Wheel-support rolling bearing unit

a technology of rolling bearings and supporting parts, which is applied in the direction of manufacturing tools, heat treatment equipment, furniture, etc., can solve the problems of inability to solve the cutting property and drilling property of materials, and the possibility of metal fatigue cracks and other problems, to achieve the effect of increasing the cutting property, reducing the deformation, and reducing the localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

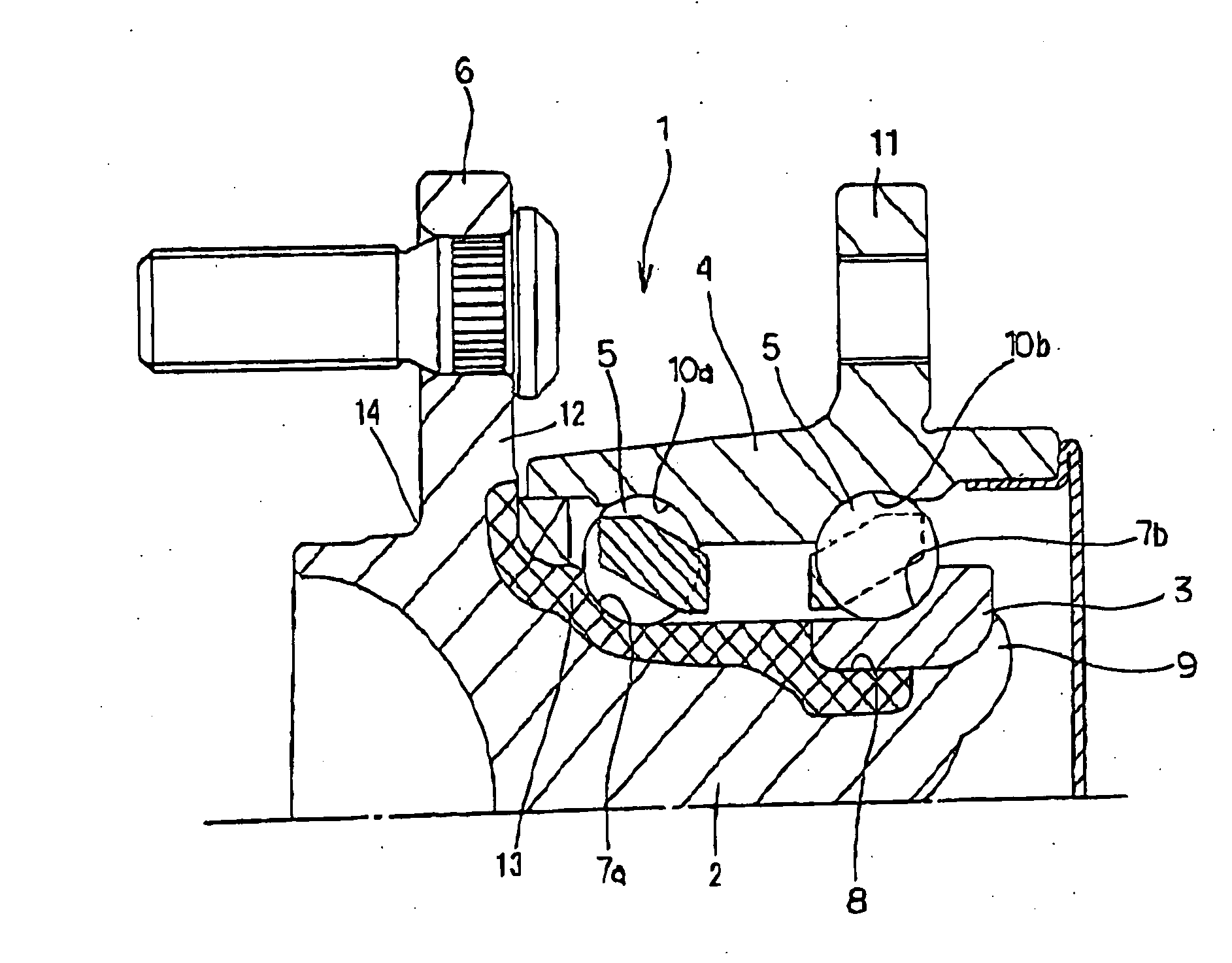

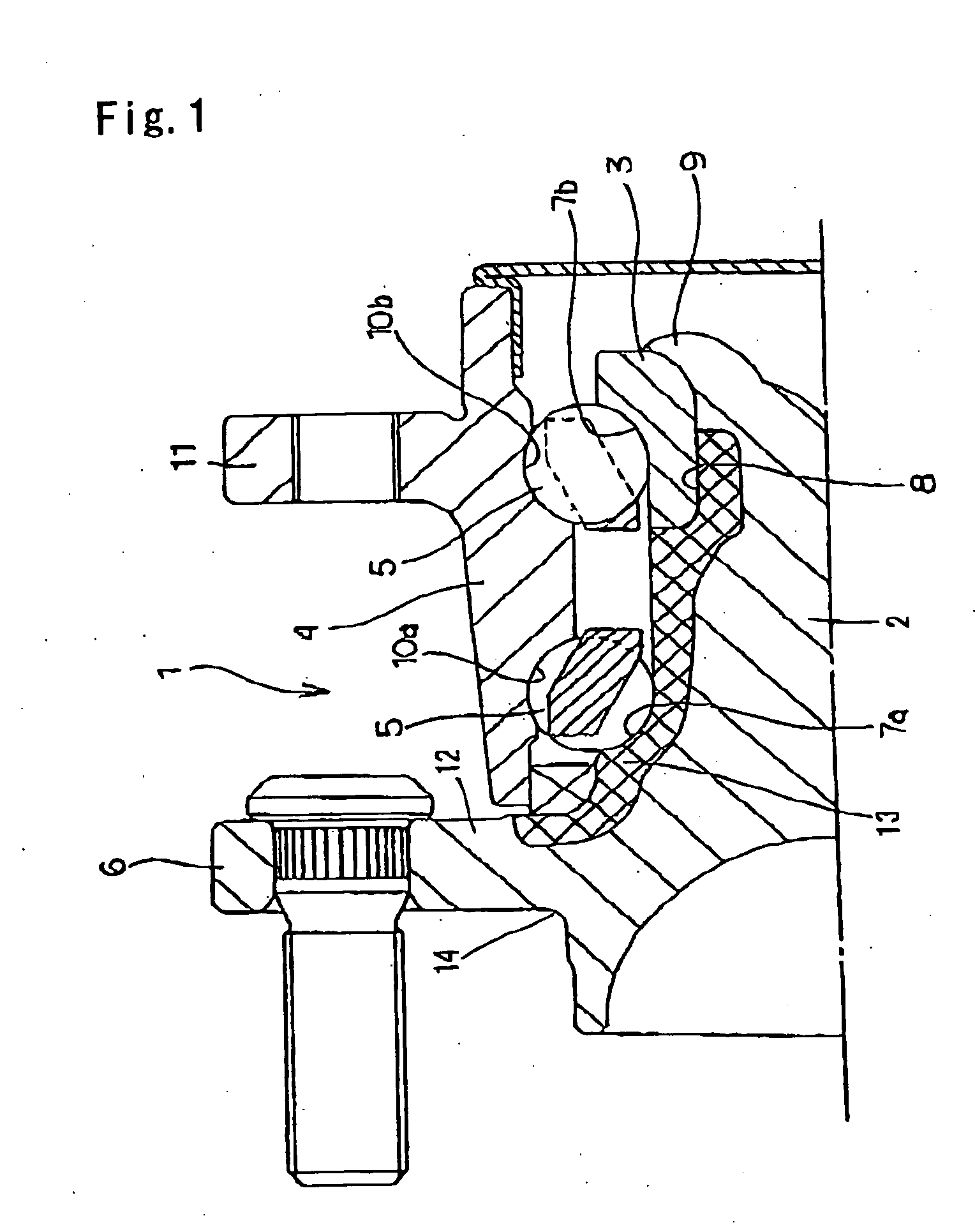

[0226] In the flanged bearing unit 1, since a radial load is produced from the road surface to the bearing while the hub ring 2 is rotating, the rotating bending stress is generated in the root portion of the wheel attaching flange 6. Particularly, at the outside root portion 14 of the wheel attaching flange 6, heat treatment such as quenching and hardening is not applied, but the rotating bending stress is concentrated. Therefore there is concern of damage occurring, depending on the use conditions and design conditions.

[0227] On the other hand, as described above, since it is required to lighten the hub ring 2, it is desirable to thin the wall of the wheel attaching flange 6. However, in order to proceed to thin the wall of the wheel attaching flange 6, it is required to increase the fatigue strength of the outside root portion 14 of the wheel attaching flange 6.

[0228] In the outside root portion (untempered steel) 14 of the wheel attaching flange 6 which is a medium carbon stee...

example a

First Example

[0274] In order to verify the effect of the present invention, the materials shown in Table 7 were used and worked in various hot forging conditions. Then the microstructures were identified, and the amount of the pro-eutectoid ferrite structure was measured by image analysis.

TABLE 7SteelCSiMnCrVSType(Weight %)(Weight %)(Weight %)(Weight %)(Weight %)(Weight %)S53C0.530.210.750.1700.017A10.540.240.790.1500.013A20.530.220.810.1600.005A30.450.220.810.1600.013A40.650.220.810.1600.013A50.560.240.790.150.080.013B10.540.230.870.1500.022B20.430.230.870.1500.013B30.680.230.870.1500.013

[0275] Regarding the hot forging, a steel bar was cut then high frequency induction heating was applied at various temperature between 950 and 1200° C. to change the fine level of the structure. Then hot forging, mainly comprising upsetting was applied and the forging was cooled at various cooling rates so as to make various precipitating conditions of the pro-eutectoid ferrite structure.

[0276]...

second example

[0299] In order to verify the effect of the present invention, the following experiment was performed.

[0300] Firstly, bar-shaped materials having the A to D components in Table 9 were used. The respective bar-shaped materials were cut then high frequency induction heating was respectively applied to give temperatures between 950 and 1200° C. They were then finished into predetermined shapes by hot forging. After that, forced air cooling or radiational cooling was performed and the oxide film was removed by shot blasting. Lathe turning, induction hardening and polishing of the raceway surface were then performed so as to produce the hub ring 2 shown in FIG. 9.

[0301] The hub rings 2 of examples 22 to 30 and comparative examples 7 to 11 in Table 10 were prepared. Moreover, the hub rings 2 of examples 22 to 30 used those for which the abovementioned distribution control of the pro-eutectoid ferrite had been performed.

TABLE 9CSiMnCrVComponent(weight %)(weight %)(weight %)(weight %)(w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| arithmetic average roughness Ra | aaaaa | aaaaa |

| arithmetic average roughness Ra | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com