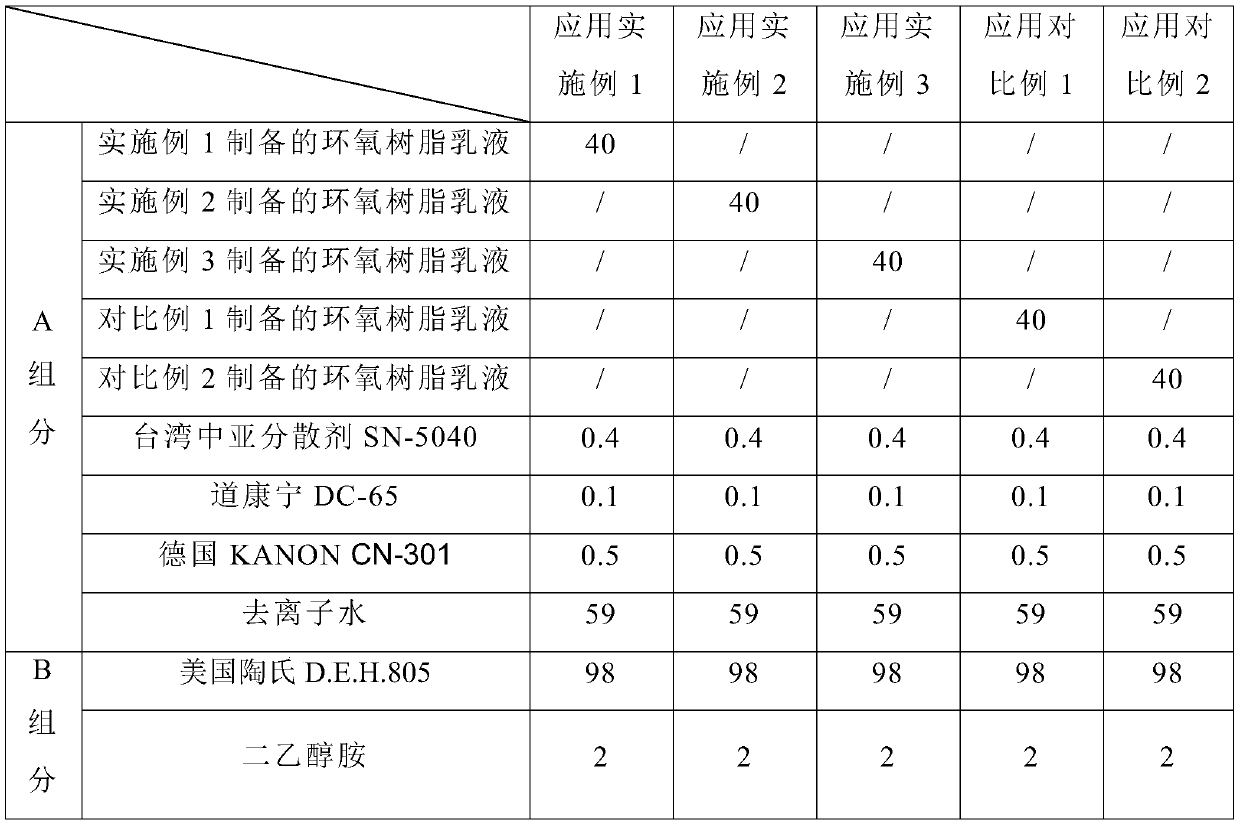

Self-emulsifying epoxy resin emulsion and preparation method and application thereof

ActiveCN110804371AGive full play to its own characteristicsMeet high standardsAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphoric Acid Esters

The invention discloses a self-emulsifying epoxy resin emulsion and a preparation method and application thereof. The self-emulsifying epoxy resin emulsion comprises following raw materials in parts by weight: 100 to 150 parts of epoxy resin, 10 to 20 parts of sorbitan polyoxyethylene ether fatty acid ester, 10 to 20 parts of polyoxyethylene aliphatic alcohol phosphate, 1 to 5 parts of an amine promoter, and 100 to 10000 parts of water. The mass ratio of epoxy resin to sorbitan polyoxyethylene ether fatty acid ester is 1: 0.075-0.18, and the mass ratio of epoxy resin to polyoxyethylene aliphatic alcohol phosphate is 1: 0.07-0.2. The preparation method comprises following steps: carrying out first reactions between epoxy resin and sorbitan polyoxyethylene ether fatty acid ester in the presence of the amine promoter, then carrying out second reactions with polyoxyethylene aliphatic alcohol phosphate, and mixing the reaction product with water. The invention also discloses an applicationof the emulsion in epoxy paints. The provided emulsion can carry out self-emulsifying in the absence of a co-solvent to obtain stable and uniform emulsion. The storage period is long, no VOC is discharged, and after curing, the coating has high toughness and an excellent anti-rust performance.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

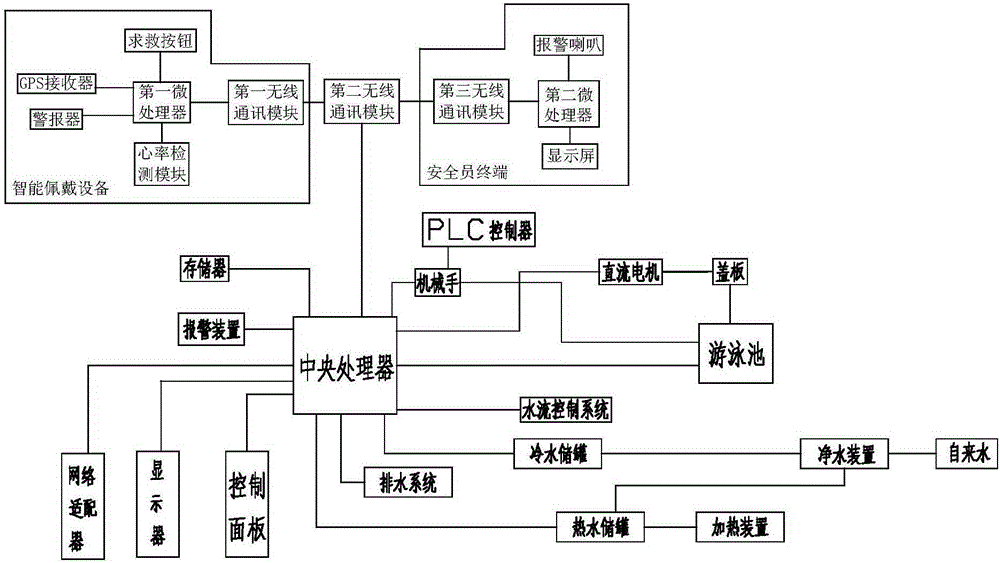

Control method of intelligent swimming pool

The invention provides a control method of an intelligent swimming pool. The control method comprises the following steps: setting an upper limit value of a water level in a cold-water storage tank, the lower limit value of a water level in the cold-water storage tank, the upper limit value of water temperature in the cold-water storage tank, and the lower limit value of water temperature in the cold-water storage tank; when the water level in the cold-water storage tank is lower than the lower limit value, starting a water purifying device and injecting purified tap water into the cold-water storage tank; when the water level in the cold-water storage tank reaches the upper limit value, closing the water purifying device and stopping injecting water; and when the water temperature in the cold-water storage tank is higher than the upper limit value, starting the water purifying device and injecting purified tap water into the cold-water storage tank. The control method of the intelligent swimming pool integrates a highly intelligent drainage system, a water feeding system and a cleaning system; when the water temperature, the water level and the water quality do not meet requirements, the swimming pool can automatically adjust; the drainage system, the water feeding system and the cleaning system cooperate with each other, so that the water in the swimming pool reaches the best using state, and the high-standard requirements of the public for the swimming pool are met.

Owner:江苏耀康自动化科技有限公司

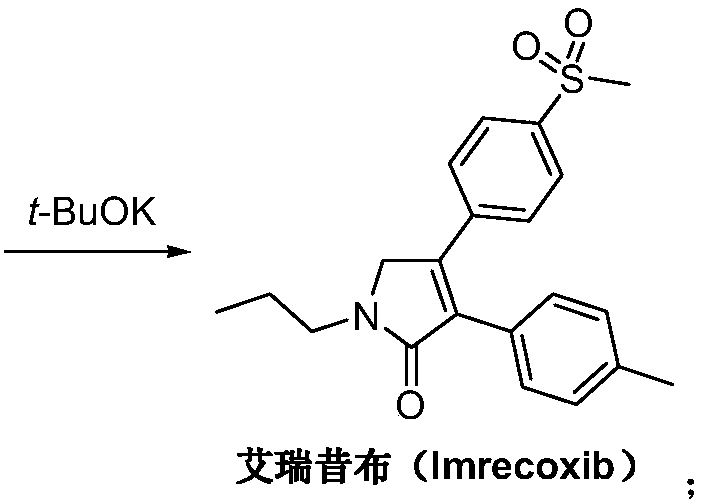

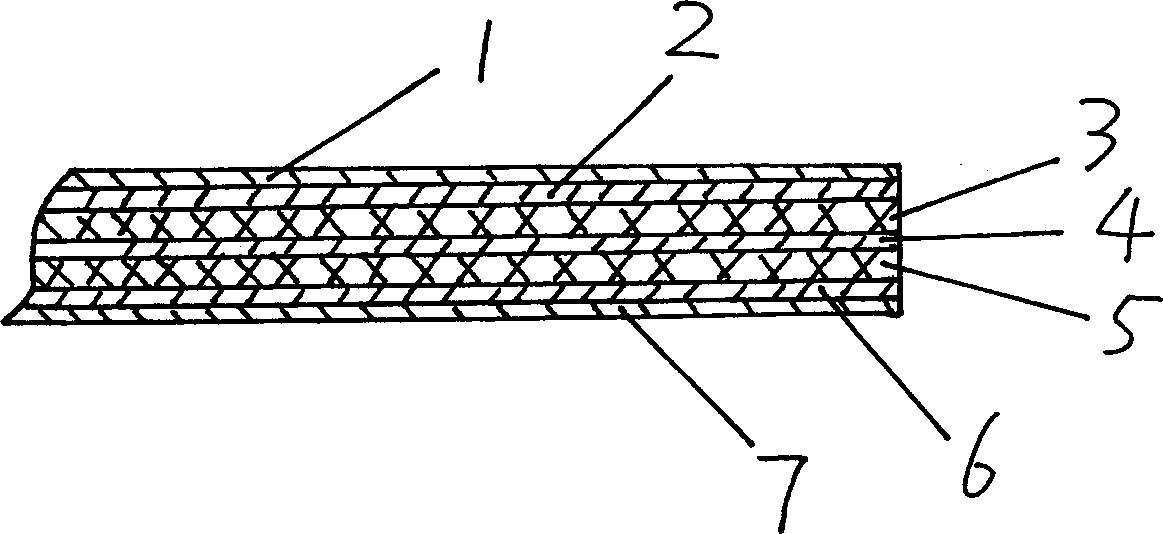

Fire-retarding thermal-shrinked indicated double pipe of radiant cross-linked and its preparation method

ActiveCN100387646CGood weather resistanceGood wipe resistanceTubular articlesCross-linkCarvacryl acetate

A radiant cross-linking fire-retardant and heat-shrinkage indicating double pipe and its production are disclosed. The process is carried out by taking ethane-vinyl acetate multi-polymer, ethane-ethyl acrylate multi-polymer, ethylene-propylene rubber, fire-retardant decabromodiphenyl ethane, antimonous oxide, surface-activated superfine-magnesium hydrate and auxiliary as raw material, mill granulating, extrude forming, radiant cross-linking, expand sizing, and finish treating. It has better weather-resisting, high and low-temperature-resisting, anti-corrosive and antibacterial performances and long-period storage. It can be used for military industry, aviation and aerospace, civil high-terminal electronic equipment and cable.

Owner:广州凯恒科塑有限公司

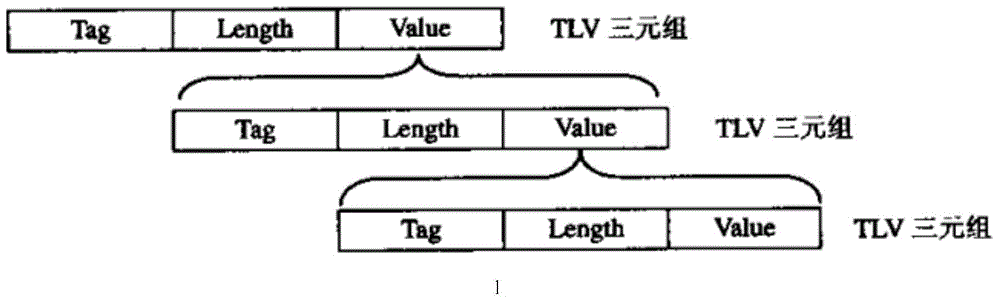

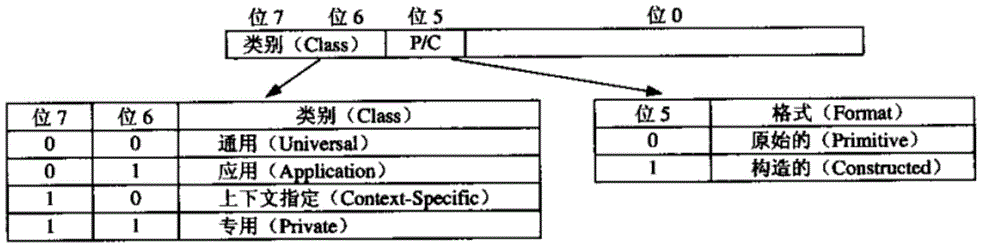

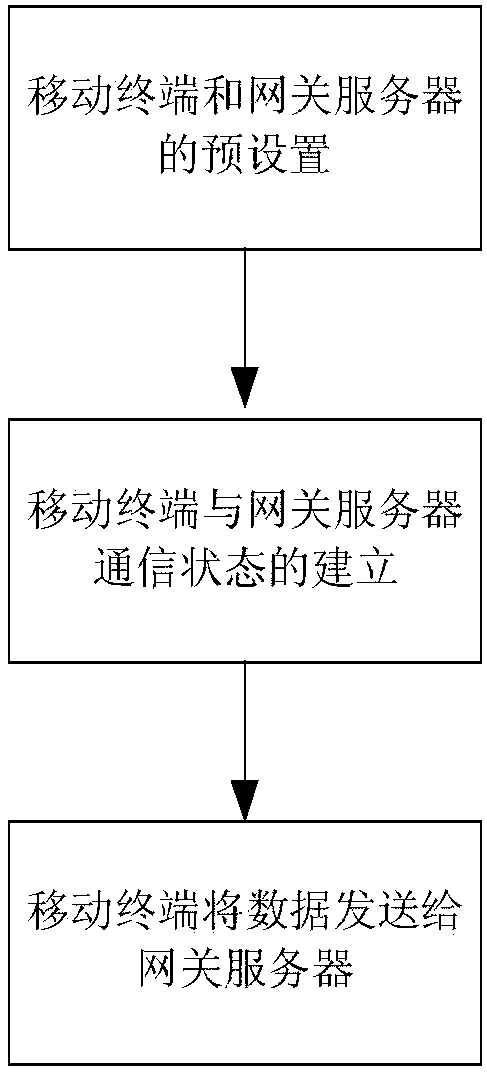

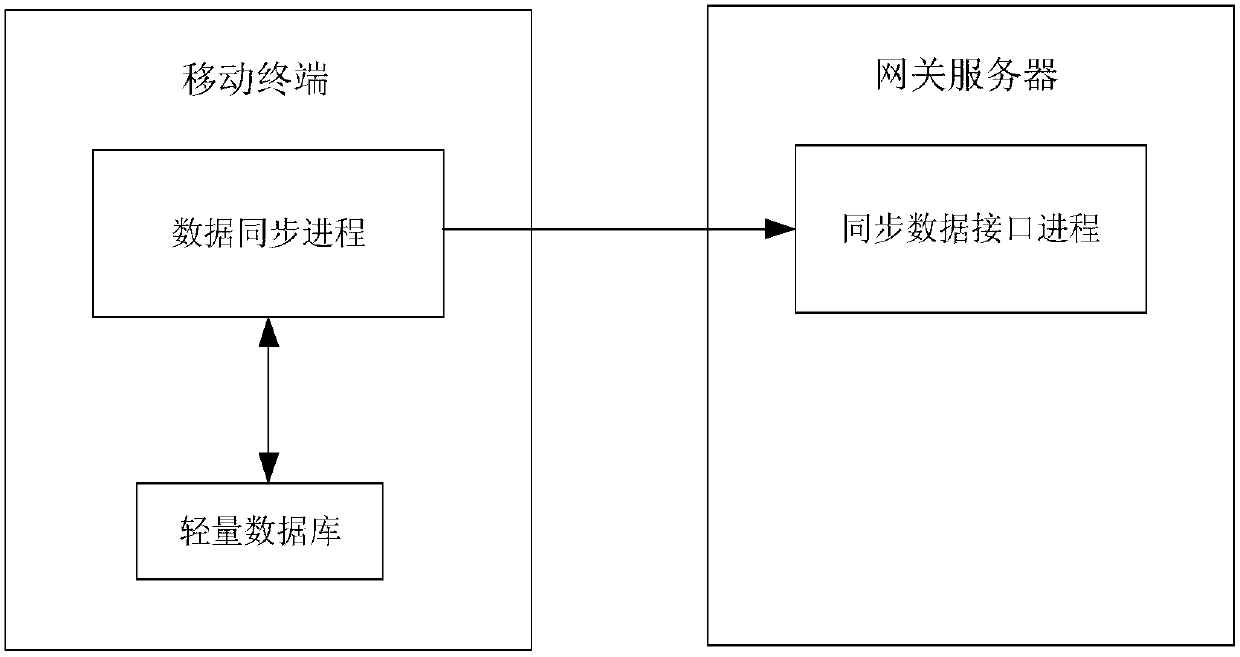

Transmission method between mobile terminal and gateway server in finance security protection environment

InactiveCN107800699AMeet high standardsGuaranteed continuous useTransmissionData transmissionHigh security

The invention relates to a transmission method between a mobile terminal and a gateway server in a finance security protection environment. Compared with the prior art, the method has the advantages that the defect that a transmission mechanism between a smart terminal and the gateway server cannot satisfy a high security demand is solved. The method comprises the following steps of presetting themobile terminal and the gateway server, specifically, carrying out offline data transmission presetting on both the mobile terminal and the gateway server; establishing a communication state betweenthe mobile terminal and the gateway server, specifically, sending a communication request by the mobile terminal, and establishing communication connection between the mobile terminal and the gatewayserver; sending data to the gateway server by the mobile terminal, and carrying out message body segmentation on the data by the mobile terminal and then sending message bodies to the gateway server;and receiving the message bodies sent by the mobile terminal by the gateway server and combining the message bodies. According to the method, the data transmission between the mobile terminal and thegateway server can be realized.

Owner:安徽兆尹信息科技股份有限公司 +1

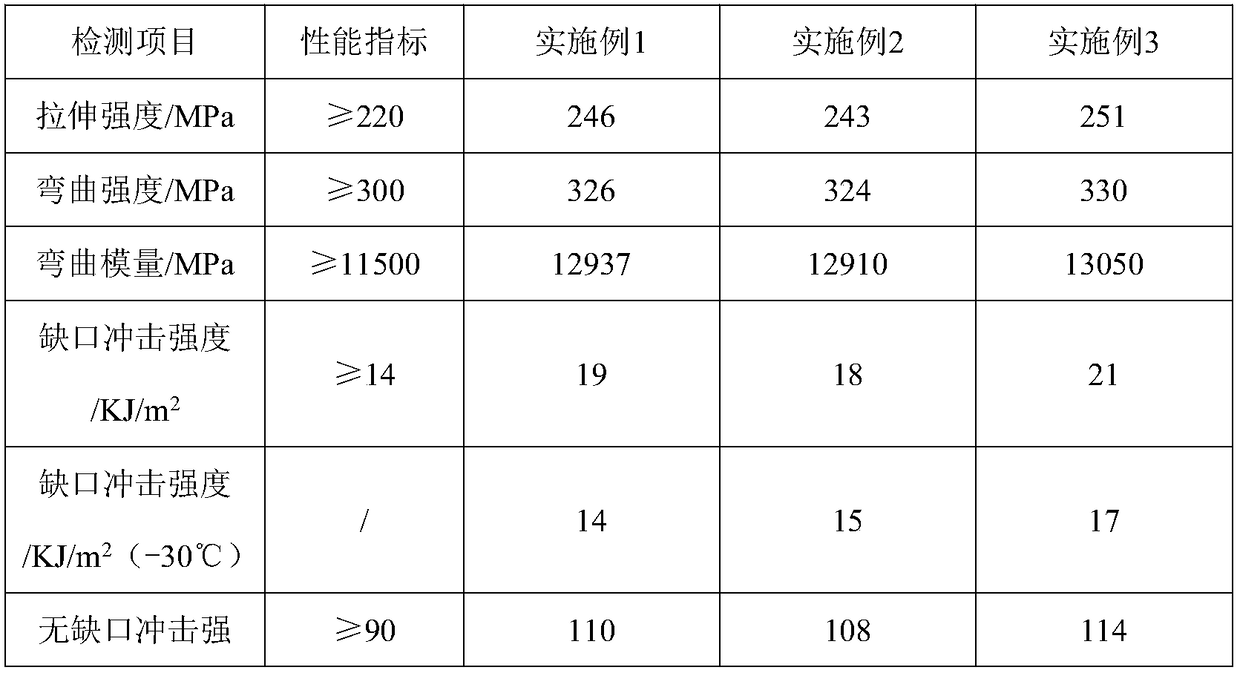

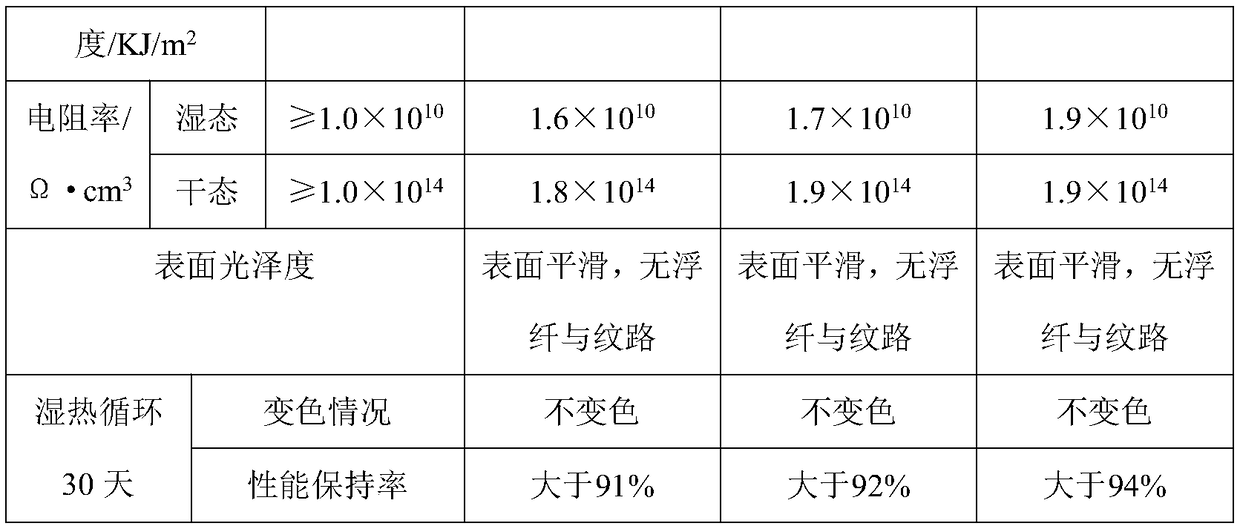

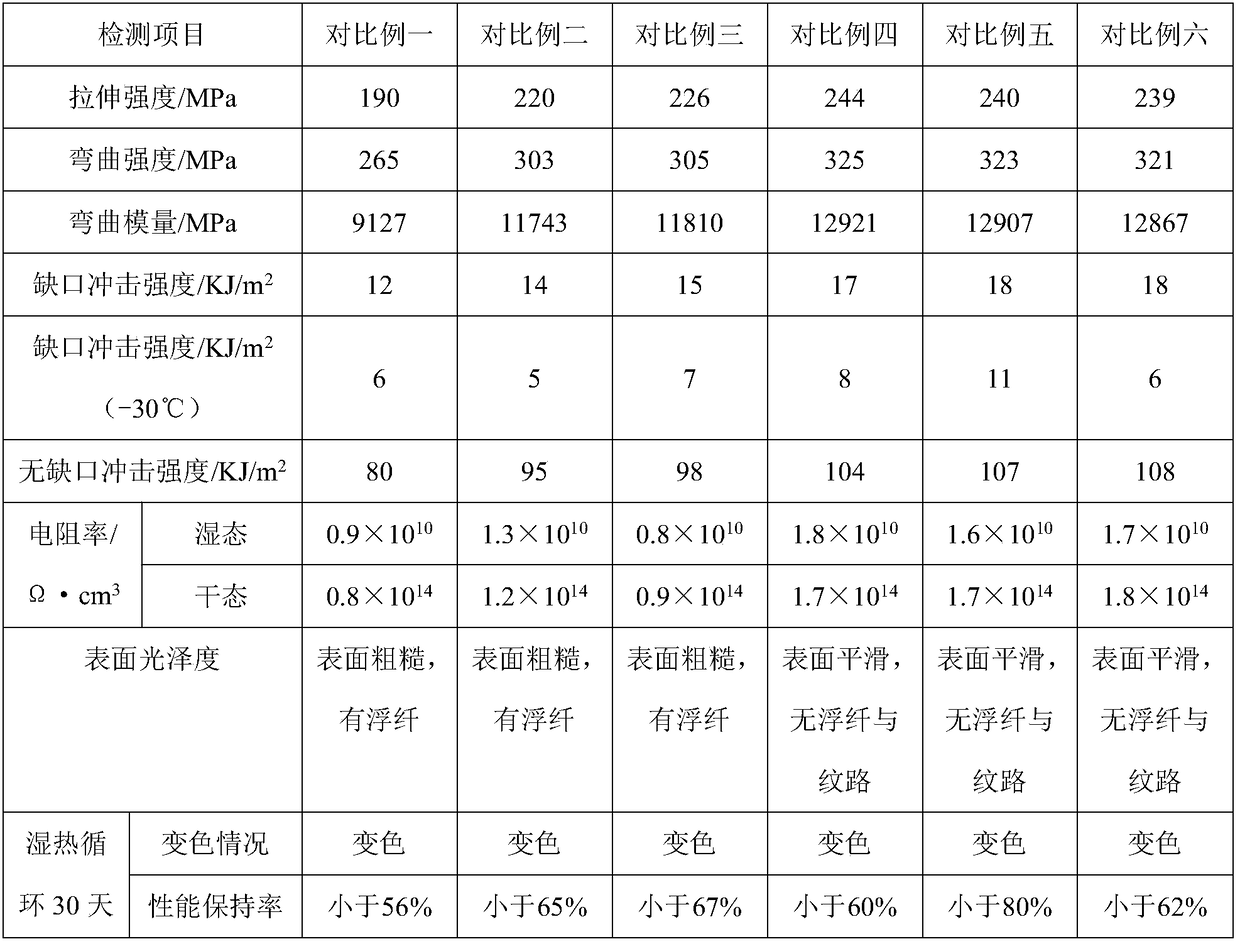

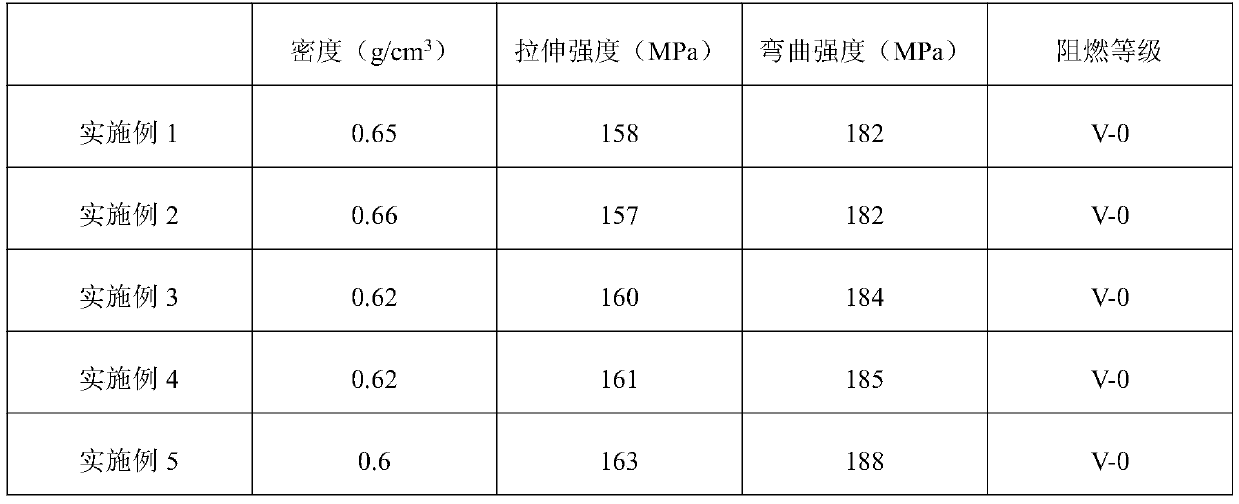

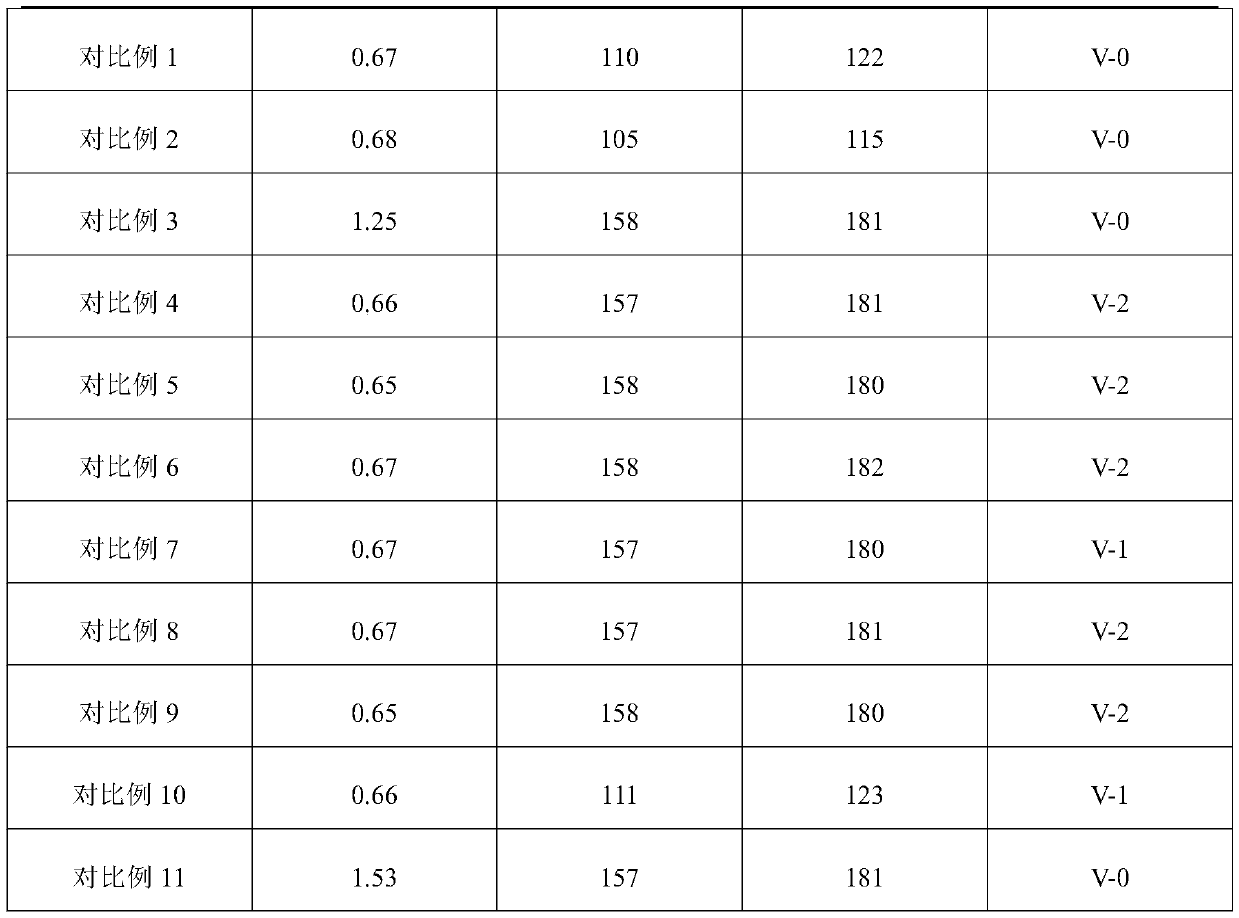

Glass fiber enhanced PA66 base plate material for high speed rail and preparation method thereof

ActiveCN109181292AImprove water absorption and dimensional stabilityHigh tensile strengthAntioxidantHigh standard

The invention belongs to the technical field of high molecular materials and in particular relates to a glass fiber enhanced PA66 base plate material for a high speed rail and a preparation method thereof. The glass fiber enhanced PA66 base plate material for the high speed rail is prepared from the following preparation raw materials in percent by weight: 28.0-34.0% of PA66 resin, 6.0-10.0% of PA6T resin, 0.6-1.0% of an antioxidant, 0.3-0.5% of a lubricant, 6.0-10.0% of inorganic filler, 1.0-2.0% of a flexibilizer and 49.0-51.0% of glass fibers. The material is low in water absorption and stable in dimension, considers good processing property and mechanical property, is good in toughness, high in strength, good in impact resistance, resistant to ageing, high temperature, high humidity and low temperature and excellent in comprehensive property, and meets the high standard demand of the high speed rail base plate.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

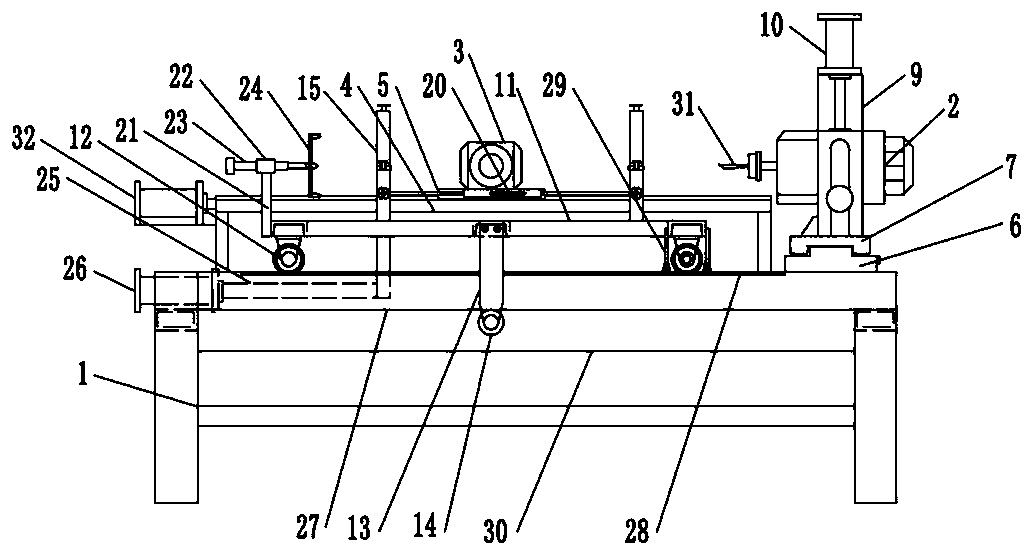

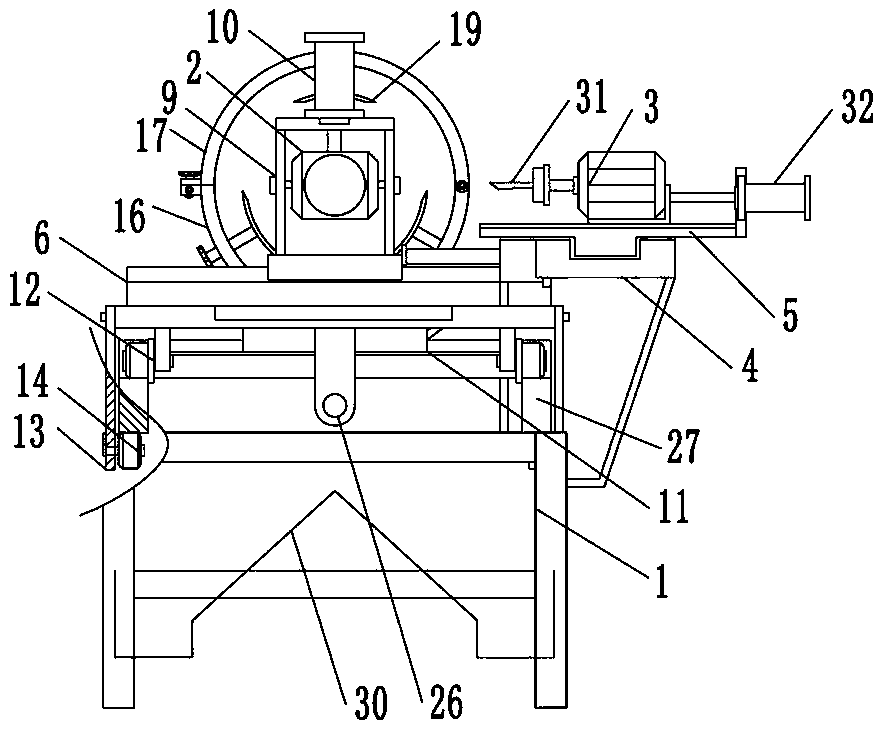

Multifunctional horizontal numerical control wood working lathe for machining elephant-foot drum

ActiveCN109333685AEasy to processGuaranteed stabilityWood-turning machinesNumerical controlMovement control

The invention discloses a multifunctional horizontal numerical control wood working lathe for machining an elephant-foot drum. The multifunctional horizontal numerical control wood working lathe comprises a lathe bed and a main turning tool mechanism arranged at any end of the lathe bed. An auxiliary guide rail parallel to the lathe bed is arranged on any side of the lathe bed and provided with anauxiliary turning tool mechanism which is in movable fit with the auxiliary guide rail. The auxiliary turning tool mechanism is perpendicular to the axis of the lathe bed. The lathe bed is provided with a sliding rail. The sliding rail is provided with a lifting frame which is in sliding fit with the sliding rail. A main turning tool mechanism is arranged on the lifting frame, the lathe bed is provided with a positioning support which is in movable fit with the lathe bed, and an adjusting groove is symmetrically provided with fixing clamps. The main turning tool mechanism, the auxiliary turning tool mechanism, a sliding block driver, a feeding driver and a lifting driver are electrically connected with a control device. The multifunctional horizontal numerical control wood working lathe can clamp and fix the two ends of elephant-foot drum machining wood at the same time, a clamping mechanism and the turning tool mechanisms can move, multi-movement control is more accurate, axial and transverse cutting, drilling and reshaping are conducted on the wood, the elephant-foot drum forming operation is rapidly finished, and the producing and machining efficiency is improved.

Owner:朗四

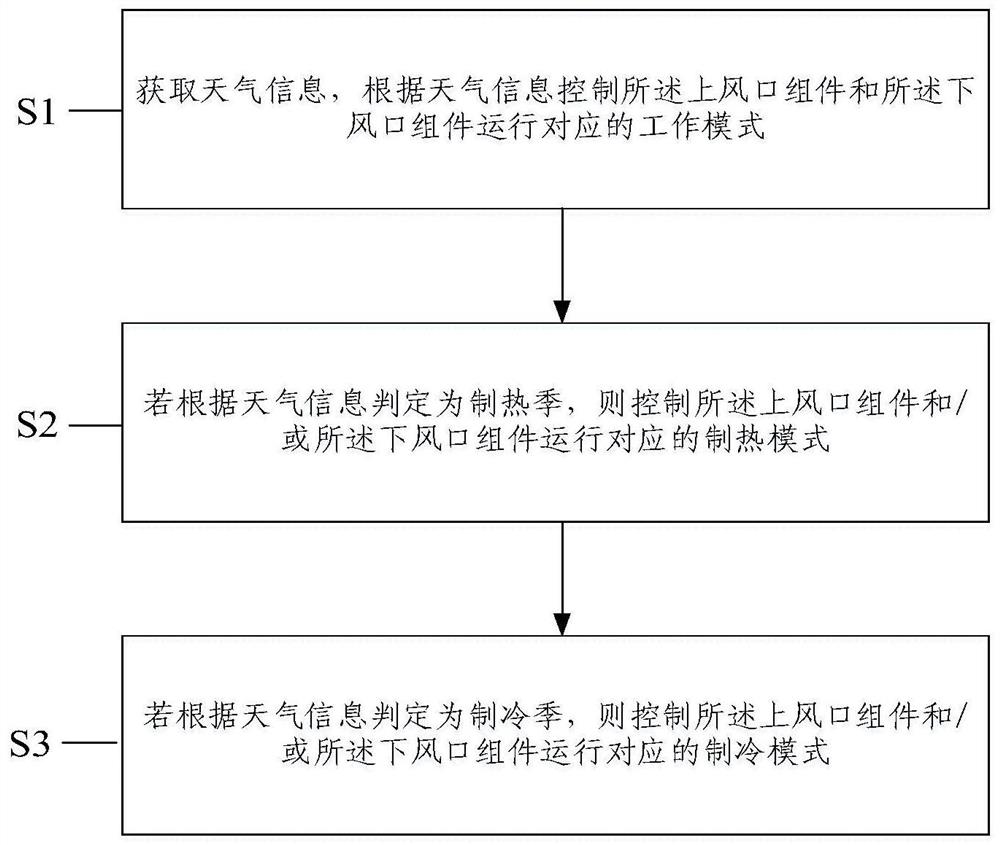

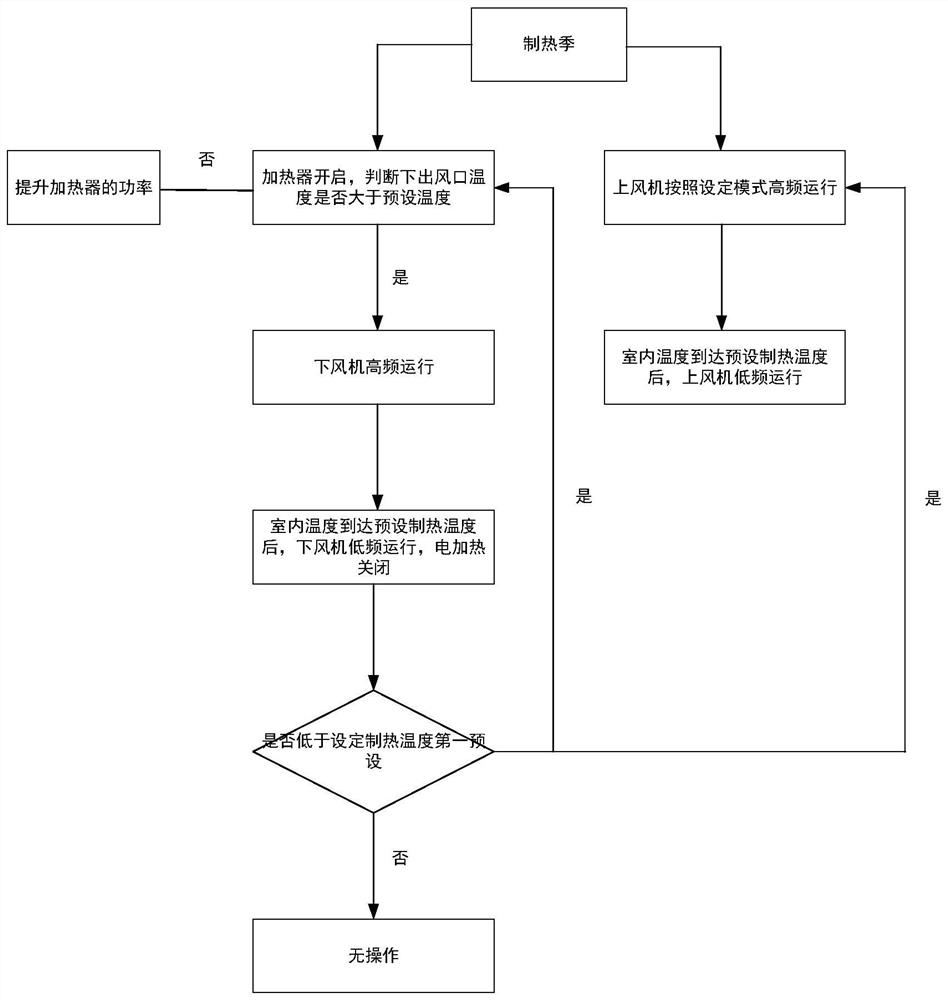

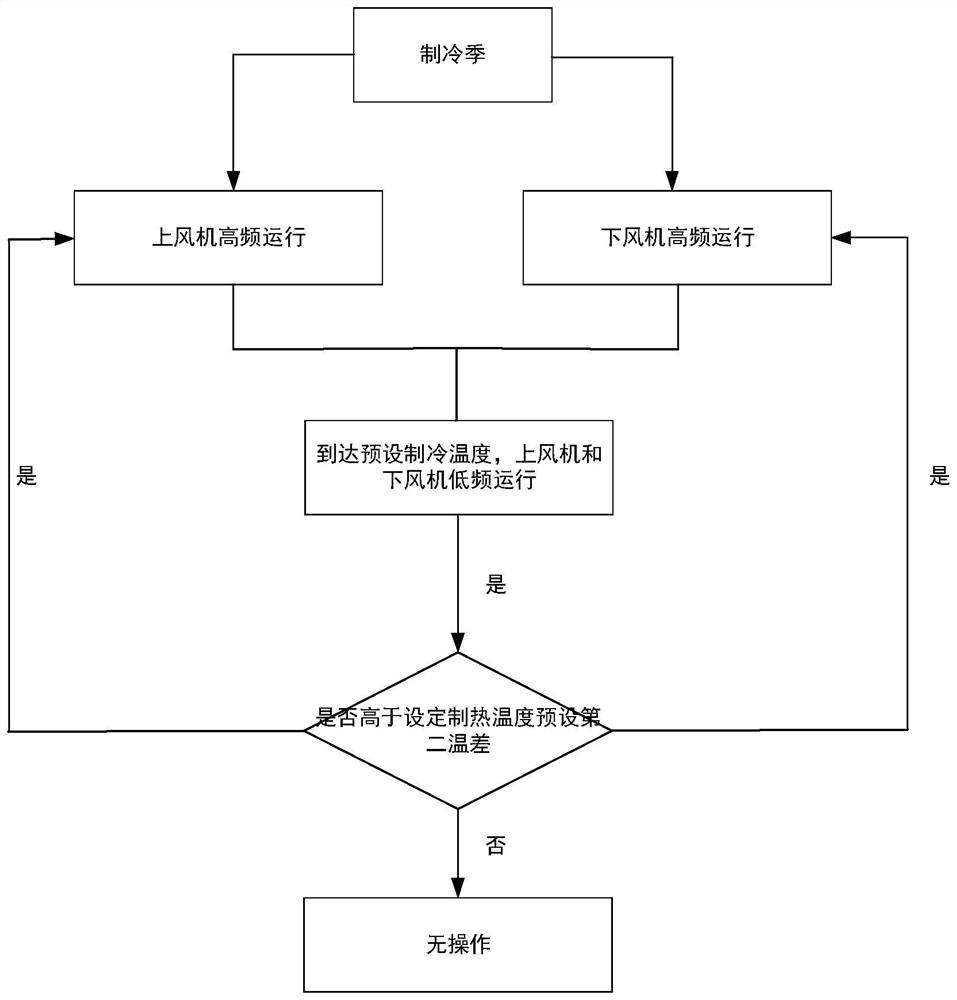

Air conditioner, up-down air outlet control method of air conditioner, and computer readable storage medium

ActiveCN113154652AImprove experienceMeeting high standards of comfortMechanical apparatusSpace heating and ventilation safety systemsInformation controlProcess engineering

The invention provides an air conditioner, an up-down air outlet control method of the air conditioner, and a computer readable storage medium. The method comprises the following steps that weather information is obtained, and an upper air opening assembly and a lower air opening assembly are controlled to operate corresponding working modes according to the weather information; if a heating season is judged according to the weather information, the upper air opening assembly and / or the lower air opening assembly are / is controlled to operate in corresponding heating modes; and if a refrigeration season is judged according to the weather information, the upper air opening assembly and / or the lower air opening assembly are / is controlled to operate in corresponding refrigeration modes. According to the up-down air outlet control method of the air conditioner, the working modes of the upper air opening assembly and the lower air opening assembly in the air conditioner are controlled through the weather information, the indoor temperature can be adjusted through the upper air opening assembly in the heating season, meanwhile, the lower air opening assembly is used for directly blowing the human body, a more intelligent and more accurate control scheme is achieved, the user experience is improved, and the high-standard requirement of a user for the comfort of the room air conditioner is met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

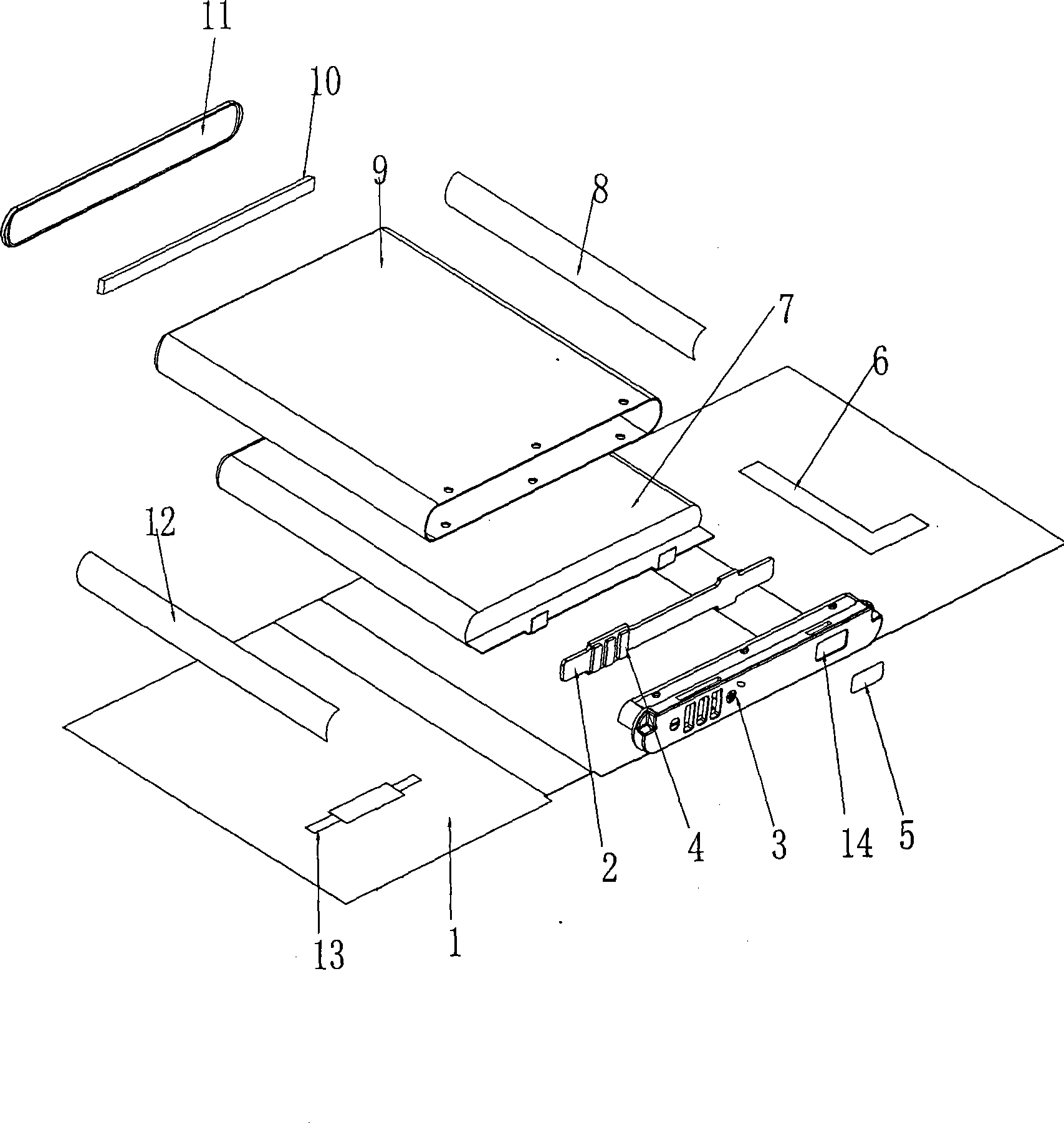

Polymer battery encapsulation method

InactiveCN101533926AIncrease capacityCapacity is easy to guaranteeFinal product manufactureOrganic electrolyte cellsEngineeringBattery cell

A polymer battery encapsulation method, including steps below: setting a PCM board on the upper bottom of a battery cell, to connect the PCM board and the battery cell electrically; clamping the PCM board on a front gluey shell; encapsulating the battery cell with the PCM board and the front glued shell into an aluminium shell; setting a bottom cover on the bottom of the aluminium shell; encapsulating the surface of the outer side of the aluminium shell with label paper. The invention is advanced with simple encapsulation, high productivity effect; the polymer battery cell is safe, secure and reliable in properties, with an appearance satisfied by the clients with high level requirements, with light weight and large upside potential of capacity, and low cost.

Owner:SUNWODA ELECTRONICS

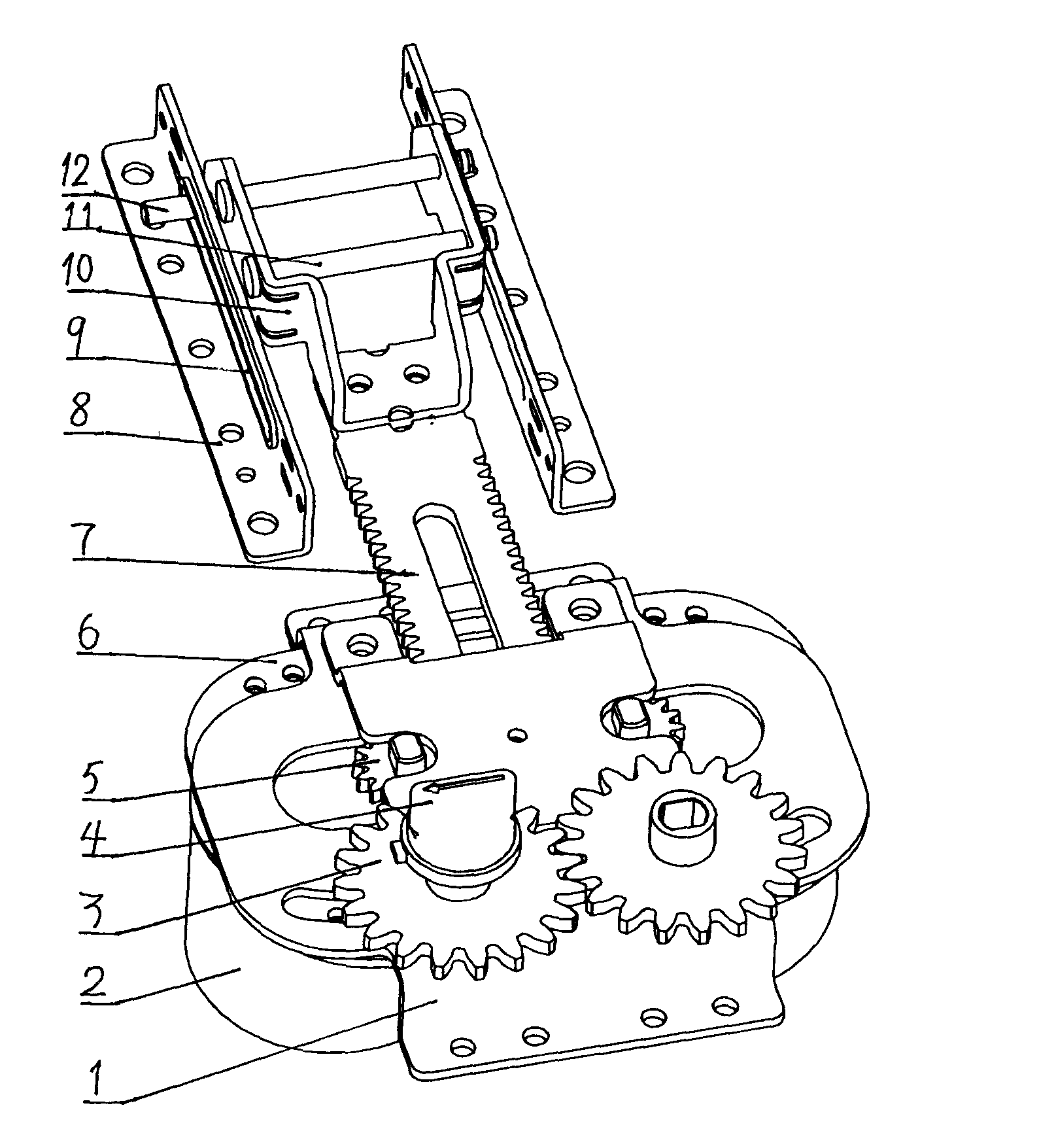

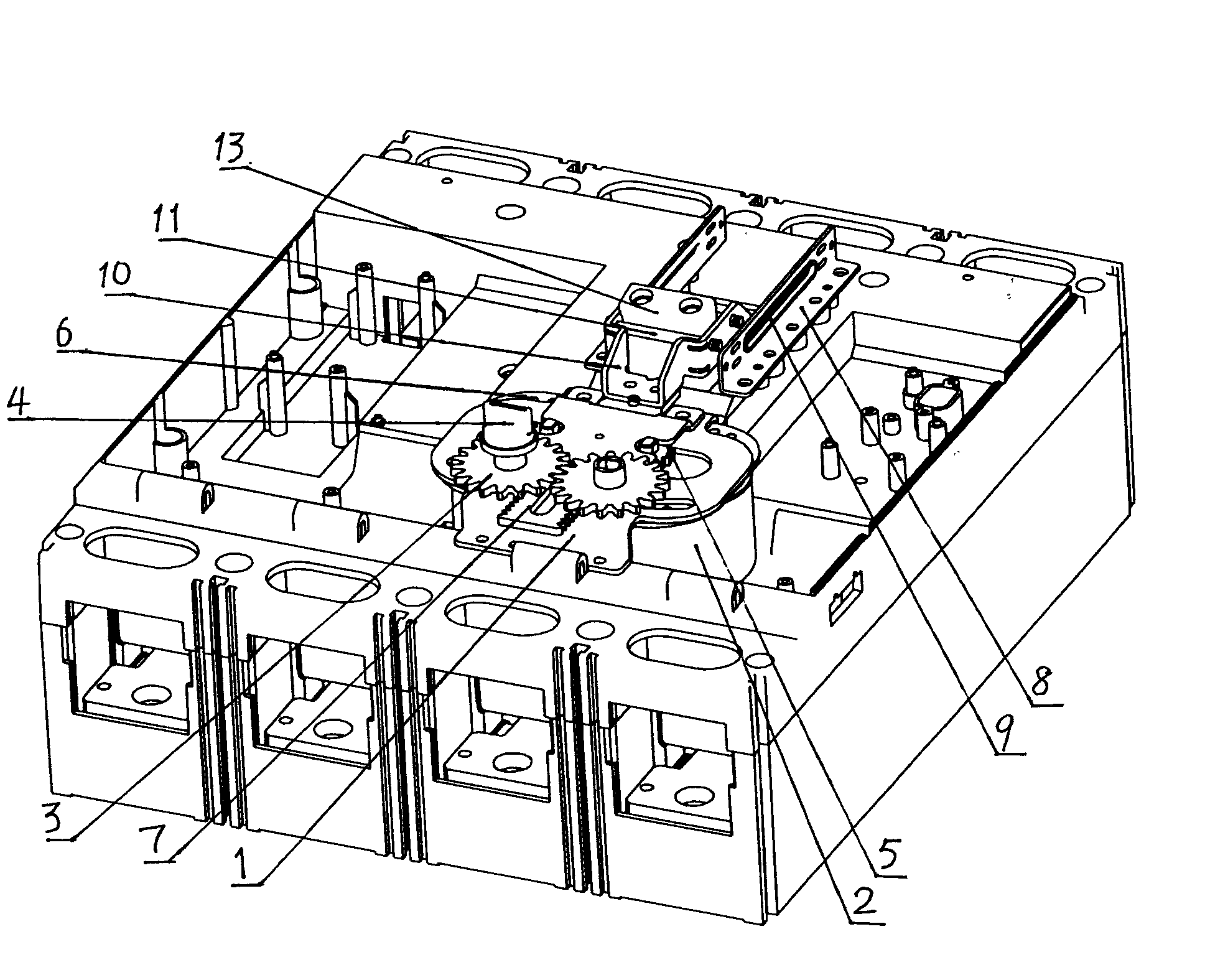

Double-motor operation device of circuit breaker

InactiveCN102842469AMeet high standardsReduce weightProtective switch operating/release mechanismsPower flowEngineering

The invention provides a double-motor operation device of a circuit breaker. The double-motor operation device comprises motors (2), transmission gears (5), a rack (7), a connecting head (10), two clamping rods (11), a slide rail (8), a slide groove (9) and a slide rod (12), wherein motors are a pair of synchronous reversible motors (2) with same specifications and models; the motors are mounted in parallel at the same horizontal height; each motor is provided with the transmission gear (5) at the same horizontal height; the two transmission gears can be respectively engaged with or disengaged from left and right teeth of the same rack (7) according to needs; an upper fixed plate (1) and a lower fixed plate (6) are respectively arranged above and below the transmission gears (5) and the rack (7); and a pair of manual or electric conversion gears (3), which are engaged with each other, are arranged on the upper fixed plate (1), and a knob (4) is arranged on one conversion gear. The double-motor operation device of the circuit breaker, provided by the invention, is suitable for electric and manual dual-purpose operation mechanisms of large-shell-frame plastic shell circuit breakers with rated currents of not less than 800 A and has the advantages of small volume, light weight, low cost, less power consumption and integral height meeting requirements.

Owner:HANGZHOU QIANLONG ELECTRIC

Special metal glaze for ceramic

The invention discloses special metal glaze for ceramic. The special metal glaze comprises 30-50 parts of zinc silicates, 30-60 parts of brown iron ore, 20-30 parts of nanometer zinc oxide, 20-30 parts of nanocrystalline iron oxide, 15-25 parts of silicon dioxide, 5-10 parts of calcium hydroxide, 10-20 parts of sodium sulfate, 10-20 parts of phosphorus pentoxide and 15-30 parts of piperonyl butoxide. The special metal glaze for the ceramic has the advantages of being high in smoothness, good in glaze quality, high in brightness and attractiveness and the like and can meet the high requirement and standard for high brightness of people.

Owner:谢伟杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com