Patents

Literature

27470results about "Engine fuctions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

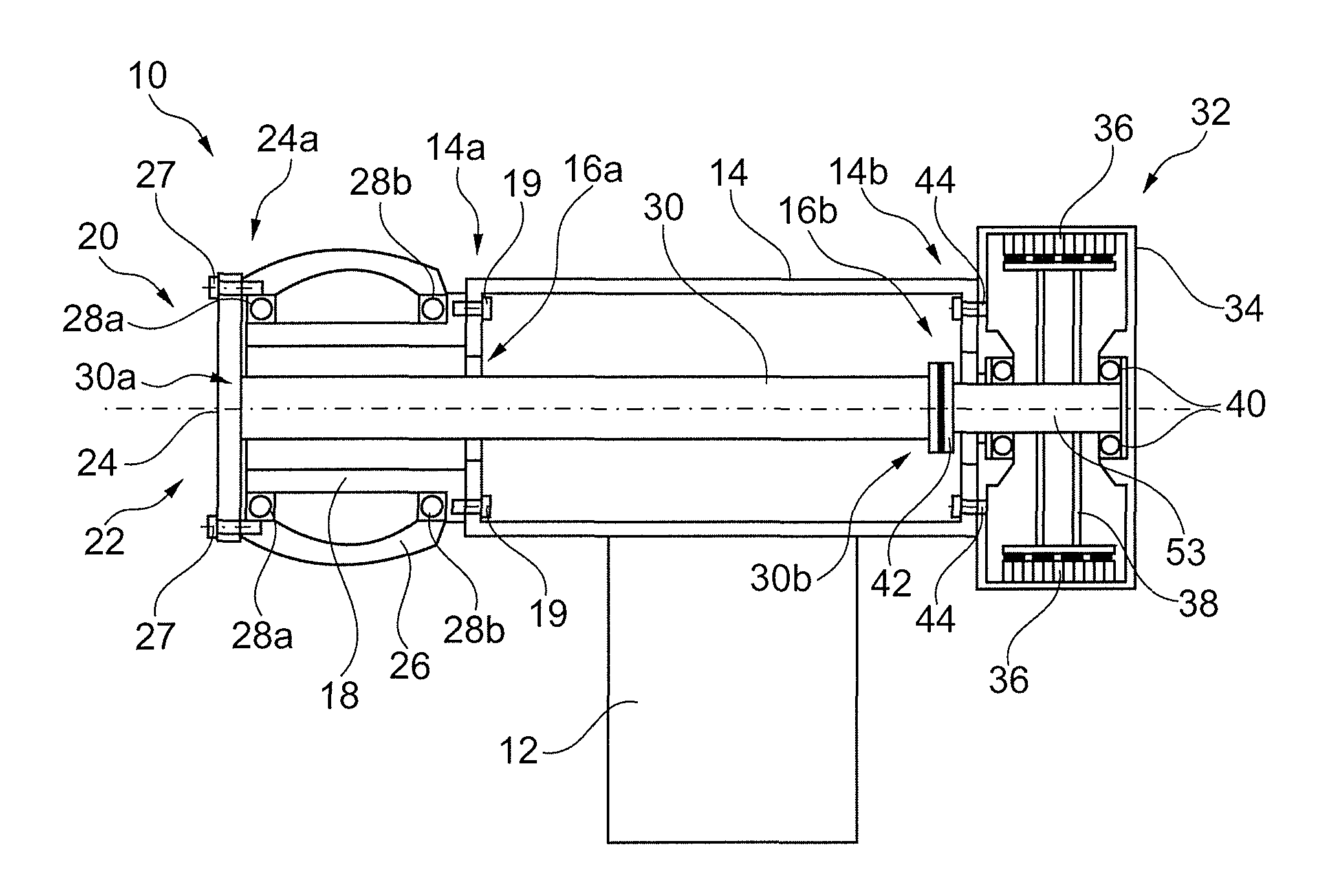

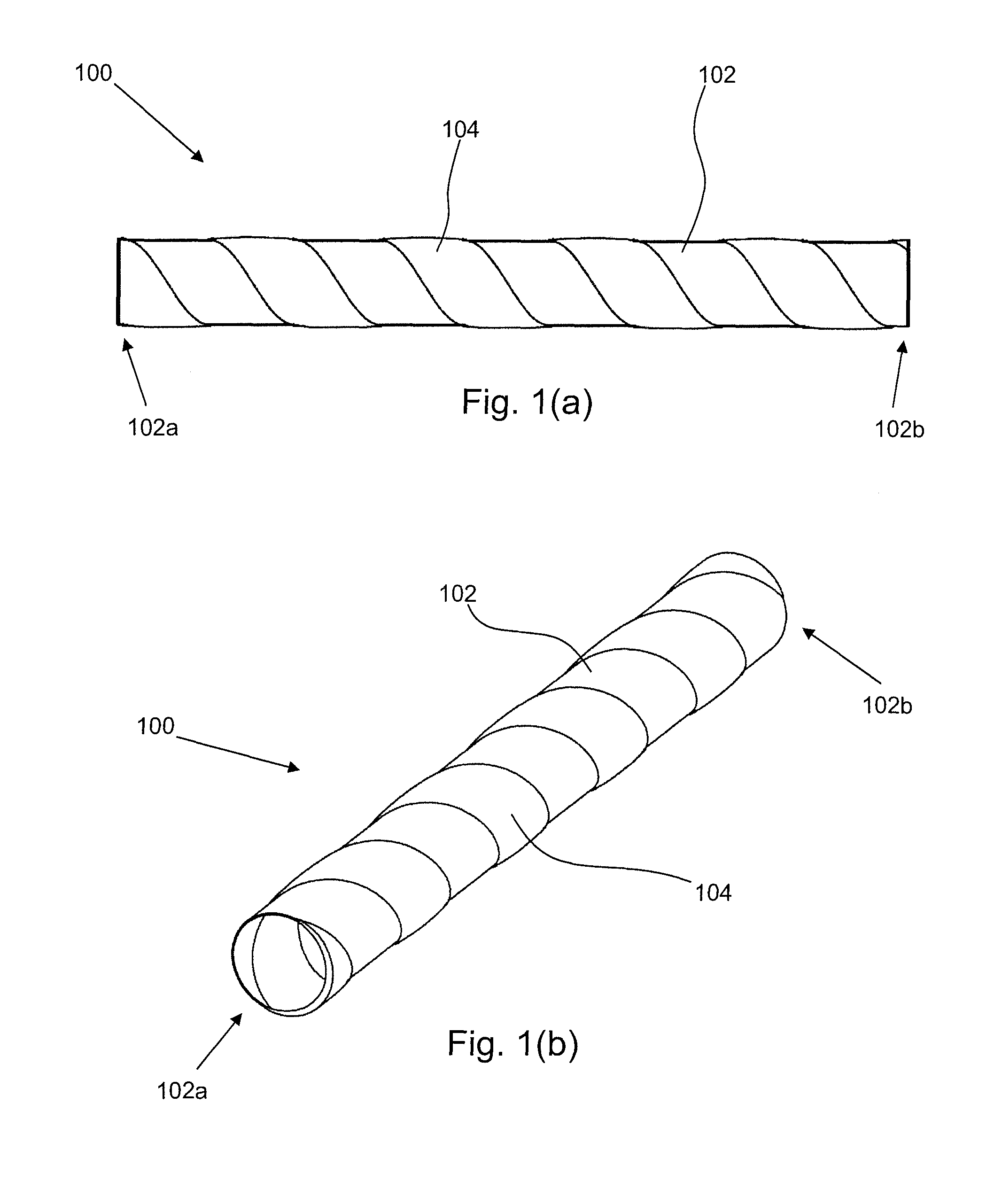

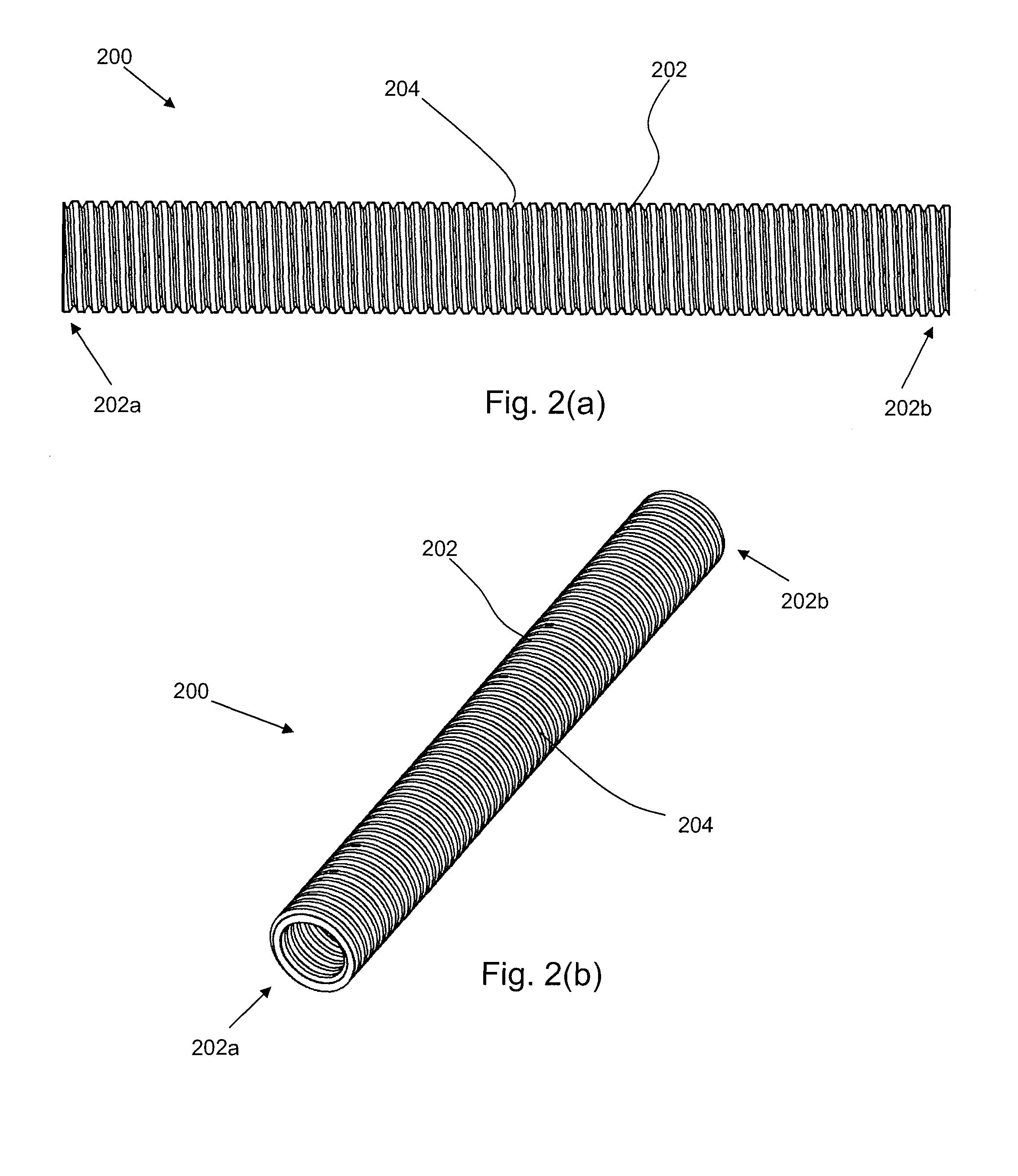

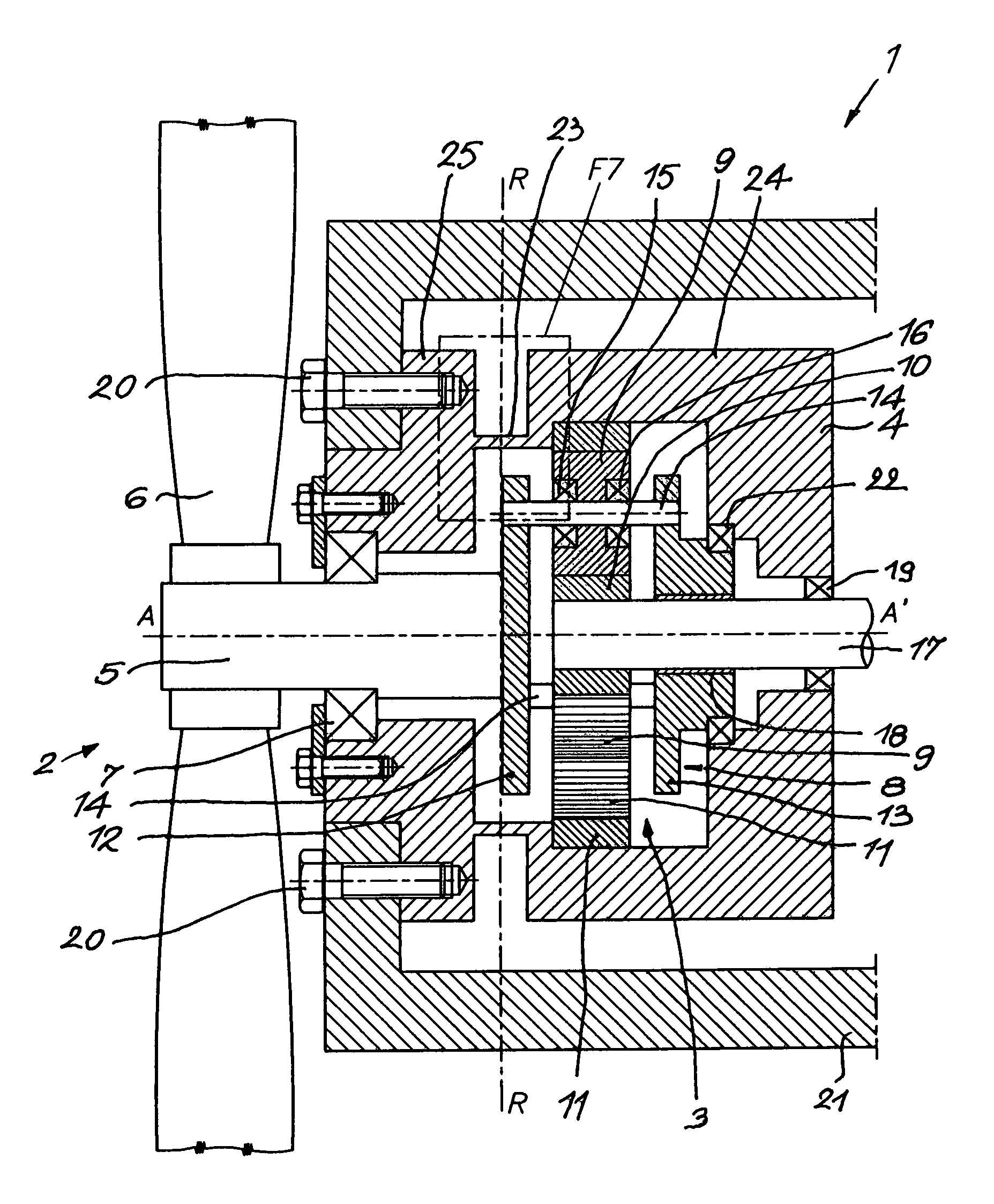

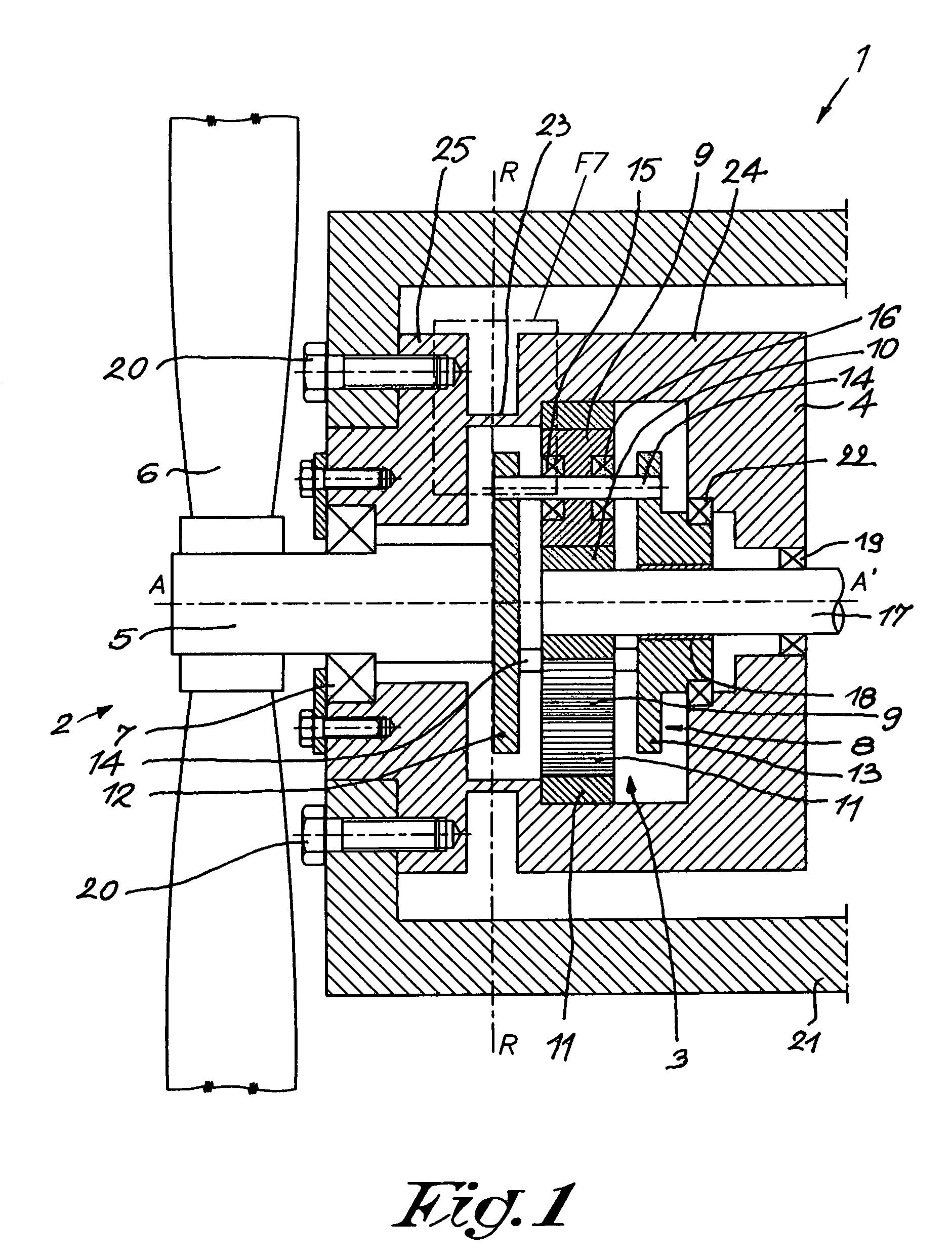

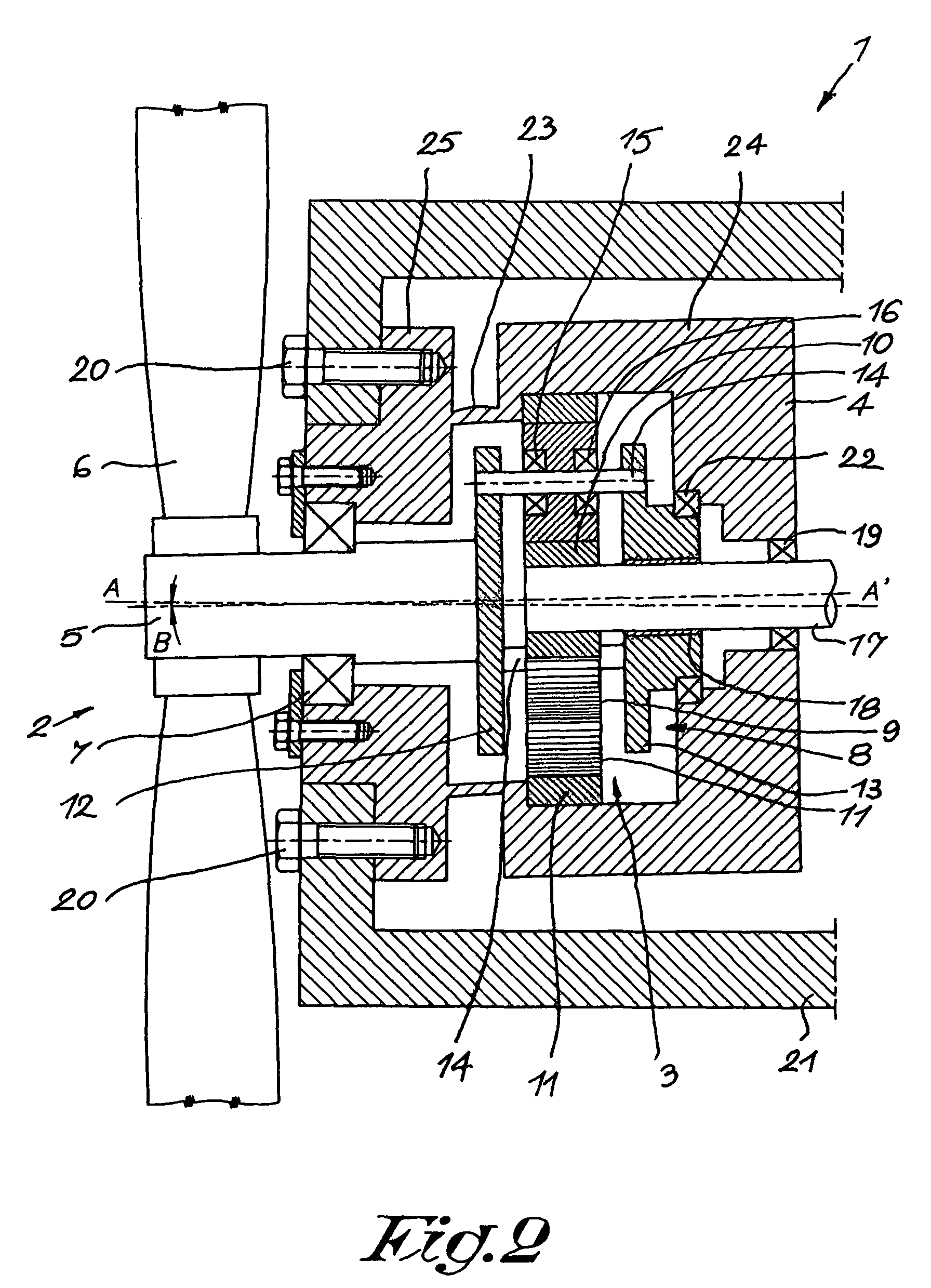

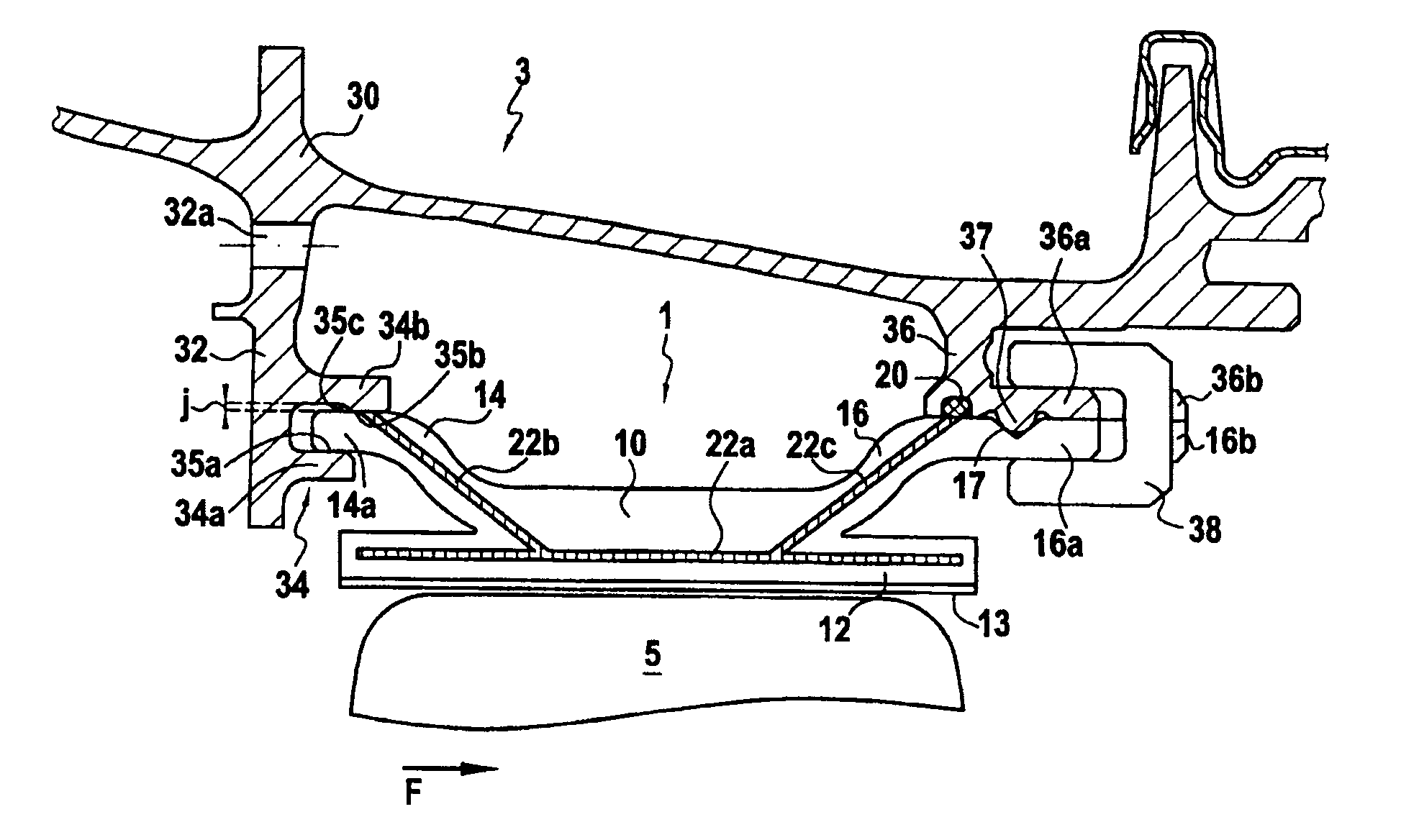

Wind turbine and a shaft for a wind turbine

InactiveUS8664792B2Little strengthImproves buckling stabilityEngine fuctionsFinal product manufactureDrive shaftTurbine

A drive shaft for a wind turbine is shaped so as to allow for increased bending of the shaft, while being suitable for transferring torque in a wind turbine system. An example of such a shaping is a drive shaft having a helical rib defined on the surface of the shaft. A wind turbine incorporating such a shaft, and a method of manufacture of such a shaft are also described.

Owner:ENVISION ENERGY DENMARK

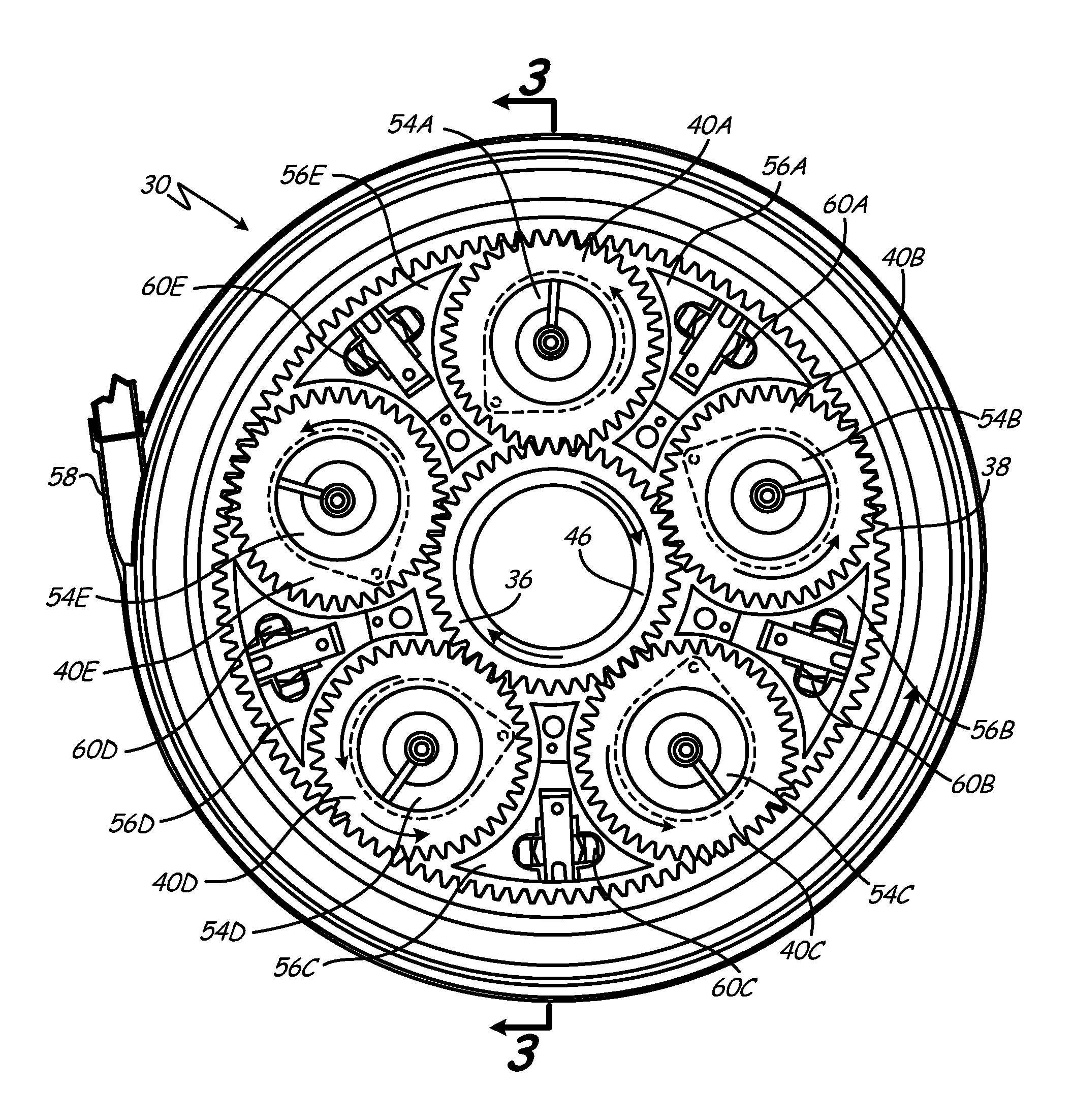

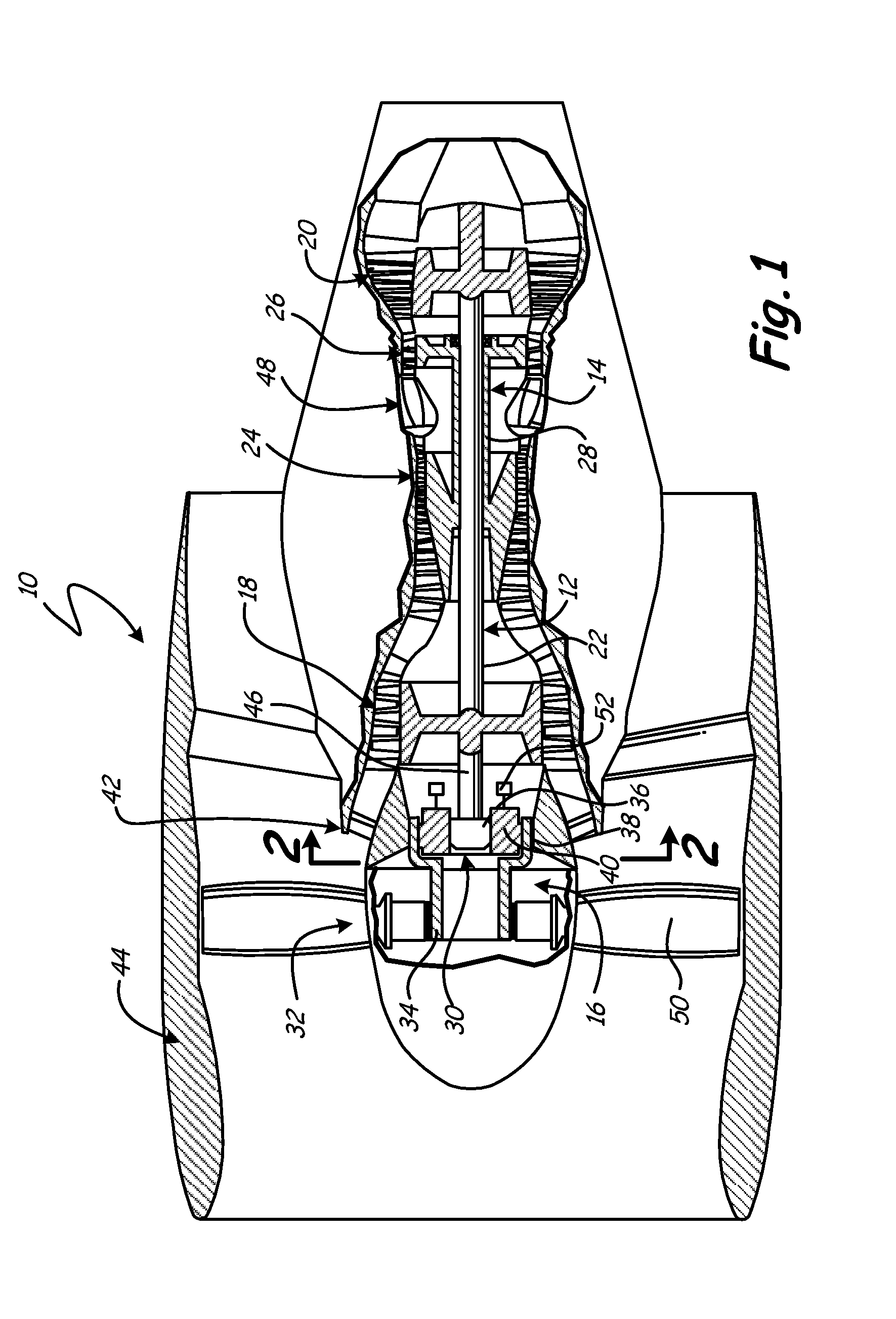

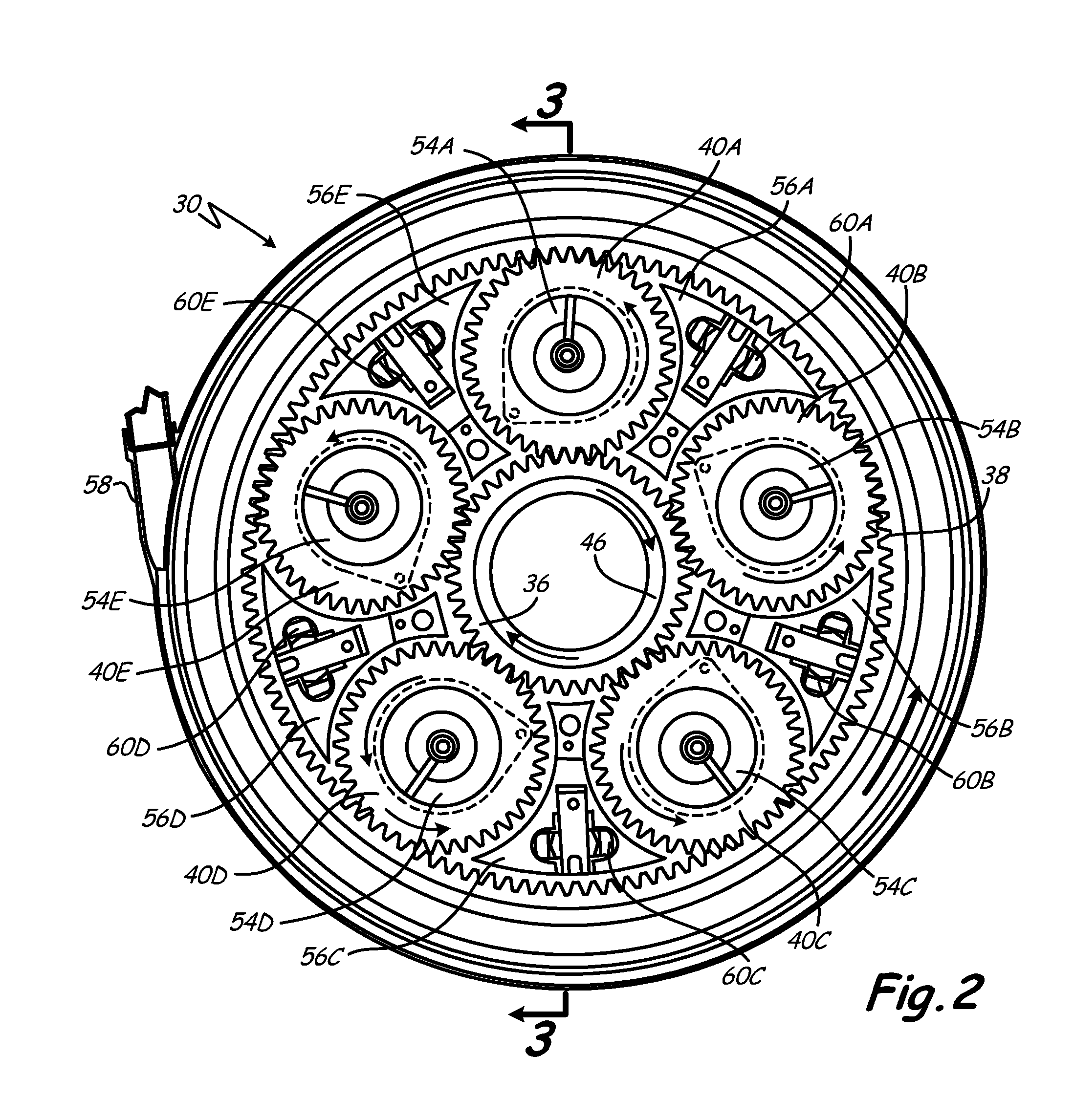

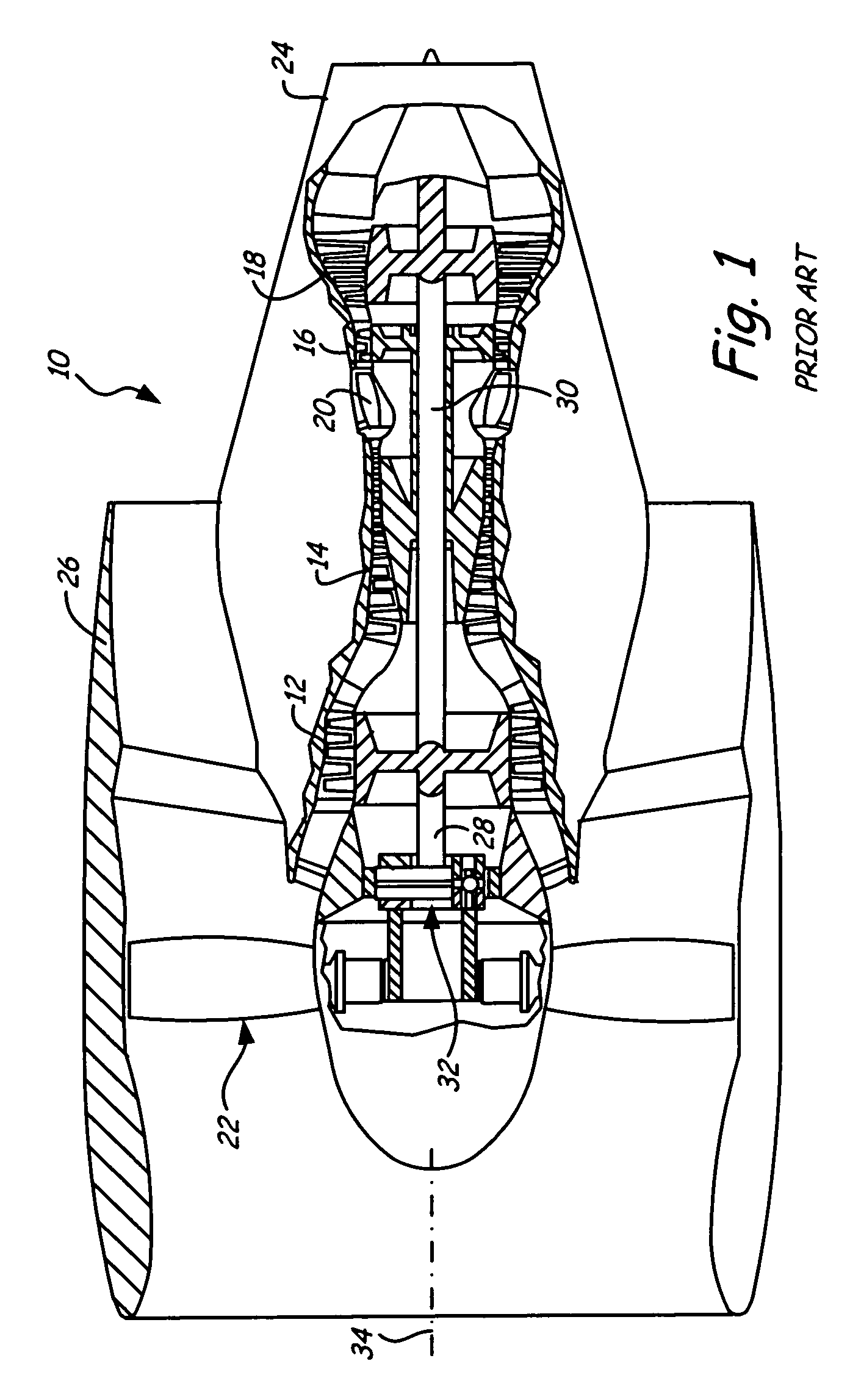

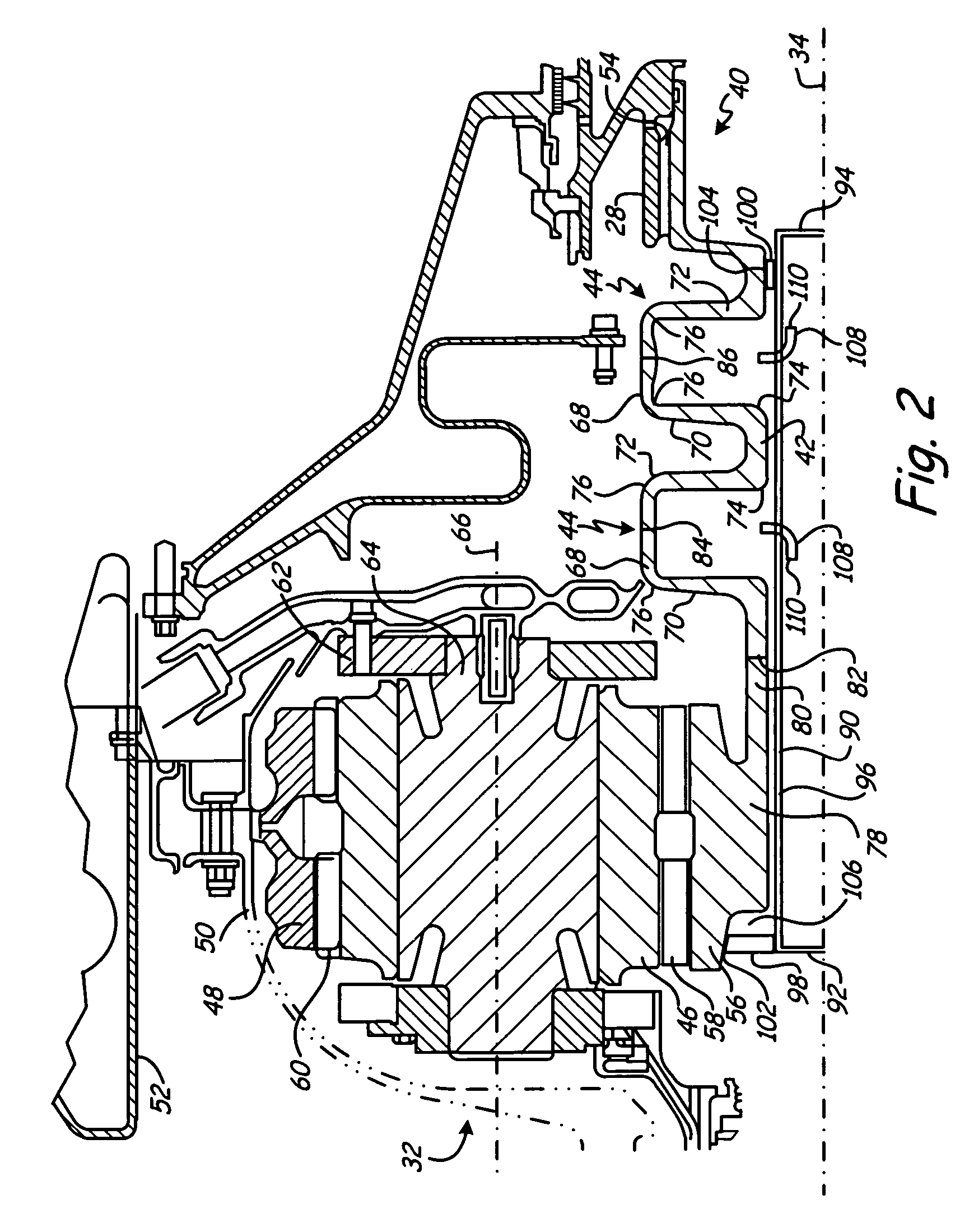

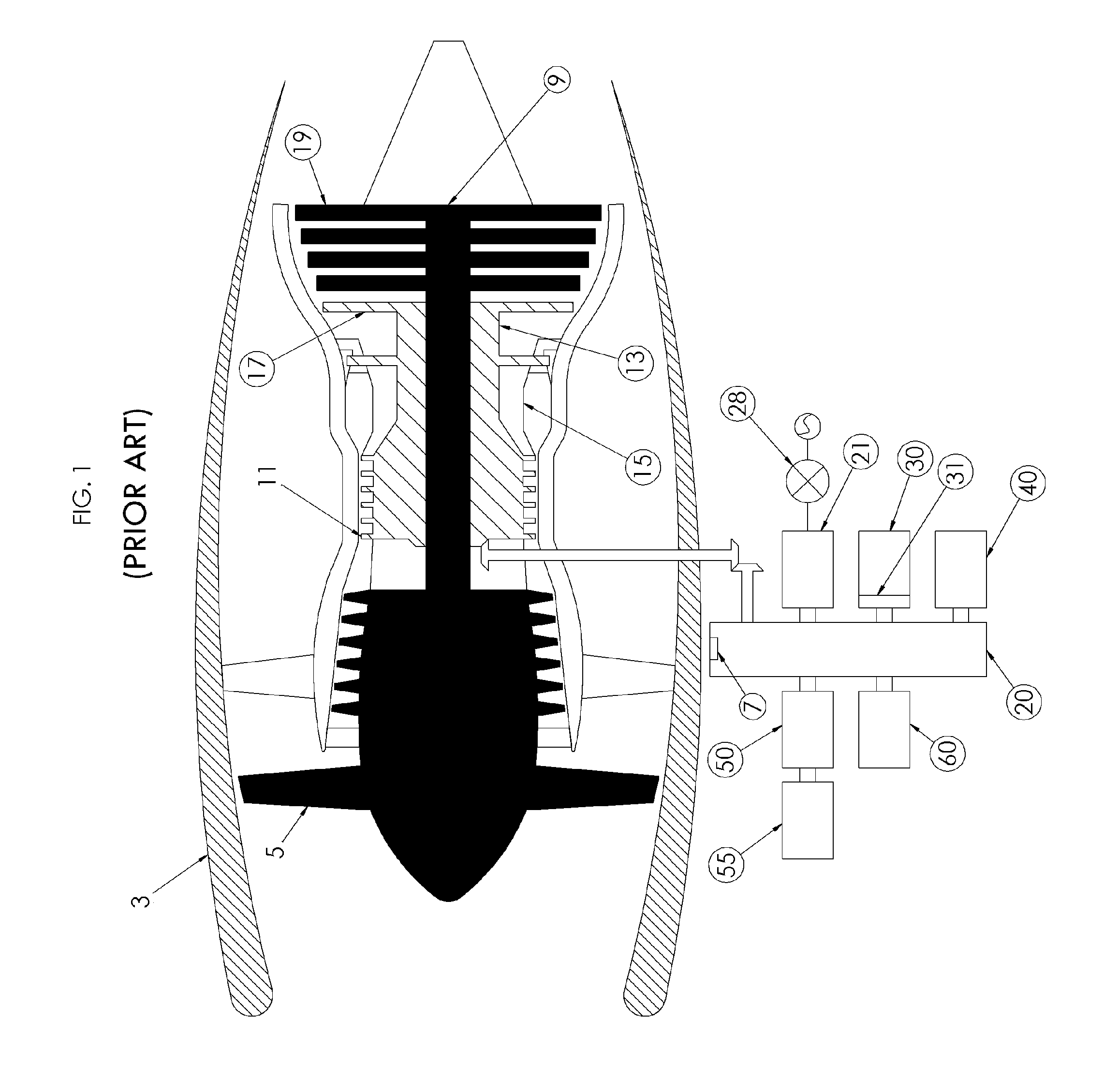

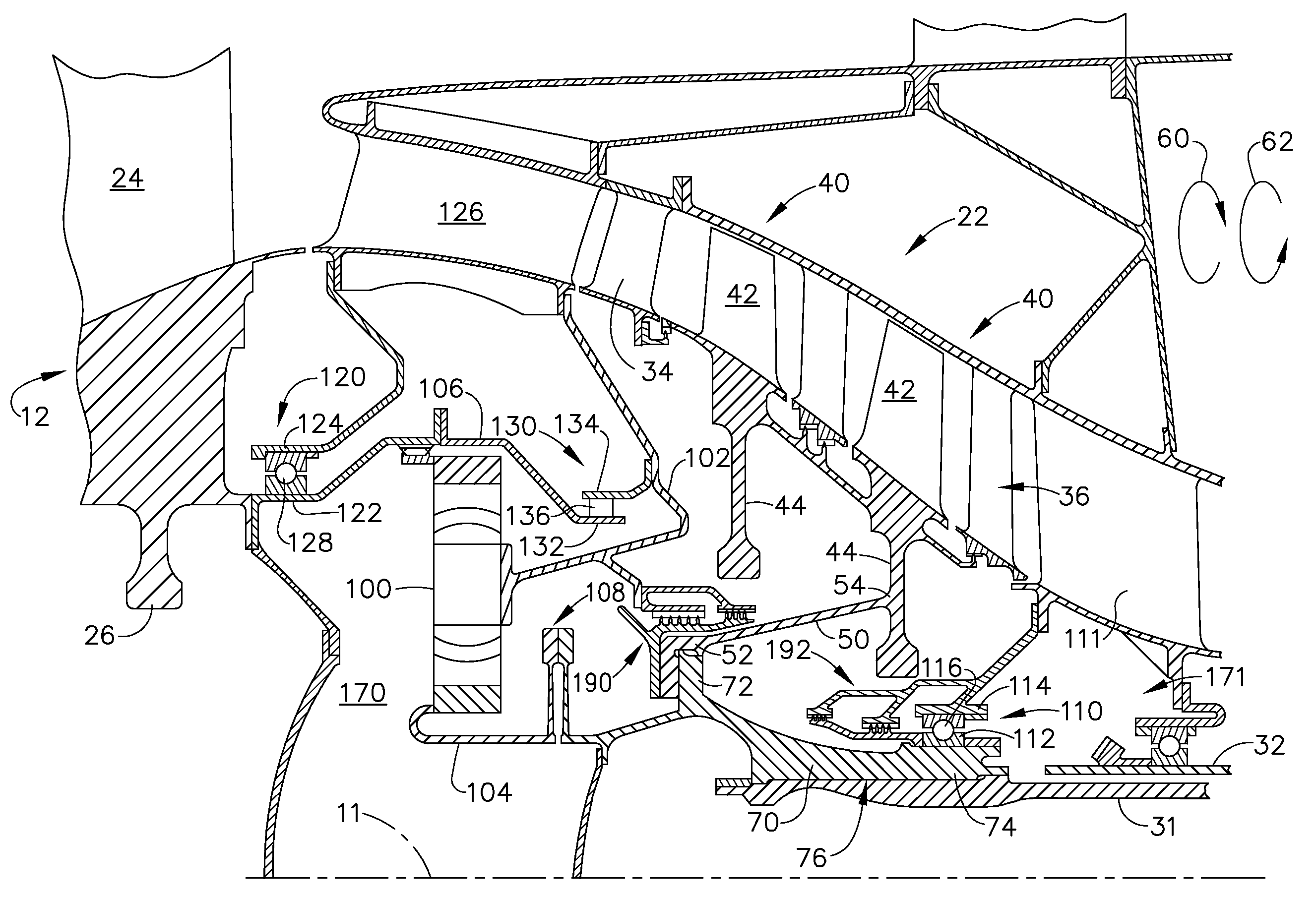

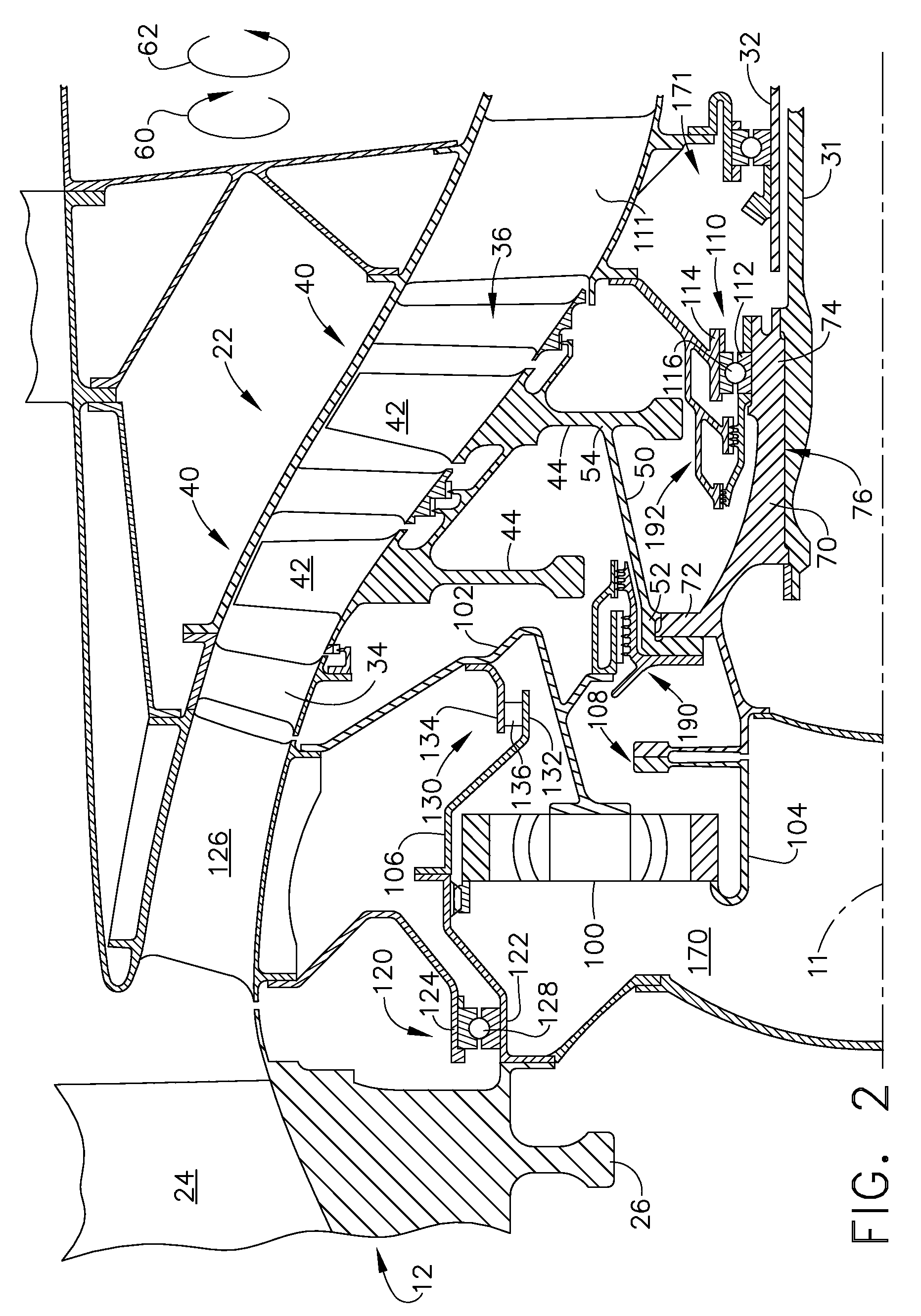

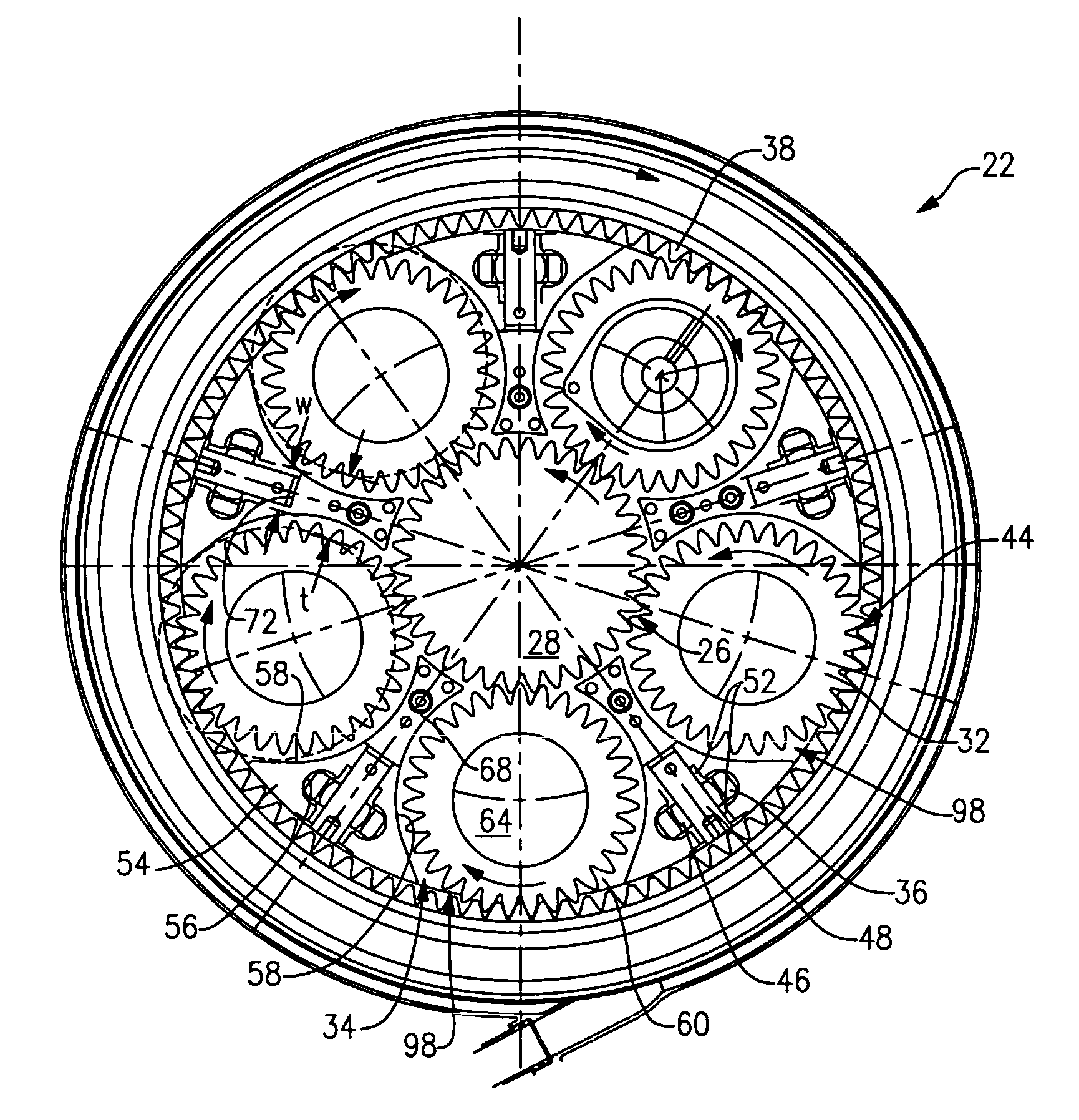

Coupling system for a star gear train in a gas turbine engine

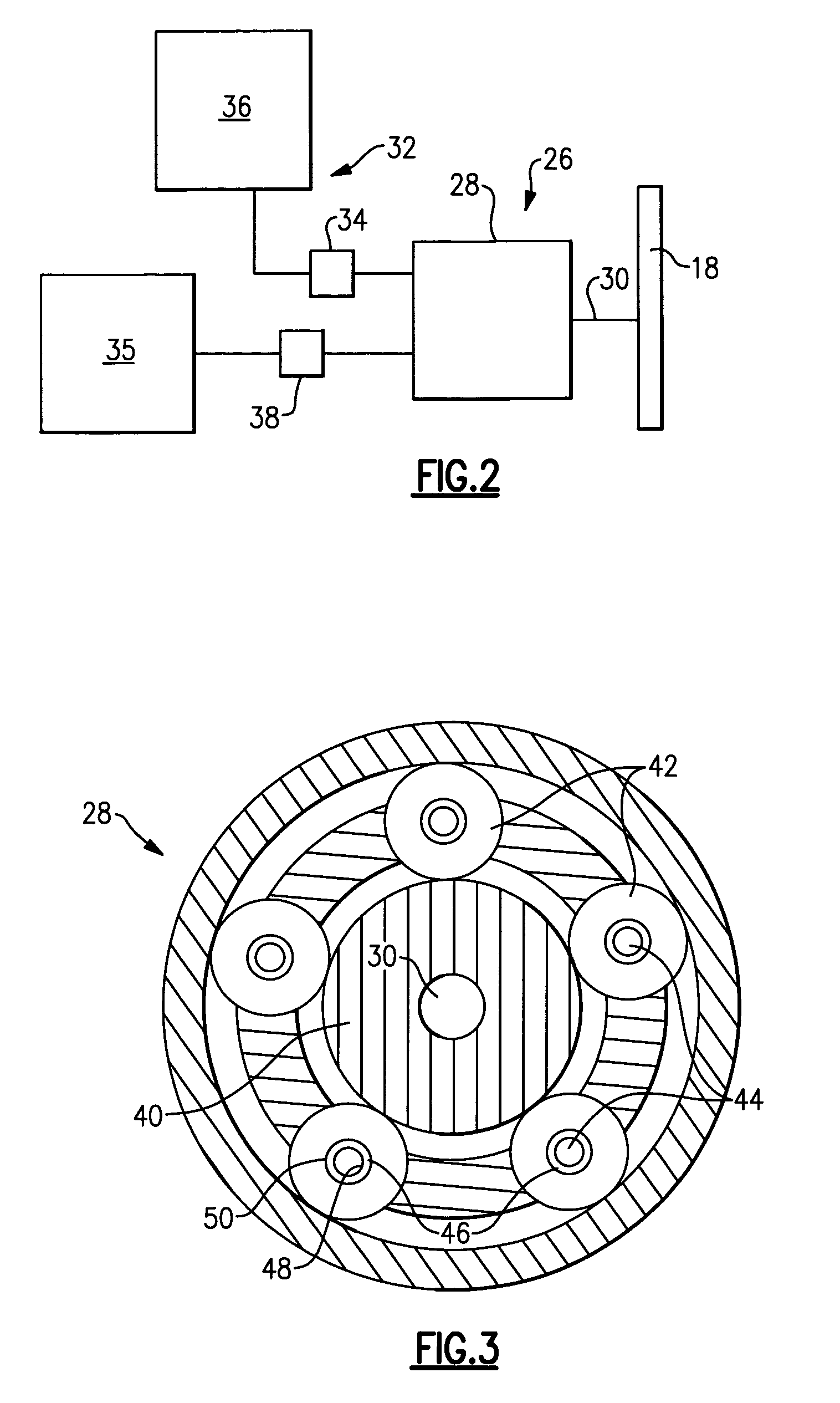

A star gear train for use in a gas turbine engine includes a sun gear, a ring gear, a plurality of star gears and a coupling system. The sun gear is rotatable by a shaft. The ring gear is secured to a ring gear shaft. Each of the plurality of star gears is rotatably mounted in a star carrier and meshes with the sun gear and the ring gear. The coupling system comprises a sun gear flexible coupling, a carrier flexible coupling and a deflection limiter. The sun gear flexible coupling connects the sun gear to the shaft. The carrier flexible coupling connects the carrier to a non-rotating mechanical ground. The deflection limiter is connected to the star carrier to limit excessive radial and circumferential displacement of the star gear train.

Owner:RTX CORP

Geartrain coupling for a turbofan engine

Molybdenum disulfide (MoS2) is used as a journal coating for a gearing system. A particular application is the planetary gear system of a geared turbofan engine. Particularly advantageous coatings are deposited via physical vapor deposition (PVD) techniques.

Owner:RAYTHEON TECH CORP

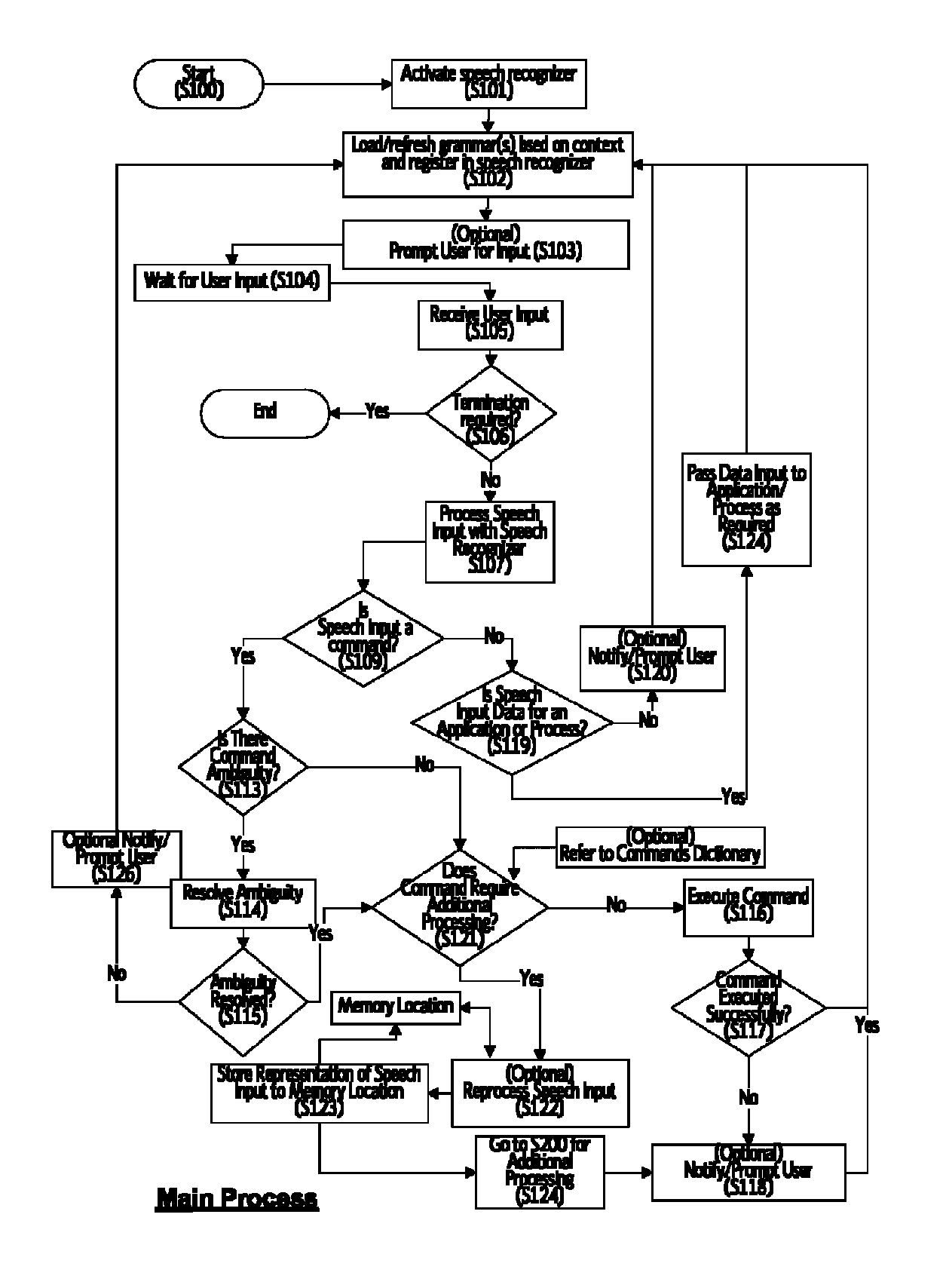

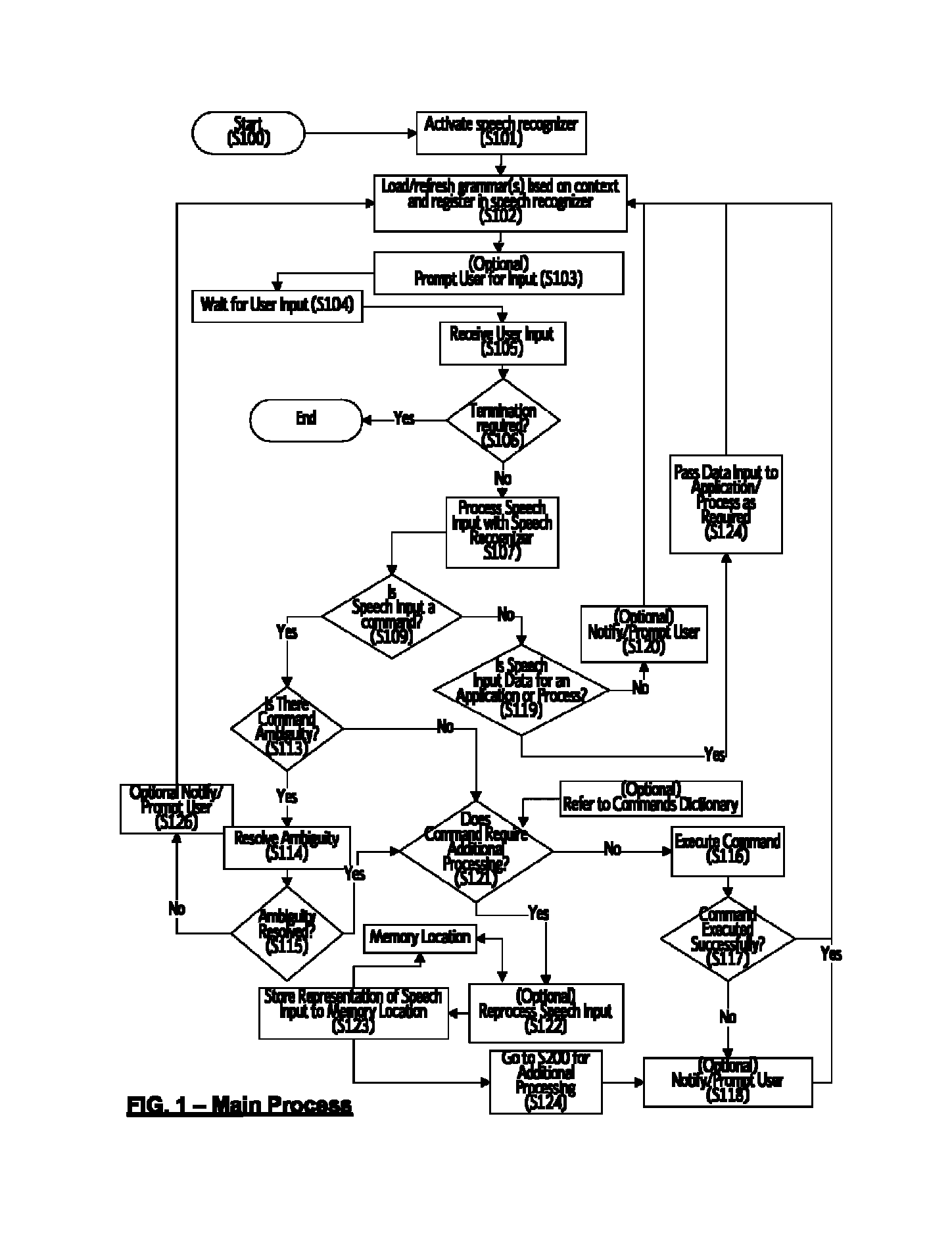

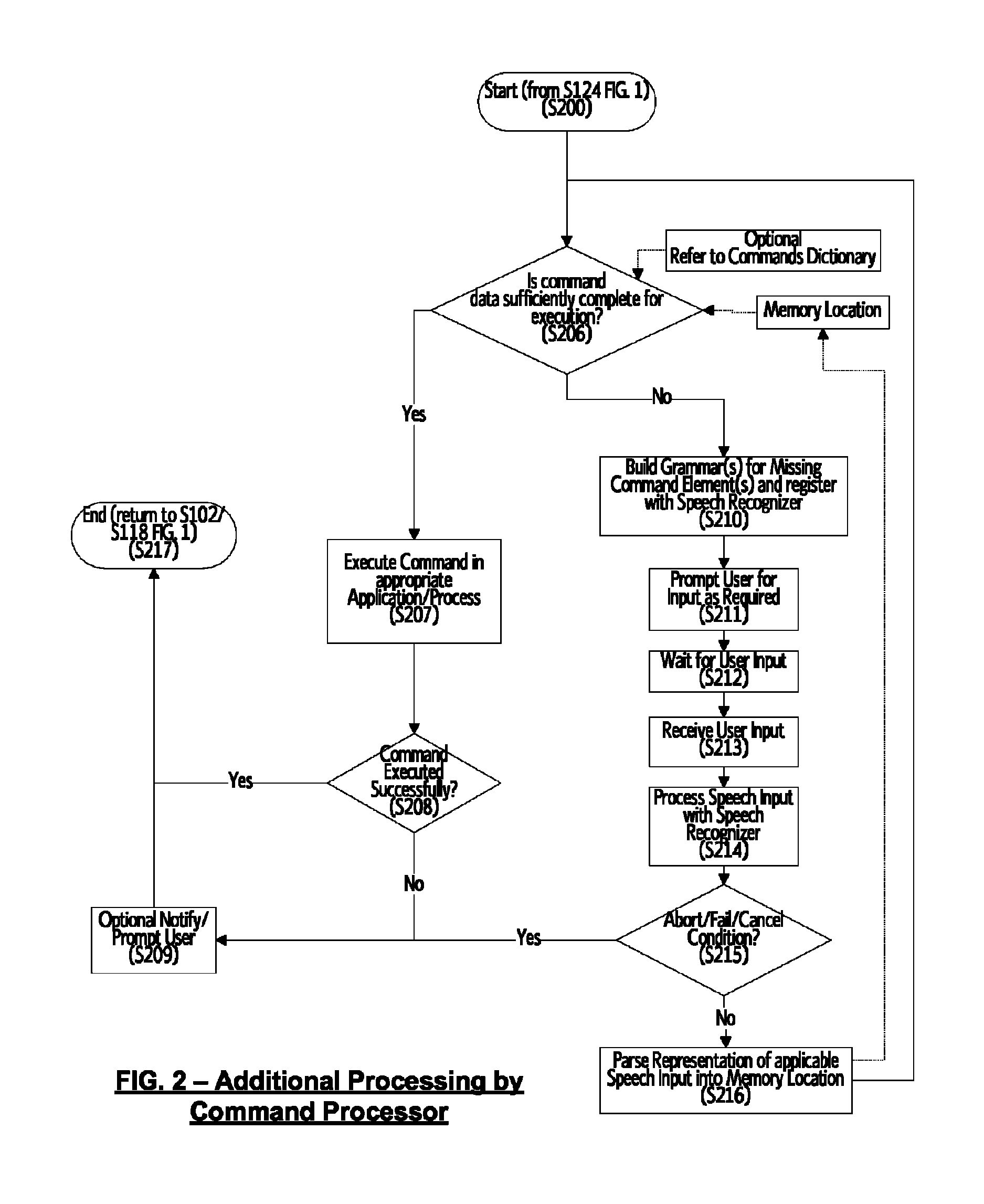

Method for processing the output of a speech recognizer

ActiveUS8219407B1Improve integrityReduce ambiguityEngine fuctionsBlade accessoriesUser inputSpeech identification

A system and method for processing speech input comprising a speech recognizer and a logical command processor which facilitates additional processing of speech input beyond the speech recognizer level. A speech recognizer receives input from a user, and when a command is identified in the speech input, if the command meets conditions that require additional processing, a representation of the speech input s stored for subsequent processing. A logical command processor performs additional processing of command input by analyzing the command and its elements, determining which elements are required for successful processing the command and which elements are present and lacking. The user is prompted to supply missing information, and subsequent user input is added to the command structure until the command input is aborted or the command structure reaches sufficient completeness to enable execution of the command. Thereby, speech input of complex commands in natural language in a system running a plurality of applications and processes is made possible.

Owner:GREAT NORTHERN RES

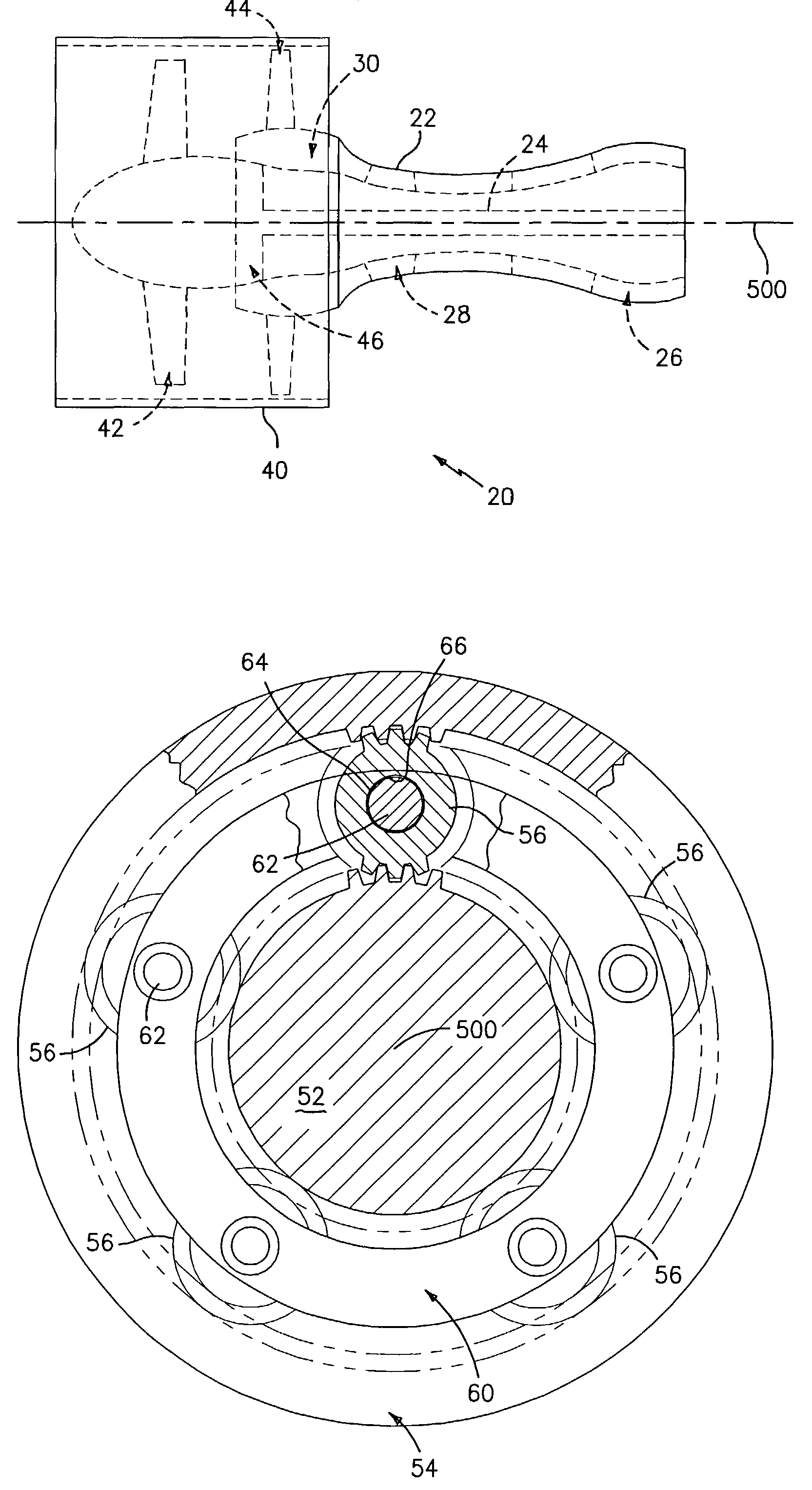

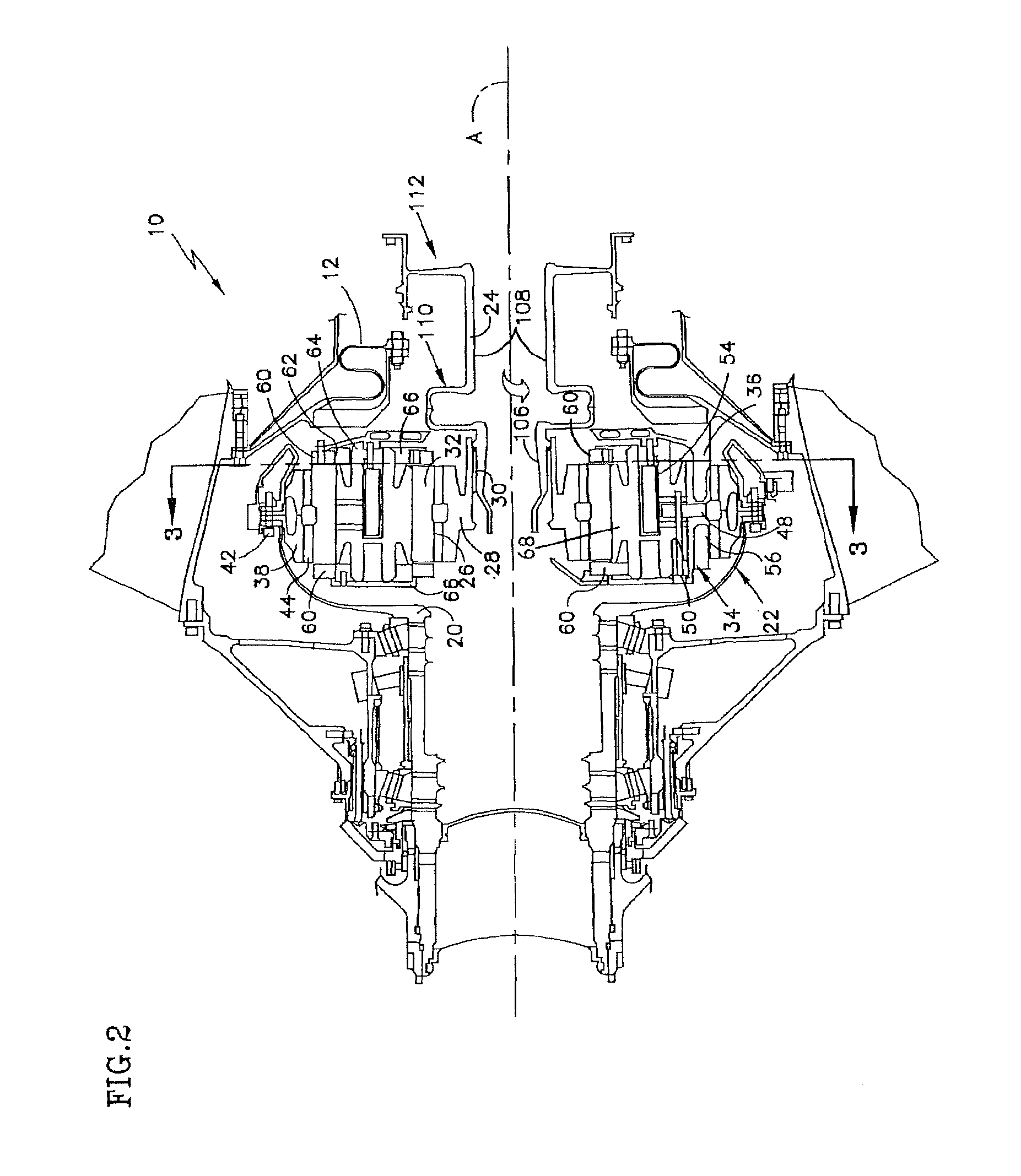

Epicyclic gear train integral sun gear coupling design

A coupling system for connecting a sun gear to a shaft within a planetary gear train, includes a sun gear coupling connecting the sun gear to the shaft. The sun gear coupling has at least one undulant flexible section joined to an inflexible spindle for accommodating misalignment between the sun gear and the shaft. The flexible section comprises a cylindrical ring having a diameter greater than the diameter of the spindle, and joined to the spindle by two longitudinally spaced apart diaphragms. The juncture between the diaphragms, the ring, and the spindle is curved in cross section on an outer side to improve flexibility and minimize stress concentrations, and the inner sides of the diaphragms are straight edges which result in a non-symmetric contour of the diaphragm walls.

Owner:RTX CORP

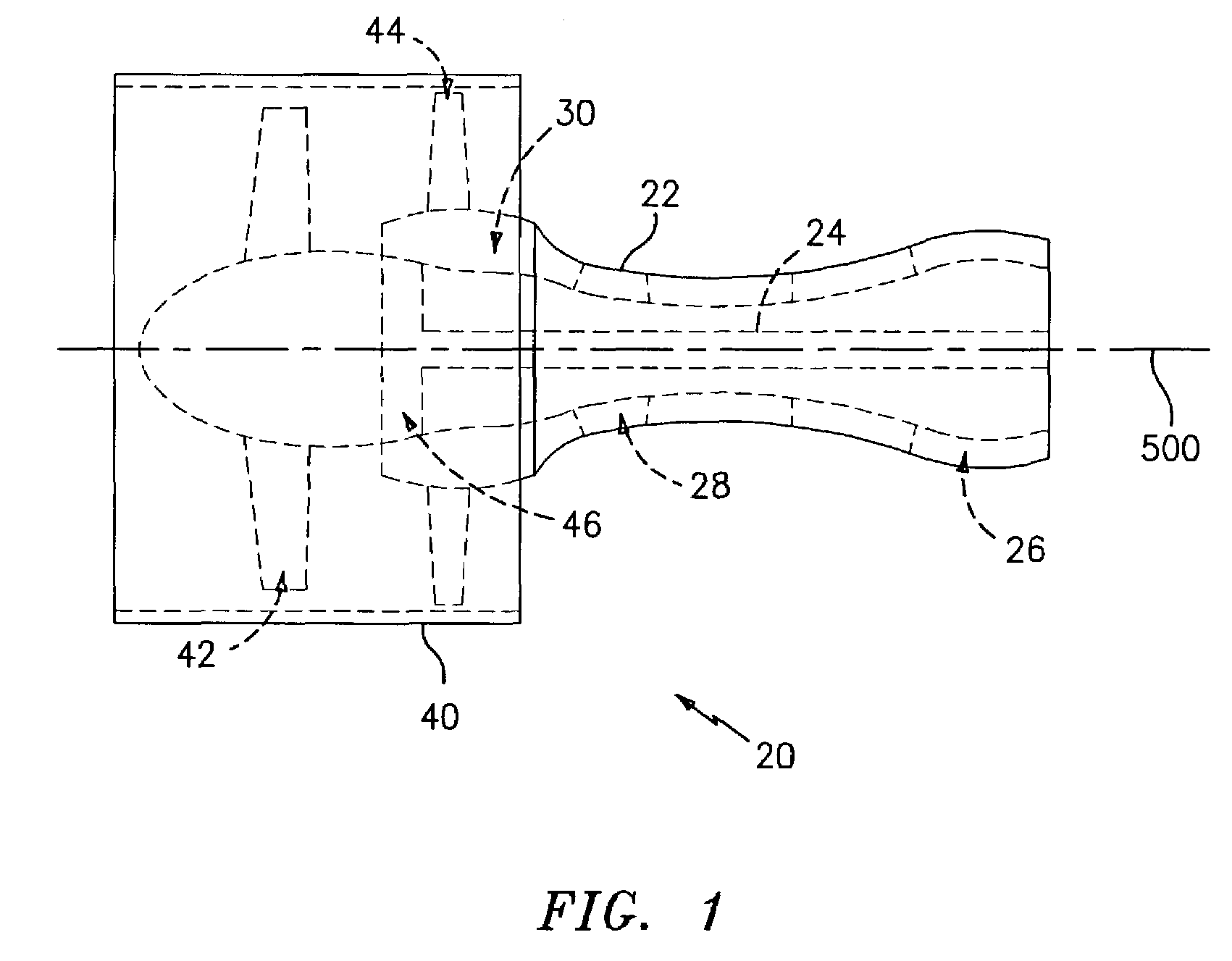

Flexible shaft for gas turbine engine

A shaft for a gas turbine engine is provided that includes a first shaft section, a second shaft section, a first flexible linkage, and a second flexible linkage. The first shaft section extends between a forward axial end and an aft axial end along a first axial centerline. The second shaft section extends between a forward axial end and an aft axial end along a second axial centerline. The first flexible linkage includes a bridge section connected between a first diaphragm and a second diaphragm. The first diaphragm is connected to the aft axial end of the first shaft section. The second diaphragm is connected to the forward axial end of the second shaft section. The second flexible linkage includes a diaphragm and a hub. The second flexible linkage diaphragm cantilevers radially outwardly from an inner radial end to an outer radial end, and is connected to the aft axial end of the second shaft section. The hub is connected to the outer radial end of the second flexible linkage diaphragm, and includes an engine shaft coupling connected to the hub.

Owner:RTX CORP

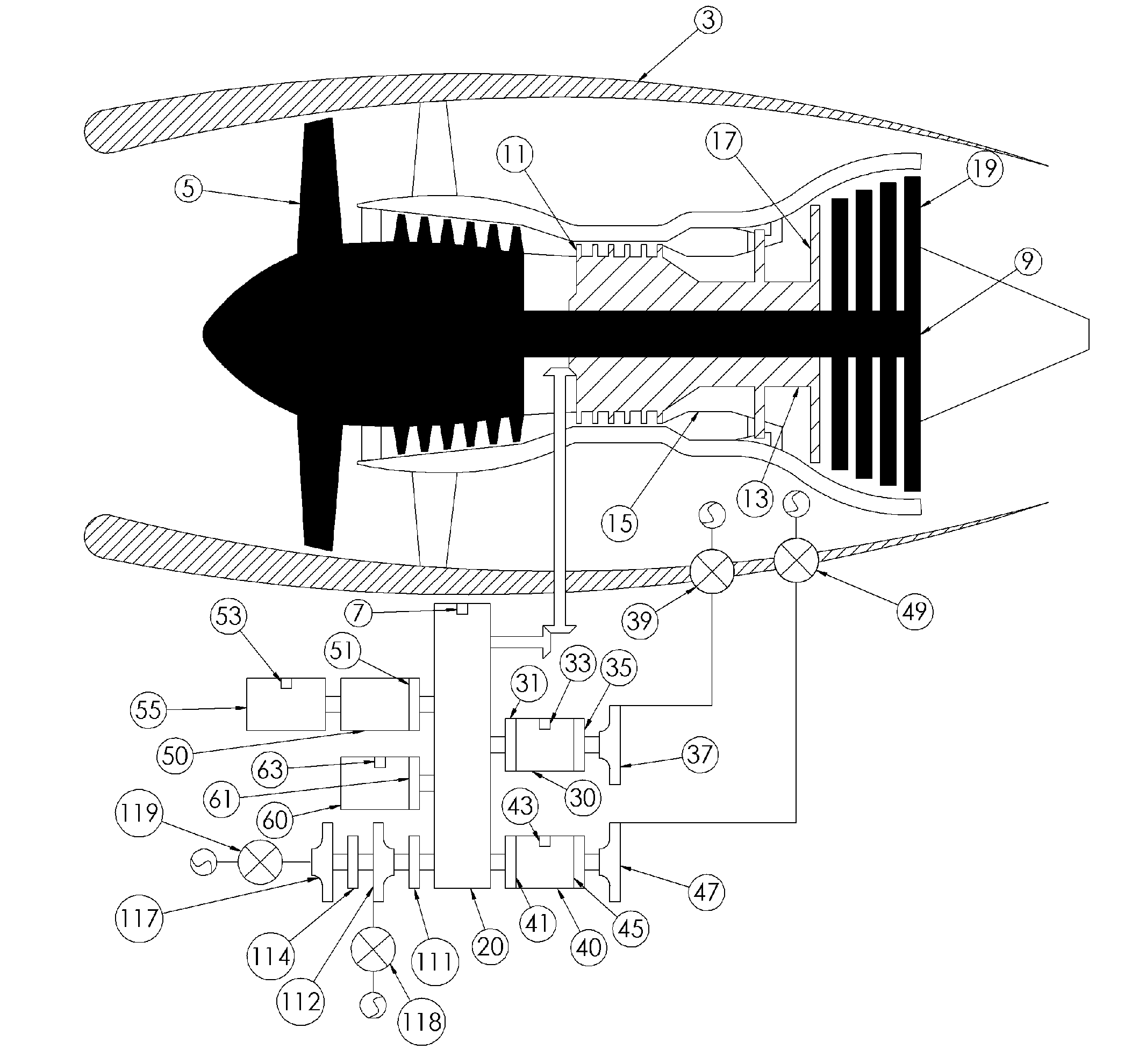

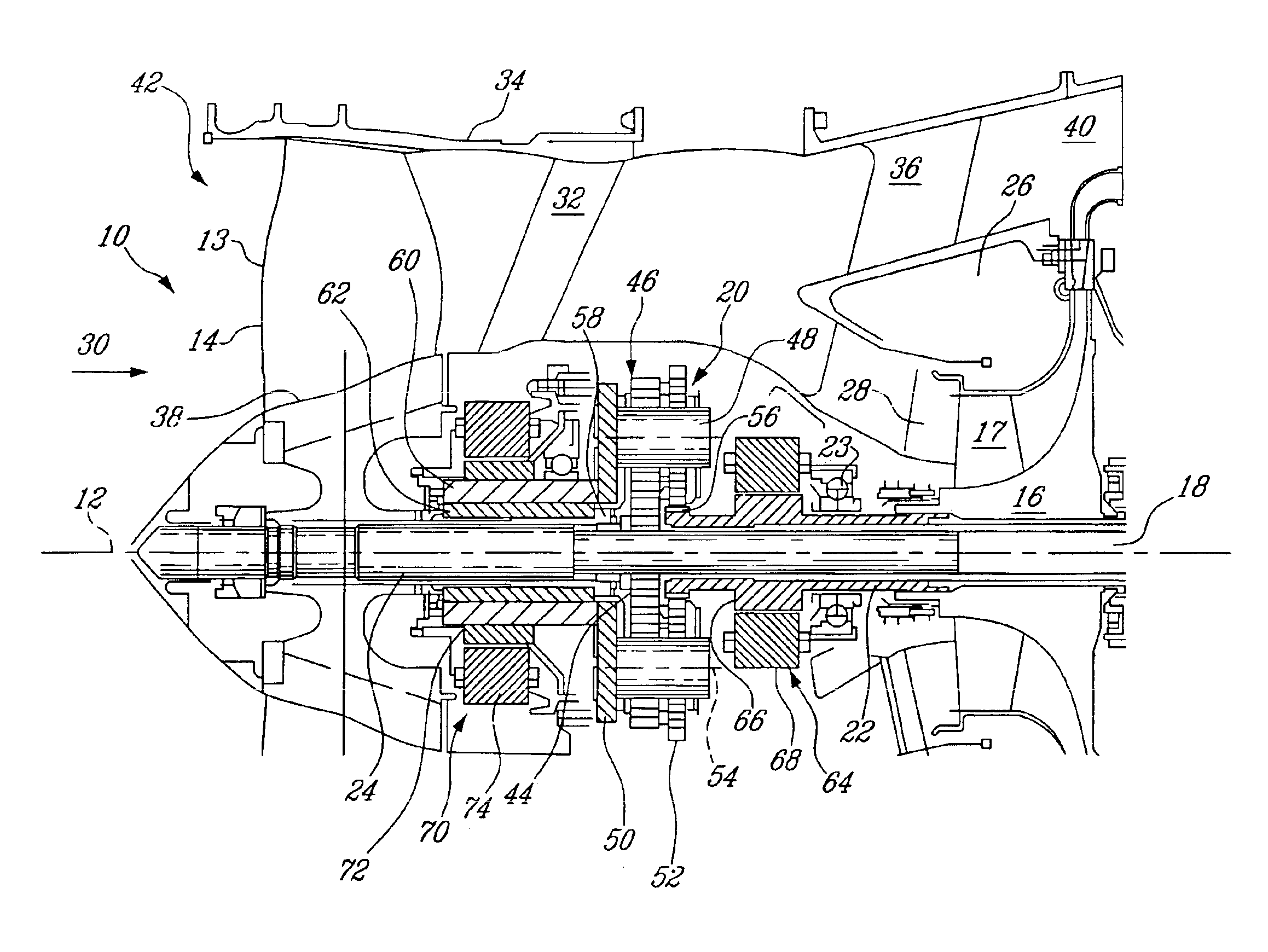

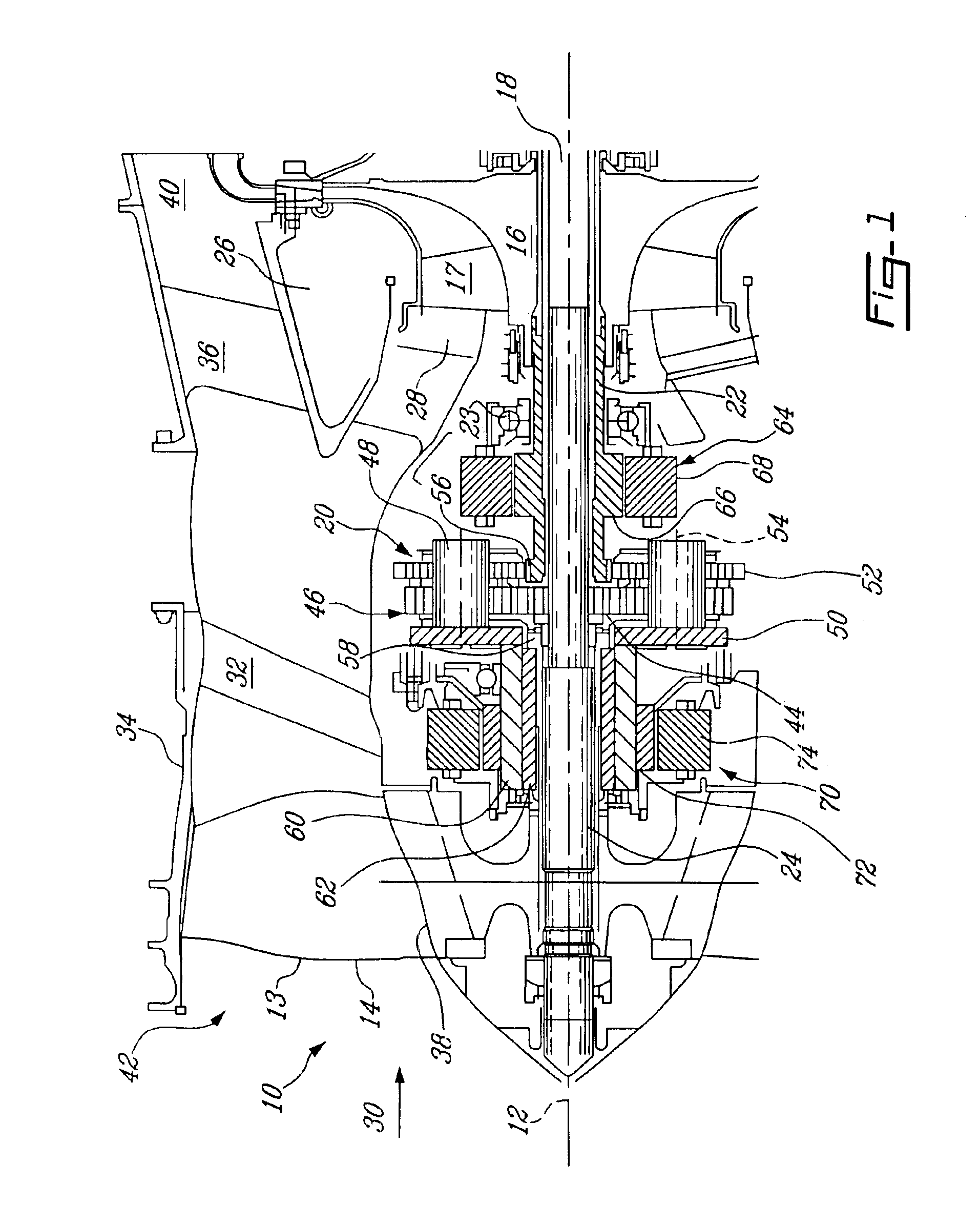

Aircraft with disengageable engine and auxiliary power unit components

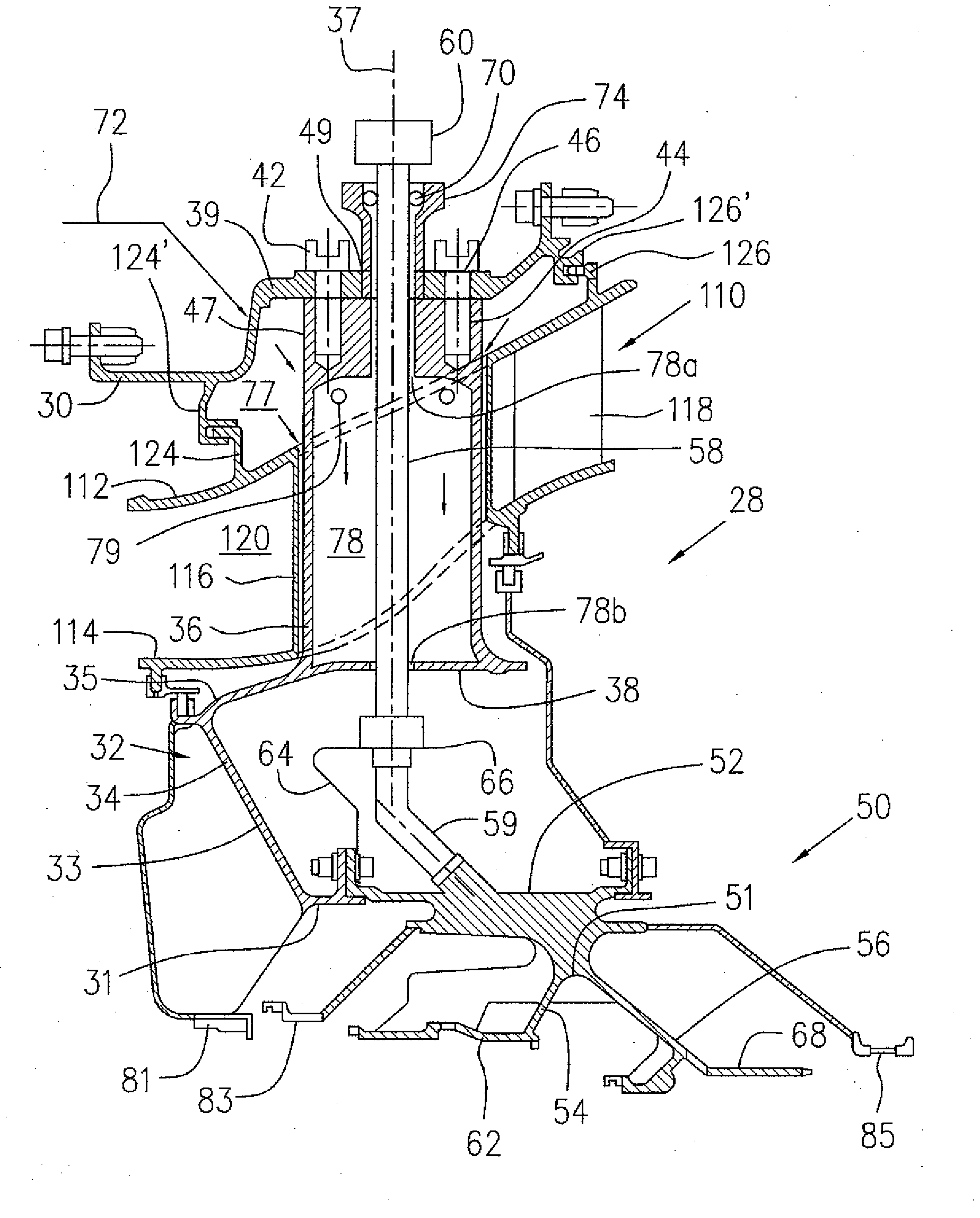

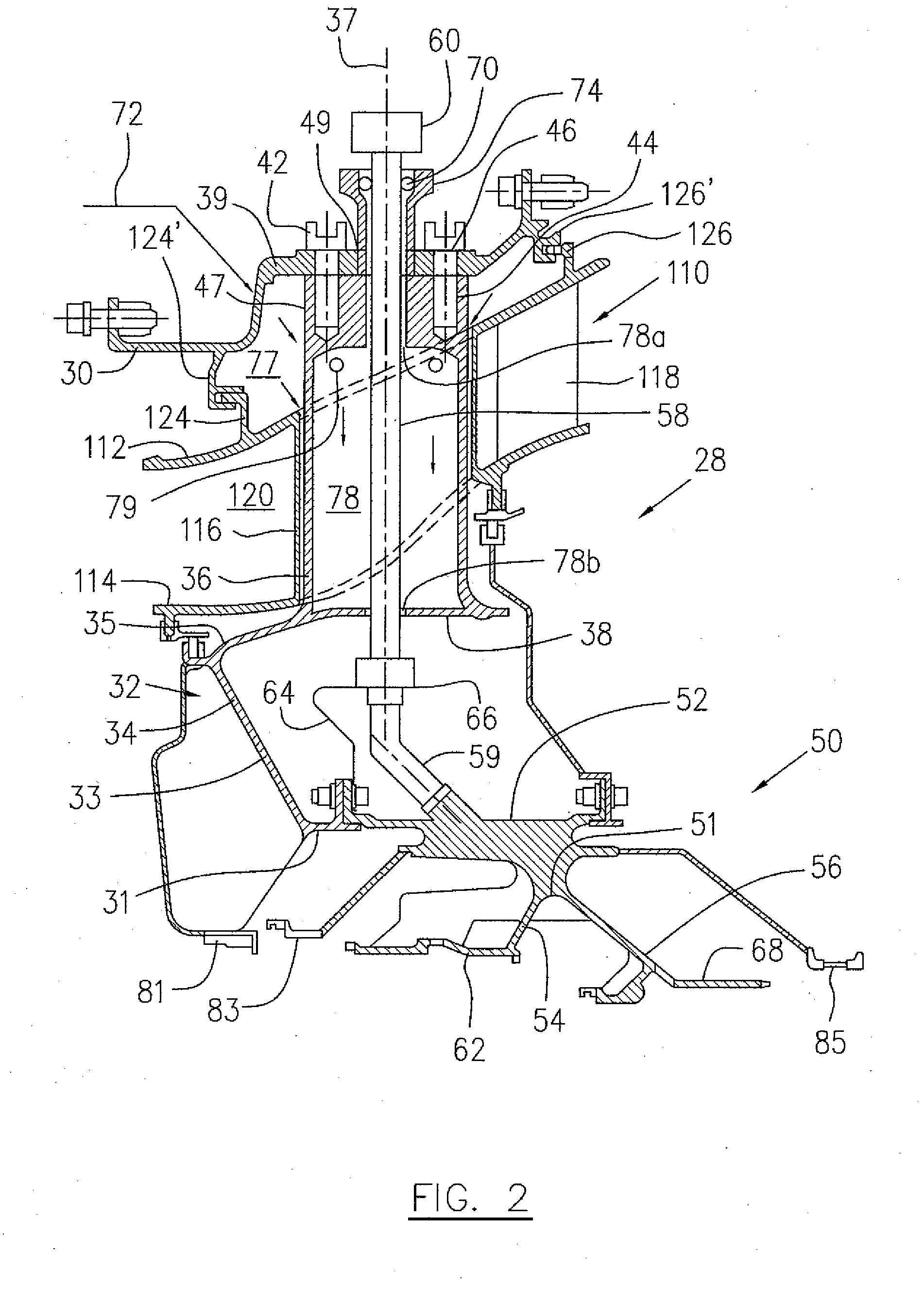

InactiveUS20060260323A1Avoid damageSufficient torqueEngine fuctionsGas turbine plantsFlight vehicleGround testing

Several improvements to an aircraft turbine engine and Auxiliary Power Unit (APU) are disclosed, as well as methods of using these improvements in routine and emergency aircraft operations. The improvements comprise the addition of cockpit-controllable clutches that can be used to independently disconnect the engine's integrated drive generator (IDG), engine driven pump (EDP), fuel pump, and oil pump from the engine gearbox. These engine components may then be connected to air turbines by the use of additional clutches and then powered by the turbines. Similar arrangements are provided for the APU components. Cranking pads, attached to various engine and APU components, are disclosed to provide a means for externally powering the components for testing purposes and to assist with engine and APU start. Detailed methods are disclosed to use the new components for routine ground-testing and maintenance and for the enhancement of flight safety, minimization of engine component damage, and extension of engine-out flying range in the case of an emergency in-flight engine shutdown.

Owner:MOULEBHAR DJAMAL

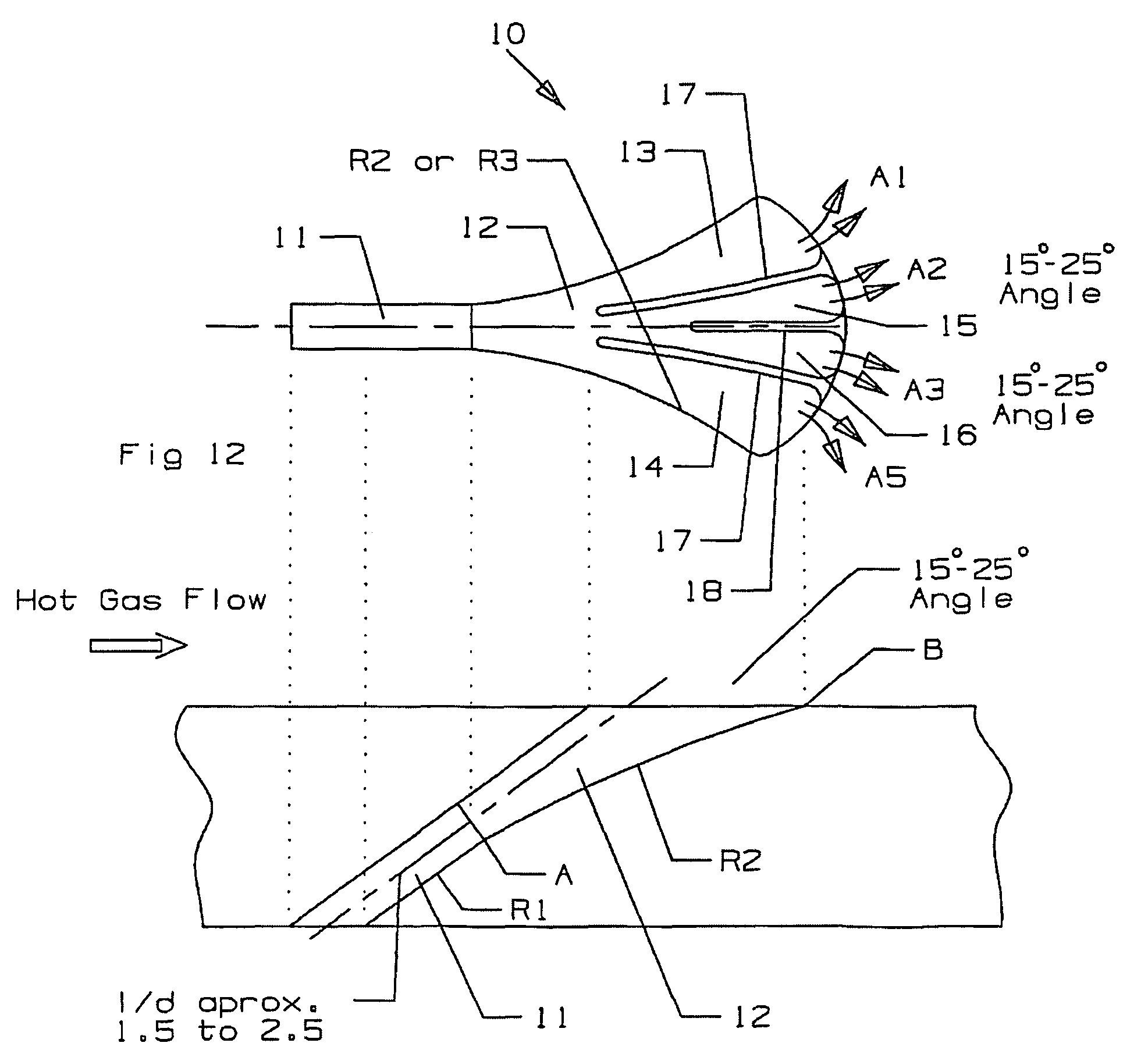

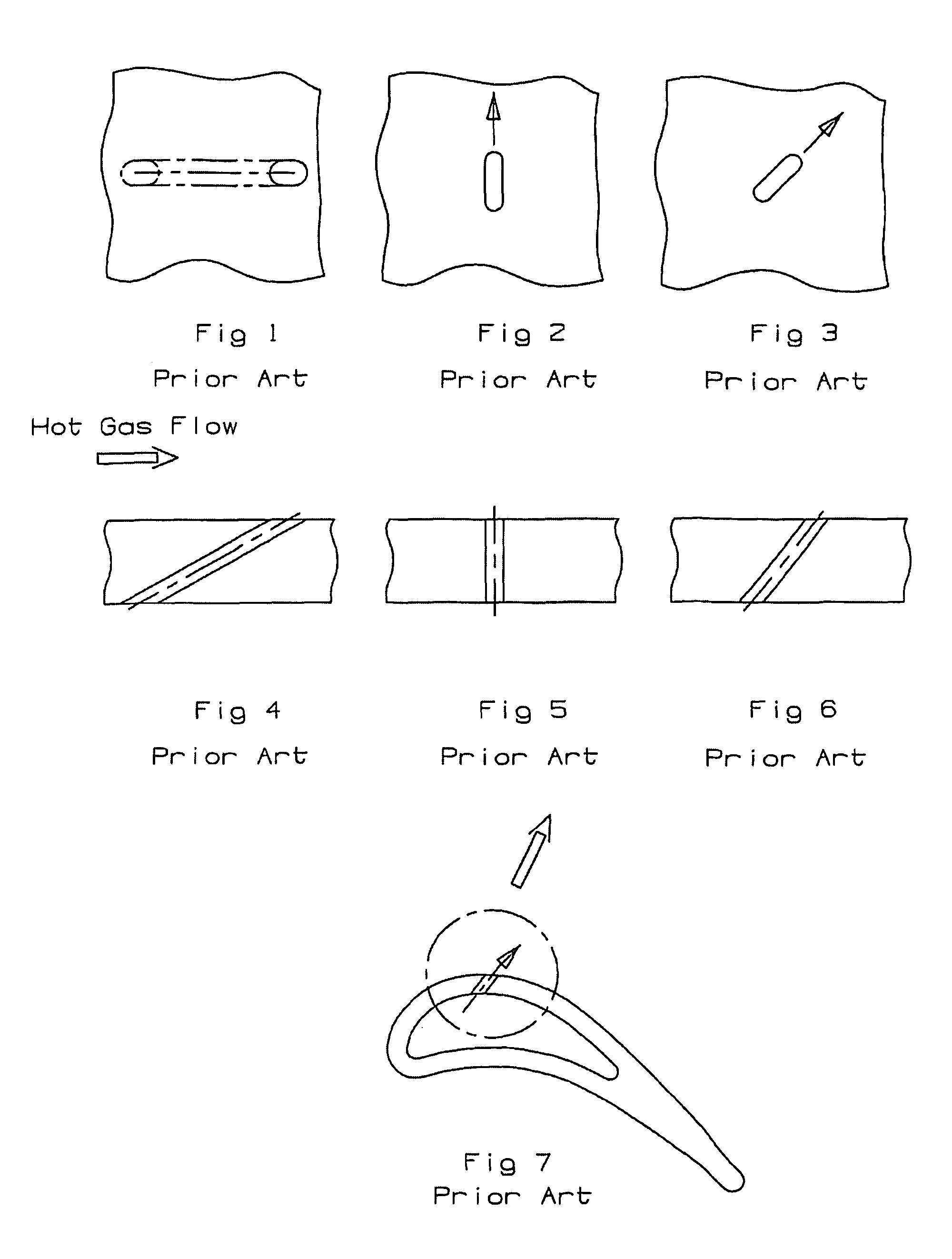

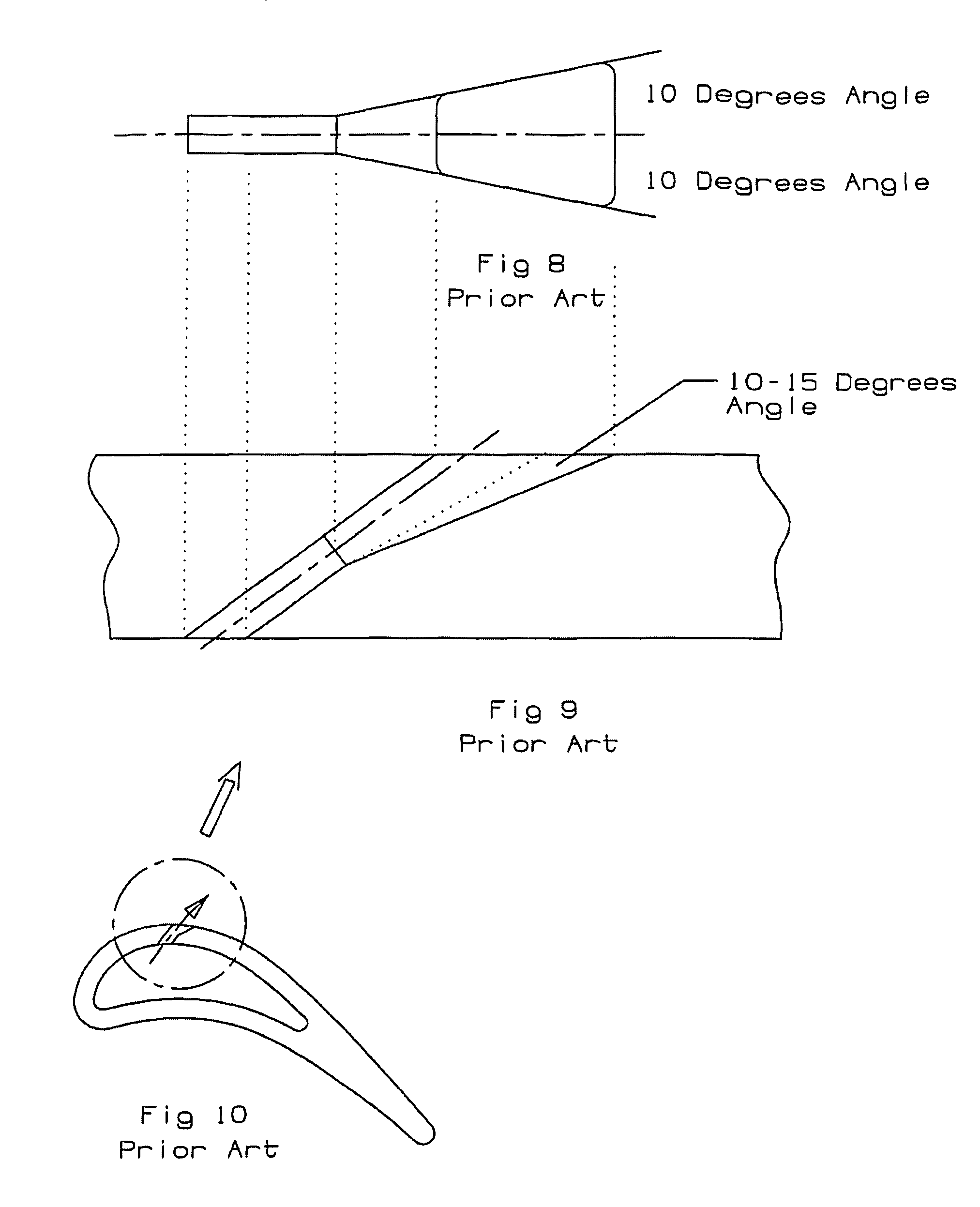

Film cooling hole for turbine airfoil

InactiveUS7997868B1Less turbulenceMinimize shear mixingEngine manufactureEngine fuctionsStructural engineeringTurbine

A turbine airfoil with a film cooling hole having a bell mouth shaped opening that has expansion in both the side walls and the downstream wall of from 15 to 25 degrees. The film cooling hole includes an expansion section formed with two long ribs and one short rib to form three inlets of equal cross sectional areas so that the flows into the three passages are the same. The short rib forms two middle passages to combine with two outer passages to form four exit passages for the film hole. The two side walls are curved outward in the stream-wise oriented film hole and have an expansion of from 0 to 5 degrees in the compound angled film hole.

Owner:SIEMENS ENERGY INC

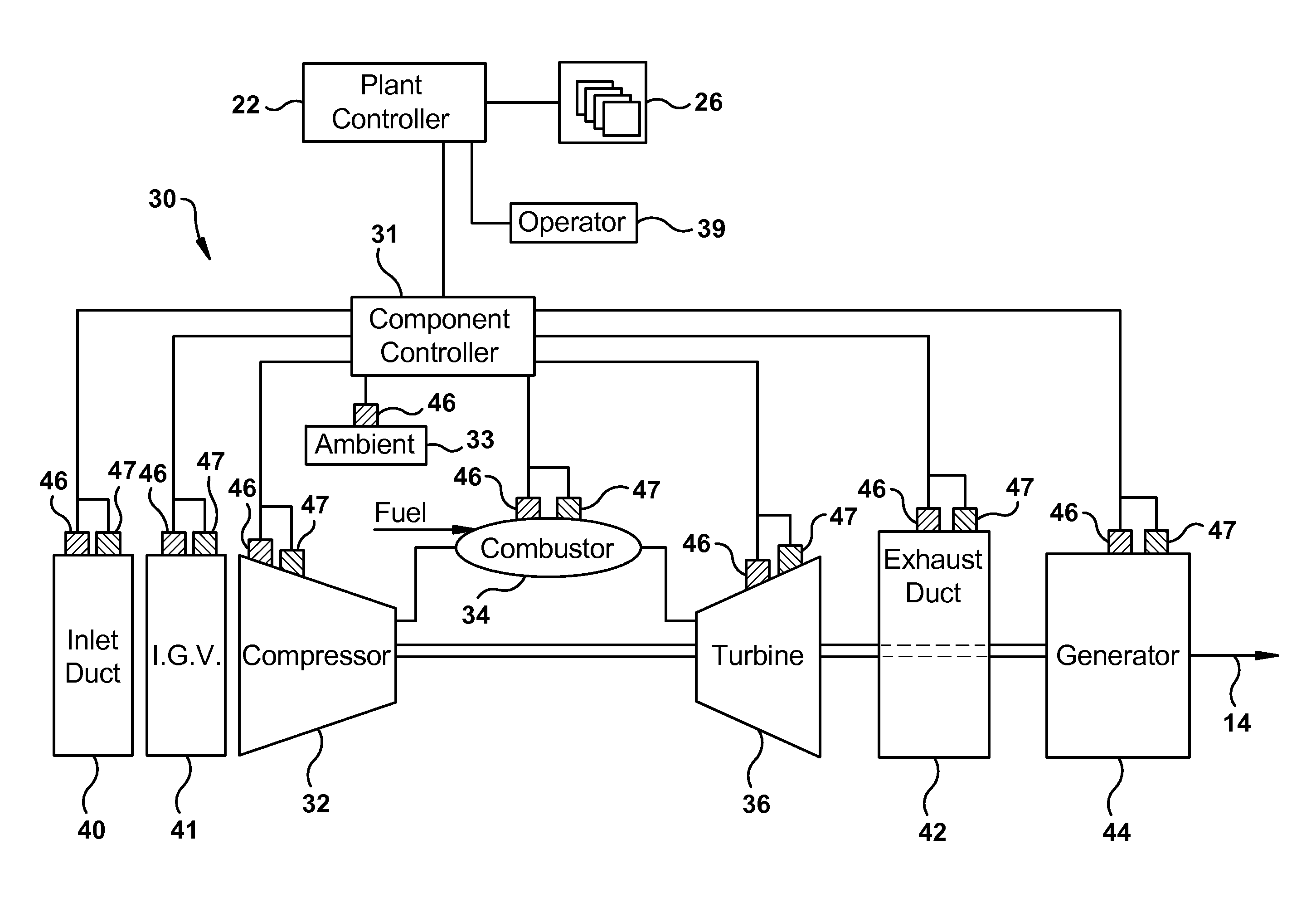

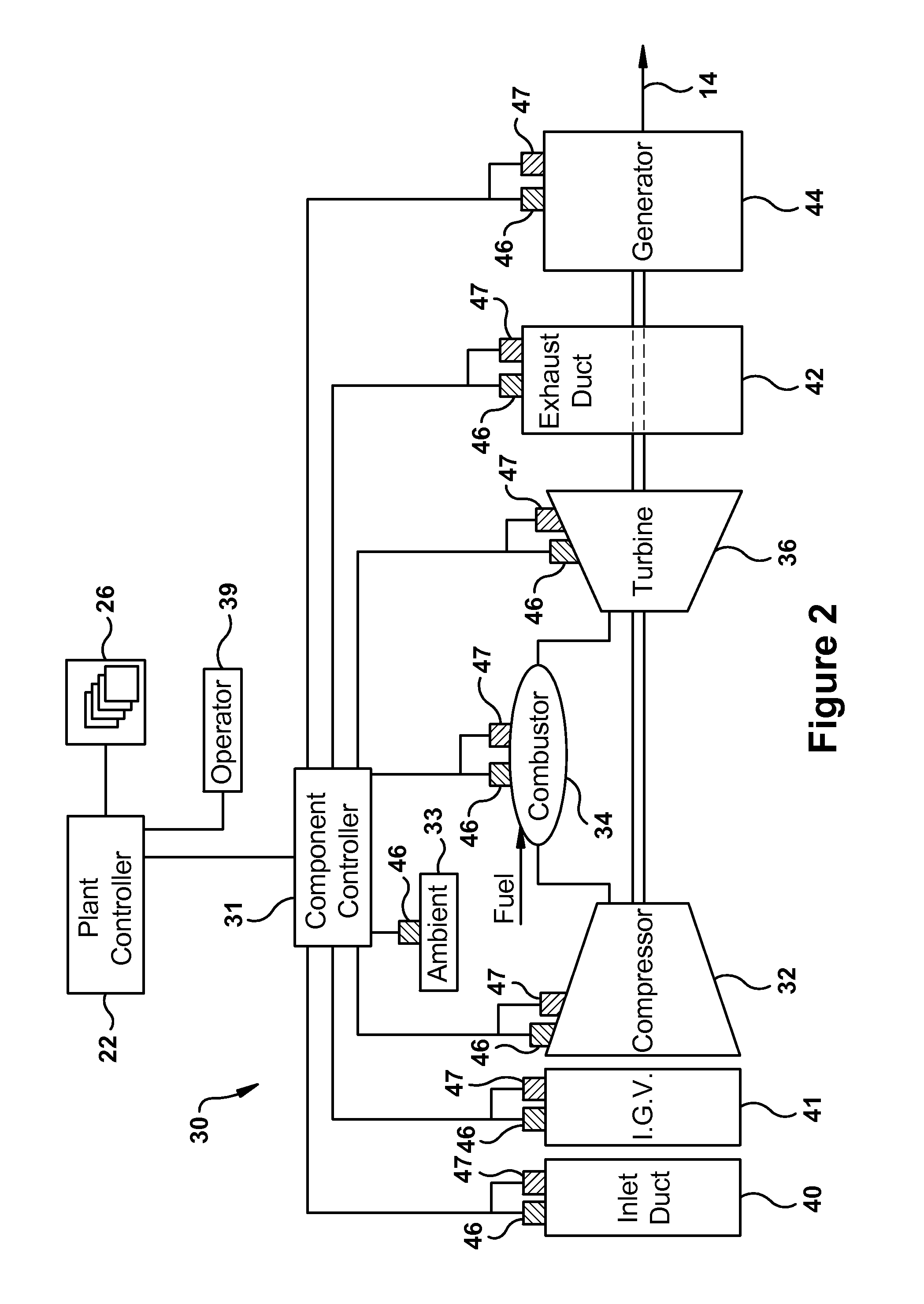

Methods and systems for enhancing control of power plant generating units

A control method for optimizing or enhancing an operation of a power plant that includes thermal generating units for generating electricity. The power plant may include multiple possible operating modes differentiated by characteristics of operating parameters. The method may include tuning a power plant model so to configure a tuned power plant model. The method may further include simulating proposed operating modes of the power plant with the tuned power plant model. The simulating may include a simulation procedure that includes: defining a second operating period; selecting the proposed operating modes from the possible operating modes; with the tuned power plant model, performing a simulation run for each of the proposed operating modes whereby the operation of the power plant during the second operating period is simulated; and obtaining simulation results from each of the simulation runs.

Owner:GENERAL ELECTRIC CO

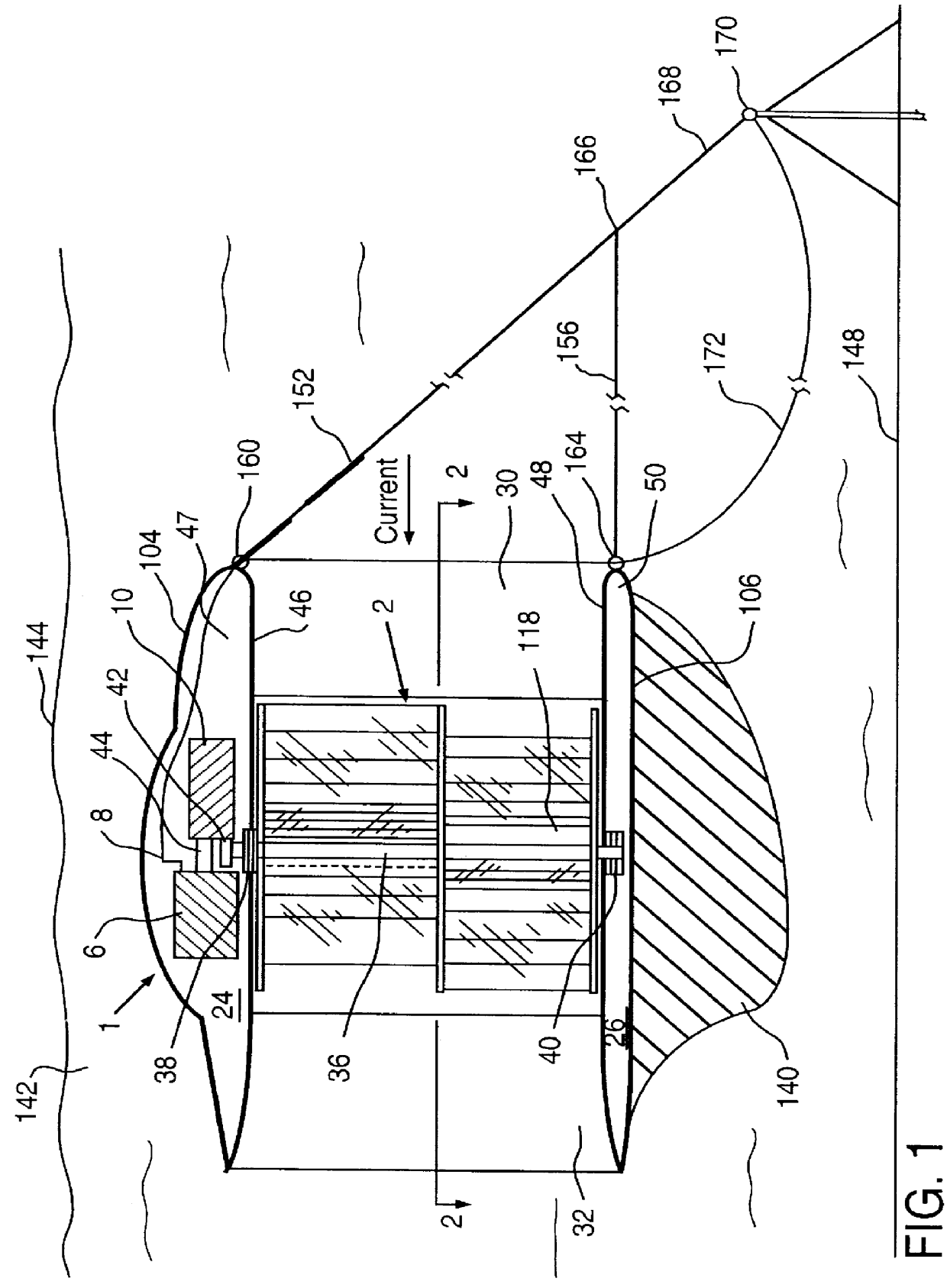

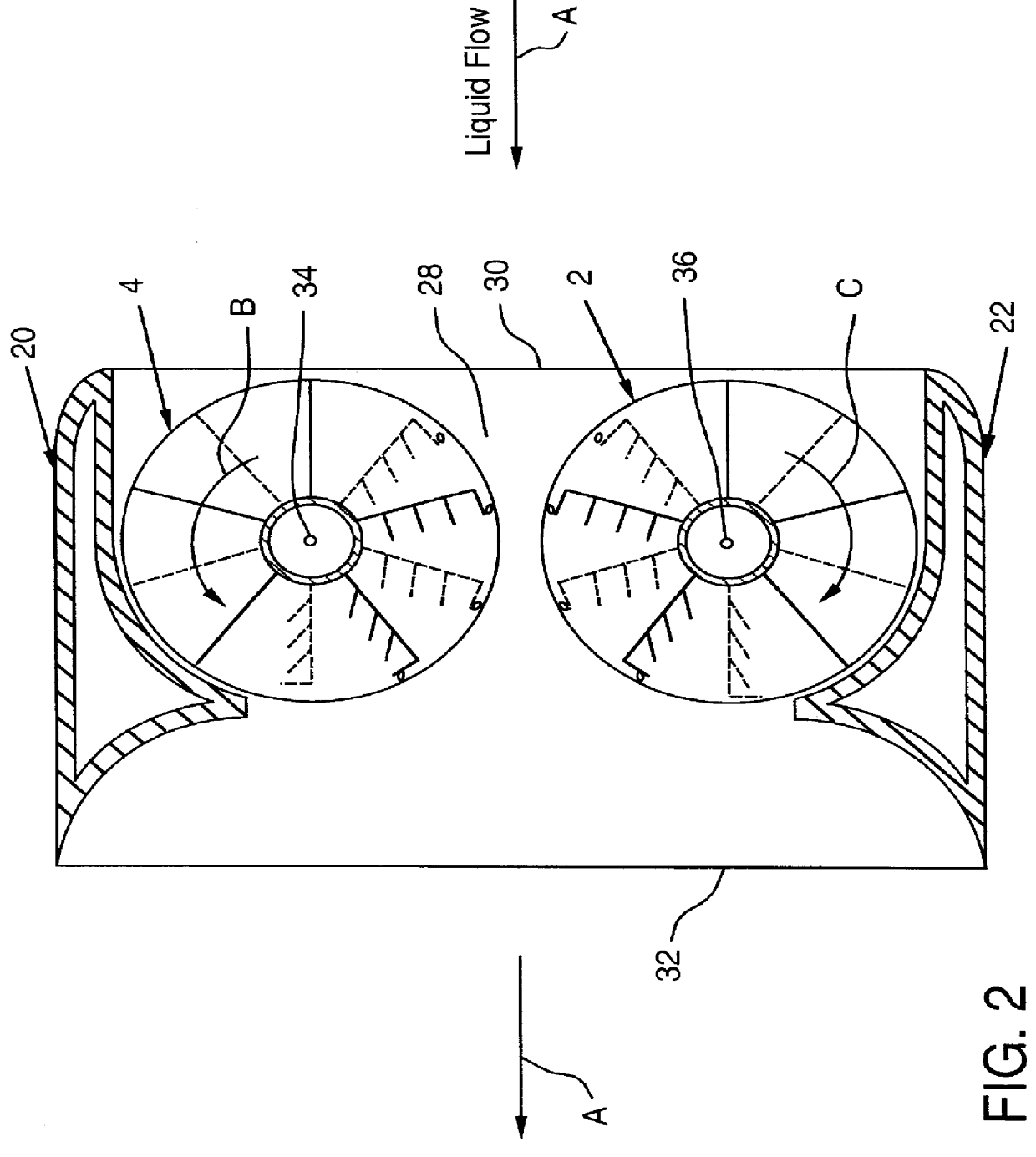

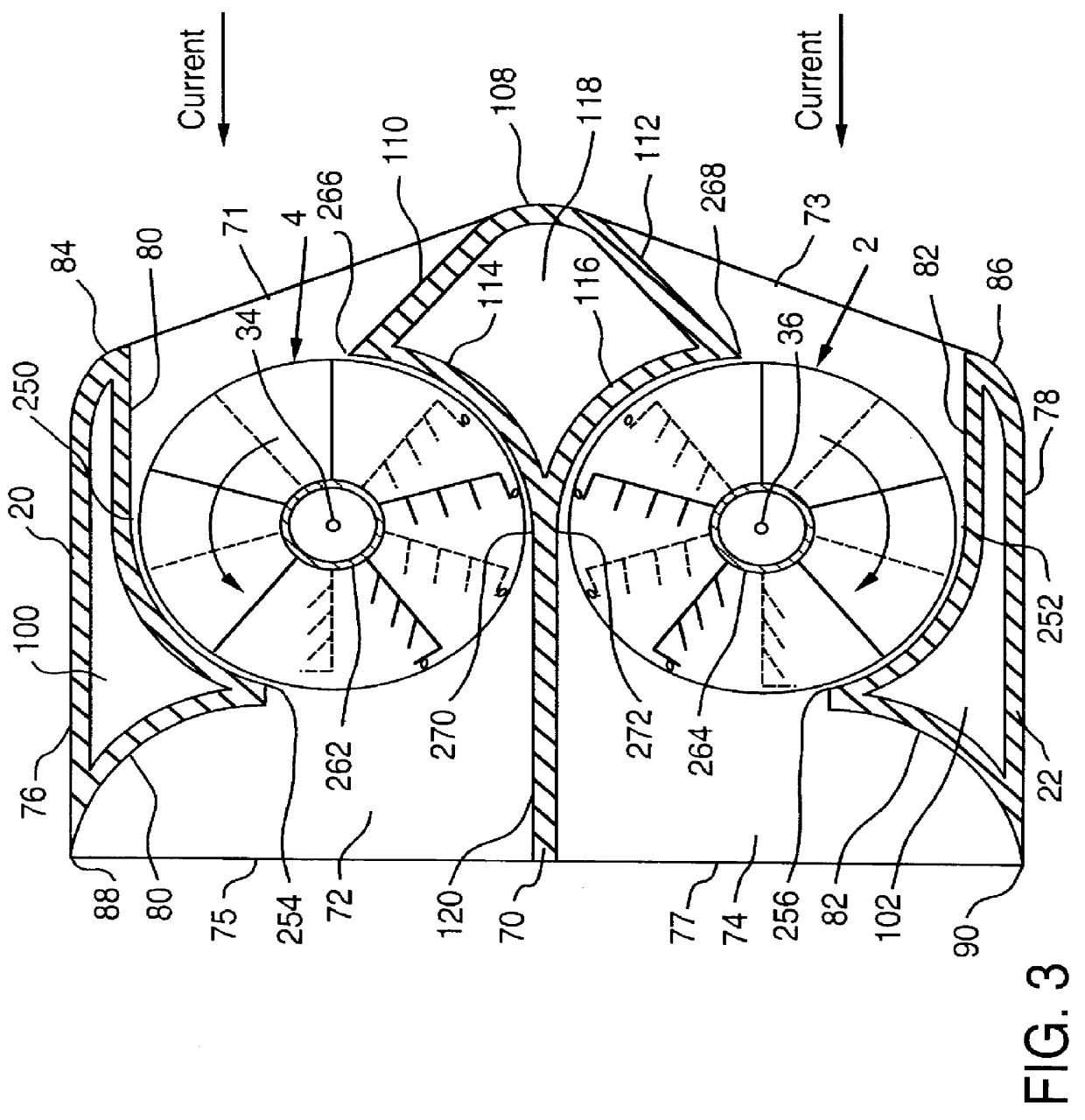

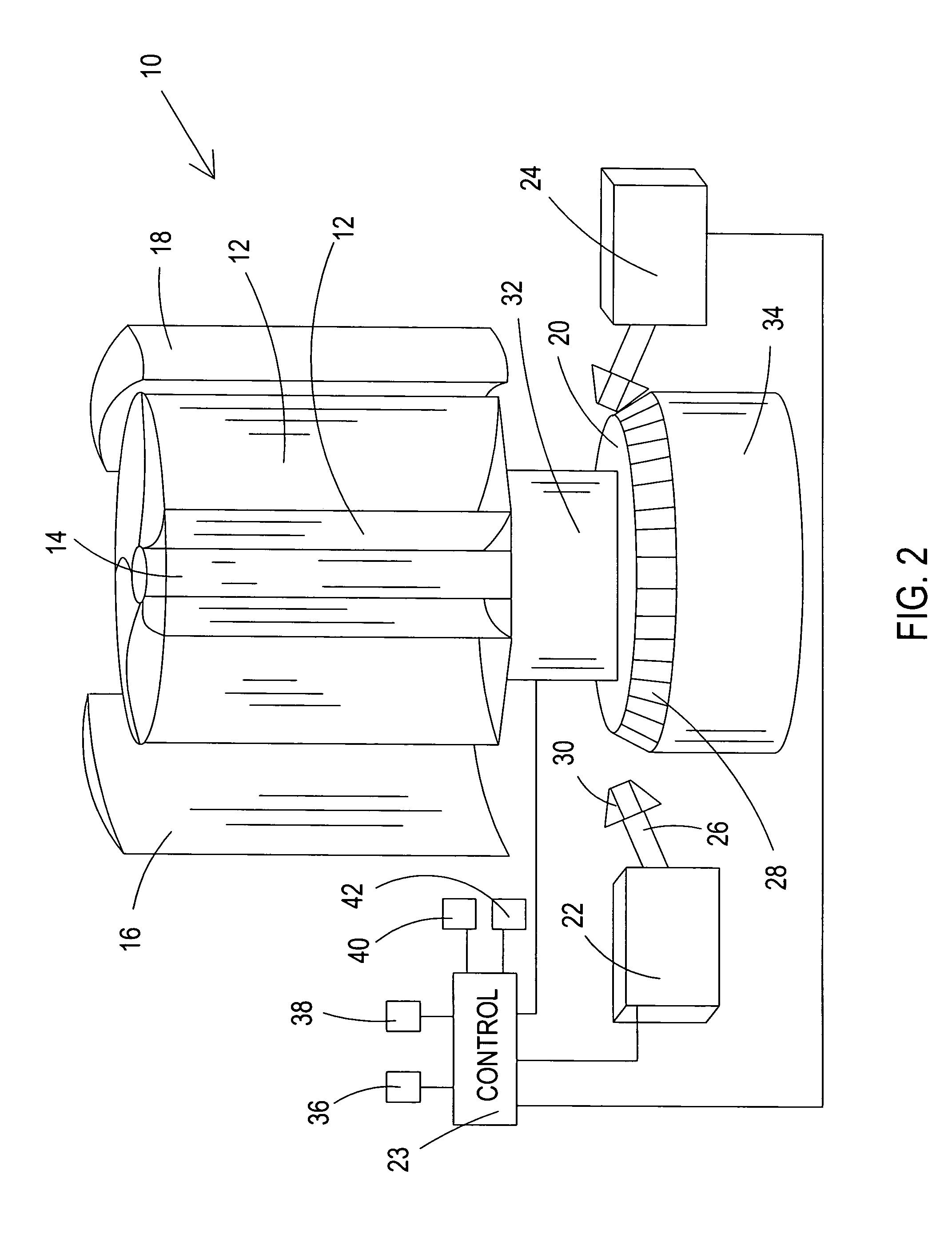

Submersible appartus for generating electricity and associated method

InactiveUS6109863AReduce the impactReduce impactCircumferential flow pumpsWind motor controlElectricityMarine engineering

A fully submersible apparatus for generating electricity from liquid flow as in an ocean or river current. A buoyant structure is fully submersible and has at least one pair of counter-rotating side-by-side motors with a plurality of angularly spaced radial vanes each having a plurality of rotatable subvanes such that current impinging upon the motor will impinge on a closed or solid vane to effect rotation of the motor and its shaft during a first phase of the rotational cycle and will impinge on open vanes for free passage therethrough on the return or second phase of rotation of the motor. Motors may also be provided with vanes in overlying and underlying relationship. An associated method is provided.

Owner:MILLIKEN LARRY D

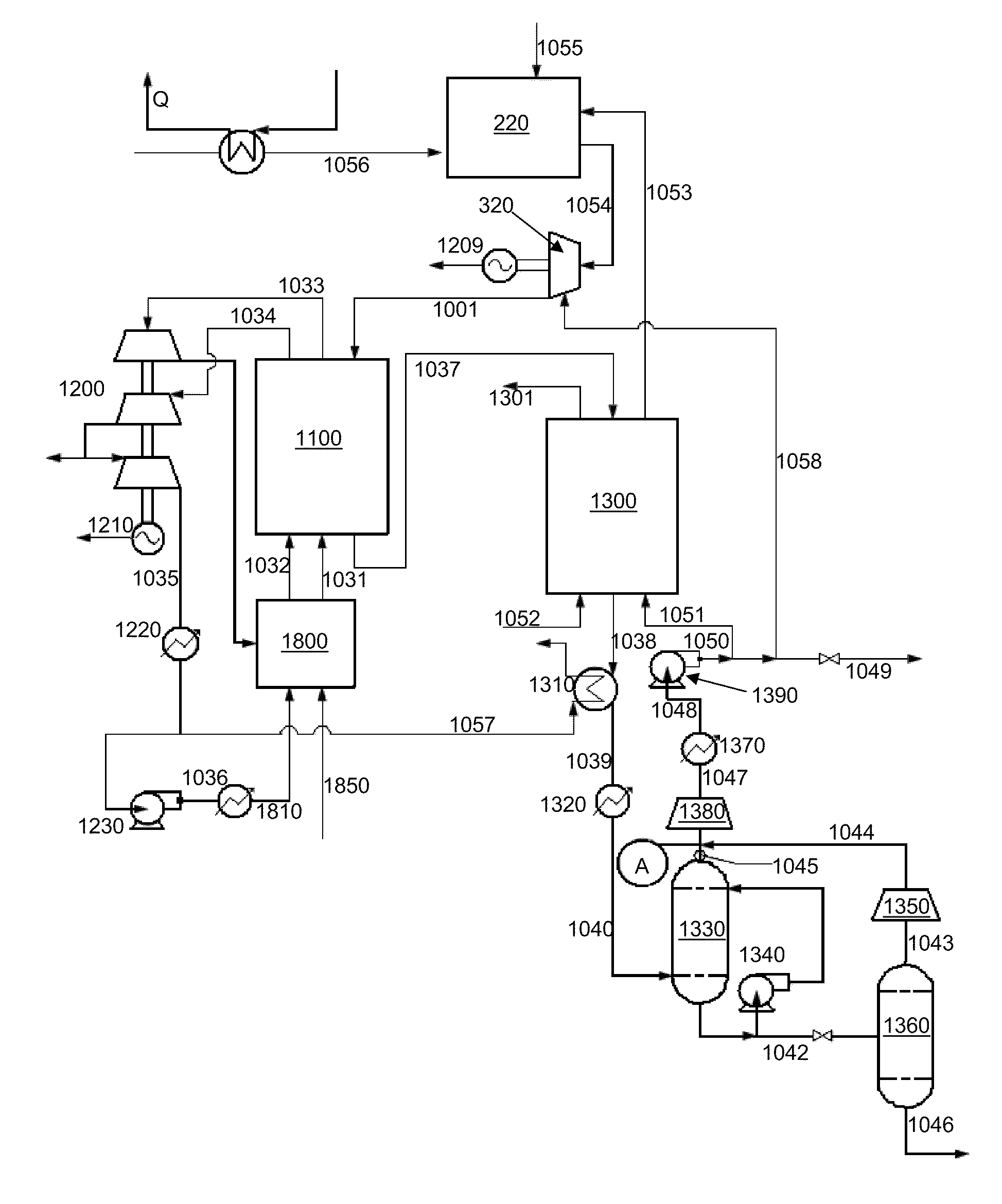

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

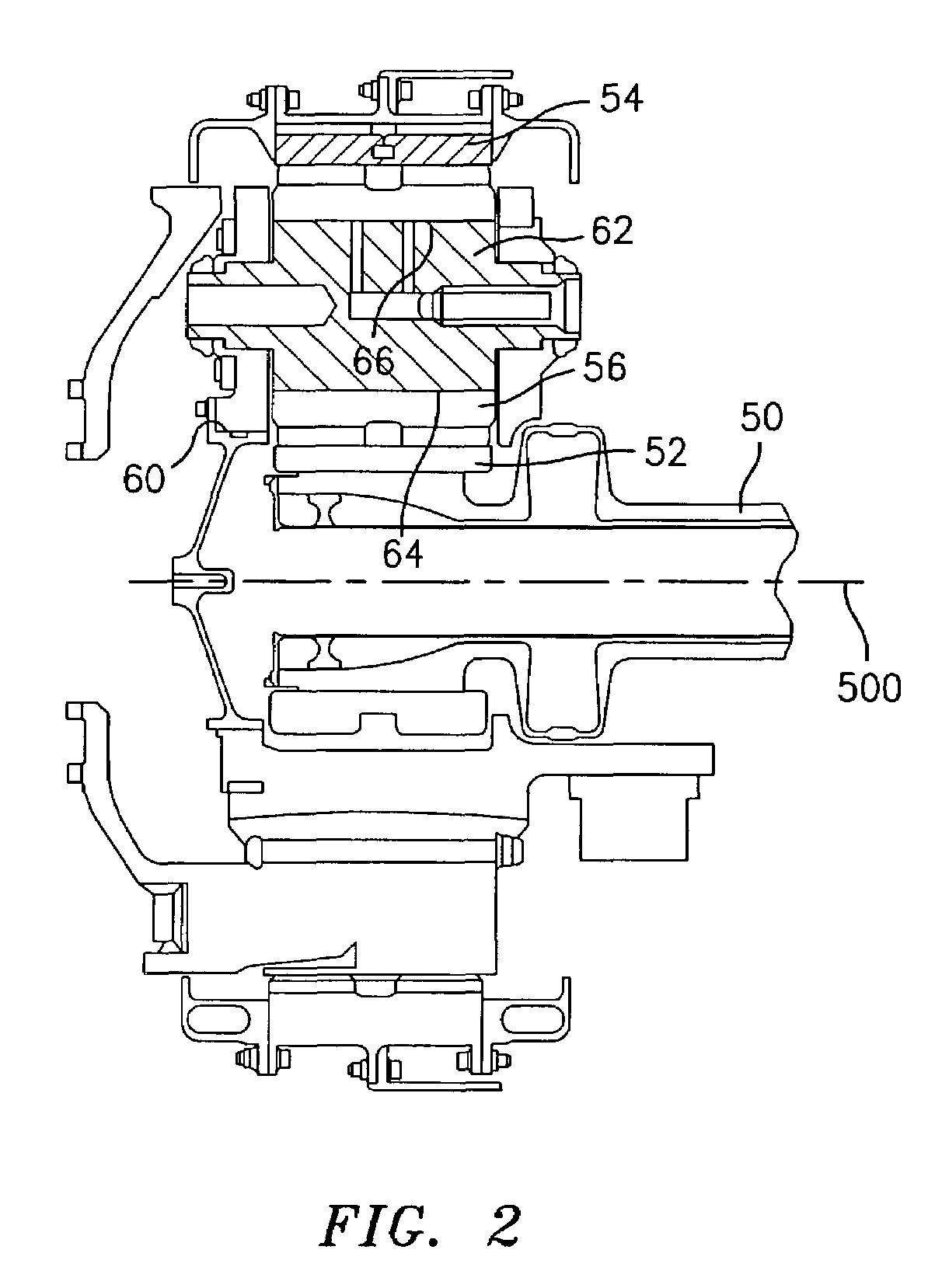

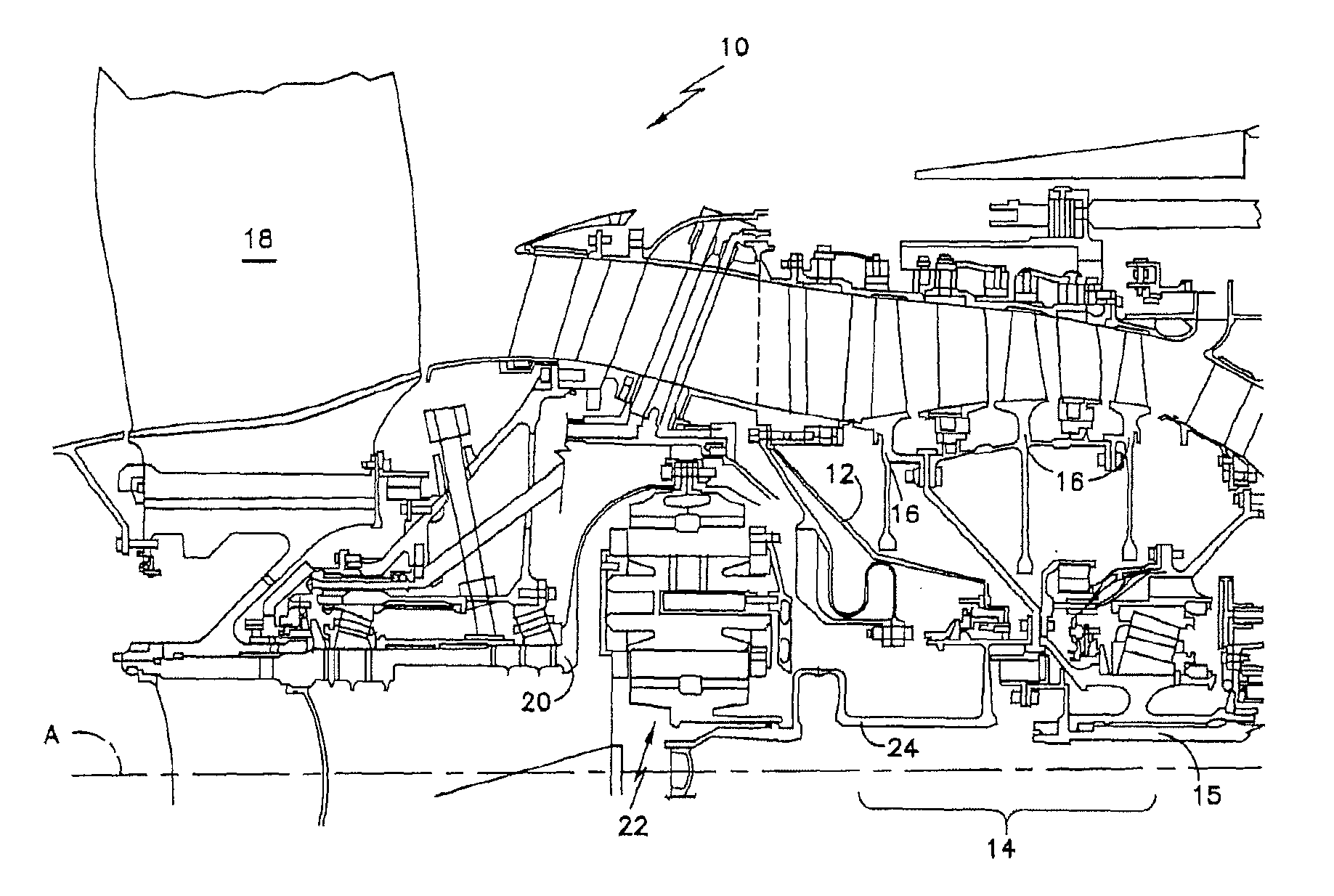

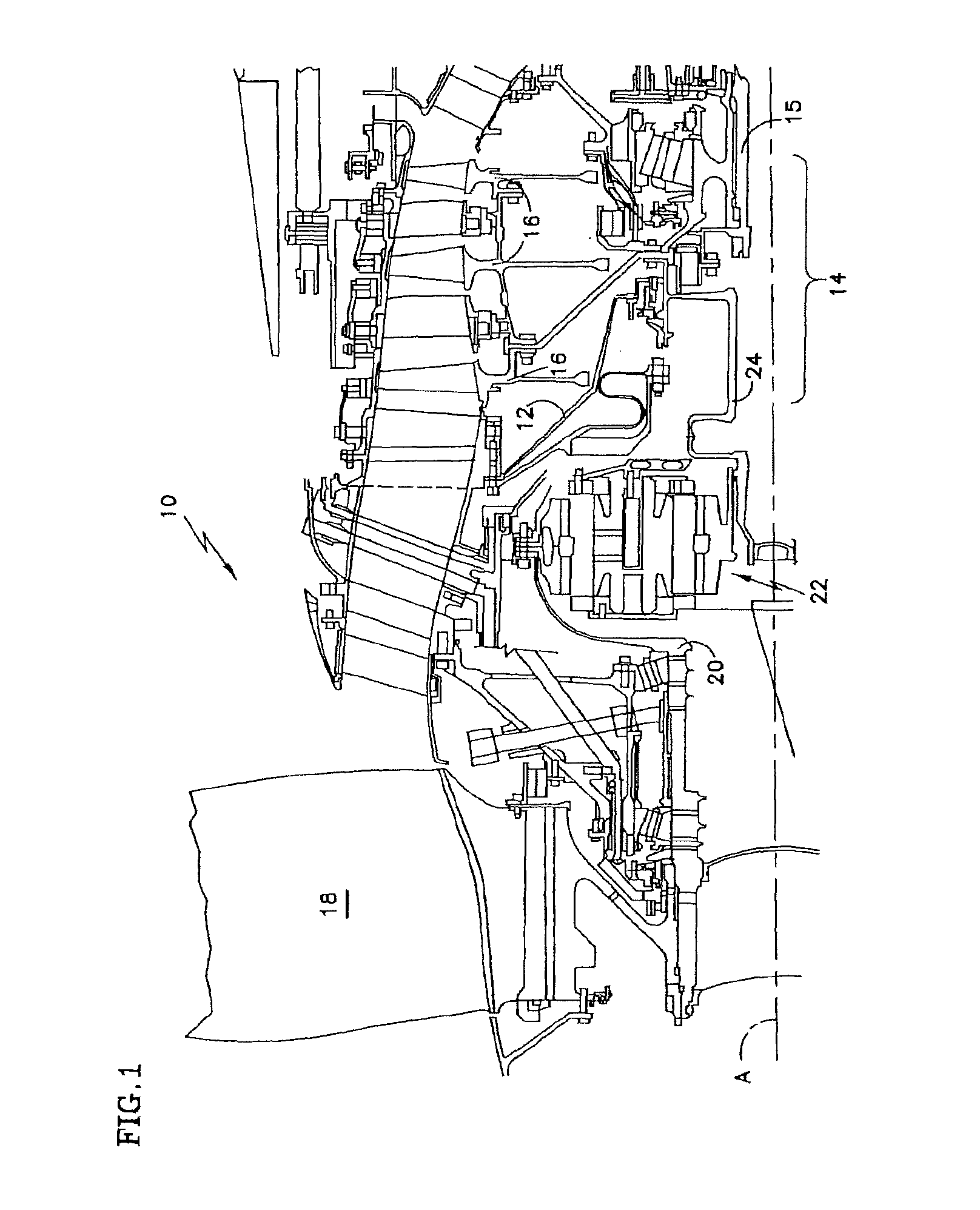

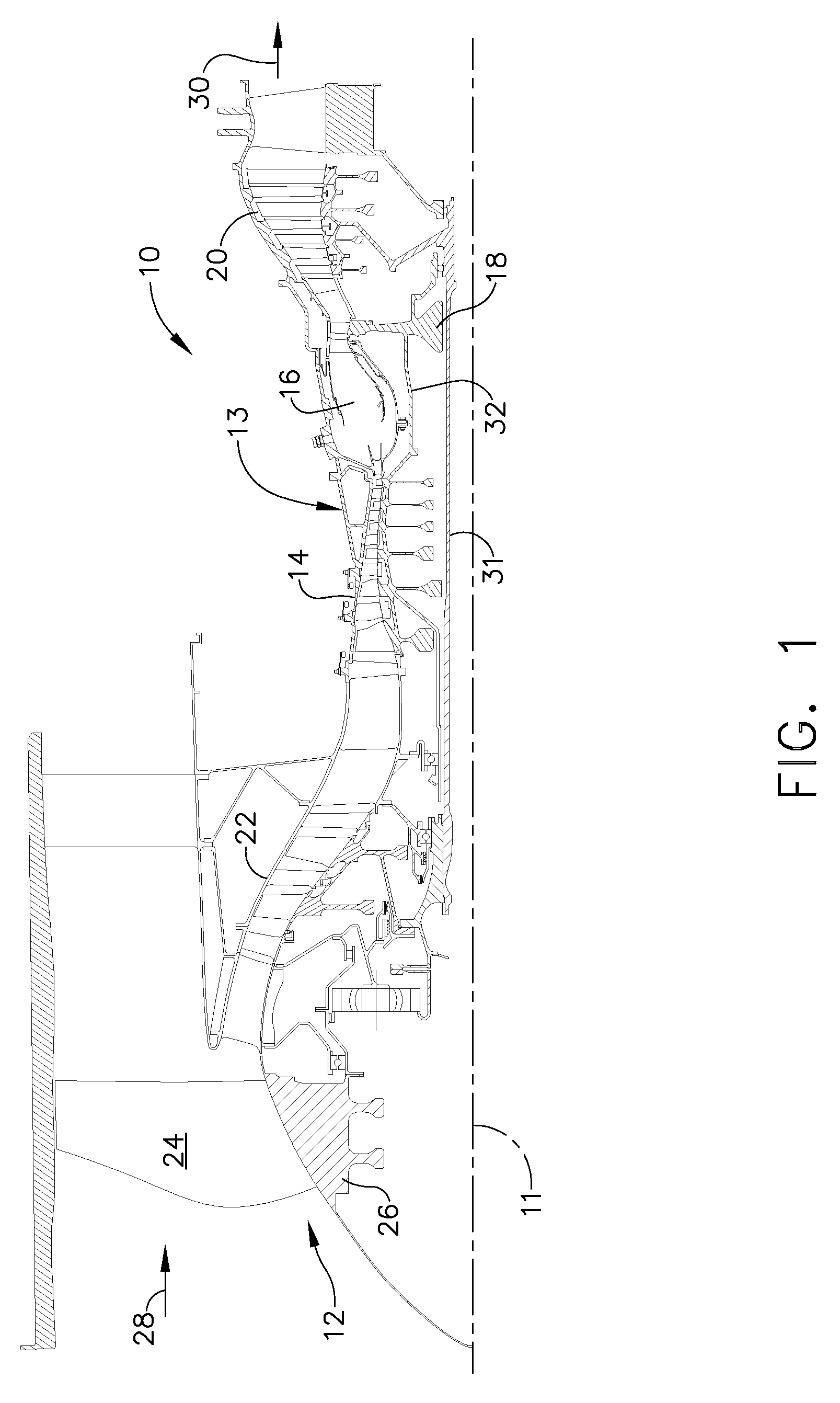

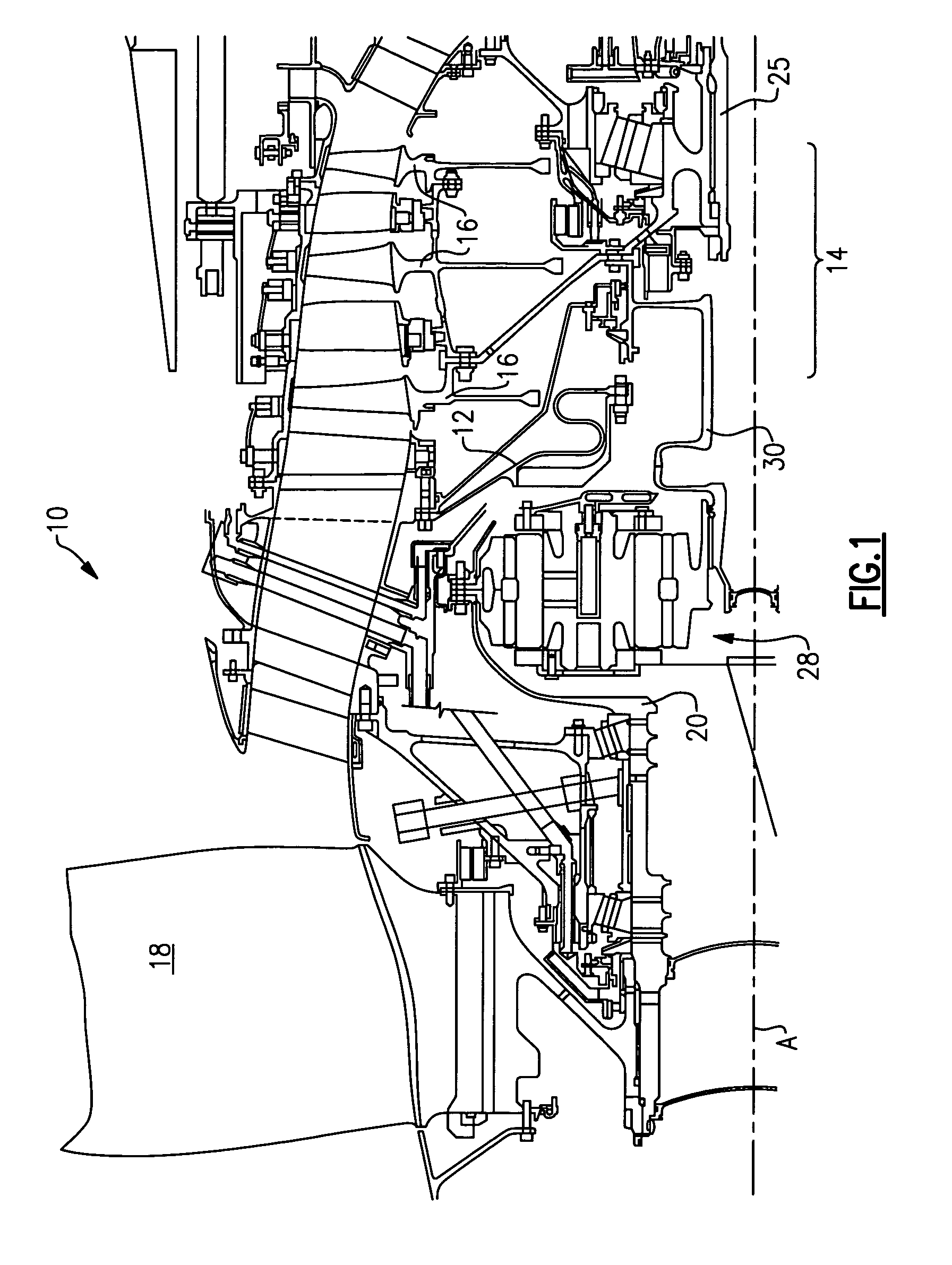

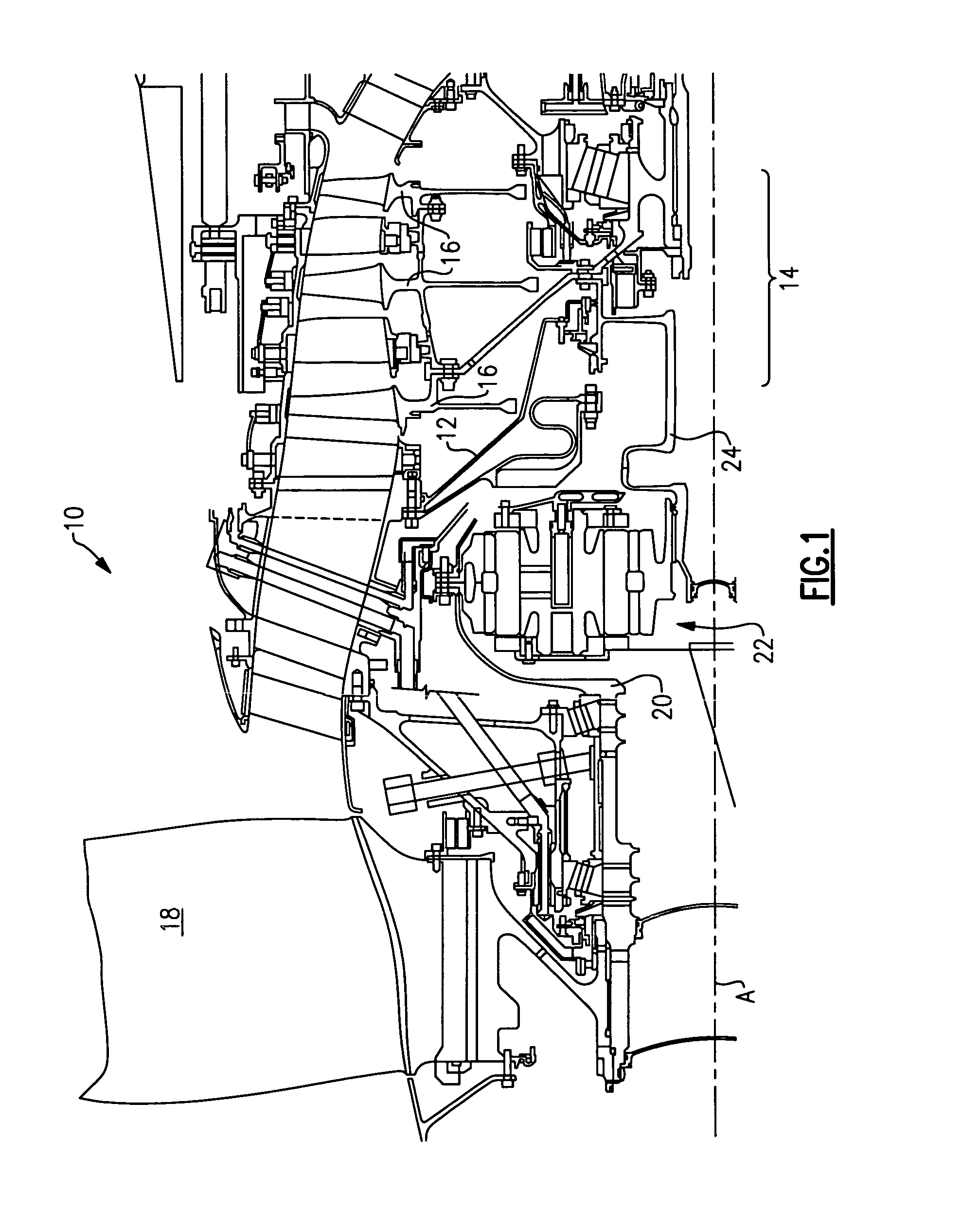

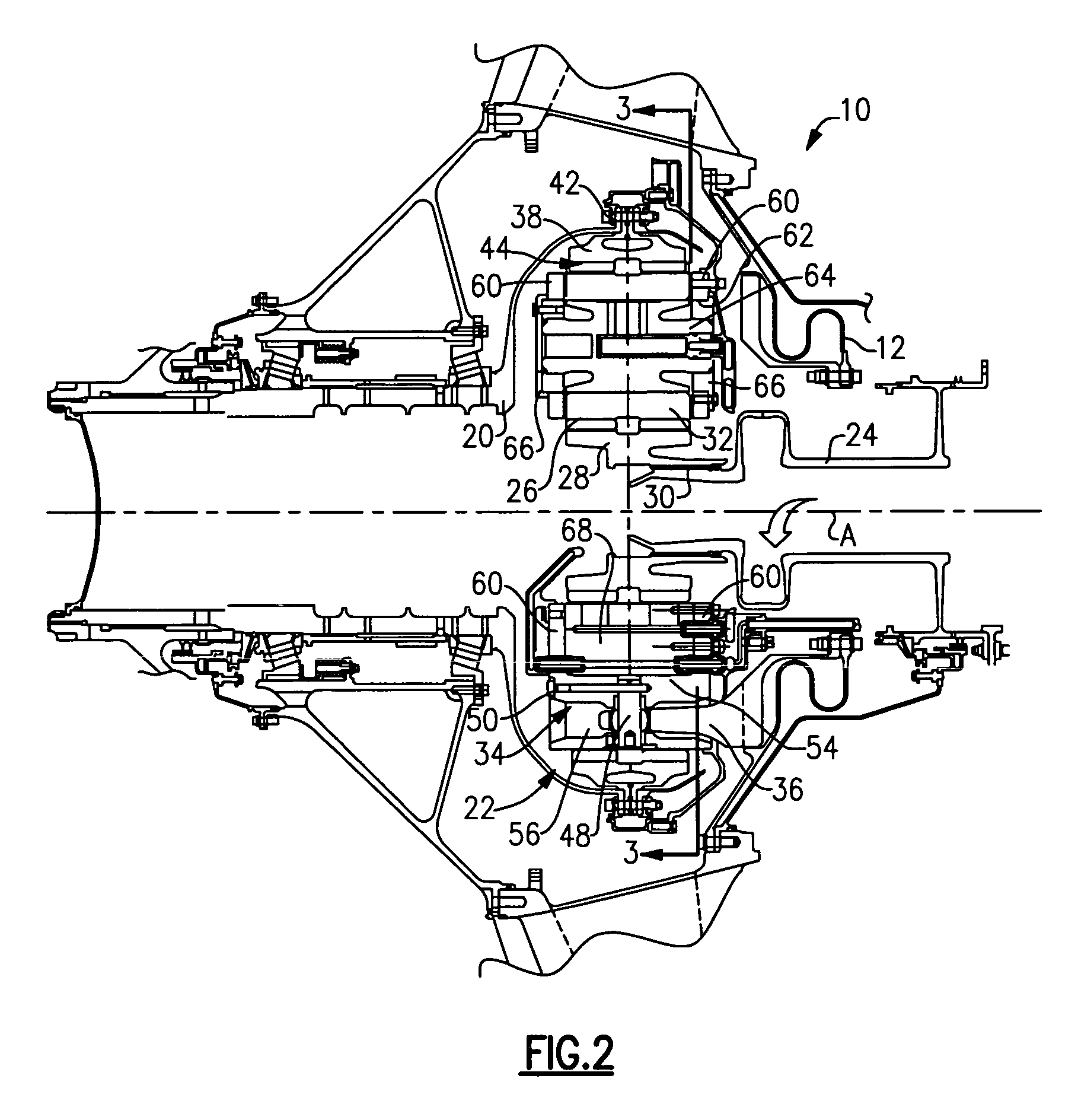

Gas turbine engine assembly and method of assembling same

A method of assembling a gas turbine assembly includes providing a core gas turbine engine including a high-pressure compressor, a combustor, and a turbine, coupling a low-pressure turbine axially aft from the core gas turbine engine, coupling a fan assembly axially forward from the core gas turbine engine, and coupling a booster compressor to the low-pressure turbine such that the booster compressor and the low-pressure turbine rotate at a first rotational speed.

Owner:GENERAL ELECTRIC CO

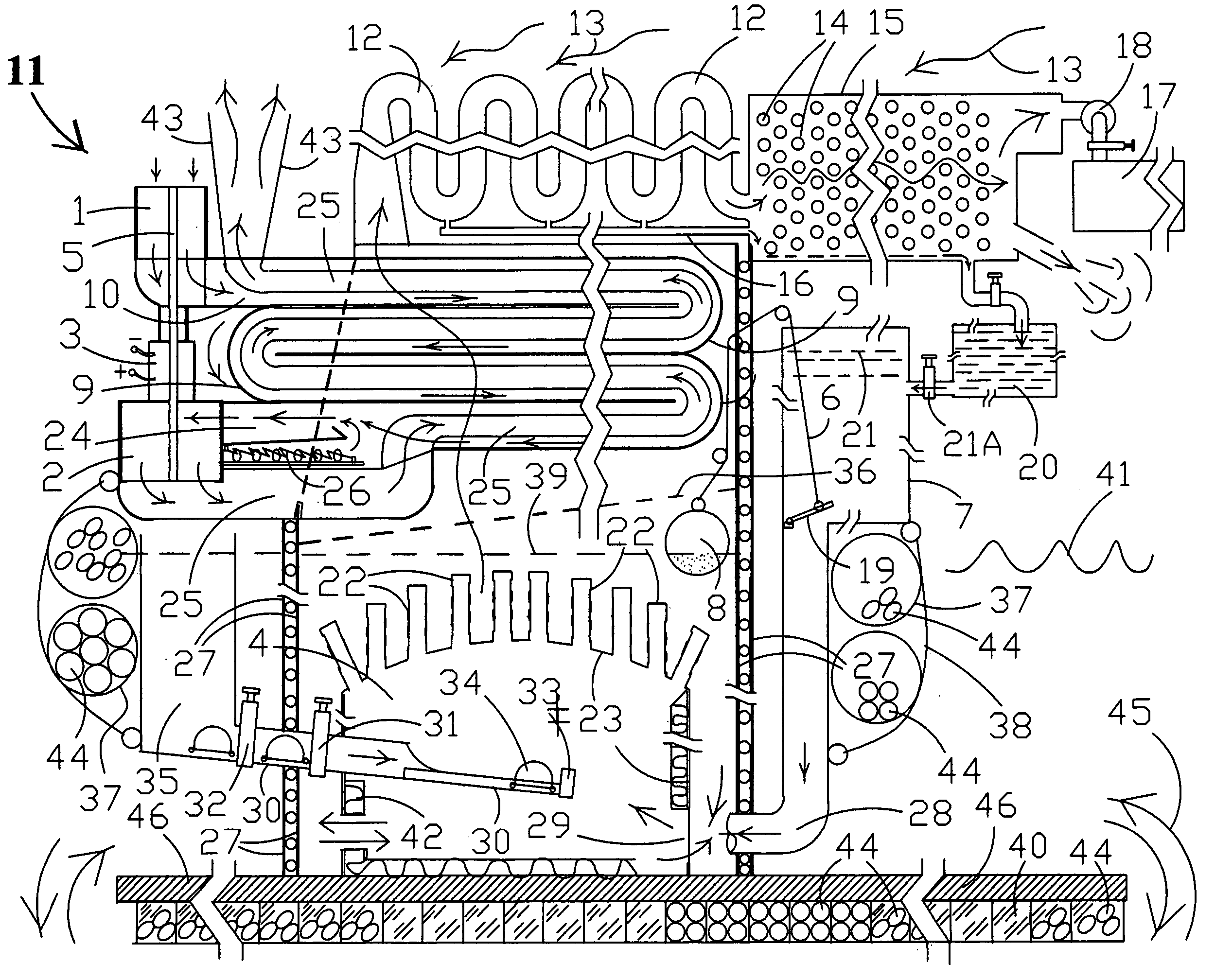

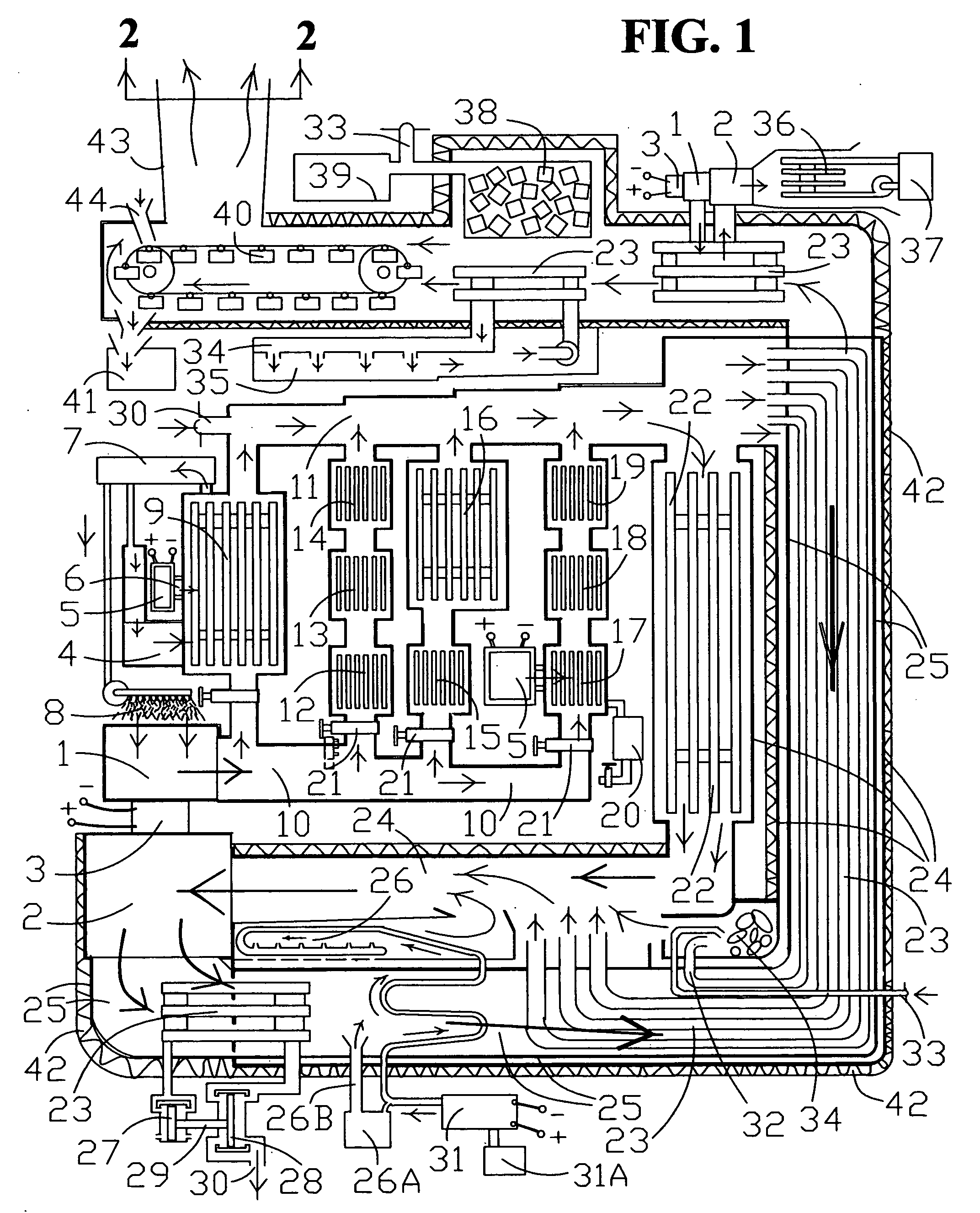

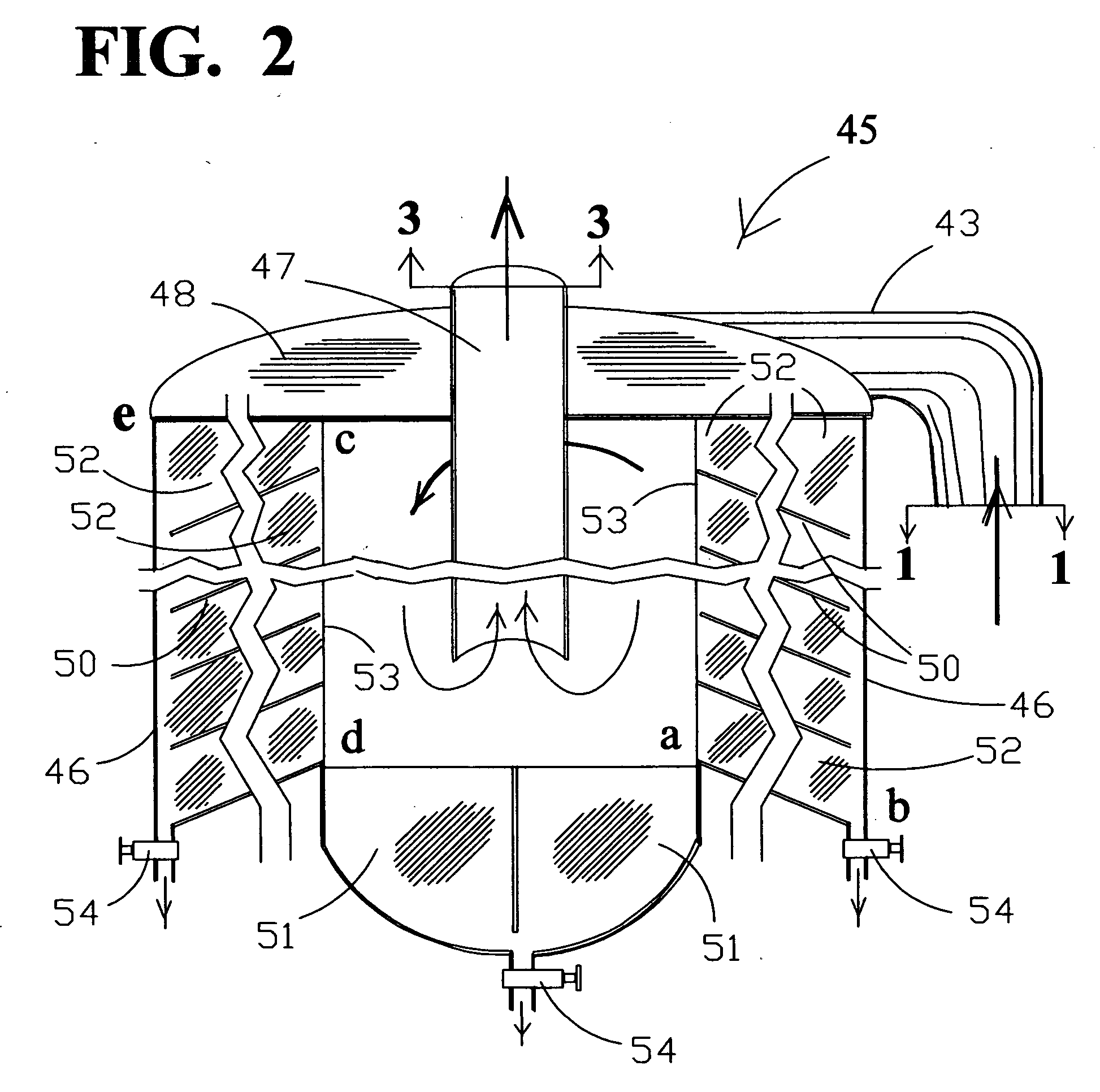

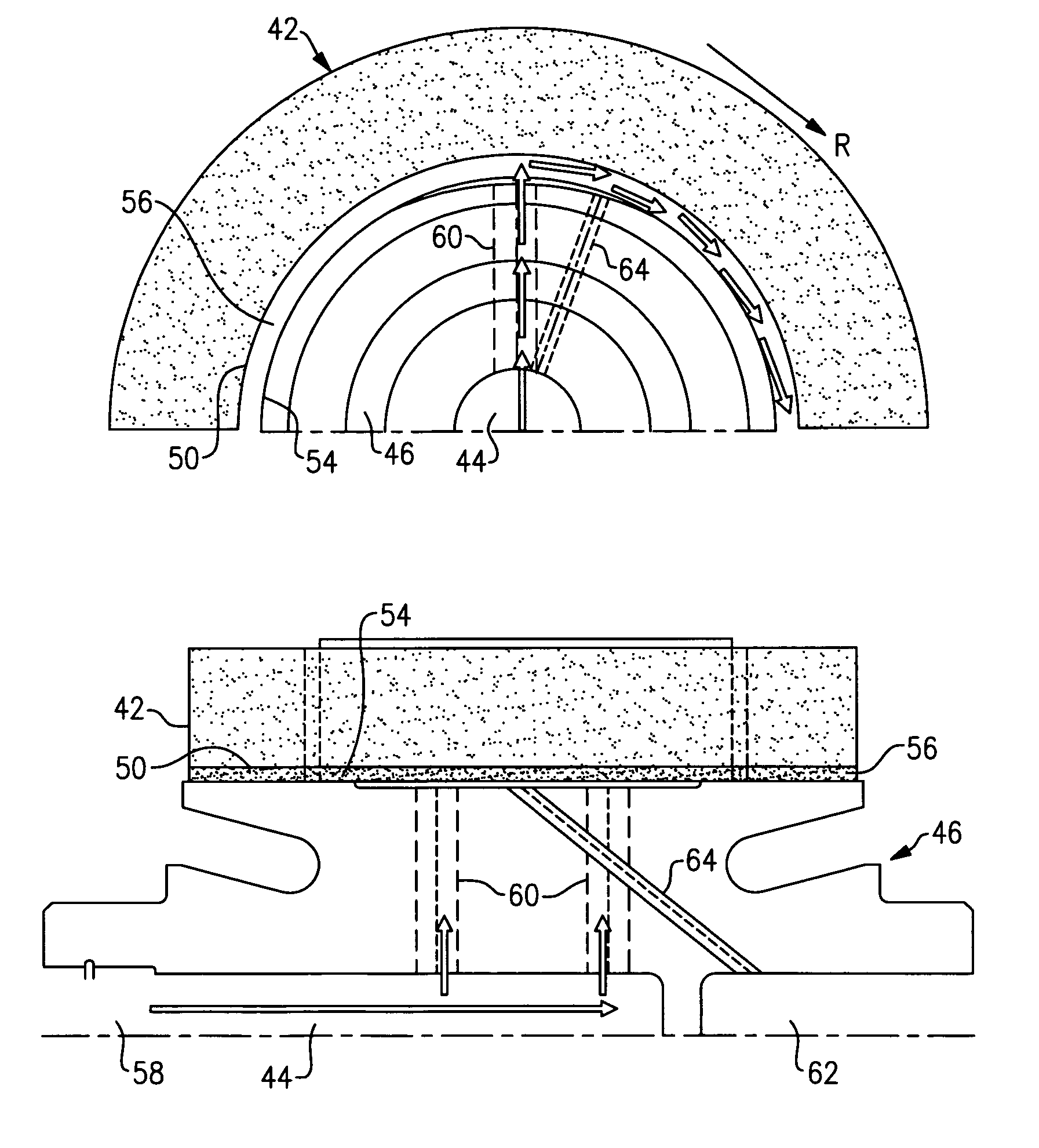

Heat energy recapture and recycle and its new applications

InactiveUS20050120715A1Increase the atmosphereGood sunshineEngine fuctionsEfficient propulsion technologiesThermal energyDistillation

What has been created is a plurality and a variety of processes and a variety of devices correspondingly supportive to each process, wherein, a new partnership between; (1) a heat absorbing radiator compressed air pipes / tubes and (2) a gas turbine engine or a reciprocating piston engine,—is used to recapture and reconvert the, otherwise wasted, heat energies expelled by engines, by factories, by smelting plants, by distillation plants, by chillers / coolers / freezers, by cooking ovens, by lamps / stoves, by trash burners, and the heat energies created by the solar heat on the desert / ocean water,—into electric power and finally into hydrogen-deuterium fuel,—by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow, to further drive and re-drive the same engine; wherein, in order to capture fusion heat energy the hydrogen bomb is detonated in the deep ocean to catch the flames by the water and the hot water is used to energize the compressed air inside the heat absorbing radiator pipes; wherein, in order to produce fusion energy, an abundant electric arc is passed across liquid deuterium or across gaseous deuterium by the electro-plasma torch and sparkplug in the internal combustion engine, and by detonating a dynamite inside a liquid deuterium; wherein diamond is produced by placing carbon inside the hydrogen bomb; and wherein, deuterium fusion flame is used first in smelting glass to large sizes before running an engine.

Owner:CHRISTIAN SCHOOL OF TECH CHARITABLE FOUND TRUST

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

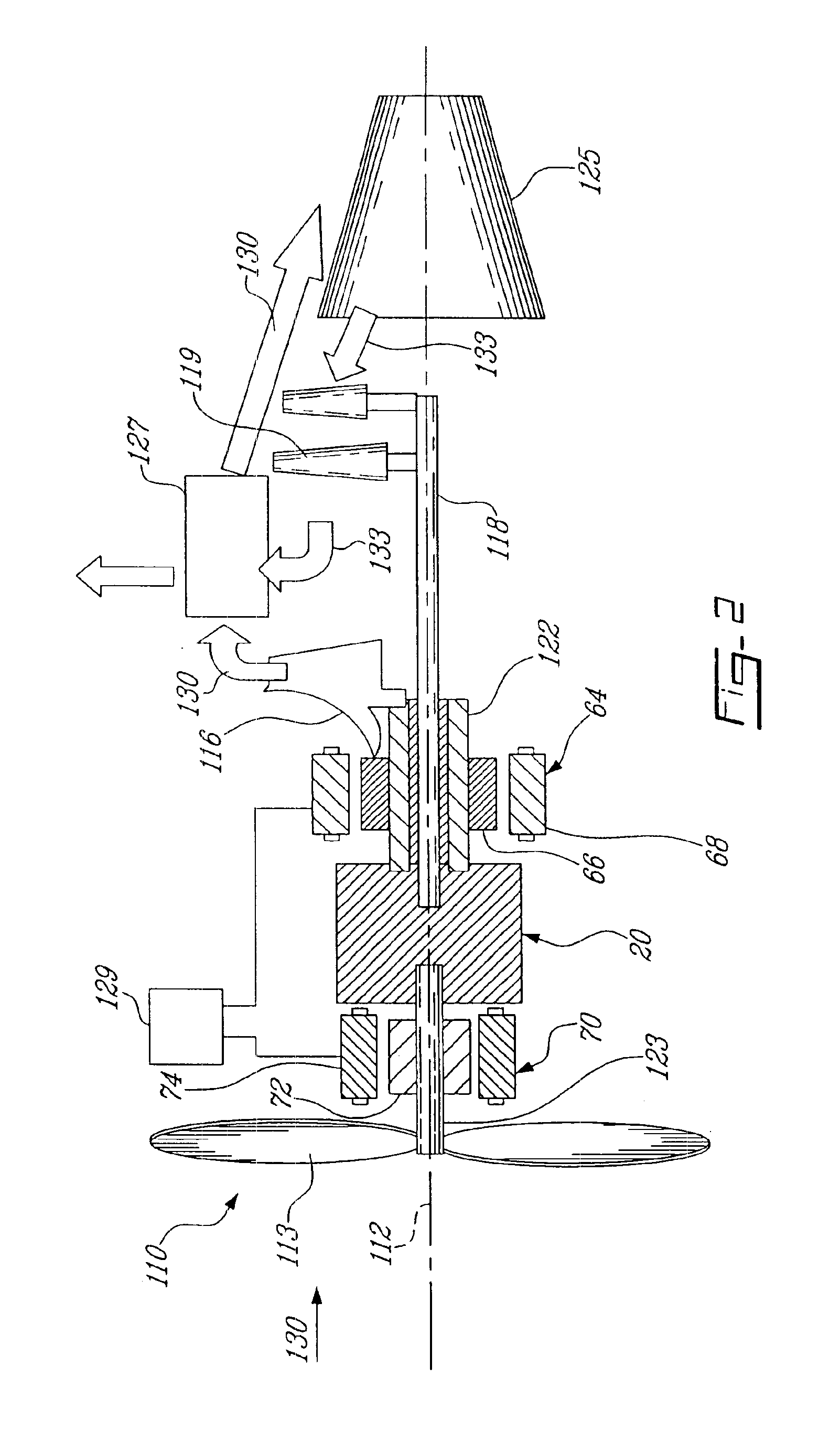

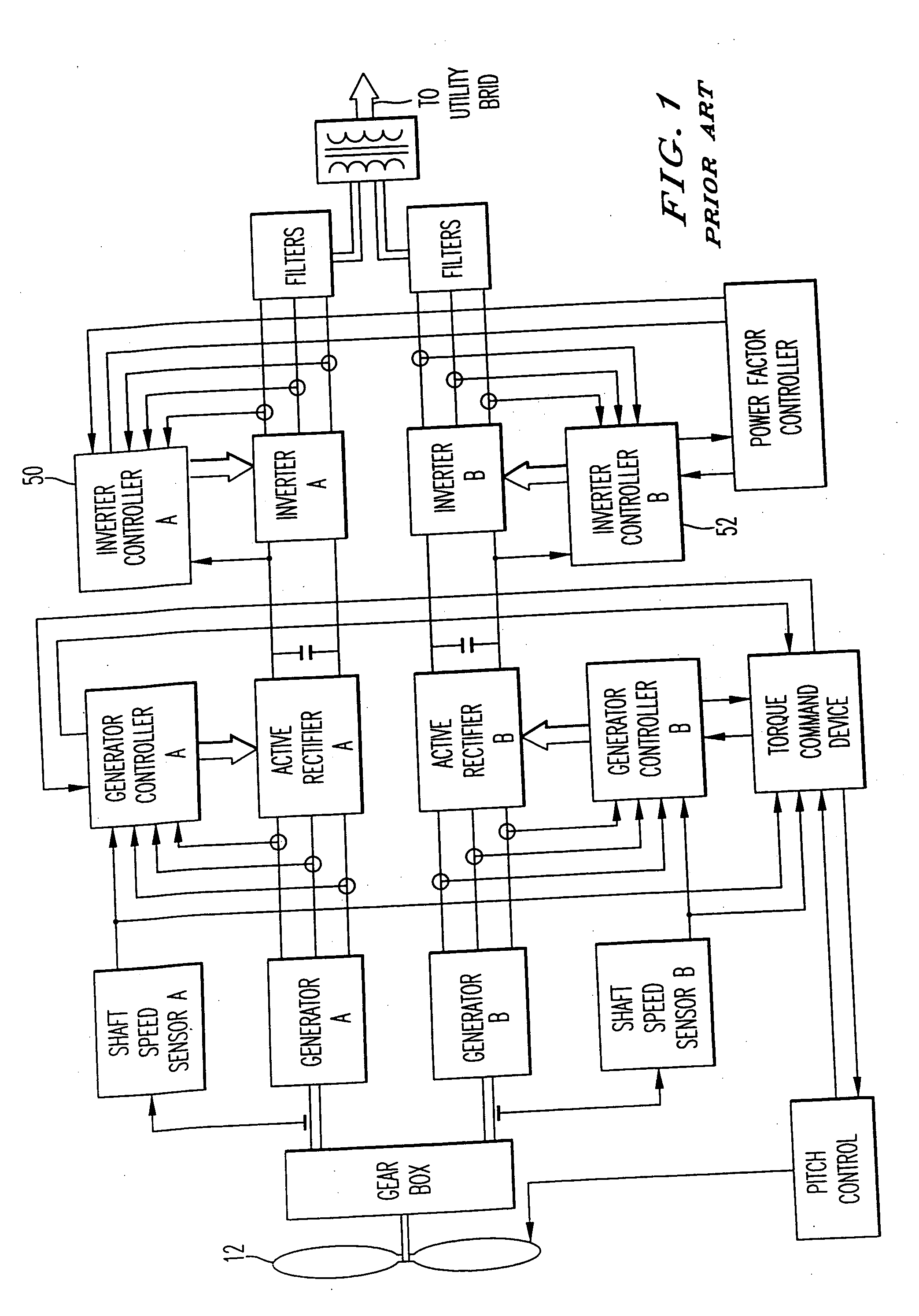

Differential geared turbine engine with torque modulation capability

InactiveUS6895741B2Improve efficiencyMinimal numberEngine fuctionsEfficient propulsion technologiesTorque regulationTurbine

A method and apparatus for controllable distribution of power from a turbine of a gas turbine engine between two rotatable loads of the gas turbine engine, comprises transferring a shaft power of the turbine to the respective rotatable loads using differential gearing operatively coupled with the turbine and the rotatable loads, respectively; and controlling the power transfer using machines operatively coupled with the respective rotatable loads, operable as a generator or a motor for selectively taking power from one of the rotatable loads to drive the other of the rotatable loads, or the reverse.

Owner:PRATT & WHITNEY CANADA CORP

System and method for monitoring wind turbine gearbox health and performance

A system and method are provided to monitor the health and performance of a wind turbine gearbox. A plurality of sensors coupled to the wind turbine gearbox provide input to a controller. The controller generates output information that includes performance and health information of the wind turbine gearbox based on the input received from each of the sensors.

Owner:GENERAL ELECTRIC CO

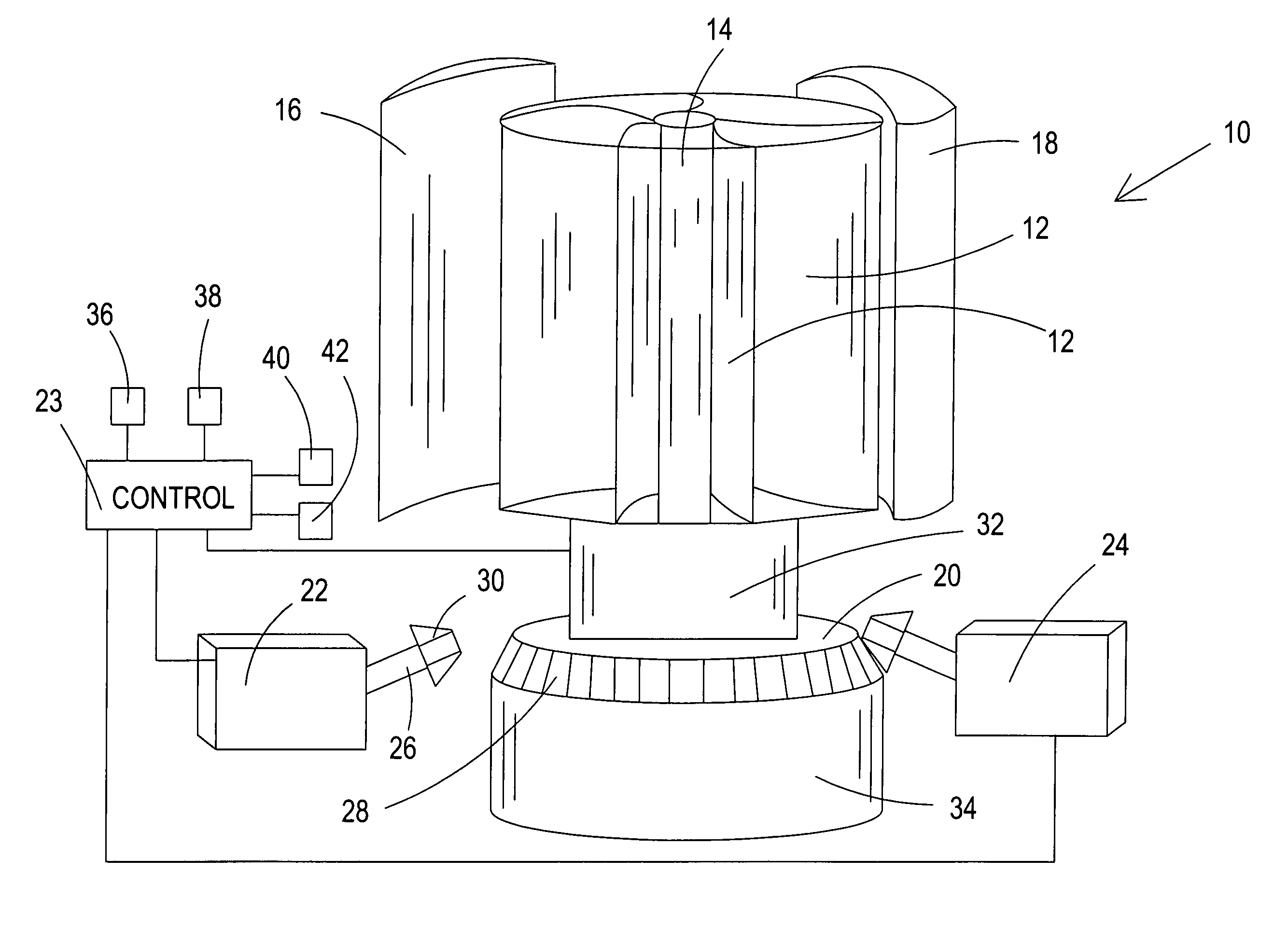

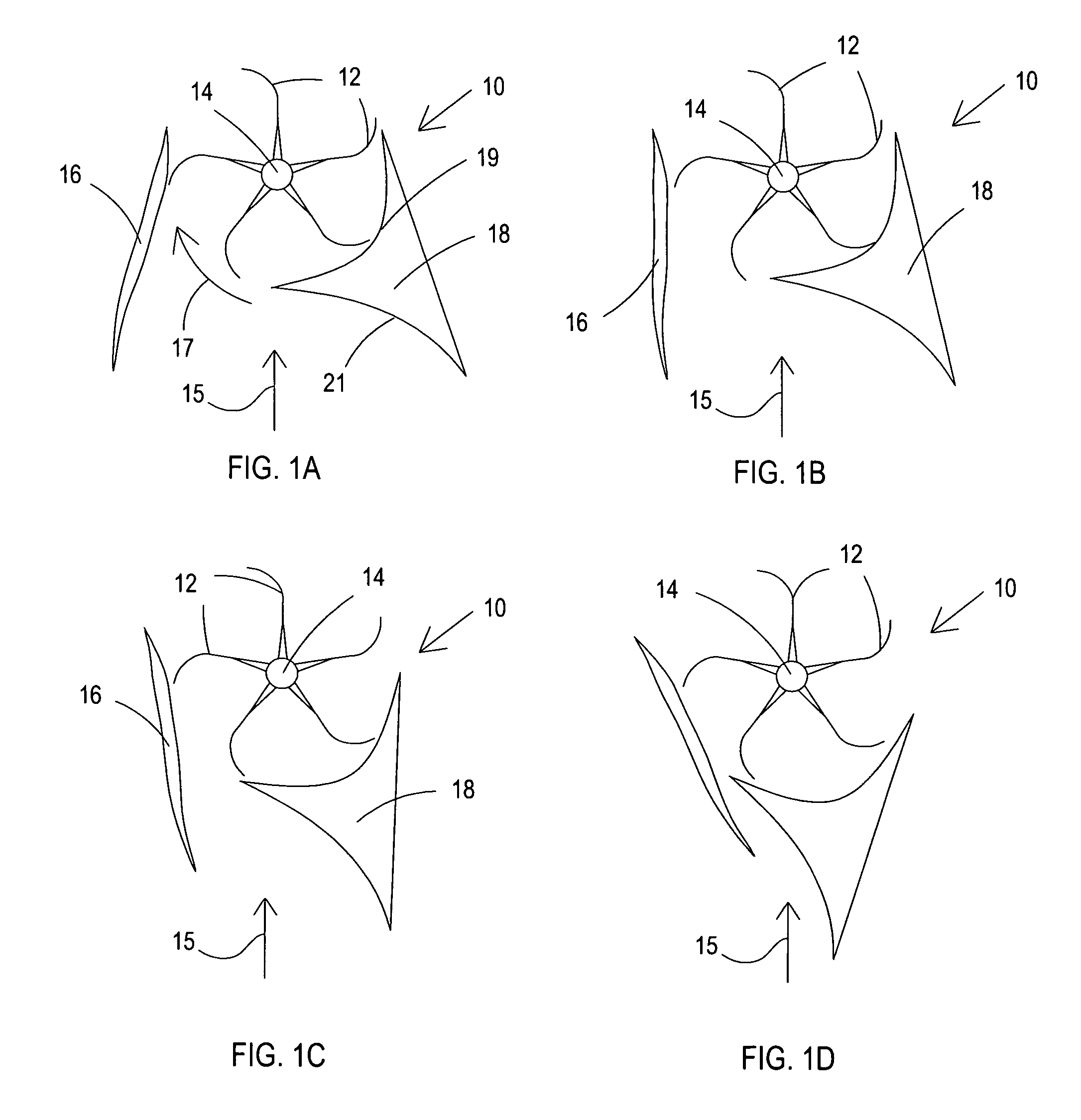

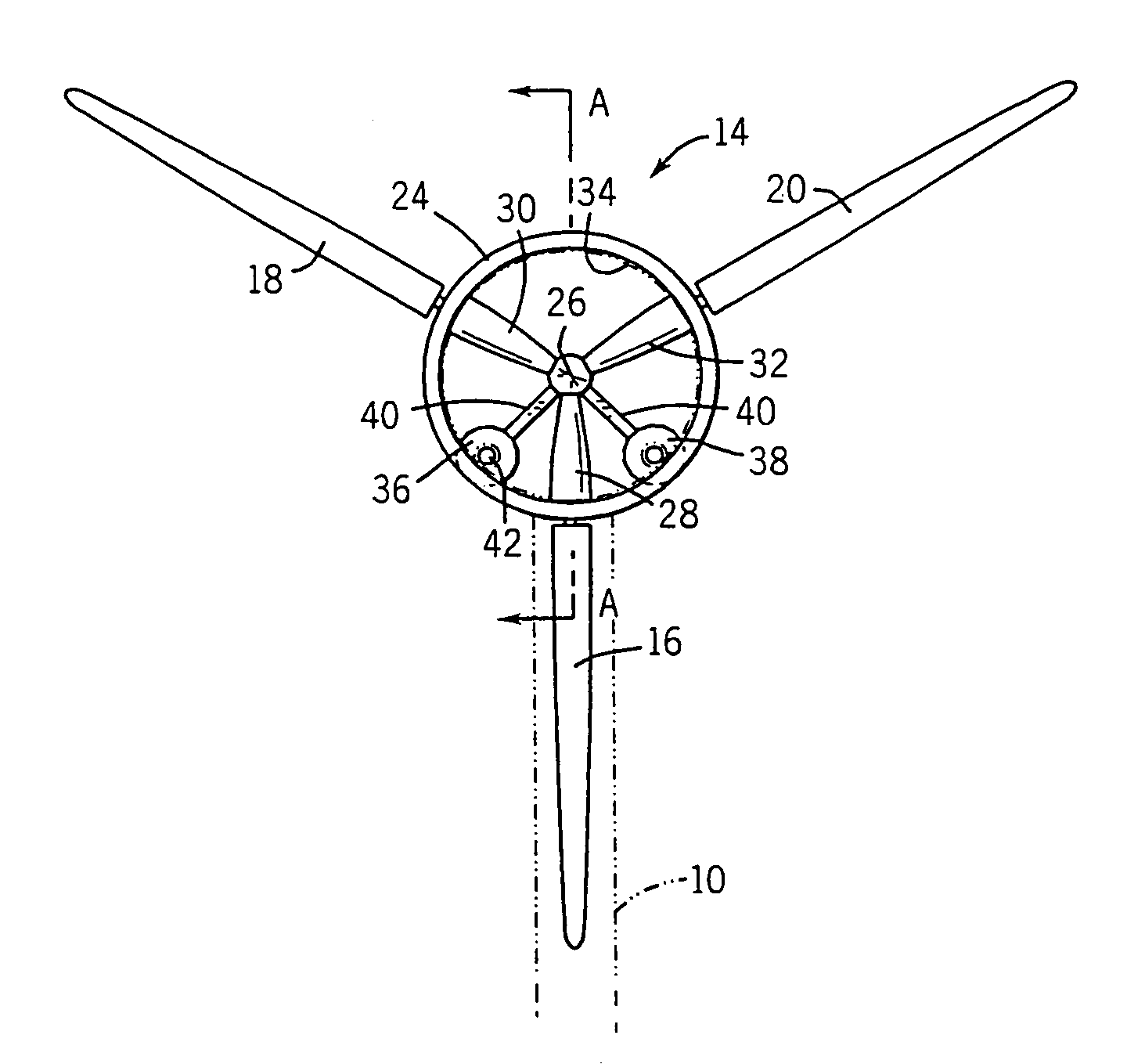

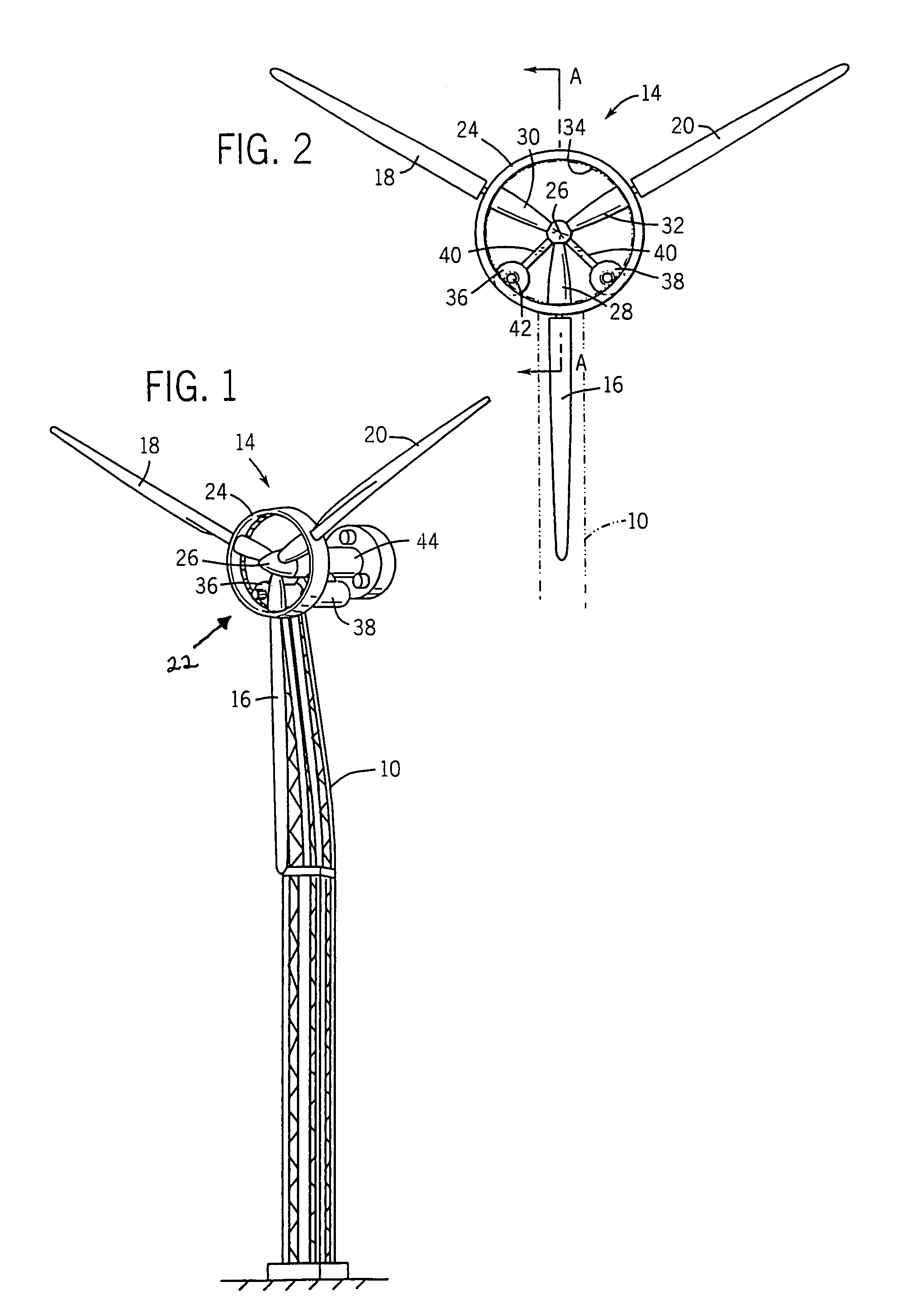

Wind dam electric generator and method

InactiveUS6984899B1Constant windmill shaft rotational speedWind motor controlEngine fuctionsAir volumeEngineering

A vertical axis windmill is provided wherein the amount of wind directed to blades in the power producing part of rotation and the mechanical load of multiple generators is controlled by a feedback control to maintain a relatively constant rotational frequency of the shaft of the windmill. In a preferred embodiment, two wind foils extend radially outwardly from the blades to thereby provide a scoop capable of pulling in more air than would normally be received by the blades. The wind foils then direct the wind flow to the power producing part of rotation of the blades for maximum power output, when necessary. The wind foils can close to control the wind flow to the blades. The generating capacity of a plurality of generators is also controlled in response to shaft rotation to maintain substantially constant shaft rotation.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

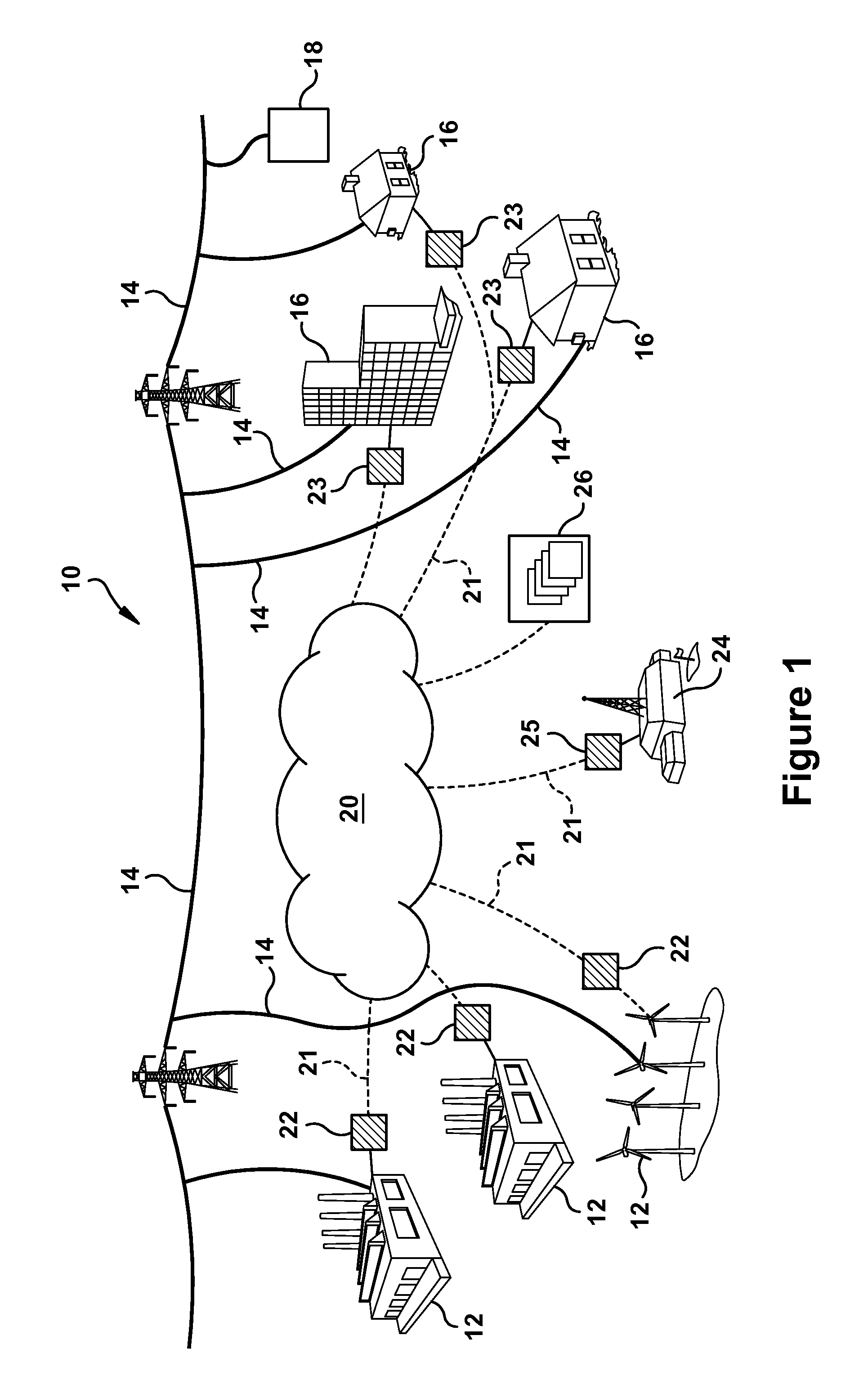

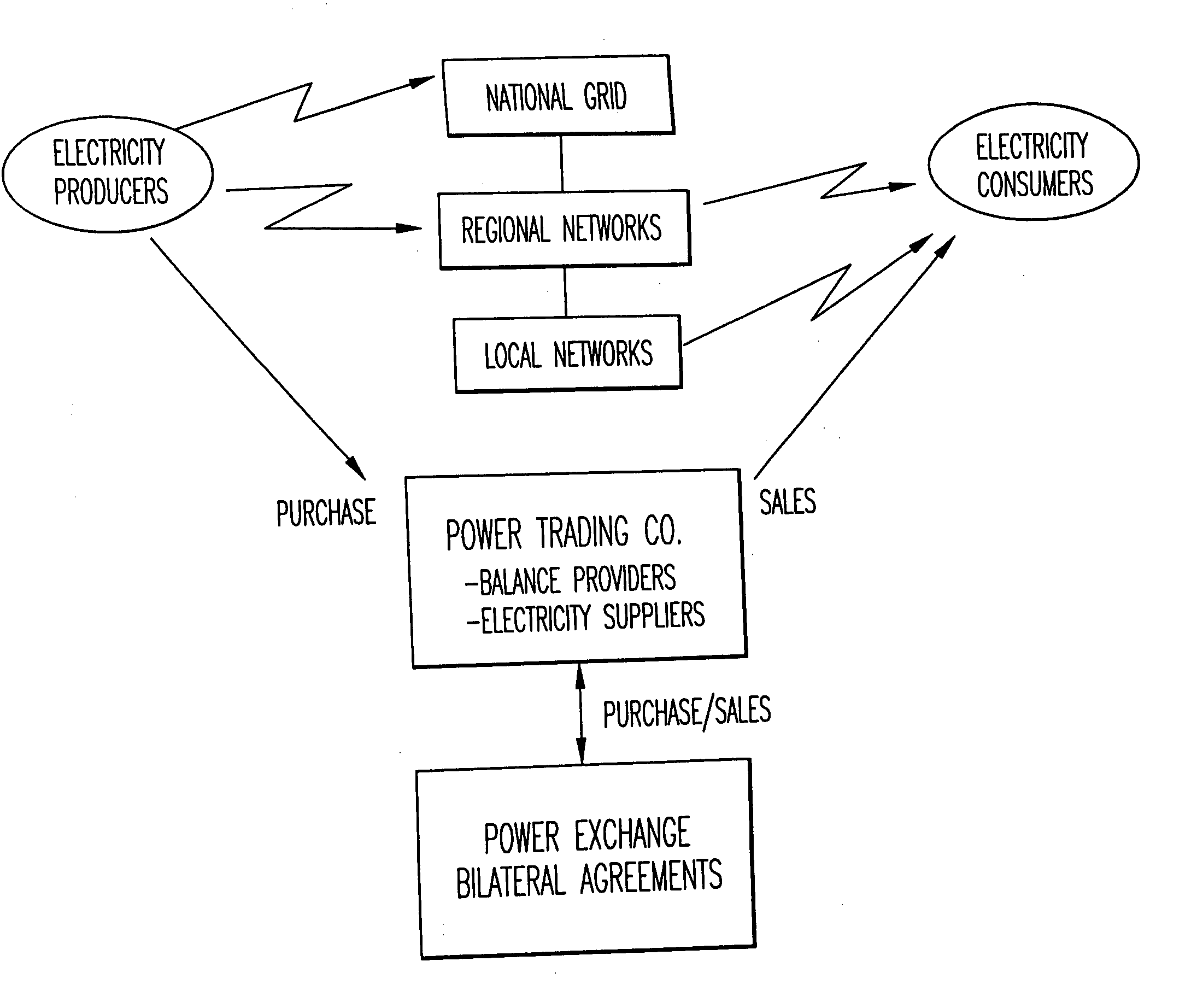

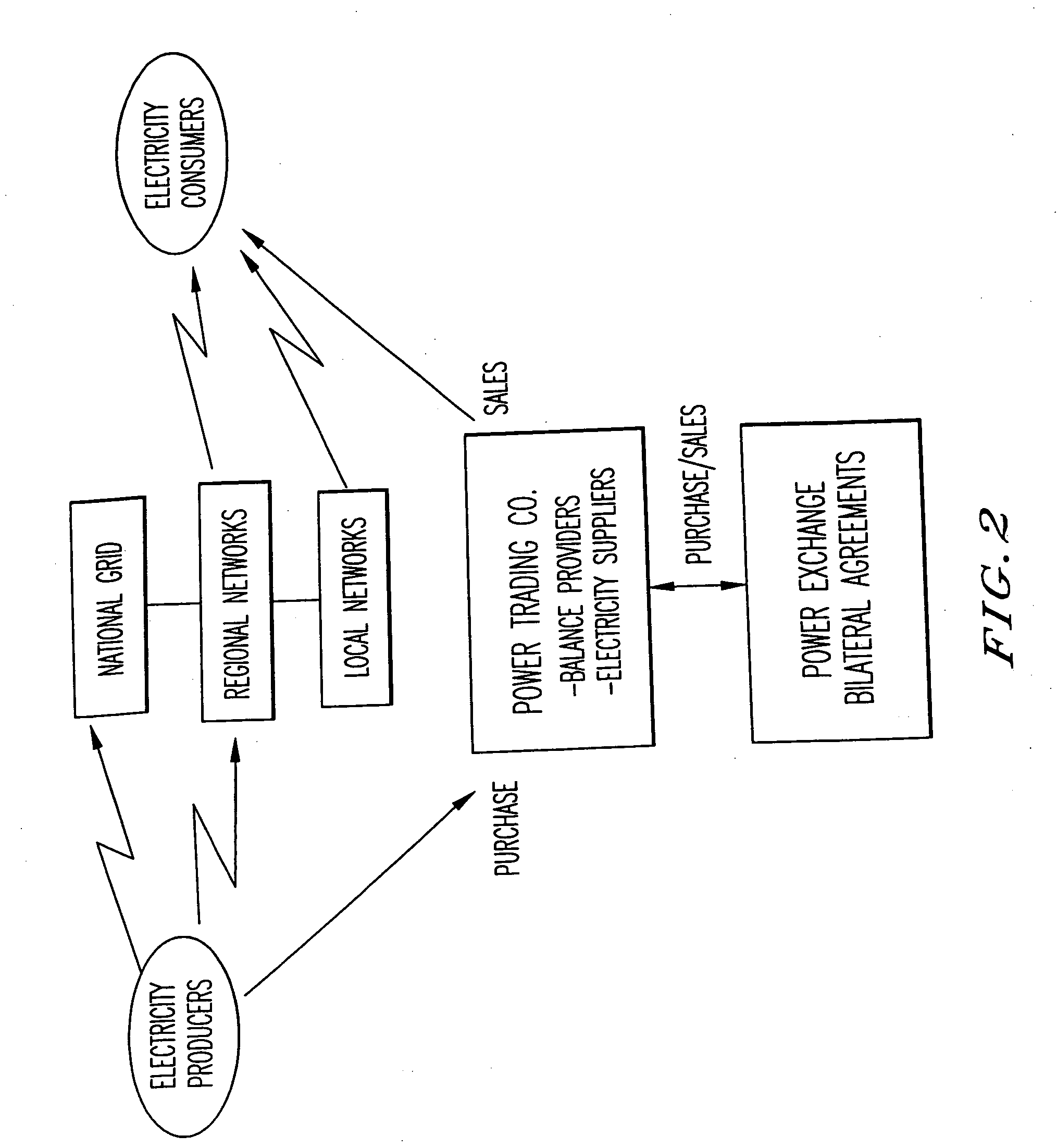

System, method and computer program product for enhancing commercial value of electrical power produced from a renewable energy power production facility

InactiveUS20050127680A1Increase power valueInherent market valueWind motor controlEngine fuctionsPower exchangeRenewable power generation

A method, system and computer program product enhance the commercial value of electrical power produced from a wind turbine production facility. Features include the use of a premier power conversion device that provides an alternative source of power for supplementing an output power of the wind turbine generation facility when lull periods for wind speed appear. The invention includes a communications infrastructure and coordination mechanism for establishing a relationship with another power production facility such that when excess electrical power is produced by the wind turbine facility, the excess may be provided to the power grid while the other energy production facility cuts back on its output production by a corresponding amount. A tracking mechanism keeps track of the amount of potential energy that was not expended at the other facility and places this amount in a virtual energy storage account, for the benefit of the wind turbine facility. When, the wind turbine power production facility experiences a shortfall in its power production output it may make a request to the other source of electric power, and request that an increase its power output on behalf of the wind turbine facility. This substitution of one power production facility for another is referred to herein as a virtual energy storage mechanism. Furthermore, another feature of the present invention is the use of a renewal power exchange mechanism that creates a market for trading renewable units of power, which have been converted into “premier power” and / or “guaranteed” by secondary sources of power source to provide a reliable source of power to the power grid as required by contract.

Owner:ABB (SCHWEIZ) AG

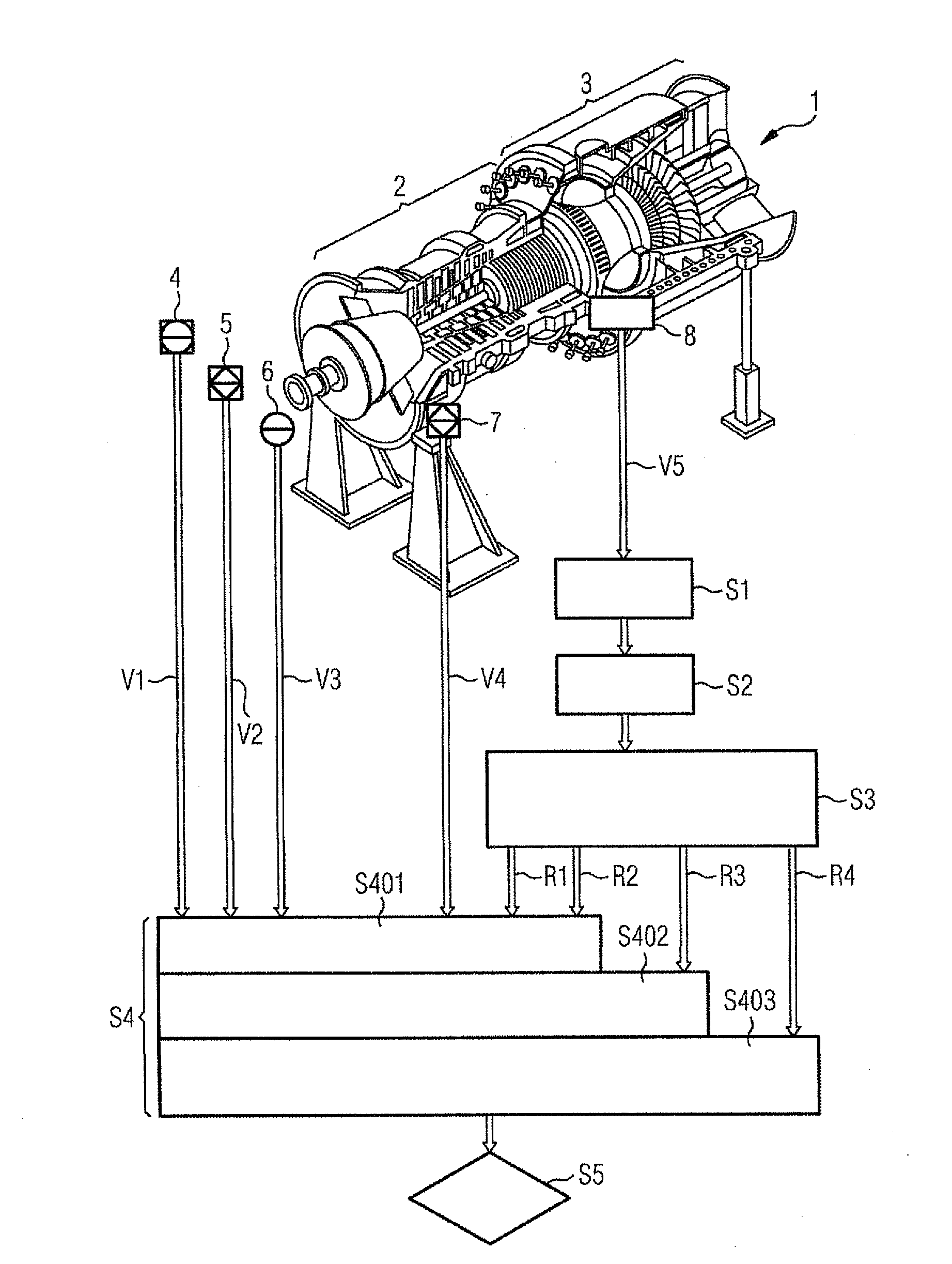

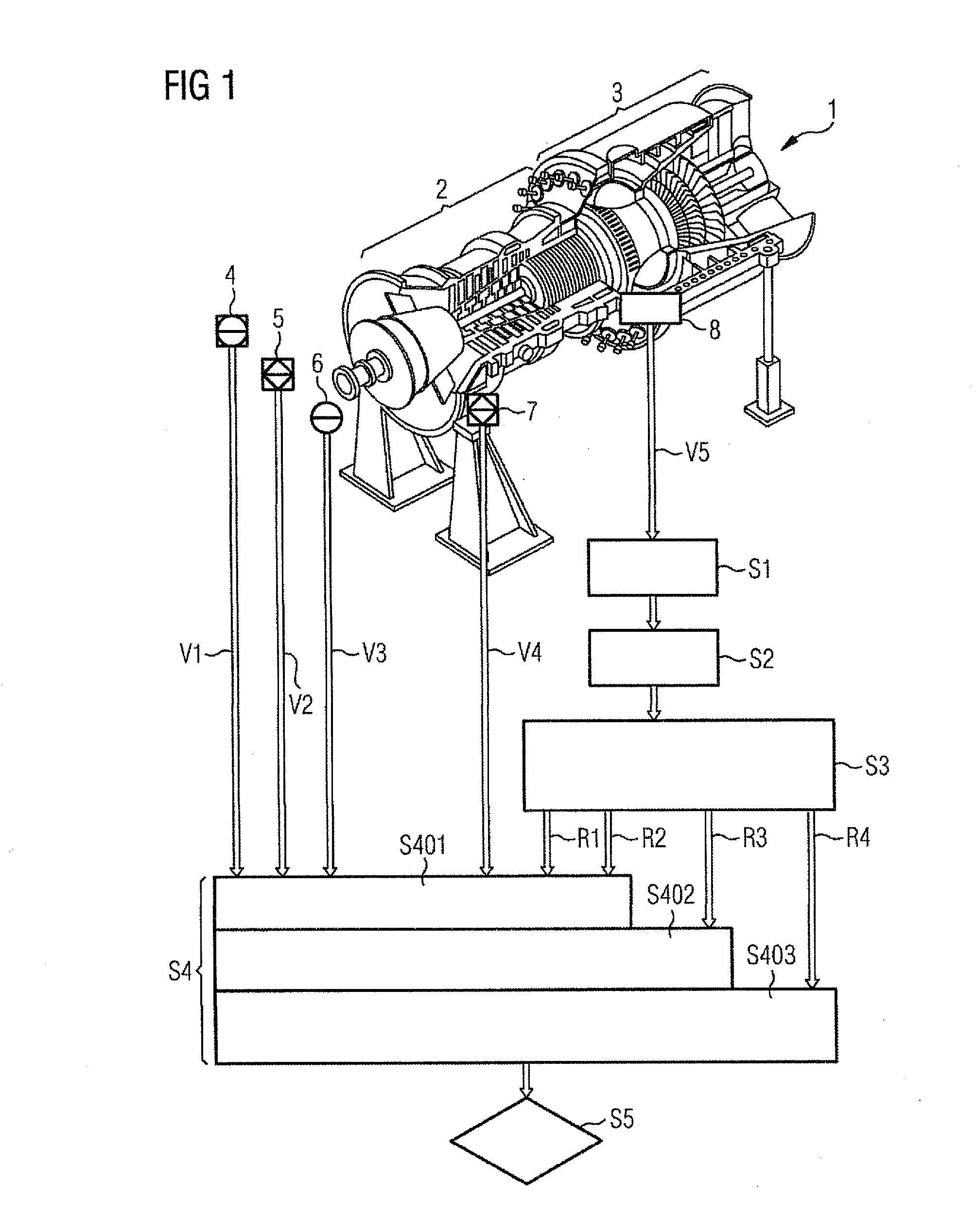

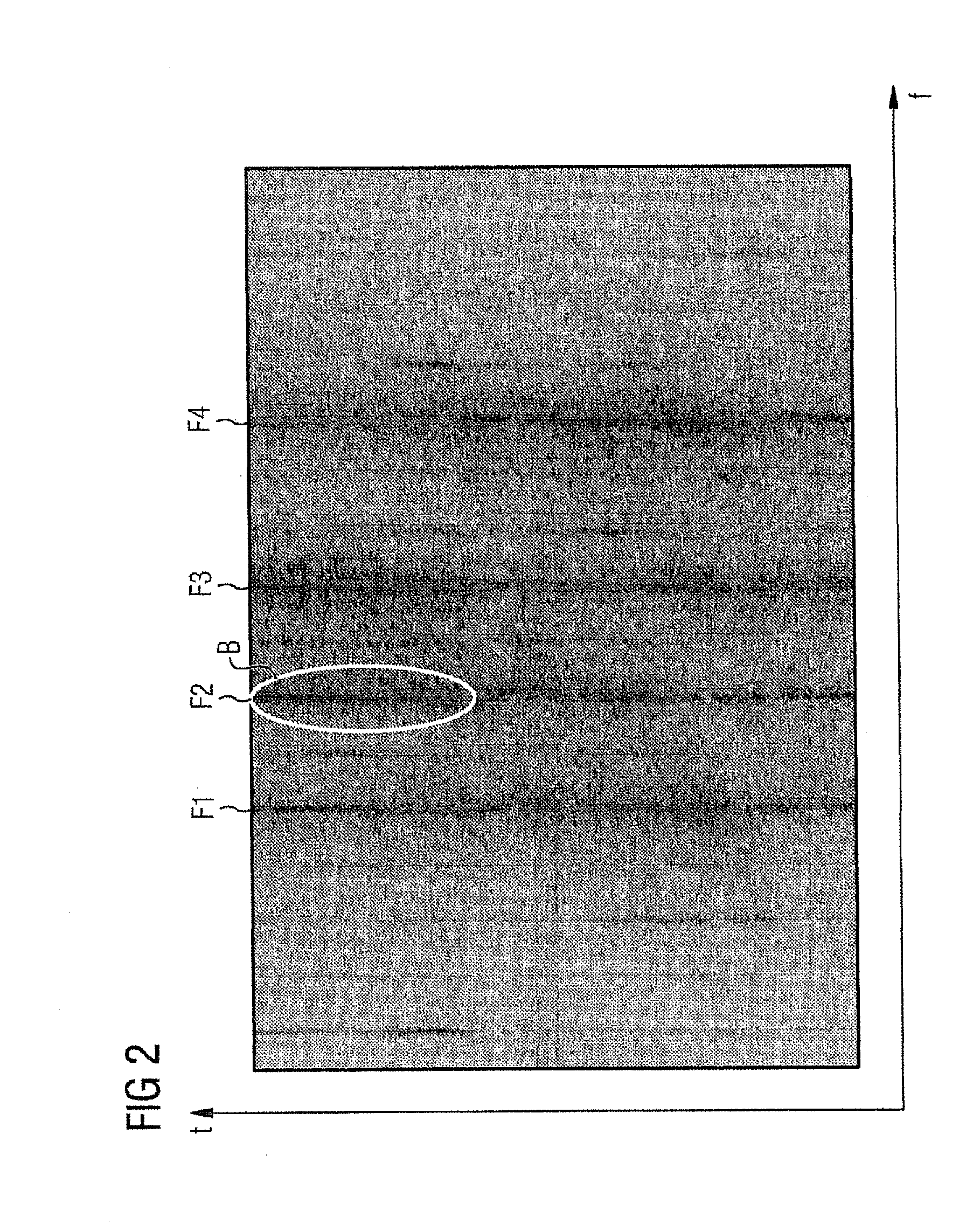

Method for analysis of the operation of a gas turbine

ActiveUS20100262401A1Accurate diagnosisLess sensorsGas-turbine engine testingEngine fuctionsFrequency spectrumEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

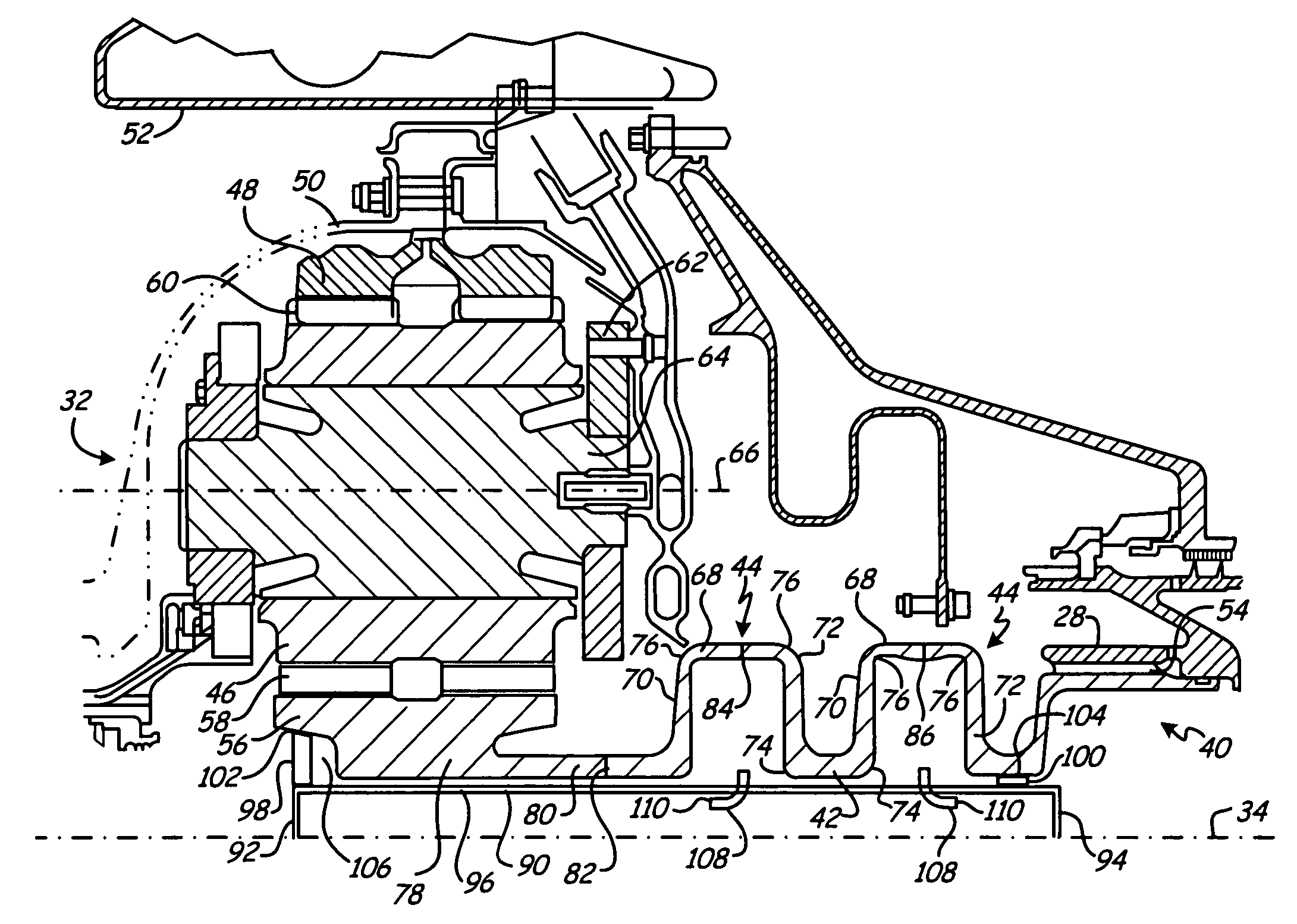

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

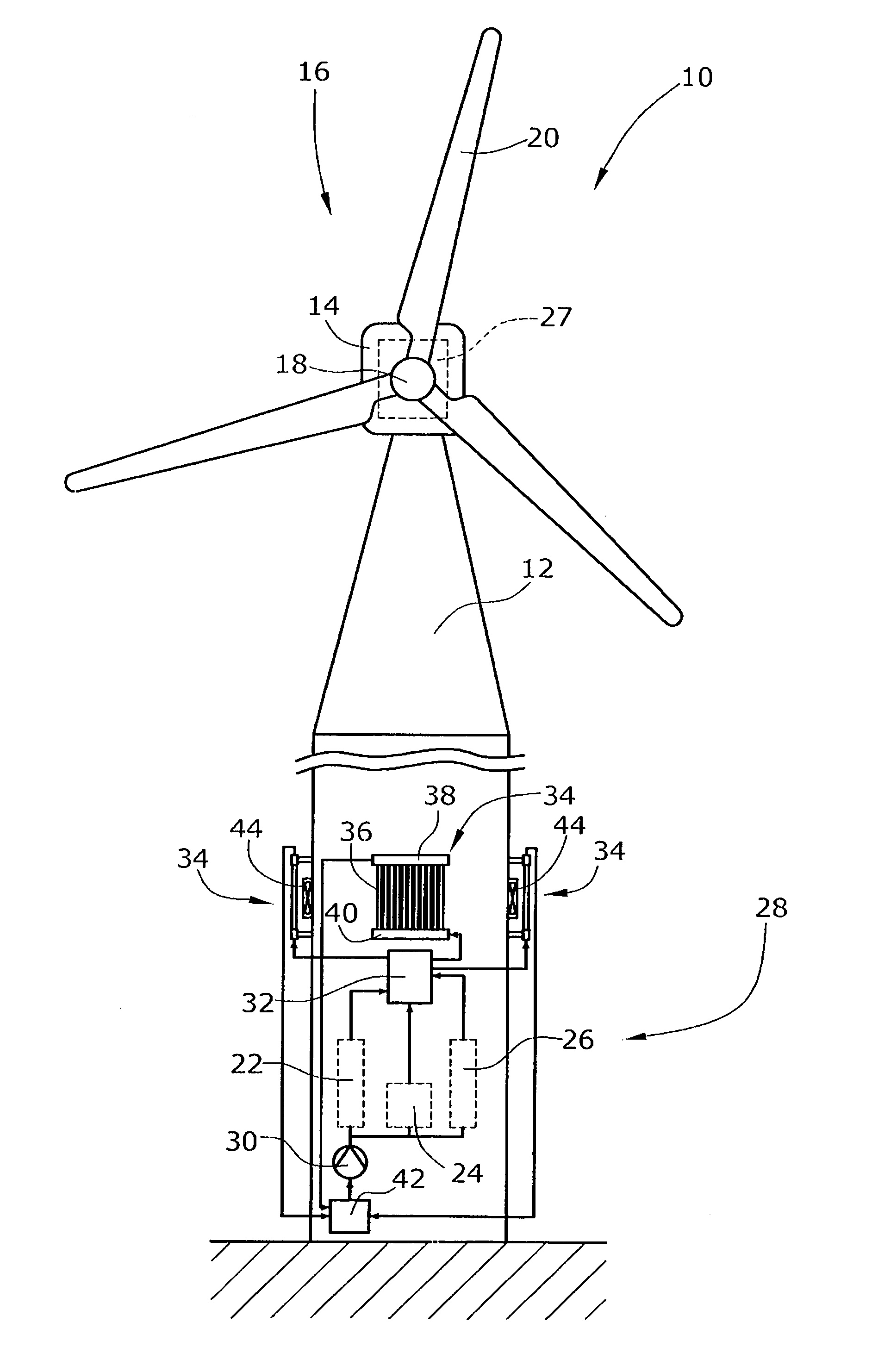

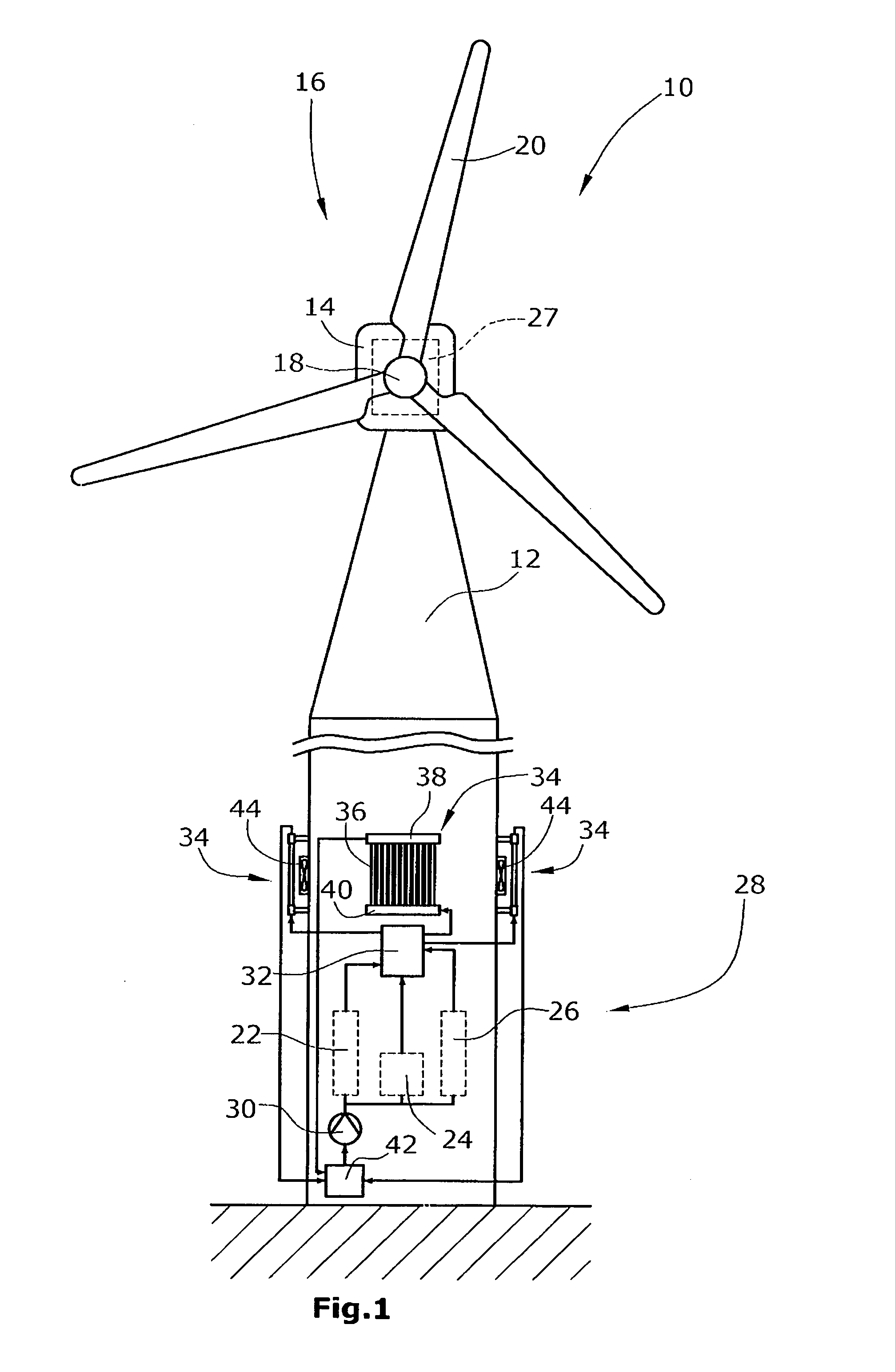

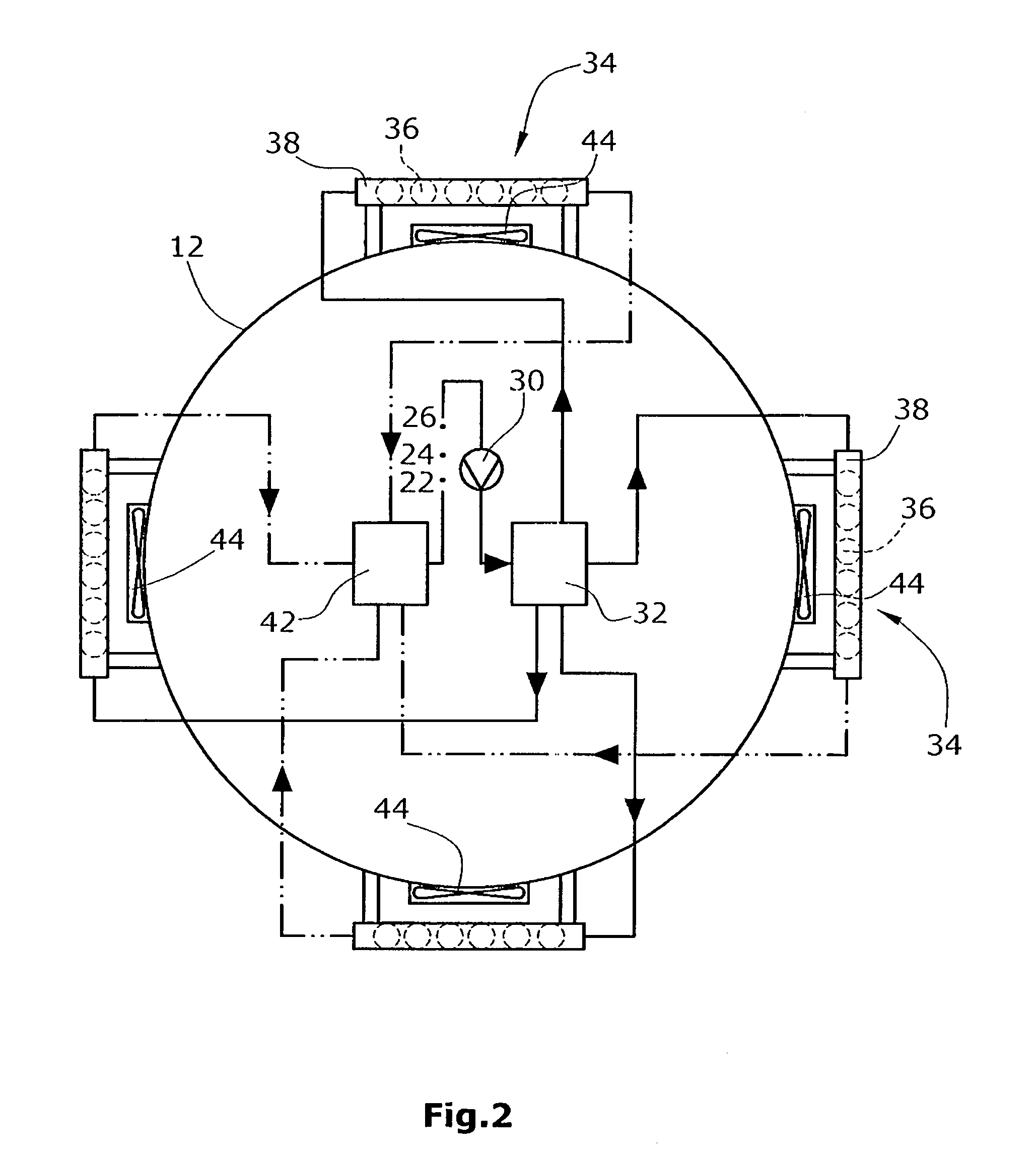

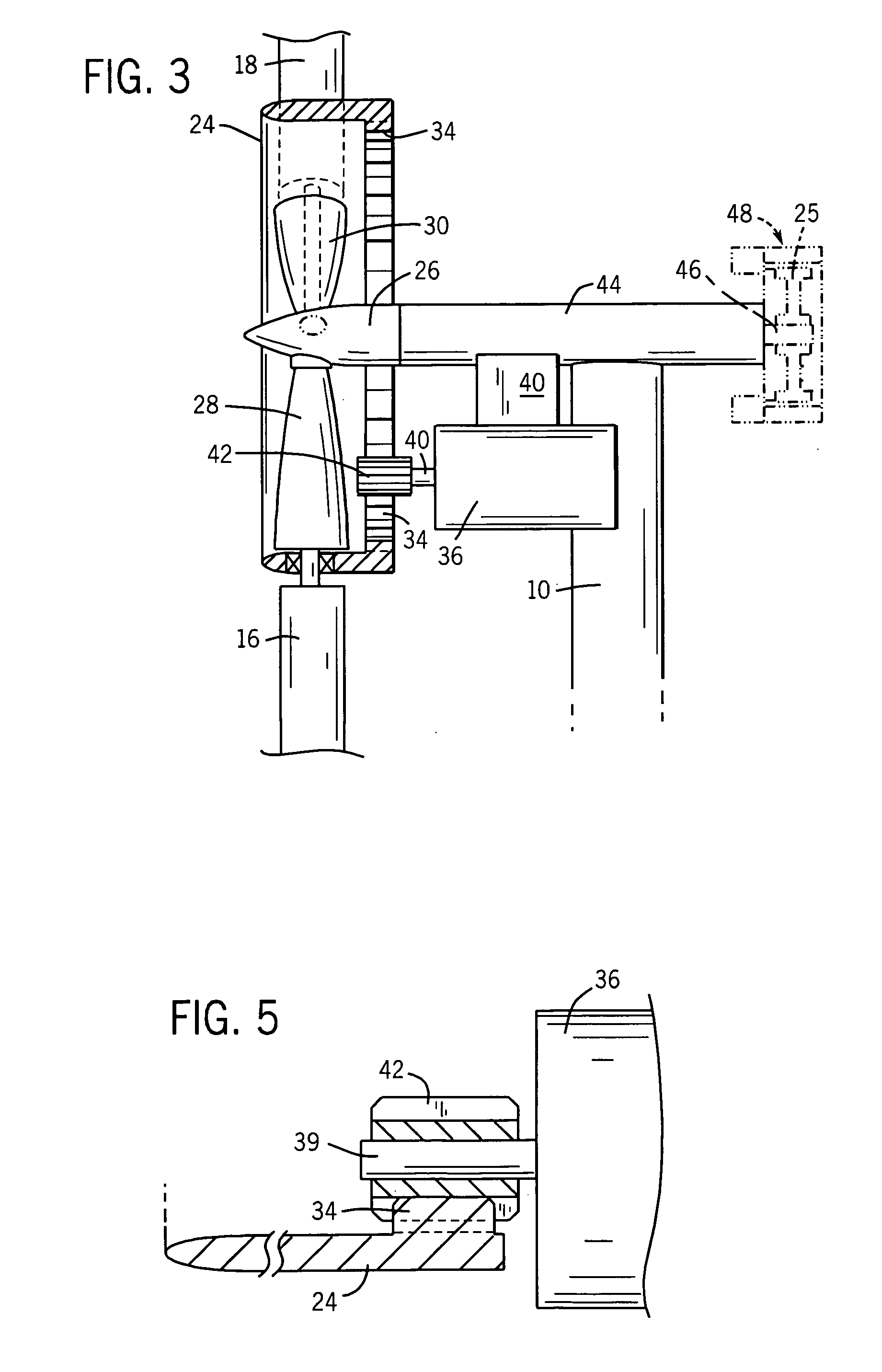

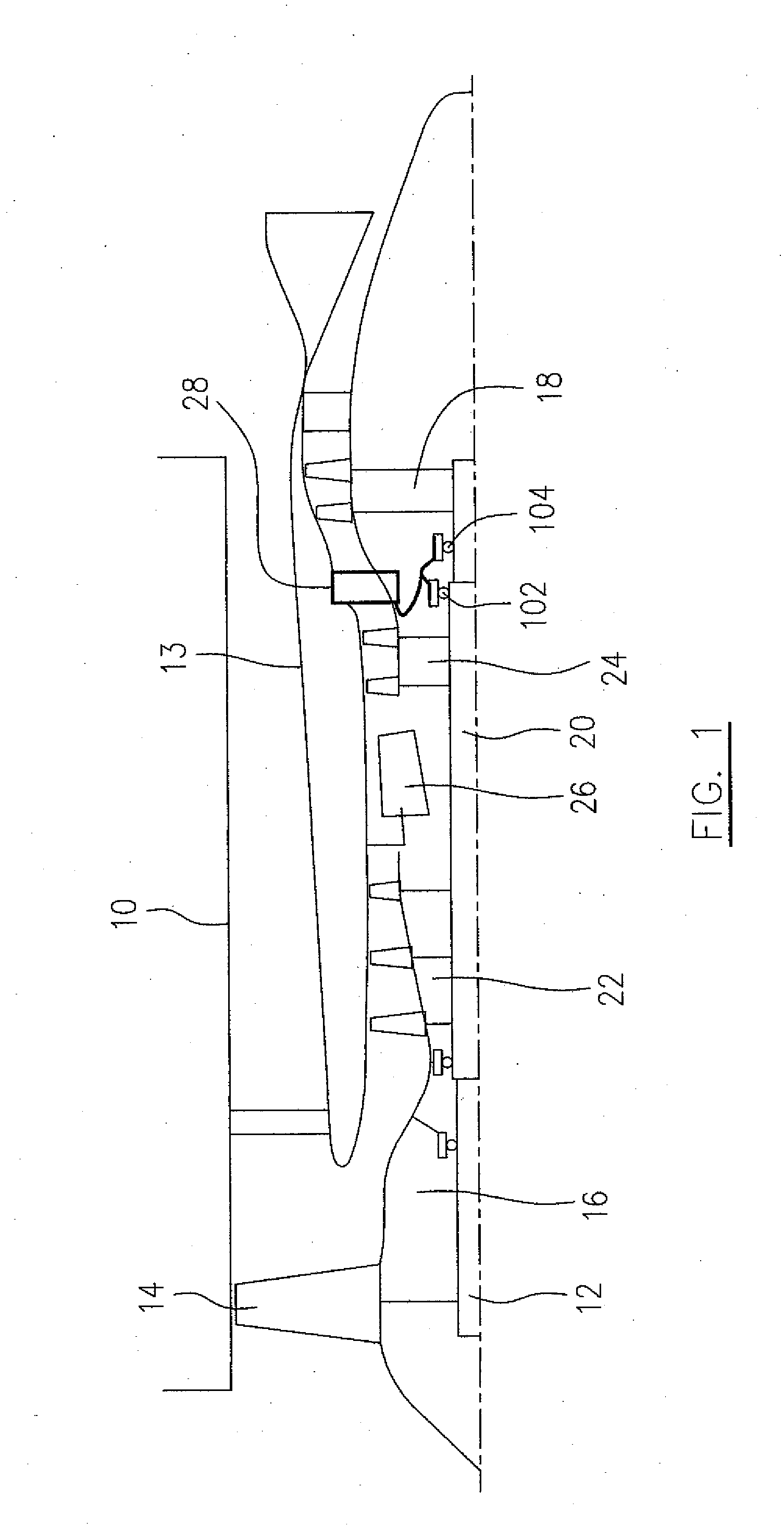

Wind energy turbine

A wind energy turbine includes a tower, a nacelle rotatably supported by the tower, a rotor rotatably supported by the nacelle, and at least one unit to be cooled and arranged in the tower and / or the nacelle. The unit is adapted to be cooled by a cooling medium flowing in a cooling circuit from the unit to at least one heat exchanger. The at least one heat exchanger is located outside of the tower and / or nacelle and configured to be cooled by ambient air.

Owner:GENERAL ELECTRIC CO

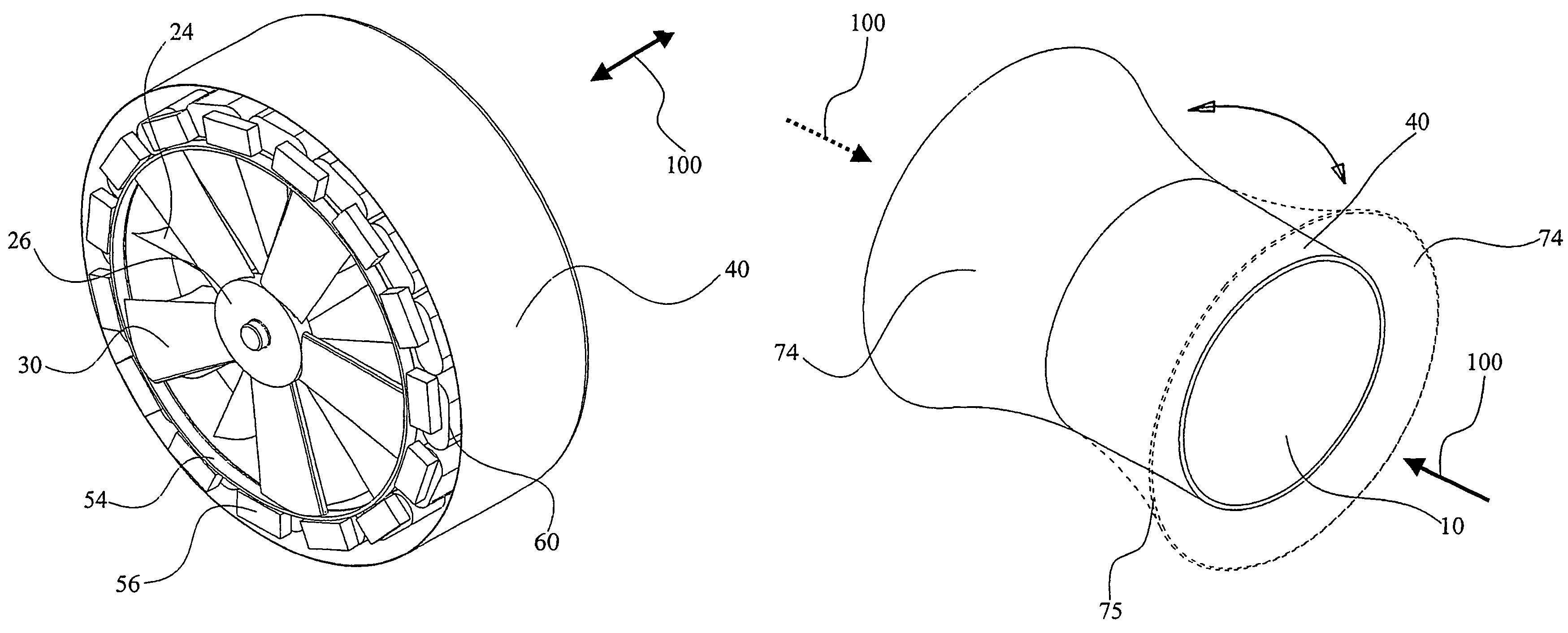

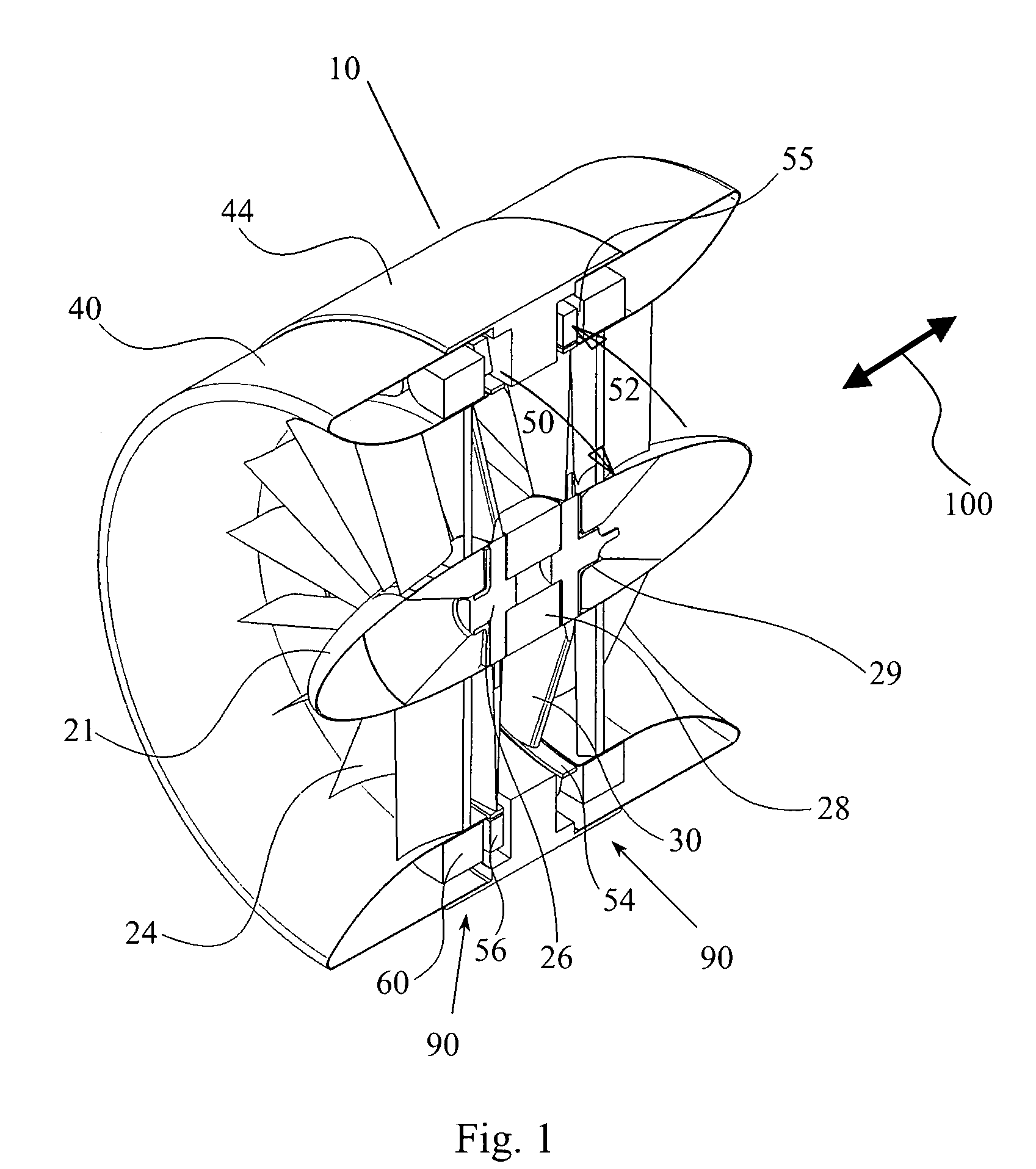

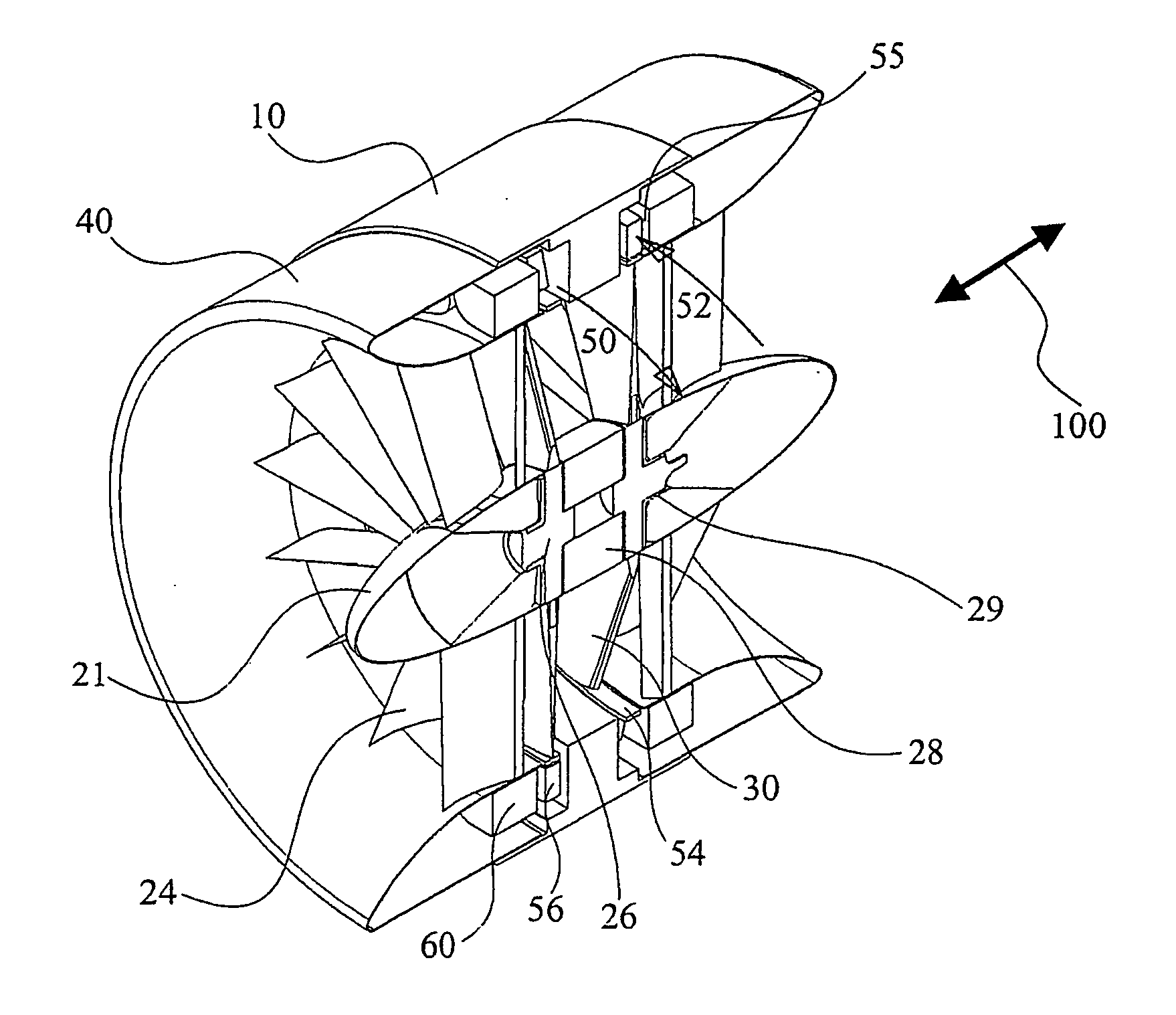

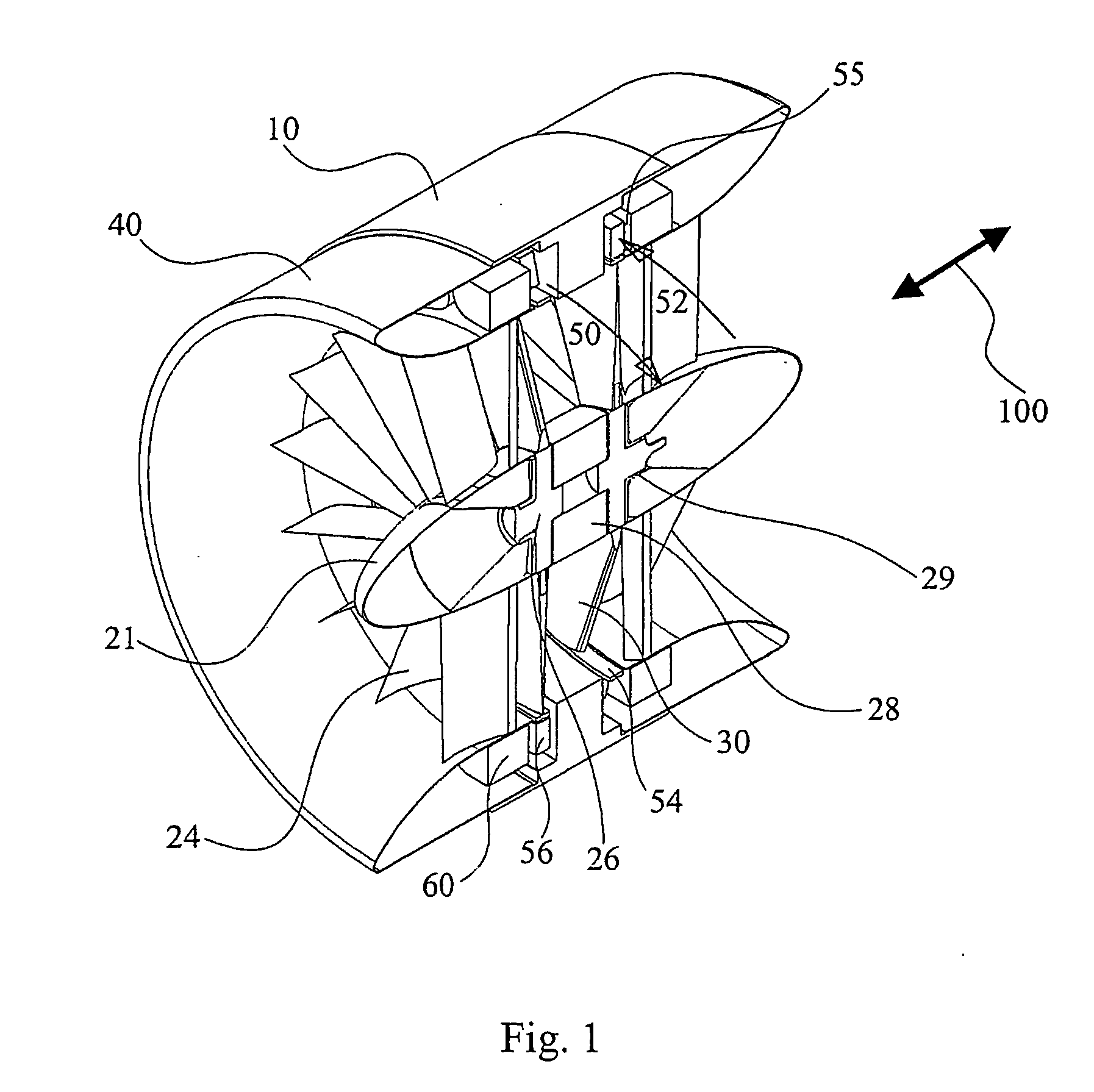

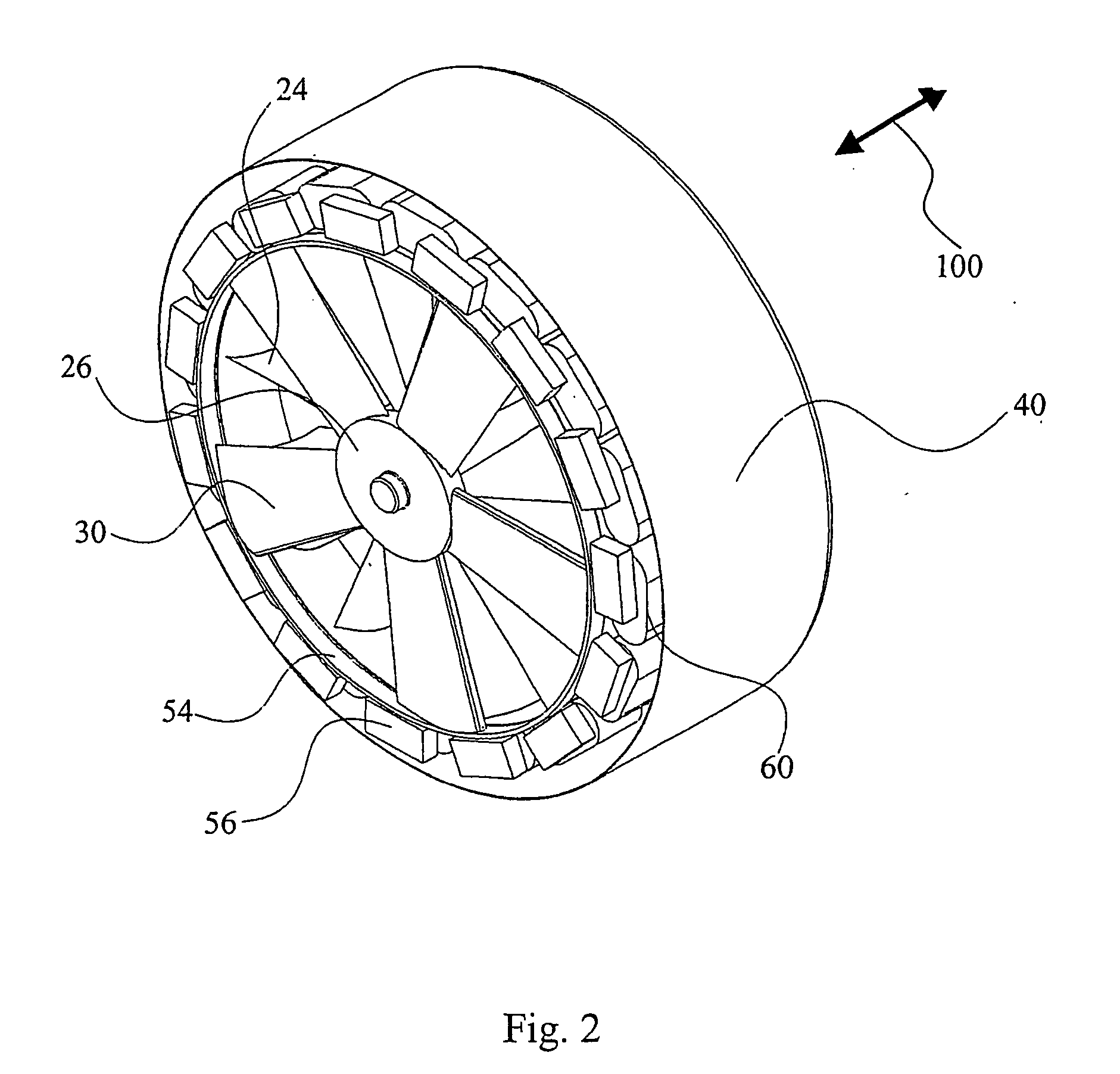

Underwater ducted turbine

InactiveUS7471009B2Minimize loss of efficiencyThe process is stable and efficientEngine fuctionsWorking fluid for enginesUnderwaterStator coil

An apparatus is disclosed for a turbine for generating electrical power from water or air flow comprising at least one rotor disk having a plurality of hydrofoil blades, a guide vanes, a cylindrical housing, and a generator means. A rim generator comprising a magnet race rotor rim and fixed stator coils in the housing is used. The apparatus is fitted with a screen to stop the ingress of debris and marine life, and a skirt augmenter device to reduce the Betz effect. The apparatus is preferably for sub-sea deployment and driven by tidal currents, but may be powered by river current or wave driven air or by wind. The apparatus may be deployed on at least one telescoping pole, tethered to the sea-bed and kept buoyant by buoyant concrete in the housing, inserted in a dam, under a barge or in a tidal power array.

Owner:CLEAN CURRENT PARTNERSHIP

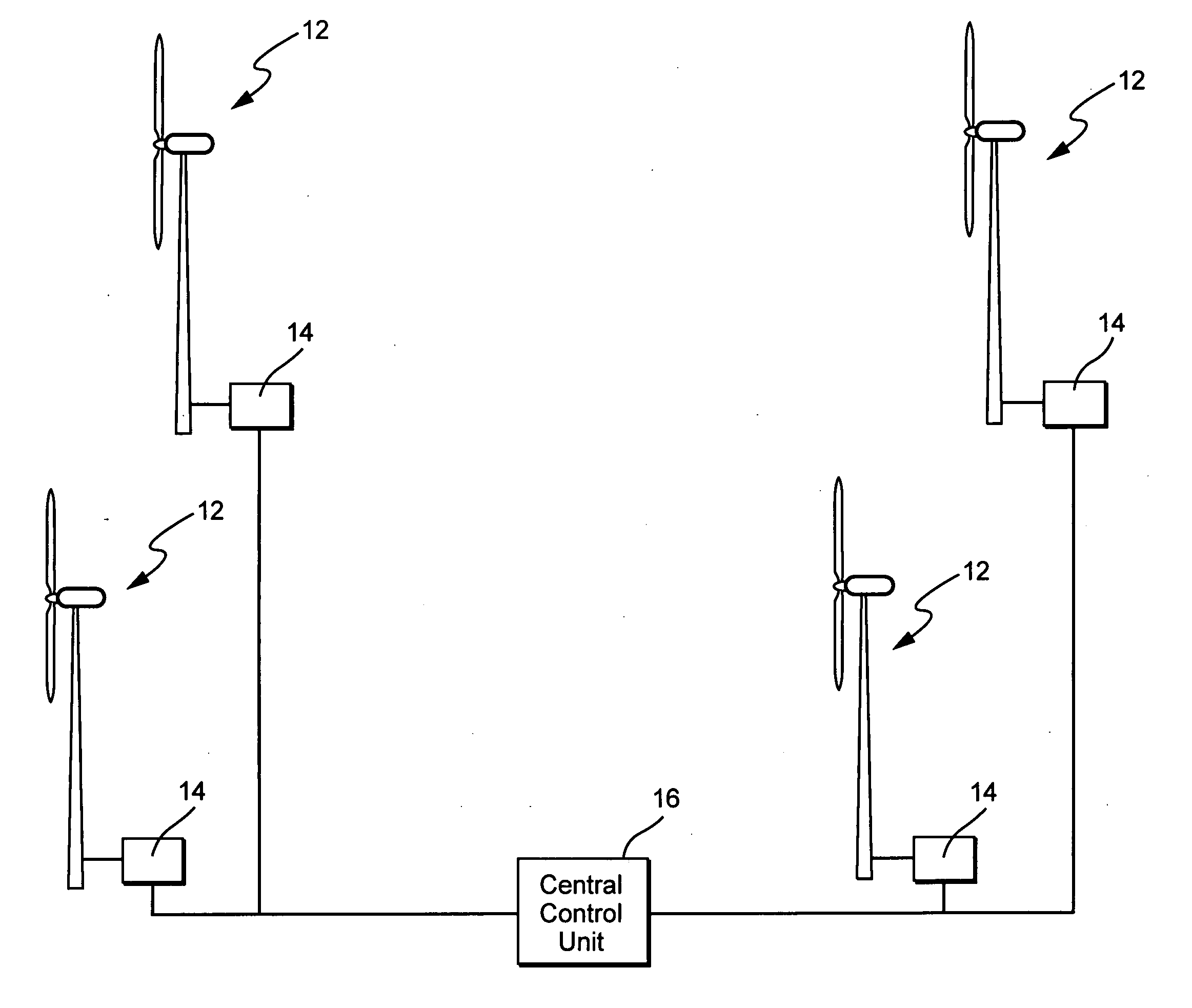

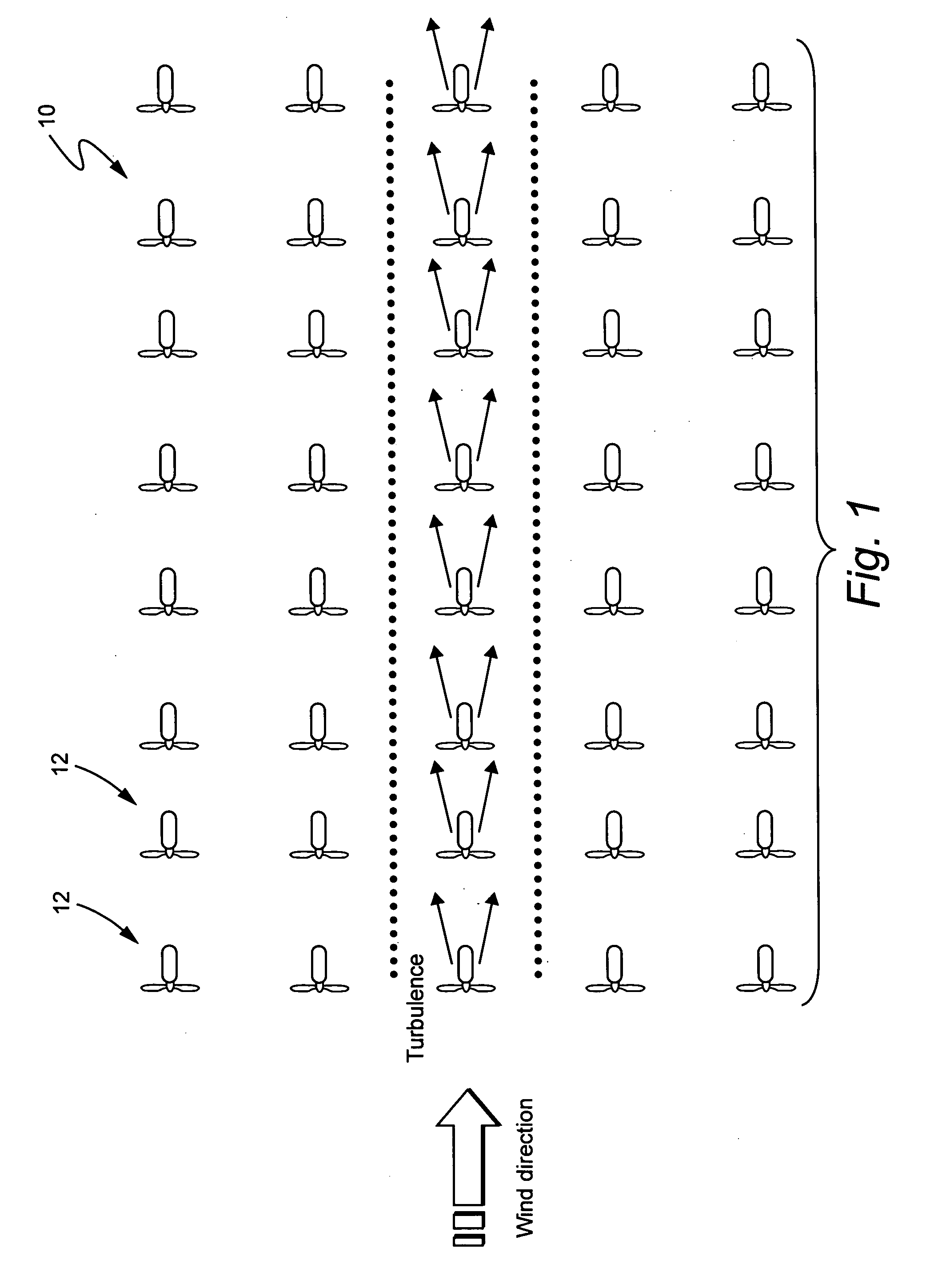

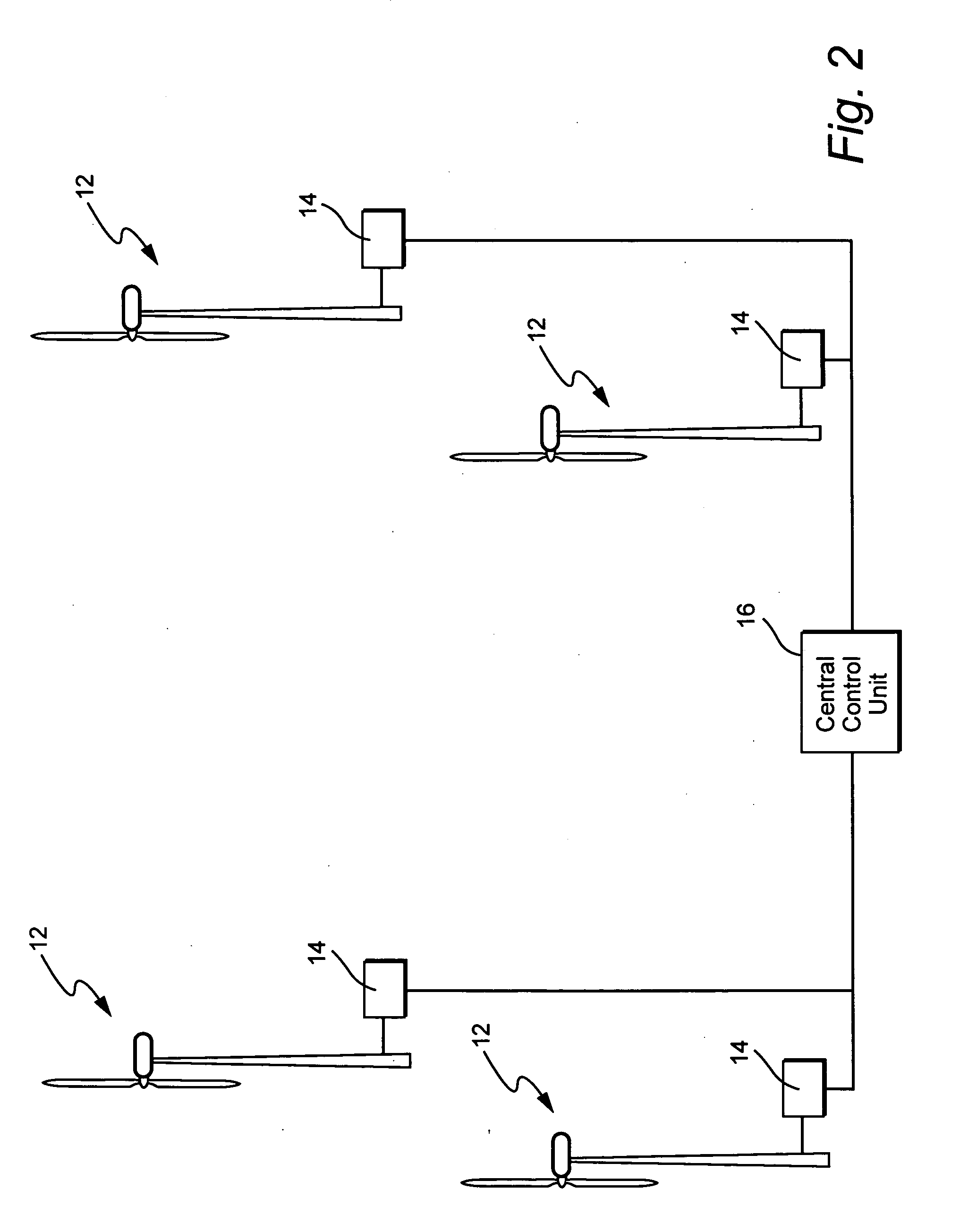

Windpark turbine control system and method for wind condition estimation and performance optimization

InactiveUS20070124025A1Minimize loading impactShorten speedLevel controlWind motor controlPower stationControl system

A method and system for controlling a windpark power plant includes a central processing and control unit operatively coupled to wind turbines in the windpark to receive data from and selectively transmit at least one of data and control signals to each wind turbine, to reduce fatigue loads and comply with power limits.

Owner:GENERAL ELECTRIC CO

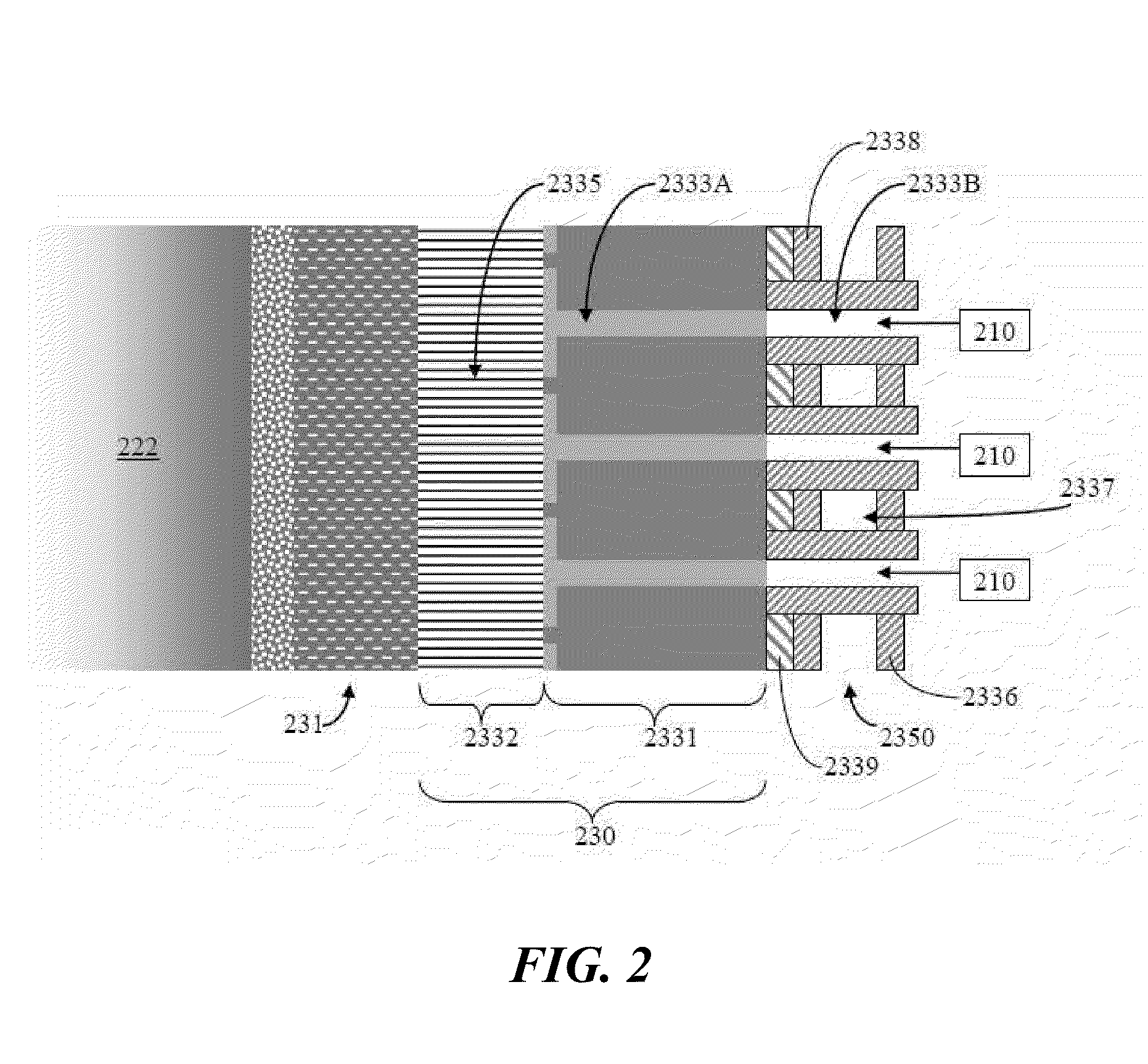

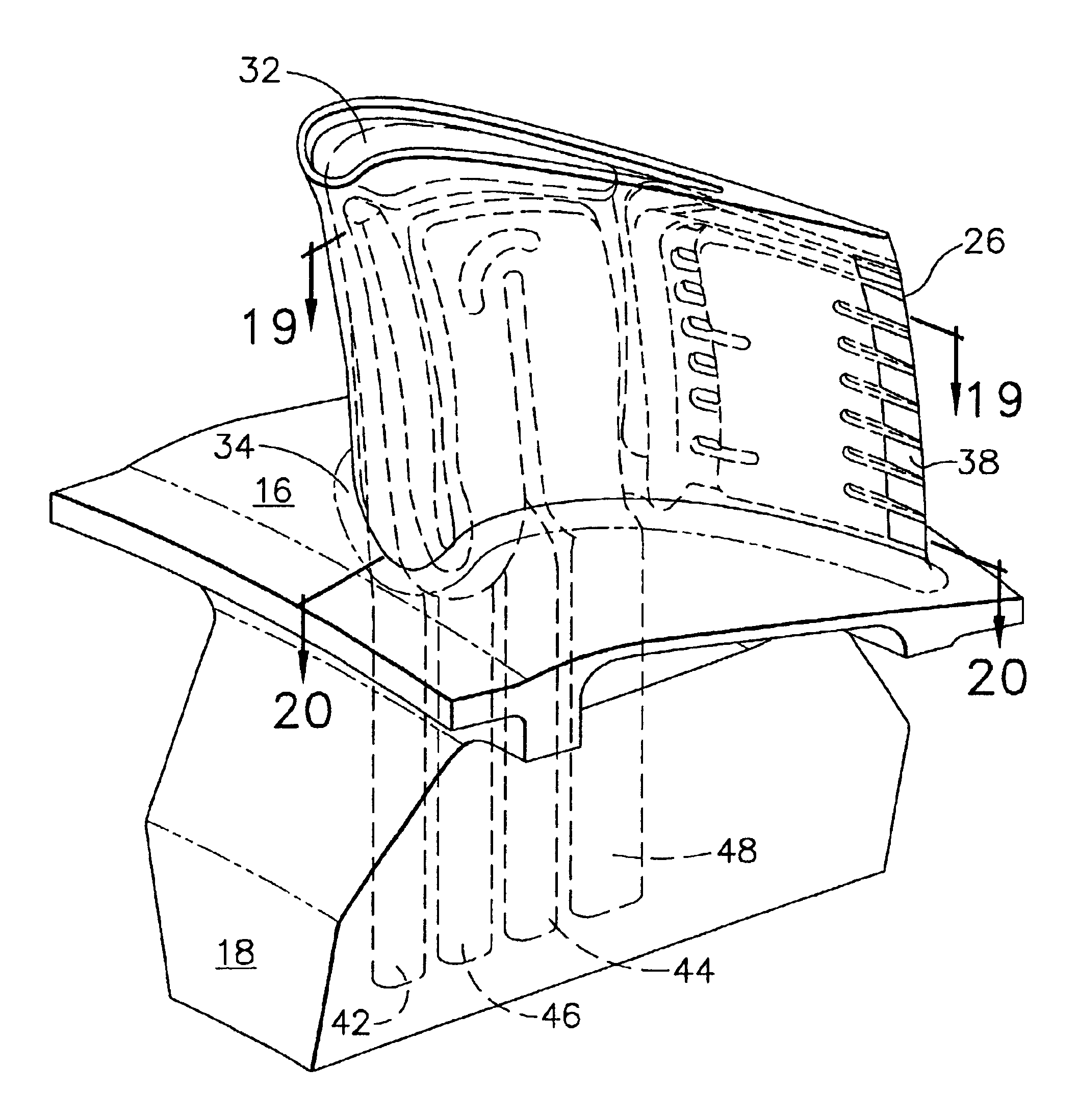

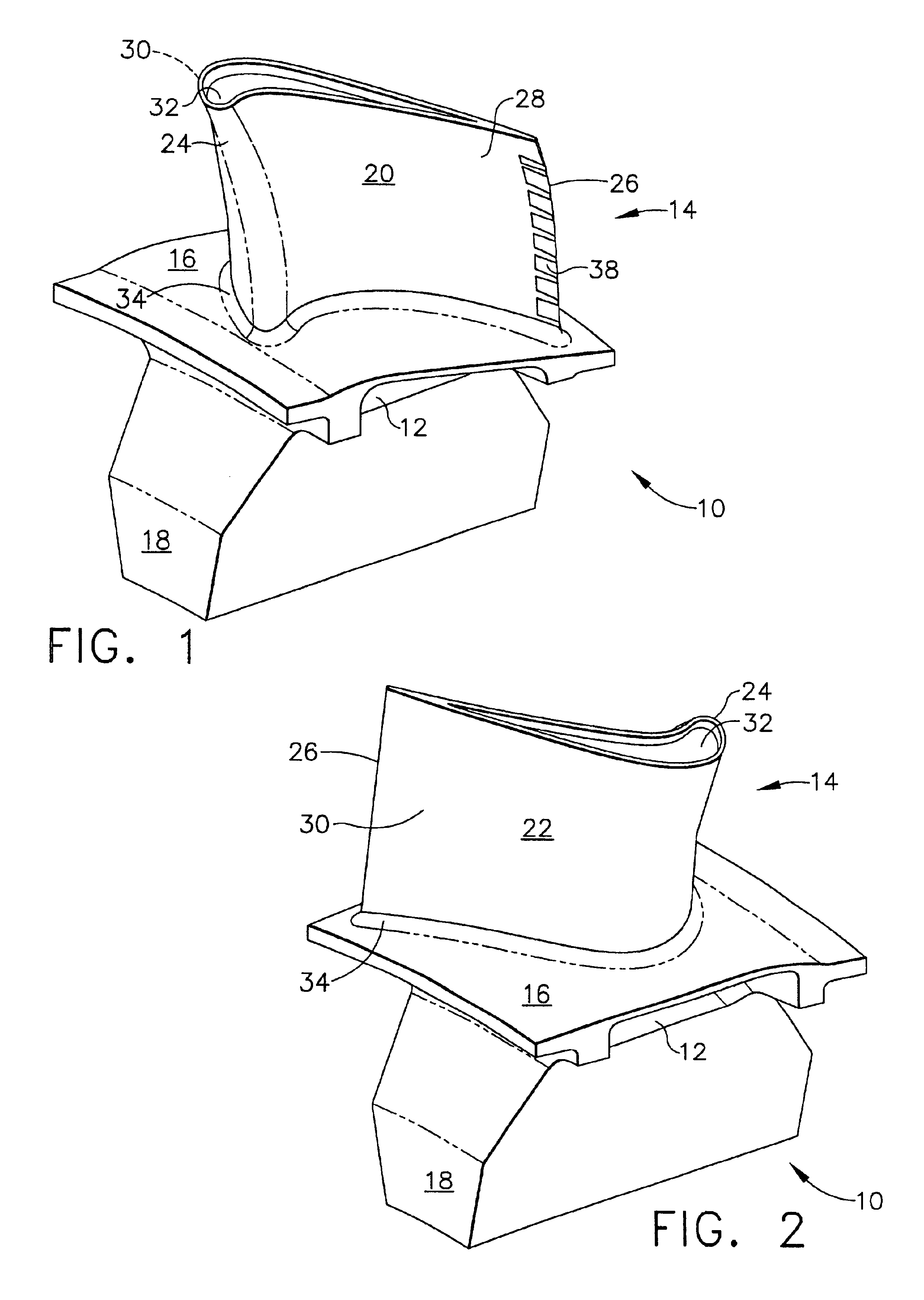

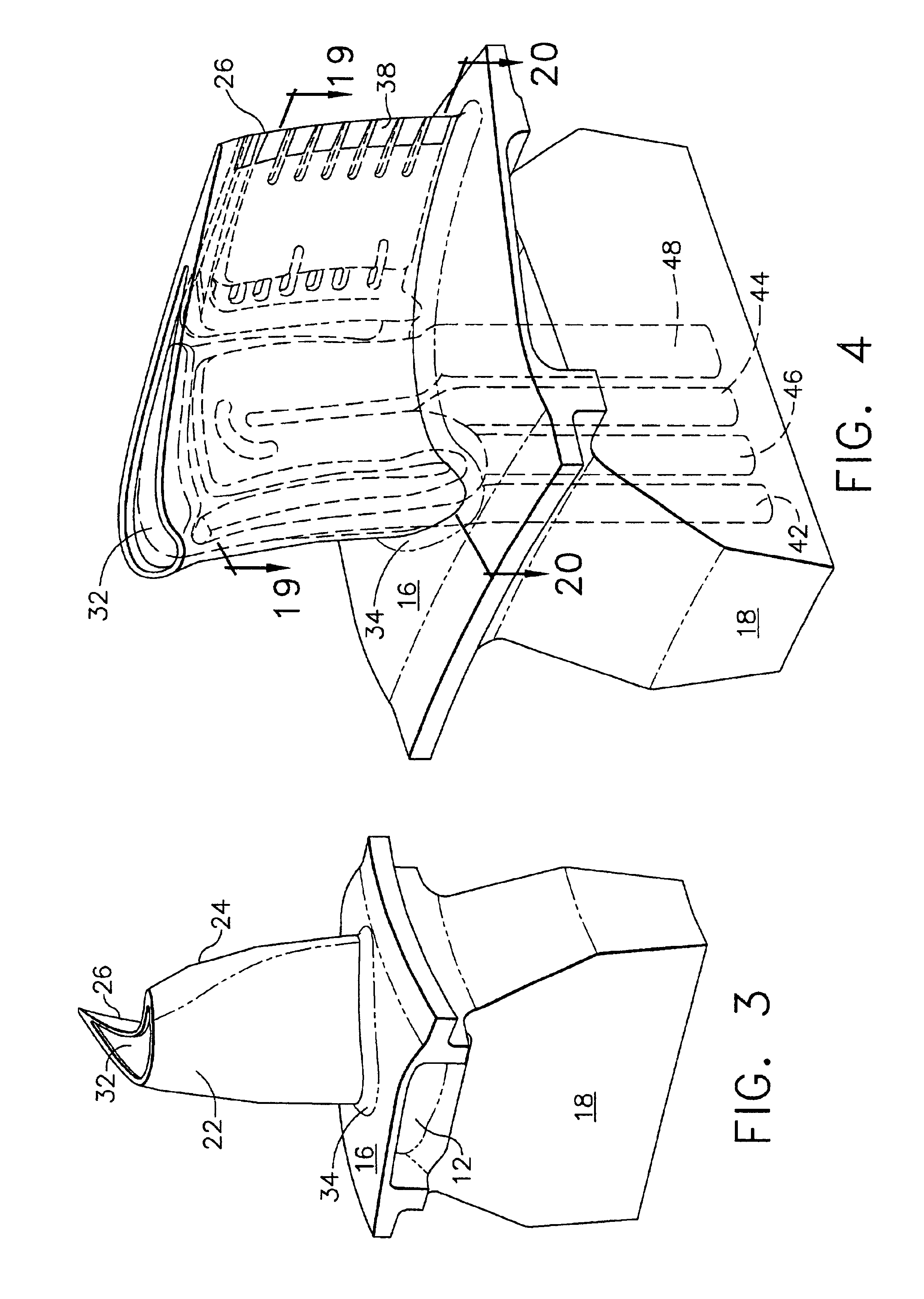

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

Hydro turbine generator

InactiveUS20050285407A1Minimize downstream efficiency lossMinimizing swirl lossEngine fuctionsWorking fluid for enginesStator coilEngineering

An apparatus is disclosed for a turbine for generating electrical power from water or air flow comprising at least one rotor disk having a plurality of hydrofoil blades, a guide vanes, a cylindrical housing, and a generator means. A rim generator comprising a magnet race rotor rim and fixed stator coils in the housing is used. The apparatus is fitted with a screen to stop the ingress of debris and marine life, and a skirt augmenter device to reduce the Betz effect. The apparatus is preferably for sub-sea deployment and driven by tidal currents, but may be powered by river current or wave driven air or by wind. The apparatus may be deployed on at least one telescoping pole, tethered to the sea-bed and kept buoyant by buoyant concrete in the housing, inserted in a dam, under a barge or in a tidal power array.

Owner:CLEAN CURRENT PARTNERSHIP

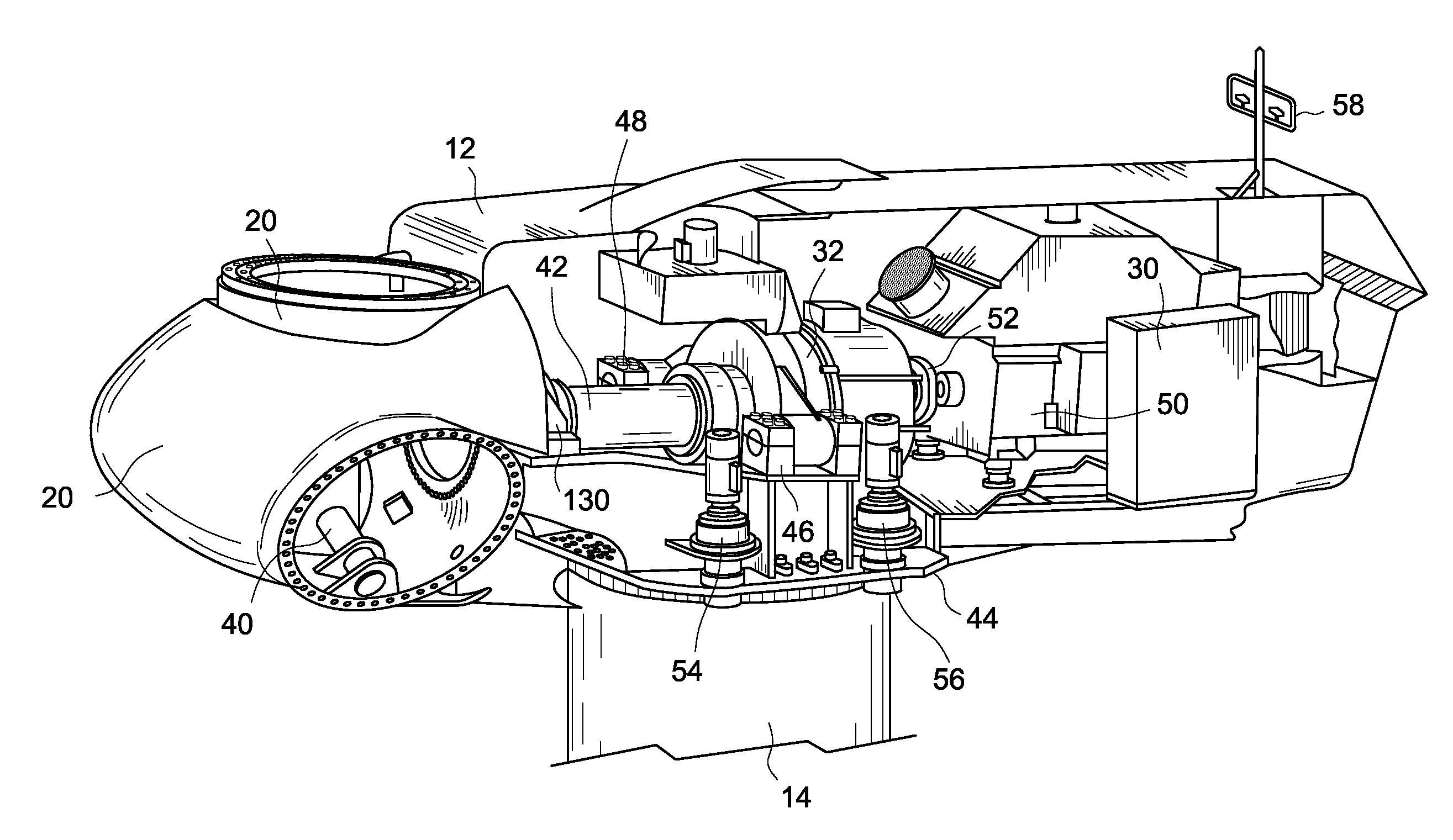

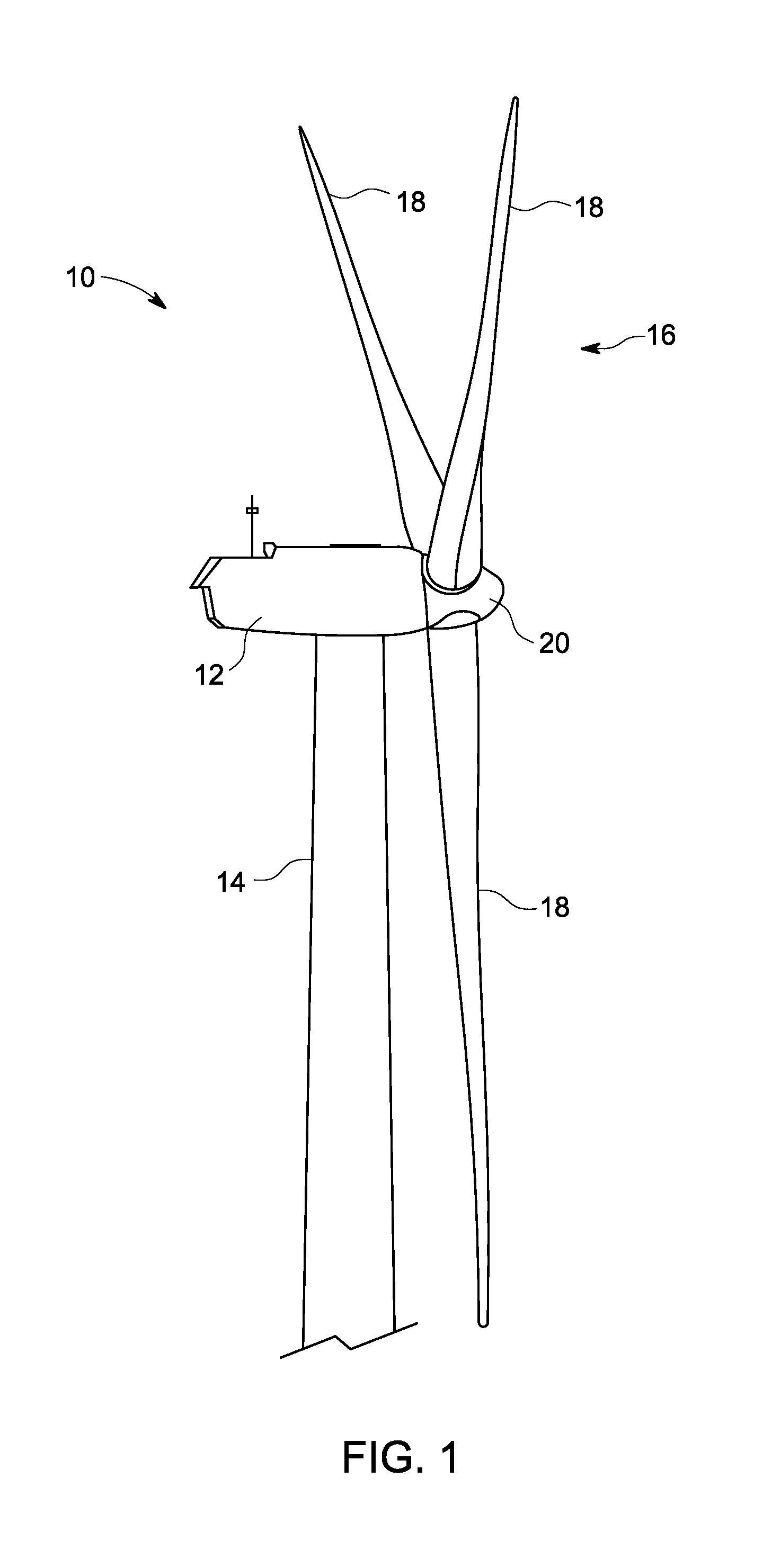

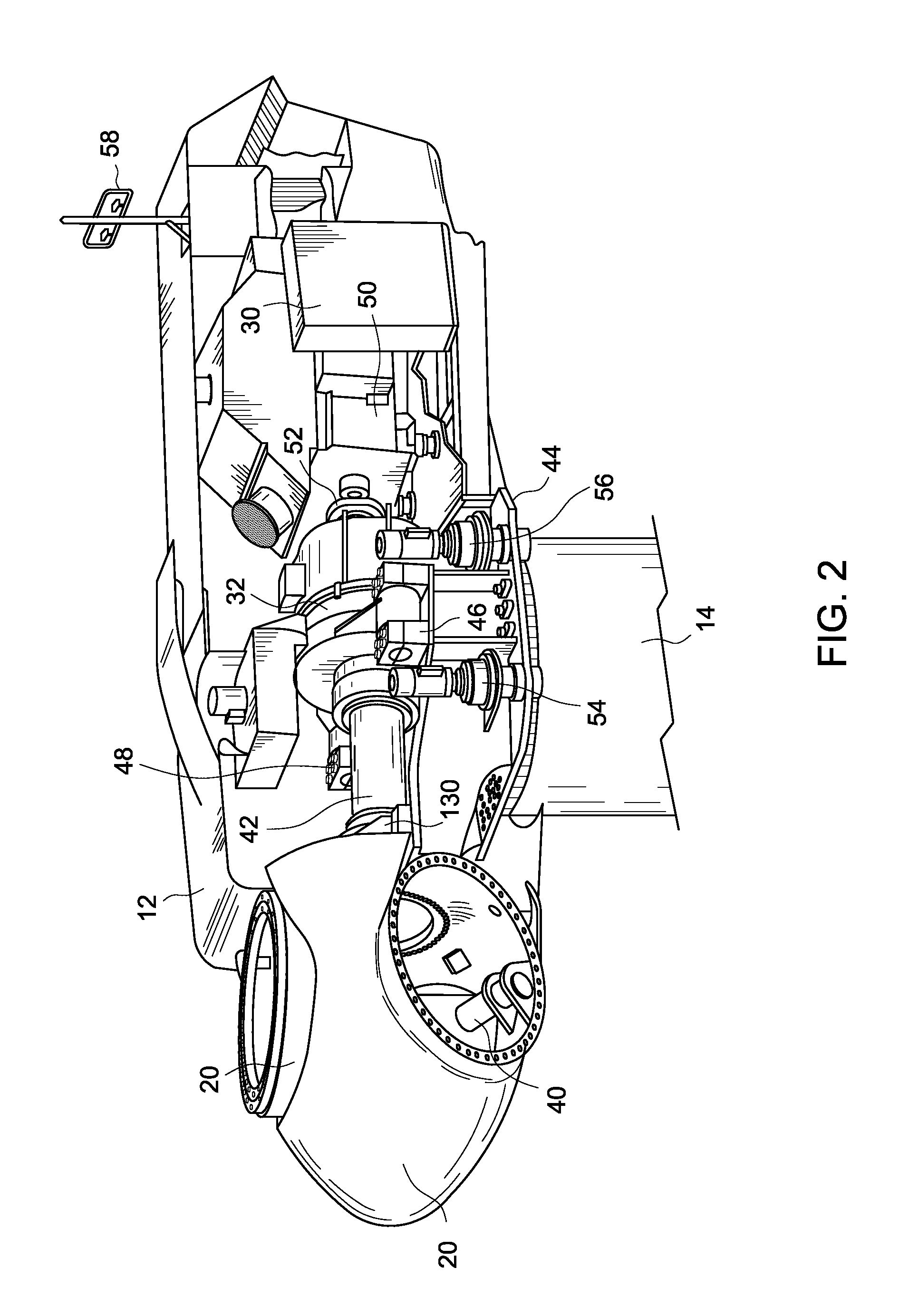

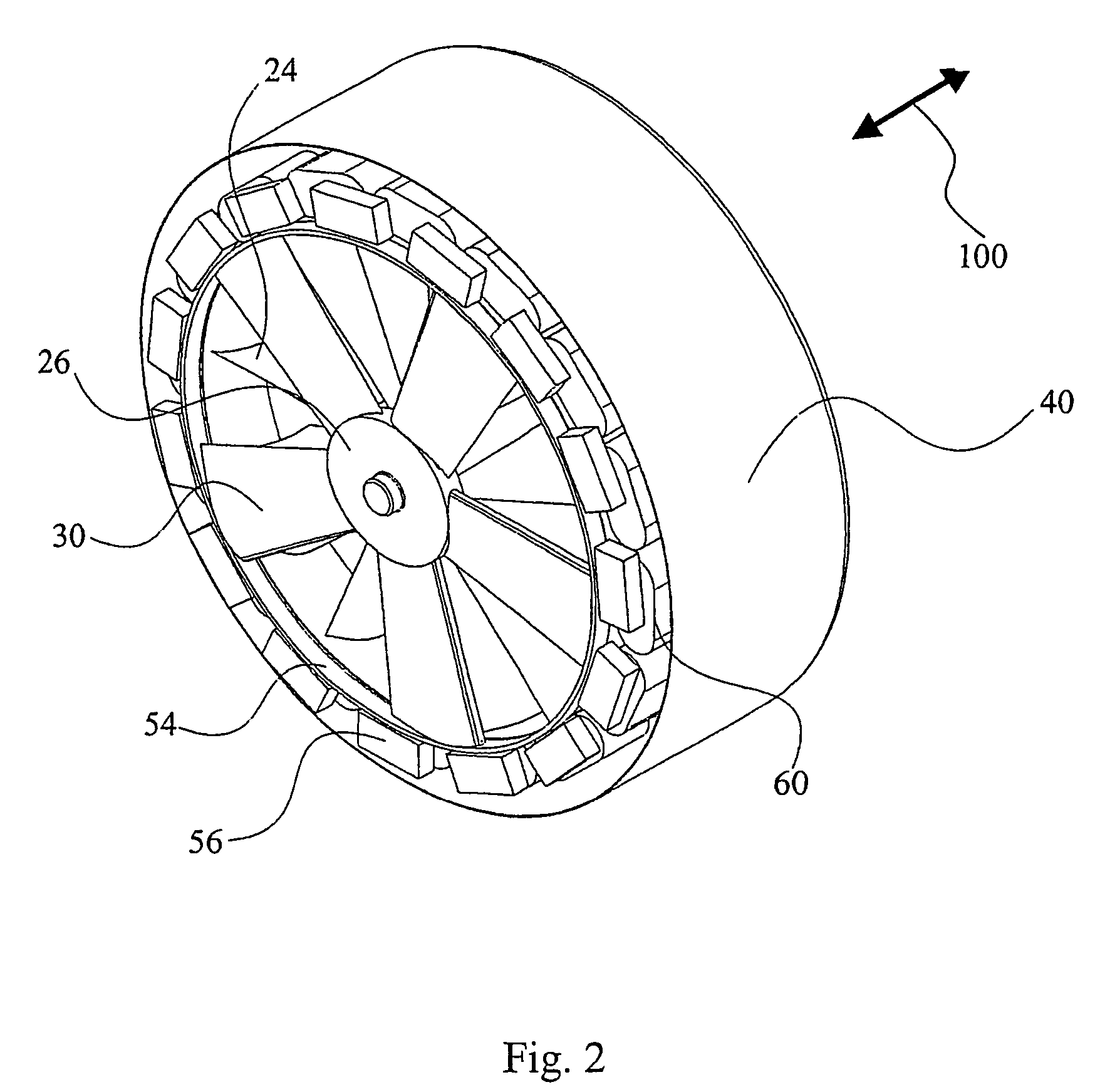

Wind turbine ring/shroud drive system

InactiveUS6951443B1Easy to adaptEliminate structureWind motor controlPump componentsNacelleGear drive

A wind turbine capable of driving multiple electric generators having a ring or shroud structure for reducing blade root bending moments, hub loads, blade fastener loads and pitch bearing loads. The shroud may further incorporate a ring gear for driving an electric generator. In one embodiment, the electric generator may be cantilevered from the nacelle such that the gear on the generator drive shaft is contacted by the ring gear of the shroud. The shroud also provides protection for the gearing and aids in preventing gear lubricant contamination.

Owner:GENERAL ELECTRIC CO

Oil line insulation system for mid turbine frame

A gas turbine engine having a mid turbine frame comprising an annular outer case providing a portion of an engine casing; an interturbine duct (ITD) disposed within the outer case, the ITD including outer and inner rings radially spaced apart one from another and being interconnected by a plurality of radially extending and circumferentially spaced hollow strut fairings, the inner and outer rings co-operating to provide a portion of a hot gas path through the engine; a tube for delivering or discharging a lubricant fluid to or from a bearing housing, the tube extending radially through one of the hollow struts; and an insulation structure radially extending through one said hollow strut fairing, the insulation structure surrounding the tube and being spaced apart from the tube and from a hot internal surface of the one hollow strut fairing for shielding the tube from heat radiated from the hot internal surface of the one hollow strut fairing and for preventing the lubricant fluid from contacting the hot internal surface of said one hollow strut fairing when lubricant fluid leakage occurs.

Owner:PRATT & WHITNEY CANADA CORP

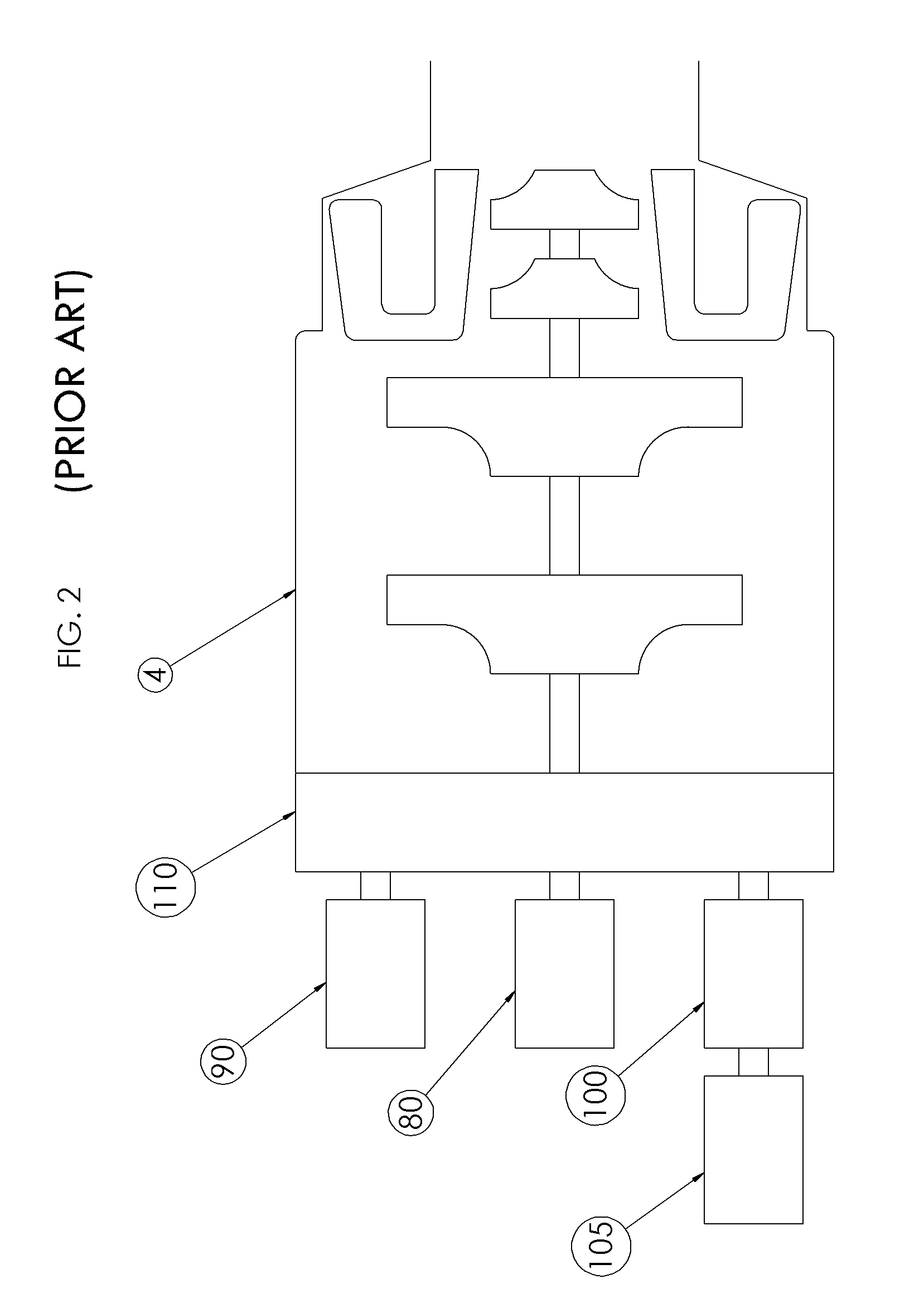

Gearbox for a wind turbine

A gearbox for a wind turbine includes a ring wheel unit provided in a housing; a driving shaft designed to be coupled to the rotor of the wind turbine and a single main bearing or a pair of main bearings which rotatably support the driving shaft in the housing. The ring wheel unit is formed of a sun wheel, a planet wheel, ring wheel which is fixed to the housing in a non-rotating manner and a planet carrier which is rigidly connected to the driving shaft. An additional bearing rotatably supports the planet carrier or the driving shaft relative to the housing. Between the part of the housing having the main bearing or the main bearings and the part of the housing with the additional bearing and the ring wheel, an elastic part is provided with relative torsional stiffness, yet relatively flexible to loads in the axial and / or radial direction.

Owner:HANSEN TRANSMISSIONS INT NV

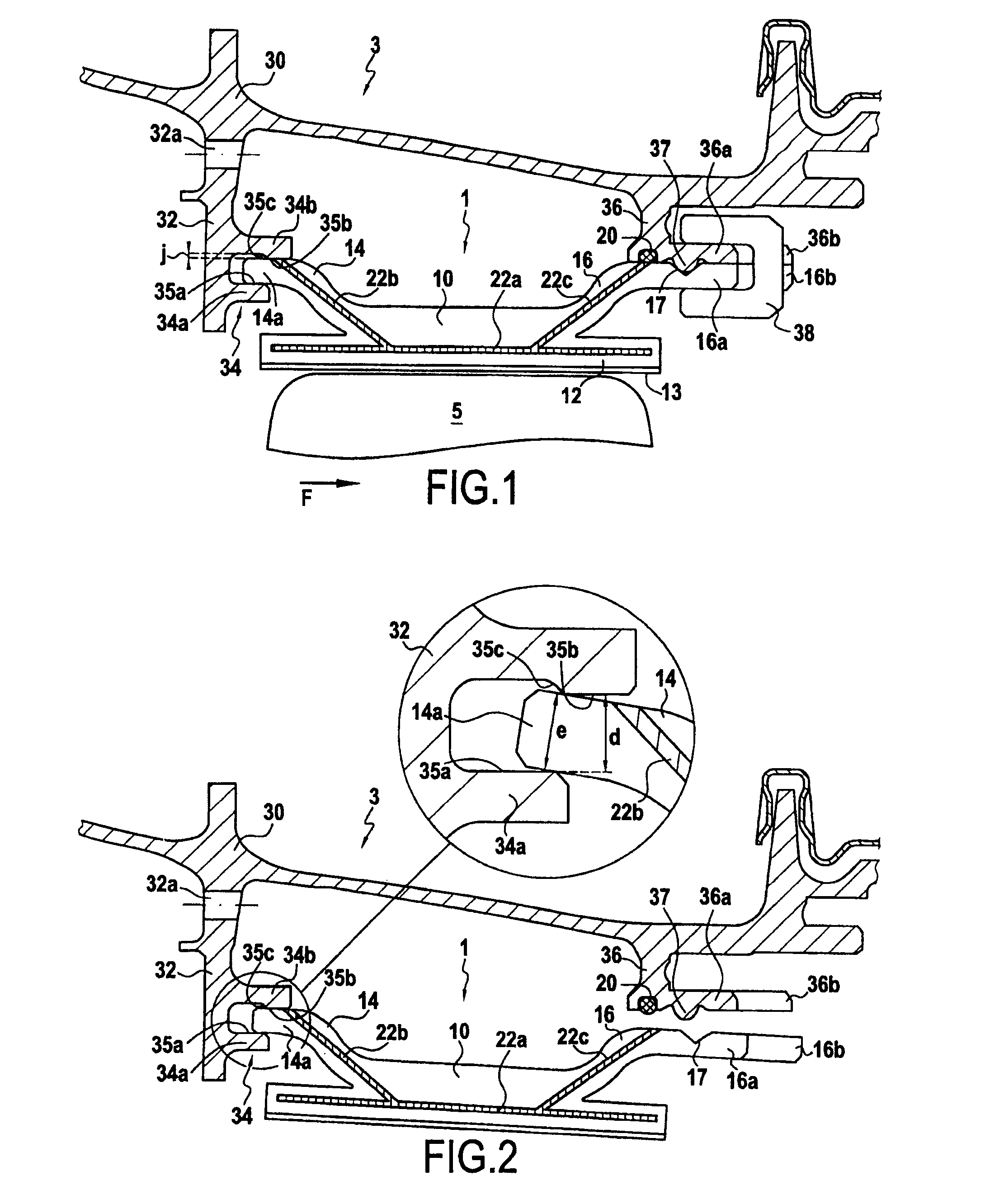

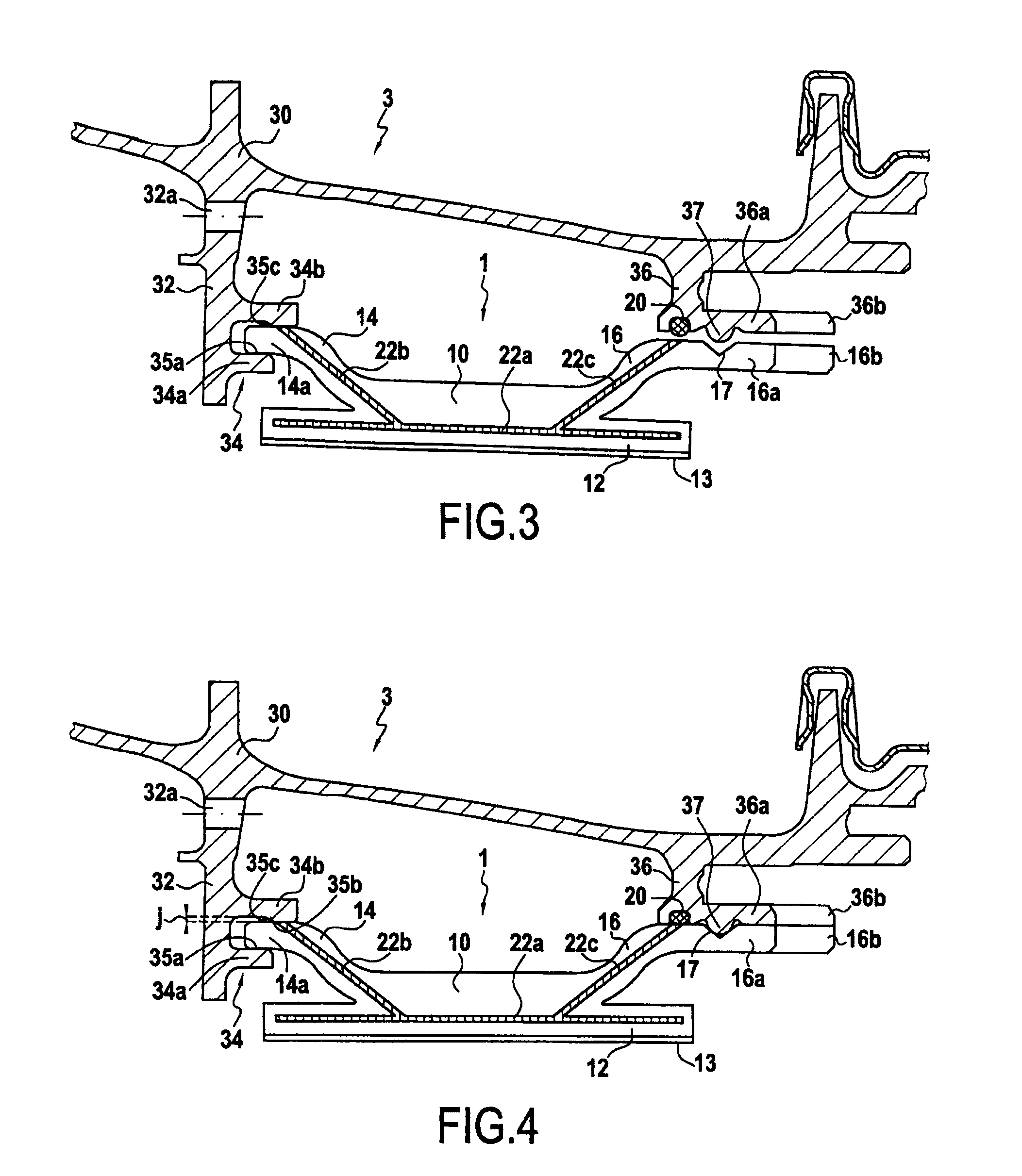

Turbine ring assembly

A turbine ring assembly includes a ring support structure and a plurality of ring sectors, each including a single piece of ceramic matrix composite material. Each ring sector includes a first portion forming an annular base with an inside face defining an inside face of the turbine ring and an outside face from which there extends two tab-forming portions including ends that are engaged in housings in the ring support structure. The ring sectors present a section that is substantially π-shaped and the ends of the tabs are held without radial clearance by the ring support structure. The tabs can have a free length in meridian section that is not less than three times their mean width.

Owner:GERAKL

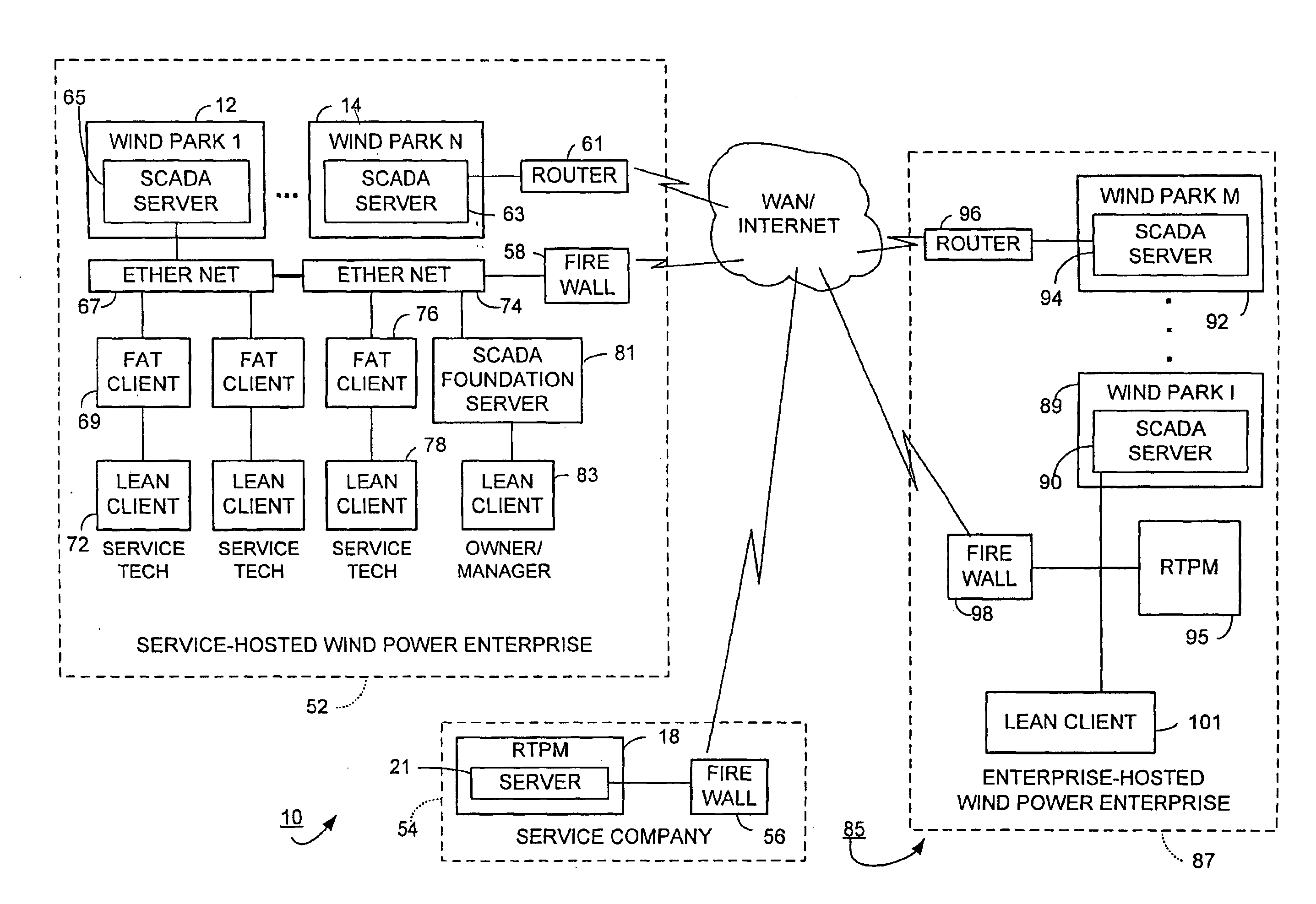

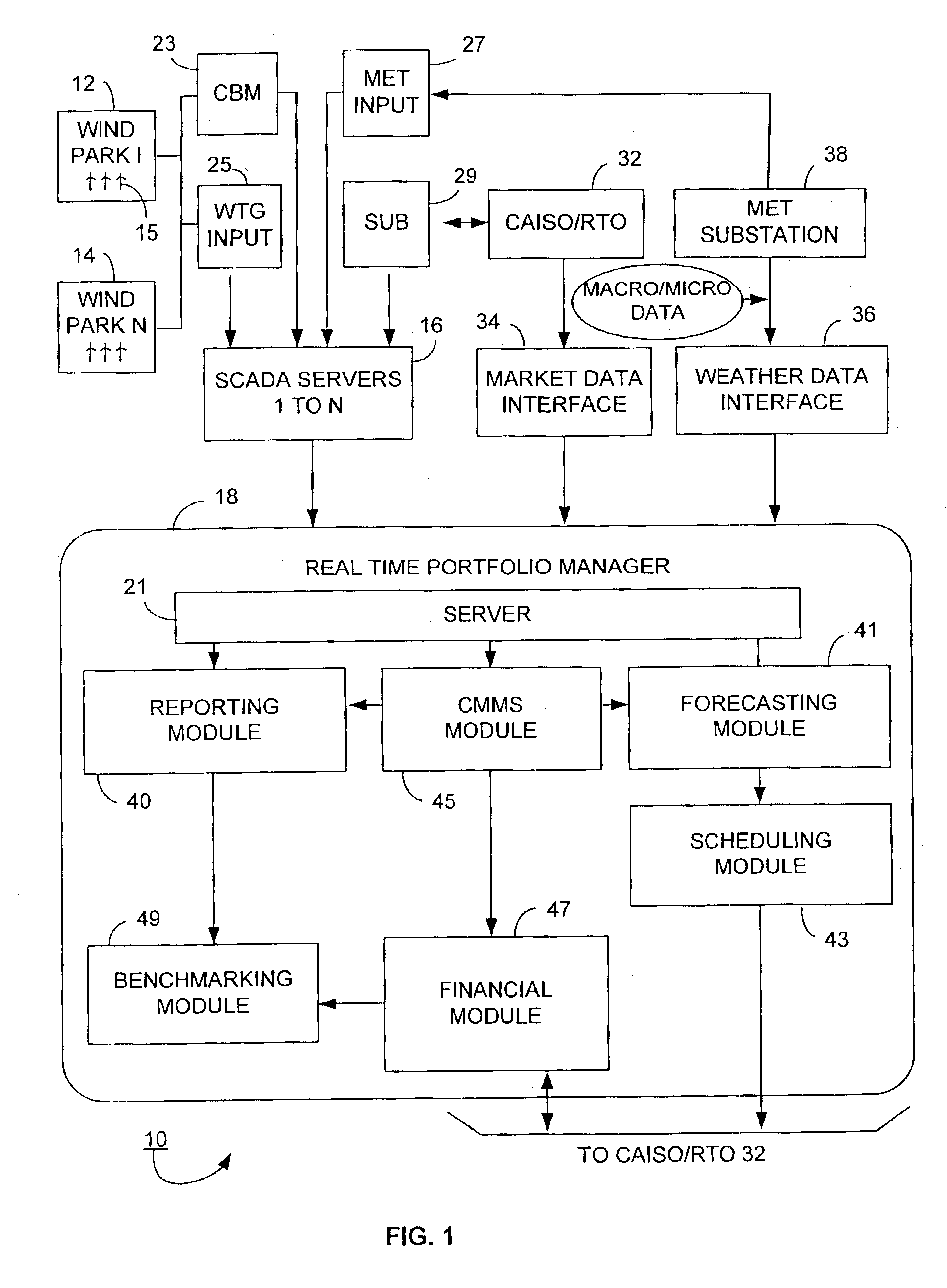

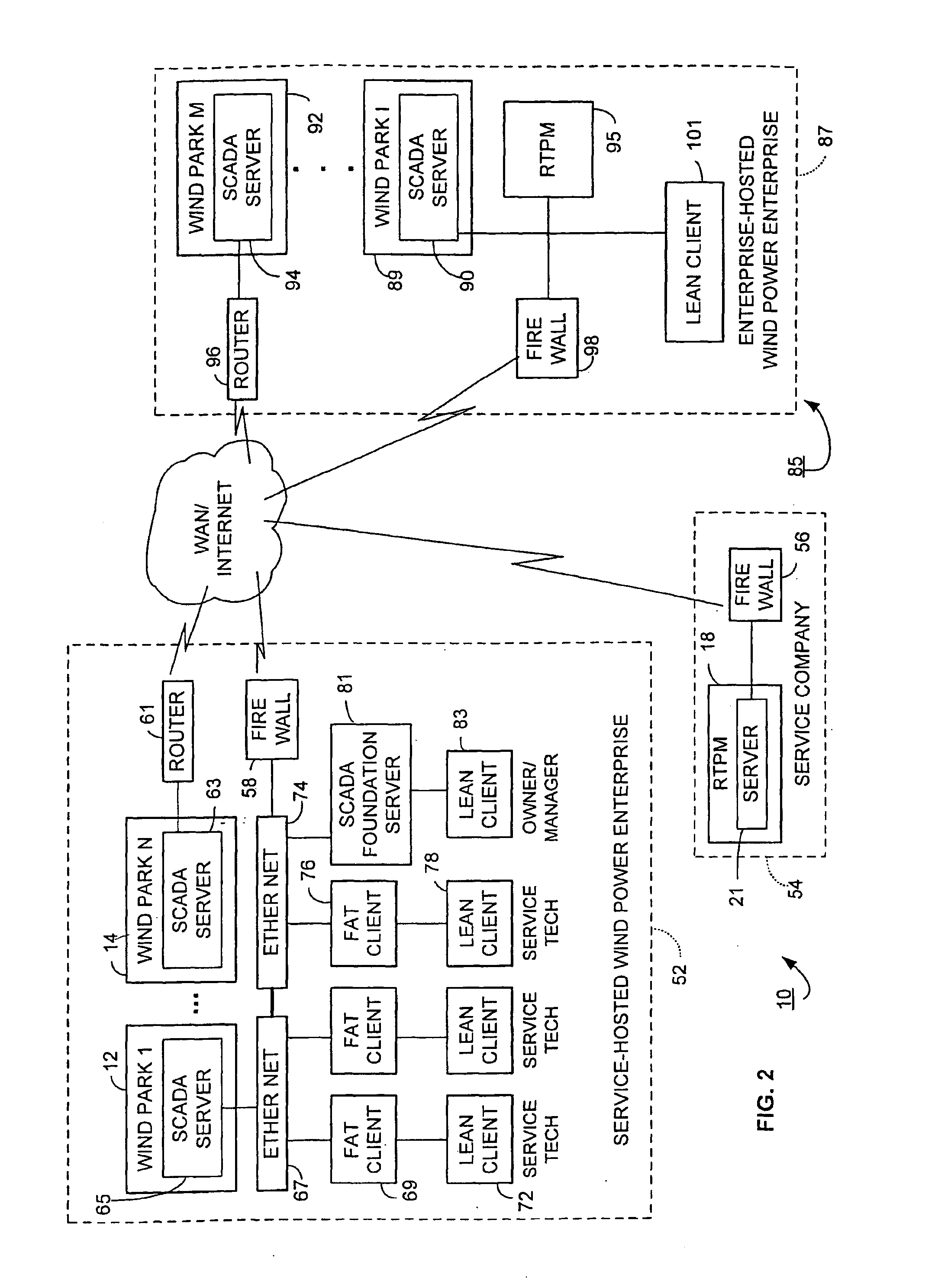

Wind power management system and method

According to certain disclosed embodiments of the invention, there is provided a wind power management system to monitor performance of wind turbine generators situated in wind farms, each having a number of wind turbine generators. A real-time wind power portfolio manager receives and stores in real-time data being produced by the wind turbine generator parks. The manager has a reporting module for generating profile reports for the performance of the wind turbine generators. The manager has a server to provide the reports on-line regarding the wind turbine generators. The server stores the real-time data to enable the reports to be based on the history of the project for each one of the parks.

Owner:SEAWEST HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com