Patents

Literature

1499results about How to "Improve cutting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

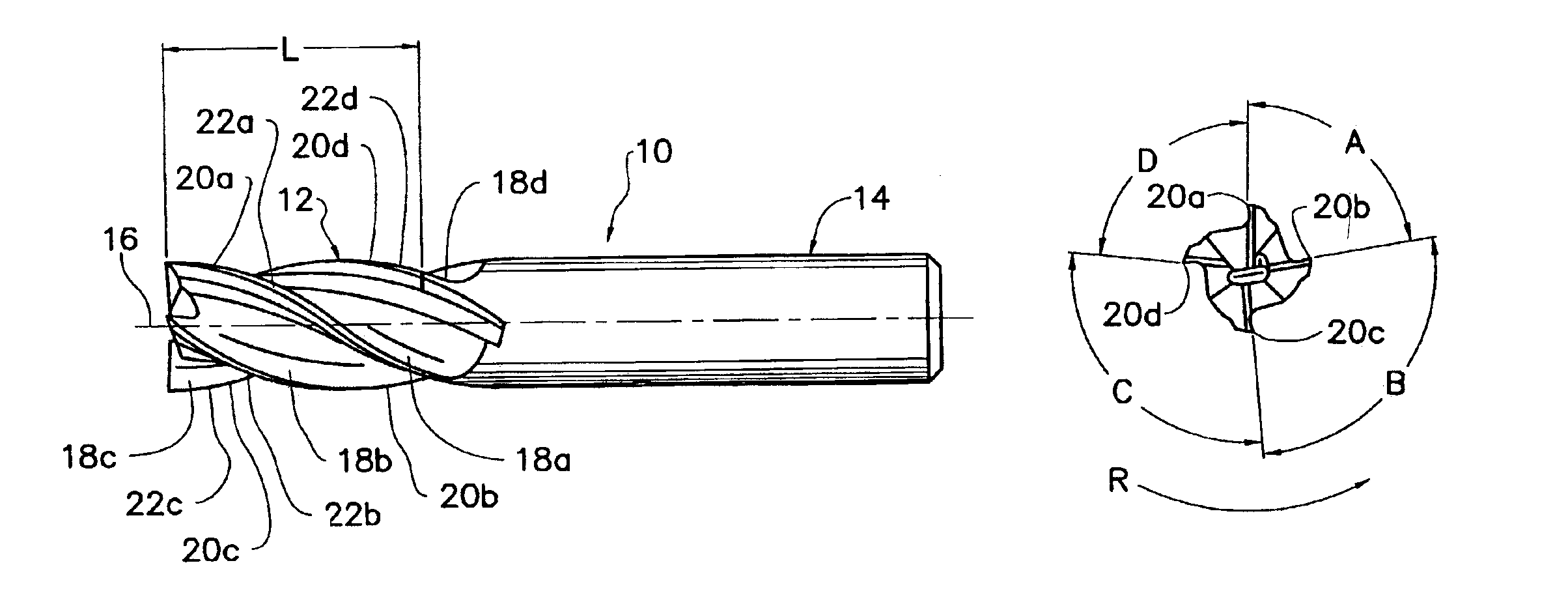

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

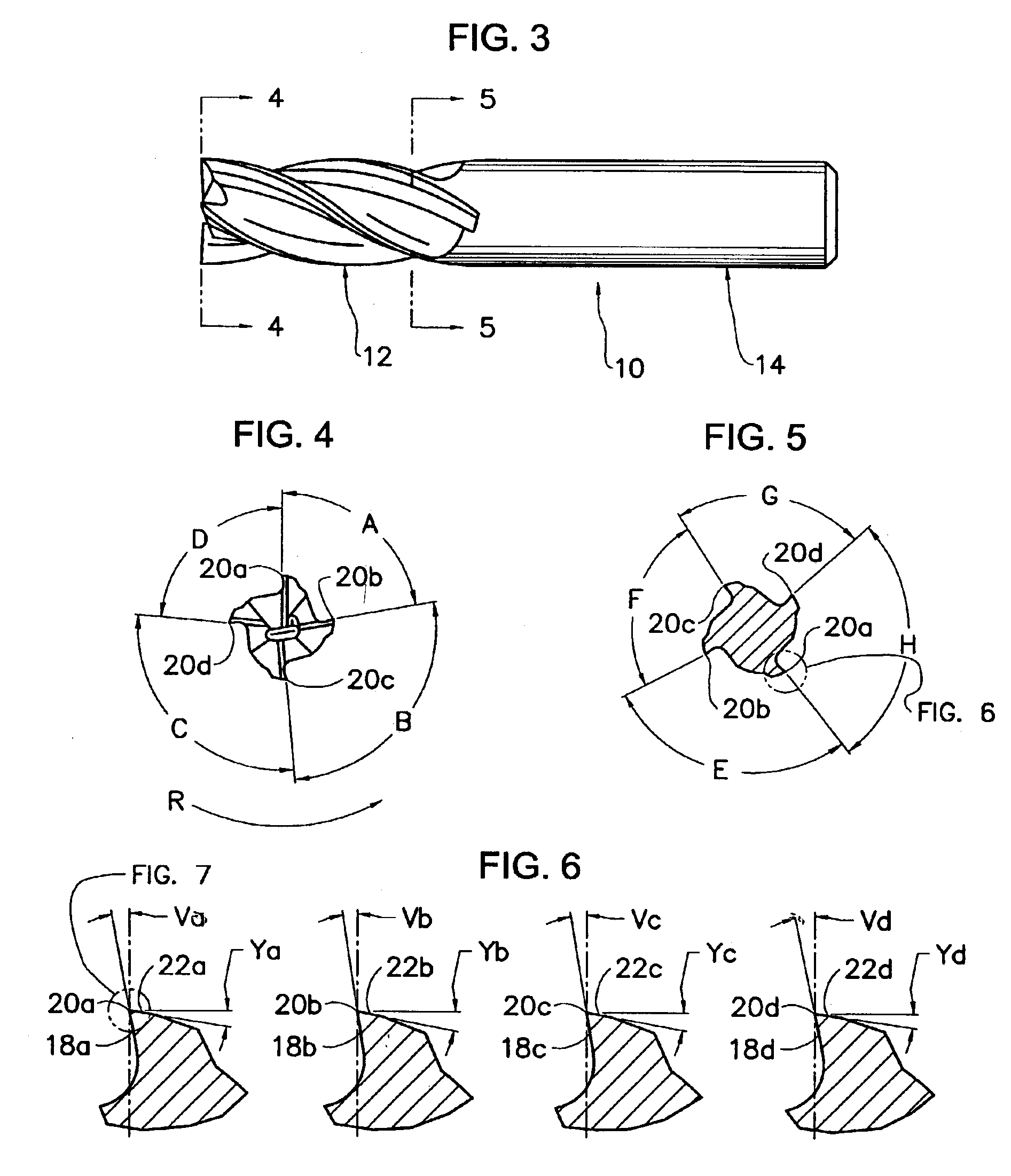

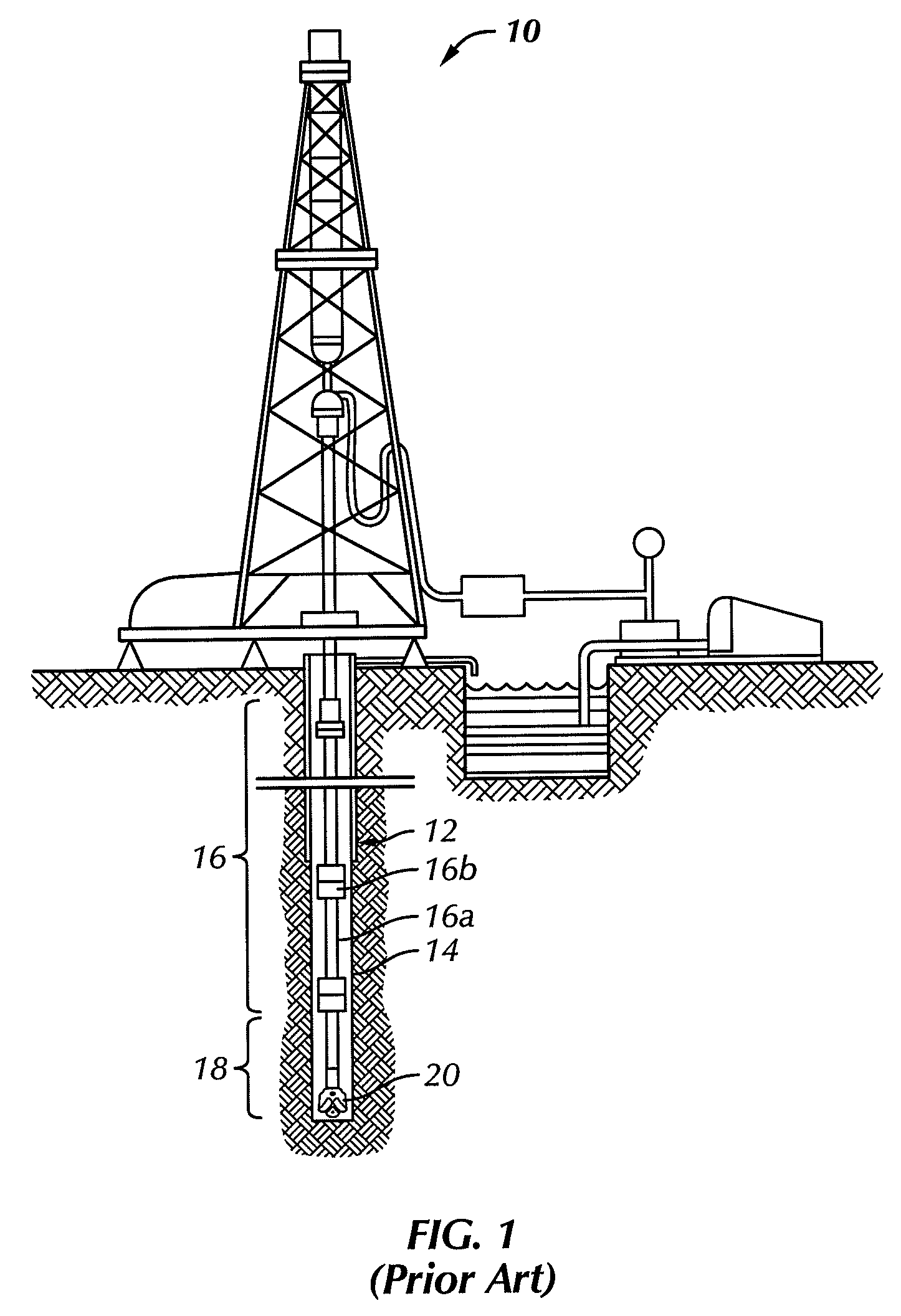

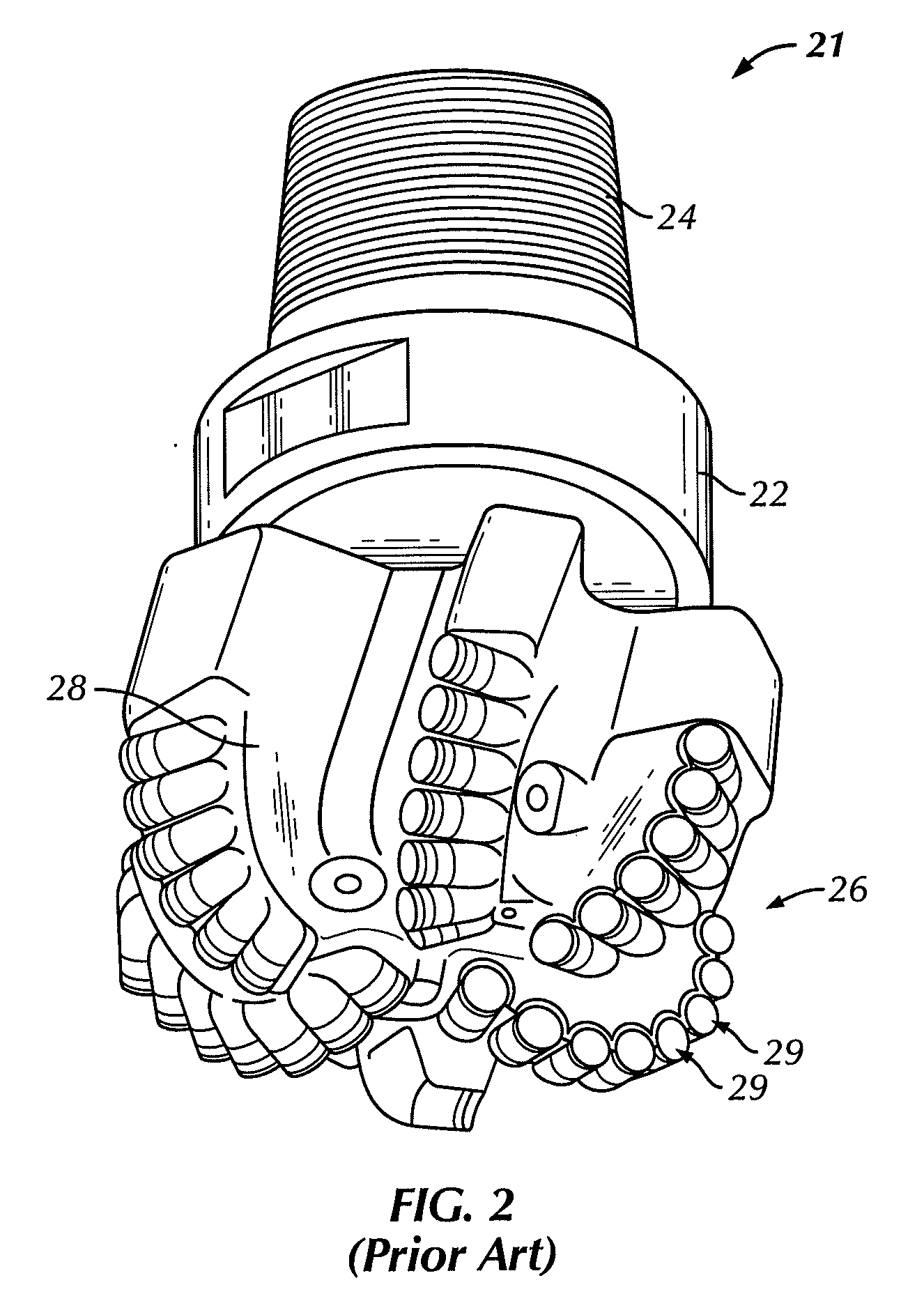

Methods for designing secondary cutting structures for a bottom hole assembly

InactiveUS20090055135A1Improve the situationImprove cutting performanceGeometric CADSurveyStructure basedBottom hole assembly

A method for designing a secondary cutting structure for use in a bottom hole assembly, the method including defining initial design parameters for the secondary cutting structure and analyzing forces acting on the secondary cutting structure. Additionally, the method includes modifying at least one design element of the secondary cutting structure and simulating an effect of the modifying on both the secondary cutting structure and a primary cutting structure to determine if an improved condition is met. Also, a method for designing a drilling tool assembly, the method including defining initial drilling tool assembly design parameters including a primary cutting structure and a secondary cutting structure, and simulating a dynamic response of the drilling tool assembly. Additionally, the method includes adjusting at least one design element of the secondary cutting structure based on the dynamic response of the drilling tool assembly, determining if the adjusted design element improved a condition of the drilling, and repeating the simulating and adjusting until the condition is optimized.

Owner:SMITH INT INC

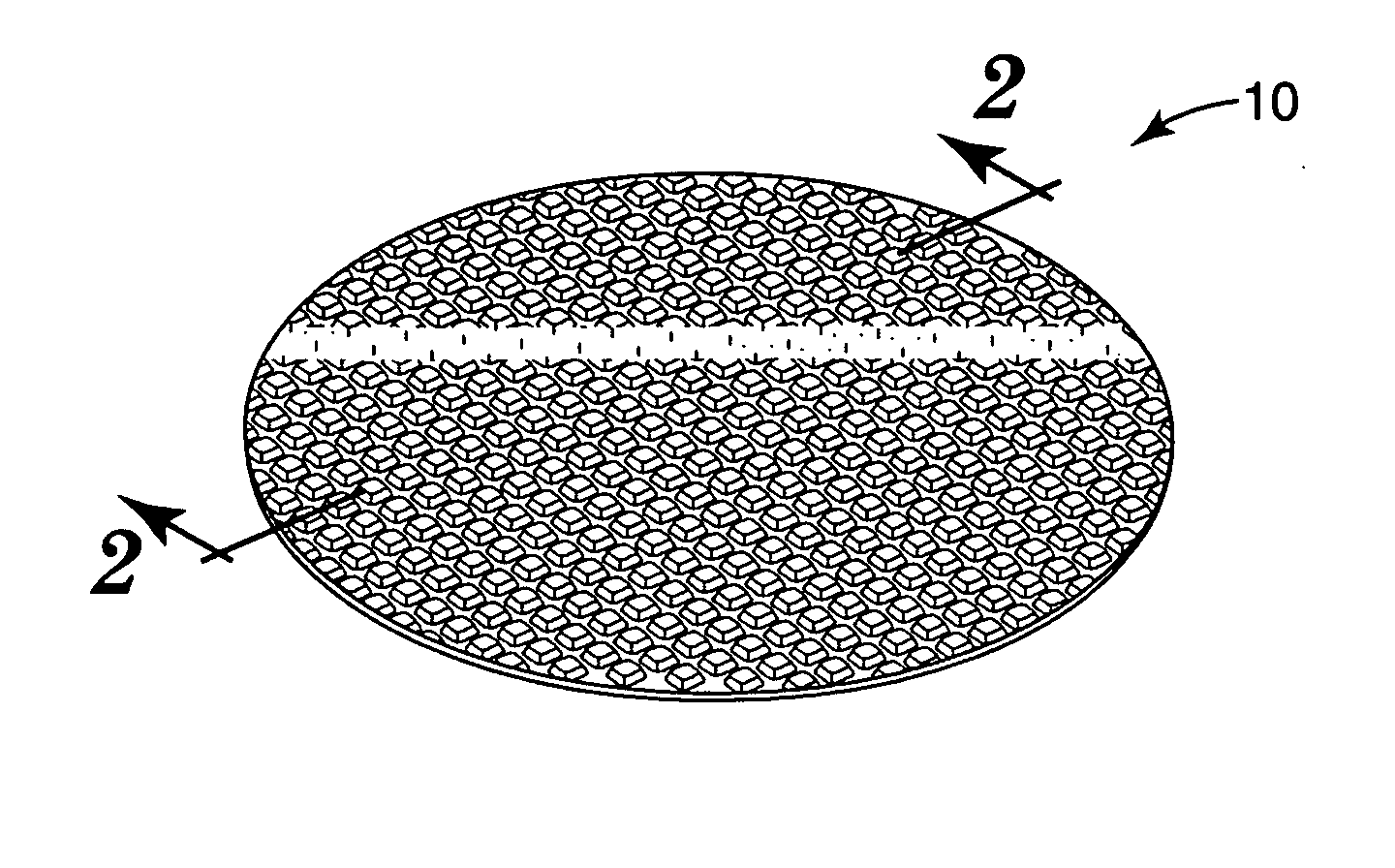

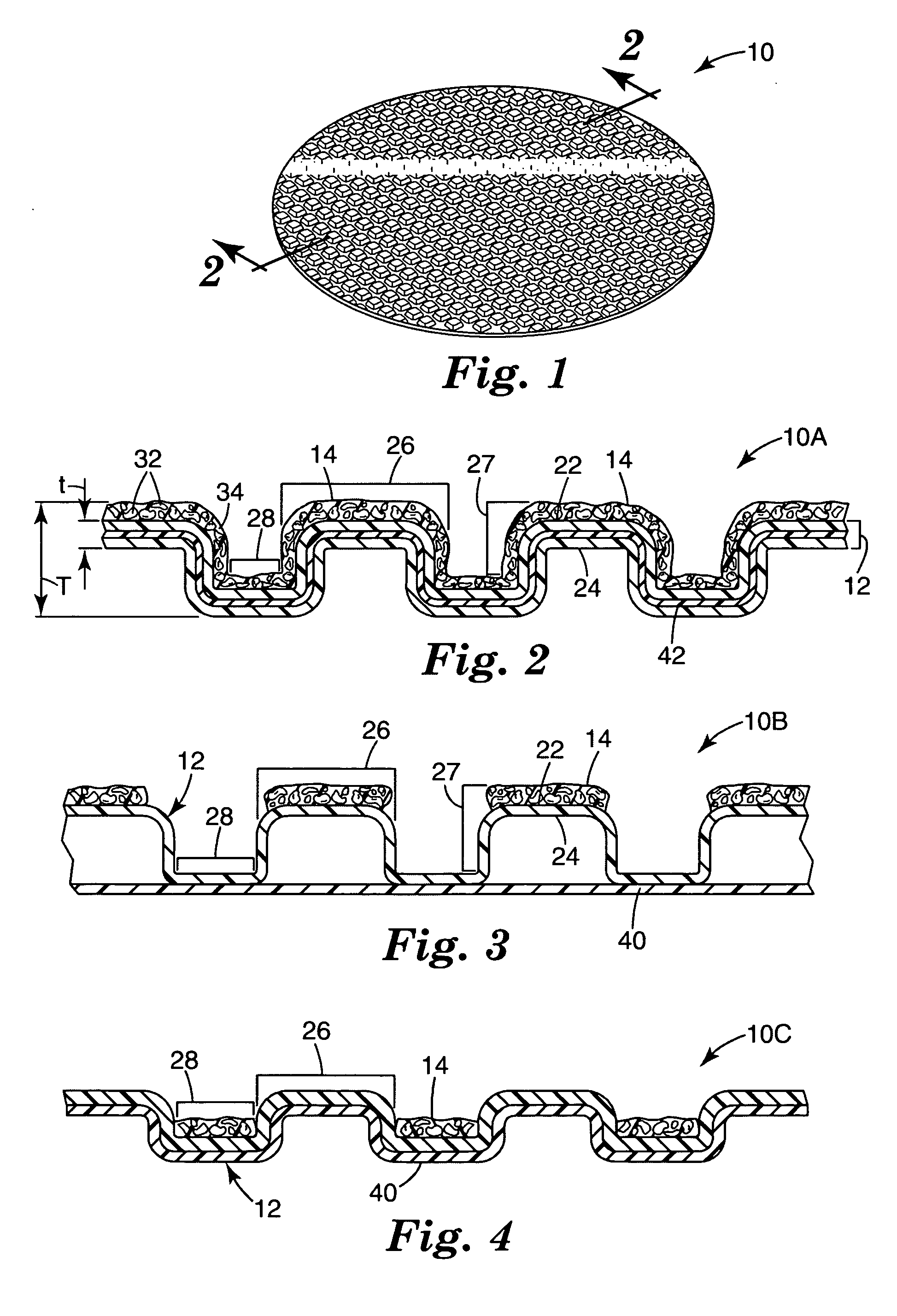

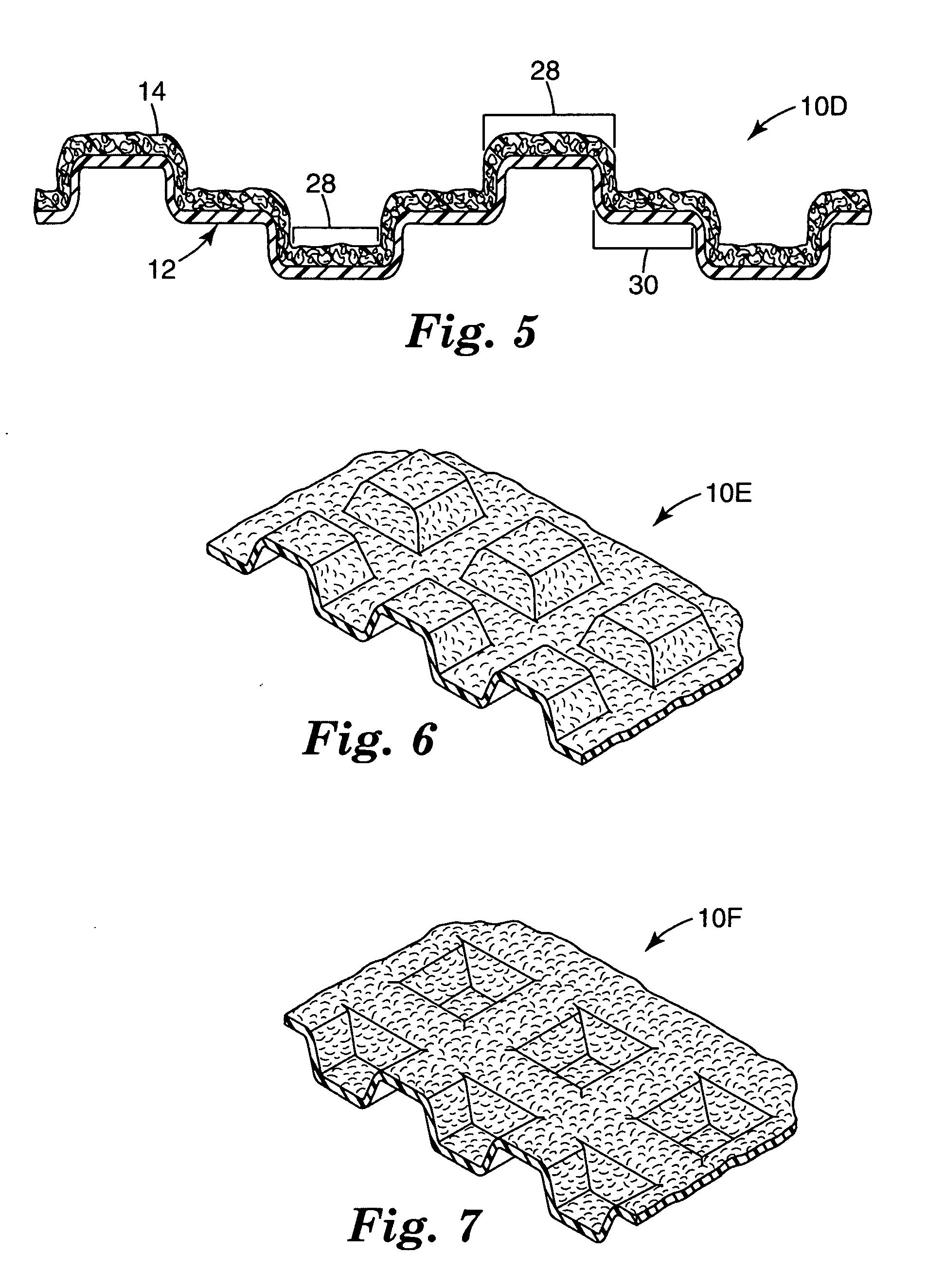

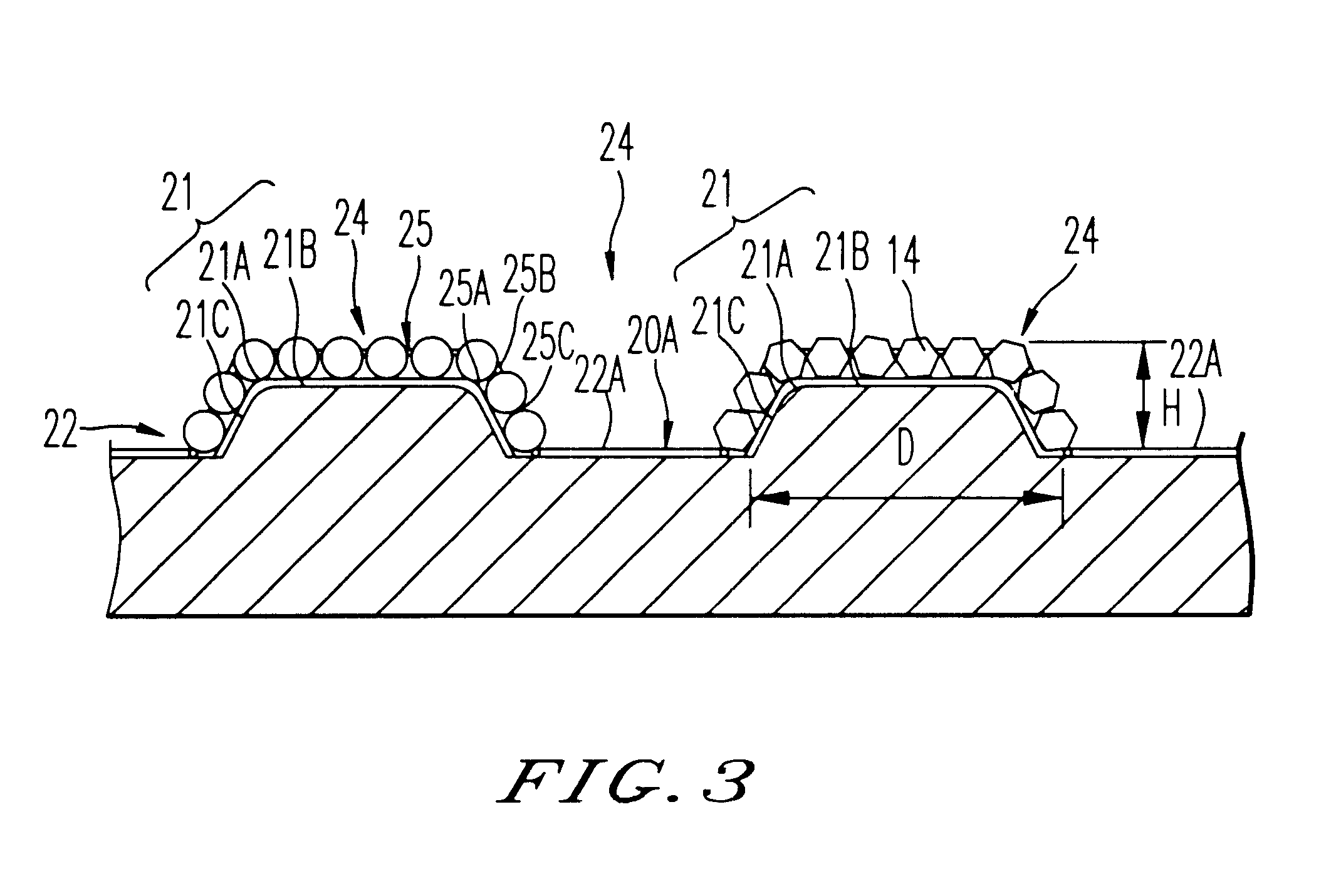

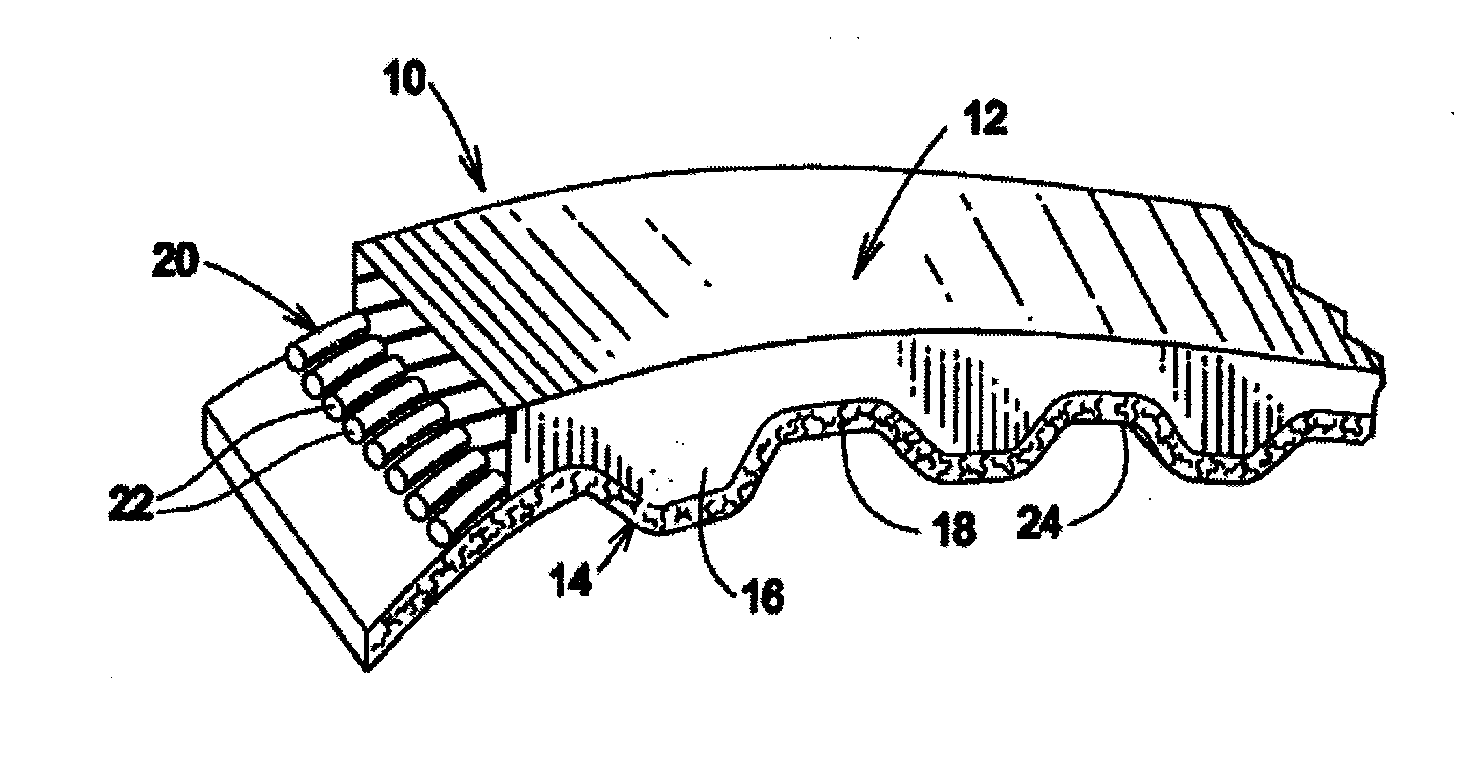

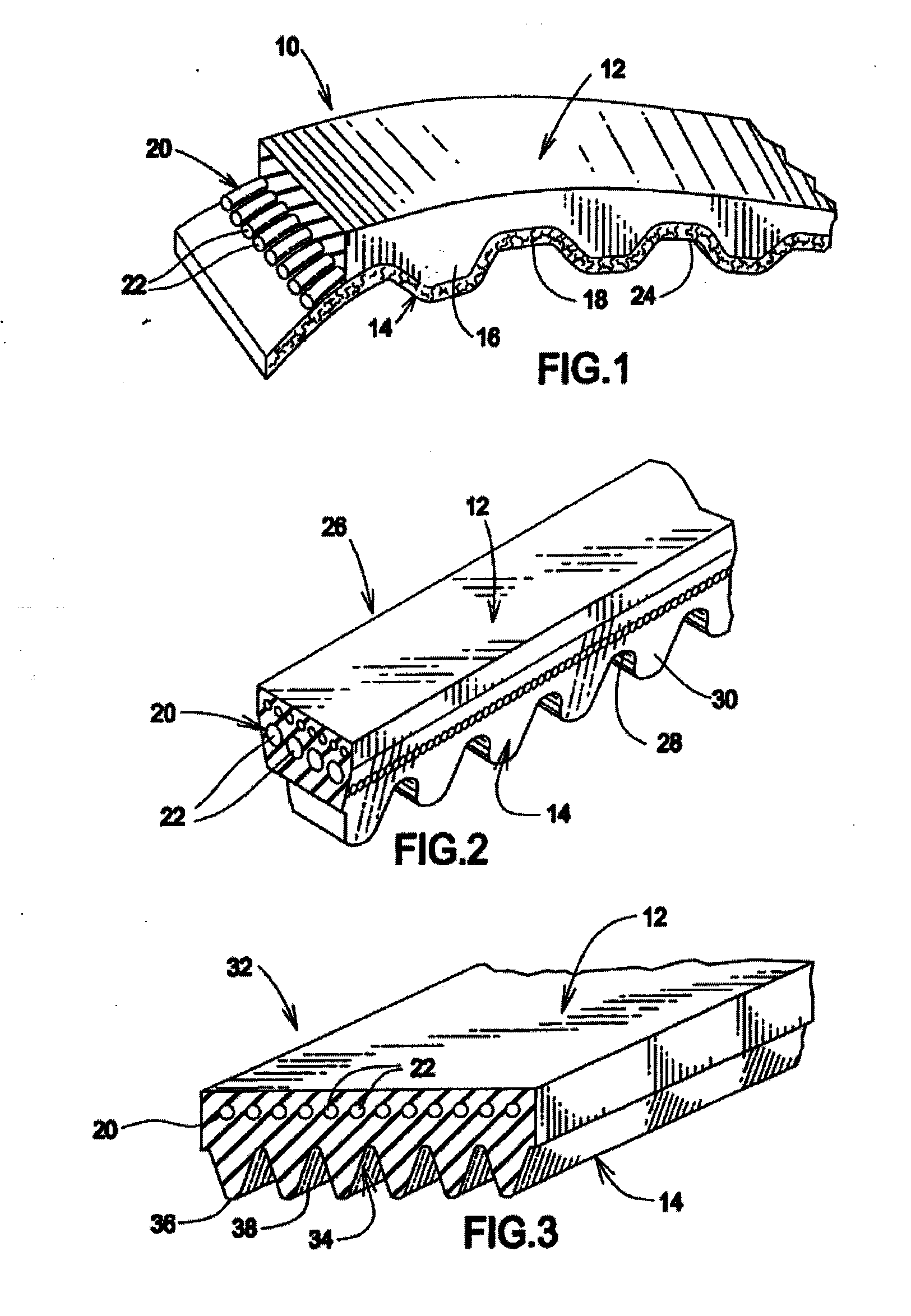

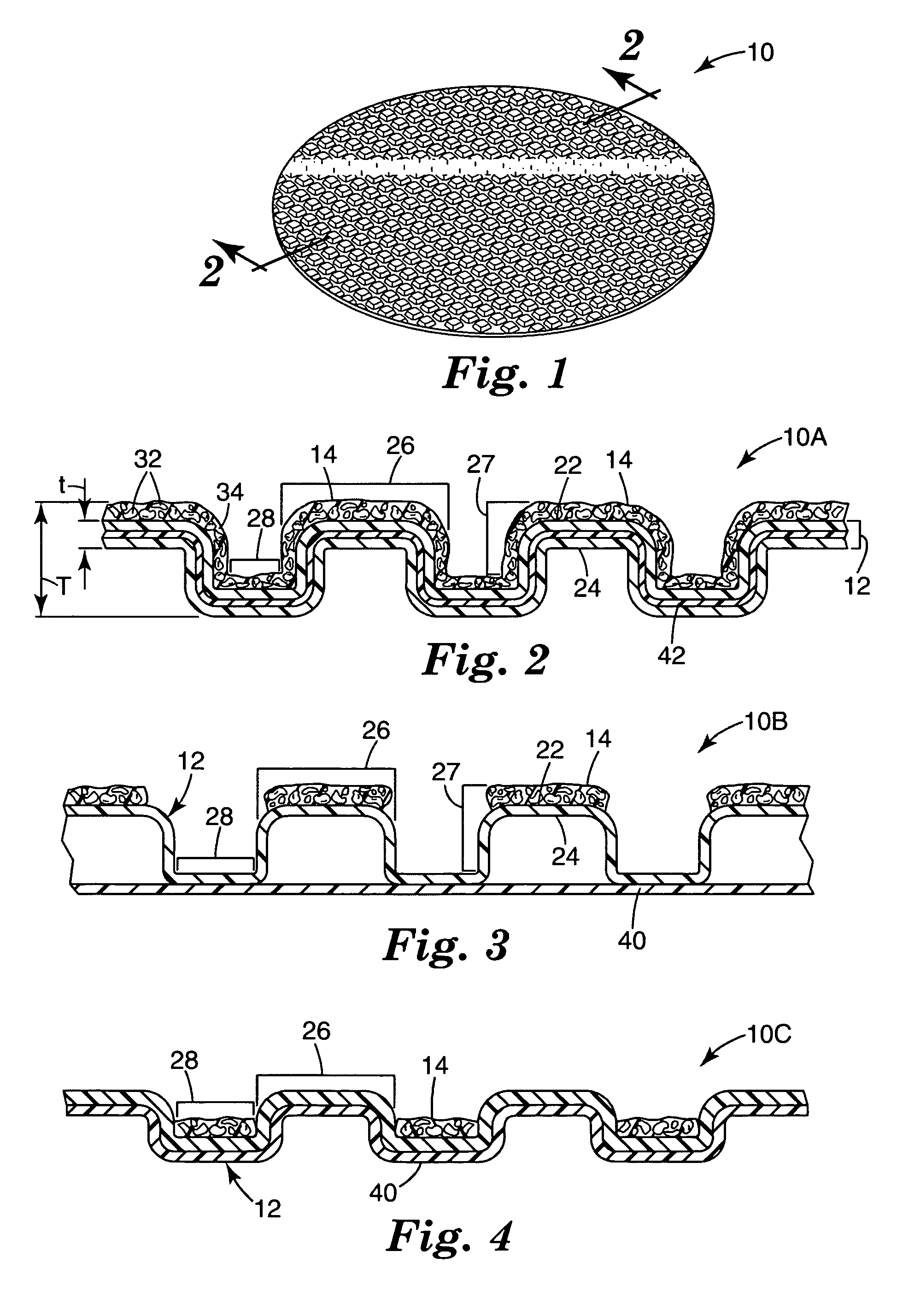

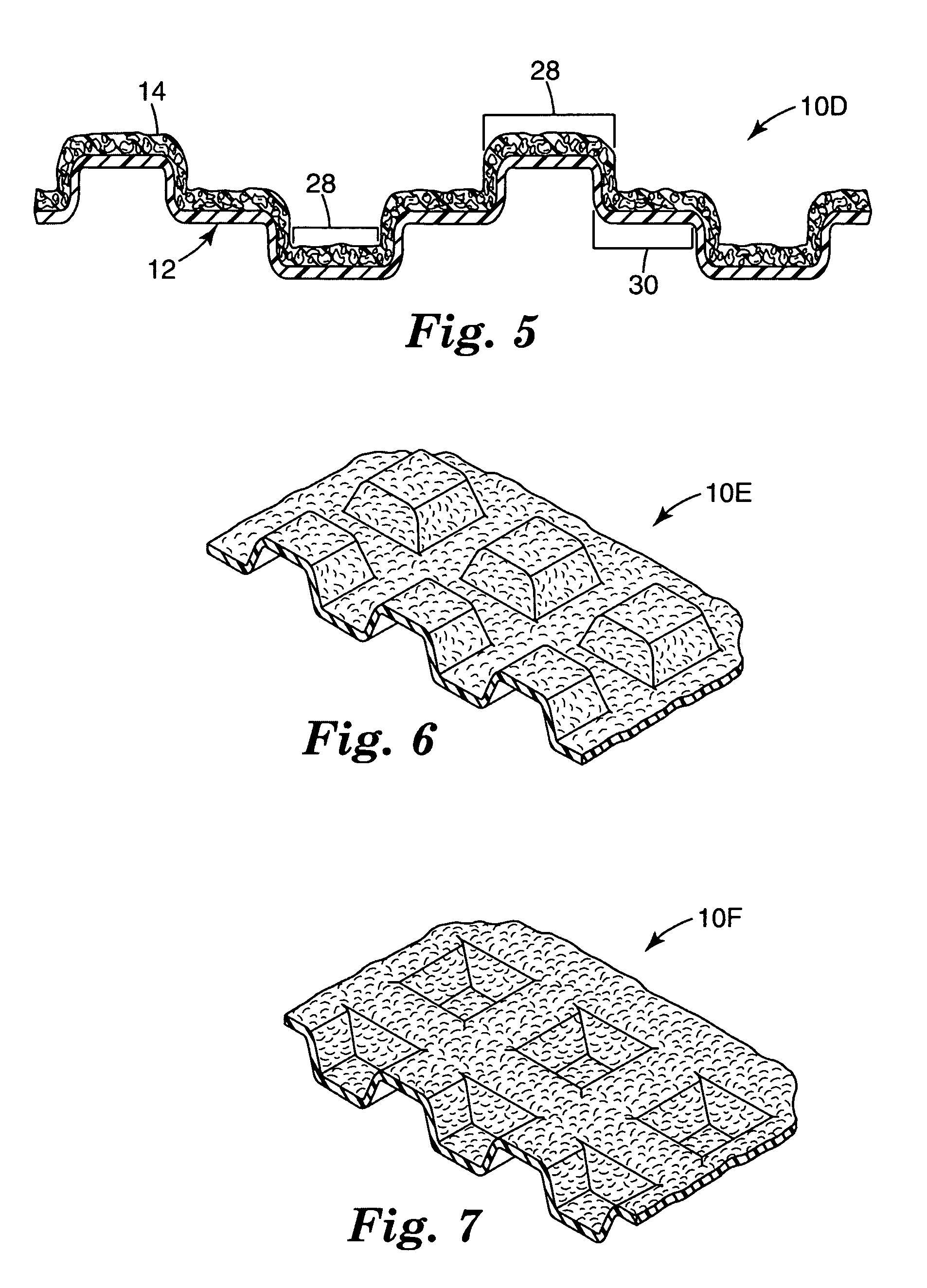

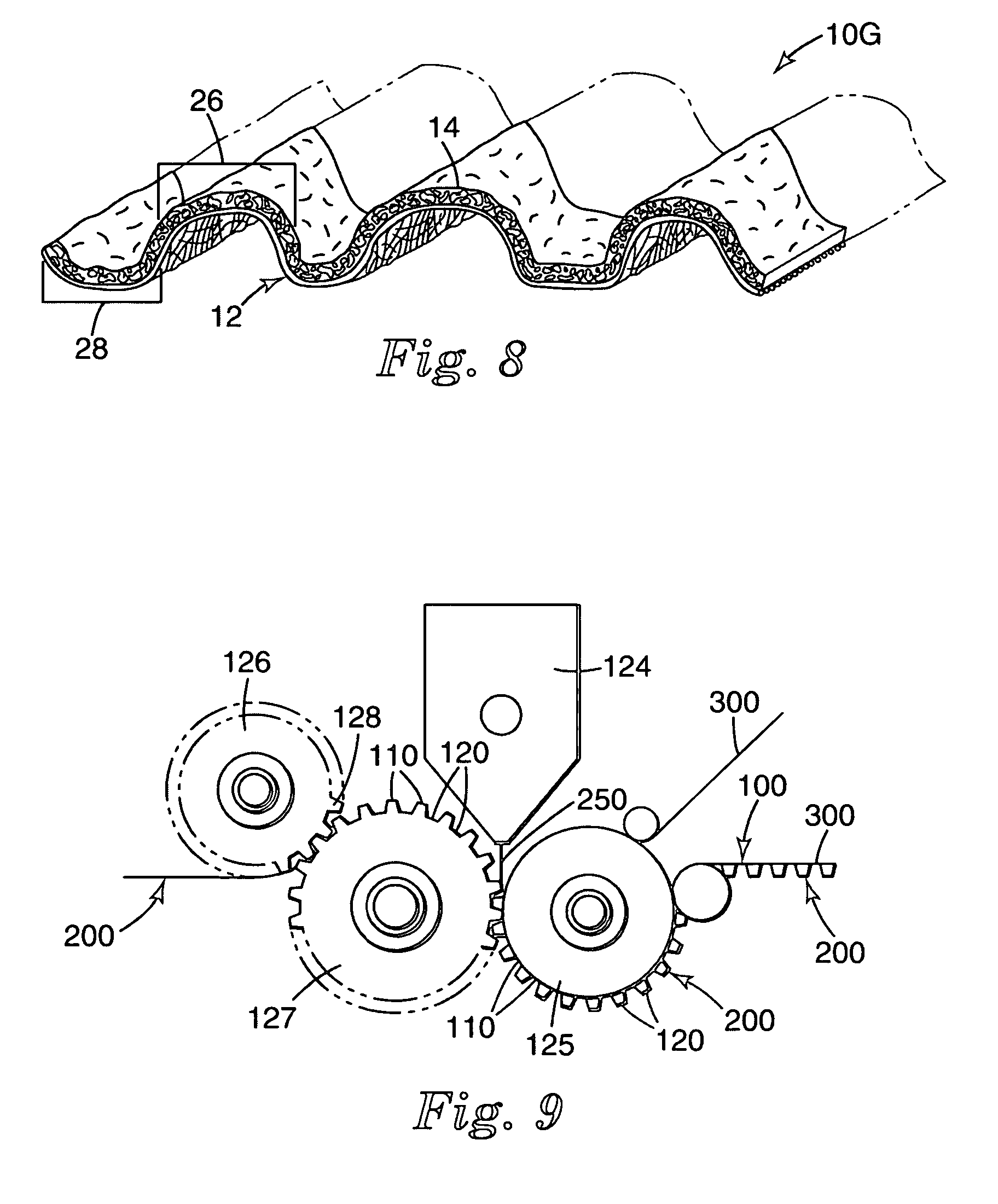

Nonwoven abrasive articles and methods

ActiveUS20050223649A1Improve cutting performancePigmenting treatmentOther chemical processesMaterials scienceCoating

Nonwoven abrasive articles, particularly lofty nonwoven abrasive articles, with a textured, non-planar surface and an abrasive coating thereon. The coating may cover the entire surface or only portions of the surface. The textured surface, composed of peaks or high regions and valleys or recessed regions, provides improved cut performance over nonwoven abrasive articles having a generally planar abrading surface.

Owner:3M INNOVATIVE PROPERTIES CO

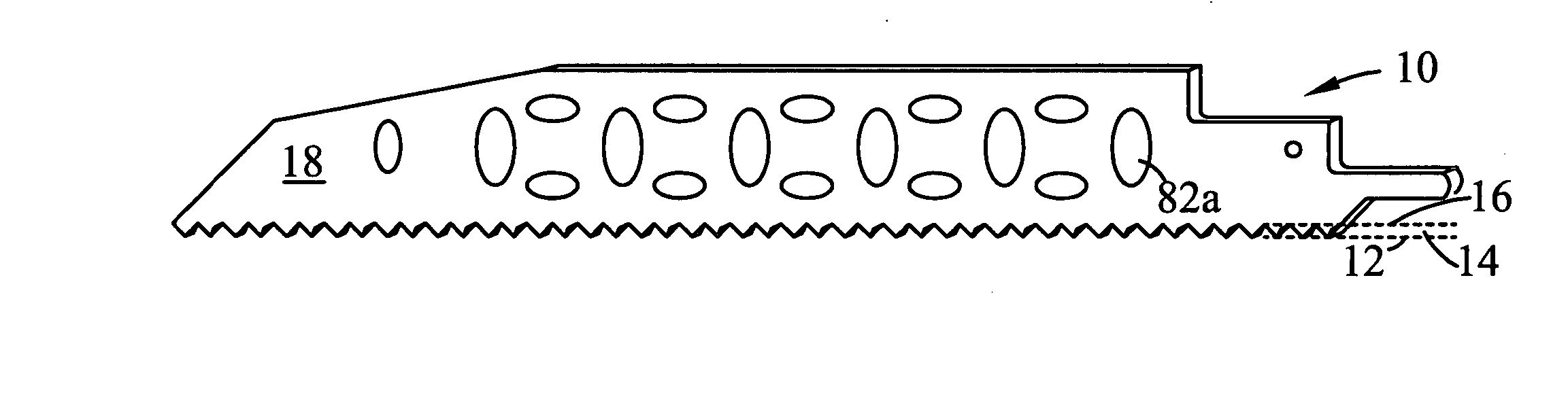

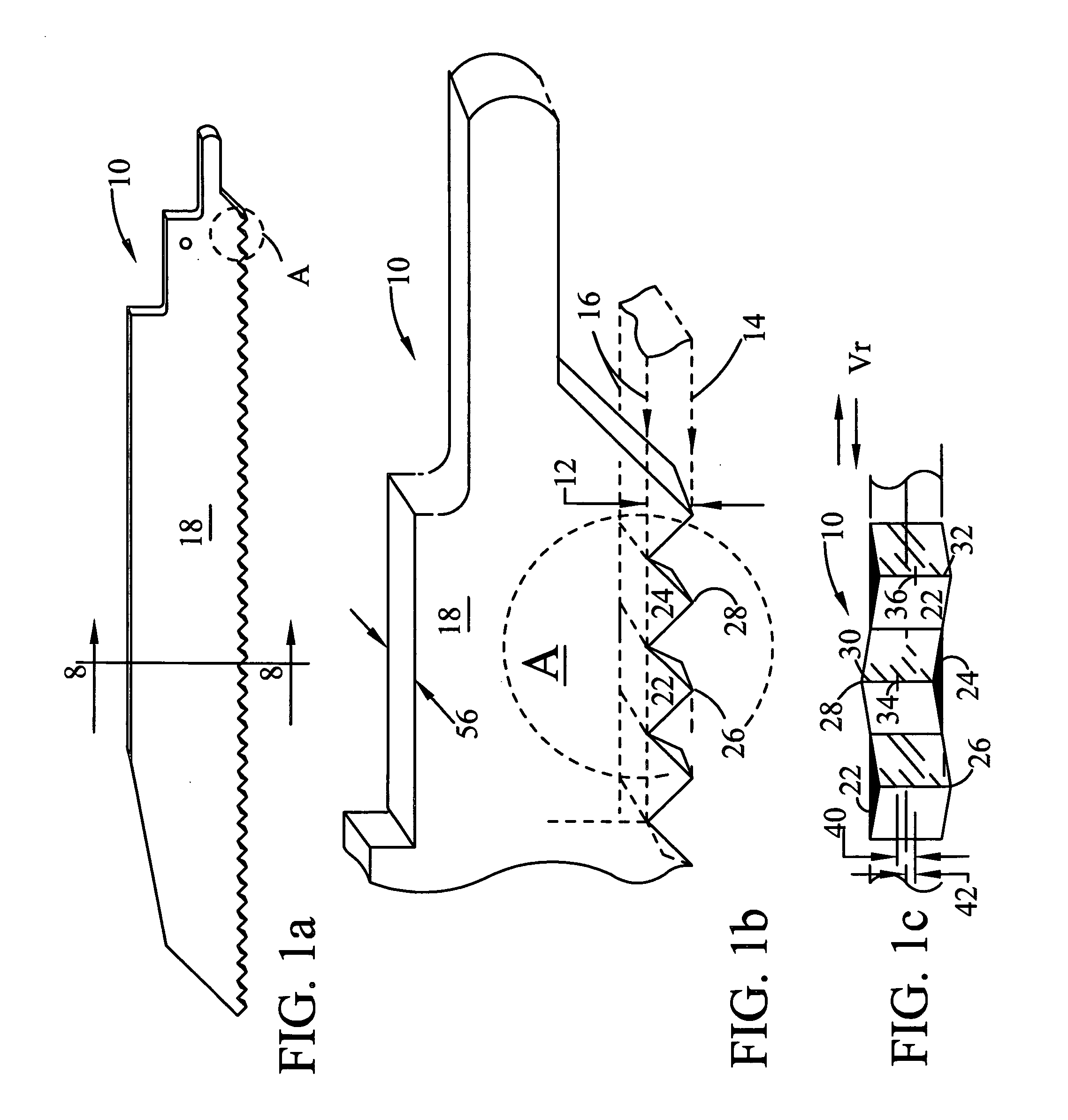

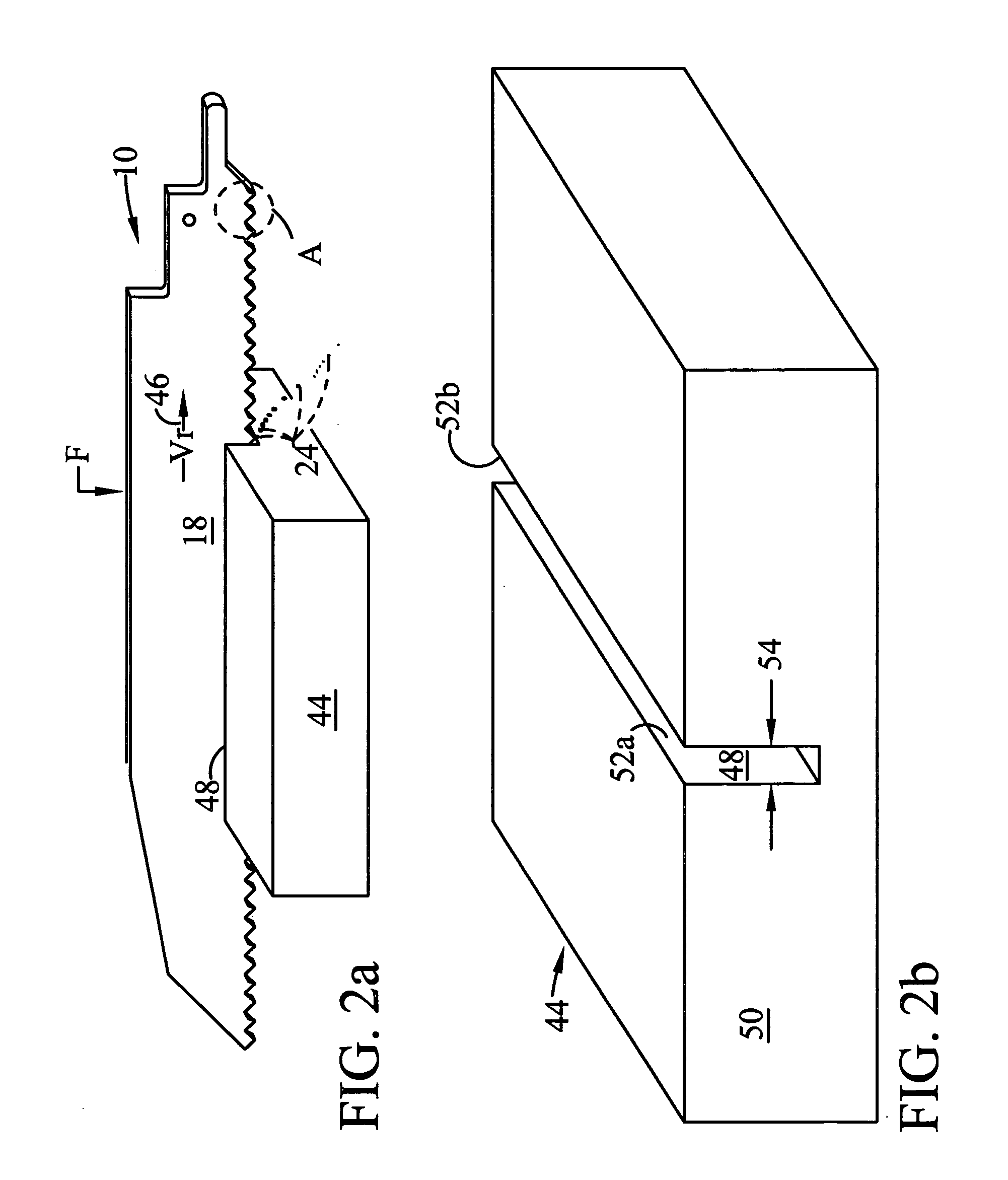

Saw cutting blade

InactiveUS20060016315A1Small sizeGood removal effectMetal sawing devicesMetal sawing toolsLinear motionEngineering

A saw blade having blade body supporting a leading cutting edge for cutting through a workpiece. A force and motion are applied to drive the cutting edge against the work piece as the body of the saw blade is driven with a reciprocating, rotational or linear motion transverse to the applied direction of the force. The solid rectangular cross section of a saw blade is modified to improve its ability to cut through a workpiece. The body of the blade is characerized as having cut out areas distributed throughout the blade body to capture and remove the debris from the kerf. This improved cutting performance can be further enhanced by reducing the cross section of the body. Secondary cutting edges may also be incorporated around the perimeter of the cutouts and as part of the reduced geometry portion of the blade body.

Owner:ZORICH TIMOTHY A +1

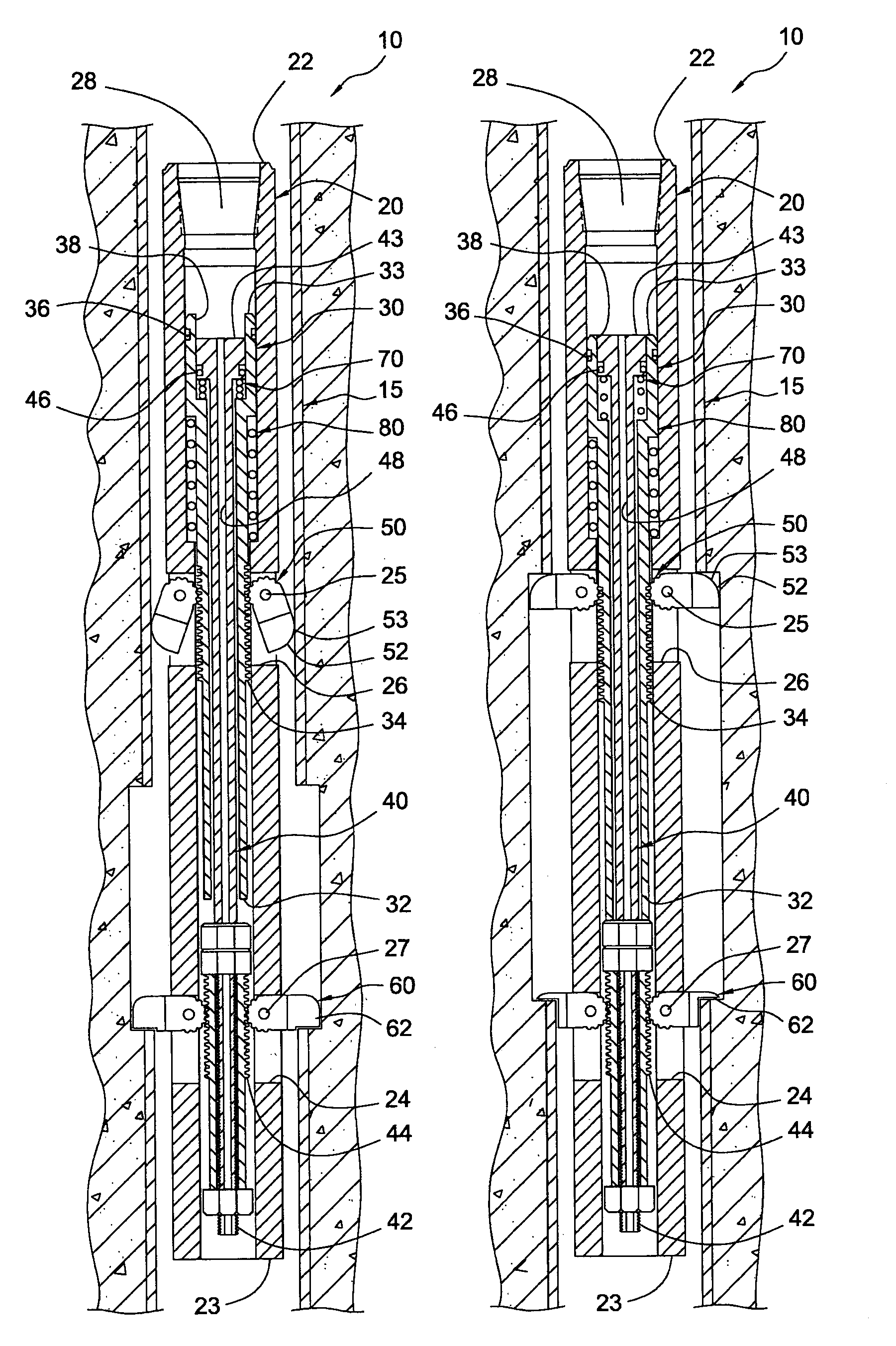

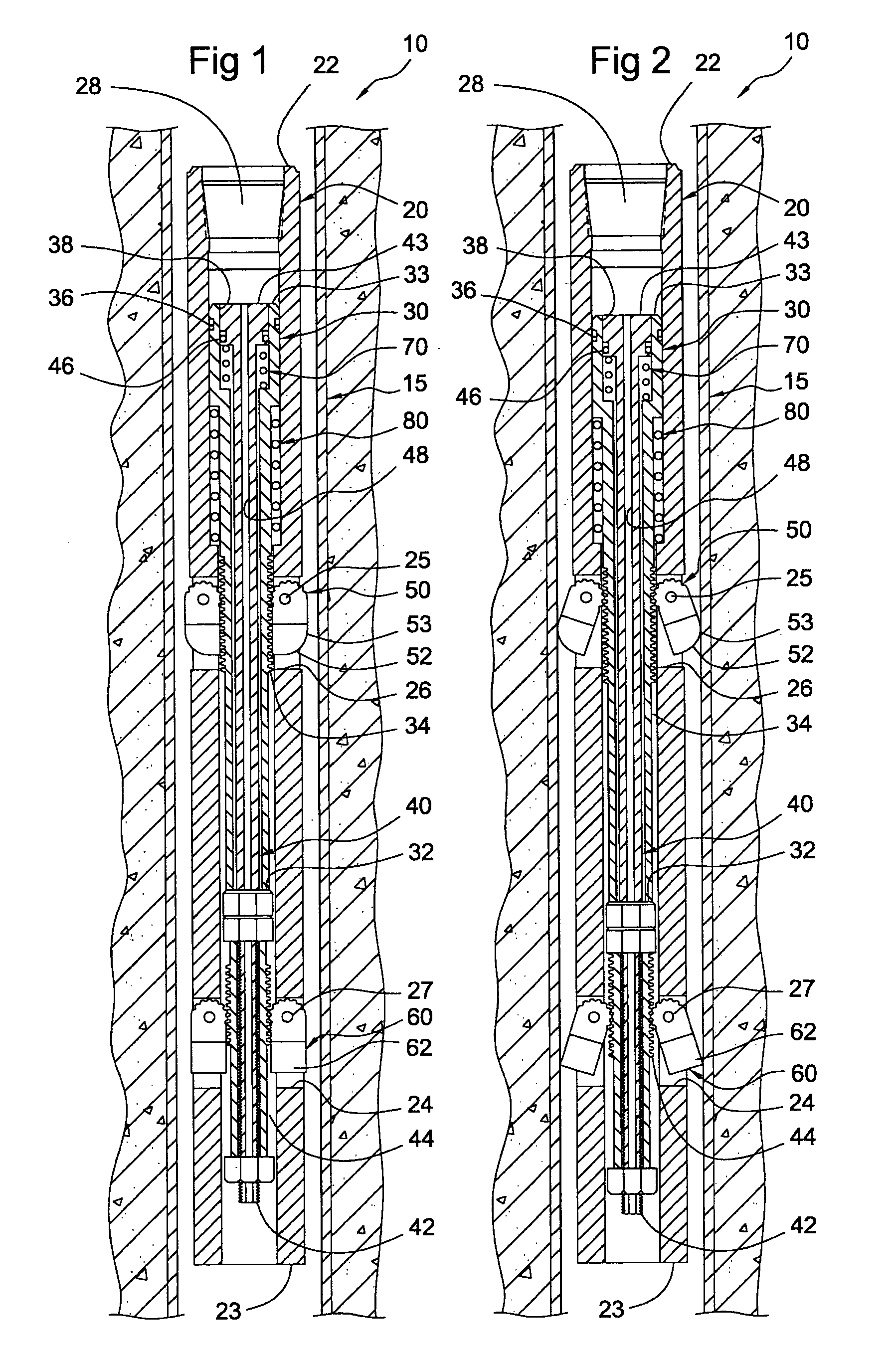

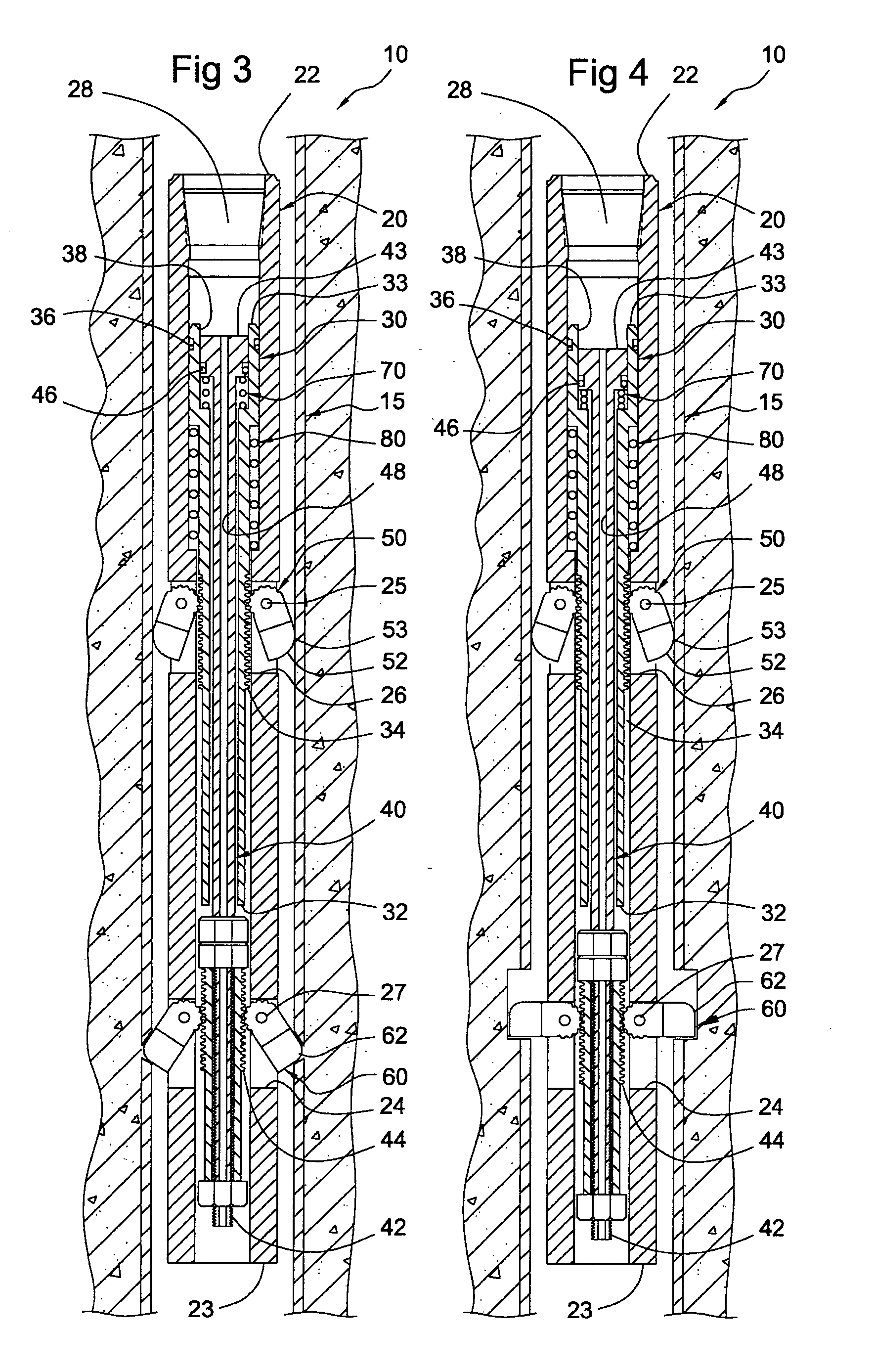

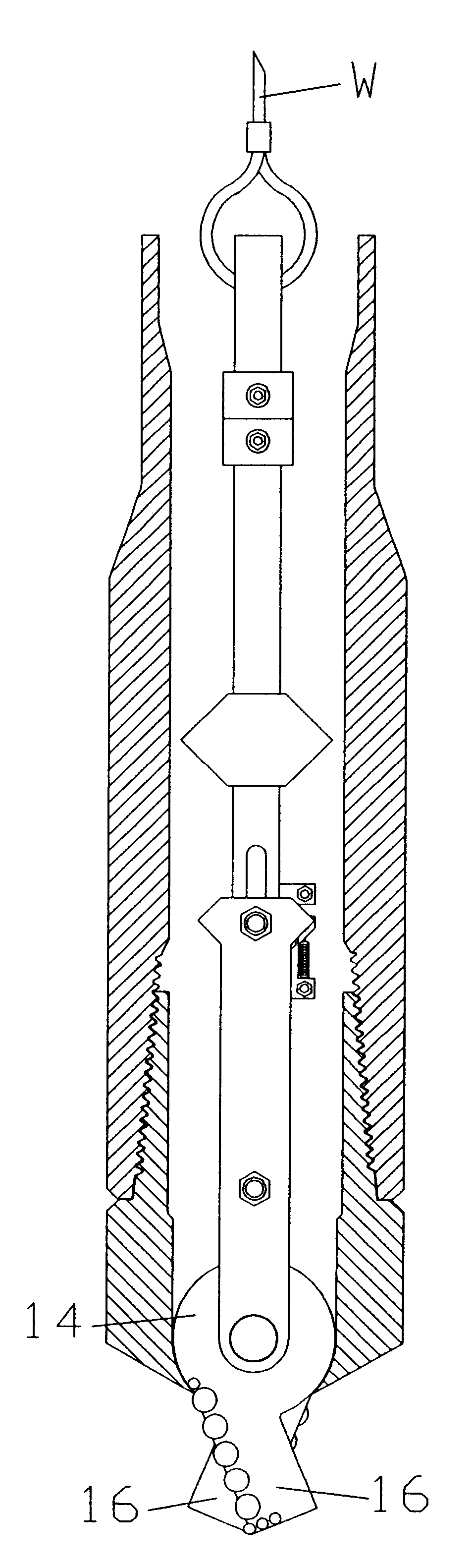

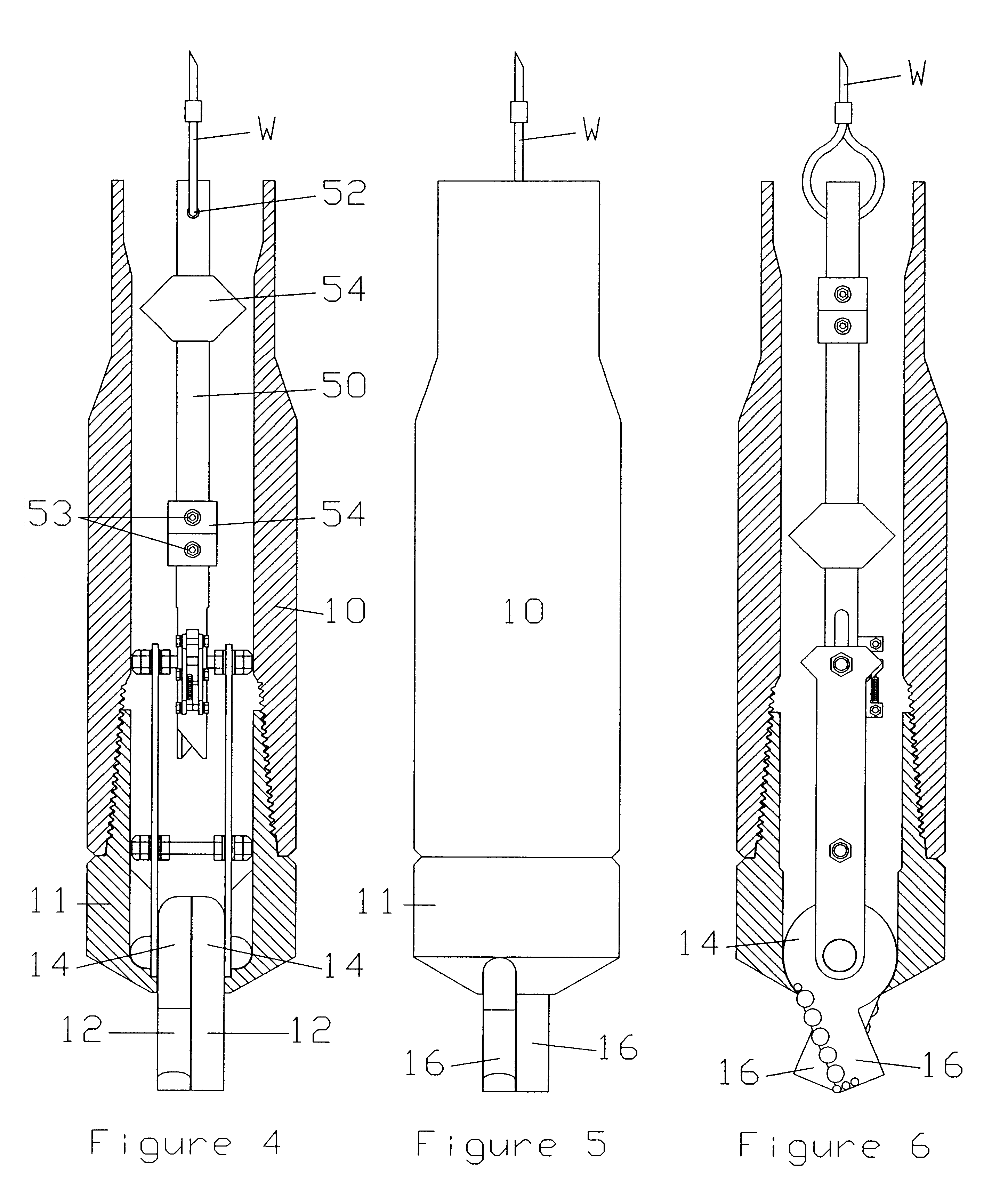

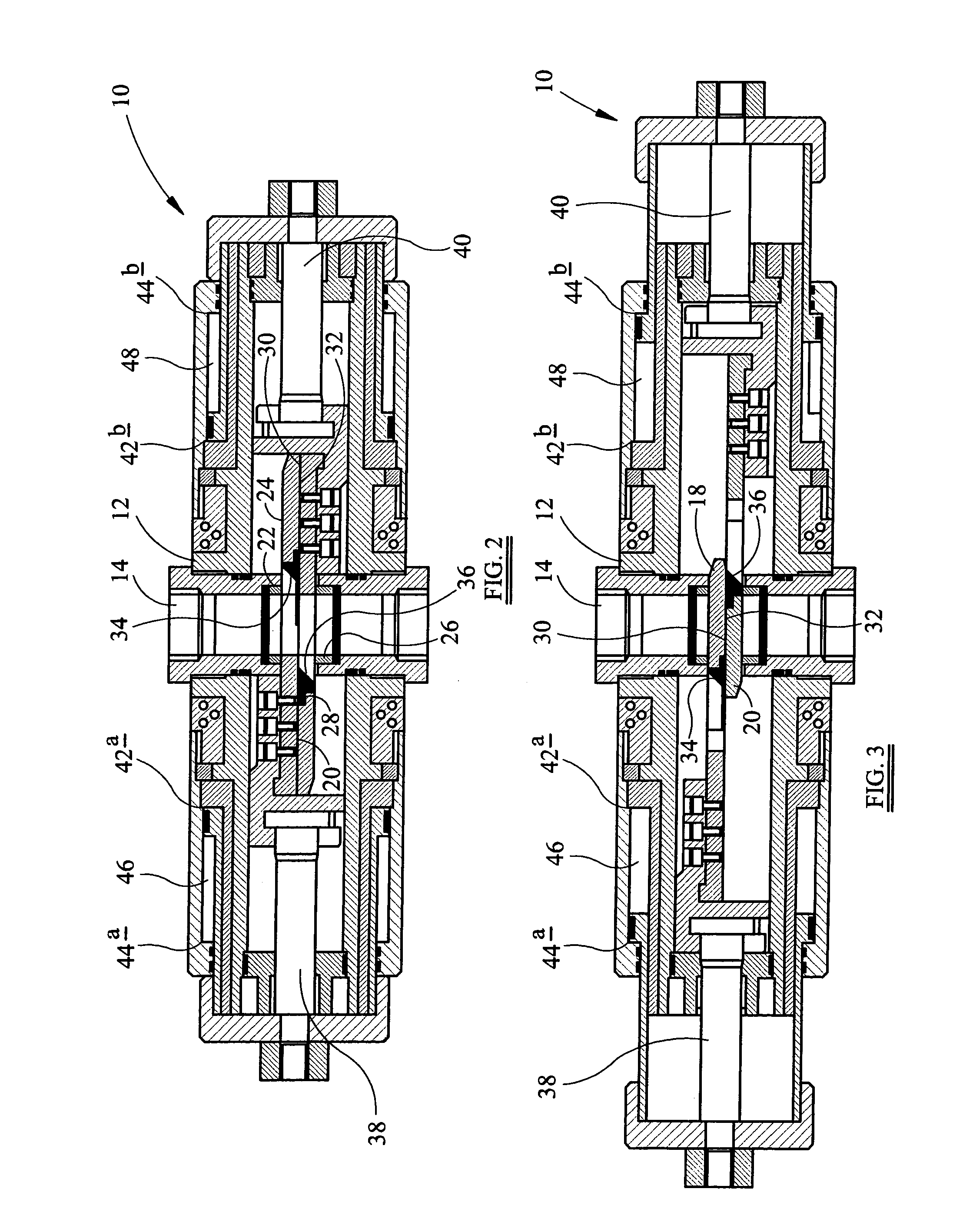

Section mill for wells

ActiveUS6920923B1Improve cutting performanceEasy to installDrill bitsFluid removalExtreme positionOil well

A section mill for casings used in oil wells to cut predetermined portions for repair purposes. An elongated cylindrical assembly is inserted through the casing and it includes at least two spaced apart apertures with one blade member pivotally mounted within each aperture. First and second coaxially disposed tubular shaft assemblies with teethed portions to coact with the blades to selectively move them between two extreme position upon the application of a pressurized fluid. The fluid needs to overcome the spring biased applied to the shaft assemblies. The first set of blades is stopped and slidably rotates in contact with the internal surface of the casing. The second set cuts through the casing with one end and sections the casing with the other end. After wearing off, the first set of blades continues the sectioning work.

Owner:MECOL OIL TOOLS

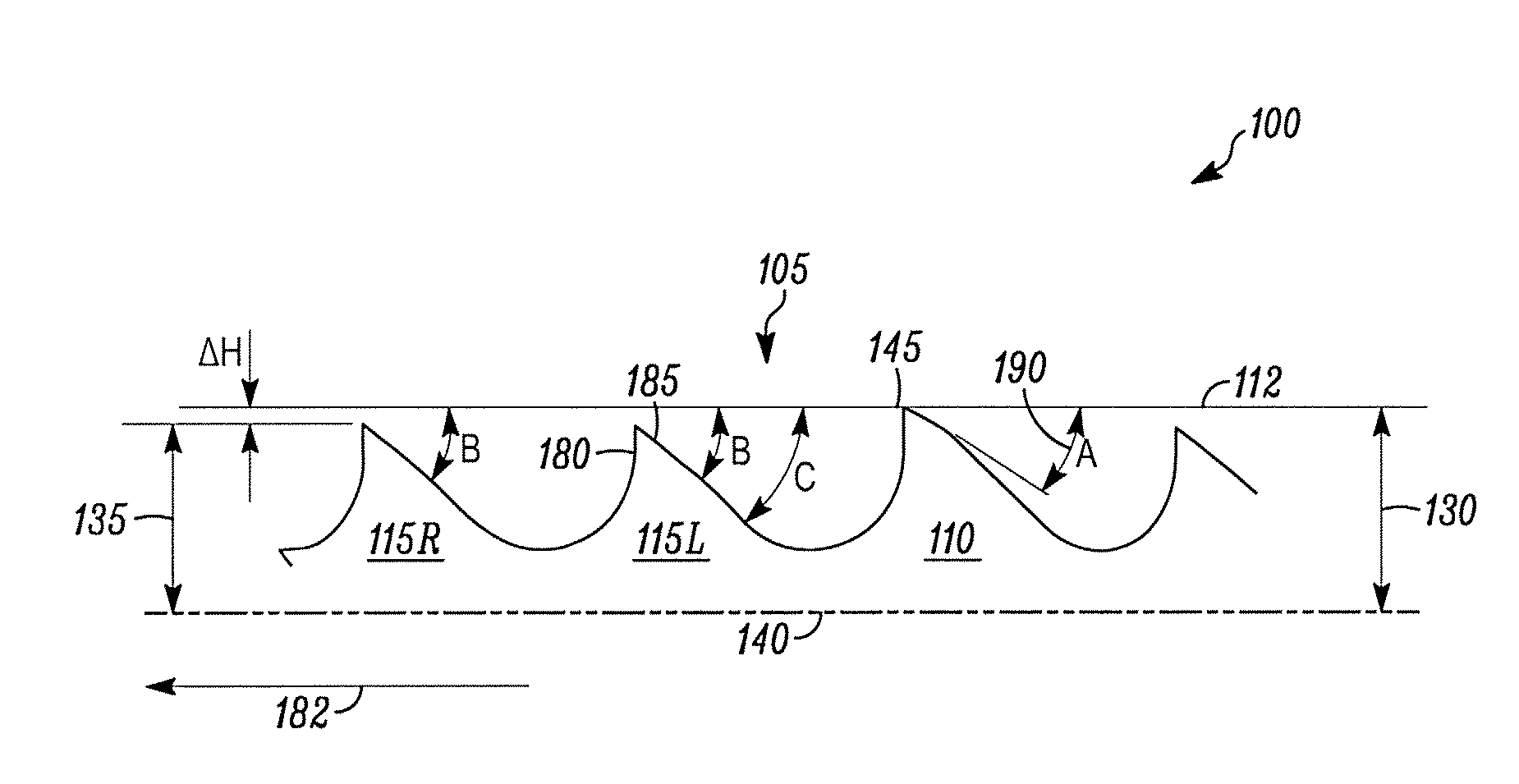

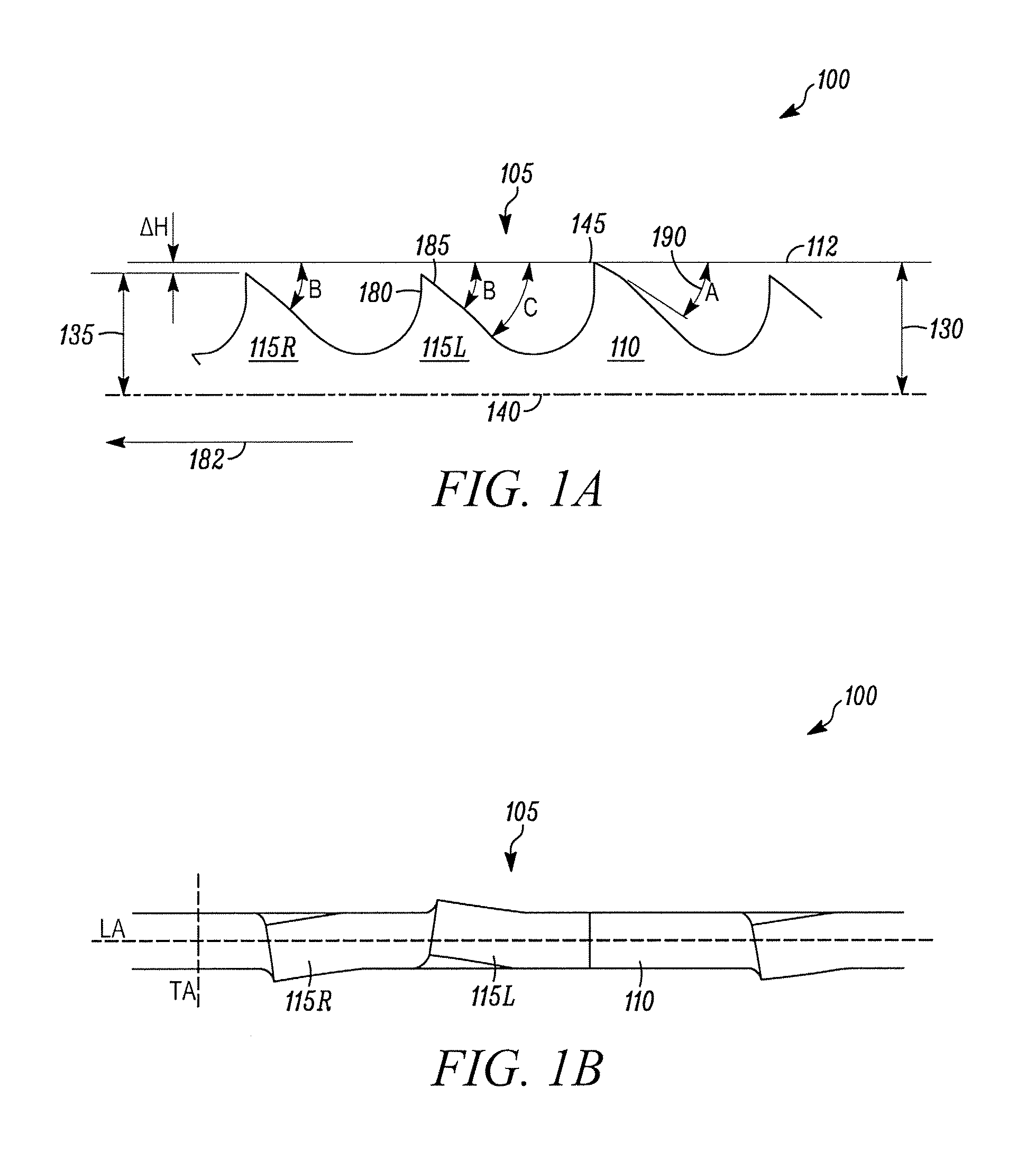

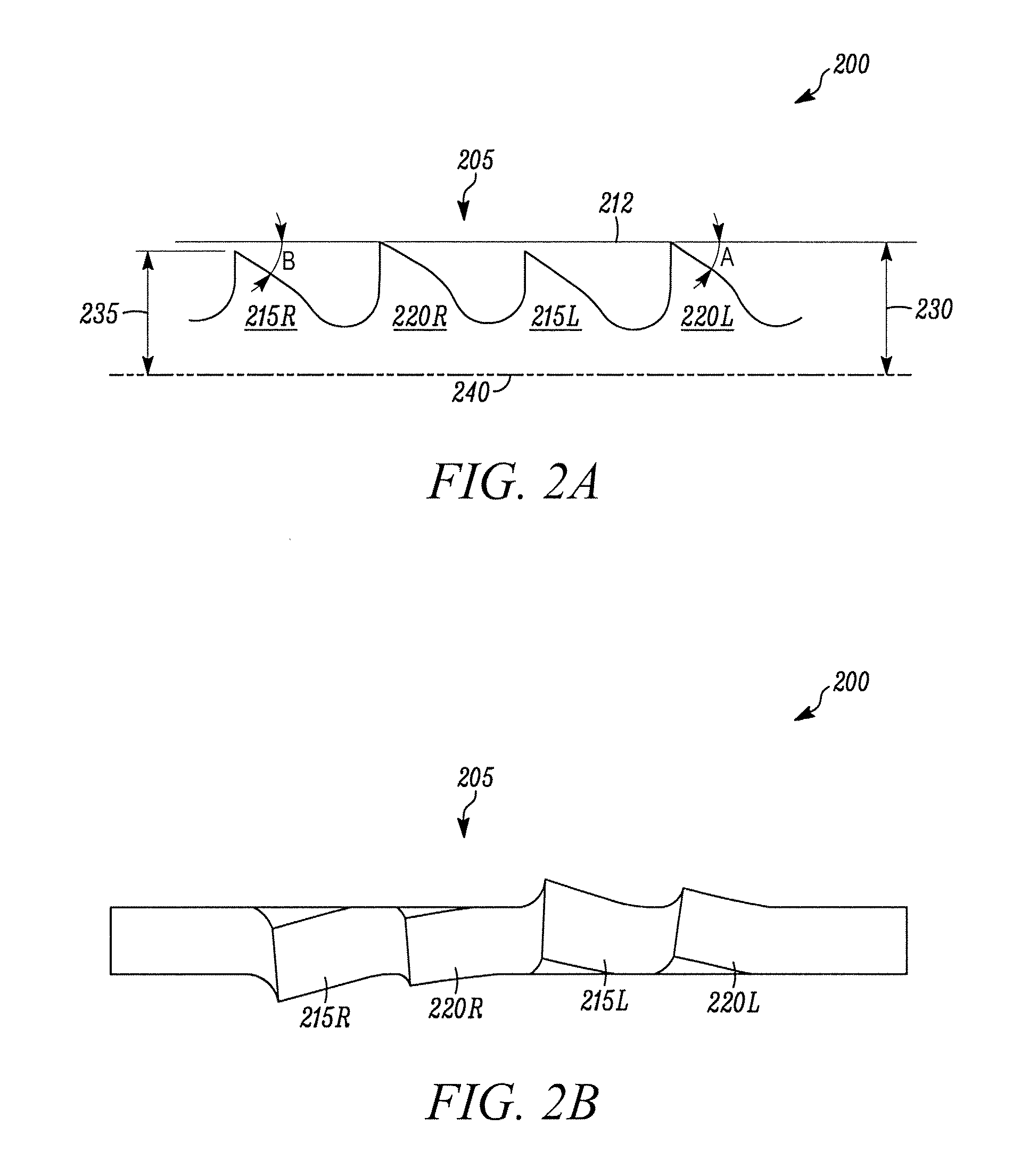

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

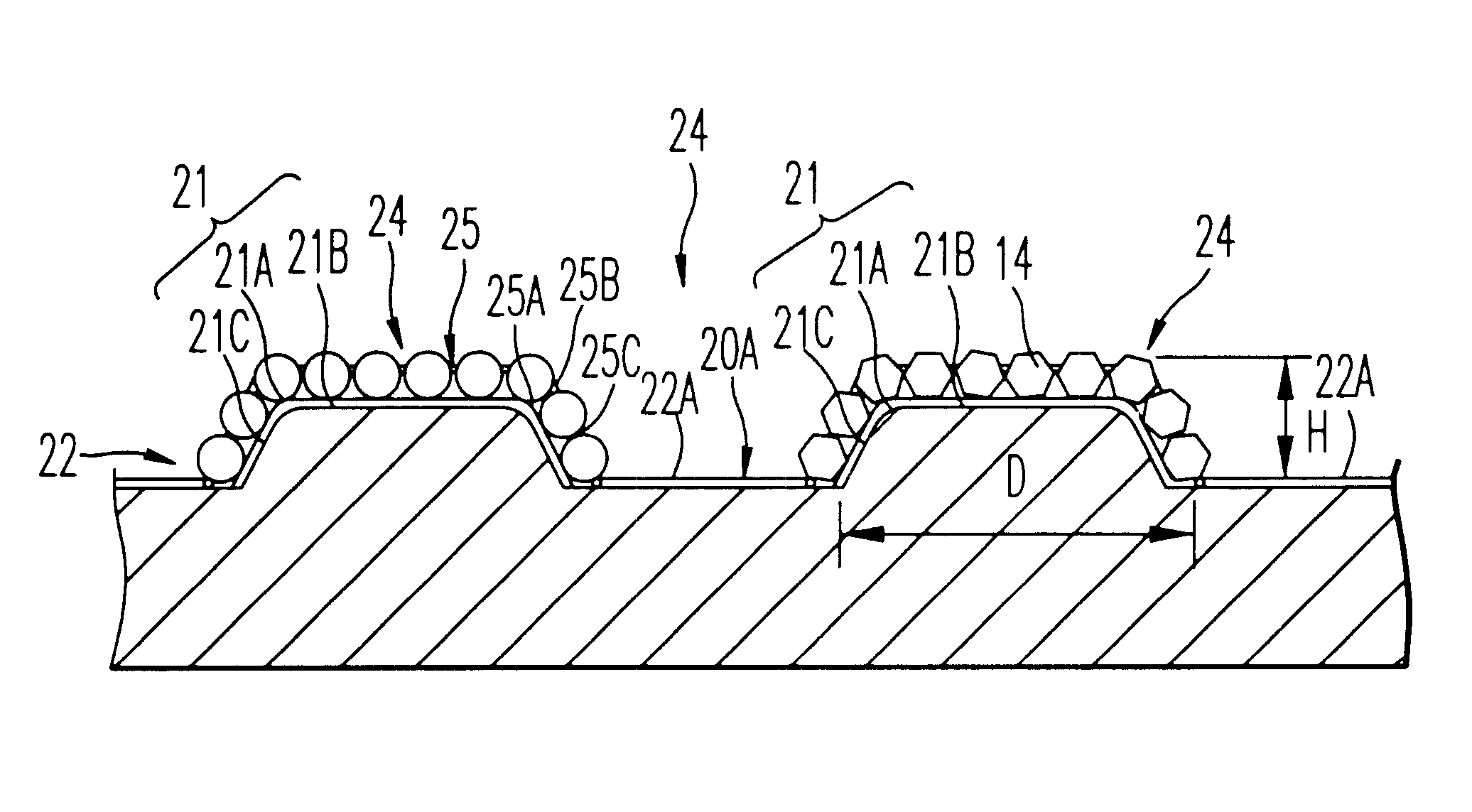

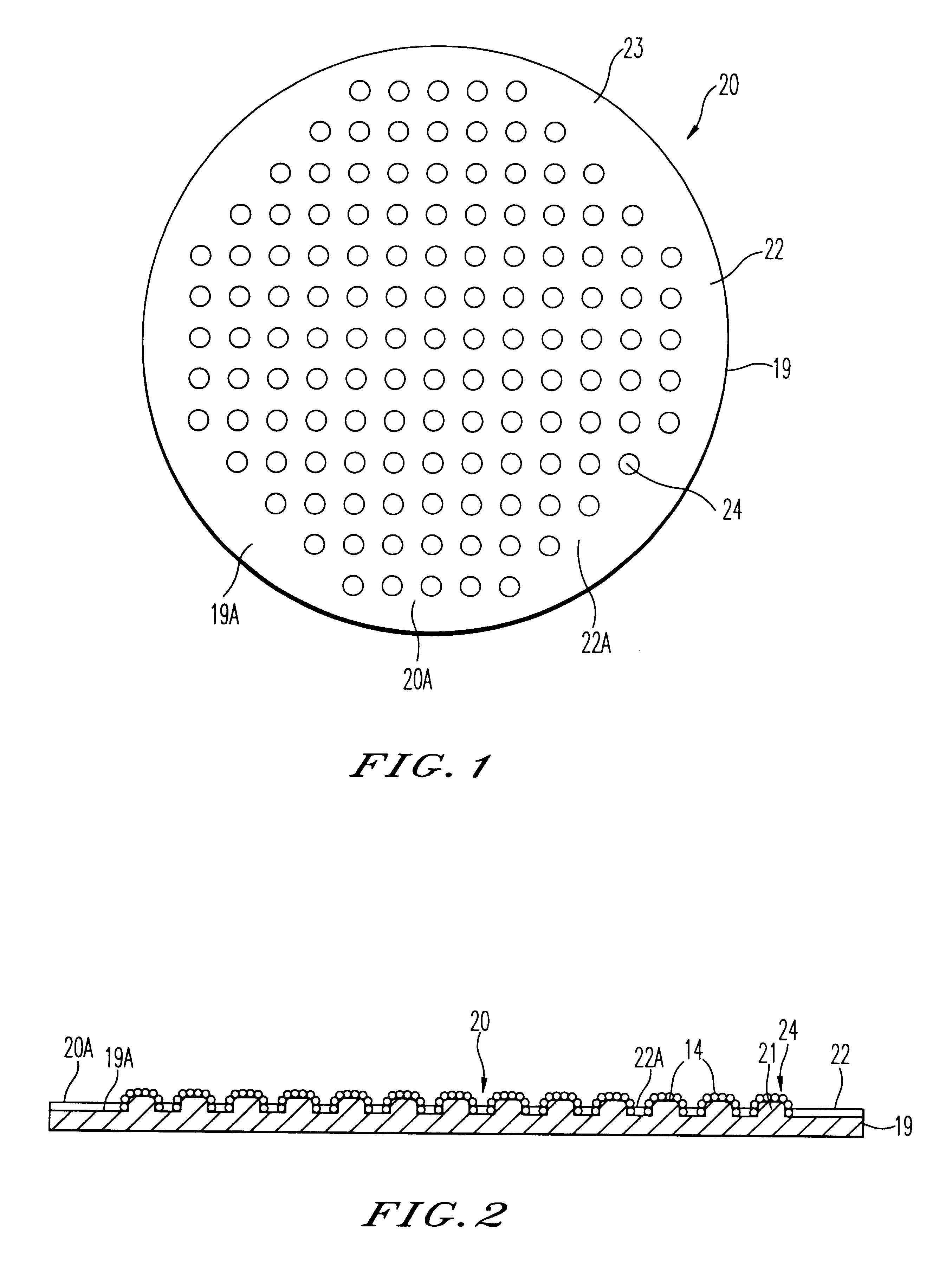

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

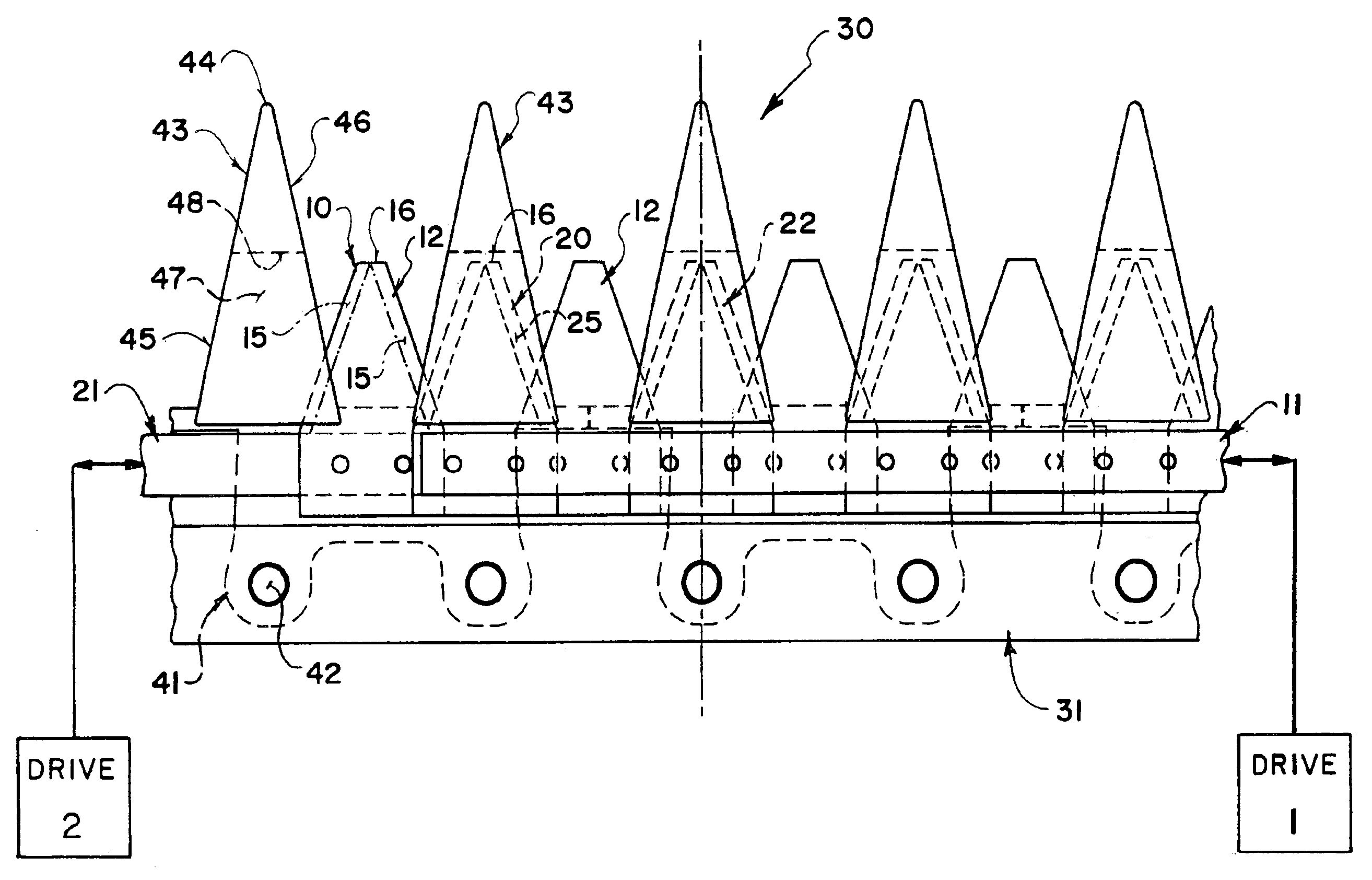

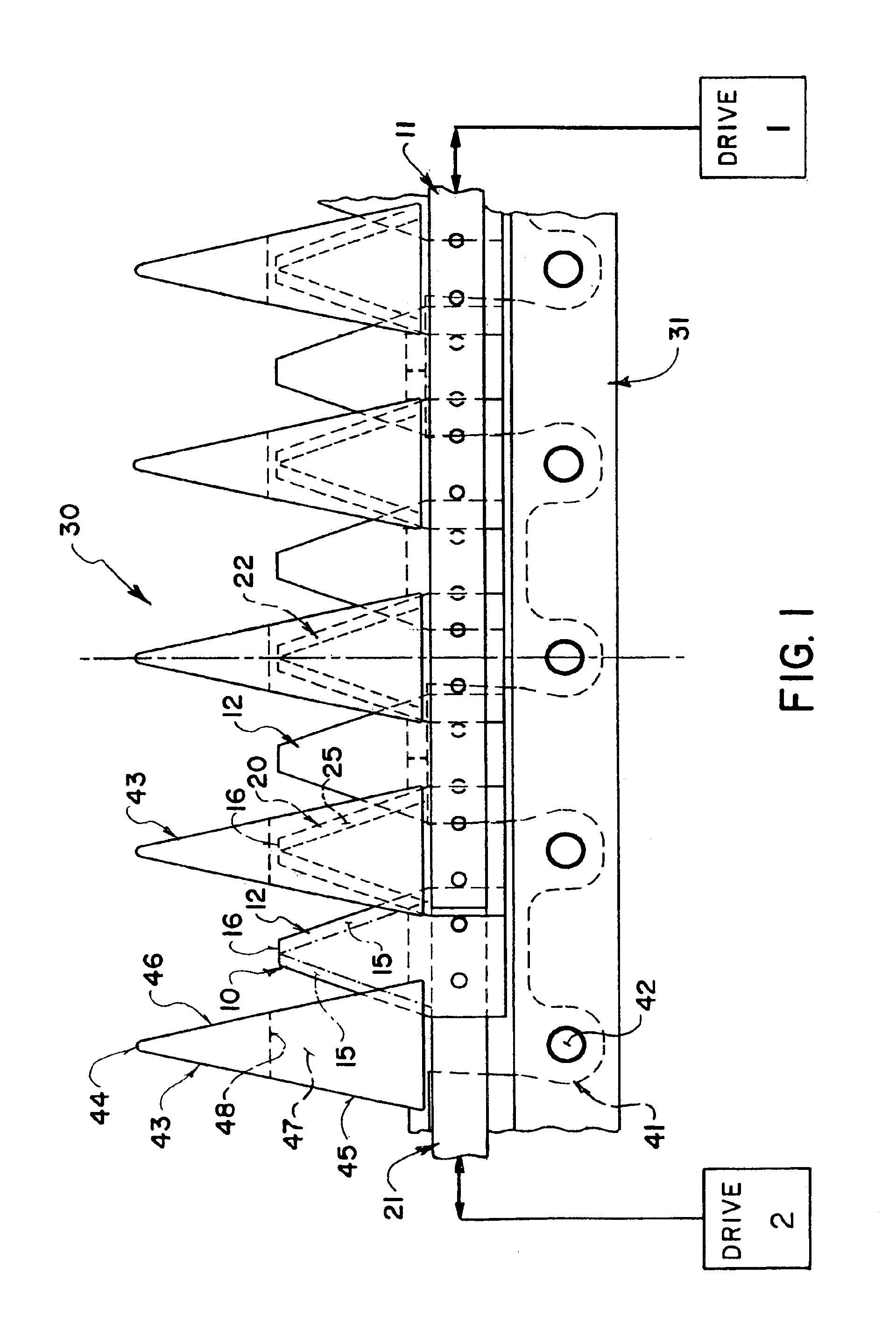

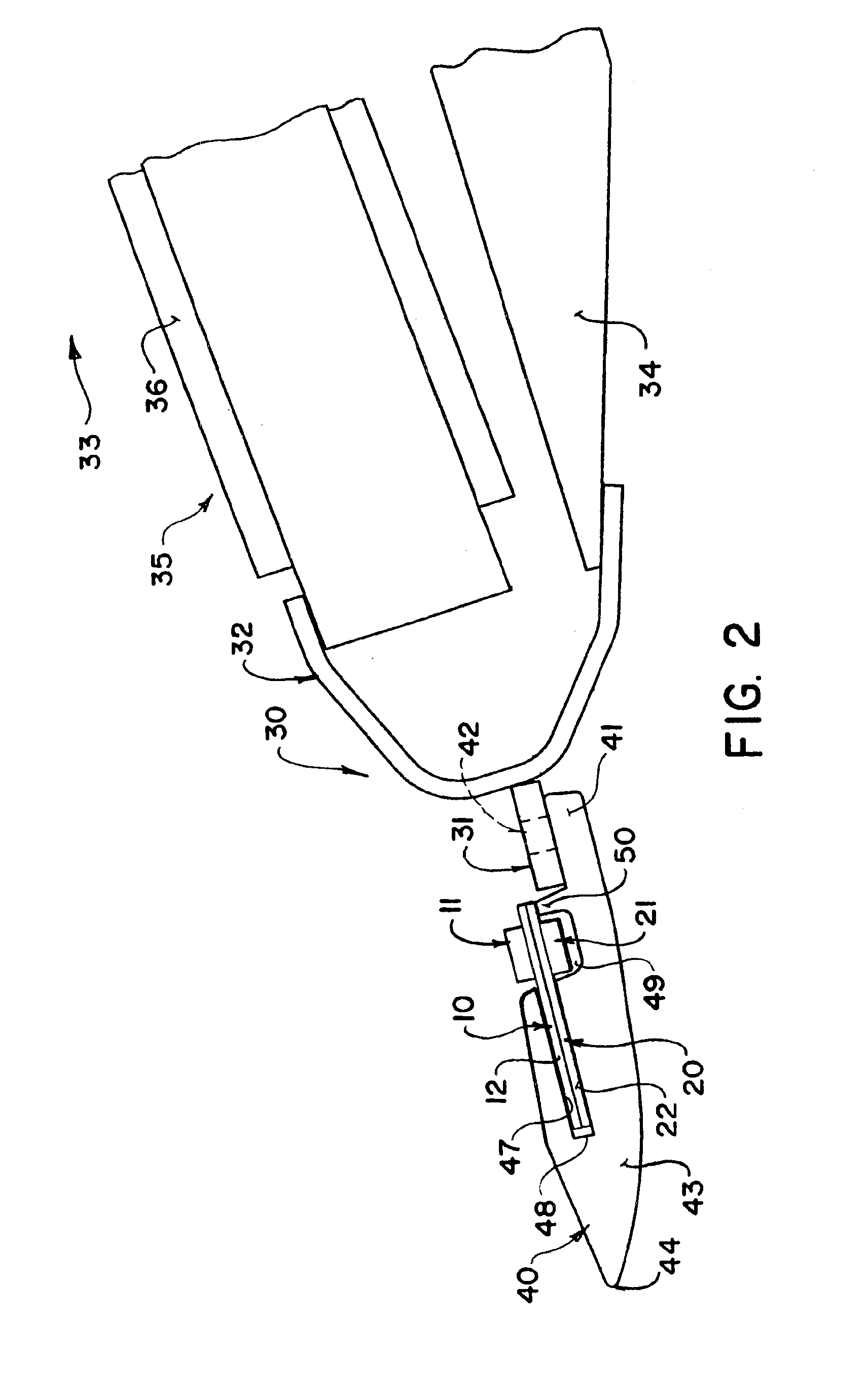

Sickle knife with double overlapping out of phase sickles

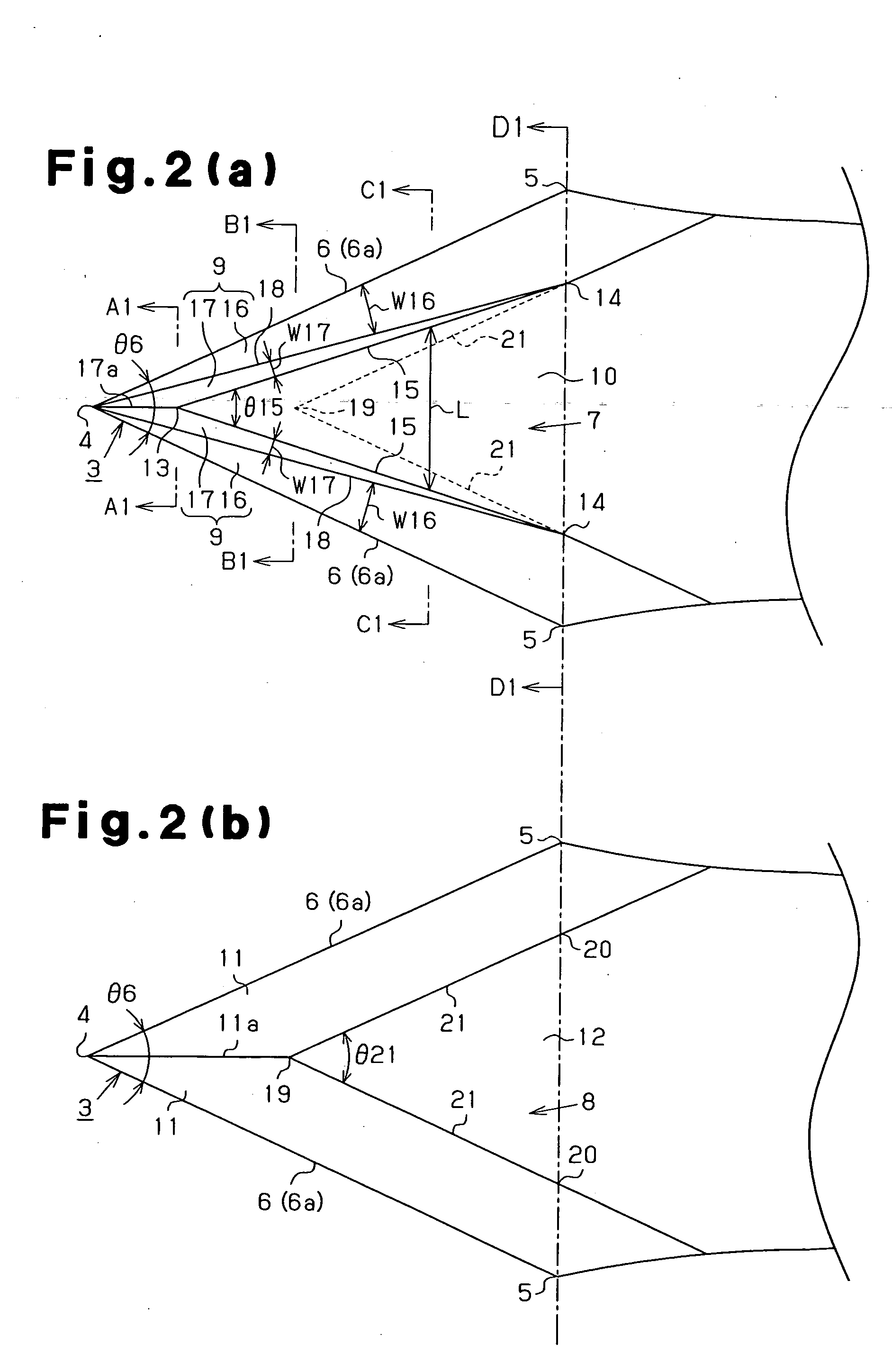

A sickle knife system includes two reciprocating sickles each cooperating the same fixed knife guards and each extending across the full width of the cutter bar. The guards have slots approximately twice the height of the guard of a conventional single sickle arrangement so that the two sickles can be run one on top of the other inside the guards. The width of the sickle blades at the rear edge is similar to that of the guard near the rear of its cutting edge. The blades of the top sickle are sharpened to cut against the top surface of the slot and the blades of the bottom sickle are sharpened to cut against the bottom surface of the slot. The two sickles are run out of phase, preferably about 90 degrees, so that as a result, when one sickle is near the end of its stroke within the guard where it decelerates, stops, then accelerates in the opposite direction, the other sickle is starting its cut against the side surface of the next guard.

Owner:MACDON INDS

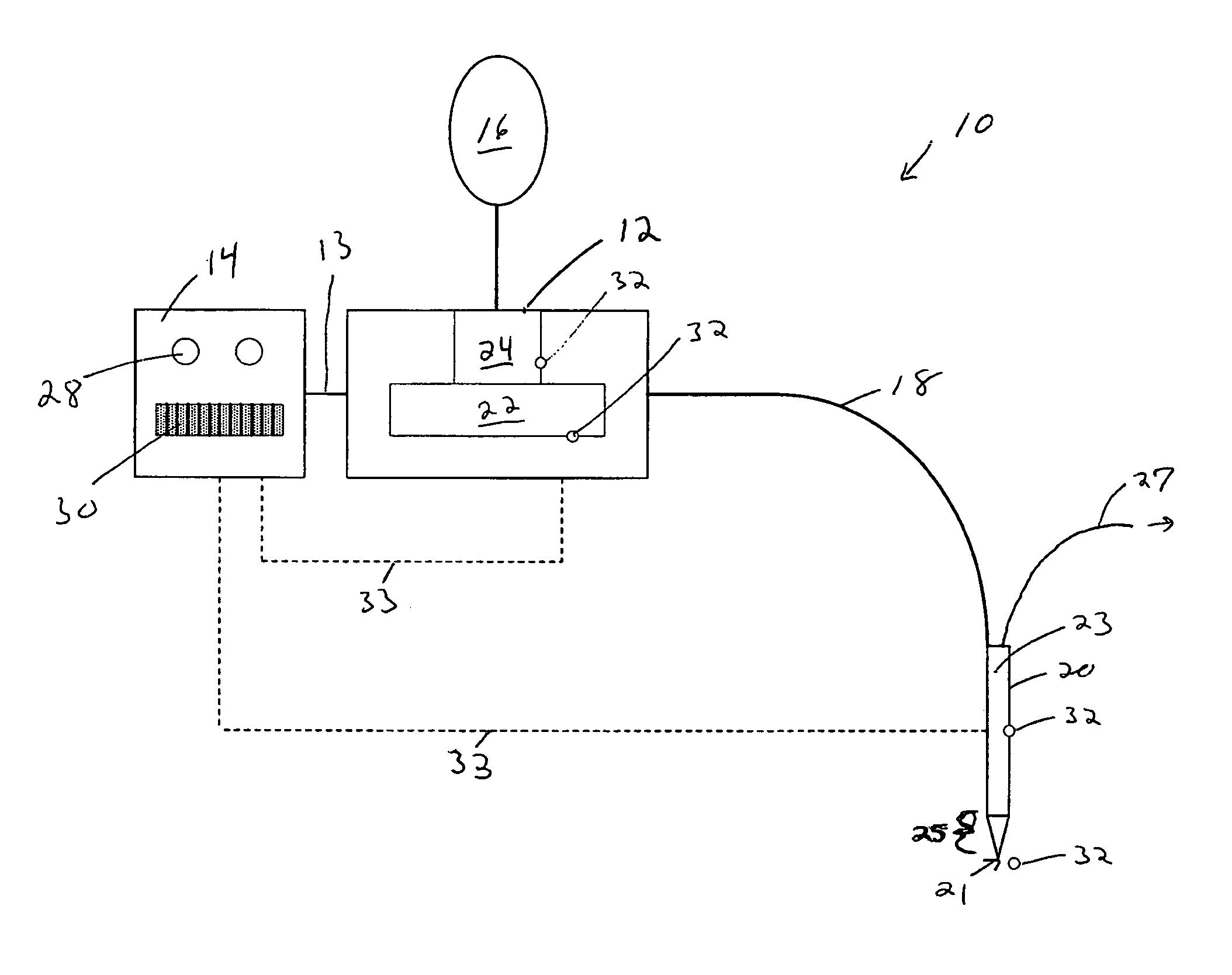

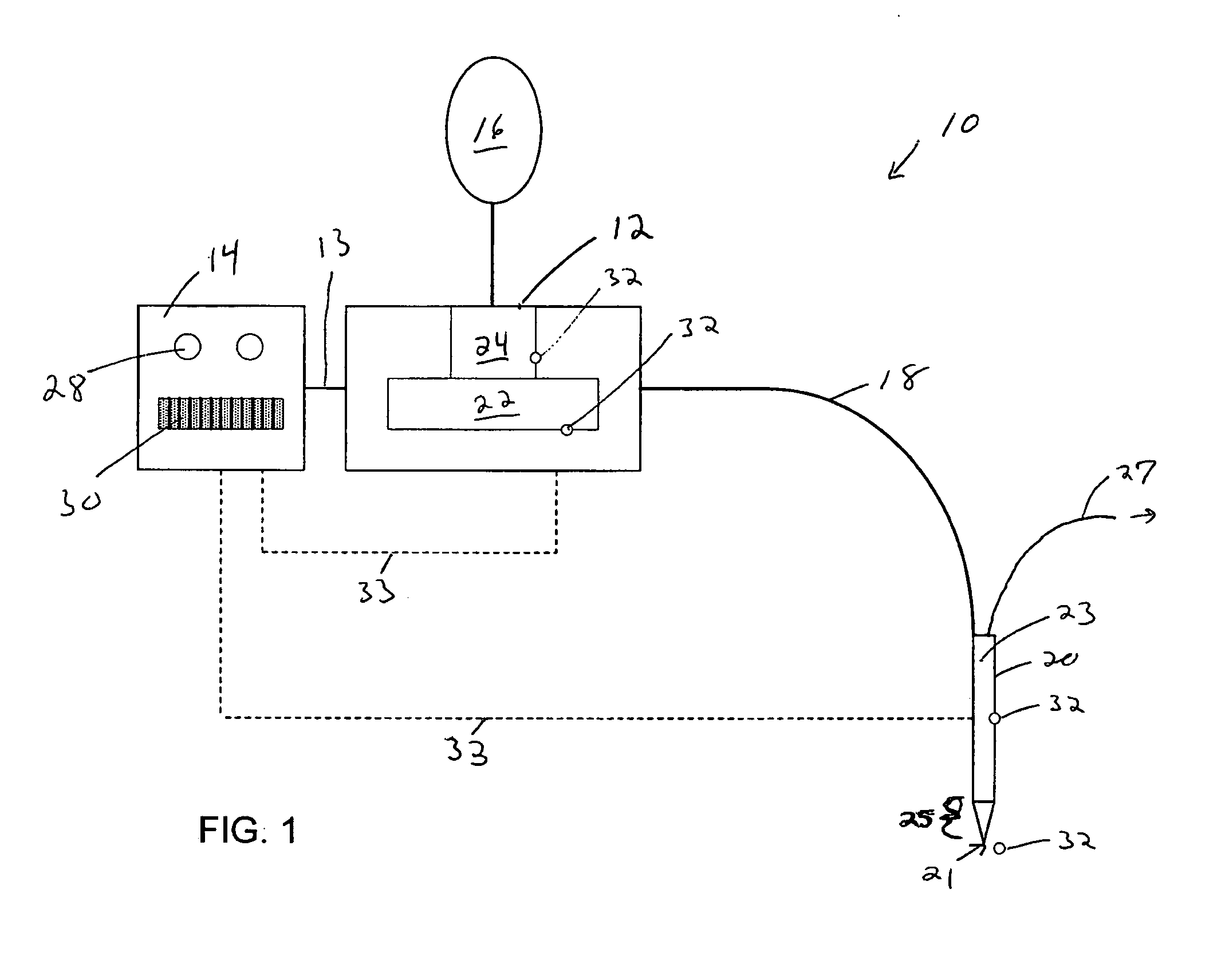

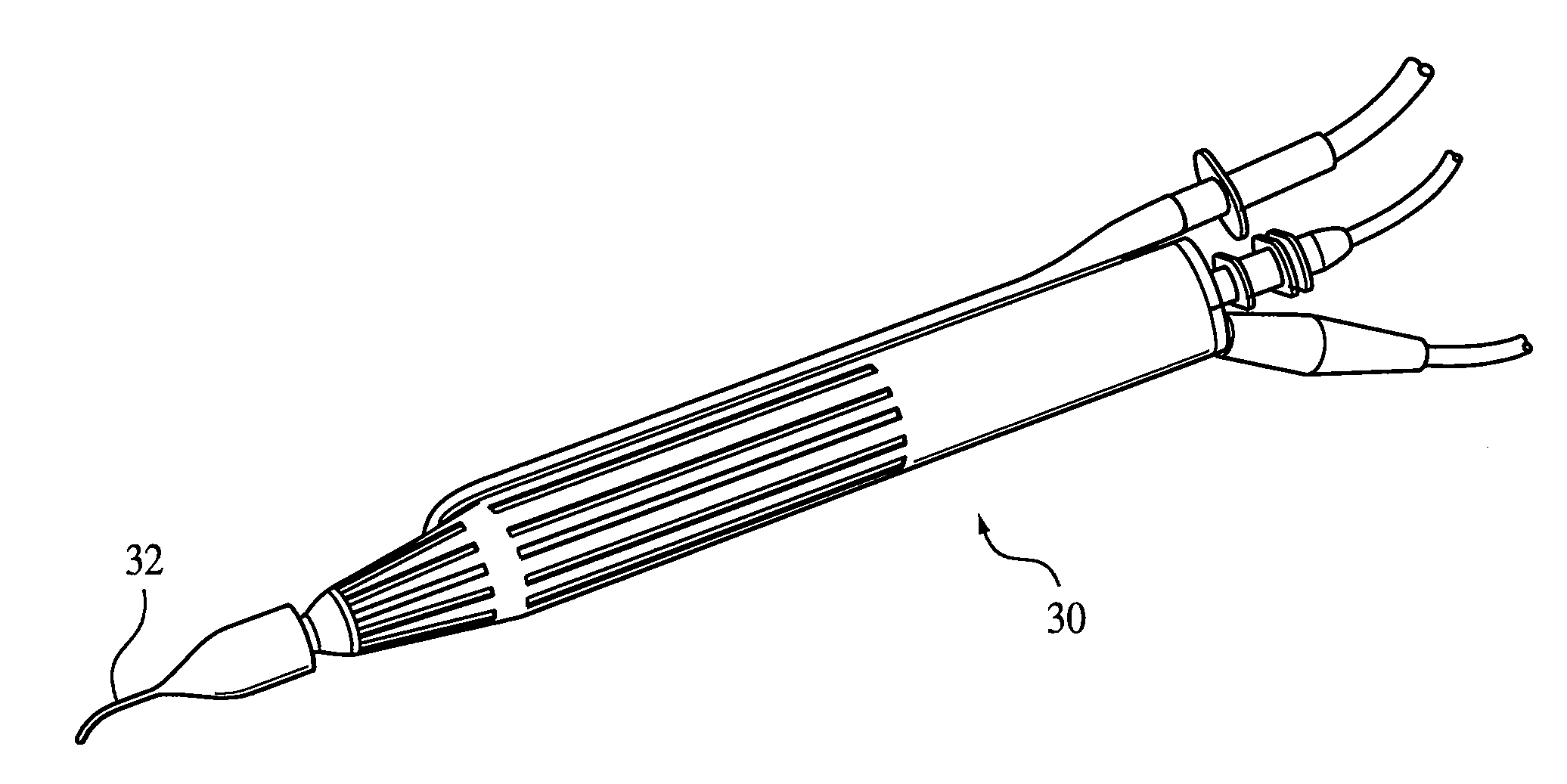

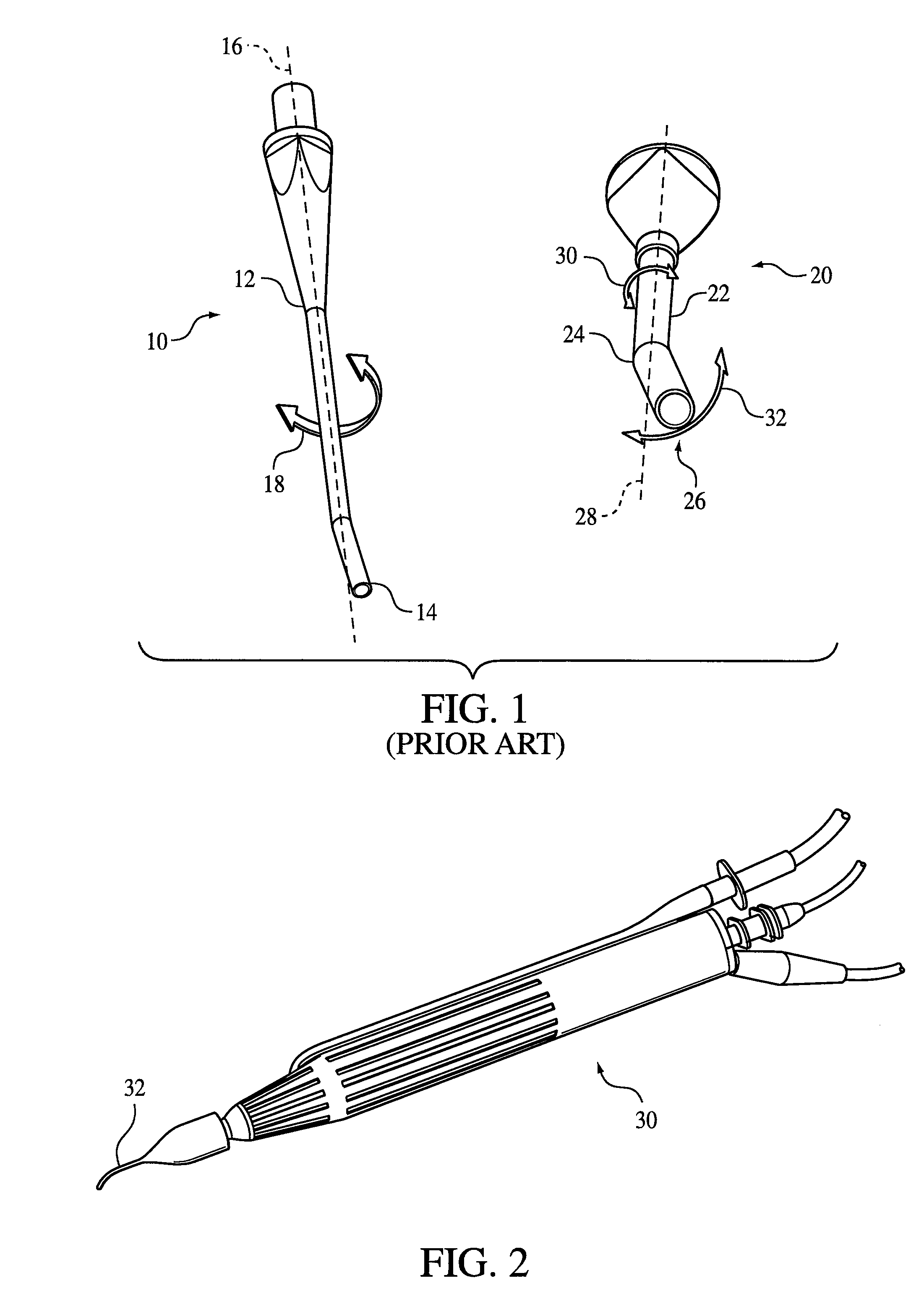

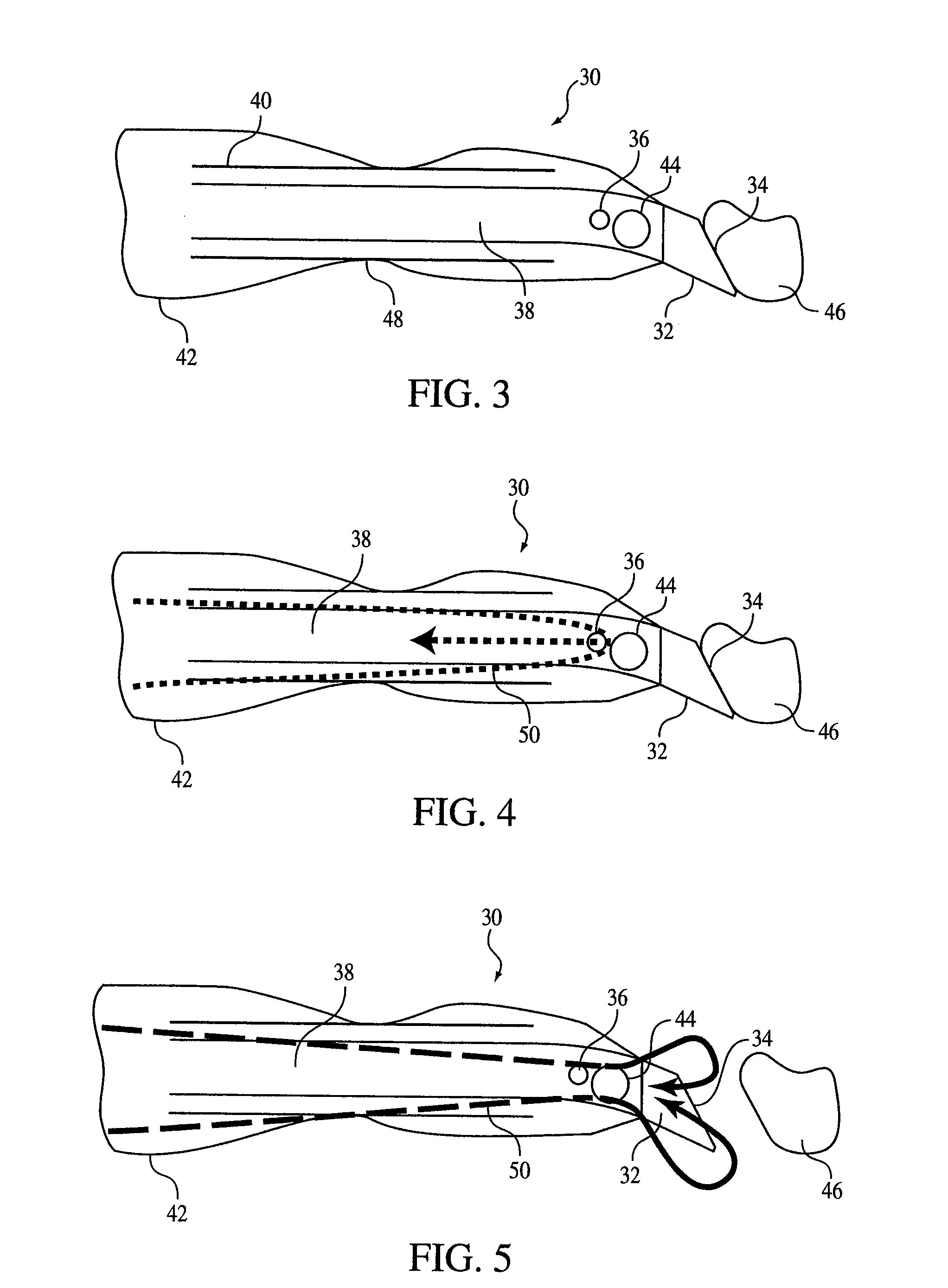

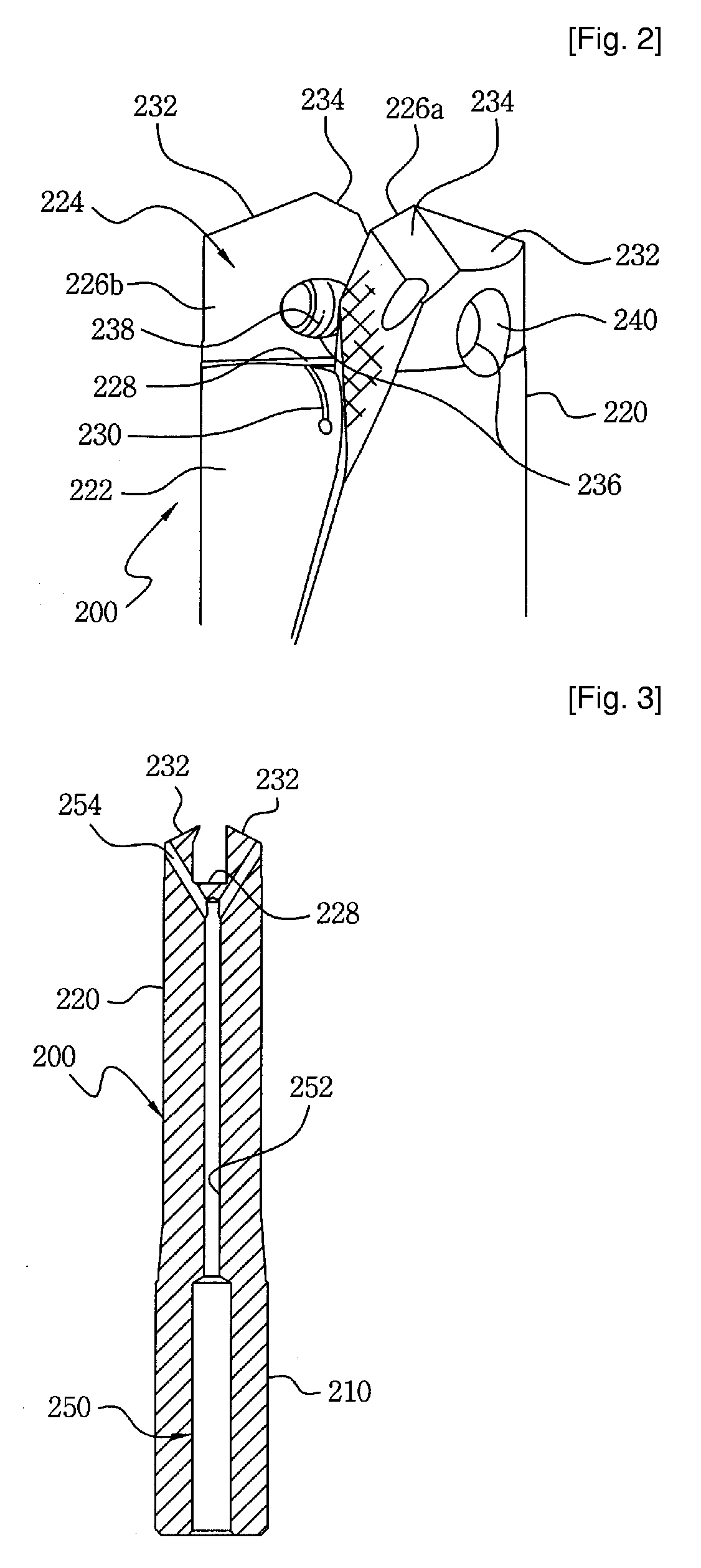

Fluid cutting device and method of use

InactiveUS20060156875A1Improve cutting performanceLess sensitive to variationFluid jet surgical cuttersMetal working apparatusBiomedical engineeringActuator

A fluid jet cutting system that provides more consistent cutting jet performance is disclosed. The system includes a fluid pump for pressurizing fluid having a fluid inlet and a fluid outlet. The pump delivers pressurized fluid to a delivery tube that is in fluid communication with an end effector. The end effector includes an orifice for delivering pressurized fluid to tissue. The power delivered to the pump is controlled to produce a desired fluid cutting jet.

Owner:DEPUY MITEK INC

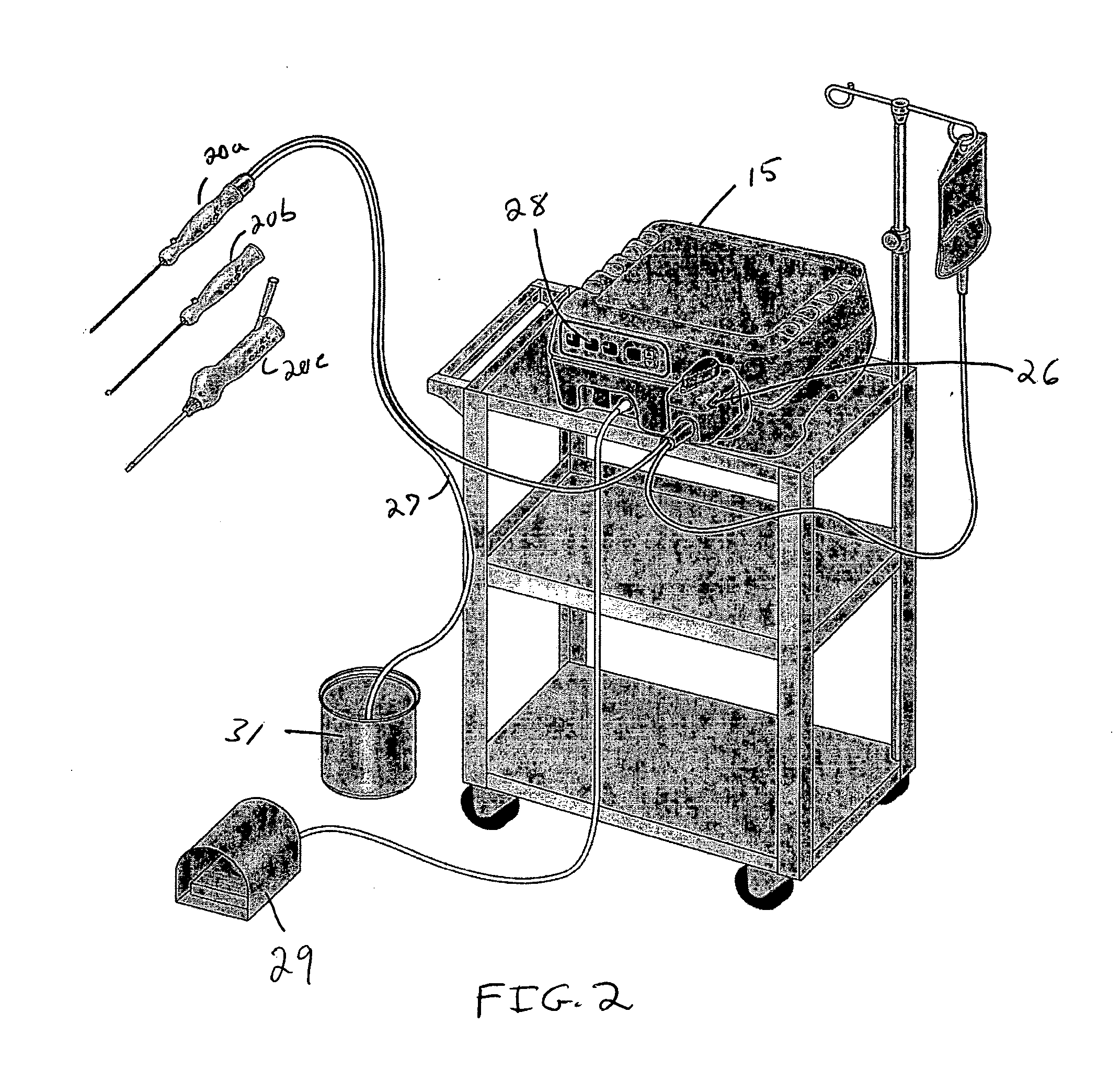

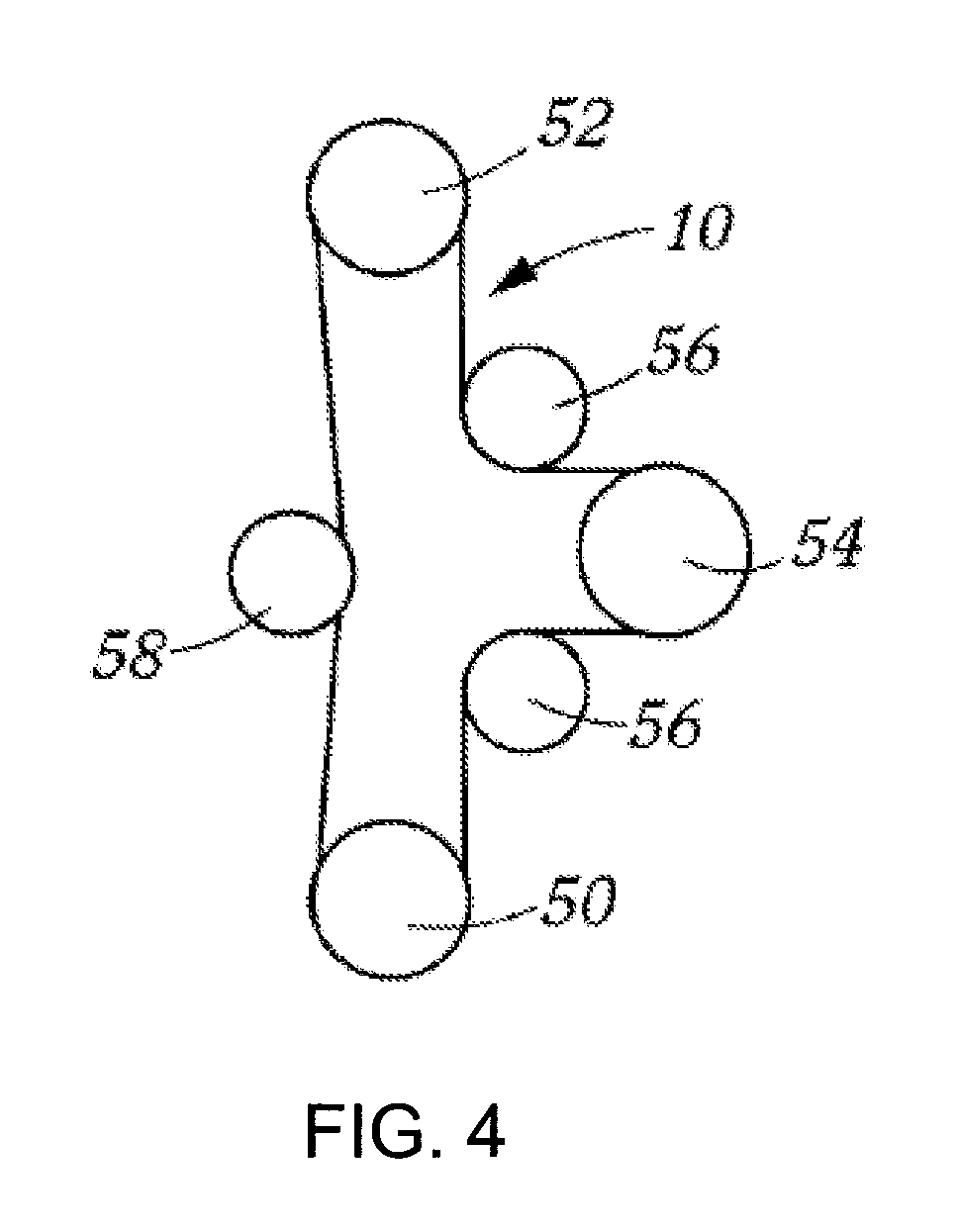

Polyurea-Urethane Cord Treatment for Power Transmission Belt and Belt

ActiveUS20110129647A1Improve adhesionGood compatibilityV-beltsPolyureas/polyurethane adhesivesPolyesterElastomer

A belt with a tensile cord embedded in an elastomeric body, having a polyurea-urethane adhesive composition impregnating the cord and coating the fibers. The composition is reaction product of a polyurethane prepolymer and a diamine curative or water. The prepolymer is a reaction product of a compact, symmetric diisocyanate and a polyester, polyether, or polycarbonate polyol. The belt body may be of cast polyurethane, vulcanized rubber, or thermoplastic elastomer. The cord may have an adhesive overcoat.

Owner:THE GATES CORP

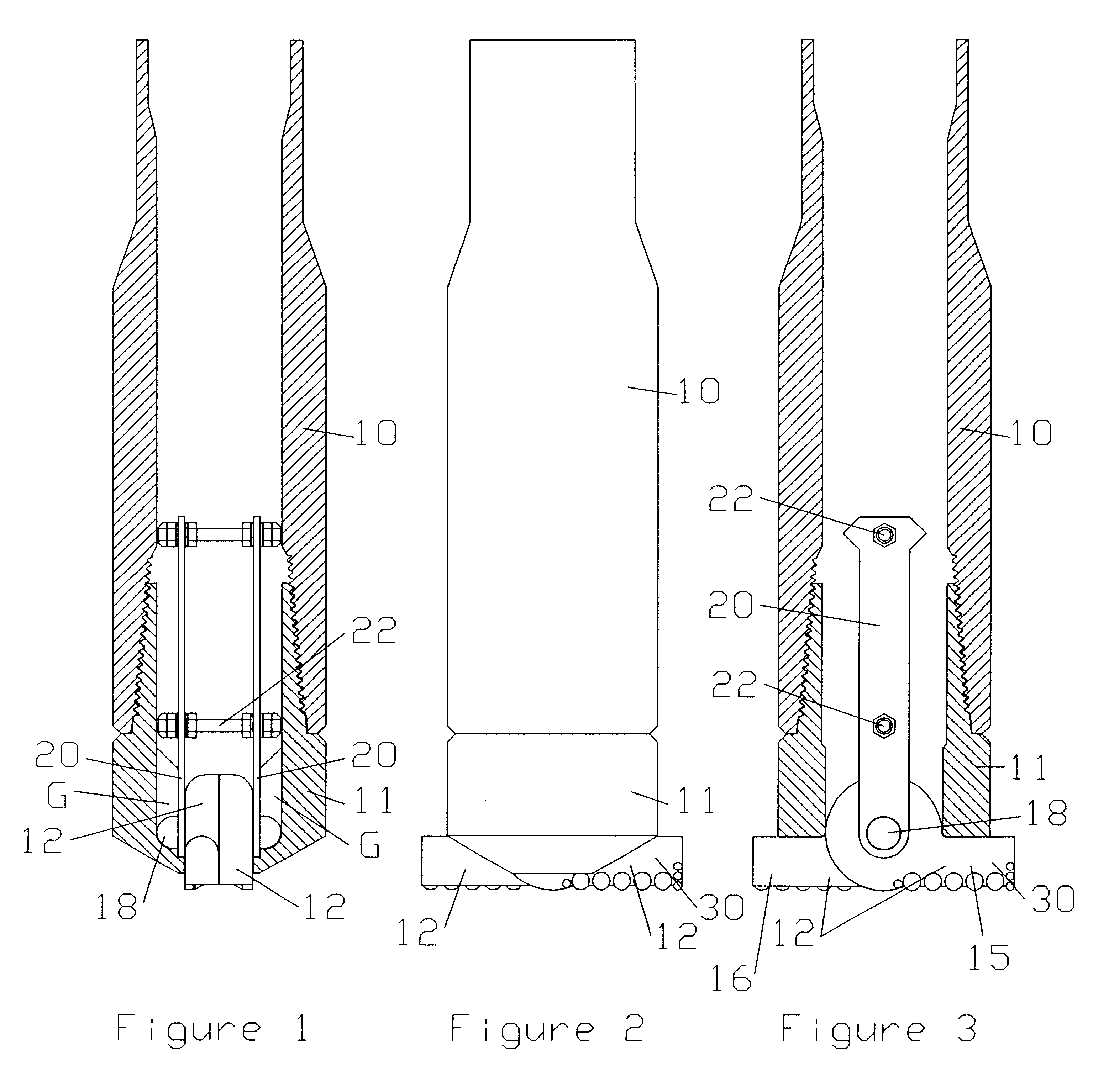

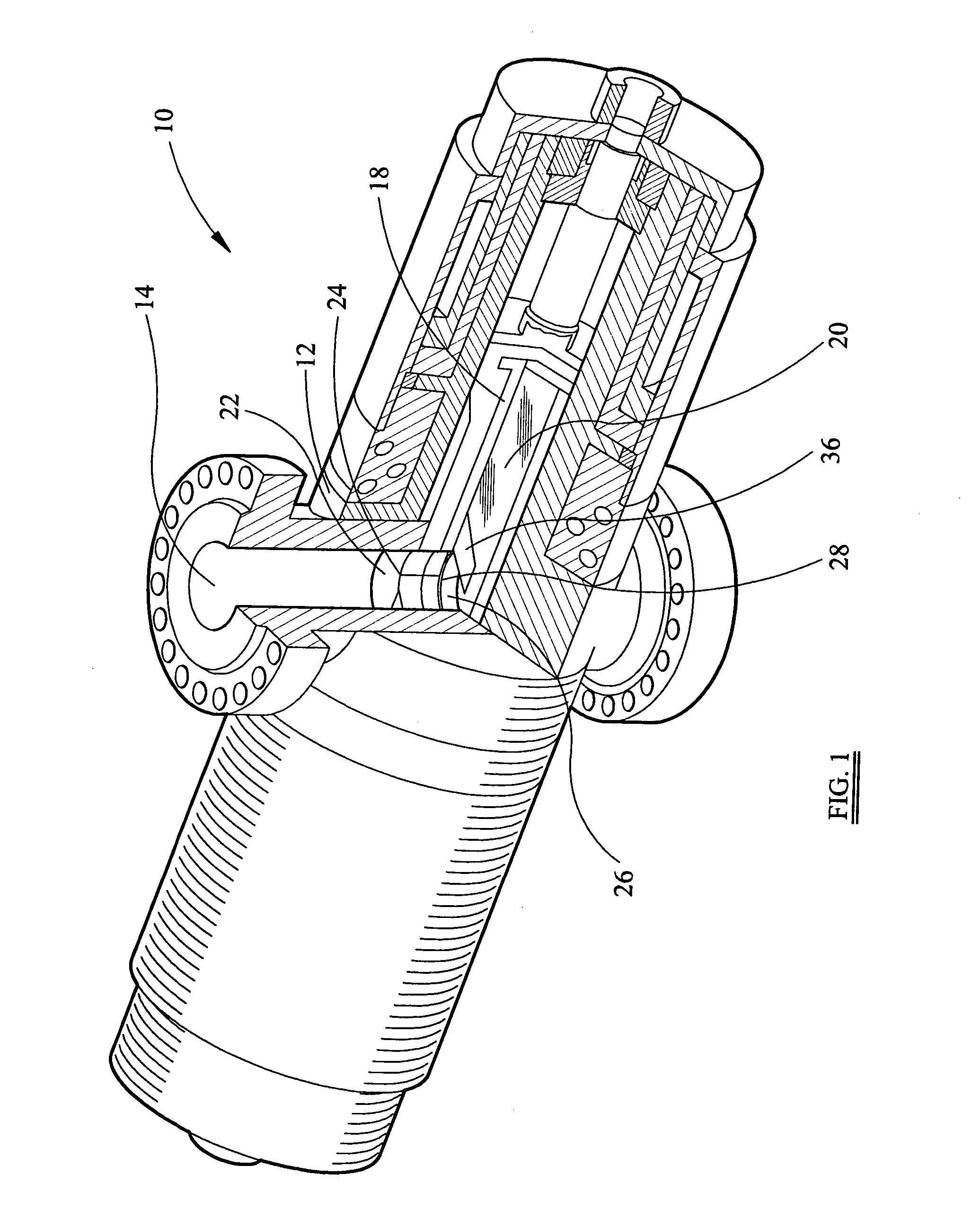

Replaceable drill bit assembly

InactiveUS6454024B1Quickly replaceableQuickly retrievableDrill bitsDrilling machines and methodsLeading edgeKnife blades

Owner:NACKERUD ALAN L

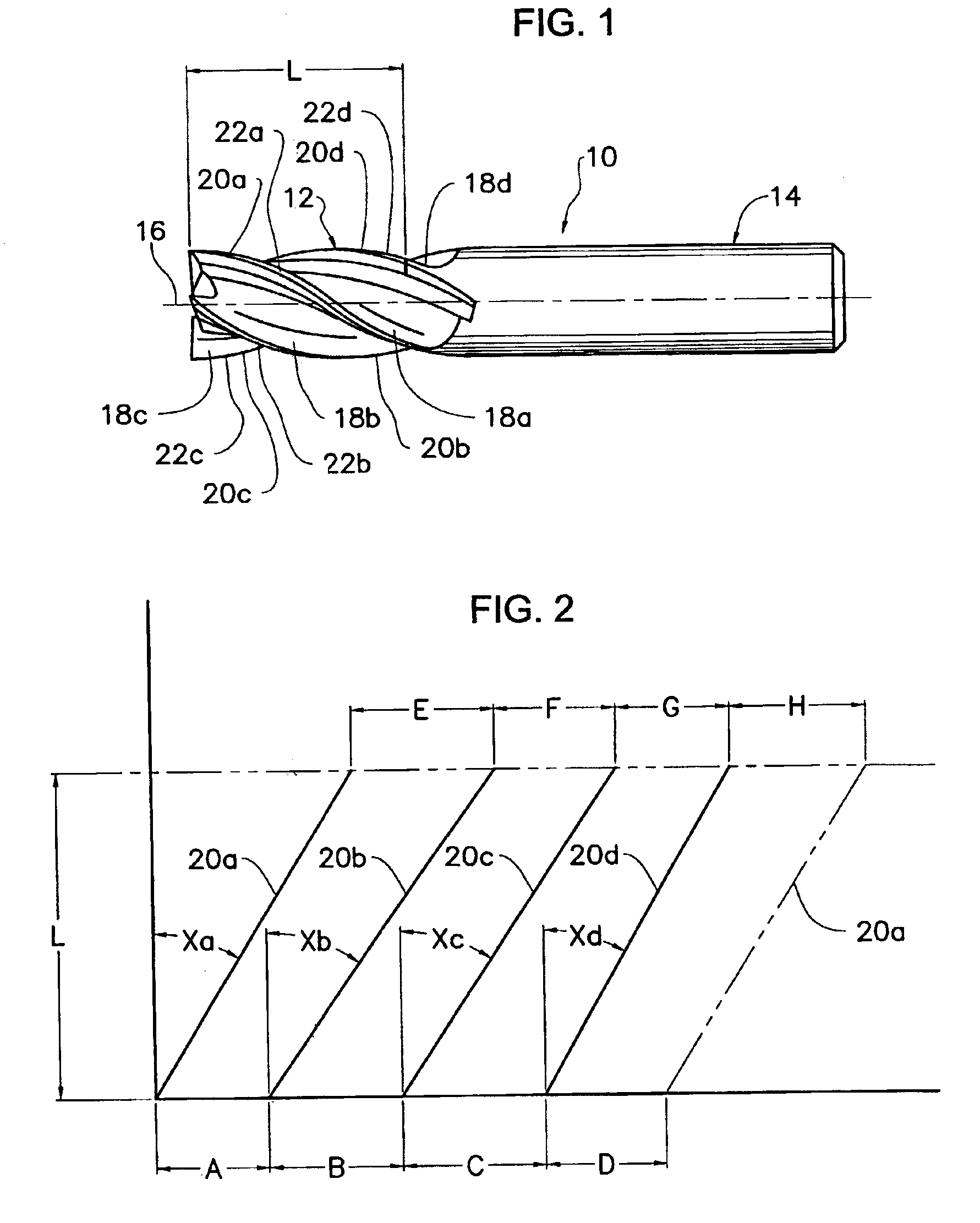

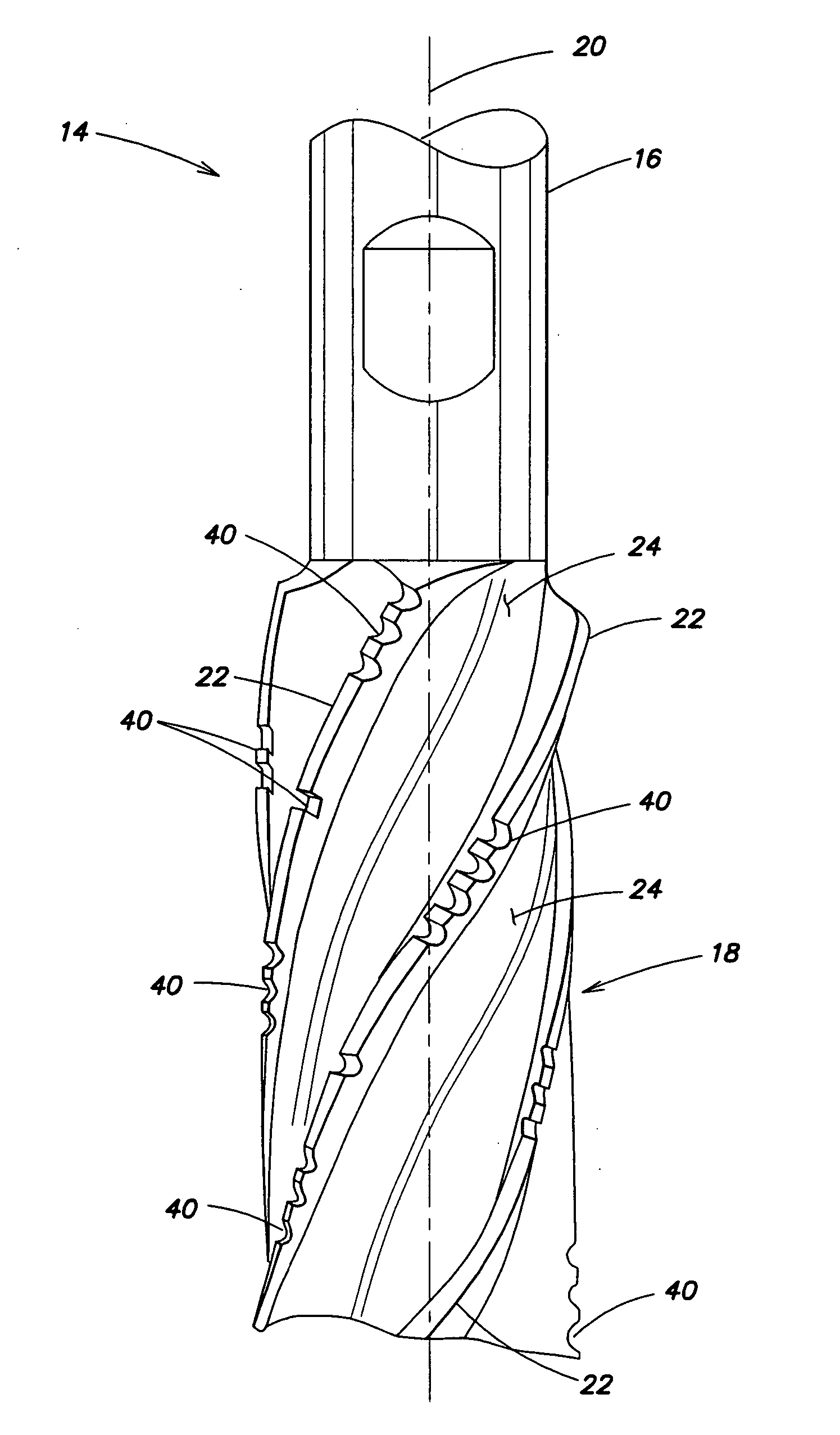

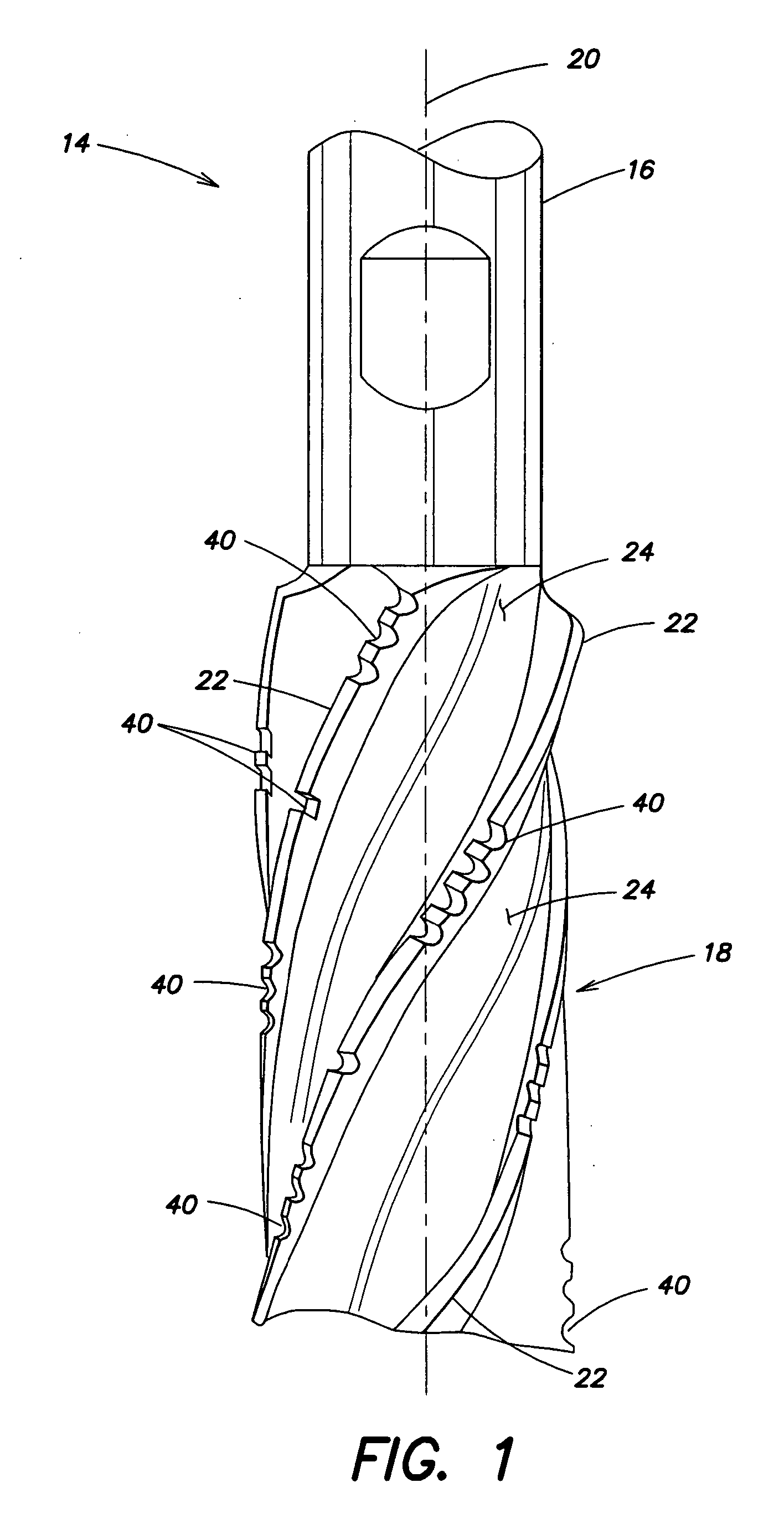

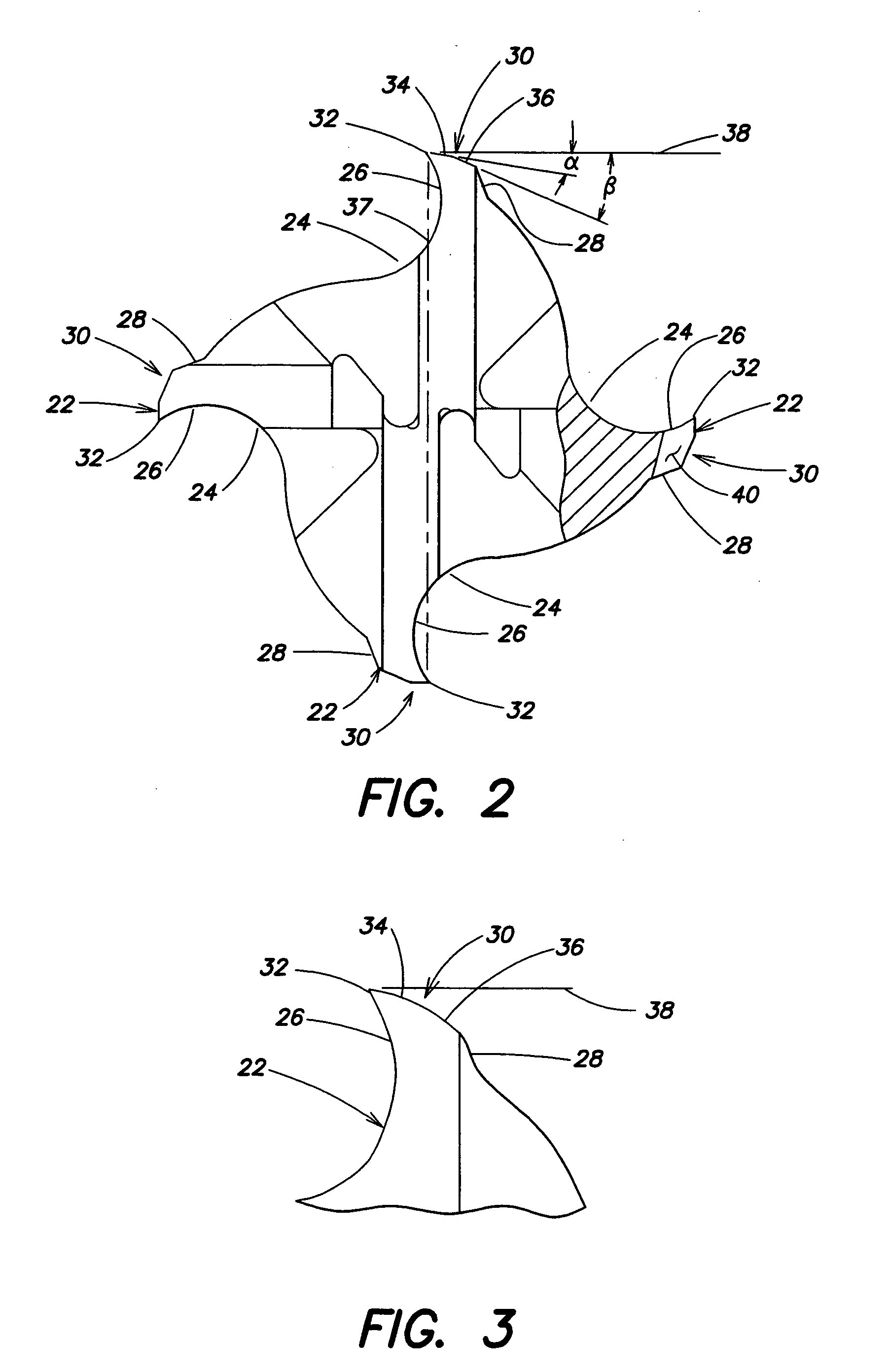

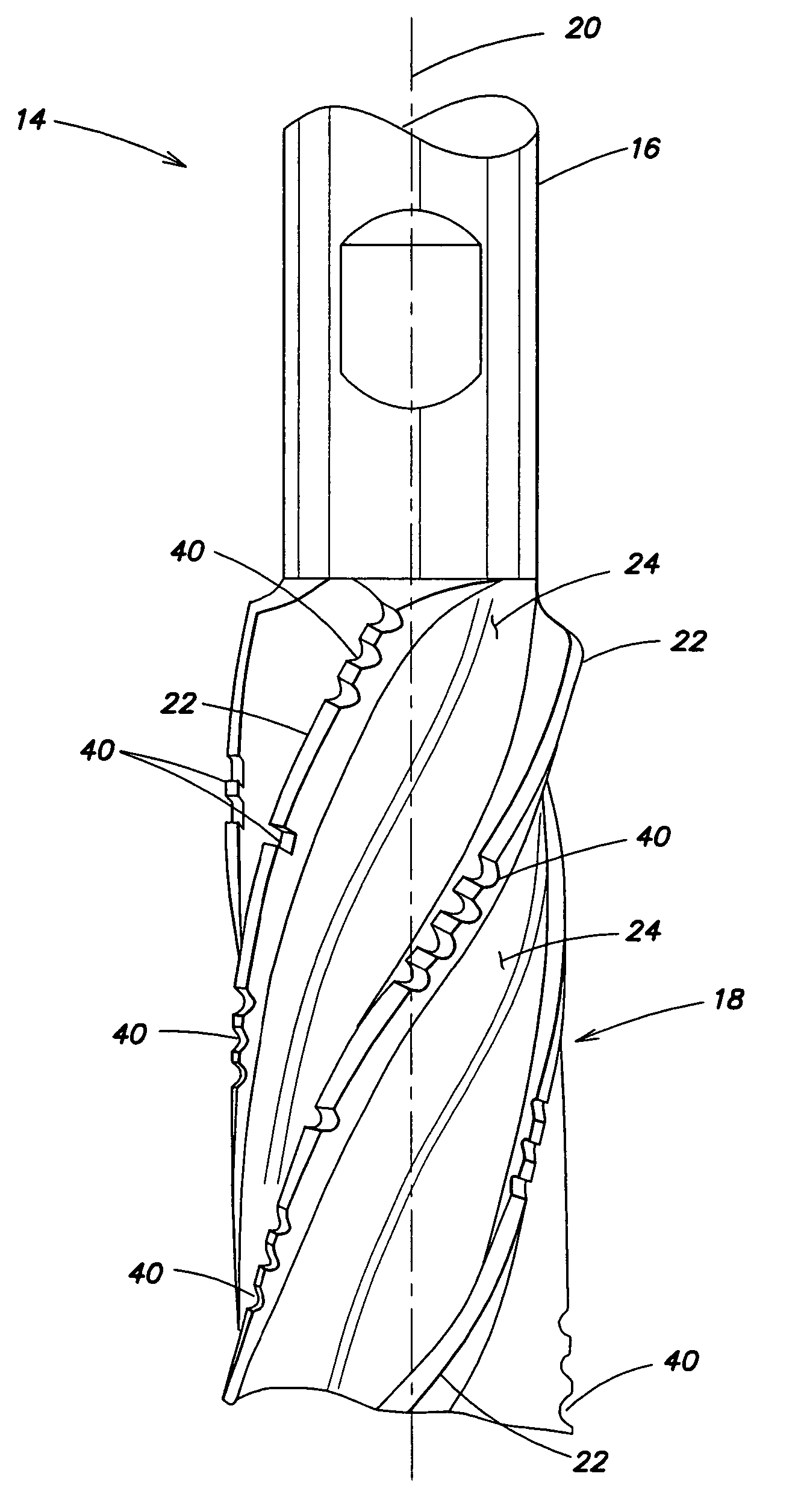

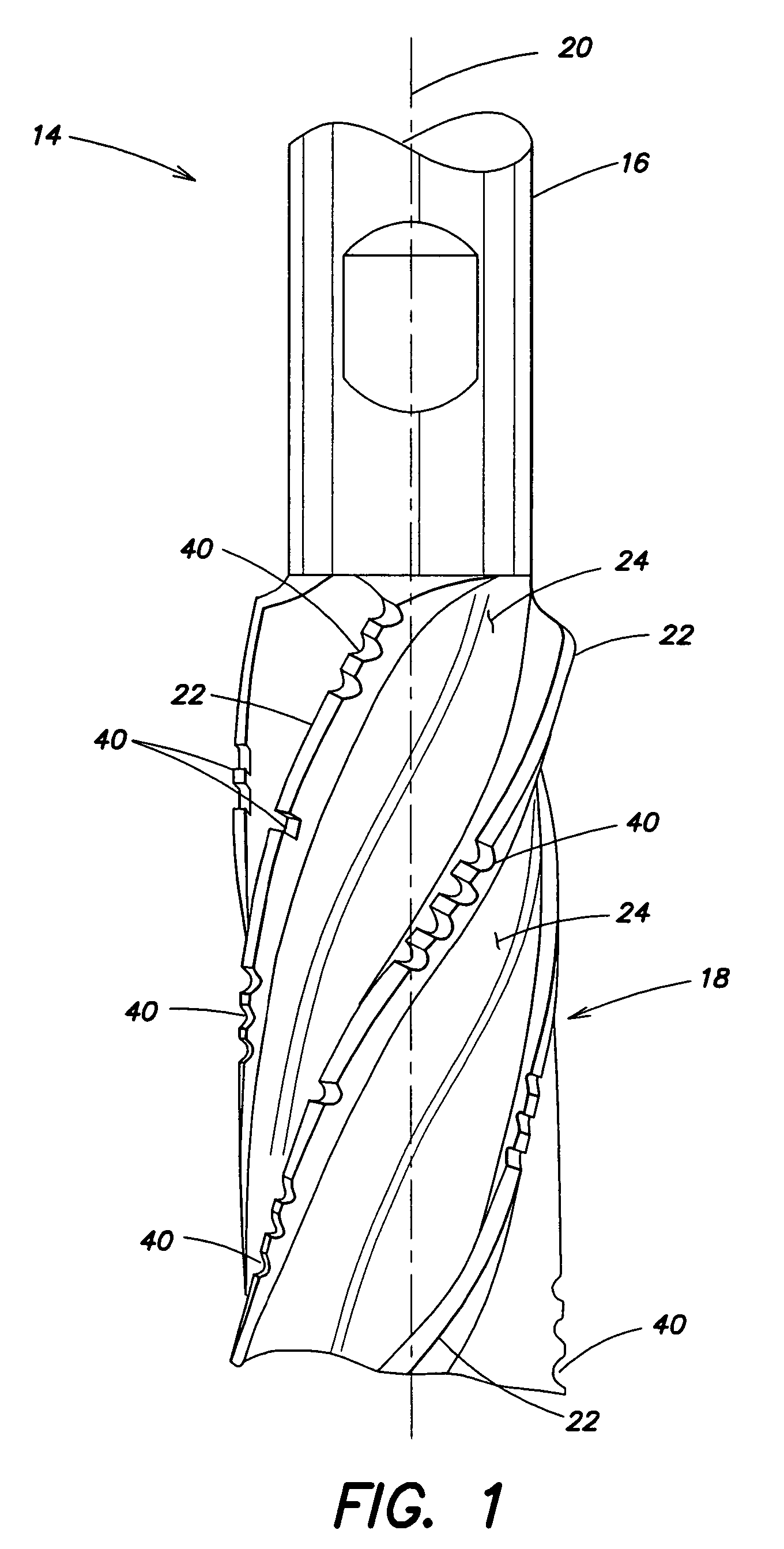

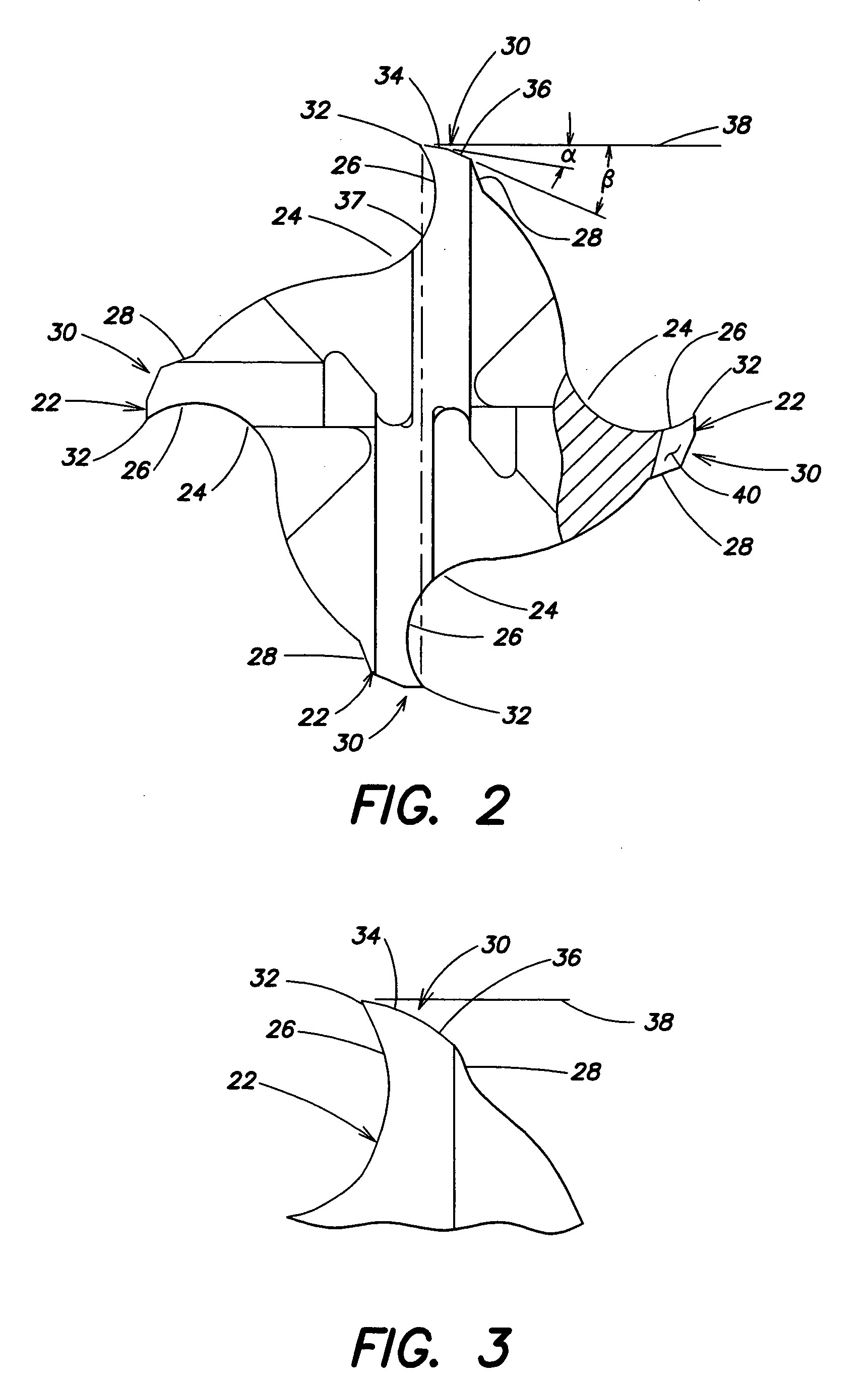

Rotary cutting tool with non-uniform distribution of chip-breaking features

ActiveUS20070098506A1Less materialCut performance be enhanceWood turning toolsTransportation and packagingFluteMechanical engineering

A rotary cutting tool with a longitudinal axis is provided that includes a shank portion, a cutting portion, and a plurality of chip-breaking features. The cutting portion, which extends out from the shank portion, includes a length, a plurality of blades and a plurality of flutes. The blades and flutes extend substantially all of the length of the cutting portion. Each blade includes a leading face side, a trailing face side, and a land surface that extends between the leading face side and the trailing face side. The plurality of chip-breaking features are disposed in the land surfaces of the blades, and non-uniformly distributed among the blades.

Owner:BERKSHIRE PRECISION TOOL

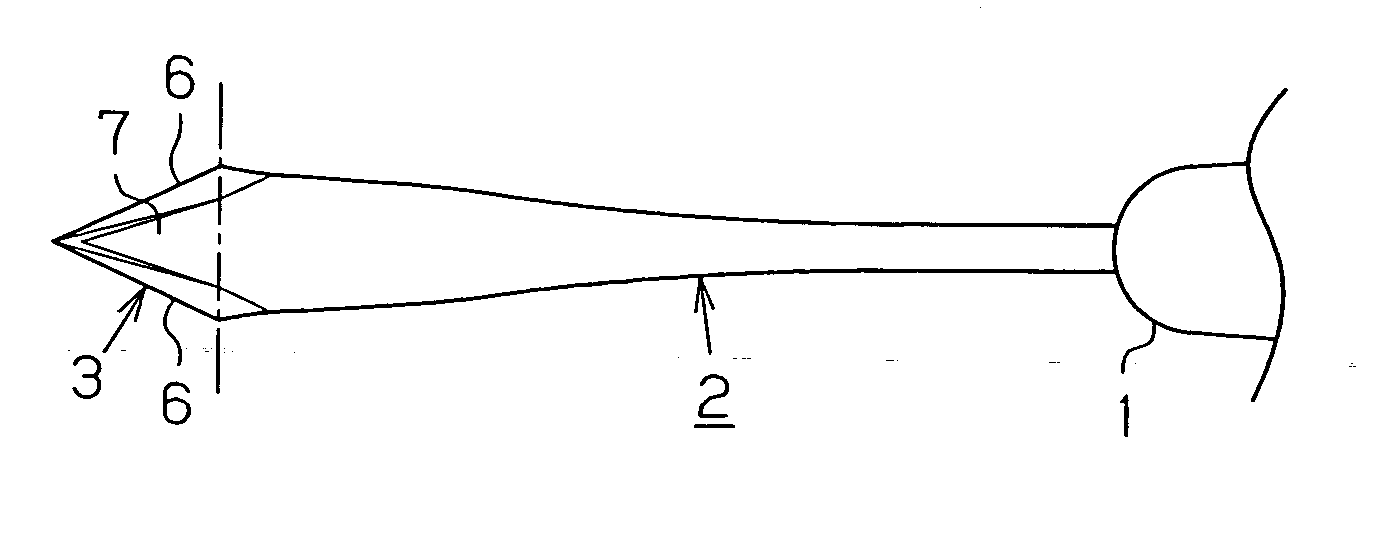

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

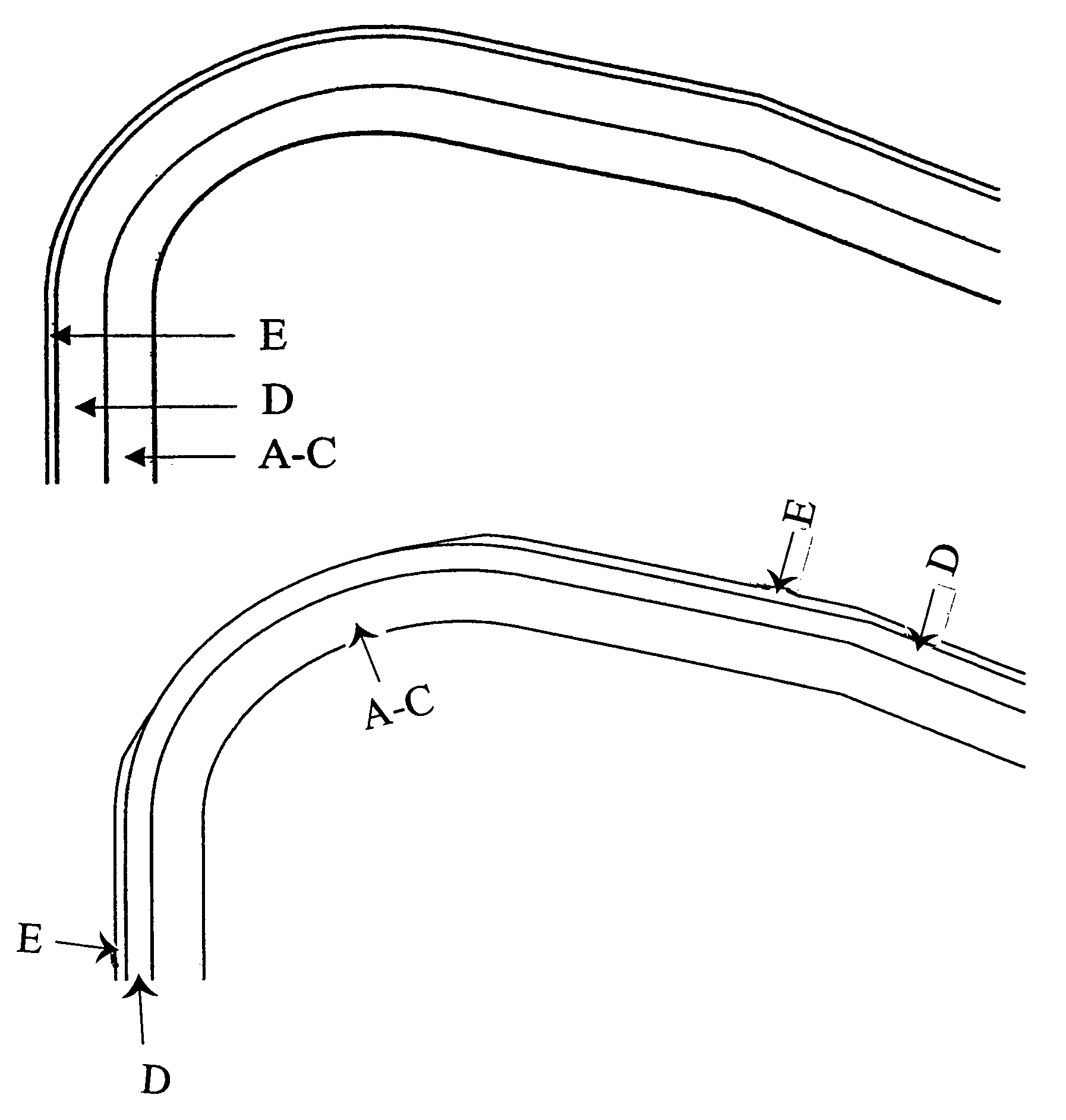

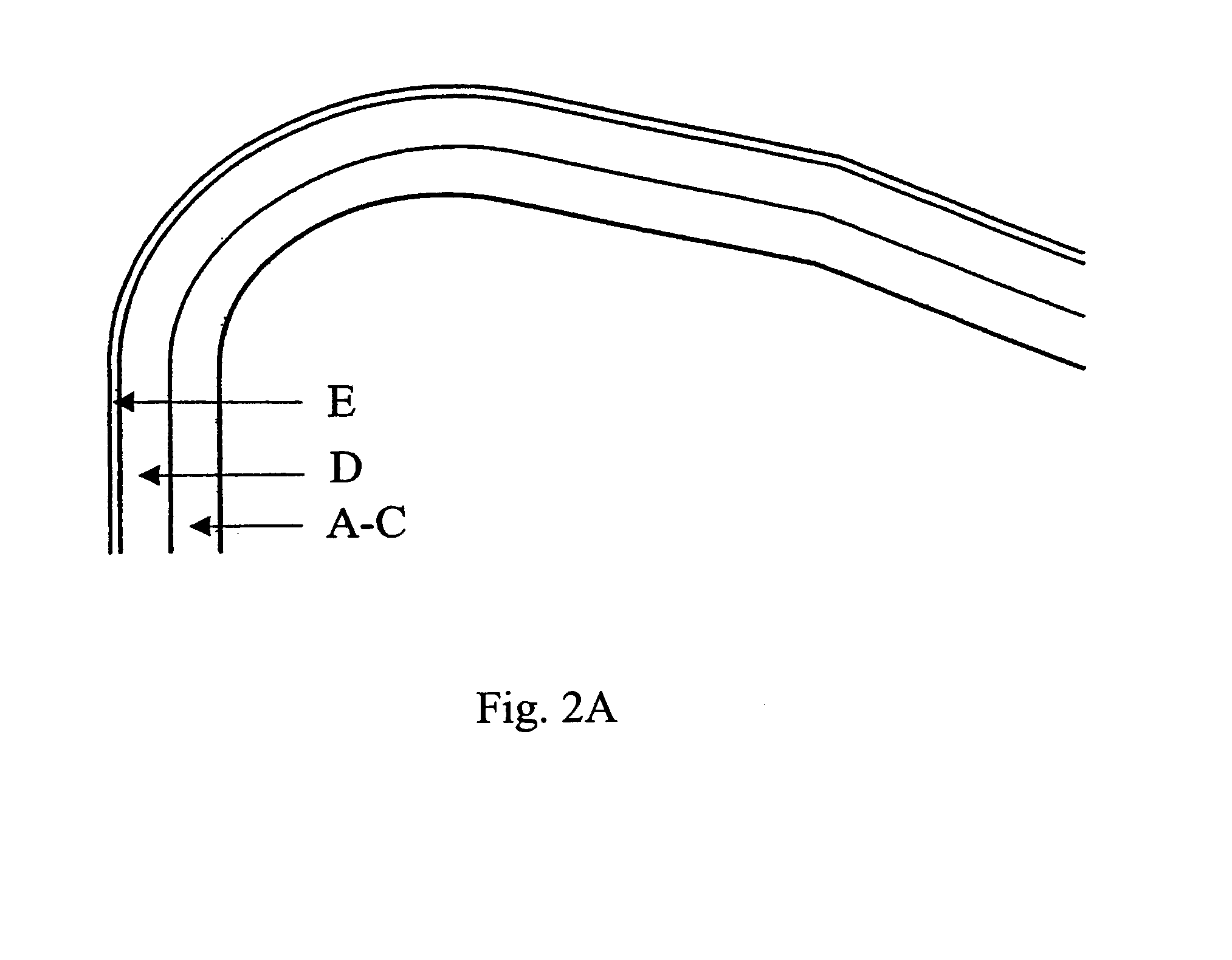

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

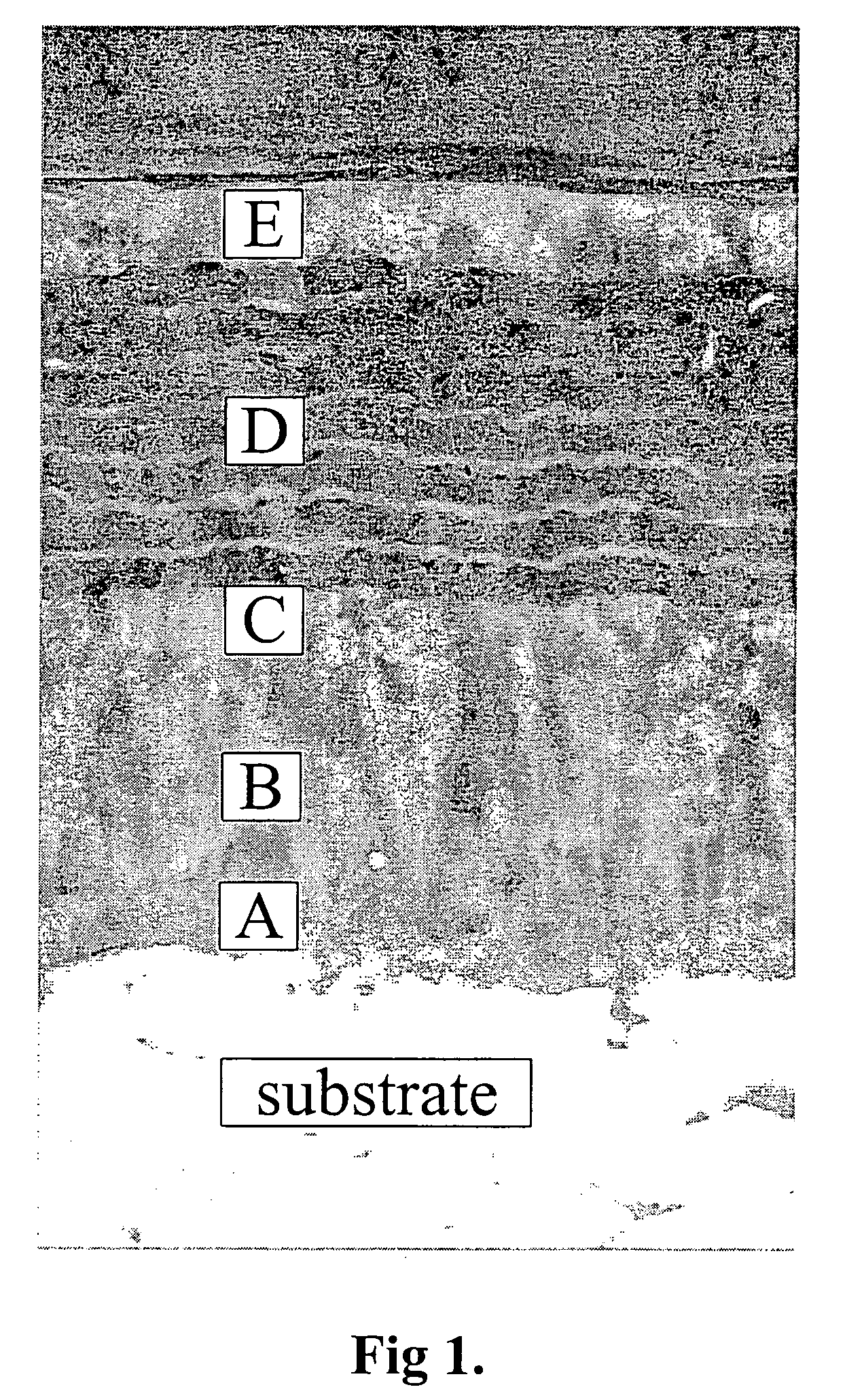

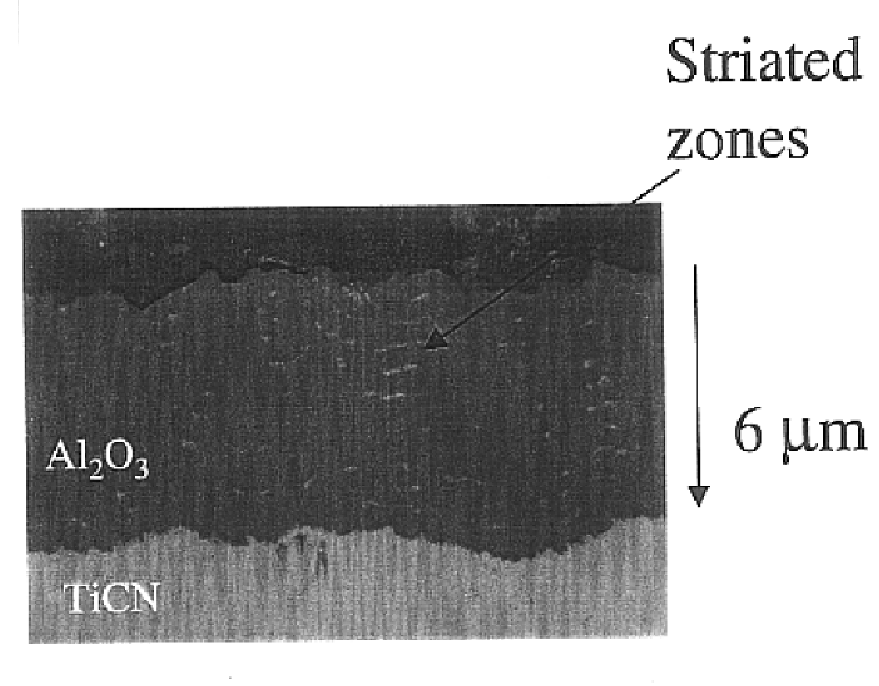

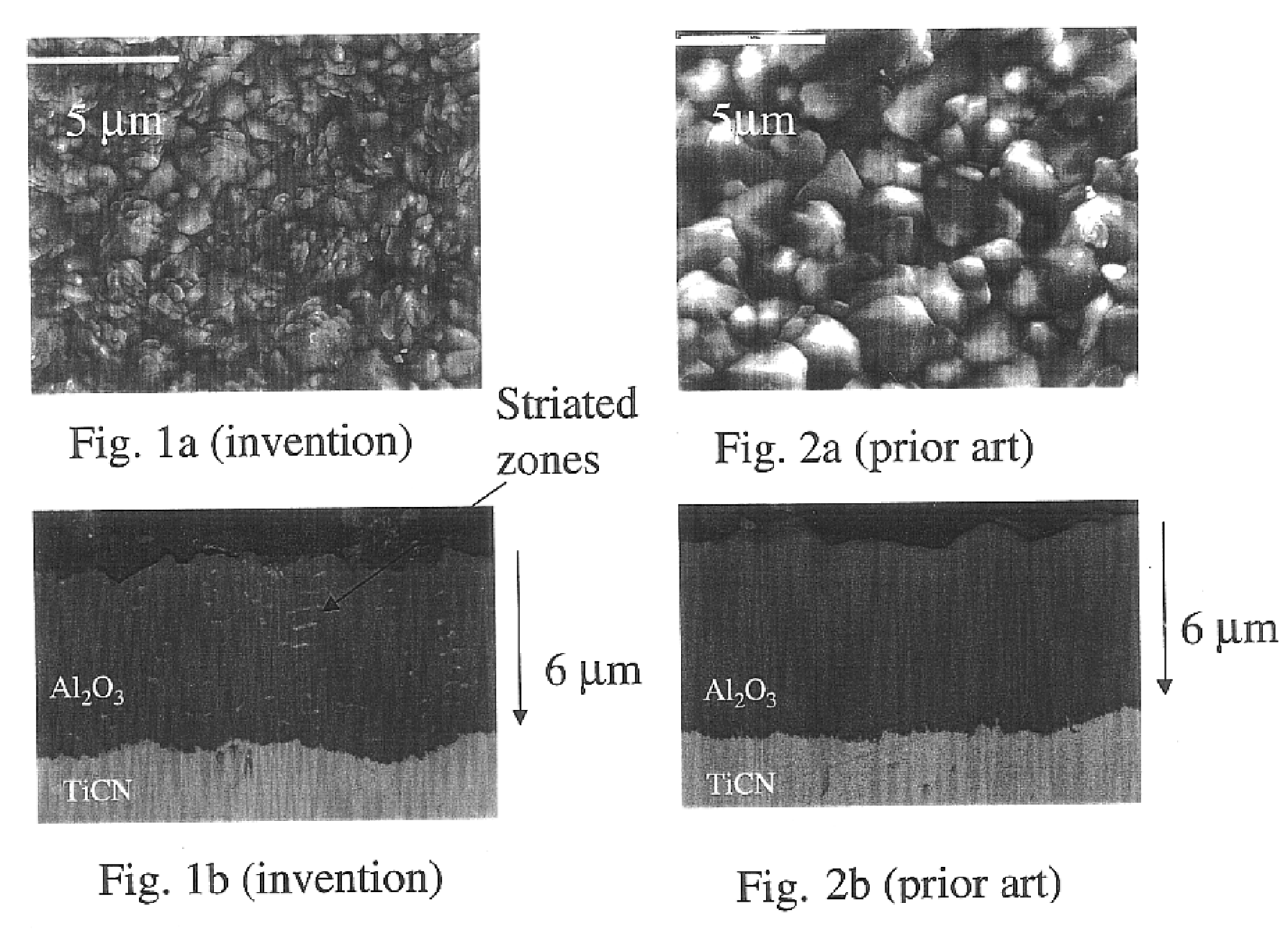

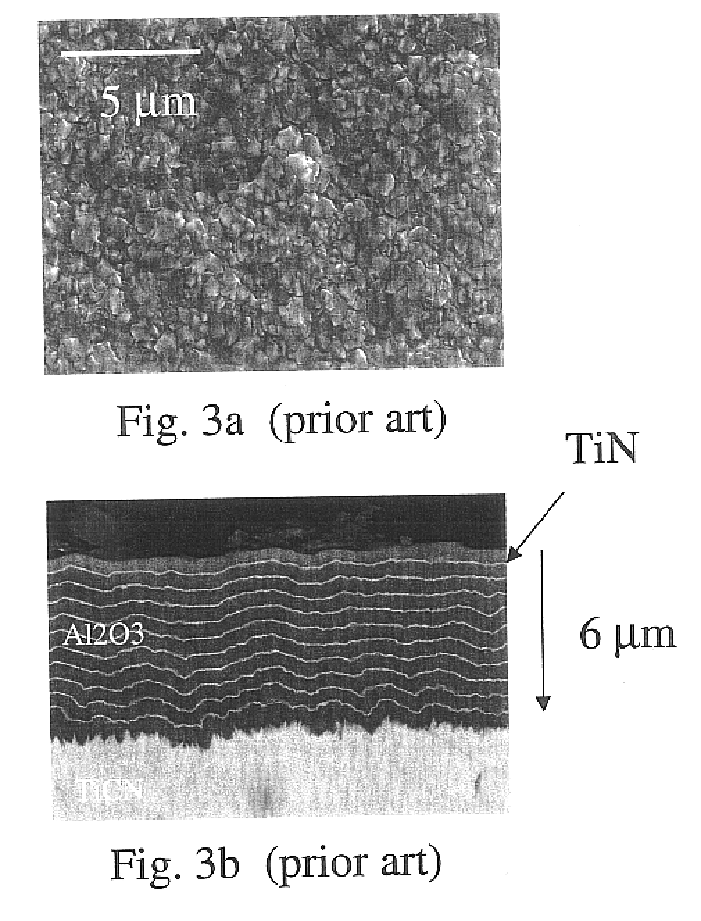

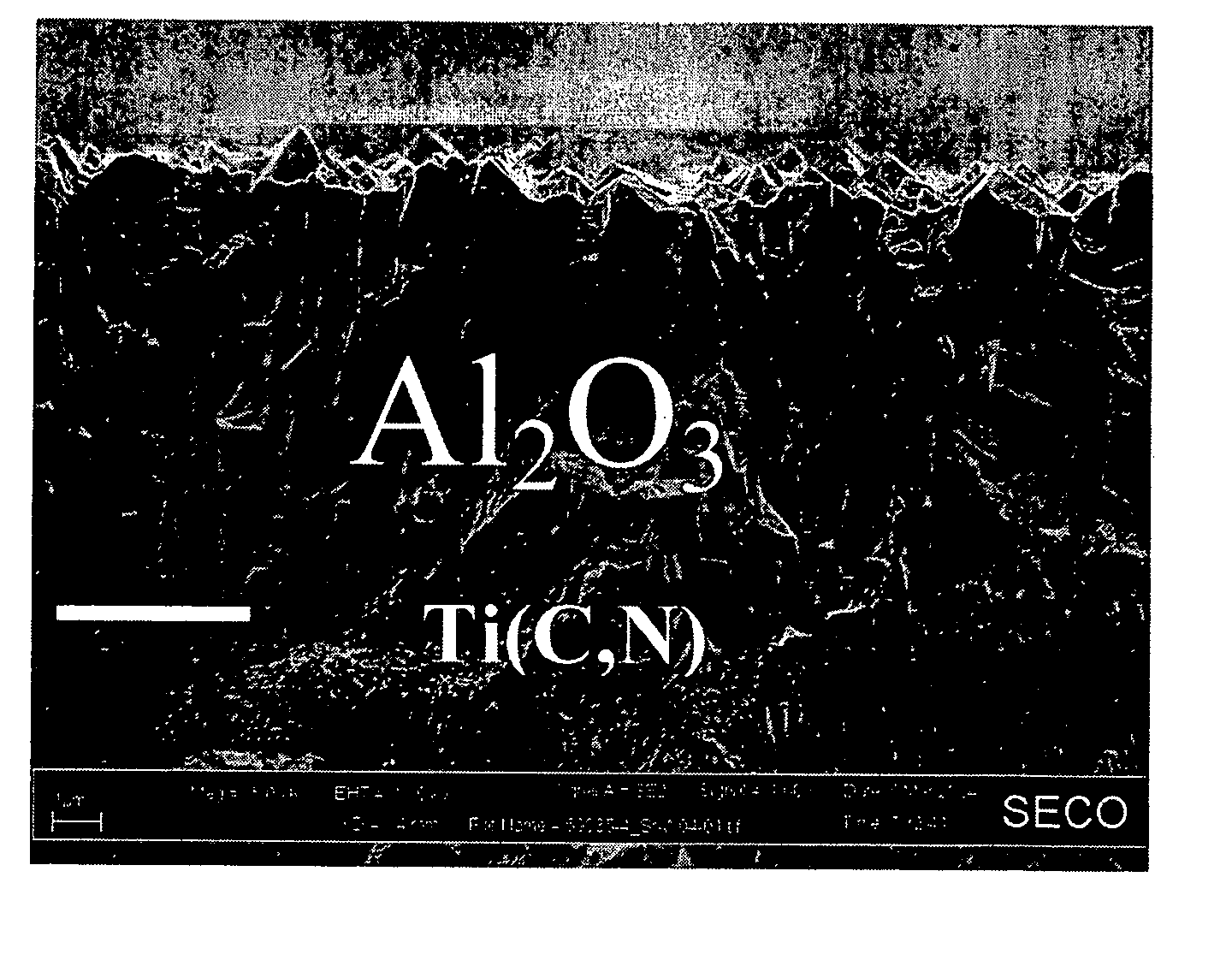

Oxide coated cutting tool

InactiveUS6713172B2Improve cut performanceImprove cutting performancePigmenting treatmentOther chemical processesCrystalliteTitanium

According to the present invention there is provided a body at least partially coated with one or more refractory layers of which at least one layer essentially consist of alpha-Al2O3. Said alpha-Al2O3 layer consists of essentially equiaxed grains with an average grain size of <1 mum and with a bimodal grain size distribution with coarser grains with an average grainsize in the interval 0.5-1 mum and finer grains with an average grainsize of <0.5 mum. The Al2O3 layer further contains striated zones containing titanium (>5 at %) but no nitrogen or carbon. This particular microstructure is obtained by temporarily stopping the gases needed for the growth of the Al2O3 layer and introducing TiCl4.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

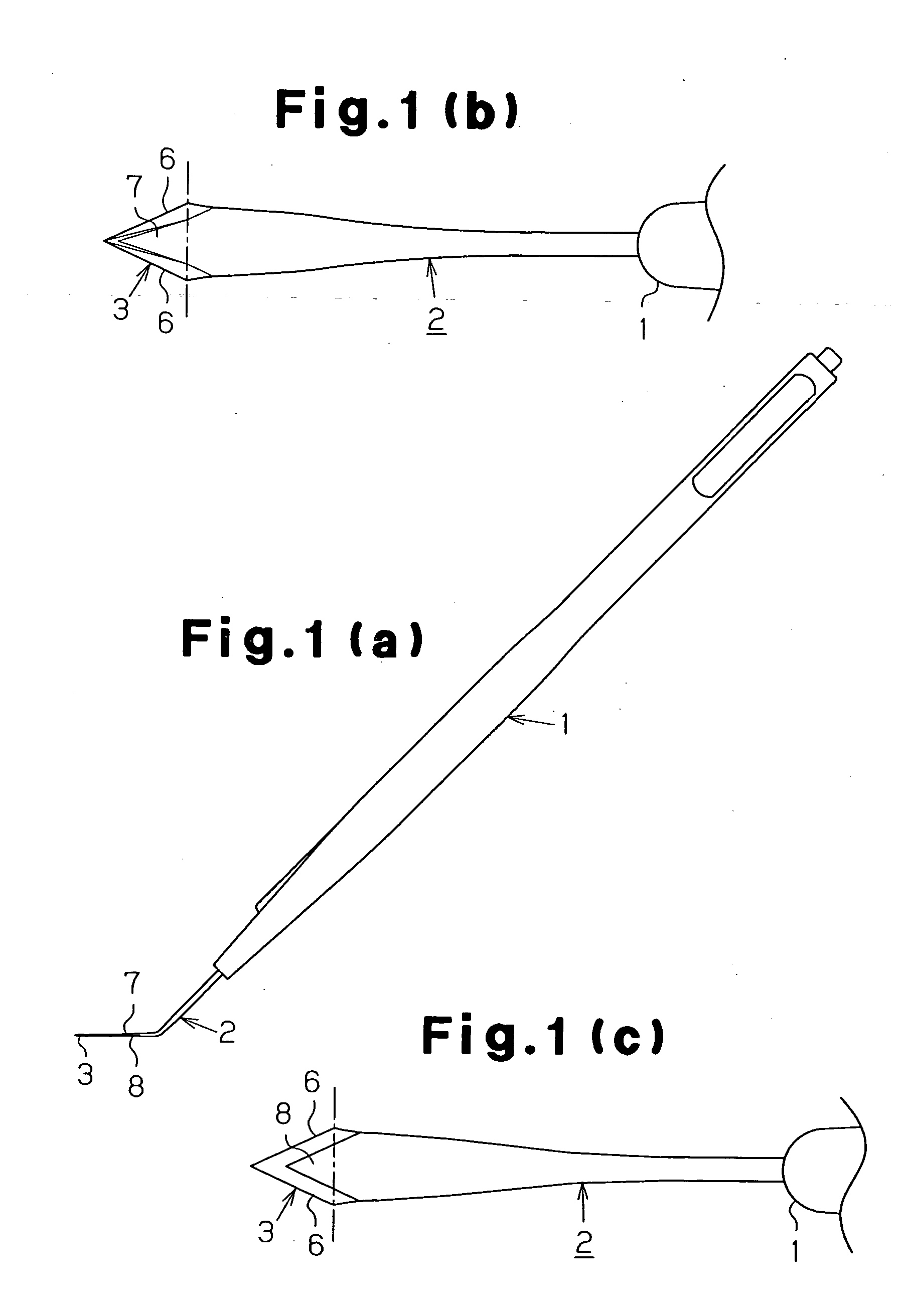

Medical knife

InactiveUS20050070941A1Improve cut performanceImprove configurationIncision instrumentsEye surgeryMechanical engineeringBoundary line

A section of a first side of a blade between a cutting edge and a boundary line forms a cutting surface. An angle of a section of the cutting surface in the vicinity of the boundary line with respect to a hypothetical plane extending from the cutting edge and defined between the first and second sides of the blade is larger than an angle of a section of the cutting surface in the vicinity of the cutting edge with respect to the hypothetical plane. Therefore, the medical knife has an improved configuration such that the cutting performance of the knife is improved.

Owner:KAI R&D CENT CO LTD

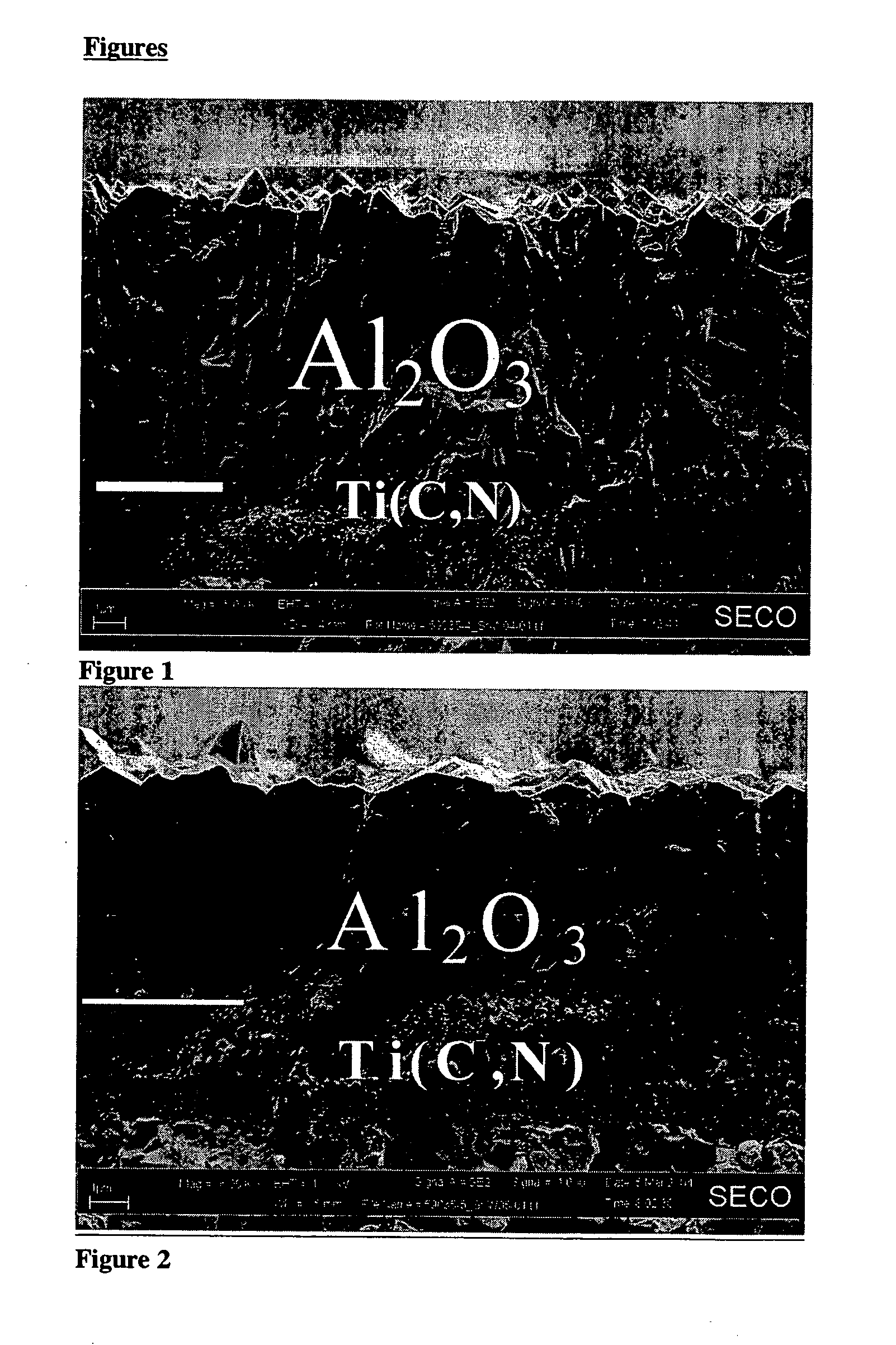

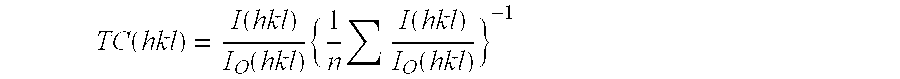

Alumina layer with controlled texture

InactiveUS20060199026A1Improve toughnessReduce dislocation densityPigmenting treatmentOther chemical processesNucleationWear resistance

A new and refined method to produce α-Al2O3 layers in a temperature range of from about 750 to about 1000° C. with a controlled growth texture and substantially enhanced wear resistance and toughness than the prior art is disclosed. The α-Al2O3 layer of the present invention is formed on a bonding layer of (Ti,Al)(C,O,N) with increasing aluminium content towards the outer surface. Nucleation of α-Al2O3 is obtained through a nucleation step being composed of short pulses and purges consisting of Ti / Al-containing pulses and oxidising pulses. The α-Al2O3 layer according to the present invention has a thickness ranging from about 1 to about 20 μm and is composed of columnar grains. The length / width ratio of the alumina grains is from about 2 to about 12, preferably from about 4 to about 8. The layer is characterized by a strong (104) growth texture, measured using XRD, and by low intensity of (012), (110), (113), (024) and (116) diffraction peaks.

Owner:SECO TOOLS AB

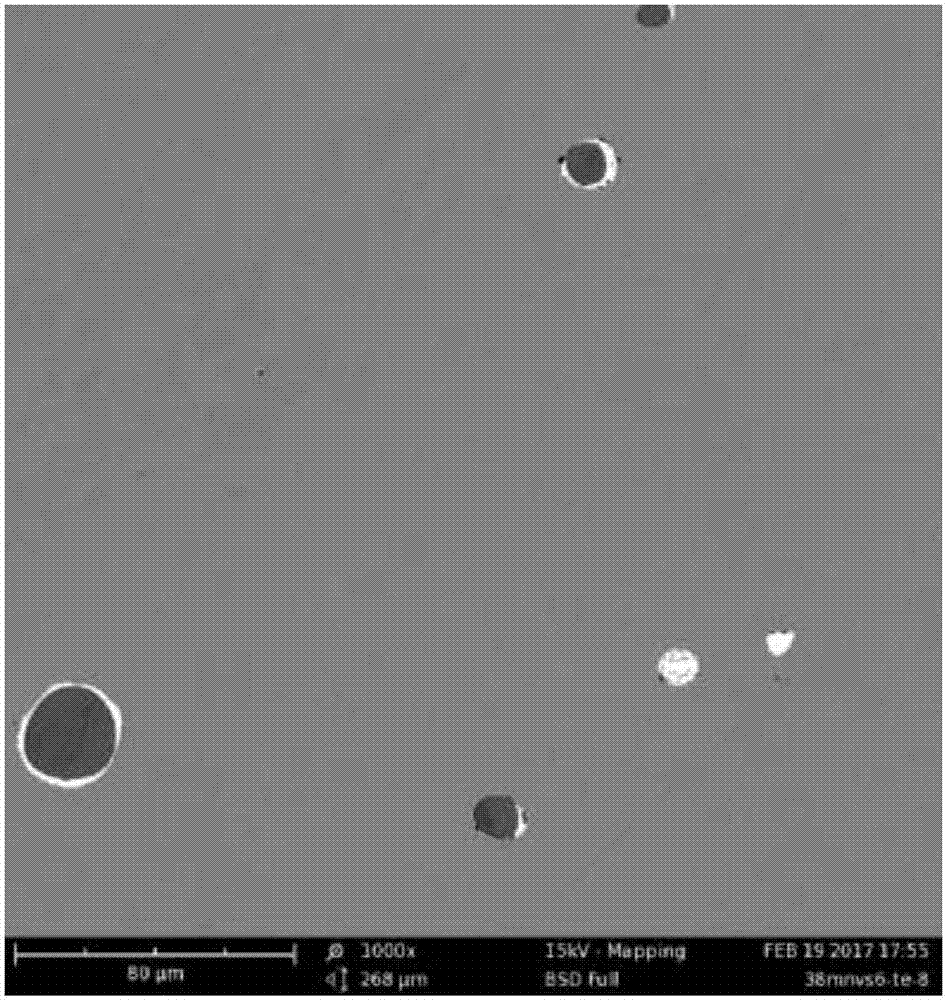

Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

ActiveCN107287504AExcellent machinabilityReduce precipitationProcess efficiency improvementSulfurImpurity

The invention discloses medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and a production technological method thereof. The non-quenched-and-tempered steel mainly comprises 0.35%-0.50% of C, 0.10%-0.80% of Si, 0.75%-1.60% of Mn, 0-0.03% of P, 0.02%-0.08% of S, 0-0.08% of Mo, 0-0.025% of Nb, 0.02%-0.12% of V, 0.012%-0.016% of N, 0.02%-0.08% of Te, 0.001%-0.003% of Ca, and the balance Fe and inevitable impurities. The ratio of the tellurium to the sulfur is 0.25-2.5. According to the free-cutting non-quenched-and-tempered steel disclosed by the invention, occluded foreign substances in the steel can be subjected to modifying treatment by adding the tellurium, the cutting properties, fatigue resistance and the like of the non-quenched-and-tempered steel can be improved obviously, and pollution to the environment can be avoided.

Owner:SHANGHAI UNIV

Nonwoven abrasive articles and methods

ActiveUS7393371B2Improve cutting performancePigmenting treatmentOther chemical processesMaterials scienceCoating

Owner:3M INNOVATIVE PROPERTIES CO

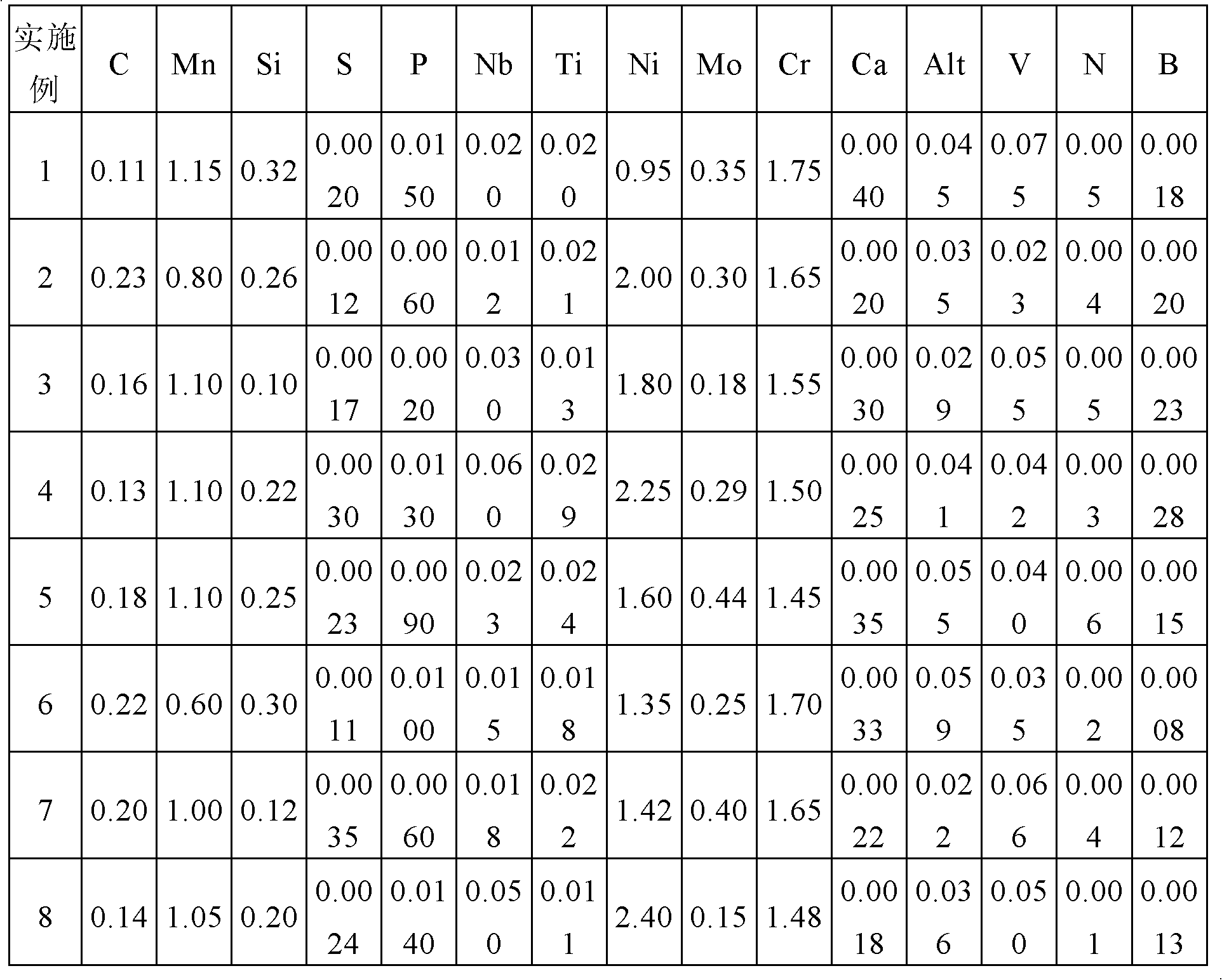

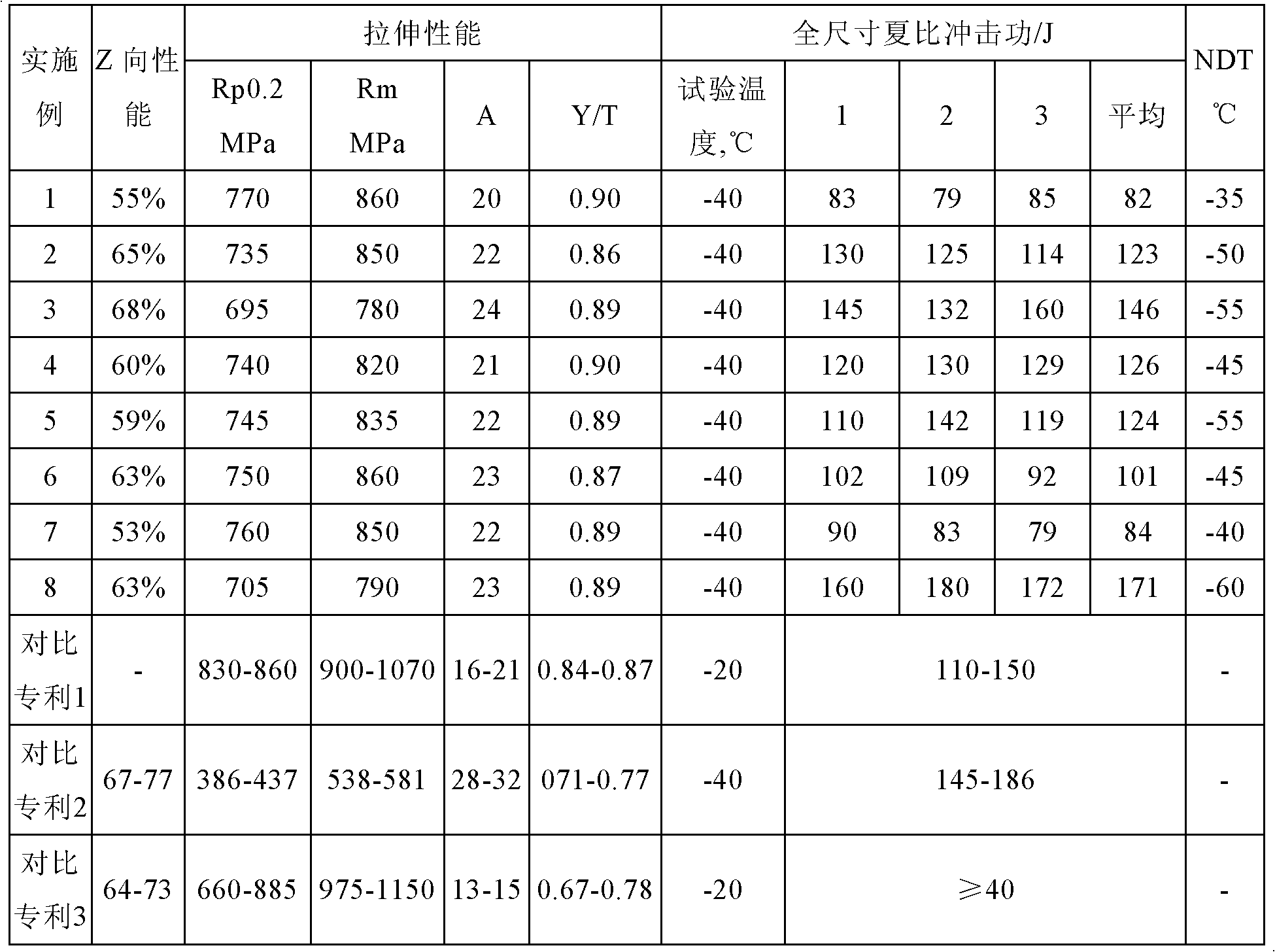

Ultra-thick high-strength high low-temperature toughness steel plates for ocean platforms and production method thereof

Disclosed are ultra-thick high-strength high low-temperature toughness steel plates for ocean platforms and a production method thereof. The steel plates comprise, in weight percentage, 0.10-0.24% of C, 0.05-0.35% of Si, 0.60-1.15% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.01-0.030% of Ti, 1.45-1.75% of Cr, 0.15-0.44% of Mo, 0.80-2.50% of Ni, 0.010-0.070% of Nb, 0.020-0.080% of V, 0.02-0.06% of Alt, 0.001-0.004% of Ca, not more than 0.006% of N, 0.0007-0.0030% of B, the balance of F3 and unavoidable impurities. The steel plates have a system of C, Ni-Cr-Mo alloyed and Nb-V-Ti microalloyed, and have yield strength not smaller than 690MPa, tensile strength not smaller than 770MPa, -40 DEG C Charpy V-notch impact work no smaller than 69J, NDT (non-destructive testing) not larger than -35 DEG C, Z not smaller than 35%, and largest thickness more than 200mm. The steel plates are applicable to production of racks for ocean platforms.

Owner:BAOSHAN IRON & STEEL CO LTD

Gradient laminated coating tool and preparation method thereof

ActiveCN102277554AHigh bonding strengthReduce residual stressVacuum evaporation coatingSputtering coatingUltimate tensile strengthWear resistance

The invention relates to a gradient multiple coating tool and a preparation method thereof, which belong to the technical field of metal cutters. The tool comprises a tool substrate with multiple coatings and is characterized in that the multiple coatings from top down comprise a ZrTiN coating, a ZrTiN and ZrN alternating gradient coating and a Ti transitional coating in turn. In the invention, the coatings are prepared by an arc coating process, the coated tool has the combined structural characteristics of the ZrN hard coating, the ZrTiN hard coating and the gradient coating, and thus, the hardness of the coatings and overall strength and impact resistance of the coatings are improved, the wear resistance of the coated tool is obviously improved and the service life of the tool is prolonged. The gradient coating tool is a novel composite ultra-hard coating tool.

Owner:篱笆斯机械科技(江苏)有限公司

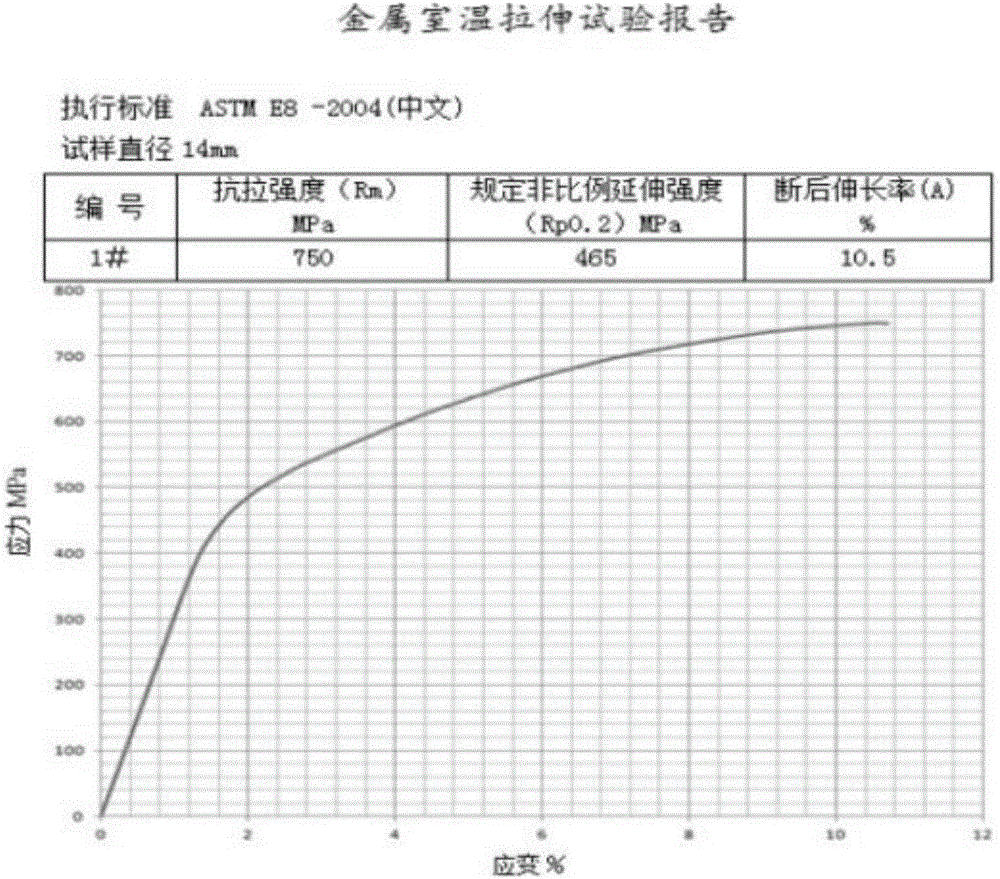

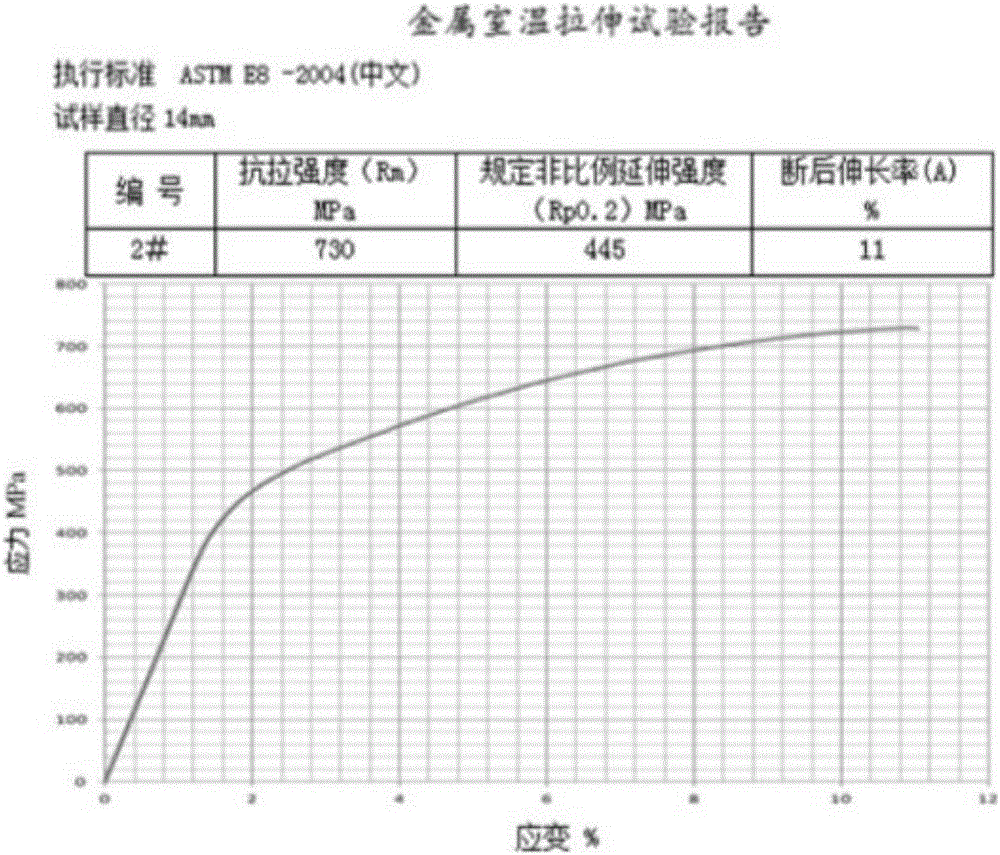

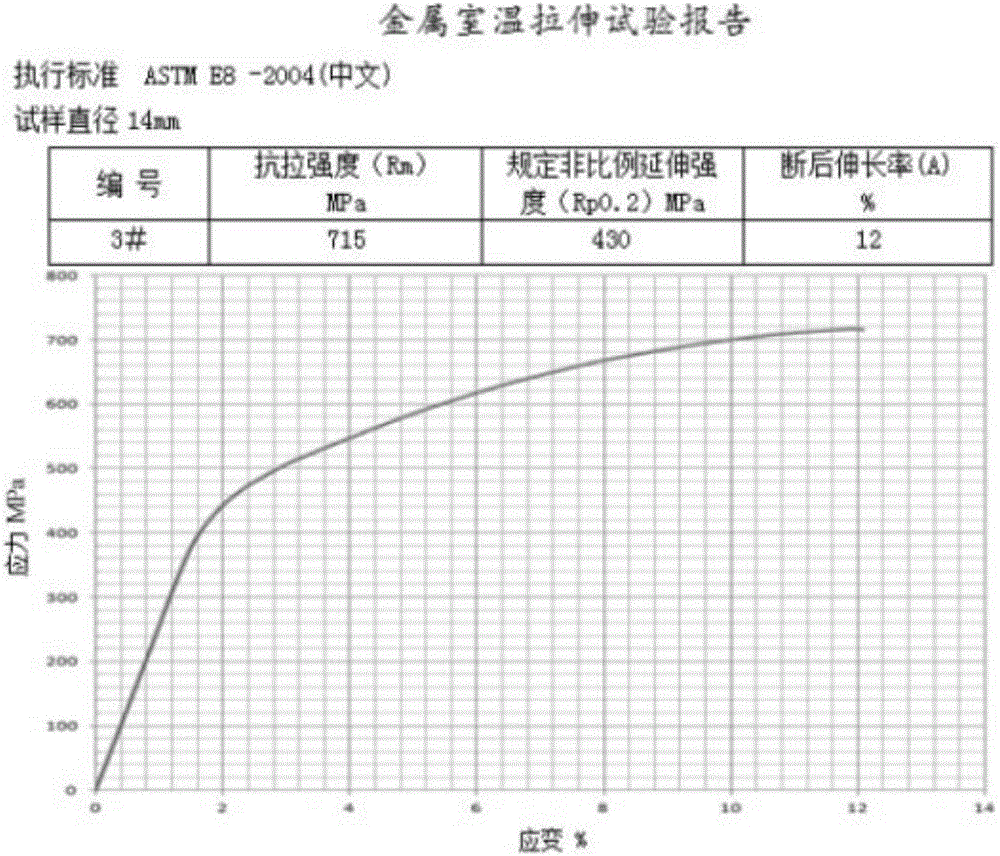

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

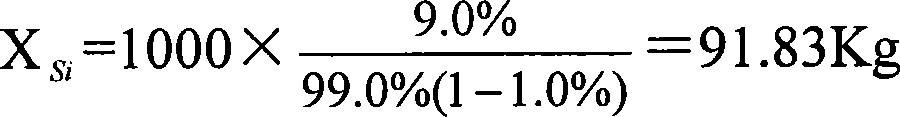

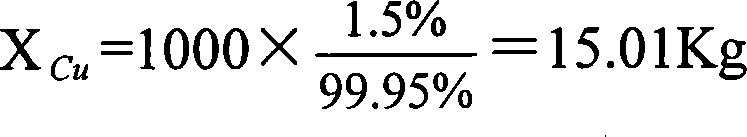

Aluminum-silicon series deforming alloy and manufacturing method thereof

The present invention discloses aluminum silicon deformable aluminum alloy and the preparation method thereof. According to the weight percentages, the alloy contains 9.0-12.6 percent of silicon, 1.5-4.0 percent of copper, 0.3-0.6 percent of magnesium, 0.1-3.5 percent of bismuth, less than 0.30 percent of iron, less than 0.20 percent of zinc, less than or equal to 0.15 percent of impurity, and aluminum as the residual. The raw material is molten and fined in a reflecting smelting furnace, after Al-Sr intermediate alloy modification to the alloy liquid, cast rods are obtained through semi continuous casting, and after hot extrusion and deformation to the cast rods, the aluminum silicon deformable aluminum alloy is produced through forging and T6 heat treatment. After adding the element bismuth into the alloy, the present invention greatly enhances the wear-resisting performance of the alloy, leads the alloy to have self lubricating property, prolongs the service life of the product produced with the alloy, reduces the use cost, and leads the alloy to have the tensile strength of above 390 MPa, the elongation rate after breaking of 6 percent, and the hardness degree of 136-141 HB. The present invention is mainly used for producing vehicle components of wheels, pistons, bearings, and two-side swash plates of vehicles and motorcycles which have high demands on the intensity, the toughness and the abrasion resistance.

Owner:李贞宽 +1

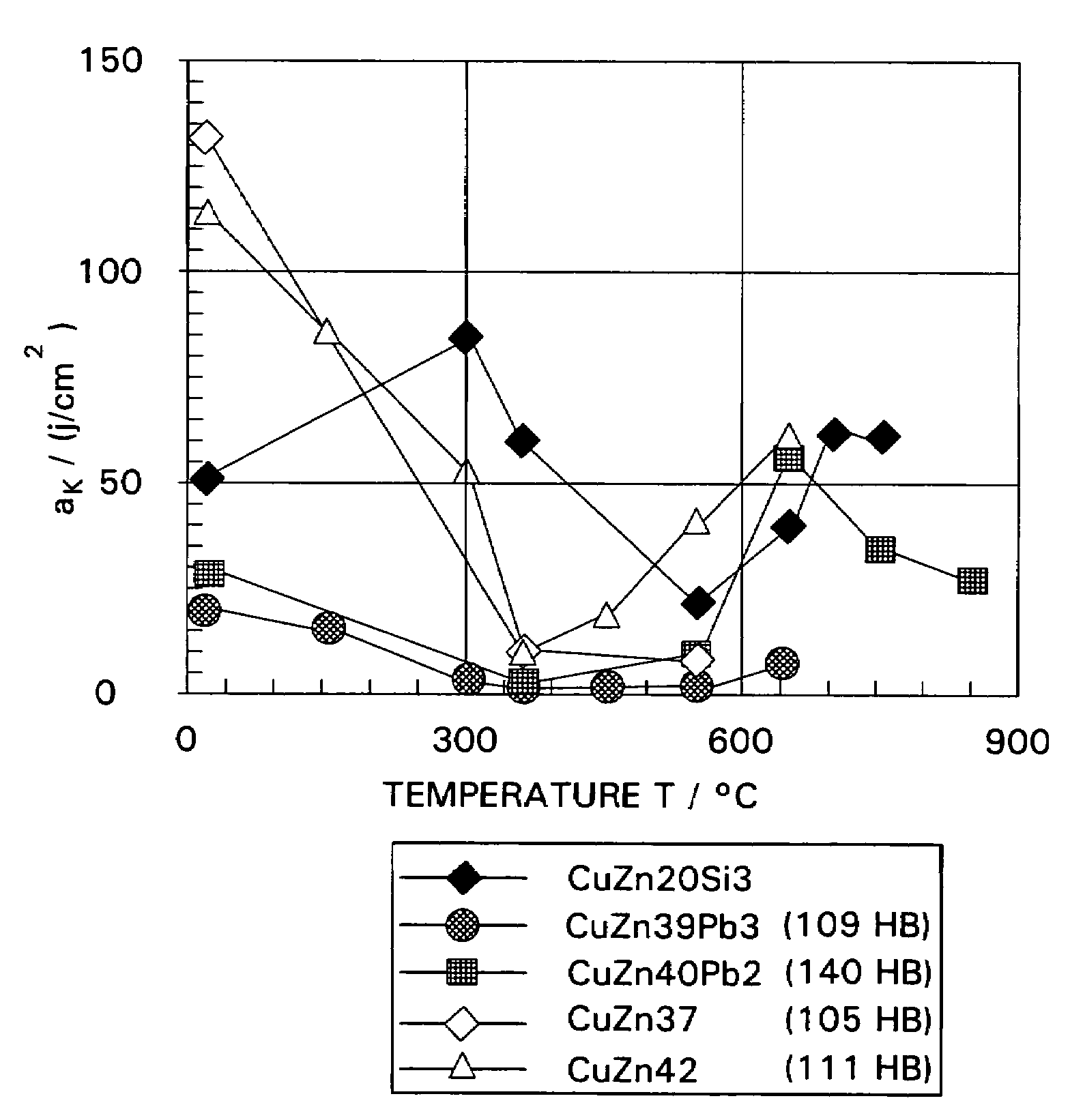

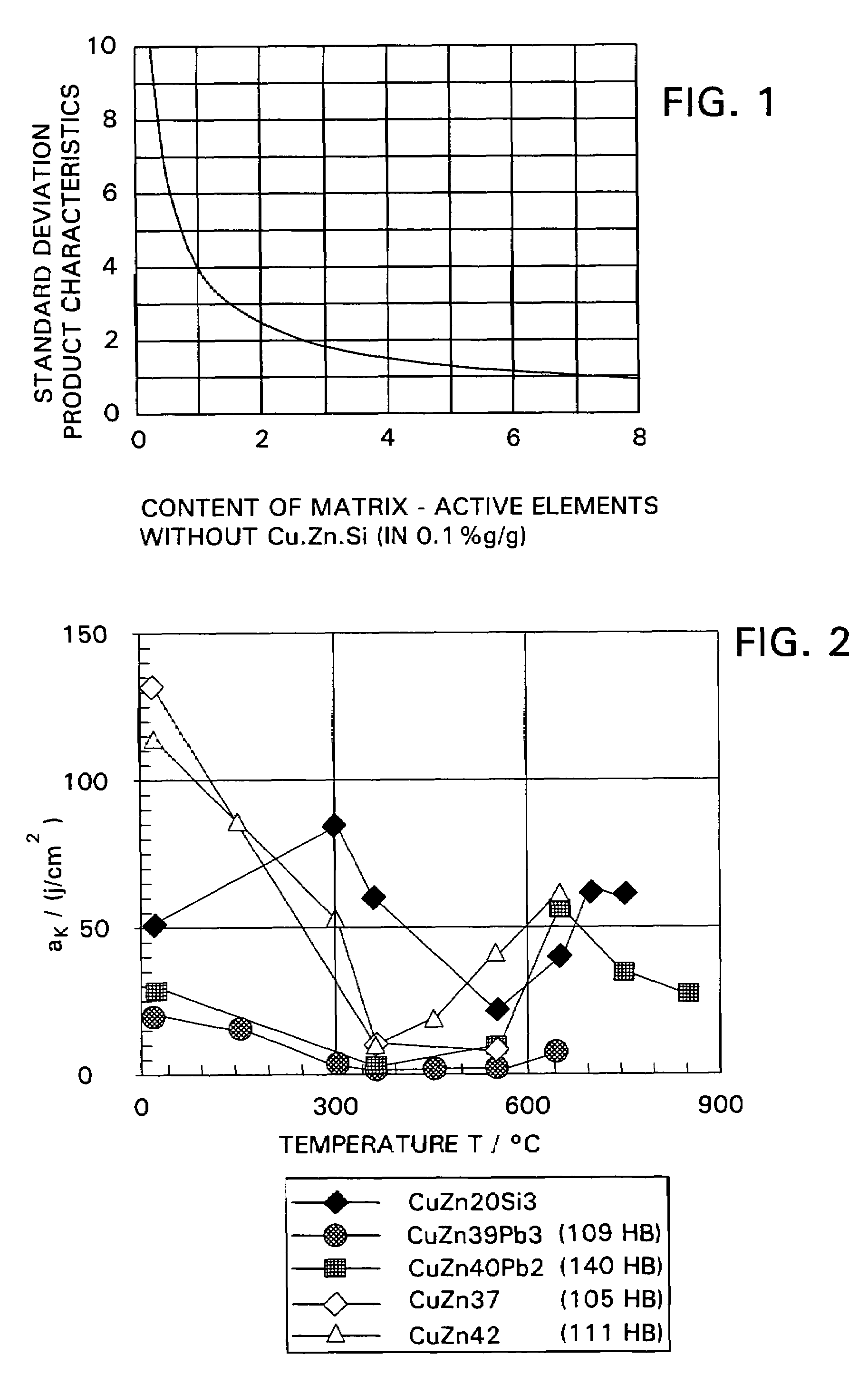

Lead-free copper alloy and a method of manufacture

A lead-free copper alloy based on Cu—Zn—Si and a method of manufacture thereof. The copper alloy is built on the basis of copper, zinc and silicon without toxic additives and consists of: 70 to 83% Cu, 1 to 5% Si and the further matrix-active elements: 0.01 to 2% Sn, 0.01 to 0.3% Fe and / or Co, 0.01 to 0.3% Ni, 0.01 to 0.3% Mn, the remainder Zn and unavoidable impurities.

Owner:WIELAND WERKE AG

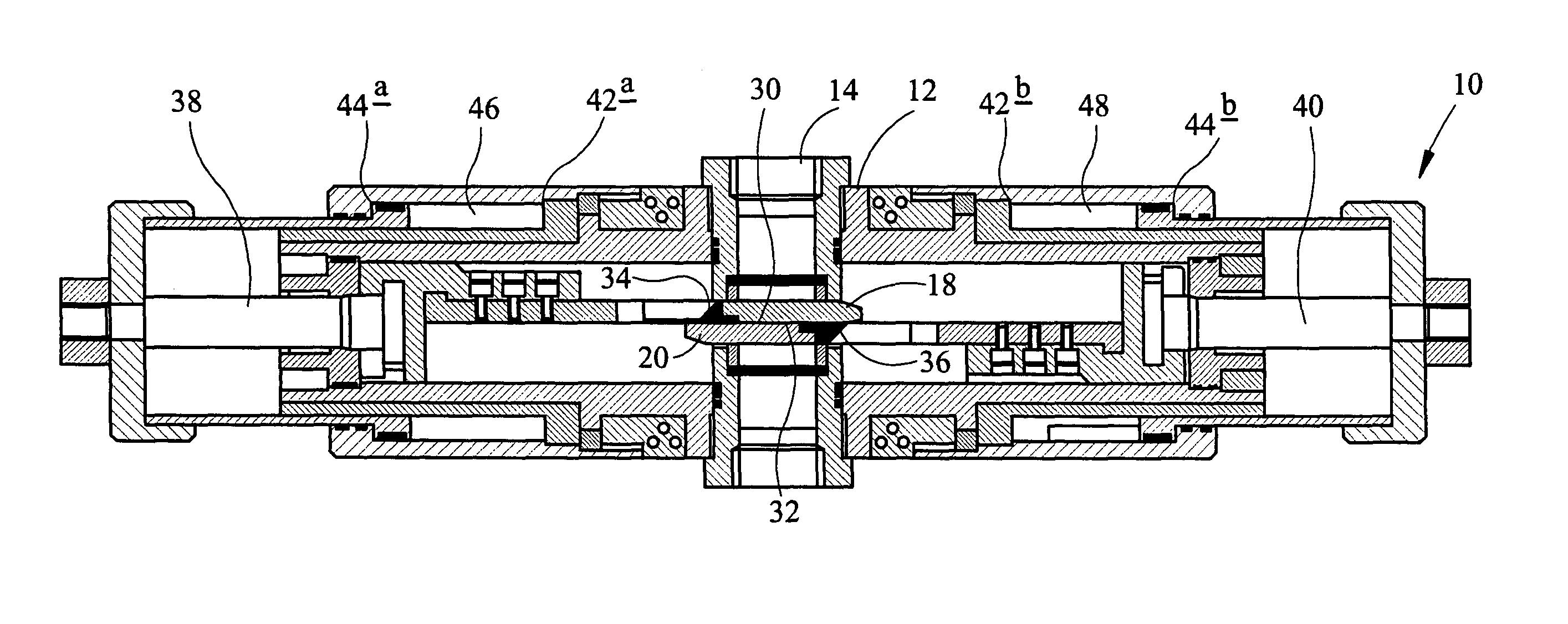

Well bore control valve

ActiveUS8353338B2Improve cutting performanceReduce the possibility of damageDrilling rodsFluid removalEngineeringControl valves

Owner:ENOVATE SYST

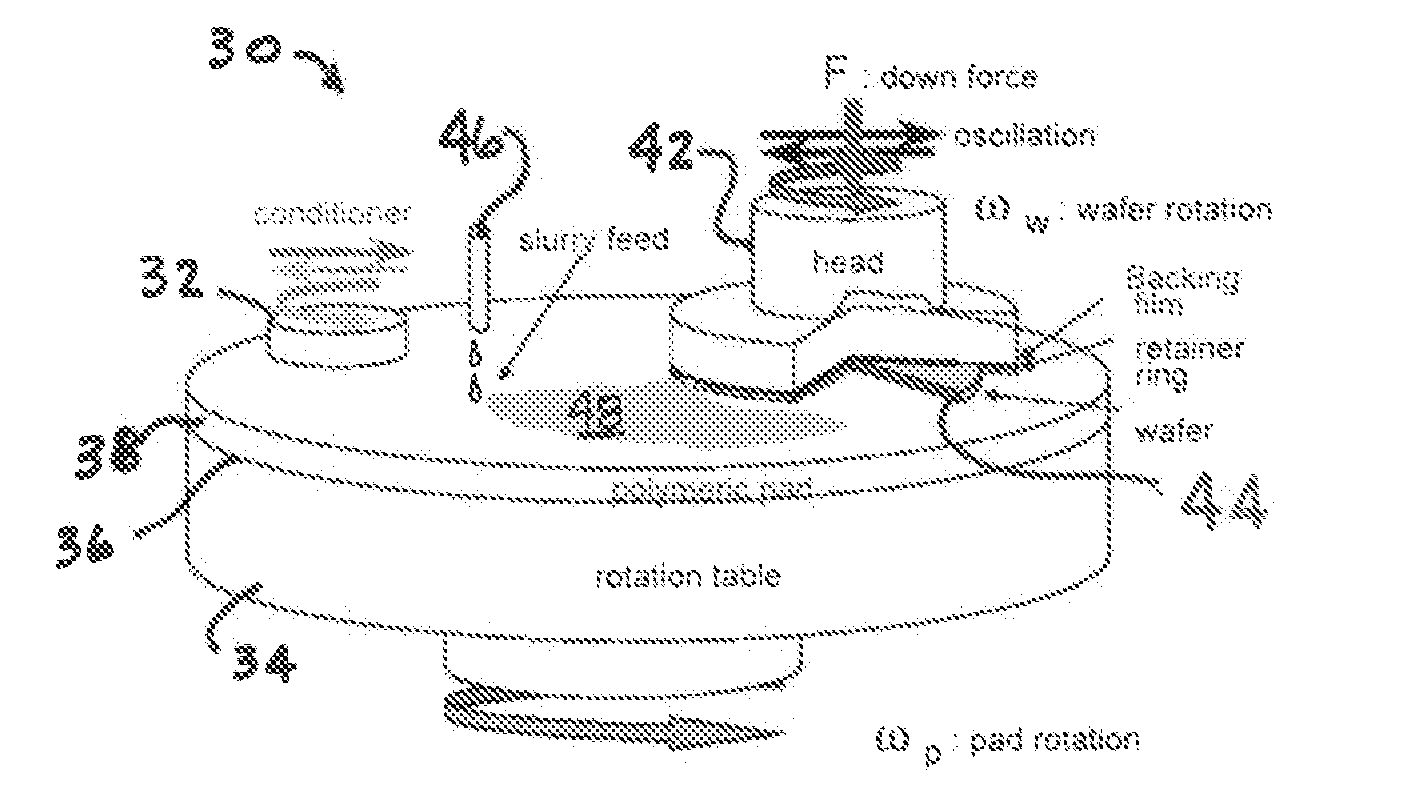

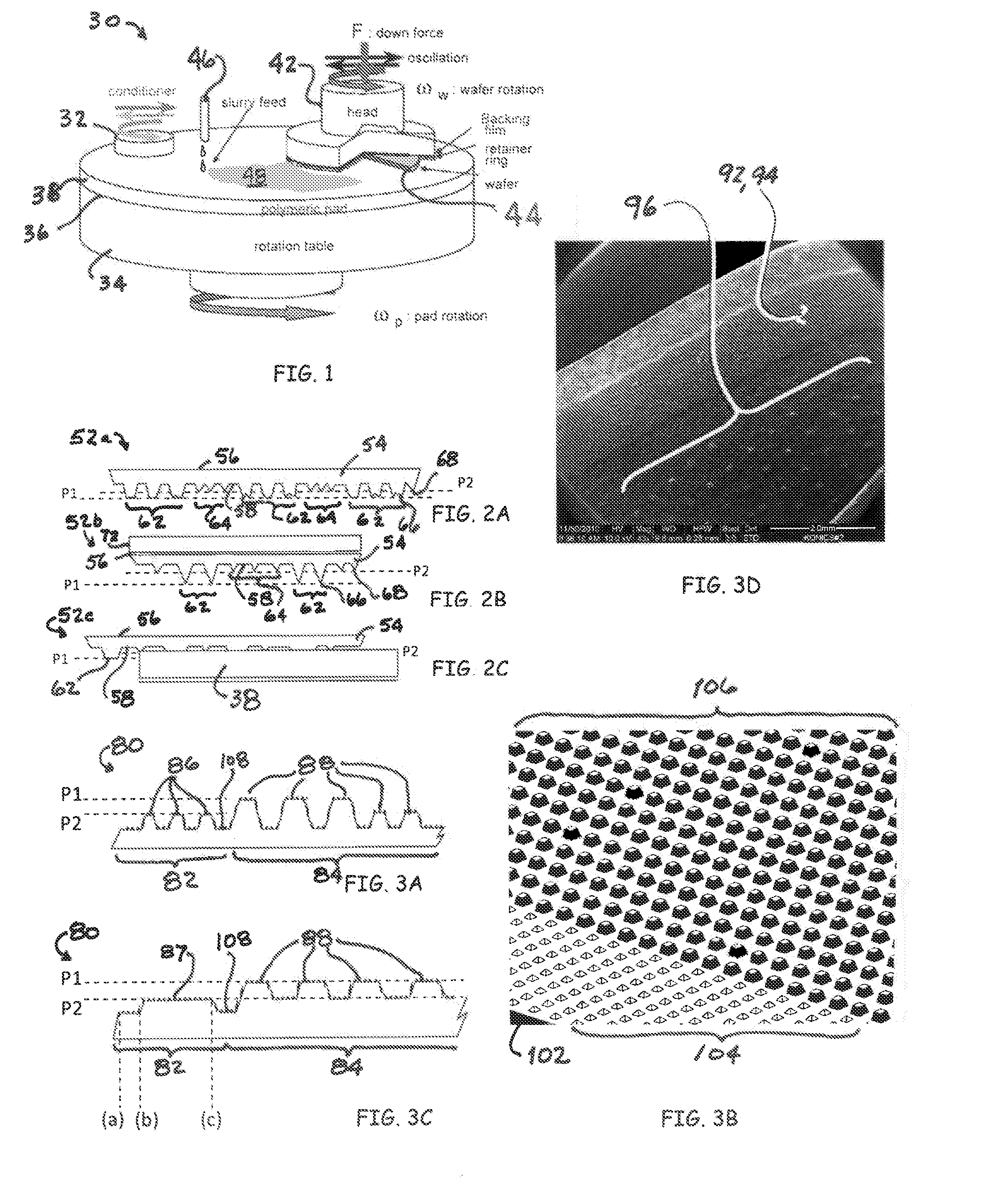

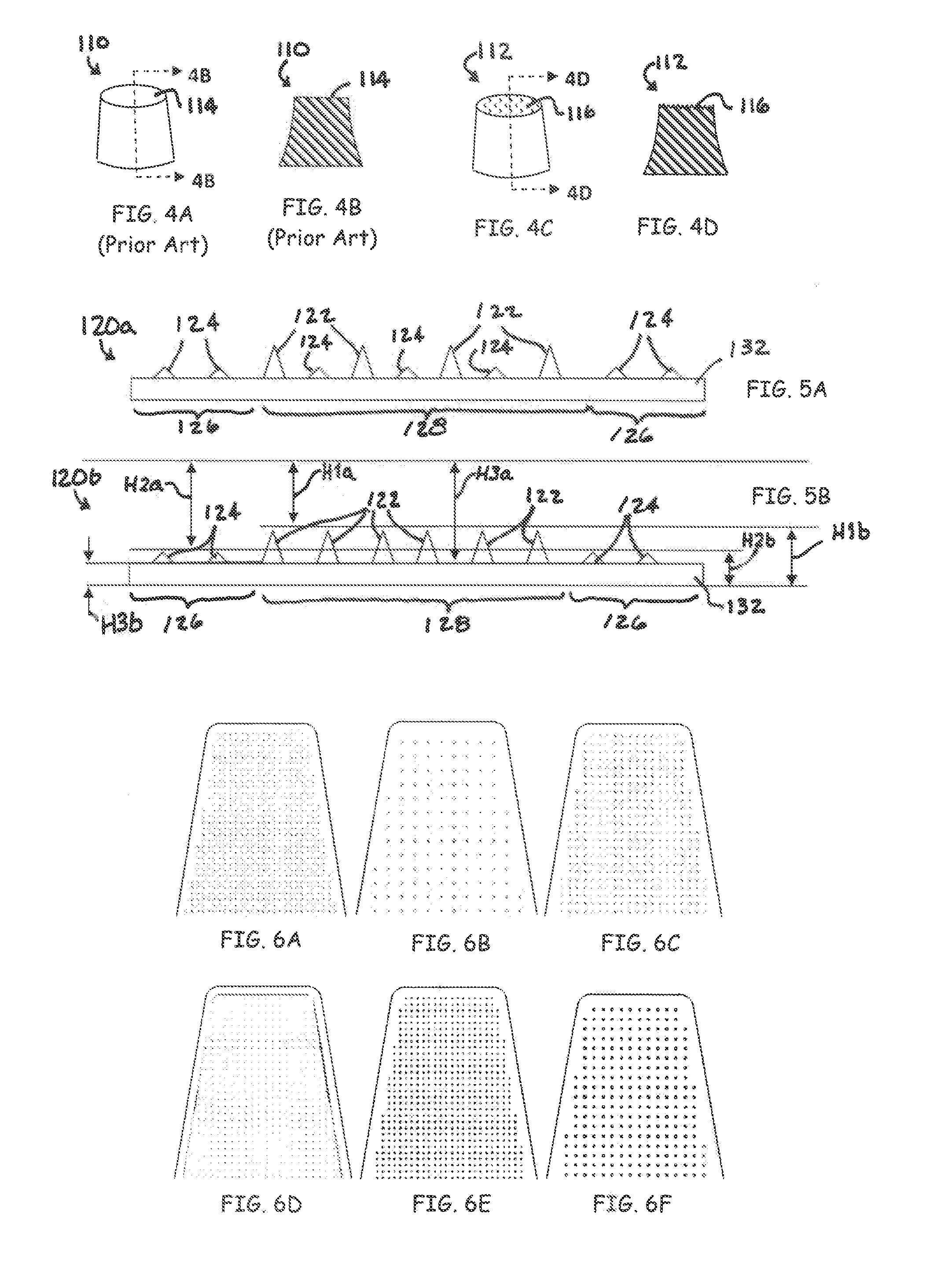

Chemical mechanical planarization conditioner

ActiveUS20140113532A1Improve cutting performanceIncreased longevityGrinding drivesBelt grinding machinesPolycrystalline diamondEngineering

A pad conditioner for a CMP polishing pad is disclosed that includes a substrate that has a matrixical arrangement of protrusions that have a layer of poly crystalline diamond on at least their top surfaces. The protrusions may have varying shapes and elevations and may comprise a first set of protrusions and a second set of protrusions, the first set of protrusions have a first average height and the second set of protrusions have a second average height, the first average height different from the second average height, a top of each protrusion in the first set of protrusions has a non-flat surface and a top of each protrusion in the second set of protrusions has a non-flat surface.

Owner:ENTEGRIS INC

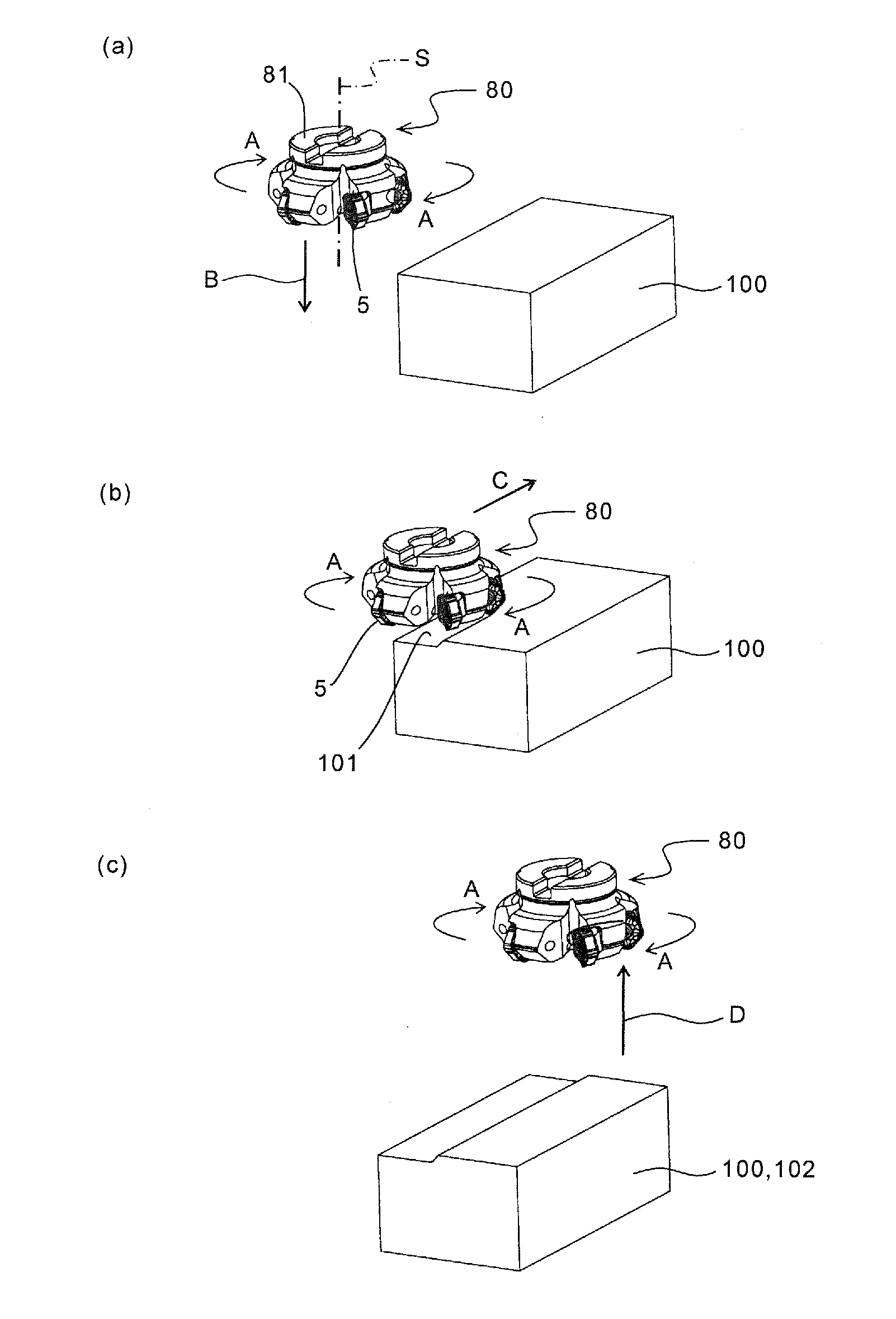

Torsional Ultrasound at Resonant Frequencies That Eliminate Chatter

InactiveUS20080139994A1Less movementShort strokeUltrasound therapyEye surgerySonificationSyringe needle

A torsional ultrasound surgical instrument that lessens or eliminates chatter from lens material by imparting a twisting, rotary motion to a tip of a phacoemulsification needle at a resonant frequency in excess of 32 kHz. Heat generation is reduced either through the use of a polyimide tubing situated between the needle and the infusion sleeve, through the use of thermal watch to prevent overheating at the incision, and / or through the use of a bypass hole in the needle that diverts flow under suction into the needle via the bypass hole instead of exiting through an irrigation opening in the infusion sleeve when a tip port is occluded by lens material.

Owner:ALCON INC

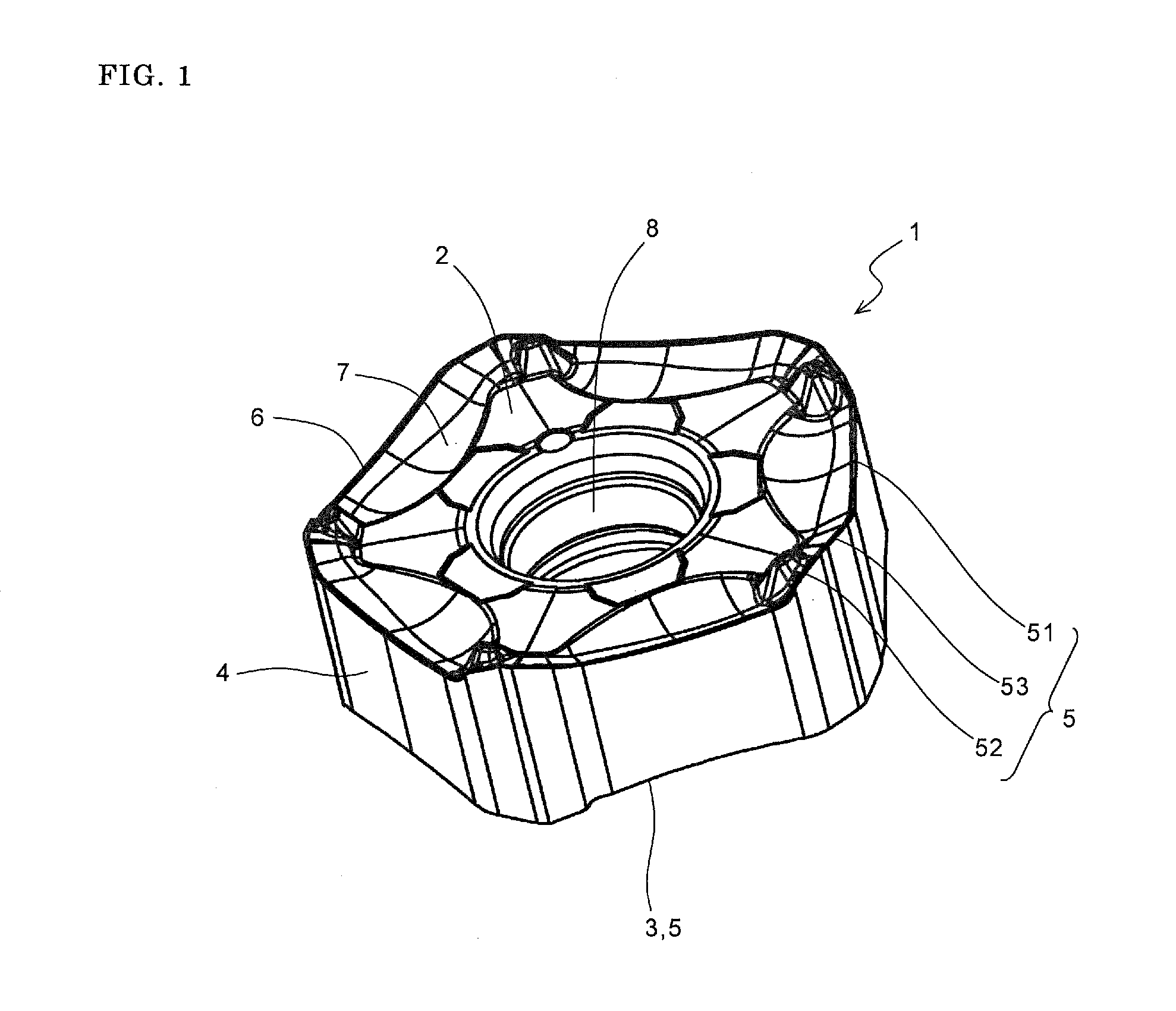

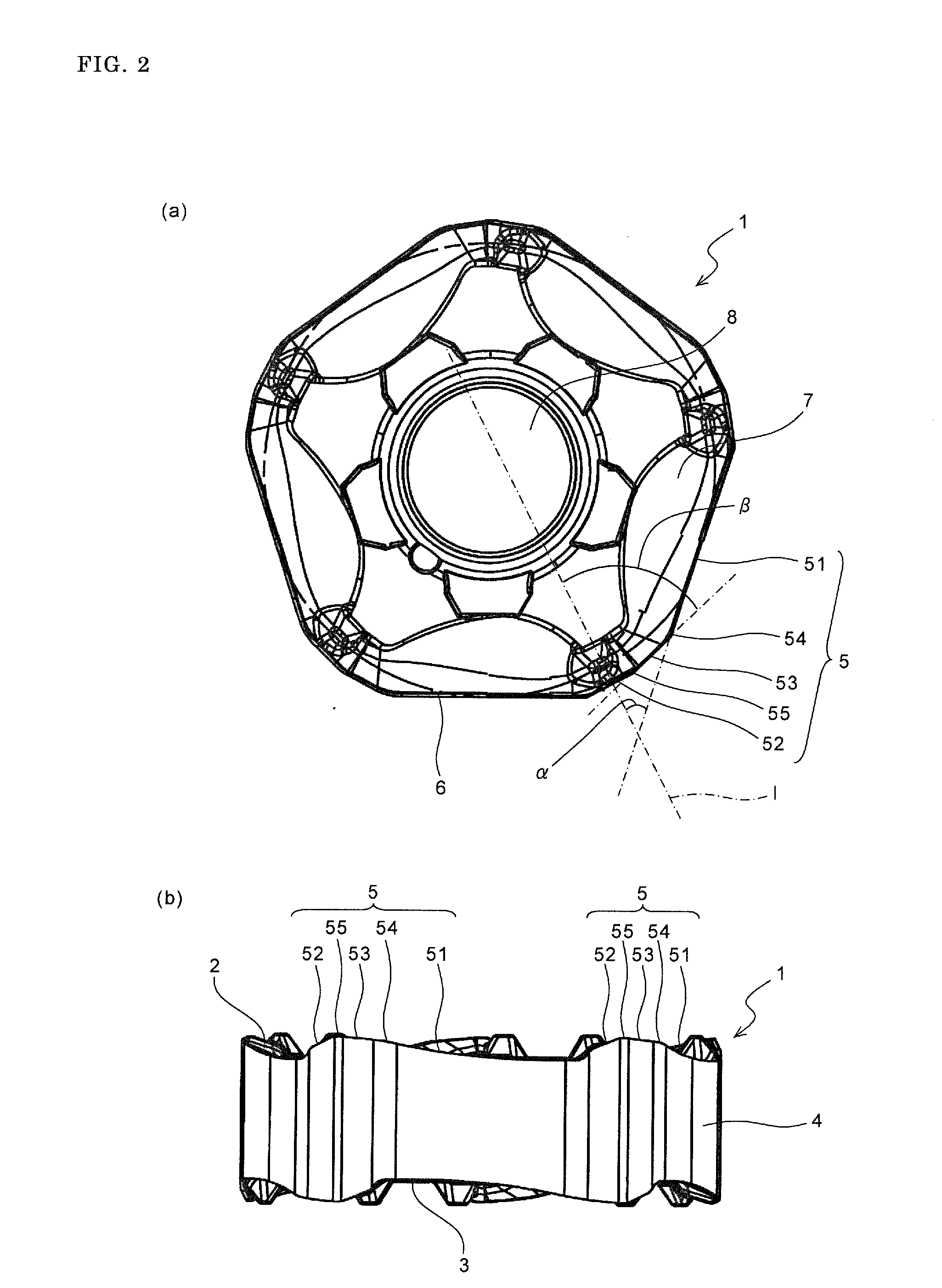

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20120070240A1Fine surfaceImproving finished surfaceMilling cuttersTurning toolsEngineeringKnife blades

A cutting insert of the present invention includes an upper surface; a lower surface; a side surface; a cutting edge which is located along an intersection of the upper surface and the side surface, and comprises a major cutting edge, a flat cutting edge, and a minor cutting edge located between the major cutting edge and the flat cutting edge; and a land part located along the cutting edge on the upper surface. The land part includes a minor cutting edge land portion located correspondingly to the minor cutting edge. The minor cutting edge land portion is inclined downward toward a central part of the upper surface. The present invention also provides a cutting tool including the cutting insert, and a method of manufacturing a machined product by using the cutting tool.

Owner:KYOCERA CORP

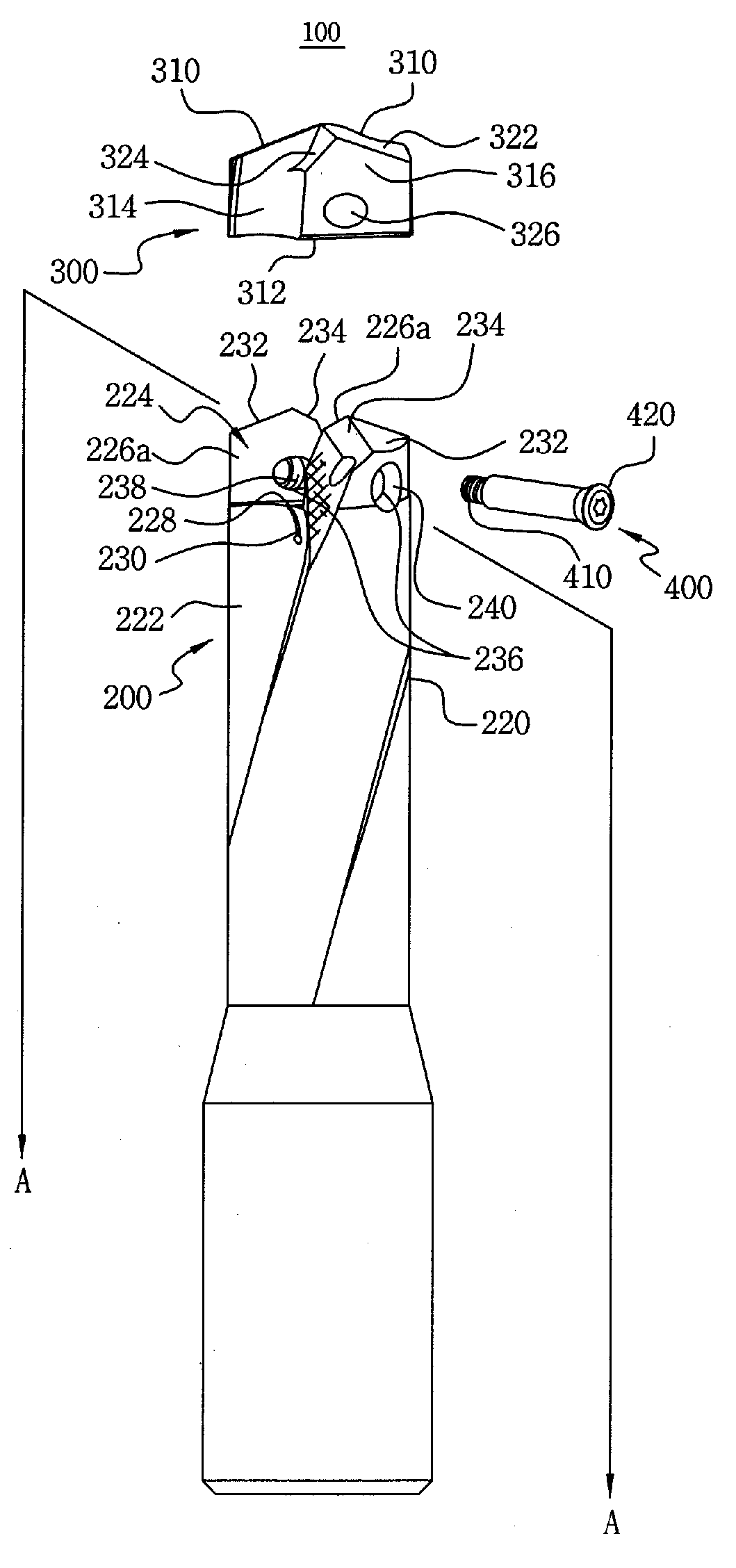

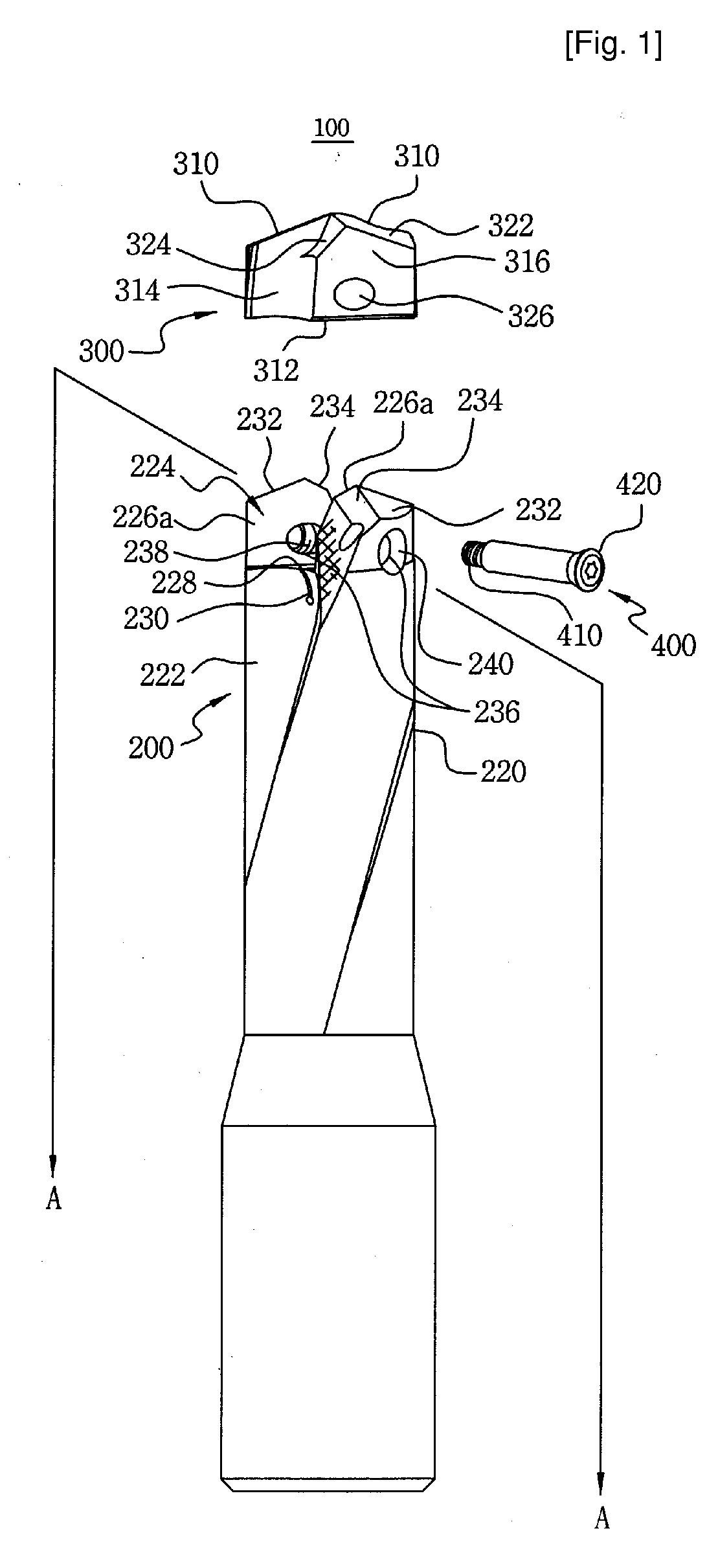

Indexable Type Cutting Tool

InactiveUS20080003072A1Improve cutting performanceSimply and quickly and precisely fastenedThread cutting toolsWood turning toolsFluteEngineering

An indexable type cutting tool comprises a drill having a shank and a drill body which extends from the shank, the drill body being defined with body flutes, and being formed with an insert seat which has seat side surfaces and a seat bottom surface and body flank surfaces and body thinning surfaces; a drill insert fitted into the insert seat of the drill body, having cutting edges and an insert bottom surface which is brought into close contact with the seat bottom surface, formed with insert flutes and insert side surfaces which are brought into close contact with the seat side surfaces, and defined with a through-hole which passes through the insert side surfaces; and a fastening screw for fastening the drill insert fitted into the insert seat to the drill.

Owner:KORLOY

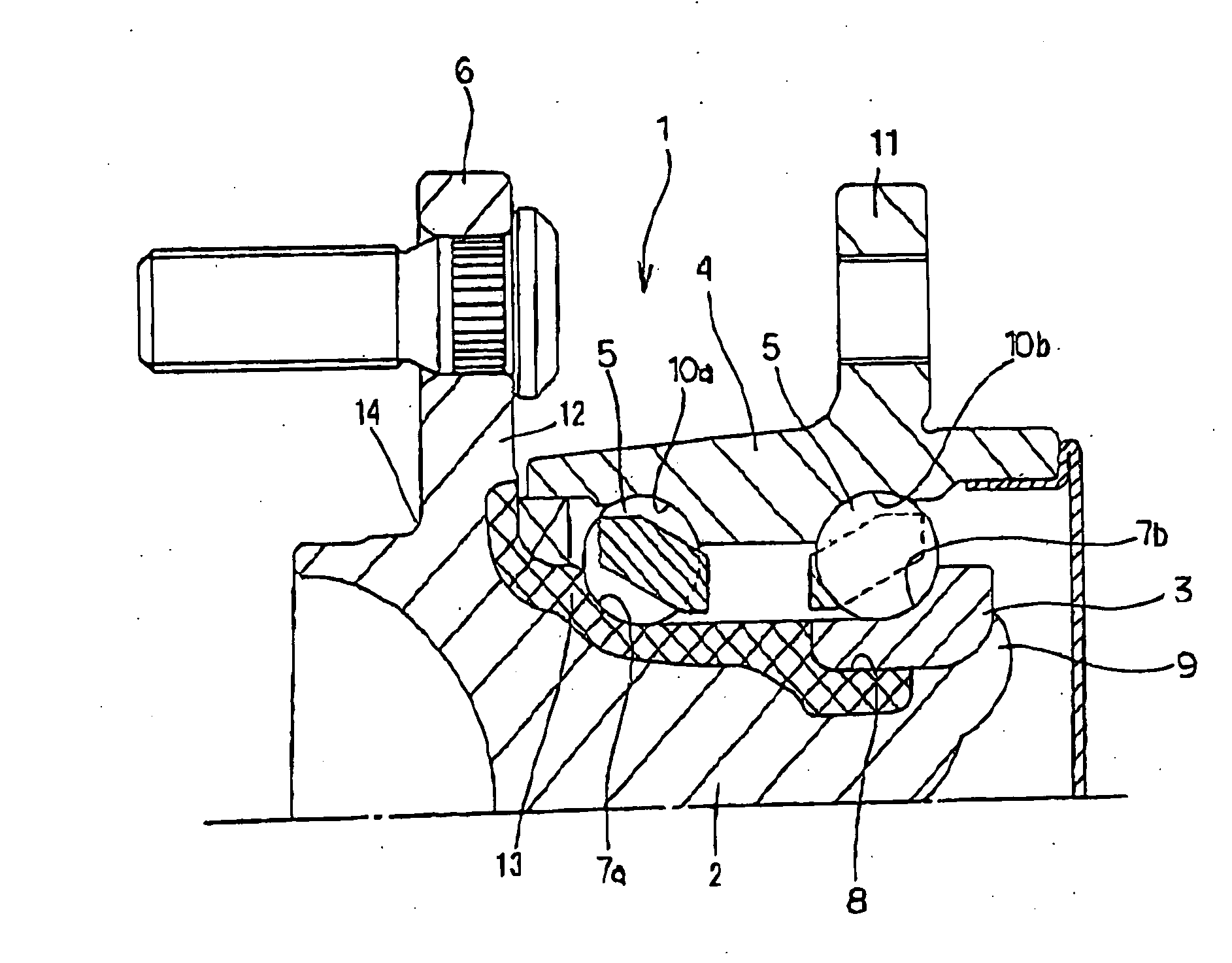

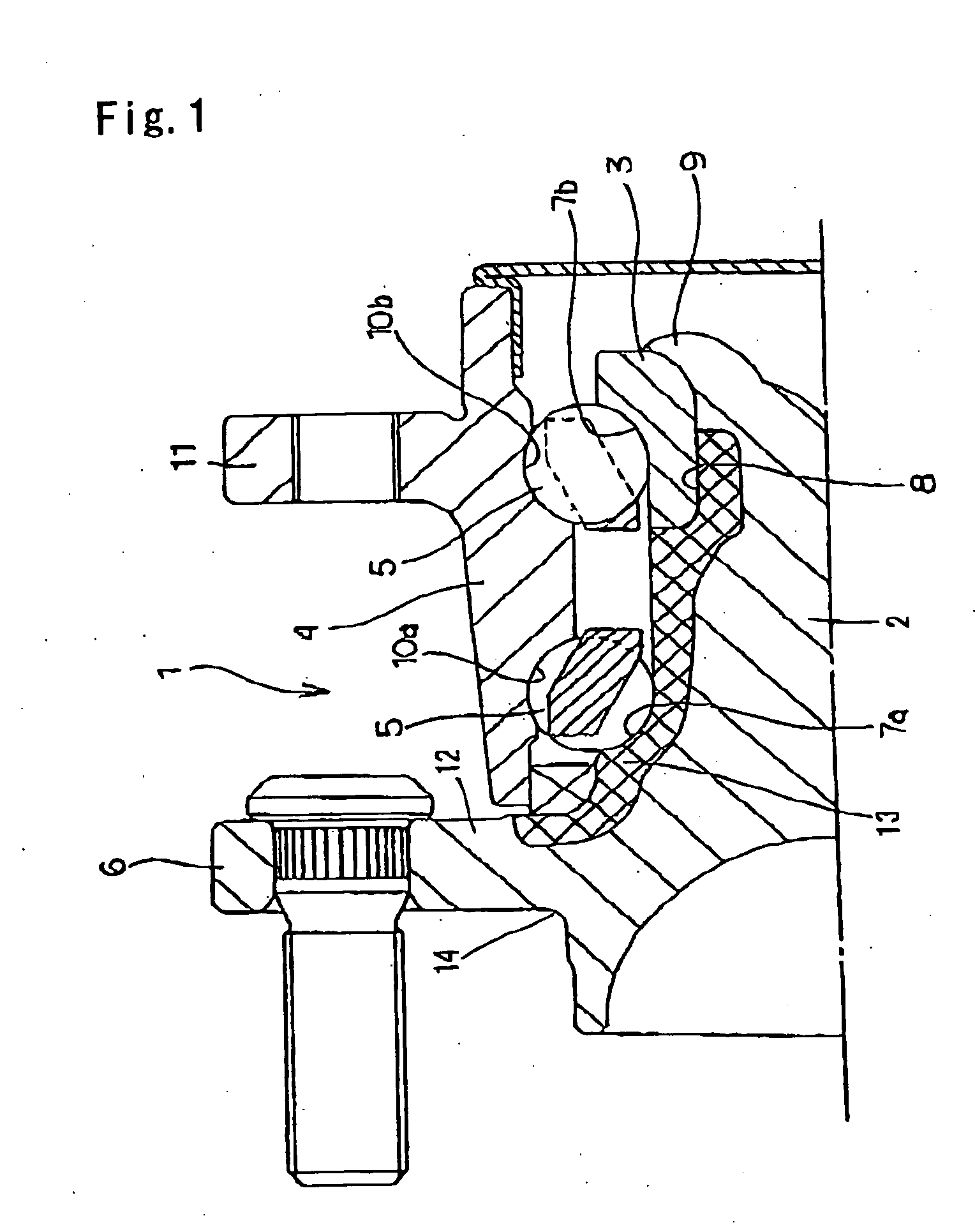

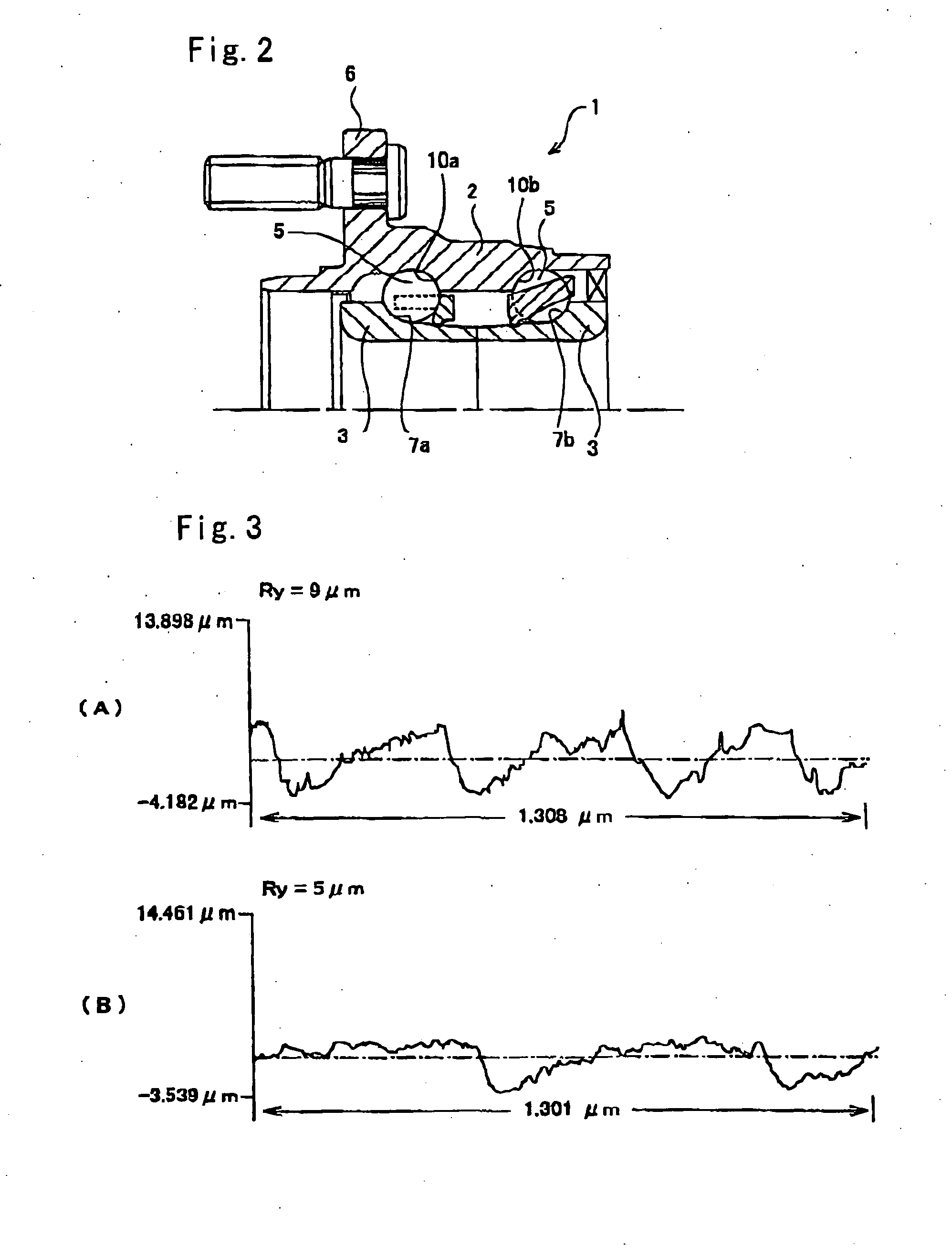

Wheel-support rolling bearing unit

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

Rotary cutting tool with non-uniform distribution of chip-breaking features

ActiveUS7544021B2Less materialValuable machining timeWood turning toolsTransportation and packagingFluteMechanical engineering

A rotary cutting tool with a longitudinal axis is provided that includes a shank portion, a cutting portion, and a plurality of chip-breaking features. The cutting portion, which extends out from the shank portion, includes a length, a plurality of blades and a plurality of flutes. The blades and flutes extend substantially all of the length of the cutting portion. Each blade includes a leading face side, a trailing face side, and a land surface that extends between the leading face side and the trailing face side. The plurality of chip-breaking features are disposed in the land surfaces of the blades, and non-uniformly distributed among the blades.

Owner:BERKSHIRE PRECISION TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com