Panel with paper honeycomb cores using as a table top

a table top and honeycomb core technology, applied in the direction of furniture parts, manufacturing tools, transportation and packaging, etc., can solve the problems of inability to move a fiber board of medium density, too heavy to maintain a particle board, and inability to meet the needs of daily necessities of furniture, etc., to achieve easy cleaning, improve production efficiency, and enhance the strength of the table top panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

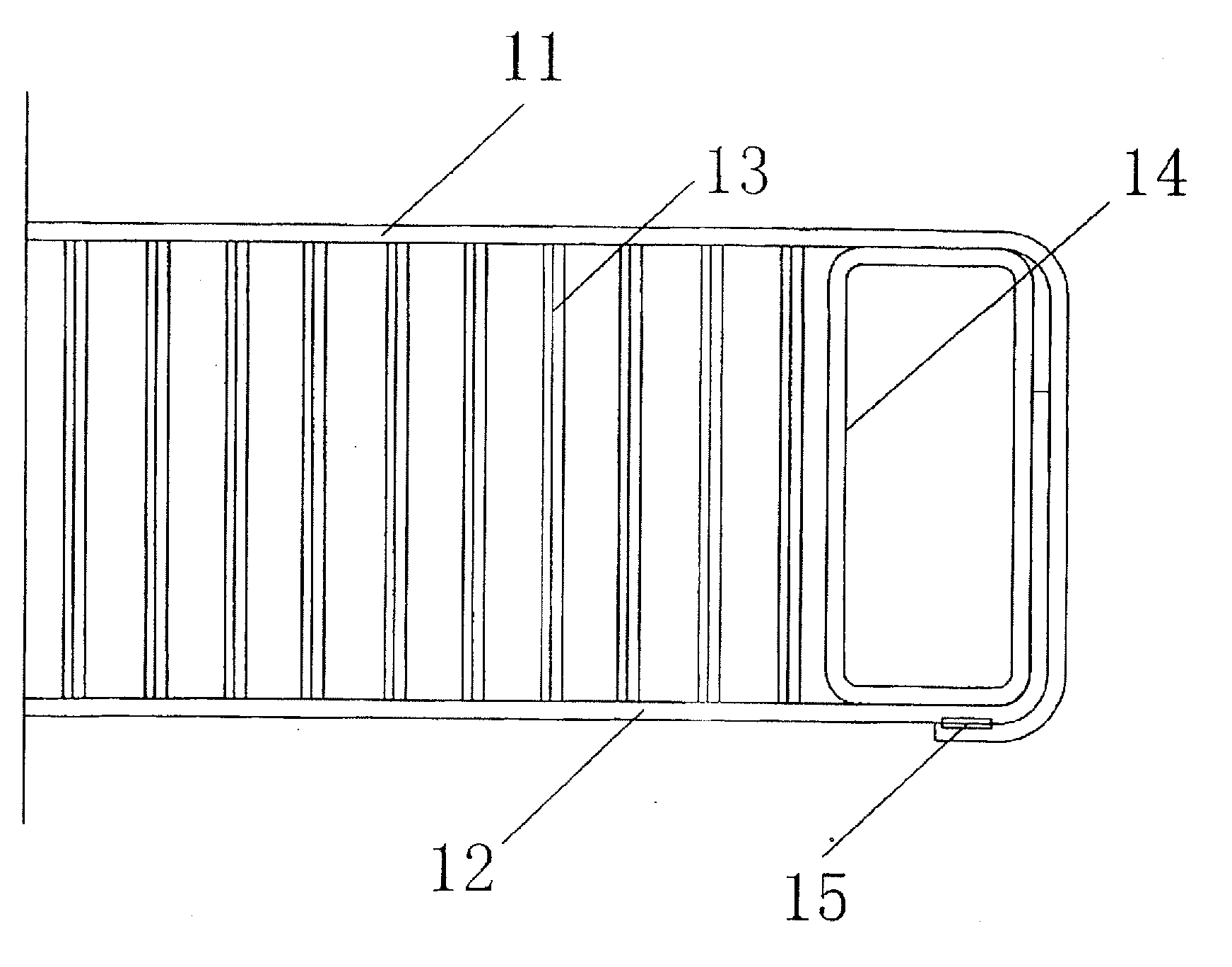

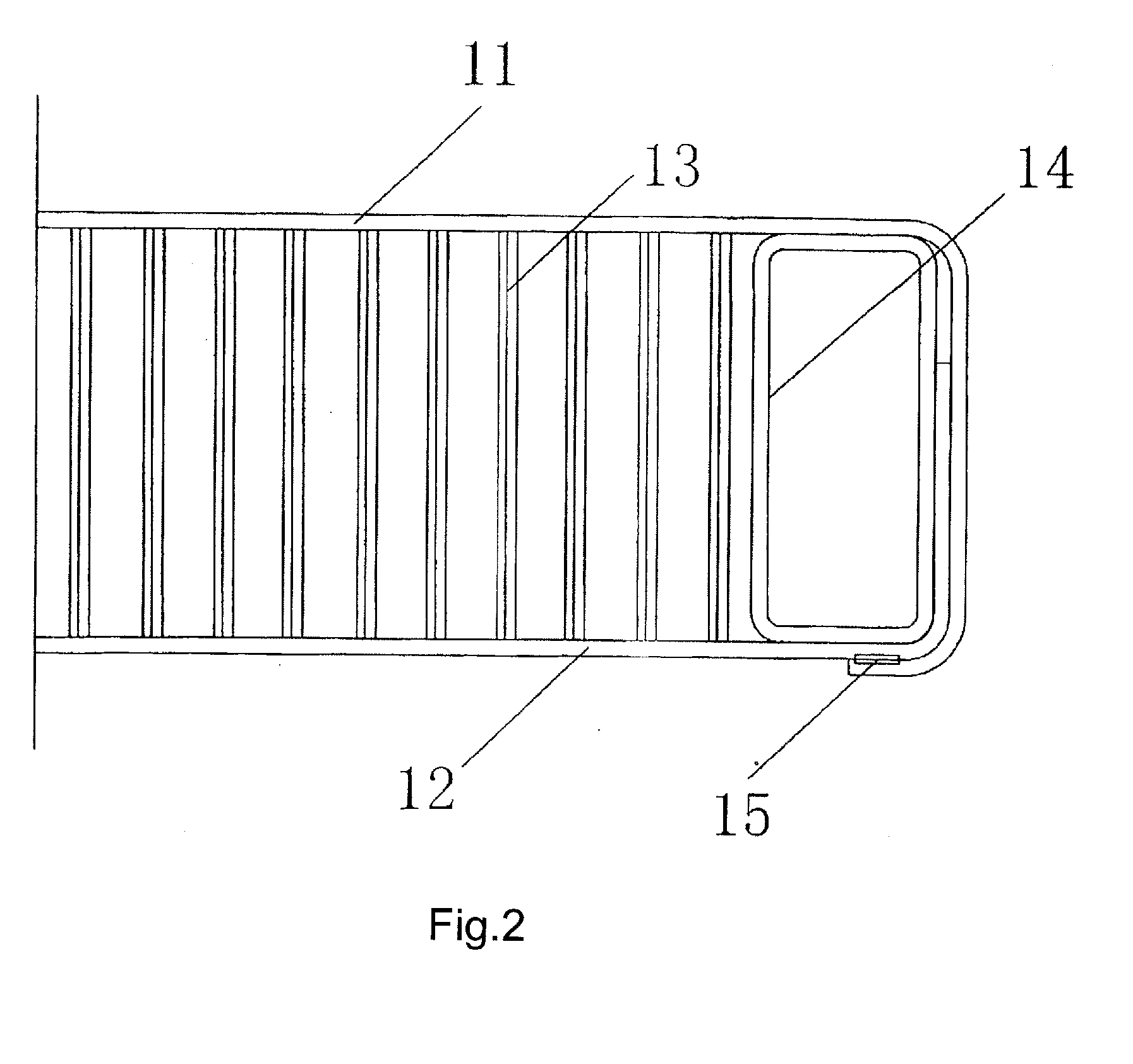

[0045]As shown from FIG. 1 to FIG. 4, an edge-sealed table top panel with paper honeycomb cores made of invert suction moulding process , is composed of plastic top panel 11, plastic bottom panel 12, paper honeycomb core 13 and internal fixed part 14, wherein the plastic top panel 11 and plastic bottom panel 12 are square, making the table top panel made of said panels is also a square one; the plastic top panel 11 and the plastic bottom panel 12 are formed by suction moulding process or contour machining process; the thickness of plastic top panel 11 and plastic bottom panel 12 is about 0.3 mm-4 mm; when the plastic top panel 11 and plastic bottom panel 12 are processed to be a square with desired size, fill the paper honeycomb core 13, composed of paper honeycomb element 133, top sheet 131 and bottom sheet 132, between plastic top panel 11 and plastic bottom panel 12; it is known that the paper honeycomb core can only be provided with the paper honeycomb core, without top sheet an...

embodiment 3

[0049, as shown in FIG. 6: The table top panel is composed of top panel 11, bottom panel 12, paper honeycomb cores 13 and internal fixed part 14; the top panel 11 and bottom panel 12 form a close space filled with paper honeycomb core which is bonded to top panel 11 and bottom panel 12 or either of them; the internal fixed part 14 is set inside all edges or partial edges of table top panel and remains the same height as paper honeycomb core; the edge of starting end of edge of bottom panel 12 bending upwardly protrudes the top panel at a thickness of 12.1, and then extends internally and upwardly a length of 12.2; the downwardly bending side 11.1 of top panel 11 bonds to the upper extension section 12.2 of bottom panel and forms a plane with 12.1. Of course, this structure can be in invert order, i.e. the top panel protrudes the bottom panel at an approximate thickness of bottom panel.

embodiment 4

[0050, as shown in FIG. 7: The table top panel is composed of top panel 11, bottom panel 12, paper honeycomb core 13 and internal fixed part 14; the downwardly bending edge of top panel 11 and the upwardly bending edge of bottom panel 12 form a close space filled with paper honeycomb core which is bonded to top panel 11 and bottom panel 12 or either of them, internal fixed part 14 is set inside all edges or partial edges of table top panel and keeps the same height as paper honeycomb core.

[0051]Embodiment 5: as shown in FIG. 8: The table top panel is composed of top panel 11, bottom panel 12, honeycomb paper core 13 and internal fixed part 14; the edge of top panel 11 bends downwardly; the upwardly bending edge of bottom panel 12 forms a cavity and then bends upwardly, forming a close space filled with paper honeycomb core which is bonded to top panel 11 and bottom panel 12; the internal fixed part 14 is set at the edge between the top panel 11 and bottom panel 12 with its height la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com