Patents

Literature

32results about How to "Wide operating speed range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fan assembly

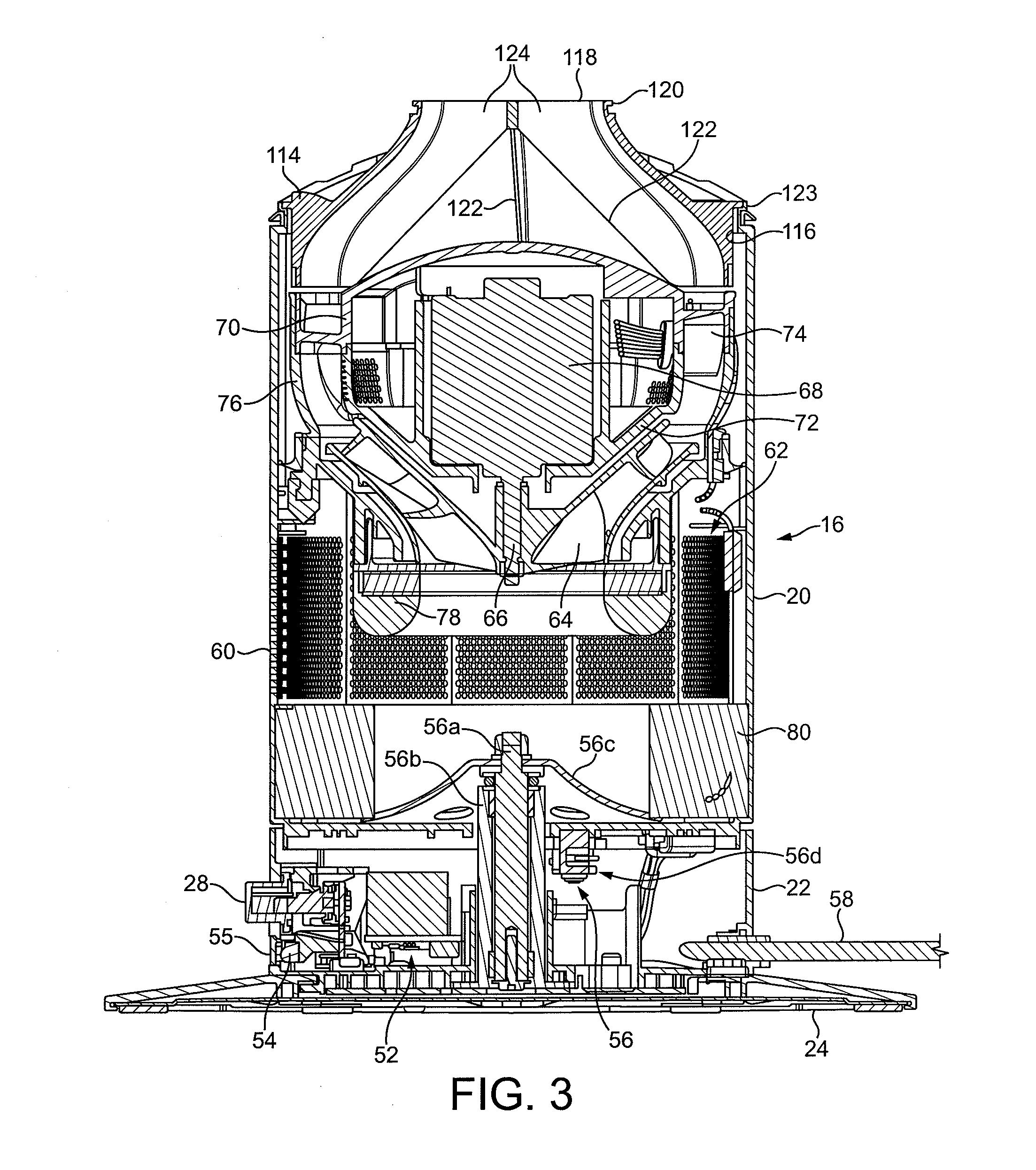

ActiveUS20100226763A1Emission reductionWide operating speed rangePump componentsJet pumpsEngineeringAirflow

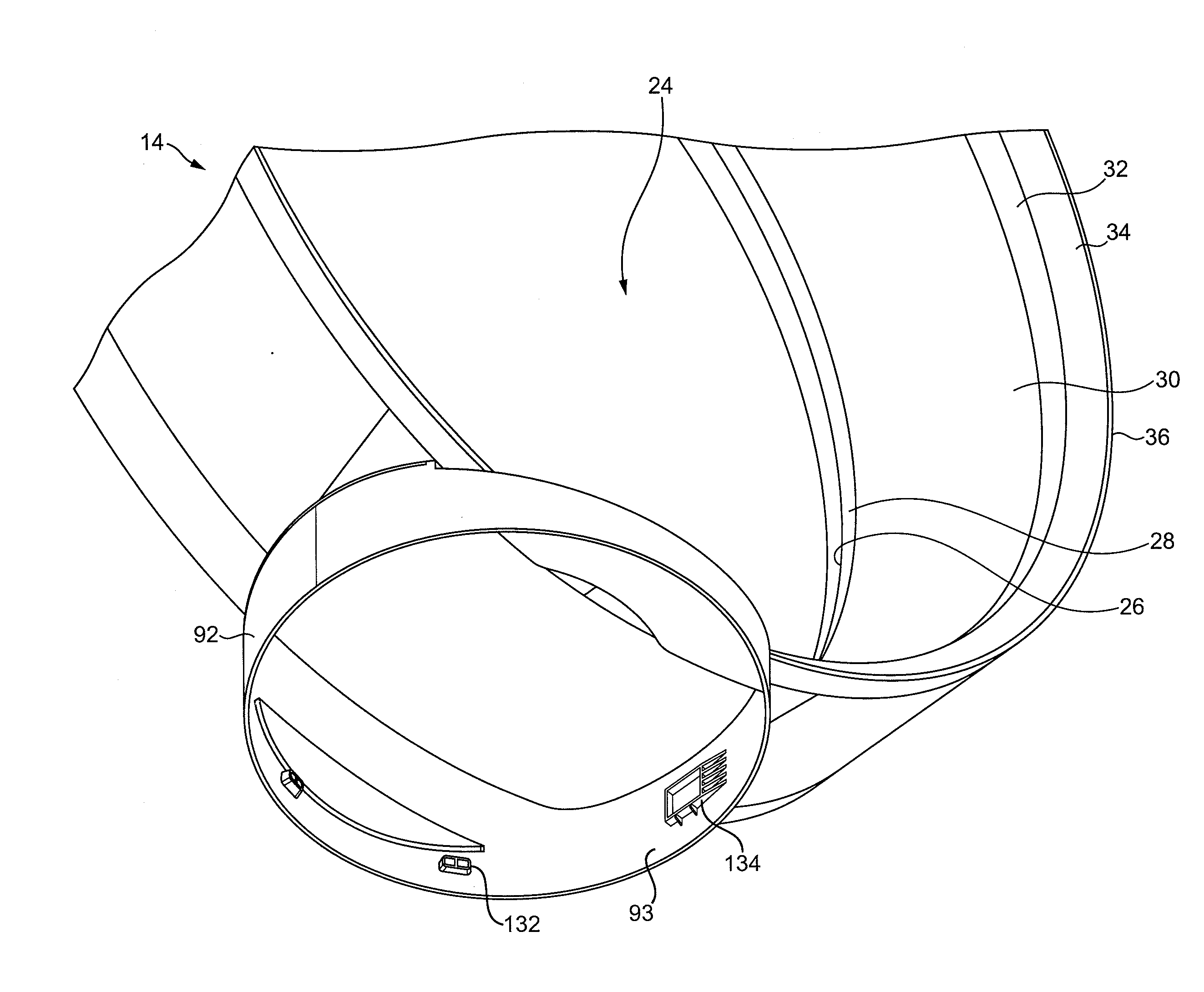

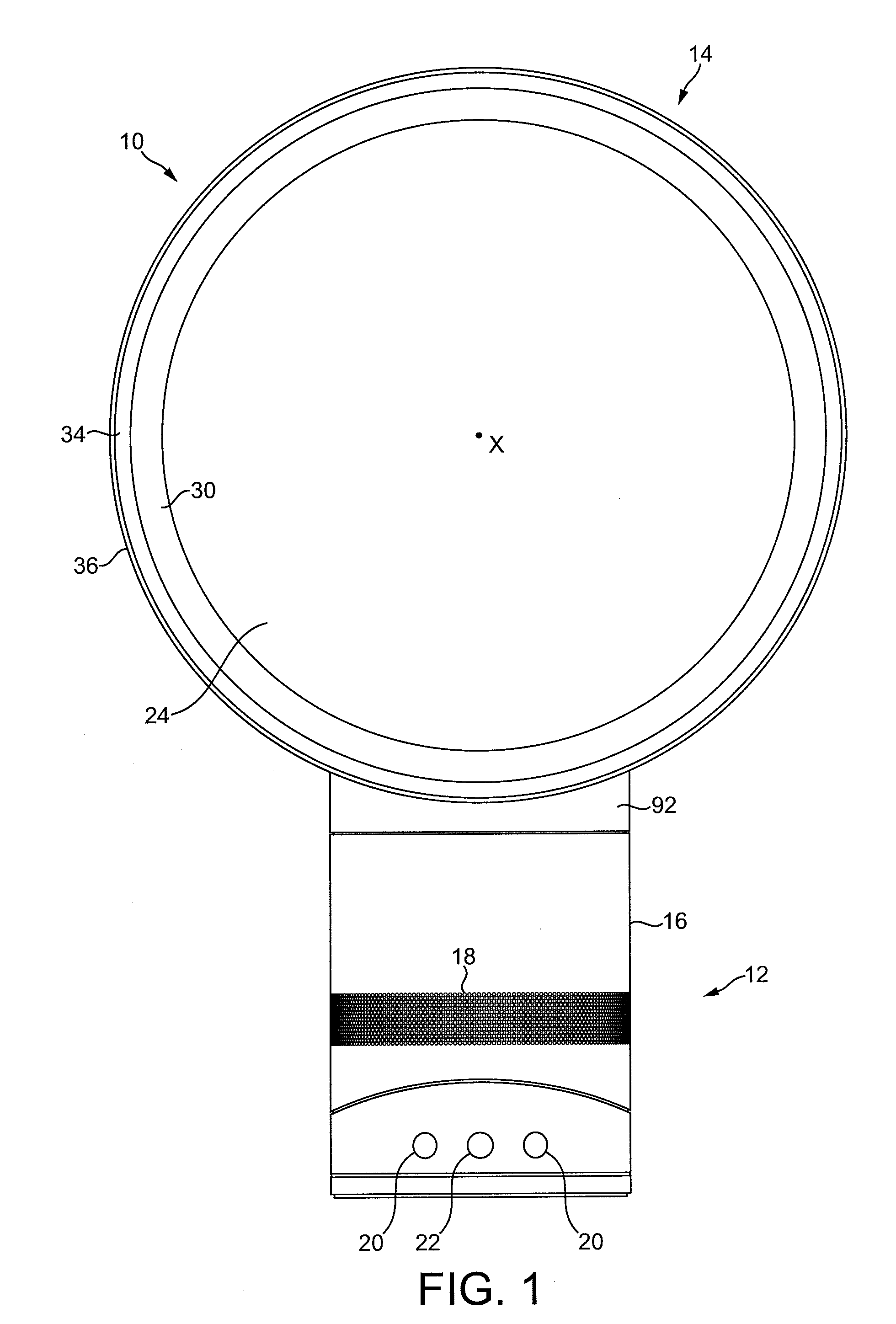

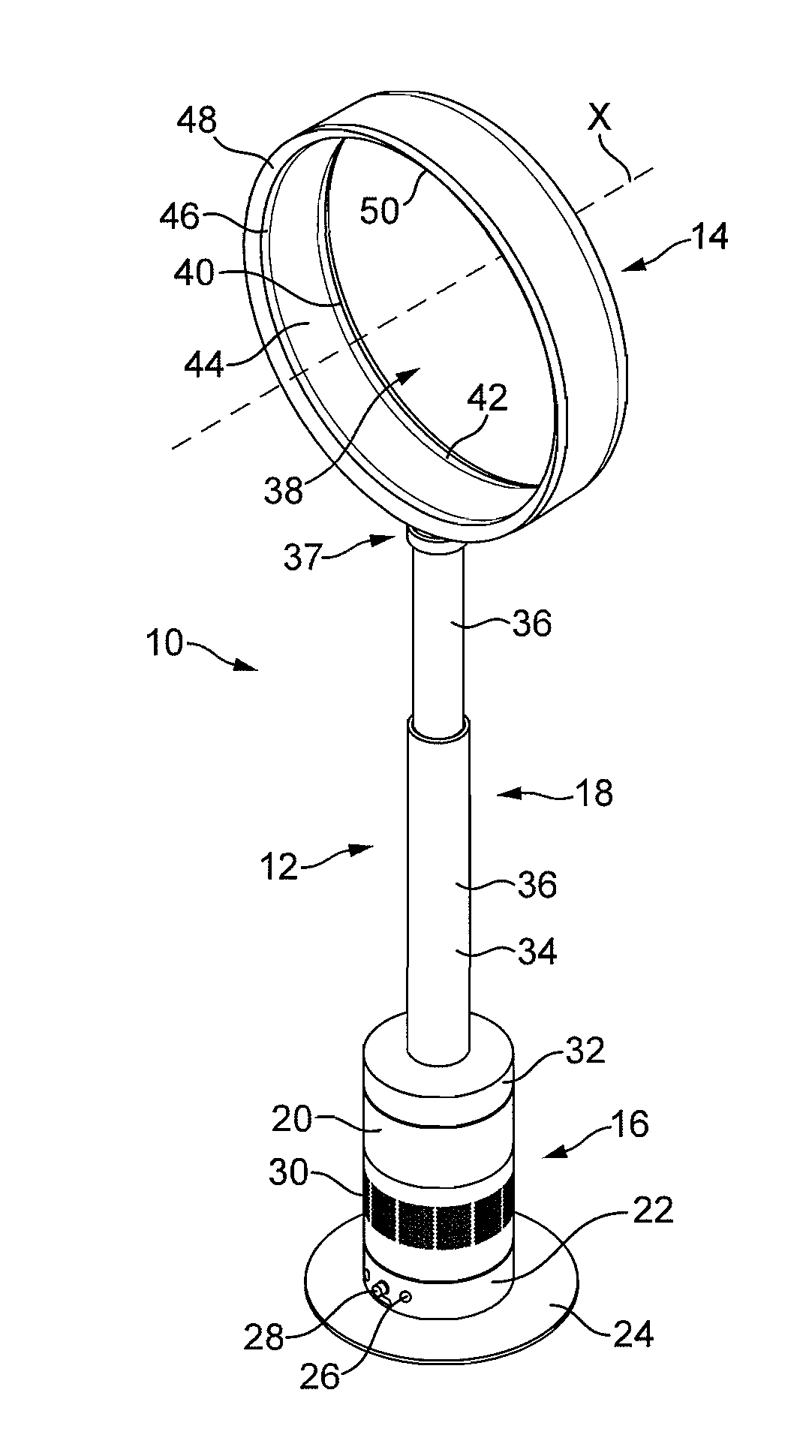

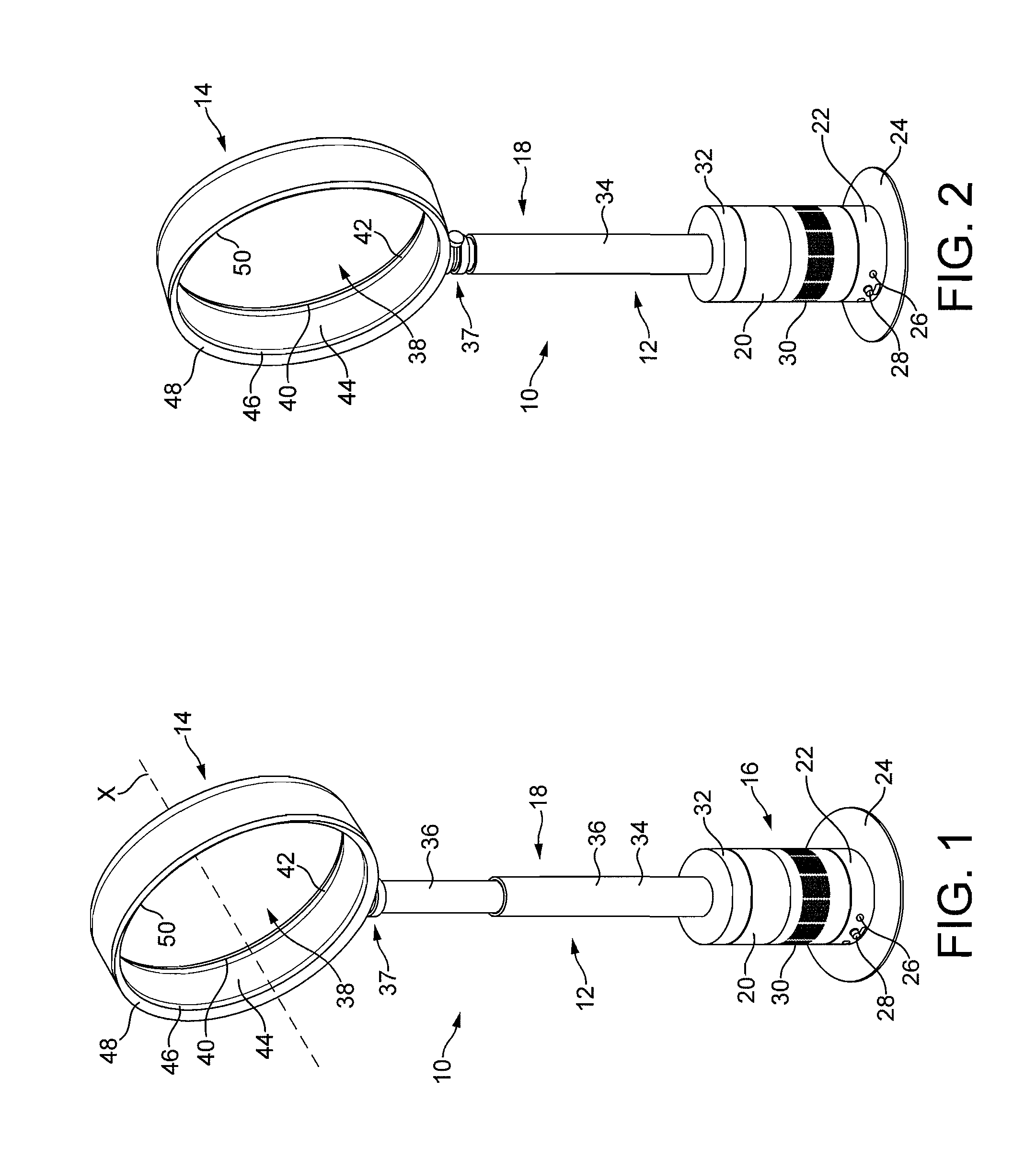

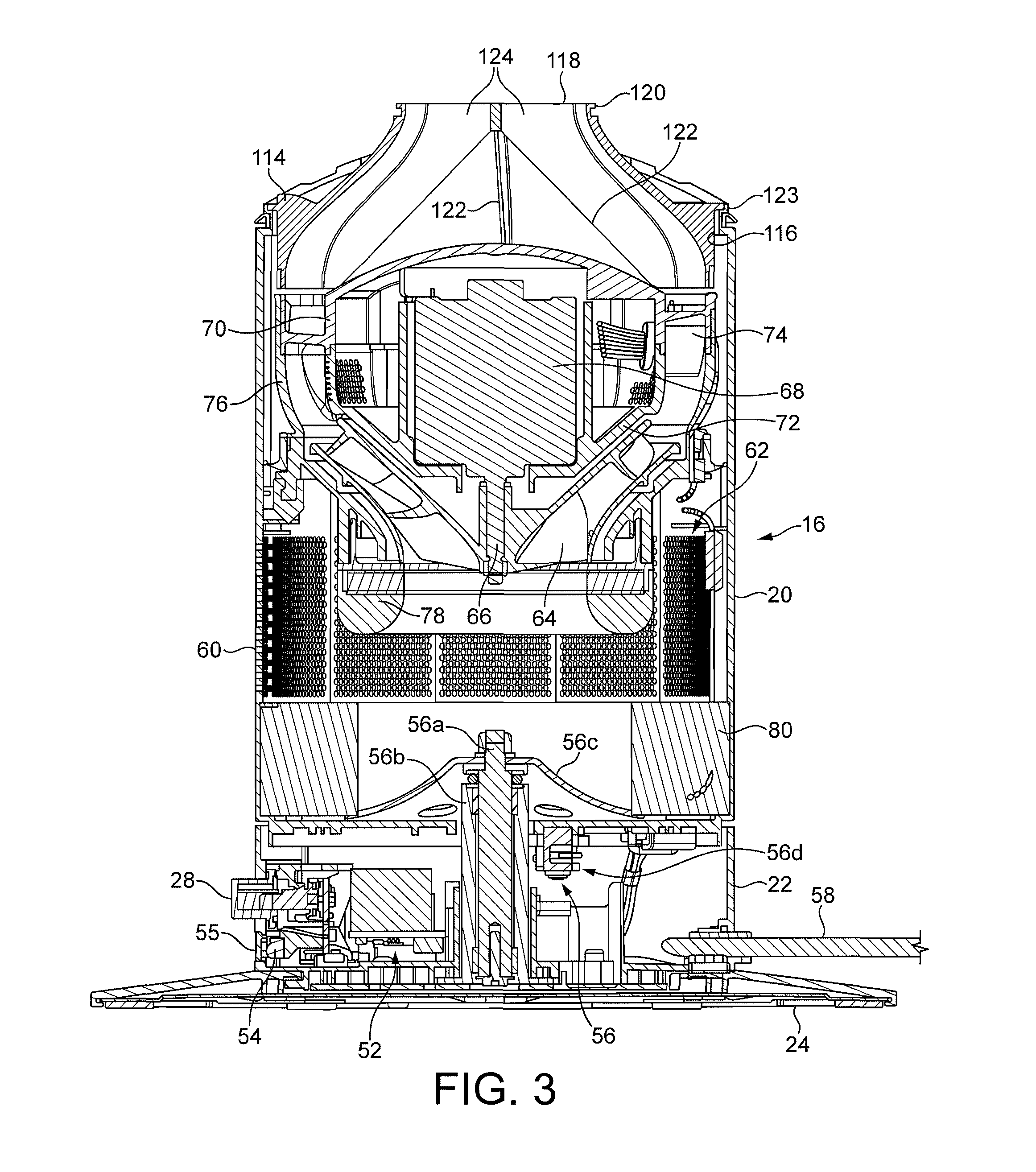

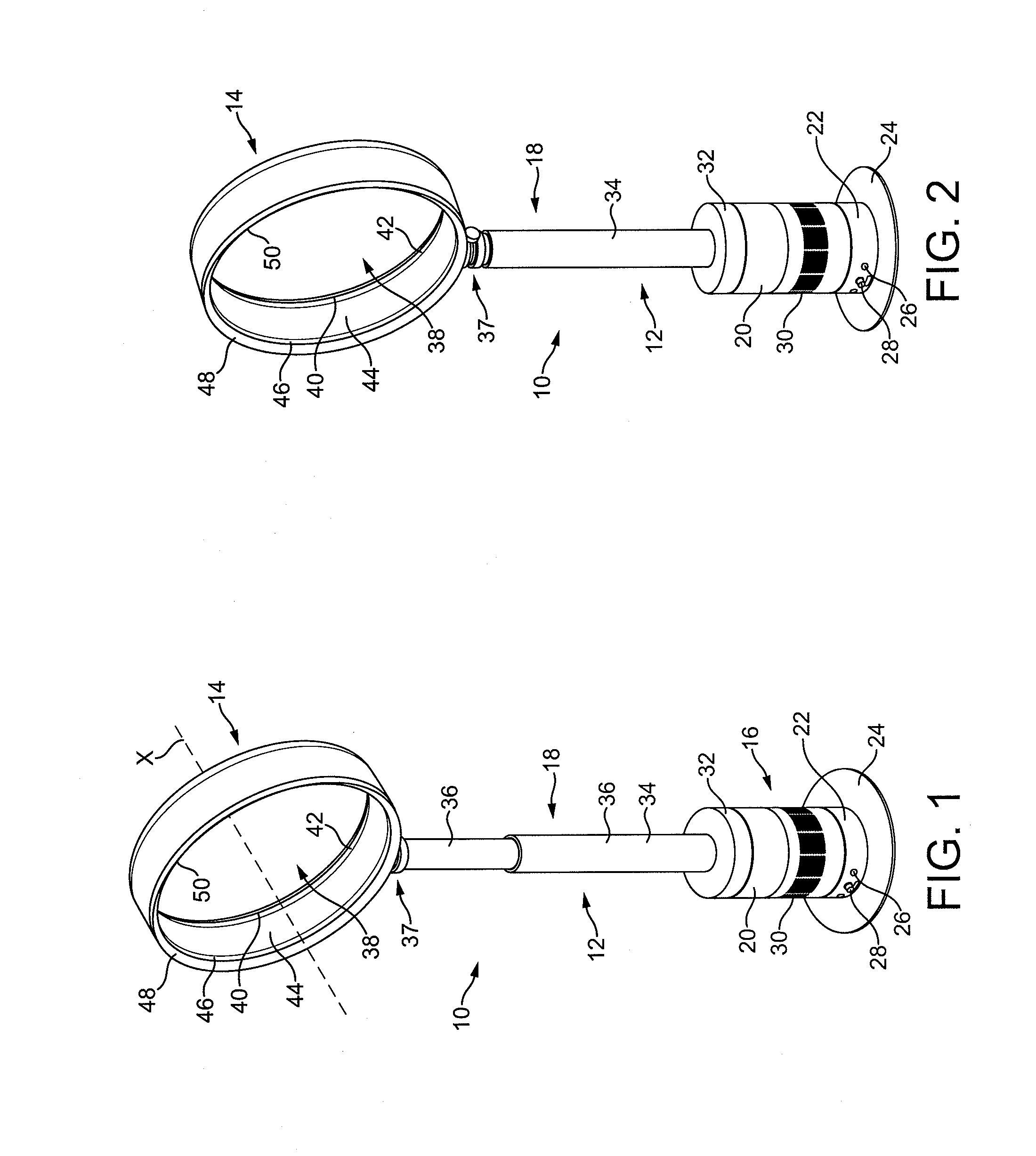

A bladeless fan assembly for creating an air current includes a nozzle mounted on a base. The nozzle comprises an interior passage and a mouth for receiving the air flow from the interior passage and through which the air flow is emitted from the fan assembly. The nozzle defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The nozzle is detachable from the base, which is preferably sized to be accommodated within the opening of the nozzle for transportation.

Owner:DYSON TECH LTD

Fan

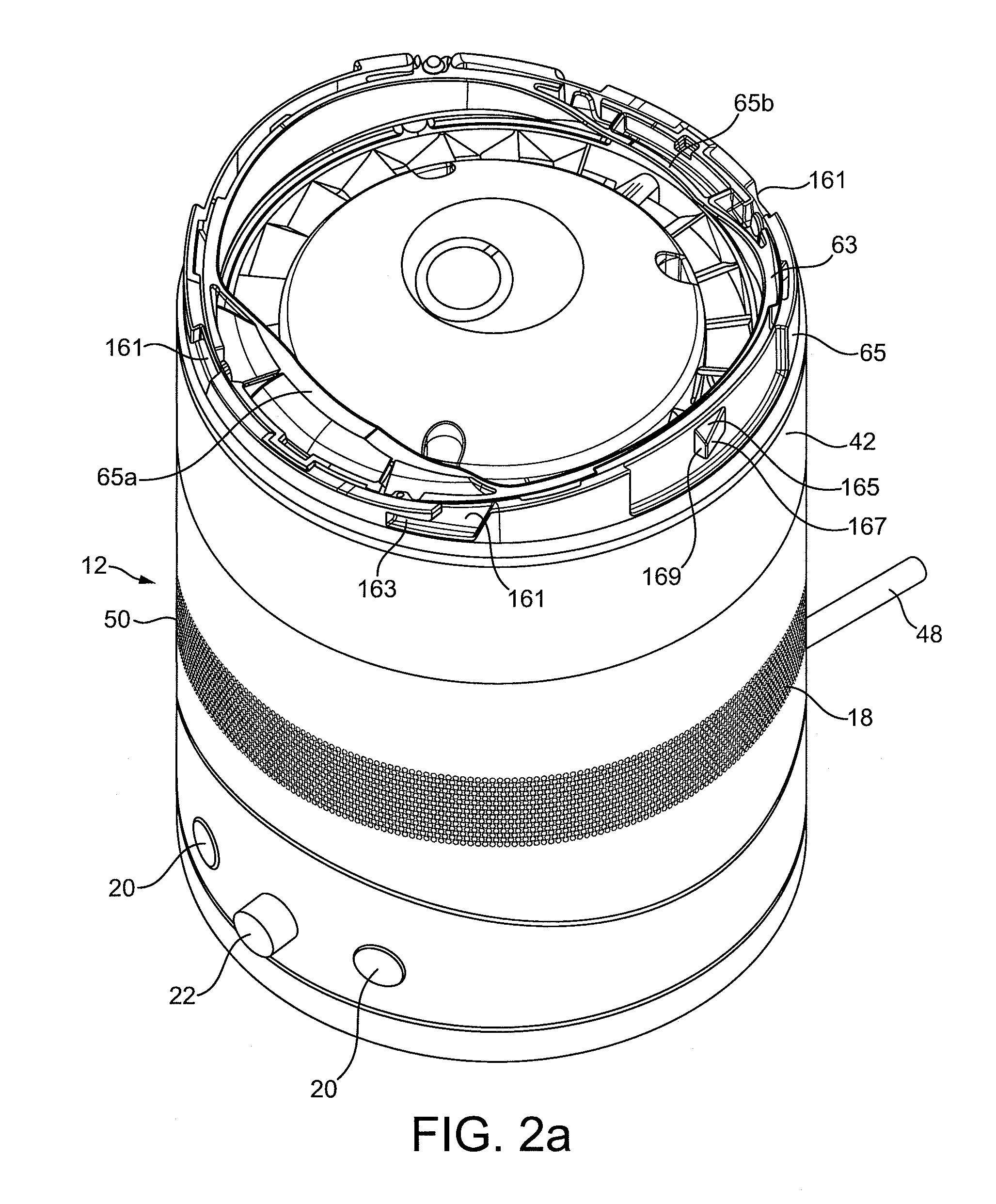

ActiveUS20110110805A1Emission reductionWide operating speed rangePositive displacement pump componentsJet pumpsImpellerRemote control

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

Fan assembly

InactiveUS20100226751A1Emission reductionWide operating speed rangePropellersPump componentsEngineeringAirflow

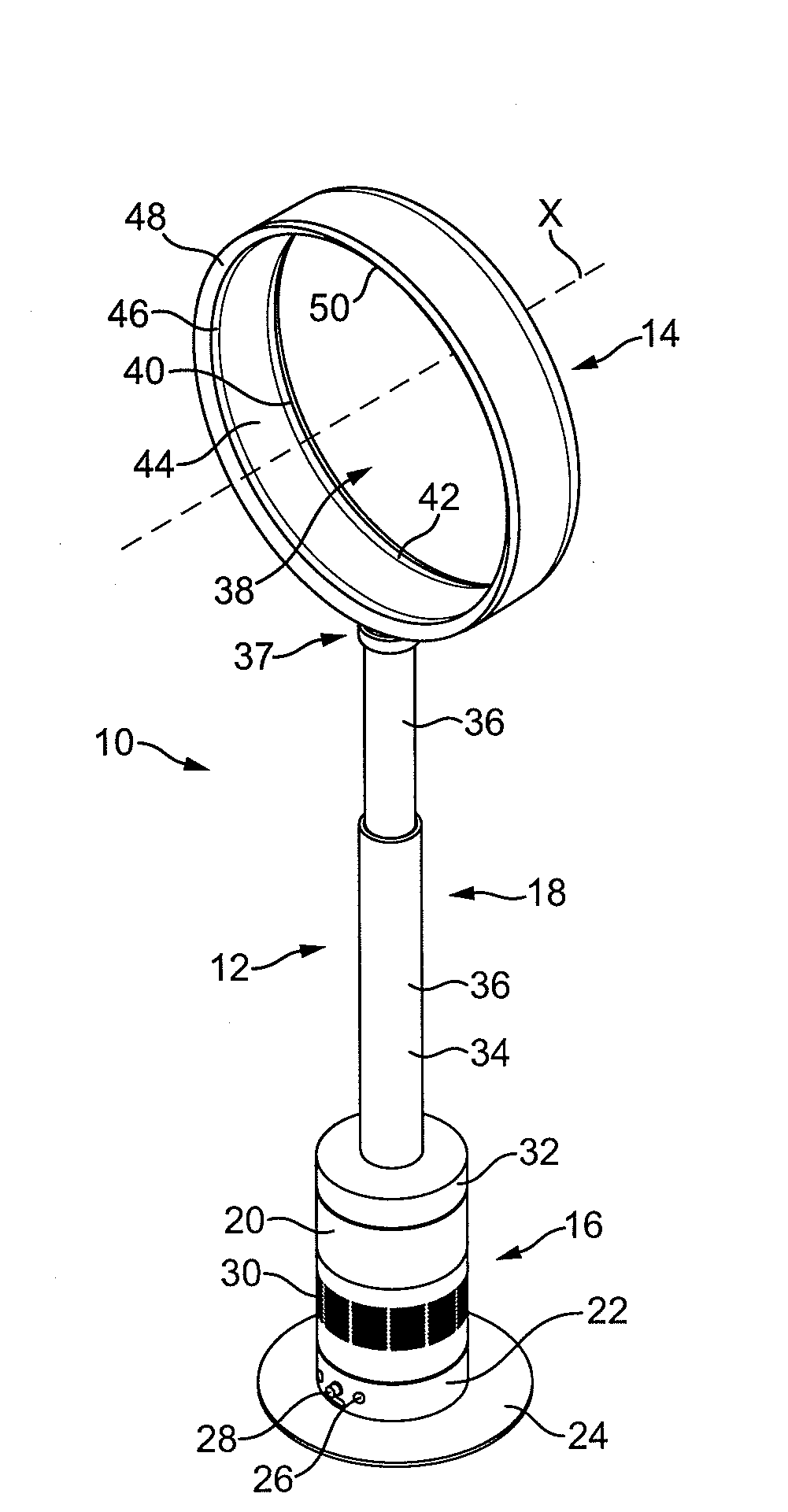

A fan assembly includes a device for creating an air flow and an air outlet for emitting the air flow, the air outlet being mounted on a pedestal including a base and a height adjustable stand. The base includes an oscillating mechanism for oscillating the stand and the air outlet.

Owner:DYSON TECH LTD

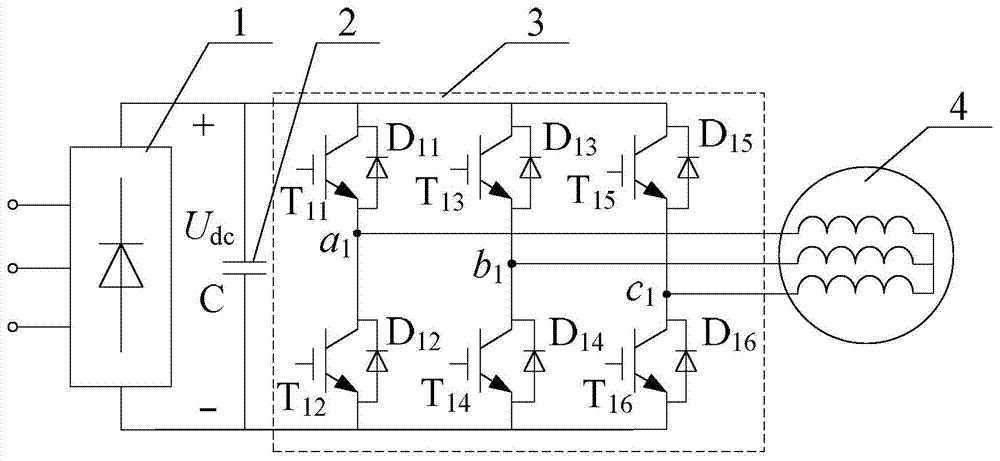

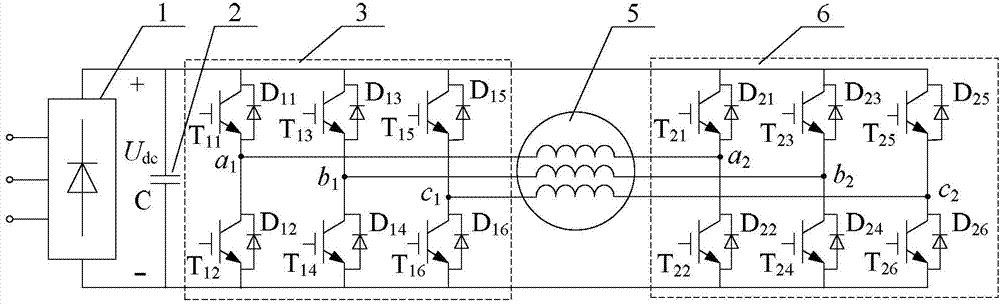

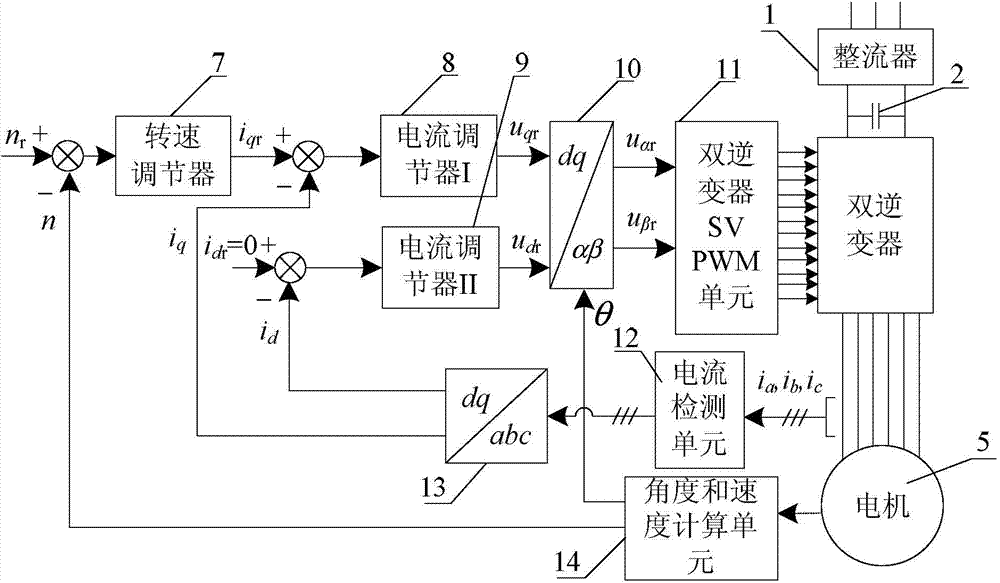

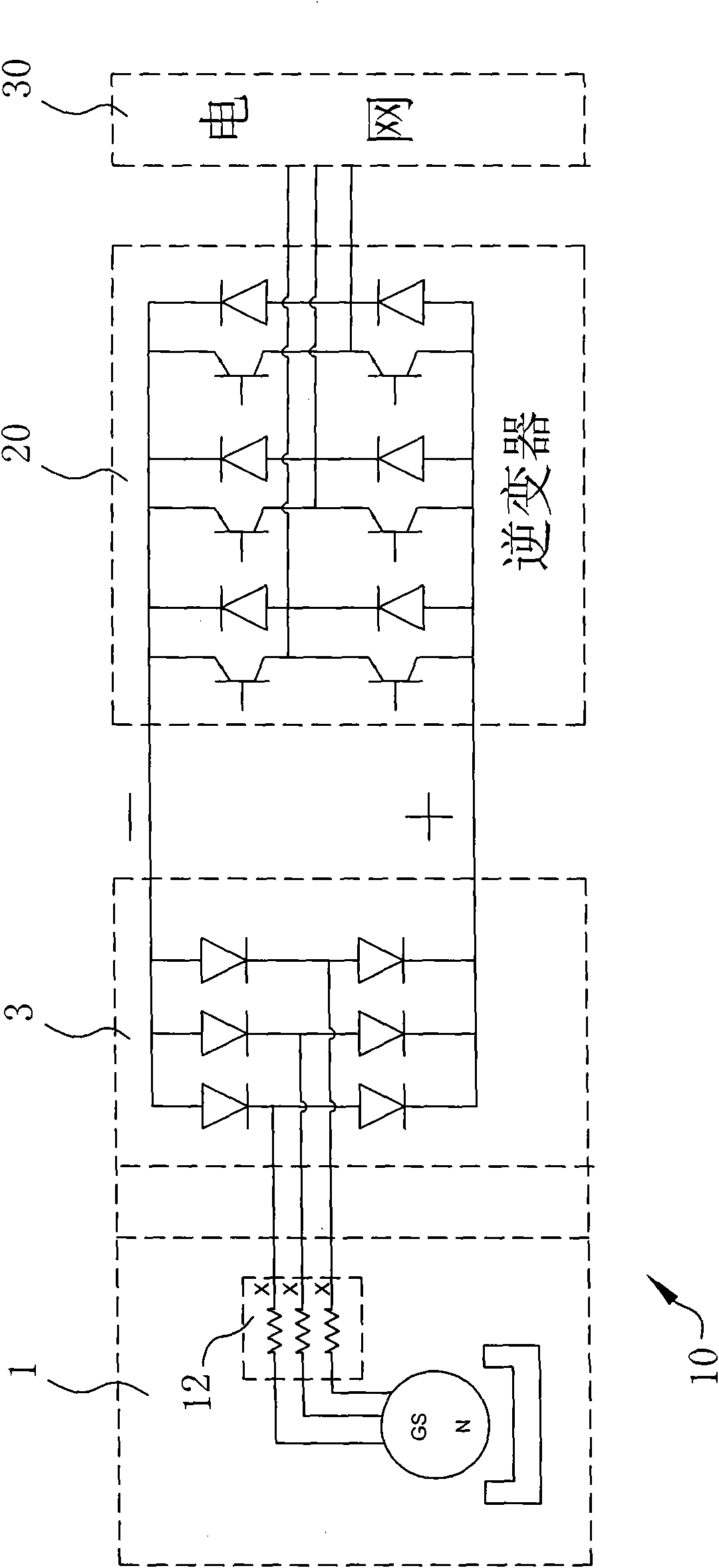

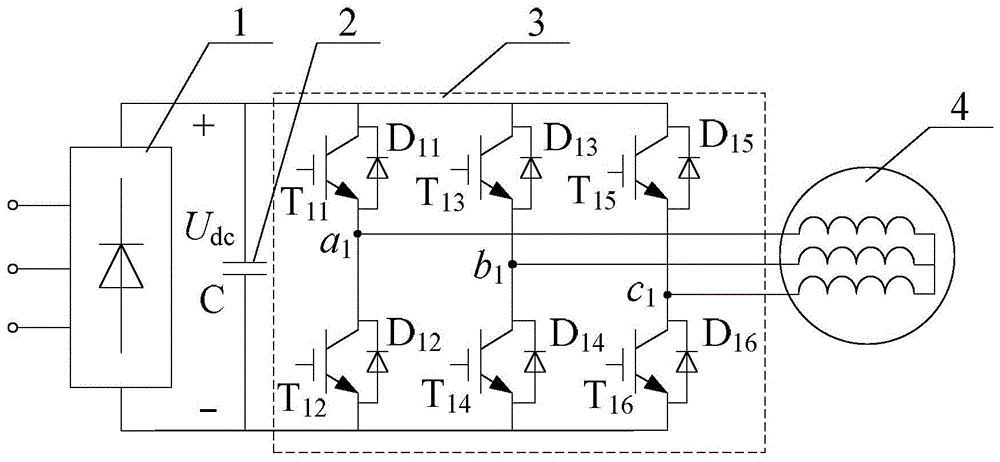

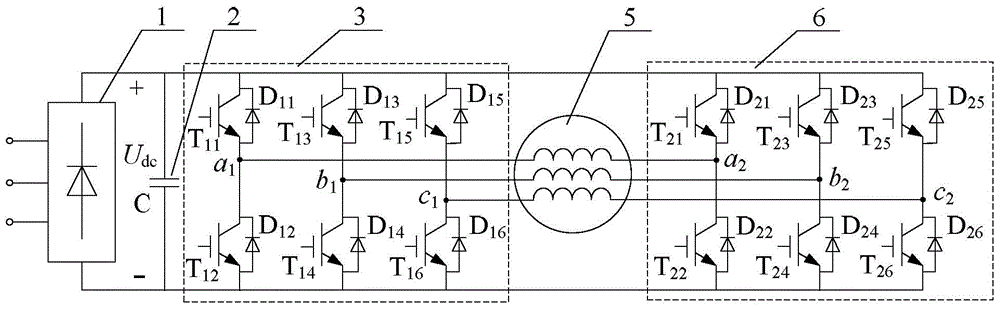

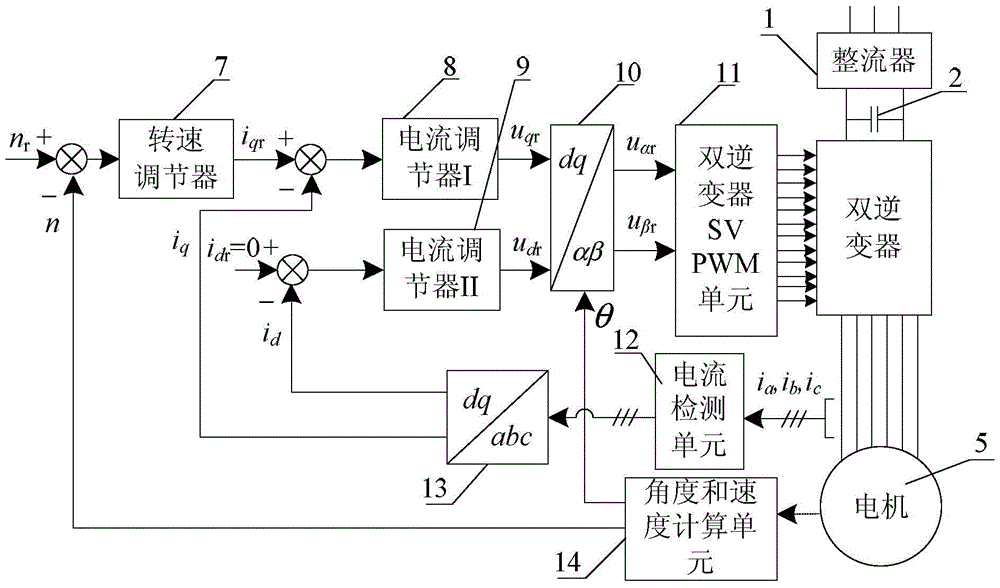

Zero-sequence current suppression method of open type permanent magnet synchronous motor with double-inverter power supply

ActiveCN104242775ALow costEnhanced inhibitory effectElectronic commutation motor controlAC motor controlLoop controlControl system

The invention provides a zero-sequence current suppression method of open type permanent magnet synchronous motor with double-inverter power supply, belongs to the technical field of motor control, and aims at solving the problem of zero-sequence current of the open type permanent magnet synchronous motor with the double-inverter power supply. The method is characterized in that the closed loop control for zero-sequence current i0=0 is added on the basis of a vector control system, so as to realize the suppression of the zero-sequence current; the zero-sequence current is calculated by detecting the three-phase current of the motor and is treated as the feedback quantity to build the closed loop control of the zero-sequence current; the output of a zero-sequence current ring is specified by zero-sequence voltage, and the zero-sequence current is suppressed by adjusting the zero-sequence voltage produced by the double inverters. The method is applied to the suppression of the zero-sequence current in the open type permanent magnet synchronous motor with double-inverter power supply.

Owner:HARBIN INST OF TECH

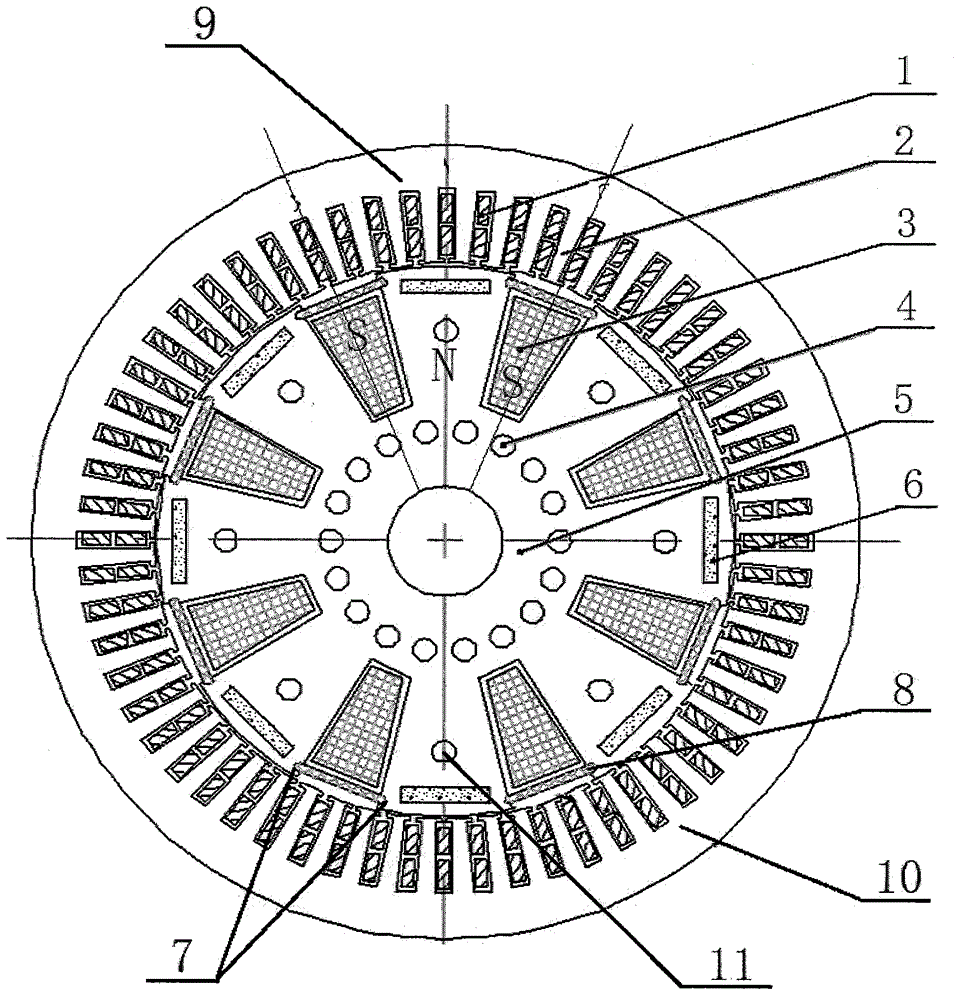

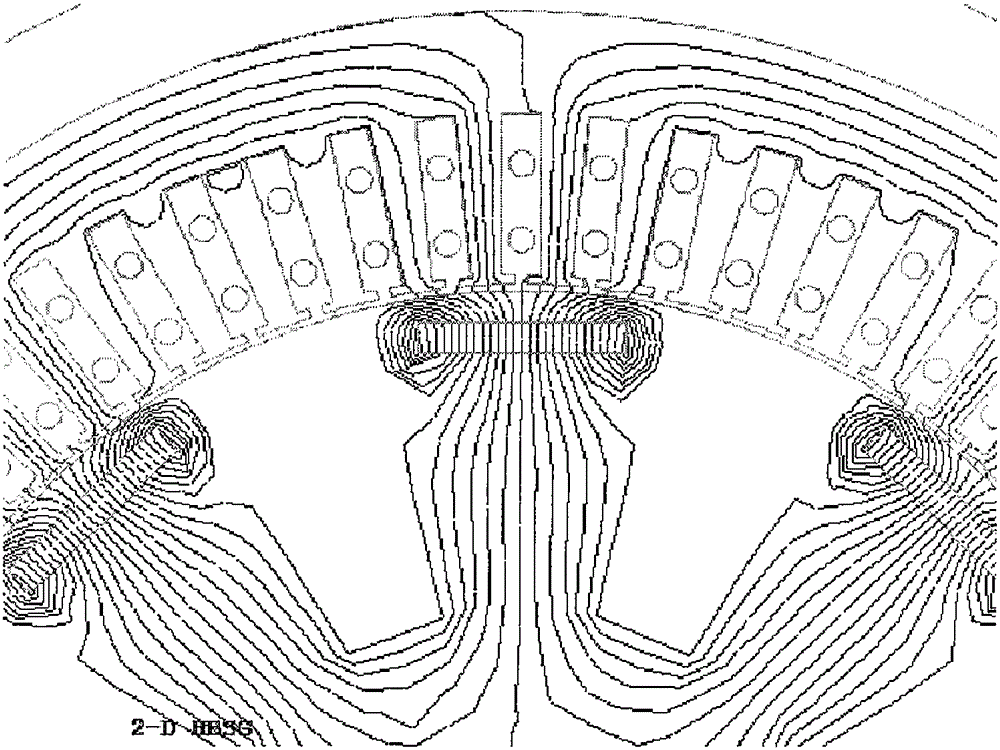

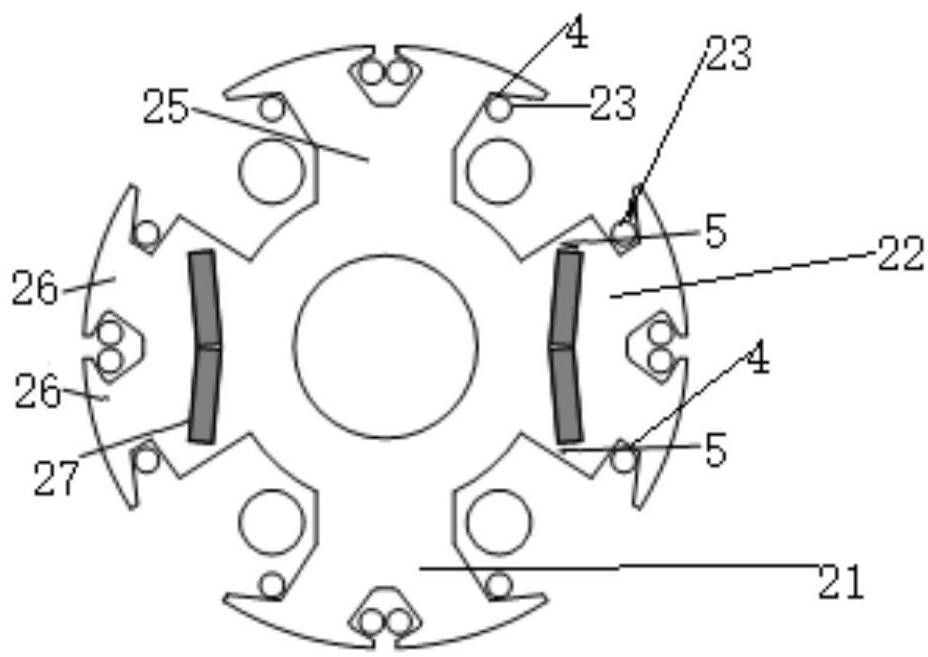

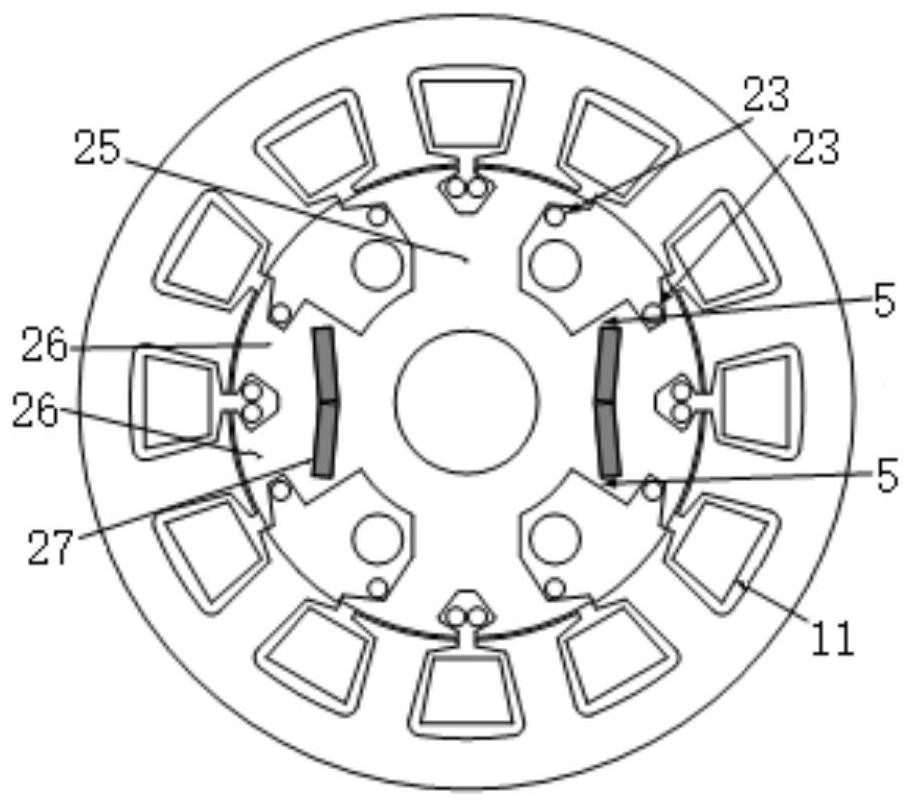

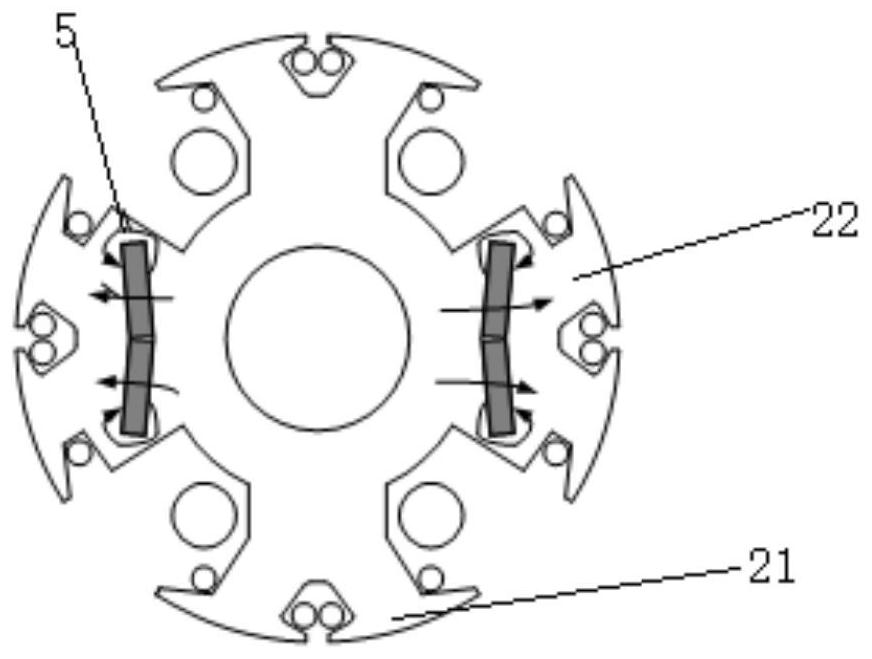

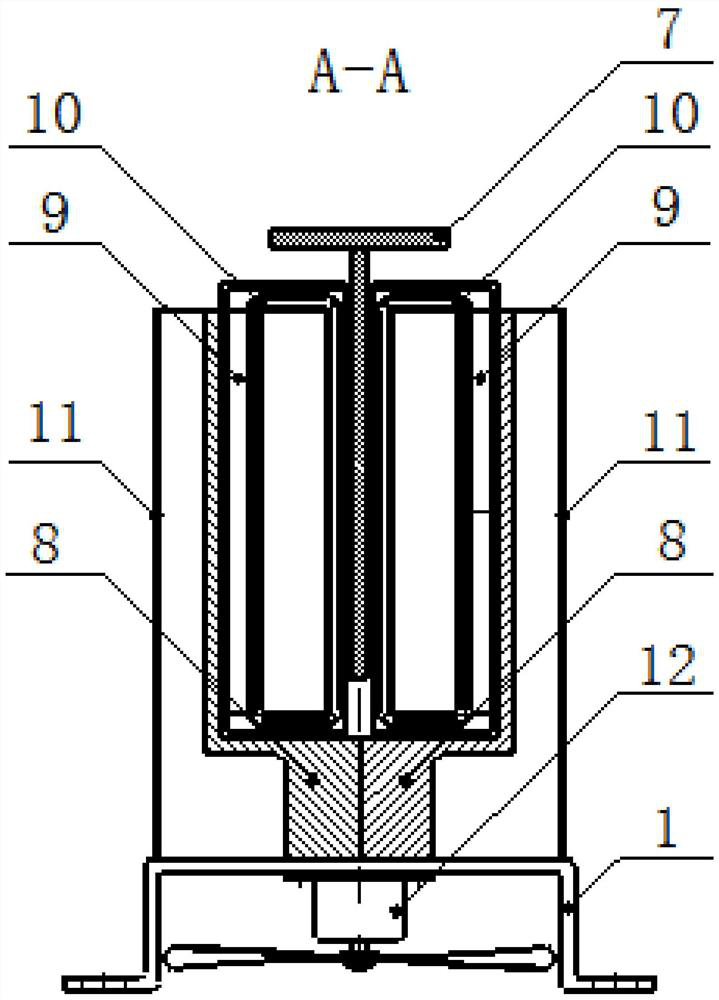

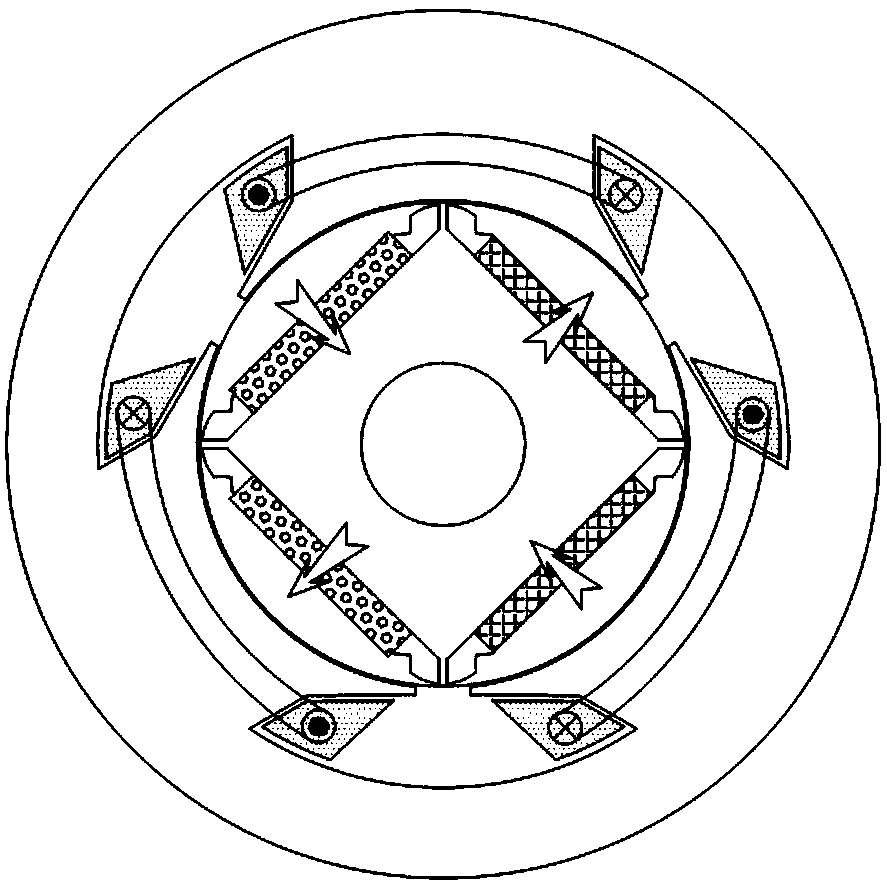

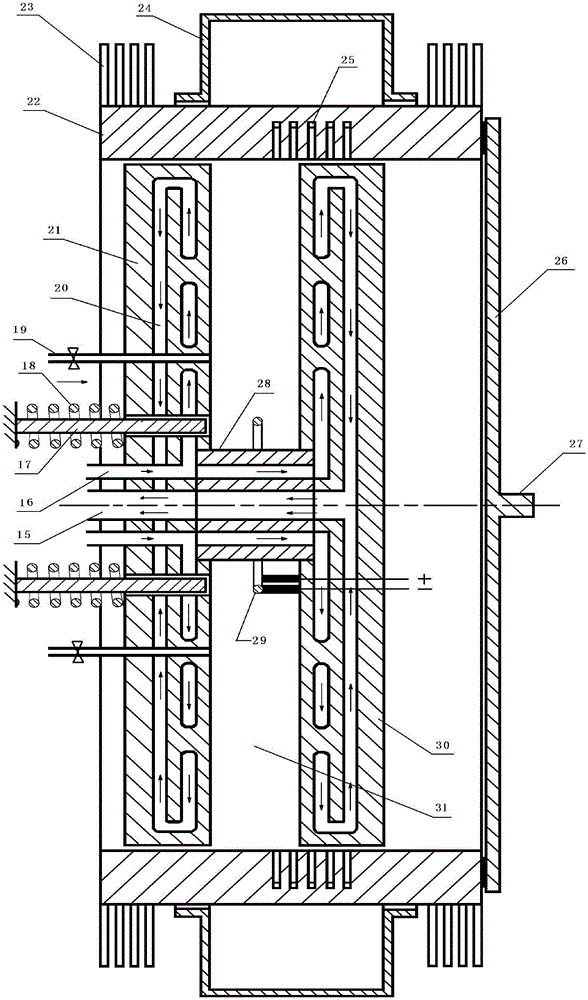

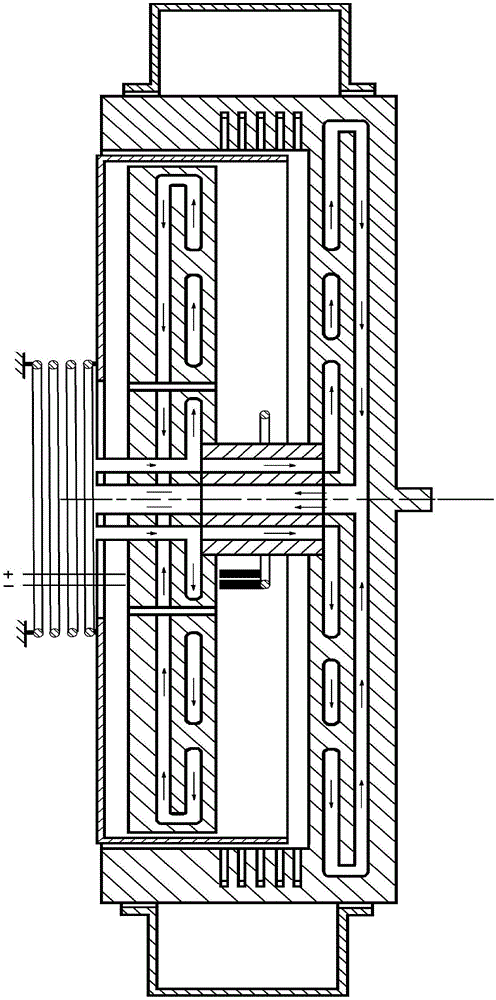

Magnetic steel embedded hybrid excitation motor

PendingCN105186744ASimple structureEasy to produceMagnetic circuit rotating partsStarter generatorPunching

The present invention relates to a magnetic steel embedded hybrid excitation motor. The magnetic steel embedded hybrid excitation motor comprises a stator 9 and a rotor 10 arranged inside the stator 9, the stator 9 is made of a stator iron core in which an armature winding 1 is embedded, and the rotor 10 comprises a rotor punching 5, magnetic steels 6 and exciting windings 23, wherein a plurality of punching grooves are arranged on the rotor punching 5 evenly, so that the rotor 10 forms a plurality of magnetic poles. The magnetic steels 6 are embedded in the sides of the magnetic poles close to an excircle and are distributed alternatively along with the N and S poles of the rotor 10, and the exciting windings 3 are wound on the magnetic poles of the rotor 10 directly and are distributed alternatively along with the N and S poles of the rotor 10 in the clockwise and anticlockwise directions. The magnetic steel embedded hybrid excitation motor of the present invention is simple in structure and low in cost, is easy to produce, use and popularize, is especially suitable for a large-power automobile integrated starter generator, enables the moment density and the working rotating speed range of a system to be improved effectively, also can used as a driving motor, and enables the motor power density to be improved effectively.

Owner:CHANGZHOU PUSHI AUTOMOTIVE POWER SYST CO LTD

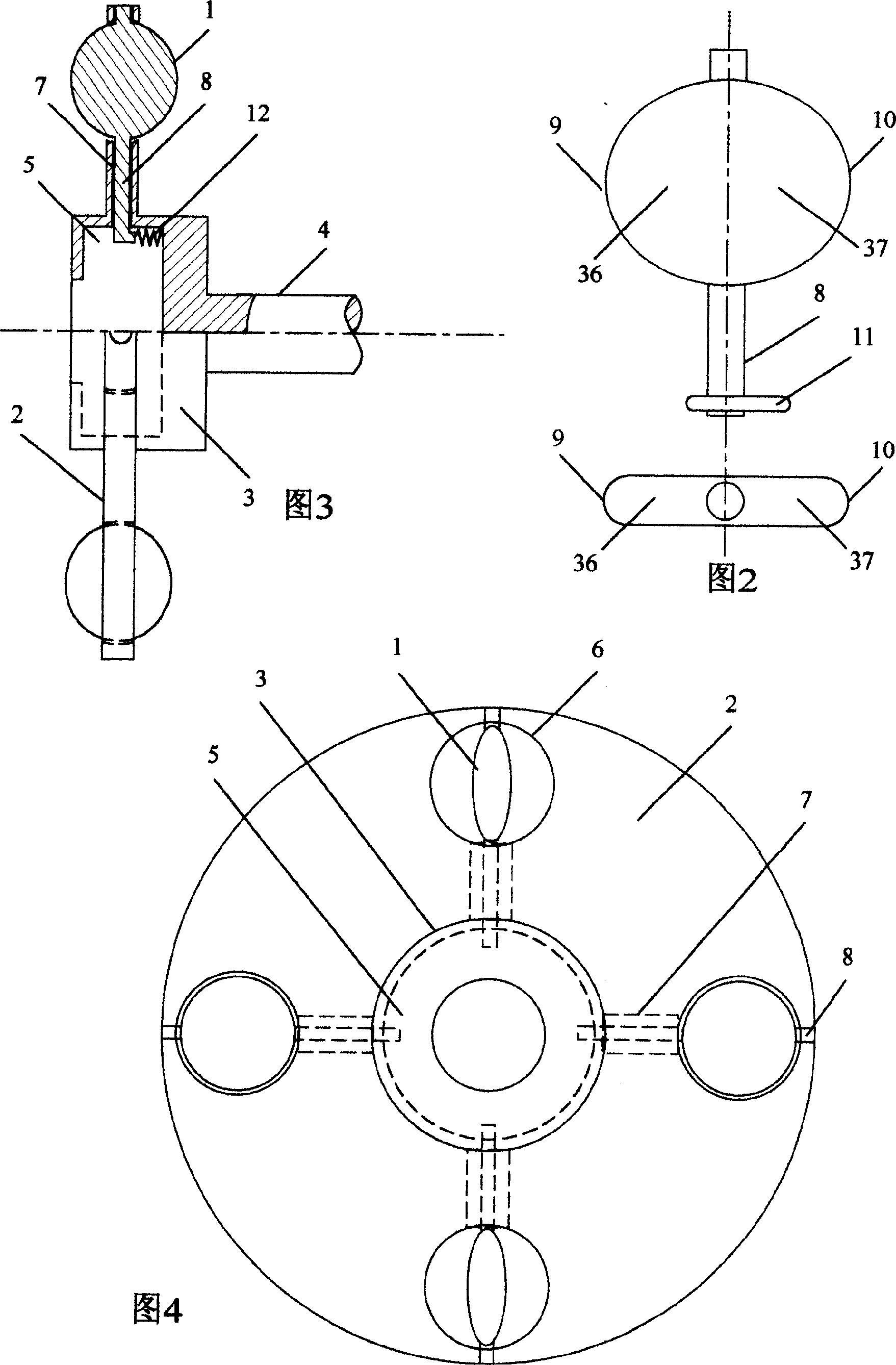

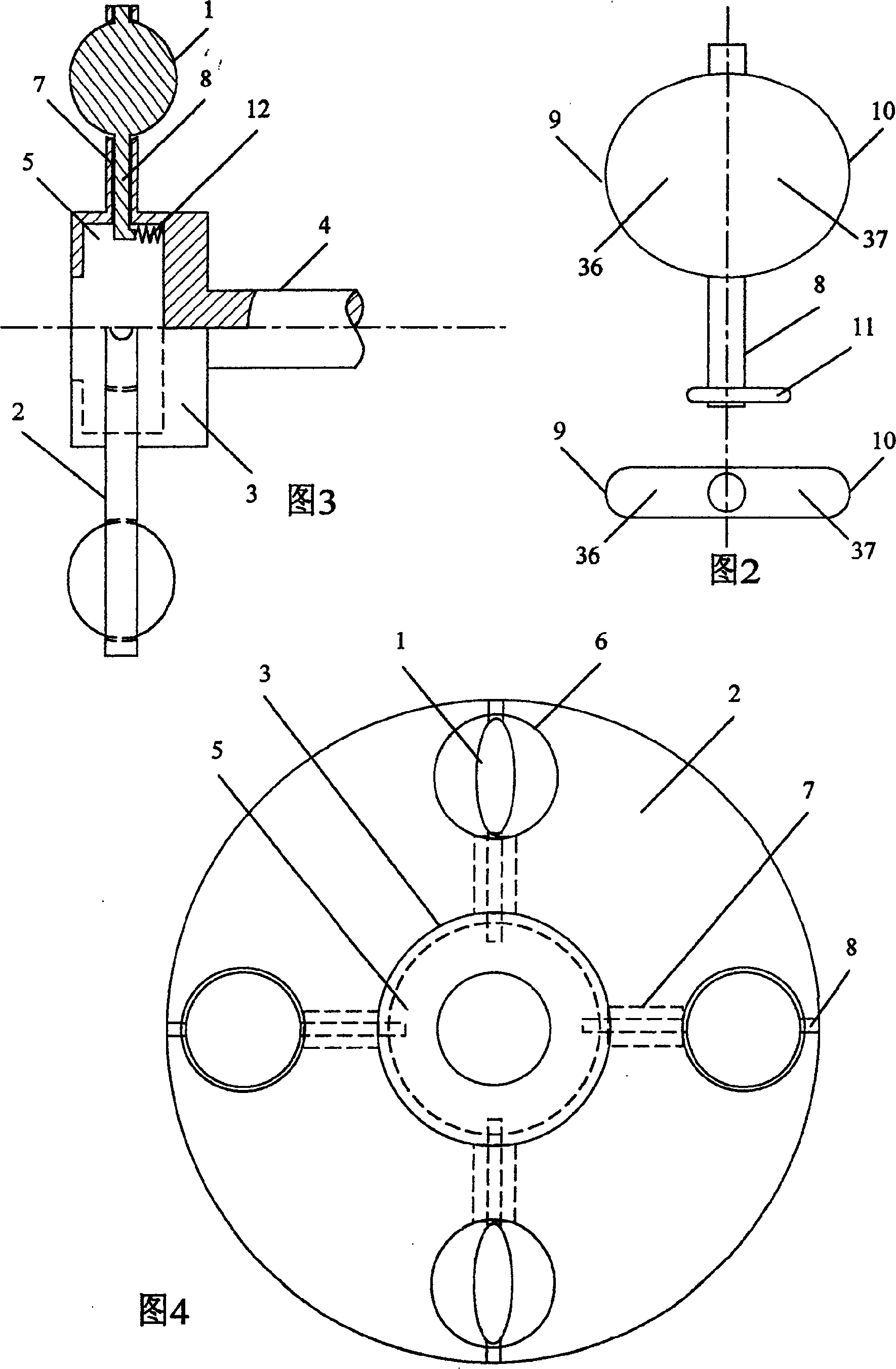

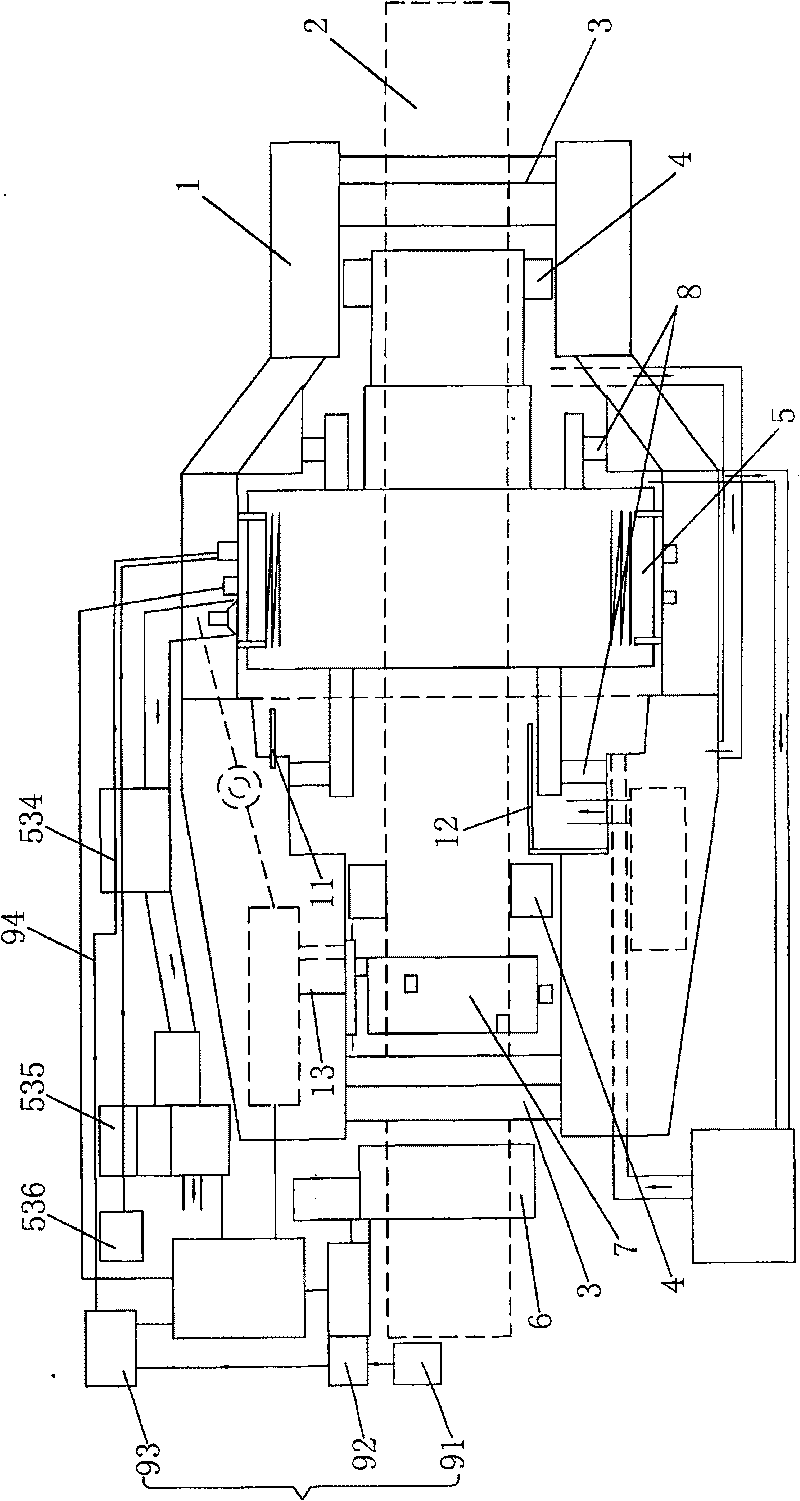

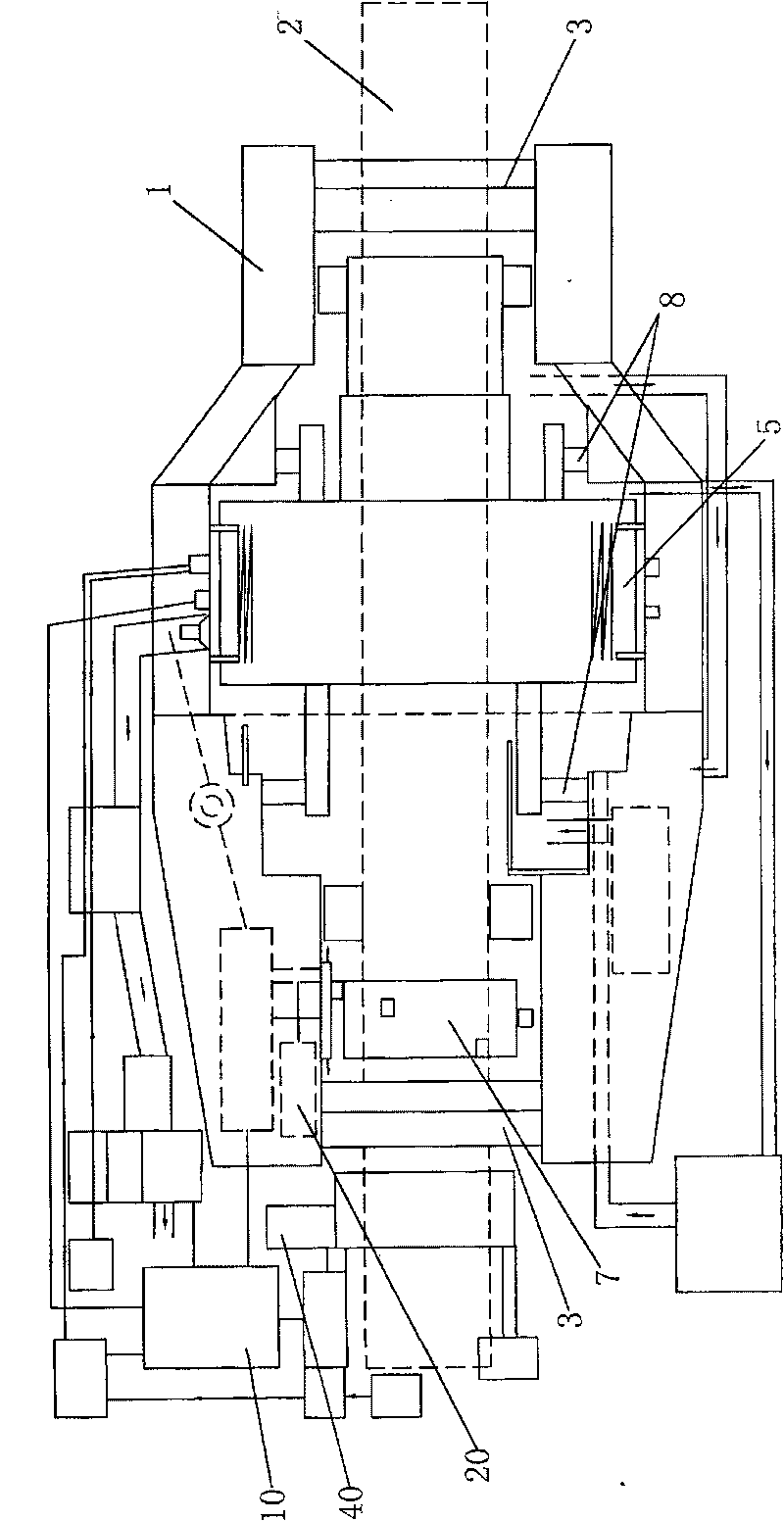

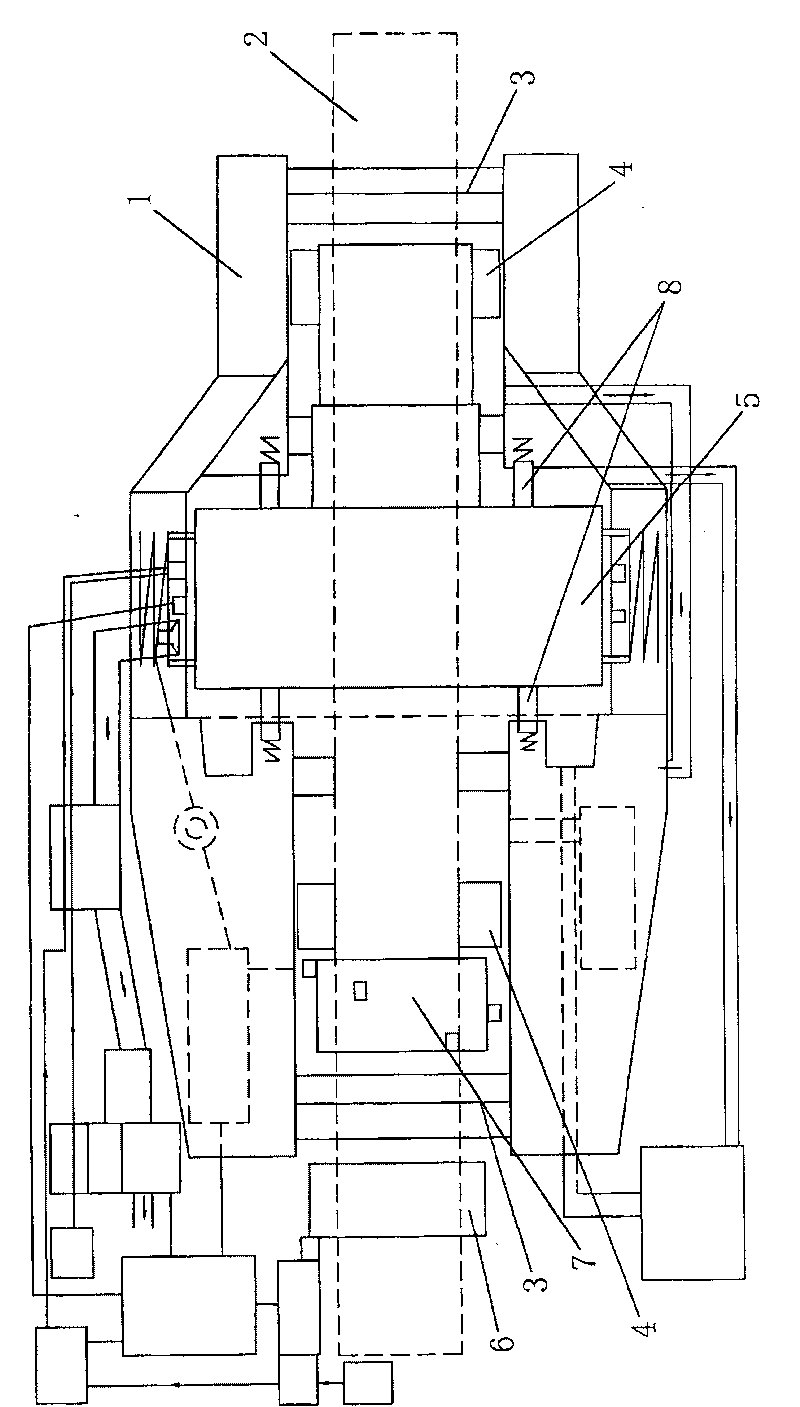

Novel rotary piston type engine

InactiveCN101333962AIncrease profitWide operating speed rangeInternal combustion piston enginesGas turbine plantsExternal combustion engineDrive shaft

The invention discloses a novel rotary piston engine which comprises an engine shell, a main transmission shaft and a piston group wheel; the piston group wheel is nested on the main transmission shaft; the main transmission shaft nested with the piston group wheel can be rotationally mounted in the inner cavity of the engine shell; the piston group wheel is composed of a rotary flywheel and at least a group of combustion chambers; the at least a group of combustion chambers are evenly arranged on the circumference surface of the rotary flywheel and on the same cross section; at least an air port composed of an exhaust port, a spark plug and an oil injection nozzle is arranged on the engine shell corresponding to the combustion chambers on the flywheel. Because the complicated crankshaft structure, the complicated cam structure and the complicated air distribution structure of the piston internal combustion engine are cancelled in the invention, the novel rotary piston engine has the advantages of more simple structure, higher fuel utilization rate, wide operation speed range, simple operation and control, good operation performance, ensuring the fuel utilization rate and the output torque to be in the best state.

Owner:敬德强

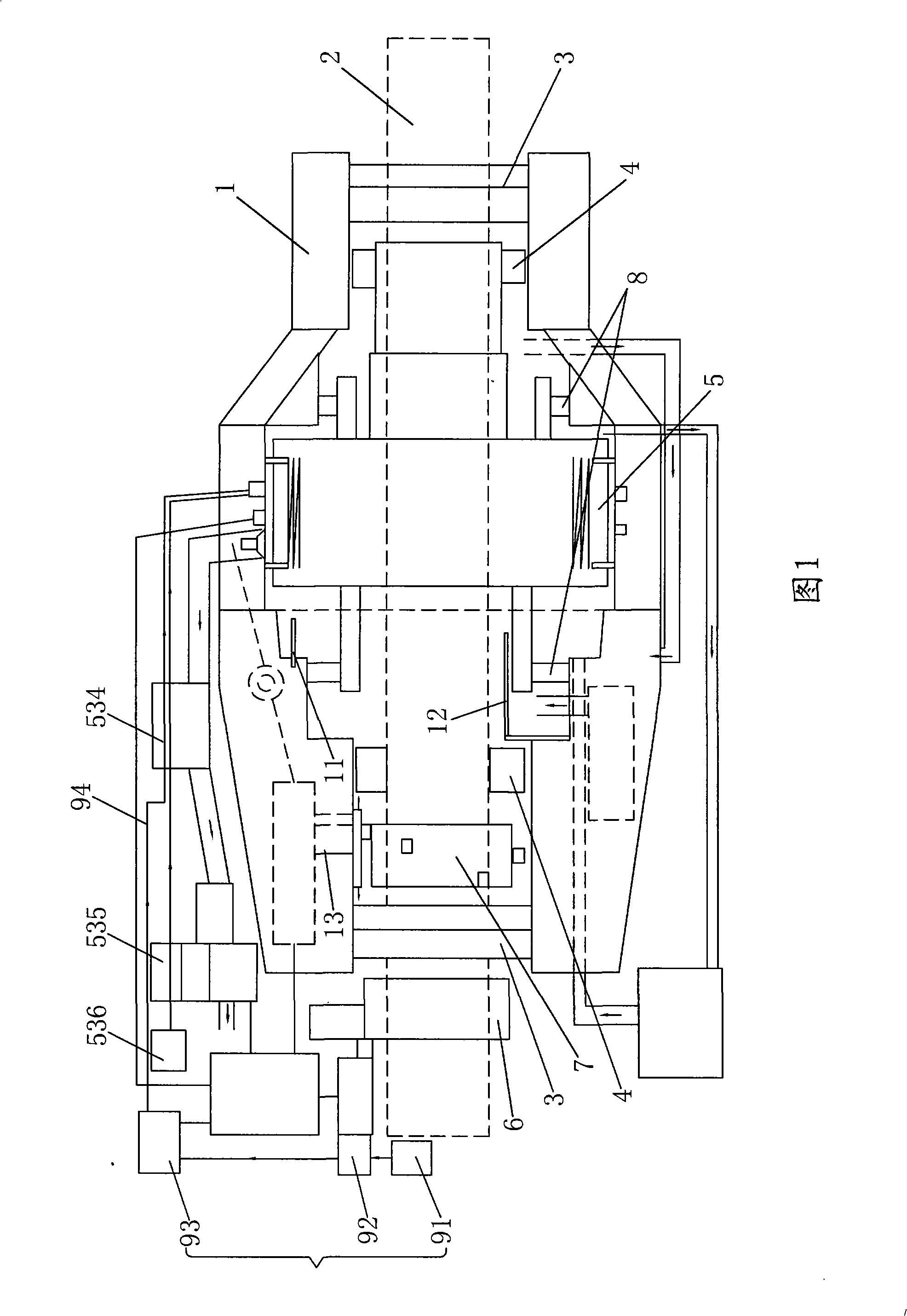

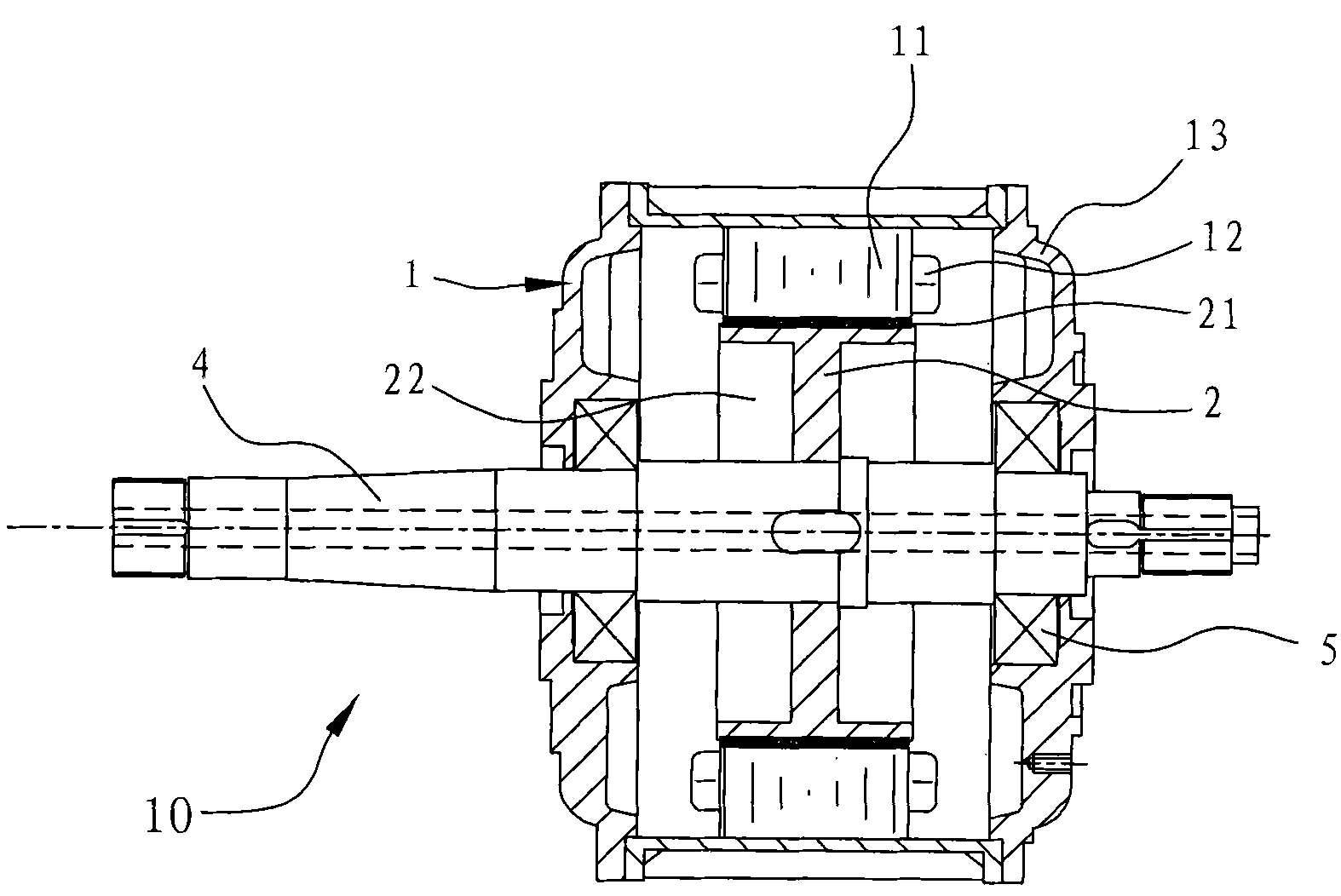

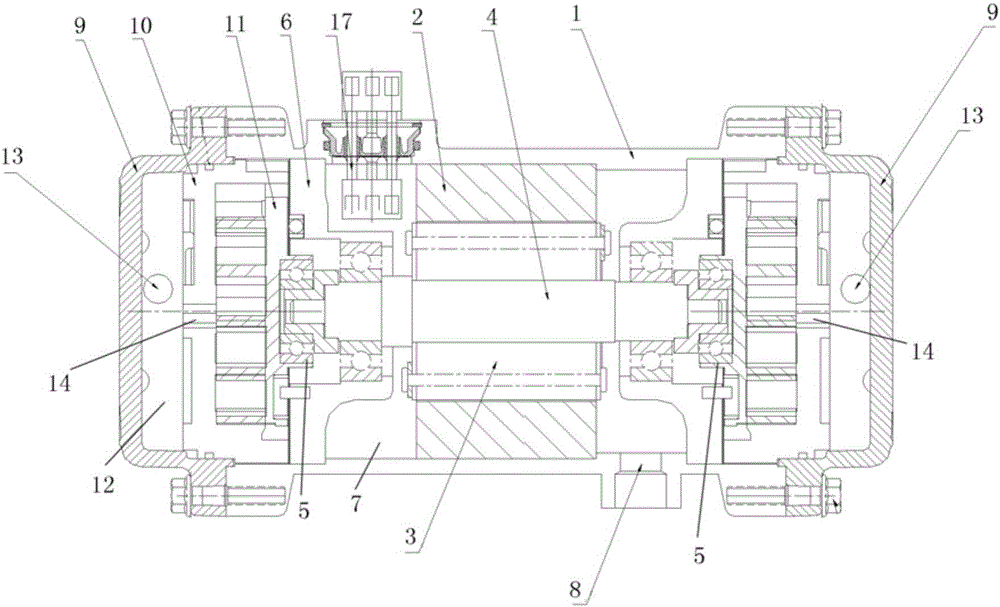

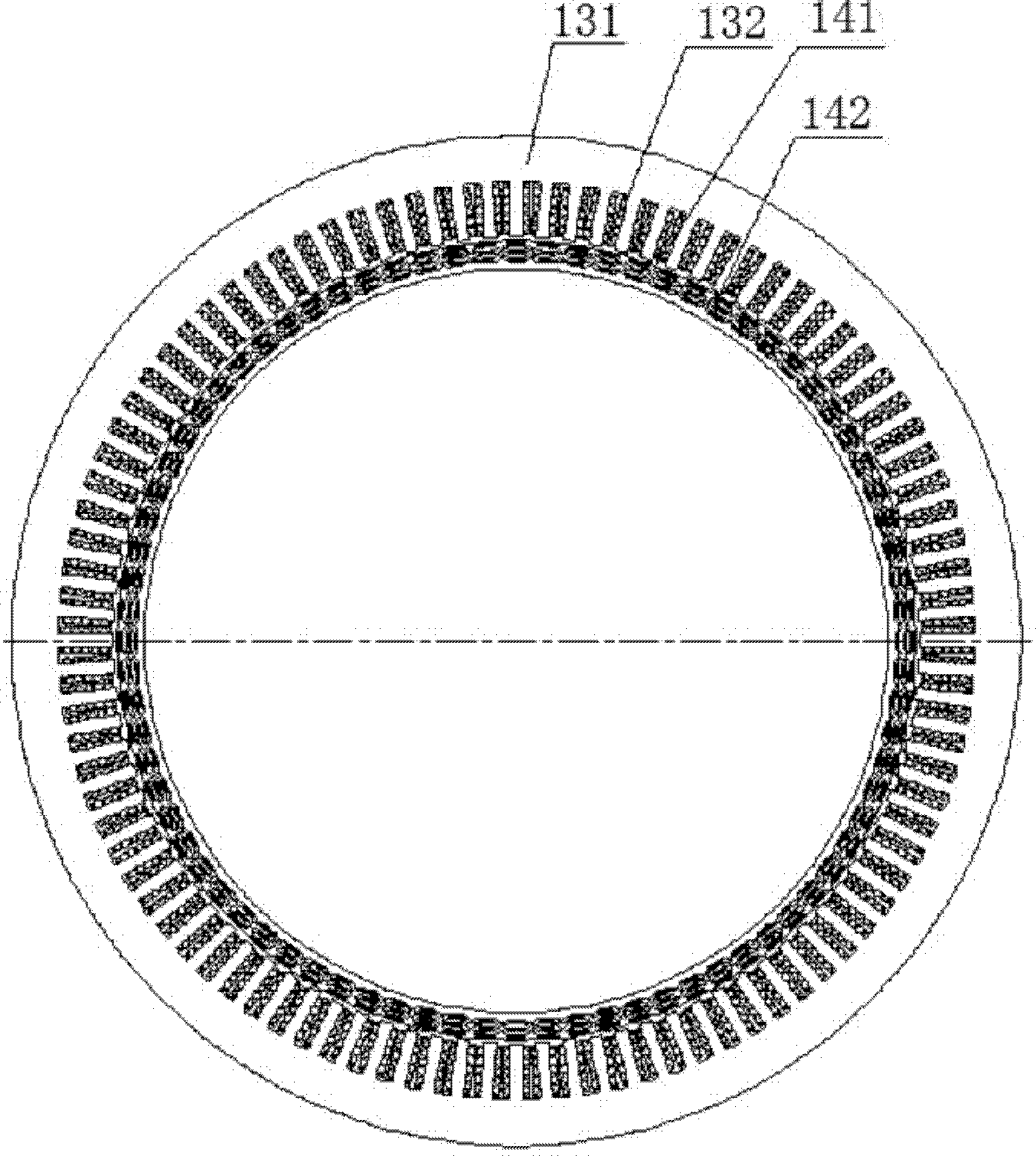

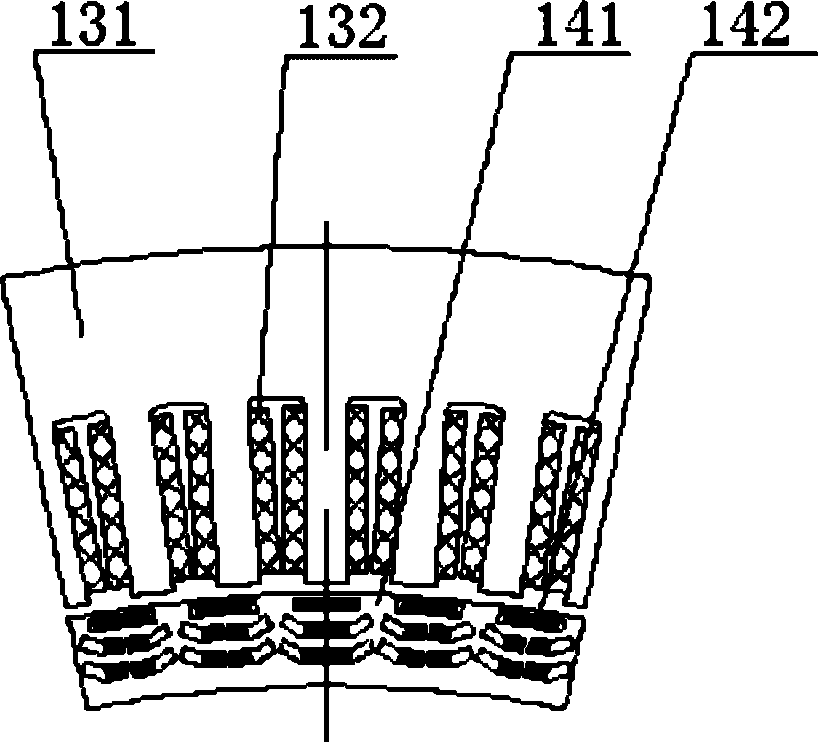

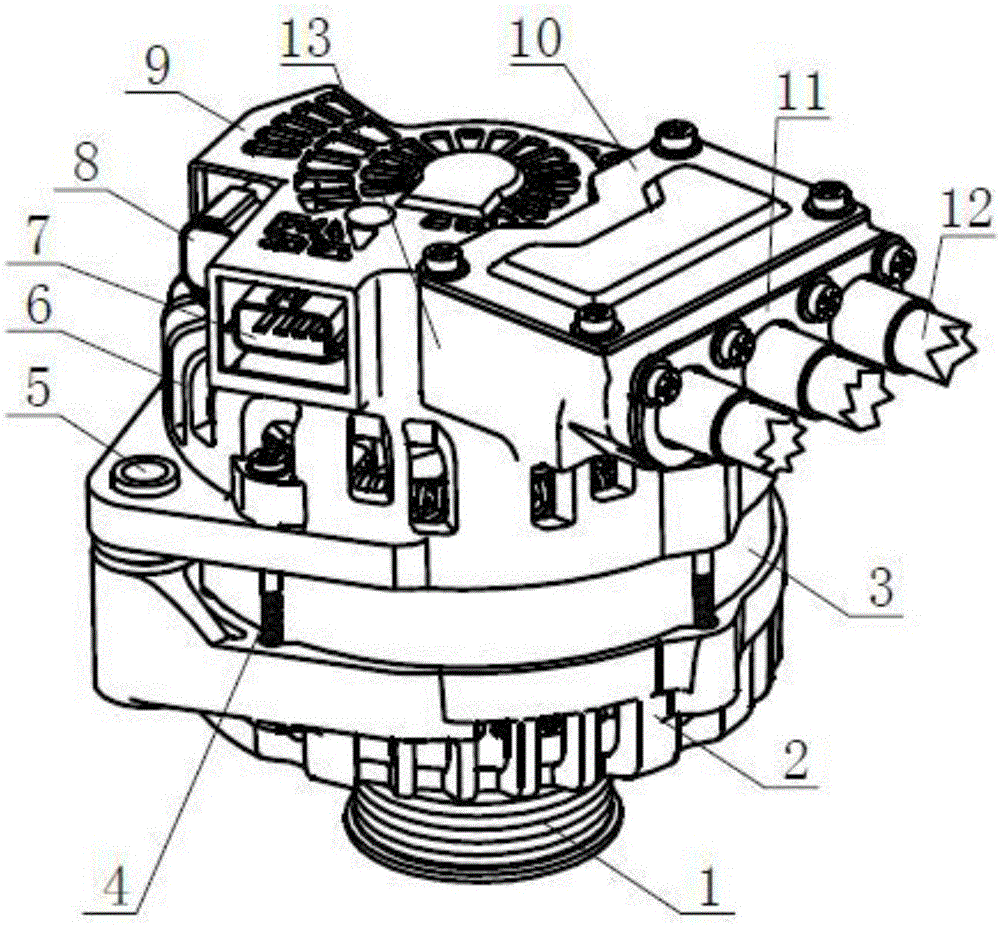

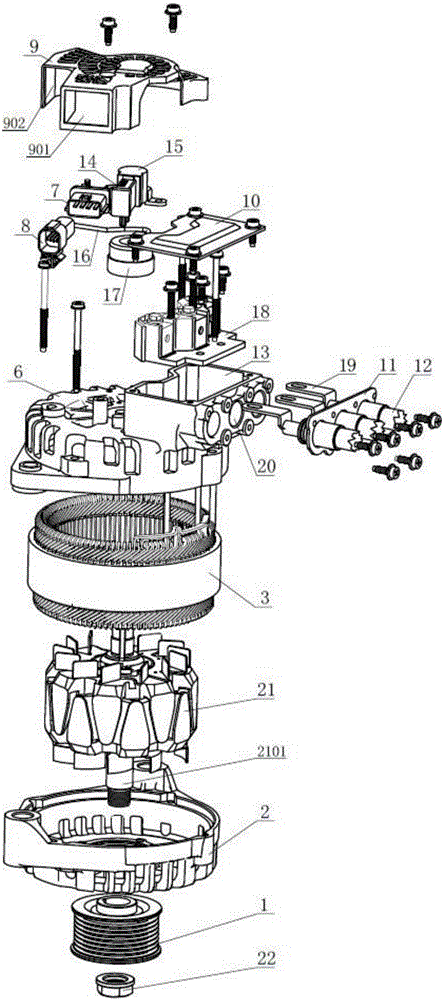

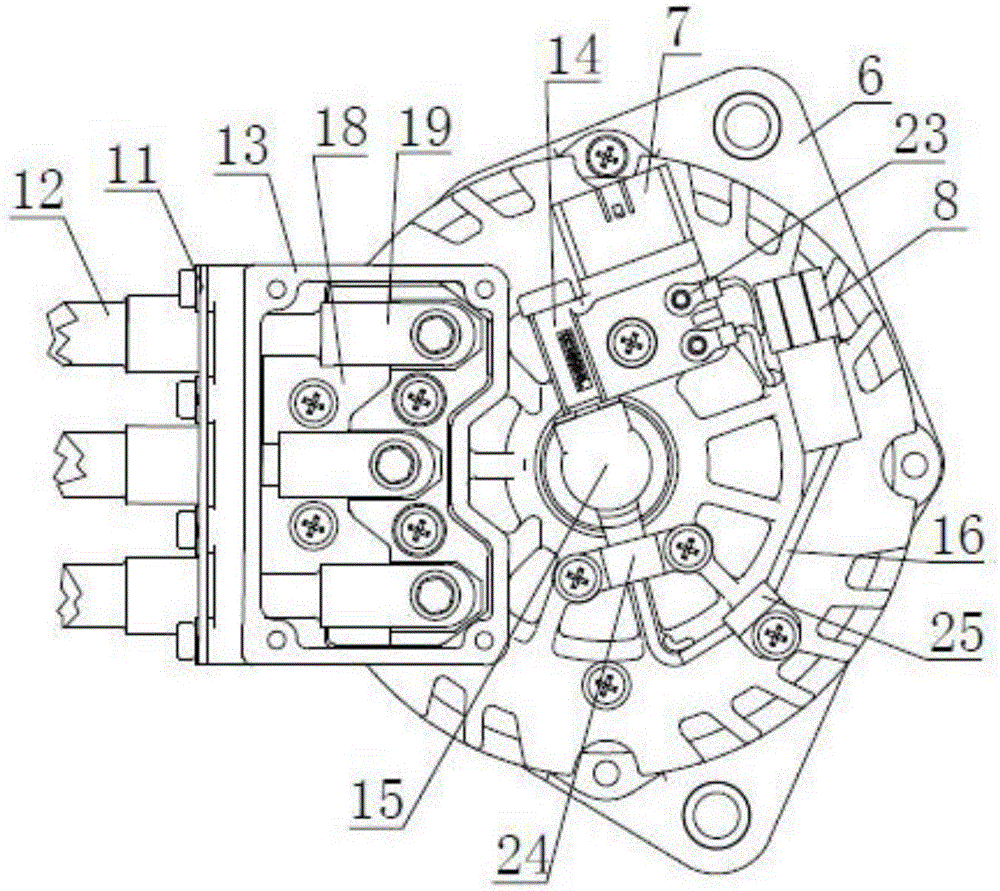

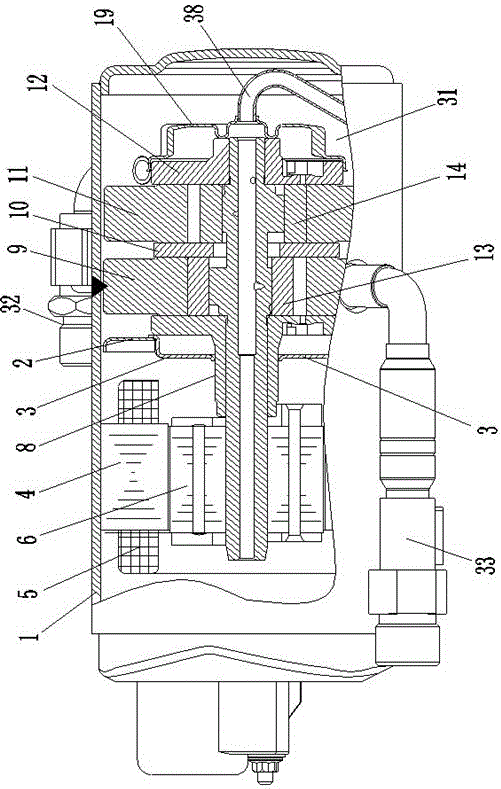

Belt transmission type starting and power generation integrated machine

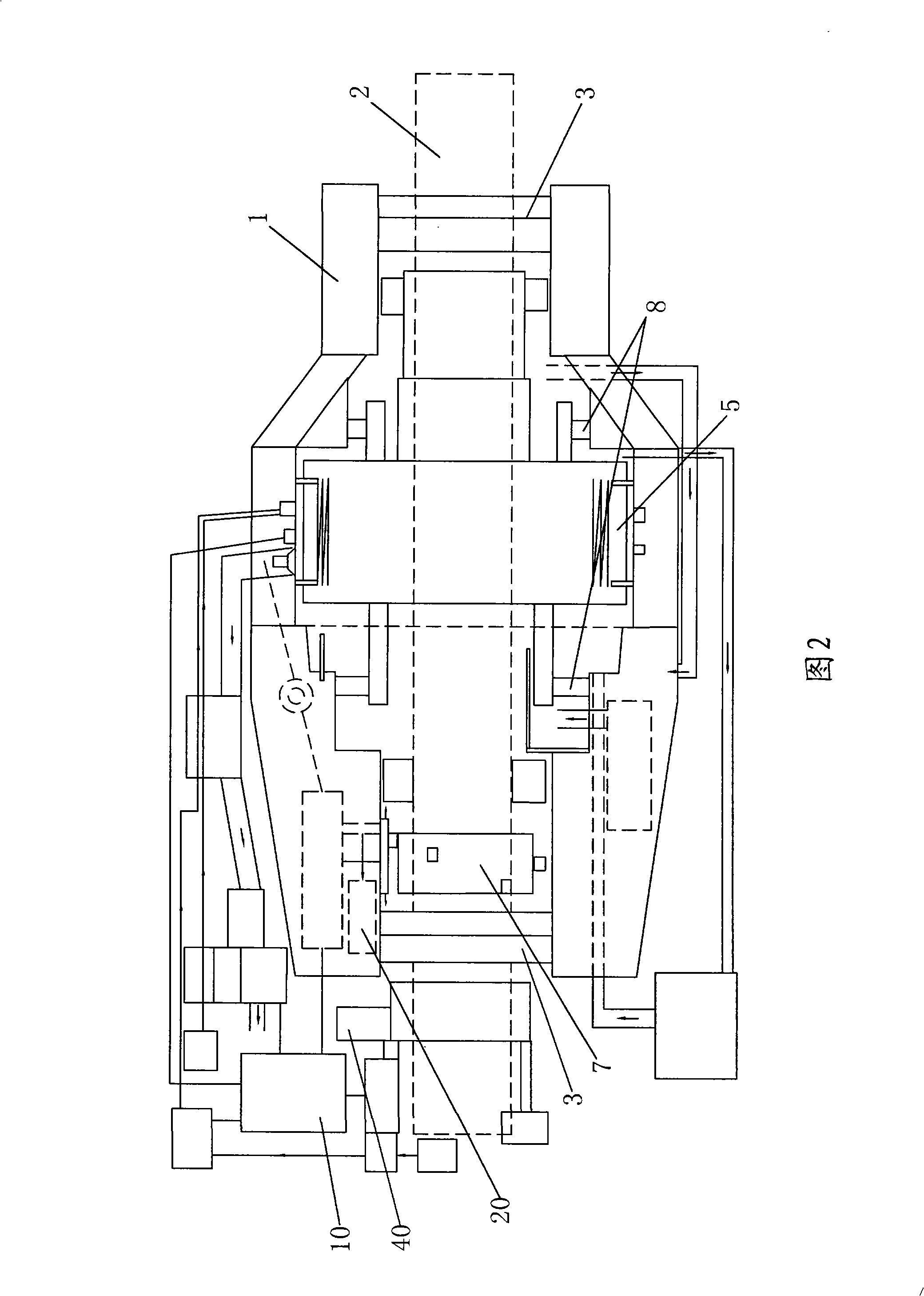

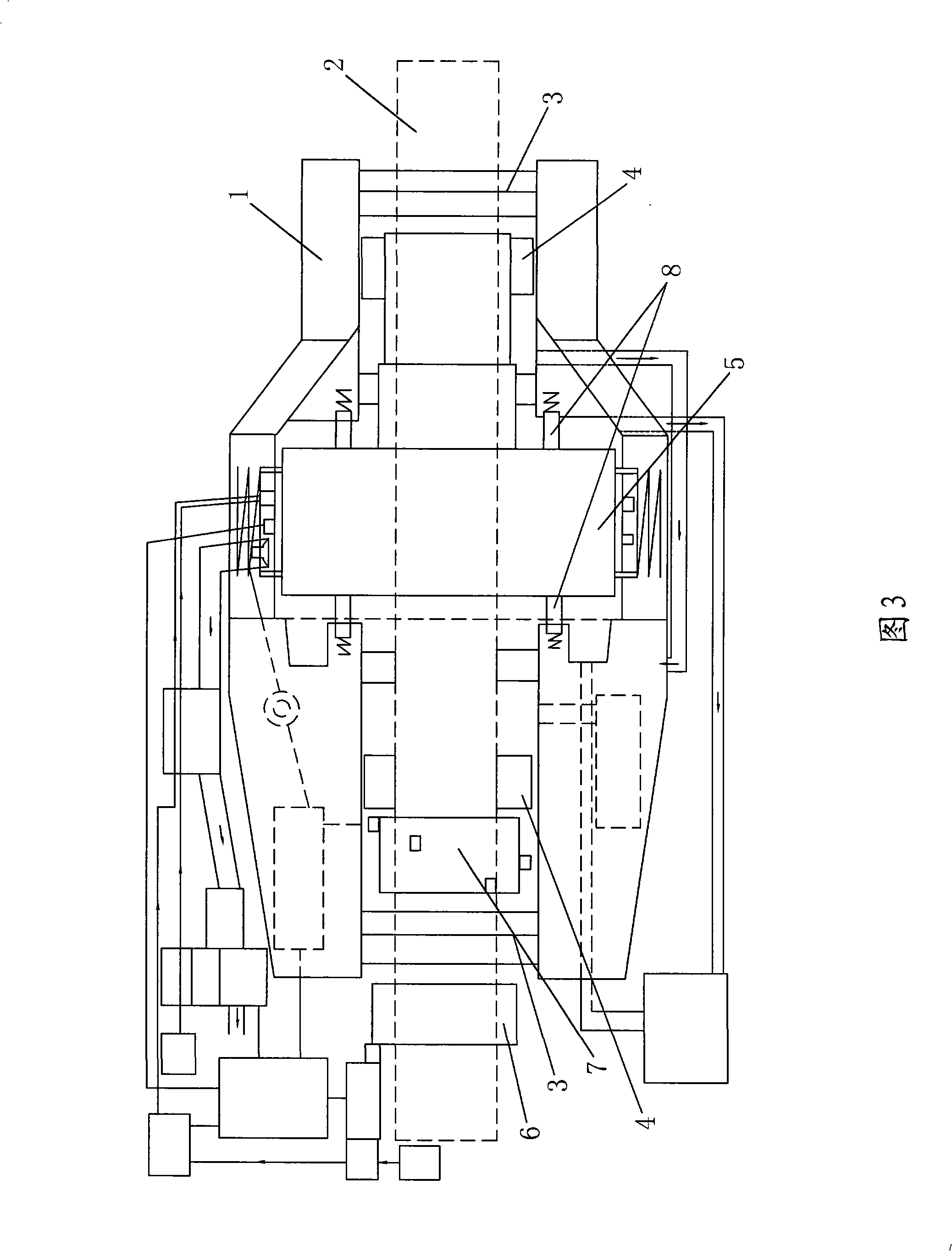

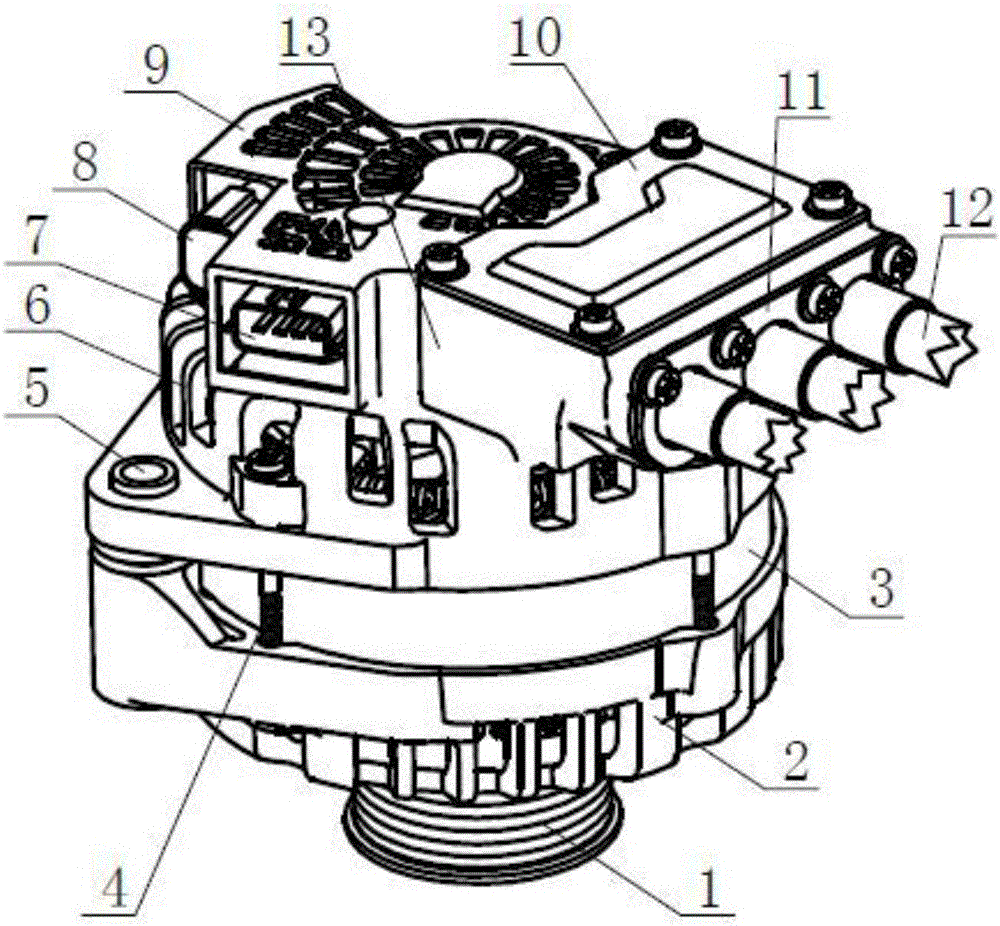

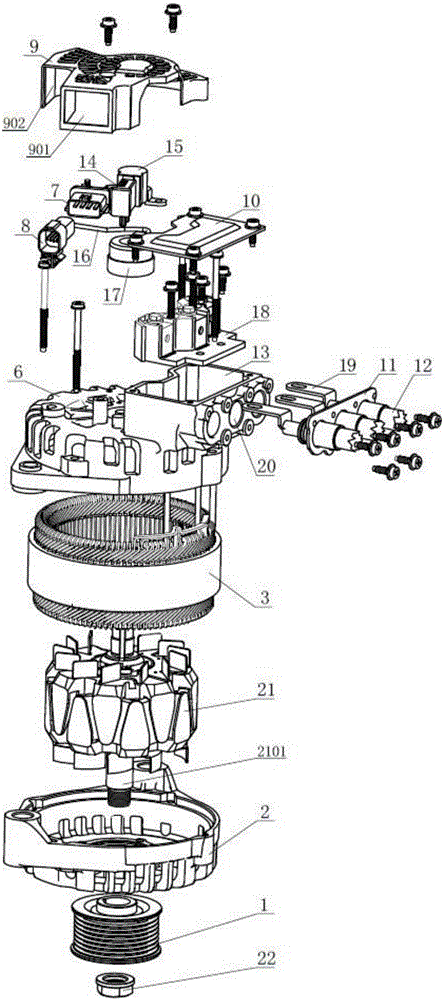

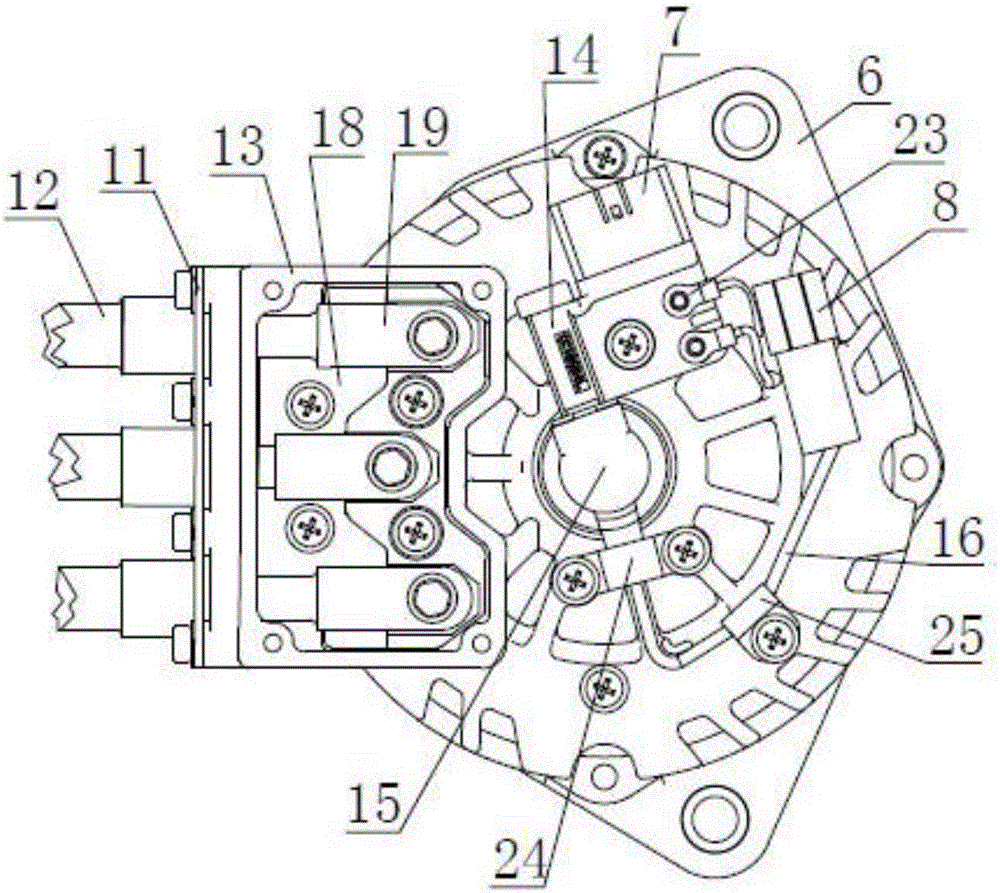

ActiveCN105743265AImprove connection strengthAvoid overheating and burningMechanical energy handlingStructural associationStatorEngineering

The invention relates to a belt transmission type starting and power generation integrated machine. The belt transmission type starting and power generation integrated machine comprises a belt pulley, a driving end cover assembly, a stator assembly, a rotor assembly and a carbon brush end cover assembly and is characterized in that a bearing chamber is arranged at a position, corresponding to a rotor shaft, at the middle of a carbon brush end cover, a bearing sensor is arranged in the bearing chamber, the end part of a carbon brush in a carbon brush rack props against the circumferential surface of a current collection ring of a rotor shaft, a junction box is further arranged outside the carbon brush end cover, a wiring seat is fixedly arranged in the junction box and is used for connecting three phase cables, cable heads of the three phase cables are separately and fixedly provided with connection sheets, the connection sheets separately pass through a socket of the junction box and enter to the junction box to be fixedly connected with the wiring seat, a sealing cover is fixedly arranged at the top of the junction box, a temperature sensor is arranged at the end part of a stator iron core, and a signal wire connector of the temperature sensor is fixed on the carbon brush rack. The belt transmission type starting and power generation integrated machine is compact in structure and has the advantages of a rapid starting function, low starting noise, automatic switching between starting and power generation and high power generation efficiency, and also has functions of assisted electric power for an engine and vehicle braking energy recycle.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

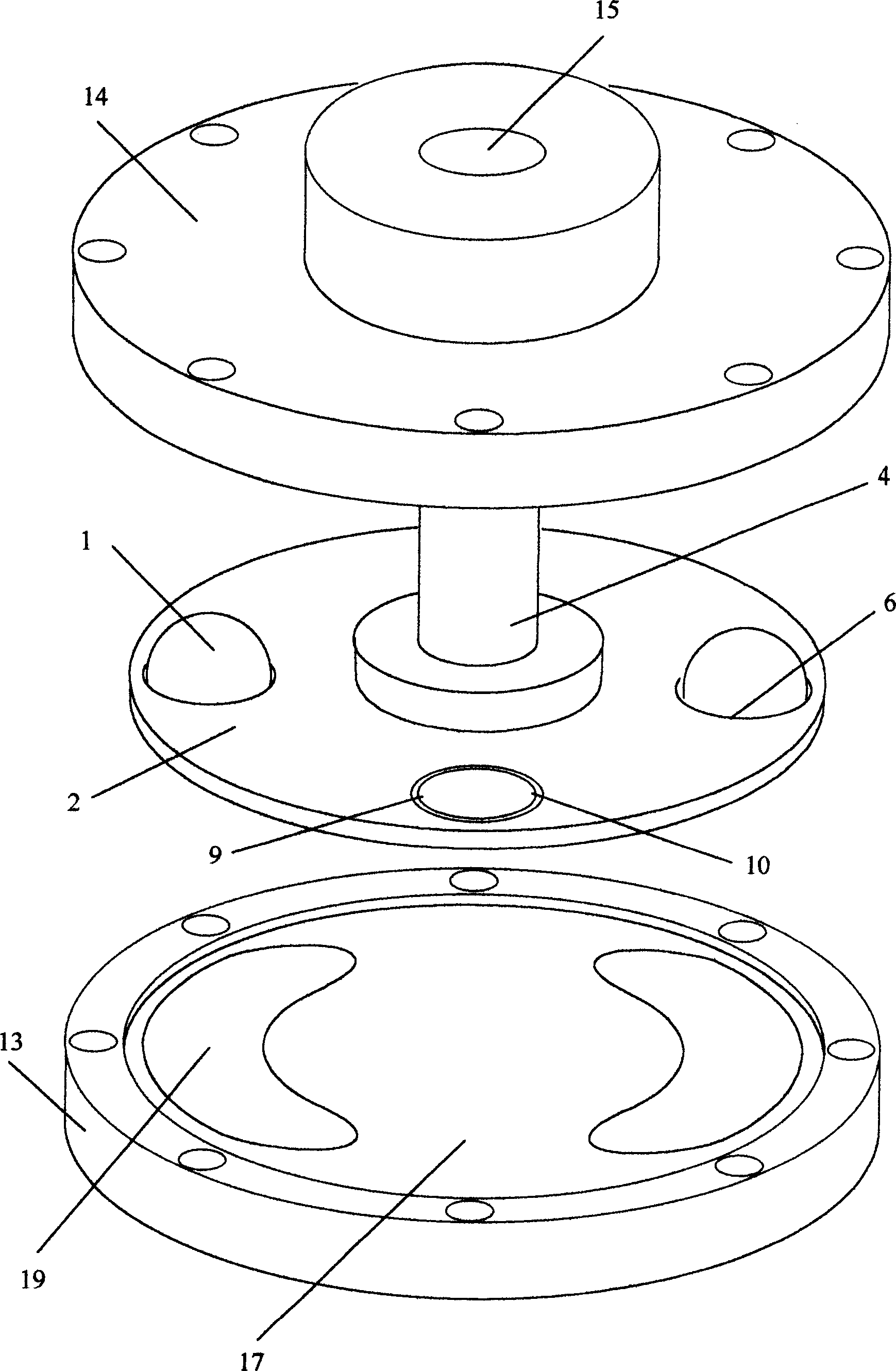

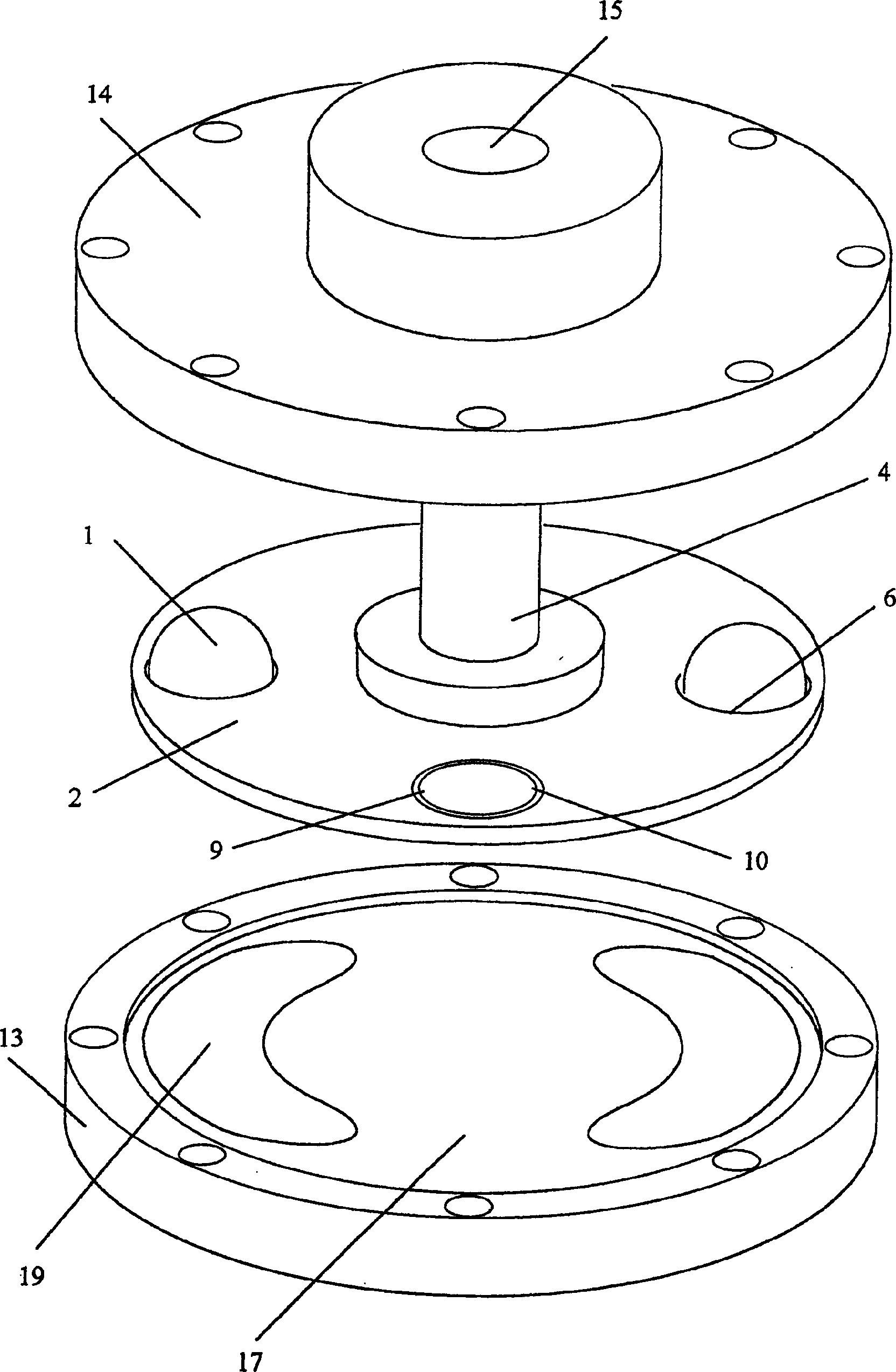

Rotary piston machine

InactiveCN1442602AImprove work efficiencyWide operating speed rangeOscillating piston pumpsInternal combustion piston enginesCylinder blockEngineering

A rotary piston unit for IC engine, water turbine, steam turbine, water pump, air compressor, etc is composed of disk-shaped piston holder on mainshaft, multiple plate pistons running directionally around mainshaft in planetary mode, and two semi-cylinders on two end faces of planetary piston to form a piston space with alternative big and small cross-sections. The left part and right part of each plate piston sequentially and periodically come in said piston space to form piston effect, realizing the conversion between fluid energy and mechanical energy.

Owner:姚平

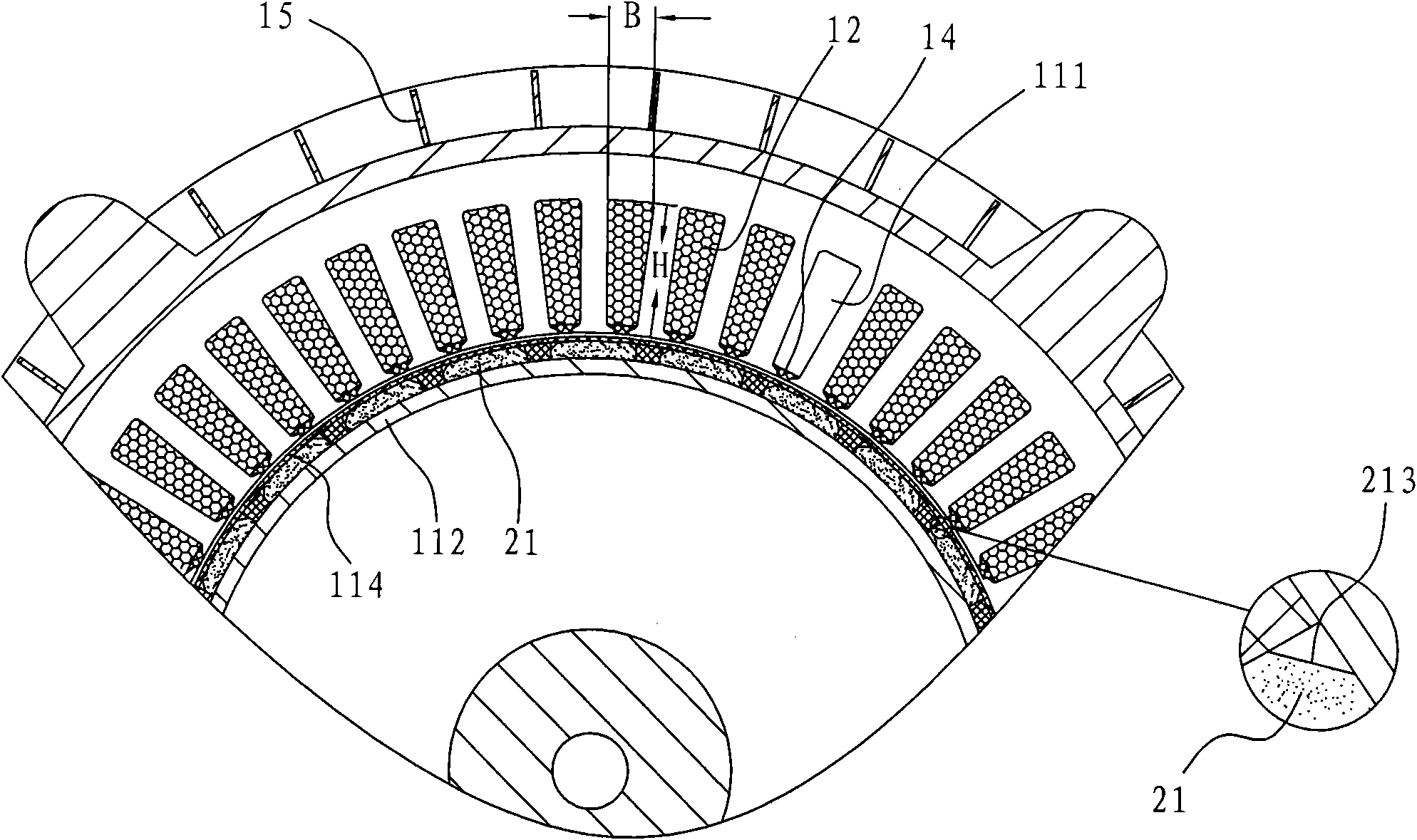

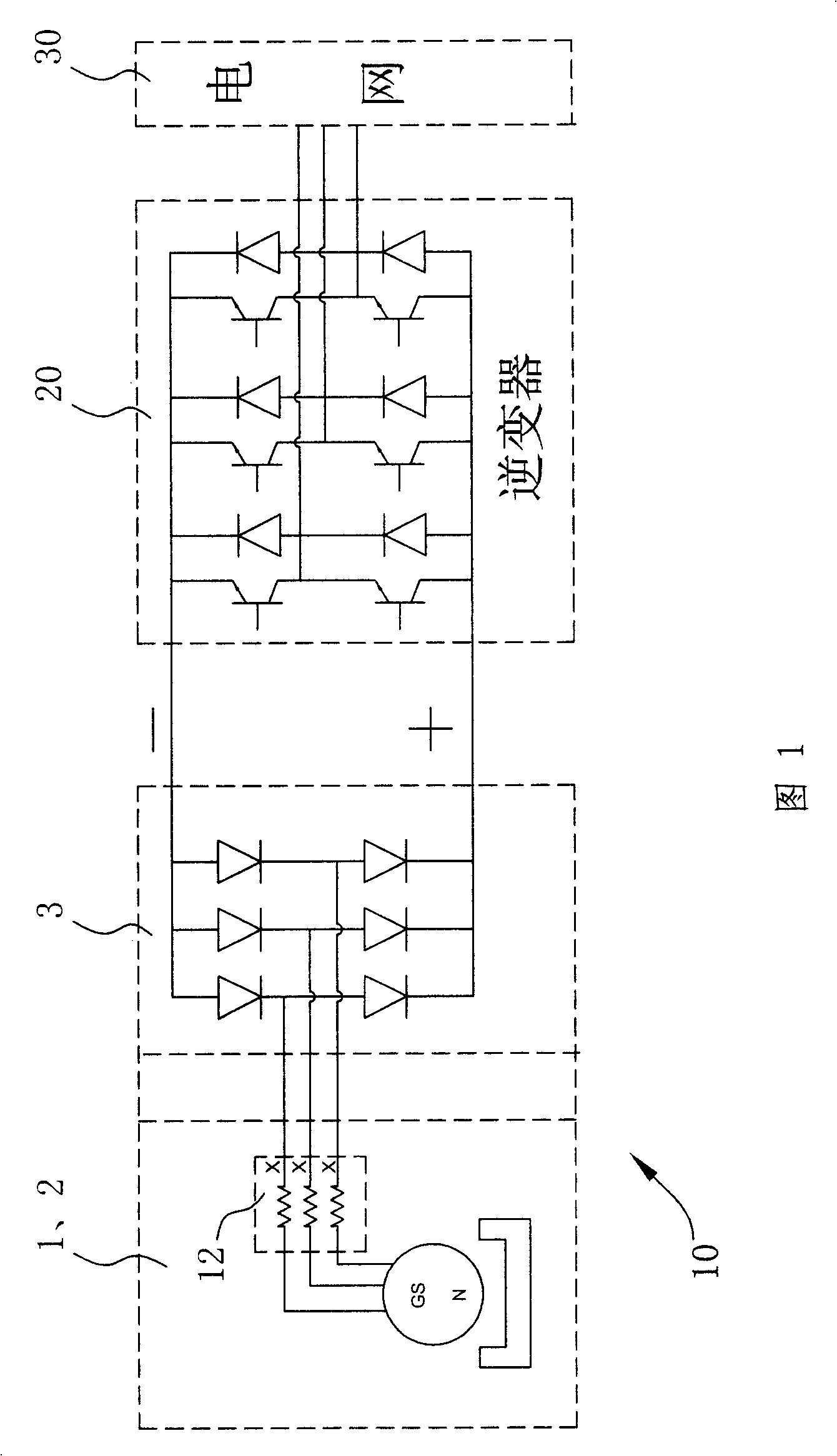

Permanent magnetic brushless constant voltage generator and voltage stabilizing method thereof

InactiveCN101783643AIncrease leakage inductance reactanceThe leakage inductance reactance is reducedSynchronous machinesGenerator control of frequency and voltageFrequency conversionPower grid

The invention relates to a permanent magnetic brushless constant voltage generator and a voltage stabilizing method thereof. The generator is driven by a speed change wind wheel, the sent constant voltage direct current is output to the electric network after the frequency conversion through an inverter, the leakage reactance per-unit value X<*> of an armature winding at the maximum work rotating speed of the generator equals to the ratio of the difference of the maximum work rotating speed and the minimum work rotating speed of the generator to the minimum work rotating speed, and the range of the leakage reactance per-unit value X<*> is from 1 to 1.8. The method increases the leakage inductance value of the armature winding of the generator through the optimized electromagnetic design on the generator per se, so the leakage inductance resistance of the armature winding of the generator in work is increased, the potential E of the generator is in isometric and synchronous change with the leakage resistance voltage reduction X.I of the armature winding when the rotating speed of the generator is changed in the work rotating speed range, and thus, the constant voltage output is realized. The generator can realize the voltage stabilization without increasing any detection and control links, executing mechanisms and the like, the structure is greatly simplified, the cost is greatly reduced, and the invention has the advantages of simplicity, economy, effectiveness and reliability.

Owner:包头长安永磁电机有限公司

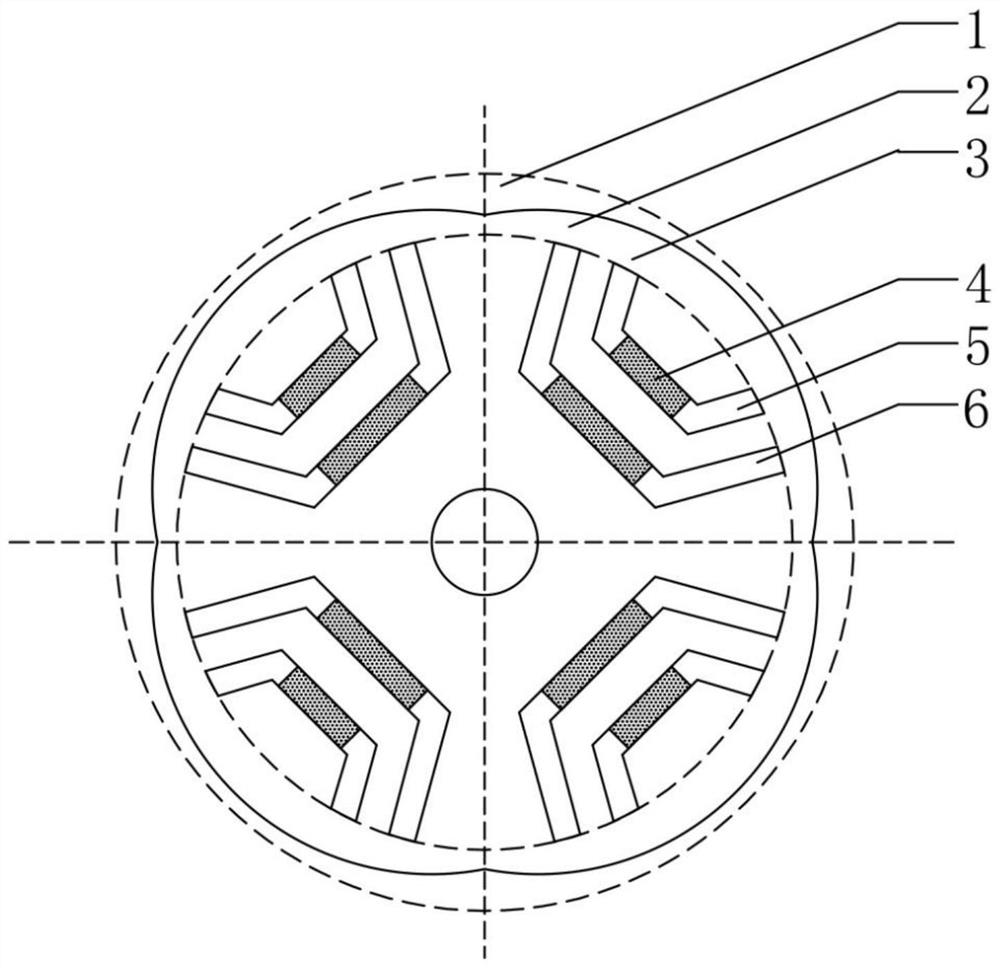

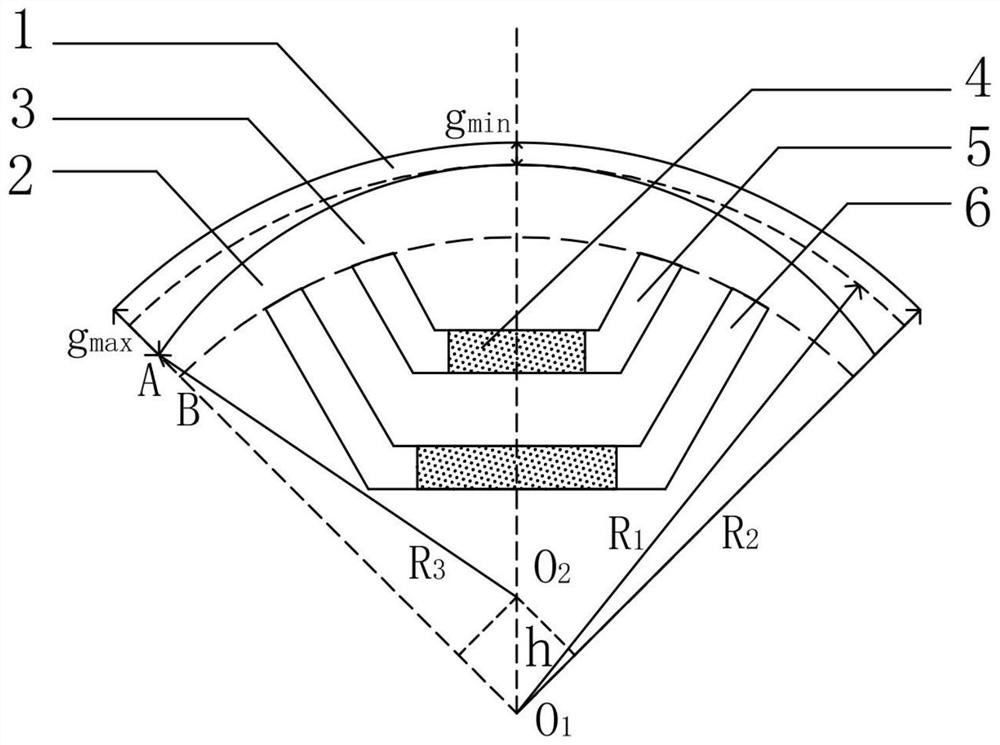

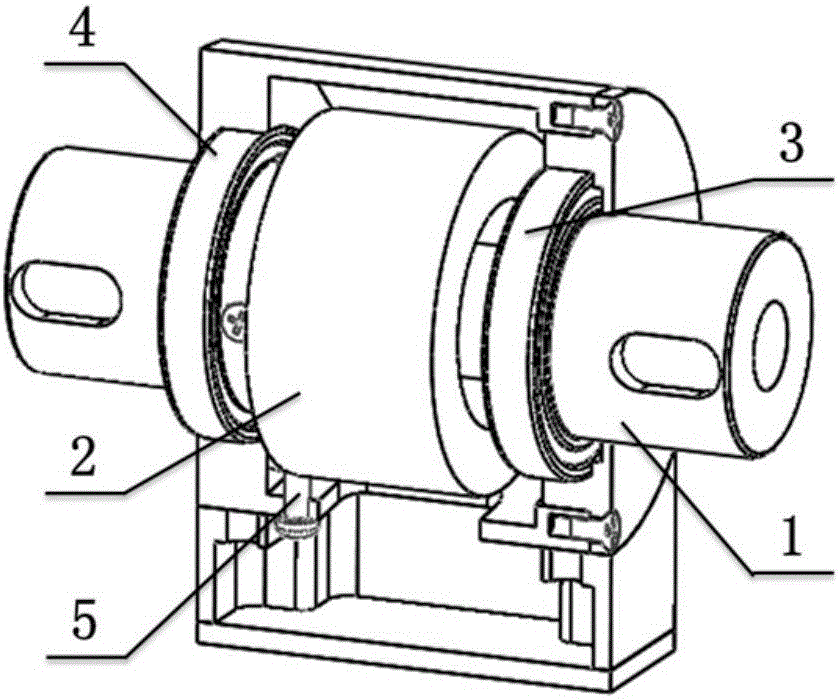

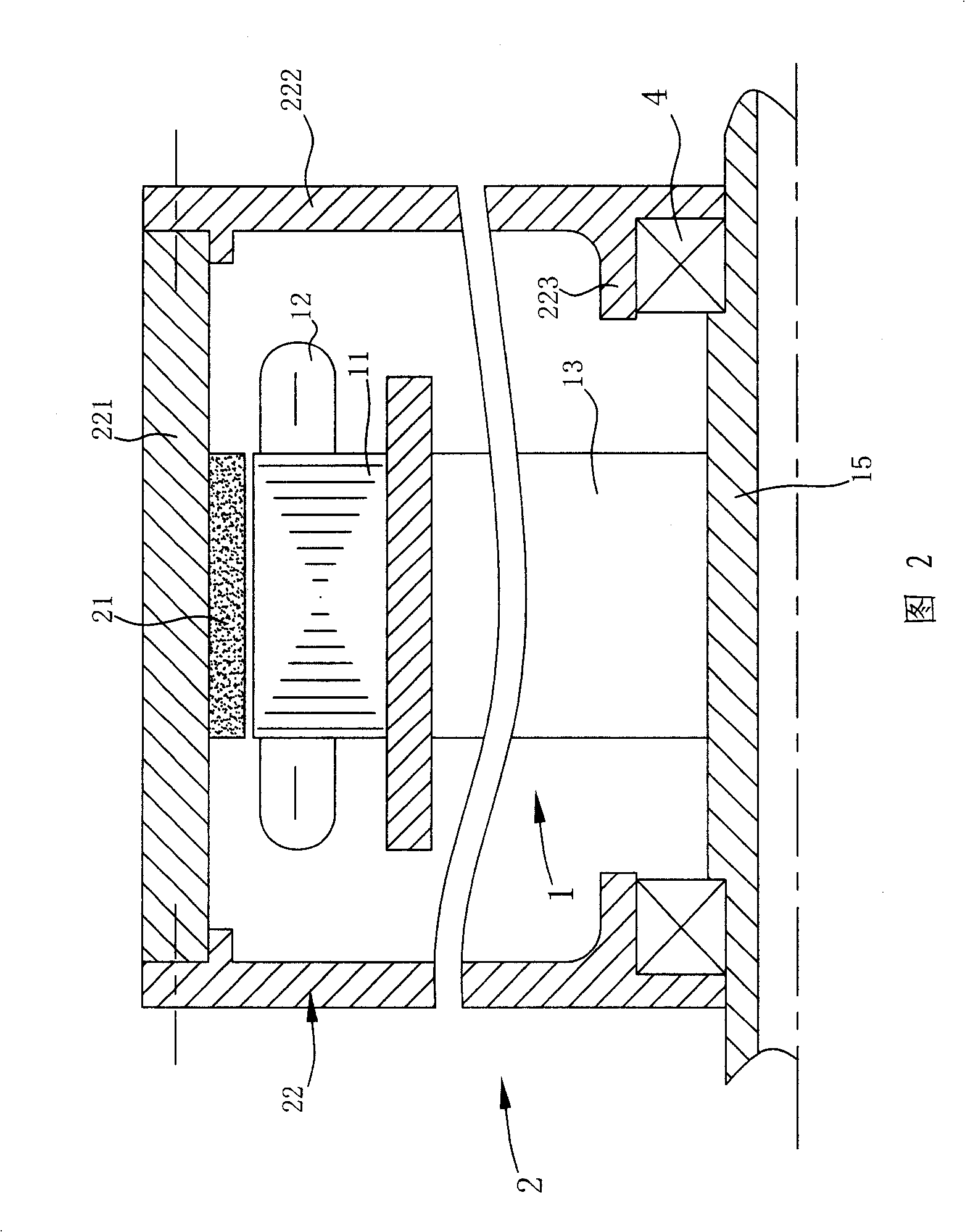

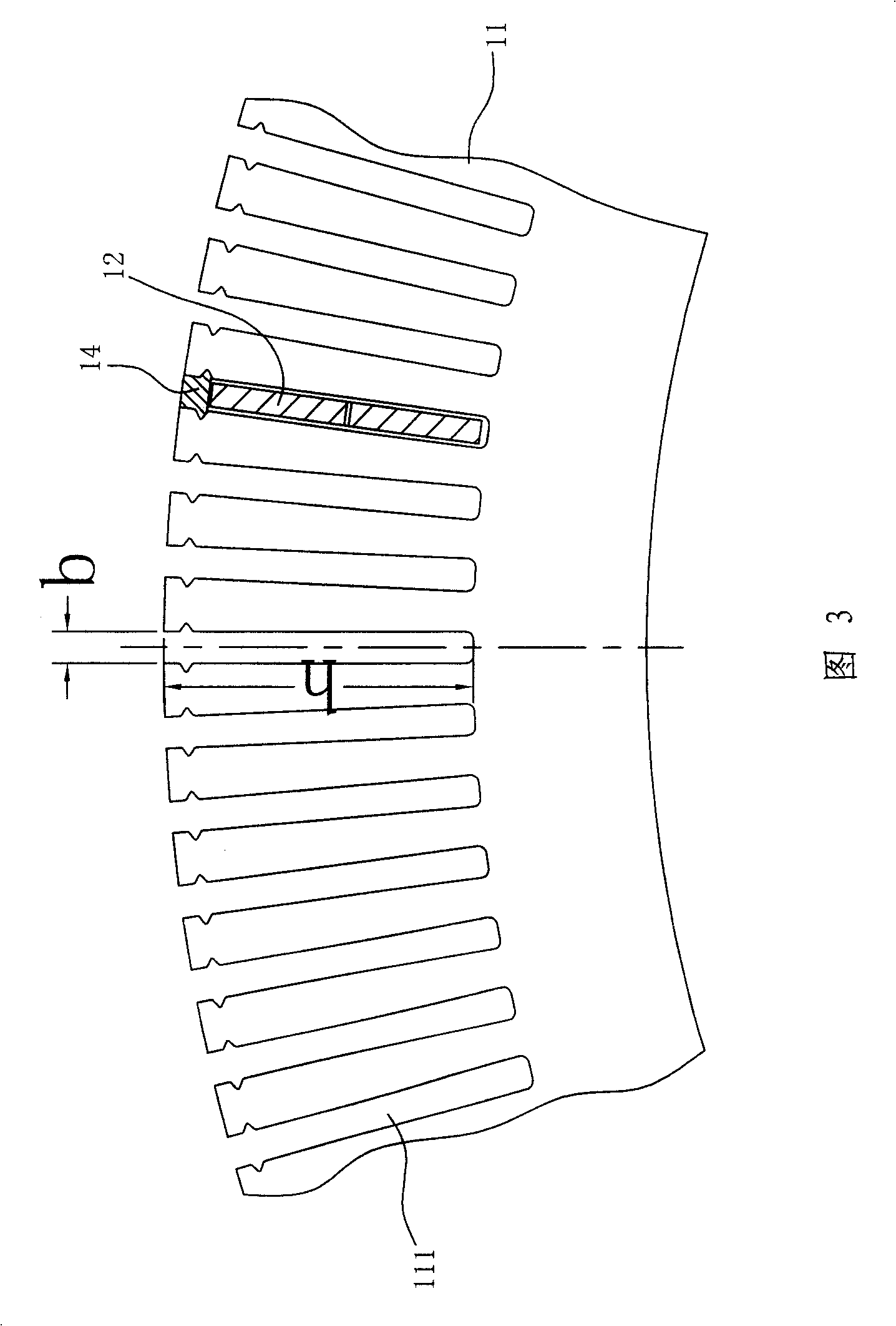

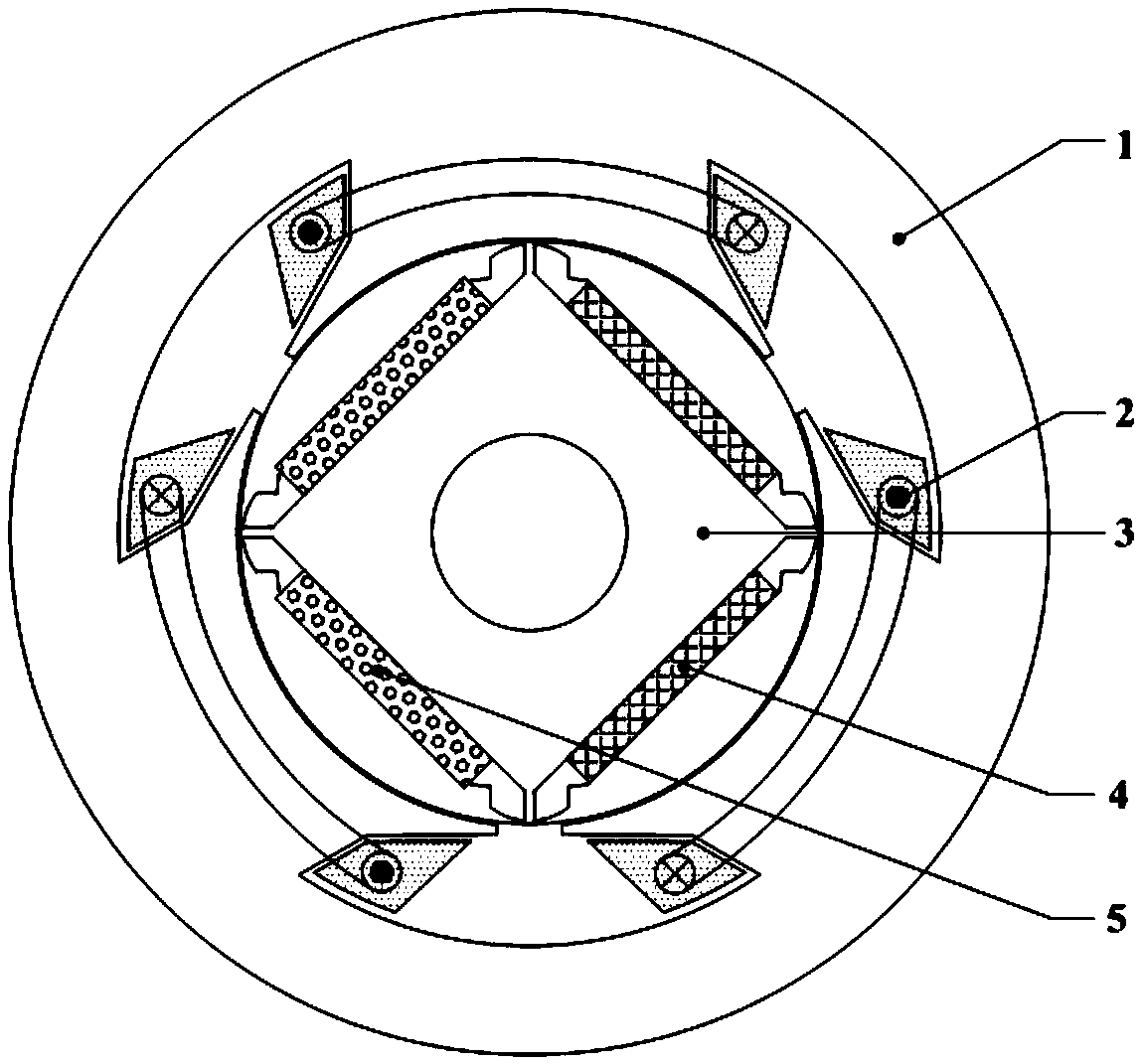

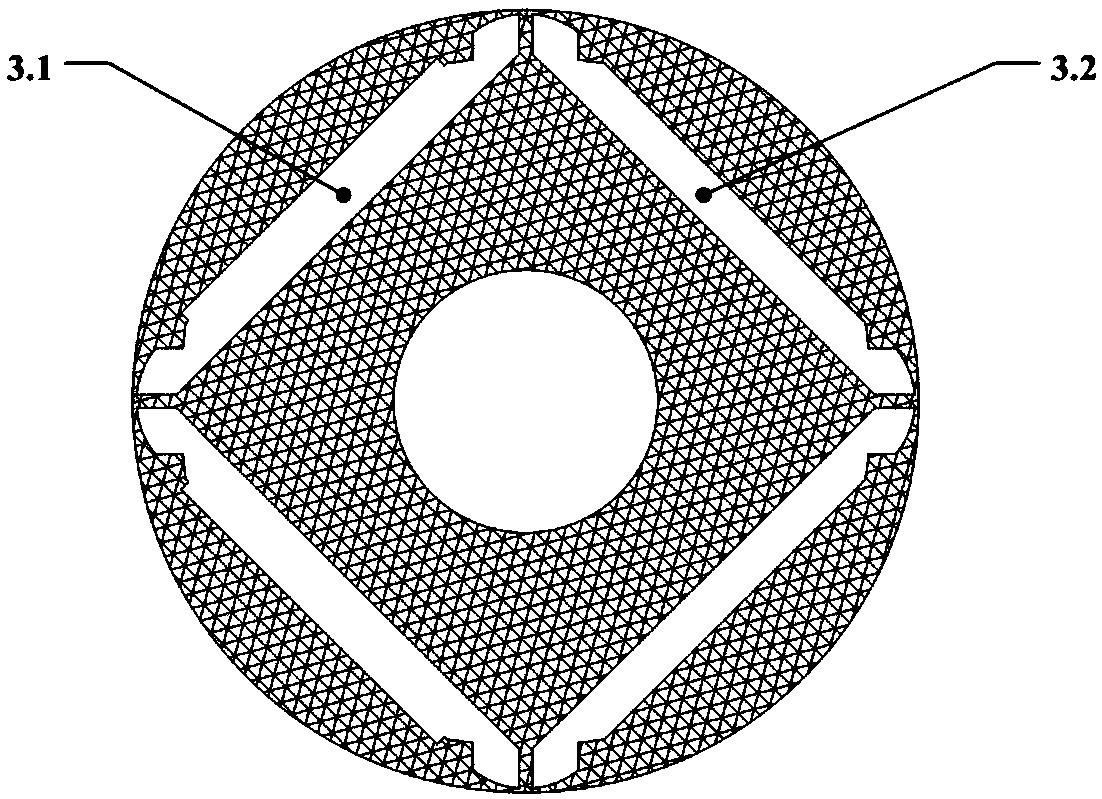

Rotor structure and design method of a permanent magnet assisted synchronous reluctance motor

ActiveCN110048530BIncrease sineImprove air gap flux density waveformMagnetic circuit rotating partsMagnetic barrierSynchronous reluctance motor

The invention belongs to the technical field of permanent magnet motors and relates to a rotor structure of a permanent magnet auxiliary synchronous reluctance motor and a design method. The rotor structure comprises a rotating shaft, a rotor iron core and a permanent magnet block; the rotor iron core is provided with a central hole, and the rotary shaft penetrates through the central hole of therotor iron core and is fixedly connected with the rotor iron core; the rotor iron core is evenly divided into an even number of poles, and at least two layers of U-shaped magnetic barriers are arranged in each pole. The distance between the circle center O1 of an outer circle formed by the U-shaped magnetic barriers in each pole and the circle center O2 of the outer circle of the rotor iron core is h, and h is larger than 0; and a magnetic pole center line formed by the U-shaped magnetic barriers in each pole passes through the circle center O1 and the circle center O2. Therefore, a non-uniform air gap and non-equal-width magnetic bridge rotor structure is constructed. According to the rotor structure and the design method in the invention, the sine degree of air gap flux density in the motor is improved, the air gap flux density waveform is optimized, the problem of torque ripple of the permanent magnet auxiliary synchronous reluctance motor is solved, the torque ripple is obviously reduced, and the motor can be guaranteed to run more stably and efficiently in an electric transmission system.

Owner:DALIAN UNIV OF TECH

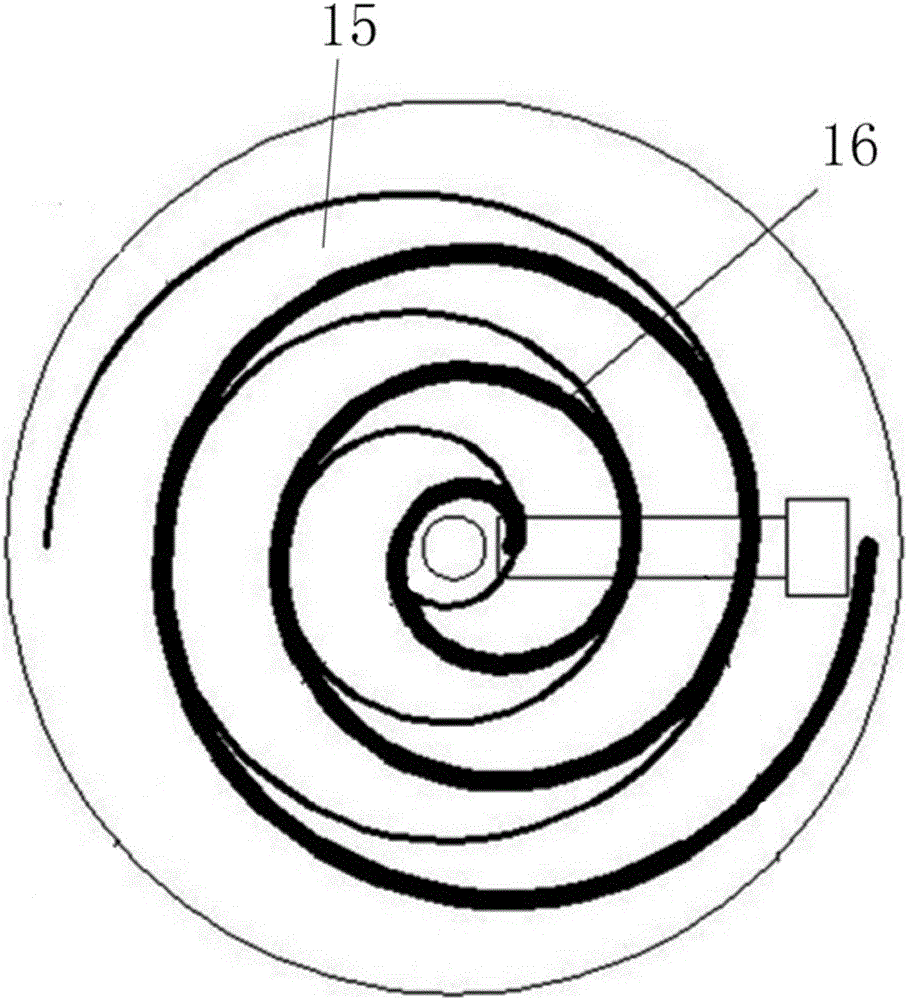

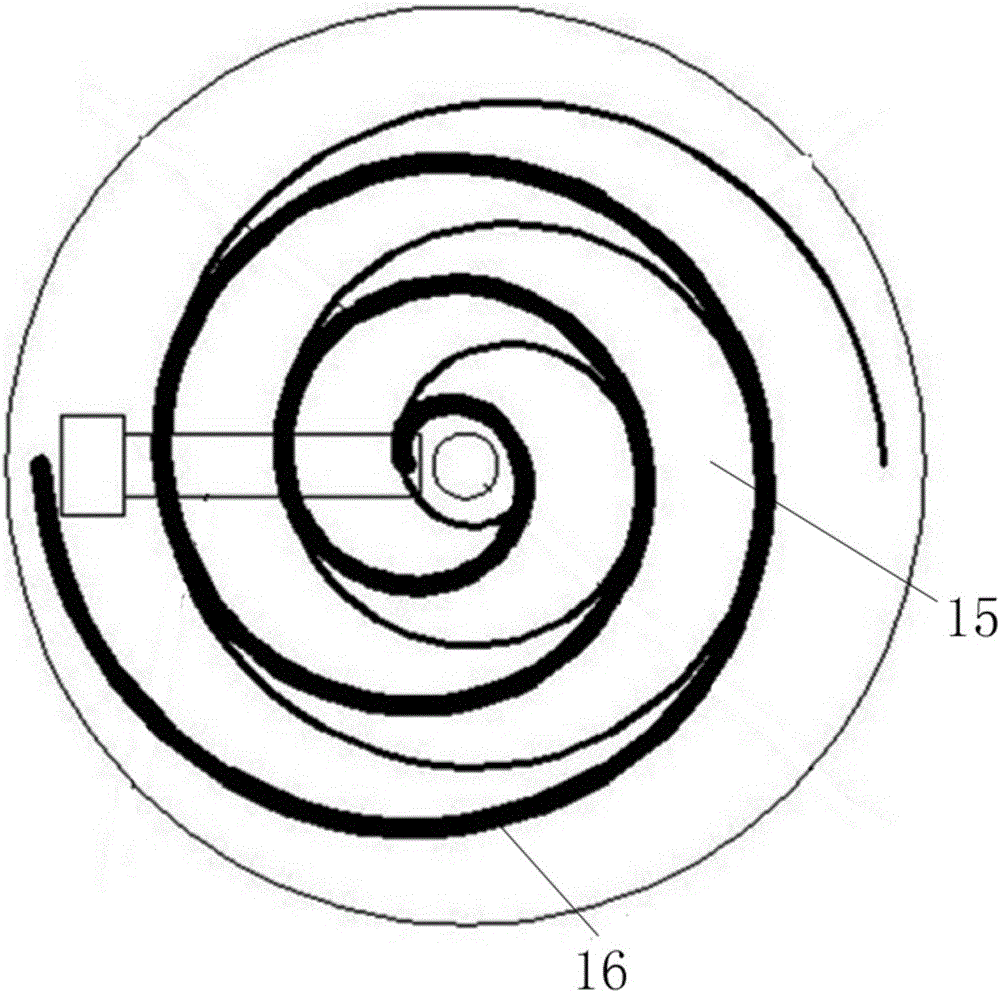

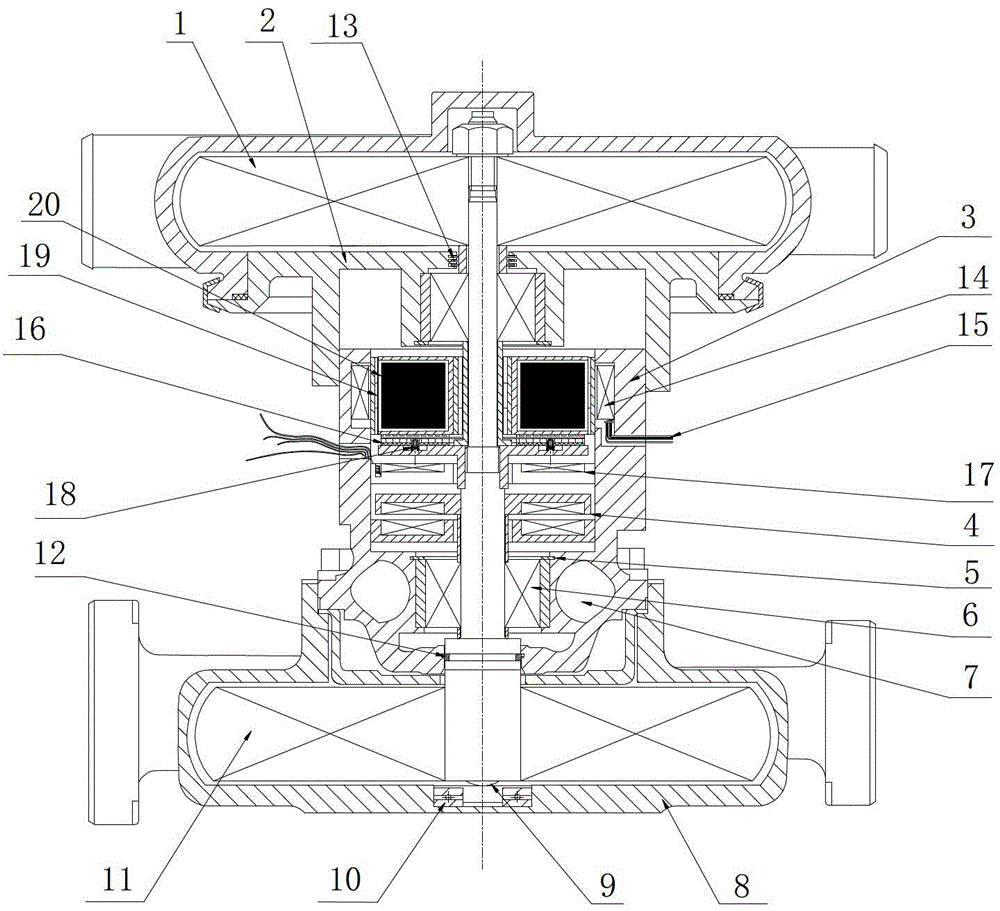

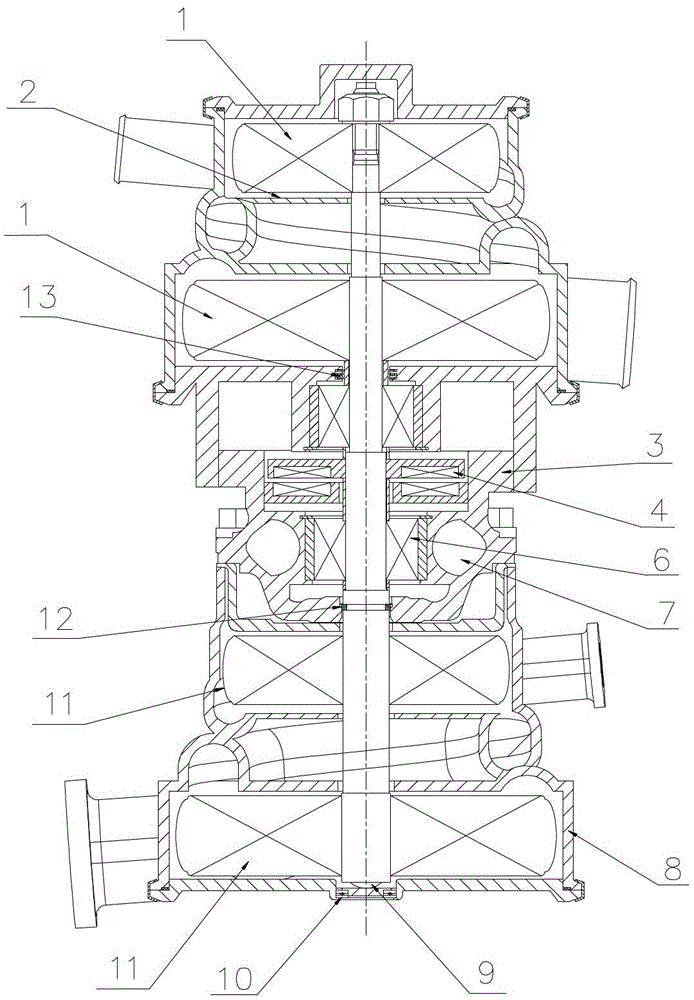

Double-turbine electric-vortex-type automotive air-conditioner compressor

InactiveCN106168217ADe-vibration factorStable jobRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectric machineEngineering

The invention discloses a double-turbine electric-vortex-type automotive air-conditioner compressor. The double-turbine electric-vortex-type automotive air-conditioner compressor comprises a motor and two vortex pump heads respectively arranged at two ends of the motor. The motor is arranged in a compressor shell, and comprises a stator, a rotor and a motor rotating shaft from outside to inside. Each vortex pump head comprises a static disc base, a static disc and a dynamic disc. The spiral directions of teeth in the two vertex pump heads at the two ends of the motor are opposite. The double-turbine electric-vortex-type automotive air-conditioner compressor has the advantages that a group of opposite vertex pump heads is adopted as a compression body, the vertex pump heads work correspondingly, vibration caused during eccentric operation of a single pump is avoided, and the compressor works smoothly, so that the range of working speed of the compressor is wide, the single variety of compressors has wider application range, and cost for enterprise production can be reduced; only pumps with 1-2 types of displacement are needed to be produced, and production of plenty of pump blanks is not needed, so that labor intensity of warehouses is reduced, and convenience and rapidness in management are achieved.

Owner:XINYU YILI NEW ENERGY CO LTD

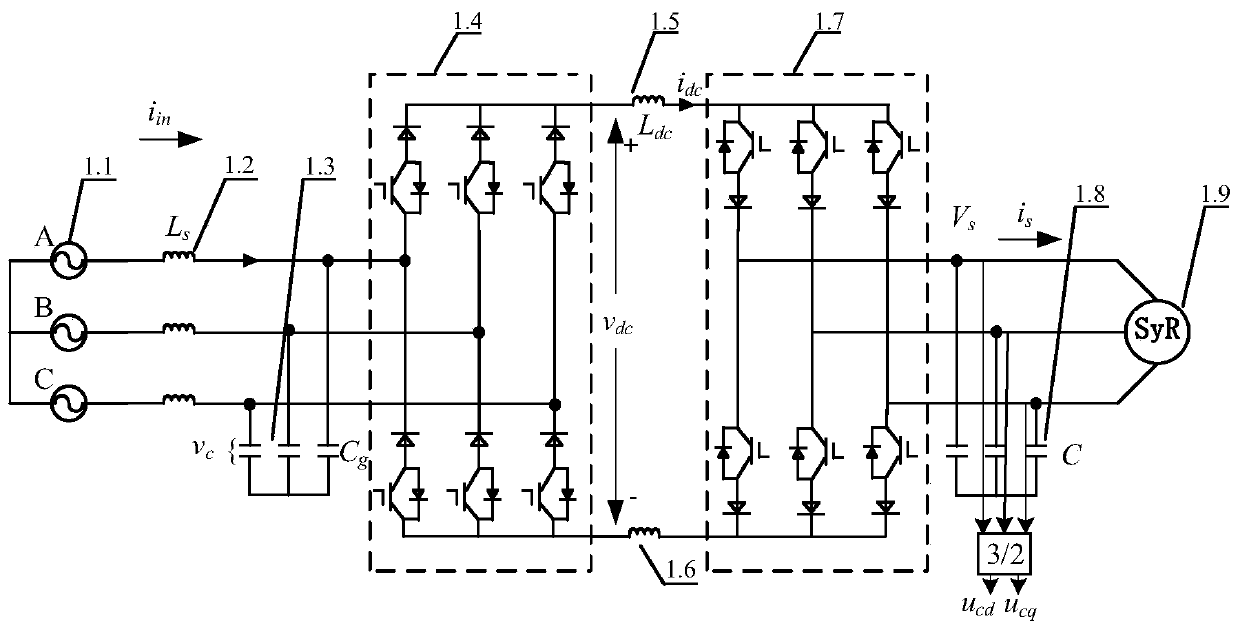

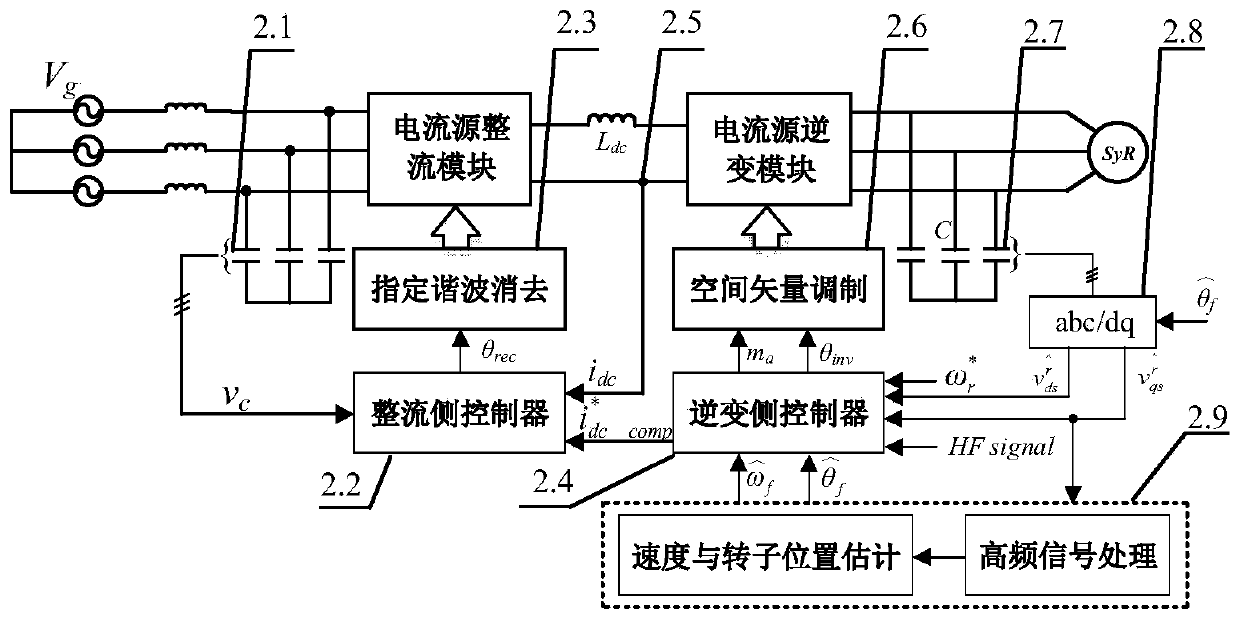

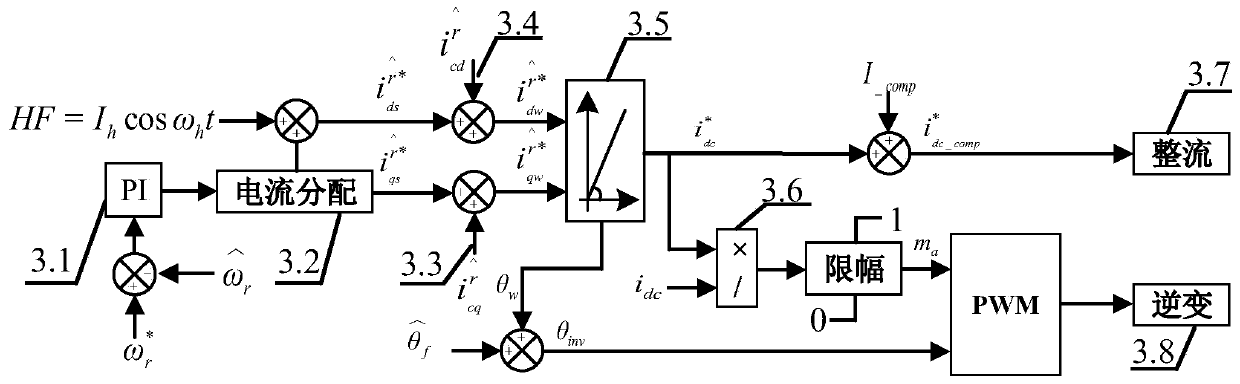

Position-free control method of current source type synchronous reluctance motor system

InactiveCN110247590AWide operating speed rangeEnhanced inhibitory effectElectric motor controlVector control systemsSynchronous reluctance motorTransformer

The invention discloses a position-free control method of a current source type synchronous reluctance motor system. The problems of reduced system reliability, sensitivity to disturbance and noise and increased system cost caused by a motor position sensor can be solved. The system structure comprises an AC power grid; a current source type rectifier unit is connected with a multi-winding transformer through a three-phase filter capacitor bank; the current source rectifier unit is connected with a current source inverter unit through a DC bus inductor; and the current source inverter unit is connected with the synchronous reluctance motor through the three-phase filter capacitor bank. The position-free control strategy comprises the following steps: injecting a high-frequency current signal into the d axis of the motor; sampling and calculating the motor stator voltage to obtain the stator q-axis voltage of the motor; extracting a high-frequency component in the q-axis voltage of the motor, and processing to obtain a position signal of a motor rotor; and establishing a predicted rotor coordinate system to realize position-free control of the synchronous reluctance motor.

Owner:SOUTHEAST UNIV

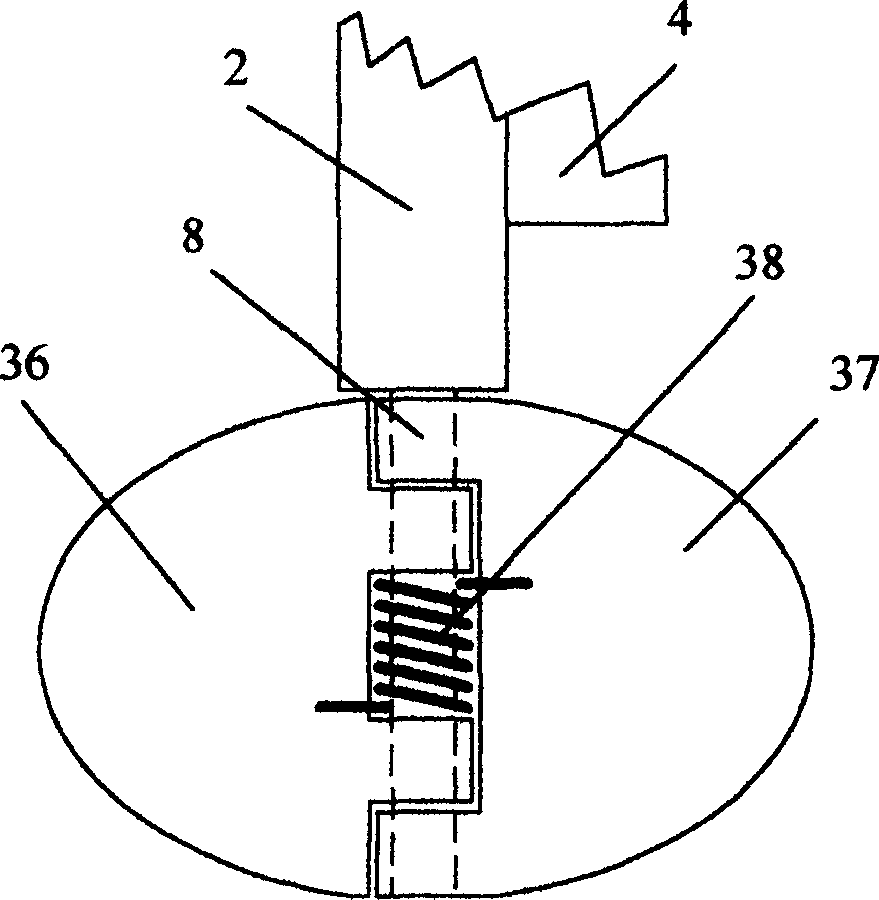

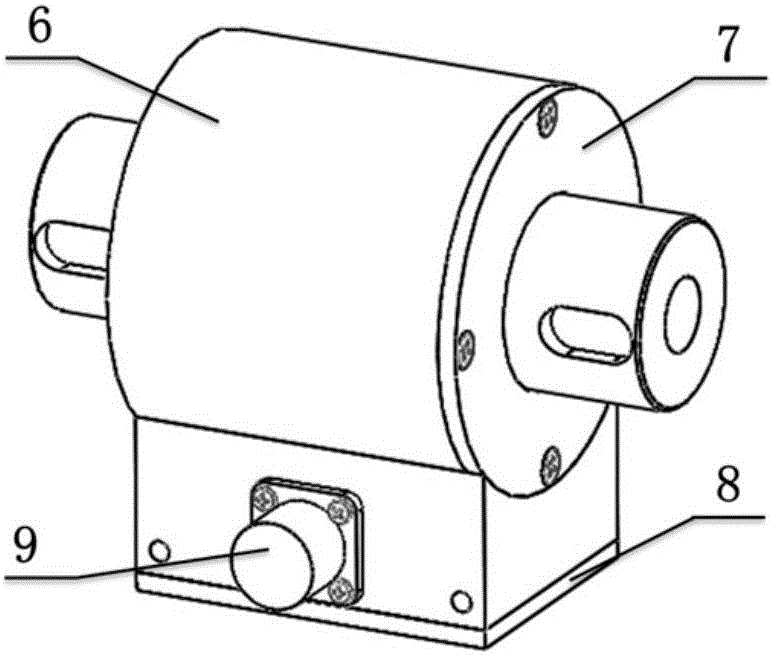

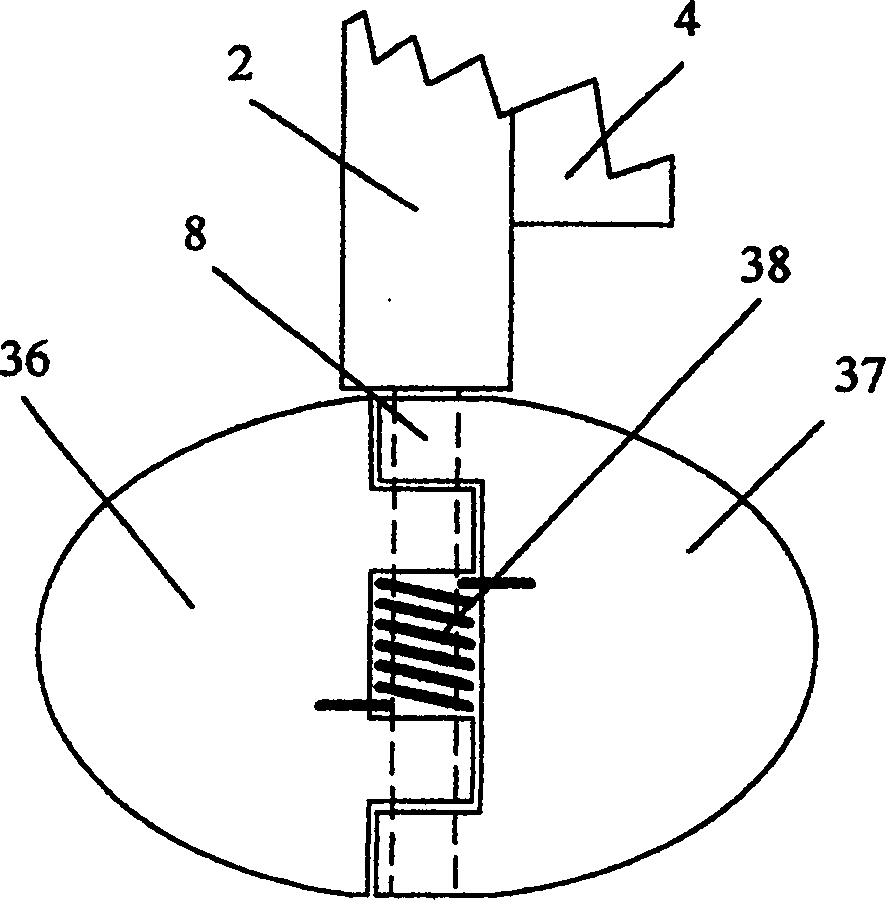

Dynamic torque measurement sensor with speed measurement function

InactiveCN106644196ASimple structureIncrease working speedForce measurementLinear/angular speed measurementElastomerEngineering

The invention discloses a dynamic torque measurement sensor with a speed measurement function. The sensor comprises an integral conductive slip ring, an elastomer spindle, bearings, a shell, and fastening screws. The integral conductive slip ring has an inner ring and an outer ring which can rotate relative to each other, and the inner ring and the outer ring lead out multiple wires respectively. The wires are connected inside the slip ring. The integral conductive slip ring sleeves the elastomer spindle. The elastomer spindle is rotationally supported on the shell through the bearings. The inner ring of the slip ring is fixed on the elastomer spindle by screws, and can rotate together with the elastomer spindle. The outer ring of the slip ring is fixed on the shell by a stop screw. The wires of the inner ring of the slip ring are connected with a strain gauge on the elastomer spindle. The wires of the outer ring of the slip ring are connected with a socket on the shell. Voltage and electrical signals are transmitted between the moving and static parts of the sensor through the integral conductive slip ring. The working speed range of the dynamic torque sensor is broadened, and the service life is prolonged. Moreover, the sensor is additionally provided with a speed measurement function.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Diirect-driven generating set

ActiveCN102510142BSimplify the drivetrainSimple structureMagnetic circuit rotating partsDynamo-electric gearsMagnetic reluctanceMotor design

The invention discloses a direct-driven generator and a direct-driven generating set formed thereby. The direct-driven generator comprises a stator and a rotor, wherein the stator further comprises a stator core and a stator winding; the rotor further comprises a rotor core and permanent magnets placed in no less than one air slot of the rotor core; and the electromagnetic torque of the direct-driven generator comprises a permanent-magnet torque and a reluctance torque. The direct-driven generator synthesizes the characteristics of both a synchronous reluctance generator and a synchronous permanent-magnet generator, reflects a brand-new motor design and running concept, has the remarkable advantages of high power density, wide operation speed range, high efficiency, small size, light weight and the like, and greatly improves the competitive advantage of a direct-driven wind turbine when applied to the large-scale direct-driven wind turbine.

Owner:GUODIAN UNITED POWER TECH

Permanent-magnet DC brushless variable speed constant-pressure wind power generator and its voltage stabilization method

InactiveCN100426656CIncrease leakage inductance reactanceThe leakage inductance reactance is reducedWindingsMagnetic circuit rotating partsWind drivenPower grid

The invention relates to a permanent magnetism dc brushless varying speed pressure-sustaining wind-driven generator and its anti-hunt means. The generator is derived by the varying speed wind-orbicular and sends the pressure-sustaining dc power which has been outputted to the power net after frequency-transferring; when the motor achieves the mix working rotate speed, the armature winding leak per-unit quantity against X* equals the rate of the difference of the motor mix rotate speed and the min rotate speed and the min working rotate speed with the range 0.1-1.7.

Owner:包头长安永磁电机有限公司

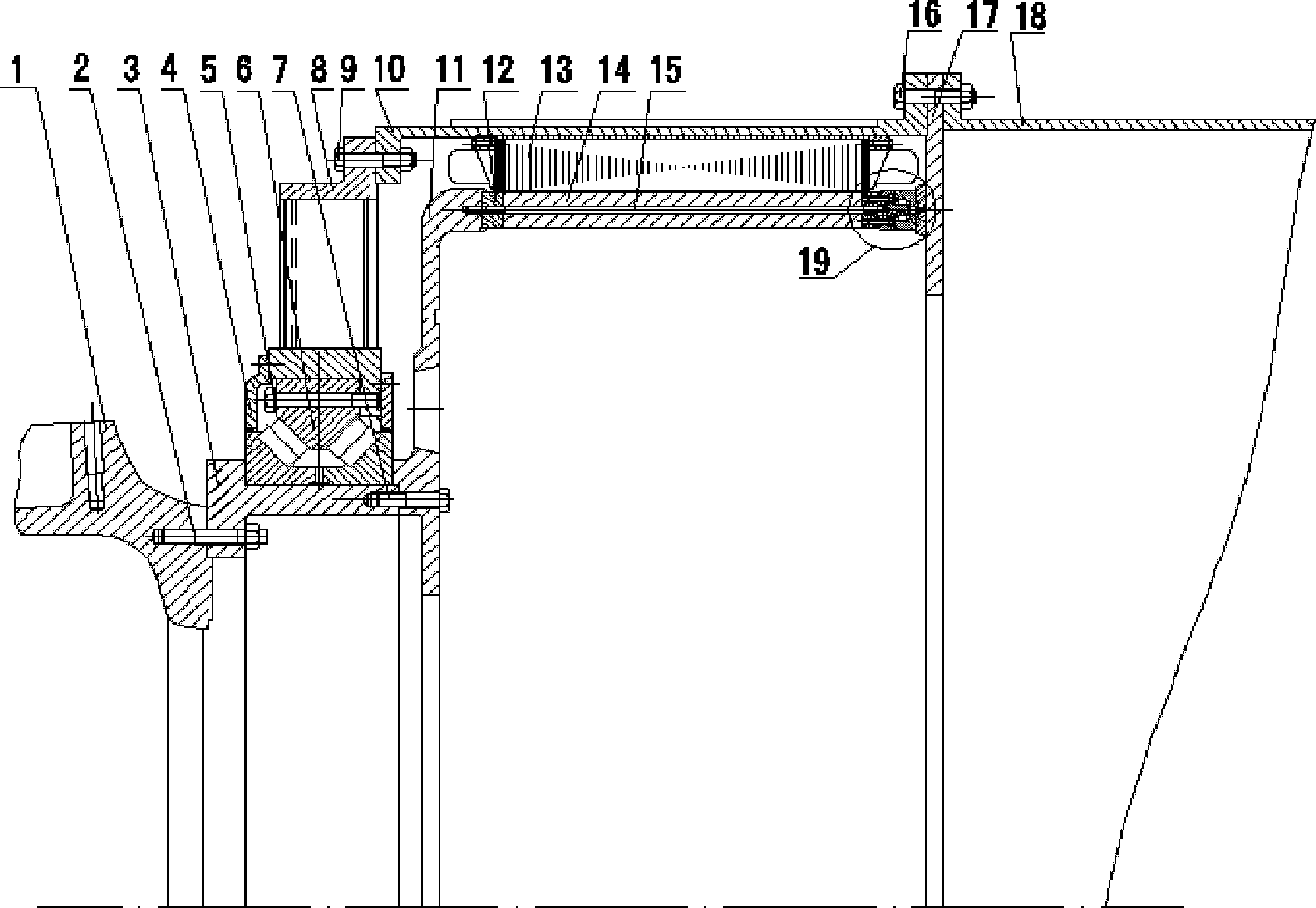

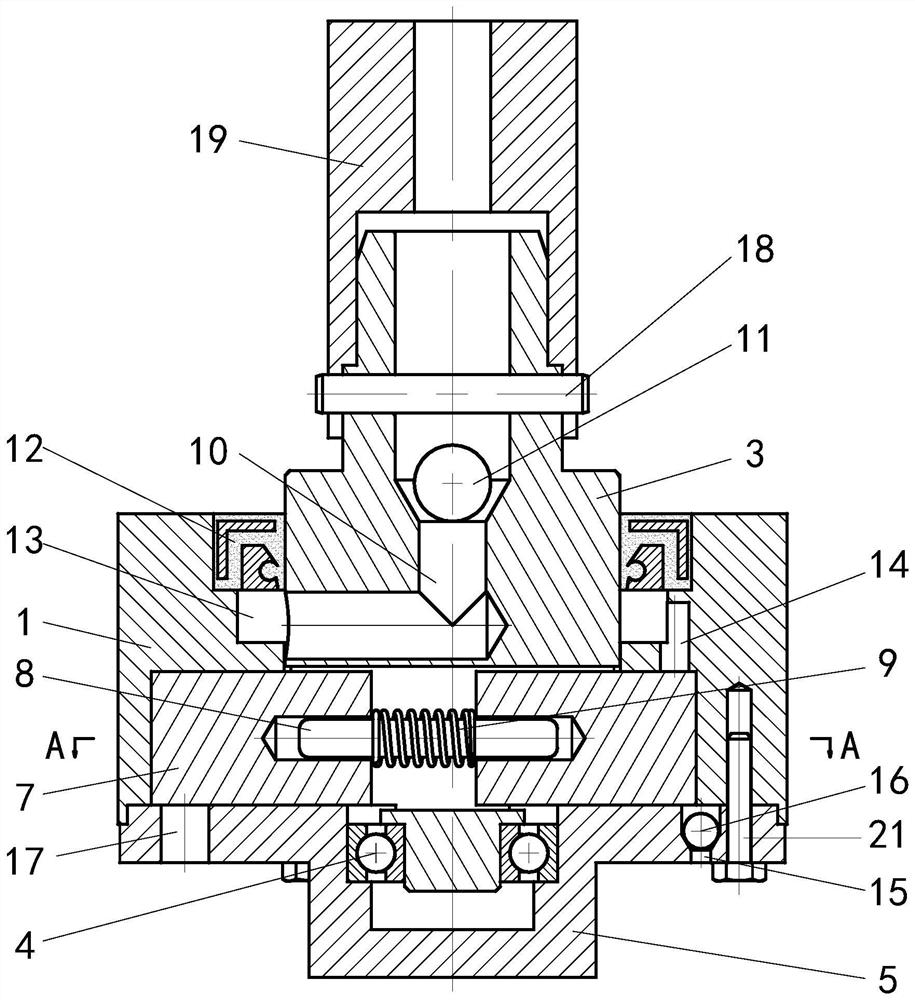

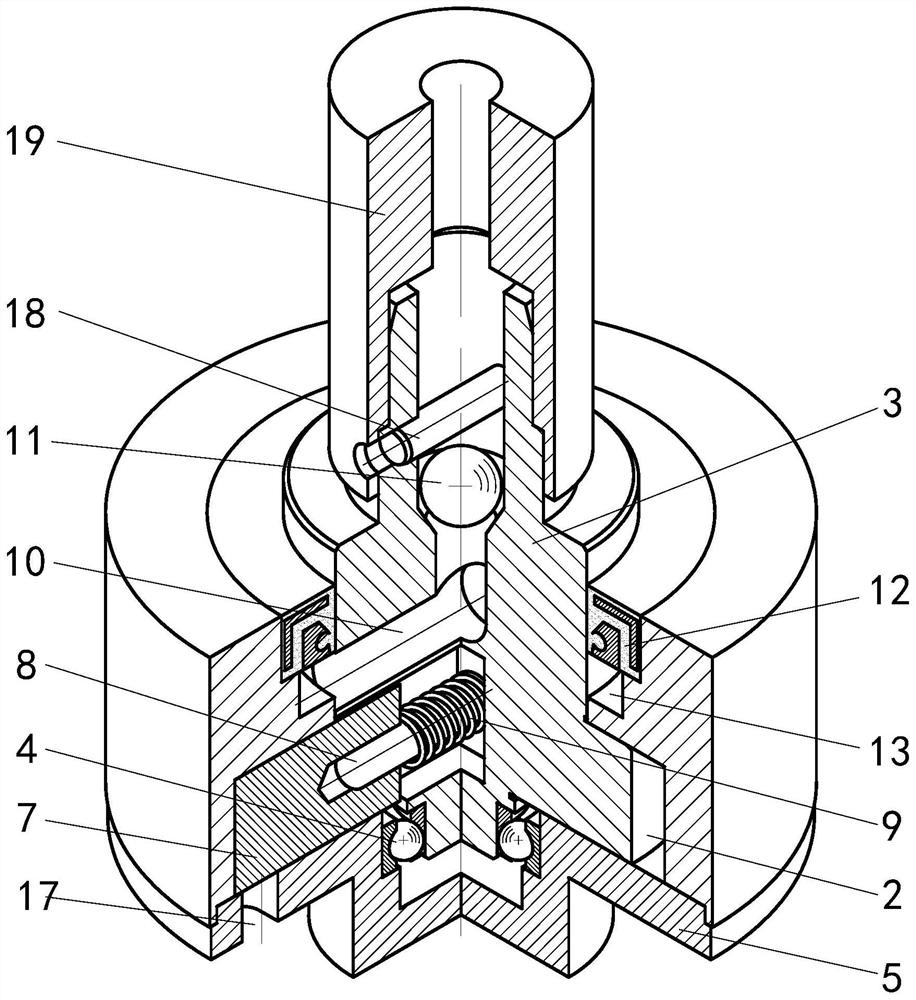

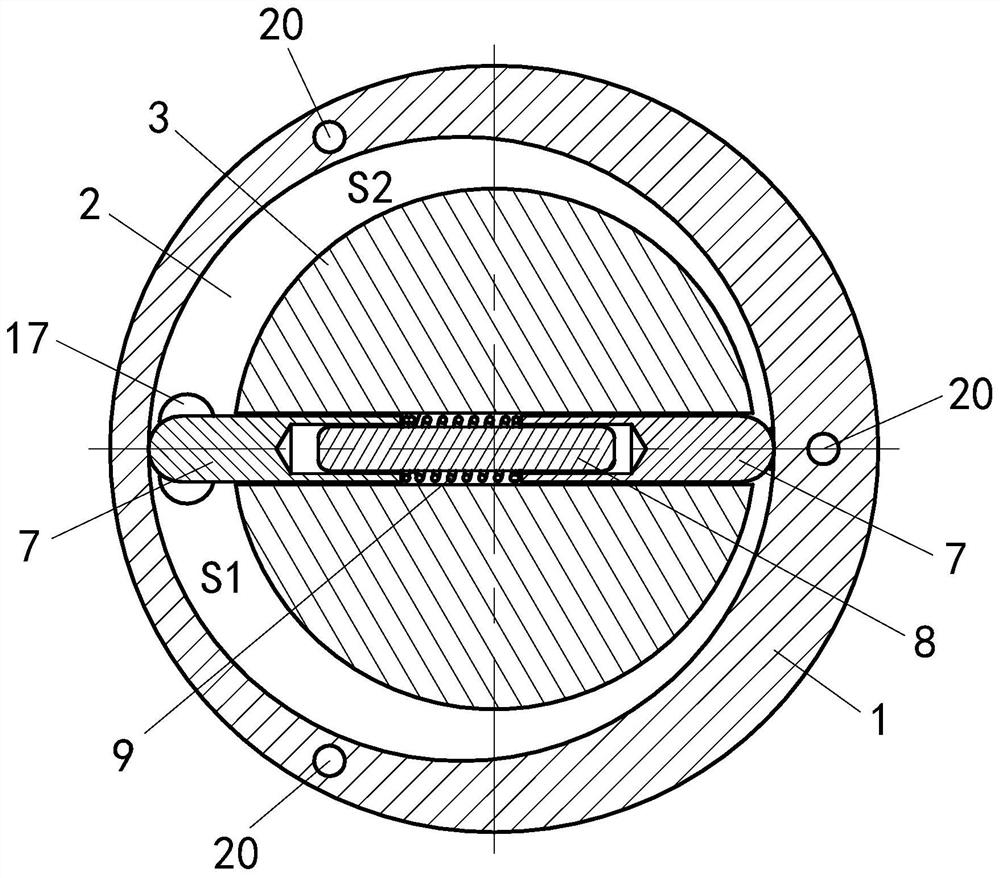

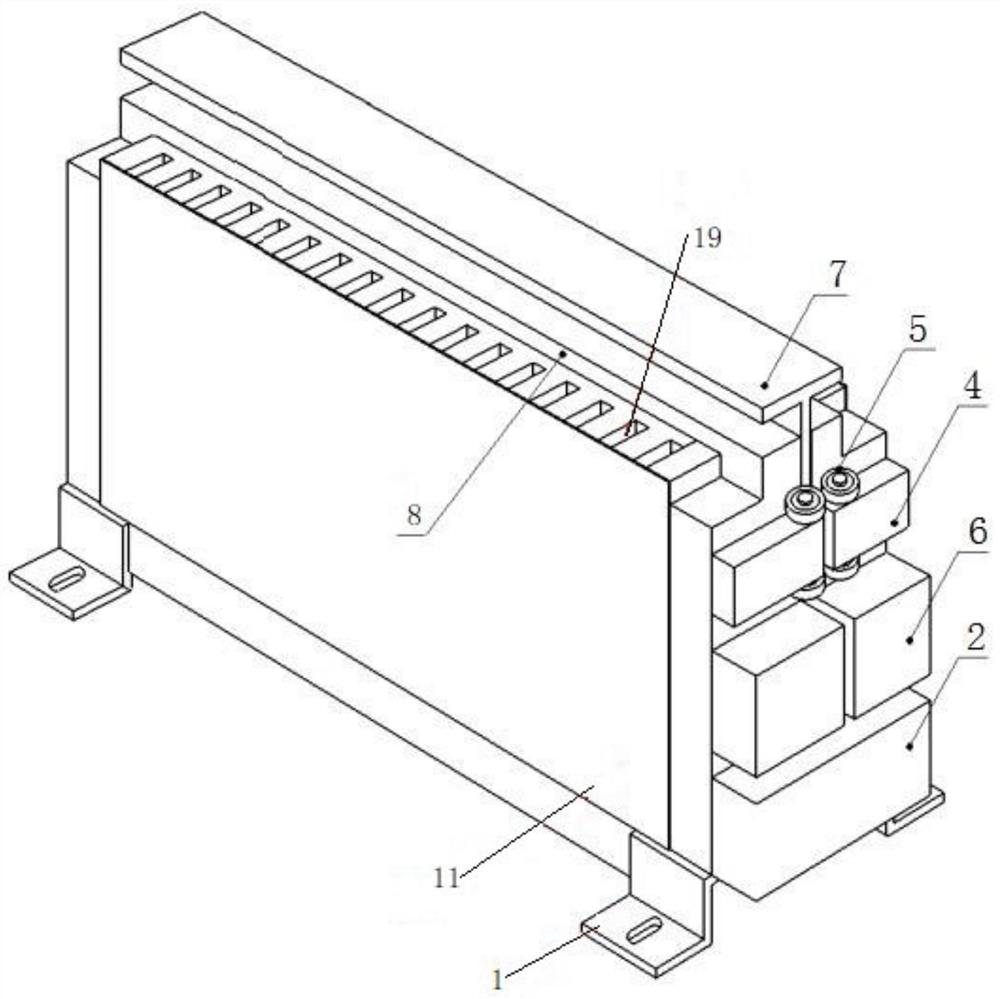

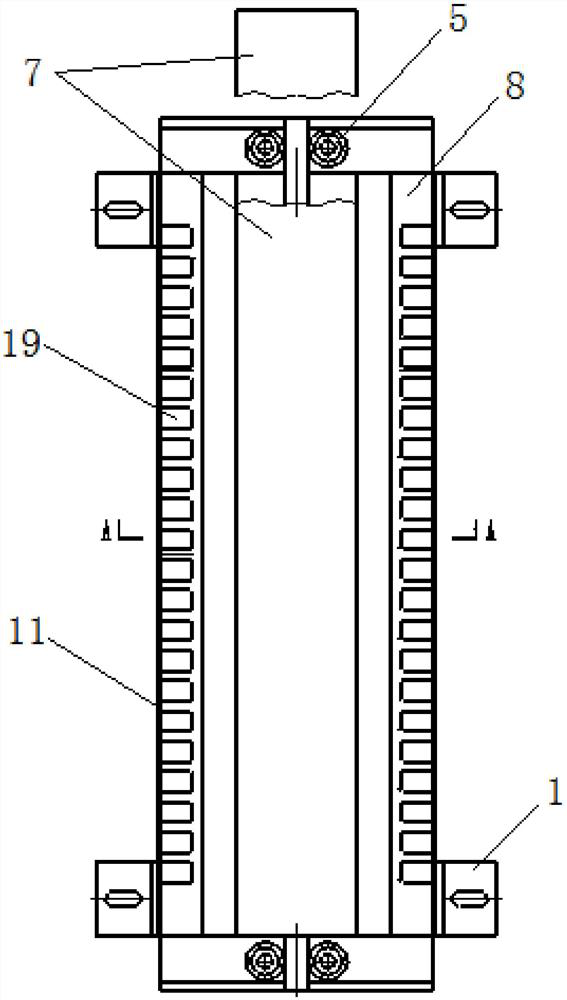

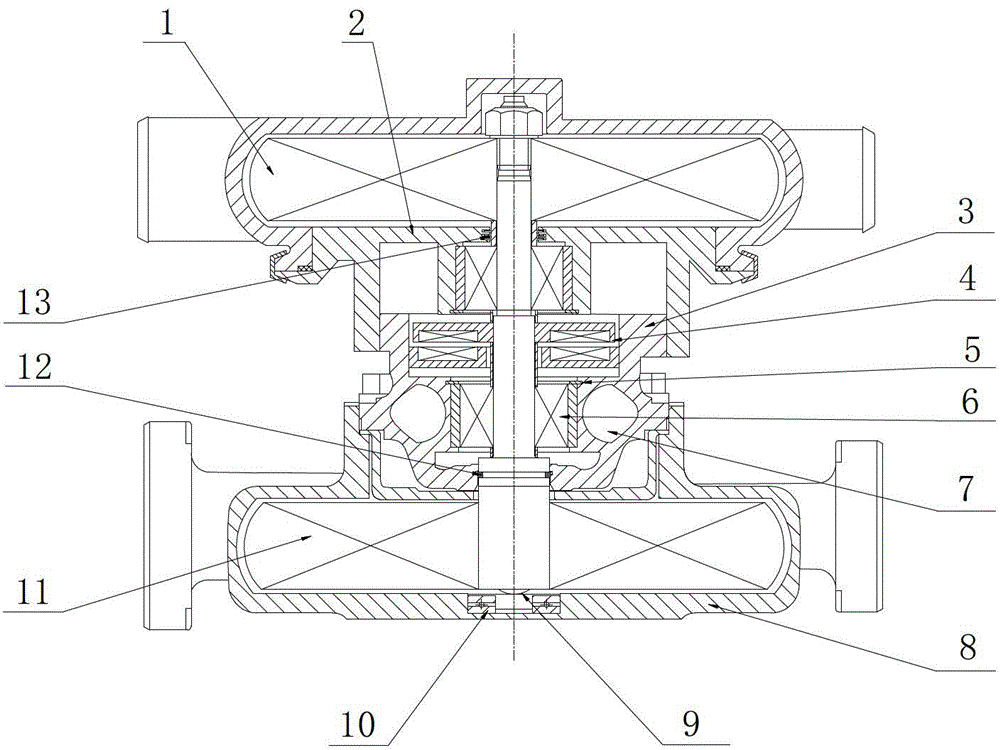

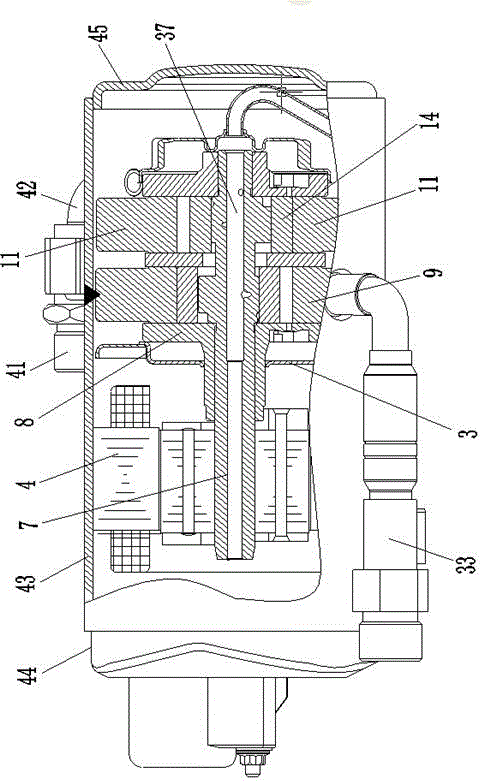

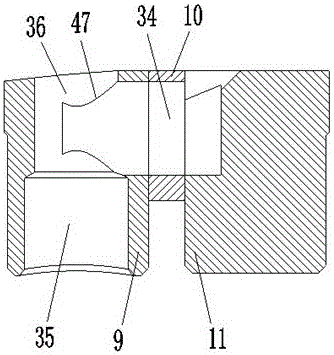

Coaxial self-lubricating device for vertical transmission mechanism

PendingCN112096843AAvoid damageTimely lubricationGear lubrication/coolingLubricating pumpsOil canEngineering

The invention discloses a coaxial self-lubricating device for a vertical transmission mechanism. The coaxial self-lubricating device comprises a pump shell (1), and a cylindrical eccentric containingcavity (2) is formed in the lower end of the pump shell (1); a rotor (3) is arranged in the cylindrical eccentric containing cavity (2), and the bottom end of the rotor (3) is rotationally connected with a pump cover (5) through a bearing (4); the part, located in the cylindrical eccentric containing cavity (2), of the rotor (3) is provided with a blade groove (6), and a pair of blades (7) is arranged in the blade groove (6); and the blades (7) are in sliding connection with the blade grooves (6). According to the device, oil can be pumped during forward and reverse rotation; the working rotating speed range is wide, and the coaxial self-lubricating device is suitable for lubricating low-speed, high-speed and rotating-speed-adjustable transmission devices; and the displacement of the lubricating device can be set through adjusting the eccentric distance of the cylindrical eccentric containing cavity or the axial height of the cylindrical eccentric containing cavity. The coaxial self-lubricating device can synchronously work along with the transmission mechanism without extra power.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

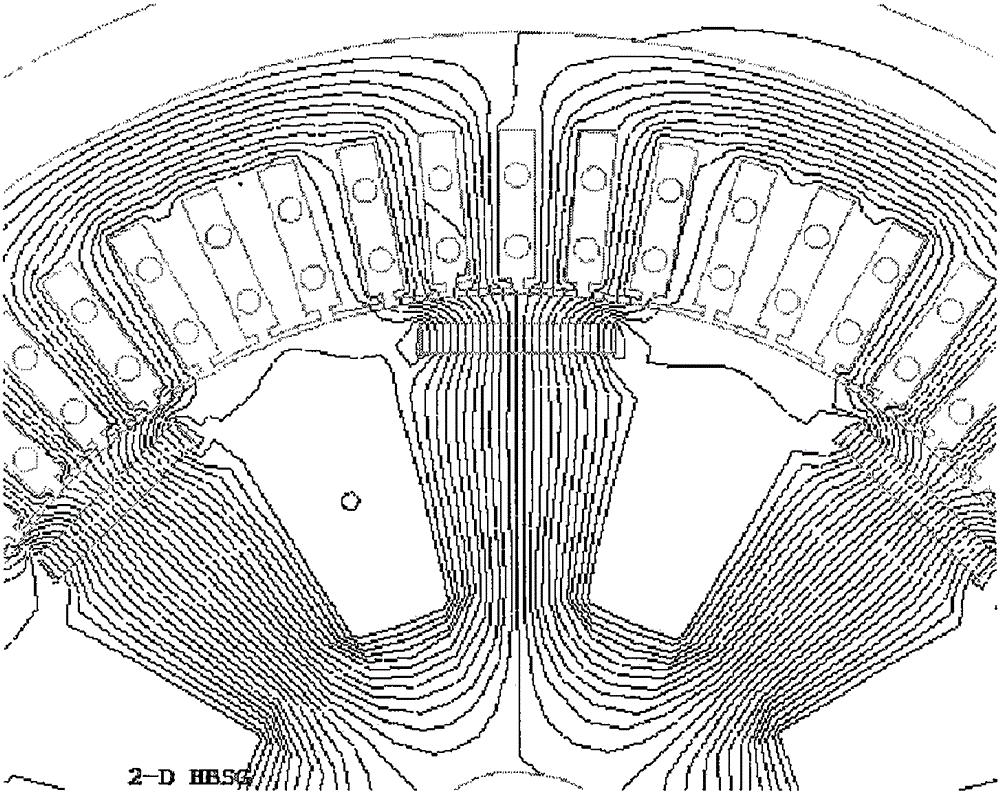

A flux leakage adjustable brushless hybrid excitation synchronous generator

ActiveCN111082626BExcitation adjustment is easy to implementWiden the field weakening rangeSynchronous generatorsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesEngineering

The invention provides a brushless hybrid excitation synchronous generator with adjustable flux leakage, which includes a stator and a rotor. Alternately arranged into at least a four-pole structure, the rotor harmonic winding is connected to the excitation winding, the electric excitation pole adopts harmonic current brushless excitation, the permanent magnet pole adopts a V-shaped embedded arrangement of permanent magnets, and the two ends of the permanent magnet and the permanent magnet A leakage flux path is provided between the magnetic poles, the leakage flux path is used for the leakage flux of the permanent magnet when the field is weakened, and the excitation flux is passed by the leakage flux path when the magnetization is increased. Based on the existing harmonic excitation technology, the present invention proposes a harmonic excitation-permanent magnet flux leakage adjustable brushless hybrid excitation synchronous generator, which can be applied to various industrial fields such as wind power generation and hybrid electric vehicles.

Owner:DONGHUA UNIV

Planar linear thrust motor

InactiveCN112910214ASimple structureReduce volumePropulsion systemsMagnetic holding devicesMagnetic levitationControl engineering

The invention discloses a planar linear thrust motor which comprises a machine body and a T-shaped sliding block. A linear sliding channel for the T-shaped sliding block to slide is arranged in the machine body, a plurality of iron cores are arranged in the sliding channel at intervals, a coil is arranged between every two adjacent iron cores, and an iron stress piece is arranged on the T-shaped sliding block. The planar linear thrust motor also comprises a start-stop valve used for controlling the coil to be electrified; and a controller in point connection with the start-stop valve. The magnetic suspension linear thrust motor is directly used, the planar linear thrust motor can be applied to elevator transformation of old housing communities, tower cranes are not needed, and energy conservation and environmental protection are achieved.

Owner:裘苗全

Zero-sequence current suppression method for open-winding permanent magnet synchronous motor system powered by double inverters

ActiveCN104242775BLow costEnhanced inhibitory effectElectronic commutation motor controlAC motor controlPhase currentsLoop control

The invention discloses a zero-sequence current suppressing method for an open winding permanent magnet synchronous motor system powered by double inverters, belonging to the technical field of motor control. The invention aims to solve the problem of zero-sequence current in an open winding permanent magnet synchronous motor system powered by double inverters. It increases the zero-sequence current i on the basis of the vector control system 0 = 0 closed-loop control, to achieve the suppression of zero-sequence current, it calculates the zero-sequence current by detecting the three-phase current of the motor, and uses it as a feedback value to build a closed-loop control of zero-sequence current; the output of the zero-sequence current loop is zero-sequence voltage Given, the zero-sequence current is suppressed by regulating the zero-sequence voltage generated by the dual inverters. The invention is used for suppressing zero-sequence current in an open winding permanent magnet synchronous motor system powered by double inverters.

Owner:HARBIN INST OF TECH

Belt drive starter generator

ActiveCN105743265BStart fastWide operating speed rangeMechanical energy handlingStructural associationStarter generatorEngineering

The invention relates to a belt transmission type starting and power generation integrated machine. The belt transmission type starting and power generation integrated machine comprises a belt pulley, a driving end cover assembly, a stator assembly, a rotor assembly and a carbon brush end cover assembly and is characterized in that a bearing chamber is arranged at a position, corresponding to a rotor shaft, at the middle of a carbon brush end cover, a bearing sensor is arranged in the bearing chamber, the end part of a carbon brush in a carbon brush rack props against the circumferential surface of a current collection ring of a rotor shaft, a junction box is further arranged outside the carbon brush end cover, a wiring seat is fixedly arranged in the junction box and is used for connecting three phase cables, cable heads of the three phase cables are separately and fixedly provided with connection sheets, the connection sheets separately pass through a socket of the junction box and enter to the junction box to be fixedly connected with the wiring seat, a sealing cover is fixedly arranged at the top of the junction box, a temperature sensor is arranged at the end part of a stator iron core, and a signal wire connector of the temperature sensor is fixed on the carbon brush rack. The belt transmission type starting and power generation integrated machine is compact in structure and has the advantages of a rapid starting function, low starting noise, automatic switching between starting and power generation and high power generation efficiency, and also has functions of assisted electric power for an engine and vehicle braking energy recycle.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

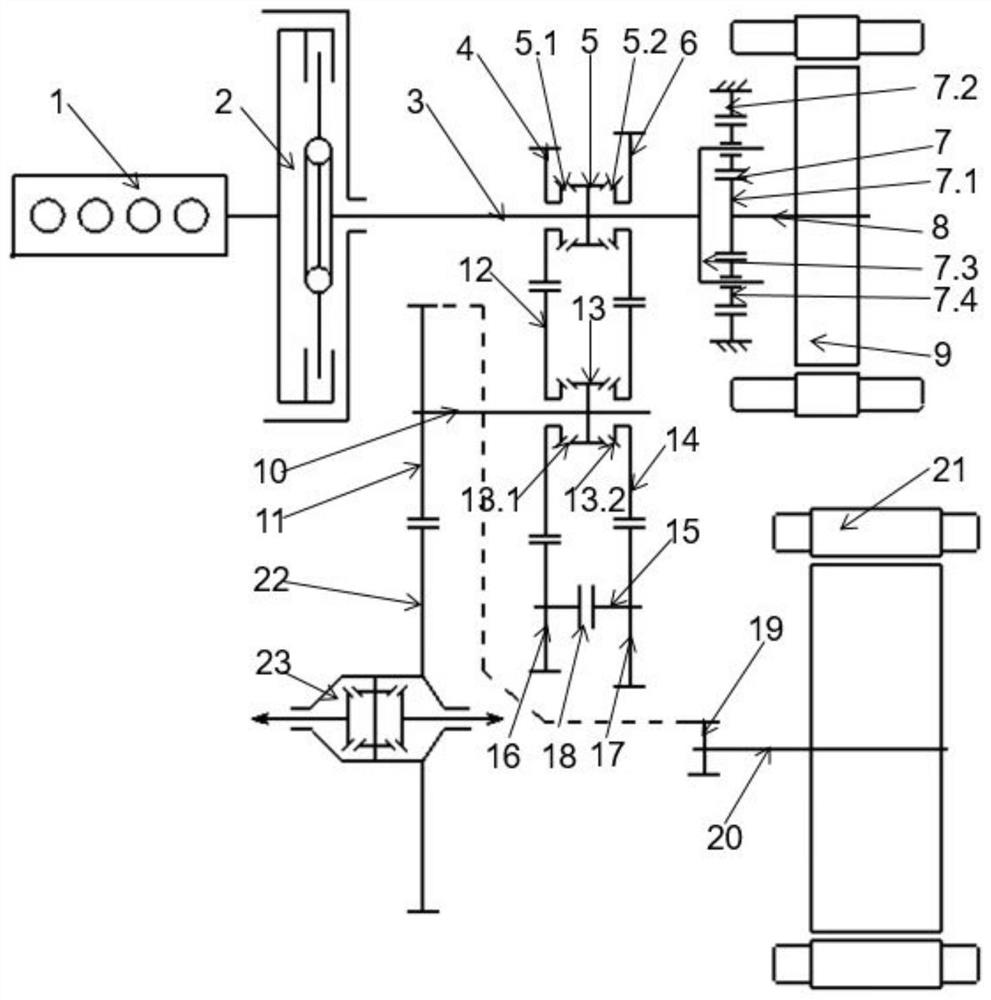

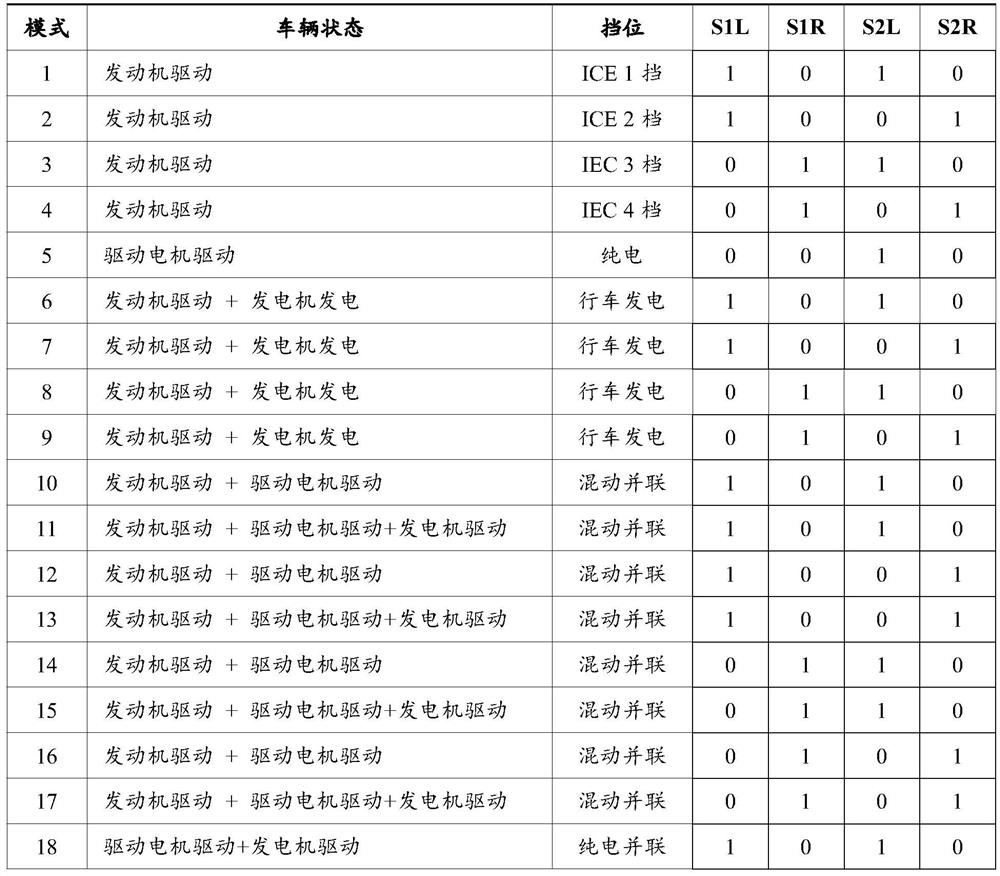

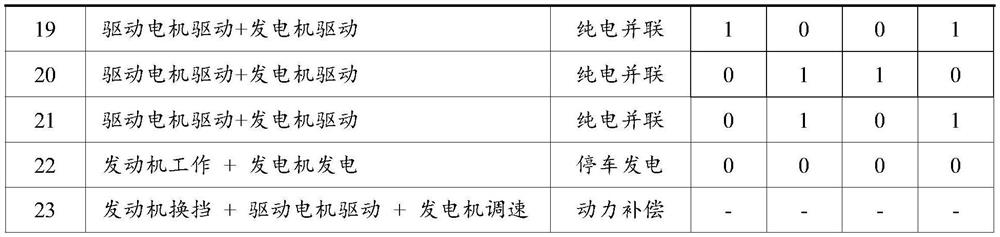

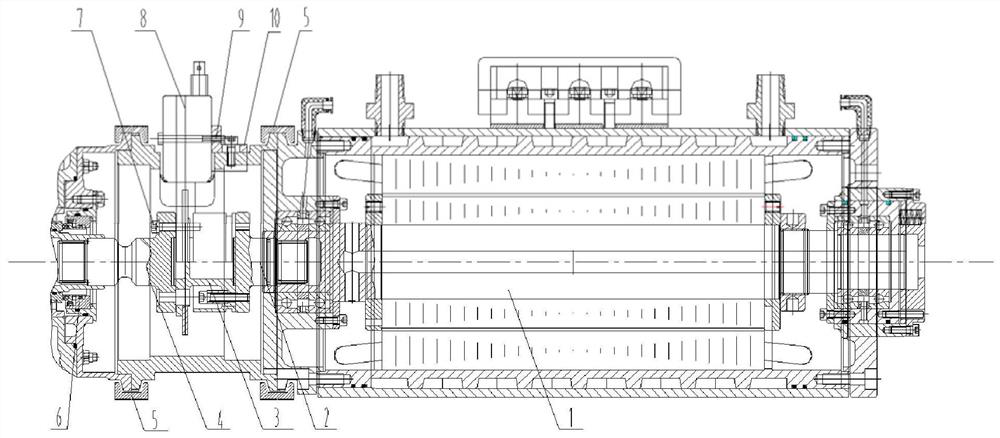

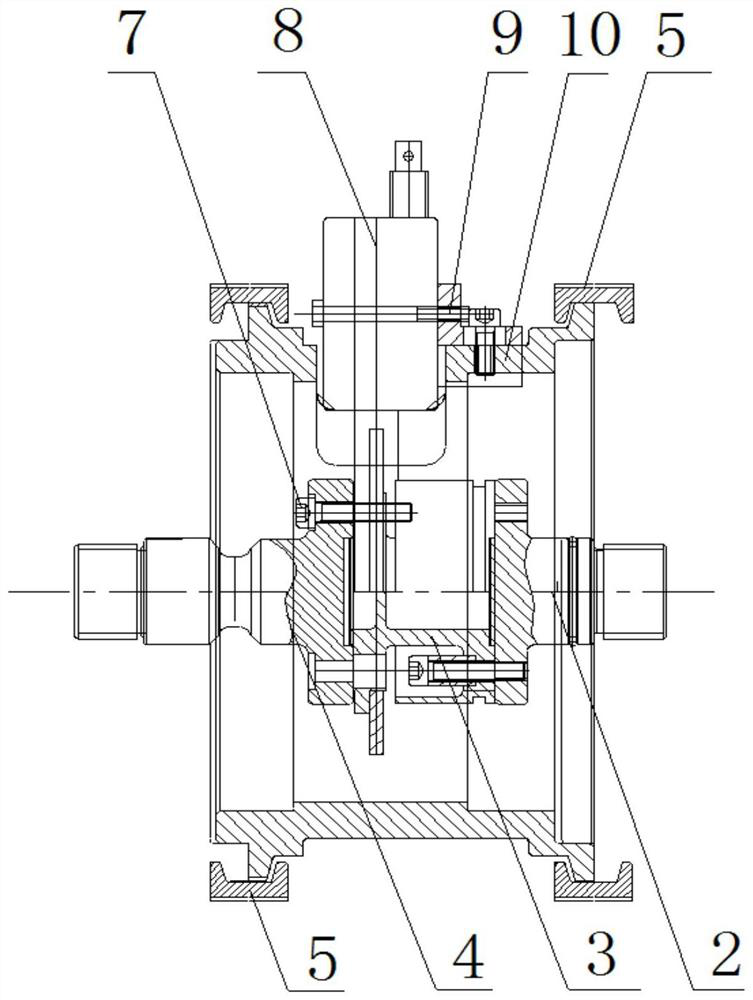

A multi-mode drive system for a hybrid vehicle

ActiveCN112193048BReduce fuel consumptionImprove economyHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machinery

The present invention proposes a multi-mode drive system for a hybrid vehicle, including an engine, a generator, a drive motor, a planetary gear mechanism, an input shaft, an input shaft of a generator, an intermediate shaft, an output shaft of a drive motor, an output shaft and a differential, The engine is connected to the input shaft through a torsional shock absorber. The input shaft is coaxially arranged with the input shaft of the generator, and arranged parallel to the output shaft, intermediate shaft and output shaft of the driving motor. The planetary gear mechanism is installed on the input shaft of the generator. The end of the shaft is connected with the planet carrier, the first gear and the second gear are installed on the input shaft, the third gear and the fourth gear are installed on the intermediate shaft, and the fifth, sixth, and seventh gears are installed on the output shaft in sequence. The eighth gear is arranged on the output shaft of the driving motor, the sixth gear and the seventh gear mesh with the first and second gears, the third gear and the fourth gear respectively, and the differential gear is arranged on the differential, and the second The fifth gear meshes with the differential gear and the eighth gear respectively. The present invention has a compact structure and can realize driving in various functional modes.

Owner:DONGFENG MOTOR CORP HUBEI

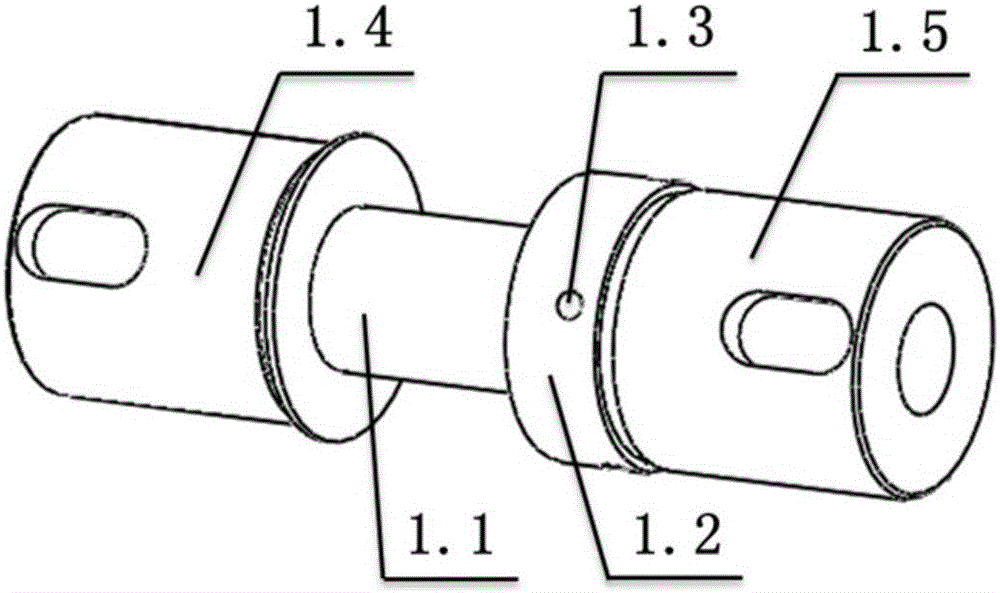

A cantilever mounted device capable of measuring torque at high speed

ActiveCN109655270BReduce in quantityThe design idea is simpleMeasurement of torque/twisting force while tighteningEngine testingElectric machineryMechanical equipment

The invention discloses a cantilever-mounted device capable of measuring torque at high rotational speed, which comprises a lap joint structure casing sheathed on a motor spline shaft and a mounting bracket. The motor spline shaft includes a motor spline shaft I and a motor which are separated from each other. Spline shaft II; an opening is opened on the shell of the overlapping structure, and the stator of the torque sensor used to measure the torque is set in the opening and detachably connected to the shell of the overlapping structure through the mounting bracket; the rotor of the torque sensor is set on the motor The spline shaft I and the motor spline shaft II are detachably connected to the motor spline shaft I and the motor spline shaft II respectively. In the present invention, the torque sensor is mounted on a cantilever, and the number of components on the transmission chain is reduced as much as possible. The overall structure is compact, and the axial length, that is, the length of the cantilever, is reduced as much as possible. The invention has a wide working speed range and a wide application range, and can be applied to power extraction tests of multi-type high-speed mechanical equipment.

Owner:中国航发贵阳发动机设计研究所

Low-speed high-thrust-density linear motor

The invention relates to a low-speed high-thrust-density linear motor which comprises a motor short primary and a motor long secondary arranged opposite to the motor short primary, wherein an air gap (5) is reserved between the motor short primary and the motor long secondary; the motor short primary comprises a stator core (1), stator teeth (3) uniformly distributed at the periphery of the stator core (1), a stator winding (2) and stator permanent magnets (4); the stator core (1) is of an open slot stator structure, i.e., the stator core (1) is provided with a stator slot (8), the stator permanent magnets (4) are uniformly distributed between every two adjacent stator teeth (3), and the stator winding (2) is inserted into the stator slot (8); the motor long secondary comprises an active cell yoke (7) and active cell permanent magnets (6); and the active cell permanent magnets (6) are embedded into the active cell yoke (7) alternately and equidistantly in a horizontal direction. In the low-speed high-thrust-density linear motor provided by the invention, the magnetic modulation rings in a magnetic gear are replaced by the stator teeth, thereby simplifying the machining process, improving the reliability of the device and reducing the system manufacturing cost.

Owner:SOUTHEAST UNIV

Rotary piston machine

InactiveCN1177131CAvoid or reduce reciprocating motionImprove work efficiencyOscillating piston pumpsInternal combustion piston enginesWater turbineMechanical energy

A rotary piston unit for IC engine, water turbine, steam turbine, water pump, air compressor, etc is composed of disk-shaped piston holder on mainshaft, multiple plate pistons running directionally around mainshaft in planetary mode, and two semi-cylinders on two end faces of planetary piston to form a piston space with alternative big and small cross-sections. The left part and right part of each plate piston sequentially and periodically come in said piston space to form piston effect, realizing the conversion between fluid energy and mechanical energy.

Owner:姚平

Novel rotary piston type engine

InactiveCN101333962BIncrease profitWide operating speed rangeInternal combustion piston enginesGas turbine plantsExternal combustion engineDrive shaft

The invention discloses a novel rotary piston engine which comprises an engine shell, a main transmission shaft and a piston group wheel; the piston group wheel is nested on the main transmission shaft; the main transmission shaft nested with the piston group wheel can be rotationally mounted in the inner cavity of the engine shell; the piston group wheel is composed of a rotary flywheel and at least a group of combustion chambers; the at least a group of combustion chambers are evenly arranged on the circumference surface of the rotary flywheel and on the same cross section; at least an air port composed of an exhaust port, a spark plug and an oil injection nozzle is arranged on the engine shell corresponding to the combustion chambers on the flywheel. Because the complicated crankshaft structure, the complicated cam structure and the complicated air distribution structure of the piston internal combustion engine are cancelled in the invention, the novel rotary piston engine has the advantages of more simple structure, higher fuel utilization rate, wide operation speed range, simple operation and control, good operation performance, ensuring the fuel utilization rate and the output torque to be in the best state.

Owner:敬德强

Vertical Turbocharger

ActiveCN103277184BExtend your lifeImprove reliabilityInternal combustion piston enginesEngine componentsTurbochargerAxial thrust

The invention provides a vertical turbocharger. The vertical turbocharger comprises an air compressor, a middle body, a rotor shaft, a turbine, a sealing ring and a non-liquid oil lubrication bearing, wherein the rotor shaft is perpendicular to the ground, the air compressor and the turbine are arranged at the upper end and the lower end of the rotor shaft respectively, an axial thrust bearing is arranged between the lower end of the rotor shaft and a turbine shell of the turbine, the middle body is arranged between the air compressor and the turbine, the two ends of the middle body are respectively connected with the air compressor and the turbine, the middle body is matched with the rotor shaft through the non-liquid oil lubrication bearing, the sealing ring is arranged between the end, close to the turbine, of the middle body and the rotor shaft, an air inlet of the air compressor and an air inlet of the turbine are both radial air inlets, and an air outlet of the air compressor and an air outlet of the turbine are both radial air outlets. The vertical turbocharger eliminates the influences of the gravity of a rotor on system stability, improves dynamics performance of the turbocharger, and improves the pneumatic efficiency, the pressure ratio and the mechanical efficiency. Compared with a traditional turbocharger, the vertical turbocharger is more compact in structure, and smaller in gas flow loss.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A Fractional Slot Concentrated Winding Pole-changing Memory Motor Without Changing the Winding Arrangement

ActiveCN106787281BSimplify the peripheral control circuitReduce manufacturing costMagnetic circuit rotating partsAsynchronous induction motorsElectric machineMemory motor

Owner:SOUTHEAST UNIV

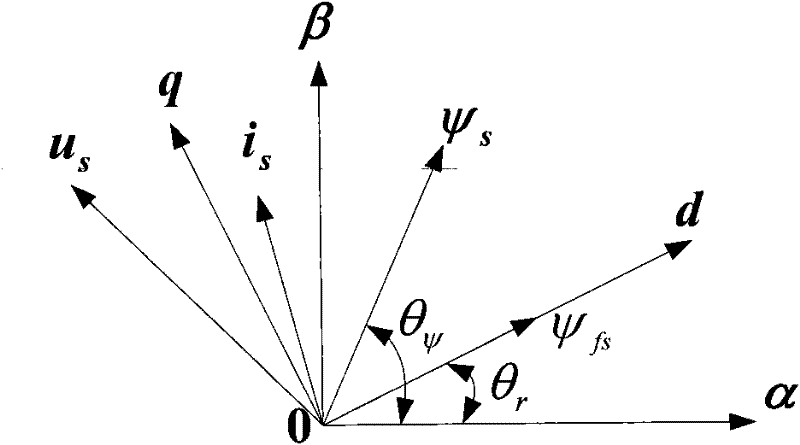

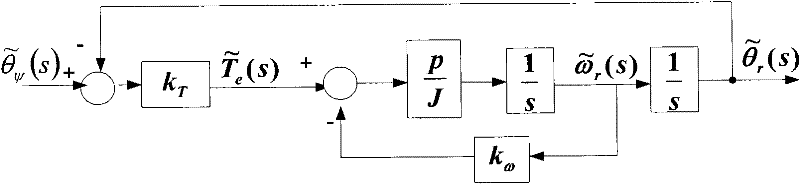

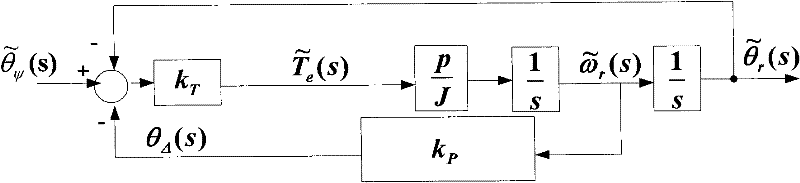

Control system for speed of rotor of hybrid stepping motor and control method therefor

ActiveCN101753090BGood current sineReduce running noiseElectronic commutation motor controlVector control systemsBandpass filteringPosition angle

The invention relates to a control system for speed of a rotor of a hybrid stepping motor and a control method therefor used for inhibiting the rotating oscillating of the rotor in a speed / position open-loop driving system of the hybrid stepping motor. The device and the method adopt a stator flux closed-loop structure. In the preferred embodiment, a bandpass filter is also utilized for extracting the flutter component in an electromagnetic torque, and the rotor position angle flutter component is obtained through integration thereof. The stator flux phase is modulated in real time by the rotor position angle flutter component so as to inhibit the rotor oscillating. The invention has the advantages that the cost is low, no position angle accumulated error occurs in the rotating of the rotor, the range of the operating speed of the motor is wide, and the load capability of the motor in medium and high speed is strong.

Owner:CHINA LEADSHINE TECH CO LTD

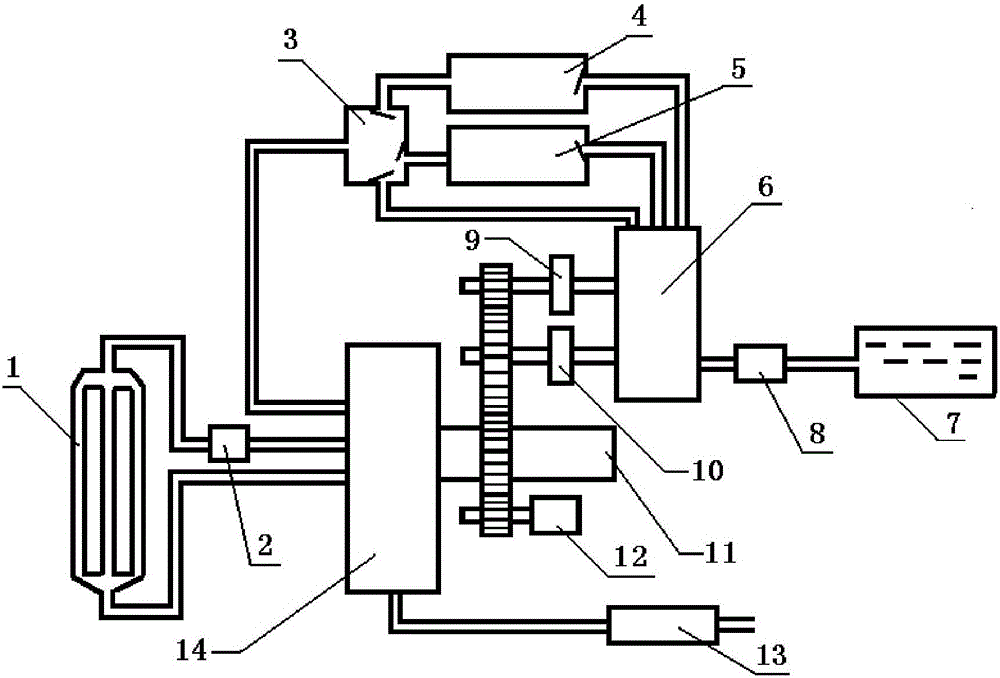

rotary jet internal combustion engine

InactiveCN104265456BIncrease the compression ratioGuaranteed uptimeGas turbine plantsAir compressionJet engine

The invention relates to a rotating jet internal combustion engine. The rotating jet internal combustion engine comprises an electric control unit, a rotating jet combustion chamber assembly, an air compression system, an air storage device, a cooling system, a fuel supply system, a lubricating system, power generation storage equipment, an emergency starting motor and a tail gas treatment device. The fuel supply system is connected with the air compression system; the air compression system is connected with the air storage device; the air storage device is connected with the rotating jet combustion chamber assembly; the rotating jet combustion chamber assembly is connected with a power output shaft; the power output shaft is connected with the air compression system; the rotating jet combustion chamber assembly is further connected with the cooling system and the tail gas treatment device. According to the rotating jet internal combustion engine, the air storage tank is combined with the rotating jet combustion chamber assembly, a fuel and air mixture is combusted in the rotating jet combustion chamber assembly to output power, and the internal combustion engine can stably run under various working conditions; the problems that an existing internal combustion engine is low in heat efficiency, narrow in working rotating speed range and the like are solved; the internal combustion engine has the advantages of being wide in working rotating speed range, high in compression ratio, high in combustion efficiency and the like.

Owner:向兵

Electric Vehicle DC Power Supply Air Conditioning Compressor

ActiveCN104632628BPulsation loss does not generateNo suction shut-off lossesRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsLow speedElectric machine

The DC power supply air-conditioning compressor for electric vehicles includes a sealed casing. The inner cavity of the sealed casing is divided into a motor component side and a pump body component side by an intermediate partition and a muffler cover. The motor component includes a stator component and a rotor component. The stator component passes through The controller is connected to the DC power supply in the electric vehicle. After the stator assembly is energized, it drives the rotor assembly to rotate. The pump body assembly includes a first bearing, a first cylinder, a second cylinder, a second bearing, the first cylinder and a second The cylinders are arranged in parallel, the first bearing forms the left end surface of the first cylinder, and the second bearing forms the right end surface of the second cylinder. The crankshaft is rotatably installed in the inner holes of the first bearing and the second bearing, and the crankshaft is eccentrically The fixed set has a first piston and a second piston, and the first piston and the second piston are arranged in reverse symmetry. Advantages: Stable operation at both low and high speeds, low vibration, and low noise; the fit gap can be strictly controlled, small refrigerant leakage, high cooling capacity, low power consumption, and low price.

Owner:ZHEJIANG BOYANG COMPRESSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com