Patents

Literature

9726results about "Leakage prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

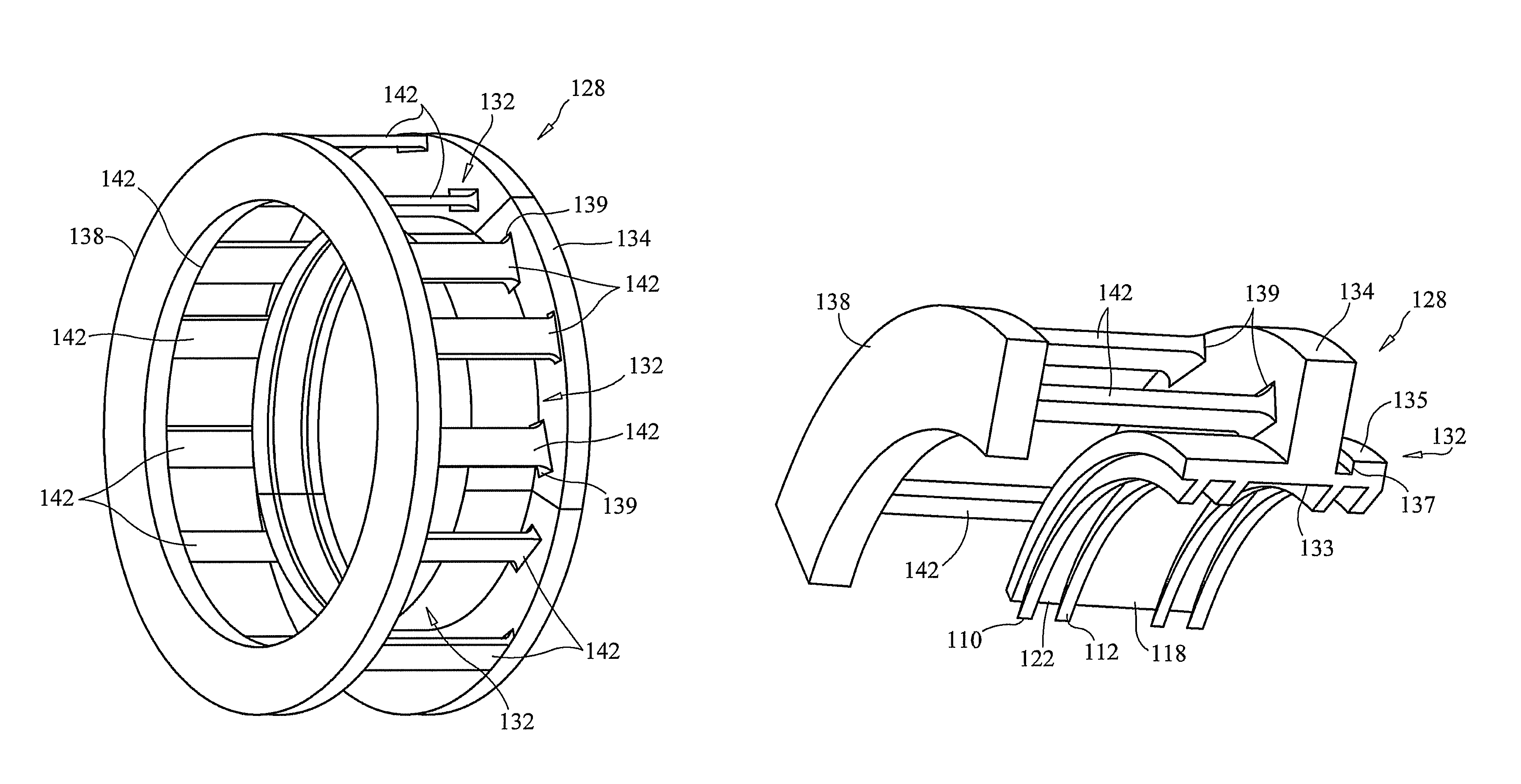

Flexible shaft for gas turbine engine

A shaft for a gas turbine engine is provided that includes a first shaft section, a second shaft section, a first flexible linkage, and a second flexible linkage. The first shaft section extends between a forward axial end and an aft axial end along a first axial centerline. The second shaft section extends between a forward axial end and an aft axial end along a second axial centerline. The first flexible linkage includes a bridge section connected between a first diaphragm and a second diaphragm. The first diaphragm is connected to the aft axial end of the first shaft section. The second diaphragm is connected to the forward axial end of the second shaft section. The second flexible linkage includes a diaphragm and a hub. The second flexible linkage diaphragm cantilevers radially outwardly from an inner radial end to an outer radial end, and is connected to the aft axial end of the second shaft section. The hub is connected to the outer radial end of the second flexible linkage diaphragm, and includes an engine shaft coupling connected to the hub.

Owner:RTX CORP

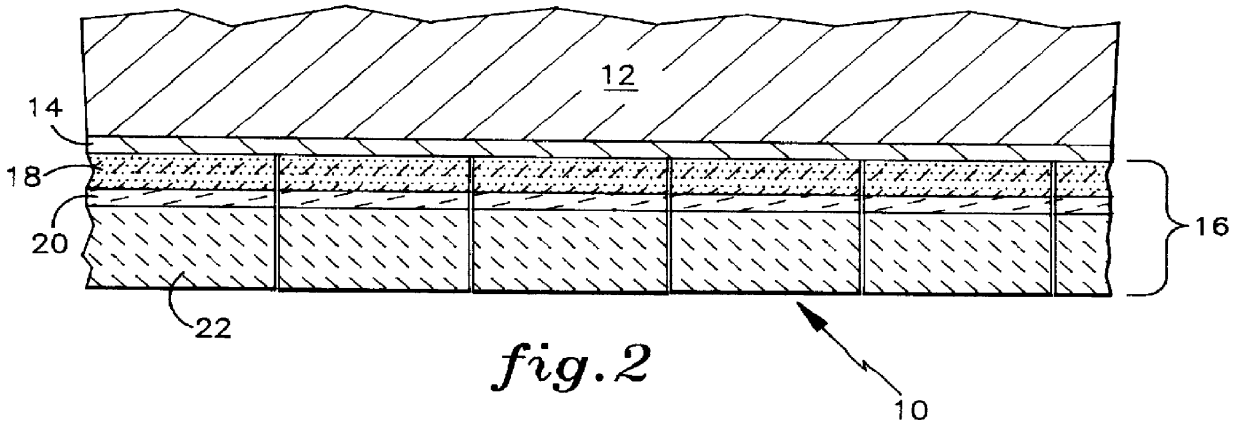

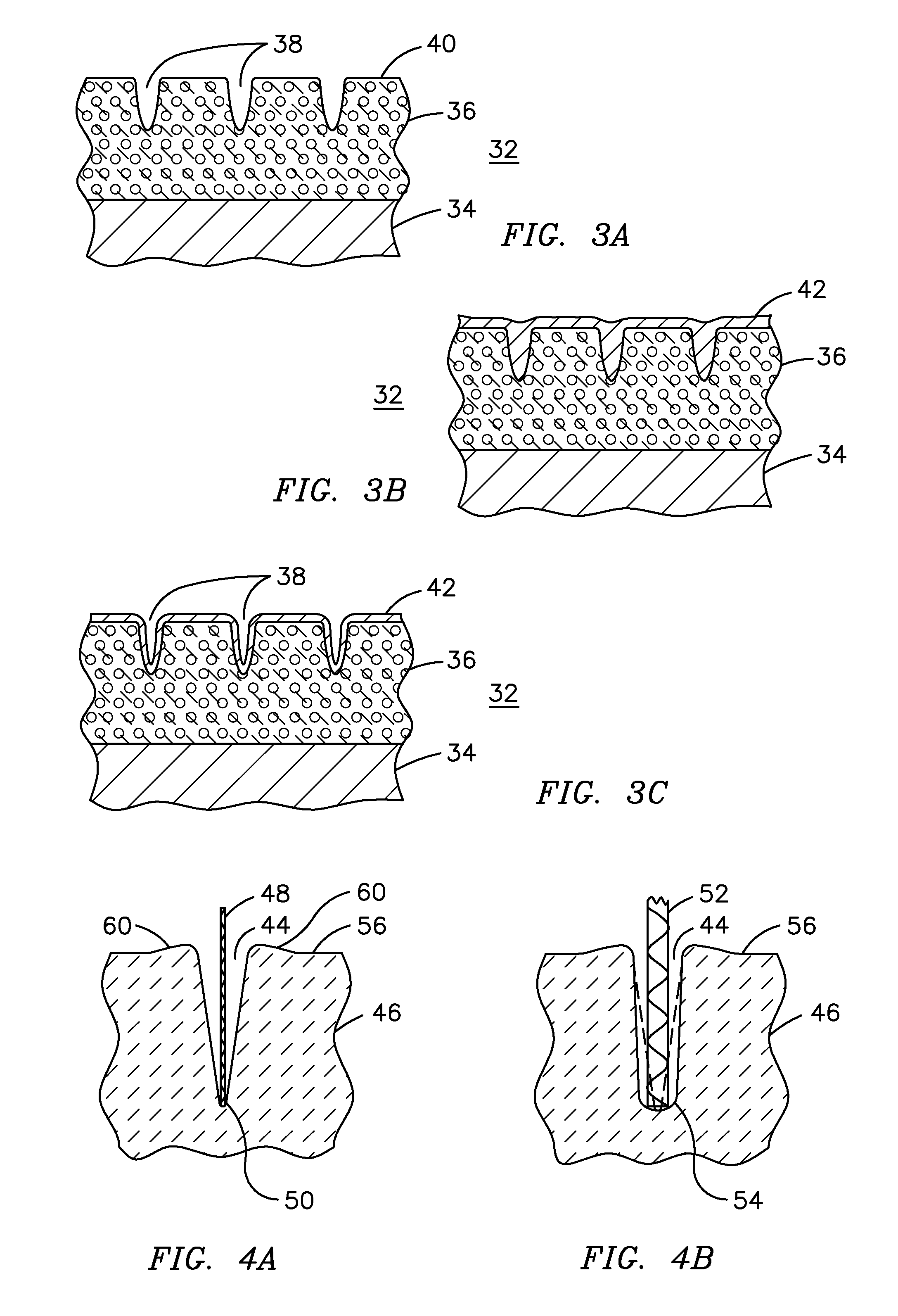

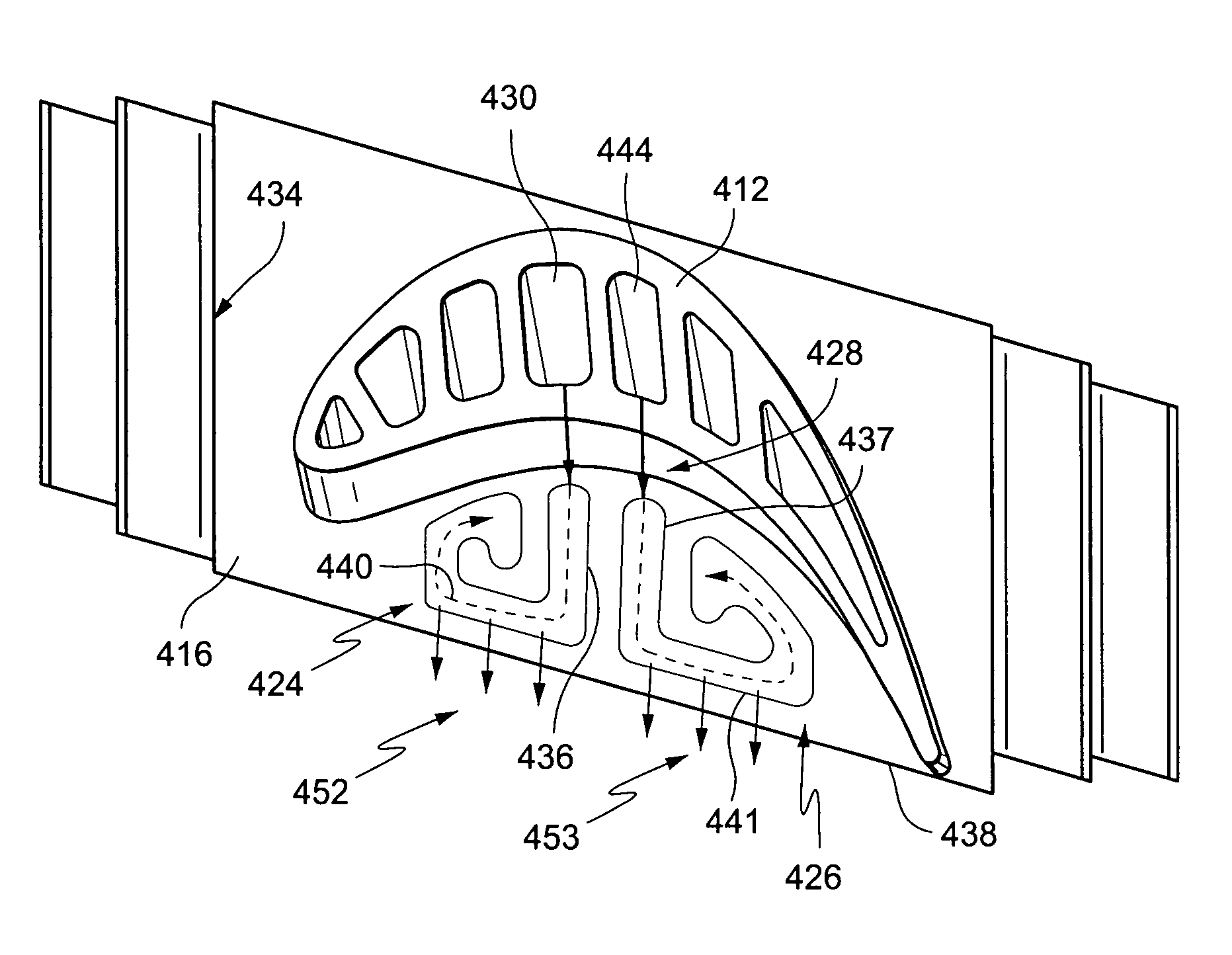

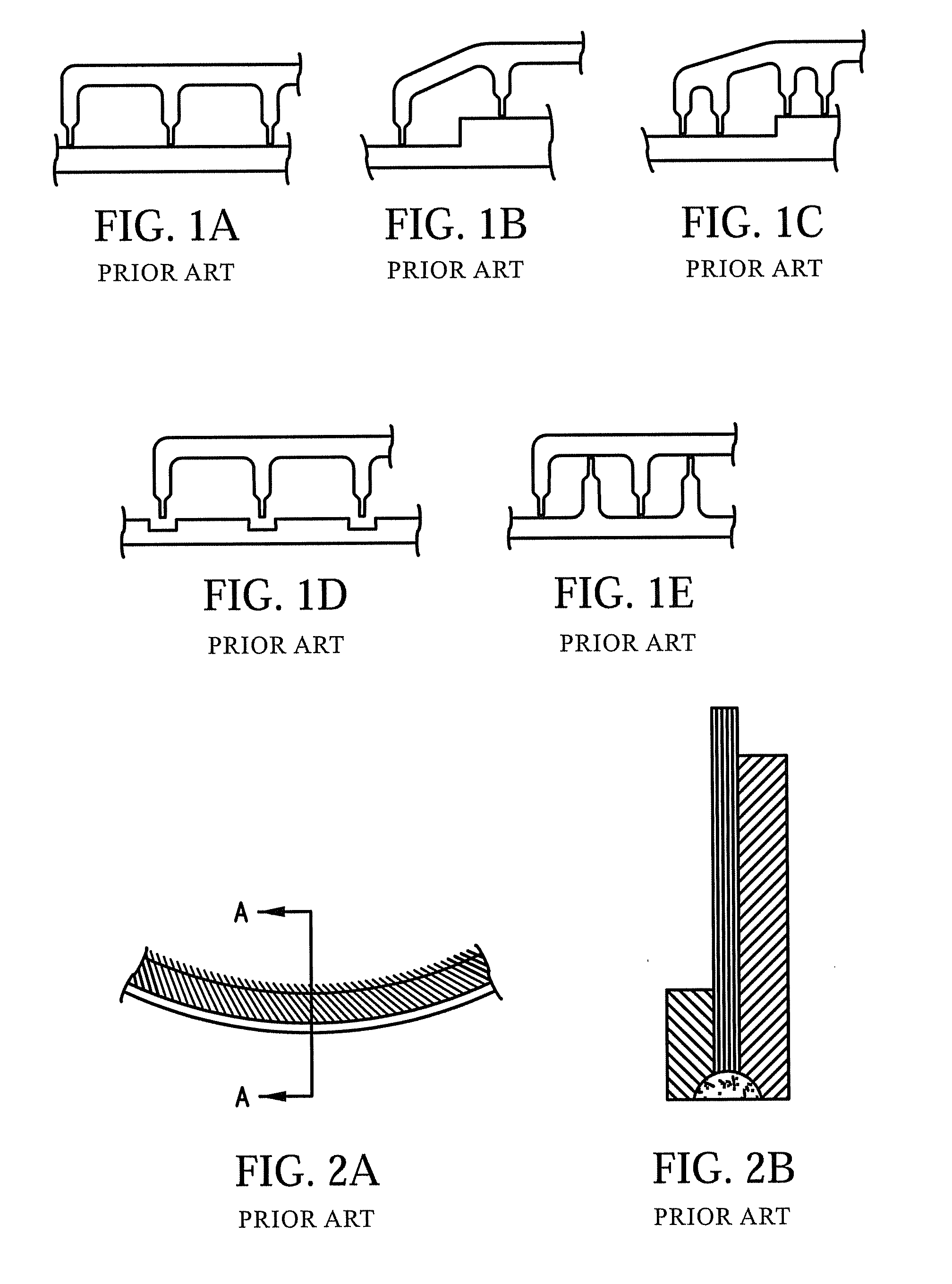

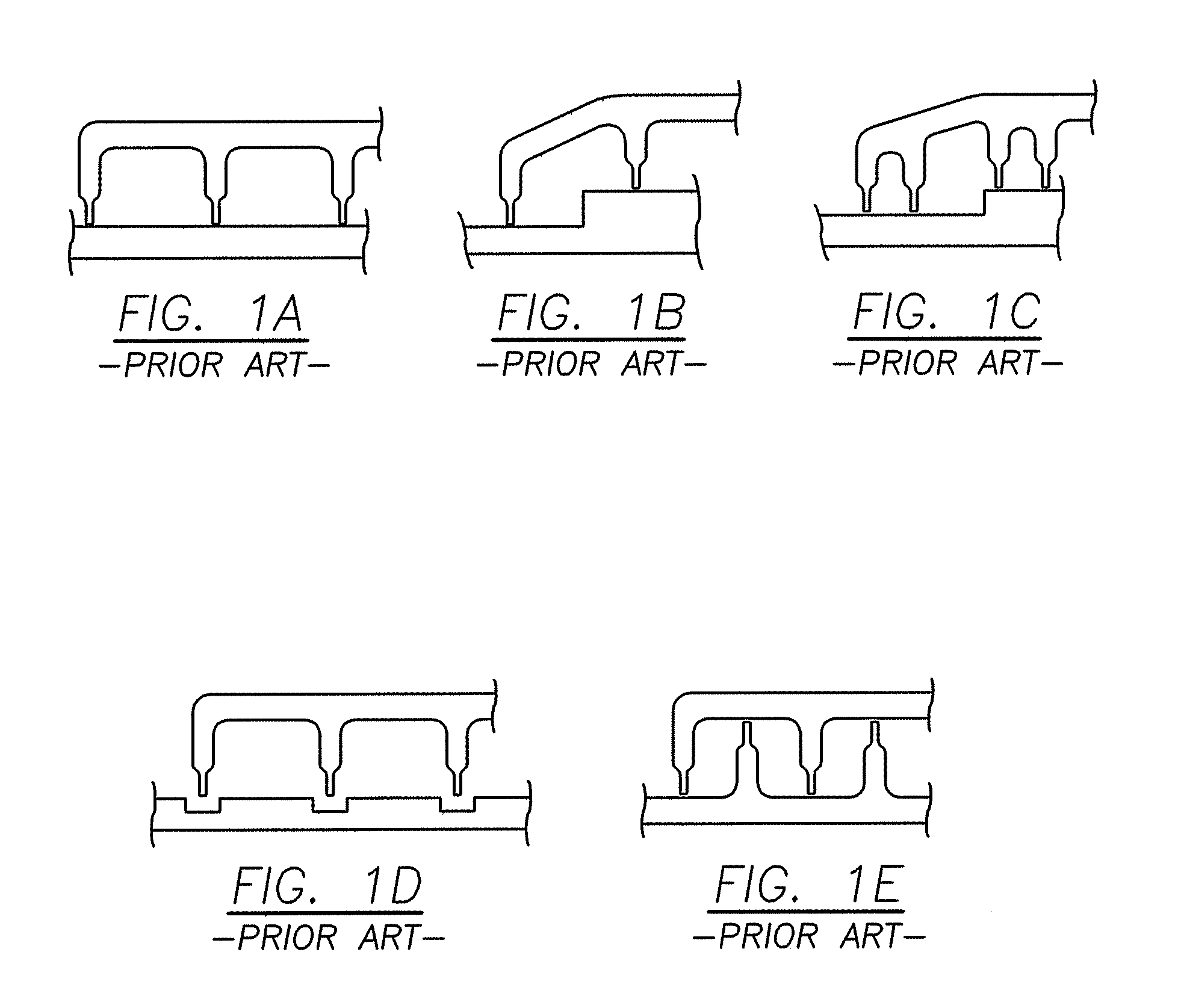

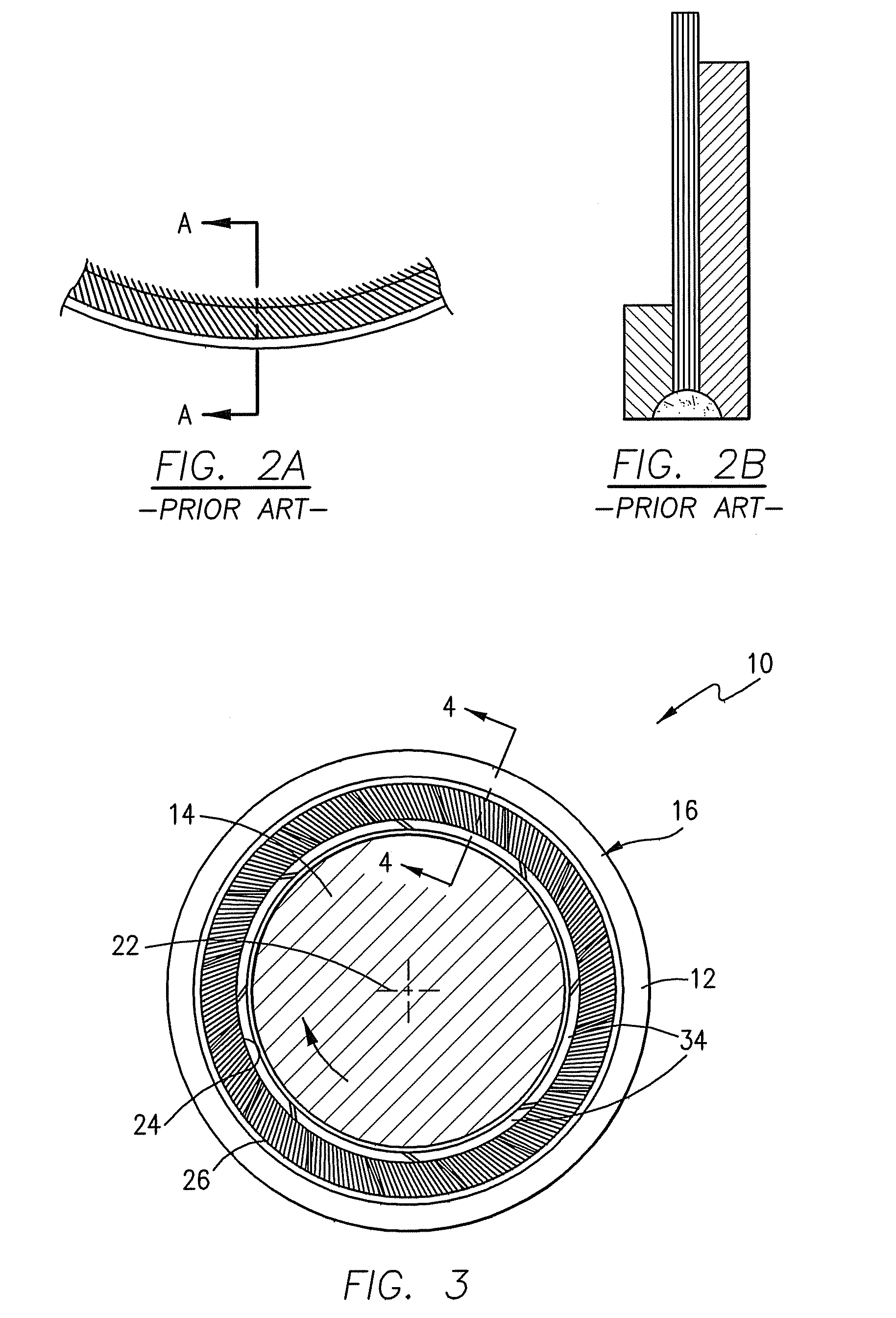

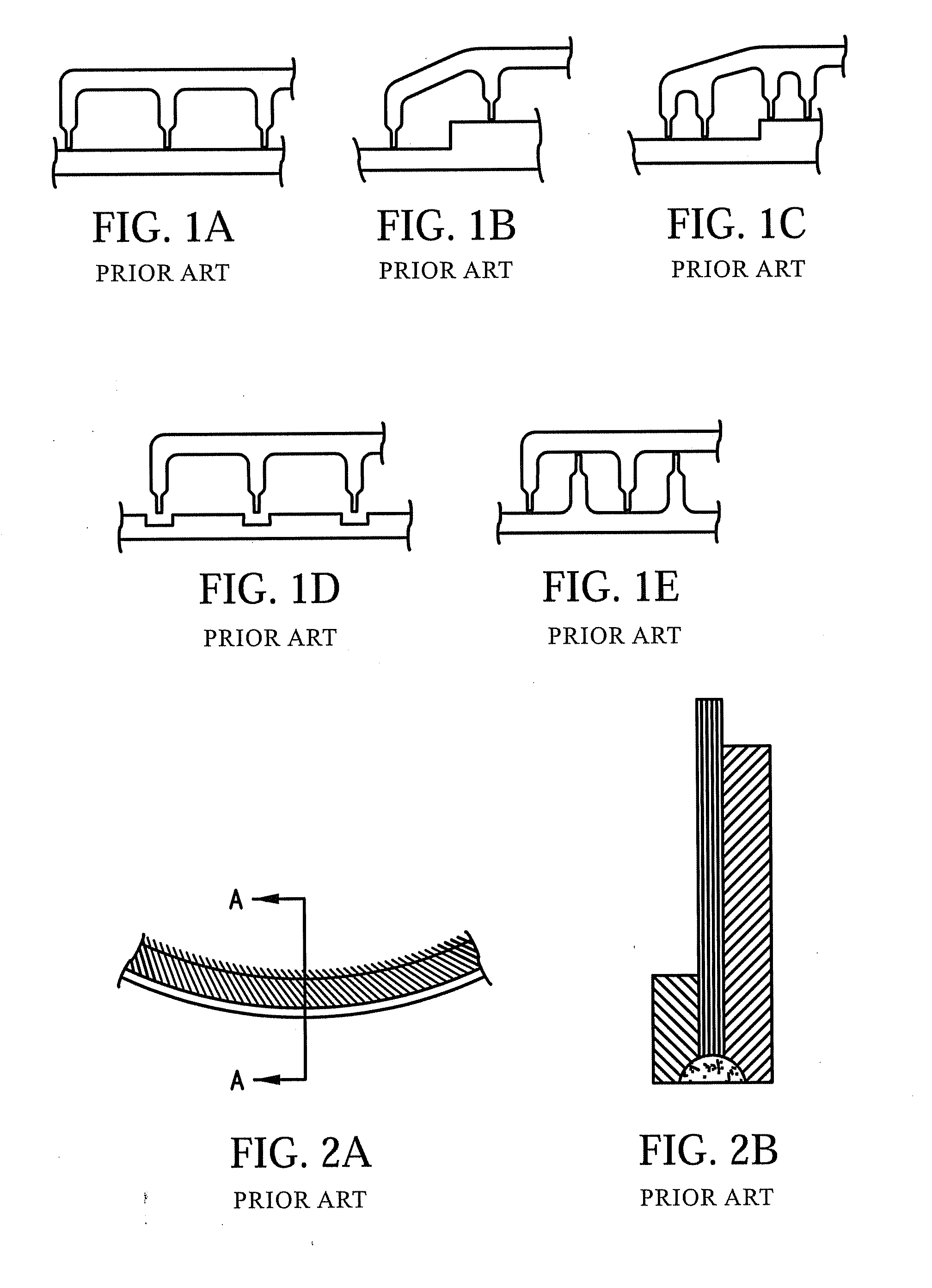

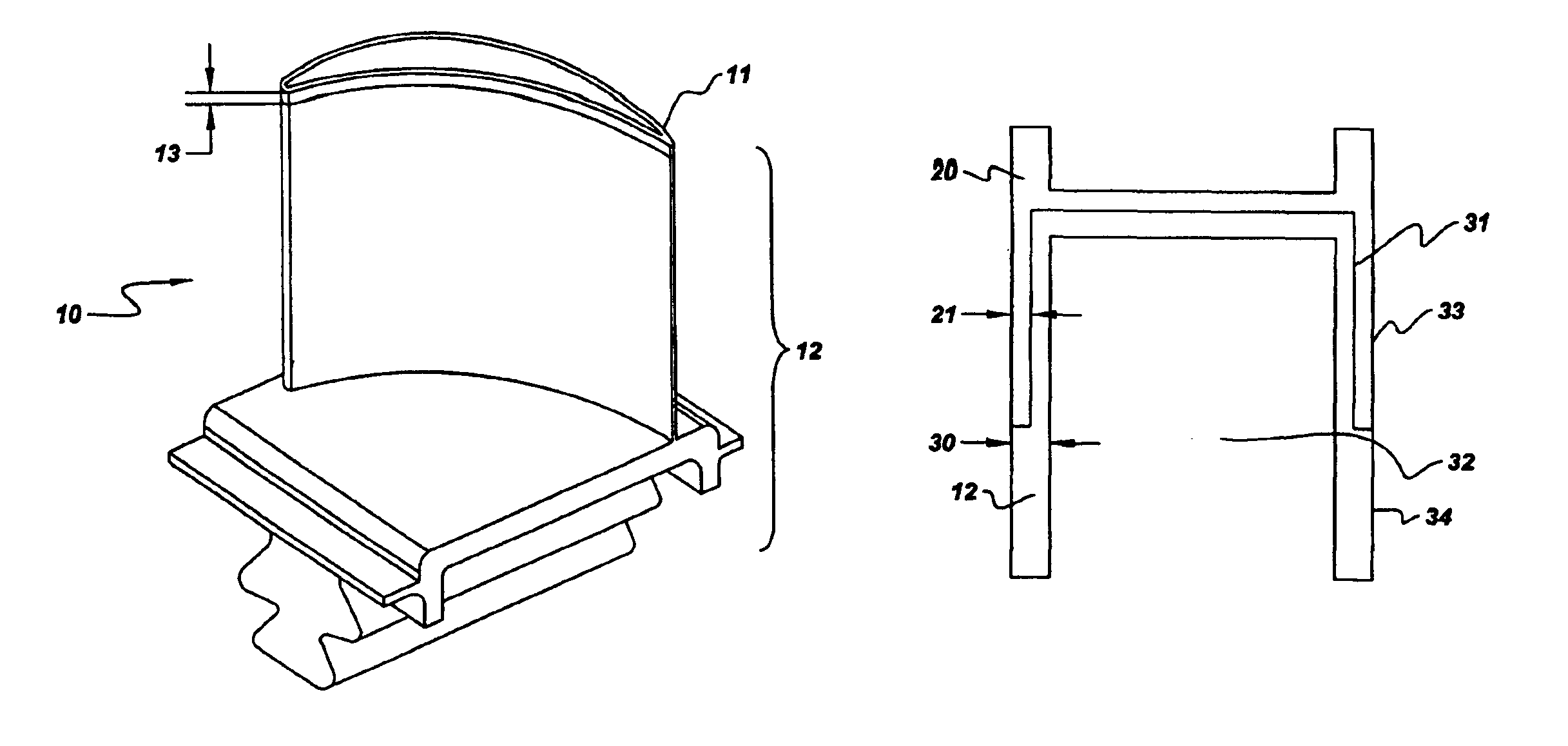

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

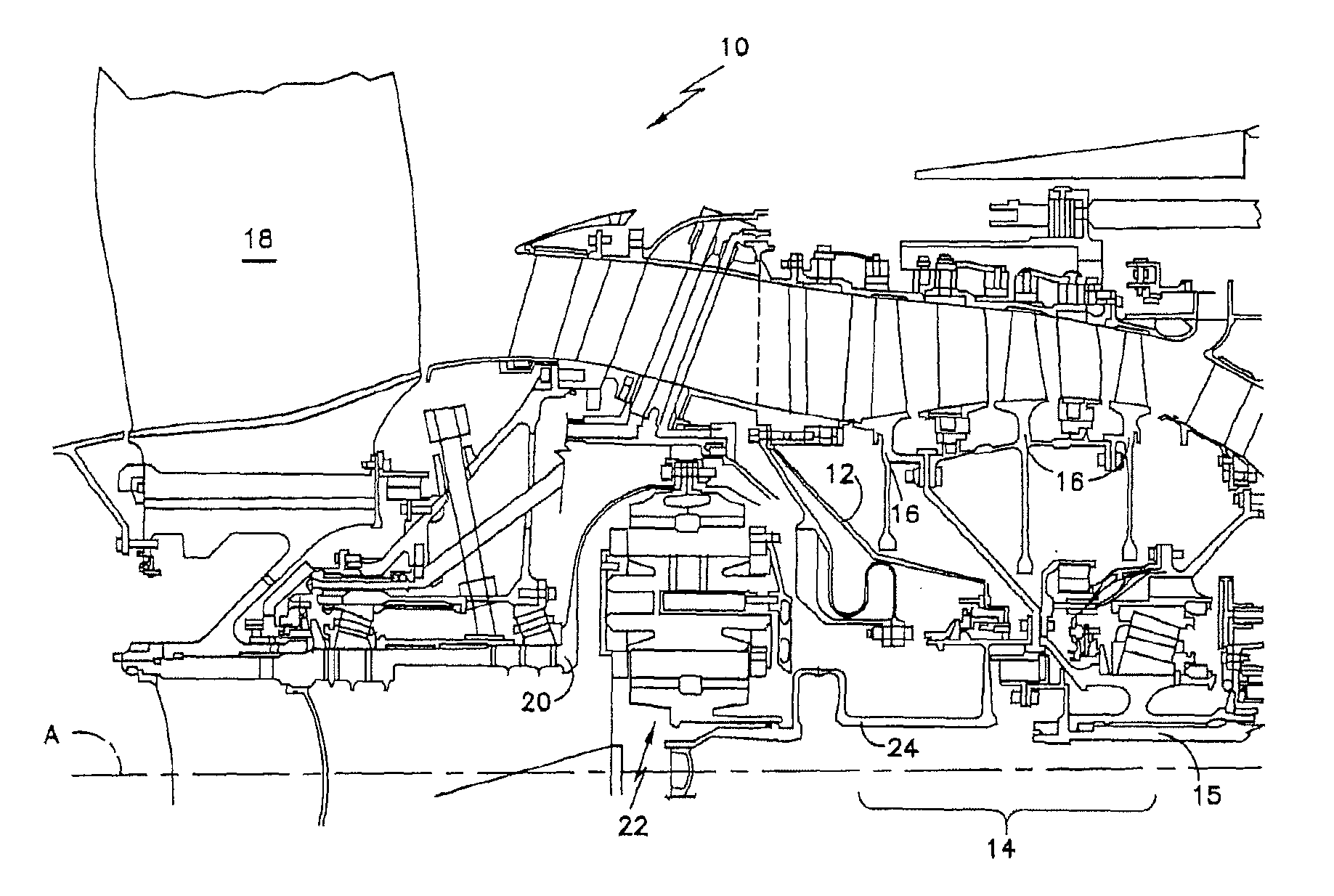

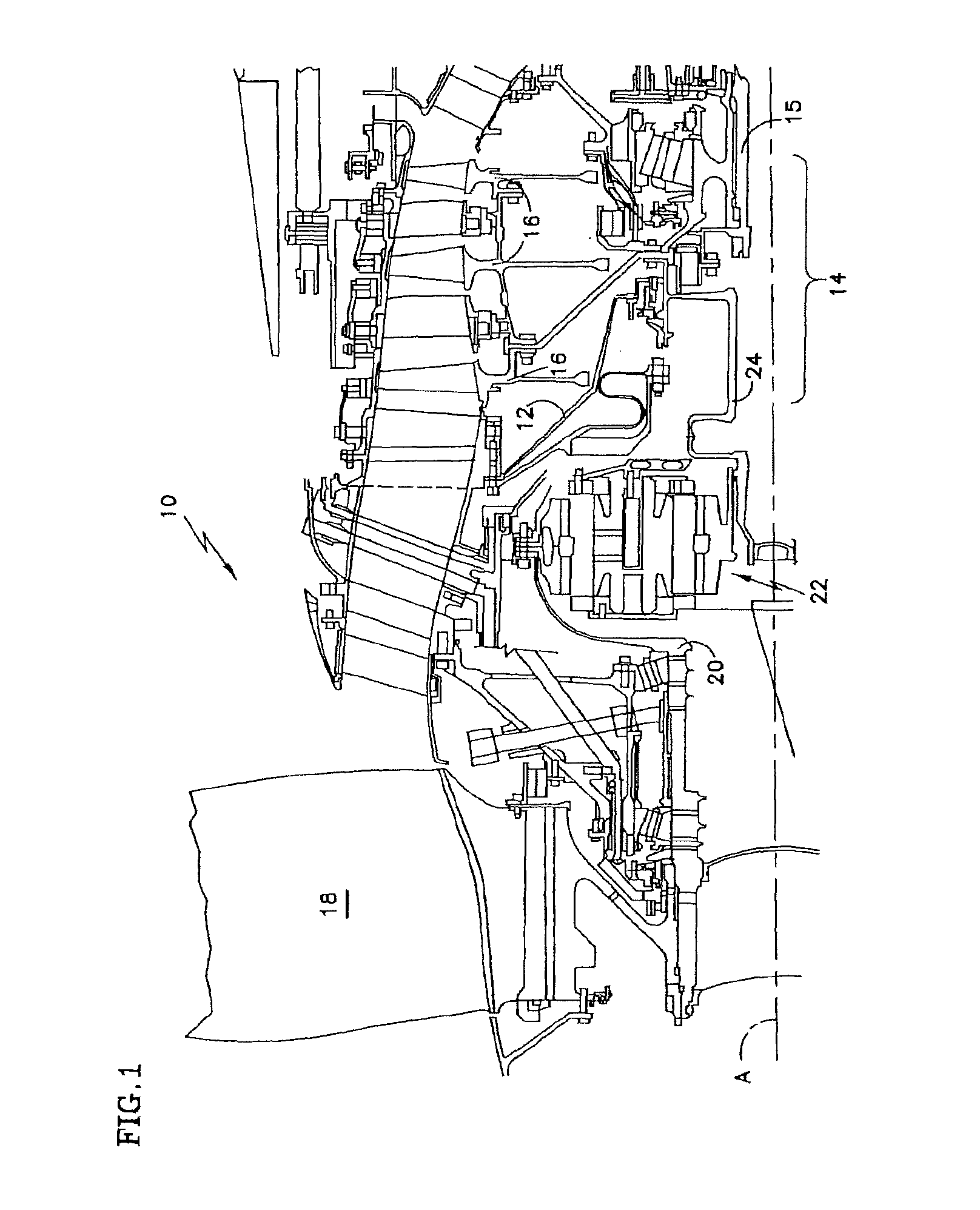

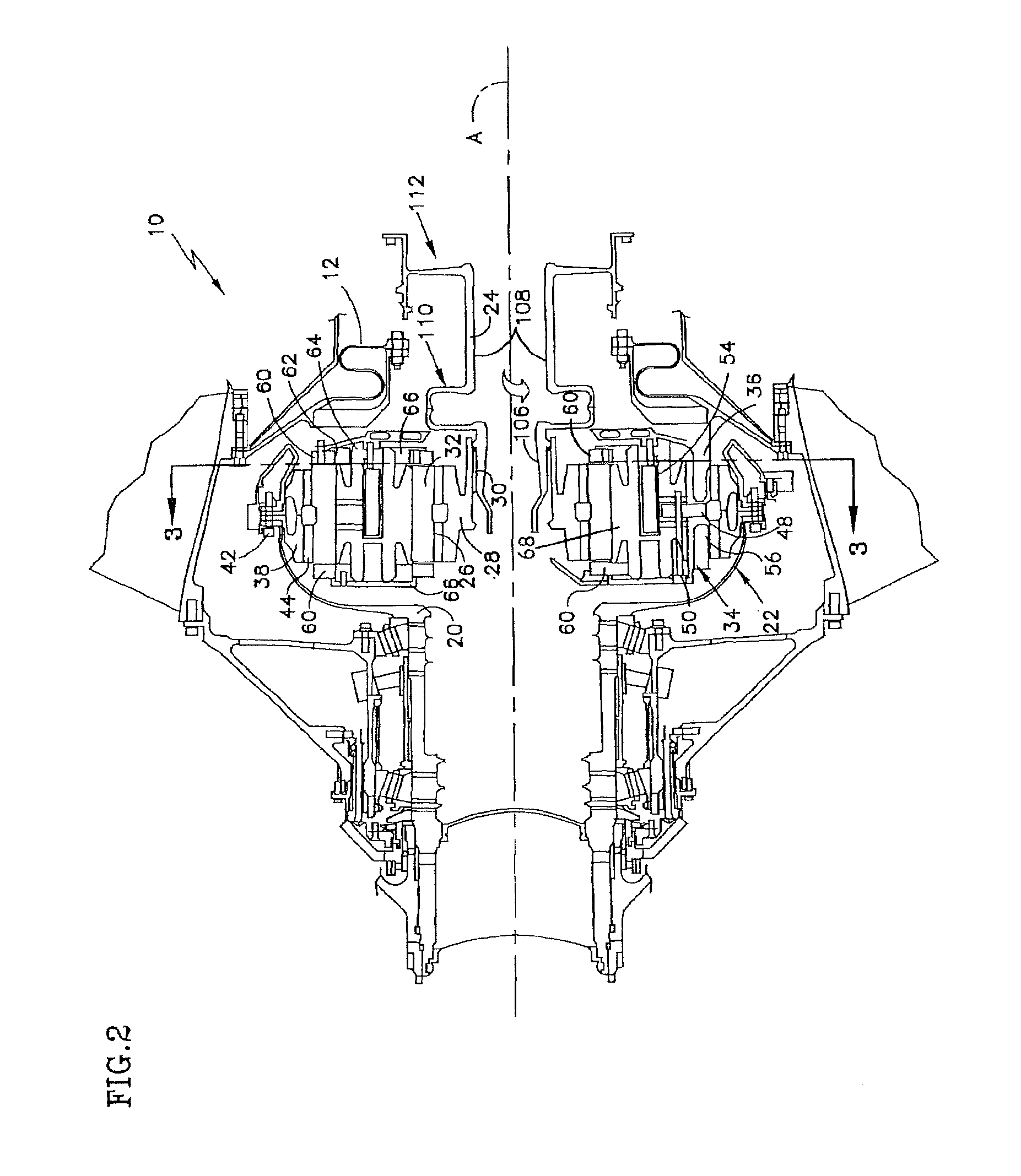

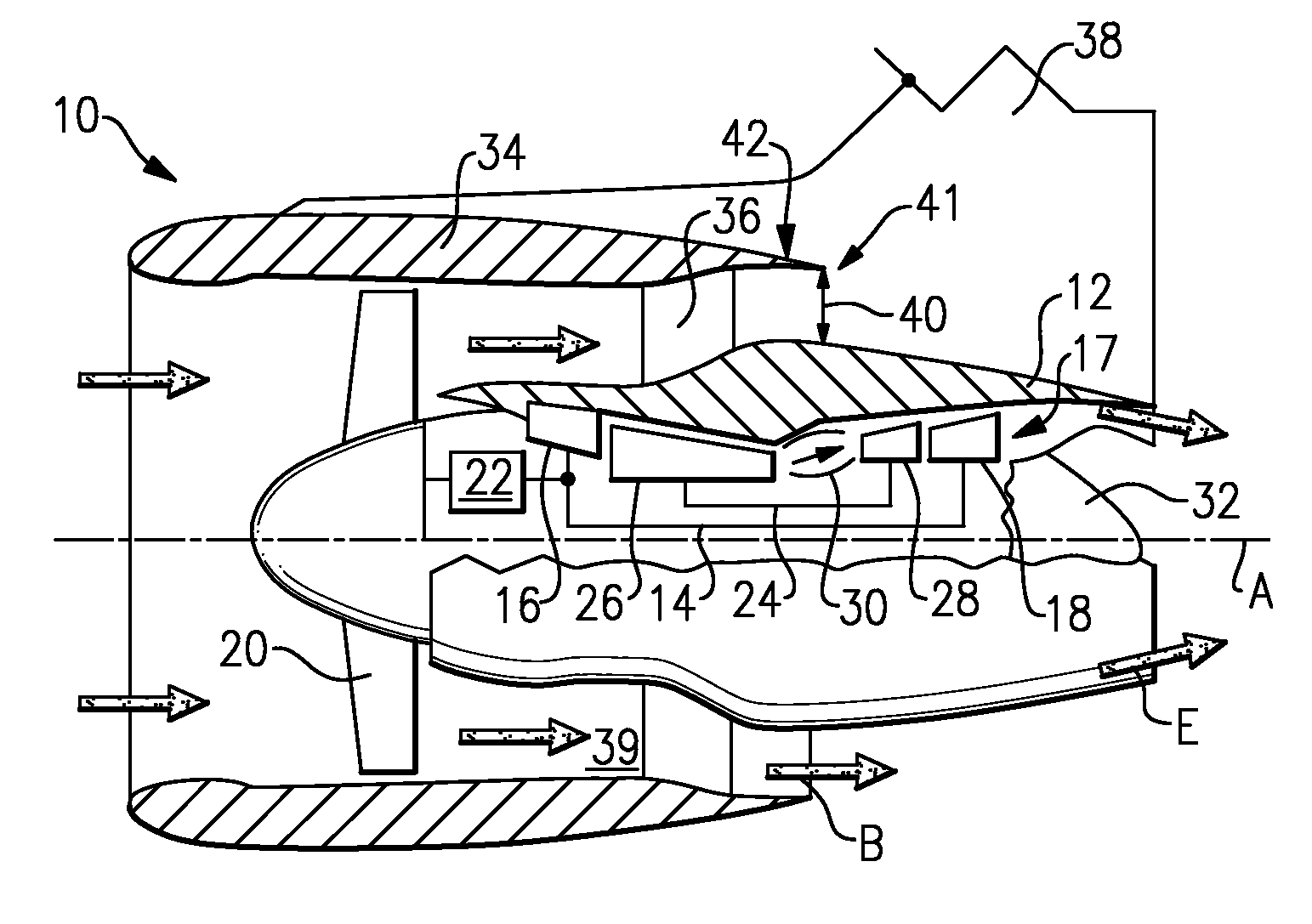

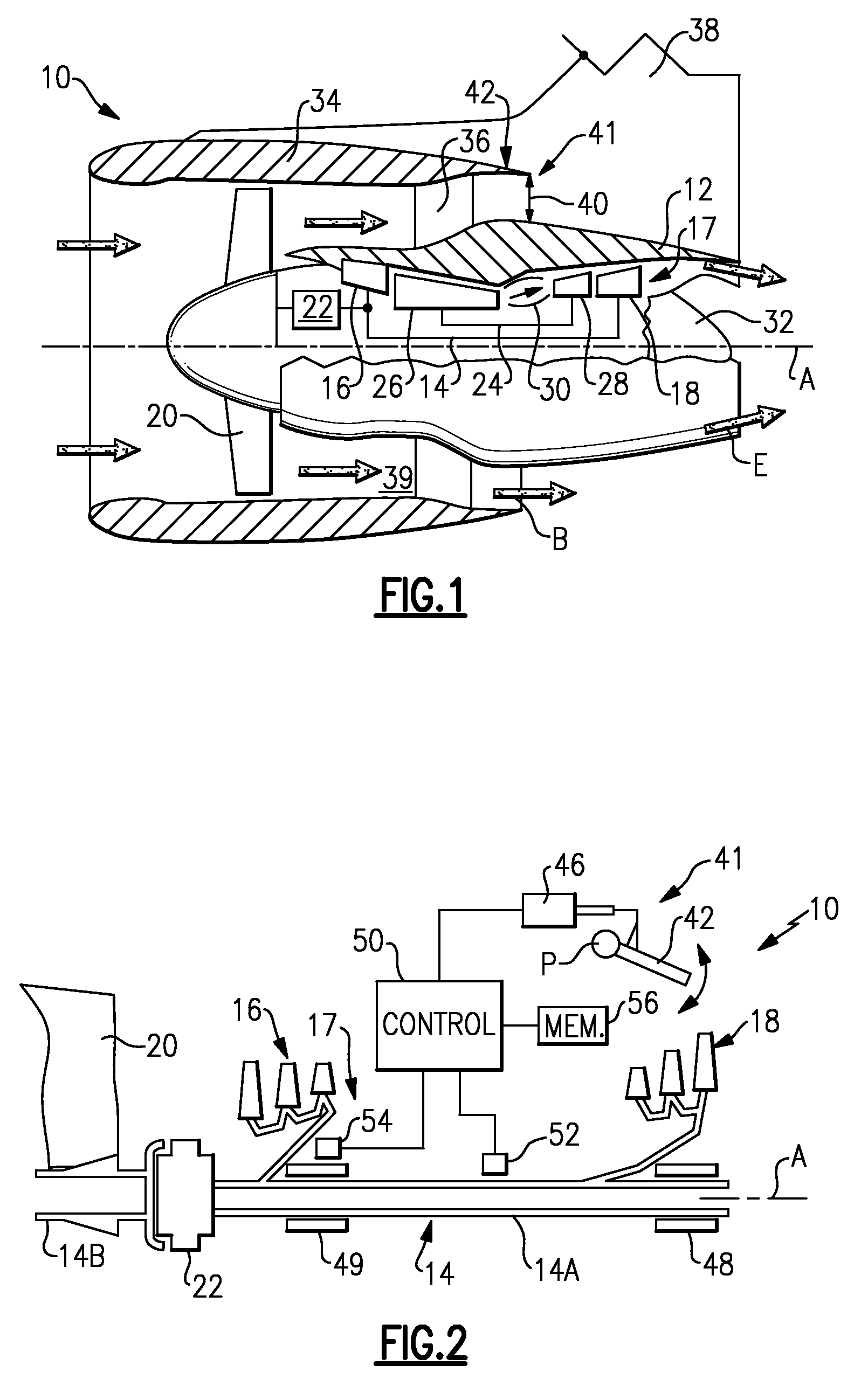

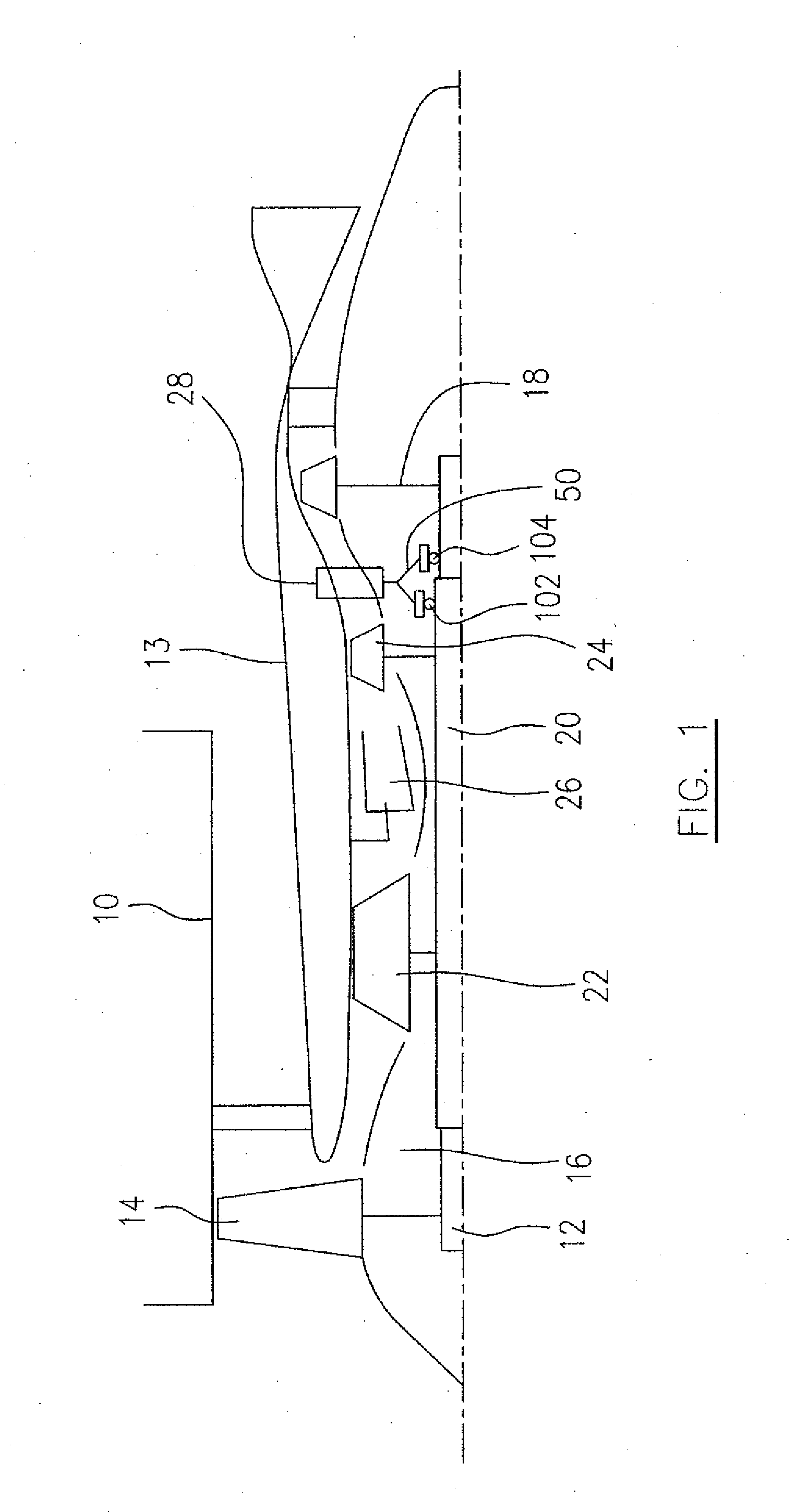

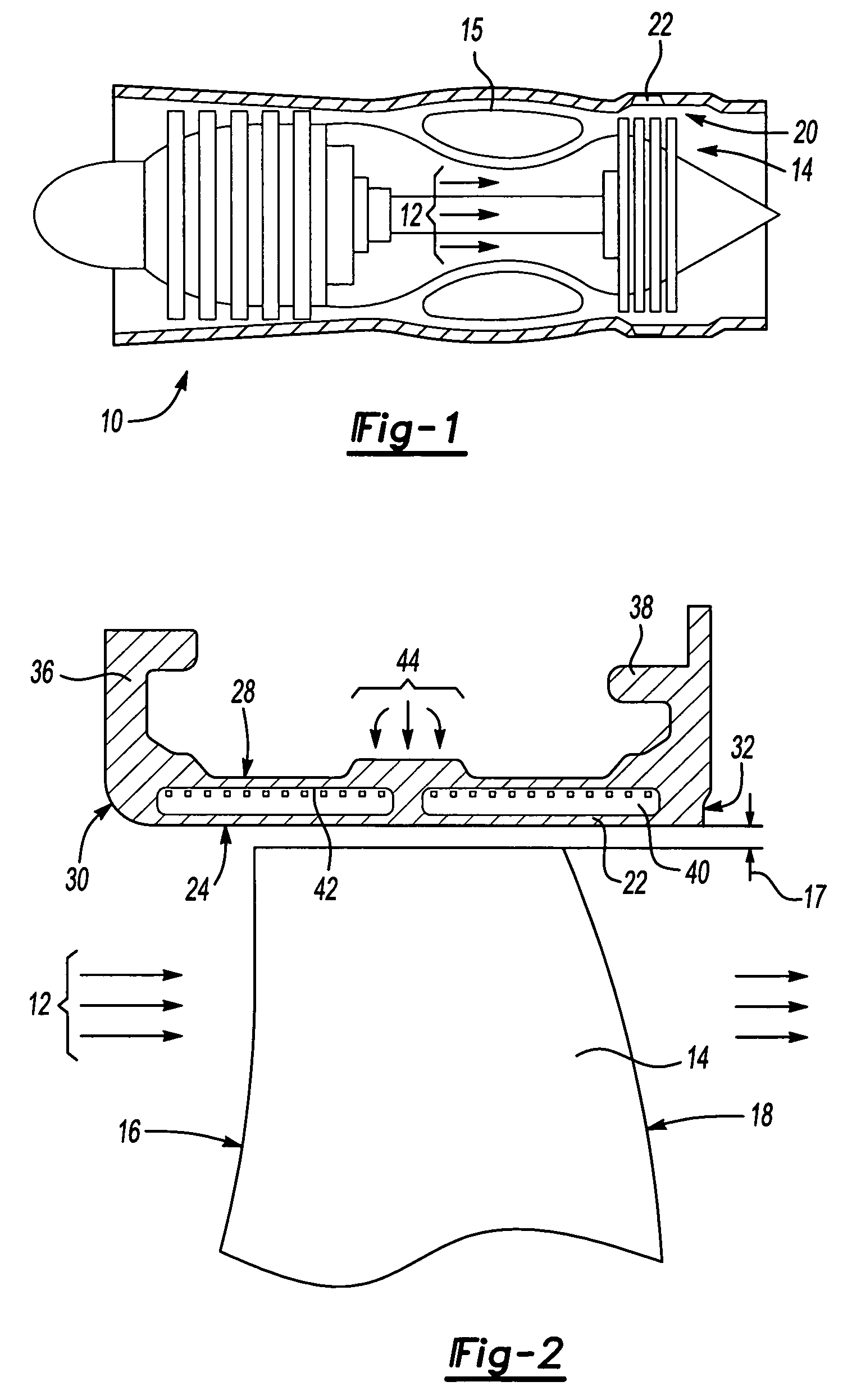

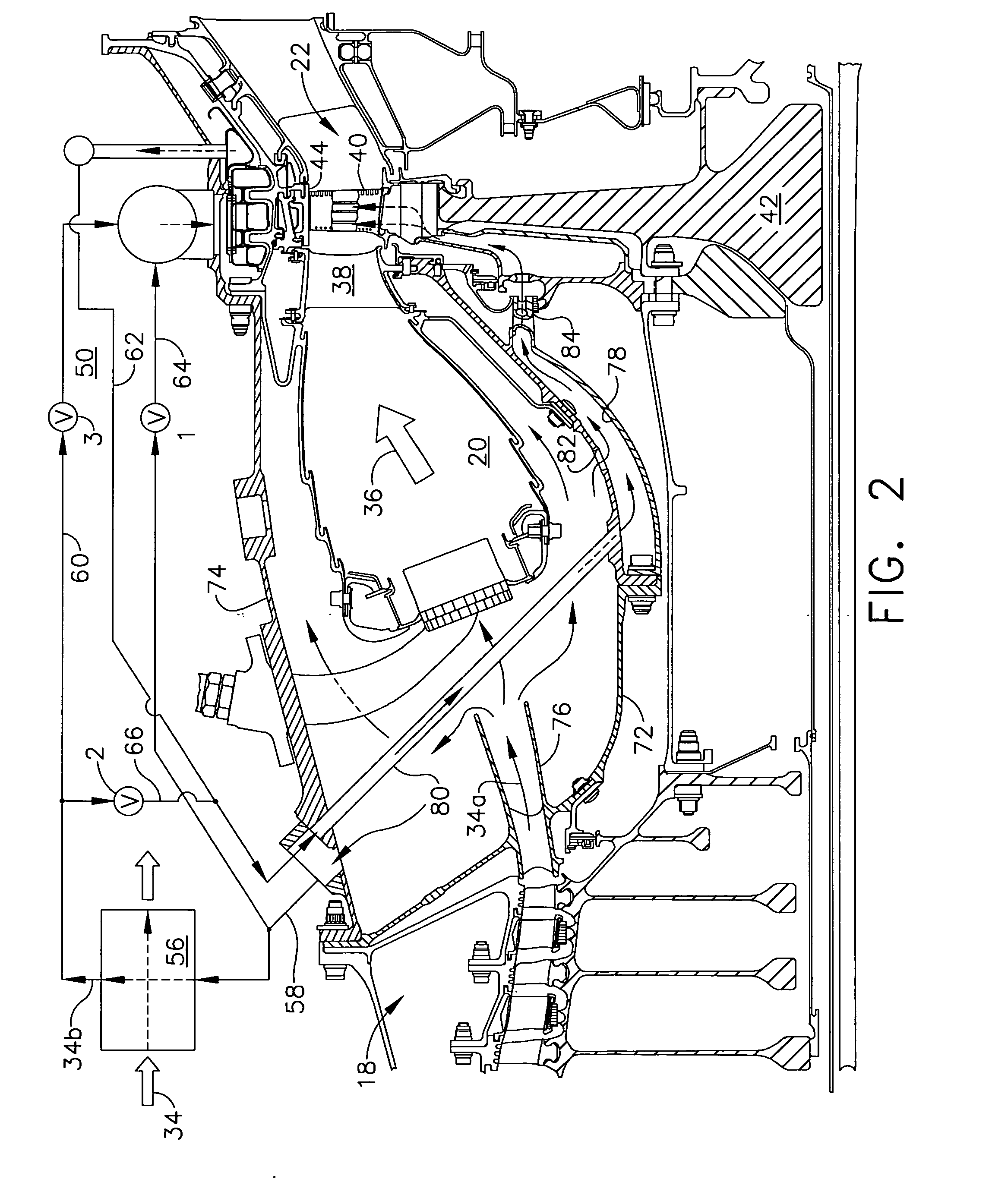

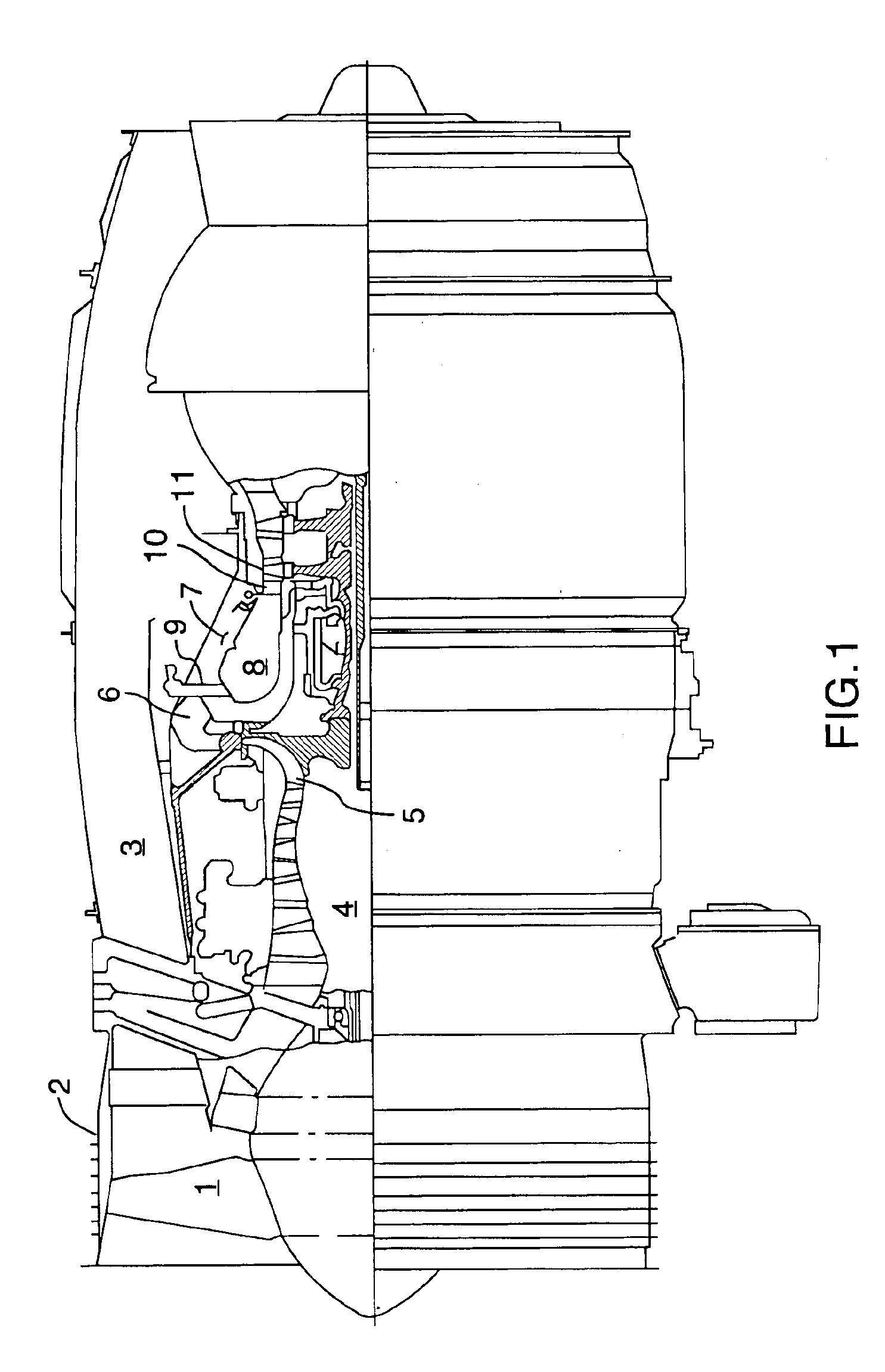

Managing spool bearing load using variable area flow nozzle

A turbine engine provides a spool supporting a turbine. The spool is arranged in a core nacelle and includes a thrust bearing. A fan is arranged upstream from the core nacelle and is coupled to the spool. A fan nacelle surrounds the fan and core nacelle and provides a bypass flow path that includes a fan nozzle exit area. A flow control device is adapted to effectively change the fan nozzle exit area. A controller is programmed to monitor the thrust bearing and command the flow control device in response to an undesired load on the thrust bearing. Effectively changing the fan nozzle exit area with the flow control device actively manages the bearing thrust load to desired levels.

Owner:RTX CORP

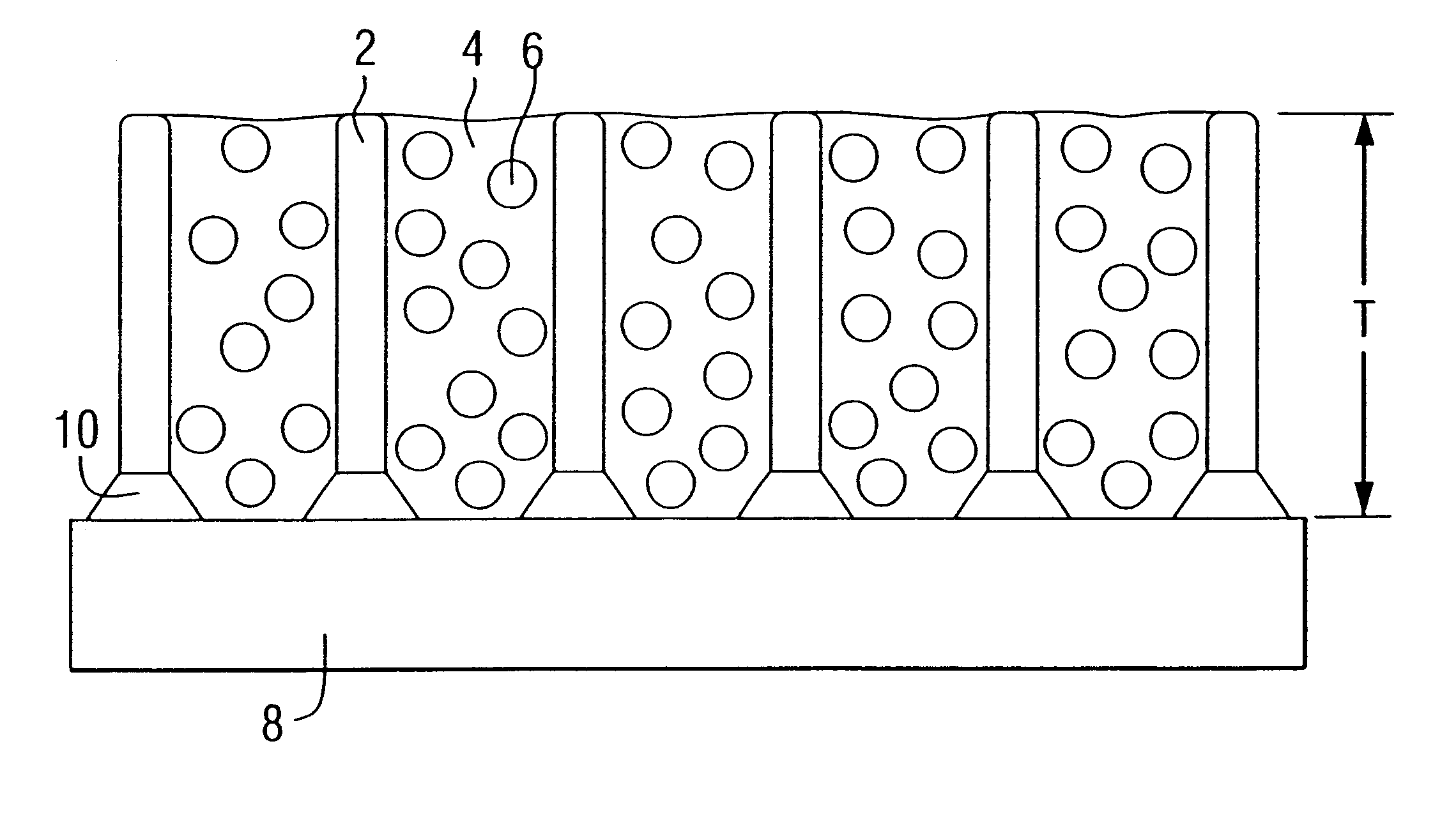

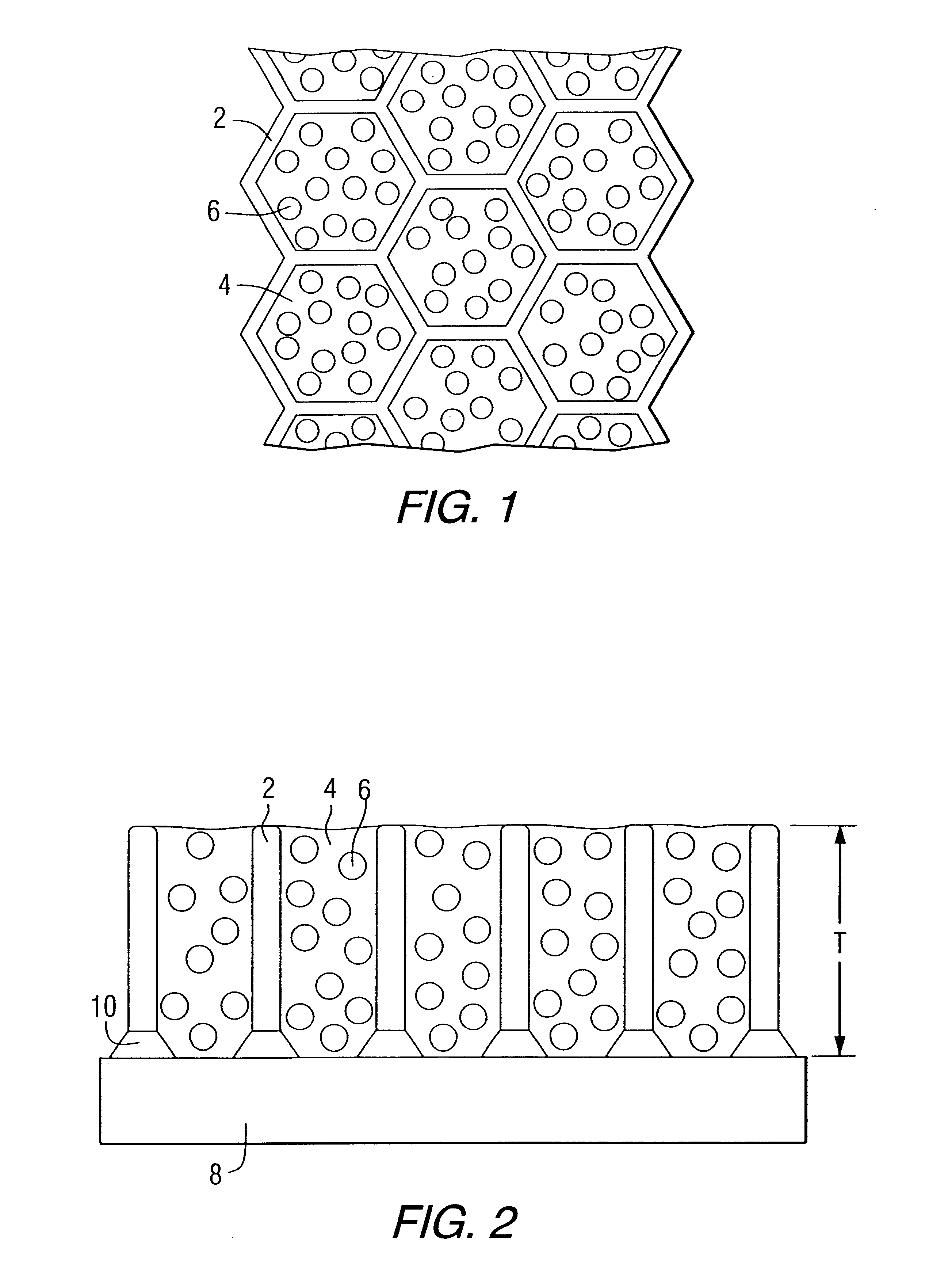

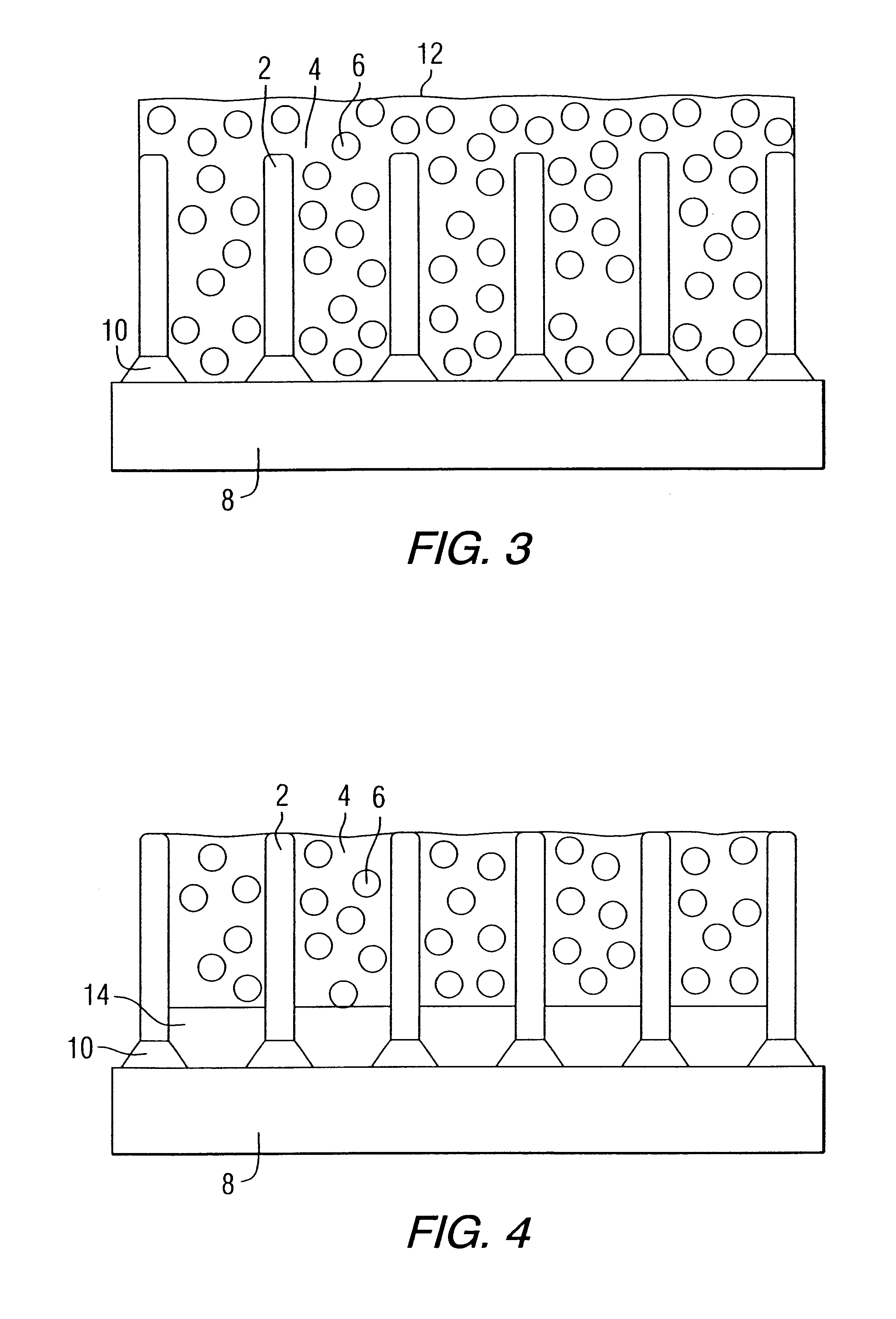

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

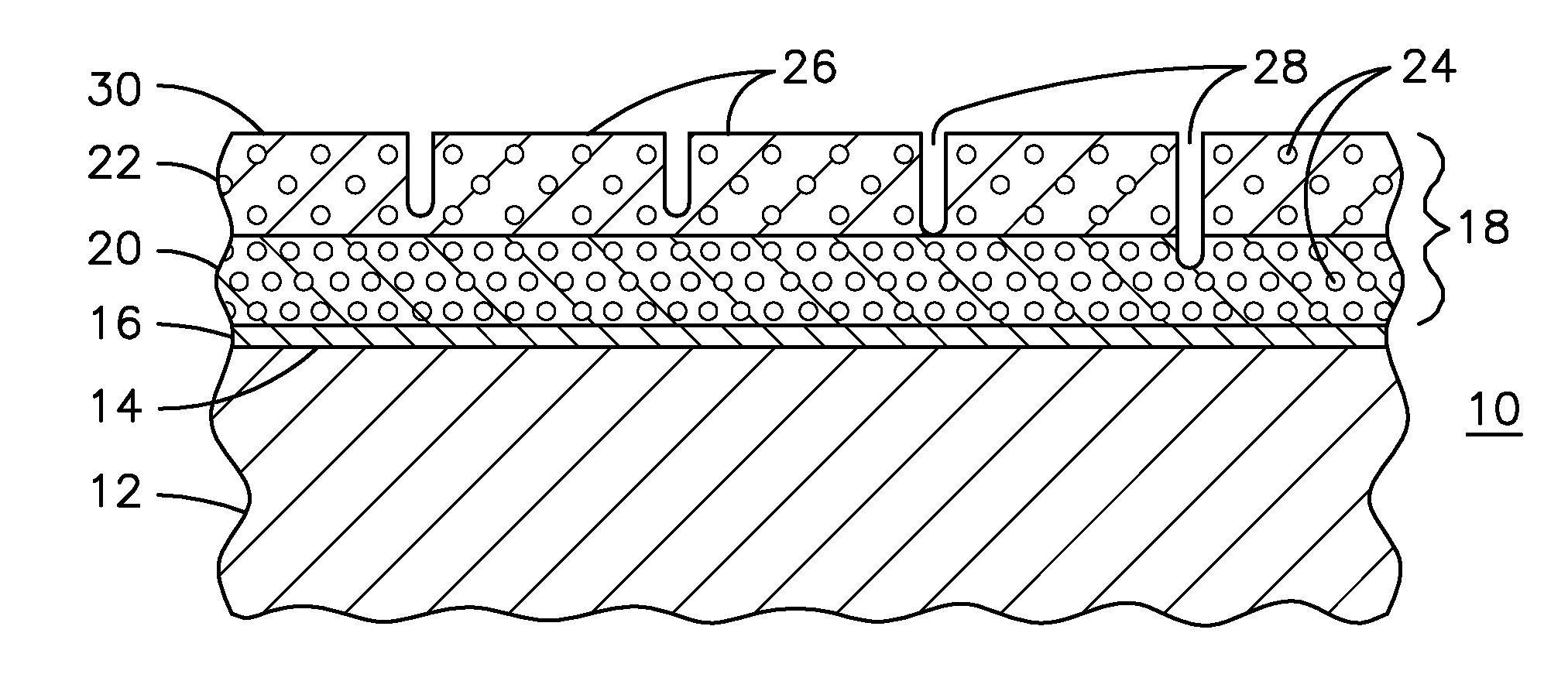

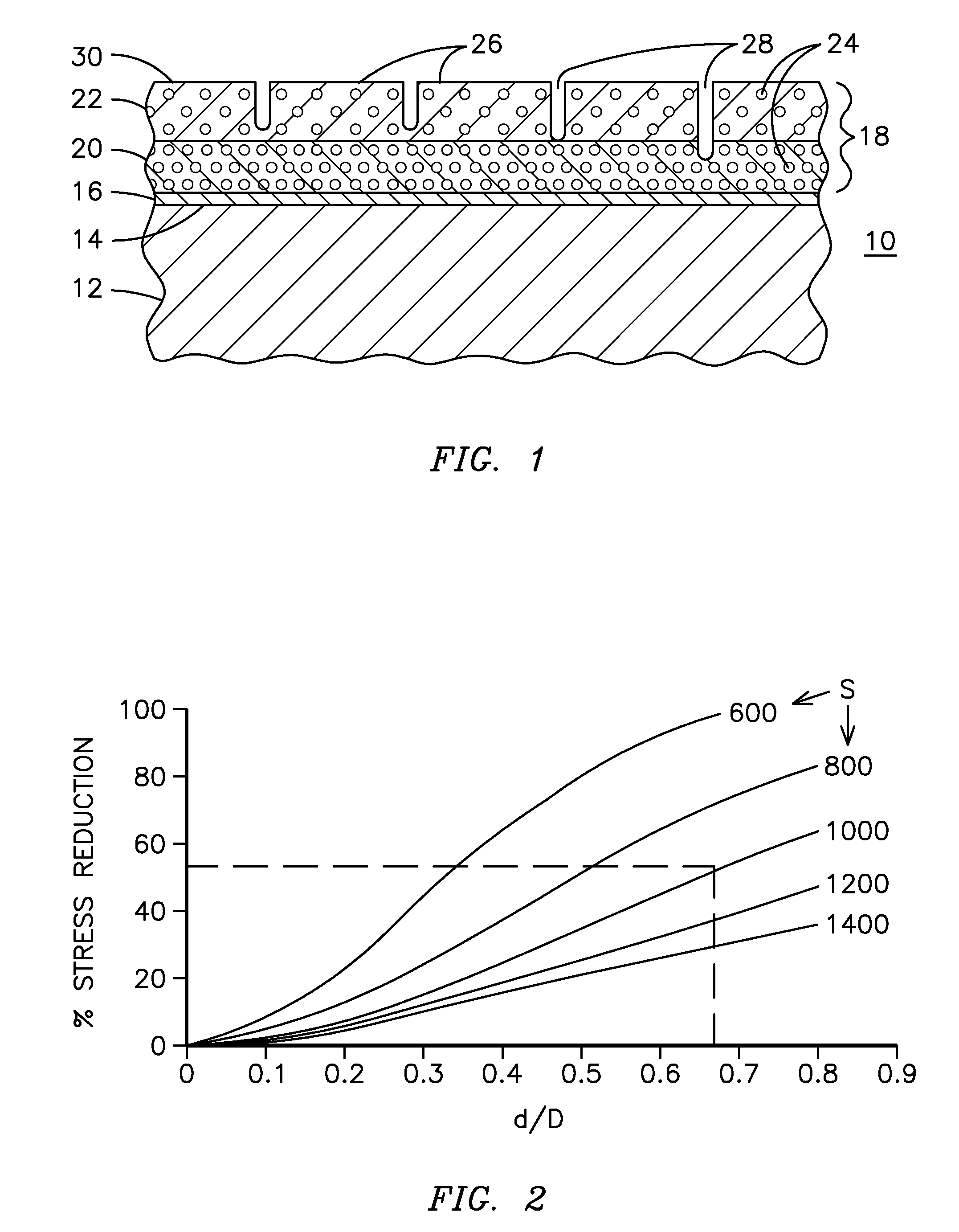

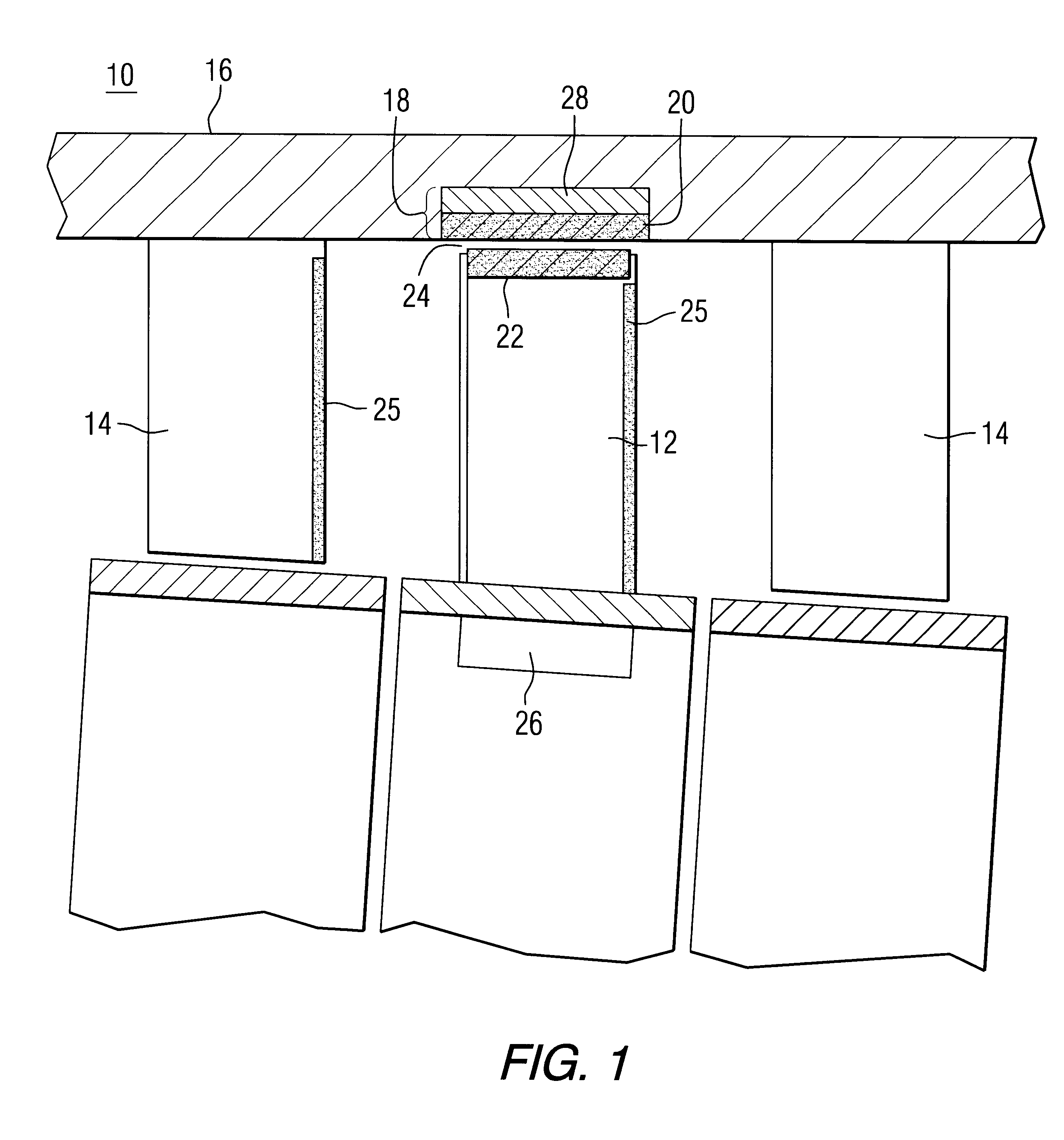

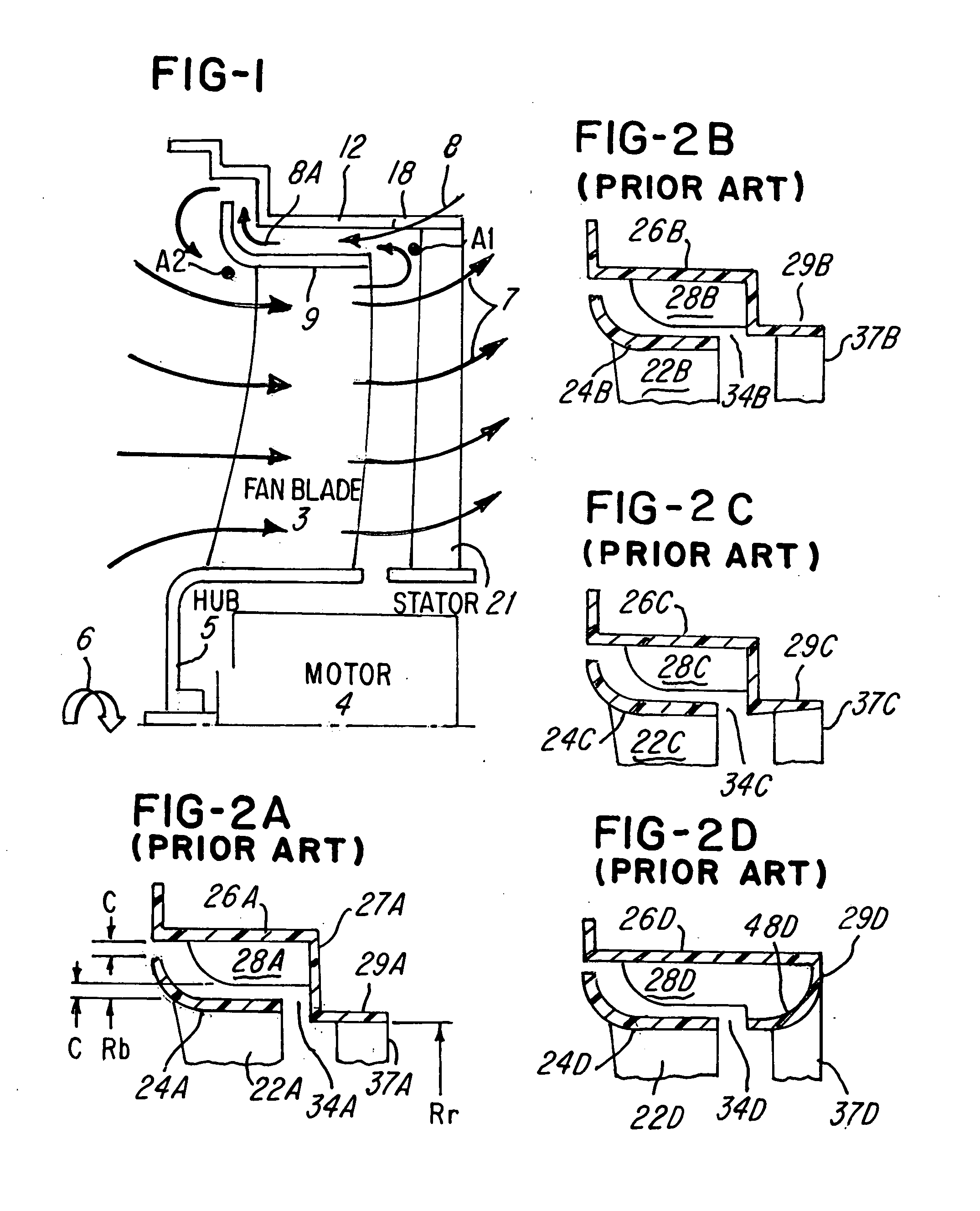

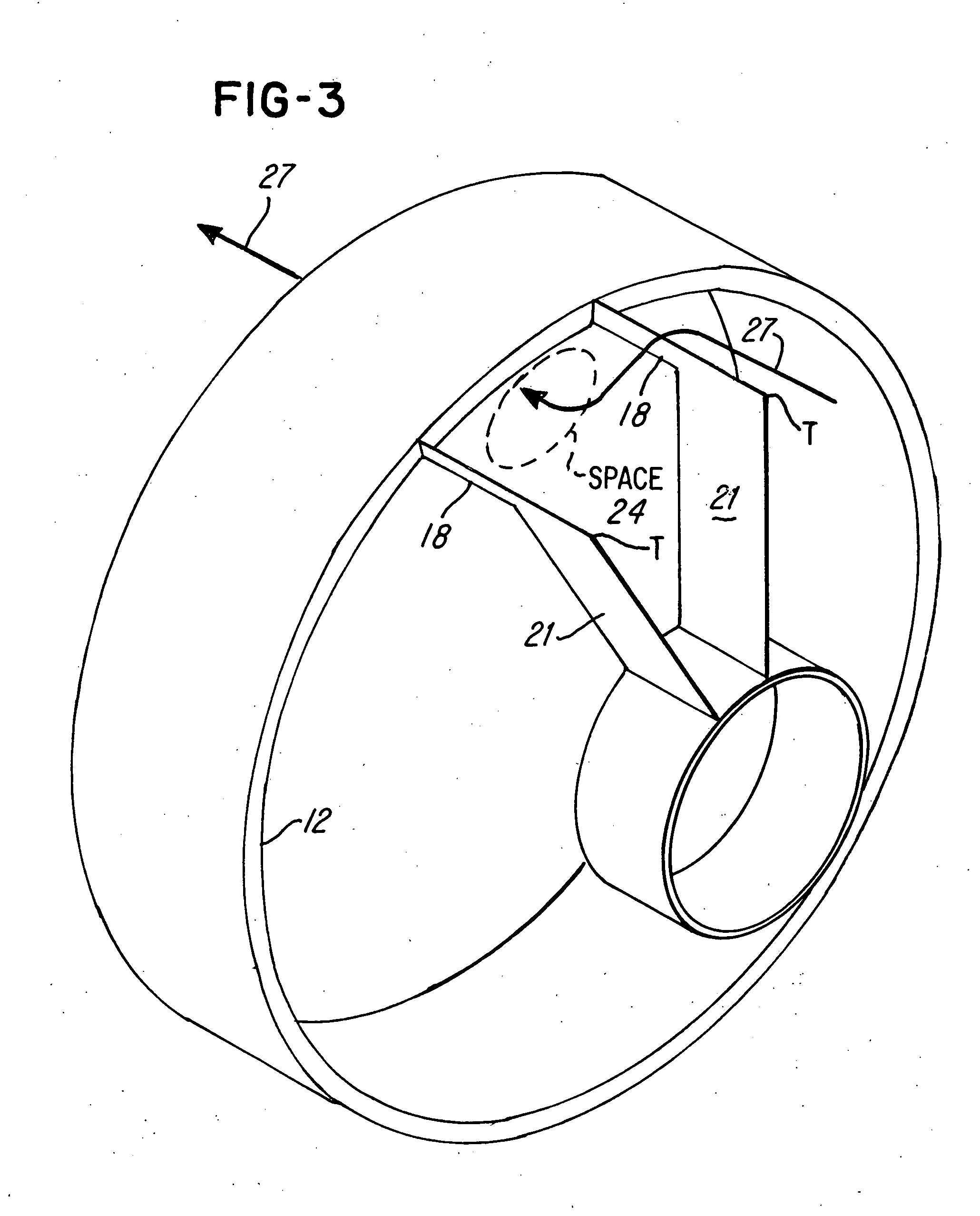

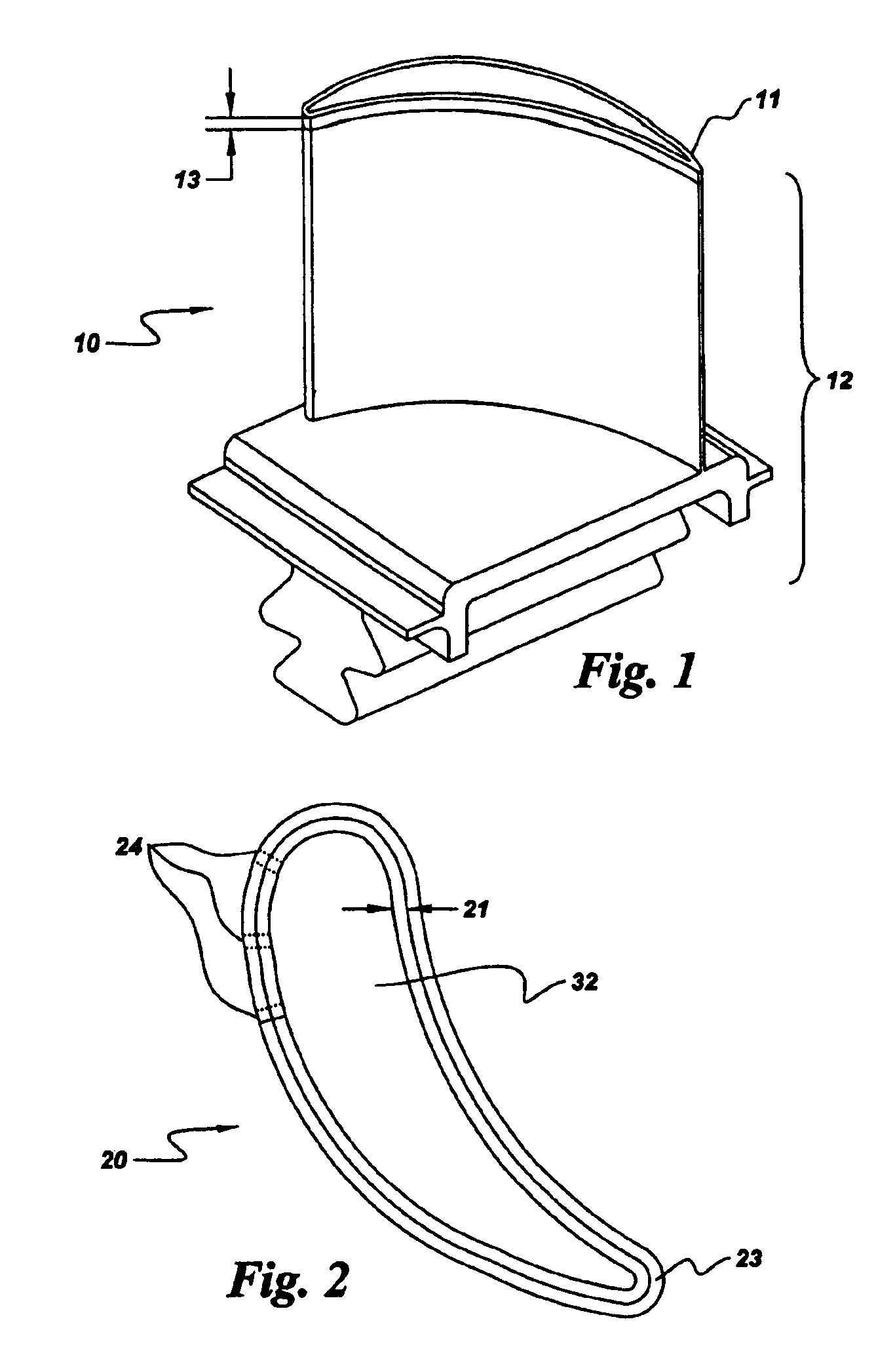

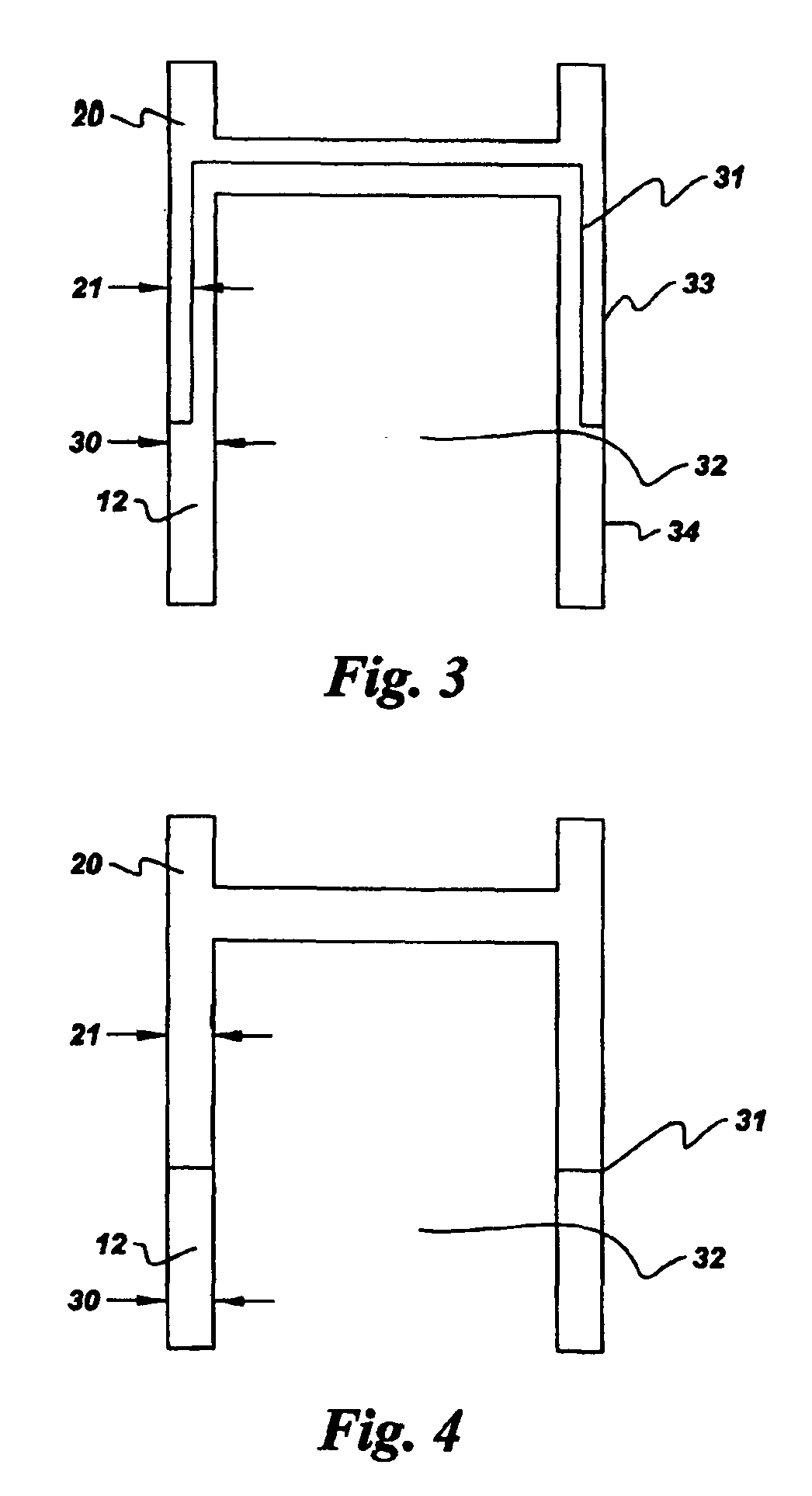

Segmented thermal barrier coating

A ceramic thermal barrier coating (TBC) (18) having first and second layers (20, 22), the second layer (22) having a lower thermal conductivity than the first layer for a given density. The second layer may be formed of a material with anisotropic crystal lattice structure. Voids (24) in at least the first layer (20) make the first layer less dense than the second layer. Grooves (28) are formed in the TBC (18) for thermal strain relief. The grooves may align with fluid streamlines over the TBC. Multiple layers (84, 86,88) may have respective sets of grooves (90), Preferred failure planes parallel to the coating surface (30) may be formed at different depths (A1, A2, A3) in the thickness of the TBC to stimulate generation of a fresh surface when a portion of the coating fails by spalling. A dense top layer (92) may provide environmental and erosion resistance.

Owner:SIEMENS ENERGY INC

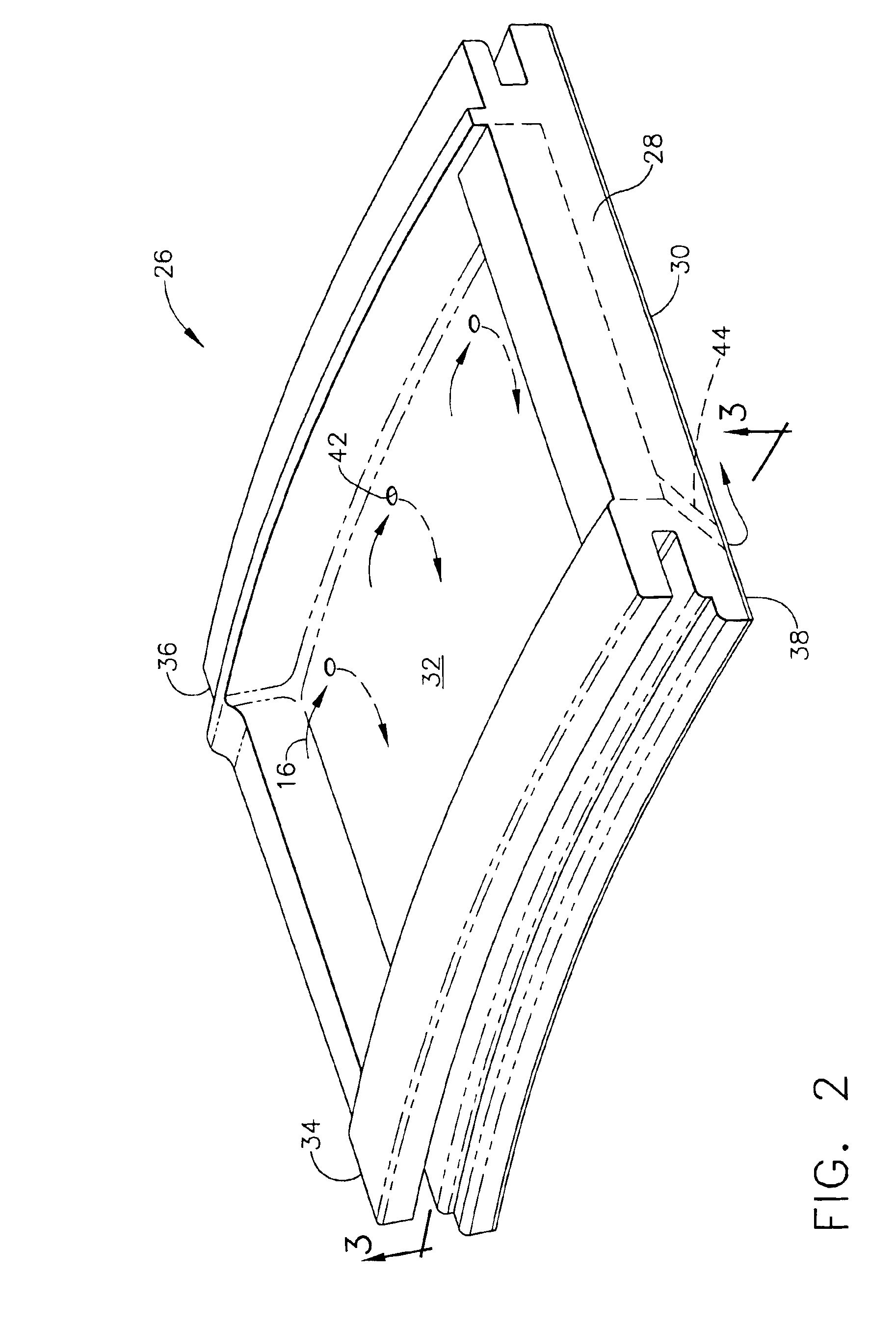

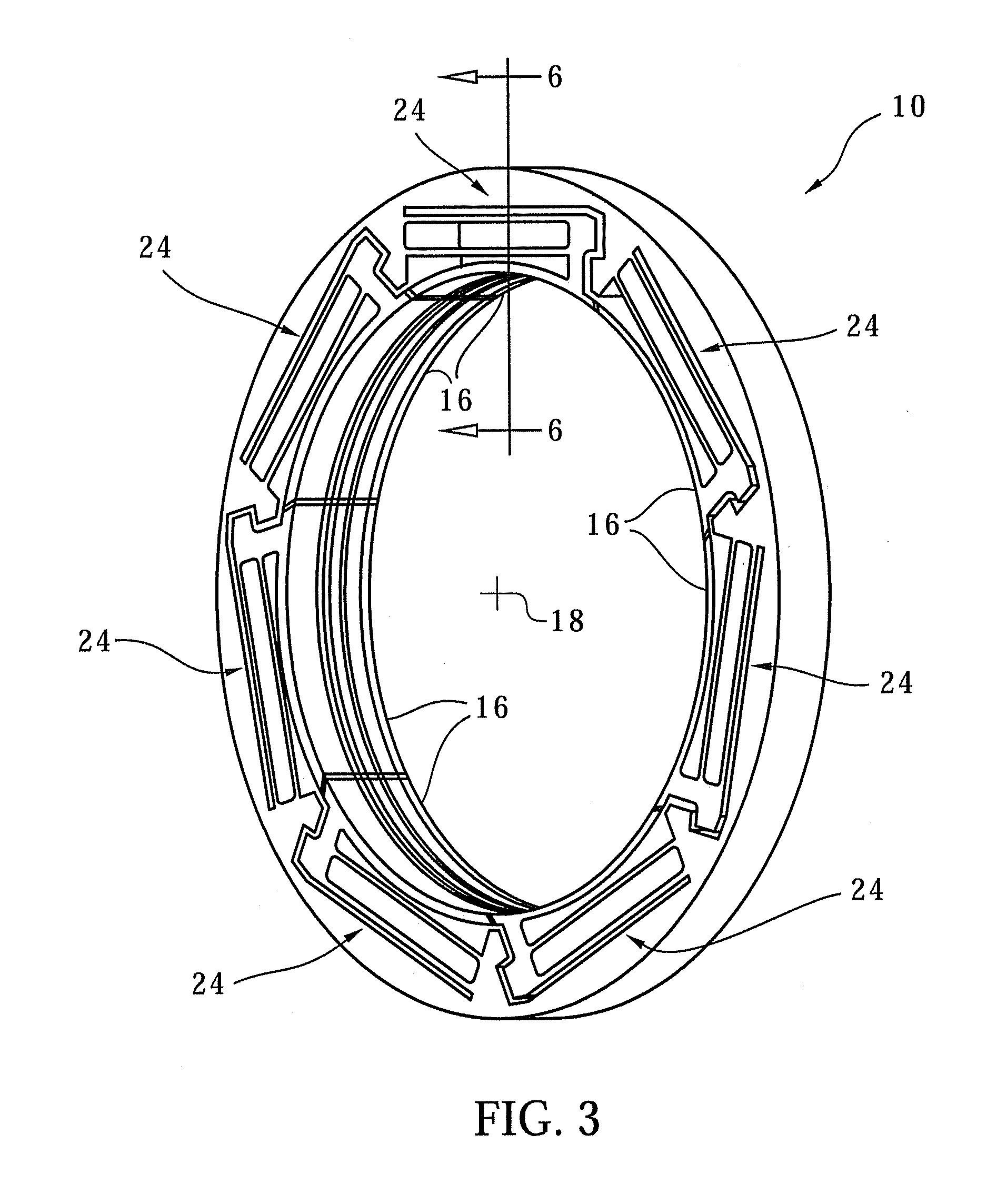

Turbine ring assembly

A turbine ring assembly includes a ring support structure and a plurality of ring sectors, each including a single piece of ceramic matrix composite material. Each ring sector includes a first portion forming an annular base with an inside face defining an inside face of the turbine ring and an outside face from which there extends two tab-forming portions including ends that are engaged in housings in the ring support structure. The ring sectors present a section that is substantially π-shaped and the ends of the tabs are held without radial clearance by the ring support structure. The tabs can have a free length in meridian section that is not less than three times their mean width.

Owner:GERAKL

Sealing for vane segments

A seal housing is provided to substantially cover at least one duct wall of vane array duct of a gas turbine engine, and one example arrangement is employed in a mid-turbine frame. The arrangement provides improved sealing of the vane array duct through the provision of a plurality of cavities extending along the duct wall. The arrangement may also include insulation tubes to assist in sealing around load transfer spokes passing through the vane array.

Owner:PRATT & WHITNEY CANADA CORP

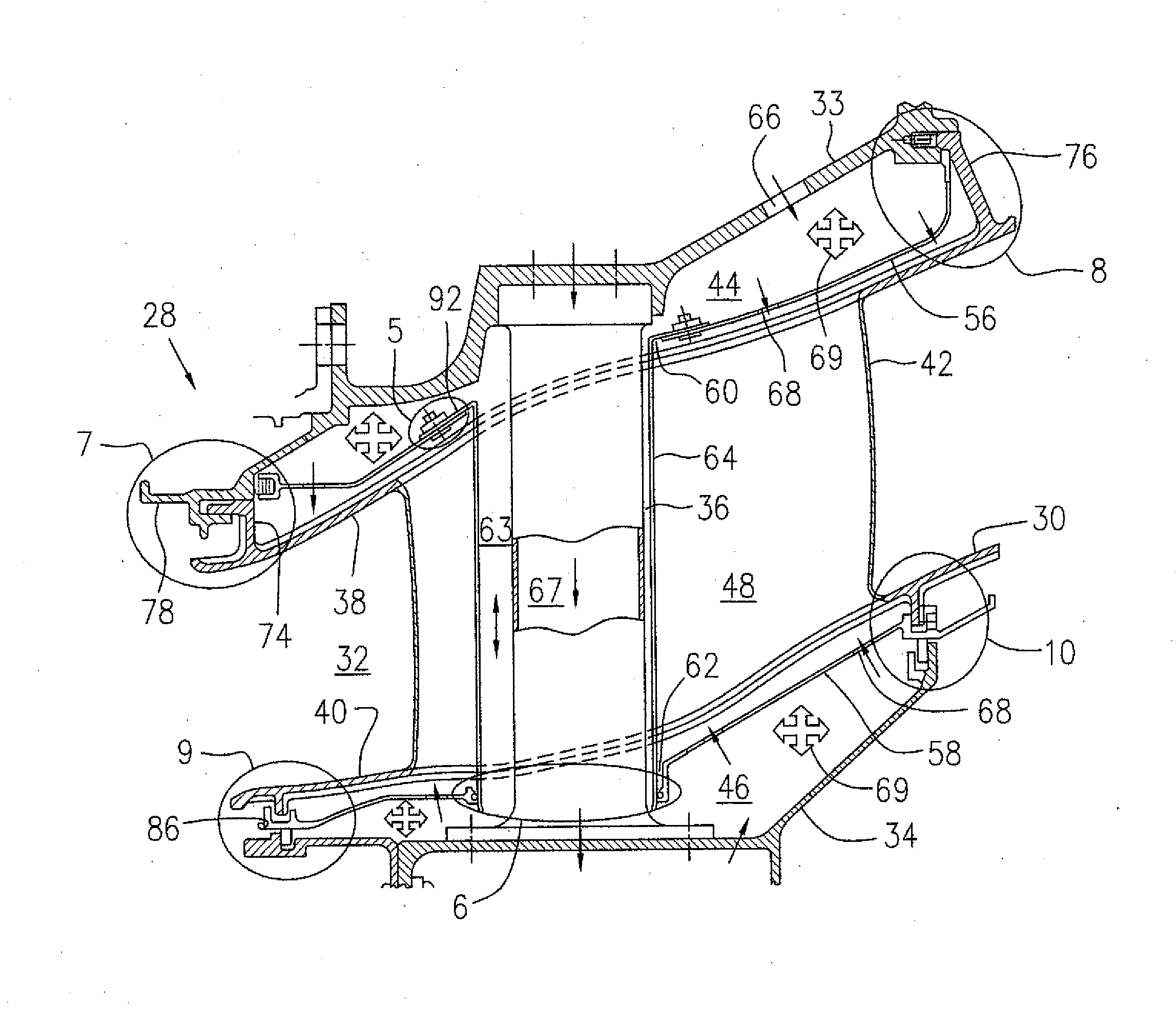

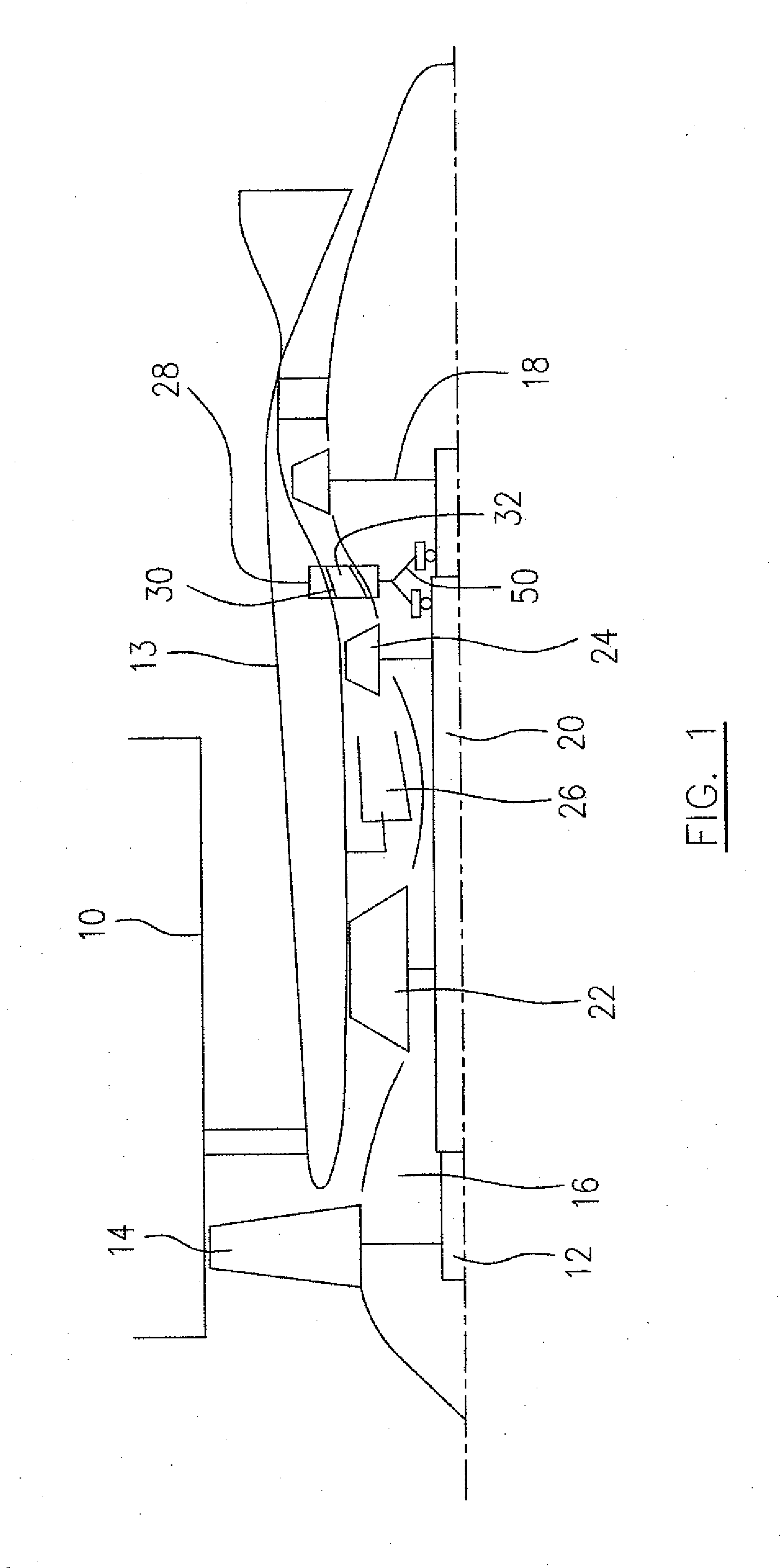

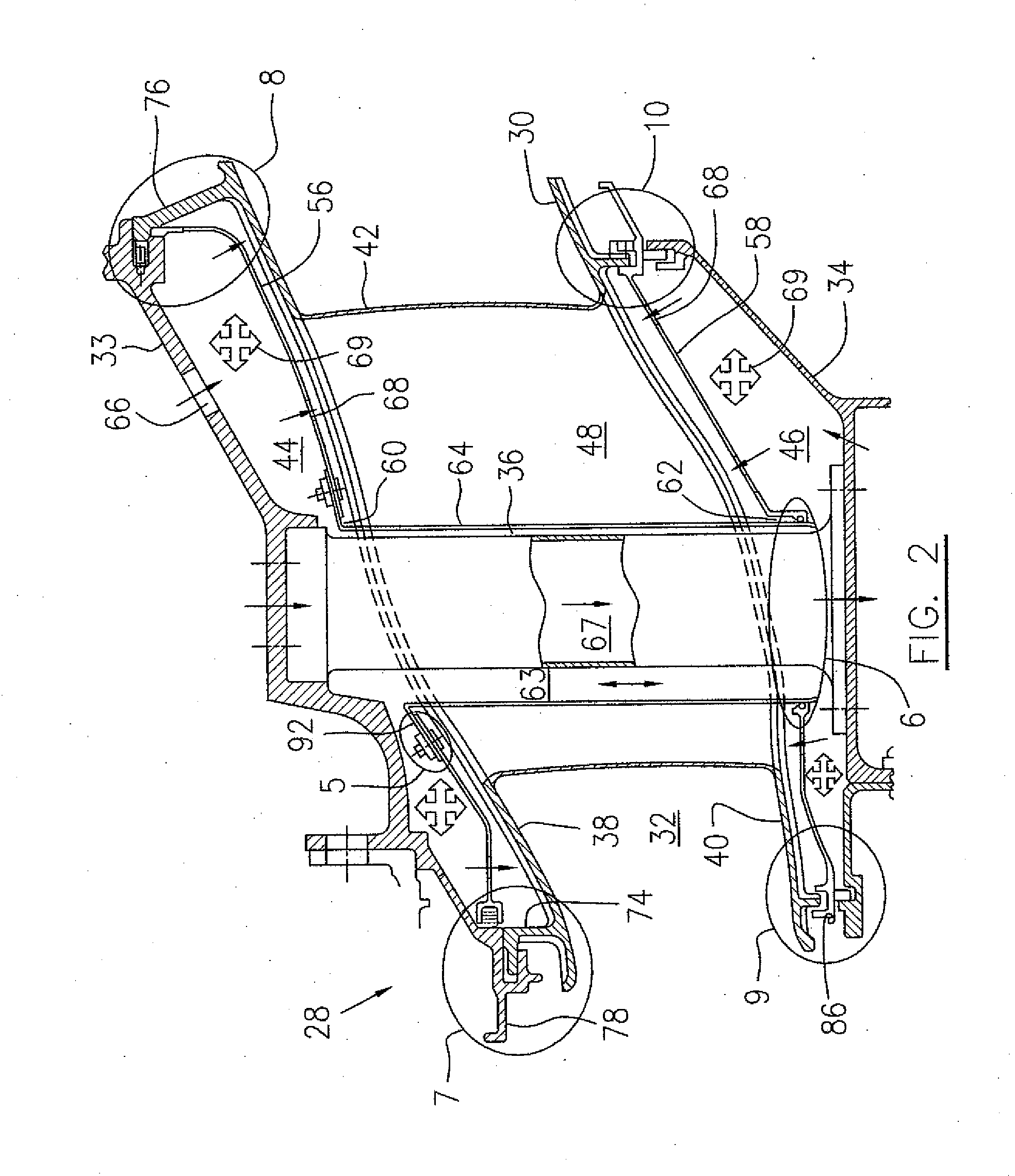

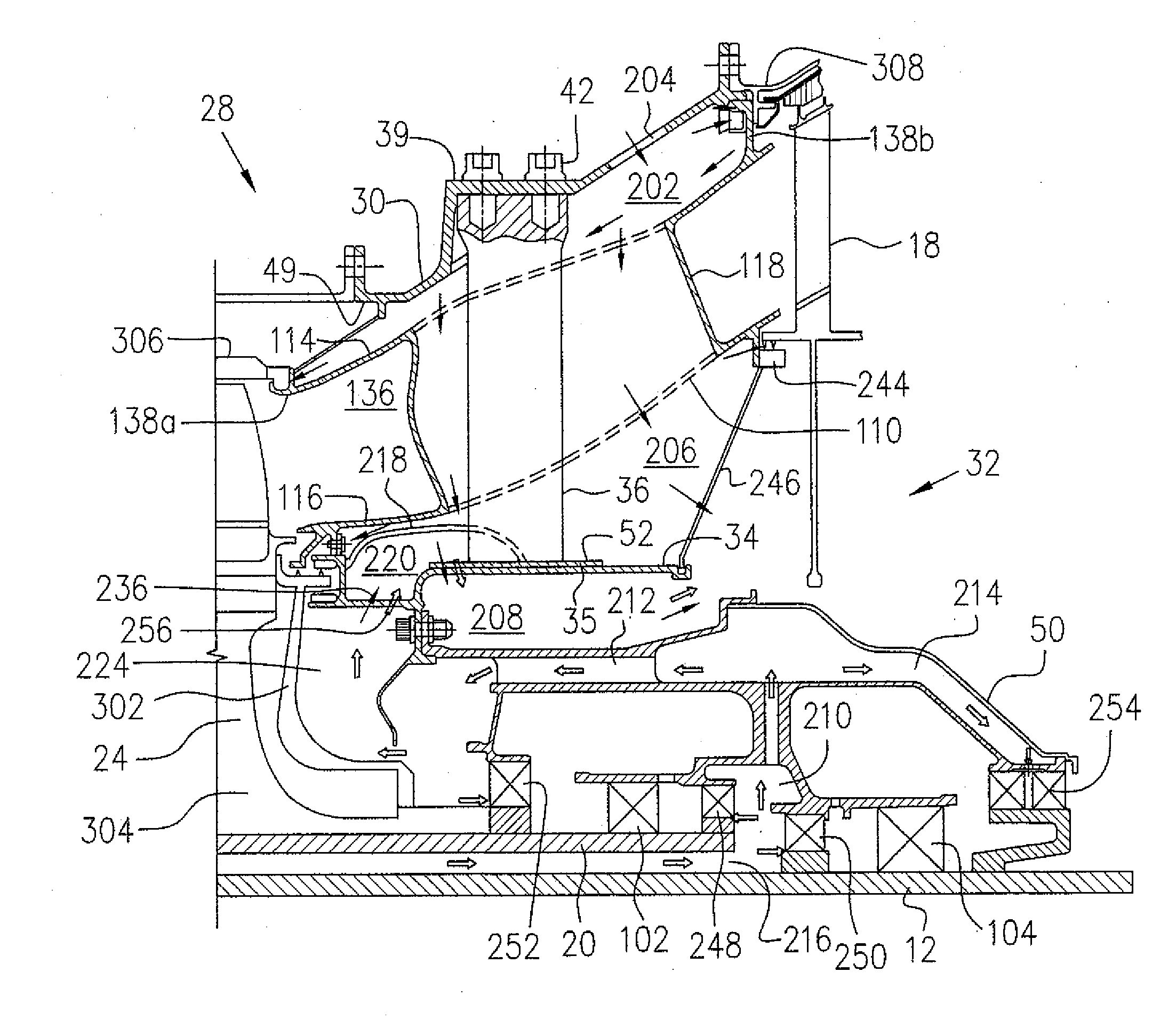

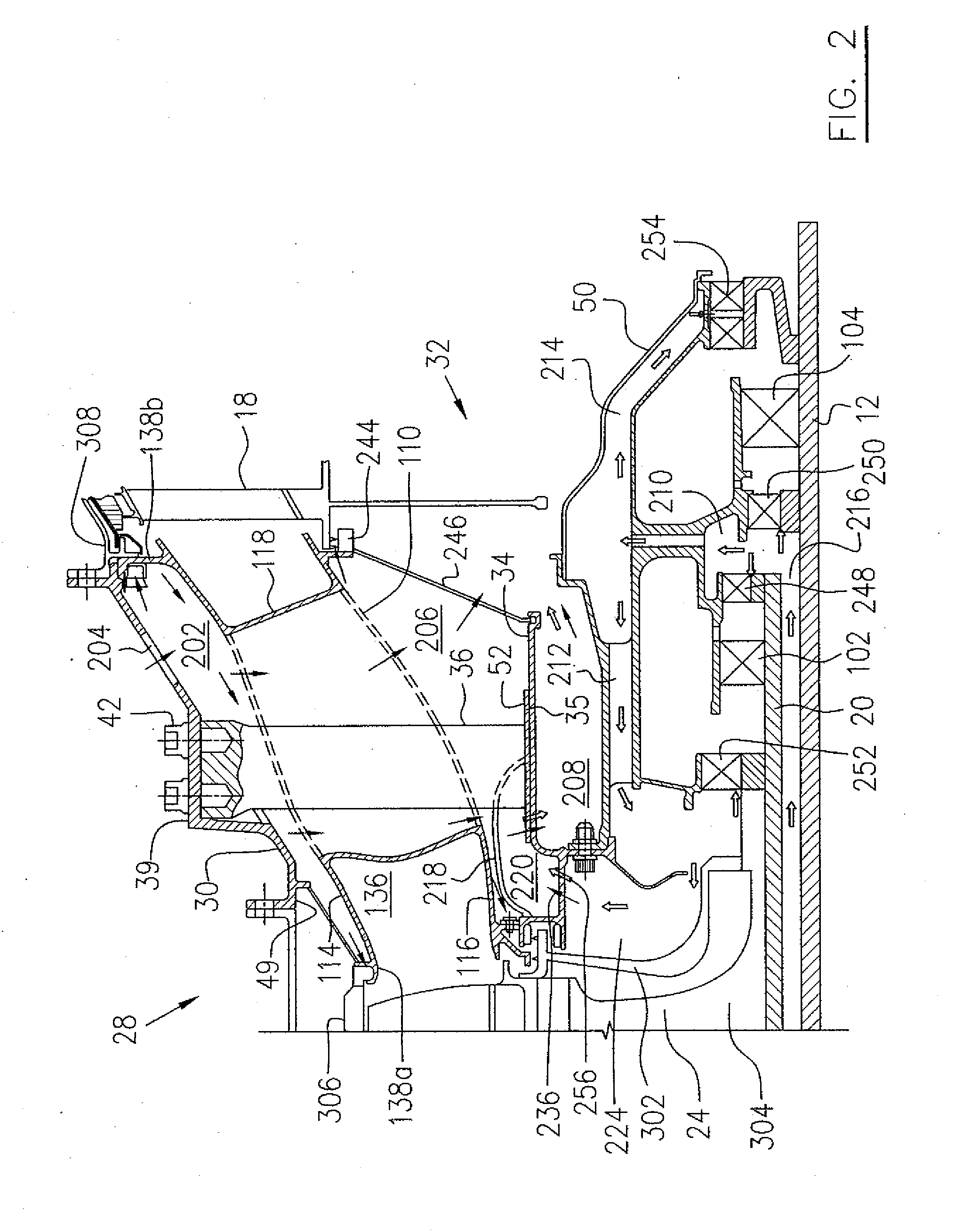

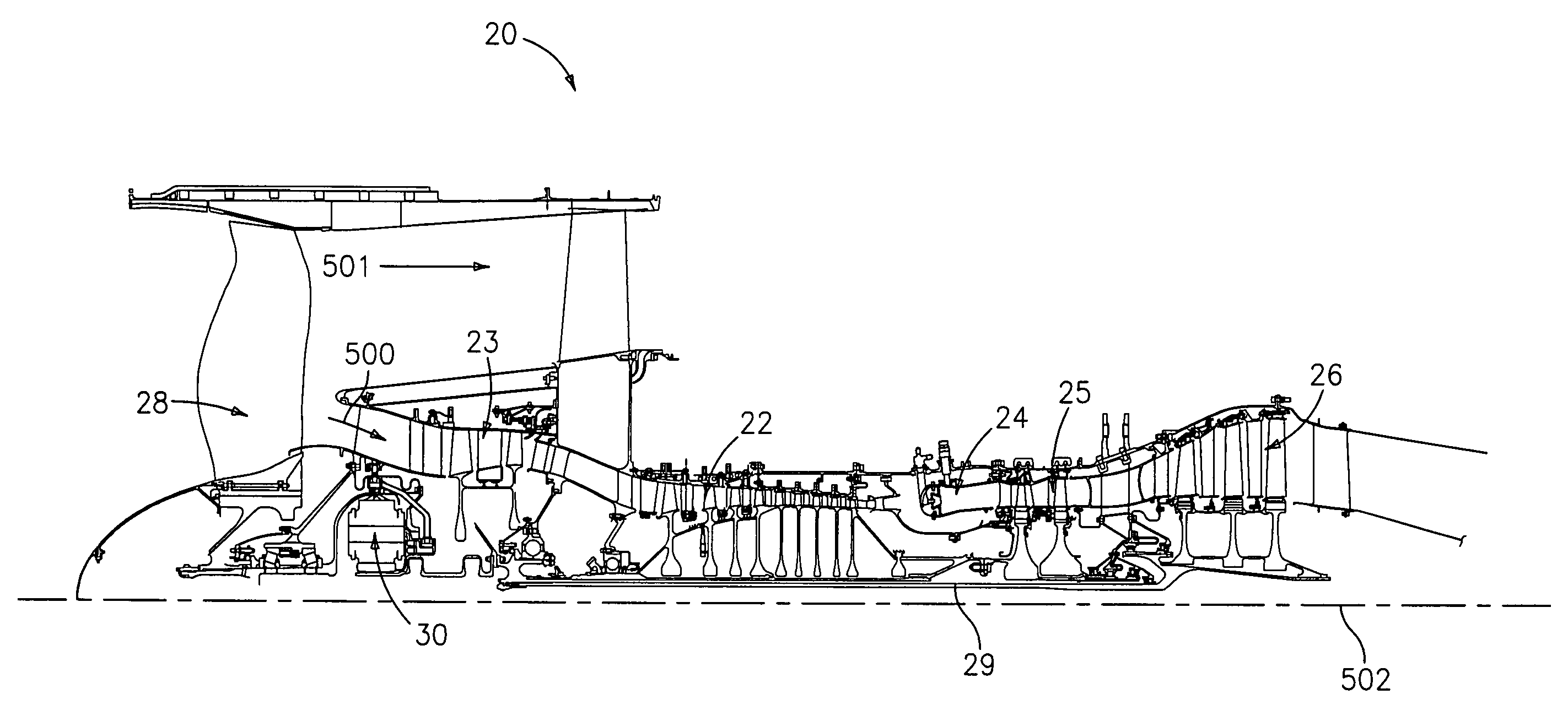

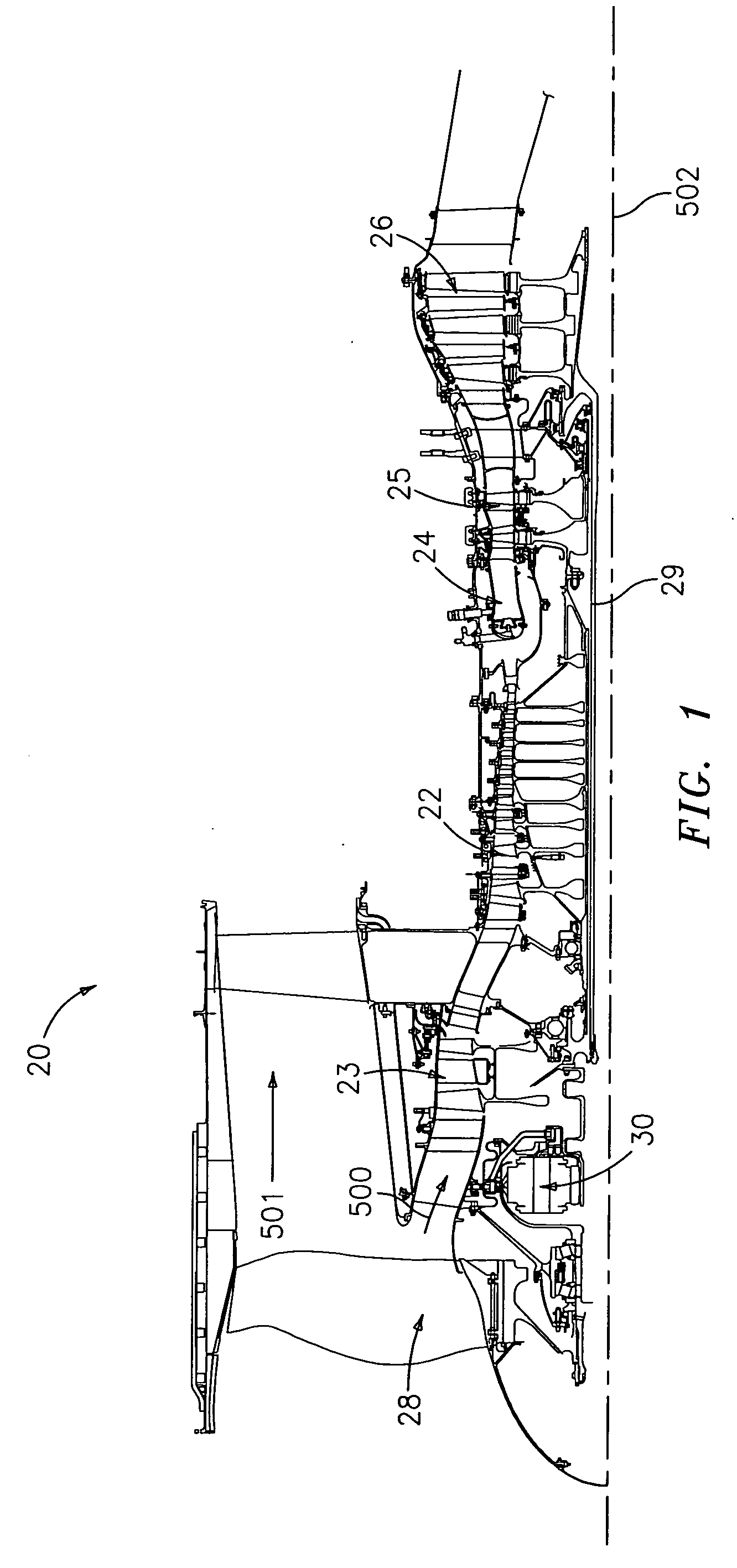

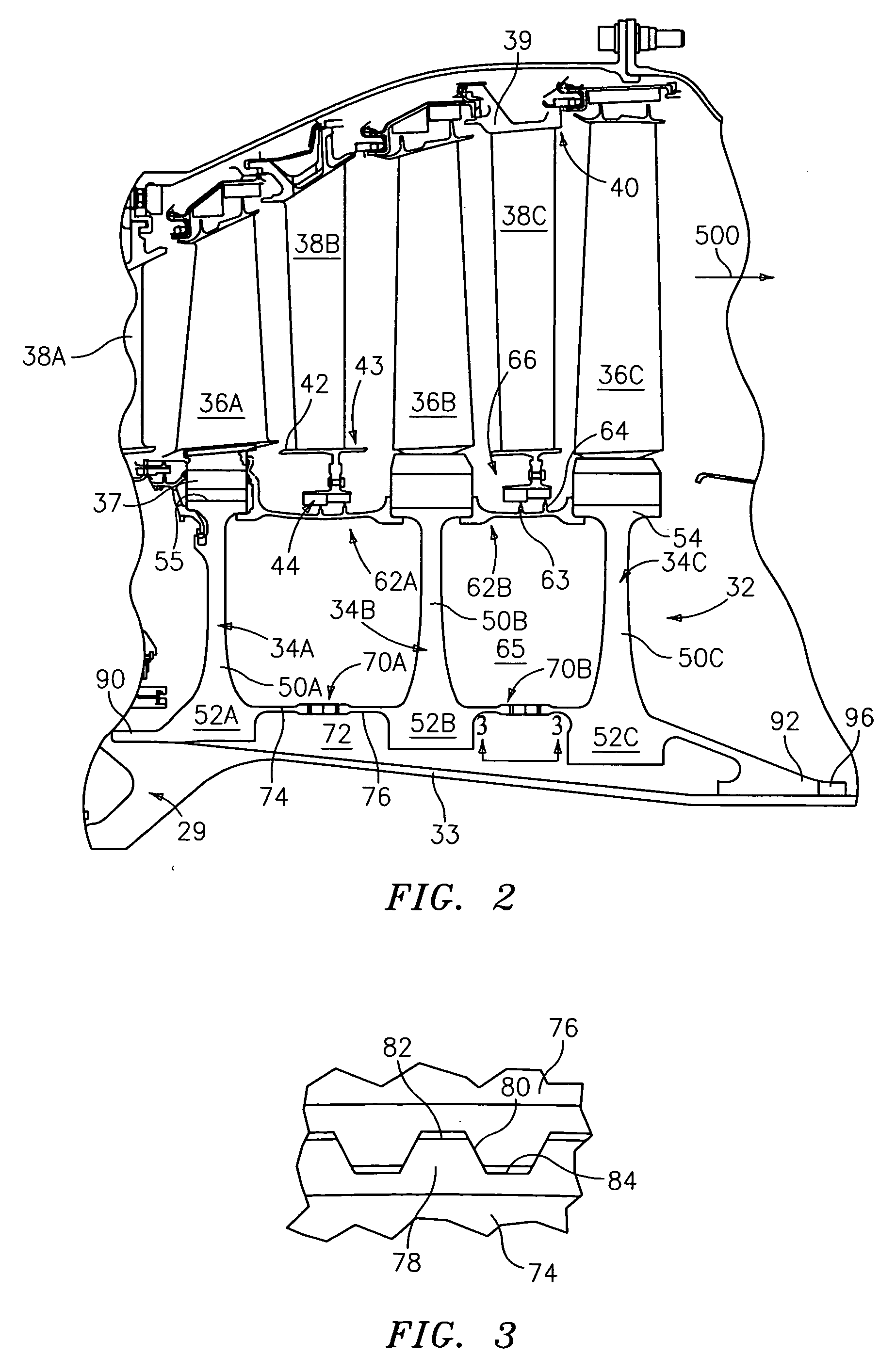

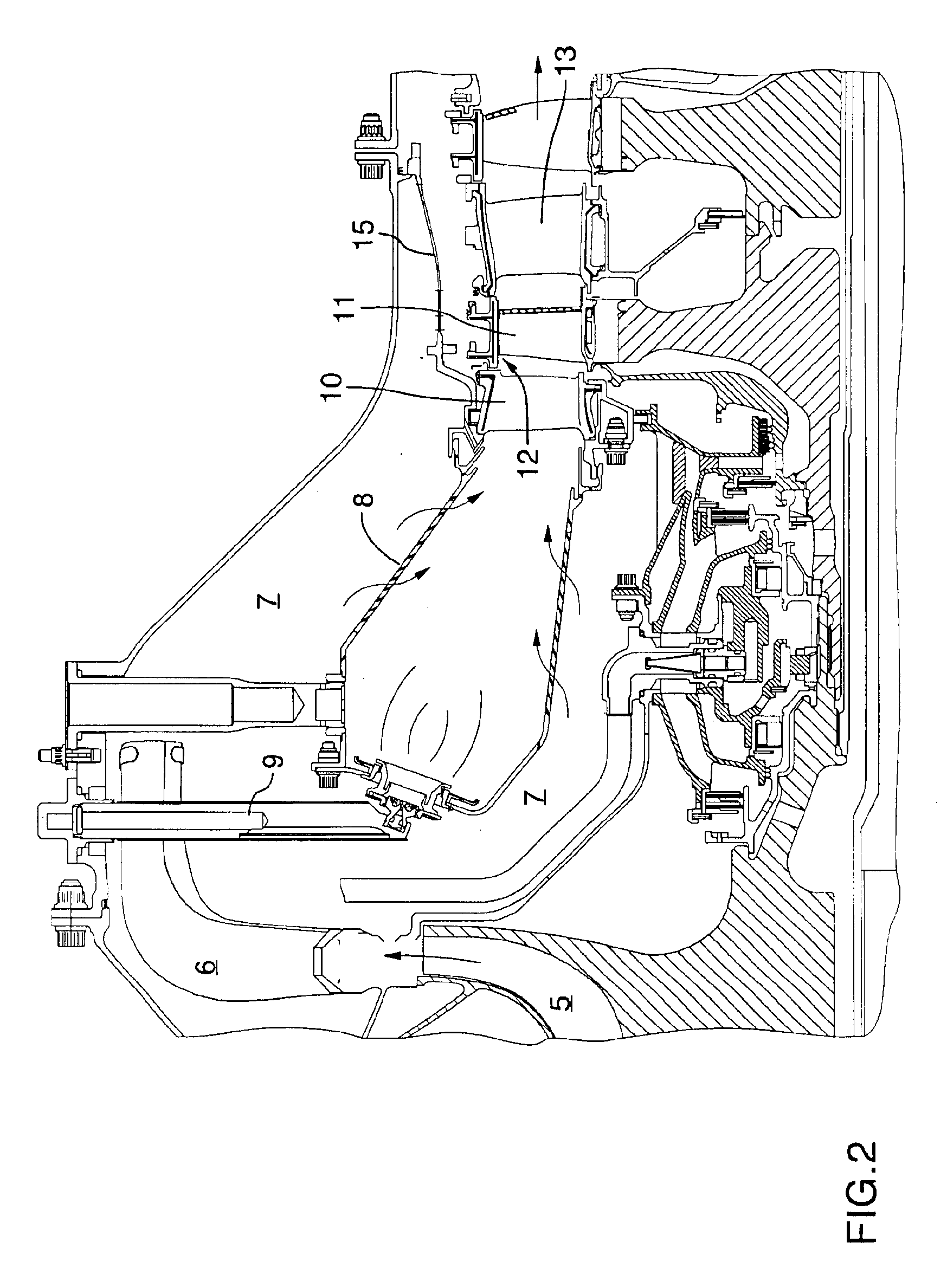

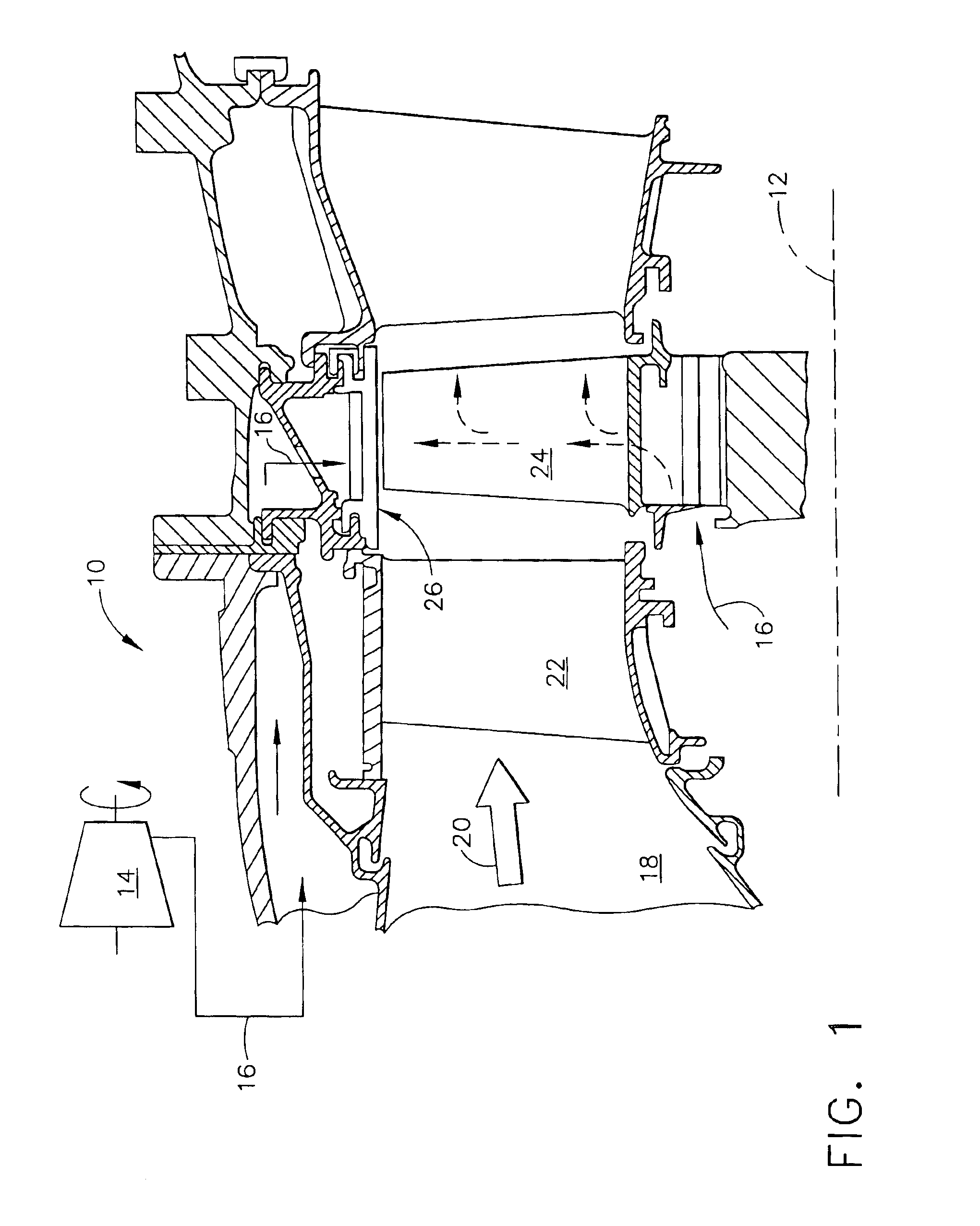

Cooling air system for mid turbine frame

A mid turbine frame is disposed between high and low pressure turbine assemblies. A cooling air system defined in the mid turbine frame of a gas turbine engine includes internal cavities for containing pressurized cooling air to cool the inter-turbine duct and the hollow struts, and discharges the used cooling air to further cool respective high and low pressure turbine assemblies.

Owner:PRATT & WHITNEY CANADA CORP

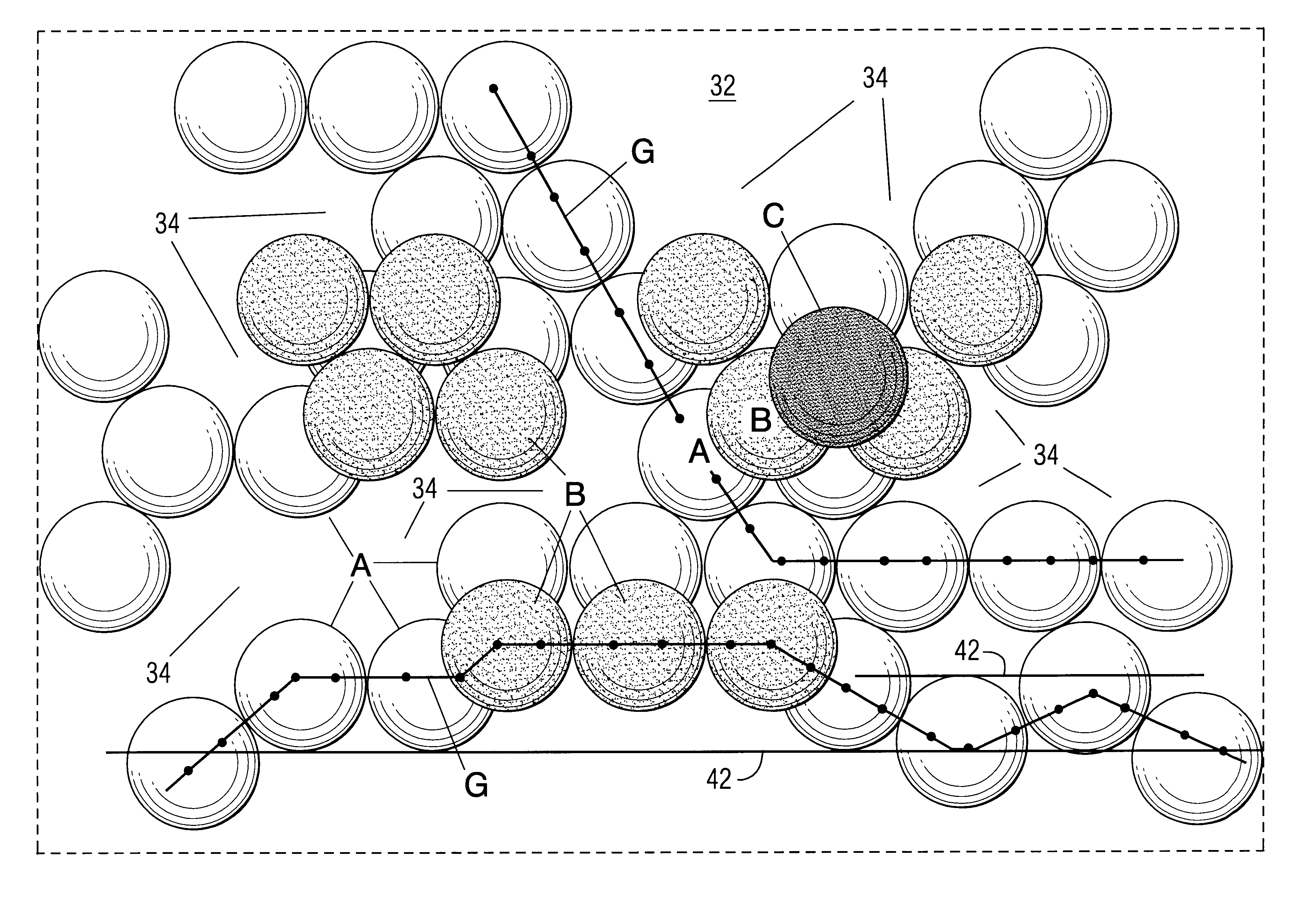

High temperature erosion resistant coating and material containing compacted hollow geometric shapes

InactiveUS6641907B1Improve corrosion resistanceReduce void volumeEngine manufactureBlade accessoriesPorosityMetallurgy

A material system (60) contains close packed hollow shapes (50, 70) having a dense wall structure (52, 66), which are bonded together and which may contain a matrix binder material (56) between the shapes, where the system has a stable porosity, and is abradable and thermally stable at temperatures up to possibly 1700° C., where such systems are useful in turbine apparatus.

Owner:SIEMENS ENERGY INC

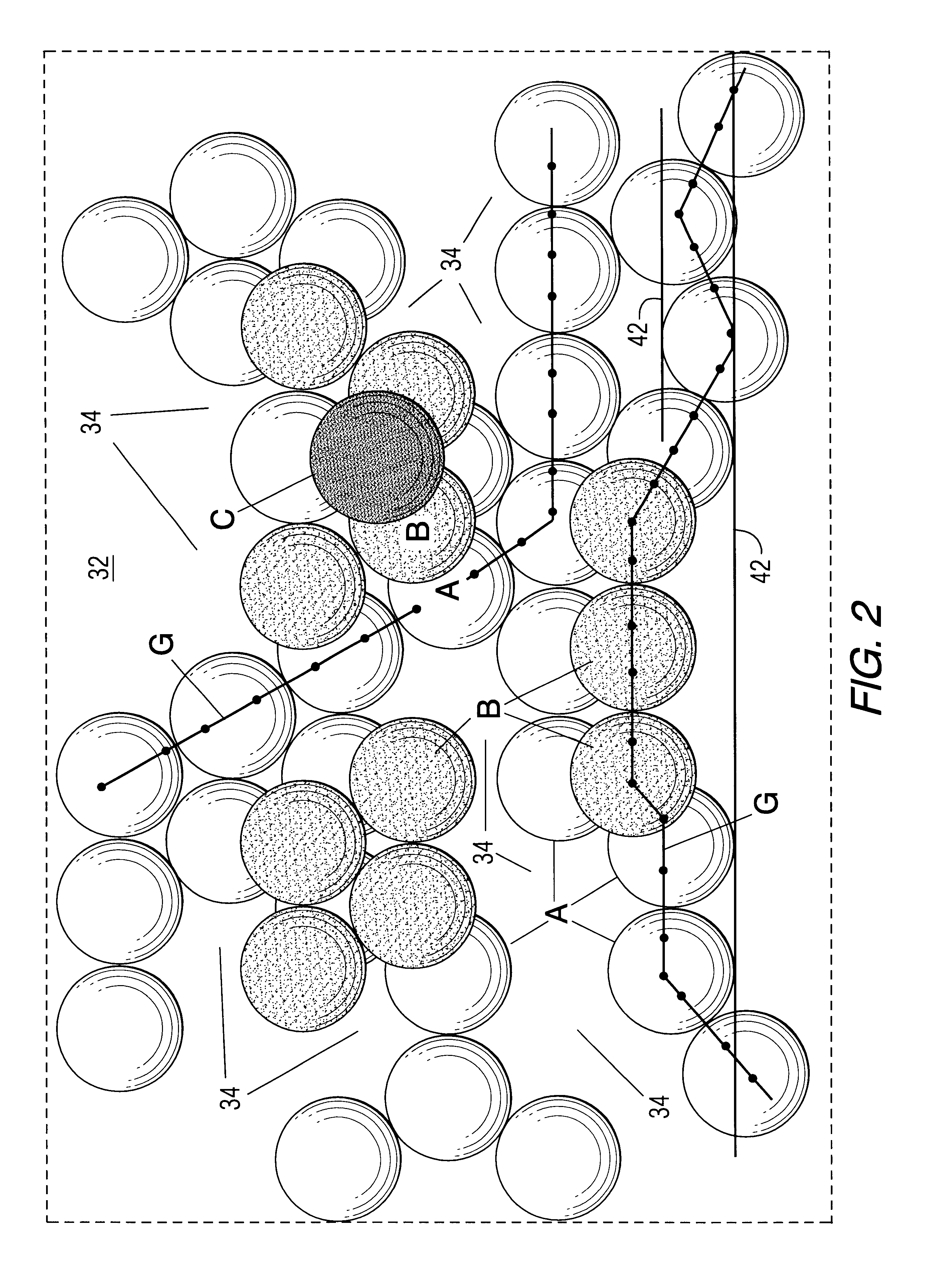

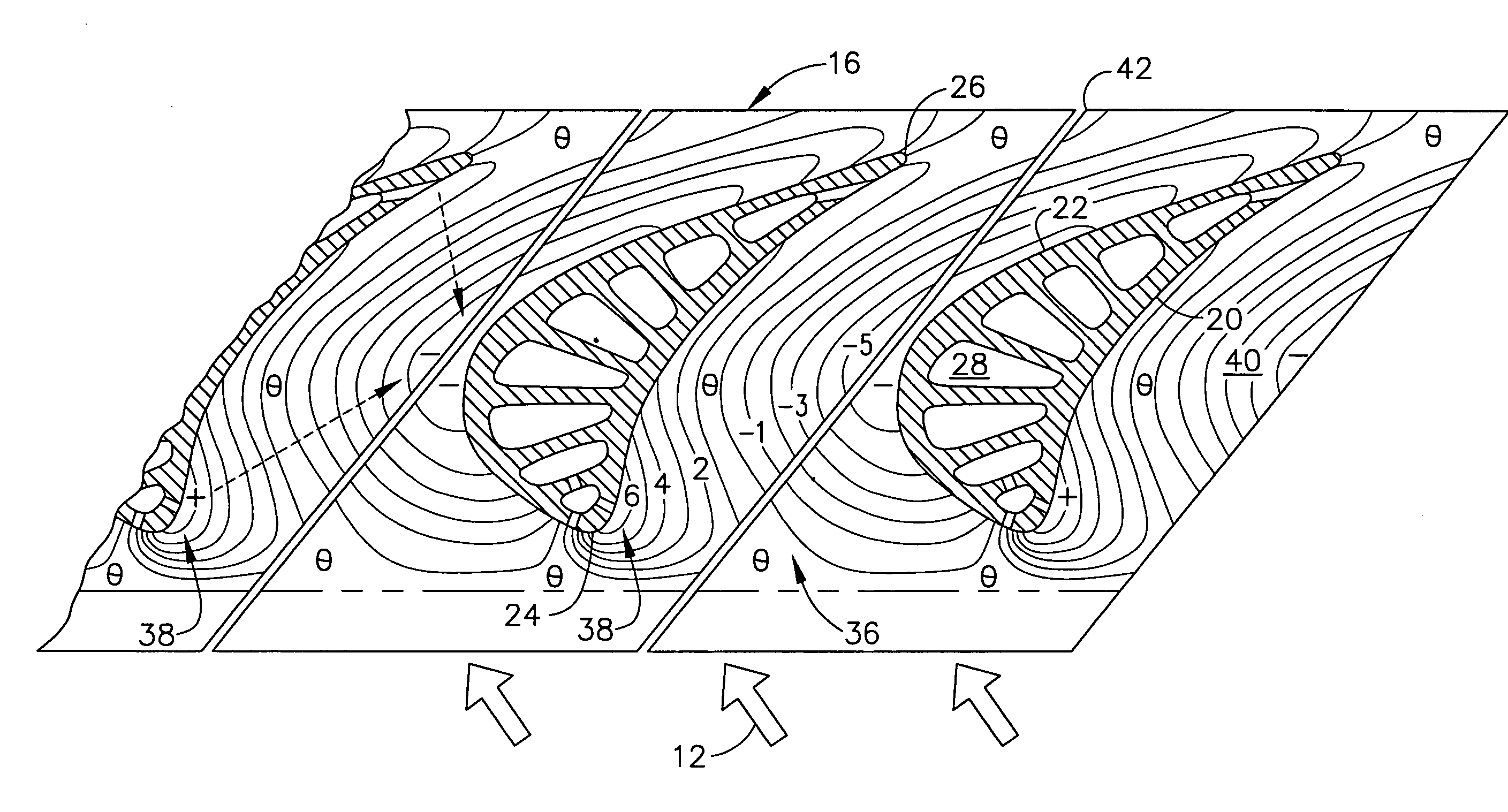

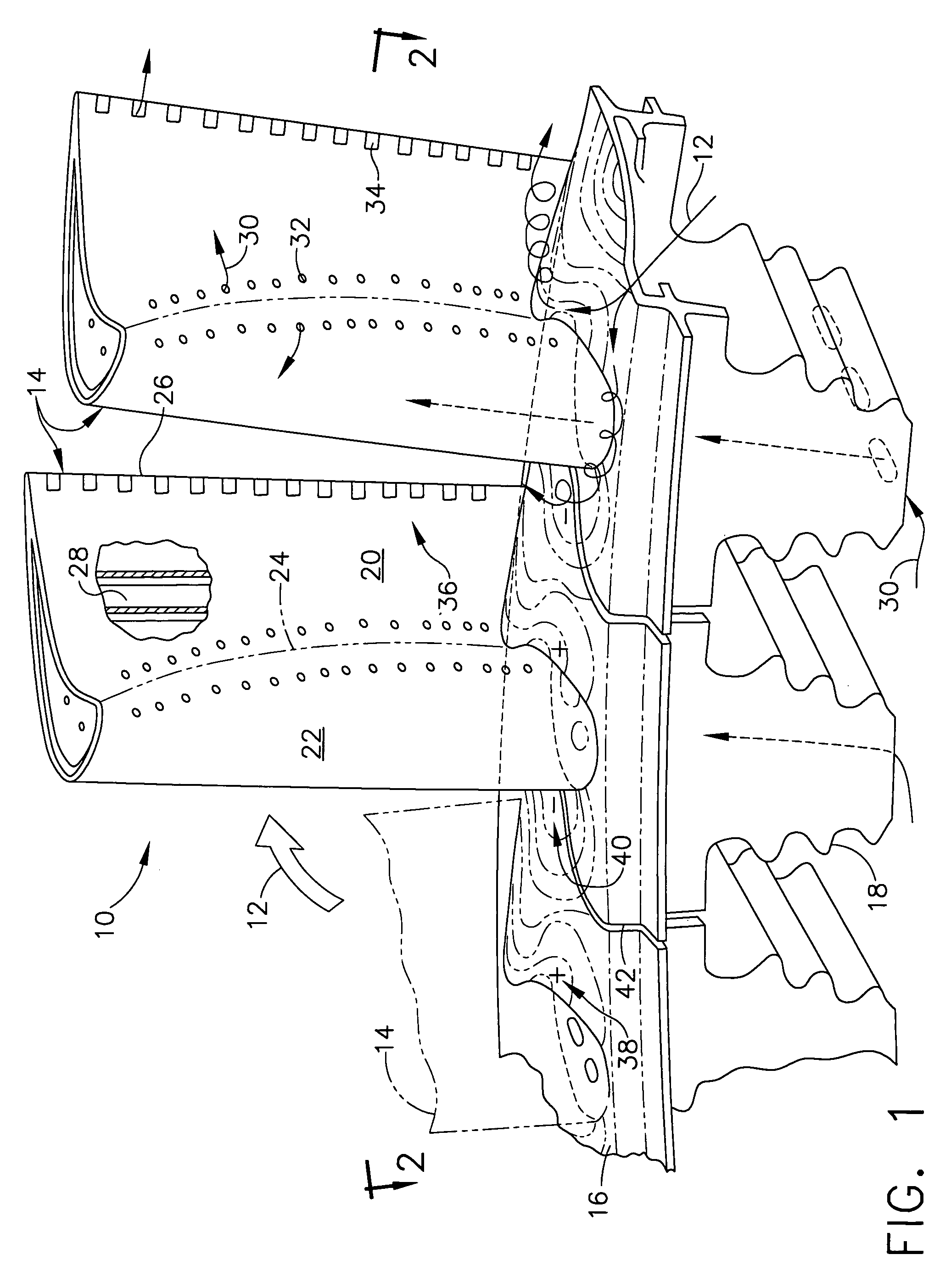

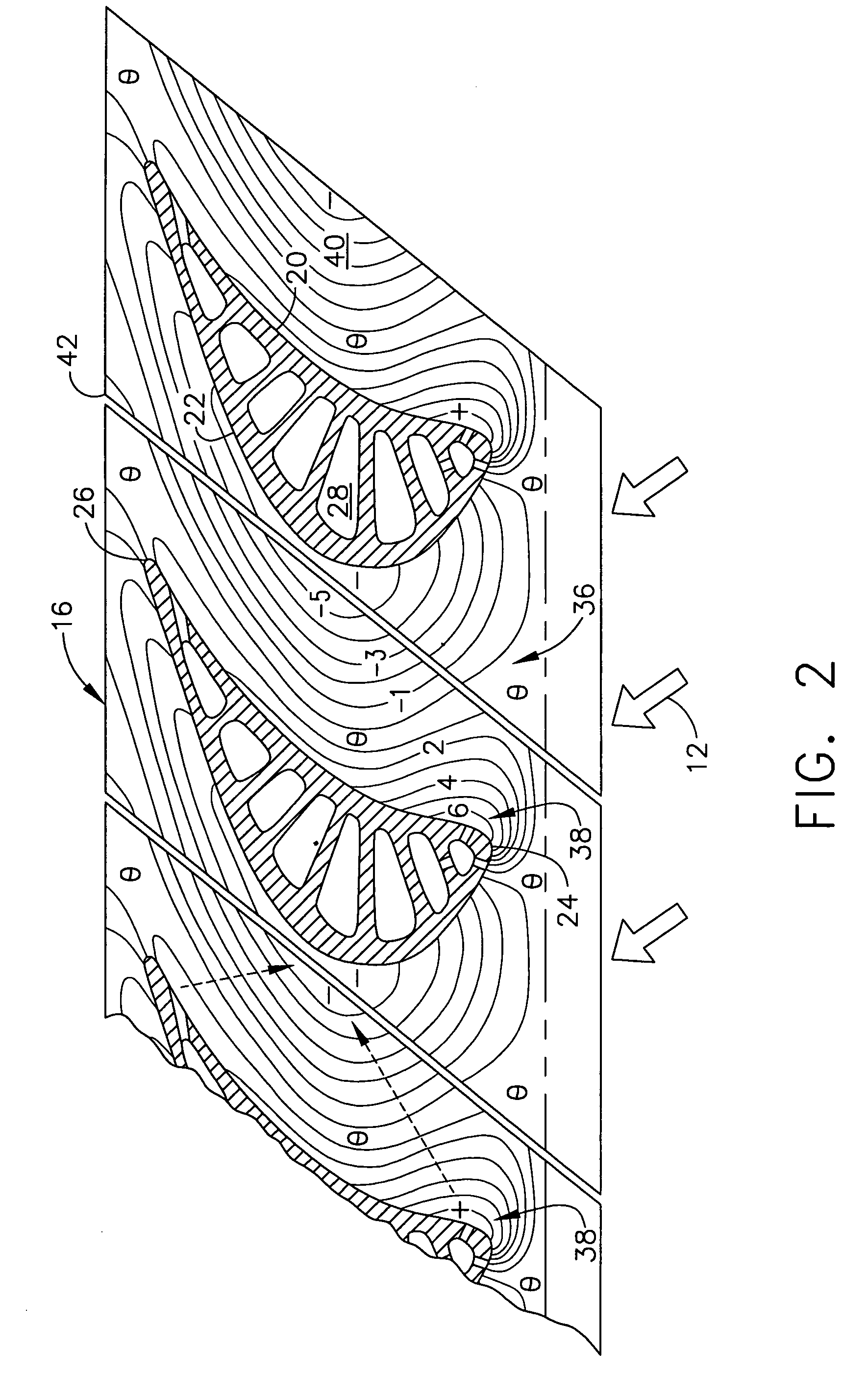

Scalloped surface turbine stage

A turbine stage includes a row of airfoils joined to corresponding platforms to define flow passages therebetween. Each airfoil includes opposite pressure and suction sides and extends in chord between opposite leading and trailing edges. Each platform has a scalloped flow surface including a bulge adjoining the pressure side adjacent the leading edge, and a bowl adjoining the suction side aft of the leading edge.

Owner:GENERAL ELECTRIC CO

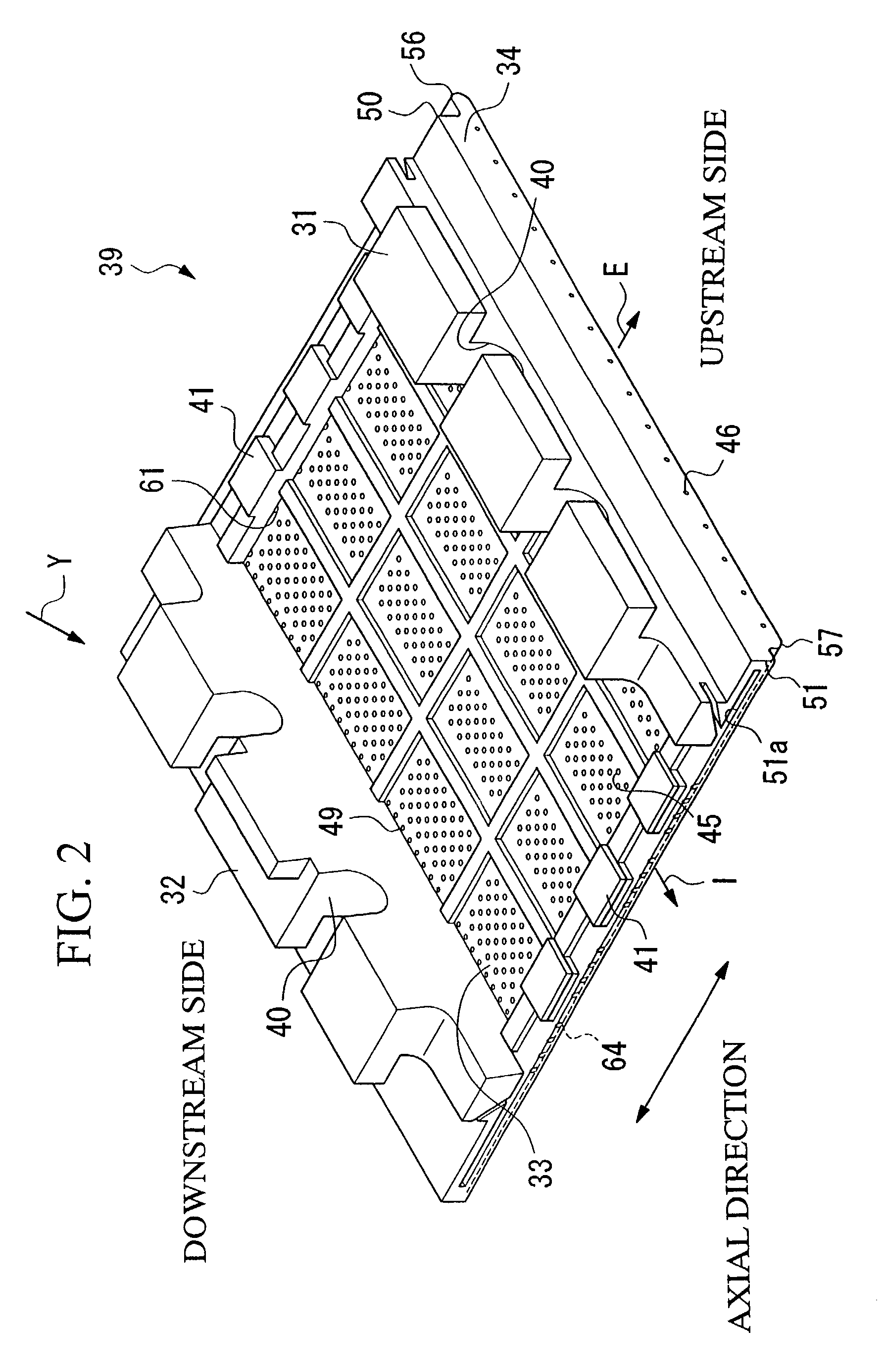

Gas turbine high temperature turbine blade outer air seal assembly

A turbine shroud assembly includes forward and aft hangers, an axisymmetric plenum assembly, ceramic shroud segments, ceramic spacers, and forward and aft rope seals. The plenum assembly supplies impingement cooling to the shroud and the hangers. The impingement cooling to the forward and aft hangers is controlled independently to improve blade tip clearance. The rope seals are radially inward from the hangers and reduce cooling flow leakage. The turbine shroud assembly can operate in a higher temperature environment using less cooling flow than the prior art.

Owner:HONEYWELL INT INC

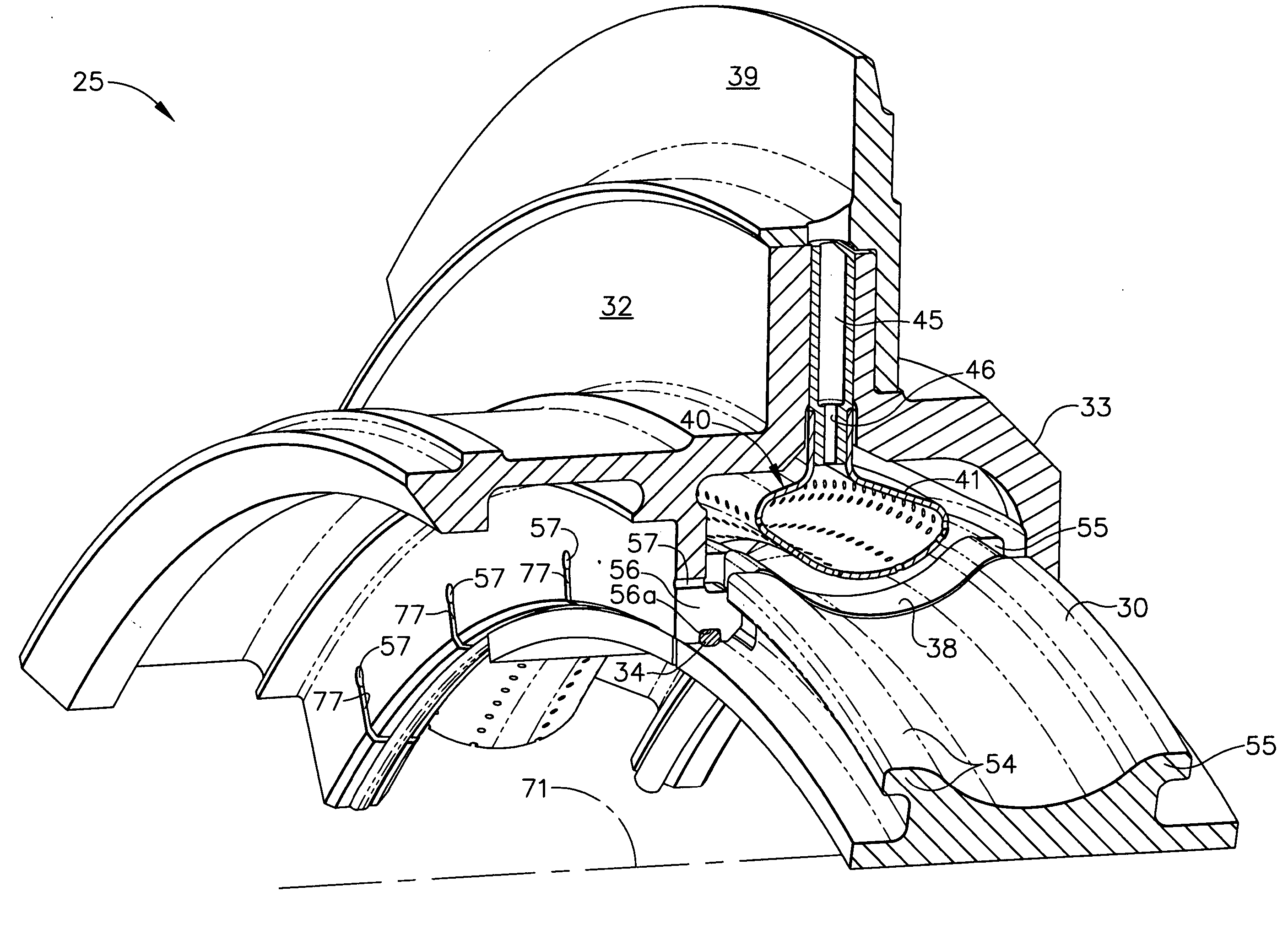

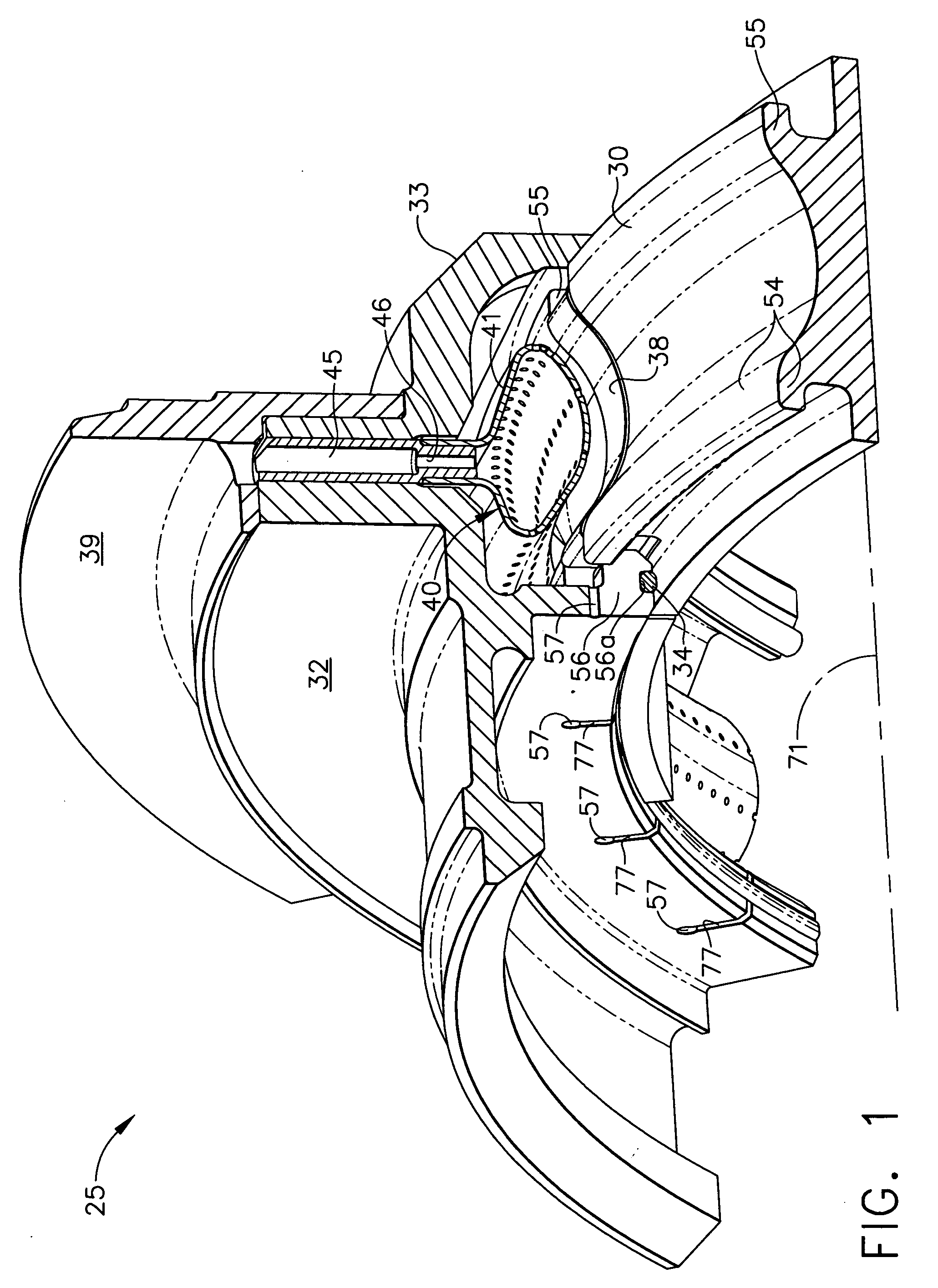

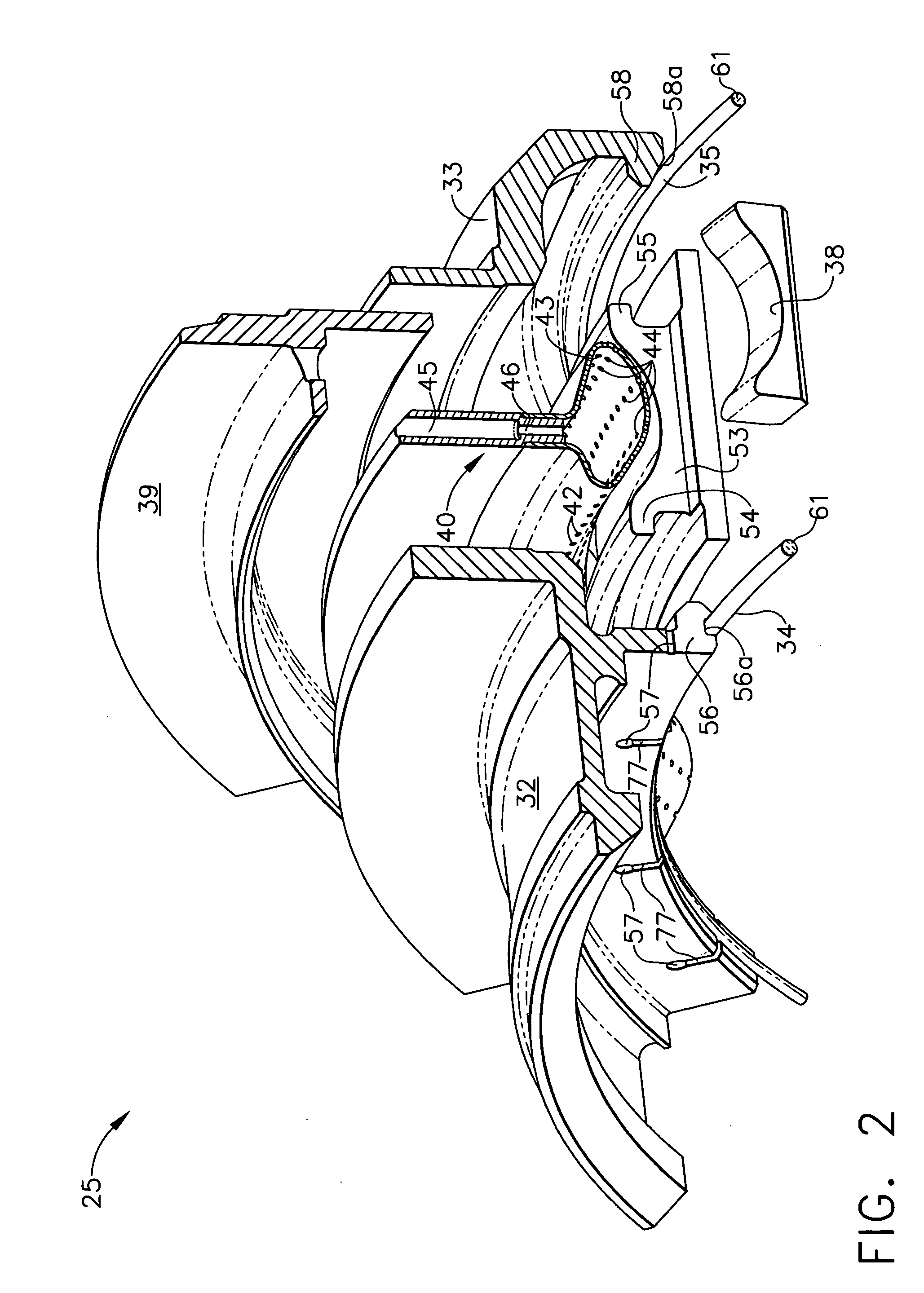

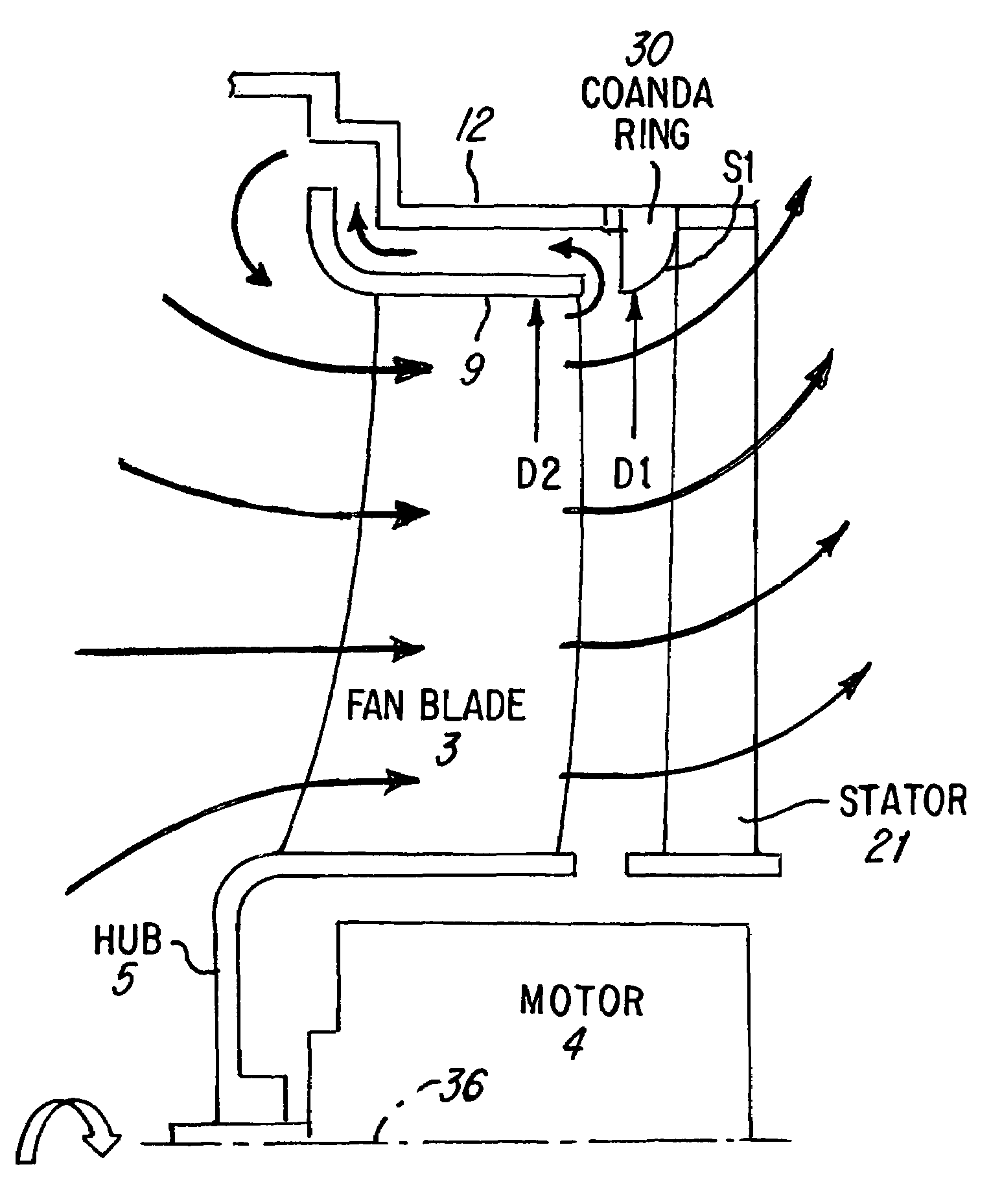

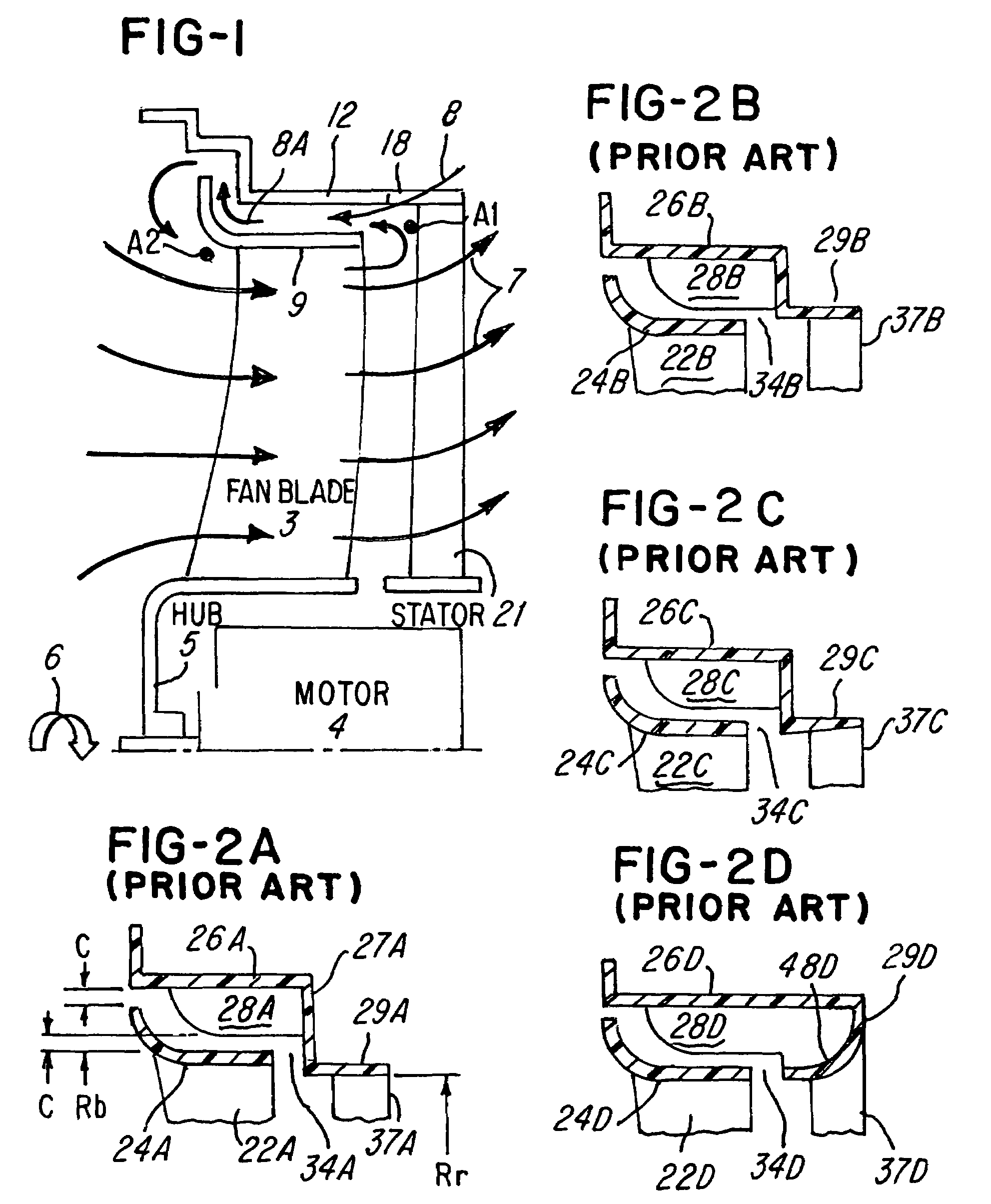

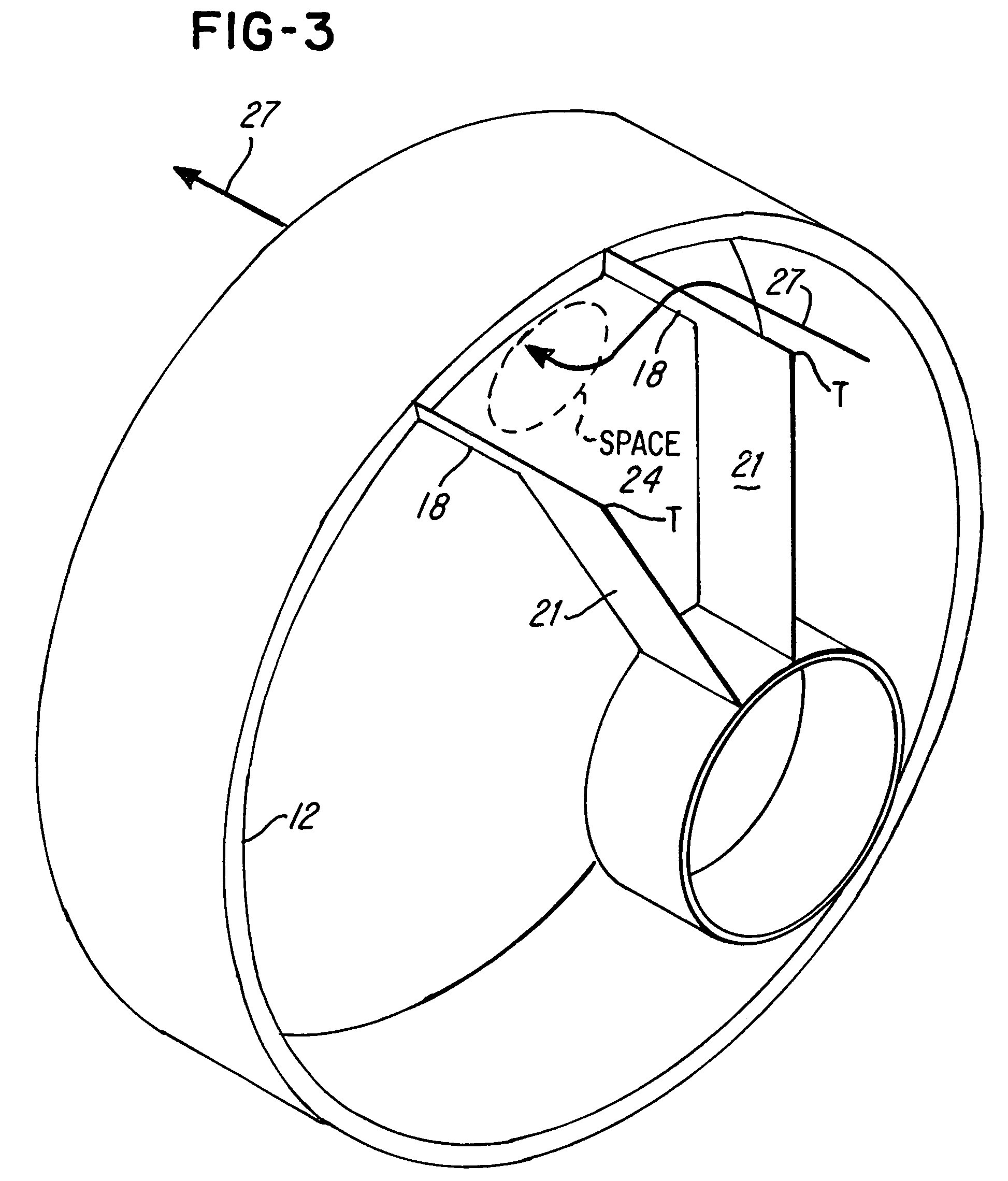

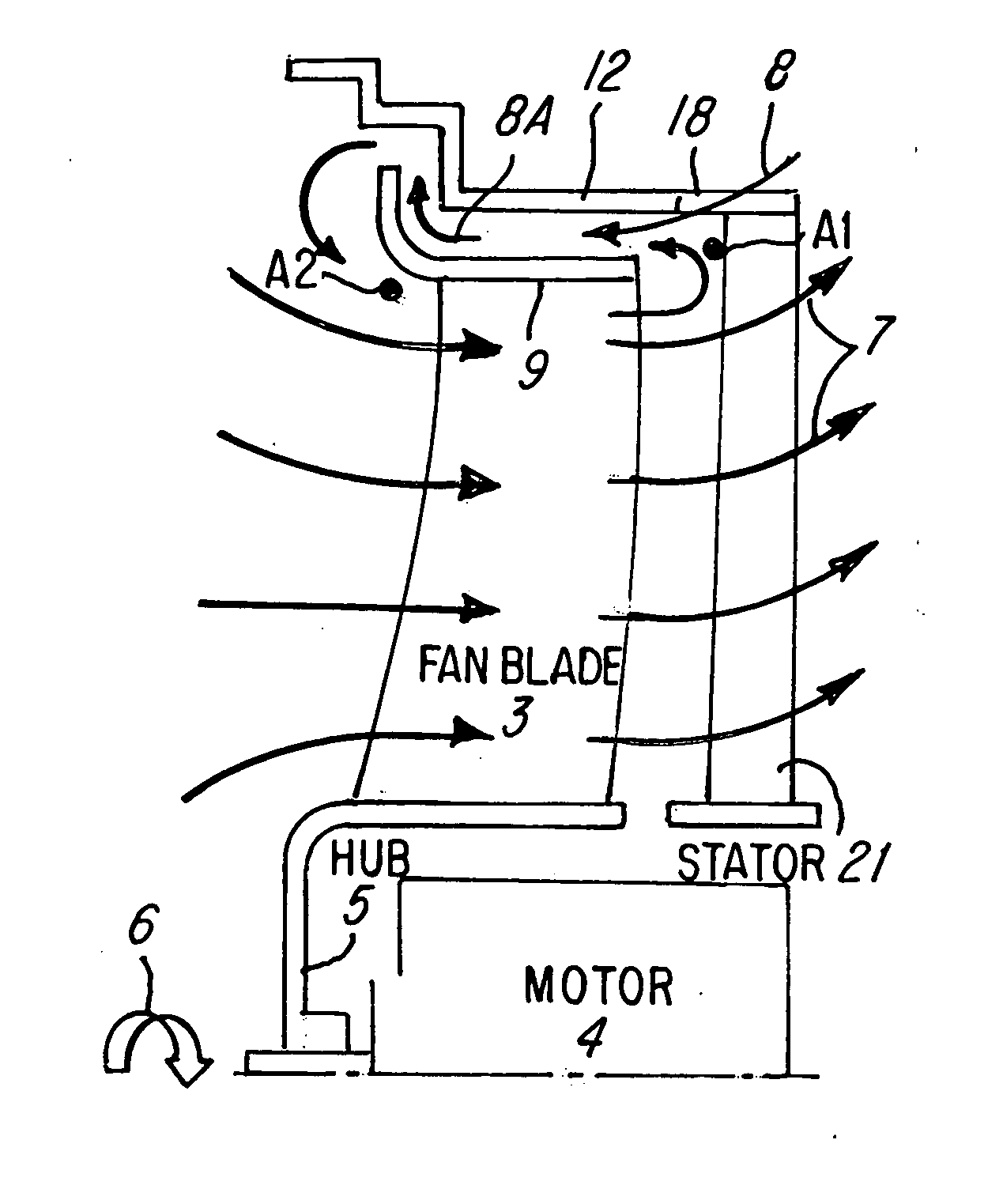

Cooling fan using Coanda effect to reduce recirculation

ActiveUS7478993B2Trend downIncrease the cross-sectional areaPump componentsReaction enginesEngineeringFan blade

Owner:VALEO INC

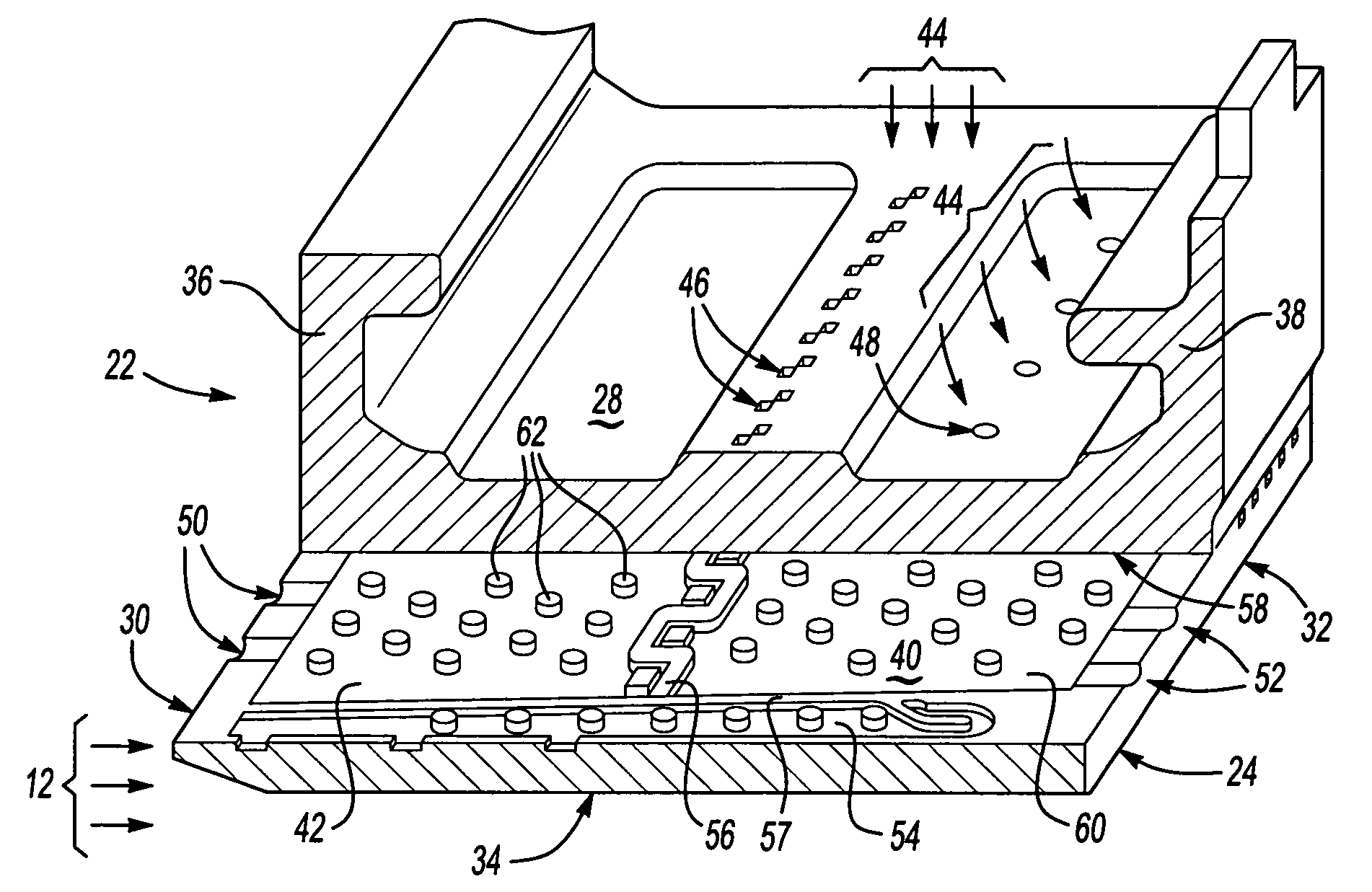

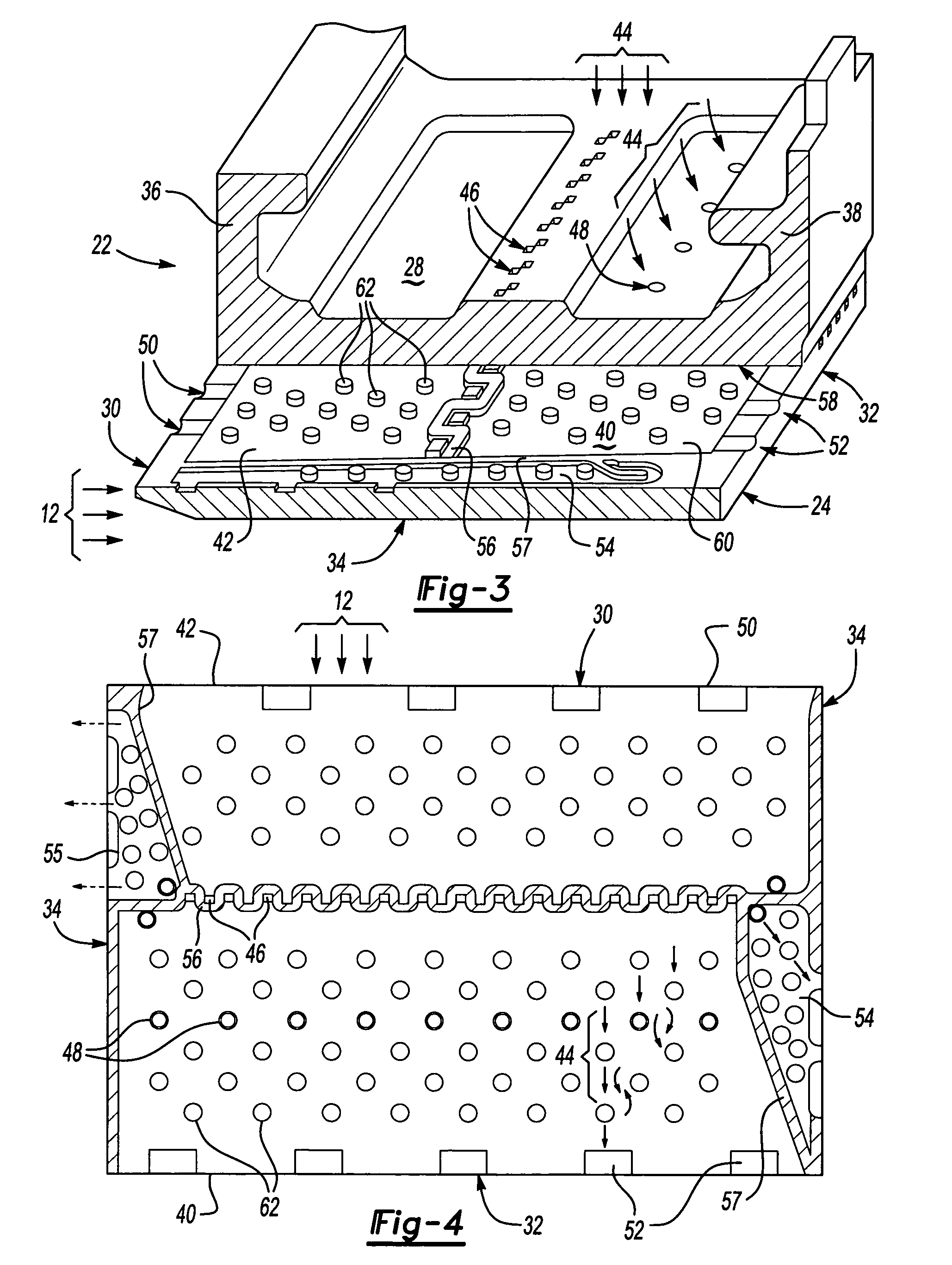

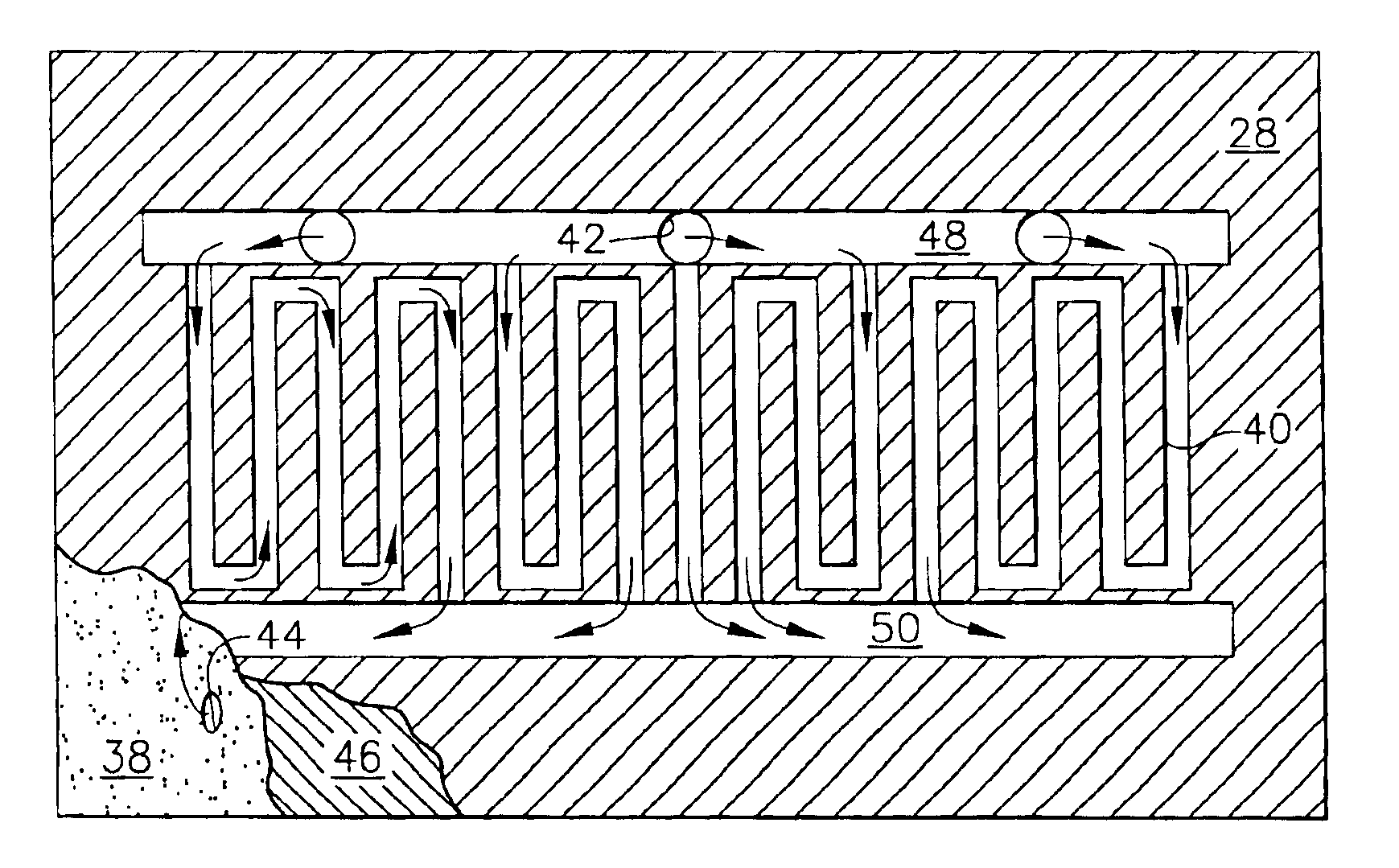

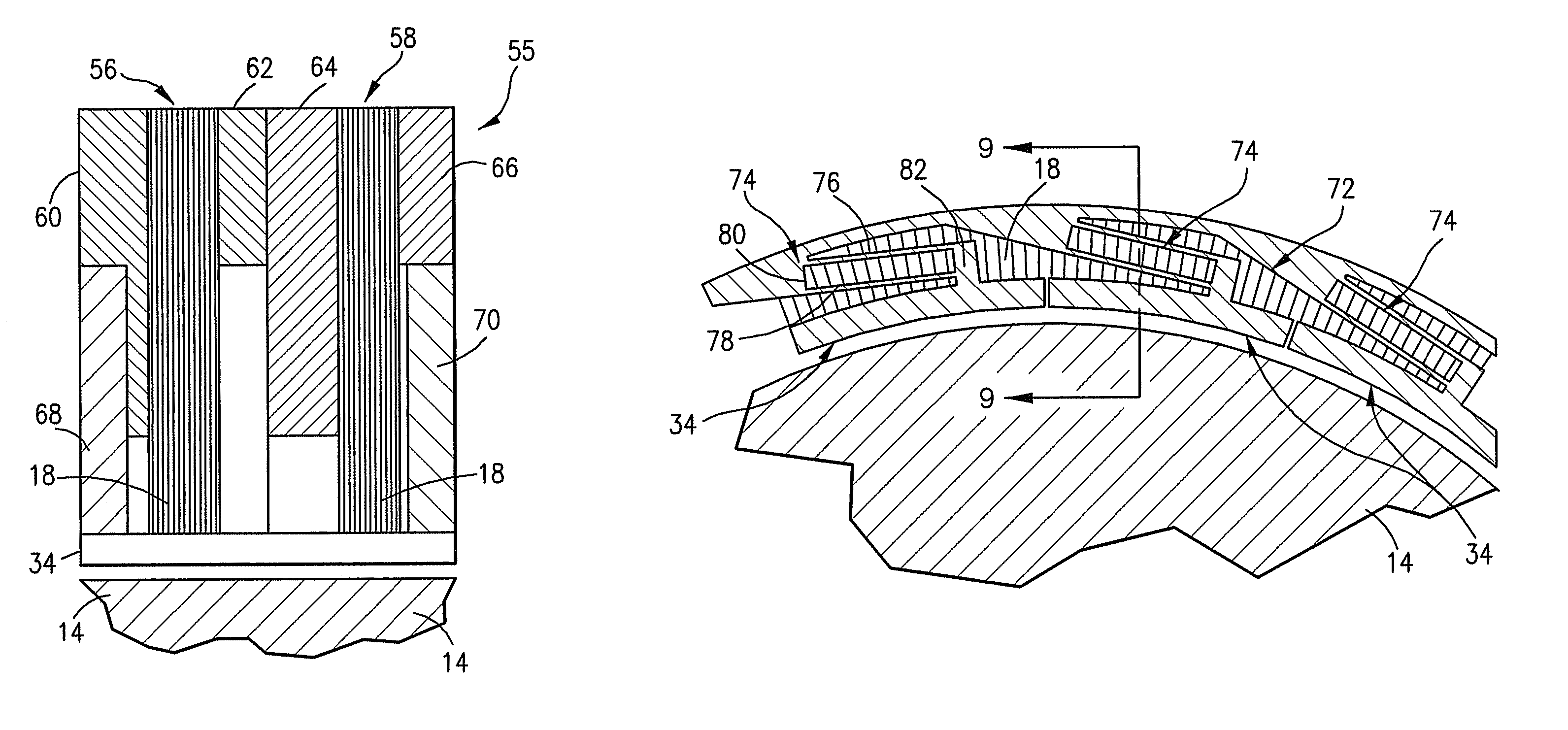

Blade outer seal with micro axial flow cooling system

ActiveUS7306424B2Increase surface areaImprove cooling effectPump componentsEngine fuctionsLeading edgeCombustion

A turbine blade outer air seal assembly includes a hot side exposed to a combustion hot gas flow, and a back side that is exposed to a supply of cooling air. The outer air seal segment includes a trailing edge cavity and a leading edge cavity separated by a divider. The cavities are feed cooling air through a plurality of inlet openings disposed transverse to the gas flow. The cooling air enters the cavities and flows toward a plurality of outlets at the leading edge and a plurality of outlets along the trailing edge. A plurality of pedestals within each of the cavities disrupts cooling air flow to increase heat absorption capacity and to increase the surface area capable of transferring heat from the hot side.

Owner:RTX CORP

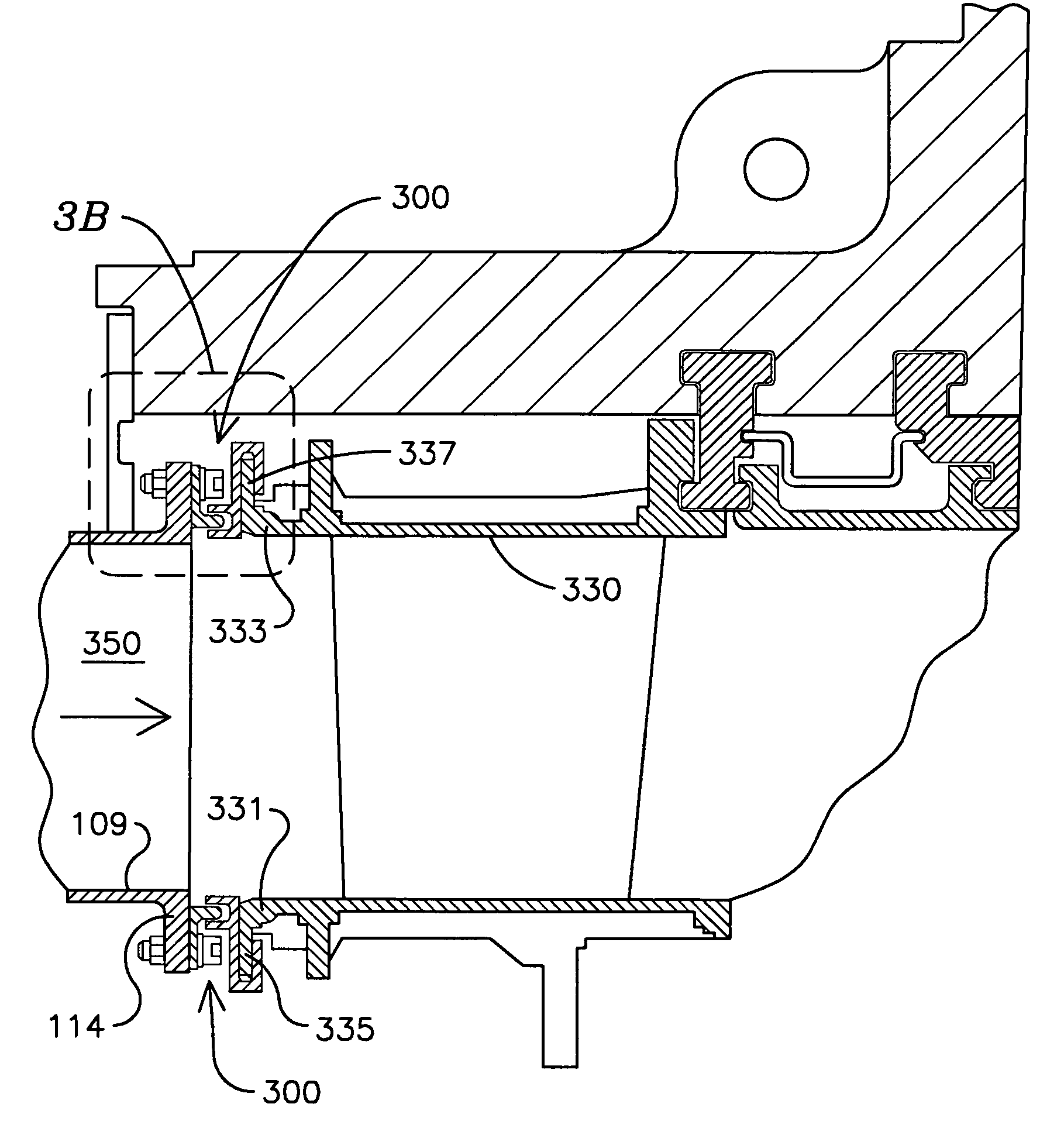

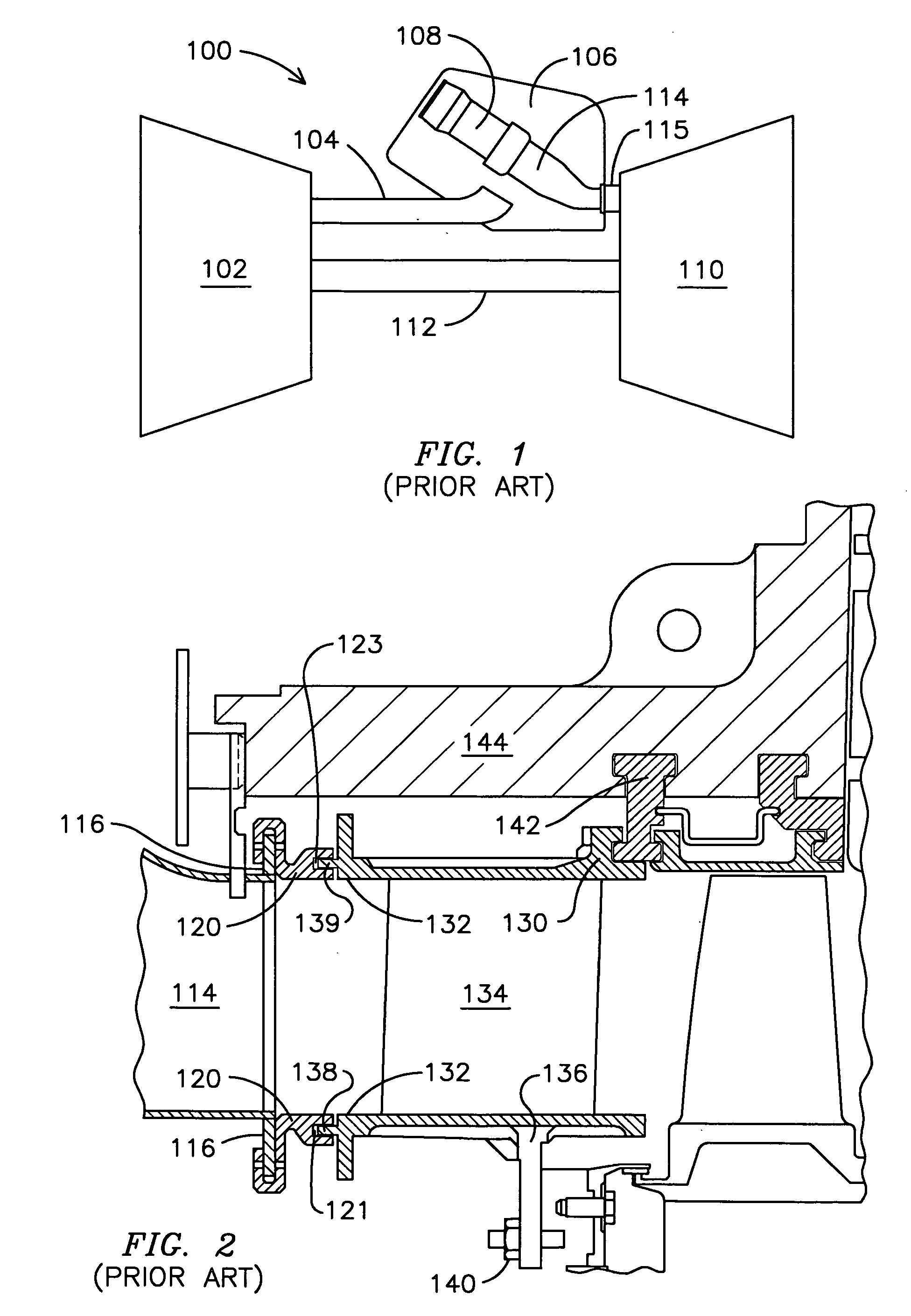

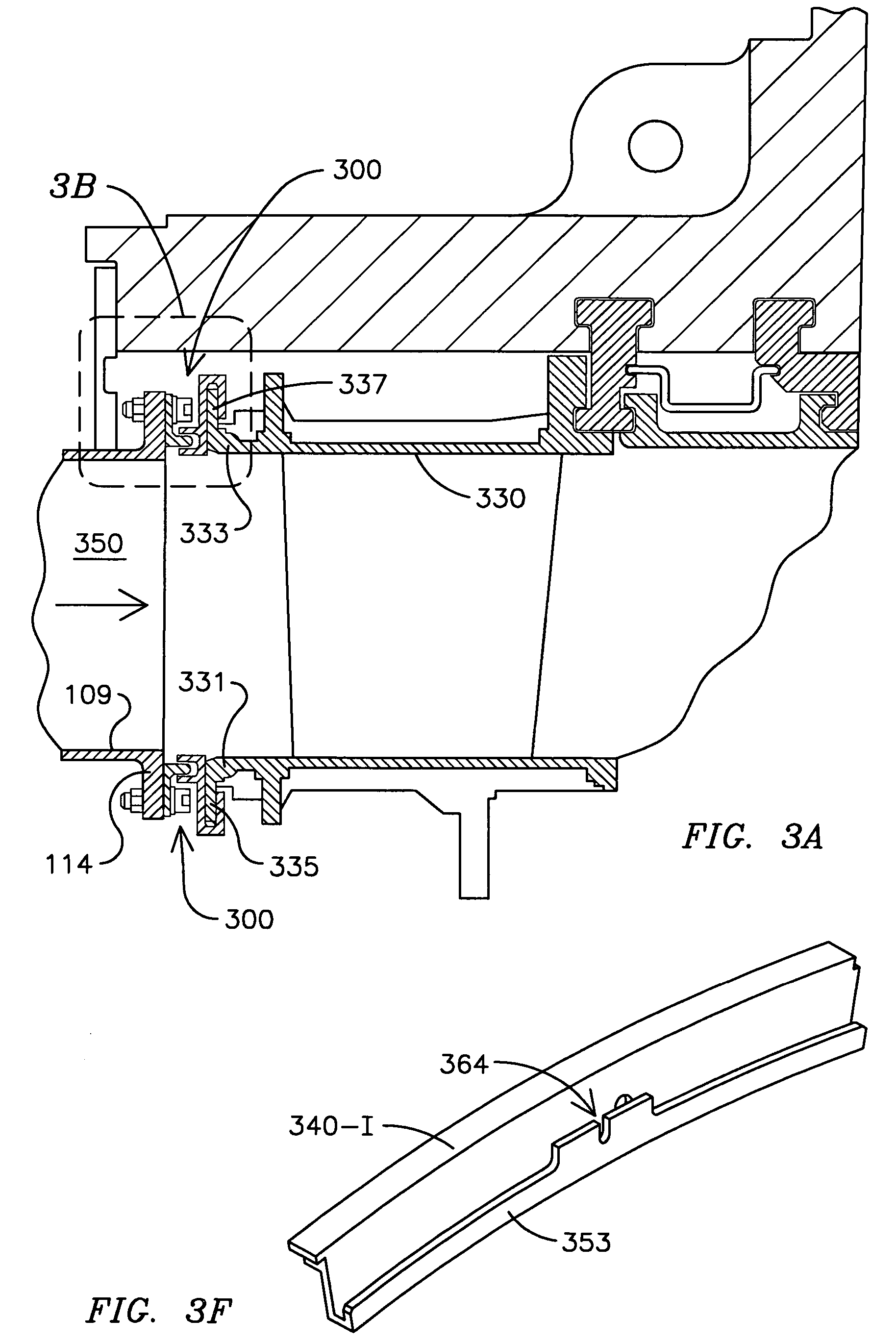

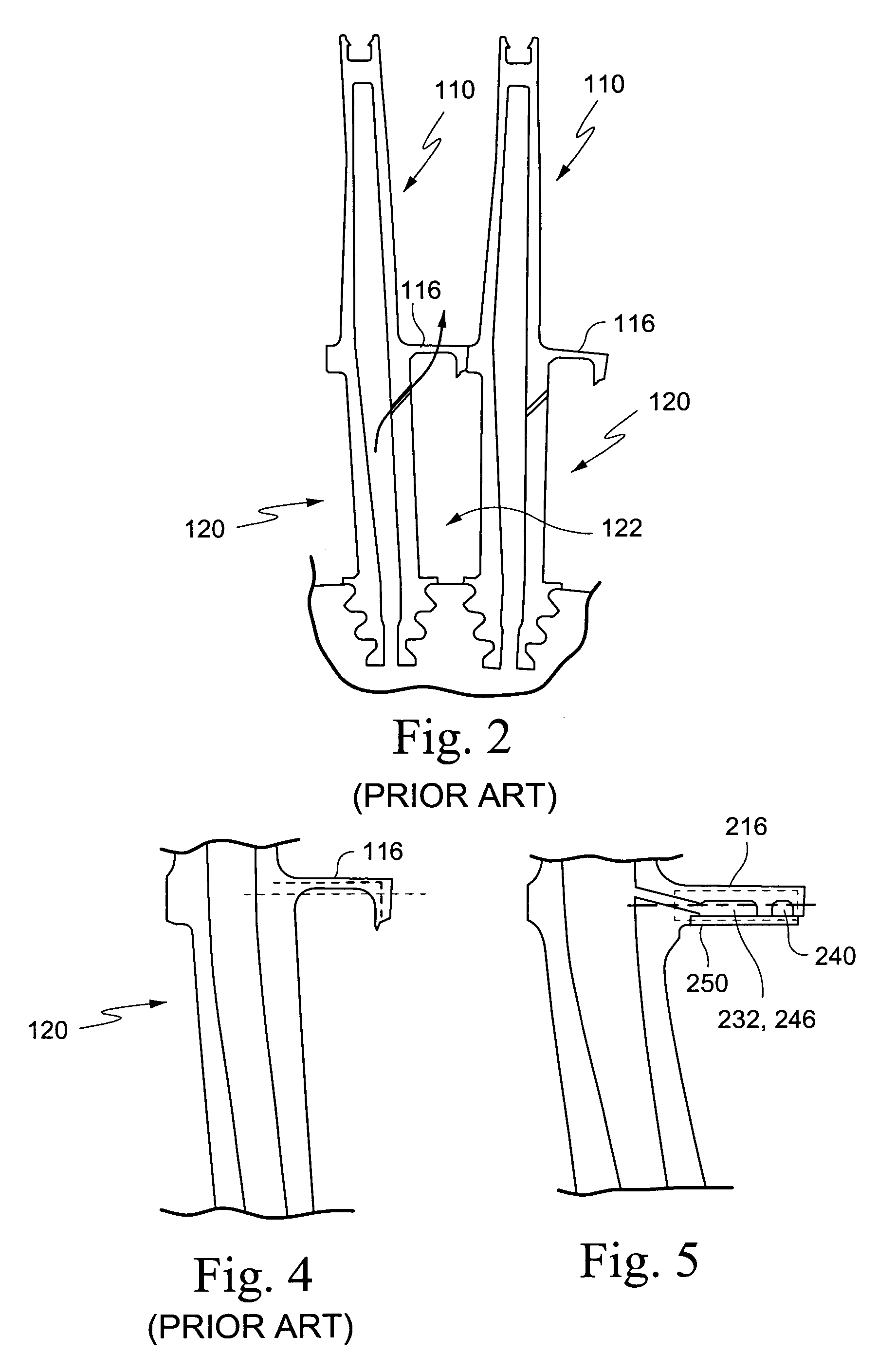

Transition-to-turbine seal apparatus and kit for transition/turbine junction of a gas turbine engine

One embodiment of a transition-to-turbine seal (300) comprises a transition exit seal (302) adapted for fixed attachment to an exit rail (116) of a transition (109), and a stage-1 seal (340). The stage-1 seal (340) comprises an axial seal slot (348) comprising parallel walls (346, 347) adapted to slidingly engage a first male member (310) of the transition exit seal (302). The stage-1 seal (340) also comprises a radial seal slot (354) comprising parallel walls (351, 353) adapted to slidingly engage a plate (338) of a row 1 vane segment (330). The transition-to-turbine seal (300) thus provides both axial and radial freedom of movement. Materials and coatings for the transition exit seal (302) and the stage-1 seal (340) are selected to promote preferential wear of these components relative to wear of the surface of the row 1 vane segment (330). Wear of the exit rail (116) is reduced or eliminated due to the noted fixed attachment.

Owner:SIEMENS ENERGY INC

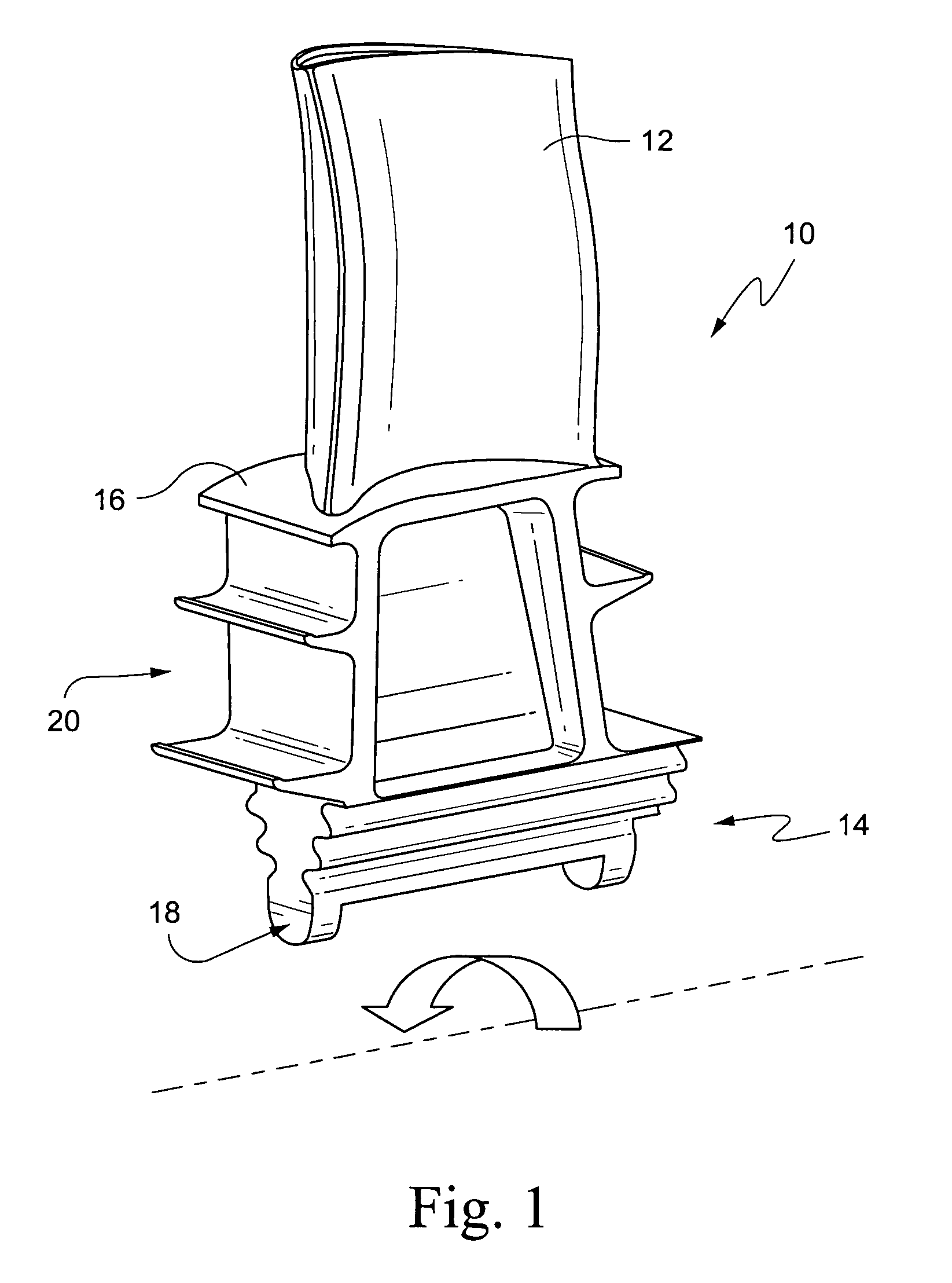

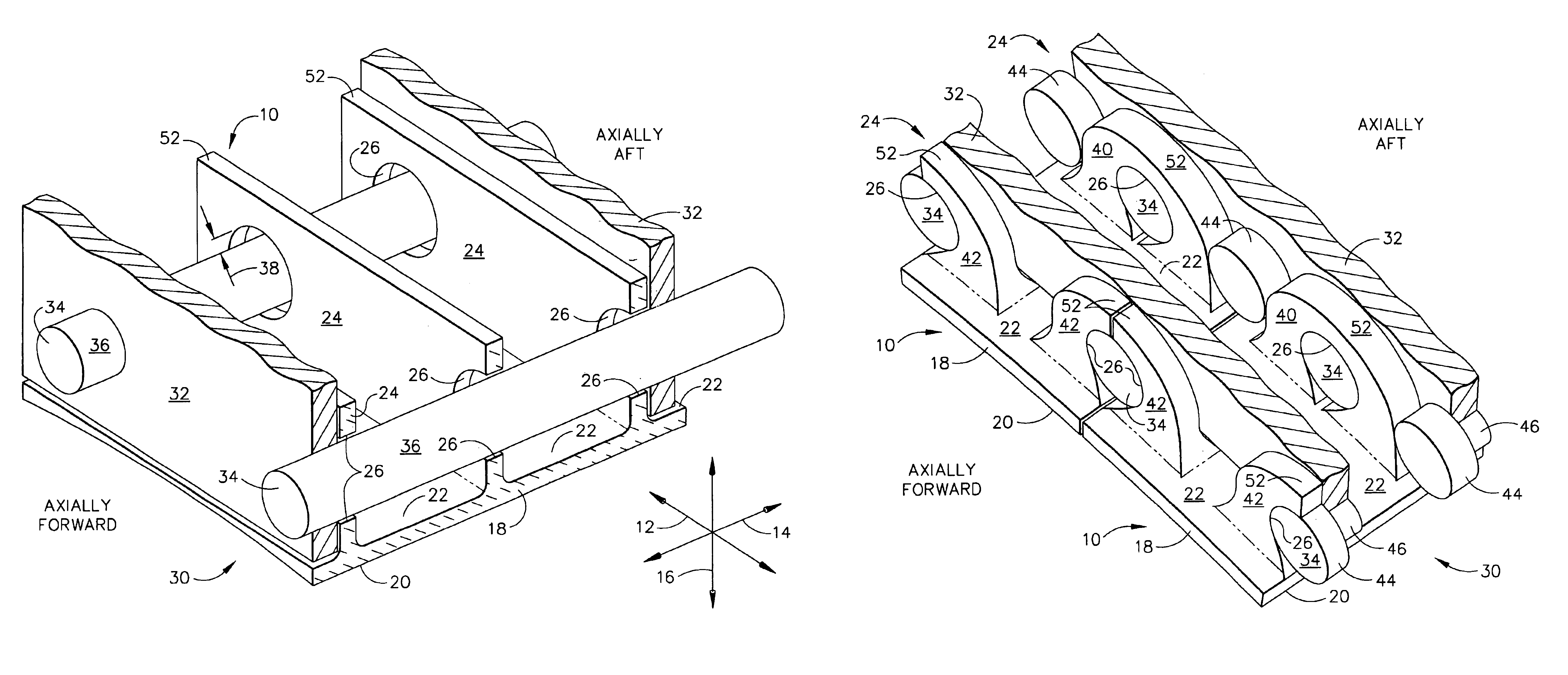

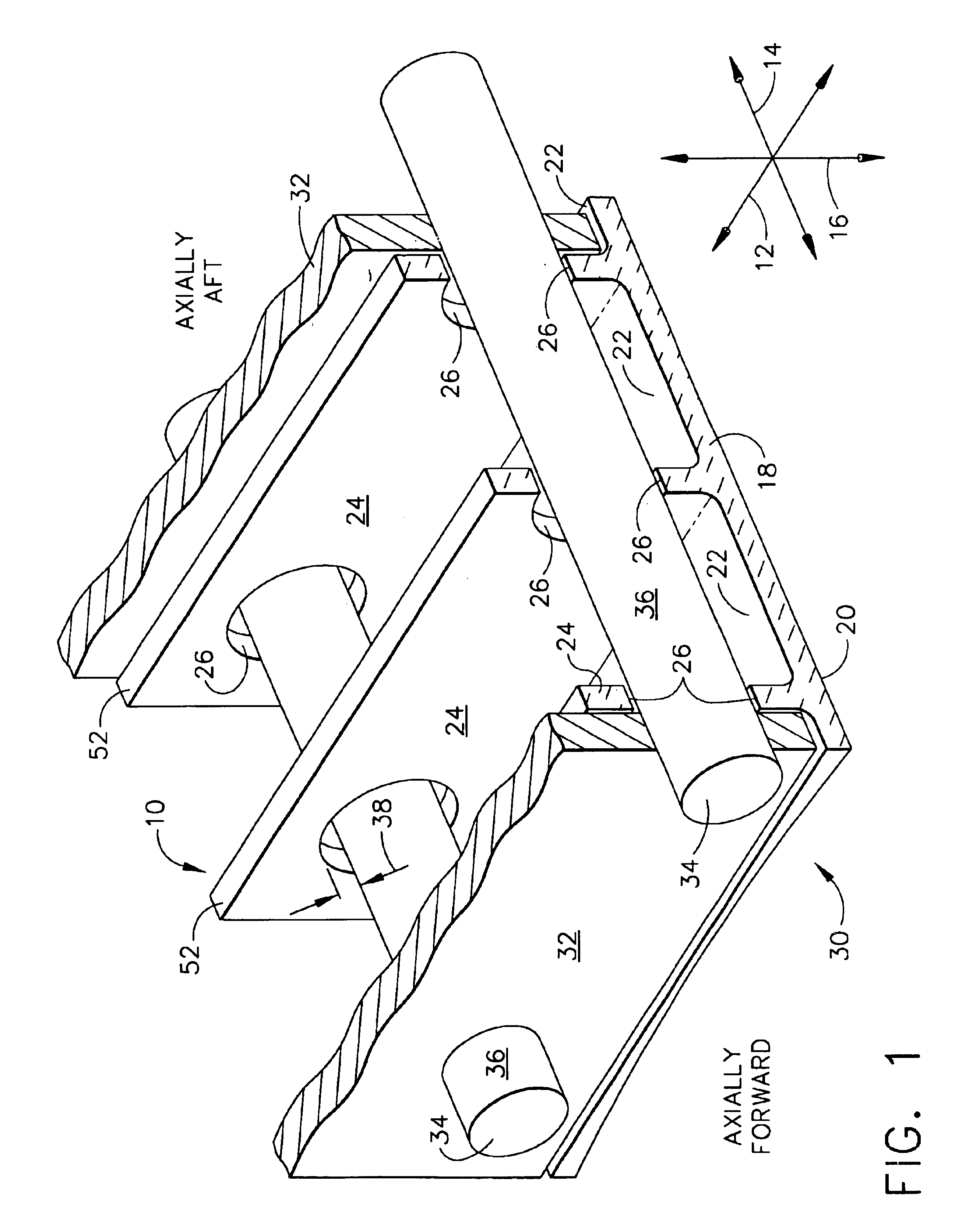

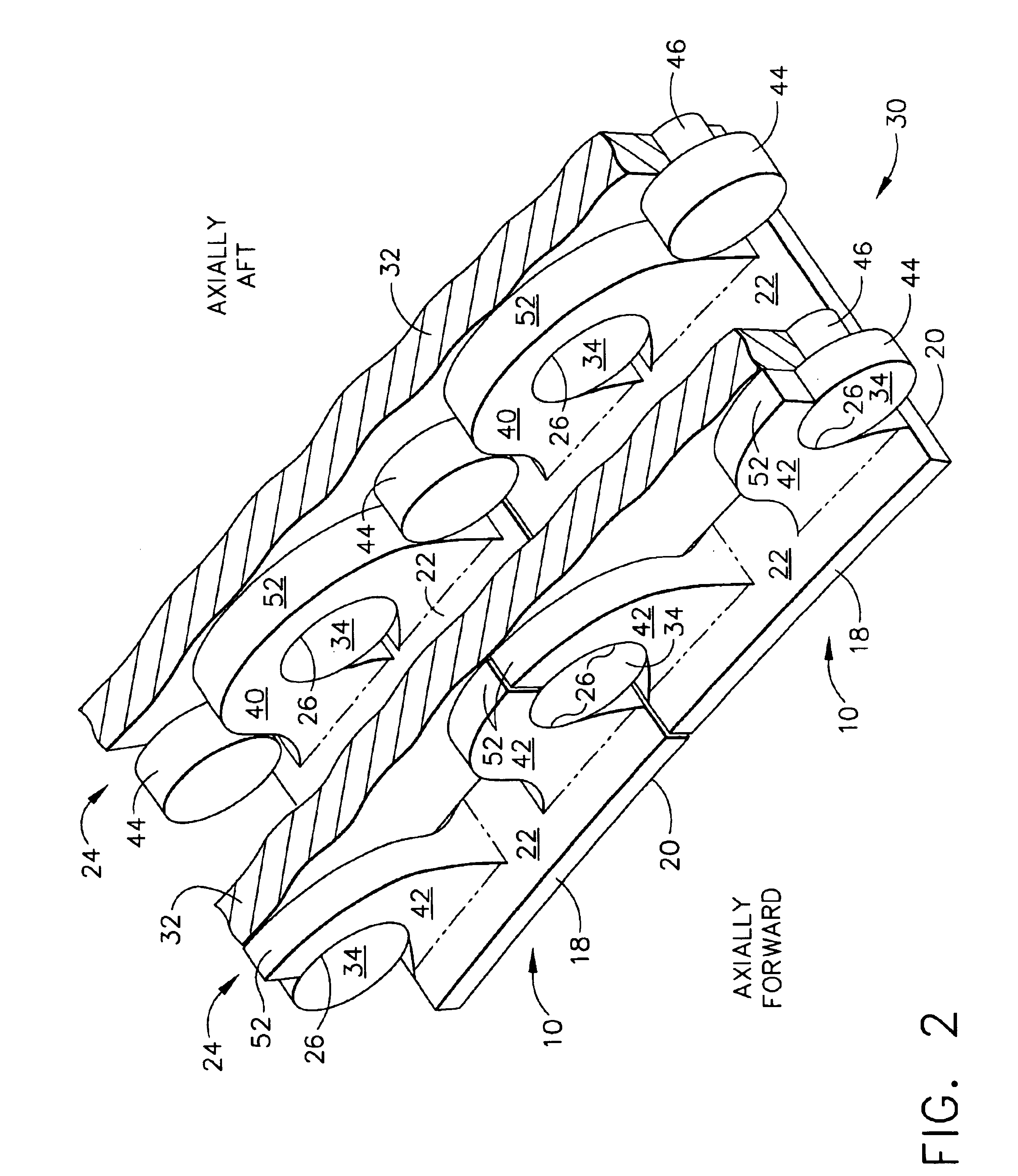

Turbine engine rotor stack

A turbine engine has a first disk and a second disk, each extending radially from an inner aperture to an outer periphery. A coupling, transmits a torque and a longitudinal compressive force between the first and second disks. The coupling has first means for transmitting a majority of the torque and a majority of the force and second means, radially outboard of the first means, for vibration stabilizing.

Owner:RAYTHEON TECH CORP

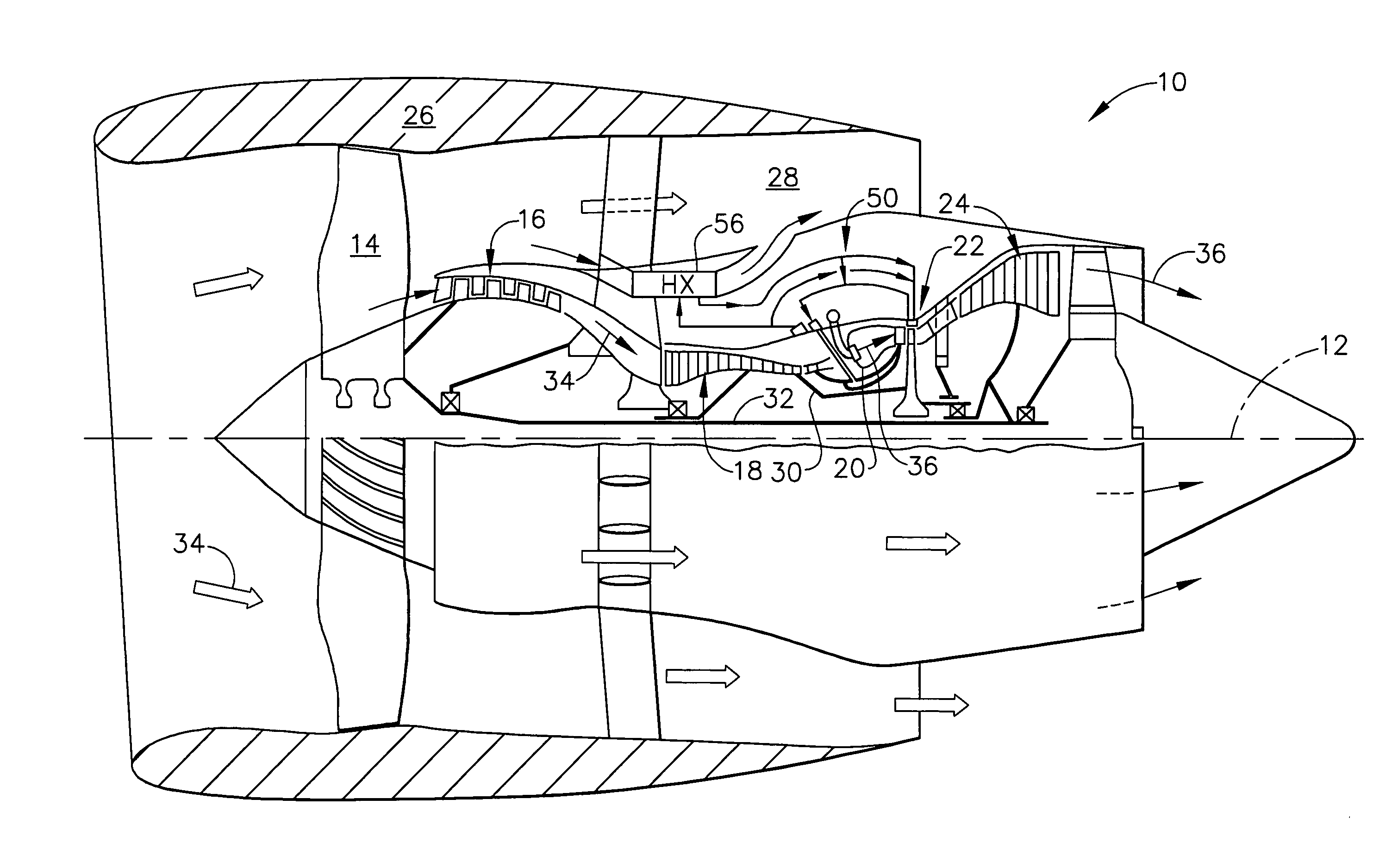

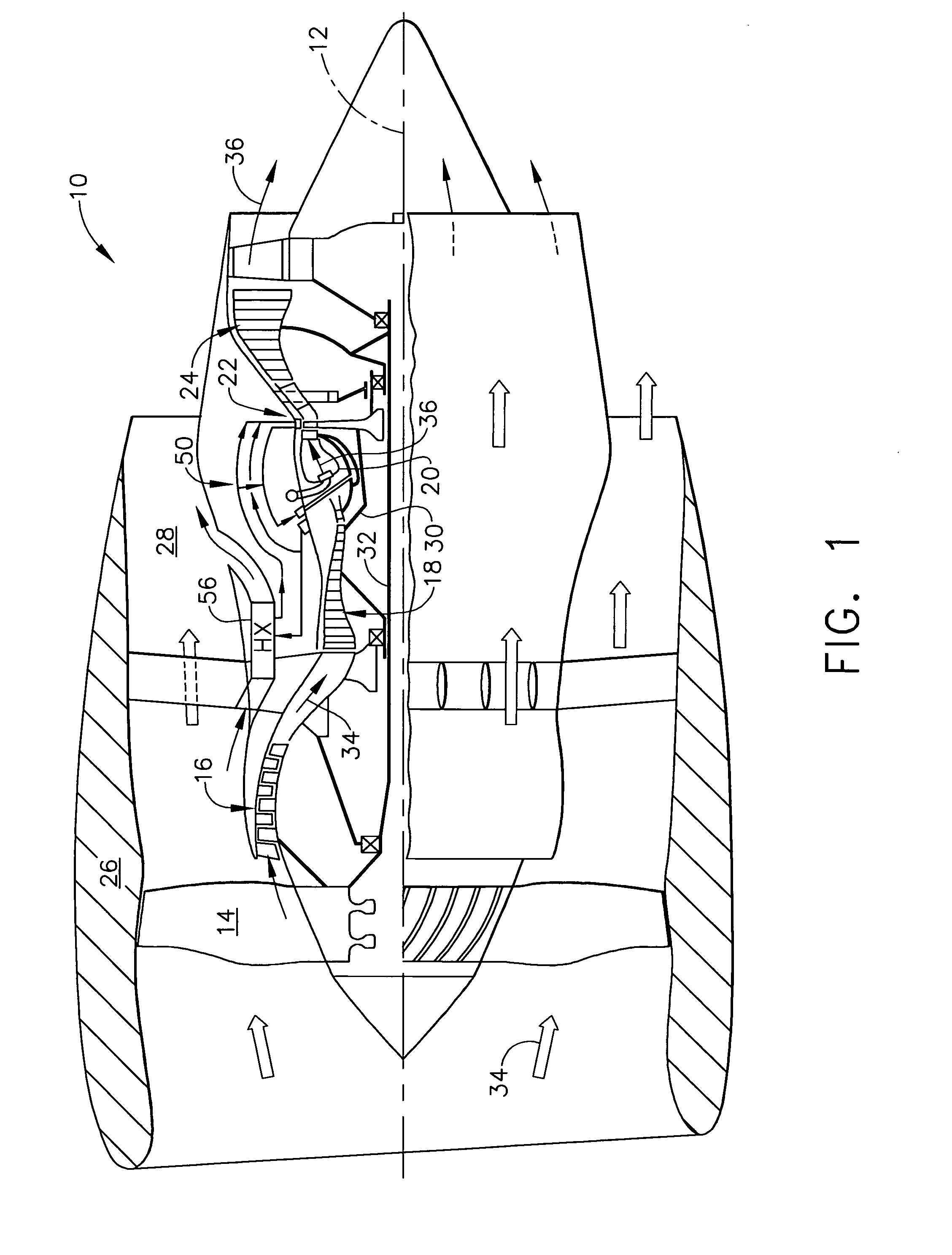

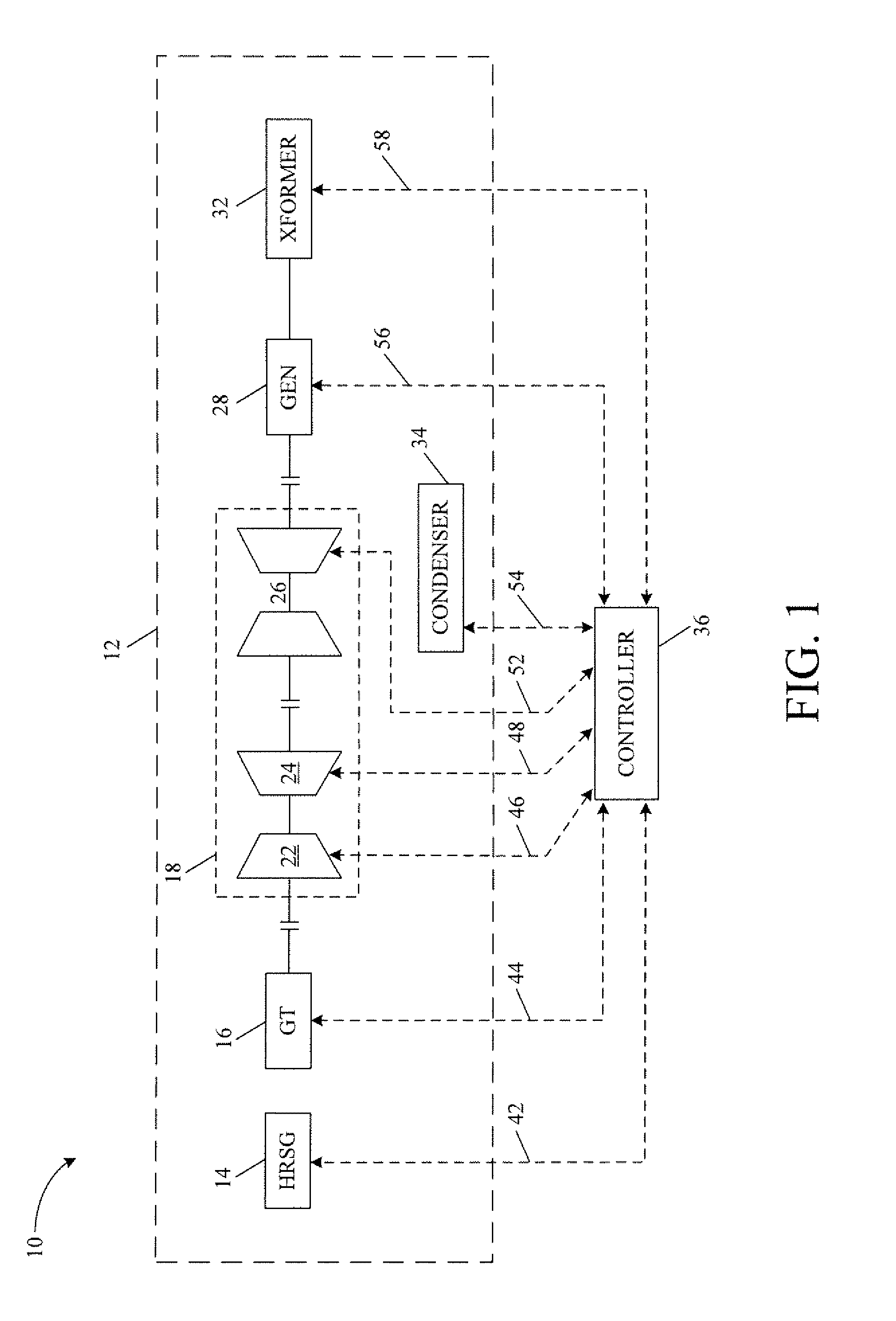

Compound clearance control engine

A gas turbine engine includes a compressor, combustor, and turbine having a row of blades mounted inside a surrounding turbine shroud. A heat exchanger is used for cooling pressurized air bled from the compressor. A distribution network joins the heat exchanger to the turbine for selectively channeling air from the heat exchanger below the blades and above the shroud for controlling blade tip clearance.

Owner:GENERAL ELECTRIC CO

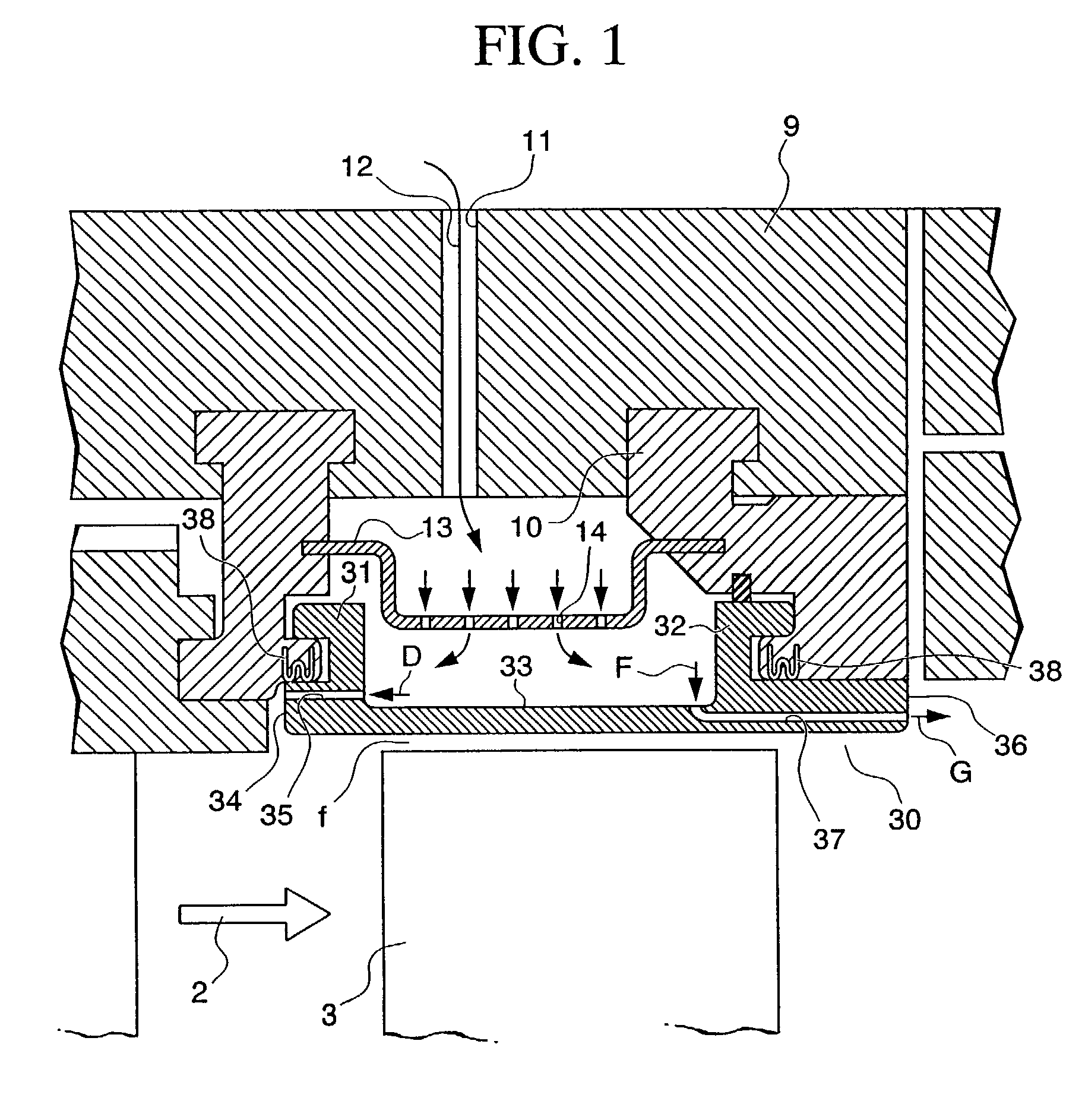

Ring segment of gas turbine

An object of the present invention is to provide a ring segment of a gas turbine in which the temperature is maintained low, damage due to high temperature oxidation is prevented, and high temperature deformation is prevented. In order to achieve the object, the present invention provides a ring segment of a gas turbine which comprises a blade ring, a main shaft and moving blades comprising a plurality of individual units which define an annular form by being arranged around the peripheral direction of the main shaft, and disposed so that its inner peripheral surface is maintained at a constant distance from the tips of the moving blades, wherein grooves which extend along the axial direction of the main shaft of the turbine are formed upon of the individual units so as mutually to confront one another; a seal plate which is inserted into each mutually confronting pair of the grooves so as to connect together the adjacent pair of individual units; and contact surfaces which are formed at positions more radially inward than the seal plates, which extend in the axial direction and the peripheral direction and which mutually contact one another.

Owner:MITSUBISHI HEAVY IND LTD

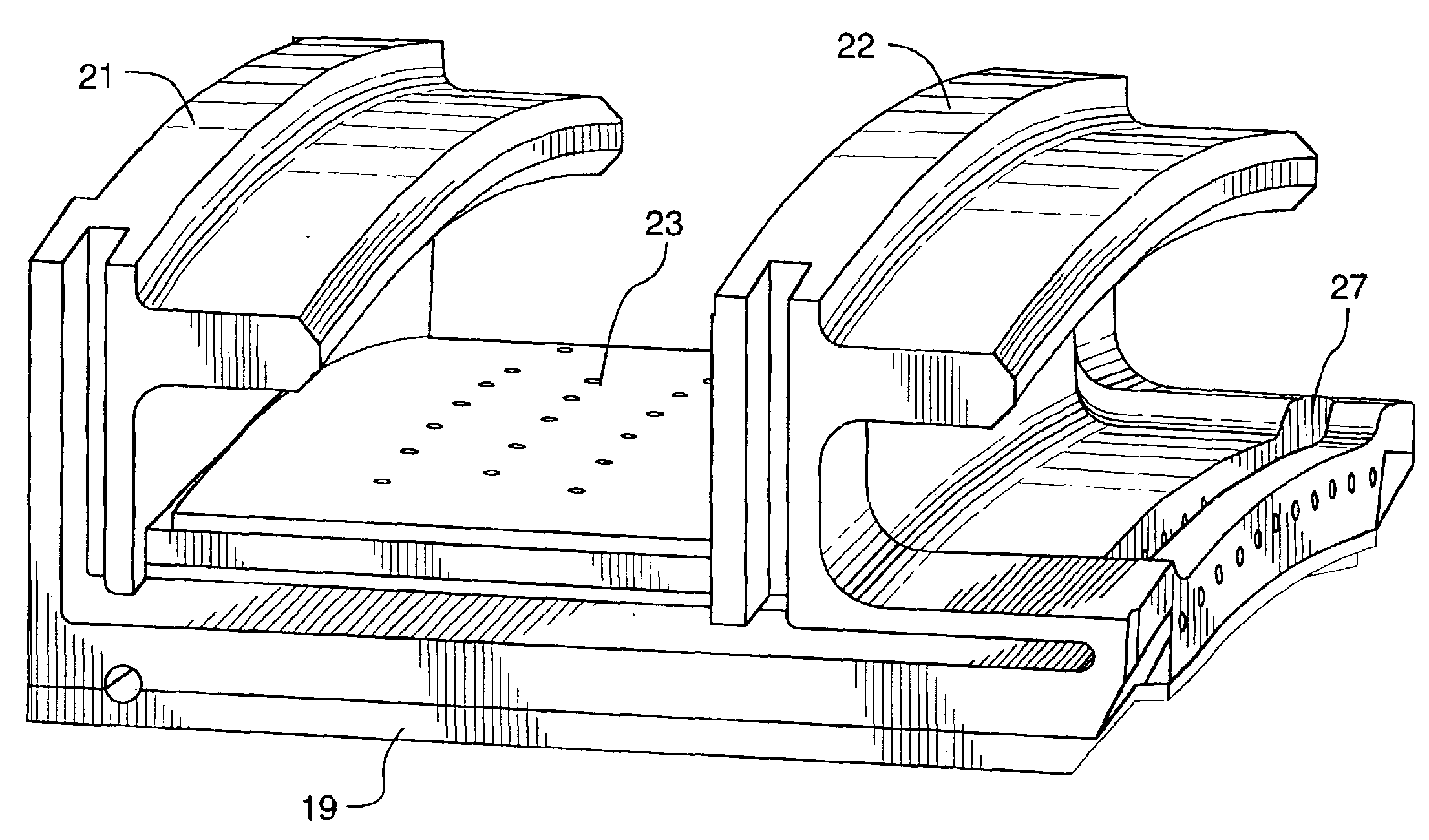

Turbine shroud segment apparatus for reusing cooling air

A cooled turbine shroud segment for a gas turbine engine, having an axially extending shroud ring segment with an inner surface, an outer surface, an upstream flange and a downstream flange. The flanges mount the shroud ring within an engine casing. A perforated cooling air impingement plate is disposed on the outer surface of the shroud ring between the upstream flange and the downstream flange, with an impingement plenum defined between the impingement plate and the outer surface. Axially extending cooling bores in the ring segment extend between the impingement plenum and an outlet. A trough adjacent the outlet directs cooling air from the outlet towards a downstream stator vane to cool the stator vane.

Owner:PRATT & WHITNEY CANADA CORP

Crescentic ramp turbine stage

A turbine stage includes a row of airfoils joined to corresponding platforms to define flow passages therebetween. Each airfoil includes opposite pressure and suction sides and extends in chord between opposite leading and trailing edges. Each platform includes a crescentic ramp increasing in height from the leading and trailing edges toward the midchord of the airfoil along the pressure side thereof.

Owner:GENERAL ELECTRIC CO

Bucket platform cooling circuit and method

InactiveUS7416391B2Reduce stressReduce the temperatureEngine manufactureEngine fuctionsTurbineCooling channel

In a turbine bucket having an airfoil portion and a root portion with a platform at an interface between the airfoil portion and the root portion, a platform cooling arrangement including: a cooling passage defined in the platform to extend along at least a portion of a concave, pressure side of the airfoil portion, at least one cooling medium inlet to said cooling passage extending from an airfoil cooling medium cavity in a vicinity of an axial center of the airfoil portion, and at least one outlet opening for expelling cooling medium from said cooling passage.

Owner:GENERAL ELECTRIC CO

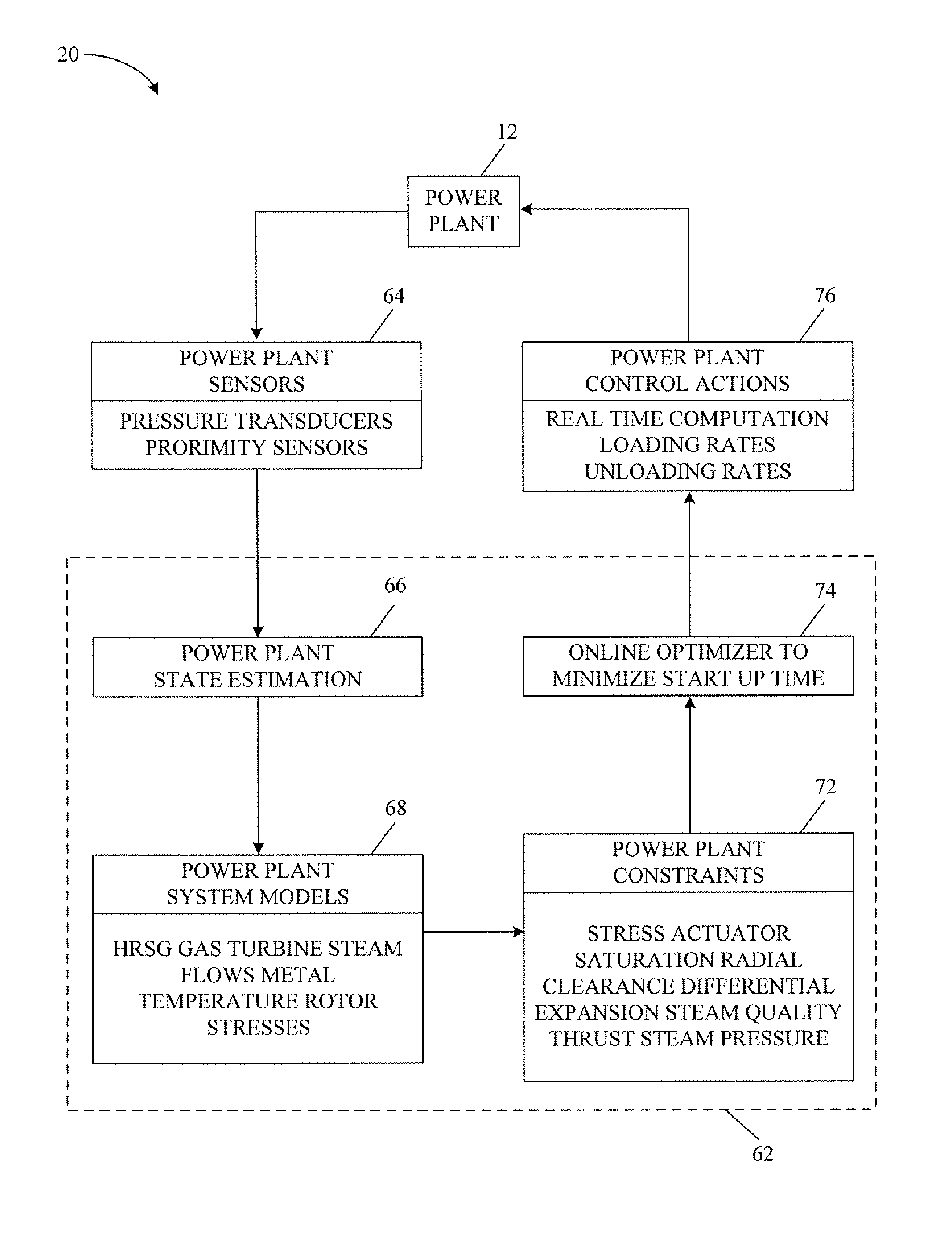

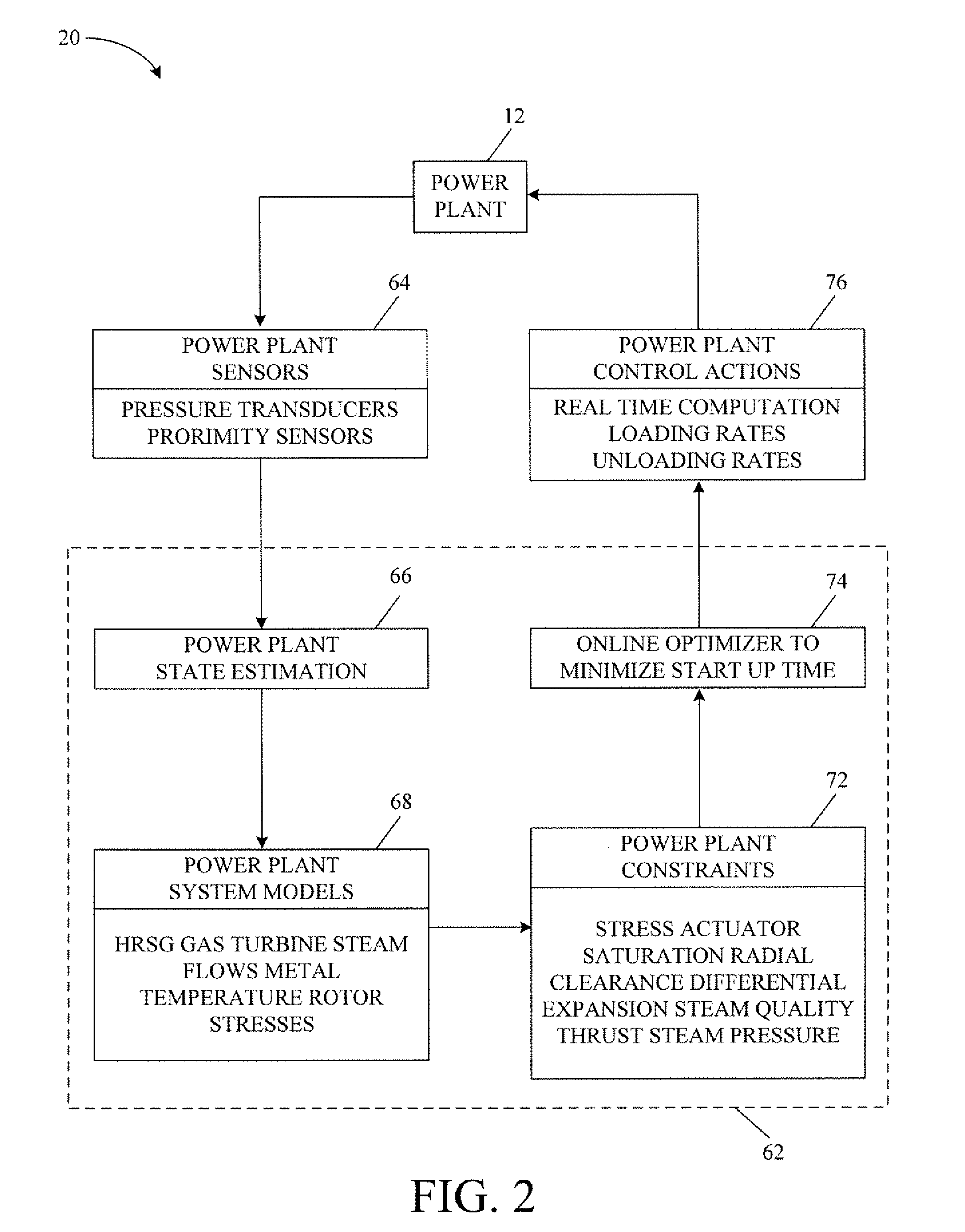

Methods and Systems for Neural Network Modeling of Turbine Components

Embodiments of the invention can include methods and systems for controlling clearances in a turbine. In one embodiment, a method can include applying at least one operating parameter as an input to at least one neural network model, modeling via the neural network model a thermal expansion of at least one turbine component, and taking a control action based at least in part on the modeled thermal expansion of the one or more turbine components. An example system can include a controller operable to determine and apply the operating parameters as inputs to the neural network model, model thermal expansion via the neural network model, and generate a control action based at least in part on the modeled thermal expansion.

Owner:GENERAL ELECTRIC CO

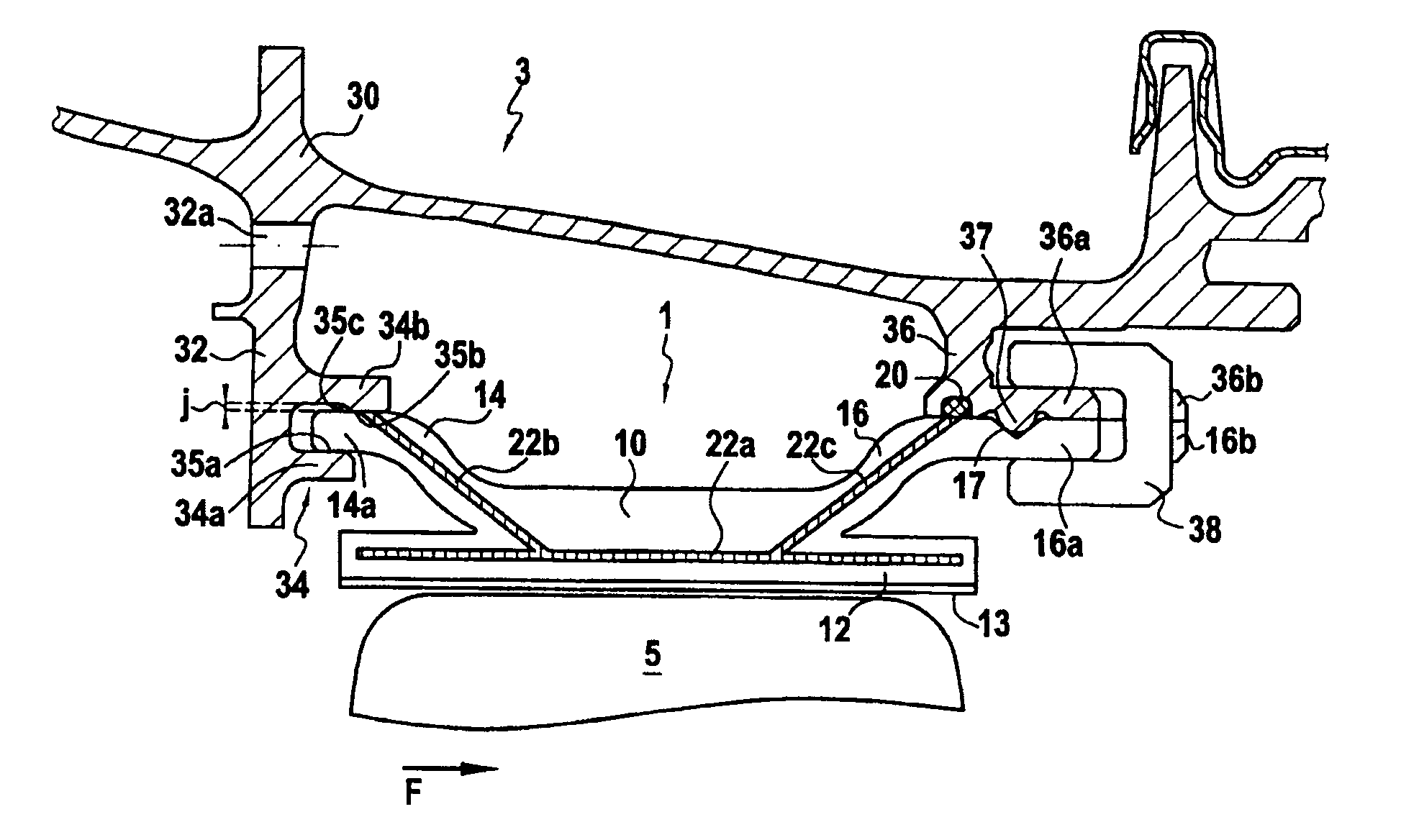

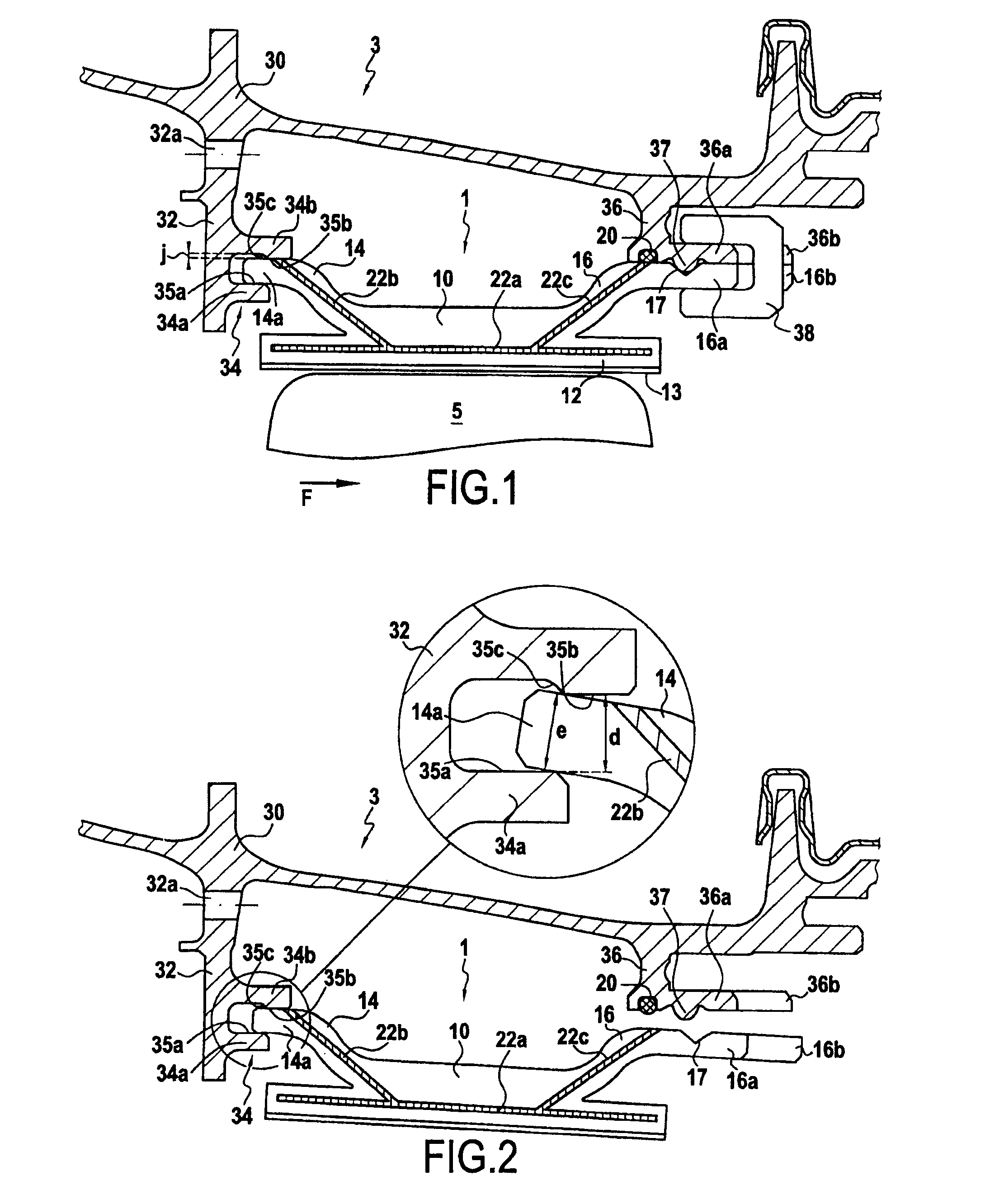

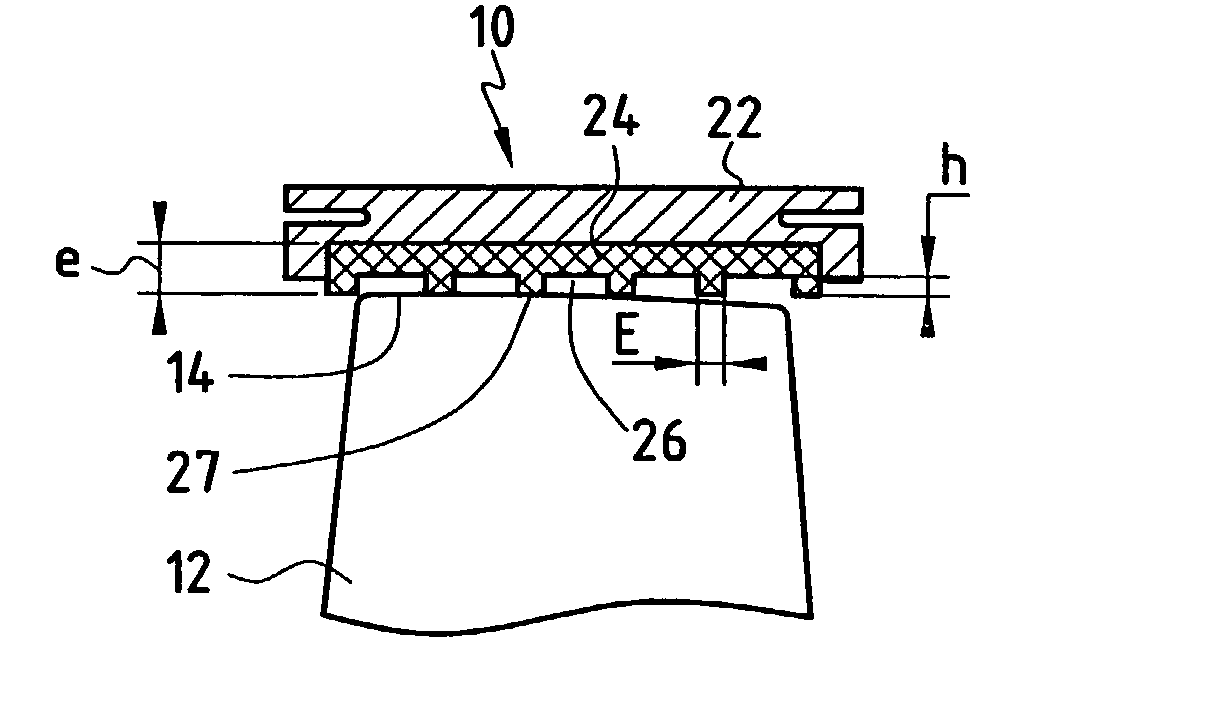

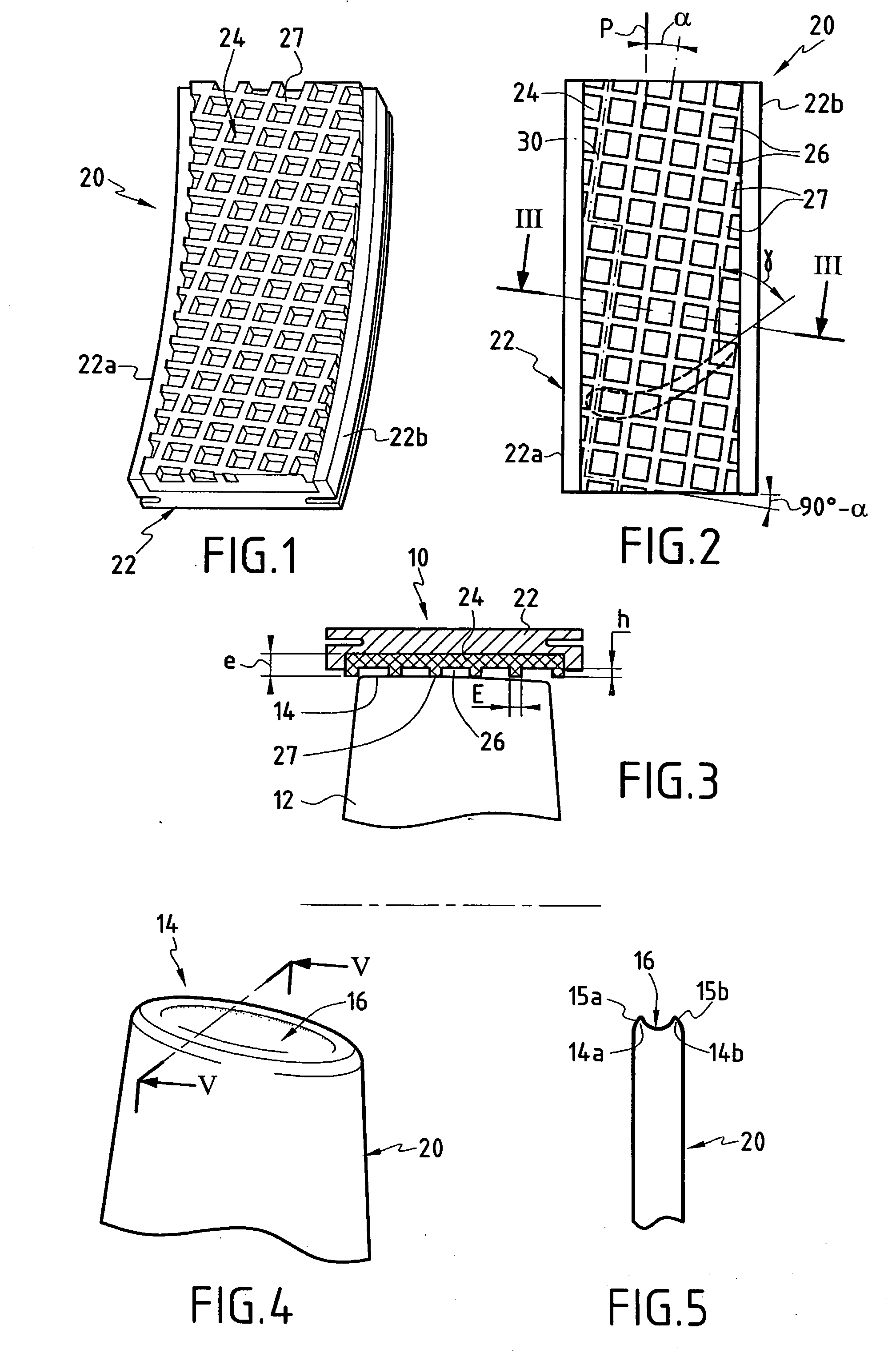

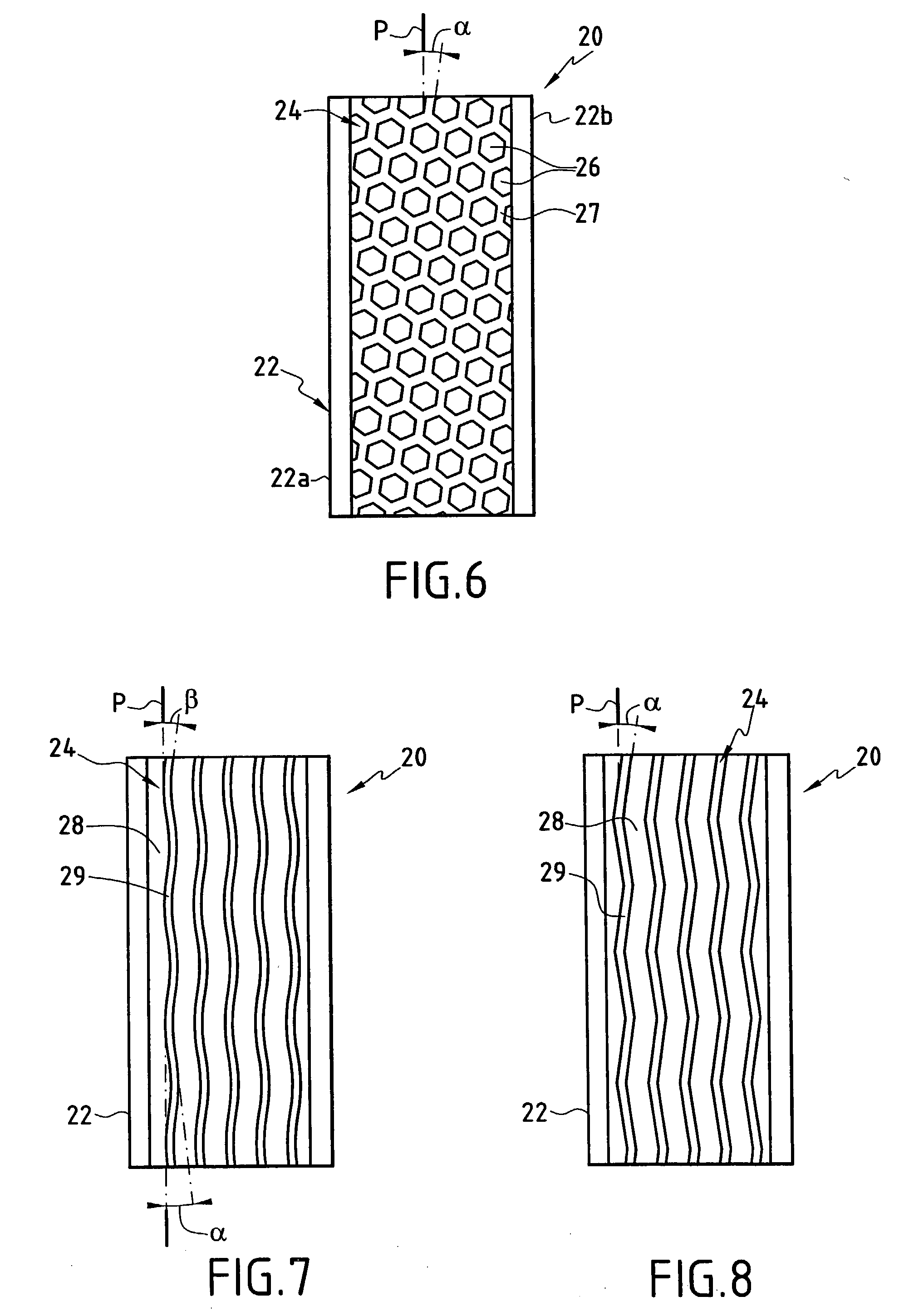

Abradable coating for gas turbine walls

InactiveUS20030175116A1Improve wear resistanceEffective thermal protectionPump componentsBlade accessoriesCoated surfaceEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

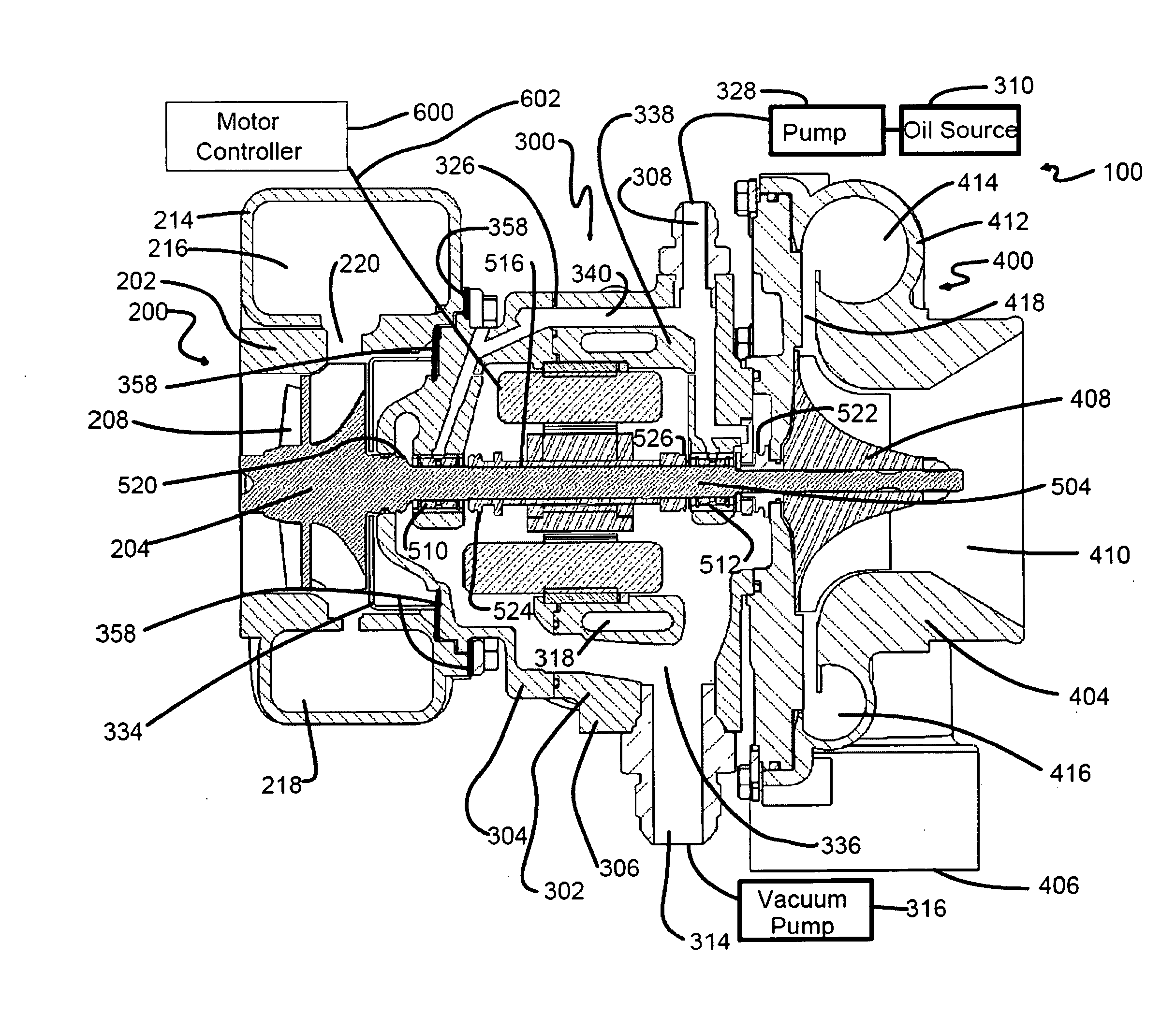

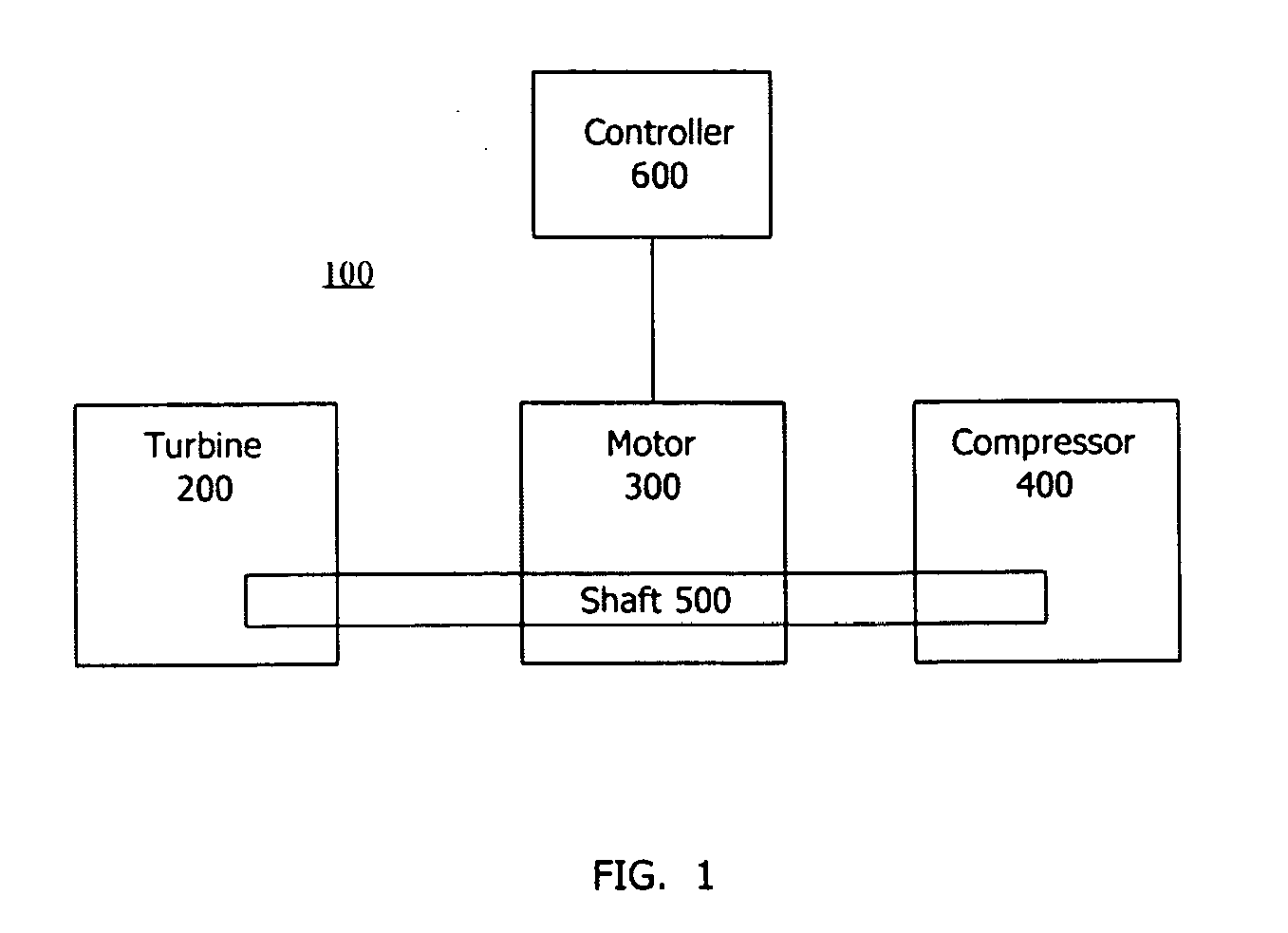

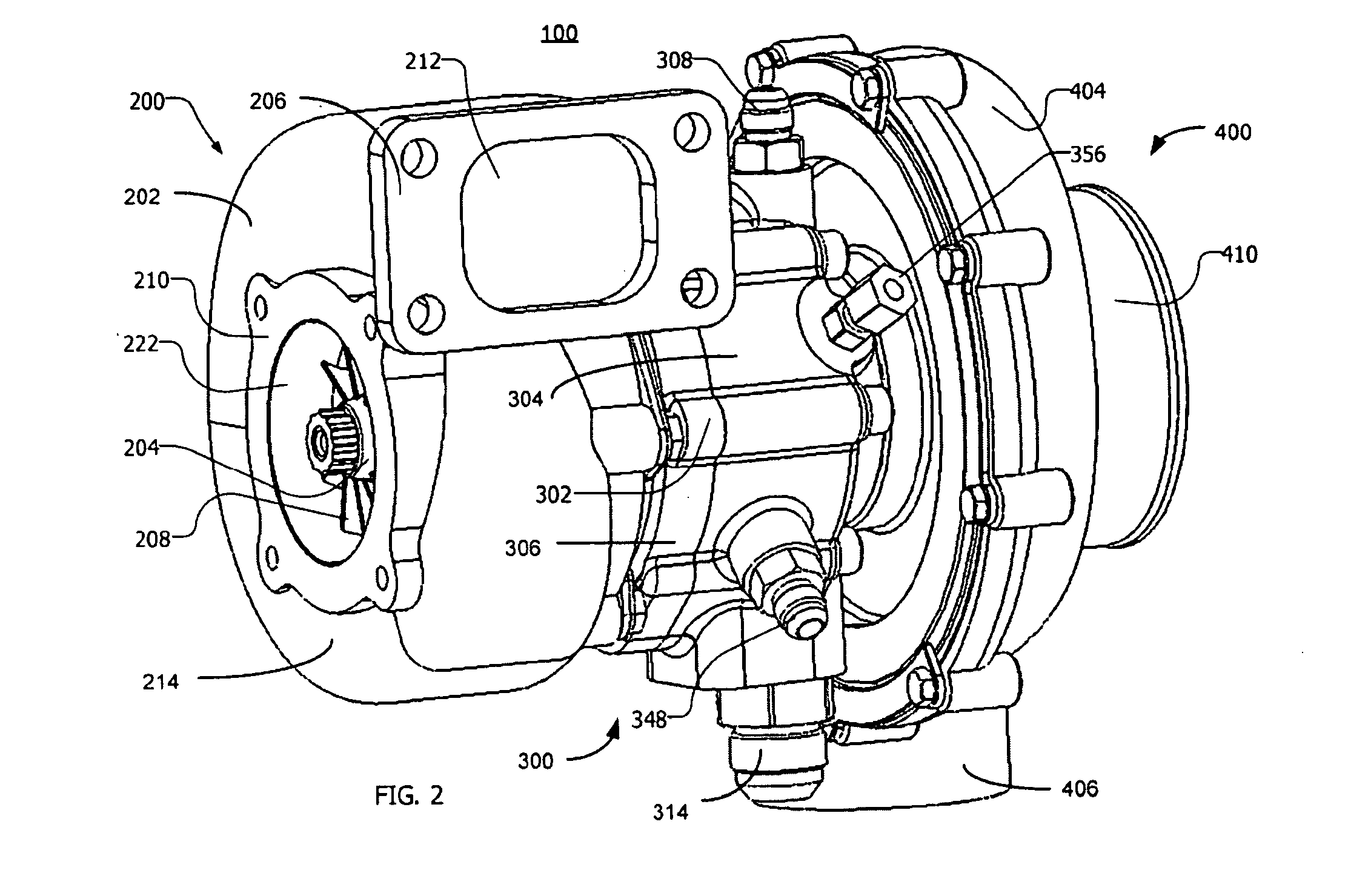

Cooling an Electrically Controlled Turbocharger

ActiveUS20100284824A1Internal combustion piston enginesGas turbine plantsTurbochargerElectric machine

An electrically controlled turbocharger has a motor mounted on a shaft in a motor housing between a turbine and compressor. Oil is sprayed onto the motor stator to cool the stator. An oil gallery is disposed above the stator to receive lubricating oil and contains apertures that perform as jets to allow oil to be sprayed directly on the motor stator. A coolant jacket is formed in the turbocharger housing between the turbine and the motor to allow liquid coolant to circulate therein and dissipate heat from the turbine end prior to reaching the motor components. Other embodiments provide for a stator component to be submerged in flowing cooling oil.

Owner:ECOMOTORS INT

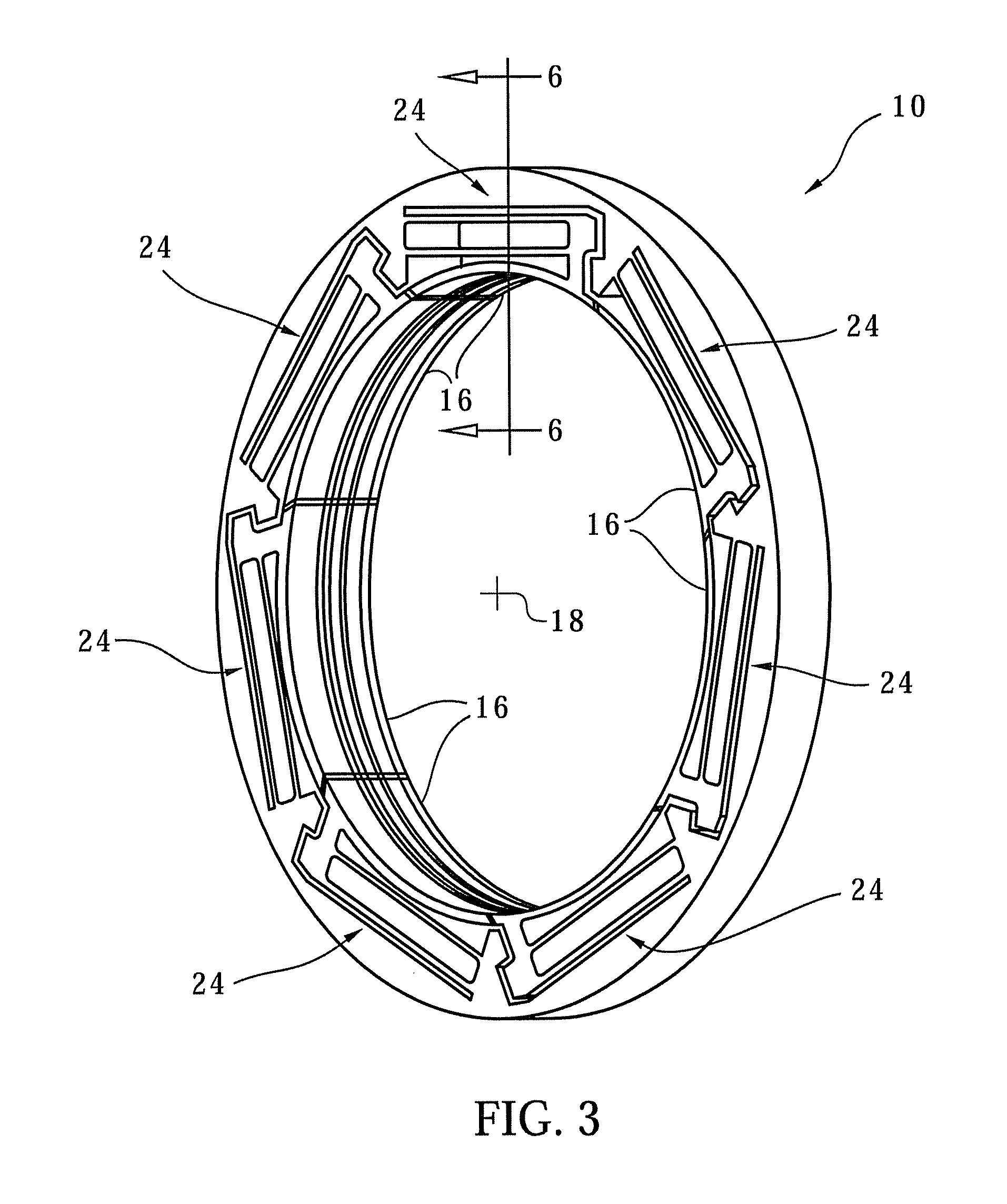

Non-contact seal for a gas turbine engine

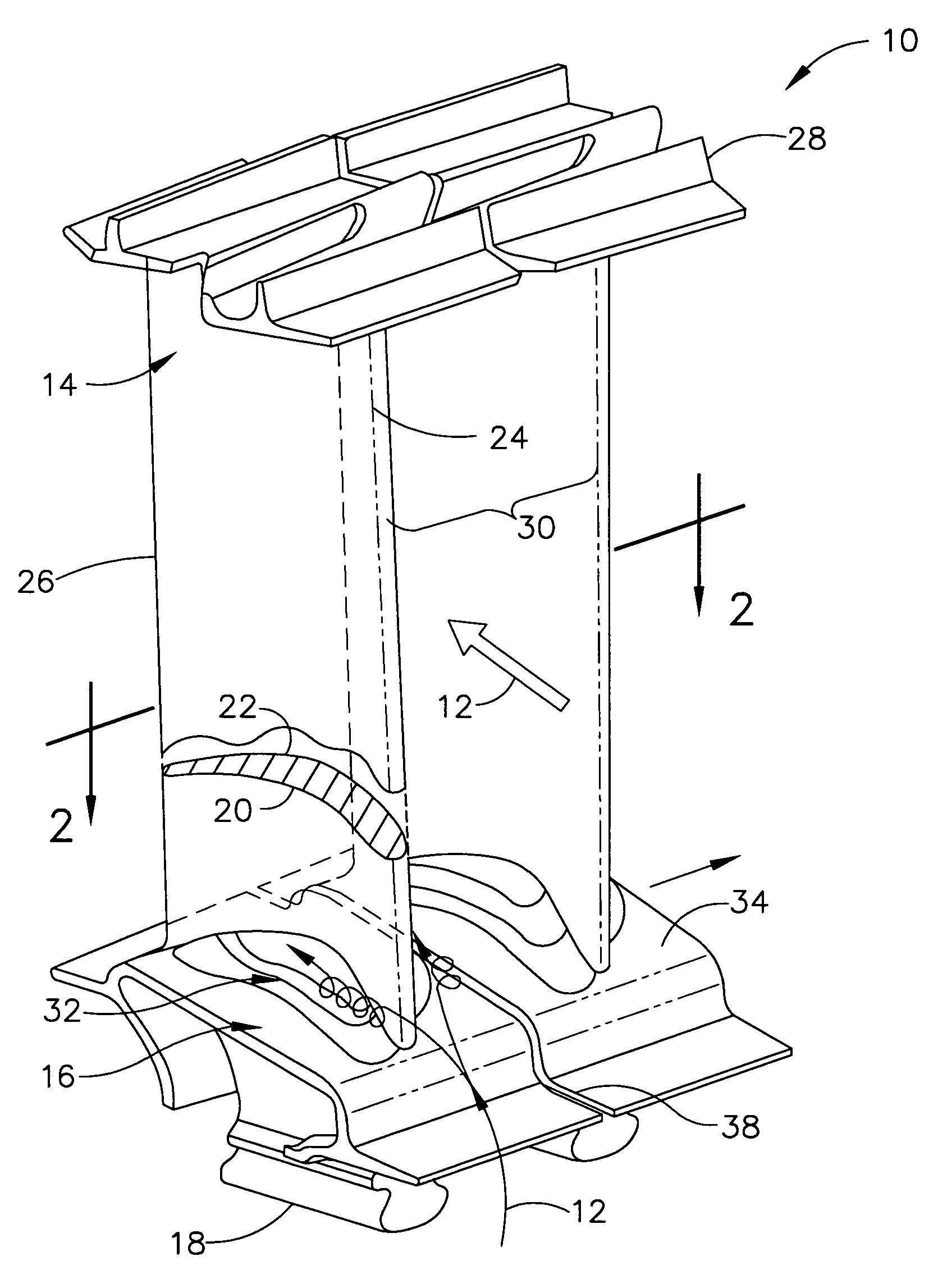

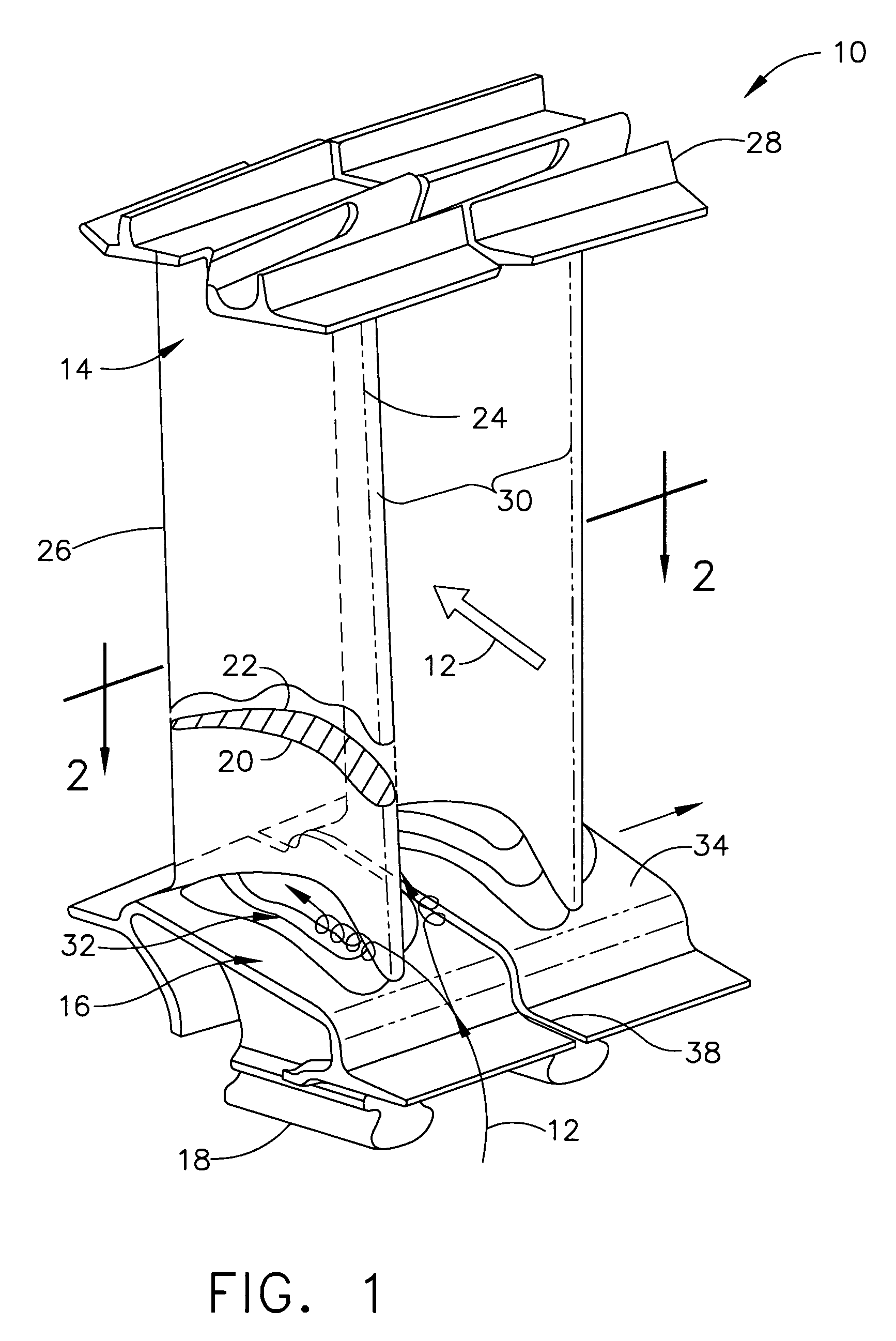

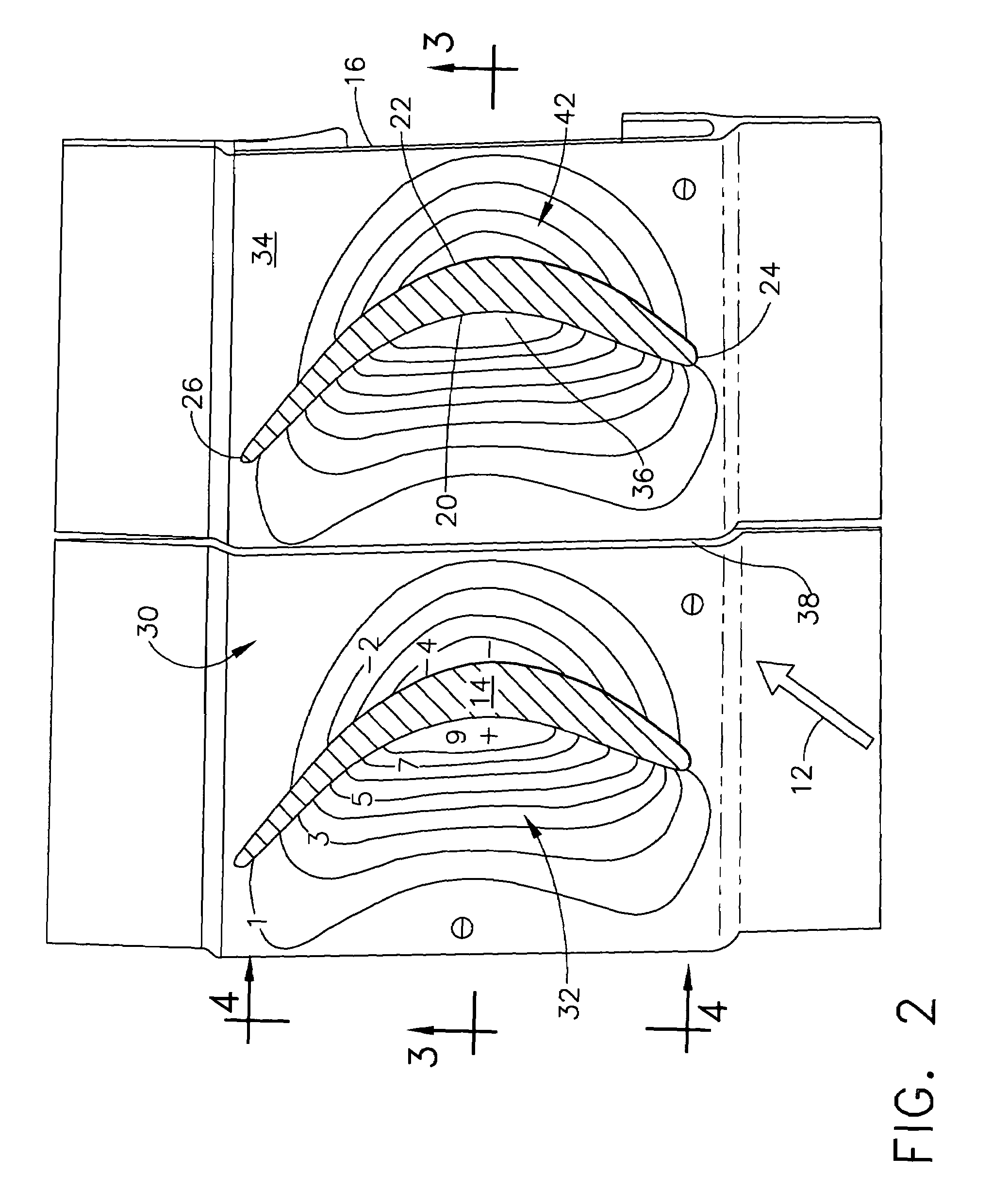

ActiveUS8172232B2Prevent rollingImprove sealingEngine sealsLeakage preventionEngineeringSurface geometry

A seal comprises the combination of a primary seal and a secondary seal each of which acts on at least one shoe that is installed with clearance relative to one of a rotor and a stator in a position to create a non-contact seal therewith. The at least one shoe is provided with a surface geometry and labyrinth-type teeth that influence the inertia of fluid flowing across the seal, and, hence, the velocity of the fluid and the pressure distribution across the seal, ultimately affecting the balance of forces applied to the seal.

Owner:SIEMENS ENERGY INC

Network cooled coated wall

A turbine wall includes a metal substrate having front and back surfaces. A thermal barrier coating is bonded atop the front surface. A network of flow channels is laminated between the substrate and the coating for carrying an air coolant therebetween for cooling the thermal barrier coating.

Owner:GENERAL ELECTRIC CO

Cooling fan using coanda effect to reduce recirculation

ActiveUS20070224044A1Increase the cross-sectional areaTrend downPump componentsReaction enginesFan bladeAerospace engineering

Owner:VALEO INC

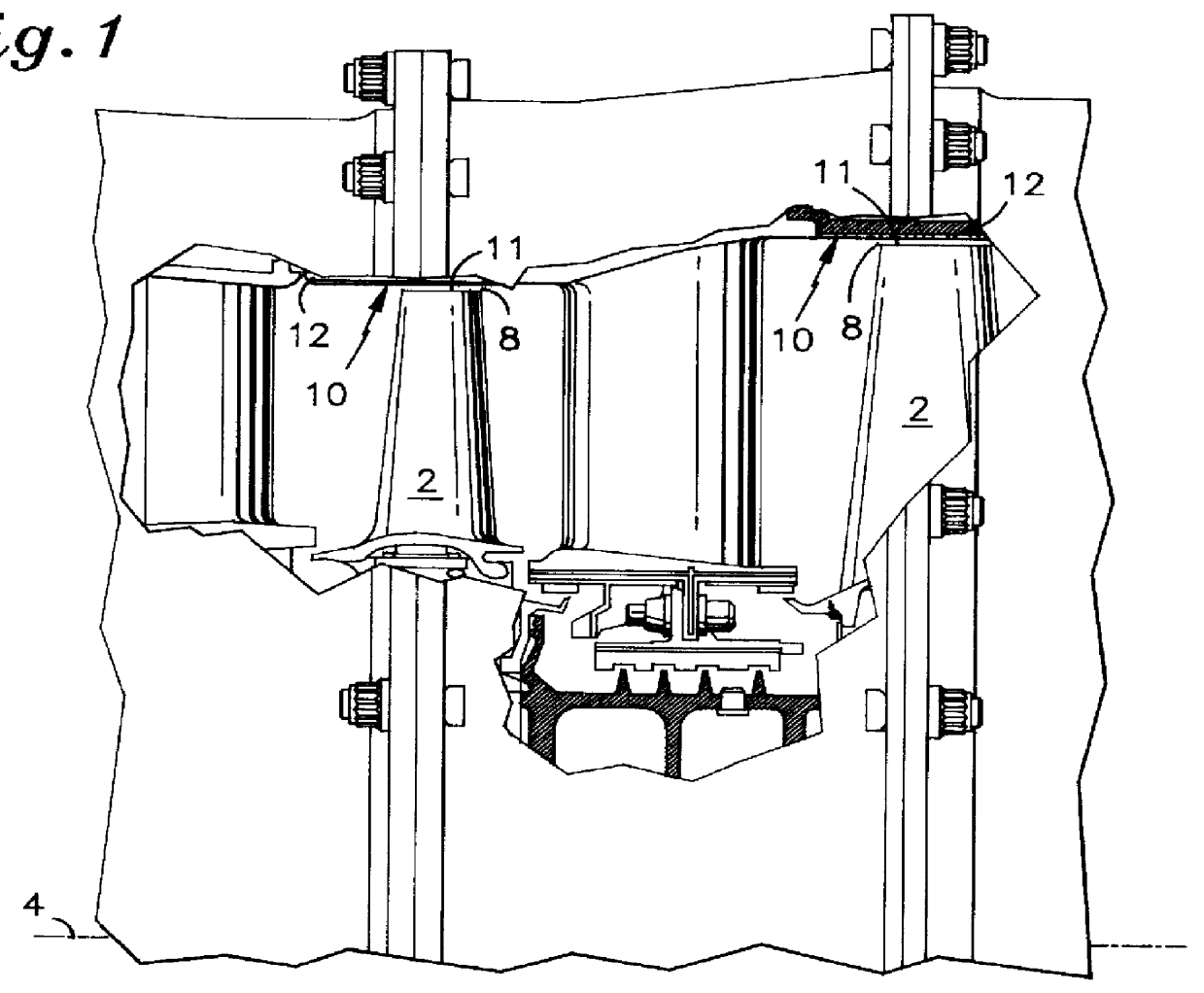

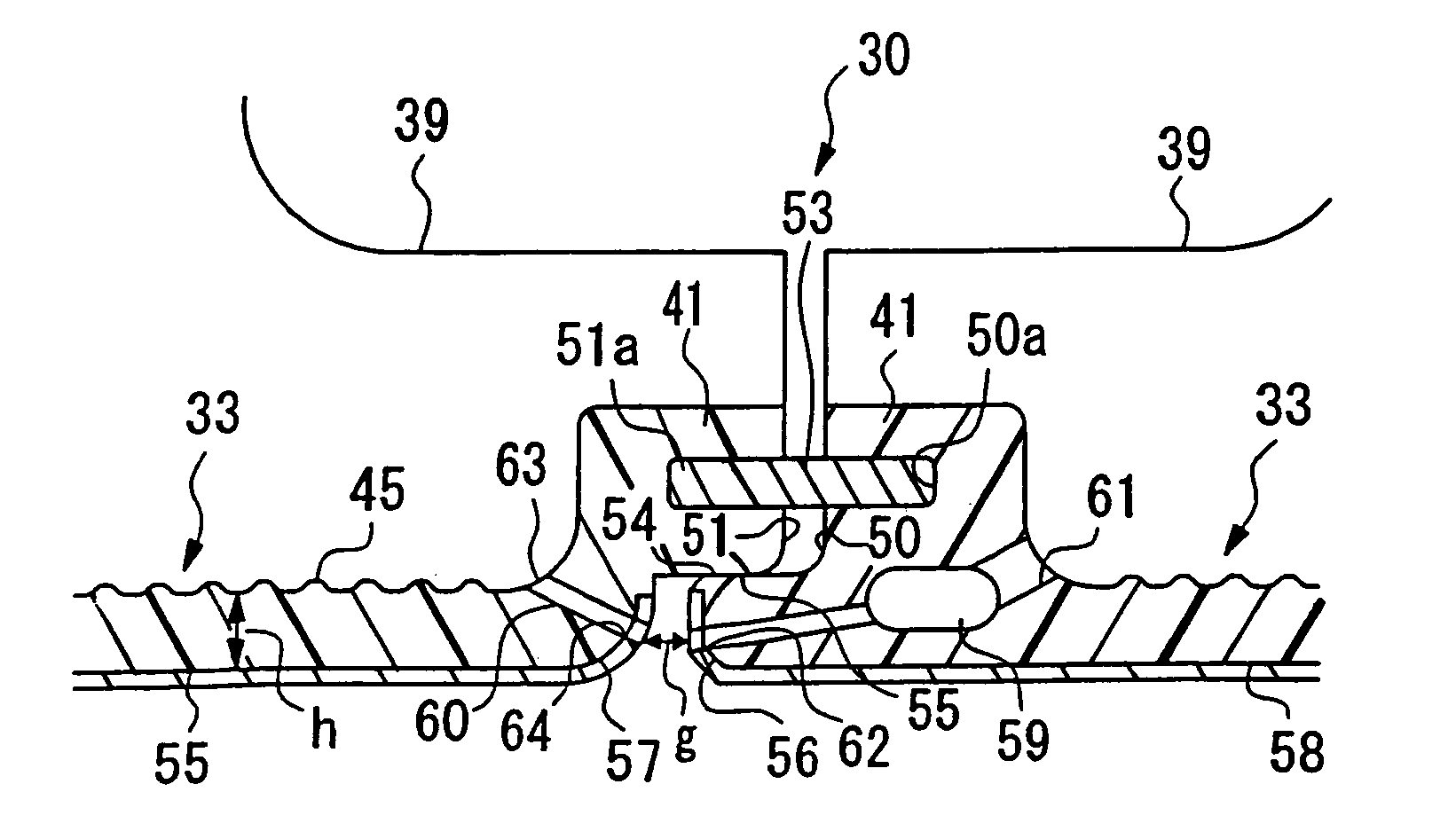

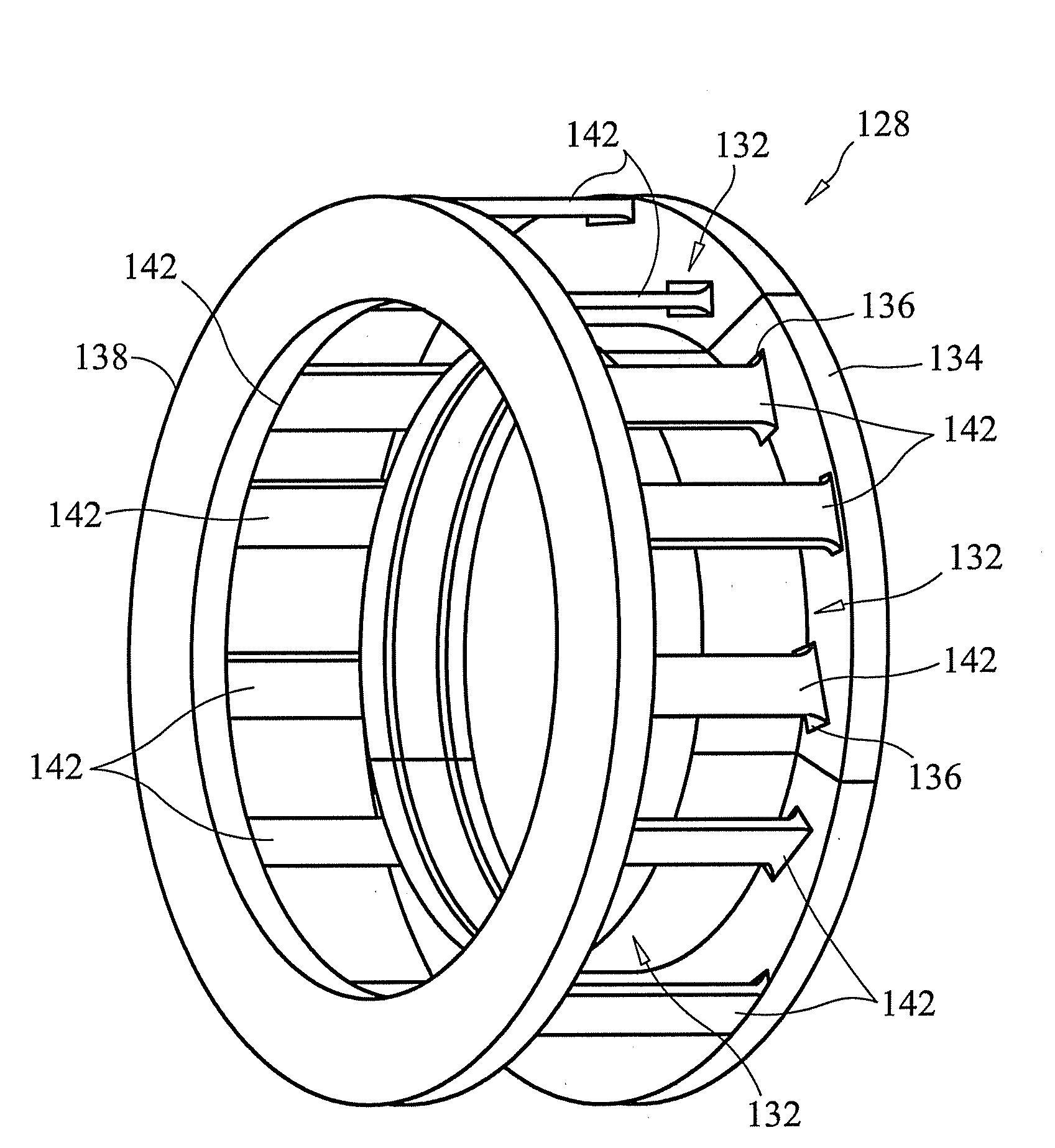

Hydrodynamic brush seal

A hybrid brush seal is provided for sealing a circumferential gap between two machine components that are relatively rotatable with respect to each other having seal bristles mounted in a ring shape on a first machine component with bristle ends directed at the sealing surface of the second, rotating machine component. The bristle ends are kept from direct contact with the rotating machine component via one or more shoes which create a non-contact seal with the rotating machine component which is enhanced by the imposition of one or more spring elements connected between the machine component and shoes.

Owner:SIEMENS ENERGY INC

Non-contact seal for a gas turbine engine

ActiveUS20080265513A1Prevent rollingImprove sealingEngine sealsLeakage preventionEngineeringSurface geometry

A seal comprises the combination of a primary seal and a secondary seal each of which acts on at least one shoe that is installed with clearance relative to one of a rotor and a stator in a position to create a non-contact seal therewith. The at least one shoe is provided with a surface geometry and labyrinth-type teeth that influence the inertia of fluid flowing across the seal, and, hence, the velocity of the fluid and the pressure distribution across the seal, ultimately affecting the balance of forces applied to the seal.

Owner:SIEMENS ENERGY INC

Turbine engine shroud assembly including axially floating shroud segment

At least one shroud segment, floating axially independently of adjacent turbine engine shroud assembly members, includes a segment body comprising a radially outer surface and a radially outwardly projecting segment support that includes an axial support wall surface therein. The assembly includes a shroud hanger in axial juxtaposition with the segment support, and at least one axial support projection from the shroud hanger into the segment support at the support wall surface. The support projection supports the shroud segment releasably at the support wall surface sufficiently to enable relative axial movement of the shroud segment on the support projection independently of the shroud hanger and adjacent engine members.

Owner:GENERAL ELECTRIC CO

Repair of advanced gas turbine blades

InactiveUS6908288B2Improve antioxidant capacityLack needed strengthPump componentsReaction enginesGas turbinesRepair method

Methods for repairing and manufacturing a gas turbine blade, and the gas turbine blade repaired and manufactured with such methods are presented with, for example, the repair method comprising providing a gas turbine blade, the blade comprising a blade tip and a blade body; removing at least one portion of the blade tip; providing at least one freestanding tip insert; and disposing the at least one tip insert onto the gas turbine blade body such that the at least one tip insert replaces the at least one removed portion of the blade tip.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com