Patents

Literature

1237results about "Motor parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

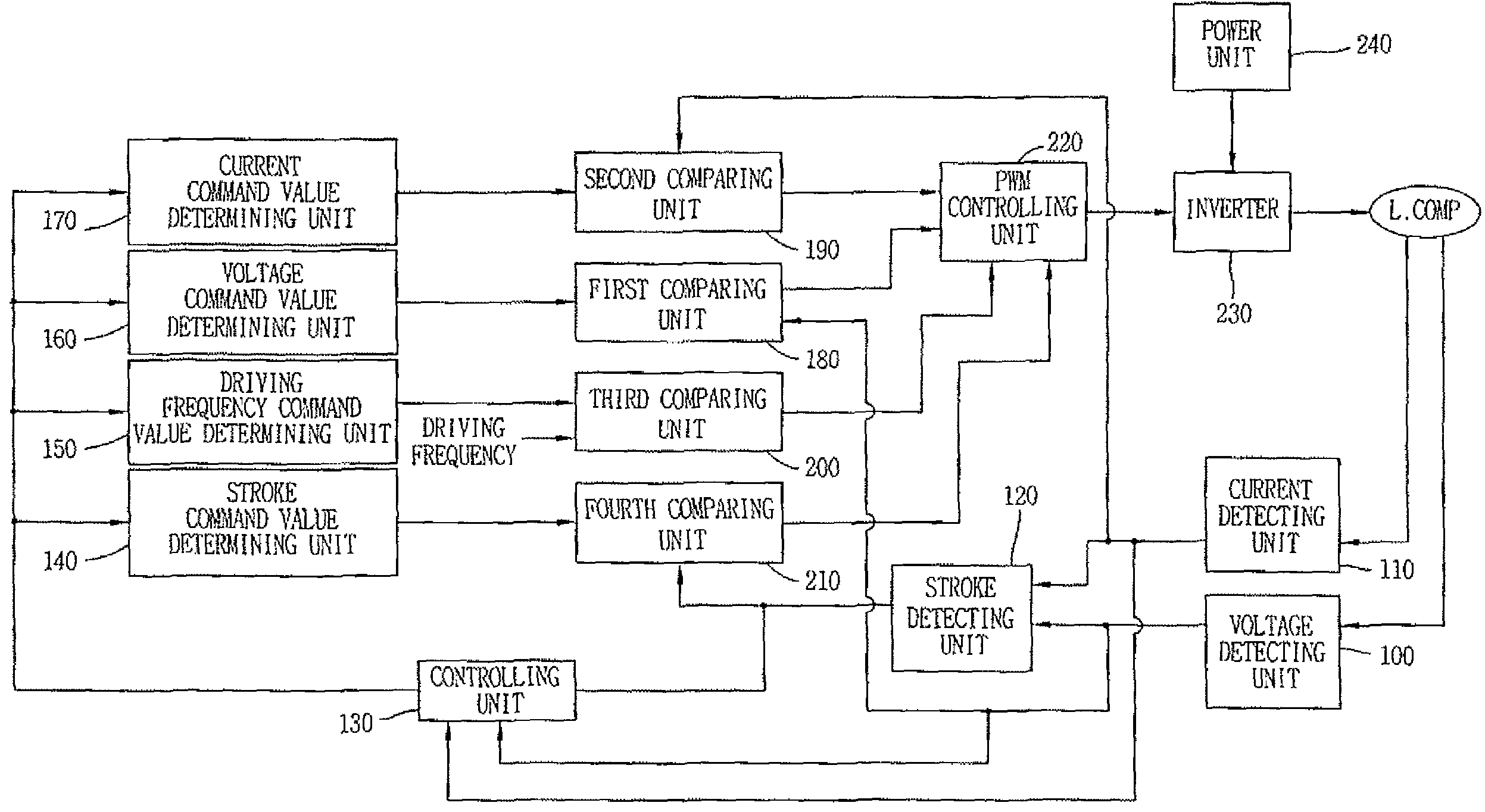

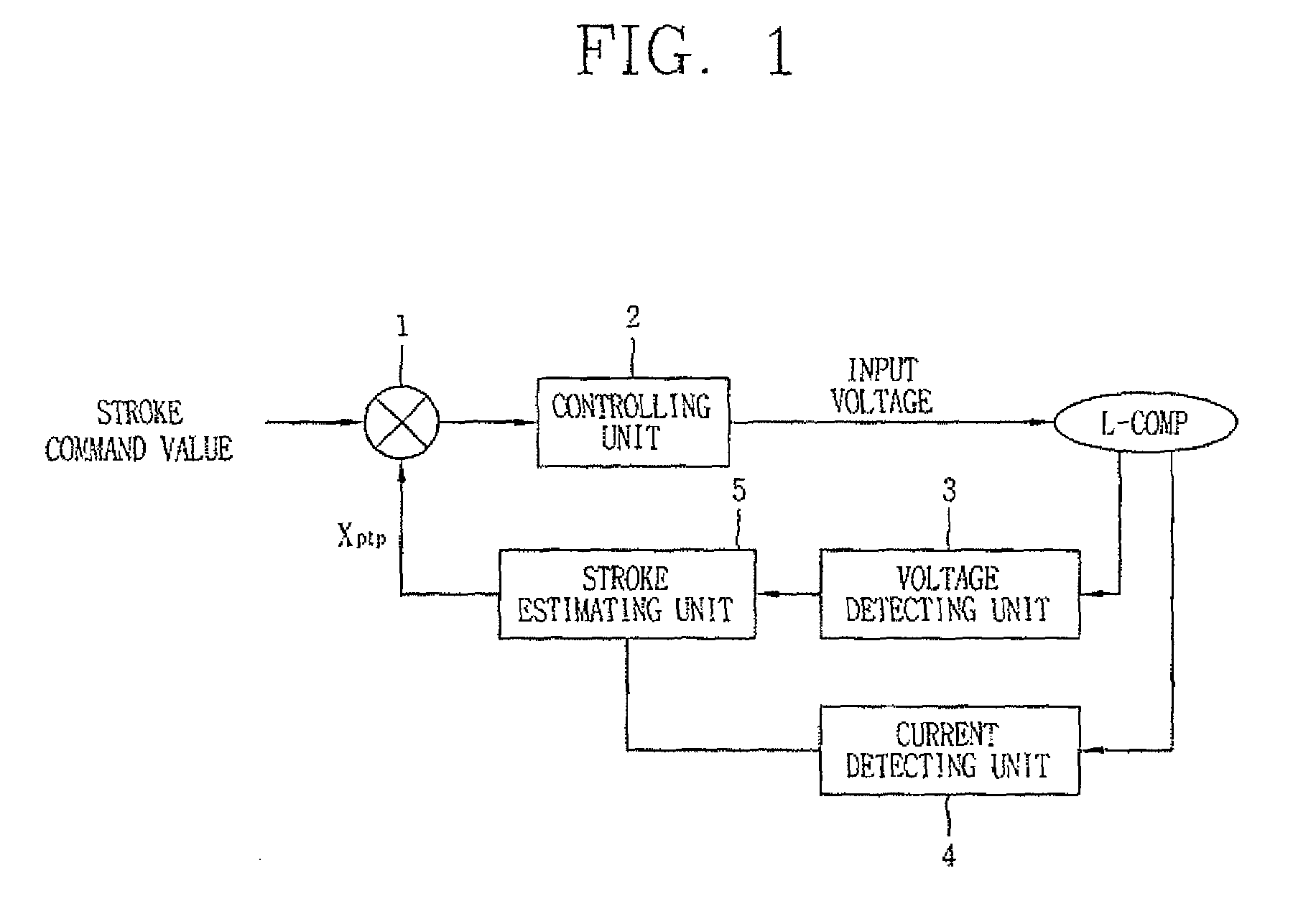

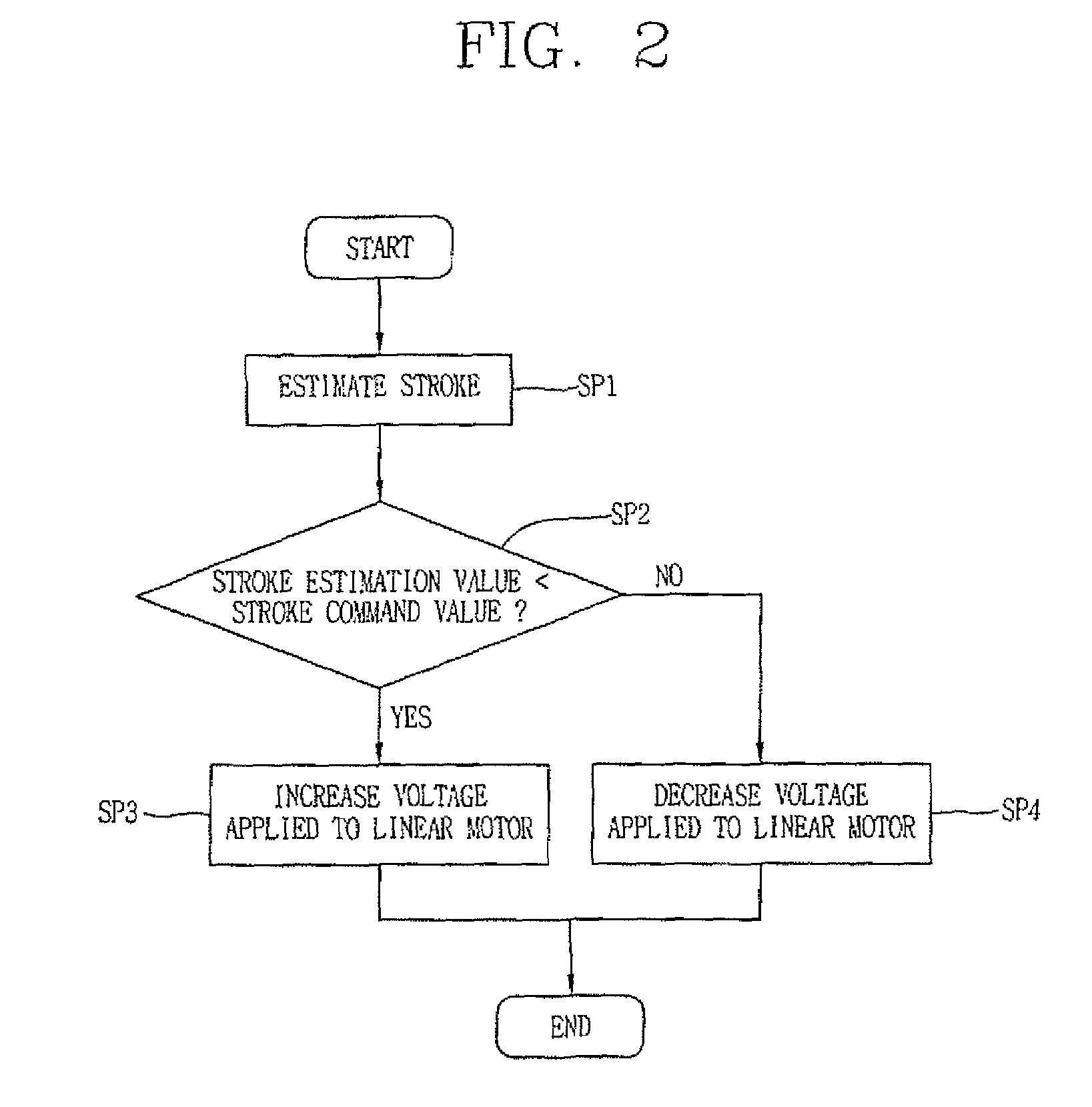

Driving controlling apparatus for linear compressor and method thereof

Owner:LG ELECTRONICS INC

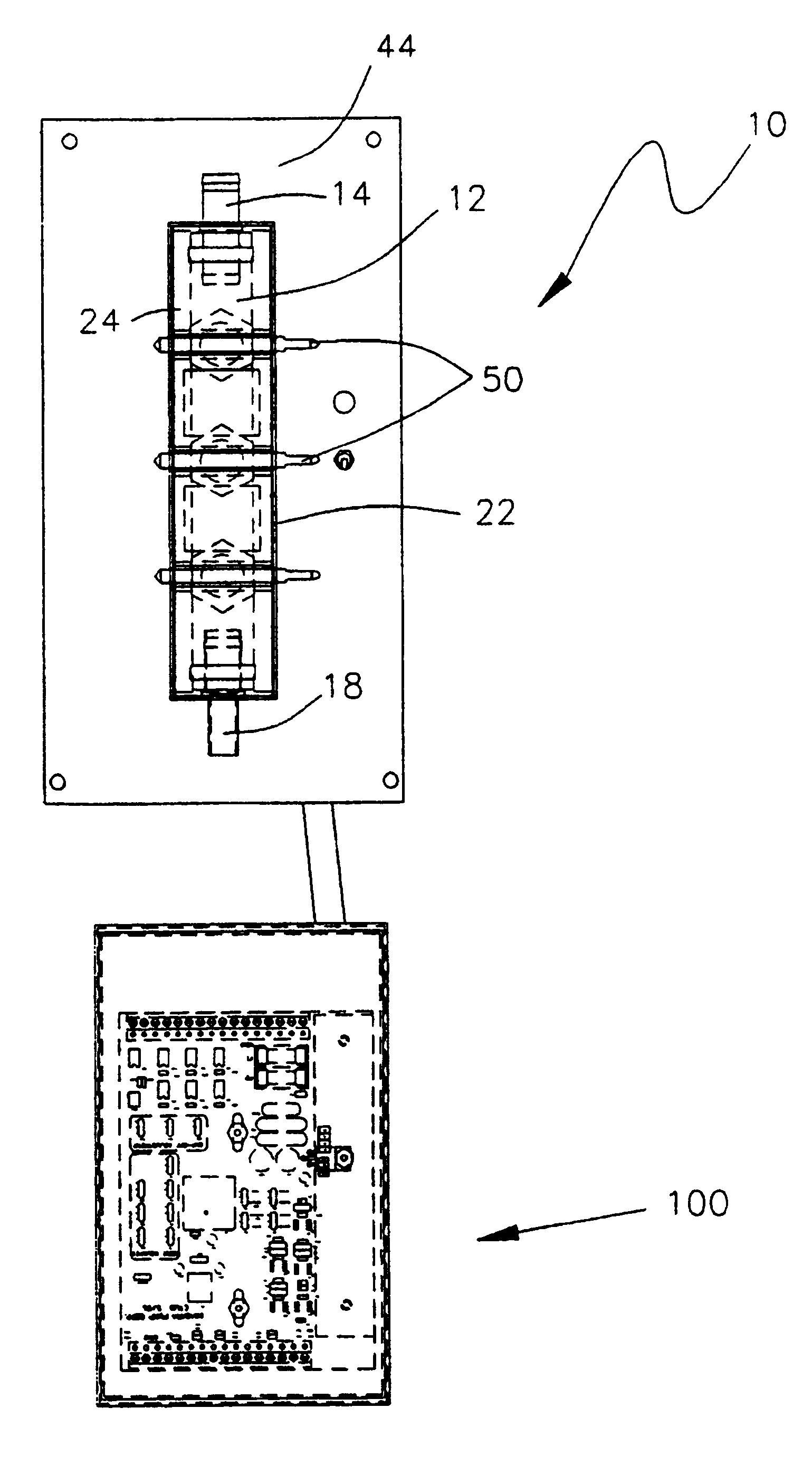

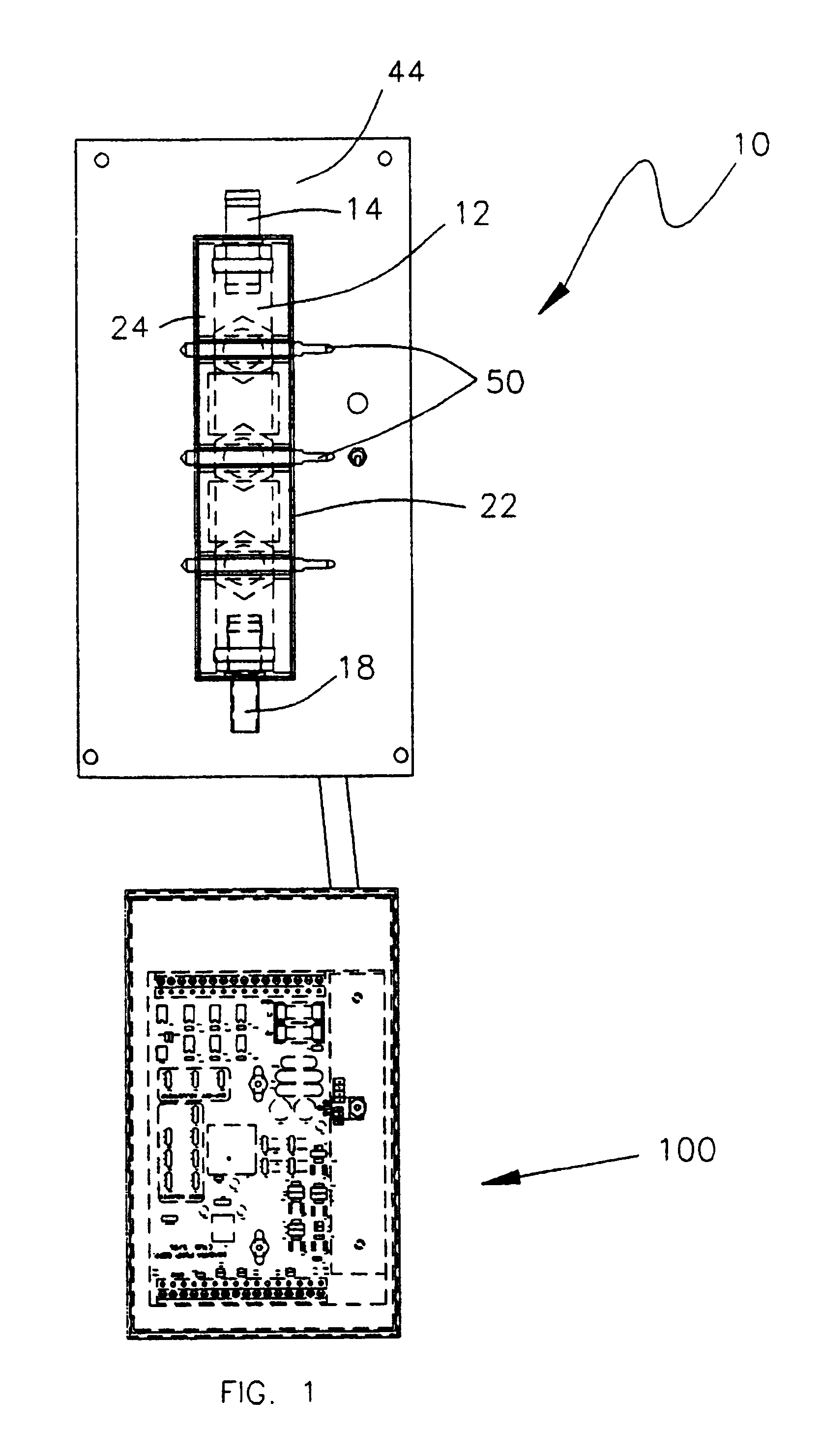

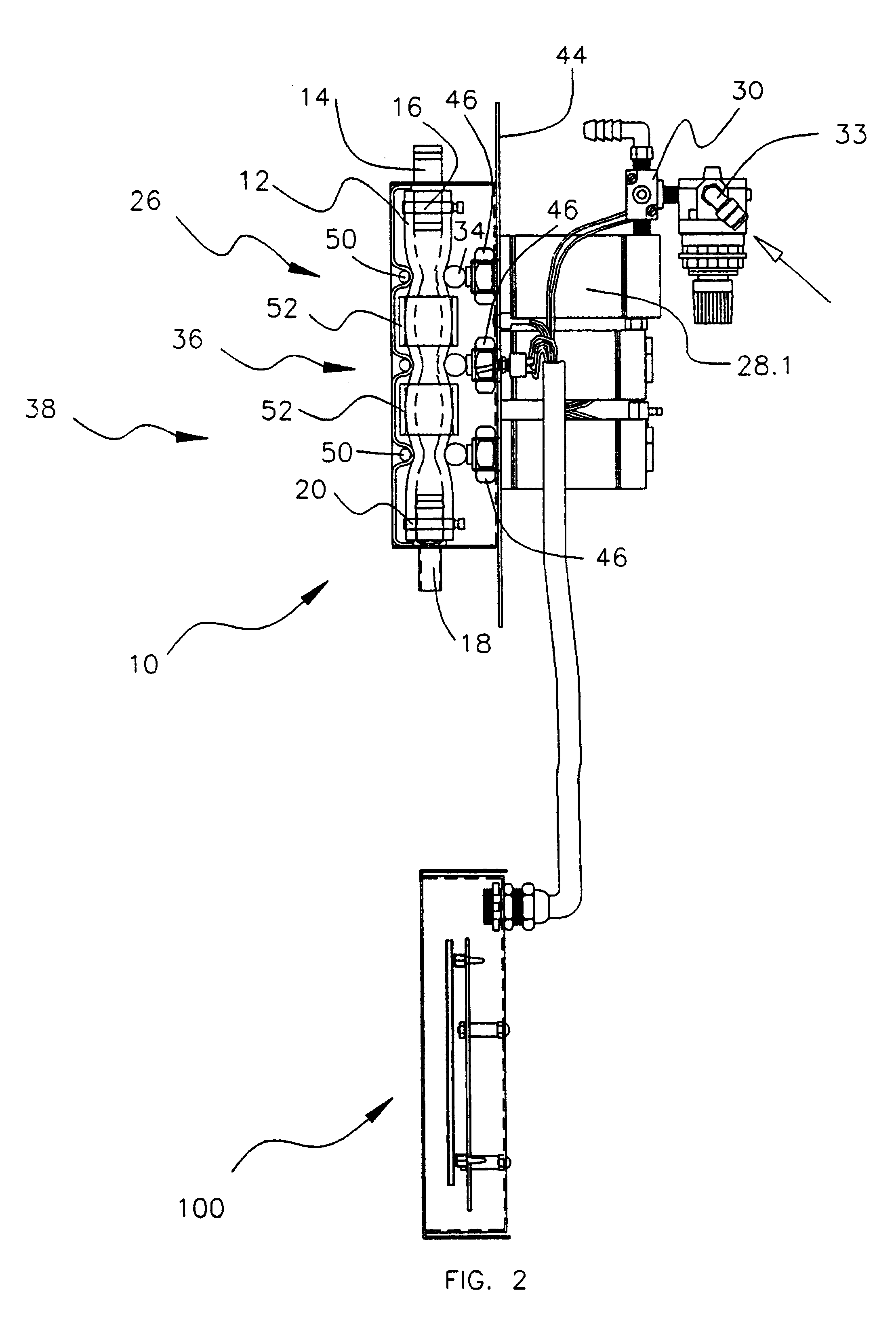

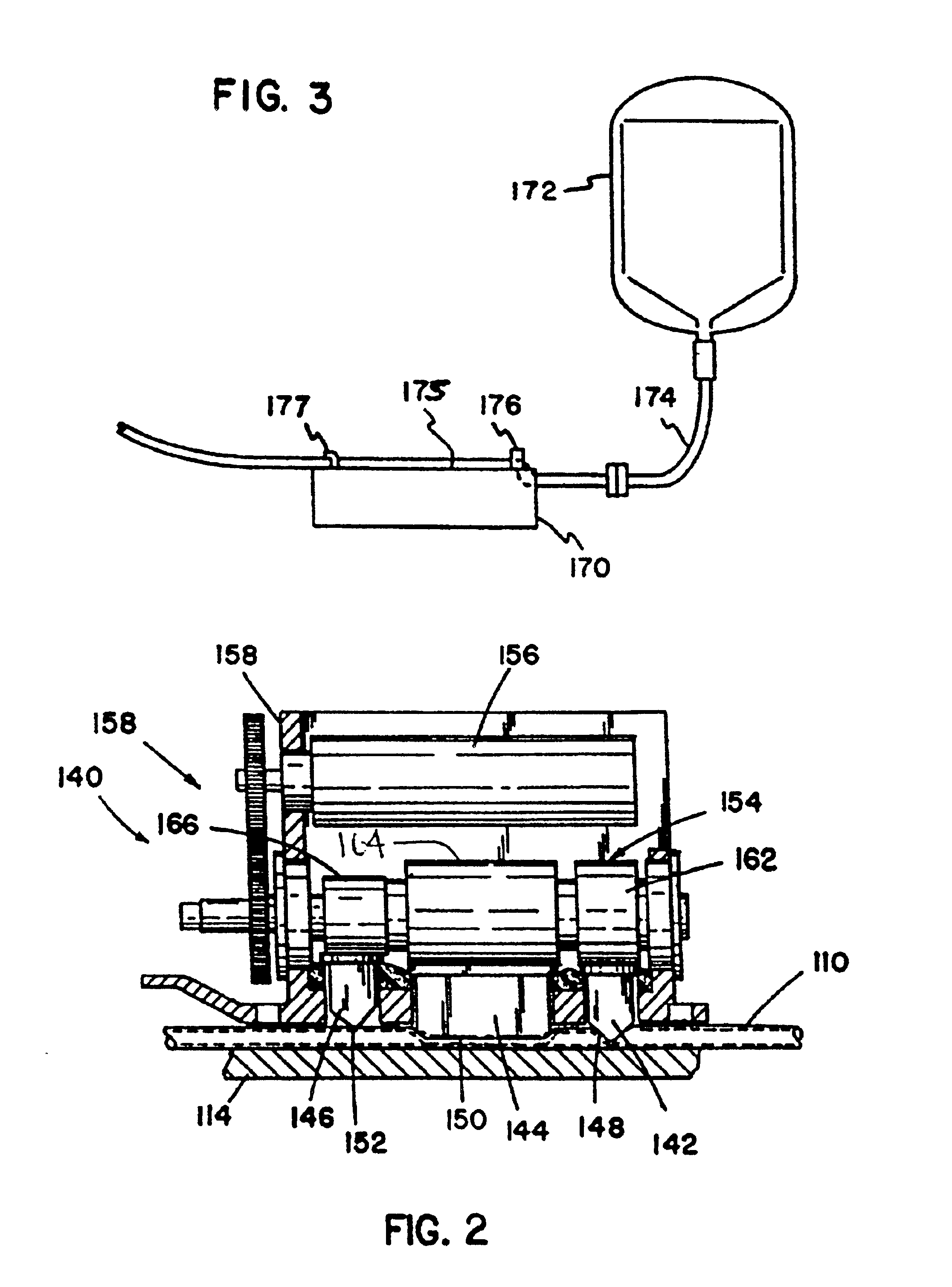

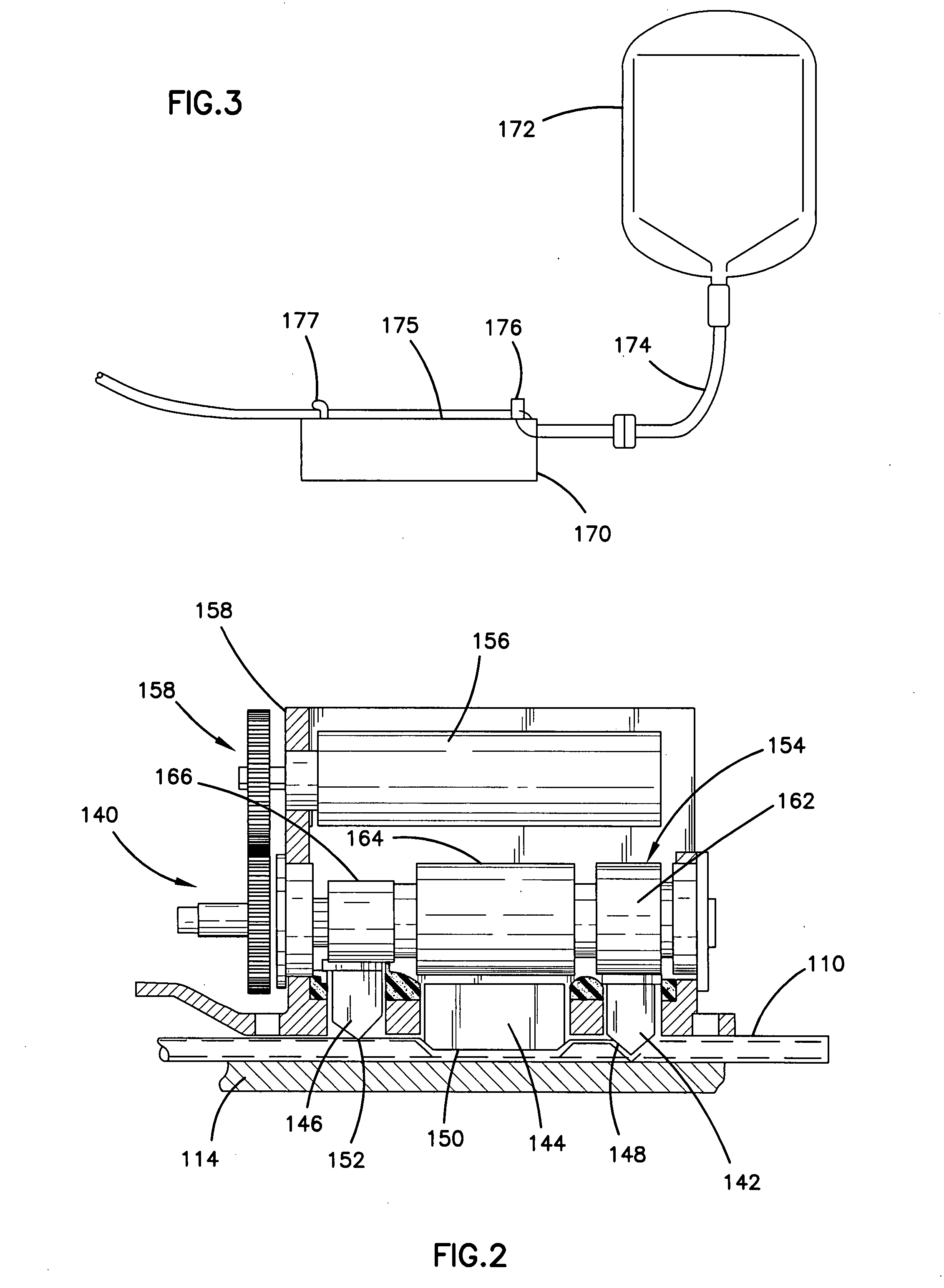

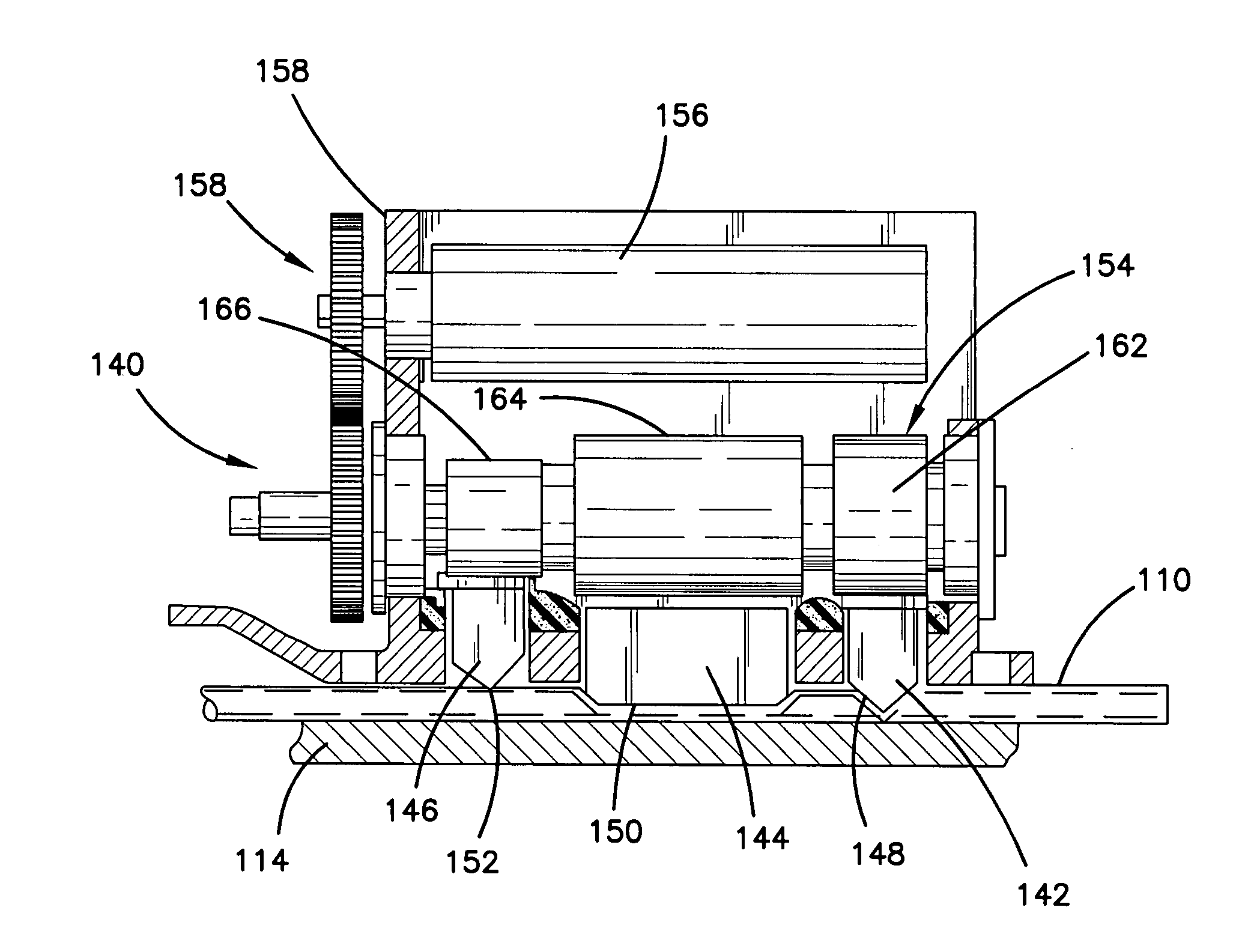

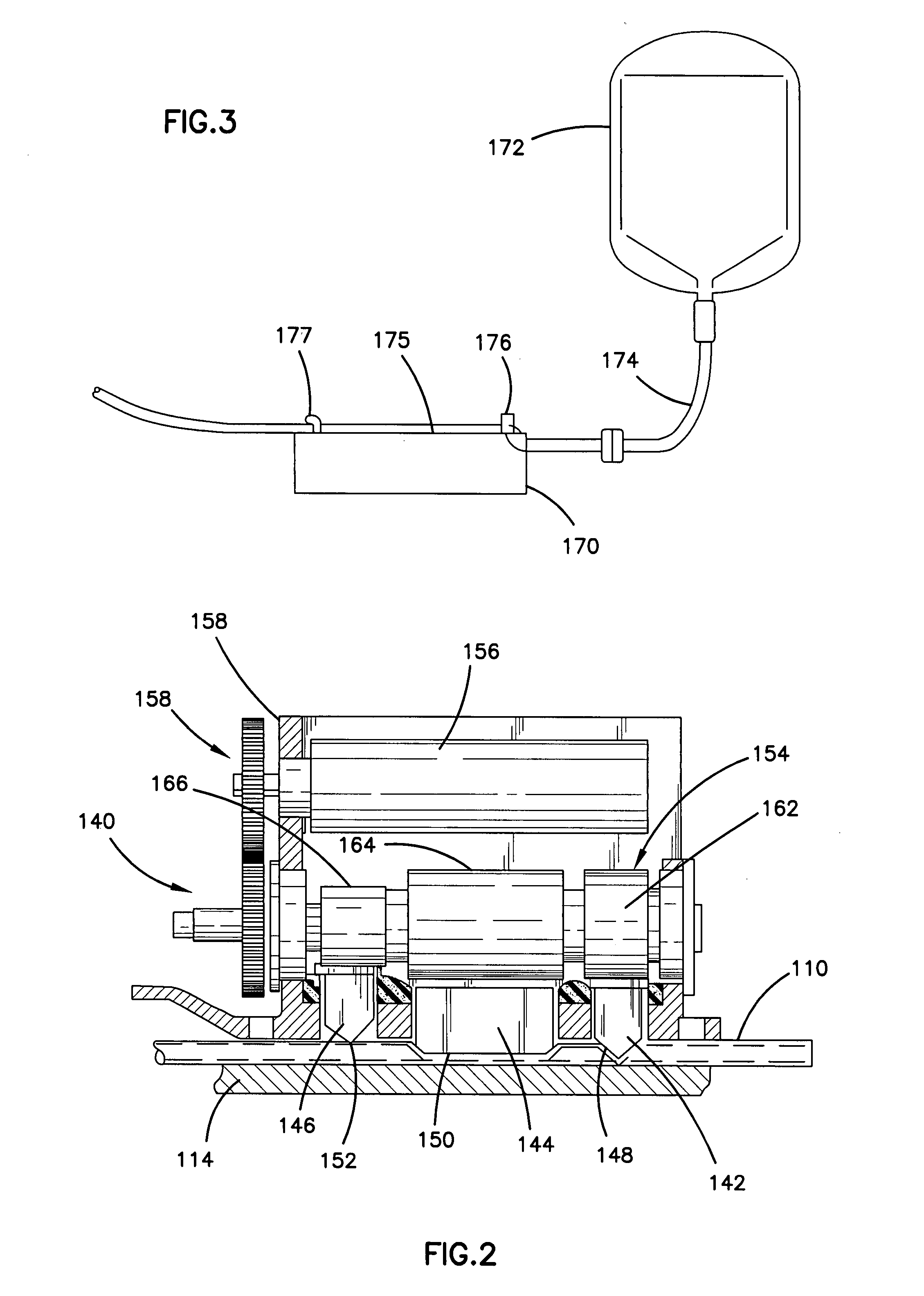

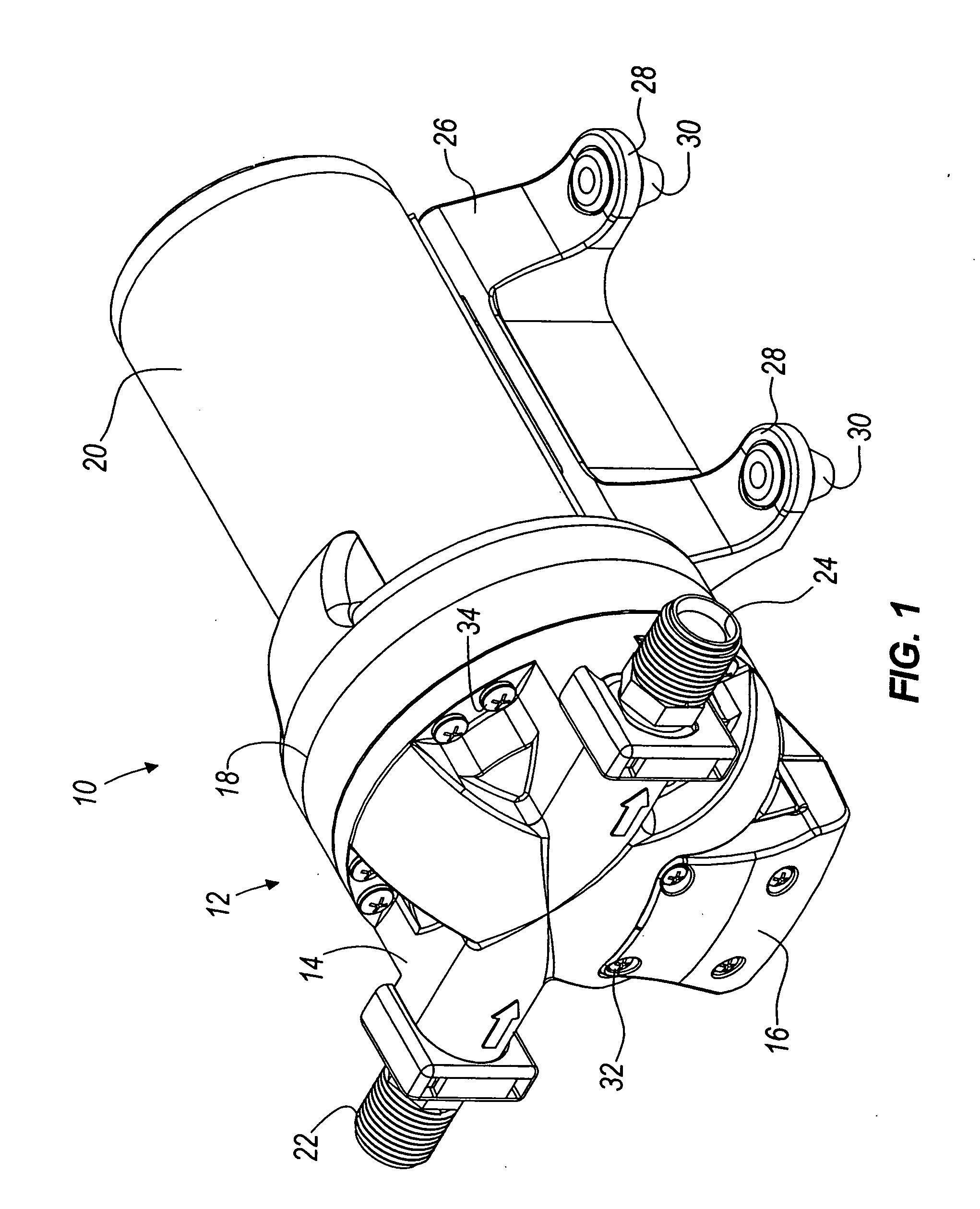

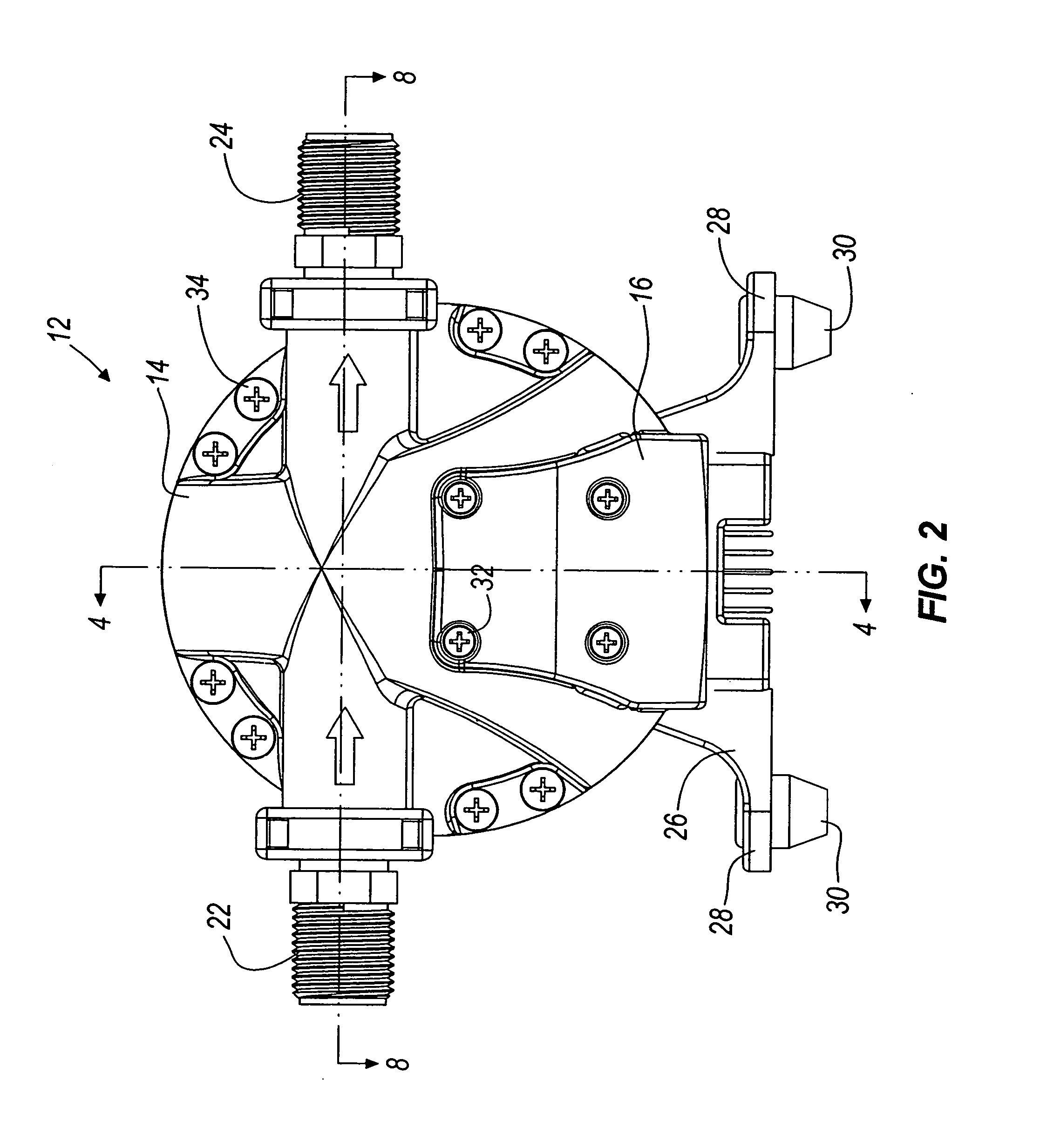

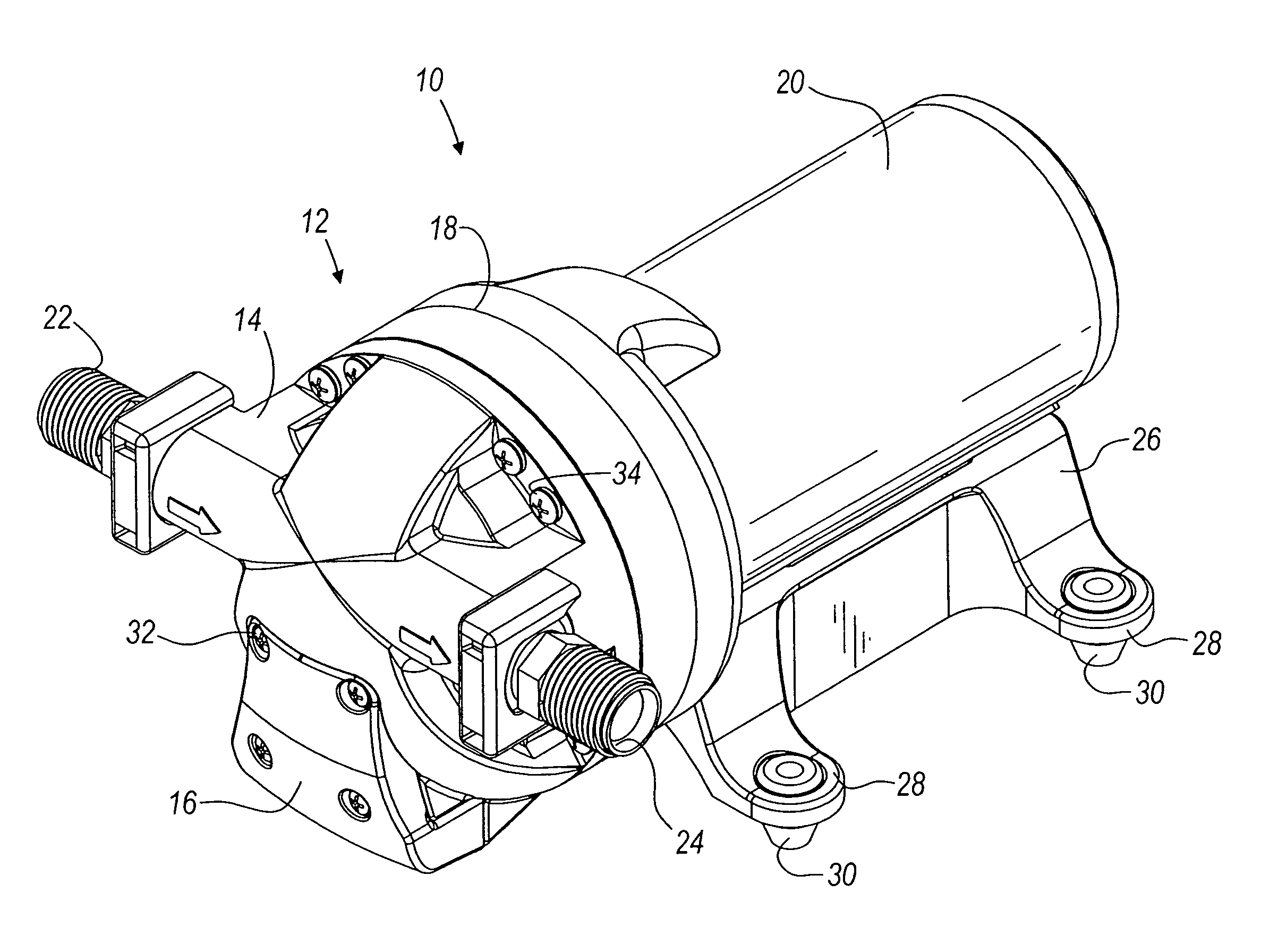

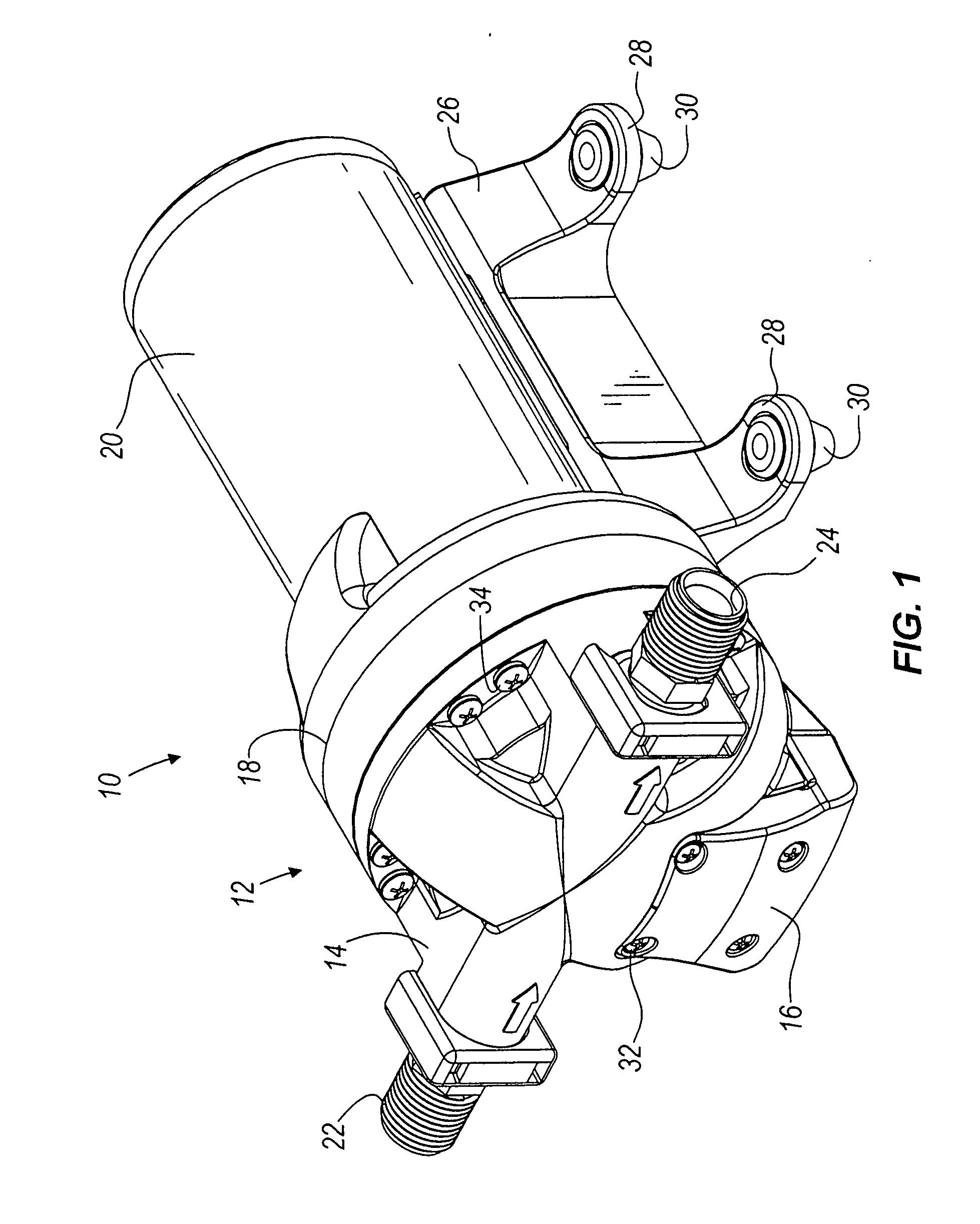

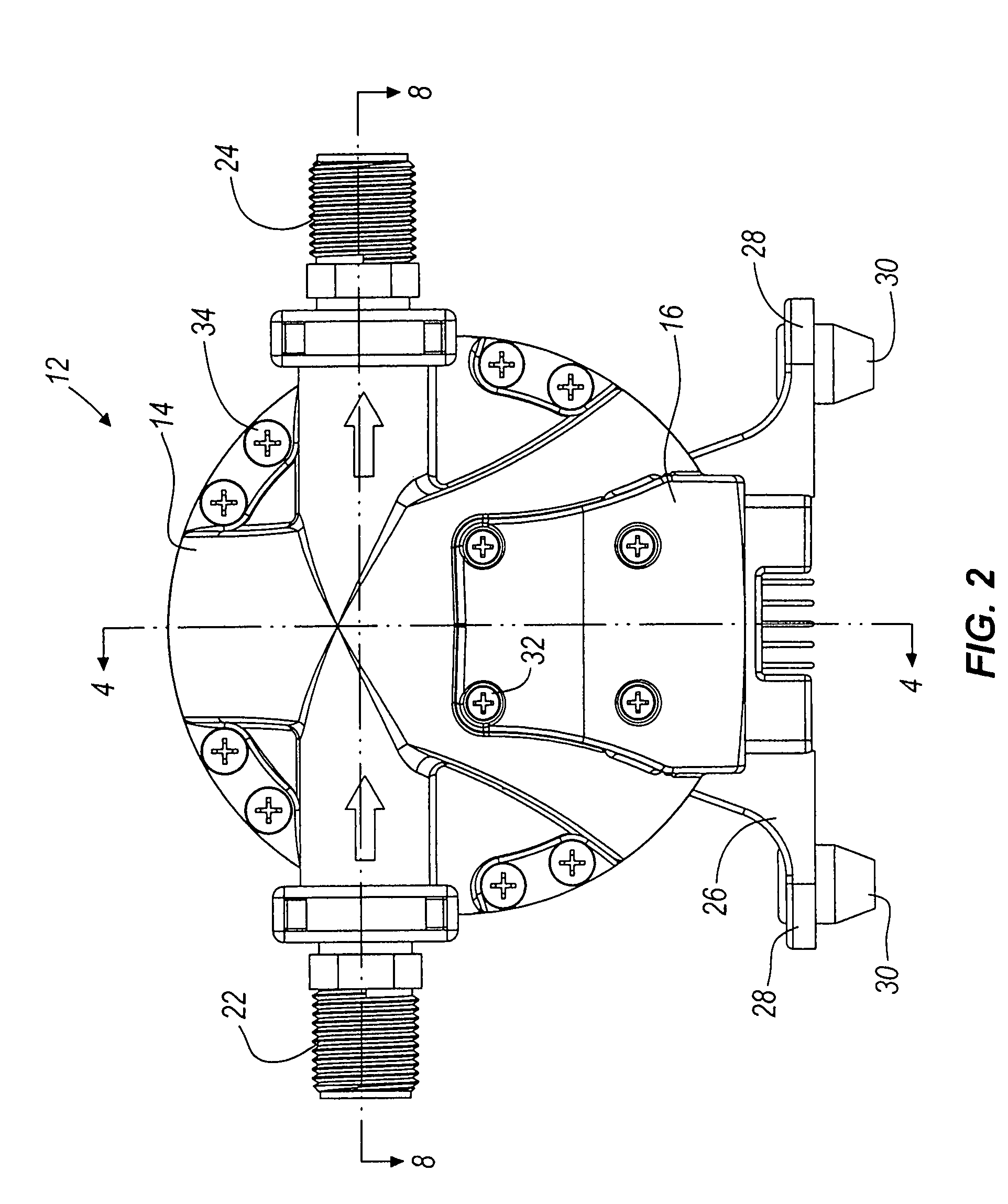

Linear peristaltic pump

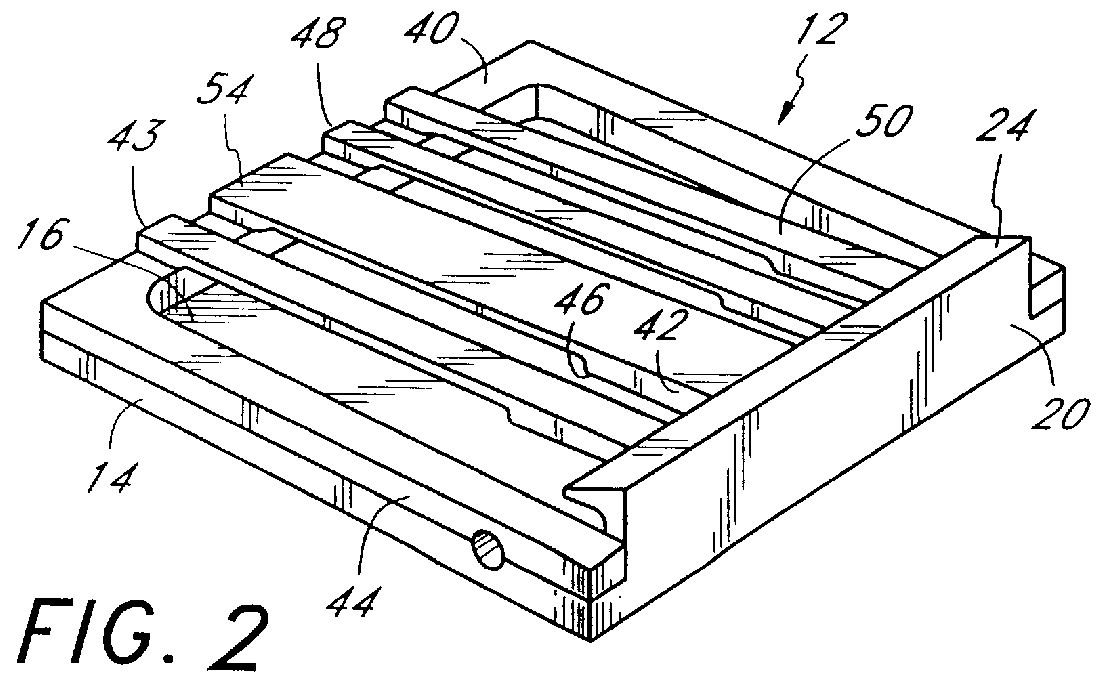

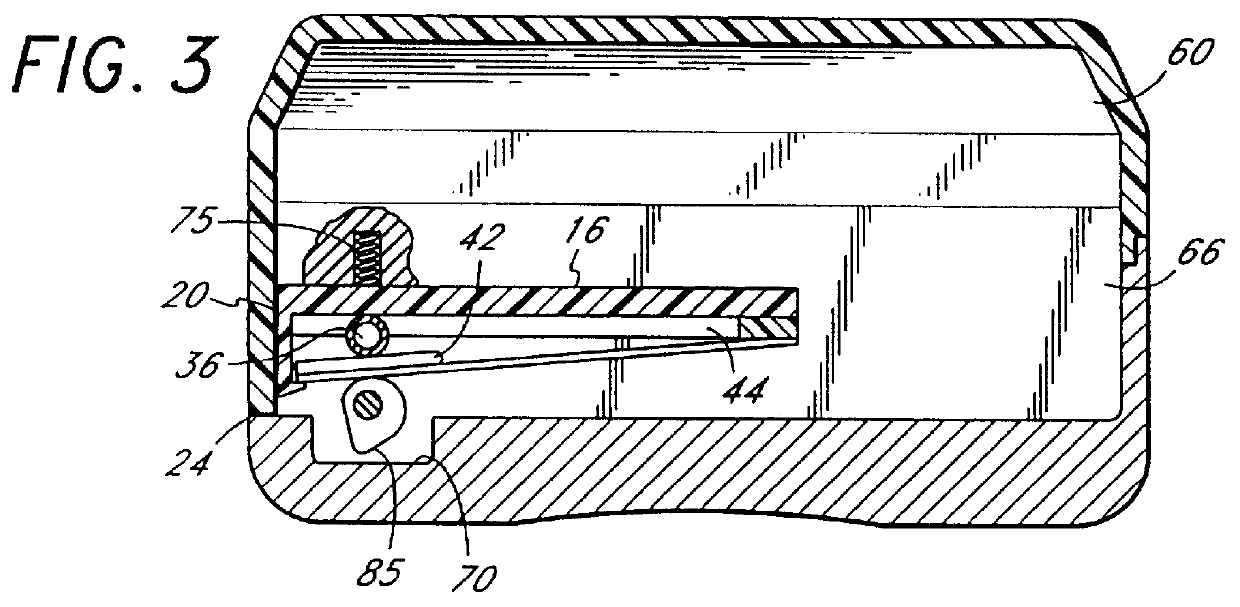

InactiveUS6213739B1High liquid pumping pressureExtends useful pump tube lifeFluid parameterFlexible member pumpsPeristaltic pumpActuator

A liquid pumping apparatus for pumping liquids, more specifically a linear peristaltic pump apparatus. The apparatus consists of a high durometer compressible elastomeric liquid flow tube (12), an infeed valve assembly (26), an outfeed valve assembly (38), an extensible and retractable actuator anvil (34) having a round surface which engages the flow tube (12) at all times, an opposed anvil (24.1) having a round surface in engagement with the flow tube at all times, the flow tube being held between the anvils (34, 24.1) in a slightly compressed state when the anvil (34) is retracted, and a control assembly (100) for causing the movable anvil to be sequentially extended and retracted to cause flow within the flow tube (12) from the infeed valve assembly (26) to the outfeed valve assembly (38). With this apparatus the lumen of the flow tube (12) to the sides of the anvils is not completely reduced to zero volume during displacement compression whereby gas embolisms do not erupt or explode when discharged. Two principal embodiments are disclosed, one having infeed and outfeed check valves which oclude the flow tube, and the other having check valves.

Owner:NIAGARA PUMP CORP

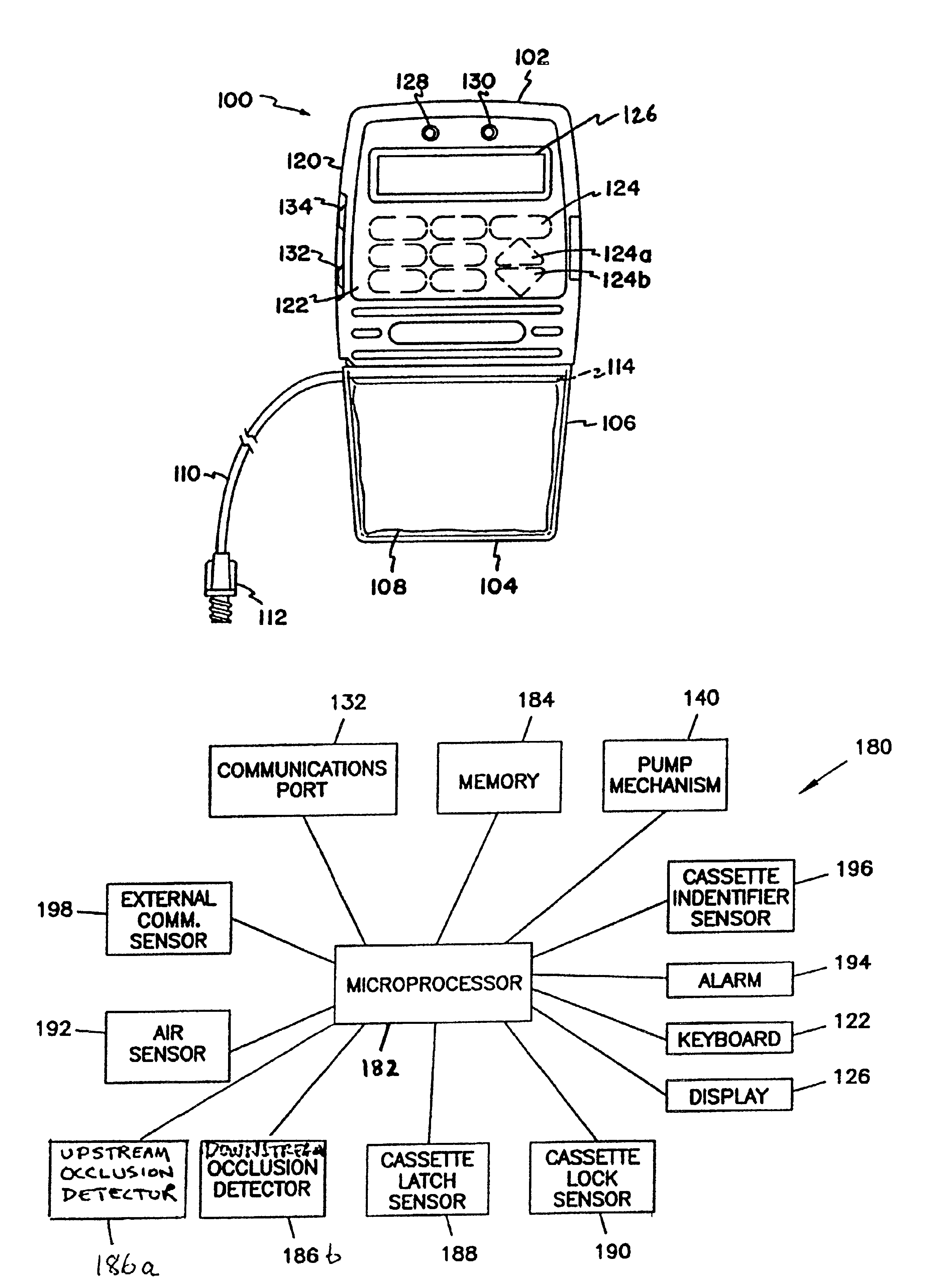

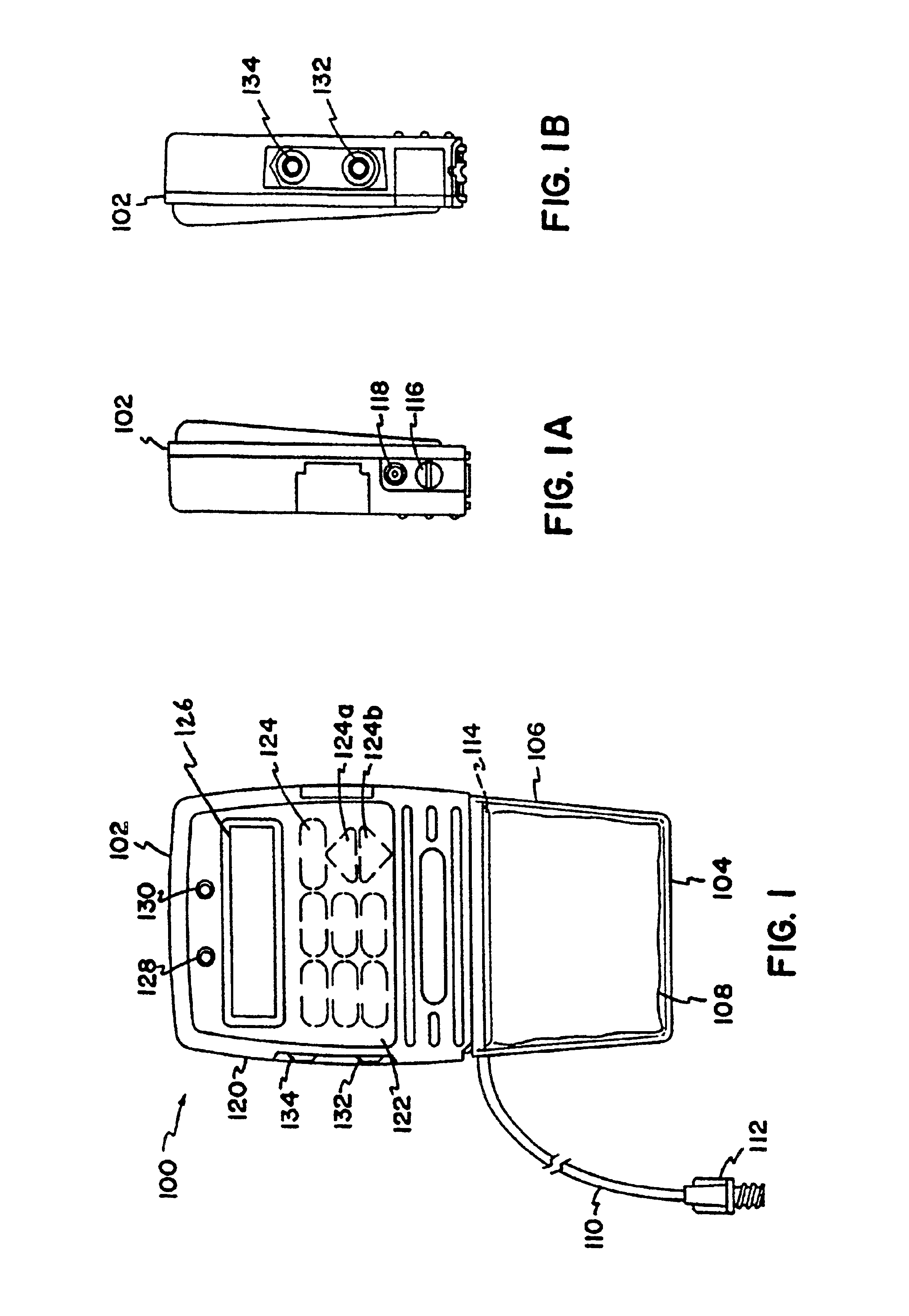

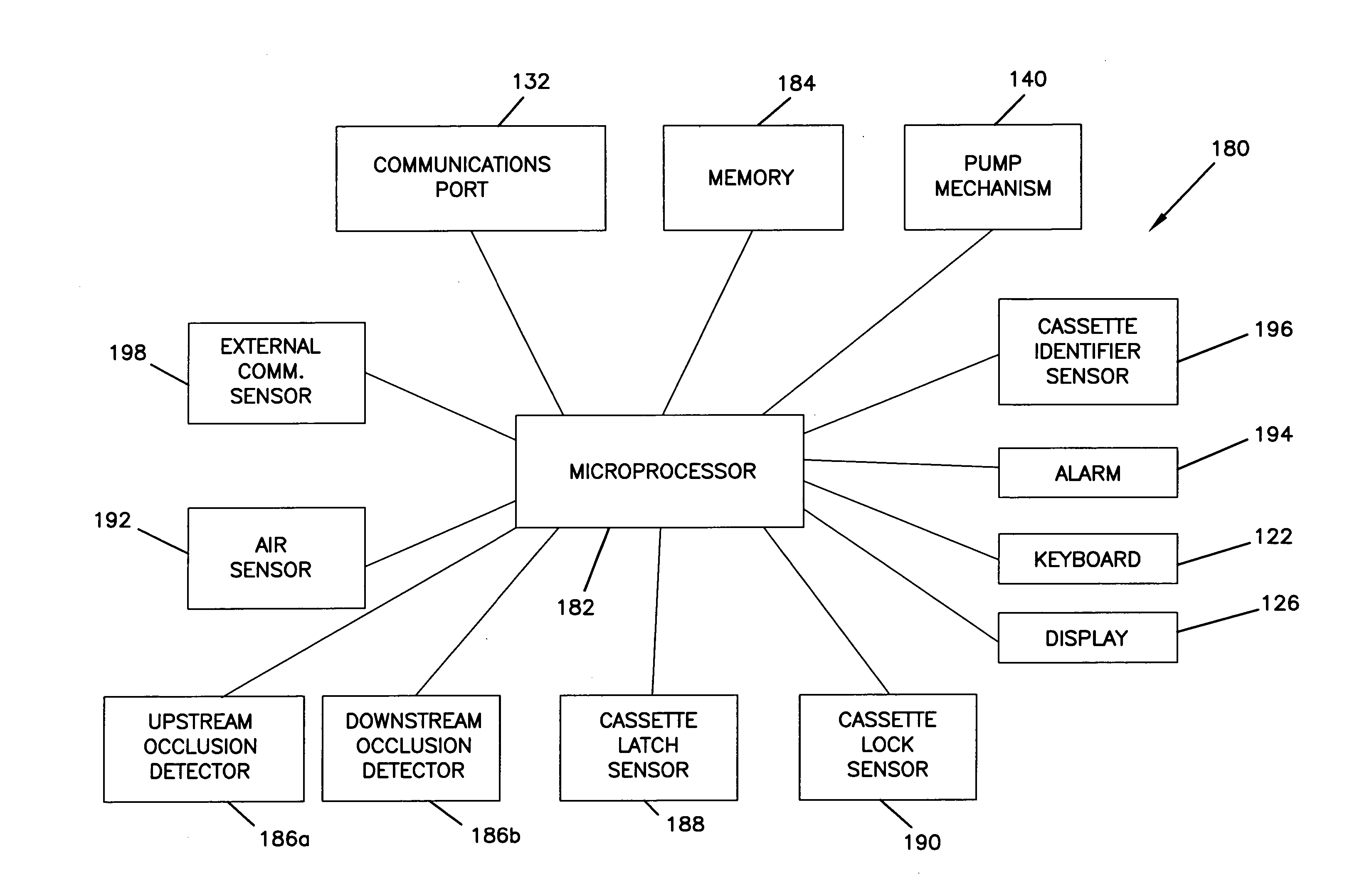

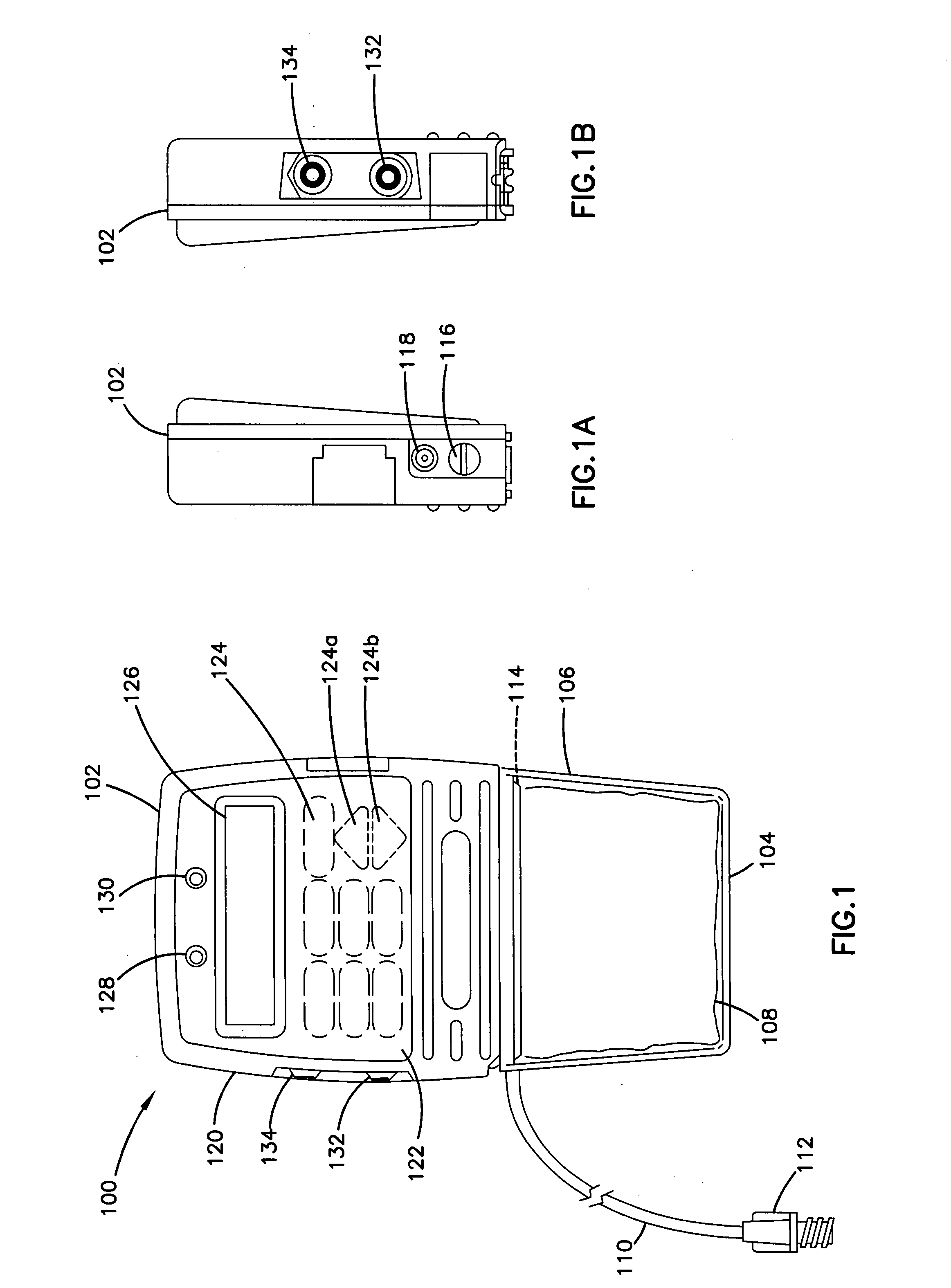

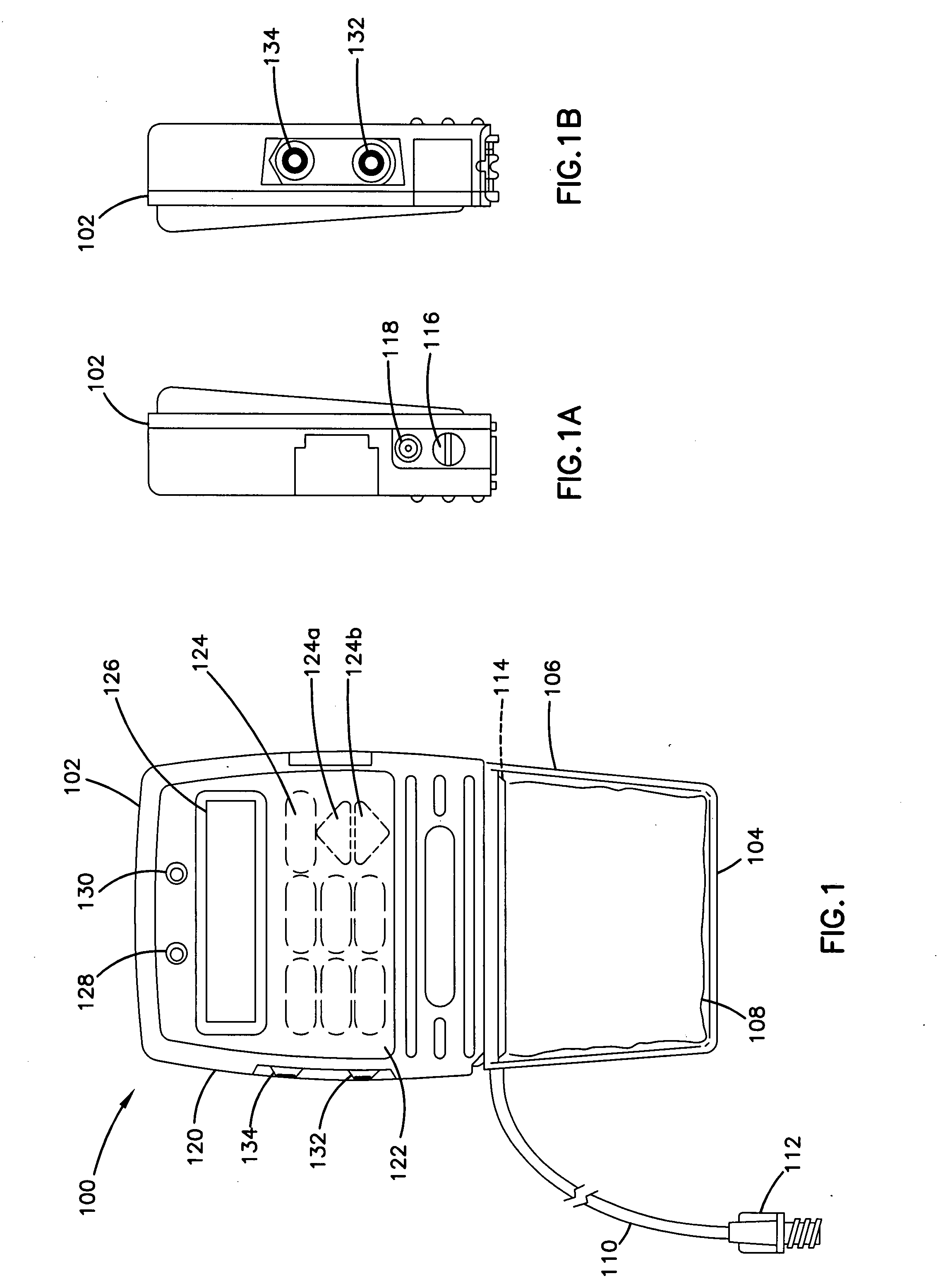

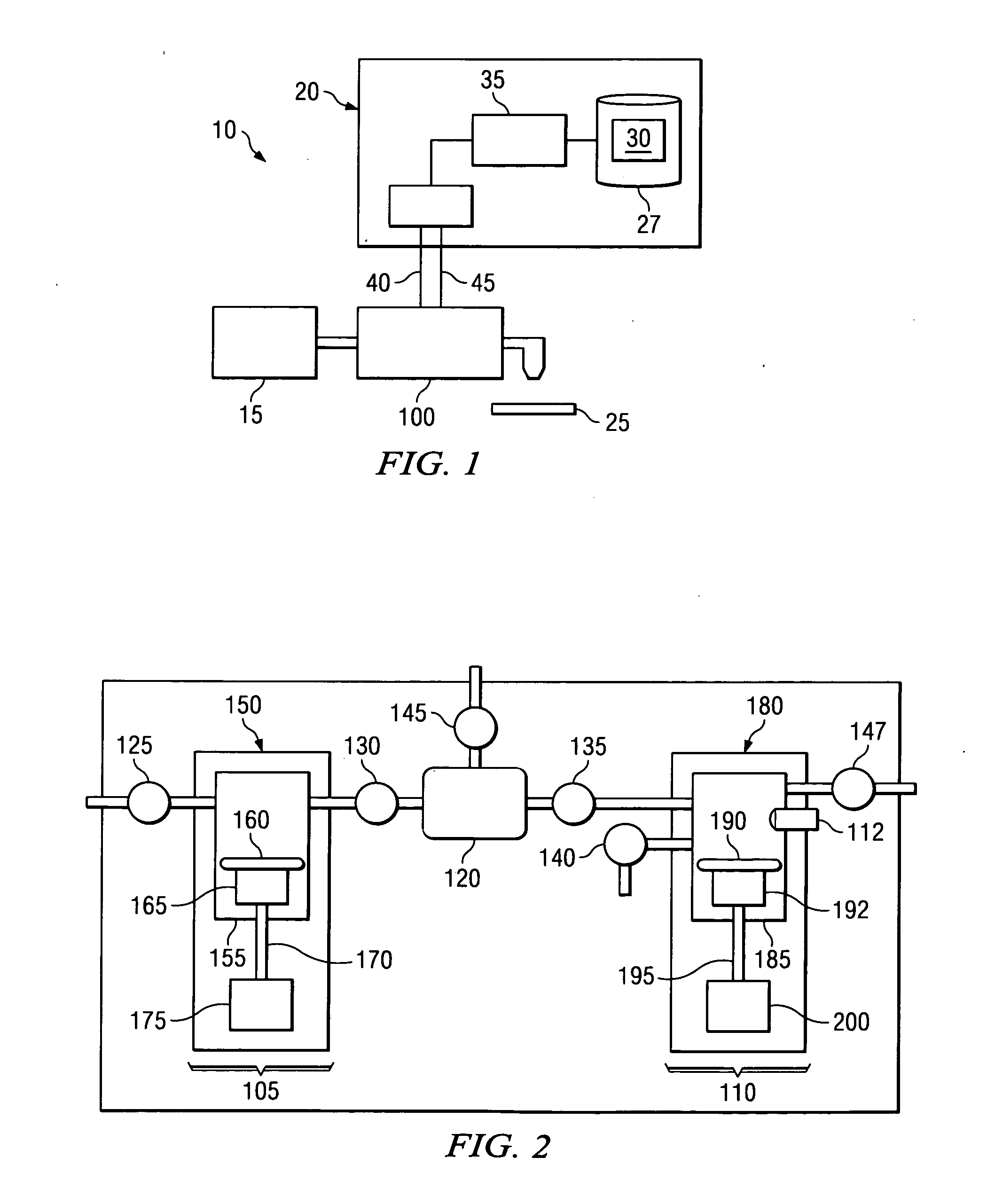

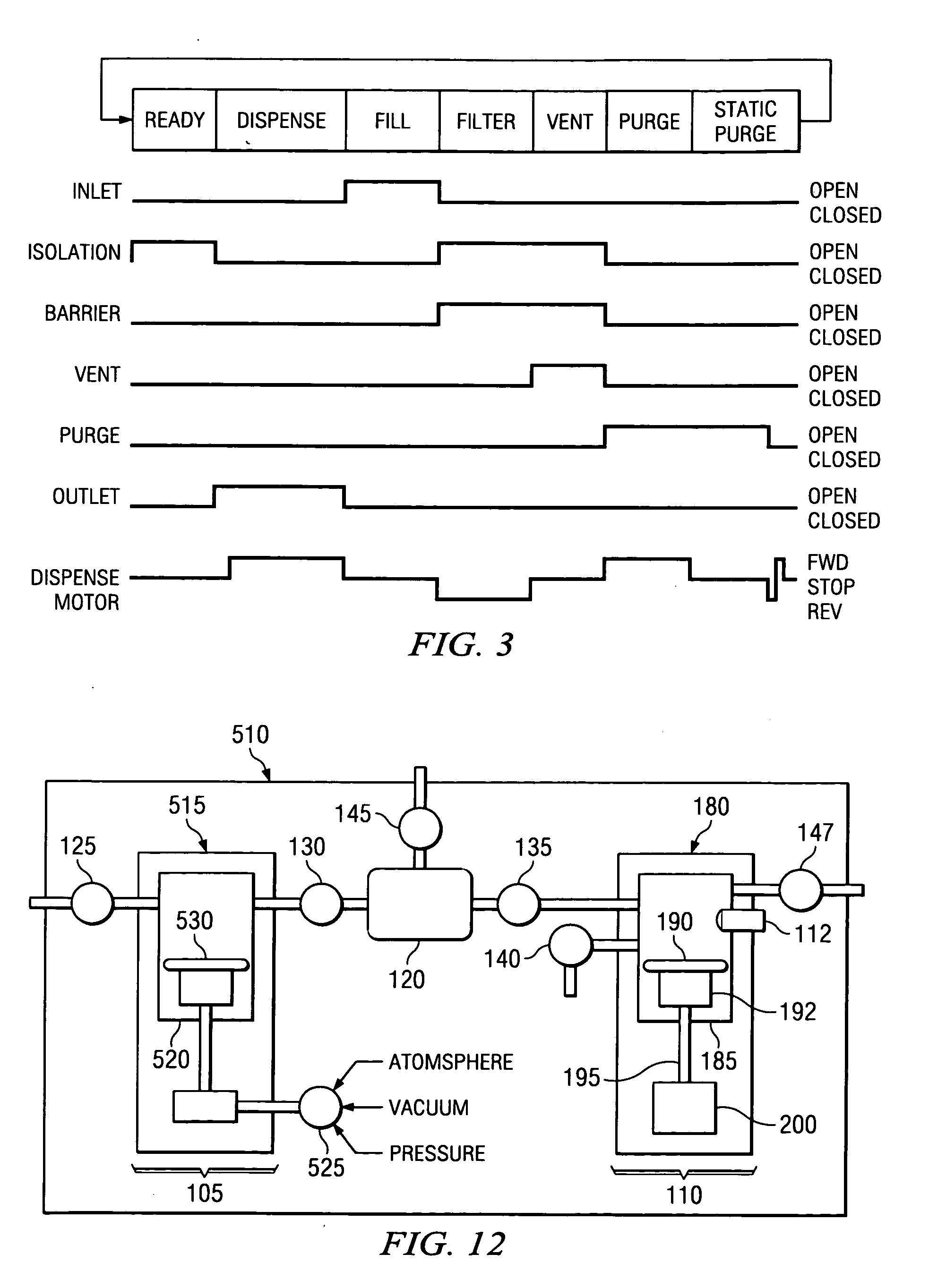

Drug pump systems and methods

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

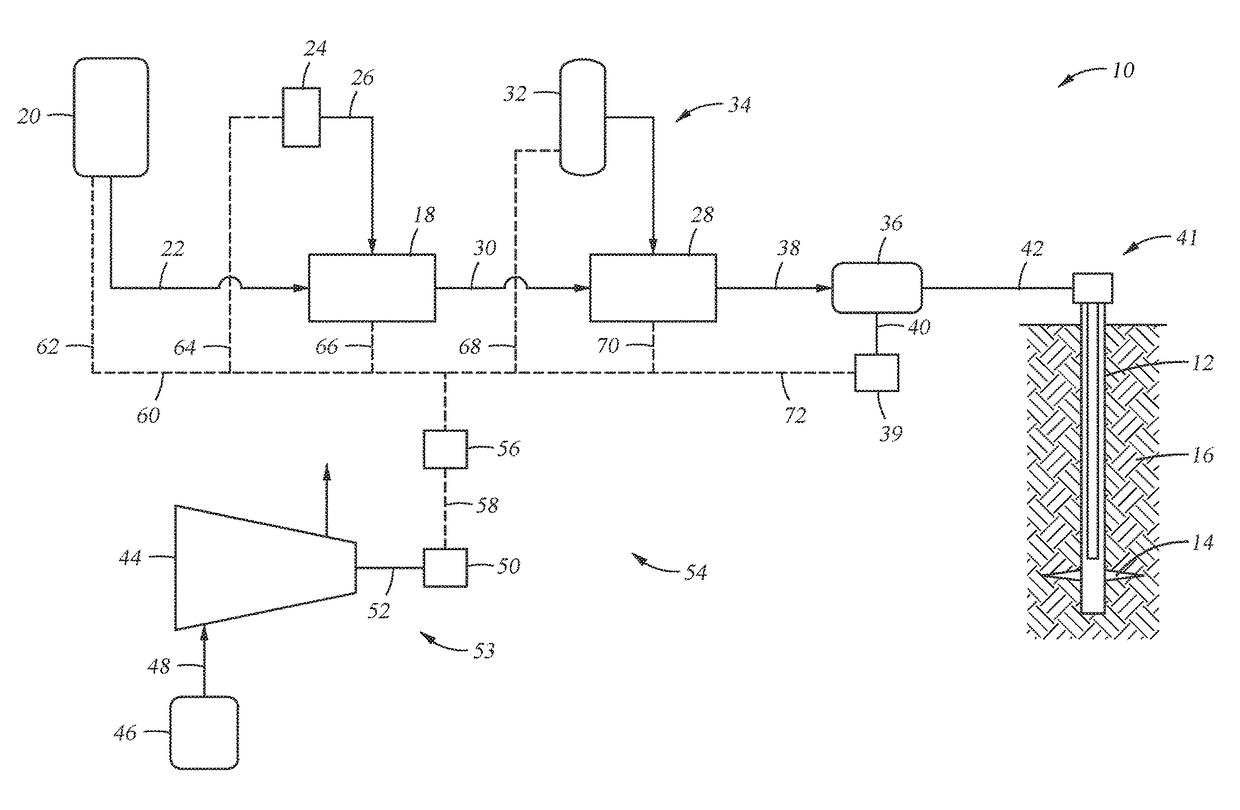

Cold weather package for oil field hydraulics

A hydraulic fracturing system includes an electrically powered pump that pressurizes fluid, which is piped into a wellbore to fracture a subterranean formation. System components include a fluid source, an additive source, a hydration unit, a blending unit, a proppant source, and a fracturing pump. The system includes heaters for warming hydraulic fluid and / or lube oil. The hydraulic fluid is used for operating devices on the blending and hydration units. The lube oil lubricates and cools various moving parts on the fracturing pump.

Owner:US WELL SERVICS LLC

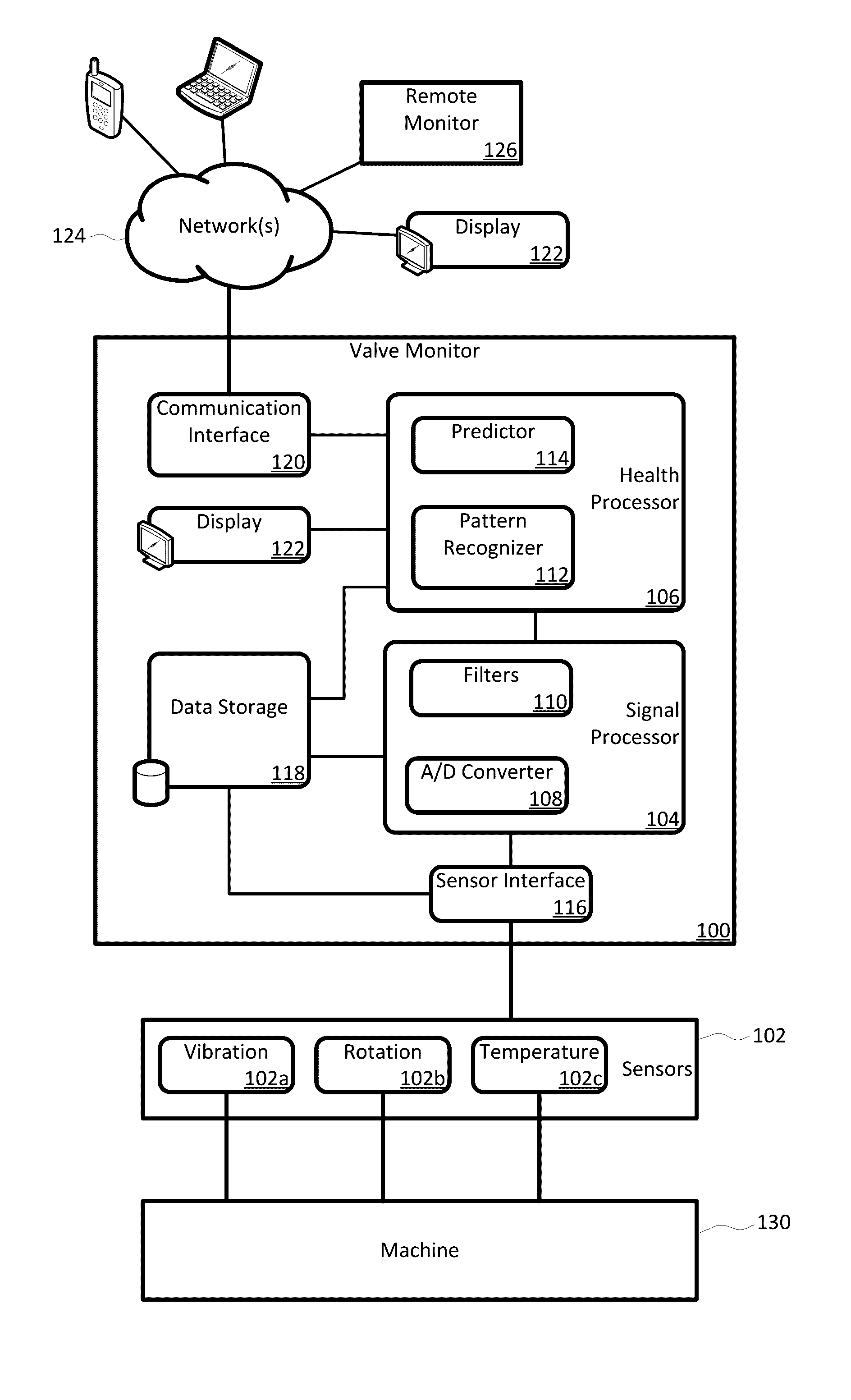

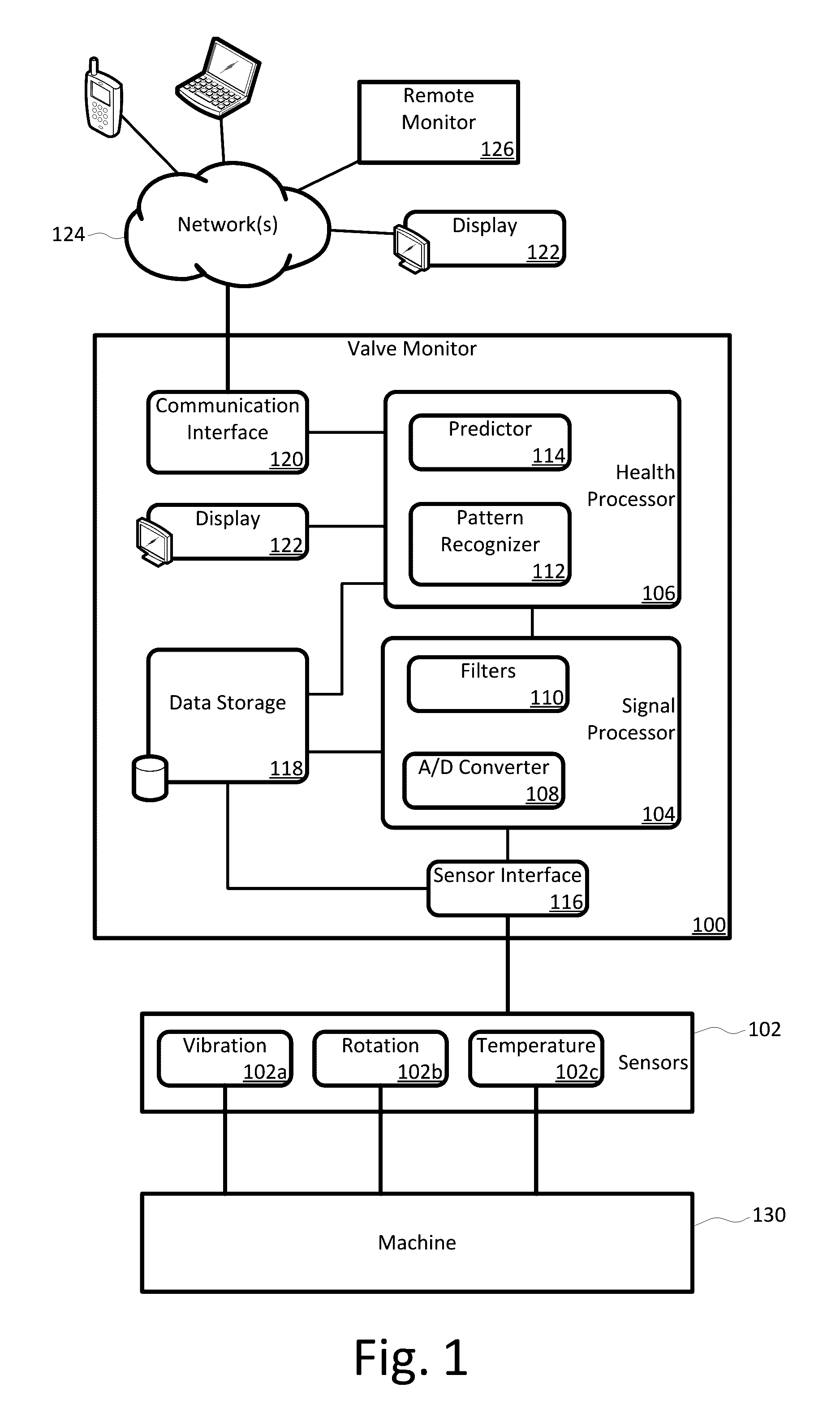

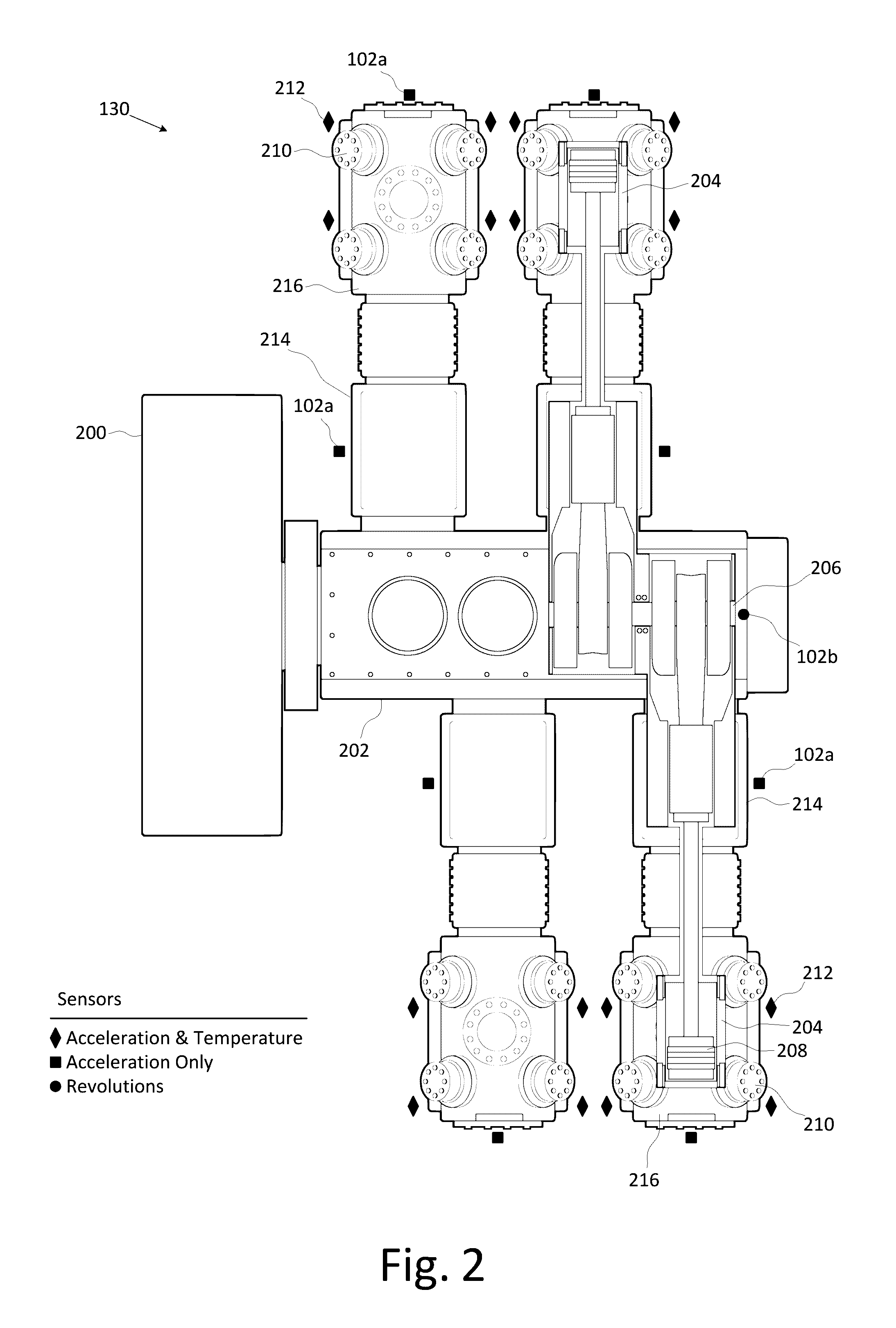

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

Drug pump systems and methods

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

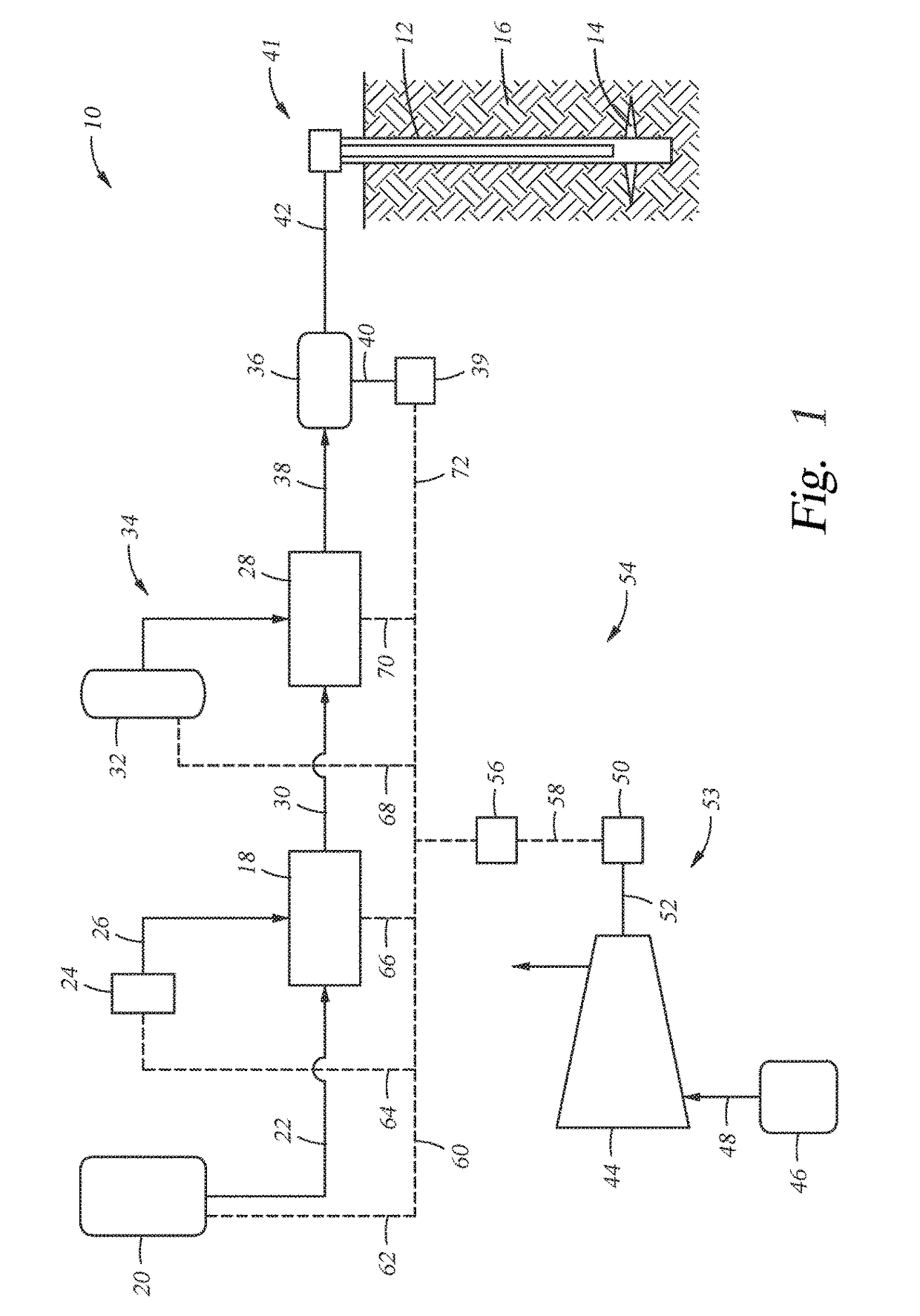

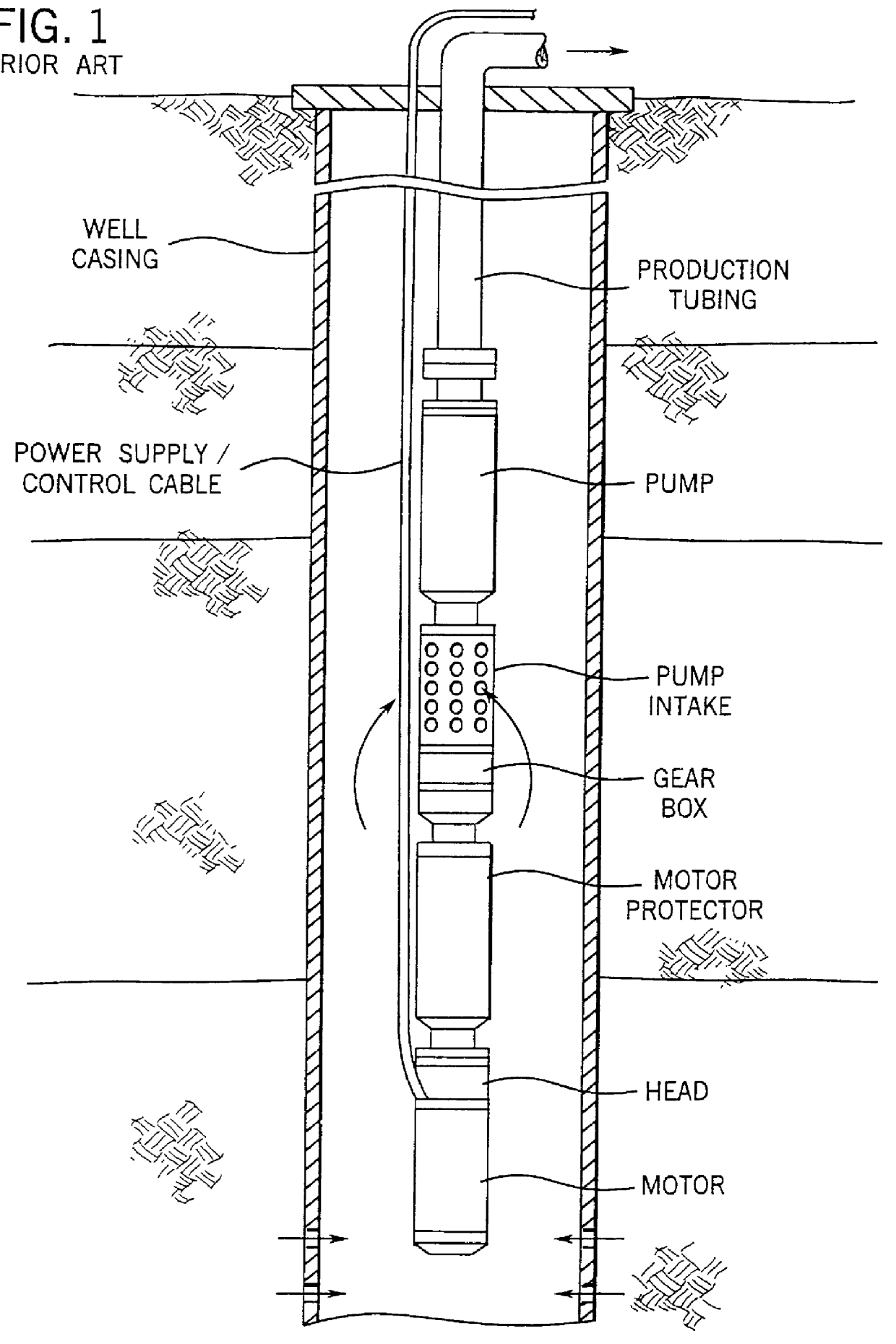

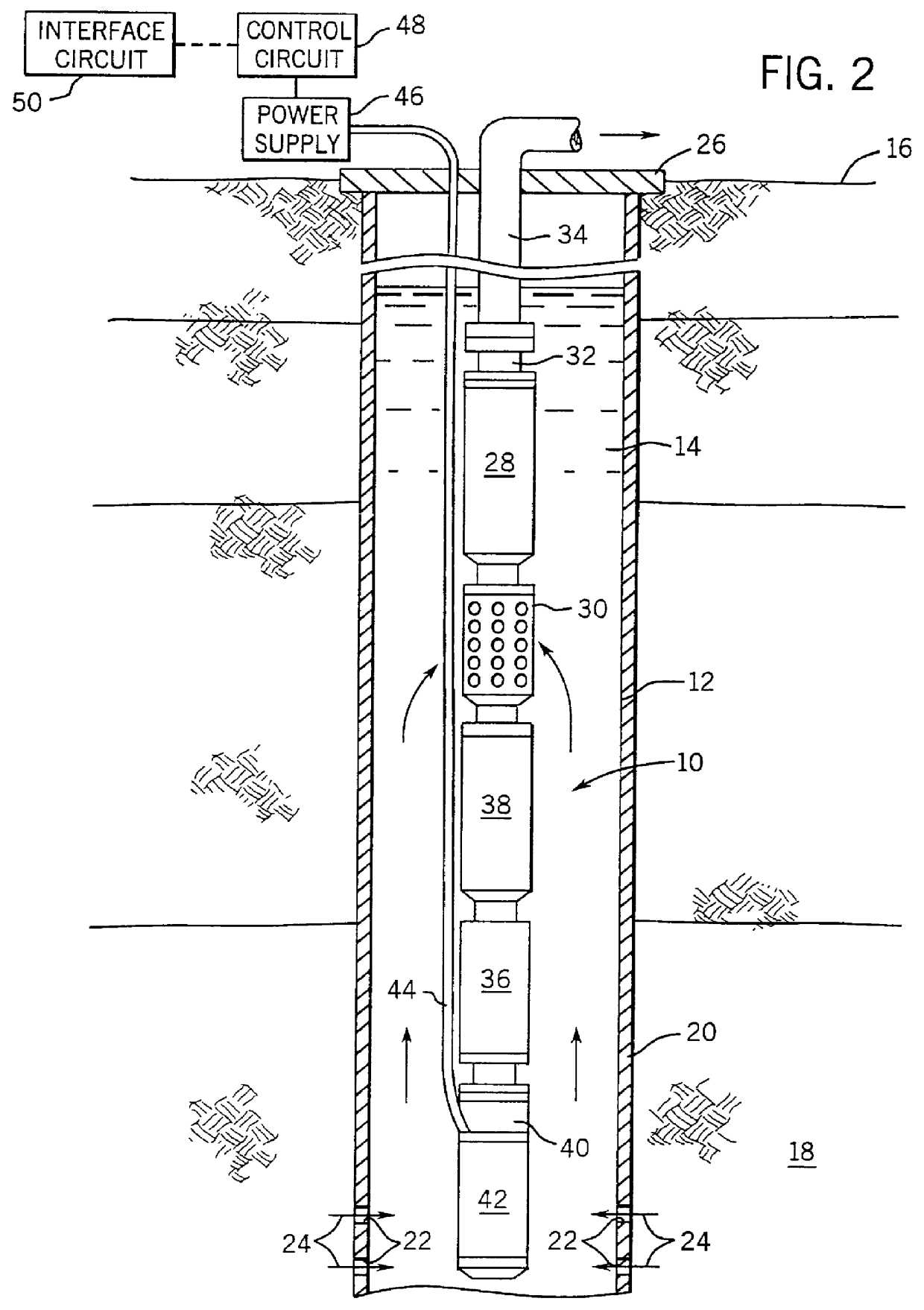

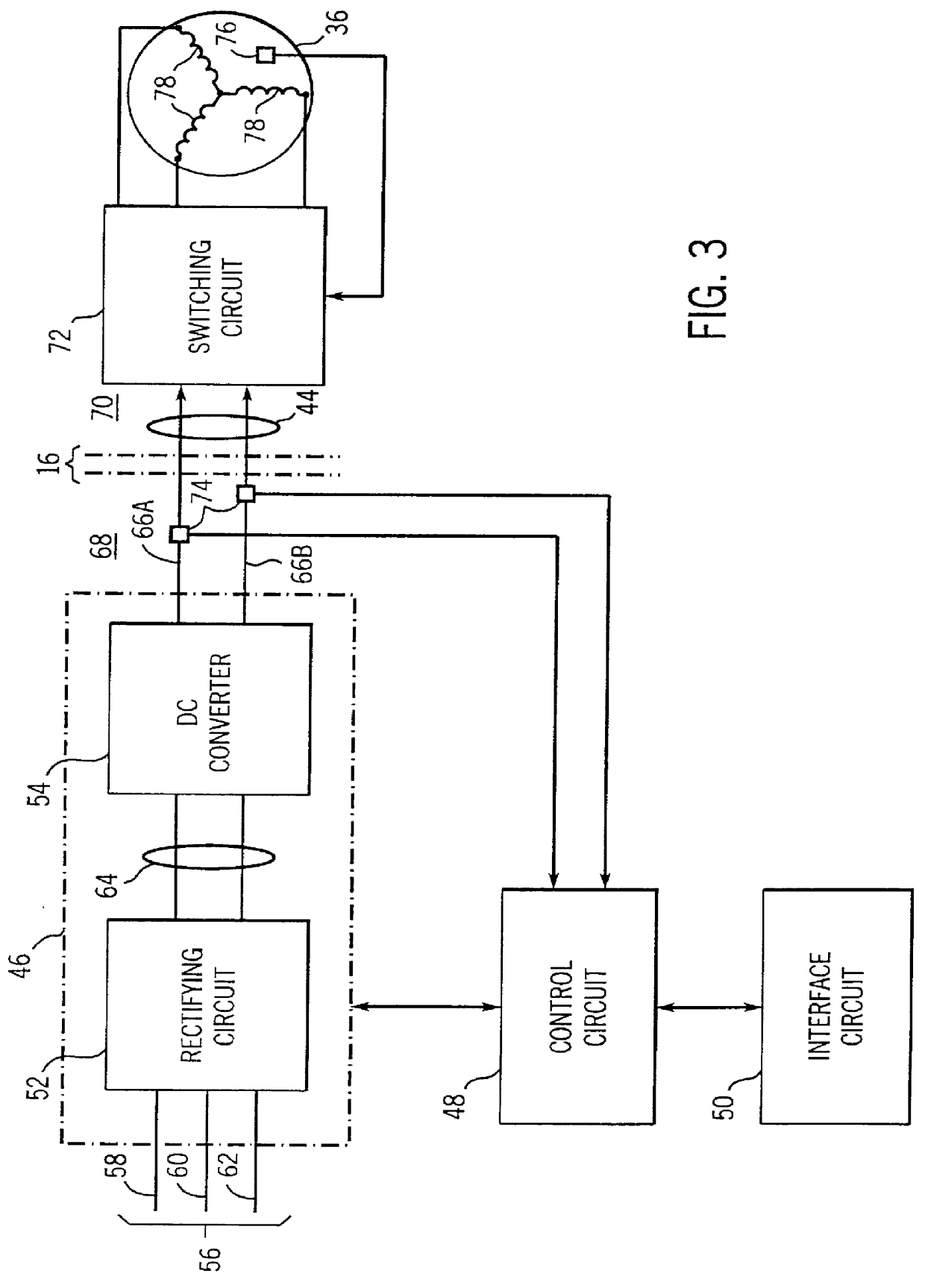

Method and apparatus for controlling a submergible pumping system

A submergible pumping unit for raising viscous fluids from a well is driven by an electronic drive and control system, a first portion of which is located above the well, and a second portion of which is coupled to the submergible pumping unit. The drive and control system includes a power supply circuit located above the well for converting AC power from a source to DC power having current and voltage levels. The DC power is transmitted to the pumping unit via a two-conductor DC bus cable. The pumping unit includes a switching circuit which receives the DC power for driving a submergible motor, such as a permanent magnet brushless motor. The speed of the motor, and of a pump coupled thereto, is proportional to the voltage of the DC power applied to the pumping unit. The pump is preferably a progressive cavity pump, and the drive and control circuitry provides sufficient torque to start the pump from a static condition. A control circuit is provided for transmitting configuration and desired flow rate and speed data to the power supply.

Owner:CAMCO INT

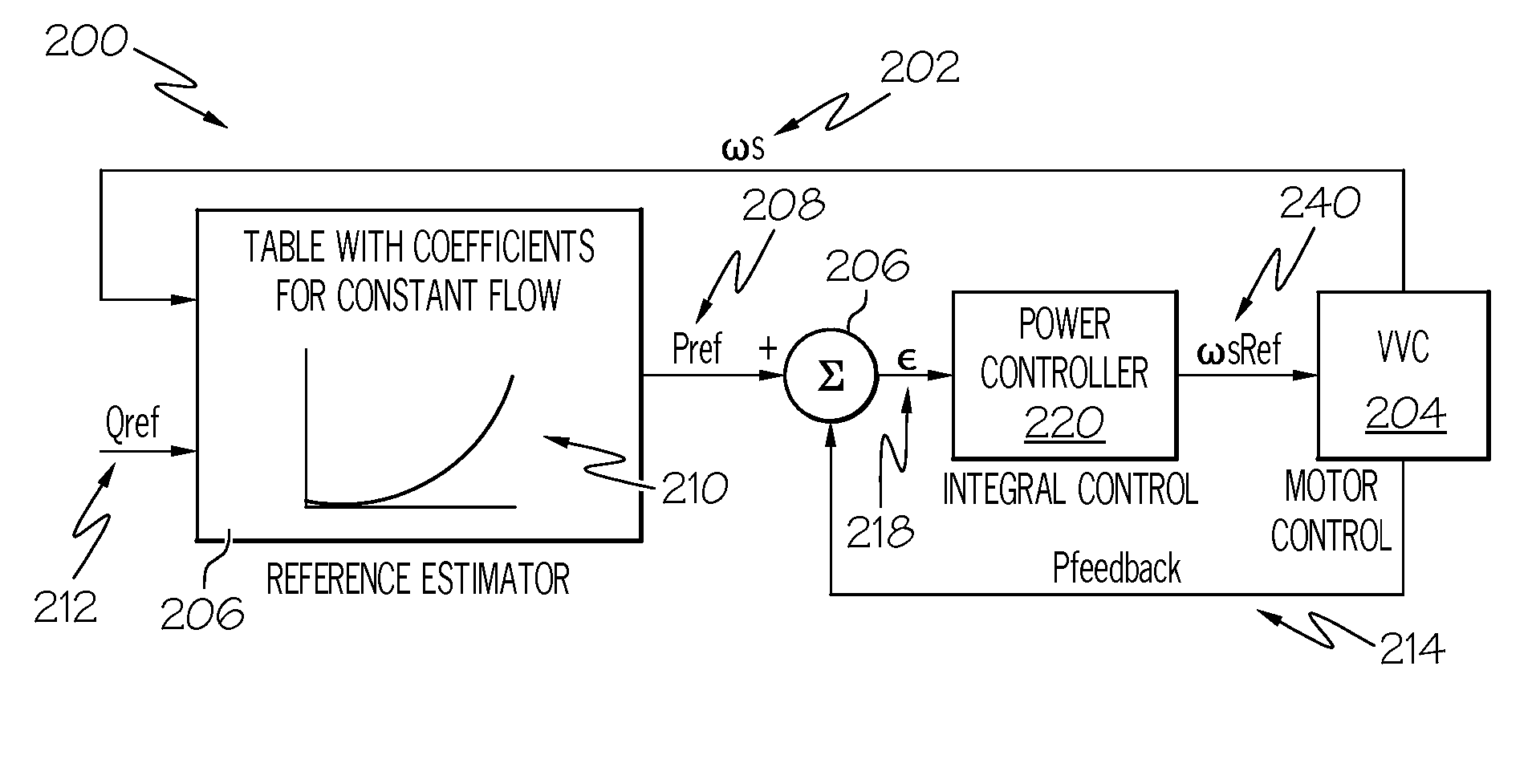

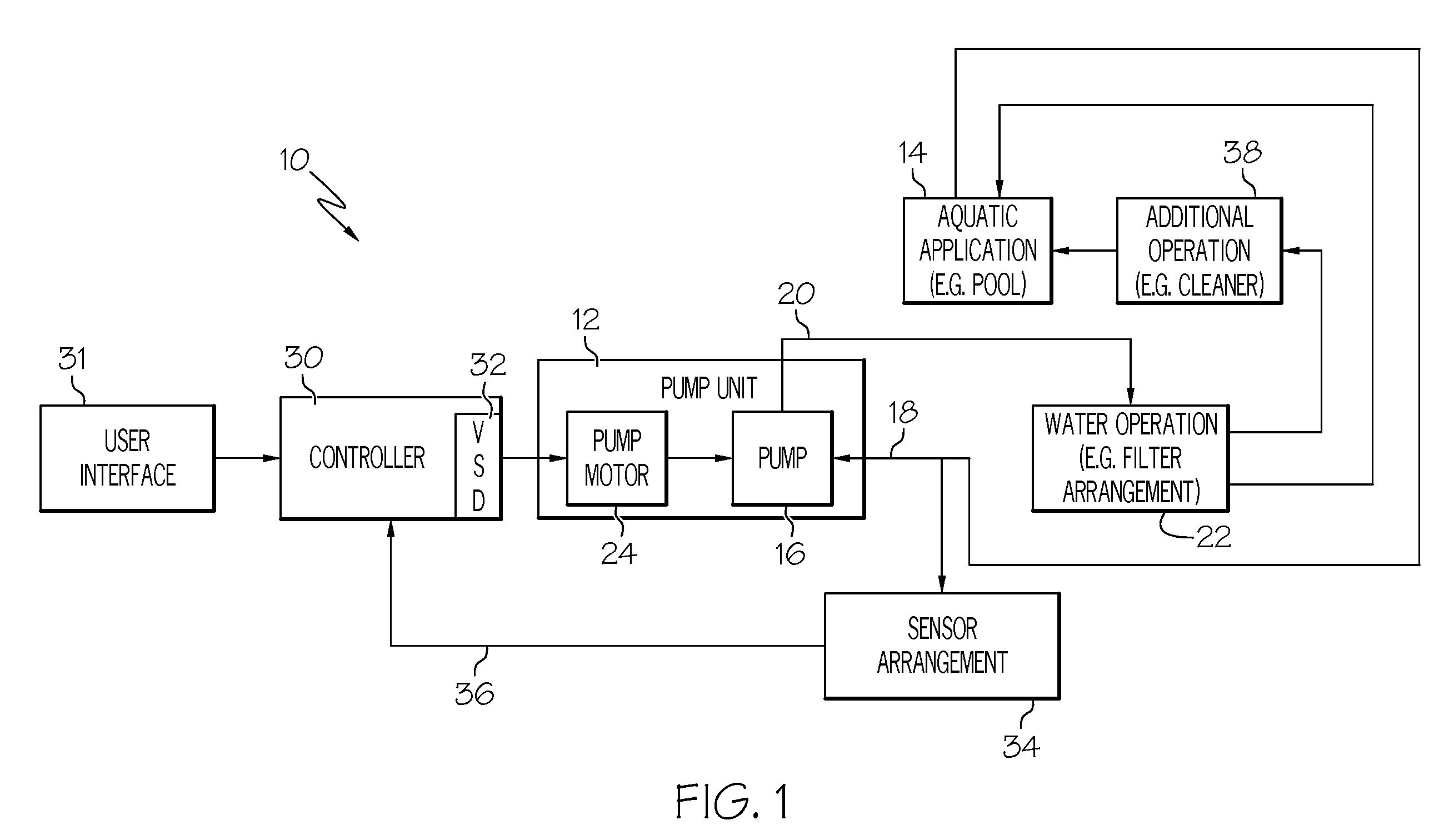

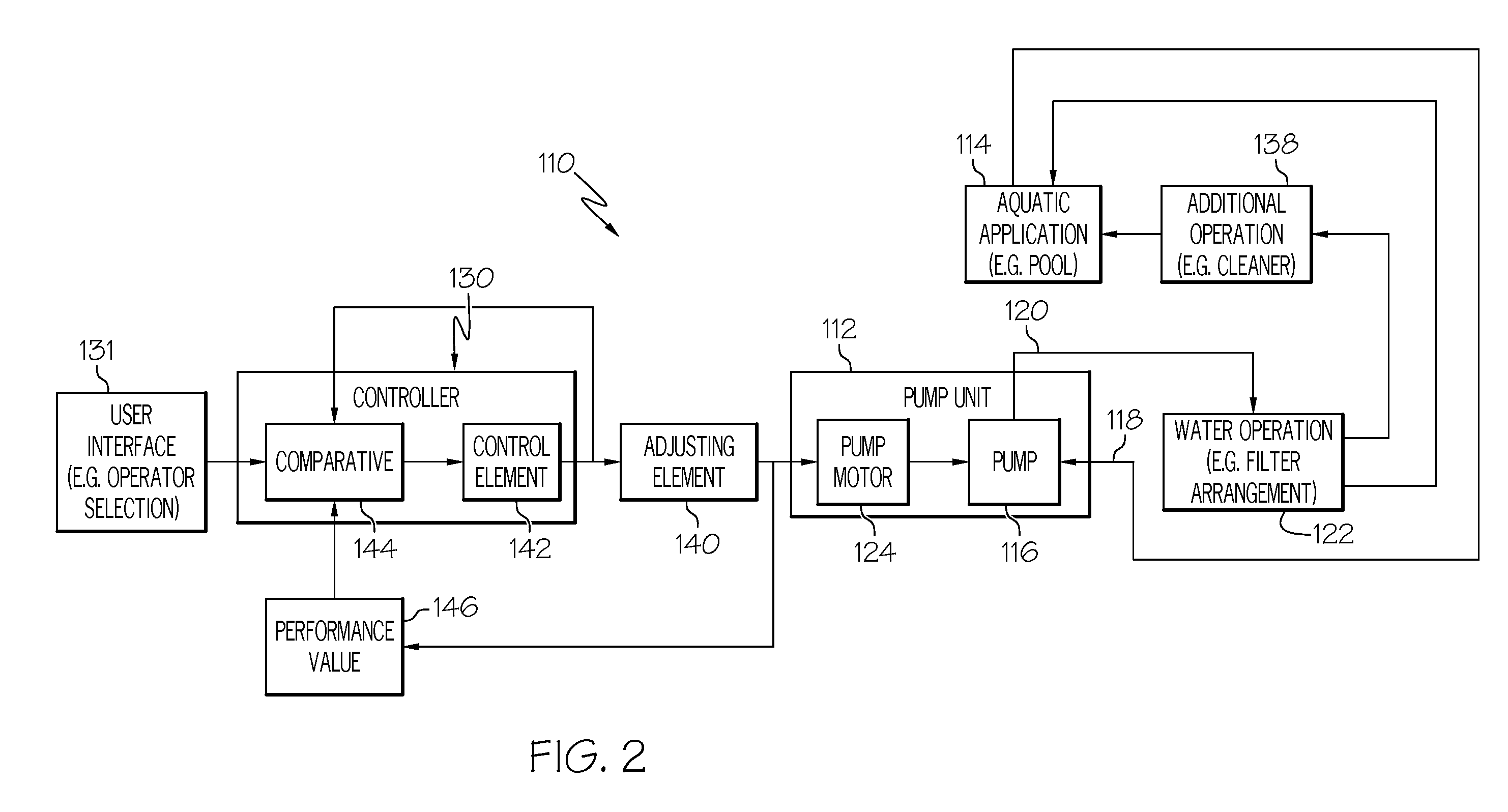

Flow control

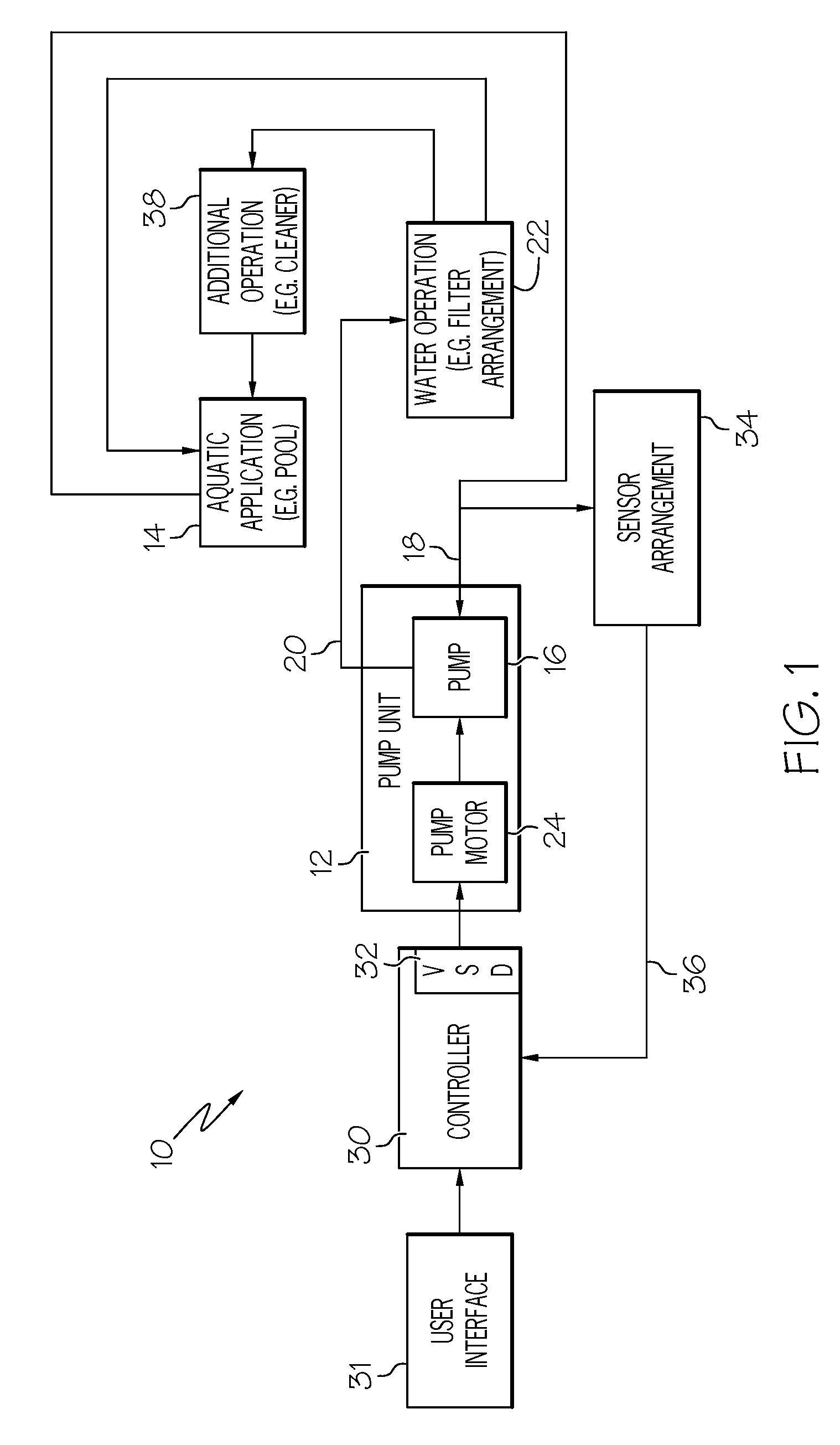

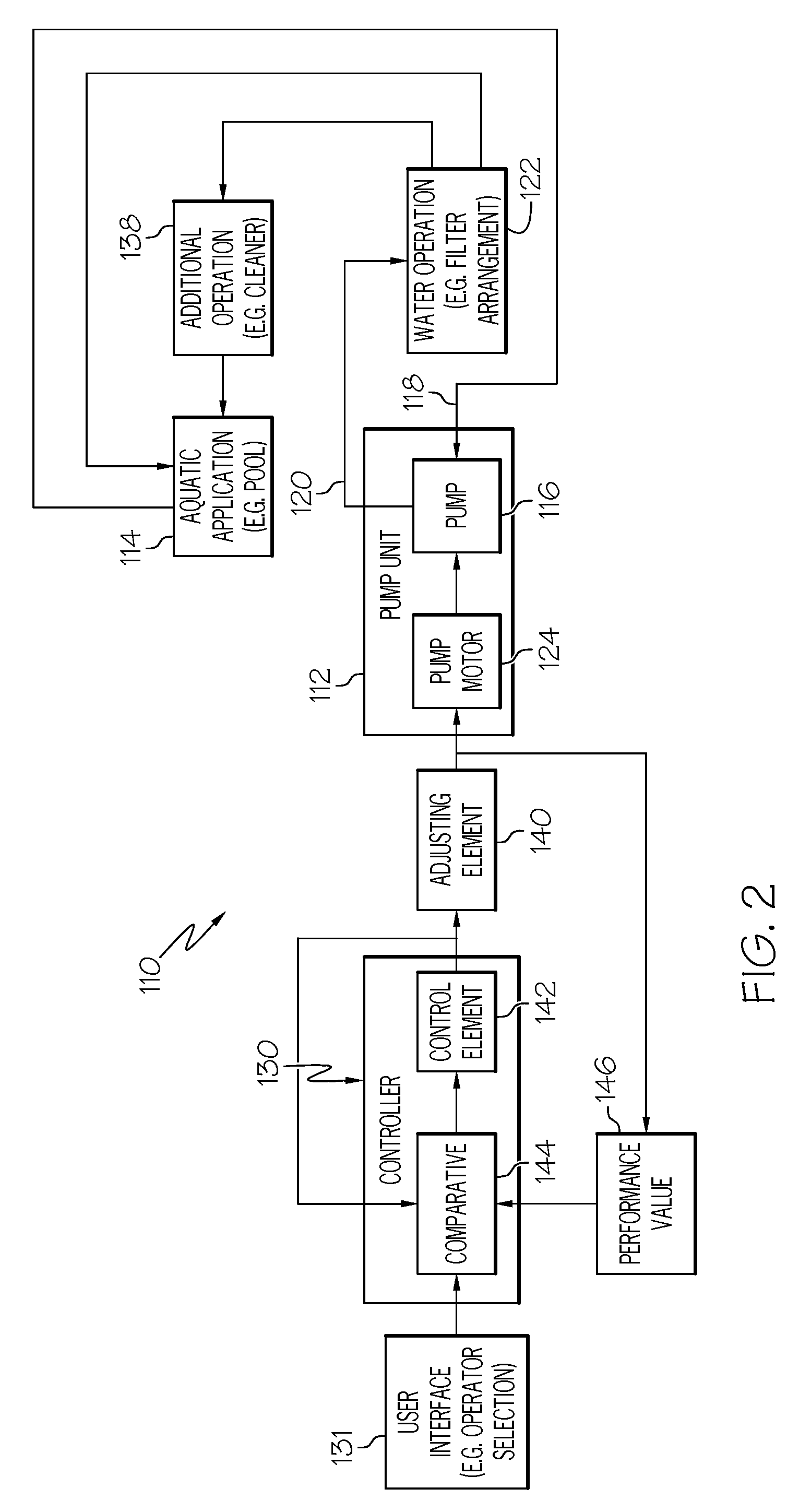

A pumping system for moving water of a swimming pool includes a water pump and a variable speed motor. The pumping system further includes means for determining a first motor speed of the motor, means for determining first and second performance values of the pumping system, and means for comparing the first and second performance values. The pumping system further includes means for determining an adjustment value based upon the comparison, means for determining a second motor speed based upon the adjustment value, and means for controlling the motor in response to the second motor speed. In one example, the pumping system includes means for determining a value indicative of a flow rate of water moved by the pump. In addition or alternatively, the pumping system includes a filter arrangement. A method of controlling the pumping system for moving the water of the swimming pool is also disclosed.

Owner:DANFOSS POWER ELECTRONICS AS +1

Drug pump systems and methods

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

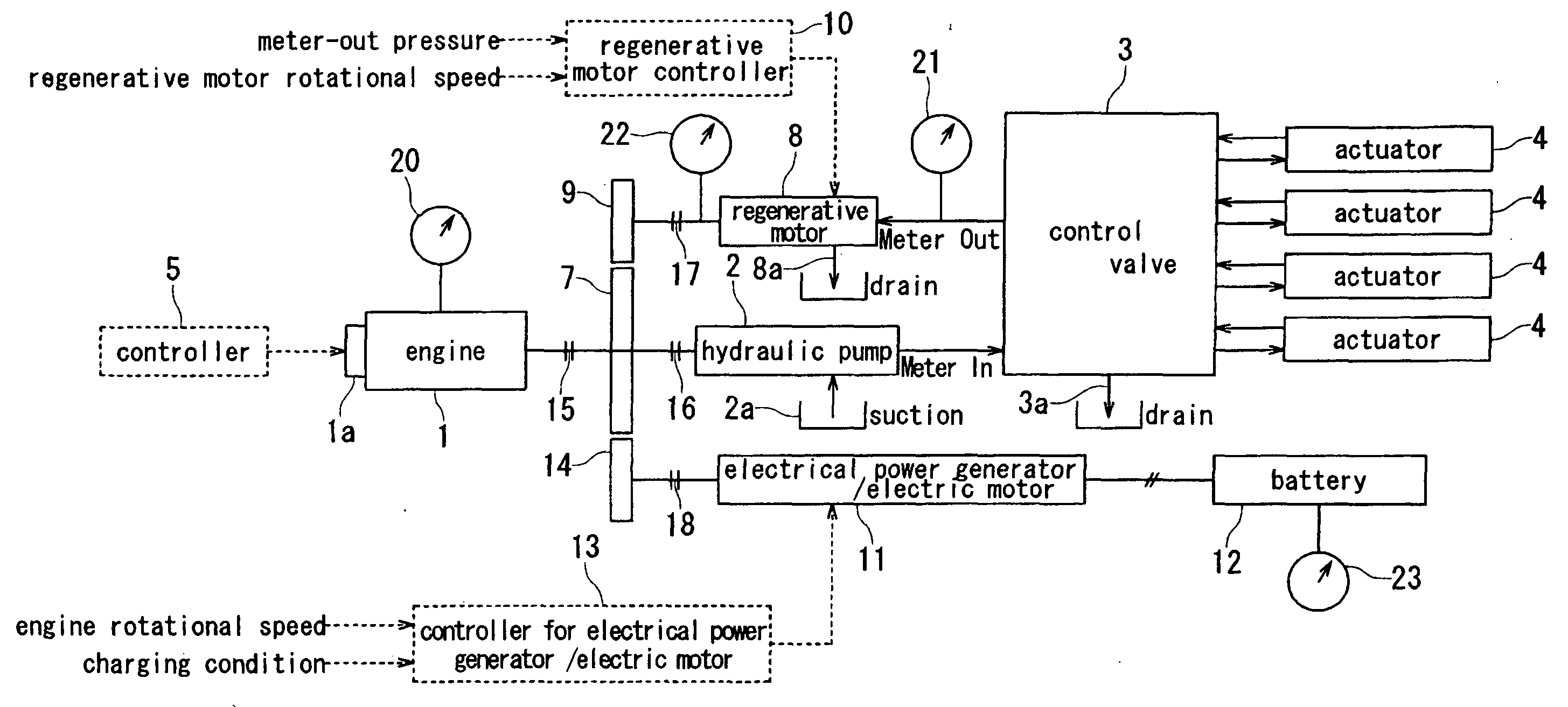

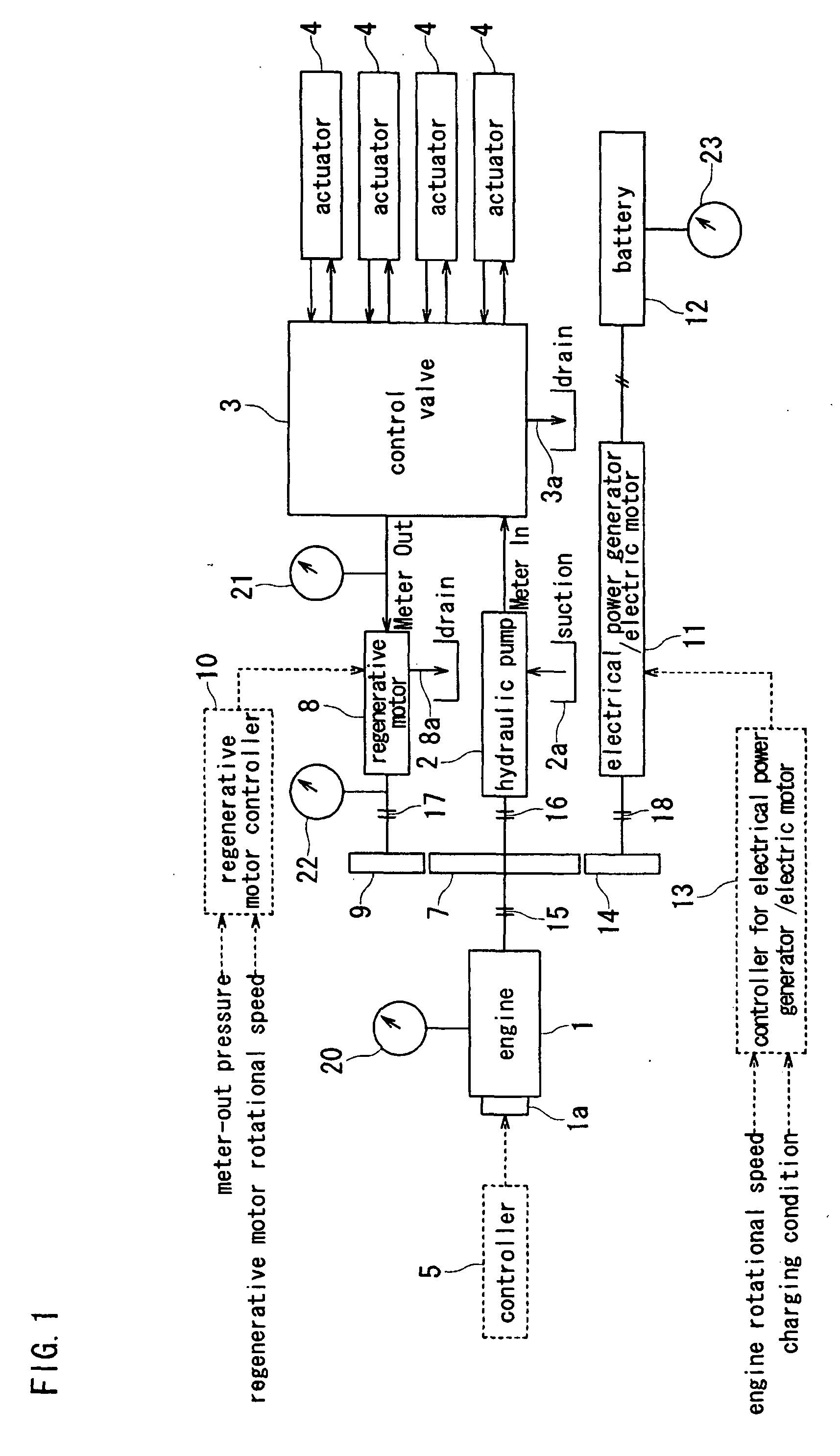

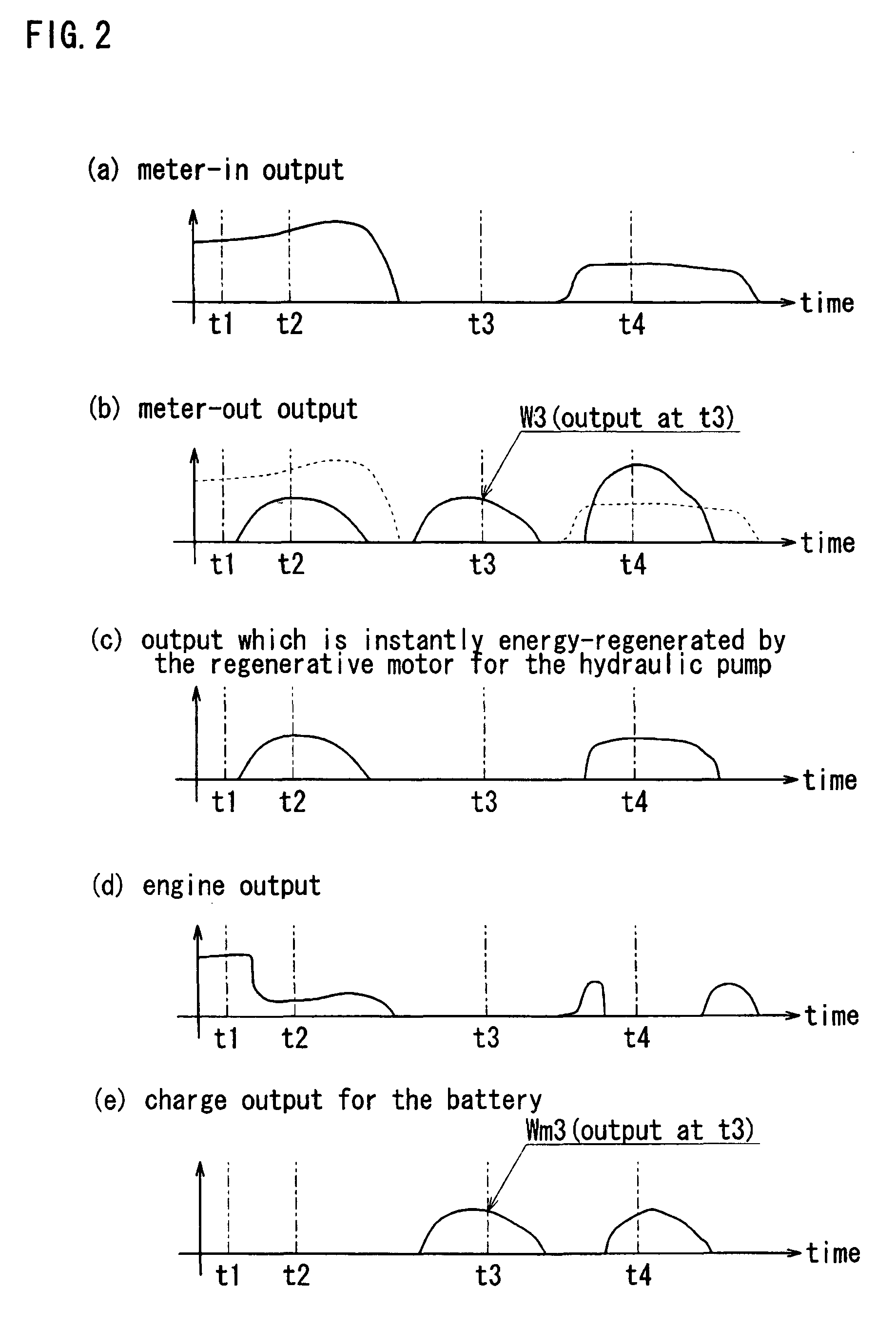

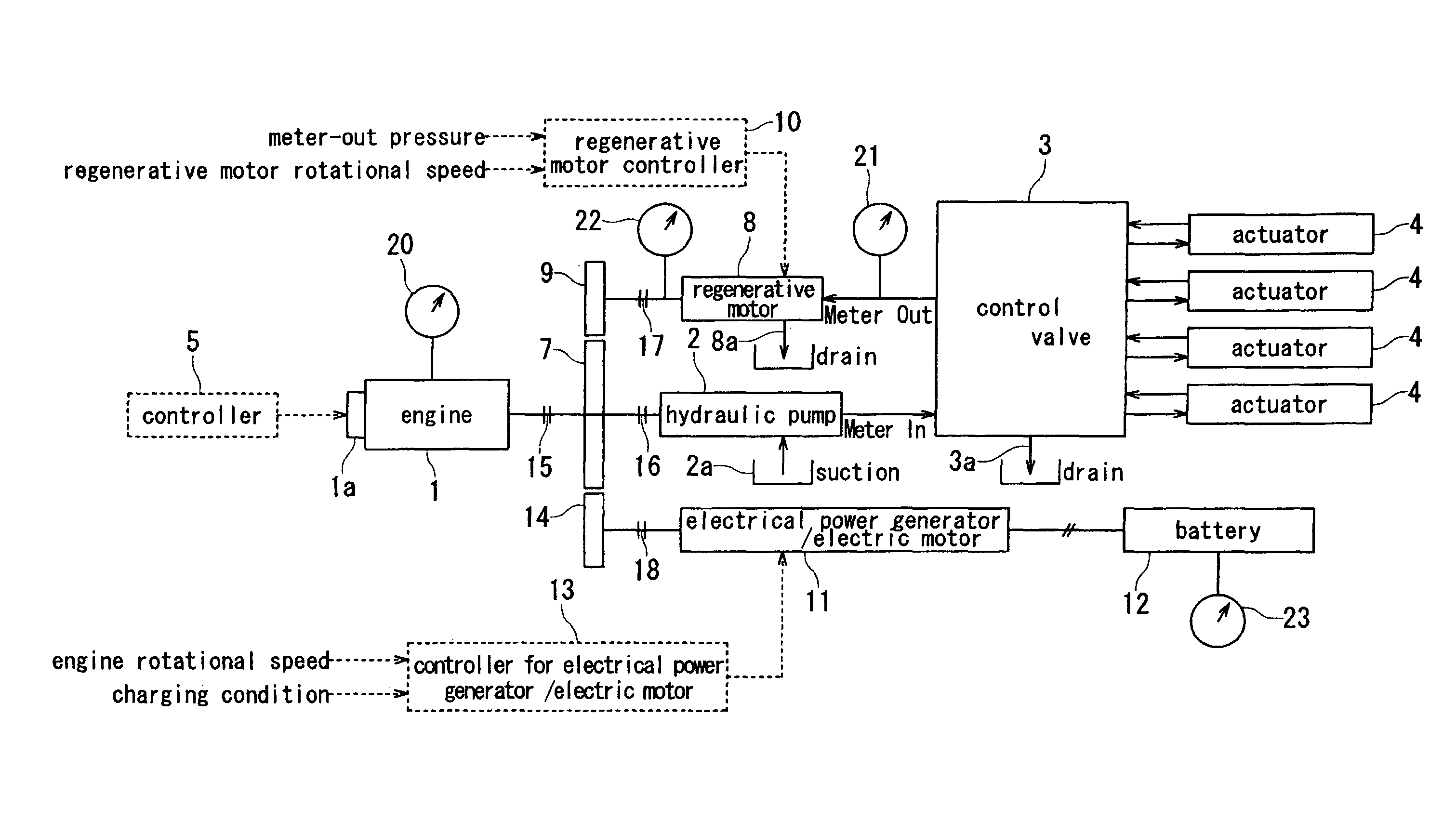

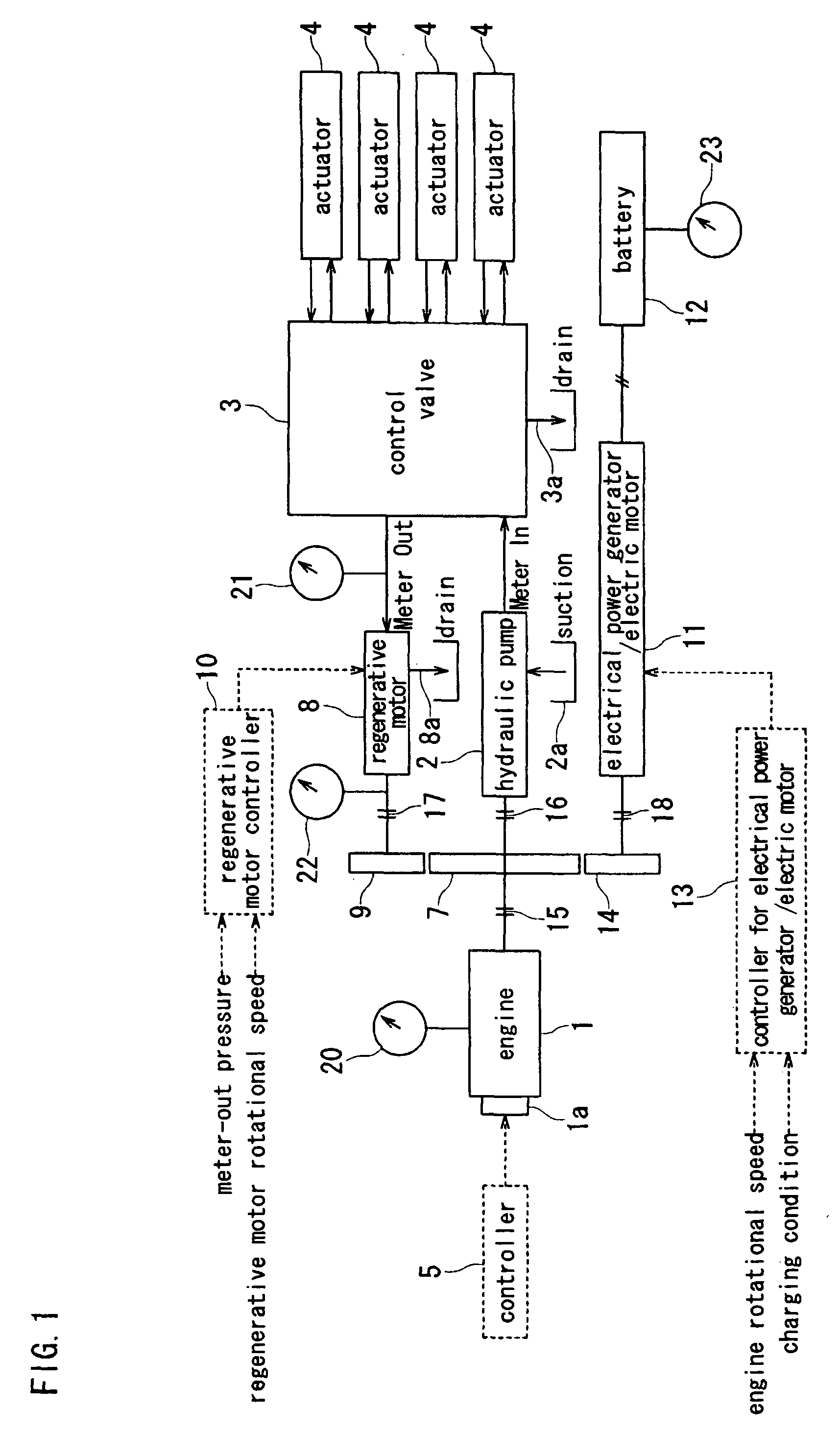

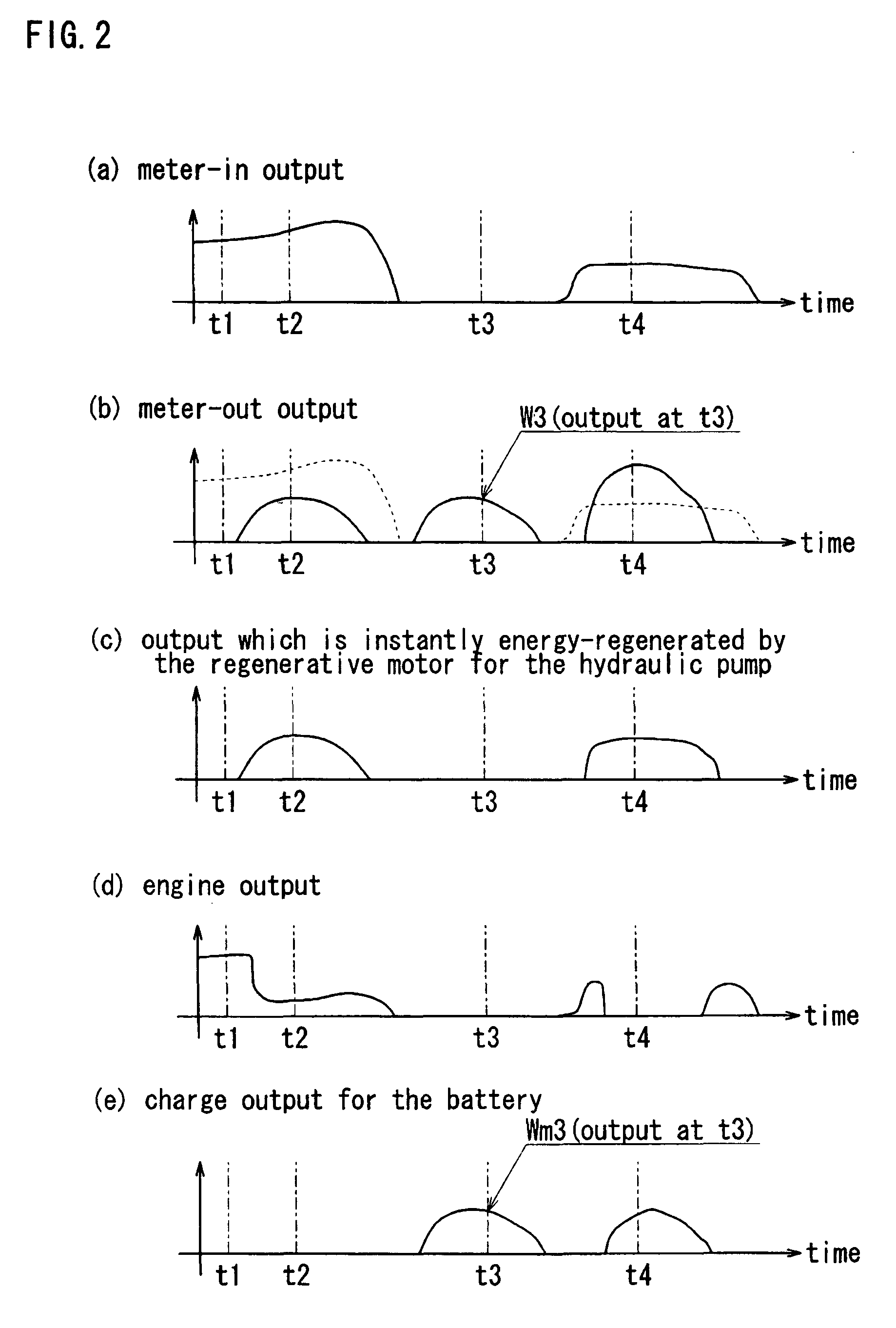

Construction machine

ActiveUS20050036894A1High electrical power generation efficiencyEfficient energy regenerationFluid couplingsMotor parameterElectricityHydraulic pump

In order to provide a construction machine by which energy regeneration can be performed reliably and battery and electrical power generator can be miniaturized, a construction machine has an engine, a hydraulic pump driven by the engine, and an actuator driven by discharge oil from the hydraulic pump, and a regenerative motor which rotates by return oil from the actuator is connected to the rotation shaft of the hydraulic pump. The hydraulic pump is driven by the engine and the regenerative motor when drive torque necessary in the hydraulic pump is larger than output torque generated by operation of the regenerative motor. Meanwhile, the hydraulic pump is driven by the regenerative motor when the drive torque of the hydraulic pump is smaller than output torque of the regenerative motor, and an electrical power generator connected to the rotation shaft of the hydraulic pump is operated to generate electricity by excess torque which has not been energy-regenerated in the hydraulic pump so that this generated electrical power is charged in a battery.

Owner:KOMATSU LTD

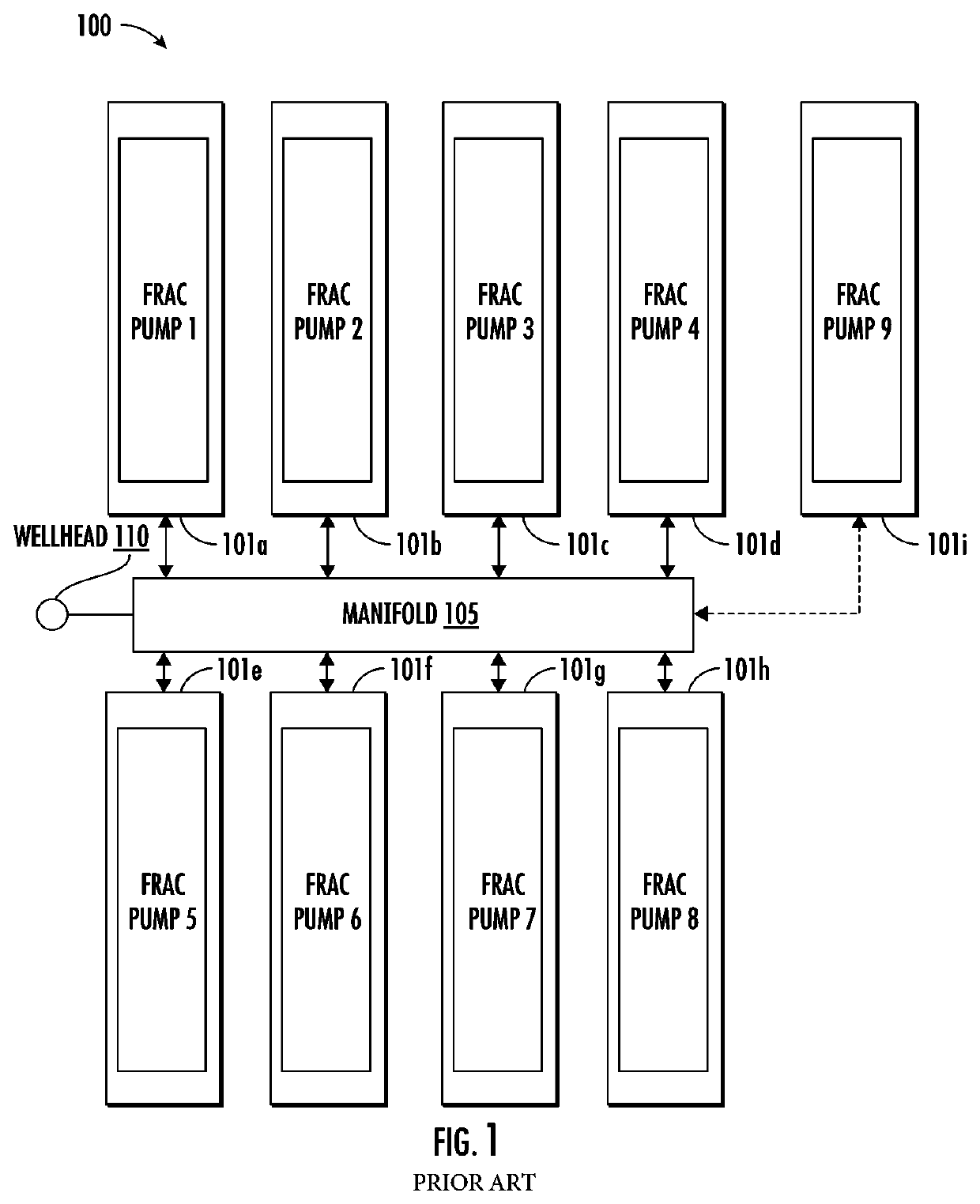

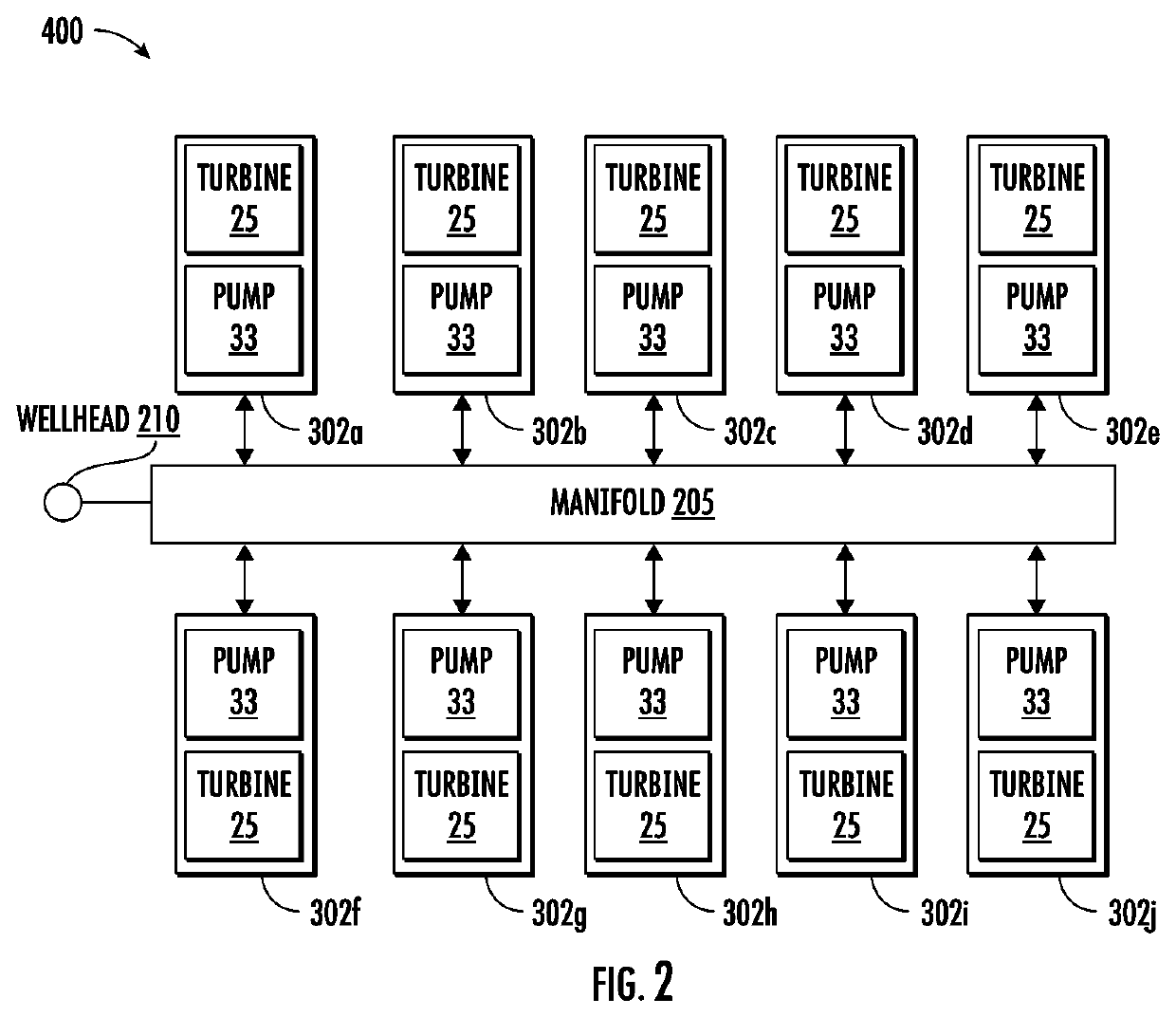

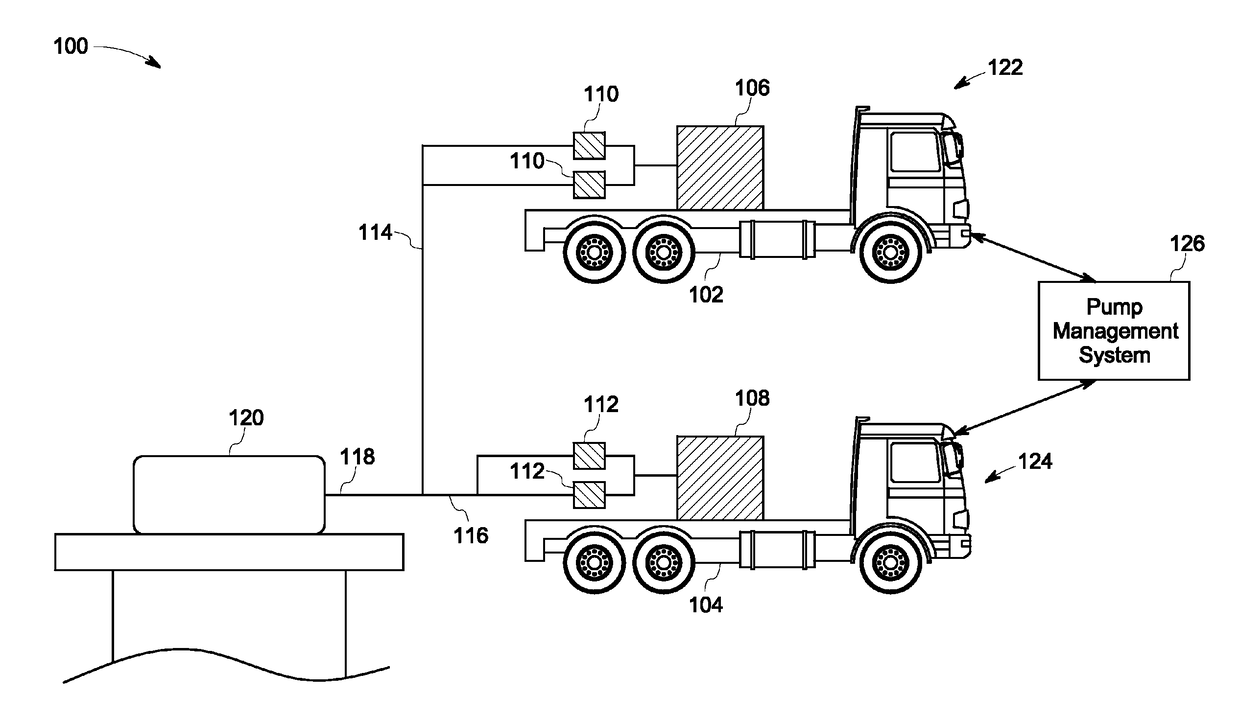

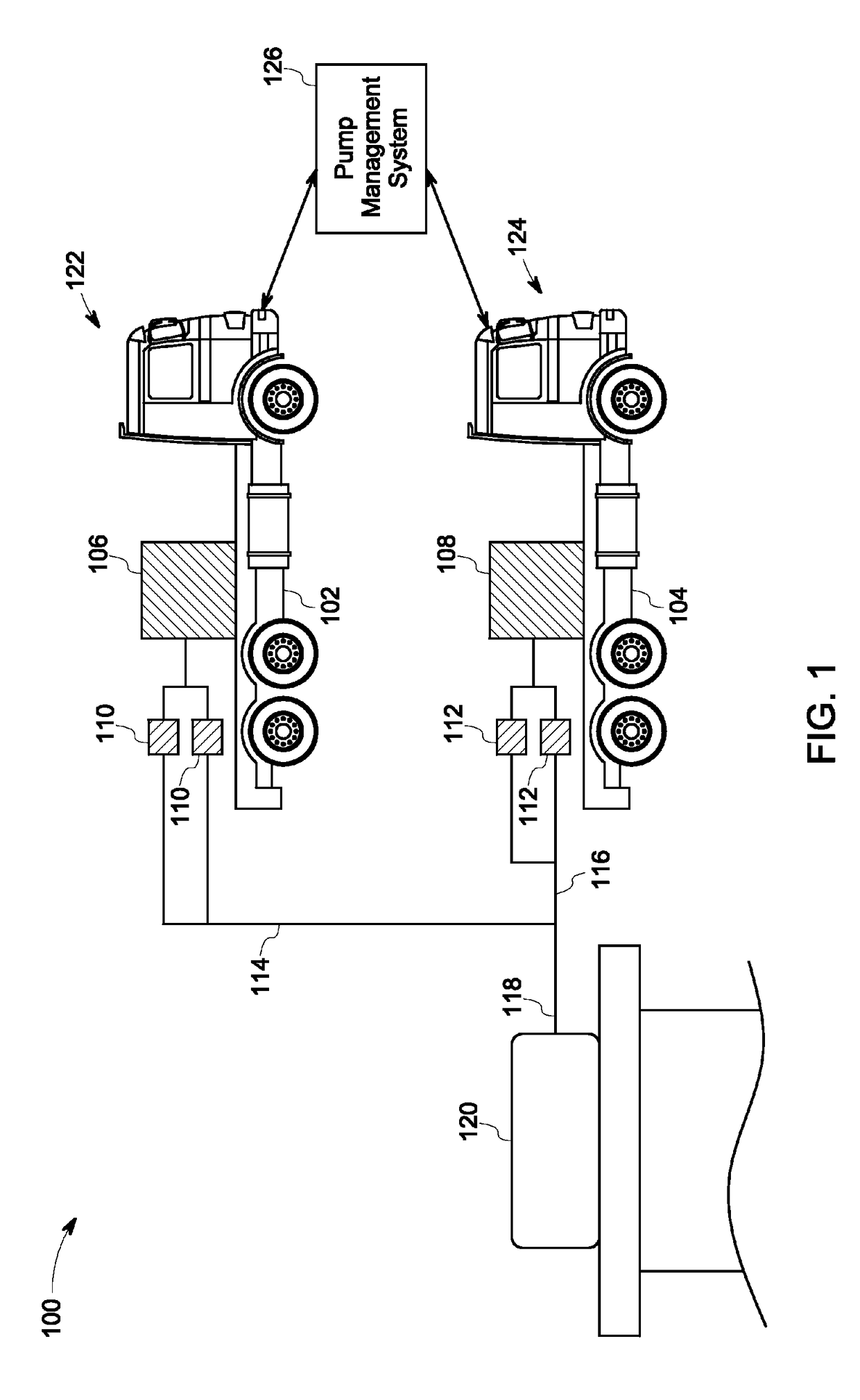

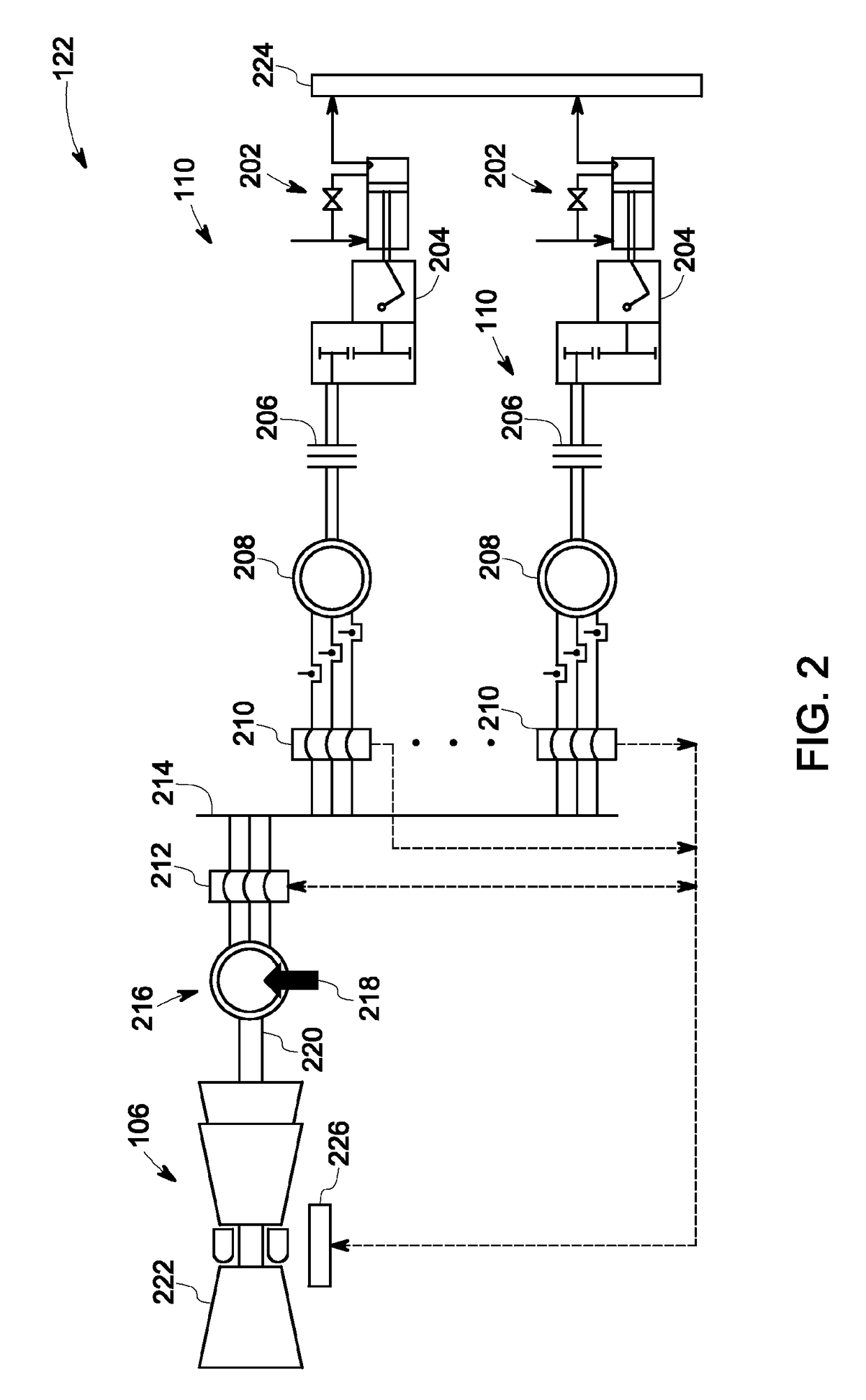

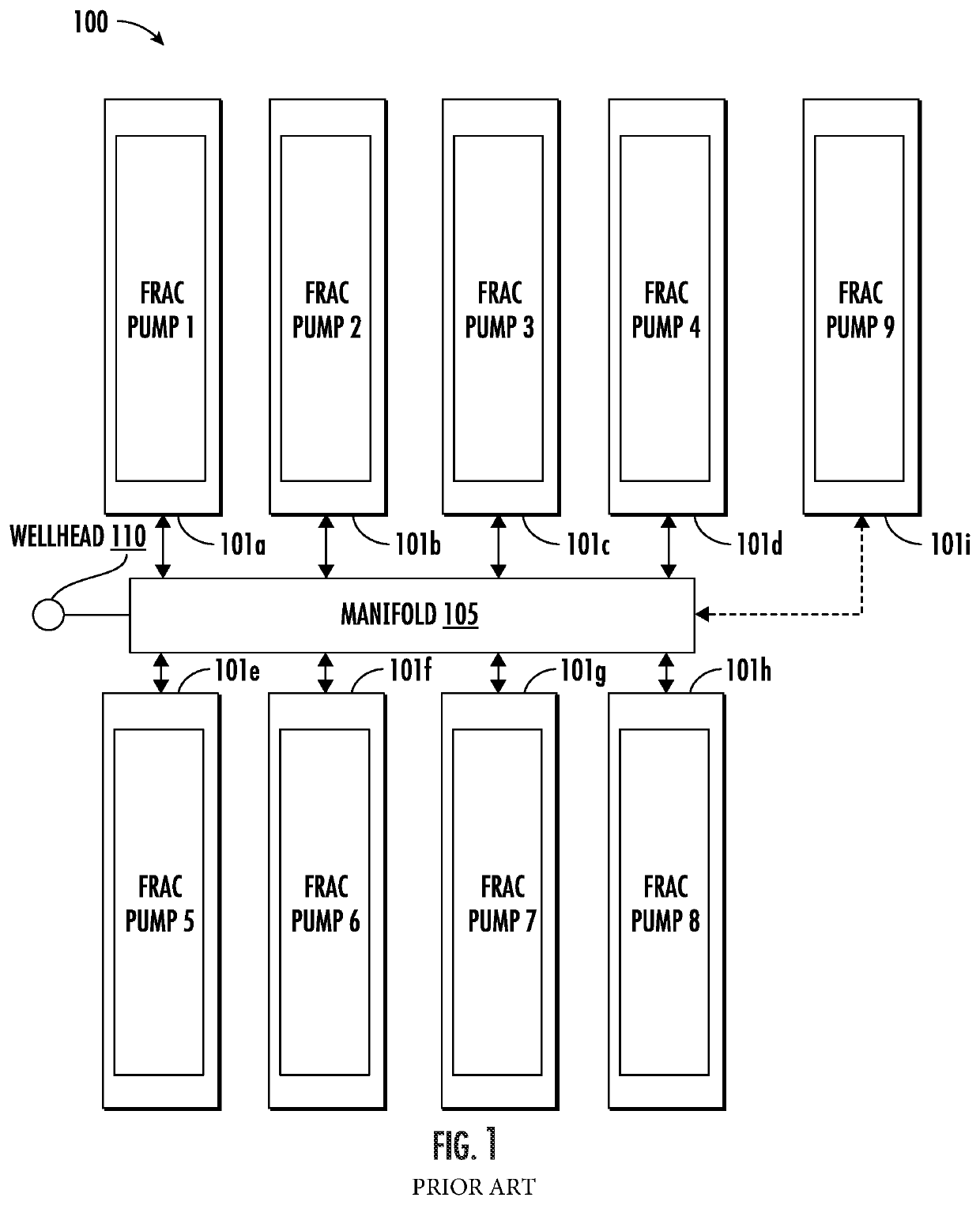

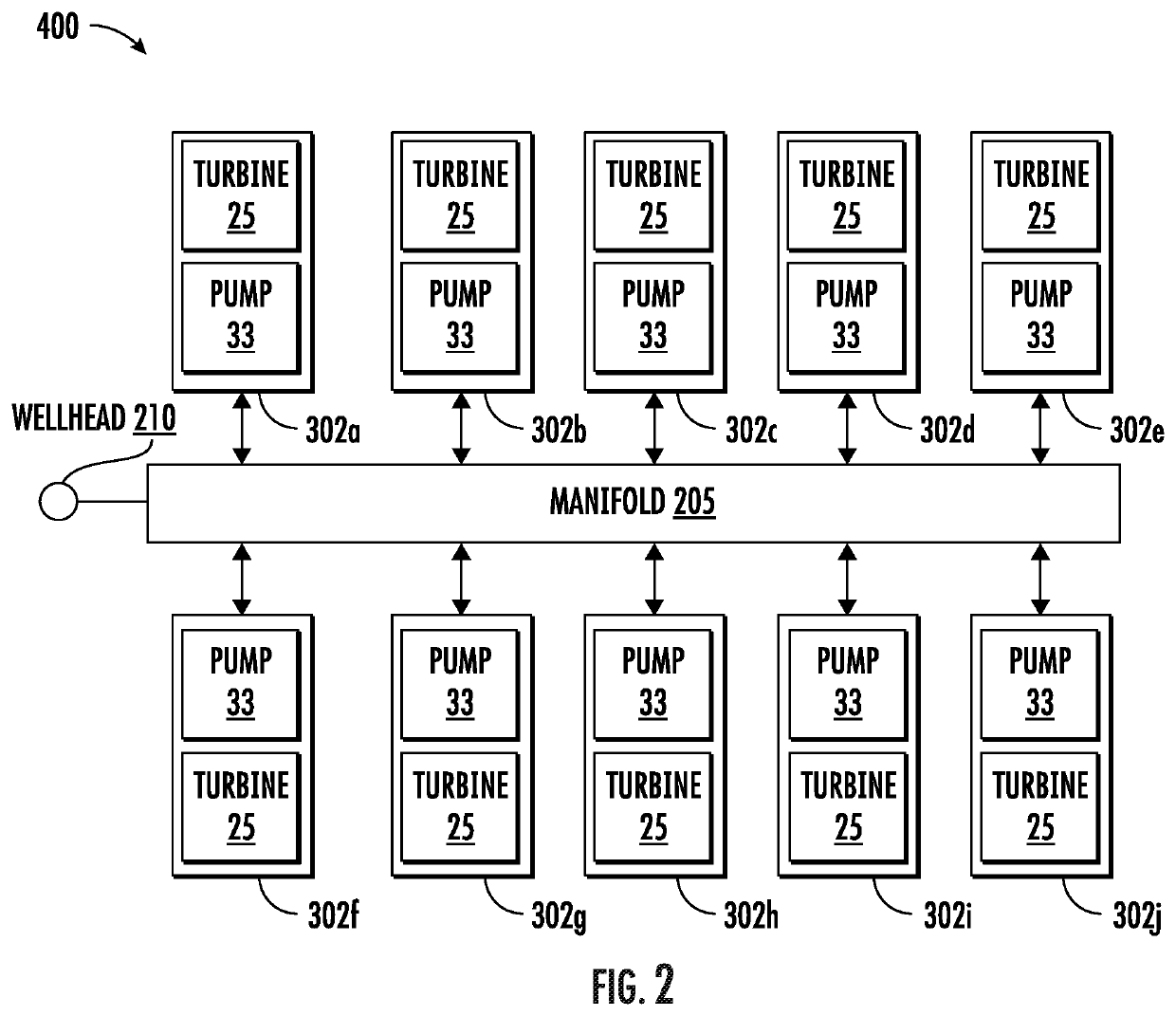

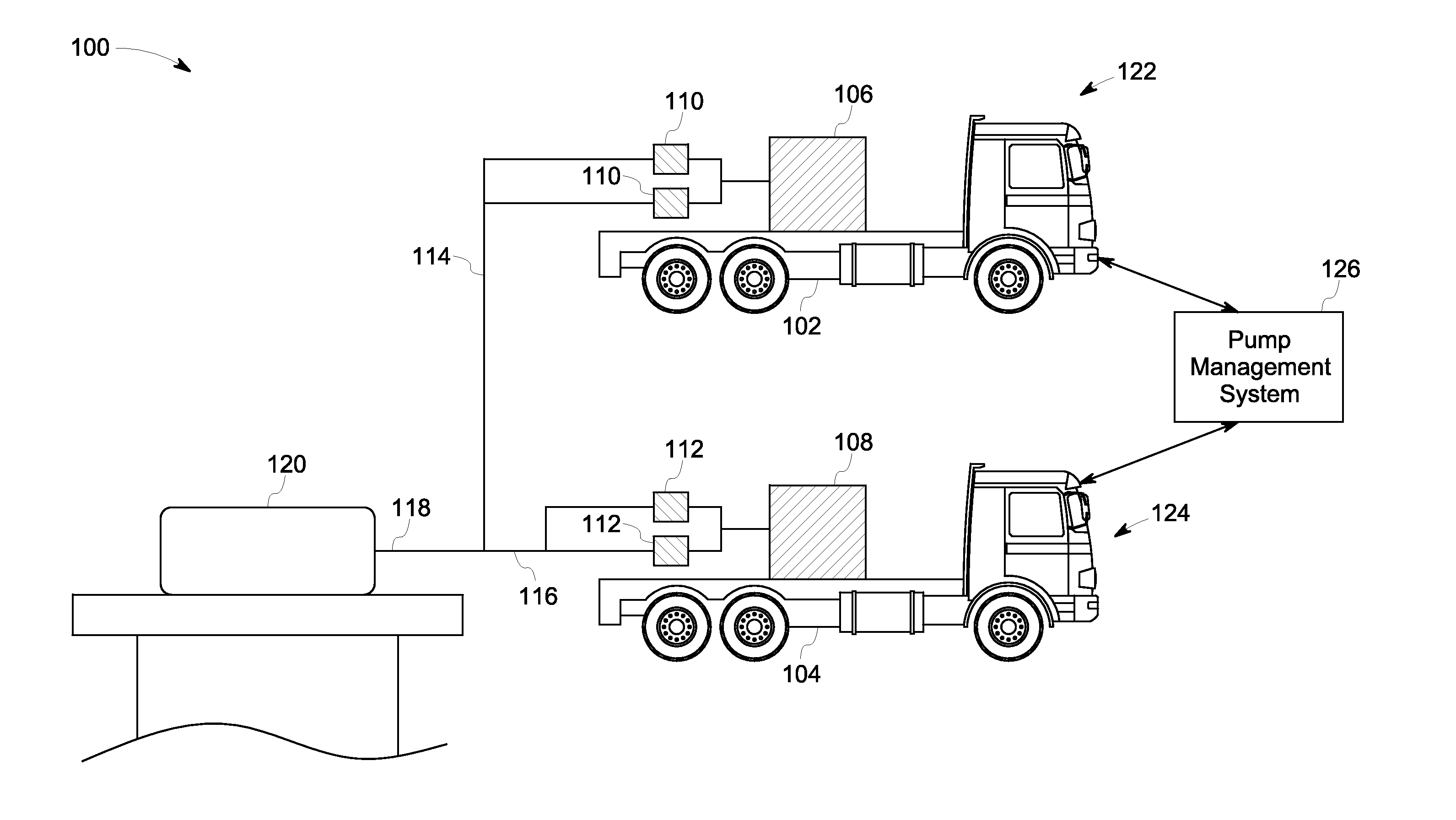

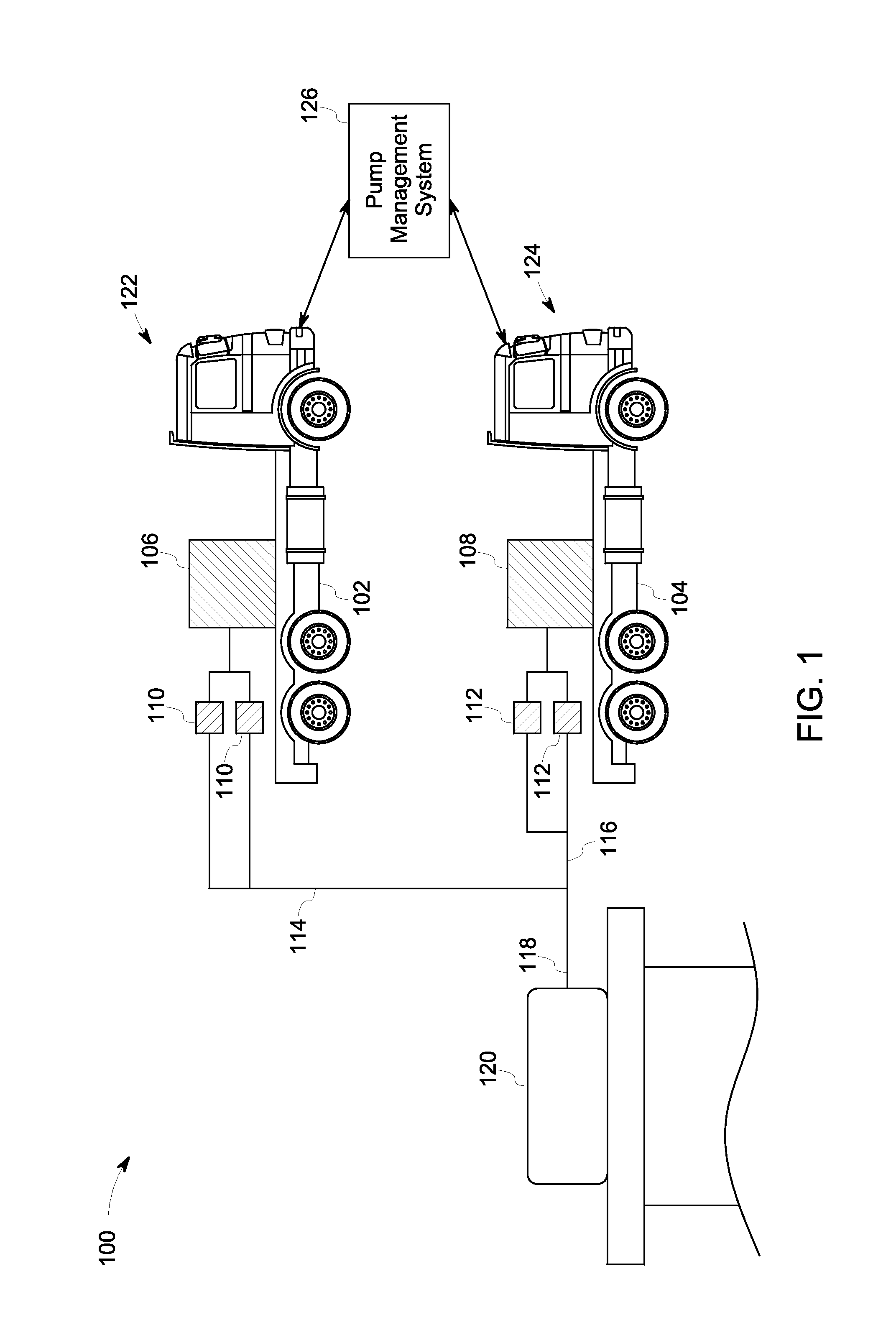

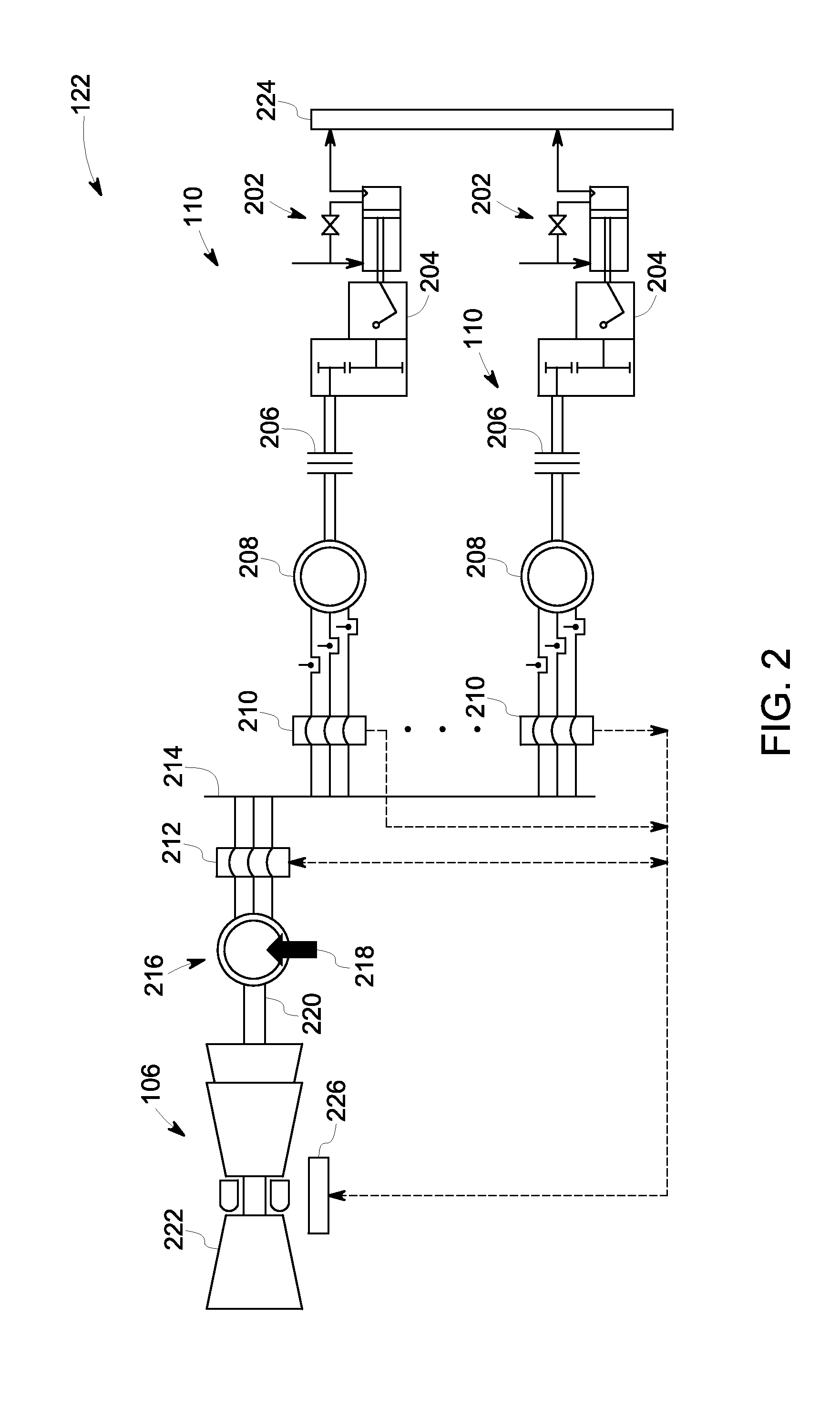

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

System and method for power management of pumping system

A method implemented by at least one processor includes receiving a pressure profile to be generated by a pumping system, wherein the pumping system includes at least one pump-unit powered by at least one generator-unit. The method also includes receiving a pump-unit parameter from at least one pump-unit and a generator-unit parameter from at least one generator unit. The pump-unit parameter is representative of an operating parameter of the pump-unit. The generator-unit parameter is representative of an operating parameter of the at least one generator-unit. The method includes generating an operating set-point corresponding to the at least one generator-unit based on the pump-unit parameter and the generator-unit parameter, wherein the operating set-point is one of at least one operating set-point corresponding to the at least one generator-unit. The method also includes determining an input parameter for the at least one generator-unit based on the at least one operating set-point.

Owner:HYDRIL USA DISTRIBUTION LLC

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC

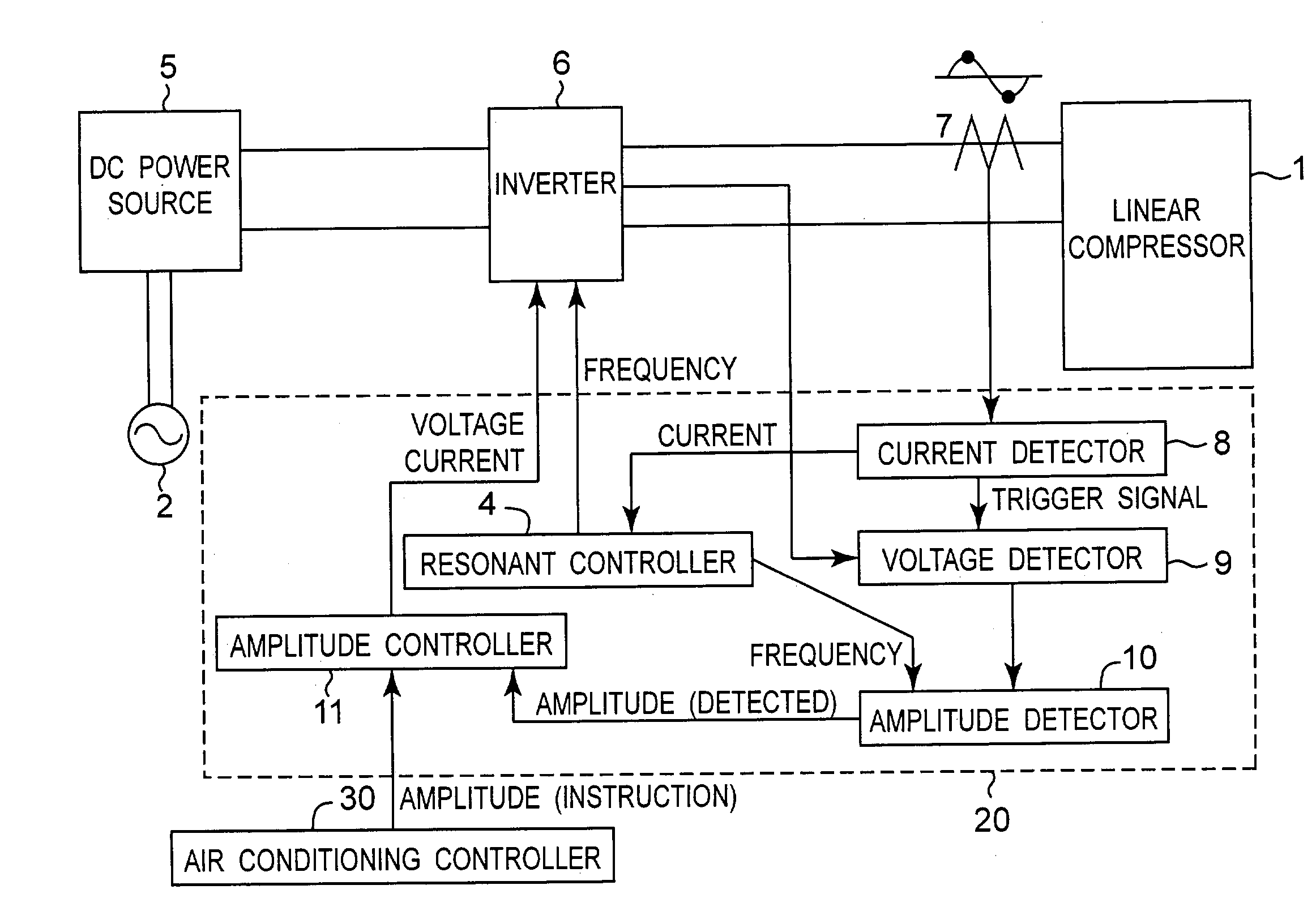

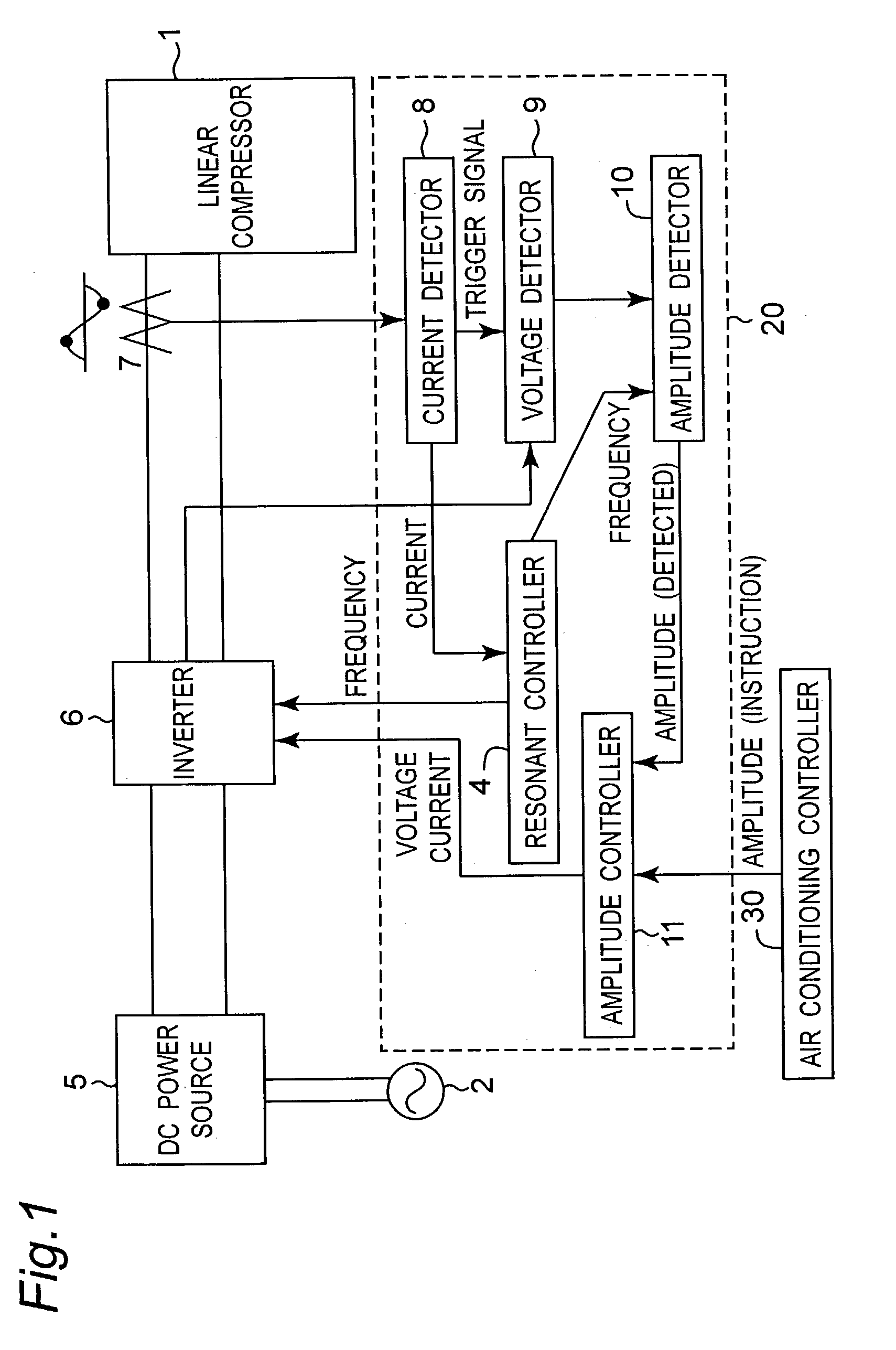

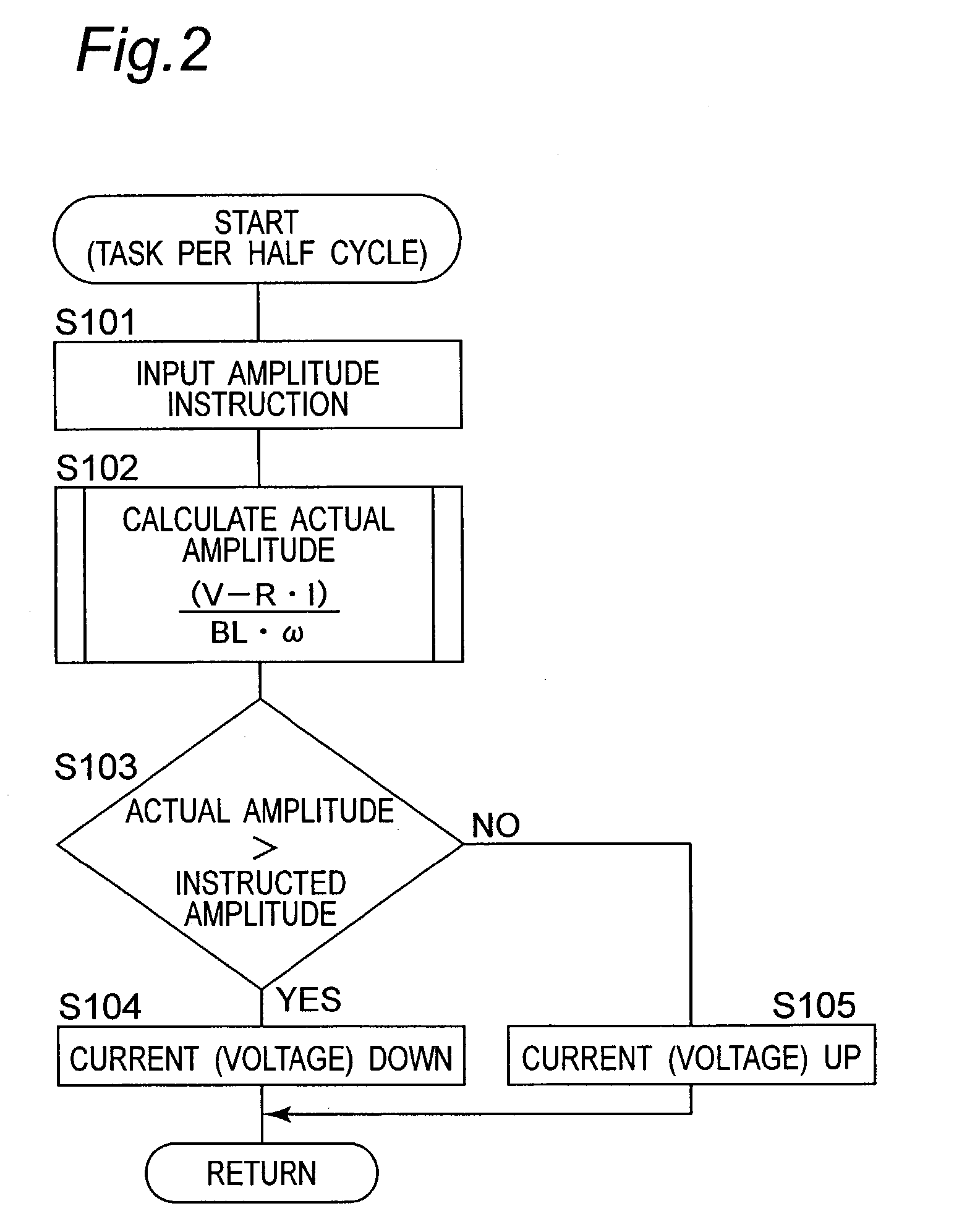

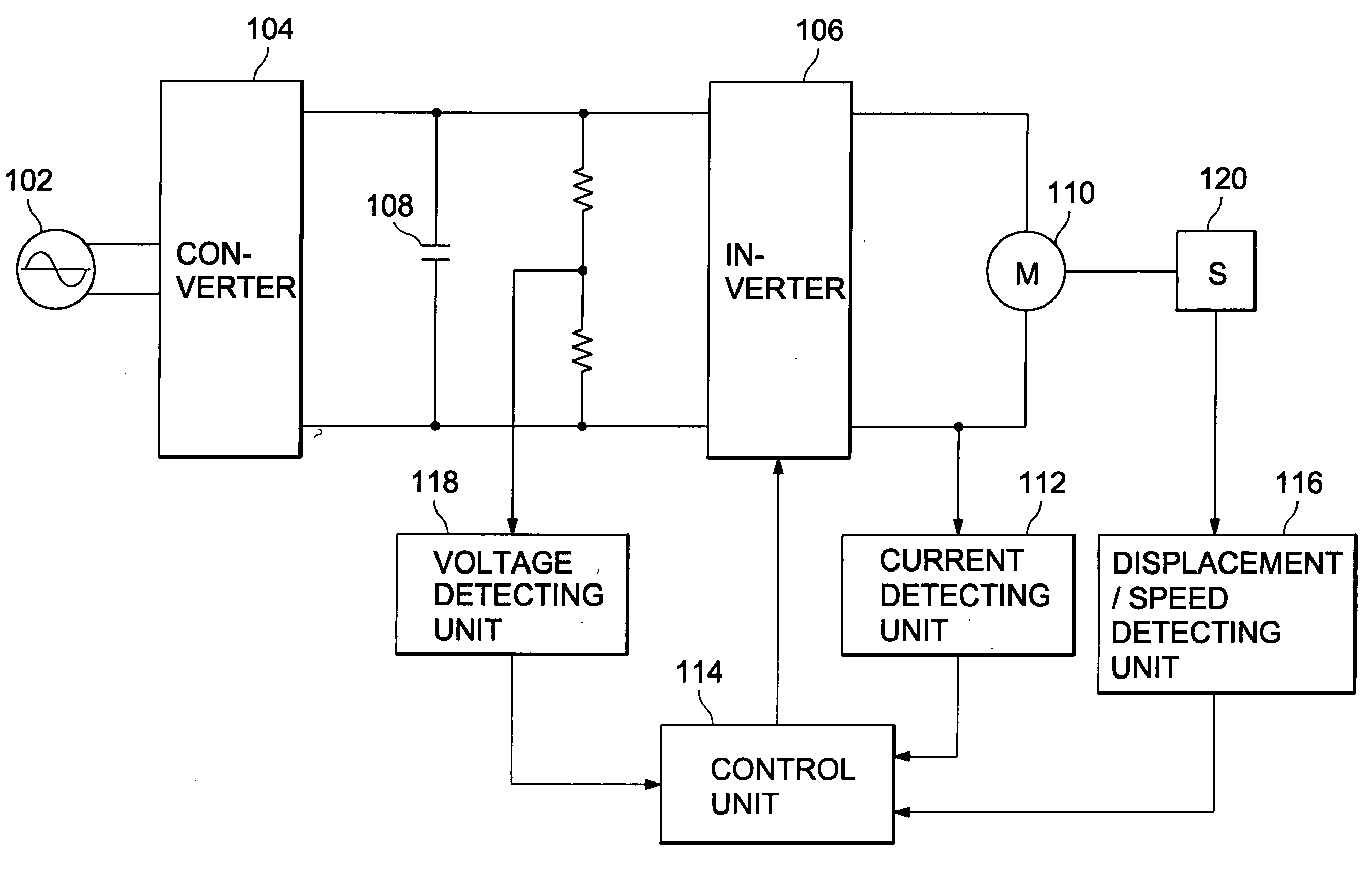

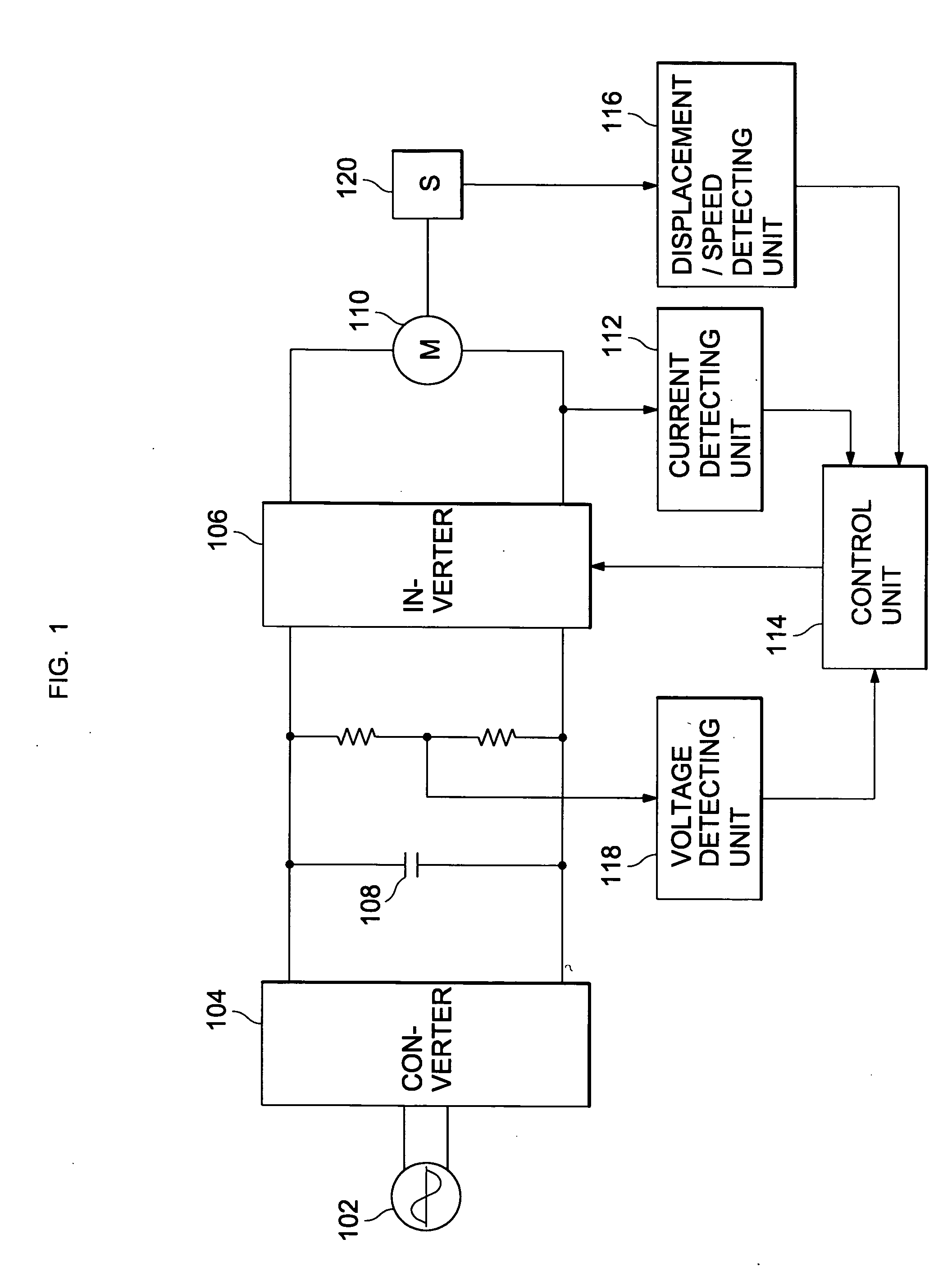

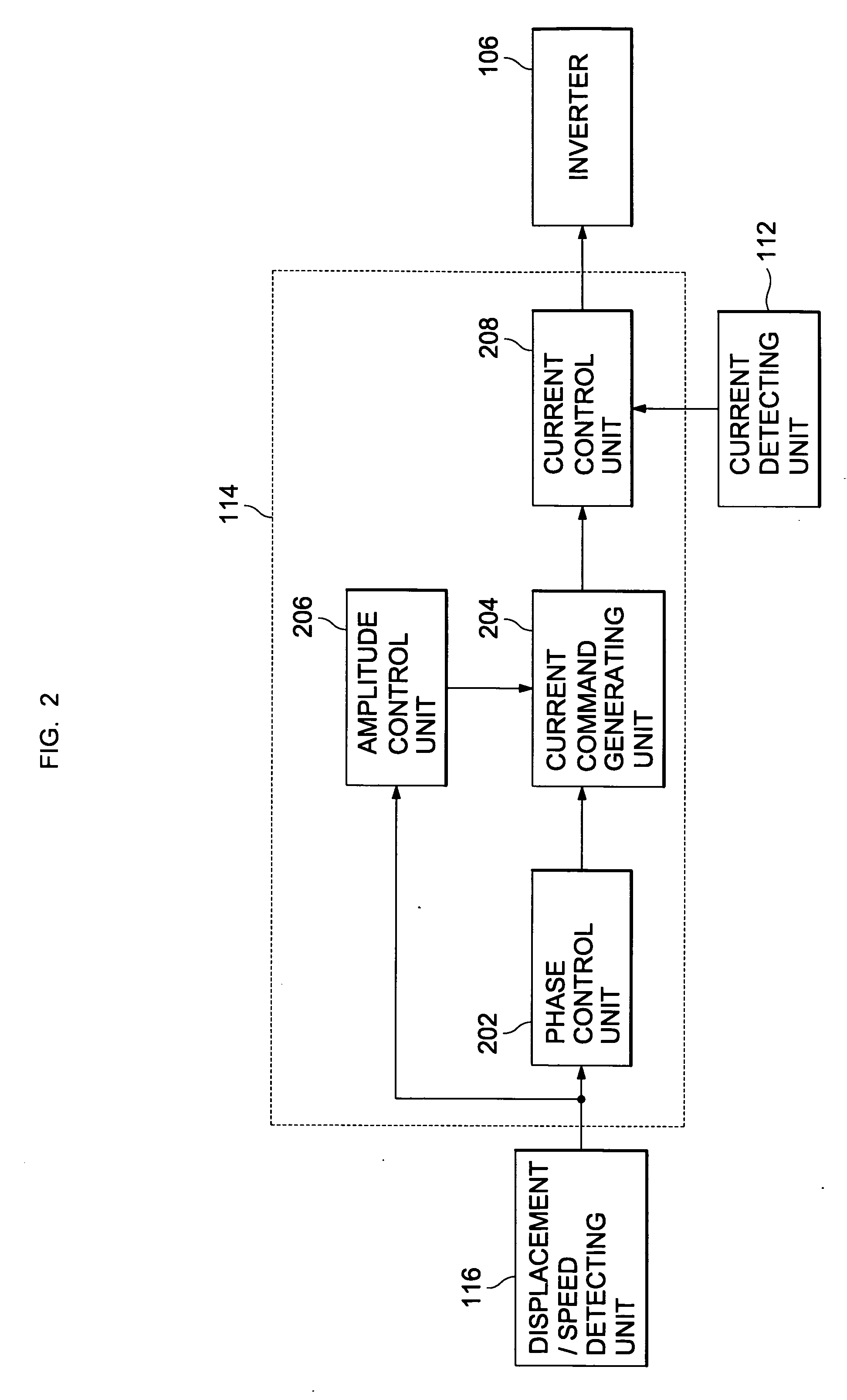

Driving apparatus of a linear motor

ActiveUS20040005222A1Accurate calculationResonance can be controlledMotor/generator/converter stoppersDC motor speed/torque controlAlternating currentLinear motor

A driving apparatus of a linear motor which reciprocally drives a movable element supported by an elastic member, includes an inverter that converts a direct current power into an alternating-current power with a specified frequency to drive the linear motor, a current detector that detects the output current of the inverter, a voltage detector that detects the output voltage of the inverter, an amplitude detector that detects an amplitude of the movable element of the linear motor, an amplitude controller adjusts the output current or output voltage in a first control cycle so that the amplitude of the movable element is a desired constant value, and a resonant controller that adjusts the output frequency of the inverter in a second control cycle which is larger than the first control cycle so that the output current of the inverter is substantially minimum on condition that the amplitude is substantially constant.

Owner:PANASONIC CORP

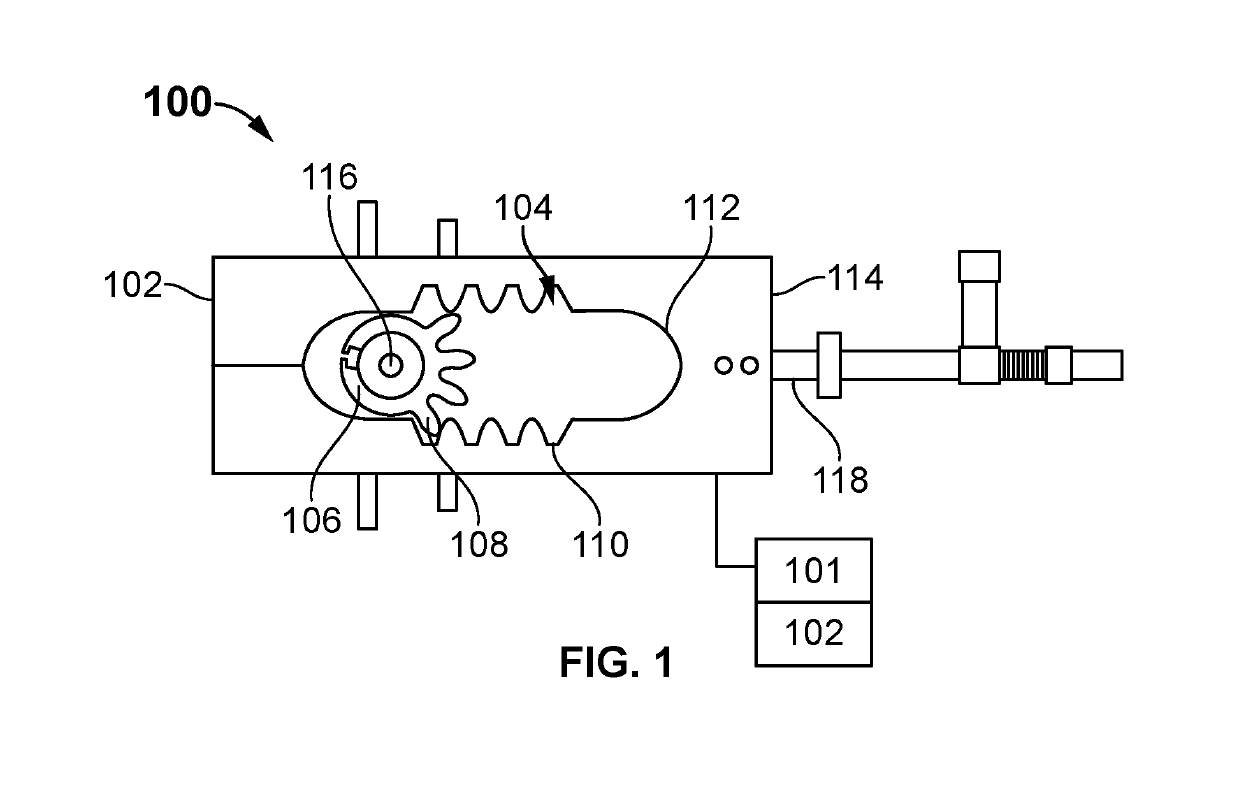

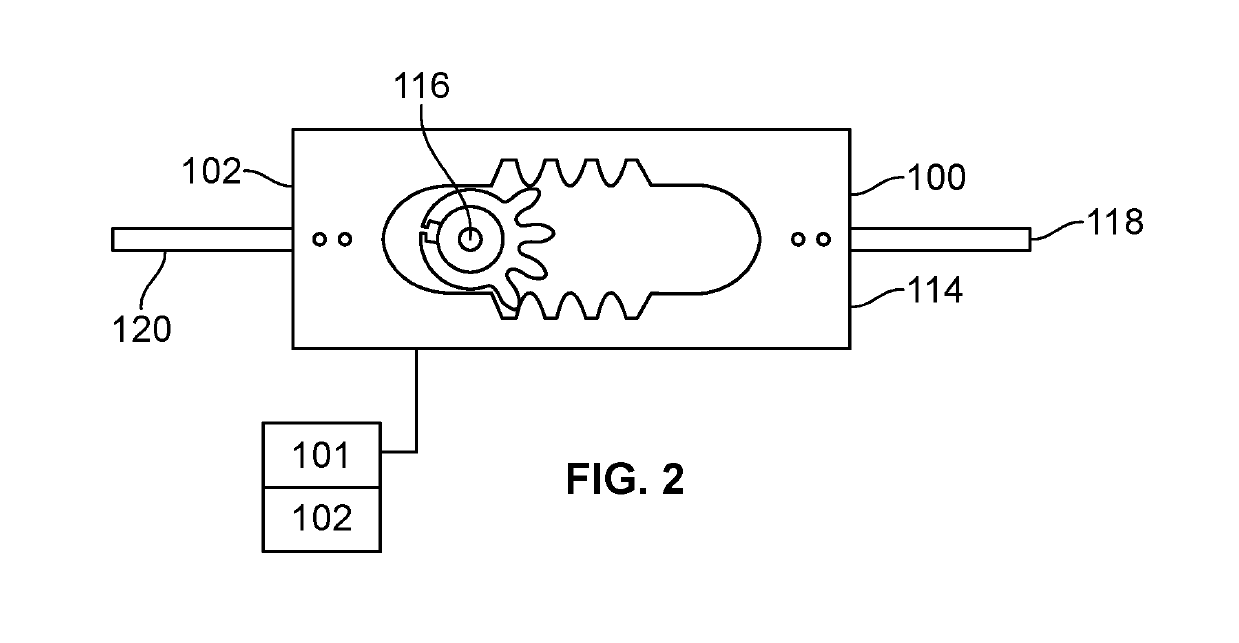

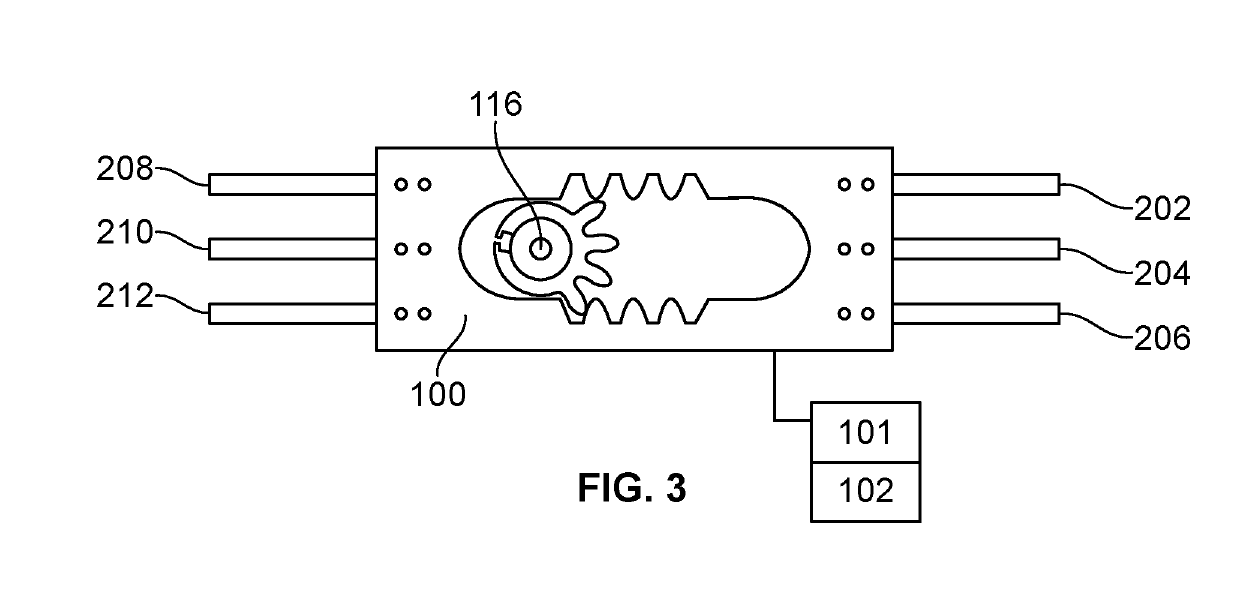

System and Method for a Reciprocating Injection Pump

A reciprocating injection pump is disclosed including but not limited to a reciprocating block driven by a rotating gear, the gear having a substantially circular shape with four gear teeth formed on the rotating gear along approximately one fourth of the substantially circular shape, the rotating gear is attached to a rotating motor, the rotating motor having a right-angle motor shaft.

Owner:PREDOMINANT PUMPS & AUTOMATION SOLUTIONS LLC

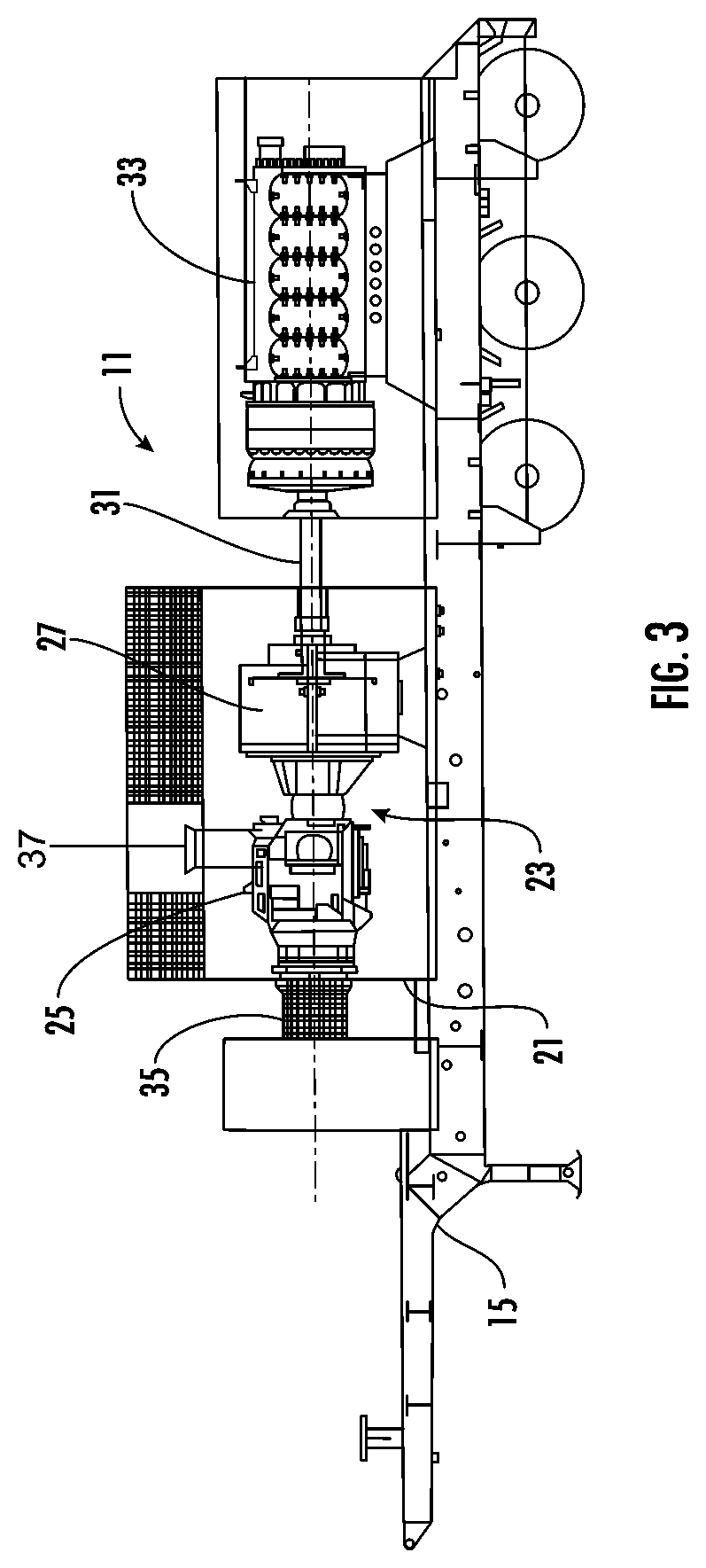

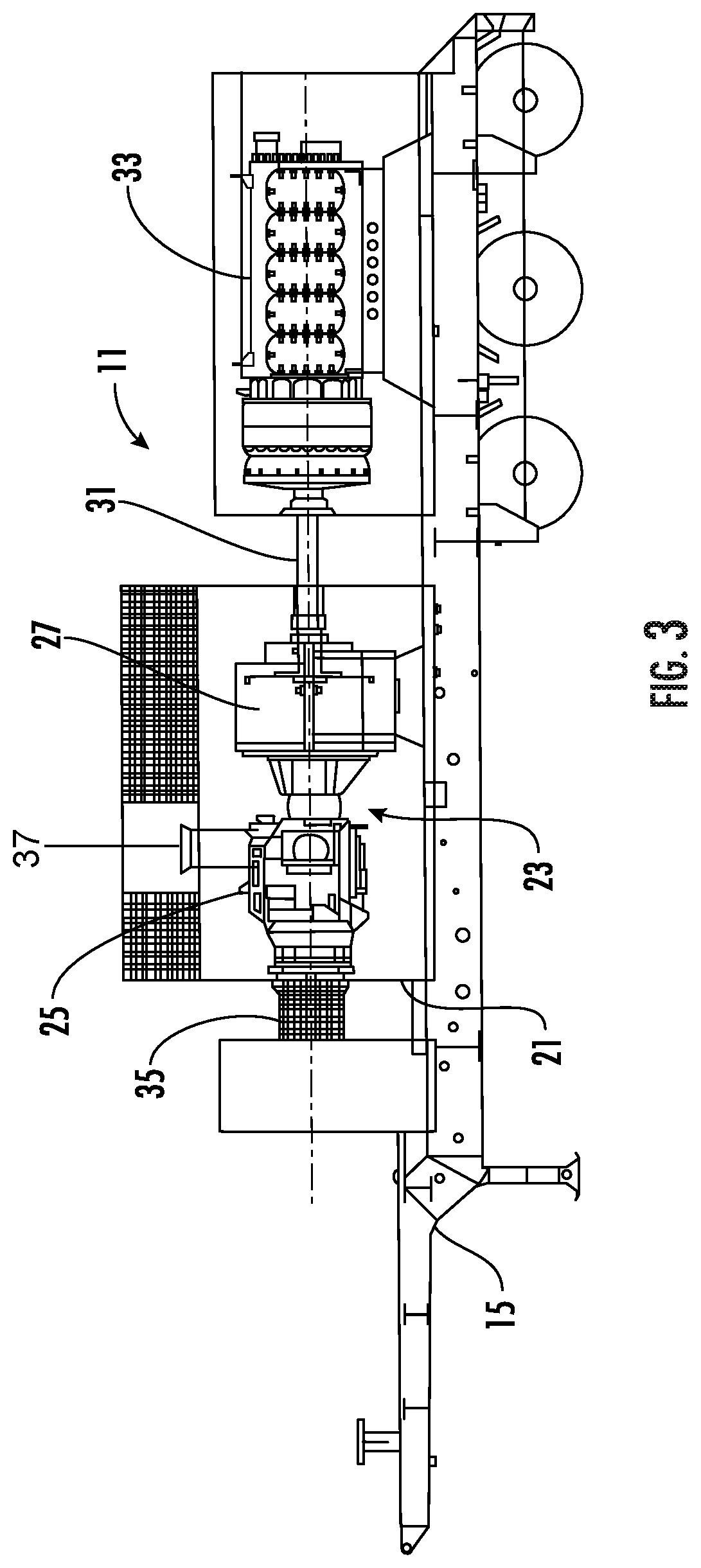

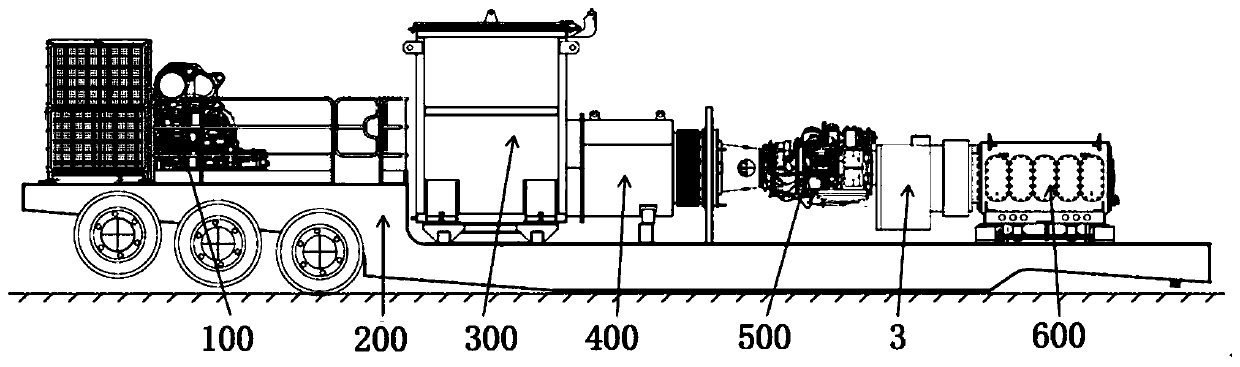

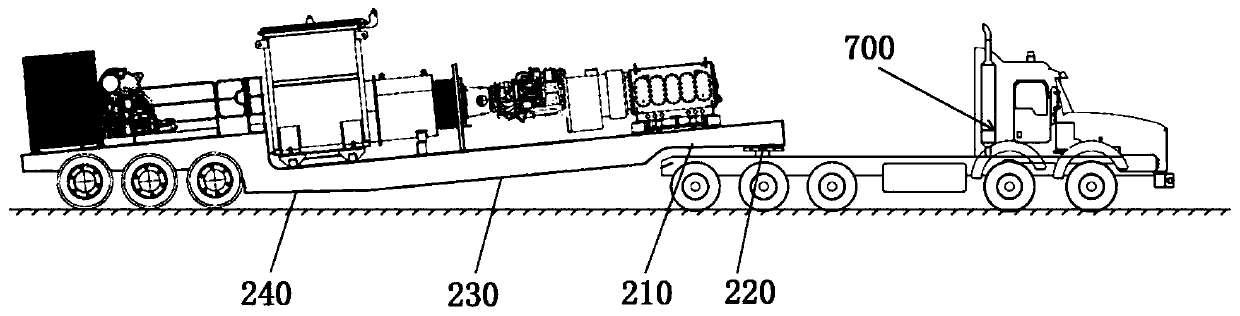

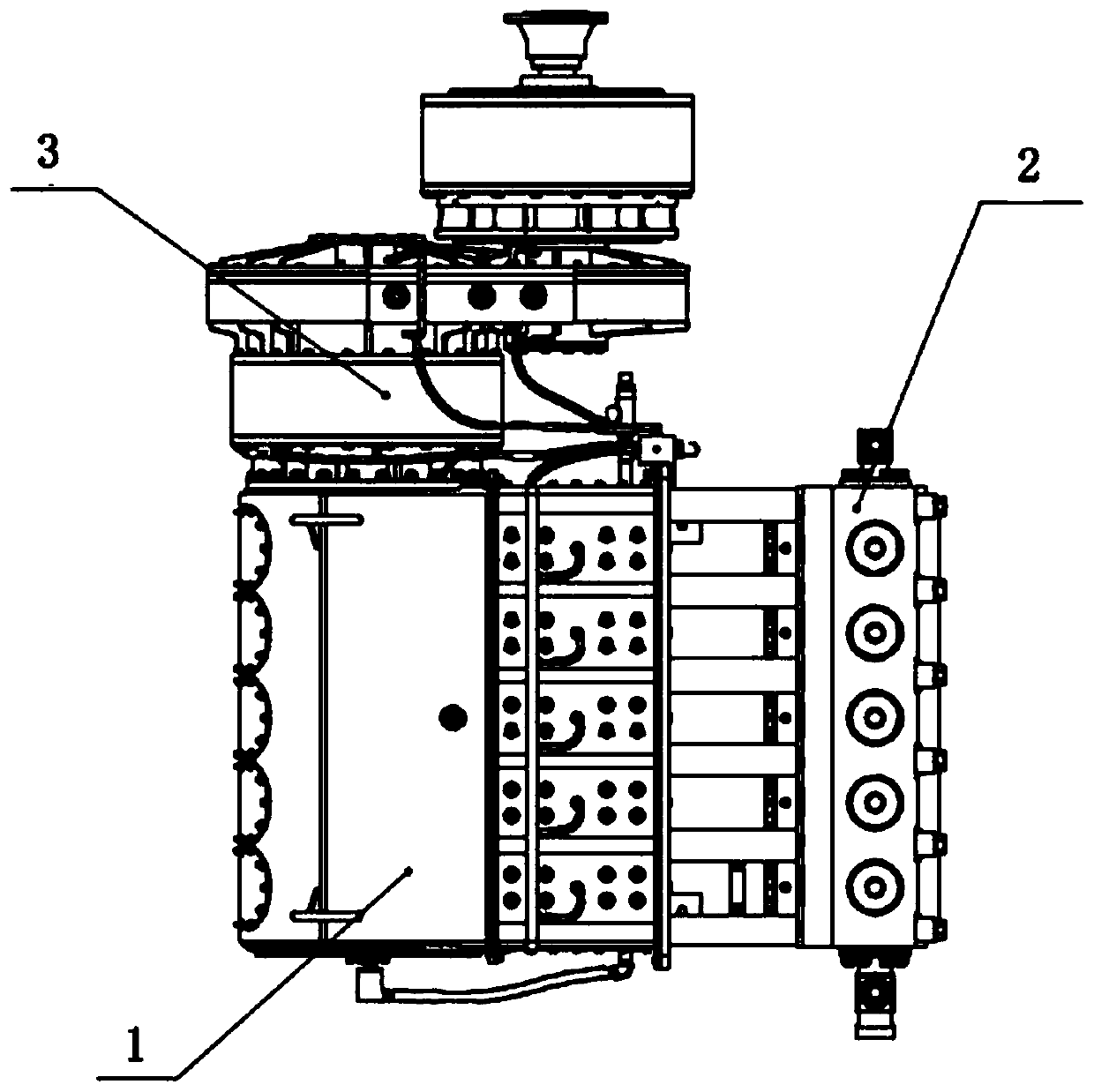

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

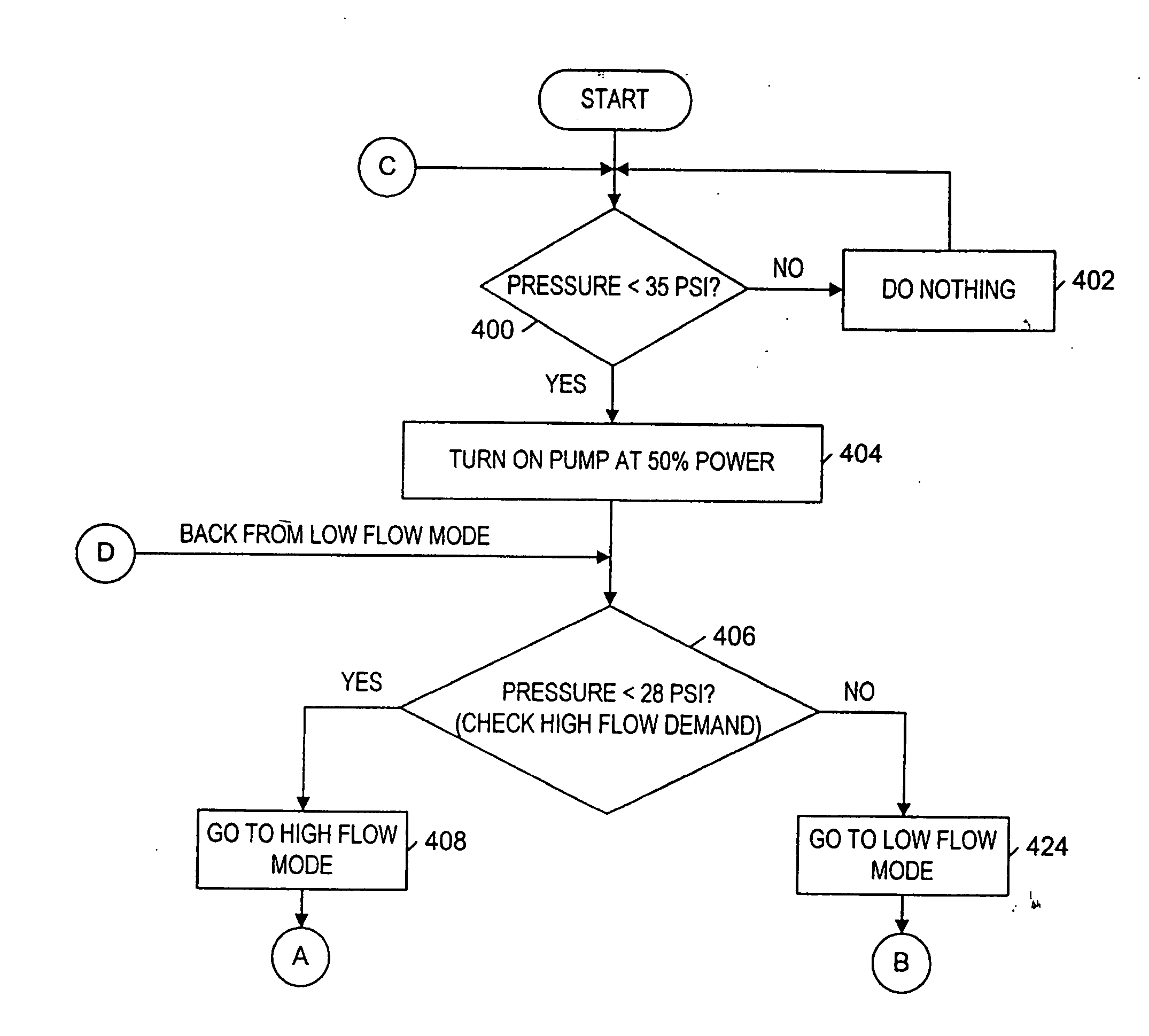

Pump and pump control circuit apparatus and method

InactiveUS20060204367A1Reduce the required powerIncrease powerMotor/generator/converter stoppersFluid parameterMicrocontrollerControl system

A method and apparatus for a pump and a pump control system. The apparatus includes a pressure sensor and a temperature sensor coupled to a pump control system. For the method of the invention, the microcontroller provides a pulse-width modulation control signal to an output power stage in order to selectively control the power provided to the pump.

Owner:SHURFLO

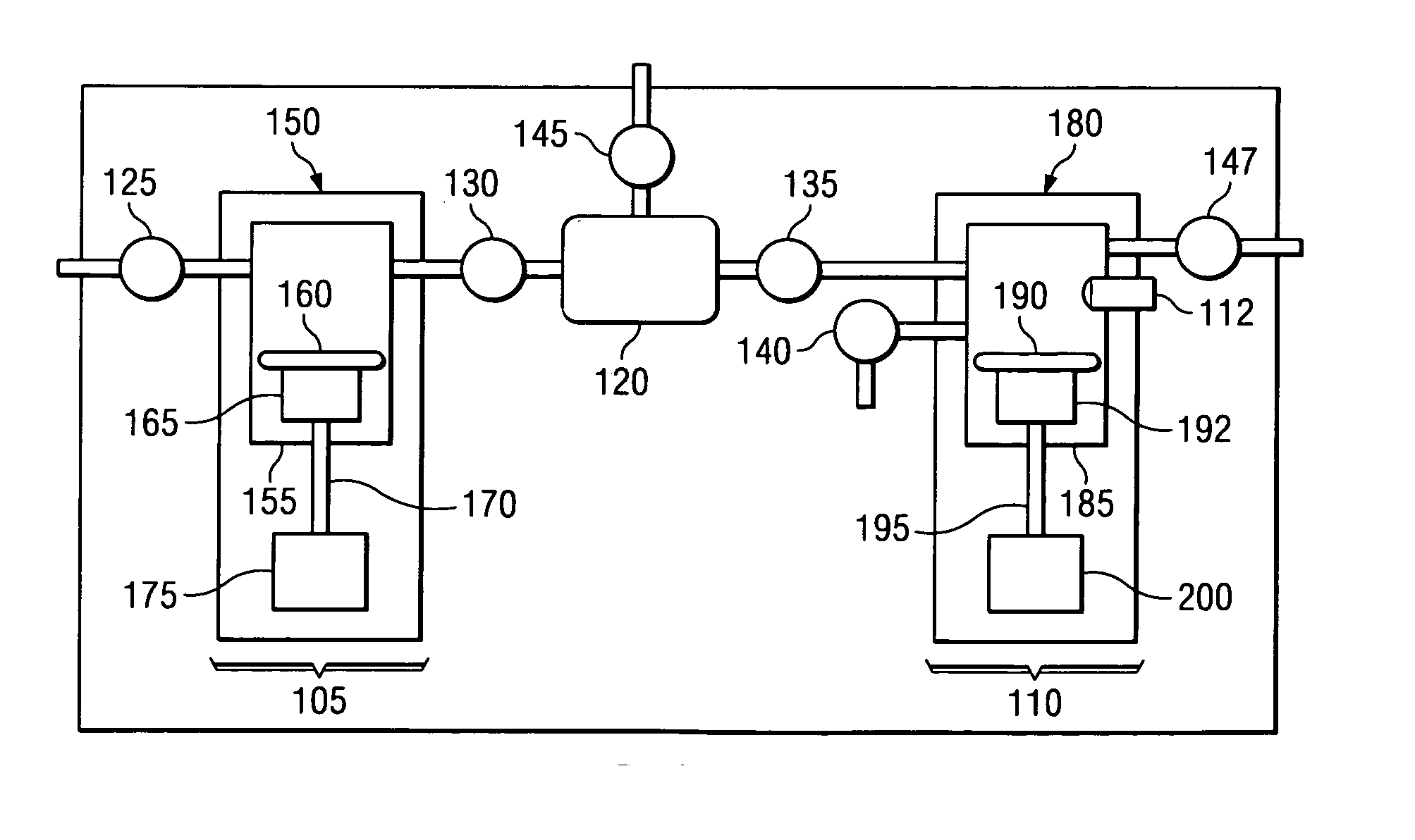

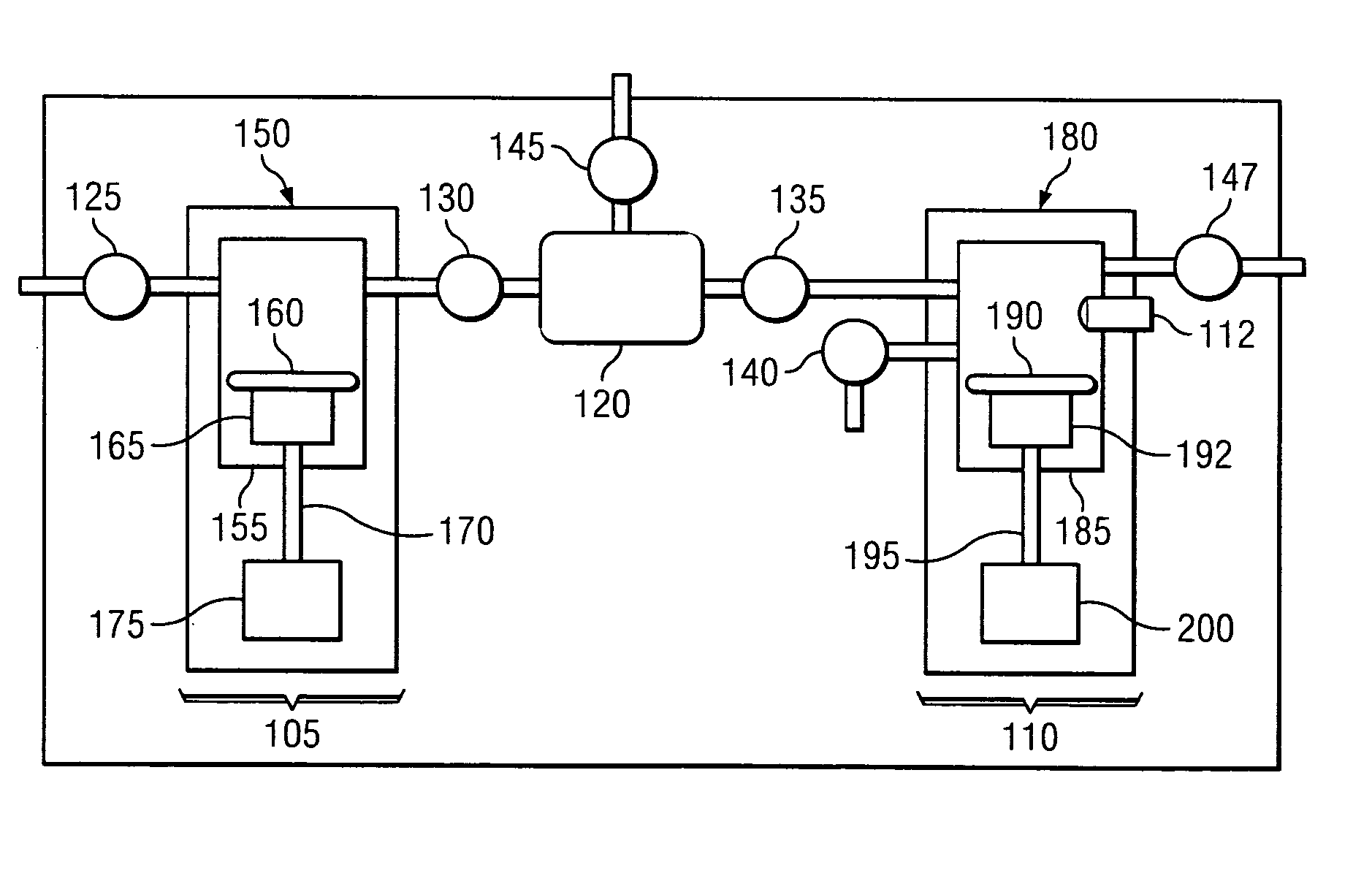

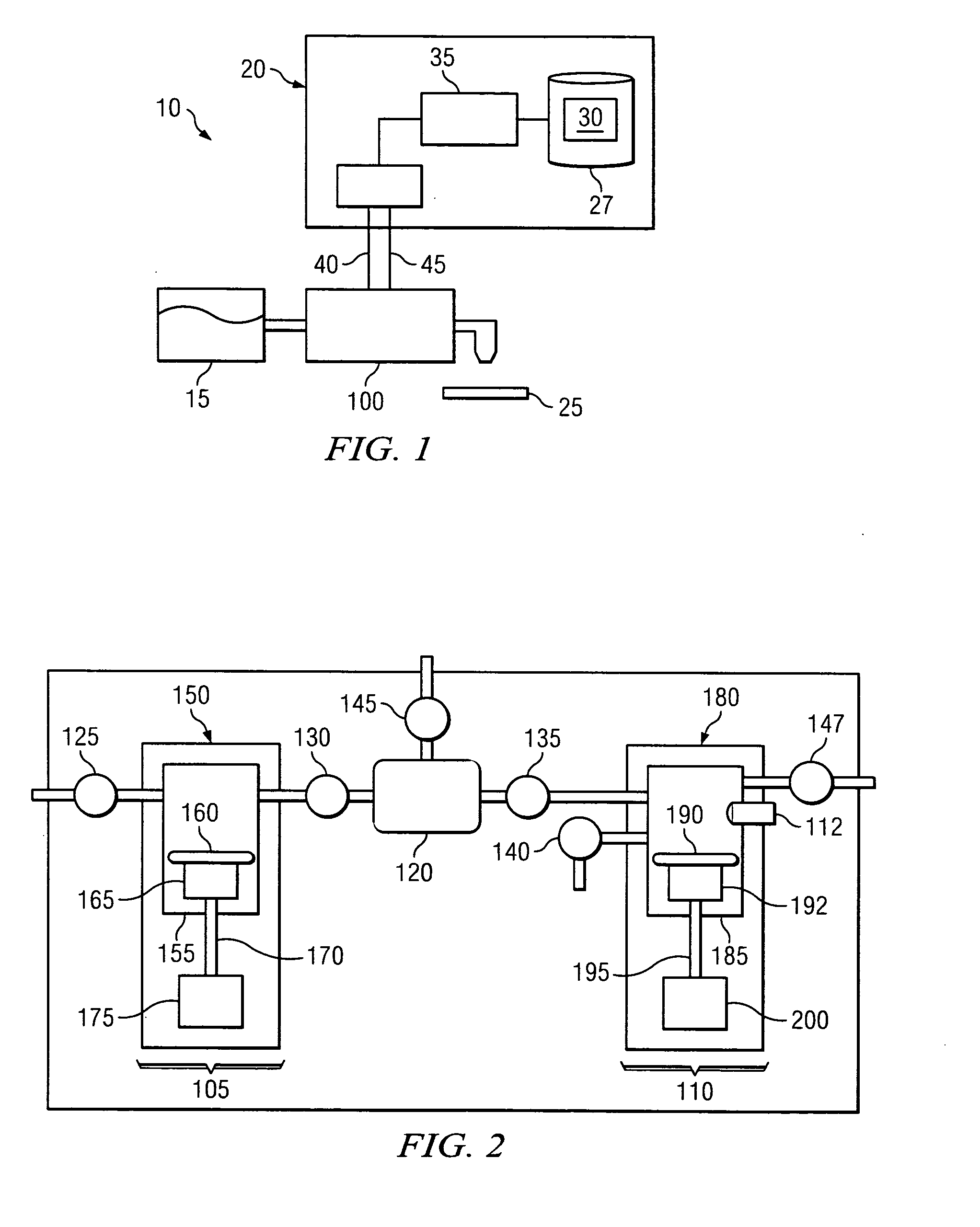

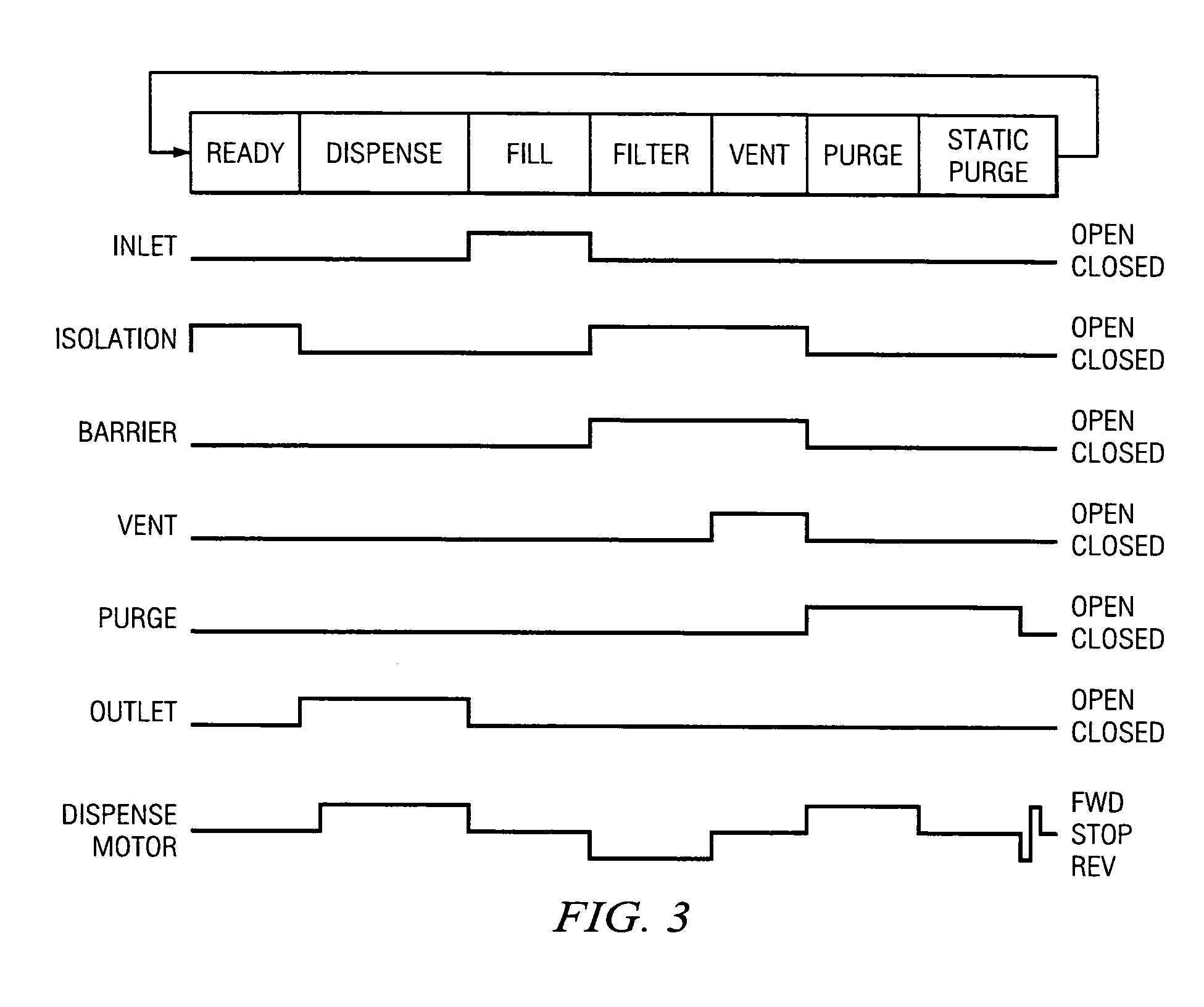

System and method for control of fluid pressure

ActiveUS20070128046A1Gentler handlingEliminates and reduces disadvantageFluid parameterFlexible member pumpsPressure decreaseEngineering

Embodiments of the present invention are related to a pumping system that accurately dispenses fluid using a multiple stage (“multi-stage”) pump. More particularly, embodiments of the present invention provide for control of a feed stage pump to regulate fluid pressure at a downstream dispense stage pump. According to one embodiment of the present invention, a pressure sensor at the dispense stage pump determines the pressure in a dispense chamber. When the pressure reaches a predefined threshold, the dispense stage pump can begin to increase the available volume of the dispense chamber, thereby causing the pressure in the dispense chamber to drop. As the pressure decreases / increases at the downstream pump, the pressure applied by the upstream pump can bed increased / decreased.

Owner:ENTEGRIS INC

Construction machine

InactiveUS7086226B2Reliable collectionReliable regenerationFluid couplingsMotor parameterElectricityEnergy regeneration

Owner:KOMATSU LTD

System and method for health management of pumping system

ActiveUS20160195082A1Guaranteed uptimeFluid parameterFlexible member pumpsSimulationManagement system

A method implemented by at least one processor includes receiving a plurality of operating parameters of a pumping system, wherein the pumping system has a plurality of pump-units powered by a generator-unit. The operating parameters include a pump-unit parameter and a generator-unit parameter. The method also includes receiving reference data of the pumping system, wherein the reference data includes measurements from the pumping system representative of performance of the plurality of pump-units. The method also includes determining one or more health parameters corresponding to one or more pump-units based on the plurality of operating parameters and the reference data. The method further includes modifying one or more input parameters of the generator-unit based on the one or more health parameters for continued operation of the pumping system.

Owner:HYDRIL USA DISTRIBUTION LLC

System and method for monitoring operation of a pump

Systems and methods for monitoring operation of a pump, including verifying operation or actions of a pump, are disclosed. A baseline profile for one or more parameters of a pump may be established. An operating profile may then be created by recording one or more values for the same set of parameters during subsequent operation of the pump. The values of the baseline profile and the operating profile may then be compared at one or more points or sets of points. If the operating profile differs from the baseline profile by more than a certain tolerance an alarm may be sent or another action taken, for example the pumping system may shut down, etc.

Owner:ENTEGRIS INC

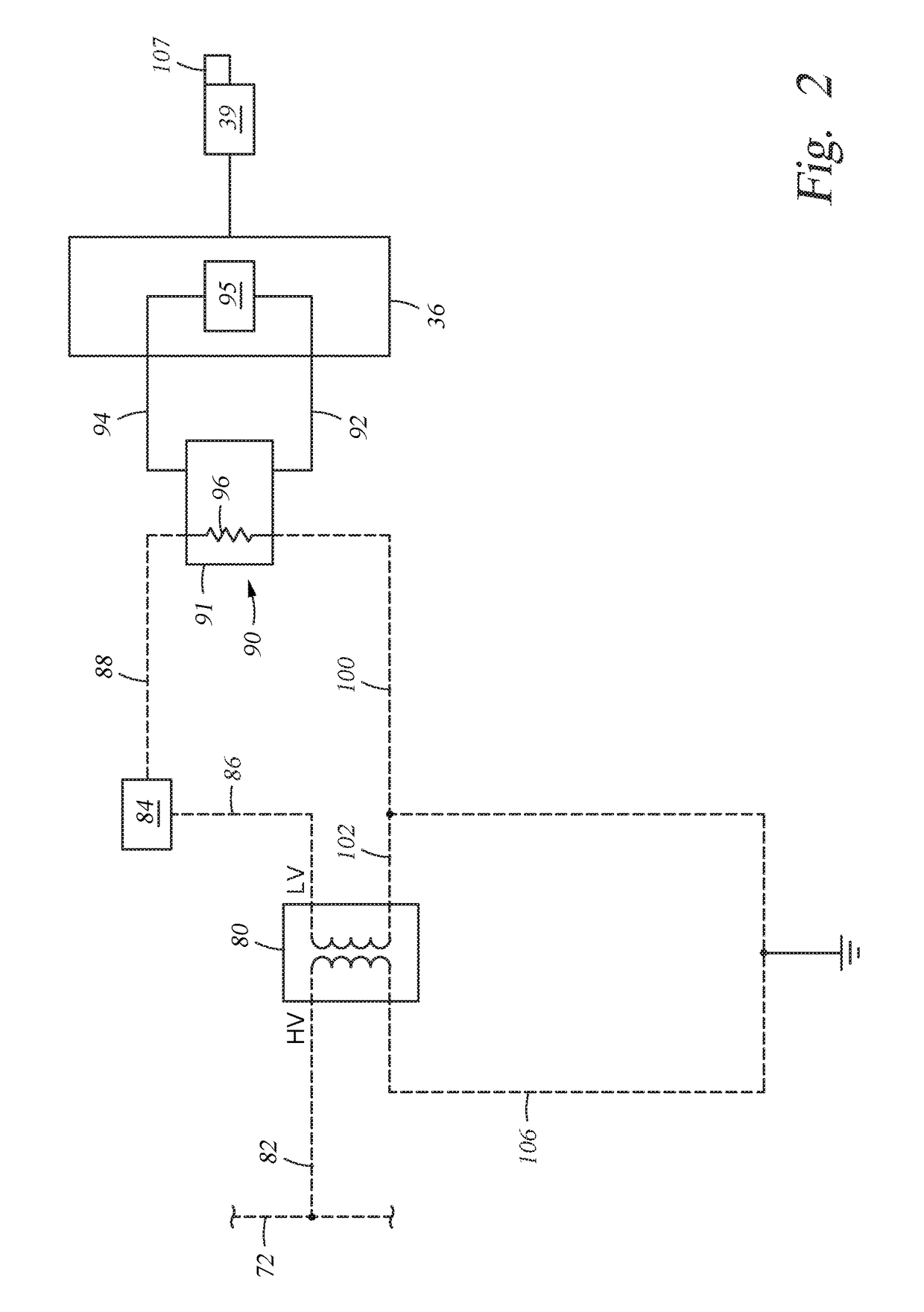

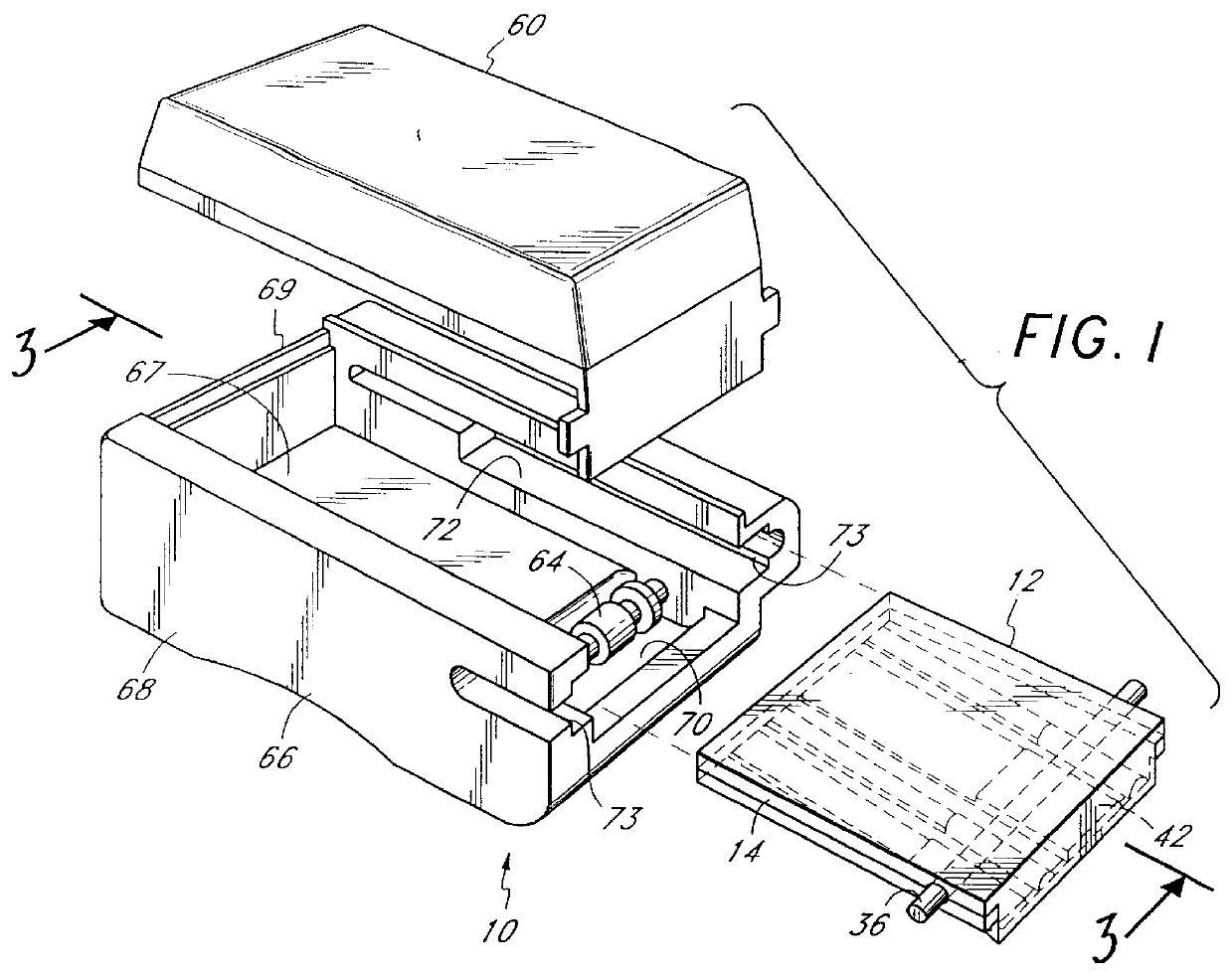

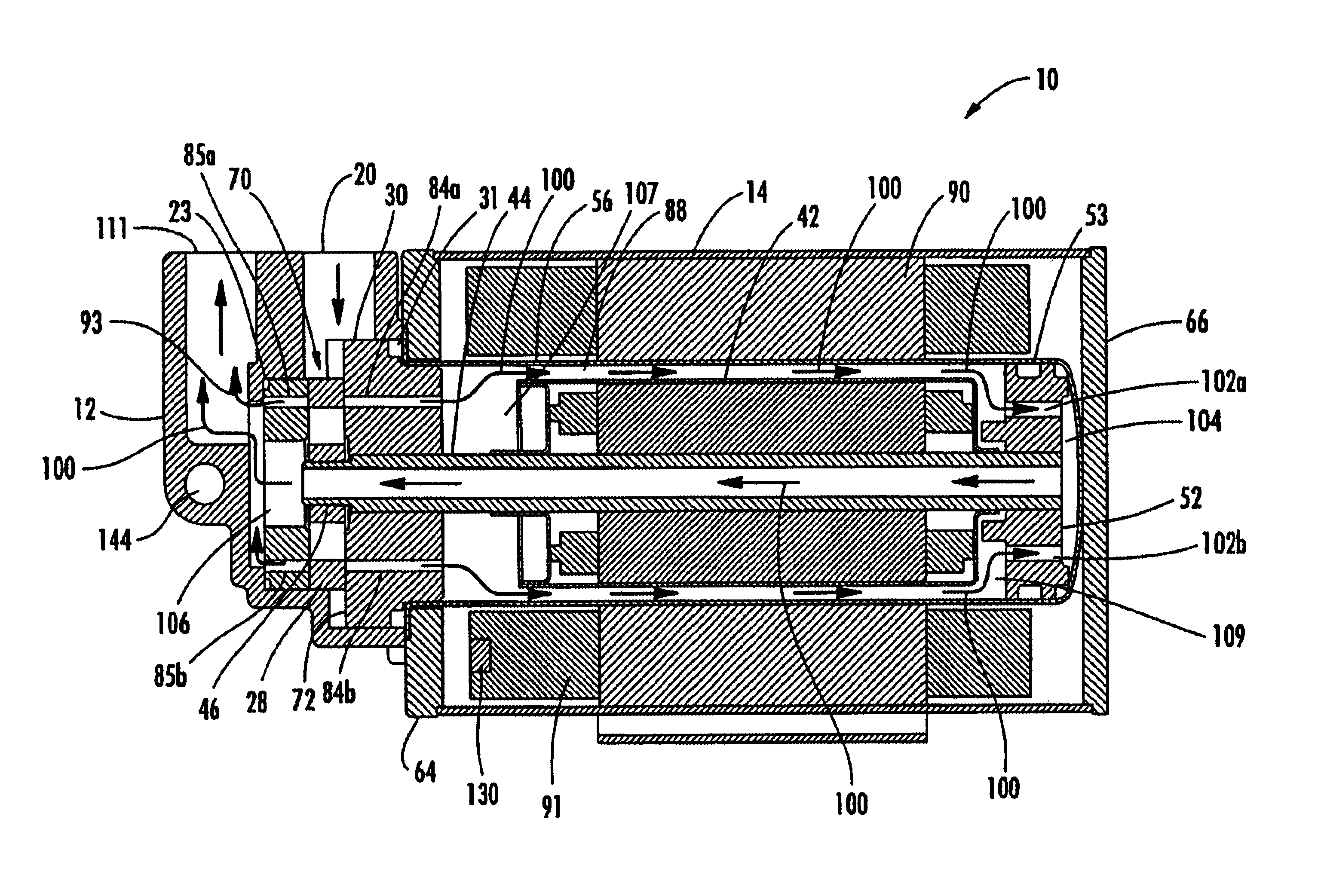

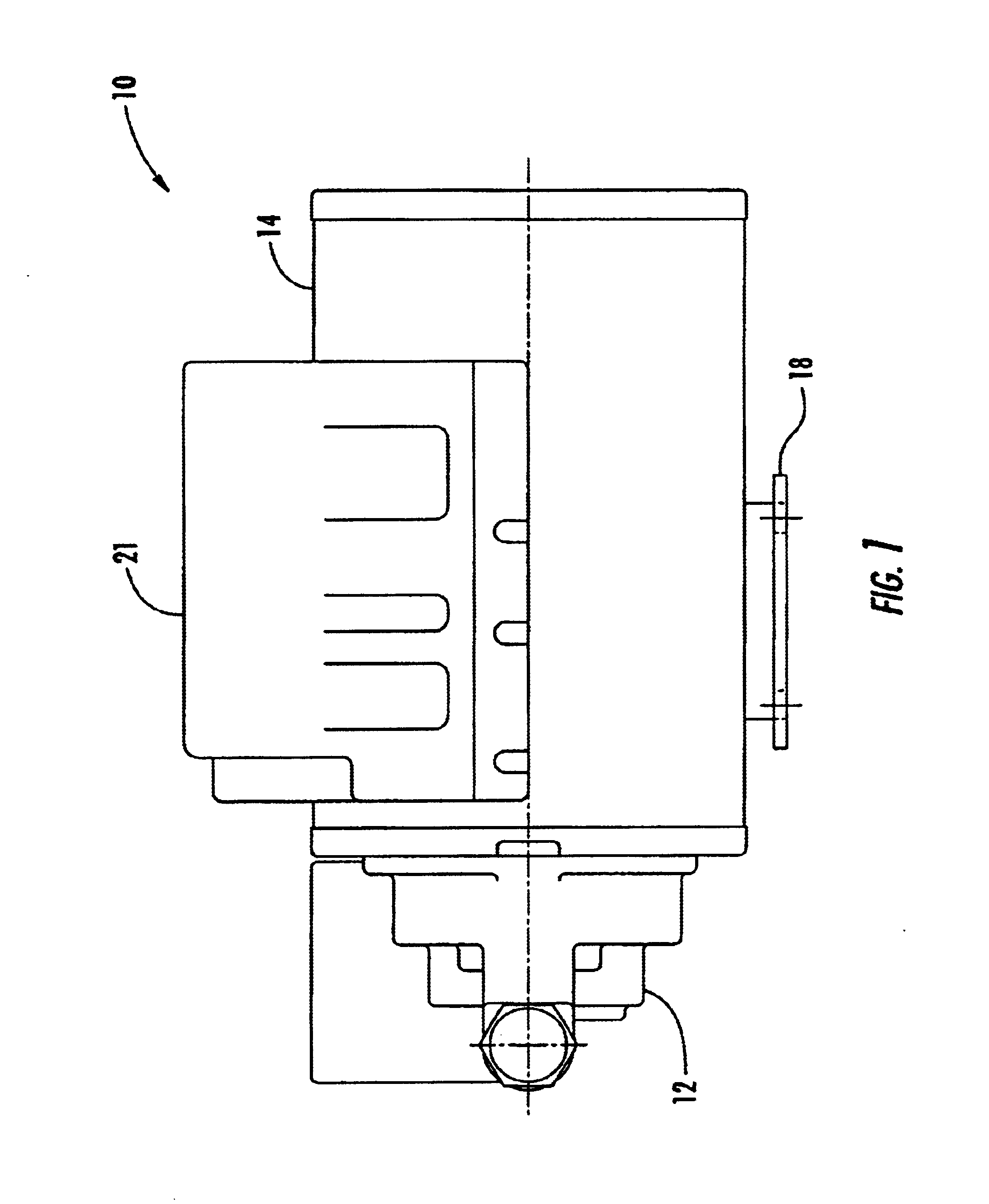

Infusion device with disposable elements

InactiveUS6146109AIncreasing the thicknessWithout sacrificing accuracyFlexible member pumpsMedical devicesDriving currentInfusion set

An infusion device with a disposable administration set which is inexpensive to manufacture. In the preferred embodiment of the present invention the disposable administration set has a plurality of elongated cam followers connected to a plate assembly, wherein the cam followers are displaced in a predetermined sequence and forced against a delivery tube by cam means driven by rotary drive means. The disposable administration set is injection molded as a single integral piece. The disposable administration set includes adjustment spacers disposed between the plate assembly and the cam followers which adjust the distance between them to keep the device accurate. In the preferred embodiment of the present invention the cam assembly is configured to provide fluid delivery at a consistent and uniform rate. The device may also incude a pressure sensing pin positioned on the cam assembly which contacts the tubing during the pumping cycle. The drive current is sampled and processed at predetermined phases during the cam rotation cycle to detect the presence of an occlusion in the tubing.

Owner:CARDINAL HEALTH INC

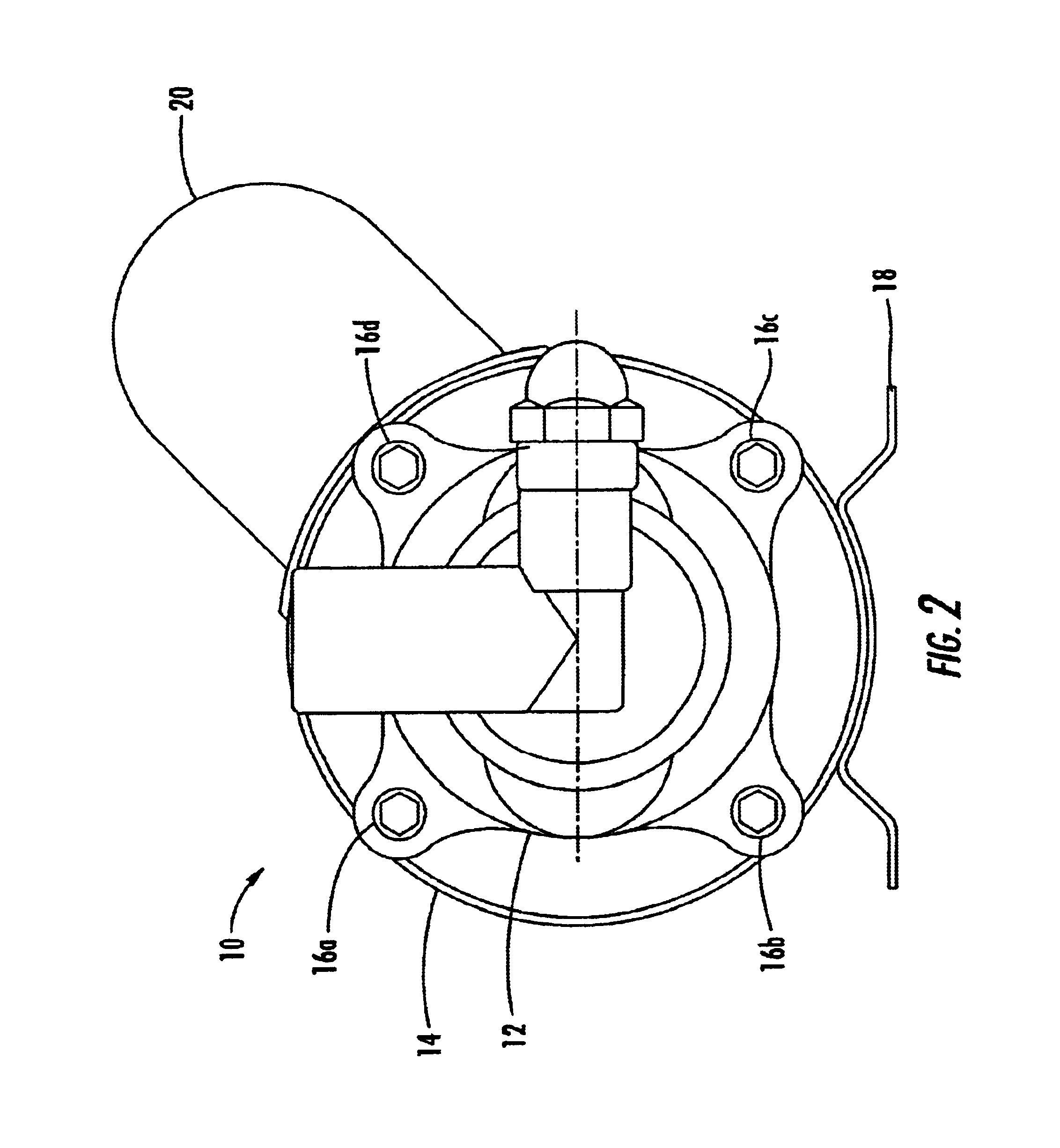

Overheat protection for fluid pump

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

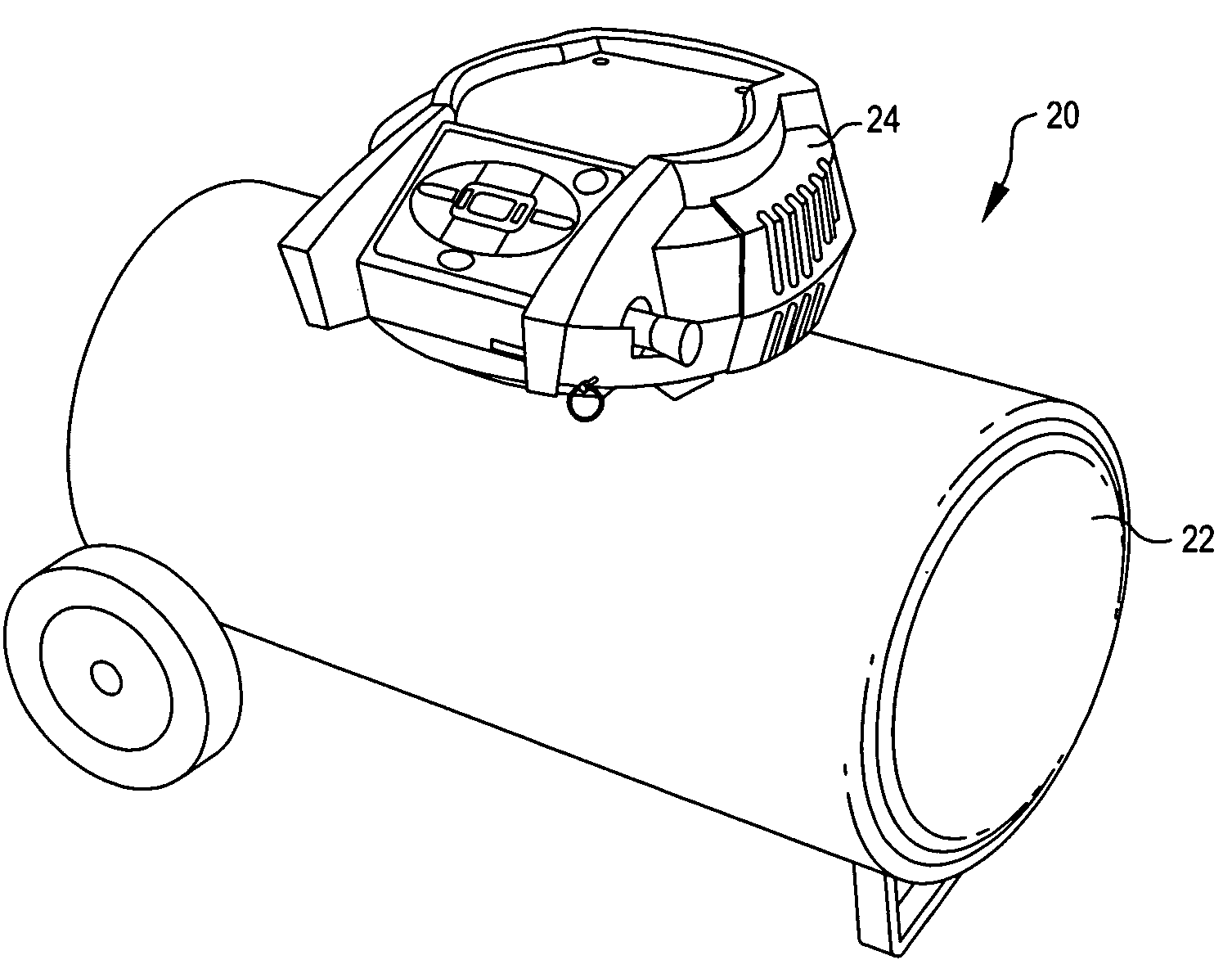

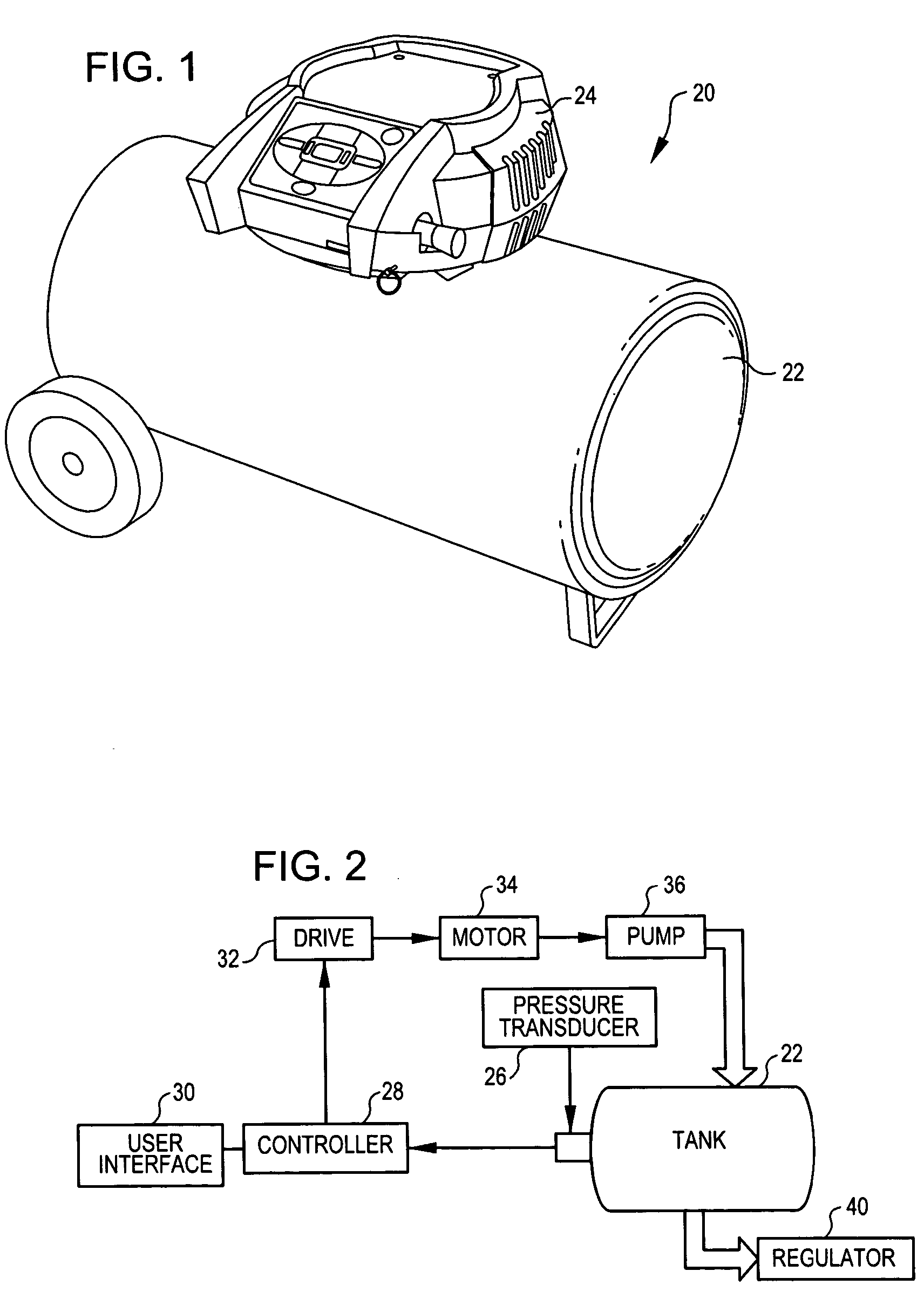

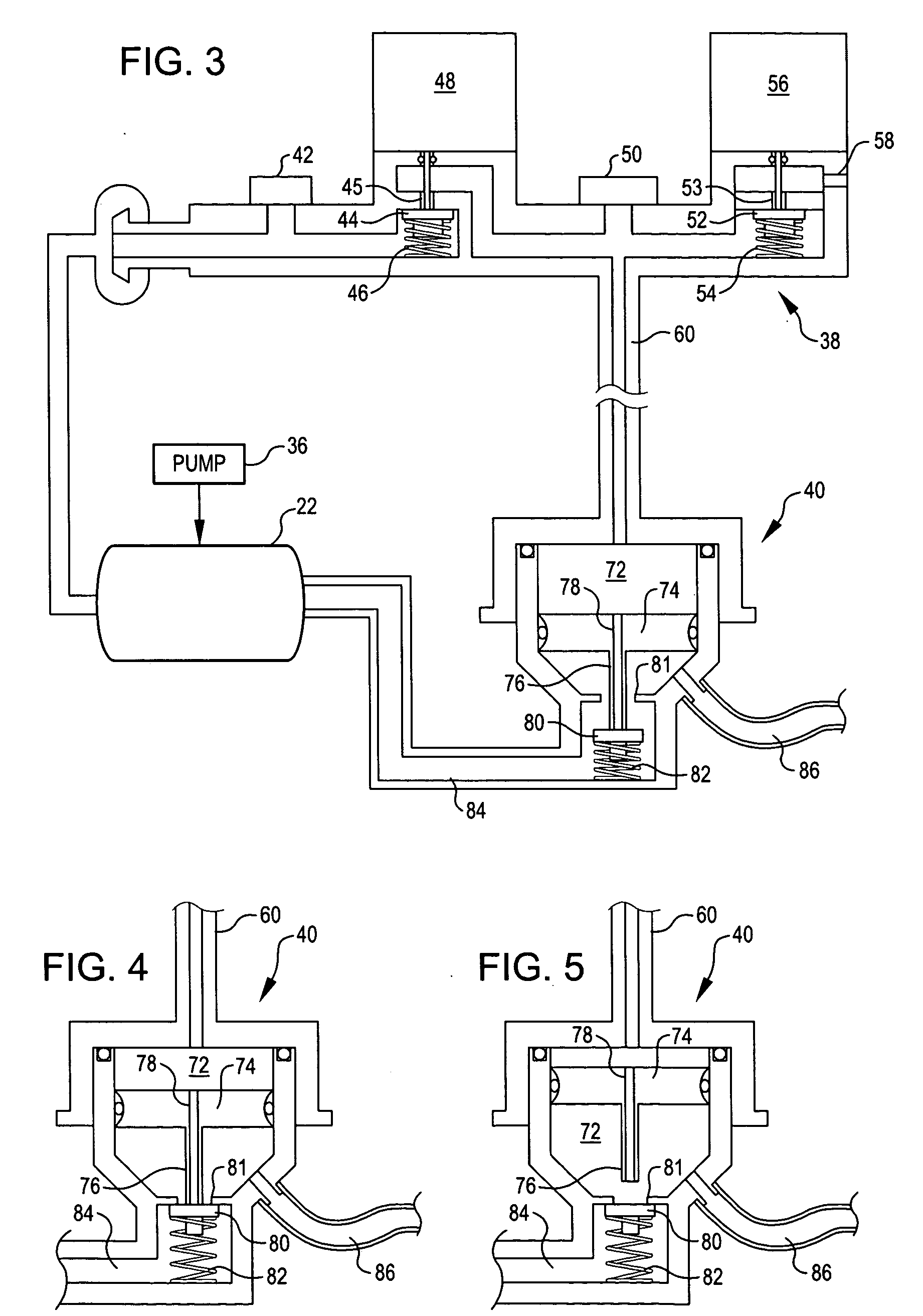

Air compressor with variable speed motor

InactiveUS20060045751A1Resistance may varyEliminate confusionMotor parameterPump controlMotor speedControl system

An air compressor utilizing an electronic control system. A pneumatically controlled regulator is provided for controlling output pressure for an air compressor. Digital gauges are provided on the air compressor to replace conventional mechanical gauges. A variable speed motor is used, which in turn varies the speed of the pump. Tools are provided for an air compressor that are capable of transmitting a signal to the air compressor indicating a desired pressure and / or motor speed at which the air compressor is to operate.

Owner:DEVILBISS AIR POWER COMPANY

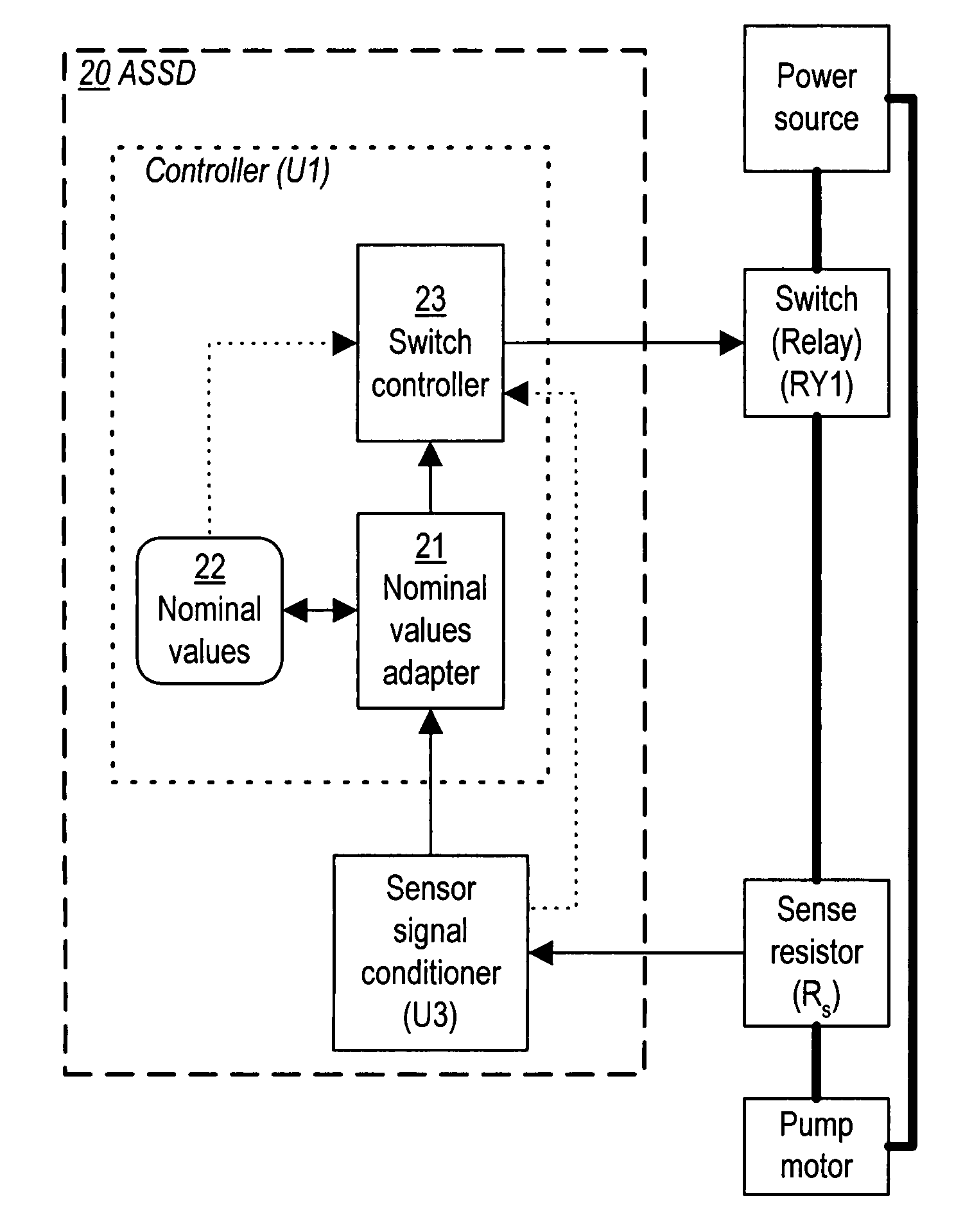

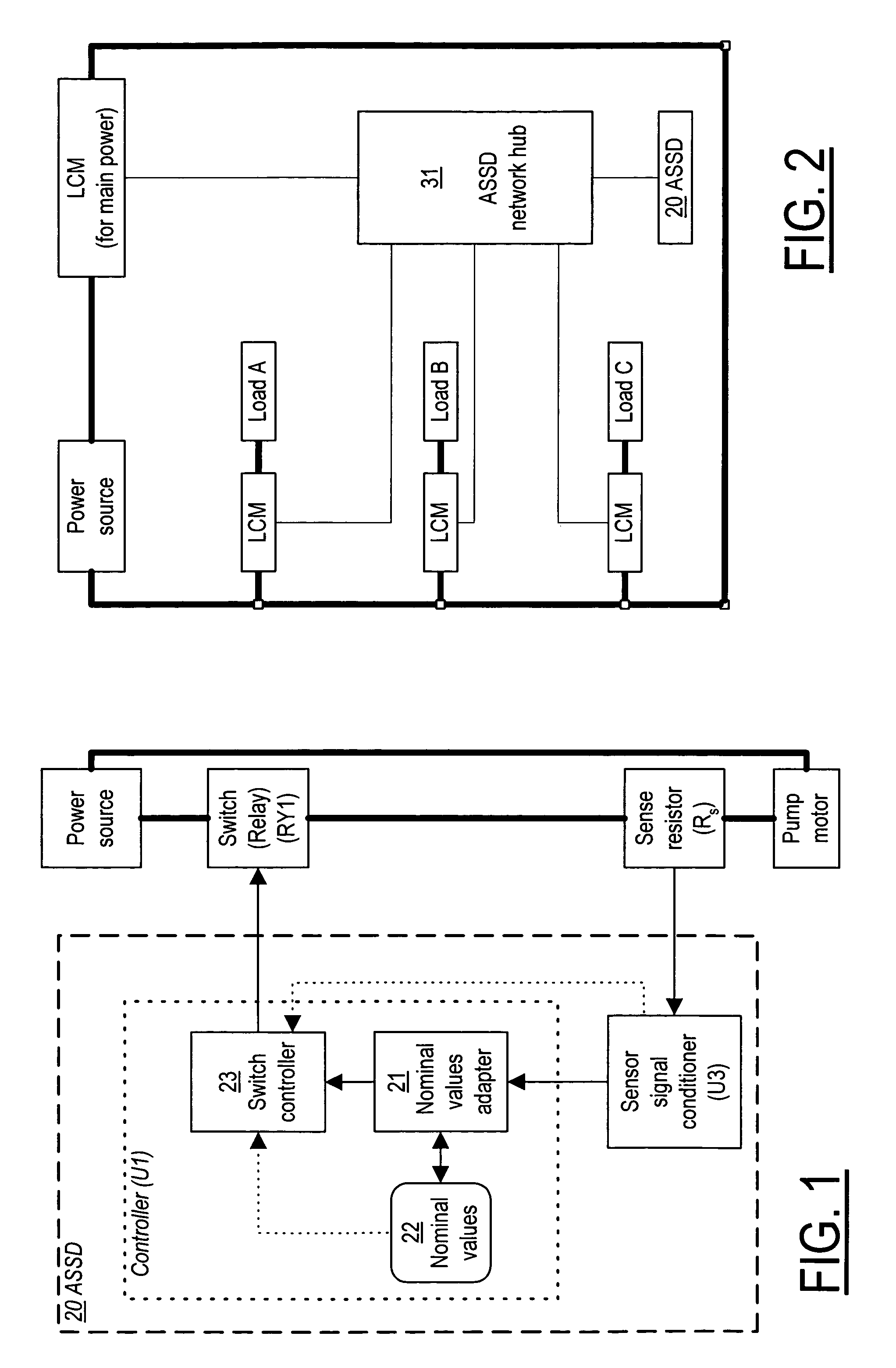

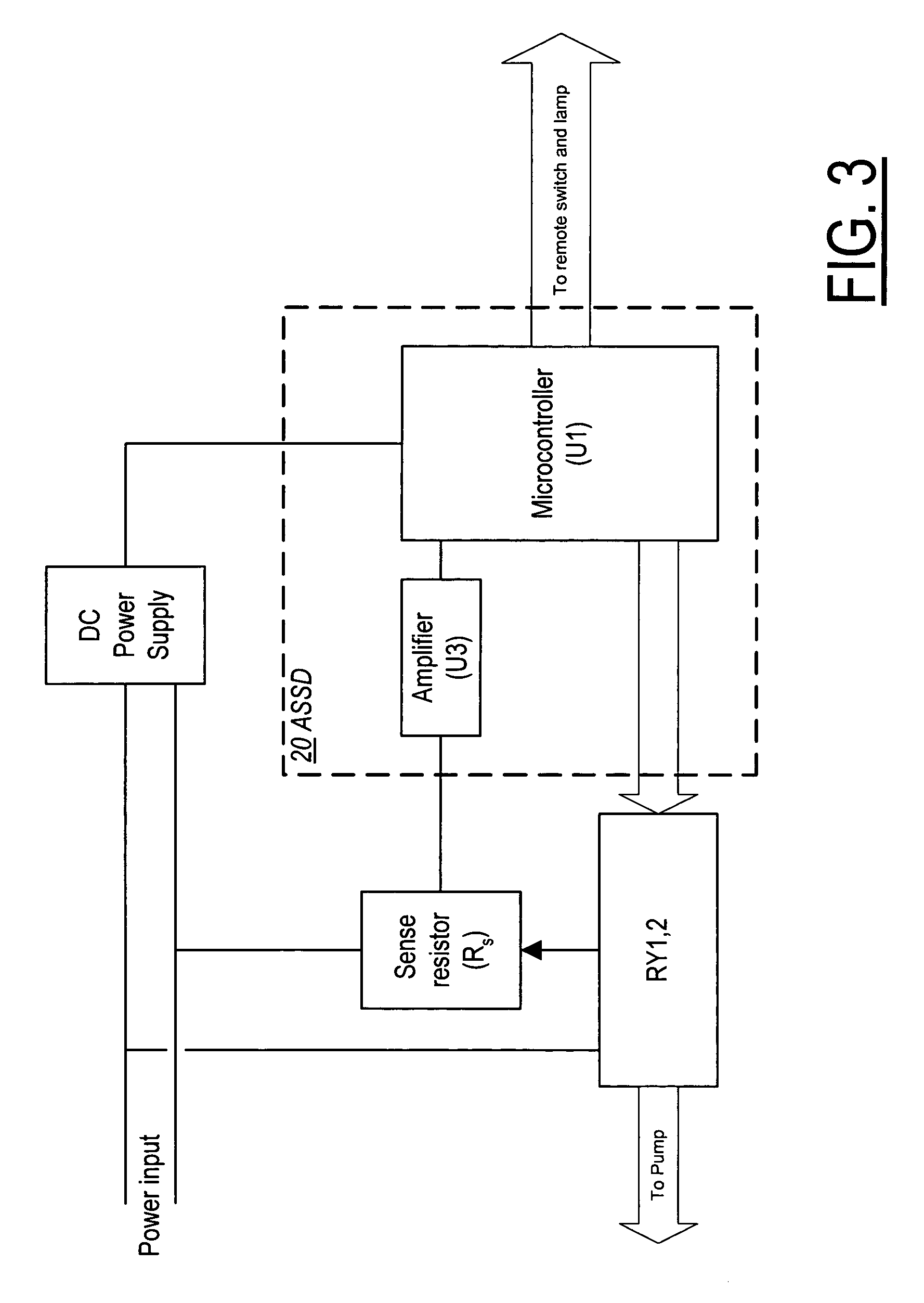

Active sensing and switching device

ActiveUS6998807B2Motor/generator/converter stoppersDC motor speed/torque controlPower flowControl system

An active sensing and switching device for use in controlling current to a load, comprising a controller means (U1) for disconnecting the load from a power source by providing a switch-open control signal based on a signal indicating a sensed value of electrical current to the load, characterized in that the controller means (U1) determines a nominal value for the electrical current to the load based on monitoring the signal indicating the sensed value of electrical current to the load. A load control system is also provided, including a single ASSD adapted to receive signals indicating sensed values of electrical current to a plurality of respective loads, and further comprising a plurality of load control modules adapted so as to be disposed in proximity to respective loads or a main power line, wherein the load control modules provide respective signals indicating sensed values of electrical currents to the respective loads.

Owner:XYLEM IP HLDG

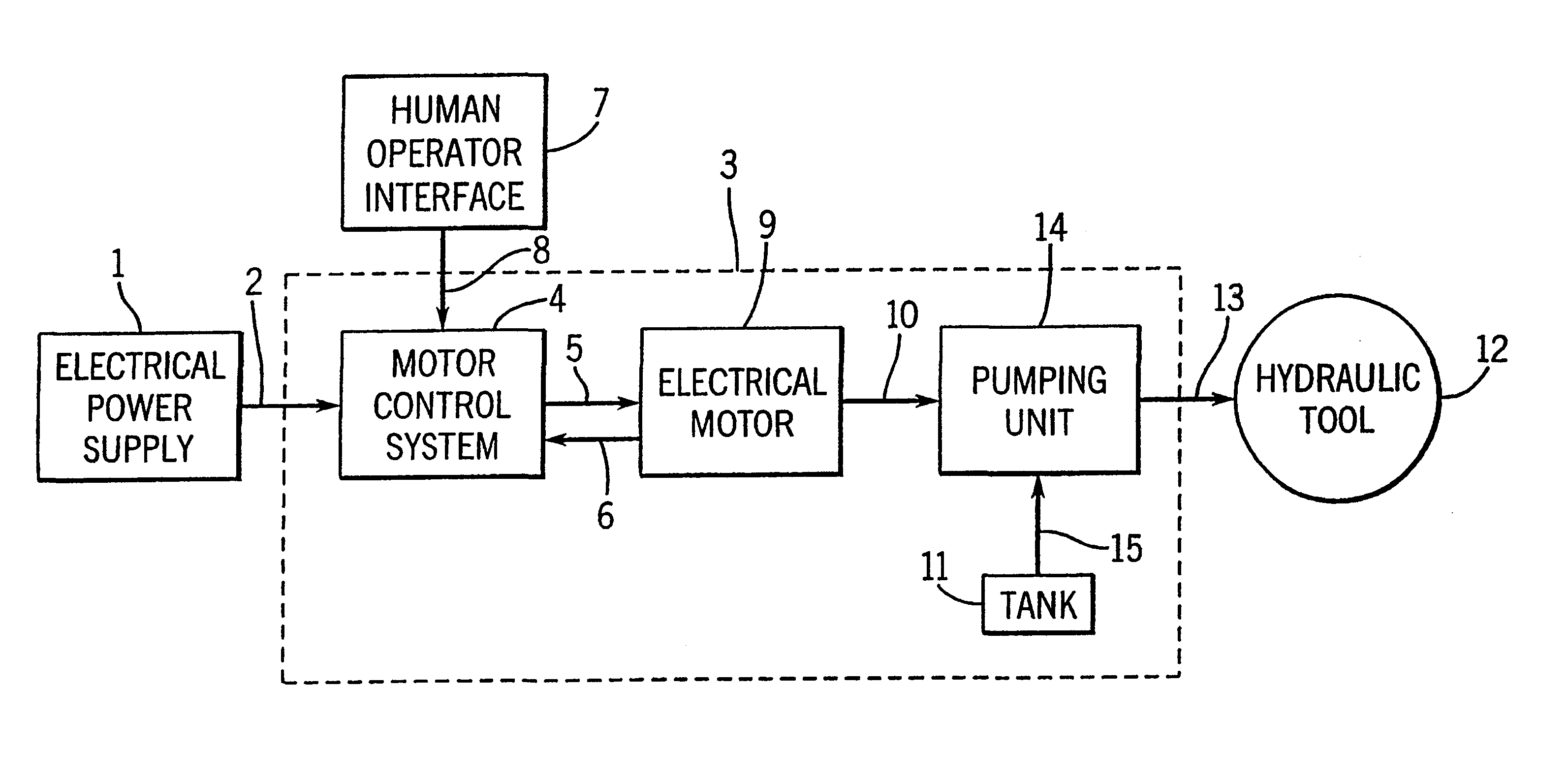

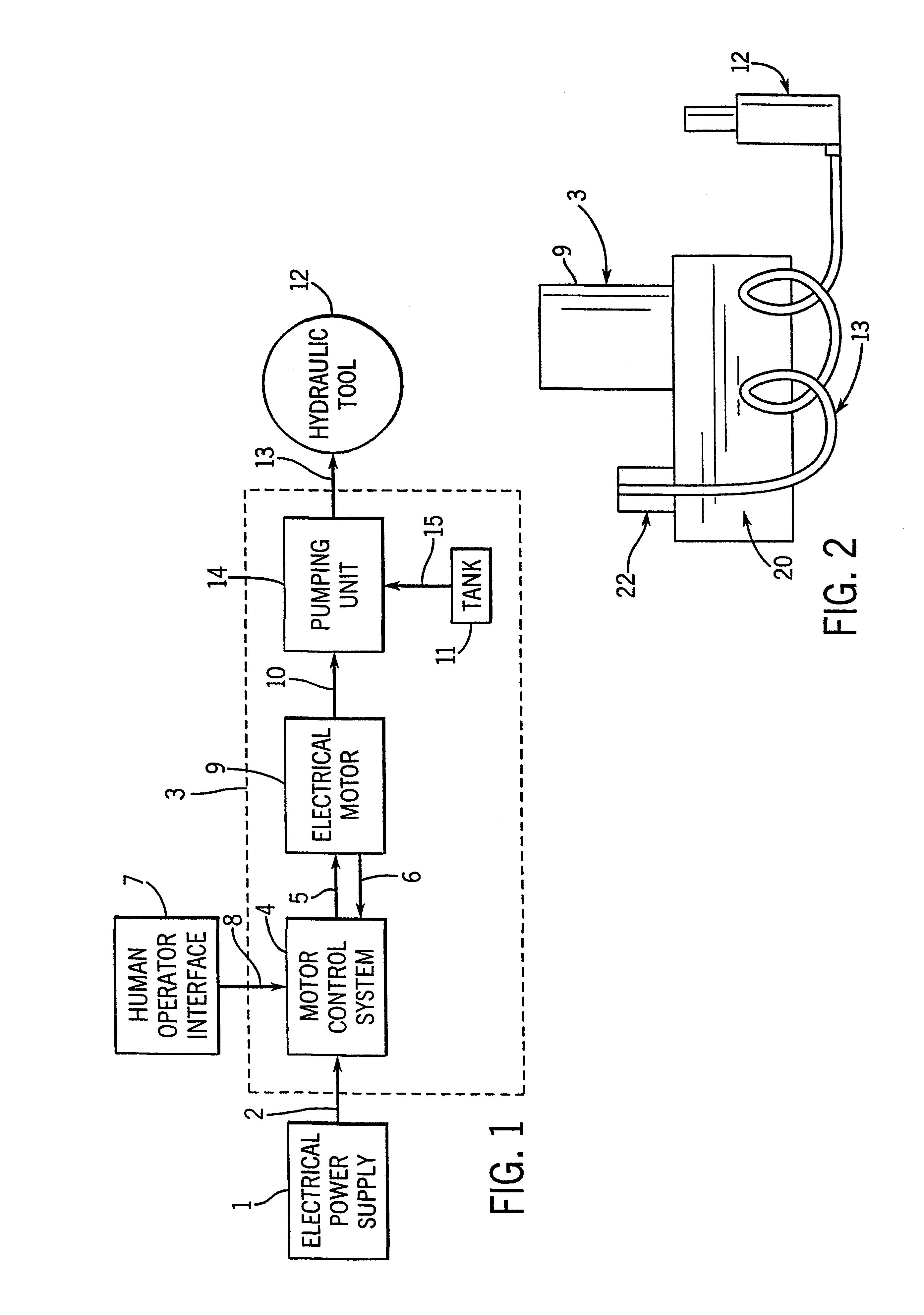

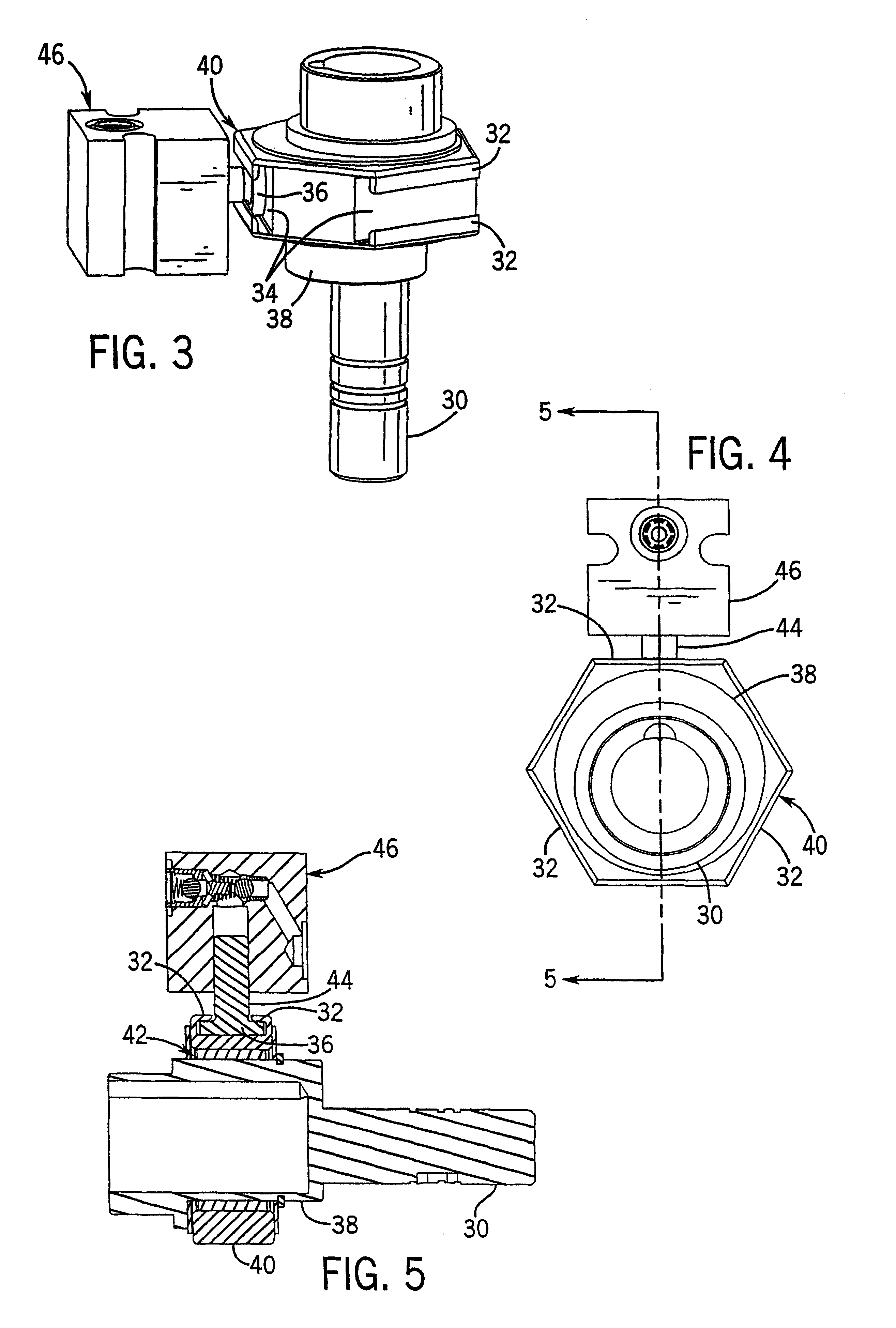

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Linear compressor and apparatus to control the same

InactiveUS20050031470A1Most efficientDC motor speed/torque controlAC motor controlDriving currentResonance

A linear compressor and apparatus to control the linear compressor are provided which allows a frequency of a drive current supplied to a drive motor to synchronize with a resonance frequency varying according to a load fluctuation, in real time, thus obtaining a maximum efficiency of the linear compressor. The linear compressor includes a drive motor, a piston reciprocating by the drive motor and a control unit generating a reference current having a phase difference of 90° with respect to a displacement waveform of the piston and a frequency equal to the displacement waveform of the piston, and controls a drive current supplied to the drive motor to synchronize with a resonance frequency of the piston by synchronizing the drive current with the reference current.

Owner:SAMSUNG ELECTRONICS CO LTD

Pump and pump control circuit apparatus and method

InactiveUS20080181786A1Large range of motionRelieve pressureFluid parameterFlexible member pumpsMicrocontrollerControl system

A method and apparatus for a pump and a pump control system. The apparatus includes pistons integrally formed in a diaphragm and coupled to the diaphragm by convolutes. The convolutes have a bottom surface angled with respect to a top surface of the pistons. The apparatus also includes an outlet port positioned tangentially with respect to the perimeter of an outlet chamber. The apparatus further includes a non-mechanical pressure sensor and a temperature sensor coupled to a pump control system. For the method of the invention, the microcontroller provides a pulse-width modulation control signal to an output power stage in order to selectively control the power provided to the pump. The control signal is based on the pressure within the pump, the current being provided to the pump, the voltage level of the battery, and the temperature of the pump.

Owner:SHURFLO

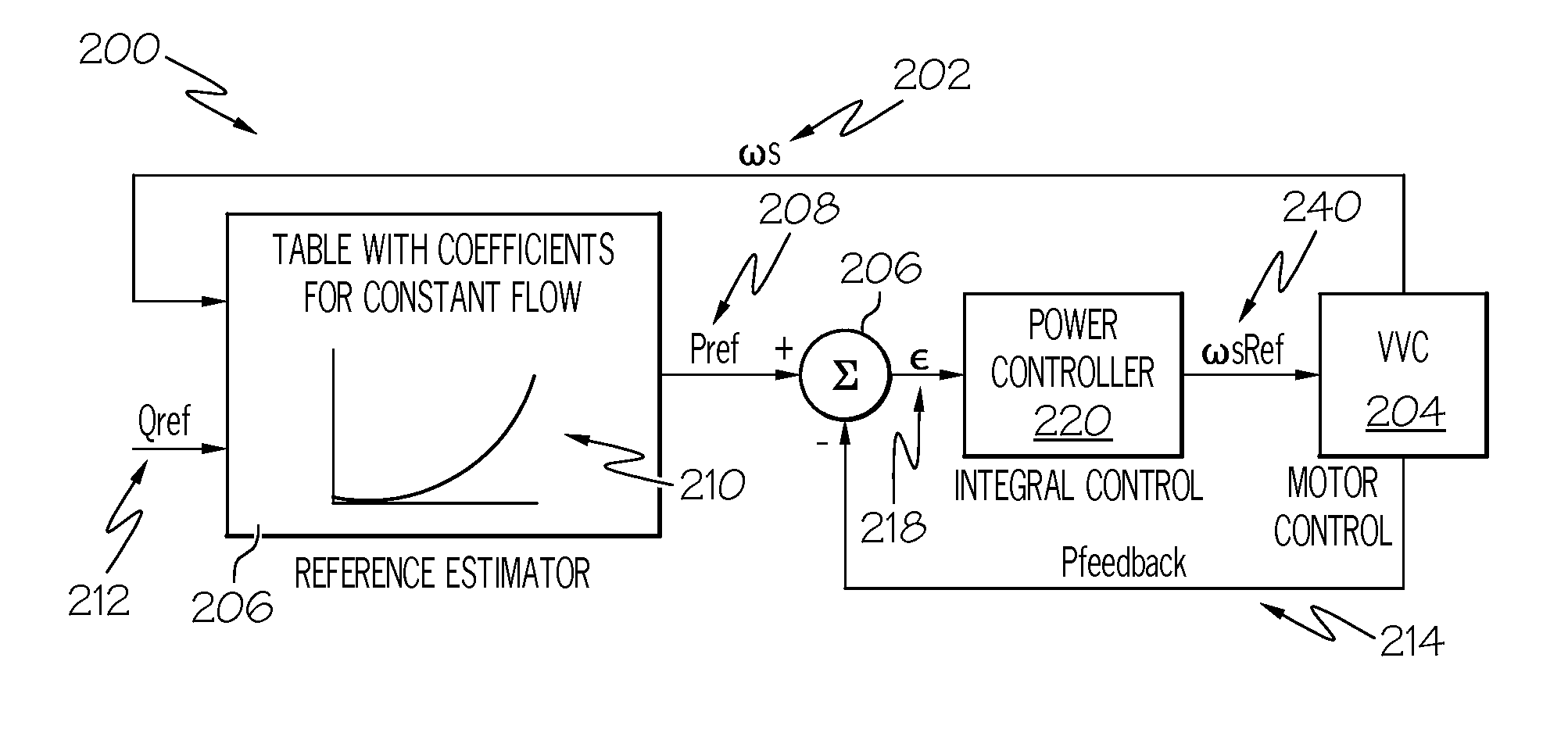

Flow control

A pumping system for moving water of a swimming pool includes a water pump and a variable speed motor. The pumping system further includes means for determining a first motor speed of the motor, means for determining first and second performance values of the pumping system, and means for comparing the first and second performance values. The pumping system further includes means for determining an adjustment value based upon the comparison, means for determining a second motor speed based upon the adjustment value, and means for controlling the motor in response to the second motor speed. In one example, the pumping system includes means for determining a value indicative of a flow rate of water moved by the pump. In addition or alternatively, the pumping system includes a filter arrangement. A method of controlling the pumping system for moving the water of the swimming pool is also disclosed.

Owner:DANFOSS POWER ELECTRONICS AS +1

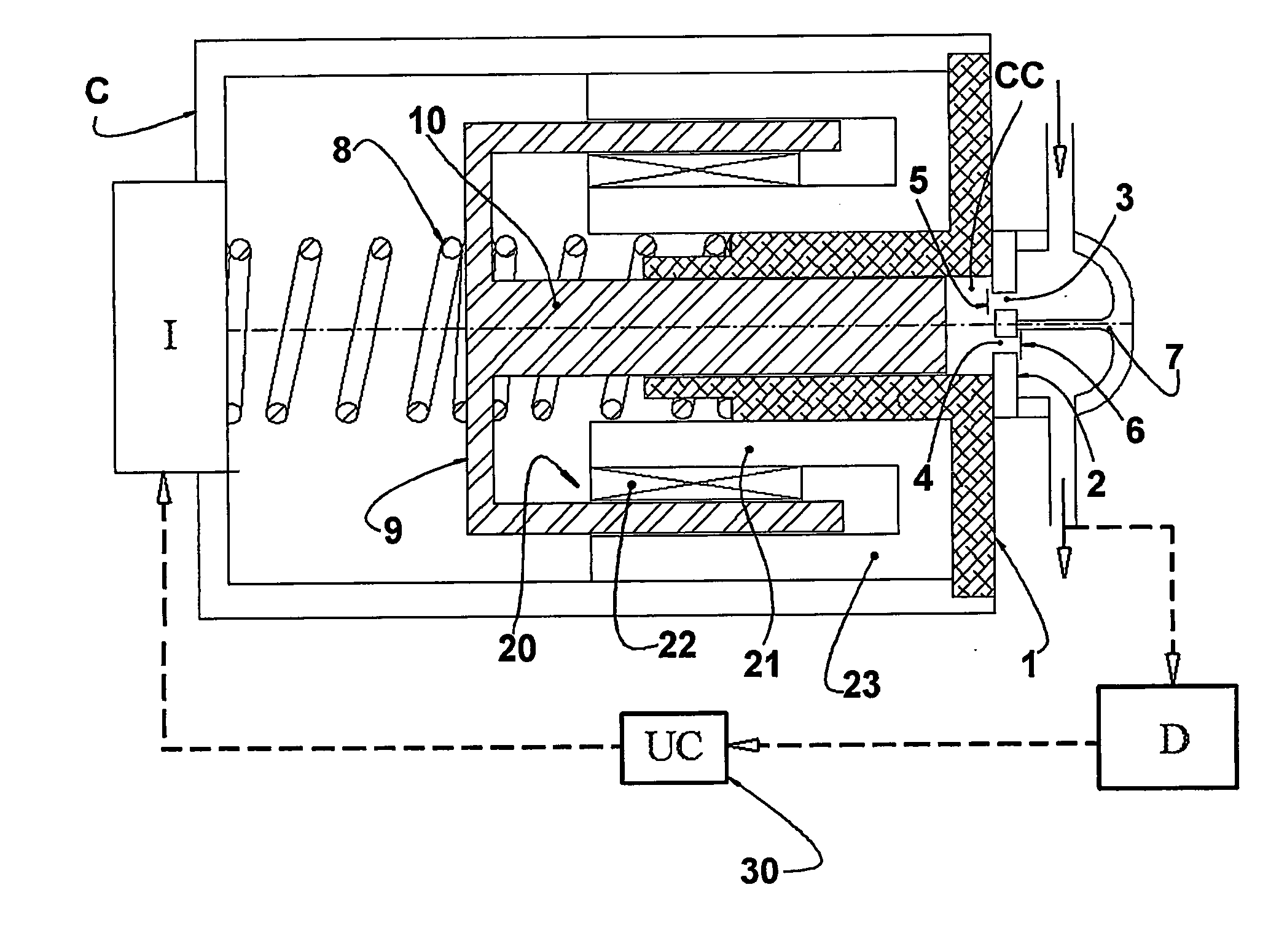

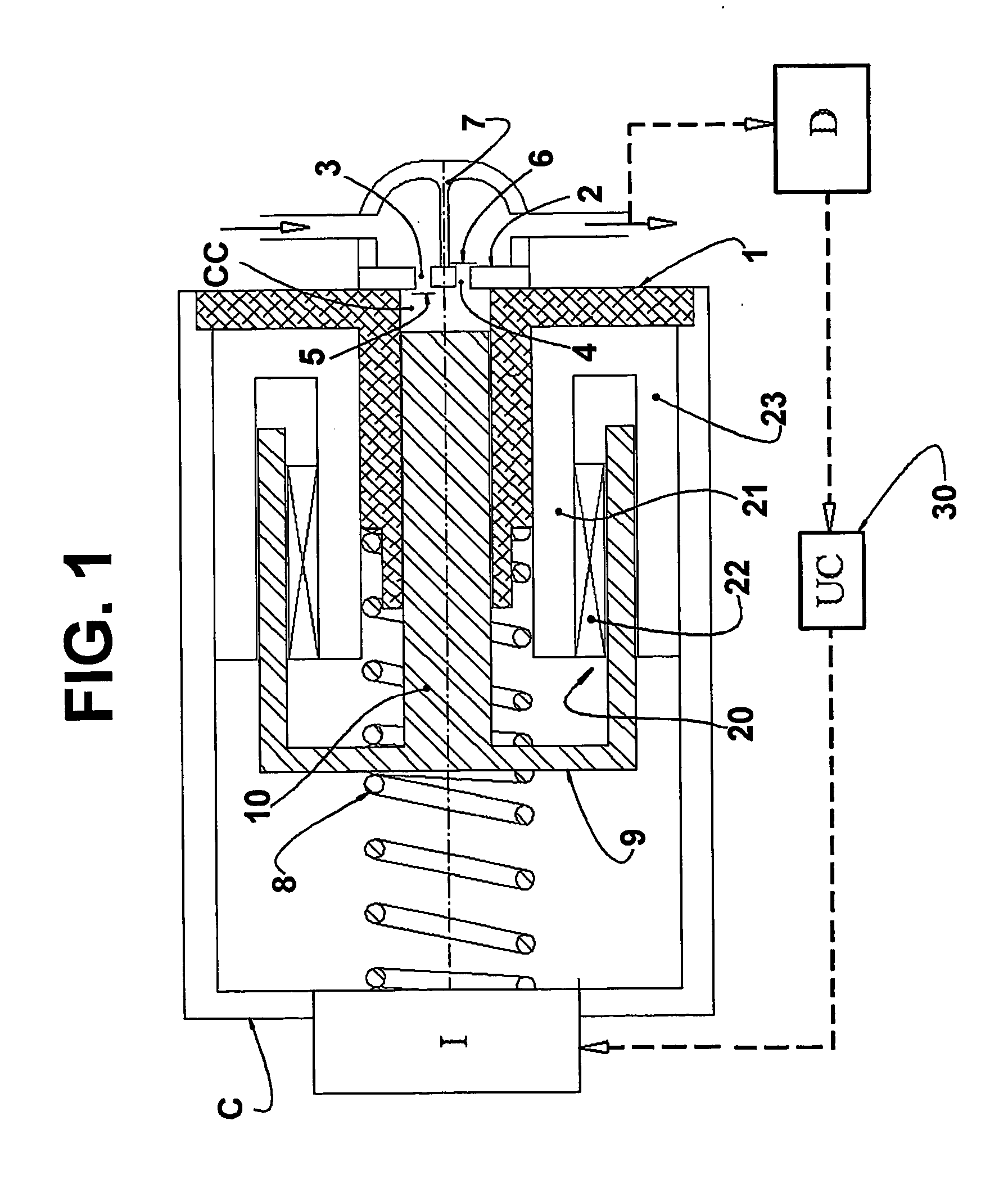

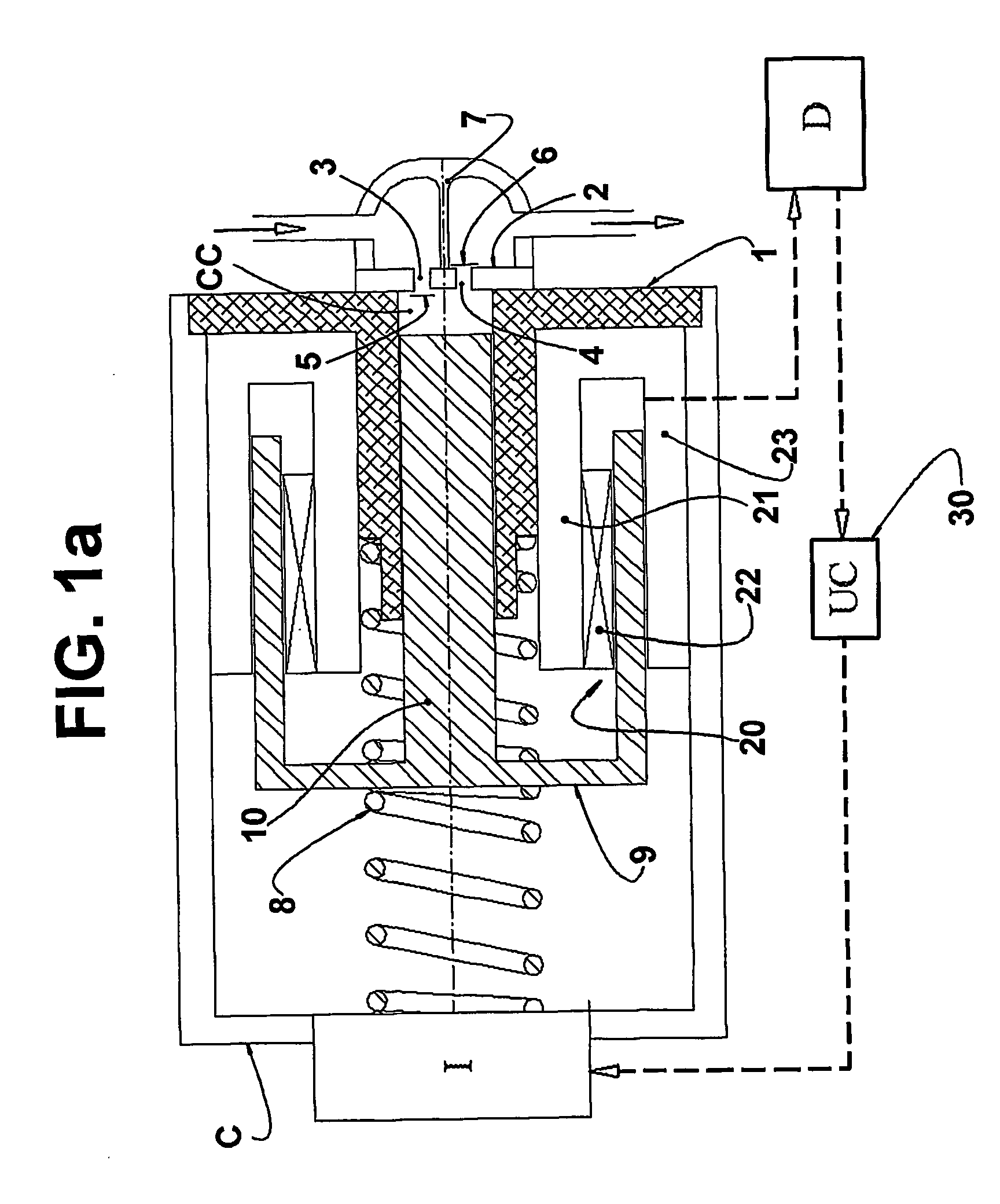

System for adjusting resonance frequencies in a linear compressor

InactiveUS20060110259A1Low costIncreased energy lossFluid parameterPositive displacement pump componentsReciprocating motionLinear compressor

A system for adjusting resonant frequencies in a linear compressor comprising, in the interior of a shell: a linear motor: a cylinder; a piston reciprocating inside the cylinder; and an actuating means operatively coupling the piston to the linear motor, said system comprising: a detecting means to detect a load imposed to the linear motor, in an operational condition of the latter related to the gas pressure in the discharge thereof; and a frequency adjusting means operatively associated with the detecting means and with the resonant assembly, in order to define, as a function of said operational condition, a frequency adjustment, by varying at least one of the values related to the mass of the resonant assembly and to the average stroke of the piston, to a value of the mechanical resonance frequency corresponding to the electrical supply frequency.

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com