Patents

Literature

2538results about "Combination engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

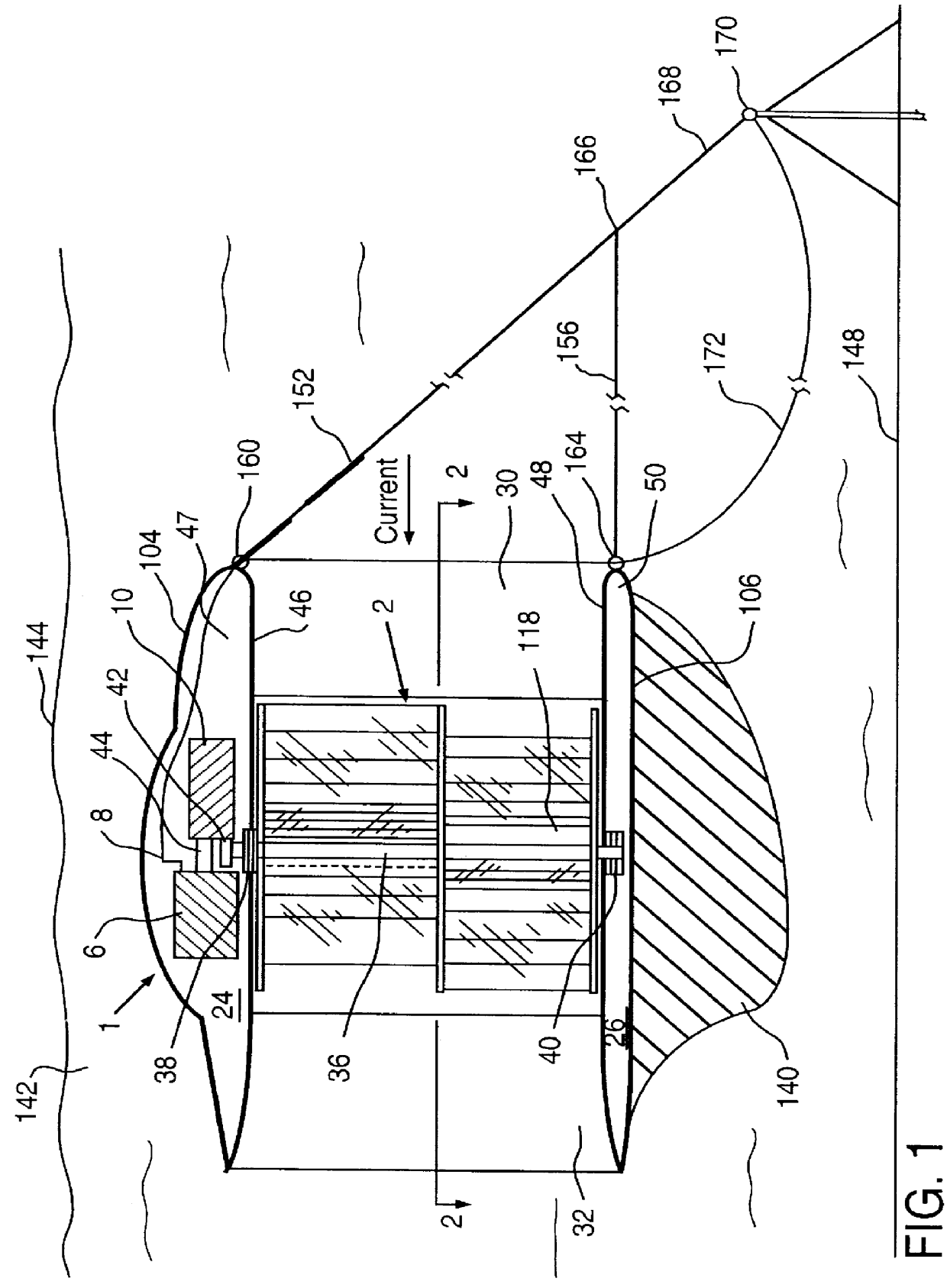

Submersible appartus for generating electricity and associated method

InactiveUS6109863AReduce the impactReduce impactCircumferential flow pumpsWind motor controlElectricityMarine engineering

A fully submersible apparatus for generating electricity from liquid flow as in an ocean or river current. A buoyant structure is fully submersible and has at least one pair of counter-rotating side-by-side motors with a plurality of angularly spaced radial vanes each having a plurality of rotatable subvanes such that current impinging upon the motor will impinge on a closed or solid vane to effect rotation of the motor and its shaft during a first phase of the rotational cycle and will impinge on open vanes for free passage therethrough on the return or second phase of rotation of the motor. Motors may also be provided with vanes in overlying and underlying relationship. An associated method is provided.

Owner:MILLIKEN LARRY D

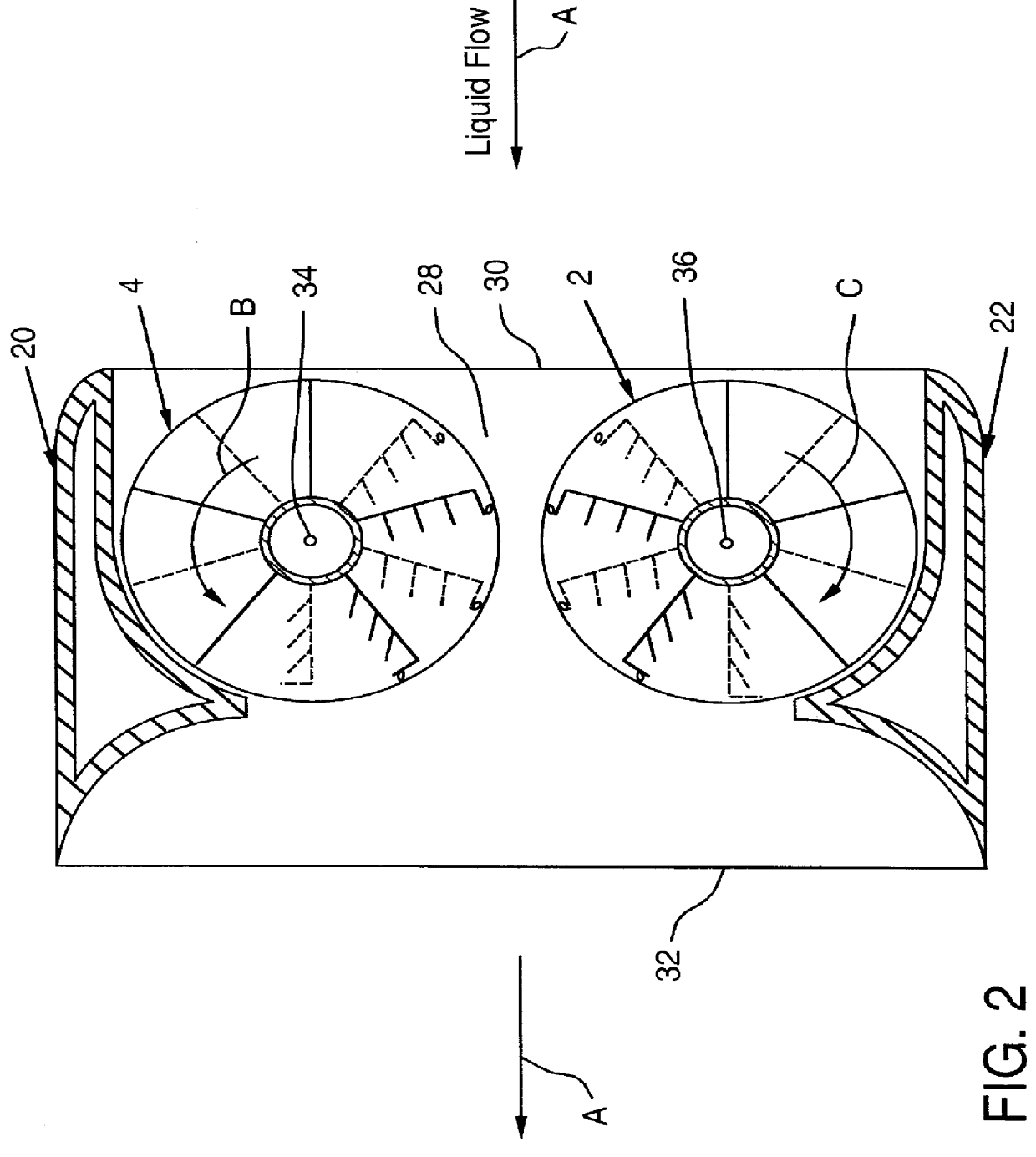

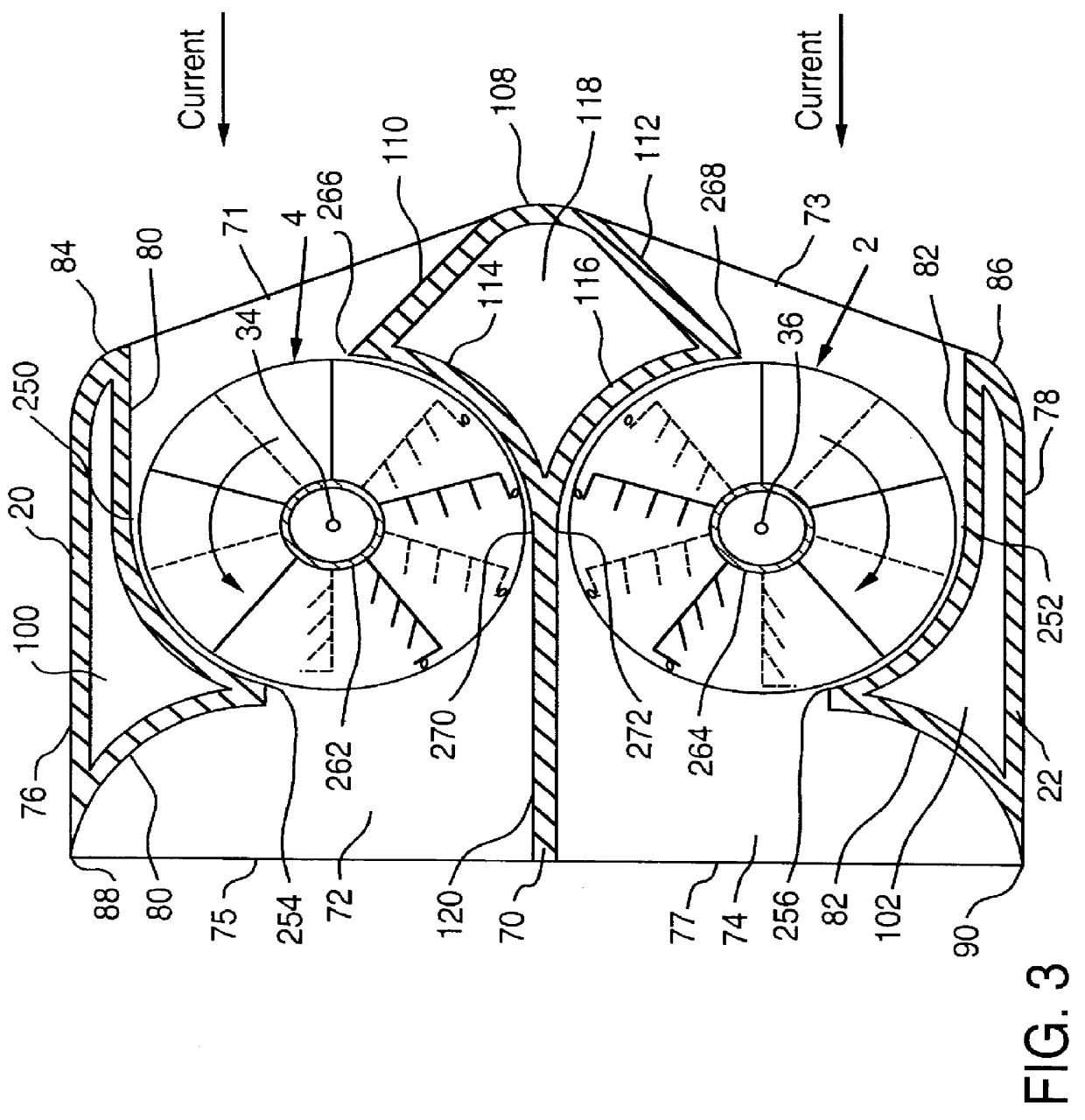

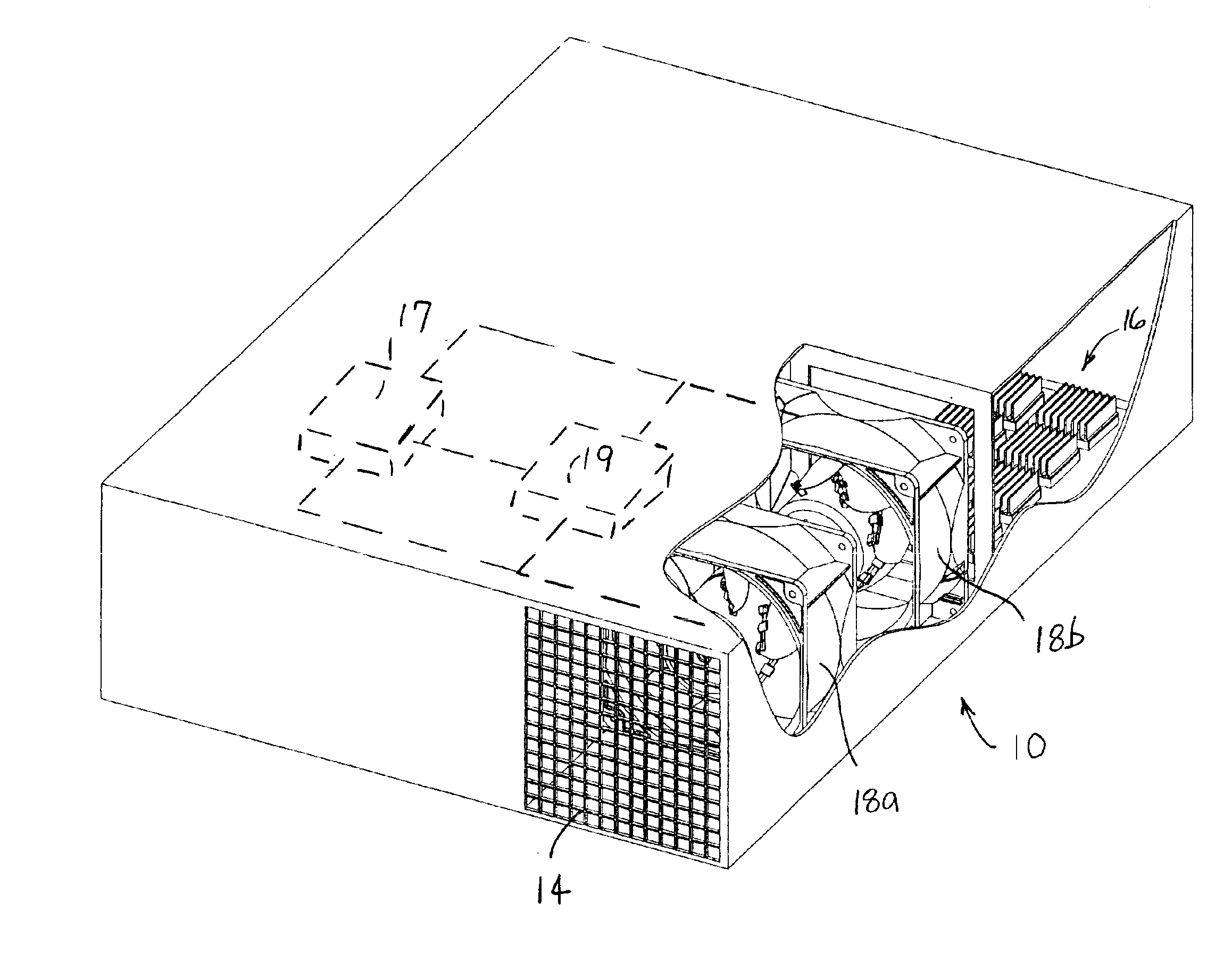

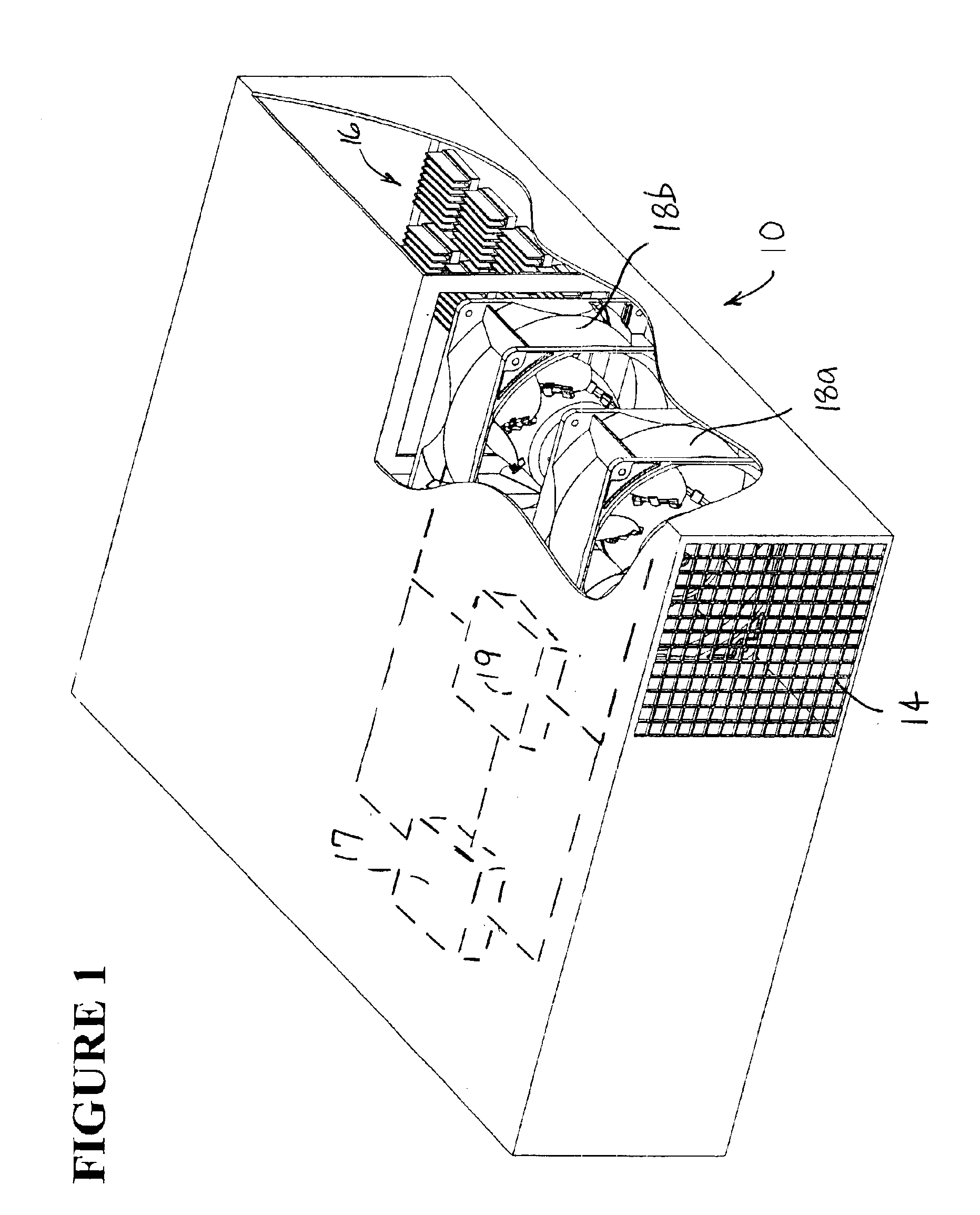

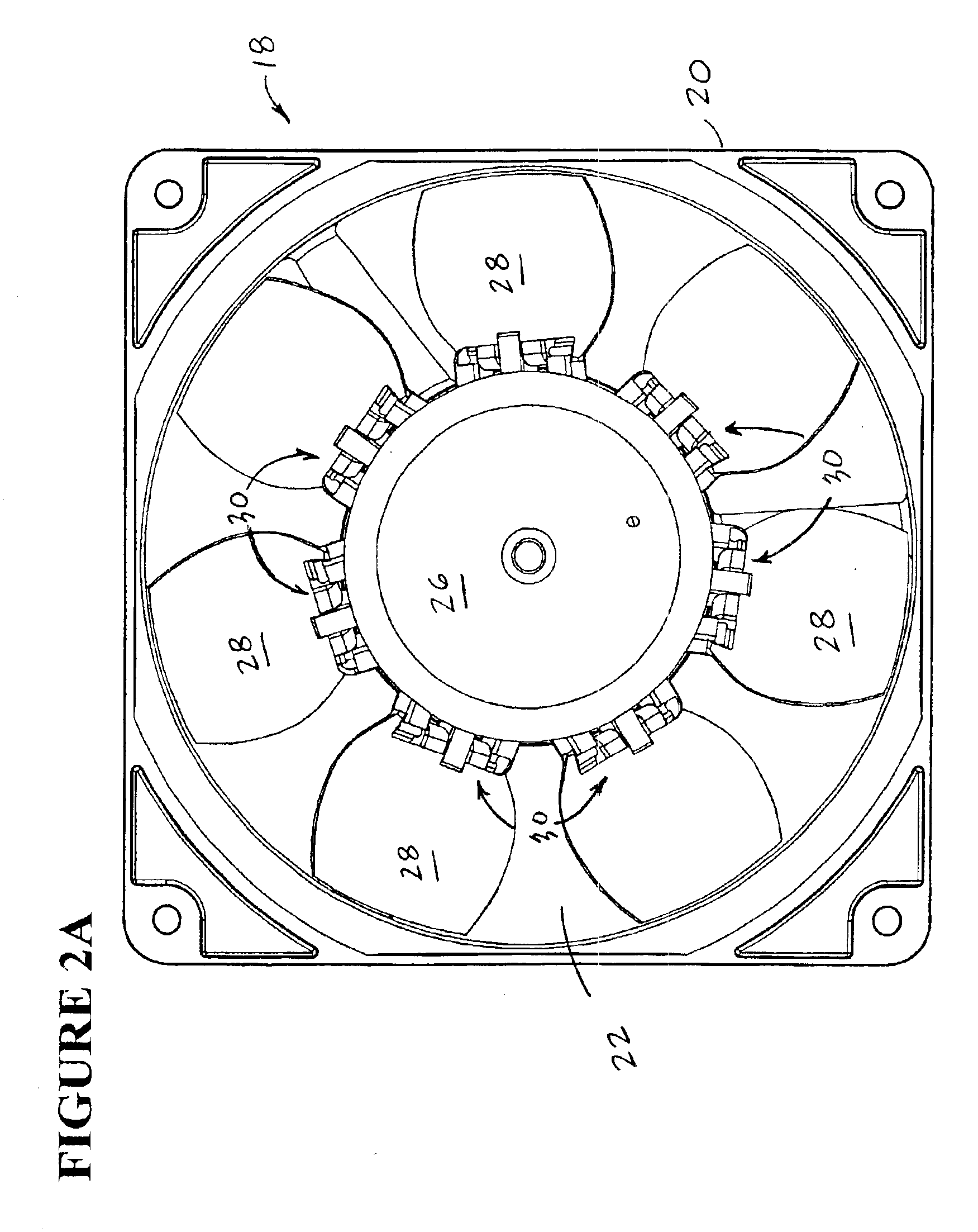

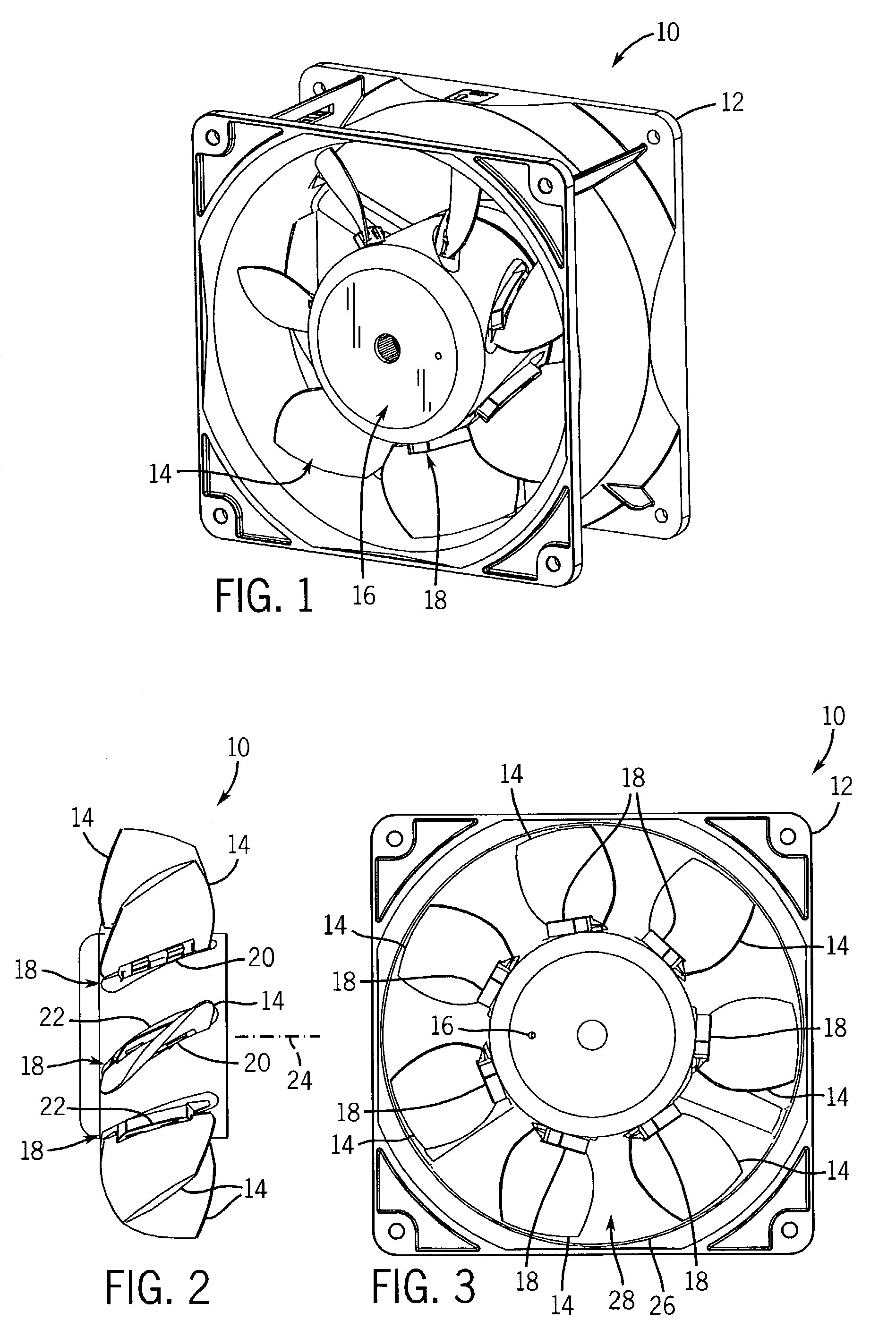

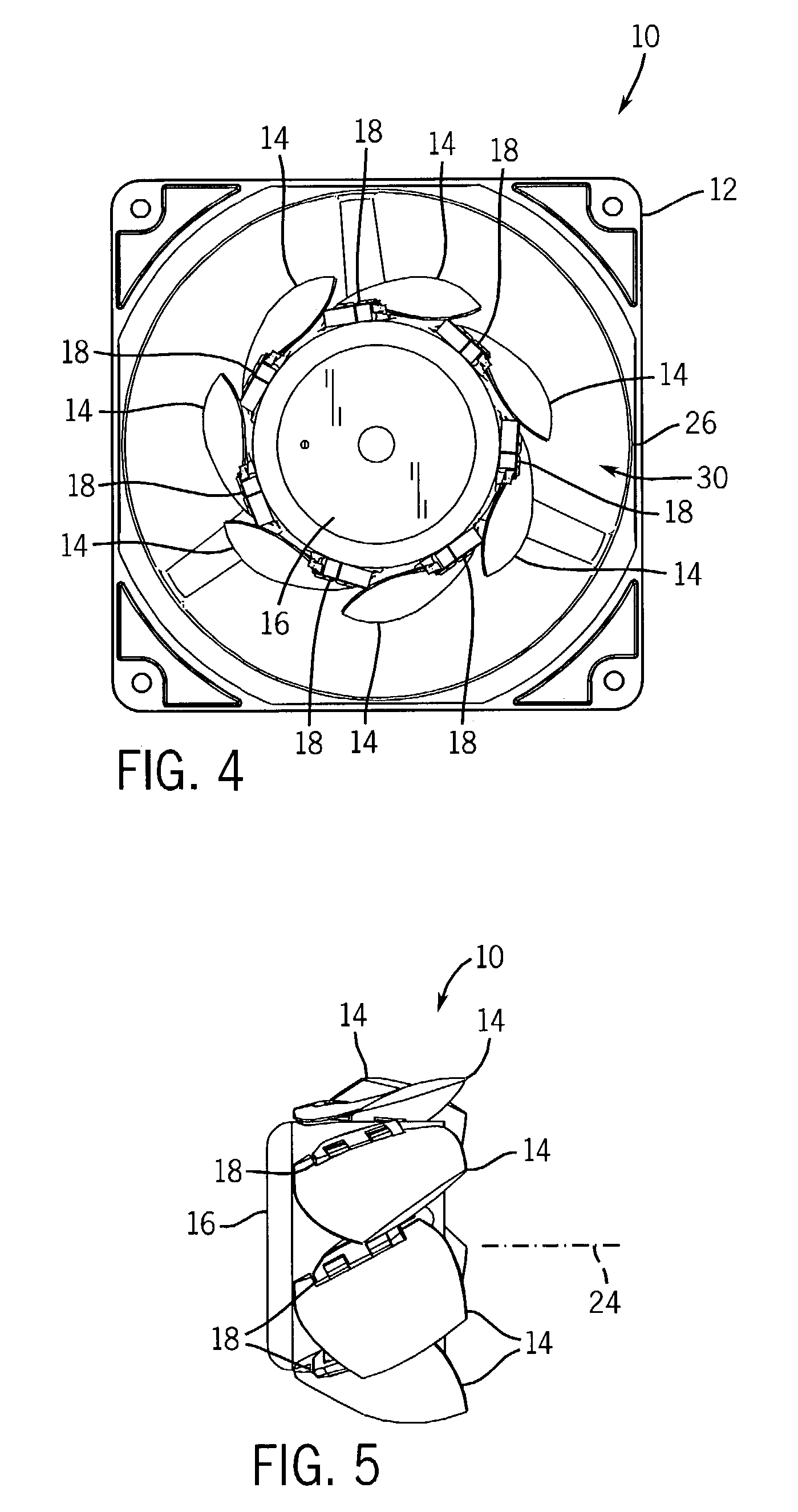

Fan with collapsible blades, redundant fan system, and related method

InactiveUS6860713B2Reduces fan inefficiencyPrevent undesirable blockagePropellersPump componentsFan bladeAirflow

A redundant fan system for a computer includes two fans installed in series with at least one of the fans having collapsible blades. A fan system of this type reduces the fan inefficiency caused when one fan in a series mounted pair is not operating, either because it is free-wheeling or in a locked rotor condition. When non-operational, the fan blades of the collapsible fan fold inward due to airflow generated by the operational fan over the collapsible blades. The ability of the blades to fold reduces the inefficiency of the operational fan, having less of an effect on fan life. Also, because the flow of air is less restricted, proper airflow can be maintained, thus preventing overheating of the computer.

Owner:NIDEC AMERICA CORP

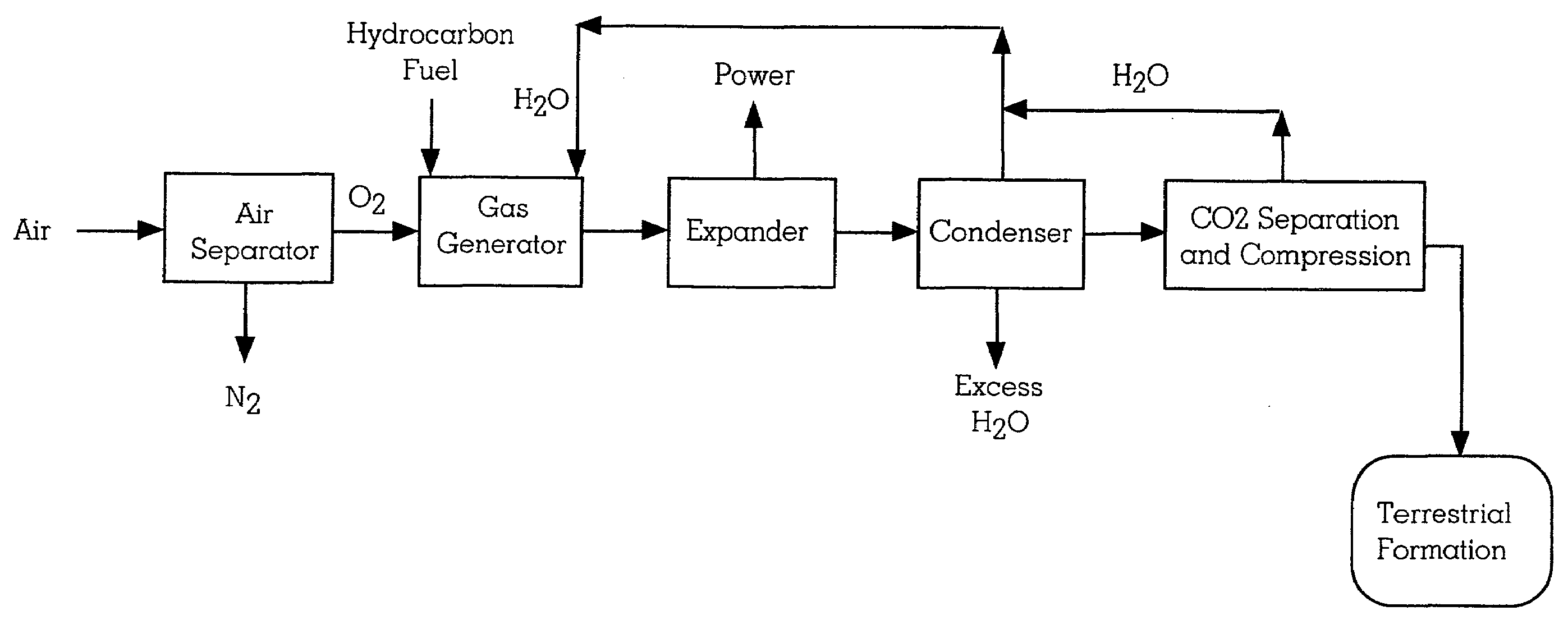

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

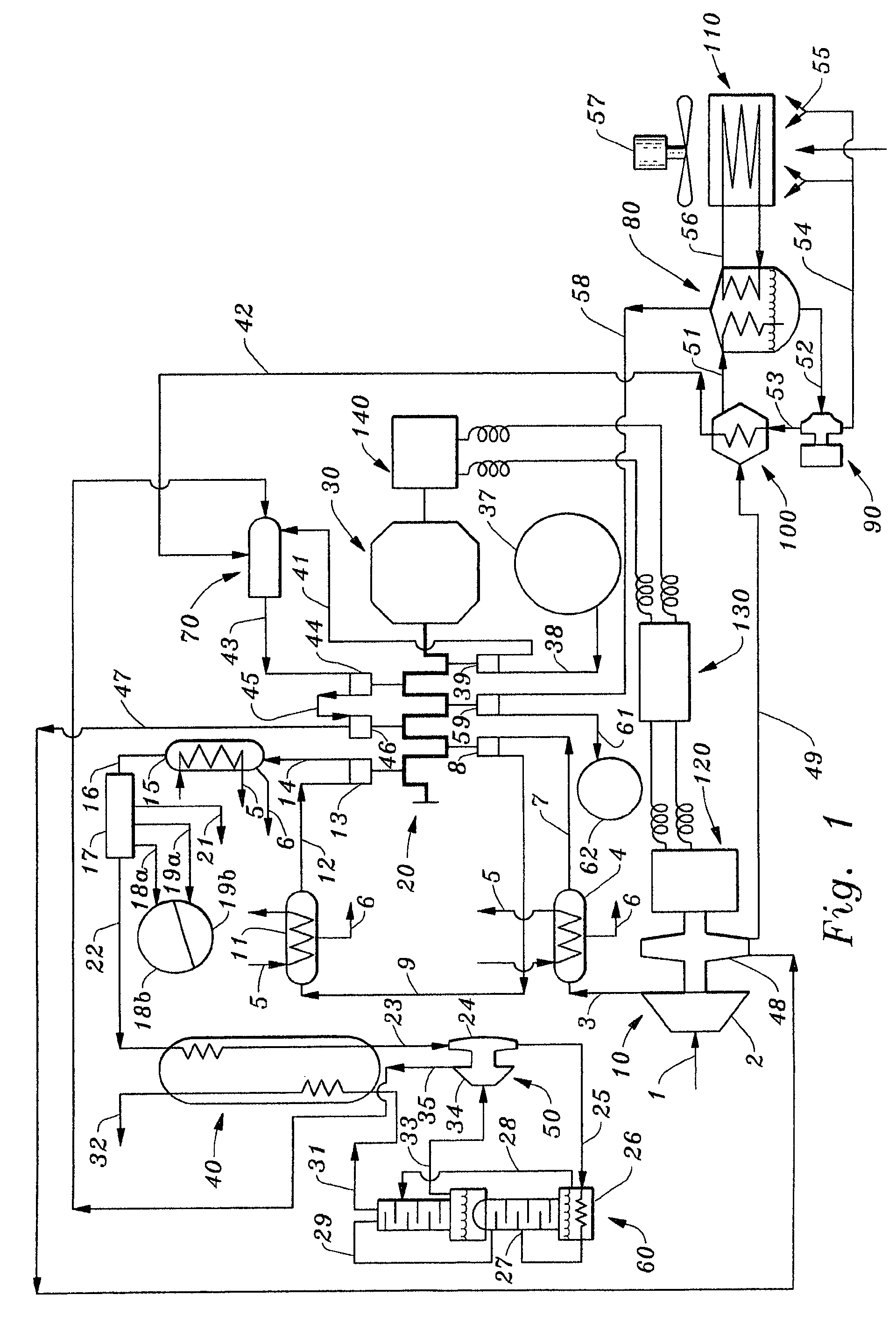

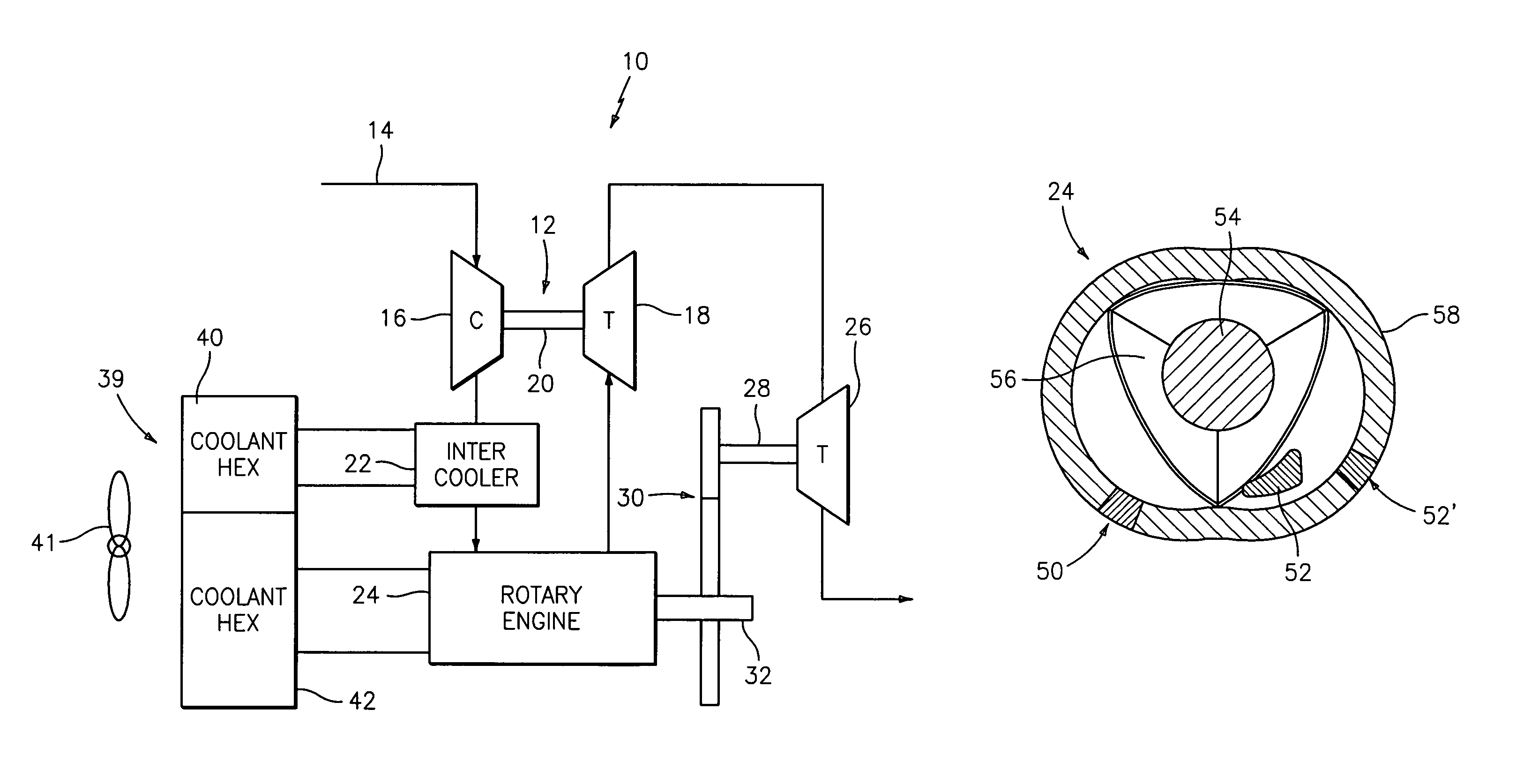

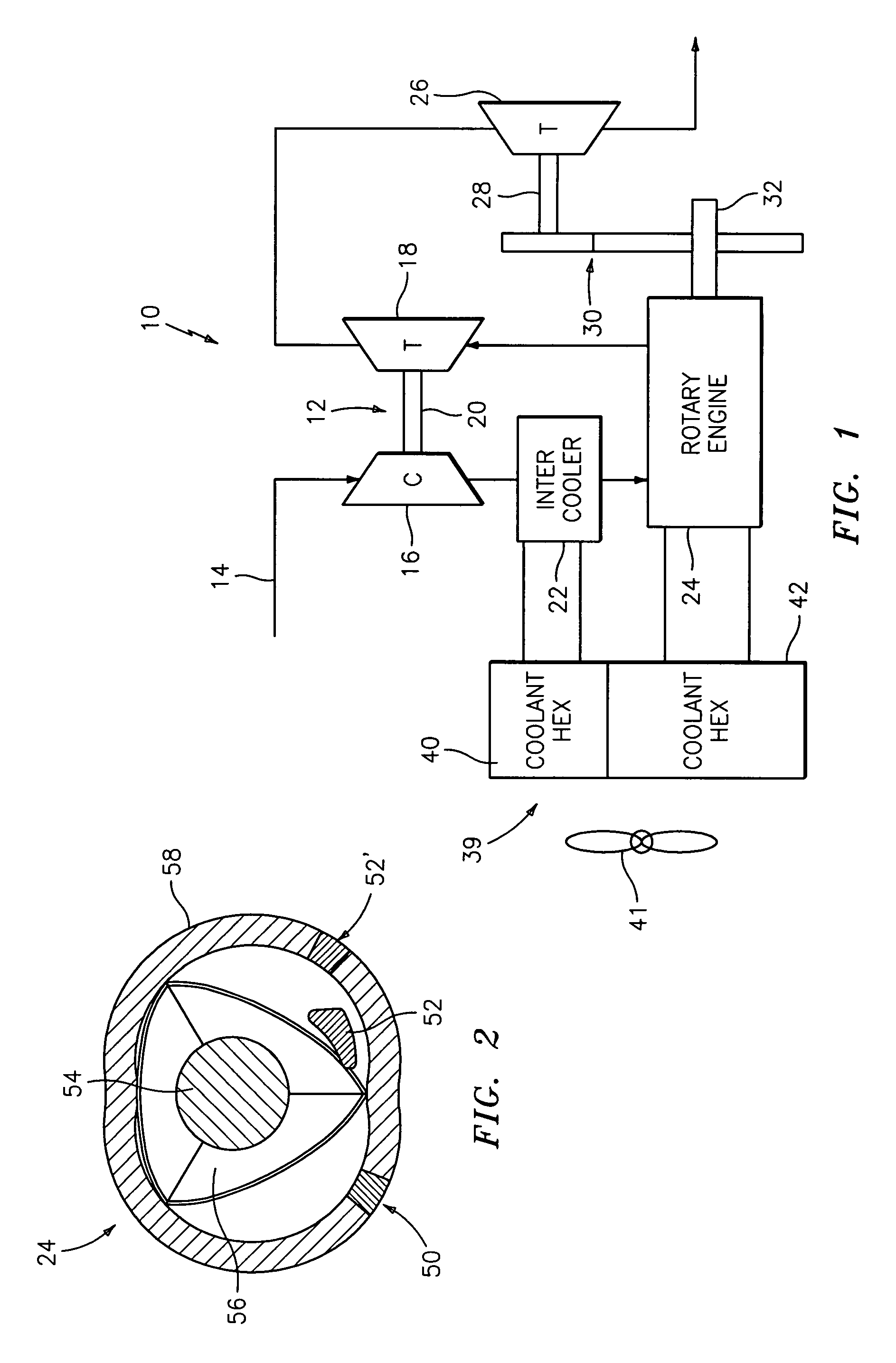

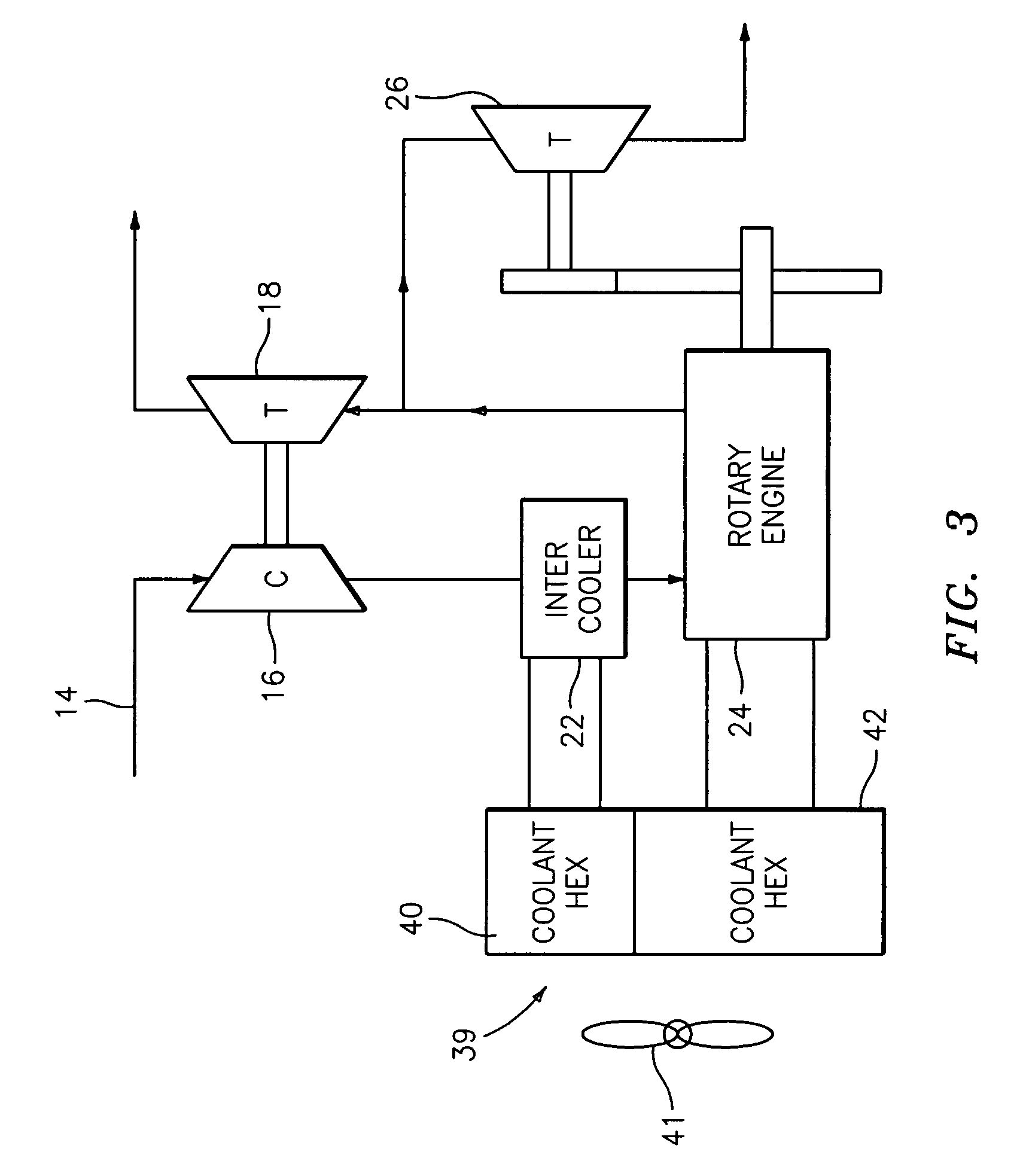

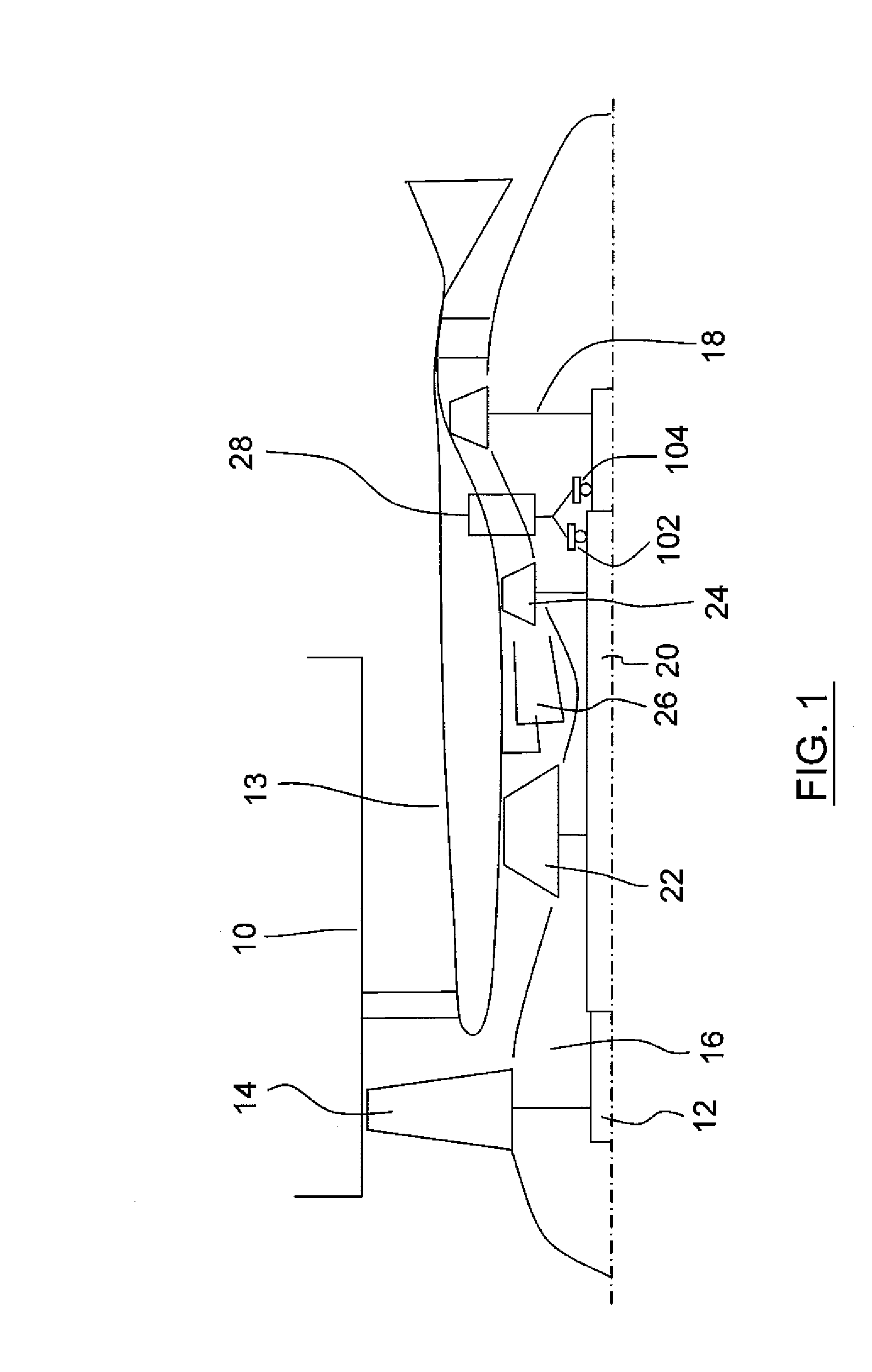

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

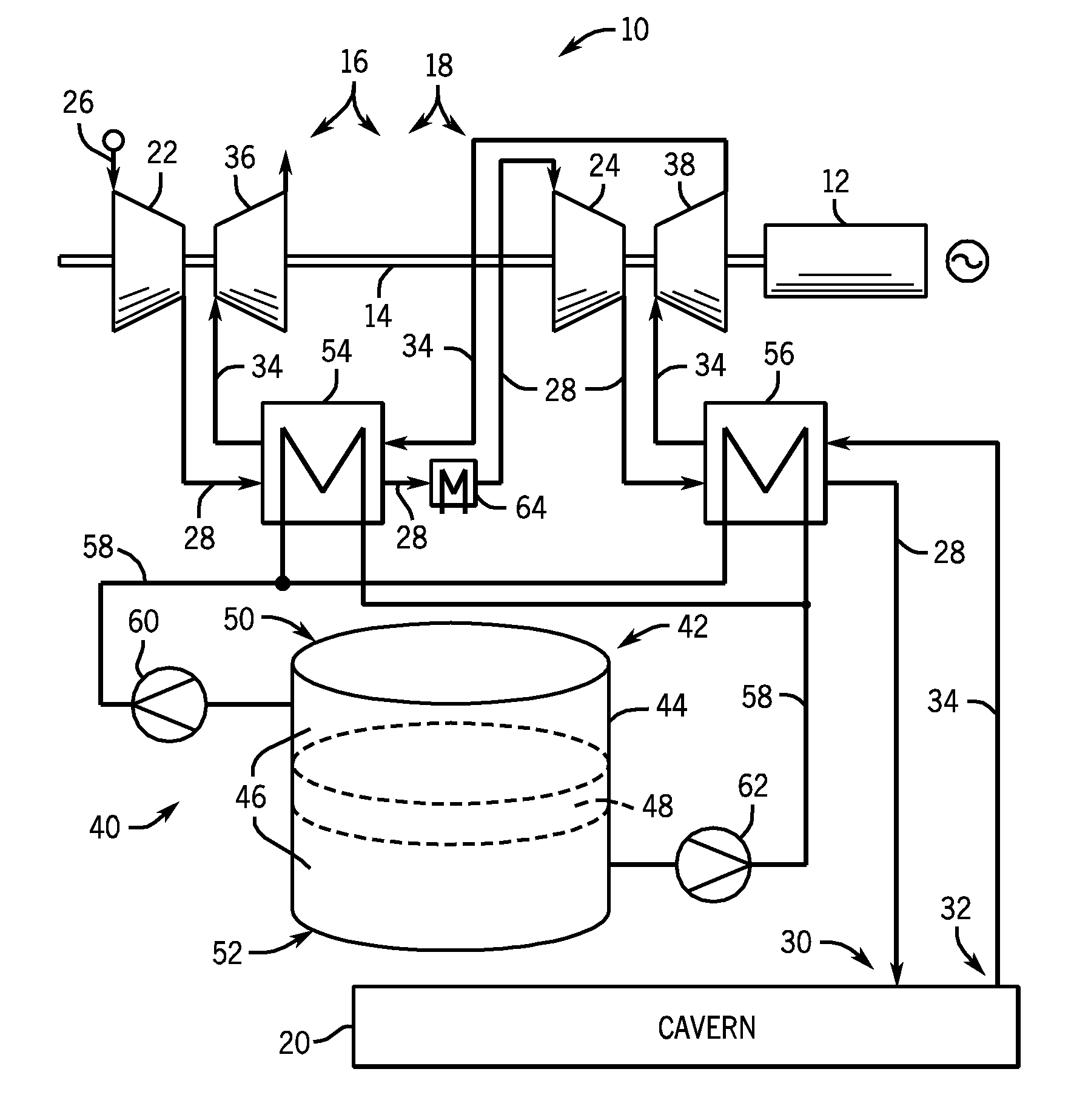

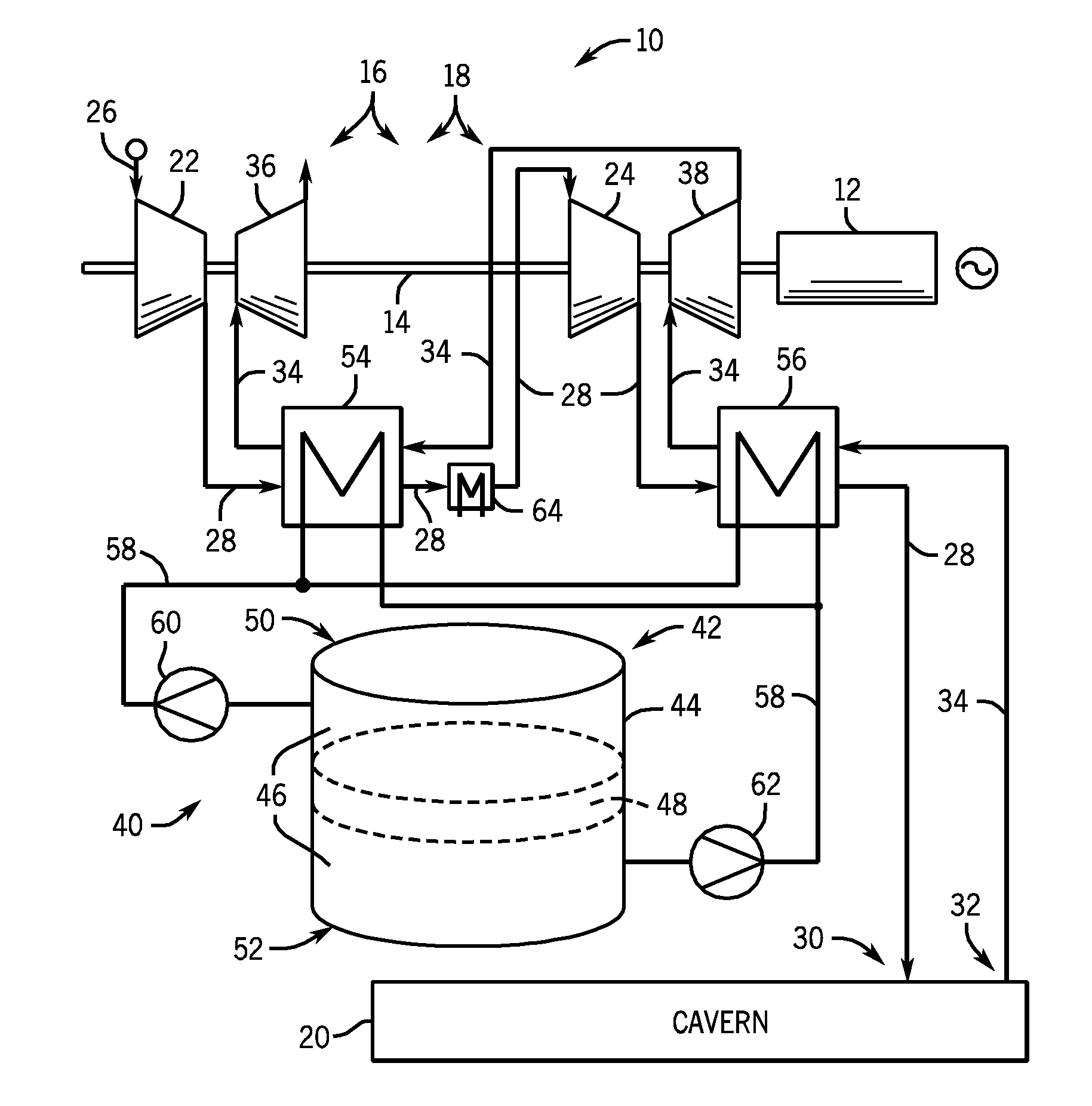

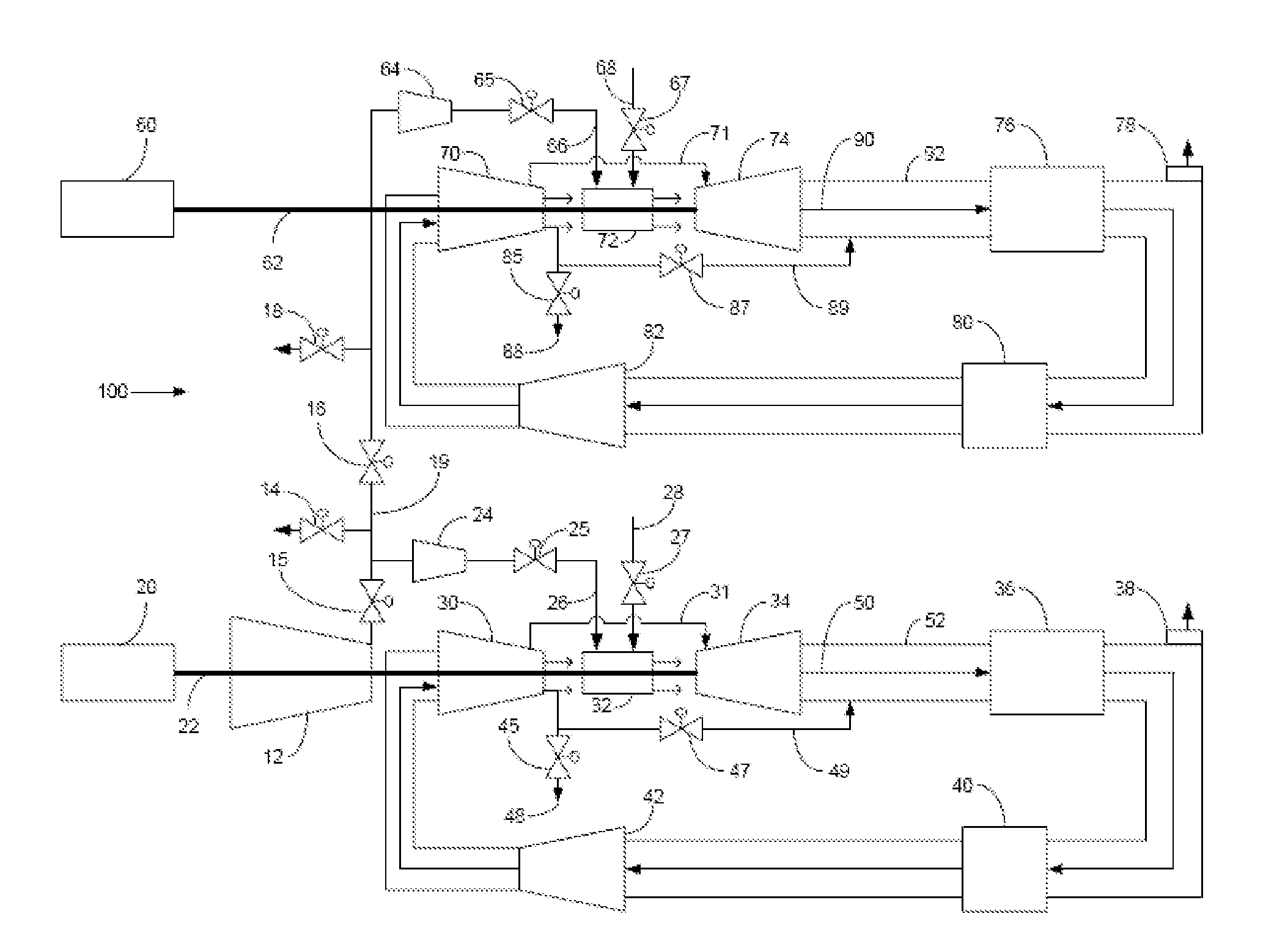

Adiabatic compressed air energy storage system with liquid thermal energy storage

InactiveUS20110100010A1Reciprocating combination enginesCombination enginesThermal energyThermal energy storage

An adiabatic compressed air energy storage (ACAES) system includes a compressor system, an air storage unit, and a turbine system. The ACAES system further includes a thermal energy storage (TES) system that includes a container, a plurality of heat exchangers, a liquid TES medium conduit system fluidly coupling the container to the plurality of heat exchangers, and a liquid TES medium stored within the container. The TES system also includes a plurality of pumps coupled to the liquid TES medium conduit system and configured to transport the liquid TES medium between the plurality of heat exchangers and the container, and a thermal separation system positioned within the container configured to thermally isolate a first portion of the liquid TES medium at a lower temperature from a second portion of the liquid TES medium at a higher temperature.

Owner:GENERAL ELECTRIC CO

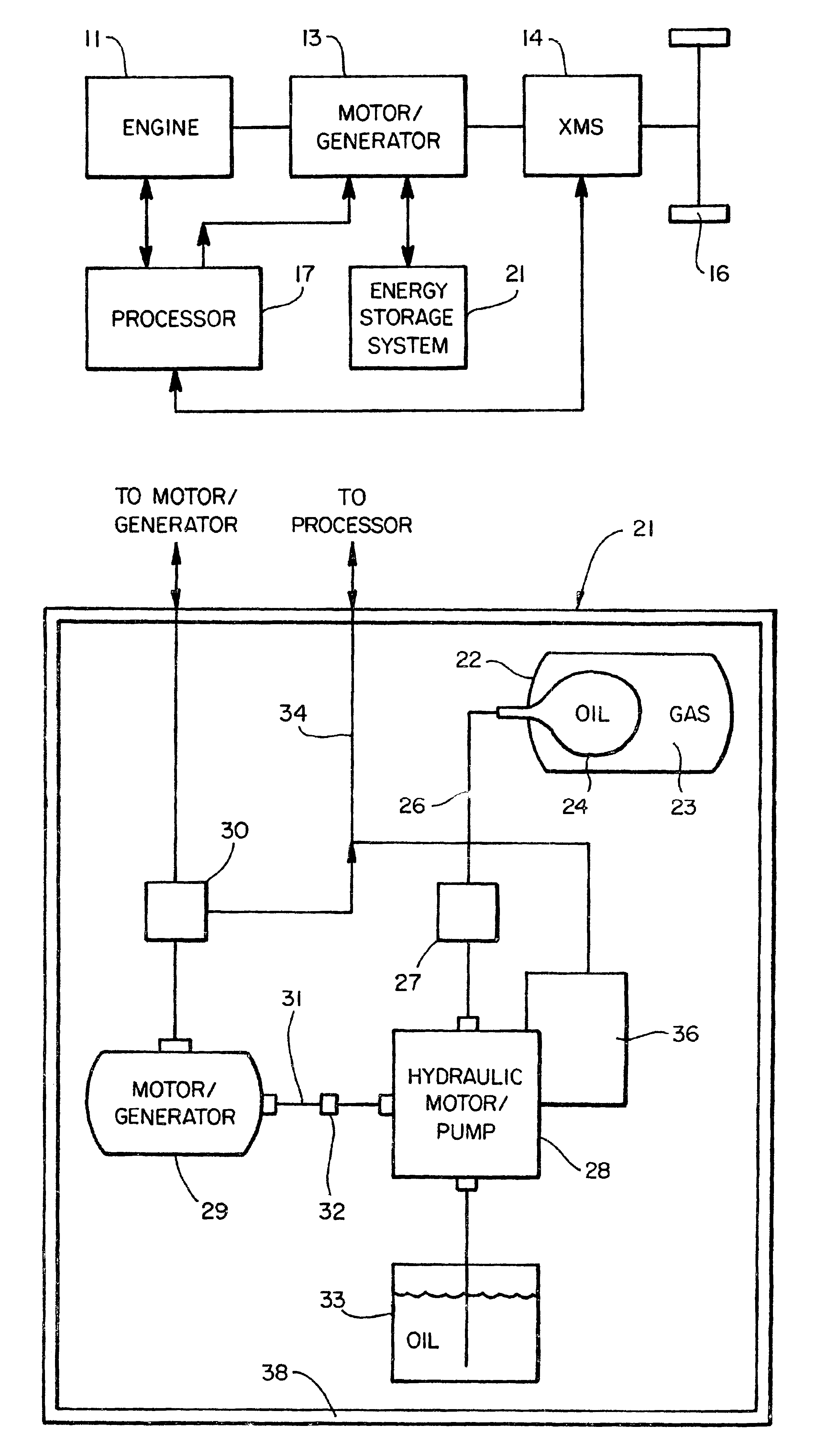

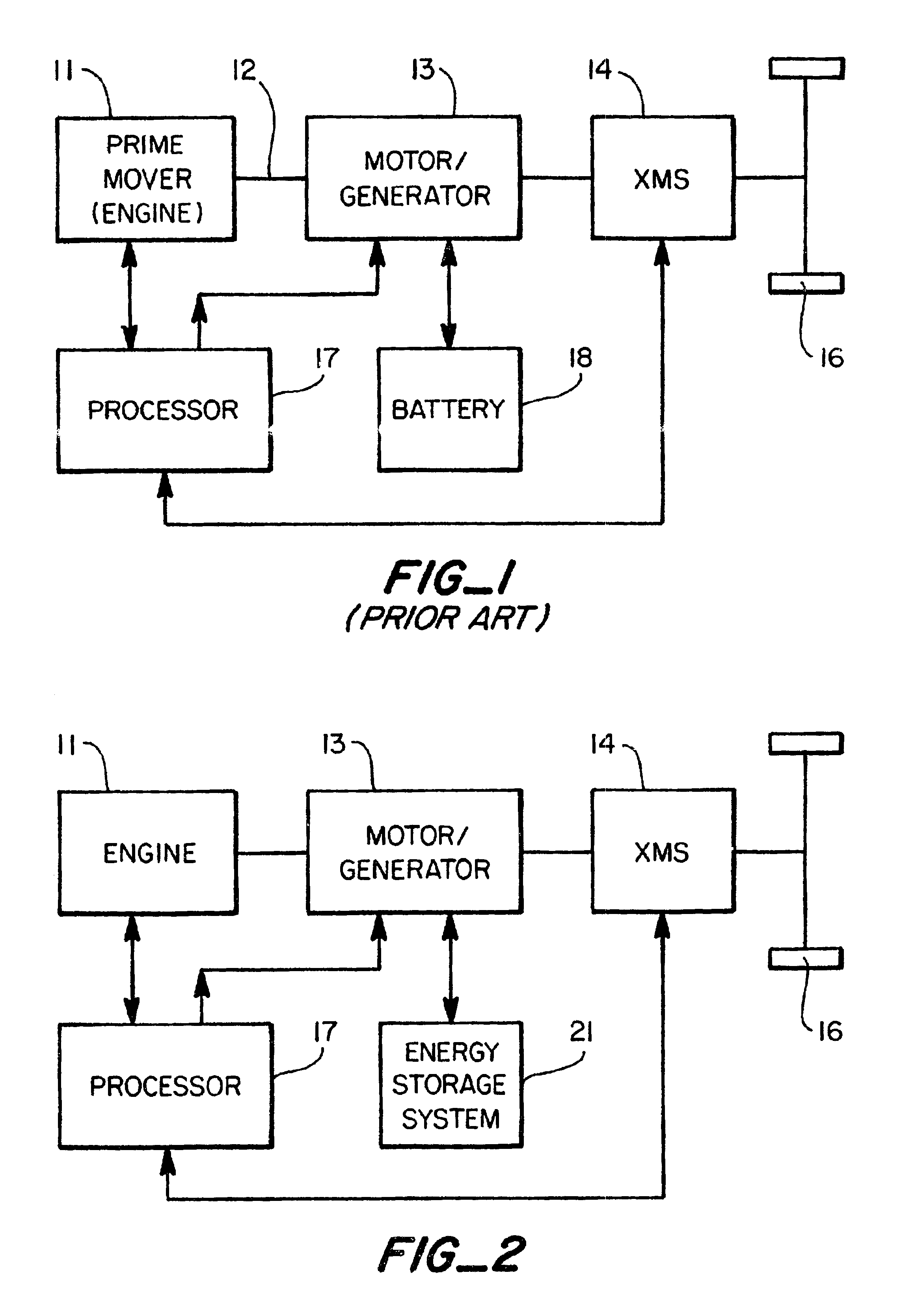

Hybrid vehicle and energy storage system and method

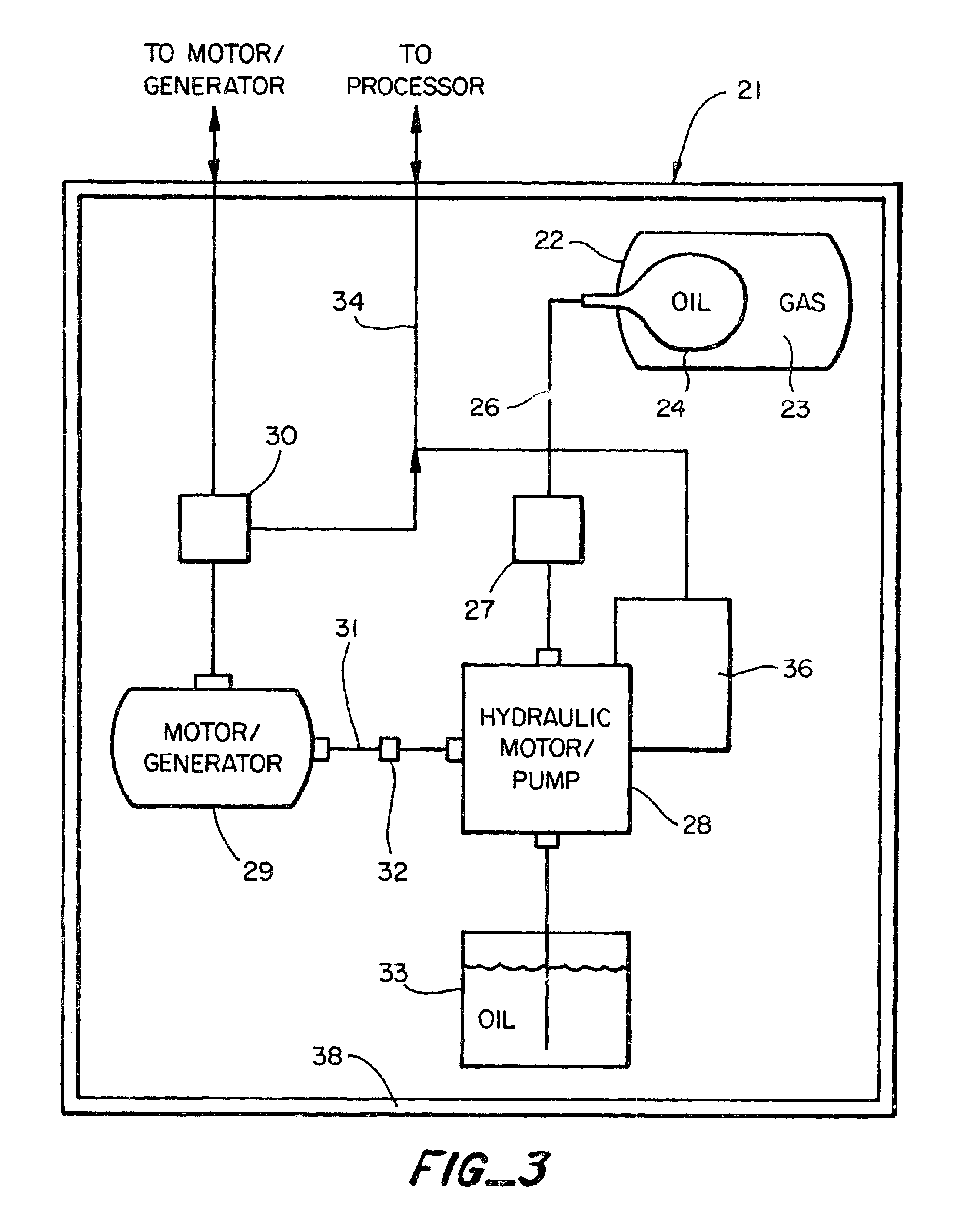

InactiveUS6834737B2Conveniently and inexpensively adaptableSmall packageReciprocating combination enginesAuxillary drivesStored energyPower mode

A system for providing a hybrid vehicle with a practical source of auxiliary power. The system includes two electric motor / generators connected to each other in such a fashion so that when one electric motor / generator functions as a motor, the other becomes a generator with their roles being reversed depending on whether the system is in an auxiliary power mode or energy storage mode. Connected to one motor / generator is the vehicle drive train. Connected to the other motor / generator is a pressure energy storage system, which in the energy storage mode converts the force of rotation into pressurized gas for storage in an energy system and delivered in the form of electric current by the one motor / generator, and in the energy delivery mode converts the stored energy of the energy storage system into electric current for delivery to the one motor / generator which is part of the vehicle drive train to provide auxiliary power for practical hybrid vehicles.

Owner:BLOXHAM STEVEN R

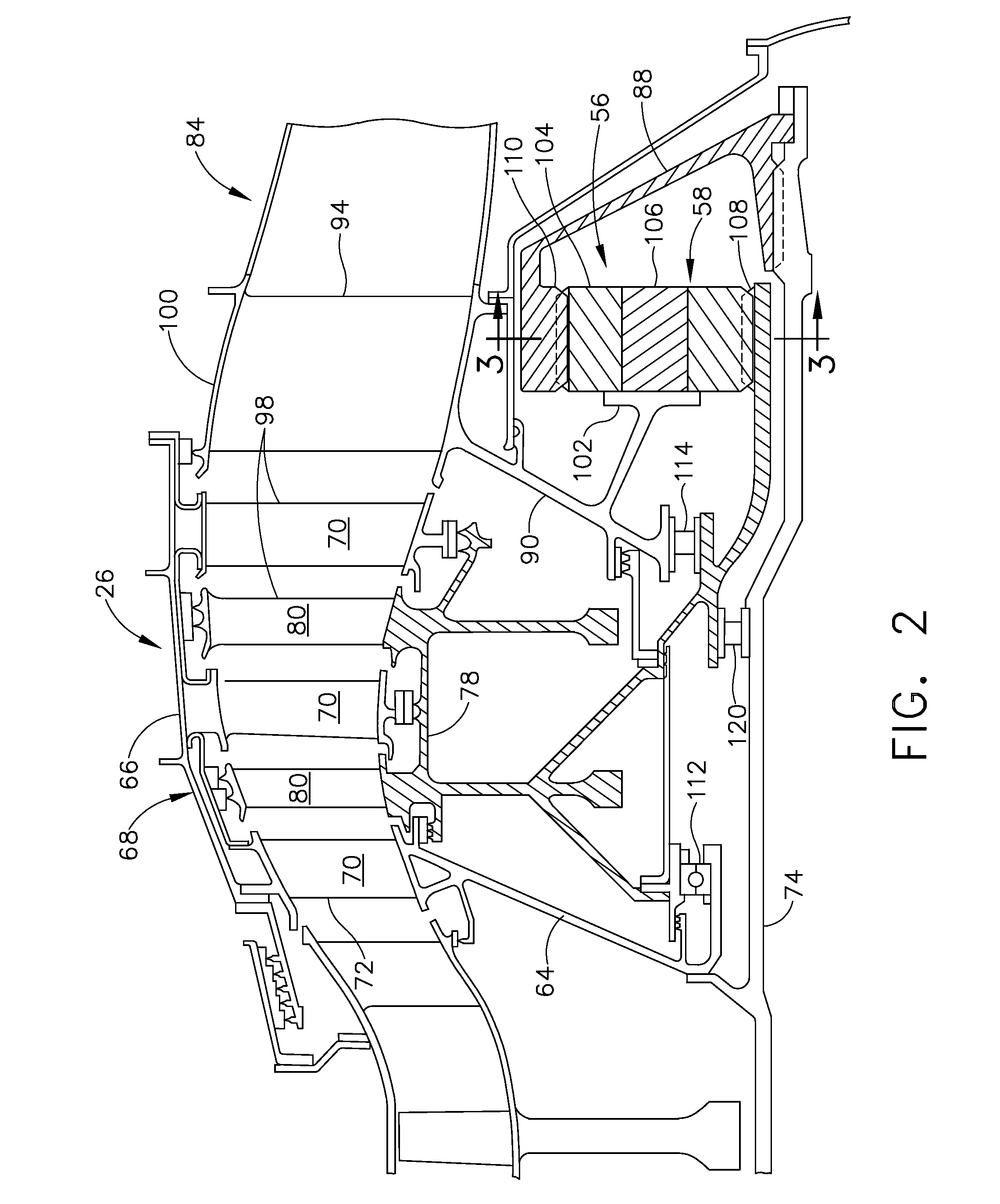

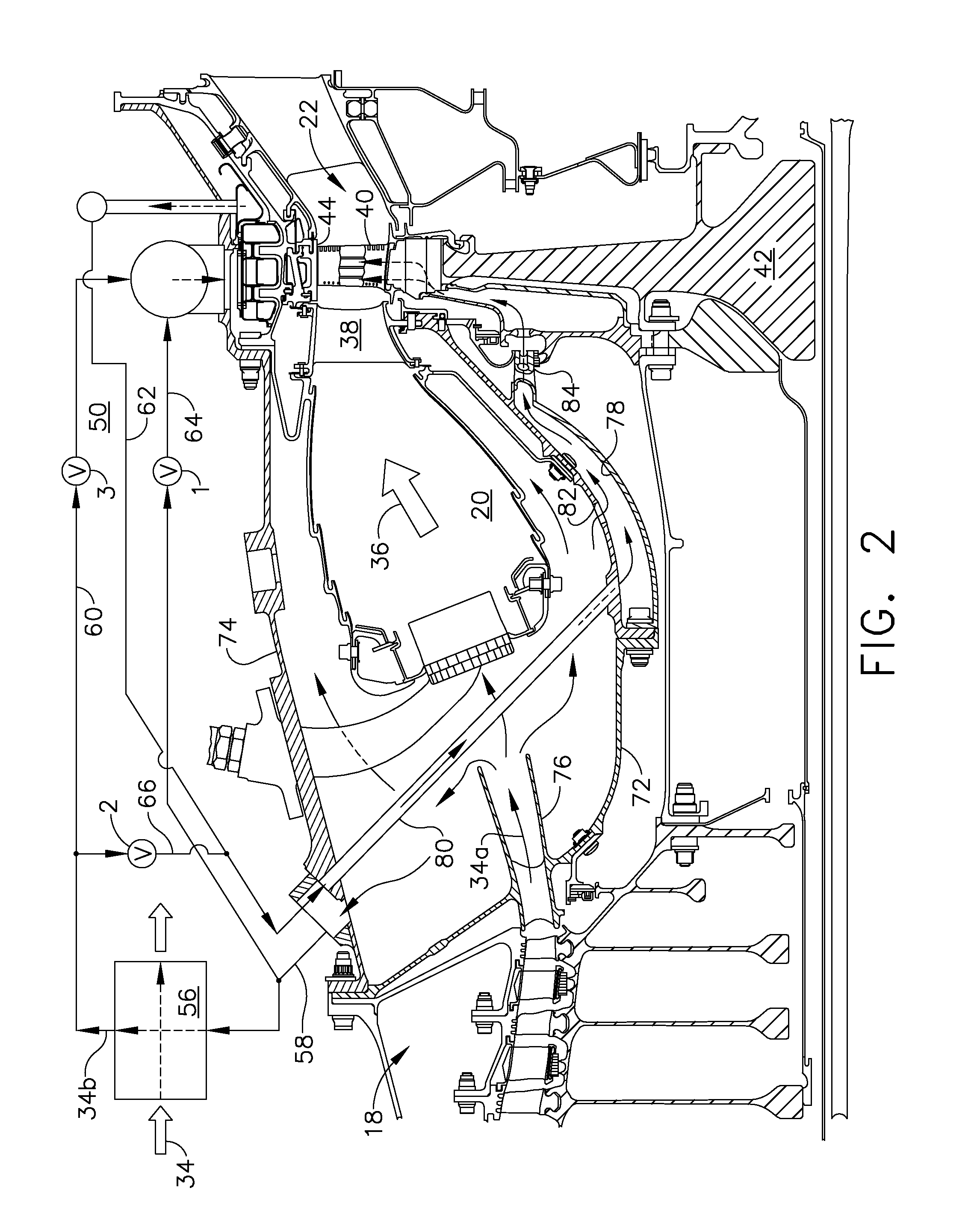

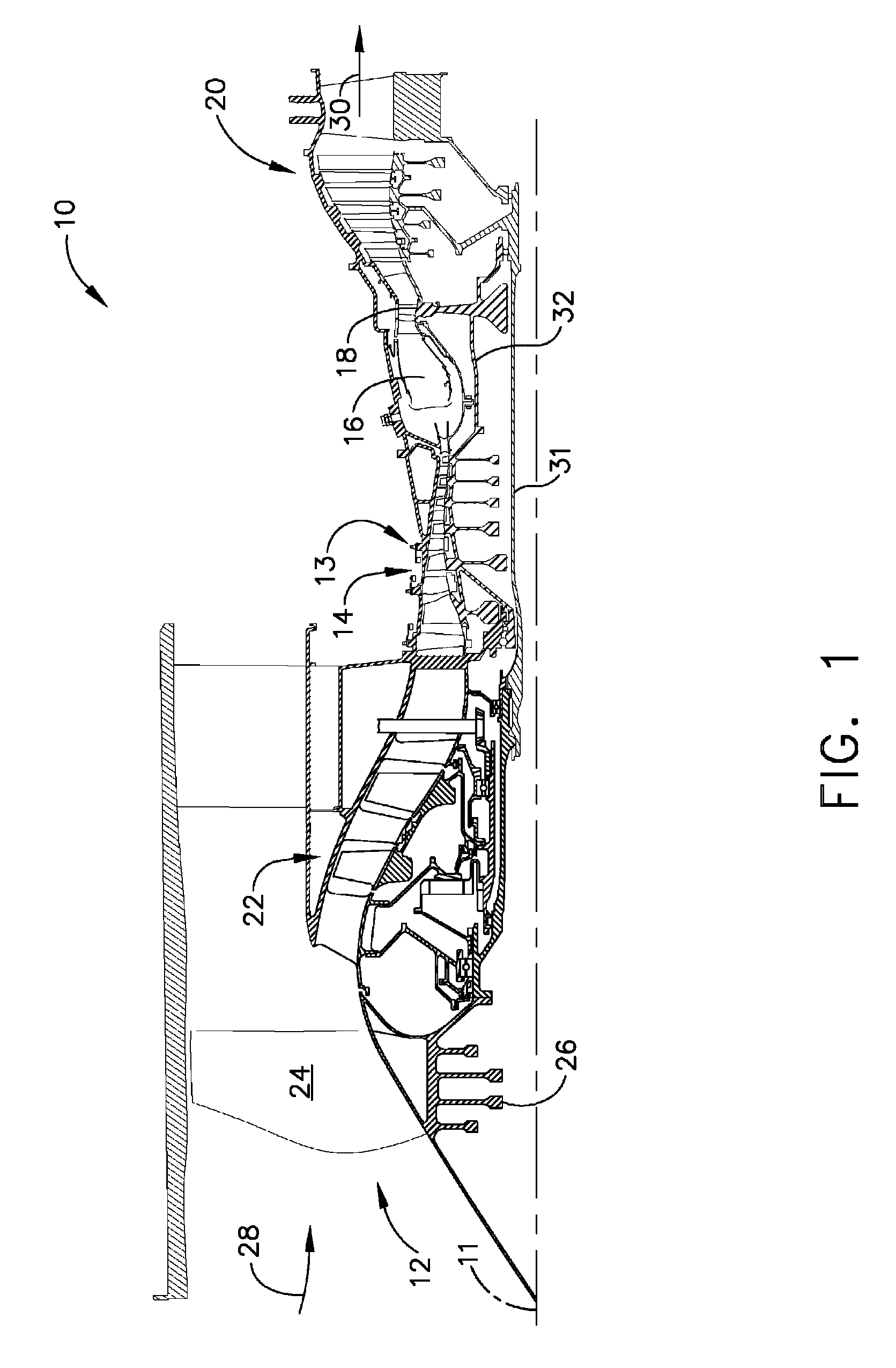

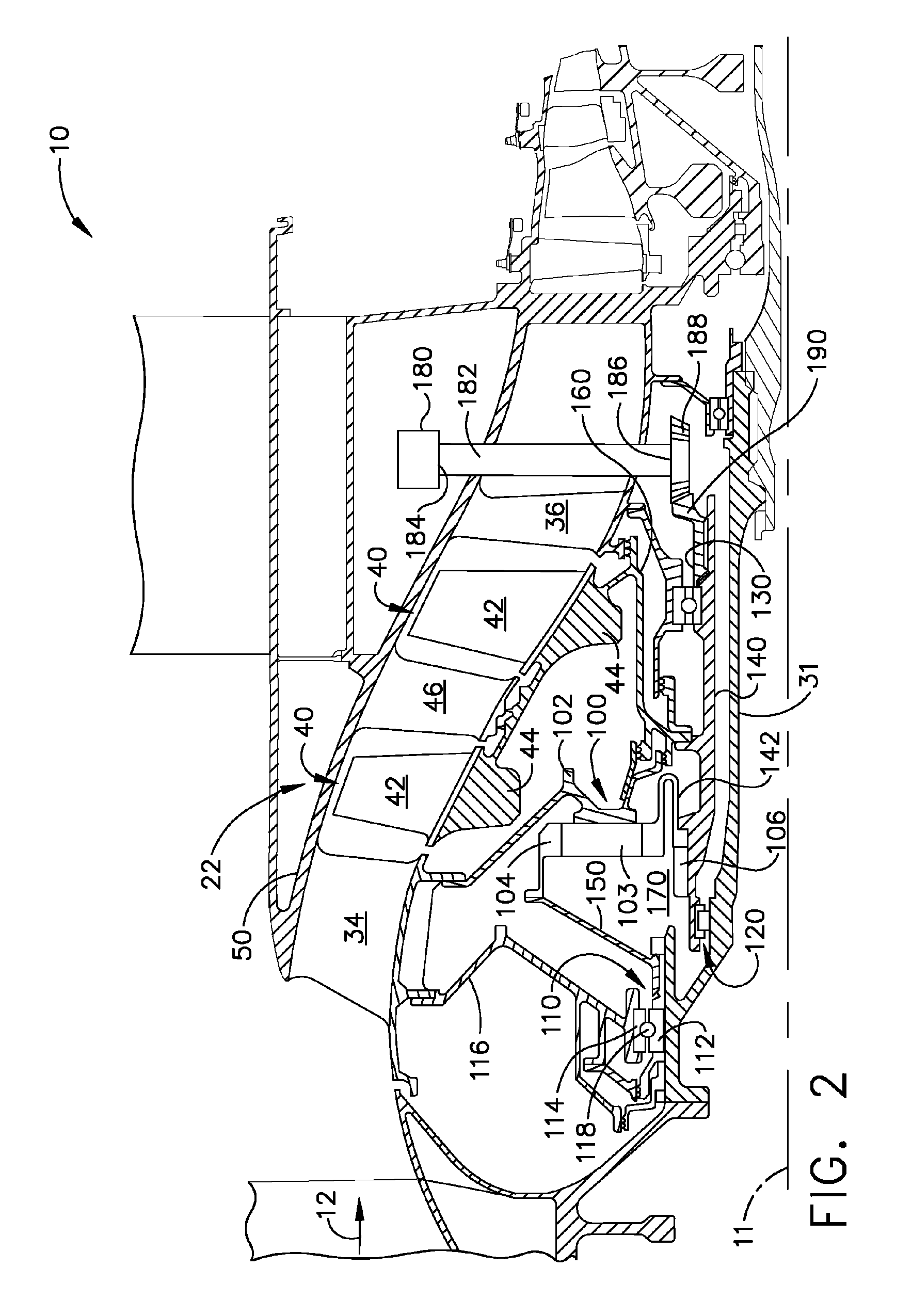

Mid turbine frame system for gas turbine engine

Owner:PRATT & WHITNEY CANADA CORP

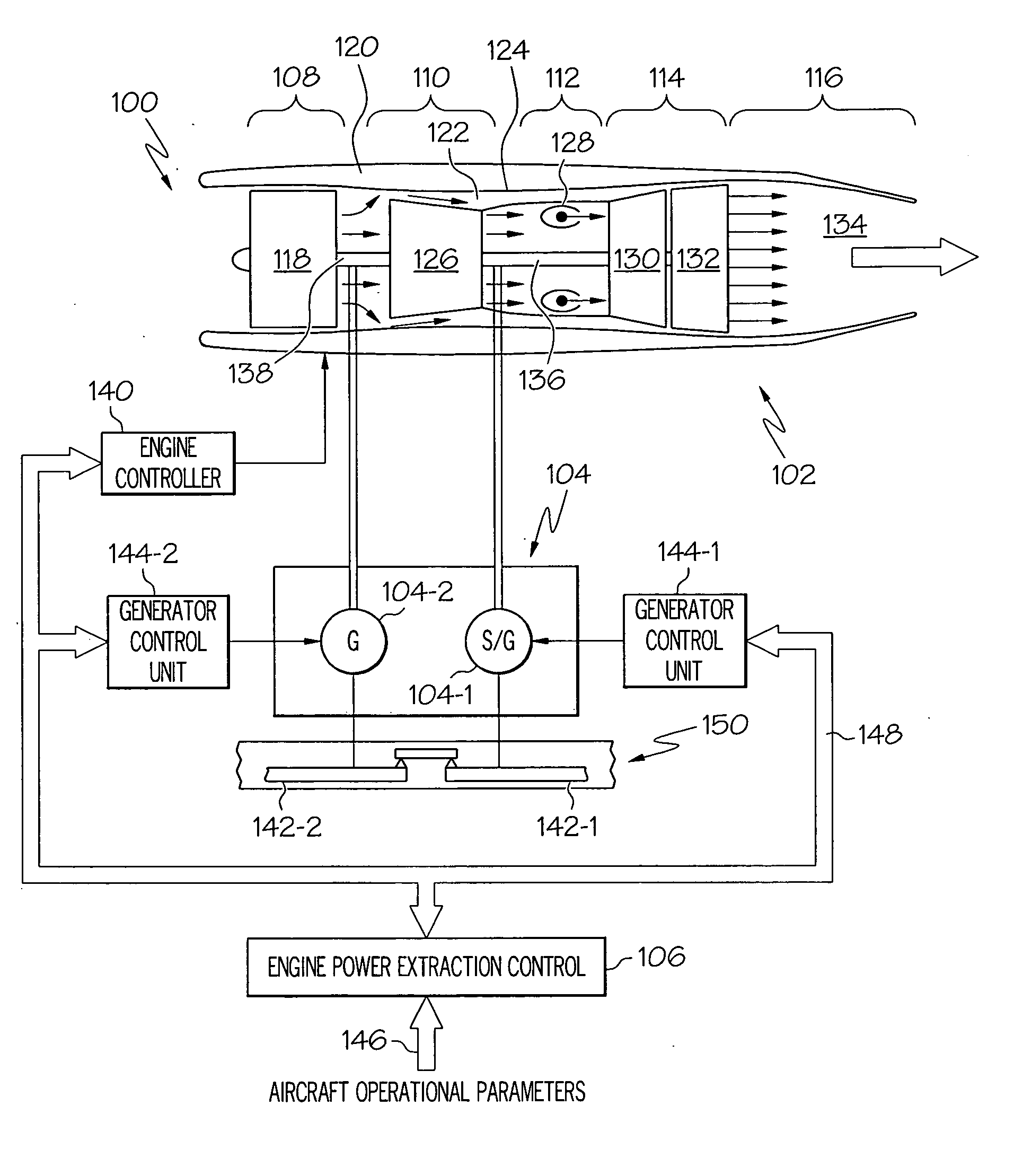

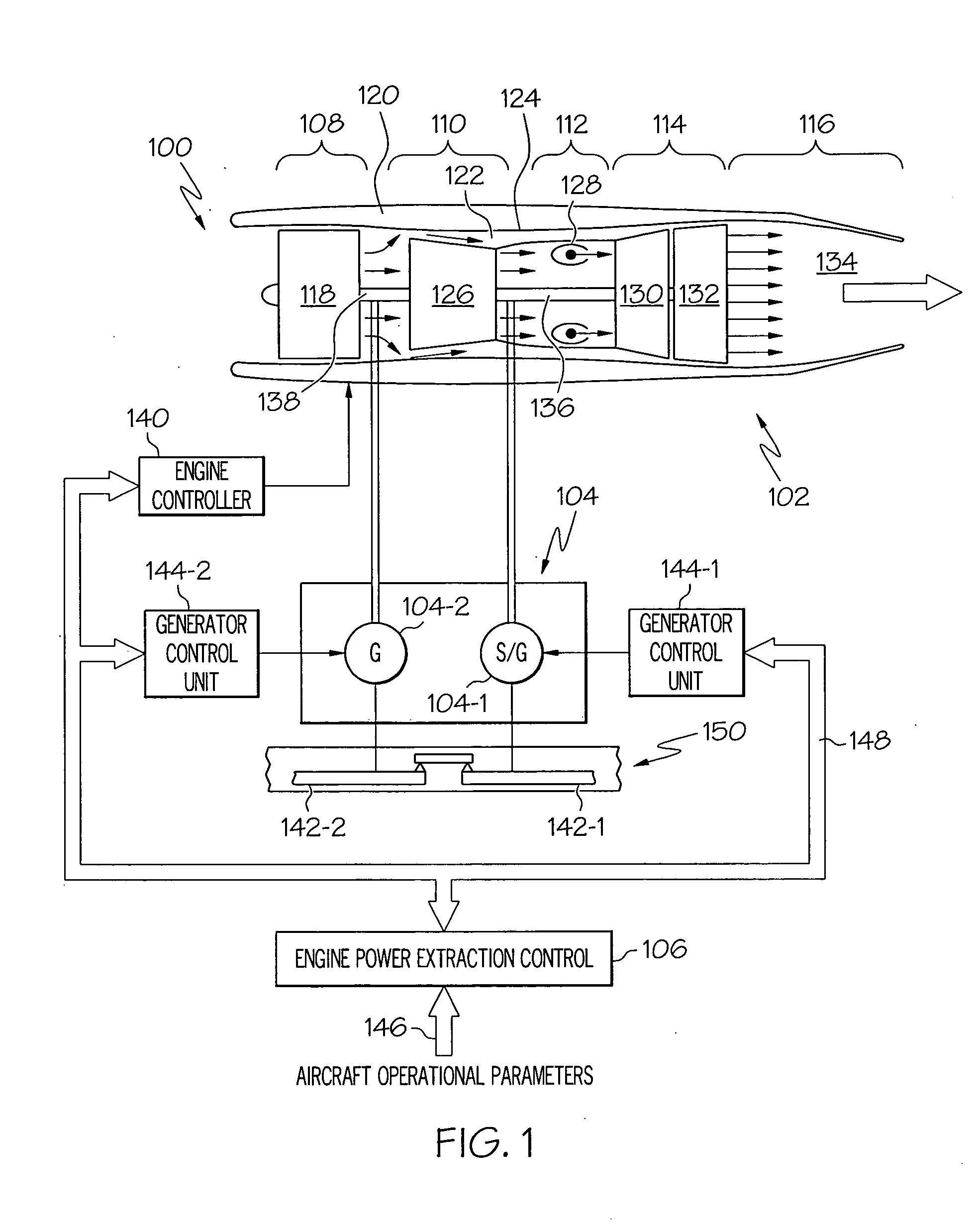

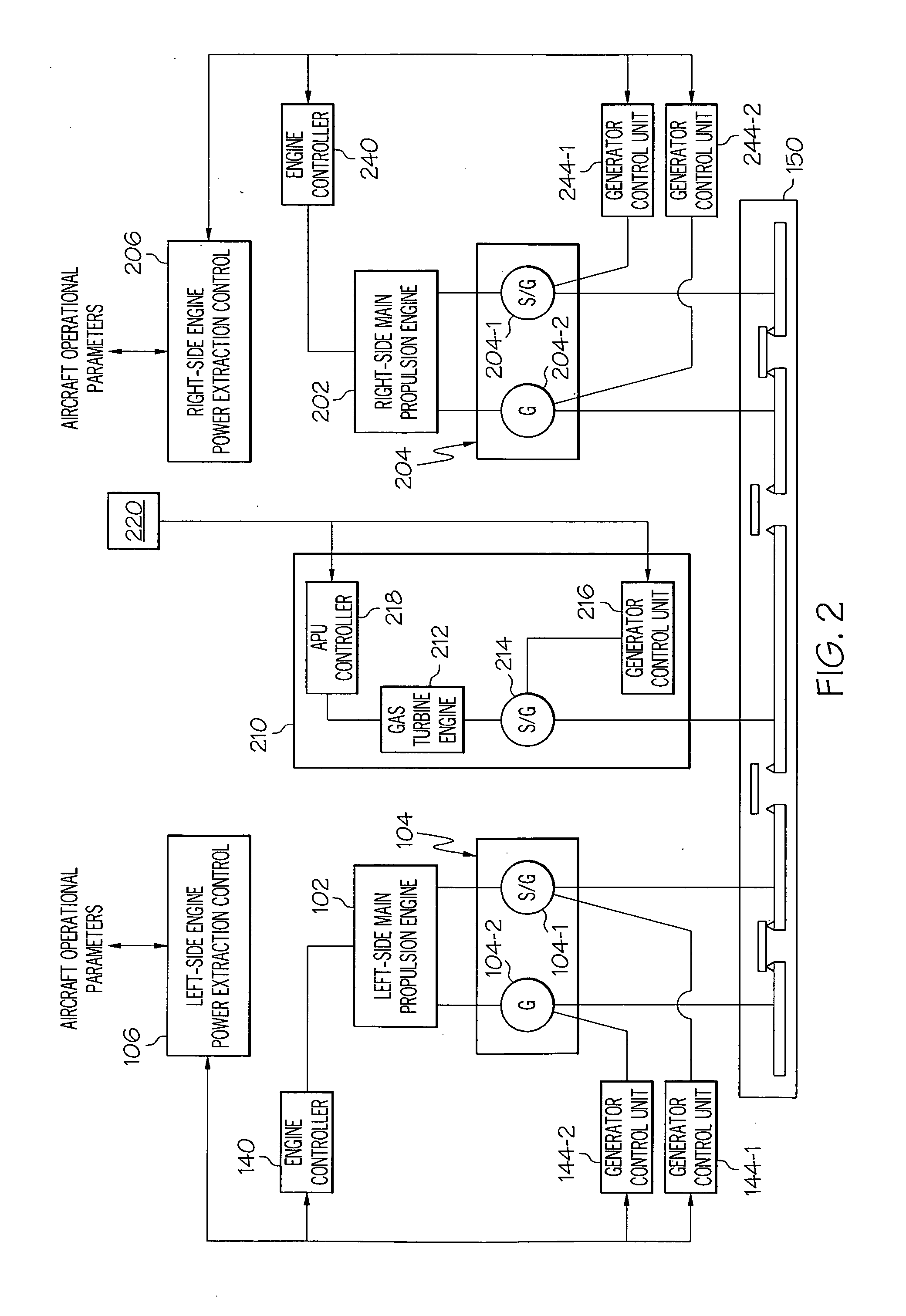

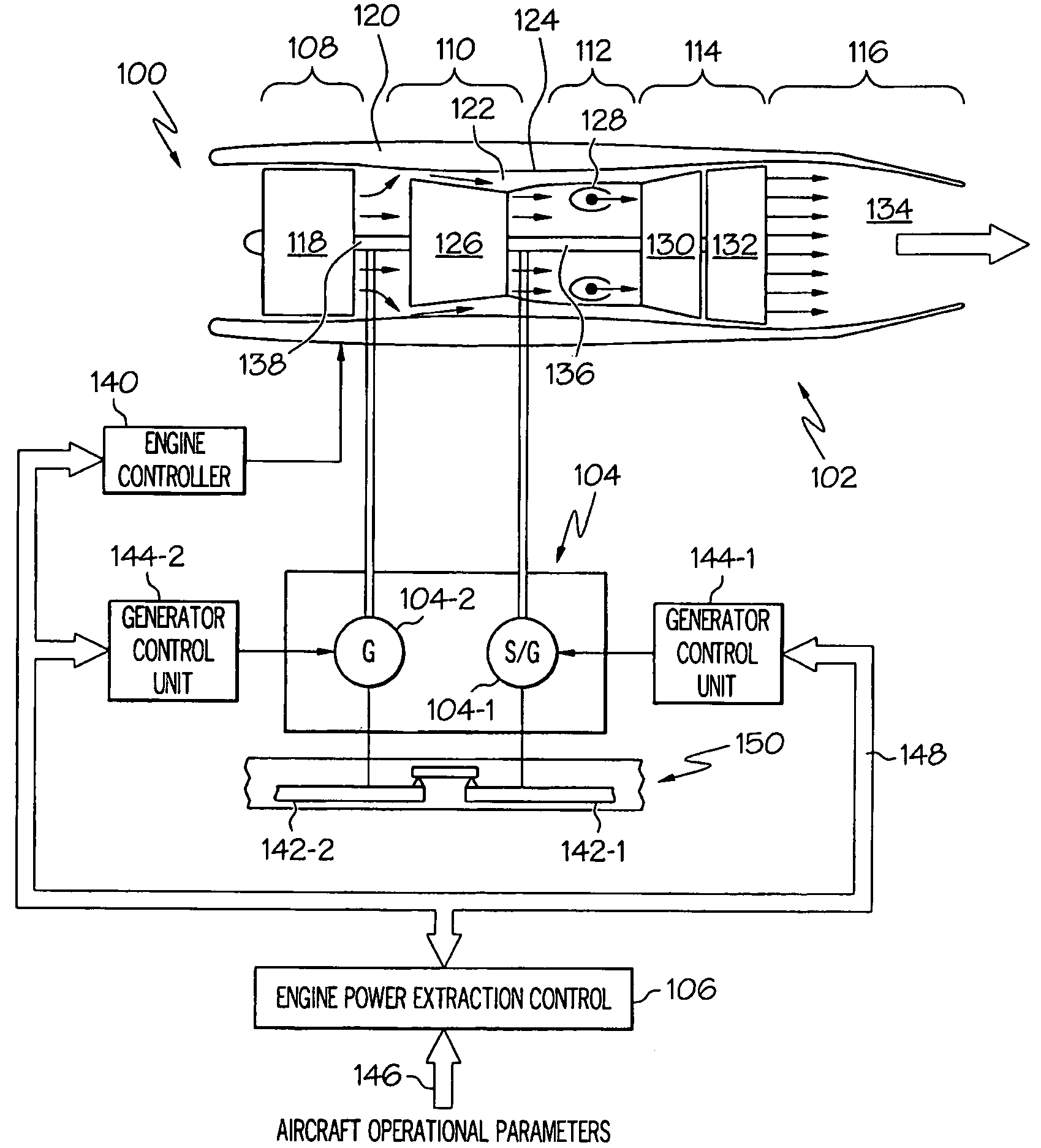

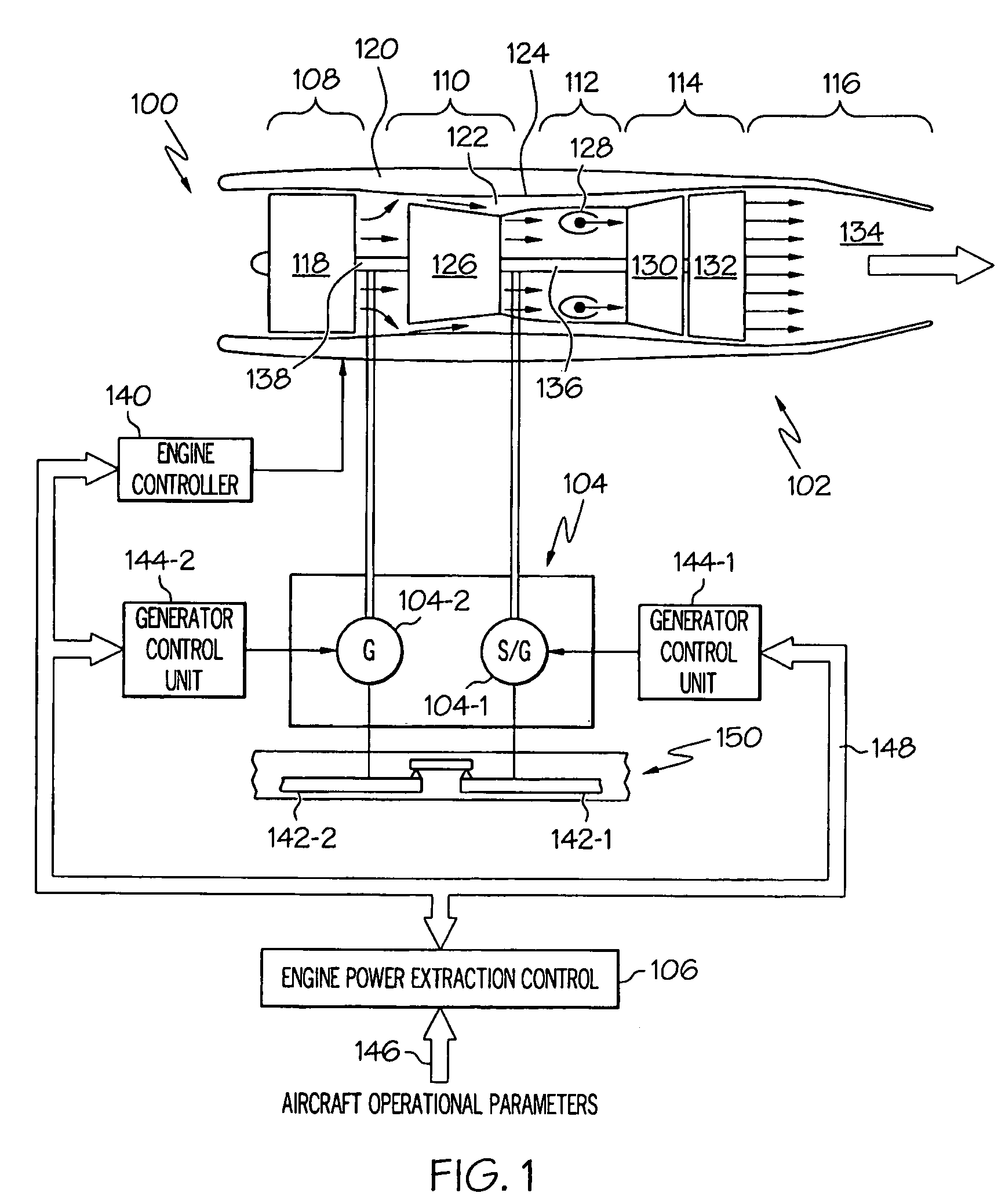

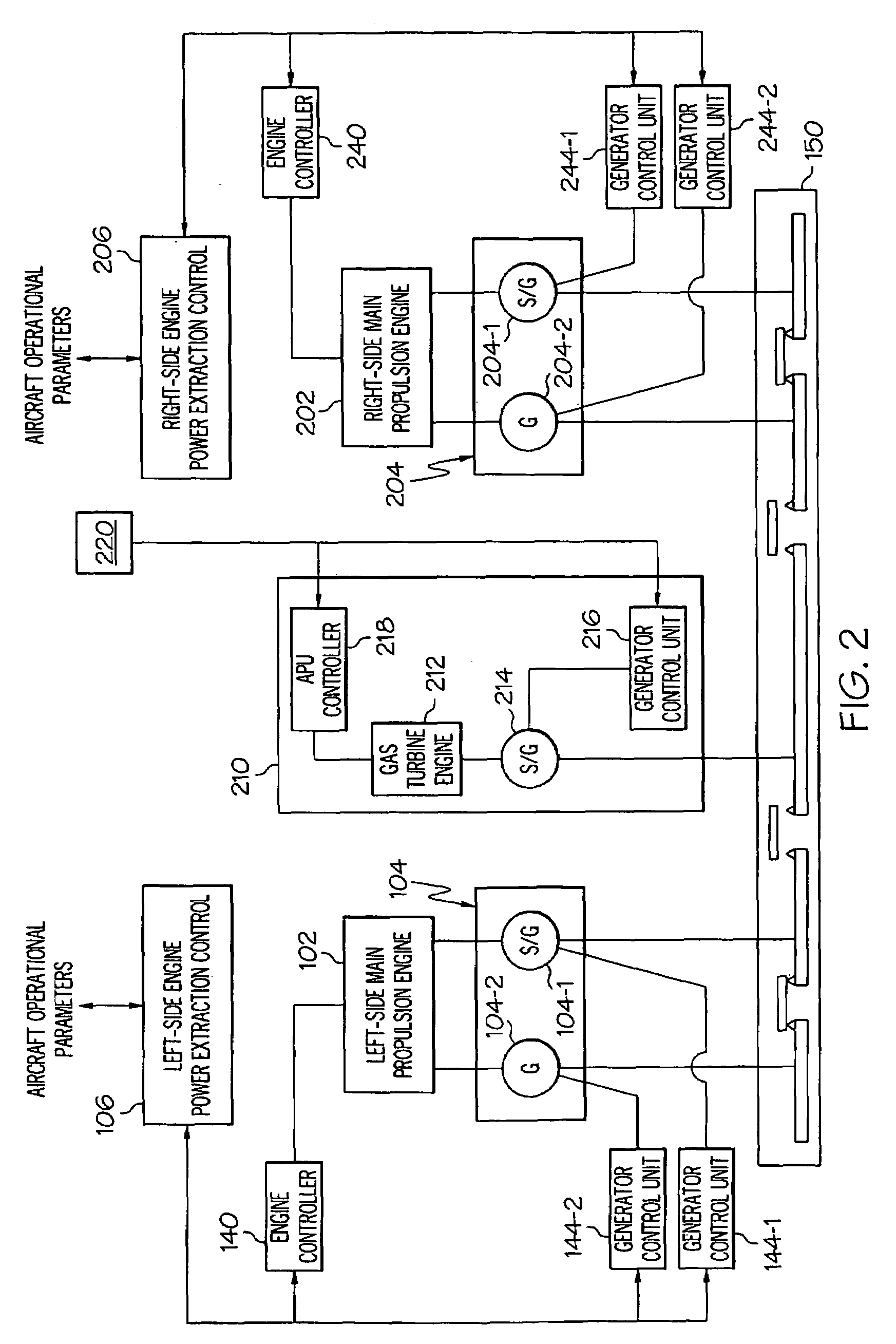

Engine power extraction control system

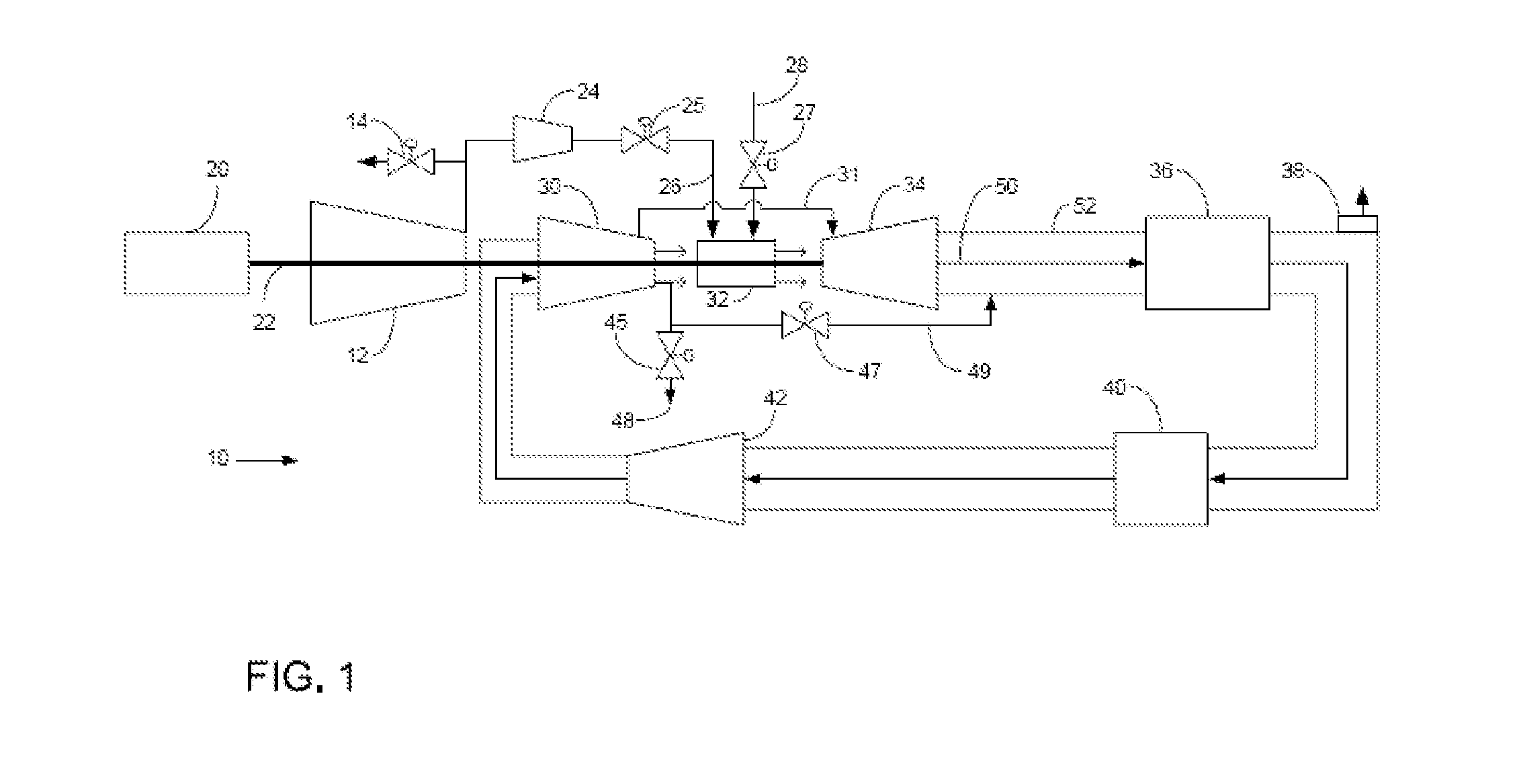

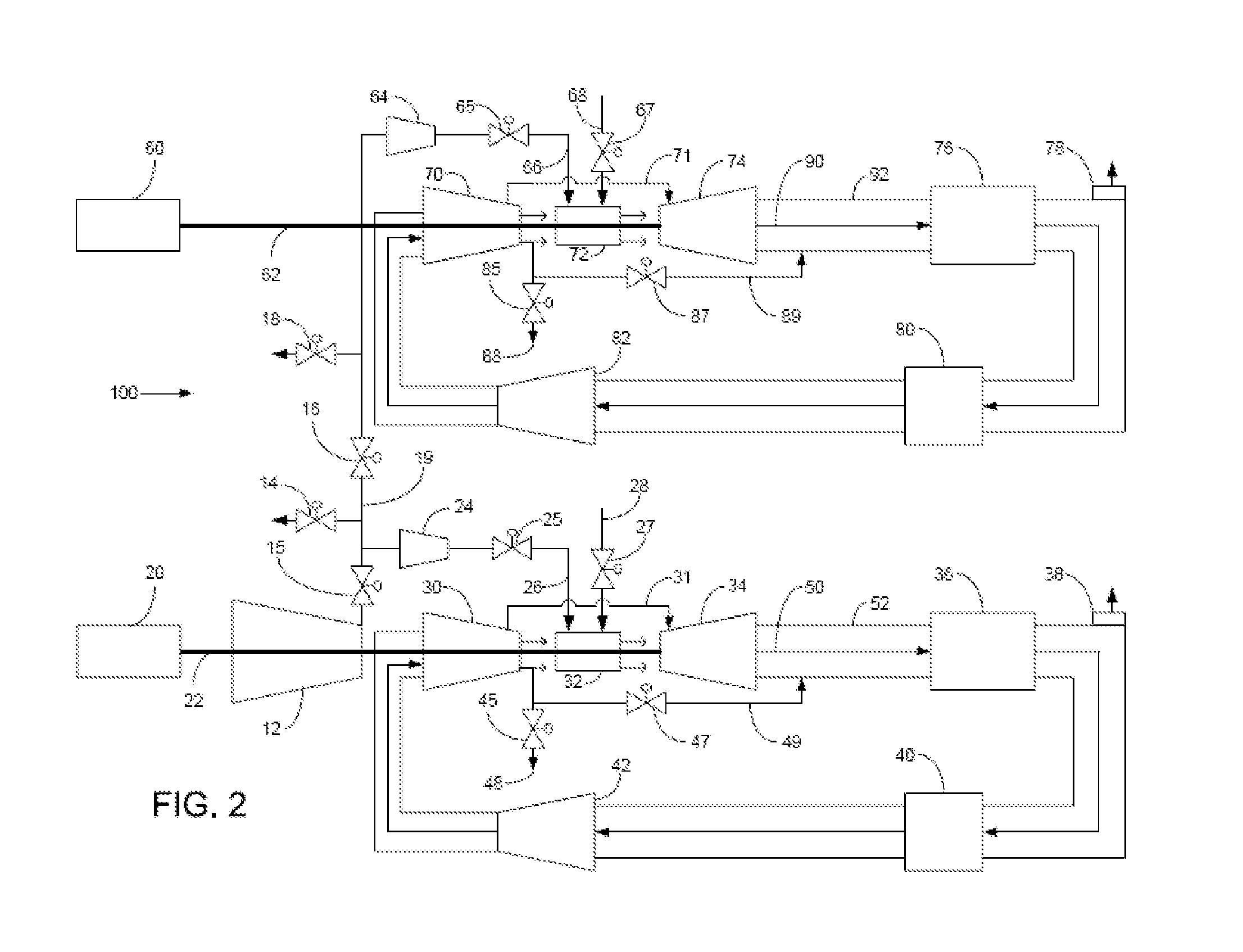

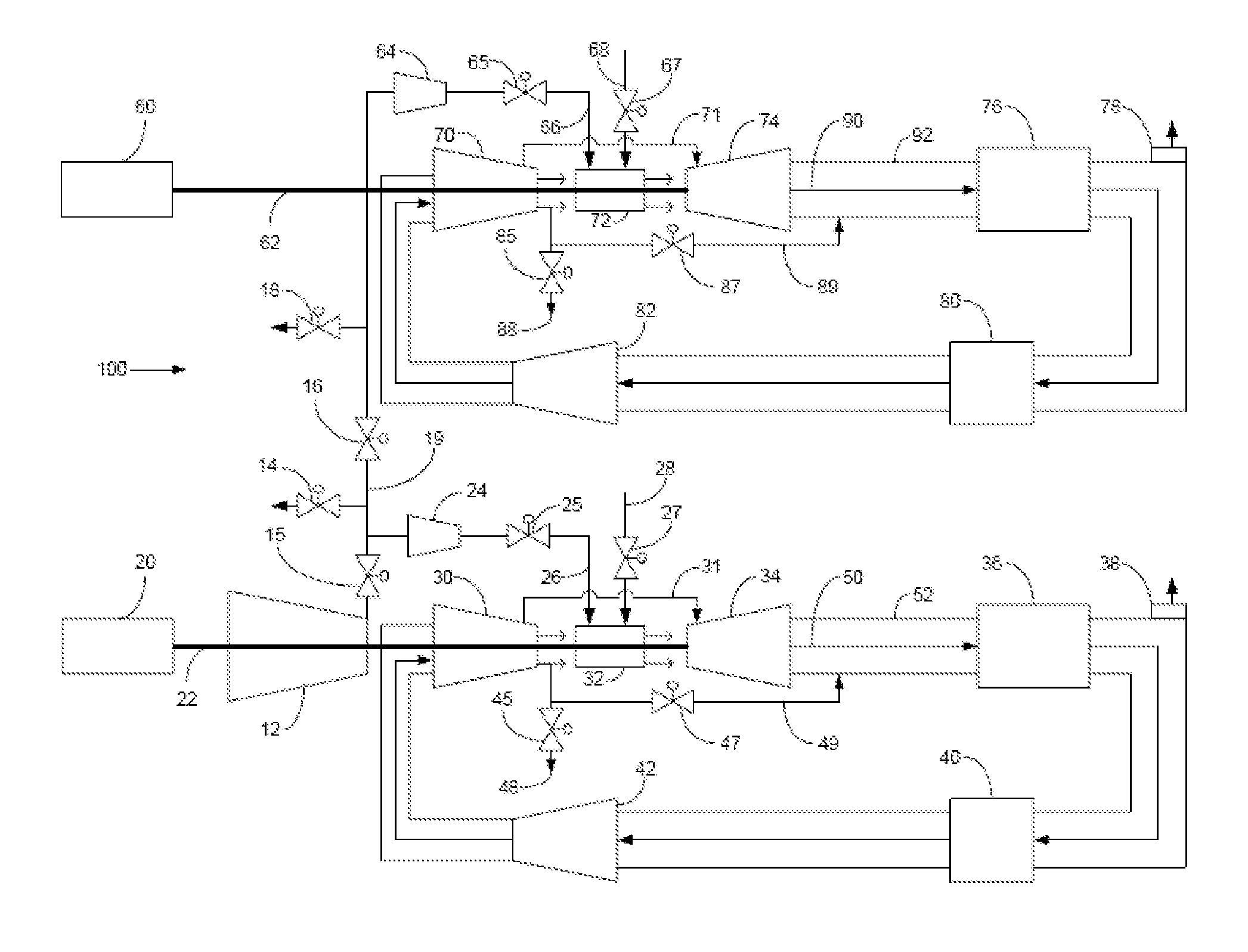

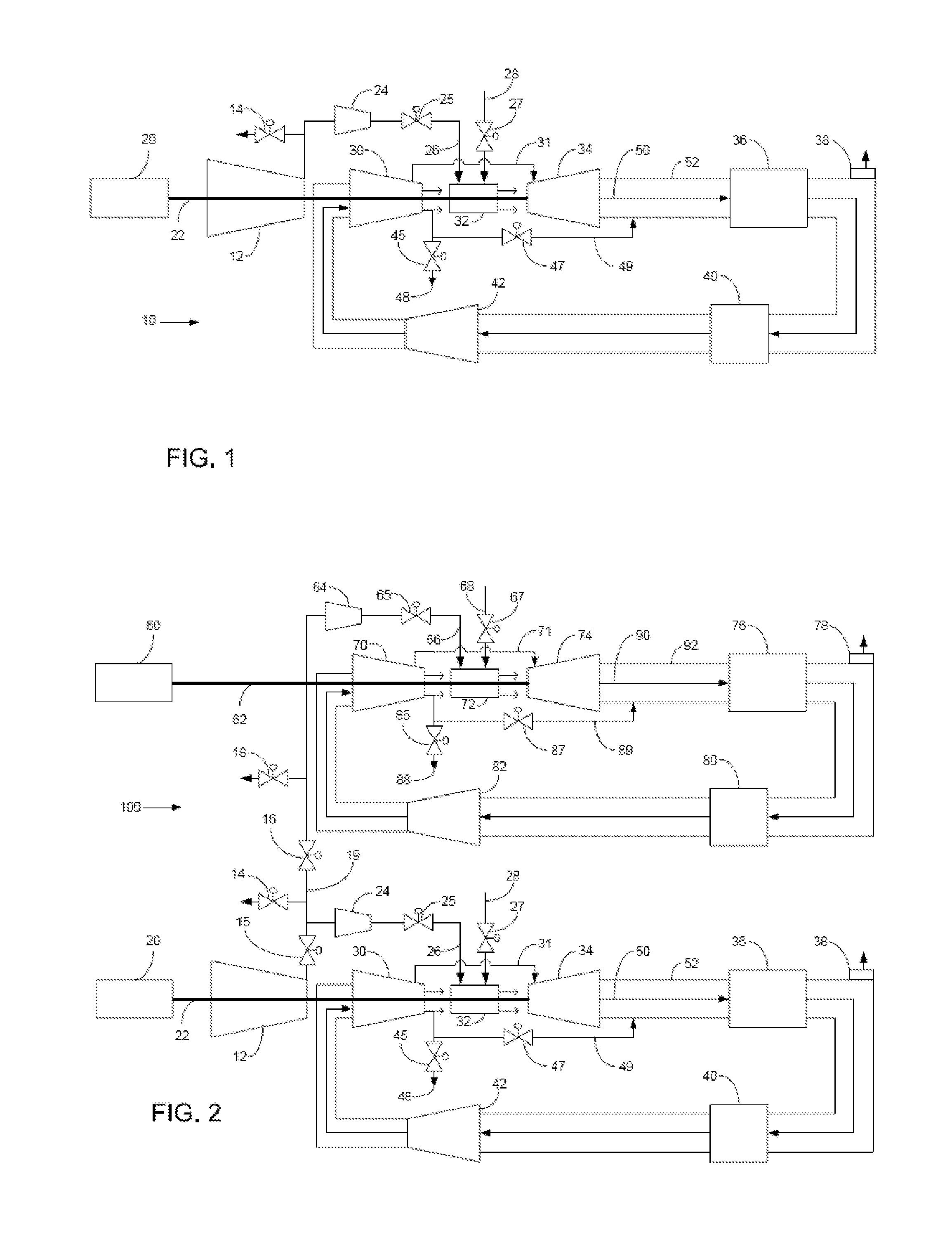

ActiveUS20060042252A1Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemElectric machine

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

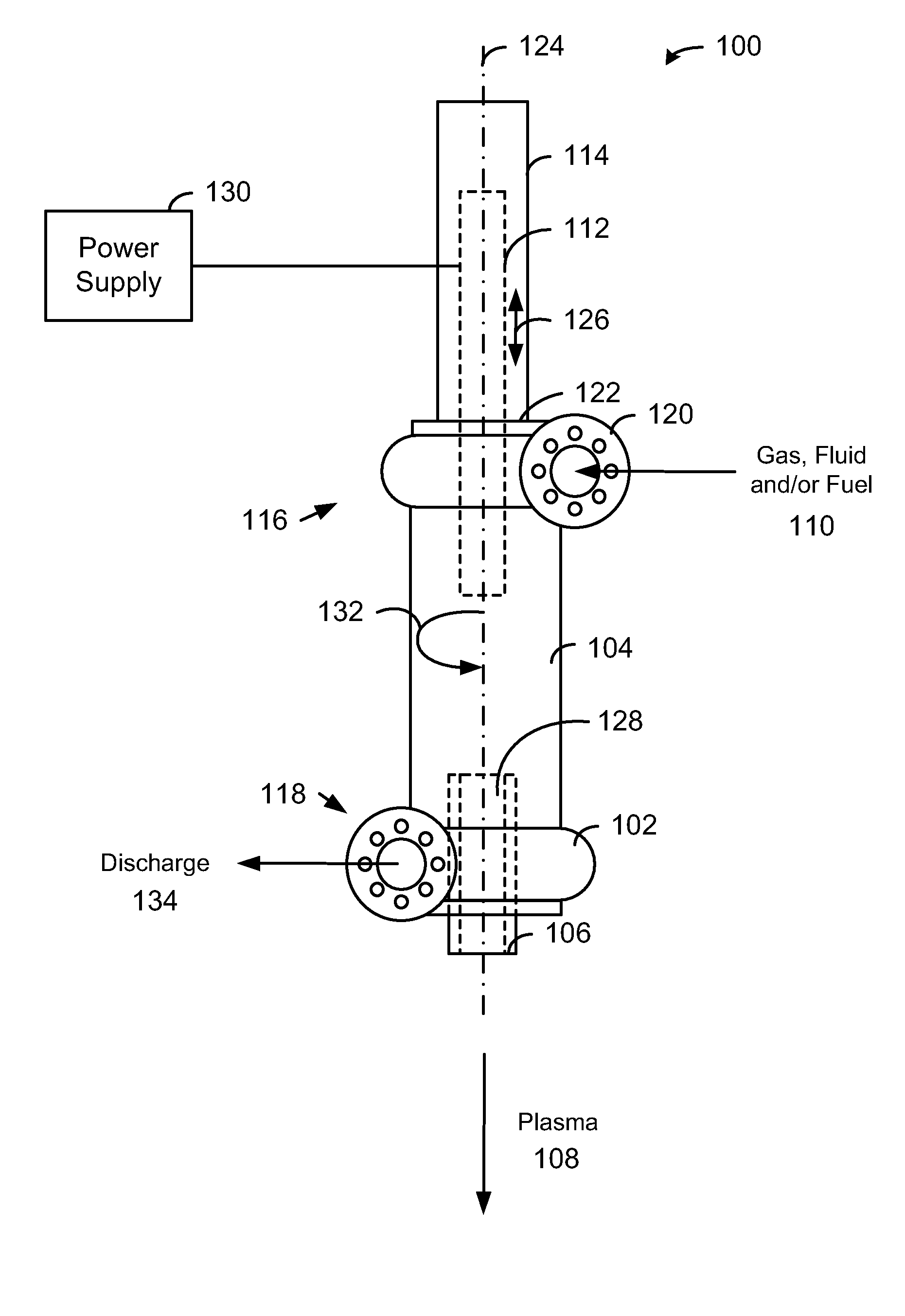

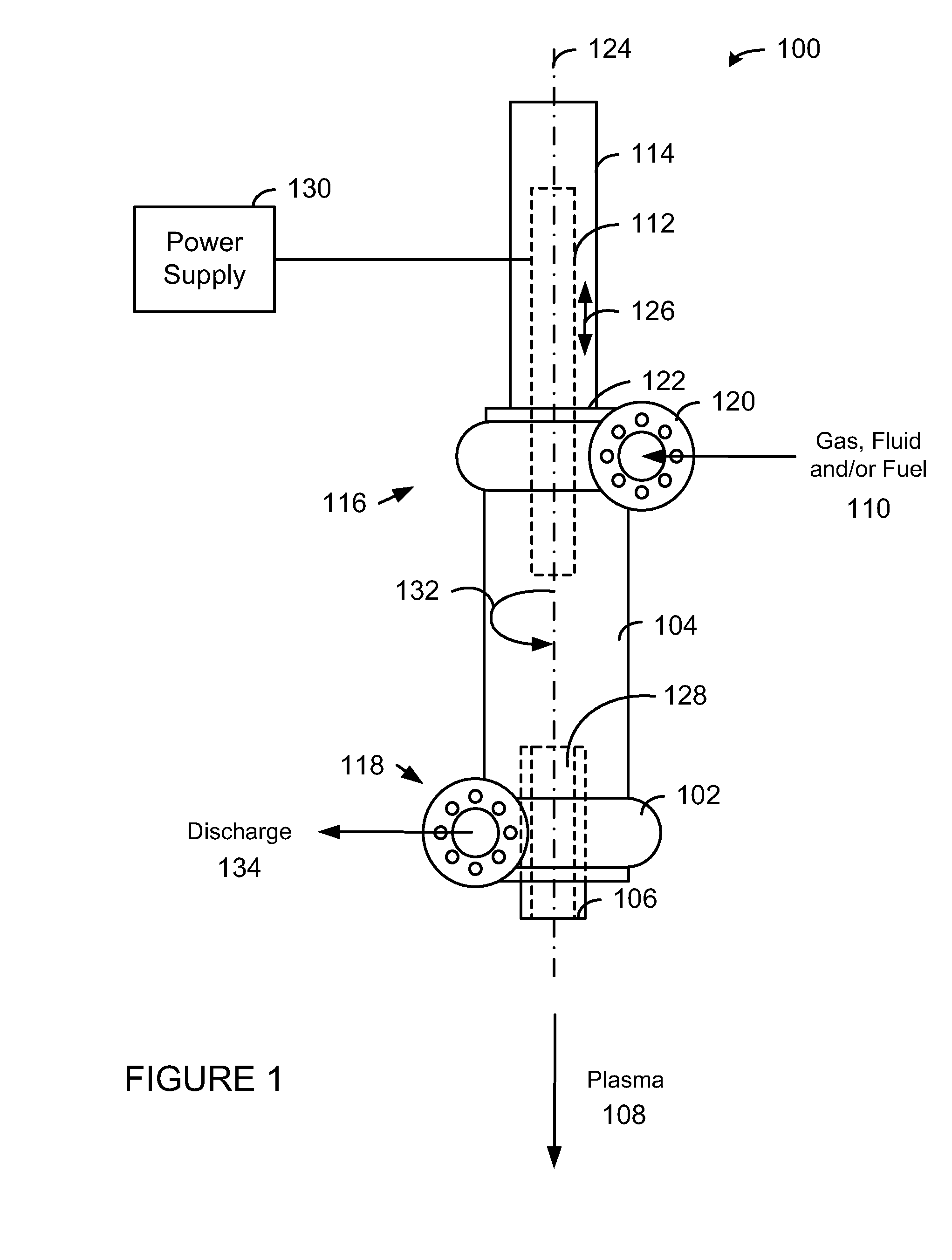

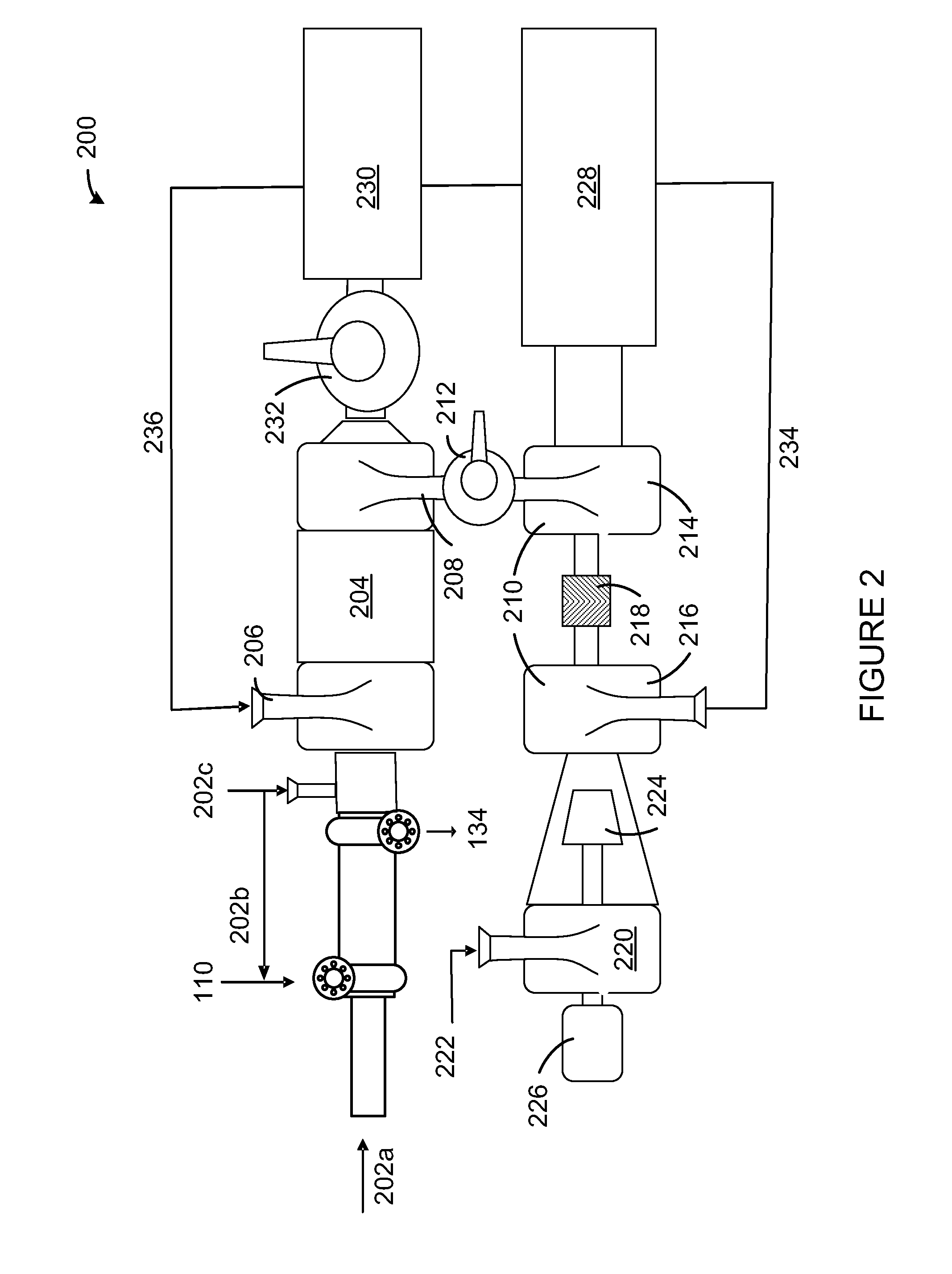

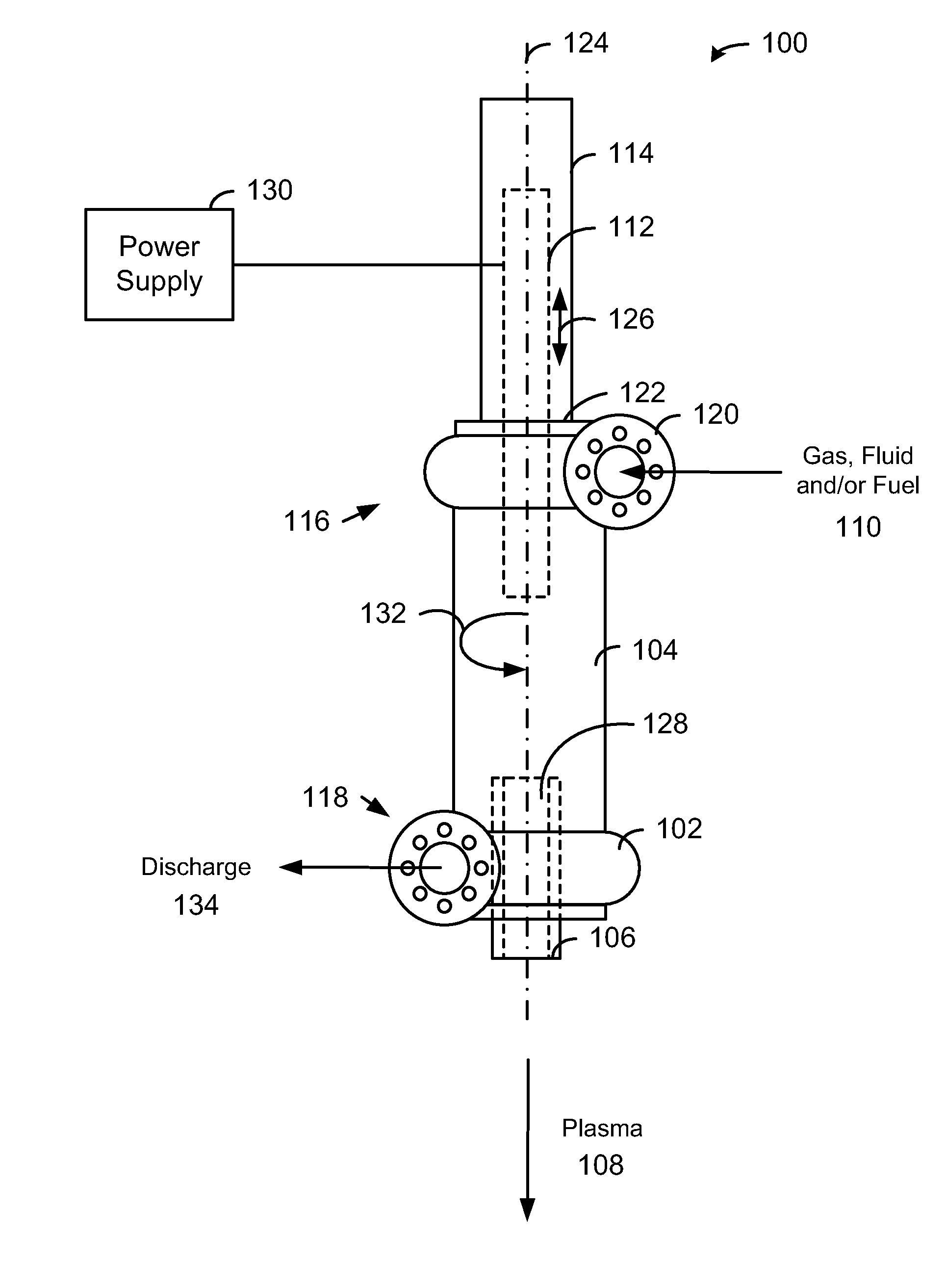

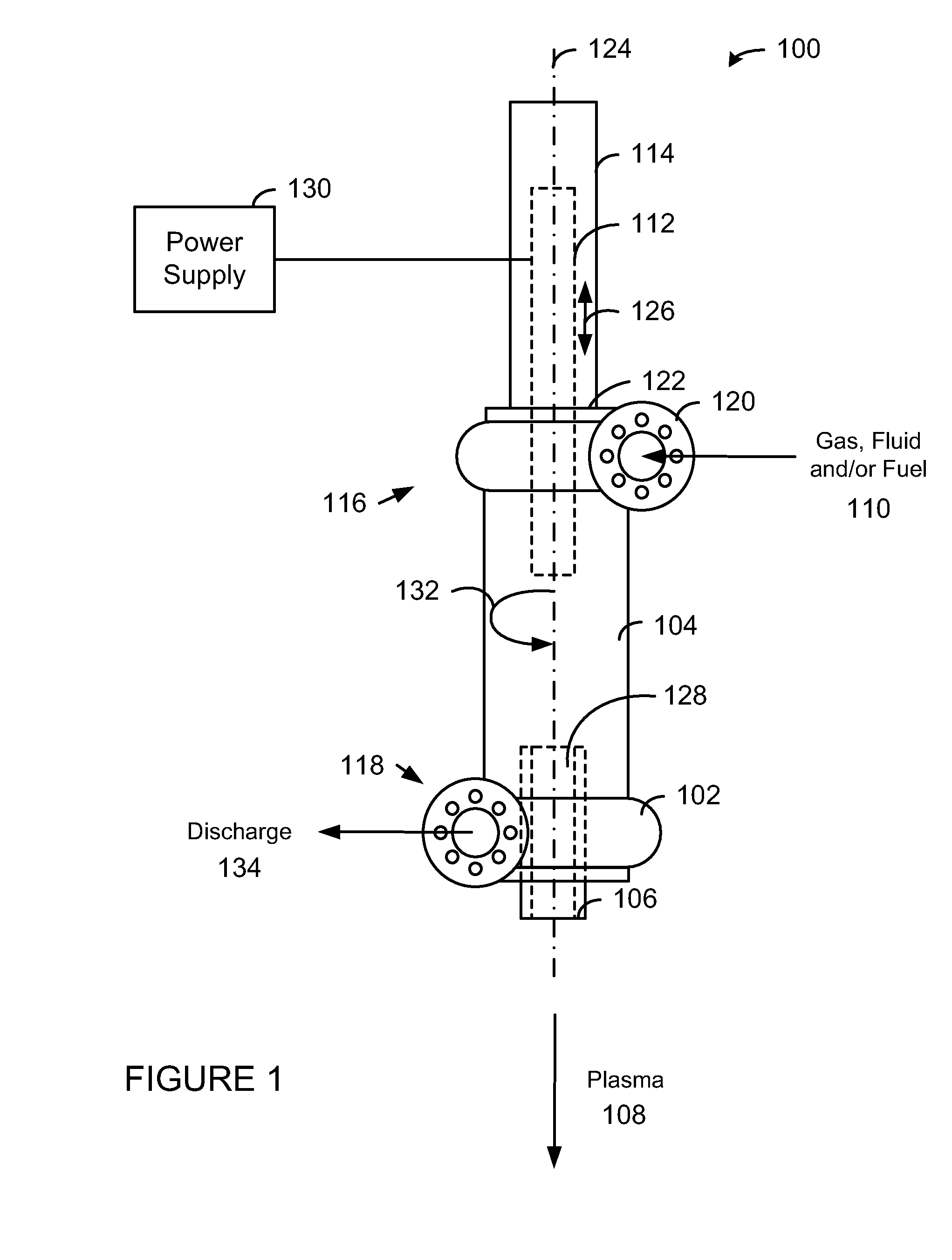

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle creates a plasma that discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle crate a plasma the discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

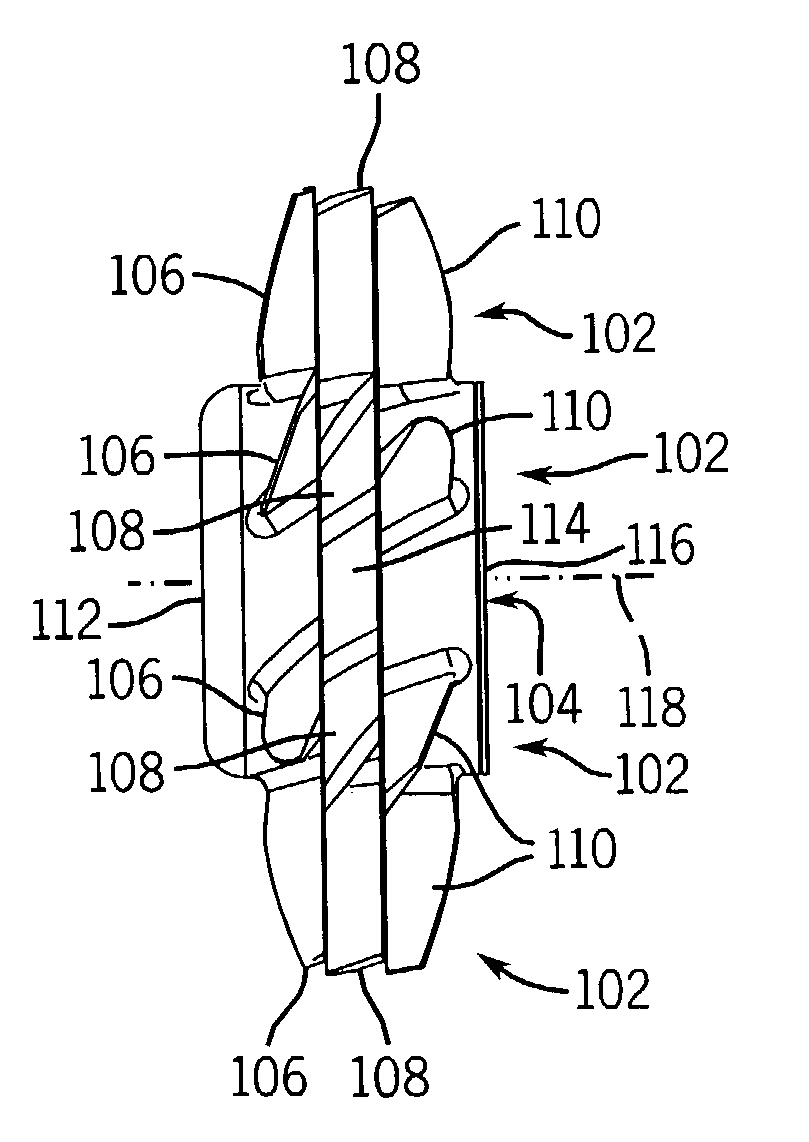

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

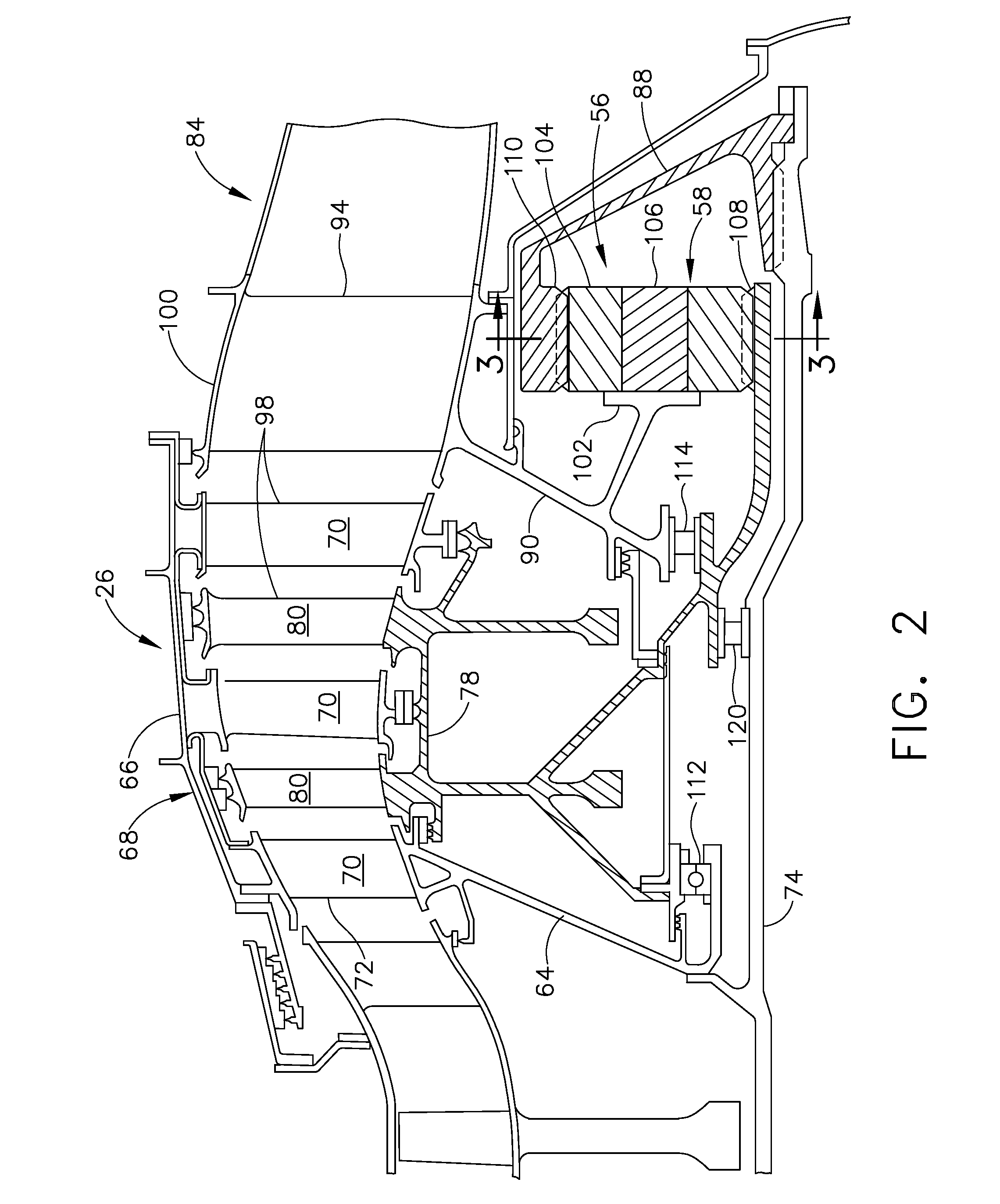

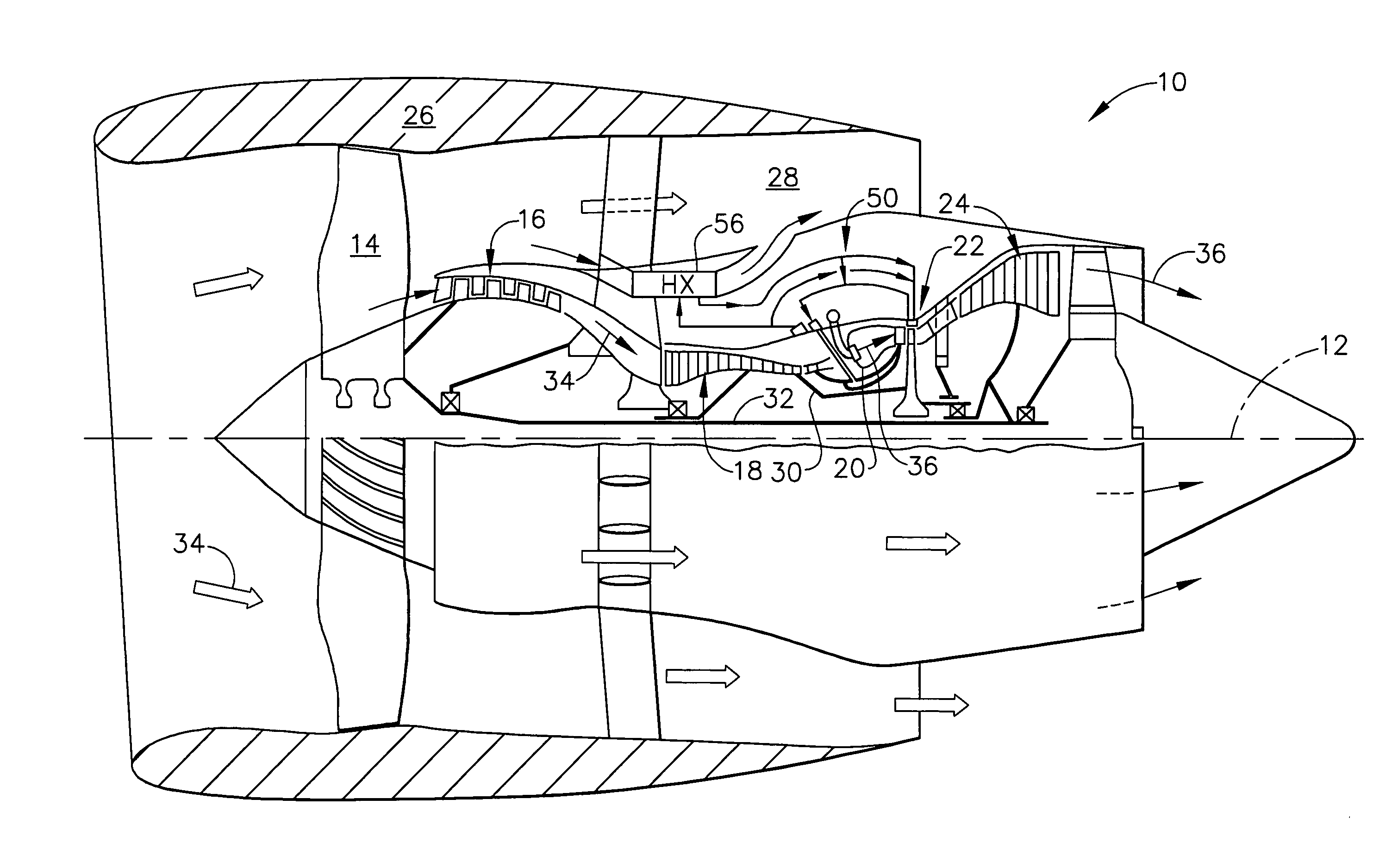

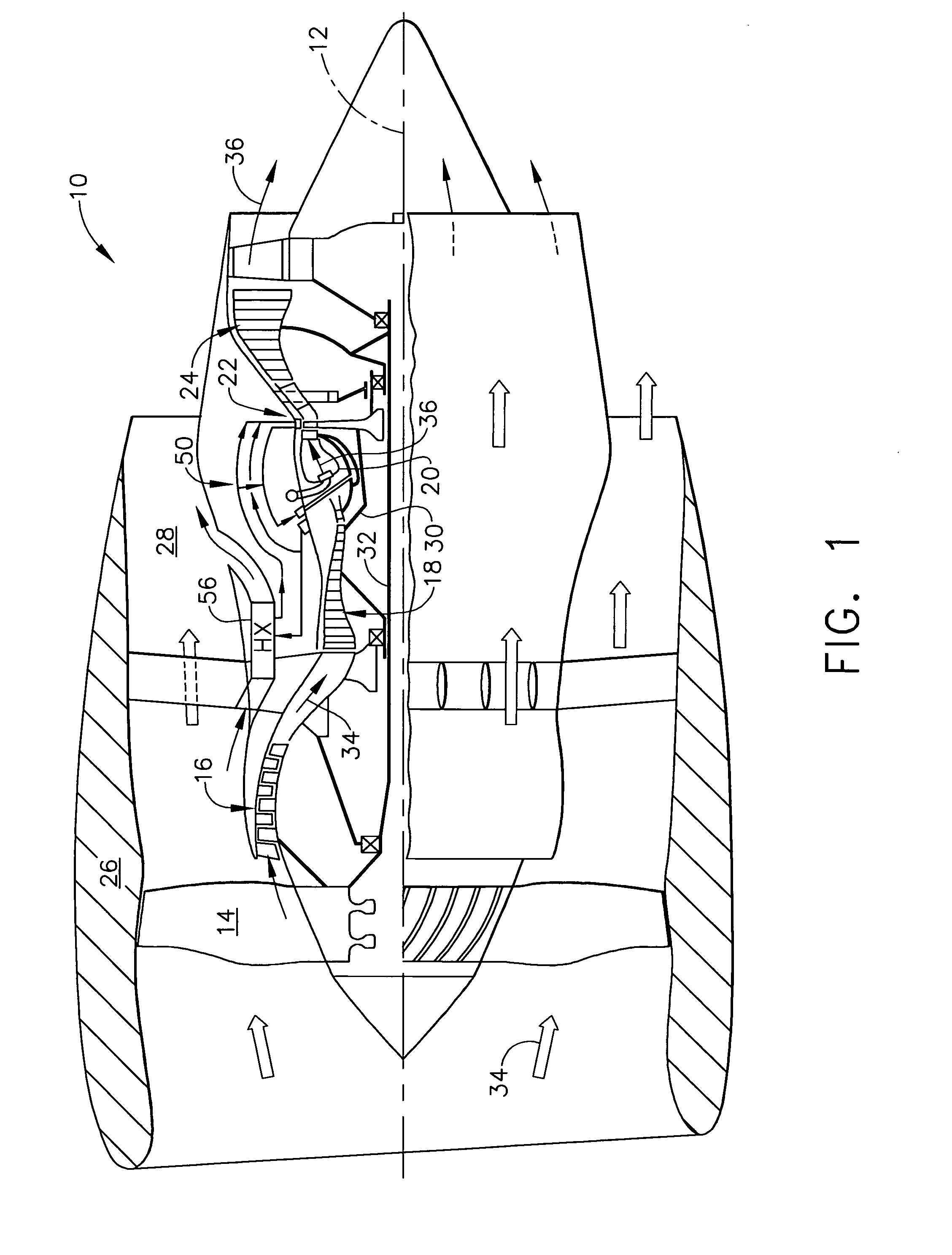

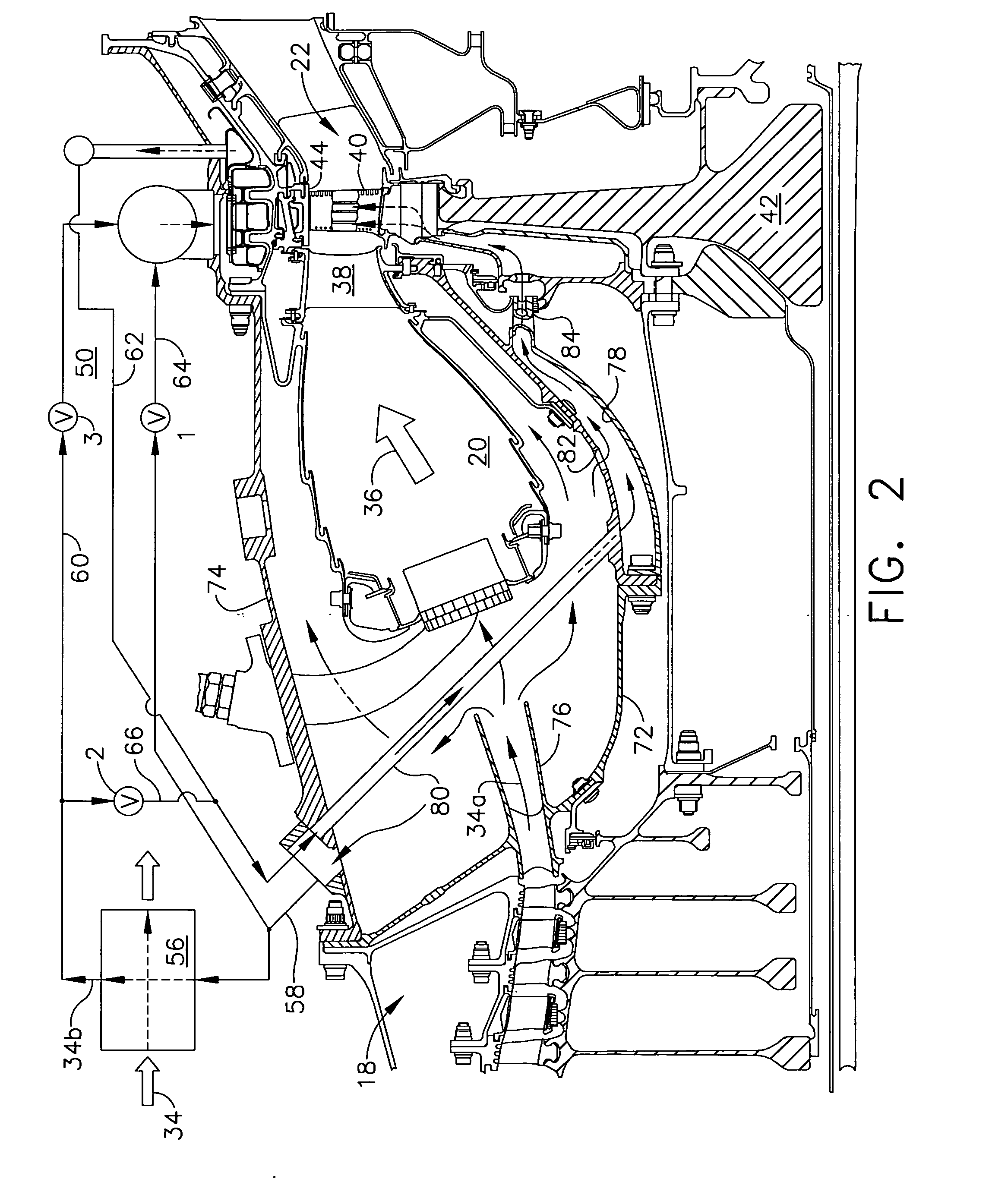

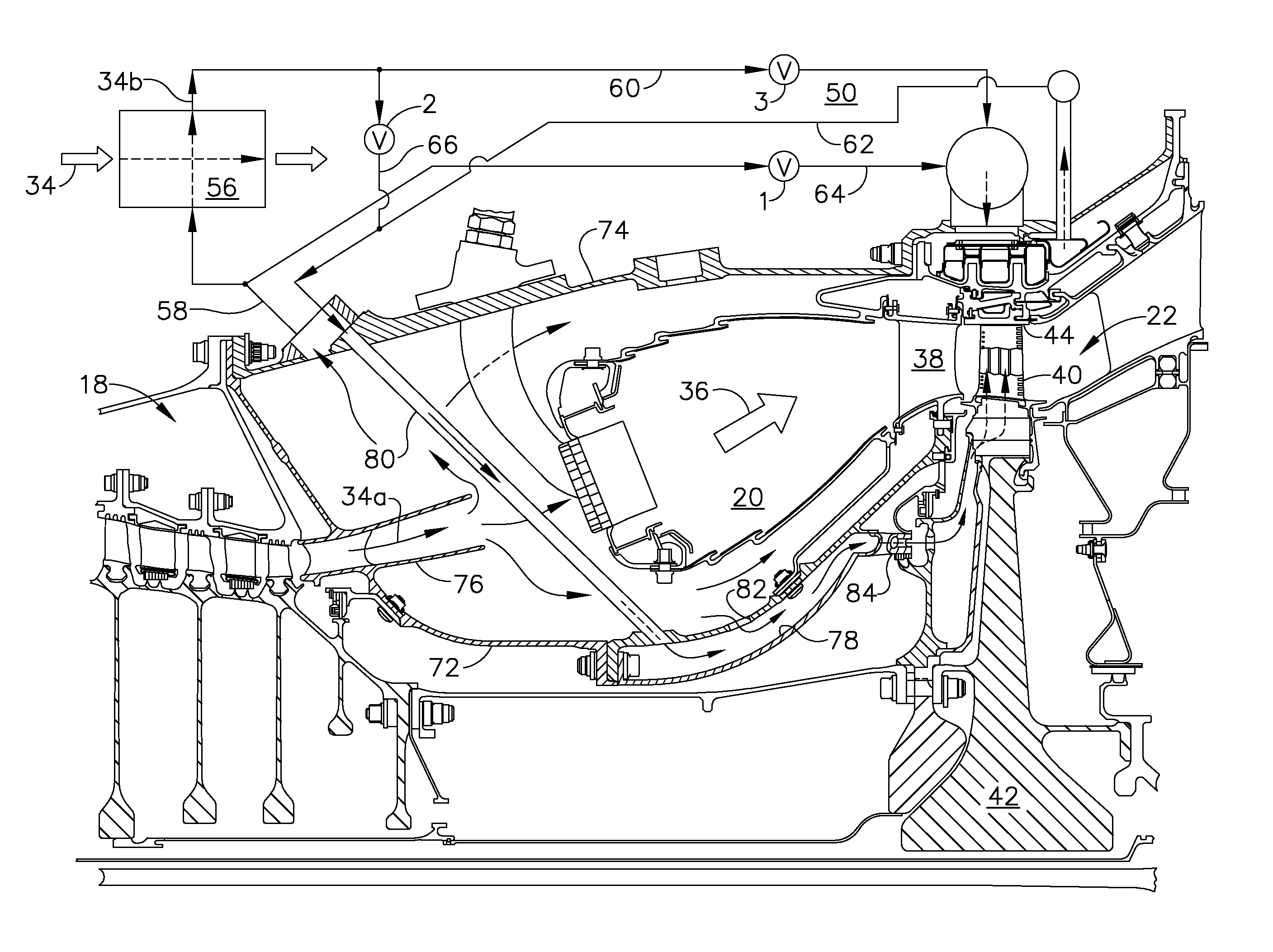

Compound clearance control engine

A gas turbine engine includes a compressor, combustor, and turbine having a row of blades mounted inside a surrounding turbine shroud. A heat exchanger is used for cooling pressurized air bled from the compressor. A distribution network joins the heat exchanger to the turbine for selectively channeling air from the heat exchanger below the blades and above the shroud for controlling blade tip clearance.

Owner:GENERAL ELECTRIC CO

Engine power extraction control system

ActiveUS7285871B2Increase propulsionEasy to operateReciprocating combination enginesTurbine/propulsion engine ignitionControl systemEngine power

An engine power extraction control system controls the main propulsion engines and the electrical machines that are coupled thereto to supply an appropriate amount of aircraft thrust and electrical energy to the aircraft. The engines and electrical machines are also controlled so that the propulsion thrust that is generated is split between the various turbines in the main propulsion engines to maintain an adequate surge margin and to minimize residual thrust generation.

Owner:HONEYWELL INT INC

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

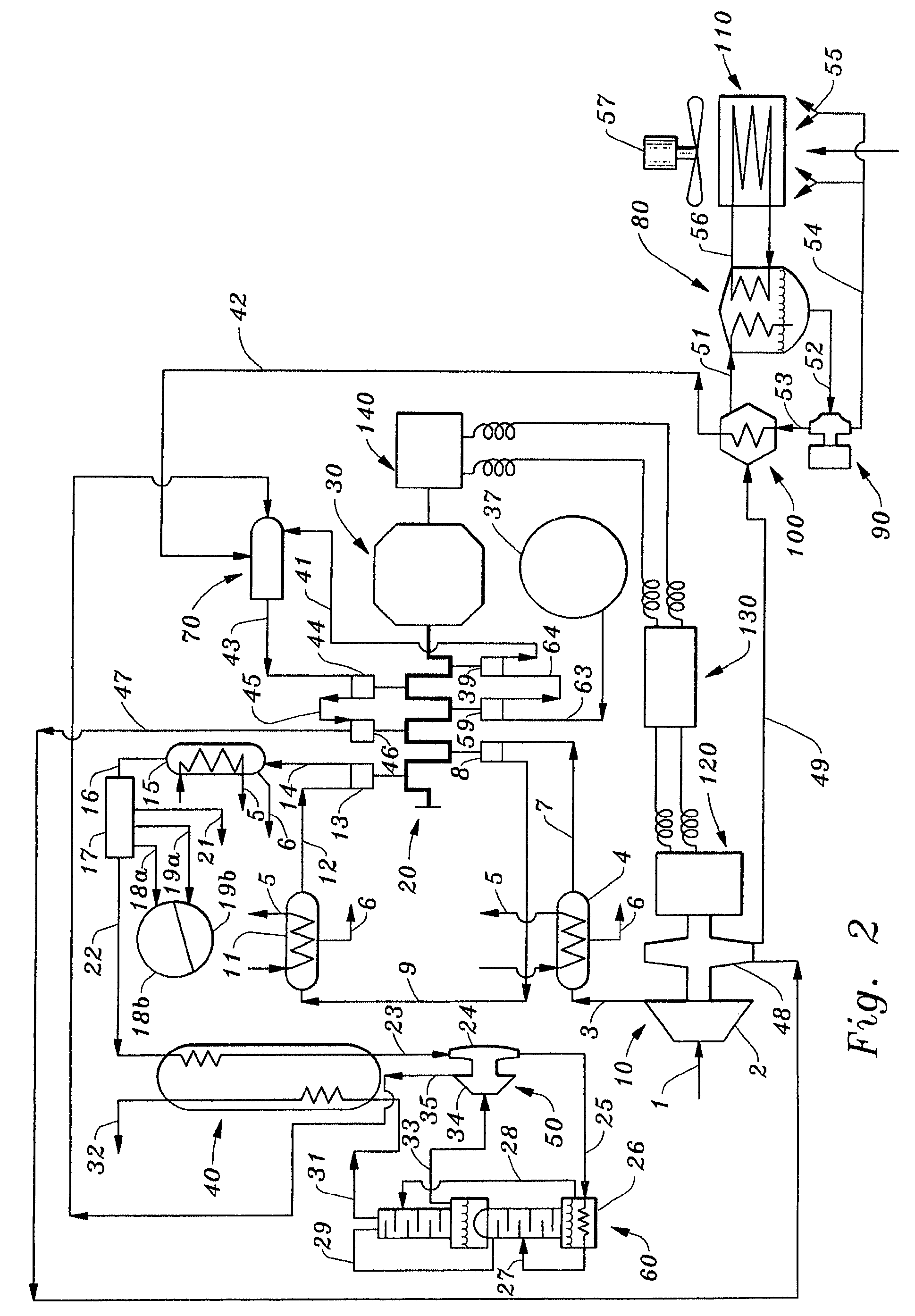

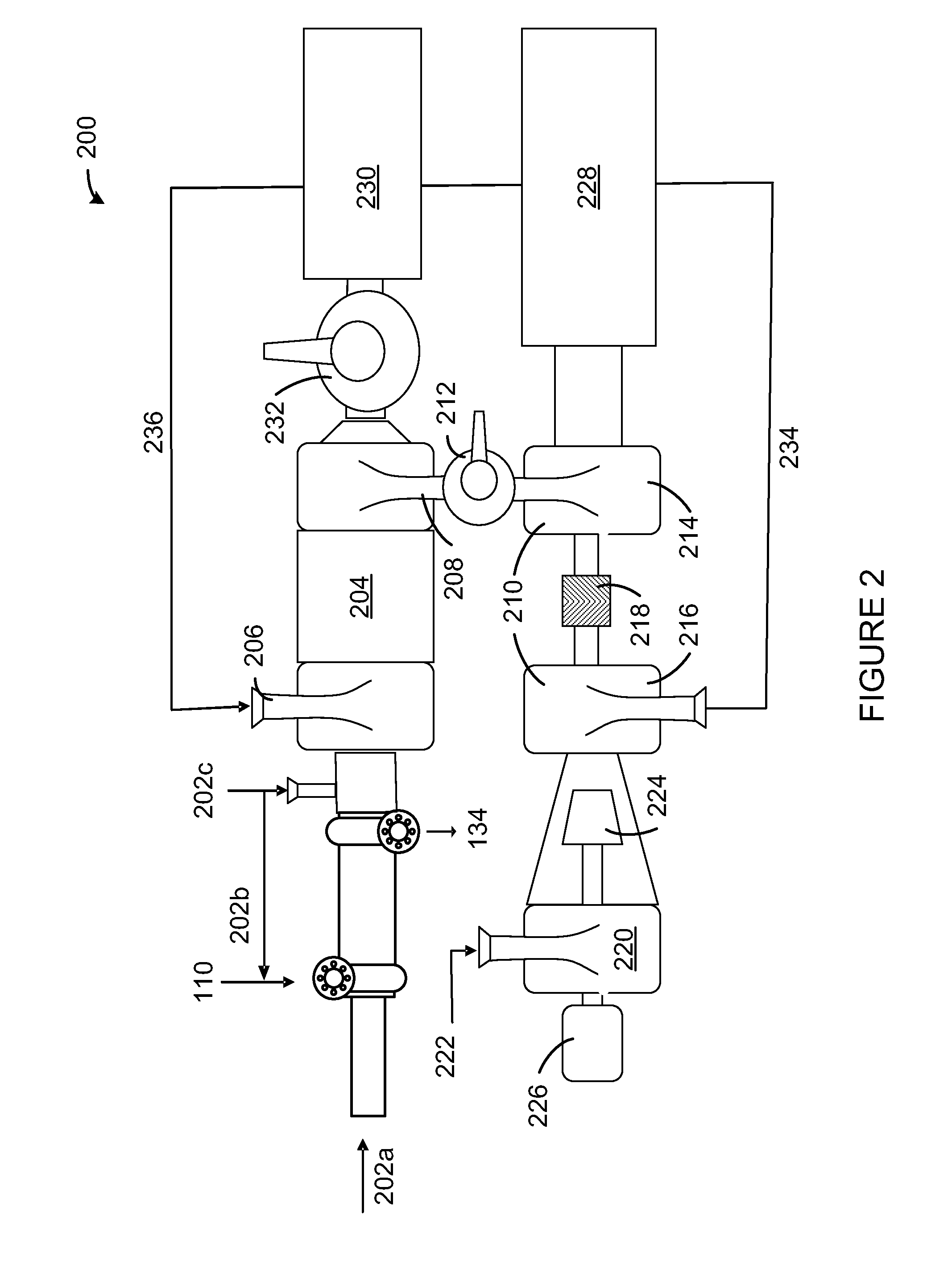

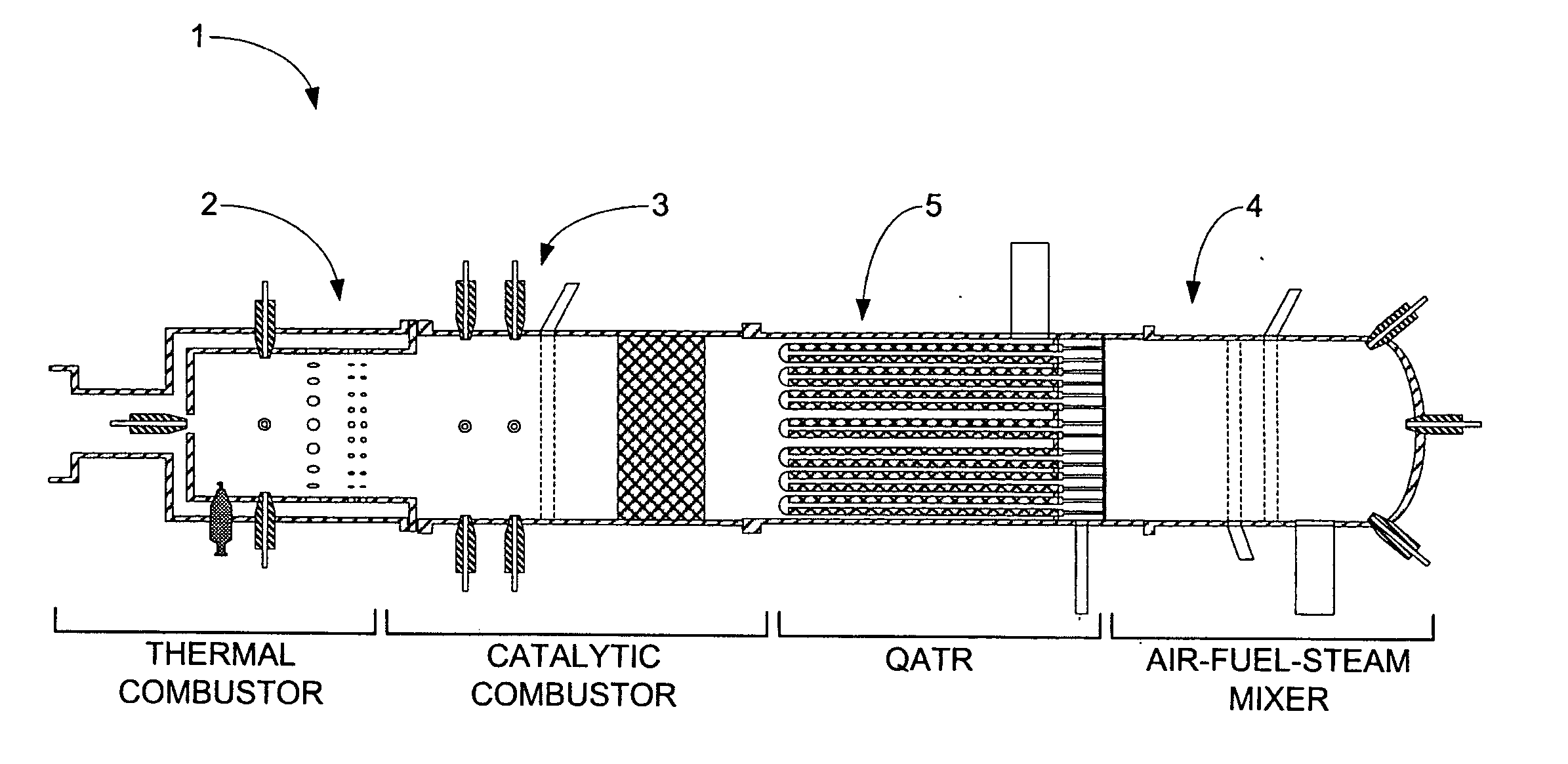

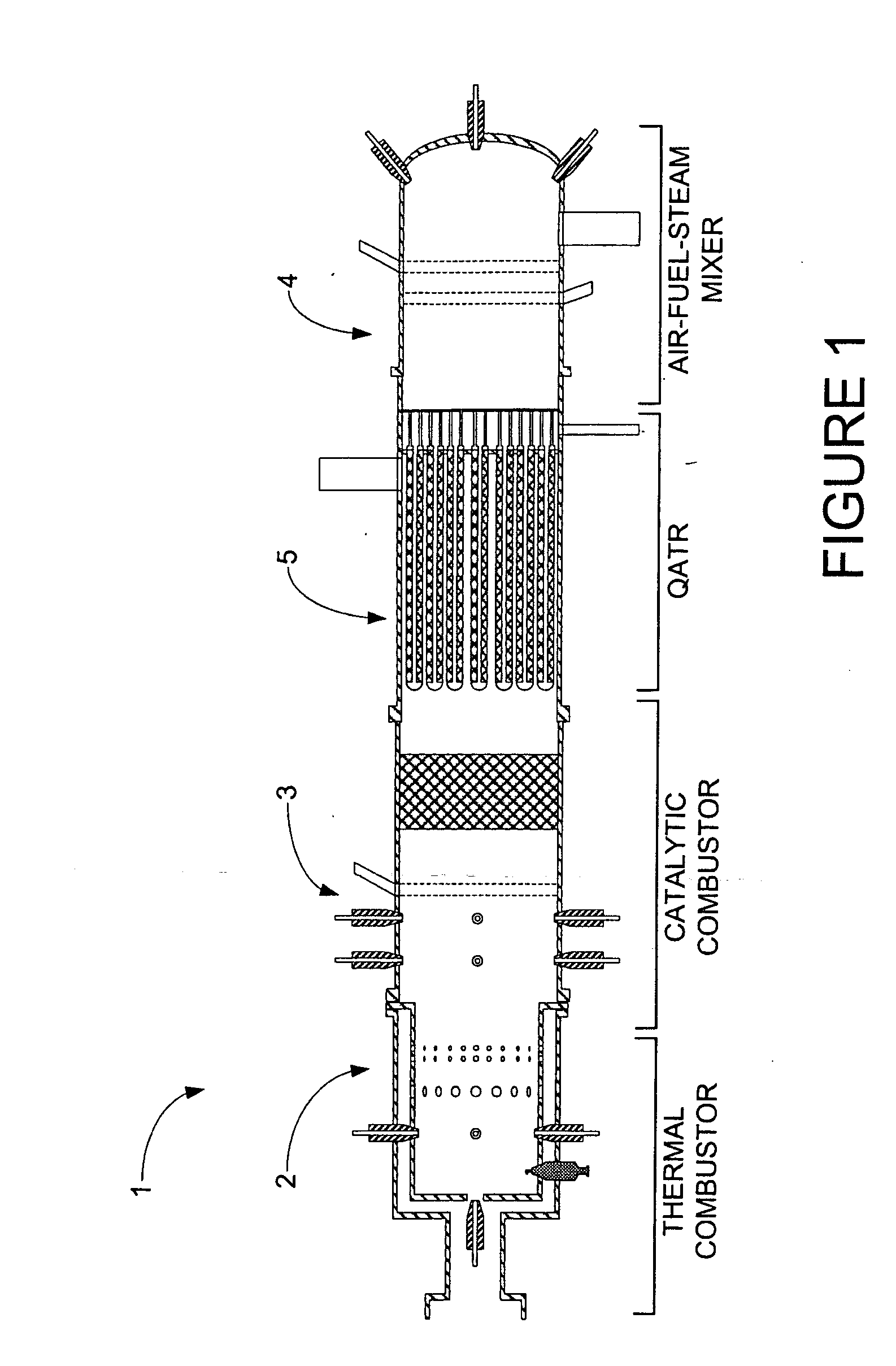

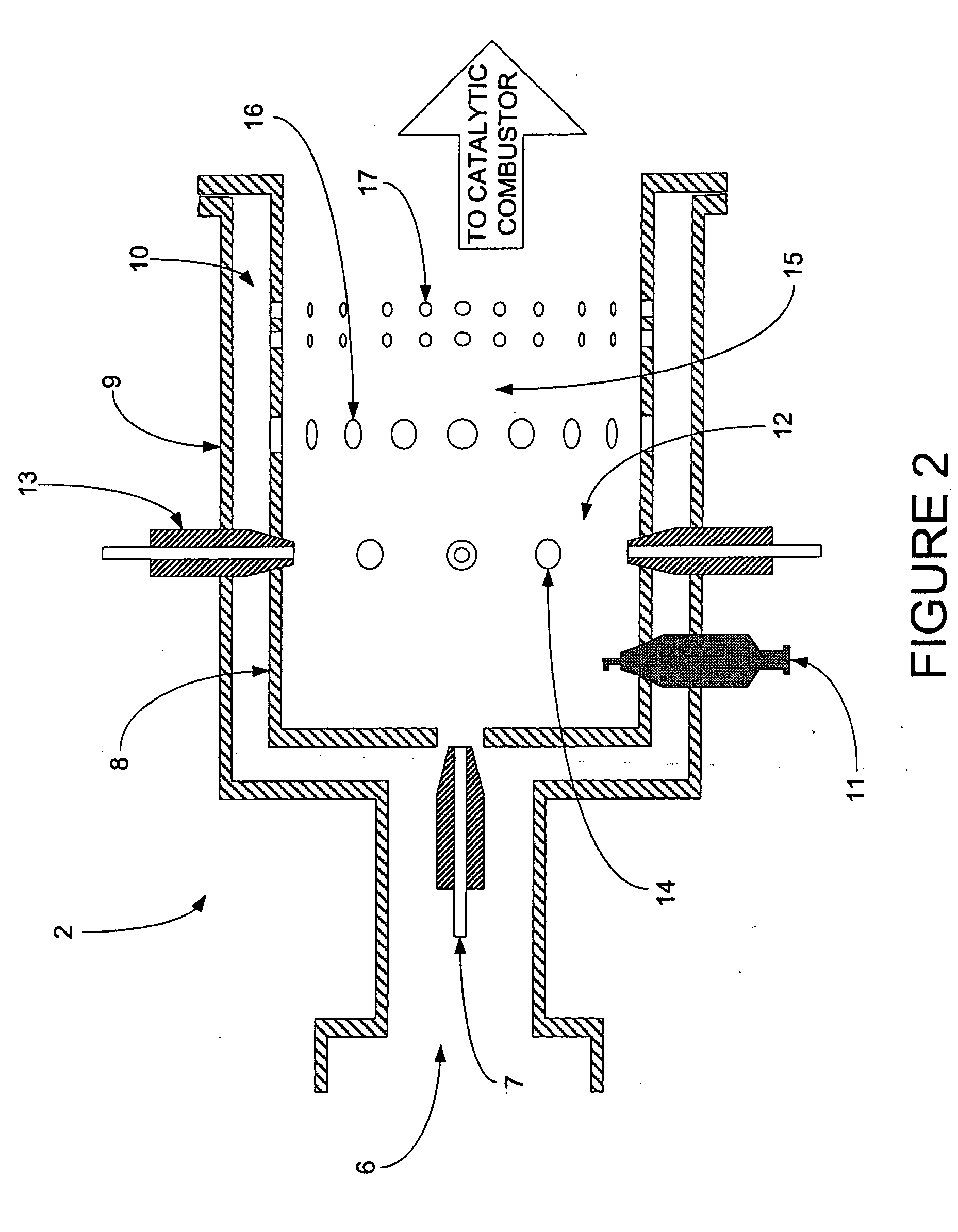

Integrated fuel processor subsystem with quasi-autothermal reforming

InactiveUS20050188615A1Provide flexibilitySufficient flexibilityReciprocating combination enginesExhaust apparatusSteam reformingFuel treatment

The present invention includes an integrated fuel processor subsystem incorporating a thermal combustor, a catalytic combustor, a quasi-autothermal reactor (QATR) and a air-fuel-steam (AFS) mixer to provide a range of operating modes exhibiting performance between that of a pure steam reformer and a pure autothermal reformer to increase the flexibility of the fuel processor to handle transient system demands such as cold starts, suppress emissions and carbon formation and improve efficiency.

Owner:FLARION TECH +1

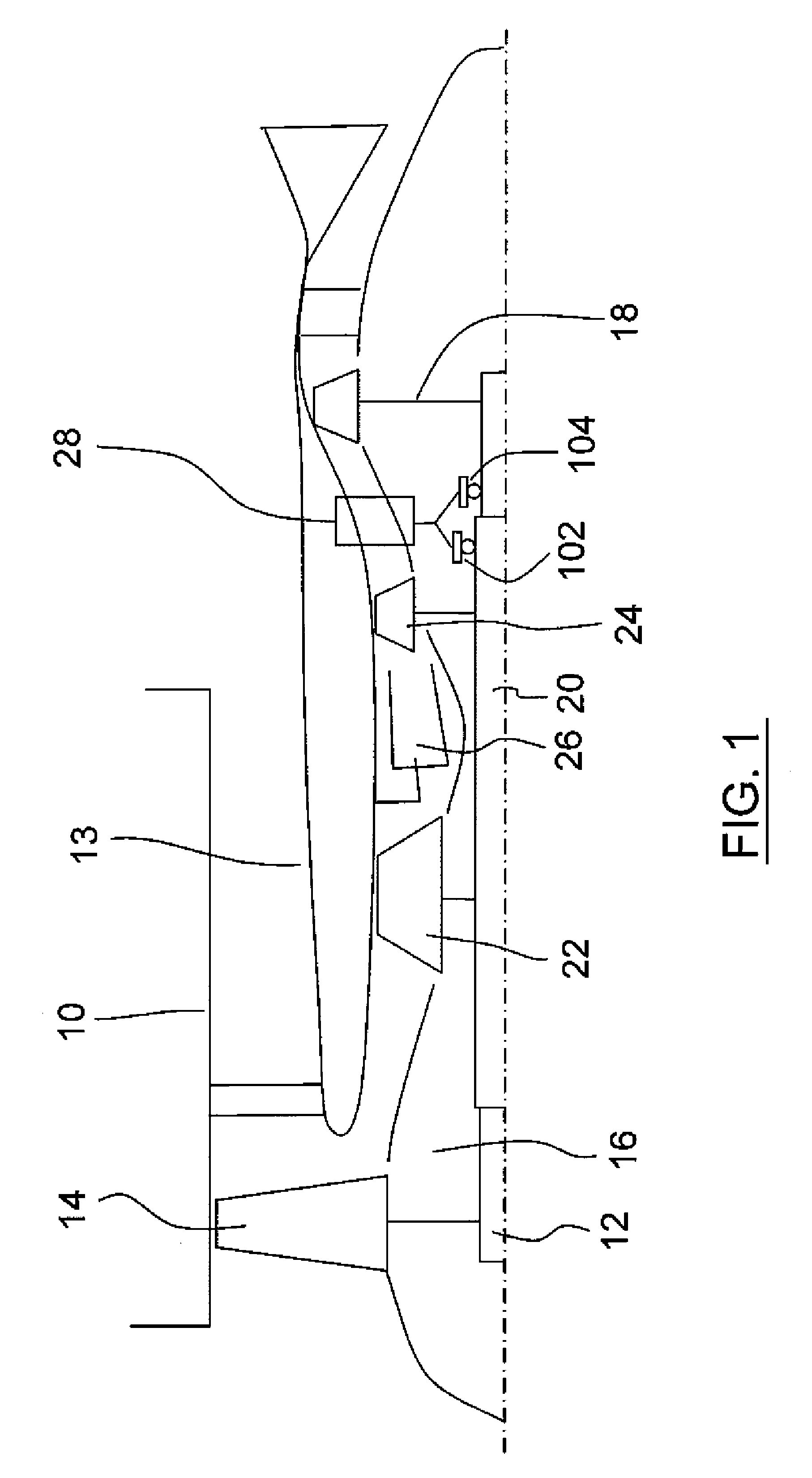

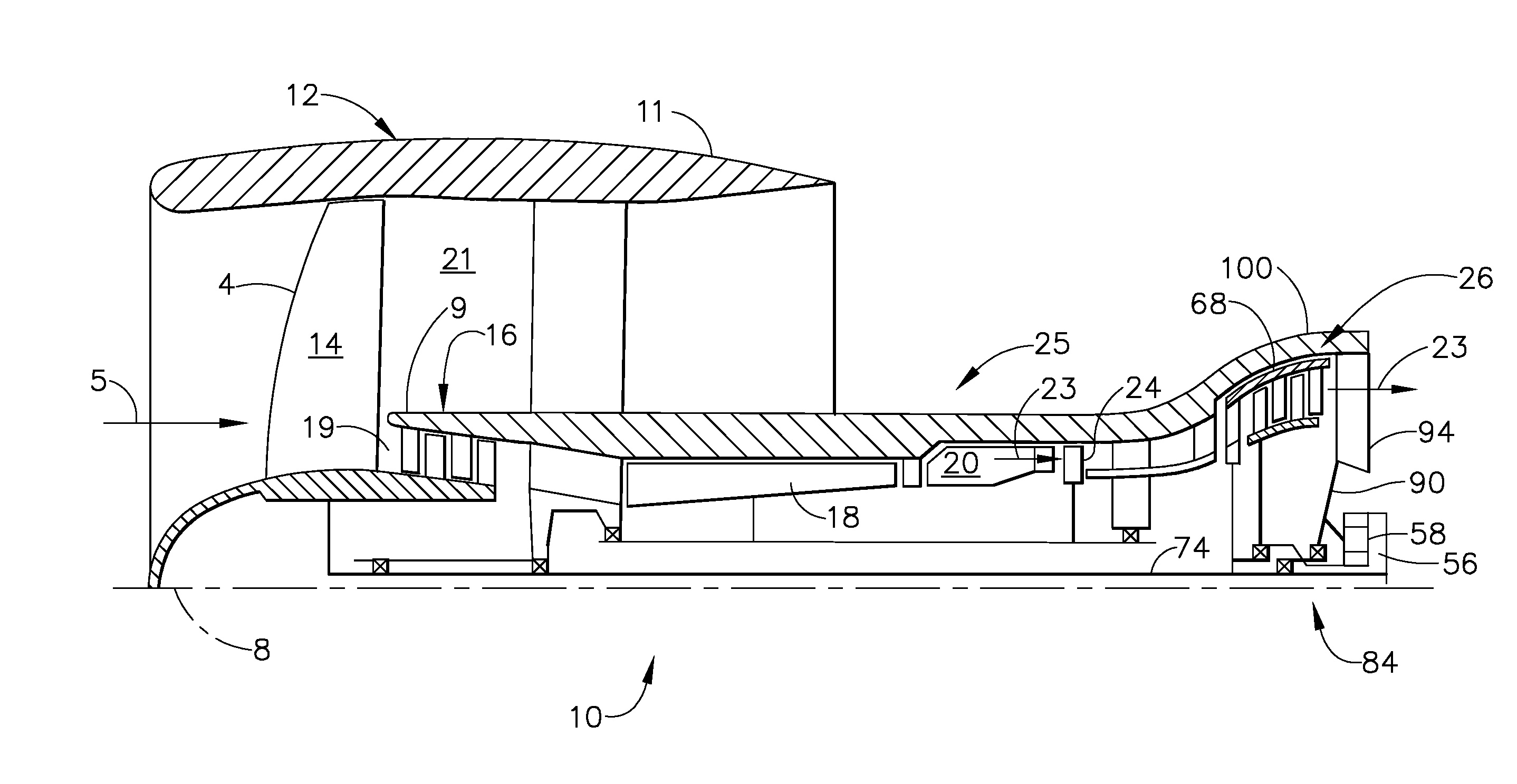

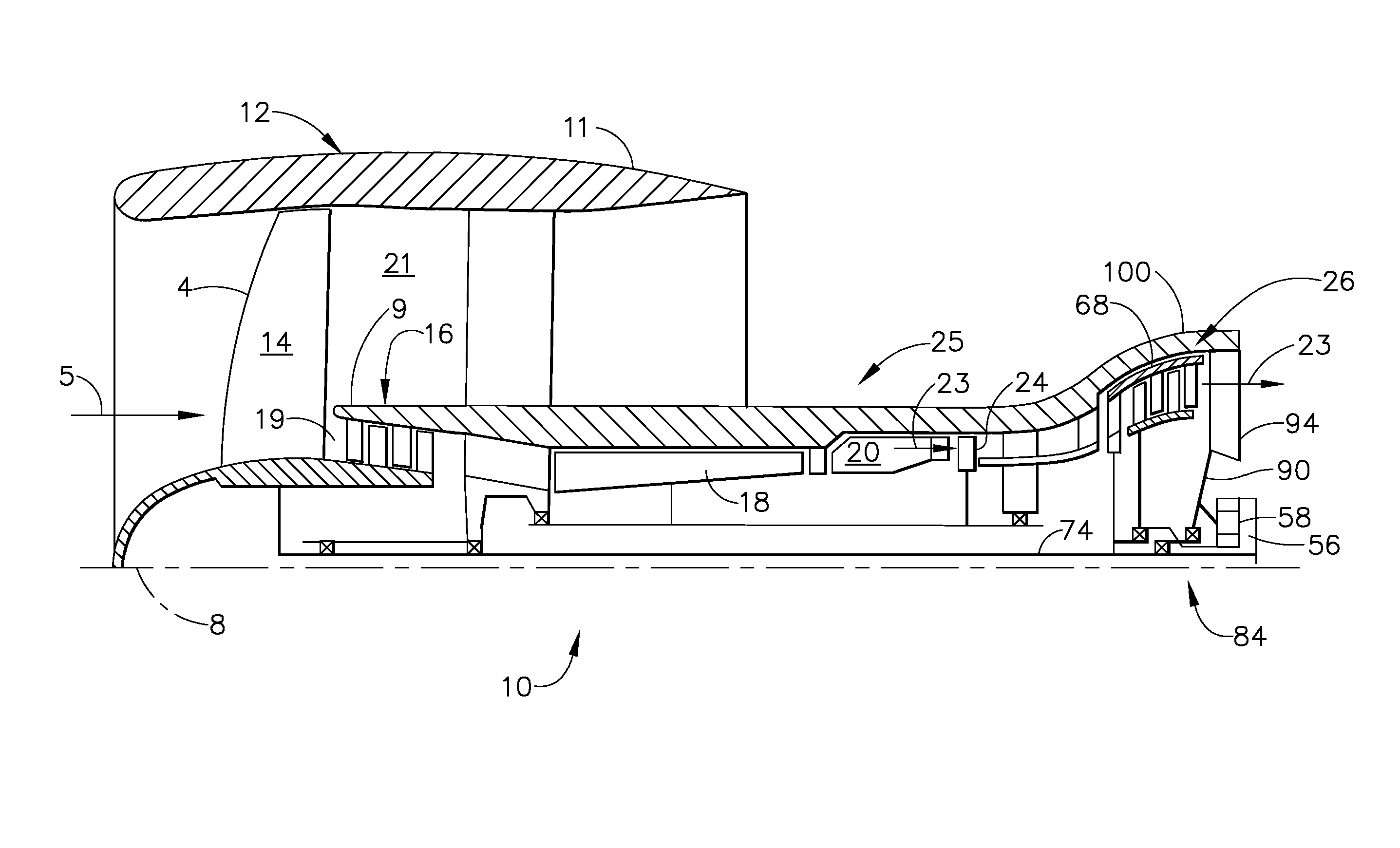

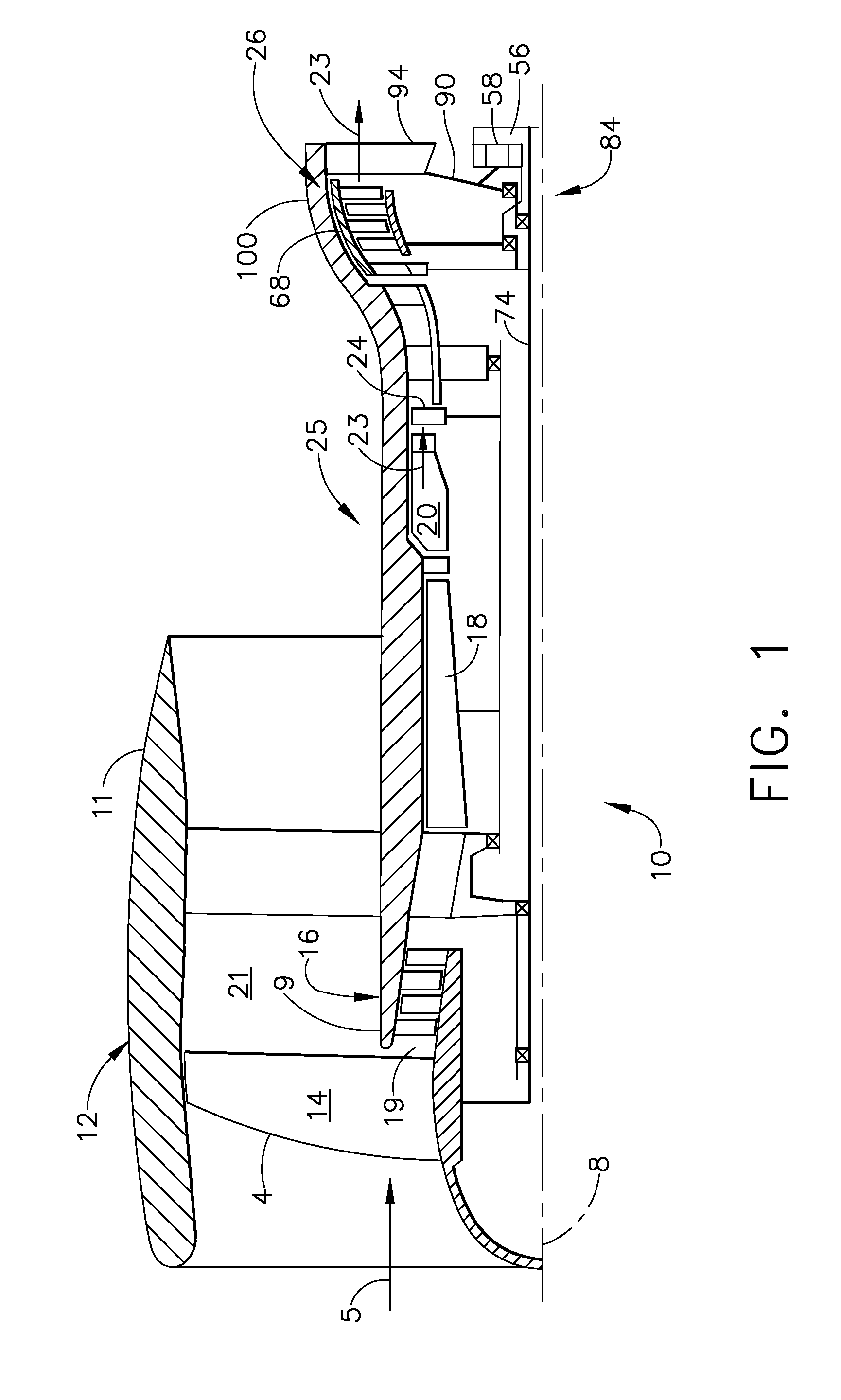

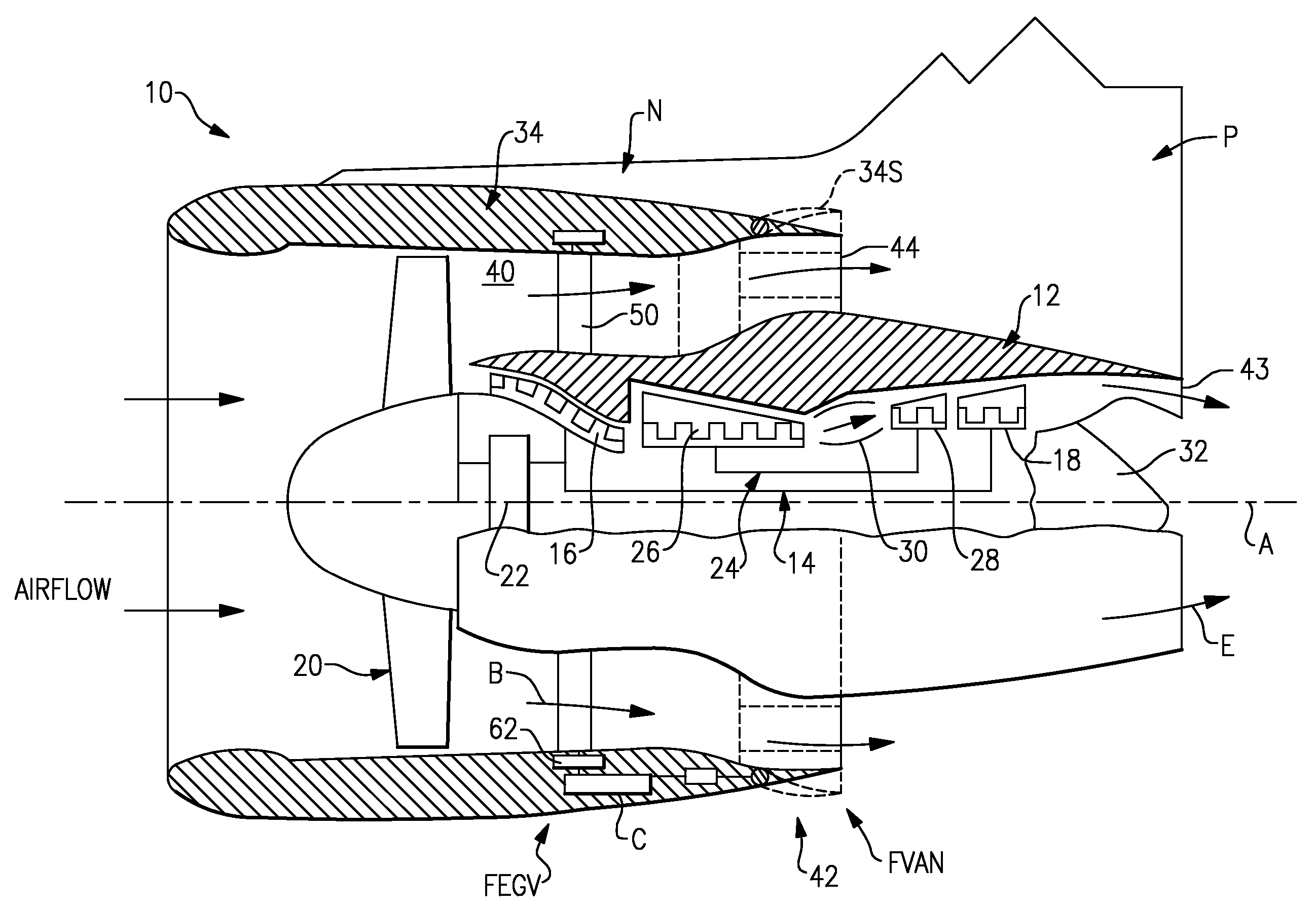

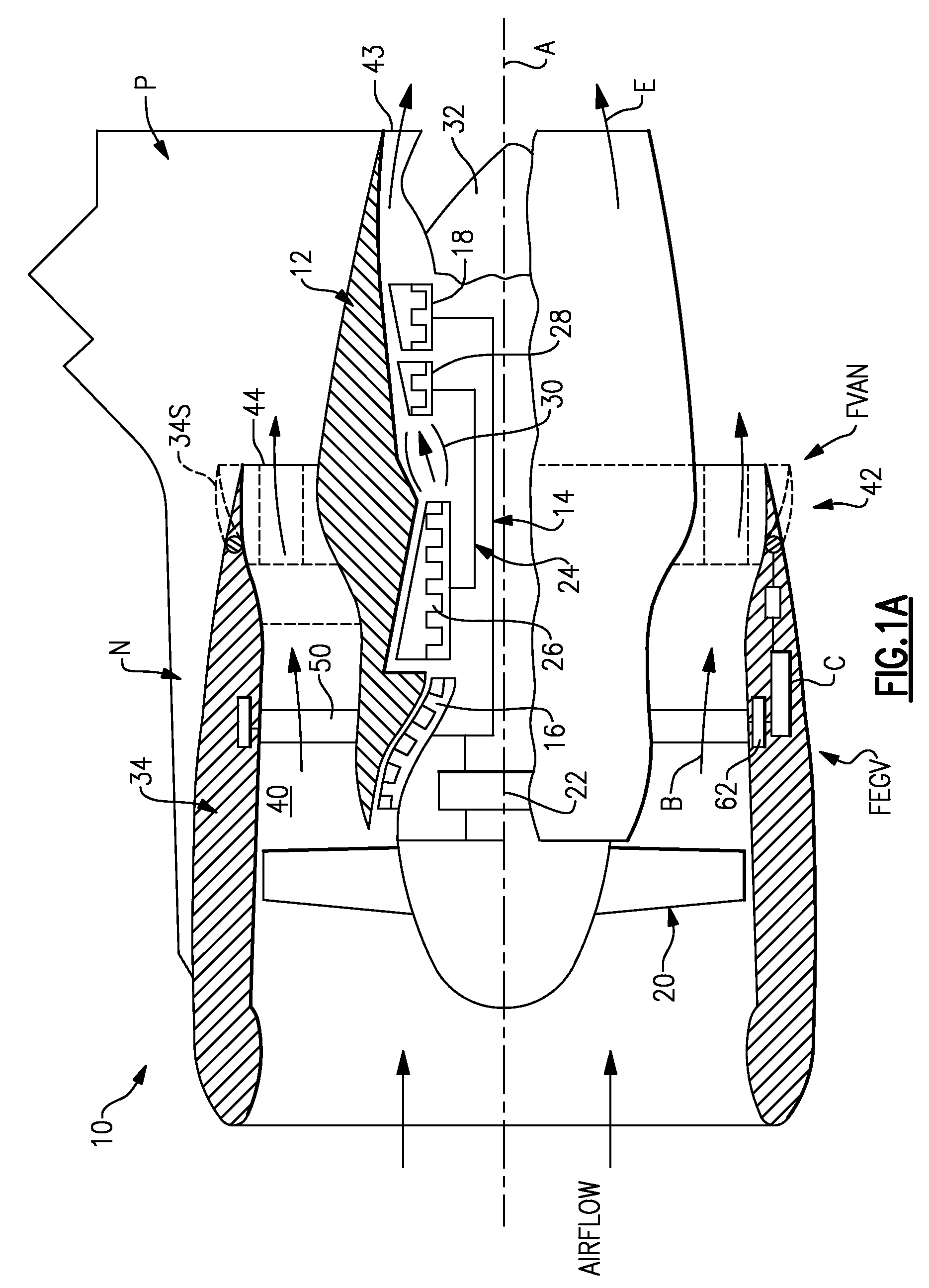

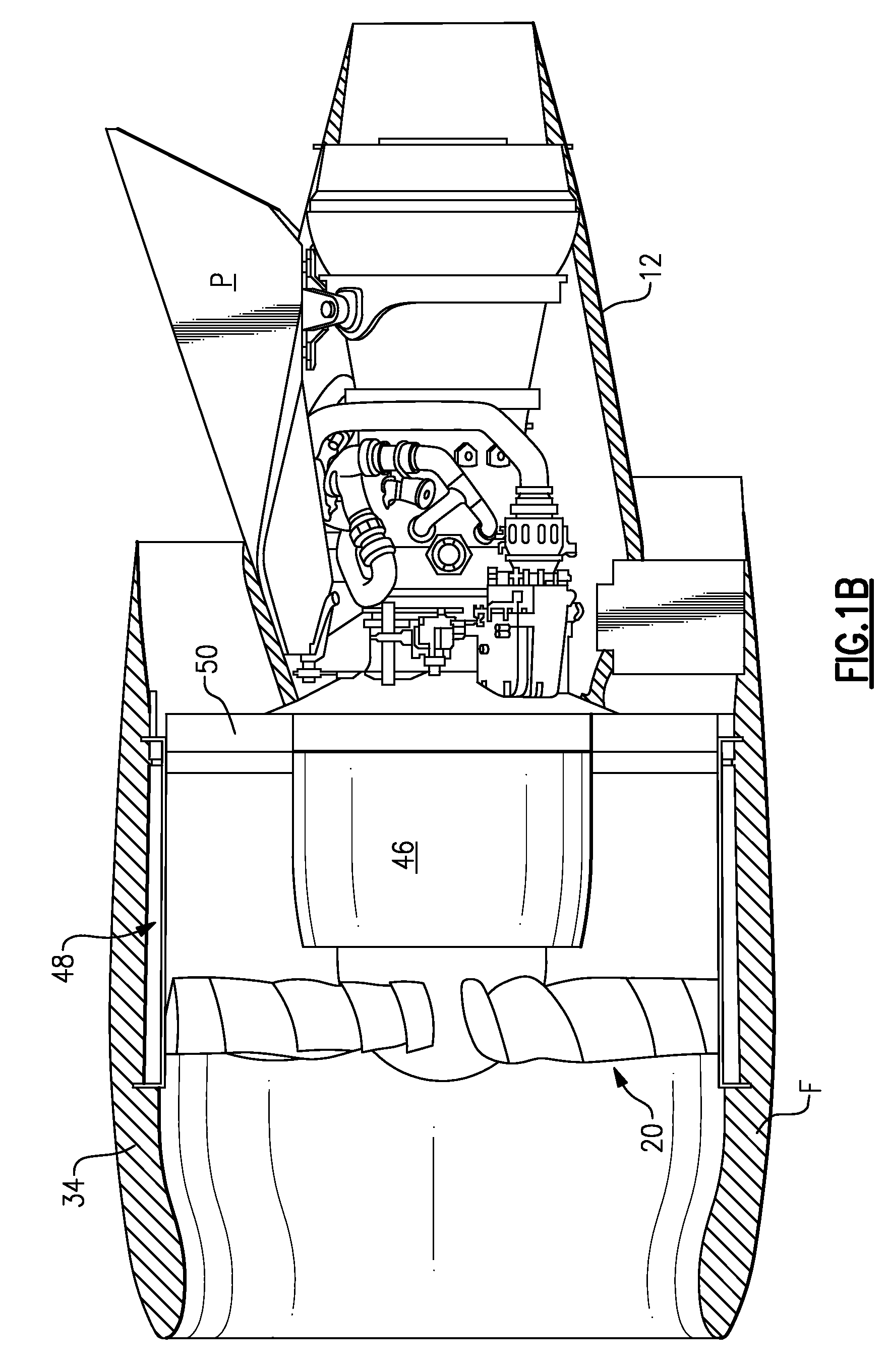

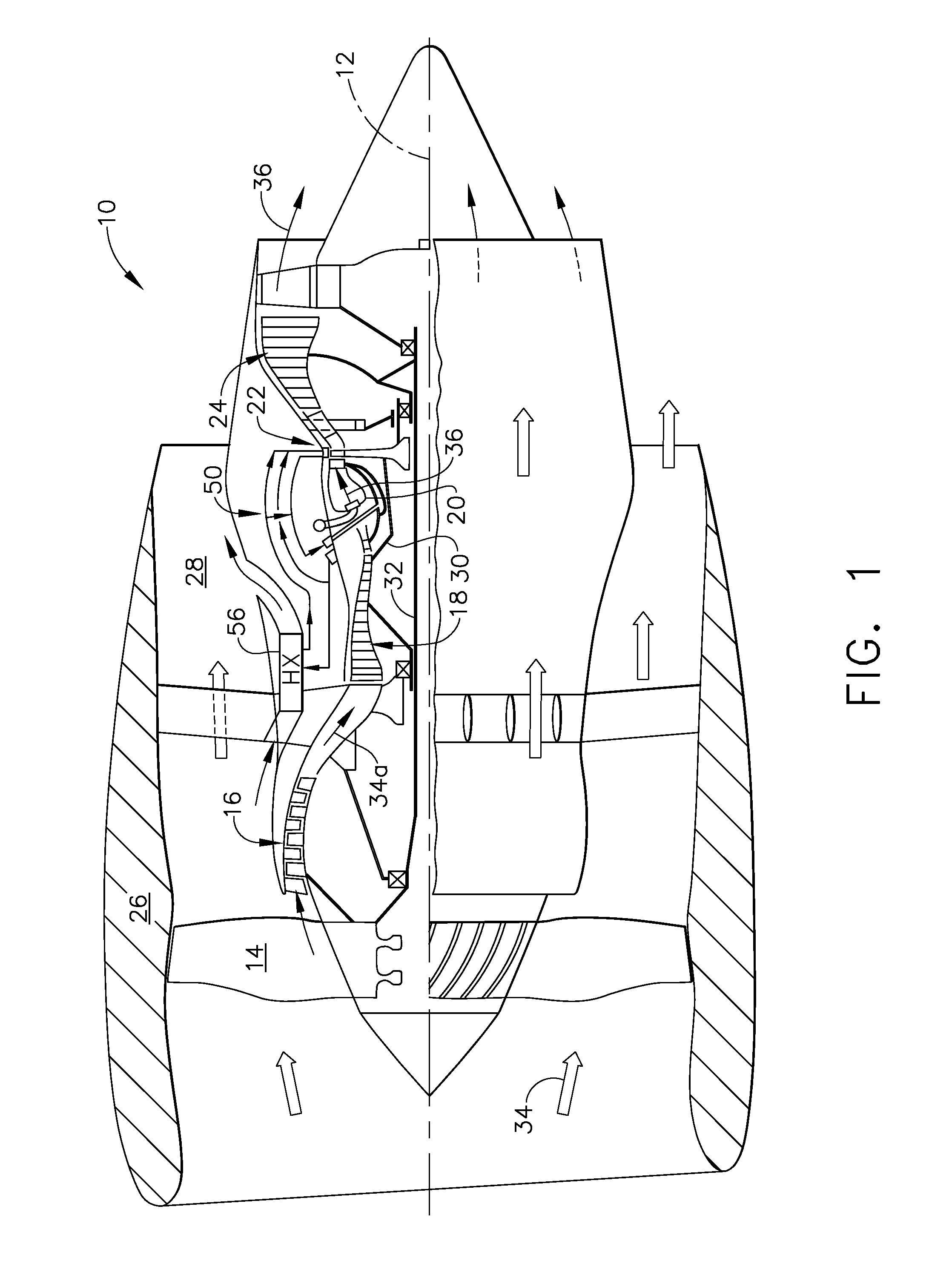

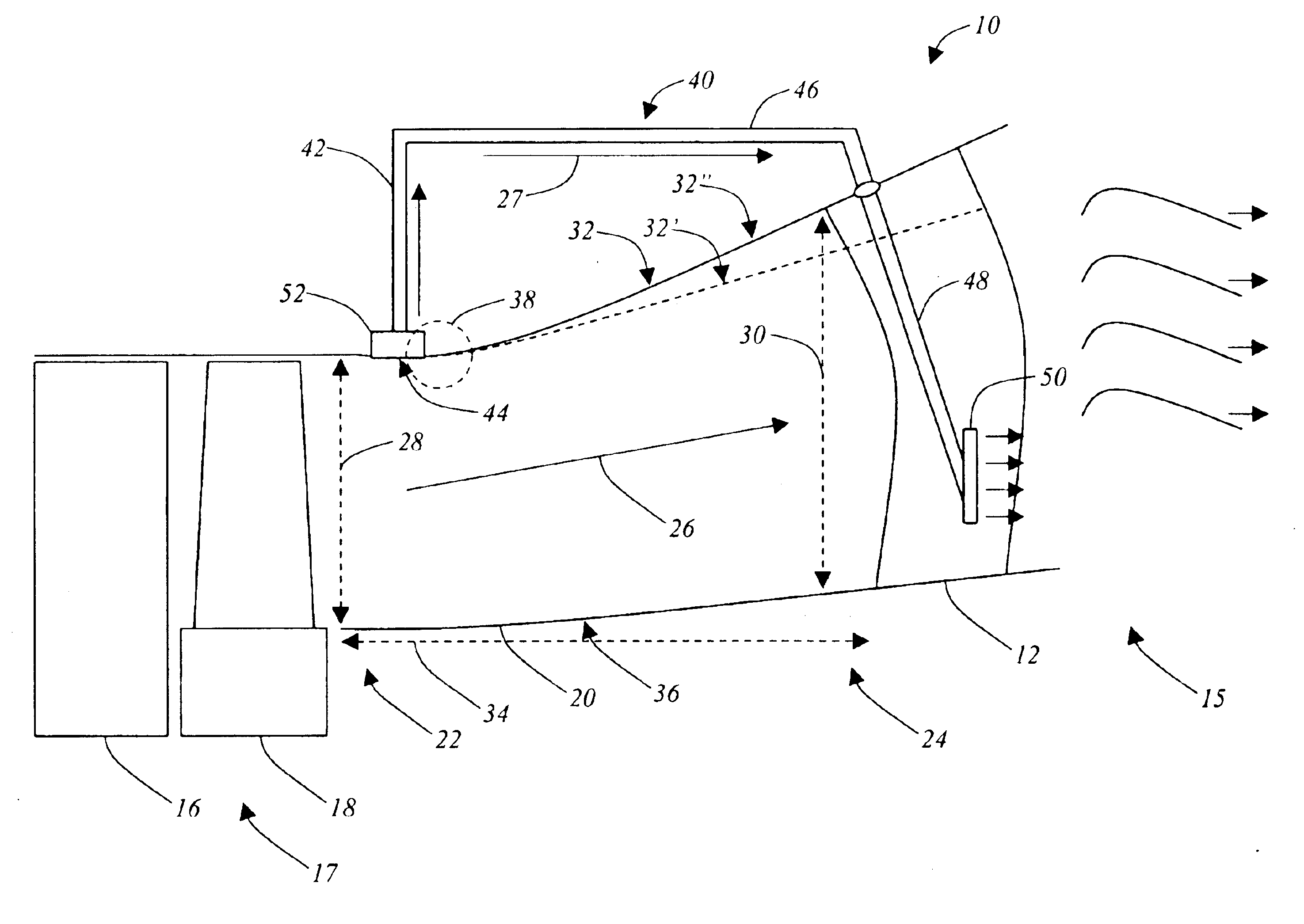

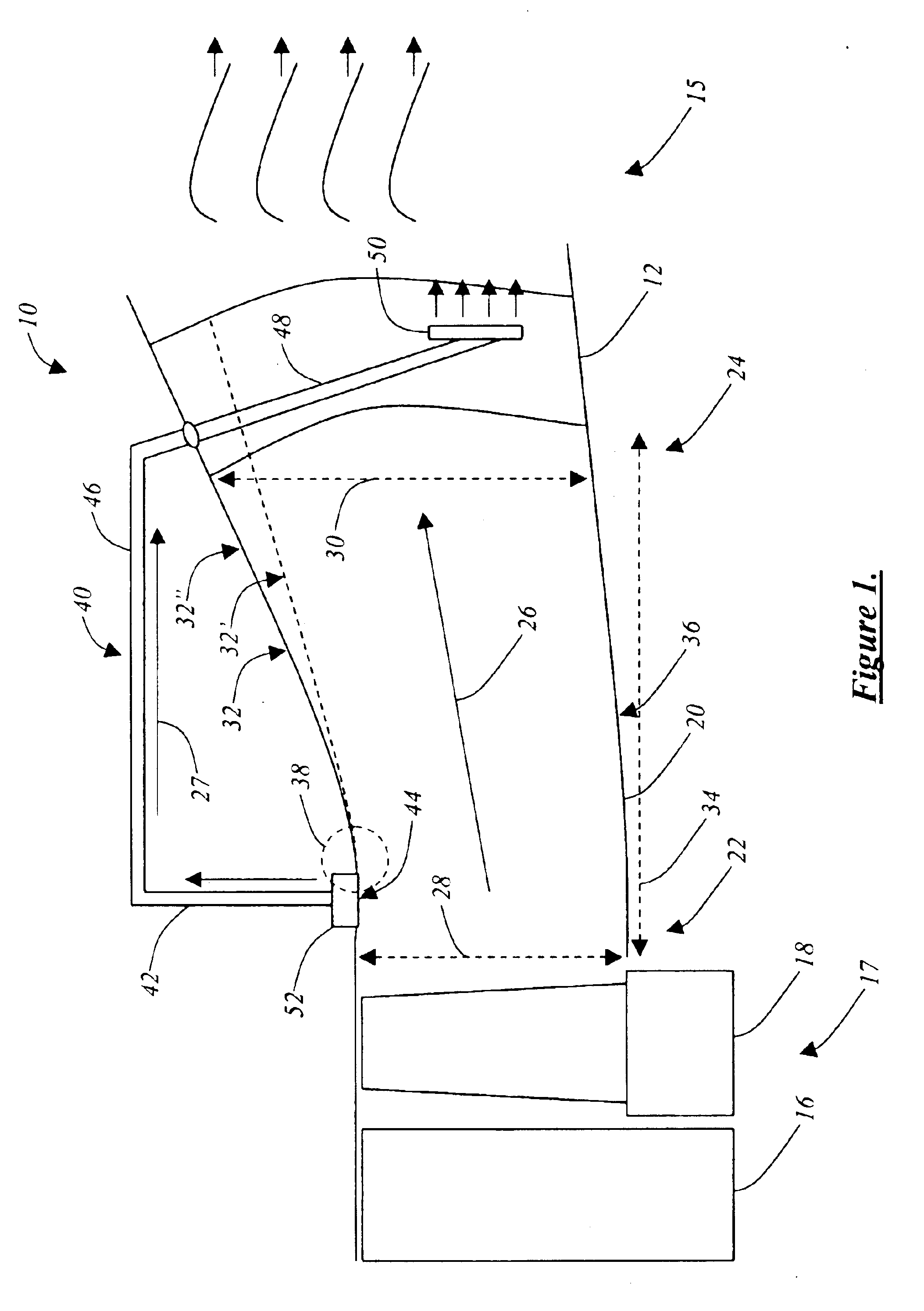

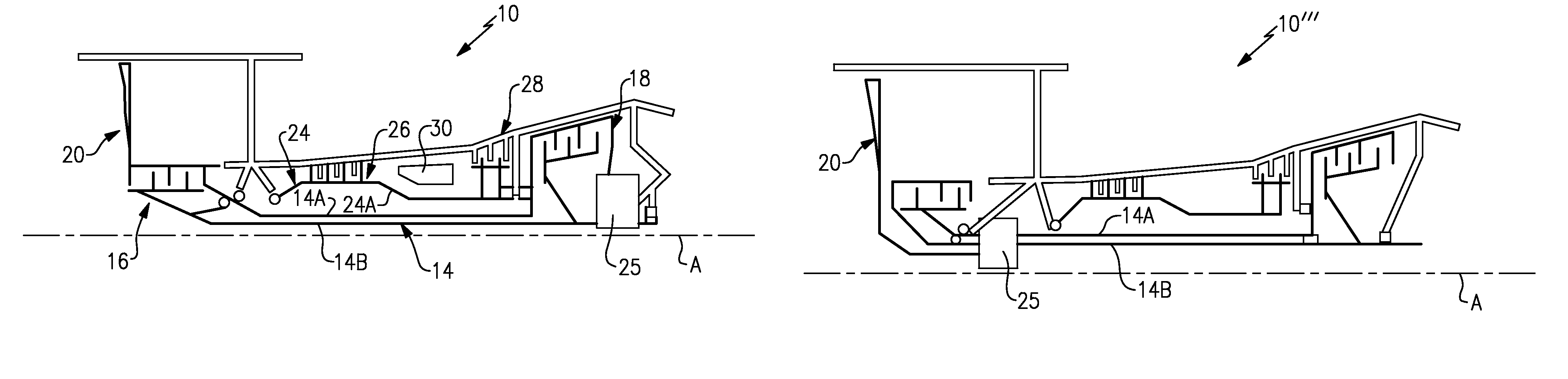

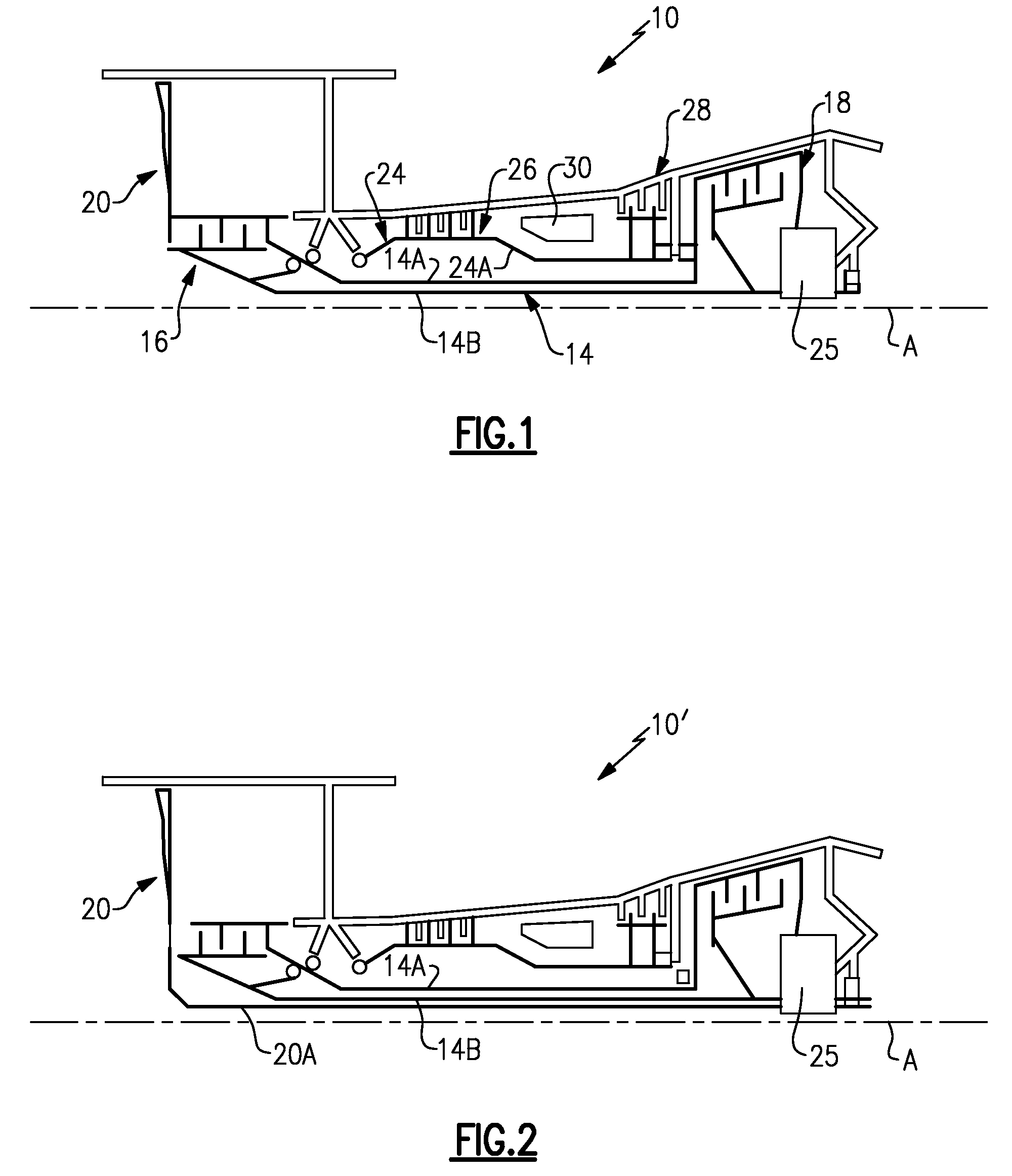

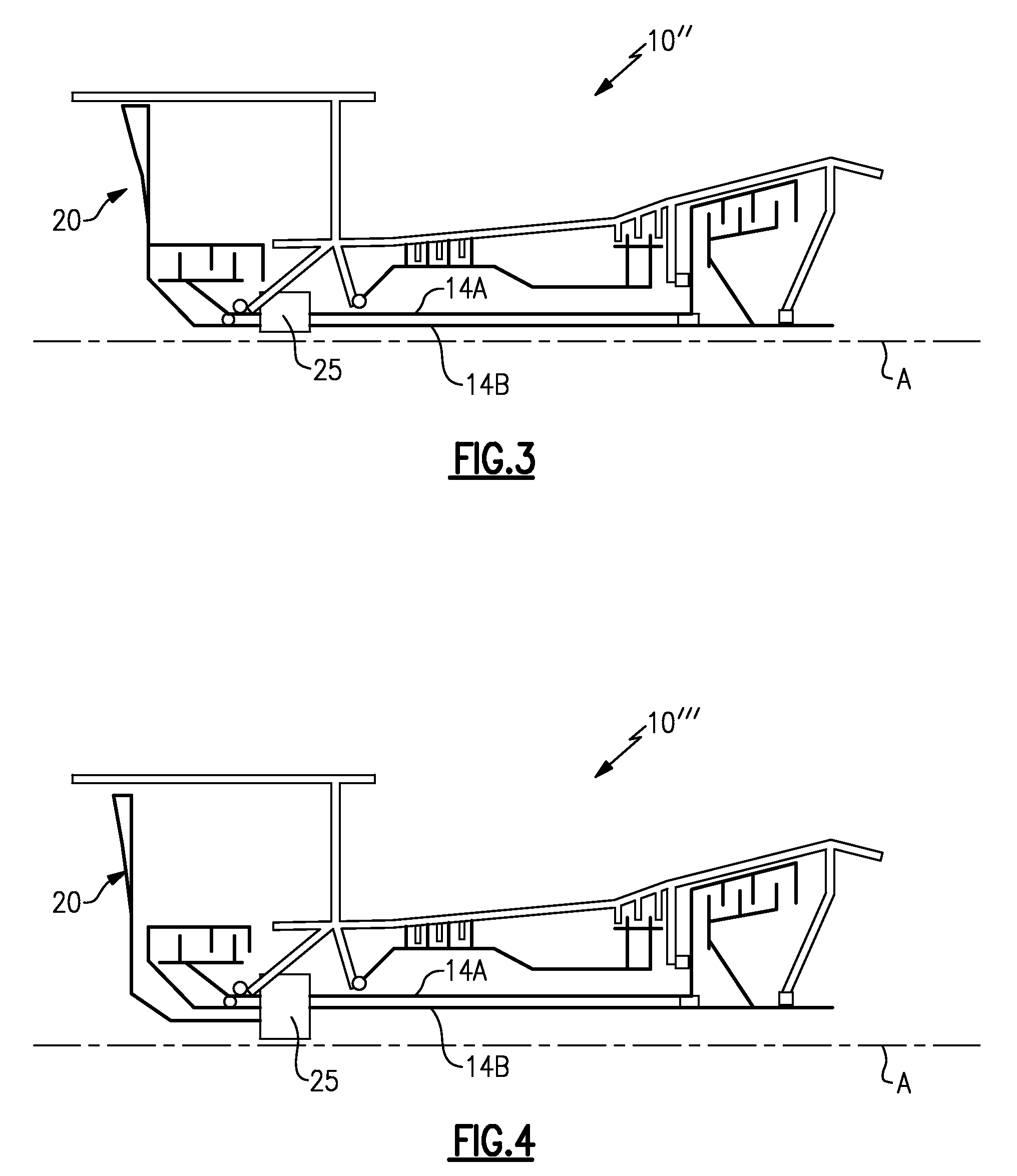

Gas turbine engine with variable geometry fan exit guide vane system

ActiveUS20090097967A1Reduce bypass flowMinimize thrust reverser requirementWind motor controlPump componentsTurbofanVariable geometry

A turbofan engine includes a variable geometry fan exit guide vane (FEGV) system having a multiple of circumferentially spaced radially extending fan exit guide vanes. Rotation of the fan exit guide vanes between a nominal position and a rotated position selectively changes a fan bypass flow path to permit efficient operation at various flight conditions.

Owner:RAYTHEON TECH CORP

Collapsible fan and system and method incorporating same

A collapsible fan. The collapsible fan may be disposed in parallel or series with one or more other fans. If the collapsible fan becomes inactive or non-operable, such as by malfunction or failure, then its fan blades collapse to a less restrictive flow configuration allowing the remaining fans to operate more effectively. The fan blades may have any suitable expansion and contraction mechanism, such as a hinge, a pivot joint, or a multi-section inner or outer support structure having different sections of the fan blades.

Owner:HTC CORP

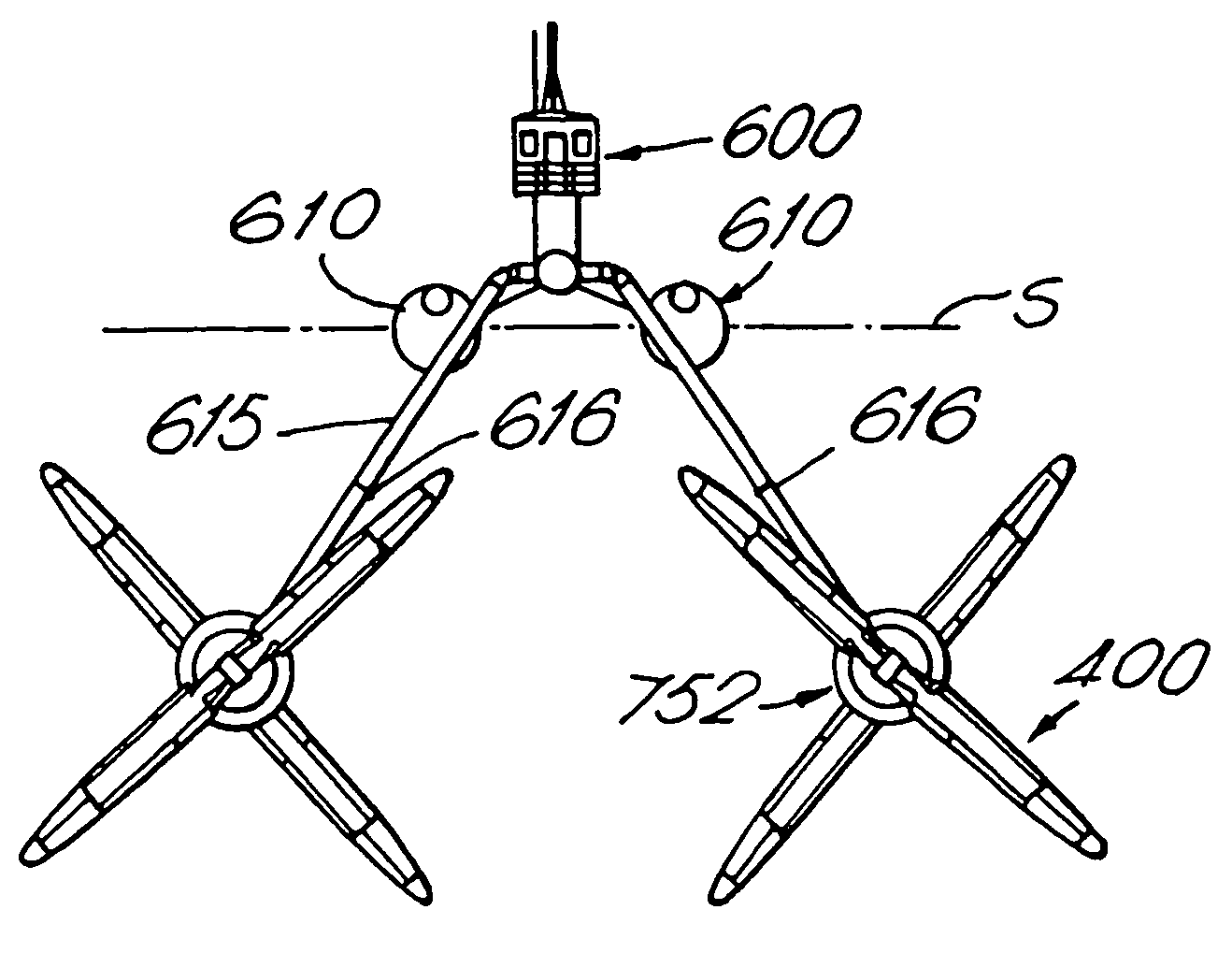

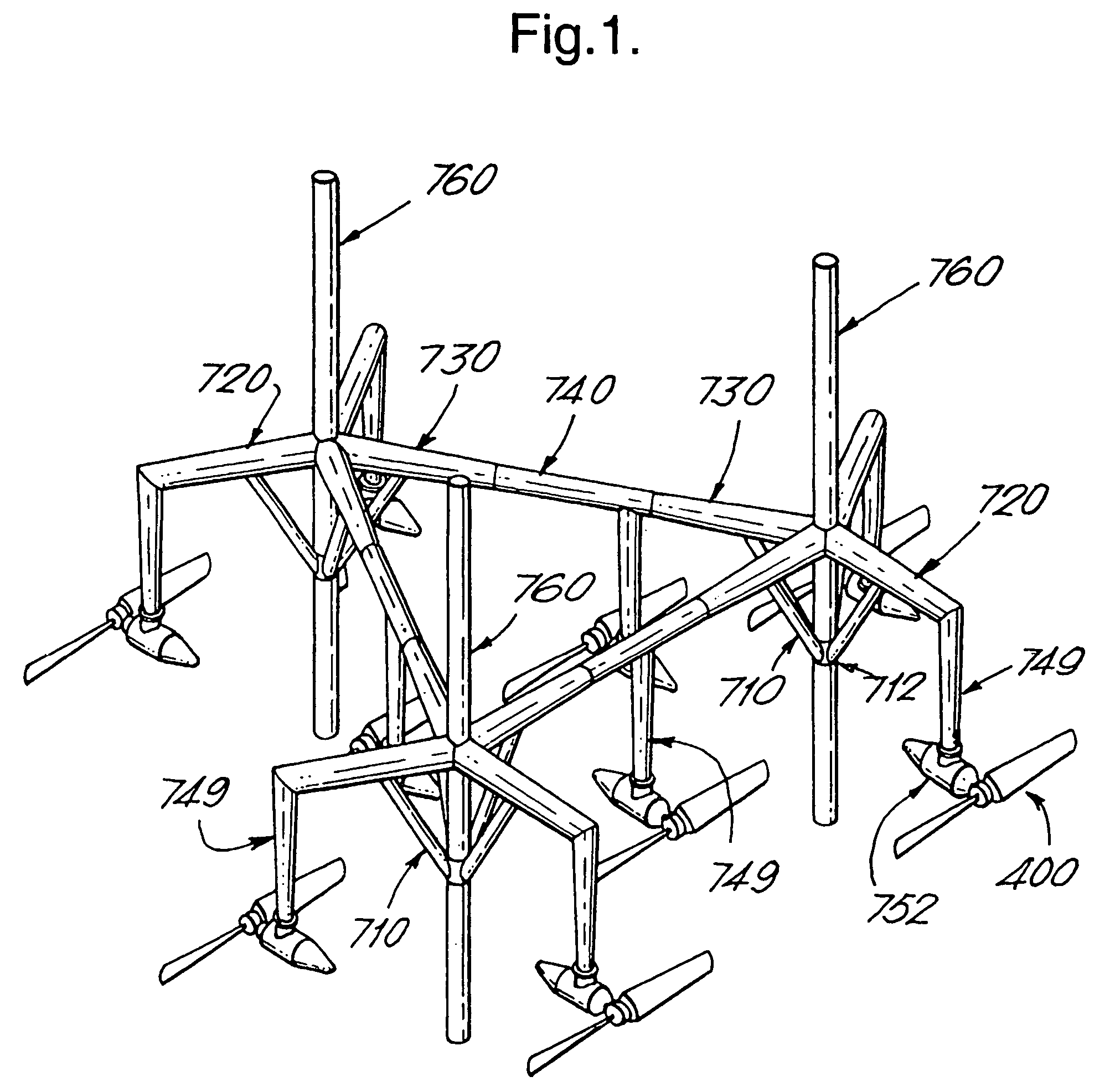

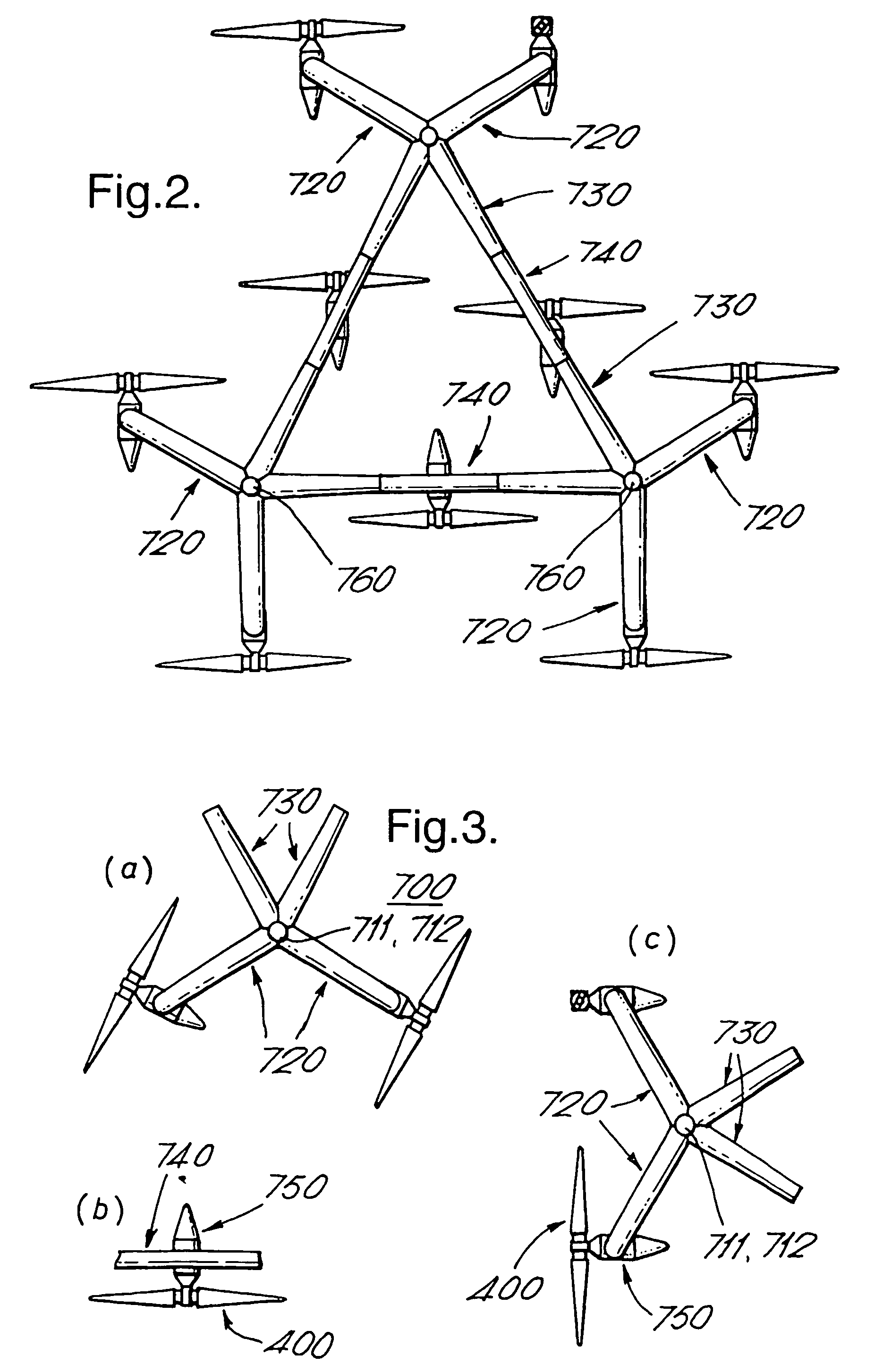

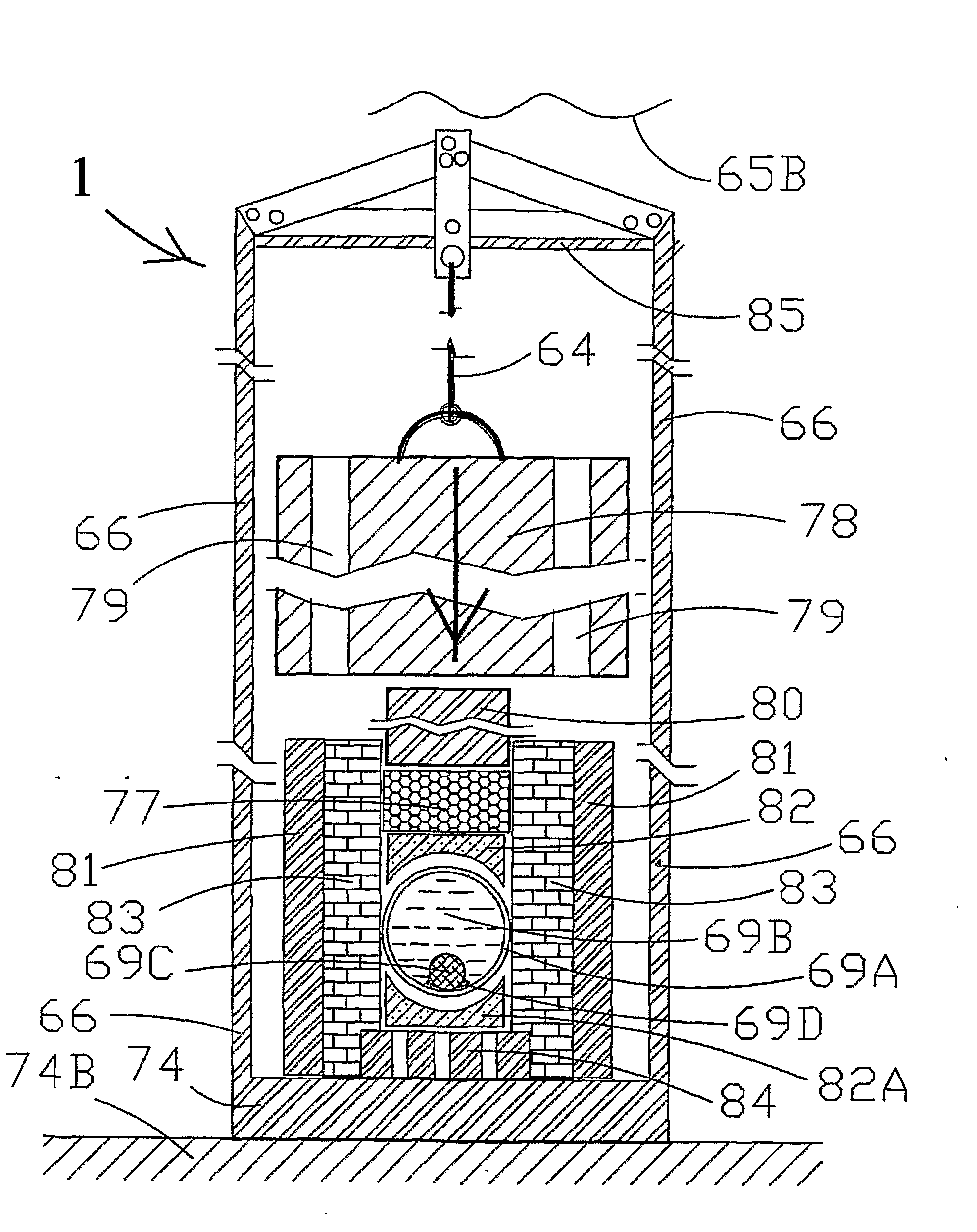

Plant, generator and propeller element for generating energy from watercurrents

A plant, generator and rotating member for the production of power from currents in a body of water, comprising a fixedly mounted of floating structure, and a plurality of replaceable generator units (750) supported by the structure and which are driven by the water currents. The structure comprises arms (615, 720, 730). The rotating member (400) comprises a plurality of member sections (410) rotatably mounted on a shaft (405) between an end piece (407) and a tip (406). The generator comprises a contra-rotating rotor (550) and stator (800) connected to respective shafts (500, 820) and bearings, where the stator frame (800) is axially supported (810) on the first shaft (500) and the first shaft (500) at one end thereof is axially supported (810) on the stator frame. The generator according to the invention can be used for the production of electric power, and as an electromotor for the production of mechanical rotational energy.

Owner:HYDRA TIDAL ENERGY TECH

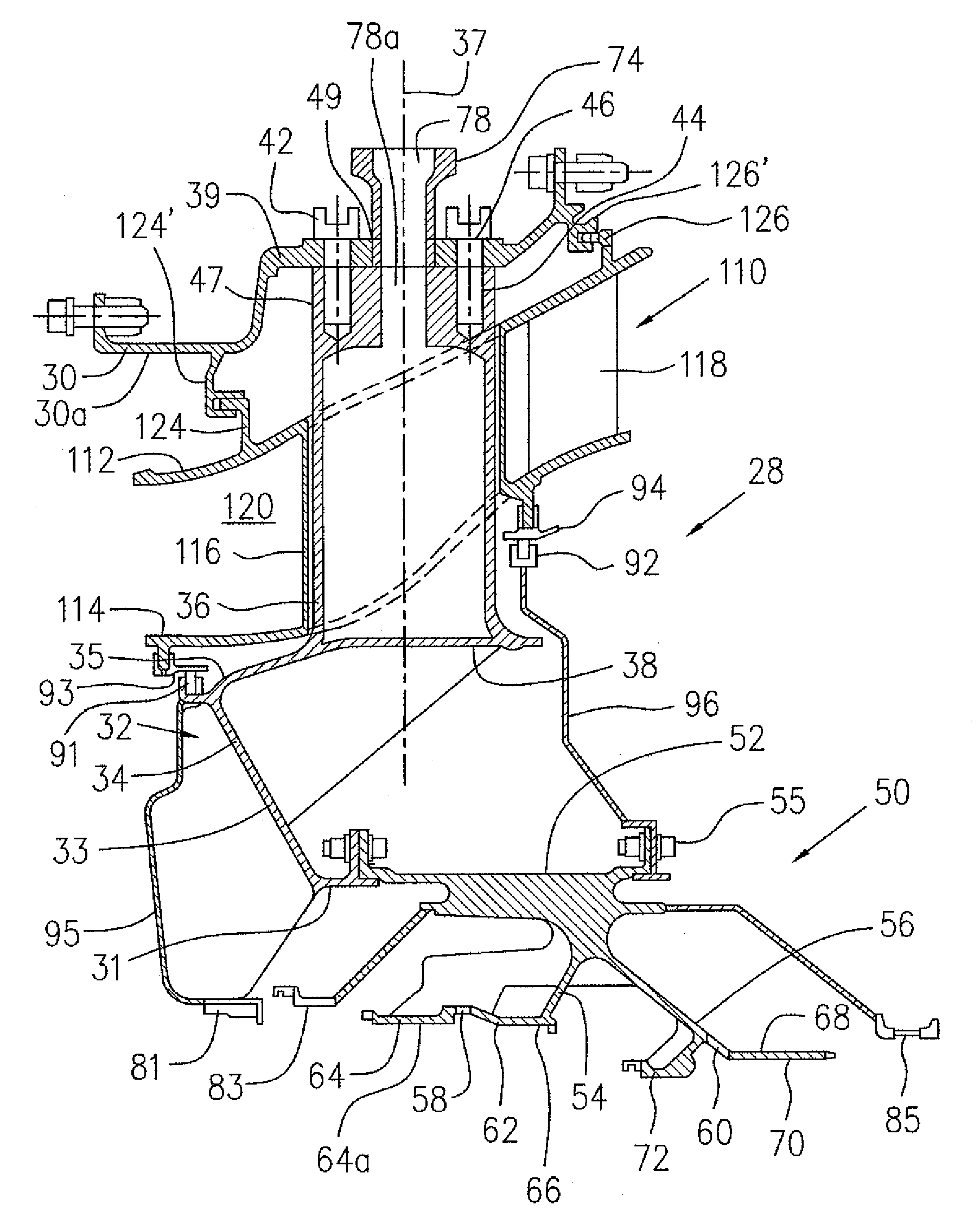

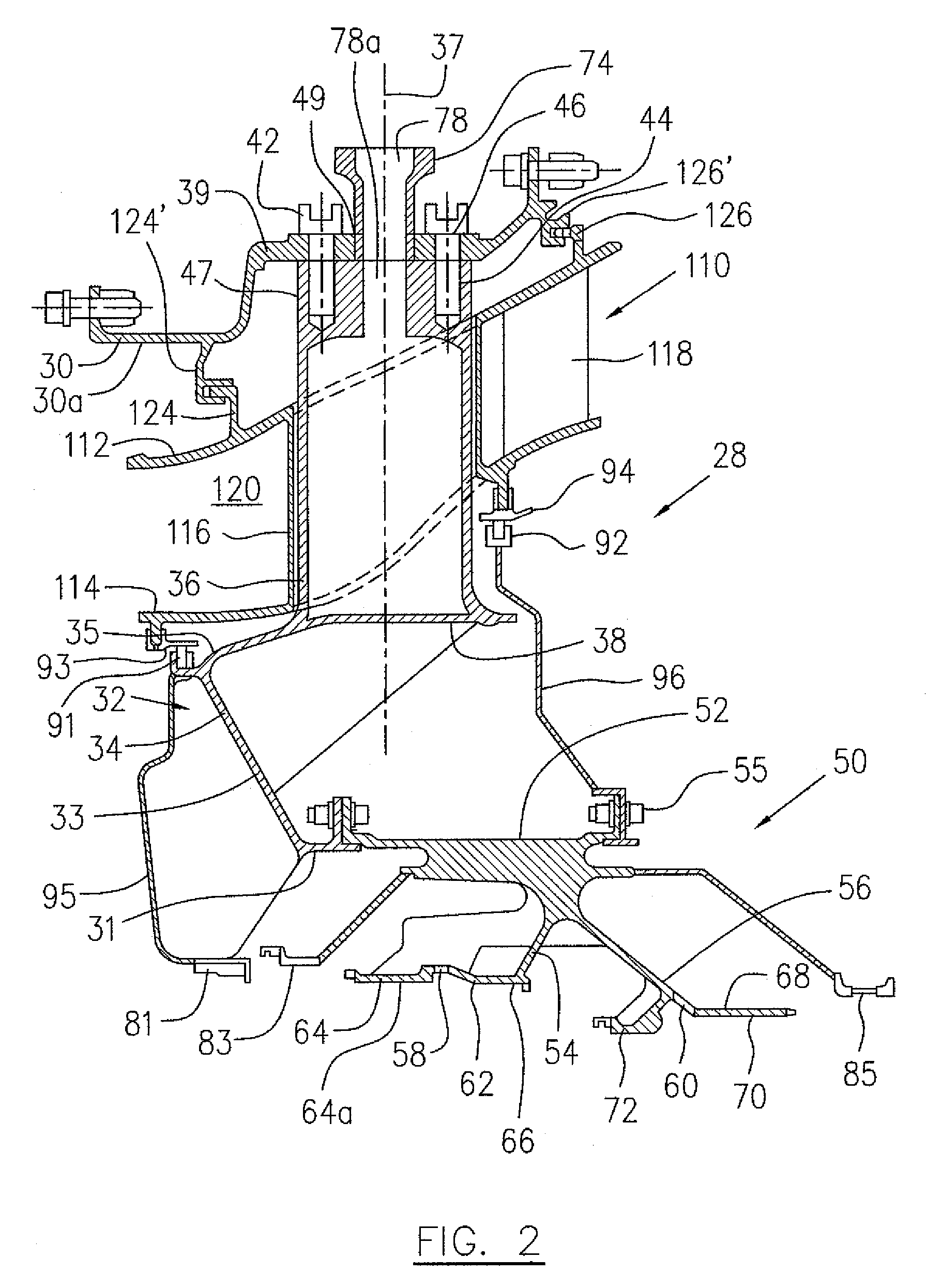

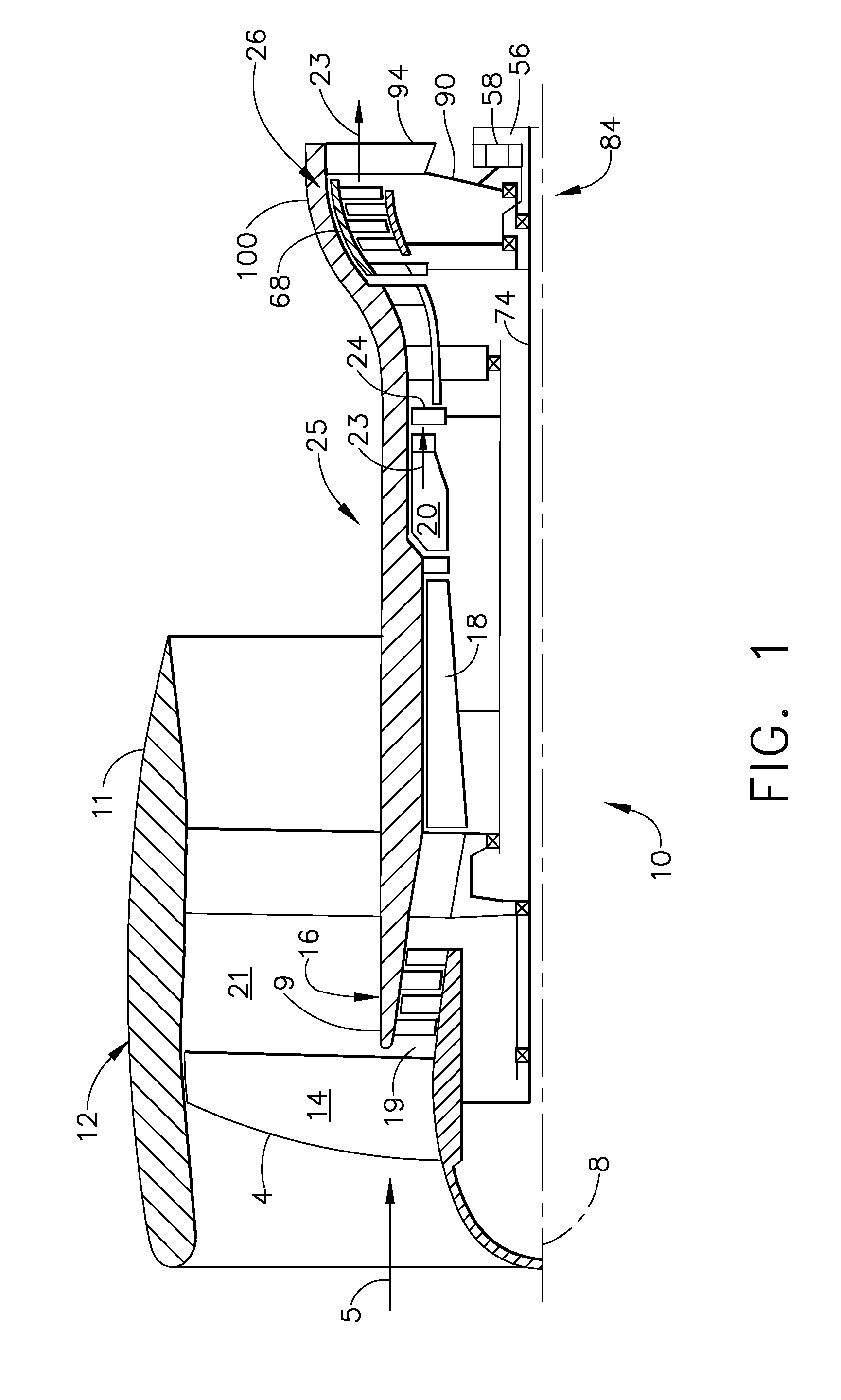

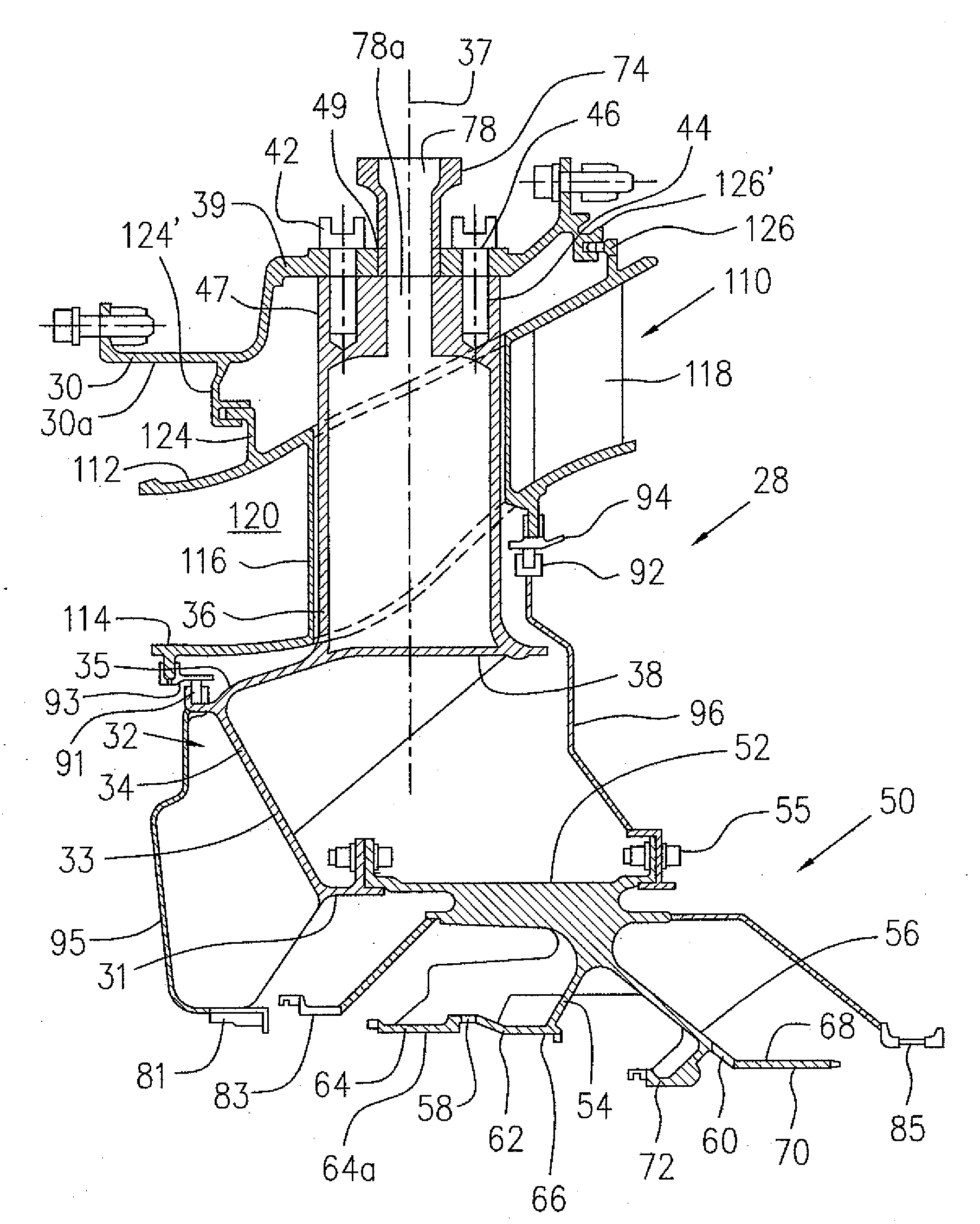

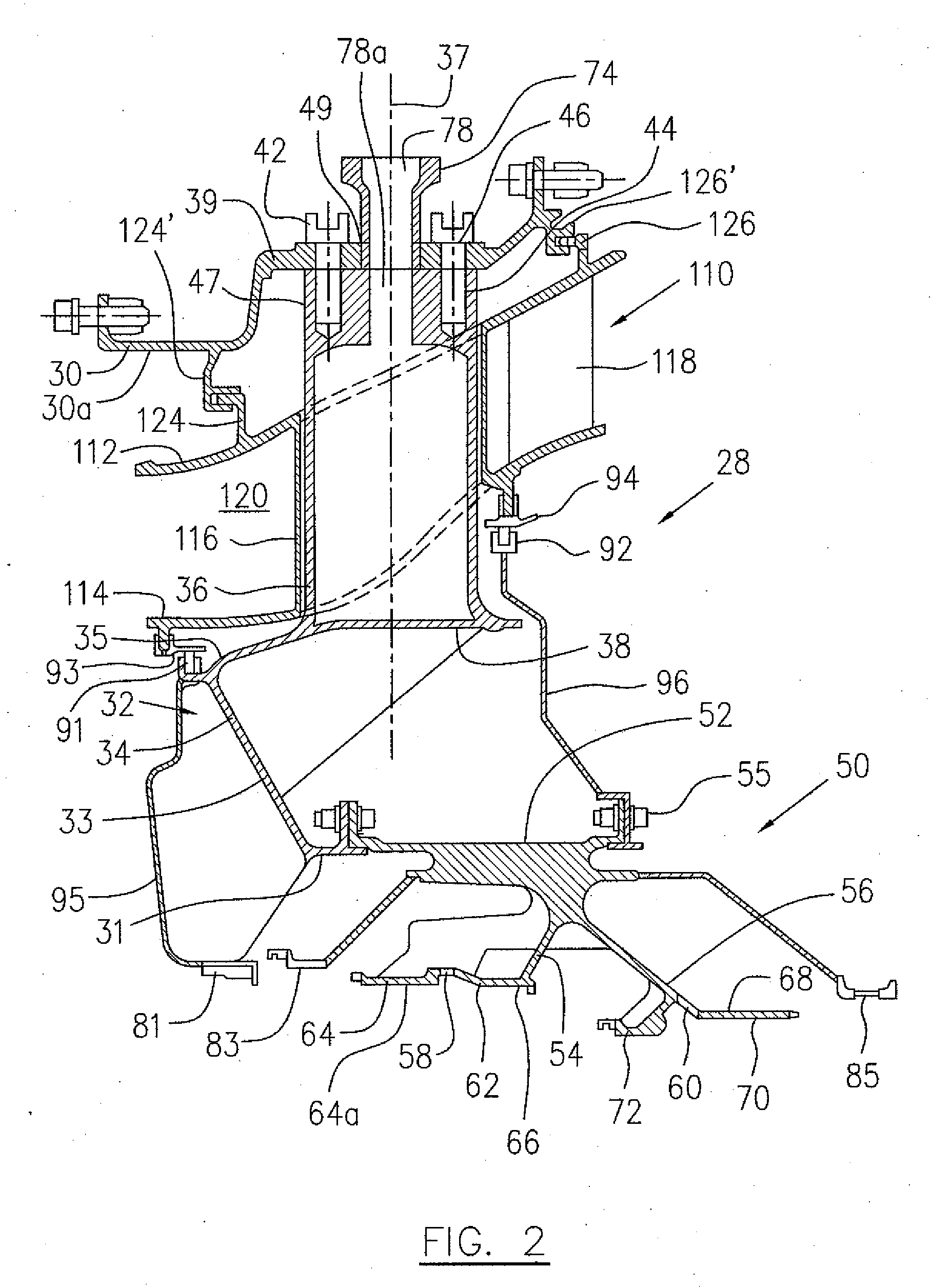

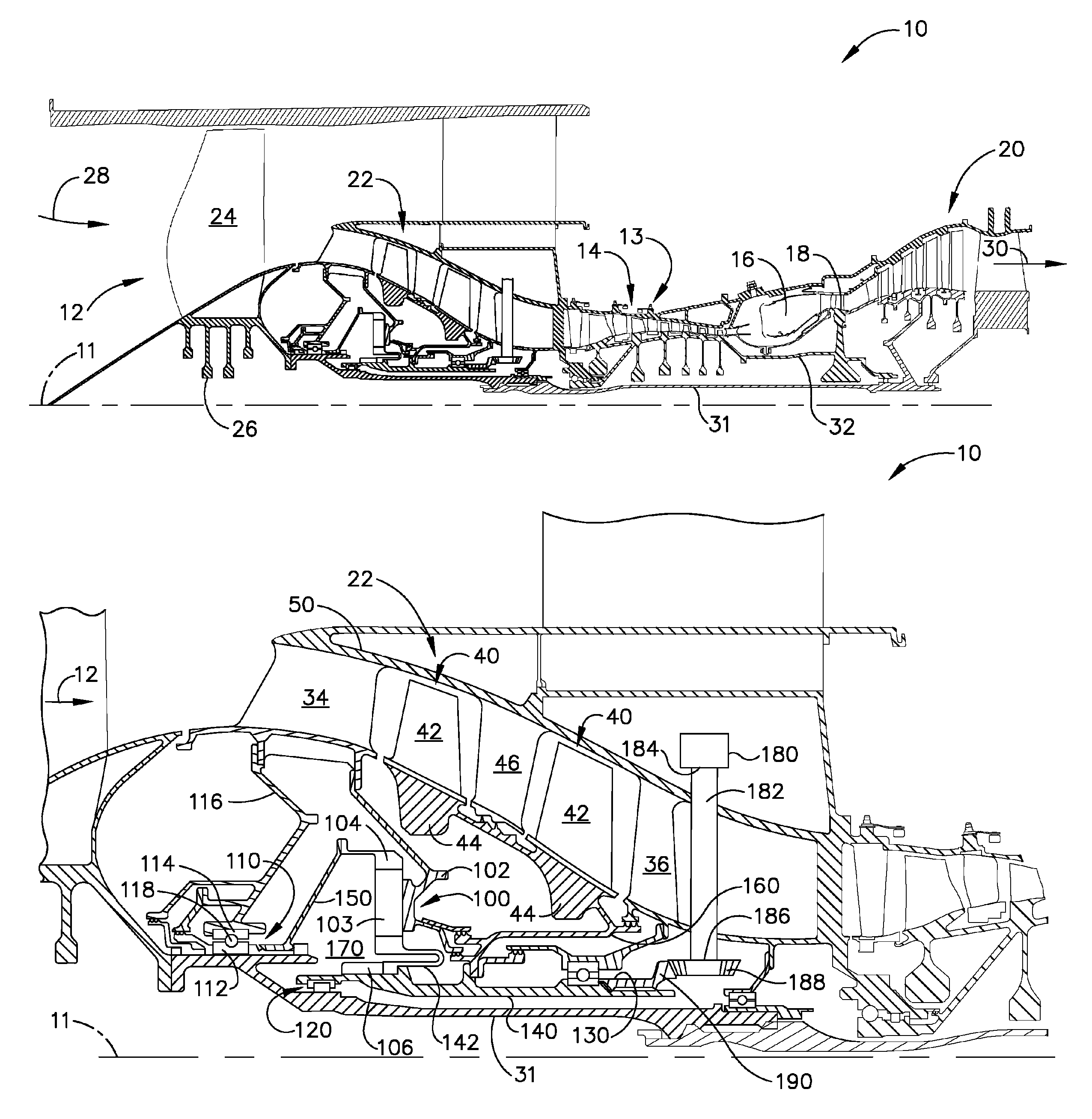

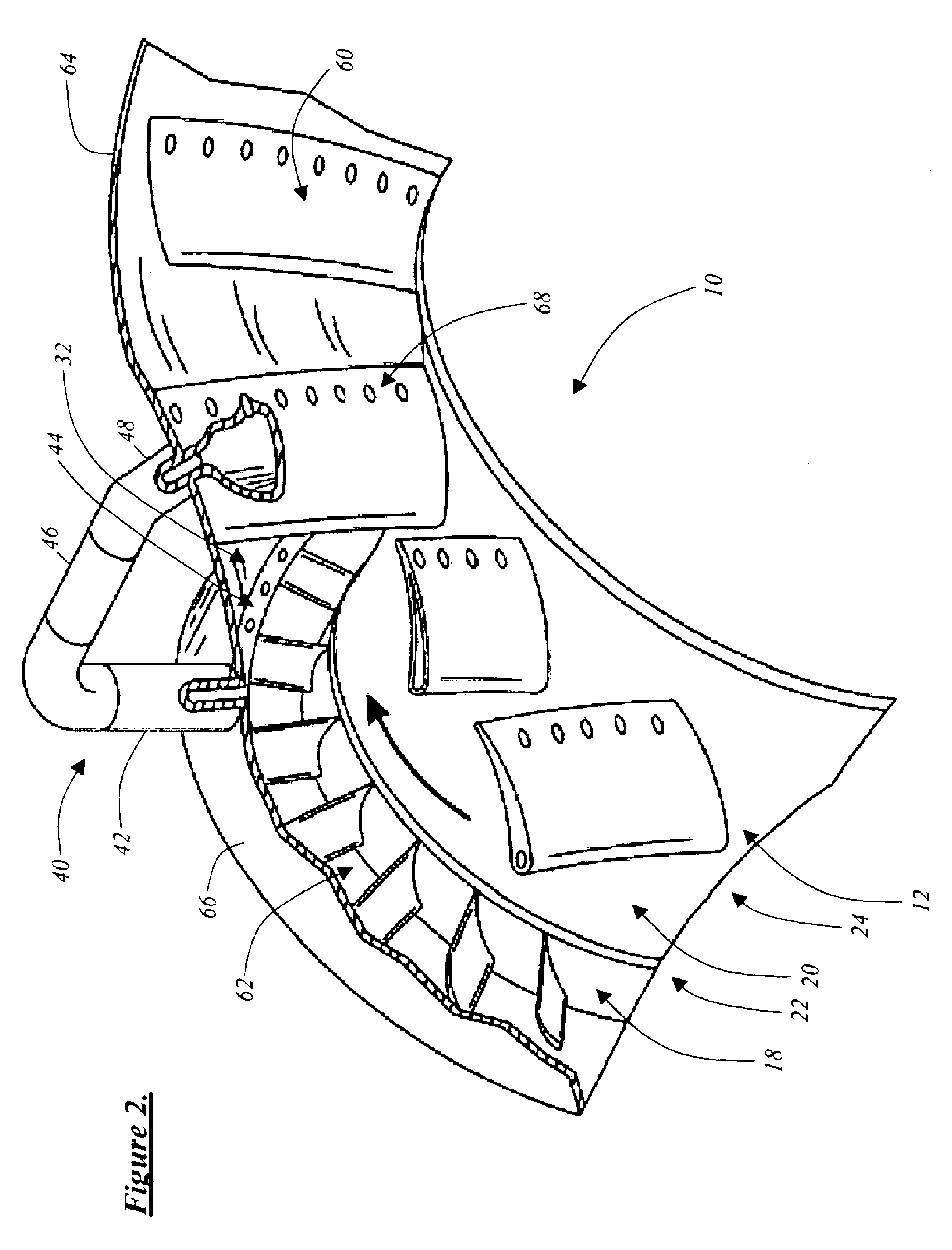

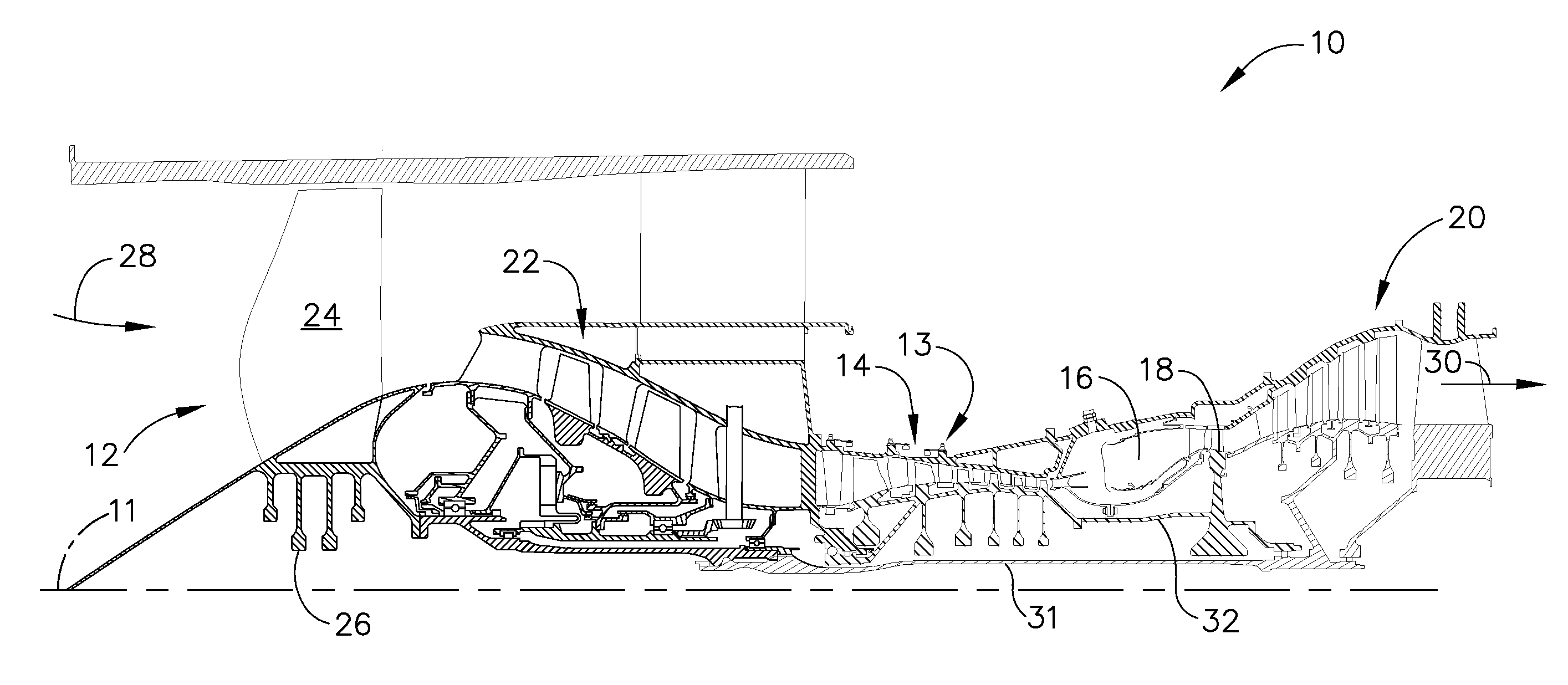

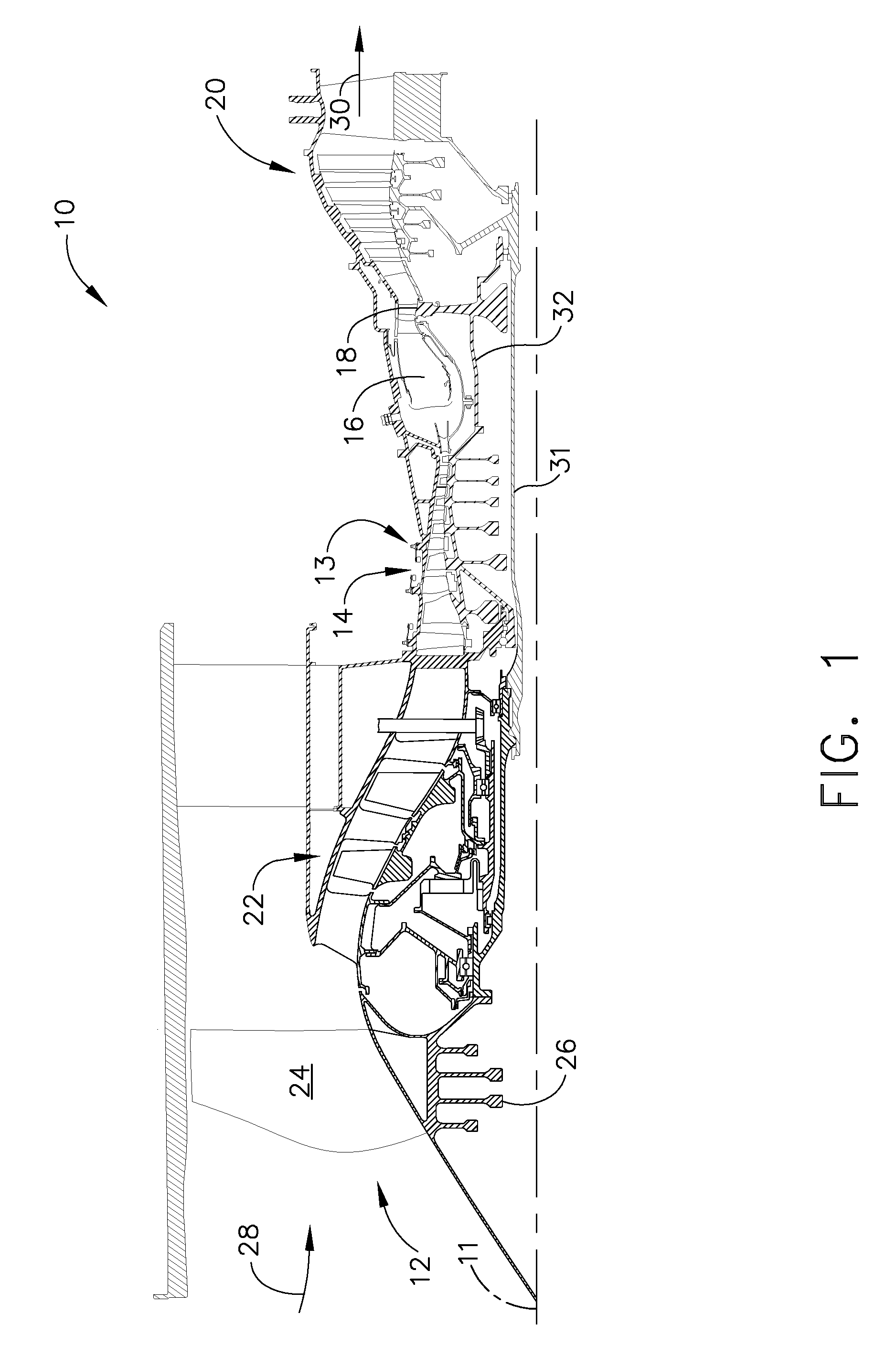

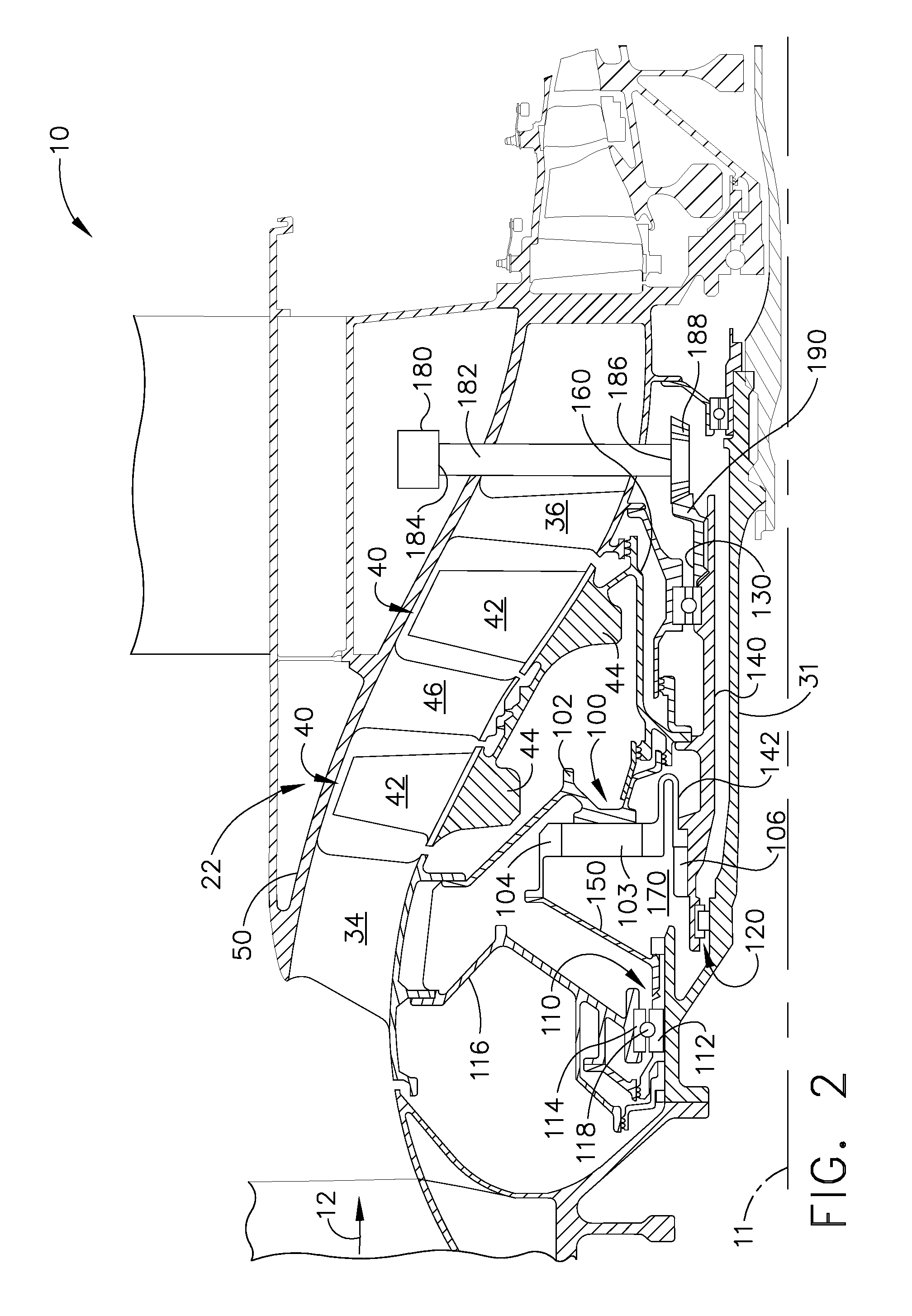

Mid turbine frame system for gas turbine engine

A gas turbine engine mid turbine frame having an inner case supporting at least one bearing and at least three spokes extending radially outwardly to an outer case, the mid turbine frame having an interturbine duct extending through the mid turbine frame, the interturbine duct spaced axially closer to an upstream turbine disc than a bearing supporting structure of the mid turbine frame and mounted axially slidingly relative to the bearing supporting structure to substantially isolate the bearing supporting structure from axial loads, for example such as disc loads incurred in the unlikely event a turbine disc shaft shears within the engine.

Owner:PRATT & WHITNEY CANADA CORP

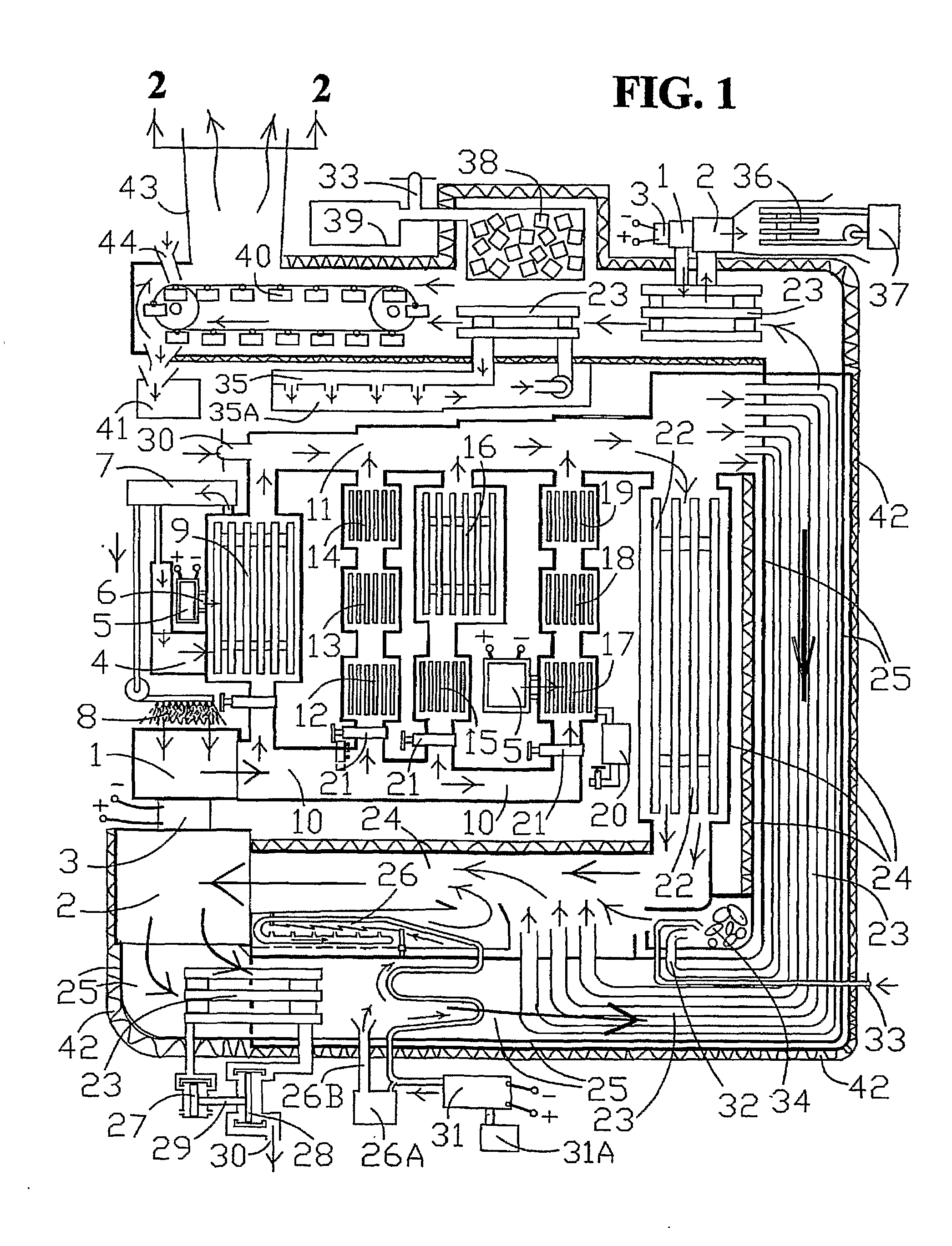

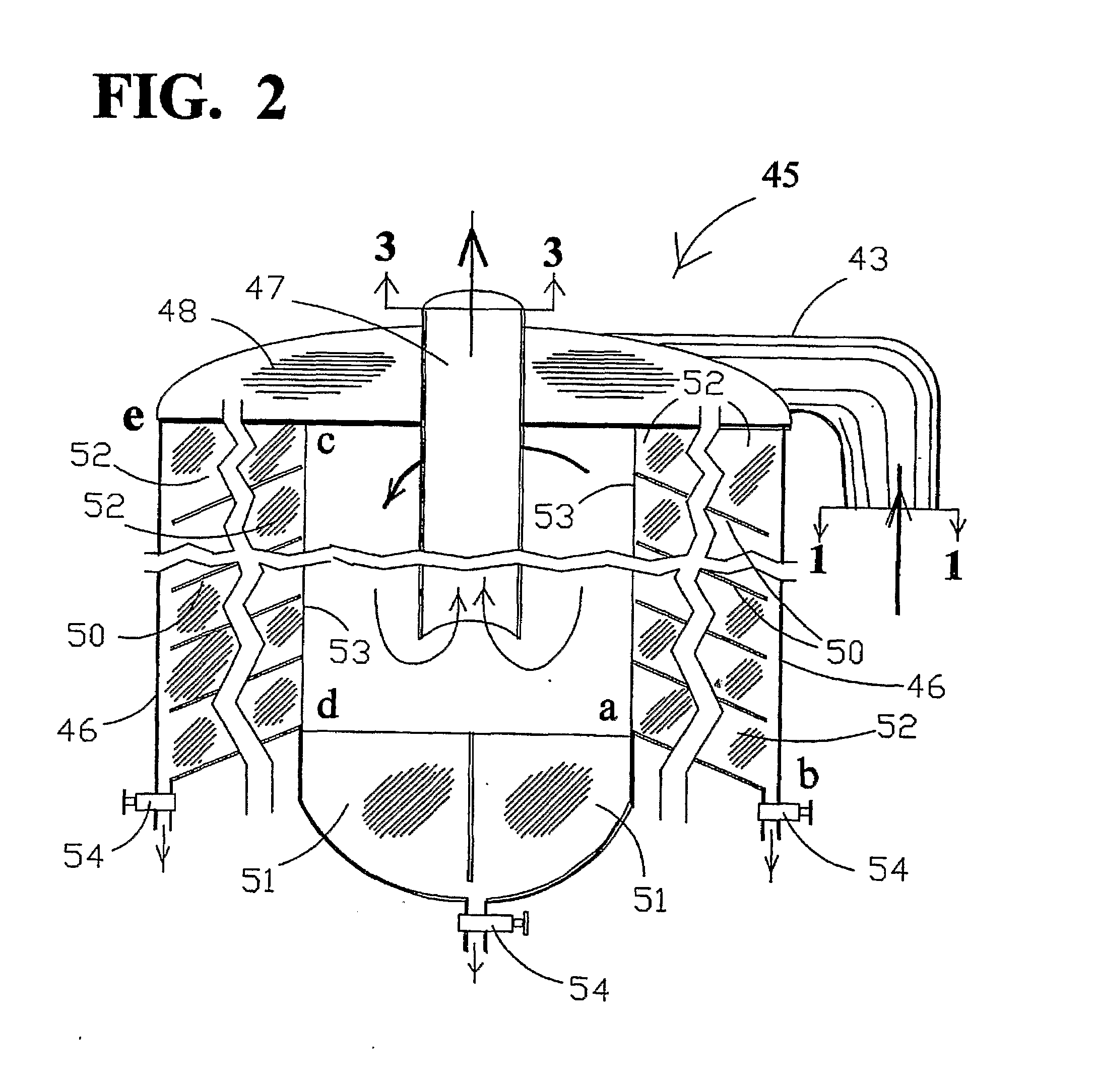

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

Power plant and control method

Ambient air is compressed into a compressed ambient gas flow with a main air compressor. The compressed ambient gas flow having a compressed ambient gas flow rate is delivered to a turbine combustor and mixed with a fuel stream having a fuel stream flow rate and a portion of a recirculated low oxygen content gas flow to form a combustible mixture. The combustible mixture is burned and forms the recirculated low oxygen content gas flow that drives a turbine. A portion of the recirculated low oxygen content gas flow is recirculated from the turbine to the turbine compressor using a recirculation loop. The compressed ambient gas flow rate and the fuel stream flow rate are adjusted to achieve substantially stoichiometric combustion. An excess portion, if any, of the compressed ambient gas flow is vented. A portion of the recirculated low oxygen content gas flow is extracted using an extraction conduit.

Owner:GENERAL ELECTRIC CO

Compound clearance control engine

A gas turbine engine includes a compressor, combustor, and turbine having a row of blades mounted inside a surrounding turbine shroud. A heat exchanger is used for cooling pressurized air bled from the compressor. A distribution network joins the heat exchanger to the turbine for selectively channeling air from the heat exchanger below the blades and above the shroud for controlling blade tip clearance.

Owner:GENERAL ELECTRIC CO

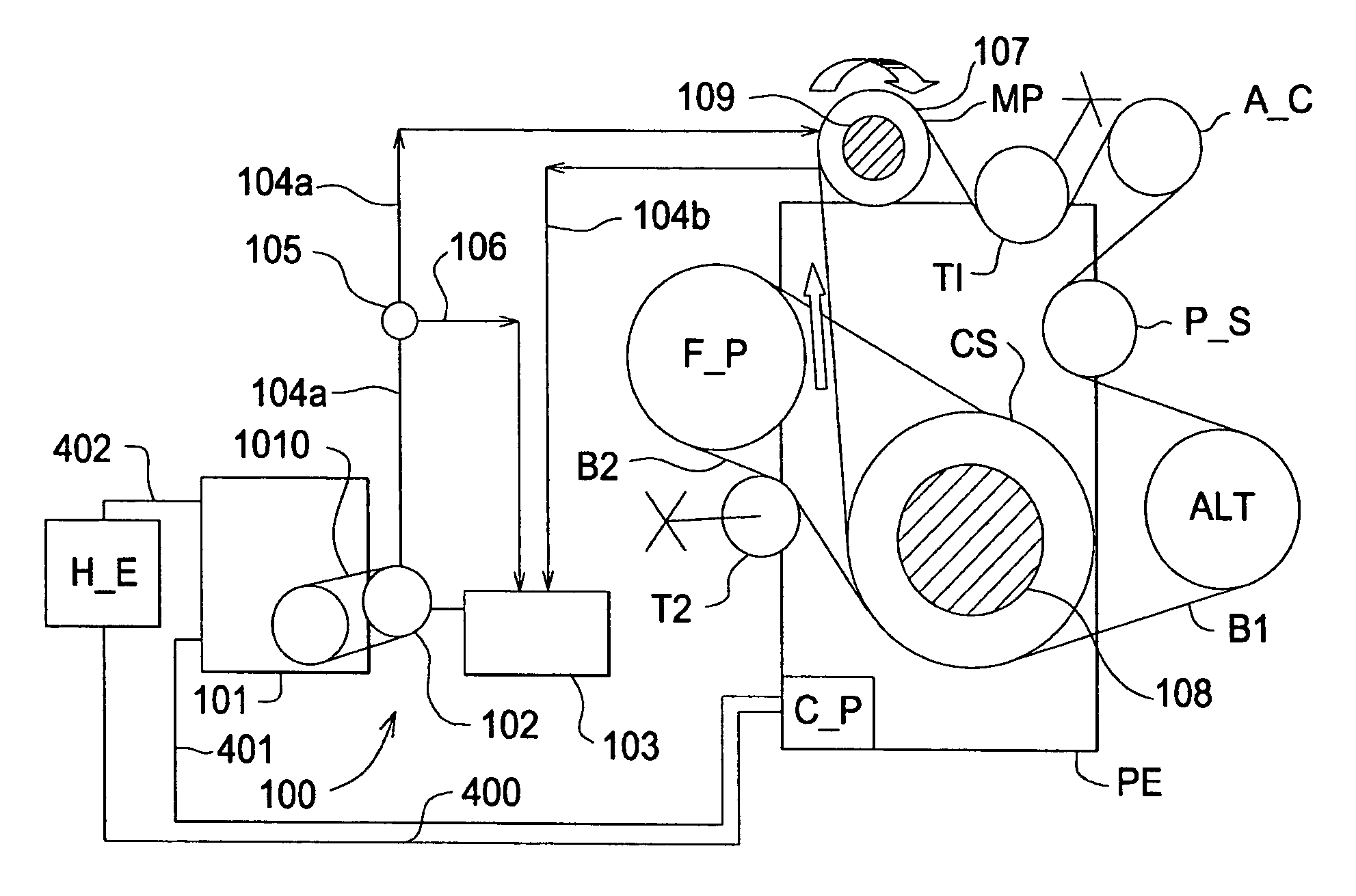

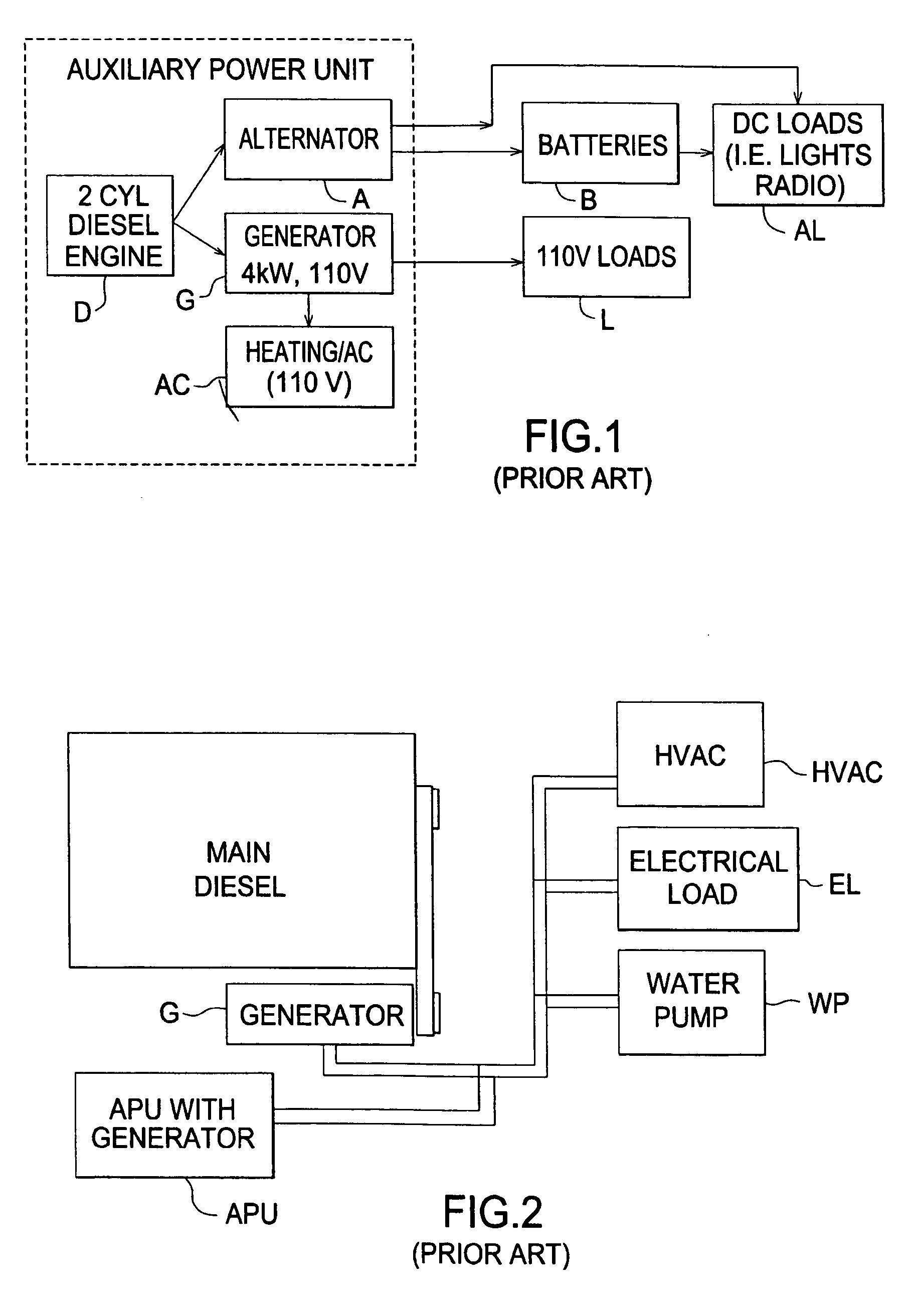

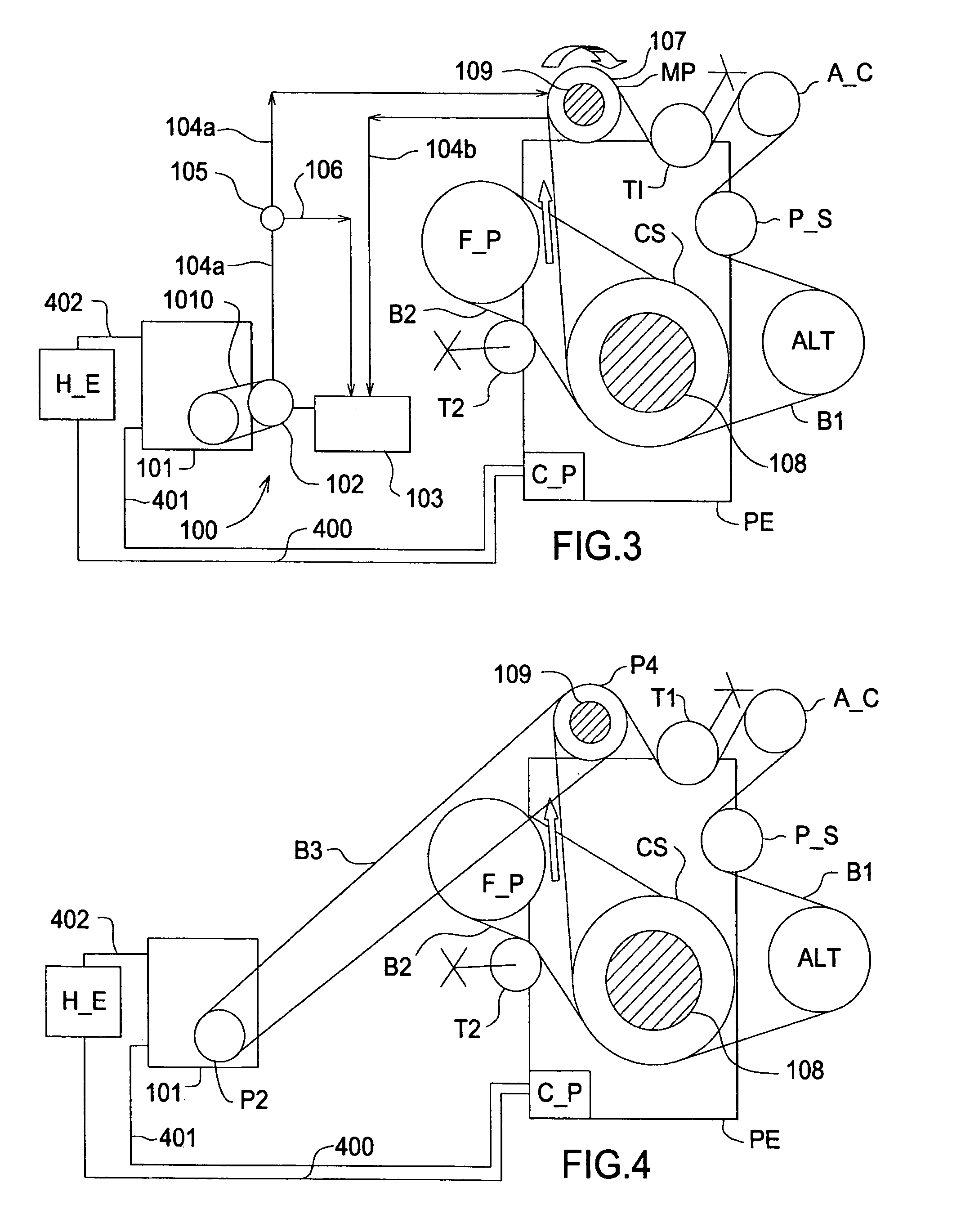

Auxiliary power system for a motor vehicle

An auxiliary power system for a motor vehicle primary engine used to drive primary engine accessories when the primary engine is not operating. The system comprises a secondary engine that drives a hydraulic pump. The hydraulic pump is connected to a hydraulic motor. The hydraulic motor is integrated with an accessory belt drive system on a primary engine. The secondary engine drives the ABDS system through the hydraulic pump and hydraulic motor when the primary engine is not operating, thus allowing various primary engine accessories such as air conditioning to be operated while the primary engine is off. A one-way clutch on the primary engine crankshaft prevents the primary engine crankshaft from being turned when the hydraulic motor is driving the belt. A one-way clutch on the hydraulic motor prevents it from being driven when the primary engine is in operation.

Owner:THE GATES CORP

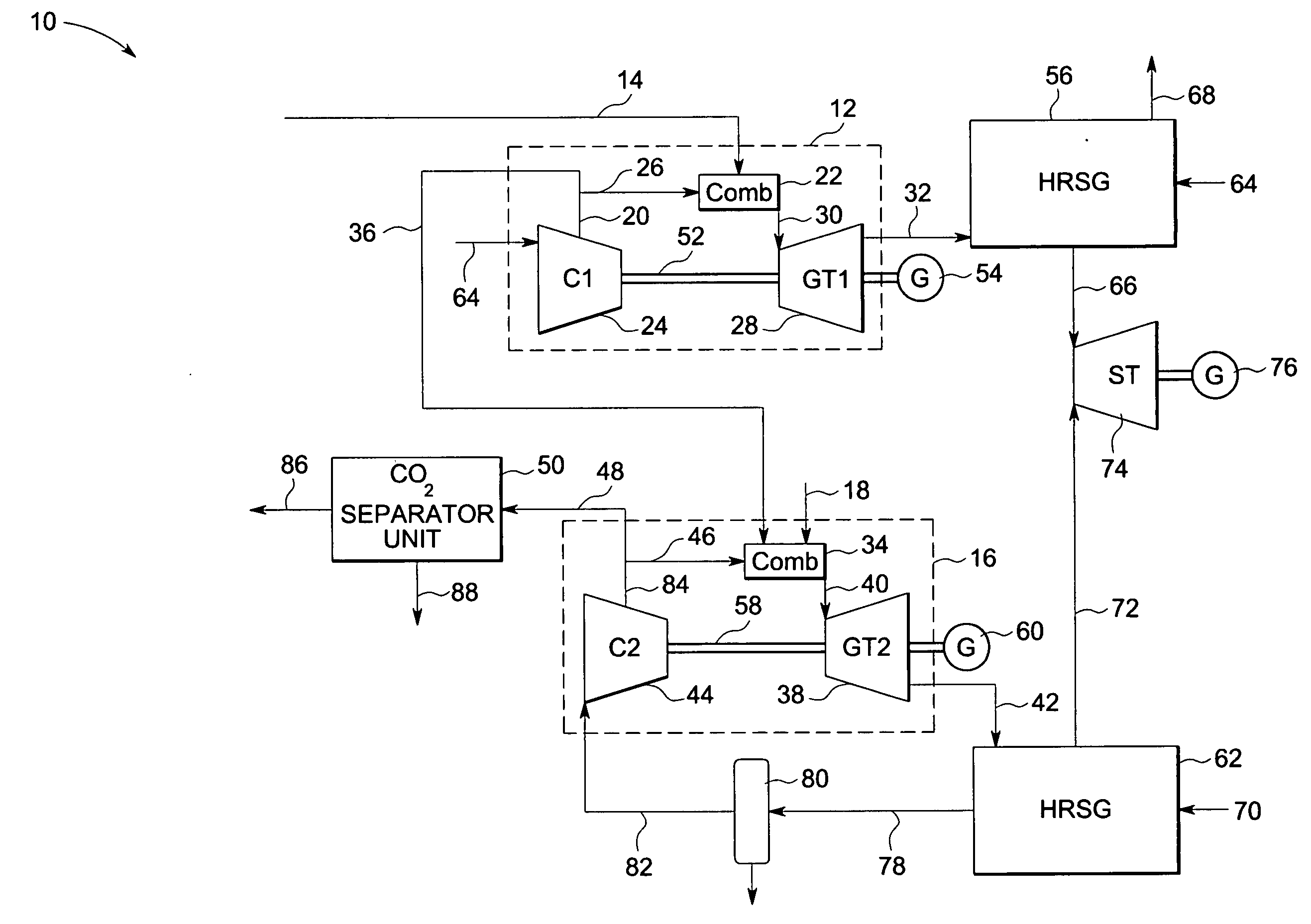

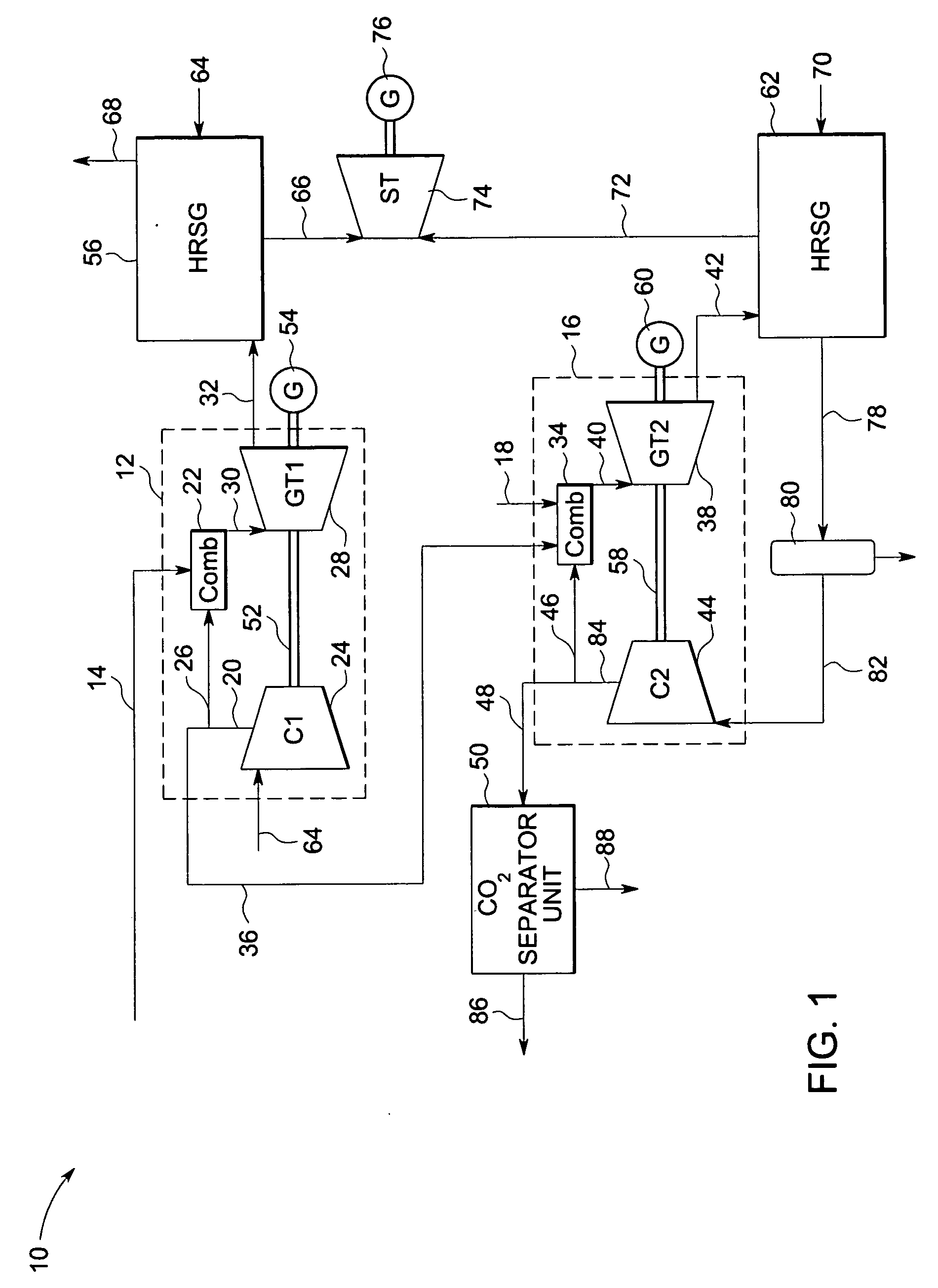

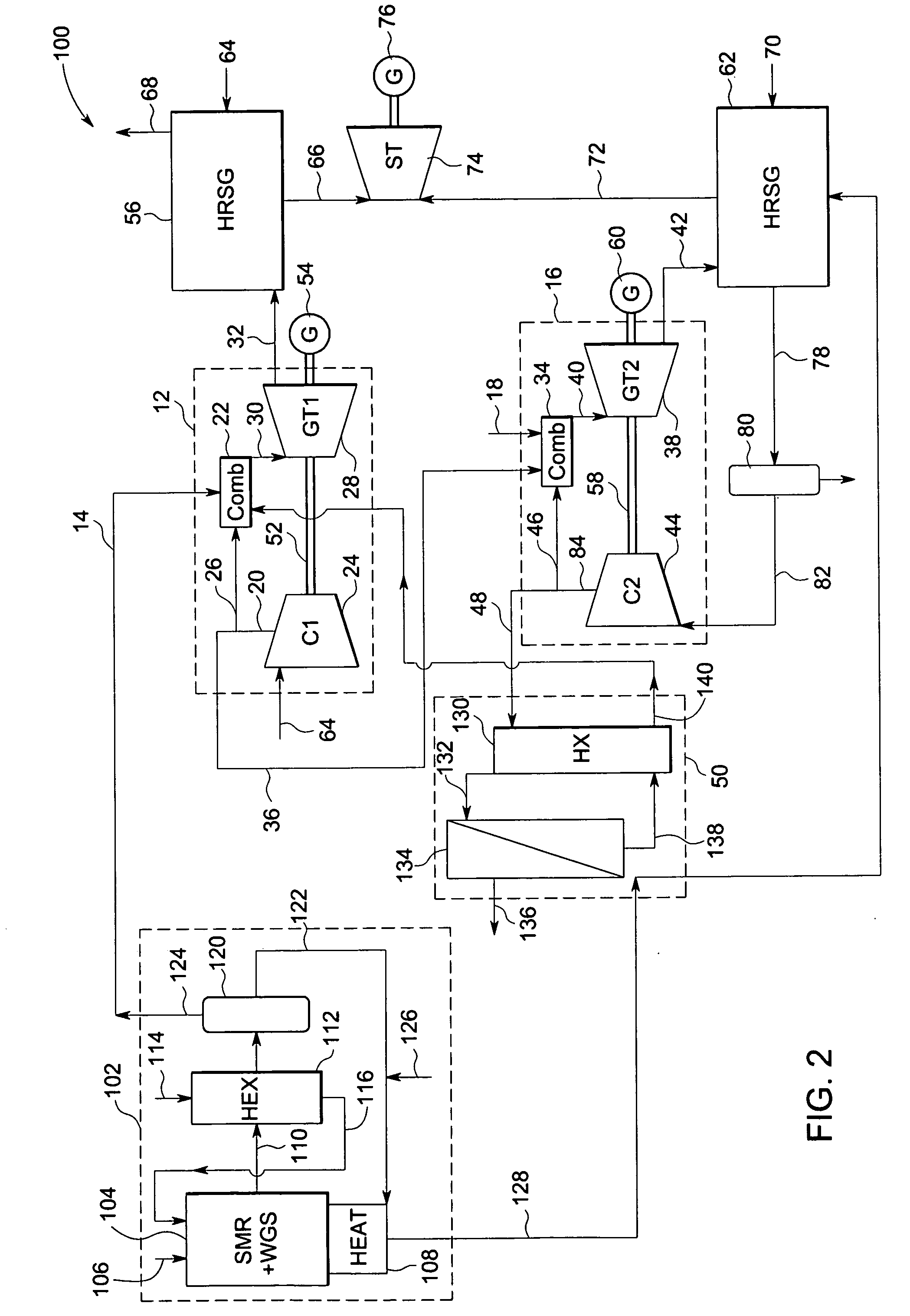

Systems and methods for power generation with carbon dioxide isolation

A power generation system and method includes a first gas turbine system comprising a first combustion chamber configured to combust a first fuel stream of primarily hydrogen that is substantially free of carbon-based fuels. The first gas turbine system also includes a first compressor configured to supply a first portion of compressed oxidant to the first combustion chamber and a first turbine configured to receive a first discharge from the first combustion chamber and generate a first exhaust and electrical energy. The power generation system further includes a second gas turbine system comprising a second combustion chamber configured to combust a second fuel stream to generate a second discharge. The first compressor of the first gas turbine system is configured to supply a second portion of compressed oxidant to the second combustion chamber. The second turbine system also includes a second turbine configured to receive the second discharge from the second combustion chamber to generate a second exhaust and electrical energy and a second compressor configured to receive the second discharge comprising carbon dioxide. The second compressor is also configured to discharge a recycle stream to the second combustion chamber and a split stream to a separator system adapted to recover carbon dioxide.

Owner:GENERAL ELECTRIC CO

Gas turbine engine assembly and methods of assembling same

A method of assembling a gas turbine assembly includes providing a core gas turbine engine including a high-pressure compressor, a combustor, and a turbine, coupling a low-pressure turbine to the core gas turbine engine, coupling a booster compressor to a gearbox, and coupling the gearbox to the low-pressure turbine such that the booster compressor is driven by the low-pressure turbine.

Owner:GENERAL ELECTRIC CO

Self-aspirating high-area-ratio inter-turbine duct assembly for use in a gas turbine engine

InactiveUS6851264B2Improve performanceEnhanced aerodynamic benefitWind motor controlCombination enginesPressure differenceHigh pressure

In various embodiments, the present invention provides a means for improving gas turbine engine performance by applying fluid flow control to the inter-turbine duct joining a high-pressure turbine spool and an associated low-pressure turbine spool, allowing the low-pressure turbine spool to have a relatively larger diameter than the high-pressure turbine spool. One or more unobstructed fluid flow paths between one or more boundary layer suction ports disposed within the upstream end of the outer-body surface of the inter-turbine duct and the suction side of the associated low-pressure turbine nozzle are provided. Advantageously, the natural static pressure difference between these points results in a self-aspirating assembly. The fluid flow control provided by the respective suction and blowing forces generated allows for a relatively larger diameter low-pressure turbine spool and / or relatively fewer low-pressure turbine nozzles to be used than is possible with conventional systems, assemblies, and methods. Thus, a gas turbine engine weight savings and optimized performance may be achieved.

Owner:GENERAL ELECTRIC CO

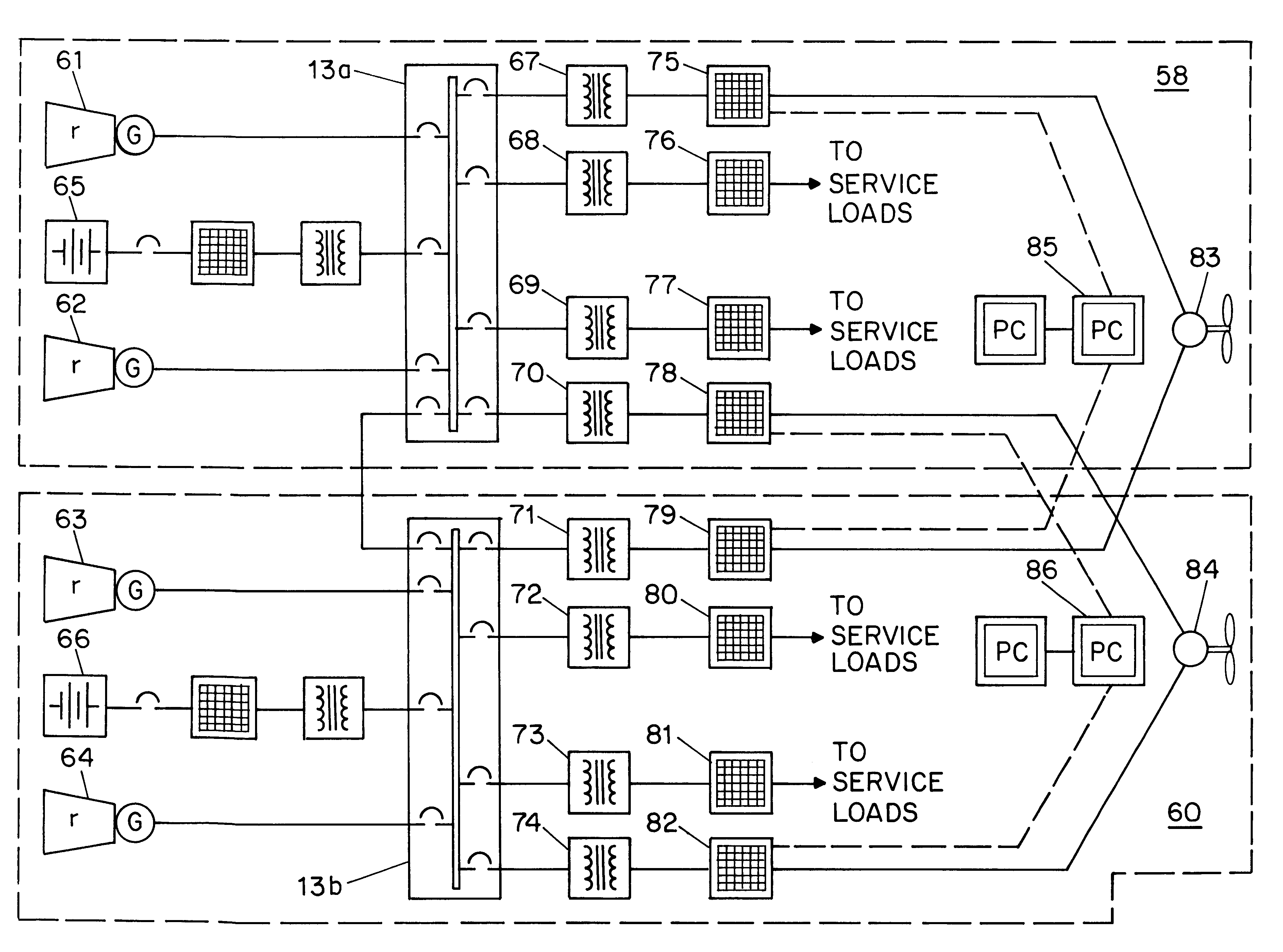

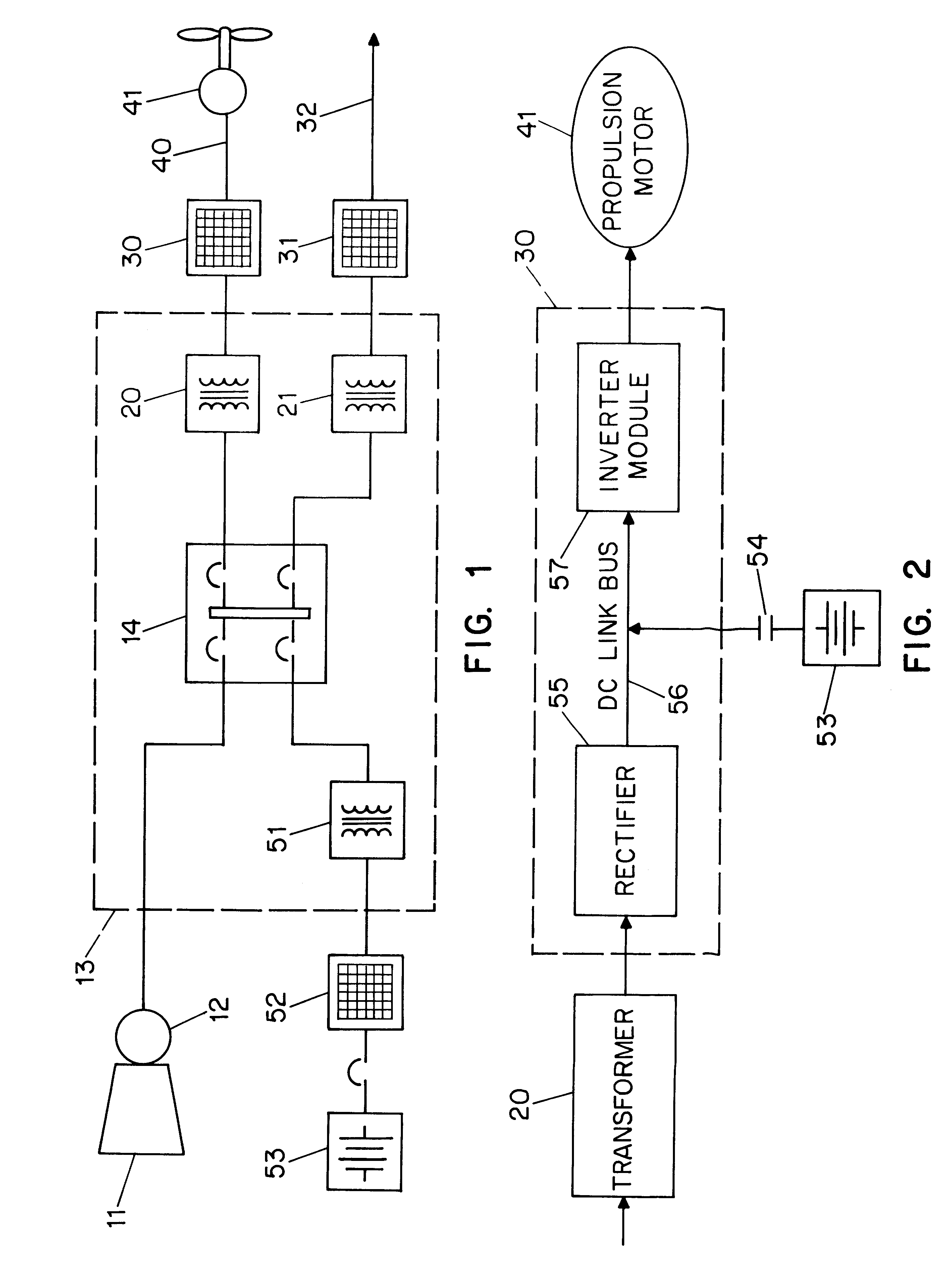

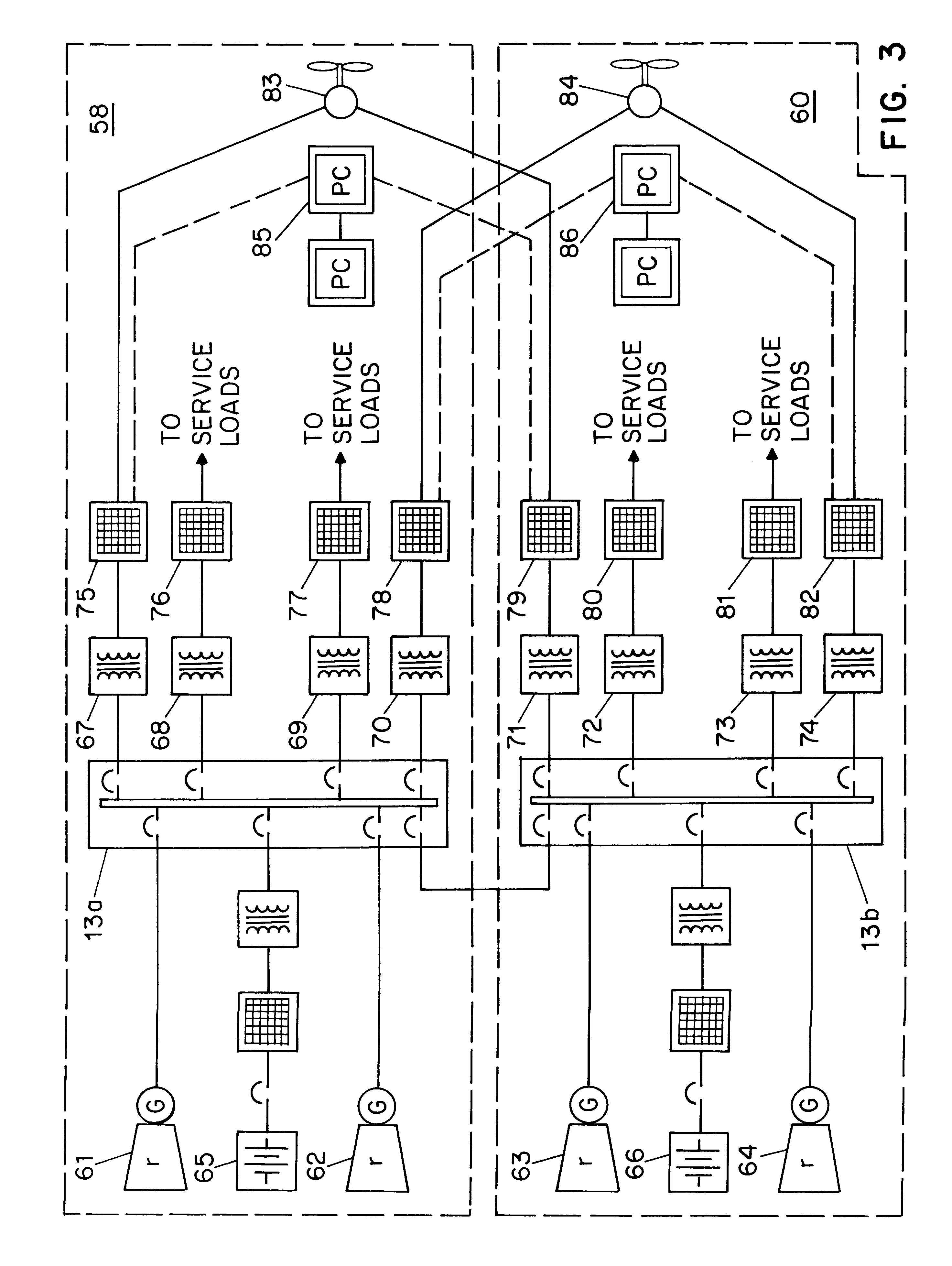

Integrated marine power distribution arrangement

InactiveUS6188139B1Reduce weightImprove power densityAuxillariesCombination enginesElectrical batteryTransformer

A marine power distribution arrangement includes a turbine-driven AC generator which supplies AC power at a frequency of 240 Hz through a switchgear unit to a transformer and a first power converter by which the power is converted to a variable frequency, variable voltage AC output for ship propulsion and to a second power converter by which the AC power is converted to a fixed voltage, fixed AC frequency or DC power to supply the ship service loads. A battery backup power supply may be switched in an emergency. In another embodiment four turbine-driven AC generators and two emergency power supplies are provided to drive two propulsion shafts as well as to supply the ship service loads.

Owner:GENERAL DYNAMICS C4 SYSTEMS +1

Power plant start-up method

Ambient air is compressed into a compressed ambient gas flow and delivered to a turbine combustor. At least one of an exhaust port, a bypass conduit, or an extraction conduit is opened to vent the power plant. A turbine shaft is rotated at an ignition speed and a fuel stream is delivered to the turbine combustor for mixing with the compressed ambient gas flow to form a combustible mixture. The combustible mixture is burned and forms a recirculated gas flow that drives the turbine. The recirculated gas flow is recirculated using the recirculation loop. The turbine is operated at a target operating speed and then reaches substantially stoichiometric combustion. At least a portion of the recirculated gas flow is extracted using an extraction conduit that is fluidly connected to the turbine compressor.

Owner:GENERAL ELECTRIC CO

Gas turbine engine assembly and methods of assembling same

A method of assembling a gas turbine assembly includes providing a core gas turbine engine including a high-pressure compressor, a combustor, and a turbine, coupling a low-pressure turbine to the core gas turbine engine, coupling a booster compressor to a gearbox, and coupling the gearbox to the low-pressure turbine such that the booster compressor is driven by the low-pressure turbine.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com