Belt transmission type starting and power generation integrated machine

A technology of starting power generation and belt transmission, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor pressure resistance, fatigue fracture, and high cost of the whole machine, and achieve the effect of preventing overheating and burning and improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

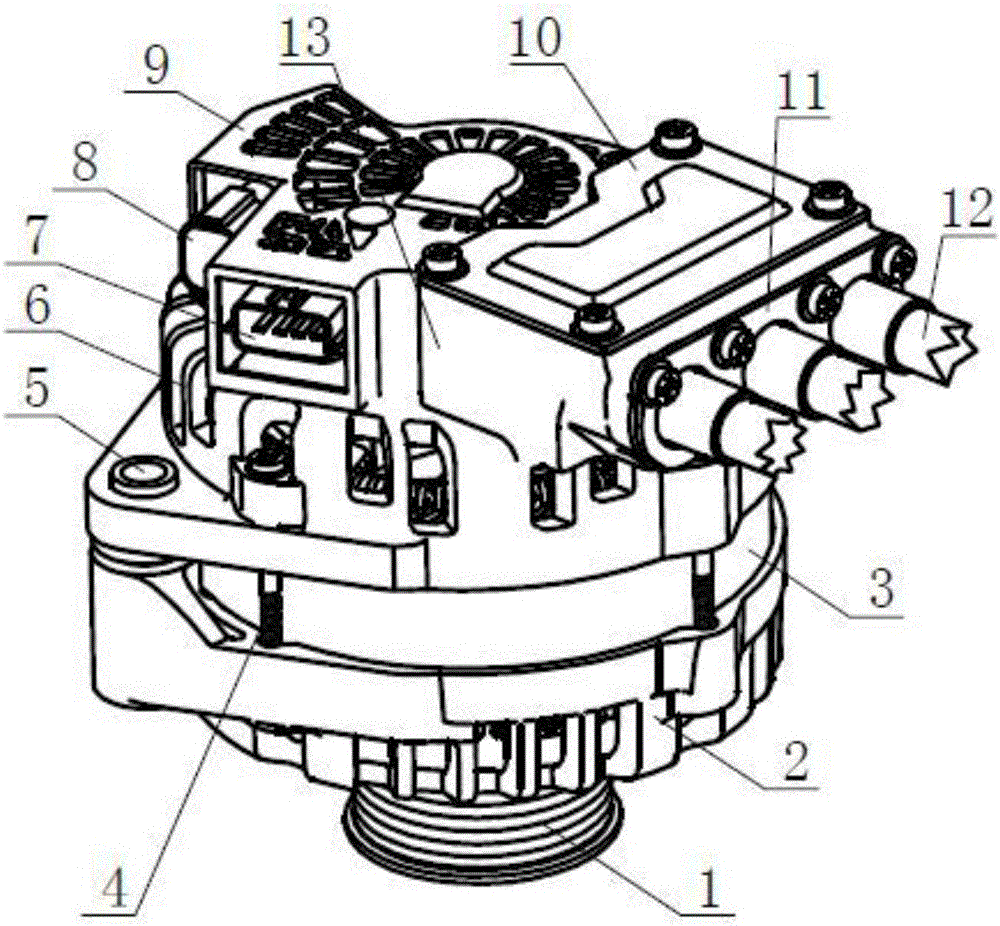

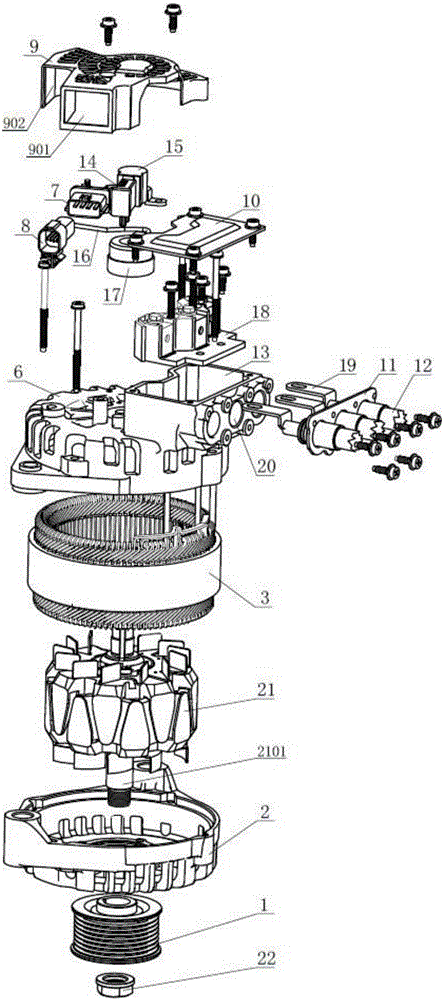

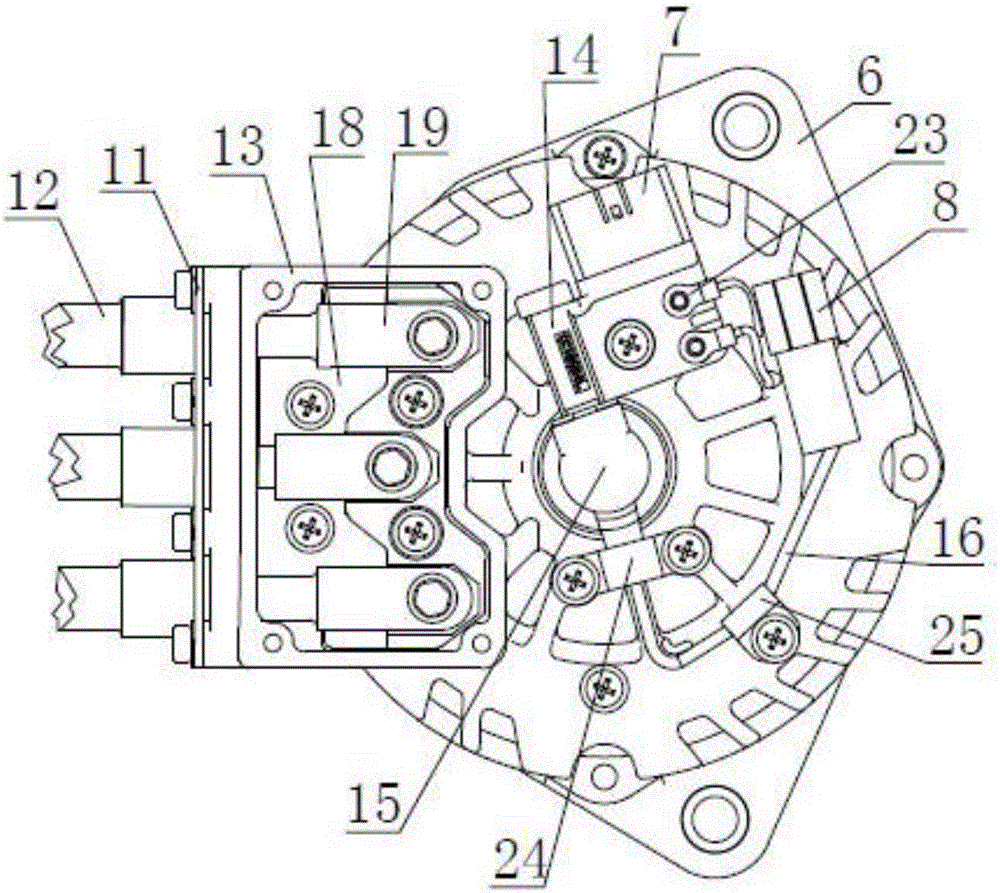

[0018] As shown in the figure, the belt-driven starter generator includes a pulley 1, a drive end cover assembly 2, a stator assembly 3, a rotor assembly 21, and a carbon brush end cover assembly. The drive end cover assembly 2 Including drive end cover, front bearing, bearing cover, the stator assembly 3 includes stator iron core, insulating paper, enameled copper wire, and the rotor assembly 21 includes front and rear claw poles, rotor shaft, excitation coil, slip ring , front and rear fans, permanent magnet magnetic steel, and the carbon brush end cover assembly includes a carbon brush end cover 6 and a carbon brush holder 14. The carbon brush end cover 6 and the drive end cover of the drive end cover assembly 2 are connected and fixed by the through bolt 4 and the compensation sleeve 5, and the stator assembly 3 and the rotor assembly are assembled on the carbon brush end cover 6 and the drive end cover assembly 2 in the space formed by the drive end cap. The pulley 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com