Preparation methods of imrecoxib intermediate and imrecoxib

A technology for erecoxib and intermediates, which is applied in the preparation of erecoxib and the field of erecoxib intermediates, can solve the problems of high toxicity in the operation process and waste water, difficulty in controlling and researching impurities of raw materials, and difficult purification. , to achieve the effect of being conducive to industrialized large-scale production, avoiding heavy metal oxidizing reagents, and optimizing the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

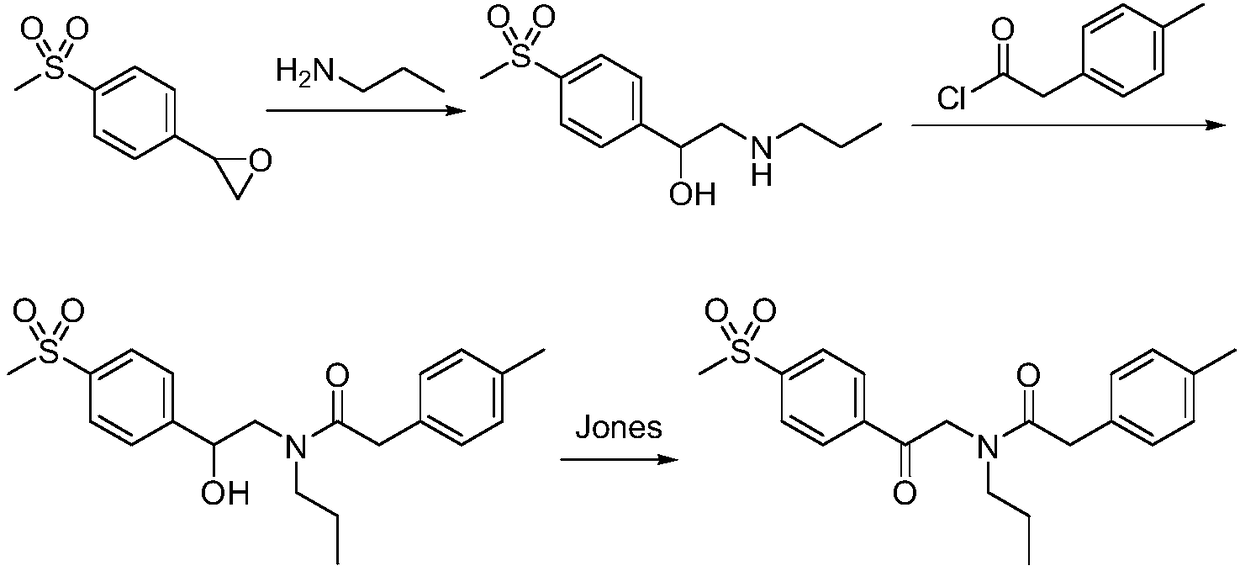

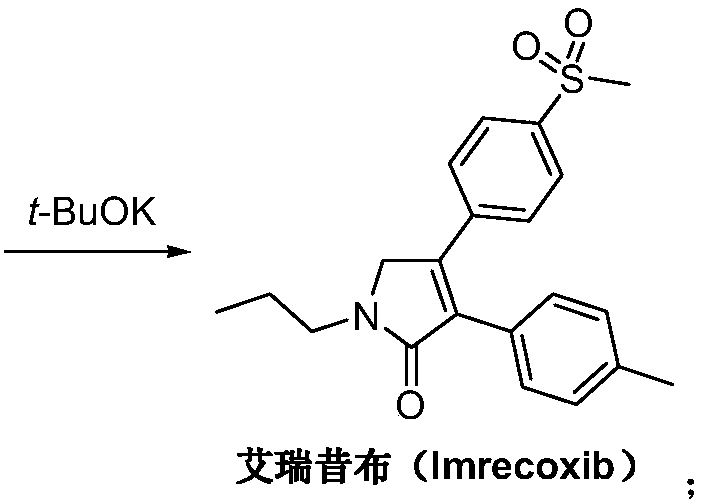

Method used

Image

Examples

Embodiment 1

[0055] A) Preparation of 2-propylamino-1-p-methylsulfonylacetophenone (compound (II)):

[0056] 2-Amino-1-p-methylsulfonylacetophenone (25.6g, compound (I)) was dissolved in N,N-dimethylformamide (150mL), potassium carbonate (41.5g) was added, stirred and cooled in an ice bath To 5~10°C, add 1-chloropropane (10.4g, R is chlorine) dropwise, rise to 100°C and react for 6h until the reaction is complete, then cool down to room temperature, adjust to neutral with 1N hydrochloric acid, remove the organic solvent by rotary evaporation under reduced pressure , added ethyl acetate and water for extraction, separated the organic phase, washed with water and saturated brine successively, dried over anhydrous sodium sulfate, concentrated to dryness by rotary evaporation under reduced pressure, and the obtained crude product was recrystallized with ethanol to obtain 2-propylamino-1 - p-methylsulfonylacetophenone, off-white solid 29.2g, yield 95.3%, purity 98.7%.

[0057] B) Preparation o...

Embodiment 2

[0062] A) Preparation of 2-propylamino-1-p-methylsulfonylacetophenone (compound (II)):

[0063] 2-Amino-1-p-methylsulfonylacetophenone (100.0g, compound (I)) was dissolved in tetrahydrofuran (550mL), cesium carbonate (306g) was added, stirred and cooled to 5-10°C in an ice bath, and 1 -Bromopropane (69.5g, R is bromine), rise to 50°C and react for 24h until the reaction is complete, cool down to room temperature, adjust to neutral with 1N hydrochloric acid, remove the organic solvent by rotary evaporation under reduced pressure, add ethyl acetate and water for extraction, The organic phase was separated, washed with water and saturated brine successively, dried over anhydrous sodium sulfate, concentrated to dryness by rotary evaporation under reduced pressure, and the obtained crude product was recrystallized with ethanol to obtain 2-propylamino-1-p-methylsulfonylacetophenone, Off-white solid 108.8g, yield 90.9%, purity 98.2%.

[0064] B) Preparation of N-n-propyl-N-[2-oxo-2-...

Embodiment 3

[0069] A) Preparation of 2-propylamino-1-p-methylsulfonylacetophenone (compound (II)):

[0070] 2-Amino-1-p-methylsulfonylacetophenone (131.0g, compound (I)) was dissolved in toluene (700mL), added sodium hydroxide (73.7g), stirred and cooled to 5-10°C in an ice bath, dropwise Add 1-bromopropane (151.1g, R is bromine), rise to 70°C and react for 12h until the reaction is complete, cool down to room temperature, adjust to neutral with 1N hydrochloric acid, remove the organic solvent by rotary evaporation under reduced pressure, add ethyl acetate and water Extract, separate the organic phase, wash with water and saturated brine successively, dry over anhydrous sodium sulfate, concentrate to dryness by rotary evaporation under reduced pressure, and recrystallize the obtained crude product with ethanol to obtain 2-propylamino-1-p-methylsulfonylphenethyl Ketone, off-white solid 144.3g, yield 92%, purity 98.3%.

[0071] B) Preparation of N-n-propyl-N-[2-oxo-2-(4-methylsulfonylpheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com