Patents

Literature

6016results about "Rolling contact bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

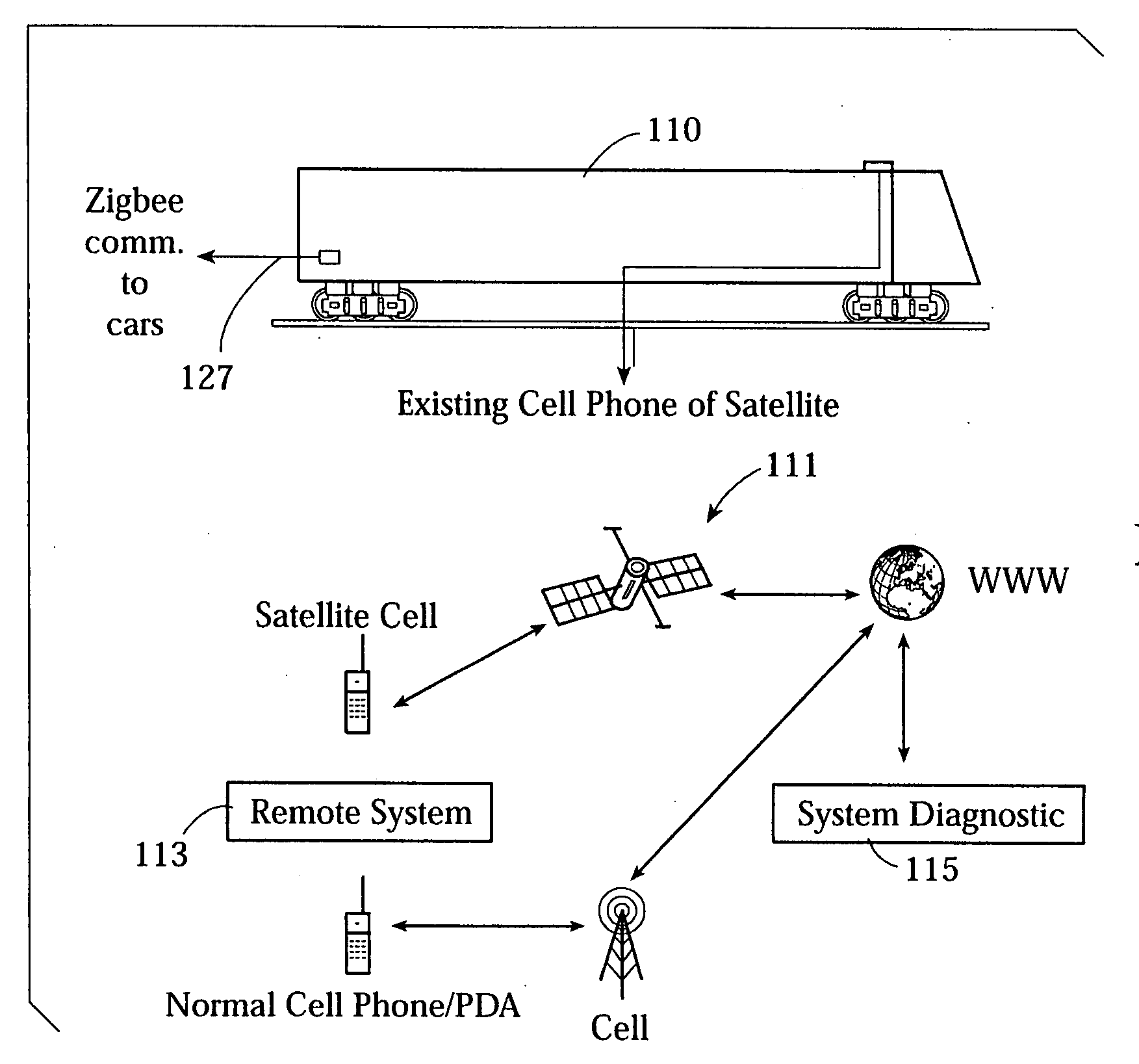

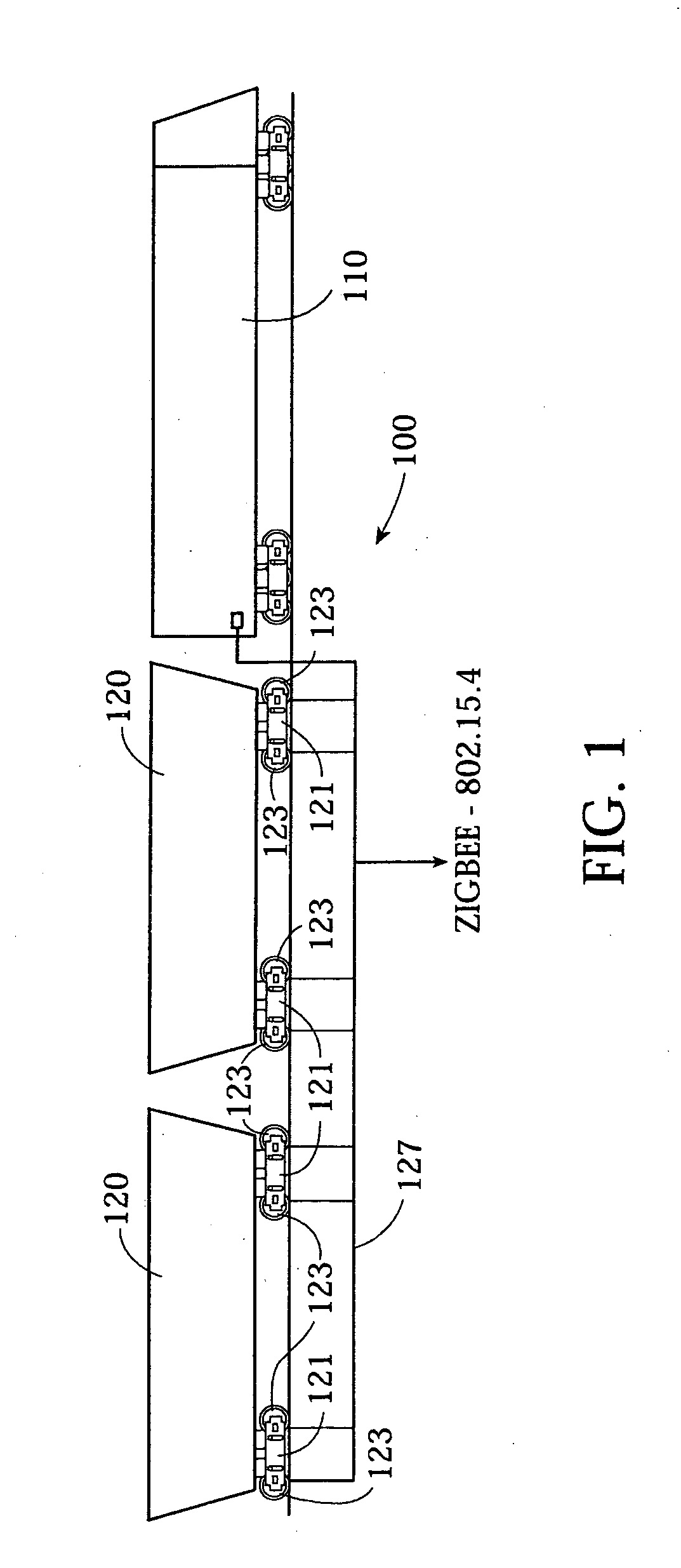

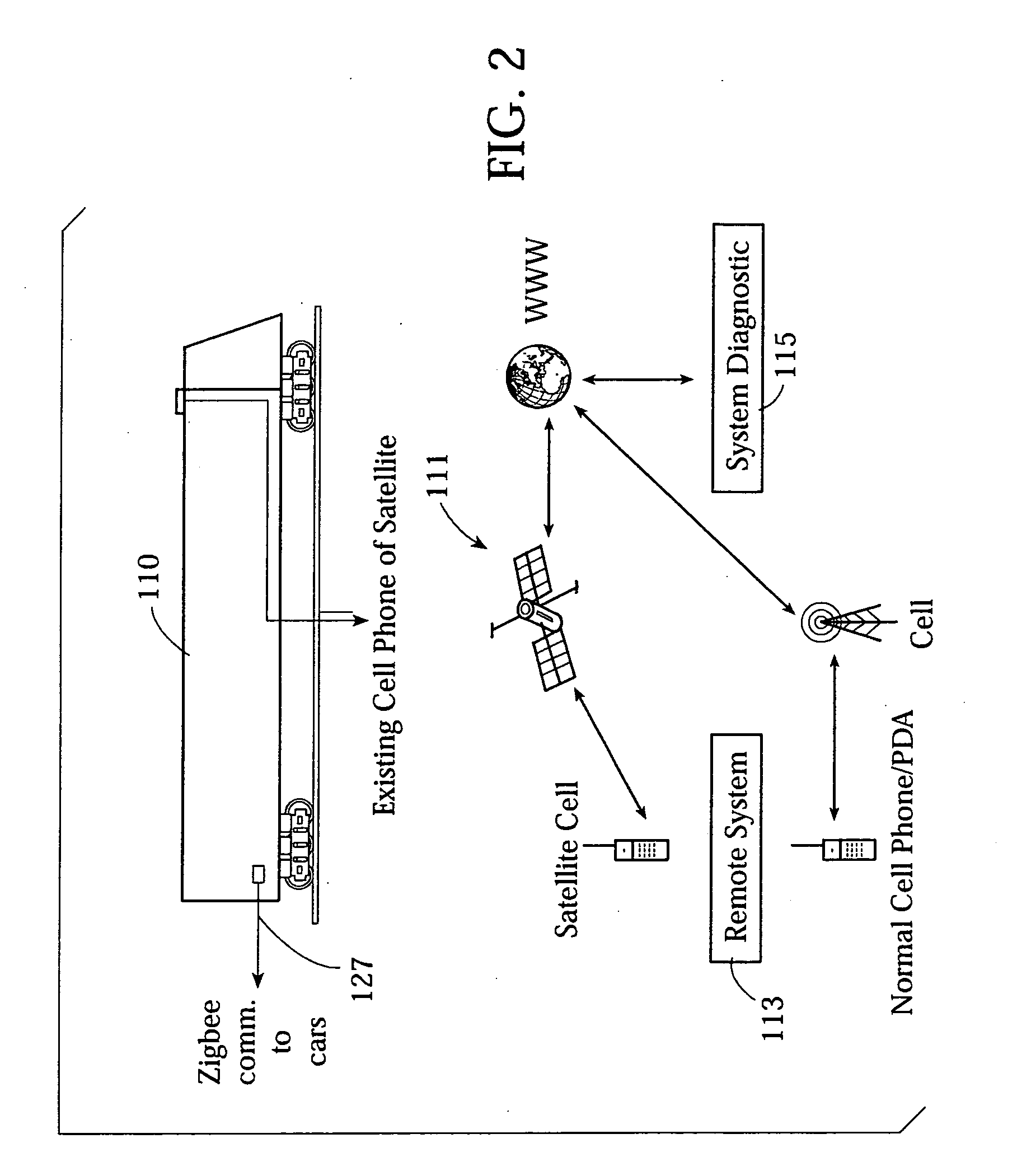

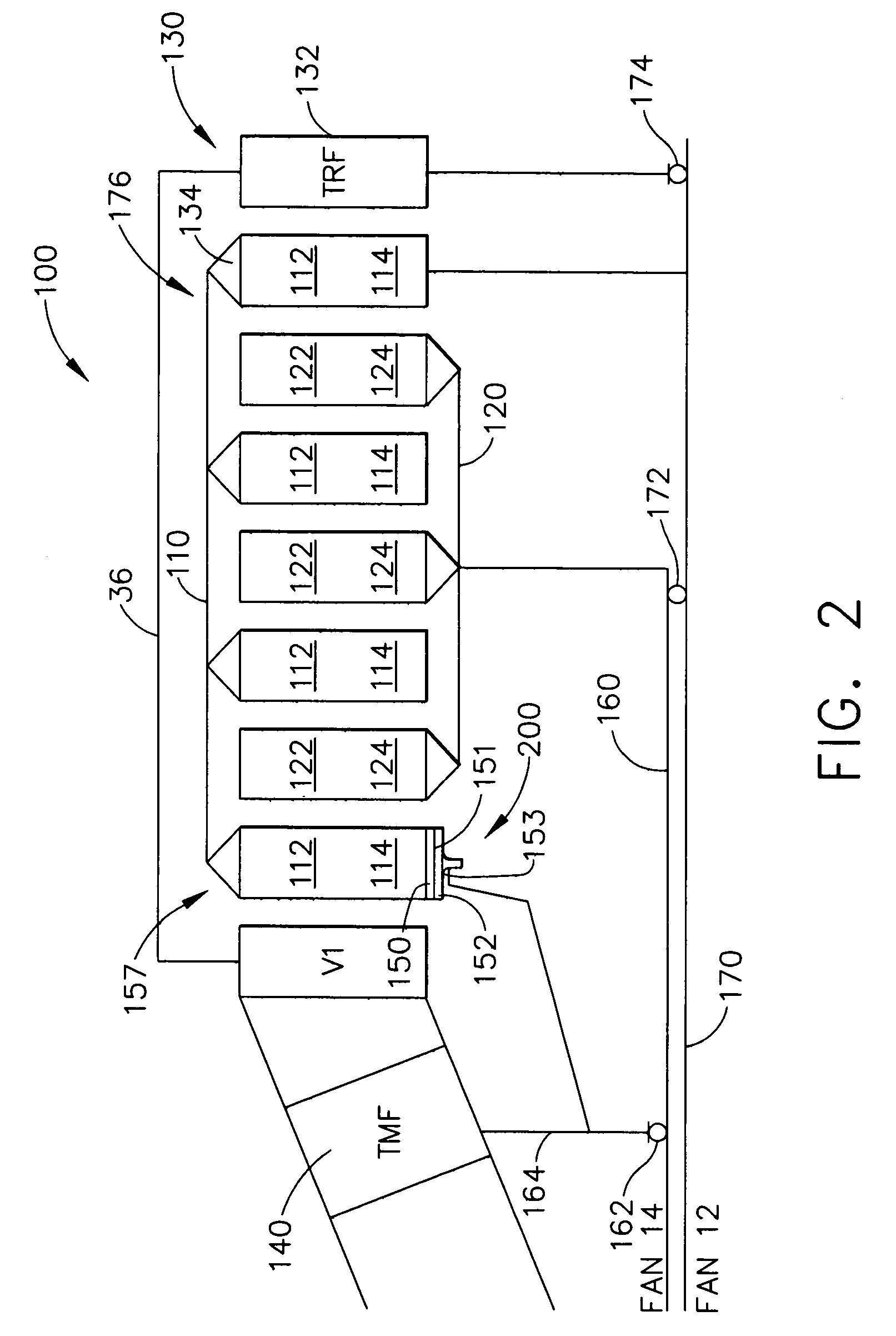

Self-assembling wireless network, vehicle communications system, railroad wheel and bearing monitoring system and methods therefor

ActiveUS20070208841A1Continuous monitoringAccurate data analysisRolling contact bearingsMeasurement devicesWireless mesh networkCommunications system

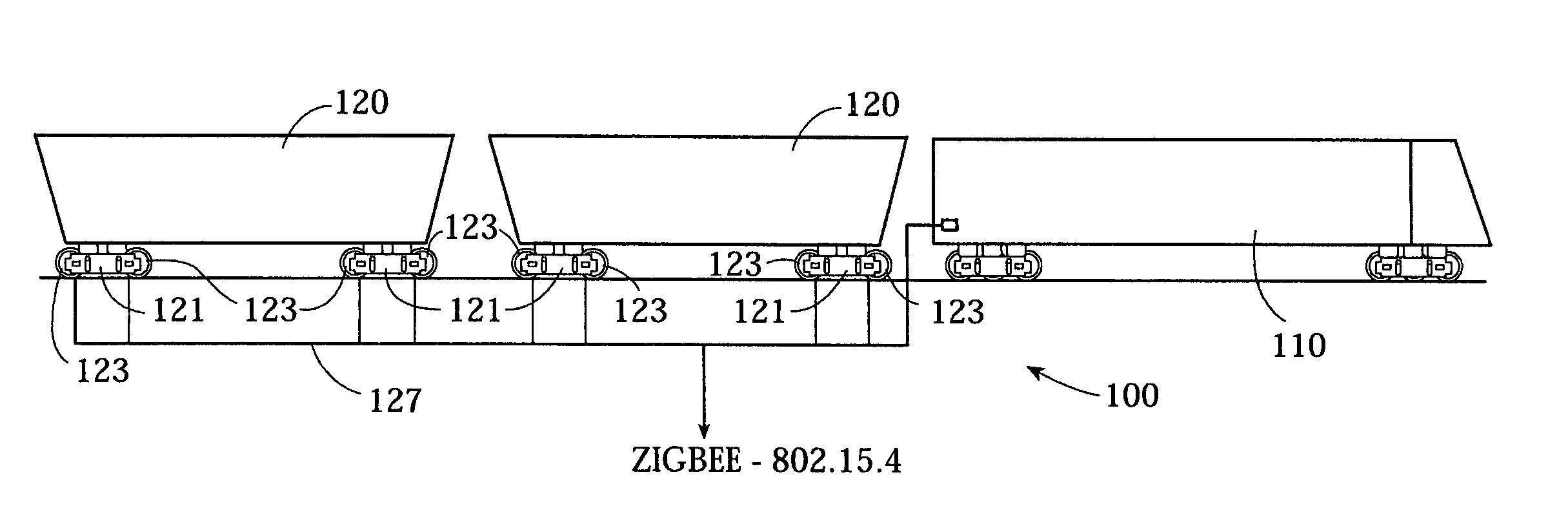

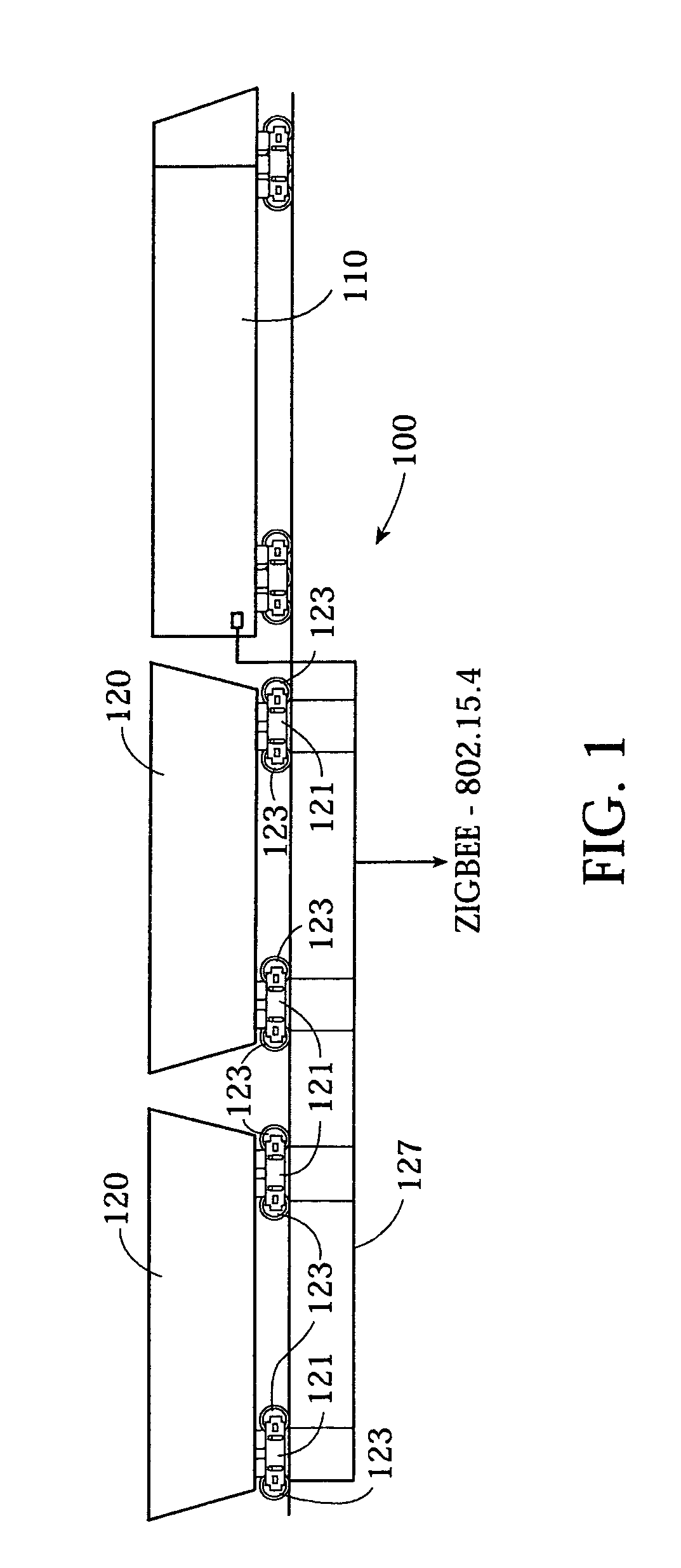

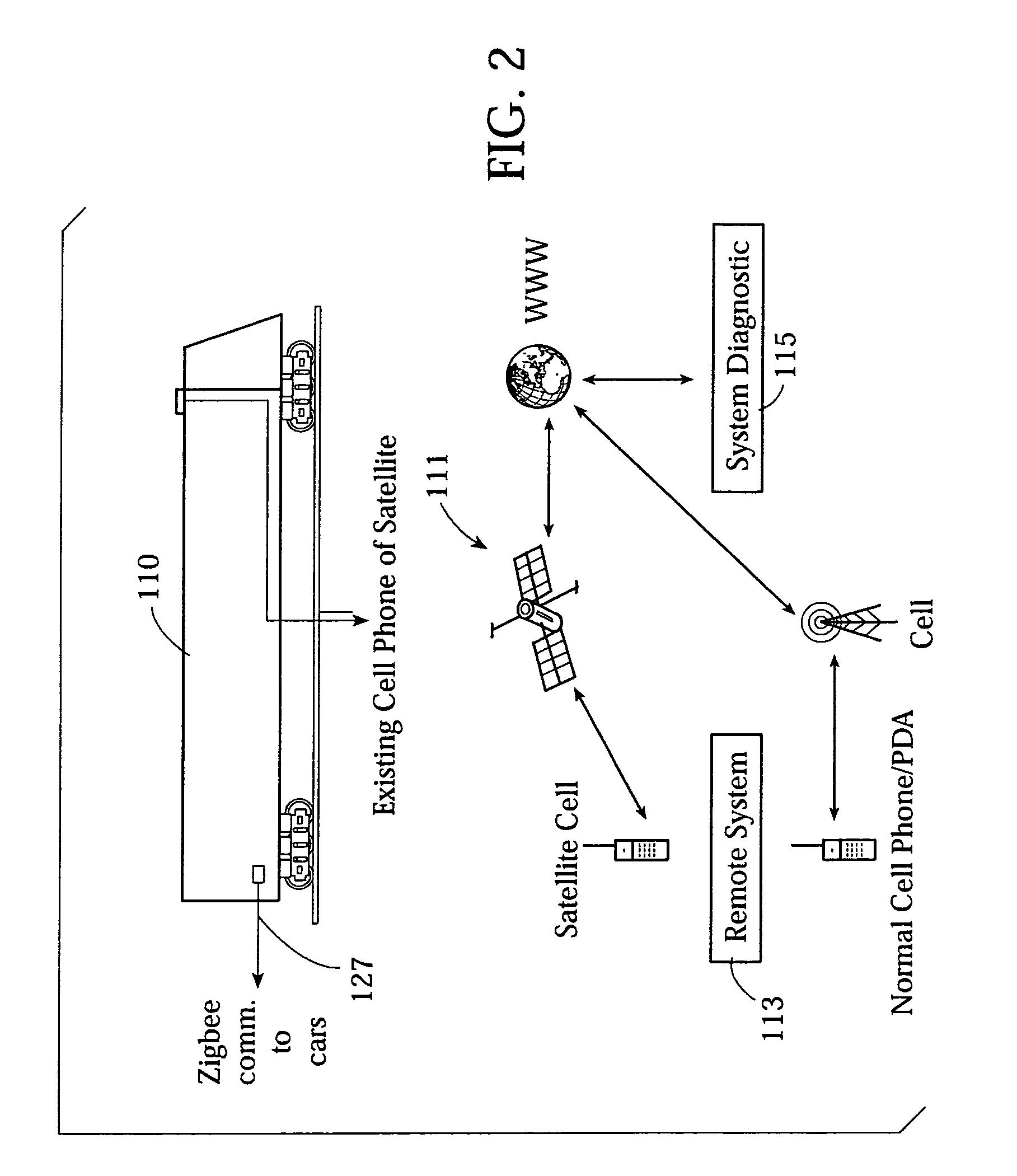

A low power self-organizing network is made up of a plurality of wireless communication nodes communicating wirelessly with each other. The nodes each have a sensor providing a respective sensor data value indicative of a physical parameter in the environment of that node. The wireless network discontinues communication with any nodes in which the sensor data value is outside a range of network sensor data values. The network is preferably a group of vehicles moving together, especially a train in which each node is associated with a respective wheel of a railroad car. The nodes are low-power devices that communicate using wireless communications according to a Zigbee protocol. The nodes each have an additional sensor sensing a physical parameter the respective wheel thereof and determines from said electrical signal a degree of degradation of a bearing of the wheel, and transmits data of the degree of degradation to the main node. The main node communicates with another computer system using a higher power communication system and transmits thereto data indicative of degradation of said bearings.

Owner:CONVEY INC

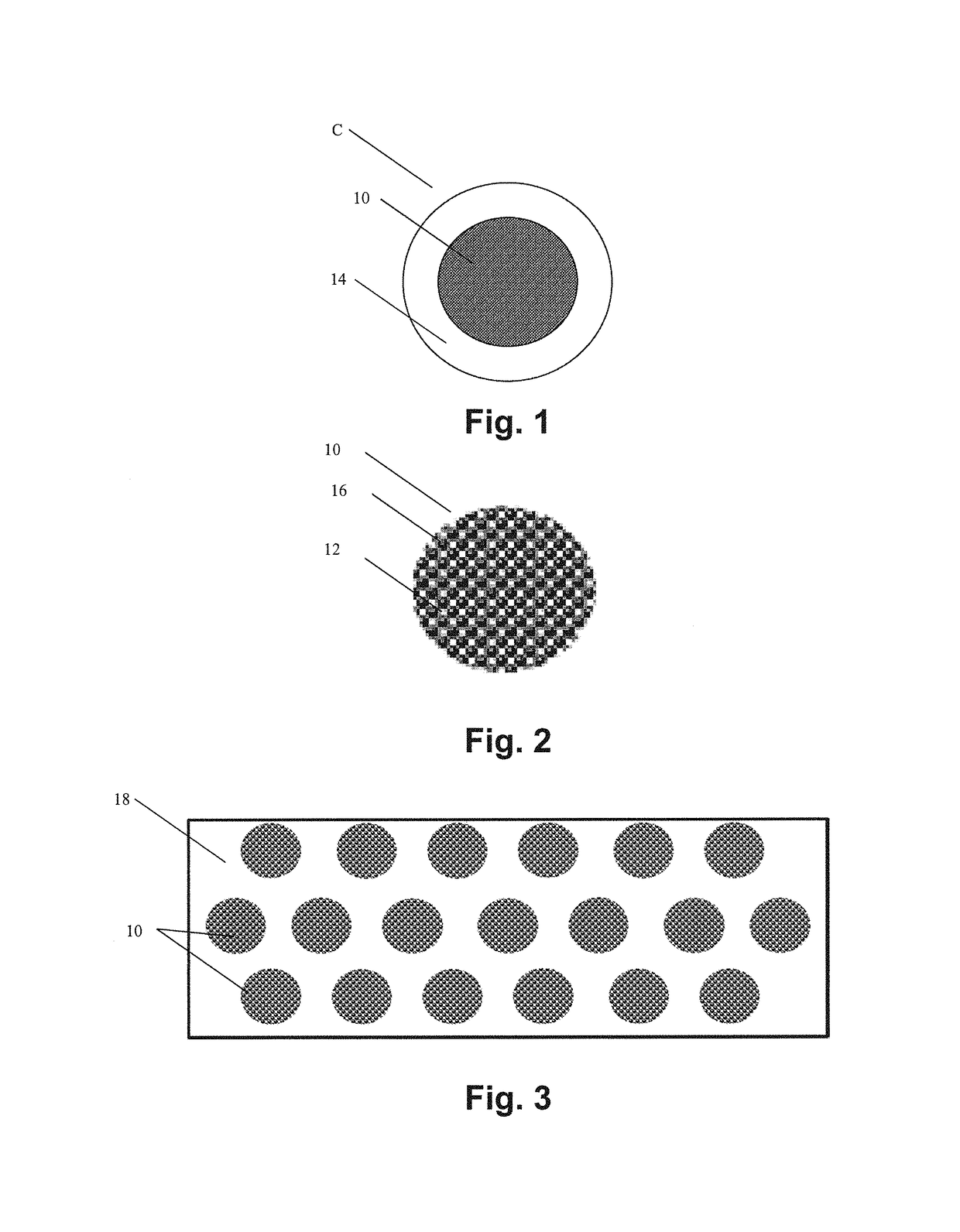

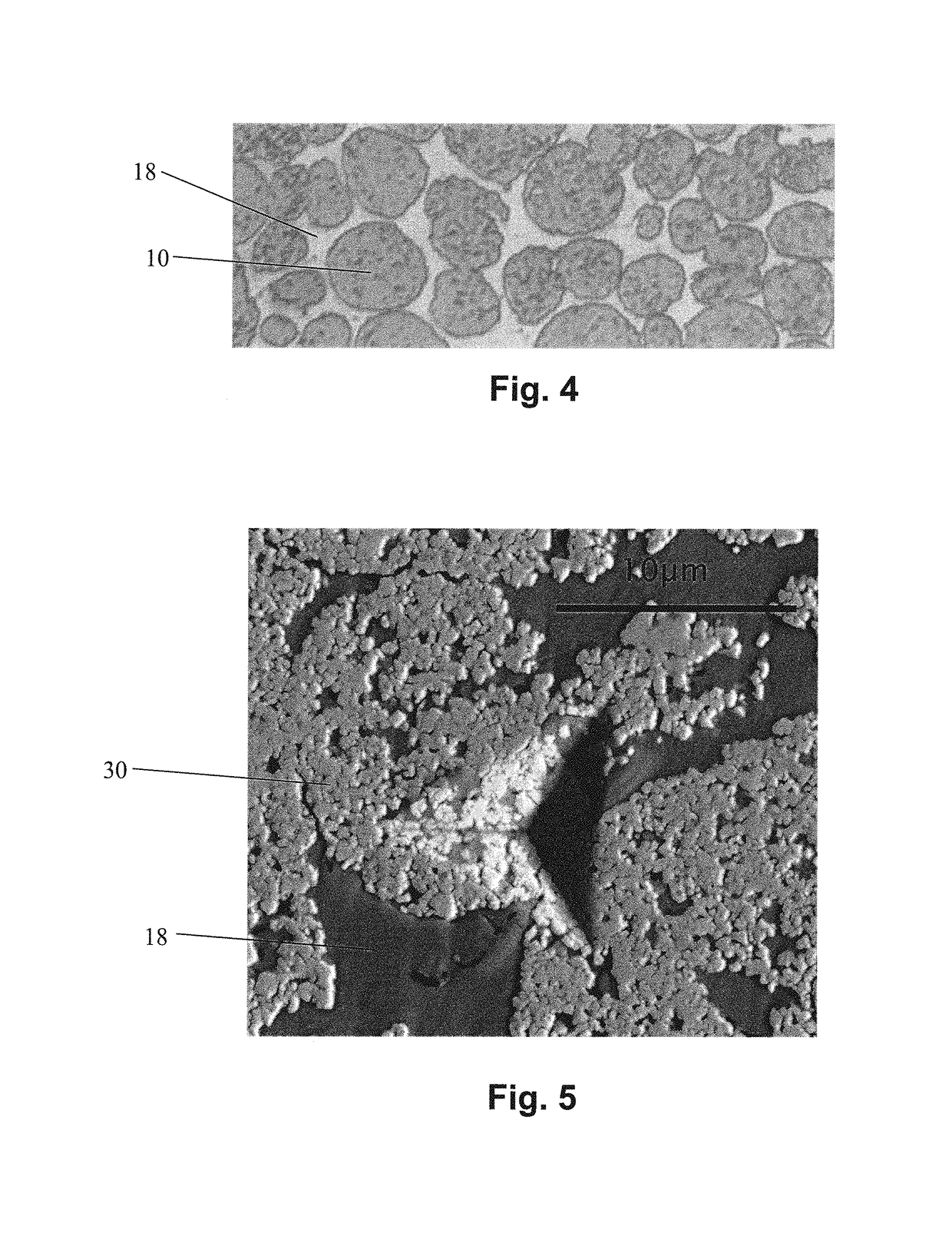

Heterogeneous composite bodies with isolated cermet regions formed by high temperature, rapid consolidation

ActiveUS9943918B2Increase spacingUniform compositionRolling contact bearingsTransportation and packagingNanoparticleNanometre

A heterogeneous composite consisting of near-nano ceramic clusters dispersed within a ductile matrix. The composite is formed through the high temperature compaction of a starting powder consisting of a core of ceramic nanoparticles held together with metallic binder. This core is clad with a ductile metal such that when the final powder is consolidated, the ductile metal forms a tough, near-zero contiguity matrix. The material is consolidated using any means that will maintain its heterogeneous structure.

Owner:POWDERMET

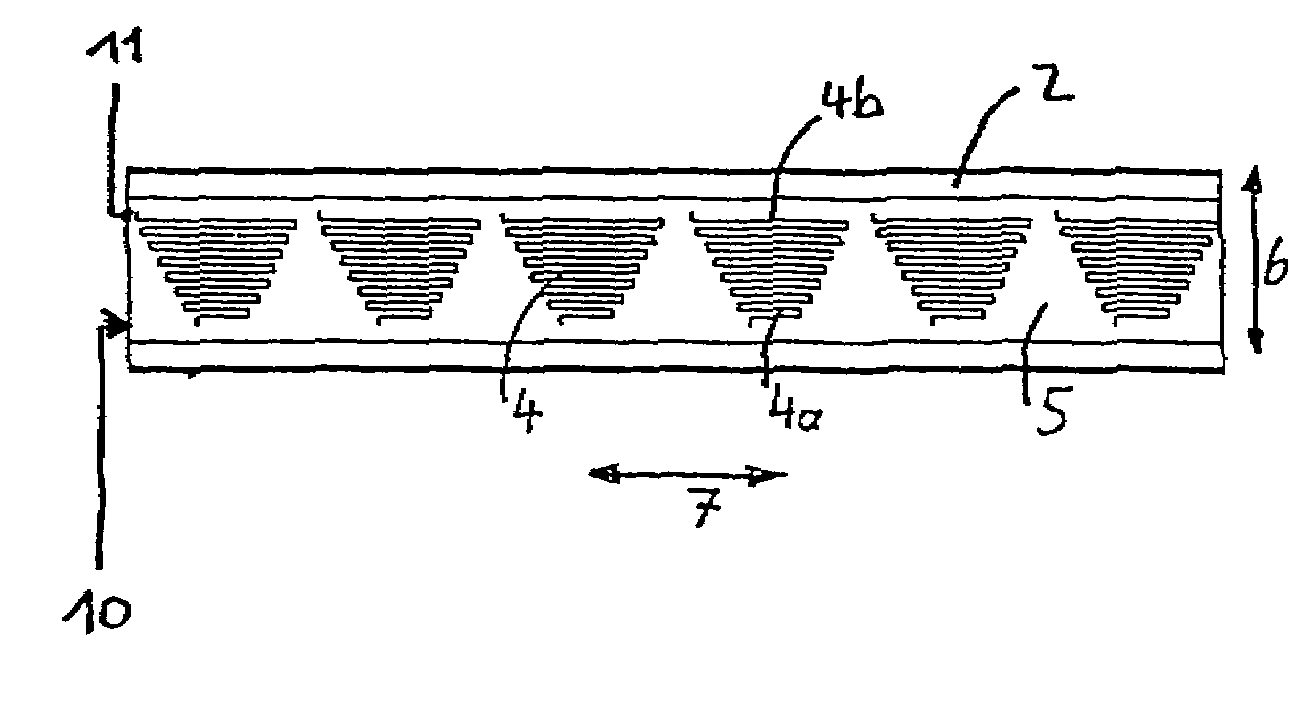

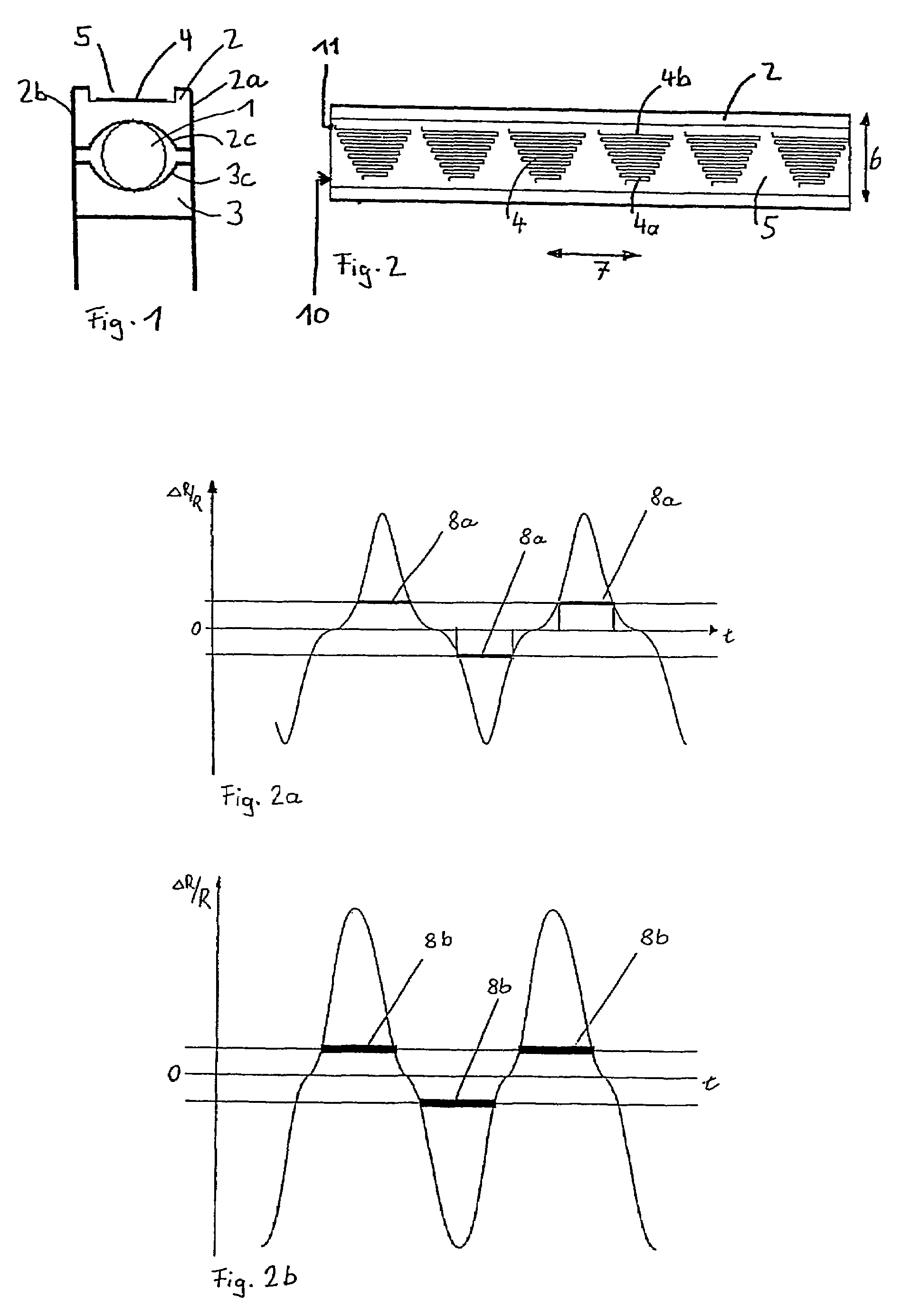

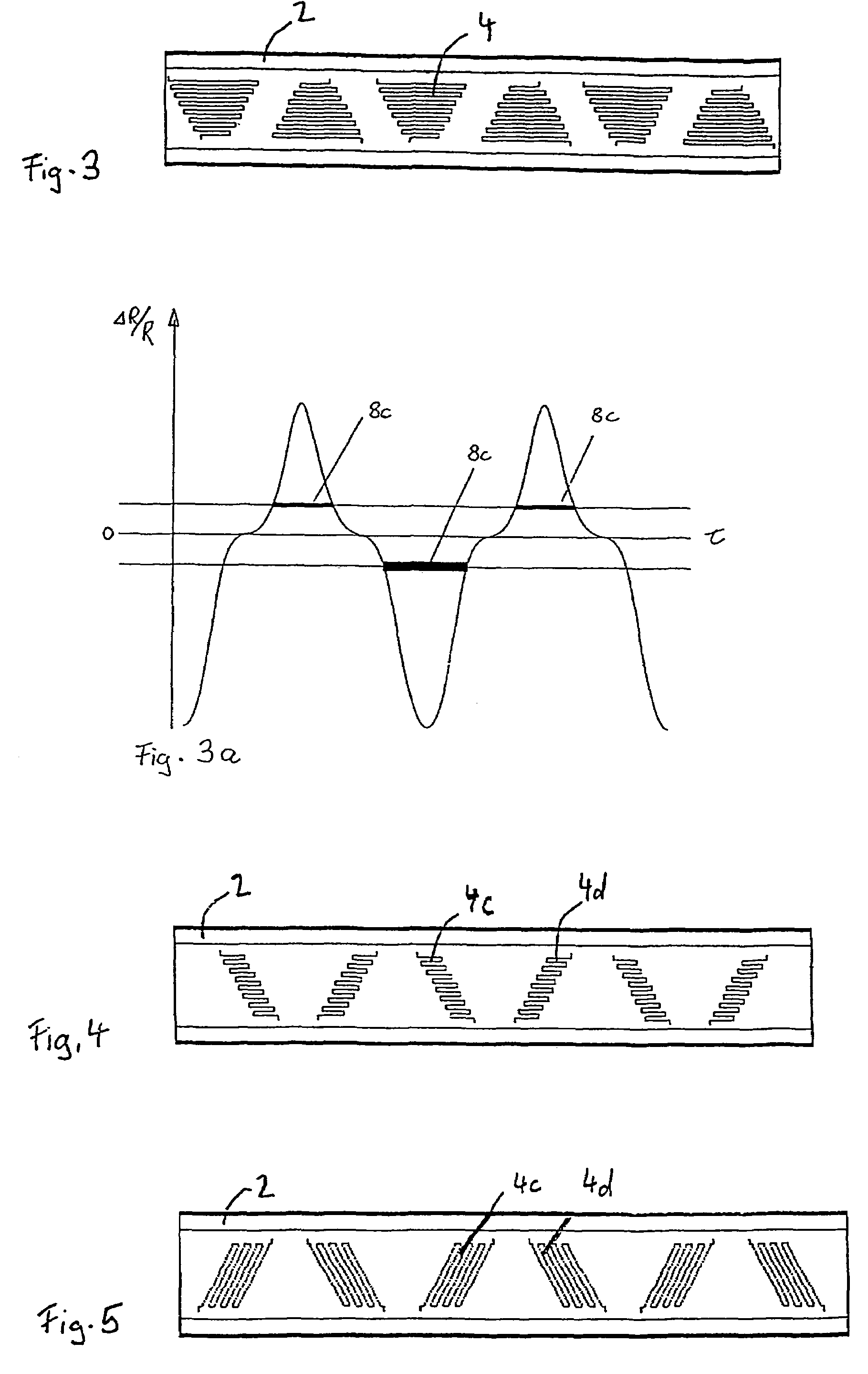

Force-sensing bearing

InactiveUS7316168B2Rolling contact bearingsMachine bearings testingElectrical conductorPulp and paper industry

The invention relates to a roller bearing comprising curved running paths, in addition to roller bodies and strain gauge sensors which are arranged between said running paths, said sensors being located in a groove on the outer diameter of the outer ring and / or on the inner diameter of the inner ring. The length of two adjacent strip conductor sections of the strain gauge sensor varies in such a way as to measure the angular position of the roller bodies between the strip conductors.

Owner:INA SCHAEFFLER KG

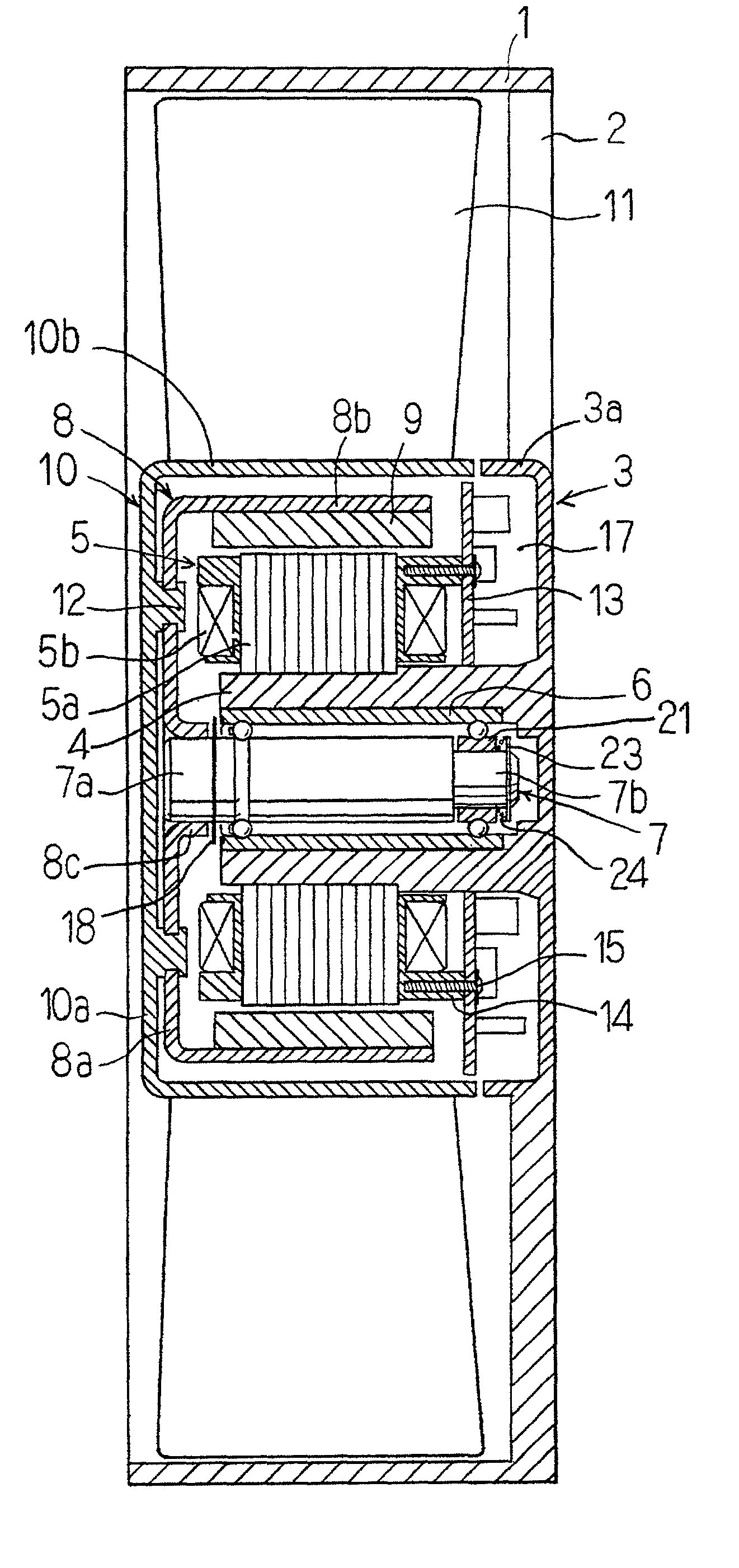

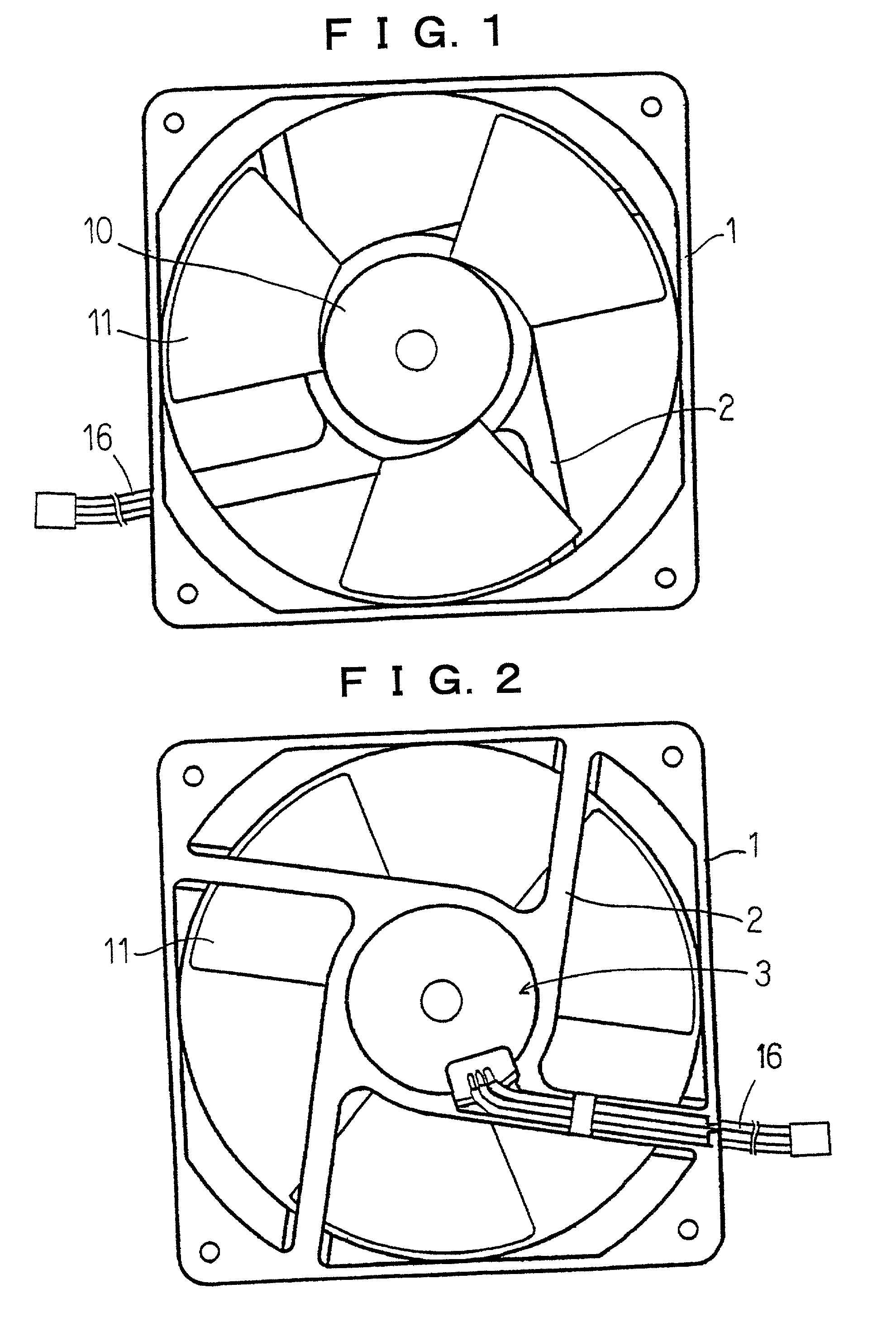

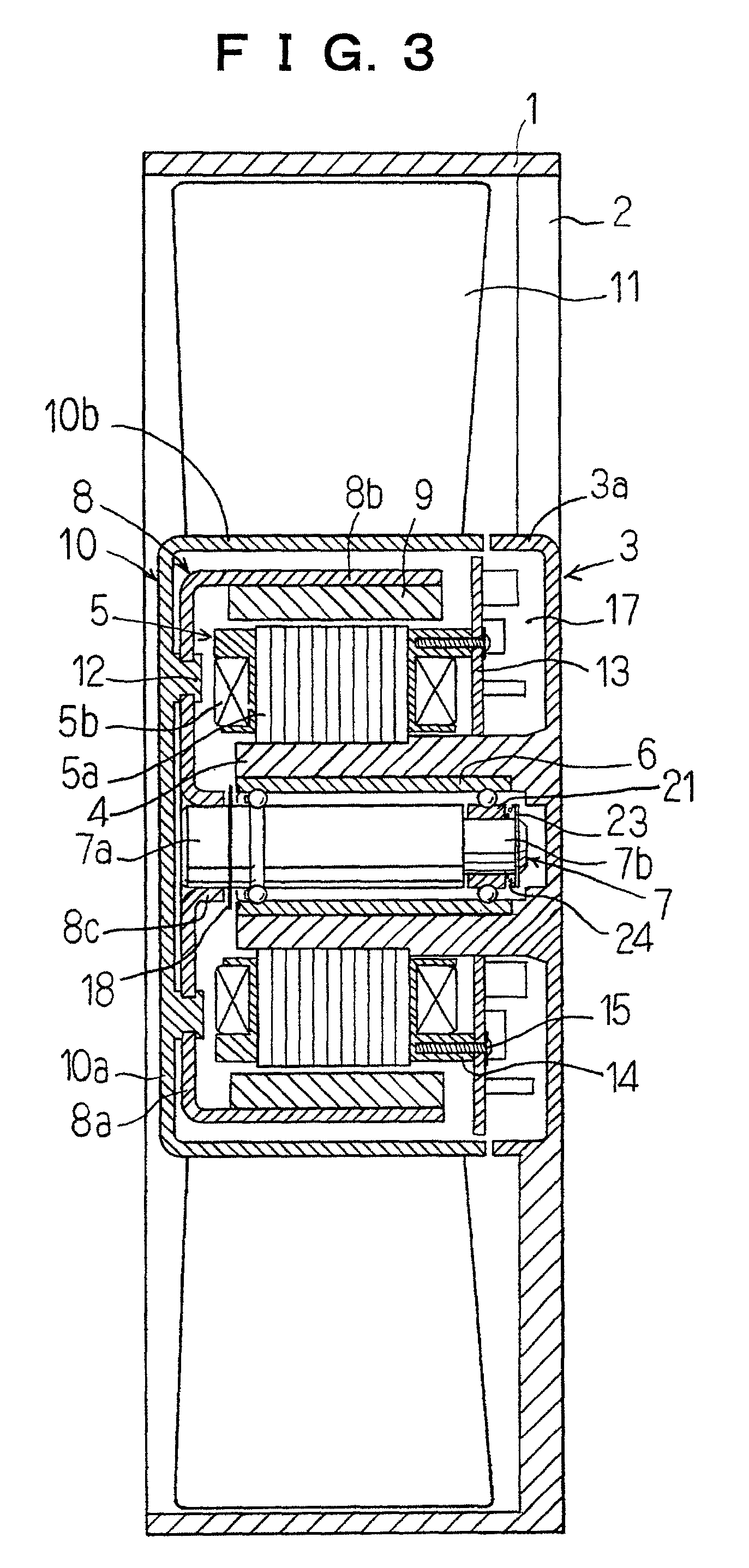

Blower

The object of the present invention is to provide a blower including a bearing structure wherein the number of components is reduced, the cost for manufacturing can be reduced, and the diameter of the shaft can be increased. The bearing structure is good at its durability, eliminates or reduces the rotational run out, and provides superior quietness. The blower of the present invention having an impeller adapted to be rotated upon energizing the blower comprising; a bearing device for supporting a rotational center portion of the impeller, the bearing device including; a sleeve, a stepped shaft including a larger diameter portion and a reduced diameter portion provided at one end thereof, the first inner raceway groove formed at an appropriate position around the outer peripheral surface of the larger diameter portion, the first outer raceway groove formed on an inner peripheral surface of the sleeve so as to correspond with the first inner raceway groove, balls of the first row interposed between the first and second grooves, an inner ring slidably fit over the reduced diameter portion, the second inner raceway groove formed around an outer peripheral surface of the inner ring, the second outer raceway groove formed on the inner peripheral surface of the sleeve so as to correspond with the second inner raceway groove, balls of the second row interposed between the second inner and outer raceway grooves, a stop ring provided around the inner periphery of the distal end of the reduced diameter portion, and a pre-loading spring interposed between the stop ring and an end surface of the inner ring to provide a suitable amount of pre-loading force to the inner ring.

Owner:MINEBEA CO LTD

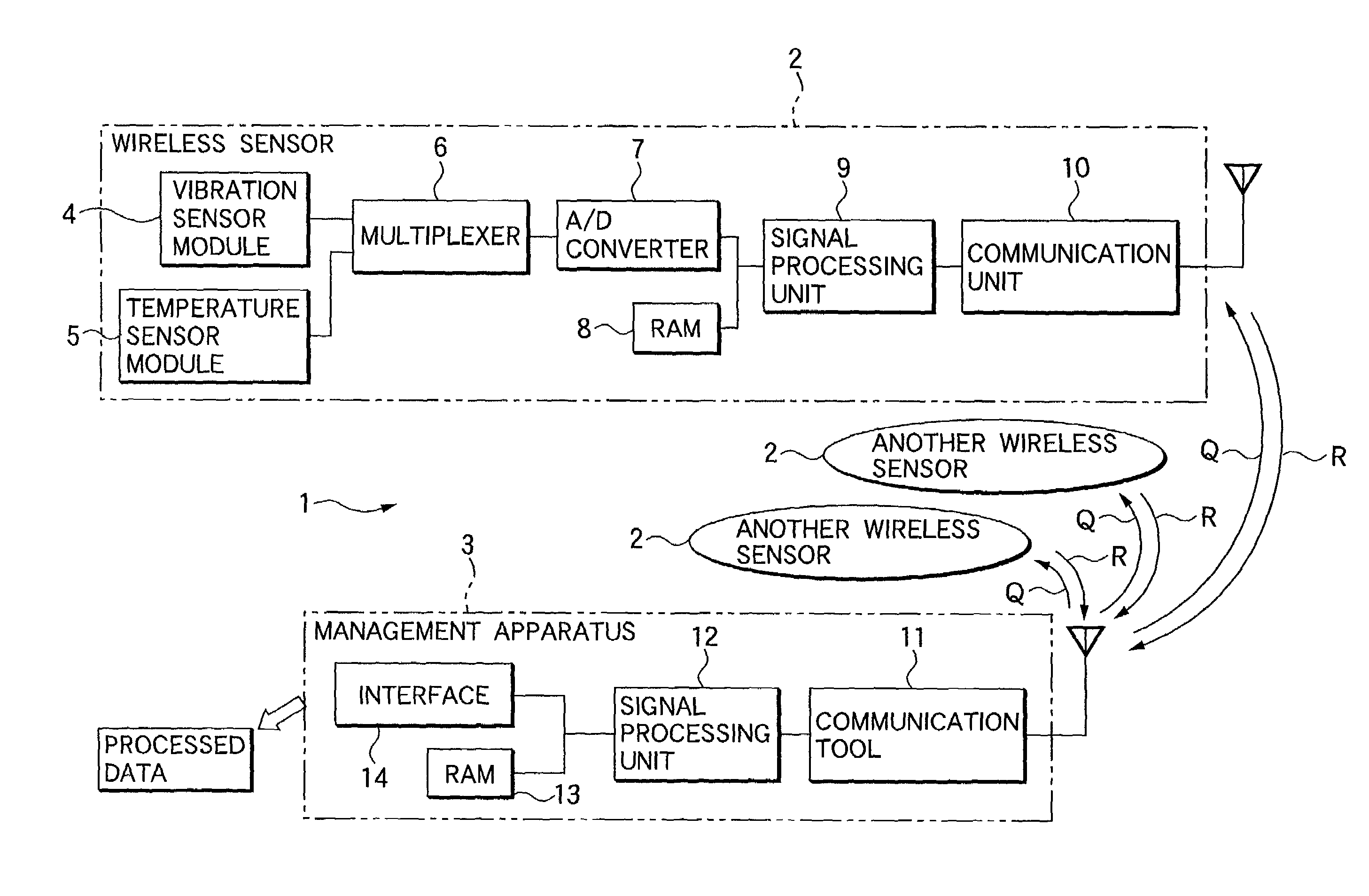

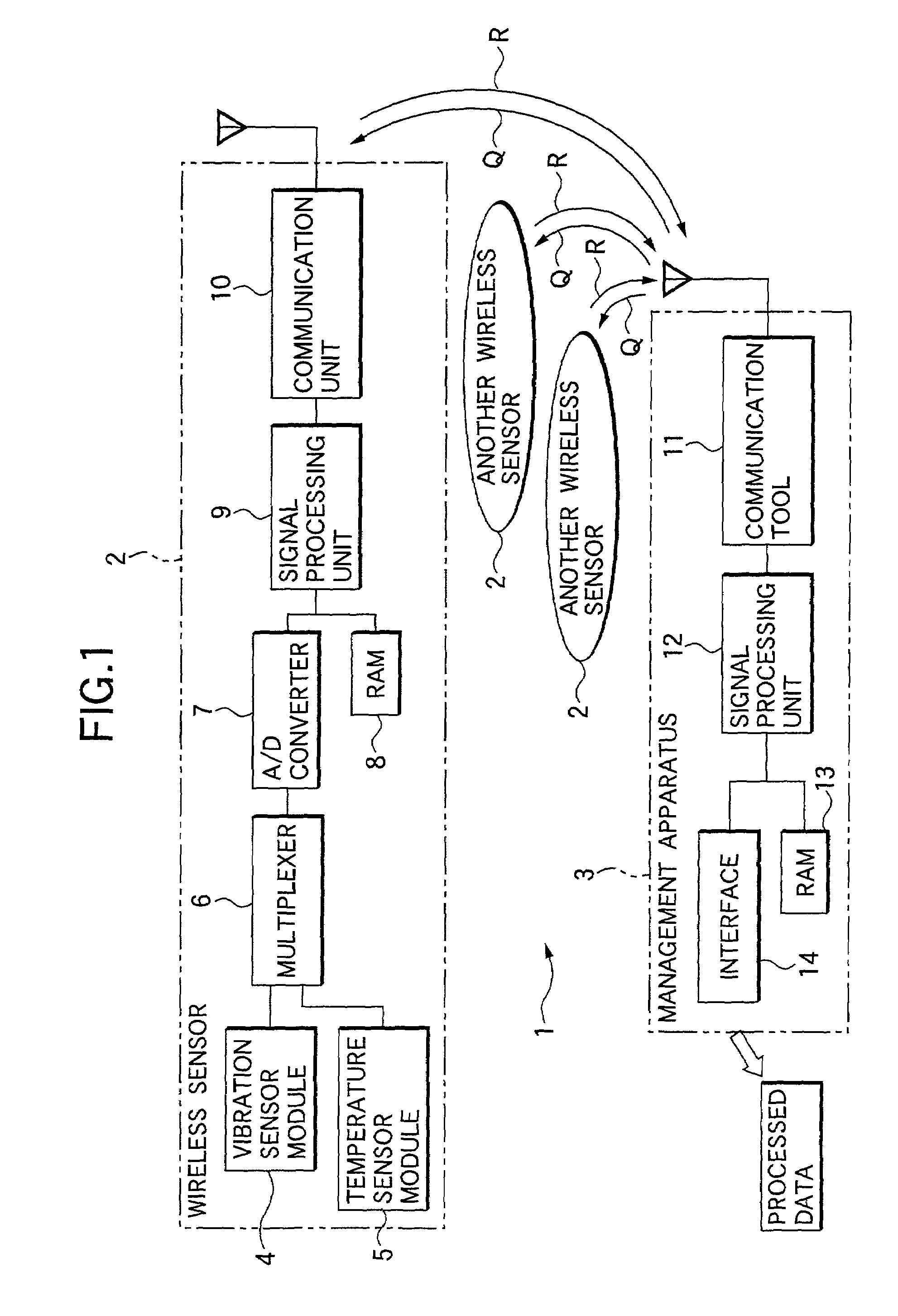

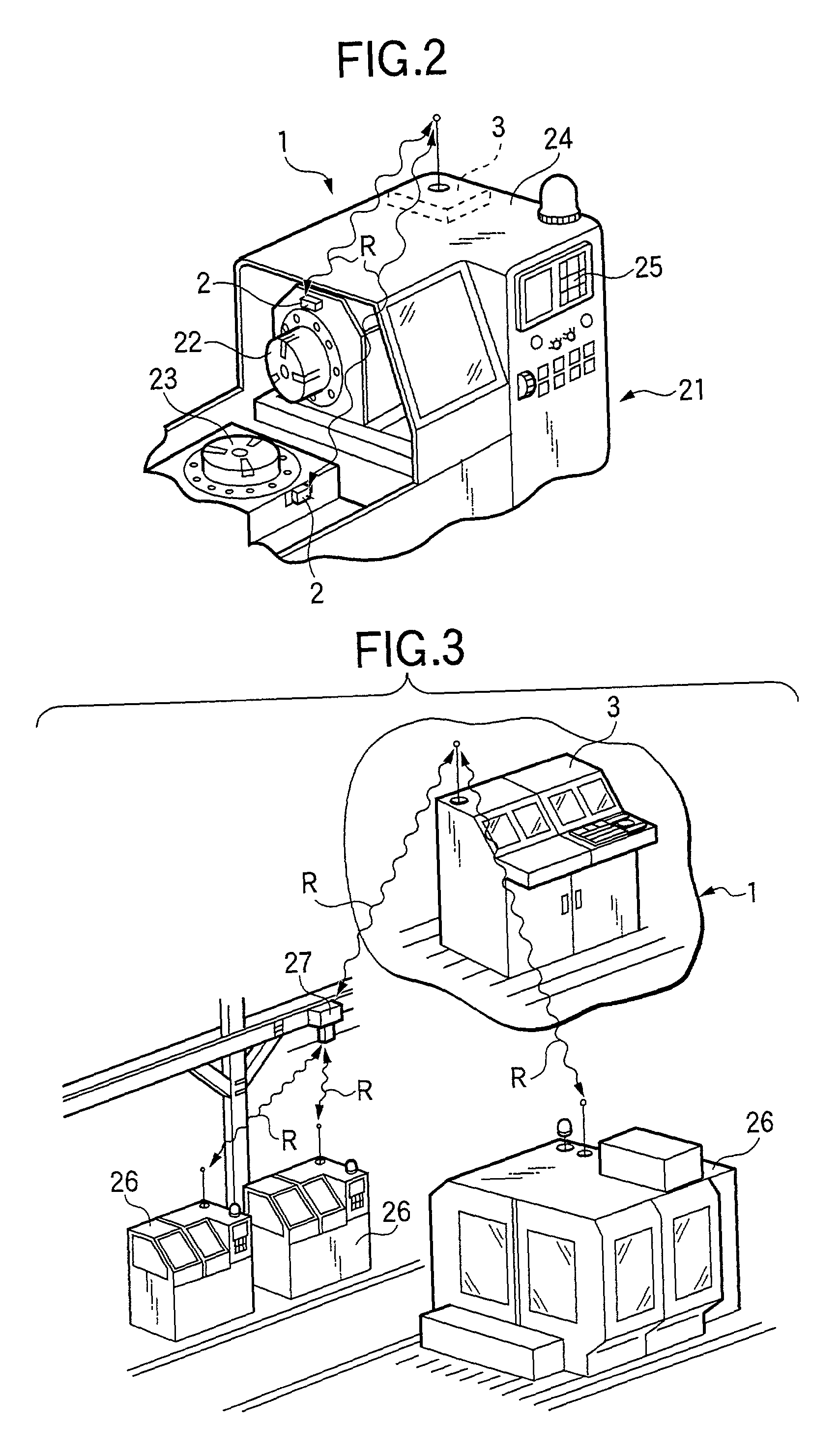

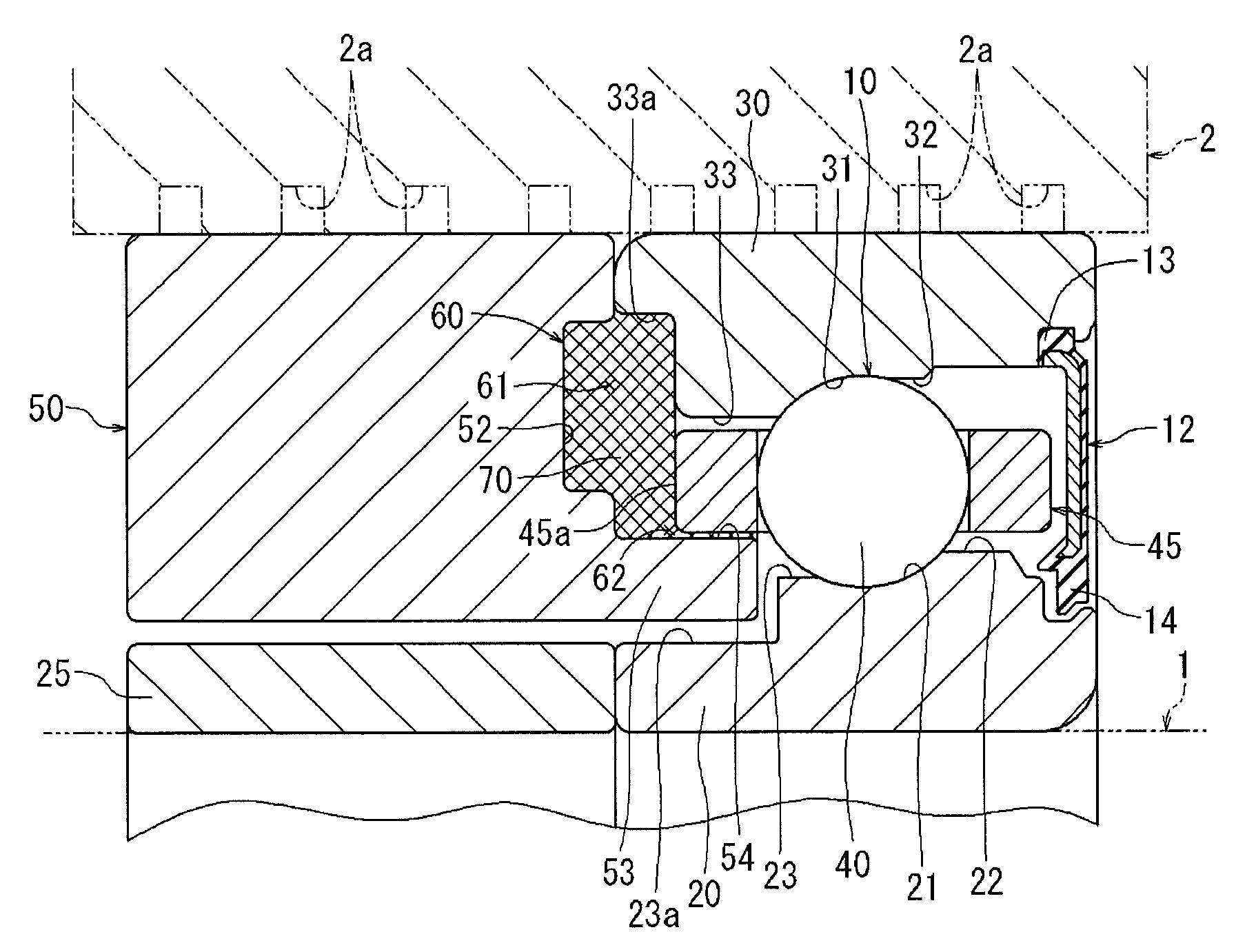

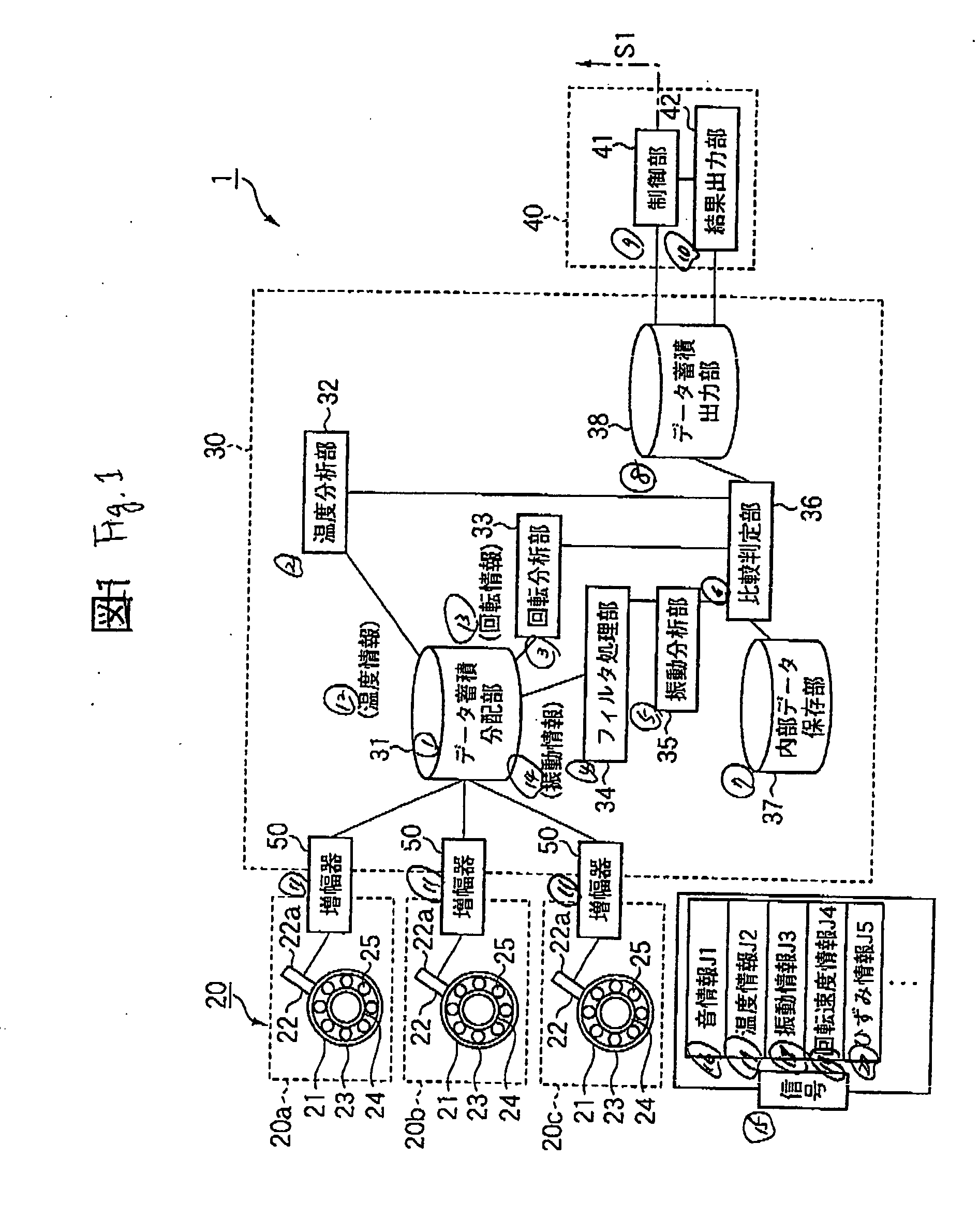

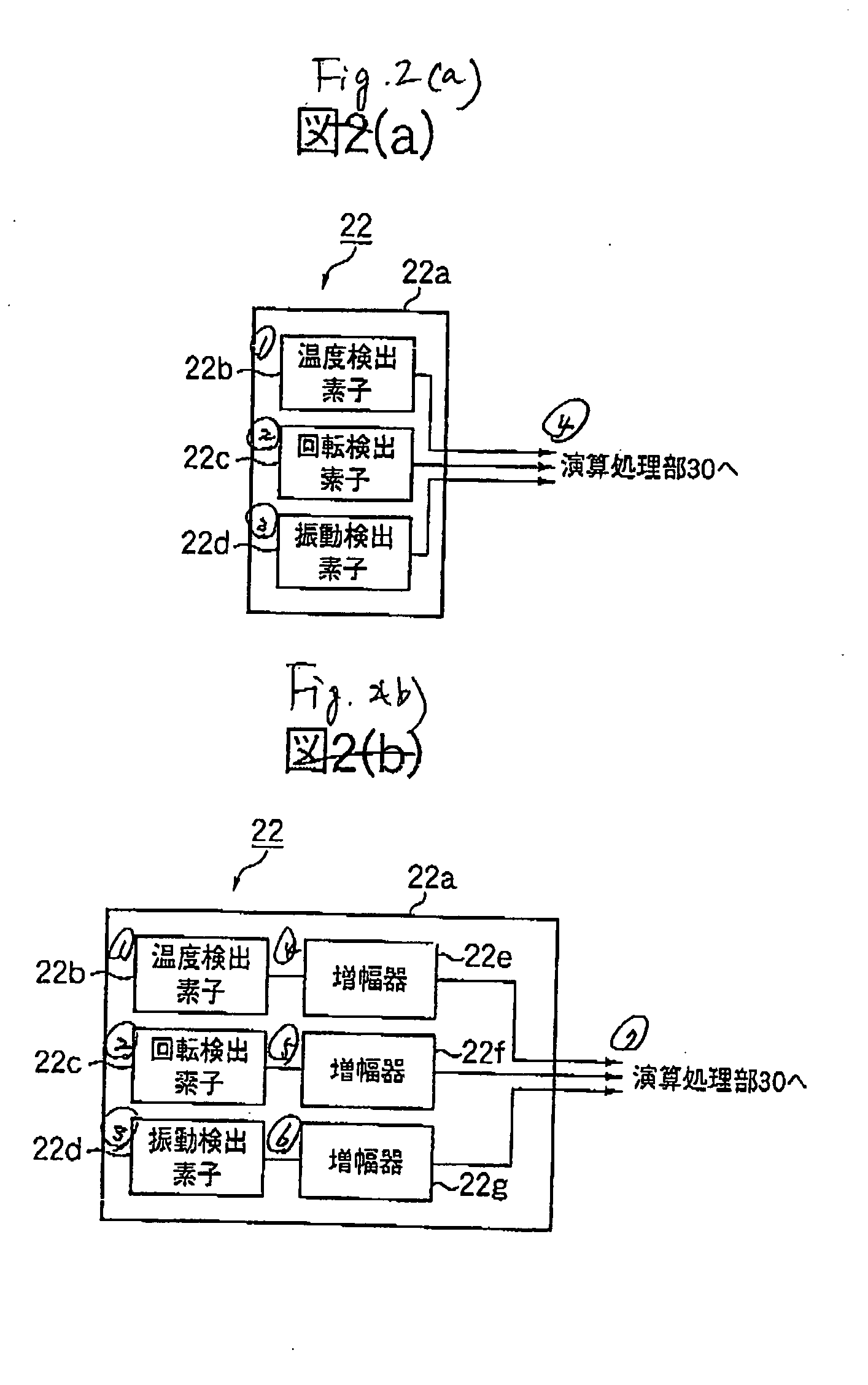

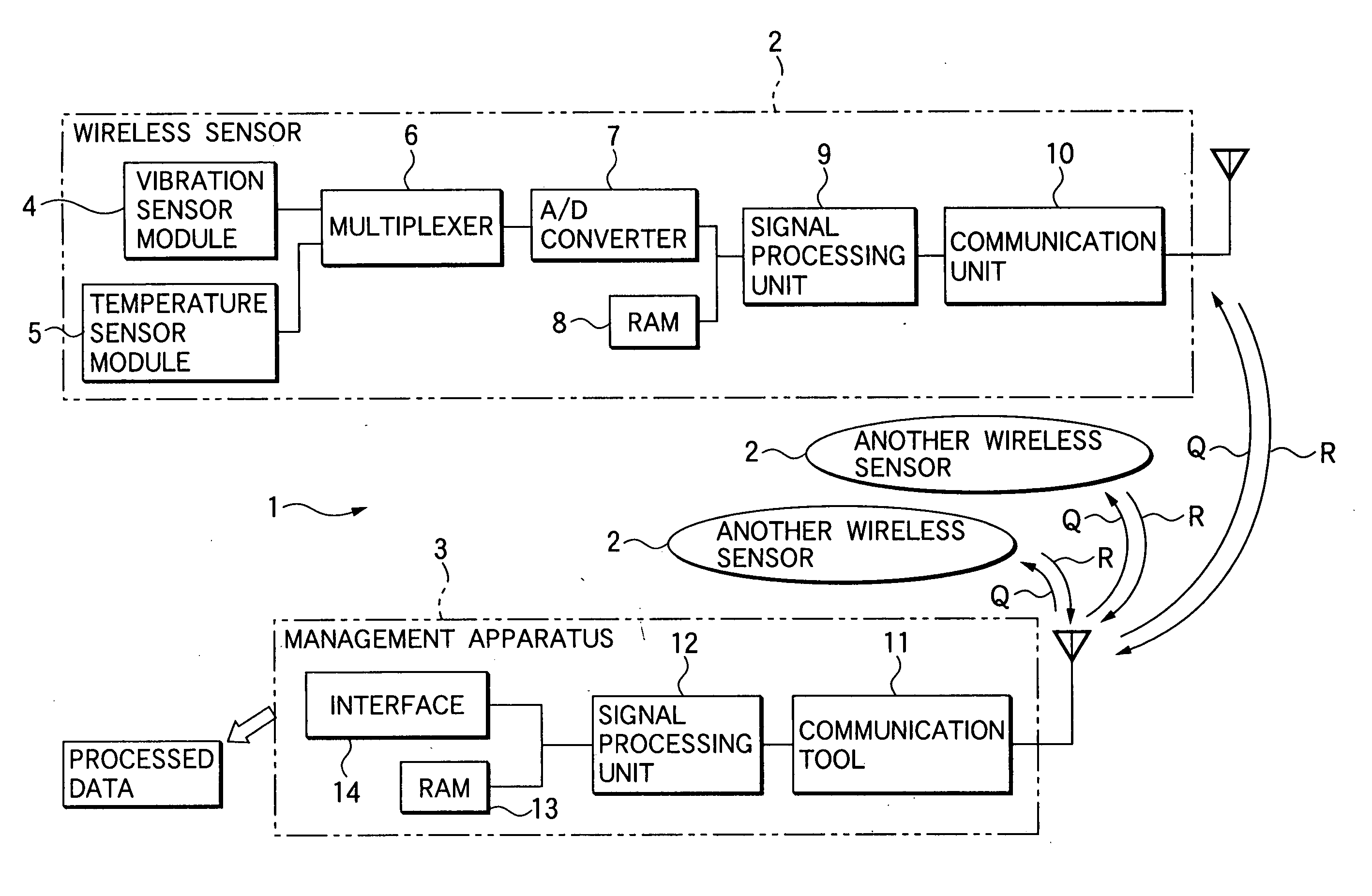

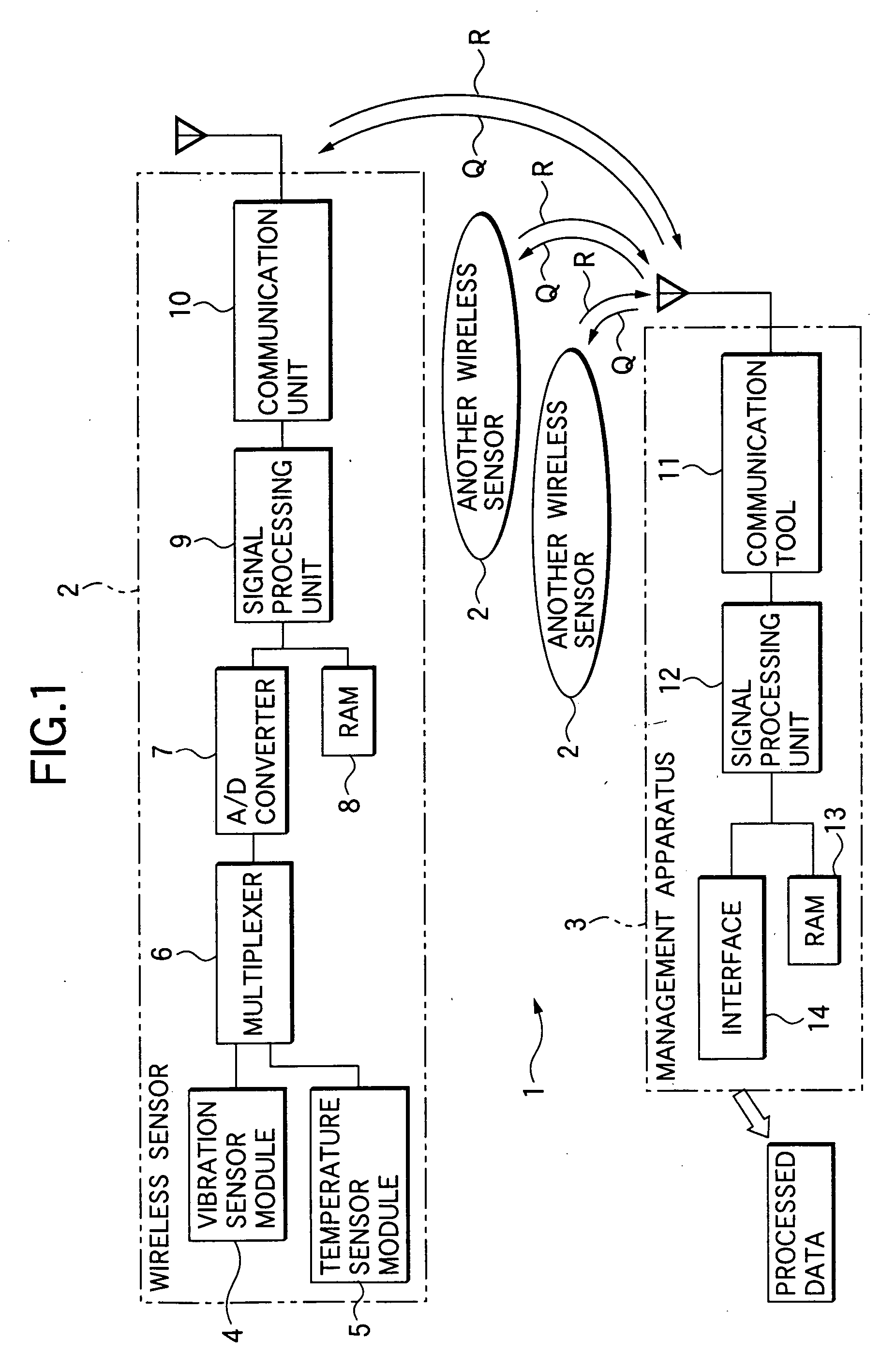

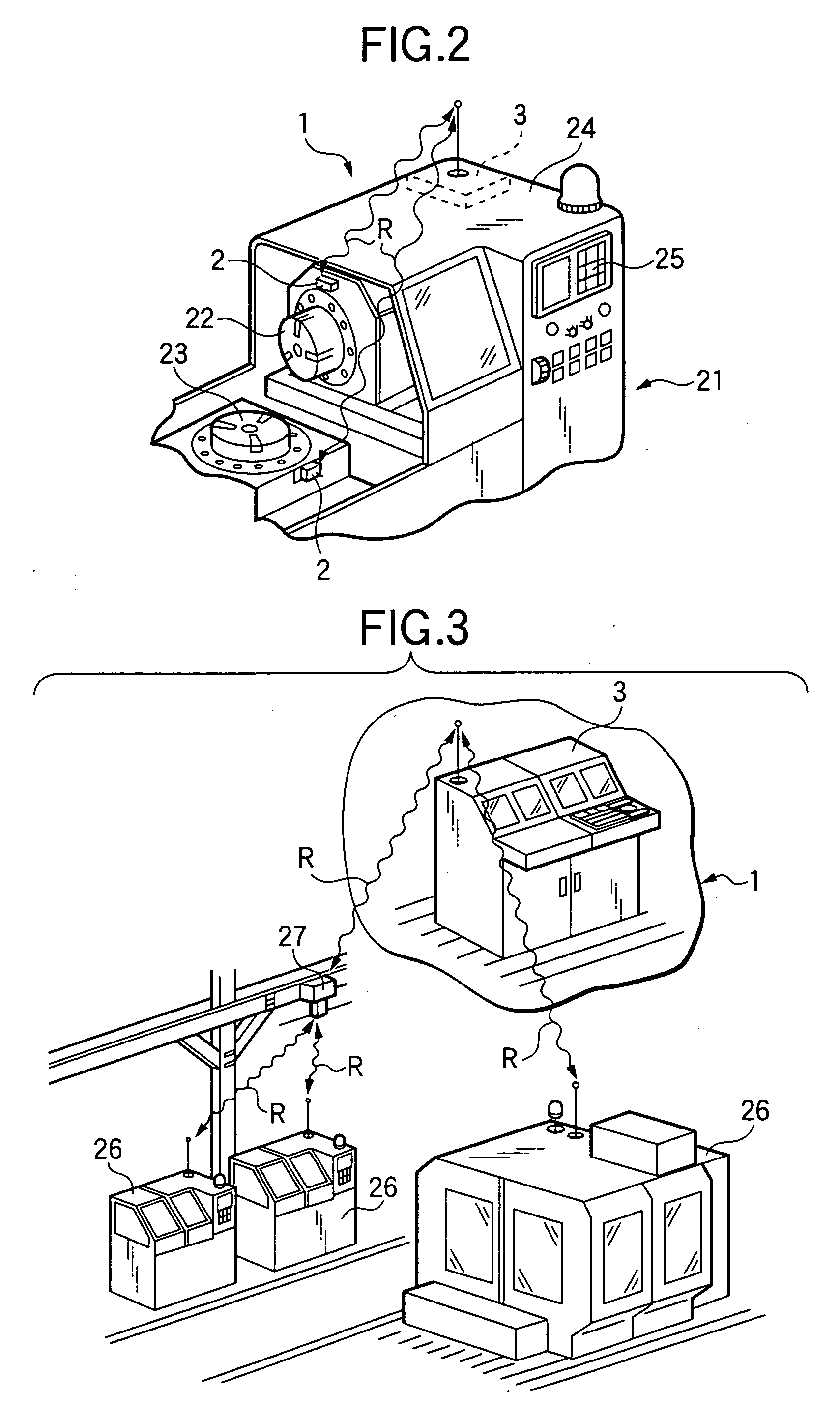

Wireless sensor, rolling bearing with sensor, management apparatus and monitoring system

InactiveUS7034711B2Improve accuracyCondition can be detectedVibration measurement in solidsMachine part testingLine sensorCommunication unit

The wireless sensor adds identification information peculiar to respective sensor modules to detection data of vibration, temperature, and so on, detected by the sensor modules respectively. The wireless sensor transmits the detection data with the identification information as a signal through a communication unit by radio waves. On the other hand, the management apparatus receiving the signal classifies and files the detection data on the basis of the identification information included in the signal. Then, the monitoring system is designed to make the management apparatus manage a plurality of wireless sensors attached to movable shafts of processing machines or the like.

Owner:NSK LTD

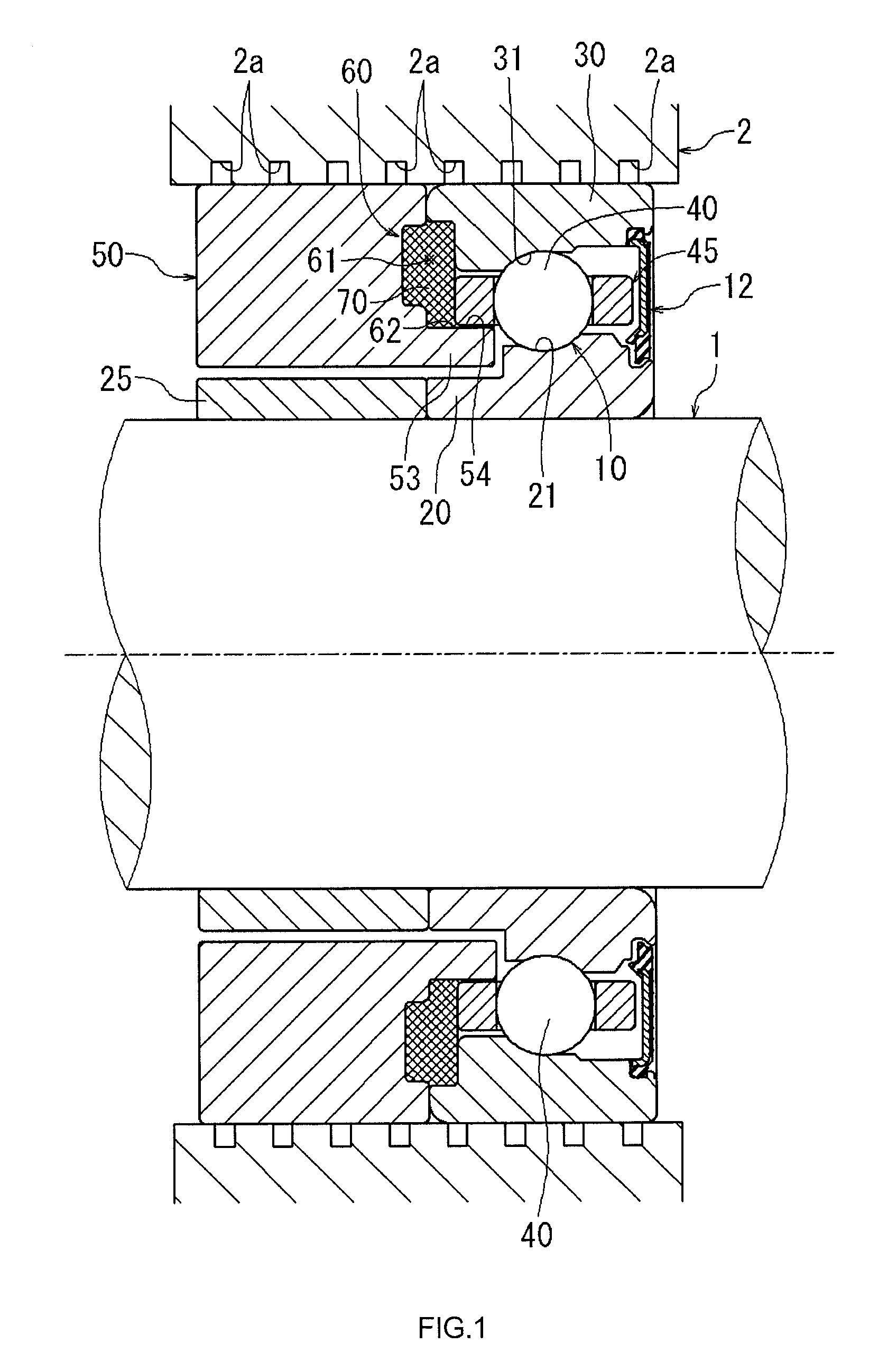

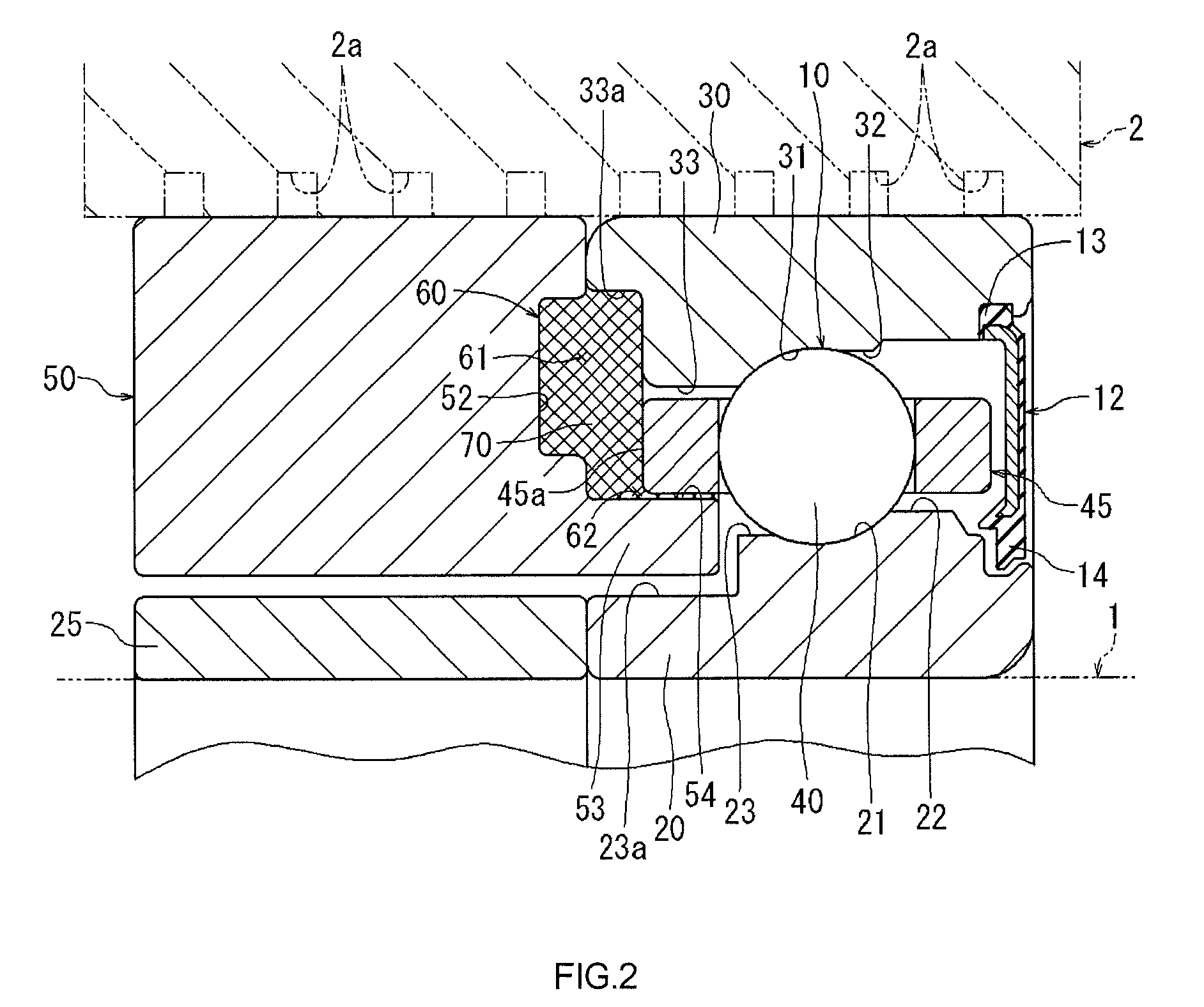

Rolling bearing unit

InactiveUS9109630B2Rolling contact bearingsBearing coolingRolling-element bearingMechanical engineering

Owner:JTEKT CORP

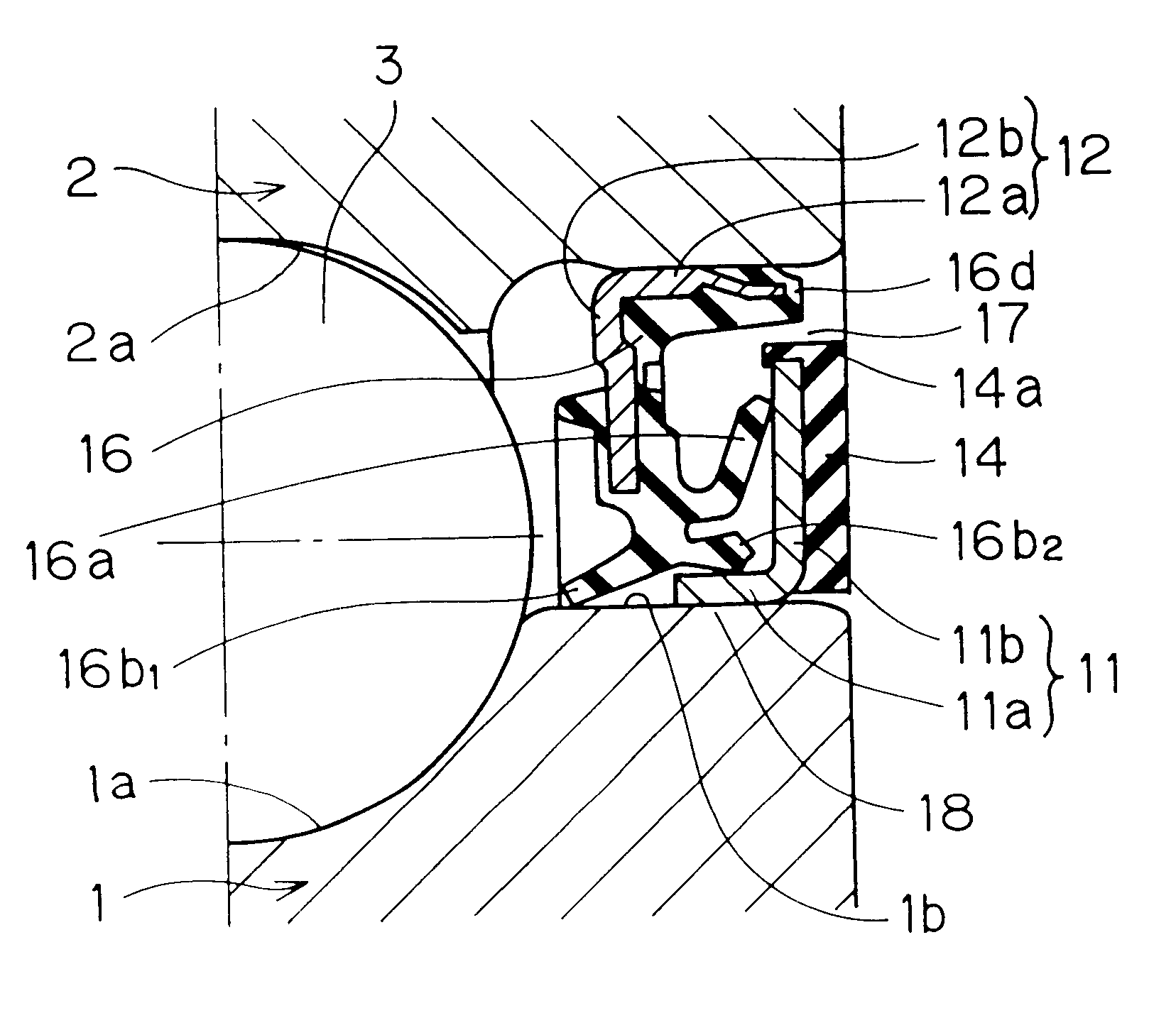

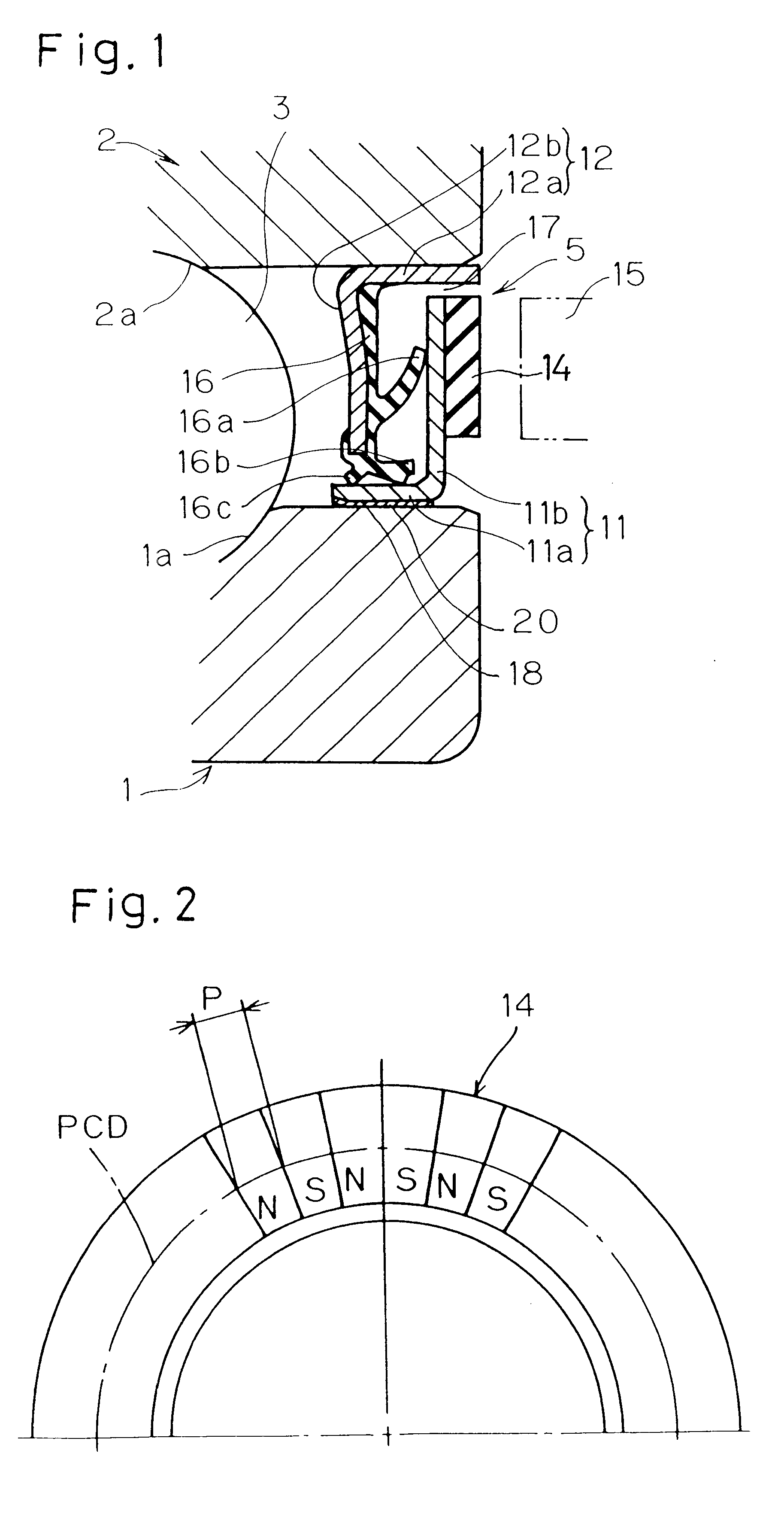

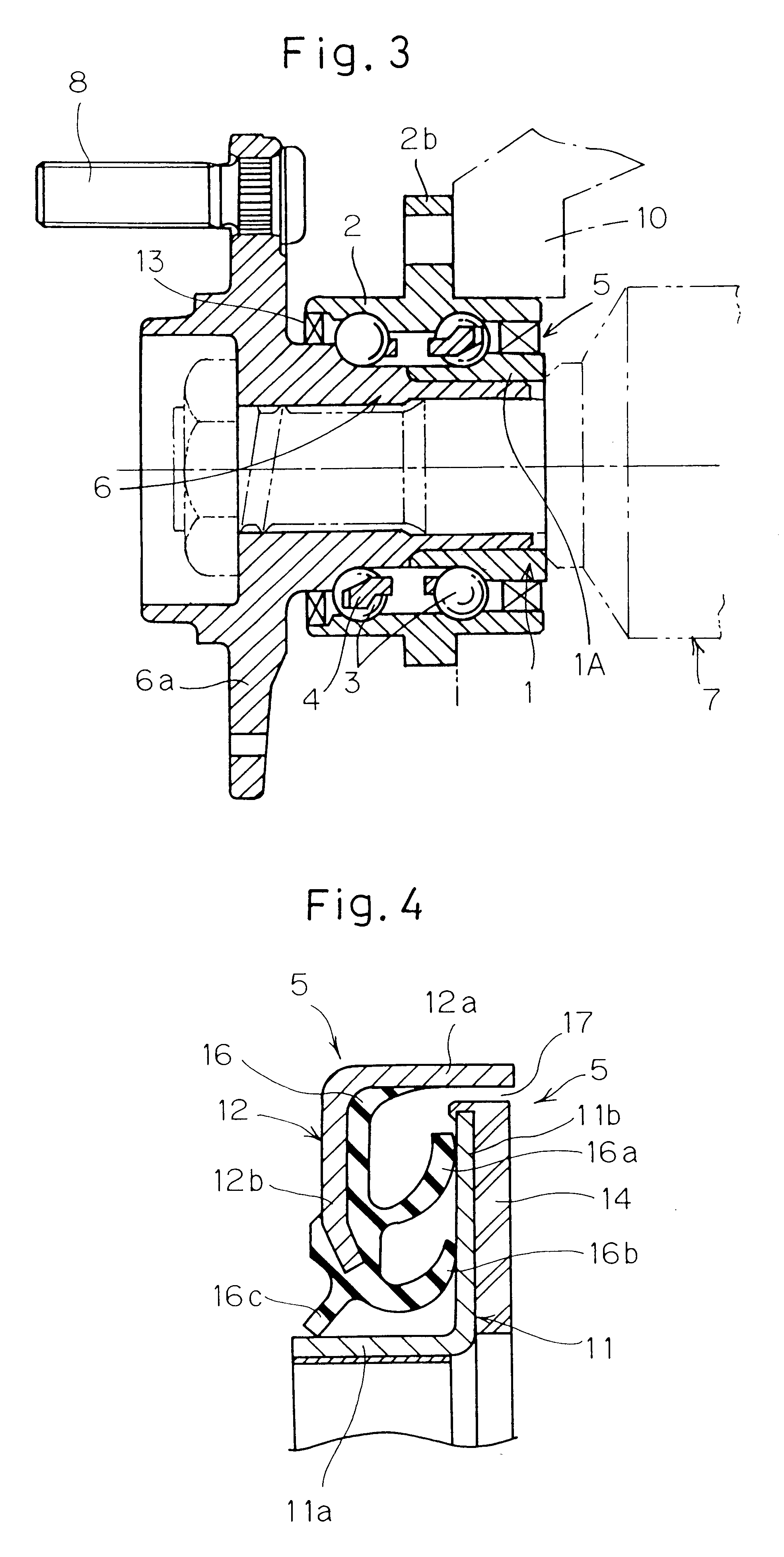

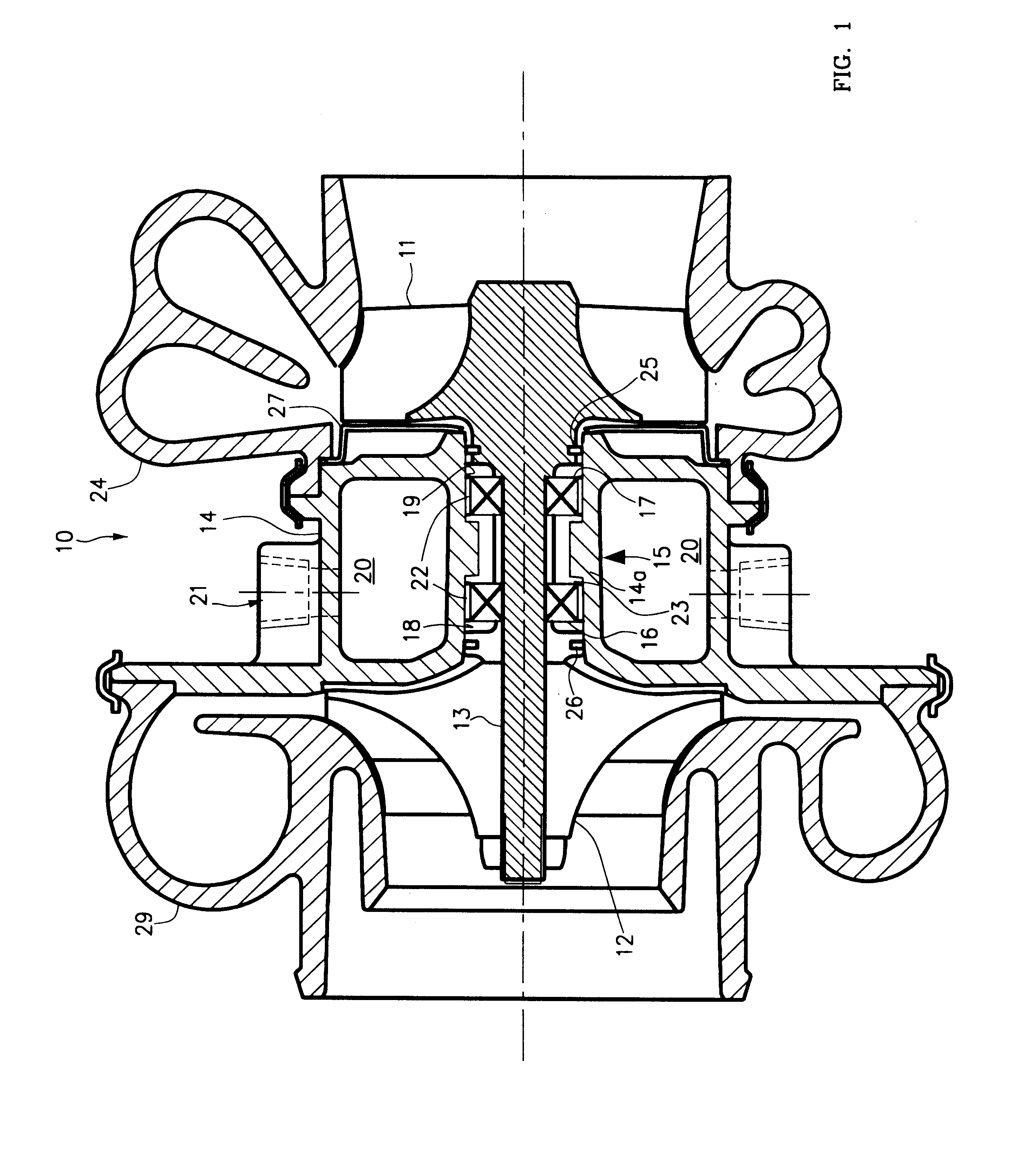

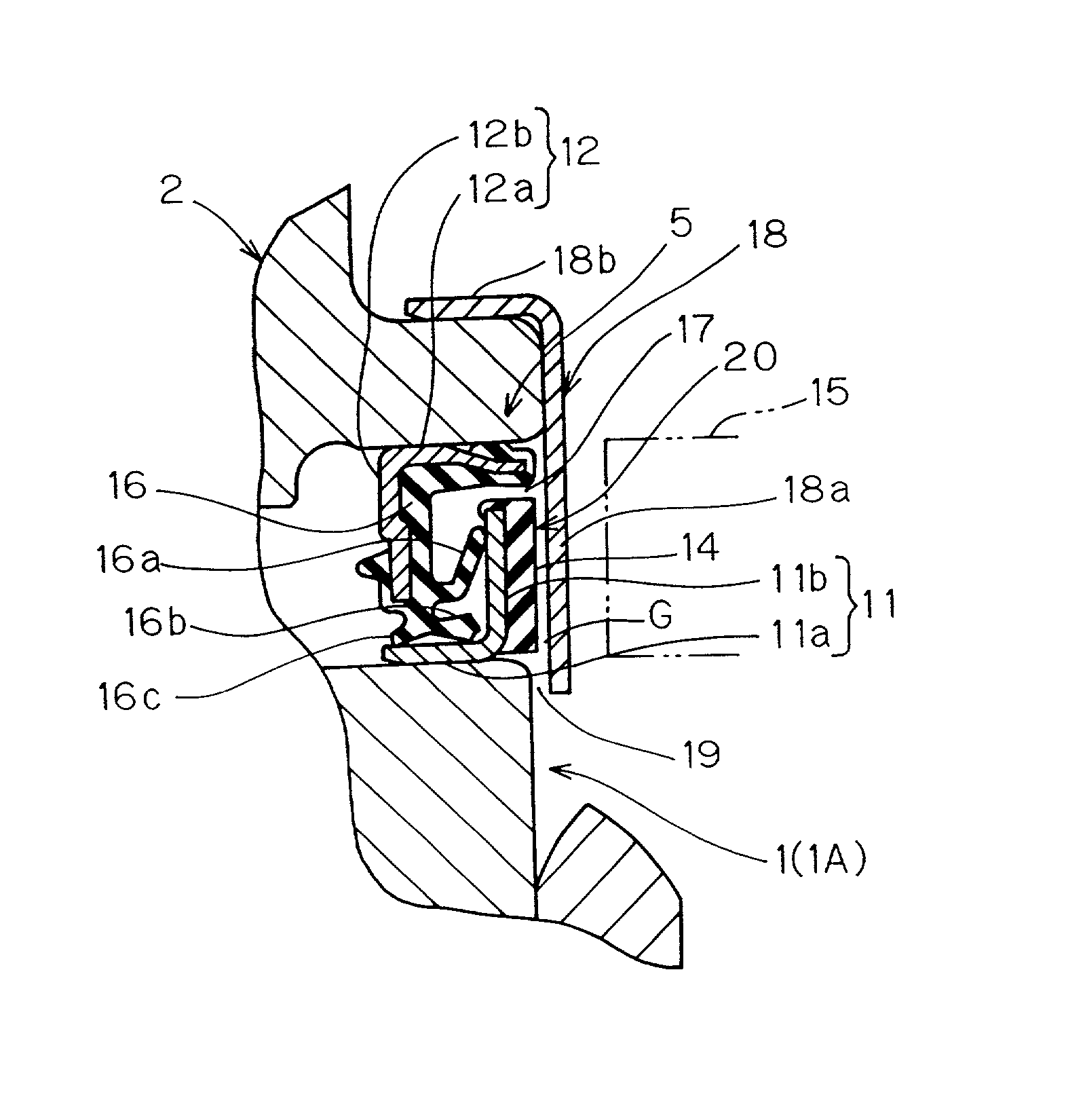

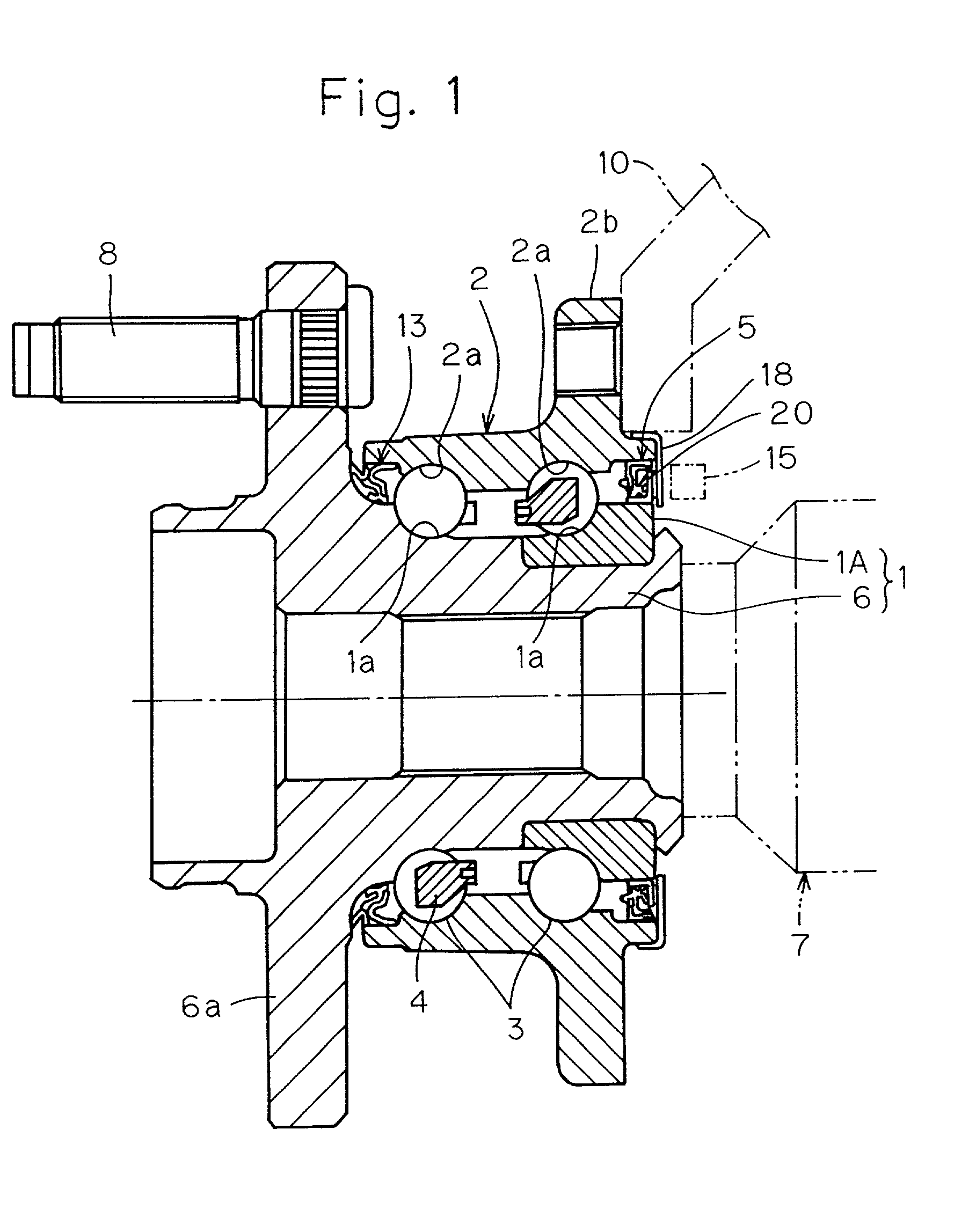

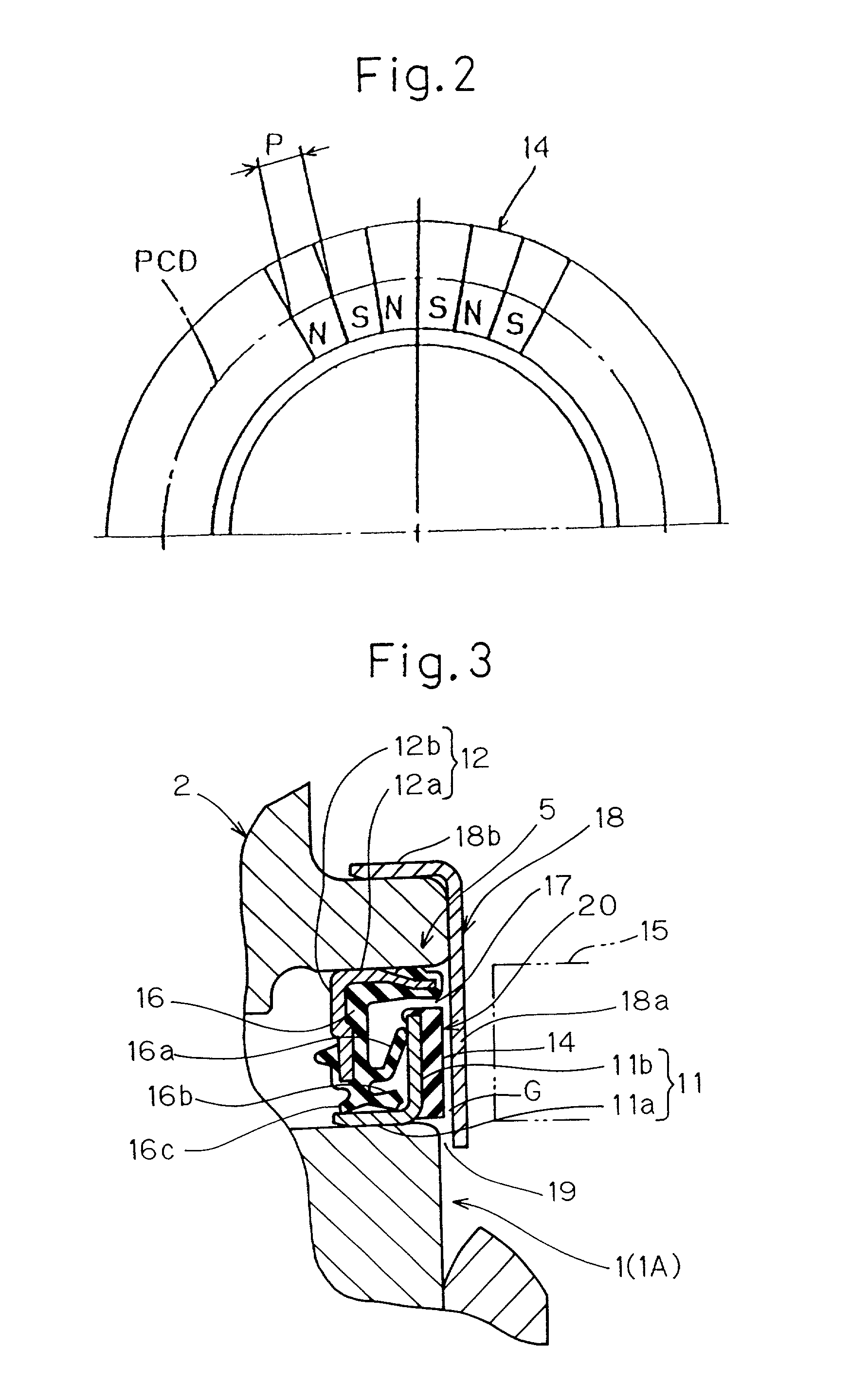

Wheel bearing and sealing device therefor

A wheel bearing includes a sealing device 5 positioned between inner and outer members 1 and 2. This sealing device 5 includes an elastic member 14, which eventually forms an encoder grid and is provided on a first annular sealing plate 11. A second annular sealing plate 12 is provided with sealing lips 16a to 16c. An engagement 18 between a cylindrical wall 11a of the first annular sealing plate 11 and the inner member 1 is provided with an elastic member 20 made of a material dissimilar to that for the elastic material 14. This elastic member 20 may be a rubber coated layer, resin paint layer, a thin film of adhesive material or a ring-shaped rubber member. Thereby, any possible ingress of water across an engagement surface of the annular sealing plate is prevented, accompanied by increase of the lifetime of the bearing, with no problem associated with separation and displacement of the annular sealing plates. The magnetic flux density can also be easily secured.

Owner:NTN CORP

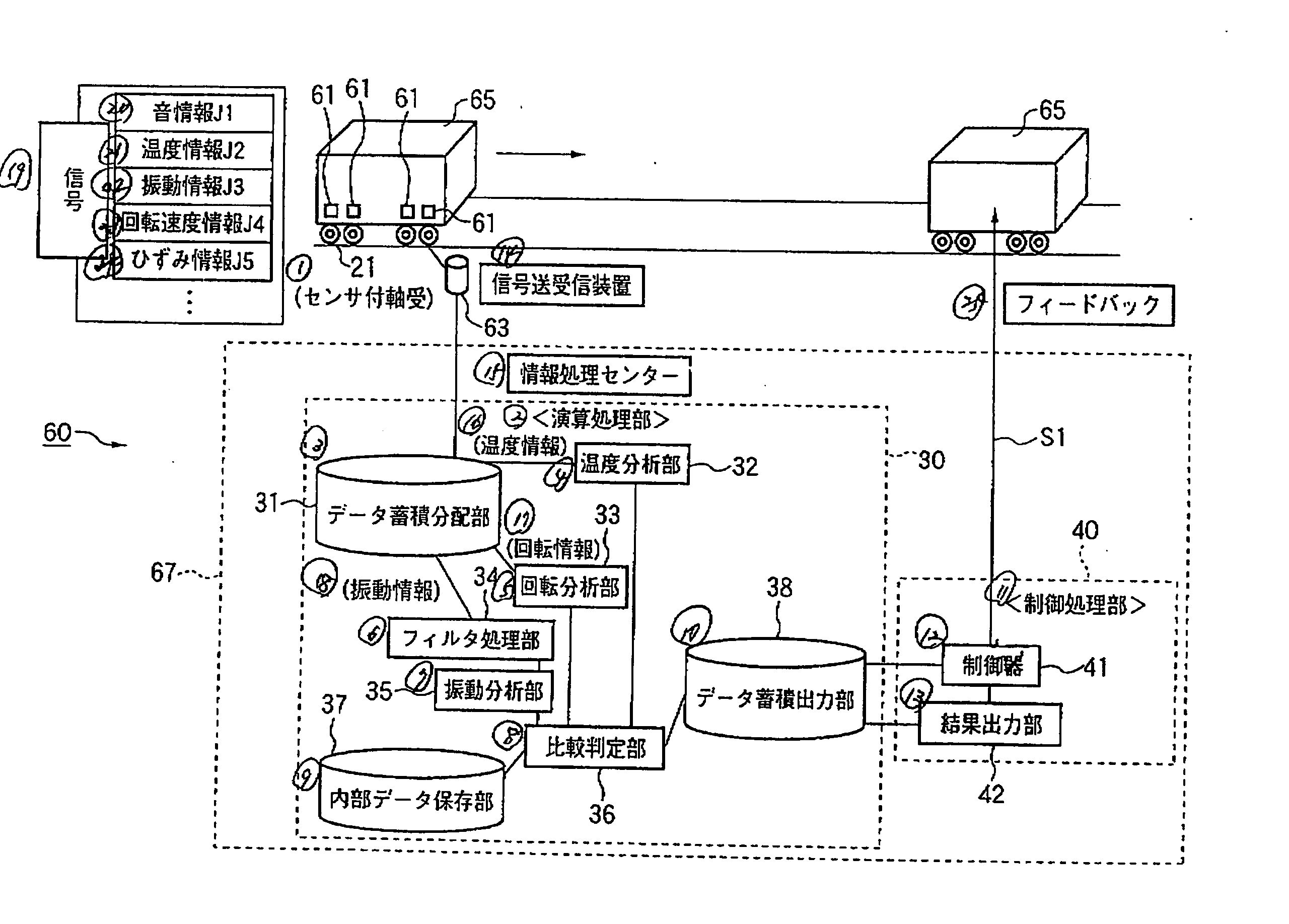

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality-diagnosing device is used to diagnose if a bearing device used on the axle of a railway vehicle is normal. The abnormality-diagnosing device comprises a detection processing part, an operation processing part, a result output part and a control processing part, wherein, the detection processing part outputs the signal generated by the bearing device, which is regarded as an electric signal, the operation processing part conducts an abnormality diagnosis on the bearing device according to the output of the detection processing part, the result output part outputs the judgement result of the operation processing part, and according to the judgement result, the control processing part returns a control signal to the control system of the railway vehicle.

Owner:NSK LTD

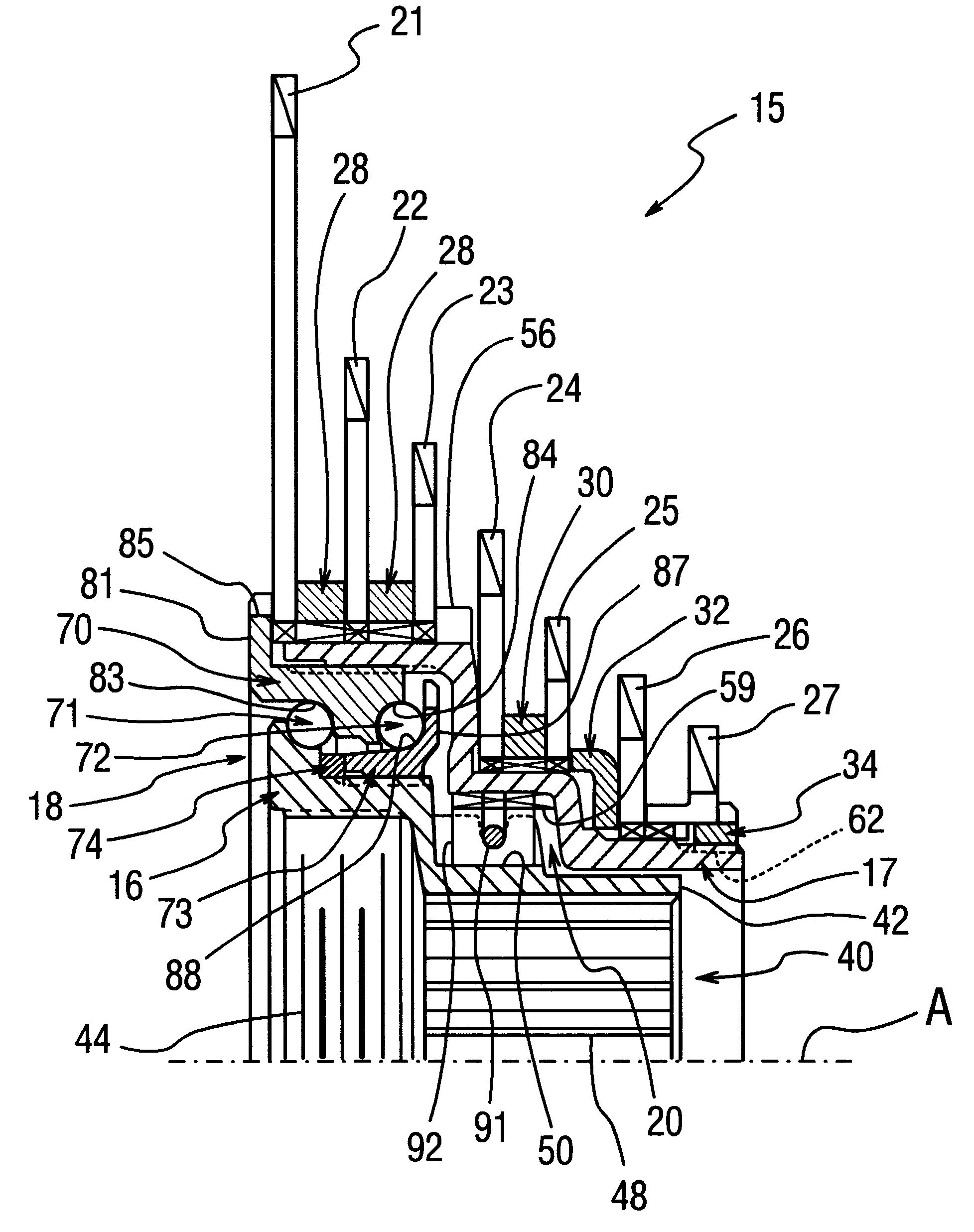

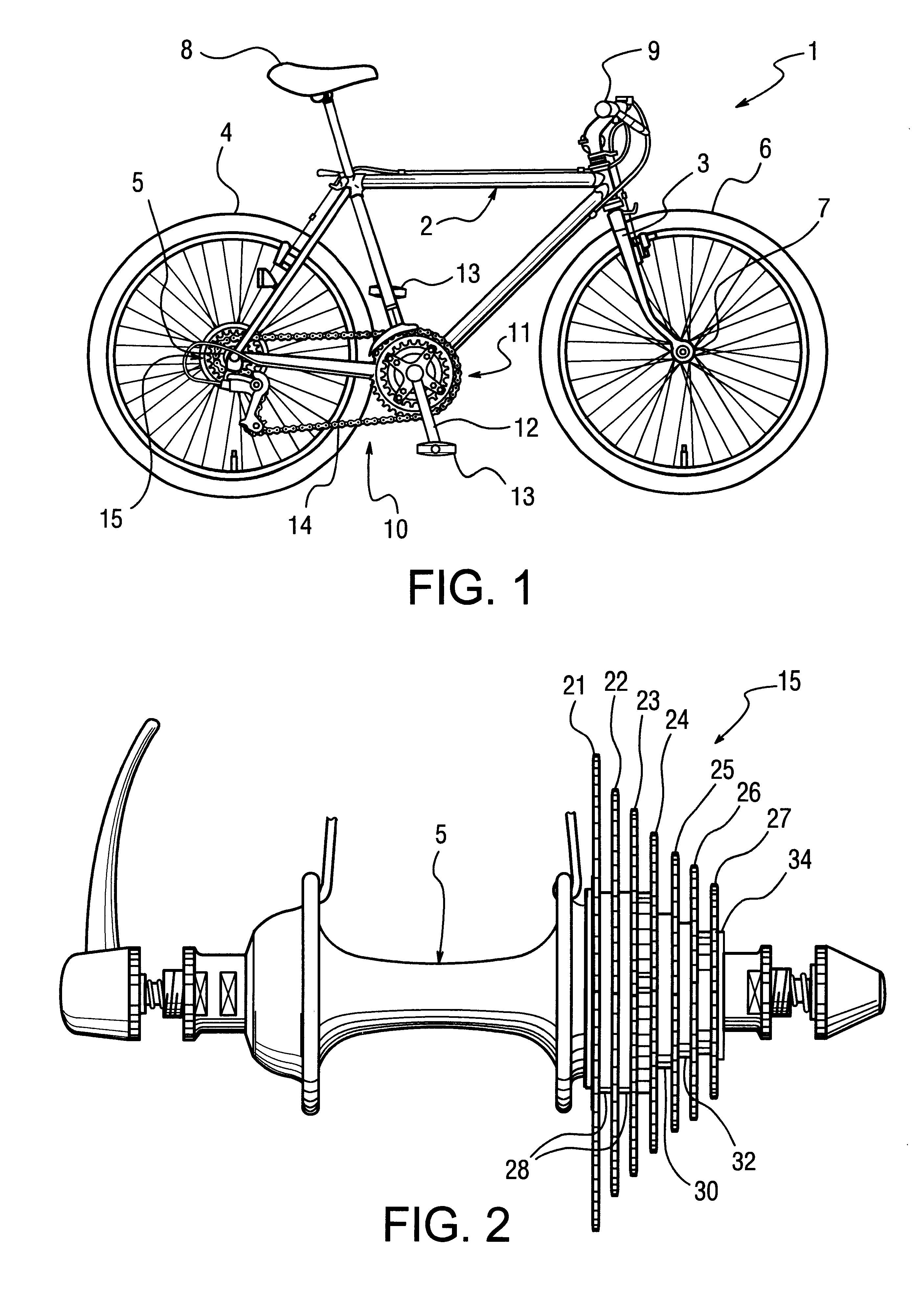

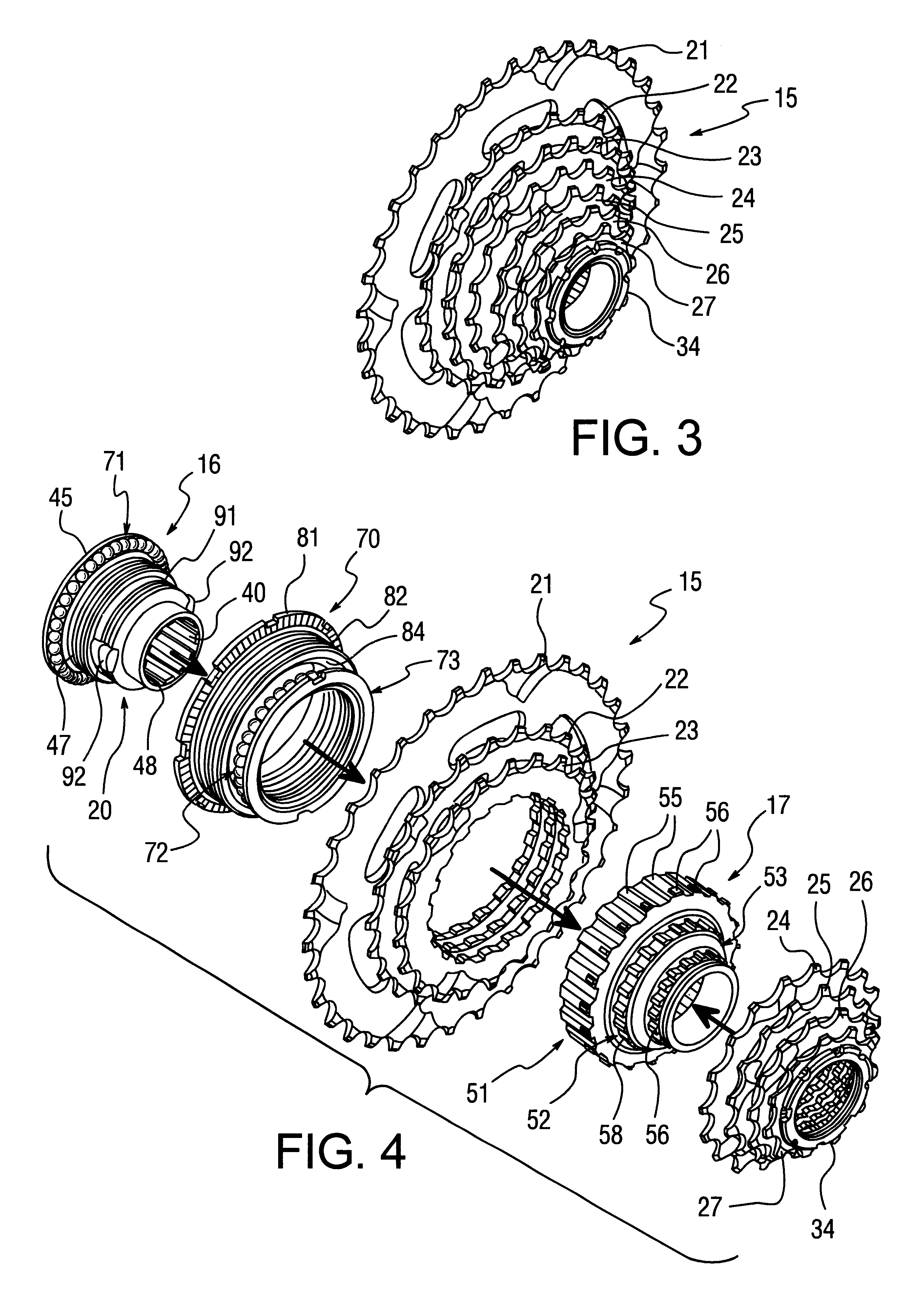

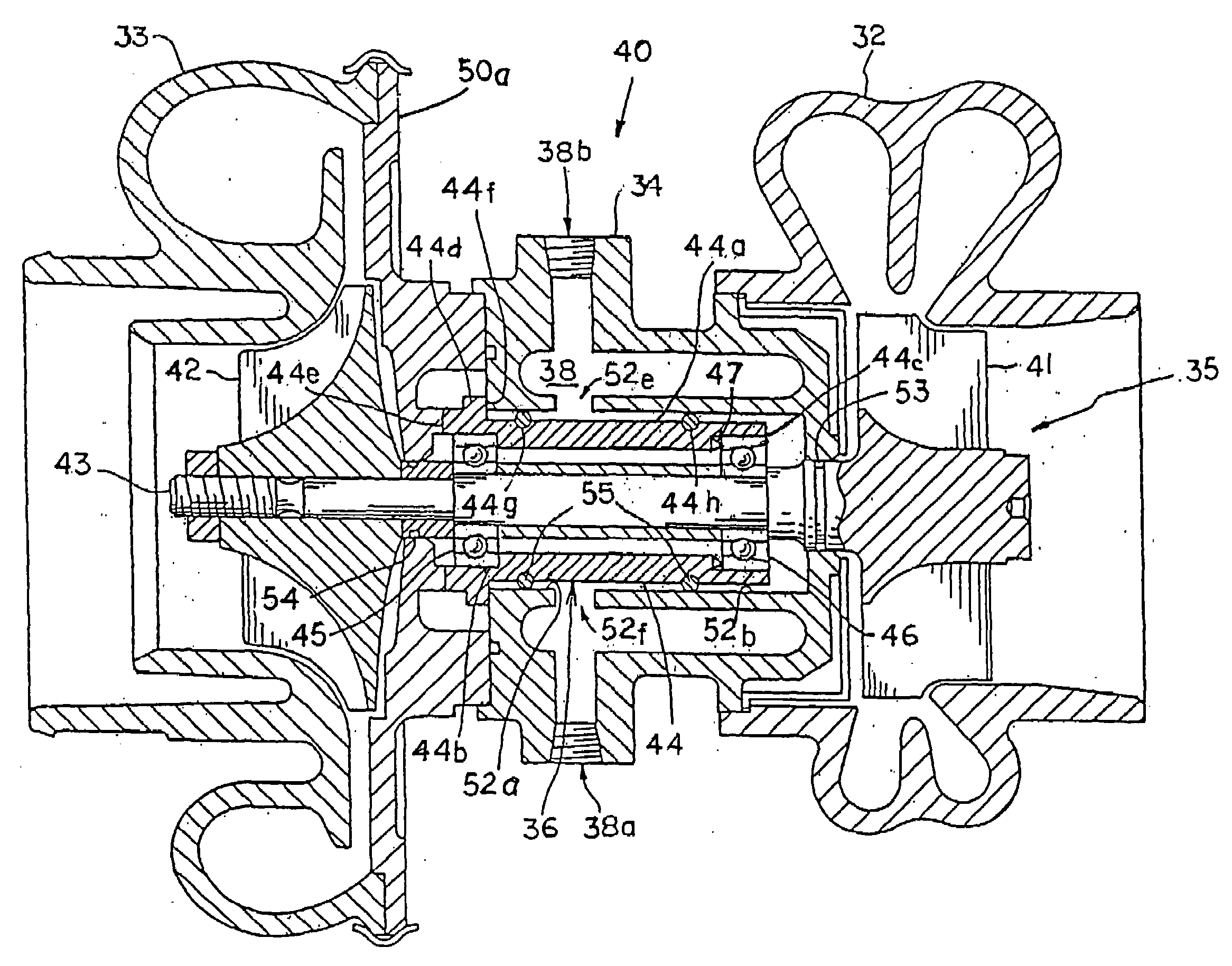

Freewheel for a bicycle

A freewheel is provided for mounting a plurality of sprockets on an axle of a bicycle. The freewheel basically includes an inner tubular body, an outer tubular body coaxially mounted on the inner tubular body with a bearing assembly rotatably coupling the inner tubular body to the outer tubular body. A one-way clutch is coupled between the inner tubular body and the outer tubular body to allow one-way rotation between the inner and outer tubular bodies. In the preferred embodiment, seven sprockets are mounted on the exterior of the outer tubular body. The bearing assembly has a pair of ball bearing races of the same diameter located at one end. An outer ball race or housing and a side plate are utilized in conjunction with the inner tubular body to fixedly secure the first and second ball bearings on the exterior surface of the inner tubular body. The inner tubular body with the bearings is then fixedly coupled to the outer tubular body so that the outer tubular body can rotate relative to the inner tubular body. The one-way clutch includes a pair of pawls attached to the inner tubular body and a set of ratchet teeth formed on the inner tubular body. The ratchet teeth are rotated between splines that are formed on the exterior surface of the outer body so as to maximize strength and minimize material. The outer tubular body has a step-shaped configuration with a plurality of abutment stoppers formed on the splines of the largest section such that some of the sprockets are installed from one direction and the other sprockets are installed in a second direction.

Owner:SHIMANO SINGAPORE PRIVATE LTD +1

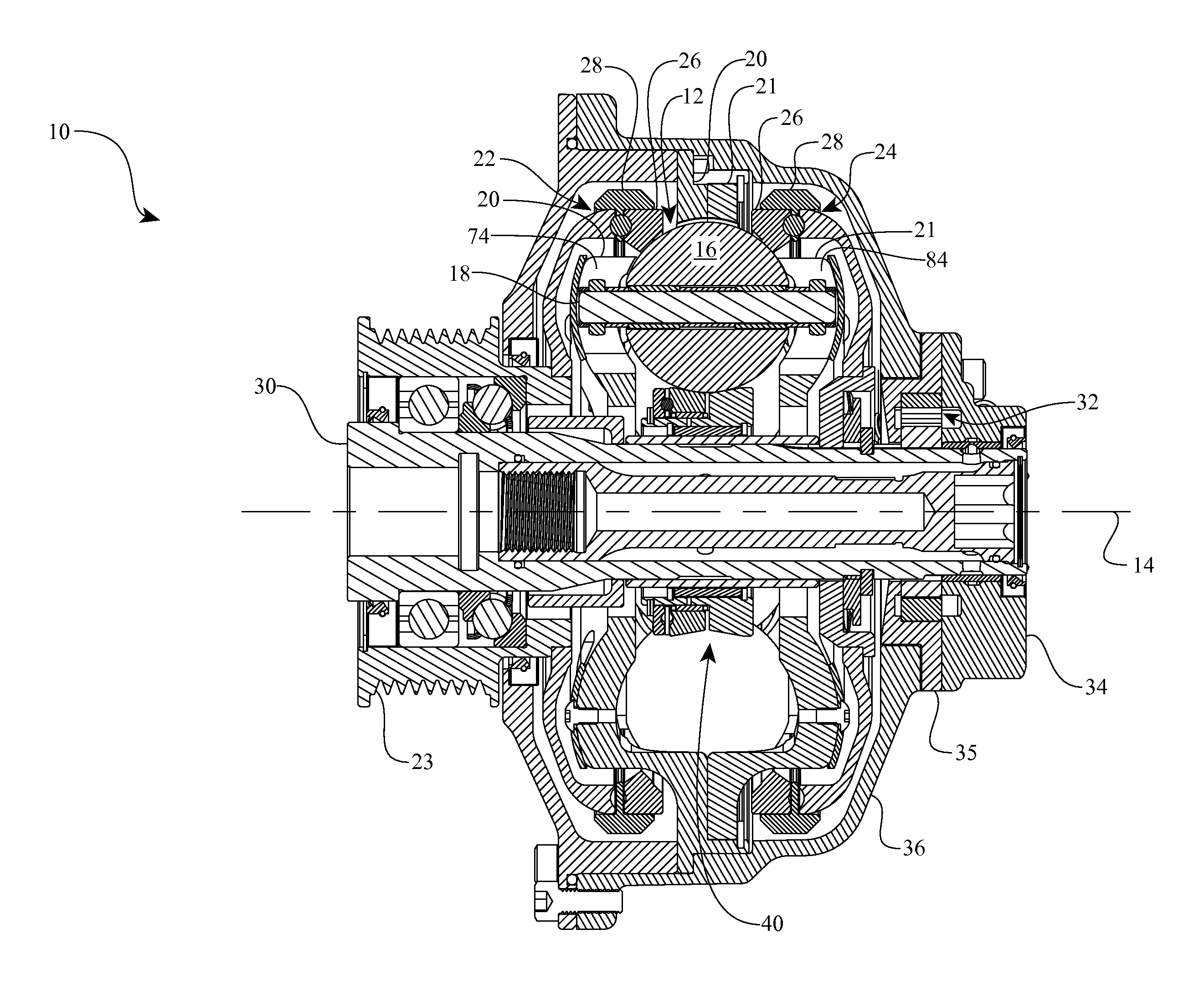

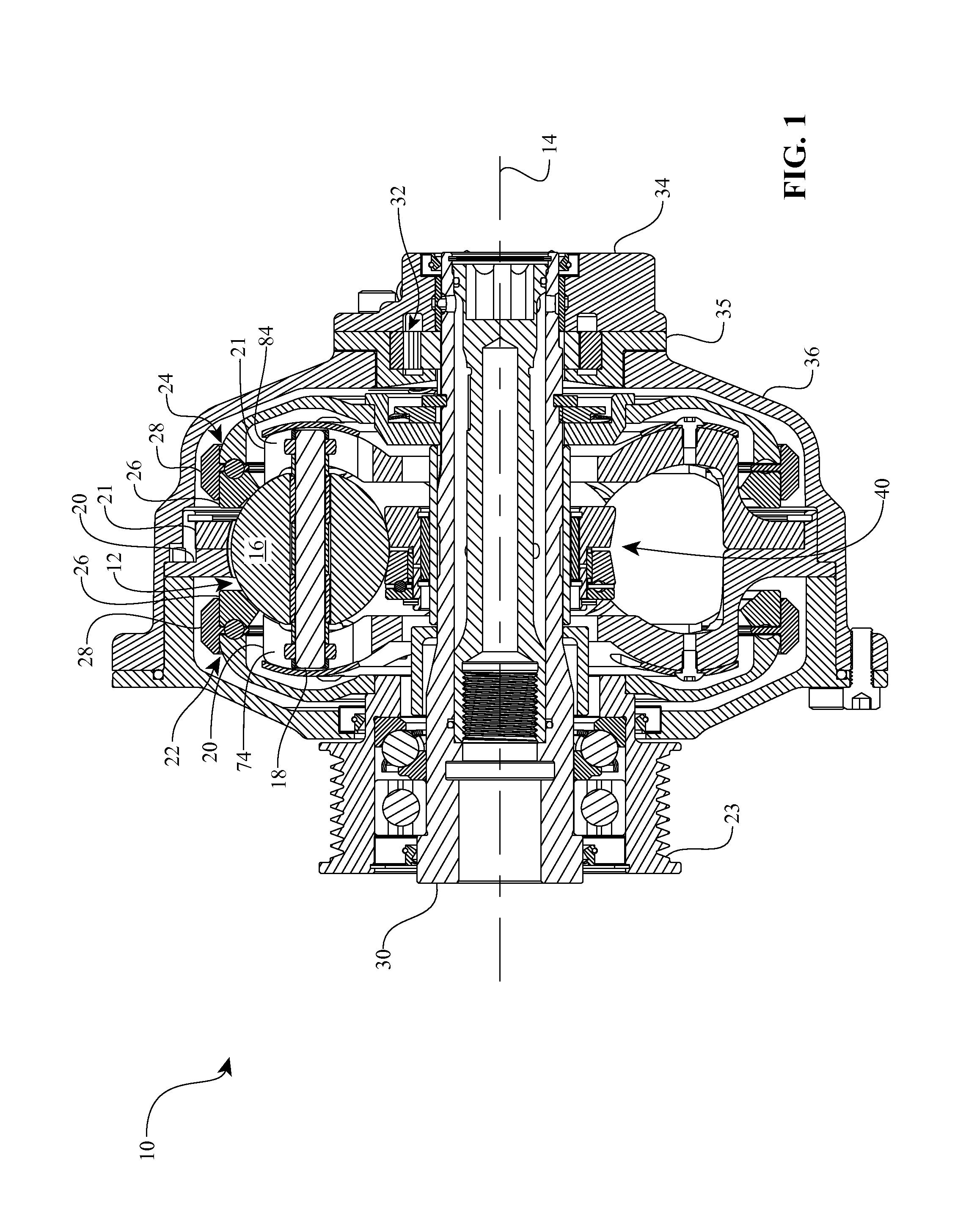

Continuously variable transmission

Owner:FALLBROOK INTPROP COMPANY

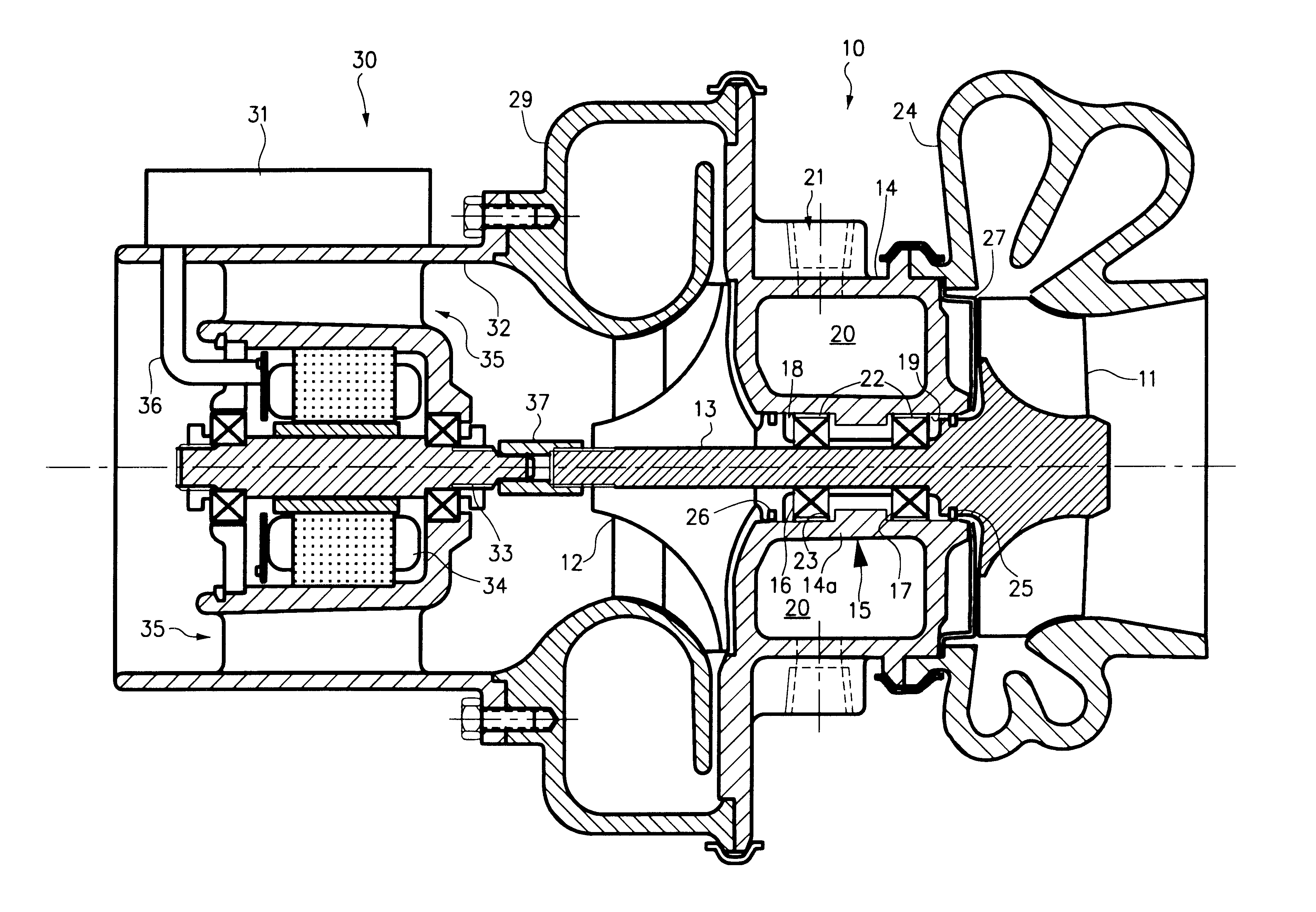

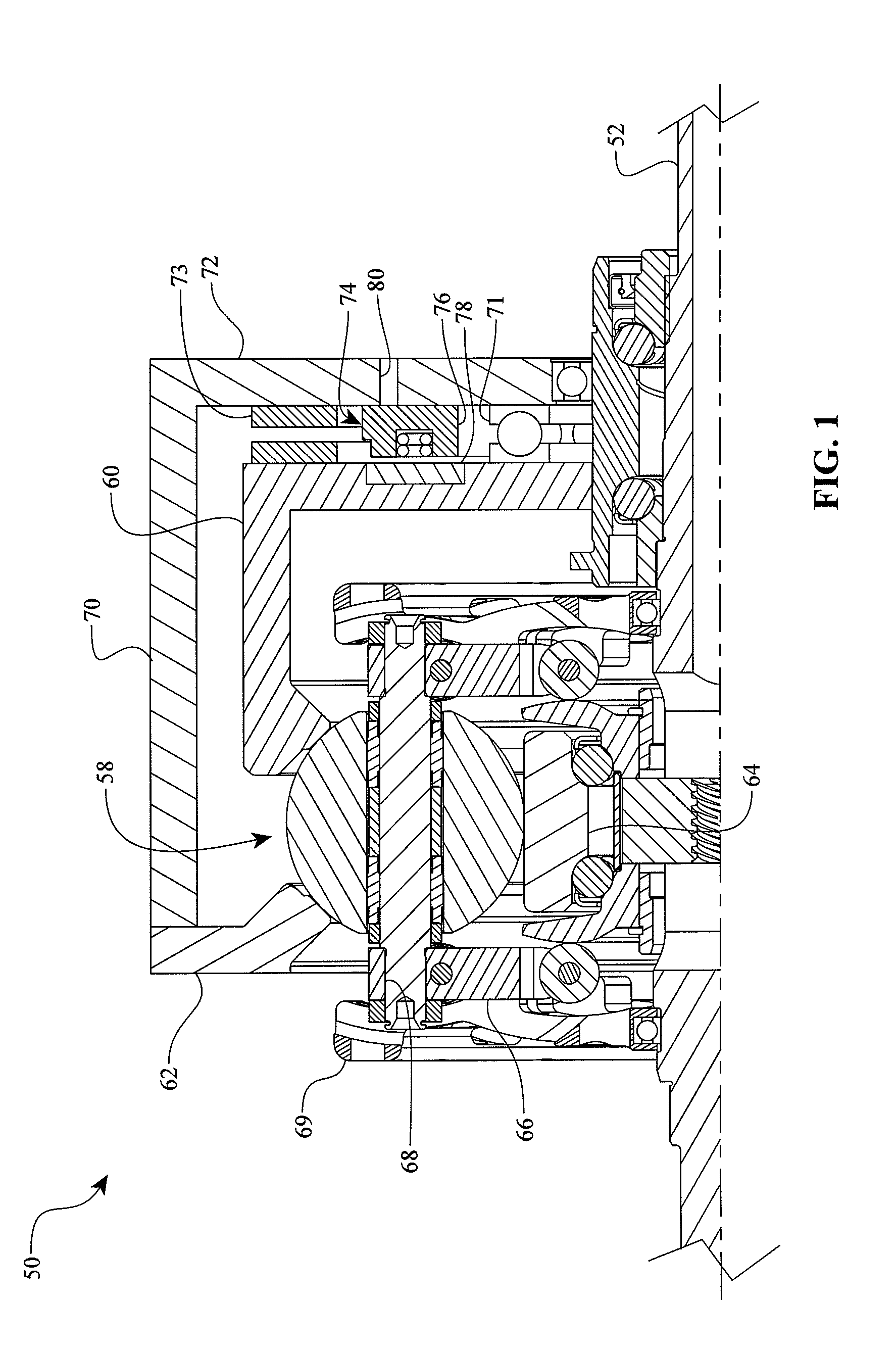

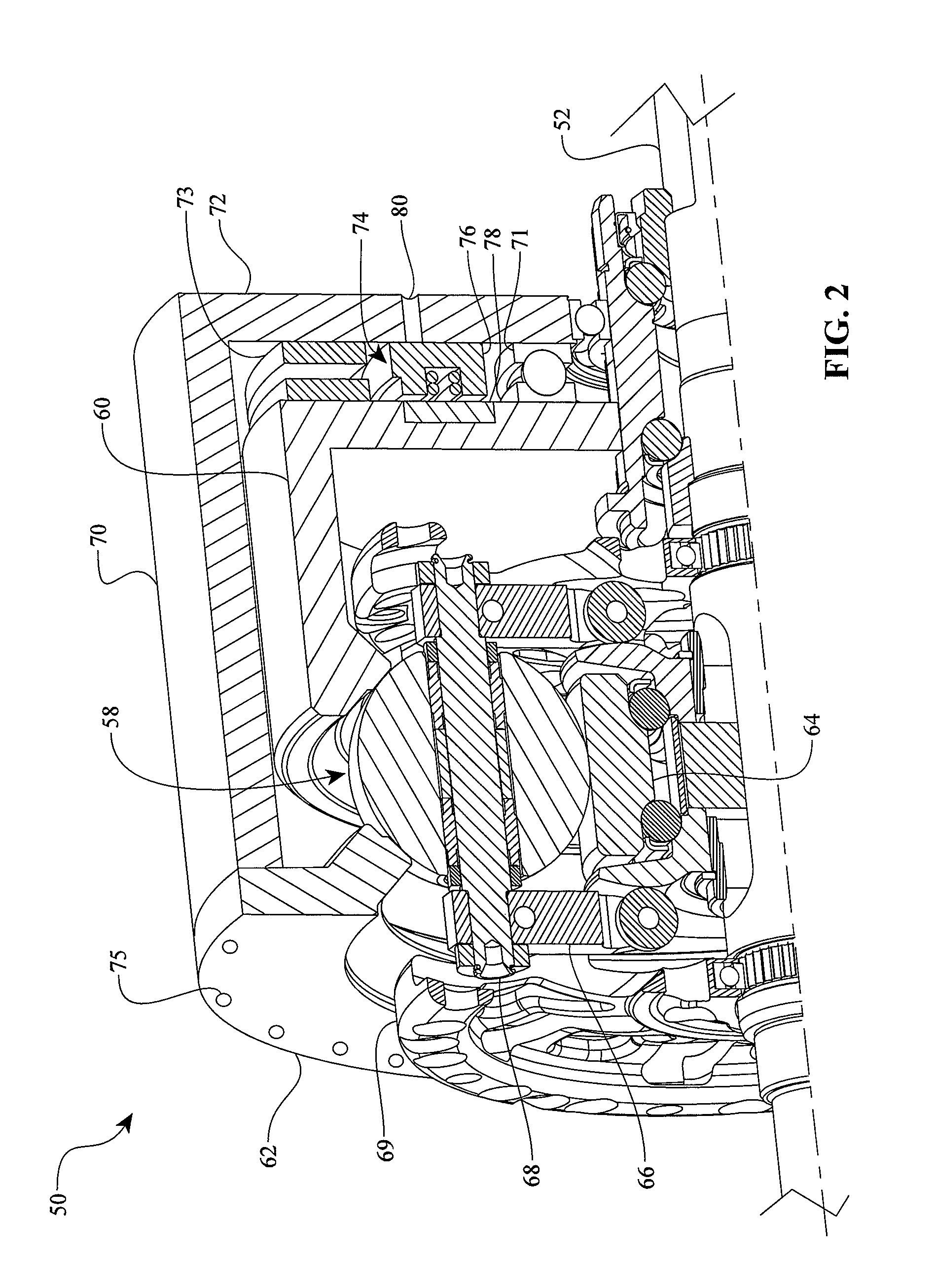

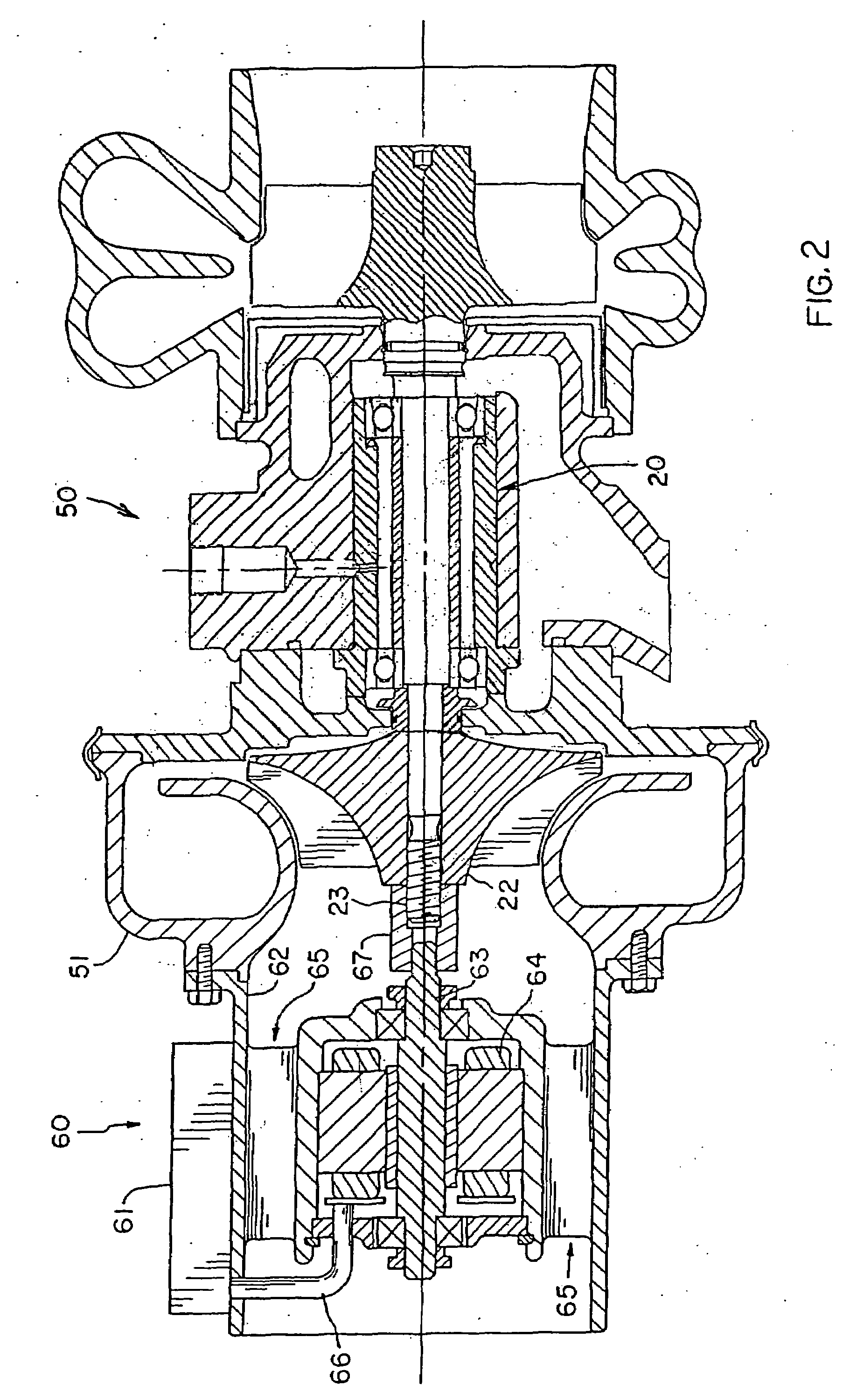

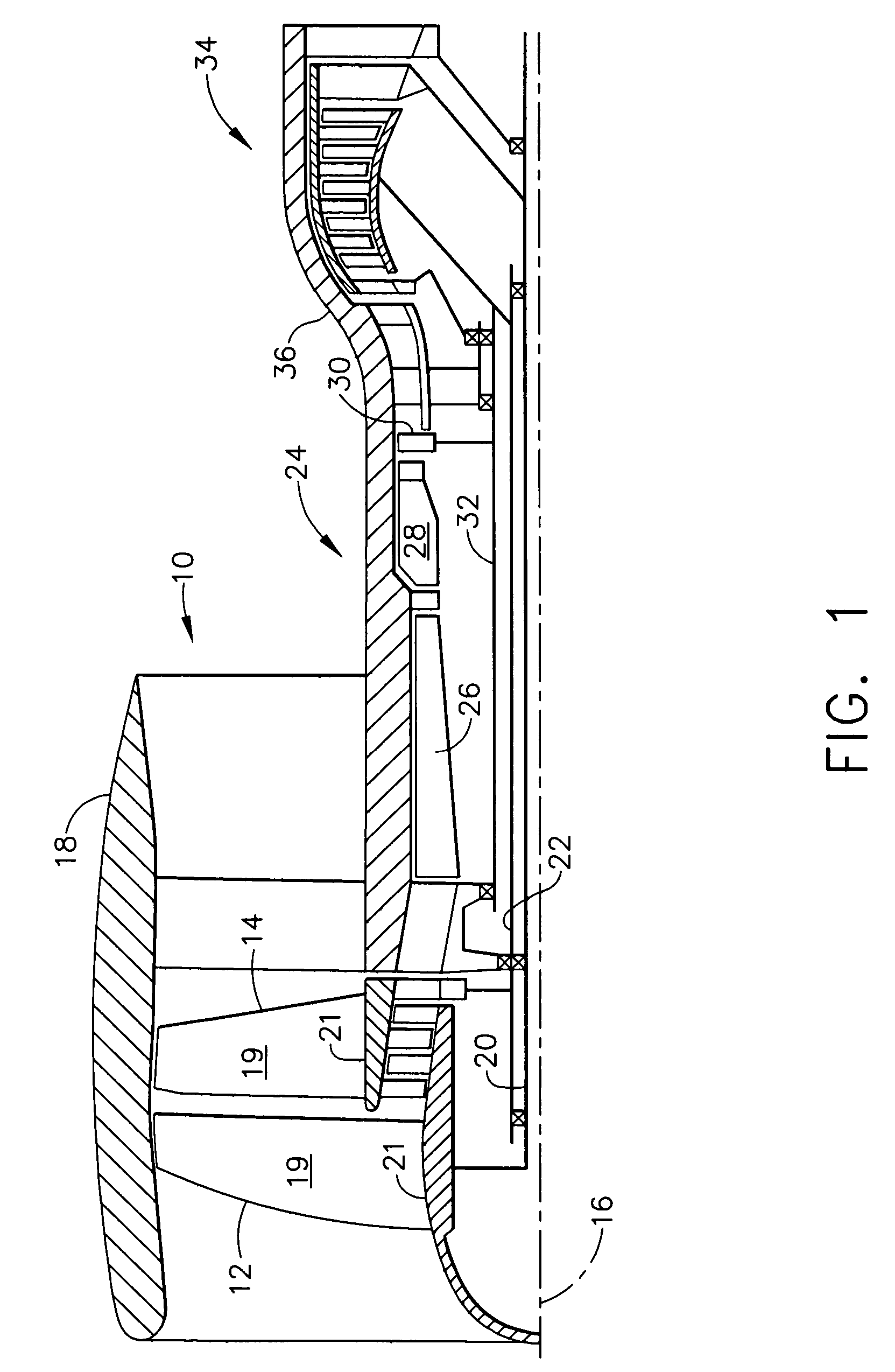

Compact turbocharger

InactiveUS6739845B2Minimal lengthLow thermal expansionInternal combustion piston enginesPump componentsTurbochargerControl theory

A turbocharger comprising two closely spaced ball bearings that does not require lubricating oil from an engine. The bearing housing forms a cooling jacket with two bearing engagement surfaces engaged with the outer races of the ball bearings through an intermediate radial spring. Closely spacing the ball bearings provides a rotor shaft of minimal length. In addition, an external motor-generator may be by mounted on the turbocharger, with the motor rotor solidly connected to the turbocharger rotor. In such an assembly, an electronic control is energizes the motor from battery power during acceleration up to approximately torque peak speed; thereafter, the control changes to a generator mode when there is excess energy in the engine exhaust gas.

Owner:WOOLLENWEBER WILLIAM E

Apparatus for providing a load on a bearing, the bearing having an inner race mounted to a shaft and the bearing retained by a nut

Owner:TEMPER +1

Self-assembling wireless network, vehicle communications system, railroad wheel and bearing monitoring system and methods therefor

ActiveUS7705743B2Increase power consumptionWide bandwidthRolling contact bearingsMeasurement devicesCommunications systemMonitoring system

A low power self-organizing network is made up of a plurality of wireless communication nodes communicating wirelessly with each other. The nodes each have a sensor providing a respective sensor data value indicative of a physical parameter in the environment of that node. The wireless network discontinues communication with any nodes in which the sensor data value is outside a range of network sensor data values. The network is preferably a group of vehicles moving together, especially a train in which each node is associated with a respective wheel of a railroad car. The nodes are low-power devices that communicate using wireless communications according to a Zigbee protocol. The nodes each have an additional sensor sensing a physical parameter the respective wheel thereof and determines from said electrical signal a degree of degradation of a bearing of the wheel, and transmits data of the degree of degradation to the main node. The main node communicates with another computer system using a higher power communication system and transmits thereto data indicative of degradation of said bearings.

Owner:CONVEY INC

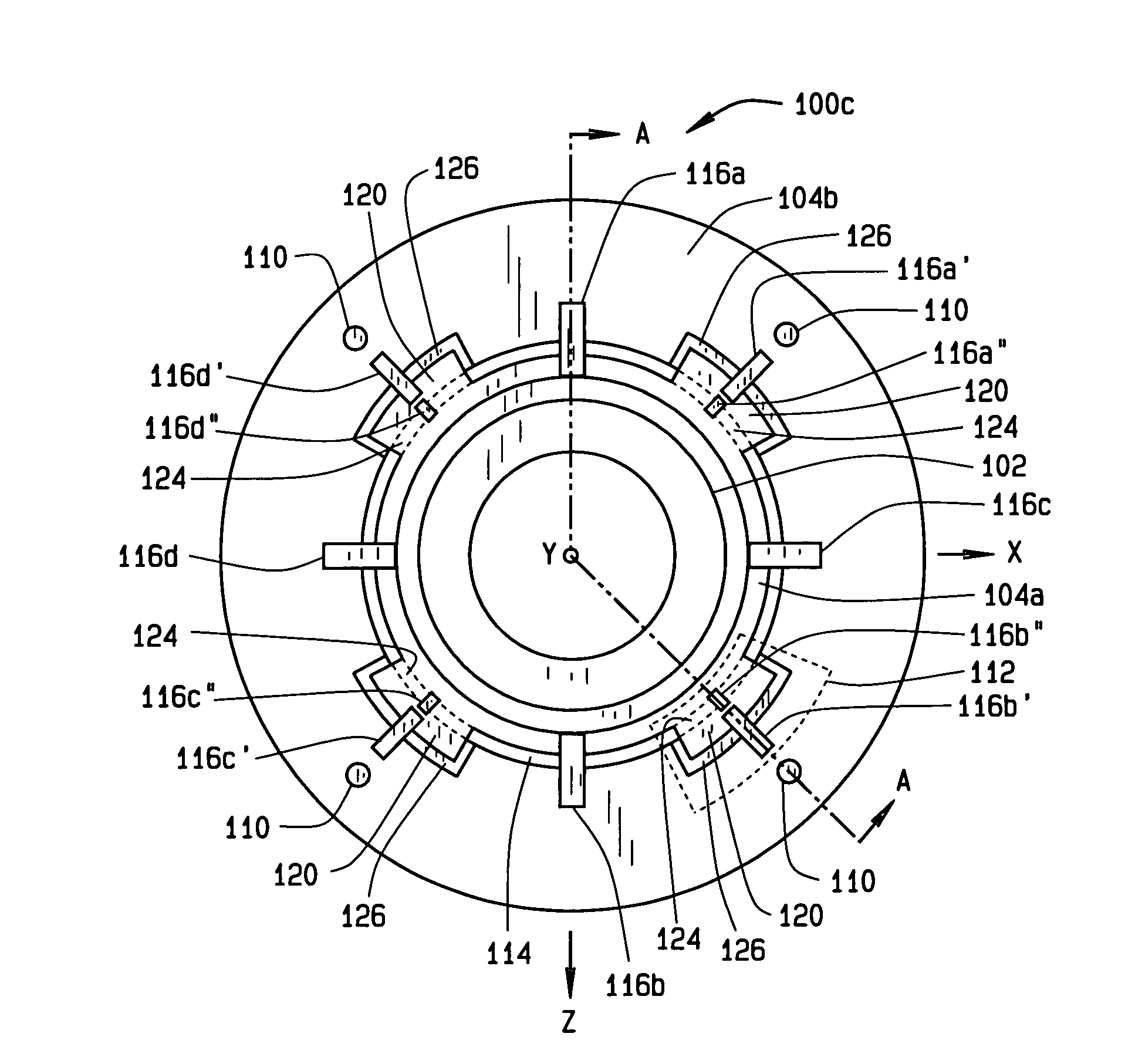

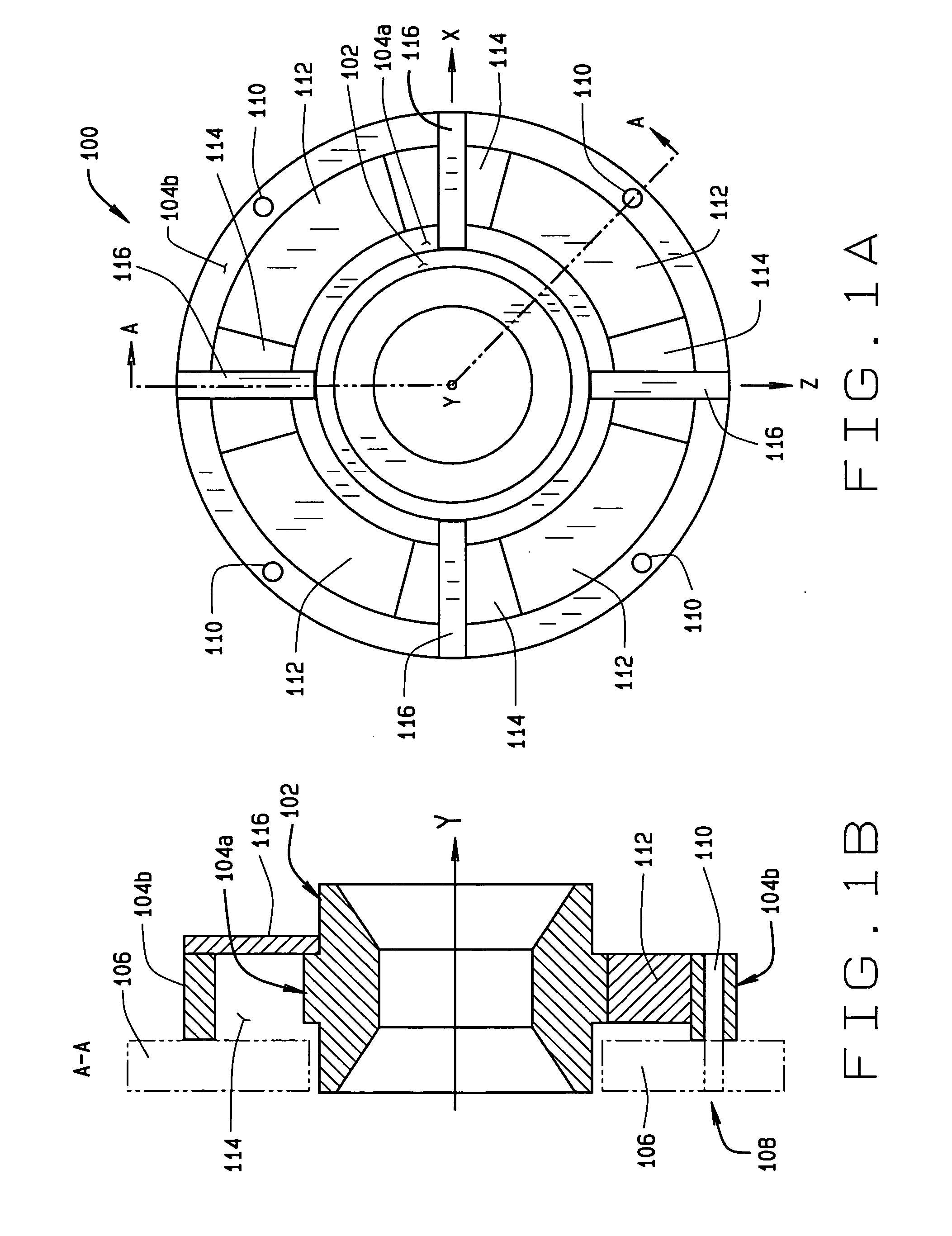

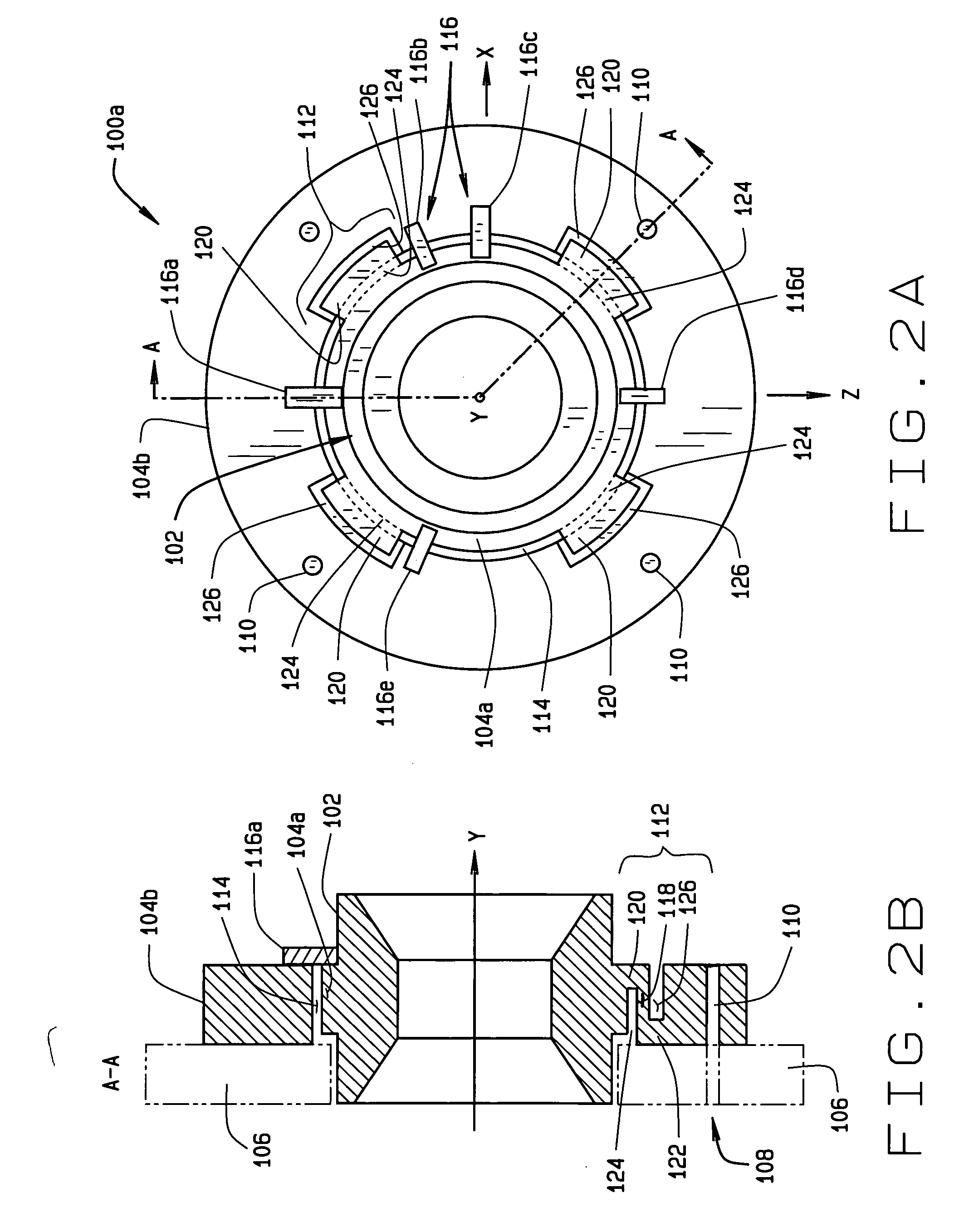

Assemblies and methods for clamping force generation

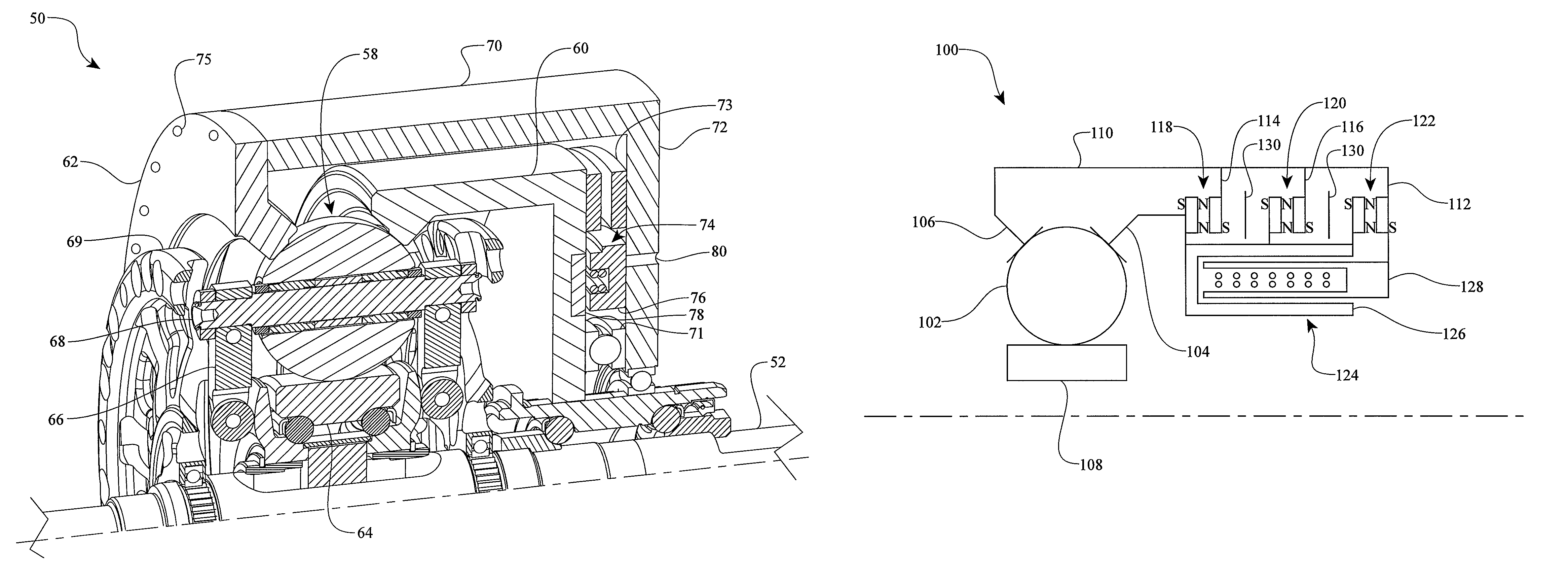

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

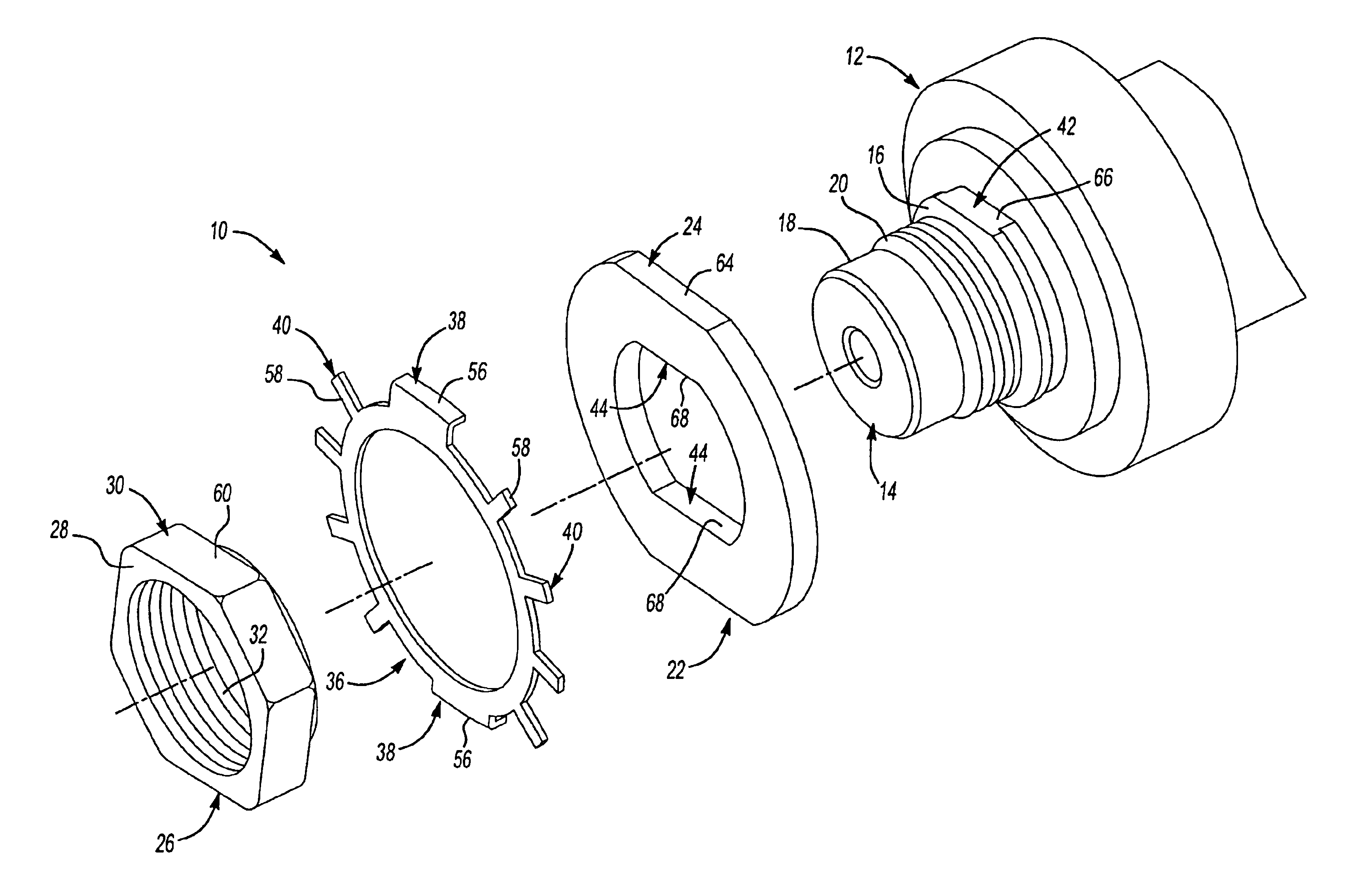

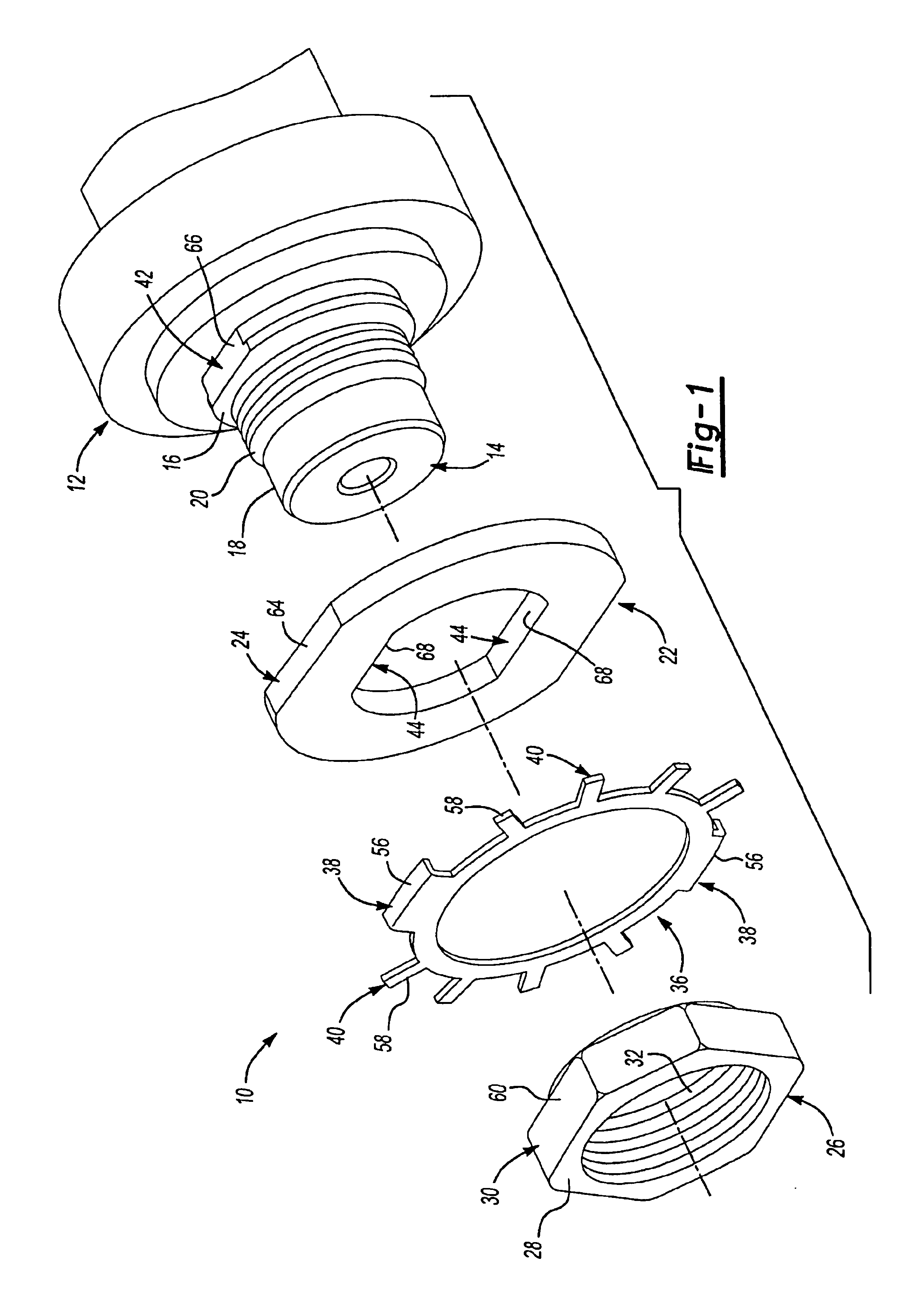

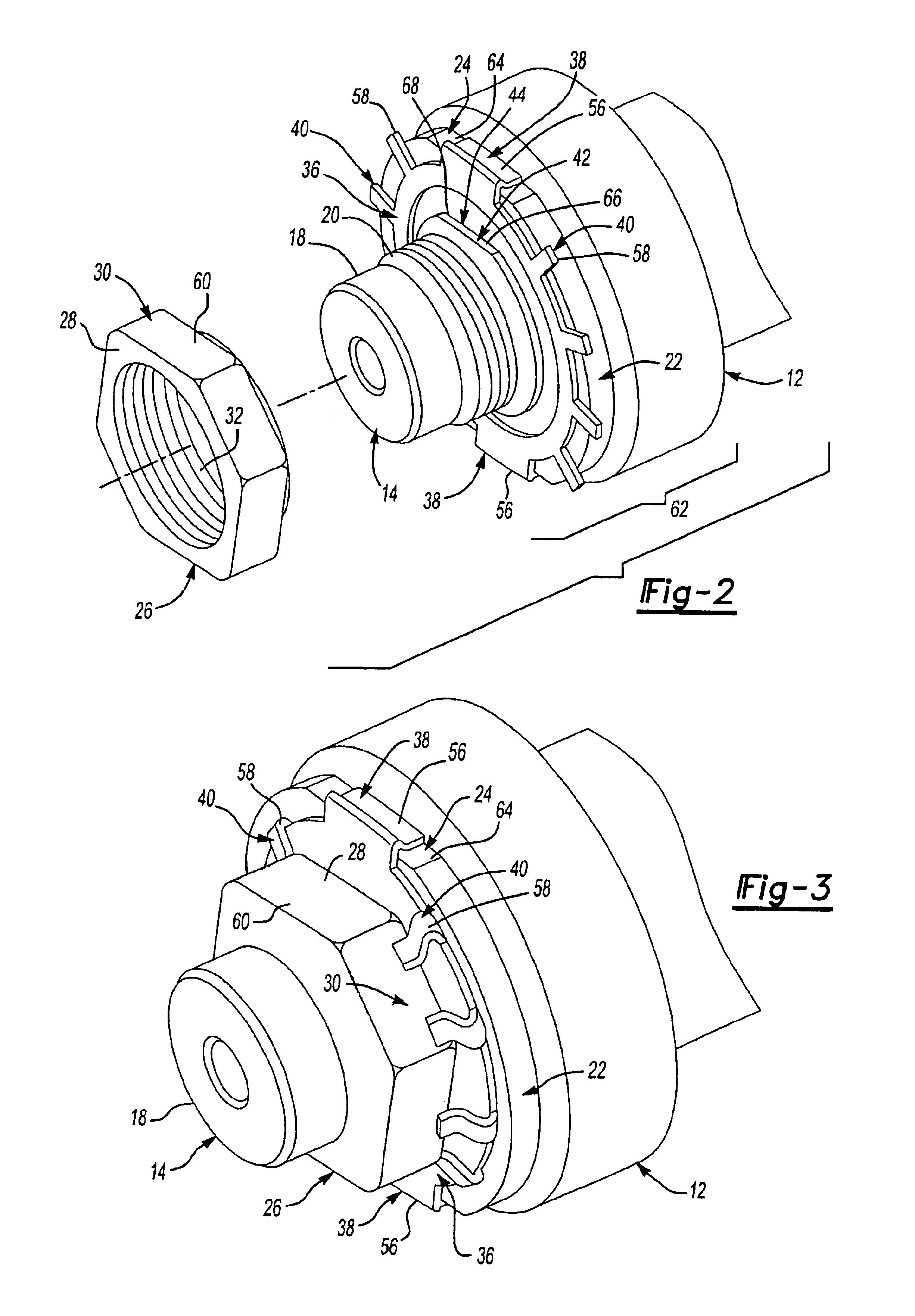

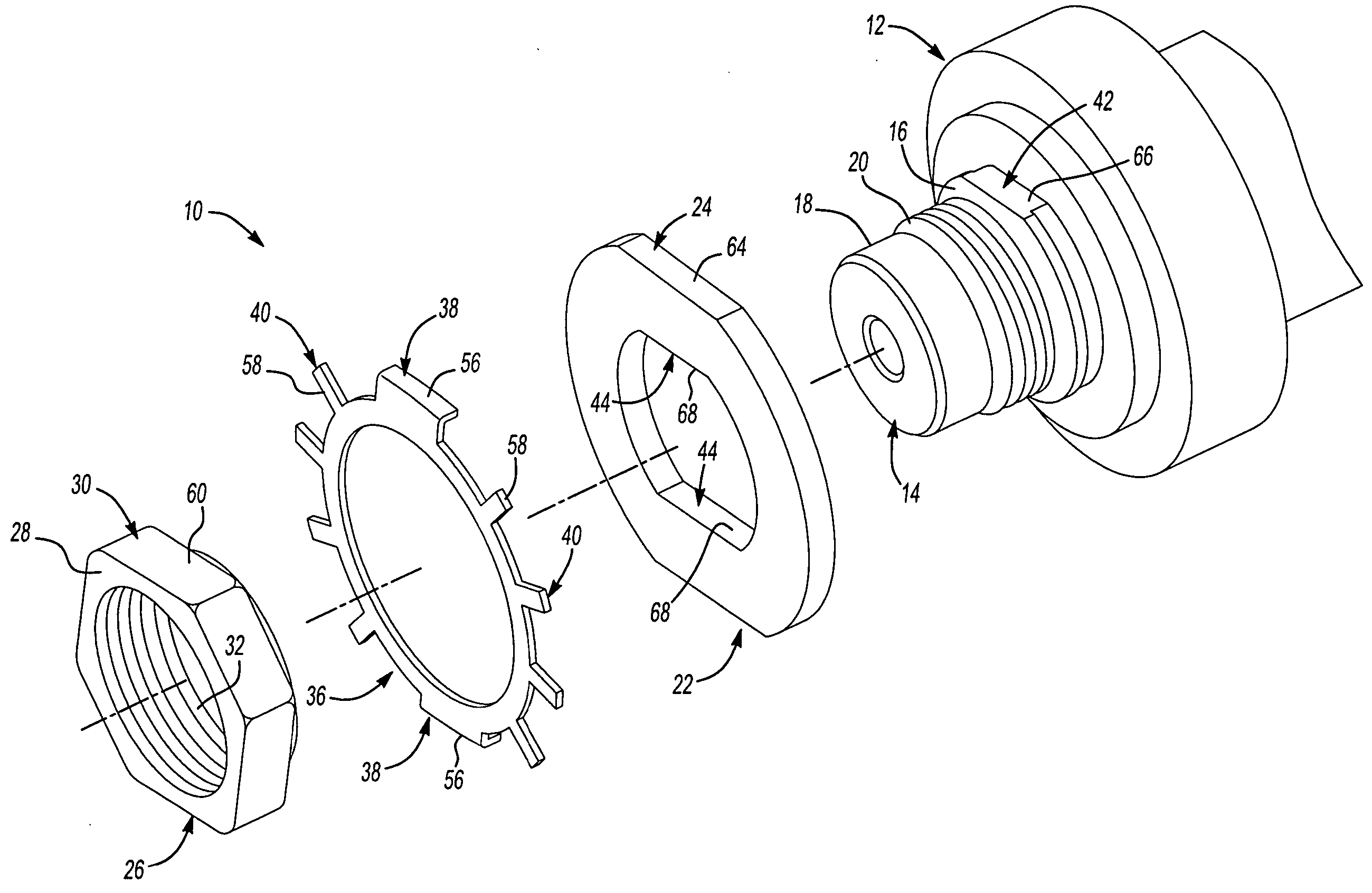

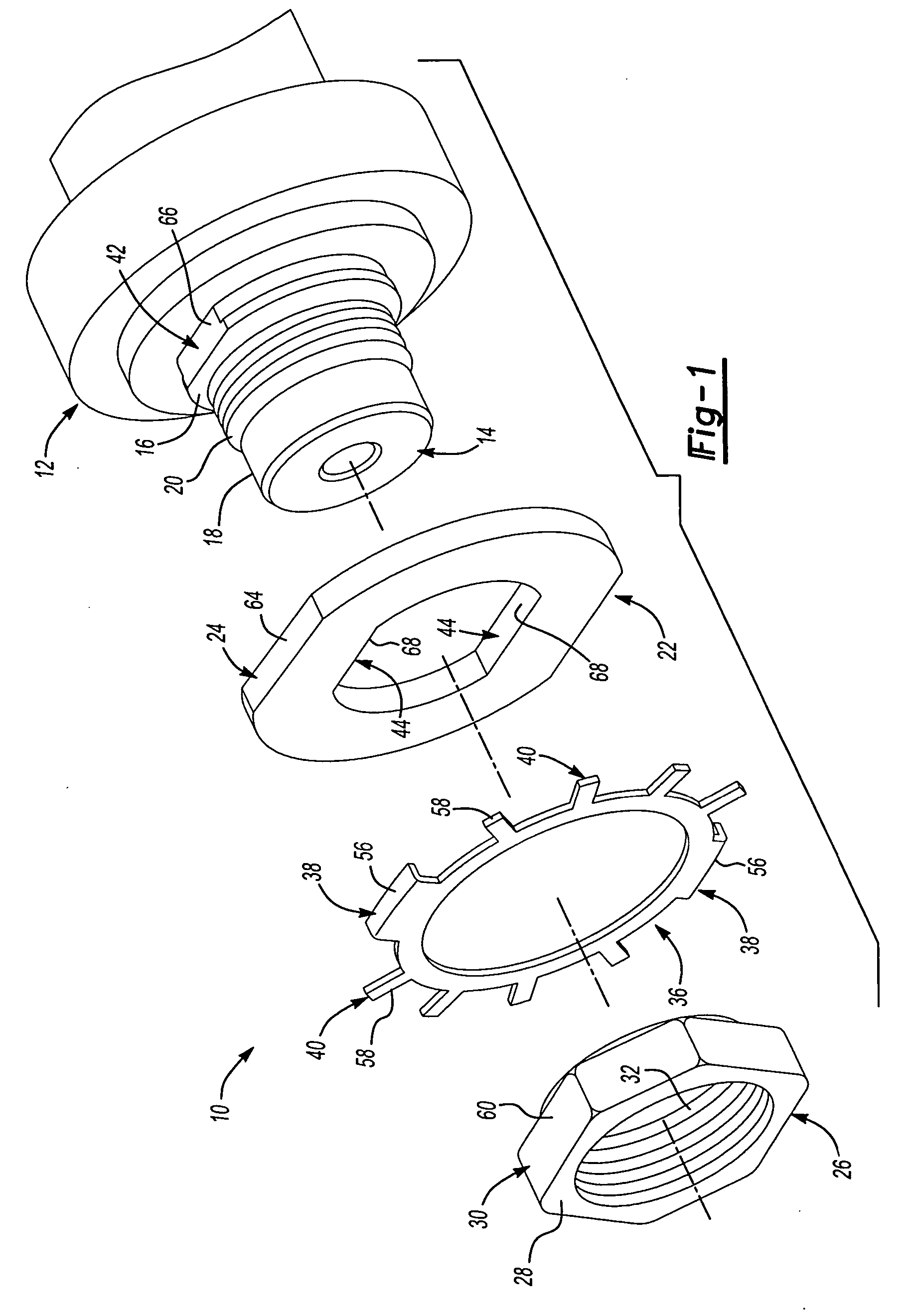

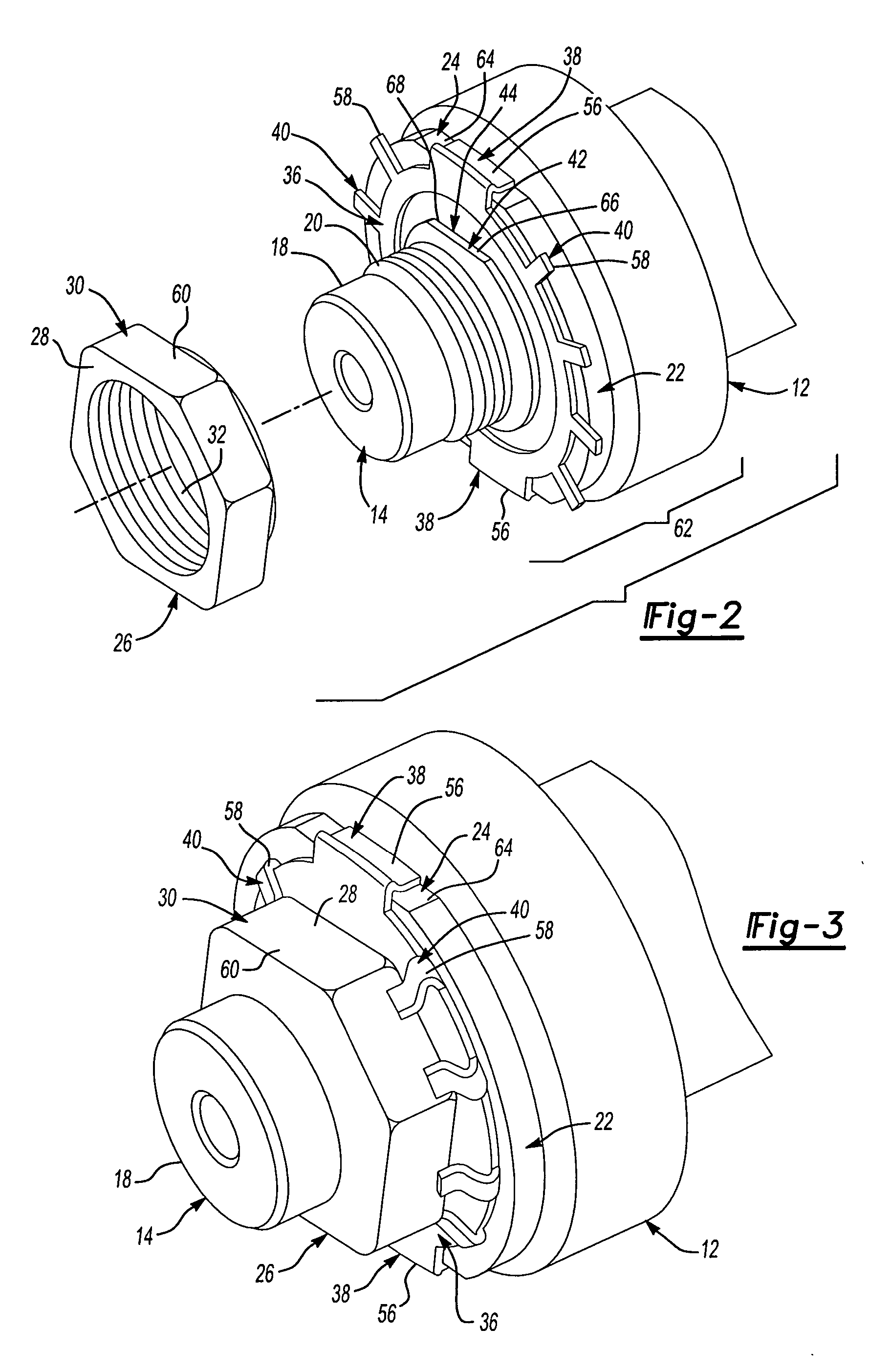

Combination lock washer and spindle bearing assembly

The present invention relates to a connection between a spindle and a bearing assembly to retain the bearing assembly on the spindle. A combination lock washer and spindle bearing assembly is provided to include a spindle, thrust washer, lock washer and nut in which the lock washer simultaneously locks the inner thrust washer and an outer spindle nut. According to the present invention, the thrust washer, lock washer and nut may be oriented at any angle relative to one another allowing for infinite bearing adjustment positions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

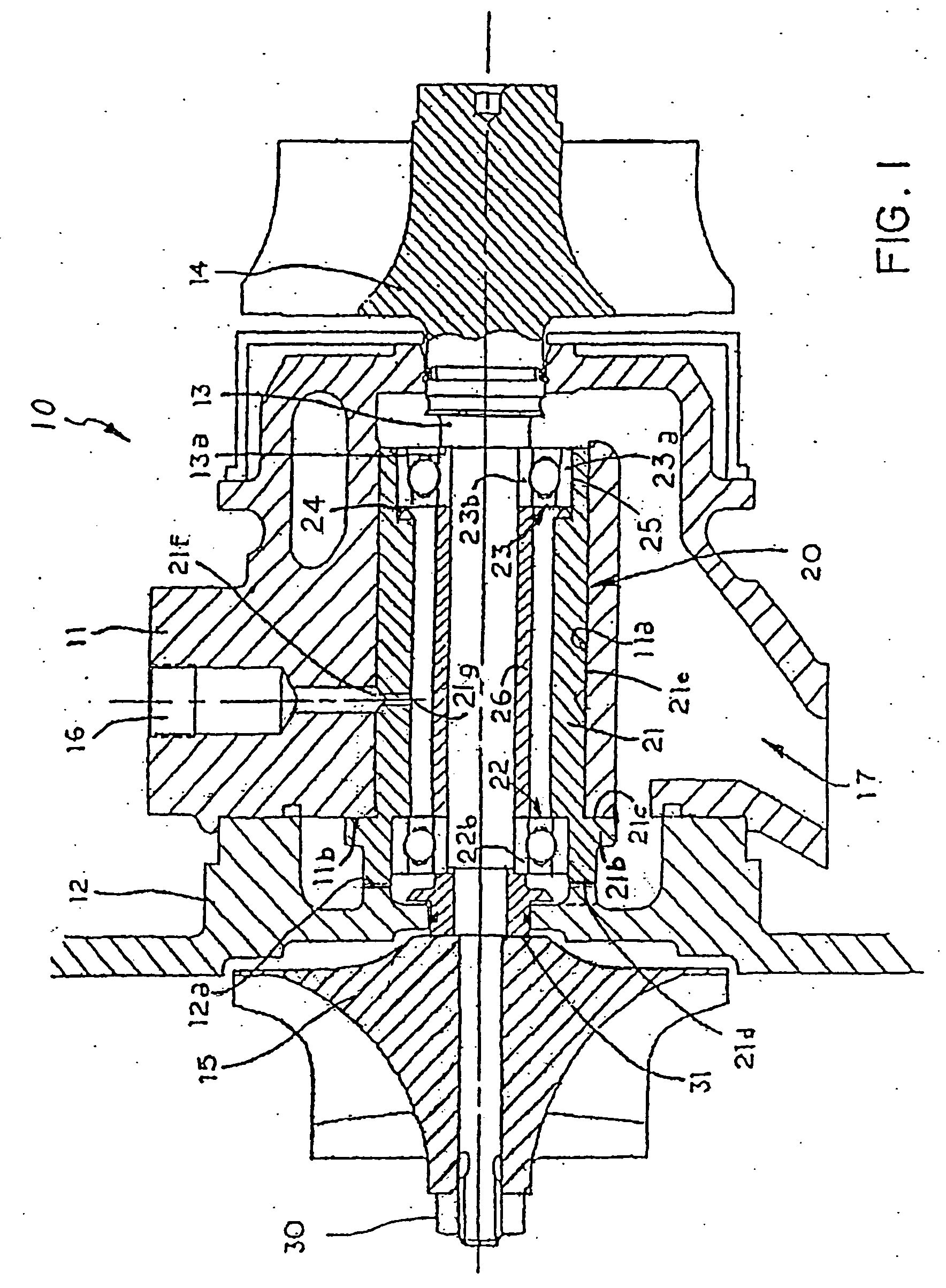

Bearing systems for high-speed rotating machinery

InactiveUS20080087018A1Improve performanceMaintain integrityRolling contact bearingsShaftsBall bearingTurbocharger

Bearing systems for high speed rotating shafts, such as turbocharger shafts, include a first ball bearing in one end of an elongated cylinder capable of carrying axial thrust in both directions and a second ball bearing in the opposite end of the elongated cylinder with its outer race slideably mounted in the cylinder against the biasing force of a preload spring. The second ball bearing is free to move axial with the shaft upon axially expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are clamped to and rotate with the shaft as part of the rotating assembly.

Owner:DELGADO LAUREN N

Load-sensing bearing

A load sensing bearing assembly comprises a bearing outer race secured to an application structure by a flange assembly incorporating a plurality of anisotropic spring regions which enable a limited range of displacement and / or rotation of the bearing outer race relative to the application structure in response to applied forces or moments. A set of sensor modules disposed through the bearing outer race and flange assembly acquire measurements from which the radial forces, thrust forces, and tilting moments exerted on the bearing outer race can be determined.

Owner:THE TIMKEN CO

Wheel support bearing assembly

A wheel support bearing assembly includes inner and outer members (1 and 2) and at least one row of rolling elements (3) operatively interposed between the inner and outer members (1 and 2) and an annular sealing device (5) sealing an open end of an annular space defined between the inner and outer members (1 and 2). The sealing device (5) includes first and second annular sealing plates (11 and 12) fitted to different members out of the inner and outer members (1 and 2). Each of the first and second sealing plates (11 and 12) includes a generally cylindrical wall (11a or 12a) and a radial wall (11b or 12b) assembled together to represent a generally L-shaped section. The first sealing plate (11) is fitted to one of the inner and outer members (1 and 2) that serves as a rotating member. An elastic member (14) mixed with a powdered magnetic material is bonded by vulcanization to the radial wall (11b) of the first sealing plate (11). A protective cover (18) made of a non-magnetic material is positioned on one side adjacent an exterior of the multi-pole magnet (14) with a predetermined air gap left therebetween that the number of revolution can be detected through the protective cover (18).

Owner:NTN CORP

Combination lock washer and spindle bearing assembly

The present invention relates to a connection between a spindle and a bearing assembly to retain the bearing assembly on the spindle. A combination lock washer and spindle bearing assembly is provided to include a spindle, thrust washer, lock washer and nut in which the lock washer simultaneously locks the inner thrust washer and an outer spindle nut. According to the present invention, the thrust washer, lock washer and nut may be oriented at any angle relative to one another allowing for infinite bearing adjustment positions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

InactiveUS20060167659A1Diagnose abnormalityMachine part testingEngine fuctionsMonitoring statusControl system

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

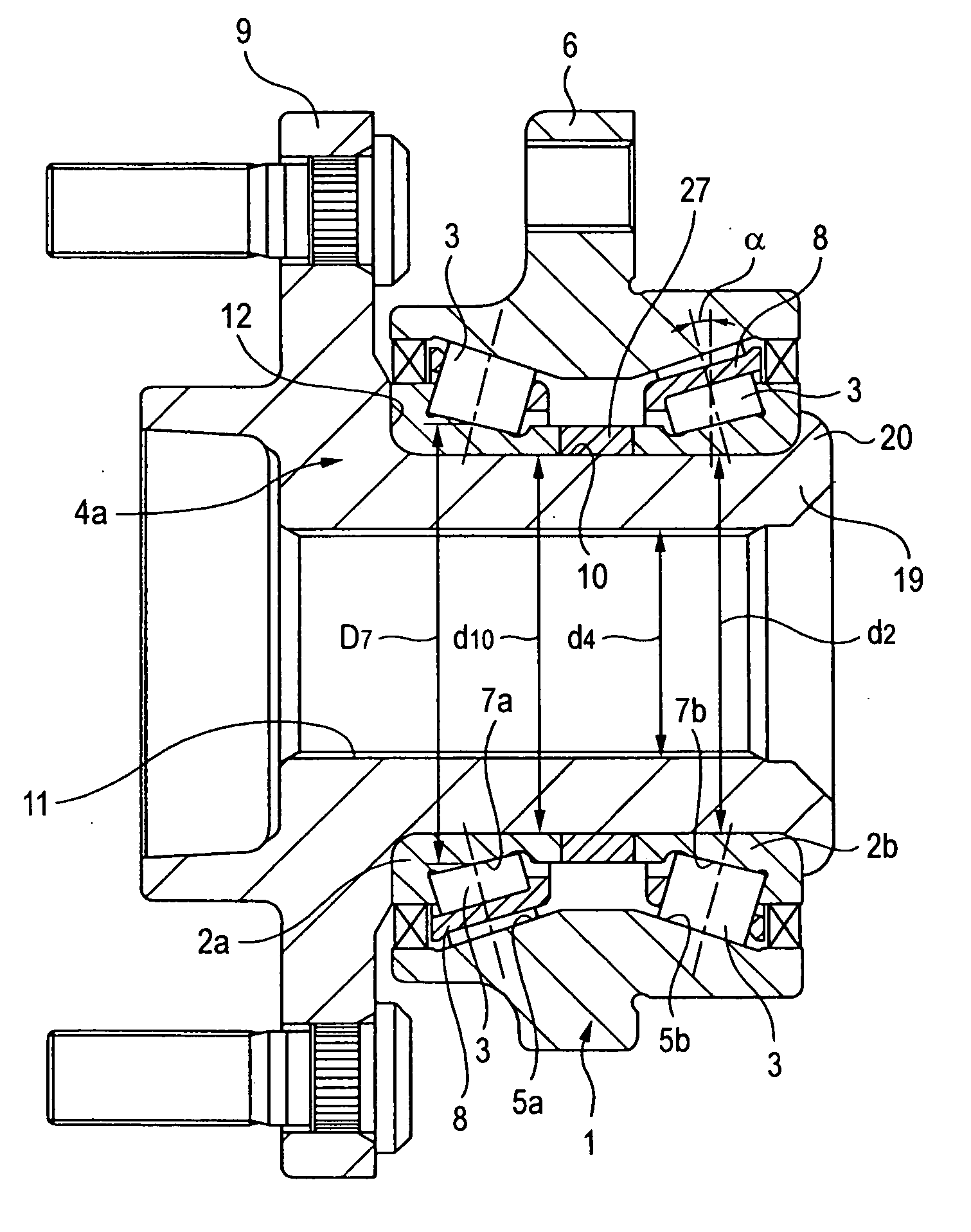

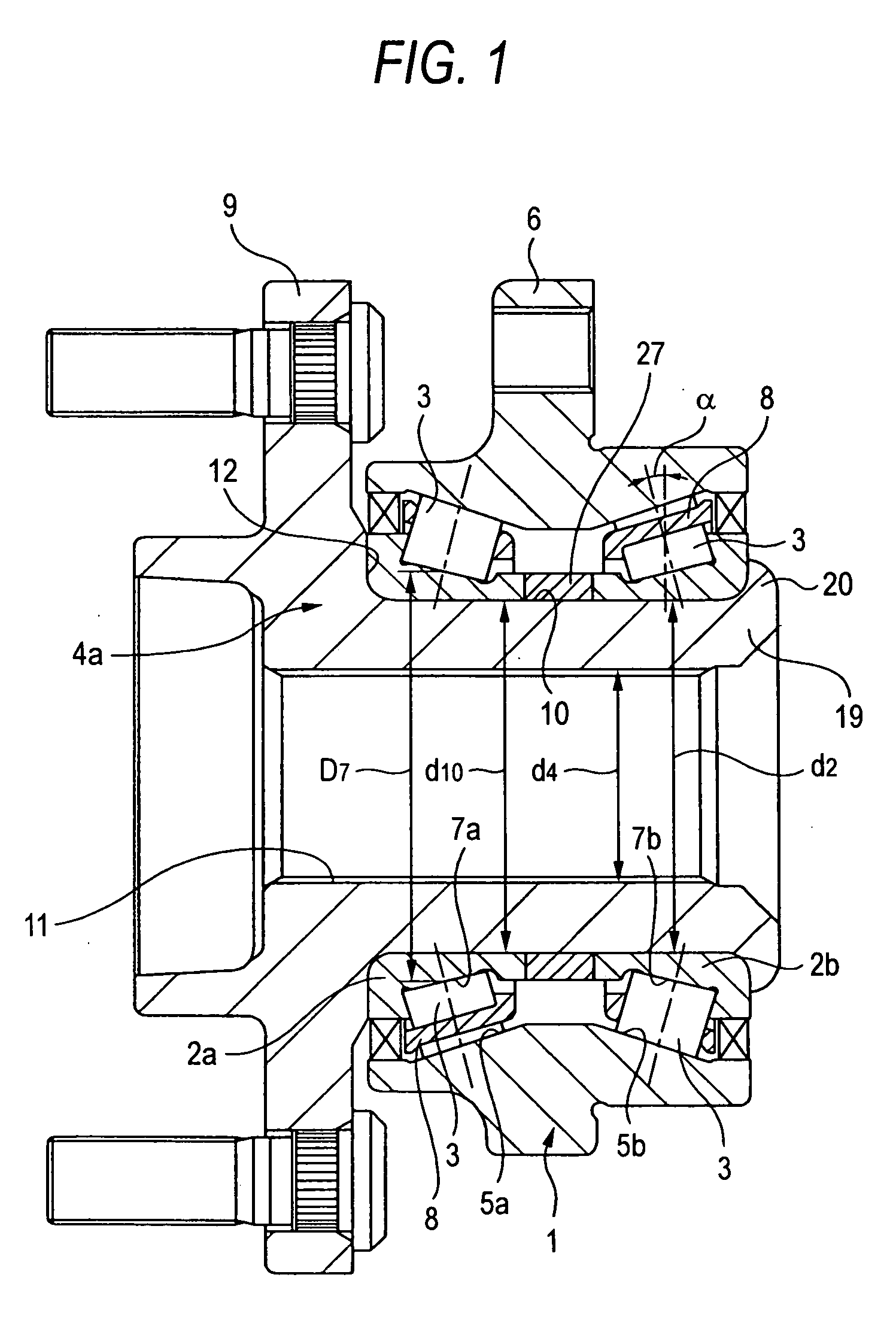

Wheel supporting bearing assembly and method for producing the same

A construction is adopted in which an annular spacer 27 is held between first and second inner races 2a, 2b. An internal clearance in a double-row bearing unit is measured in a middle step of assembling work of a wheel supporting bearing assembly, and in the event that a resultant measured value does not become a proper value, an axial dimension of the spacer 27 is adjusted, so that the internal clearance becomes the proper value. Thereafter, the assembling work is made to continue until the assembling work is completed. A problem which is to be solved by the invention is solved in the way described above.

Owner:NSK LTD

Assemblies and methods for clamping force generation

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

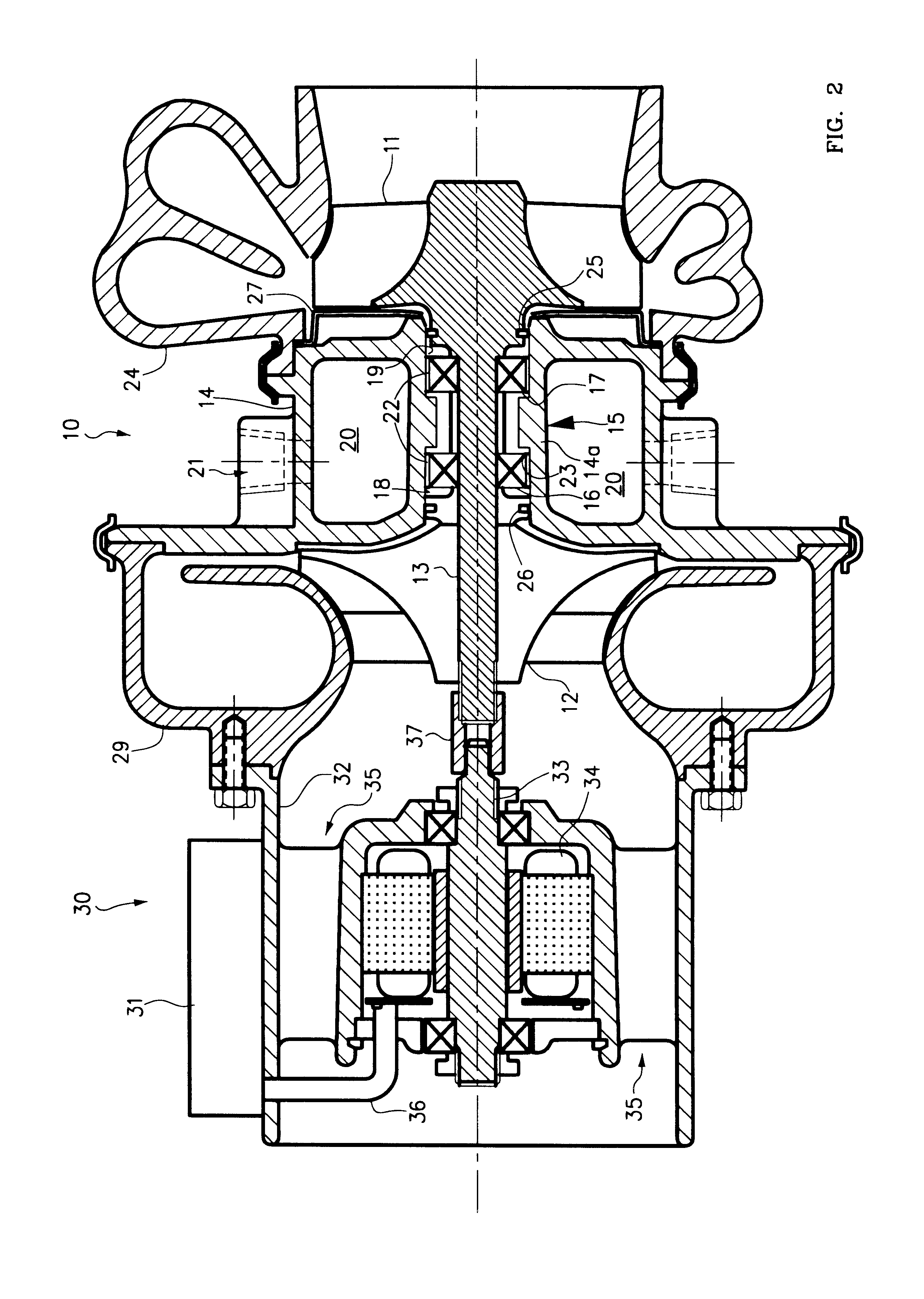

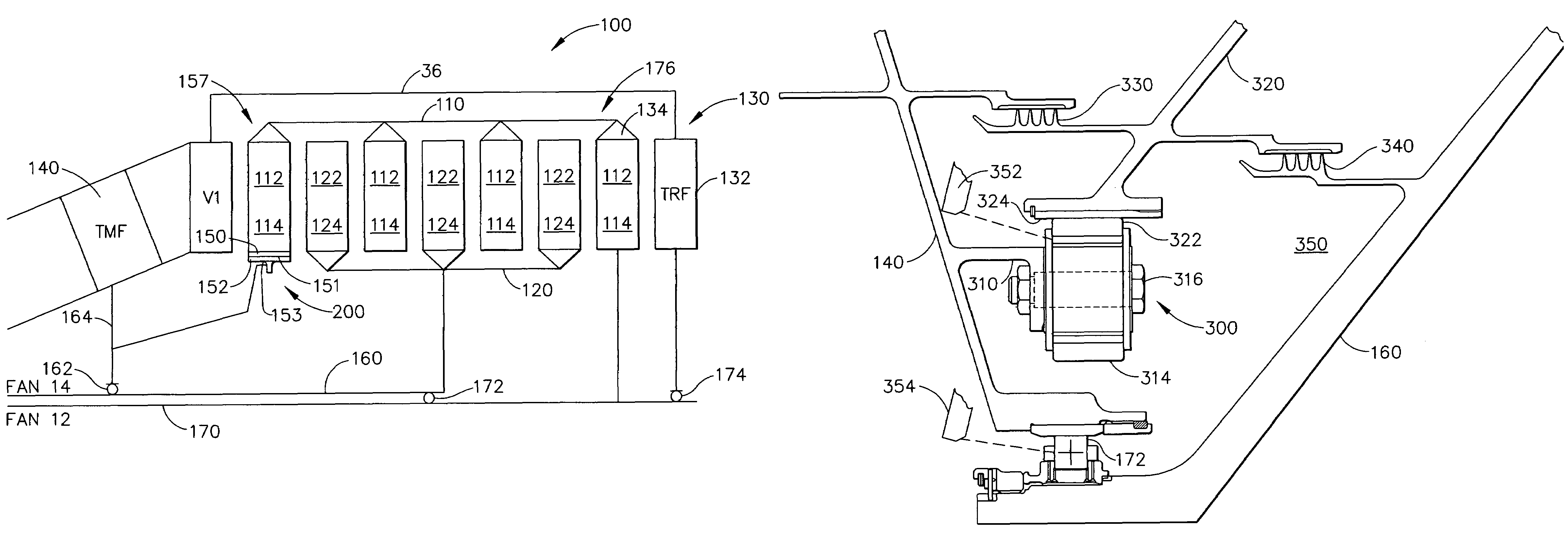

Counter-rotating gas turbine engine and method of assembling same

A method for assembling a gas turbine engine includes providing a high pressure turbine, providing a low-pressure turbine inner rotor that includes a first plurality of turbine blade rows configured to rotate in a first direction, providing a low-pressure turbine outer rotor that includes a second plurality of turbine blade rows configured to rotate in a second direction that is opposite the first direction, and coupling a plurality of bearings between the outer rotor and a turbine mid-frame between the high pressure turbine and at least one of the inner and outer rotors such that the plurality of bearings support a forward end of the outer rotor.

Owner:GENERAL ELECTRIC CO

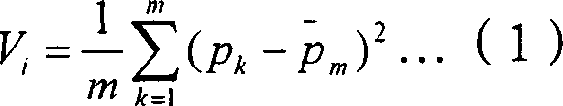

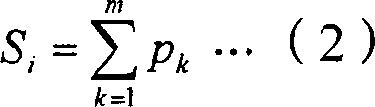

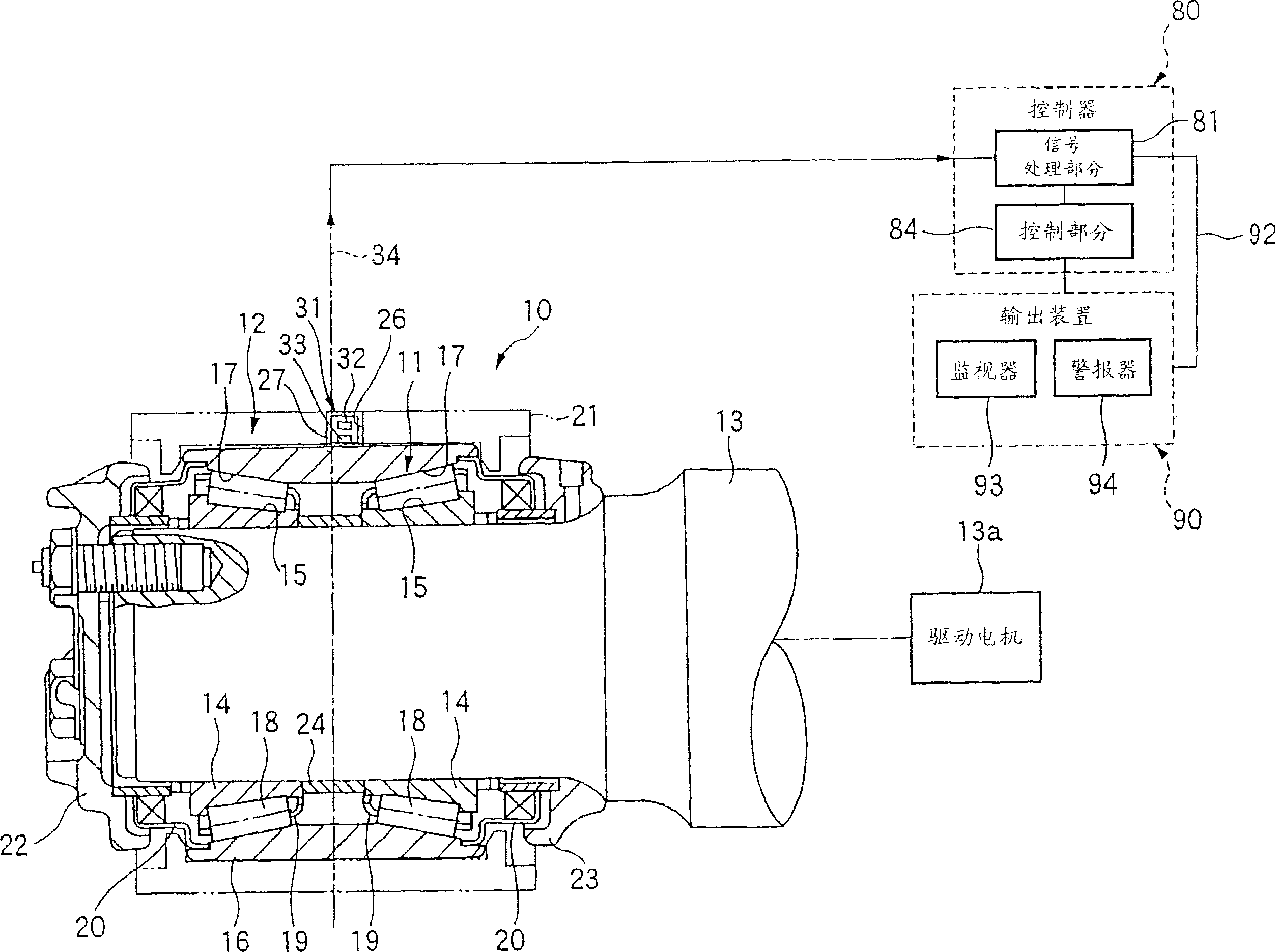

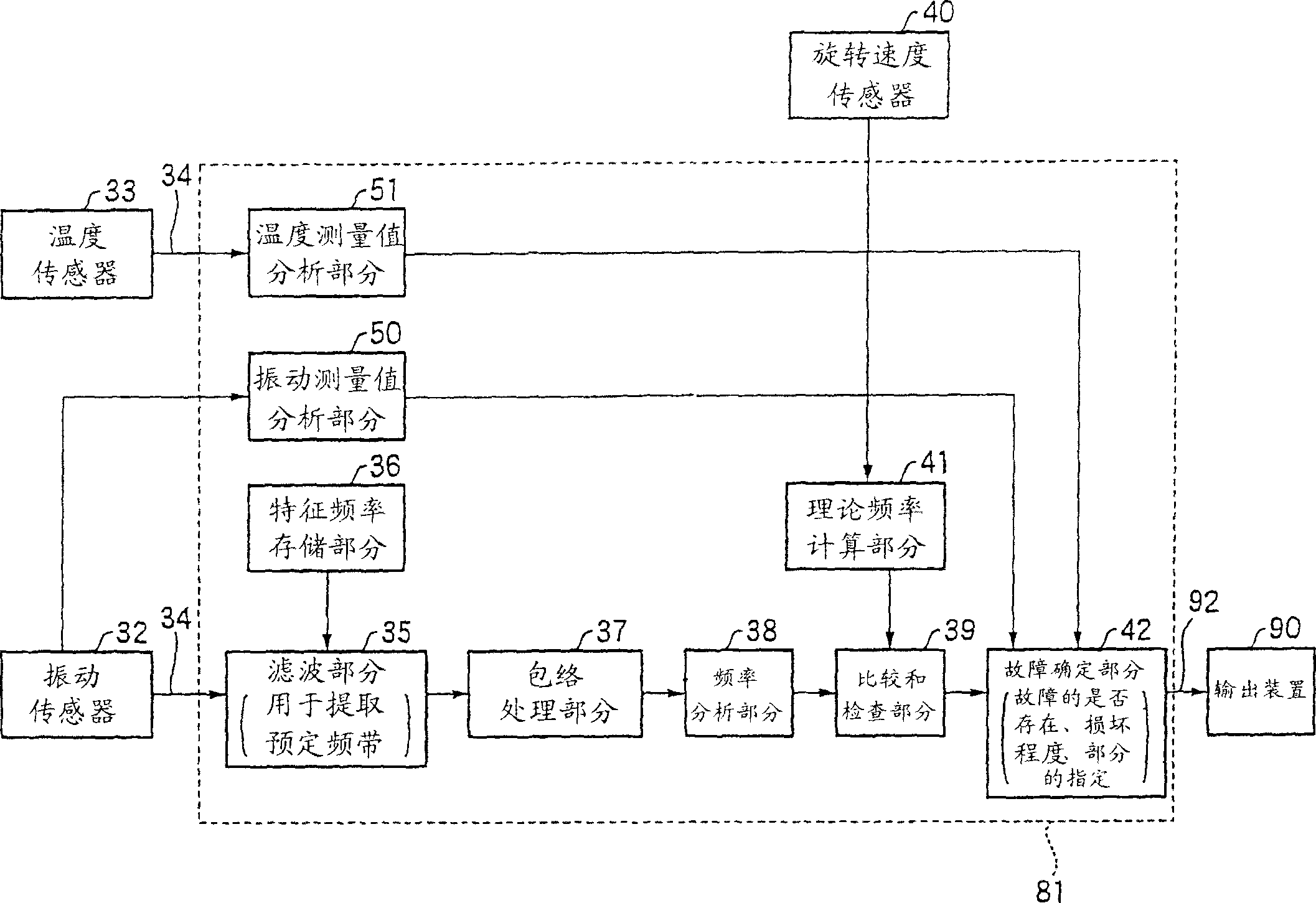

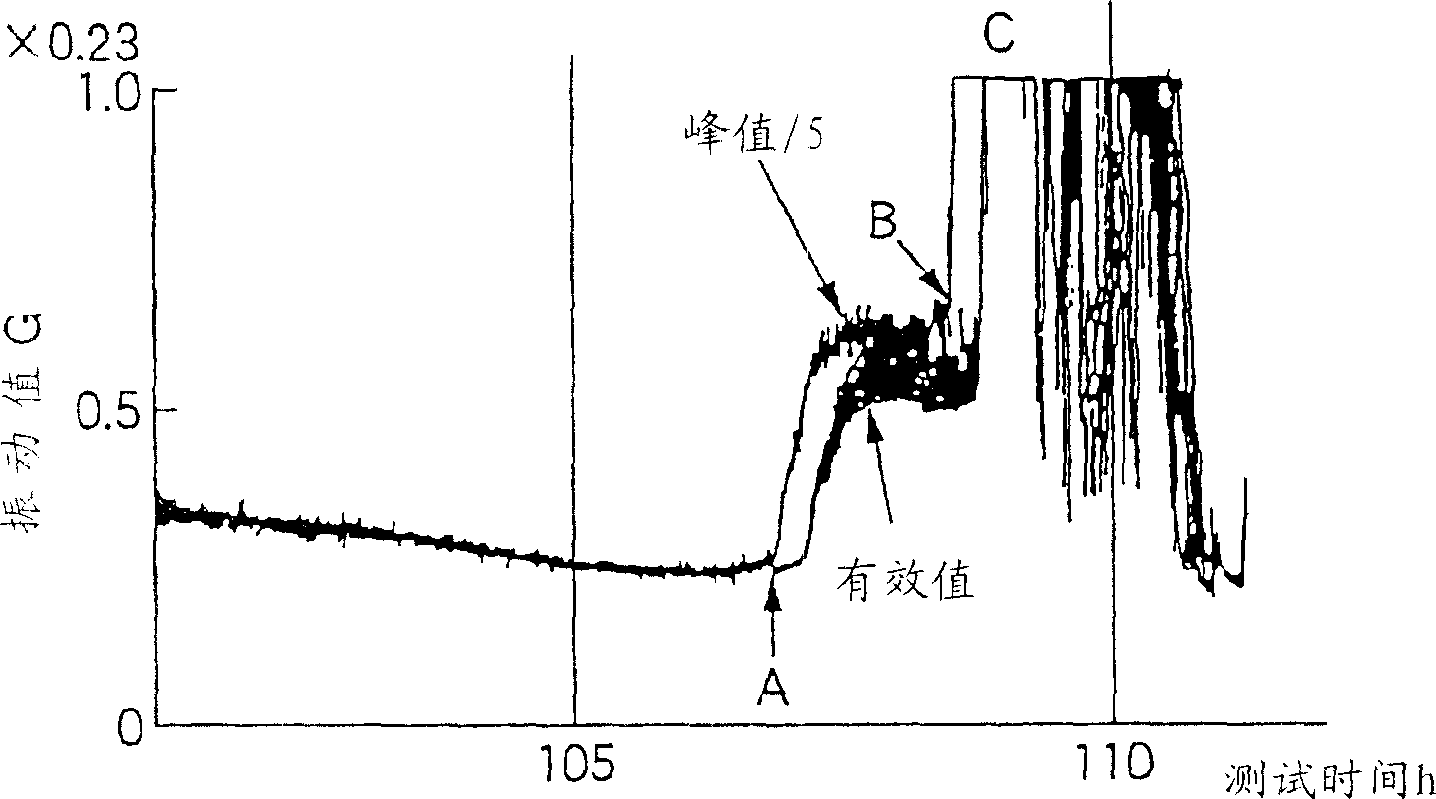

Abnormality diagnosis device and abnormality diagnosis method

InactiveCN1906473AImprove reliabilityEffective maintenanceRolling contact bearingsSubsonic/sonic/ultrasonic wave measurementDiagnosis methodsBiomedical engineering

An abnormality diagnosis device used for a machine apparatus having a part rotating and sliding relative to a stationary member is provided with a detection section (31) and a signal processing section (81). The detection section (31) is fixed to the part rotating or sliding or to the stationary member and has a vibration sensor (32) and a temperature sensor (33). The signal processing section (81) determines the condition of the part based on a signal detected and outputted by the detection section (31). The signal processing section (81) determines whether there is an abnormality in the part, or whether there is an abnormality in the part and the degree of damage of the part.

Owner:NSK LTD

Wireless sensor, rolling bearing with sensor, management apparatus and monitoring system

InactiveUS20060145881A1Improve accuracyCondition can be detectedVibration measurement in solidsMachine part testingLine sensorCommunication unit

The wireless sensor adds identification information peculiar to respective sensor modules to detection data of vibration, temperature, and soon, detected by the sensor modules respectively. The wireless sensor transmits the detection data with the identification information as a signal through a communication unit by radio waves. On the other hand, the management apparatus receiving the signal classifies and files the detection data on the basis of the identification information included in the signal. Then, the monitoring system is designed to make the management apparatus manage a plurality of wireless sensors attached to movable shafts of processing machines or the like.

Owner:NSK LTD

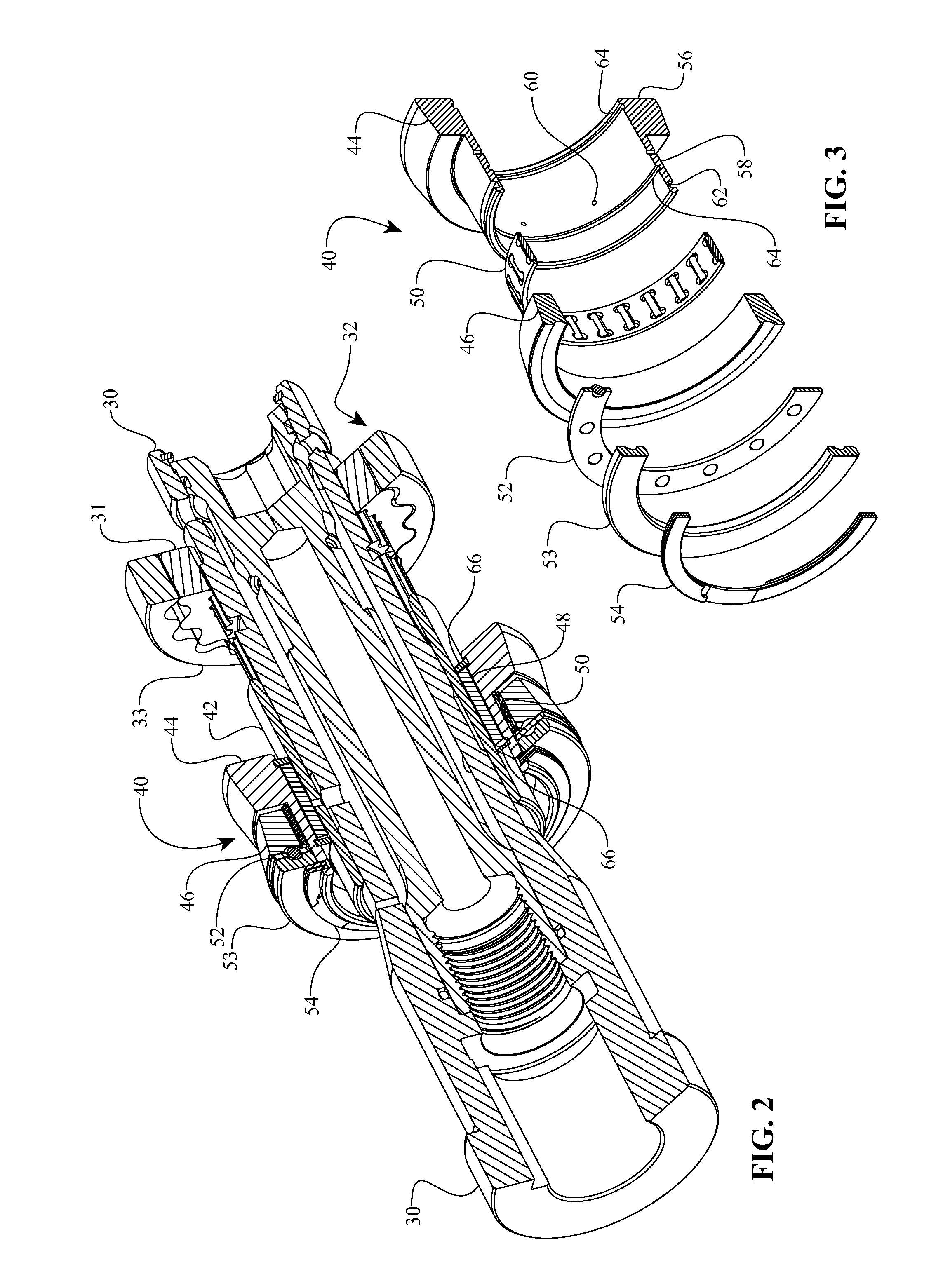

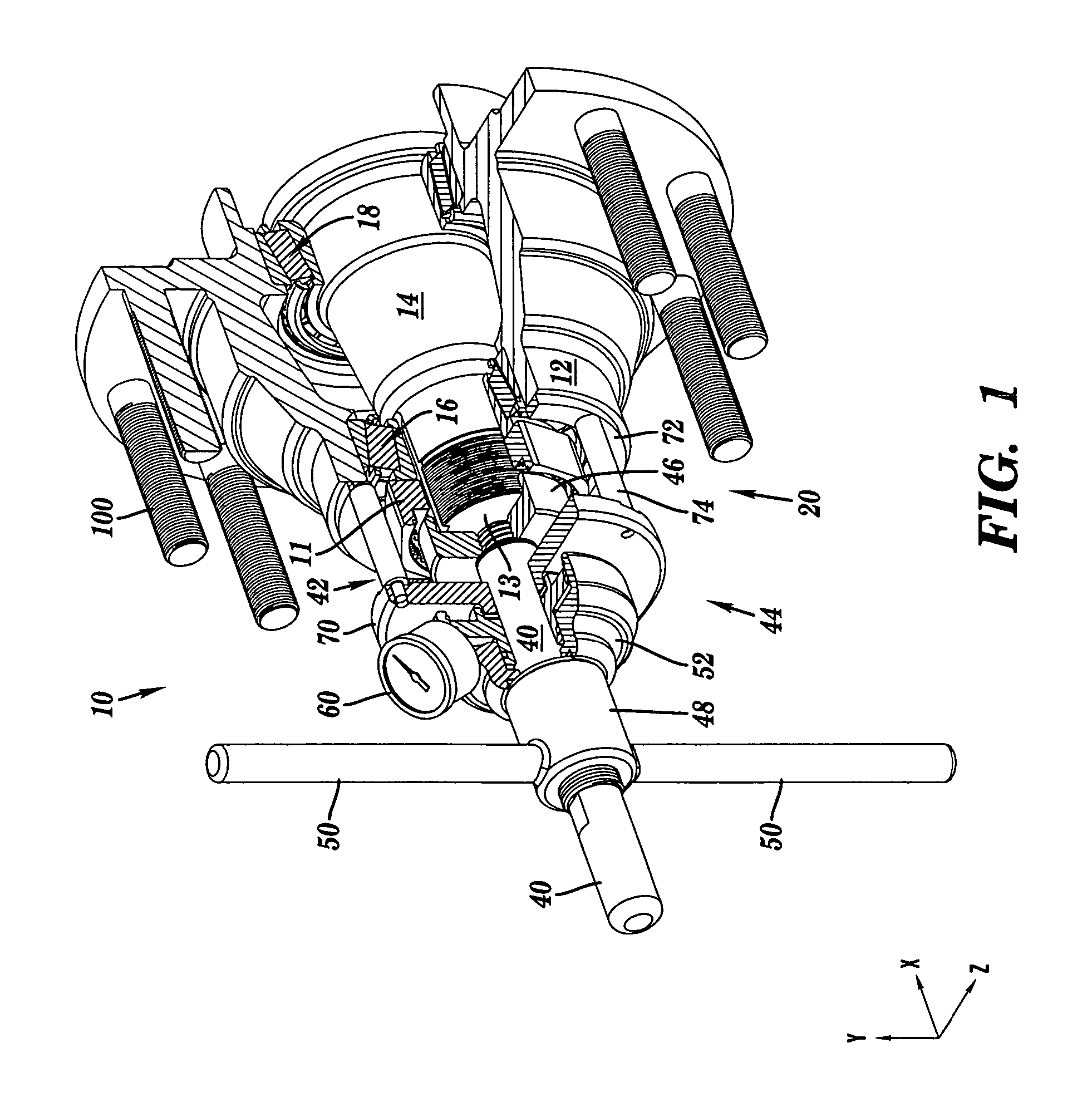

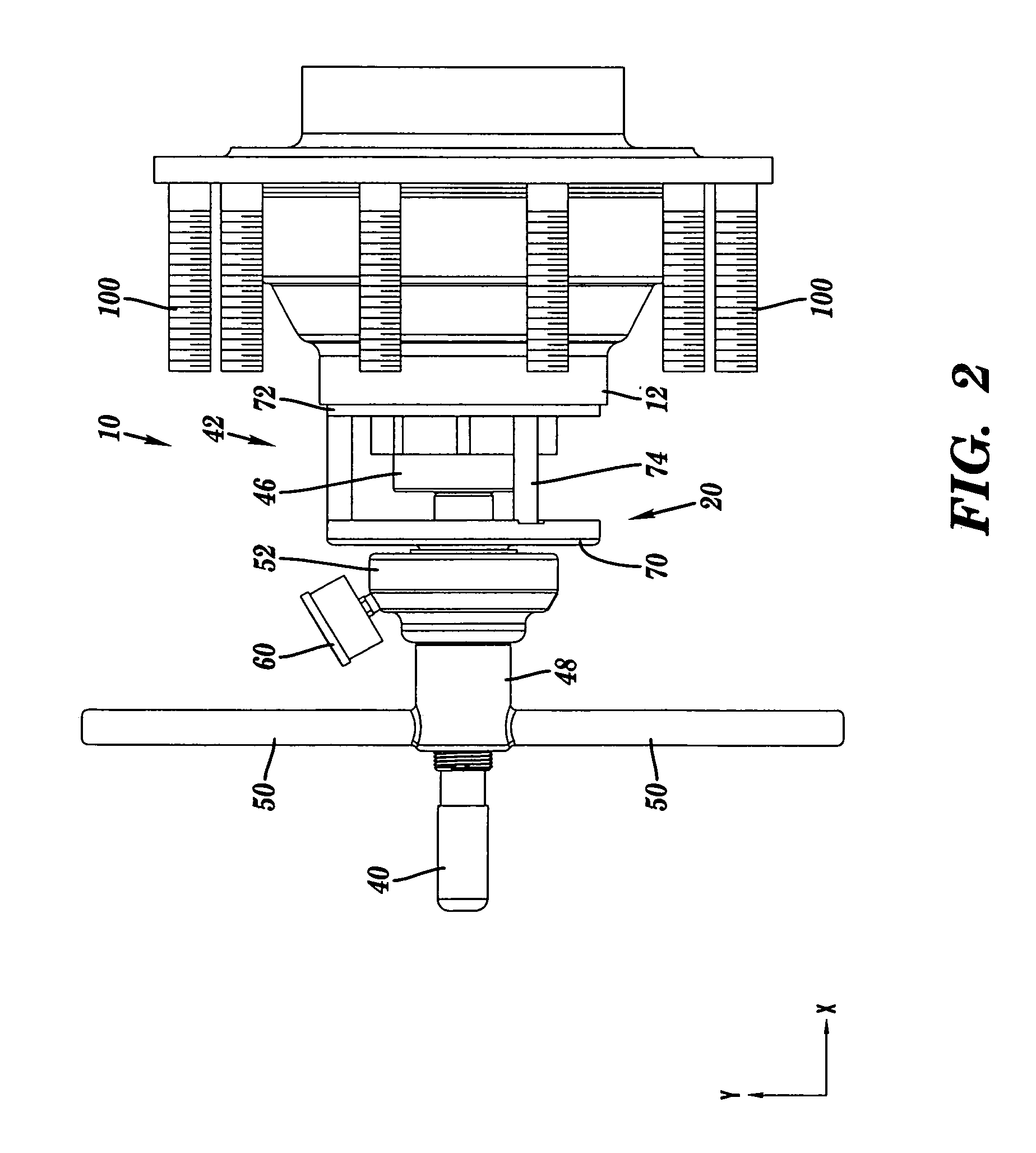

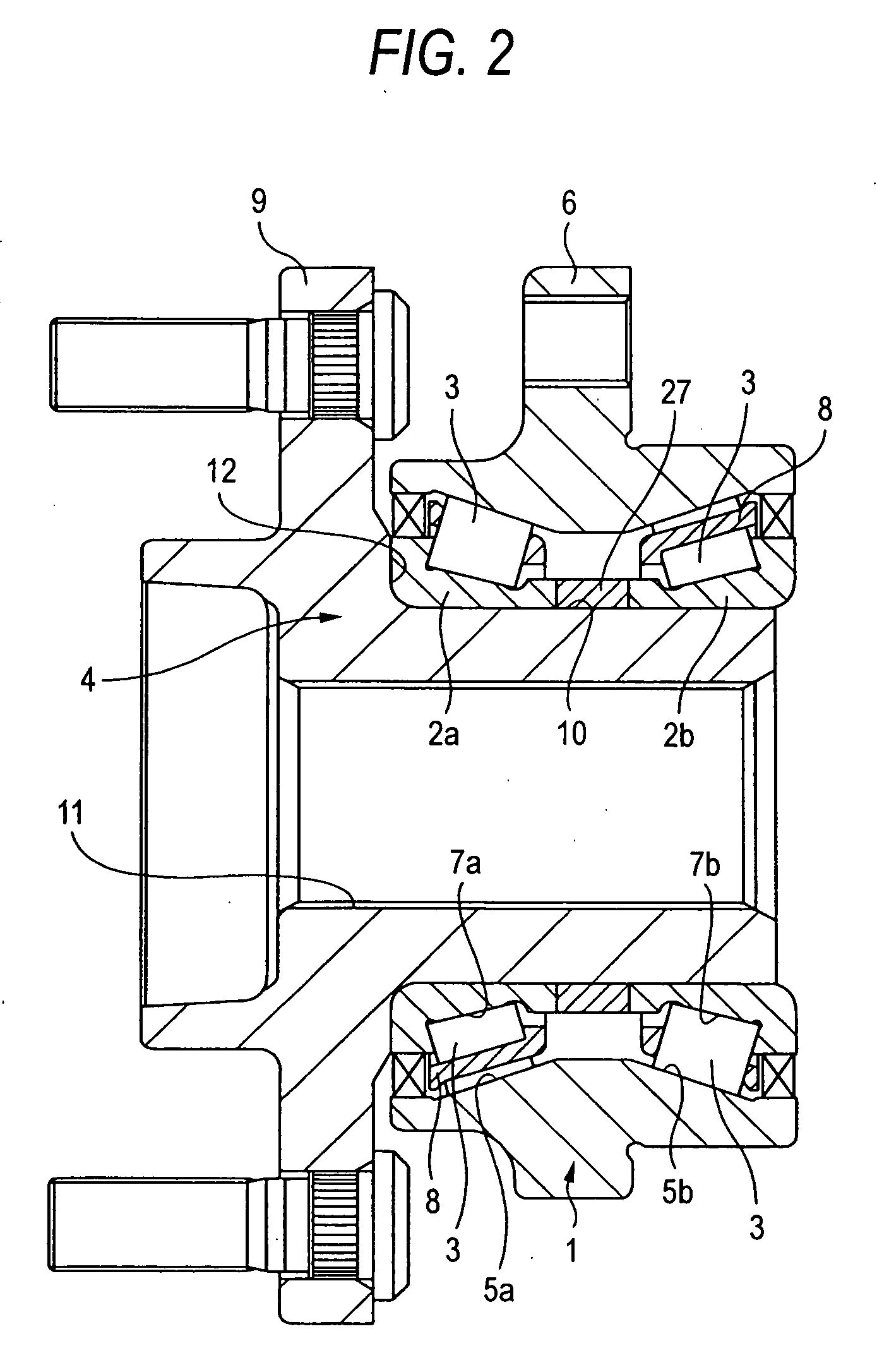

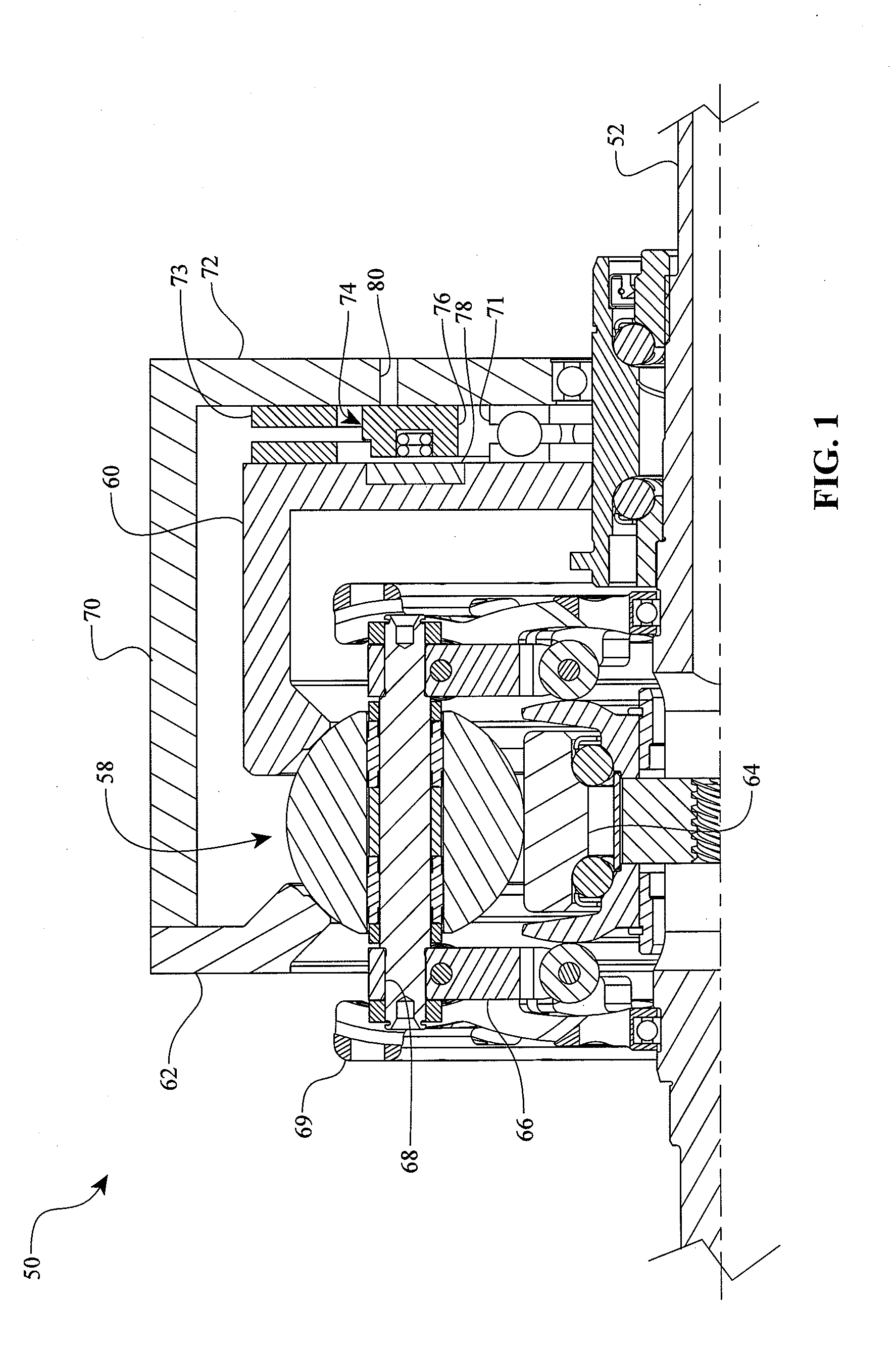

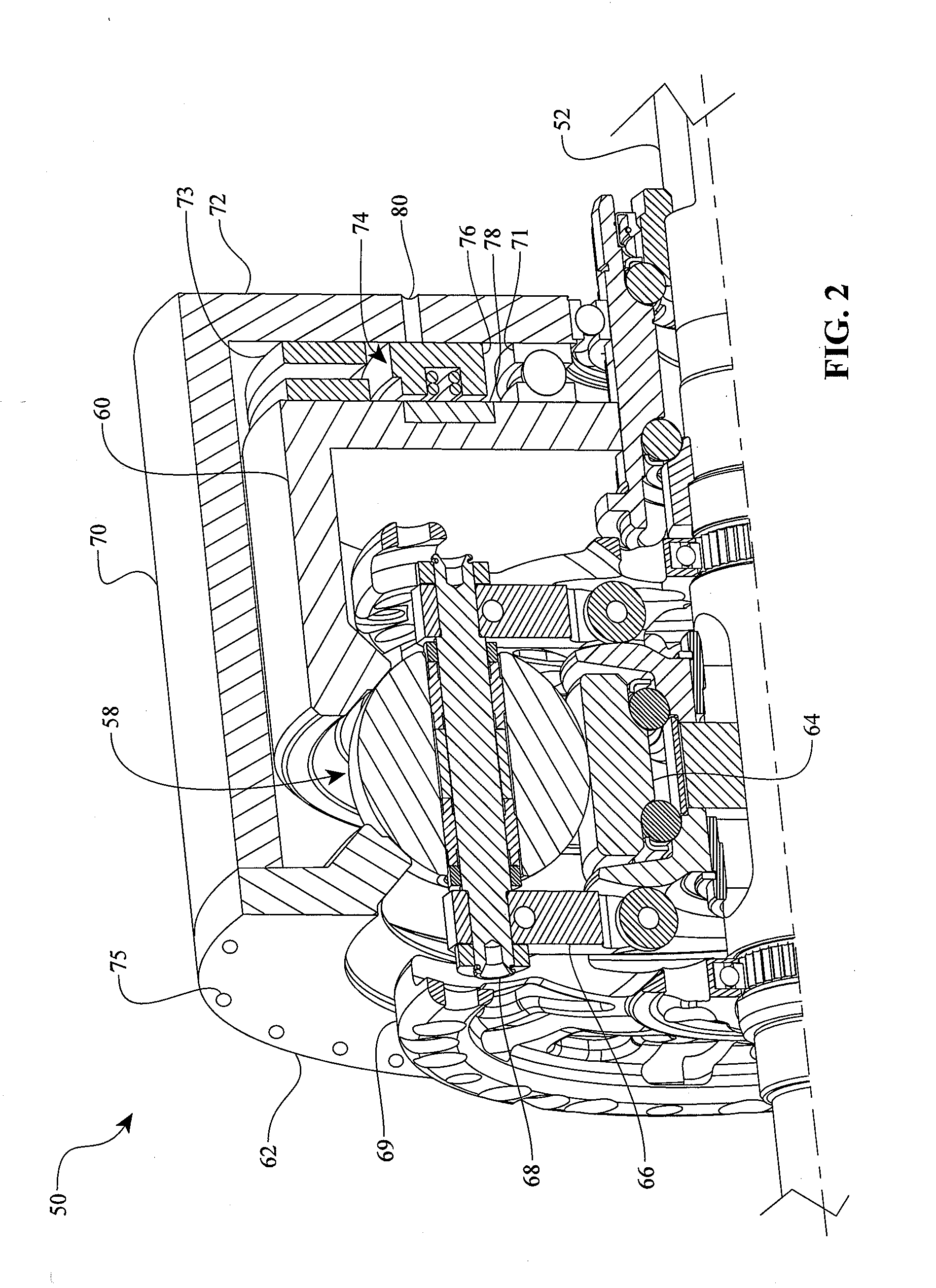

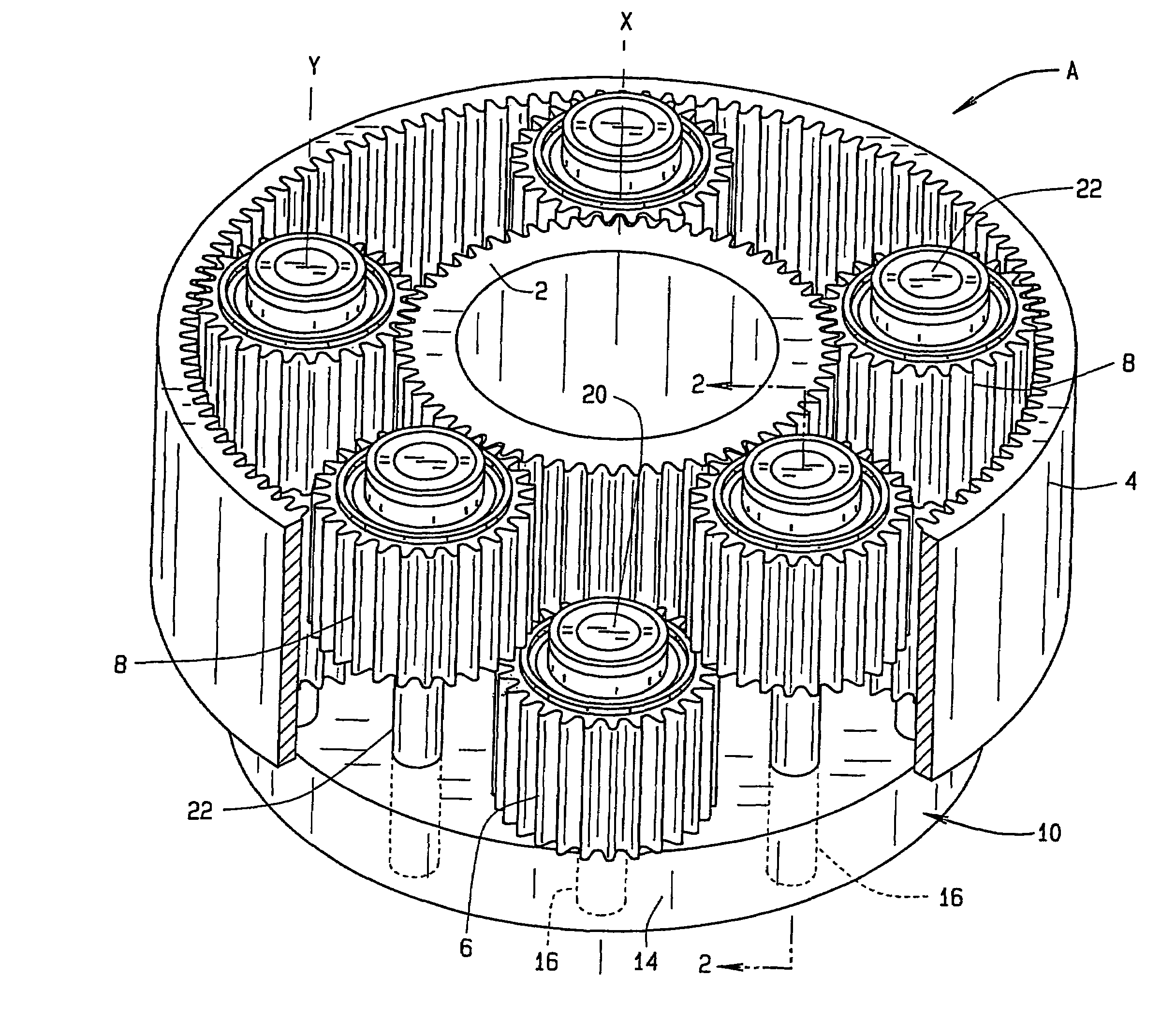

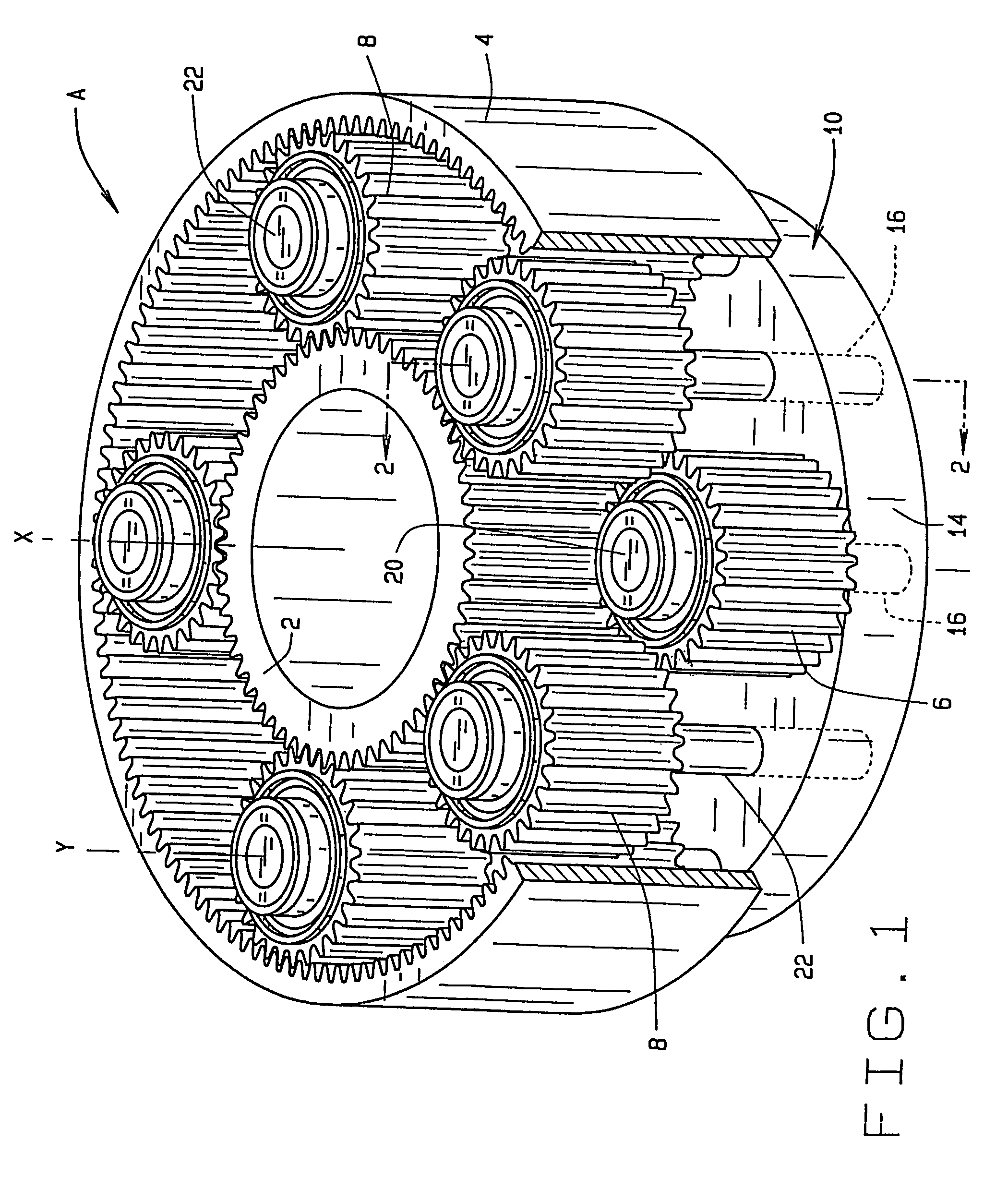

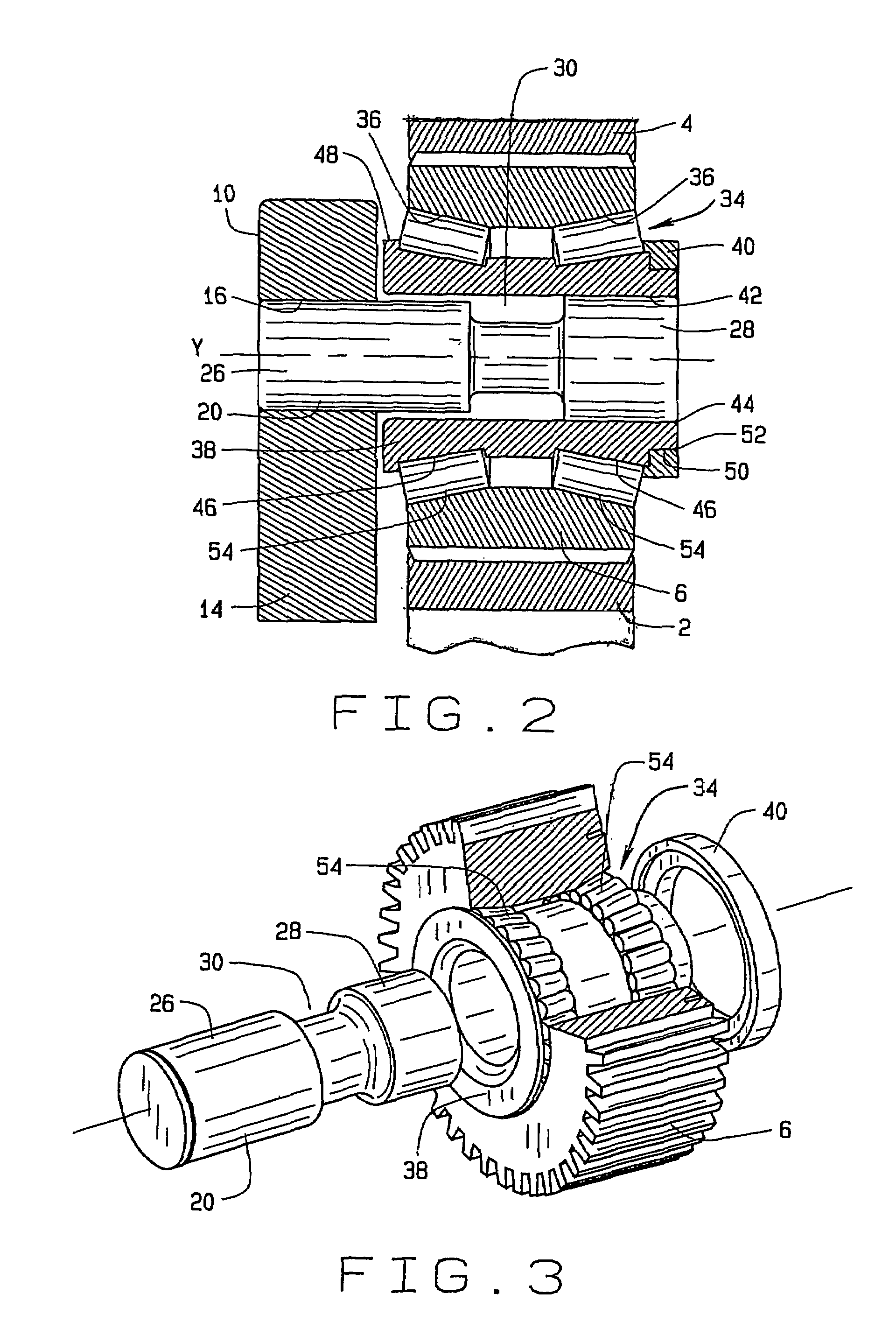

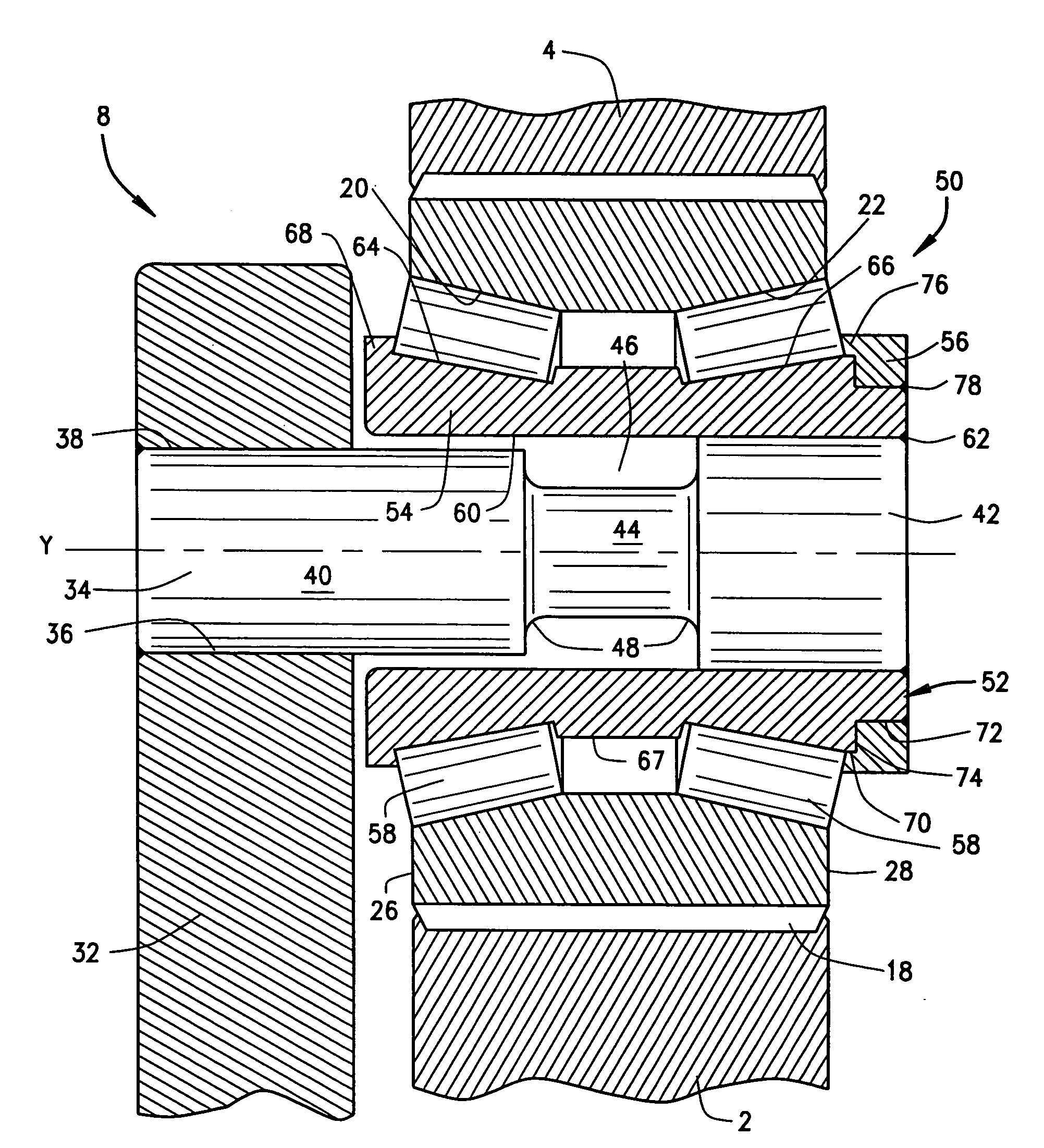

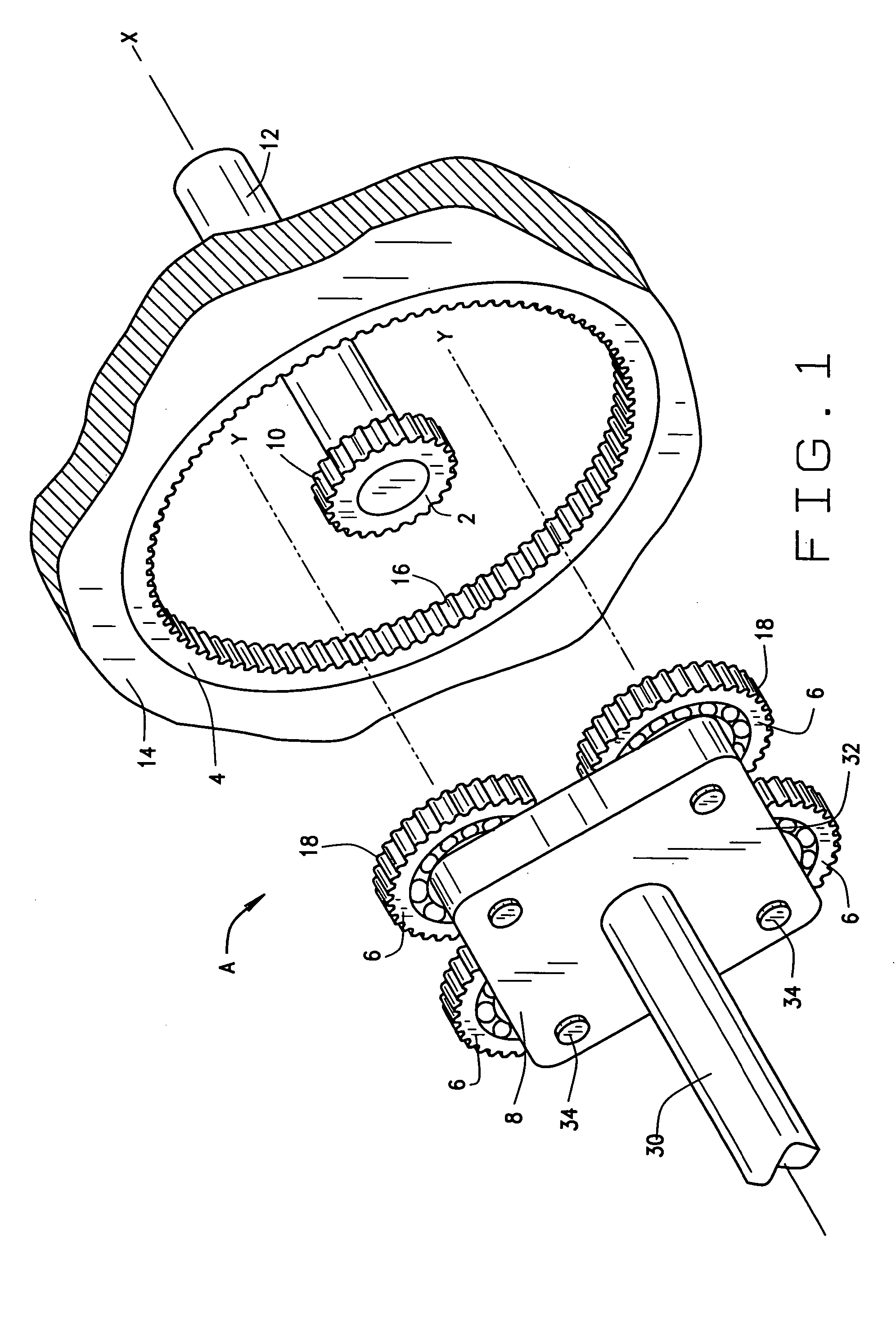

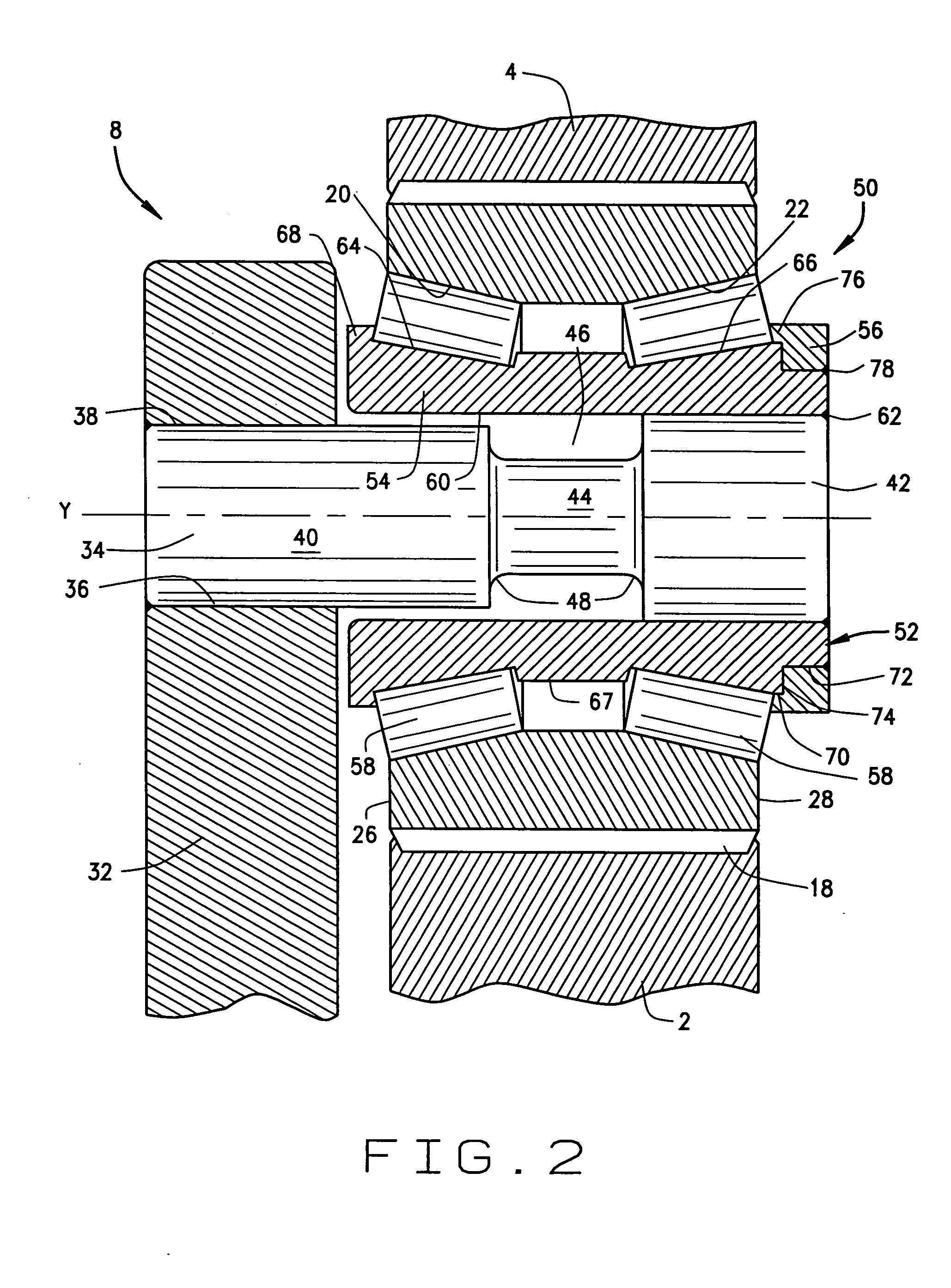

Epicyclic gear systems

An epicyclic gear system (A, B), which is highly compact, yet capable of transferring substantial torque, includes a sun gear (2, 62), a ring gear (4, 64) around the sun gear, and planet gears (6, 8, 66, 68) organized in two rows between the sun and ring gears. In addition, the gear system has a carrier (10, 70) provided with one or two flanges (14, 72, 74) and flexible pins (20, 22, 80, 82) around which the planet gears revolve. The planet gears are mounted on the pins in a double cantilever arrangement to improve the mesh with the sun and ring gears and achieve better load distribution.

Owner:THE TIMKEN CO

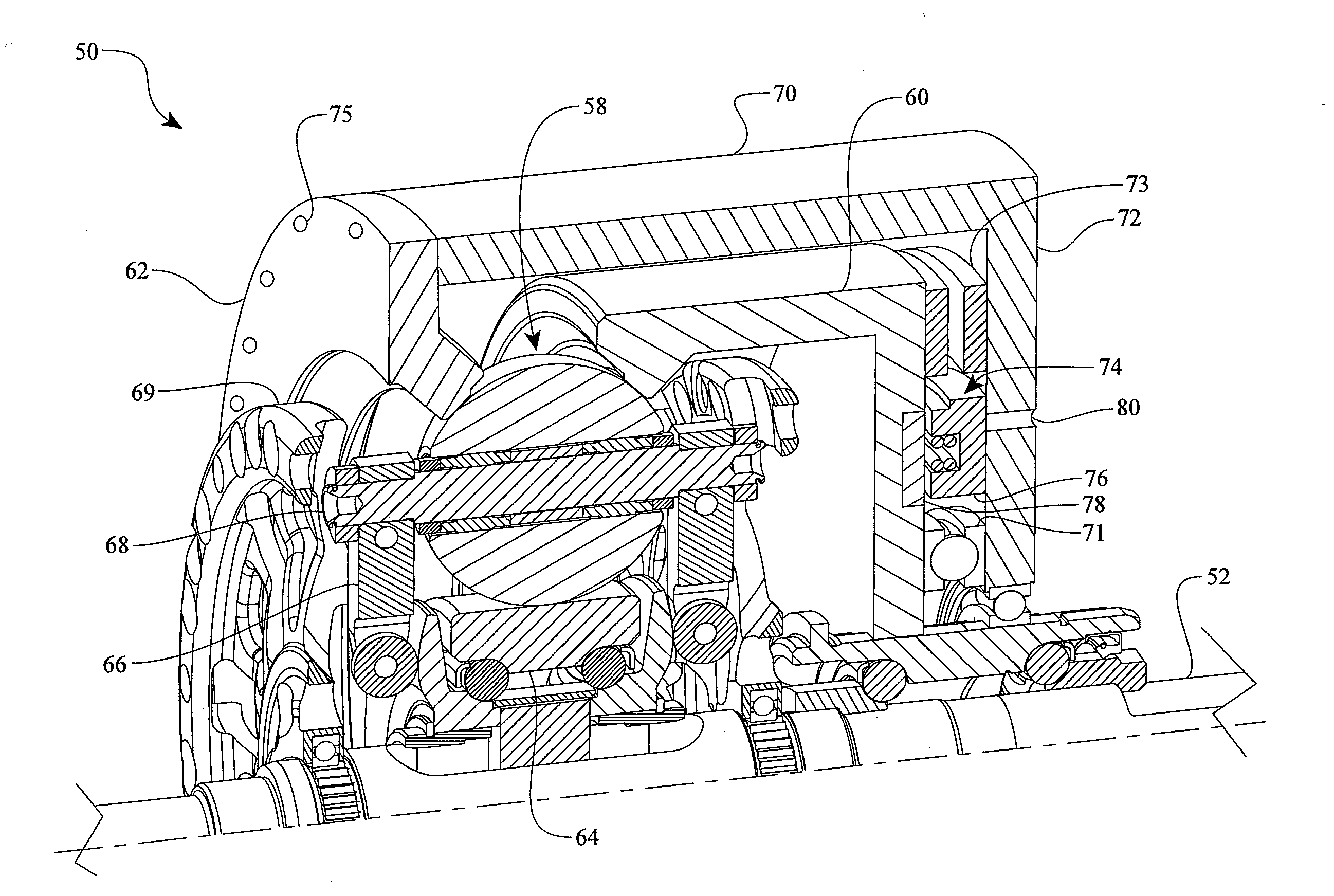

Epicyclic gear system

An epicyclic gear system has a sun gear, a ring gear, and planet gears between the sun and ring gears. In addition, it has a carrier including a carrier flange offset axially from the planet gears and carrier pins that project from the flange into the planet gears, each with a shank anchored to the flange, a head remote from the flange, and a groove between the shank and head. Between the planet gears and the carrier pins are bearings, each including an inner race and rollers between the inner race and planet gear. Whereas the carrier pins are cantilevered from the carrier flange, the inner races are cantilevered from the heads of the carrier pins. The grooves in the pins enhance pin deflection, so that the axes about which the planet gears rotate remain parallel to the central axis of the system.

Owner:THE TIMKEN CO

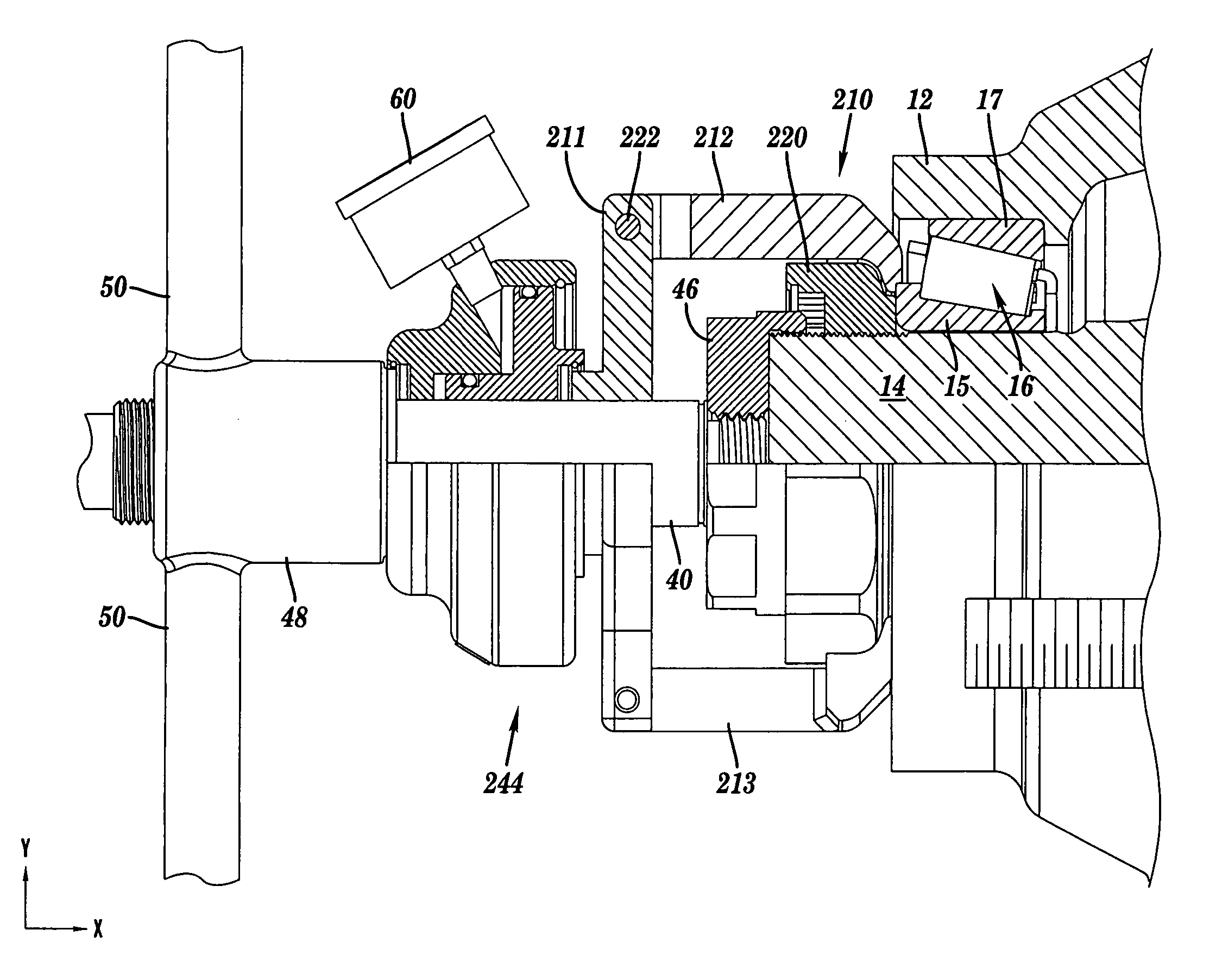

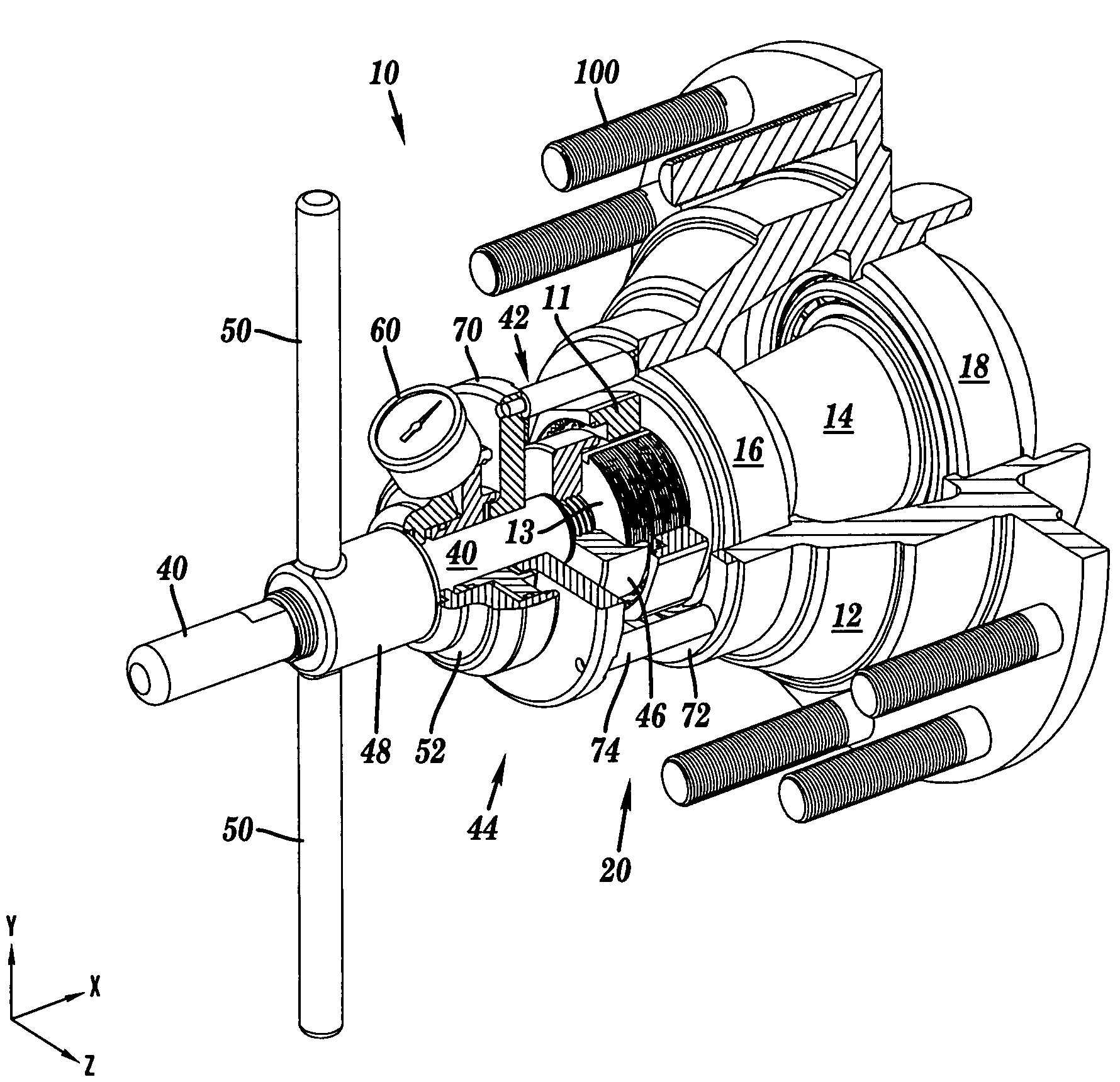

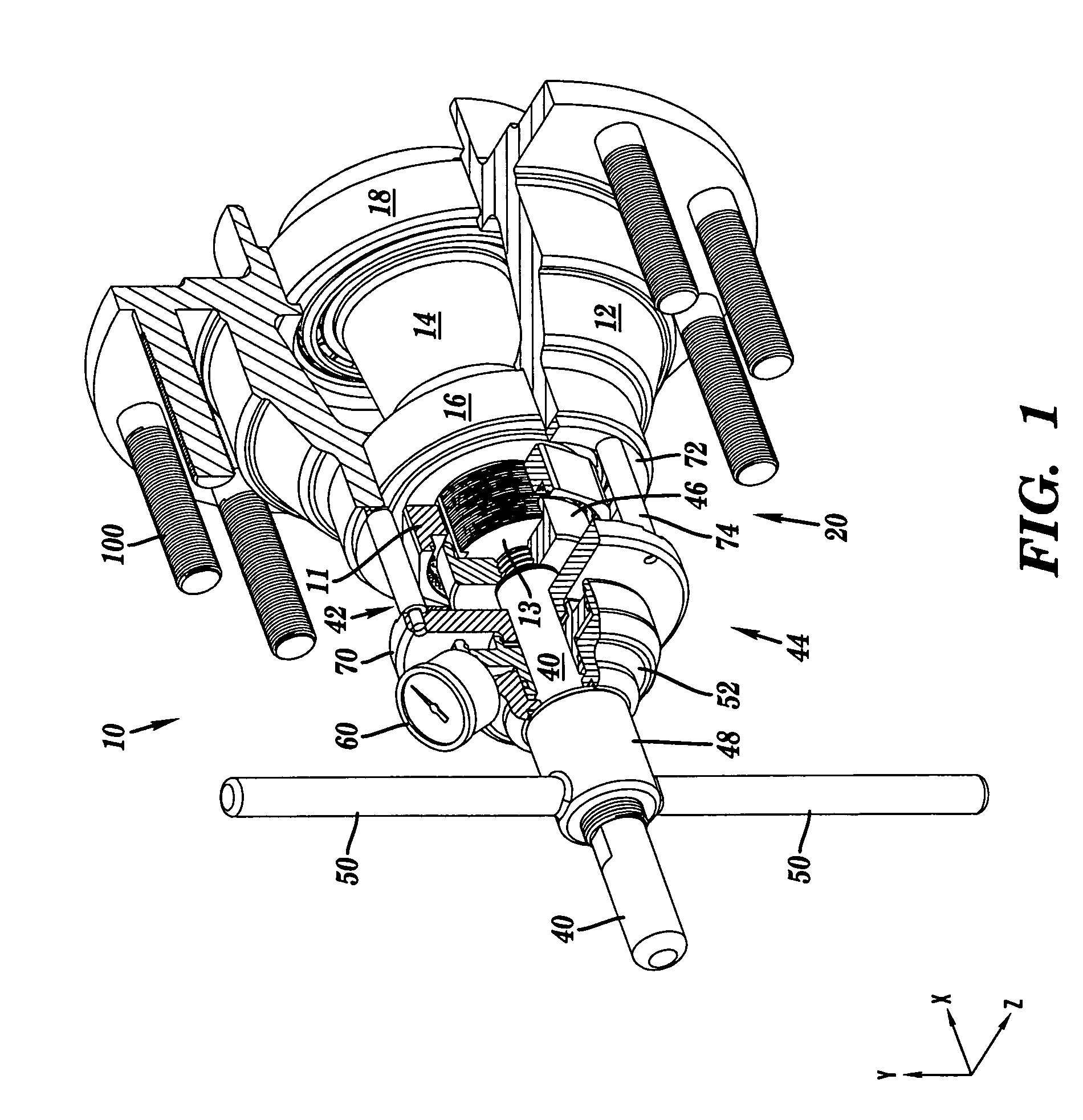

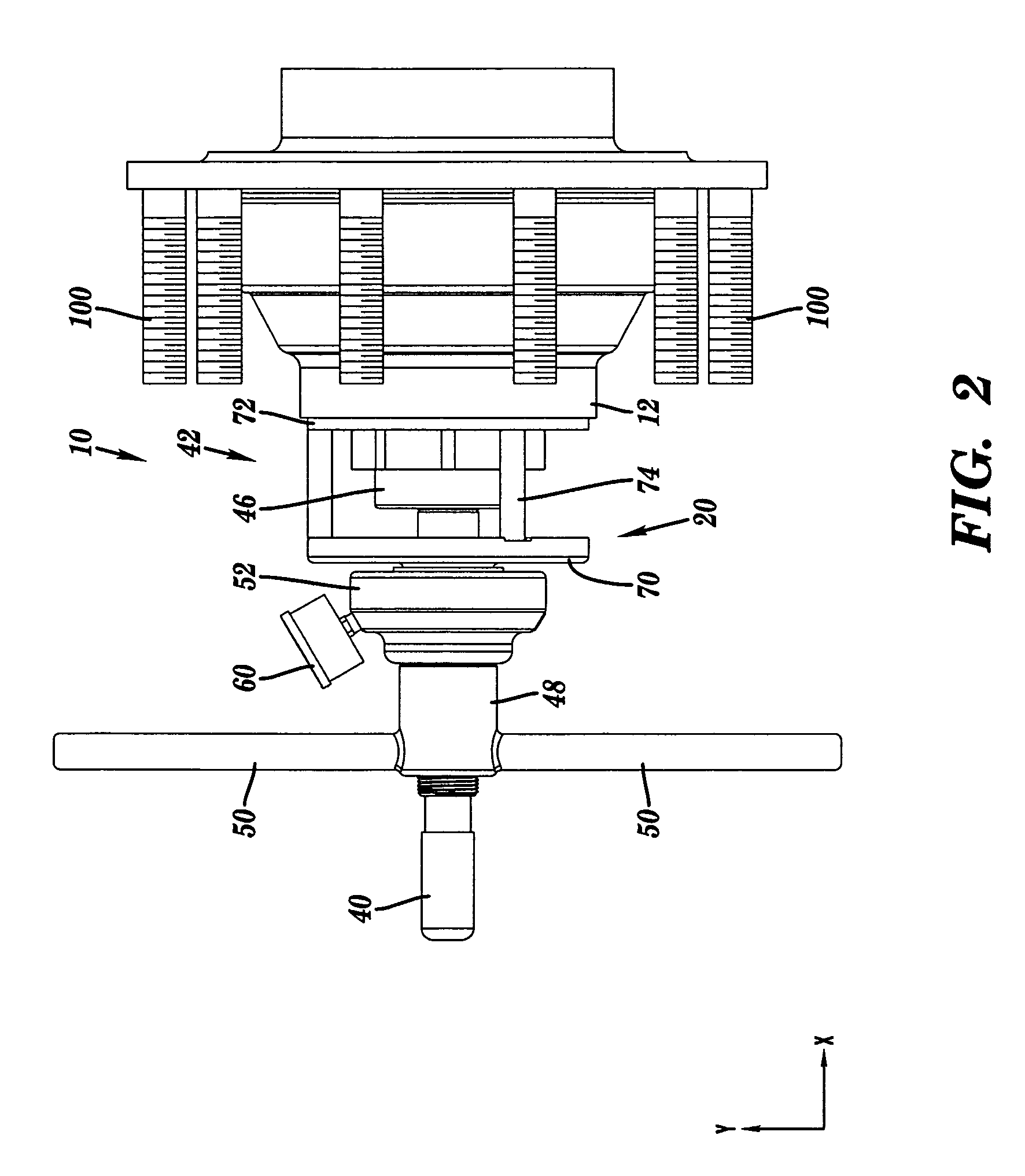

Method and apparatus for preloading a bearing

Methods and apparatus for preloading a bearing are provided. The apparatus includes a rod having a first end and a second end adapted to be removably mounted to a shaft; a device for compressing a hub against the outer race of a bearing to provide the preload to the bearing; and a cylindrical frame positioned between the device for compressing the hub and the hub. These methods and apparatus include preload monitoring devices whereby the mechanic can accurately monitor and regulate the preload to a bearing or bearing assembly. Aspects of the invention may also be used to adjust the endplay on a bearing or a bearing assembly. In one aspect, the preload to the bearing is transmitted through a housing having a fluid whose pressure can be detected and monitored. An apparatus for precisely rotating a nut and a tool for precisely rotating a nut are also provided.

Owner:TEMPER +1

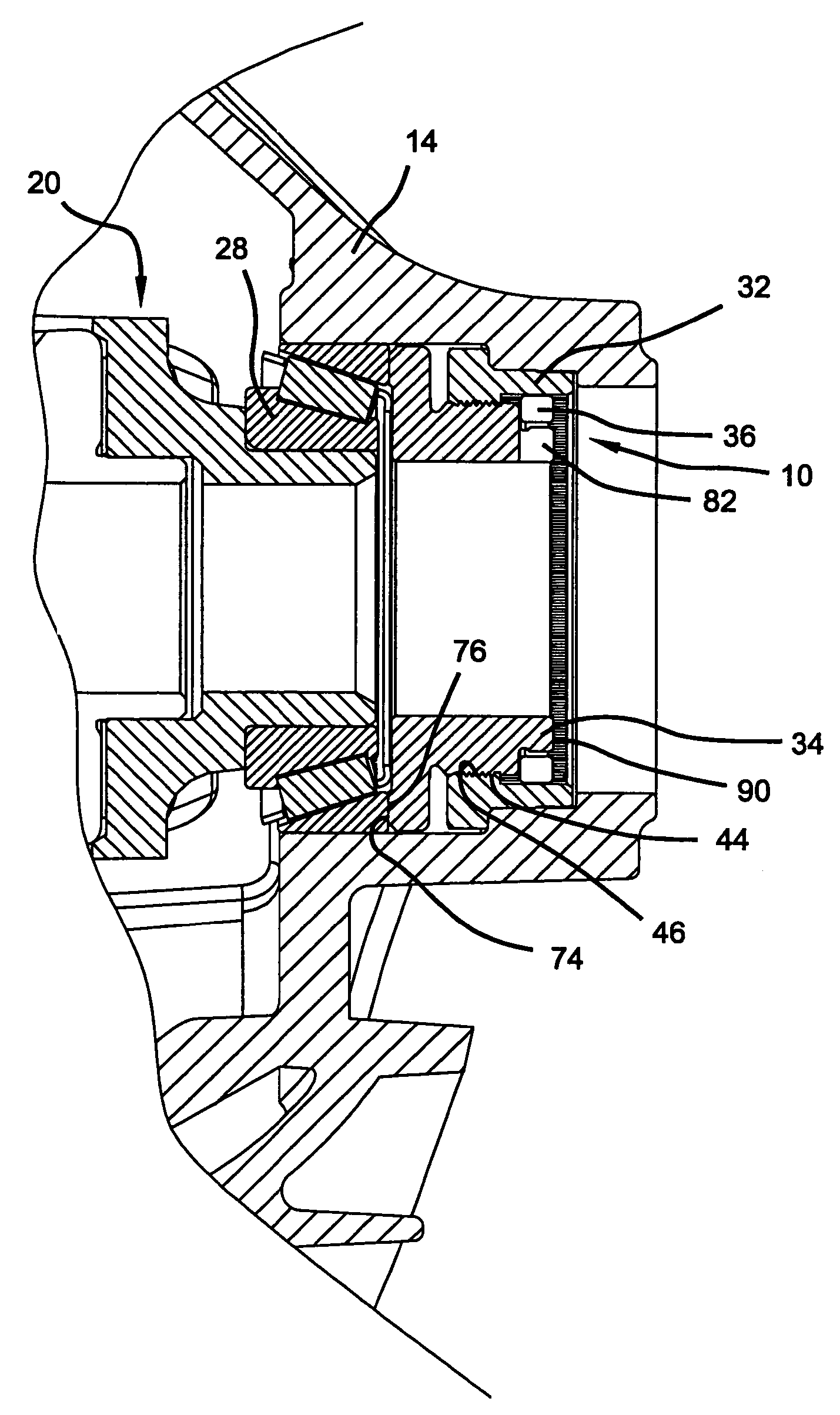

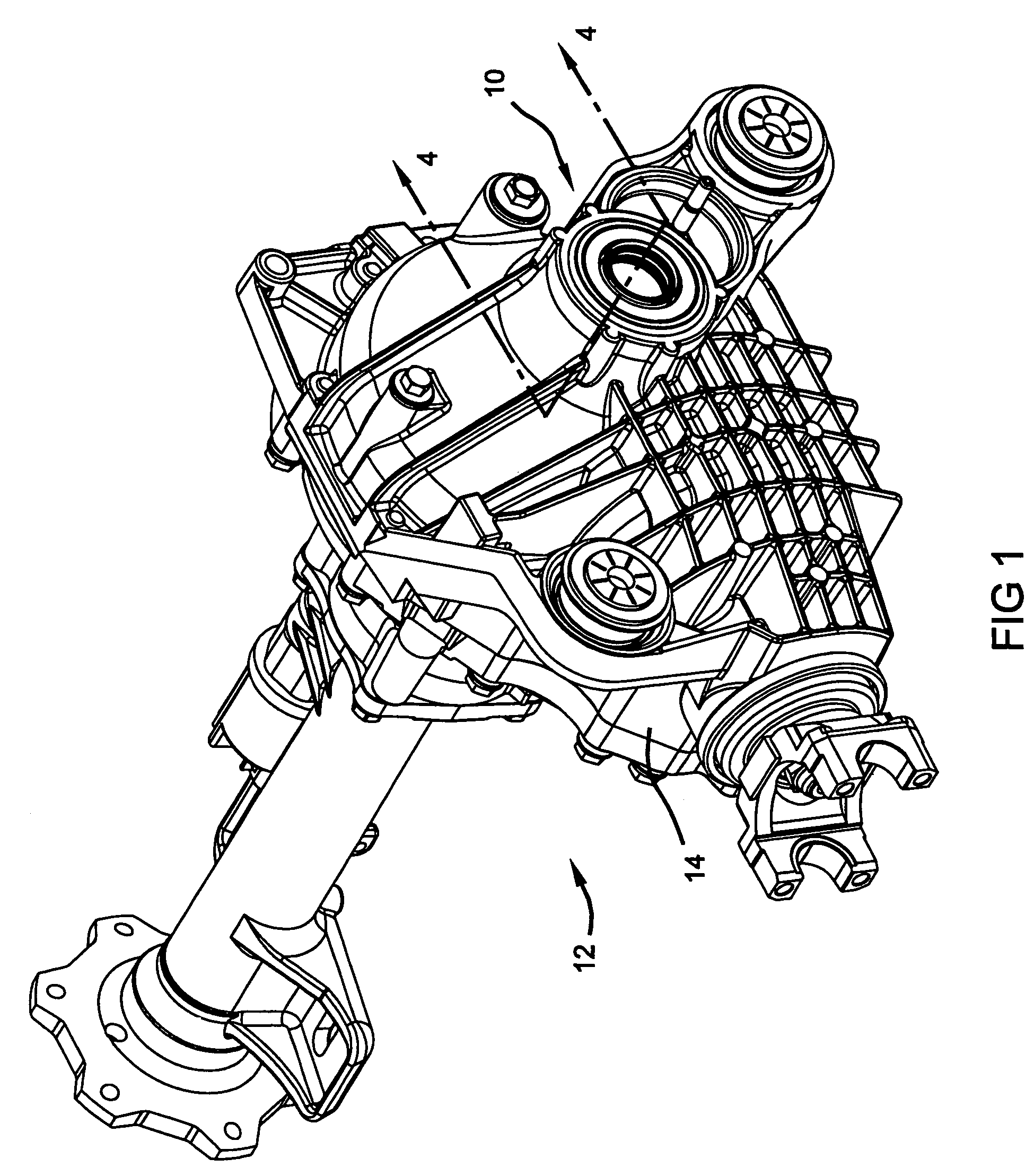

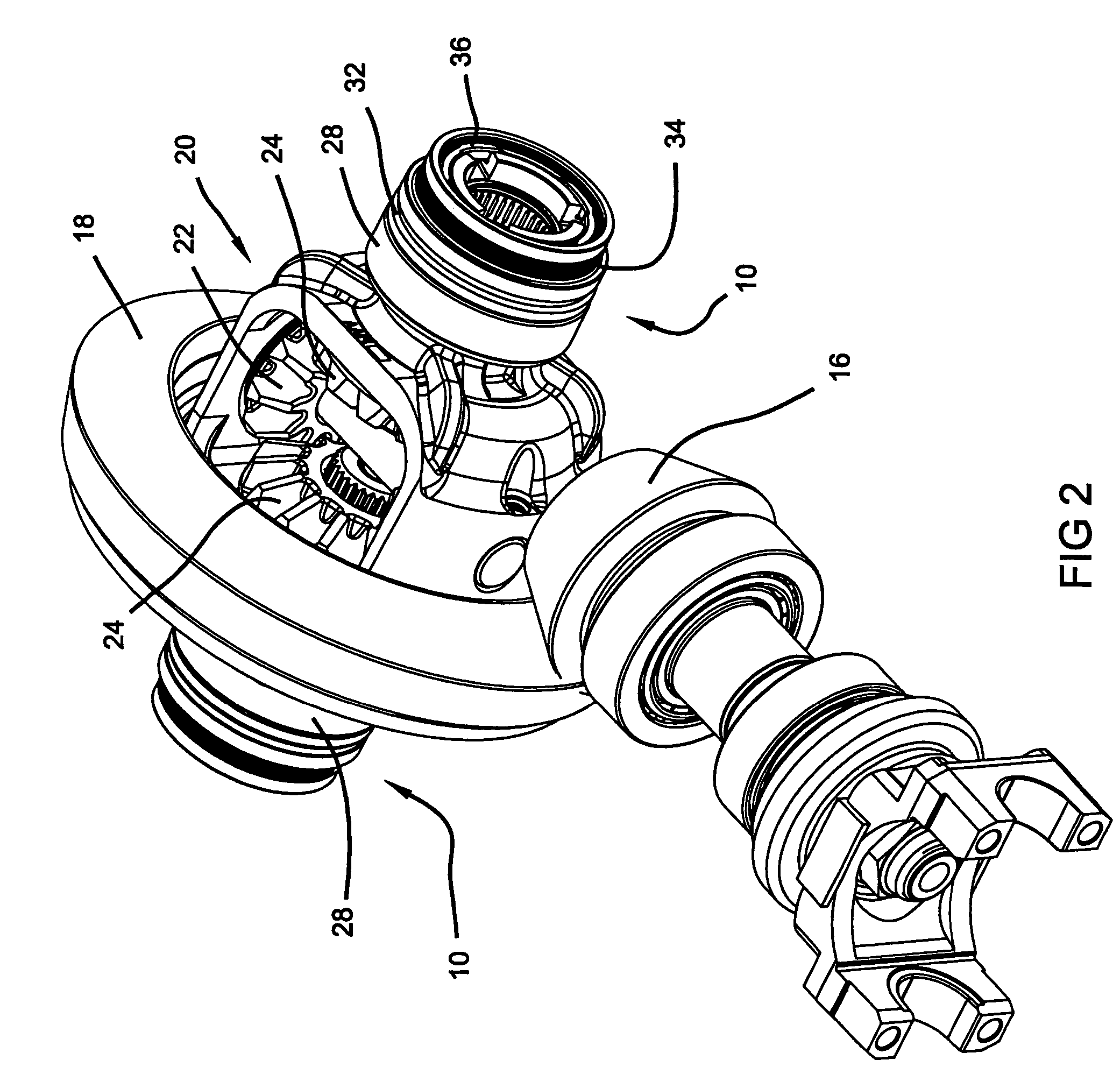

Axle assembly with bearing adjustment mechanism

Owner:AMERICAN AXLE & MFG

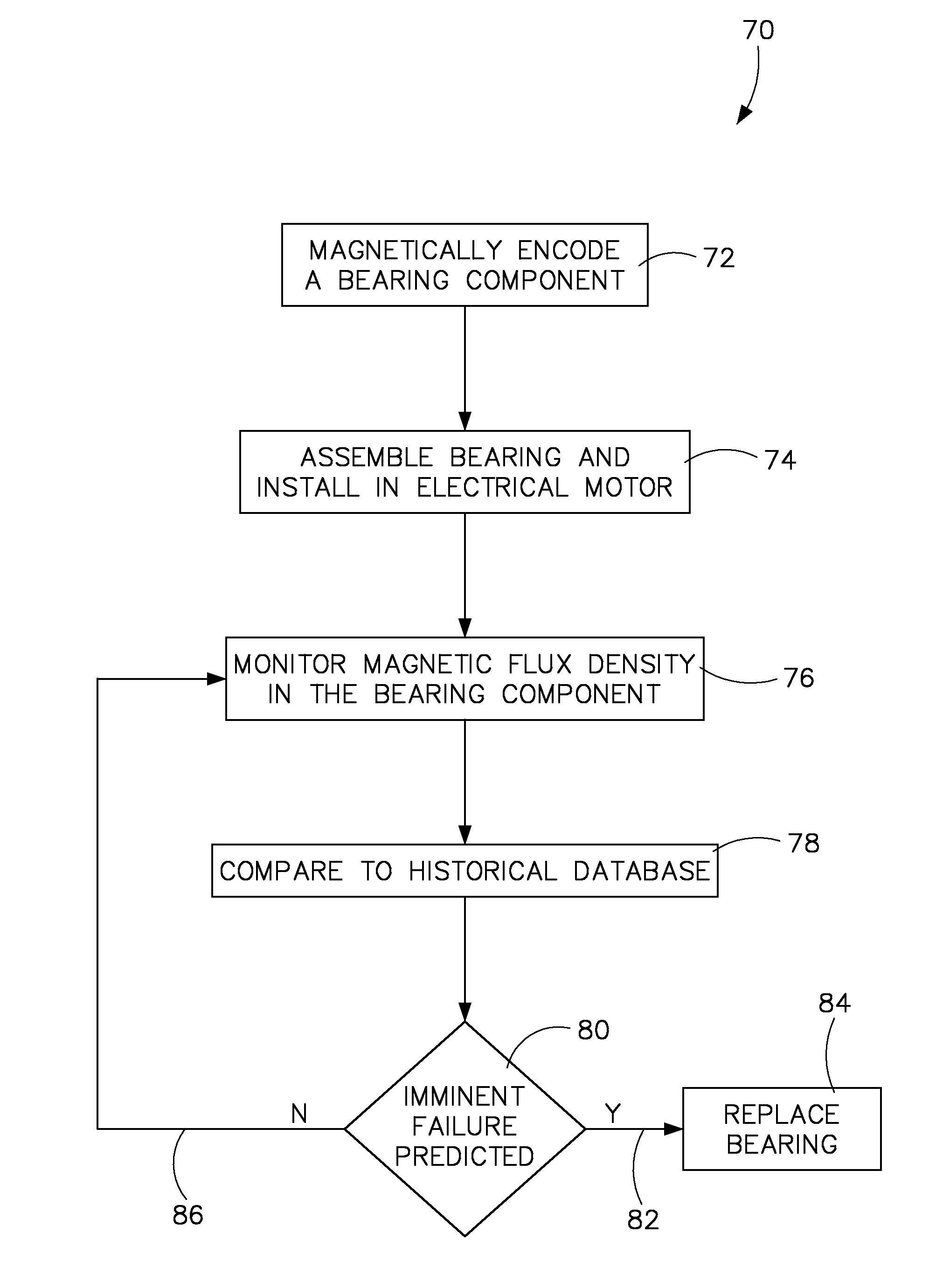

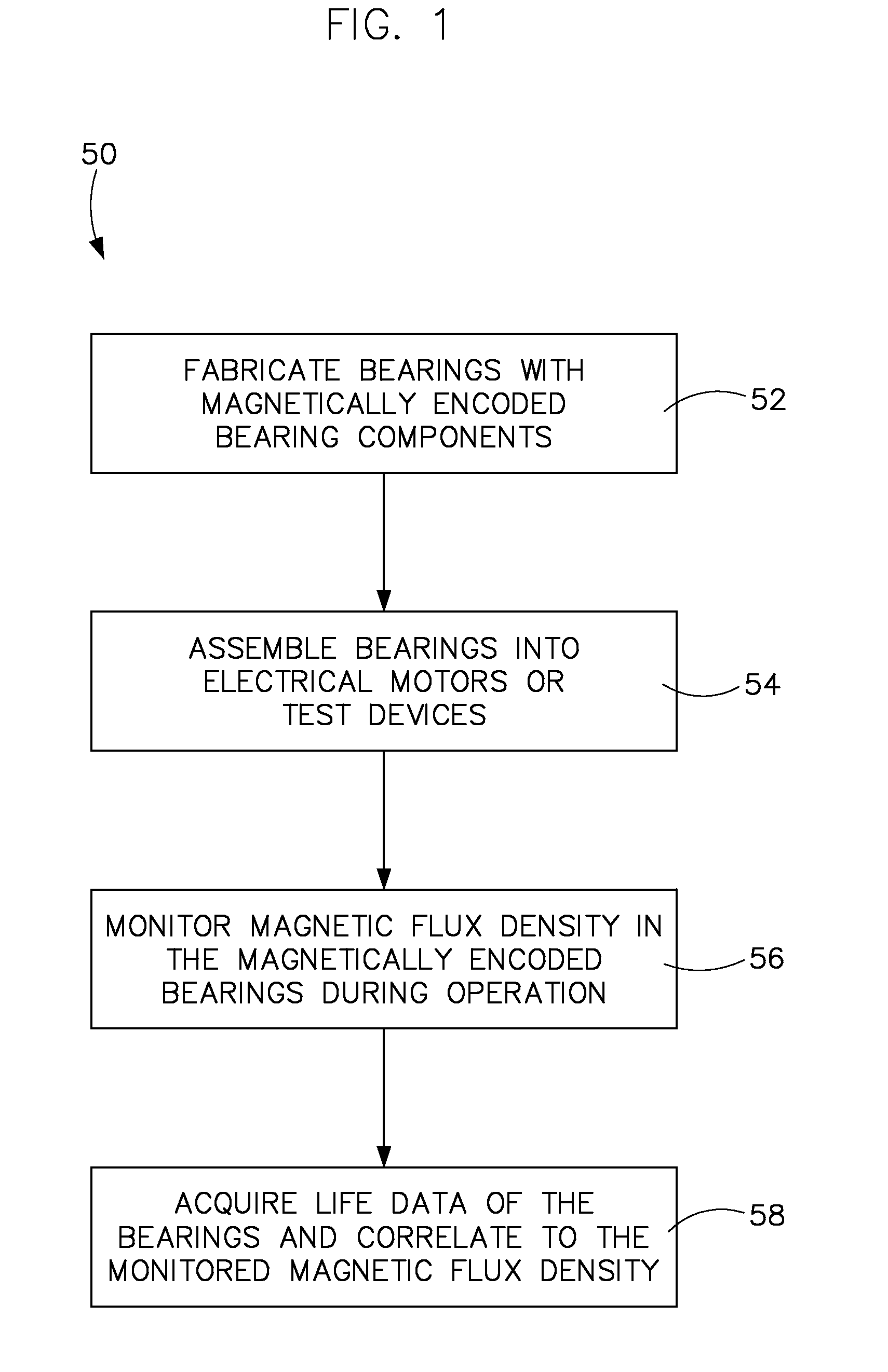

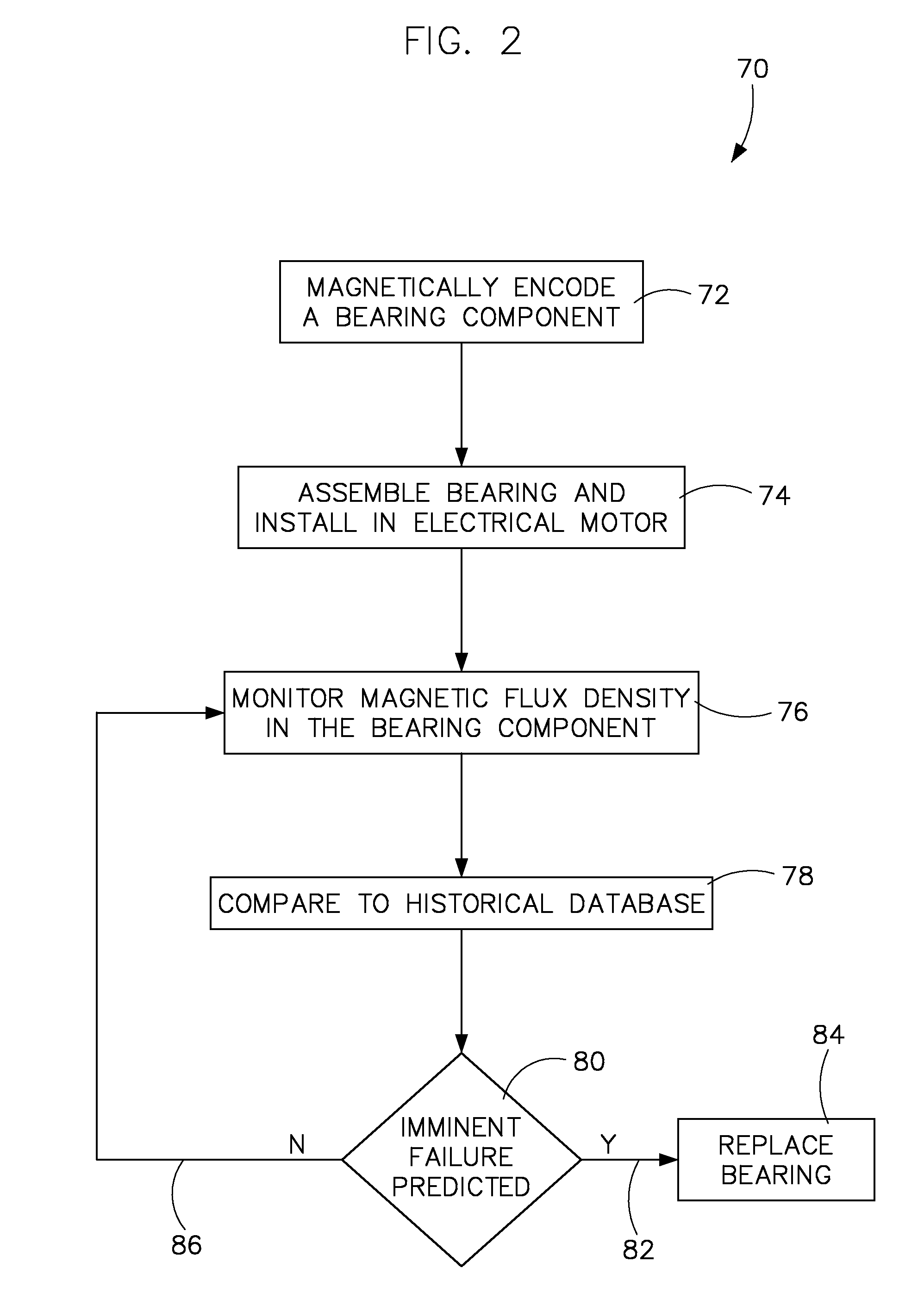

Apparatus and method for bearing condition monitoring

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com