Patents

Literature

3769results about "Axle units" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

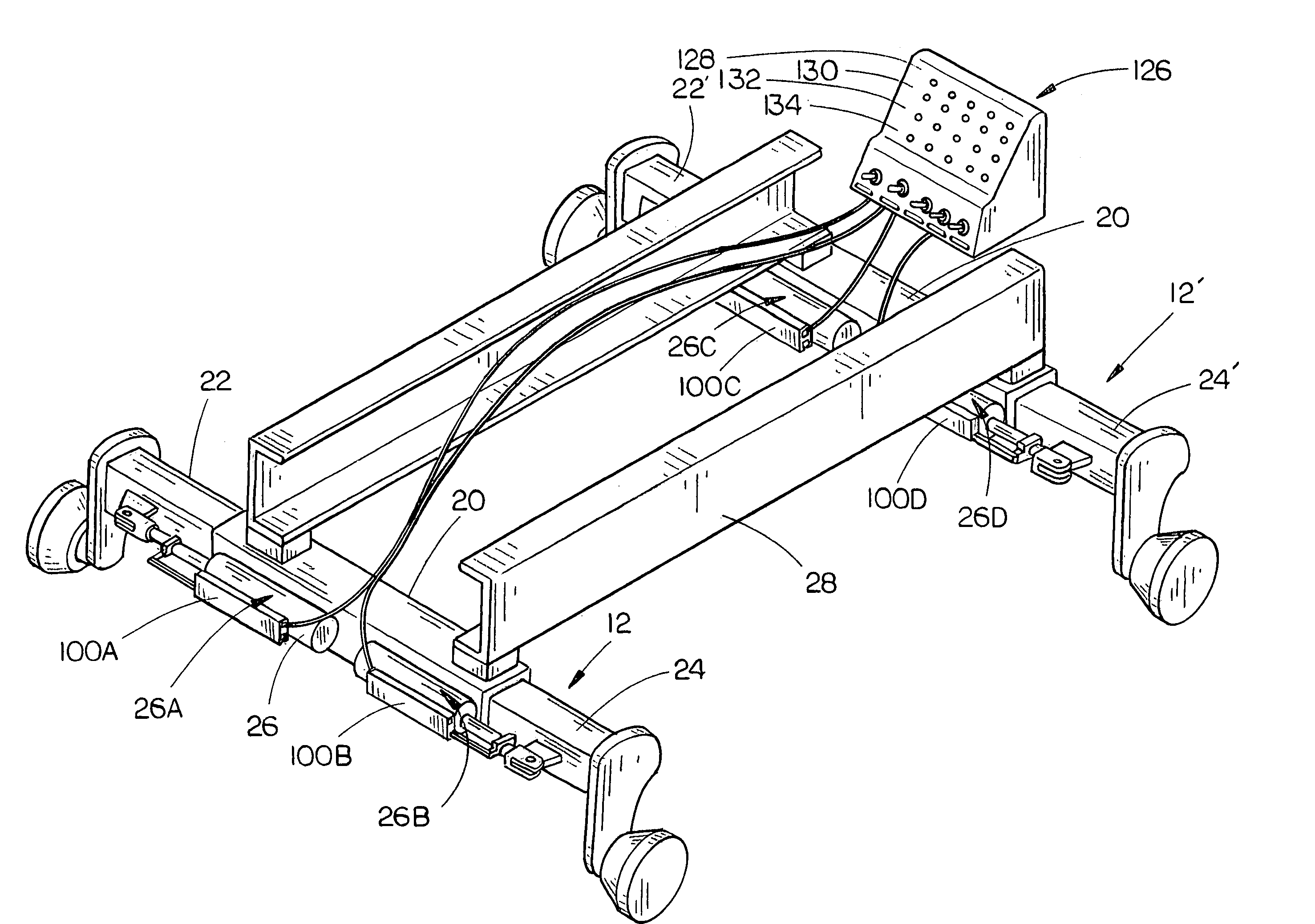

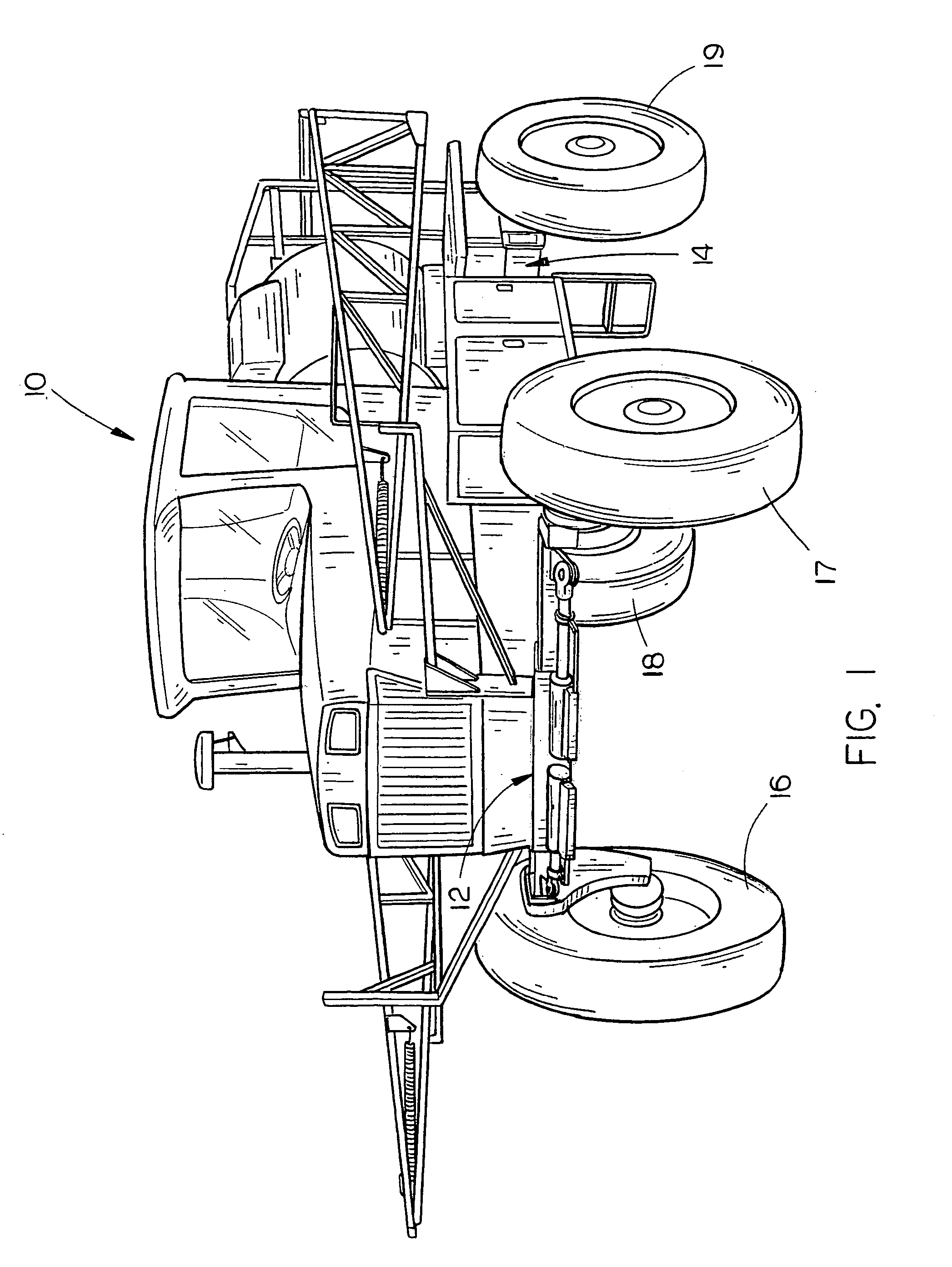

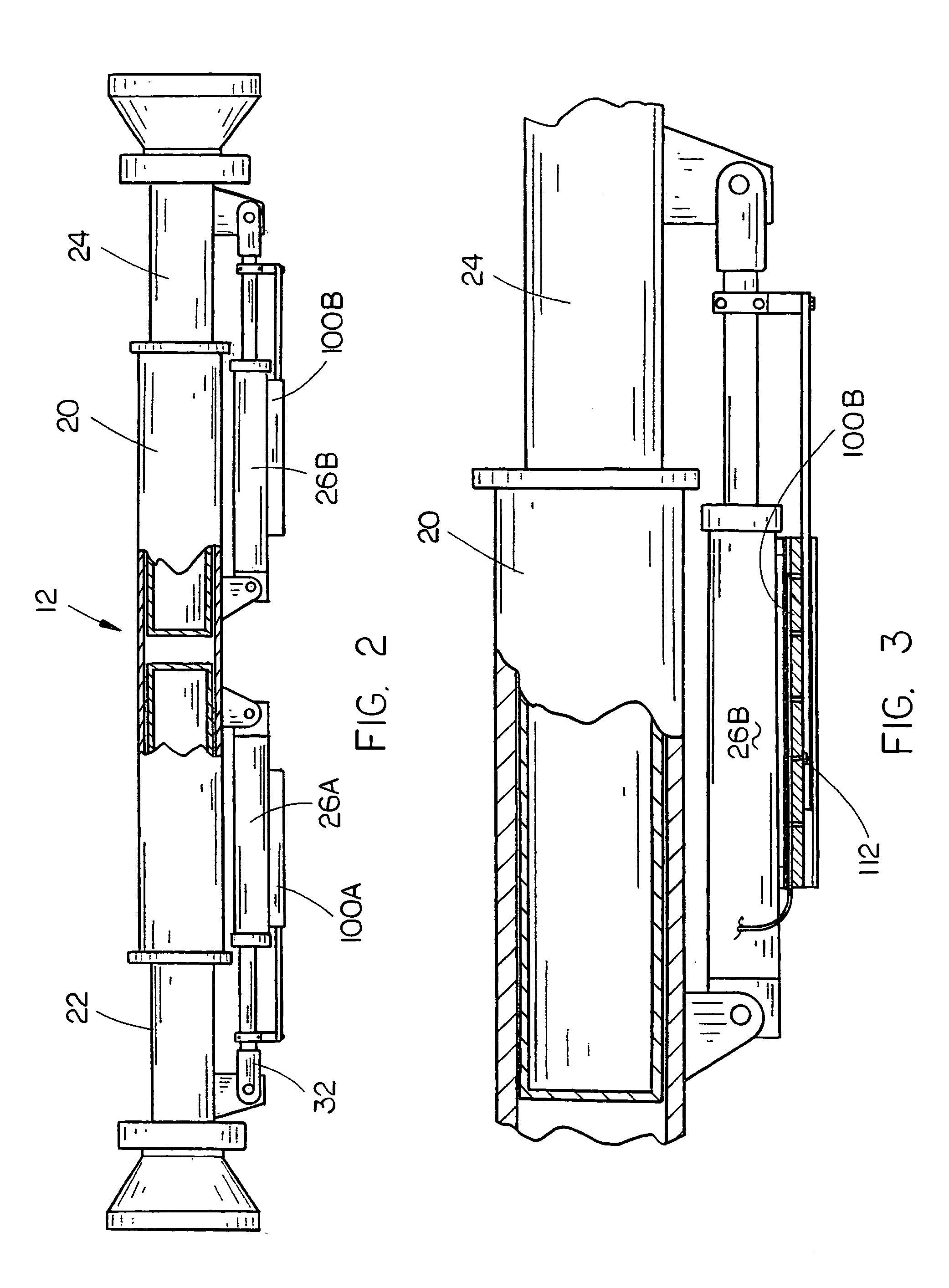

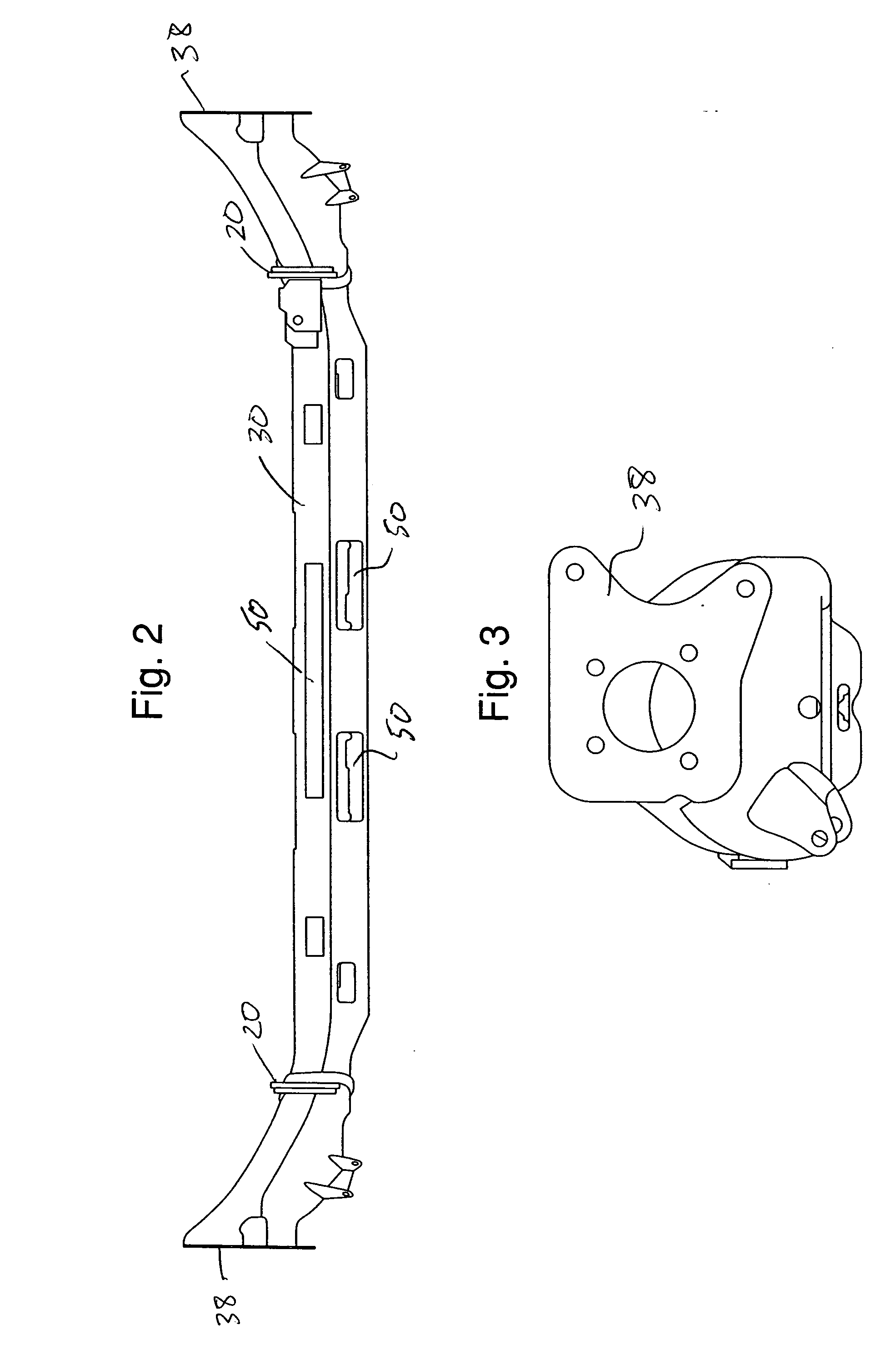

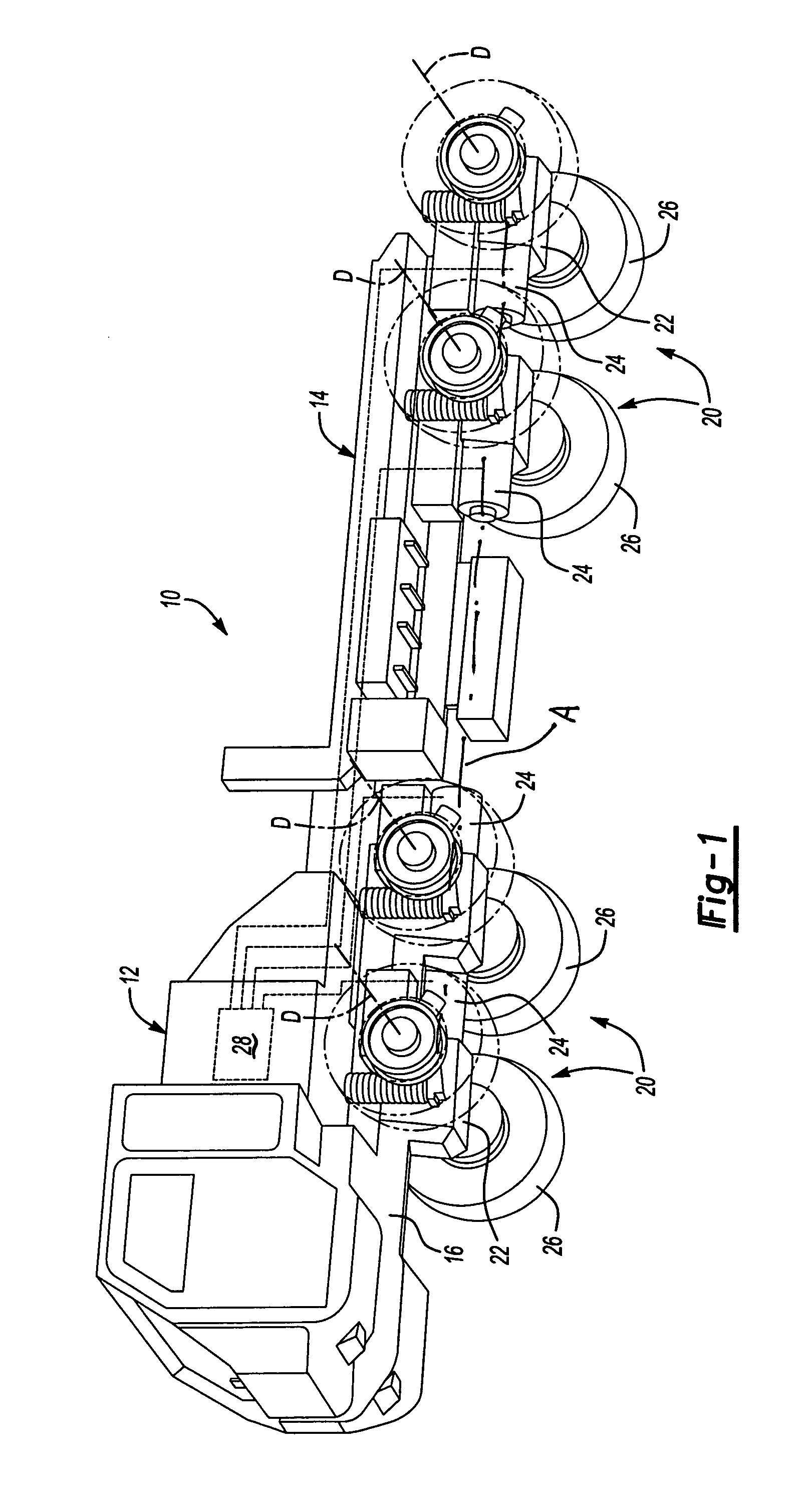

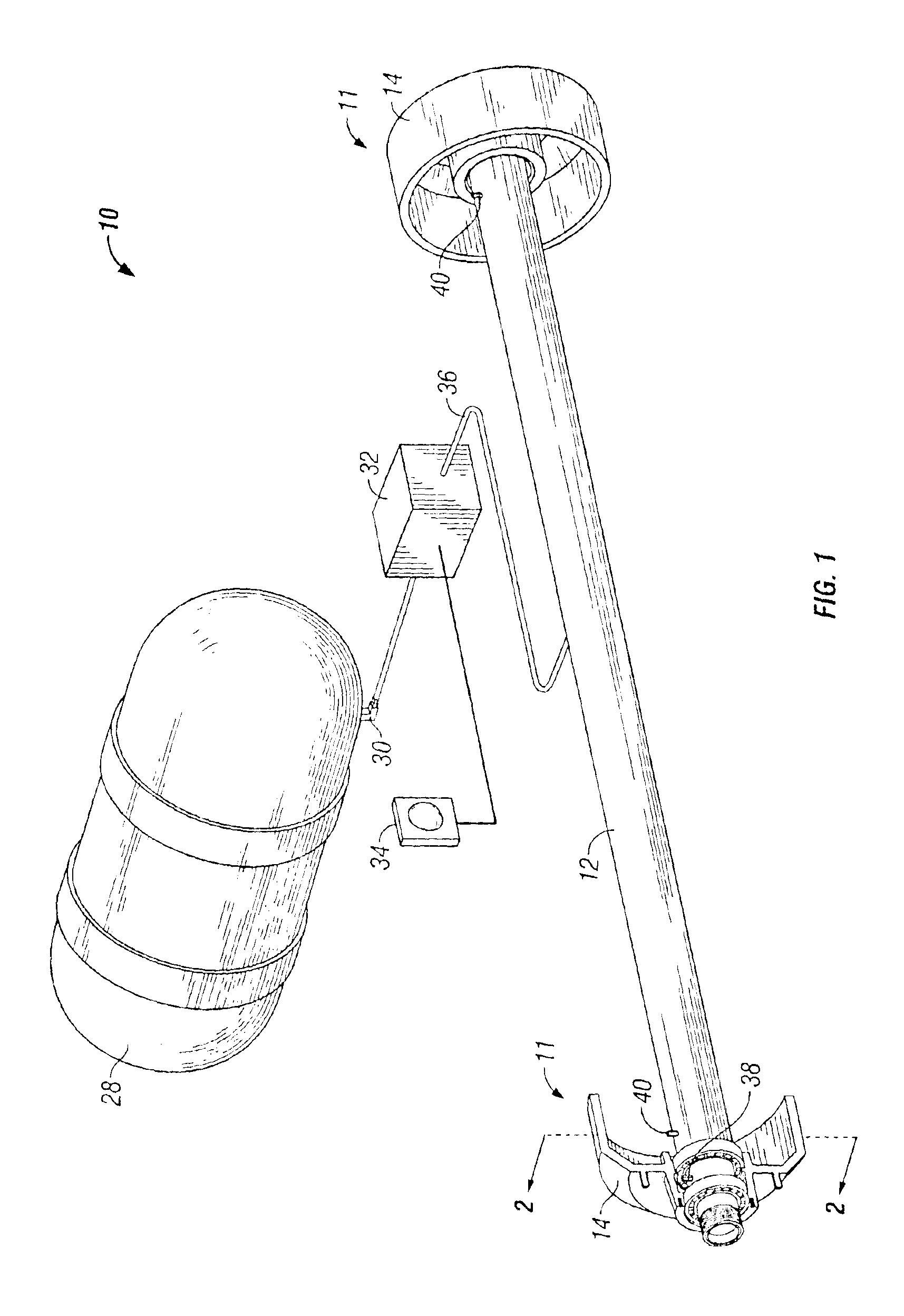

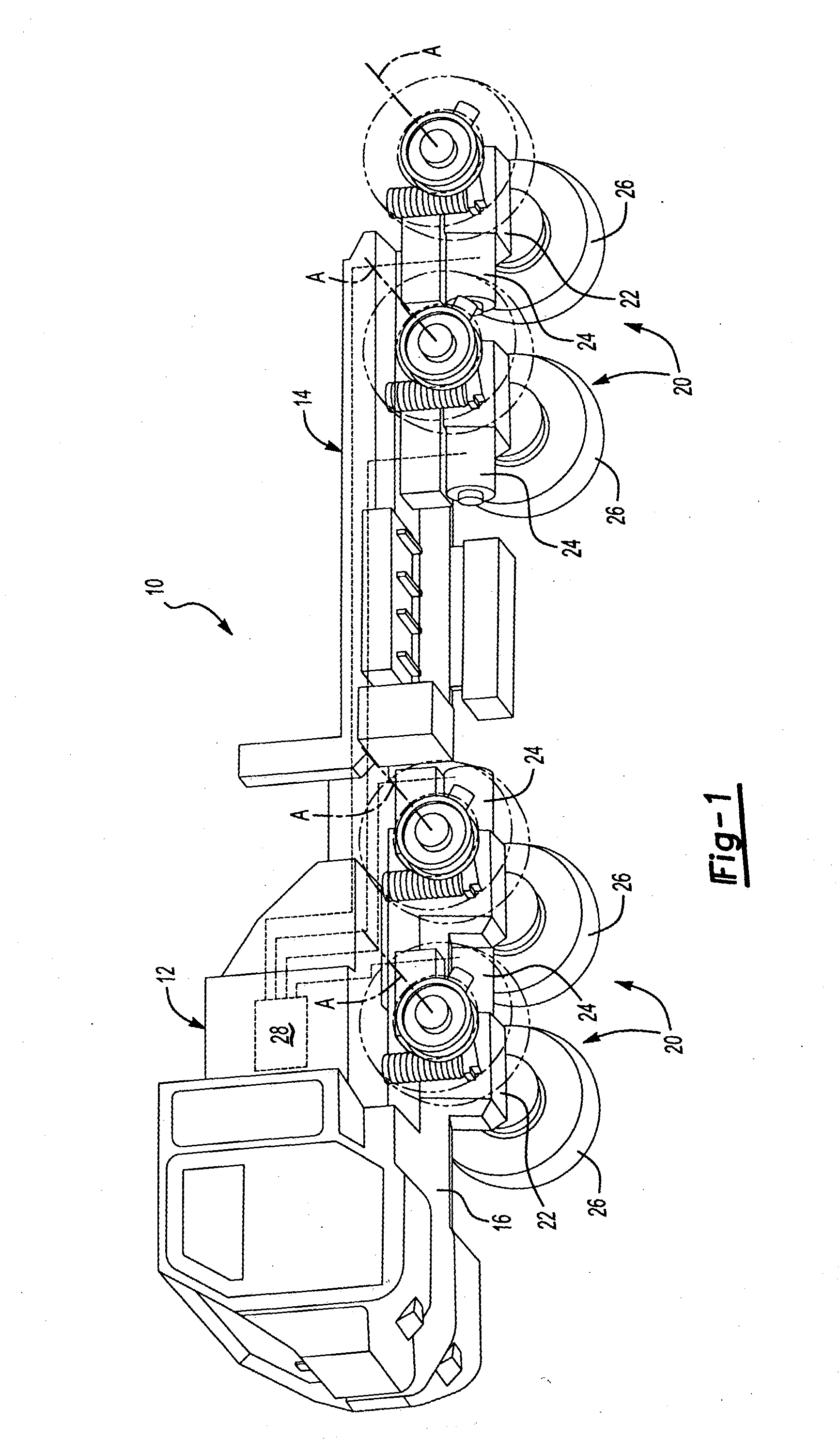

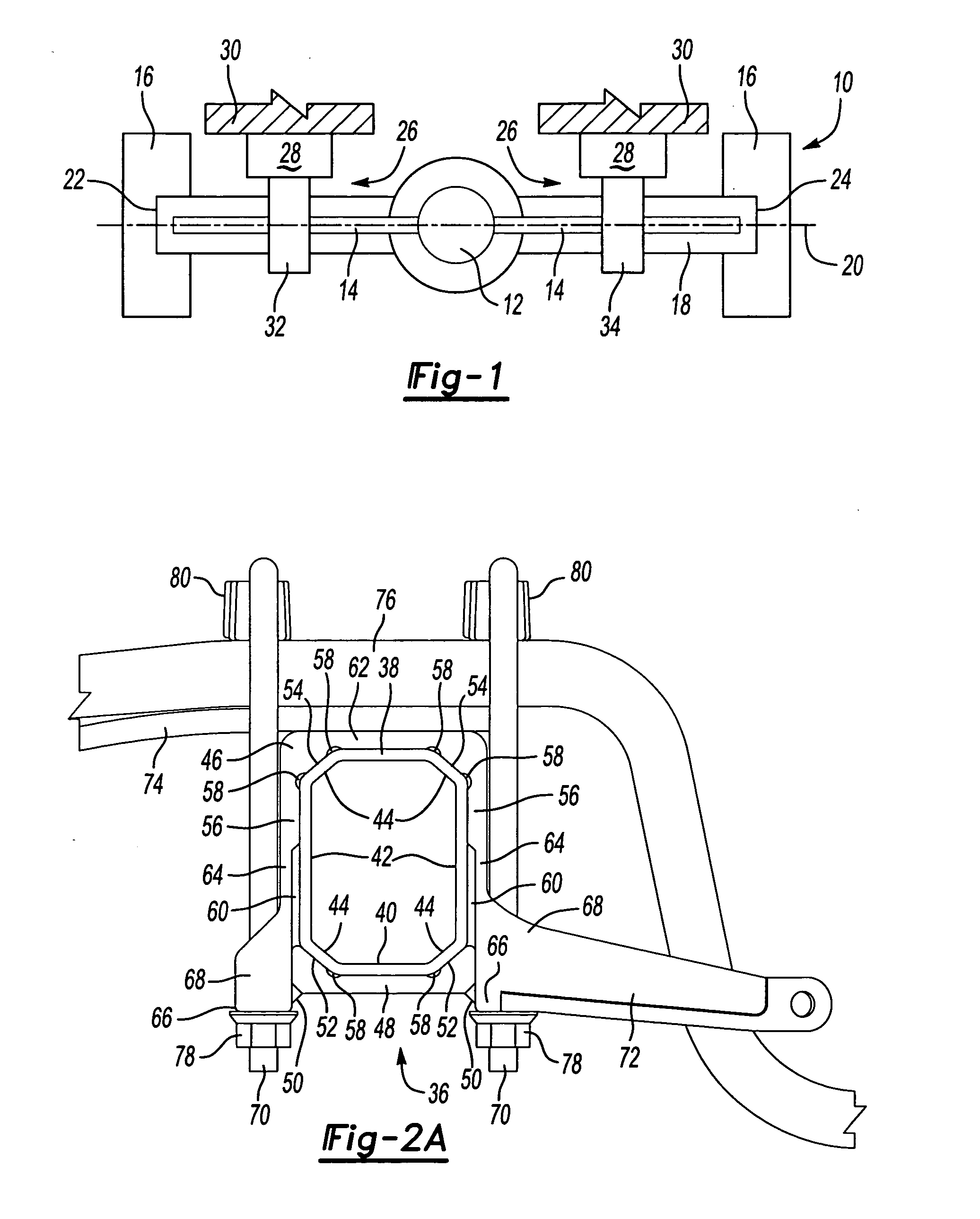

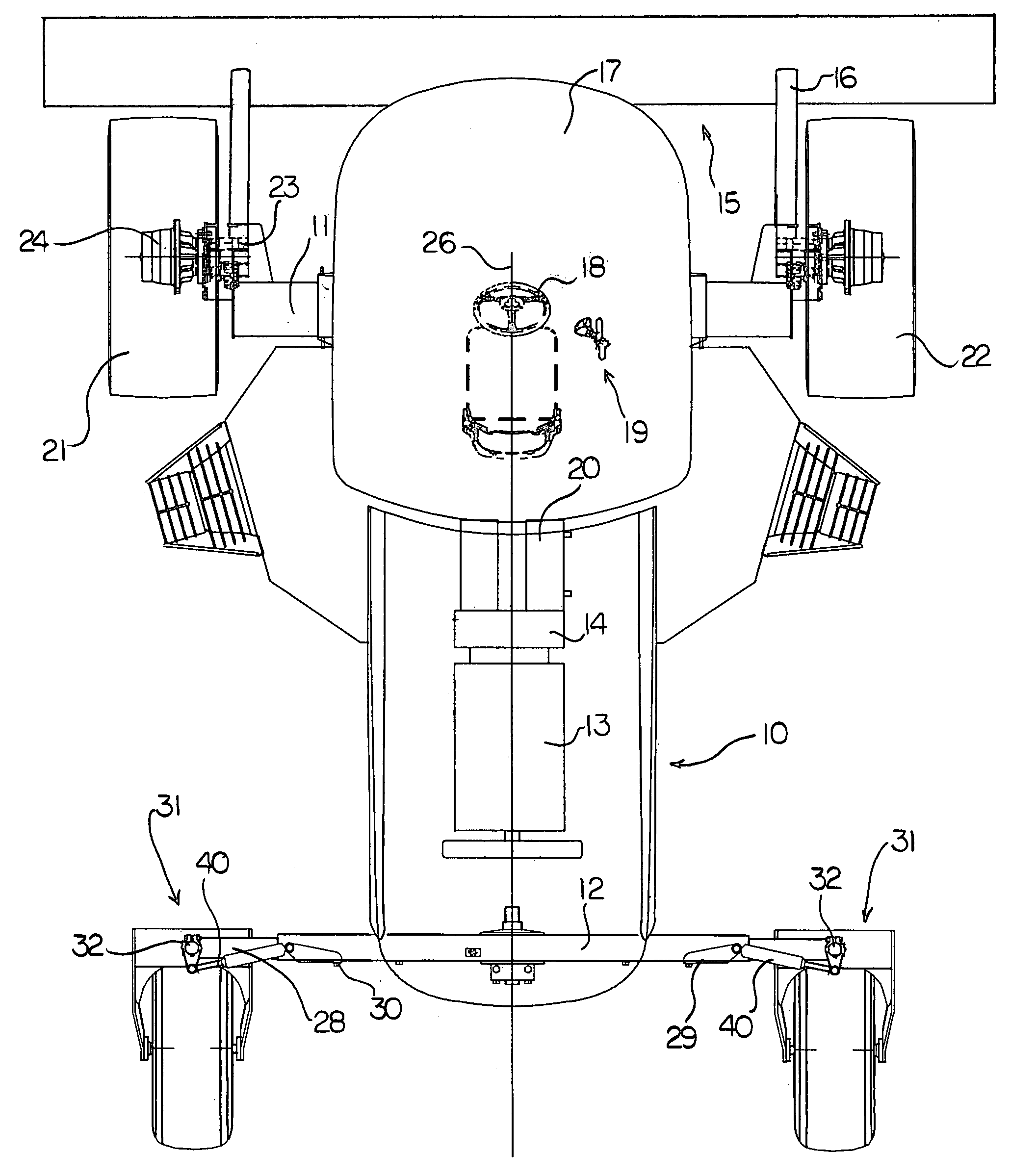

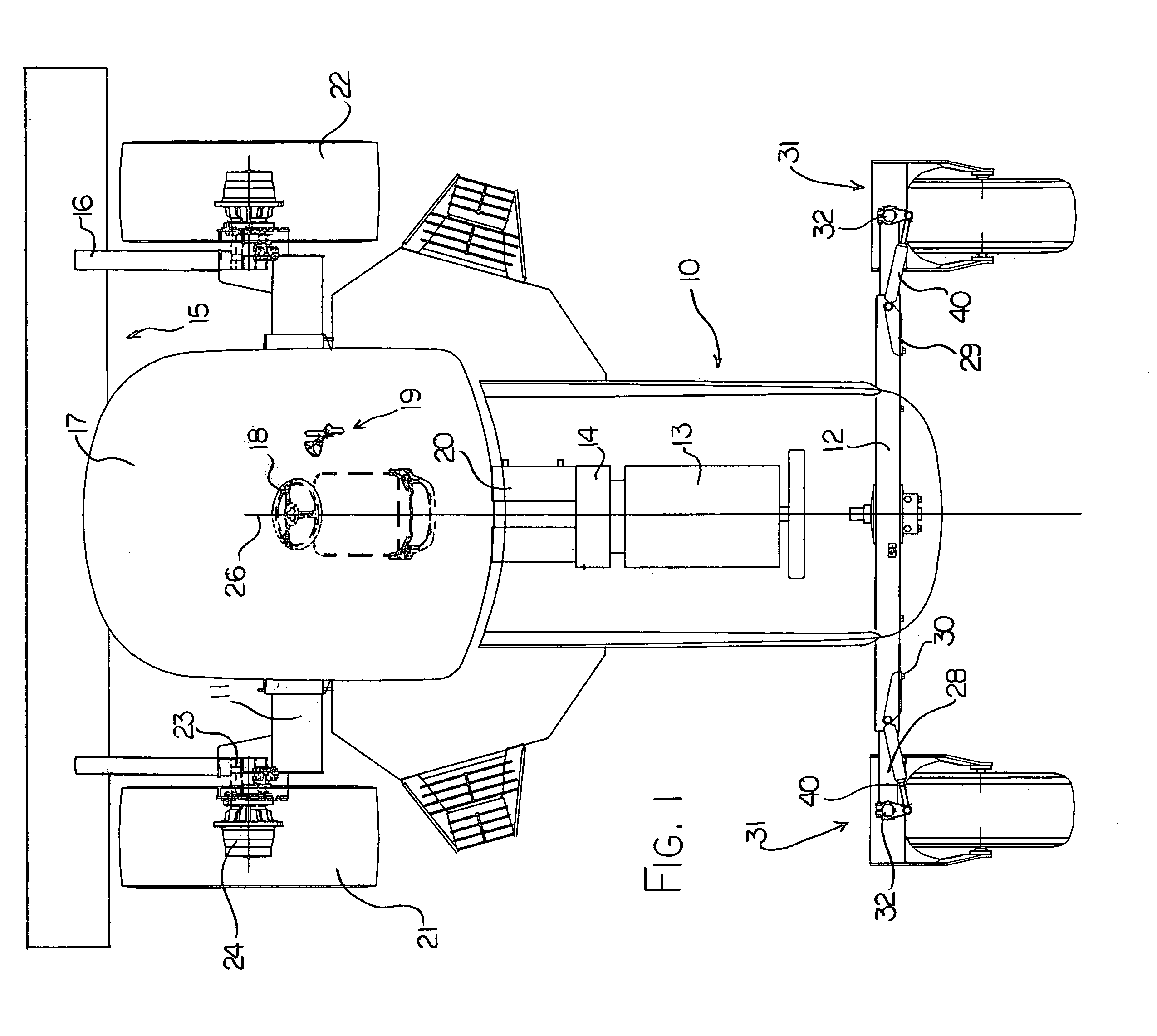

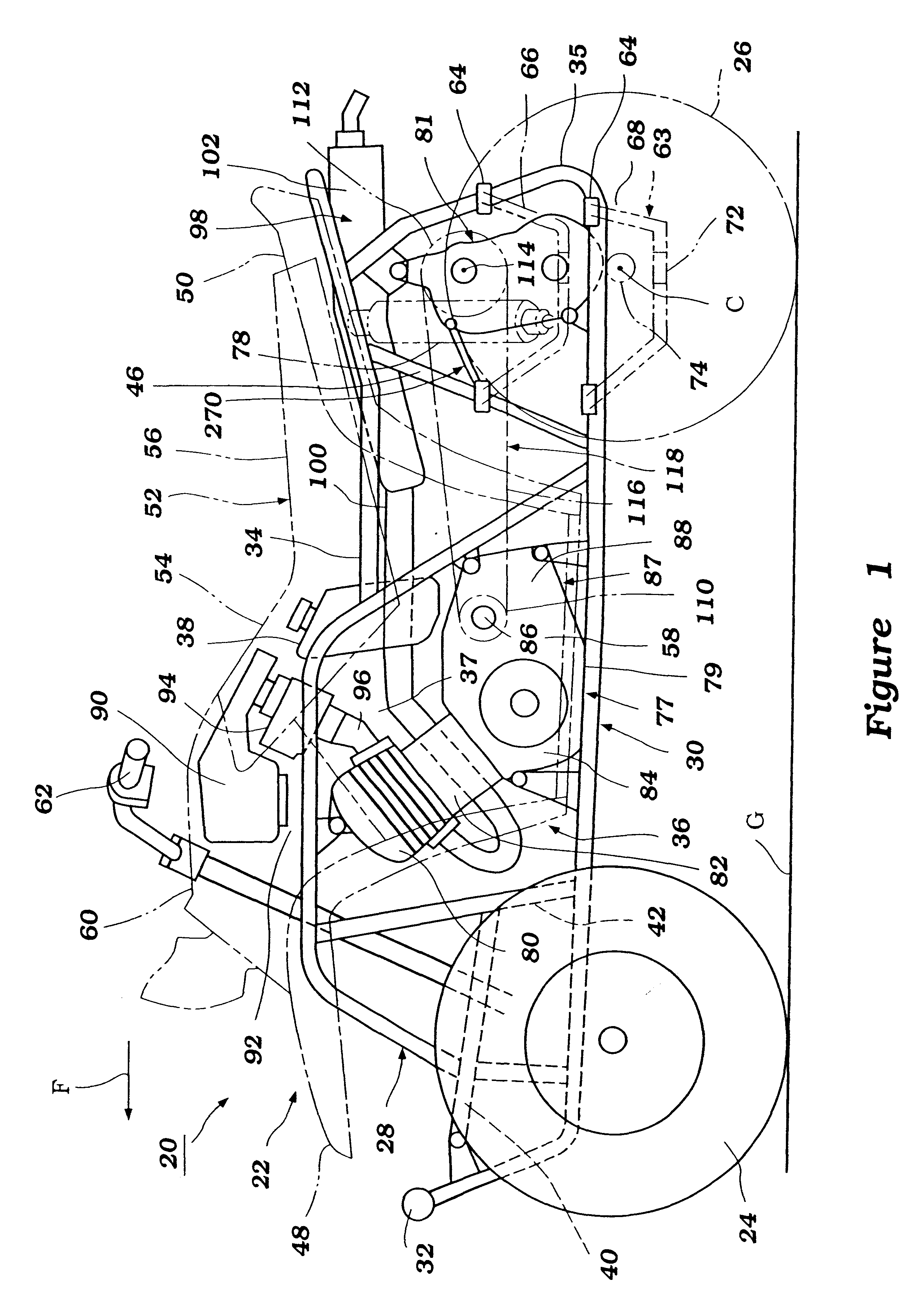

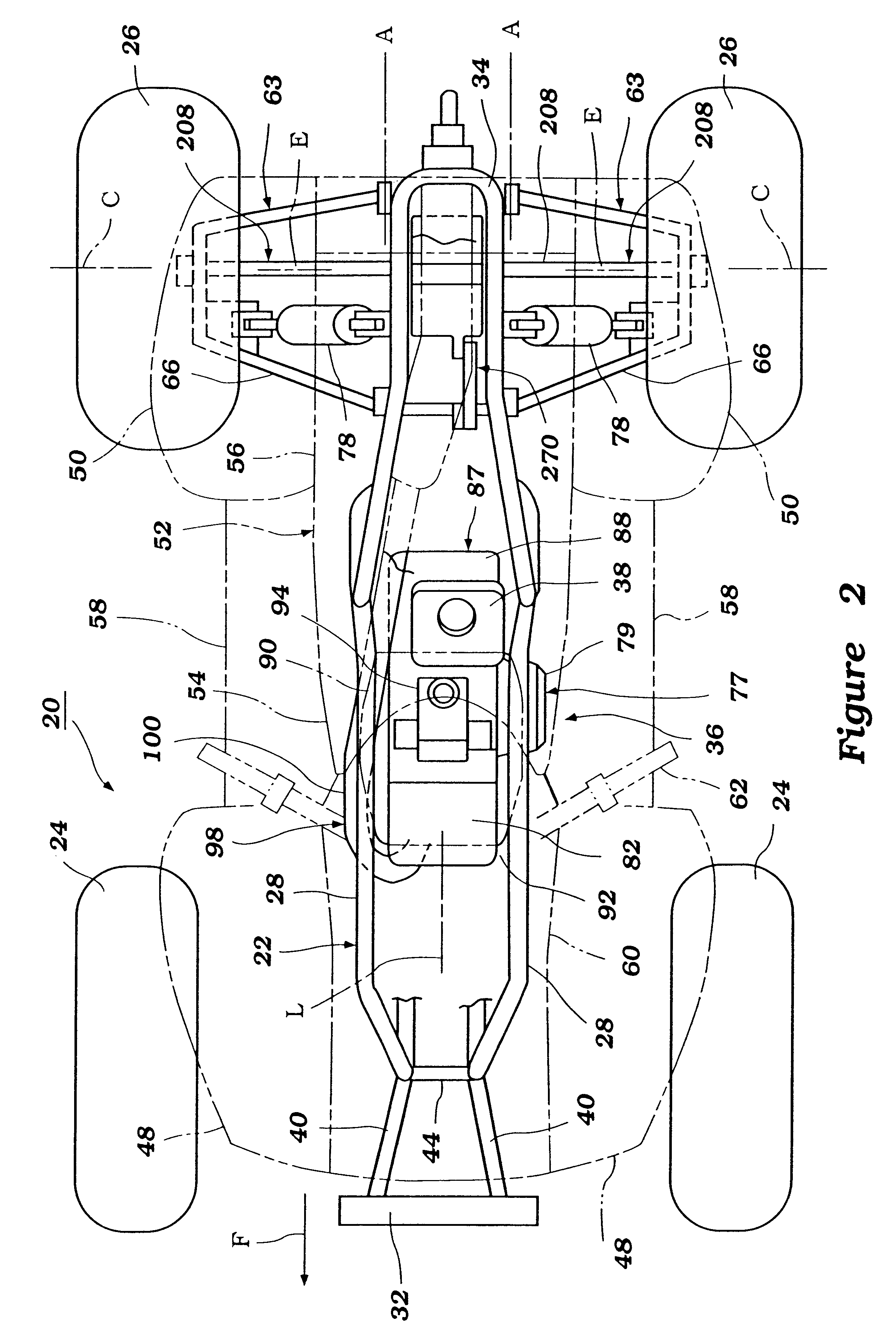

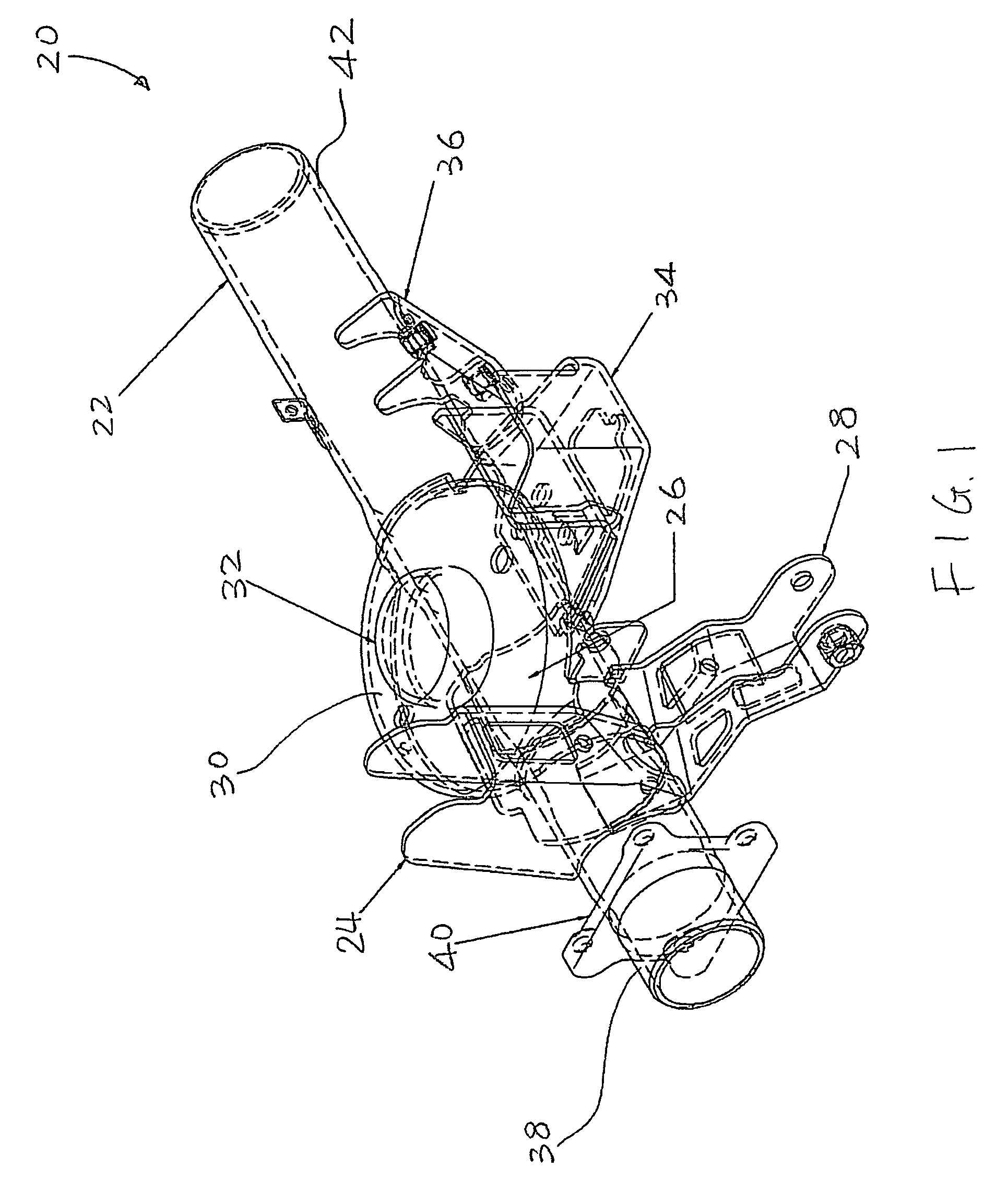

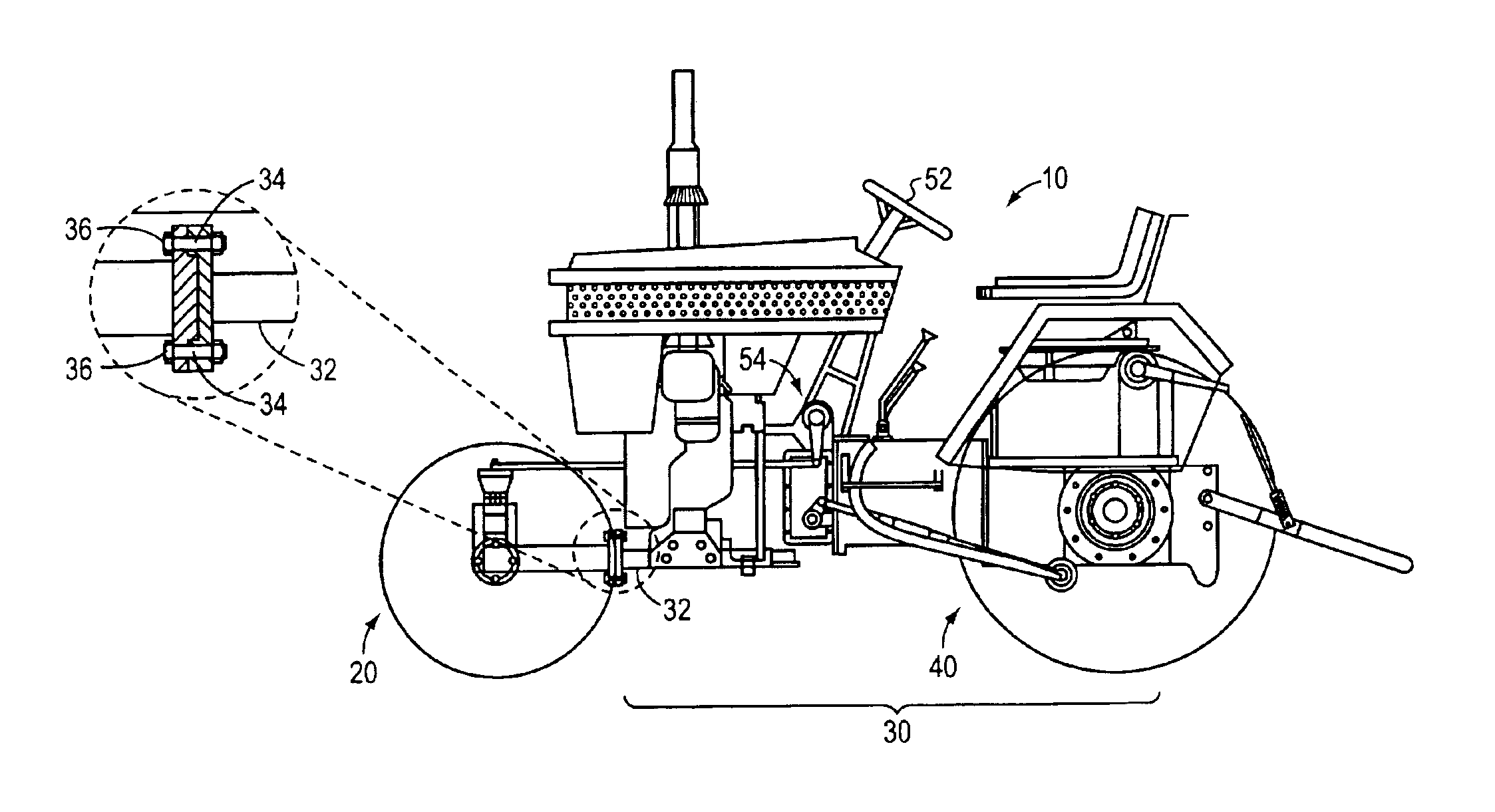

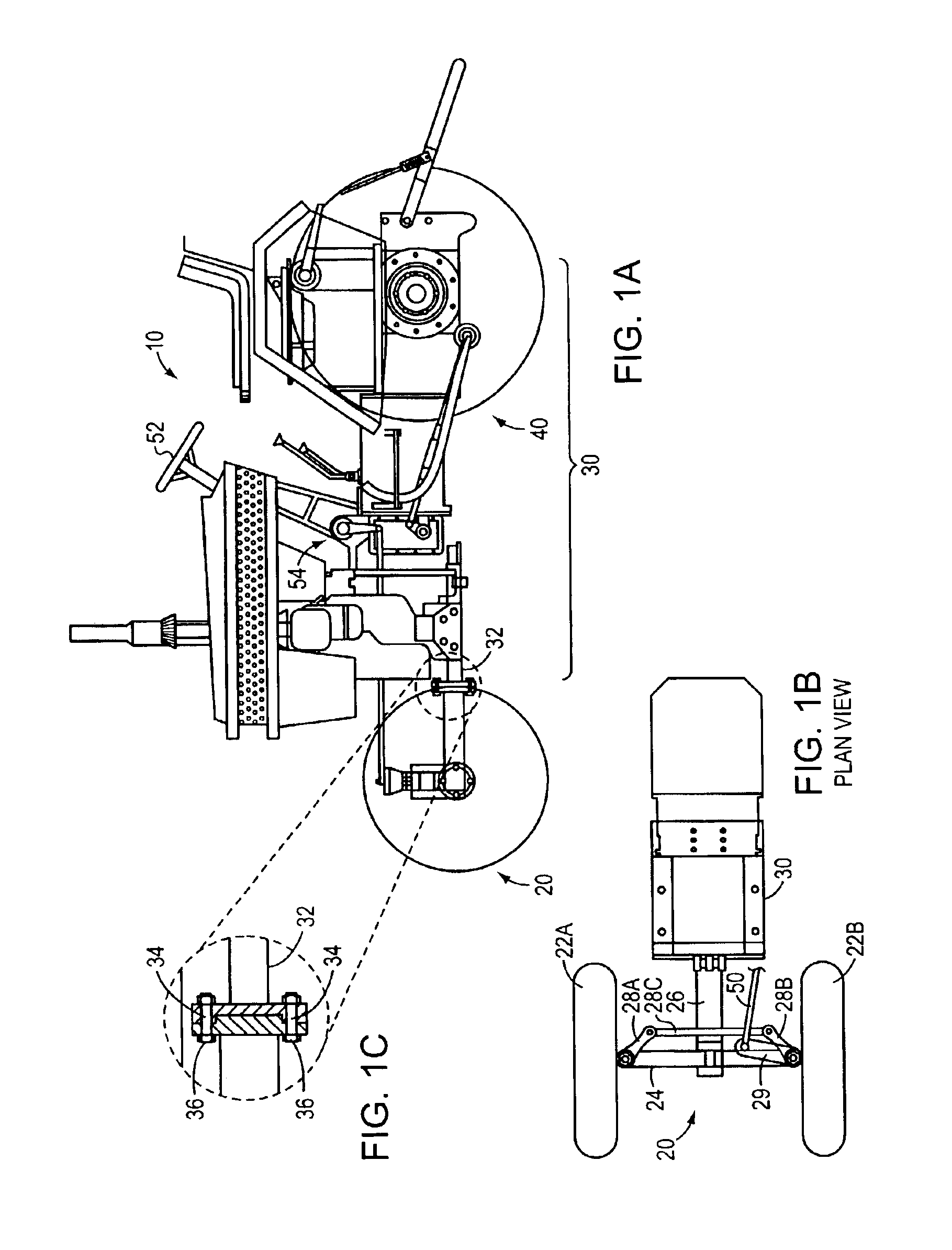

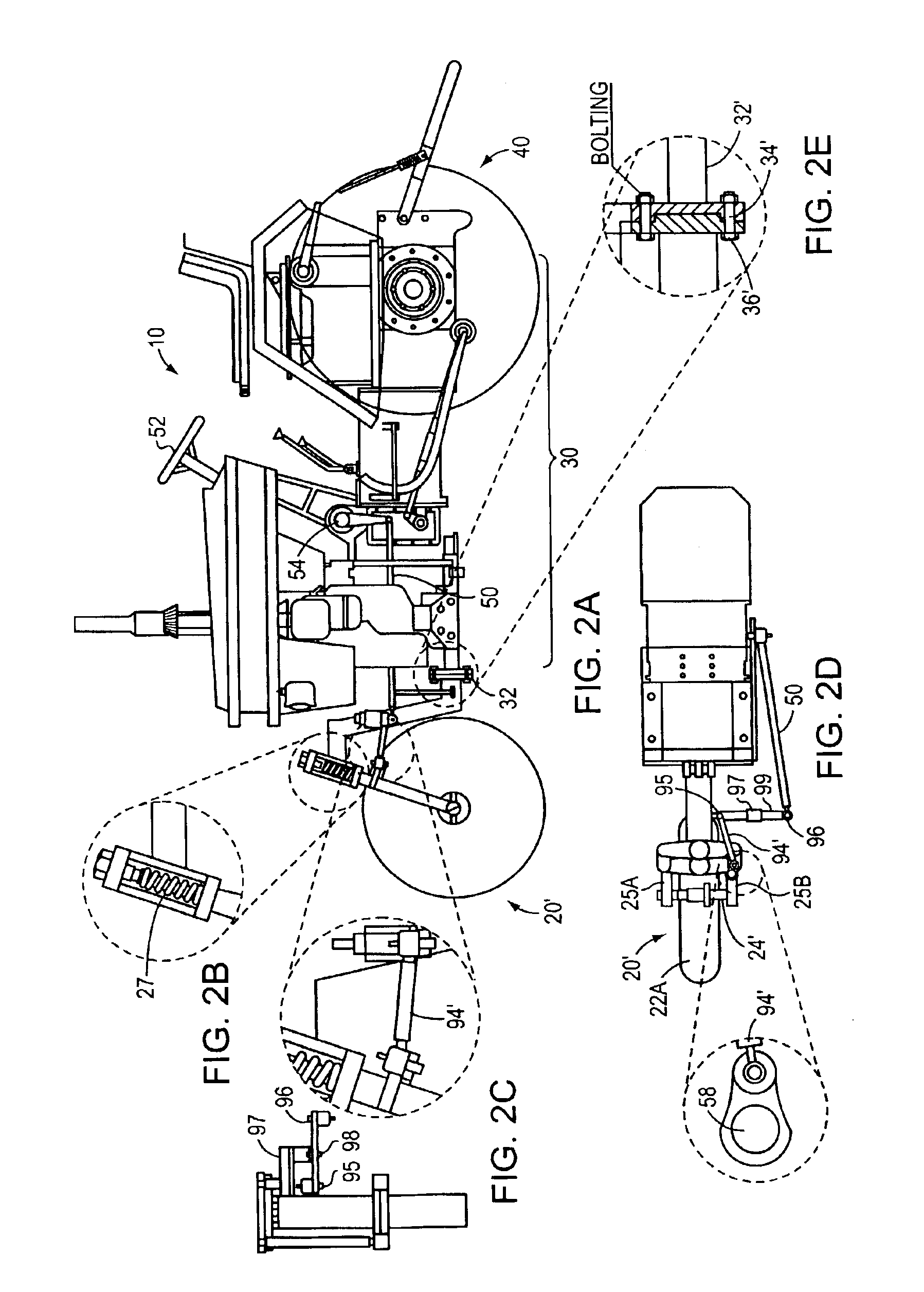

Multi-position track width sensor for self-propelled agricultural sprayers

InactiveUS7163227B1Track width can be easily and quicklyPositioning is simple and fastAgricultural vehiclesCarriage/perambulator accessoriesSprayerEngineering

A multi-position track width sensor for agricultural sprayers wherein a piston rod position sensor is connected to each of the adjustable axle members of the front and rear axle assemblies of the sprayer. A display panel is mounted in the cab of the sprayer and includes LEDs which indicate various positions of the piston rods with respect to the respective cylinder.

Owner:BURNS KERRY C

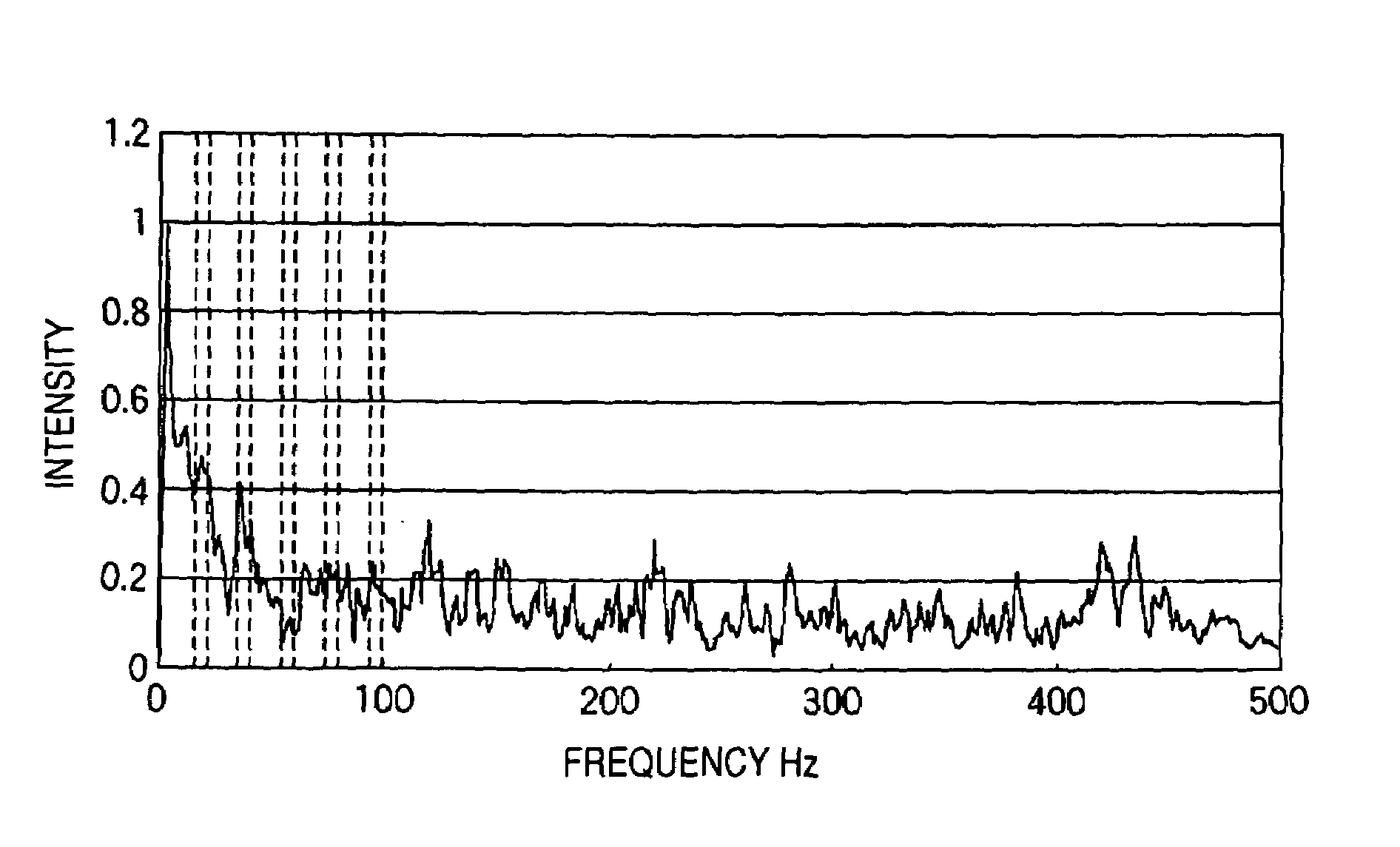

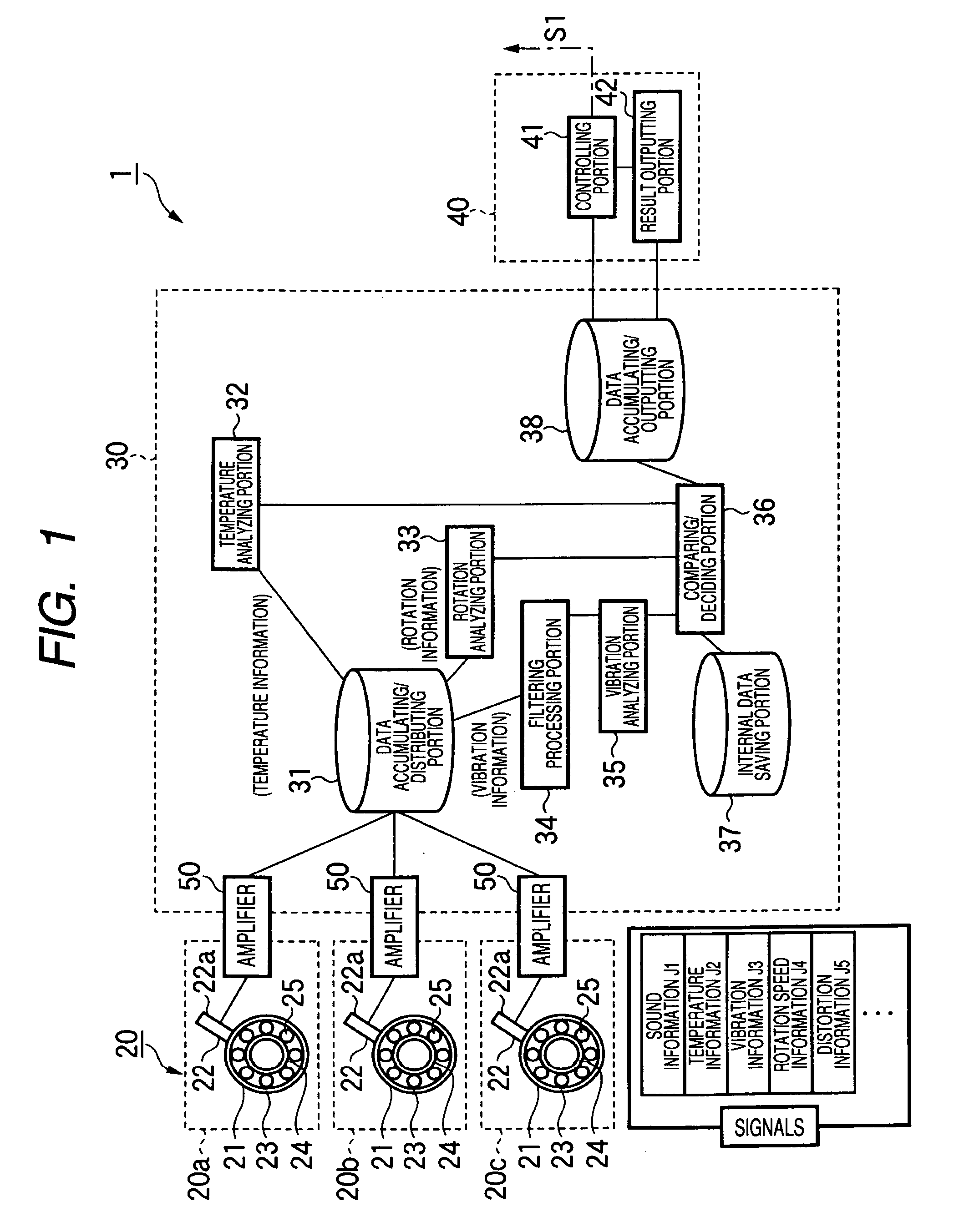

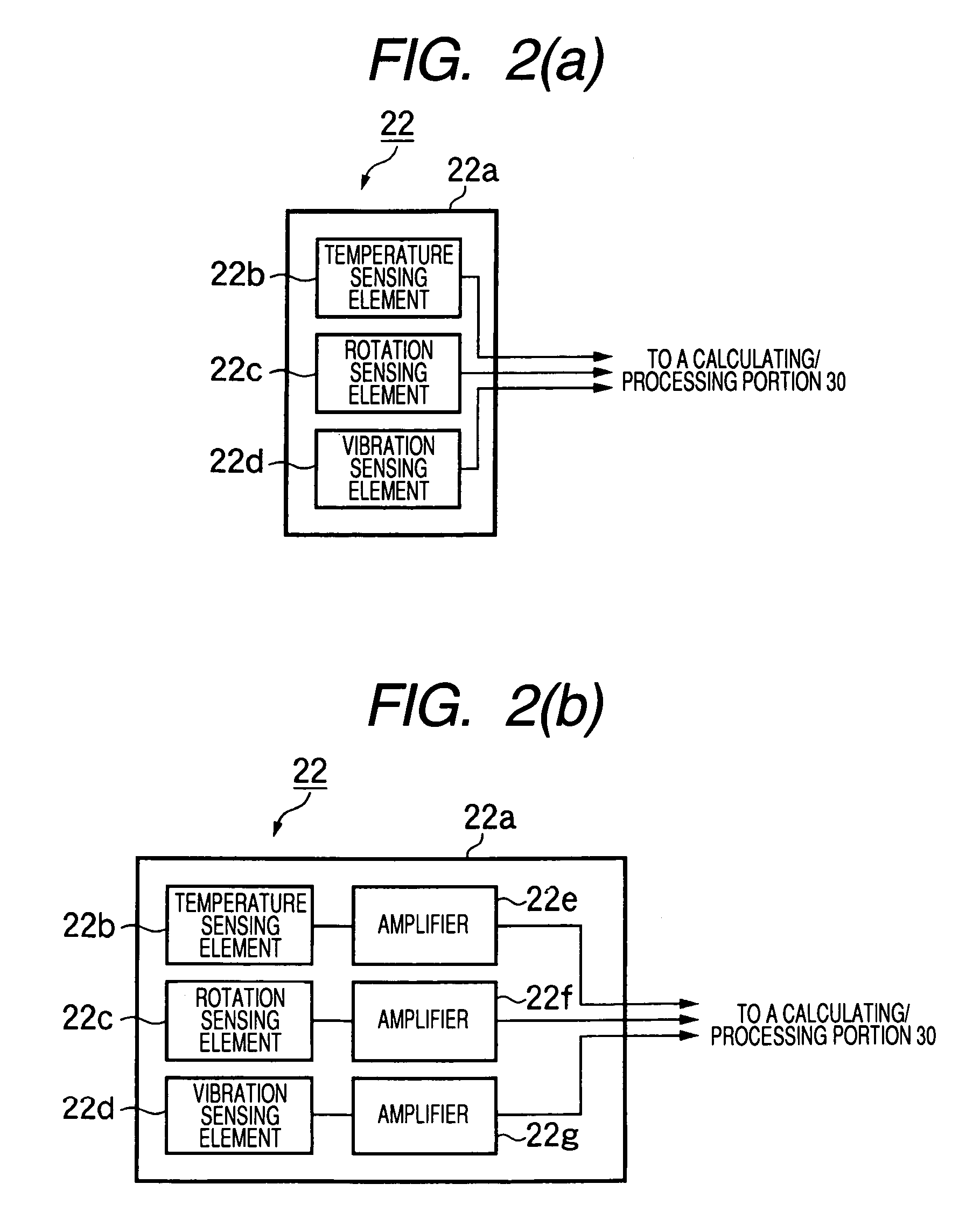

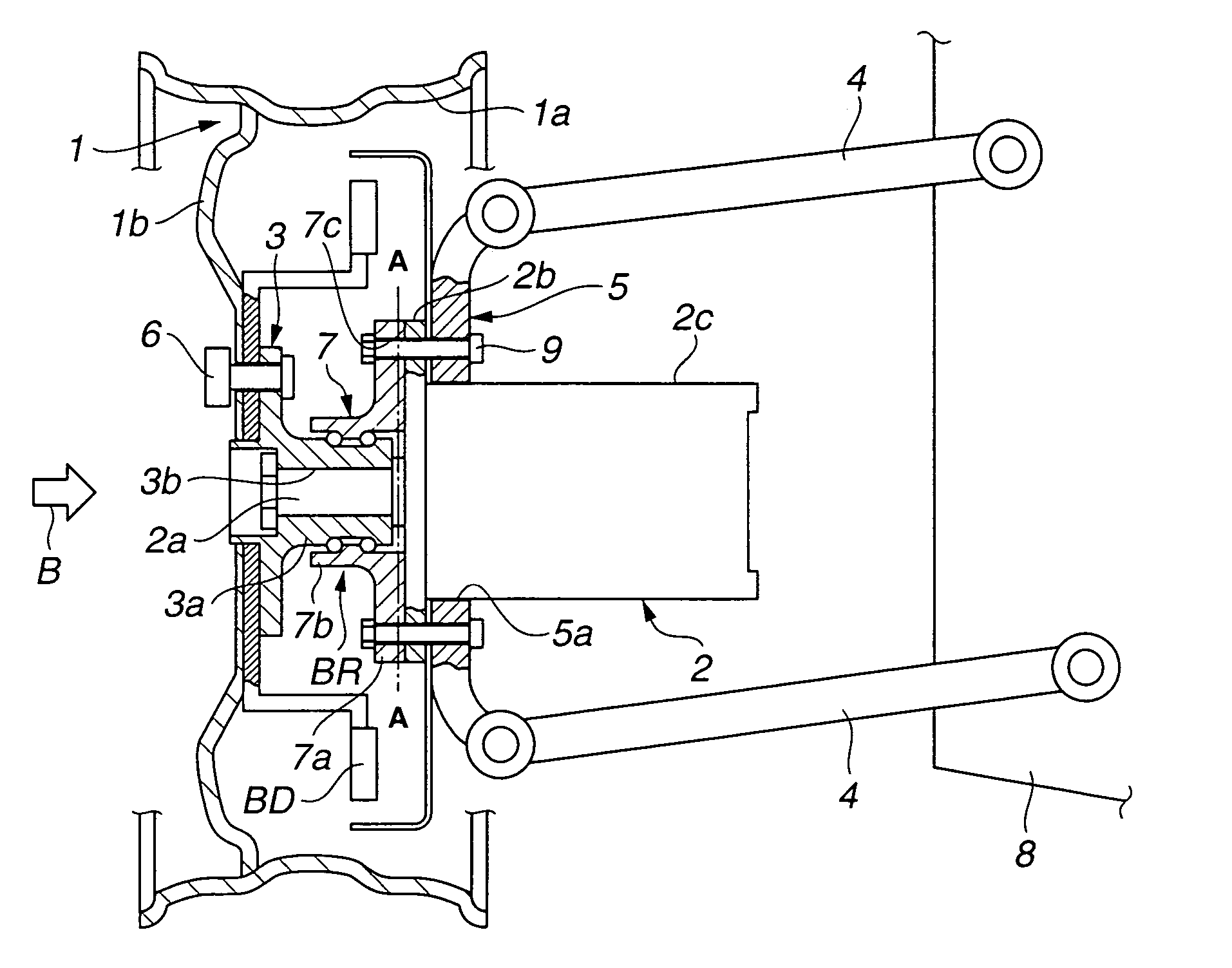

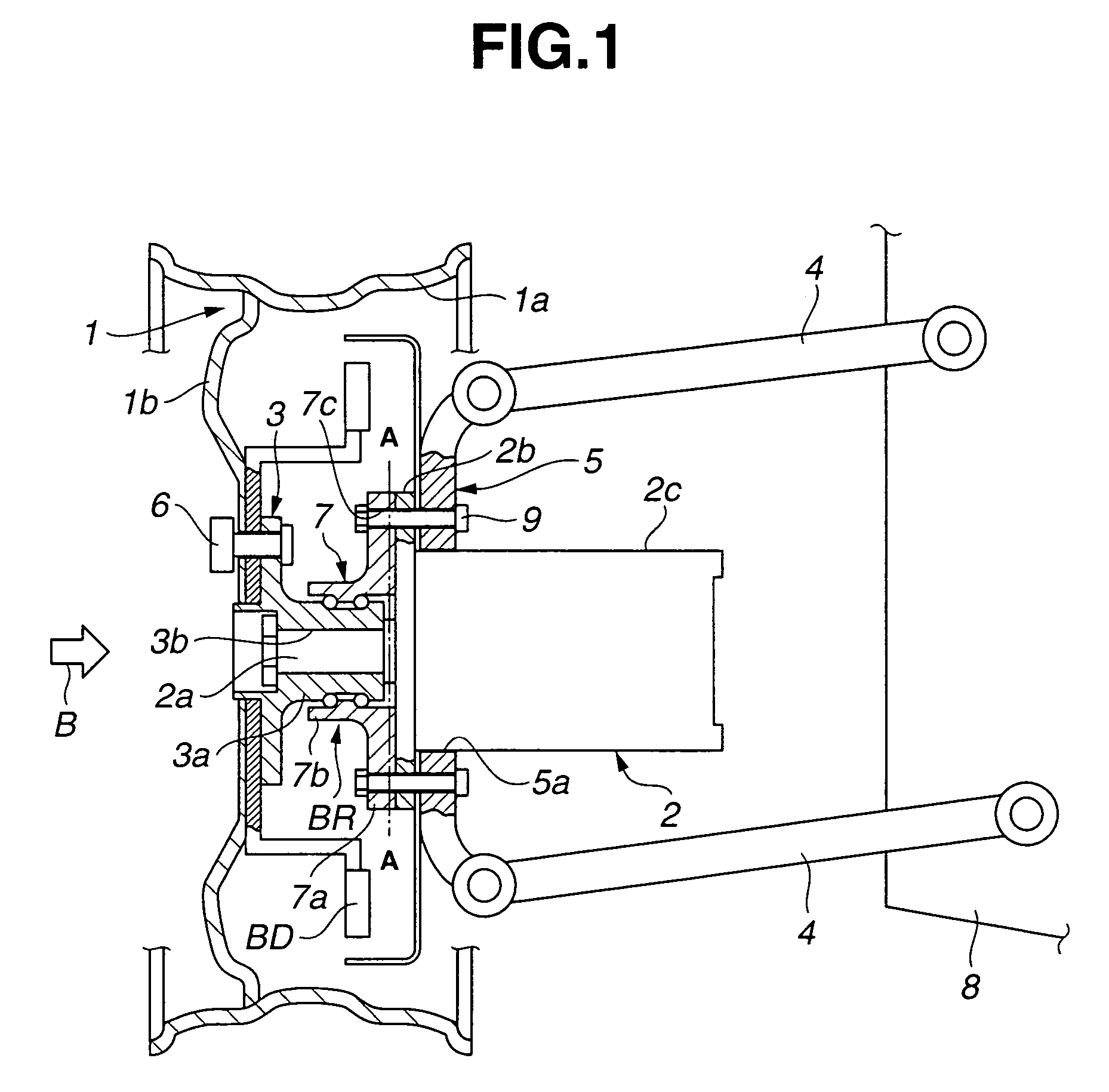

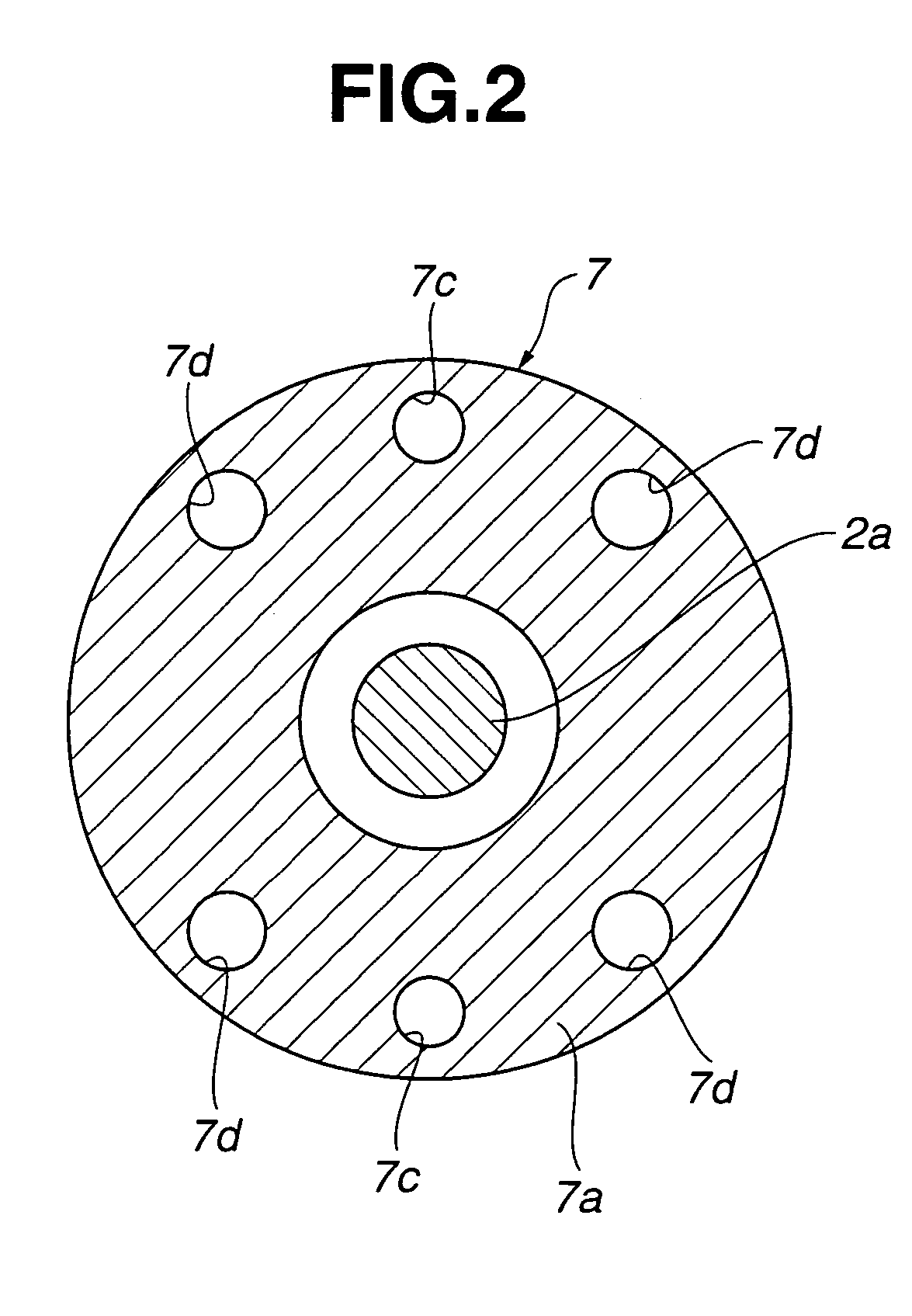

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

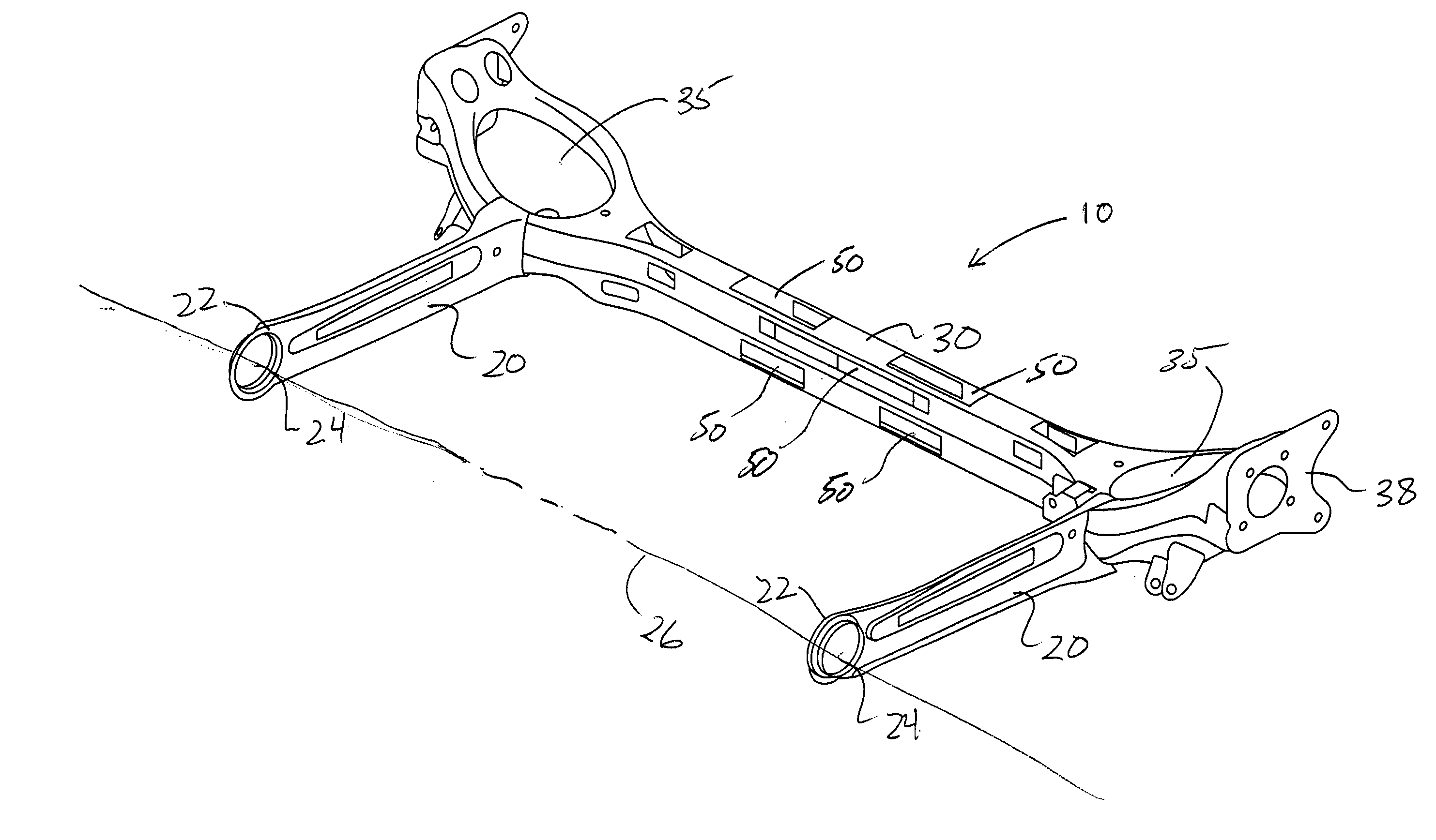

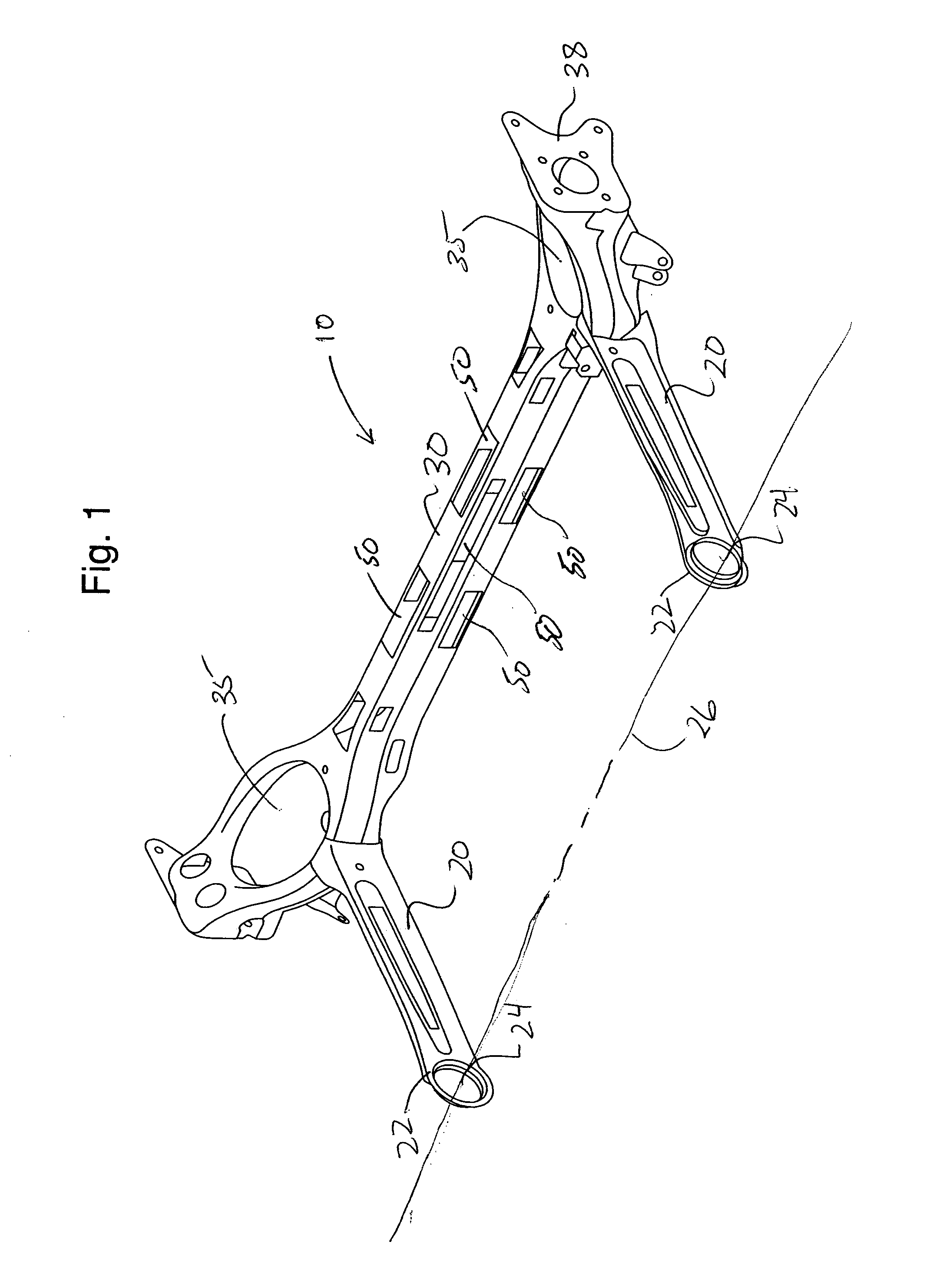

Torsion beam suspension member

A torsion beam suspension member using two u-shaped, stamped members that are superimposed and welded to form a torsion arm. No additional torsion tube or bar is needed. Tuning holes (rectangular, oblong, round or any other suitable shape) are used to change or tune the torsional resilience of the suspension. In the preferred embodiment, the tuning holes are oblong and located near the center of the cross member. The tuning holes are selected based on having target value for torsional compliance or resilience. The size, quantity and location of the tuning hole are chosen based on computer analysis. An optimization or iterative process is used to arrive at the final hole size, quantity and location.

Owner:DANA AUTOMOTIVE SYST GRP LLC

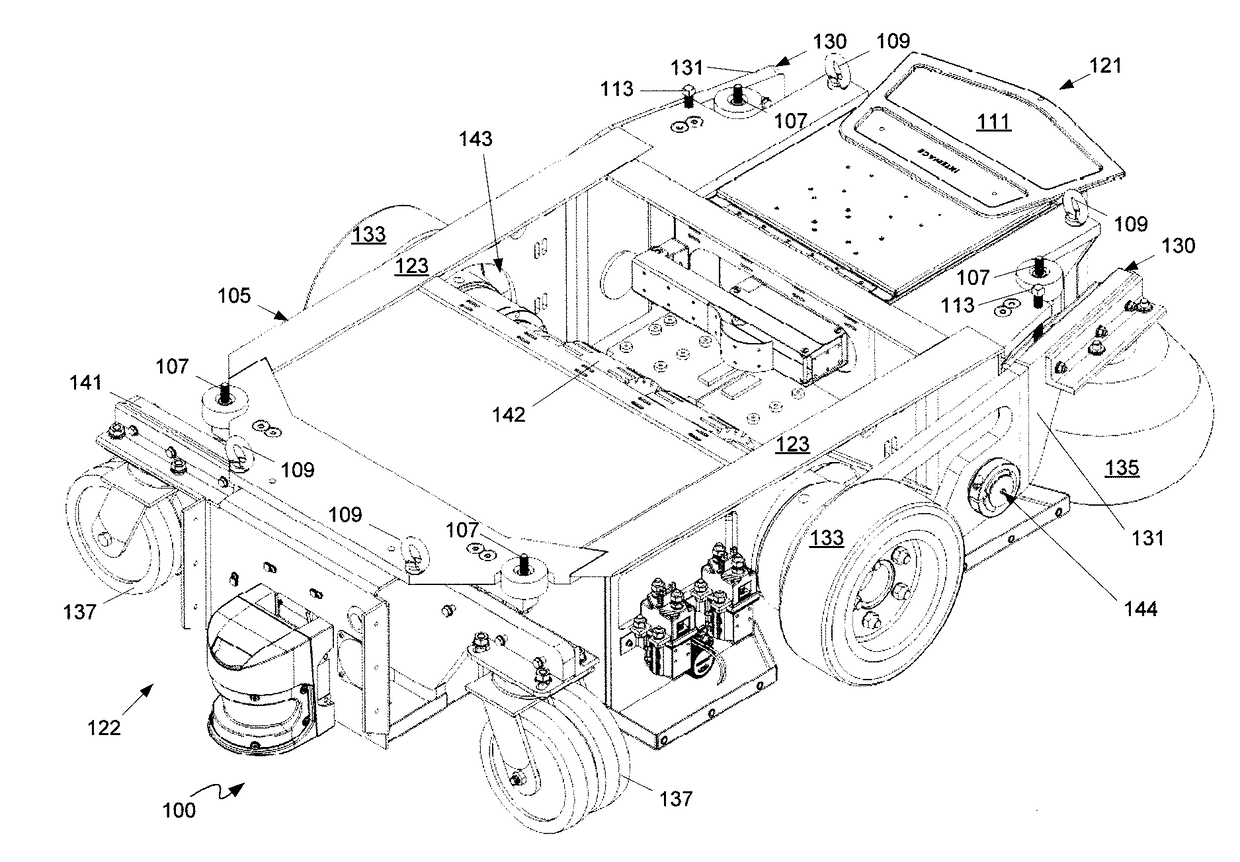

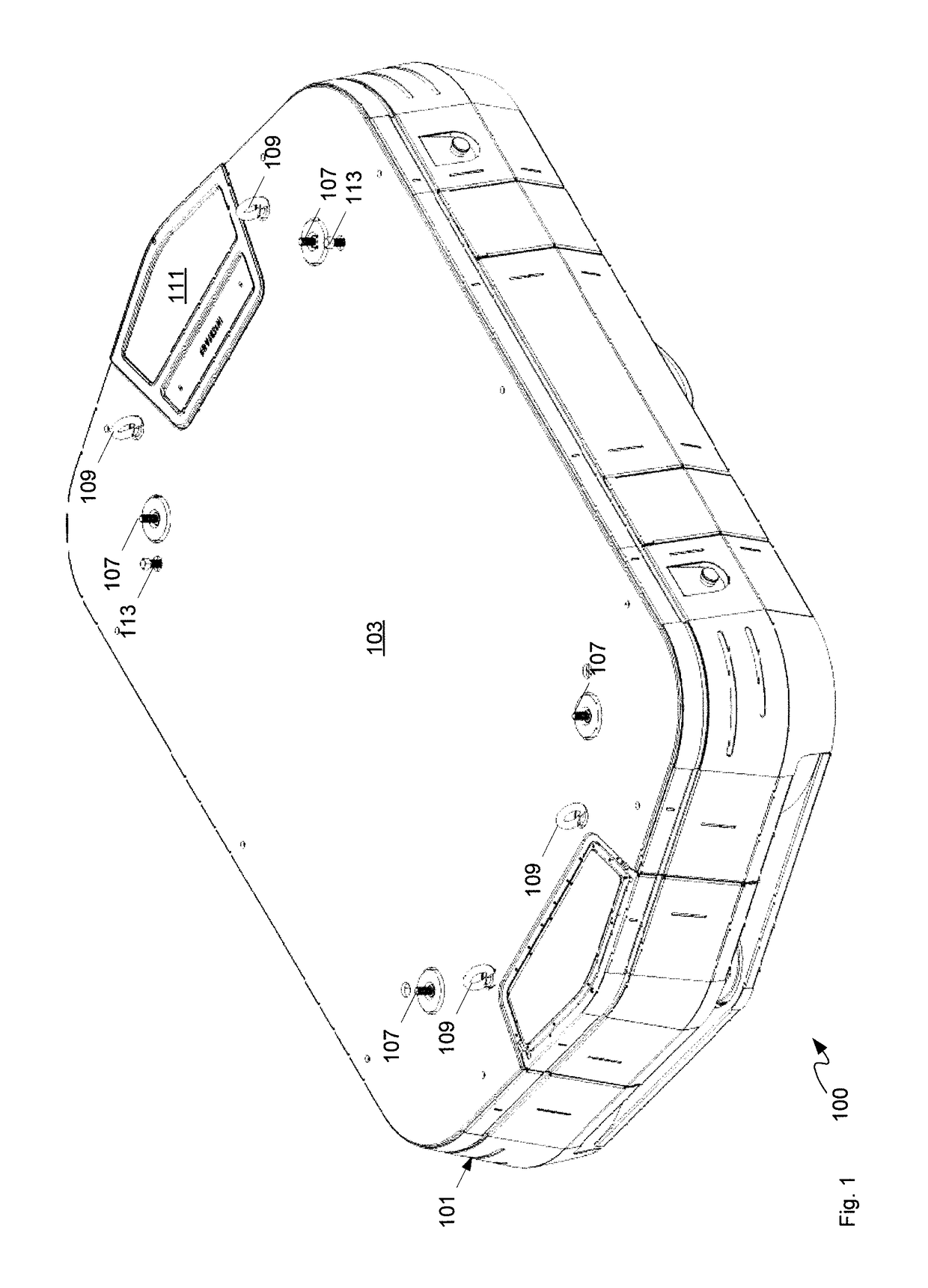

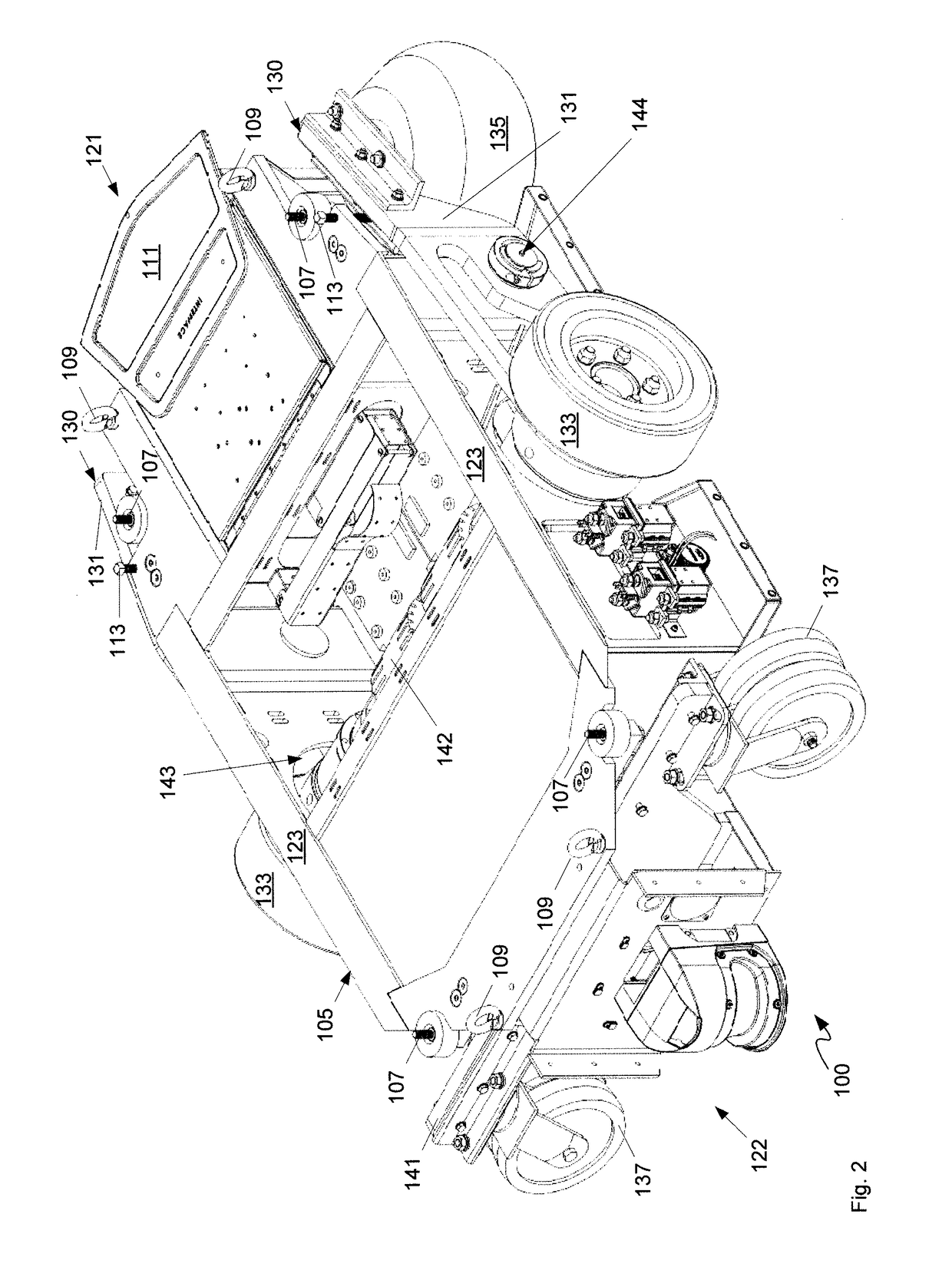

Mobile platform for materials transport

A mobile platform for materials transport is provided. The platform includes a pair of suspension devices that in turn include a pair of rocker beams which can be rotated between two positions: a first position where central wheels attached thereto can be used to drive the platform; and a second position where the central wheels are retracted and the platform can be rolled on end wheels without the friction of the central wheels, and an associated drive system, impeding movement of the platform. Furthermore, data from sensors and / or load cells can be used to control movement of the platform; specifically, shifts in load distribution and / or sensed forces at the suspension devices can indicate that a load (and / or materials) has shifted and / or is shifting and movement of the platform is adjusted accordingly, for example to prevent the platform and / or the load (and / or materials) from tipping.

Owner:CLEARPATH ROBOTICS

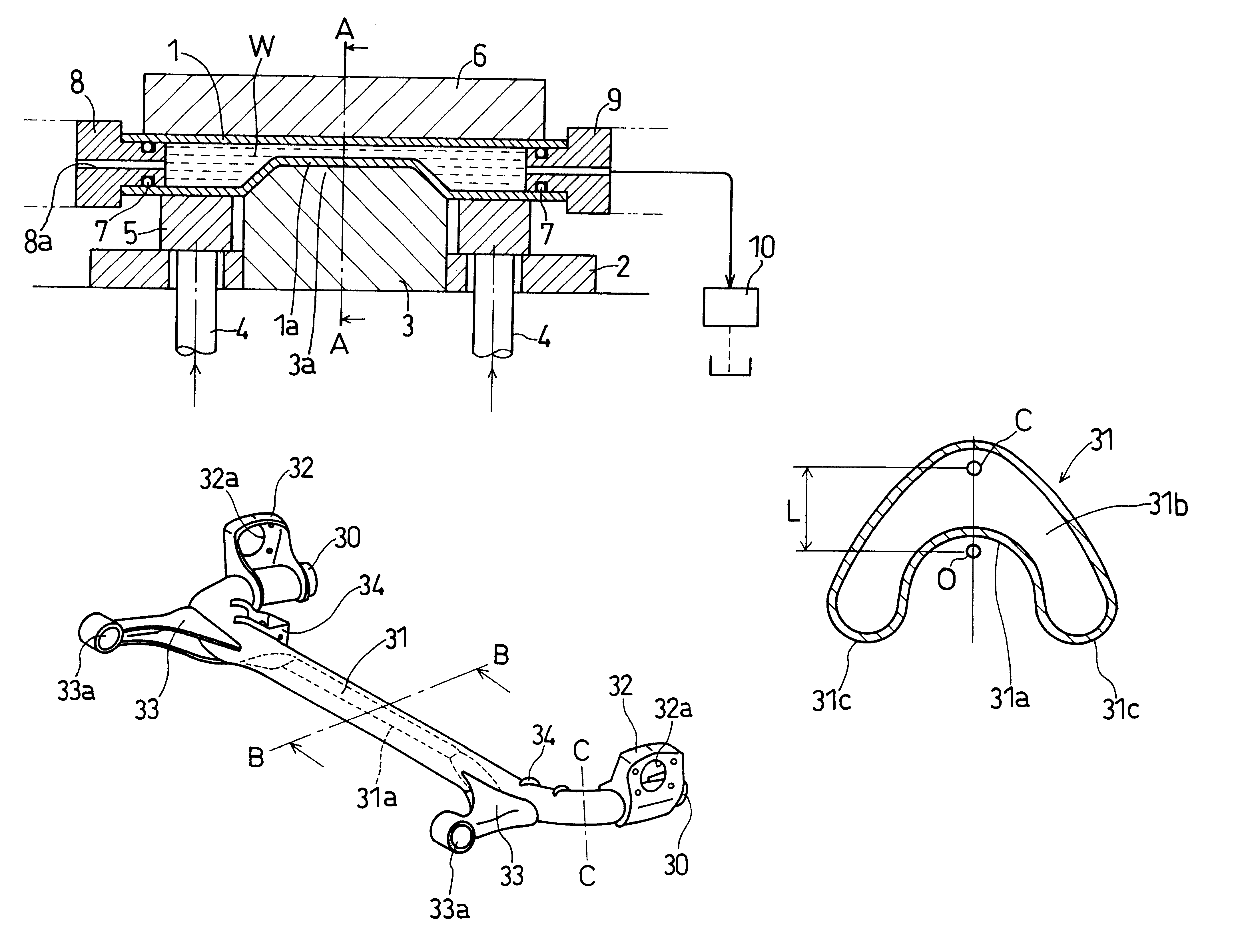

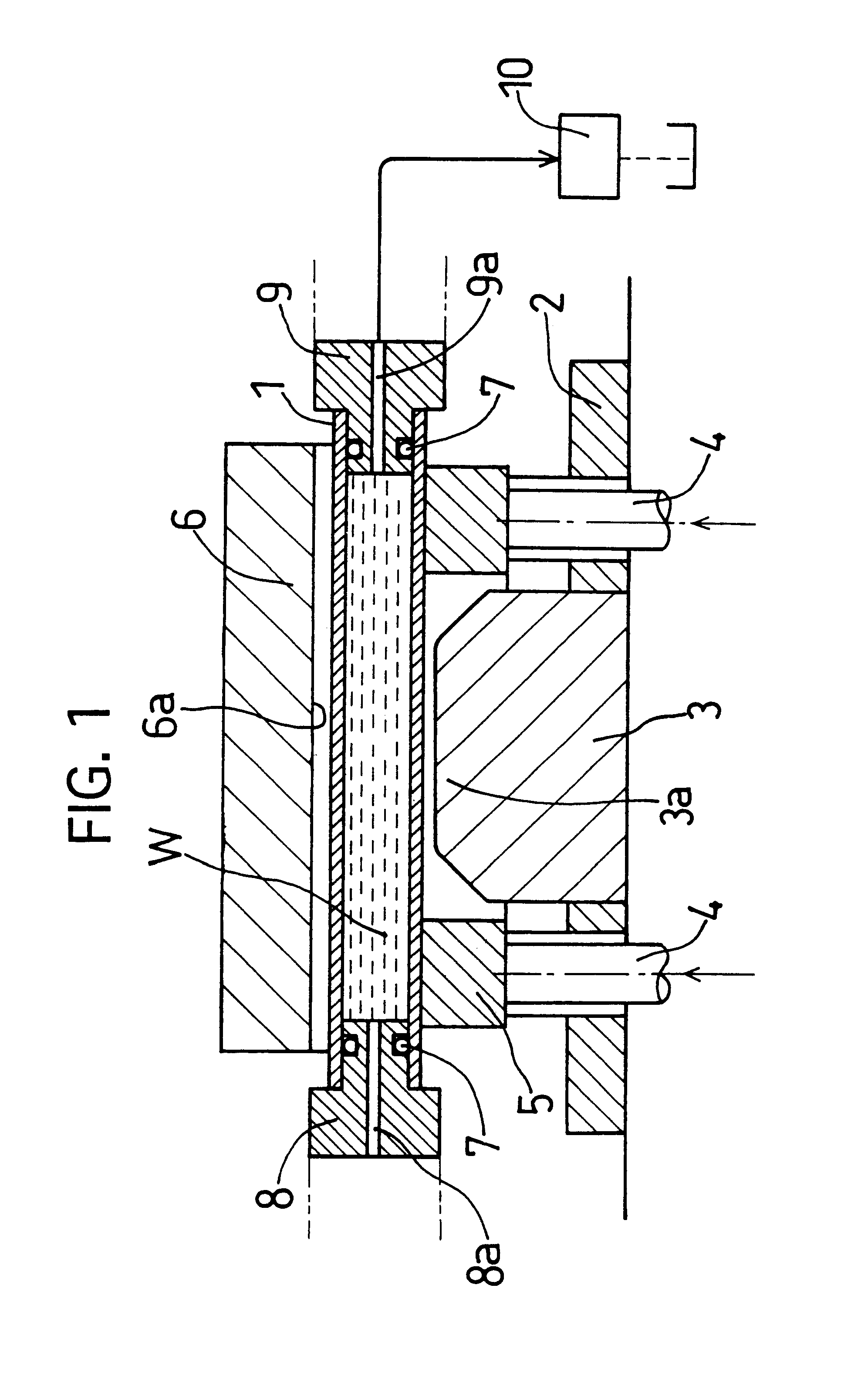

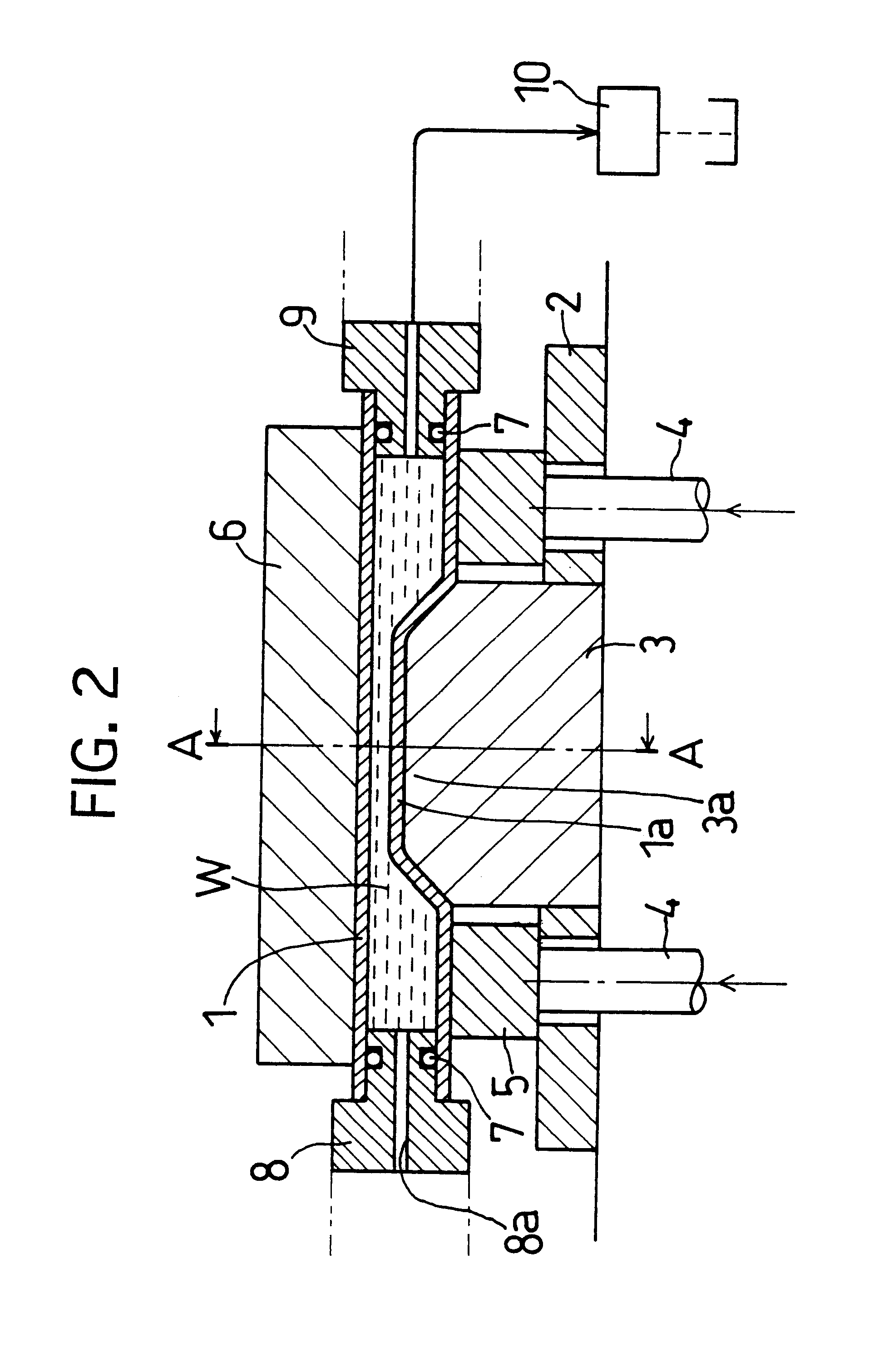

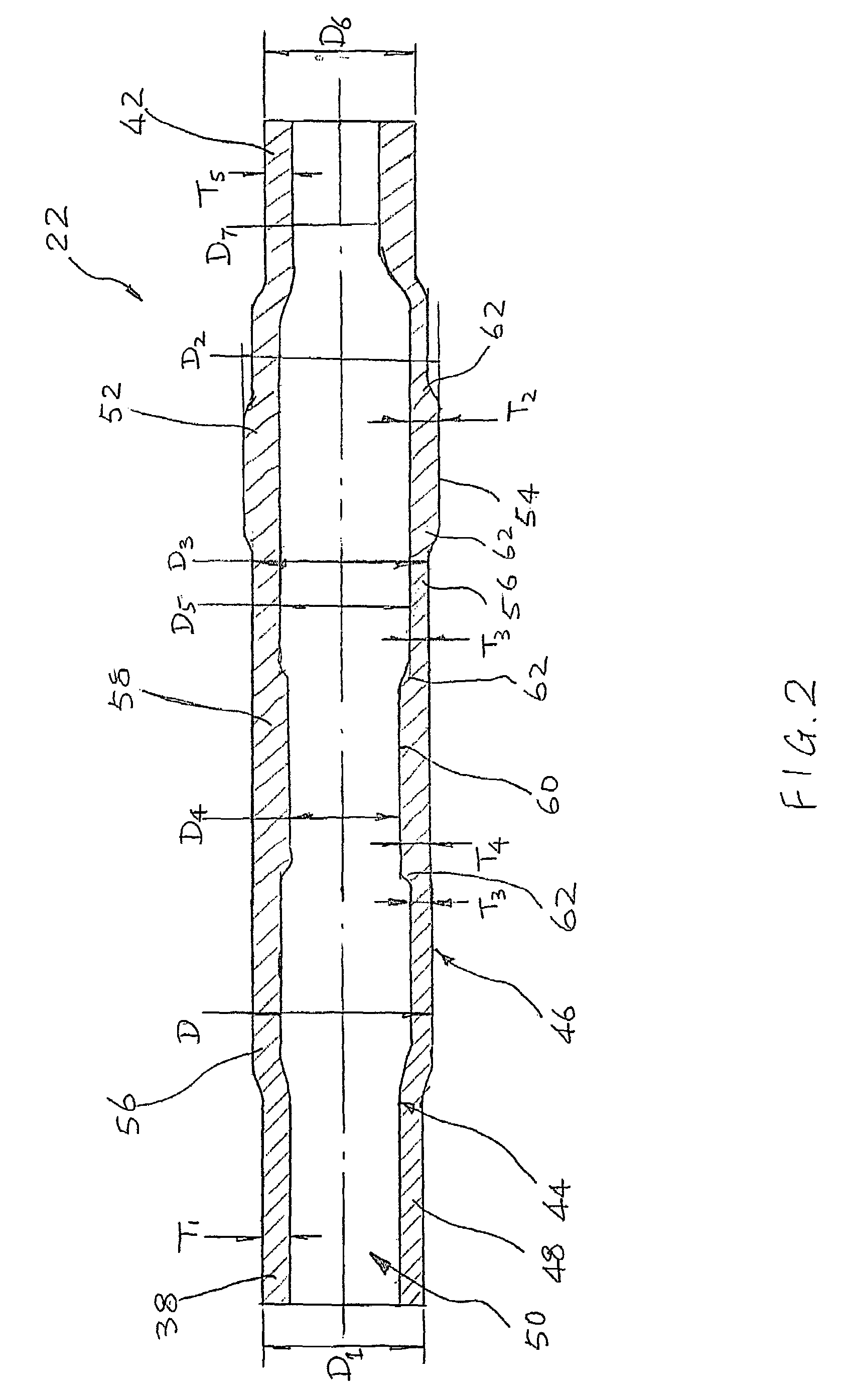

Irregular-section tubular body and axle beam for torsion beam and method of manufacturing the same

The invention provides a method of manufacturing an irregular section tubular body and axle beam. The axle beam has a tubular worked body that has sealed liquid therein and is press-formed by upper and lower press molds. One of the press molds has a convex mold portion to form a concave portion concaved in an axis perpendicular direction at an axial part of the axle beam. The press-forming of the tubular worked body is completed by a one stroke process using liquid pressure that increases as the internal volume of the worked body decreases due to formation of the concave portion. The concave portion extends substantially the length of the axle beam and has a substantially U-shaped or V-shaped cross-section forming a closed and sealed space.

Owner:TOYOTA JIDOSHA KK

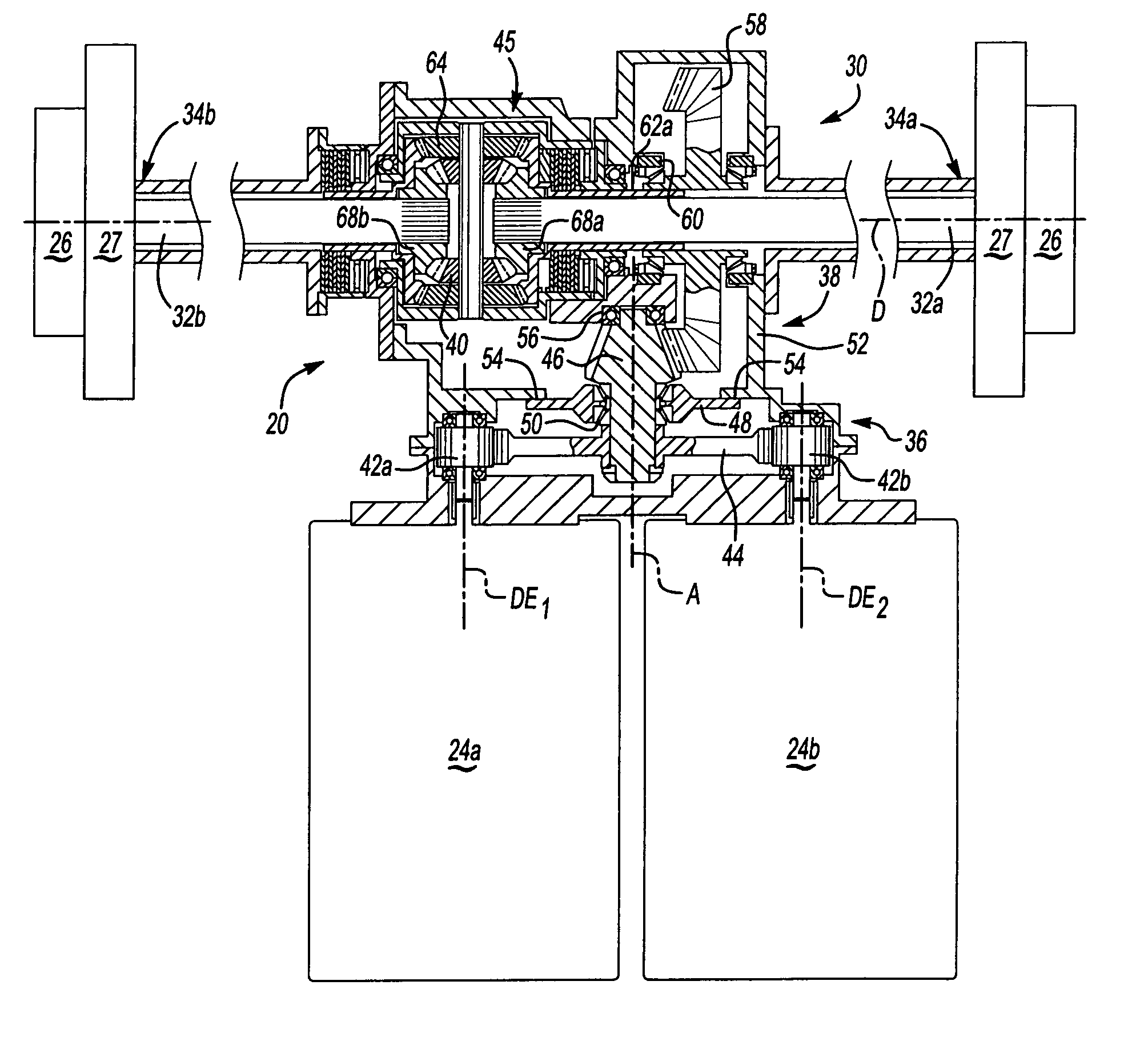

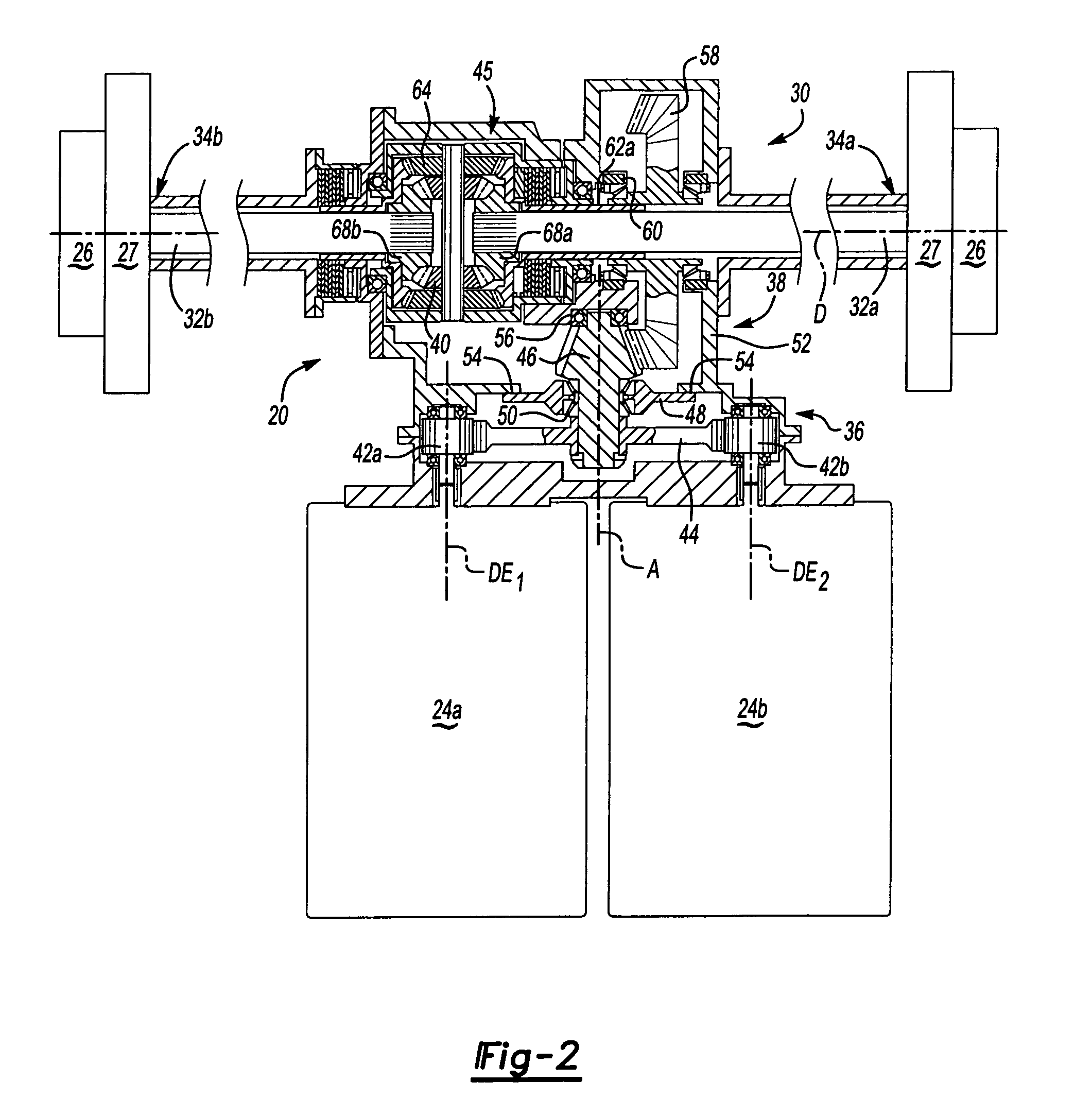

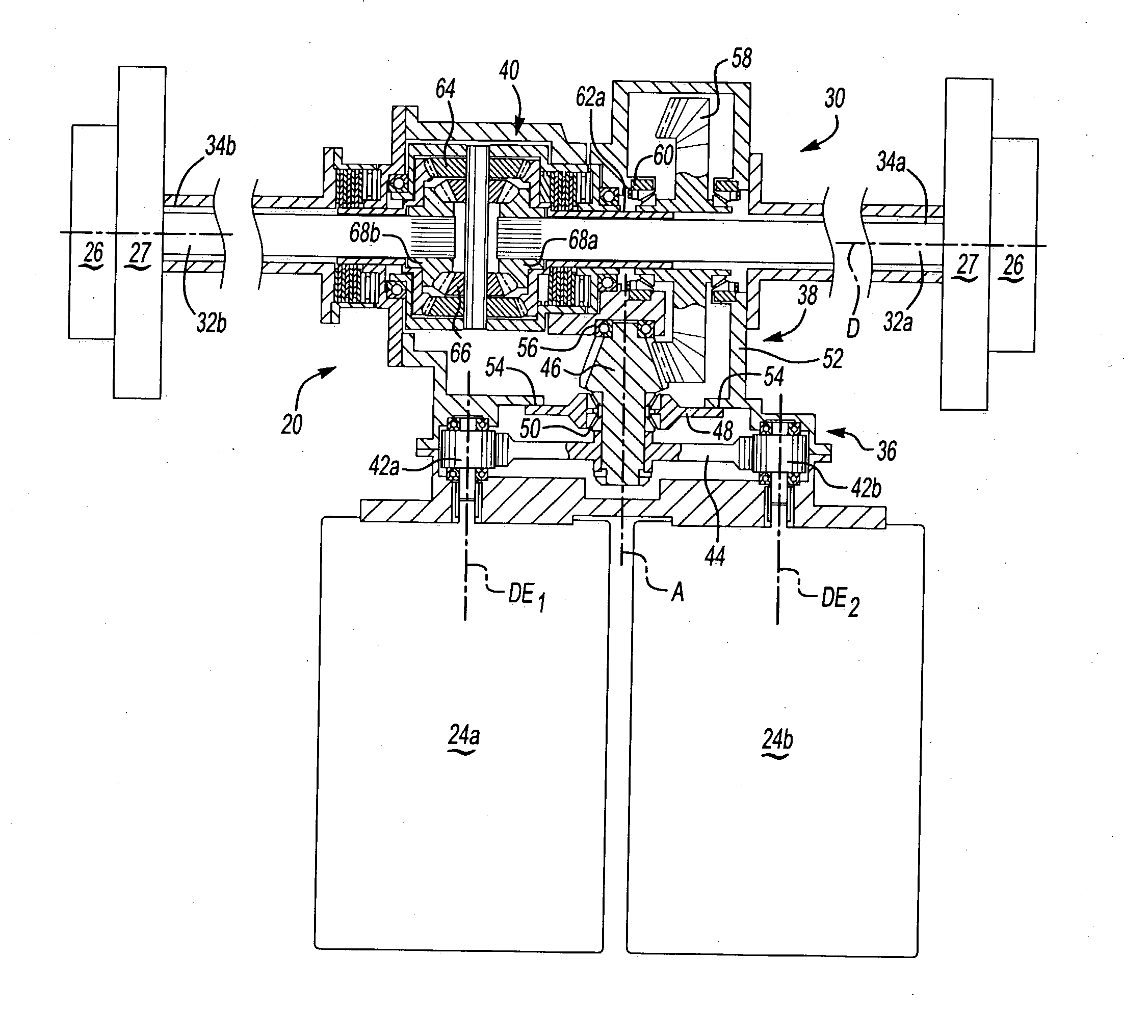

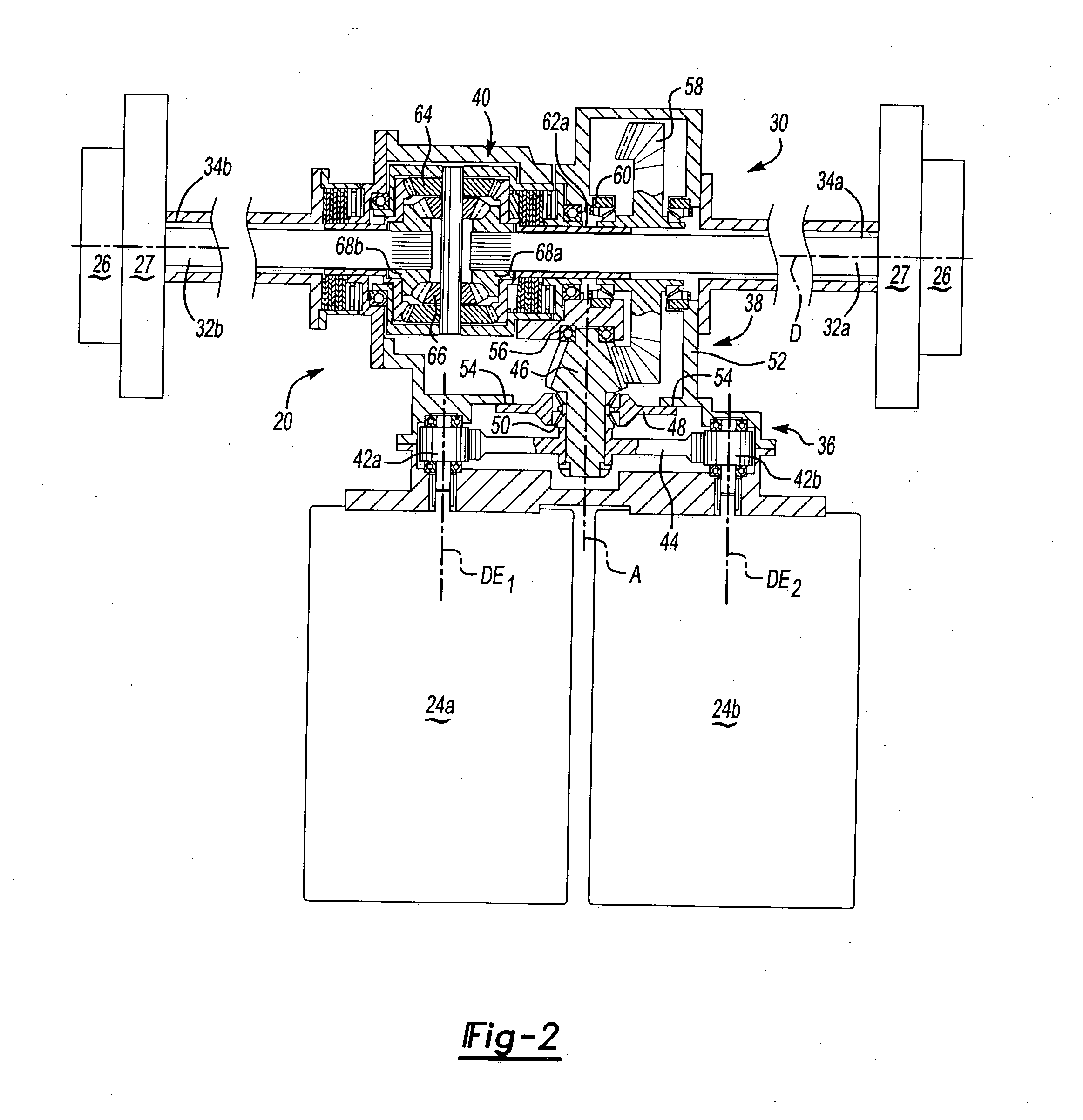

Axle assembly with transverse mounted electric motors

InactiveUS7028583B2Small sizeAllow useOff-road vehiclesTransmission elementsReduced sizeAutomotive engineering

An axle assembly includes a first and a second electric motor which drive a gearbox assembly substantially therebetween. The electric motors drive the gearbox assembly which drives the vehicle wheels through a first and second axle shaft located along a first axis. The electric motors are located along axes which are substantially transverse to the first axis. The electric motors drive the gearbox assembly which includes a first stage gear reduction, a second stage gear reduction and a third stage gear reduction. A relatively lightweight and compact axle assembly is thereby provided which will benefit from an electric motor of reduced size.

Owner:ARVINMERITOR TECH

Plastic wheel assembly and mounting sleeve with stabilizing recess

Owner:GEO PLASTICS

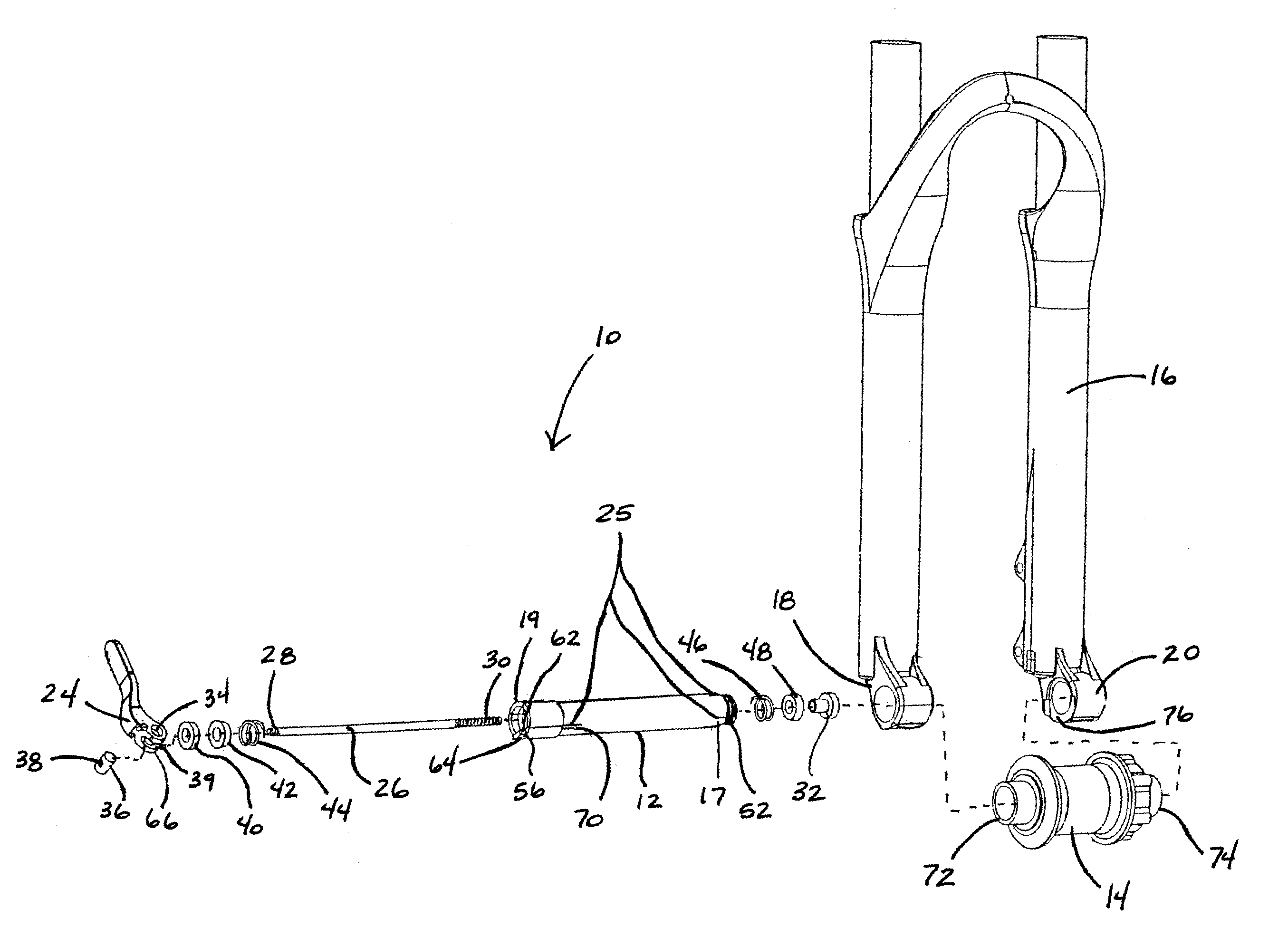

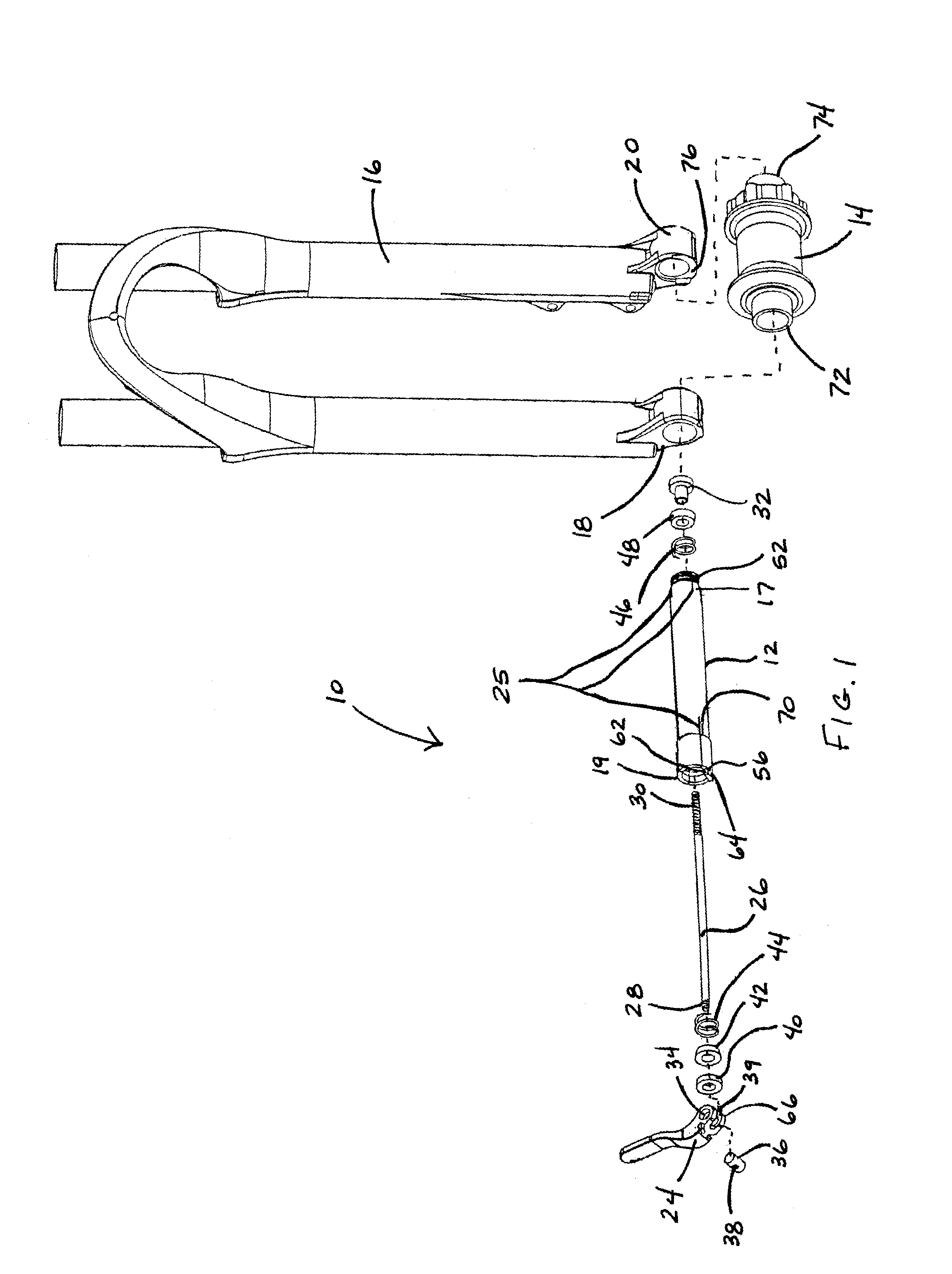

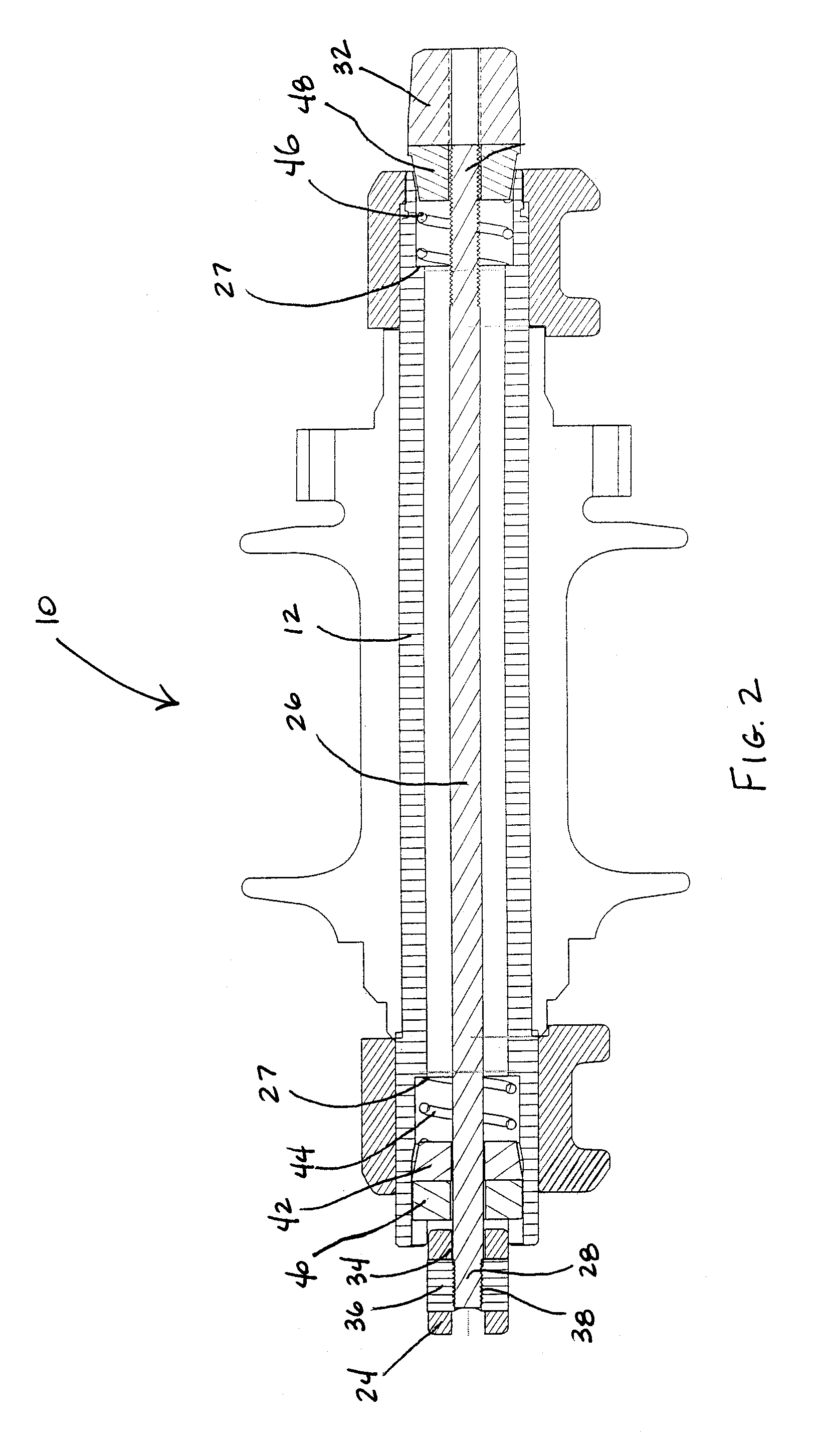

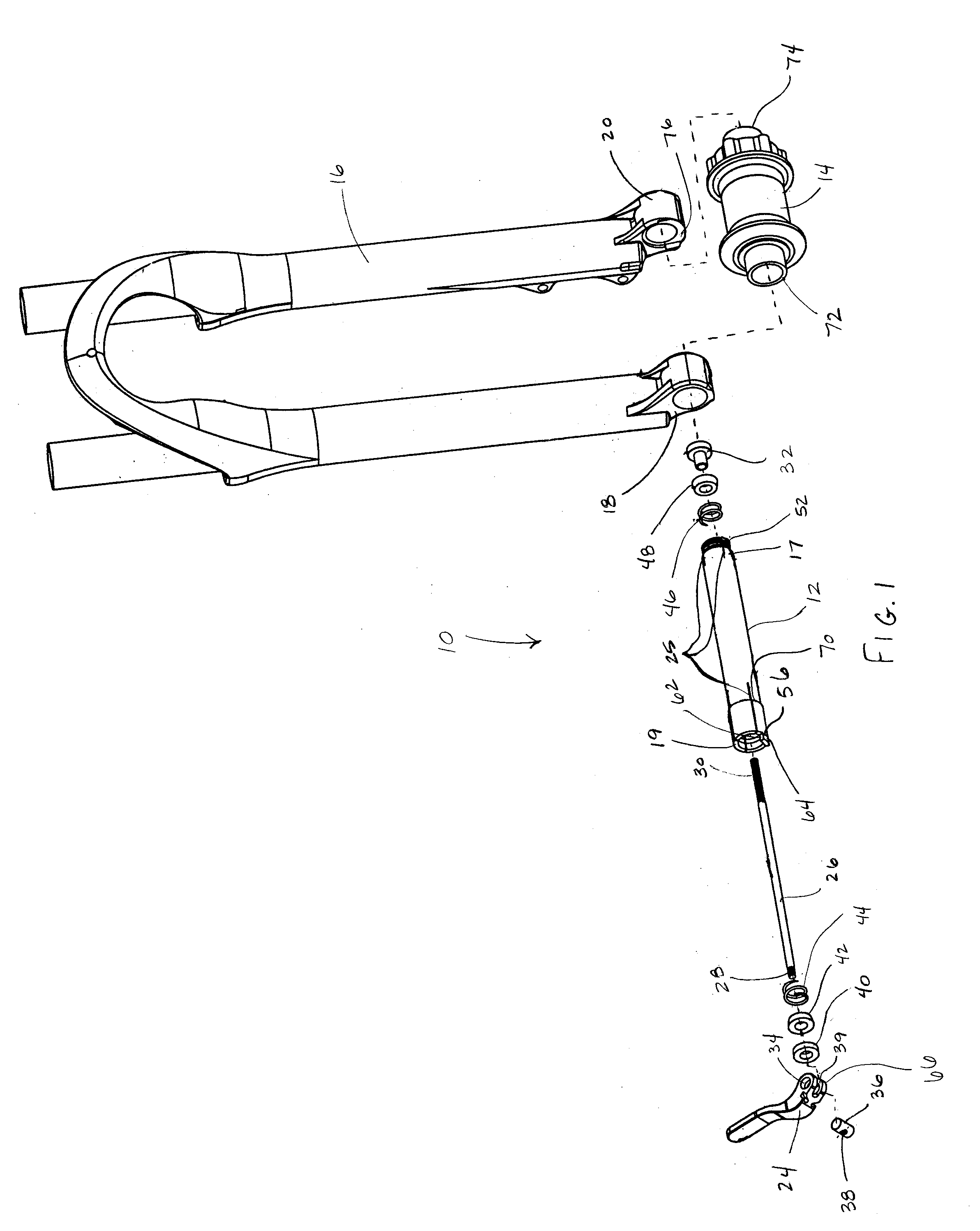

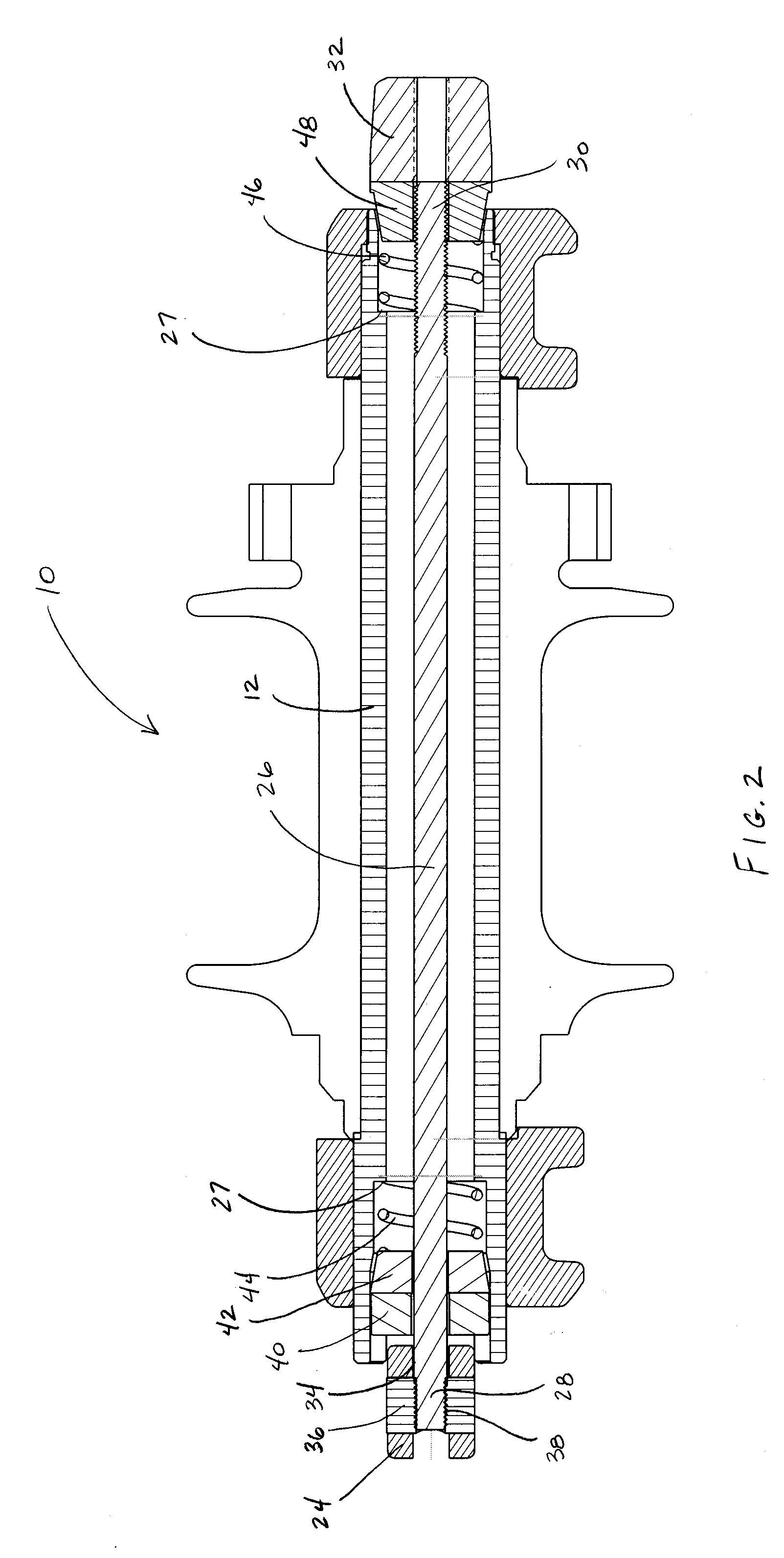

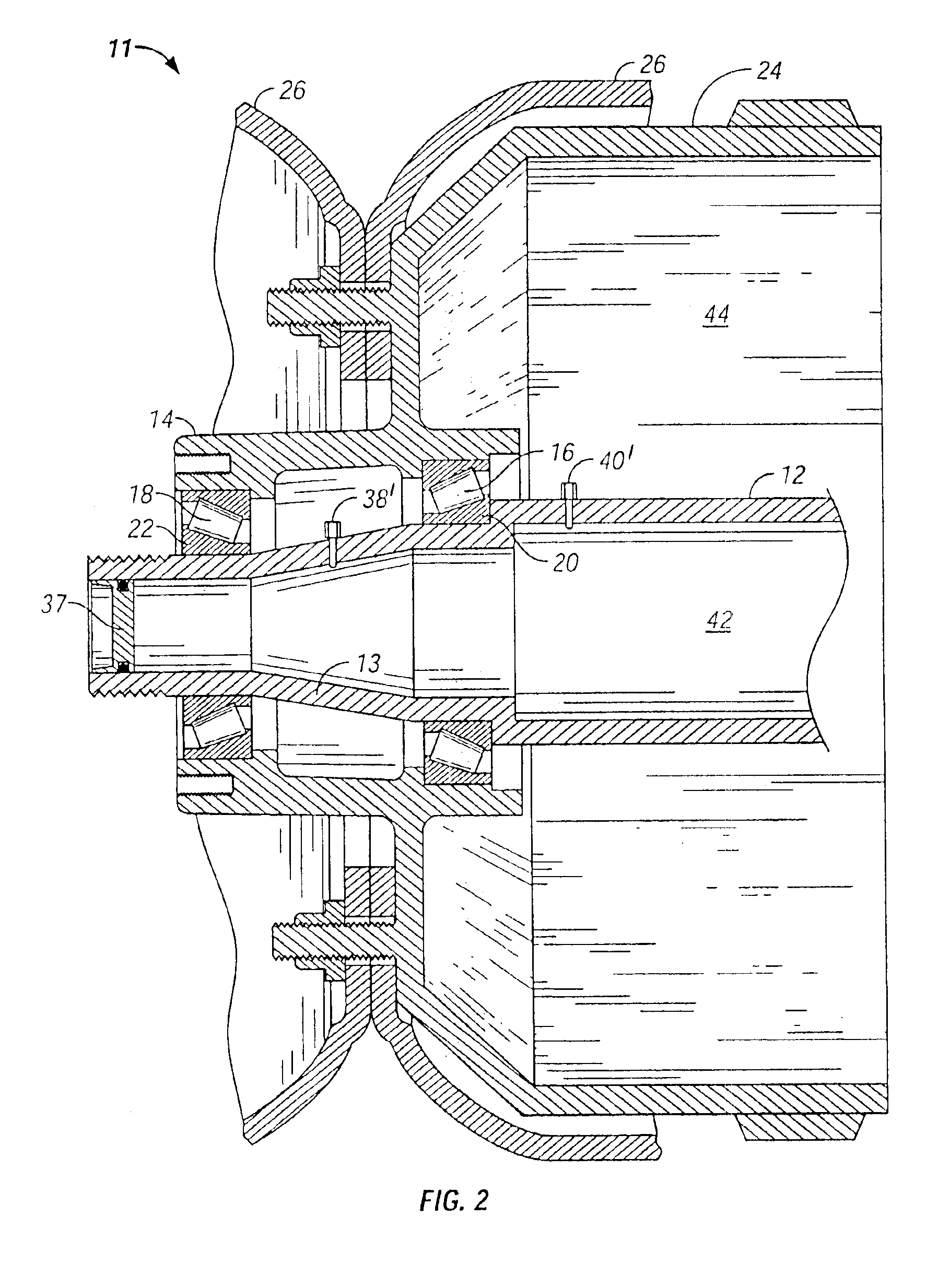

Axle assembly for mounting a wheel to a vehicle

An axle assembly connecting a wheel assembly to a vehicle frame. The axle assembly includes a tubular body having first and seconds connectable to the vehicle frame and open-ended slots disposed proximate at least one of the first and second ends of the tubular body. An expansion element is engageable with the tubular body to radially deform the tubular body at a mounting point to the vehicle frame. This configuration provides a rigid connection between the axle assembly and the vehicle frame in both the linear and radial directions.

Owner:SRAM CORPORATION

Axle assembly for mounting a wheel to a vehicle

ActiveUS20050110335A1Torsional stiffness sufficientSolve the lack of stiffnessHubsAxle suspensionsVehicle frame

An axle assembly connecting a wheel assembly to a vehicle frame. The axle assembly includes a tubular body having first and seconds connectable to the vehicle frame and open-ended slots disposed proximate at least one of the first and second ends of the tubular body. An expansion element is engageable with the tubular body to radially deform the tubular body at a mounting point to the vehicle frame. This configuration provides a rigid connection between the axle assembly and the vehicle frame in both the linear and radial directions.

Owner:SRAM CORPORATION

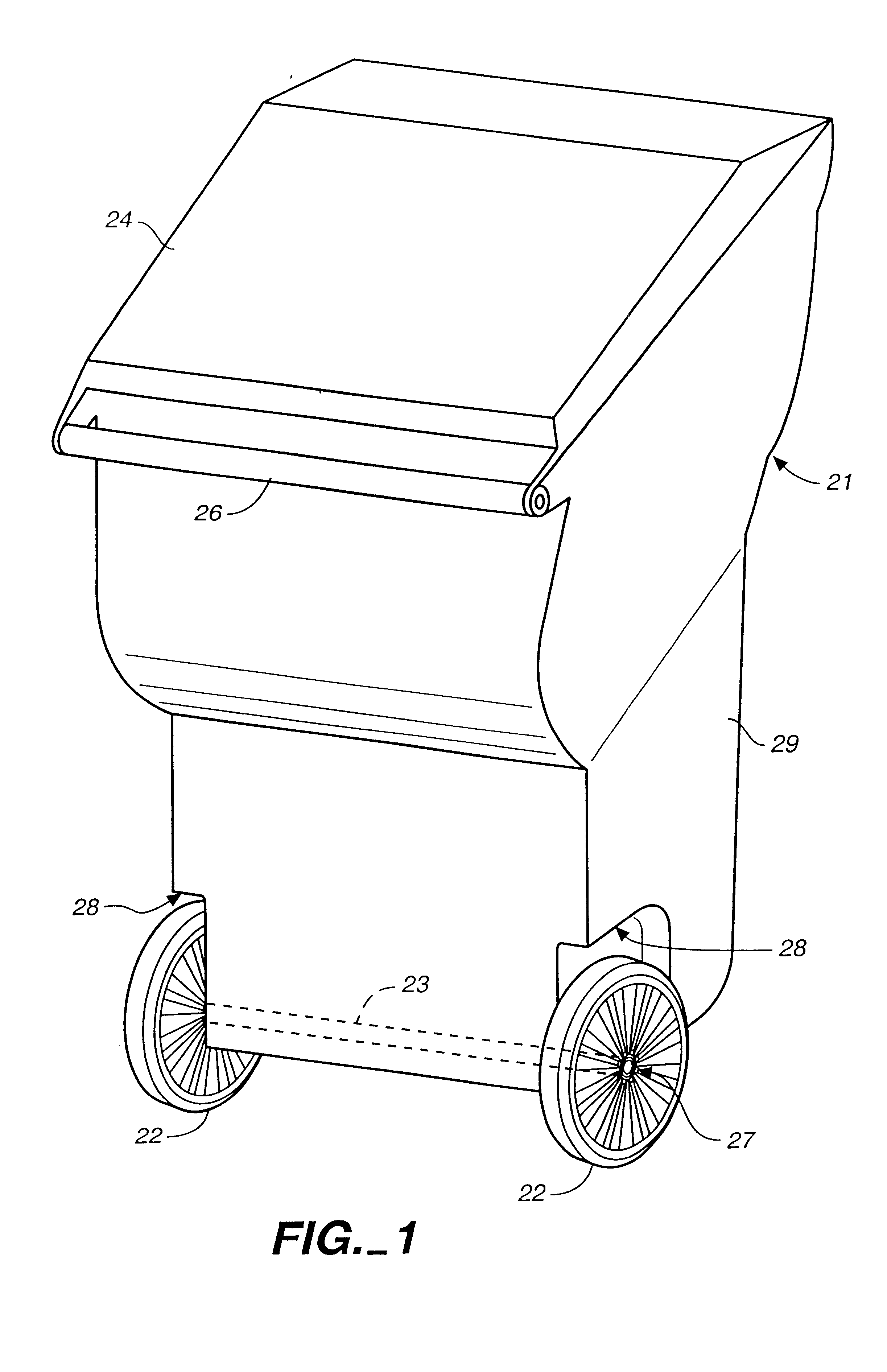

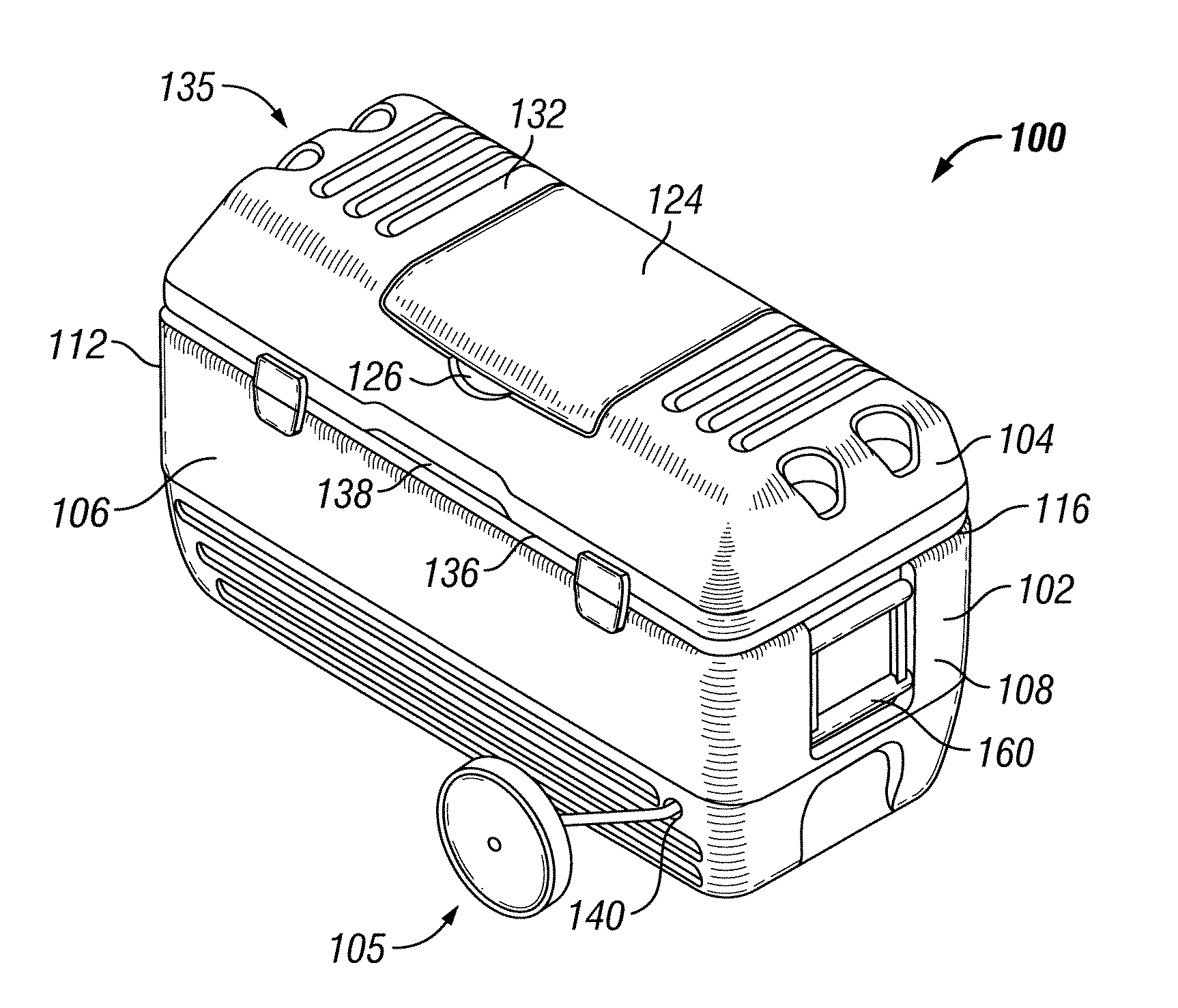

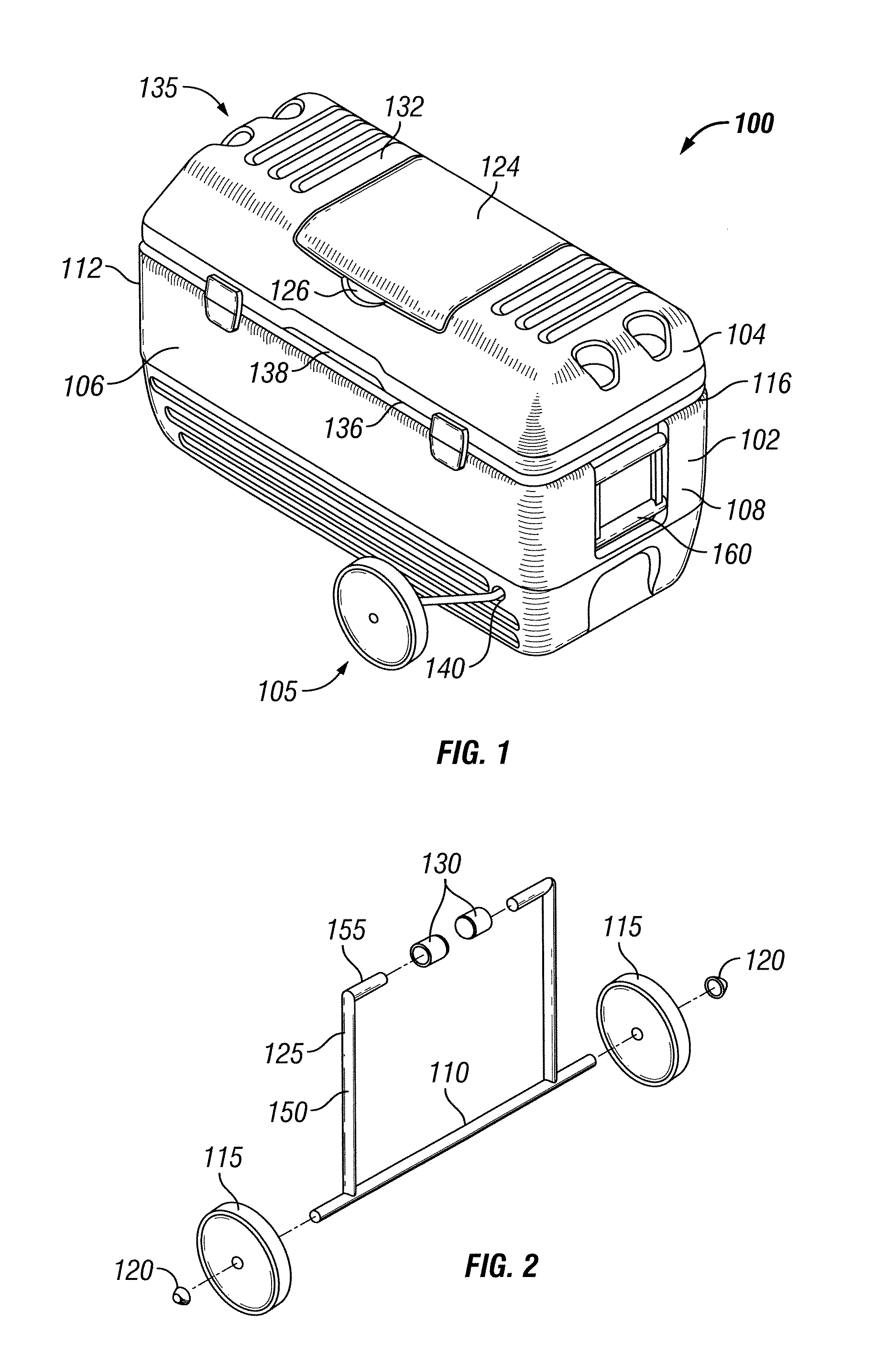

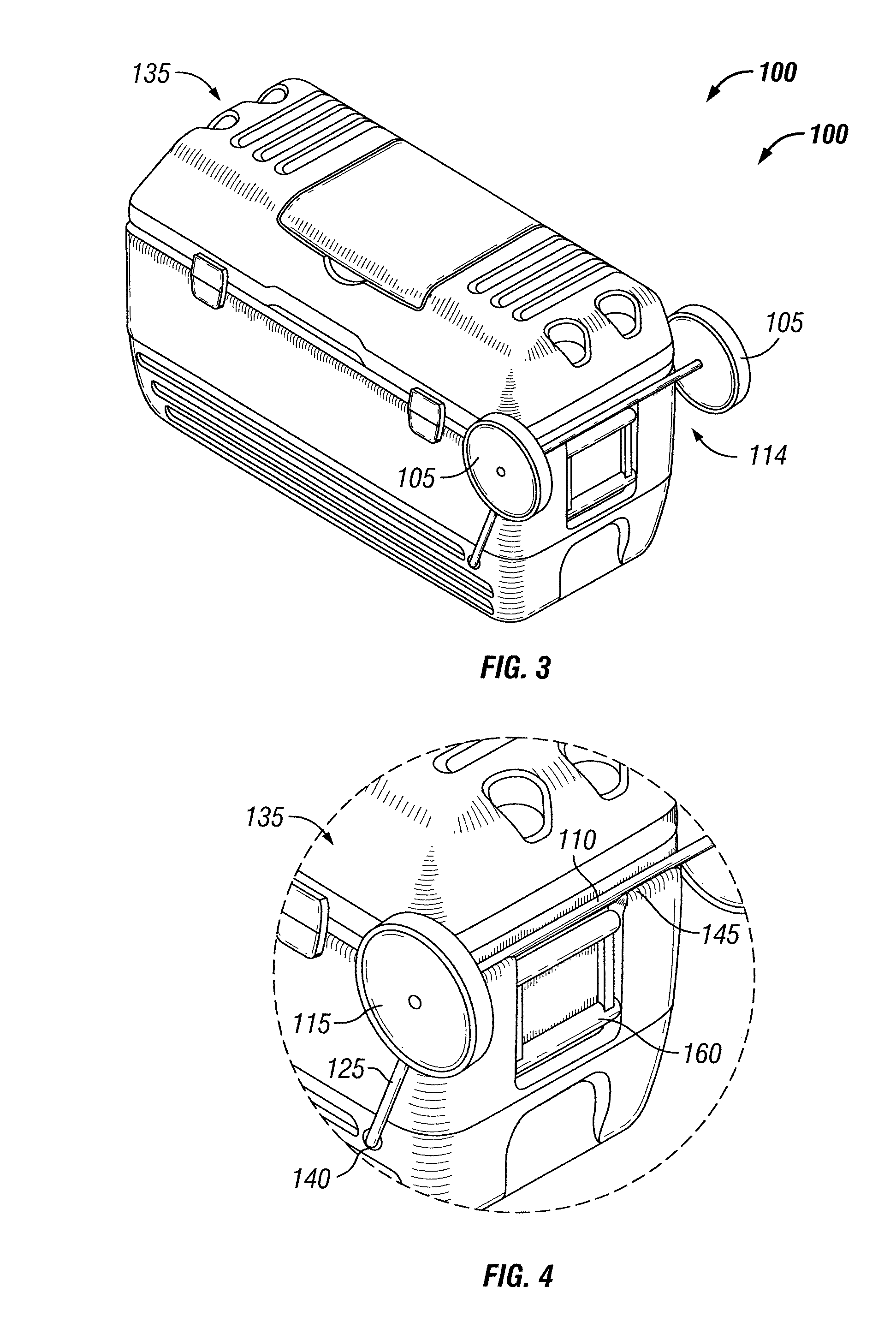

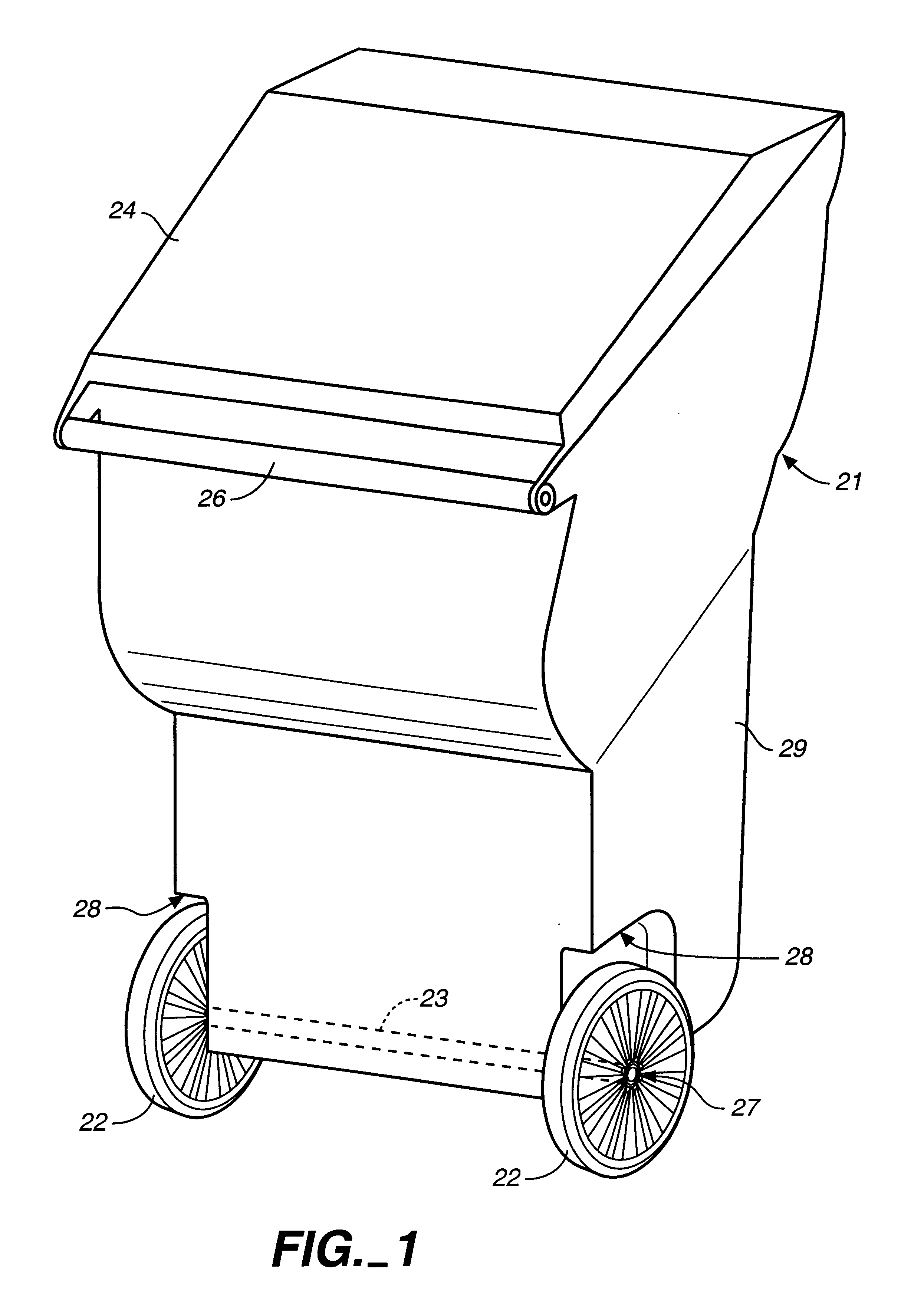

Rotatable wheel assembly for coolers

InactiveUS20080001373A1Increase distanceReducing unstable natureCarriage/perambulator with single axisLighting and heating apparatusRest positionEngineering

The rotatable wheel assembly includes an axle and wheels. Mounting arms with mounting pins or L-shaped rods are coupled to the axle and may include end caps covering portions of the mounting pin or rod. The mounting pin or end cap is inserted into a receptacle on opposing sides of a cooler. Alternatively, the mounting arms may have an eyelet that may be rotatably coupled to a mounting stud on each side of the cooler. The assembly may be placed in a resting or rolling position along the cooler body. In the resting position, the assembly rests or snaps into a groove along the side of the cooler and out of contact with the surface. The assembly can be rotated from the resting position to a rolling position with the axle positioned under the cooler and the wheels in contact with the surface to assist in transporting the cooler.

Owner:IGLOO PROD CORP

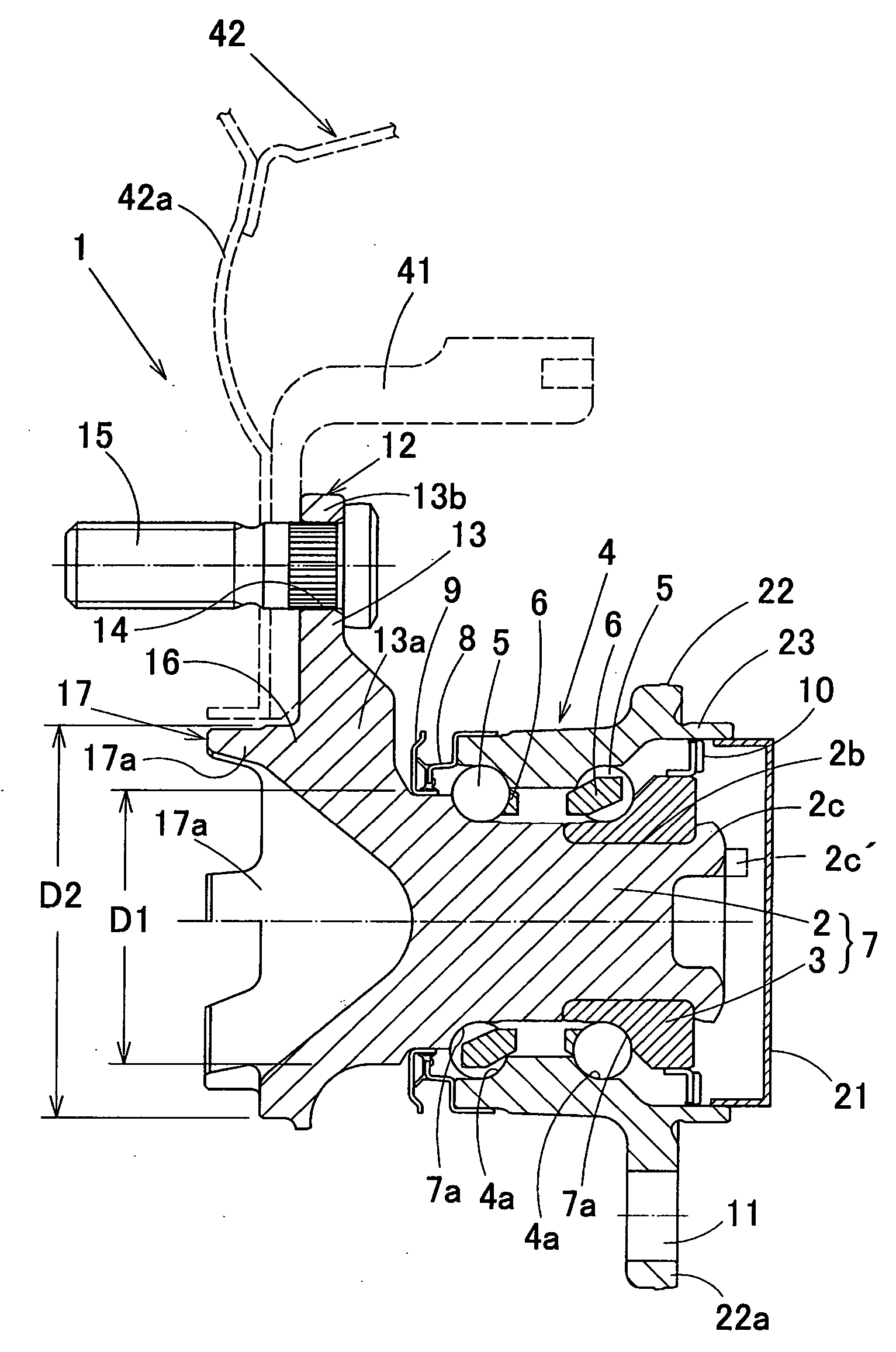

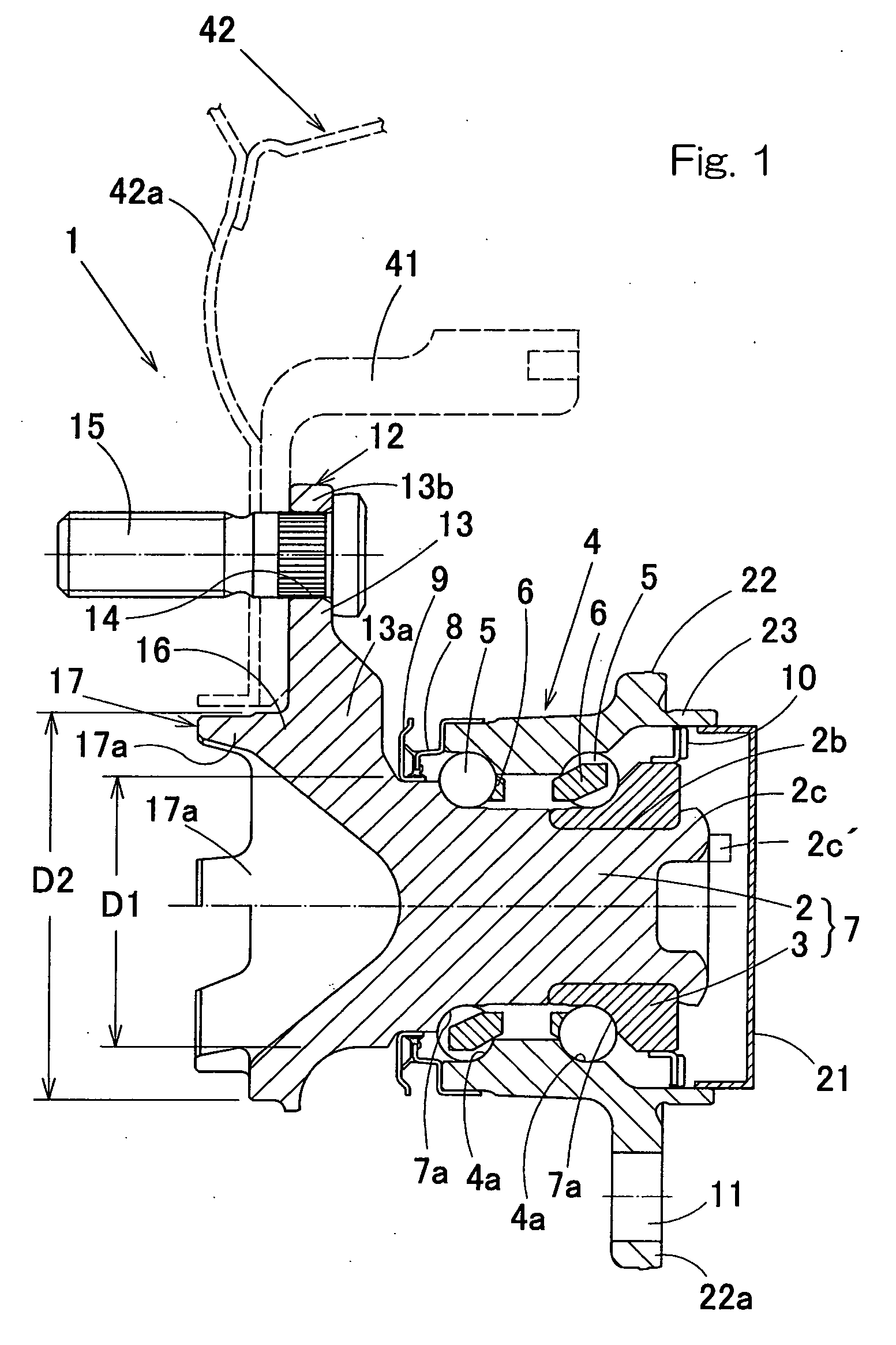

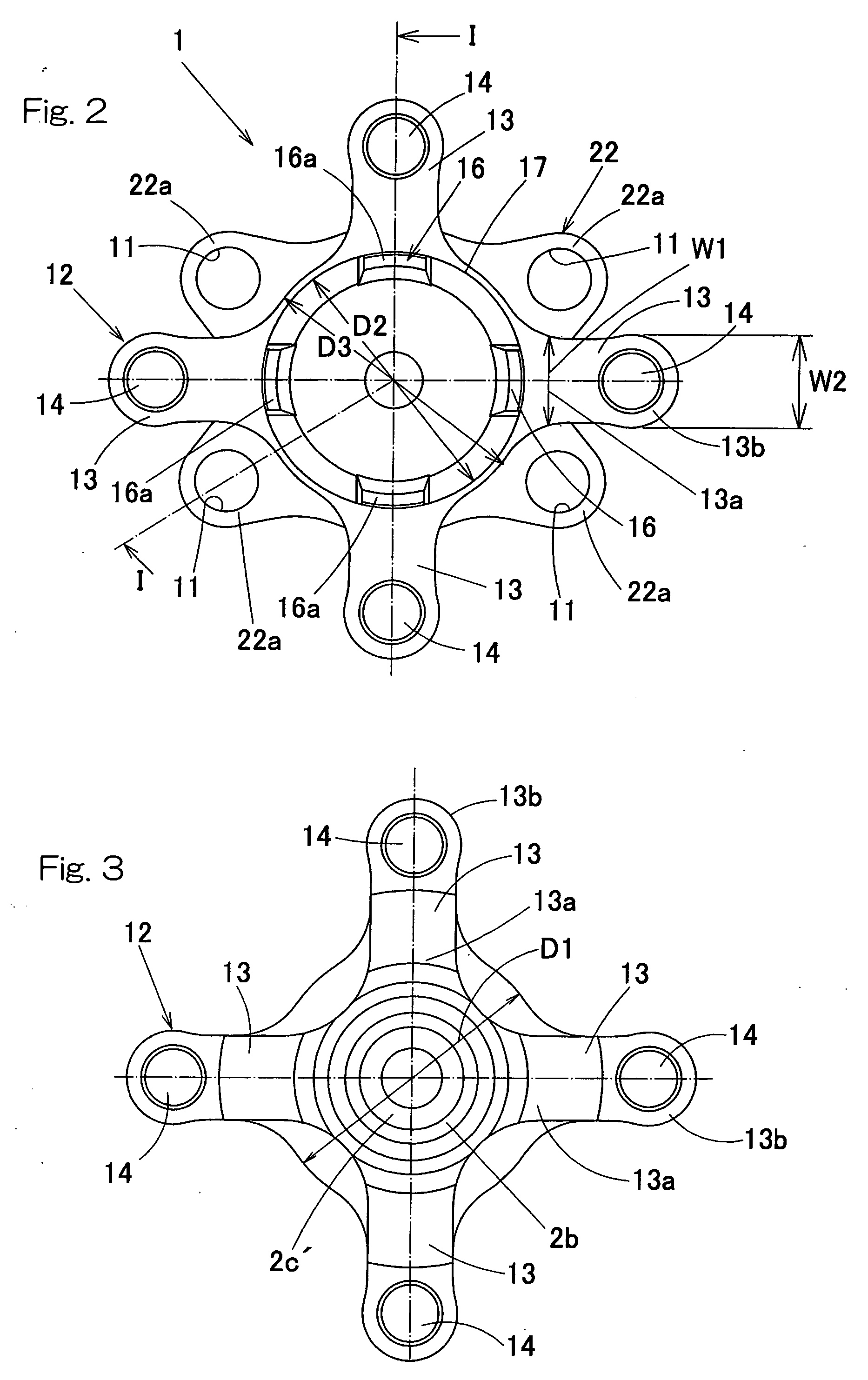

Wheel support bearing assembly

To reduce the weight of the wheel support bearing assembly without sacrificing the strength, the wheel support bearing assembly for rotatably supporting a vehicle wheel relative to a vehicle body structure includes a hub axle (2) formed with a radially outwardly extending hub flange (12). This hub flange (12) has an inner peripheral portion and a remaining wall portion other than the inner peripheral portion, and the remaining wall portion thereof is constituted by a plurality of radially outwardly extending ribs (13) each formed with a bolt insertion hole (14). The hub axle (2) also includes a brake pilot area (16) extending outwardly from an outboard face of the hub flange (12) for guiding an inner peripheral surface of the brake rotor (41). At least the root diameter (D1) of at least an inboard face of each rib (13) is chosen to be equal to or smaller than the outer diameter (D2) of the brake pilot area (16).

Owner:NTN CORP

Wheel end assembly high-temperature warning system

Owner:PRESSURE SYST INT LLC

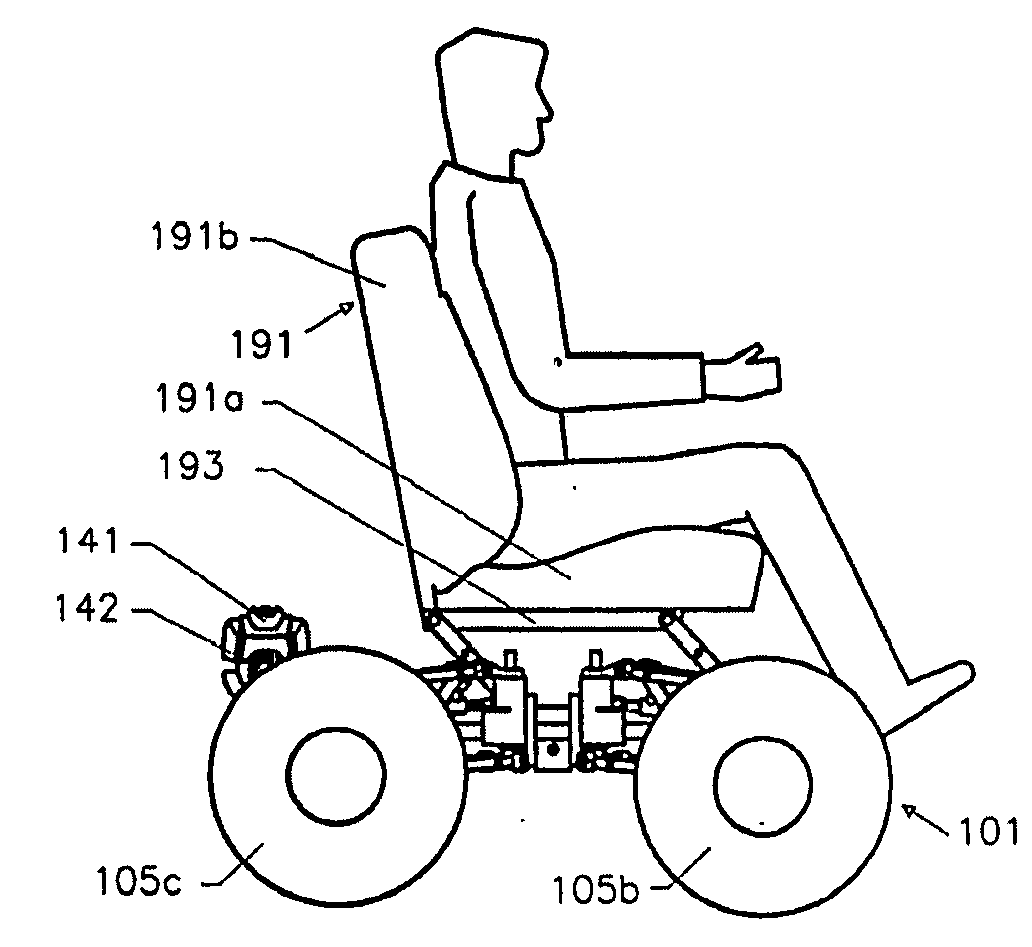

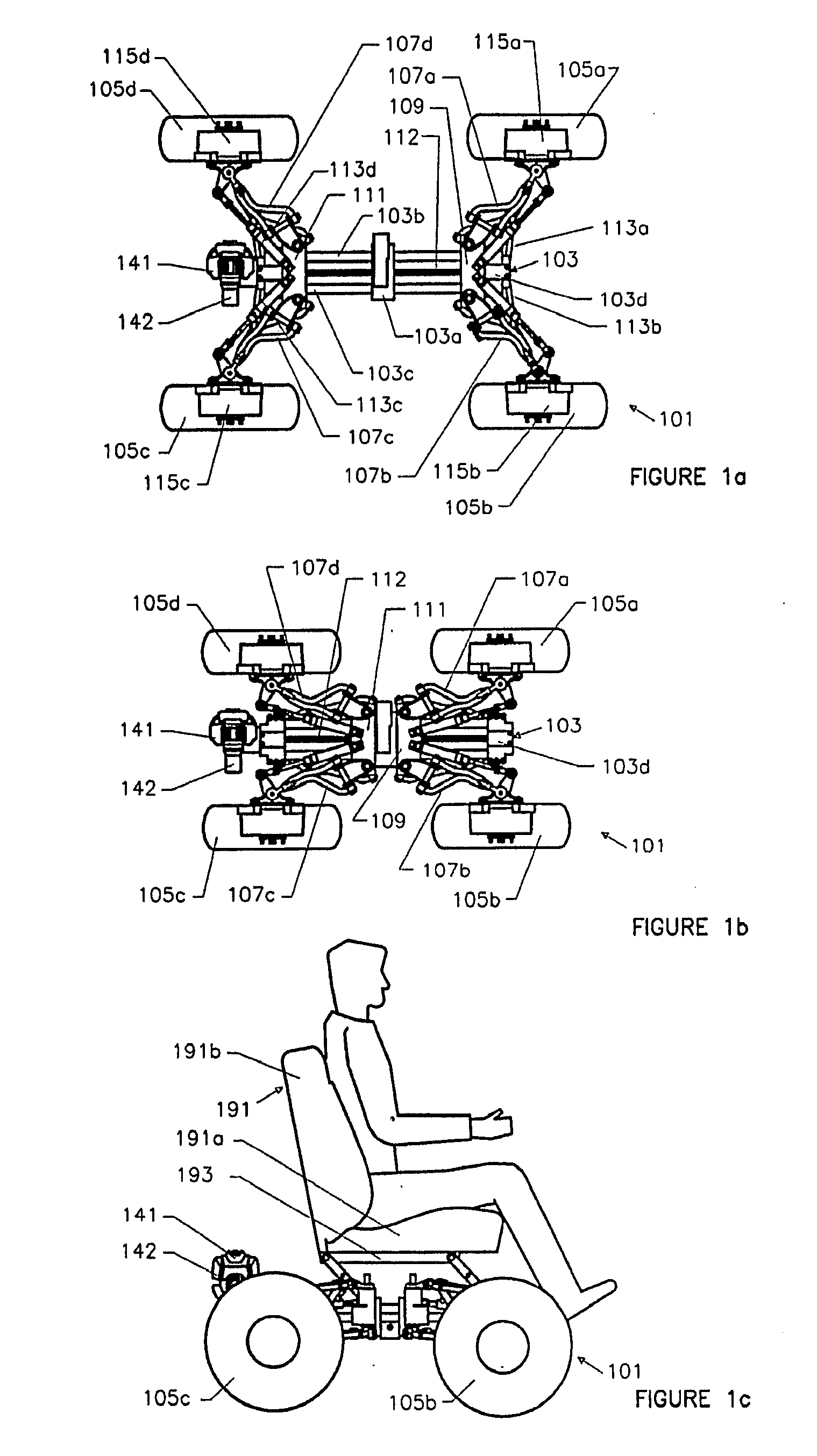

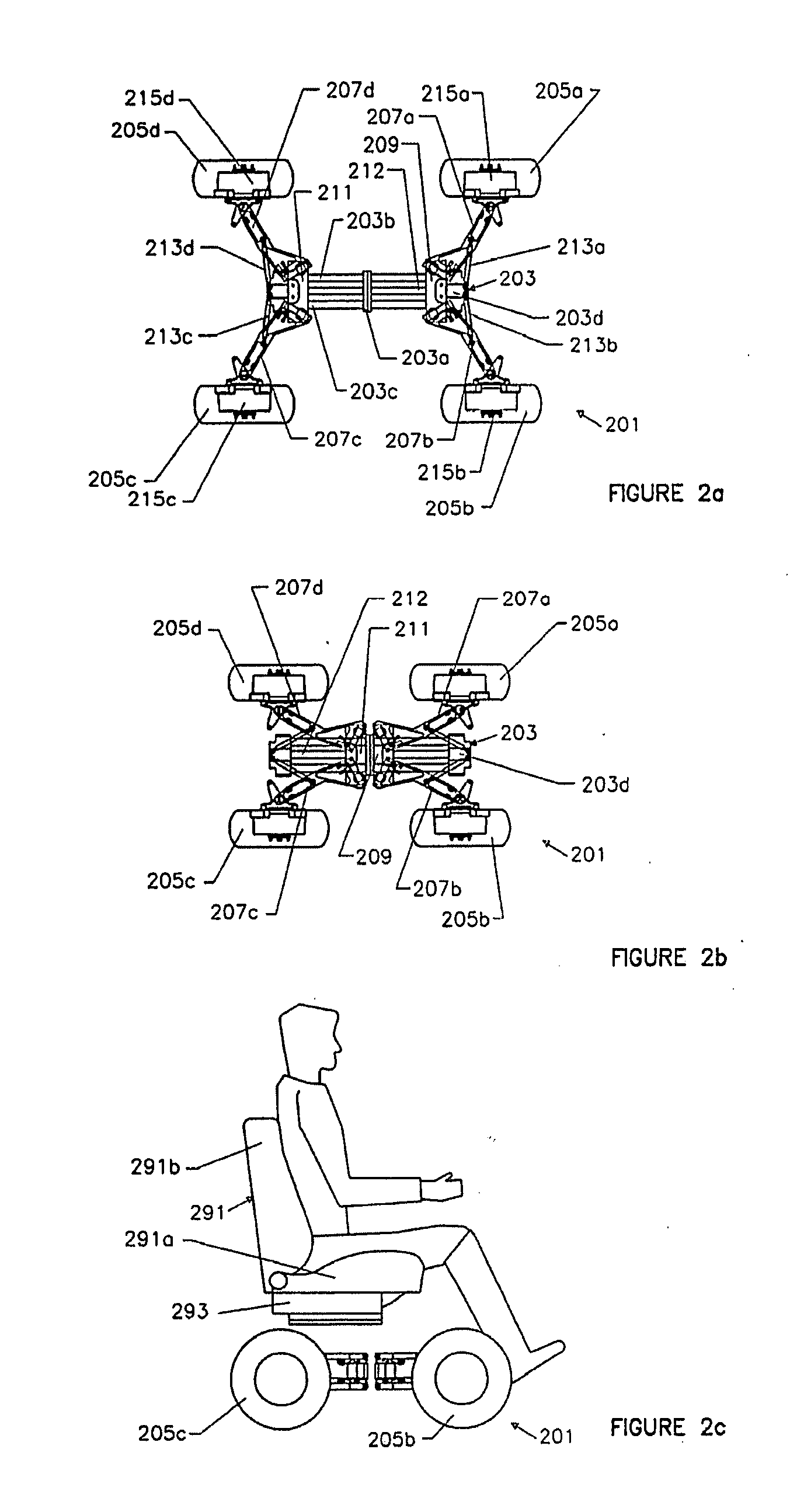

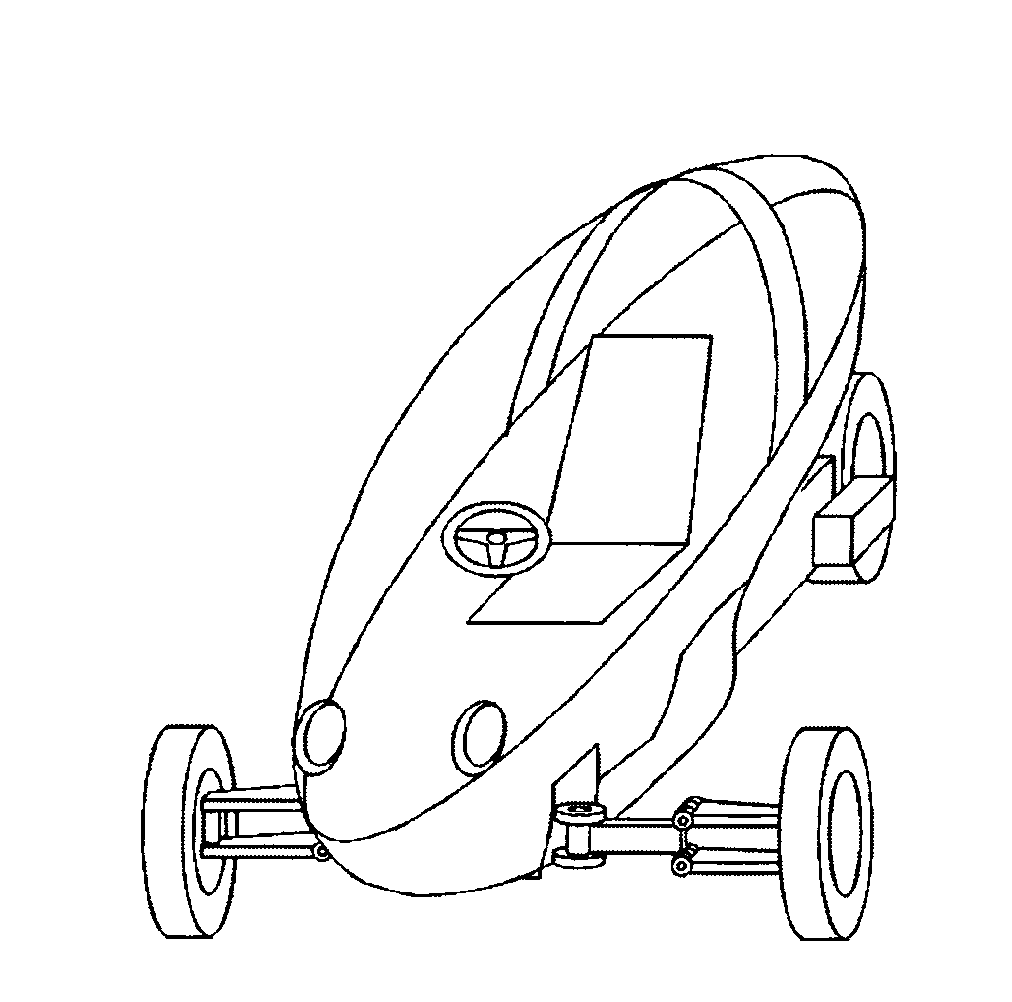

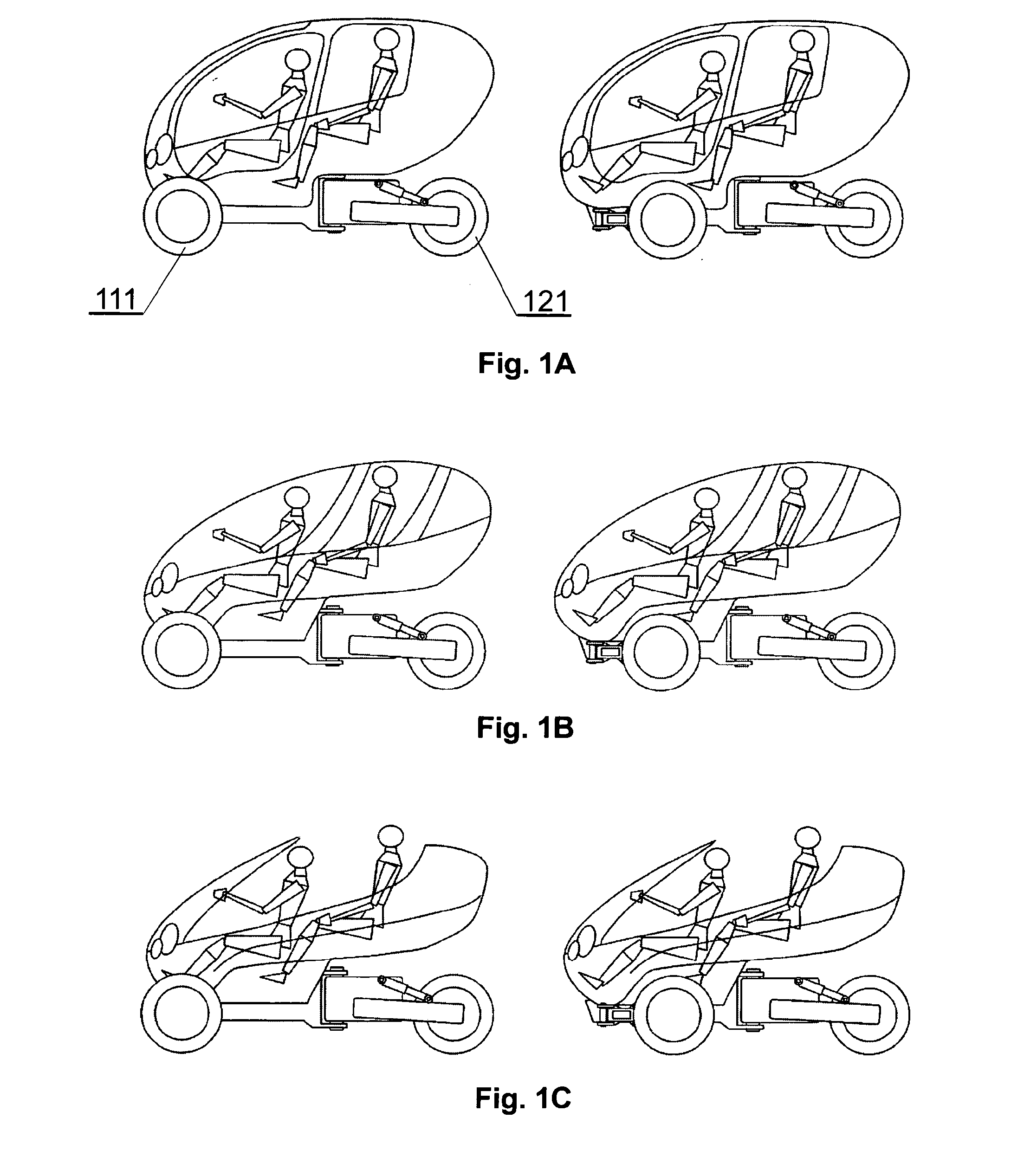

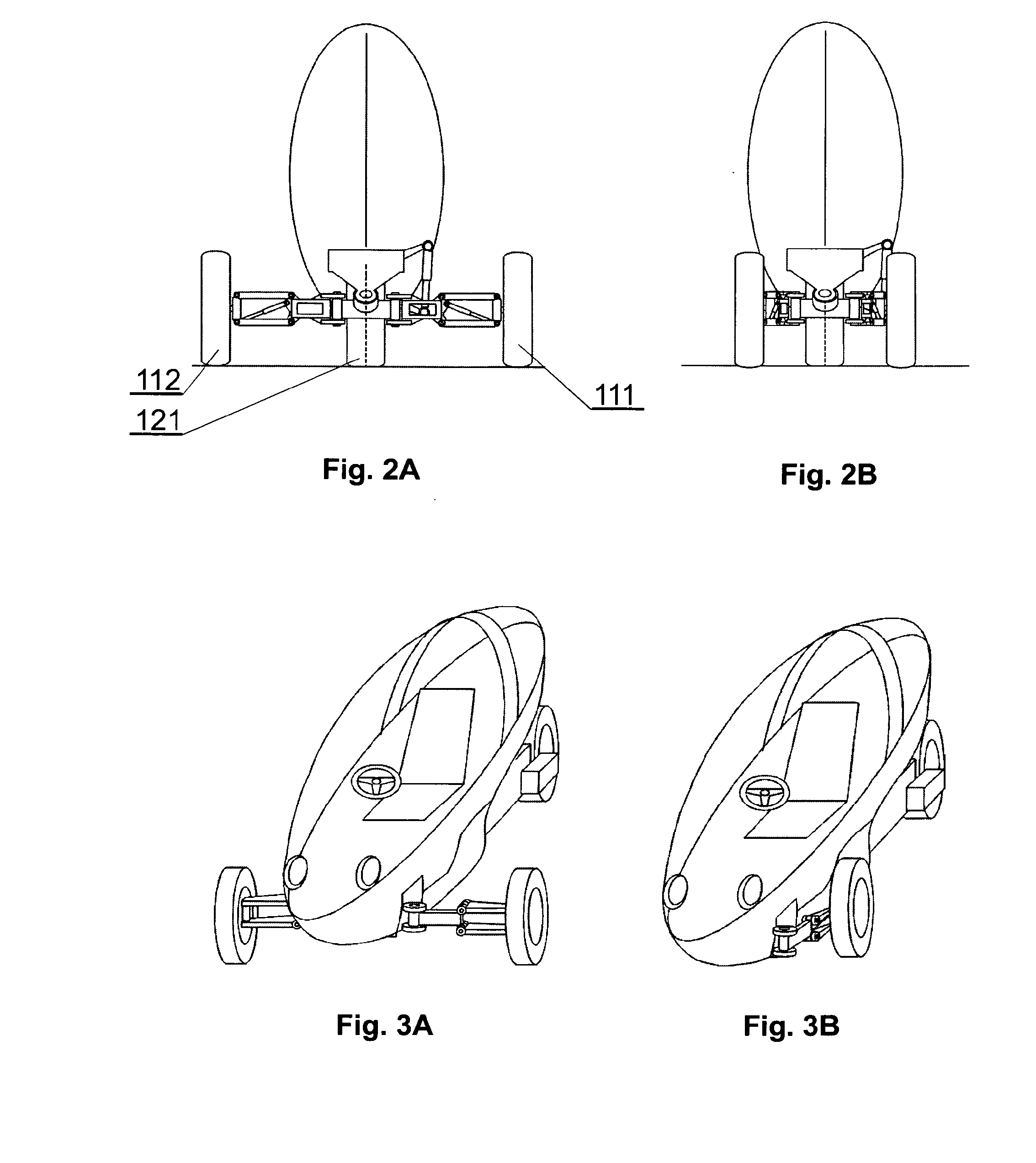

Vehicle

InactiveUS20080190682A1Minimize damageElectric propulsion mountingWheelchairs/patient conveyanceWheelbaseAxle track

A vehicle for transporting a person has a chassis (103) and four wheels (105a, 105b, 150c, 105d) supporting the chassis above a ground surface. The wheels enable the vehicle to move along the ground surface. Each of the four wheels is adjustable in position to enable the wheelbase length and track width of the vehicle to be changed. Each of the wheels is steerable to enable the changes in the wheelbase length and the track width to be effected whether the vehicle is substantially stationary or in motion.

Owner:MAHY GRAHAM JOHN +2

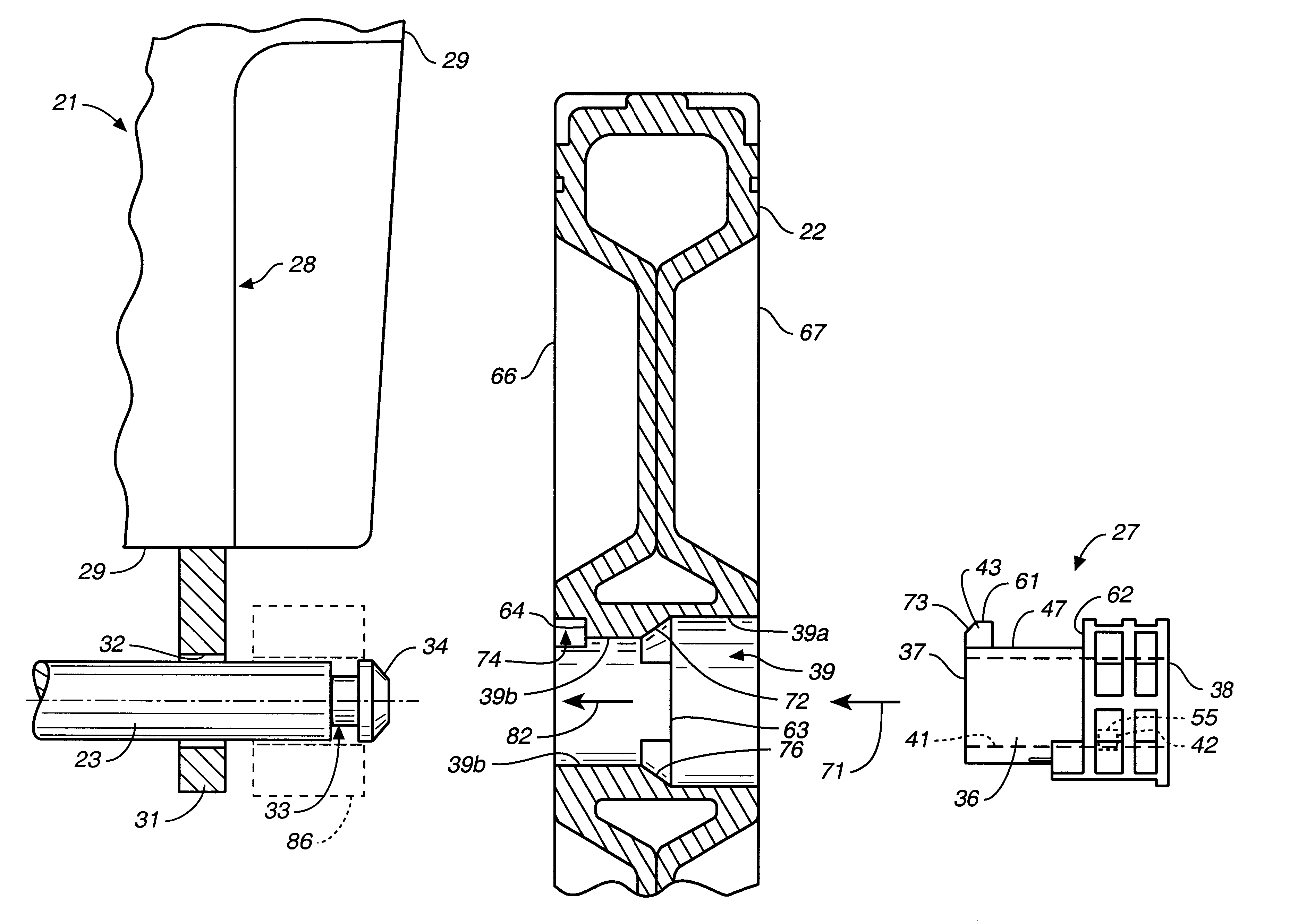

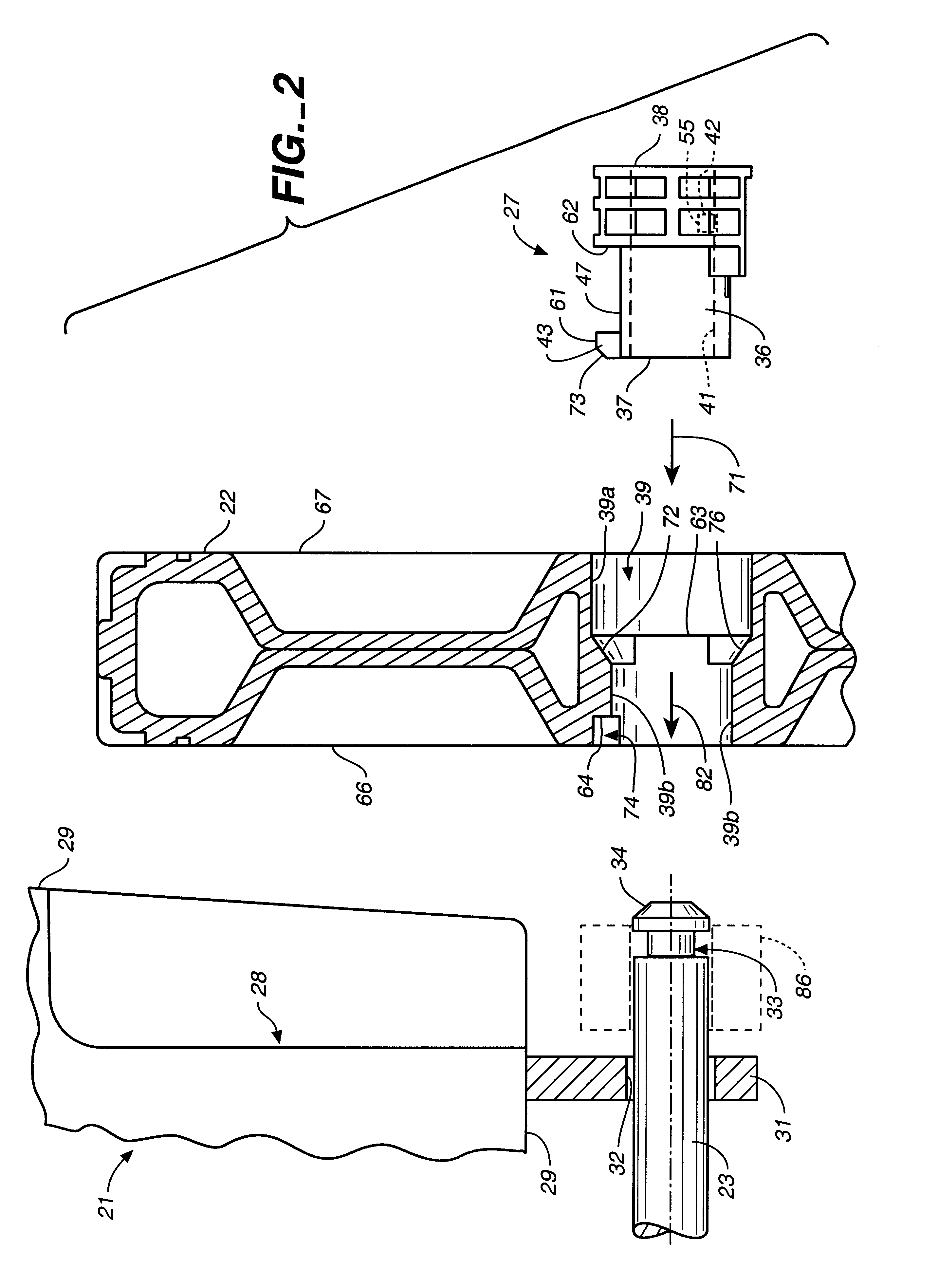

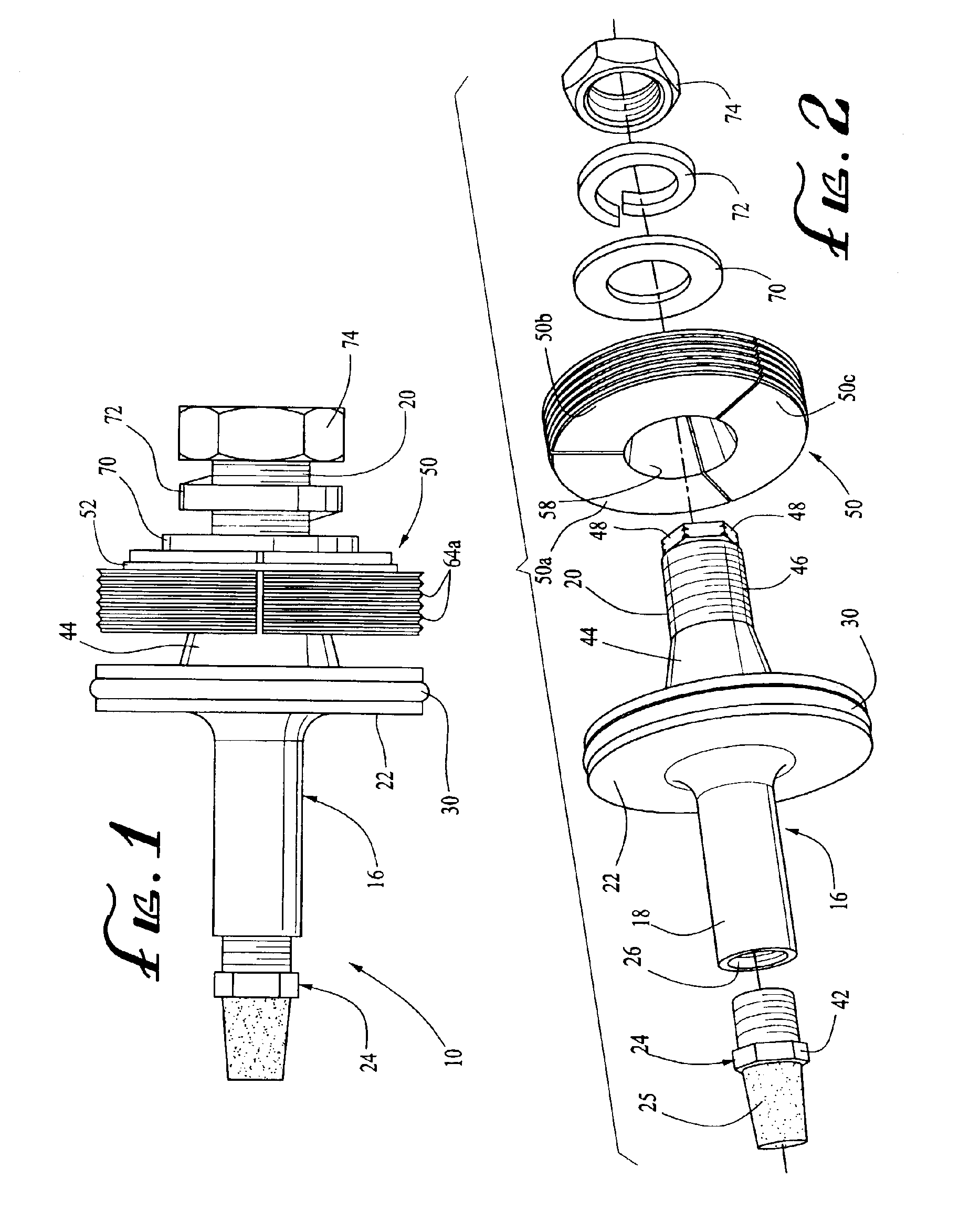

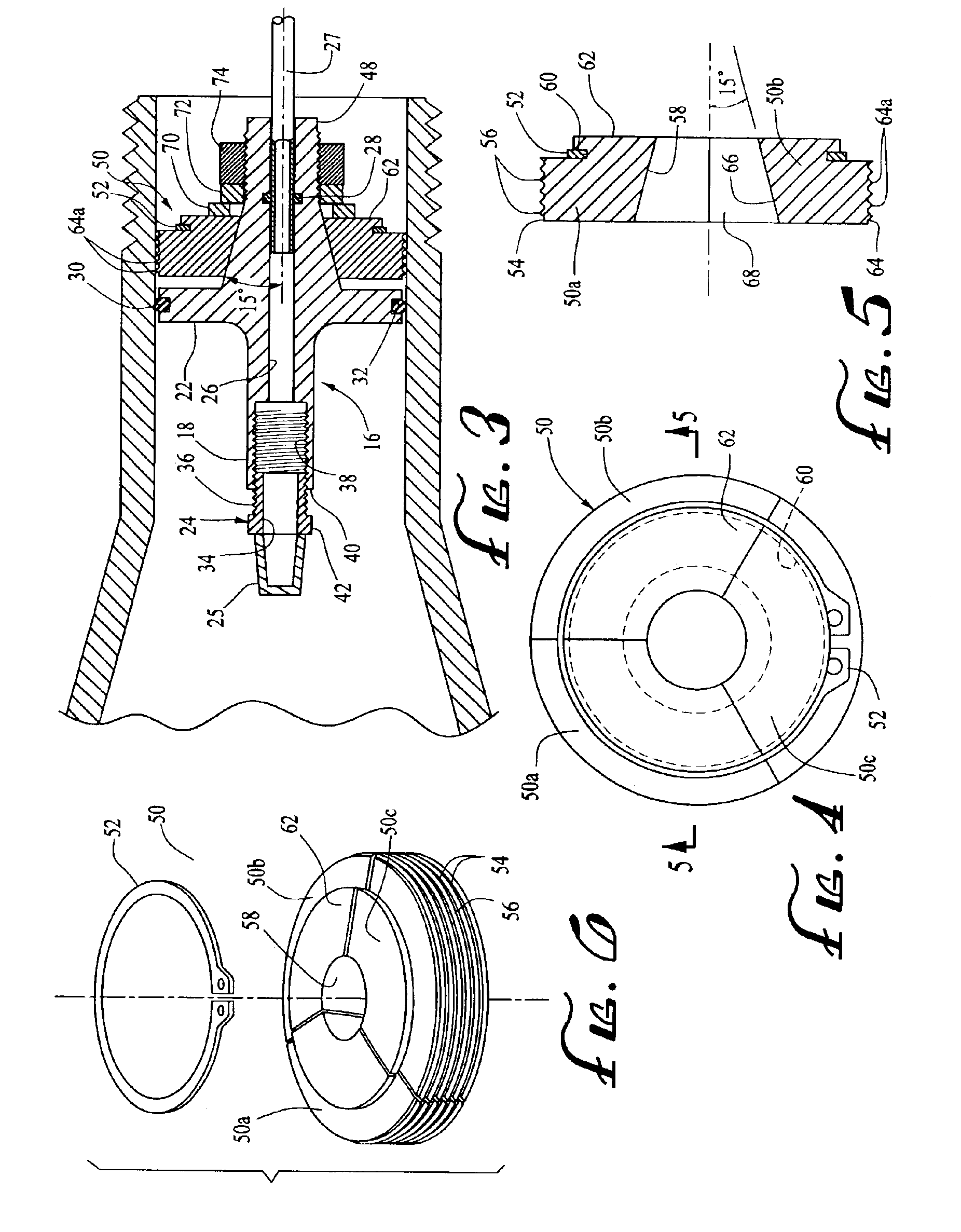

Plastic wheel assembly and mounting sleeve therefor

A plastic wheel (22) and wheel mounting sleeve (27, 27a, 27b, 27c) used to releasably secure the wheel (22) onto an axle (23). The wheel mounting sleeve (27) preferably includes two resilient, radially displaceable, axially extending, cantilevered fingers (46, 47) which are cantilevered from and extend axially in opposite directions on the sleeve (27). An axle-engaging shoulder (42) is provided on a radially inwardly extending lug (55) on one finger (46), while a wheel-engaging shoulder (43) is provided on a radially outwardly extending lug (61) on the other resilient finger (47). The respective shoulders (42, 43) cooperate with oppositely facing shoulders (58, 62) so as to releasably latch the sleeve (27) to the axle (23) and the wheel (22) to the sleeve (27). Assembly can be accomplished without any tools and a screwdriver can be used to disassemble the components. Alternative sleeves (27a, 27b, 27c) include an annular rib (101) which mates with an annular bore recess (102) to further limit relative movement between the sleeve (27a, 27b, 27c) and the wheel (22).

Owner:GEO PLASTICS

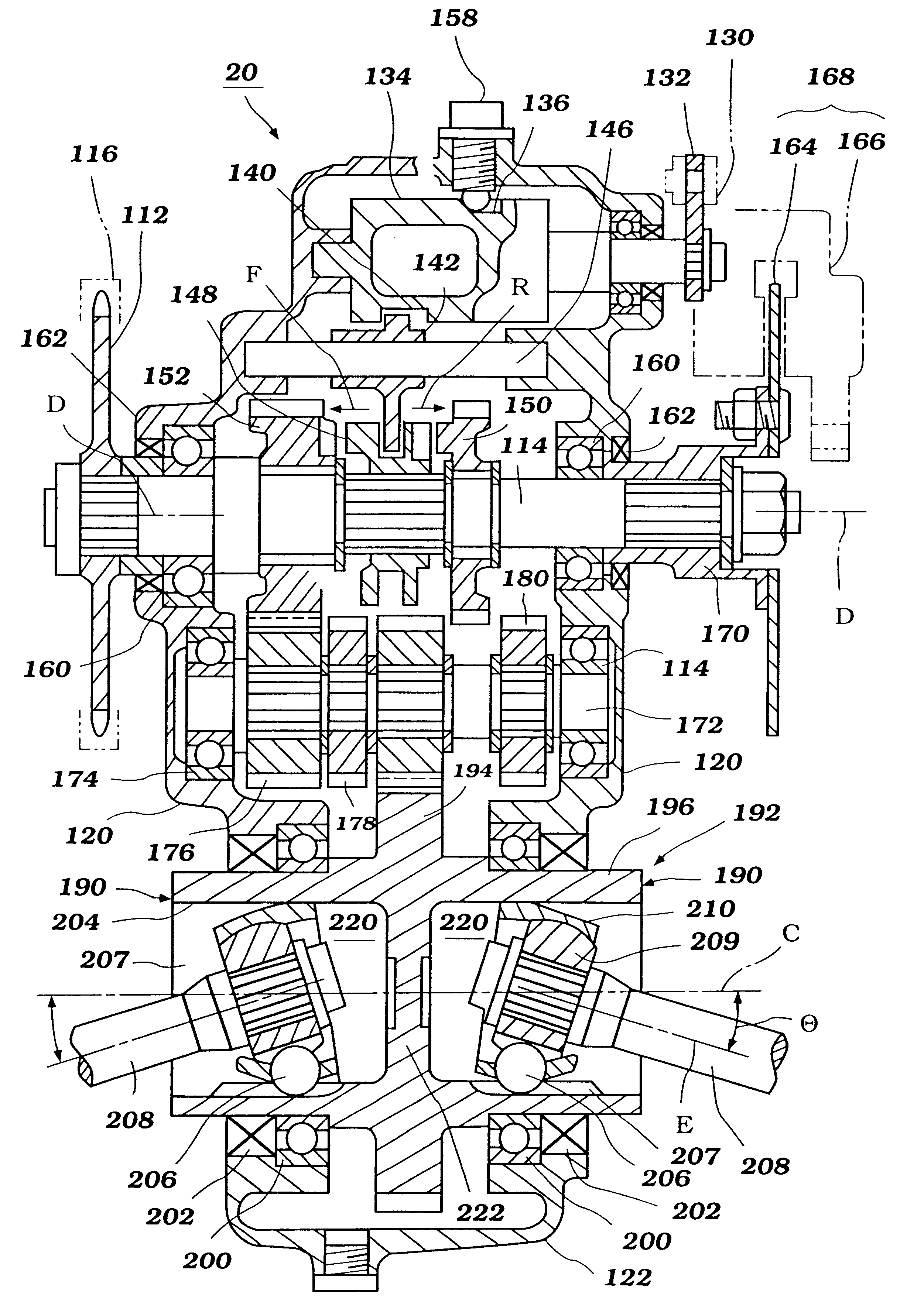

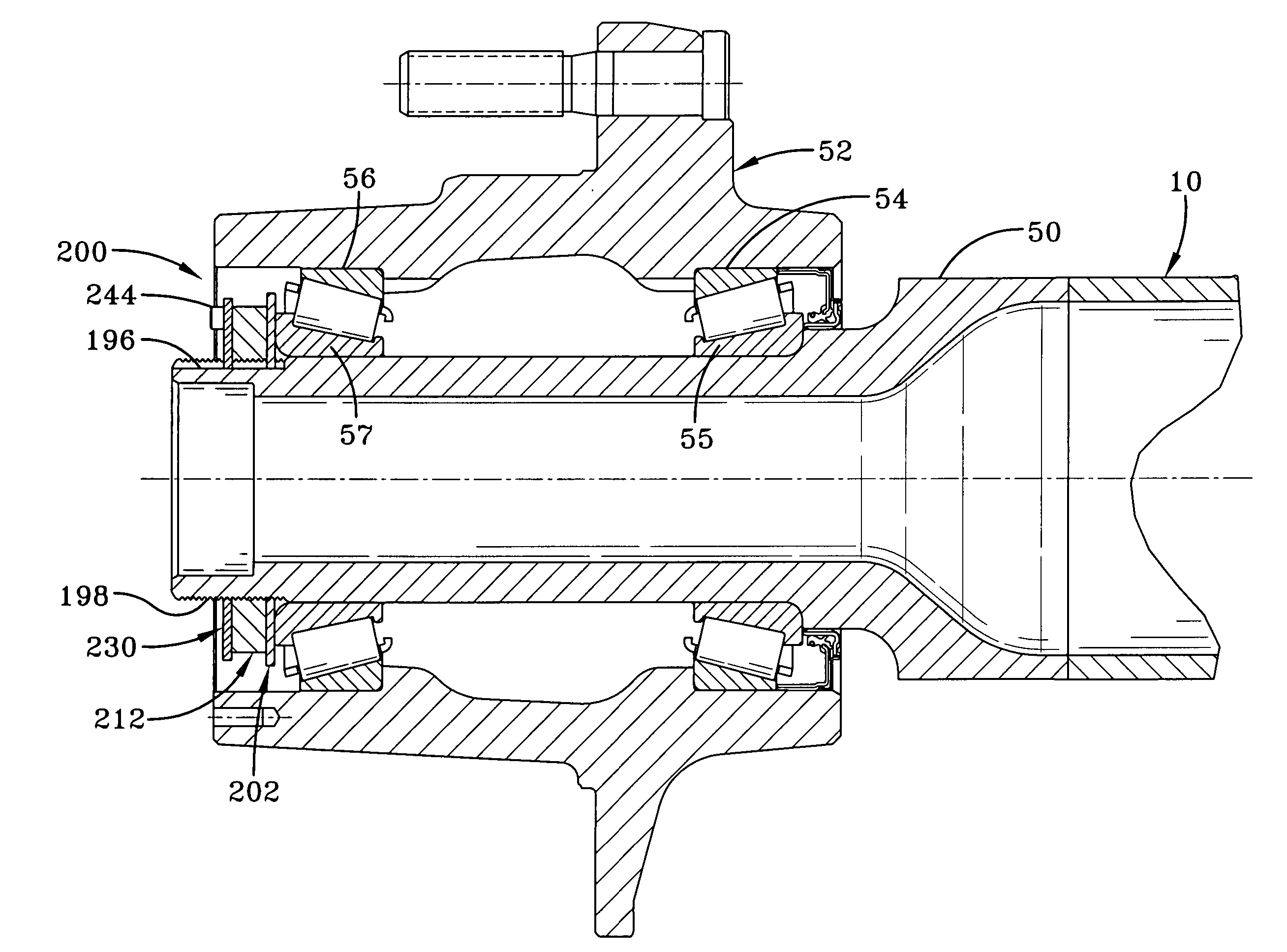

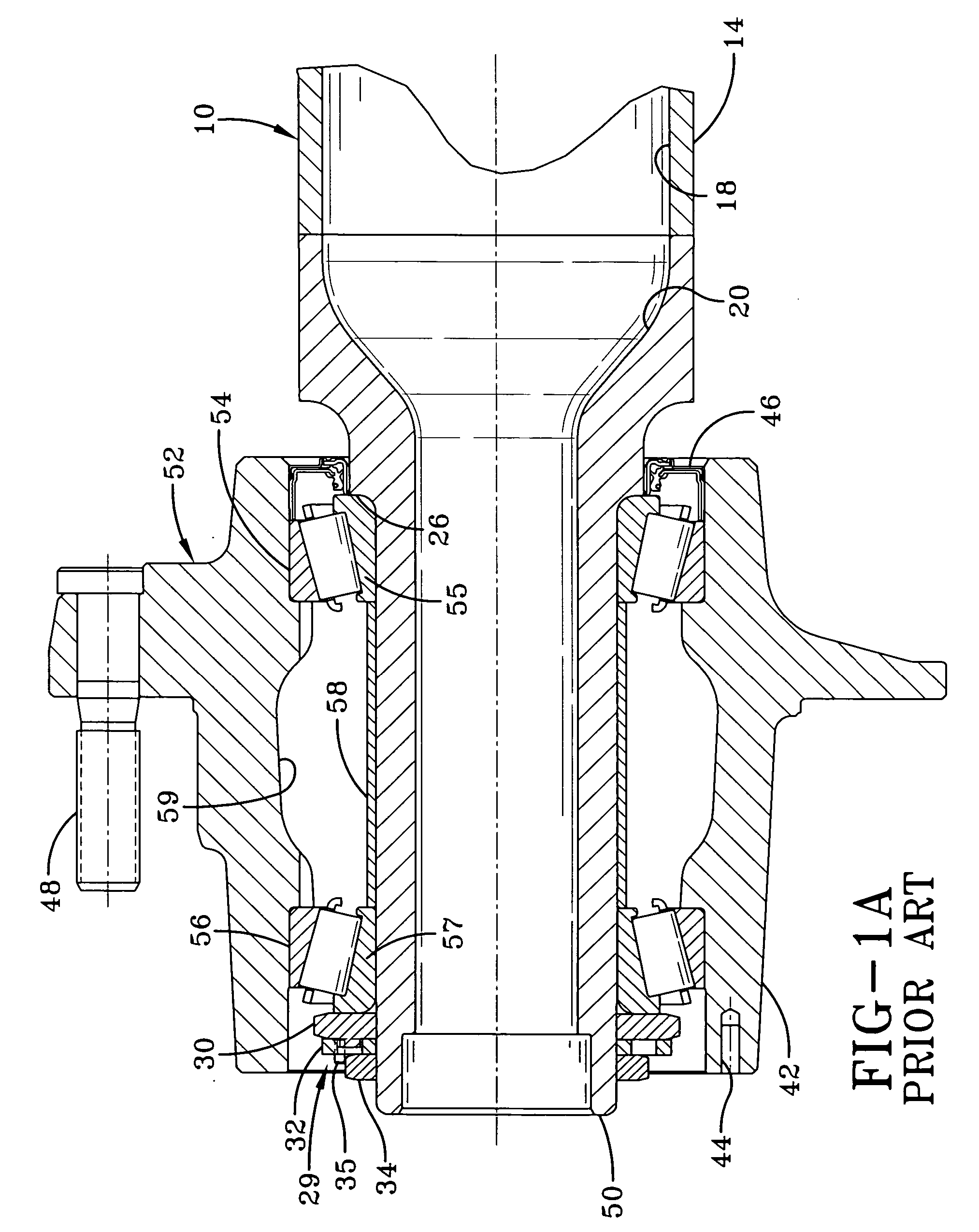

Axle assembly with transverse mounted electric motors

InactiveUS20050023885A1Small sizeAllow useOff-road vehiclesTransmission elementsReduced sizeEngineering

An axle assembly includes a first and a second electric motor which drive a gearbox assembly substantially therebetween. The electric motors drive the gearbox assembly which drives the vehicle wheels through a first and second axle shaft located along a first axis. The electric motors are located along axes which are substantially transverse to the first axis. The electric motors drive the gearbox assembly which includes a first stage gear reduction, a second stage gear reduction and a third stage gear reduction. A relatively lightweight and compact axle assembly is thereby provided which will benefit from an electric motor of reduced size.

Owner:ARVINMERITOR TECH

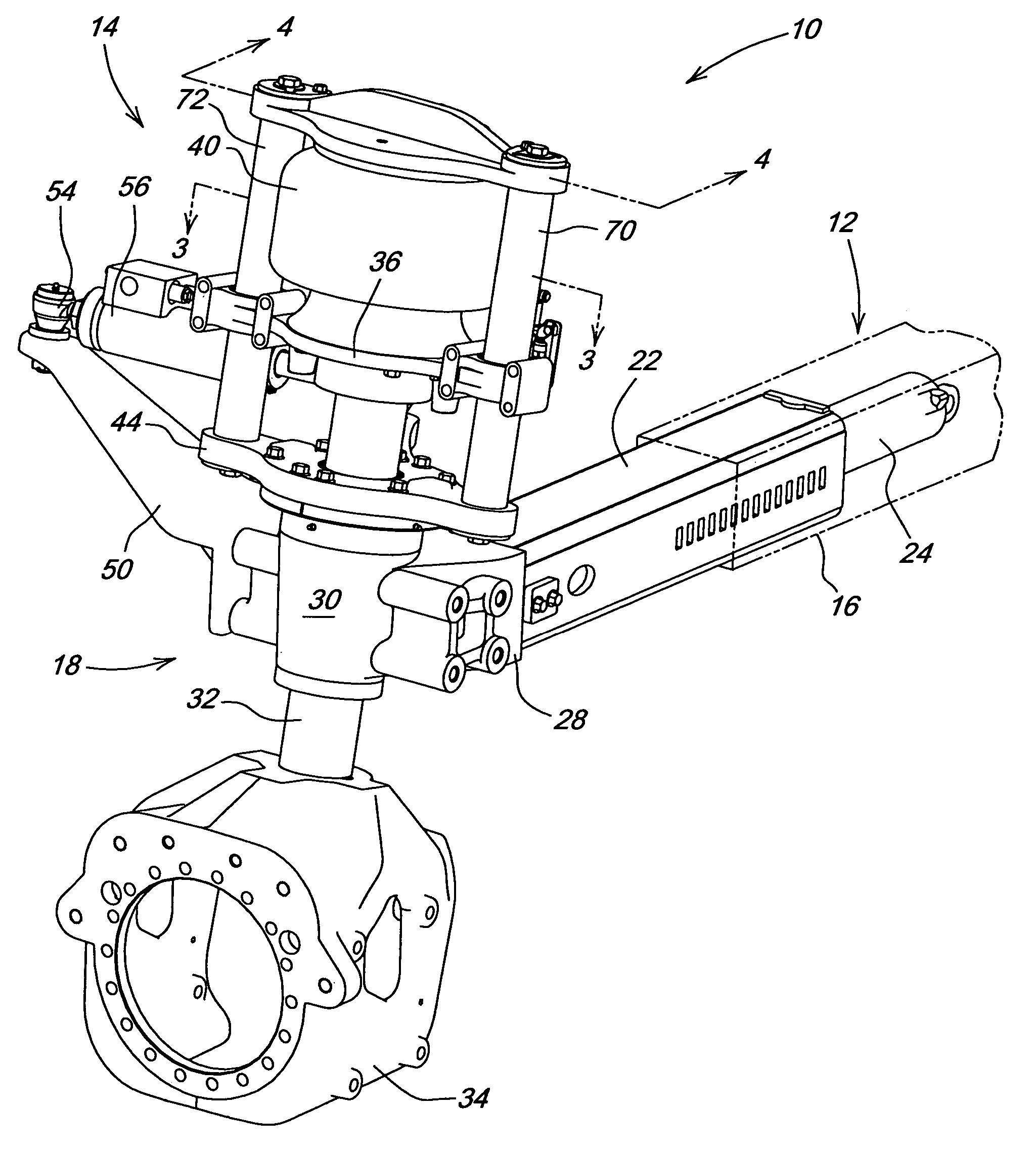

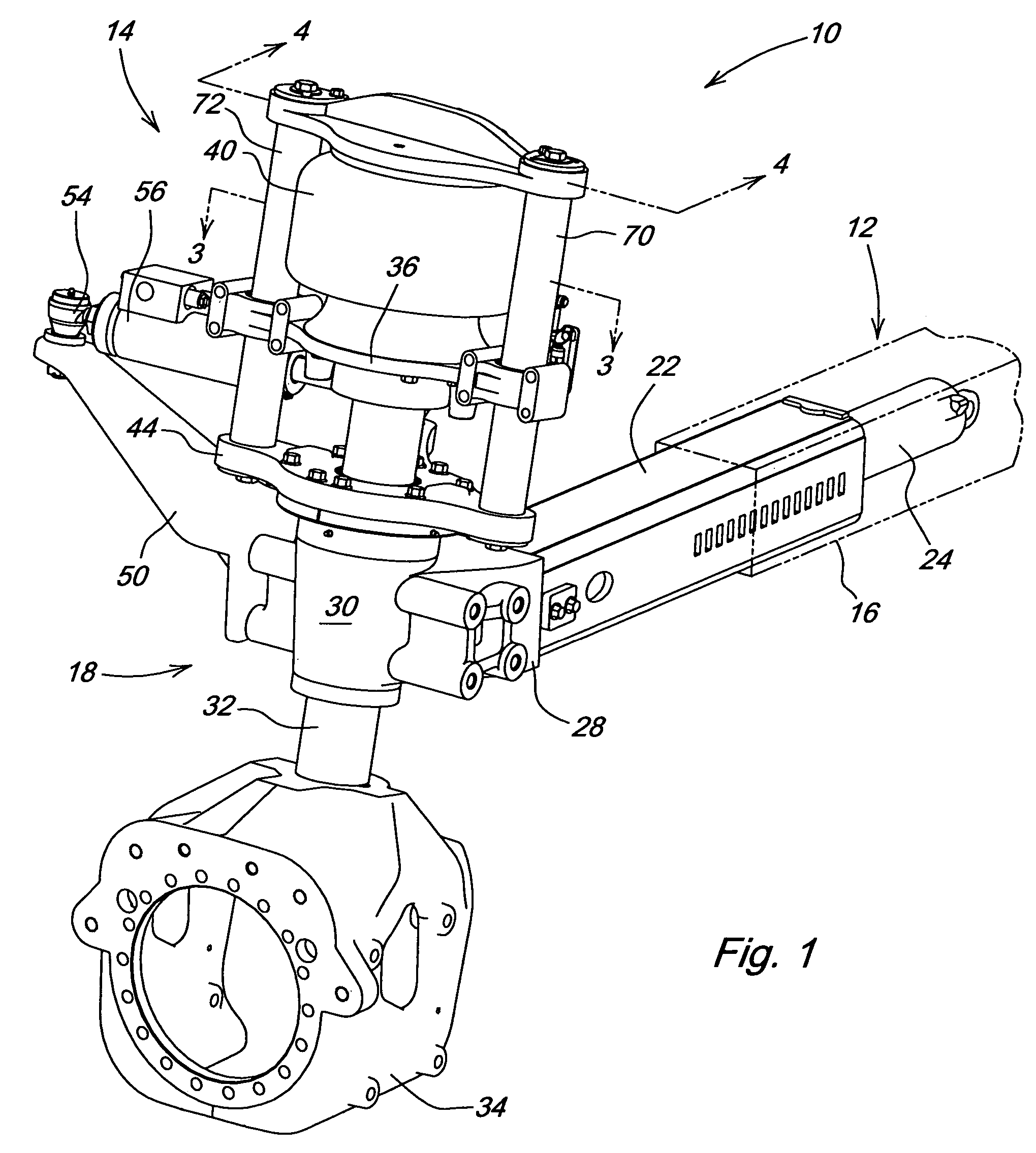

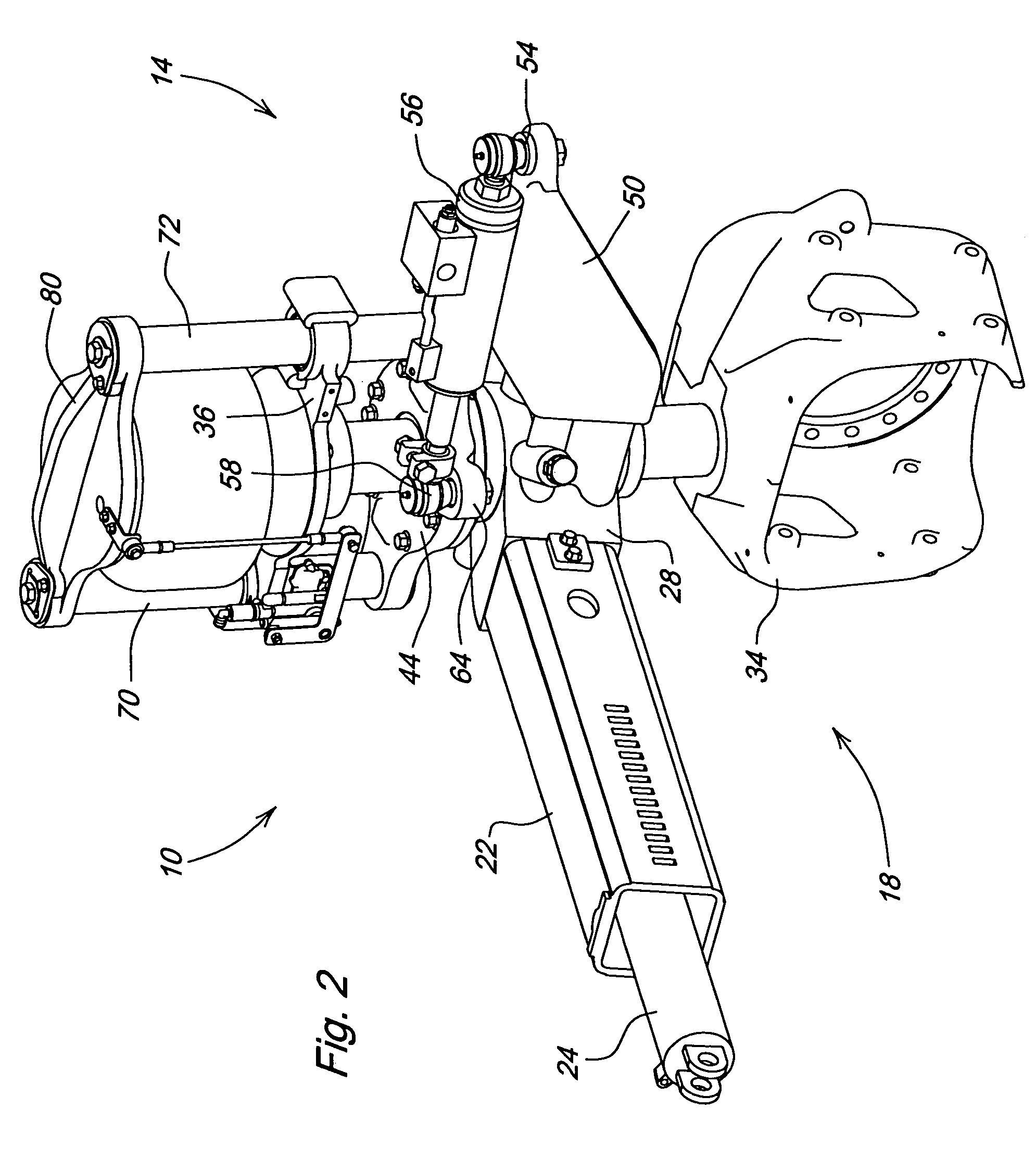

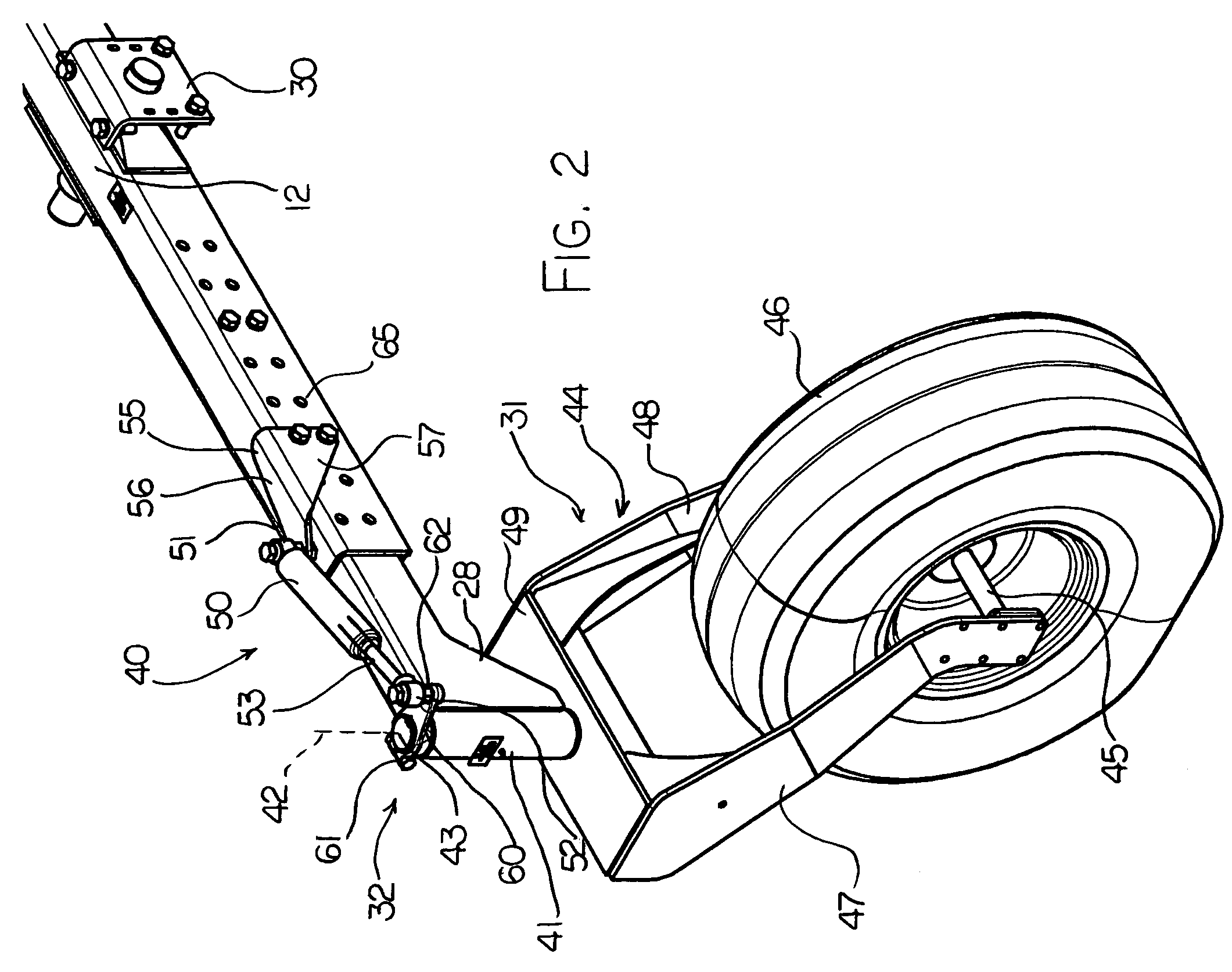

High clearance vehicle suspension with twin spindles for transferring steering torque

ActiveUS7168717B2Process controlEasy to hangAgricultural vehiclesSteering linkagesTerrainControl theory

An independent strut suspension utilizes upright twin spindles and a spindle cap linked to the spindles that translates vertically along the spindles as the suspension moves over uneven terrain. An upright strut shaft is mounted in a strut journal for axial and rotational movement with respect to the journal. A steering arm is connected for rotation about the strut shaft axis, and the strut shaft moves axially with respect to the steering arm as the frame moves over the uneven terrain. The upright spindles connect the steering arm and the upper mount, and a spring is supported between the upper end of the strut shaft and the upper mount and provides cushioning for the wheel support as the strut shaft moves axially in the journal.

Owner:DEERE & CO

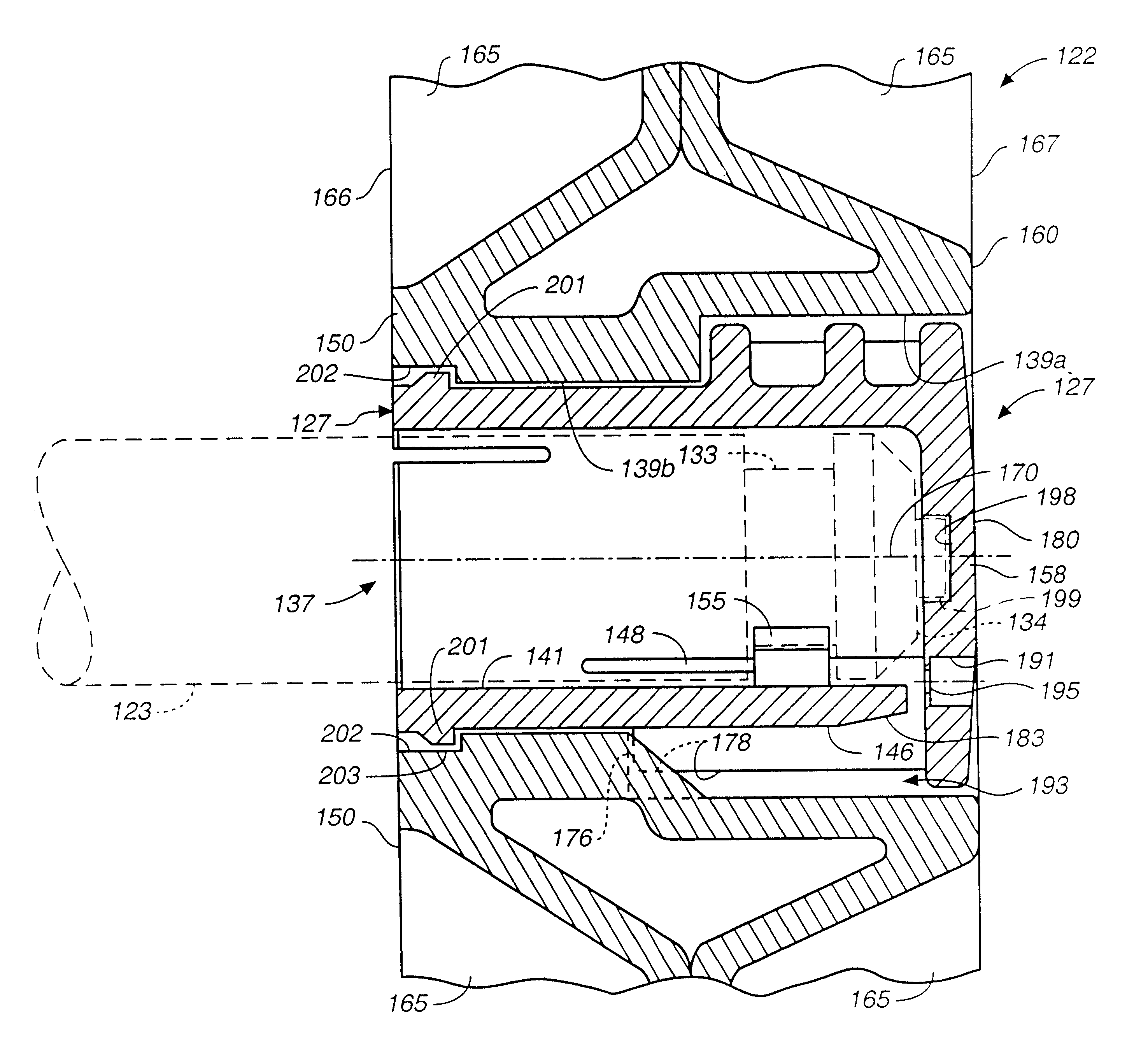

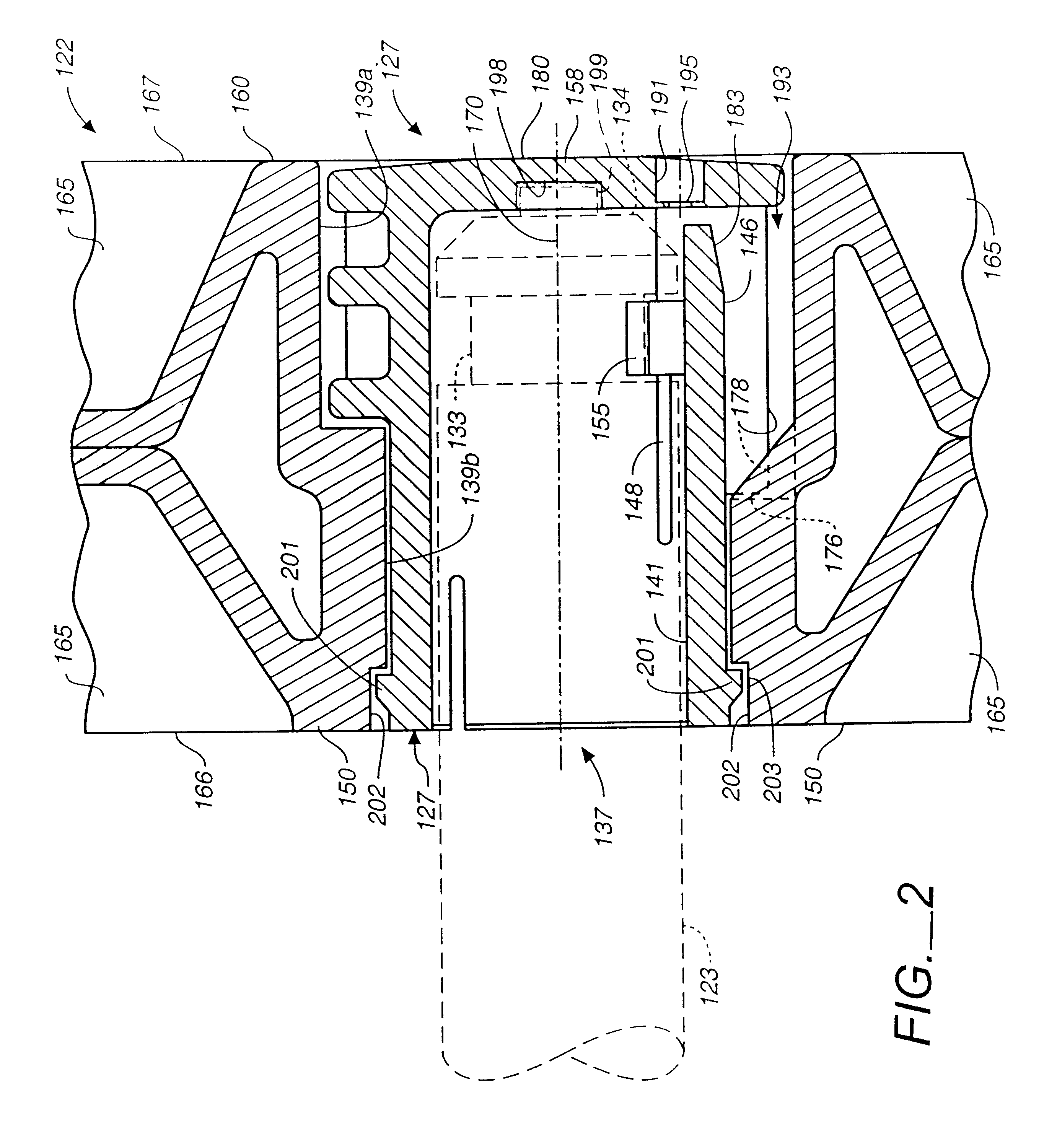

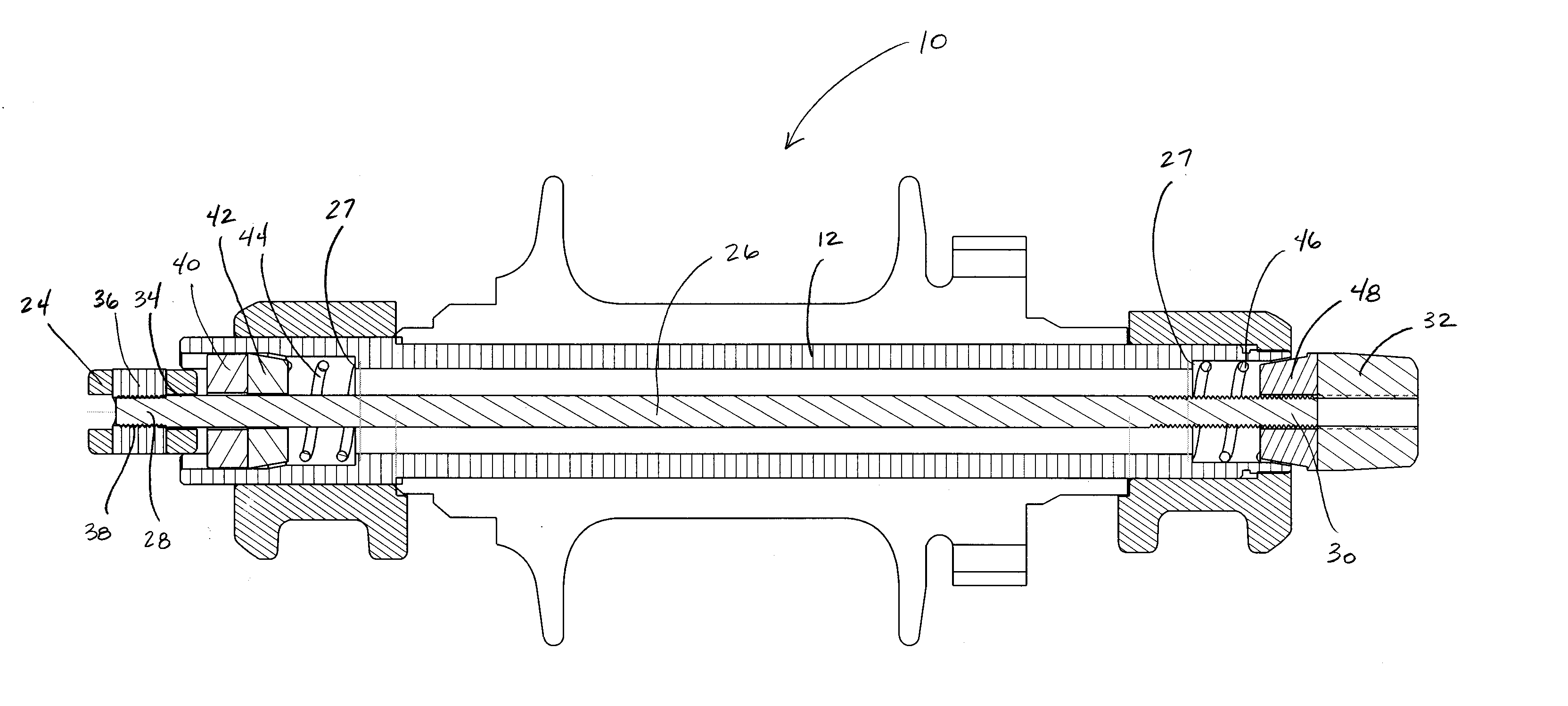

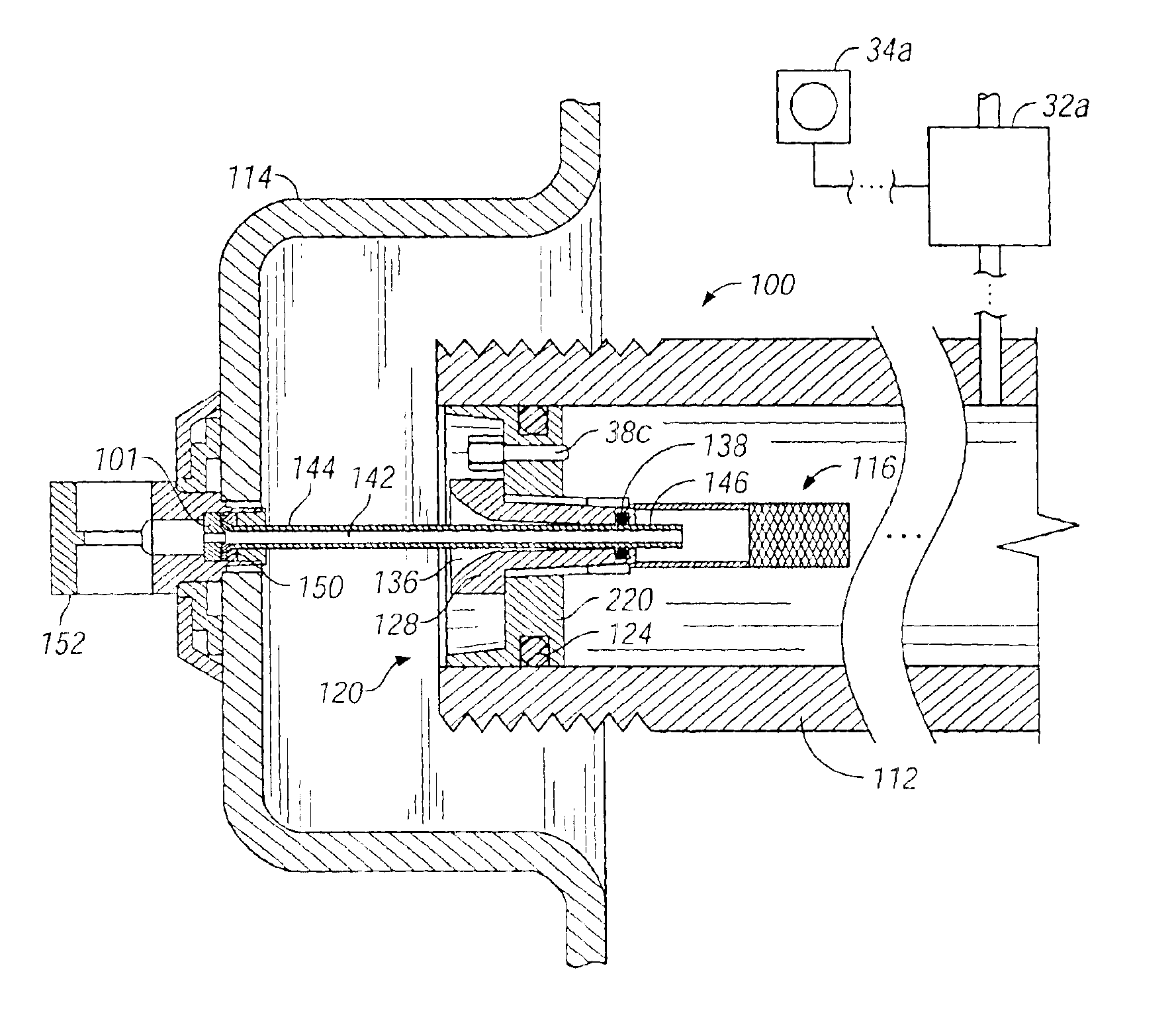

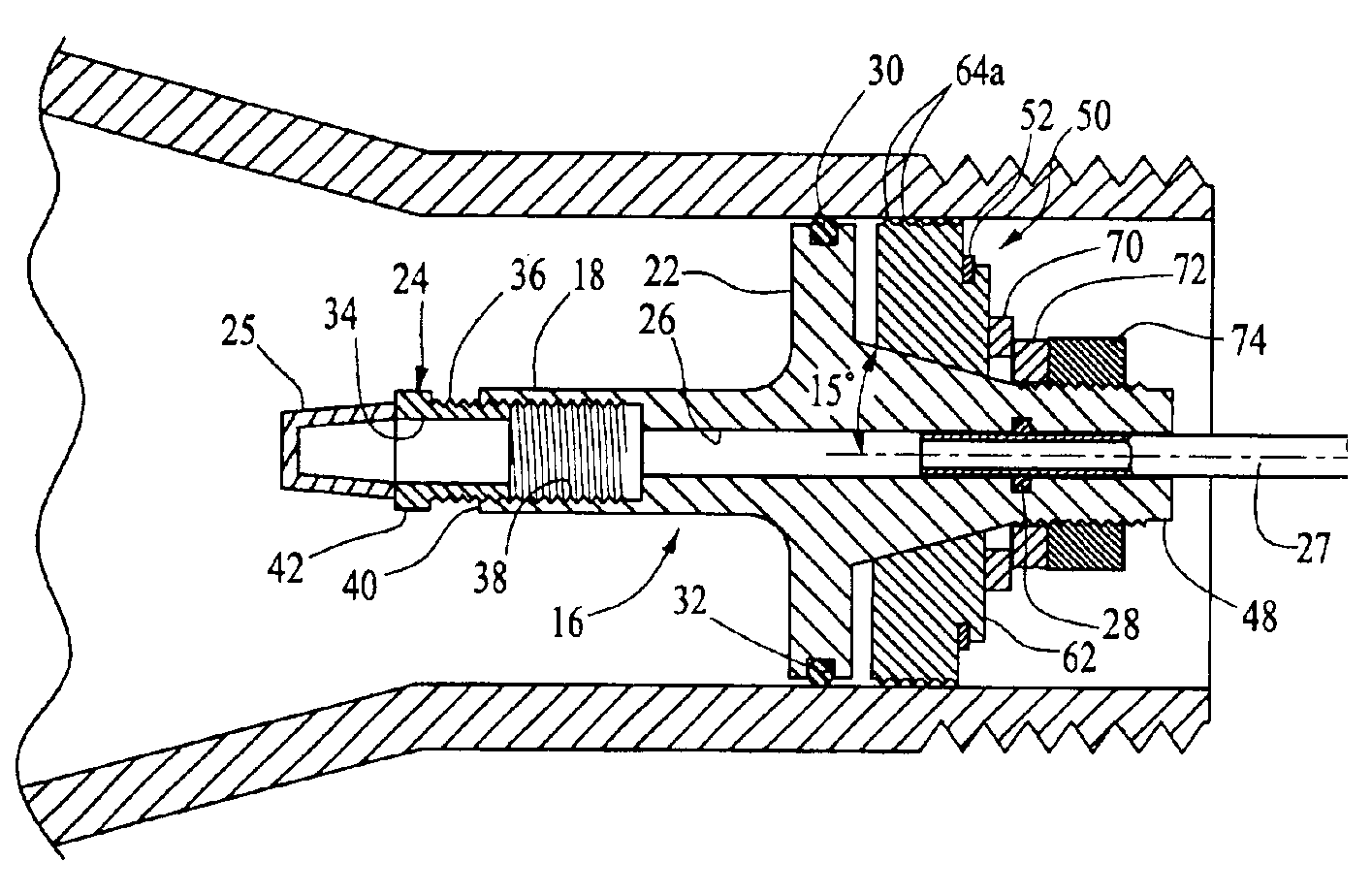

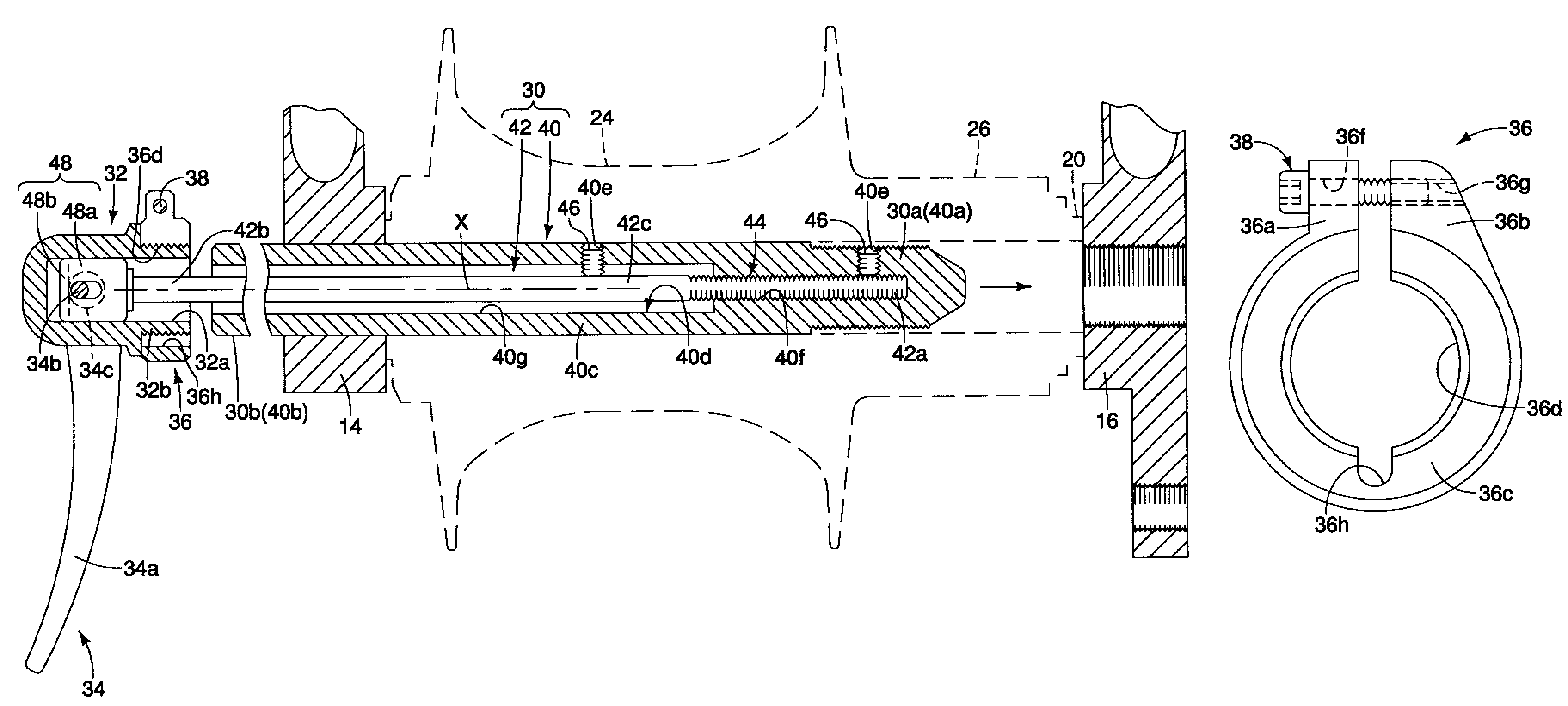

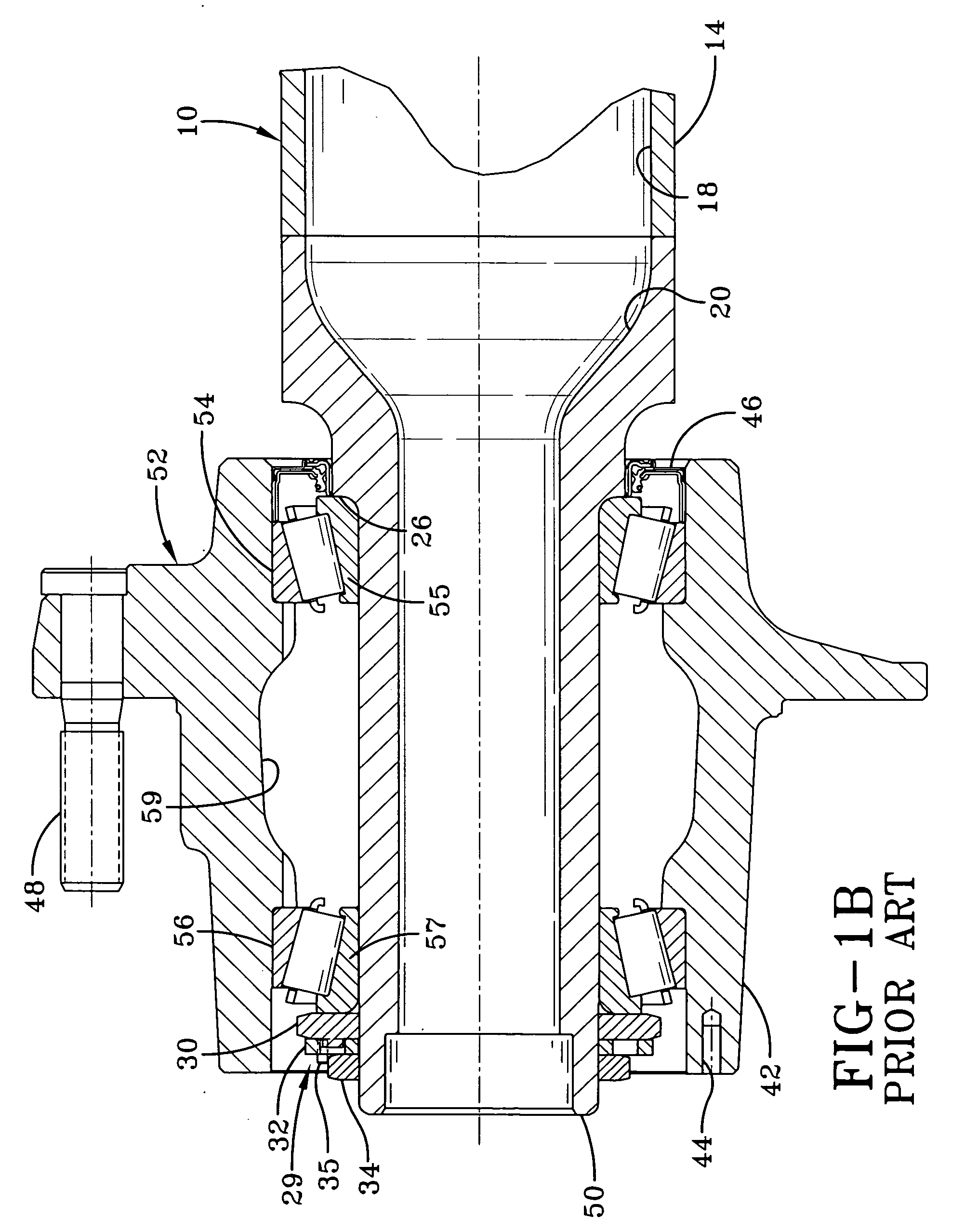

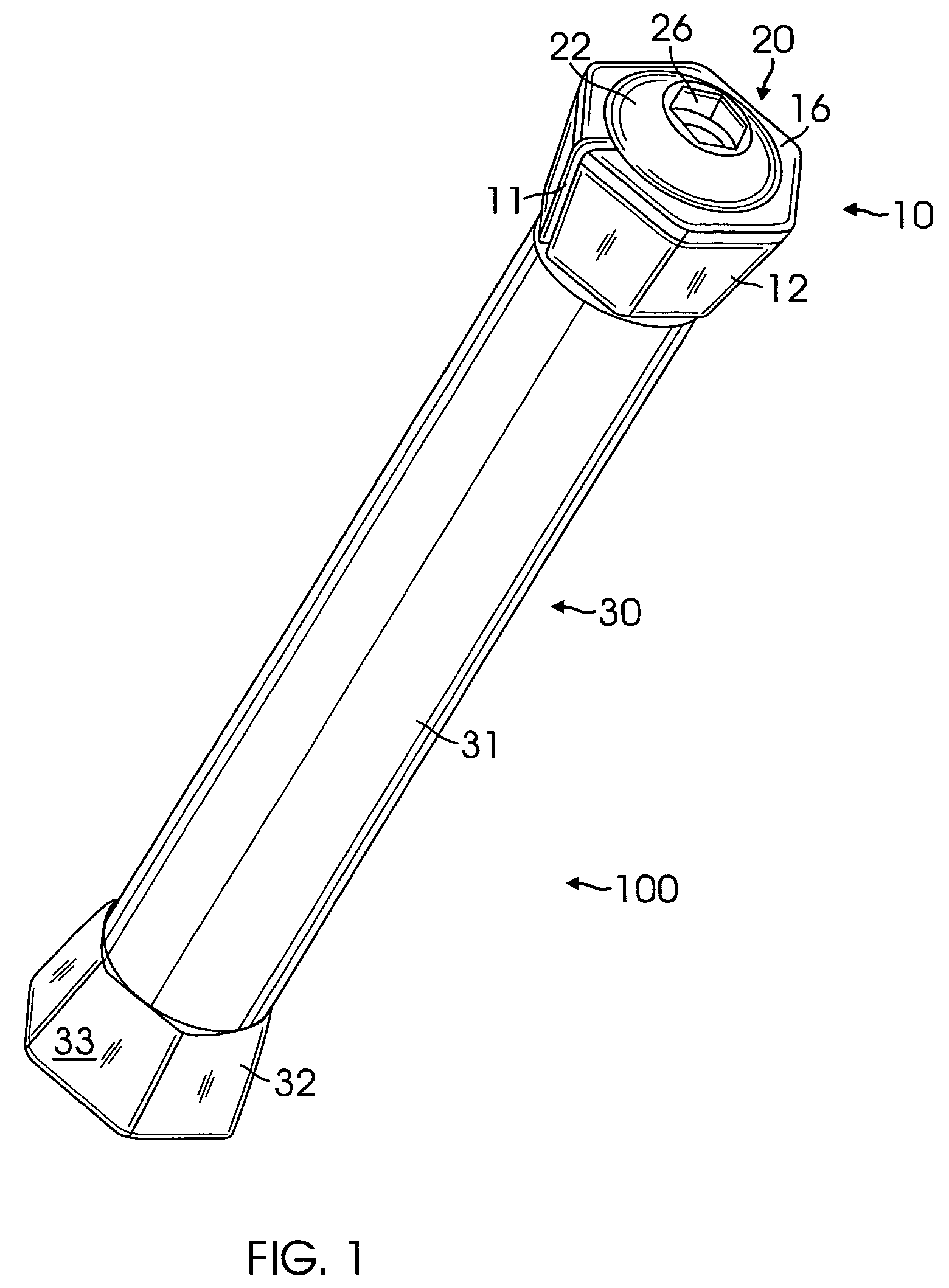

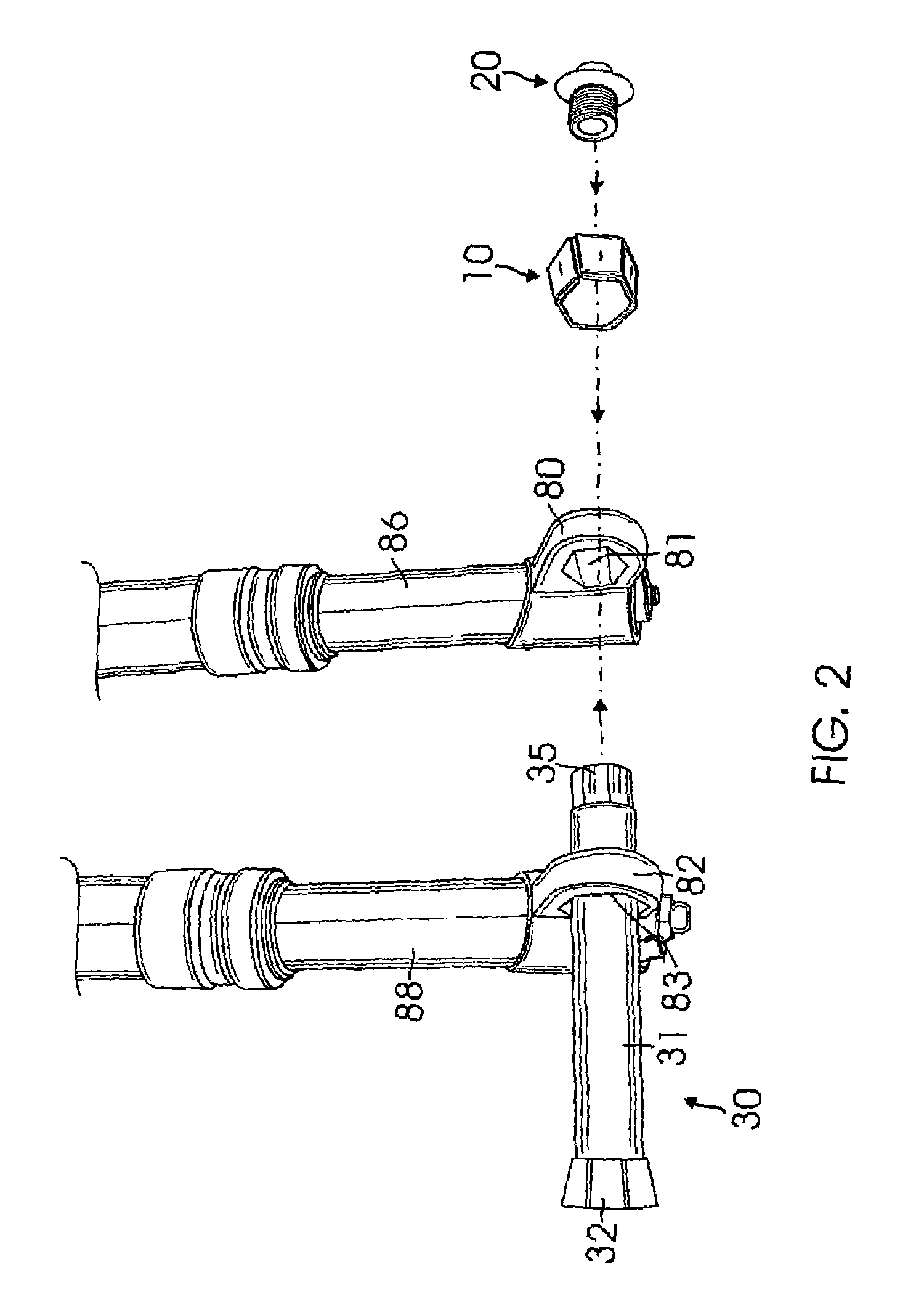

Expandable spindle plug assembly for use with automatic tire inflation systems

An assembly to be mounted in an axle spindle for communicating pressurized air from the axle to a rotary union in a tire inflation system. The assembly includes an arbor having an air flow channel extending therethrough, a flange intermediary of the arbor ends and an axially inclined portion proximate the flange. A sealing member is carried by the flange for forming an airtight seal with the axle spindle. A split ring locking assembly is disposed about the inclined portion of the arbor that is comprised of a plurality of segments held by an expansible retention spring. The segments move radially outwardly upon the locking assembly being moved along the inclined arbor portion and engage the axle spindle, securing the plug assembly within the spindle, A fastening member threadably engages the arbor for urging the locking assembly along the inclined arbor portion to effect securement of the plug assembly within the axle spindle.

Owner:AIRGO IP

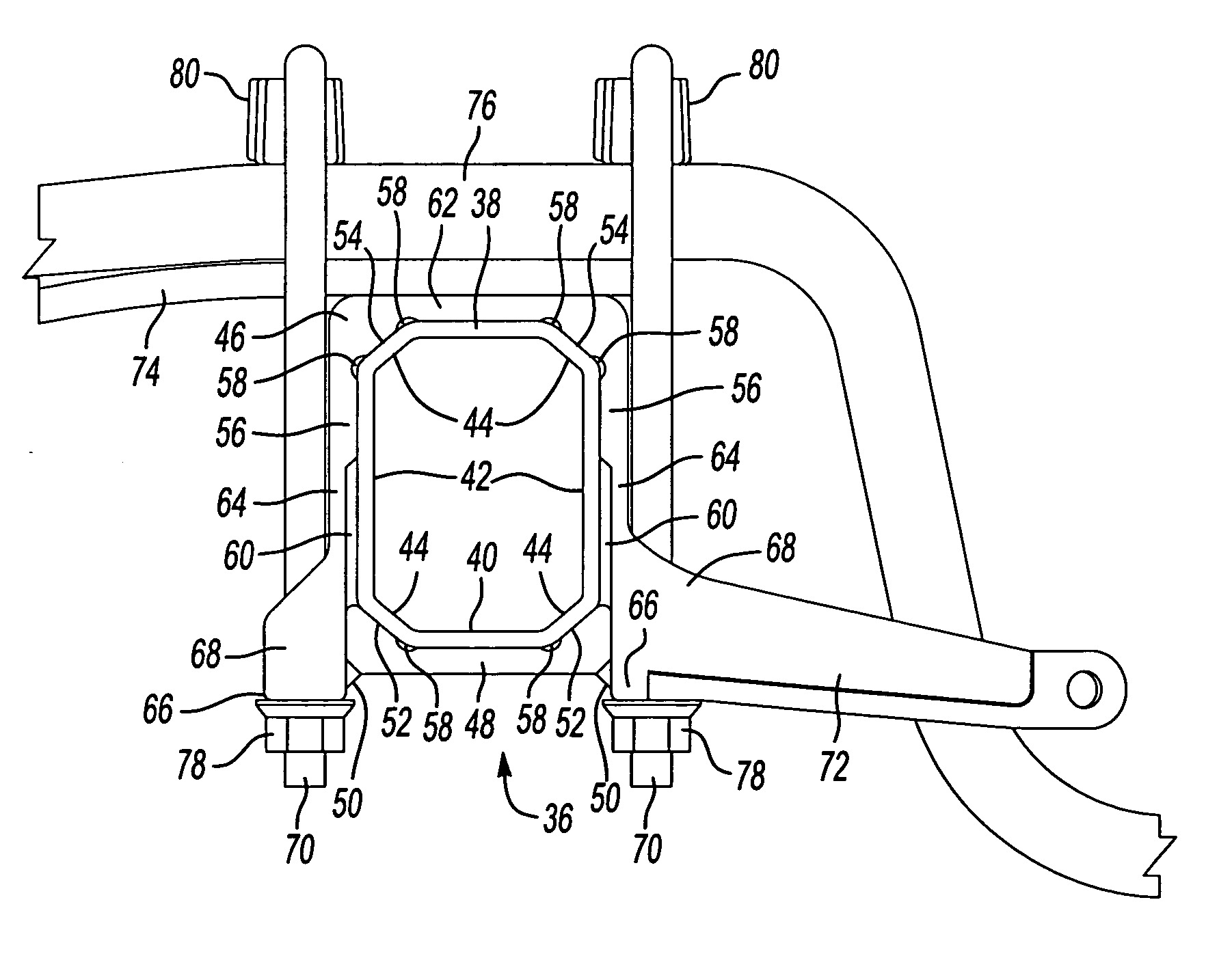

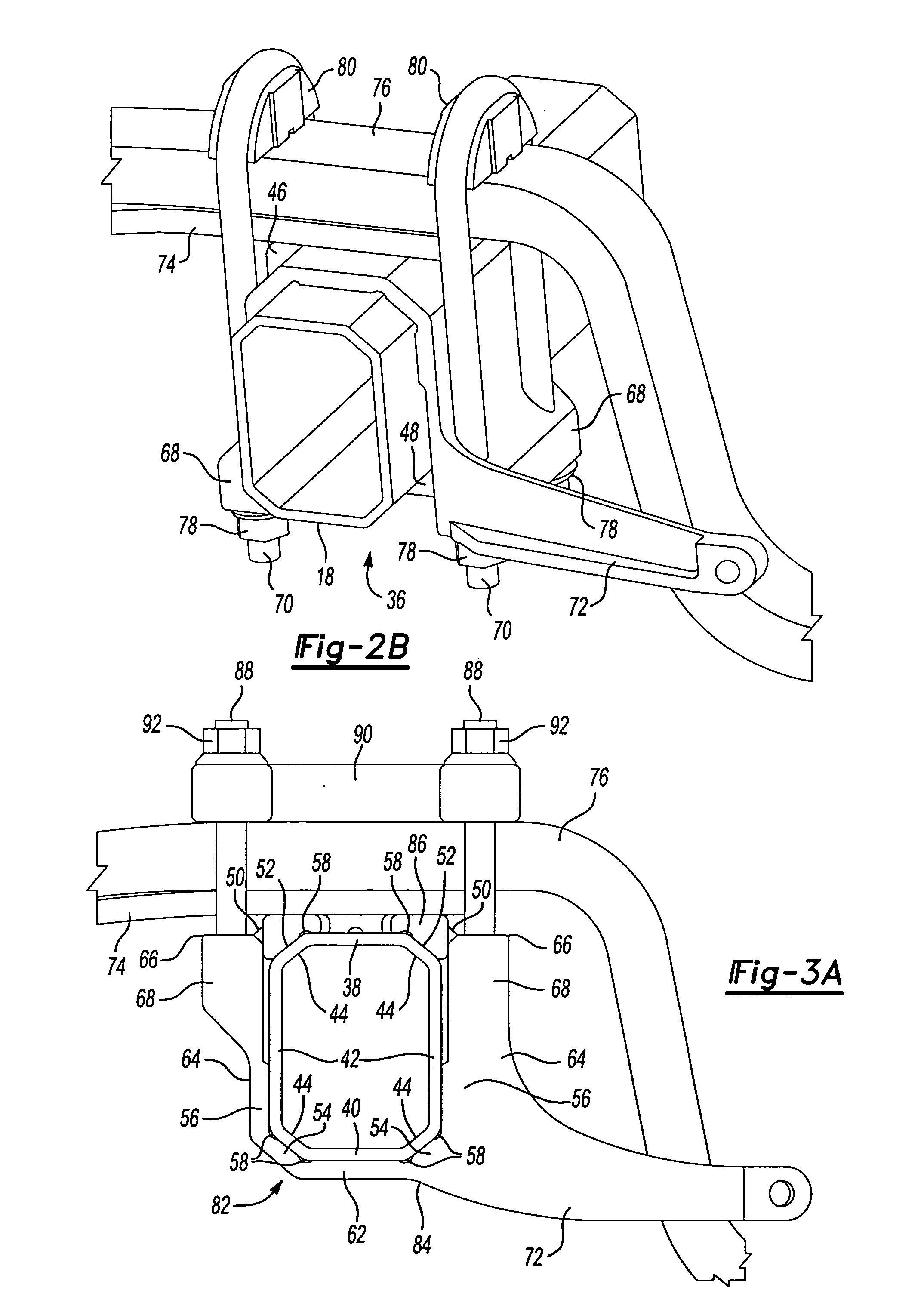

Preloaded suspension bracket assembly for axle housing

InactiveUS20050253351A1Easy to mergeSimple interfaceLeaf springsResilient suspensionsEngineeringMechanical engineering

An axle housing includes a suspension mount interface for mounting a vehicle suspension to the axle housing. The axle housing includes a first leg portion extending to a first wheel assembly and a second leg portion extending to a second wheel assembly. The first and second leg portions each include a suspension mount interface. Each suspension mount interface includes first and second bracket portions. The first and second bracket portions are clamped together prior to attachment to the axle housing to form a suspension bracket assembly. One clamped suspension bracket assembly is then slid over each axle housing leg portion. The first and second bracket portions are subjected to a preload force as they are welded or fastened to each other, providing a preload effect to define a suspension load path that has positive contact only at desired locations on the axle housing.

Owner:ARVINMERITOR TECH

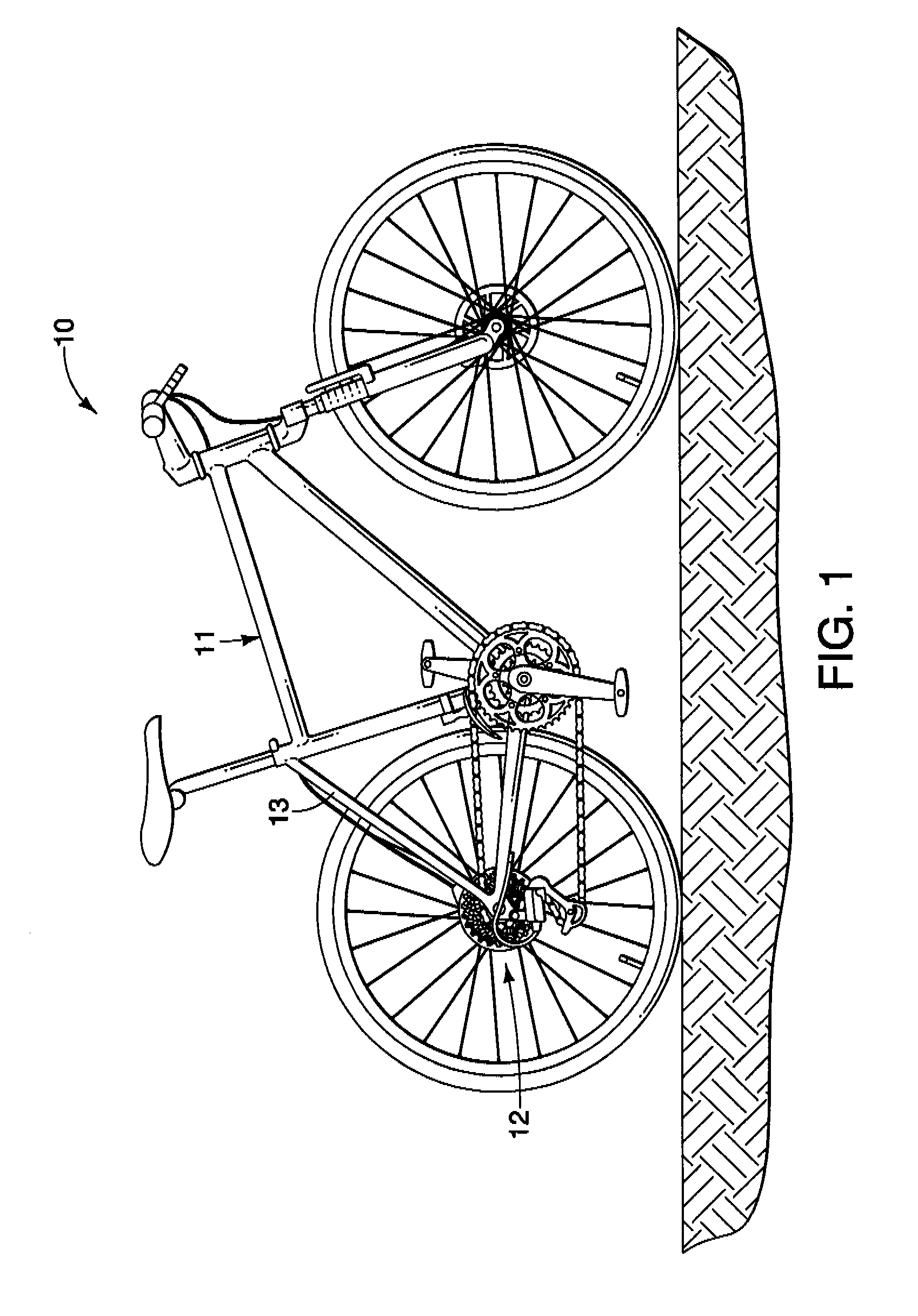

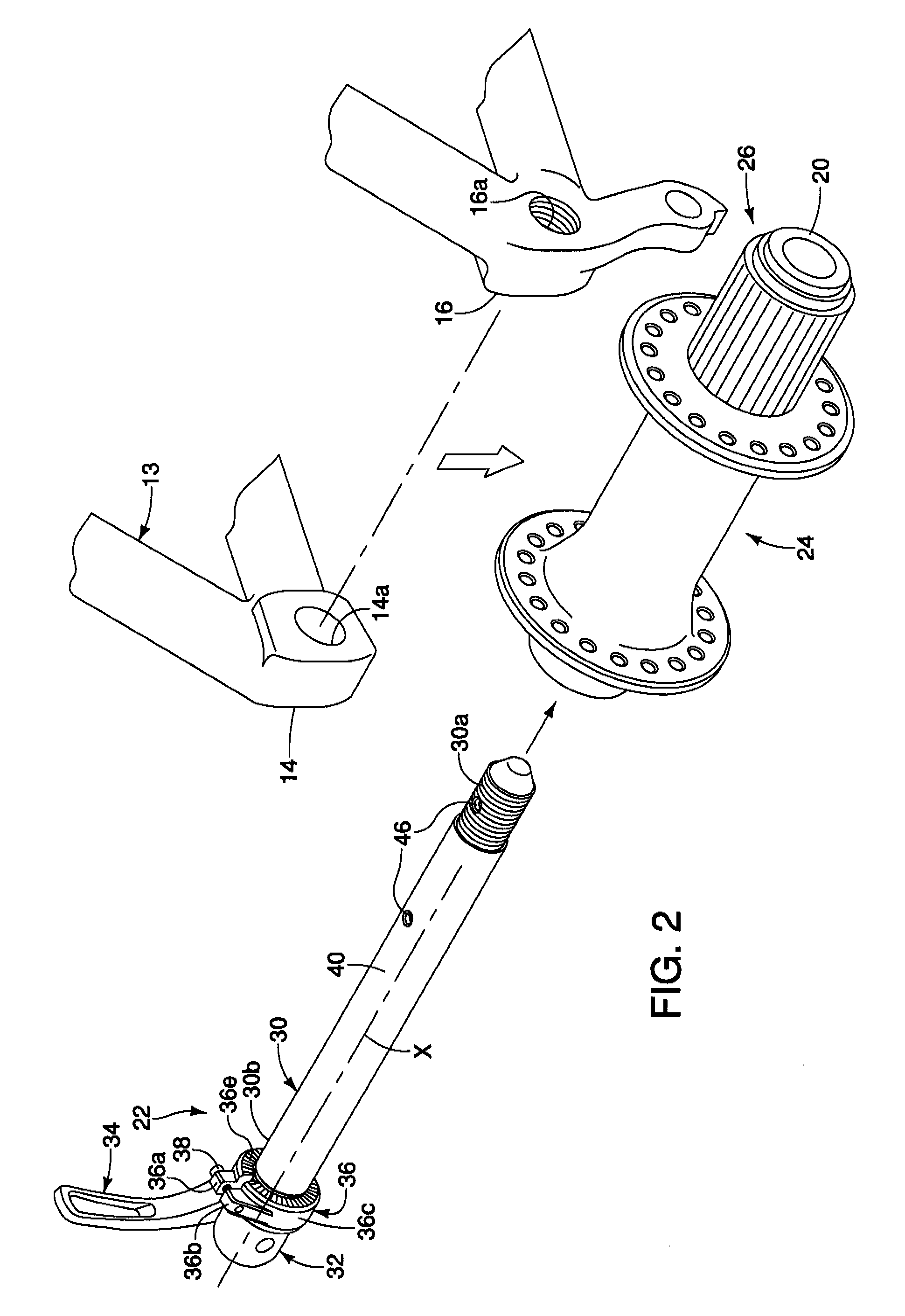

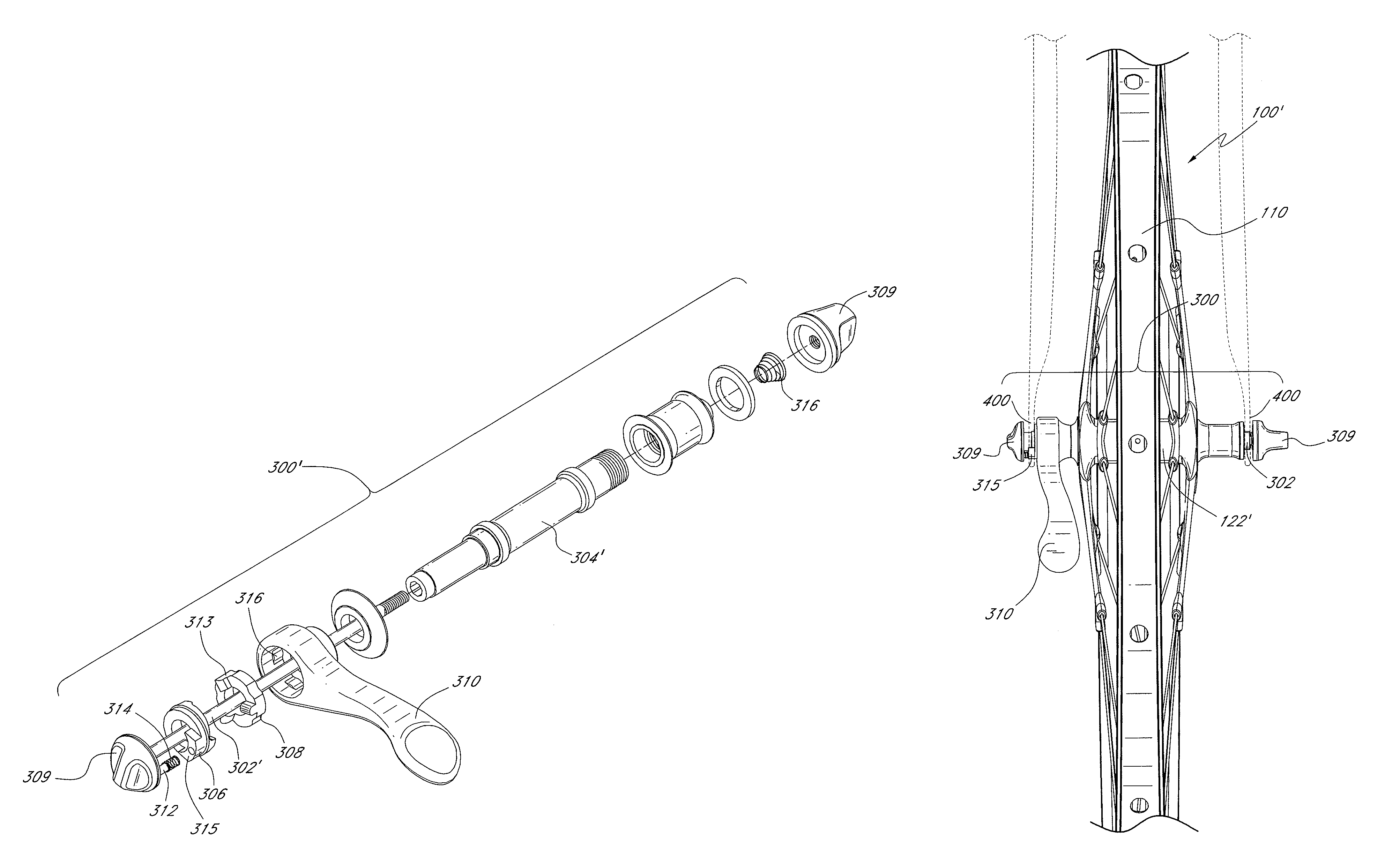

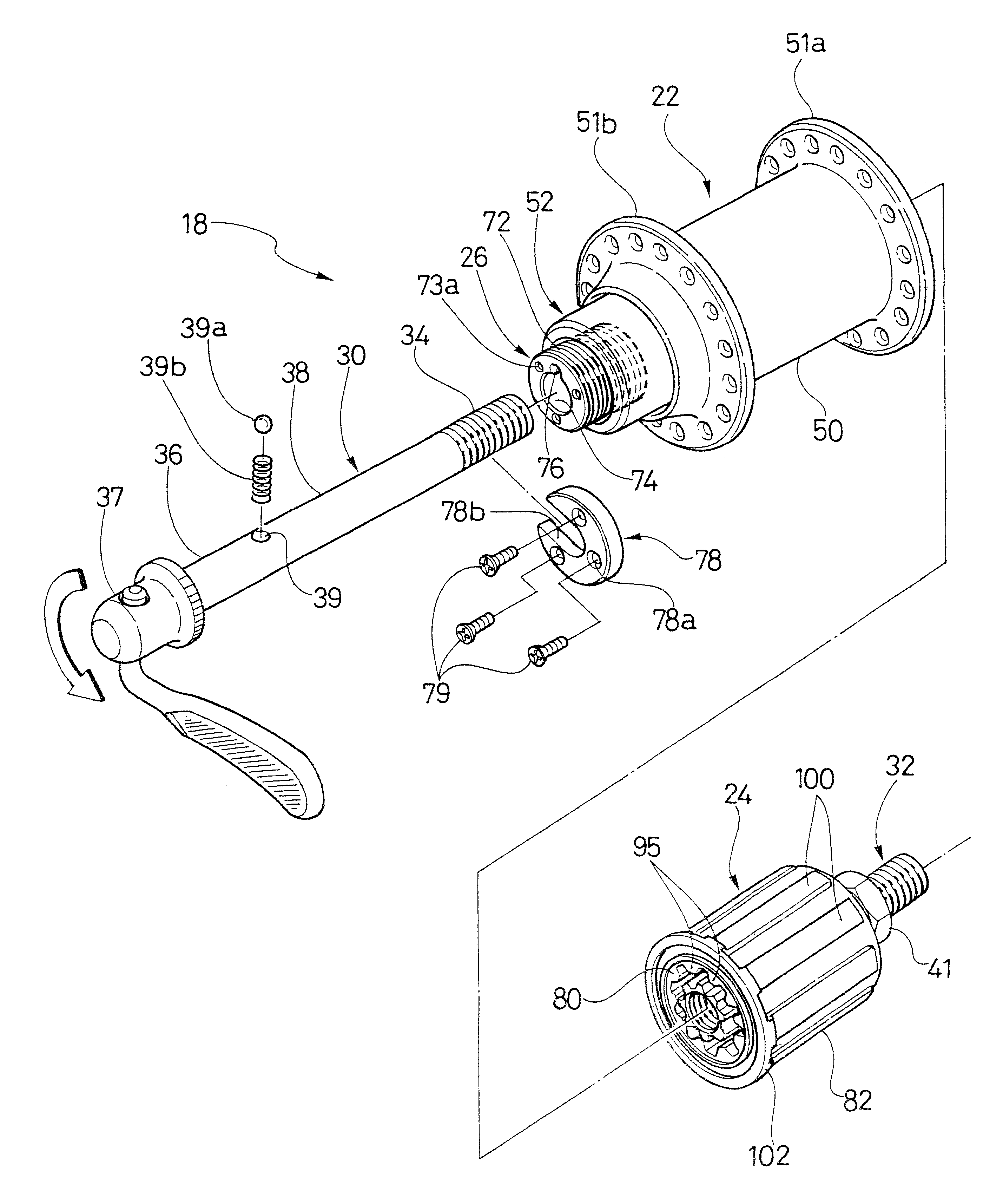

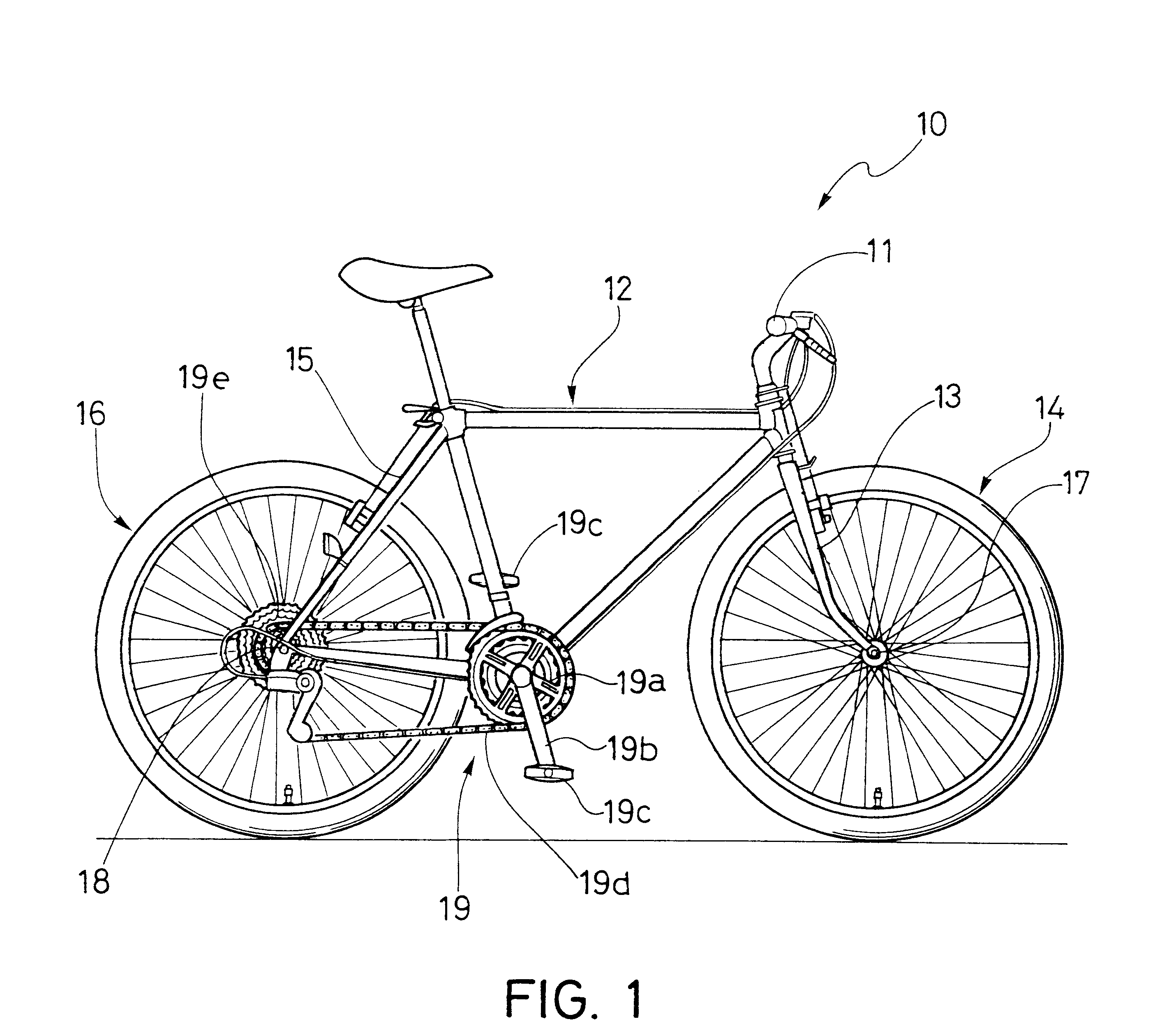

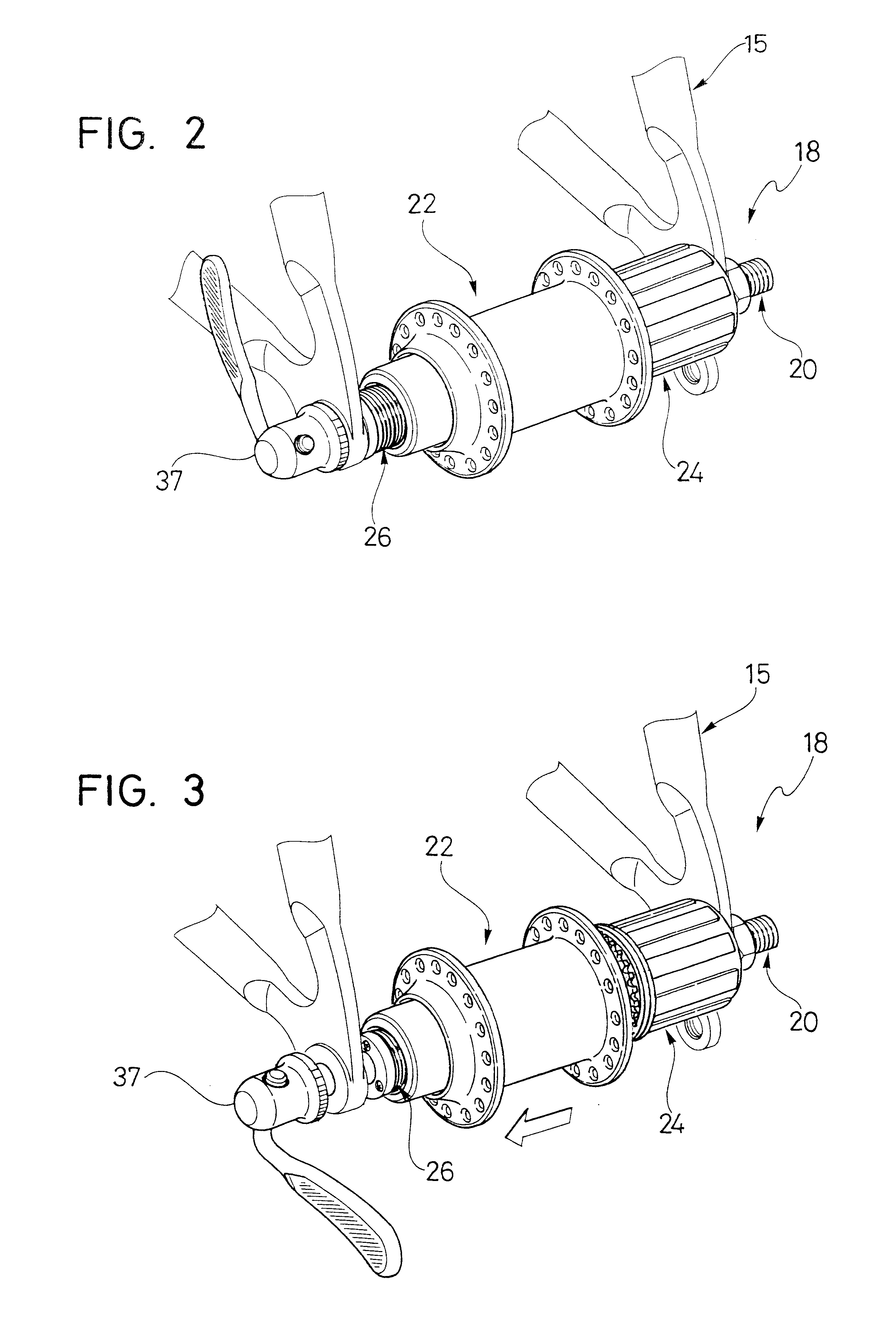

Bicycle wheel securing structure

ActiveUS7537291B2Easy to tightenClosely connectedHubsRod connectionsEngineeringMechanical engineering

A bicycle wheel securing structure includes a shaft member, a head member, a lever member and an adjustment member. The shaft member has a first threaded end and a second end with a center axis extending therebetween. The head member is disposed on the second end of the shaft member. The lever member is operatively mounted between the shaft member and the head member to move the shaft member in an axial direction relative to the head member in response to movement of the lever member. The adjustment member is axially adjustably coupled to the head member such that an axial position of an abutment surface of the adjustment member can be adjusted relative to the shaft member.

Owner:SHIMANO INC

Tractor with rear castor wheels

A hydrostatic agricultural tractor has front ground wheels mounted on the frame at fixed angles parallel to each other and parallel to a center line of the frame and rear ground wheels mounted on a respective castor, with each of the front ground wheels being driven by a respective drive motor which allows variable speed in both the first and second directions such that steering of the tractor is effected by a differential in speed between the front wheels with the rear wheels following the steering in a castoring action. A pair of damper cylinders is provided each connected between a bracket on a rear axle of the frame and a lever in the castor plane of the castor so as to provide a damping force tending to restrict rotation of the respective second wheel about the respective vertical pivot axis with the damping force at a maximum value when the rear wheels are parallel to the center line in either the forward or reverse directions.

Owner:MACDON INDS

ATV transmission

An all terrain vehicle comprises a frame supported by at least a left wheel and a right wheel. The left wheel and the right wheel being connected to said frame by a left suspension and a right suspension respectively. The independently suspended wheels preferably are drive wheels. The wheels are driven by an engine through a transmission. The transmission is connected to the left wheel by a left half shaft and to the right wheel by a right half shaft. Constant velocity couplings are used to coupling the half shafts to the respective wheels and to the transmission. The constant velocity couplings connecting the two half shafts to the transmission are joined in a single housing. The housing includes a body portion and a gear portion. The two portions can be integrally formed. A left cage and a right cage are mounted within a left axial bore and a right axial bore formed in the body portion. The cages are secured for rotation with the body portion but can move axially within the respective bores. The two half shafts similarly are secured for rotation with the cages. The half shafts can be connected to the cages with respective inner members. The two bores can be combined or separated by a dividing wall.

Owner:YAMAHA MOTOR CO LTD

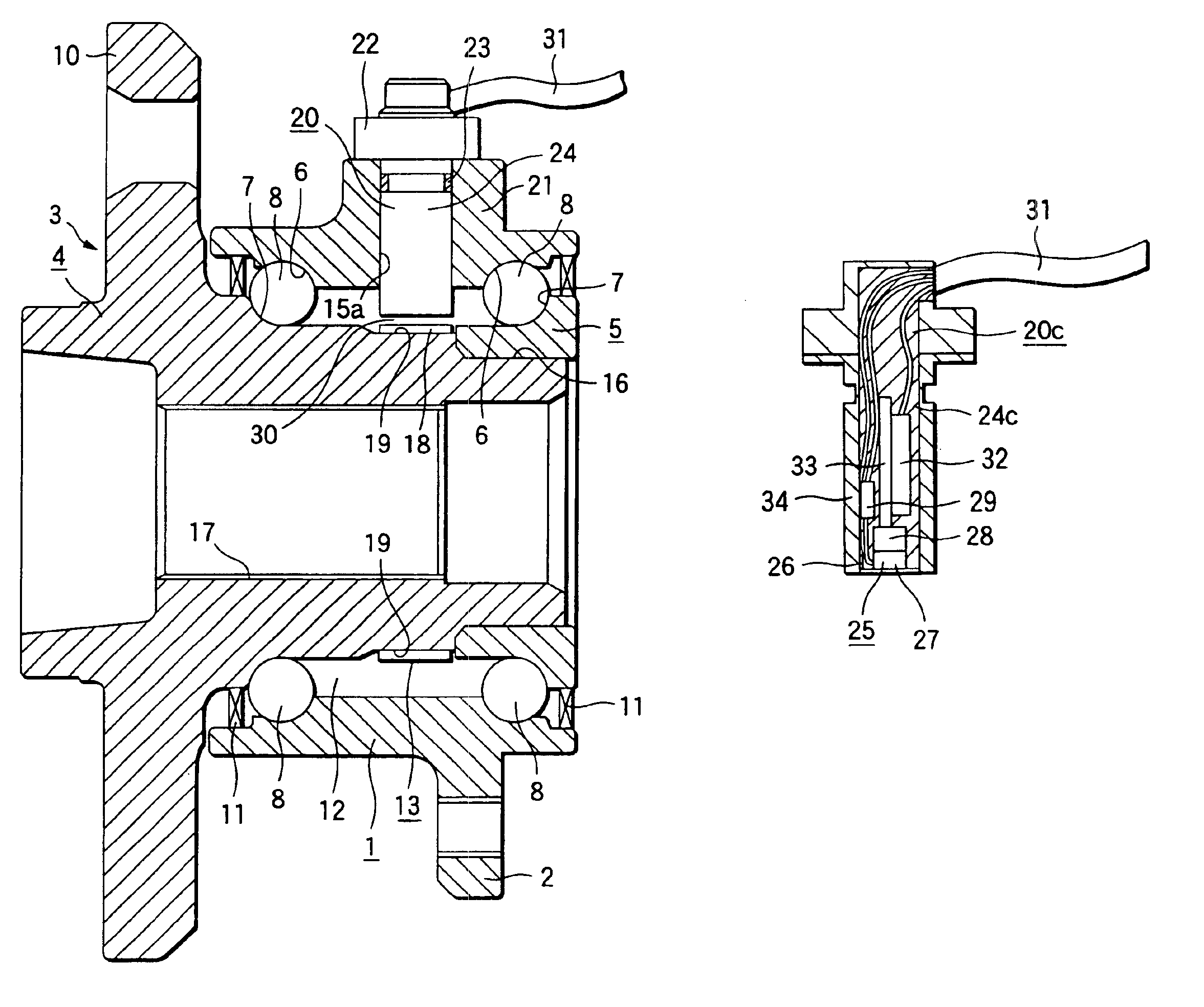

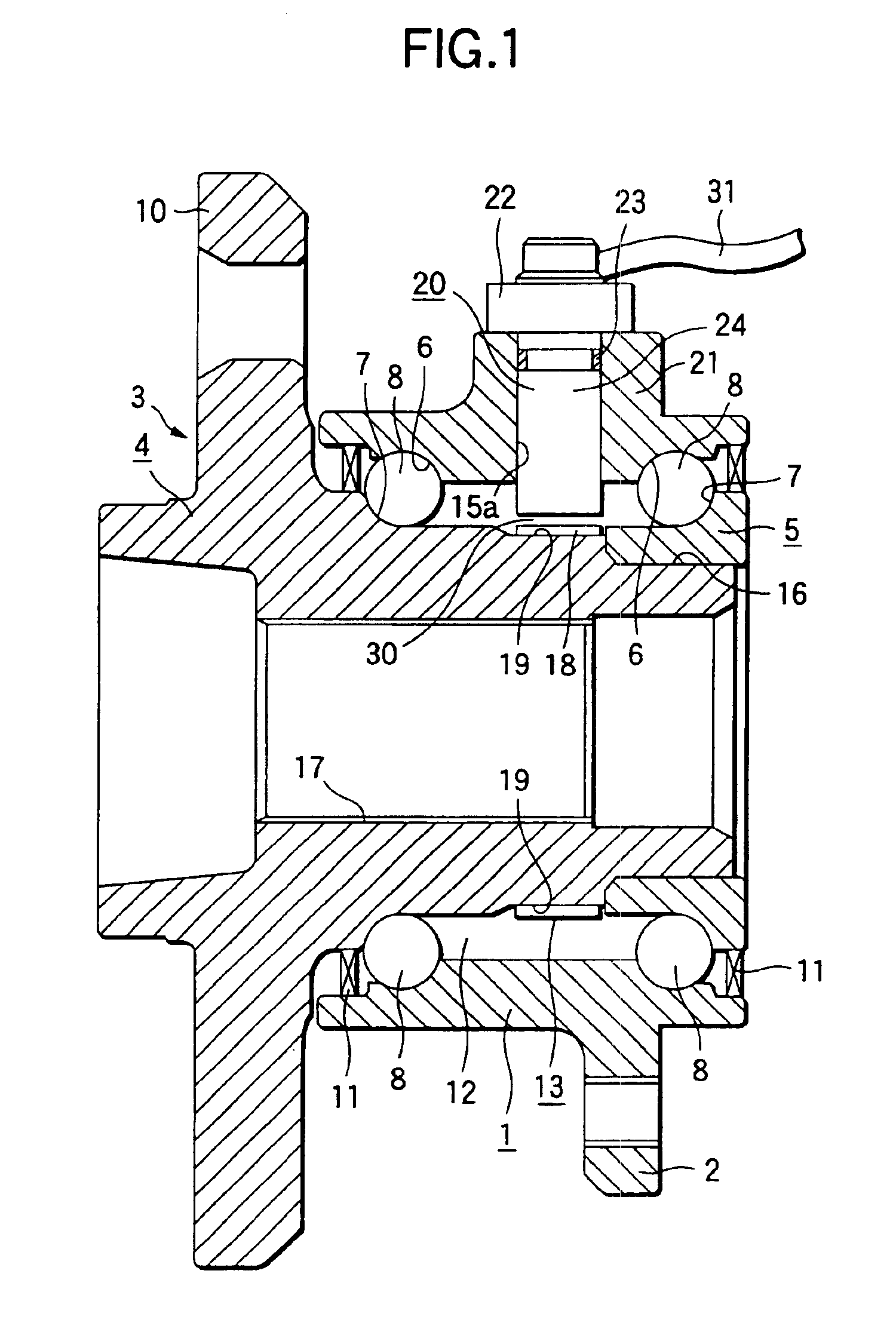

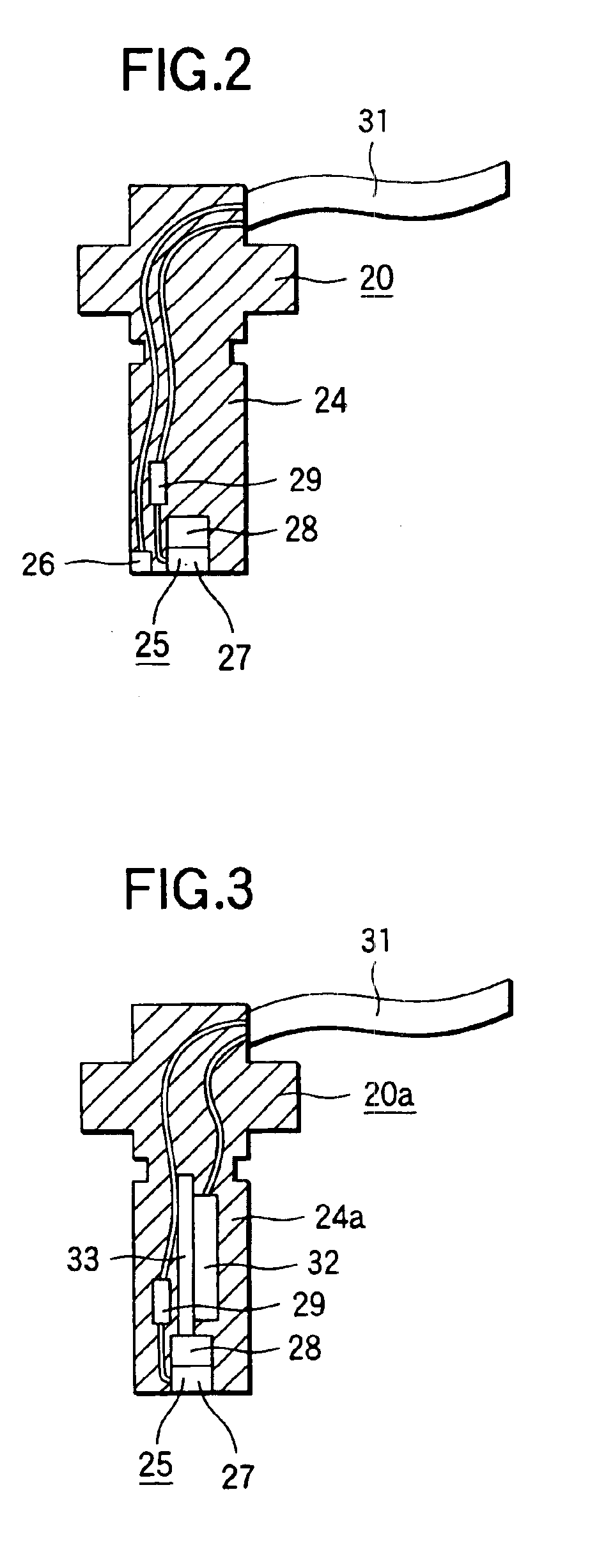

Wheel rotation detecting device

InactiveUS6894484B2Increase spacingWeight increaseVibration measurement in solidsMachine part testingCar drivingEngineering

A wheel rotation detecting device including a sensor unit that is supported on a stationary ring which does not rotate even when the wheel is in use, and the rotation of the wheel that is attached to a rotary ring can be detected by a rotation detecting sensor held within the sensor unit. Within the sensor unit, in addition to a rotation detecting sensor, there are disposed other sensors such as a temperature sensor and a vibration sensor, thereby allowing detection of the rotation speed and the rotation number of the wheel supported on the rotary ring, as well as detection of other car driving conditions.

Owner:NSK LTD

Axle spindle nut assembly for heavy-duty vehicles

InactiveUS20070052287A1Economical and durable and less to installEliminate and minimize possibilityRolling contact bearingsHubsEngineeringHeavy duty

An axle spindle nut assembly secures a wheel end assembly on an axle spindle. The wheel end assembly includes outboard and inboard outboard bearings that are immovably mounted on the axle spindle, and a wheel hub which is rotatably mounting on the bearings. The spindle nut assembly includes a nut that threads onto an outboard end of the axle spindle, and is tightened against the outboard bearing to a selected torque level. The nut includes an outboard surface that is formed with a plurality of features. A washer is formed with a tab that engages a keyway of the axle spindle outboardly of the nut, and with a plurality of mating features that mechanically engage the features formed in the outboard surface of the nut to prevent substantial rotation of the nut after the nut has been tightened to the selected torque level.

Owner:HENDRICKSON USA L L C

Vehicle having variable track

ActiveUS20130062133A1Increase widthSteering linkagesUnderstructuresEngineeringAutomotive engineering

Owner:JAXA NETWORKS

Installation structure for electric rotating machine in motor vehicle

InactiveUS7121367B2Strengthen restrictionsReduce designSuspensionsElectric propulsion mountingEngineeringFlange

An installation structure for an electric rotating machine such as an electric motor to a wheel of a motor vehicle. The installation structure comprises a wheel hub fixed to and rotatable with the wheel. A bearing through which the wheel hub is rotatably supported is provided. A suspension is installed between a vehicle body of the motor vehicle and the wheel. A bearing support member is connected to a wheel-side section of the suspension and supports the bearing. In the above installation structure, the electric rotating machine includes a power output shaft which is in fit with the wheel hub, and a flange for location of the electric rotating machine in a direction of axis of the power output shaft, the flange being brought into contact with a wheel-side section of the bearing support member.

Owner:NISSAN MOTOR CO LTD

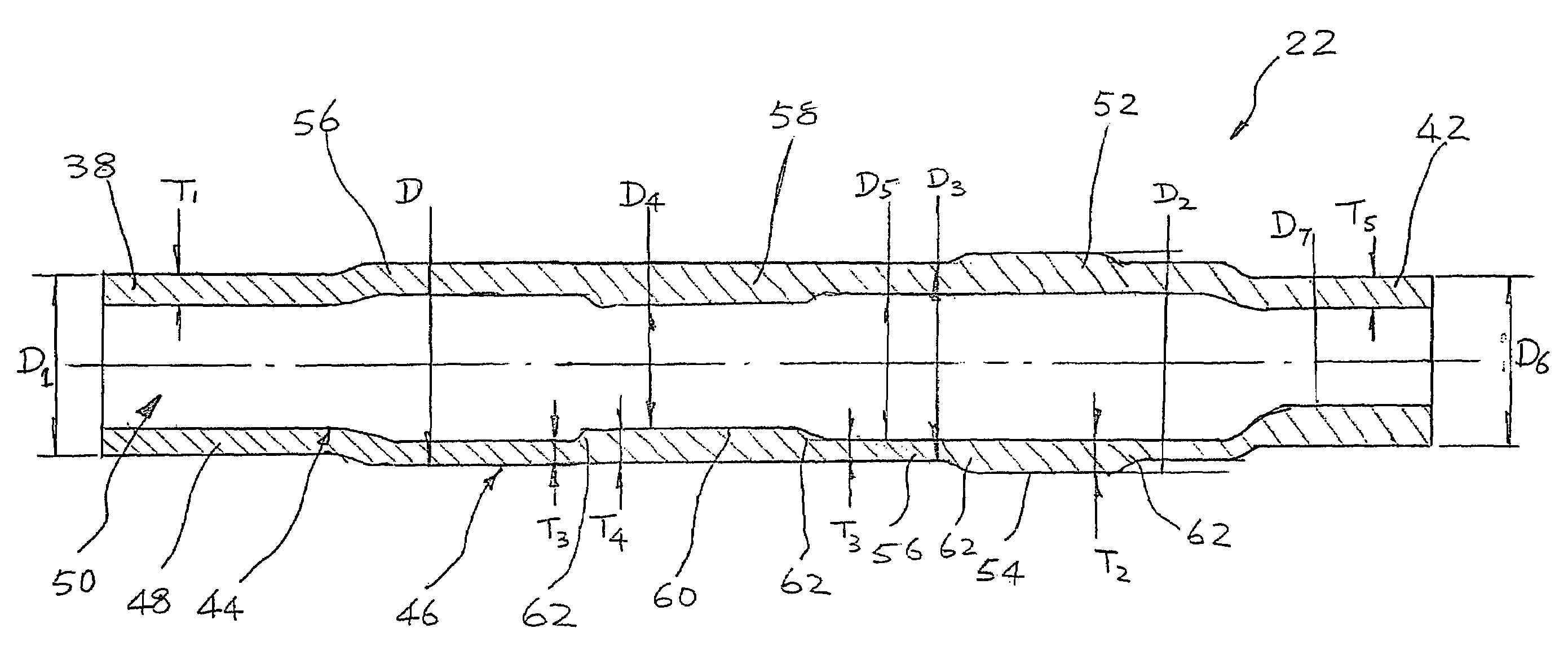

Tubular articles with varying wall thickness and method of manufacturing same

Owner:AAM INT S A R L

Tractor having a convertible front end and variable track width and related methods

InactiveUS6902022B2Promote repairPromote conversionCarriage/perambulator accessoriesSteering linkagesEngineeringActuator

A tractor having a front end and a rear end adaptable for a variety of different environments. Methods related to the conversion of the tractor are also disclosed. In one embodiment, the invention includes a front wheel assembly that is removably attached to the front end of the tractor to facilitate adaptation of the tractor a various environments. Also, a steering actuator is removably attached to the front wheel assembly and fixedly attached to the chassis of the tractor.

Owner:SOC FOR RES & INITIATIVES FOR SUSTAINABLE TECH & INSTITUTIONS

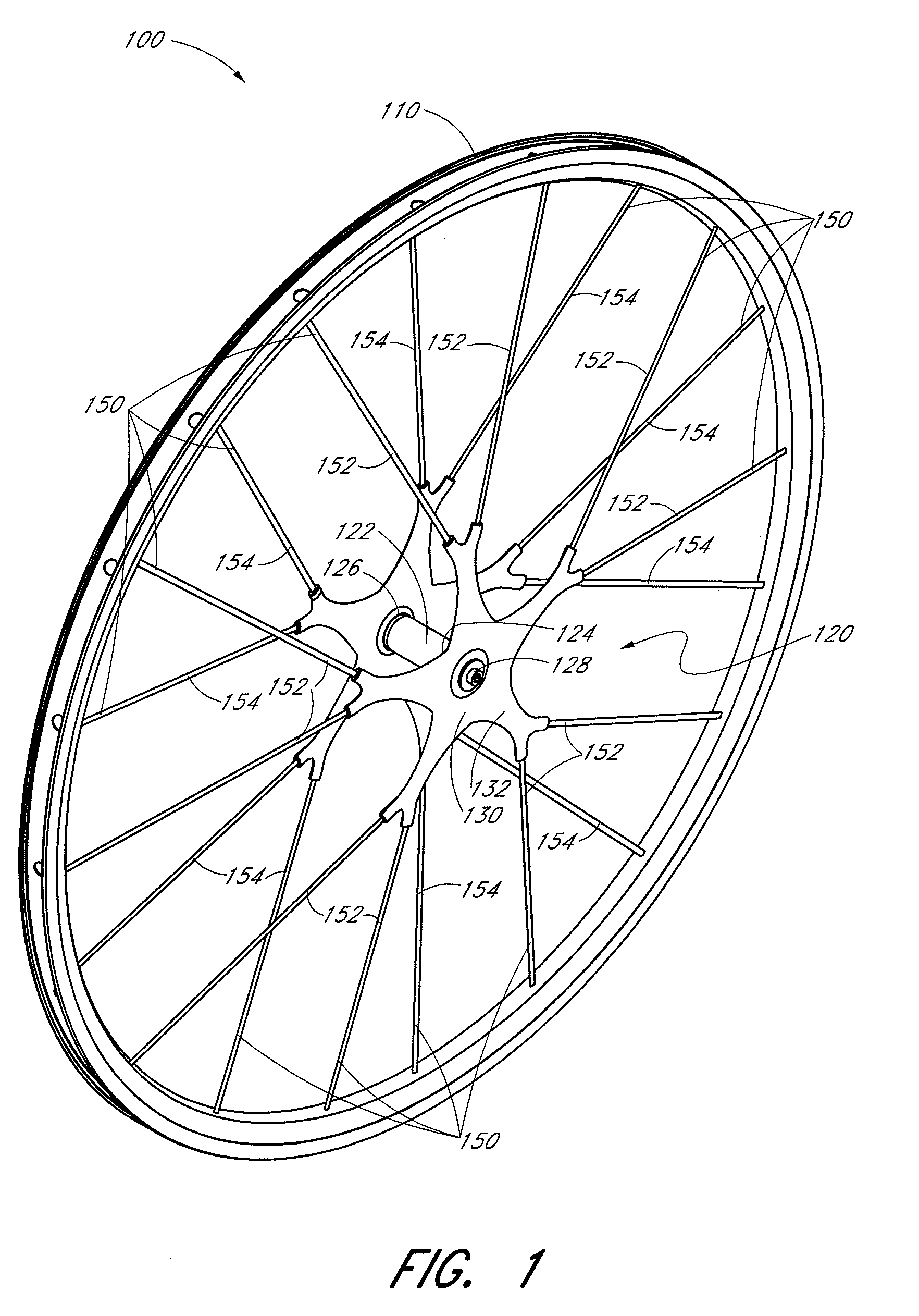

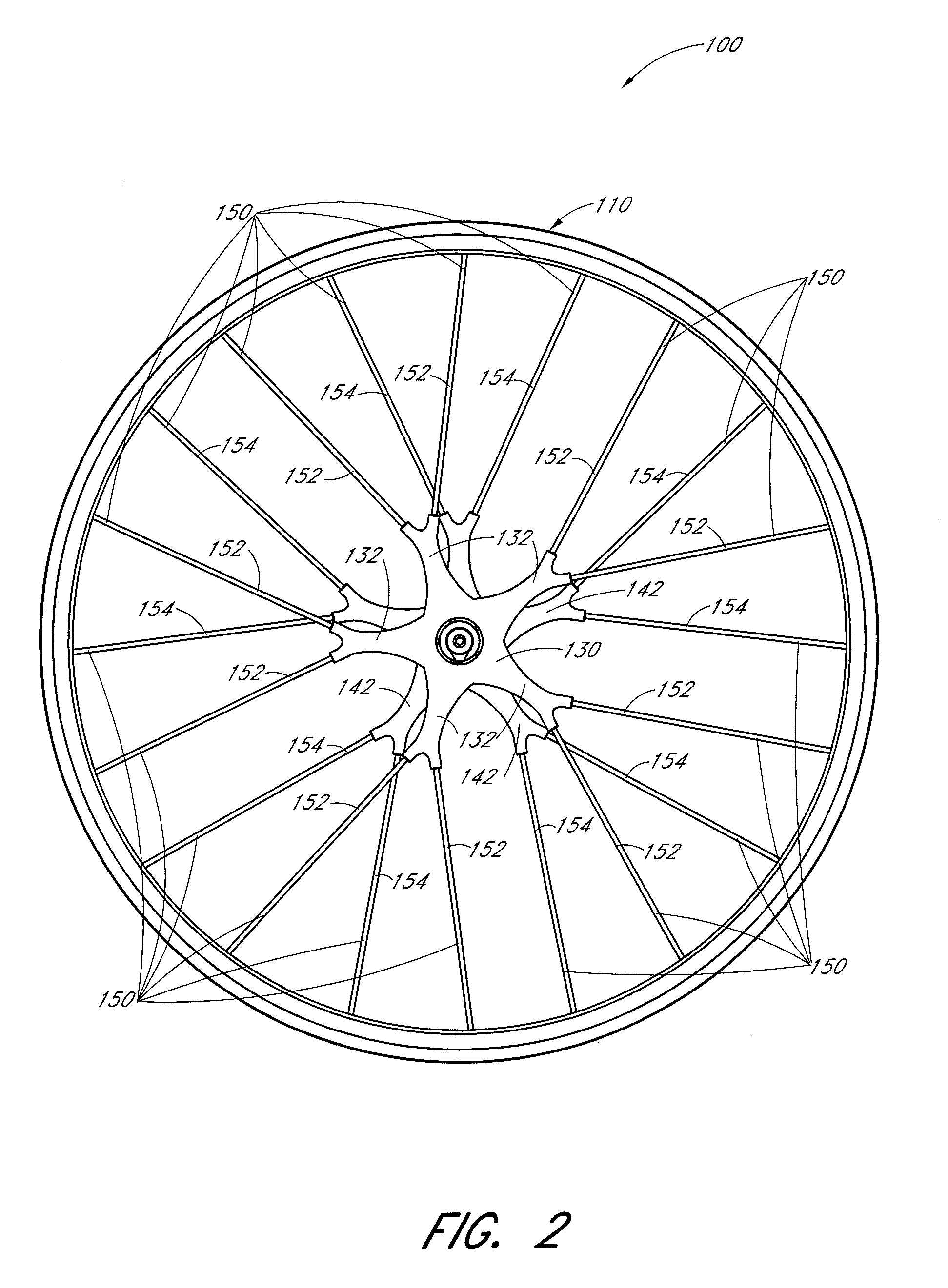

Bicycle wheel and release mechanism

InactiveUS7562942B2Reduce weightSignificant drawbackWheel based transmissionFrictional rollers based transmissionEngineeringFixed position

Owner:SPECIALIZED BICYCLE COMPONENTS INC

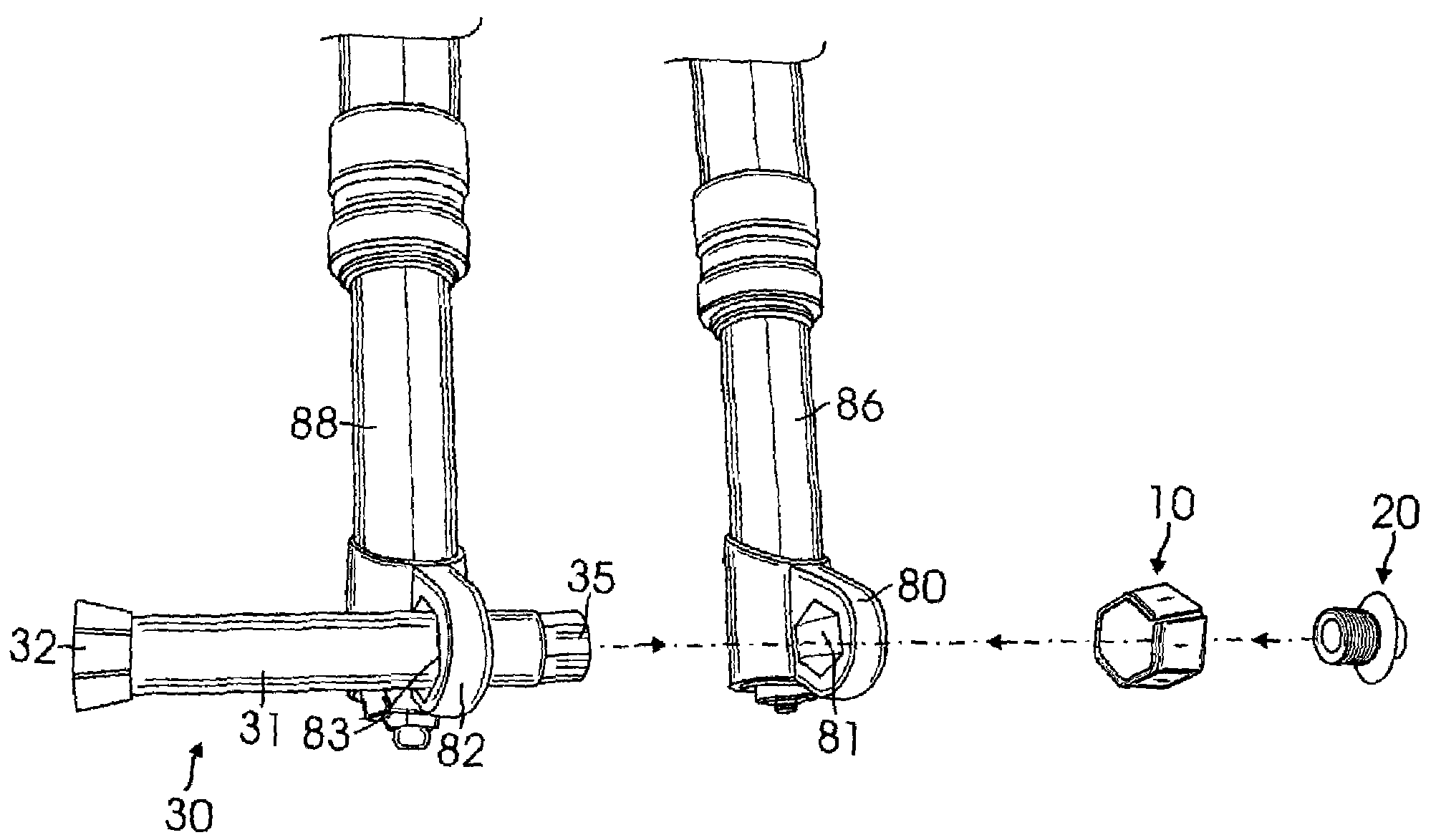

Bicycle hub with threaded spacer and detachable freewheel

InactiveUS6435622B1Easy to installSimple and inexpensive to manufactureWheel based transmissionHubsFreewheelSprocket

A bicycle hub includs a hub axle, a hub body, a sprocket support member and a spacer. The hub axle has first and second portions threadedly coupled together via a first threaded connection. The hub body has an outer tubular portion and an interior passageway with the first portion of the hub axle rotatably supported therein. The sprocket support member is releasably and non-rotatably coupled to the outer tubular portion and is mounted on the second portion of the hub axle. The spacer is non-rotatably and axially movably supported on the first portion of the hub axle and is threadedly coupled to the hub body via a second threaded connection. The first and second threaded connections are configured such that rotation of the hub axle to release the first and second portions causes the spacer to move axially toward the hub body.

Owner:SHIMANO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com