Patents

Literature

12411results about "Fluid-pressure actuator components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

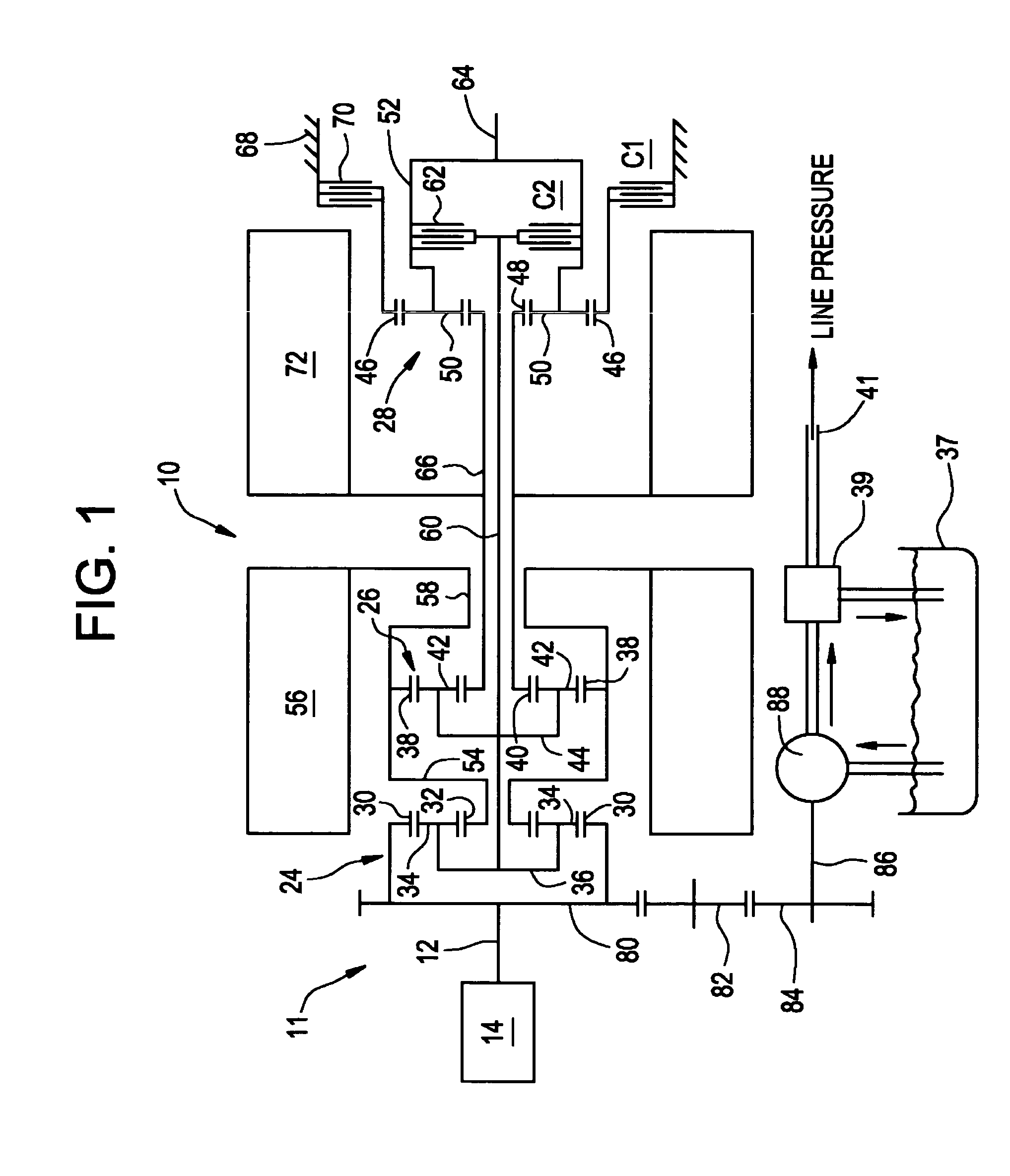

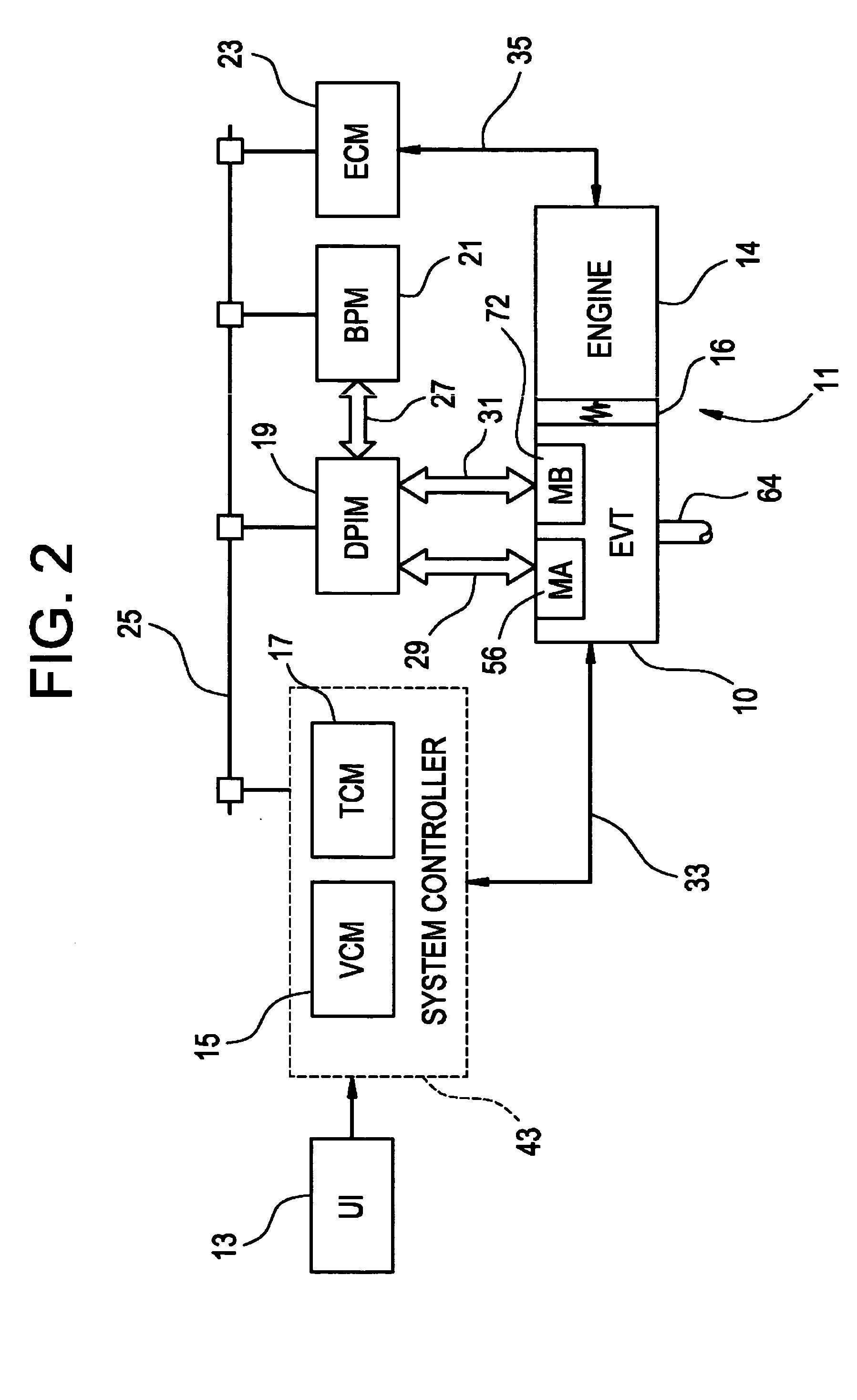

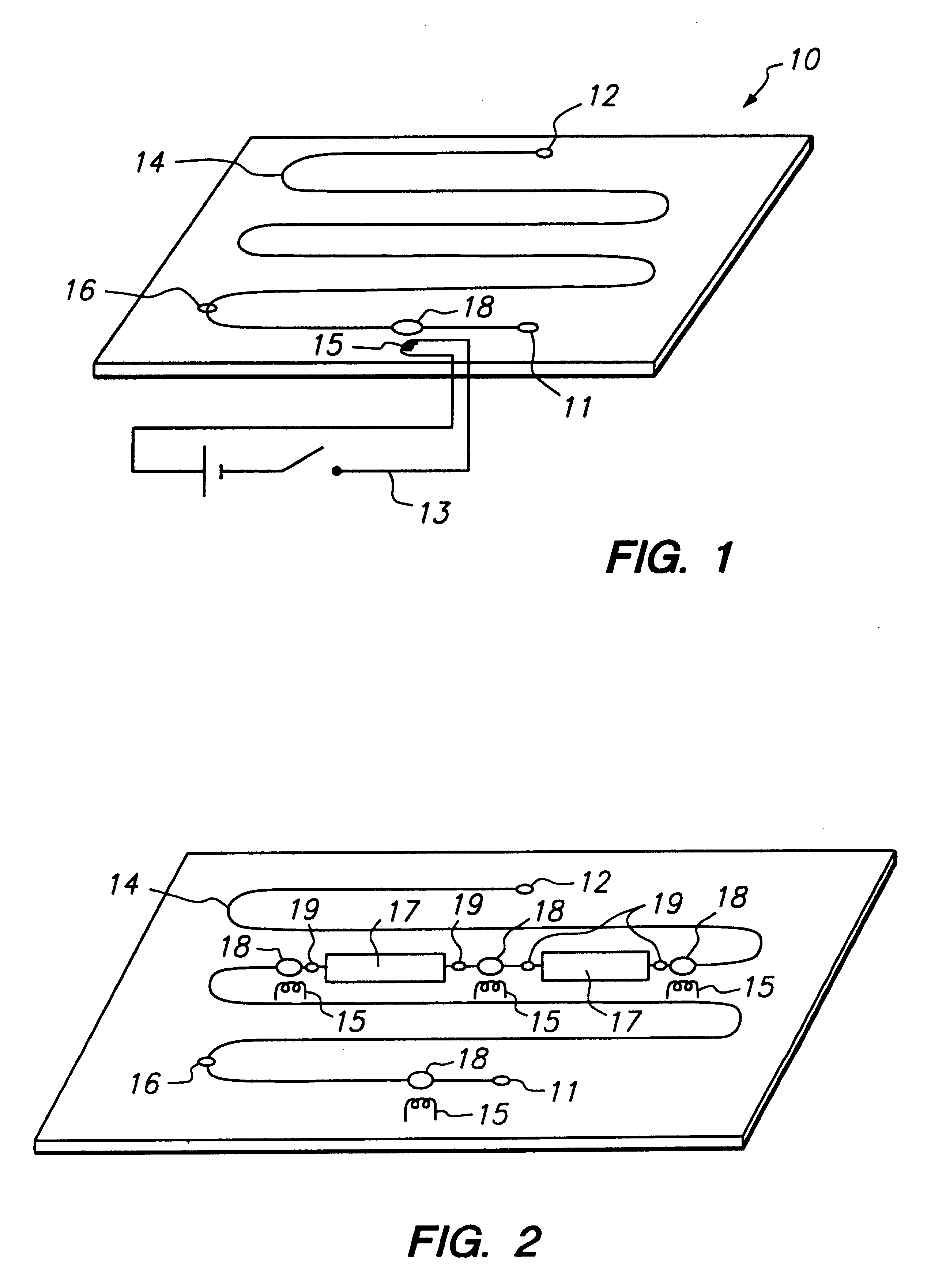

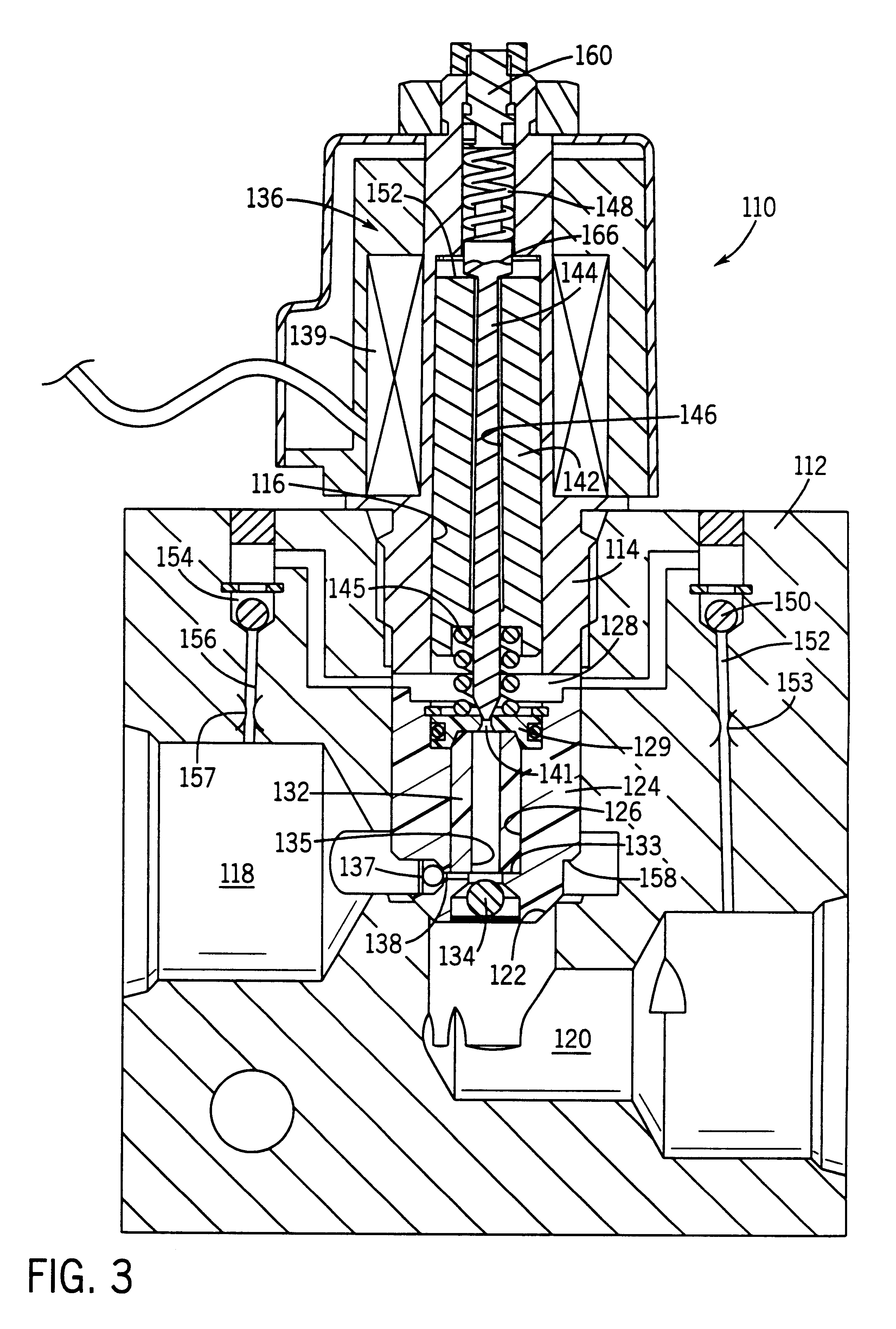

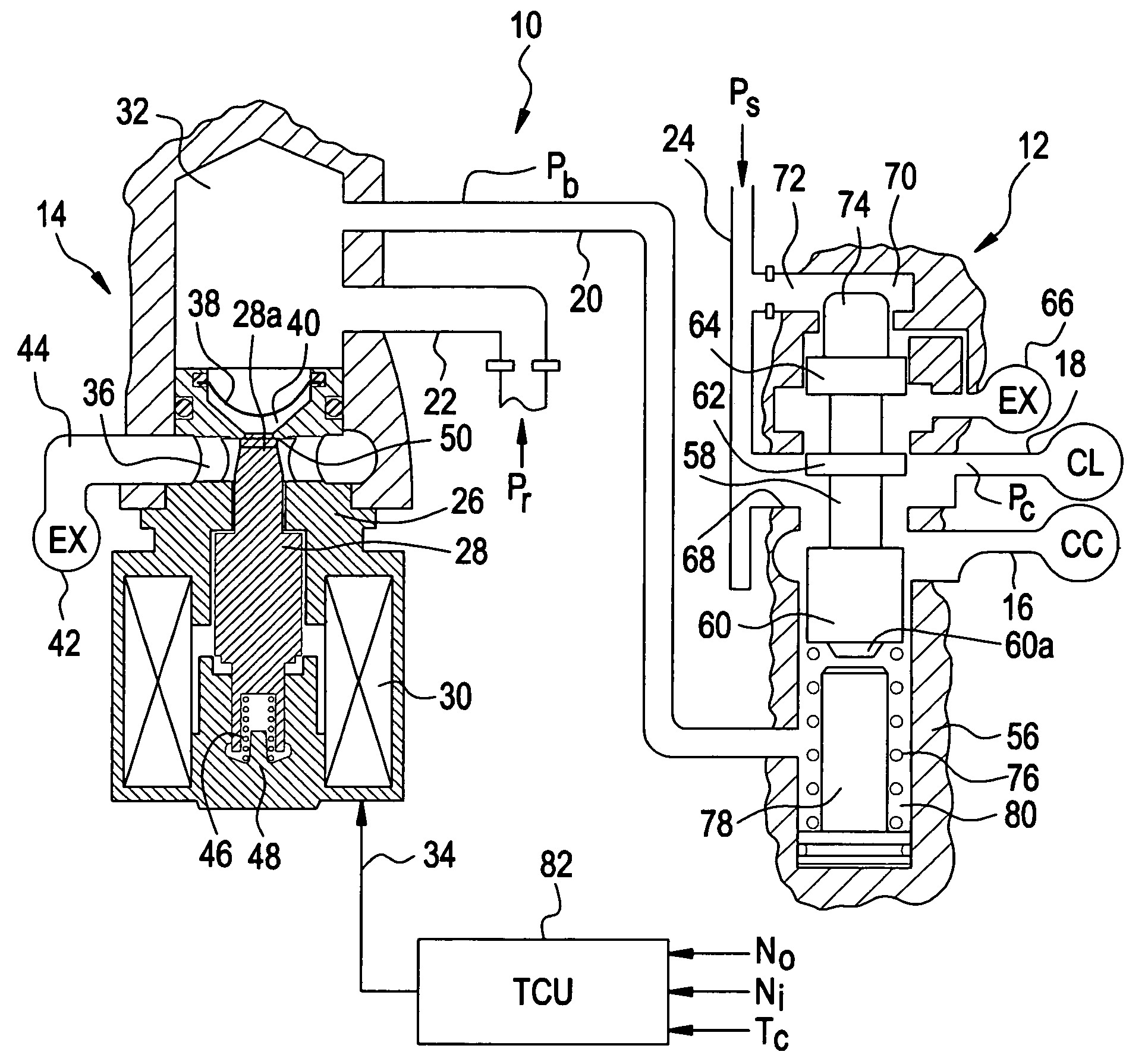

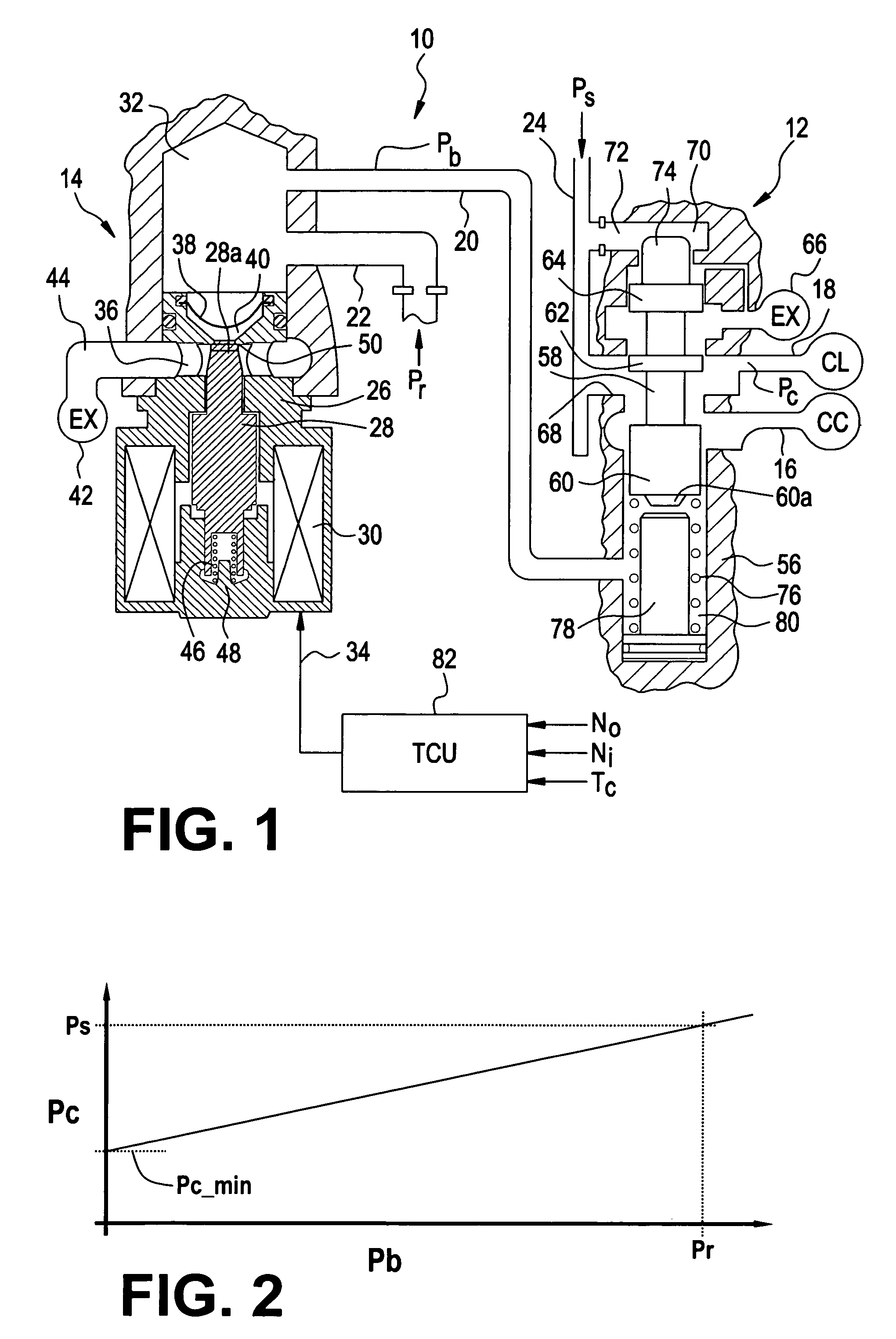

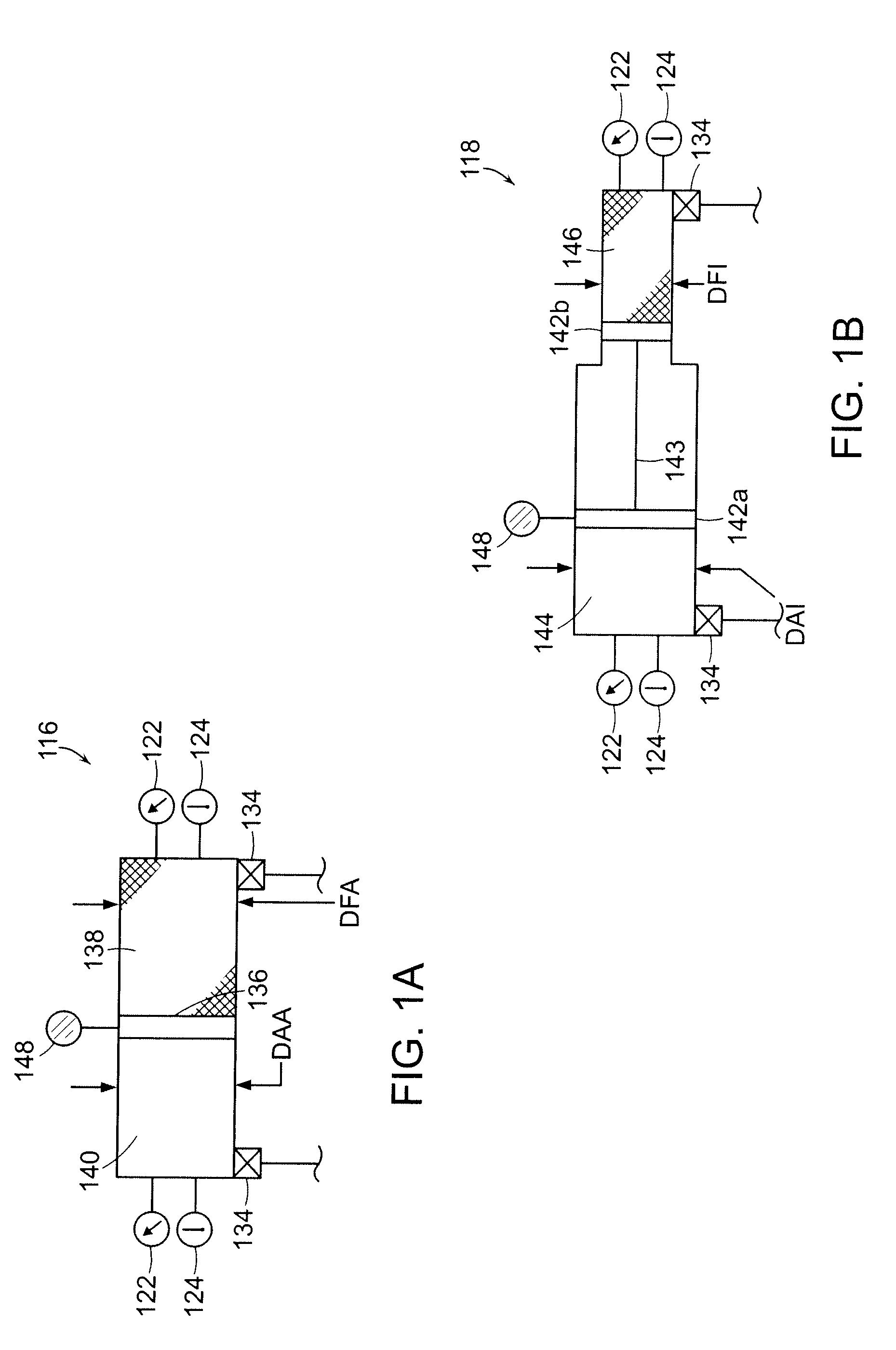

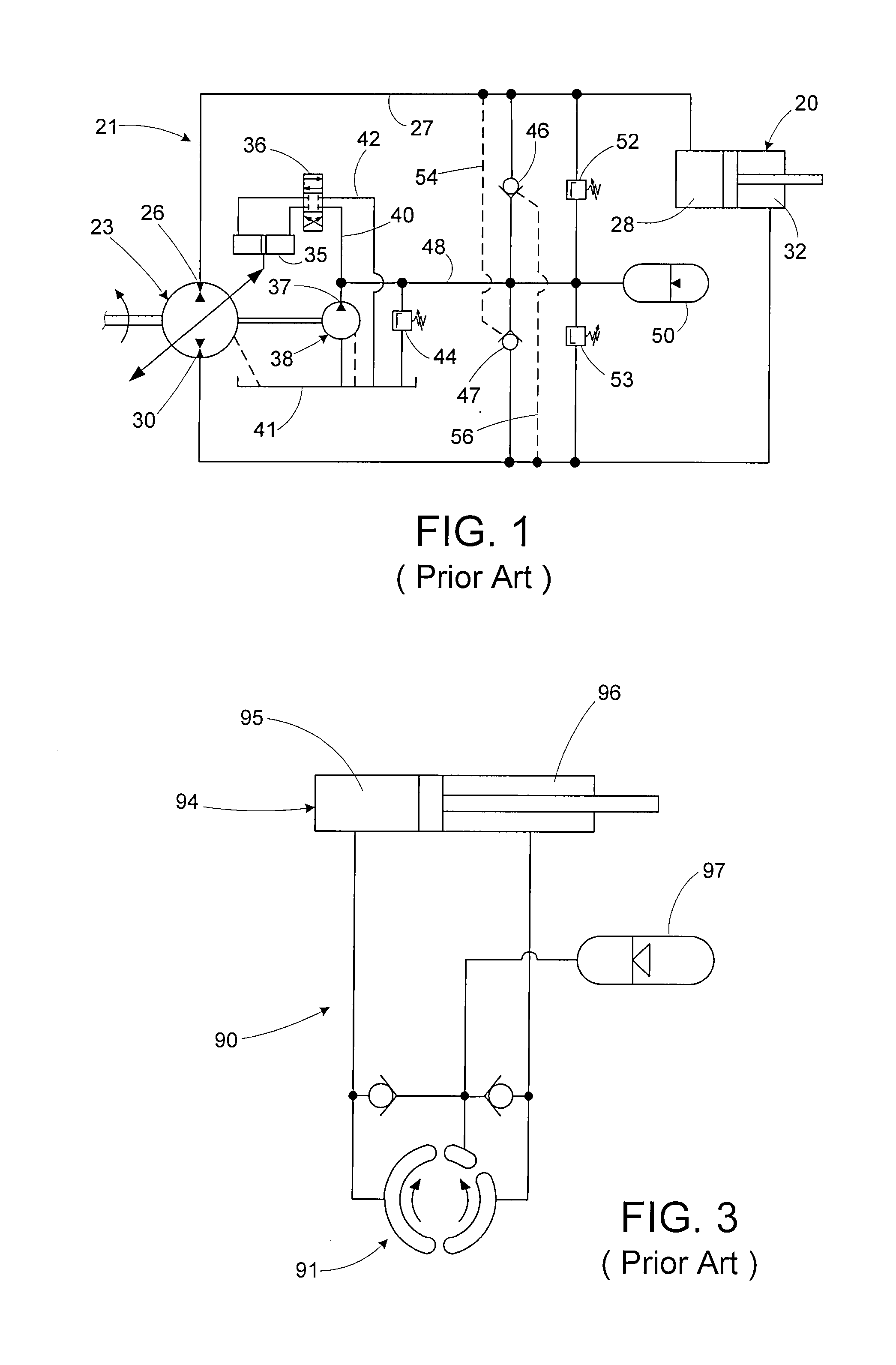

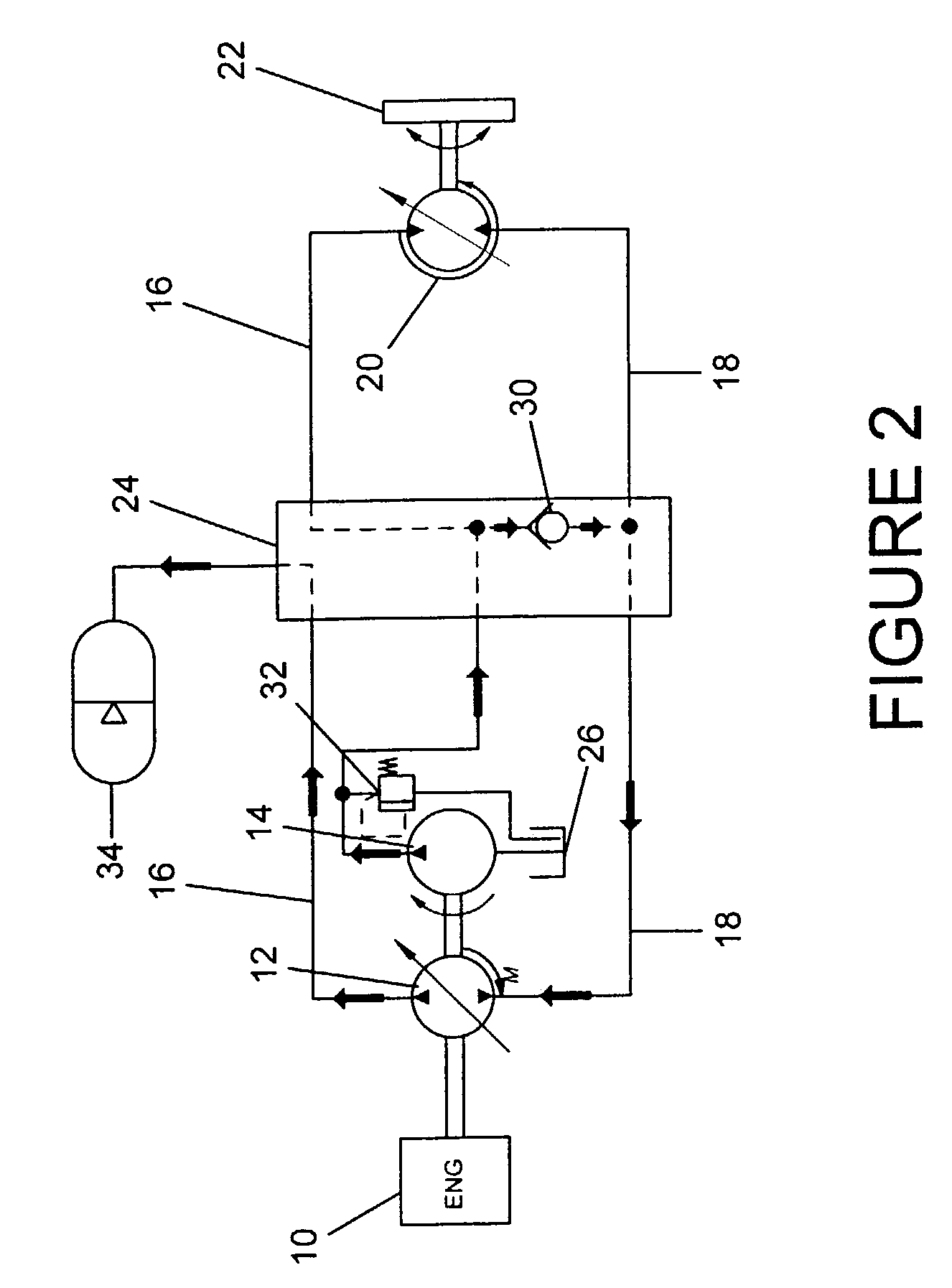

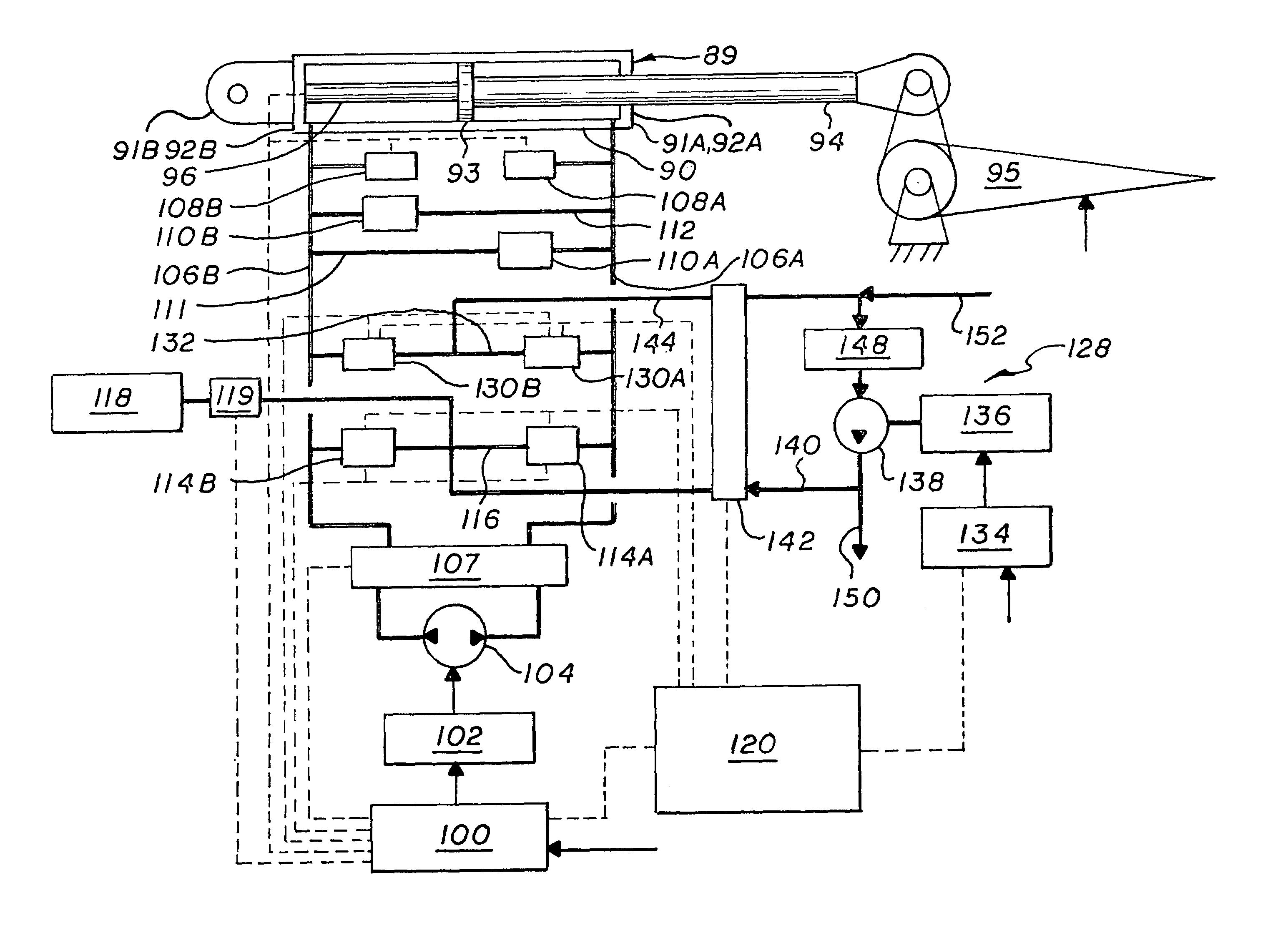

Control apparatus, method and diagnostic for hydraulic fill and drain

ActiveUS20050076958A1Improve robustnessHybrid vehiclesFluid-pressure actuator safetyControl theoryControl equipment

Hydraulic fill and drain of a clutch chamber is controlled with a blocking valve and a trim valve. The blocking valve selectively provides pressurized fluid to the trim valve which in turn selectively provides the pressurized fluid to the clutch chamber. Exhausting of the clutch chamber is effected through one of two alternate paths utilizing deactivation of one of the trim and blocking valves. Back up exhausting of the clutch chamber is effected through the other of the alternative paths. Such system allows for determination of valve failures and continued operation until such failures can be rectified.

Owner:ALLISON TRANSMISSION INC

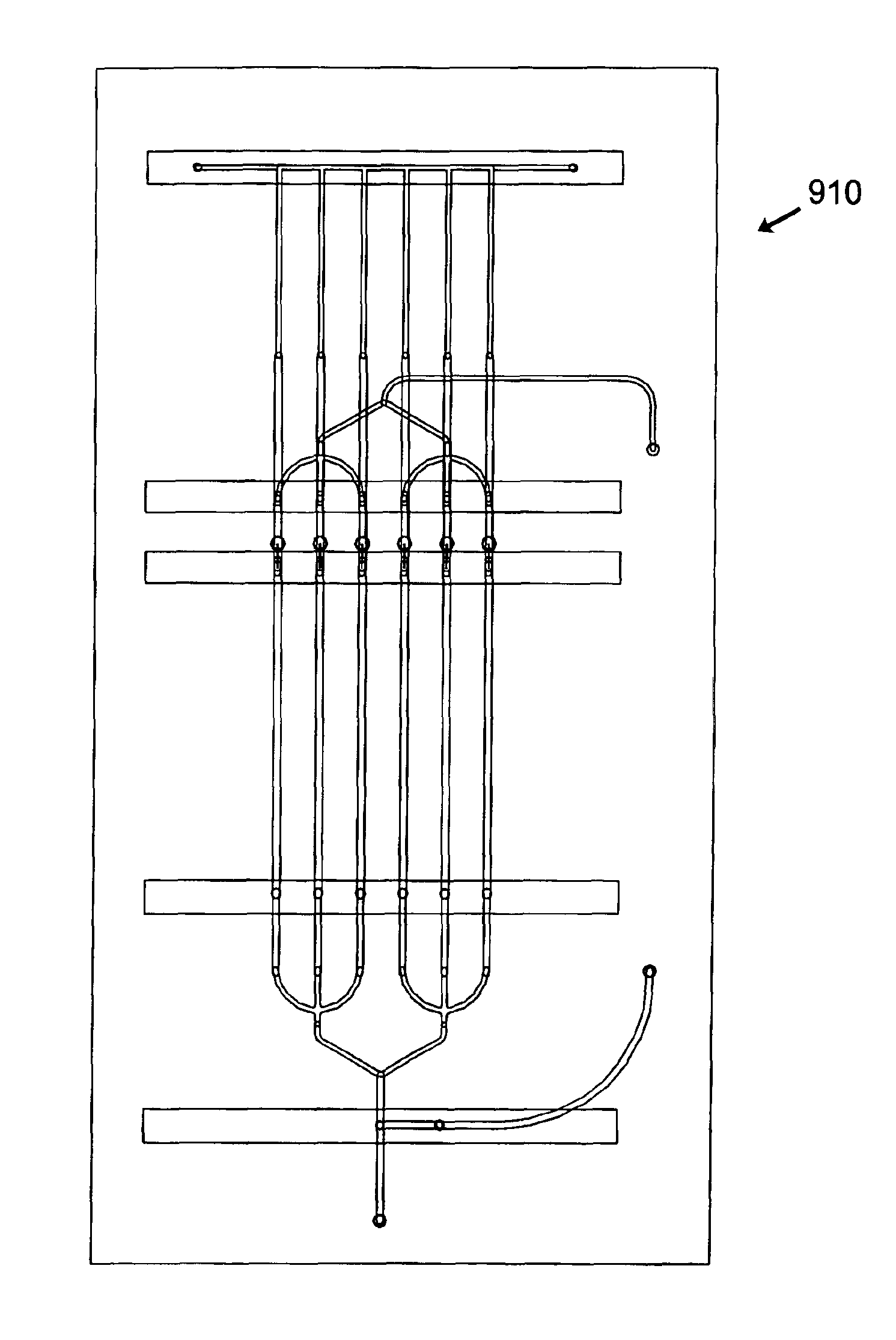

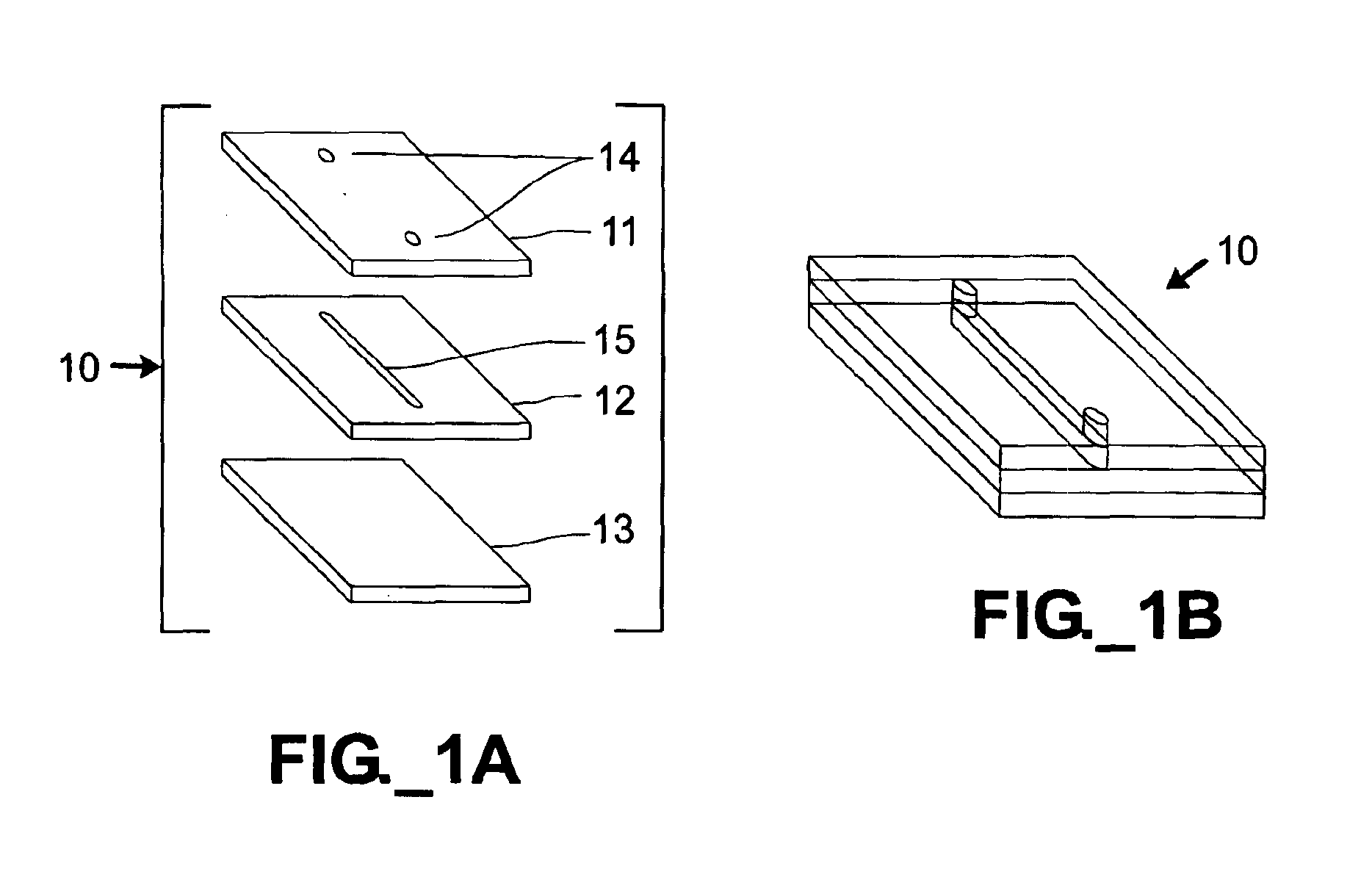

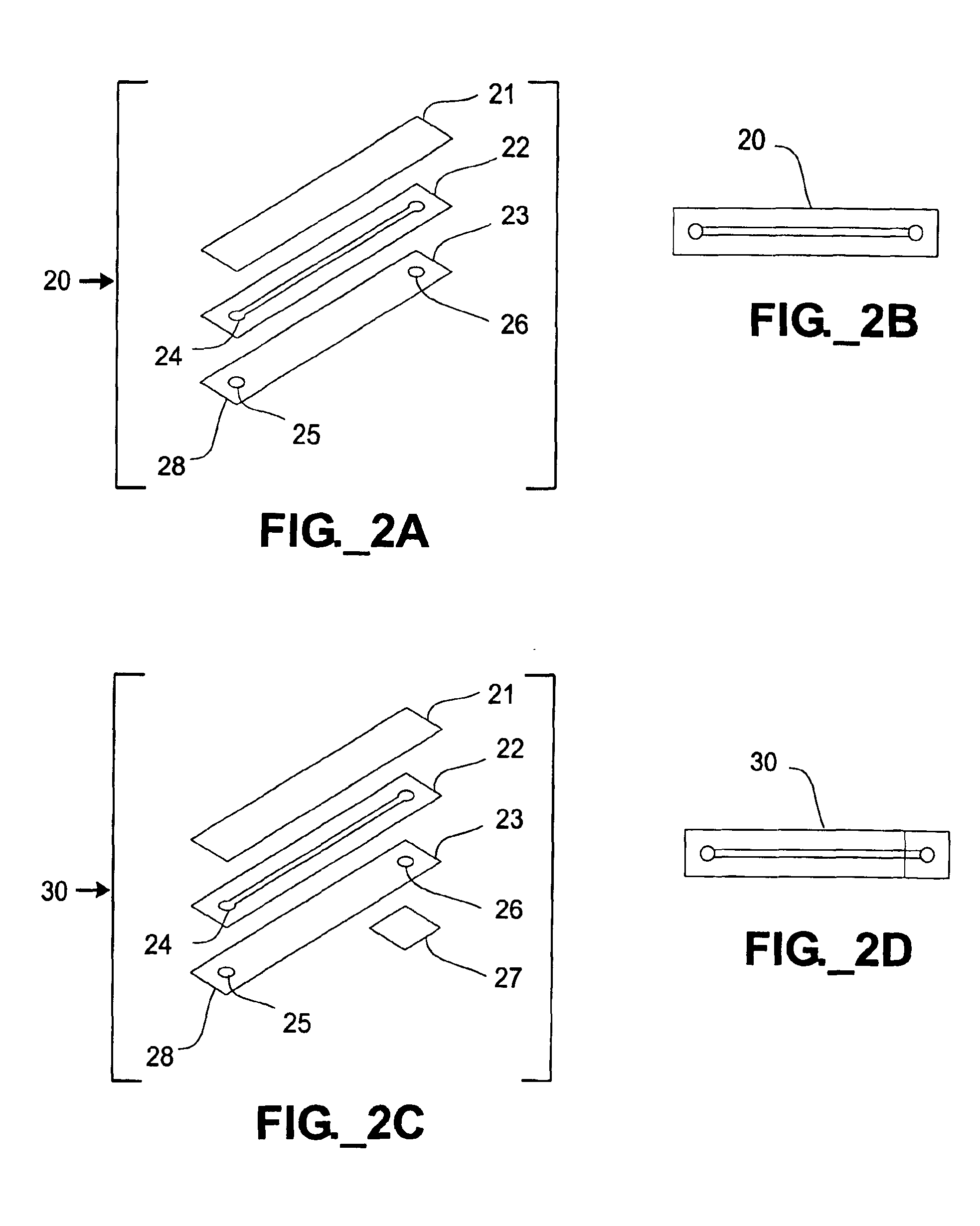

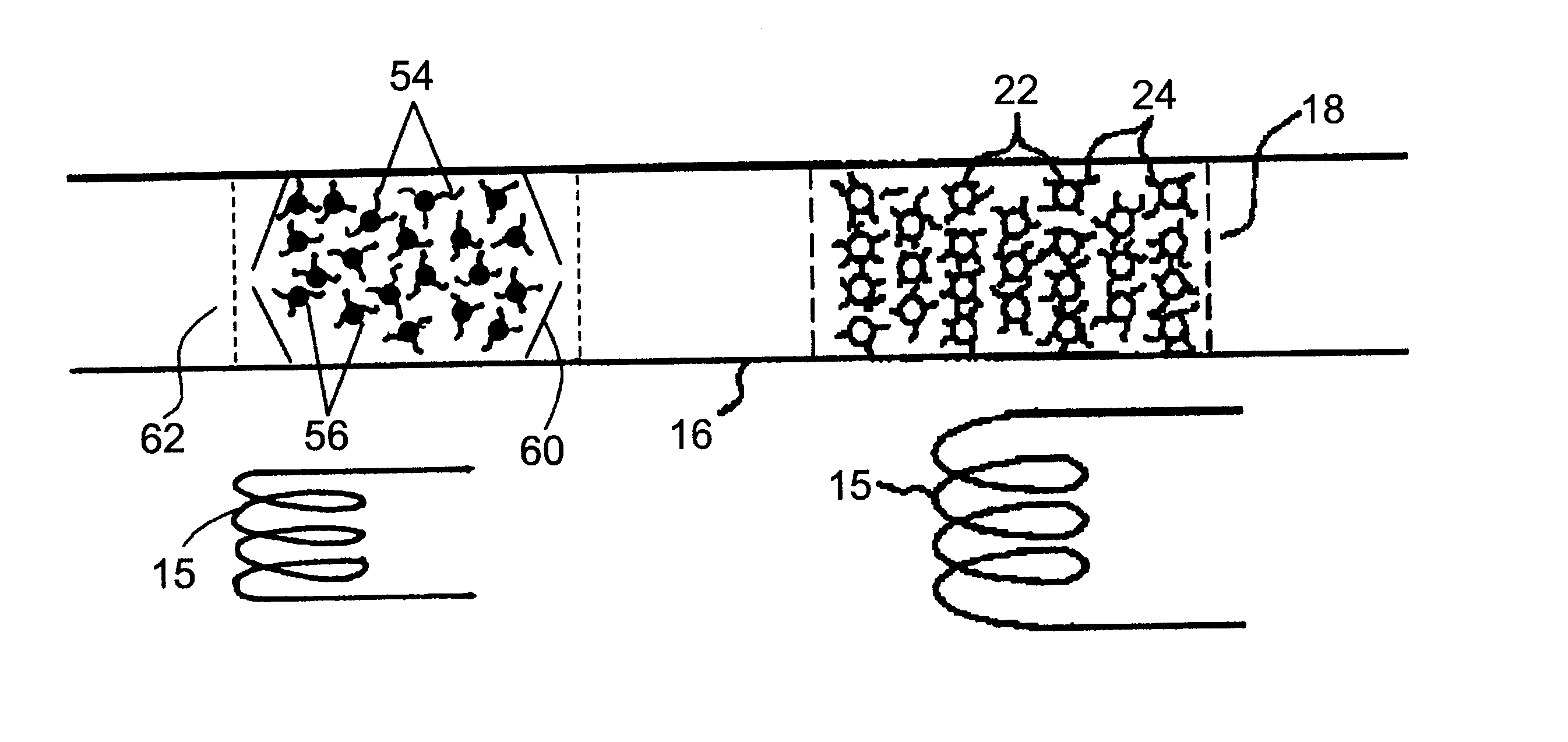

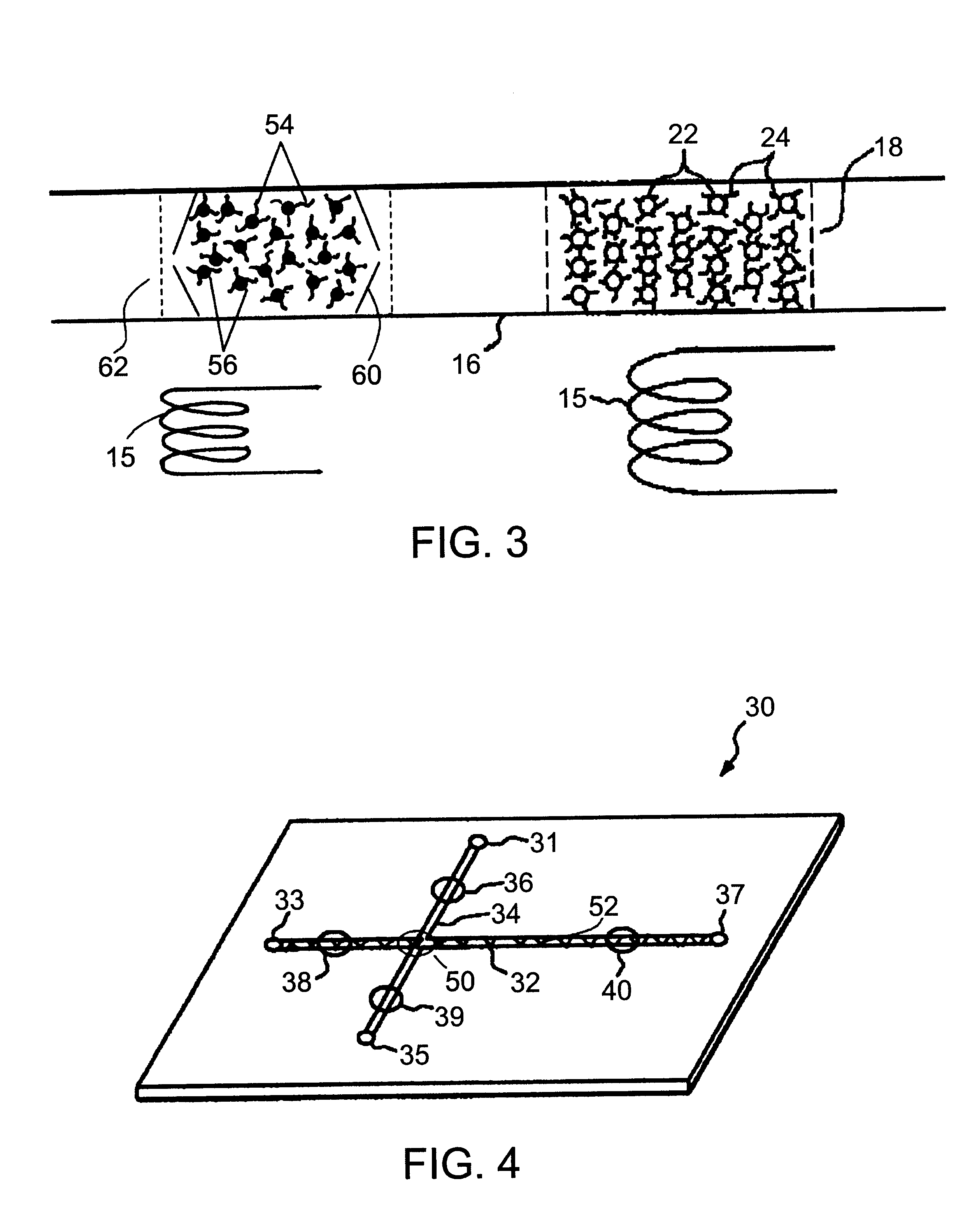

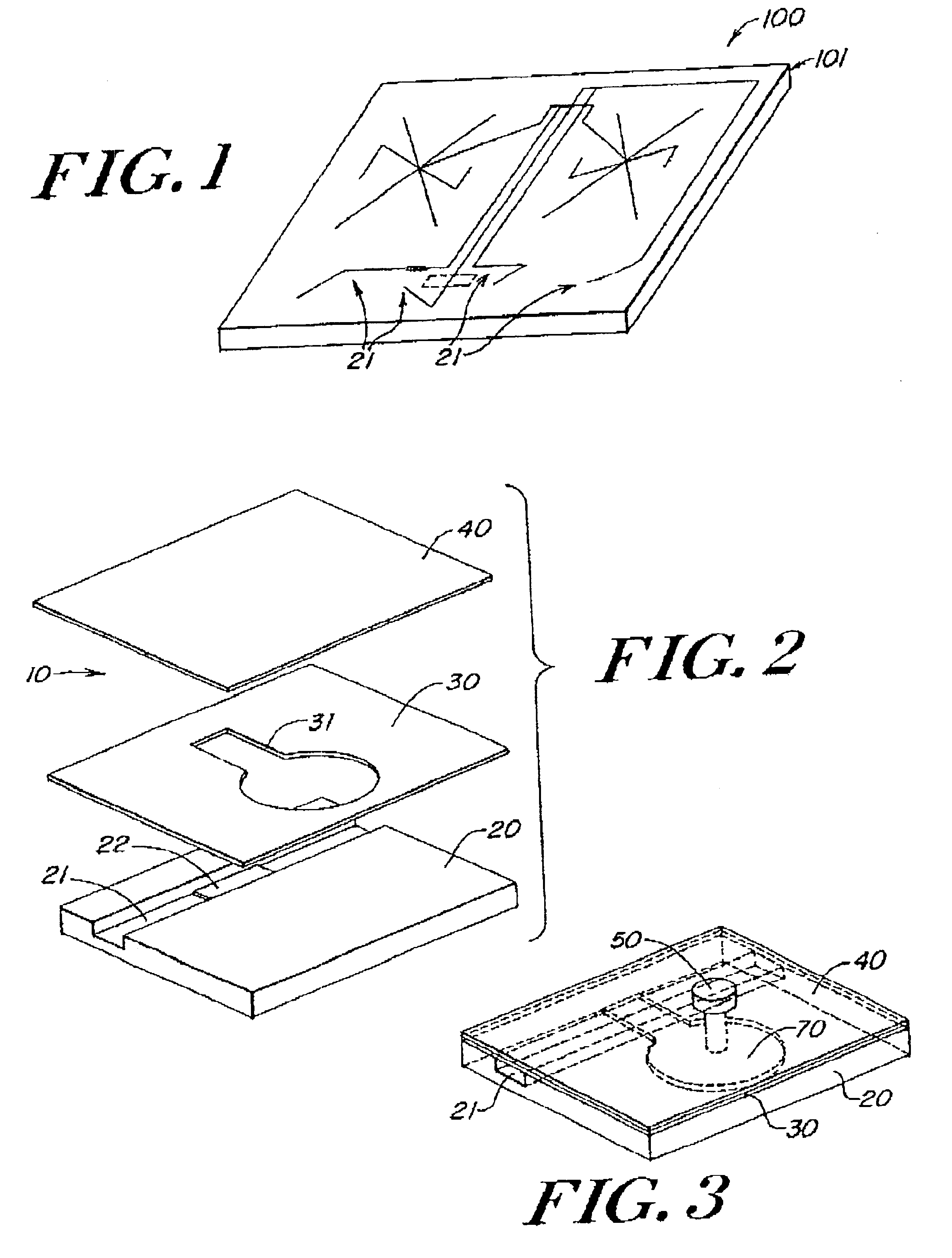

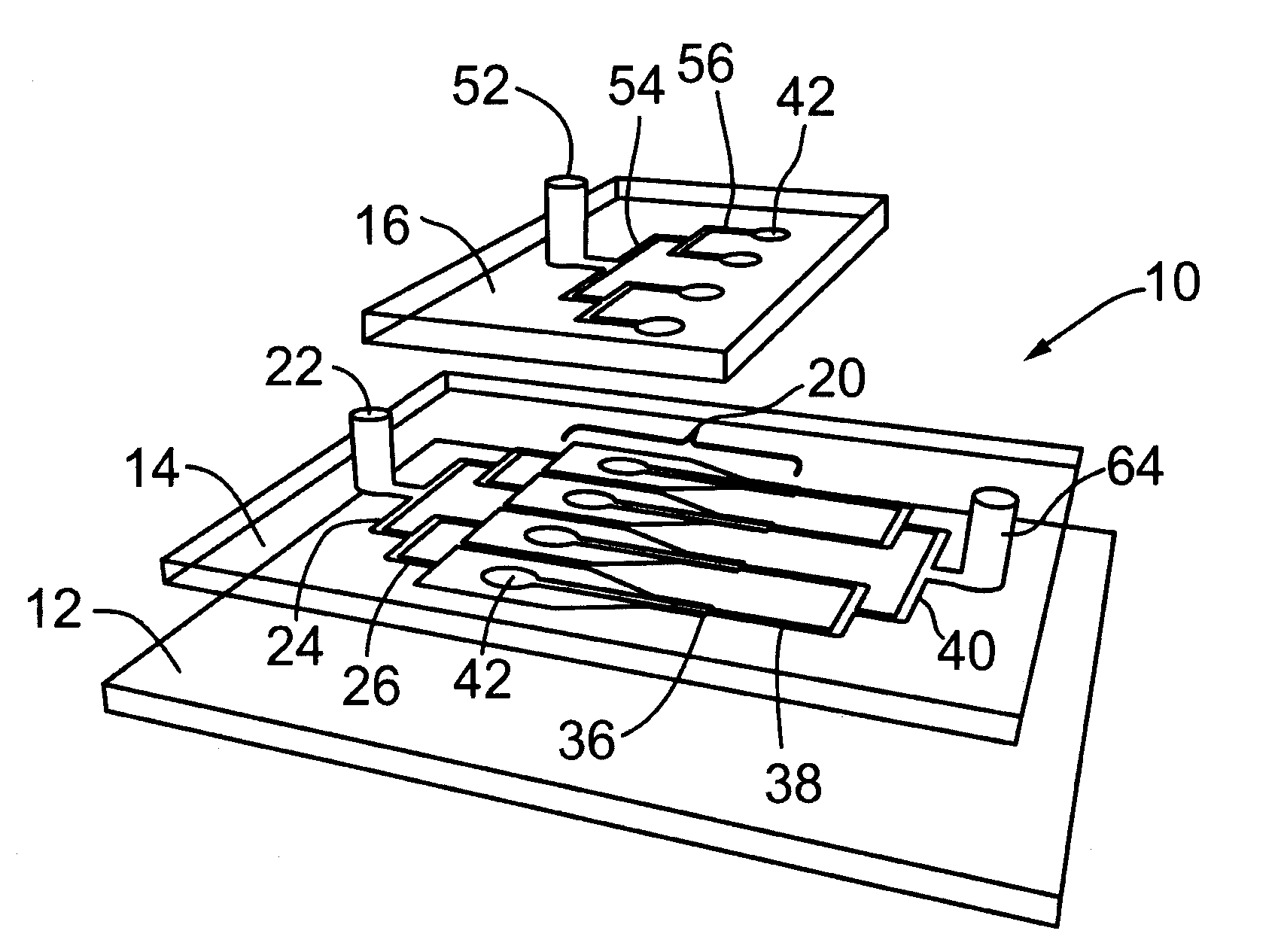

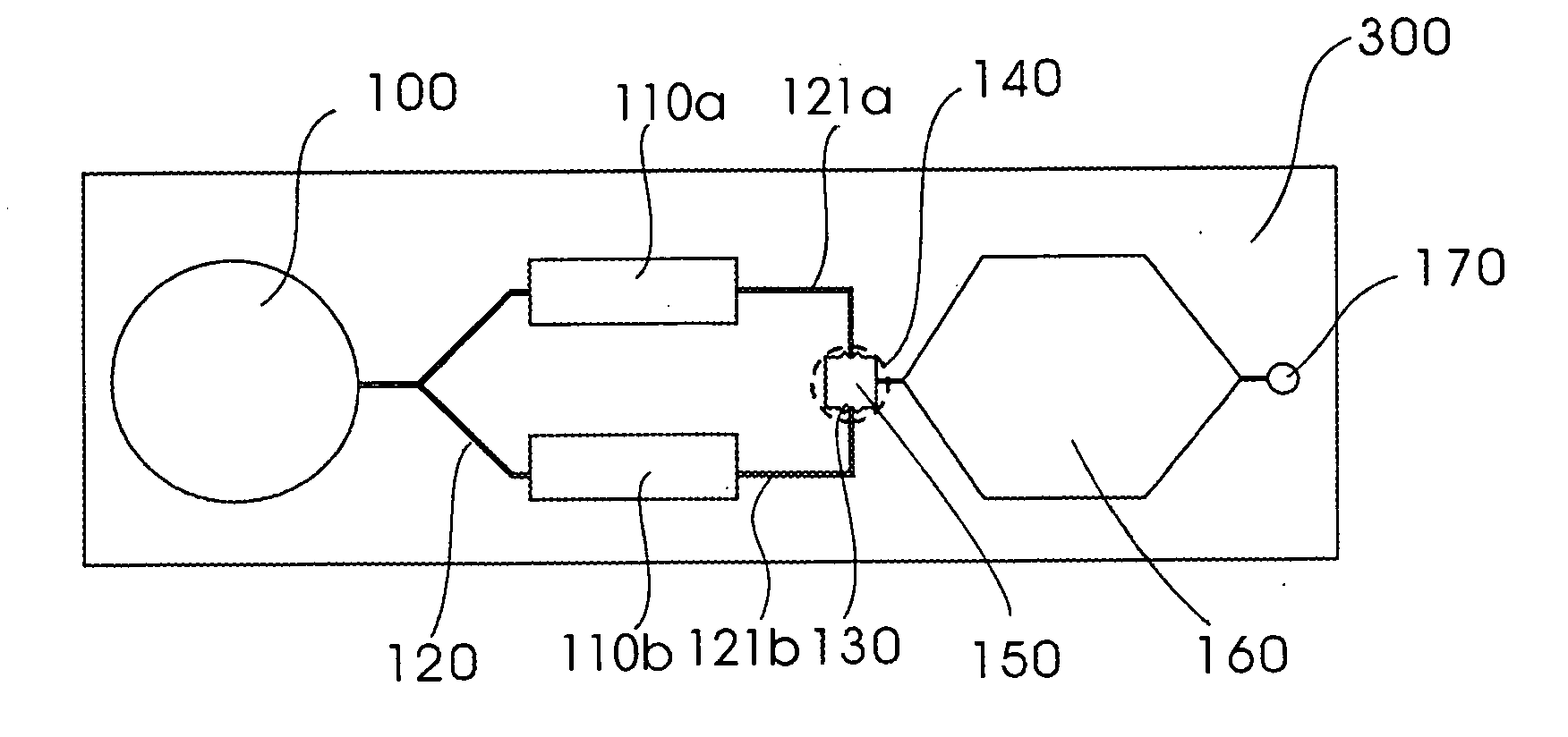

Microfluidic devices for methods development

InactiveUS6880576B2Material nanotechnologySludge treatmentChromatographic separationFlow resistivity

Microfluidic devices with multiple fluid process regions for subjecting similar samples to different process conditions in parallel are provided. One or more common fluid inputs may be provided to minimize the number of external fluid supply components. Solid materials such as chromatographic separation media or catalyst media is preferably provided in each fluid process region. Solid materials may be supplied to the devices in the form of slurry, with particles retained by porous elements or frits. Different fluid process regions may having different effective lengths, different solid material types or amounts, or may receive different ratios of common fluids supplied to the device. The flow resistances of dissimilar fluid process regions may be balanced passively with the addition of impedance elements in series with each fluid process region.

Owner:AGILENT TECH INC

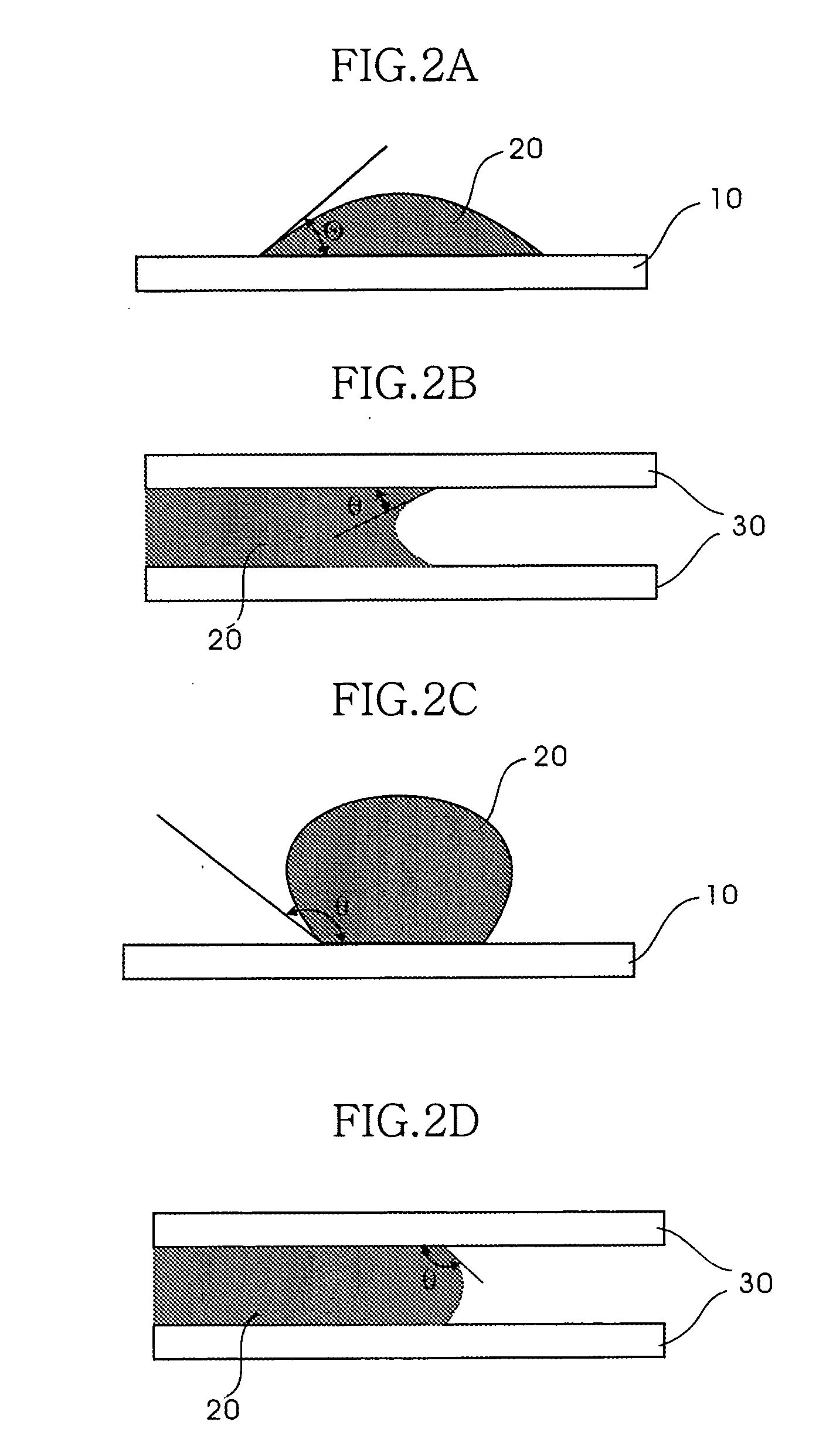

Chemico-mechanical microvalve and devices comprising the same

InactiveUS6375901B1Fixed microstructural devicesVolume/mass flow measurementBiomedical engineeringMicro valve

Owner:AGILENT TECH INC

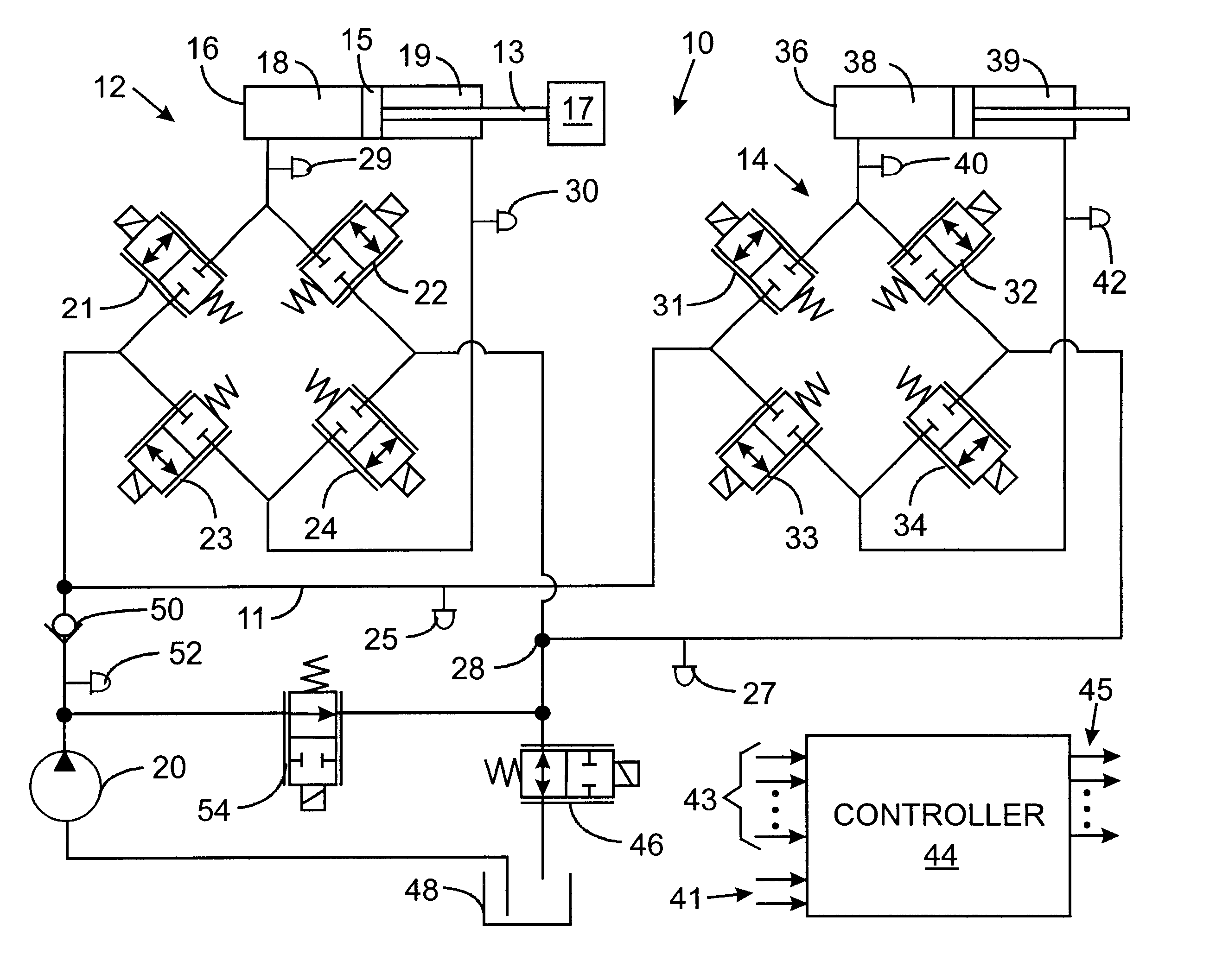

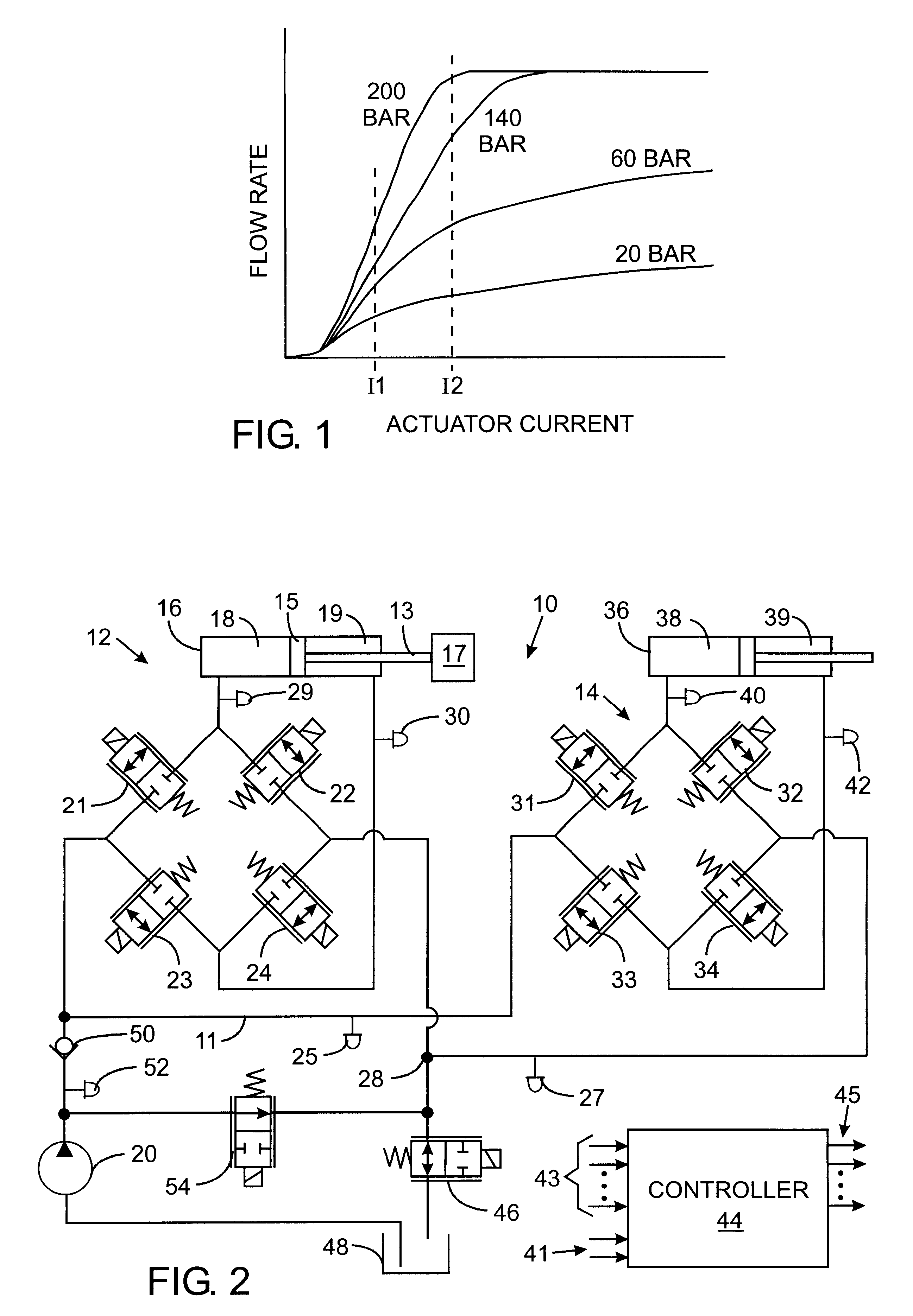

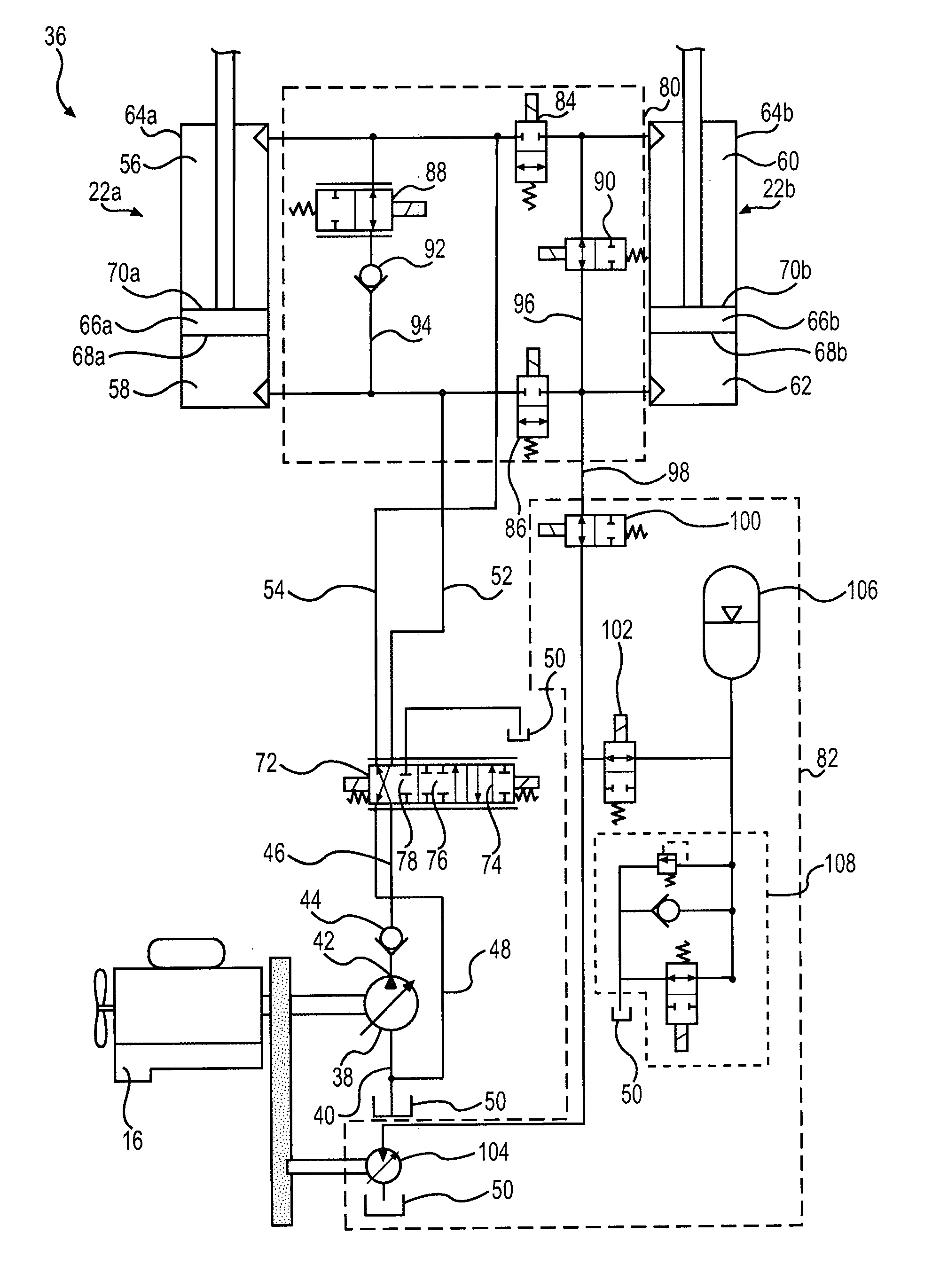

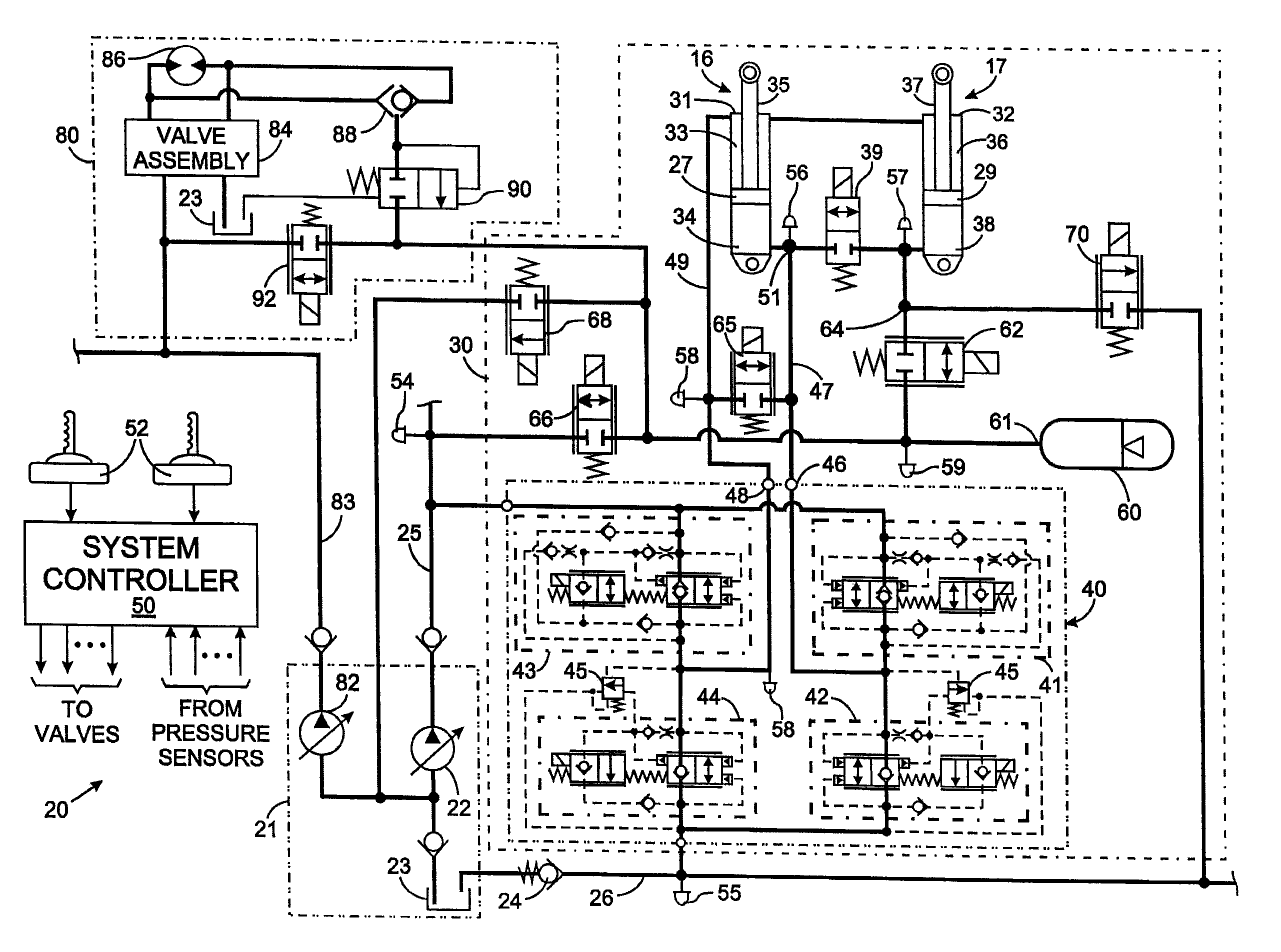

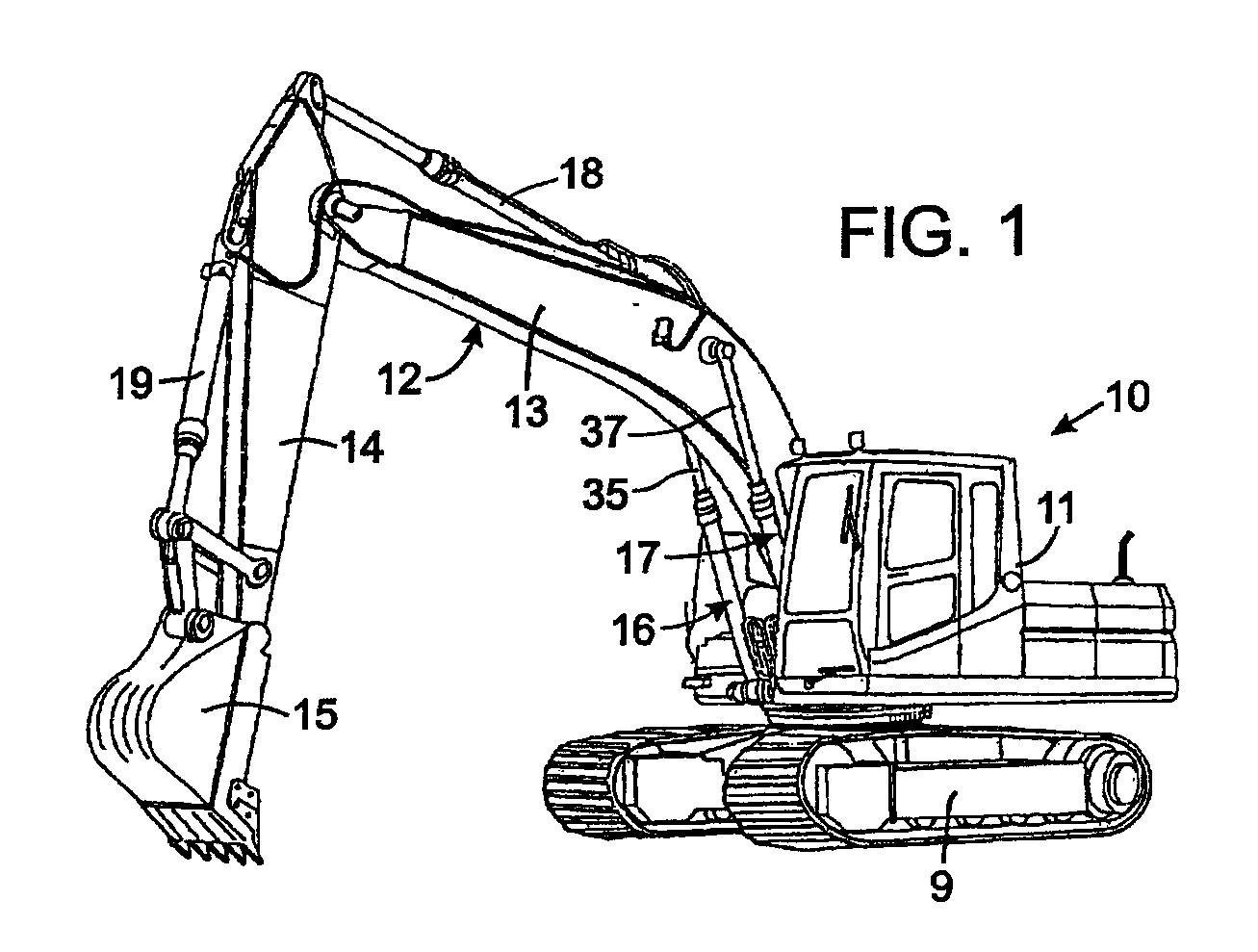

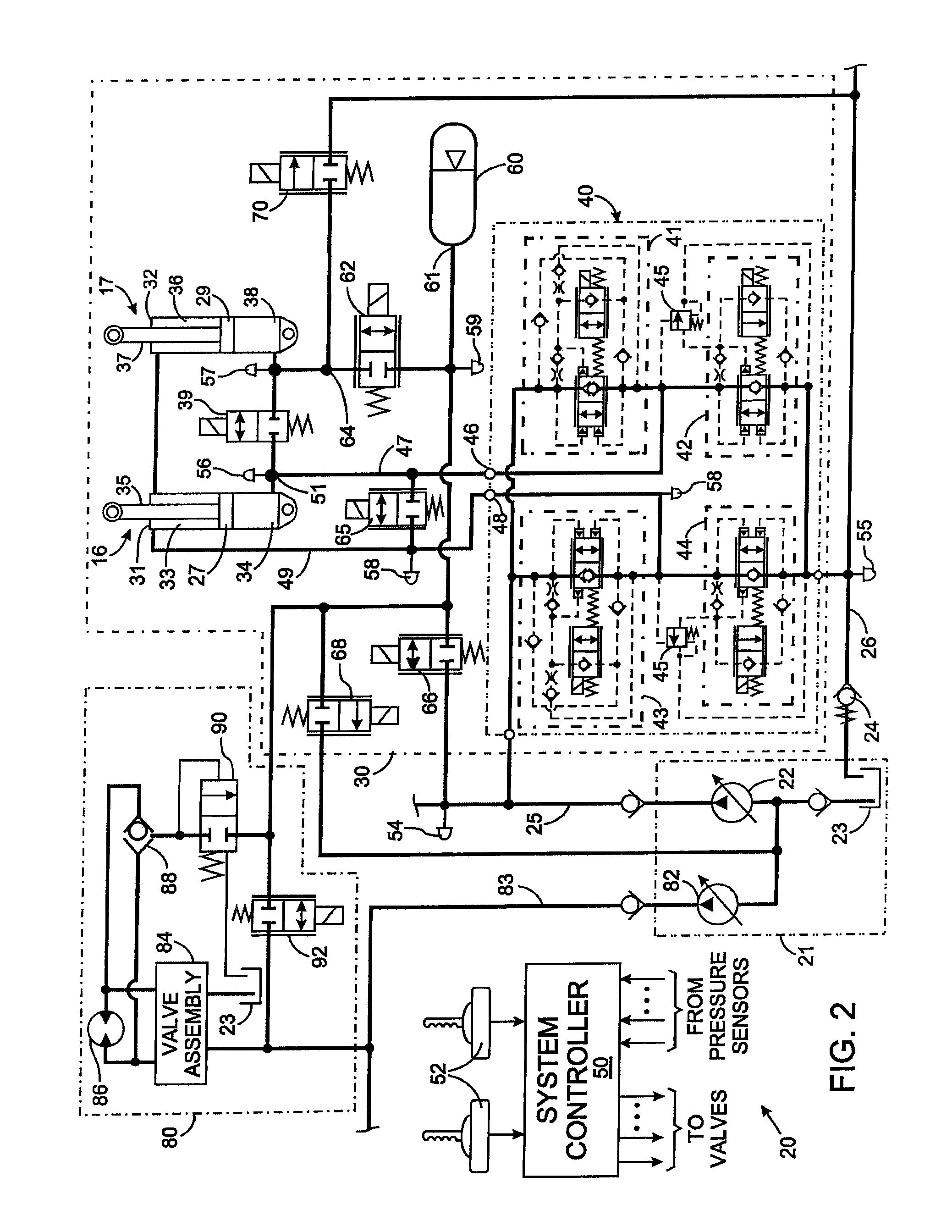

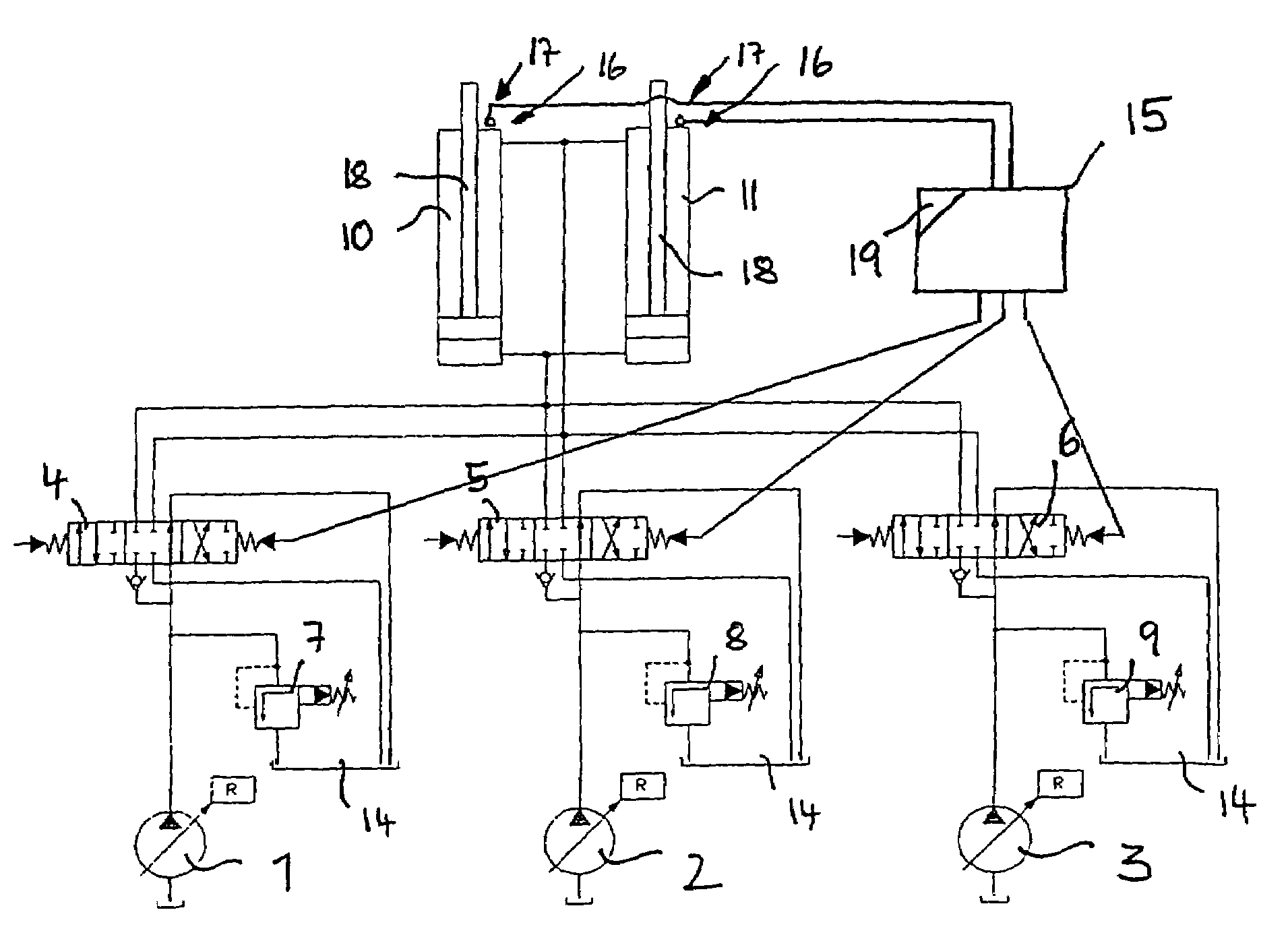

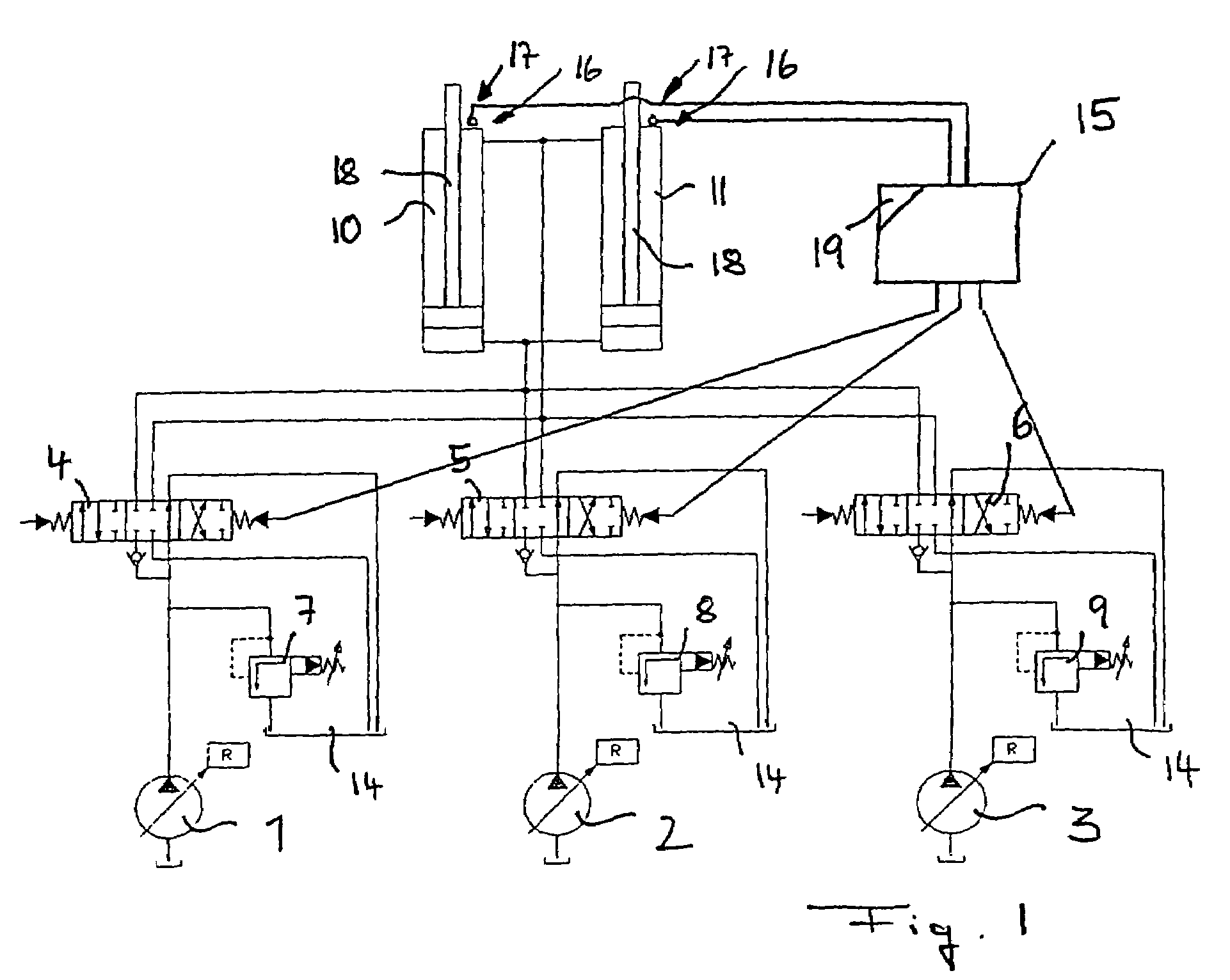

Hydraulic circuit with a return line metering valve and method of operation

A hydraulic system controls the flow of fluid to and from several functions on a machine. Each function has a valve assembly through which fluid is supplied under pressure from a source to an actuator and through which fluid returns from the actuator to a shared return line connected by a return line metering valve to the system tank. There are several regeneration modes of operation in which fluid exhausted from one port is supplied into the other port of the same actuator, which eliminates or reduces the amount of hydraulic fluid that must be supplied from the source. In some regeneration modes, input fluid for an actuator is obtained from another hydraulic function via the shared return line. In these regeneration modes an electronic controller operates the return line metering valve to restrict fluid from flowing into the tank from the shared return line, so that the fluid will be available to be supplied into an actuator port.

Owner:HUSCO INT INC

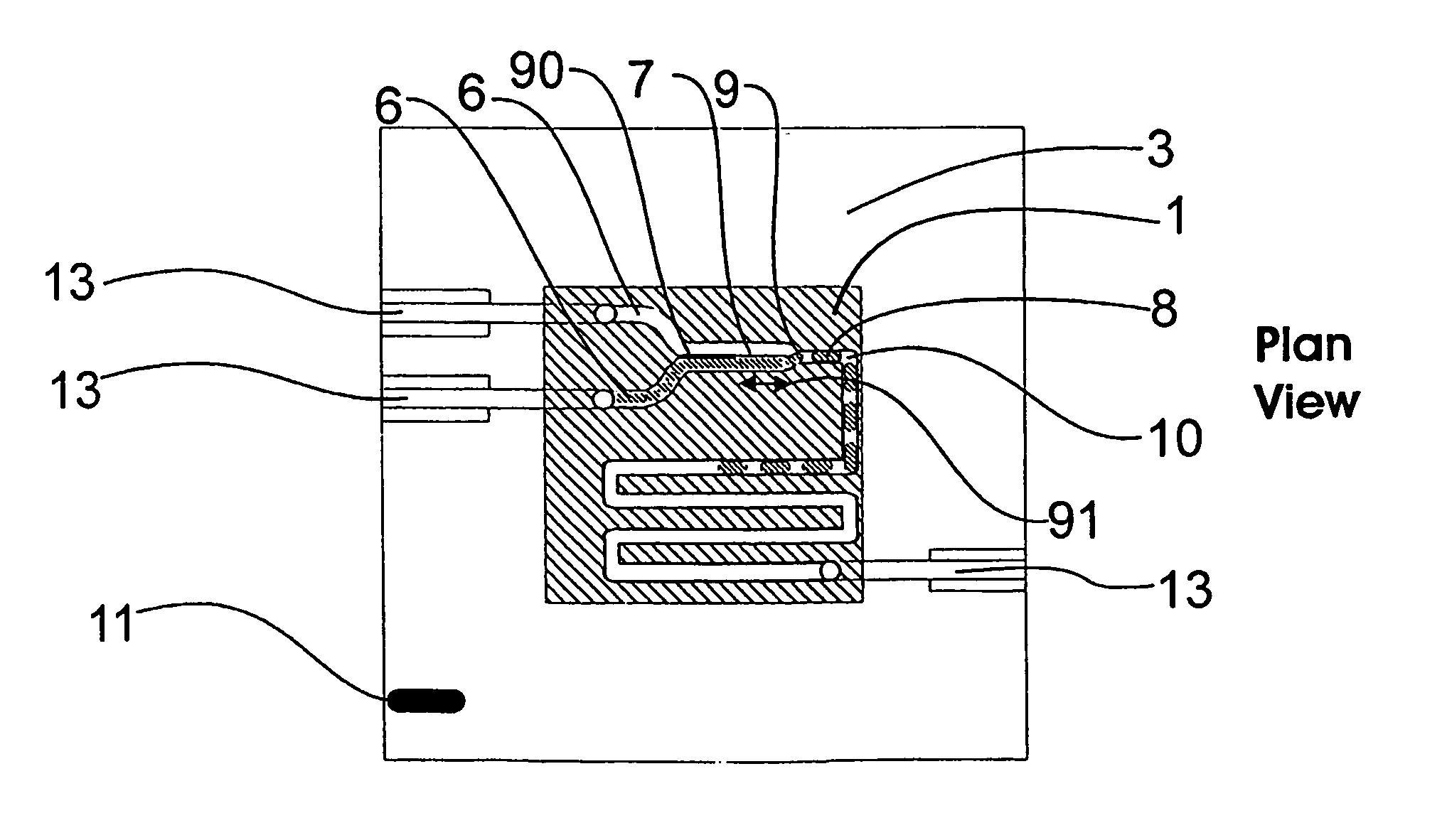

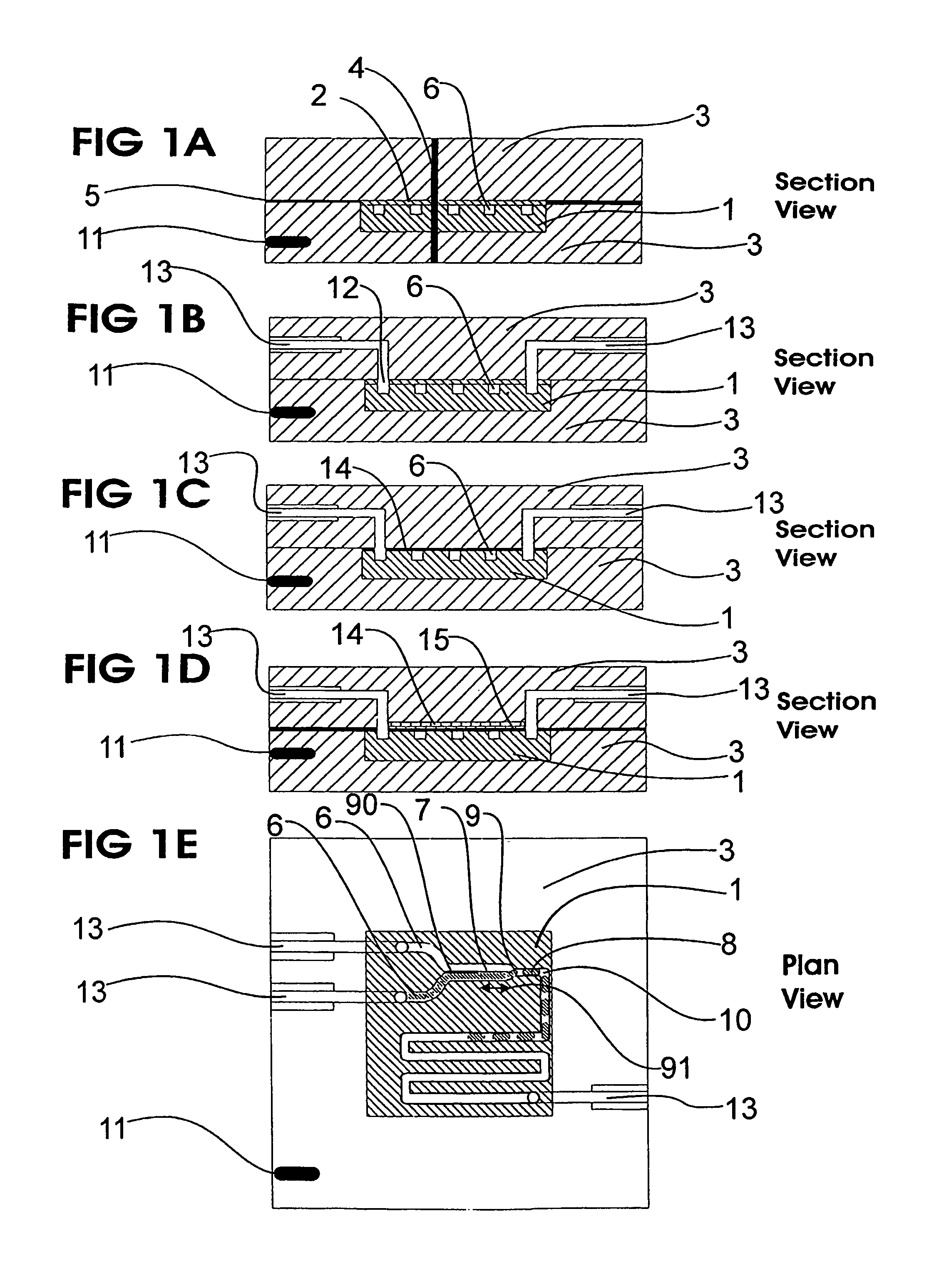

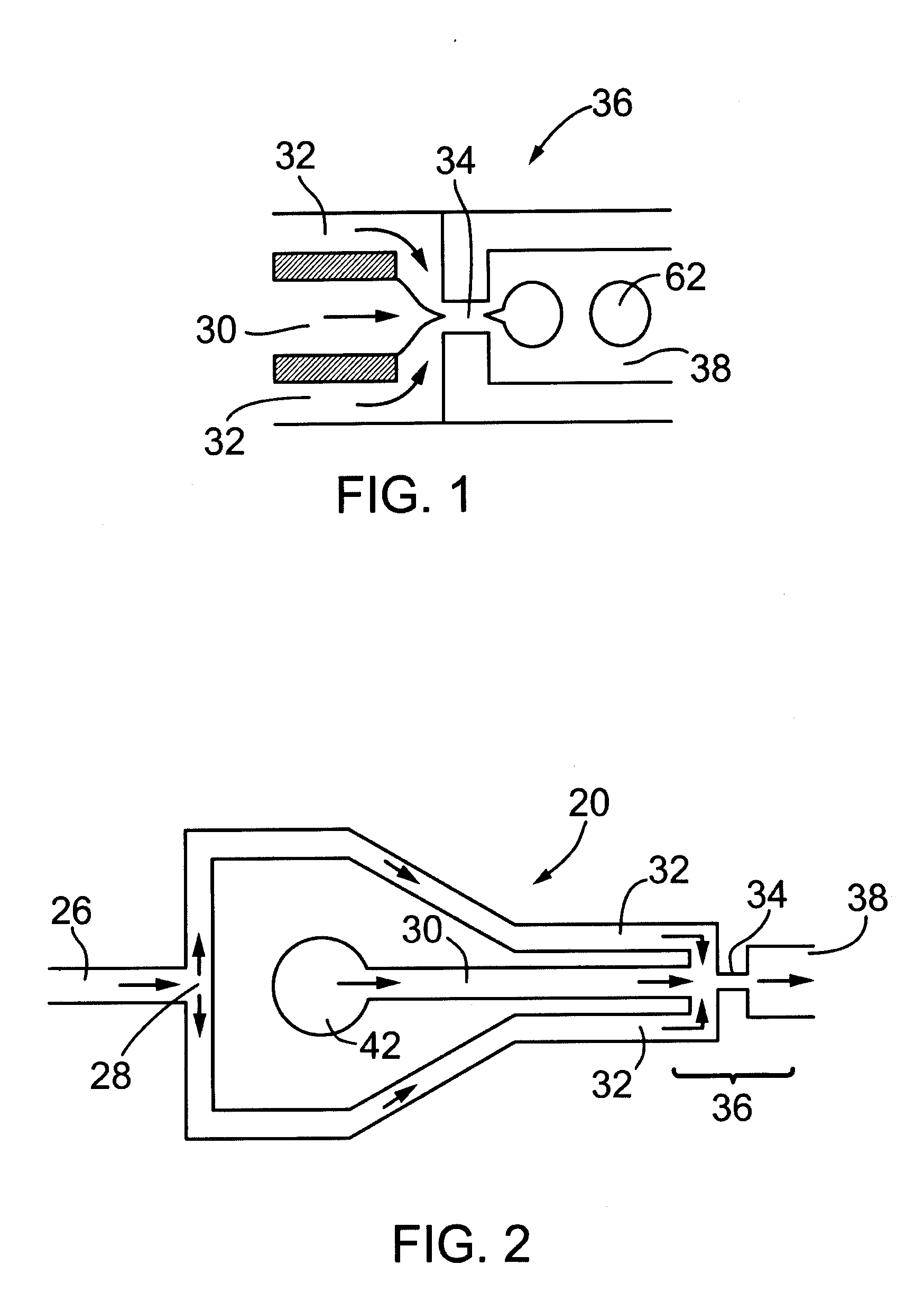

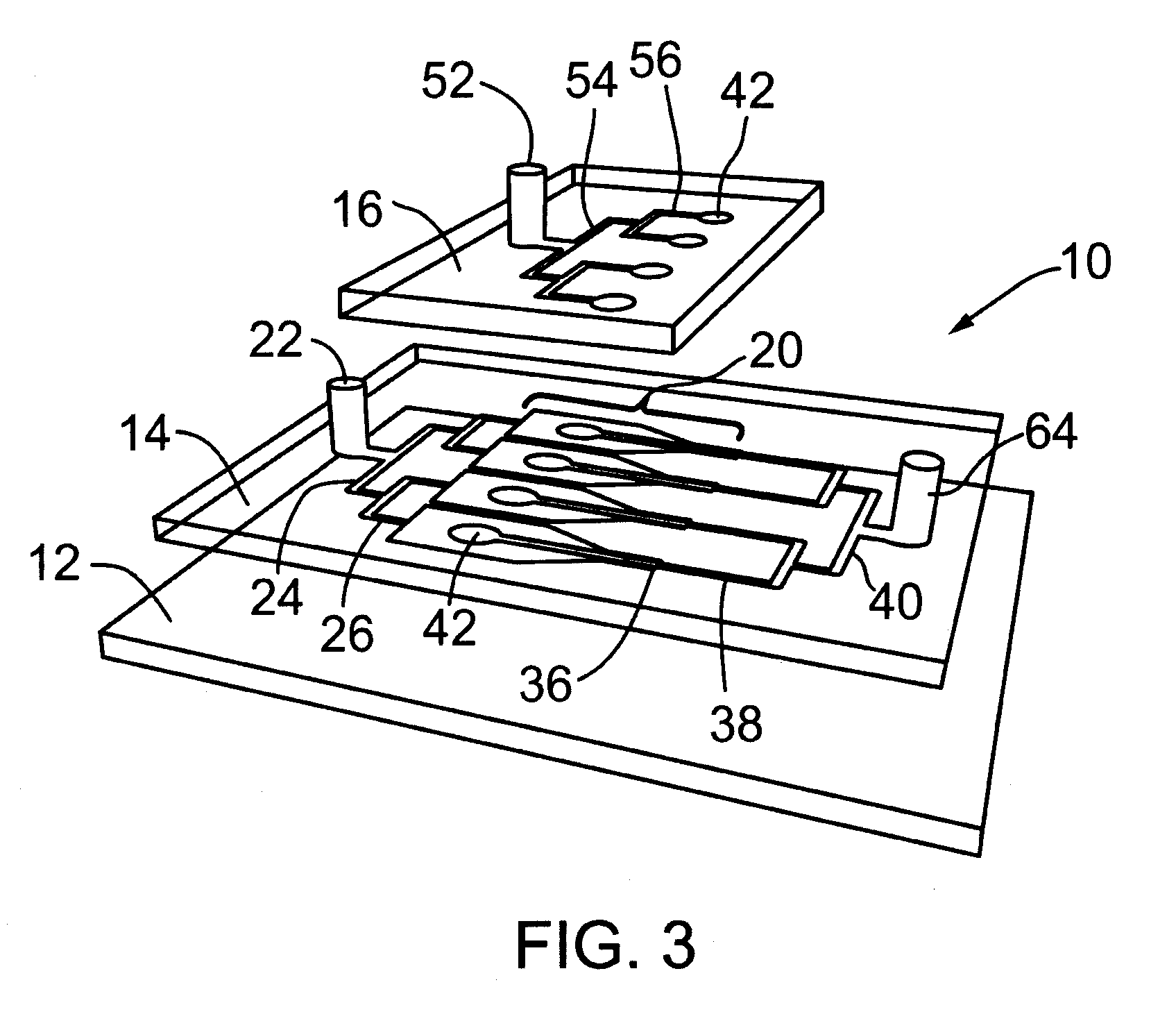

Microfluidic device and methods for construction and application

InactiveUS20060108012A1Considerable precisionEasy to controlMaterial nanotechnologyCircuit elementsEngineeringTwo fluid

A microfluidic device comprises first and second inlet passages (13) for respective immiscible fluids, these inlet passages merging into a third passage (8) along which the two fluids flow under parallel laminar flow conditions, the third passage being formed with a constriction or other discontinuity (9) causing the two fluids to form into a flow of alternate segments.

Owner:Q CHIP

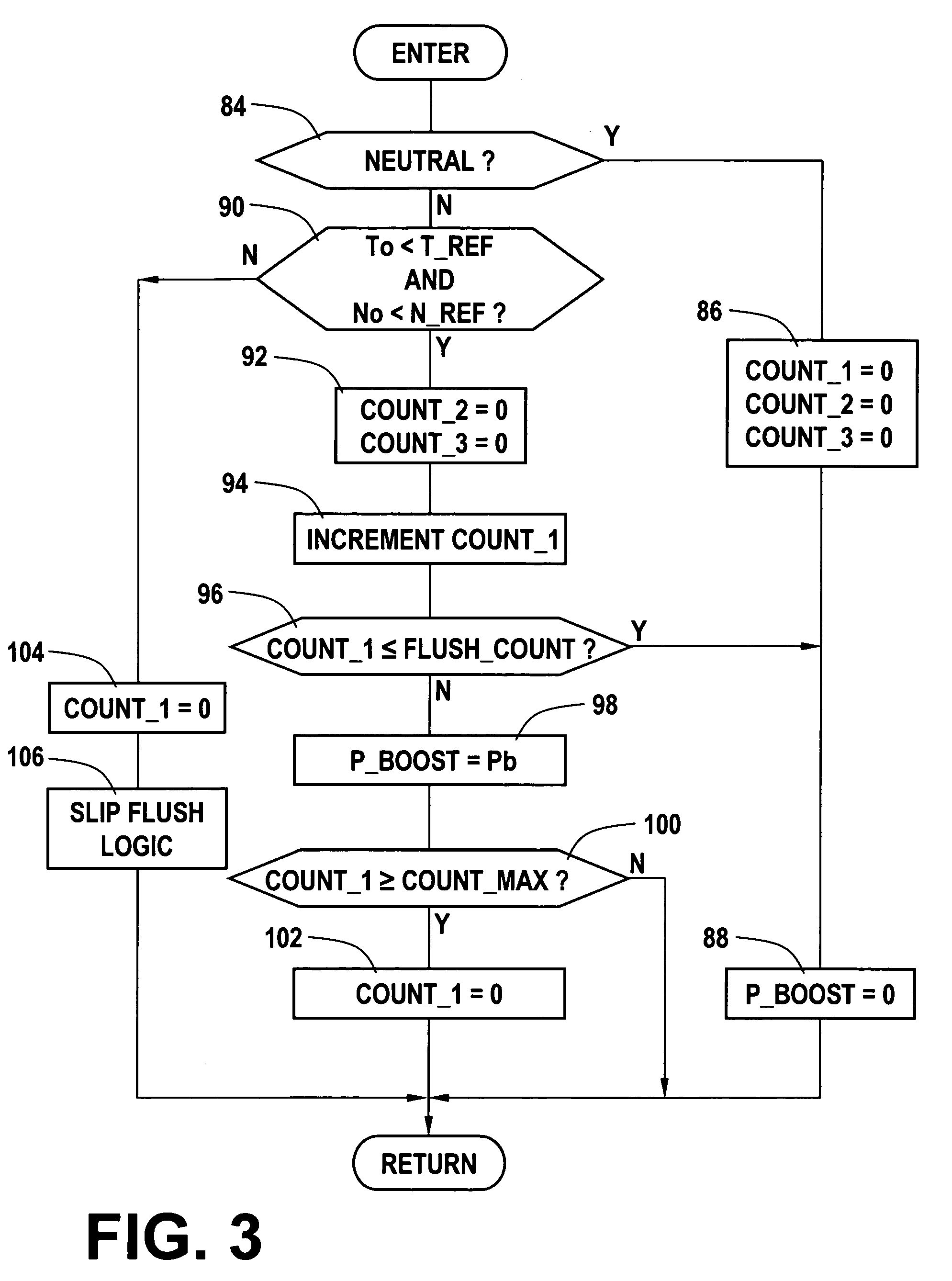

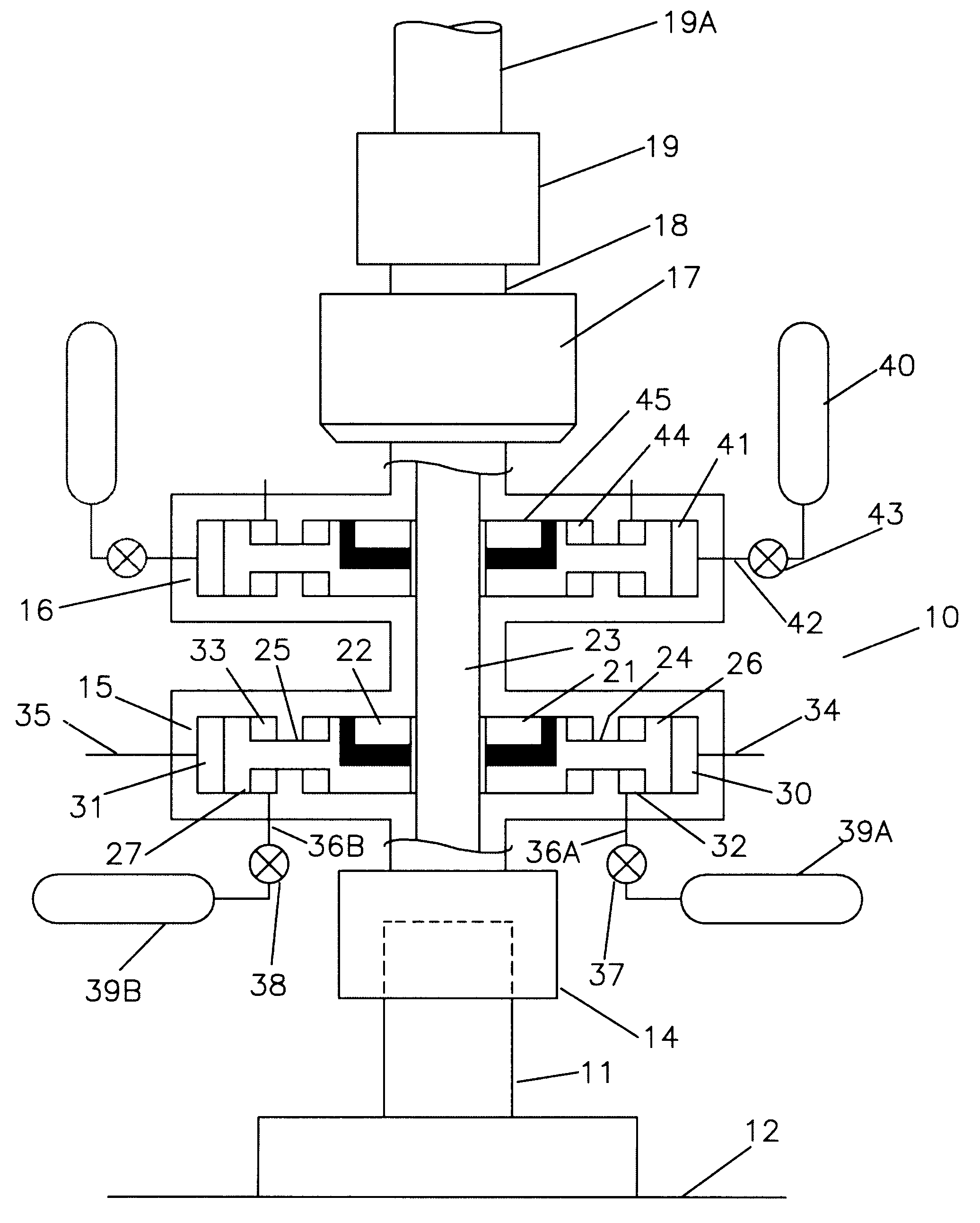

Method of automatically flushing debris from an electrically-operated hydraulic valve

InactiveUS20050255967A1Operating means/releasing devices for valvesGearing controlEngineeringHydraulic fluid

The normal control of an electrically-activated hydraulic valve armature is overridden to automatically and periodically open the armature for flushing out debris that has accumulated between the armature and a seat that the armature is designed to engage. The valve develops fluid pressure for maintaining engagement of a motor vehicle transmission clutch, and when excessive slippage of the clutch is detected, the armature is forced into engagement with the seat until the slippage is reduced or a predetermined period of time has elapsed, after which the armature is temporarily positioned away from the seat to provide full flow of hydraulic fluid across the seat to flush out debris that prevents the armature from engaging the seat. During Neutral operation of the transmission, the armature is continuously positioned away from the seat, and during low torque conditions the armature is temporarily positioned away from the seat.

Owner:GM GLOBAL TECH OPERATIONS LLC

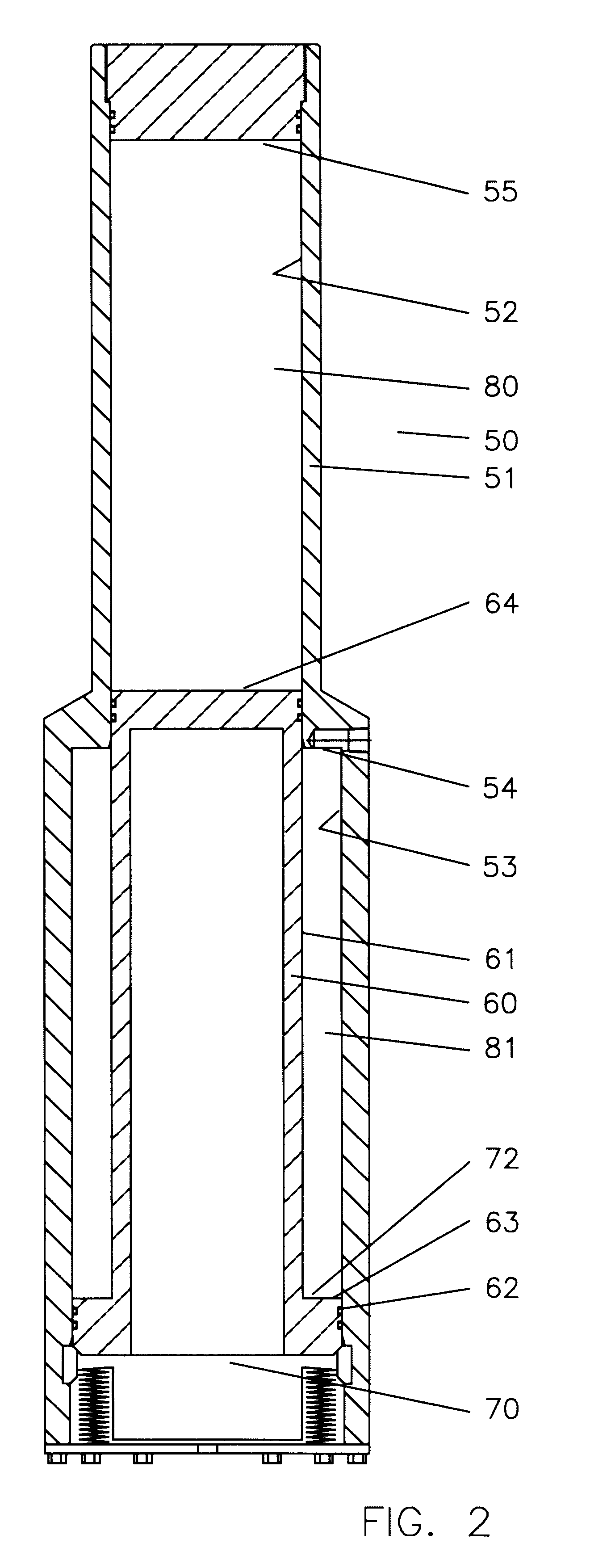

Subsea accumulator and method of operation of same

An accumulator for use in deepwater operational and control systems which uses a differential between a high pressure ambient pressure source such as sea water pressure and a low pressure source such as a chamber holding vacuum or atmospheric pressure to provide storage and delivery of hydraulic power for operation of equipment.

Owner:BAUGH BENTON F

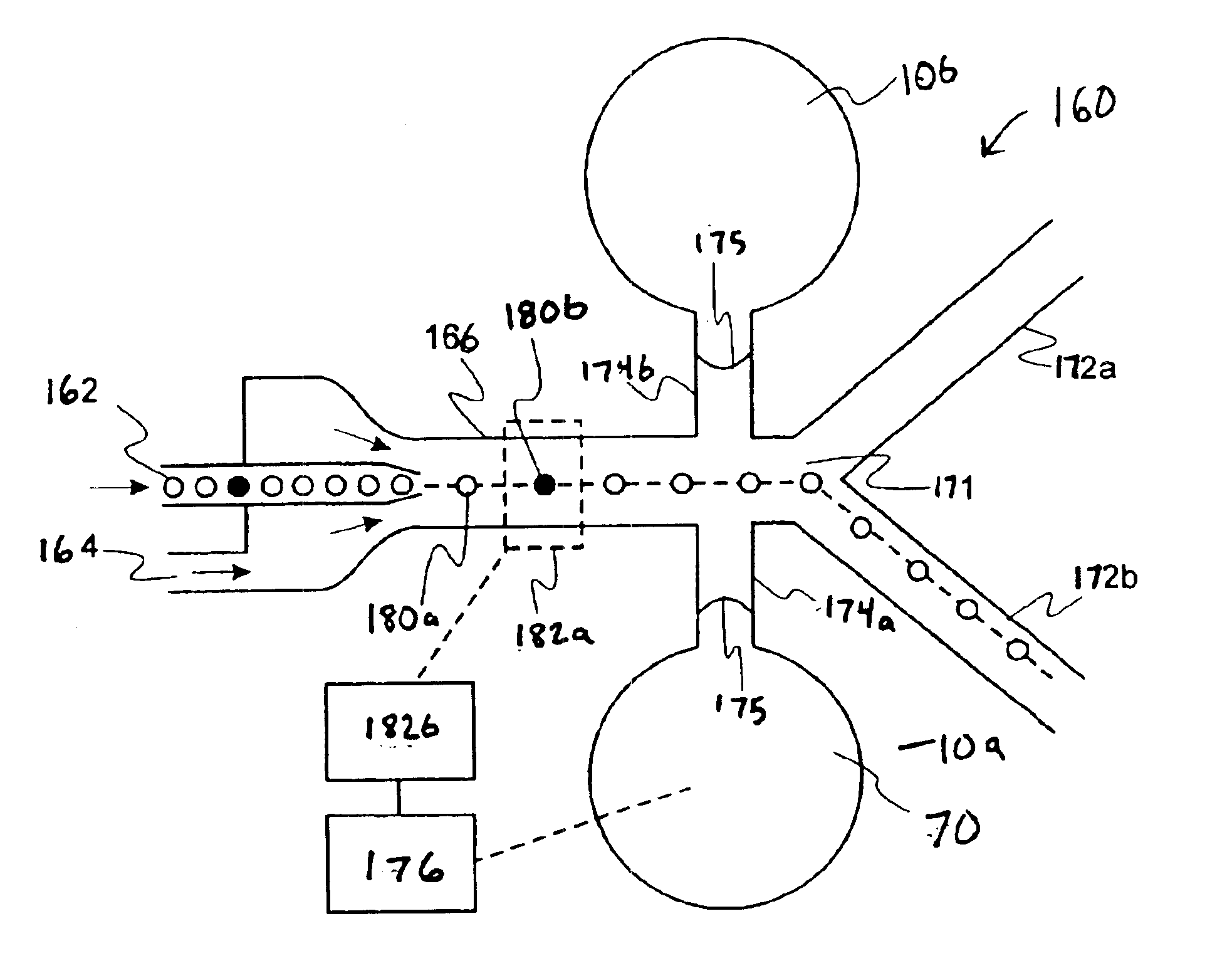

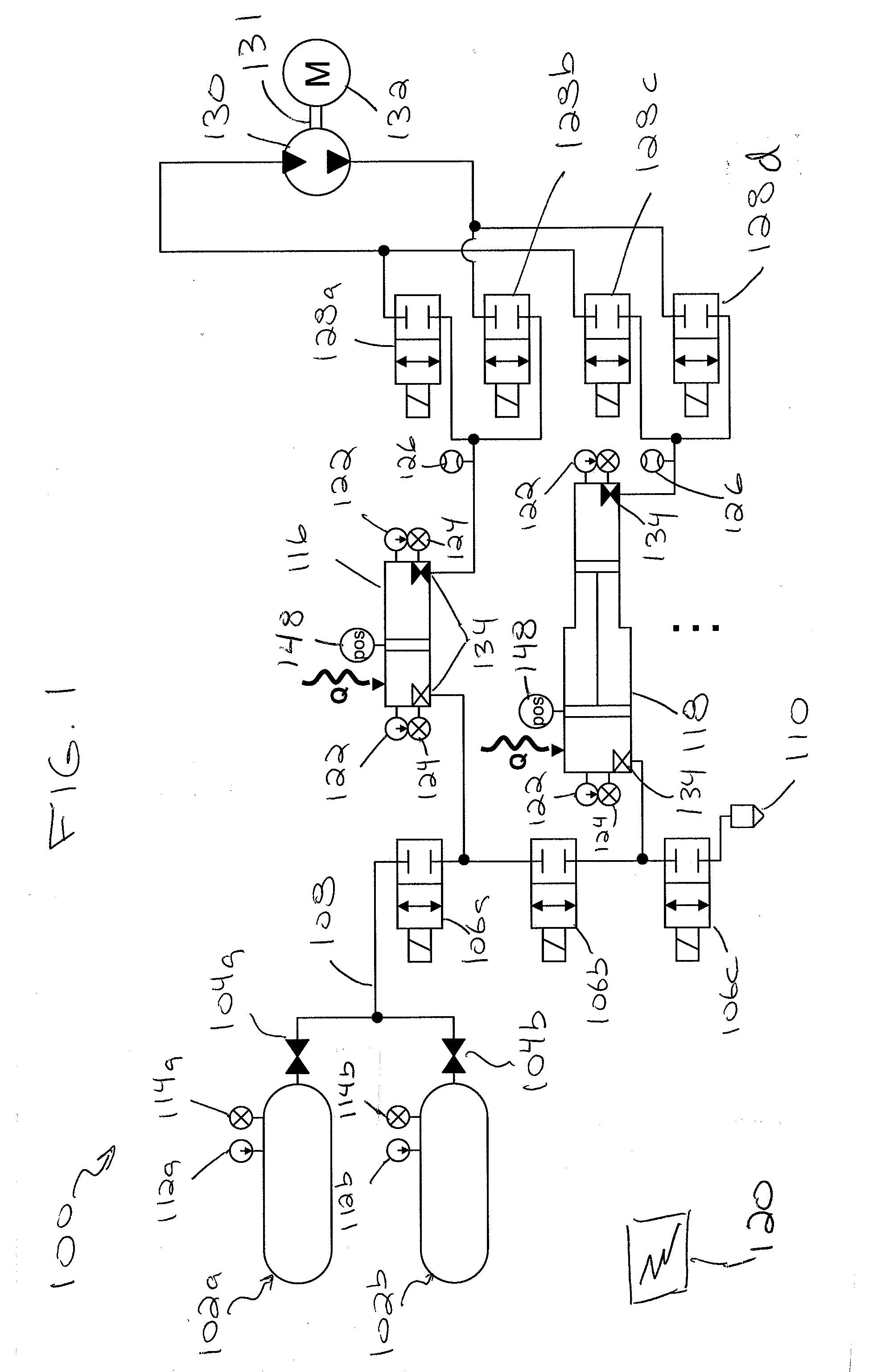

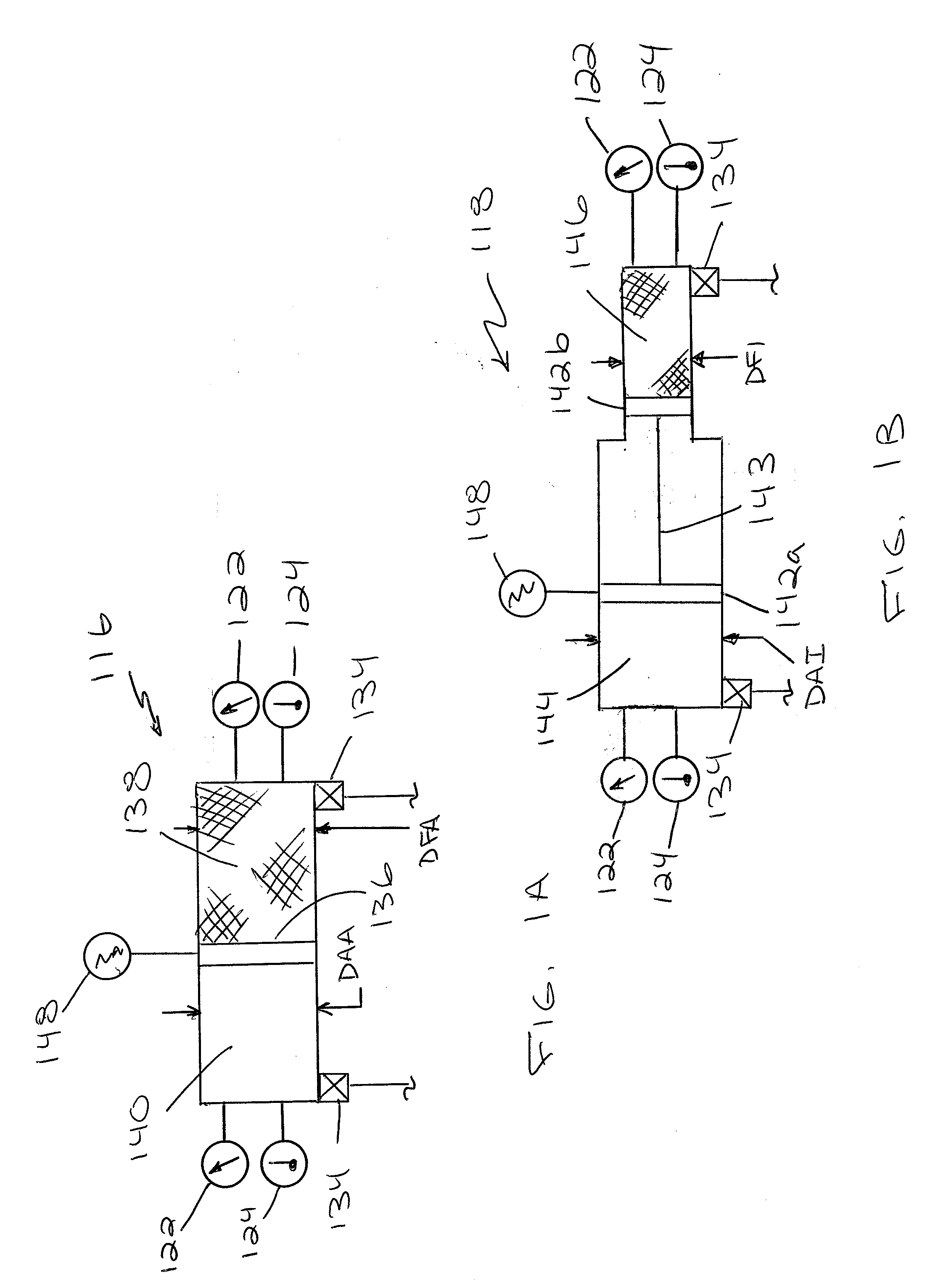

Systems and methods for energy storage and recovery using compressed gas

InactiveUS7832207B2Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsEngineeringHigh pressure

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

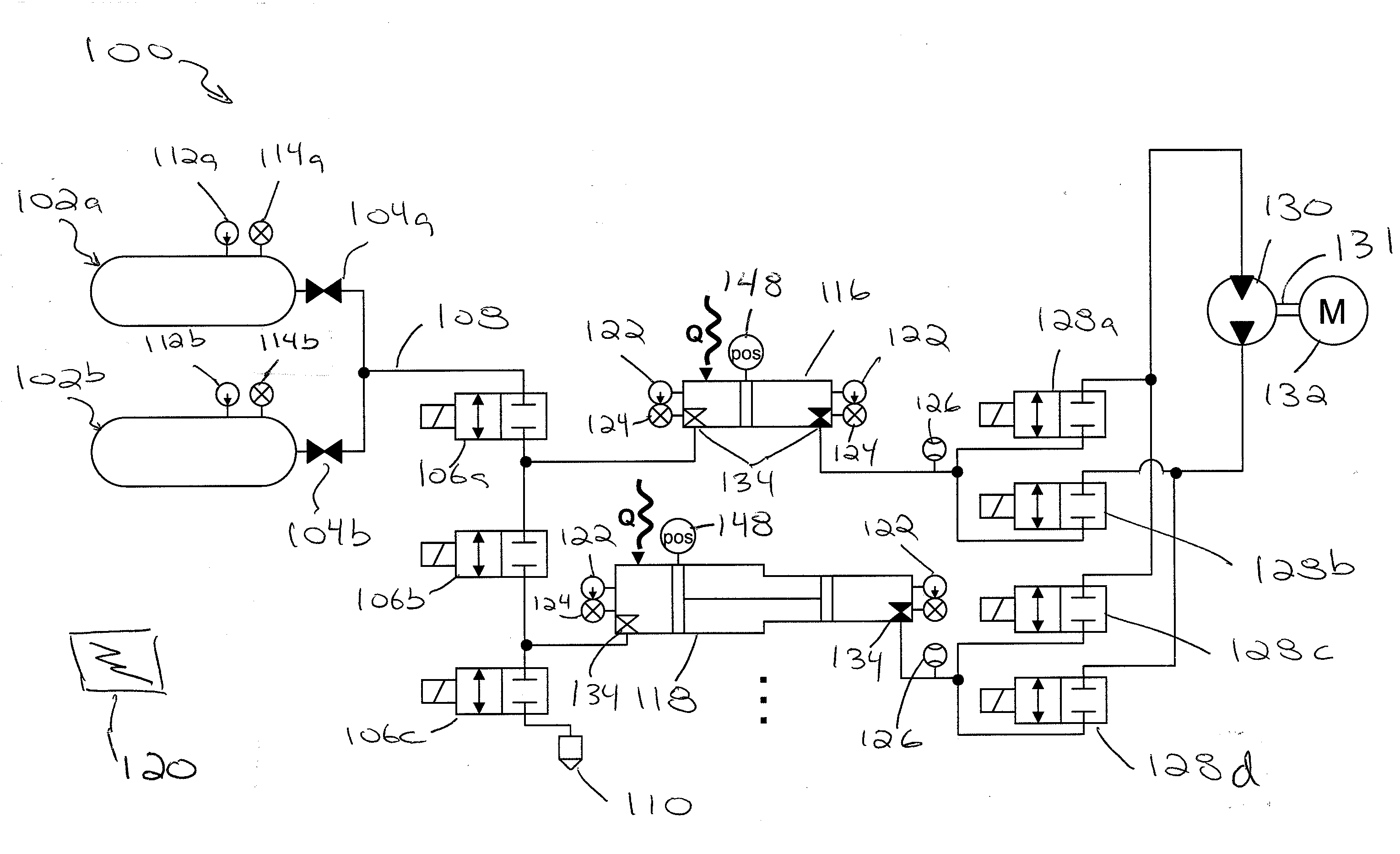

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

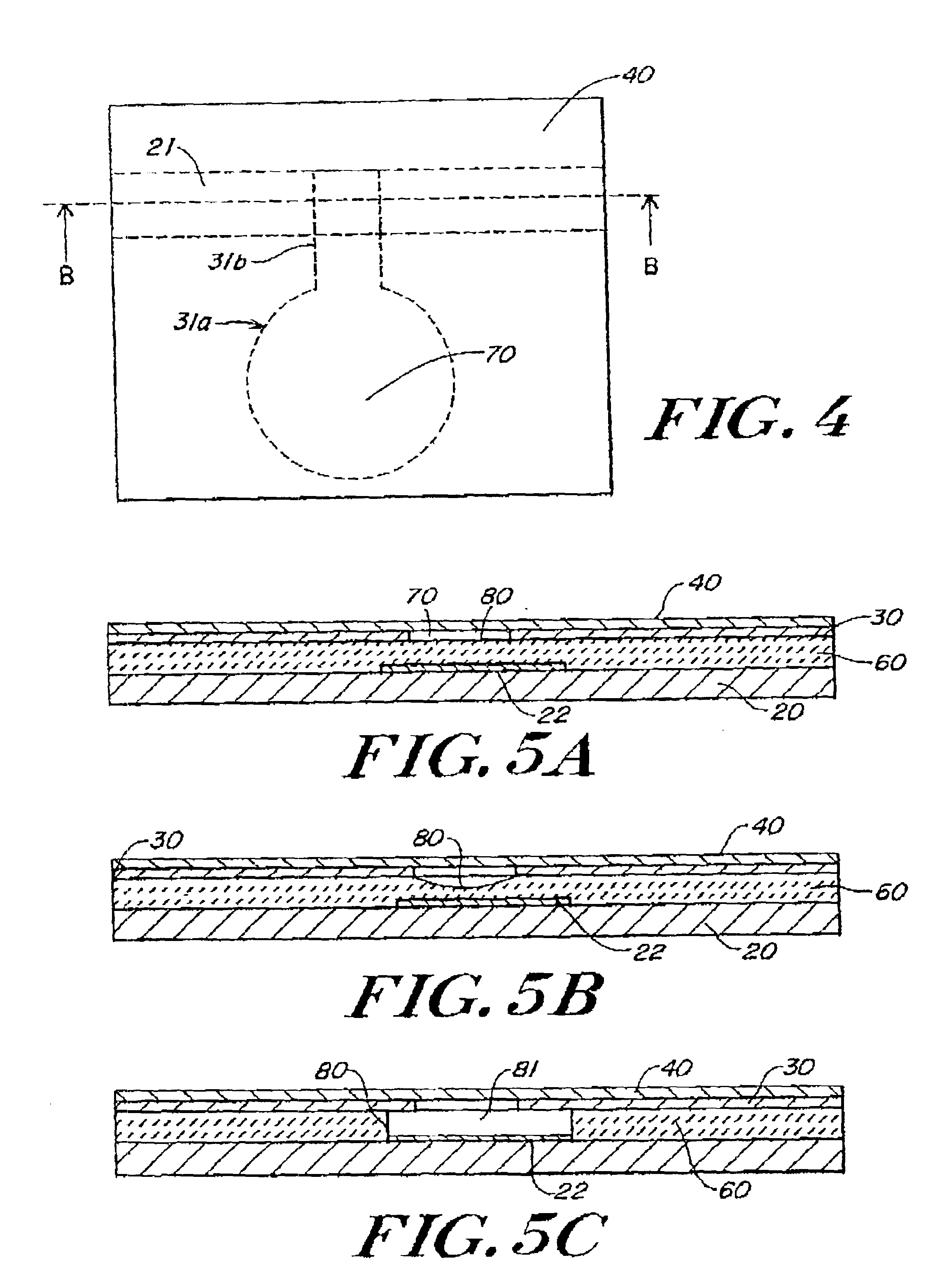

Microfluidic system including a bubble valve for regulating fluid flow through a microchannel

InactiveUS6877528B2Effective controlEnhanced on-off switchingValve arrangementsSludge treatmentEngineeringActuator

A microfluidic system includes a bubble valve for regulating fluid flow through a microchannel. The bubble valve includes a fluid meniscus interfacing the microchannel interior and an actuator for deflecting the membrane into the microchannel interior to regulate fluid flow. The actuator generates a gas bubble in a liquid in the microchannel when a sufficient pressure is generated on the membrane.

Owner:CYTONOMEST

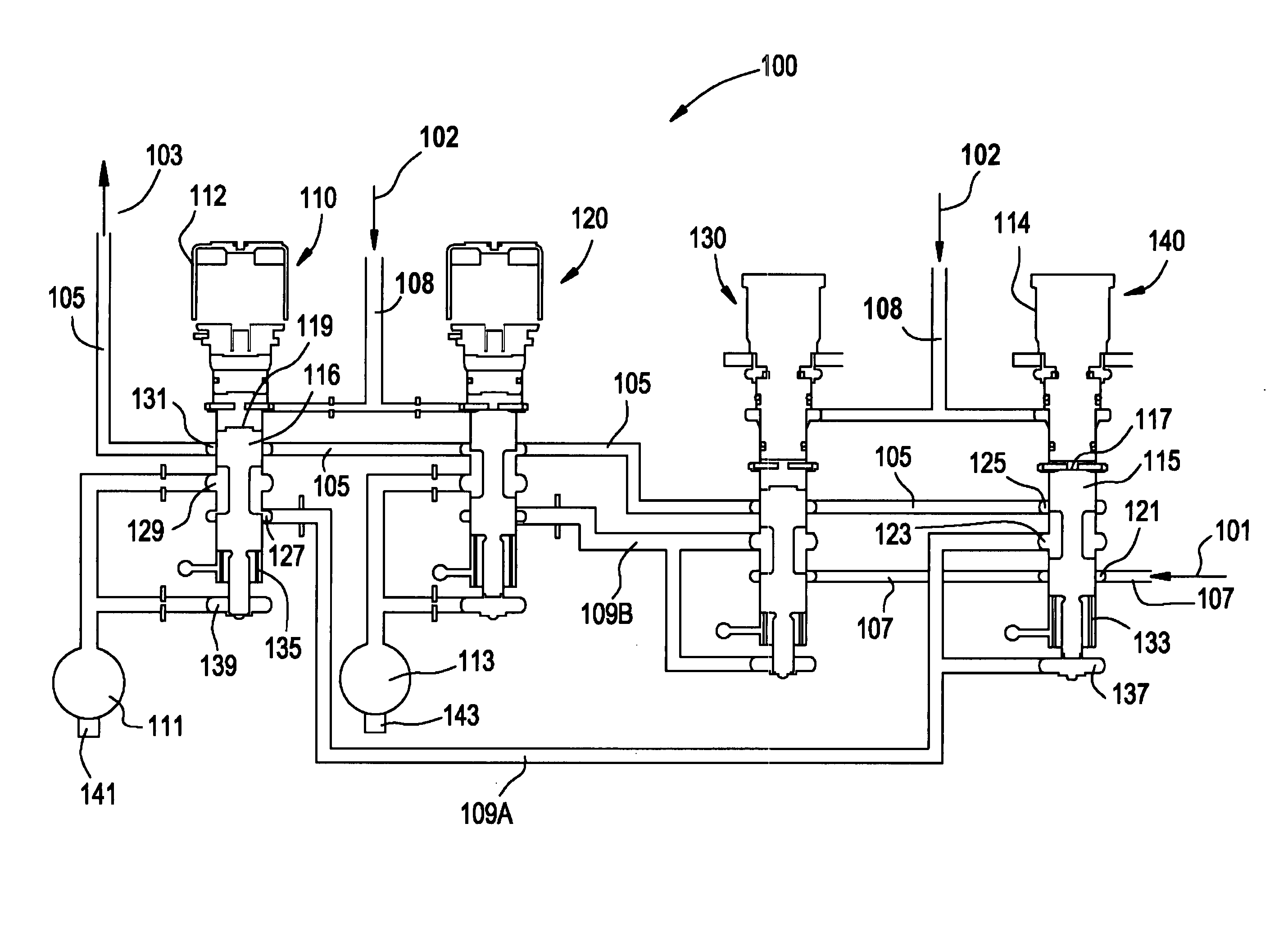

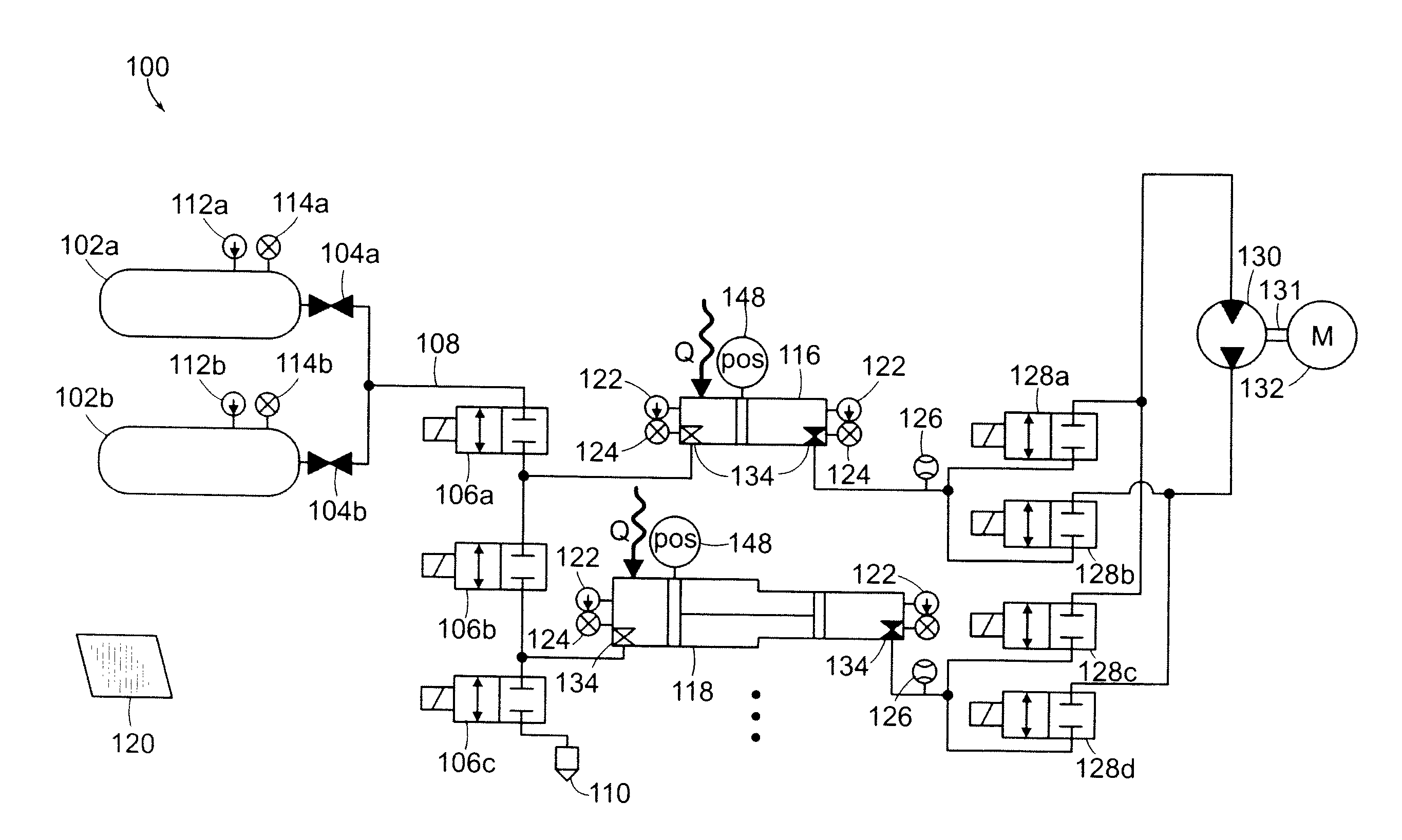

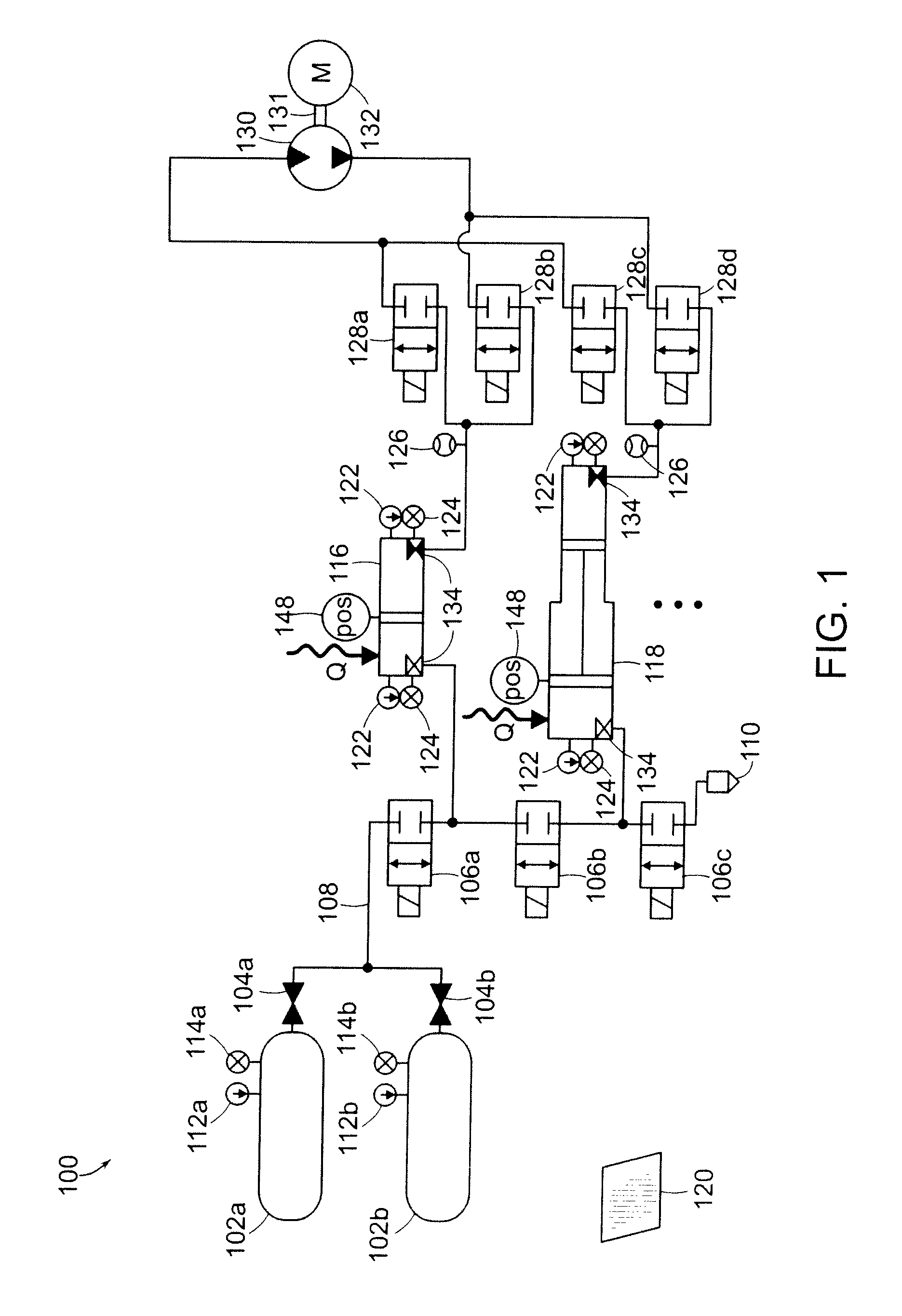

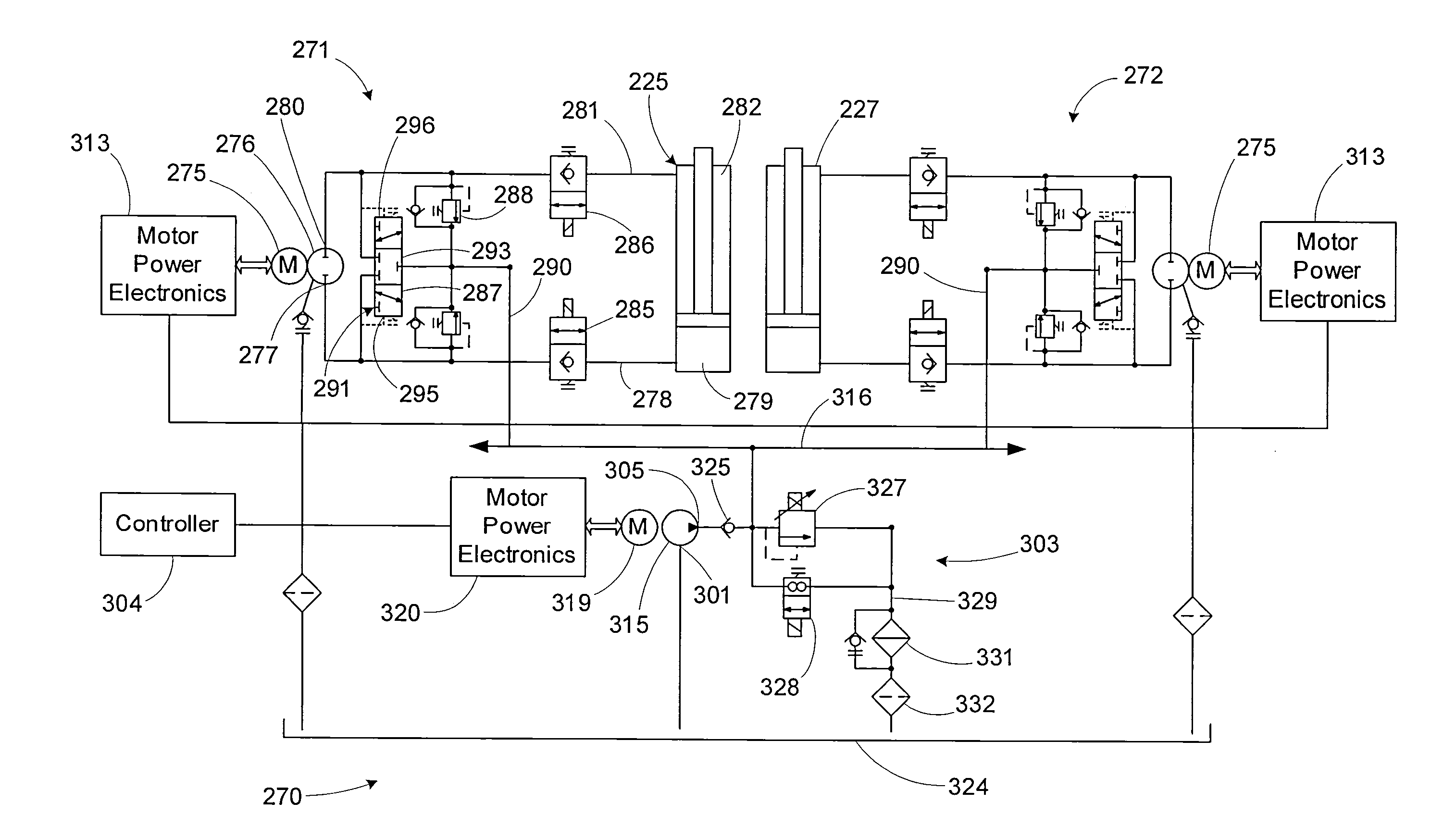

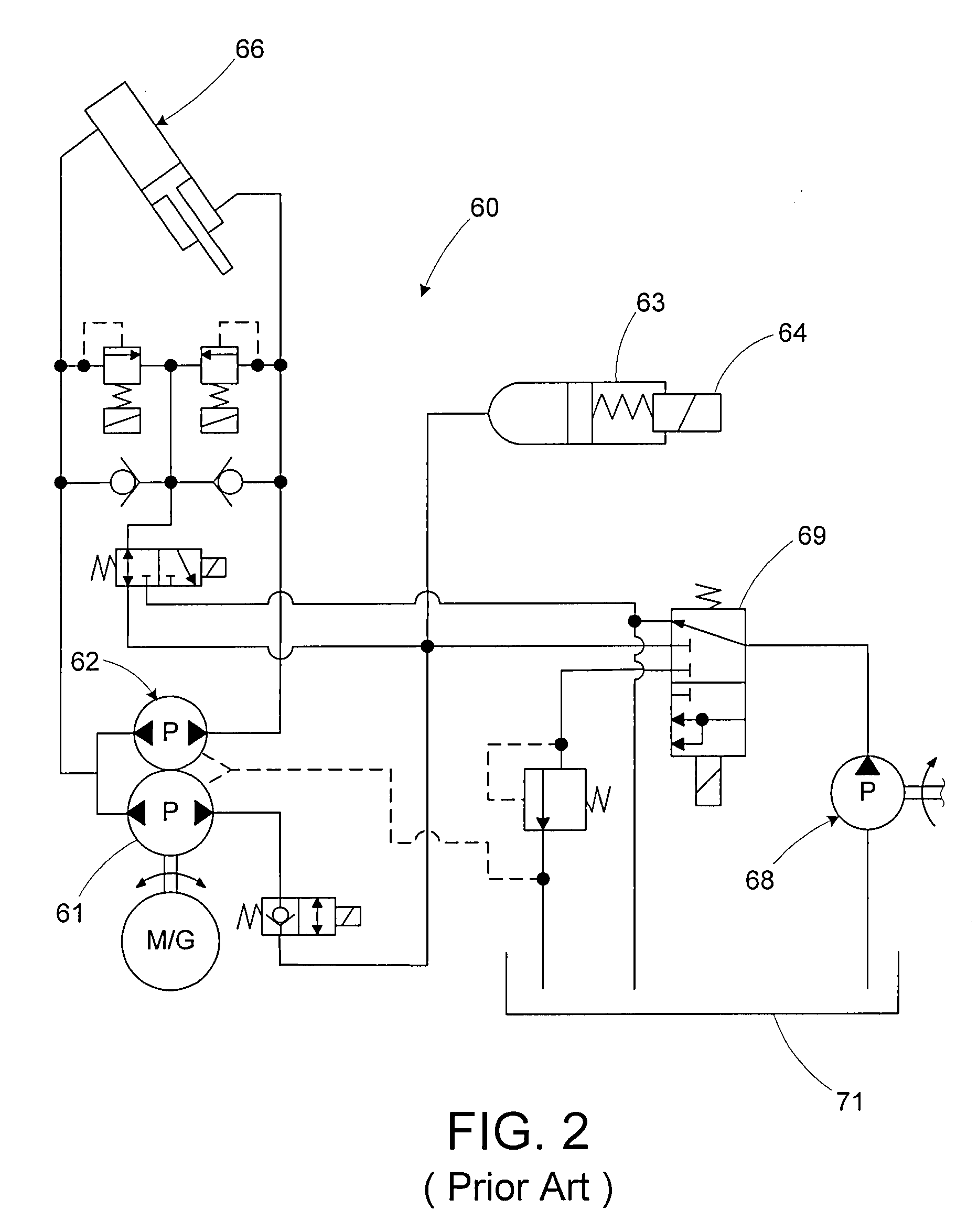

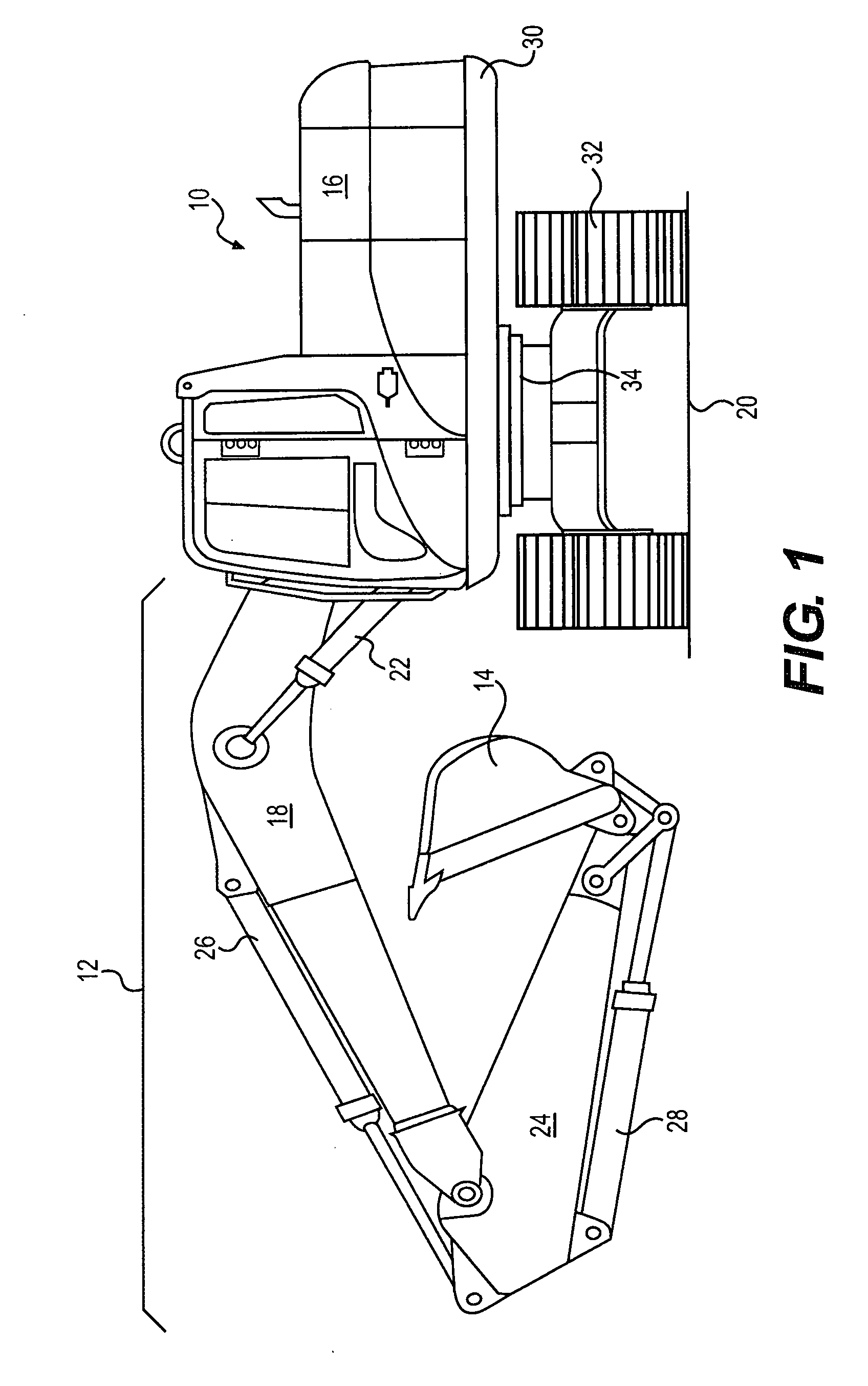

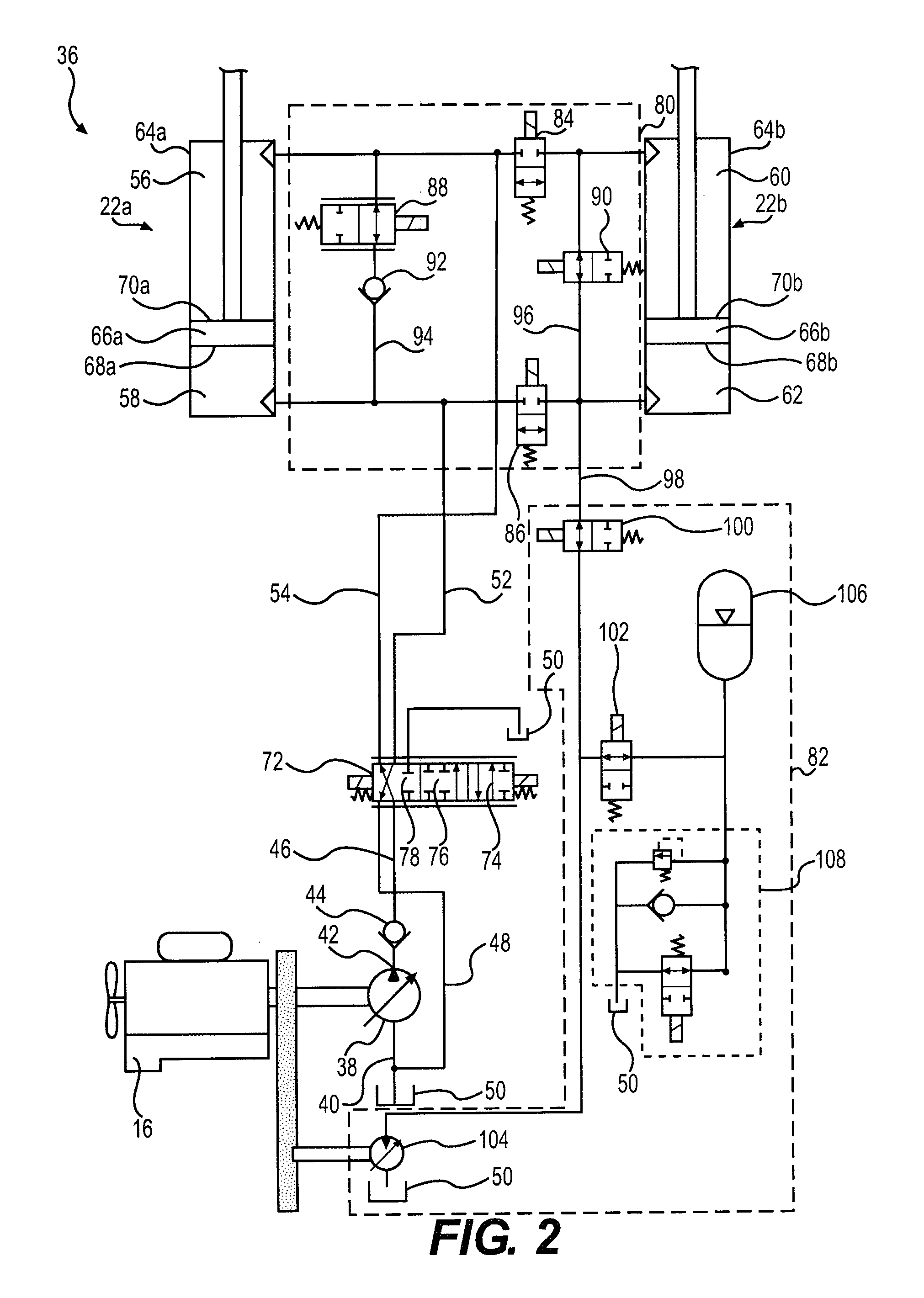

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

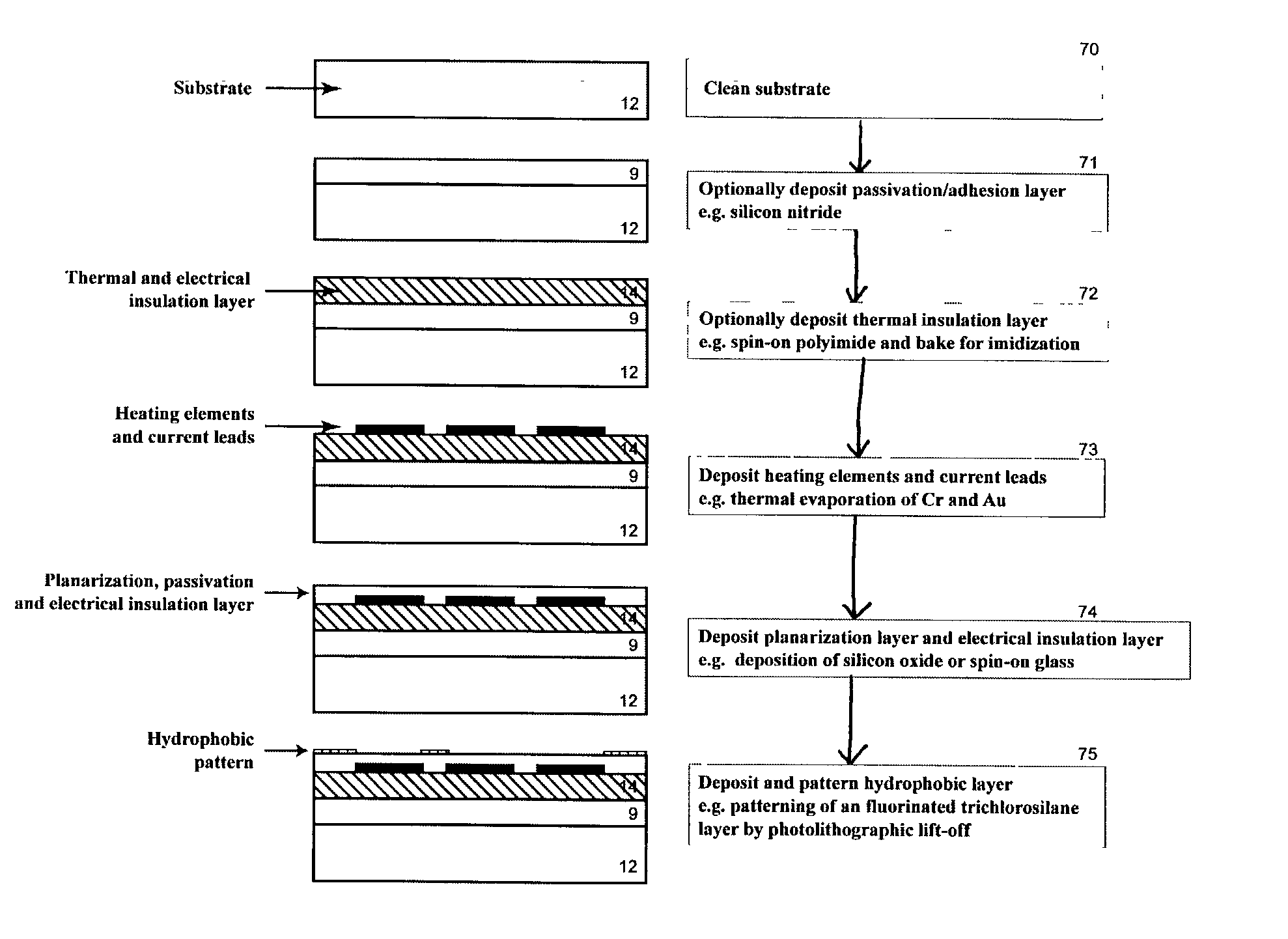

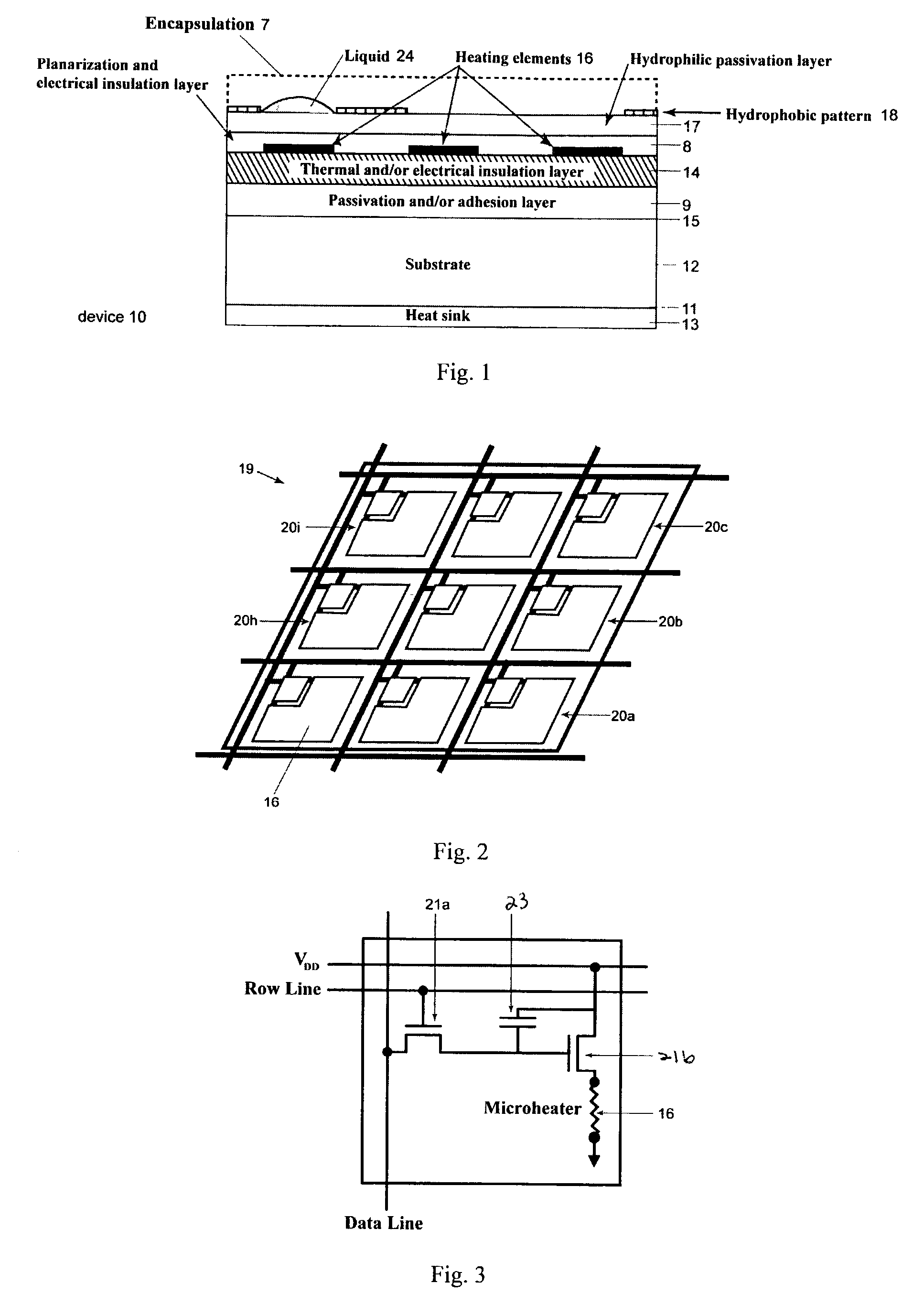

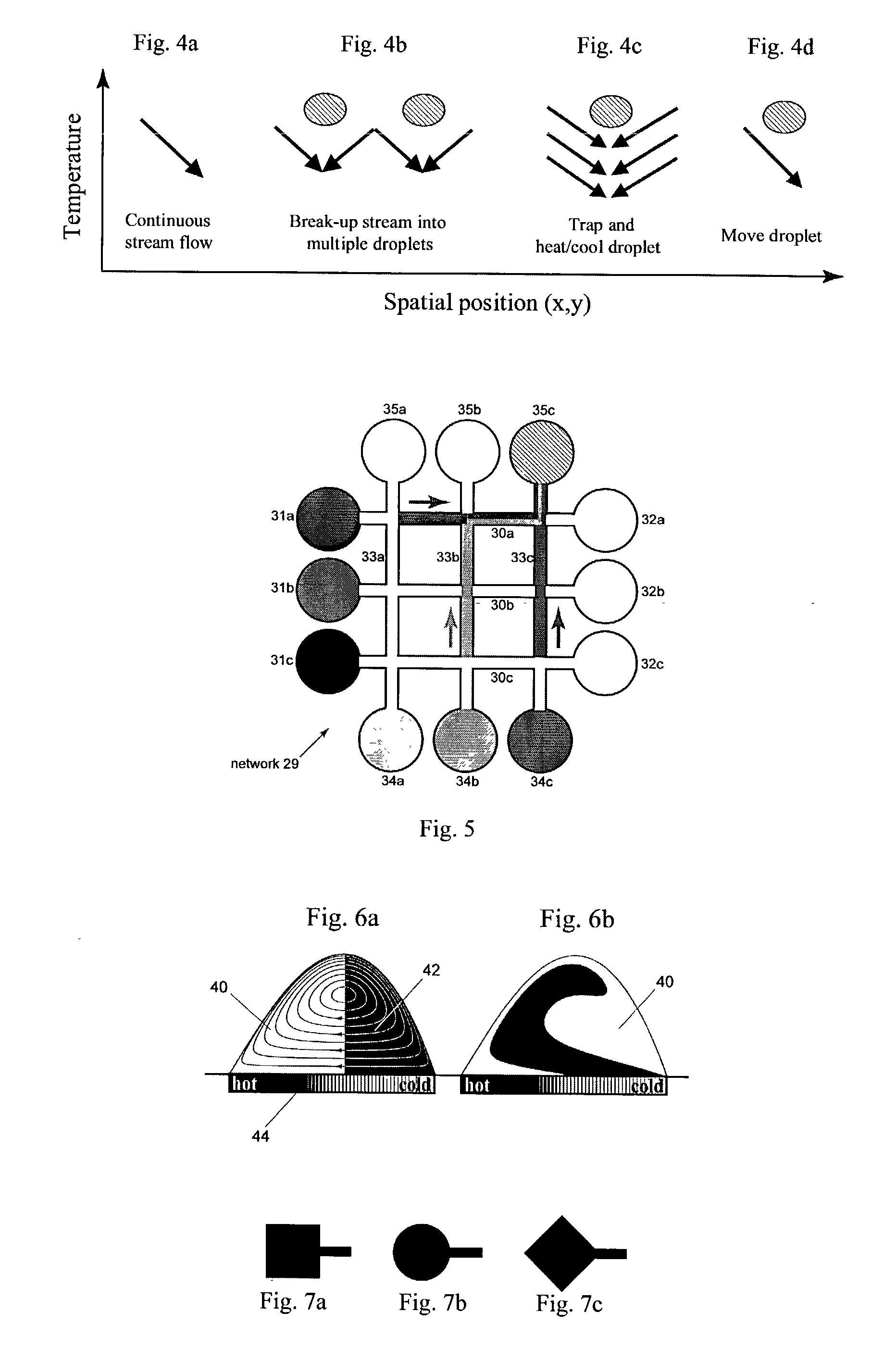

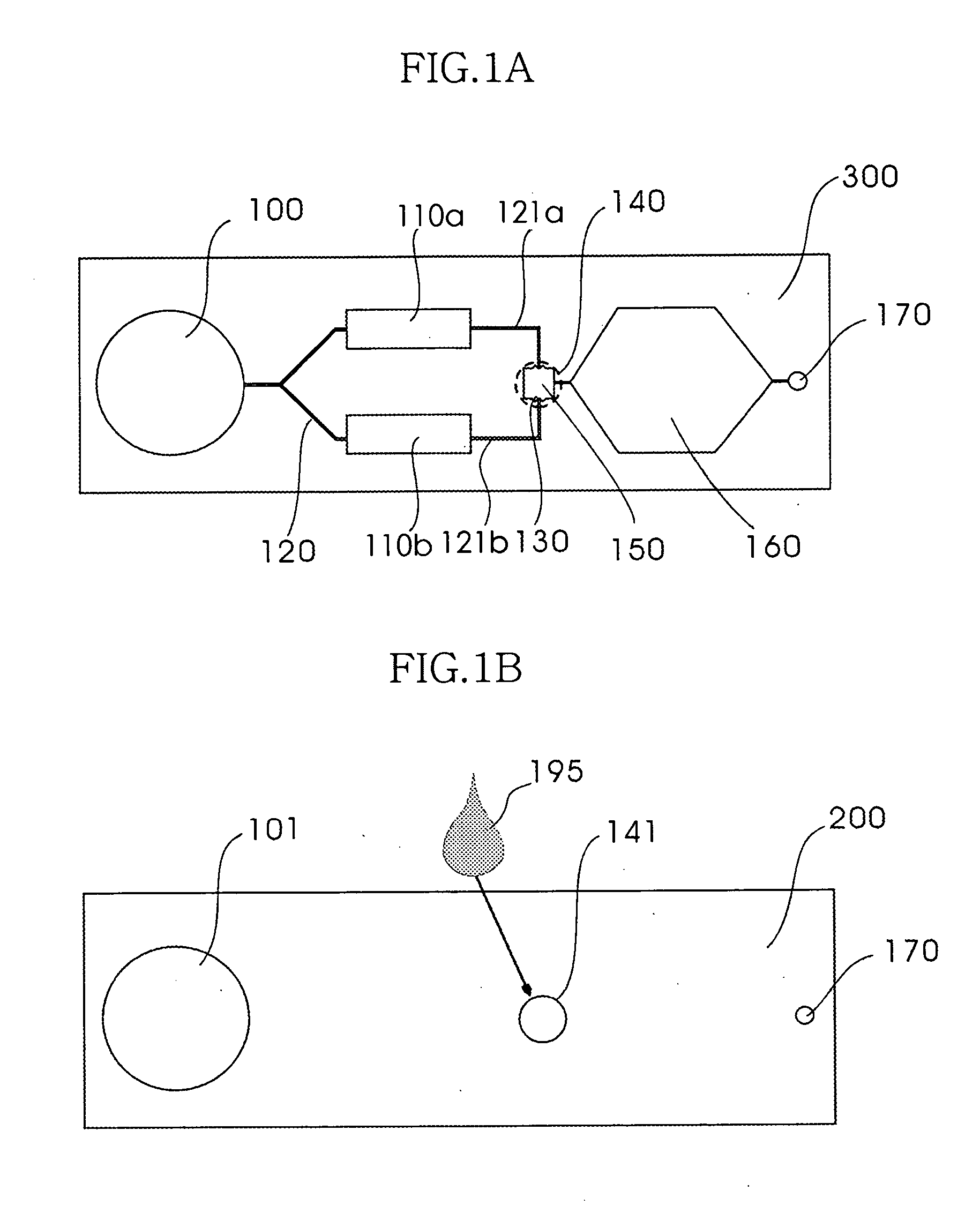

Method and device for controlling liquid flow on the surface of a microfluidic chip

The invention is directed to a method and device for routing, mixing, or reacting droplets or liquid microstreams along the surface of a flat substrate. The flow of liquid microstreams or microdroplets along designated pathways is confined by chemical surface patterning. Individually addressable heating elements, which are embedded in the substrate, can be used to generate flow via thermocapillary effects or to trigger or quench chemical reactions. The open architecture allows the liquid to remain in constant contact with the ambient atmosphere. The device can be used for microfluidic applications or as a surface reactor or biosensor, among other applications.

Owner:CALIFORNIA INST OF TECH

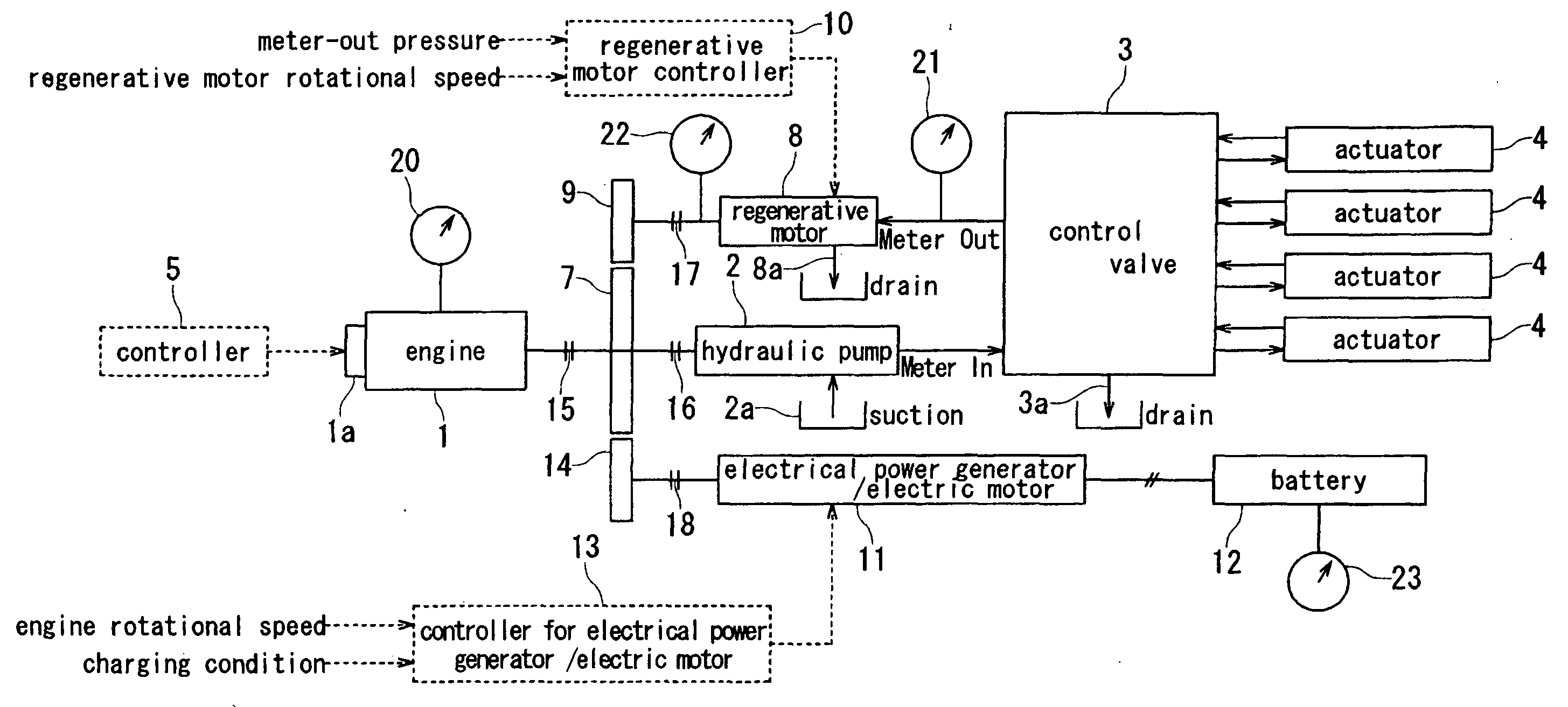

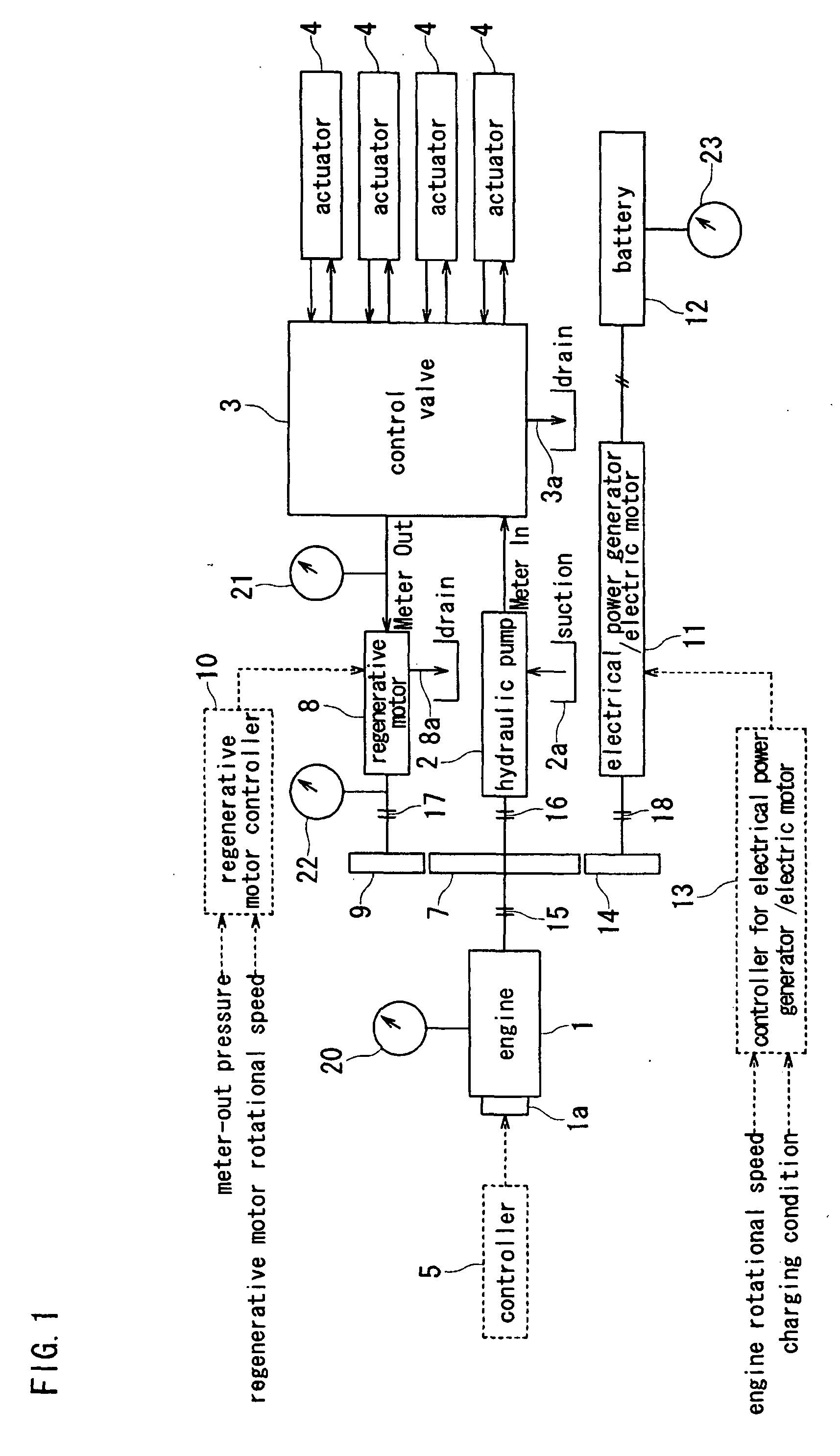

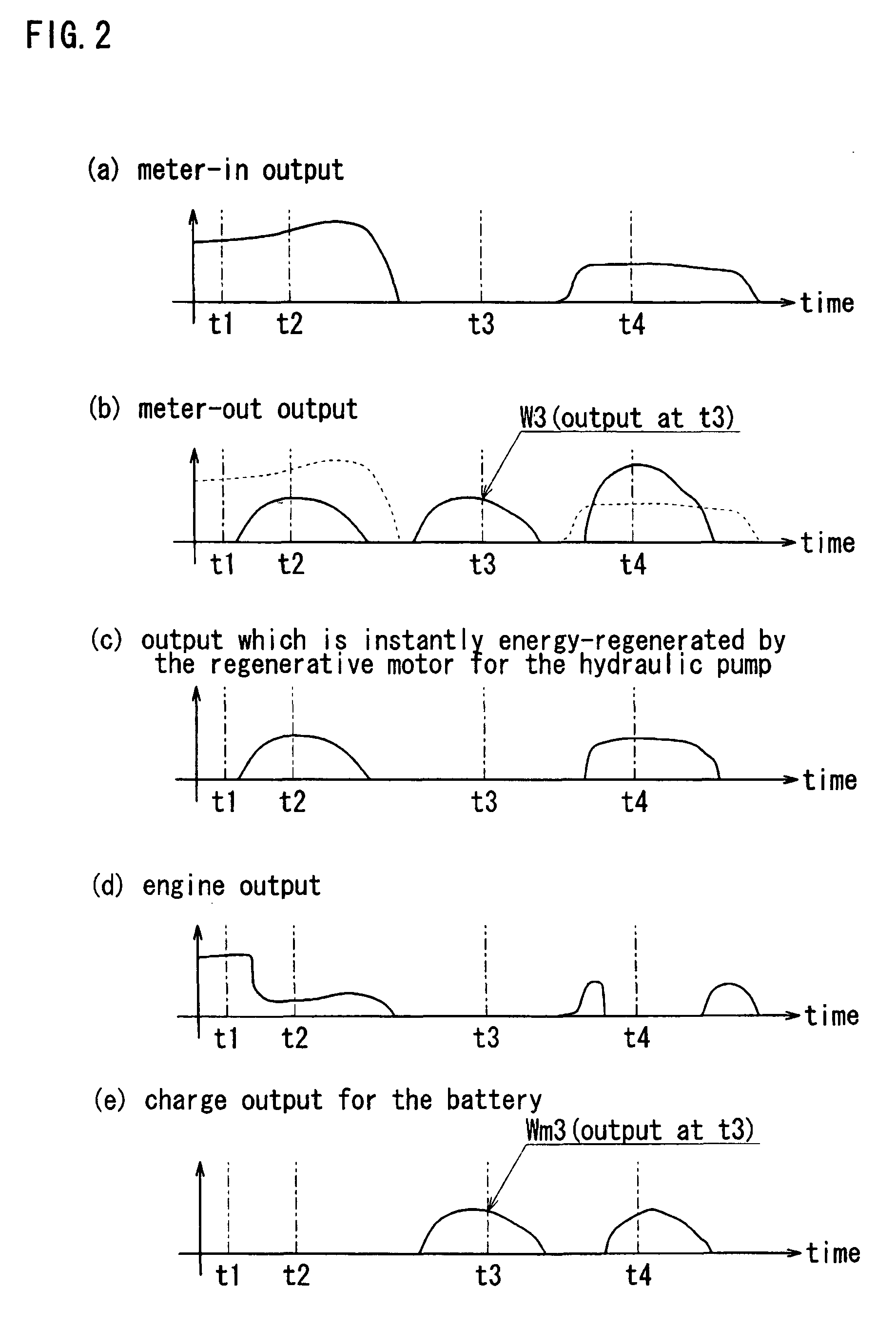

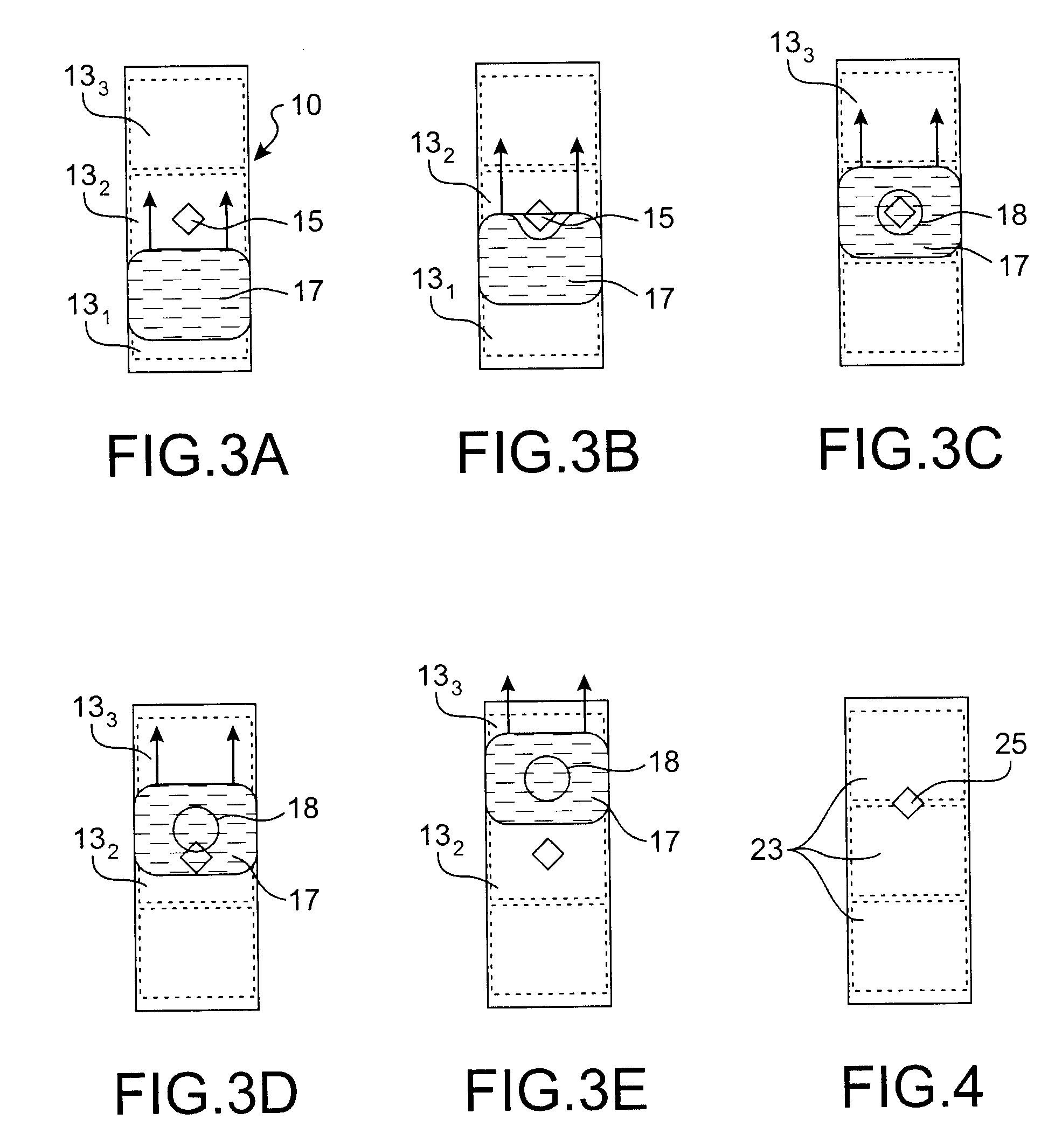

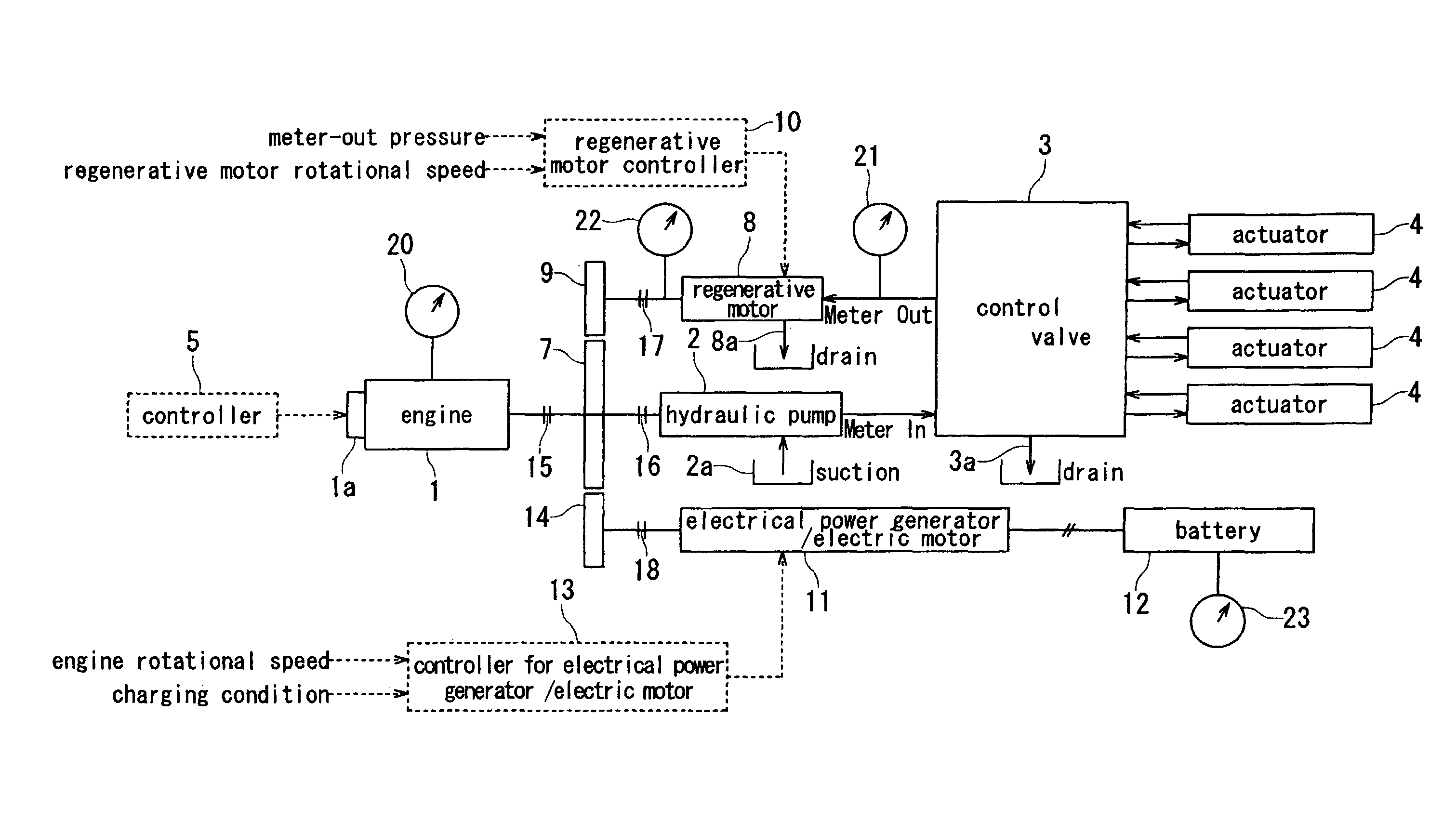

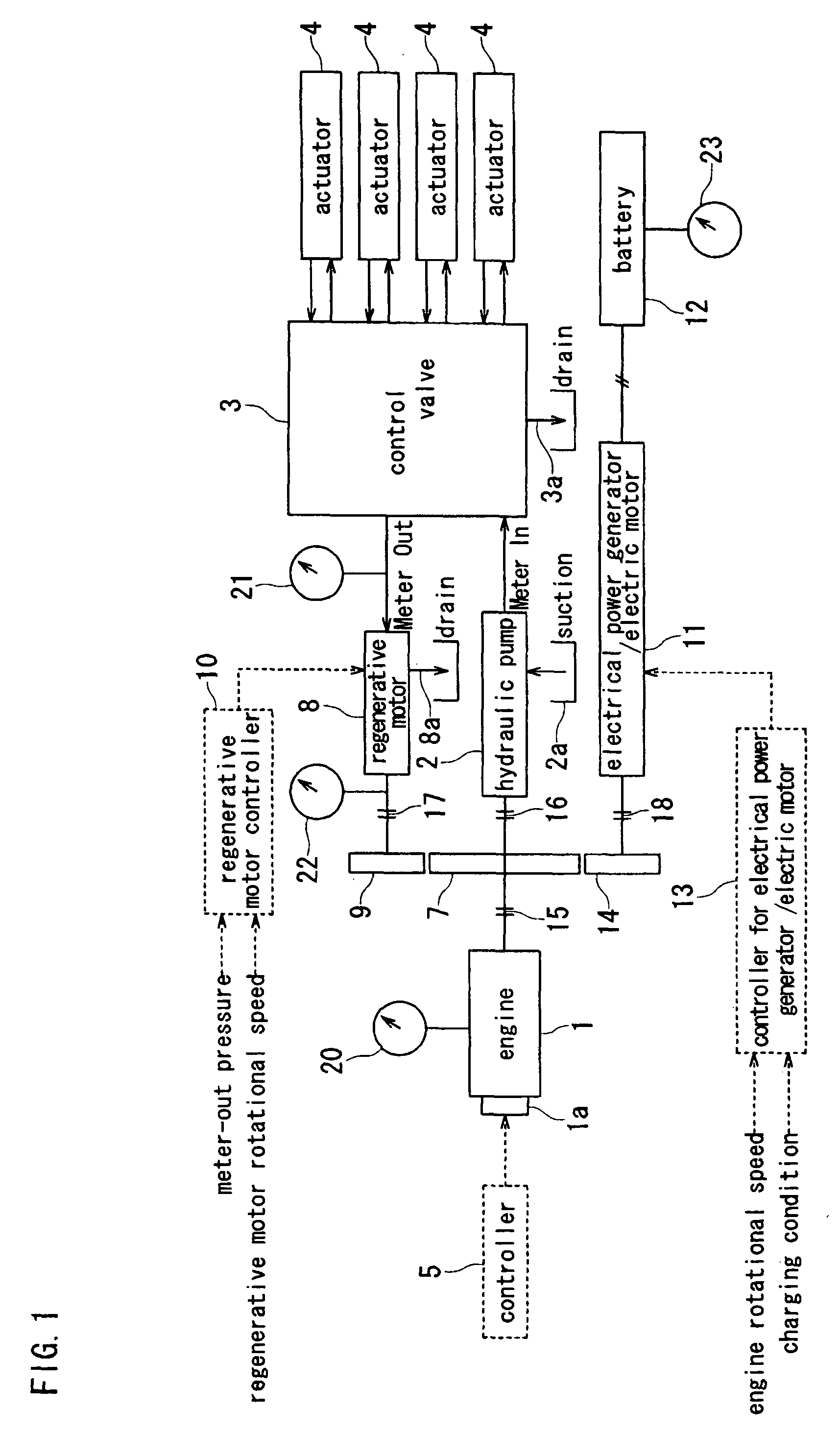

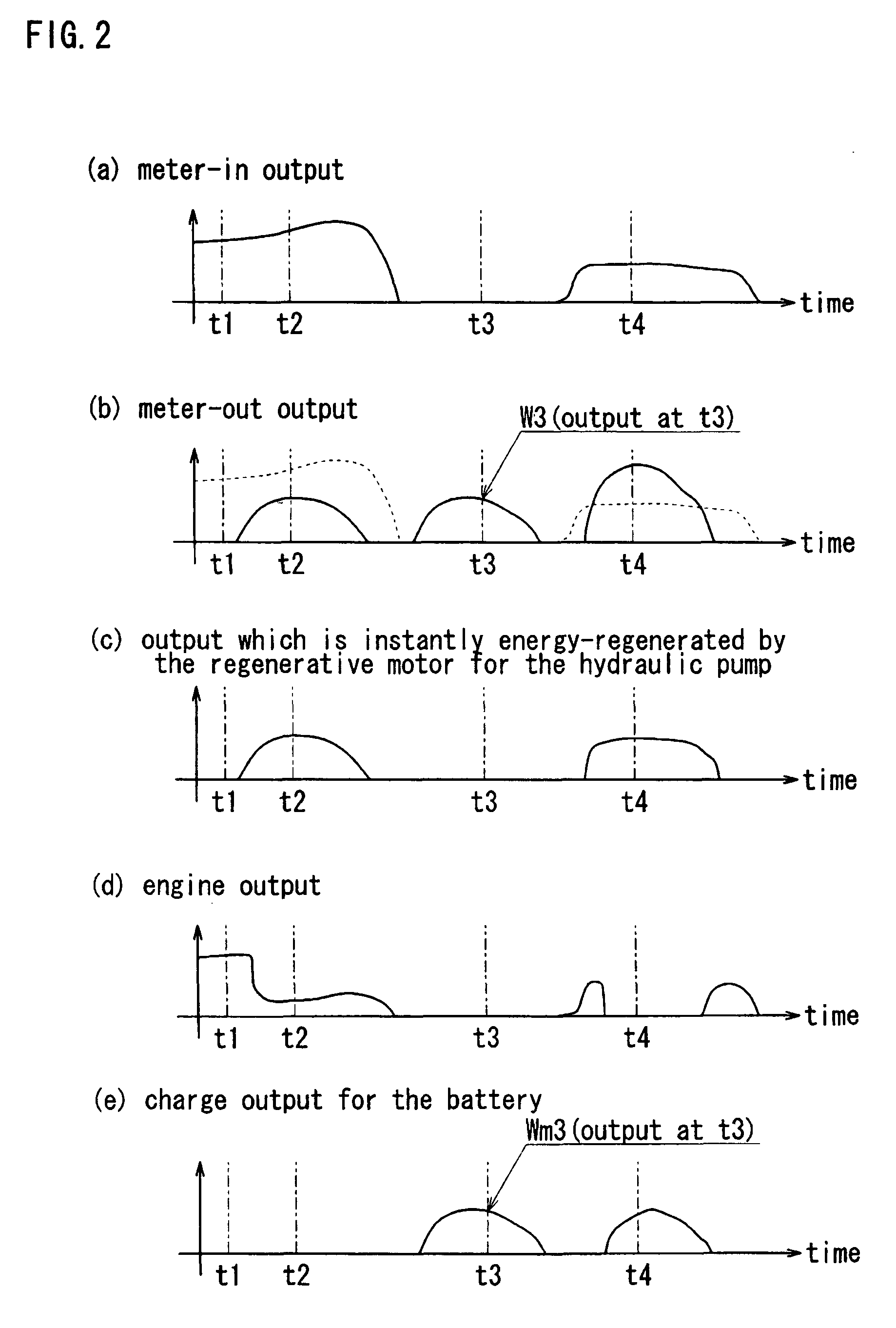

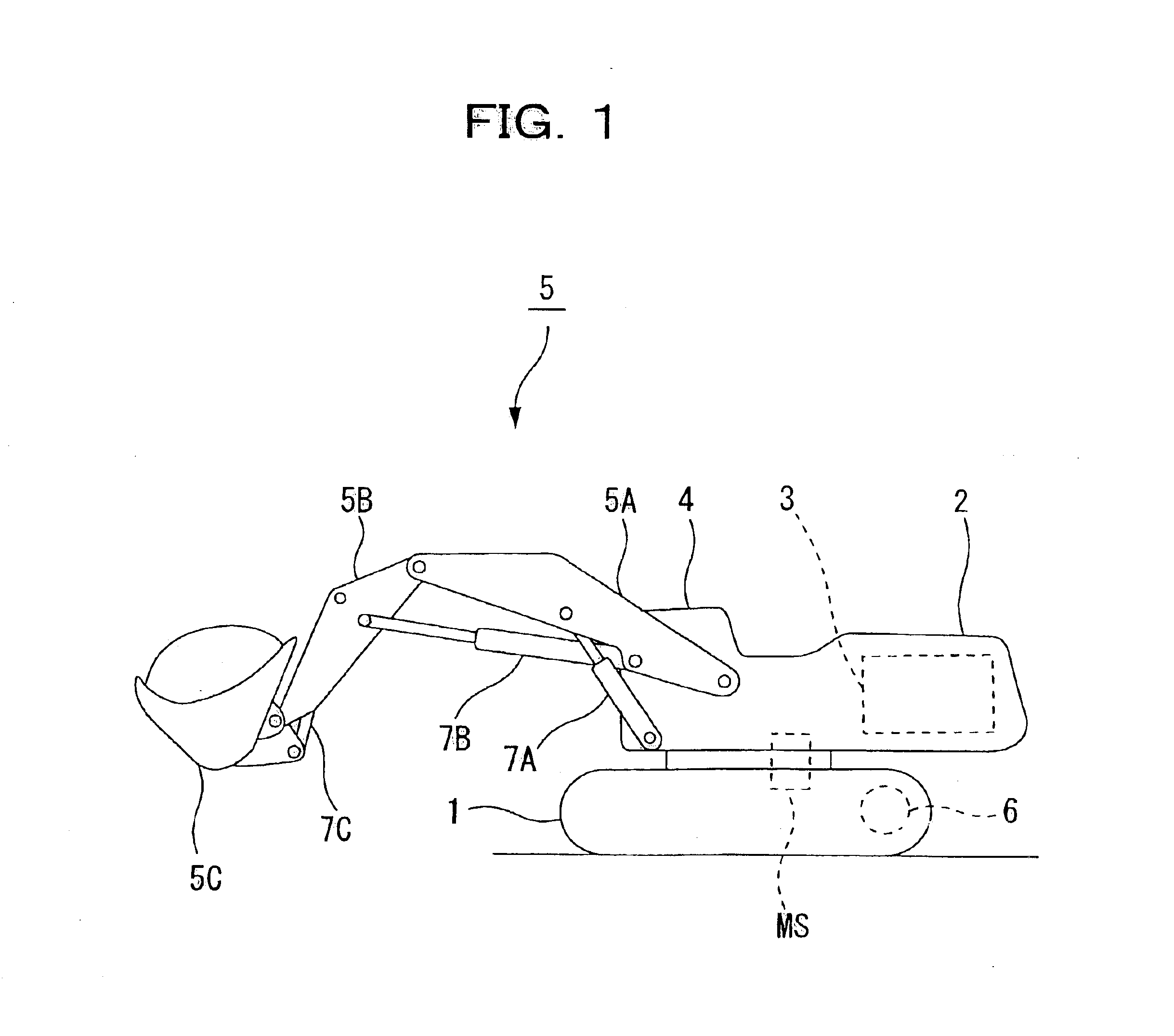

Construction machine

ActiveUS20050036894A1High electrical power generation efficiencyEfficient energy regenerationFluid couplingsMotor parameterElectricityHydraulic pump

In order to provide a construction machine by which energy regeneration can be performed reliably and battery and electrical power generator can be miniaturized, a construction machine has an engine, a hydraulic pump driven by the engine, and an actuator driven by discharge oil from the hydraulic pump, and a regenerative motor which rotates by return oil from the actuator is connected to the rotation shaft of the hydraulic pump. The hydraulic pump is driven by the engine and the regenerative motor when drive torque necessary in the hydraulic pump is larger than output torque generated by operation of the regenerative motor. Meanwhile, the hydraulic pump is driven by the regenerative motor when the drive torque of the hydraulic pump is smaller than output torque of the regenerative motor, and an electrical power generator connected to the rotation shaft of the hydraulic pump is operated to generate electricity by excess torque which has not been energy-regenerated in the hydraulic pump so that this generated electrical power is charged in a battery.

Owner:KOMATSU LTD

Energy recovery system

An energy recovery system for a machine is disclosed. The energy recovery system may have a pump configured to provide a flow of pressurized fluid. The energy recovery system may also have a first fluid actuator with a first chamber and a second chamber and being configured to receive the pressurized fluid, a second fluid actuator with a third chamber and a fourth chamber and being configured to receive the pressurized fluid, and a first valve fluidly connected between the pump and the first and second actuators. The energy recovery system may additionally include an isolation unit with a first selectively restrictable passageway fluidly connecting the first chamber, the third chamber, and a first outlet of the first valve, and a second selectively restrictable passageway fluidly connecting the second chamber, the fourth chamber, and a second outlet of the first valve, as well as an energy recovery unit in fluid communication with the isolation unit. The isolation unit may be configured to direct a flow of pressurized fluid from the second actuator to the energy recovery unit. The energy recovery unit may be configured to convert the flow of pressurized fluid to a first mechanical power output.

Owner:CATERPILLAR INC

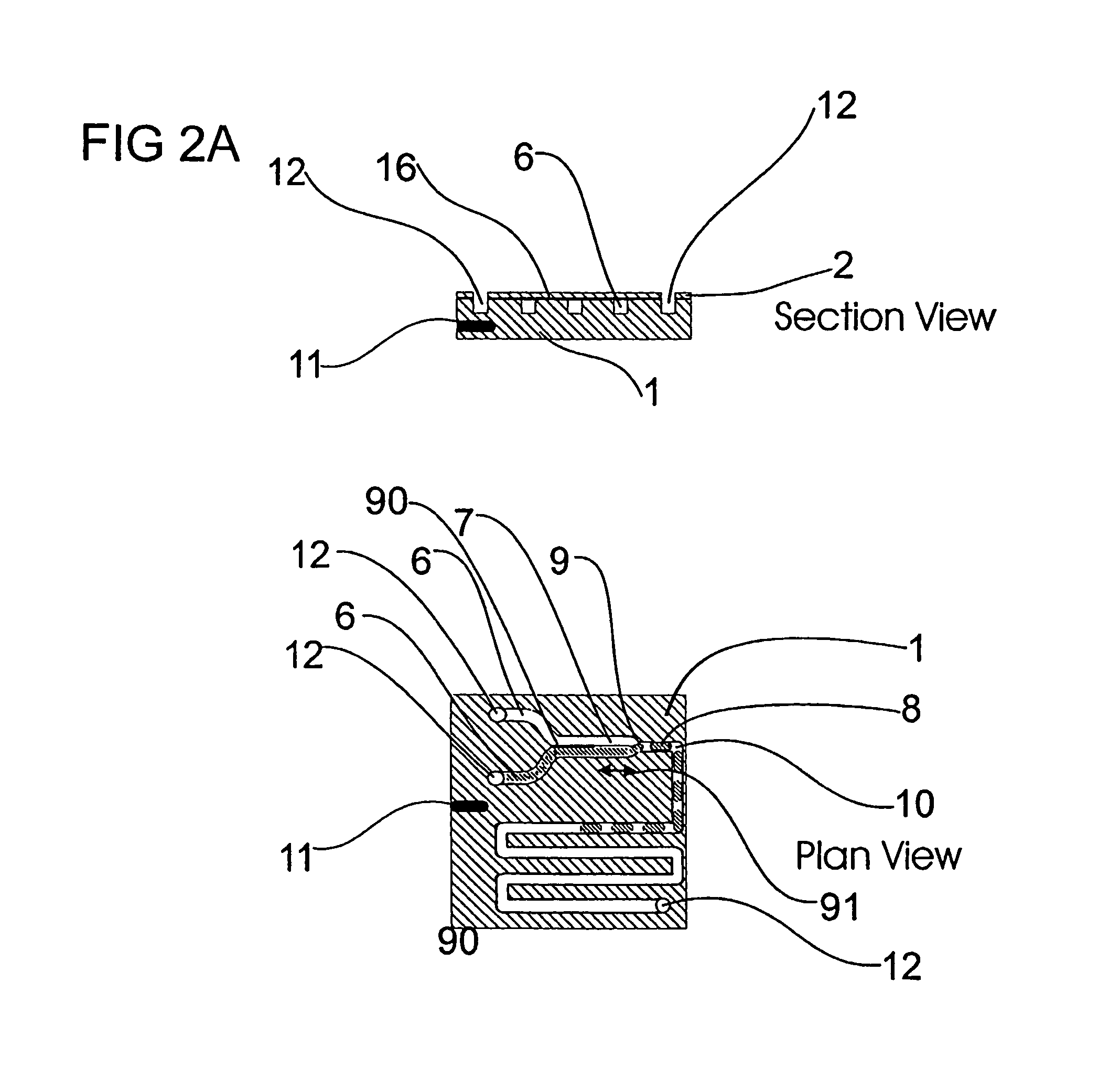

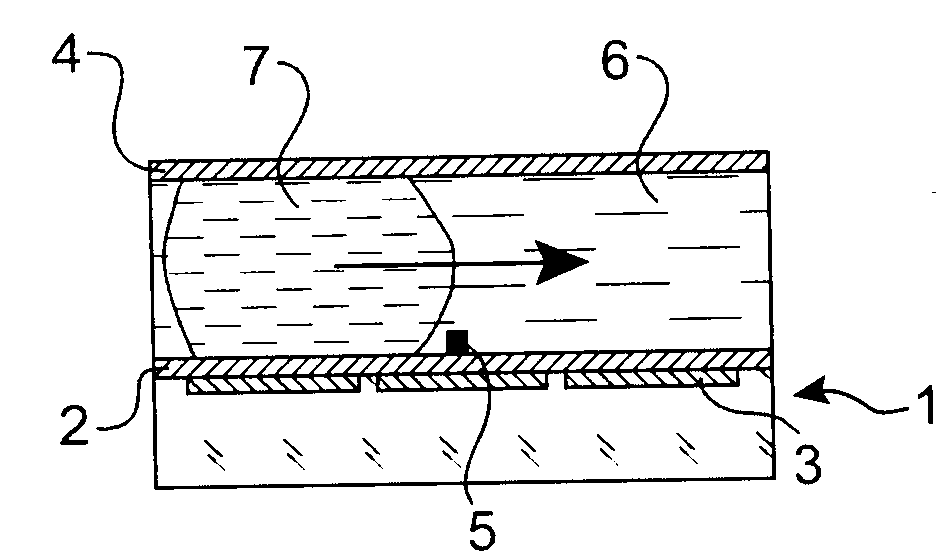

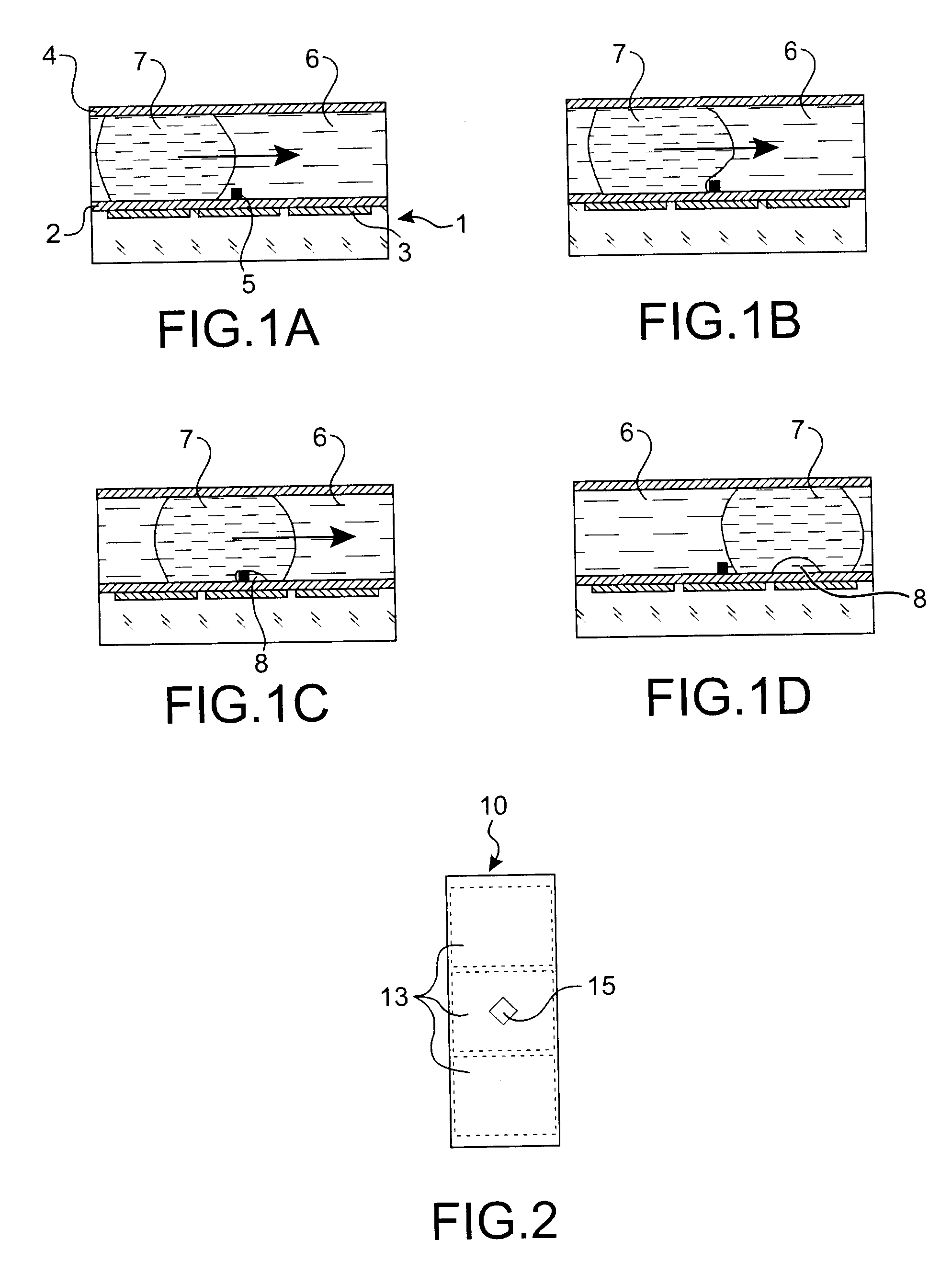

Making a two-phase liquid/liquid or gas system in microfluidics

The invention relates to a microfluidic device for making a liquid / liquid or gas biphasic system using a first liquid or a gas and a second liquid, non-miscible with each other, the device having a first hydrophobic surface for the second liquid, the first liquid forming a layer (6) on said first hydrophobic surface. The device comprises means for introducing a drop (7) of the second liquid into the layer of first liquid or gas and in contact with said first hydrophobic surface, and means for displacing the drop on said first hydrophobic surface along a determined path, the device having on the path of the drop, at least one wetting defect causing, upon passing of the drop over this defect, failure of the triple line of contact of the drop on the first hydrophobic surface and inclusion of first liquid (8) or gas into the drop.The invention also relates to the associated method.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Construction machine

InactiveUS7086226B2Reliable collectionReliable regenerationFluid couplingsMotor parameterElectricityEnergy regeneration

Owner:KOMATSU LTD

Systems and Methods for Energy Storage and Recovery Using Compressed Gas

InactiveUS20090282822A1Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsThermodynamicsGas cylinder

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

Energy recovery and reuse techniques for a hydraulic system

A hydraulic system has a valve assembly with two workports coupled to chambers of first and second cylinders which are connected mechanically in parallel to a machine component. A separation control valve is connected between first chambers of both cylinders, and a shunt control valve is connected between the workports. A recovery control valve couples an accumulator to the first chamber of the second cylinder. Opening and closing the valves in different combinations routes fluid from one or both cylinders into the accumulator where the fluid is stored under pressure, and thereafter enables stored fluid to be used to power one or both cylinders. The shunt control valve is used to route fluid exhausting from one chamber of each cylinder to the other chambers of those cylinders. Thus the hydraulic system recovers and reuses energy in various manners.

Owner:HUSCO INT INC

Multiple continuous microfluidic reactors for the scaled up synthesis of gel or polymer particles

ActiveUS20100184928A1Fast throughput screeningGaseous chemical processesFlow mixersStrong couplingPolymer

This present invention provides devices for the parallelization of the formation of droplets in a multiple droplet generator integrating two or more parallel flow-focusing devices (FFDs) with either identical, or different, geometries. In the parallel identical FFDs, emulsification generates droplets with a narrow (below 4%) polydispersity despite weak coupling between the identical flow-focusing devices. Formation of droplets in the integrated droplet generator comprising FFDs with different dimensions of the microchannels occurs with strong coupling between the FFDs and produces droplets with varying sizes and size distributions. For such devices the regime in which emulsification produces droplets with varying dimensions and a narrow size distribution have been identified. The results of this work can be used in scaling up the production of droplets and in the simultaneous production of droplets and particles with different dimensions.

Owner:KUMACHEVA EUGENIA

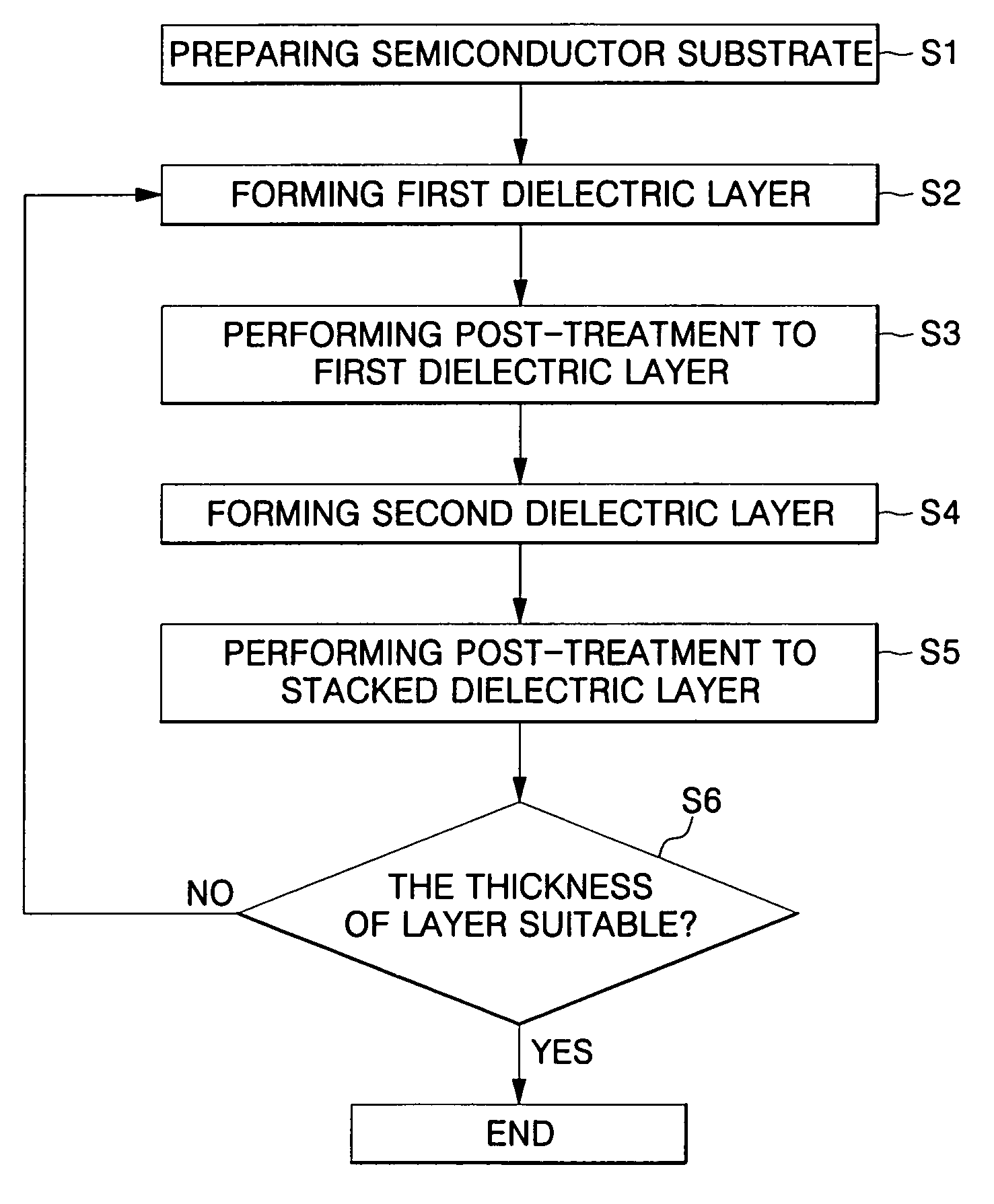

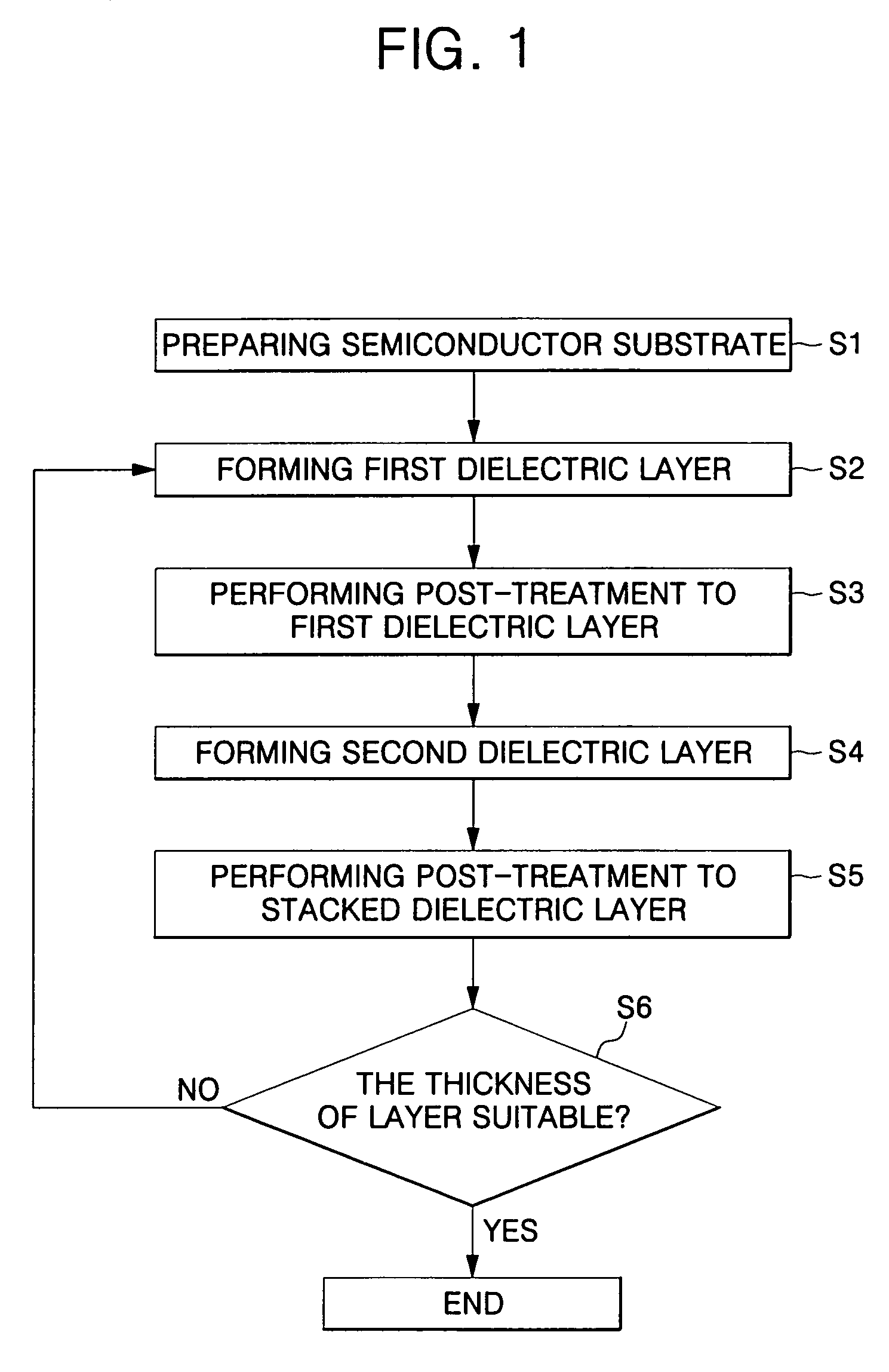

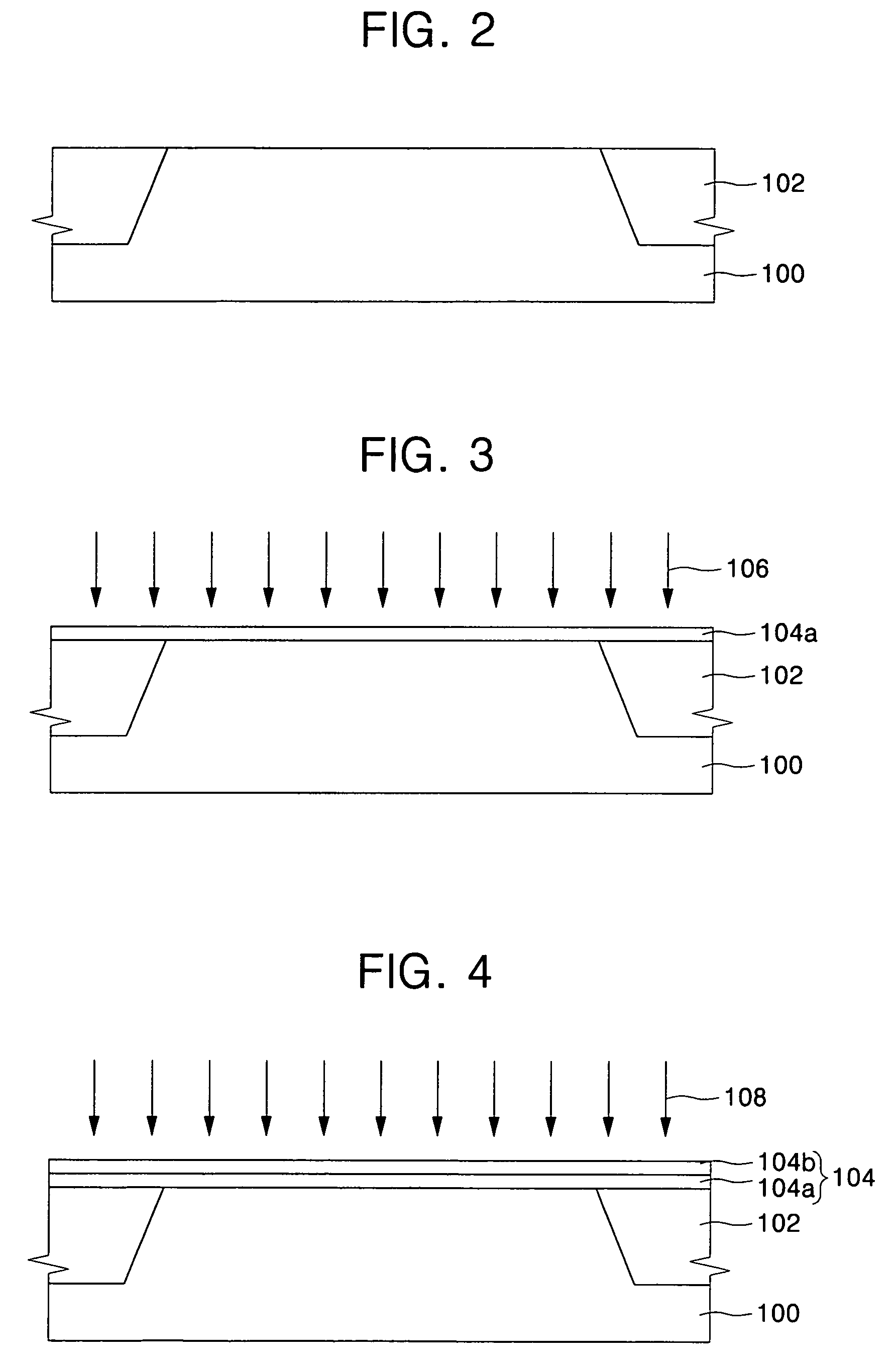

Method of fabricating high-k dielectric layer having reduced impurity

ActiveUS20050233598A1Impurity content is minimizedSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryEngineering

Methods of fabricating high-k dielectric layers having reduced impurities for use in semiconductor applications are disclosed. The methods include the steps of: forming a stacked dielectric layer having a first dielectric layer and a second dielectric layer formed on a semiconductor substrate using an ALD method, in combination with a post-treatment step performed to the stacked dielectric layer. The steps of forming the stacked dielectric layer and performing the post-treatment are repeated at least once, thereby fabricating the high-k dielectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

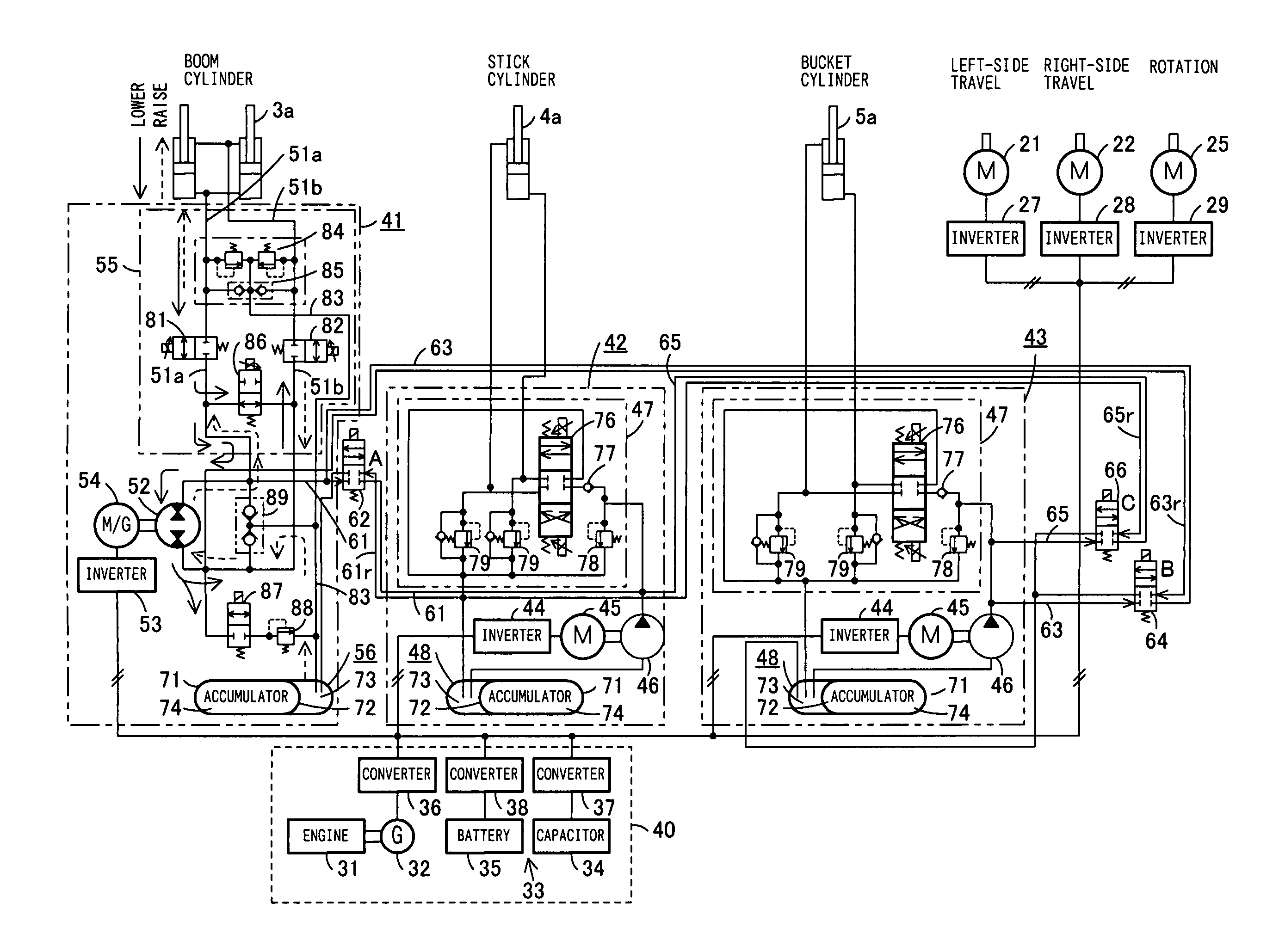

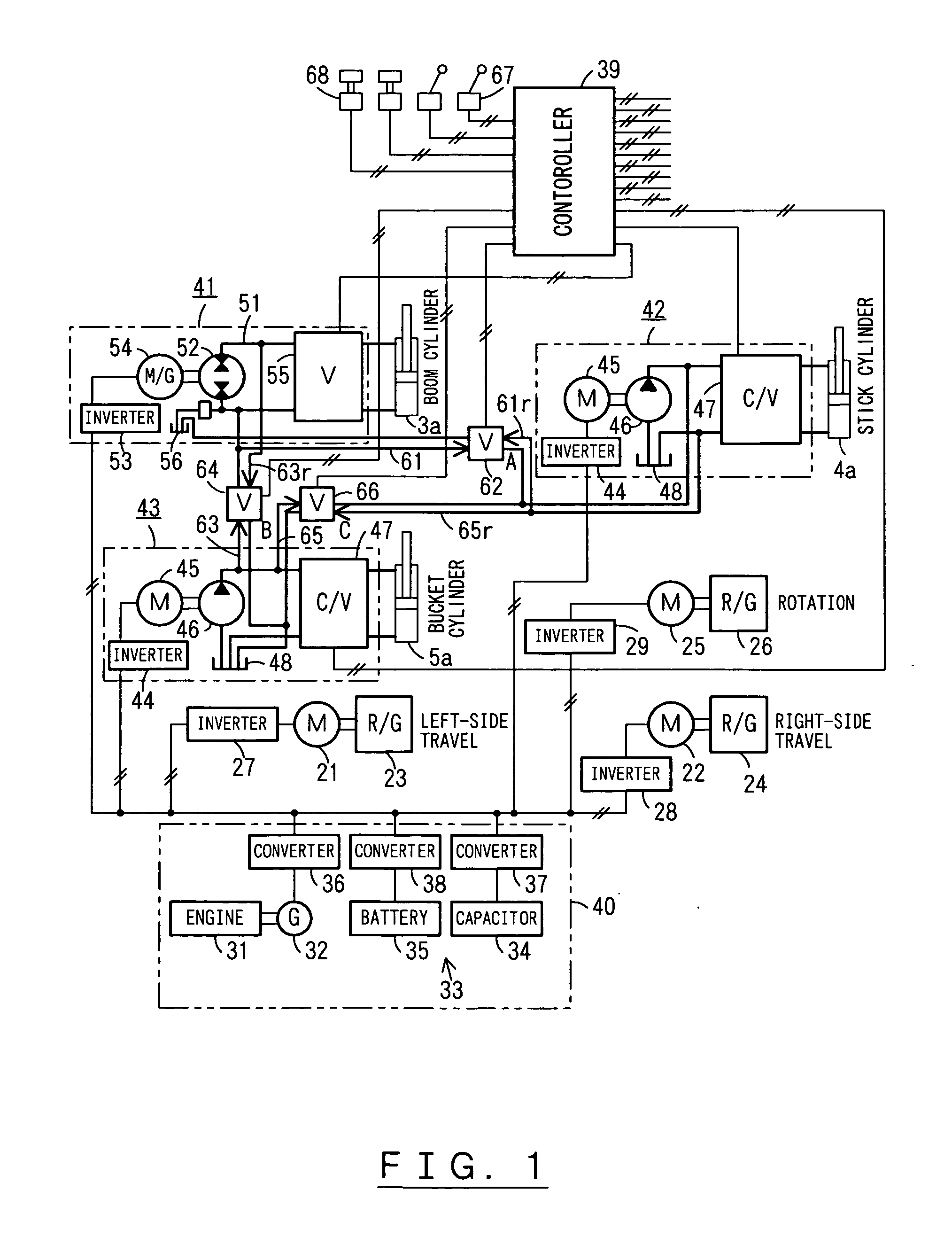

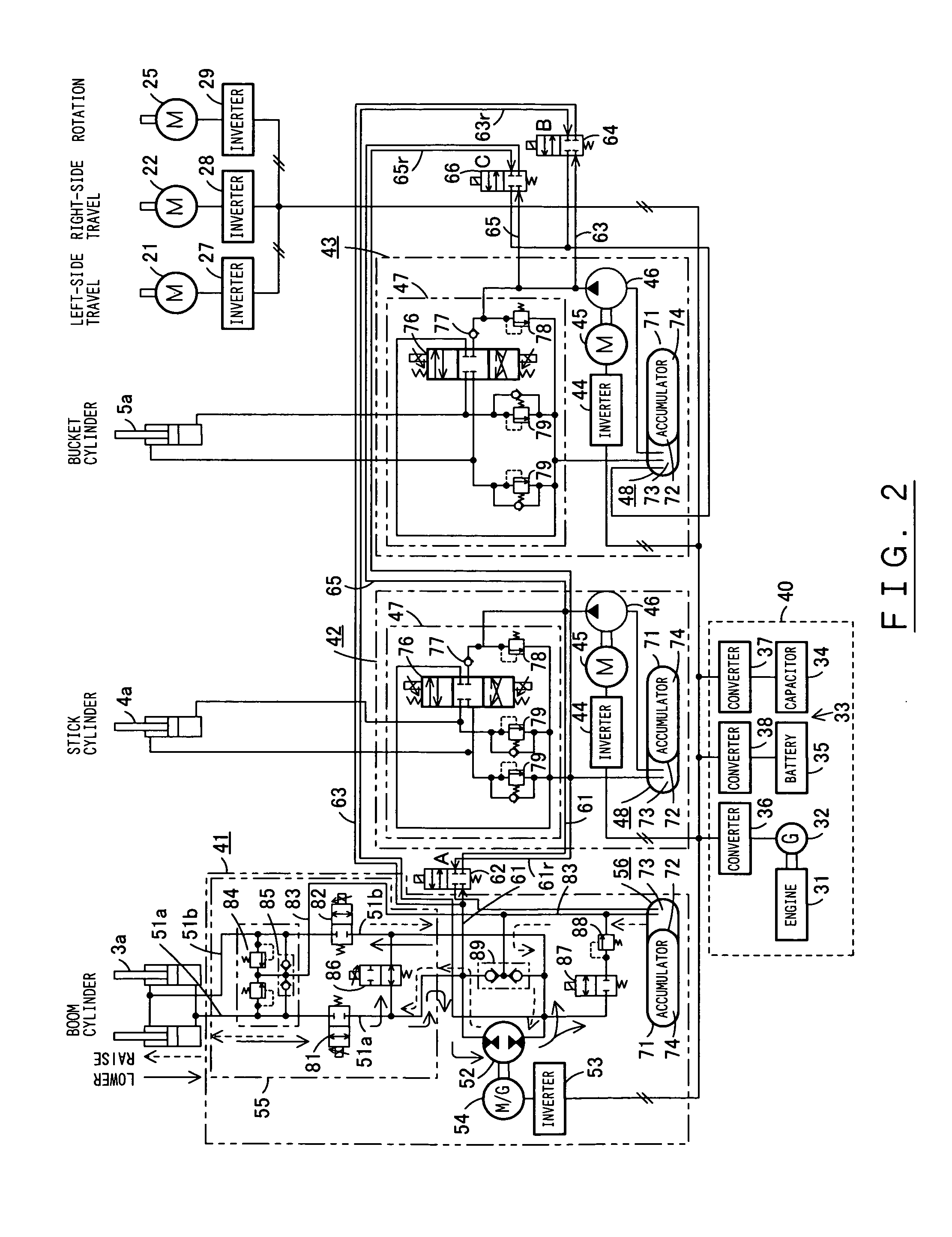

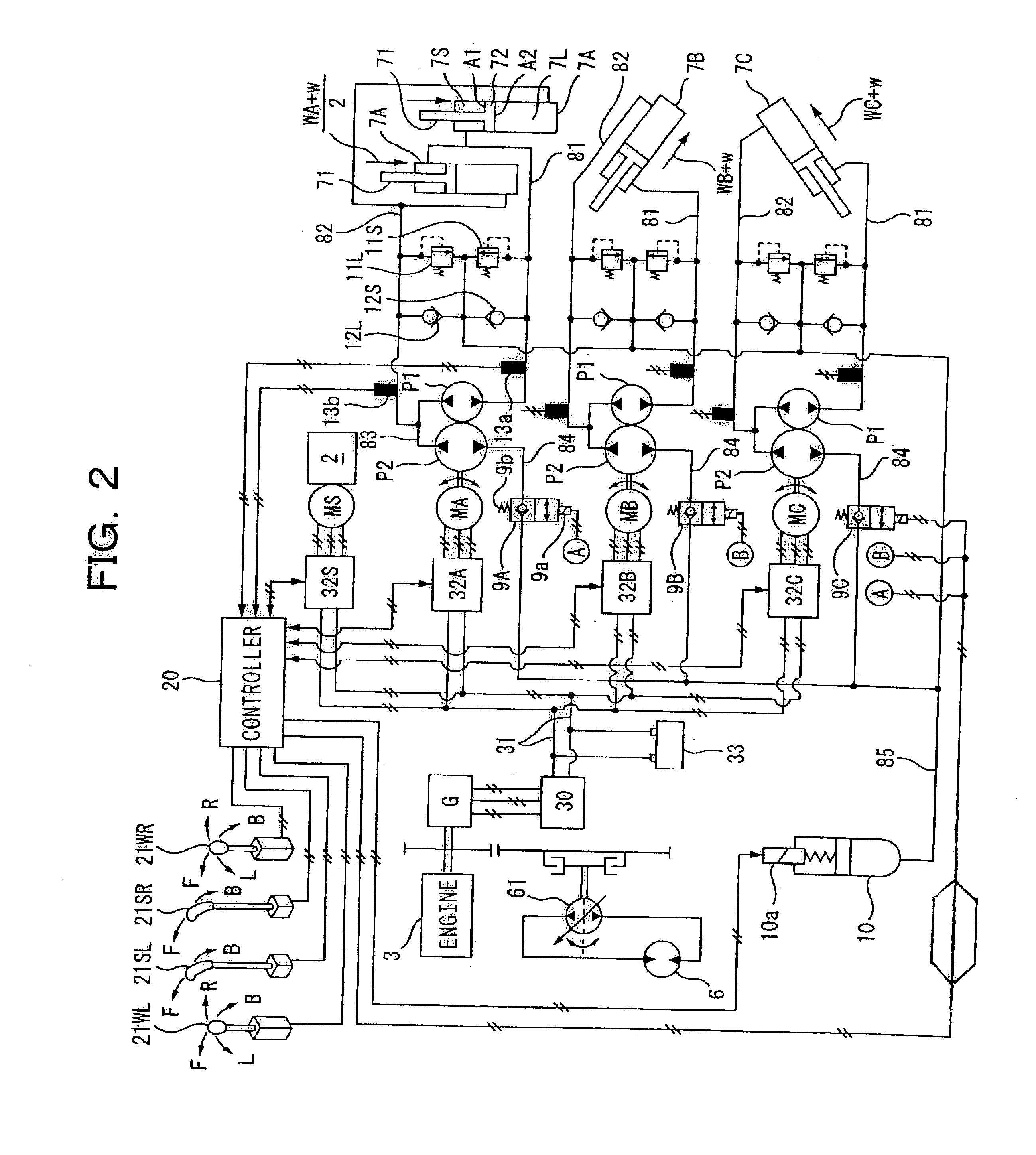

Working machine driving unit

InactiveUS20050246082A1ShortfallEfficient sharingAnalogue computers for trafficServomotorsWork unitActuator

A driving device of a work machine includes a power generator adapted to be driven by an engine, and a power storage device for storing the electric power generated by the power generator. Electric motors and a motor generator, both adapted to be operated by electric power supplied from either one or both of the power generator and the power storage device respectively drive pumps and a pump motor. Supporting circuits for feeding supporting hydraulic oil are provided between a plurality of driving circuits that drive a plurality of hydraulic actuators of a working unit by oil hydraulics generated by the pumps and the pump motor. By enabling the plurality of driving circuits to effectively share excess energy, the invention makes possible a compact construction of a driving device of a work machine.

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

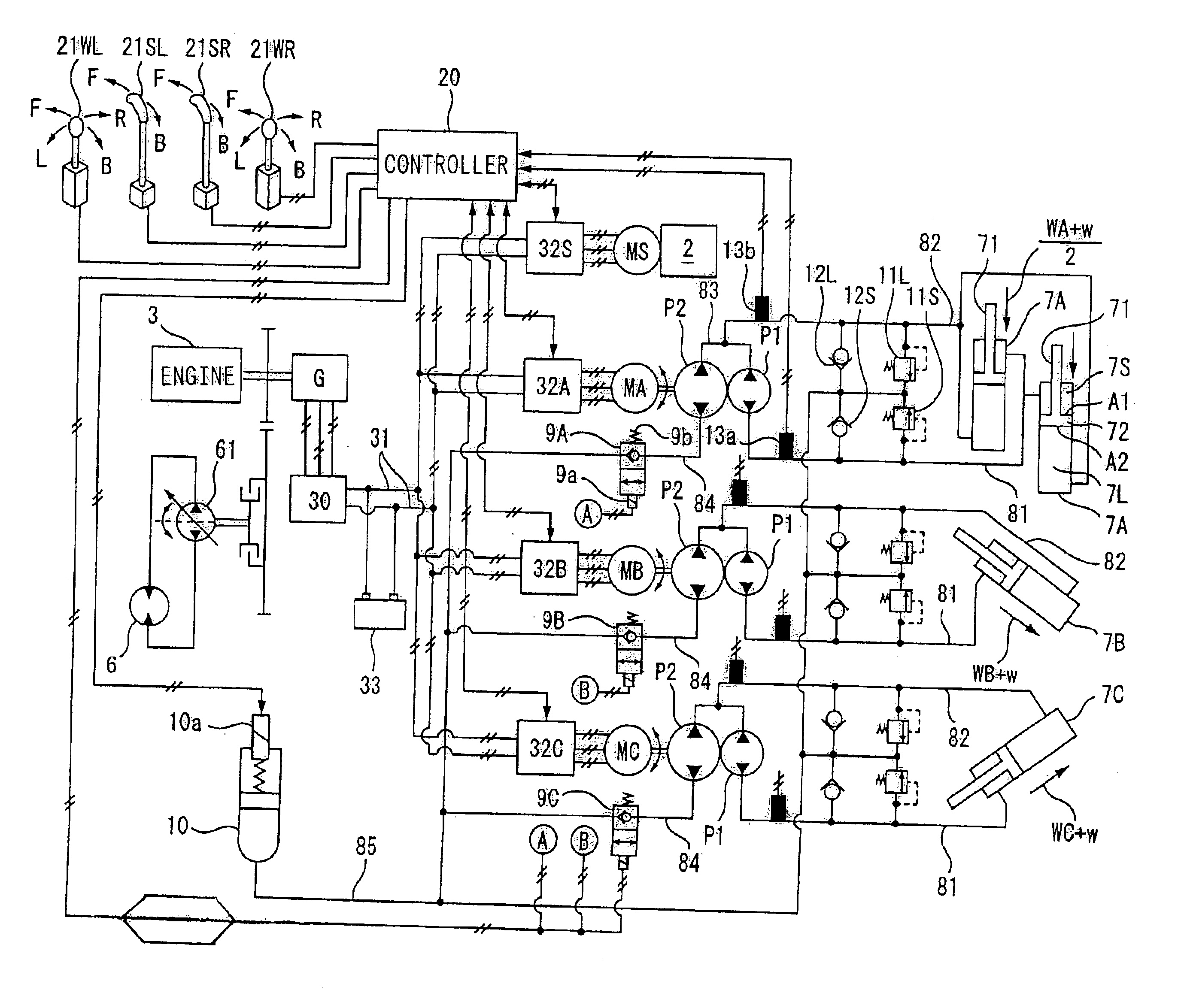

Hybrid machine with hydraulic drive device

A hybrid machine with a hydraulic drive device having hydraulic actuators allowed to operate against and by external loads is provided. To this end, the hybrid machine comprises hydraulic cylinders (7), first hydraulic pumps (P1) connected, with closed circuits, to head side pressure receiving chambers (7S) and bottom side pressure receiving chambers (7L) of the hydraulic cylinders (7), and second hydraulic pumps (P2) connected, with open circuits, to the bottom side pressure receiving chambers (7L) and an external oil chamber (10), wherein the first and second hydraulic pumps (P1, P2) are connected to electric motors (M) so as to be driven.

Owner:KOMATSU LTD

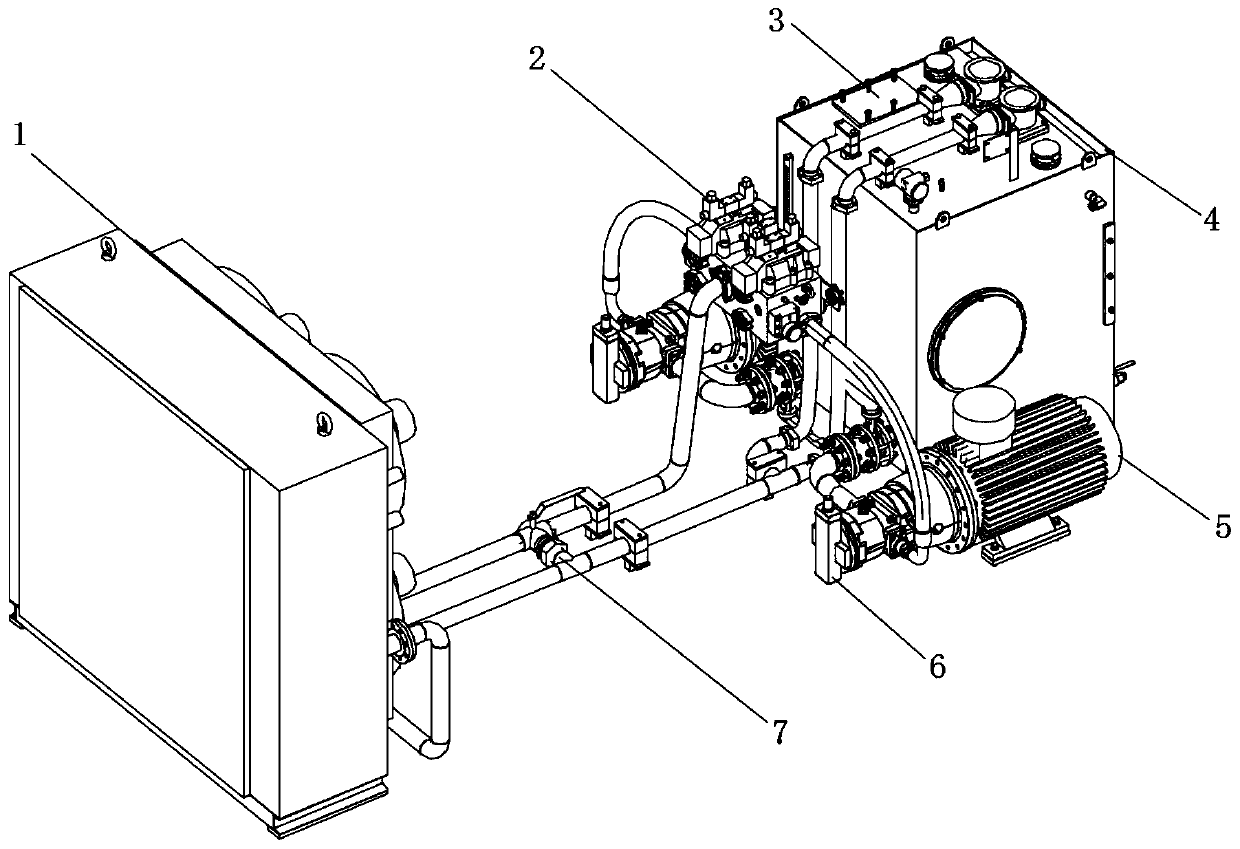

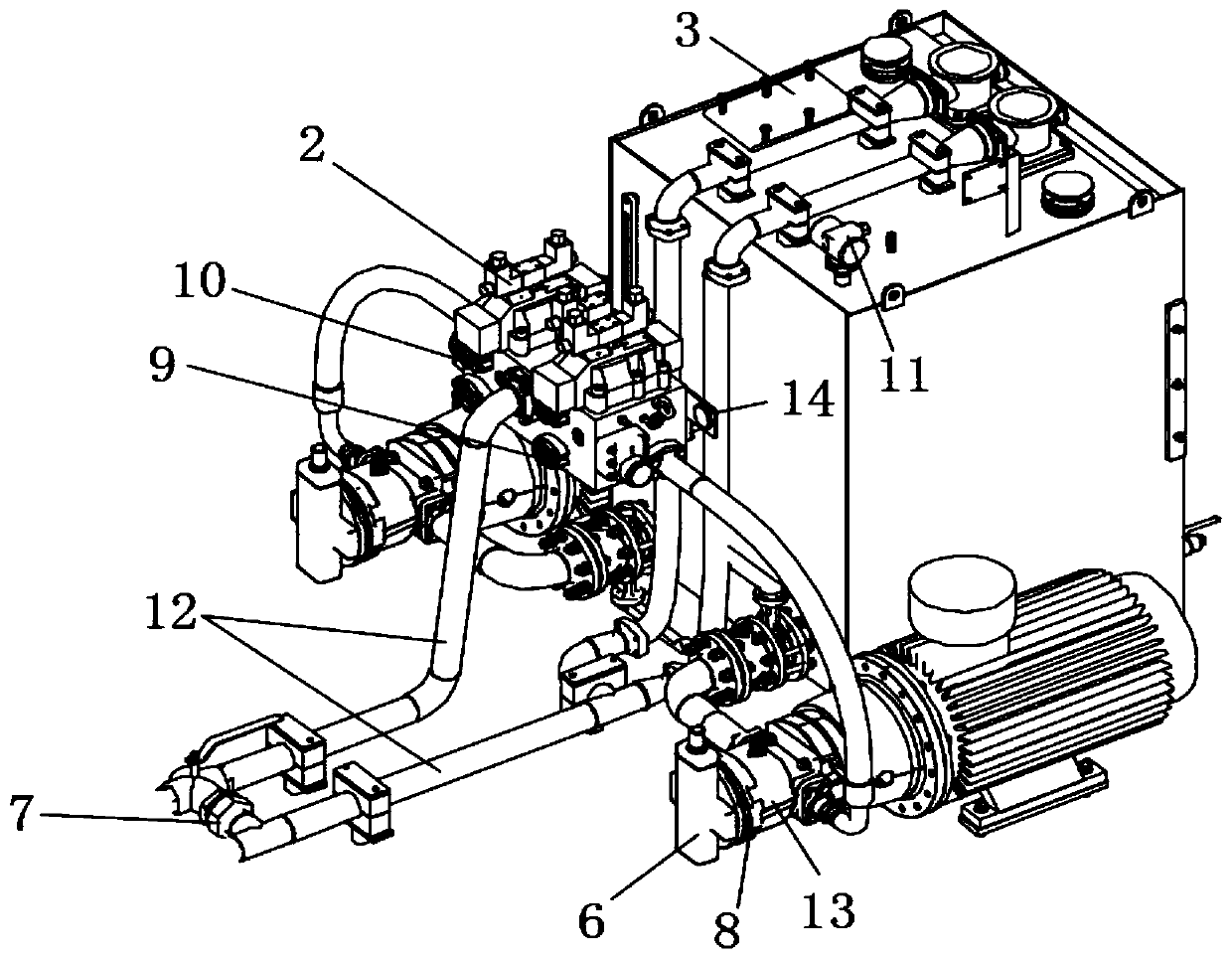

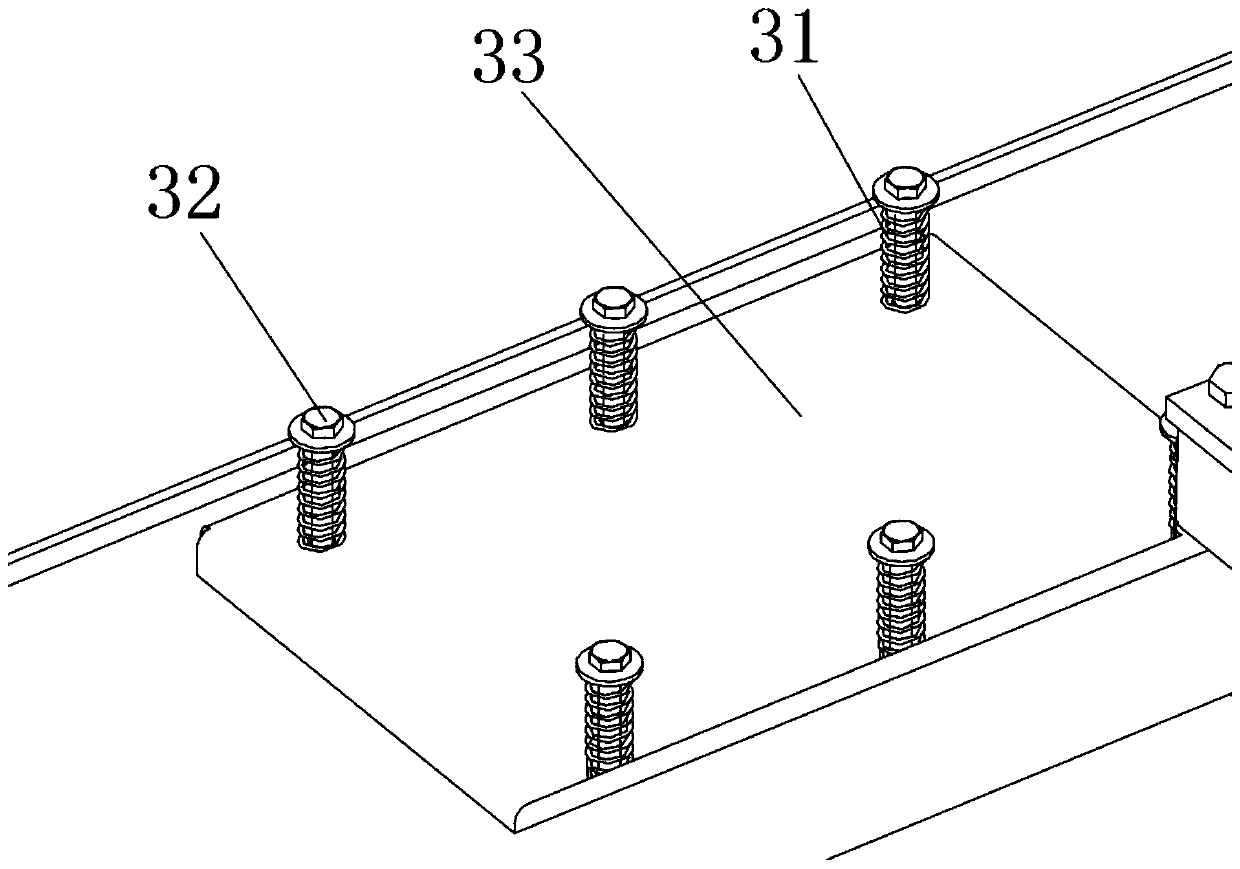

Integrated hydraulic station

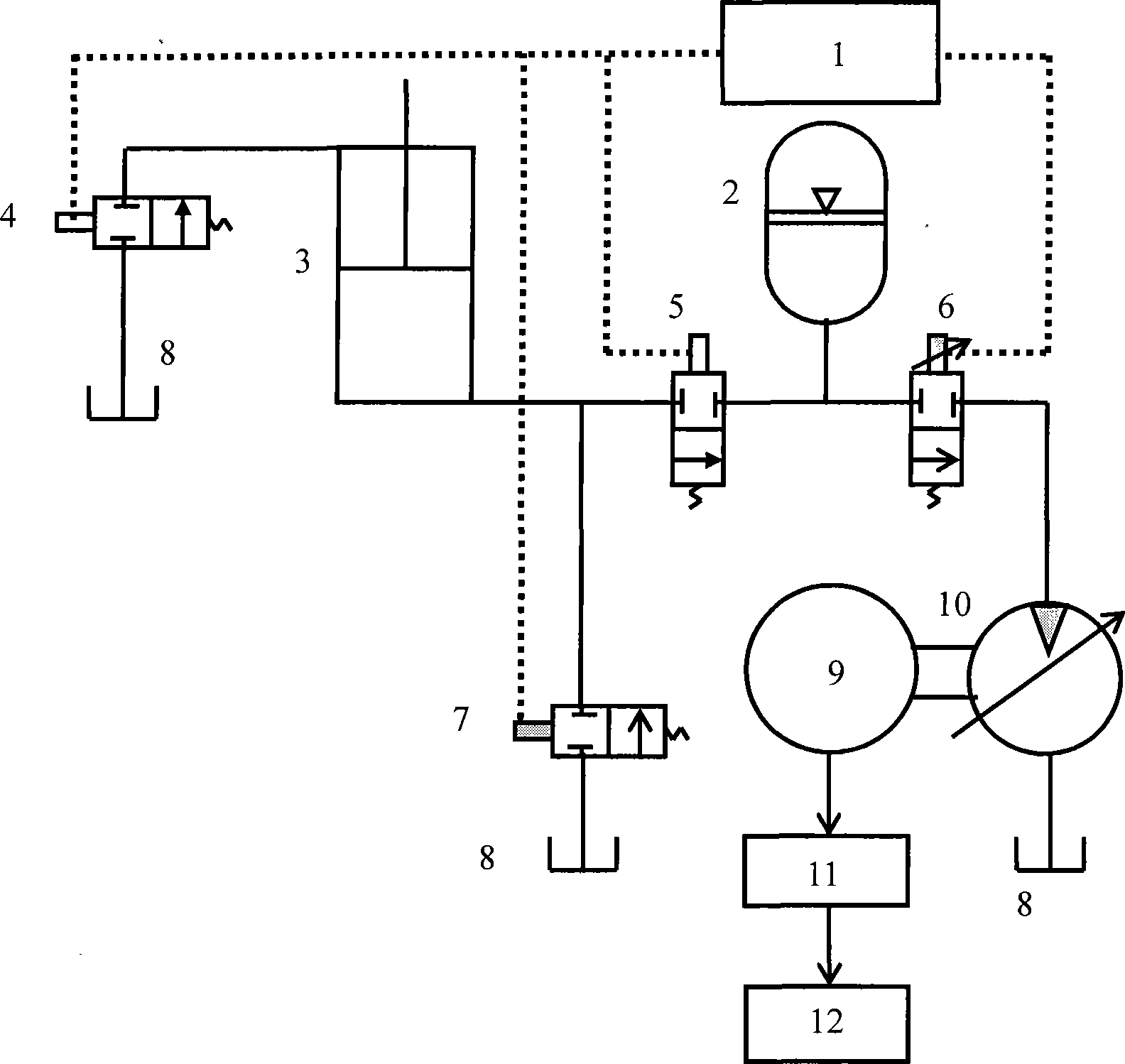

InactiveCN110873093AAchieve high integrationRealize automatic control functionFluid-pressure actuator safetyFluid-pressure actuator componentsCompressed natural gasPressure difference

The invention belongs to the technical field of compressed natural gas filling, and particularly relates to an integrated hydraulic station which realizes high integration of an oil tank, plunger pumps, motors, a valve block, a cooler, an instrument and a sensor. The reversing function of hydraulic oil is provided through cooperation of an electro-hydraulic reversing valve and a proximity switch on a hydraulic cylinder, the functions of circulating heating of the low-temperature hydraulic oil, discharging of the high-pressure hydraulic oil and avoiding the hydraulic oil channeling back betweenthe double pumps are realized through cooperation of an unloading valve, a one-way valve and the electro-hydraulic reversing valve in the valve block, the high-pressure difference automatic stop function and the high-pressure gas discharging function are provided, combustible gas leakage and expansion deformation of the oil tank which cannot be recovered caused by high-pressure gas channeling back are avoided, the functions of low oil level monitoring alarm, temperature monitoring alarm and low oil temperature automatic circulating heating before starting of the hydraulic oil tank are provided, a three-way ball valve is adopted to replace an oil return valve block in the aspect of cooling oil return of the hydraulic oil, thus the oil return control function is realize, and the cost and space of the hydraulic station are also reduced.

Owner:JEREH OIL & GAS ENG

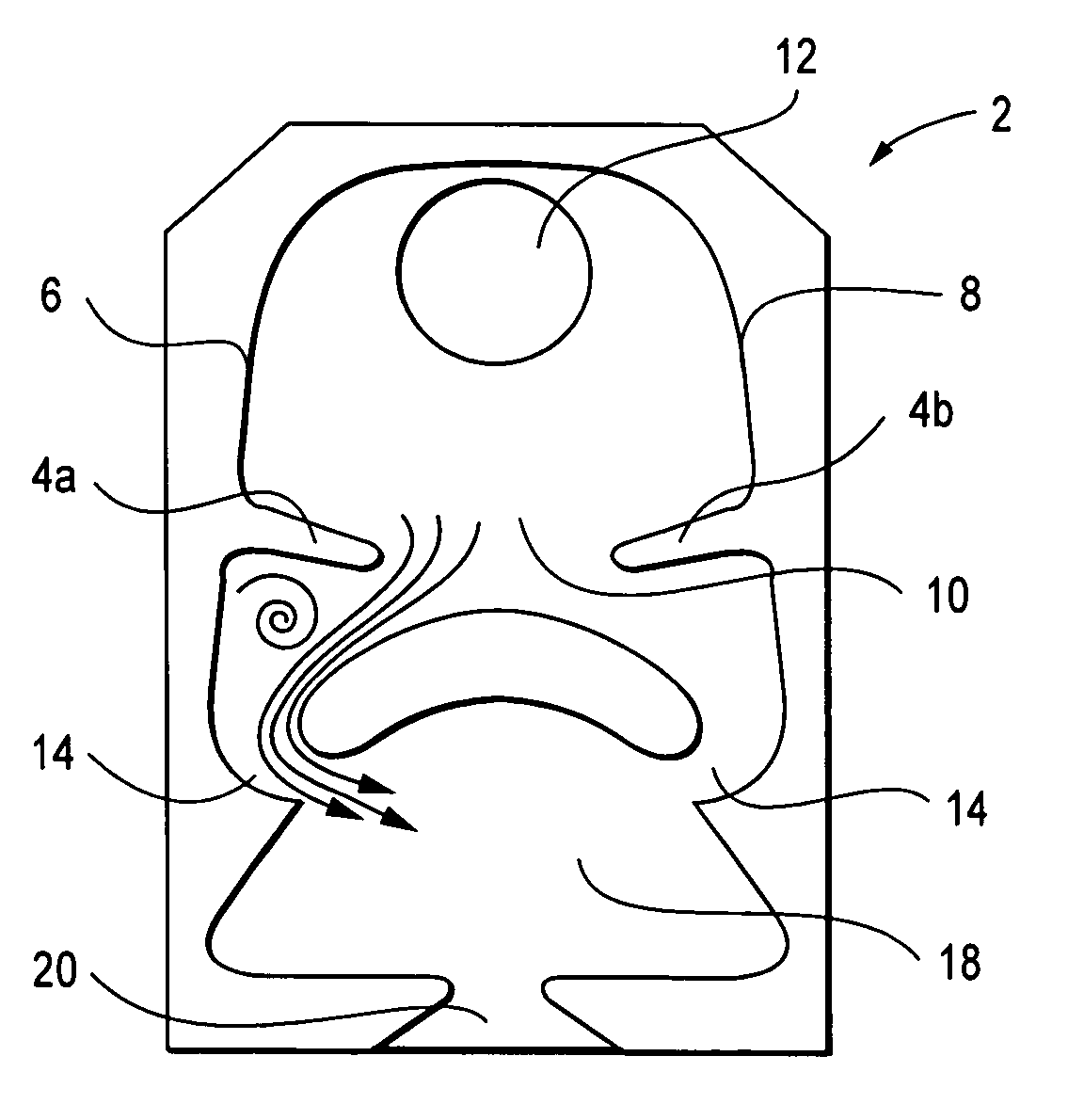

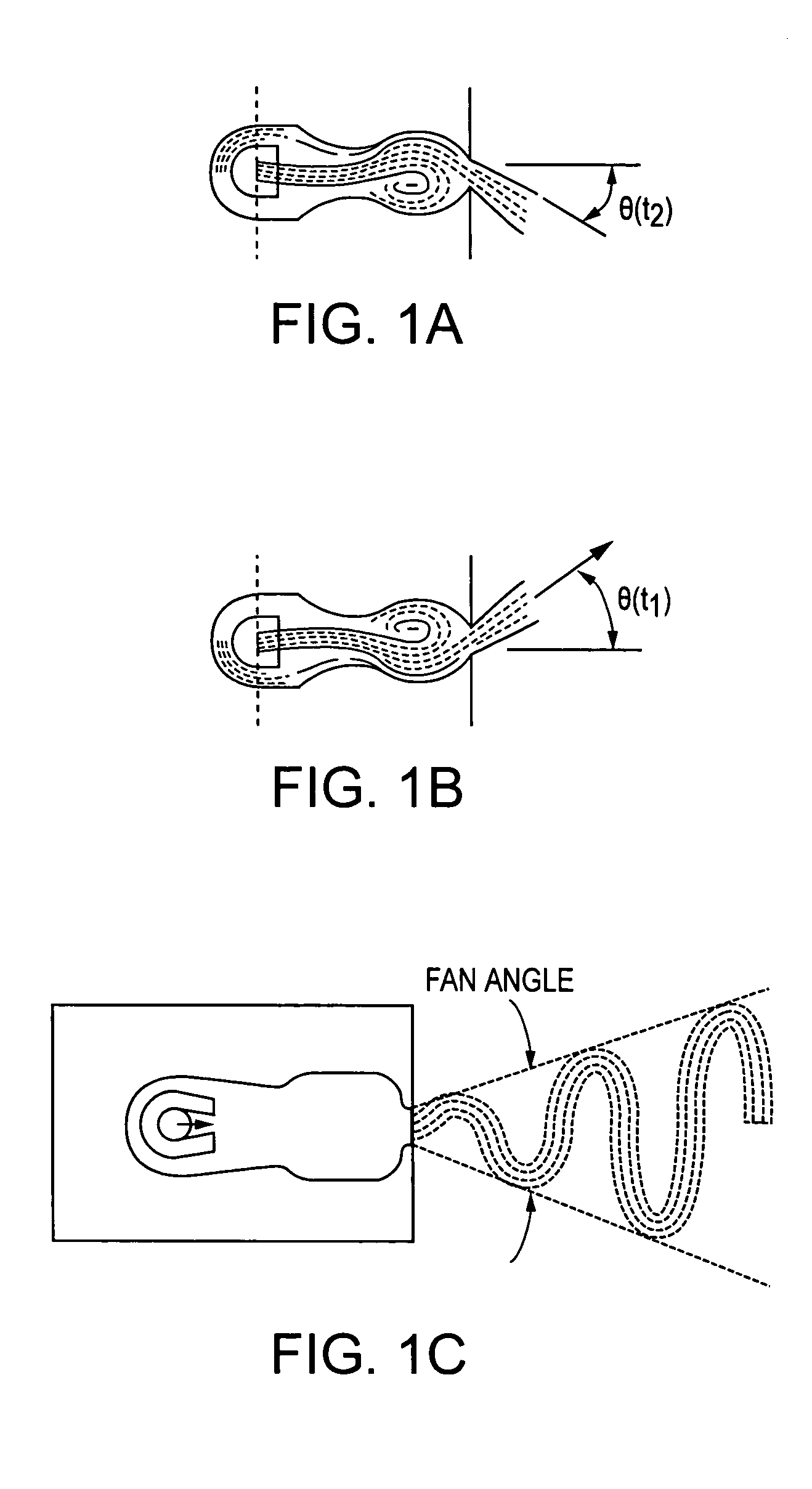

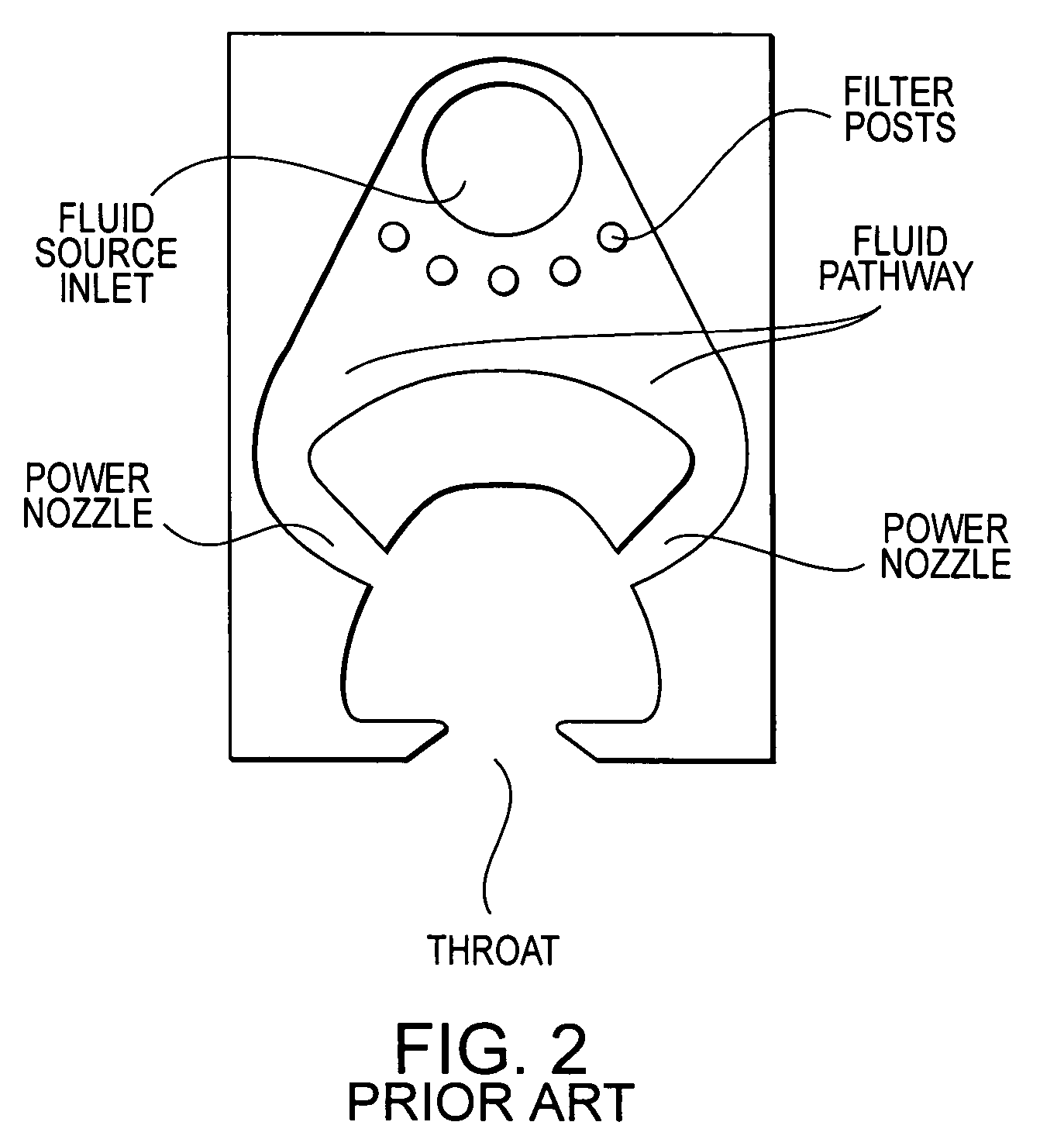

Cold-performance fluidic oscillator

A fluidic oscillator suitable for use at colder temperatures for generating an exhaust flow in the form of an oscillating spray of fluid droplets has an inlet for pressurized fluid, a pair of power nozzles configured to accelerate the movement of the pressurized fluid, a fluid pathway that connects and allows for the flow of pressurized fluid between its inlet and the power nozzles, an interaction chamber which is attached to the nozzles and receives the flow from the nozzles, a fluid outlet from which the spray exhausts from the interaction chamber, and a means for increasing the instability of the flow from the power nozzles, with this means being situated in a location chosen from the group consisting of a location within the fluid pathway or proximate the power nozzles. In a first preferred embodiment, the flow instability generating means comprises a protrusion that extends inward from each side of the fluid pathway so as to cause a flow separation region downstream of the protrusions. In a second preferred embodiment, the flow instability generating means comprises a step in the height elevation of the floor of the power nozzles with respect to that of the interaction chamber.

Owner:DLHBOWLES INC

Movable arm potential energy recovery method and apparatus of hydraulic excavator

InactiveCN101435451ASmall pressure fluctuationsWorking speed adjustmentBatteries circuit arrangementsMechanical machines/dredgersRecovery methodThrottle control

The invention discloses a method for recovering potential energy of a movable arm of a hydraulic digging machine and a device thereof. The method comprises the following steps: firstly, the potential energy is stored through an energy accumulator in the retraction process of a hydraulic cylinder; and secondly the stored energy in the energy accumulator drives a generator to generate electricity, thereby realizing the recovery of the potential energy of the movable arm of the hydraulic digging machine. A mode for storing the potential energy is to convert the potential energy into pressure energy. The energy accumulator and the generator are connected through a proportioning valve so as to control the rotational speed of the generator. The method realizes high-efficiency recovery of the potential energy of the movable arm of the hydraulic digging machine; the principle of the method is to skillfully change the working time of hydraulic oil for power generation through the function of energy storage of the energy accumulator and provide effective buffering for recovering the potential energy; in addition, through the throttling control of the proportioning valve, the method reduces pressure fluctuation of the hydraulic oil in the power generation process, realizes the adjustment of the working rotational speed of the generator, improves the working efficiency of the generator and further improves the efficiency of energy recovery.

Owner:CENT SOUTH UNIV

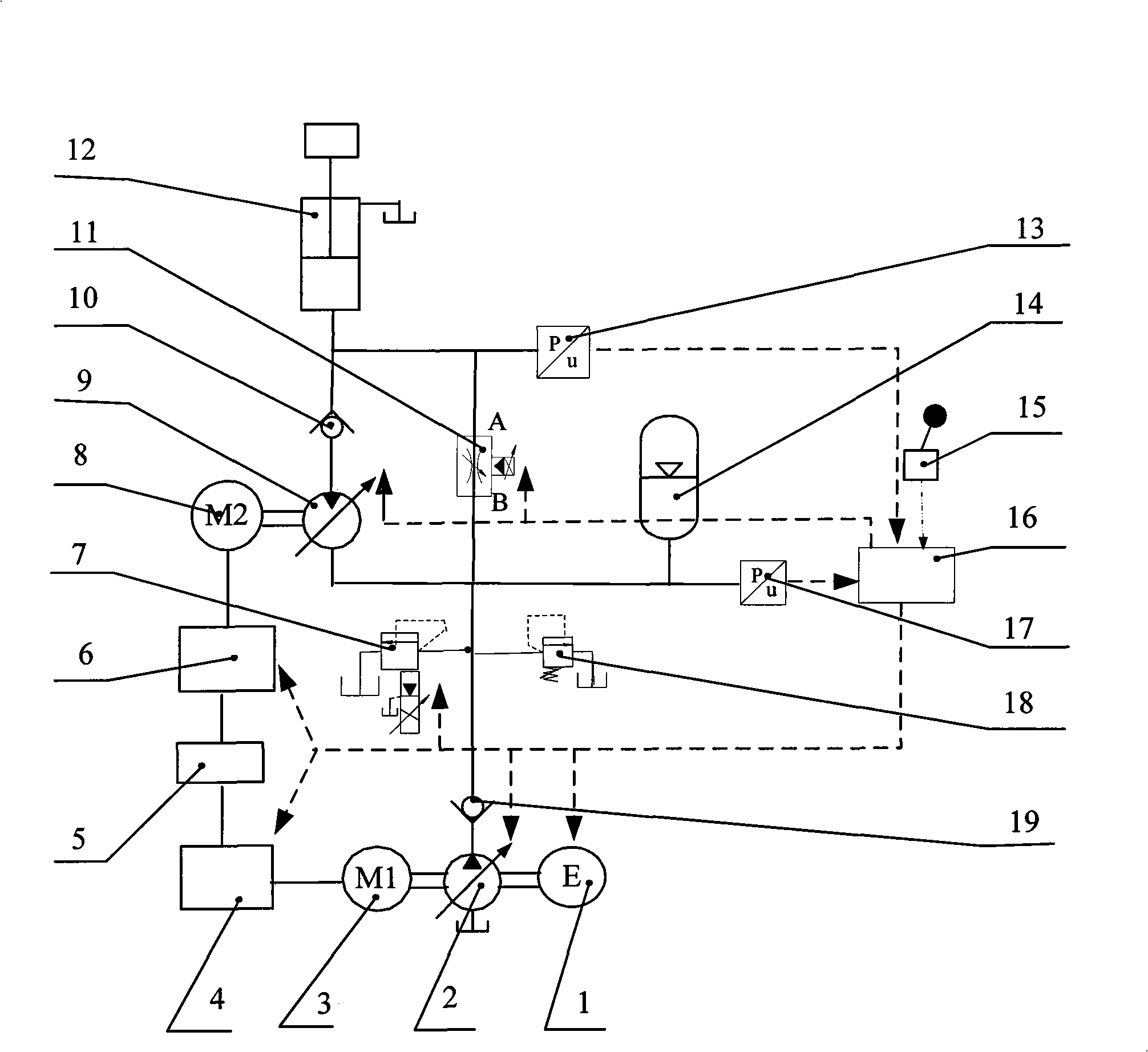

Energy recovery system of hybrid power engineering machinery energy accumulator-hydraulic motor

InactiveCN101408213AHigh specific powerFast absorptionAccumulator installationsGas pressure propulsion mountingHydraulic motorEnergy recovery

The invention discloses a hybrid power engineering mechanical accumulator-hydraulic motor energy recovery system. The system mainly comprises an engine, a variable pump, variable frequency motors, a variable motor, a signal control unit, an accumulator and a hydraulic implementation element, and the like. In the system, the variable motor is coaxially connected with a variable frequency motor M2 and forms a composite energy recovery system with the accumulator so as to recover the gravitational potential energy and braking energy in the lowering process of an implementation mechanism. The variable pump, the engine and a variable frequency motor M1 are coaxially connected; a hybrid power system which consists of the engine and the variable frequency motor M1 drives the hydraulic implementation mechanism to rise and lift heavy objects together with the accumulator. The system overcomes the defects that the variable motor-power generator energy recovery system responds slowly and the specific energy of the accumulator is low, enhances the dynamic response performance of the energy recovery system, improves the working conditions of power generation of an electric generator, and simultaneously can directly recover part of potential energy by the accumulator, thus raising the energy recovery efficiency of the system.

Owner:ZHEJIANG UNIV

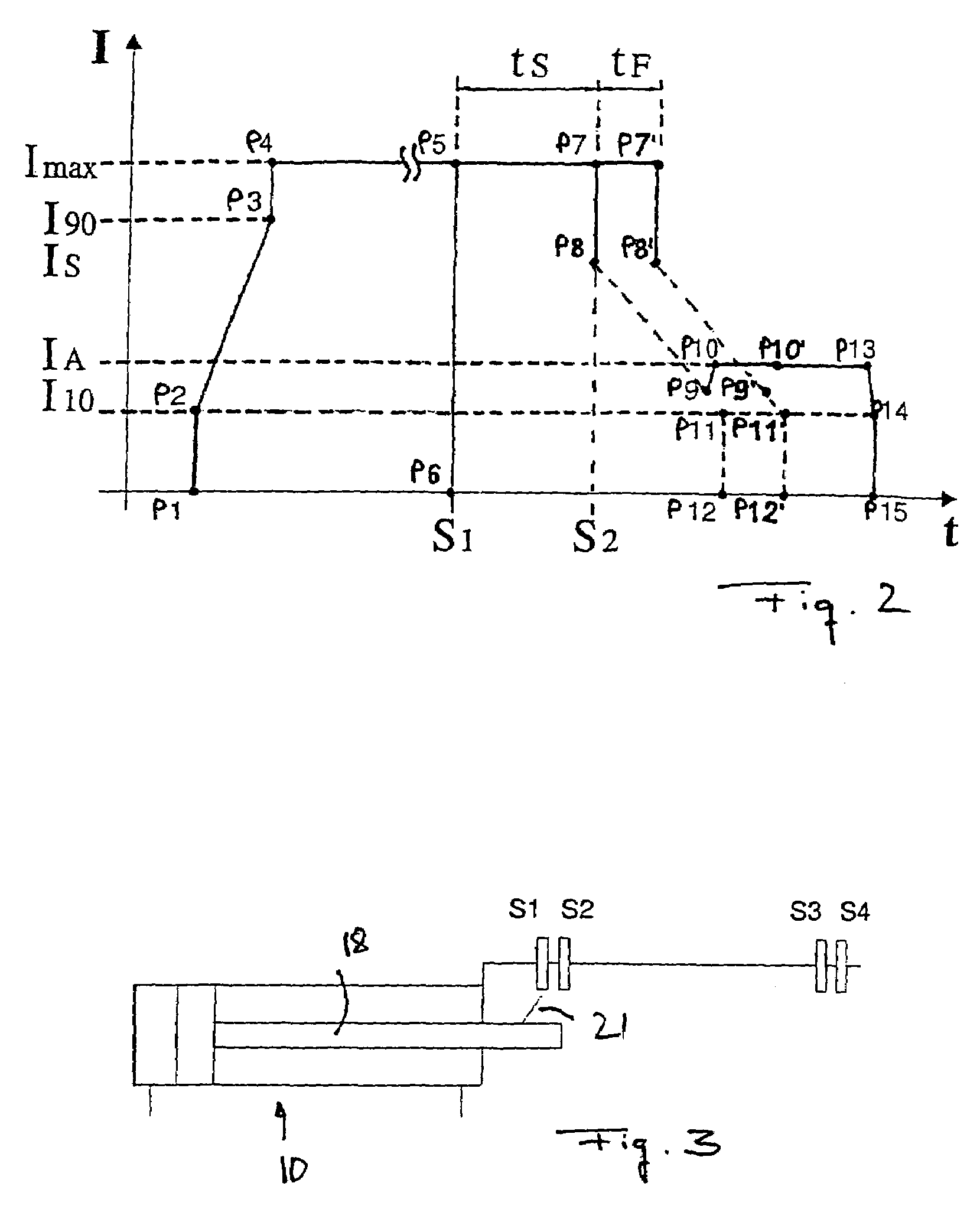

Method and device for attenuating the motion of hydraulic cylinders of mobile work machinery

InactiveUS7318292B2Good conditionServomotorsSoil-shifting machines/dredgersHydraulic cylinderEngineering

The present invention relates to a method for attenuating the motion of hydraulic cylinders of mobile work machinery, in particular of hydraulic excavators, in which prior to the hydraulic cylinder reaching one of the limits of travel, its motion speed is reduced, and the hydraulic cylinder is moved to the respective limit of travel at reduced speed; wherein for the purpose of reducing the speed, the inflow to, and / or the outflow from, the hydraulic cylinder are / is throttled by a flow control device. According to the invention, the method is characterized by, prior to the respective limit of travel being reached, the motion speed of the hydraulic cylinder is registered, and the point in time when throttling commences is changed depending on the registered motion speed. Furthermore, the present invention relates to a device for attenuating the motion of hydraulic cylinders of mobile work machinery, in particular of hydraulic excavators, a position registering device for registering a preliminary limit position of the hydraulic cylinder, a control device for throttling the inflow and / or outflow of the hydraulic cylinder, and a control device for controlling the flow control device when the preliminary limit position is reached. According the invention, the device has a speed registering device for registering the motion speed of the hydraulic cylinder when the preliminary limit position is reached, and the control device has a delay device for delaying driving the flow control device, depending on the recorded motion speed.

Owner:LIEBHERR FRANCE

Energy recovery system for work vehicle including hydraulic drive circuit and method of recovering energy

A work vehicle having a hydrostatic drive system provides for the recovery and reuse of the vehicle's kinetic energy by conducting pressurized hydraulic fluid out of the hydrostatic drive system into an accumulator during vehicle deceleration, and conducting the pressurized fluid back into the drive system during vehicle acceleration to assist the vehicle's engine in accelerating the vehicle.

Owner:BLUE LEAF I P +1

Microfluidic control device and method for controlling microfluid

InactiveUS20050133101A1Loss of functionAdditive manufacturing apparatusCircuit elementsFluid controlTime delays

Provided is a microfluidic control device and method for controlling the microfluid, and a fine amount of fluid is controlled even with natural fluid flow and solution injection, wherein a pressure barrier of a capillary is removed by a surface tension change resulted from the solution injection to thereby obtain transport, interflow, mixing, and time delay of the microfluid, and to detail this, solution is injected to meet the boundary surface of the stopped fluid when the fluid is stopped by the stop valve, so that a function of the stop valve is removed to obtain the transport, interflow, and mixing of the fluid, and the method for controlling the microfluid may be applied to the microfluidic control device for biochemical reaction, and it uses only the capillary force change resulted from solution injection to thereby have its structure simplified.

Owner:ELECTRONICS & TELECOMM RES INST

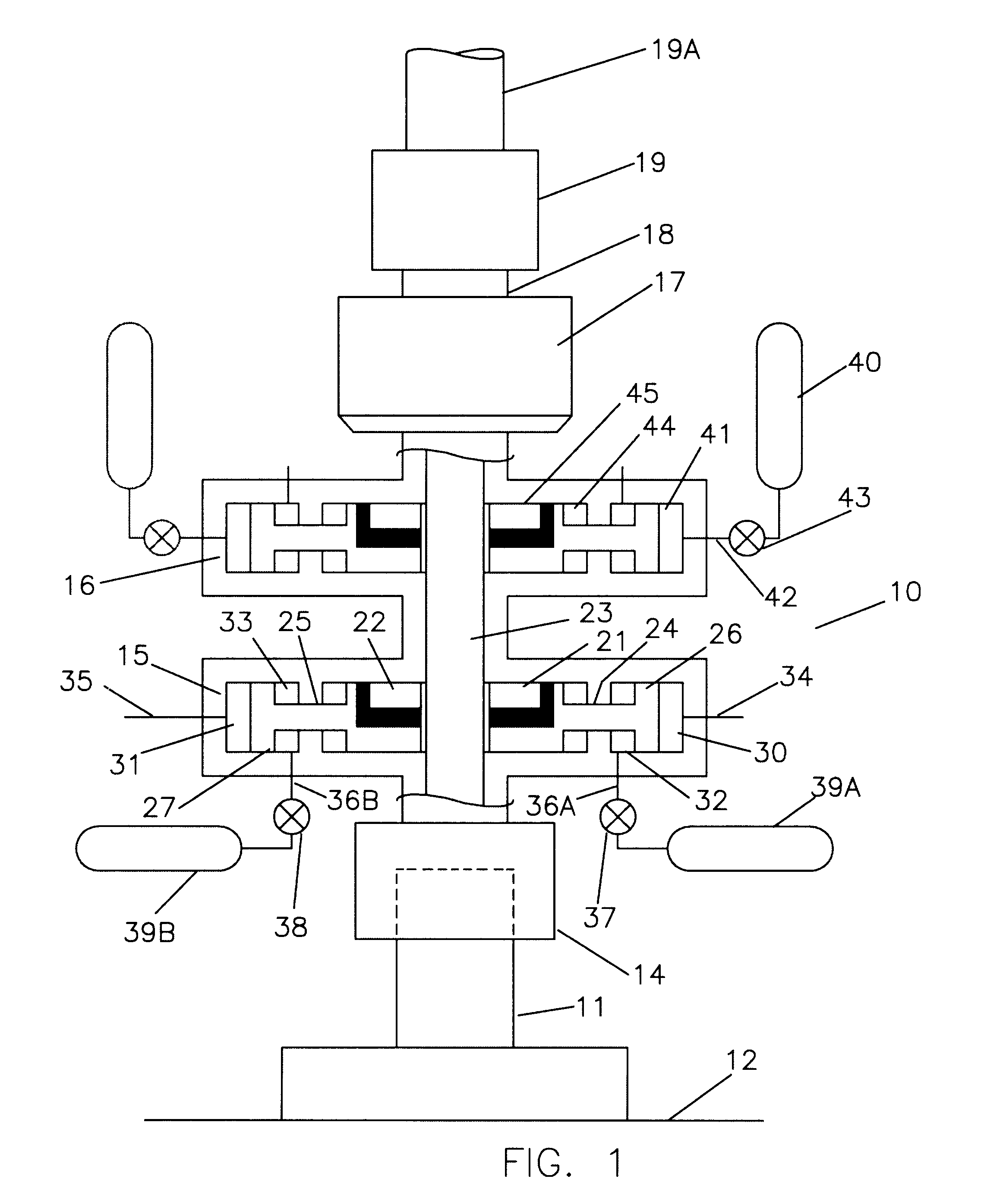

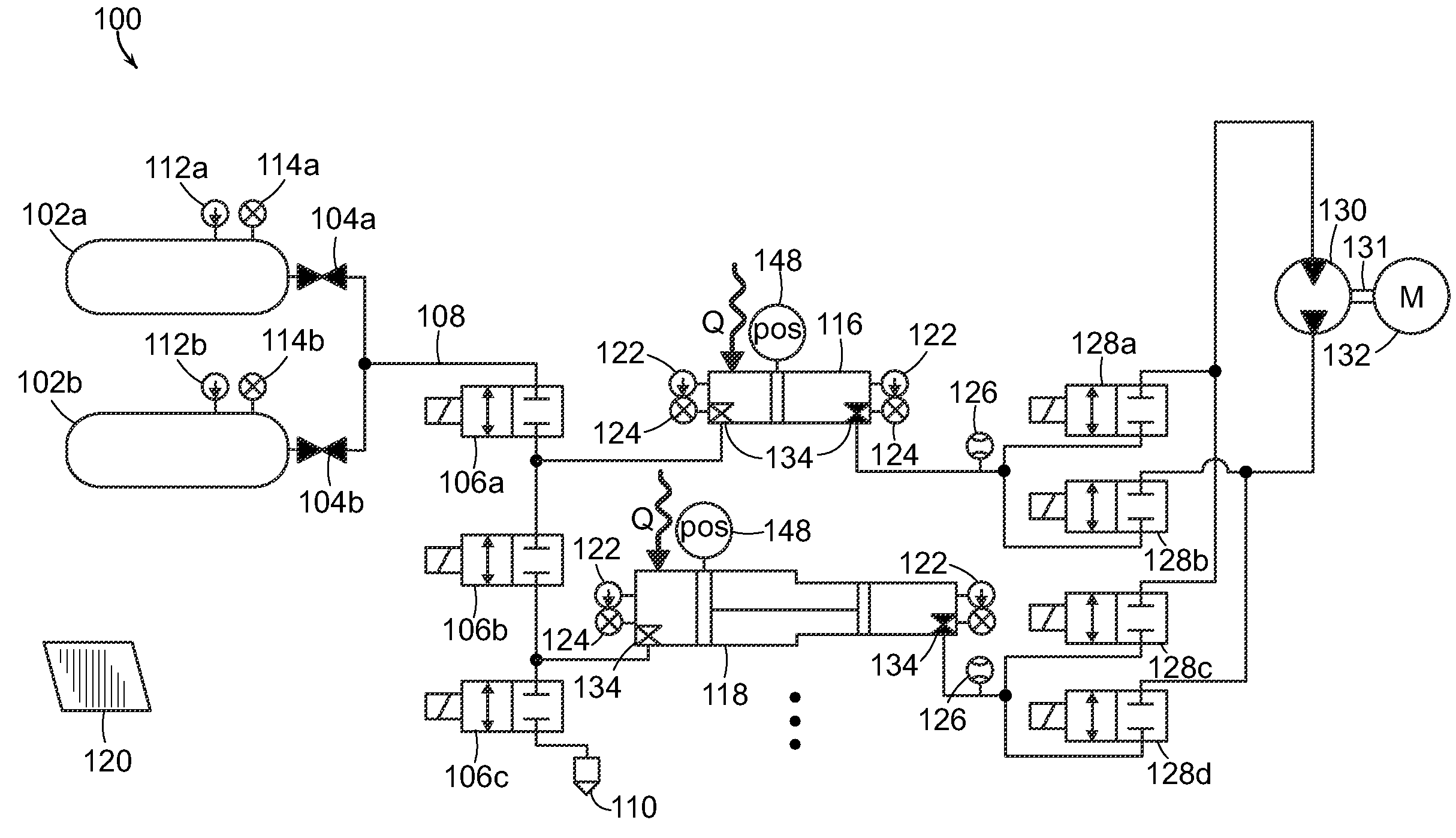

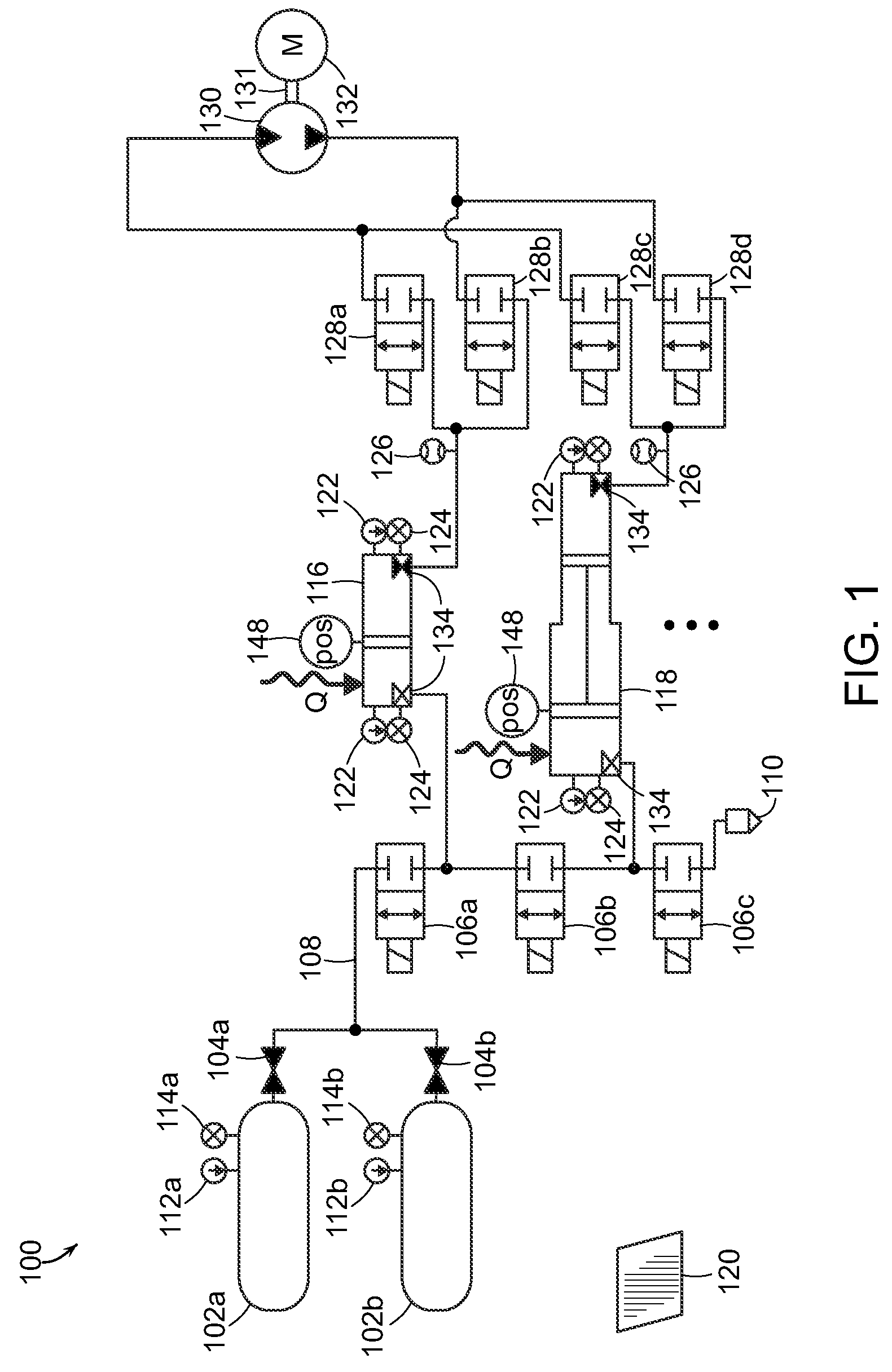

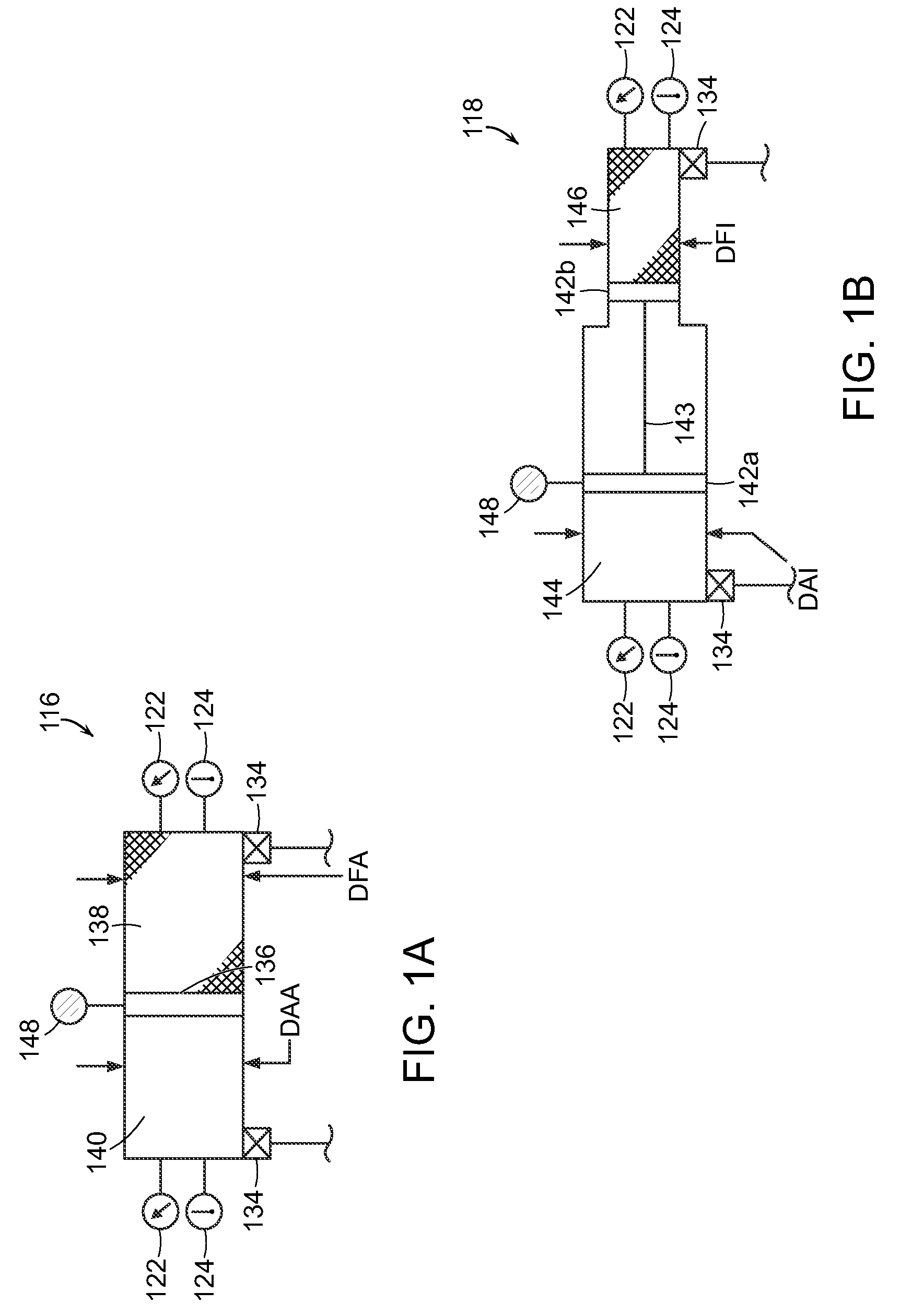

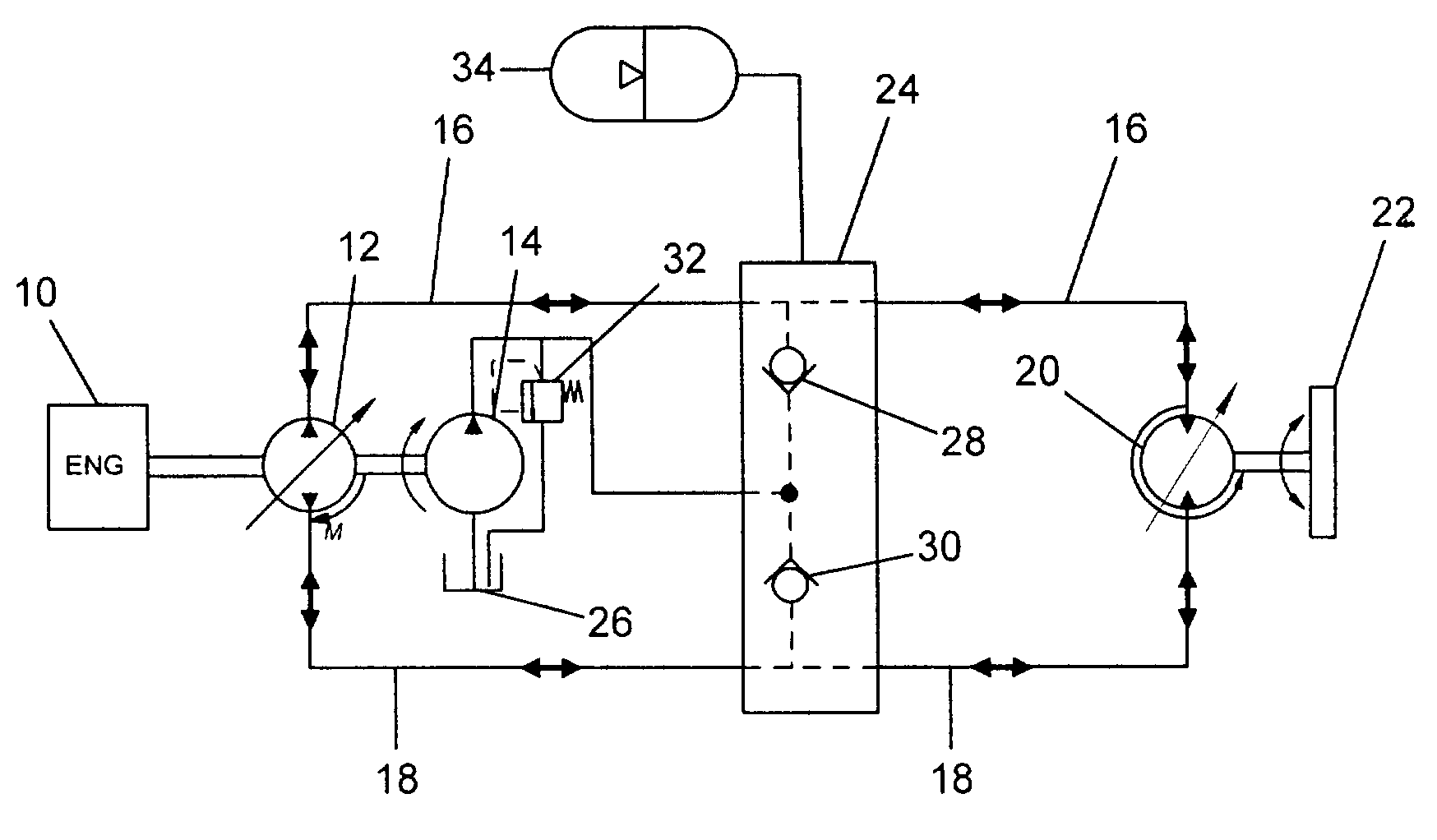

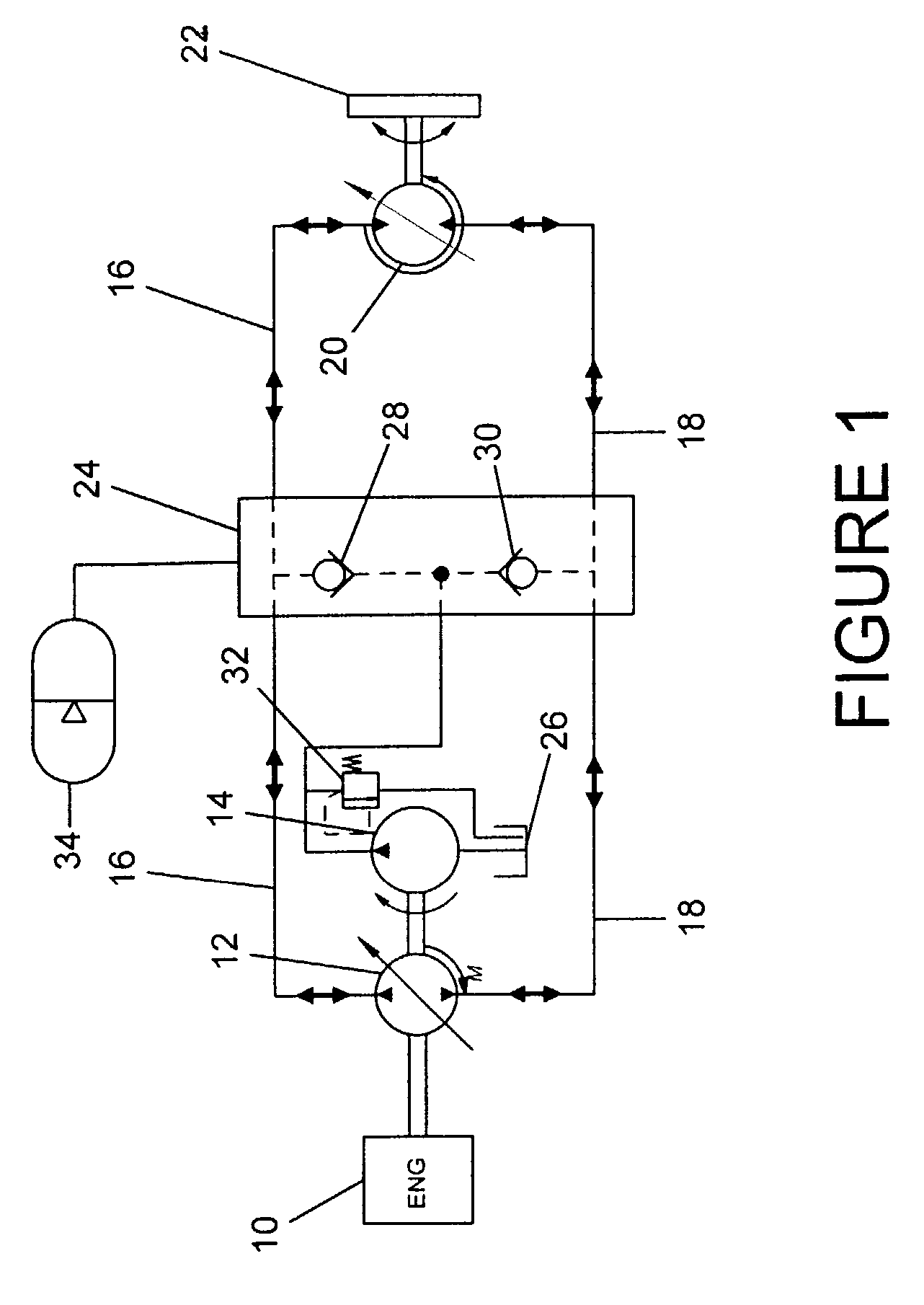

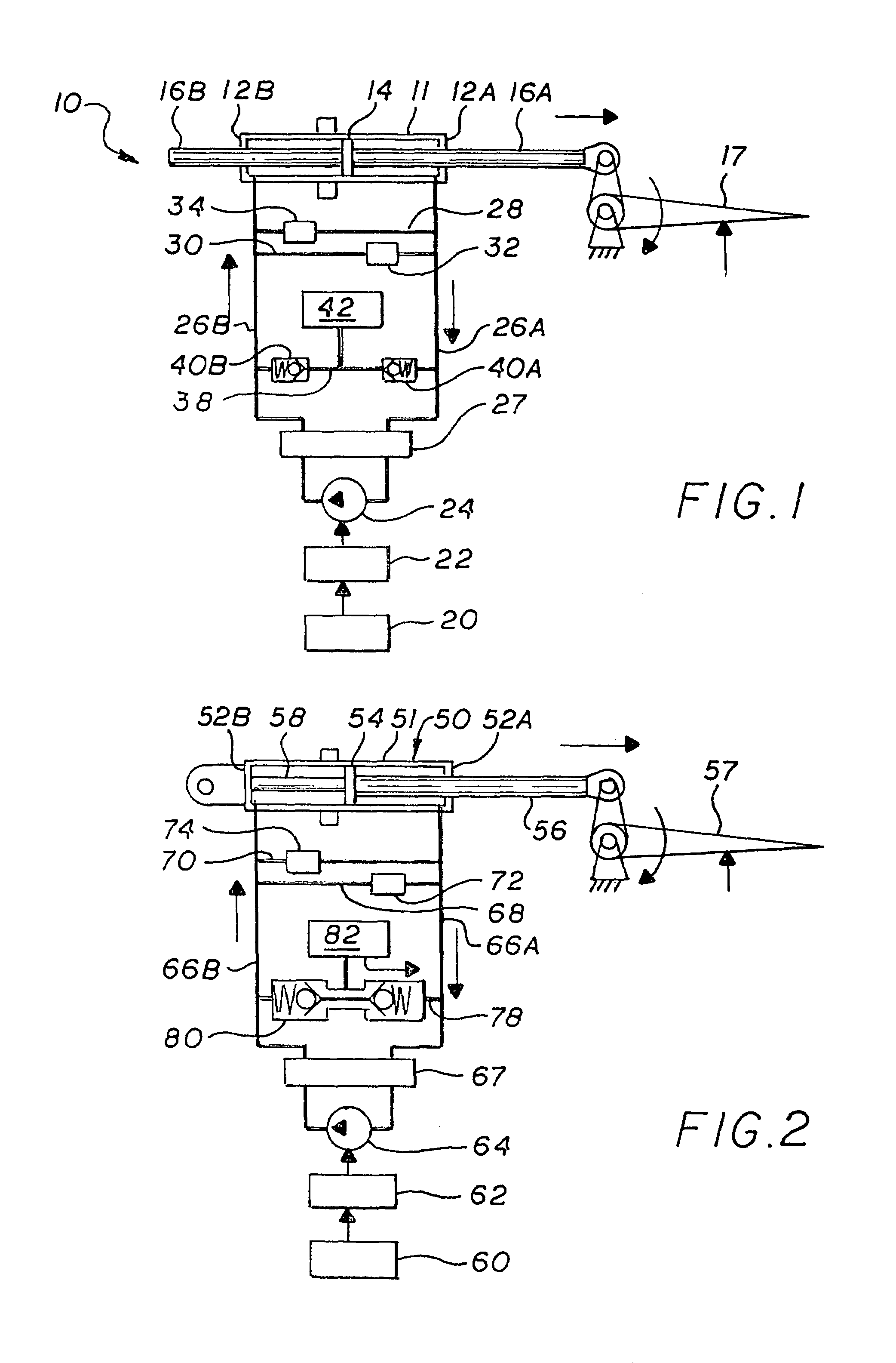

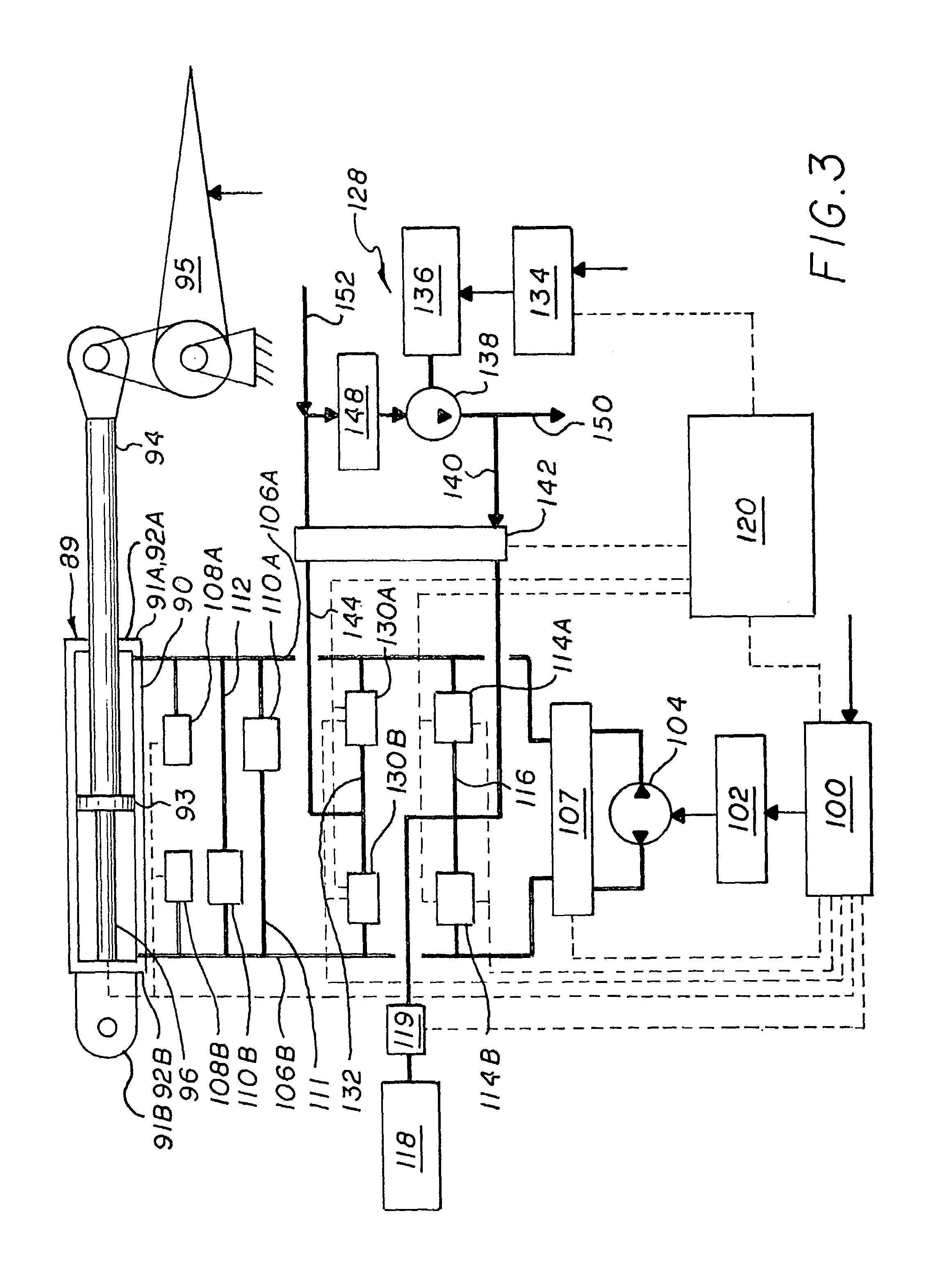

Electro-hydraulic actuator system

The system includes a hydraulic powered actuator. A pump system having first and second hydraulic lines is coupled to the first and second ports, respectively and is capable of providing hydraulic fluid to either the first and second lines. First and second pressure sensors are coupled to the first and second lines, respectively. A third line is coupled between the first and second lines and includes first and second valves mounted in series therein. Preferably, the first and second valves are capable of latching in the open position. A reservoir is coupled to the third line between the first and second valves. A shut off valve is included for cutting off the flow from the reservoir.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com