Patents

Literature

1602results about How to "Conducive to large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-rich manganese-based anode material and preparation method thereof

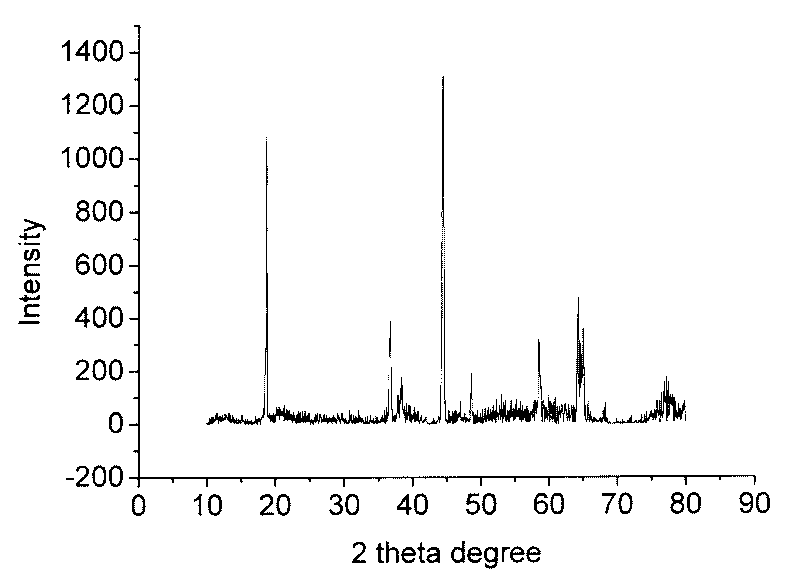

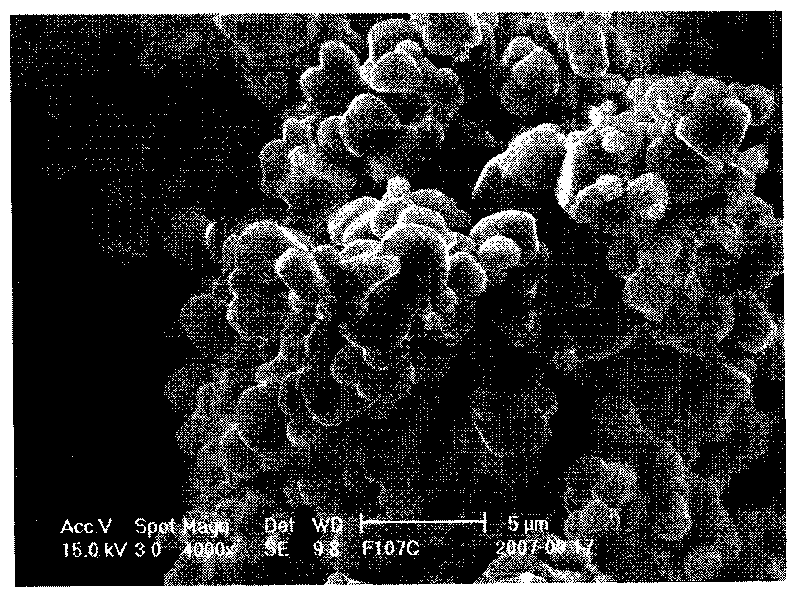

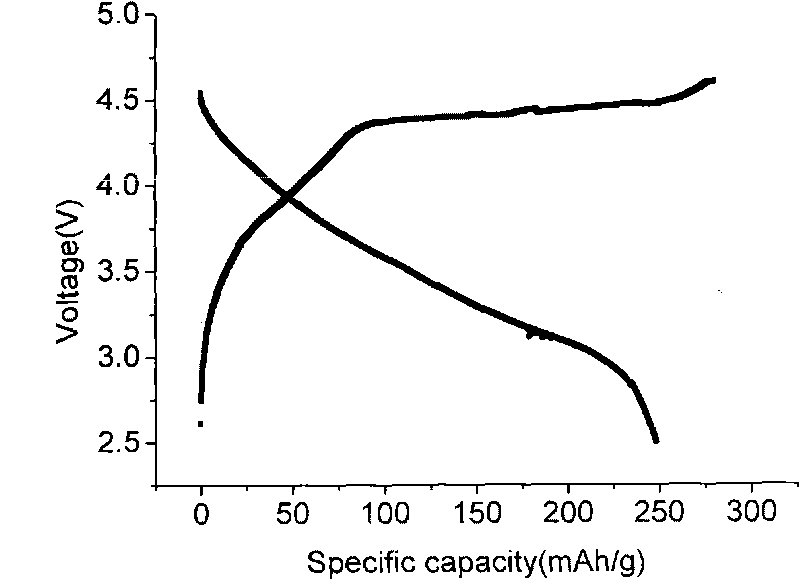

InactiveCN101694876AIncrease the charge cut-off voltageHigh specific capacityCell electrodesManganeseSpecific discharge

The invention relates to a lithium-ion secondary battery anode material technology, in particular to a lithium-rich manganese-based anode material Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu) and a preparation method thereof. A general formula of the lithium-rich manganese-based anode material is as follows: Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu), wherein x is more than 0 and less than or equal to 0.5, when M is Co and Al, y is more than 0 and less than 2x, a is equal to b, and b is equal to y / 2; when M is Ti, y is more than 0 and less than (2-x) / 3, a is equal to 0, and b is equal to y; and when M is Mg and Cu, y is more than 0 and less than x, a is equal to y, and b is equal to 0. The invention has high specific discharge capacity, excellent normal temperature and high temperature cycle performance, good safety, low raw material cost and production cost, and very high cost-performance ratio.

Owner:JIANGXI JIANGTE LITHIUM LON BATTERY MATERIAL +1

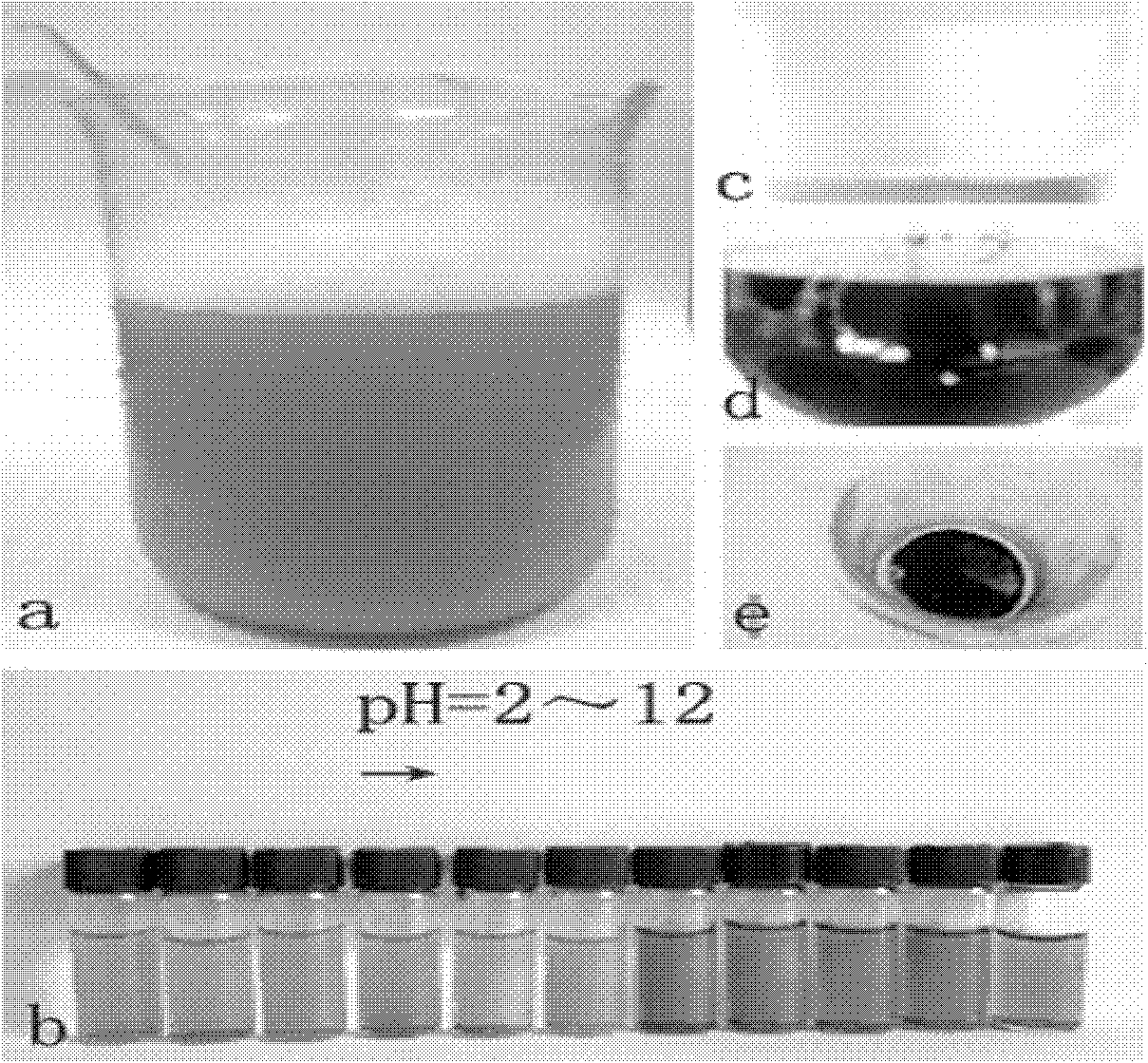

A kind of preparation method of graphene material

The invention discloses a preparation method of a graphene material. The preparation method comprises the following steps of: with graphite carbon as a raw material, adding potassium hypermanganate and concentrated sulfuric acid in batches in different stages to control an oxidation process of graphite; adjusting the pH value of the oxidized solution to obtain graphene oxide colloidal dispersing solutions (GOS) with different concentrations; dropwise adding the GOS on the surface of a carrier or spreading out the GOS on a non-intersolubility liquid / liquid interface and drawing into a grapheneoxide thin-film (GOF); carrying out high-speed centrifugation and drying treatment on the GOS to obtain graphene oxide solid powder (GOP); reducing the GOS by selecting an appropriate reducing agent,and centrifugally drying to obtain reduced graphene solid powder (GRP); dispersing a proper amount of GRP in an organic solvent to prepare a reduced graphene oxide colloidal dispersing solution (GRS); and dropwise adding the GRS on the surface of the carrier or spreading out on the non-intersolubility liquid / liquid interface and drawing into the reduced graphene thin-film (GRF). Various graphene materials prepared by the invention are easy to mutually transform; and the concentration of the colloidal solution and the thickness of the thin-film can be controlled in a certain range.

Owner:CENT SOUTH UNIV

Gel electrolyte and preparation method thereof and corresponding anode and lithium sulfur battery

ActiveCN102208680AImprove ionic conductivityImprove conductivityCell electrodesLi-accumulatorsDissolutionSolvent

The invention discloses gel electrolyte, which comprises a polymer matrix material, a non-aqueous solvent and an inorganic filler in a mass ratio of 1:5:0.1-1:20:1 and also comprises electrolyte containing 0.5 to 2.0 mol / L of electrolyte lithium salt. The invention also discloses a preparation method of the gel electrolyte. The preparation method comprises the following steps of: mixing the polymer matrix material, the non-aqueous solvent, the inorganic filler and the electrolyte containing the electrolyte lithium salt in an inert atmosphere, and stirring the mixed solution till dissolving at the temperature of between 40 and 90 DEG C. The invention also discloses an anode and a lithium sulfur battery prepared by using the gel electrolyte. The gel electrolyte provided by the invention has high ionic conductivity, and can avoid the dissolution of the sulfur anode and the reactants; the lithium sulfur battery containing the gel electrolyte has good cycle performance; and the method is simple, does not need a large amount of extracting agent, is safe and environment-friendly, and is favorable for large-scale industrialized production.

Owner:DONGFANG ELECTRIC CORP LTD

Gradient-doping positive material of lithium ion battery and preparation method of gradient-doping positive material of lithium ion battery

ActiveCN104241633AImprove discharge capacityHigh surface doping element concentrationCell electrodesSecondary cellsLithium-ion batteryLithium electrode

The invention discloses a gradient-doping positive material of a lithium ion battery and a preparation method of the gradient-doping positive material of the lithium ion battery. The structural formula of the positive material is shown as Li(1+alpha)Ni(x)M(y)M'(1-x-y)O(2), wherein alpha is greater than or equal to 0 and less than or equal to 0.2; x is greater than or equal to 0.3 and less than or equal to 1.0; y is greater than or equal to 0 and less than or equal to 0.475; 1-x-y is greater than 0 and less than or equal to 0.35; the concentration of doping element M' is subjected to gradient change from the surfaces of the material particles; on the surfaces of the material particles, the concentration of the element M' is relatively high, the concentration of element Ni is relatively low, and even the surfaces of the material particles are free of the element Ni; in the material particles, the concentration of the element Ni is relatively high, the concentration of the element M' is relatively low, and even the inside of the material particles are free of the element M'. The positive material is excellent in comprehensive performance and especially has the advantages of high discharge capacity, excellent cycle performance and the like. In addition, the method is simple; the industrial production is easy to implement.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

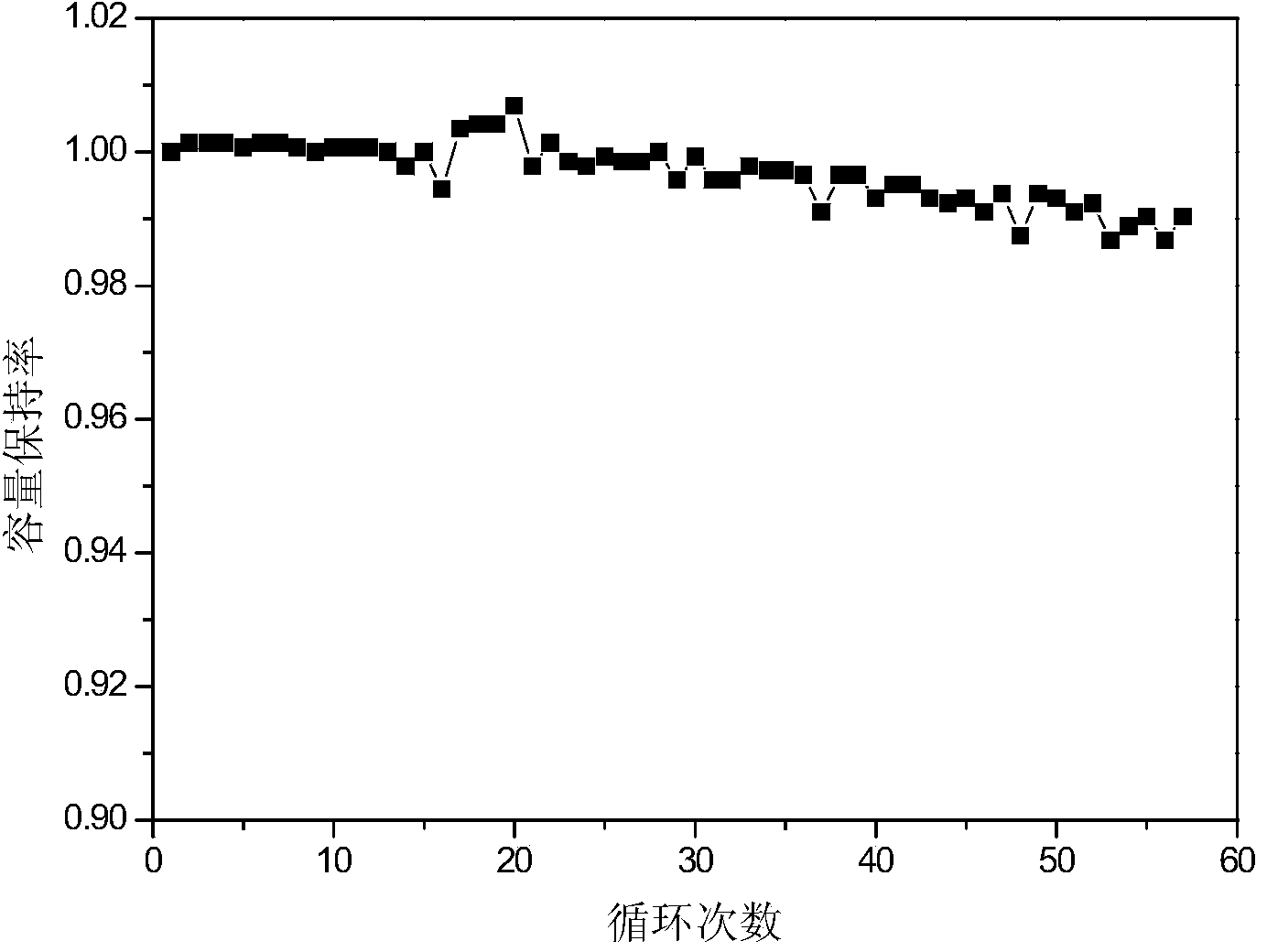

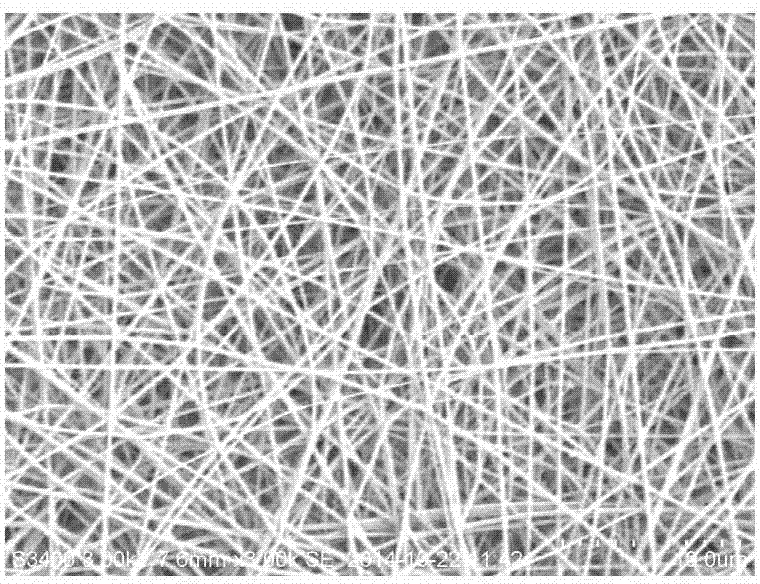

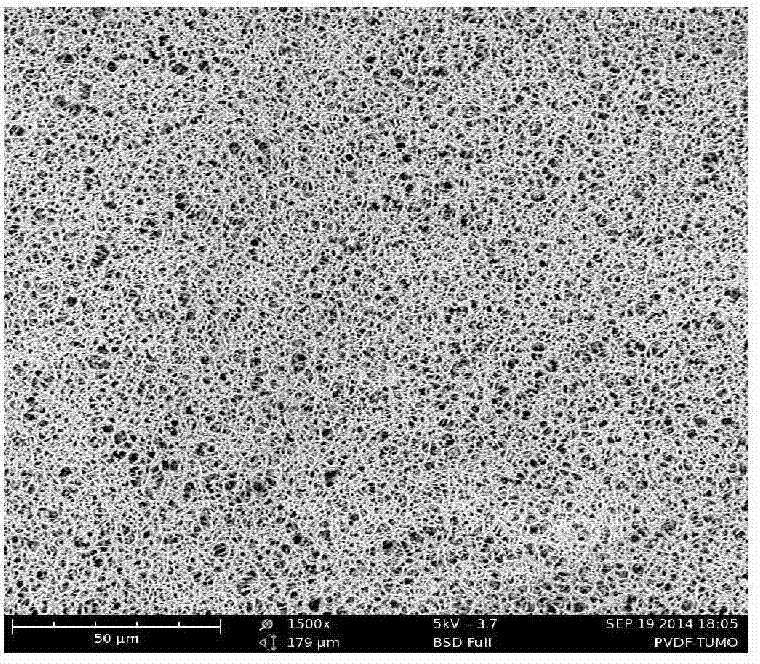

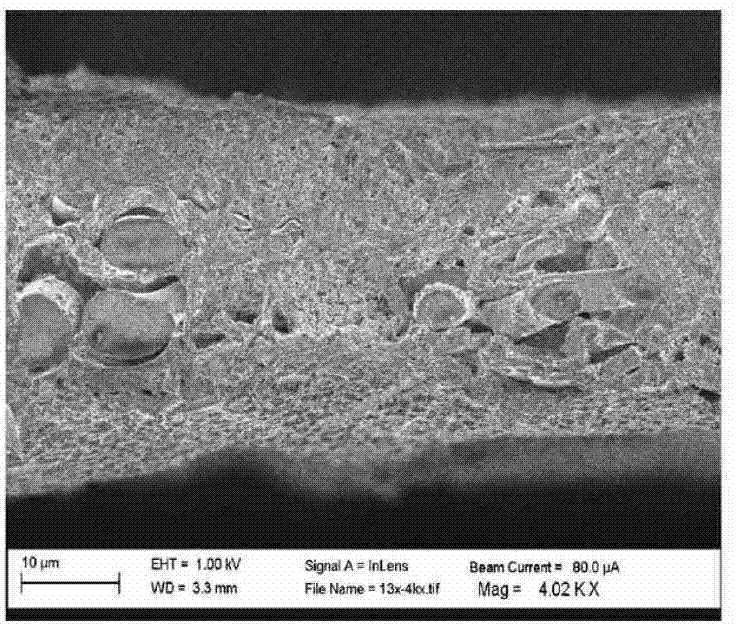

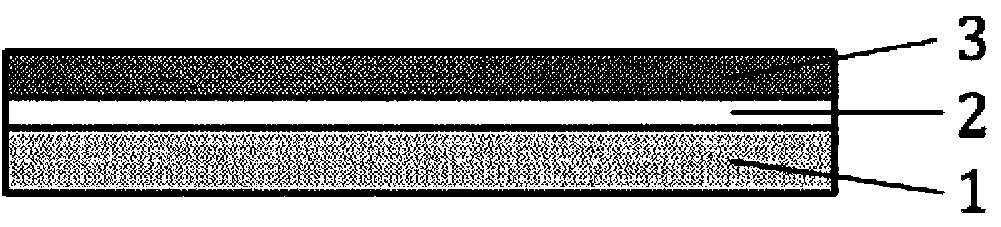

Composite lithium ion battery diaphragm and preparation method thereof

InactiveCN104766938AReduce the probability of short circuitImprove performanceCell seperators/membranes/diaphragms/spacersSecondary cellsNonwoven fabricLithium-ion battery

The invention discloses a composite lithium ion battery diaphragm comprising a nonwoven fabric substrate layer, an electrostatic spinning layer and a polymer porous coating, and the structure compound mode is as follows: polymer porous coating / electrostatic spinning layer / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; or polymer porous coating / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating. The composite lithium ion battery diaphragm uses nonwoven fabric as a substrate to ensure the diaphragm high porosity and heat resistance, electrostatic spinning layers are arranged on the upper and lower surfaces of the nonwoven fabric substrate, the nonwoven fabric pore diameter can be reduced, the pore diameter is uniform, and the problem of short circuit caused by local macropore of the nonwoven fabric diaphragm can be solved, and by the arrangement of the polymer porous coating, the absorption and electrolyte maintaining capacity of the diaphragm can be improved, battery positive and negative electrodes can be bonded, battery mechanical properties can be improved, and the battery safety can be ensured. The prepared composite lithium ion battery diaphragm can satisfy the security requirements of large current charging discharging and running in harsh environments of a high-capacity high-power power battery.

Owner:LONGYAN ZIJIN INNOVATION RES INST +1

Azepine argireline or pharmaceutically acceptable salt thereof and preparation method and application thereof

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

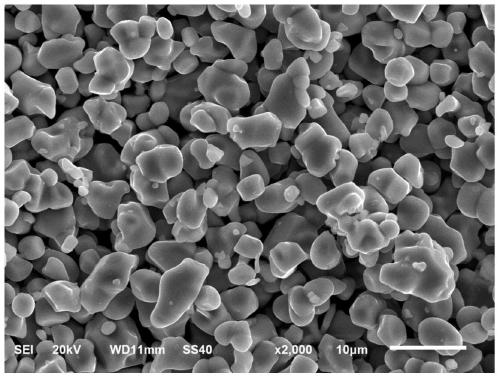

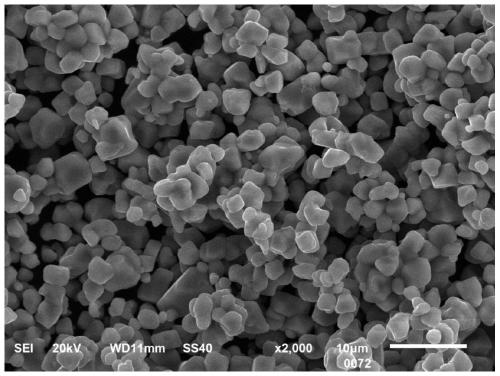

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

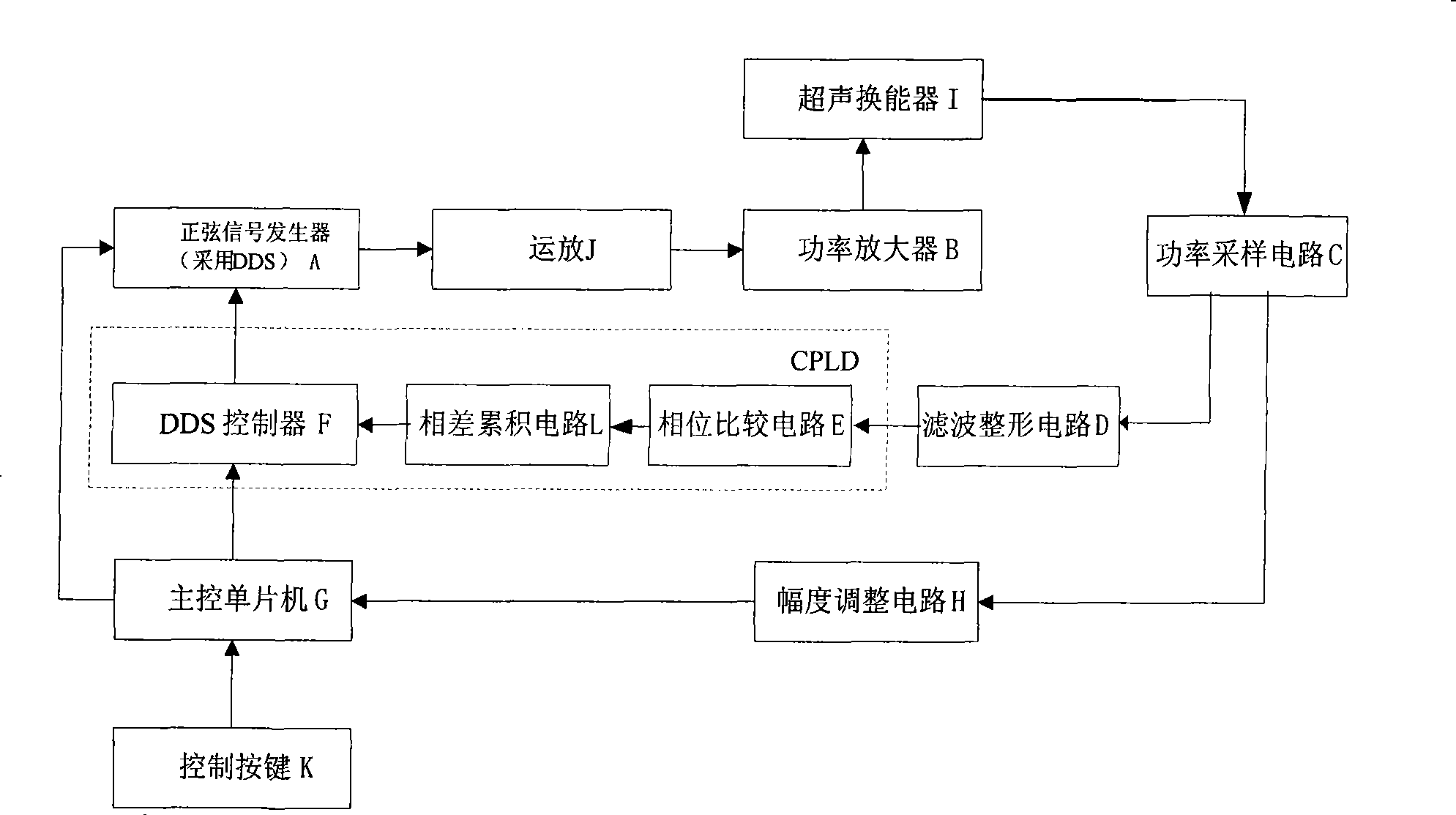

Automatic frequency tracking method of supersonic transducer and system thereof

ActiveCN101468347ARealize digital controlWork reliablyMechanical vibrations separationLogical elementUltrasonic sensor

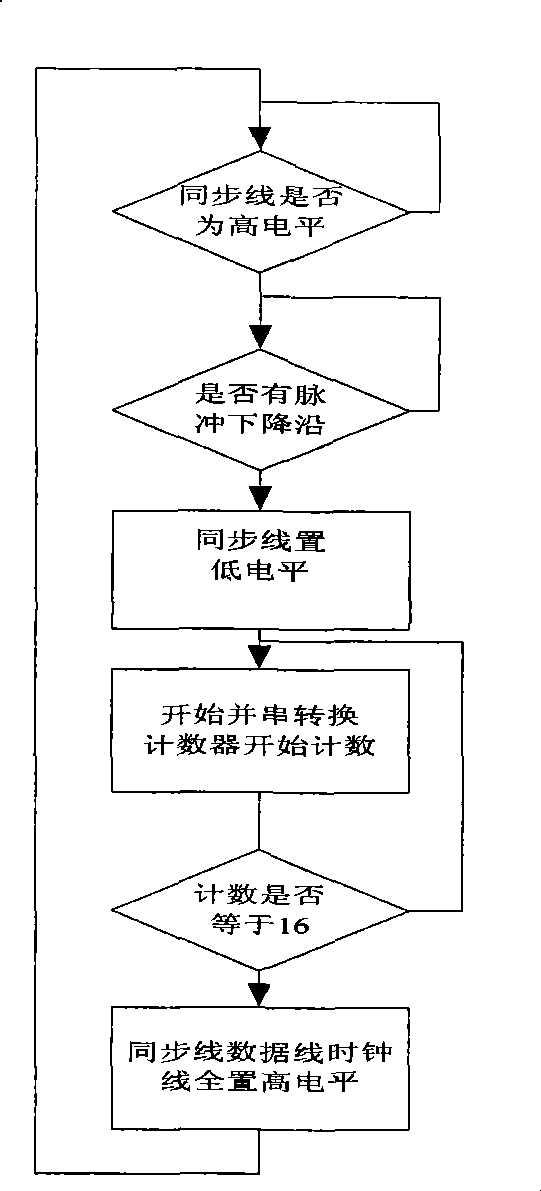

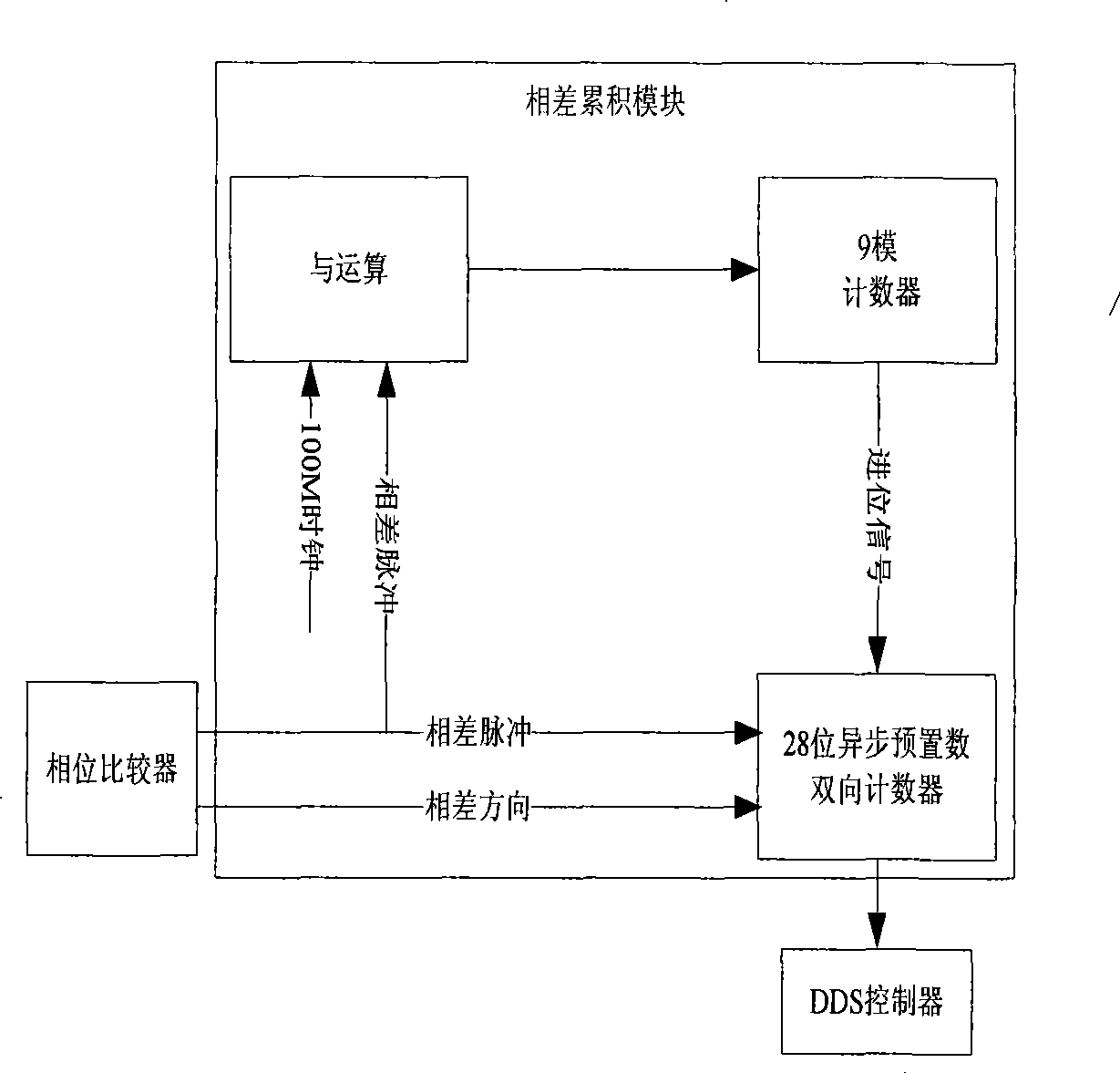

The invention relates to an automatic frequency tracking method and a system for an ultrasonic transducer. A direct digital frequency synthesizer is used as a signal source, wherein the direct digital frequency synthesizer can be an independent integrated chip and also be achieved by the method that a digital part of a DDS is integrated in a site programmable logical element FPGA and then a digital-analog converter is additionally added. The design of the invention adopts a frequency sweeping and tracking policy, and an automatic frequency controller achieved by the programmable element controls the output frequency of the DDS according to a feedback signal sampled from the self transducer end so as to achieve the full digitization automatic frequency tracking and ensure that the ultrasonic transducer work near a resonance point all the time to obtain the optimal efficiency. A phase comparator utilizes a trigger to give out the arriving time difference of two riser edge signals of two input signals I ph and V ph aiming to the sensitive characteristics of the riser edge signals, and the sequence of the riser edge signals of the two input signals I ph and V ph is given out by a Dirrect pin.

Owner:BEIJING ANHEJIALIER TECH CO LTD

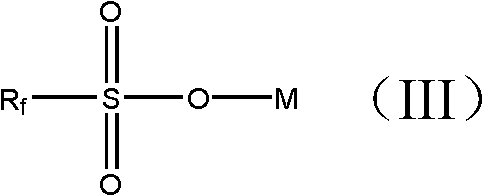

Synthesis methods of alkali metal salt containing sulfonyl chloride or phosphorus imide and alkali metal salt containing fluorine sulfonyl or phosphorus imide

ActiveCN102617414AMild experimental conditionsEasy to storeGroup 5/15 element organic compoundsSulfonic acid amide preparationImideNucleophilic substitution

The invention discloses a synthesis method of an alkali metal salt containing sulfonyl chloride or phosphorus imide: the alkali metal salt is prepared by subjecting compound (V-2) and sulfuryl chloride or phosphorus oxychloride to nucleophilic substitution under the presentation of acid binding agents; the invention further discloses a synthesis method of an alkali metal salt containing fluorine sulfonyl or phosphorus imide, the alkali metal salt is prepared by reacting (sulfonyl chloride) (perfluorinated alkyl) imide salt (V-1) or (dichloro phosphoryl) (perfluorinated alkyl sulfonyl) imide salt (V-2) with fluorinated reagents. The synthesis methods have the advantages that the experiment condition is mild, and the used materials are convenient to store and prepare; the preparation rate is high, the purification is simple, the preparation cost is low, and the methods are suitable for mass industrial preparation. The preparation rate and the purity of the resultants are high, and the resultants can be used as lithium salt electrolyte materials for lithium batteries, or for preparing catalytic agents, and for synthesizing high-performance ionic liquids.

Owner:武汉市瑞华新能源科技有限公司

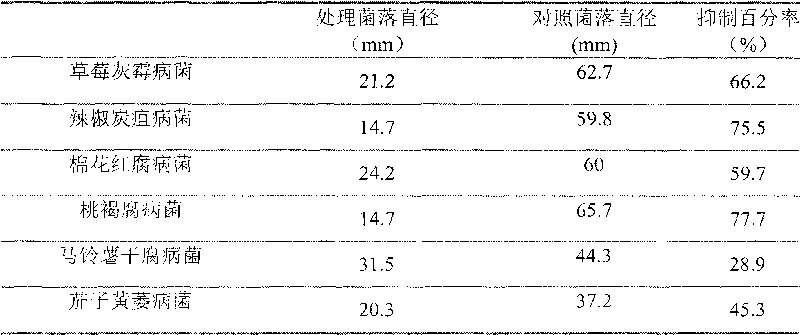

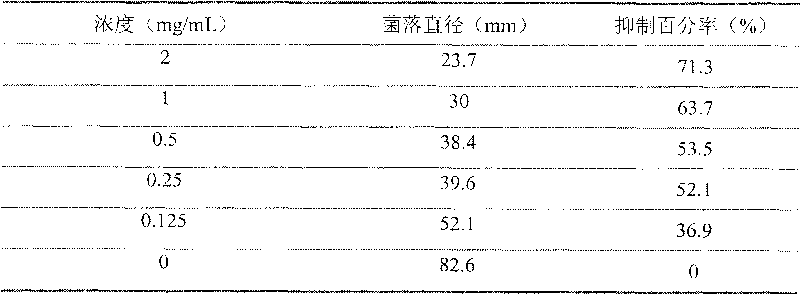

Agricultural bacteriostat of stellera chamaejasme vegetal biflavonoids and preparation method thereof

InactiveCN101755850APromote decompositionNo pollution in the processBiocideFungicidesBiflavonoidSurface-active agents

The invention relates to botanical agricultural bacteriostat used for controlling plant pathogenic fungi, a preparation method and purposes thereof. The botanical agricultural bacteriostat is prepared by the method that stellera chamaejasme is extracted chemically, mixed with the active ingredient including vegetal biflavonoids eluted by 30 percent of ethanol through macroporous absorbent resin RP-8, and then mixed with surface active agent, emulsifier, penetrant and synergistic agent. The characteristics of the agricultural bacteriostat of stellera chamaejasme vegetal biflavonoids are of high effect, low toxicity, less residue and harmoniousness with environment.

Owner:BEIJING UNIV OF AGRI

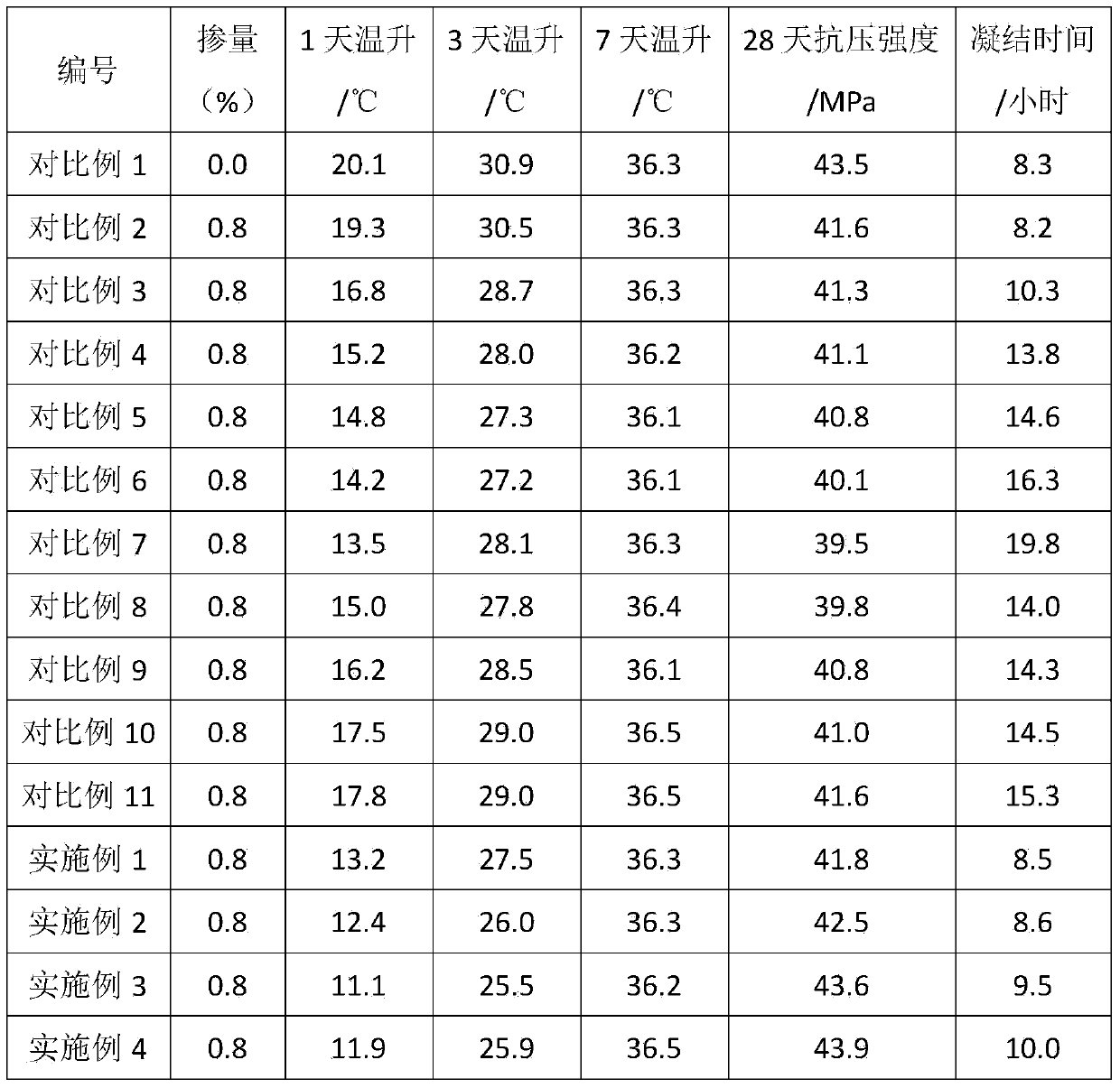

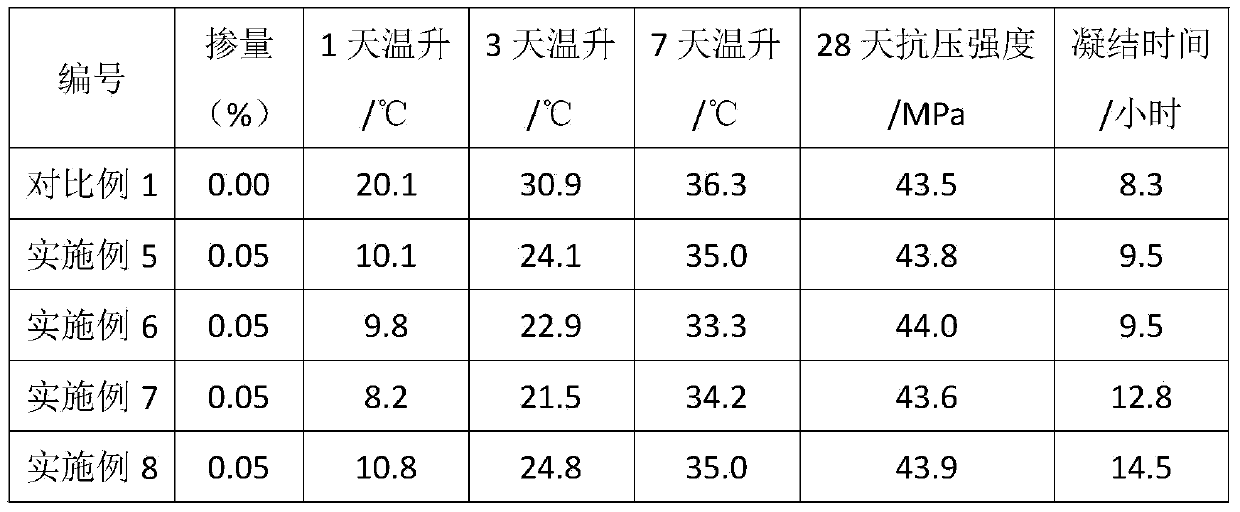

Hydration heat regulating and controlling material as well as preparation method and application thereof

The invention relates to the field of concrete admixtures and particularly relates to a hydration heat regulating and controlling material as well as a preparation method and an application thereof. According to the material with a hydration heat regulating and controlling function, a component is surface cross-linked dextrin prepared by a cross-linking reaction. The invention discloses the hydration heat regulating and controlling material which can greatly regulate and control the hydration speed of cement, reduce the temperature rise of concrete and does not influence the middle-period and post-period strength of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

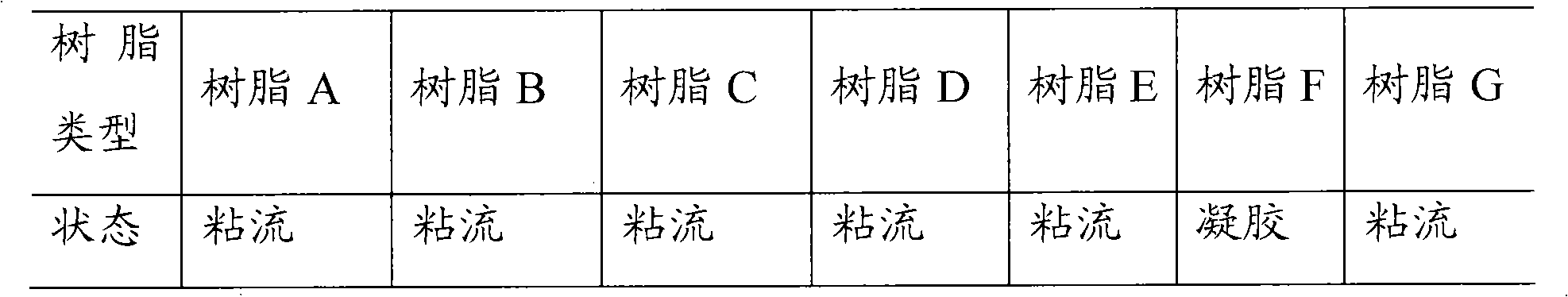

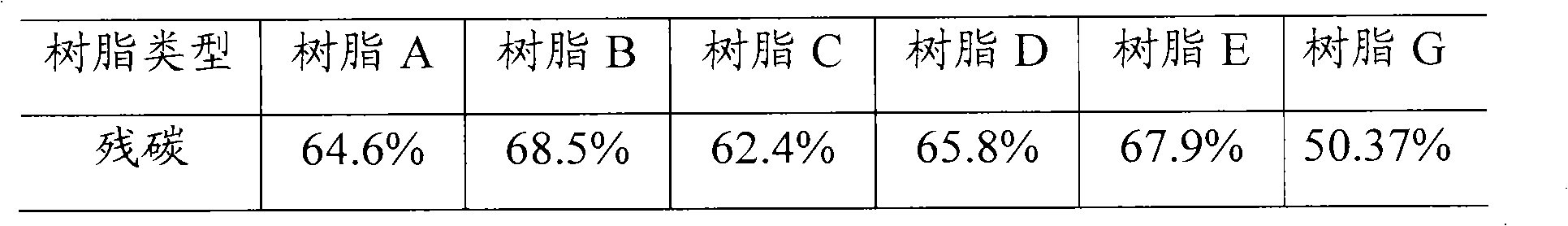

Preparation method of boron modified phenolic resin

ActiveCN101805435AMild reaction conditionsSuitable for industrial production applicationsSynthesis methodsBoron

The invention discloses a preparation method of boron modified phenolic resin, which comprises the following steps that: (1) phenol and formaldehyde in the molar ratio of 1.0:0.1 to 1.0 is added into a reactor, to be stirred under acid environment and reflux for 5 to 6 hours; (2) a reaction product prepared in step (1) is distilled and hydrated at normal pressure, until the water content is less than 10 weight percent; (3) the produce dehydrated in step (2) is added with a compound which contains boron hydroxyl, to have esterification; and the input of the compound which contains boron hydroxyl is 20 weight percent of that of the phenol at most. The synthesis method provided by the invention is simple and feasible, the prepared resin has stable performance and is beneficial to large-scaleindustrial production, and the prepared boron modified phenolic resin has excellent thermal oxidation and ablation resistant performance, and can be widely applied to high-temperature brake materials, ablation resistant materials, heat insulation materials and other fields.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

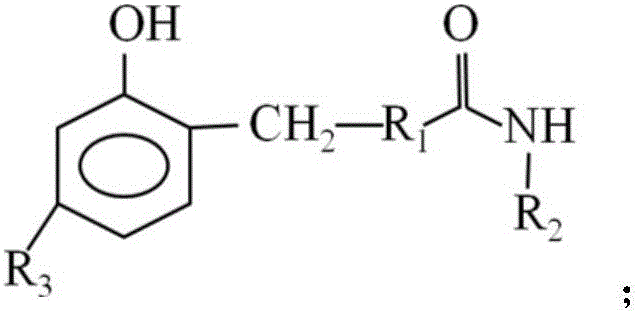

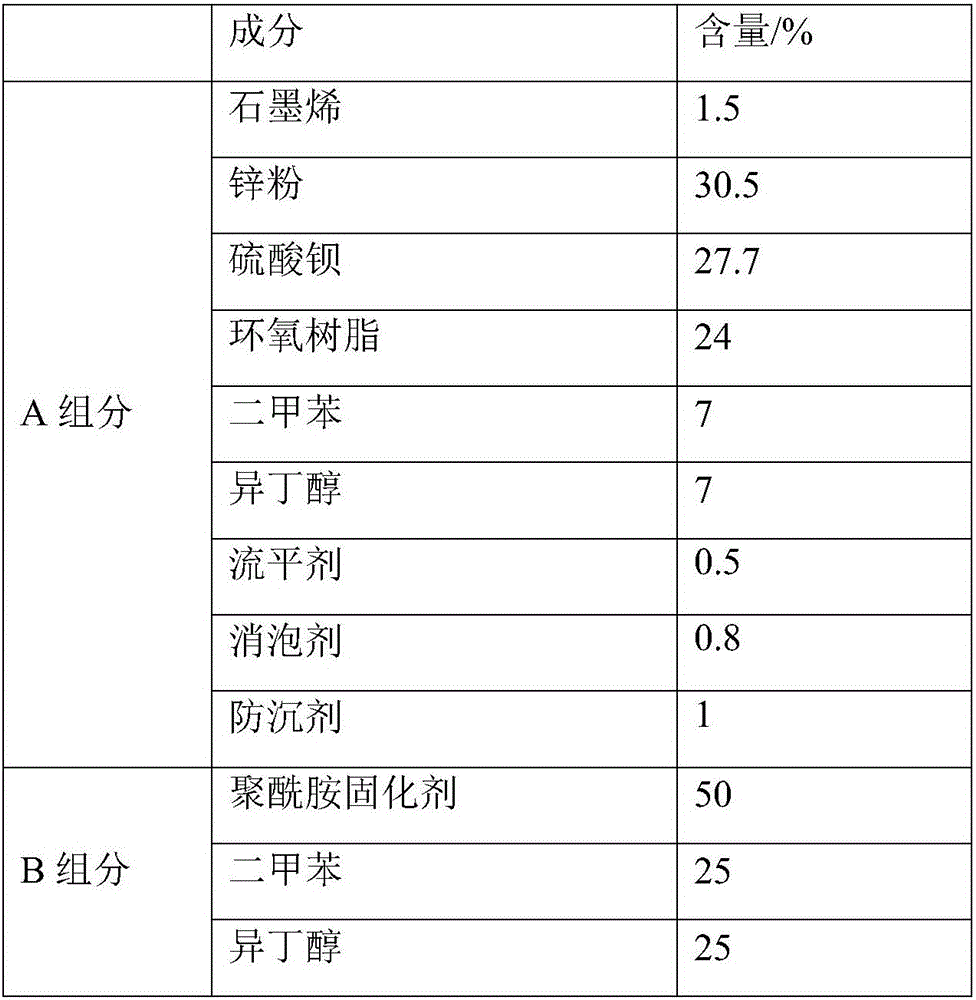

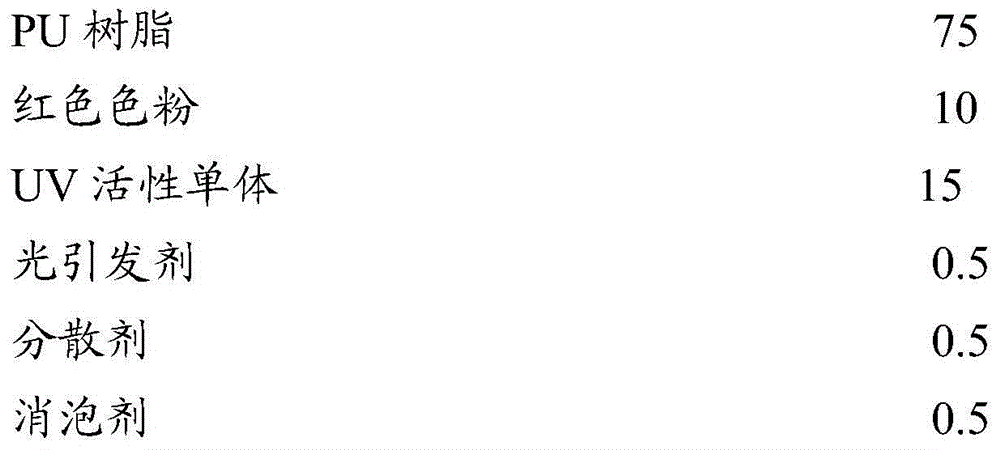

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

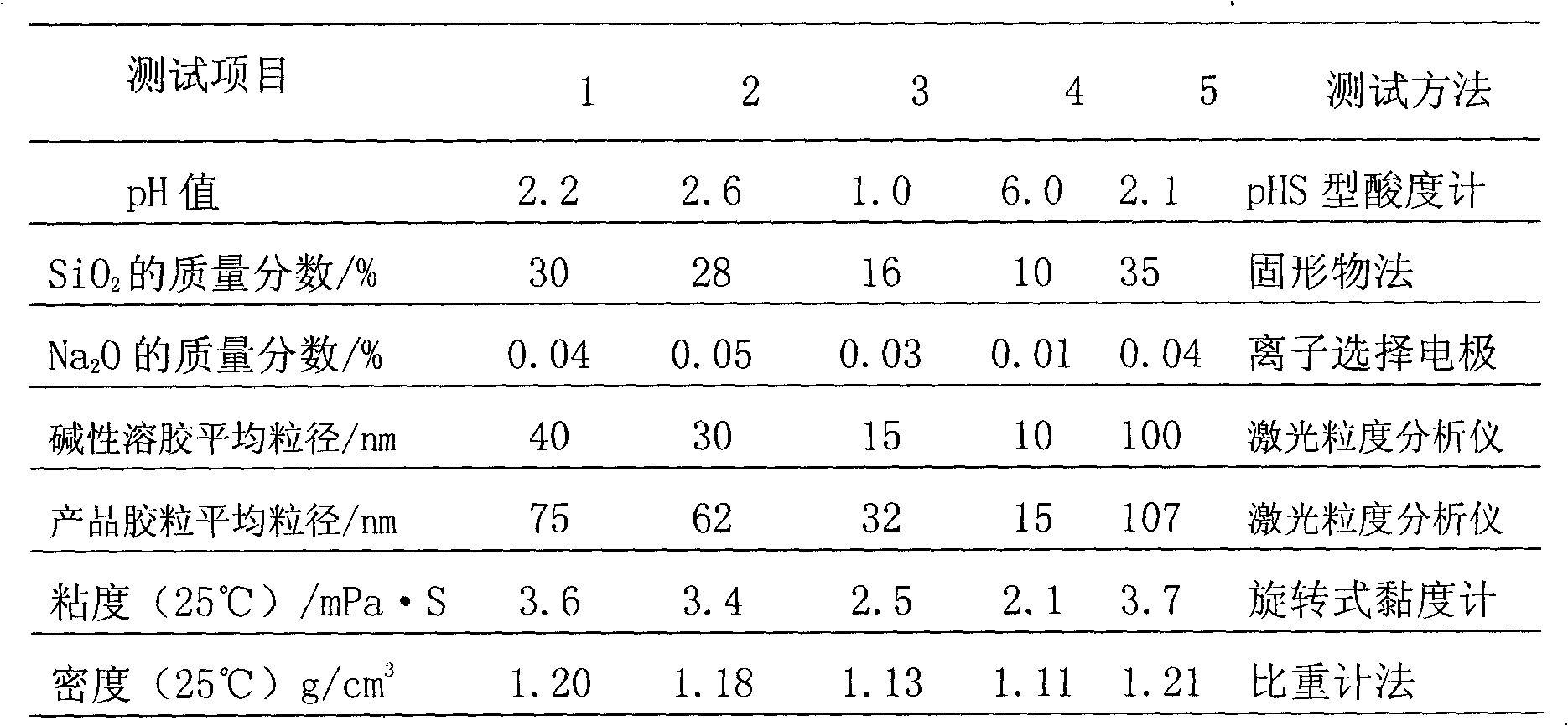

Monodisperse large-grain-diameter and high-stability acid silica sol and preparation method thereof

The invention relates to monodisperse large-grain-diameter and high-stability acid silica sol and a preparation method thereof. The silica sol comprises water and silica colloid, wherein the silica colloid is dispersed in the water and has the granularity being 10 to 100 nm, the pH value of a sol system is 1.0 to 6.0, and the solid content is 10 to 35 percent. The preparation method comprises thefollowing steps that: firstly, active silicic acid is prepared through an ion exchange method and is added into boiling water glass to be prepared into basic silica sol with the uniform granularity, organic acid is adopted for surface modification, finally, the acid silica gel is prepared through iron exchange, and the silica sol is concentrated to the required concentration. Small-granularity and low-concentration products are adopted as the mother liquid, the sol grain growth process is controlled through controlling the dripping times of the active silicic acid and simultaneously regulating the pH value and the reaction time of a reaction system, and the monodisperse large-grain-diameter and high-stability acid silica sol products are obtained. The product stability is good, the coagulation and gel phenomena can not occur after the storage for more than six months at the normal temperature, the production period is short, and the mass industrial production is favorably realized.

Owner:HUBEI UNIV

Porous ceramic prepared from red mud and coal ash and preparation method thereof

The invention belongs to the technical field of porous ceramics, and in particular relates to a porous ceramic prepared from red mud and coal ash, and a preparation method of the porous ceramic. The porous ceramic comprises the following components in percentage by weight: 40-70% of red mud, 5-40% of coal ash, 10-30% of a pore-forming agent, 1-5% of an additive, and water which is 10-20% of the total weight of the materials, and the red mud, the coal ash, the pore-forming agent, the additive and the water are uniformly mixed according to a ratio, and further formed, dried and roasted so as to prepare the porous ceramic material. The porous ceramic is prepared by utilizing the red mud and the coal ash in a composite manner, and the process is simple and the cost is low, but also a great deal of industrial waste can be consumed, and the environmental-friendliness is facilitated. Therefore, a porous ceramic material with high porosity, high bending resistance and opened pore structure can be prepared by using the method.

Owner:SHANDONG JIANZHU UNIV

Fatty acid balanced health blend oil

ActiveCN101766236AReasonable intakeSuitable for needsEdible oils/fatsFood preparationAntioxidantBlood lipids

The present invention provides fatty acid balanced health blend oil, which comprises the following components in percentage by weight: 0.01 to 2 percent of oryzanol and 0.1 to 2 percent of phytosterin. The proportion of saturated fatty acid to monounsaturated fatty acid to polyunsaturated fatty acid is (0.2 to 0.9) to 1 to 1, and the proportion of n-6 polyunsaturated fatty acid to n-3 polyunsaturated fatty acid is (3-8) to 1. The oryzanol and the phytosterin are from rice oil, or are exogenously fed, and at least a part of phytosterin can be replaced by phytosterin acetate. The fatty acid balanced health blend oil also can comprise at least one kind of antioxidant. The fatty acid proportion of the fatty acid balanced health blend oil is reasonable, and the fatty acid balanced health blendoil is beneficial for the health of the human body, in particular, the fatty acid balanced health blend oil can reduce blood fat and cholesterin and improve the vegetative nerve function of human bodies. The fatty acid balanced health blend oil has convenient preparation and is suitable for large-scale commercial production.

Owner:SOUTHSEAS OILS & FATS INDAL CHIWAN

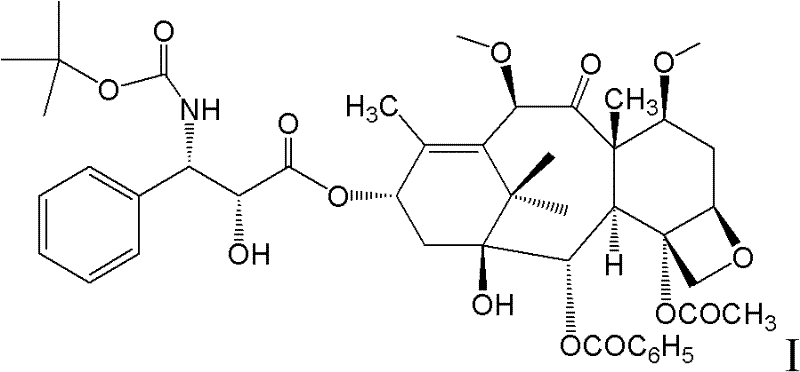

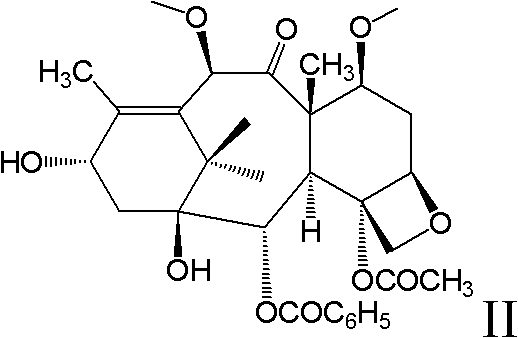

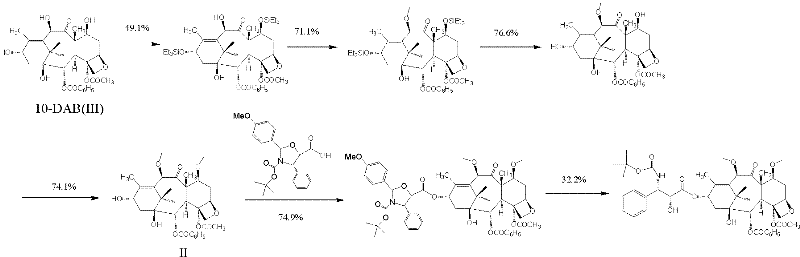

New taxane derivative and preparation method thereof

The invention provides a new taxane derivative and a preparation method thereof as well as a method of preparing antitumor medicaments (cabazitaxel, docetaxel and taxol) by utilizing new taxane isoserine ester.

Owner:SHANGHAI BIOMAN PHARMA

High-nickel ternary positive electrode material with single crystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN111463411AIncrease productionImprove product qualitySecondary cellsPositive electrodesDopantPhysical chemistry

The invention discloses a high-nickel ternary positive electrode material with single crystal morphology and a preparation method of the high-nickel ternary positive electrode material. The positive electrode material is formed by a base material and a coating layer, wherein the base material is prepared from a high-nickel ternary precursor, a lithium source and a doping agent; the doping agent comprises a doping element, the doping element is a metal element, the coating layer is formed by a coating material, the coating material comprises a coating element, and the coating element is a metalelement and / or a non-metal element. The positive electrode material is obtained by mixing the high-nickel ternary precursor, the lithium source and the doping agent, performing primary sintering, then mixing with the coating material, and performing secondary sintering. The high-nickel ternary positive electrode material disclosed by the invention has the advantages of single crystal morphology,smooth surface, small specific surface area and high compaction density, and the single crystallization of the high-nickel ternary positive electrode material improves the specific capacity and cycleperformance of the positive electrode material and prolongs the service life of the positive electrode material. The preparation method is simple in process, easy to implement and beneficial to industrial large-scale production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Penam iodide, preparation and use thereof

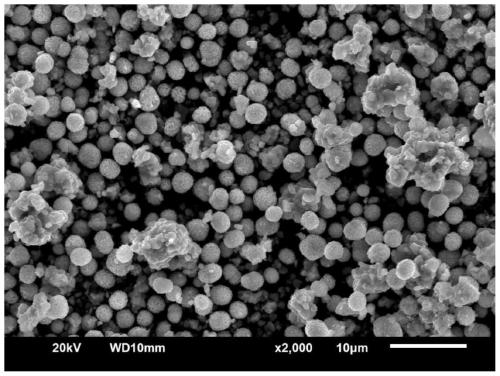

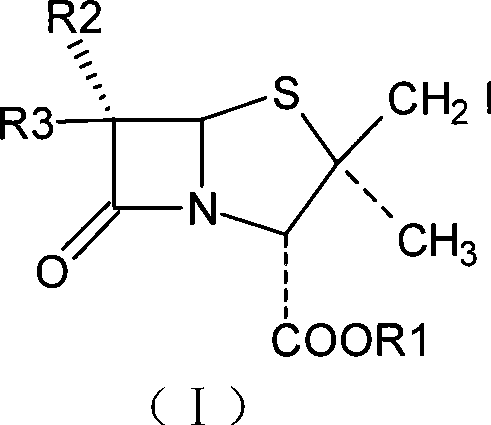

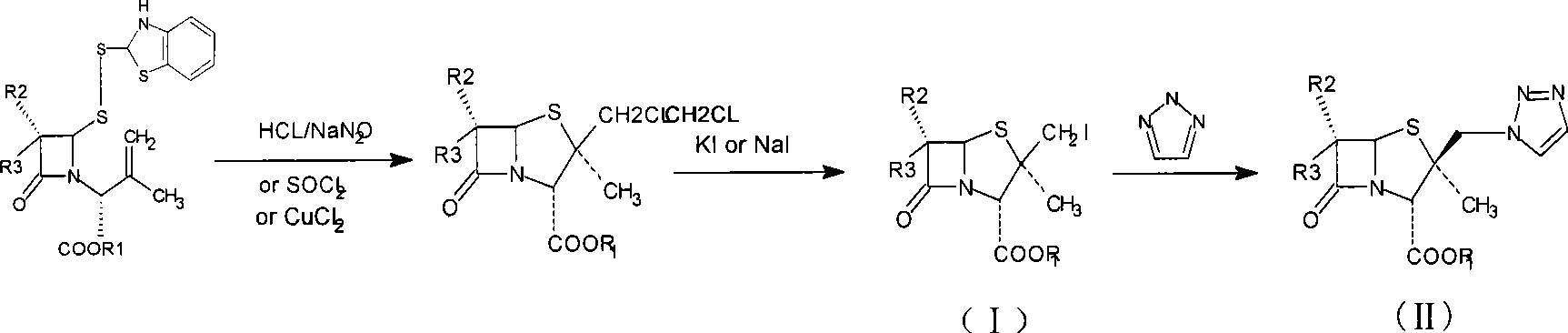

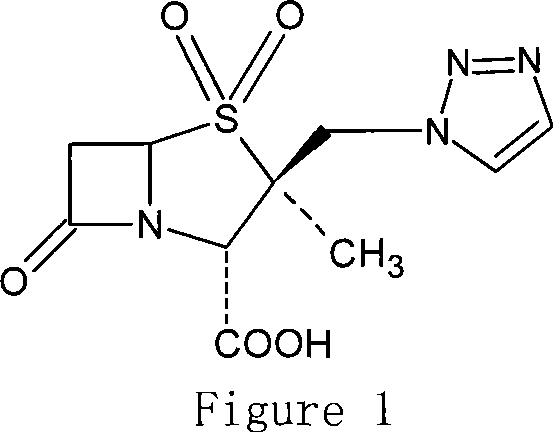

ActiveCN101434610AReduce pollutionLow production costOrganic chemistryBulk chemical productionIodideStructural formula

The invention relates to an intermediate iodide in the synthesis of Tazobactam, and a preparation method and the application thereof in preparing Tazobactam, and discloses the structural formula (I) of 2Beta-iodomethyl penicillanic acid ester. The invention has unique technique, stable product quality, mild technique condition and high yield, is easy to be controlled, requires relatively low production cost, reduces environmental pollution, needs no special equipment and is suitable for industrialized mass production.

Owner:QILU PHARMA HAINAN +1

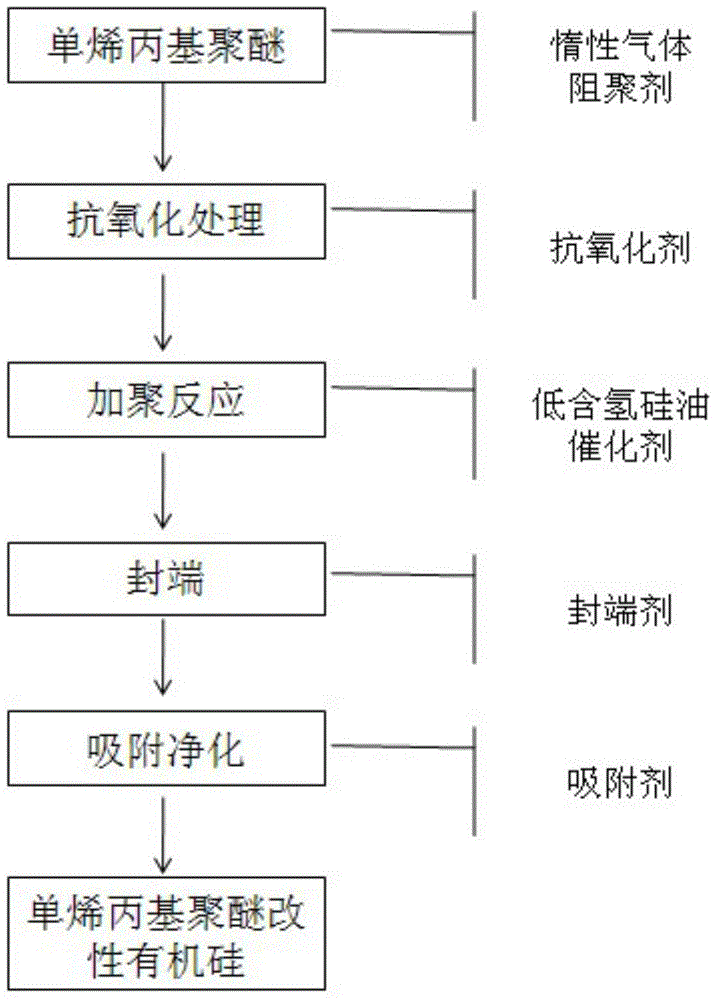

Preparation method of polyether modified organic silicon

The invention discloses a preparation method of polyether modified organic silicon, and belongs to the technical field of the preparation of leveling agent. According to the invention, silicon atom is connected to mono allyl polyether group to form a hydrolysis resistant Si-C bond, so that the prepared polyether modified silicone can effectively improve the leveling property, enhance gloss, slip degree and scratch resistance of the paint; the reaction process does not involve solvent participation, and has the advantages of low cost, green, environment-friendliness; and the preparation process is simple, efficient, easy to control and conducive to large-scale industrial production.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Preparation method of drug loaded emulsion

The invention provides a preparation method of a drug loaded emulsion, which can reduce degradation of a drug in a preparation process. The method comprises the following steps: a, preparing a blank emulsion without drug ingredients; and b, adding an effective treatment amount of the drug in the blank emulsion. The technology process is simple, avoids the use of an organic solvent, and is suitable for industrial production in a large scale.

Owner:SHANGHAI HENGRUI PHARM CO LTD +1

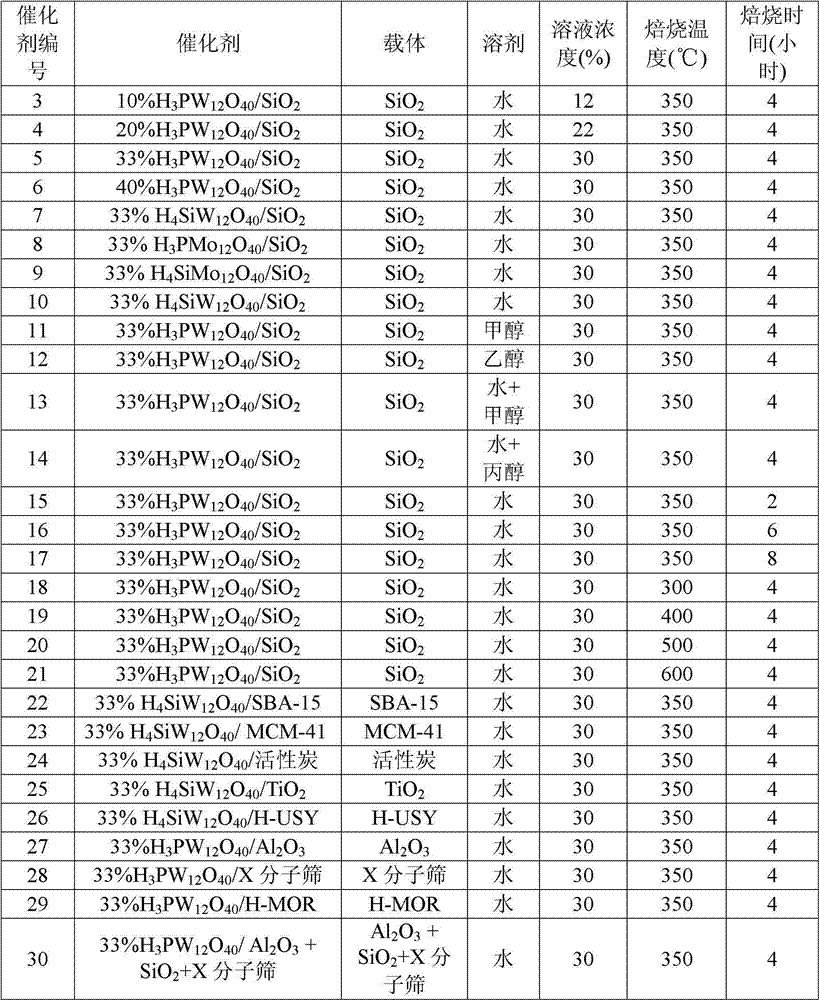

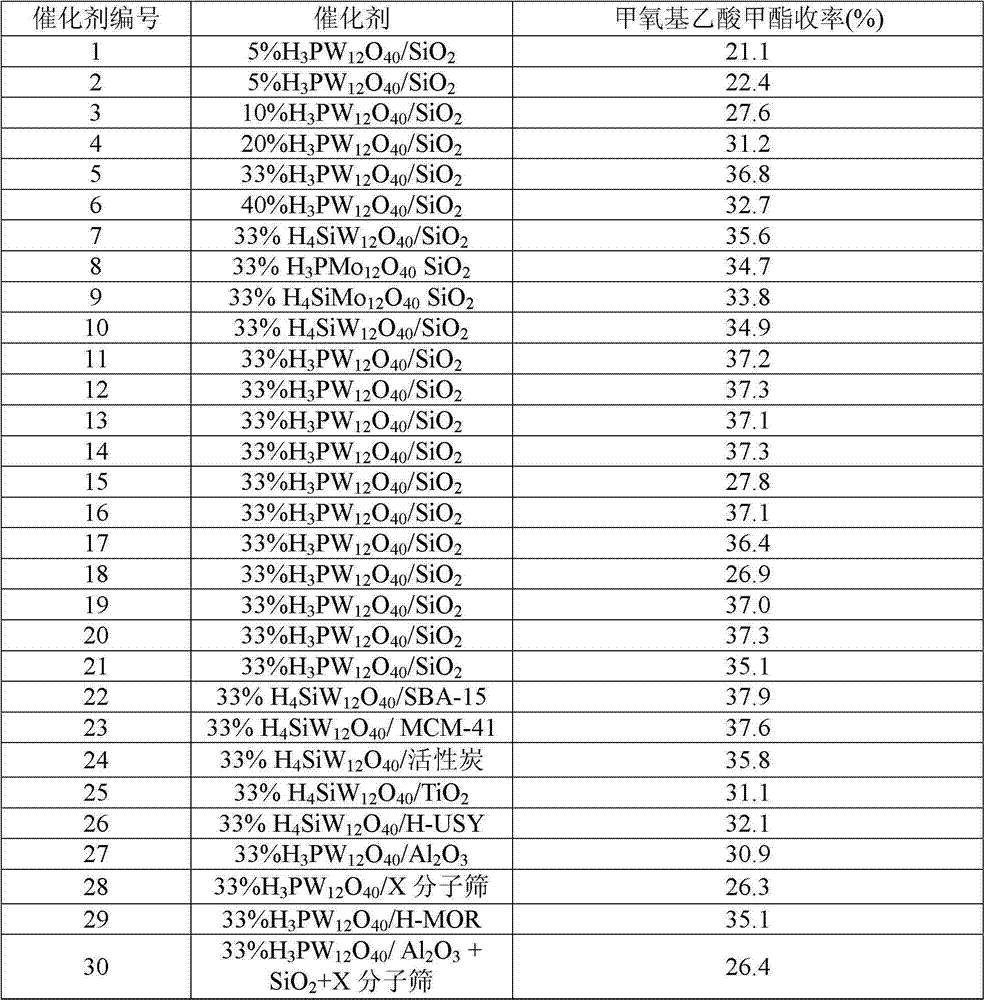

Method for producing methyl methoxyacetate by methylal vapor-phase carbonylation by using supported heteropoly acid catalyst

InactiveCN103172516AEasy to separateMild reaction conditionsPreparation by carbon monoxide or formate reactionActivated carbonHeteropoly acid

The invention relates to application of a supported heteropoly acid catalyst in production of methyl methoxyacetate by methylal vapor-phase carbonylation. The catalyst is prepared by an isometric impregnation method, and uses at least one of activated carbon, TiO2, Al2O3, SiO2, SBA-15, MCM-41 and zeolite molecular sieve as a supporter, wherein the heteropoly acid accounts for 0.1-50 wt% of the supported heteropoly acid catalyst. When being used for the reaction for producing methyl methoxyacetate by methylal vapor-phase carbonylation, the catalyst has the characteristics of mild reaction conditions and high catalytic efficiency; and since no solvent is used in the reaction, the product and catalyst can be easily separated, thereby being beneficial to large-scale industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

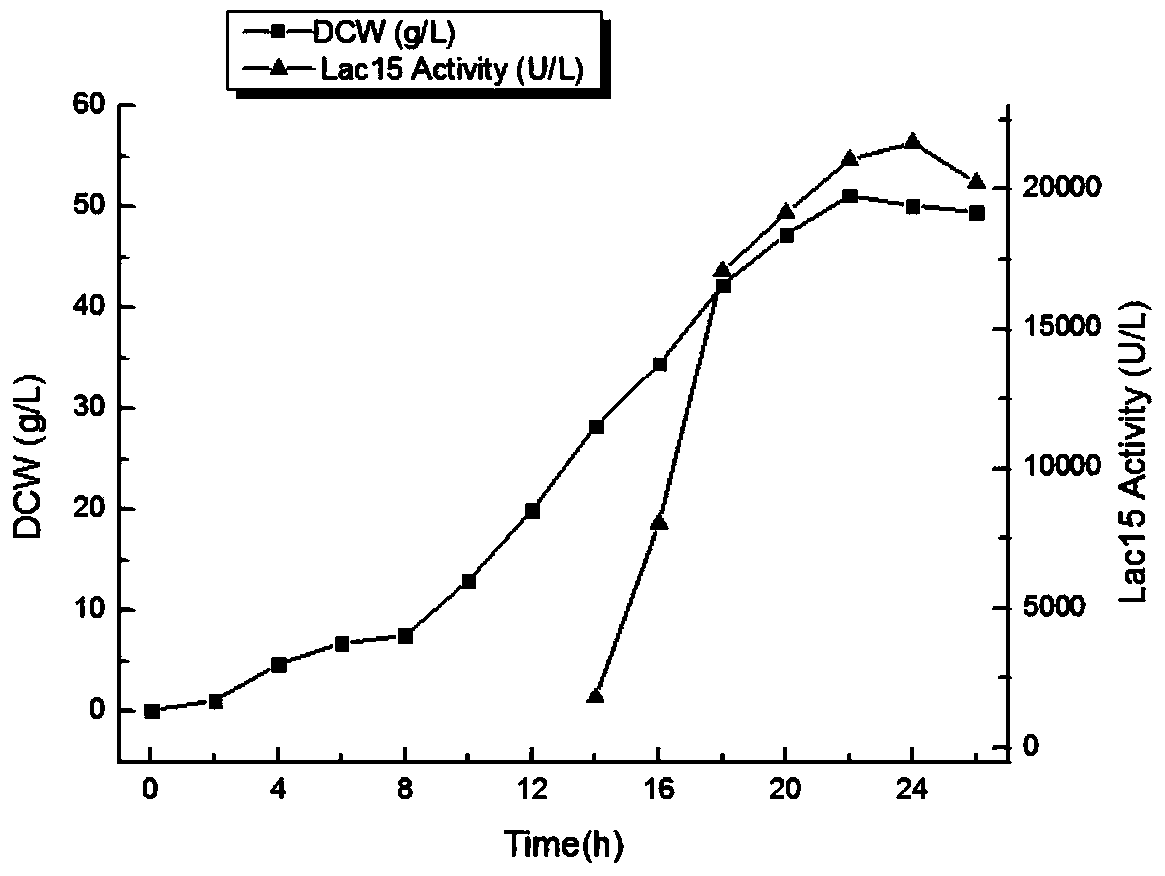

Bacterial laccase mutant protein, recombinant expression plasmid, transformed engineered strain and fermentation preparation method thereof

ActiveCN104087560AImprove stabilityIncrease temperatureBacteriaMicroorganism based processesMutated proteinGenetic engineering

The invention discloses a bacterial laccase mutant protein, which is characterized in that the mutant protein amino acid sequence is obtained by deletion mutation of the 323rd glycine residue to the 332rd glycine residue in the bacterial laccase amino acid sequence shown as SEQ ID No.1. Through a genetic engineering reconstruction method, a stability improved bacterial laccase protein coding gene, its expression plasmid and engineered bacteria can be obtained, and after large-scale fermentation and induced expression of the engineered bacteria, the stability improved bacterial laccase protein can be obtained. According to the invention, the marine uncultured microorganism source bacterial laccase Lac15 is taken as the foundation, and by means of genetic engineering reconstruction, mutant gene can be obtained. At the same time, a recombinant escherichia coli is employed to conduct high-density culture for high-efficiency expression of the bacterial laccase mutant protein. According to the invention, the stability and yield of the bacterial laccase are greatly improved.

Owner:ANHUI UNIVERSITY

Water-based mold release and preparation method thereof and release paper prepared by utilizing water-based mold release

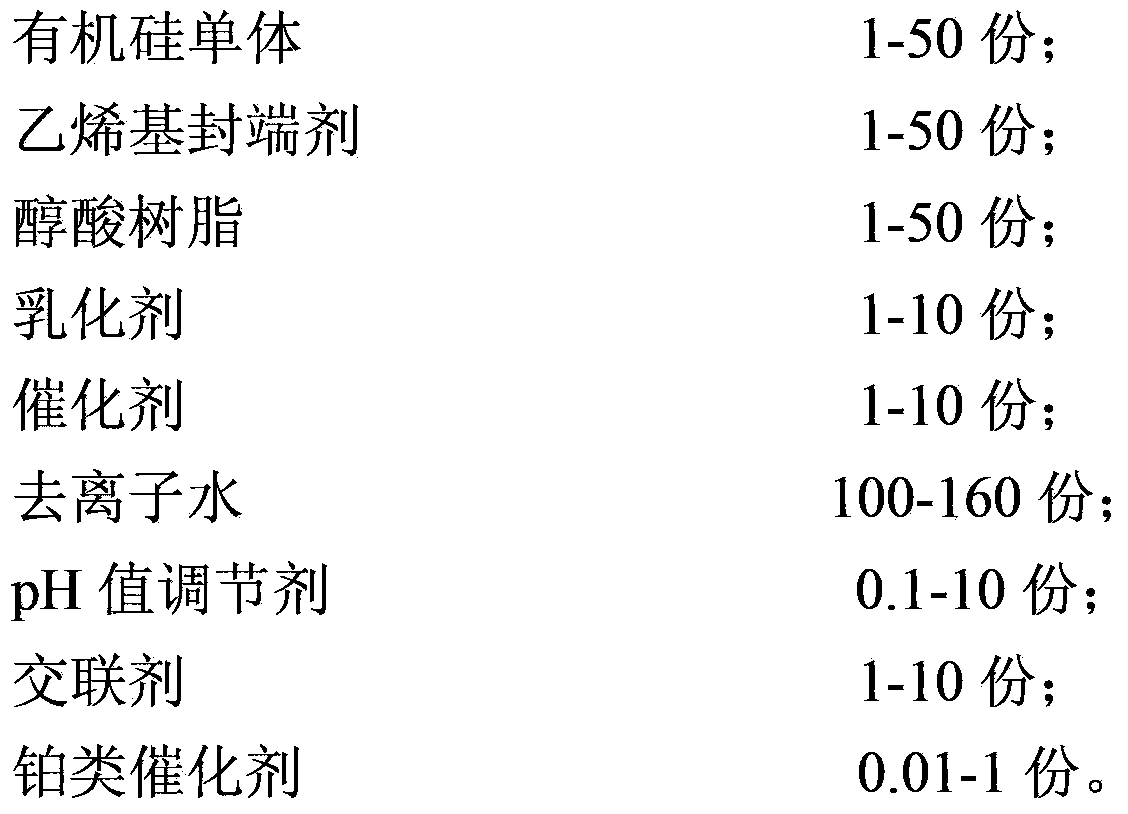

The invention discloses a water-based mold release and a preparation method thereof and release paper prepared by utilizing the water-based mold release. The mold release comprises the following raw materials by weight: 1 to 50 parts of organosilicone monomer, 1 to 50 parts of vinyl end-capping agent, 1 to 50 parts of alkyd resin, 1 to 10 parts of emulsifying agent, 1 to 10 parts of catalytic agent, 100 to 160 parts of deionized water, 0.1 to 10 parts of pH value conditioning agent, 1 to 10 parts of cross-linking agent and 0.01 to 1 part of platinum-based catalytic agent. The mold release has the advantages that the raw materials are cheap and easy to get; the preparation method is simple; the used mold release layer takes water as a dispersing agent; no organic solvent is released; the mold release is safe and environment-friendly; the release paper prepared by utilizing the mold release is short in thermosetting time, and is suitable for industrialized production; the prepared release paper is good in property.

Owner:浙江池河科技有限公司

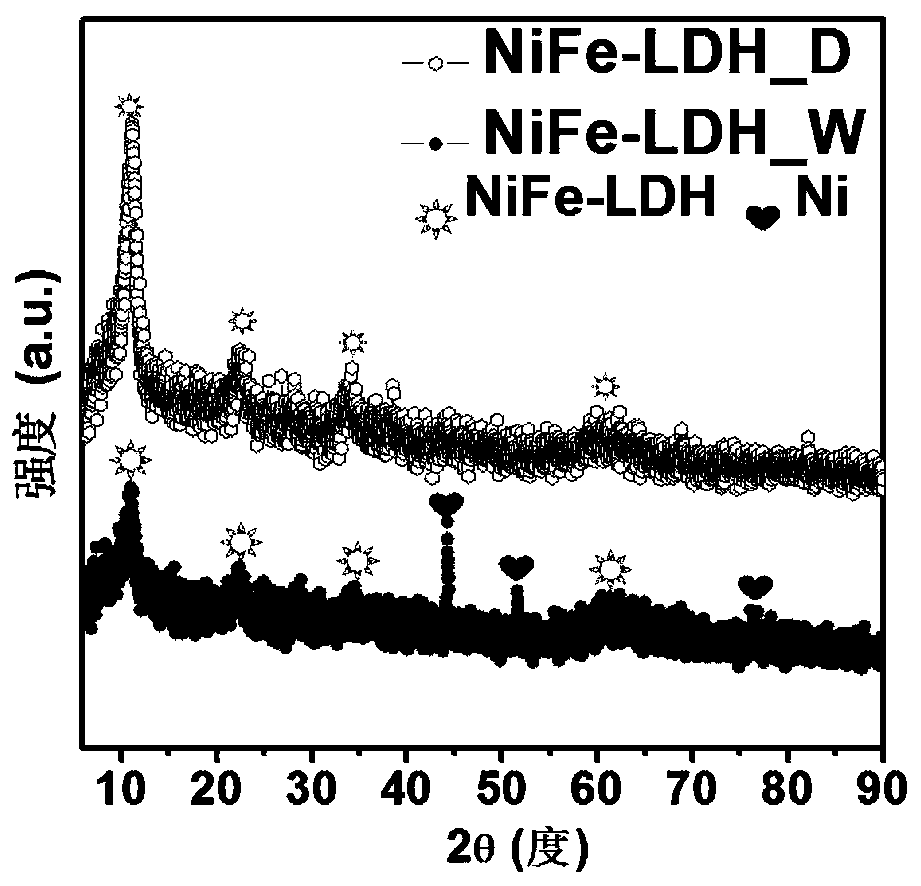

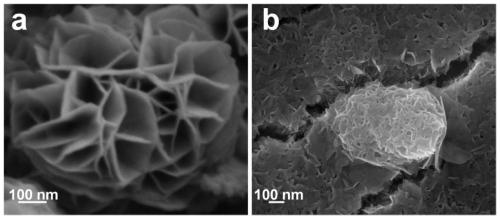

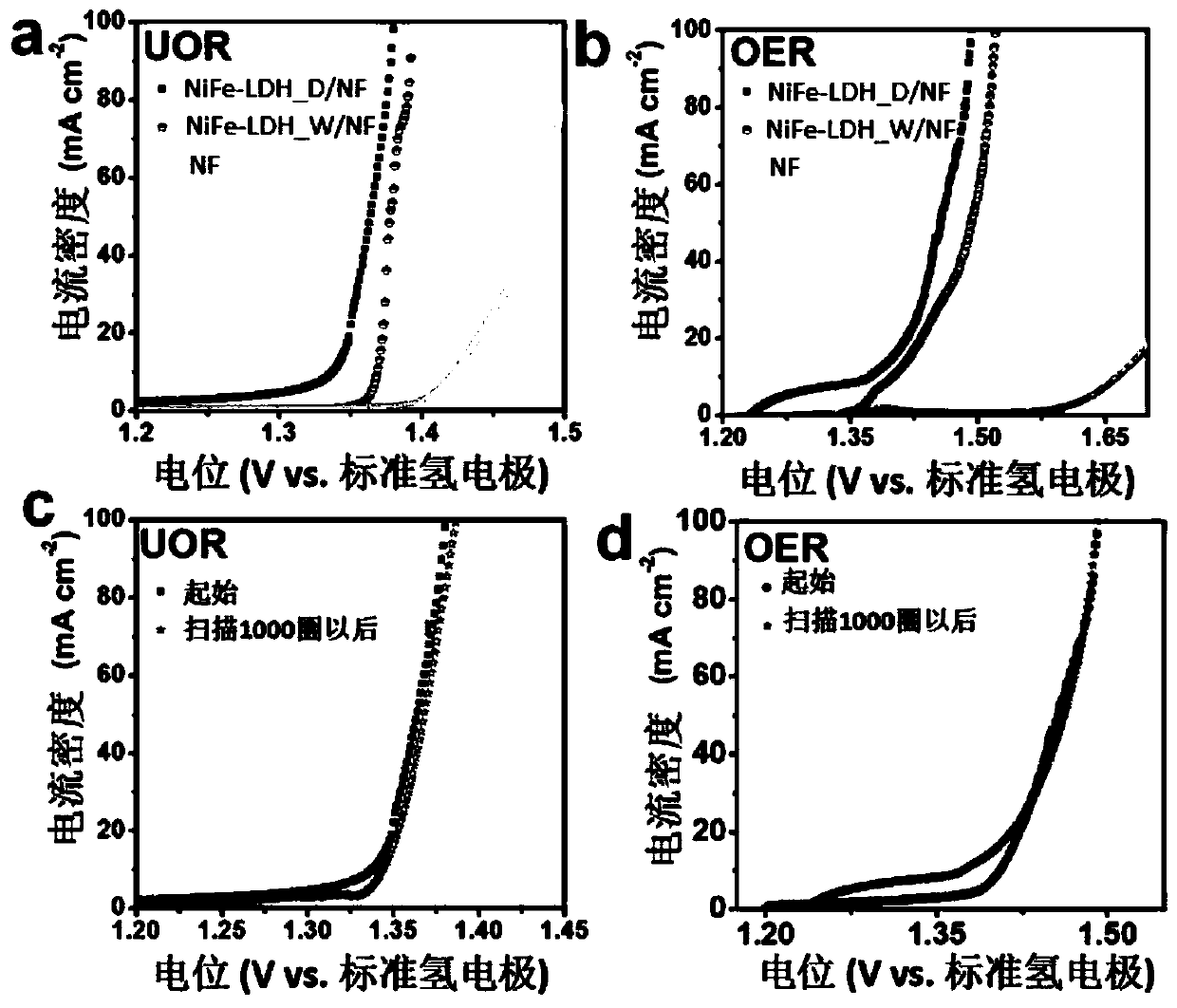

Nickel-iron double hydroxide/foamed nickel catalyst based on ferric chloride/urea eutectic solvent, and preparation method and application thereof

ActiveCN110201670ASimple processLow costCatalyst activation/preparationElectrode shape/formsElectrolysisSolvent

The invention provides a nickel-iron double hydroxide / foamed nickel catalyst based on a ferric chloride / urea eutectic solvent, and a preparation method and an application thereof. The nickel-iron double hydroxide / foamed nickel catalyst is prepared from the eutectic solvent which is prepared from ferric chloride hexahydrate and urea. The preparation method has the advantages of cheap and easily available raw materials, low cost, extremely simple operating process, easily realized reaction conditions, no high temperature, low energy consumption, short preparation period, and suitableness for industrial production. The obtained catalyst is nickel-iron double hydroxide loaded on foamed nickel, and the catalytic active component is nickel-iron double hydroxide (NiFe-LDH), and has a hierarchicalstructure that is a nanoflower structure composed of nanosheets. The catalyst has a good electrocatalytic electrolysis effect on water and urea.

Owner:SHANDONG UNIV

Method for preparing fingered citron juice

InactiveCN101099588AIncrease the juice yieldIncrease profitFruits/vegetable preservation by freezing/coolingFruit juiceCITRUS MEDICA FRUIT

The present invention discloses a fruit juice extraction method, in the concrete, it relates to a freeze-juicing method of chayote, belonging to the field of food processing technology. Said method includes the following steps: firstly, freezing chayote fruit, after the chayote fruit is completely frozen, defreezing, crushing the defrozen chayote fruit and extracting its juice, adding the water into the fruit dregs to make secondary juice extraction, combining two juices so as to obtain the invented chayote fruit juice.

Owner:CHINA AGRI UNIV

Adefovir dipivoil dispersion tablet and preparing method

InactiveCN1562046AGood disintegration timeGood dissolution rateOrganic active ingredientsAntiviralsCarboxymethyl starchLactose

A dispersing tablet of adefovirdipivoxil ester is prepared from adefovirdipivoxil ester, pregelatinized starch, microcrystalline fibres, lactose, carboxymethyl starch sodium, sodium laurylsulfate, and magnesium stearate through respective sieving, proportionally mixing and die pressing.

Owner:JIANGZHONG PHARMA

Post-fermentation of tea

The invention is concerned with a secondary fermentation method of tea. It takes Yunnan-Dayecha or the camellia related genera plant with large lamina as material to produce Pu'er crude tea, i.e. green tea, through beating, rolling and drying. Repeat the wet, ferment and dry process for some times, and age to get Pu'er ripe tea. Or it takes un-fermentation tea or half fermentation tea as material, through repeating the wet, ferment and dry process for some times, and age to get secondary fermentation tea. During the machining process, the tea does not go moldy and emanates the faint scent smell, and the color is carmine after deep dunking close to the liquor color of Pu'er crude tea stored for long time, and the smell is aromatic and natural, and the flavor is rich and tasty taste. The operation is easy and fits for industry produce in large without losing the nutritional substance.

Owner:冯磊 +1

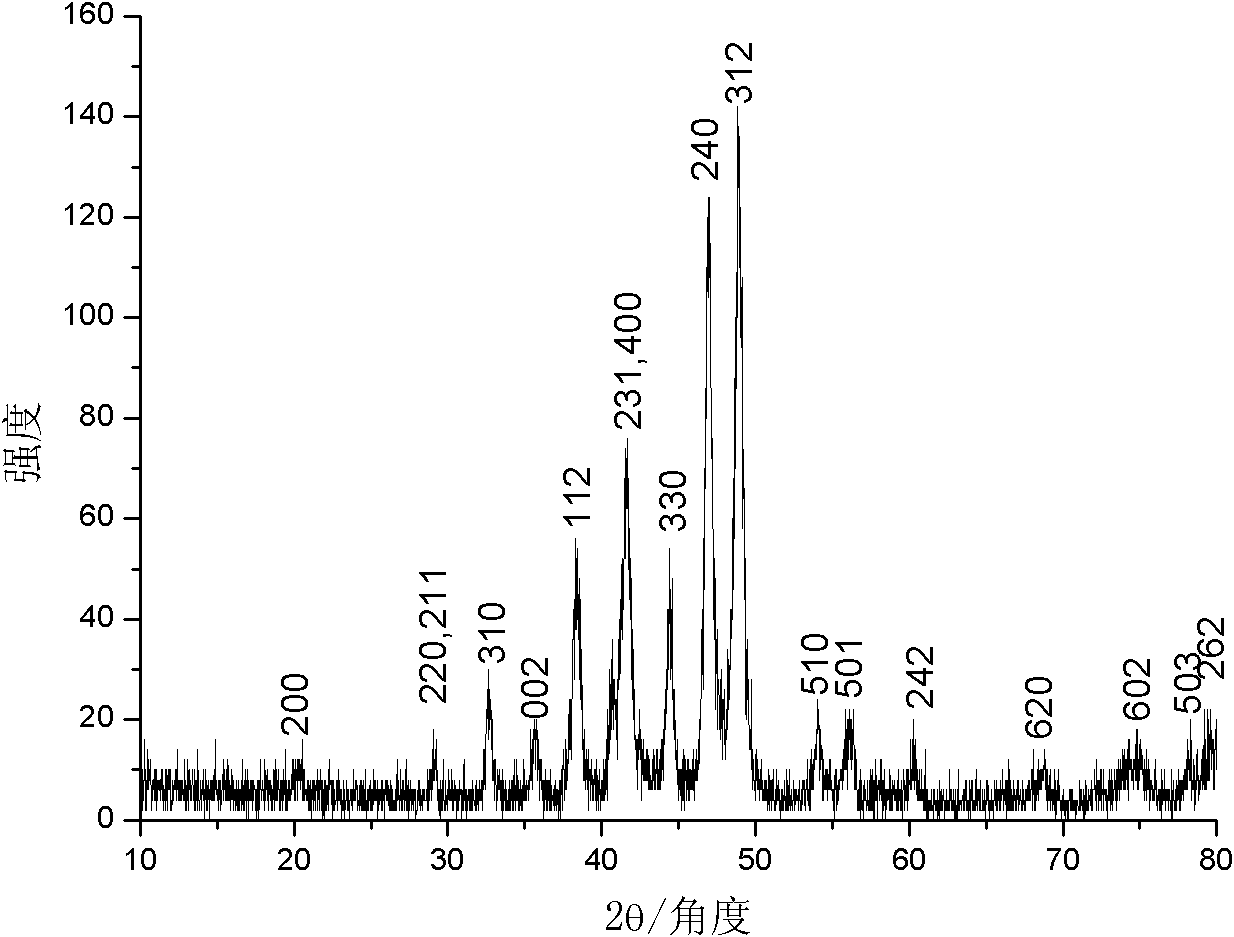

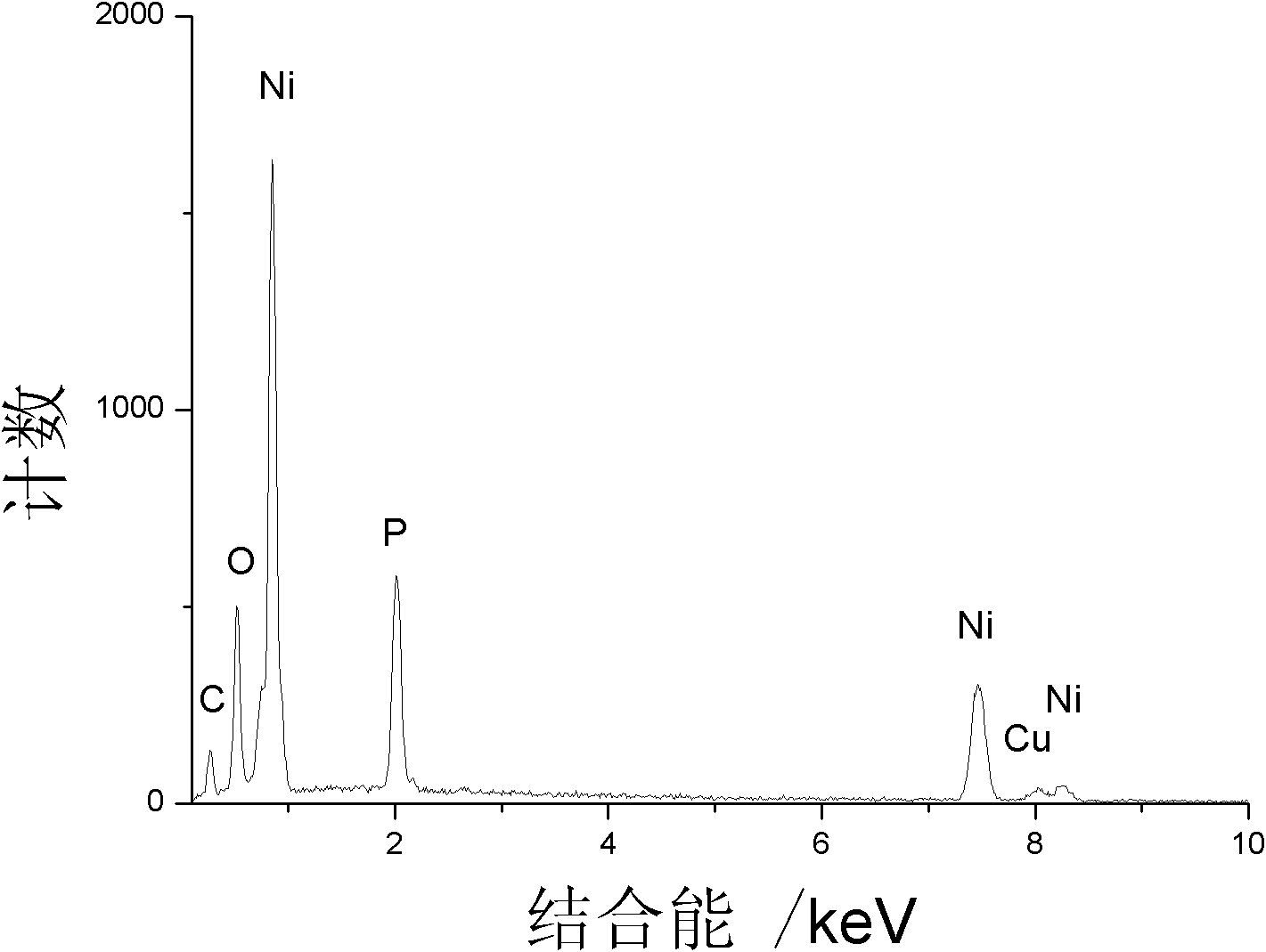

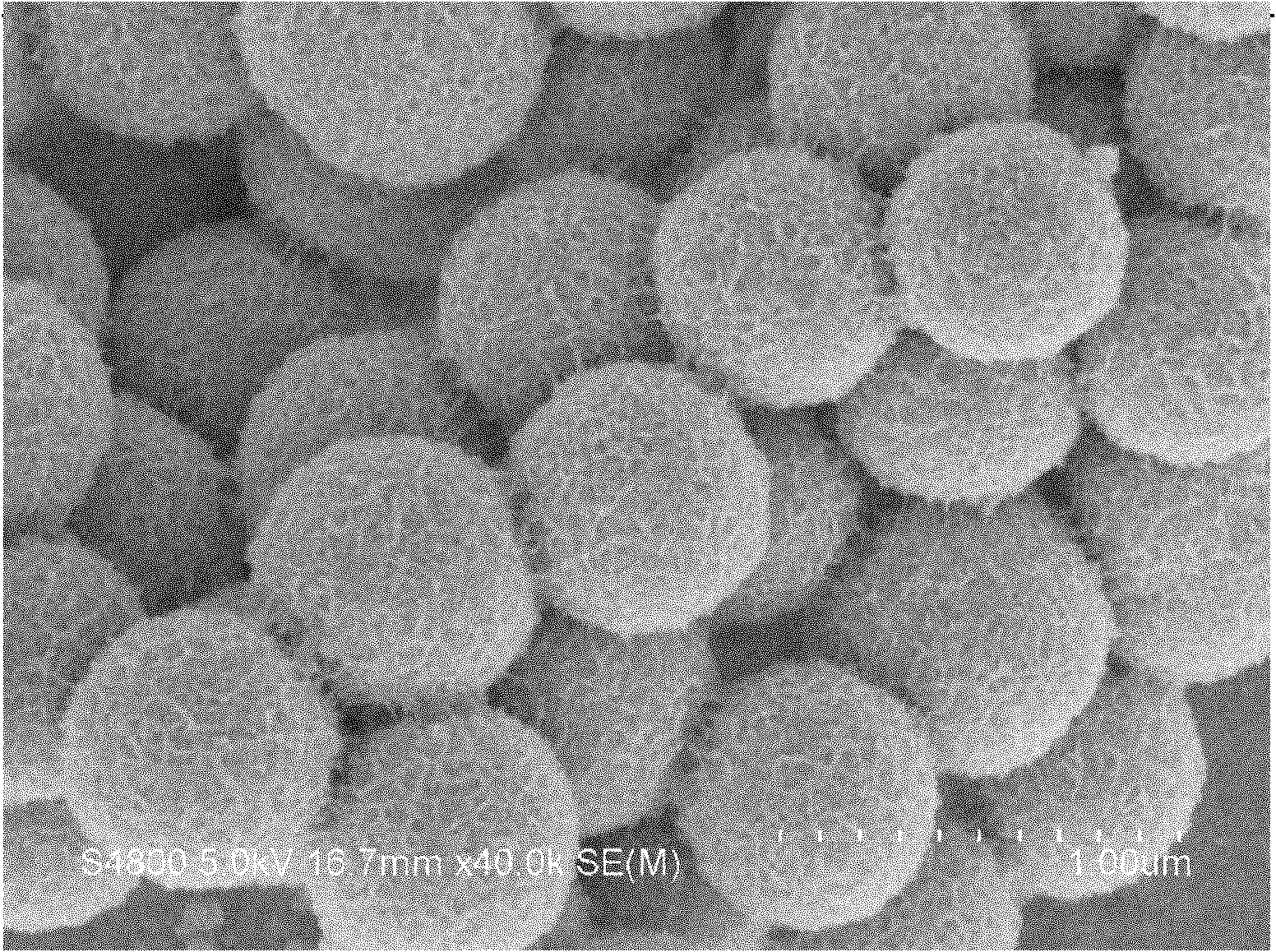

Preparation method and application of nano nickel phosphide

ActiveCN102040203ALarge specific surface areaMany catalytic sitesPhysical/chemical process catalystsNanotechnologyIonChemistry

The invention discloses a preparation method and application of nano nickel phosphide. The preparation method comprises the following steps: dissolving an anion type surfactant, soluble nickel salt and a reducing agent into distilled water, and evenly stirring; adding simple substance phosphorus; heating to 130-170 DEG C; reacting for 6-15 hours; cooling to the room temperature, and washing for multiple times with absolute ethyl alcohol and deionized water; and drying the product to the constant weight in a vacuum drying oven at 50-60 DEG C to prepare the nano nickel phosphide. Compared with the prior art, the invention has the advantages that a simple water heating method is utilized, a phosphorus source is the simple substance phosphorus, and the temperature and time of the reaction arequite short, which is beneficial to industrial mass production. When the nano particles of the prepared nickel phosphide are used in the catalytic hydrogenation production of nitrobenzene, the hydrogenation of the nitrobenzene can be catalyzed at lower temperature and under lower pressure, the reusability is good and the industrial use value is high because of porous surface structure, large specific surface area and multiple catalytic activity points.

Owner:NANTONG ZHONGXING MAGNETIC IND

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com