Automatic frequency tracking method of supersonic transducer and system thereof

An automatic frequency tracking, ultrasonic transducer technology, applied in the direction of the fluid using vibration, can solve the problem that the transducer cannot fully release the power input signal, the duty cycle is relatively high, and the frequency tracking accuracy is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

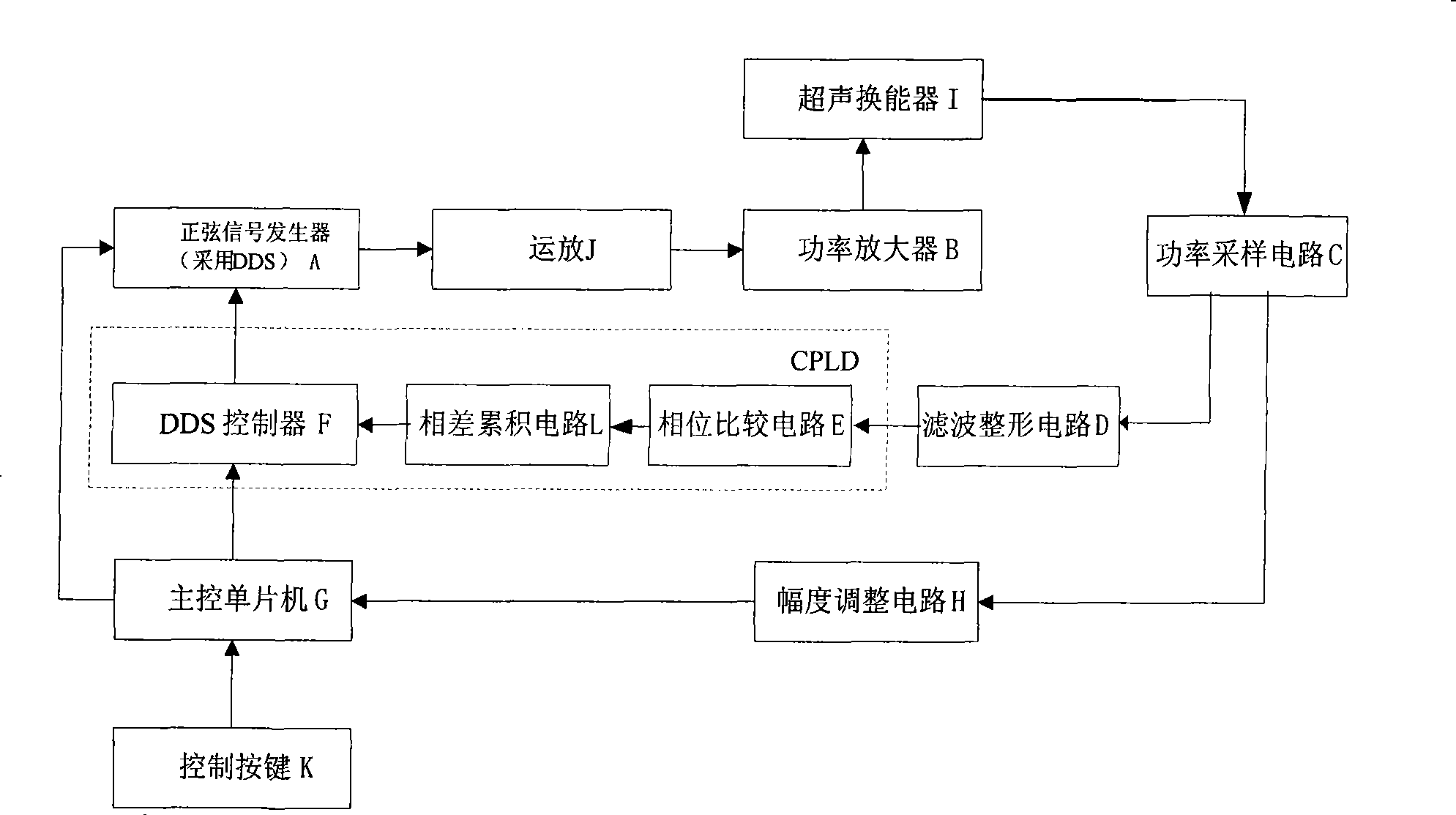

[0050] The design of the present invention is based on the principle that the excitation voltage and current of the ultrasonic transducer have the same phase at its resonant frequency point, and adopts the most advanced direct digital synthesis (DDS) and large-scale programmable devices to realize a novel fully Digital automatic frequency tracking solution.

[0051] The specific all-digital features are mainly manifested in:

[0052] ① The DDS as the excitation source of the transducer is controlled by an all-digital serial communication method.

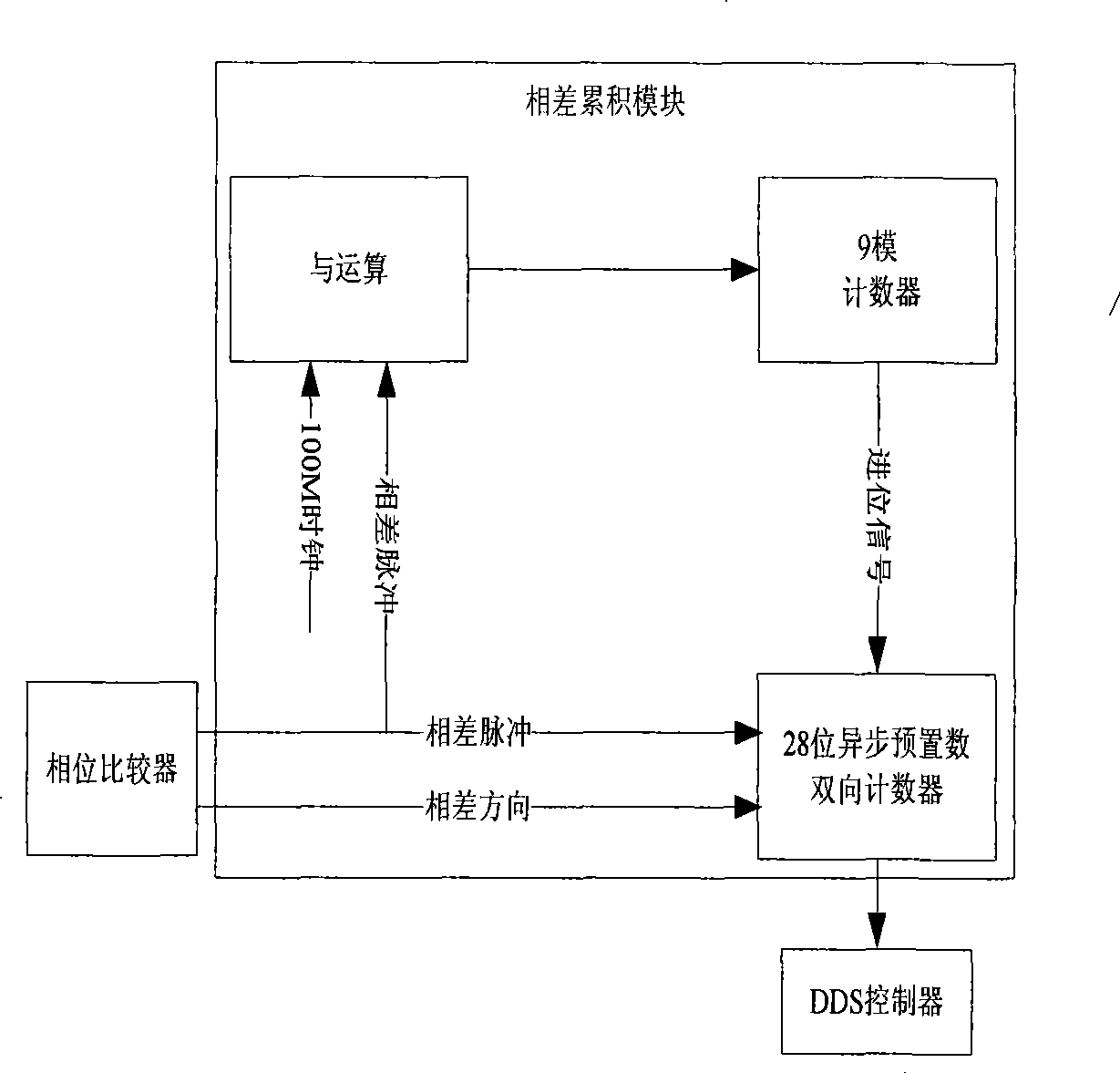

[0053] The phase difference signal given by the phase comparator is digitally processed and then fed back to the DDS to achieve frequency tracking, such as image 3 shown.

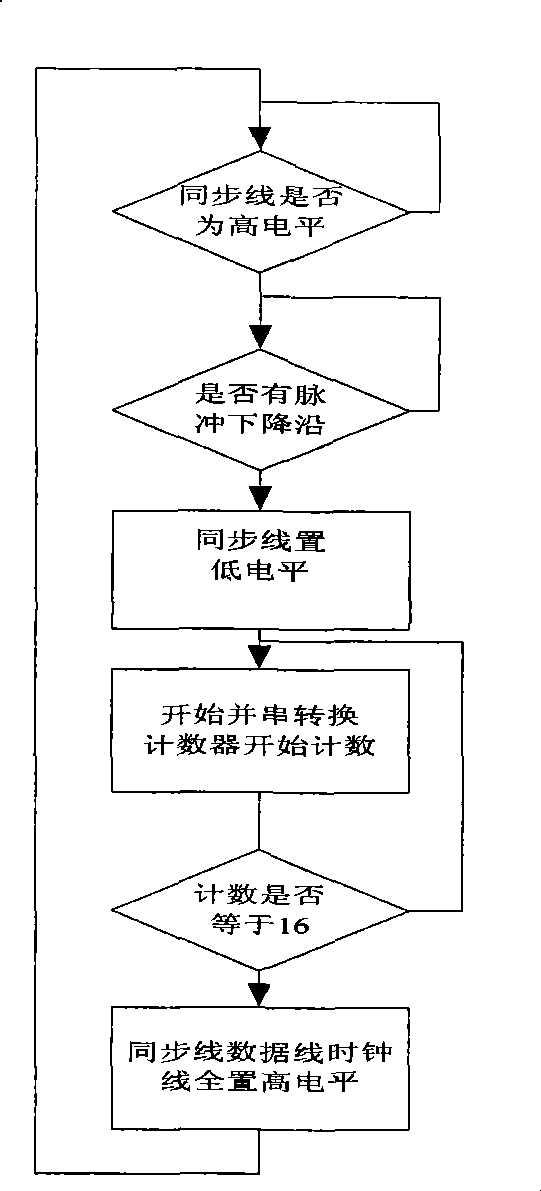

[0054] The core technology of the present invention is mainly the design of the DDS controller F and the phase comparator E which is only sensitive to the signal edge. The program flow chart of DDS controller F, such as figure 2 shown.

[0055] General bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com