Patents

Literature

4095results about "Electric motor speed/torque regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

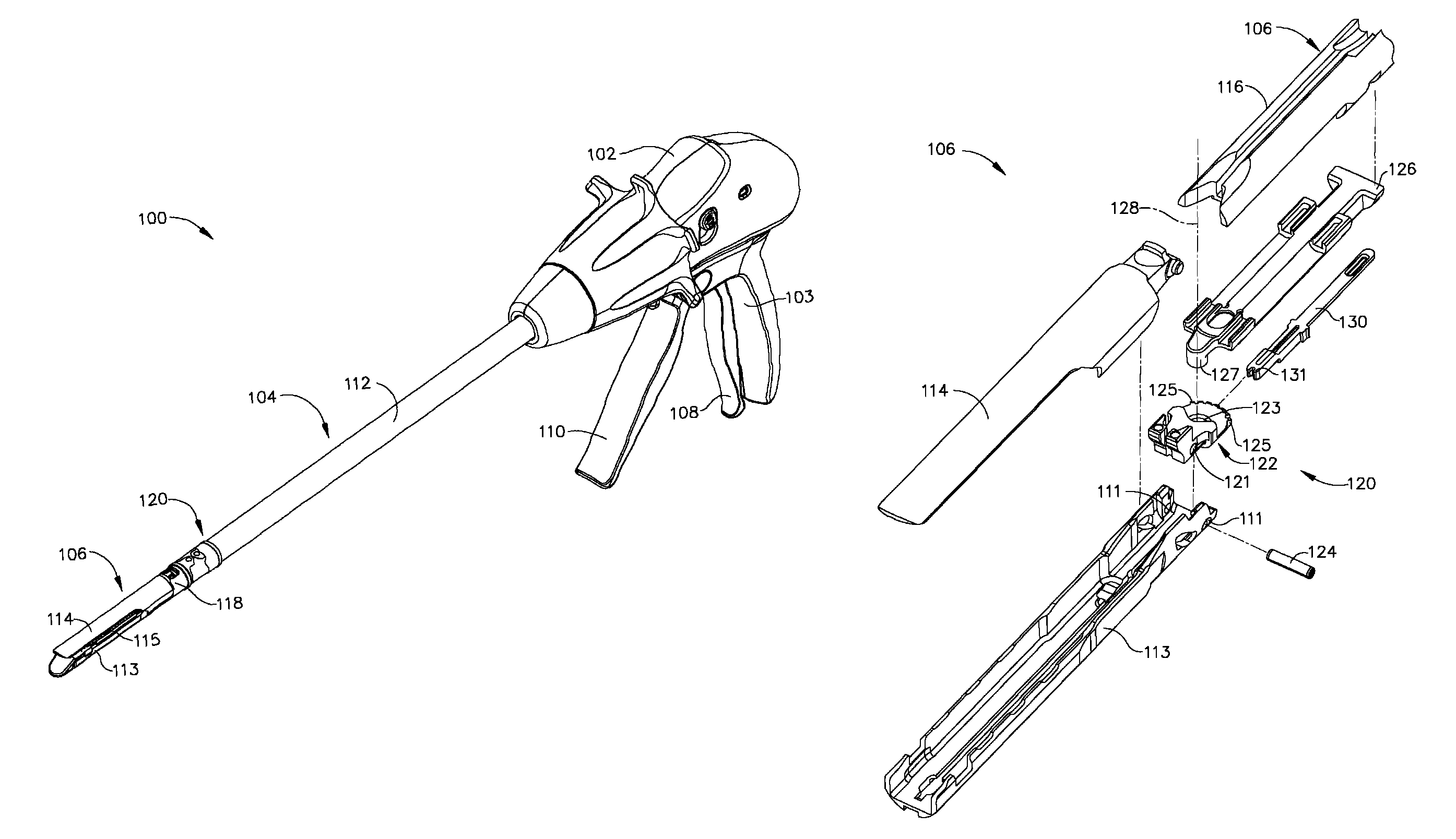

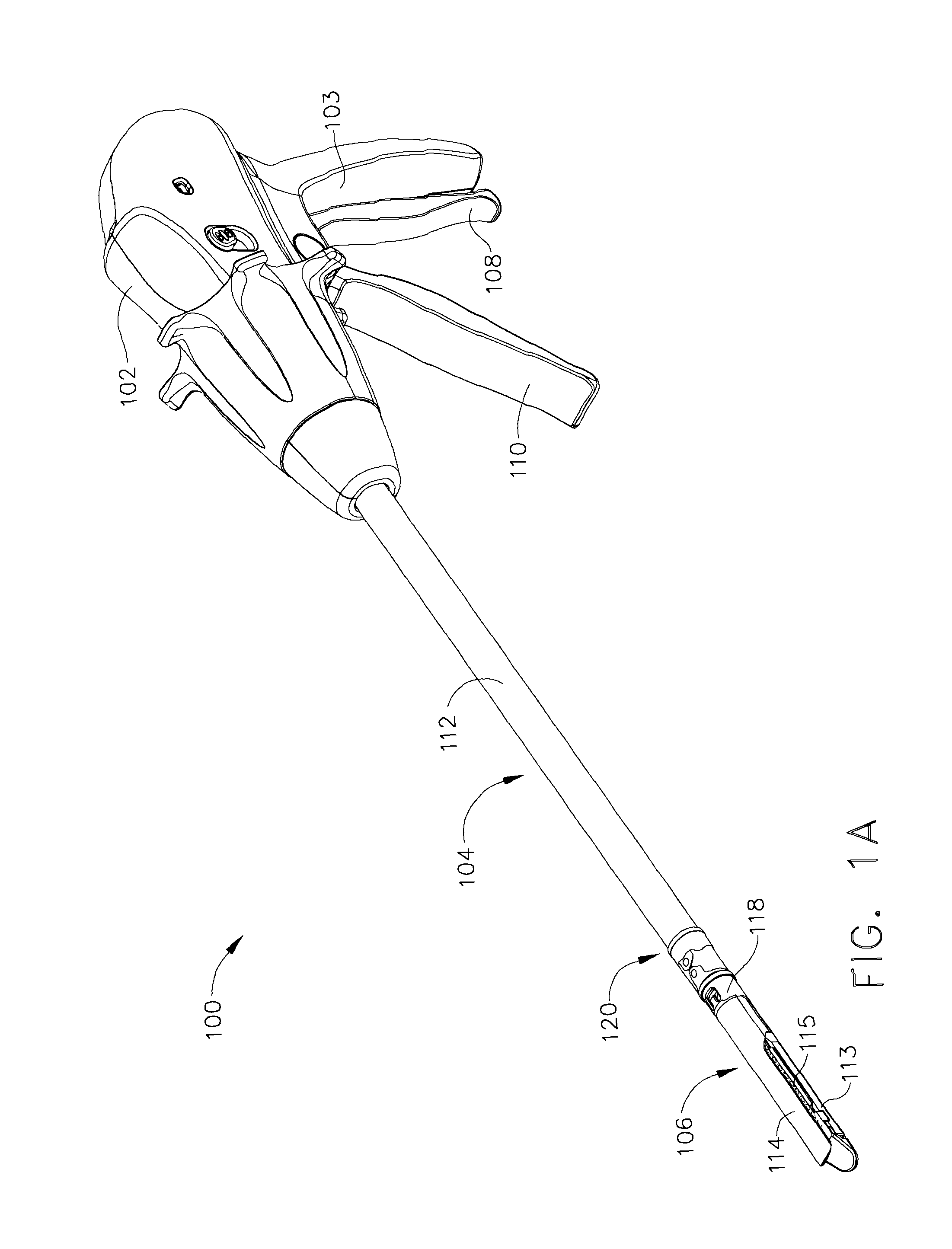

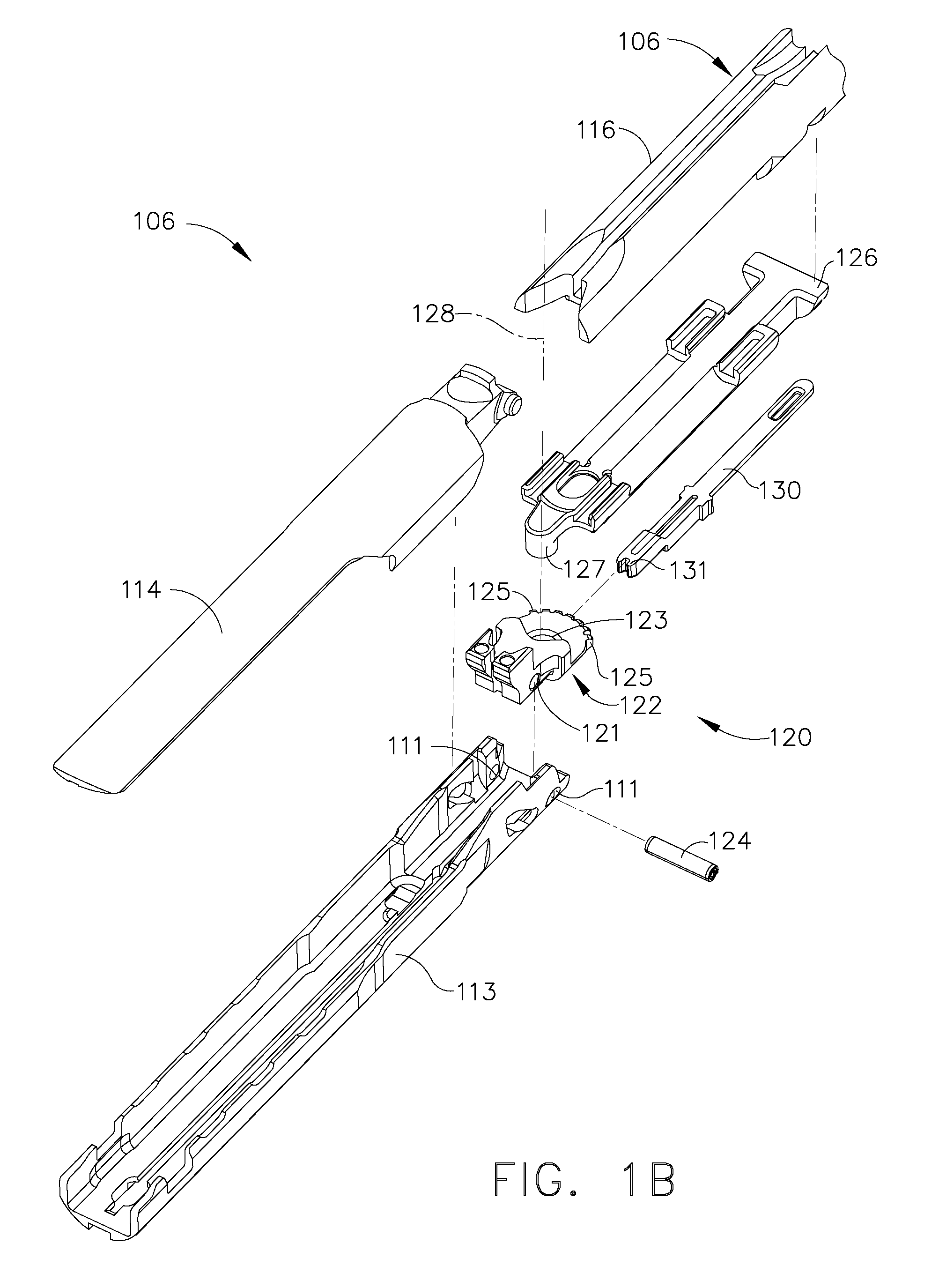

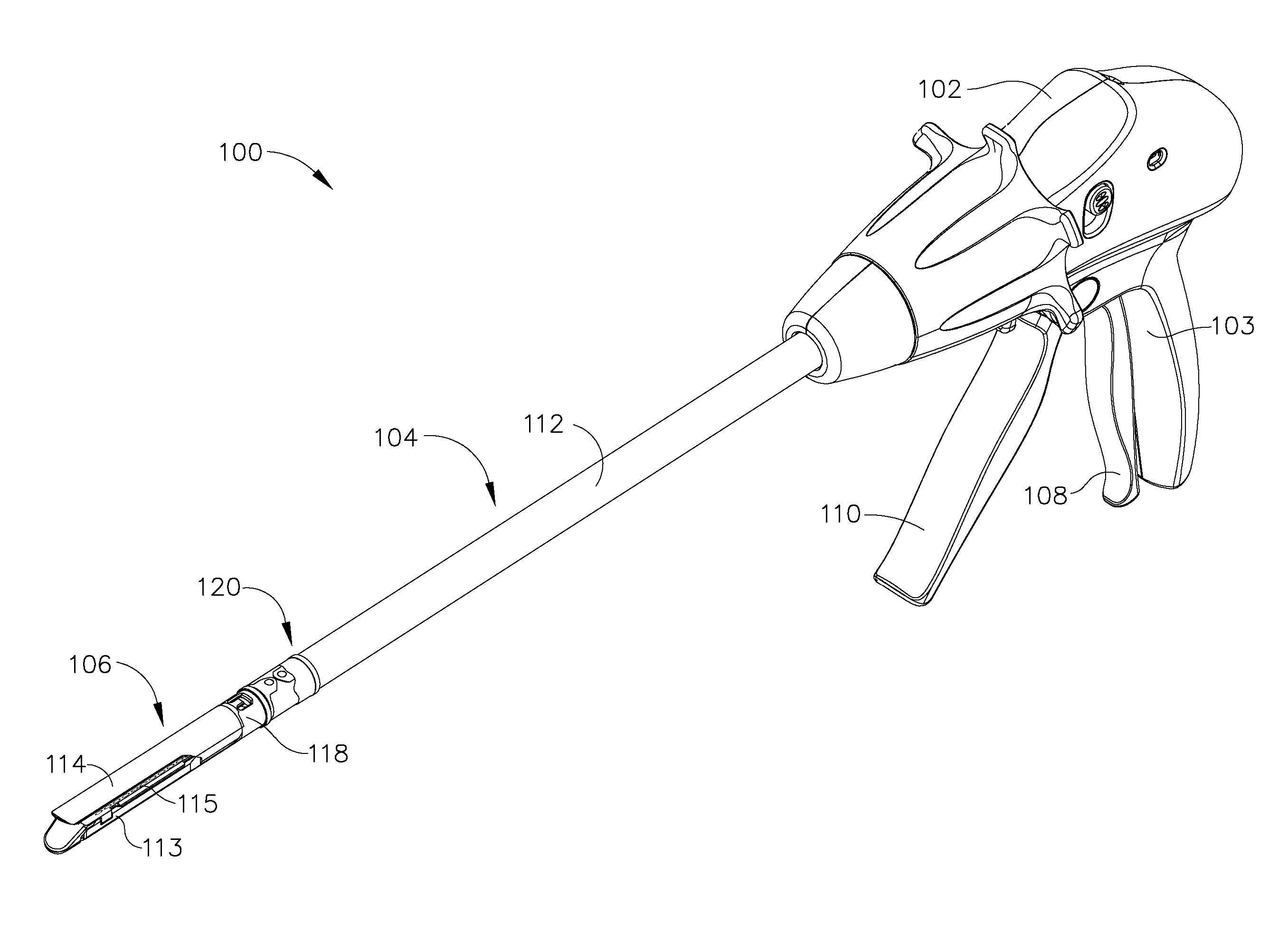

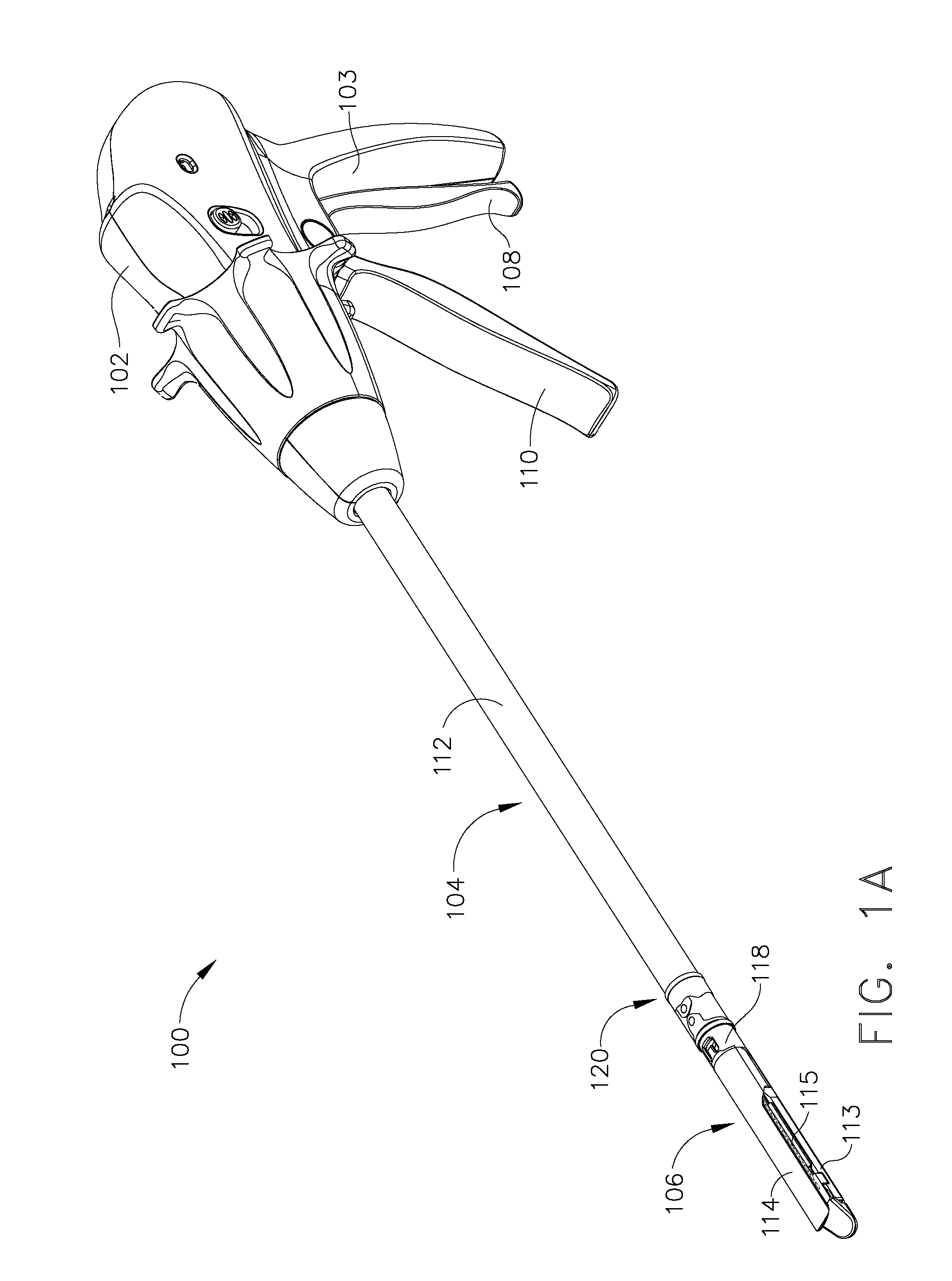

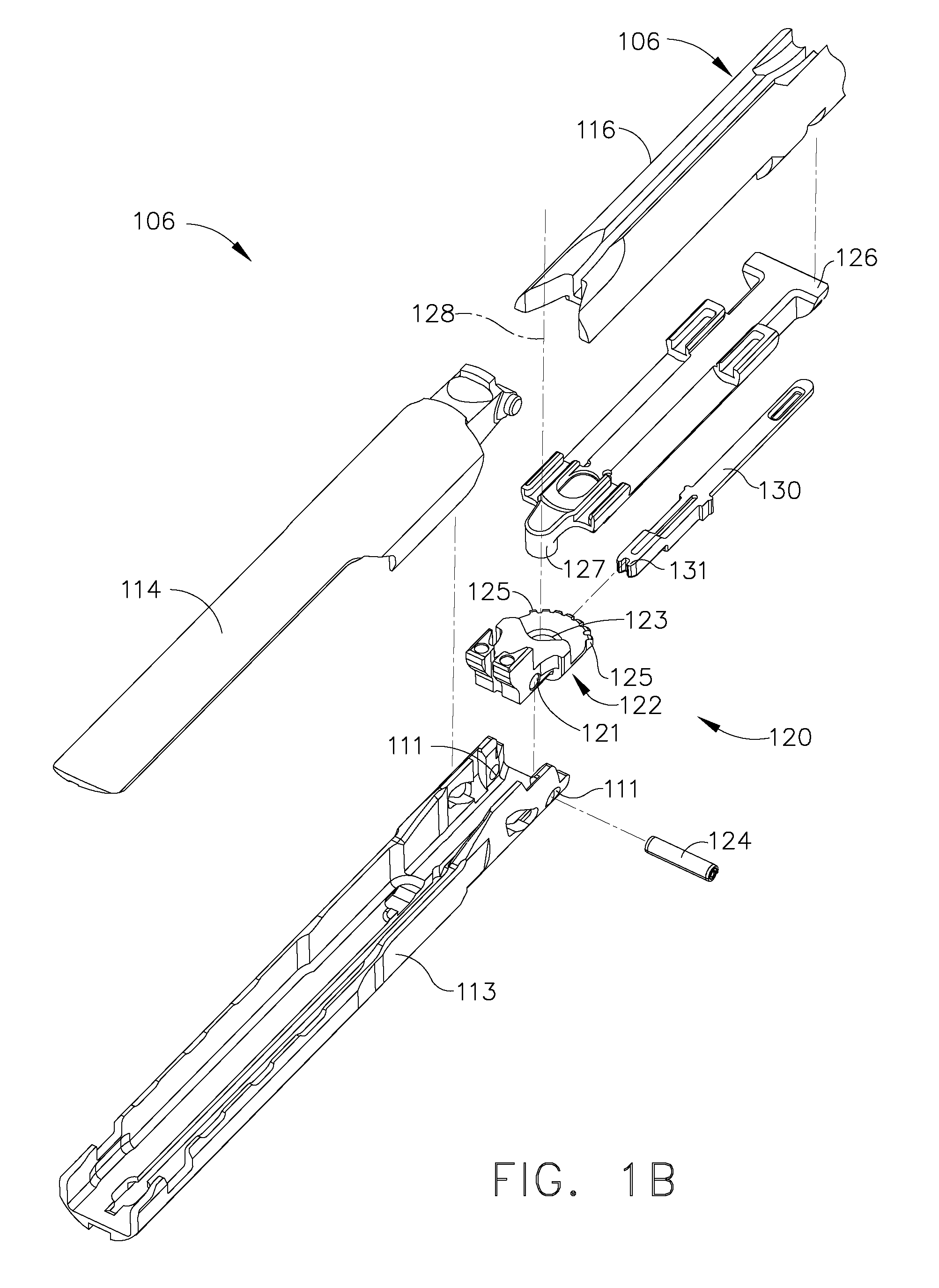

Surgical stapling instrument comprising a magnetic element driver

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

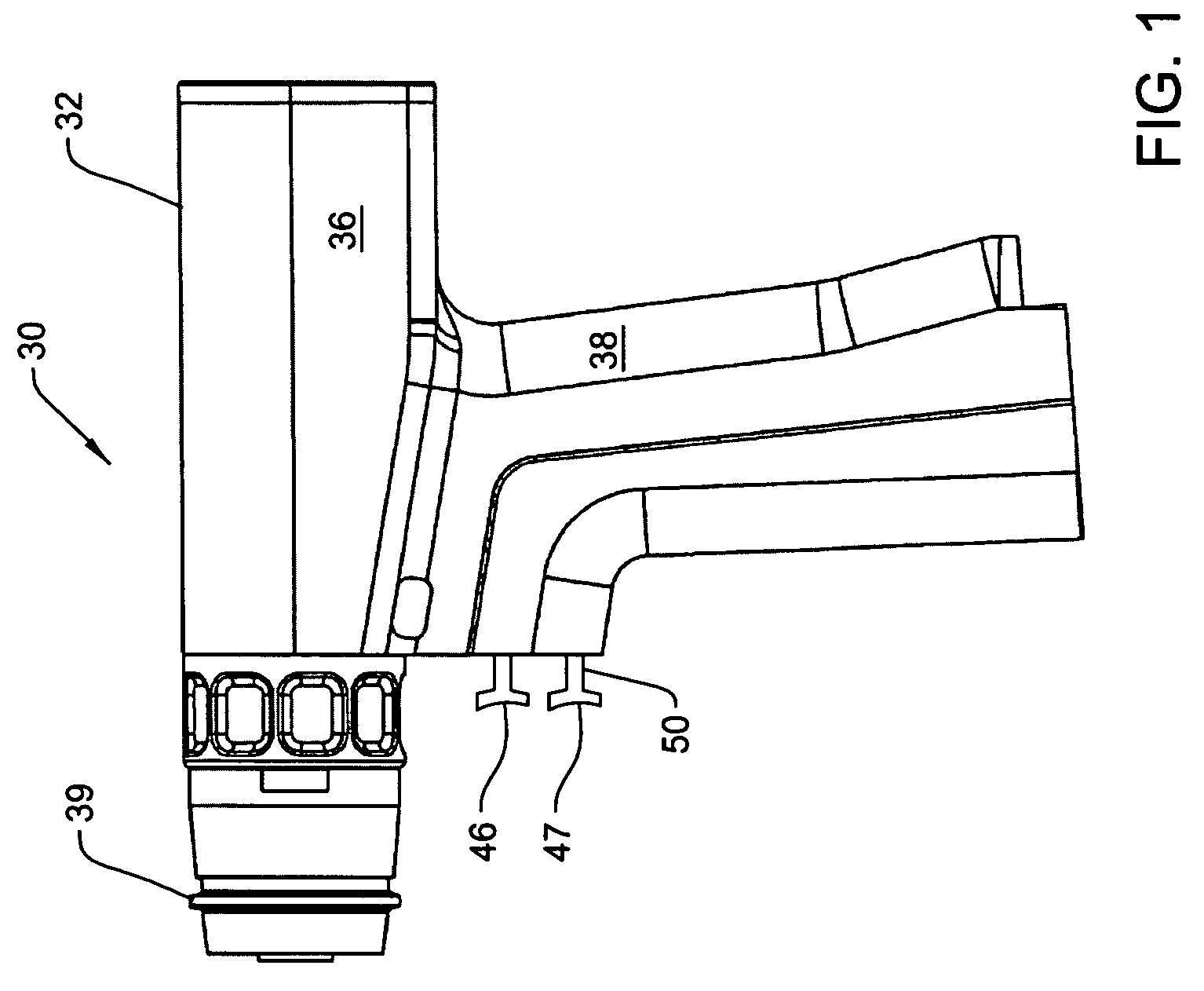

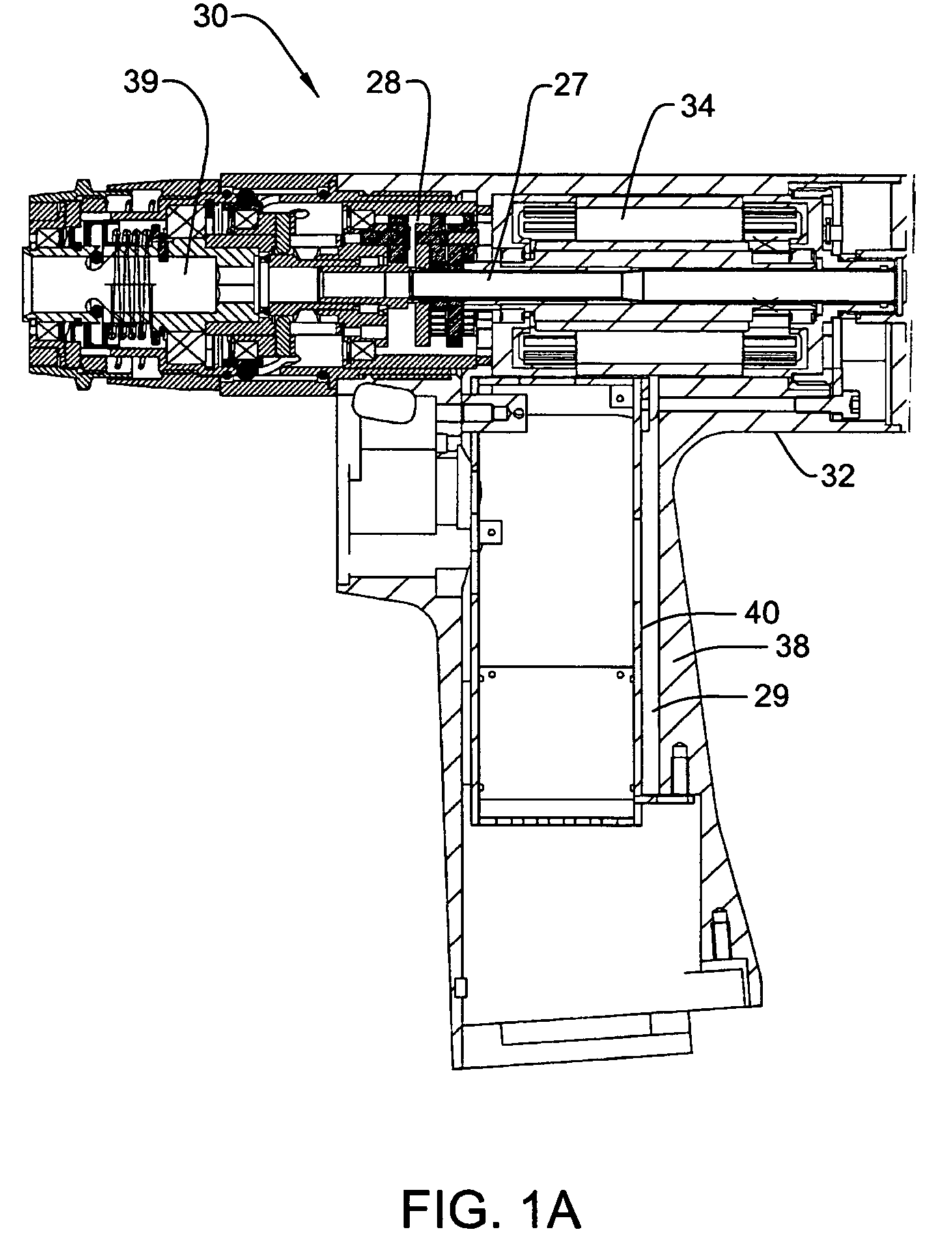

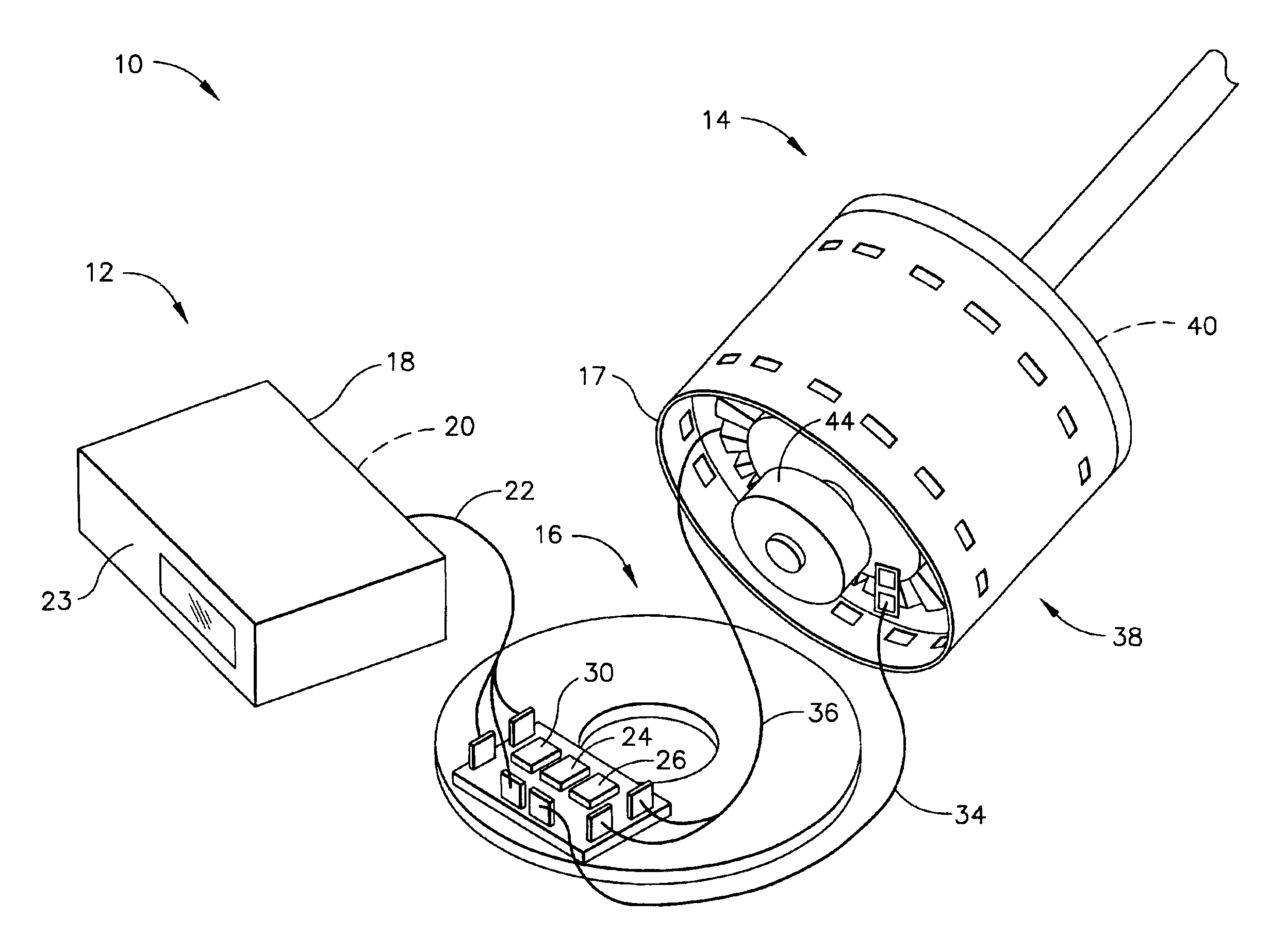

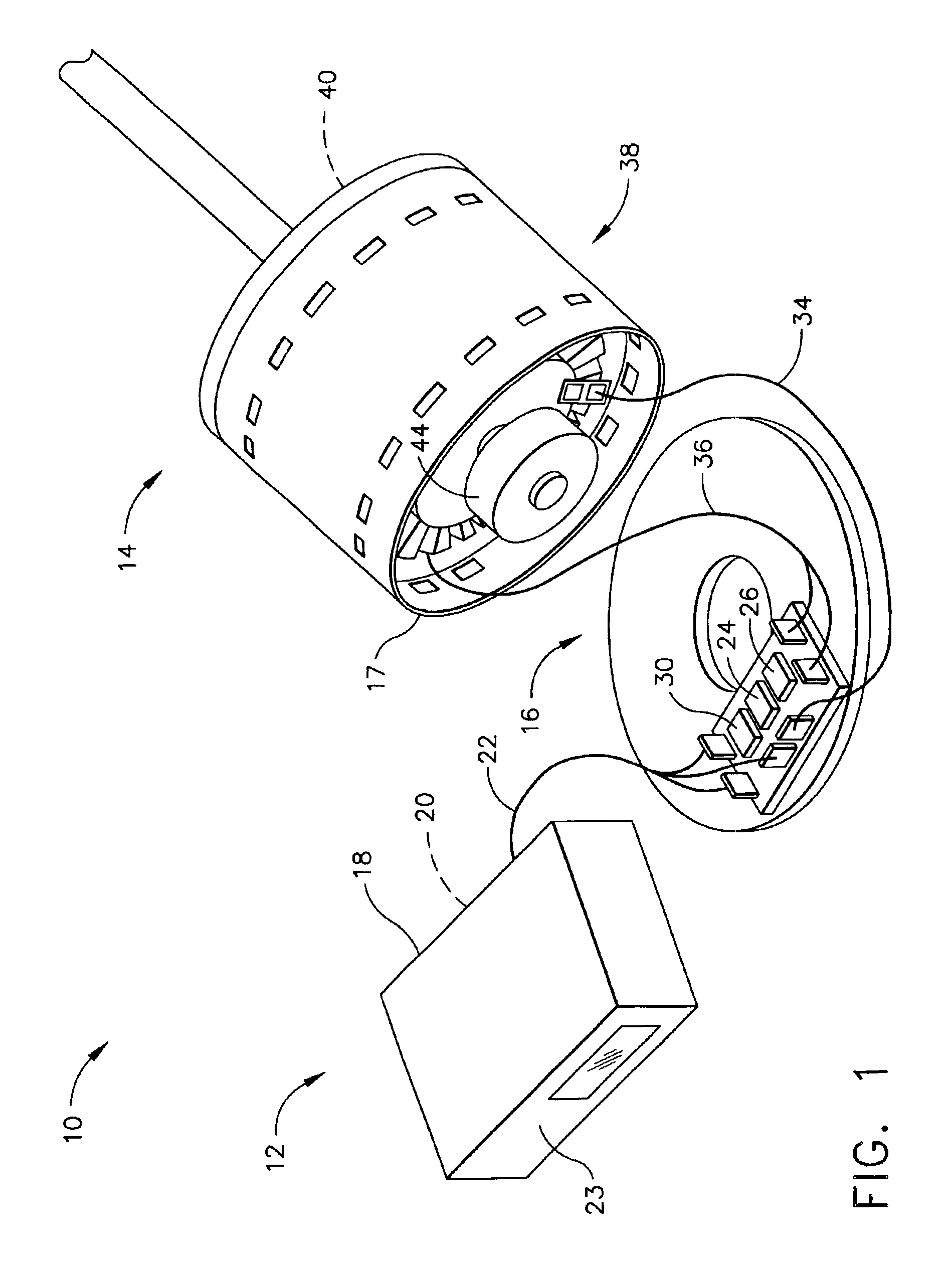

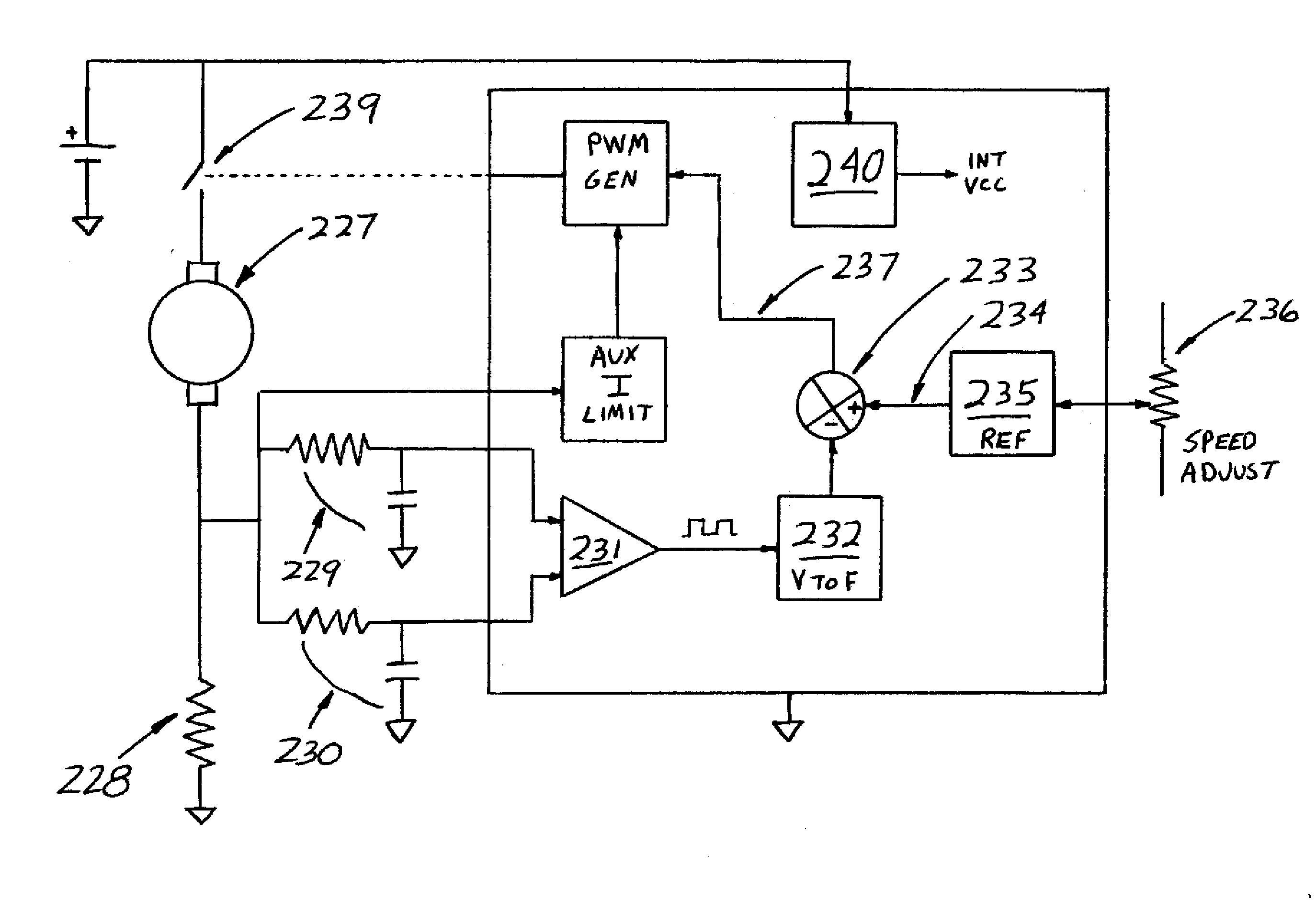

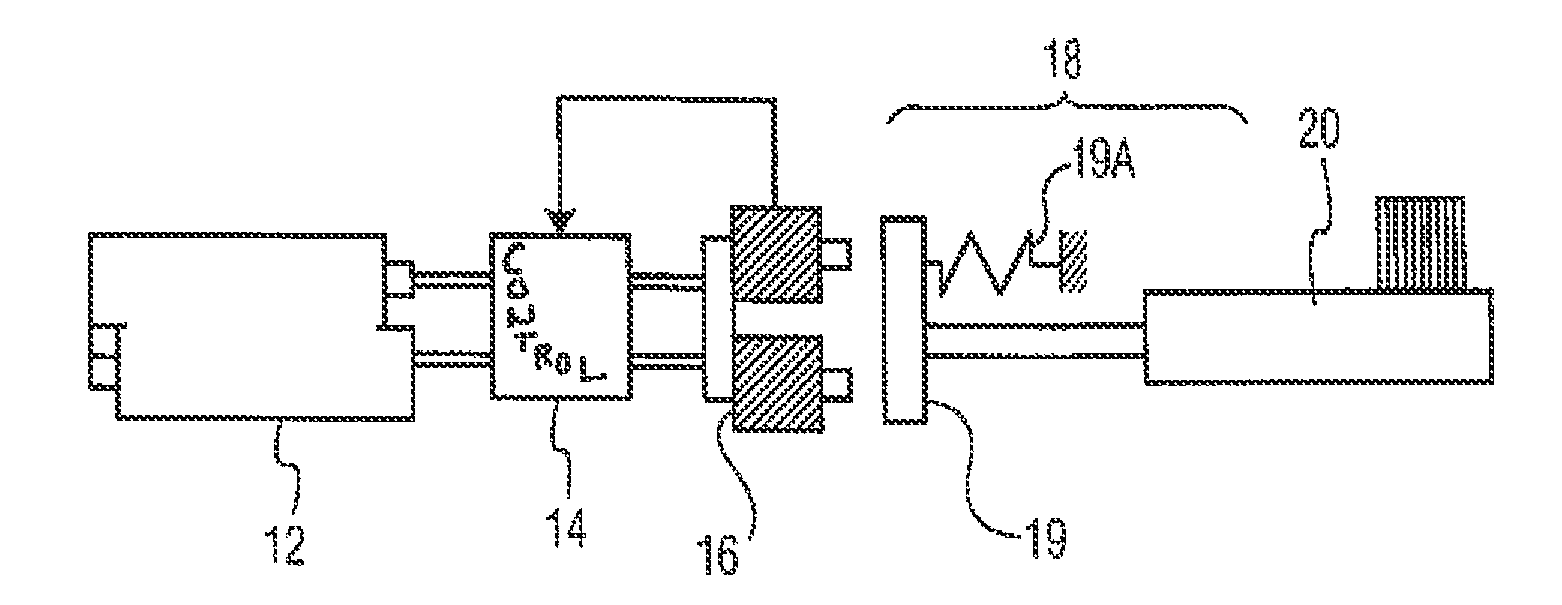

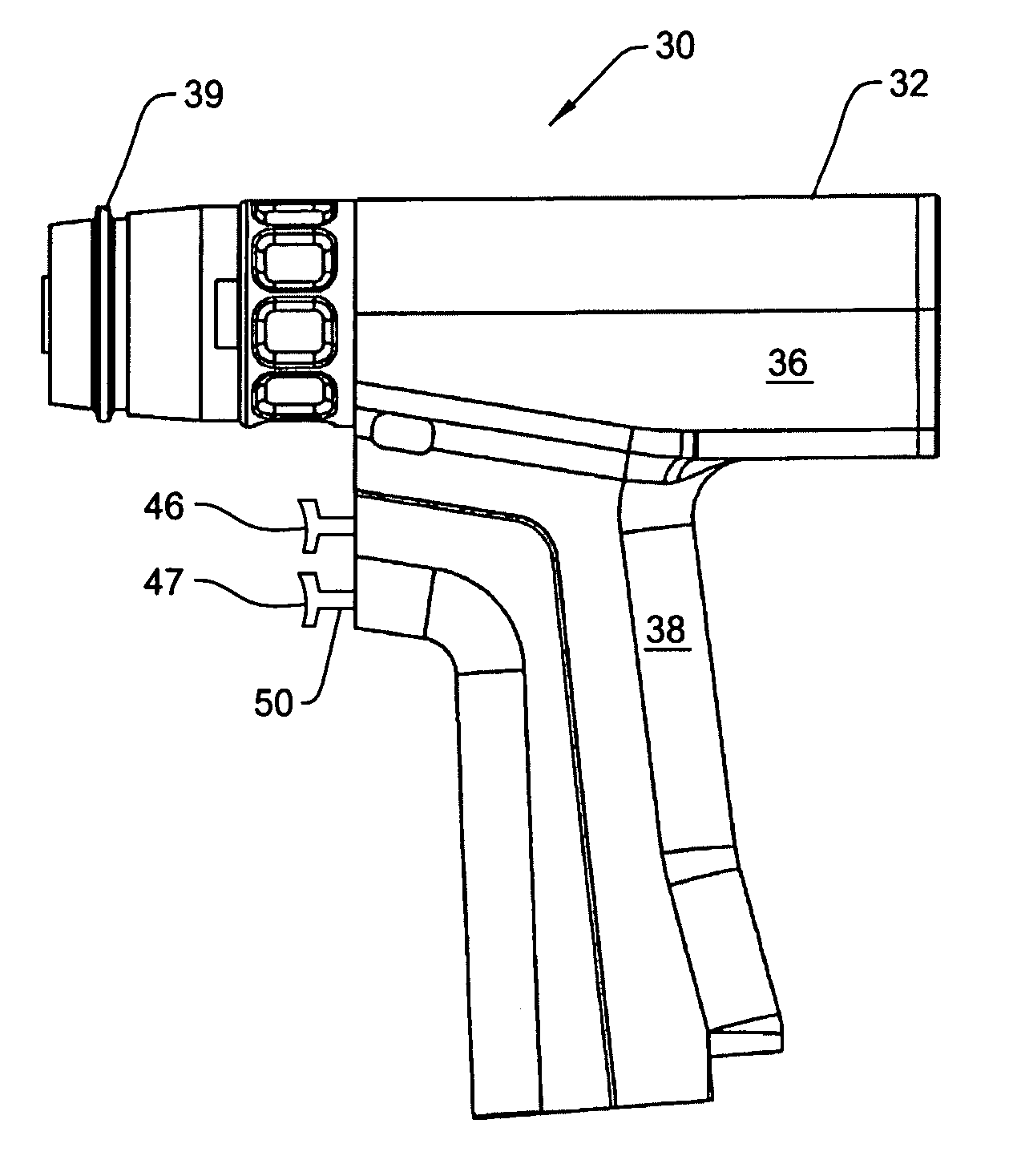

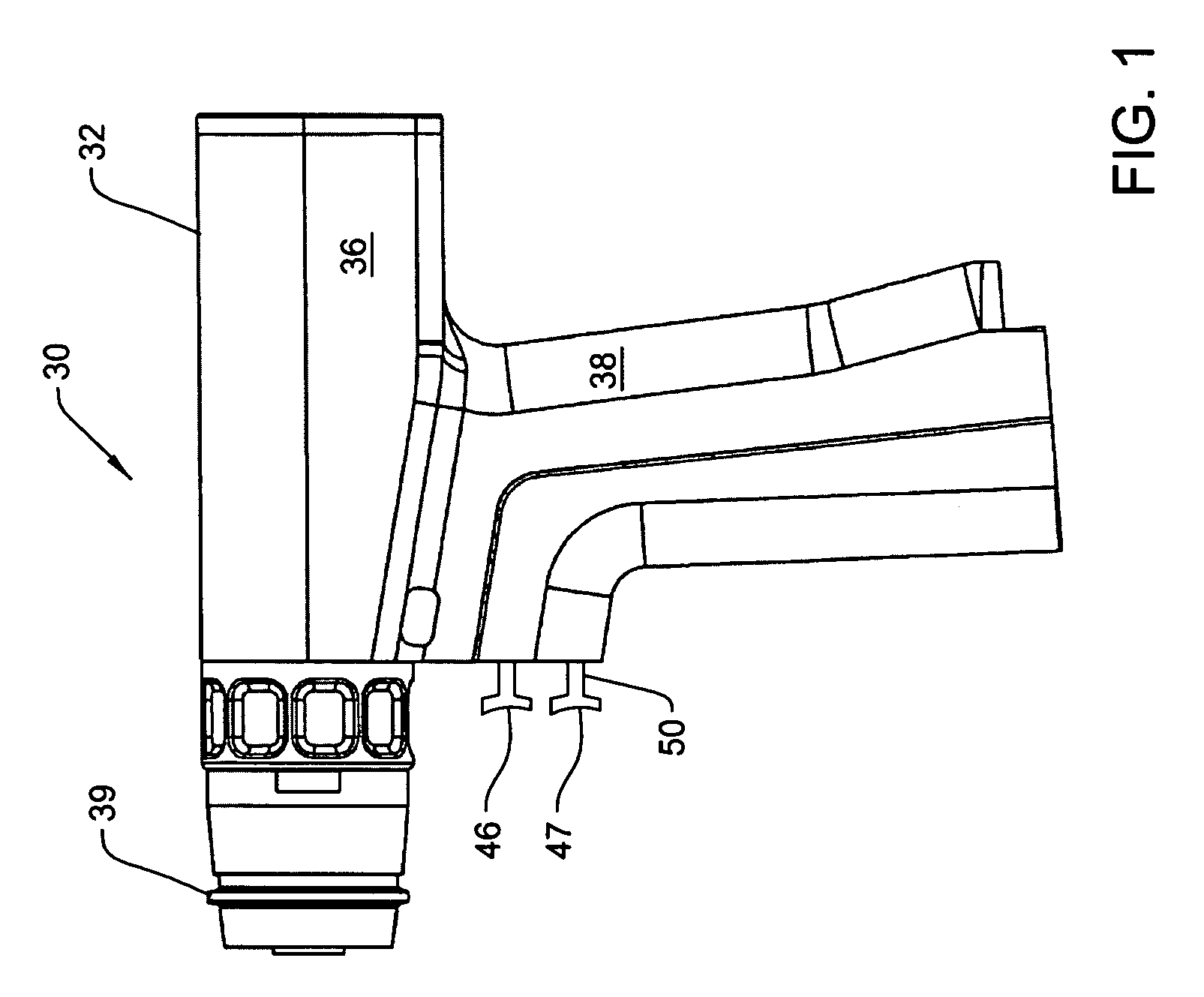

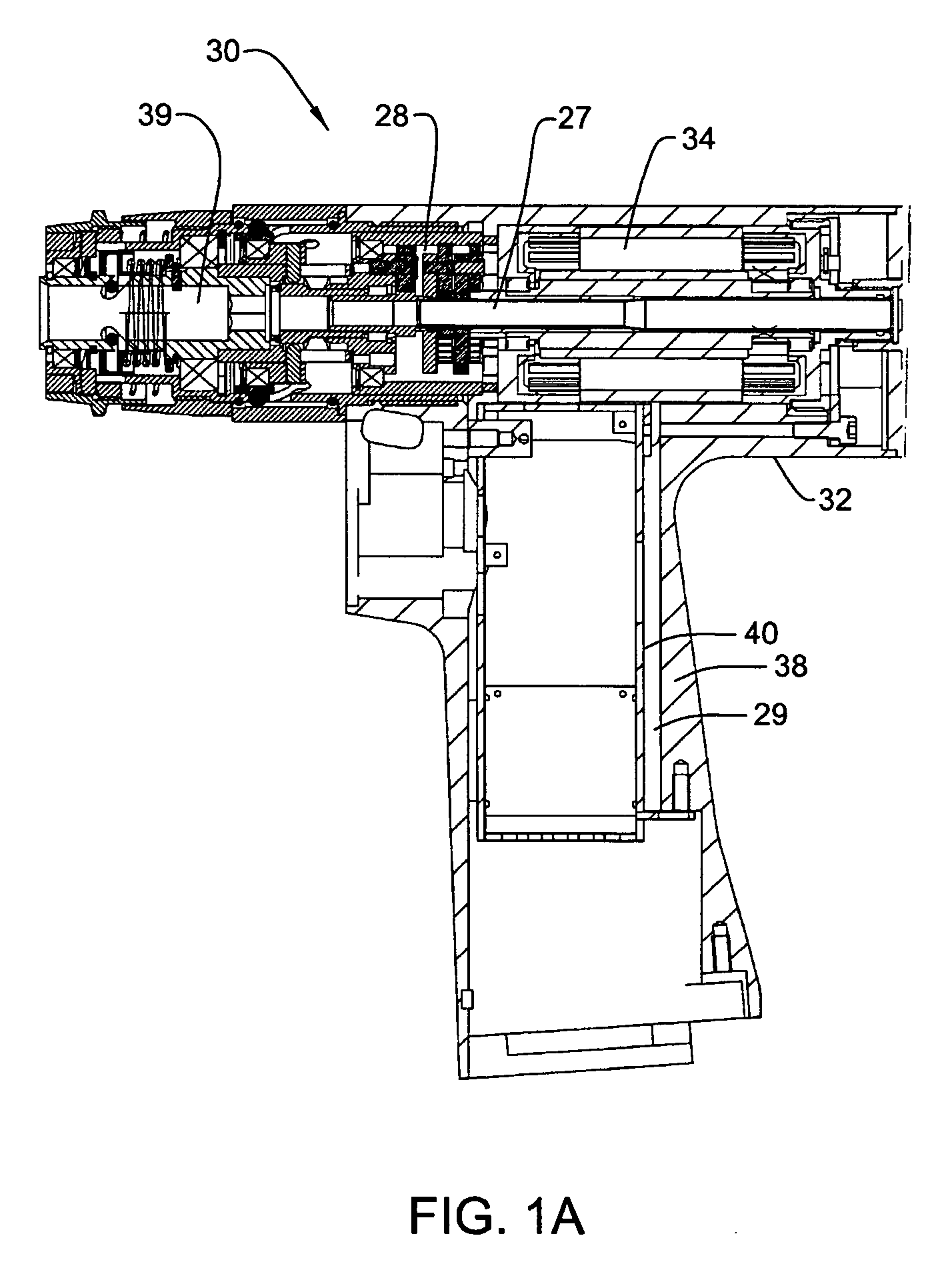

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

ActiveUS7638958B2Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringControl circuit

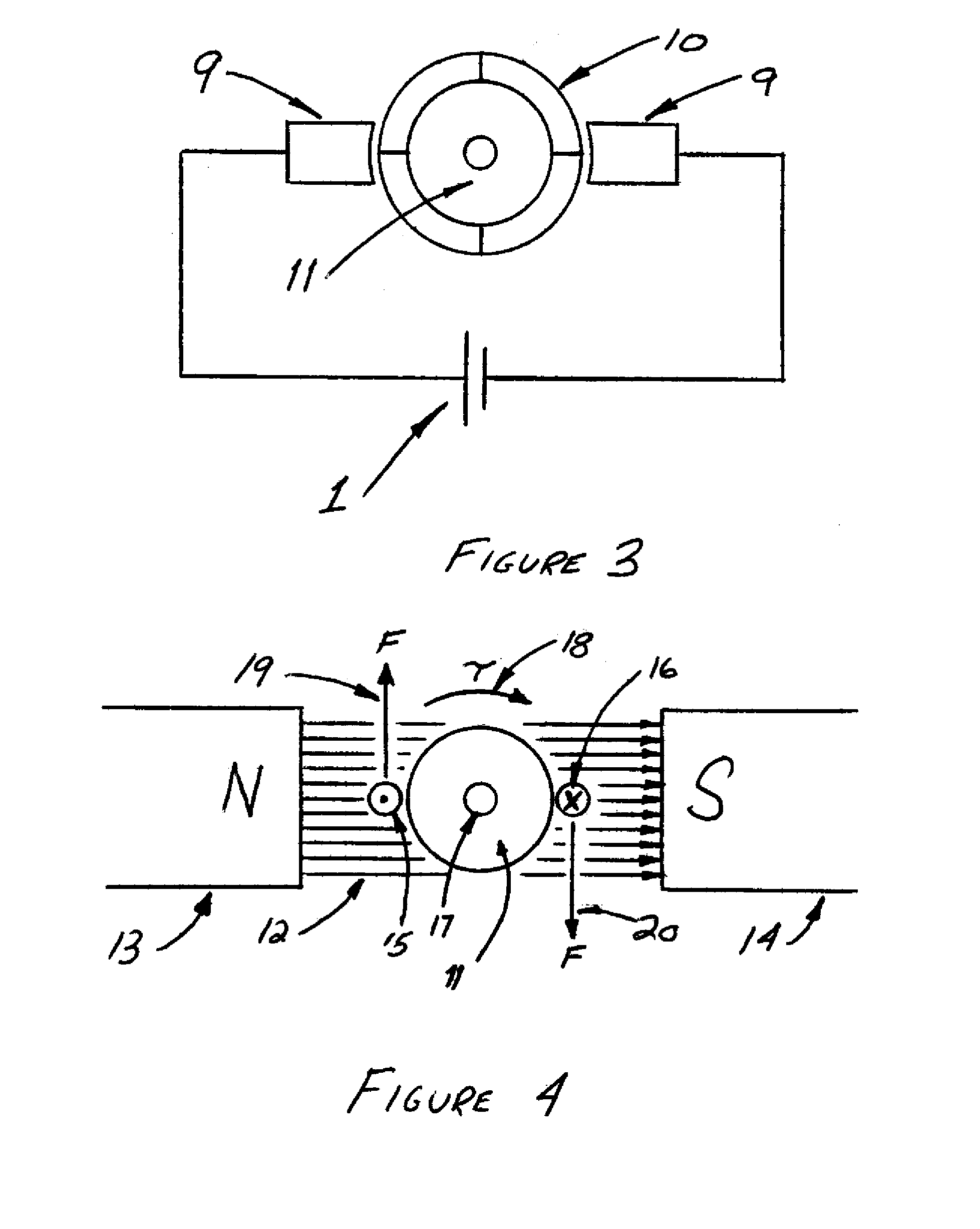

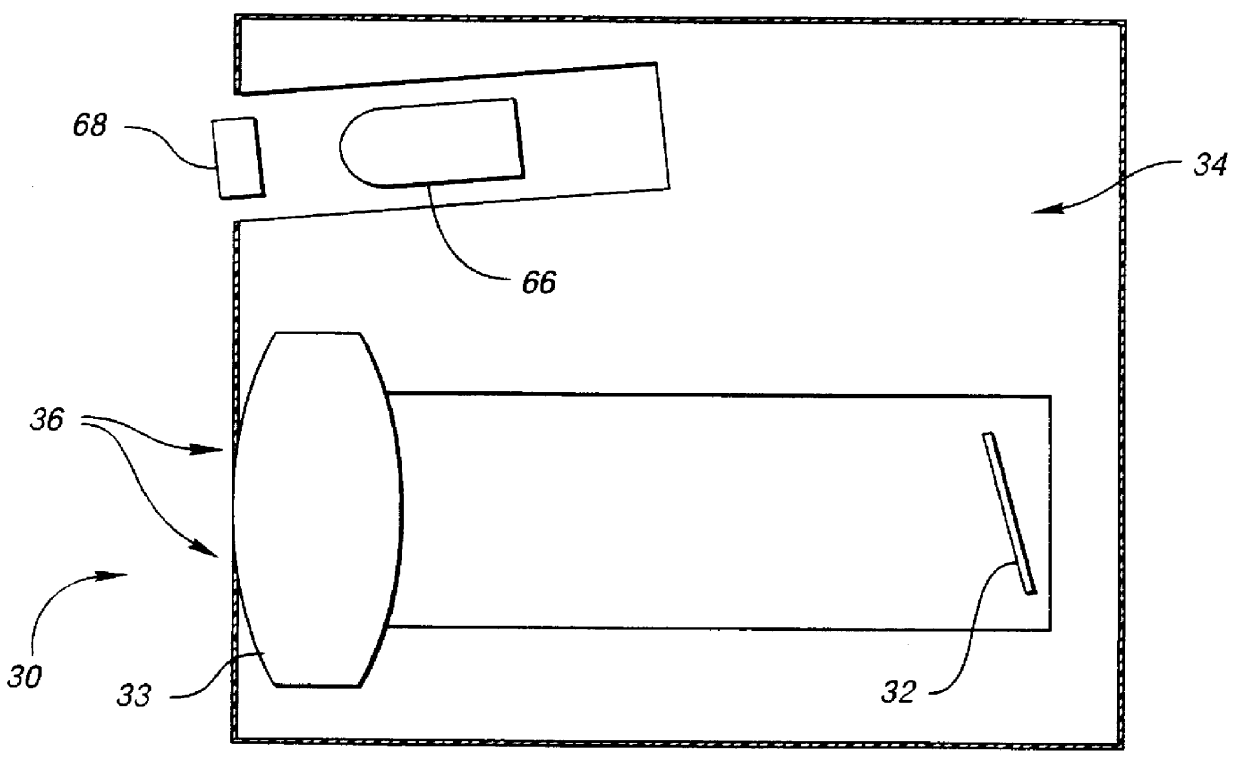

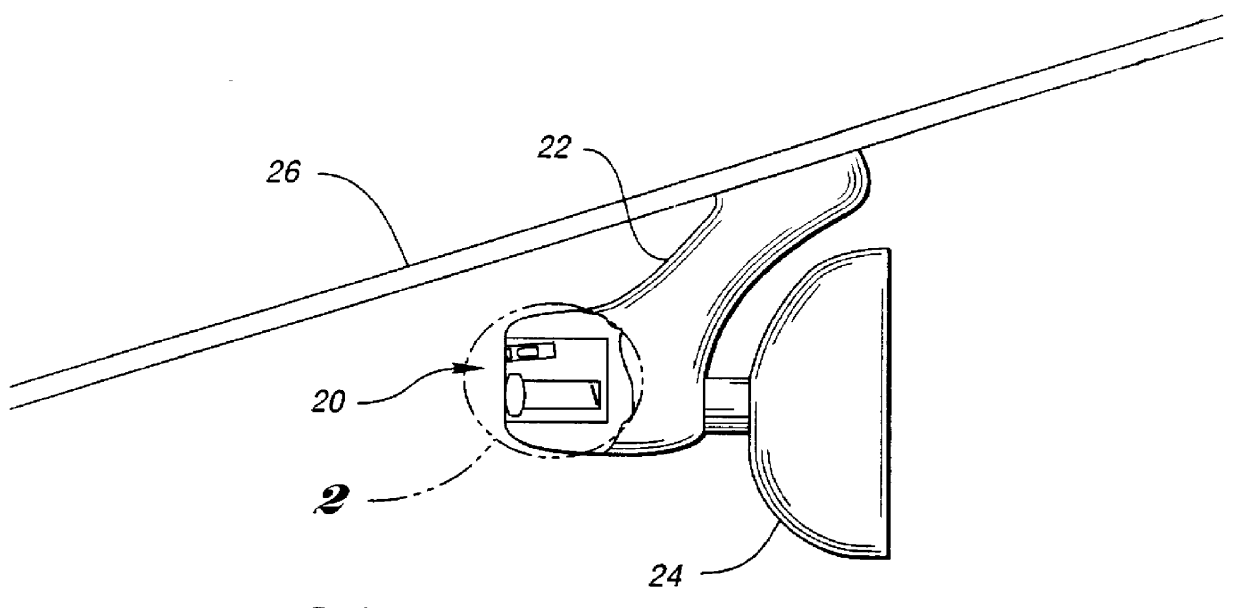

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

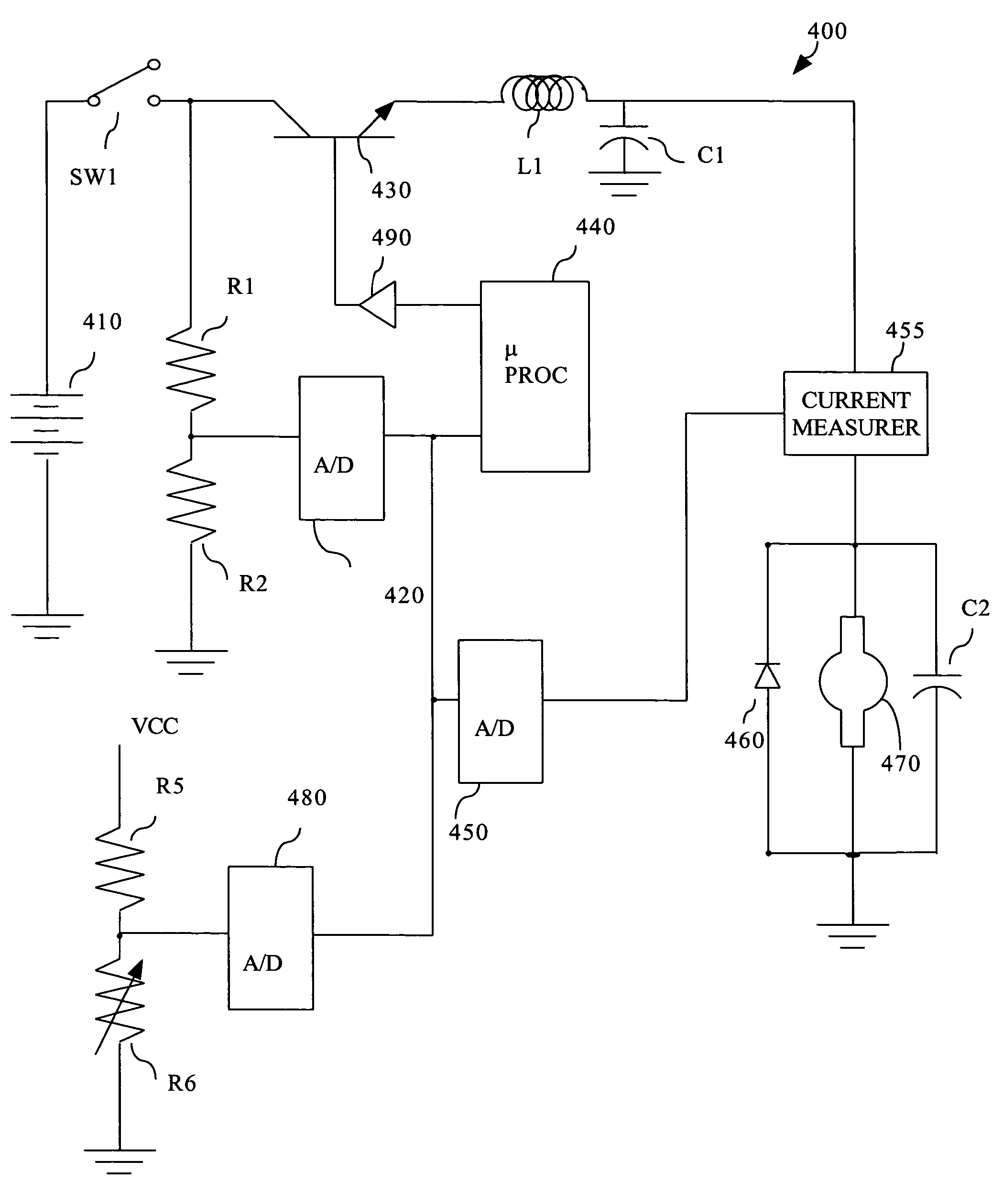

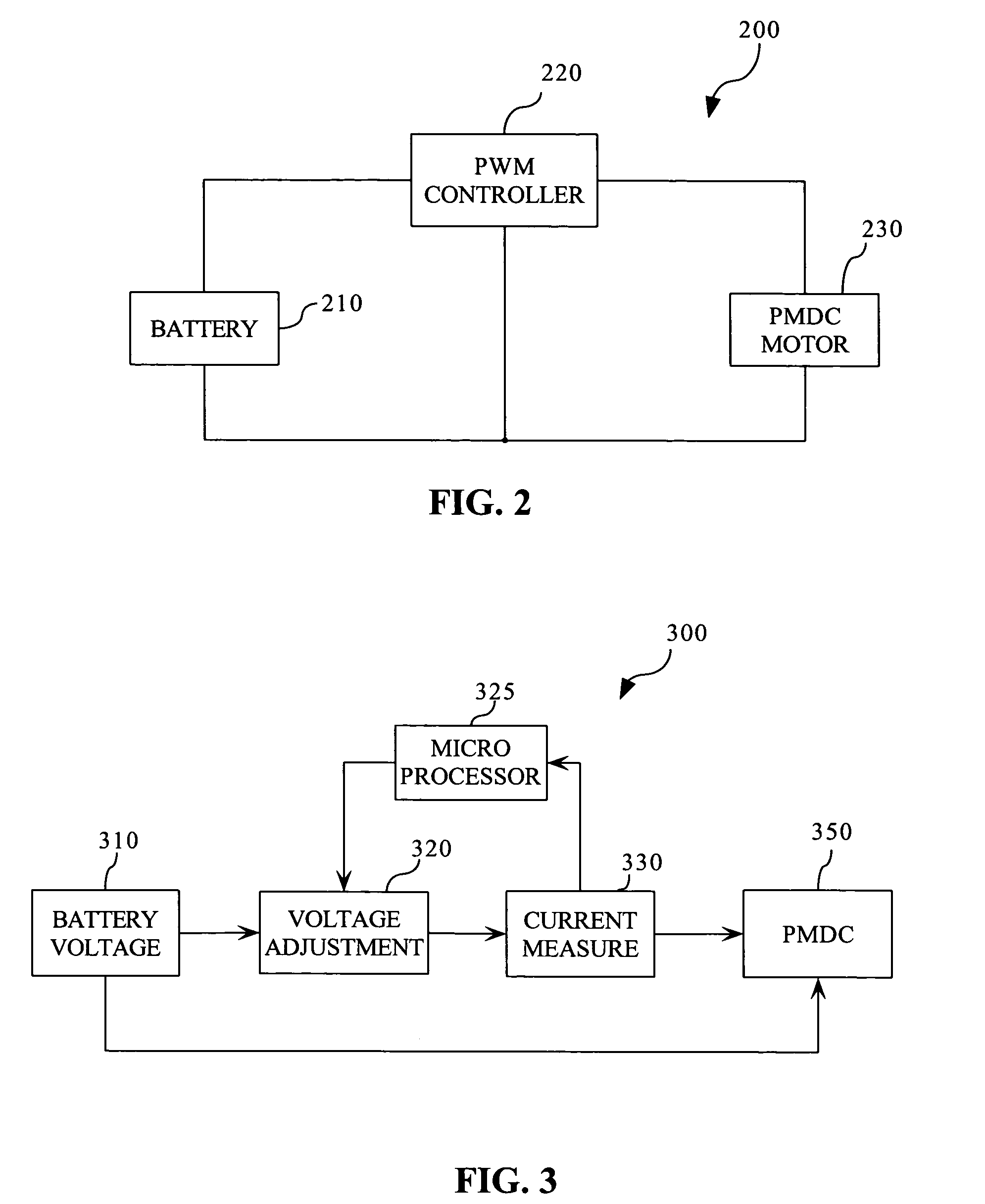

Amperage control for protection of battery over current in power tools

InactiveUS7133601B2Battery protectionHigh currentAC motor controlElectric motor controlLithiumNickel cadmium

Amperage control of a power tool motor is provided by pulse width modulation of current from a power supply. The pulse width modulation may be varied according to the determined motor current and measured power supply voltage. The power supply preferably includes a battery, such a lithium ion or nickel cadmium.

Owner:BLACK & DECKER INC

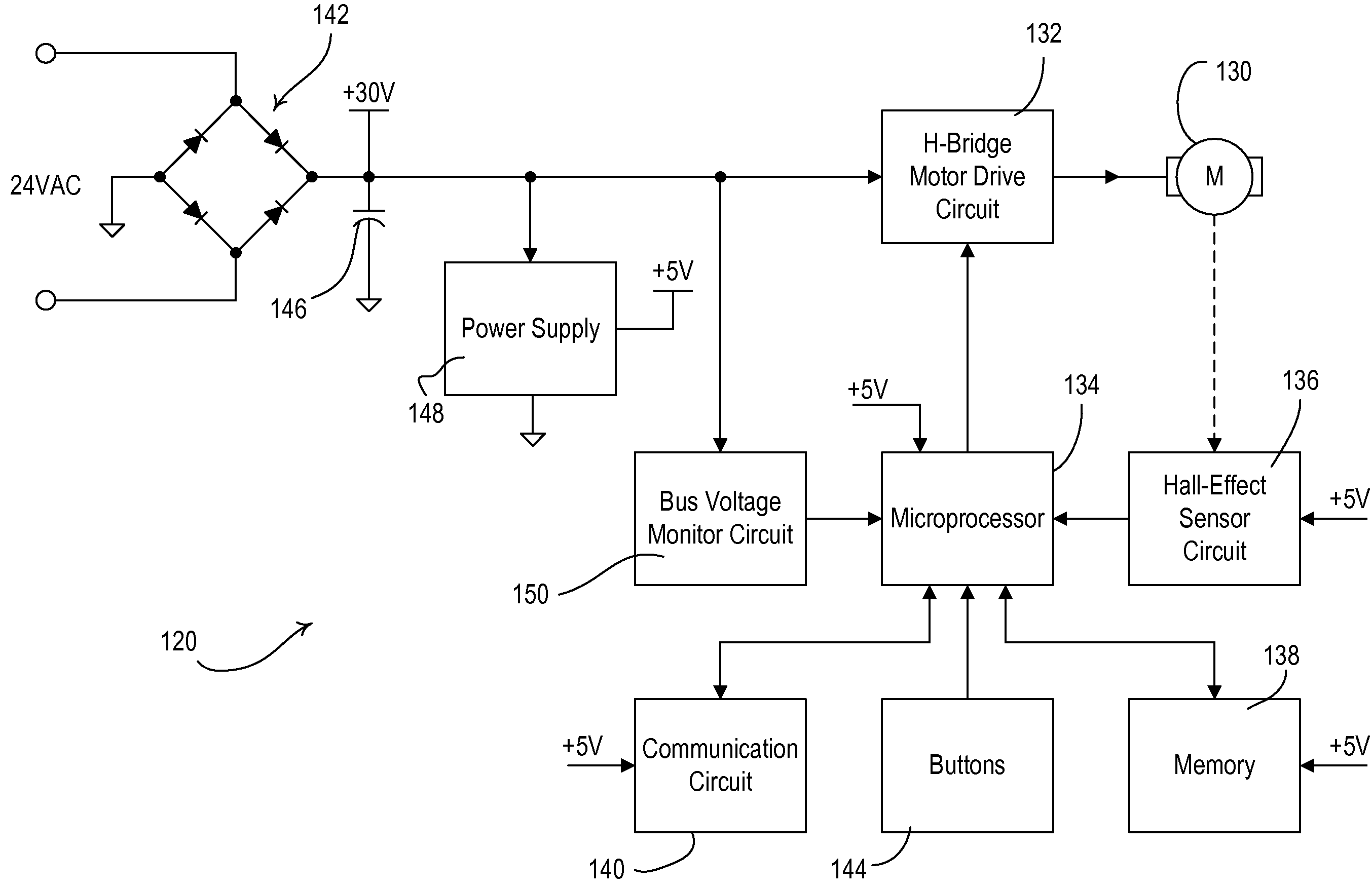

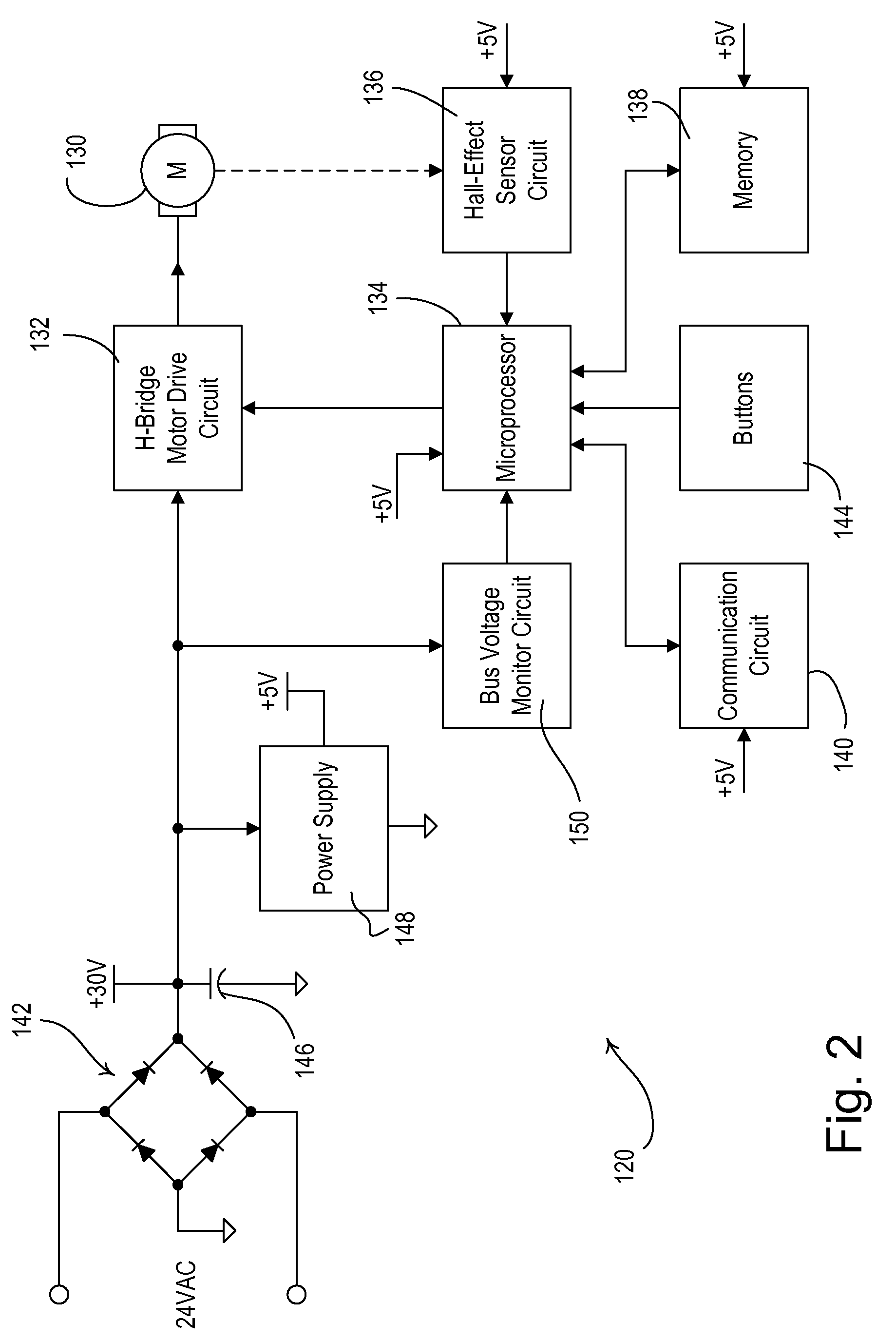

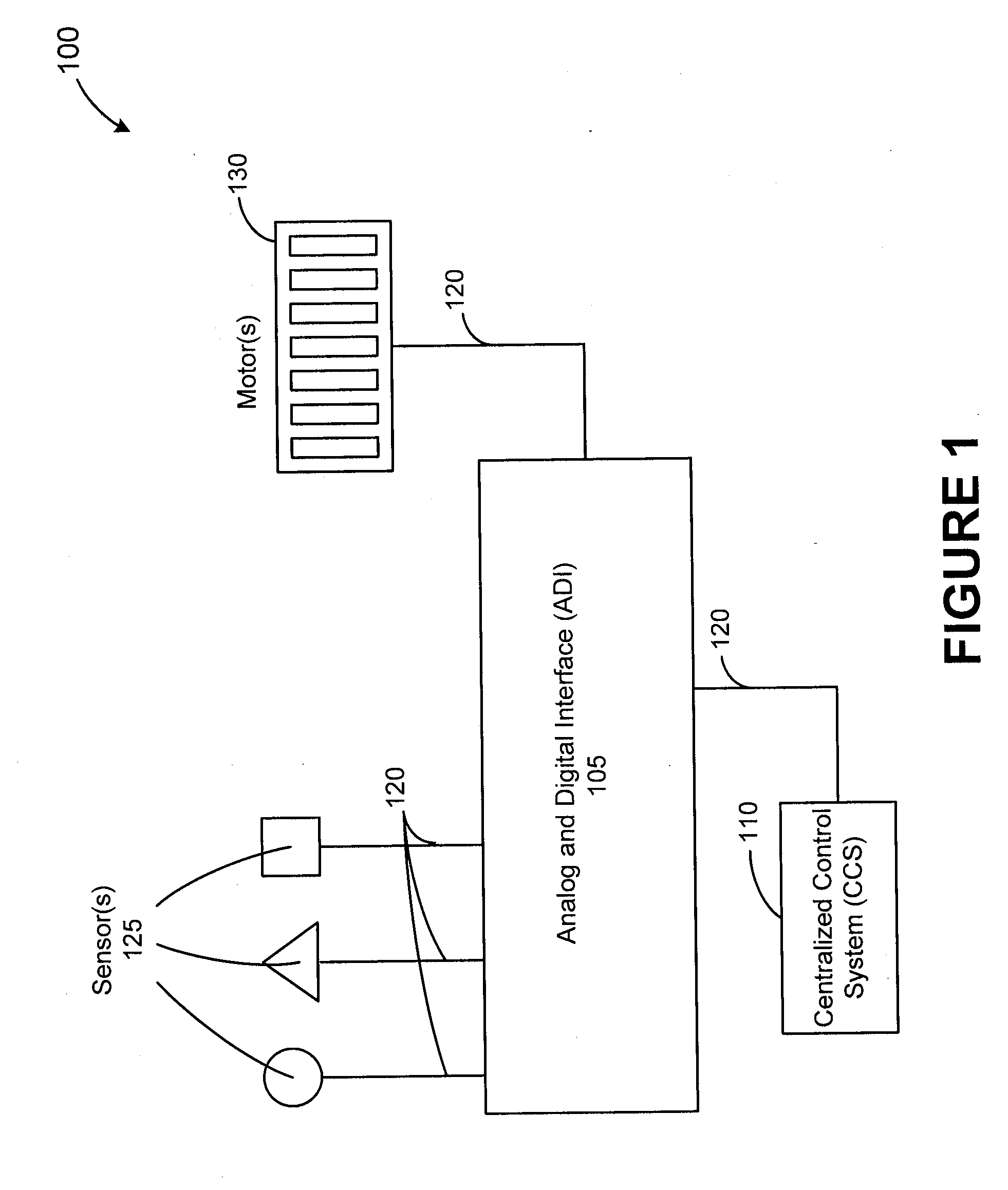

Method of controlling a motorized window treatment

ActiveUS7839109B2Motor/generator/converter stoppersDoor/window protective devicesMotor driveControl theory

A method of controlling a motorized window treatment provides for continued operation of the motorized window treatment during an overload or low-line condition. The motorized window treatment is driven by an electronic drive unit having a motor, a motor drive circuit, and a controller. The controller controls the motor drive circuit to drive the motor with a pulse-width modulated signal generated from a bus voltage. The controller is operable to monitor the magnitude of the bus voltage. If the bus voltage drops below a first voltage threshold, the controller stops the motor or reduces the duty cycle of the pulse-width modulated signal to allow the bus voltage to increase to an acceptable magnitude. When the bus voltage rises above a second voltage threshold, the controller begins driving the motor normally once again. During an overload or low-line condition, the controller is prevented from resetting, while driving the motor with minimal interruption to the movement of the motorized window treatment.

Owner:LUTRON TECH CO LLC

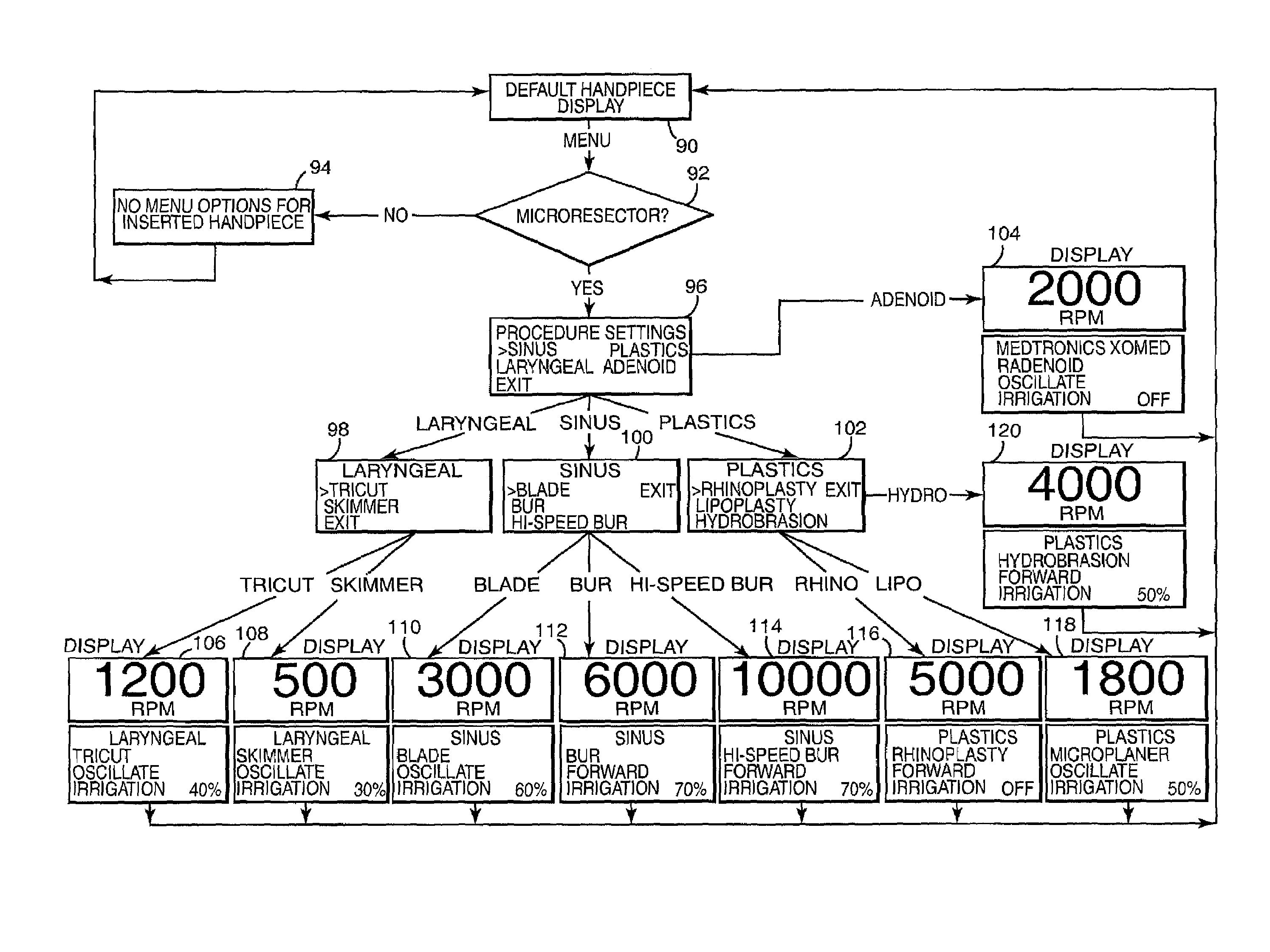

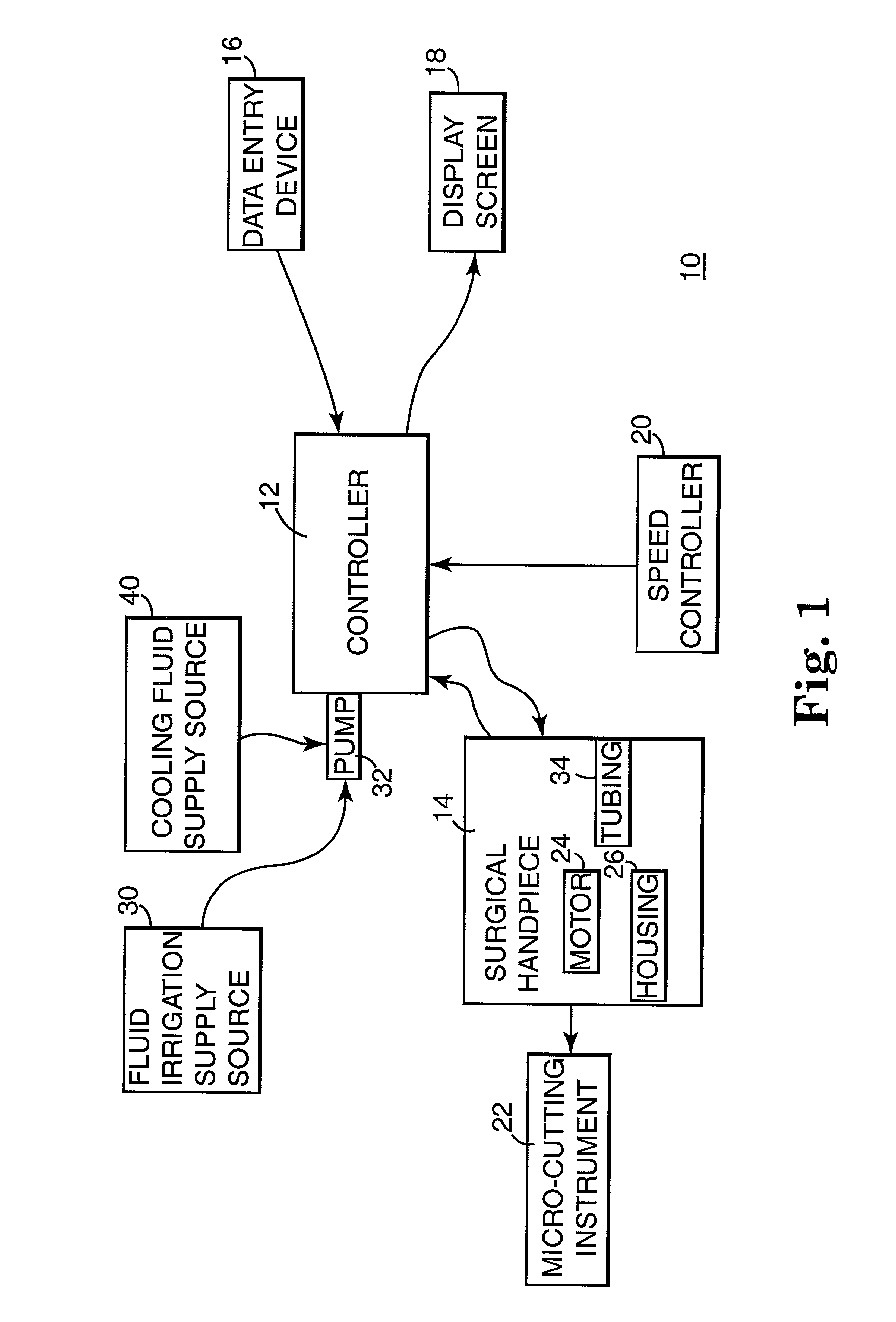

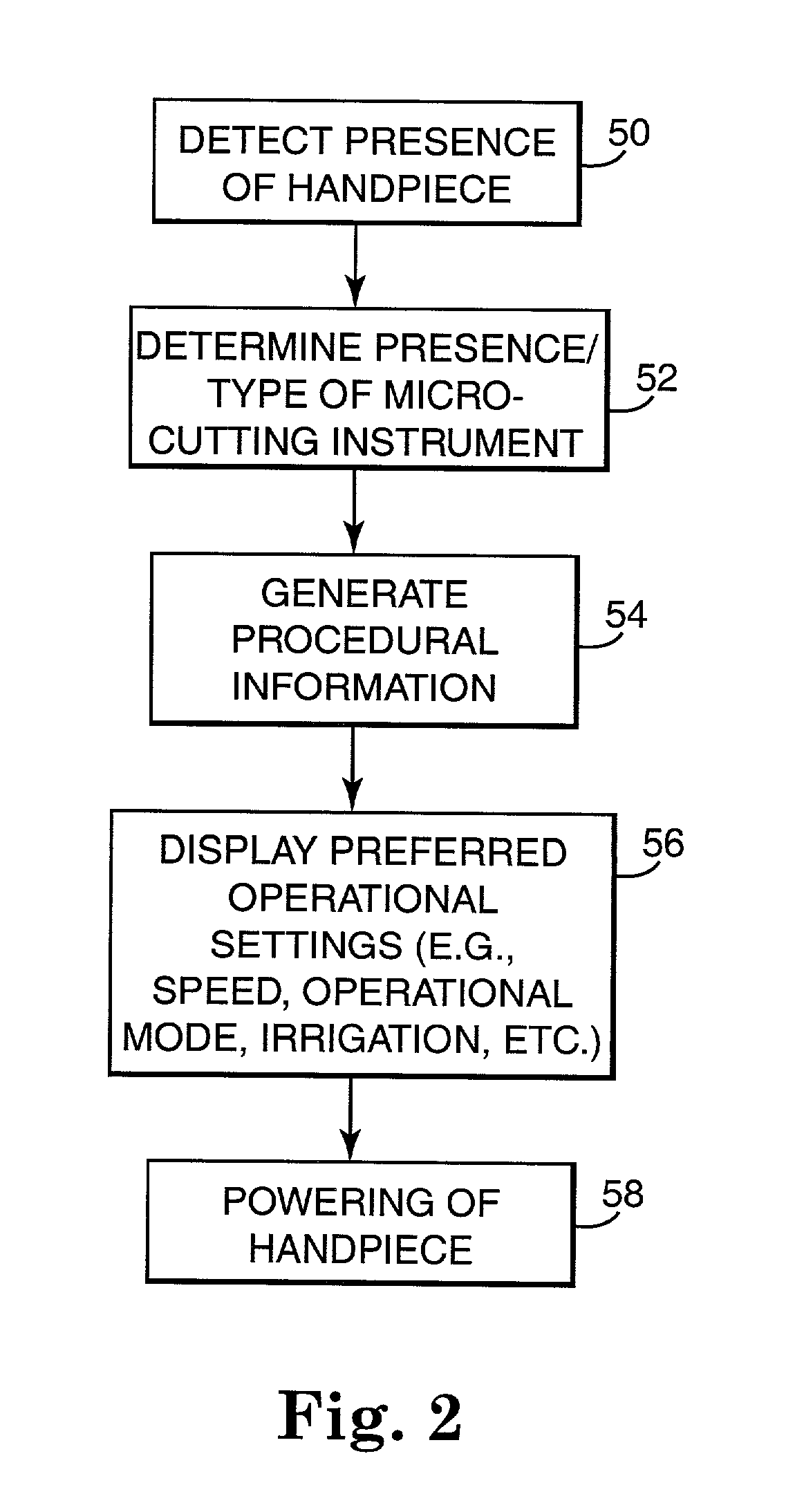

Motor control system for a surgical handpiece

A system and method for powered surgical handpiece capable of powering various micro-cutting instruments is described. The system is comprised of a controller adapted for controlling / interfacing with a powered surgical handpiece based upon user-defined procedural information. A data entry device is used for entering the user-defined procedural information used by the controller for configuring and operating the motor control system.

Owner:MEDTRONIC INC

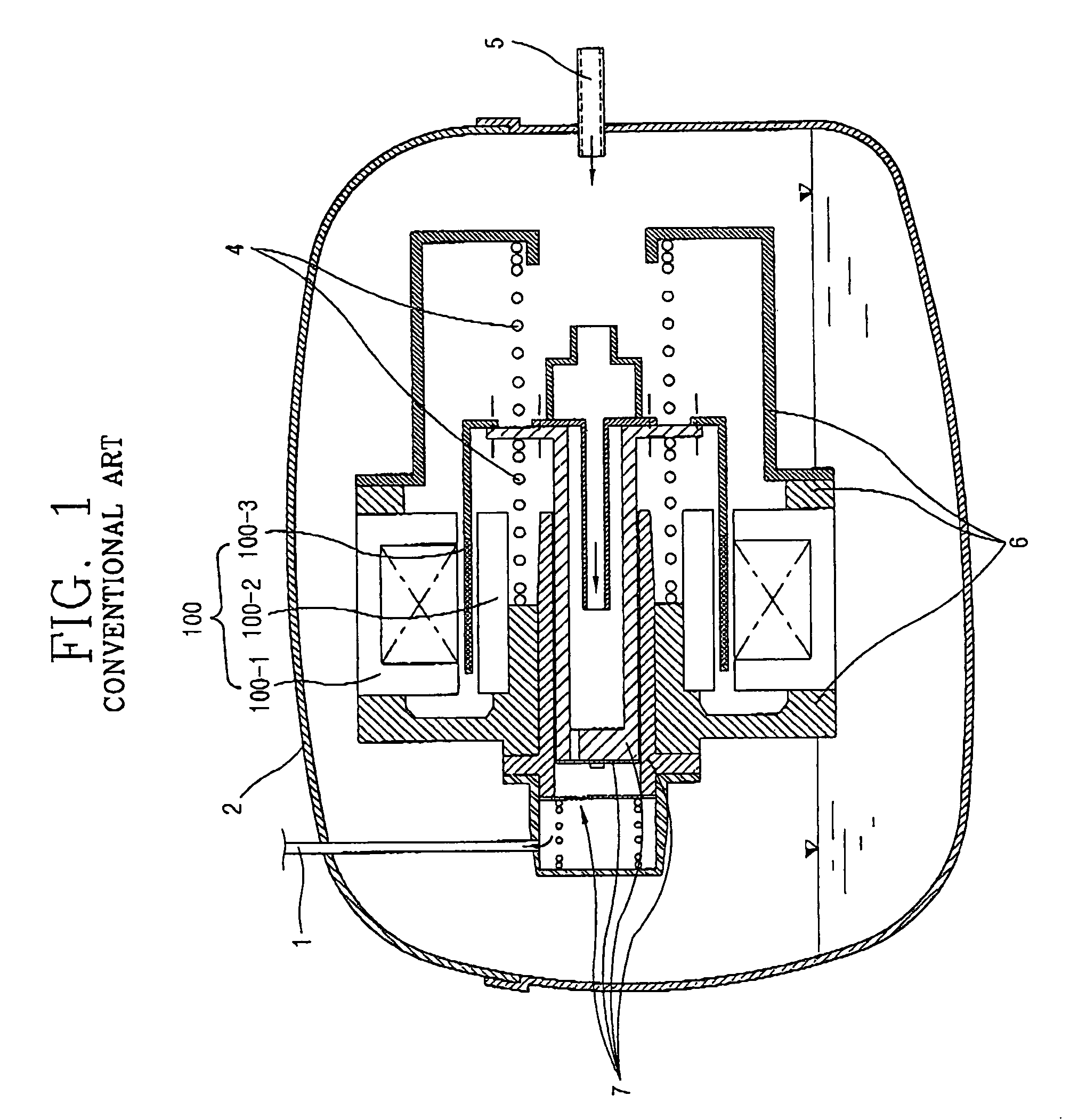

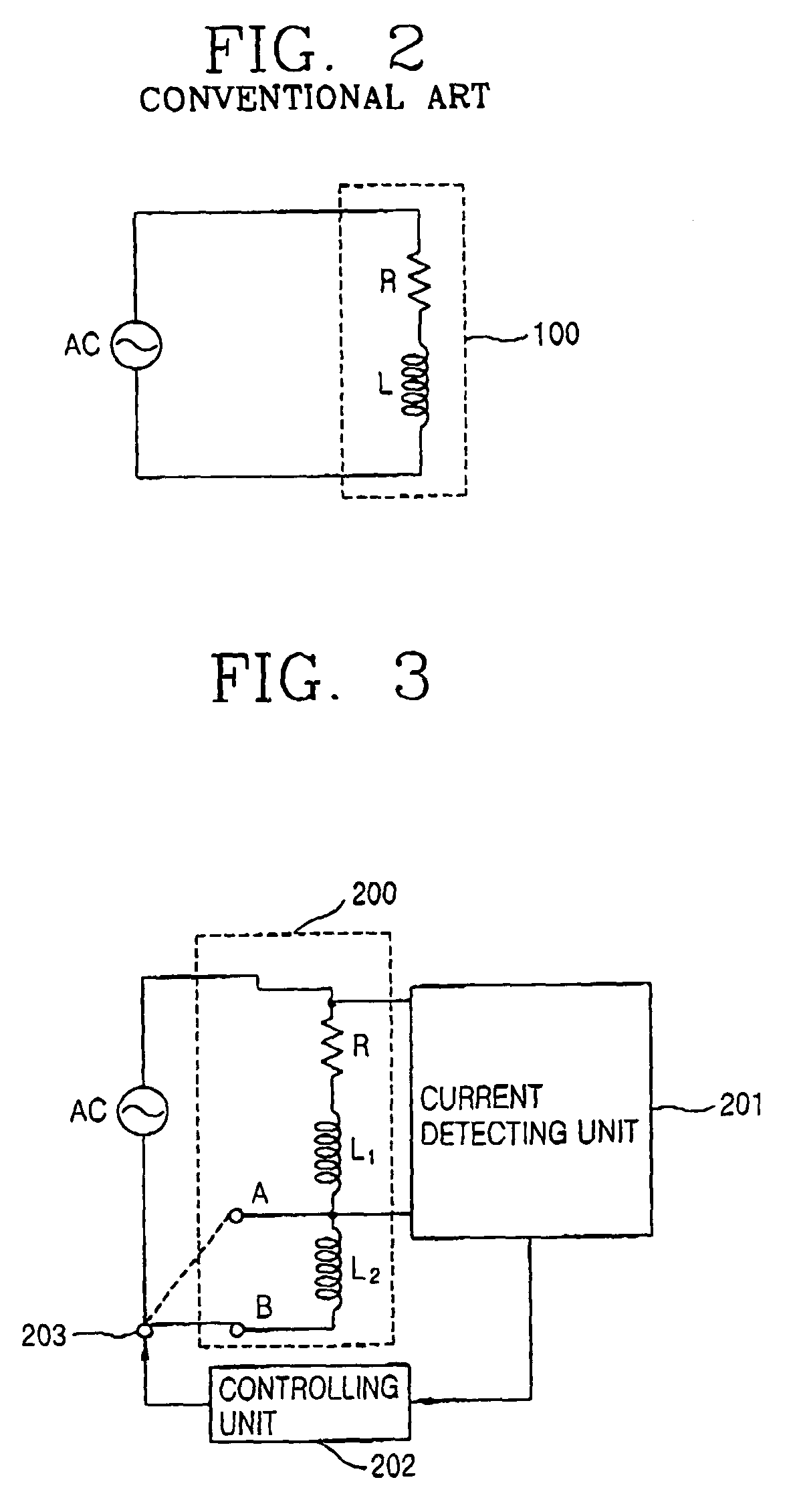

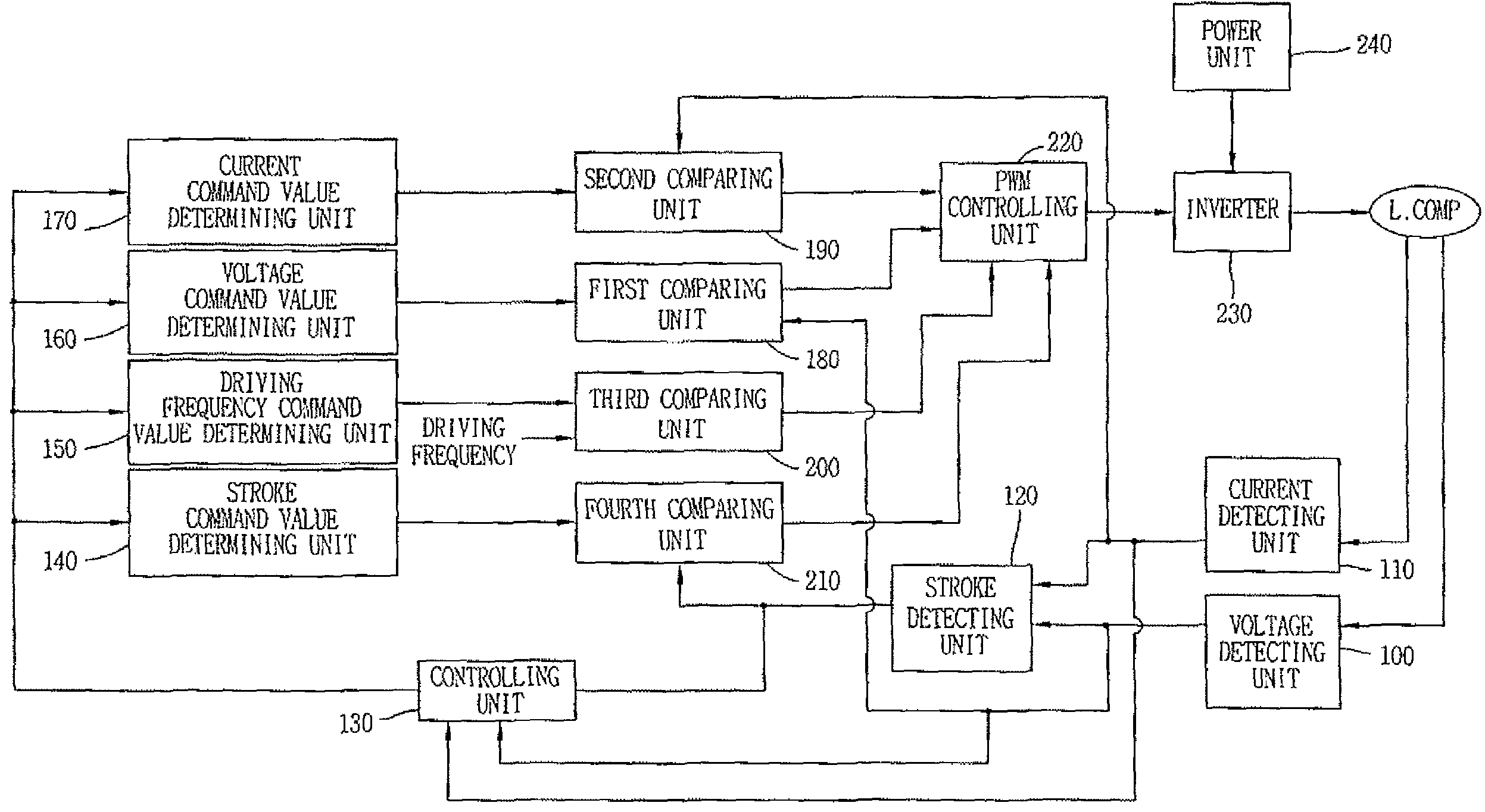

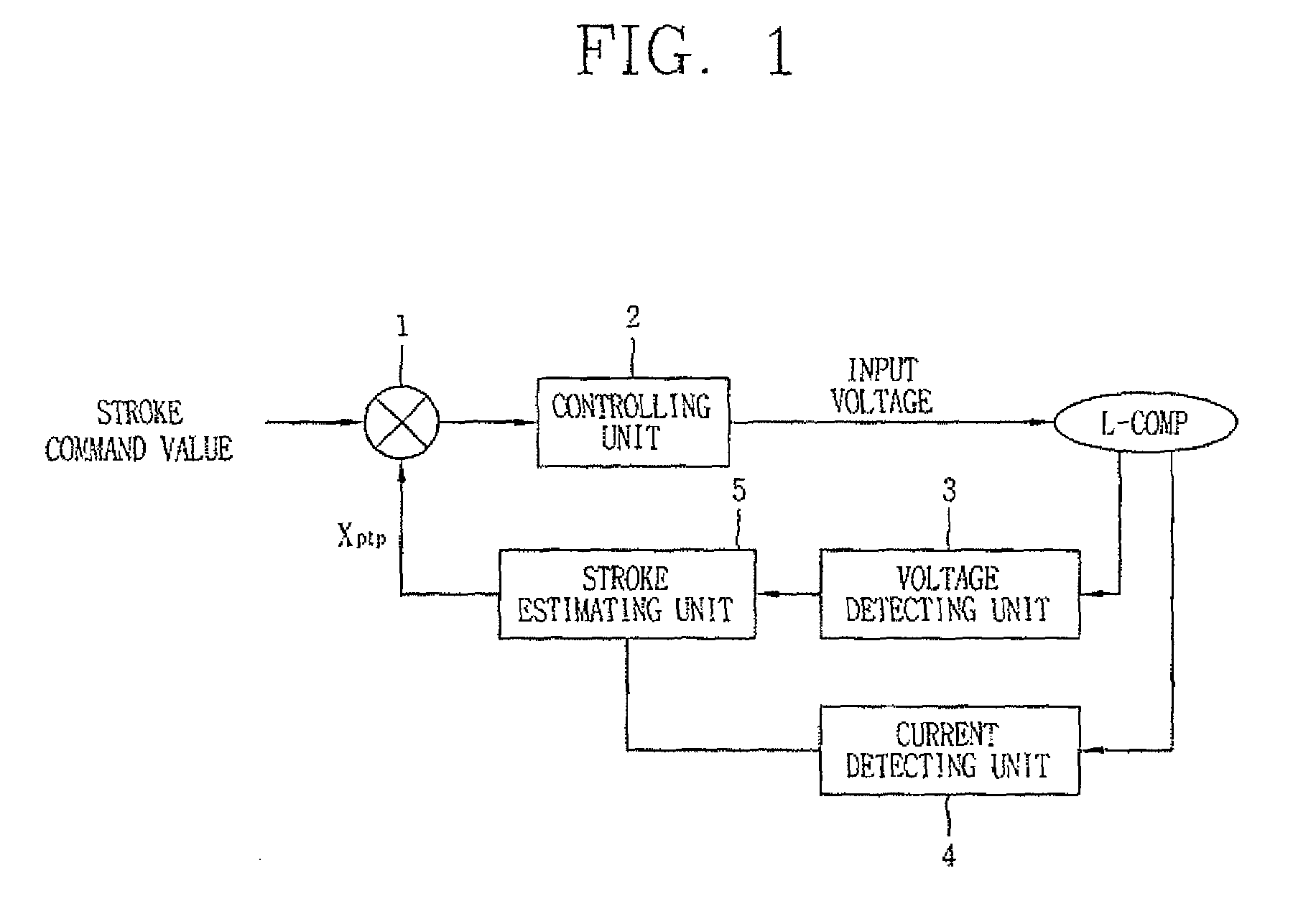

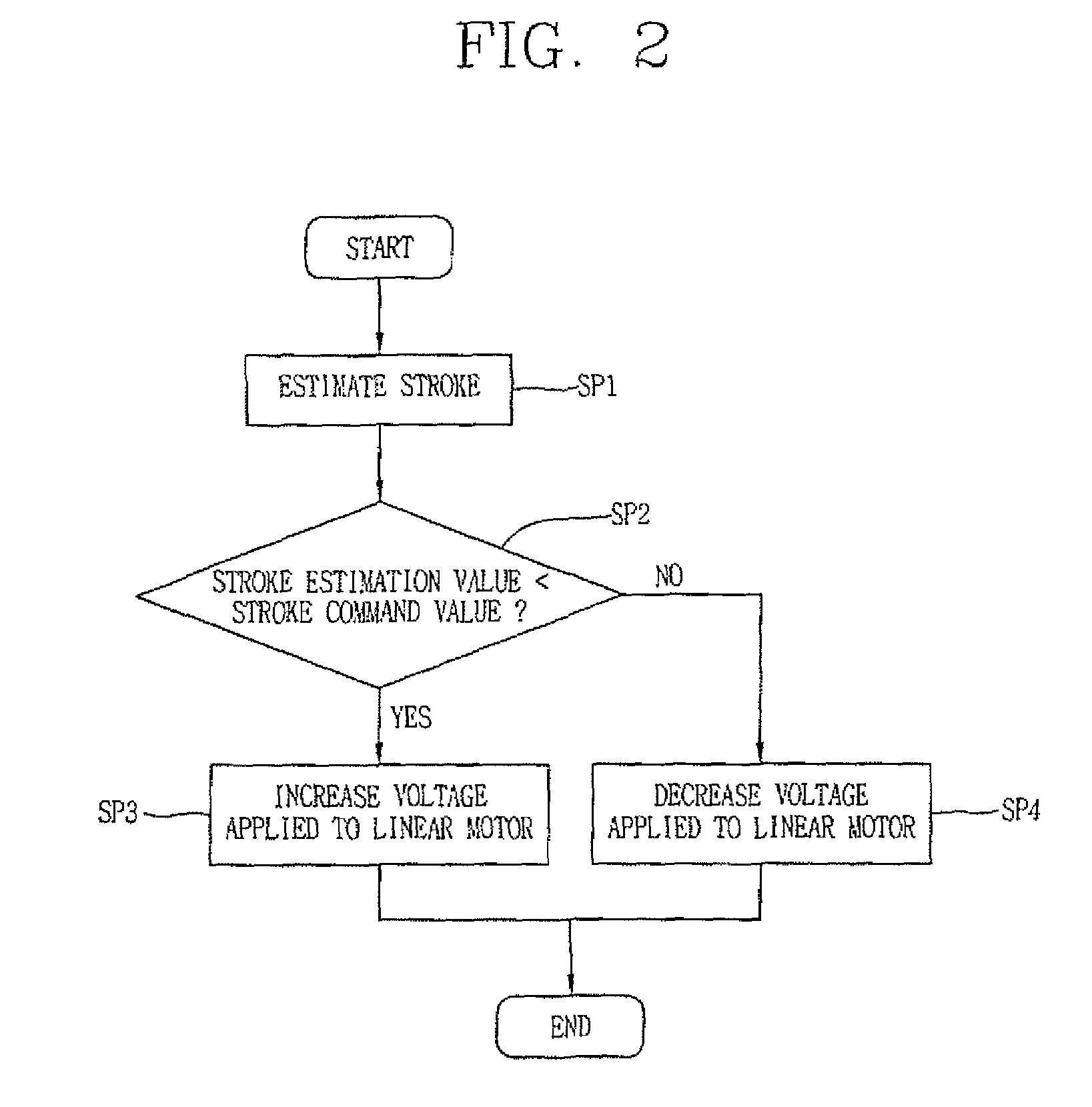

Apparatus and method for controlling driving of linear motor

InactiveUS6998736B2Increase efficiency of linearMotor/generator/converter stoppersDC motor speed/torque controlControl signalLinear compressor

Owner:LG ELECTRONICS INC

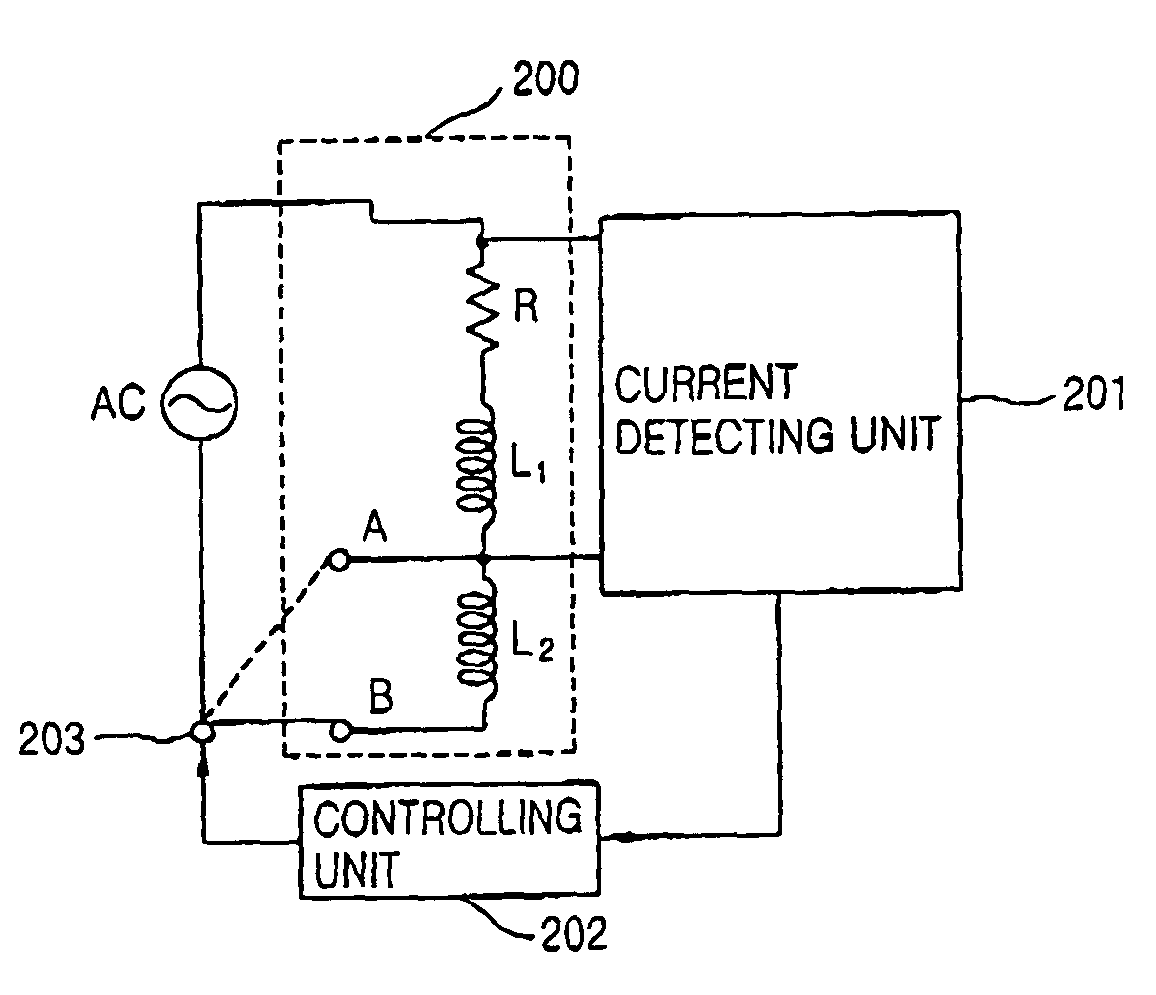

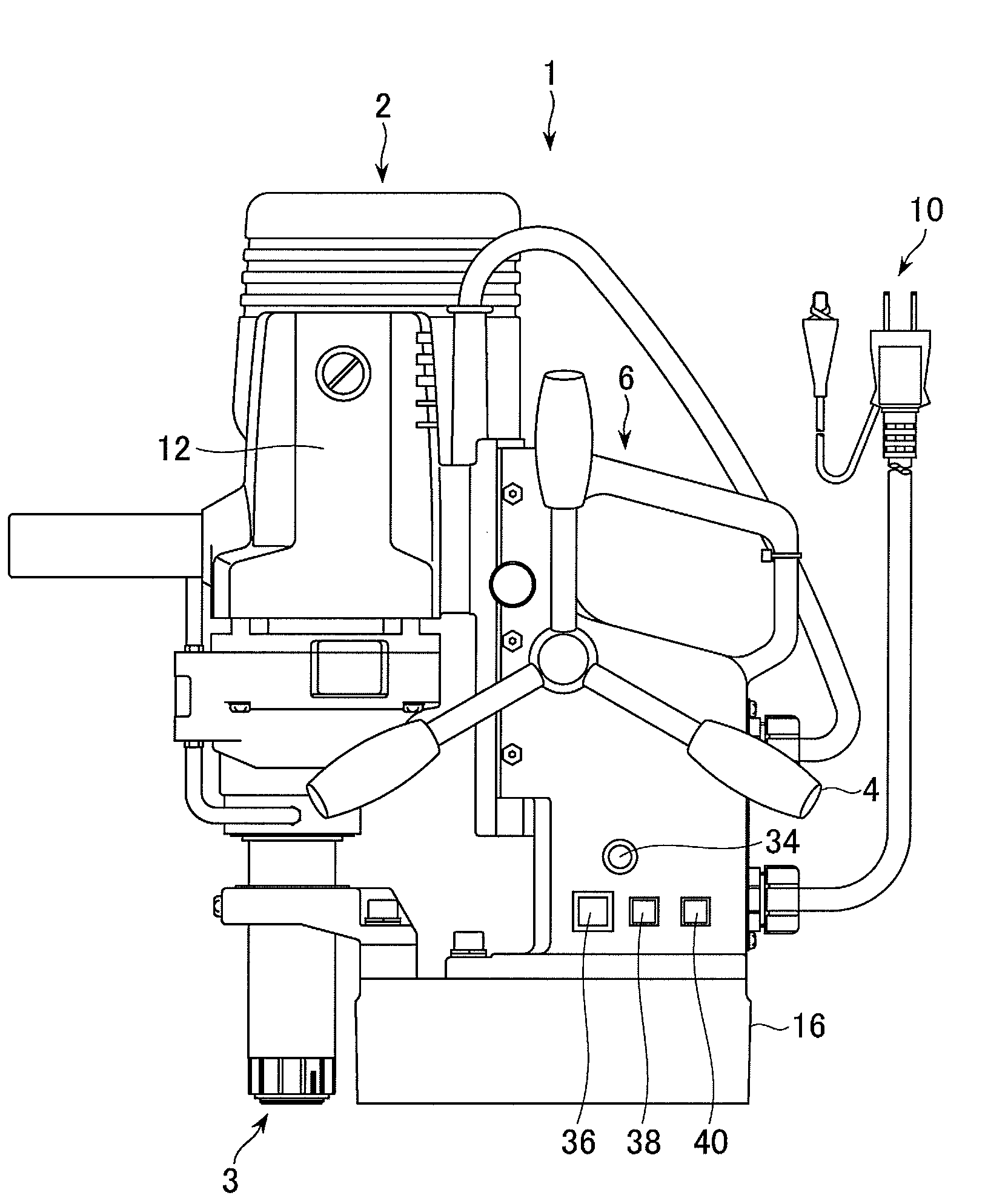

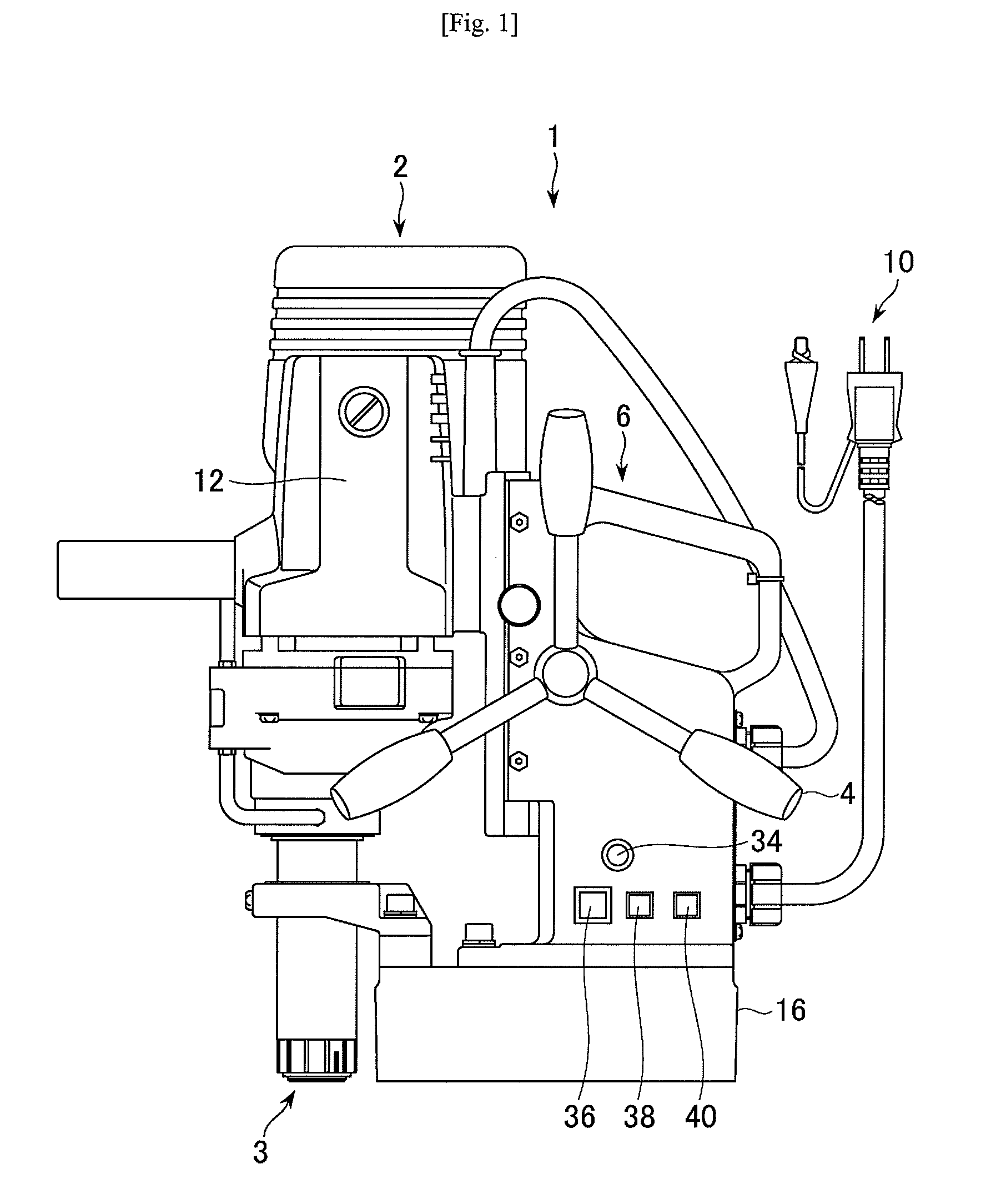

Portable drilling device

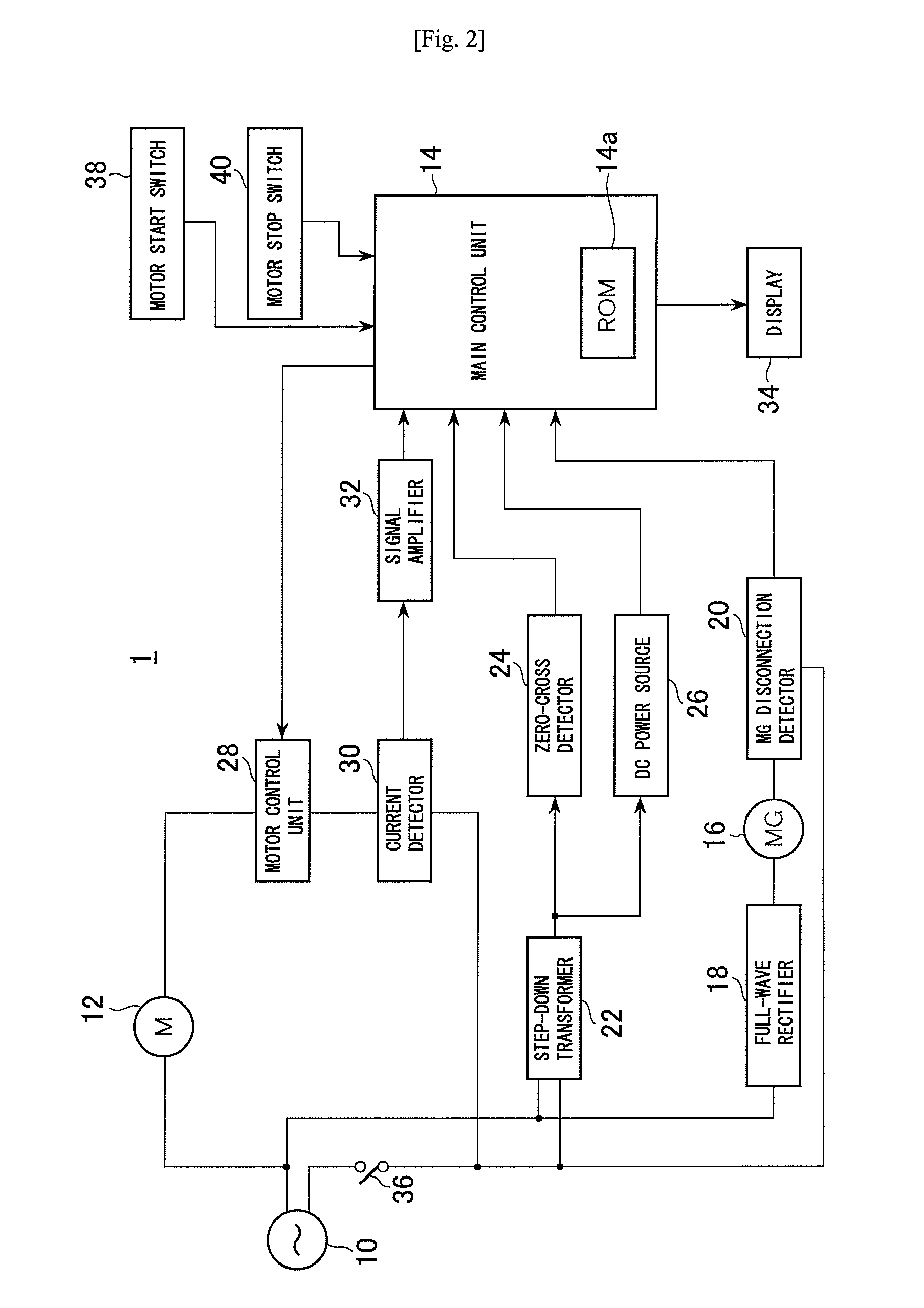

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

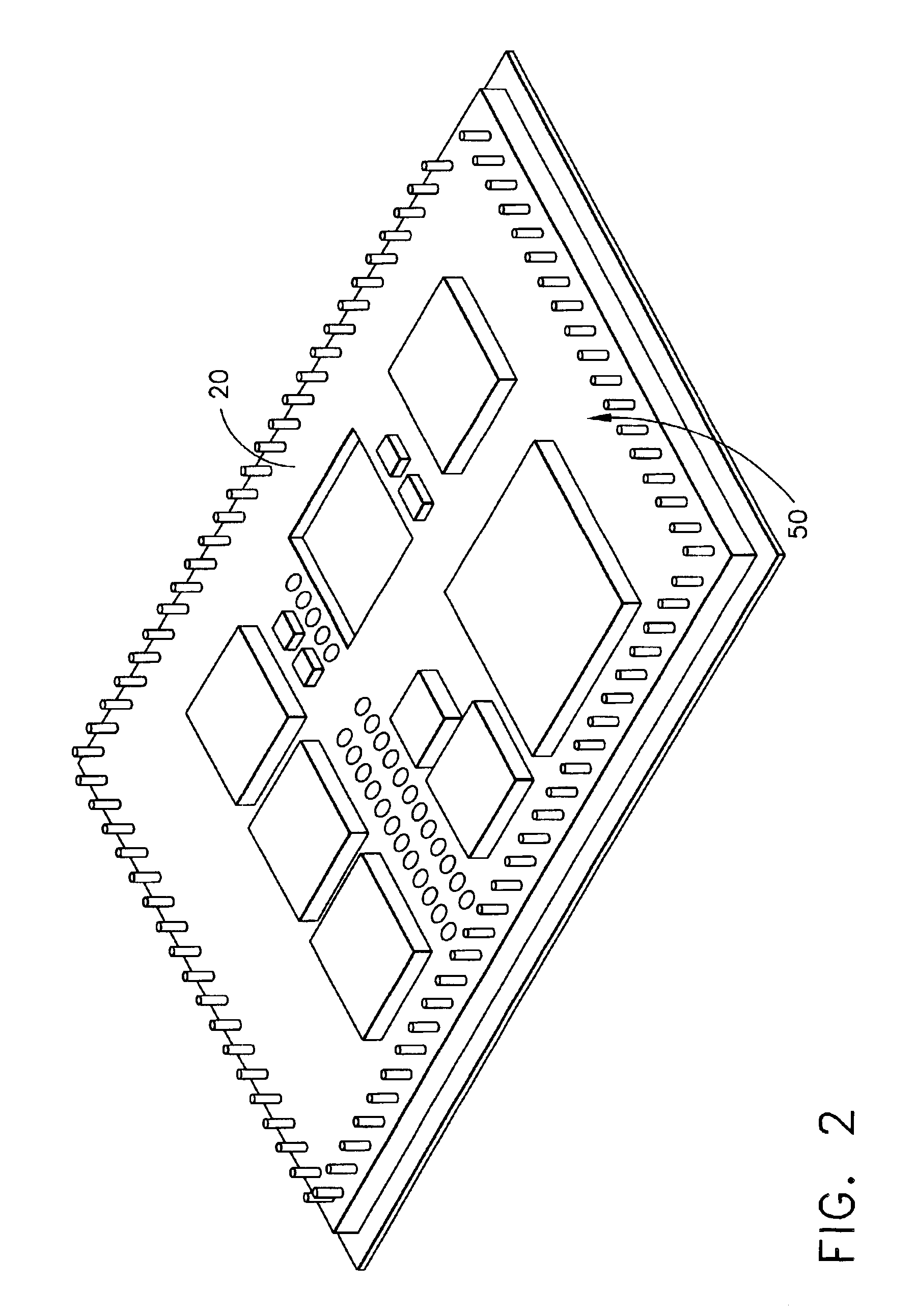

Method and apparatus for controlling electronically commutated motor operating characteristics

InactiveUS6895176B2Operation controlSingle-phase induction motor startersAC motor controlBrushless motorsControl electronics

A permanent magnet DC brushless motor control assembly permits a user to select the permanent magnet DC brushless motor operating characteristics by selecting appropriate control circuits to interface with the motor. The assembly includes a permanent magnet DC brushless motor, a commutator electrically coupled to the motor, and at least one control module electrically coupled to the commutator, to control operating characteristics of the permanent magnet DC brushless motor.

Owner:REGAL BELOIT AMERICA

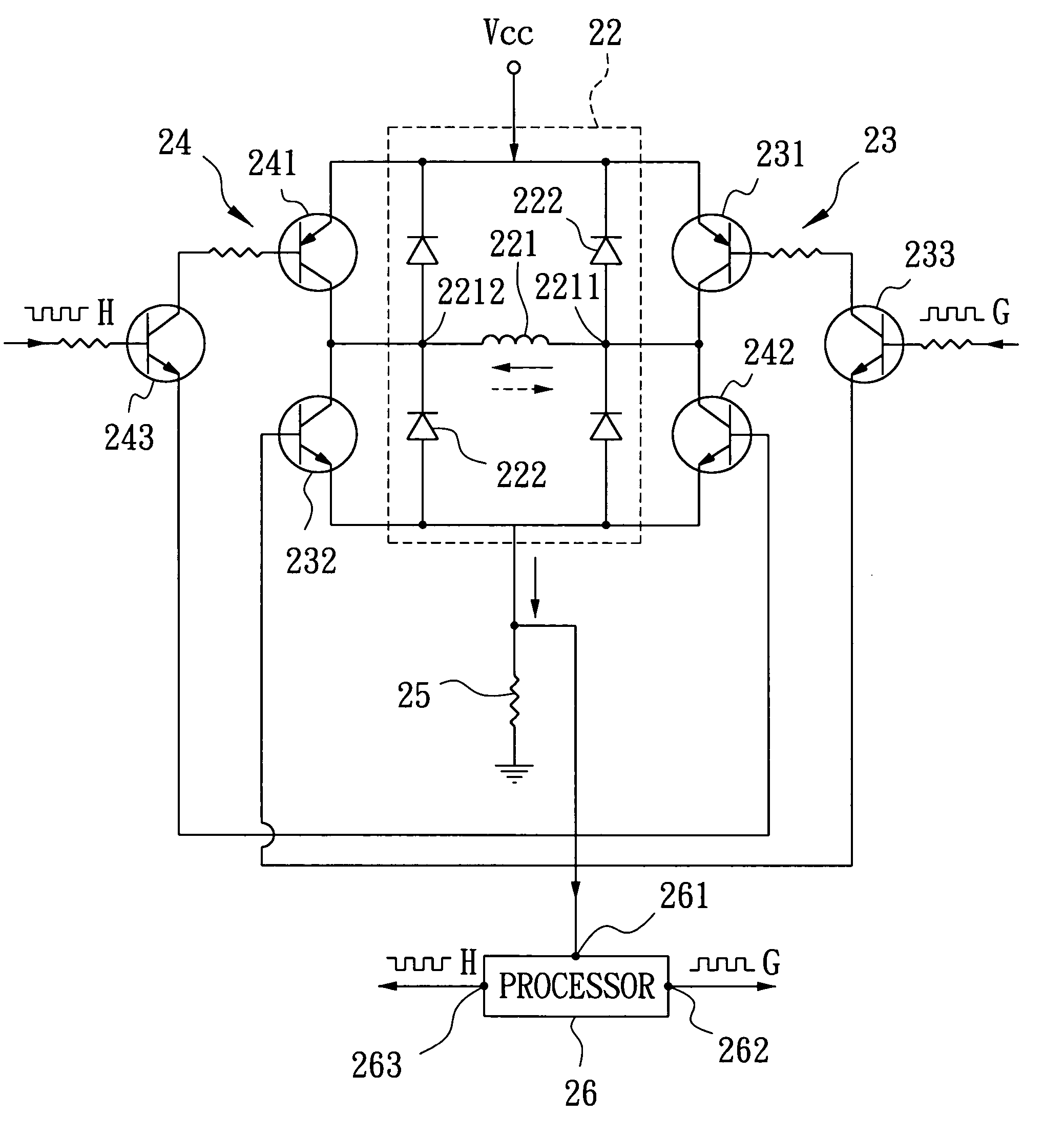

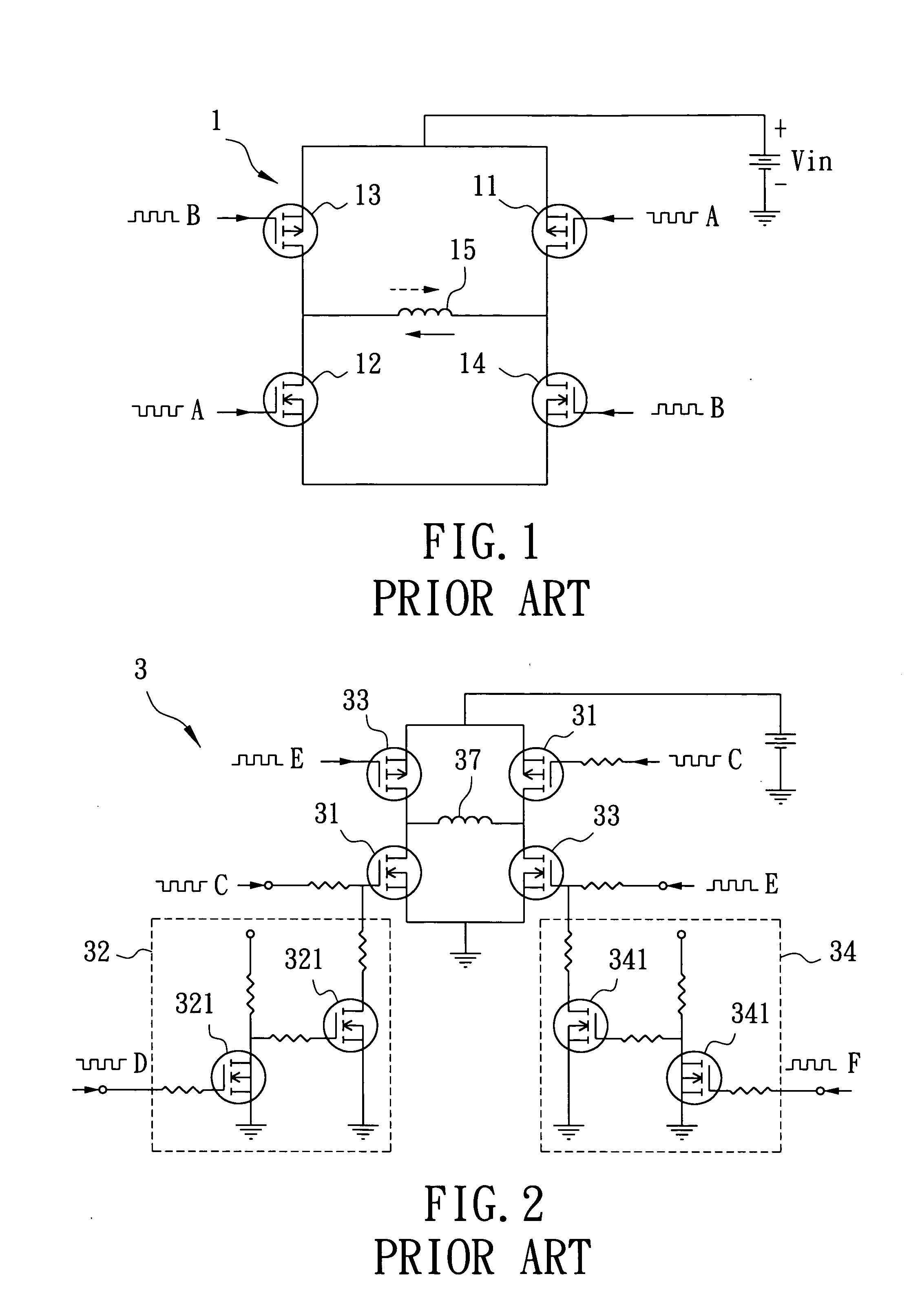

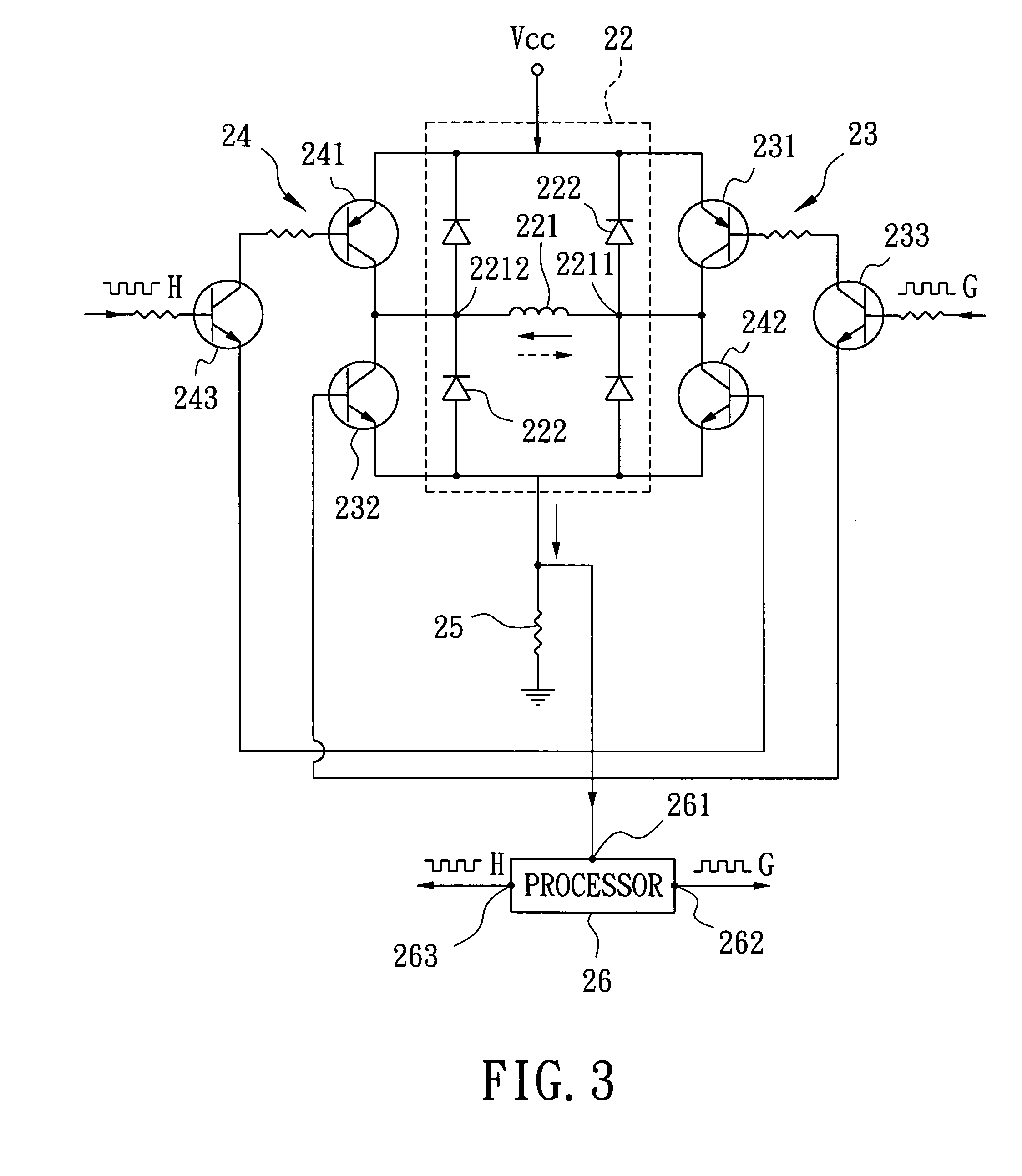

Motor controller

InactiveUS20070152612A1Accurate speed regulationAccurately control conduction and non-conduction of transistorsSingle motor speed/torque controlDynamo-electric converter controlElectricityVoltage drop

A motor controller includes a power source unit providing a direct current output, a drive unit including a drive coil, first and second transistor units, a voltage drop component, and a processor. The transistor units are coupled to the power source unit and the drive unit, and enable electricity to flow through the drive coil in a first direction when the first and the second transistor units are in conducting and non-conducting states respectively, and in an opposite second direction when the first and the second transistor units are in non-conducting and conducting states respectively. The voltage drop component has a first end coupled to the drive unit and a grounded second end. The processor is coupled to a junction of the drive unit and the voltage drop component, and provides first and second pulse-width-modulated signals to the first and second transistor units, respectively.

Owner:YEN SUN TECH CORP

Surgical stapling instrument comprising a magnetic element driver

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

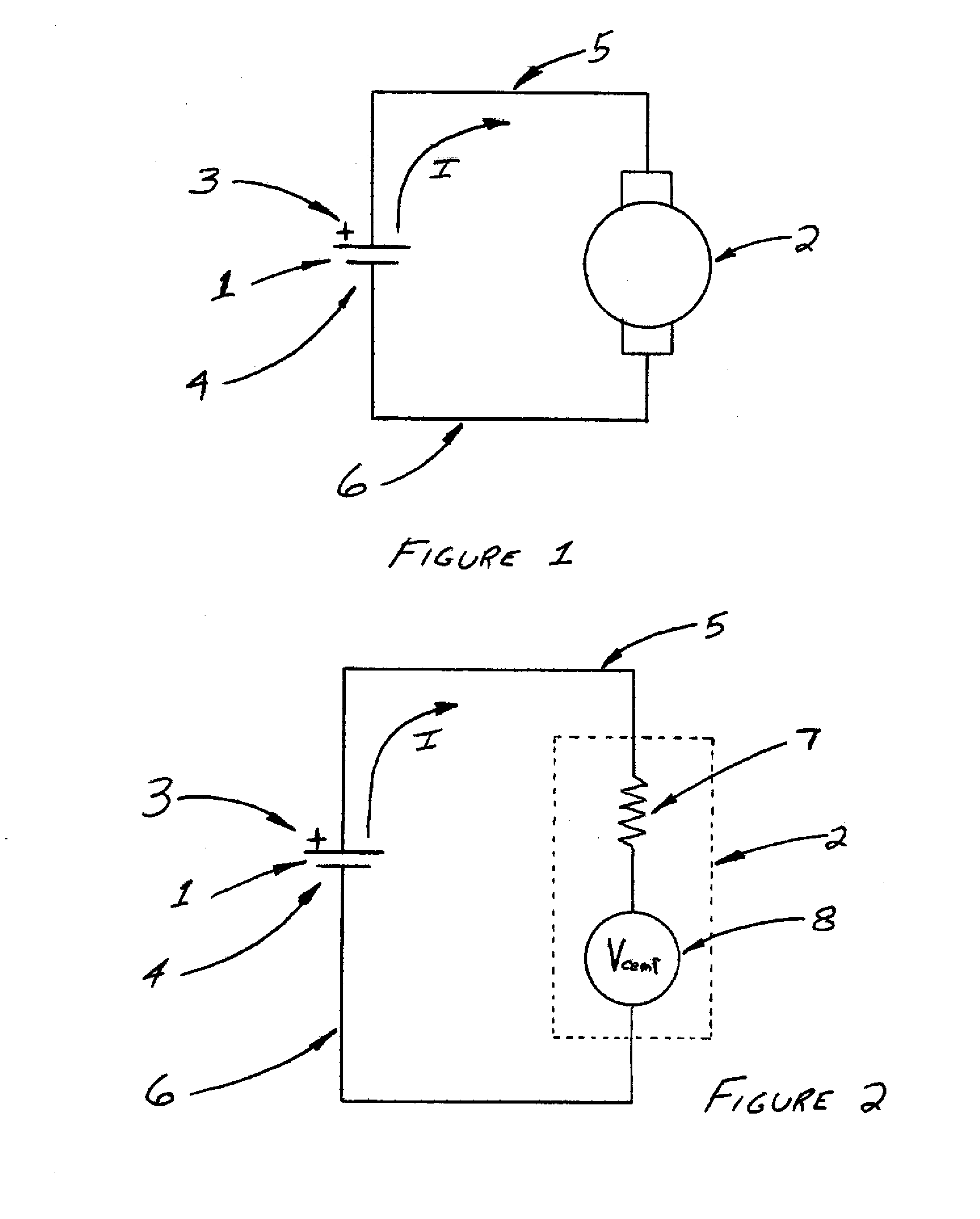

Method of Sensing Speed of Electric Motors and Generators

InactiveUS20080298784A1Simple and inexpensiveLow costMotor/generator/converter stoppersField or armature current controlMotor speedMotor control

A method and circuit for determining the speed and / or counting the revolutions of brush and commutator motors is described. The method and circuitry detects signals present on the windings of the motor due to commutation that occurs at the brushes and commutator of the motor. This method can be used to simply monitor & indicate the motor speed and revolutions or to form the basis of a motor control.

Owner:KASTNER MARK ALLEN

Moisture sensor and windshield fog detector

InactiveUS6097024AAutomatic detectionLower performance requirementsTelevision system detailsImage enhancementControl signalEngineering

A control system for automatically detecting moisture on the windshield of a vehicle. The automatic moisture detecting system includes an optical system for imaging a portion of the windshield on to an image array sensor, such as a CMOS active pixel sensor. The voltages of each of the pixels which represents the illumination level is converted to a corresponding gray scale value by an analog digital converter. The gray scale values corresponding to the image are stored in memory. The spatial frequency composition of the gray scale values are analyzed to determine the amount of rain present. In order to provide a control signal to control the operation of the windshield wipers of the vehicle as a function of the amount of moisture present. The system is also adapted to detect the level of fog both on the interior of the windshield as well as the exterior of the windshield. By providing a system for automatically detecting the presence of fog on the interior and exterior of the windshield, serious performance limitations of known automatic rain sensors are eliminated.

Owner:GENTEX CORP

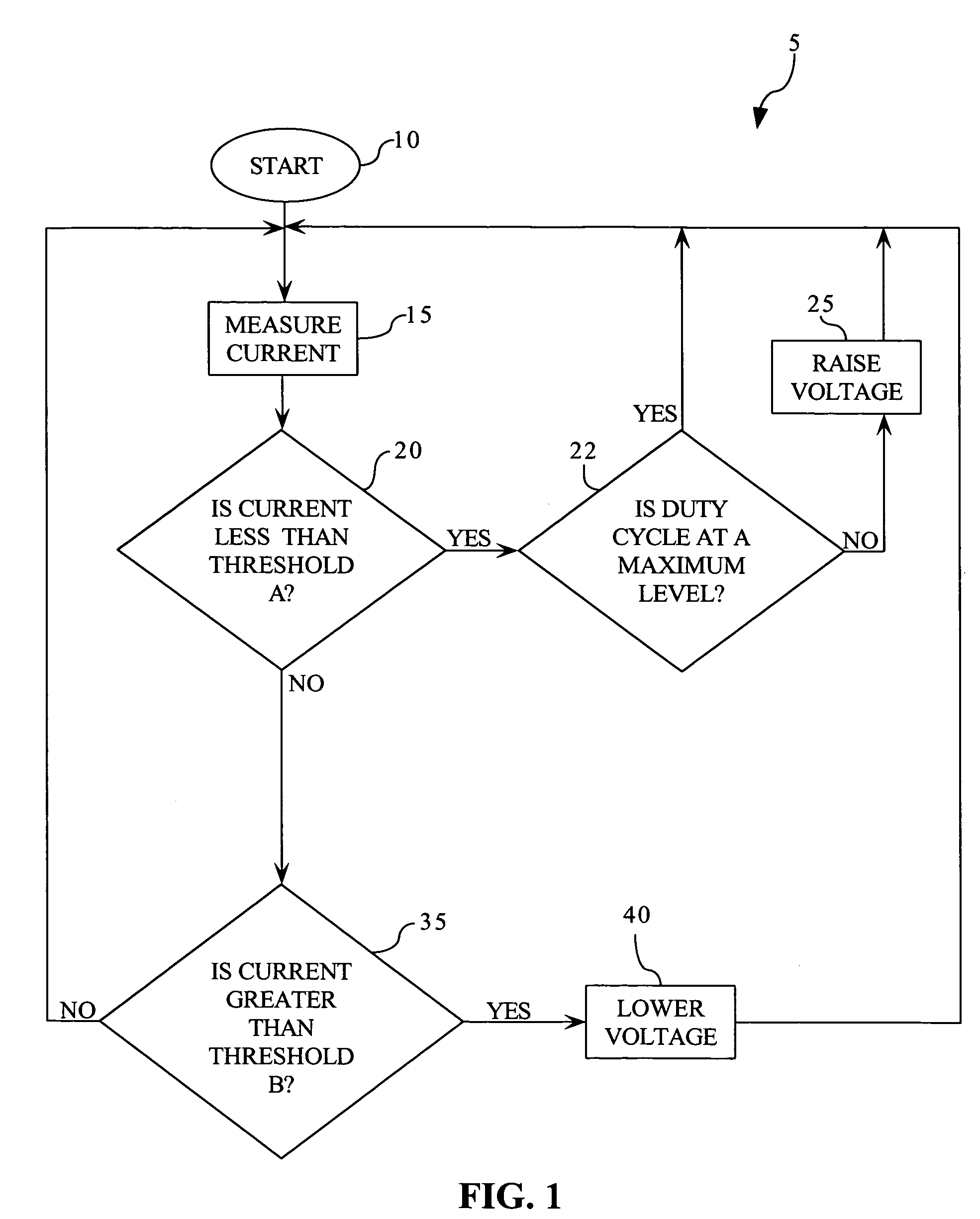

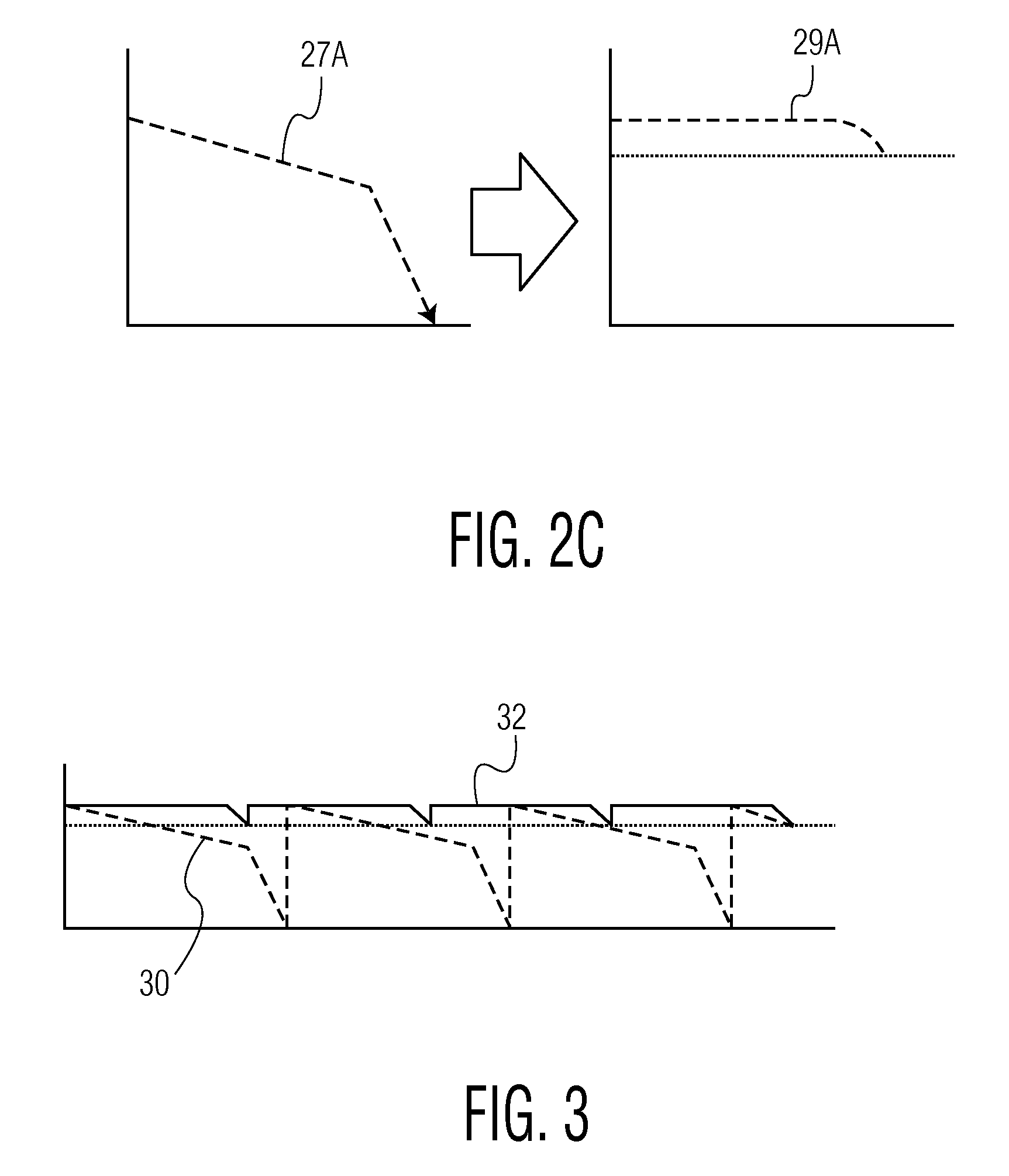

System and method for maintaining performance of battery-operated toothbrushes

ActiveUS8368327B2Maintain performanceIncrease range of motionMotor/generator/converter stoppersDC motor speed/torque controlVoltage dropEngineering

The system periodically measures the battery voltage of the toothbrush and the current in a stator portion of the motor for the appliance. The amplitude of movement of the toothbrush workpiece is determined from the measured stator current. A circuit / control program changes the duty cycle or pulse width of the drive signal from the motor if the battery voltage drops below a first threshold value and a circuit or control program changes the drive frequency of the appliance if the amplitude of the workpiece movement falls below a first threshold value. A circuit / control program terminates the operation of the toothbrush if the voltage drops below a second threshold value or if the amplitude drops below a second threshold value, both of which are less than the respective first thresholds.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Driving controlling apparatus for linear compressor and method thereof

Owner:LG ELECTRONICS INC

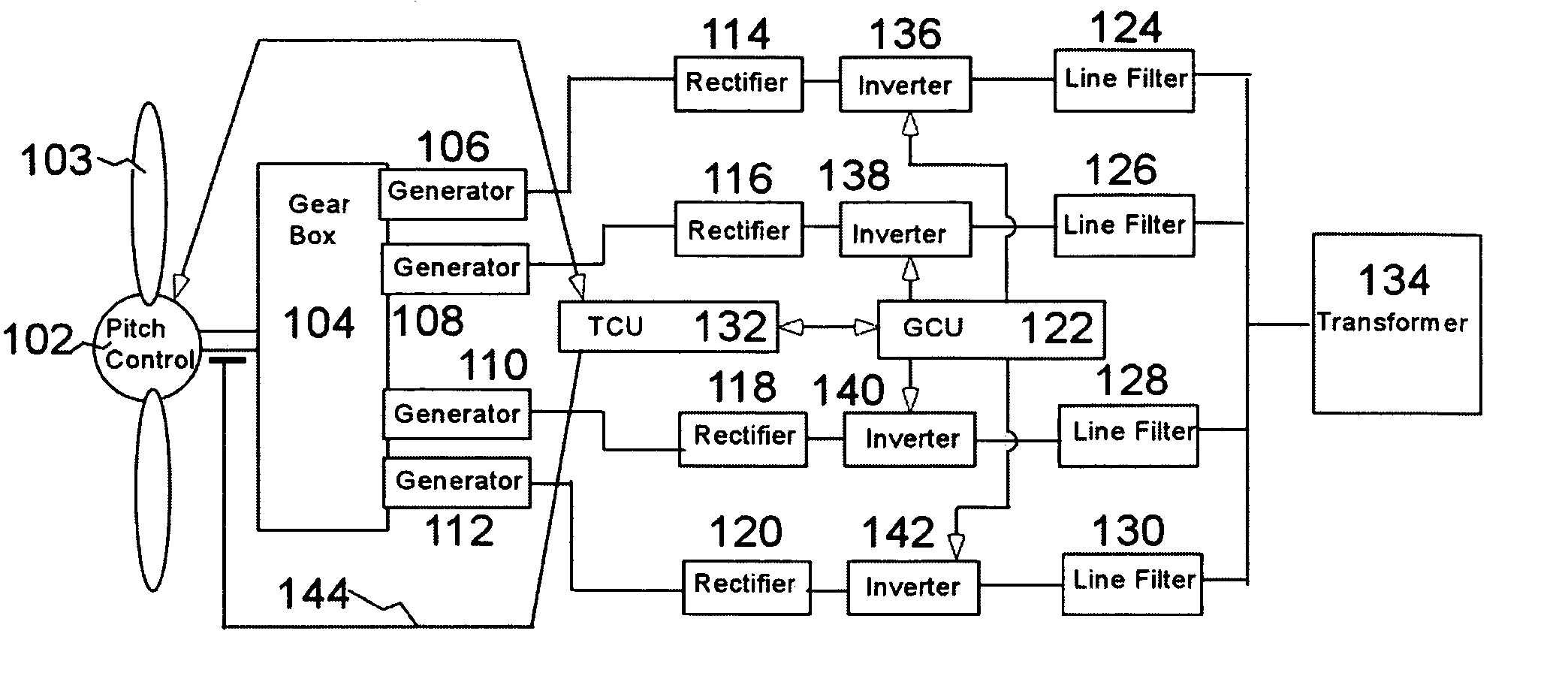

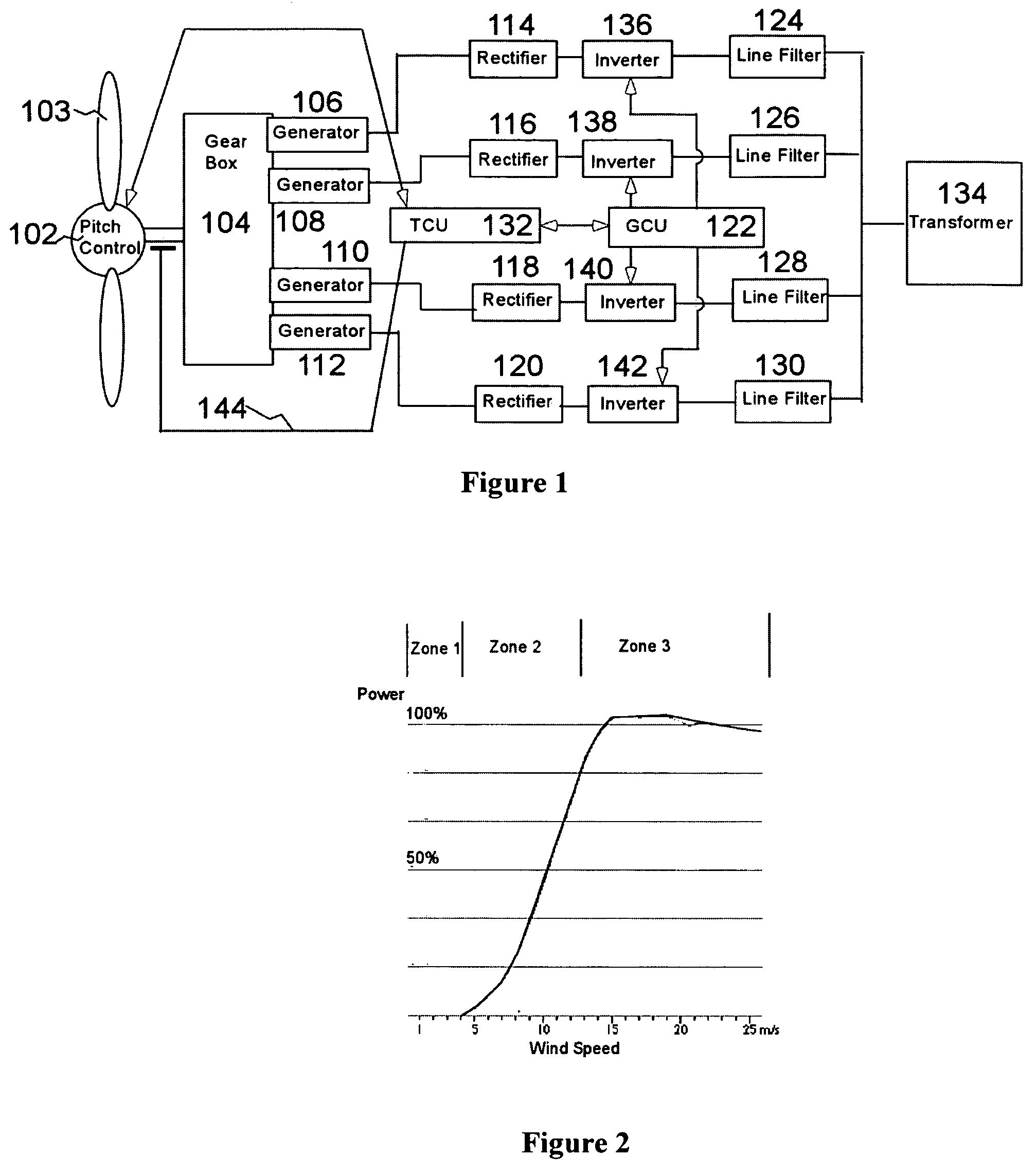

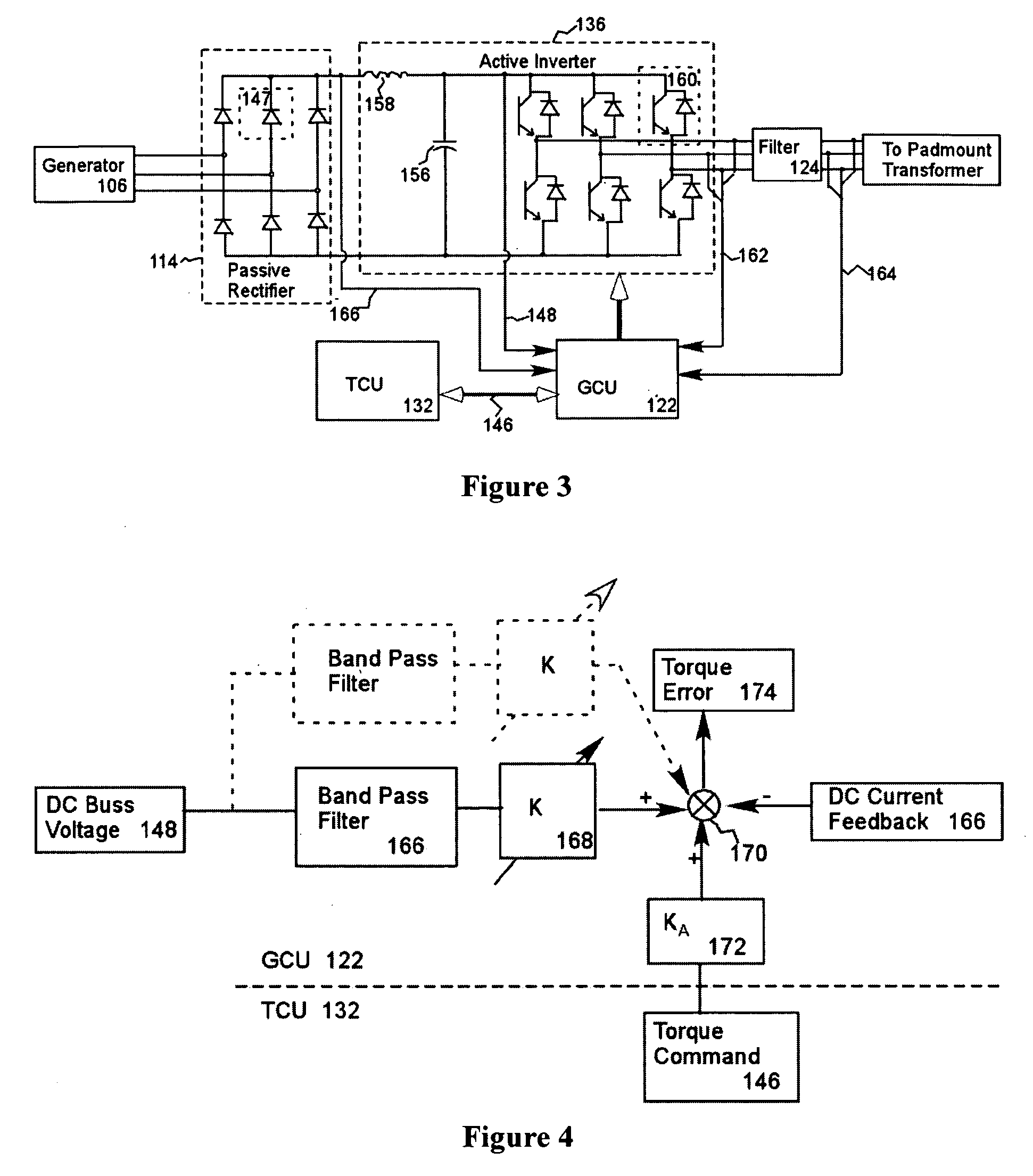

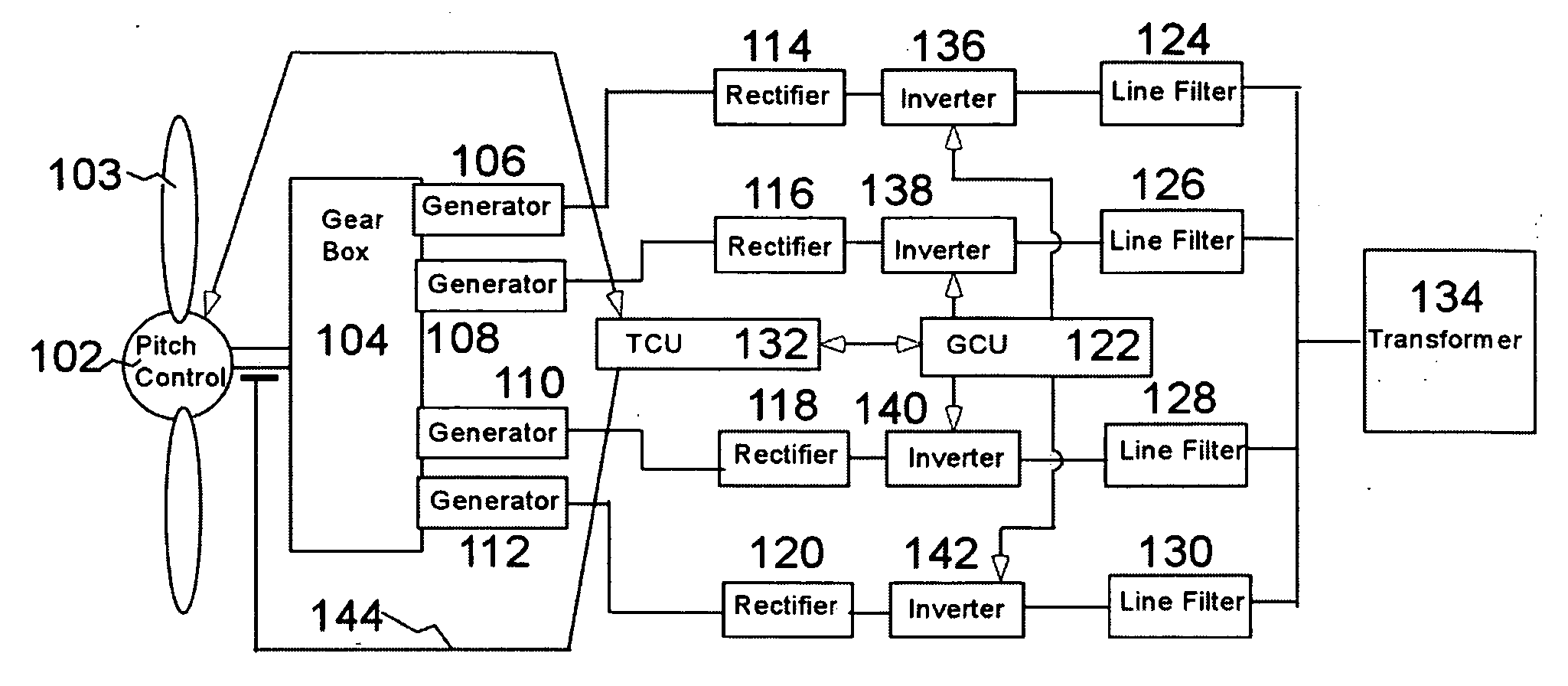

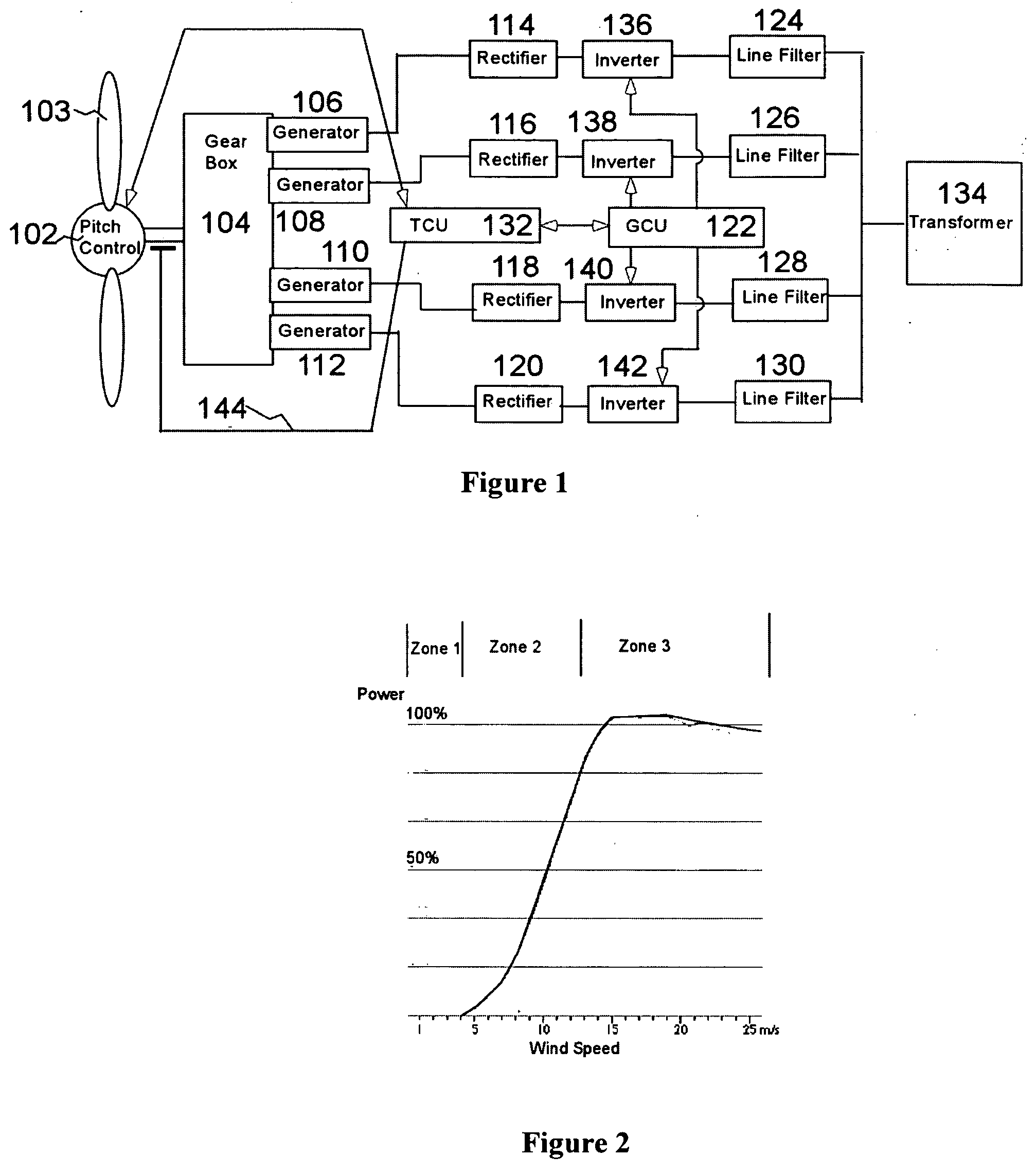

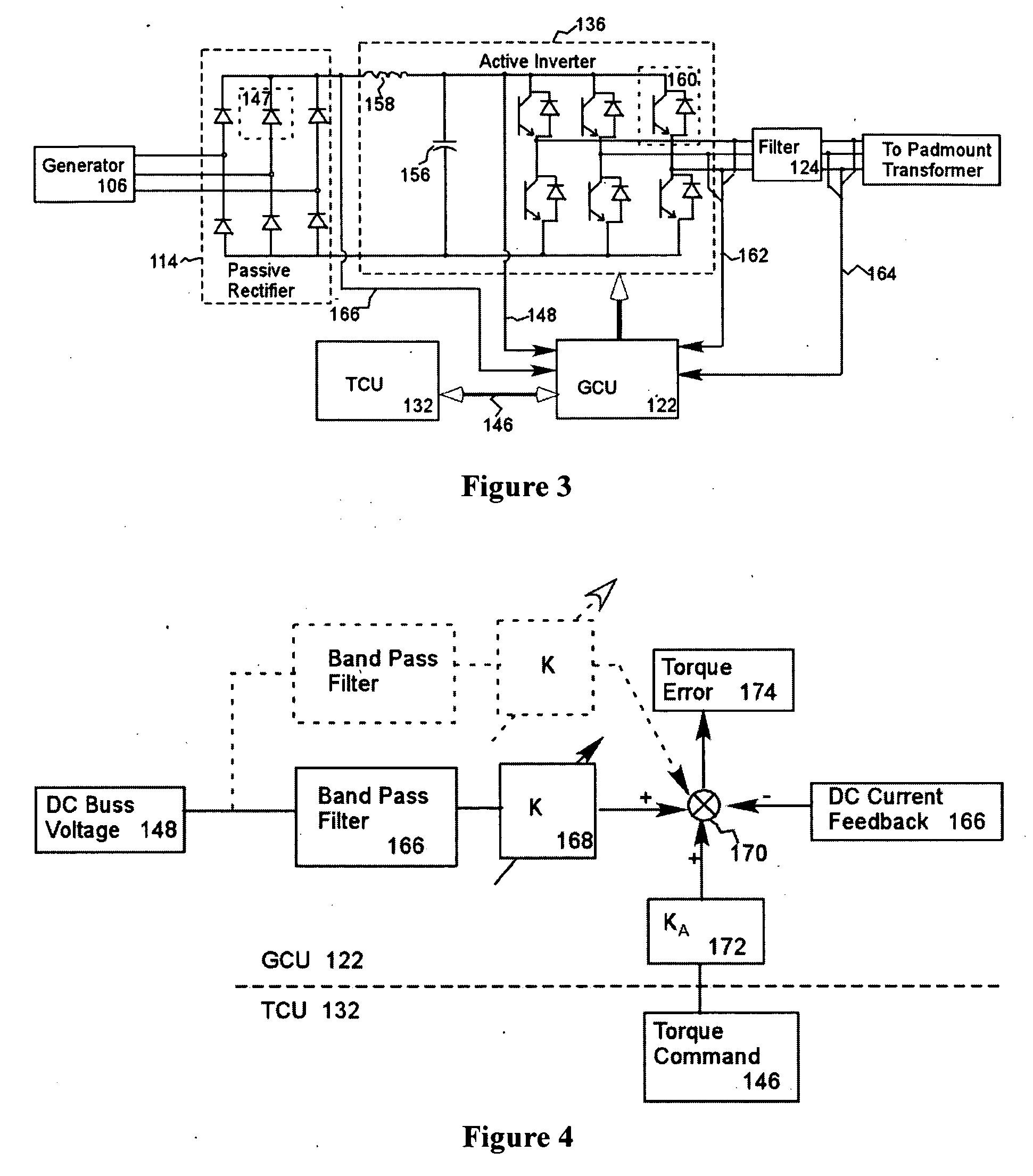

Variable speed distributed drive train wind turbine system

InactiveUS7042110B2Improve efficiencyImprove reliabilityWind motor controlEmergency protective circuit arrangementsPermanent magnet rotorDc current

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

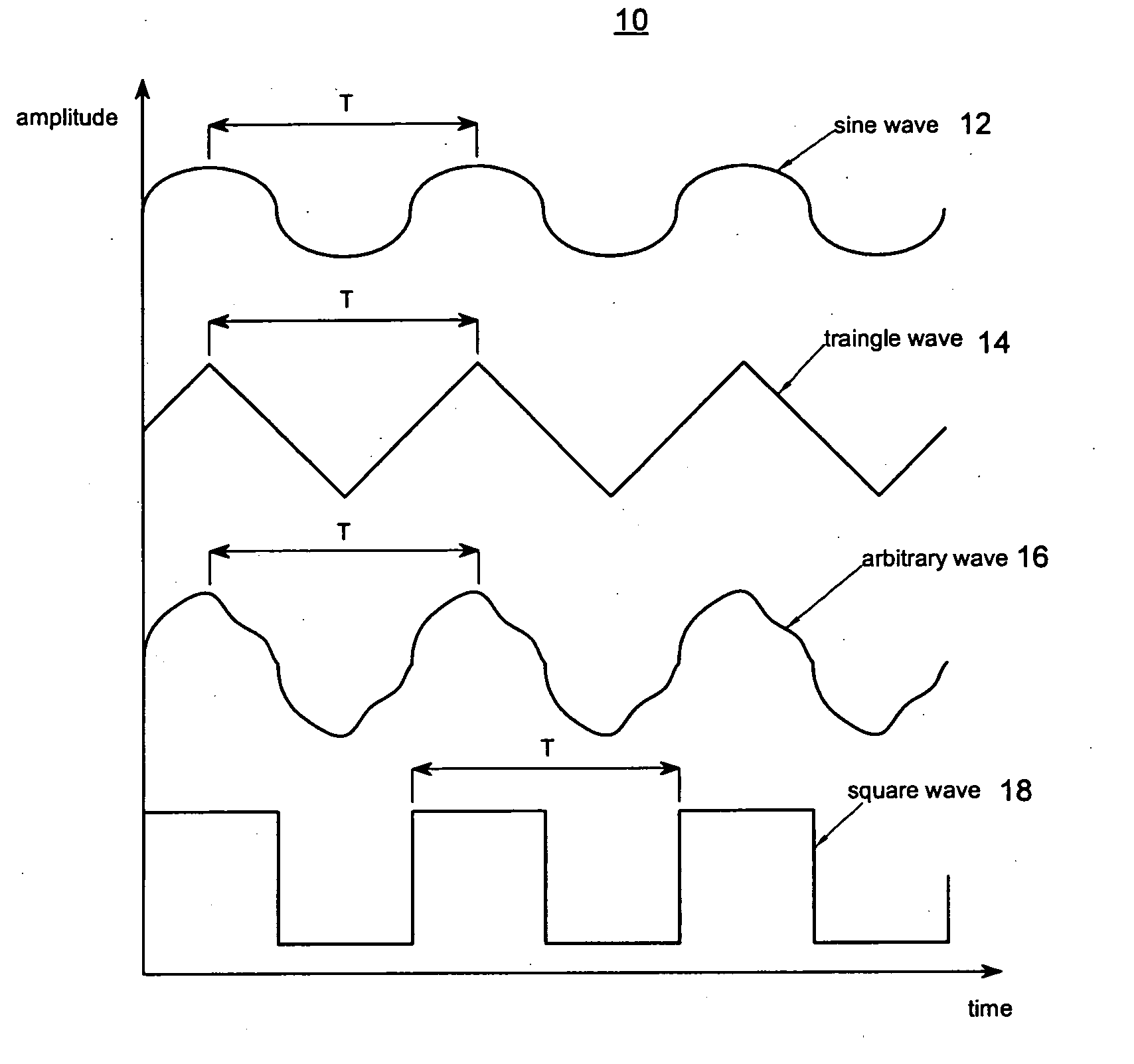

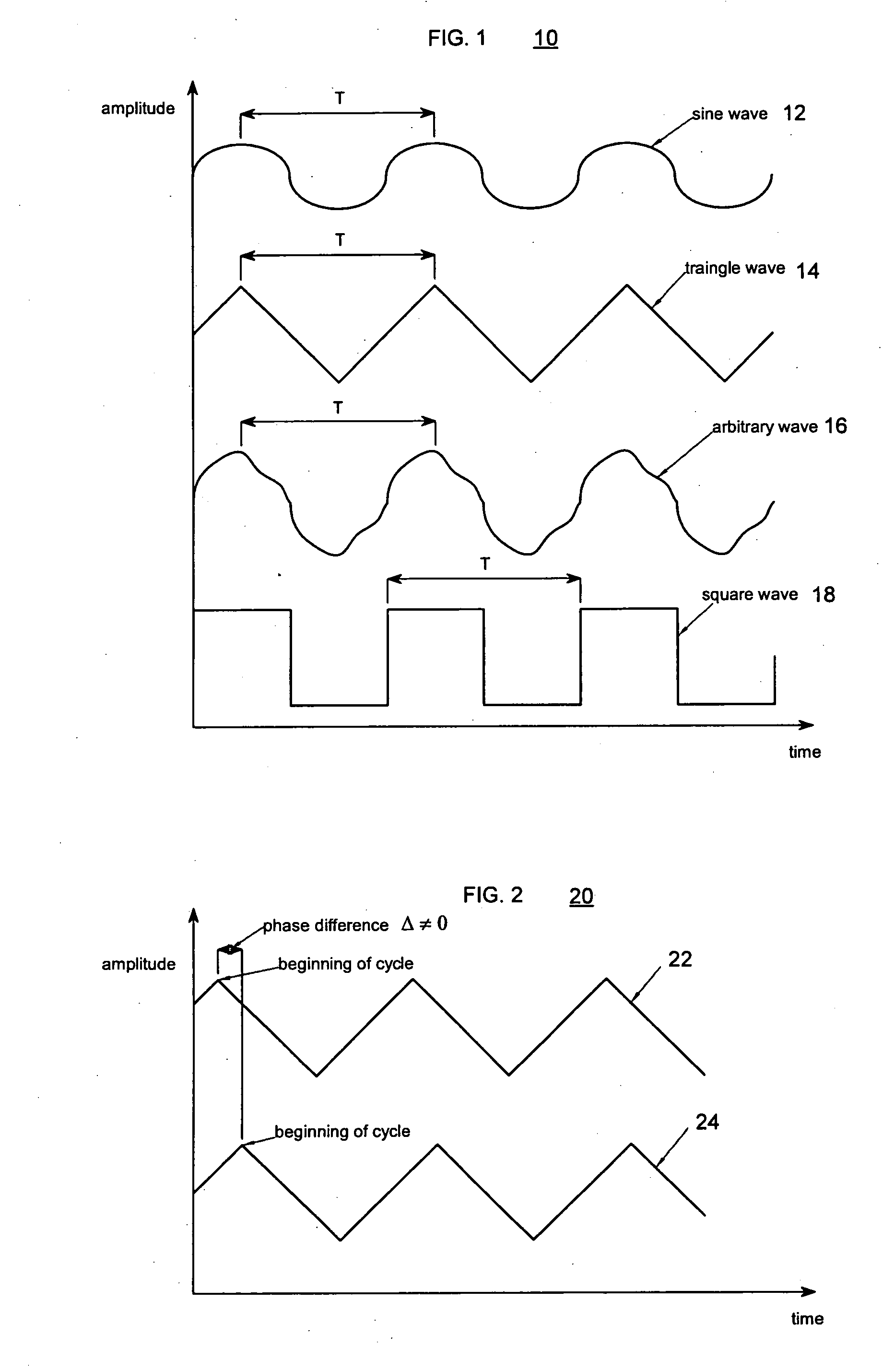

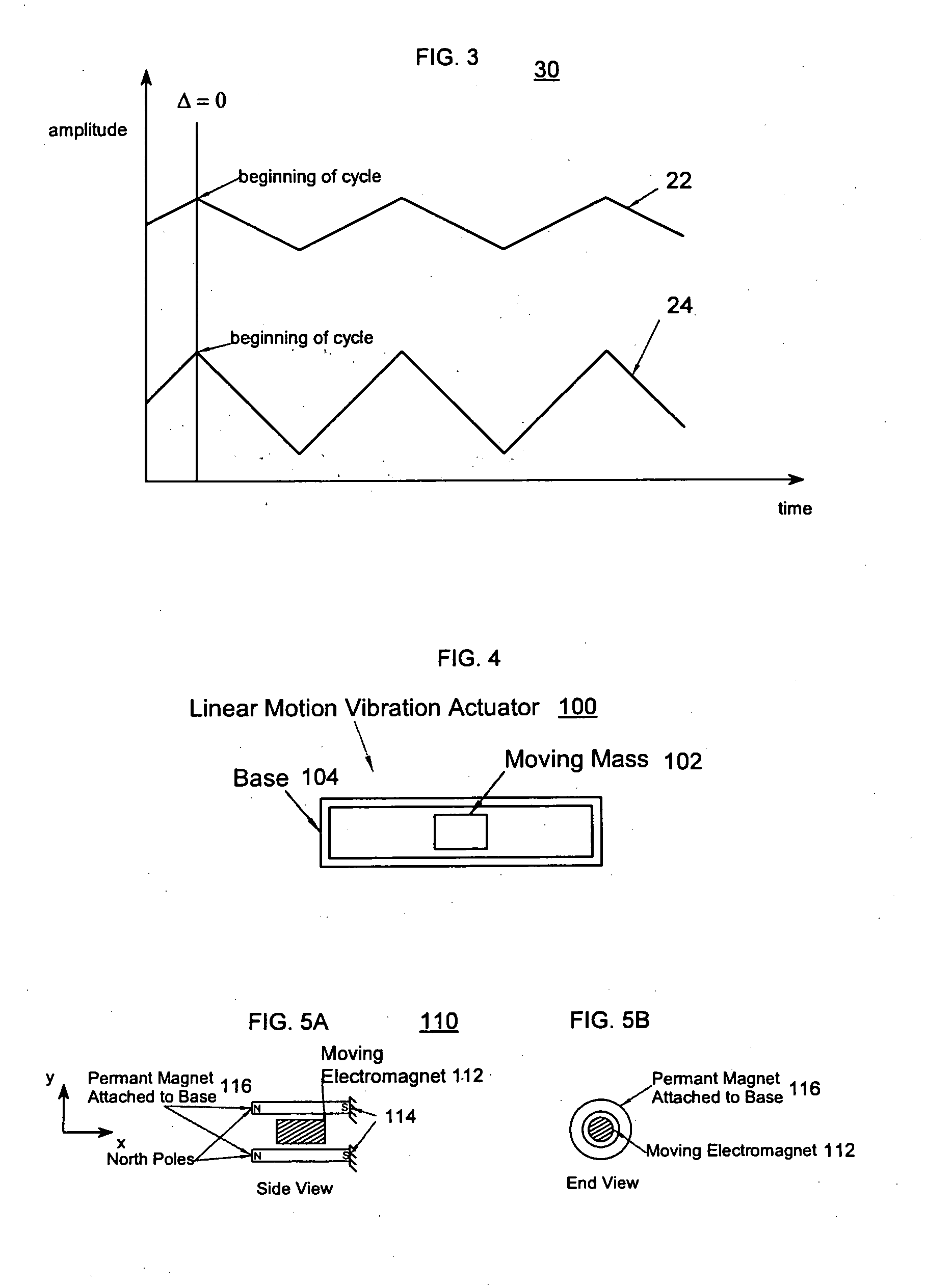

Synchronized vibration device for haptic feedback

ActiveUS20060290662A1DC motor speed/torque controlAc-dc conversion without reversalDriver circuitVibration control

The present invention relates to synchronized vibration devices that can provide haptic feedback to a user. A wide variety of actuator types may be employed to provide synchronized vibration, including linear actuators, rotary actuators, rotating eccentric mass actuators, and rocking mass actuators. A controller may send signals to one or more driver circuits for directing operation of the actuators. The controller may provide direction and amplitude control, vibration control, and frequency control to direct the haptic experience. Parameters such as frequency, phase, amplitude, duration, and direction can be programmed or input as different patterns suitable for use in gaming, virtual reality and real-world situations.

Owner:COACTIVE DRIVE CORP

Variable speed distributed drive train wind turbine system

InactiveUS20050012339A1Improve efficiencyImprove reliabilityWind motor controlWorking fluid for enginesElectric power transmissionPermanent magnet rotor

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

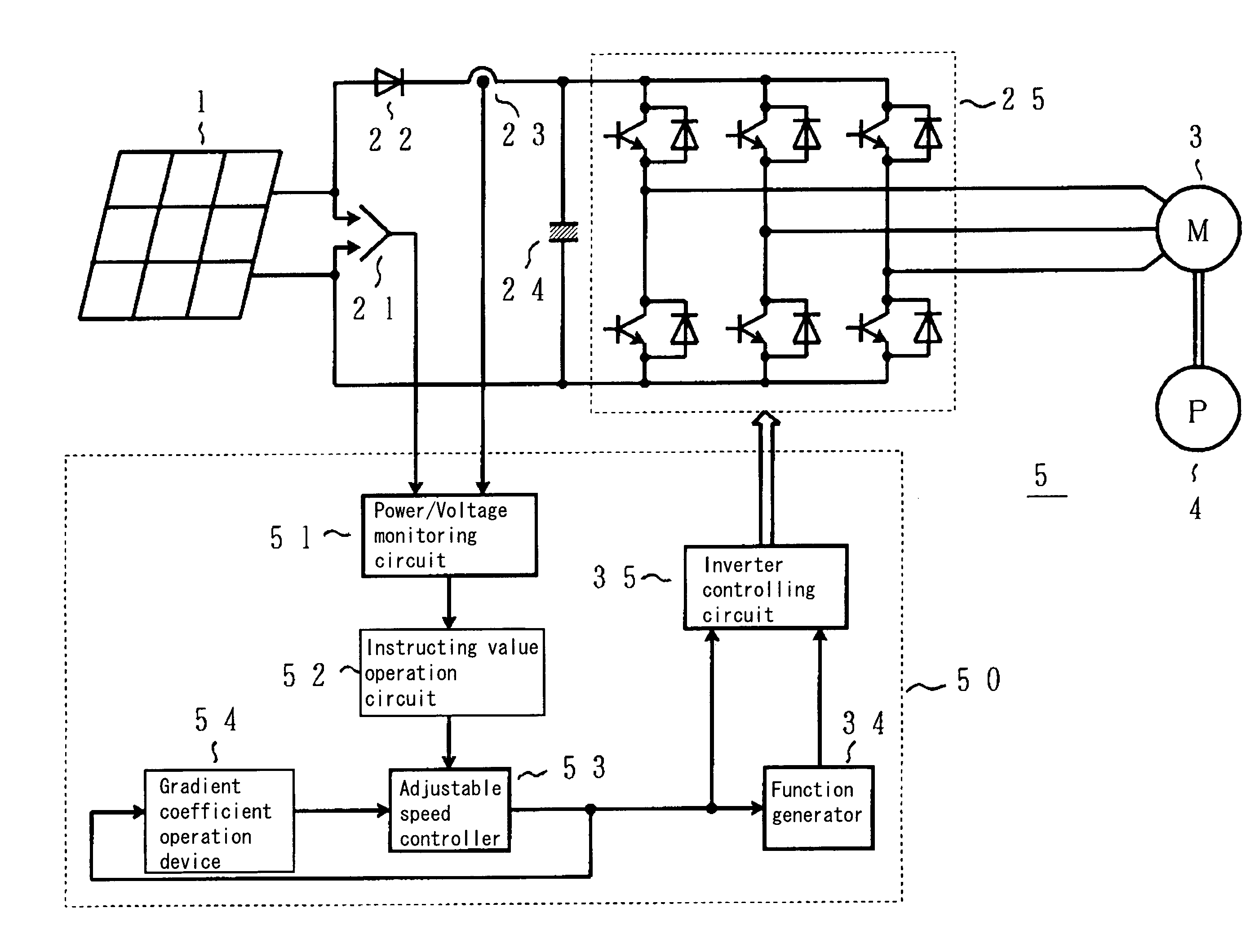

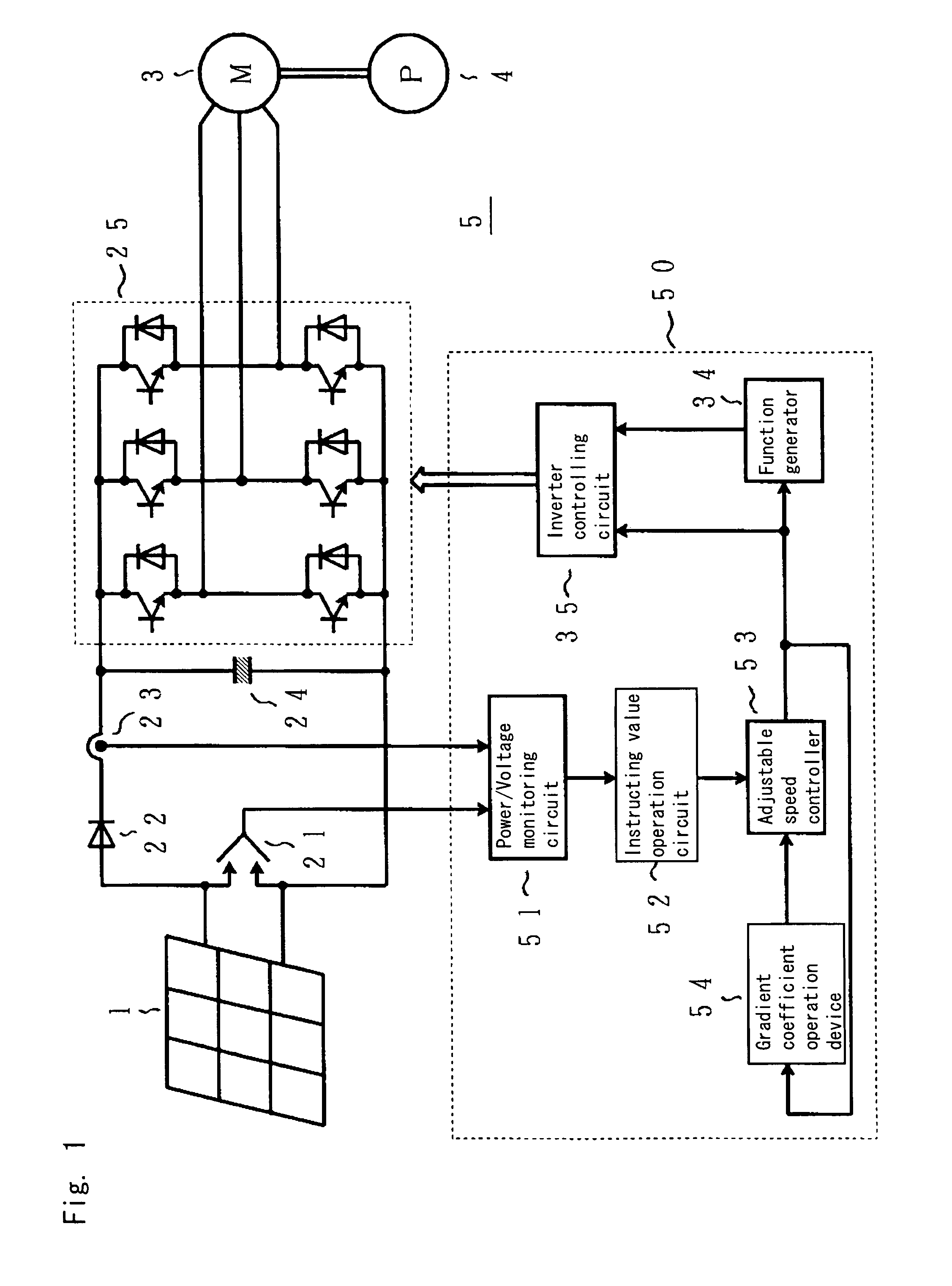

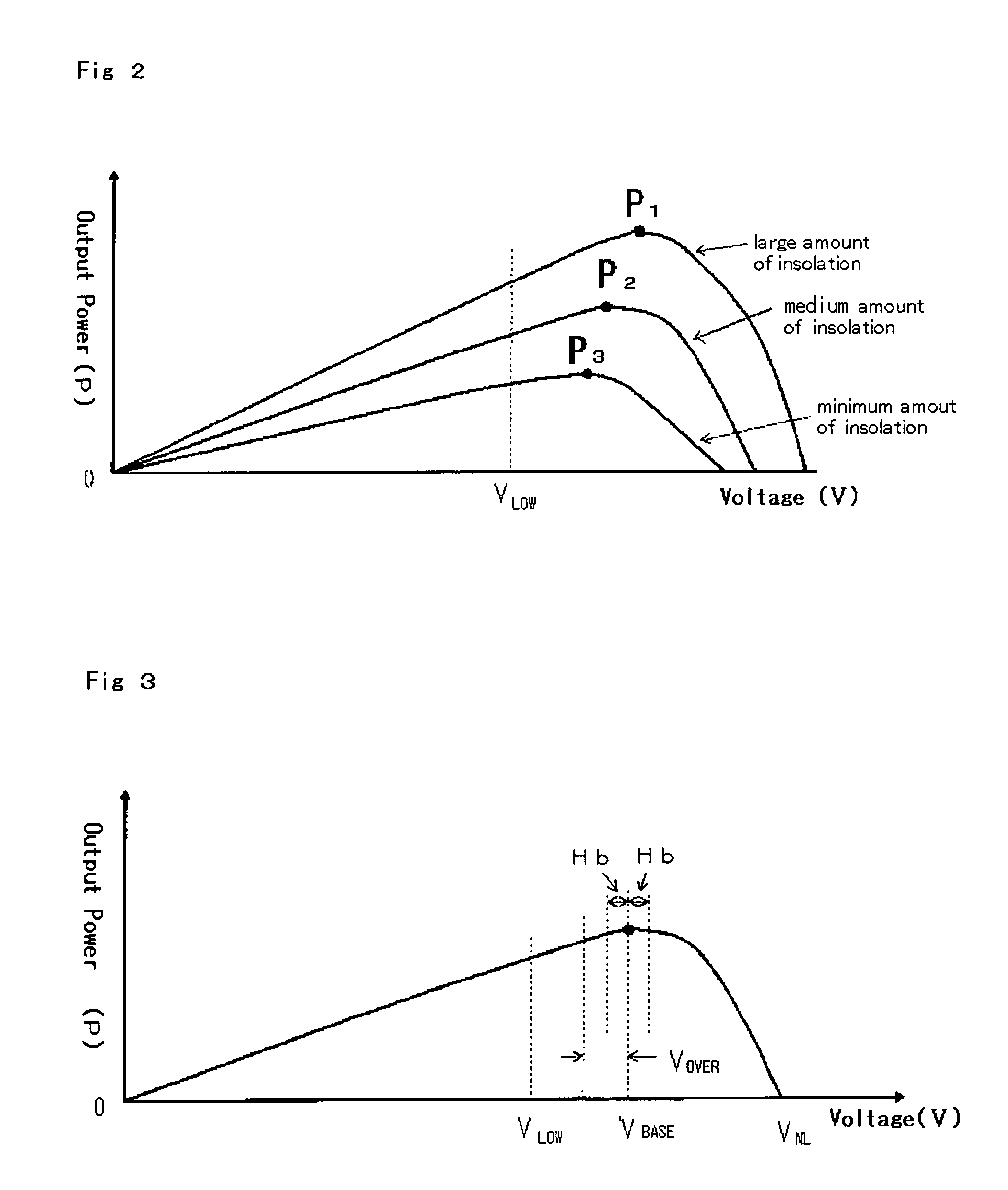

Method and device for controlling photovoltaic inverter, and feed water device

InactiveUS7126294B2Improve stabilityEasy transferBatteries circuit arrangementsAC motor controlElectrical batterySolar battery

Owner:FUJI ELECTRIC CO LTD +1

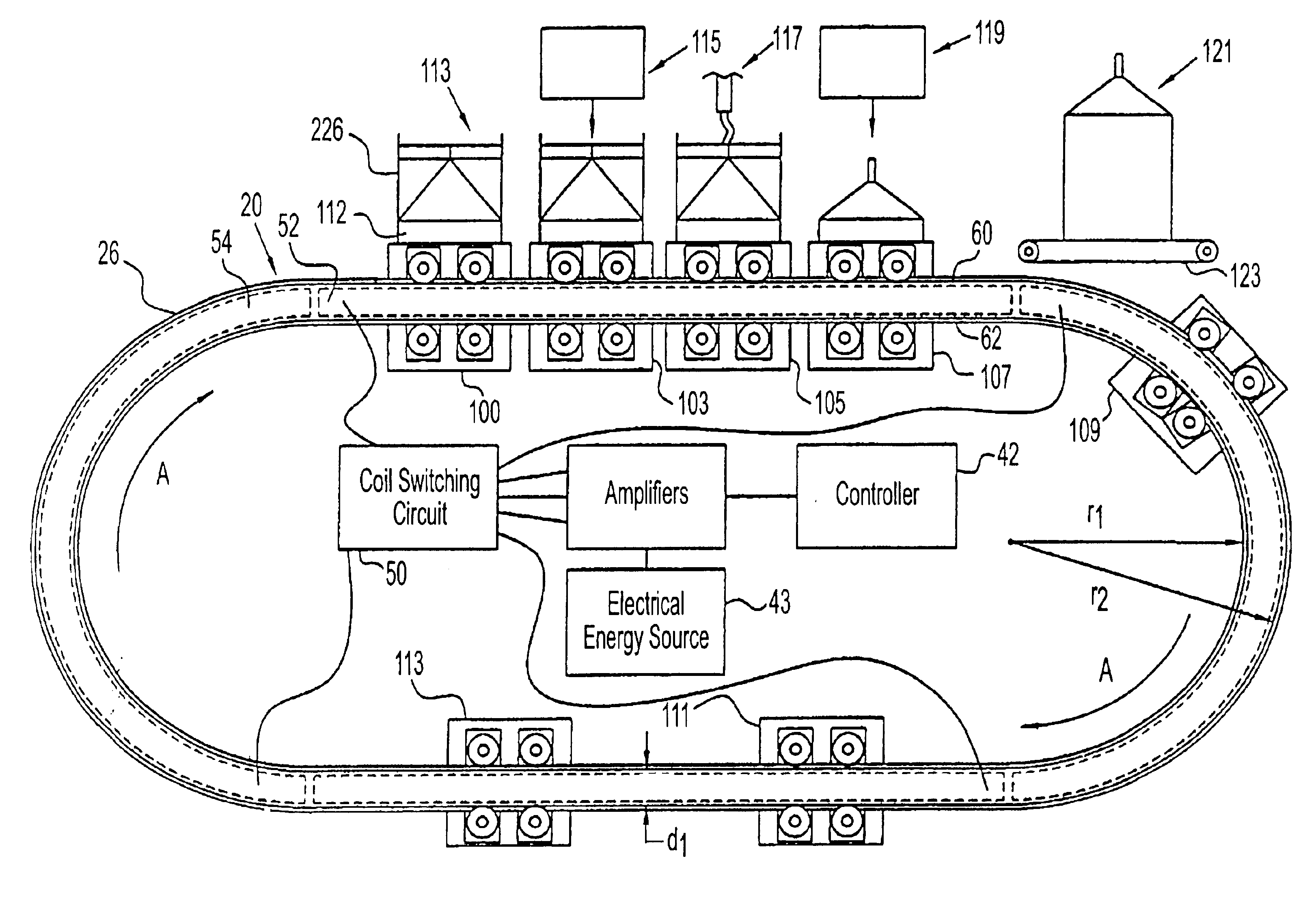

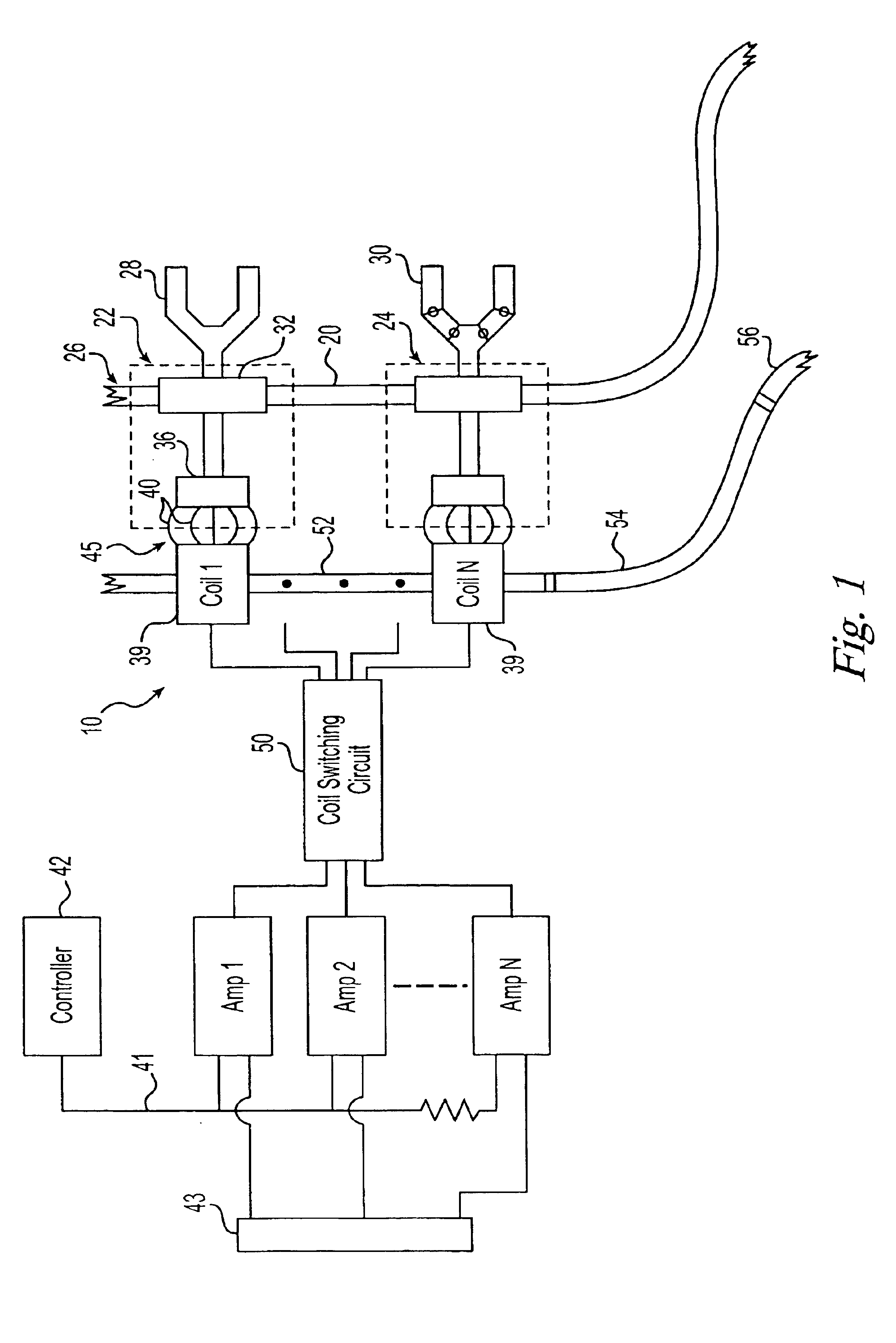

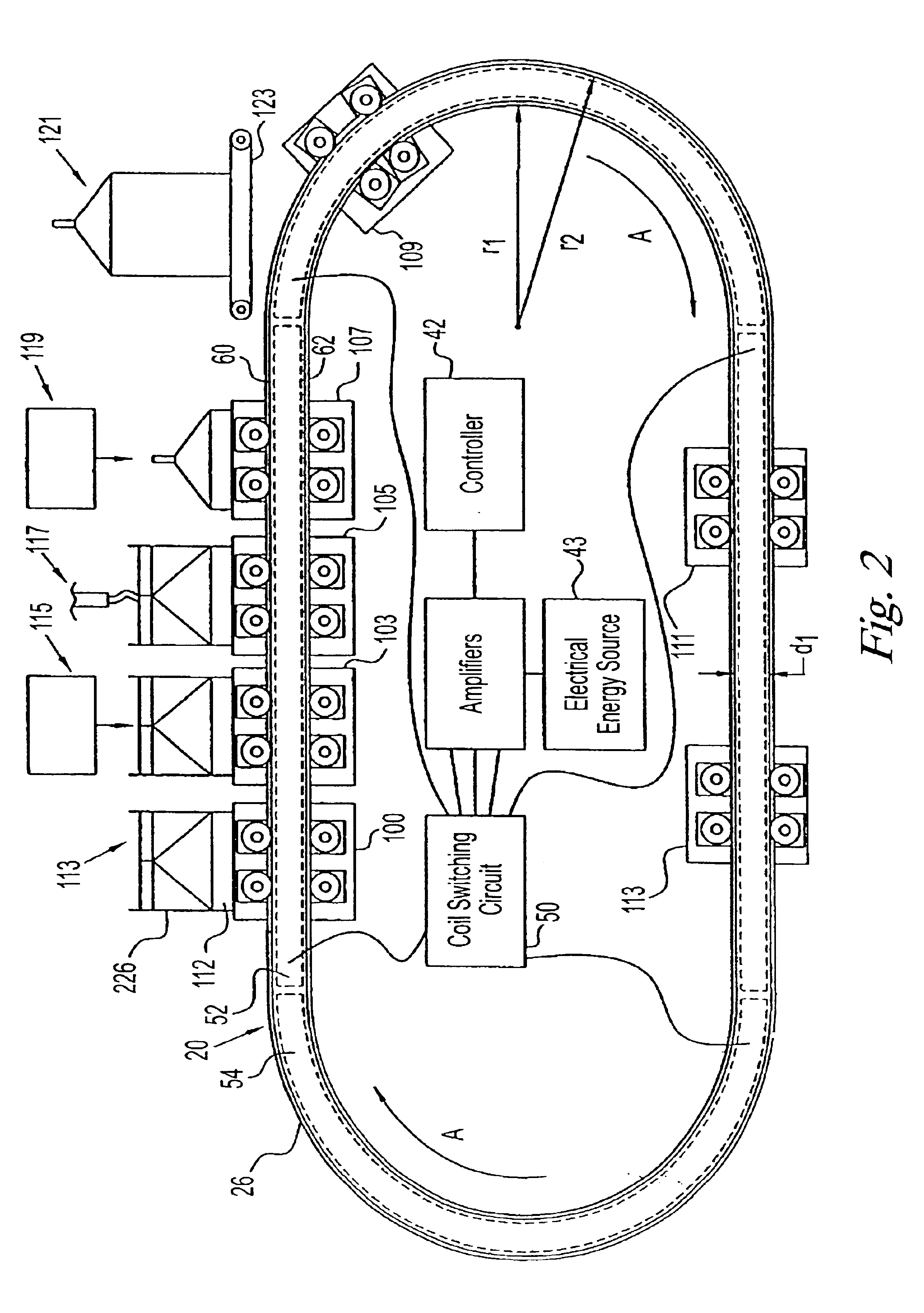

Variable motion system and method

InactiveUS6876896B1Motor/generator/converter stoppersDC motor speed/torque controlMotion parameterEngineering

The invention relates to a system and a method for performing a manufacturing operation at a predetermined position relative to a first path. The system includes a plurality of first elements mounted for movement relative to the first path. The first elements have a plurality of motion parameters which are independently controllable. Active elements are operatively associated with reactive elements to produce relative movement between the first elements and the first path, with the active elements controlling the relative movement. A controller controls the activation of the active elements and a first tool is associated with each first element for performing at least part of the manufacturing operation. The system may also include at least one second element and a second path. The method includes the steps of mounting a plurality of first carriages for movement relative to a first path, operatively associating a plurality of active elements with at least one reactive element to produce relative movement between the first carriages and the path, associating a first tool with each first carriage for performing at least part of the manufacturing process, and controlling the activation of the active elements.

Owner:TETRA LAVAL HLDG & FINANCE SA

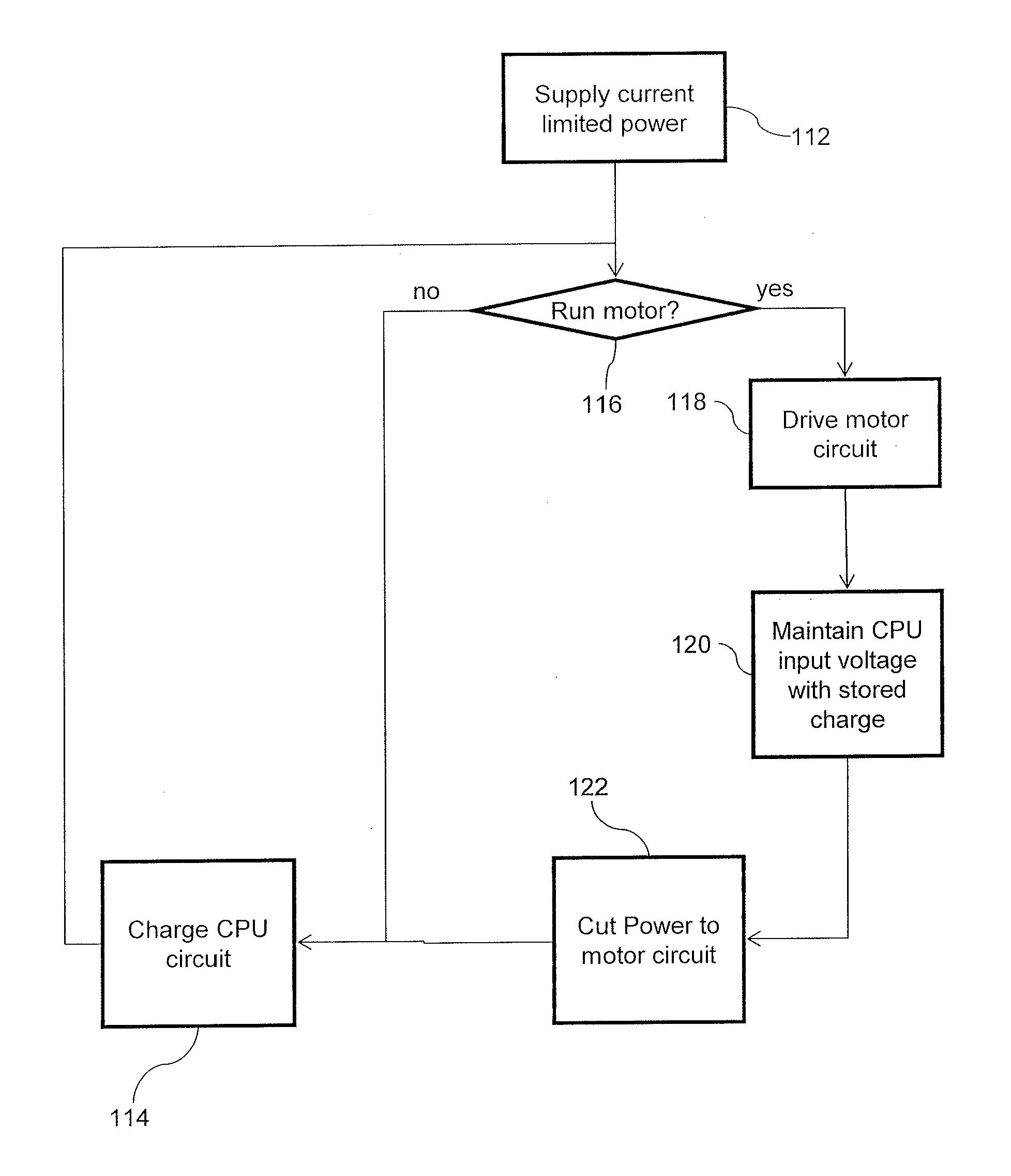

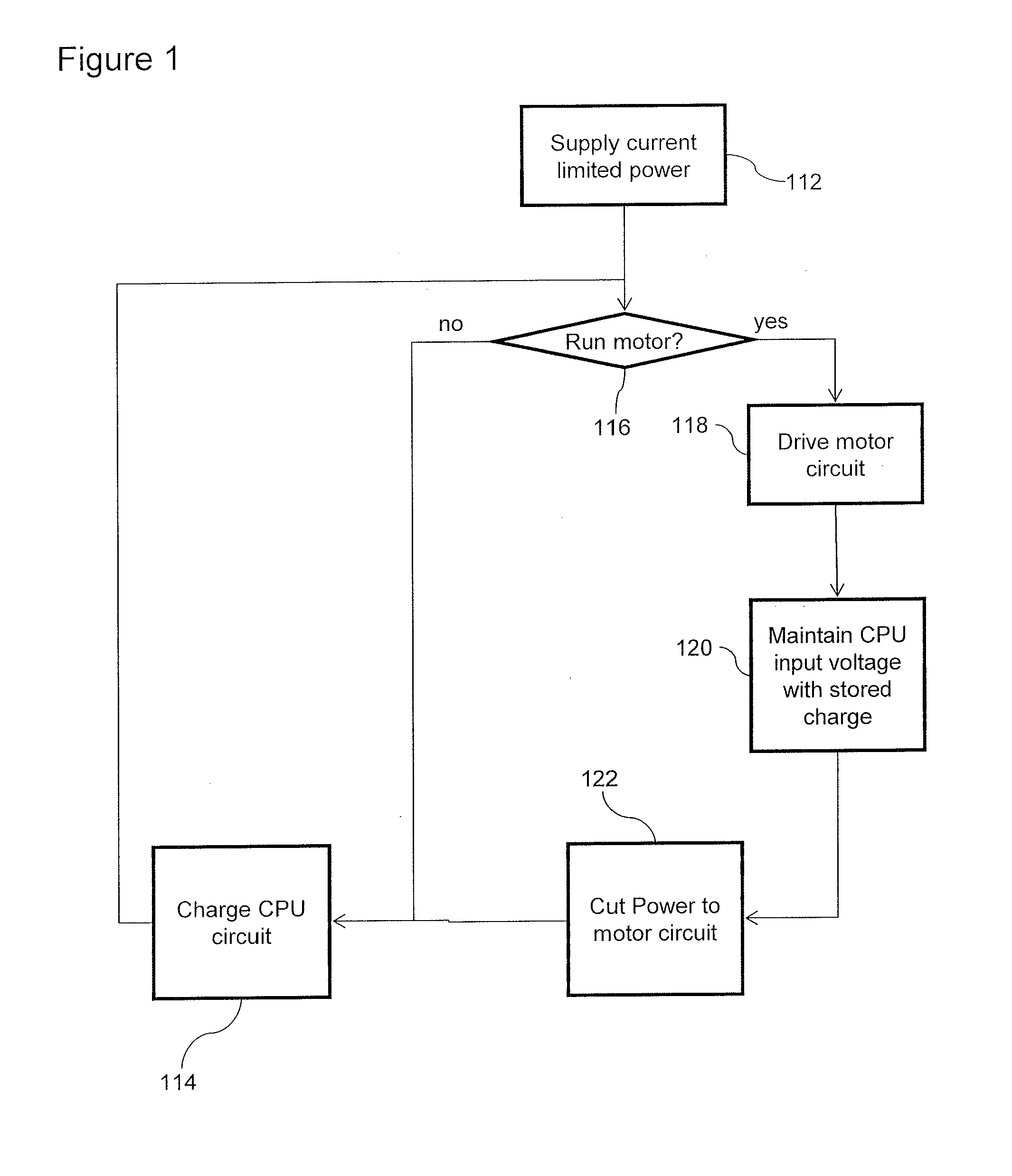

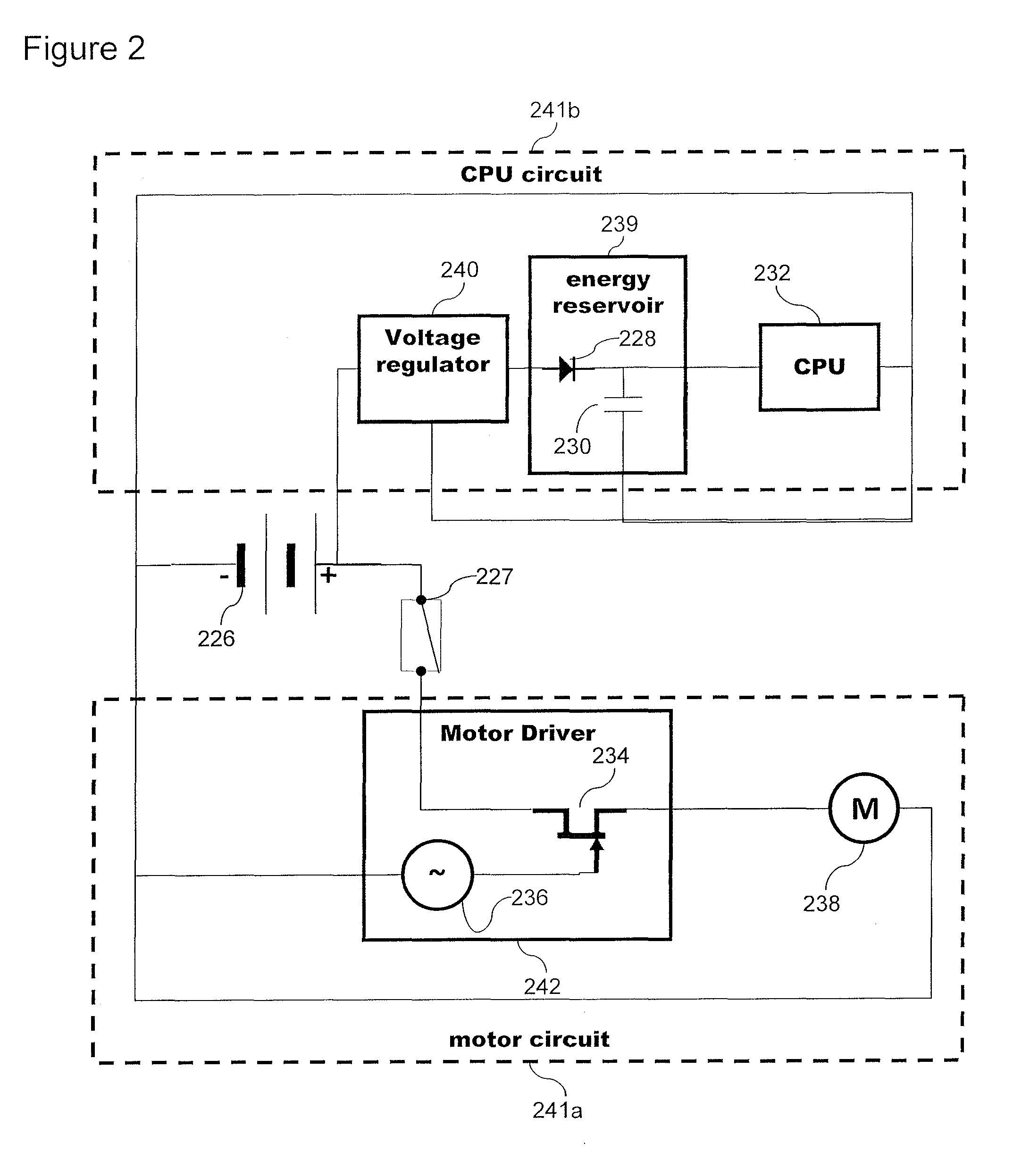

System and method to distribute power to both an inertial device and a voltage sensitive device from a single current limited power source

ActiveUS20150297824A1High voltagePrevent leakageInfusion devicesField or armature current controlCapacitanceCurrent limiting

A system may regulate voltage supplied from a power source to an integrated circuit and / or an inertial device. A minimal voltage may be maintained in the integrated circuit by temporarily cutting off current to the inertial device to supply surges of voltage to the controller. Optionally voltage may be smoothed between said surges for example by adding capacitance and / or a current restrictor.

Owner:WEST PHARM SERVICES IL LTD

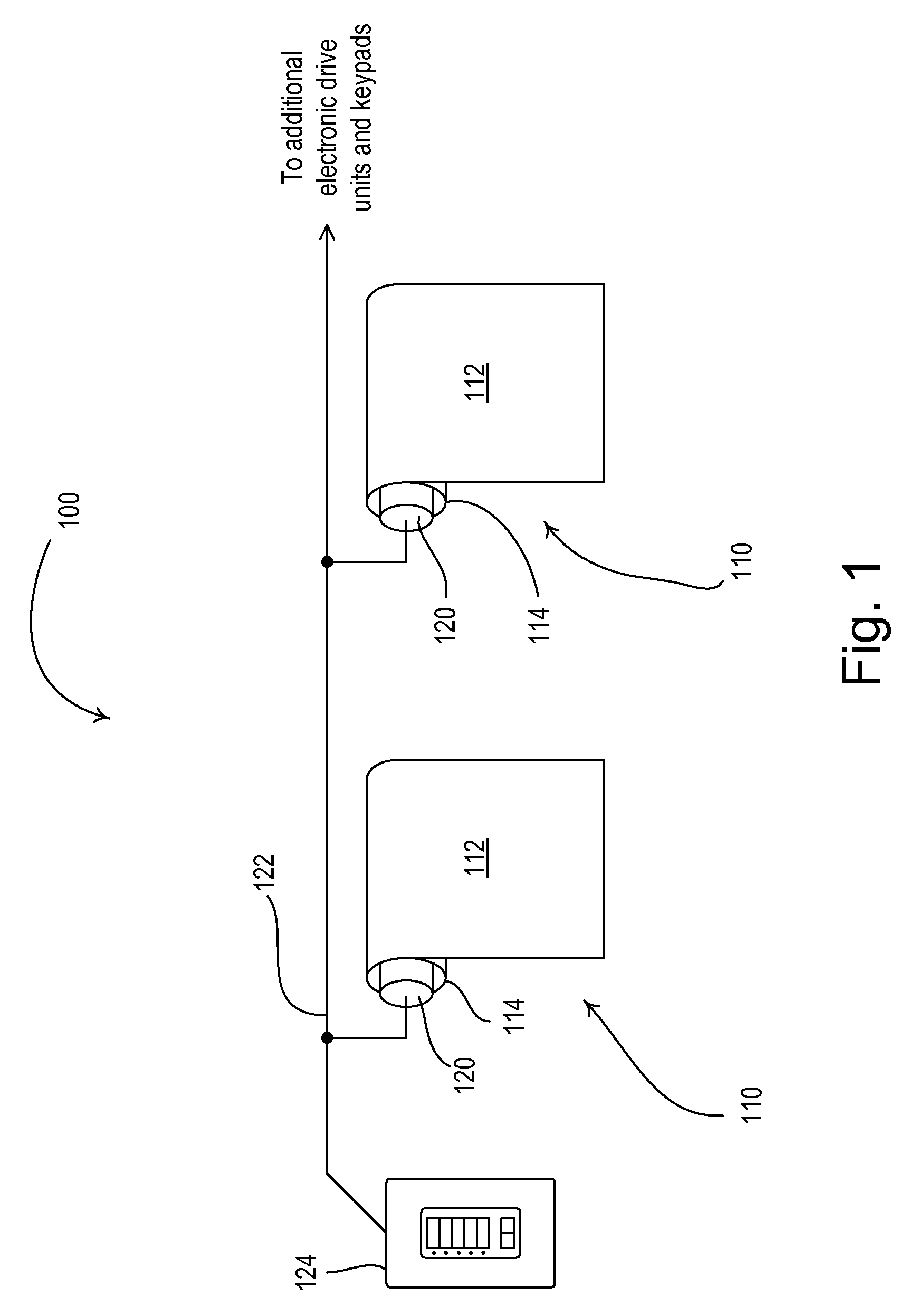

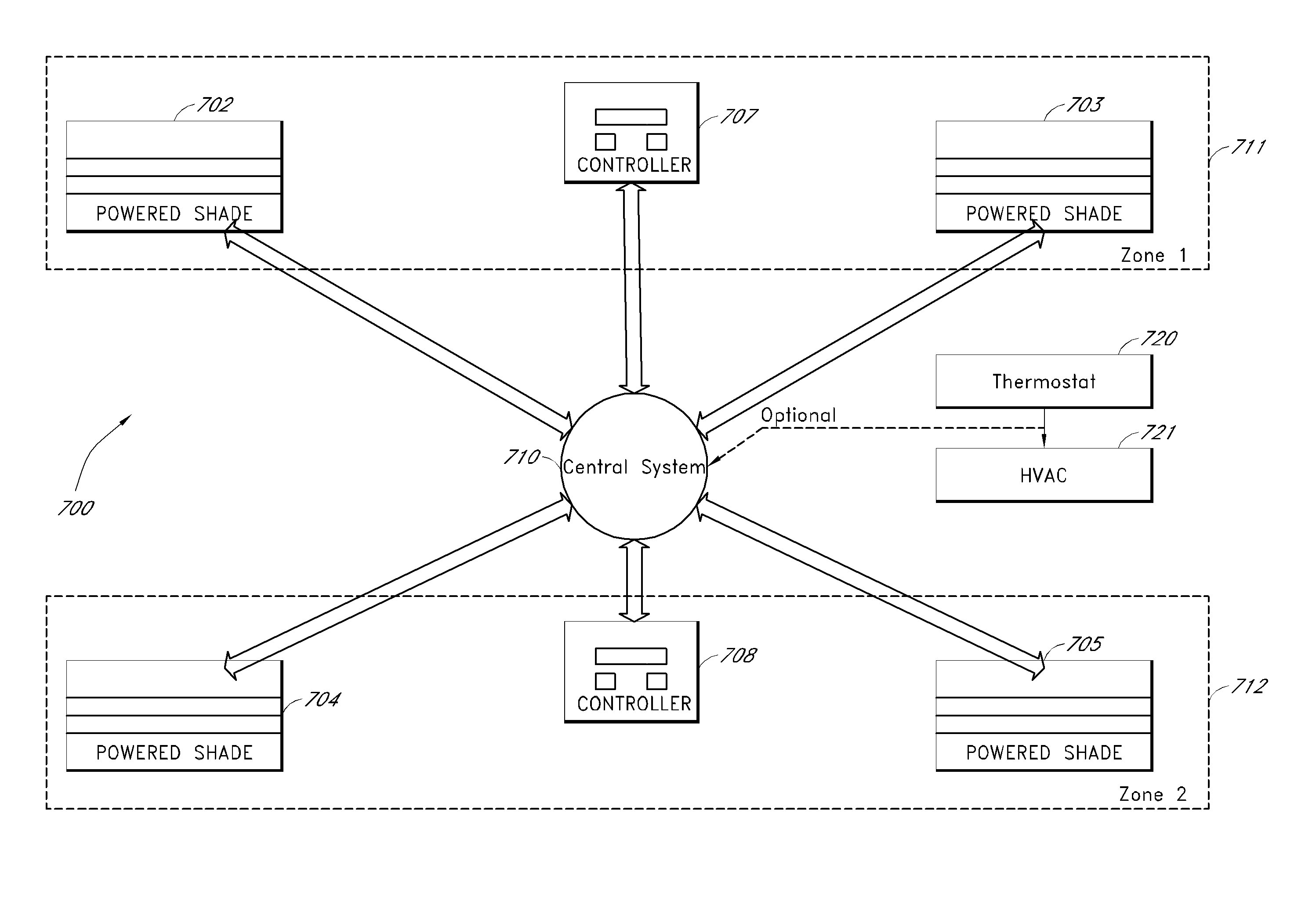

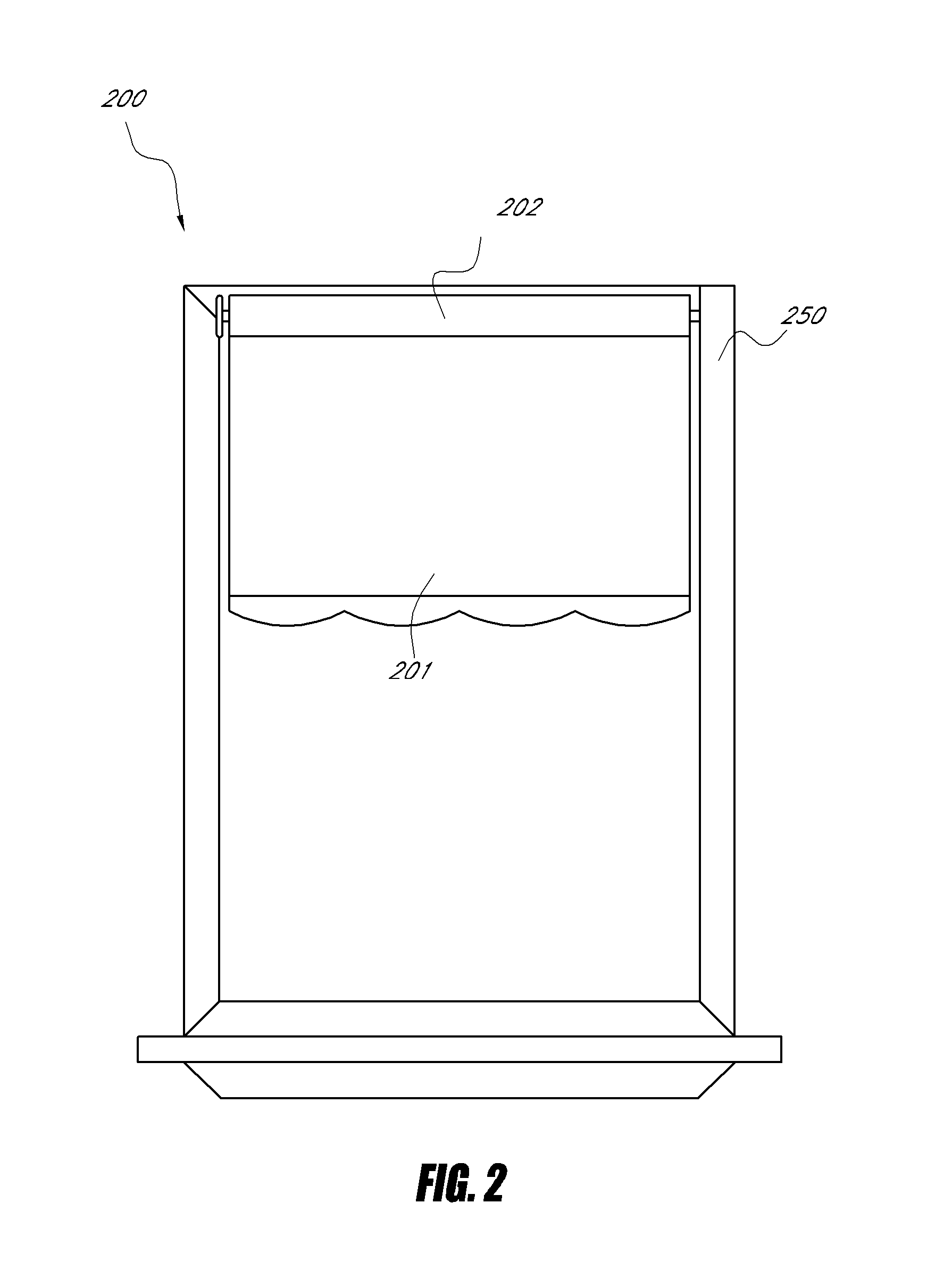

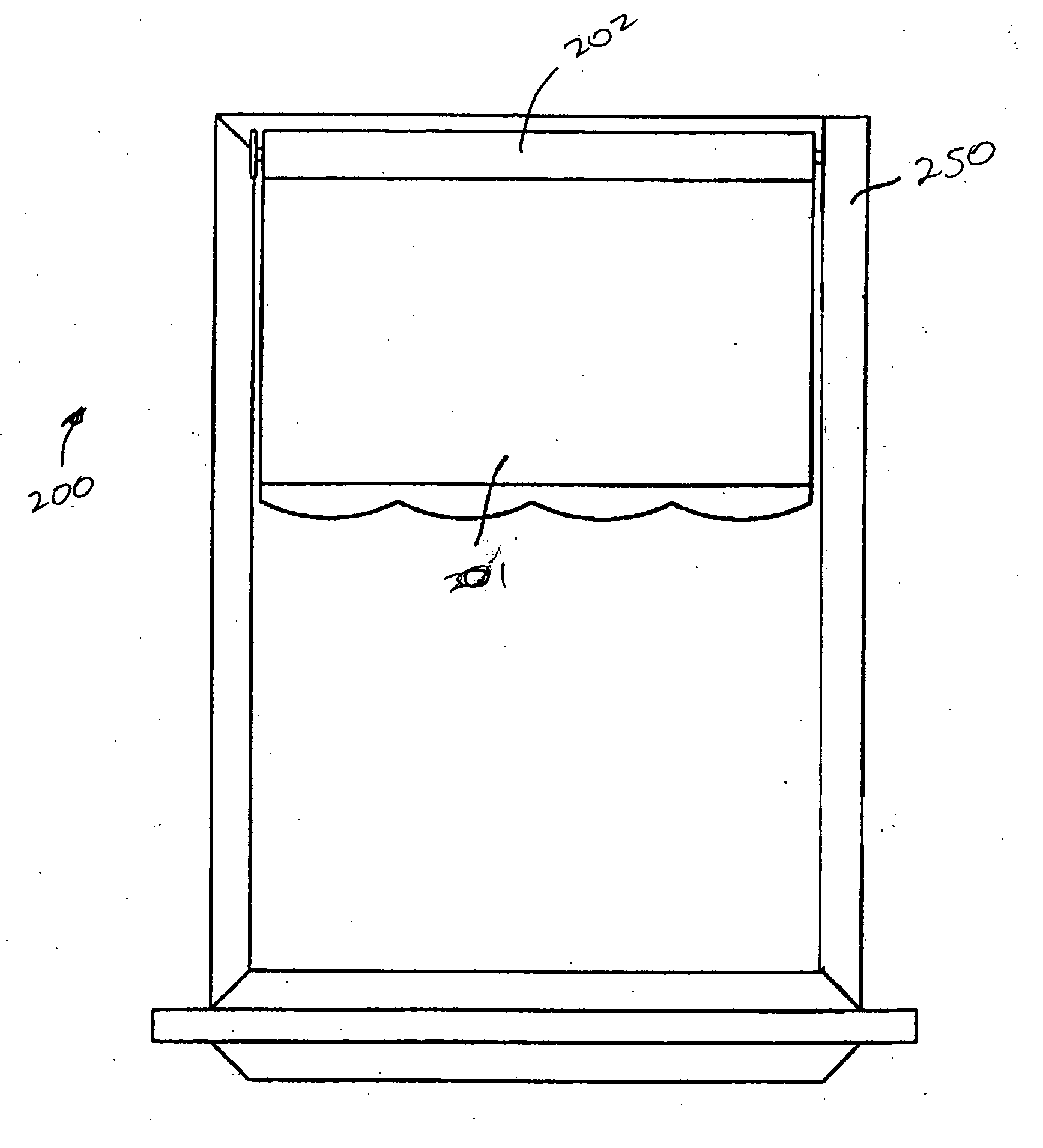

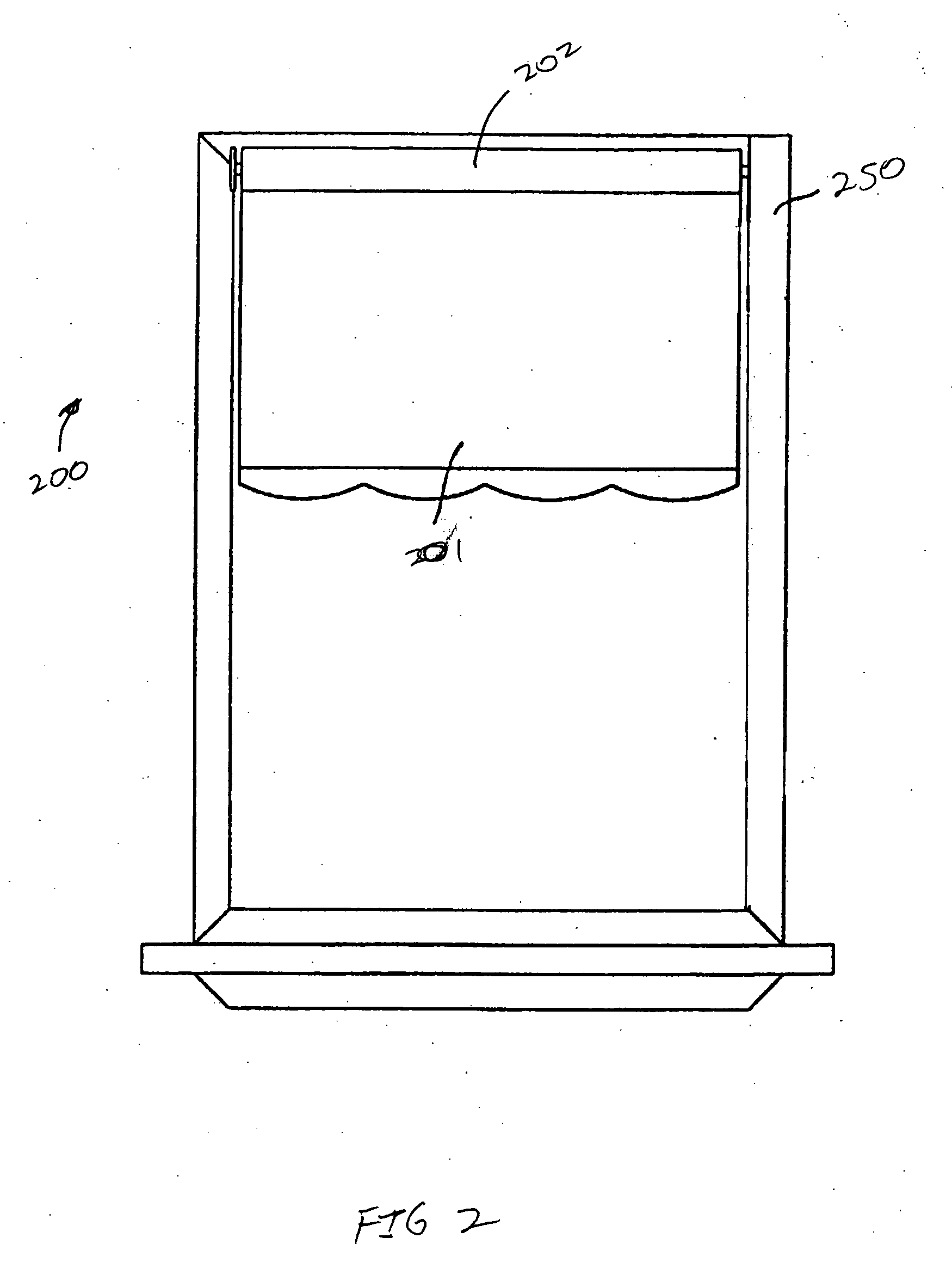

Motorized window shade system

InactiveUS7389806B2Raise and lower the window shadeReduce power consumptionScreensMechanical apparatusGroup controllerCommunications system

An electronically-controlled roll-up window shade that can easily be installed by a homeowner or general handyman is disclosed. The motorized shade includes an internal power source, a motor, and a communication system to allow for remote control of the motorized shade. One or more motorized shades can be controlled singly or as a group. In one embodiment, the motorized shades are used in connection with a zoned or non-zoned HVAC system to reduce energy usage. In one embodiment, the motorized shade is configured to have a size and form-factor that conforms to a standard manually-controlled motorized shade. In one embodiment, a group controller is configured to provide thermostat information to the motorized shade. In one embodiment, the group controller communicates with a central monitoring system that coordinates operation of one or more motorized shades. In one embodiment, the internal power source of the motorized shade is recharged by a solar cell.

Owner:GOOGLE LLC

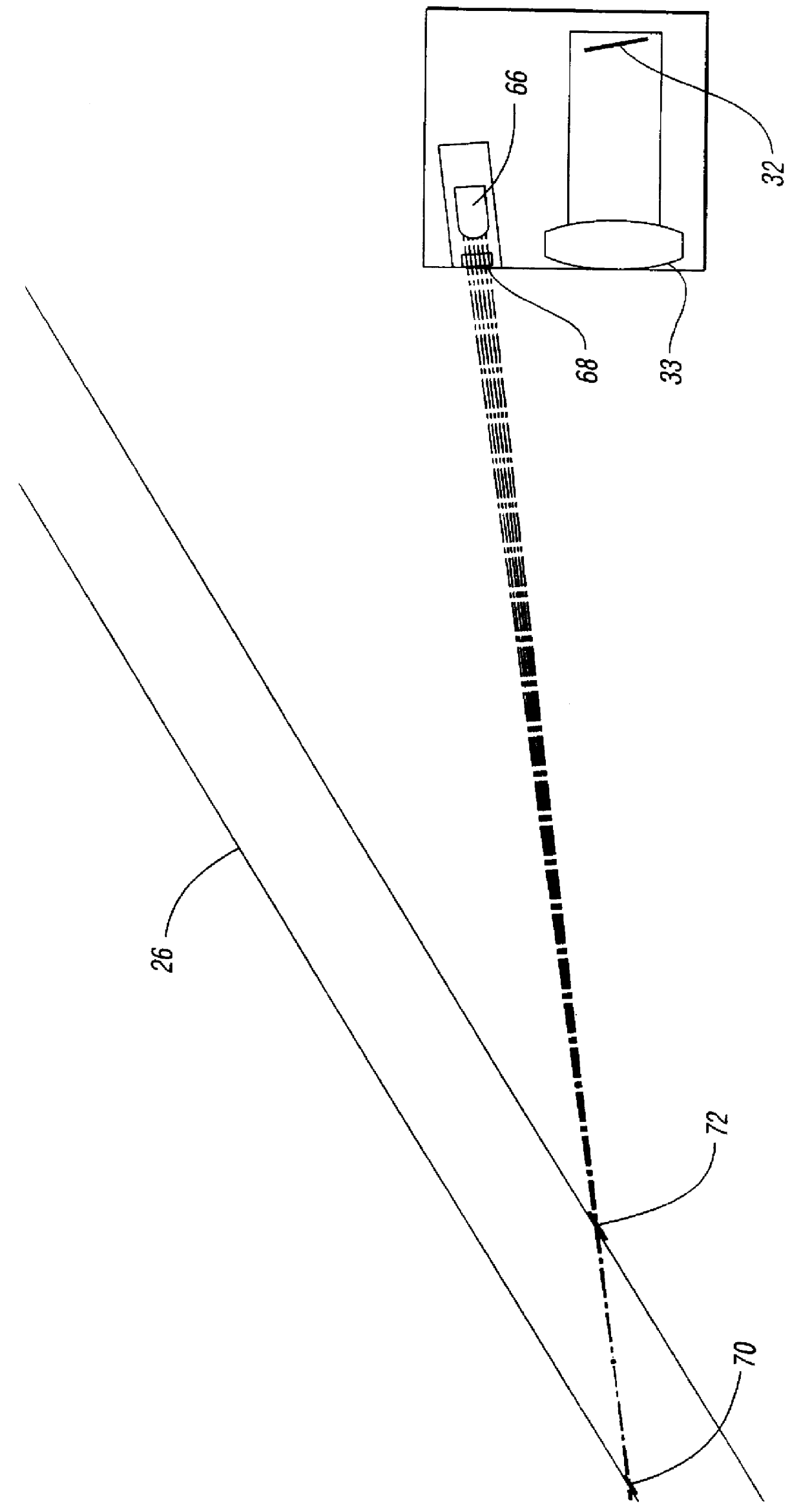

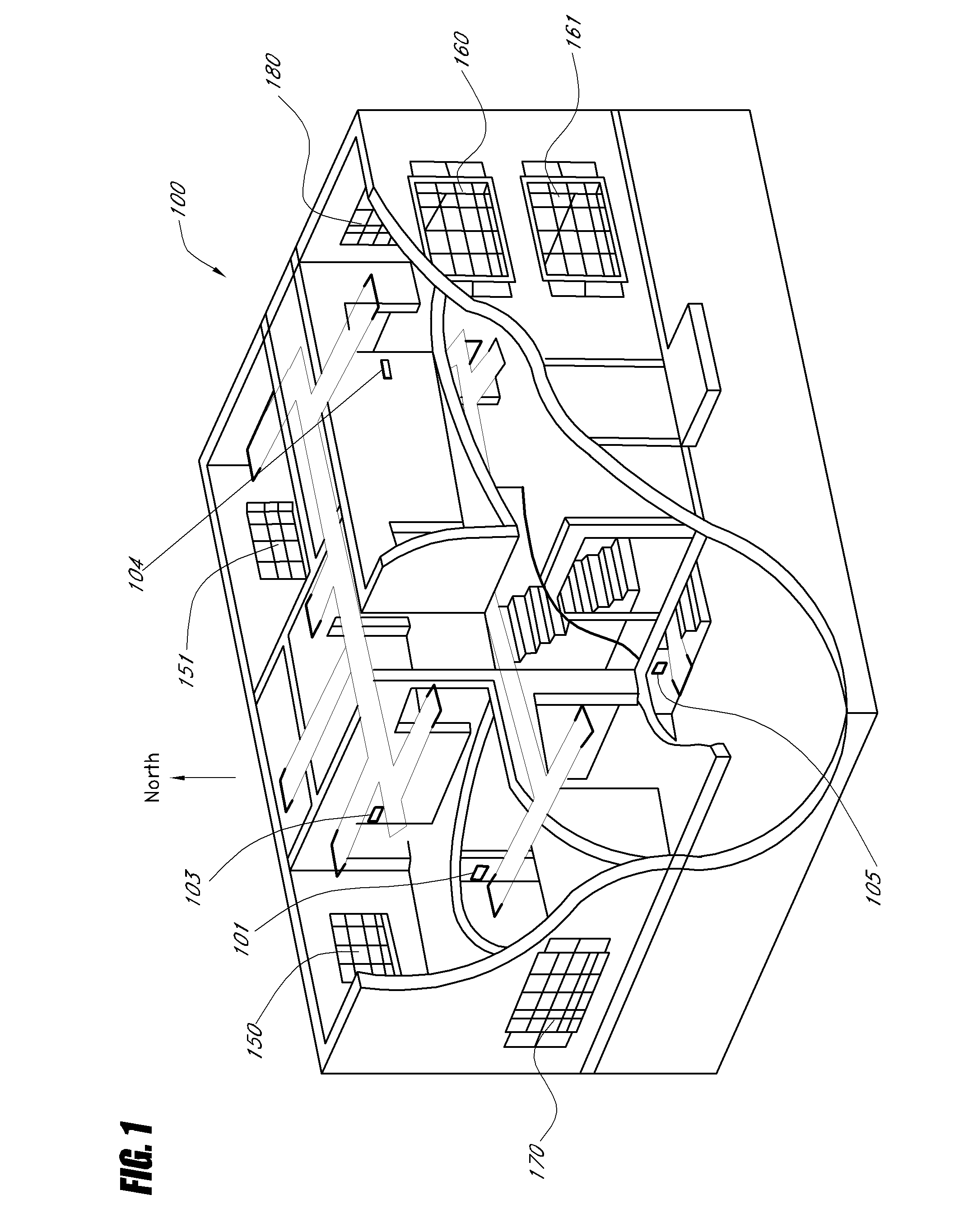

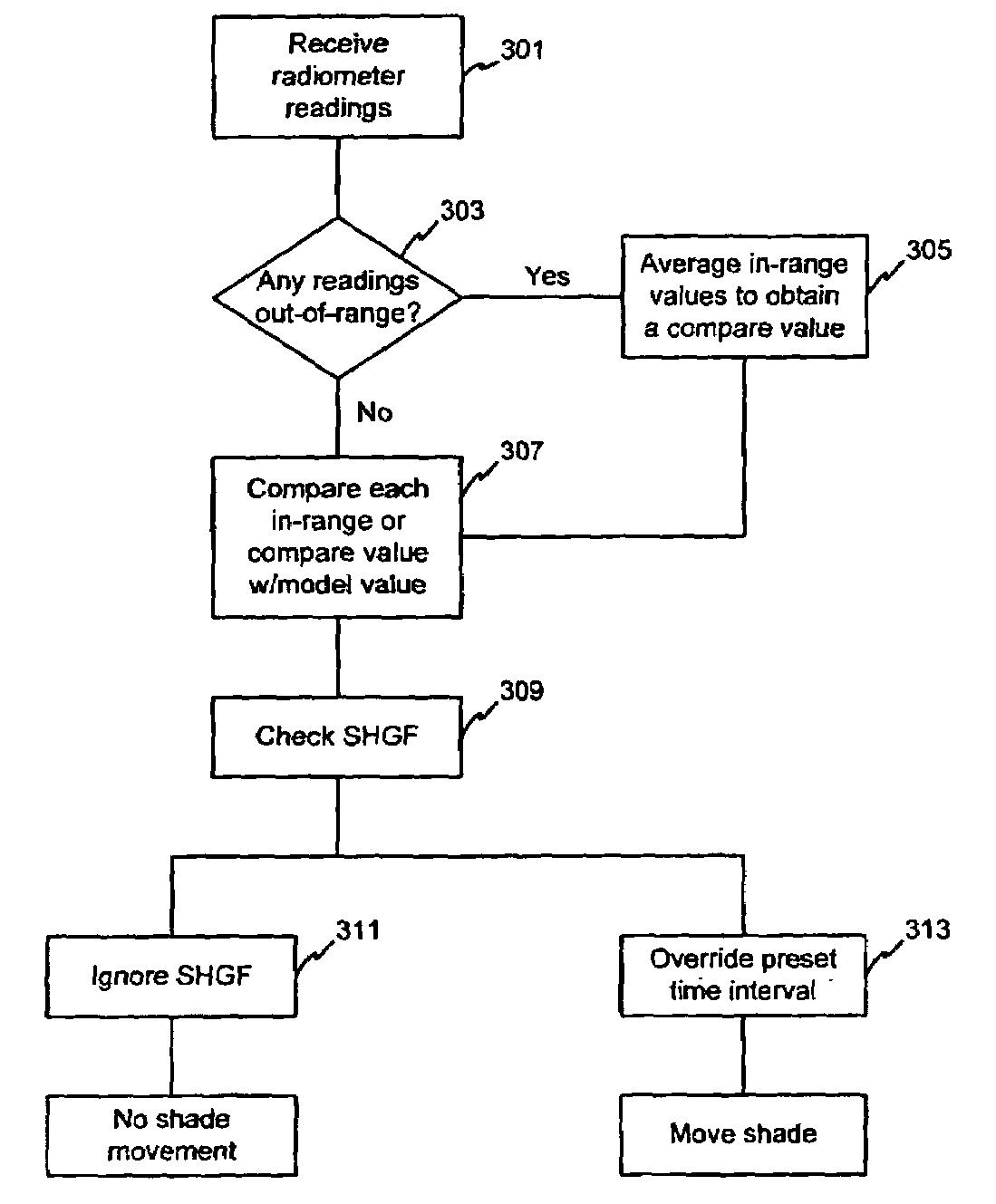

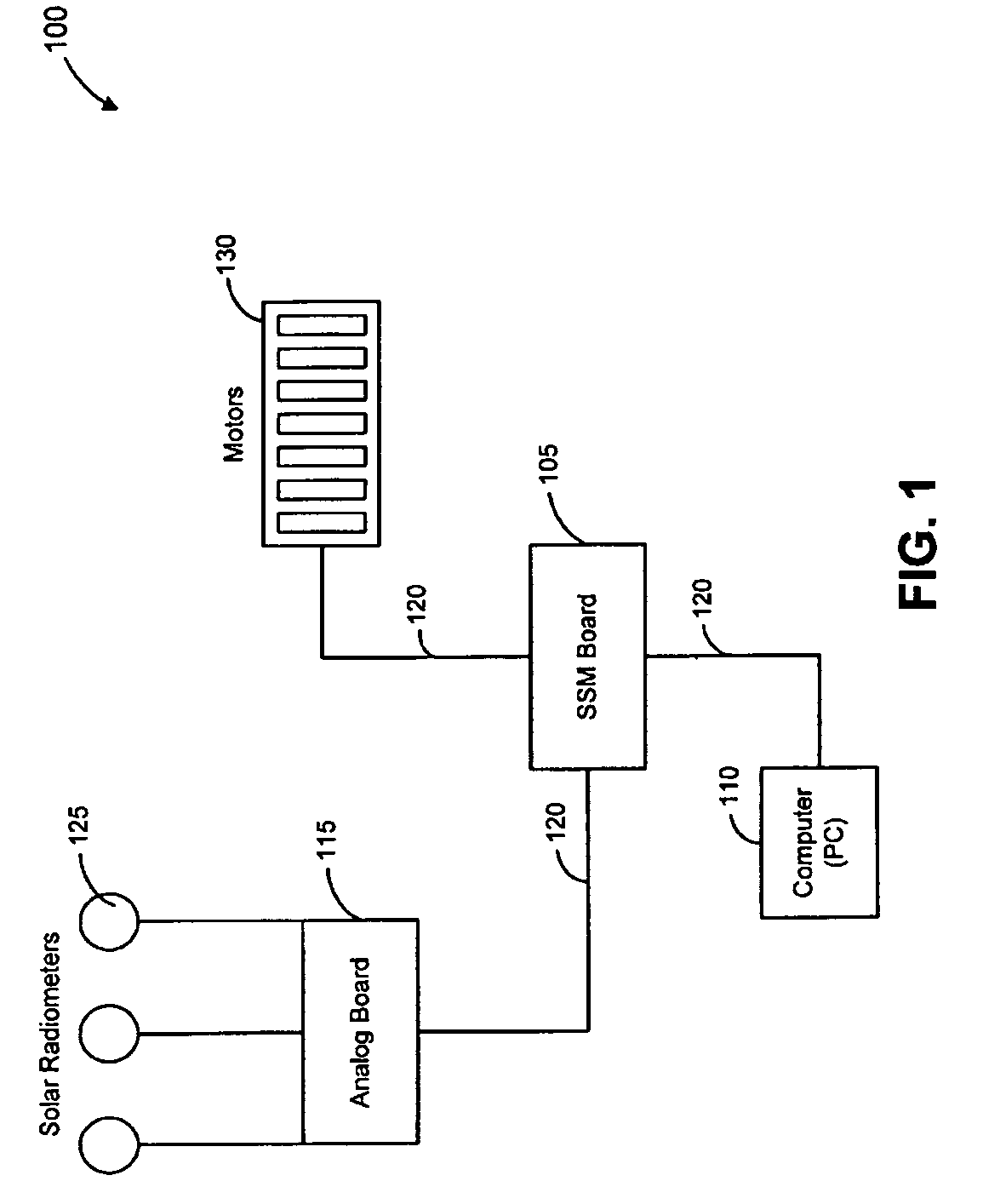

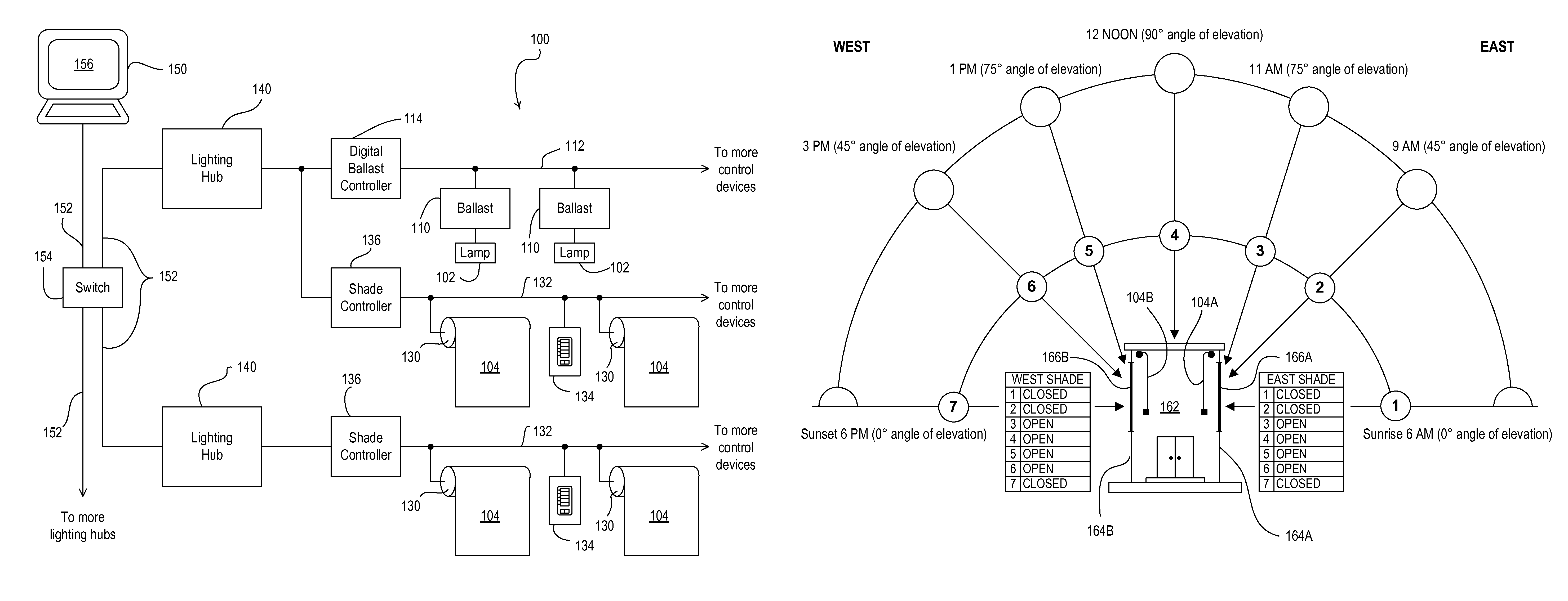

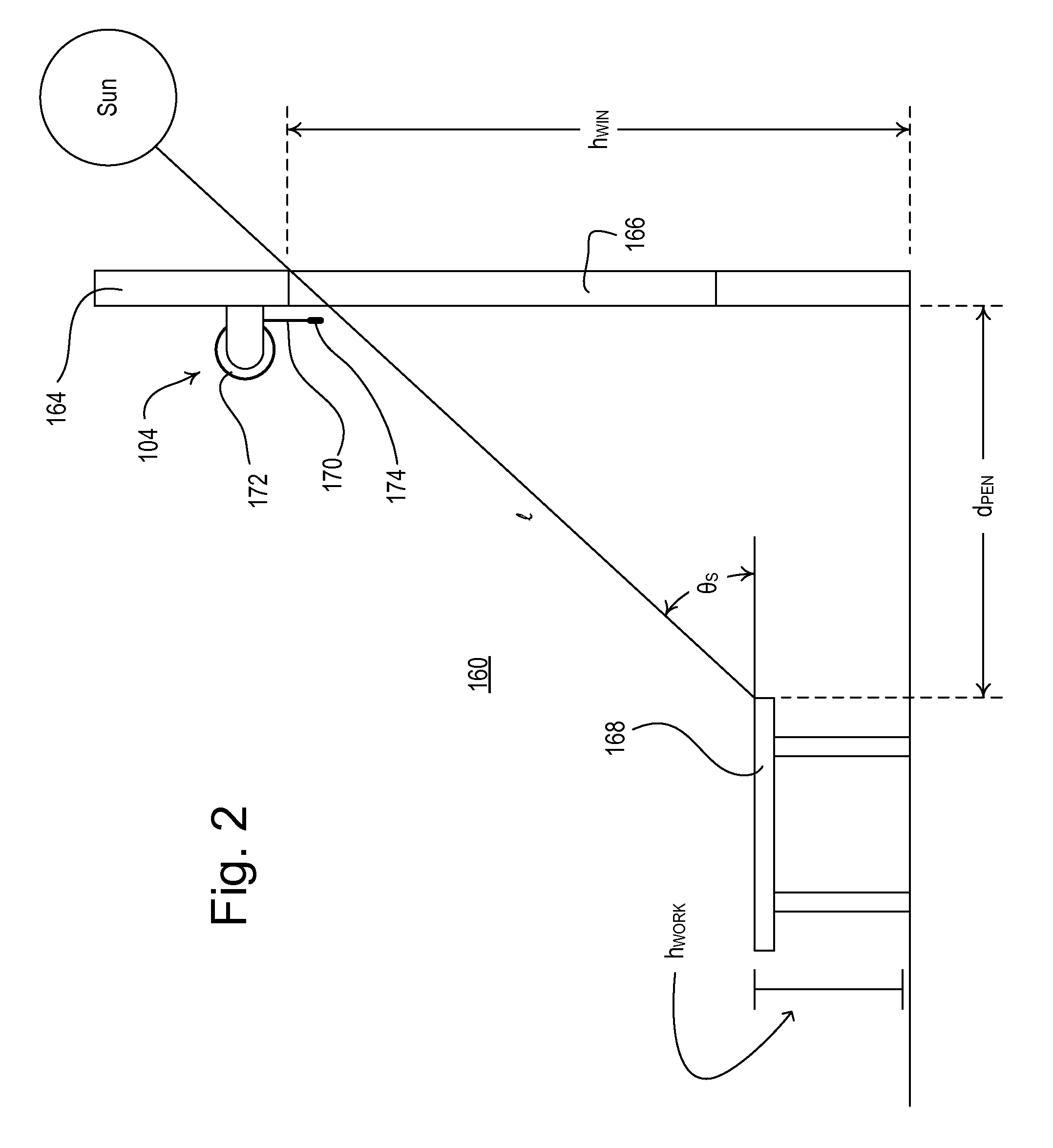

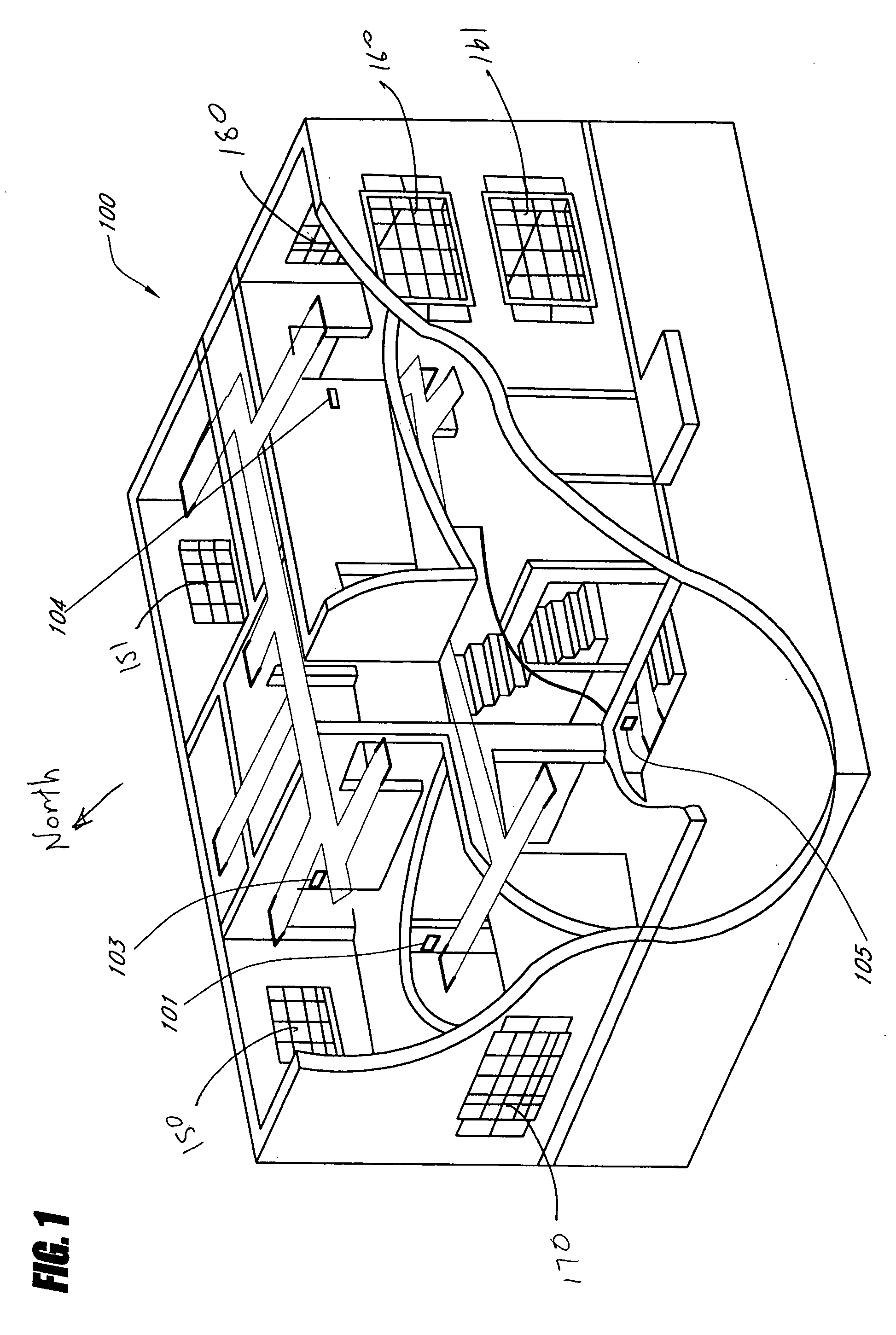

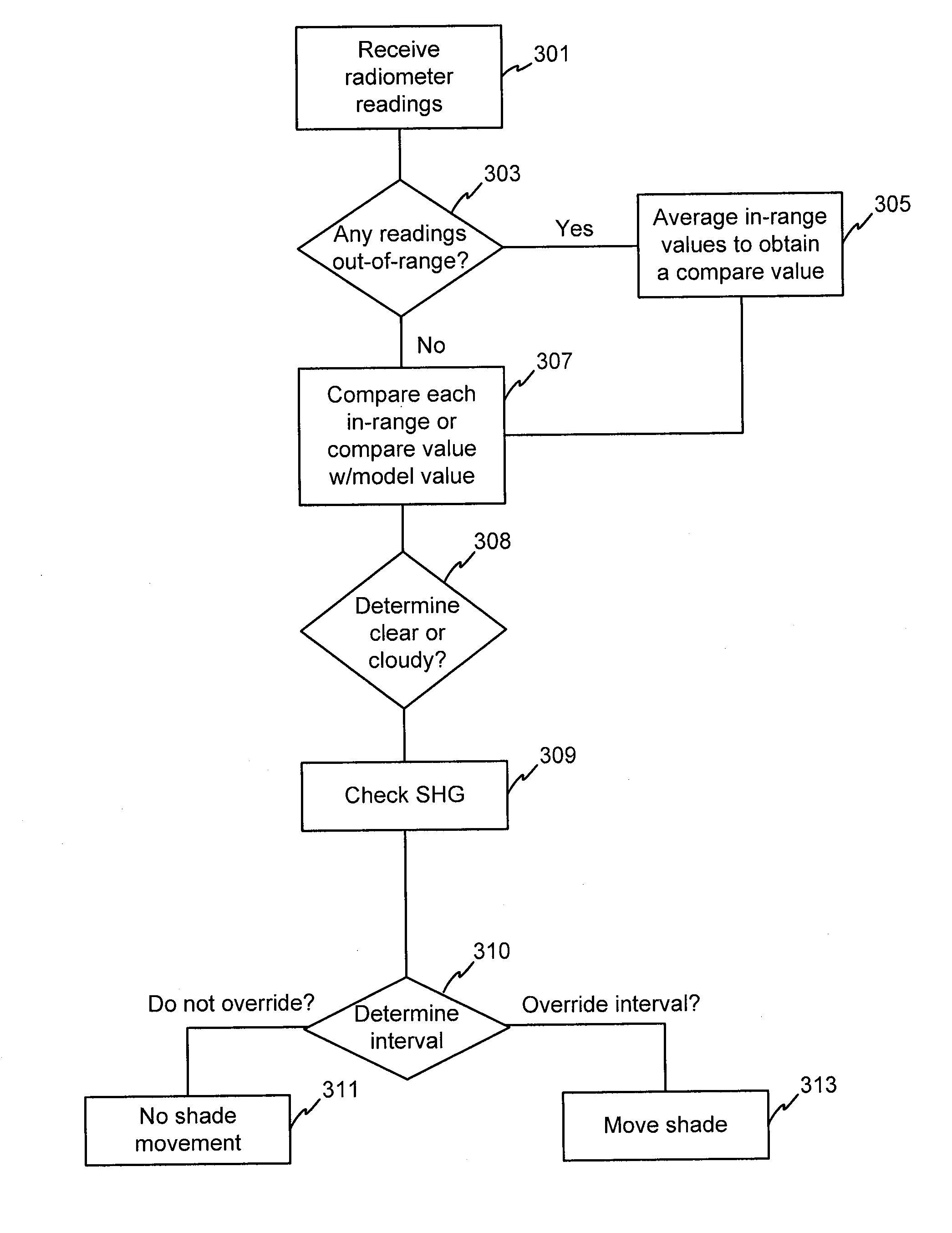

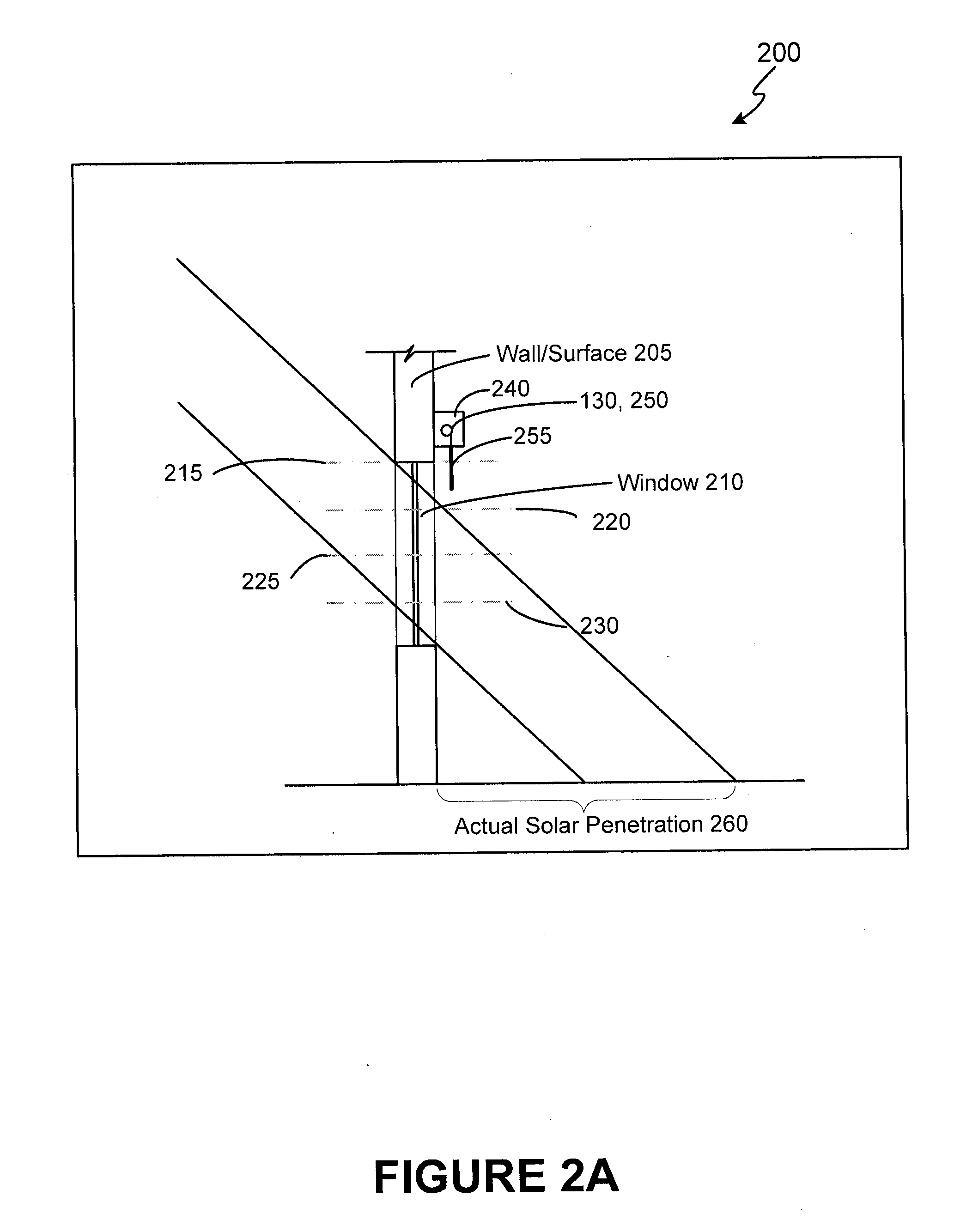

Automated shade control method and system

ActiveUS7417397B2Keep brightnessReduce brightnessLight dependant control systemsDC motor speed/torque controlRadiometerSolar angle

This invention generally relates to automated shade systems that employ one or more algorithms to provide appropriate solar protection from direct solar penetration; reduce solar heat gain; reduce radiant surface temperatures; control penetration of the solar ray, optimize the interior natural daylighting of a structure and optimize the efficiency of interior lighting systems. The invention additionally comprises a motorized window covering, radiometers, and a central control system that uses algorithms to optimize the interior lighting of a structure. These algorithms include information such as: geodesic coordinates of a building; solar position; solar angle solar radiation; solar penetration angles; solar intensity; the measured brightness and veiling glare across a surface; time, solar altitude, solar azimuth, detected sky conditions, ASHRAE sky models, sunrise and sunset times, surface orientations of windows, incidence angles of the sun striking windows, window covering positions, minimum BTU load and solar heat gain.

Owner:MECHOSHADE SYST LLC

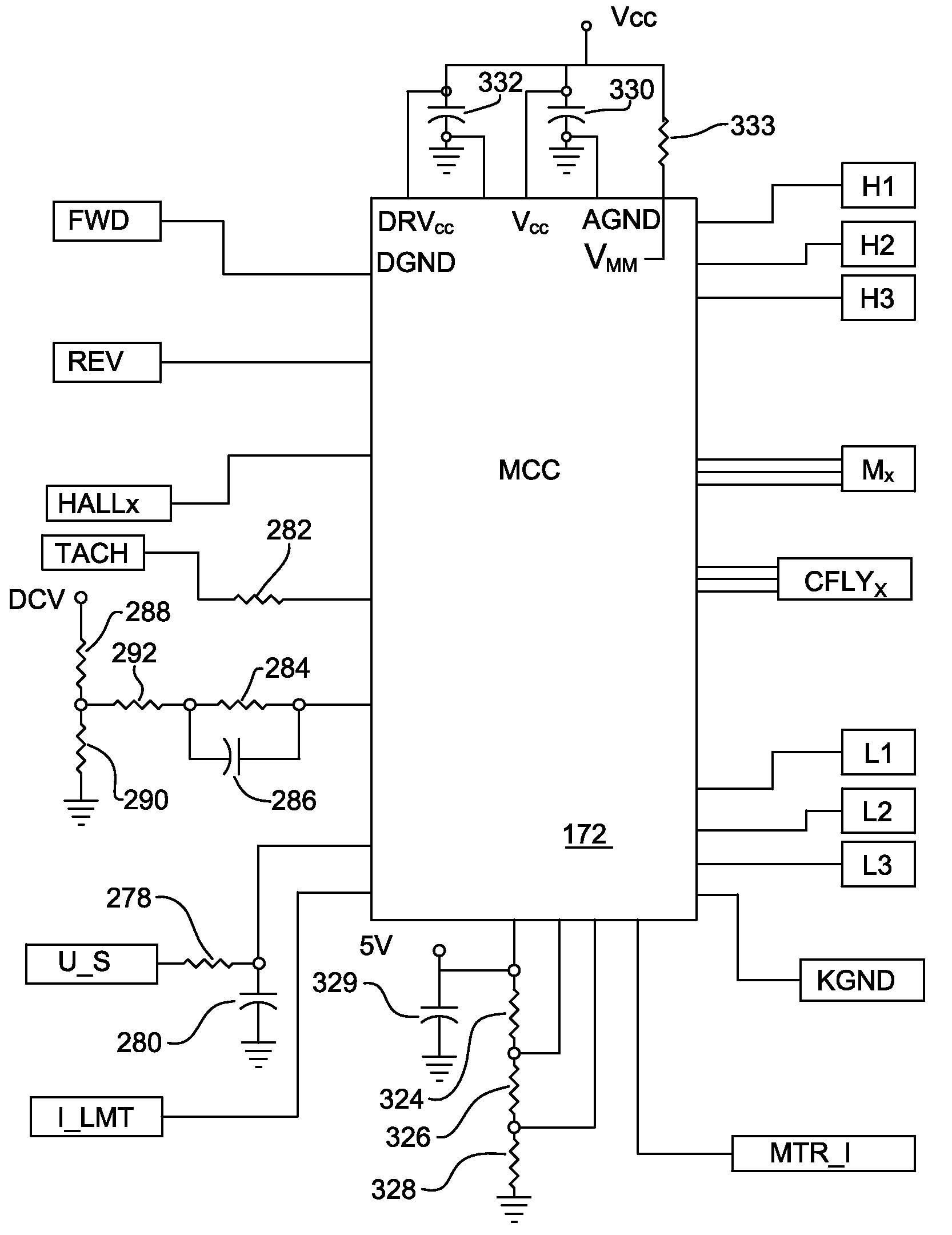

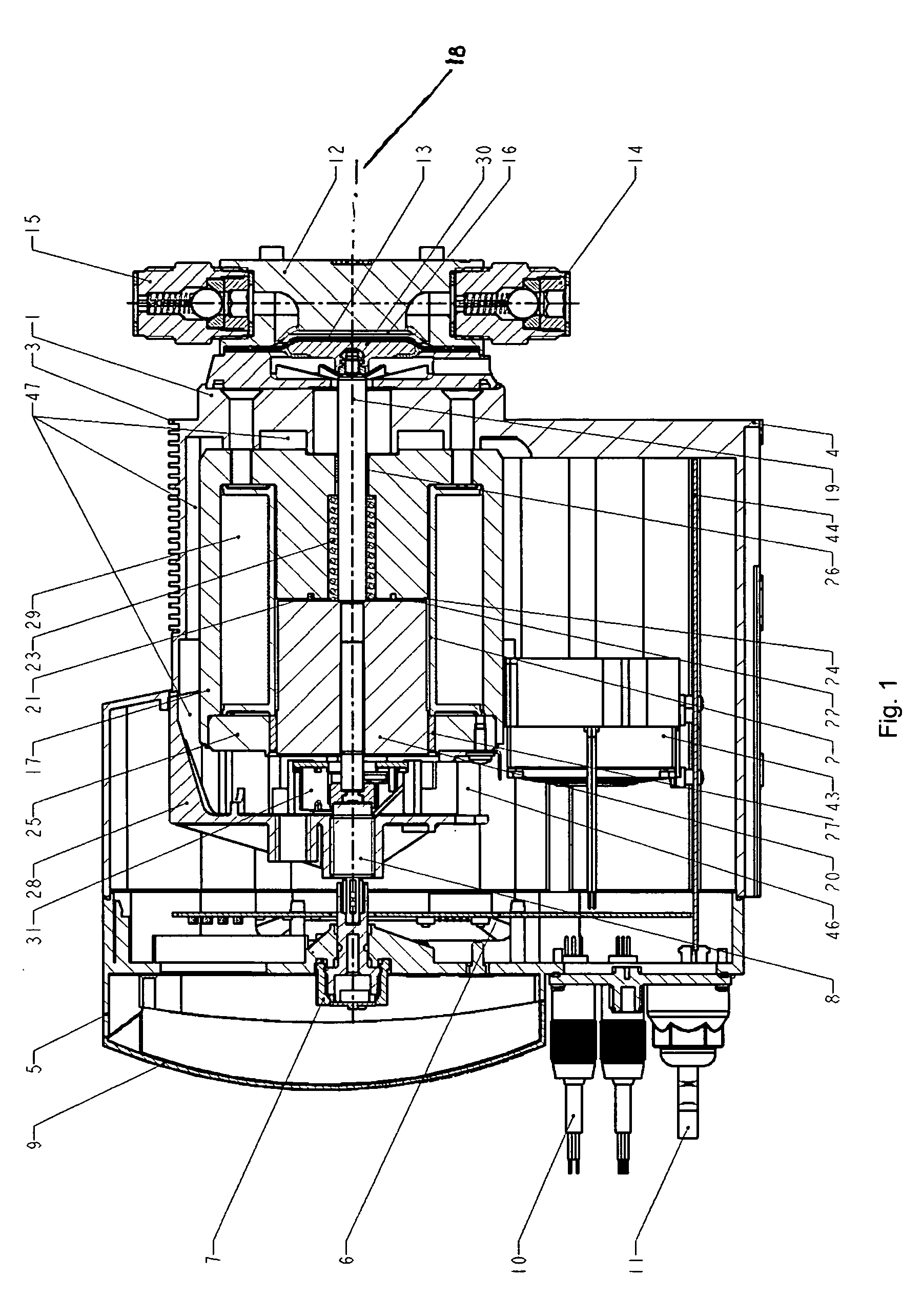

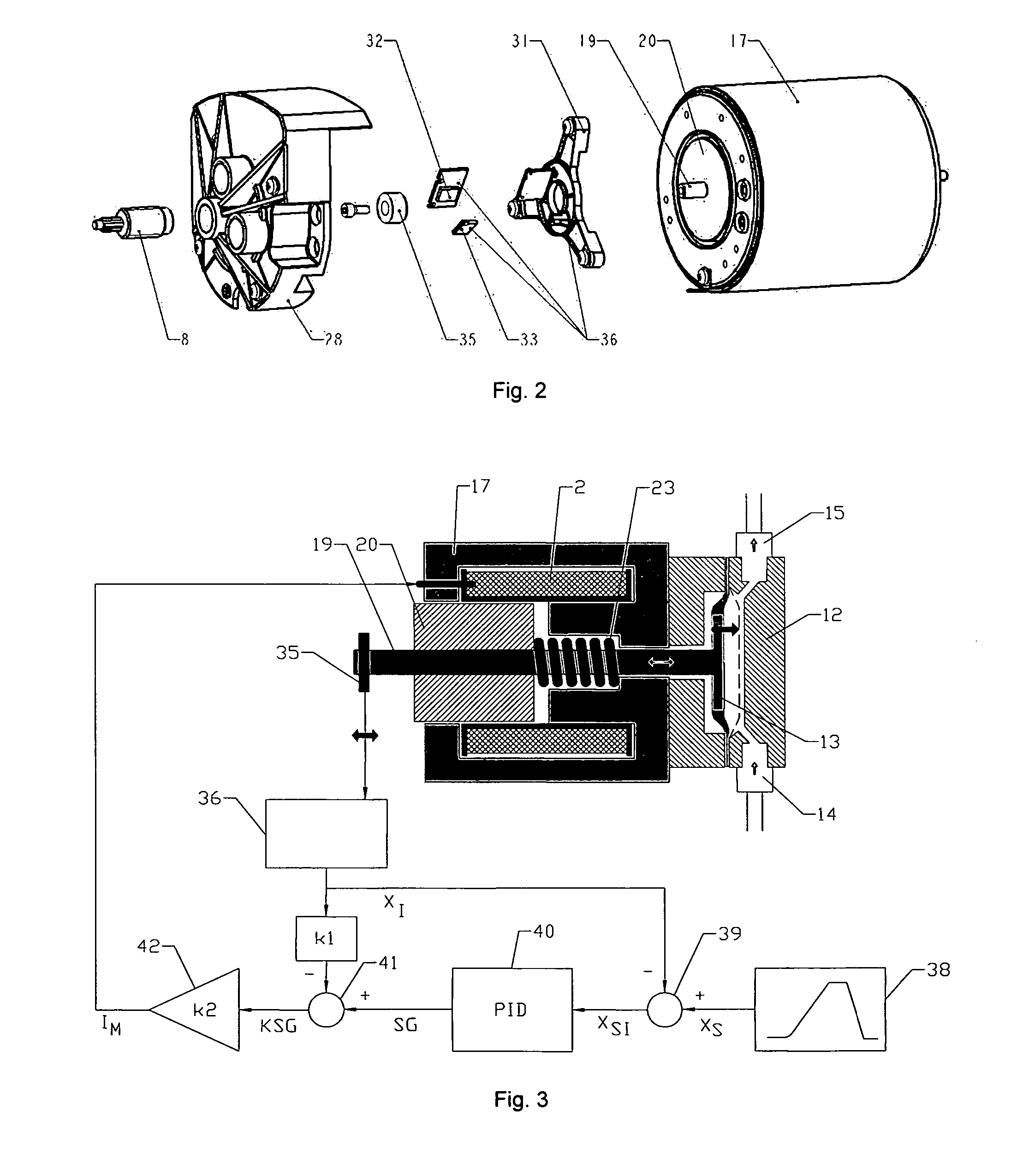

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

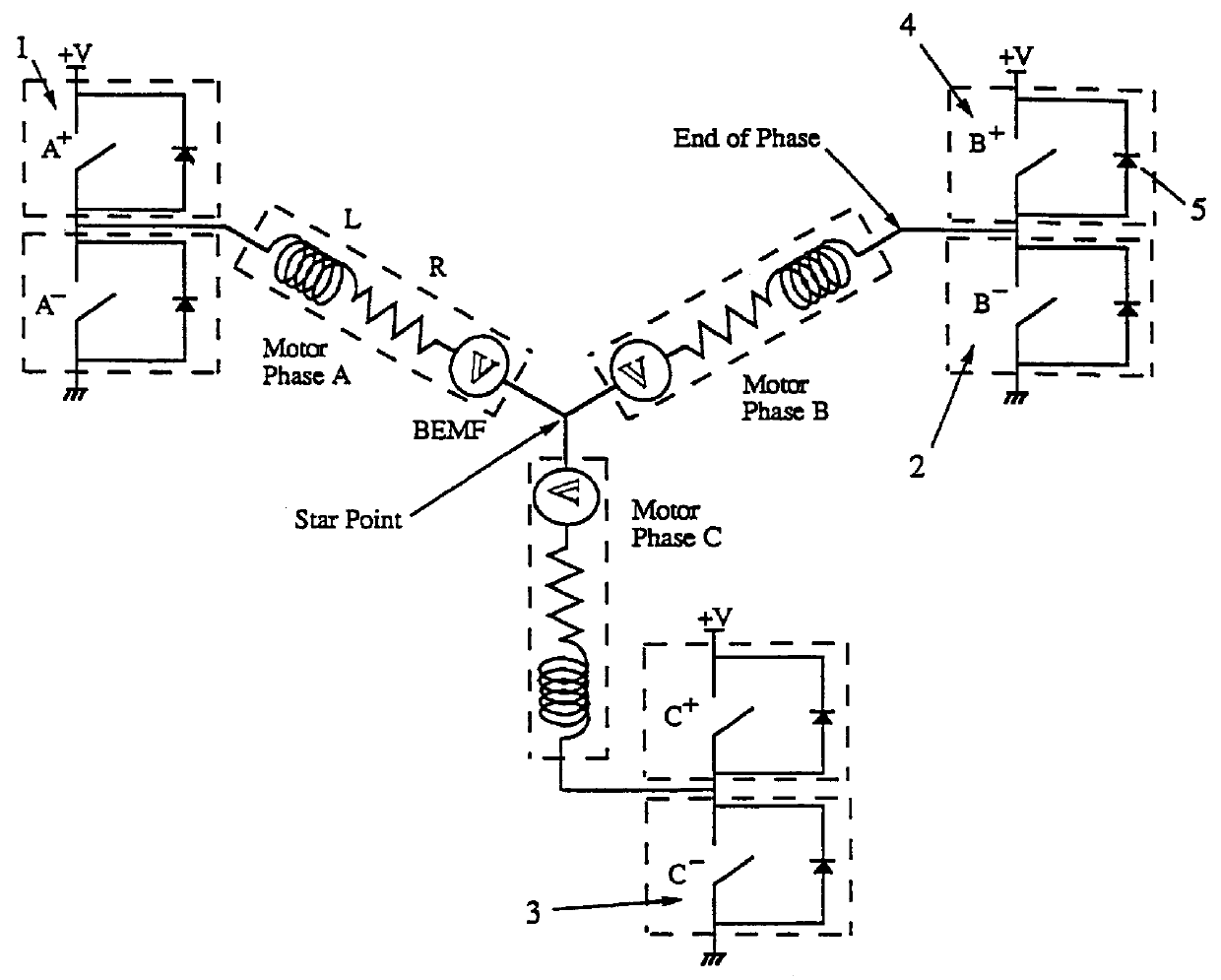

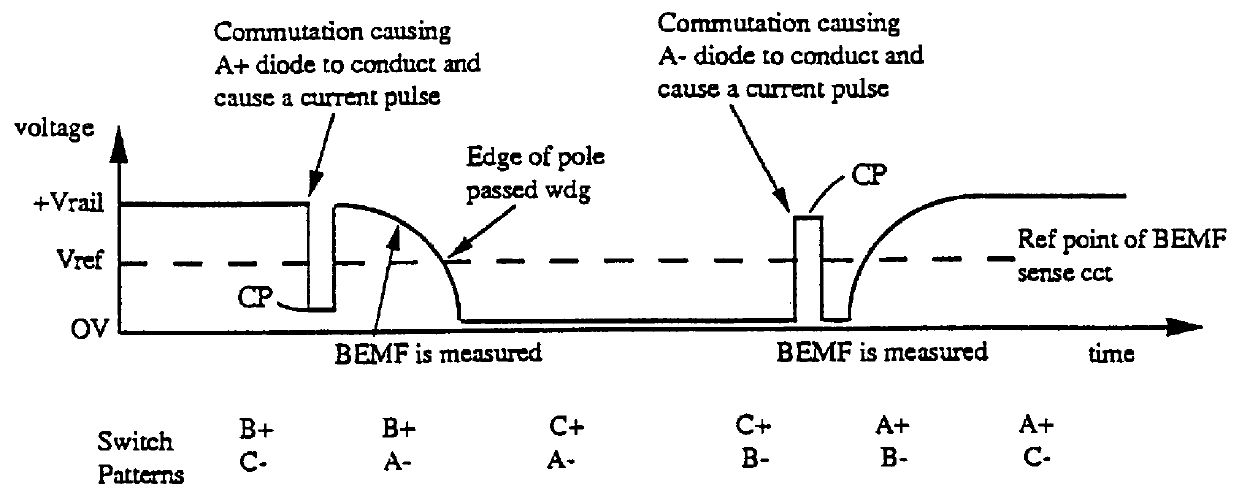

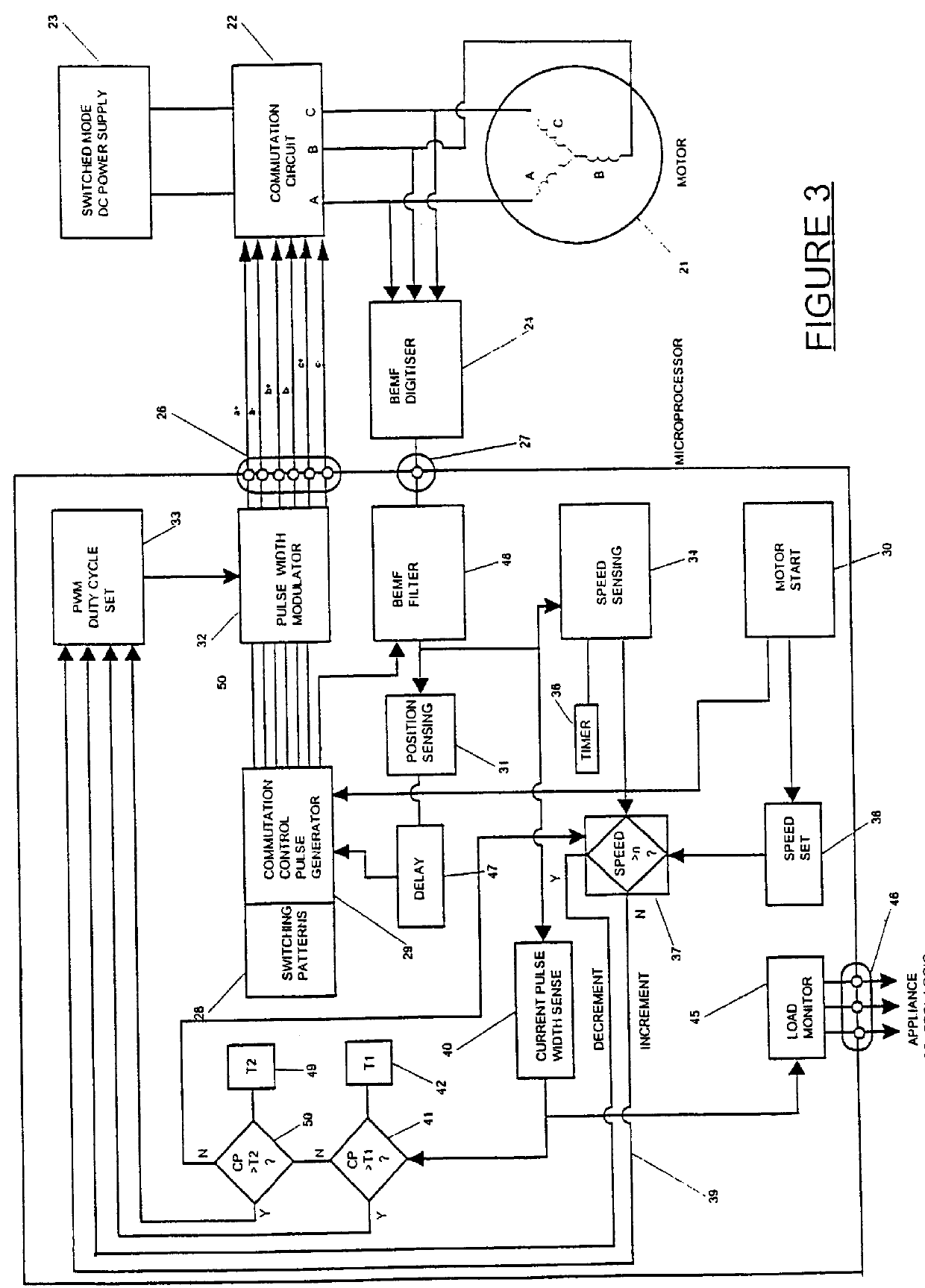

Brushless DC motor control

An electronically commutated brushless DC motor primarily for fractional horsepower applications of the type where at any instant one motor winding is unpowered and used to detect back EMF zero-crossings which information is used to initiate winding commutations. The duration of the pulse produced in this winding due to dissipation of stored energy by free-wheel diodes in parallel with the commutation devices after supply of current has been removed from this winding is used to provide a measure of motor current. This allows for simplified commutation device current limiting circuits and is available for control purposes which are a function of motor torque. There is also disclosed a method for maximizing useful power output by reducing the phase angle between the motor current and the back EMF. This is accomplished by introducing a delay in commutating the motor windings beyond the occurrence of each back EMF zero-crossing, with the delay being a function of the time between commutations.

Owner:FISHER & PAYKEL APPLIANCES LTD

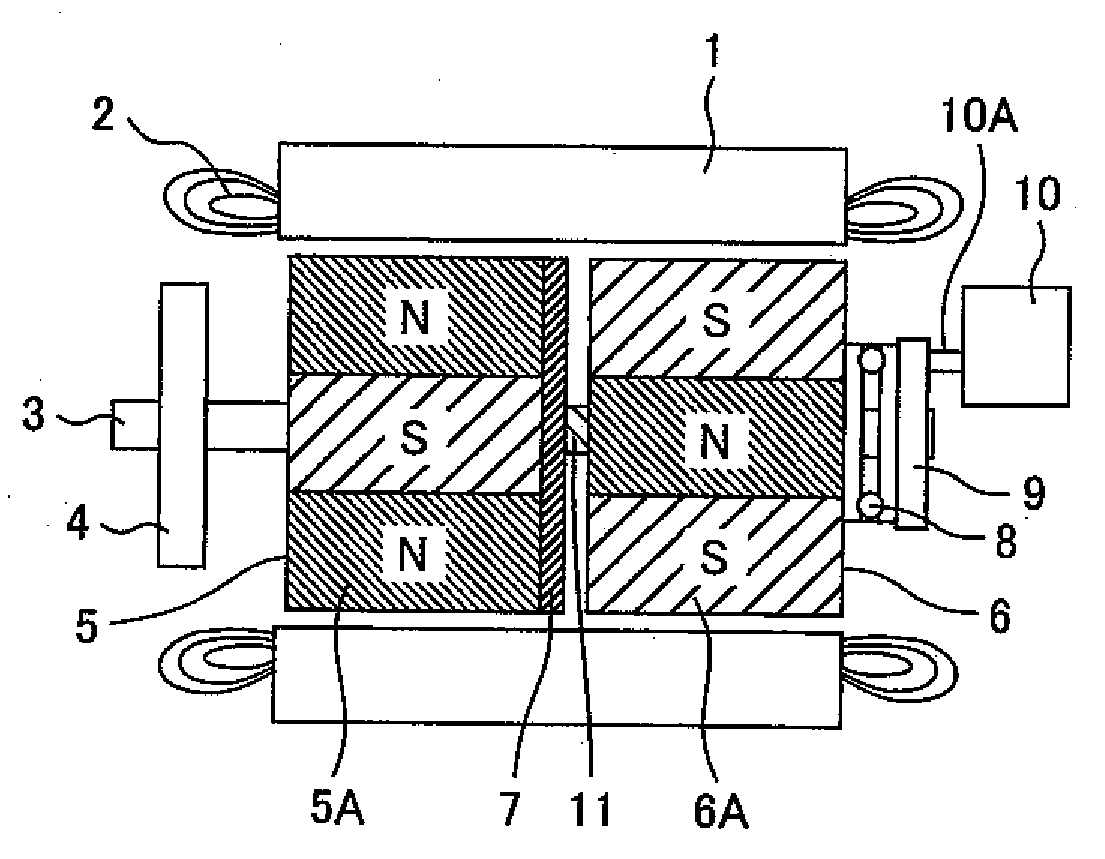

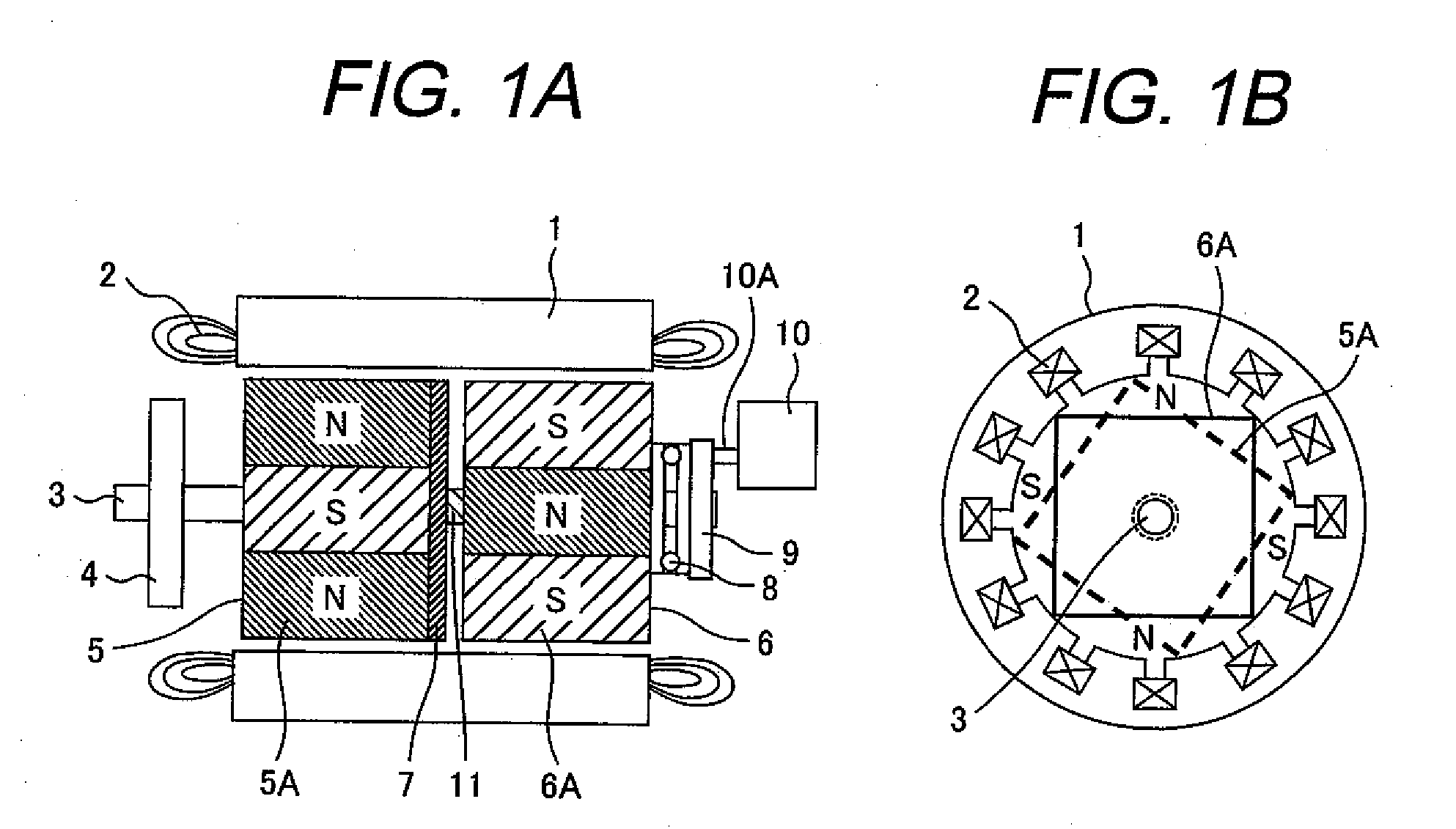

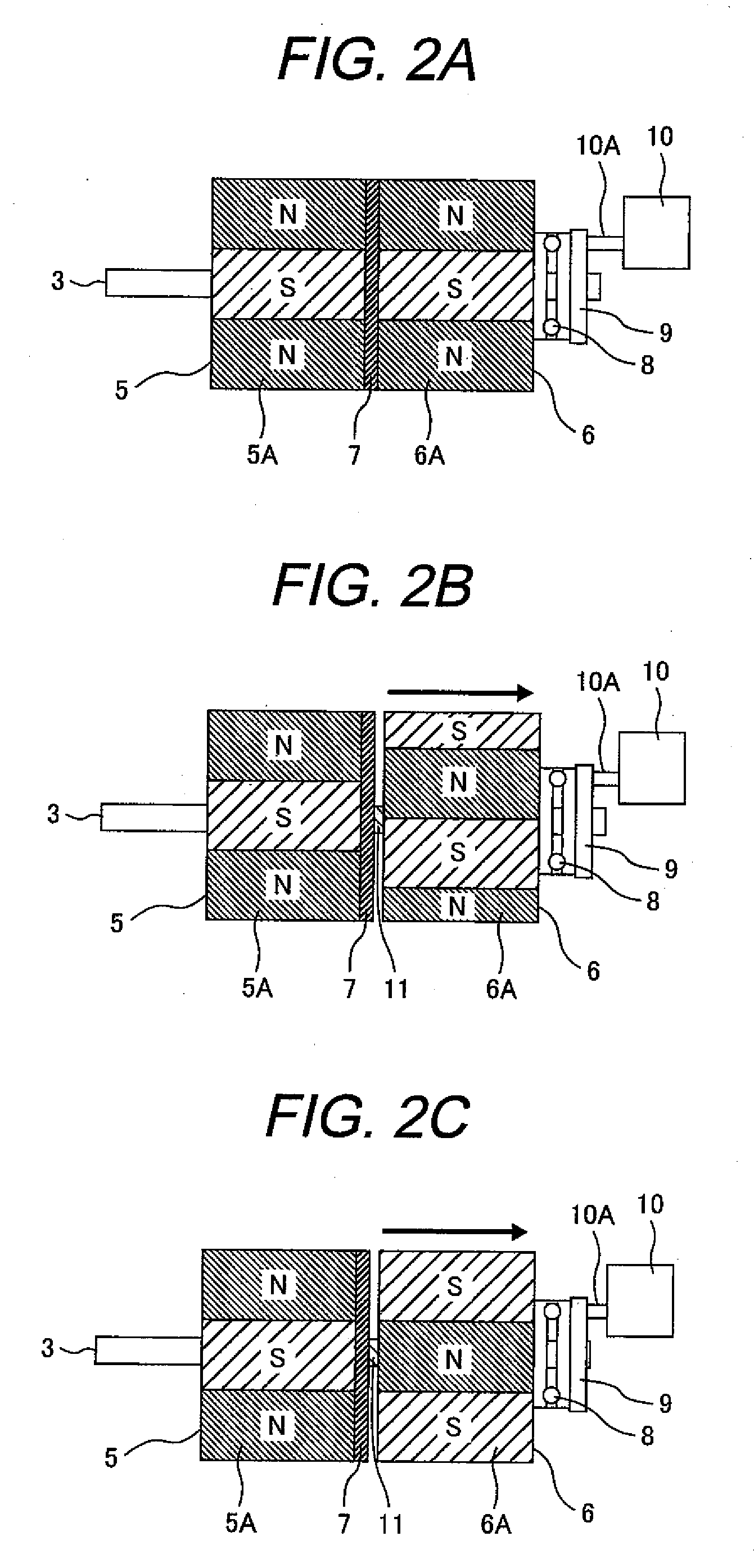

Variable magnetic flux electric rotary machine

InactiveUS20100164422A1Easy to operateWide operating speed rangeDC motor speed/torque controlRailway vehiclesElectrical polarityEngineering

An electric rotary machine is disclosed which can adjust relative angles of sub-rotors continuously and regardless of torque direction without generating an attractive force between the field magnets of the sub-rotors. The electric rotary machine includes: a stator having a winding; a dual rotor which is rotatably disposed with a gap from the stator and divided axially along a shaft into a first rotor and a second rotor each having field magnets with different polarities arranged alternately in a rotation direction; a mechanism for varying the axial position of the second rotor relative to the first rotor continuously; and a non-magnetic member located between the first rotor and the second rotor.

Owner:HITACHI LTD

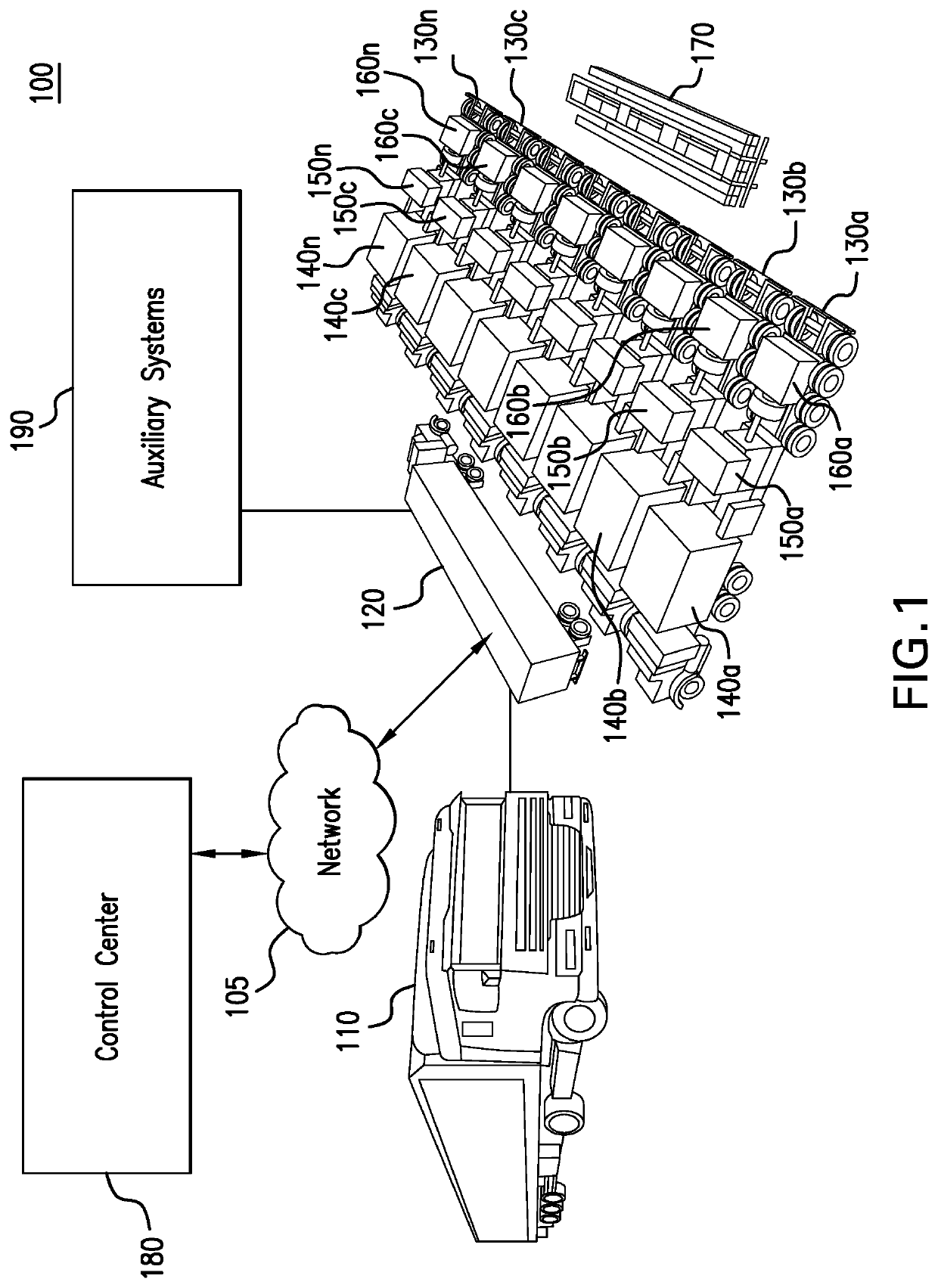

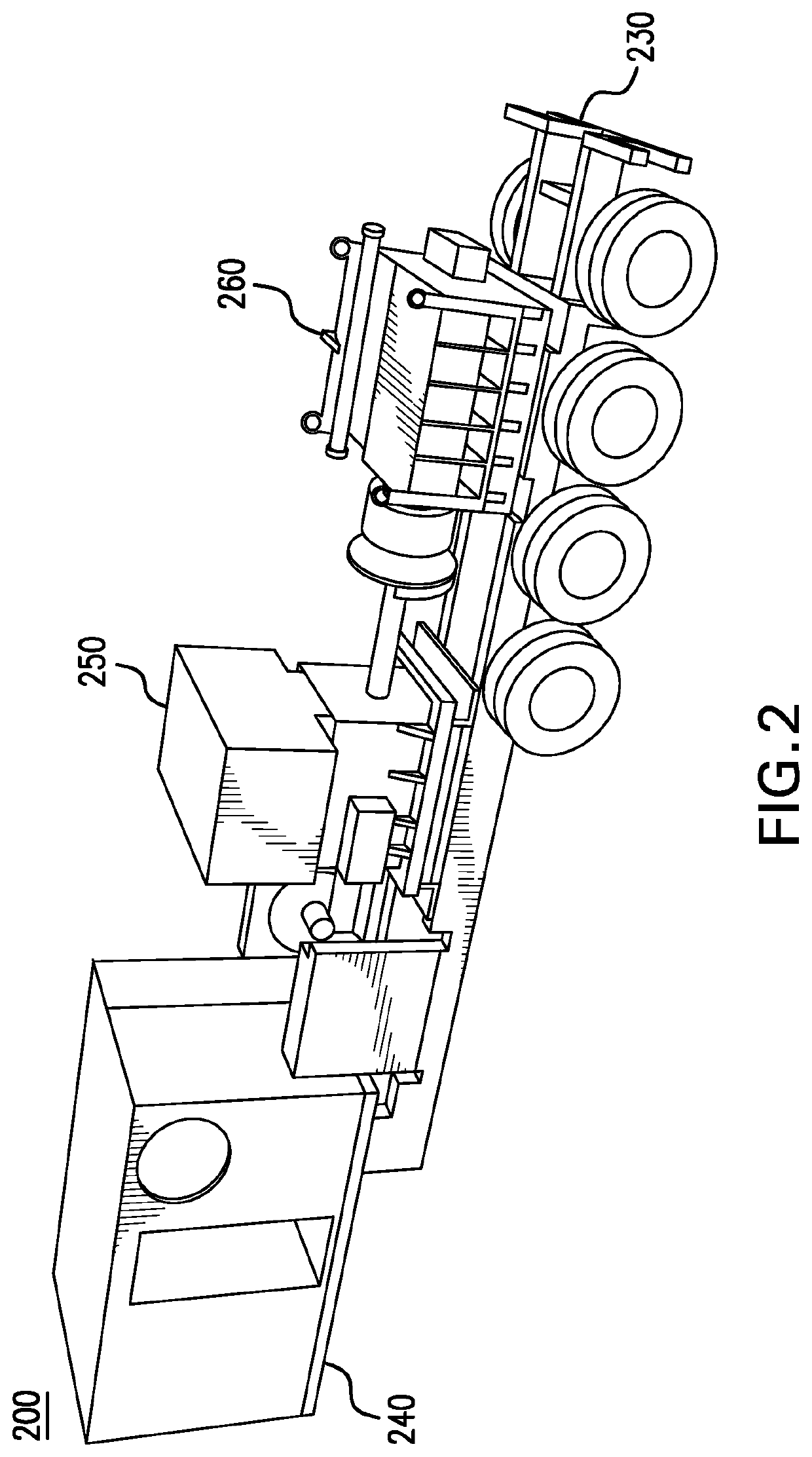

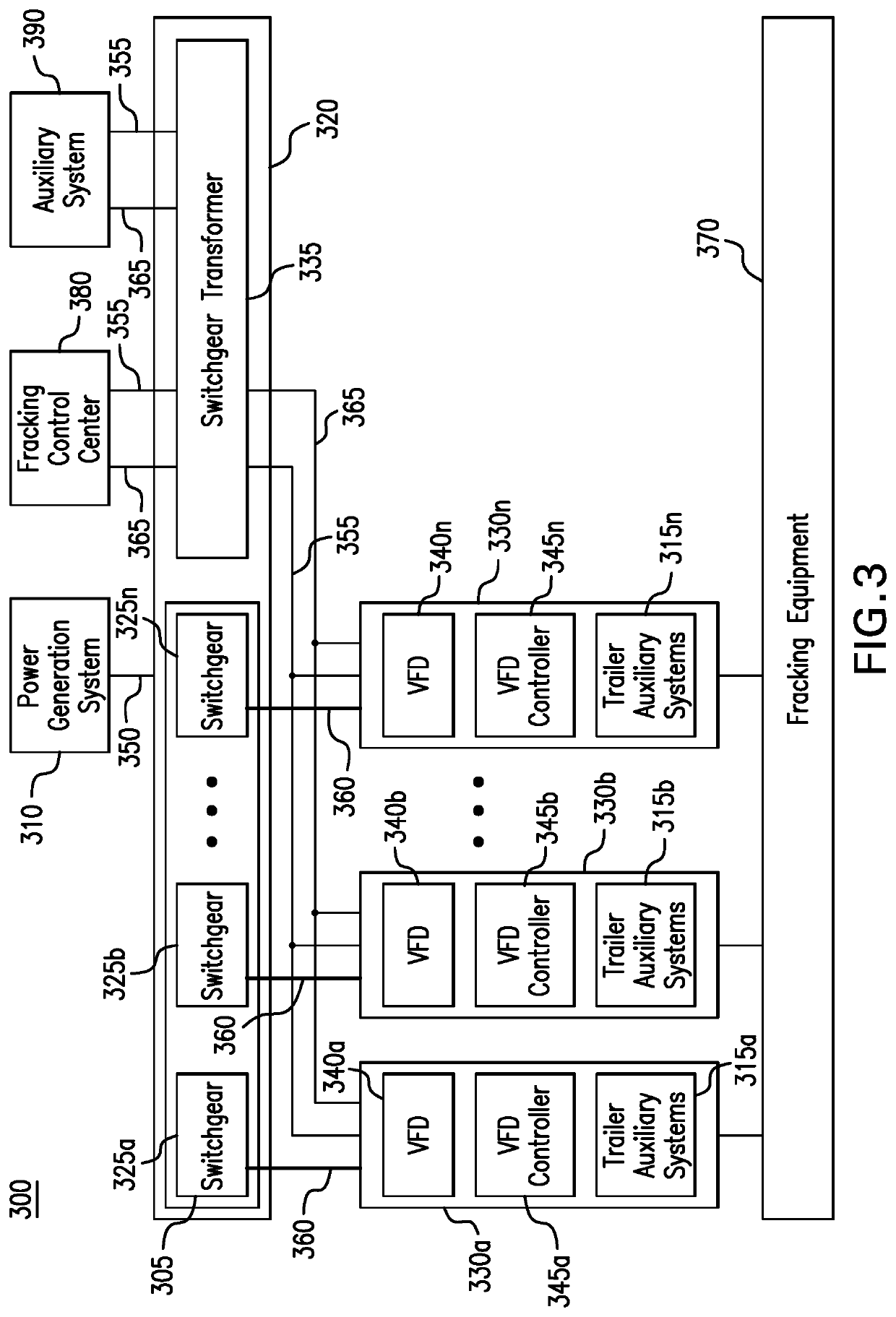

Power distribution trailer for an electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

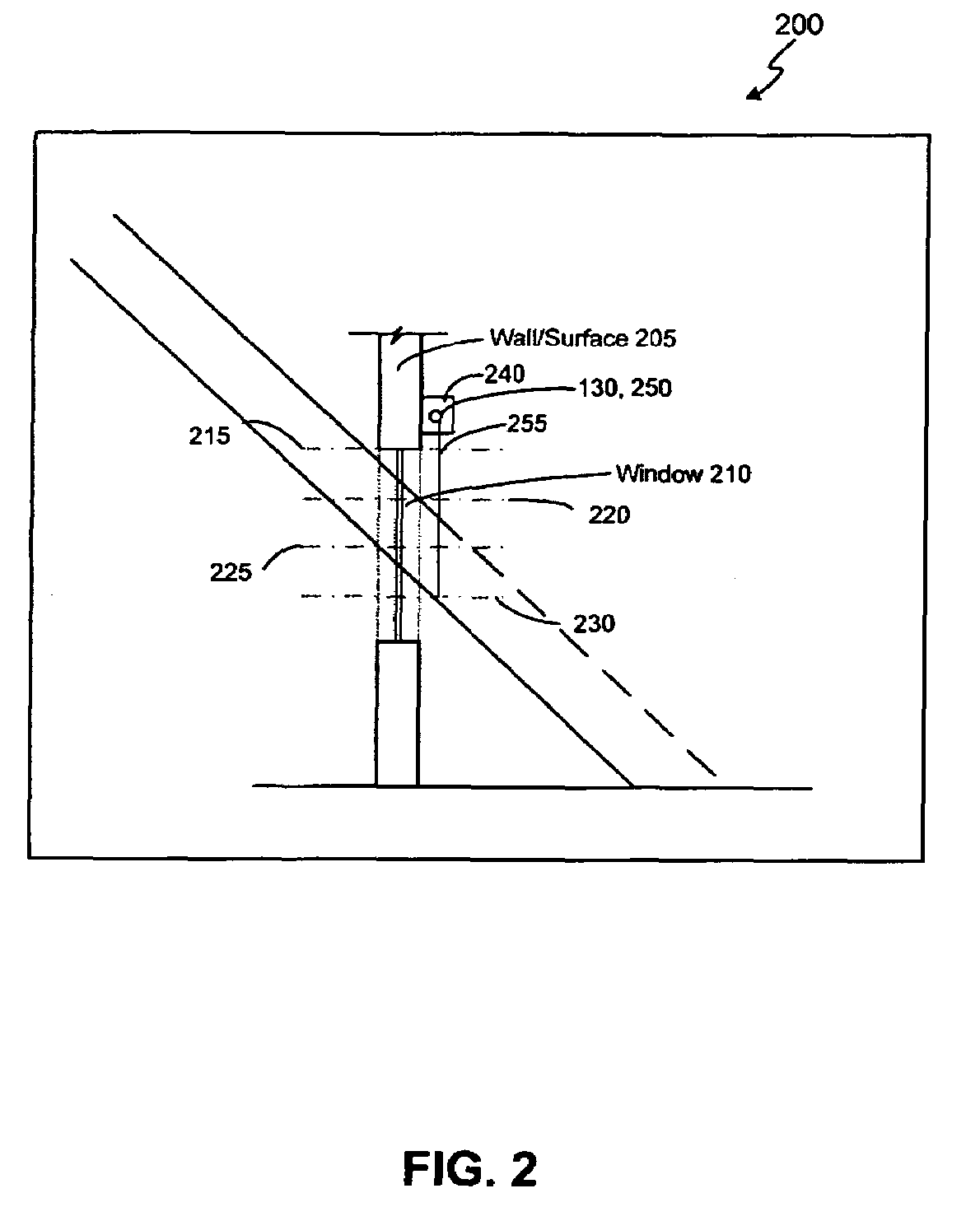

Method of automatically controlling a motorized window treatment while minimizing occupant distractions

ActiveUS8288981B2Minimize distractionDC motor speed/torque controlDoor/window protective devicesPresent dayDistraction

A load control system provides for automatically controlling a position of a motorized window treatment to control the amount of sunlight entering a space of a building through a window located in a façade of the building in order to control a sunlight penetration distance within the space and minimize occupant distractions. The load control system automatically generates a timeclock schedule having a number of timeclock events for controlling the position of the motorized window treatment during the present day. A user is able to select a desired maximum sunlight penetration distance for the space and a minimum time period that may occur between any two consecutive timeclock events. In addition, a maximum number of movements that may occur during the timeclock schedule may also be entered. The load control system uses these inputs to determine event times and corresponding positions of the motorized window treatment for each timeclock event of the timeclock schedule.

Owner:LUTRON TECH CO LLC

Motorized window shade system

InactiveUS20060185799A1Raise and lower the window shadeReduce power consumptionScreensMechanical apparatusGroup controllerCommunications system

An electronically-controlled roll-up window shade that can easily be installed by a homeowner or general handyman is disclosed. The motorized shade includes an internal power source, a motor, and a communication system to allow for remote control of the motorized shade. One or more motorized shades can be controlled singly or as a group. In one embodiment, the motorized shades are used in connection with a zoned or non-zoned HVAC system to reduce energy usage. In one embodiment, the motorized shade is configured to have a size and form-factor that conforms to a standard manually-controlled motorized shade. In one embodiment, a group controller is configured to provide thermostat information to the motorized shade. In one embodiment, the group controller communicates with a central monitoring system that coordinates operation of one or more motorized shades. In one embodiment, the internal power source of the motorized shade is recharged by a solar cell.

Owner:GOOGLE LLC

Automated shade control relectance module

Automated shade systems comprise motorized window coverings, sensors, and controllers that use algorithms to control operation of the automated shade control system. These algorithms may include information such as: 3-D models of a building and surrounding structures, shadow information, reflectance information, lighting and radiation information, ASHRAE clear sky algorithms, log information related to manual overrides, occupant preference information, motion information, real-time sky conditions, solar radiation on a building, a total foot-candle load on a structure, brightness overrides, actual and / or calculated BTU load, time-of-year information, and microclimate analysis.

Owner:MECHOSHADE SYST LLC

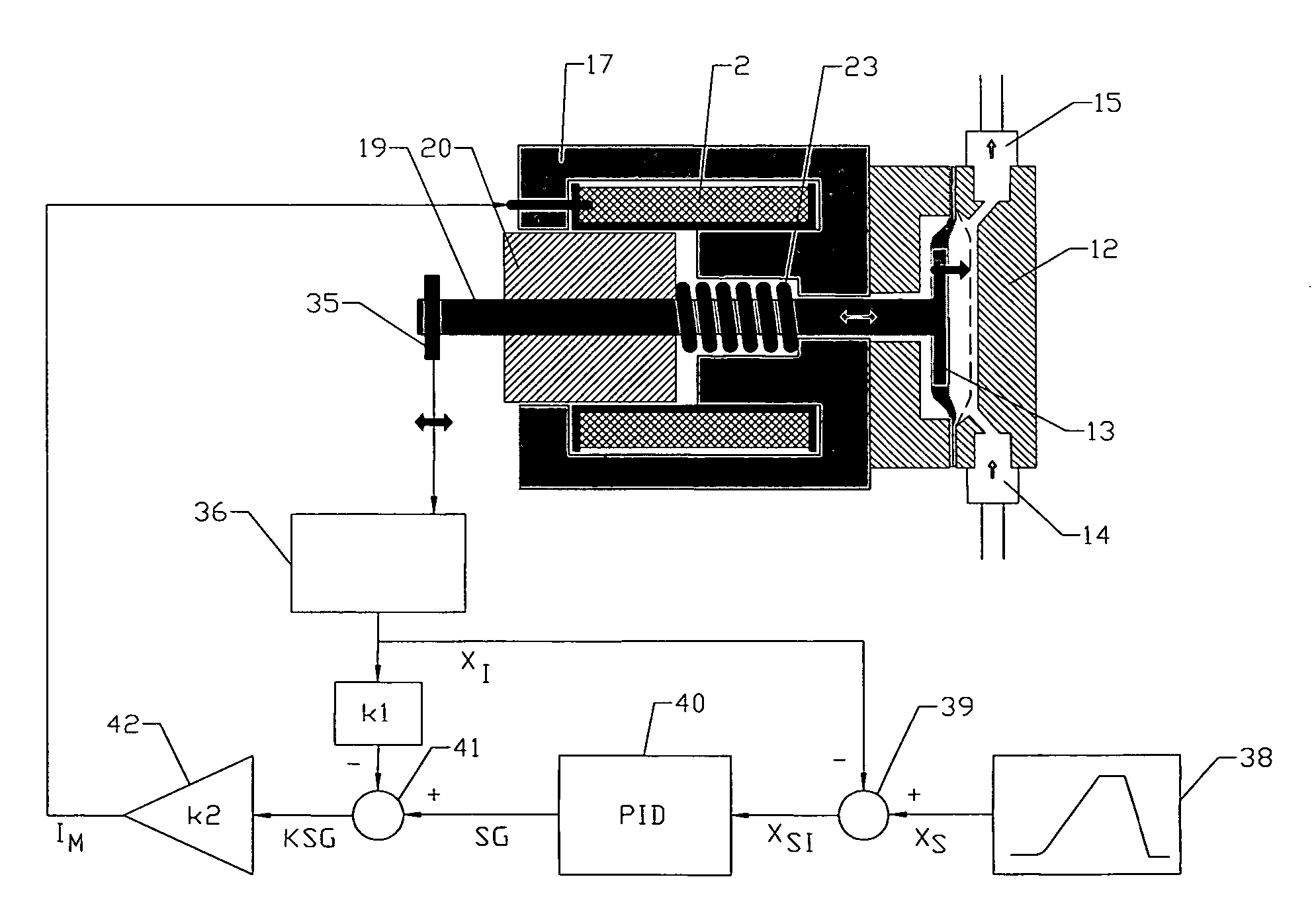

Magnetic drive metering pump

ActiveUS20070040454A1Motor/generator/converter stoppersDC motor speed/torque controlMagnetic tension forceInlet valve

A magnetic drive metering pump in which a movable thrust member fixed to a connecting rod is axially movable in a longitudinal axis in a magnet shroud anchored in a pump housing so that the thrust member with the connecting rod, on electrically driving (actuating) the magnetizing coil, is drawn into the magnet shroud against the force of a recuperating spring, reducing an air gap between the thrust member and an inner face of magnetic shroud, into a bore in the magnet shroud and after deactivating the magnet the thrust member is returned to the starting position by the recuperating spring so that the thrust member and an elastic displacement member actuated thereby on carries out an oscillating motion continued activation and deactivation of the magnetizing coil, which diaphragm cooperates alternately with an outlet and an inlet valve to produce a pump stroke (pressure stroke) and a priming stroke in a metering head arranged in the longitudinal axis. In such a magnetic drive metering pump, a reference element is associated with the module constituted by the thrust member and connecting rod, the position of which reference element is detected by a positional sensor, wherein the positional sensor provides an actual signal which is in a fixed relationship to the position of the reference element, and in that the motion of the unit formed by the thrust member and the connecting rod is influenced as regards control accuracy via a control circuit so that it follows a predetermined nominal profile.

Owner:PROMINENT

Popular searches

Dynamo-electric brakes/clutches Piezoelectric/electrostriction/magnetostriction machines Joint implants Staples Electric motor speed/torque regulation Mechanical energy handling Dynamo-electric brake control Electric/dynamo-electric converter starters Surgical staples Synchronous machines with stationary armatures and rotating magnets

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com