Patents

Literature

1623 results about "Conduit system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conduit system. noun. : a system for supplying electric power to a car or locomotive by means of one or more underground contact rails.

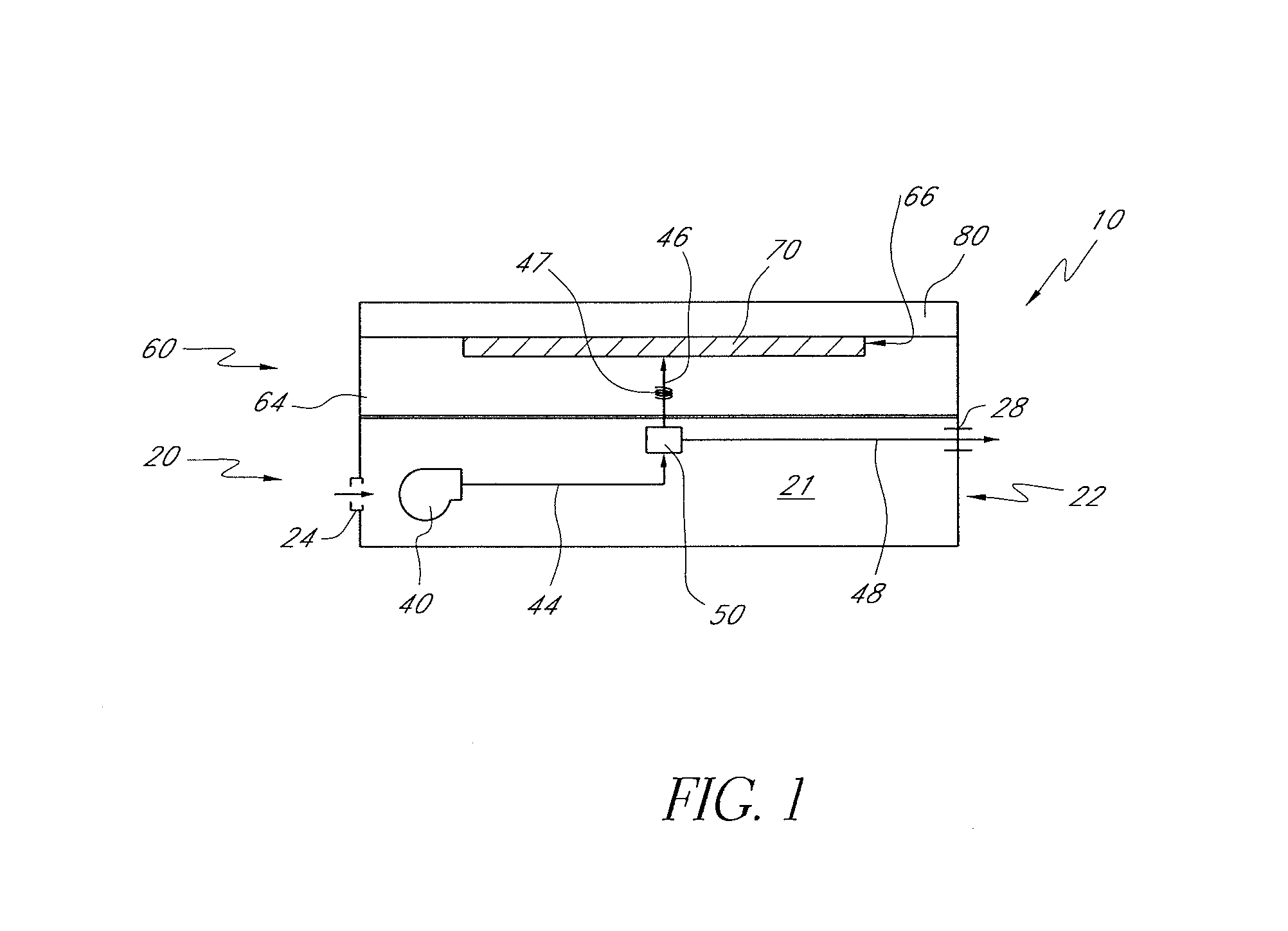

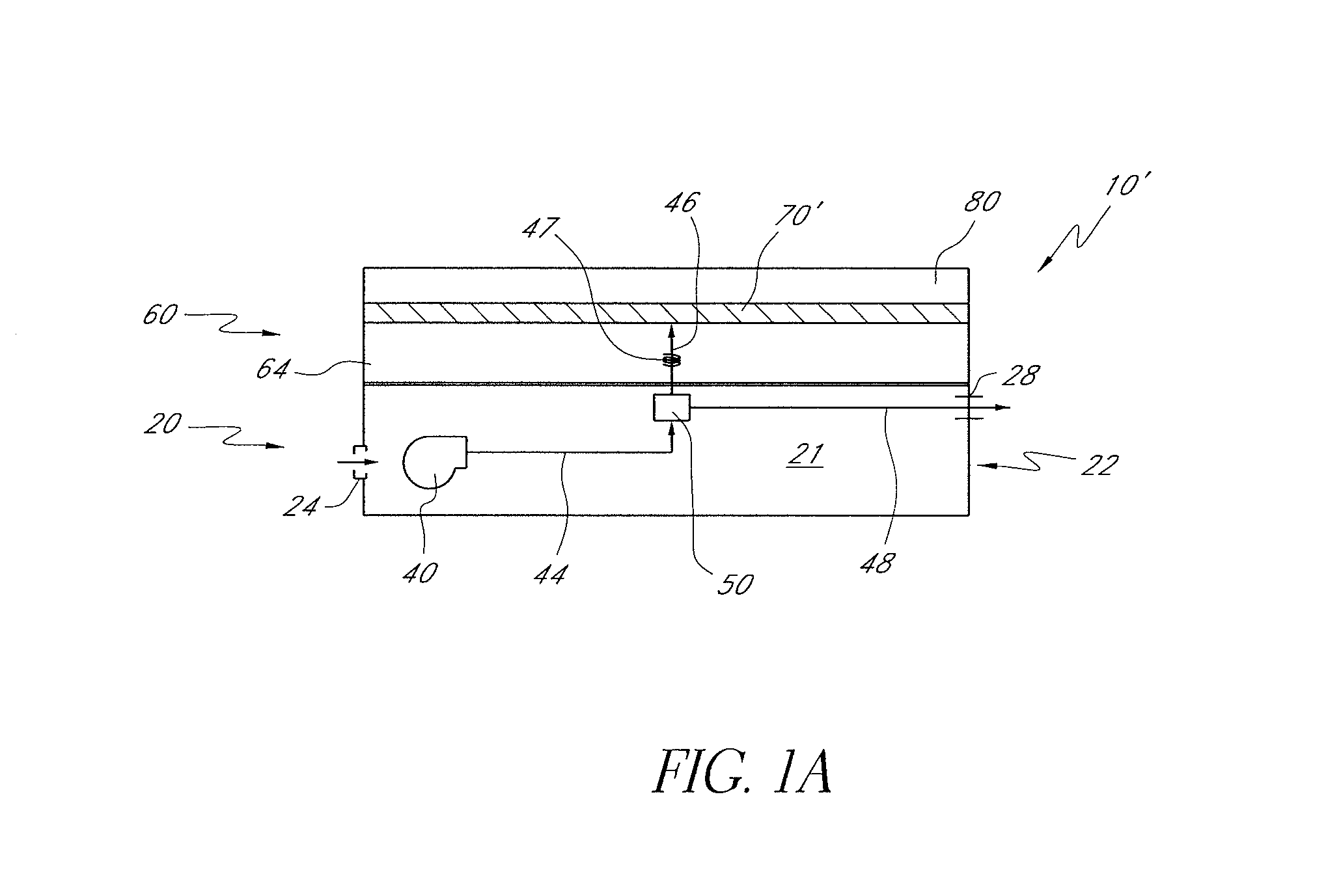

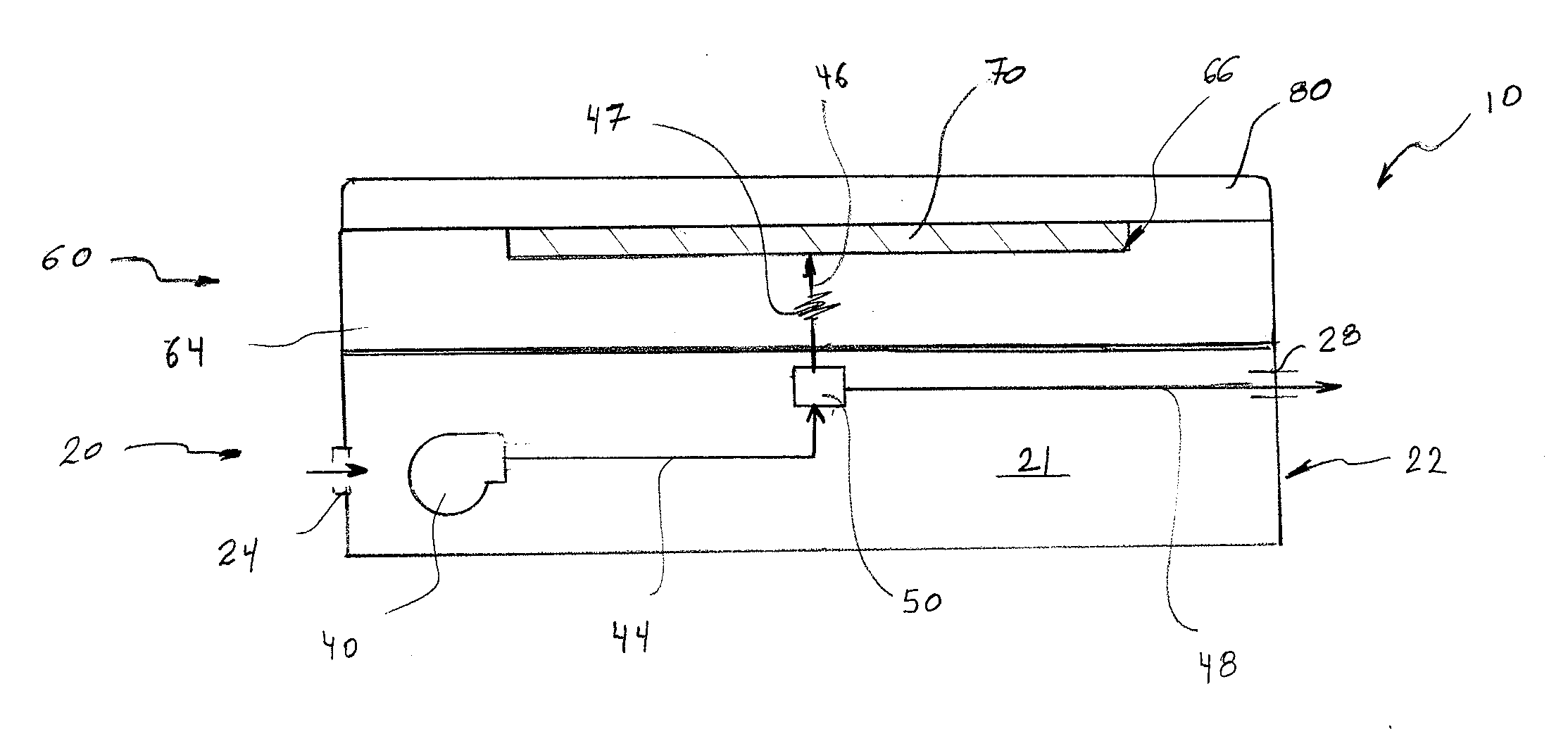

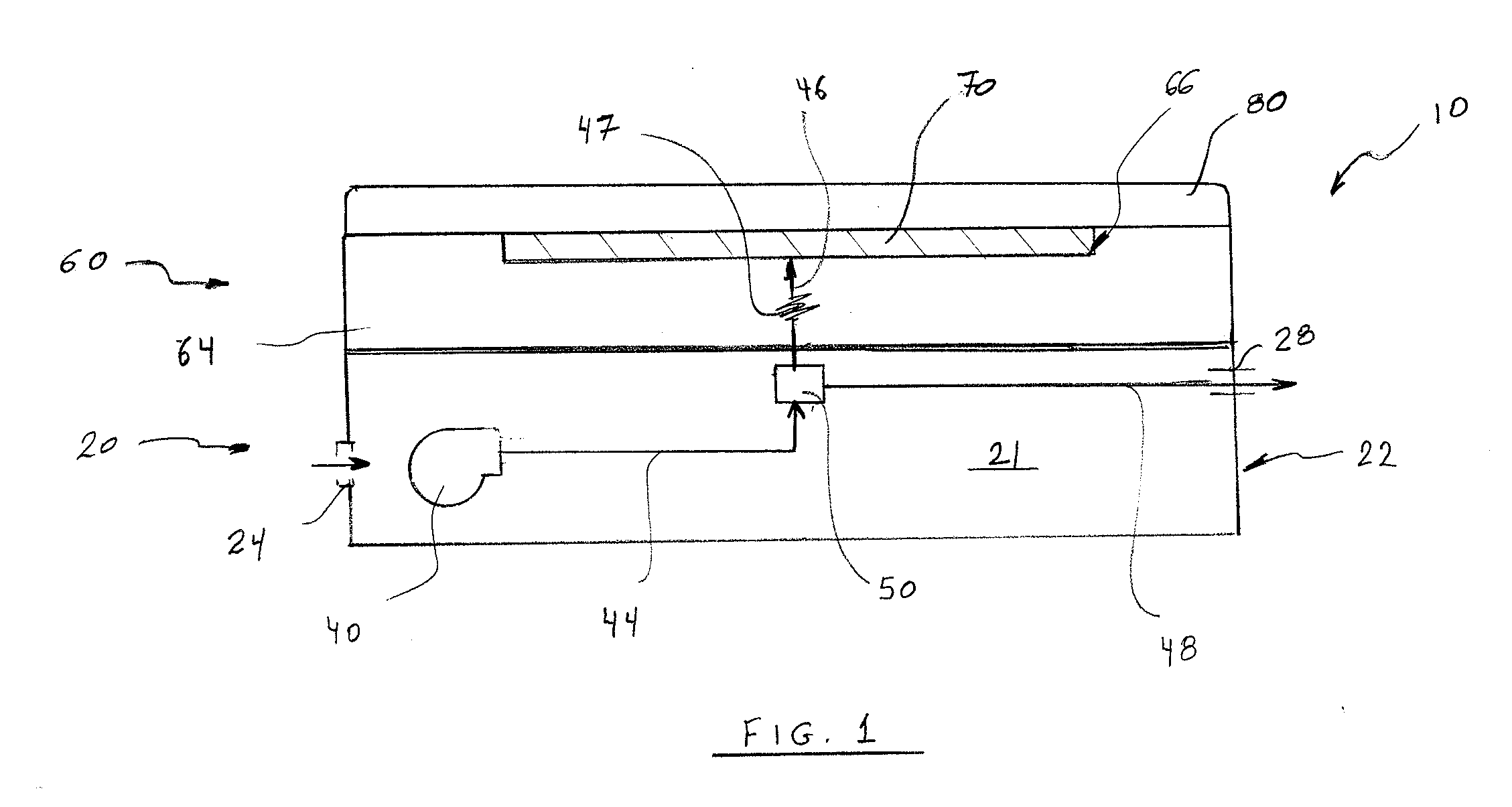

Air conditioned bed

A climate controlled bed comprises a cushion member having an outer surface comprising a first side for supporting an occupant and a second side, the first side and the second side generally facing in opposite directions. In some embodiments, the cushion member includes one or more recessed areas along its first side or its second side. In one embodiment, the bed further includes a support structure having a top side configured to support the cushion member, a bottom side and an interior space generally located between the top side and the bottom side, the top side and the bottom side of the support structure generally facing in opposite directions, a flow conditioning member that may be at least partially positioned with the recessed area of the cushion member, an air-permeable topper member positioned along the first side of the cushion member and a fluid temperature regulation system. The fluid temperature regulation system includes a fluid transfer device, a thermoelectric device and a conduit system generally configured to transfer a fluid from the fluid transfer device to the thermoelectric device. The fluid temperature regulation system is configured to receive a volume of fluid and deliver it to the flow conditioning member and the topper member.

Owner:SLEEP NUMBER CORP

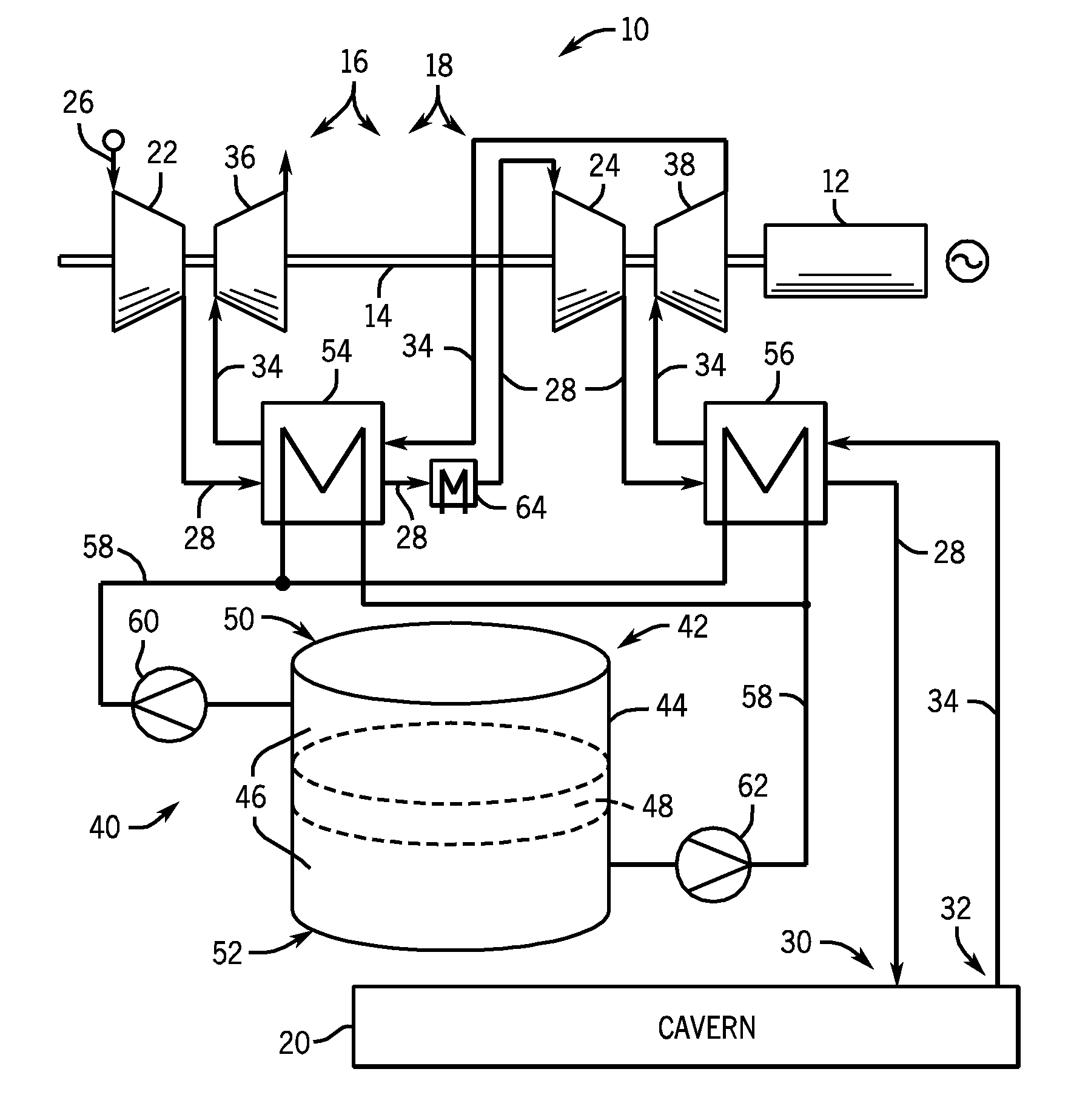

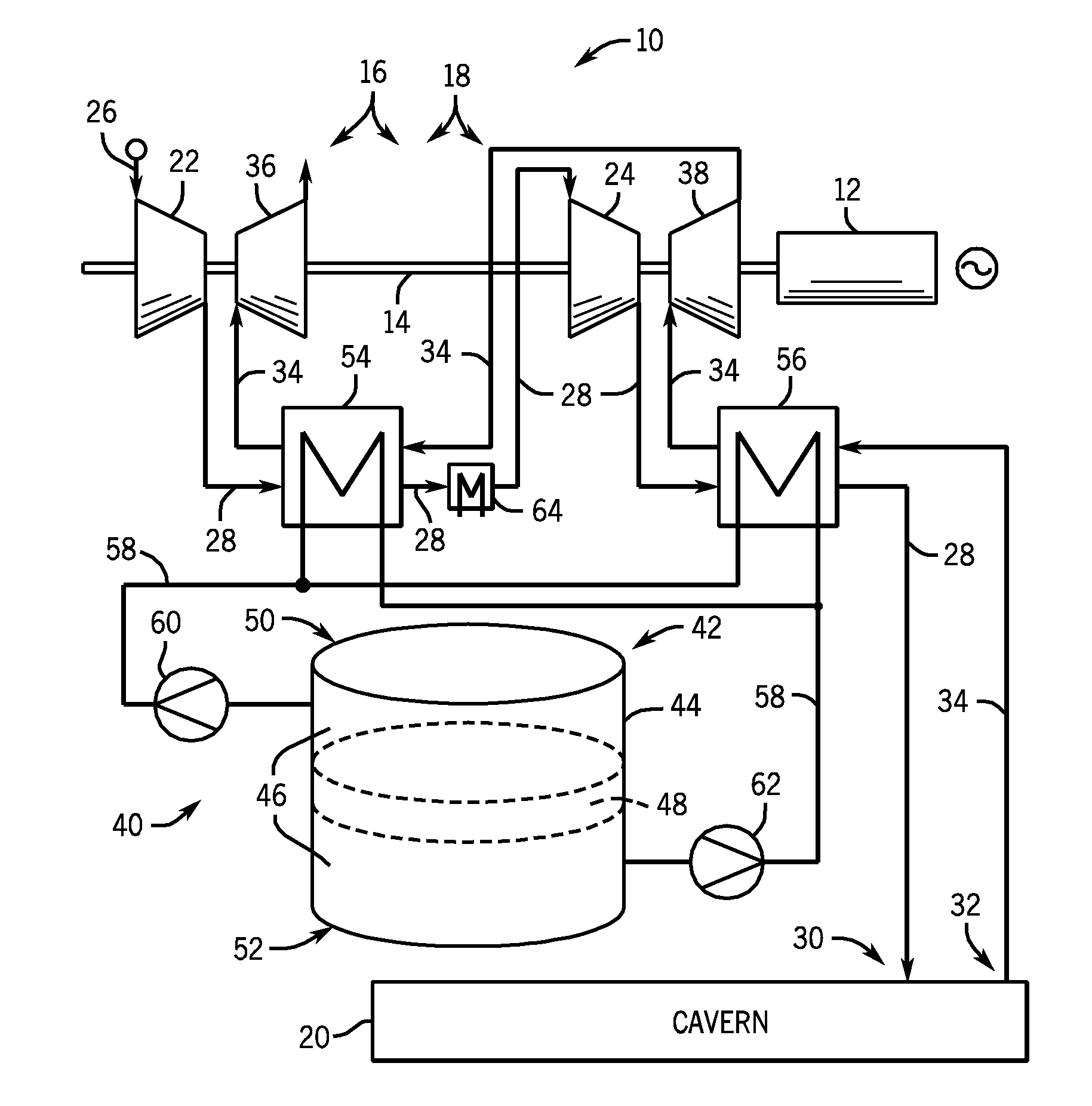

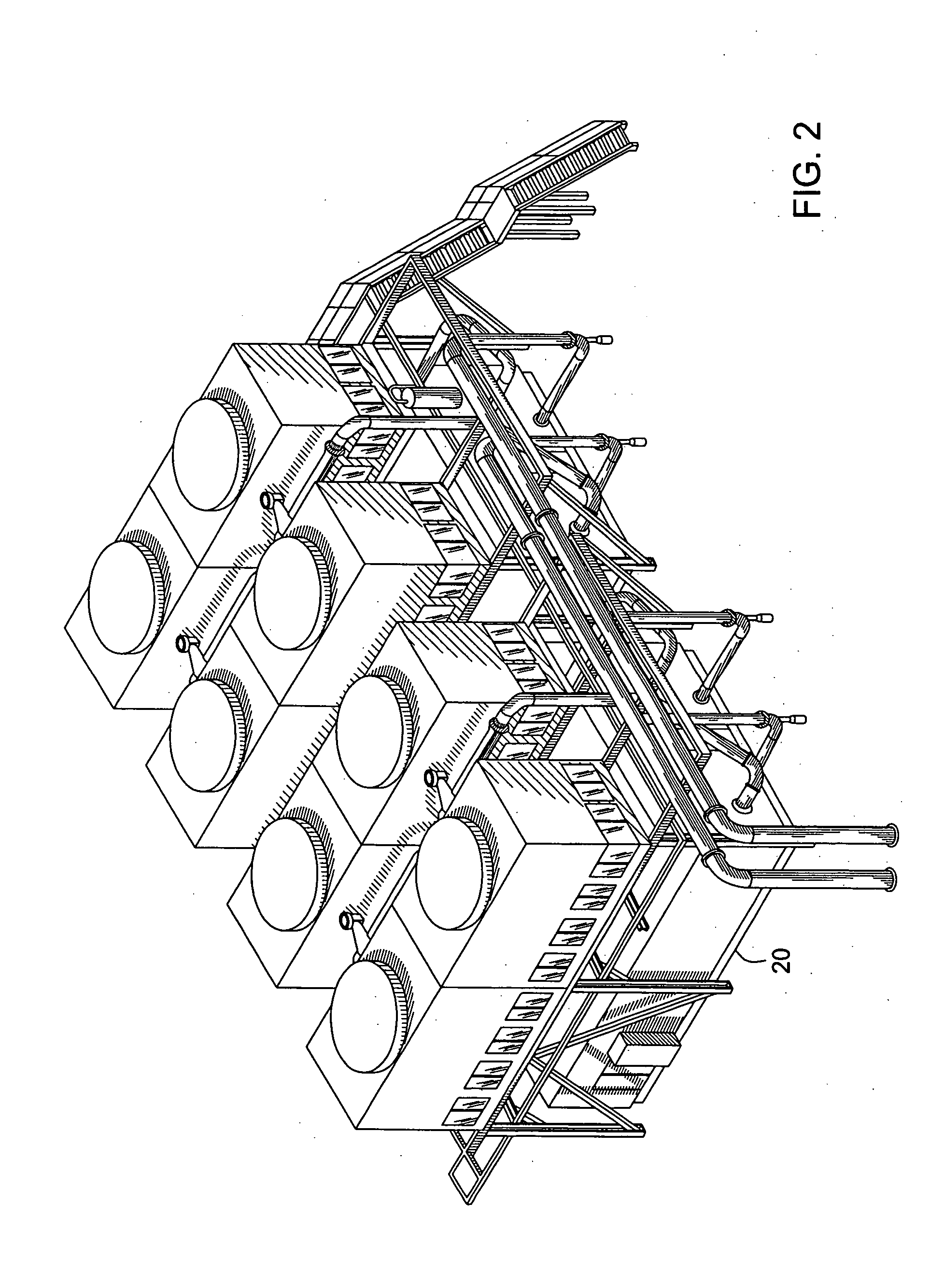

Adiabatic compressed air energy storage system with liquid thermal energy storage

InactiveUS20110100010A1Reciprocating combination enginesCombination enginesThermal energyThermal energy storage

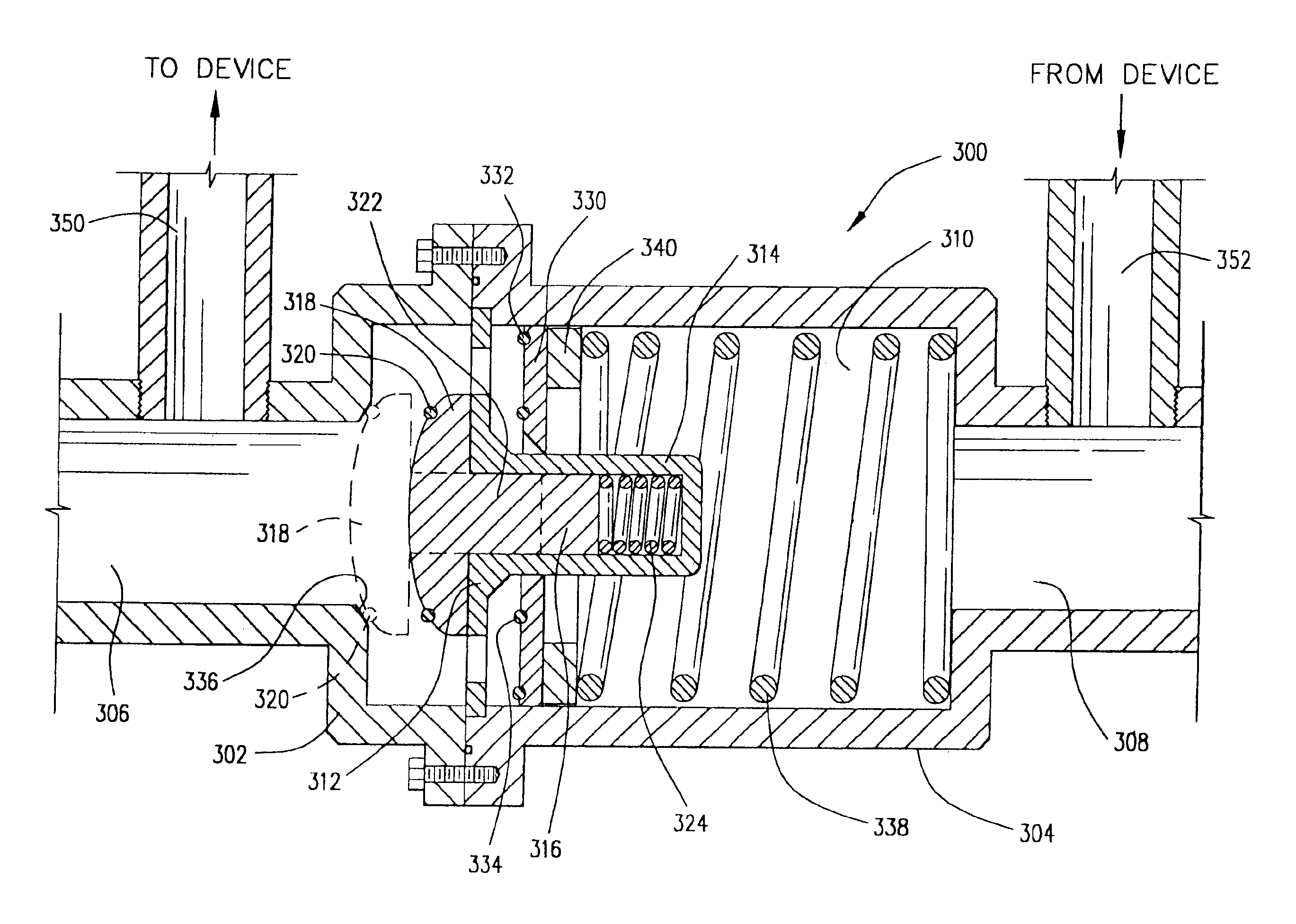

An adiabatic compressed air energy storage (ACAES) system includes a compressor system, an air storage unit, and a turbine system. The ACAES system further includes a thermal energy storage (TES) system that includes a container, a plurality of heat exchangers, a liquid TES medium conduit system fluidly coupling the container to the plurality of heat exchangers, and a liquid TES medium stored within the container. The TES system also includes a plurality of pumps coupled to the liquid TES medium conduit system and configured to transport the liquid TES medium between the plurality of heat exchangers and the container, and a thermal separation system positioned within the container configured to thermally isolate a first portion of the liquid TES medium at a lower temperature from a second portion of the liquid TES medium at a higher temperature.

Owner:GENERAL ELECTRIC CO

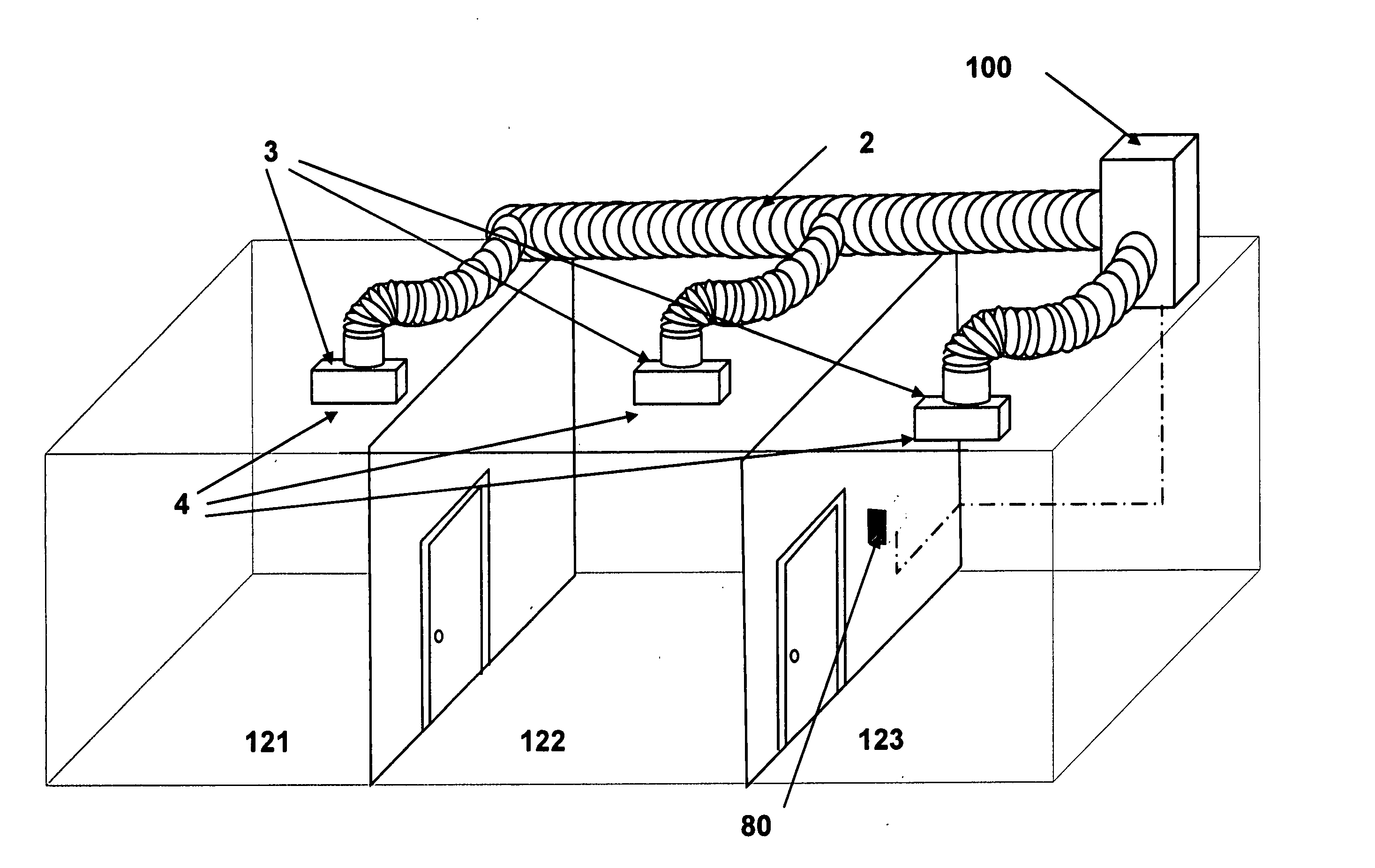

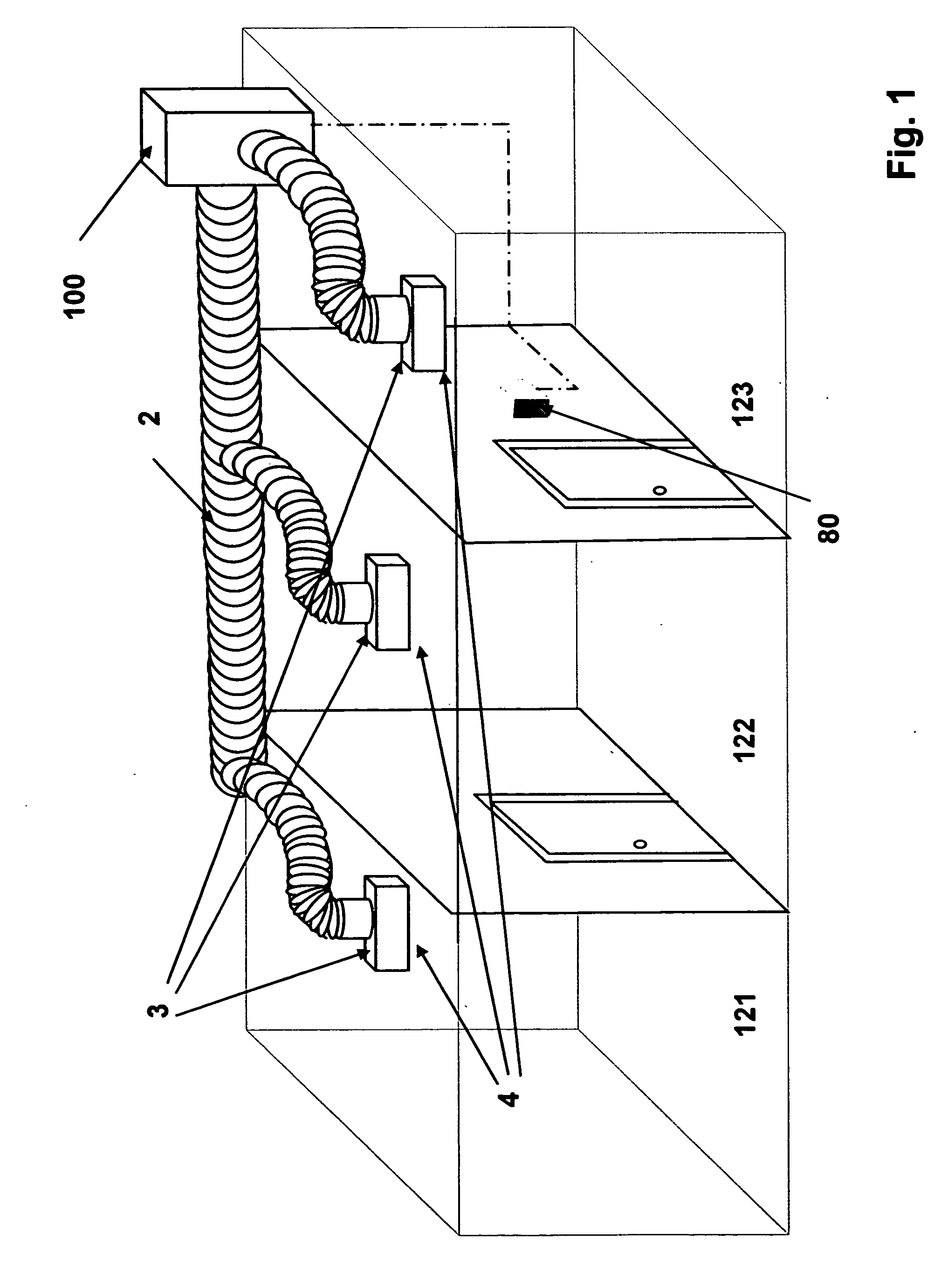

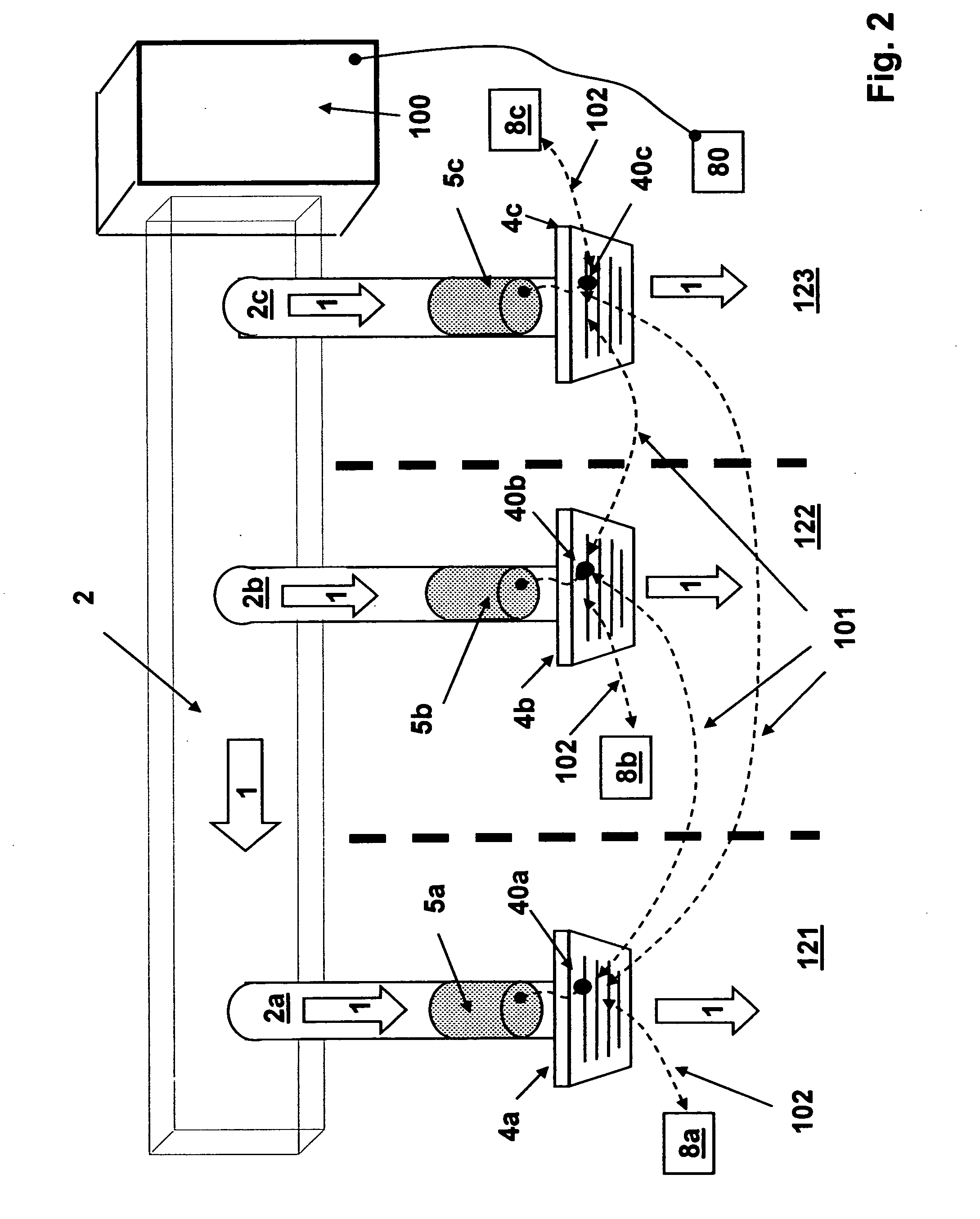

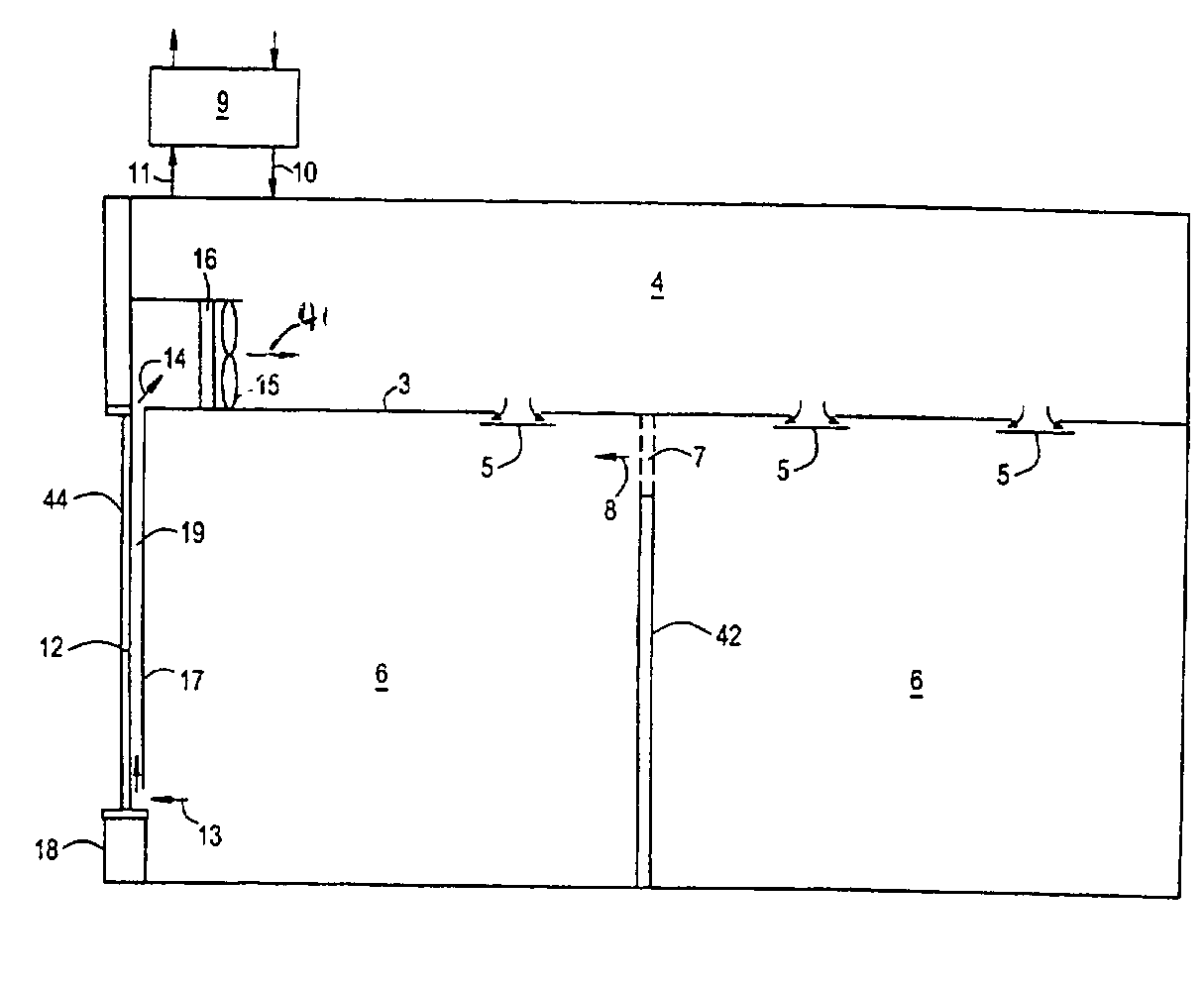

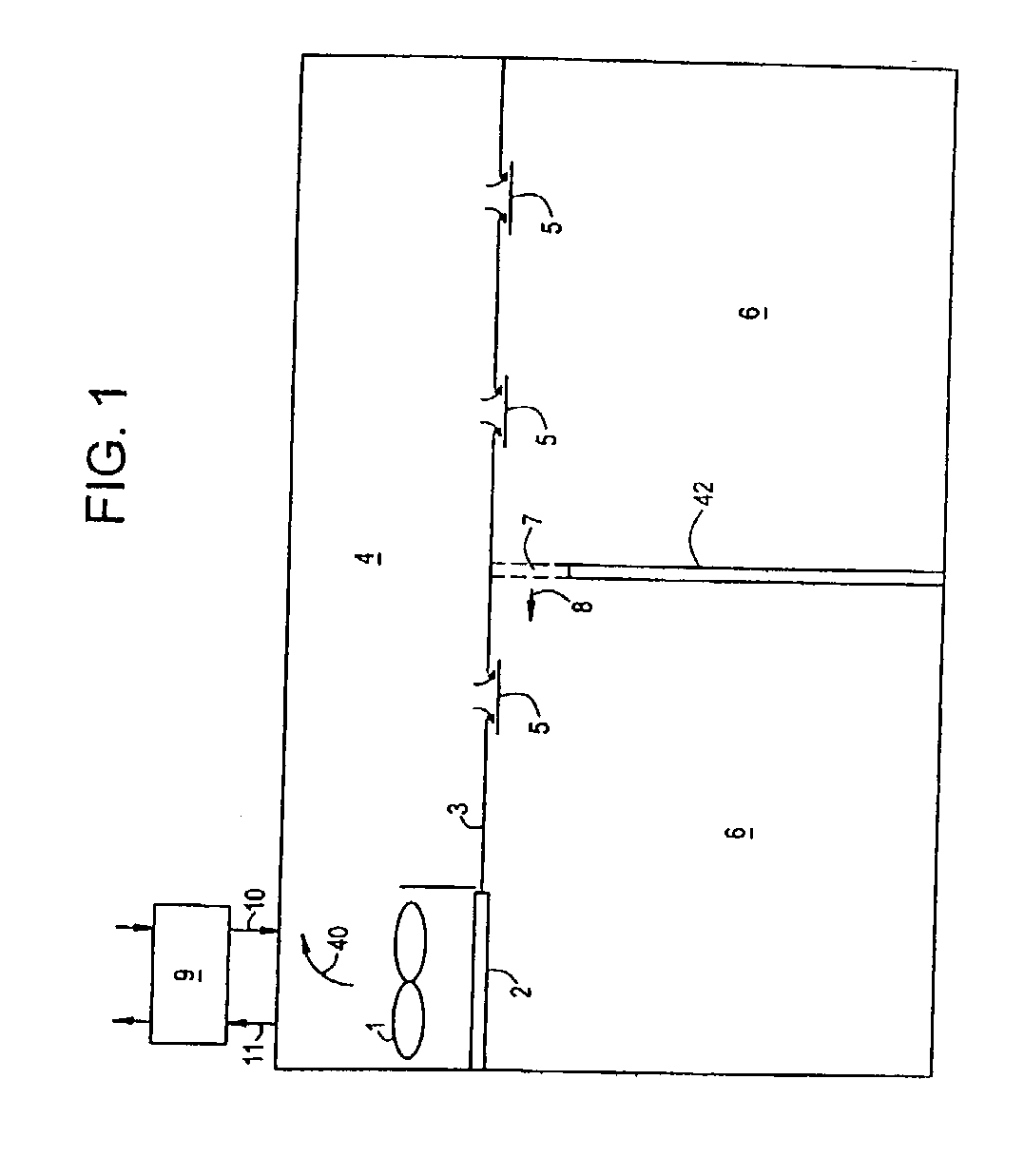

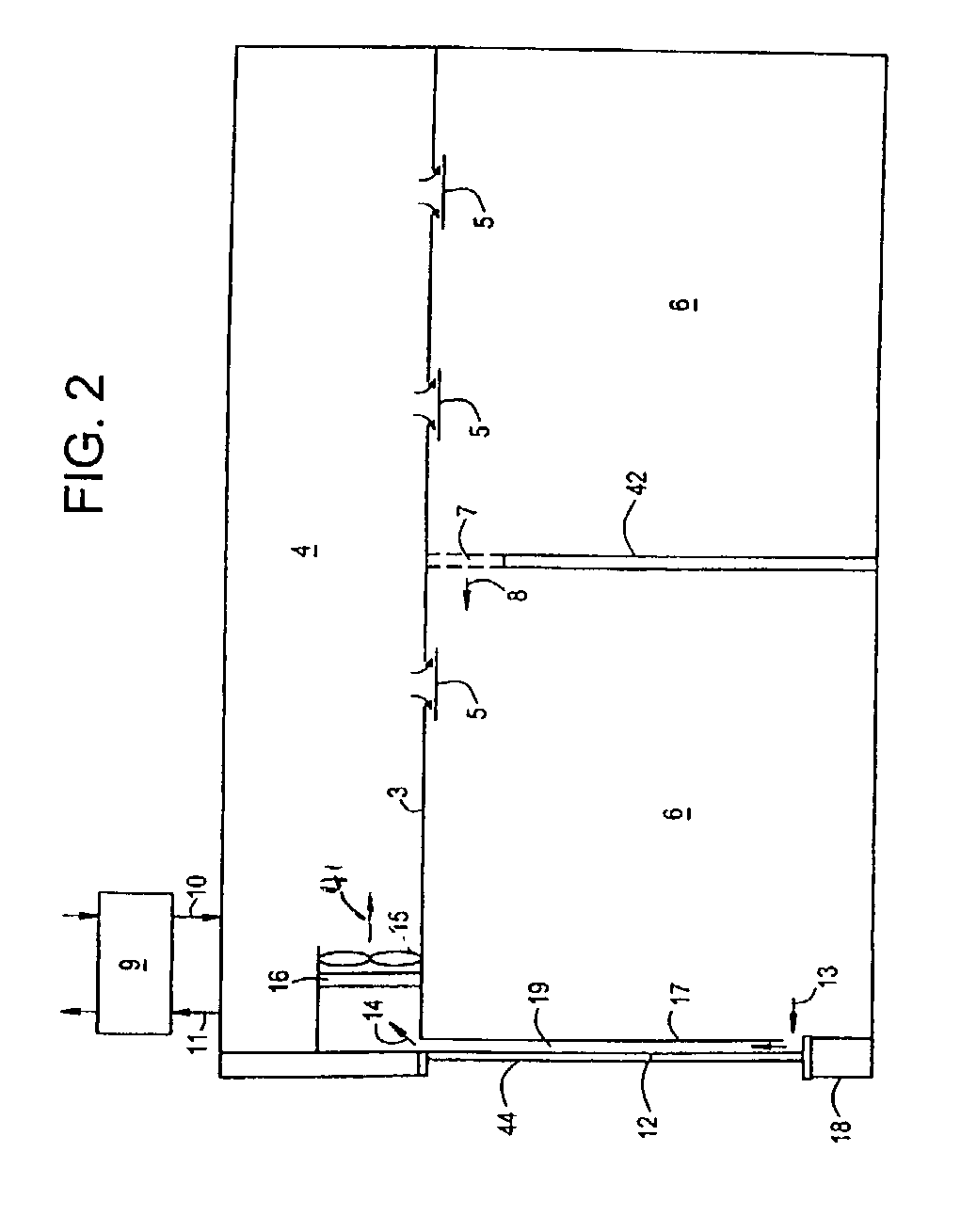

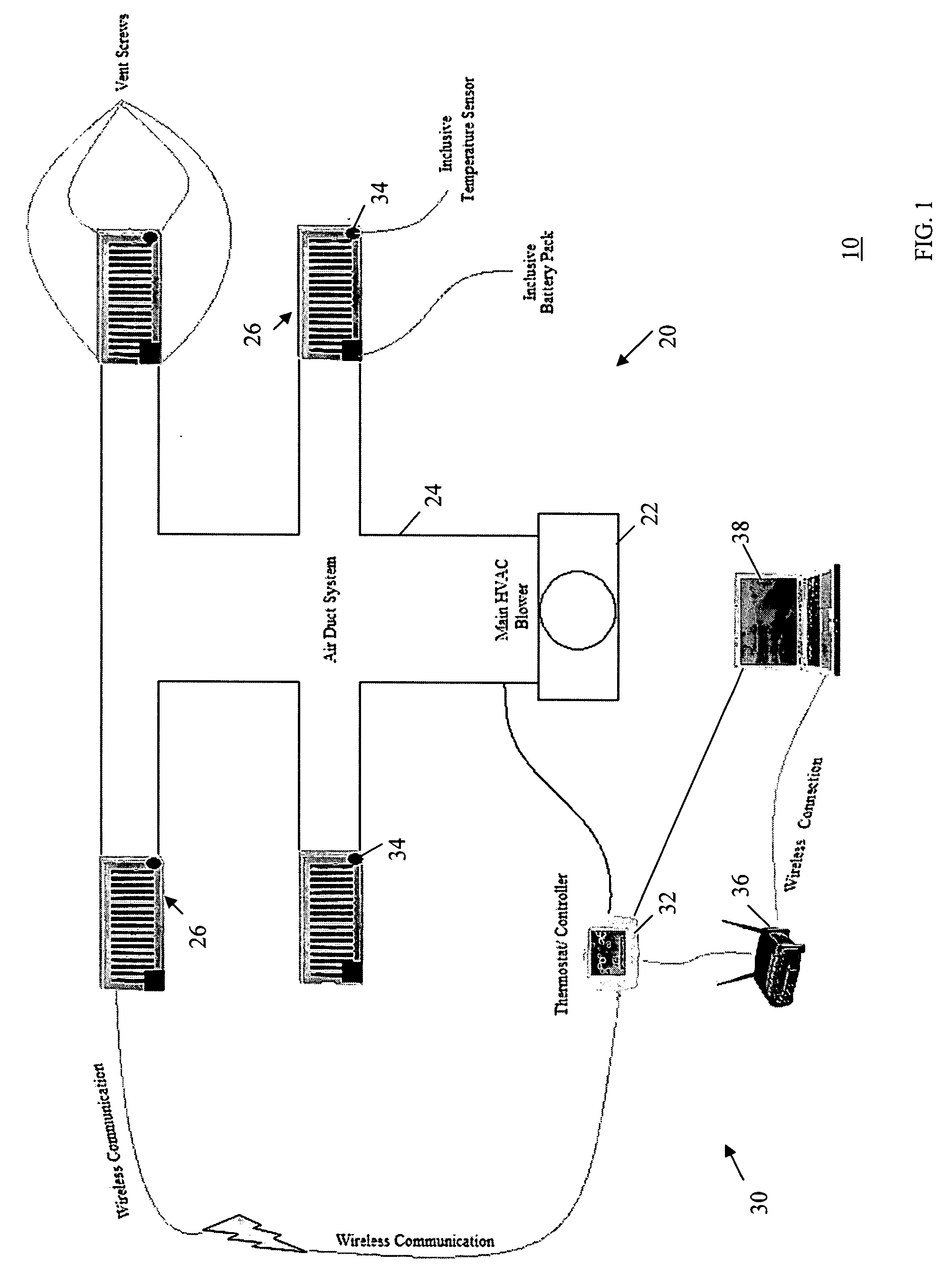

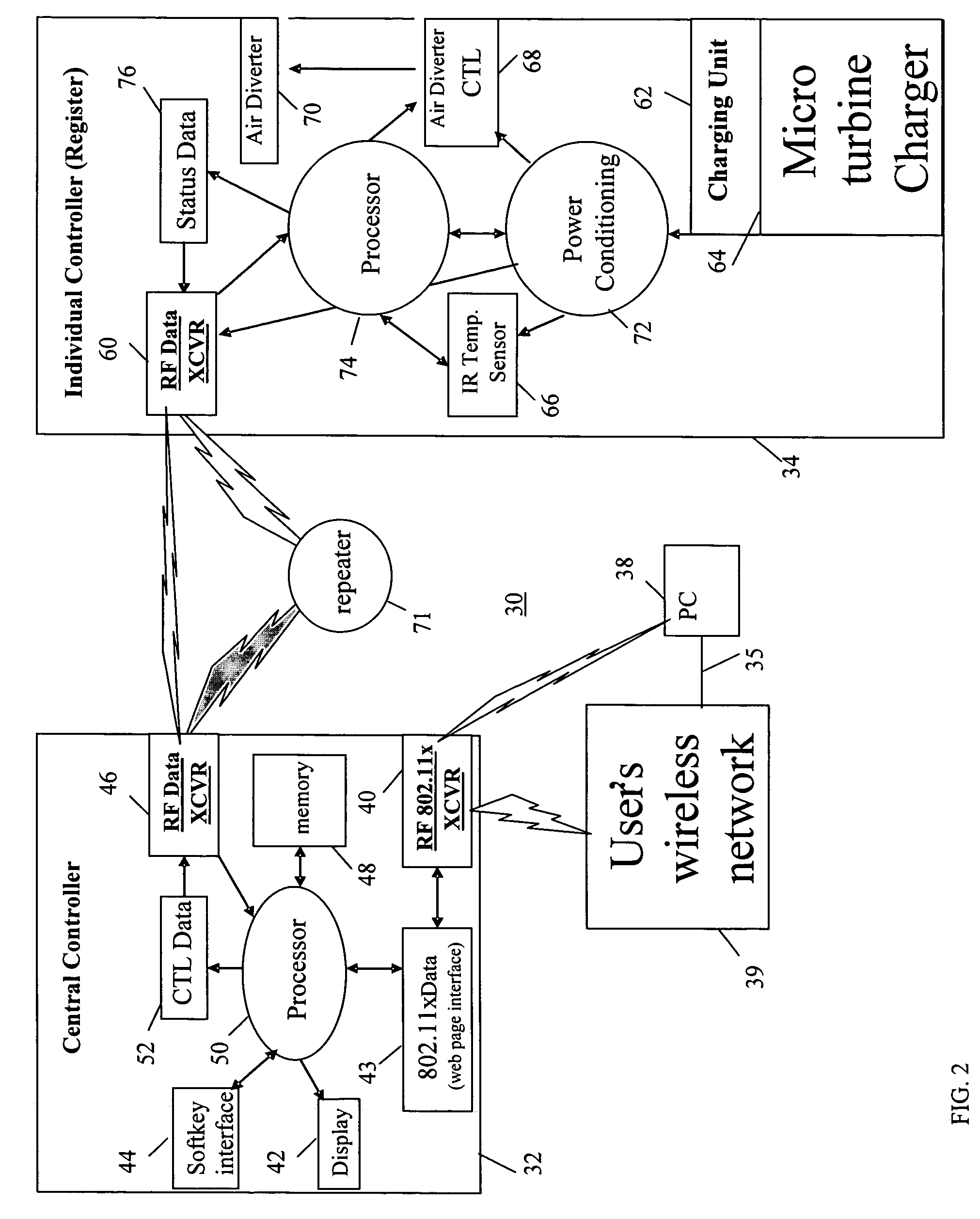

Remote autonomous intelligent air flow control system and network

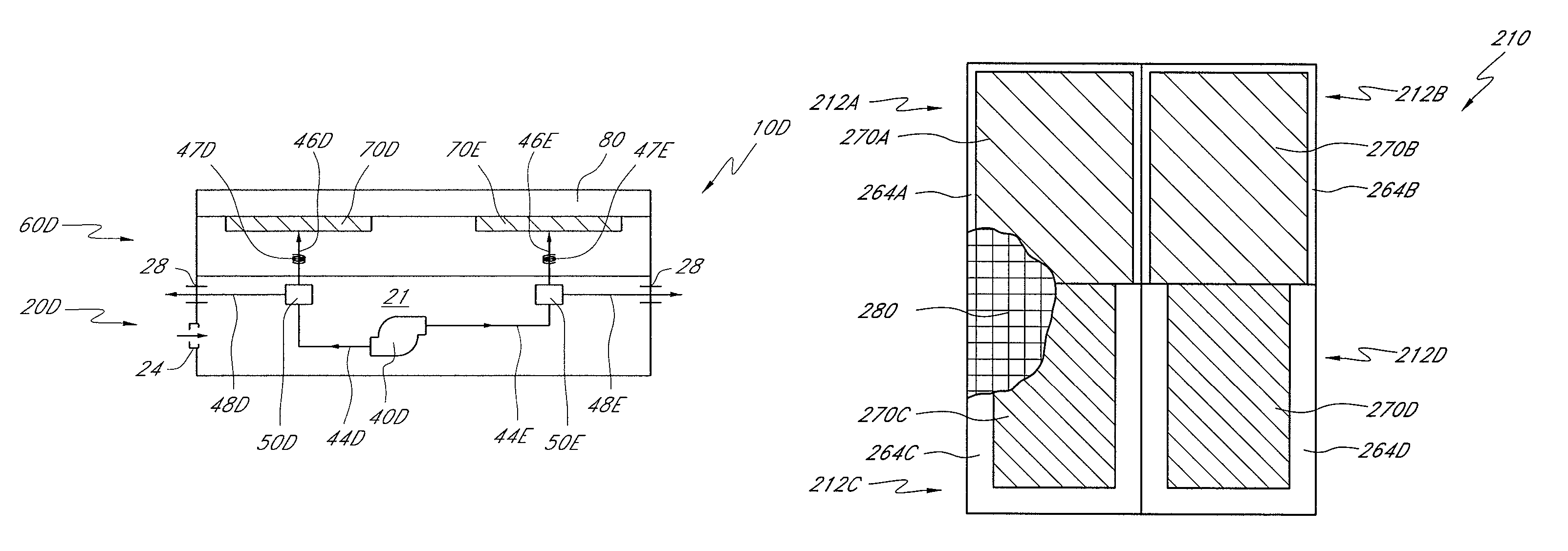

InactiveUS20060105697A1Eliminate needIncrease local flowDucting arrangementsMechanical apparatusControl systemEngineering

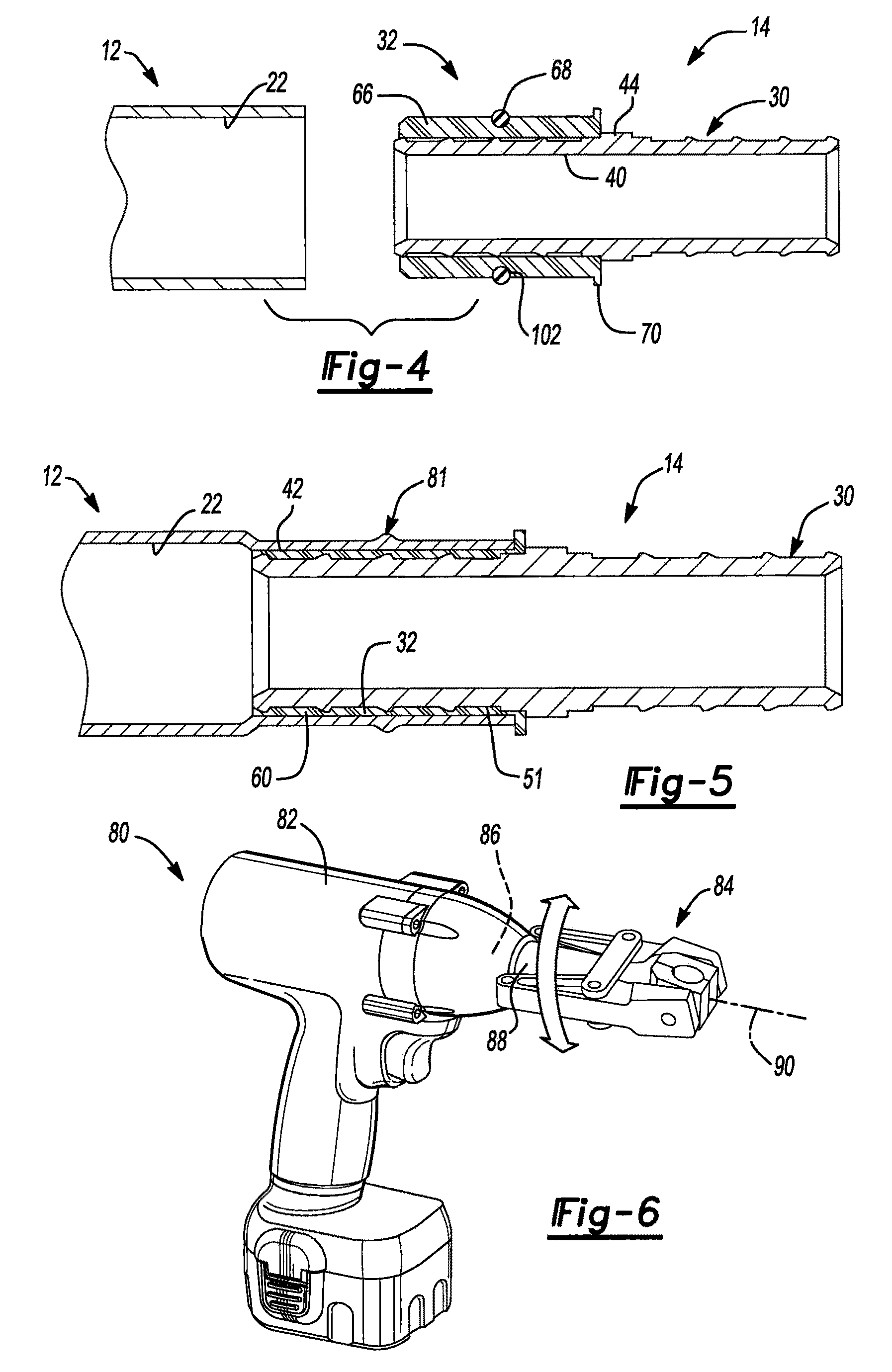

The present invention provides one or more autonomous in-duct or register grill mounted flow control devices, each of which has the capability to restrict or boost air flow through the duct or vent to which it is attached. The individual flow control devices may be in communication with other flow control devices in the duct works, having an ability to adapt in a cooperative fashion to optimize the environment served by the ductwork. In a preferred embodiment, each of the flow control devices provides its own power and does not require changing the existing ductwork or register boxes for installation.

Owner:ARONSTAM PETER S

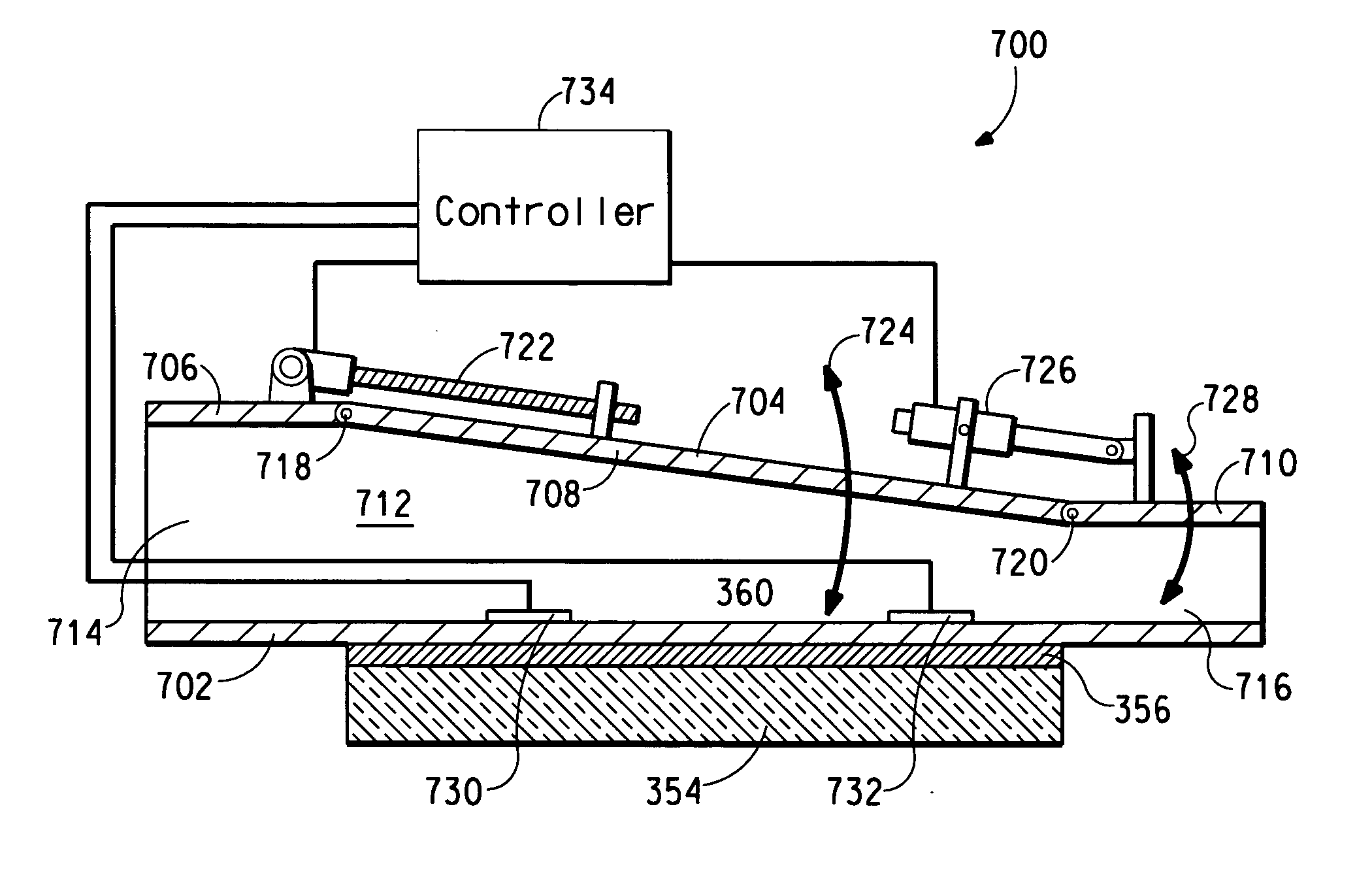

Air conditioned bed

A climate controlled bed comprises a cushion member having an outer surface comprising a first side for supporting an occupant and a second side, the first side and the second side generally facing in opposite directions. In some embodiments, the cushion member includes one or more recessed areas along its first side or its second side. In one embodiment, the bed further includes a support structure having a top side configured to support the cushion member, a bottom side and an interior space generally located between the top side and the bottom side, the top side and the bottom side of the support structure generally facing in opposite directions, a flow conditioning member that may be at least partially positioned with the recessed area of the cushion member, an air-permeable topper member positioned along the first side of the cushion member and a fluid temperature regulation system. The fluid temperature regulation system includes a fluid transfer device, a thermoelectric device and a conduit system generally configured to transfer a fluid from the fluid transfer device to the thermoelectric device. The fluid temperature regulation system is configured to receive a volume of fluid and deliver it to the flow conditioning member and the topper member.

Owner:SLEEP NUMBER CORP

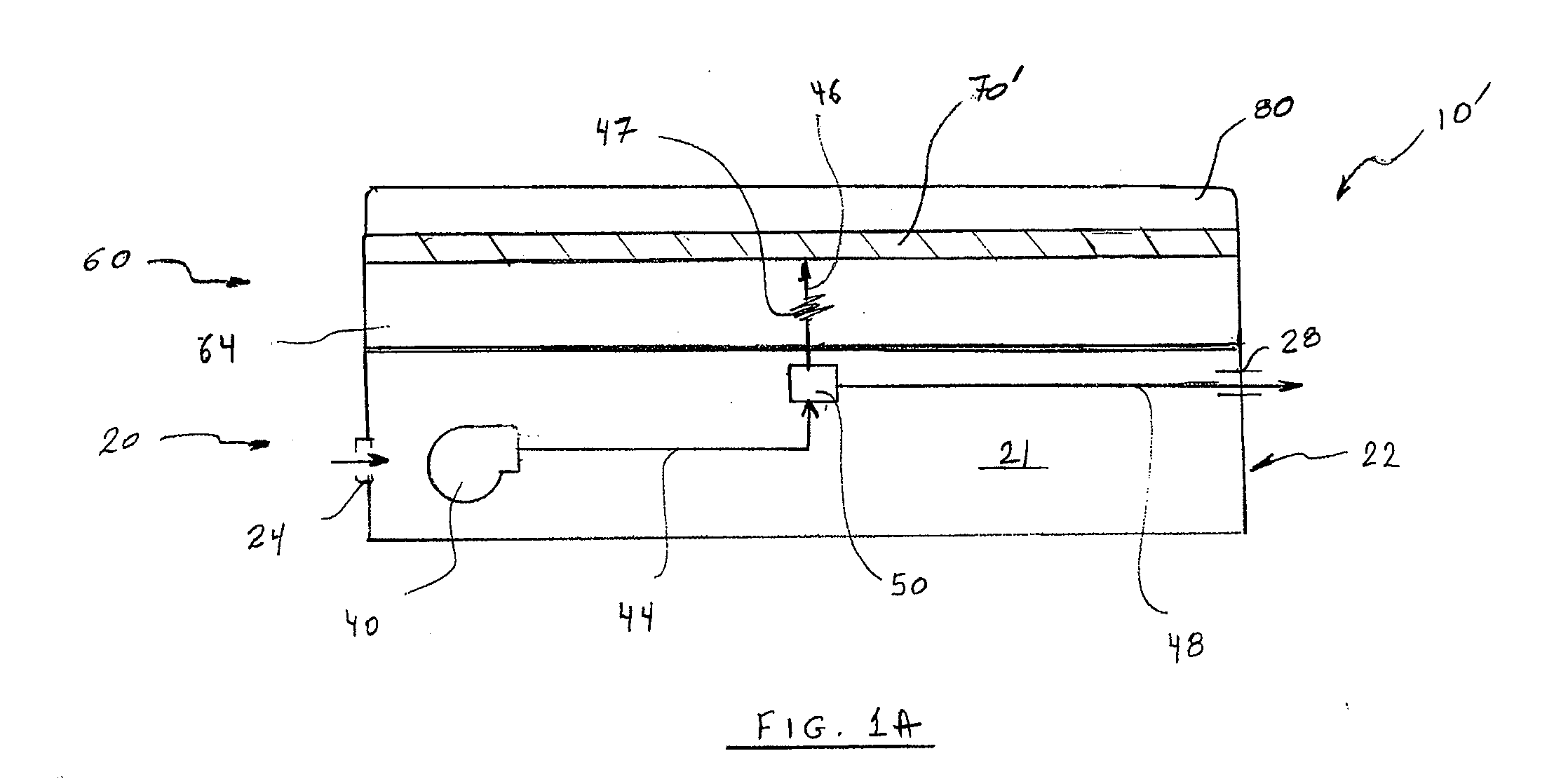

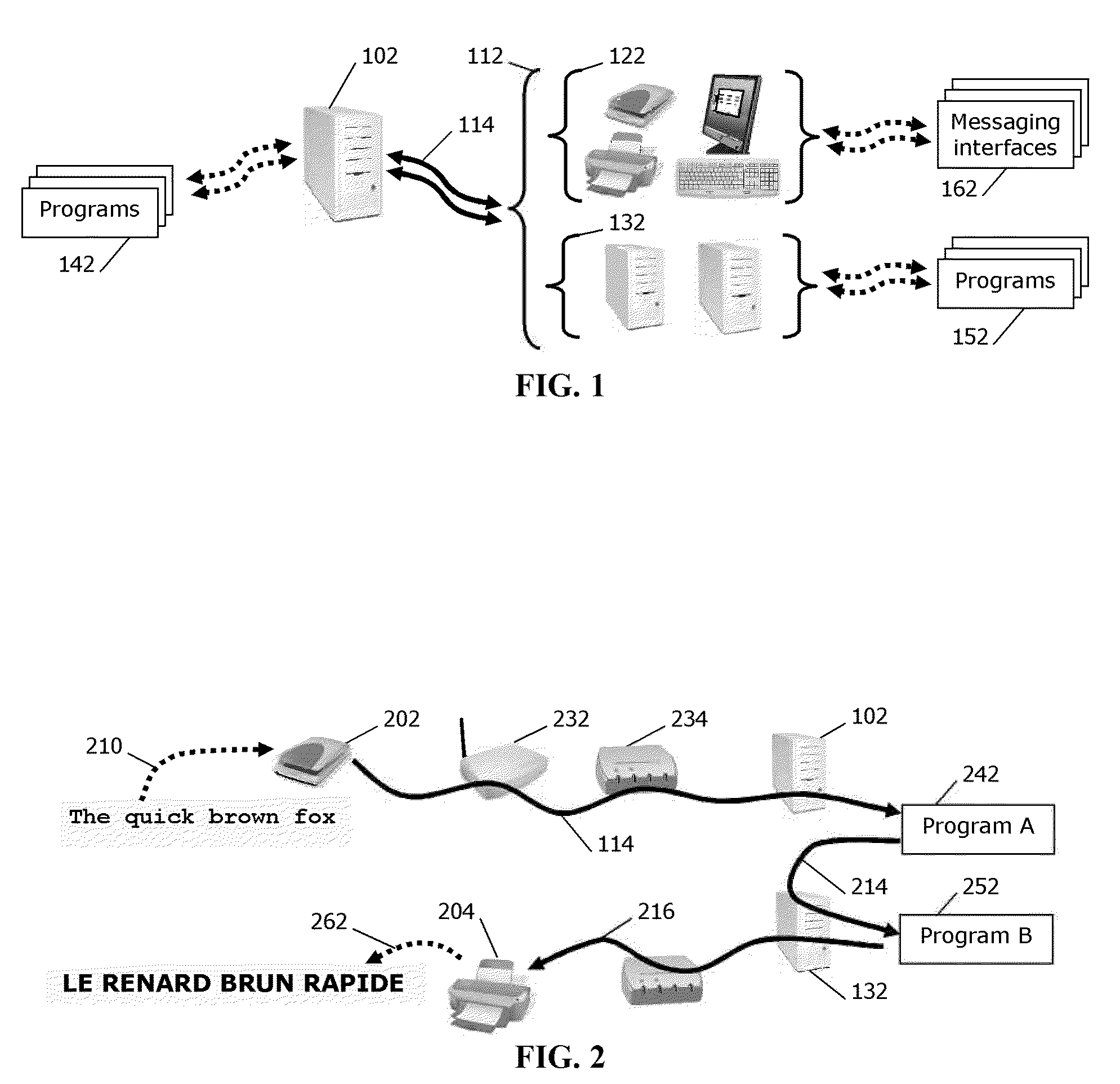

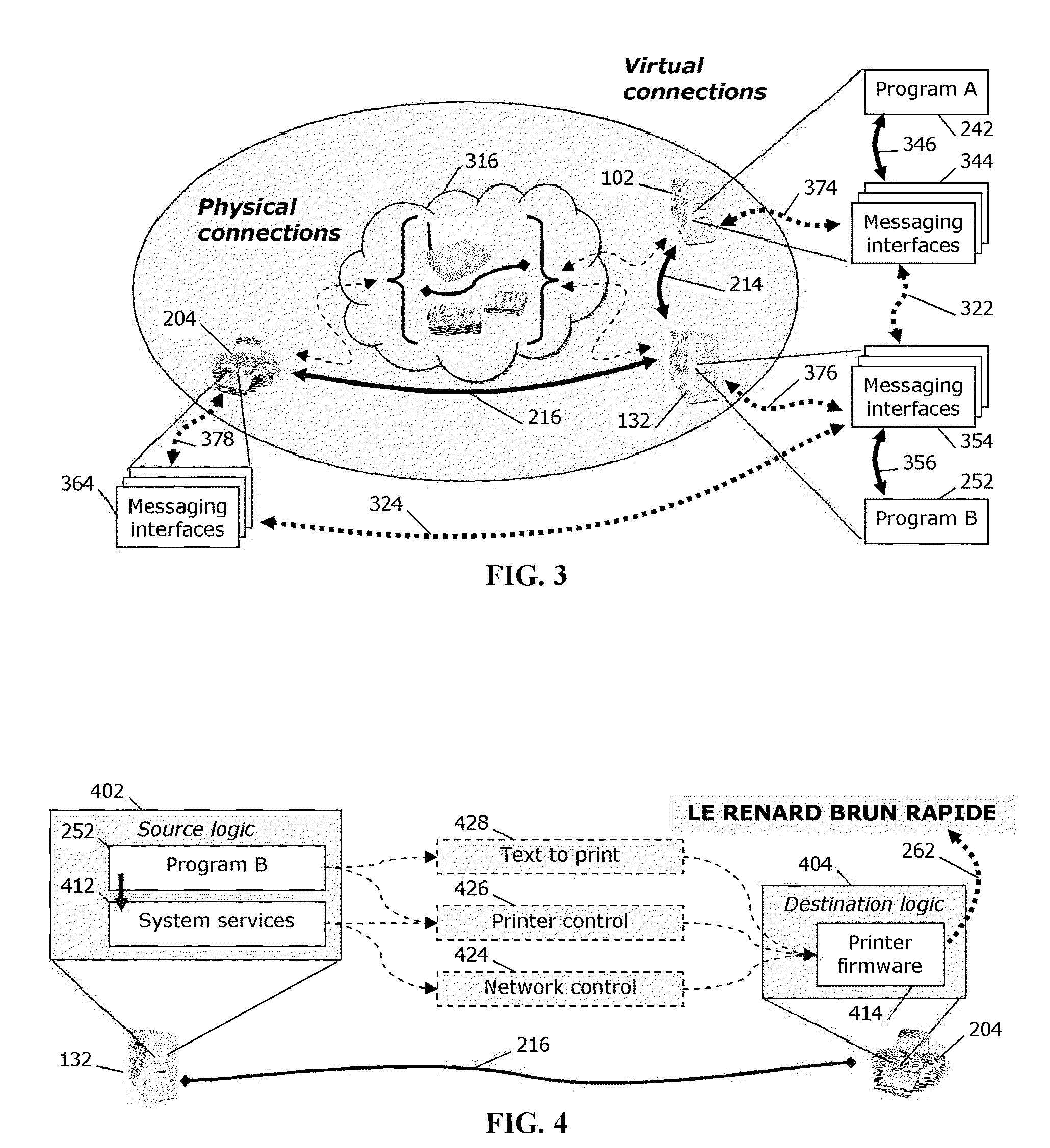

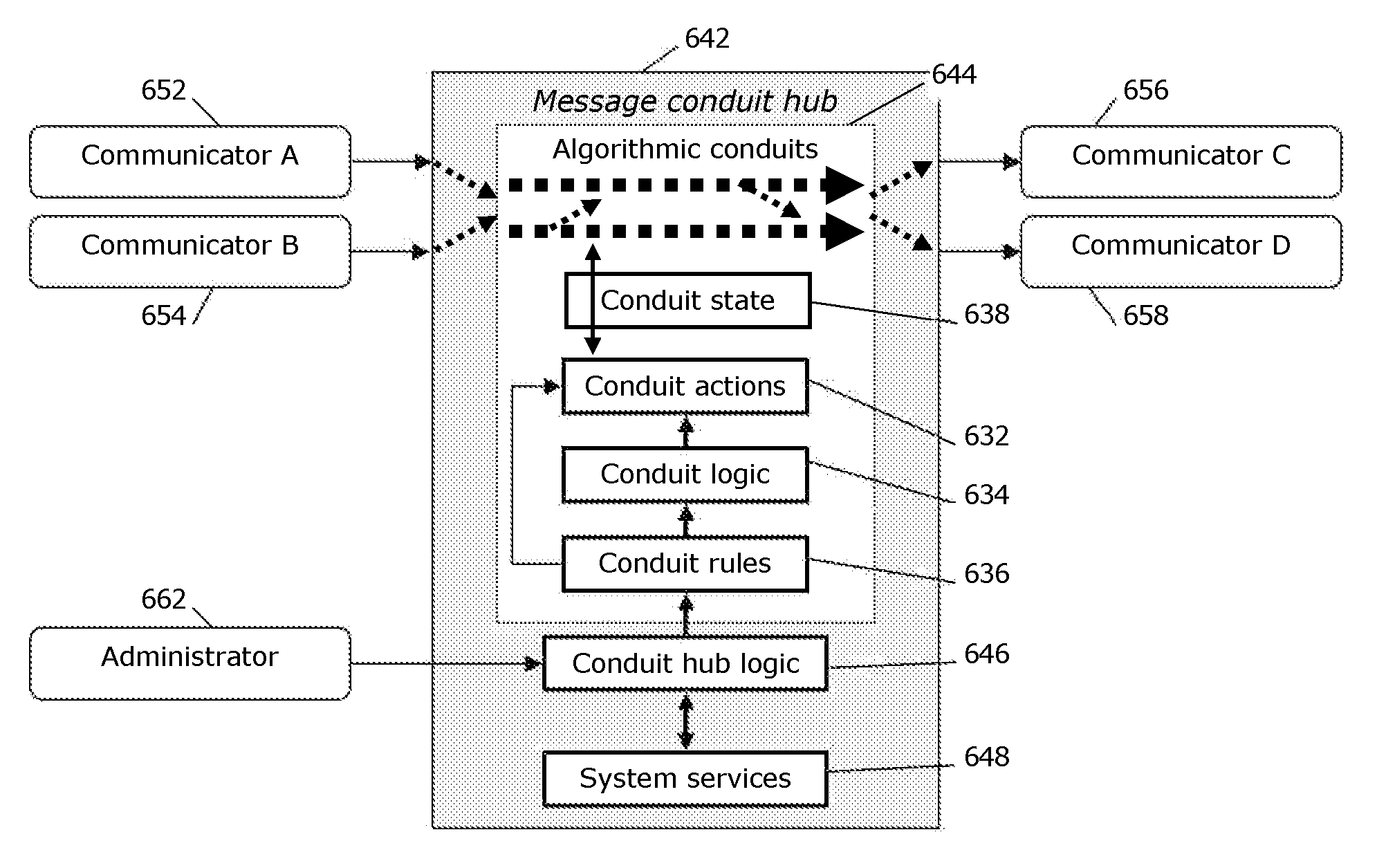

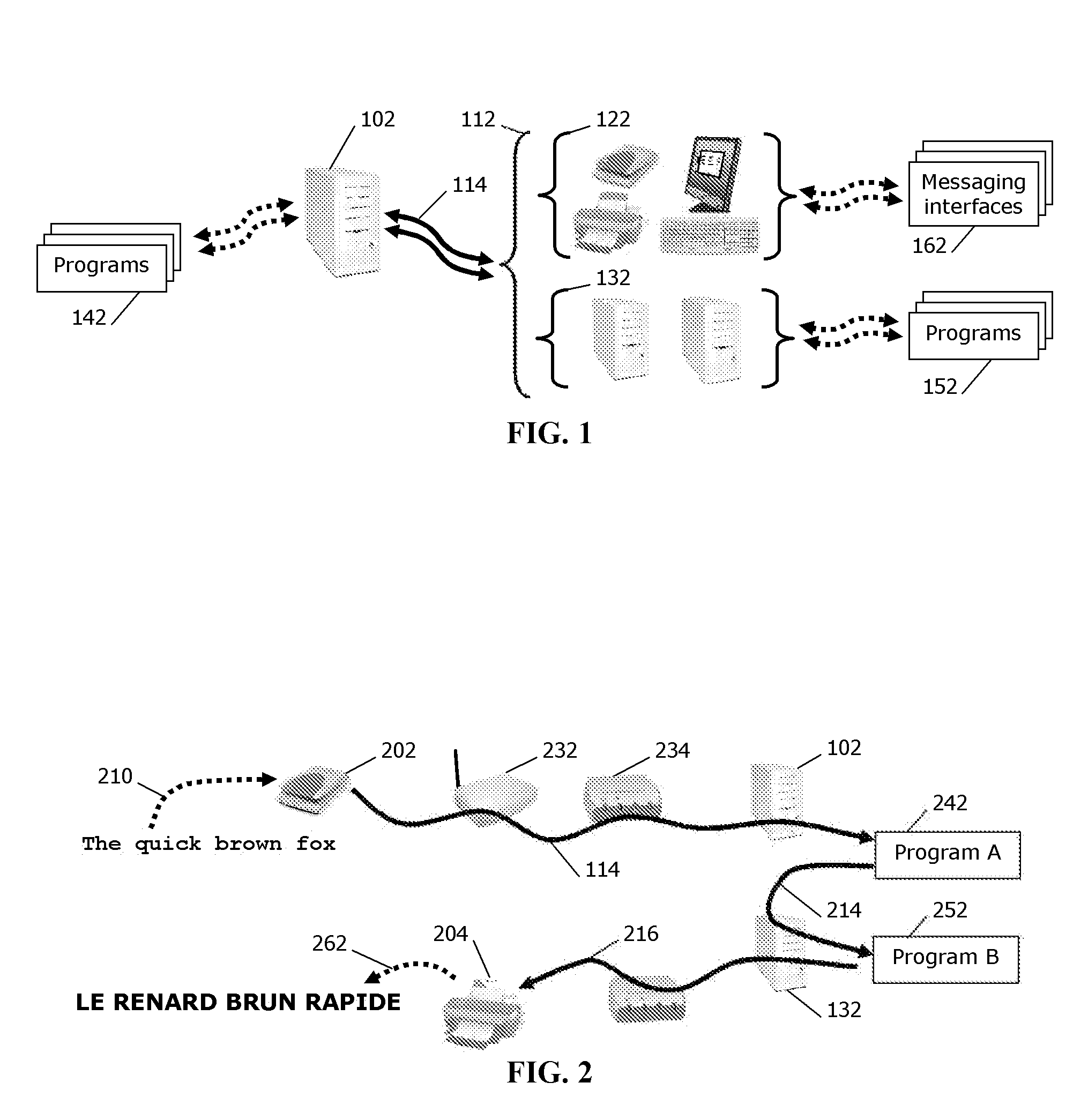

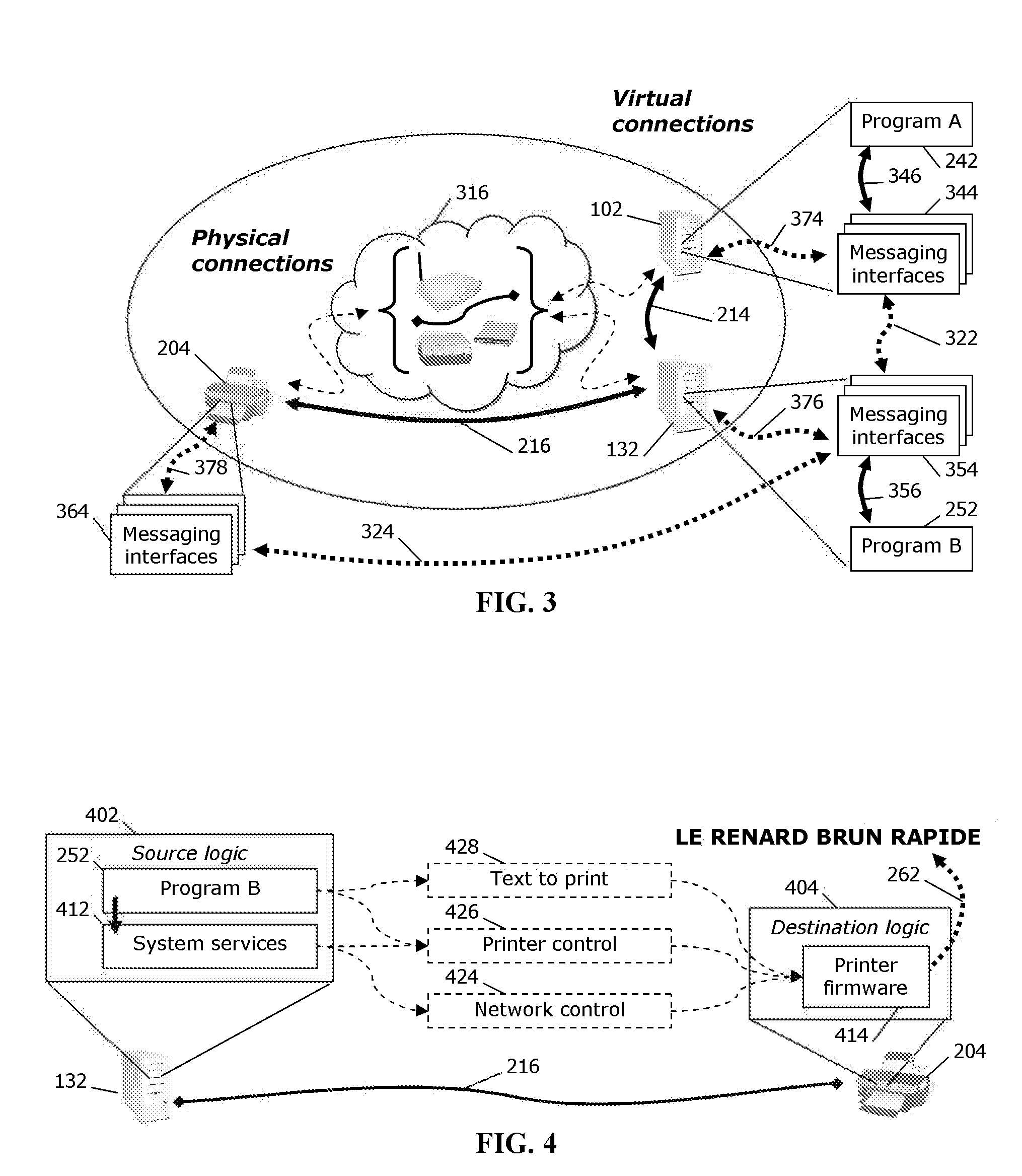

Message conduit systems with algorithmic data stream control and methods for processing thereof

InactiveUS20090259612A1Simple designEasy to build programKnowledge representationTransmissionVirtualizationManagement algorithm

A method for processing messages is provided where at least one algorithmic conduit is defined, and at least one conduit rule for controlling at least one algorithmic conduit is defined. An algorithmic conduit is a persistent connection, controlled by explicit, independent, dynamic rules, and capable of processing messages among data communicators such as devices, systems, or programs. Messages can be monitored, filtered, transformed, correlated, or processed in other ways without modifying the data communicators. A message conduit hub system allows creation and management of algorithmic conduits to serve as active, virtualized links carrying rules-based data streams among configurable endpoints. These “smart” connections are managed using parameters, logic, and other control interfaces for tailoring behavior to a particular application, site, or user. A message conduit hub system may be implemented as a stand-alone device, as part of a larger system, or as an “encapsulation layer” for an existing application.

Owner:HANSON TREVOR

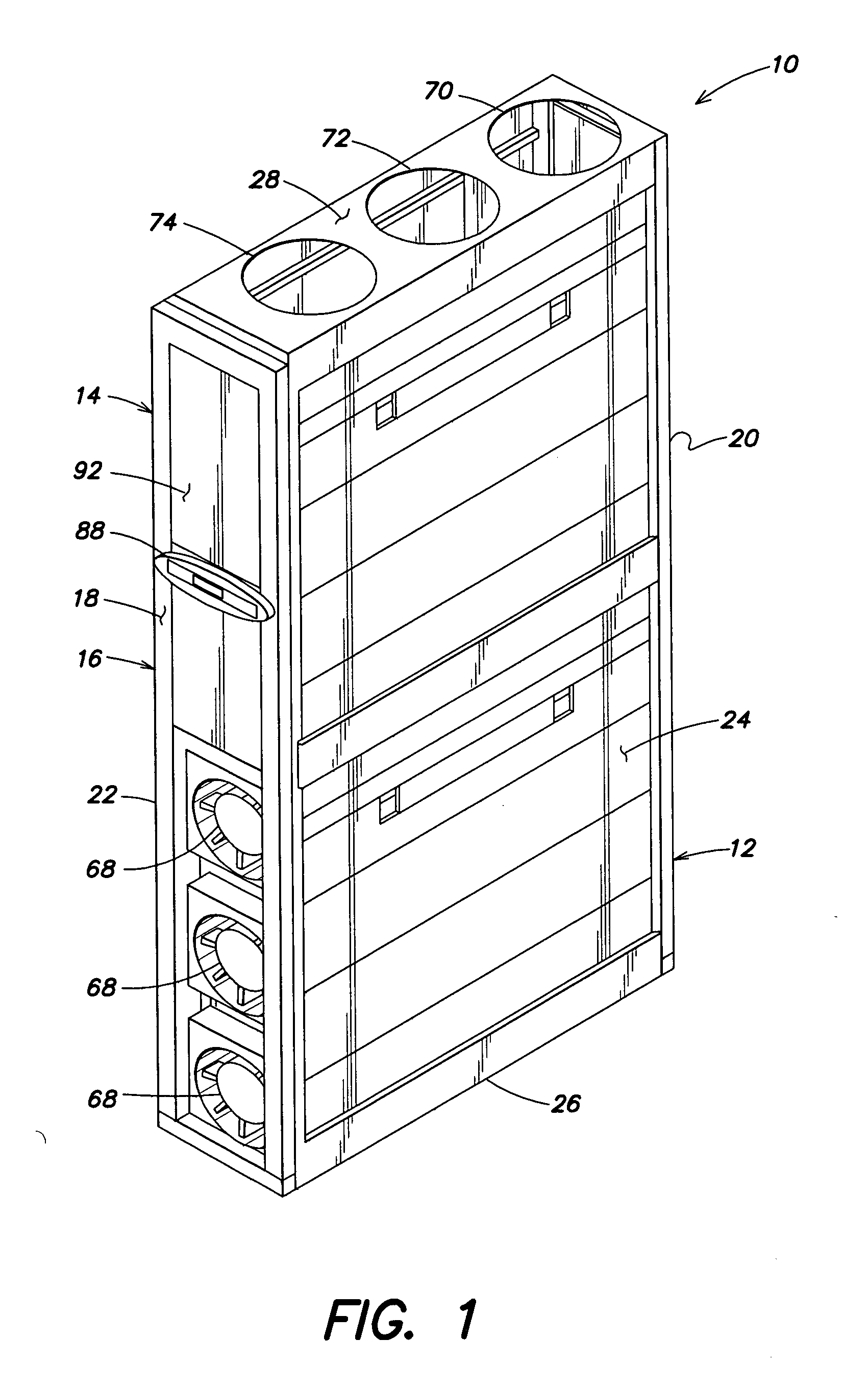

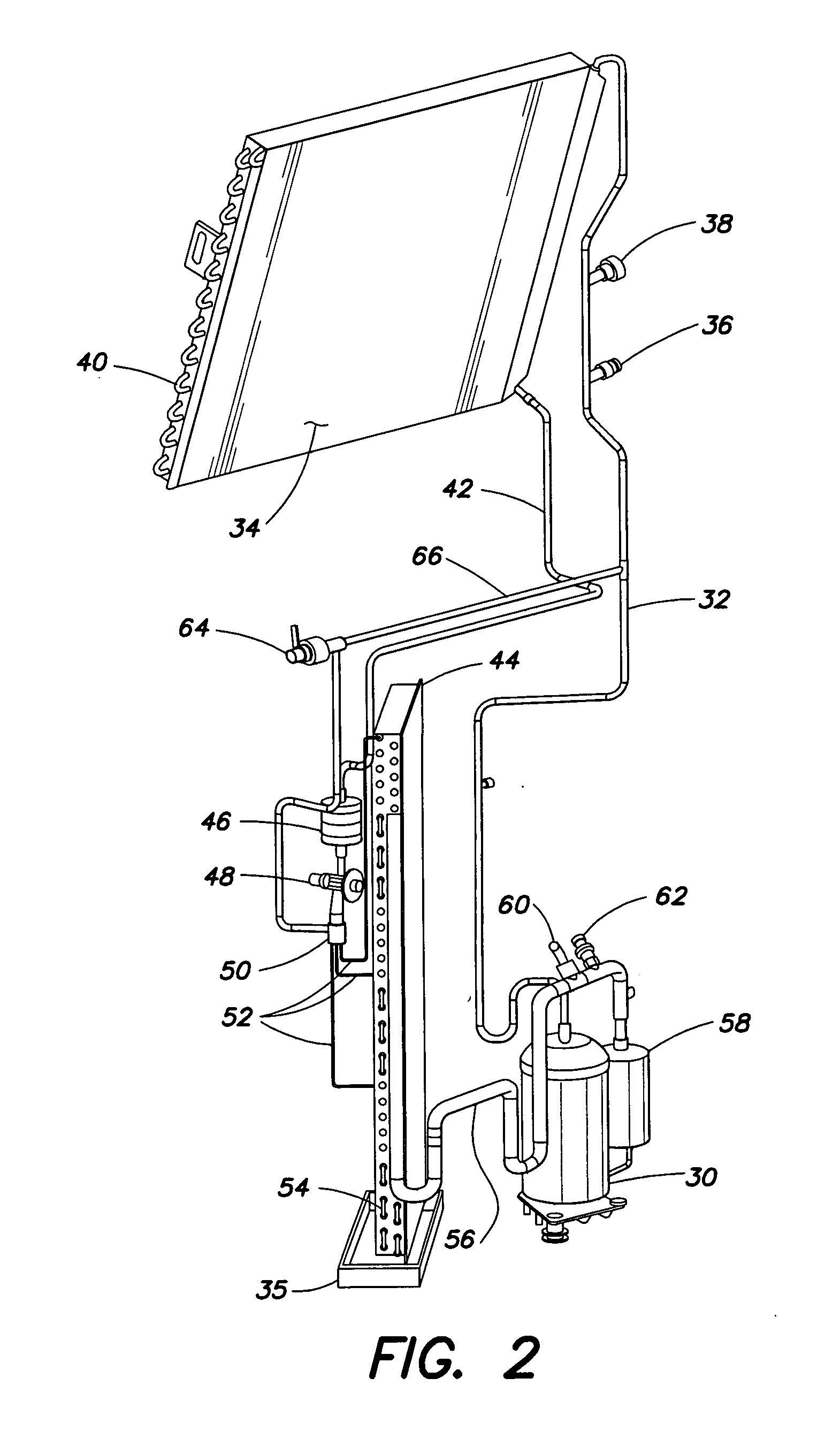

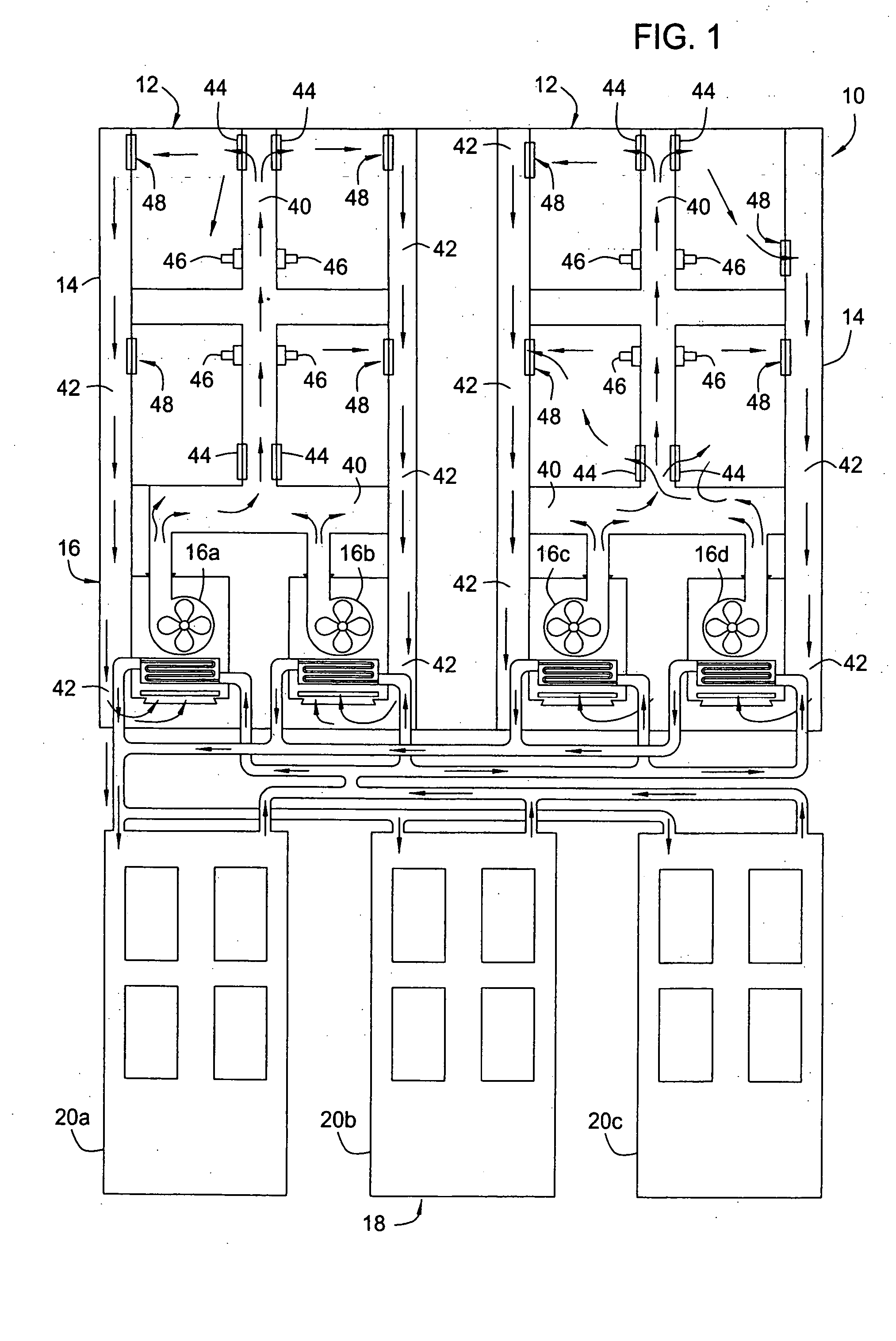

Method and apparatus for cooling

A cooling unit includes a first module having a first intake opening and a first exhaust opening formed therein. At least one first air moving device may be configured to draw air along a first flow path from the first intake opening to the first exhaust opening. A first heat exchanger may be positioned in the first flow path. The cooling unit may further include a second module having a second intake opening and a second exhaust opening. At least one second air moving device may be configured to draw air along a second flow path from the second intake opening and direct air to the second exhaust opening. A second heat exchanger may be positioned in the second flow path. A conduit system is in fluid communication with the first heat exchanger and the second heat exchanger. The conduit system may be configured to deliver coolant from the first heat exchanger of the first module to the second heat exchanger of the second module and from the second heat exchanger of the second module to the first heat exchanger of the first module. Methods of cooling a space with a cooling unit are further disclosed.

Owner:AMERICA POWER CONVERSION CORP

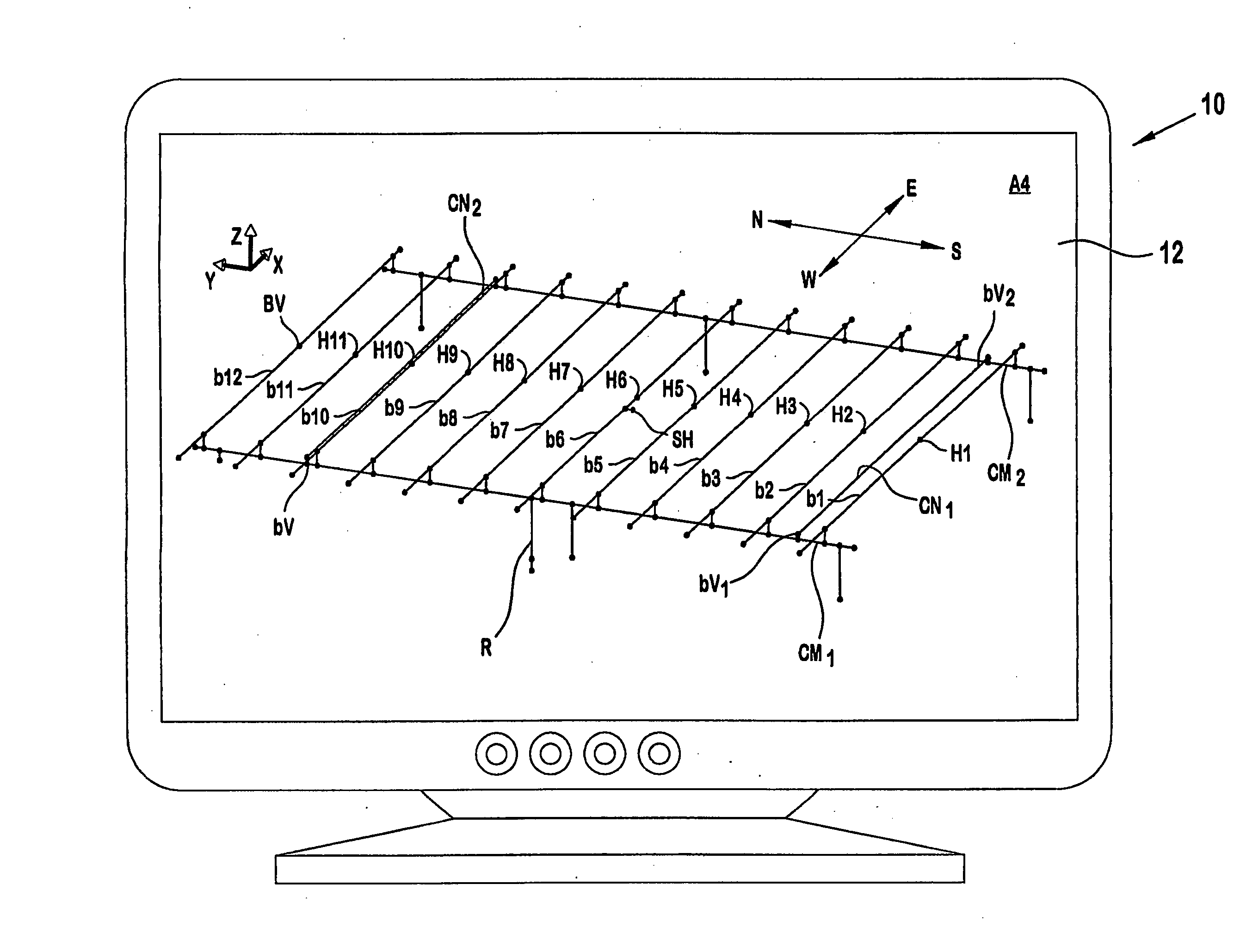

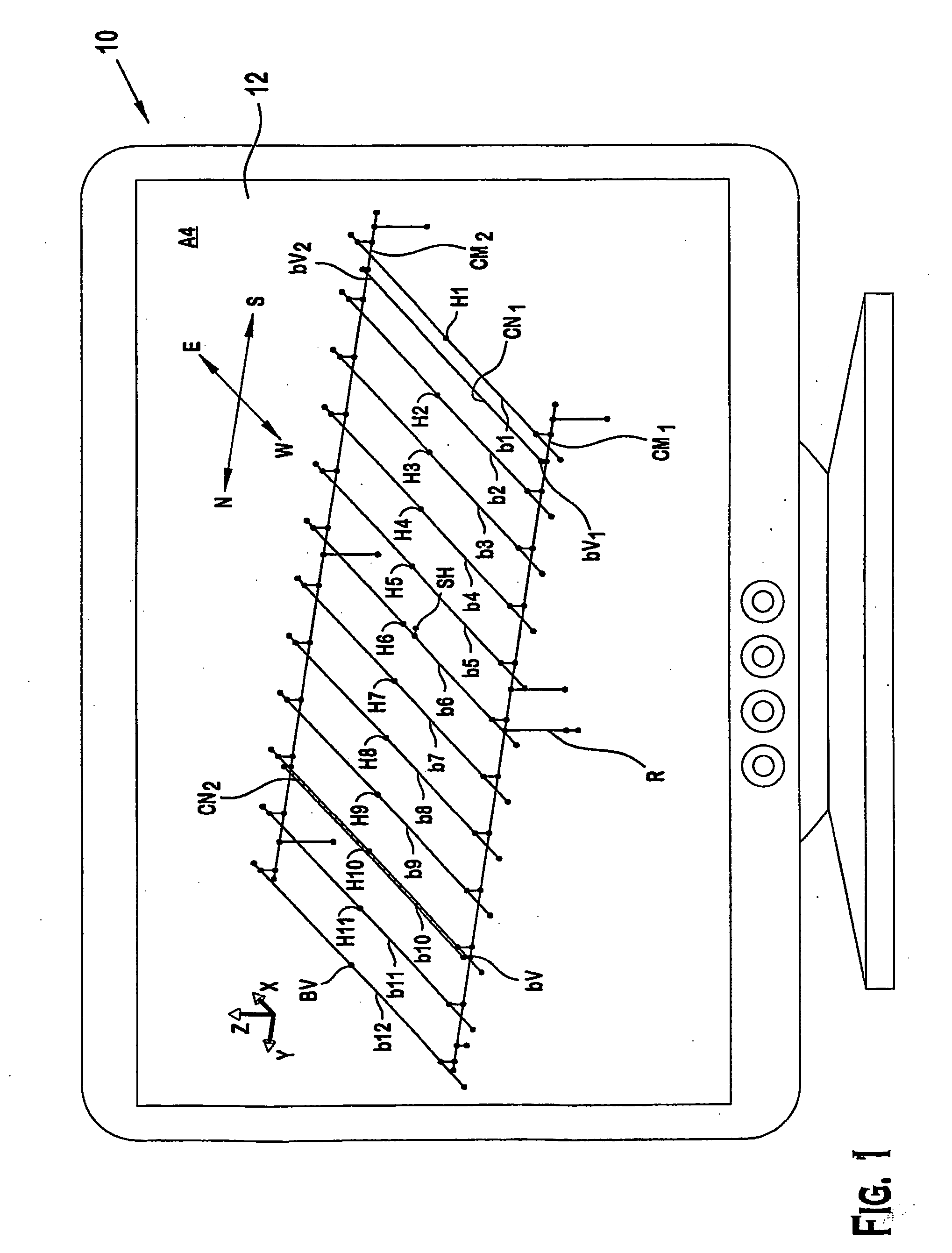

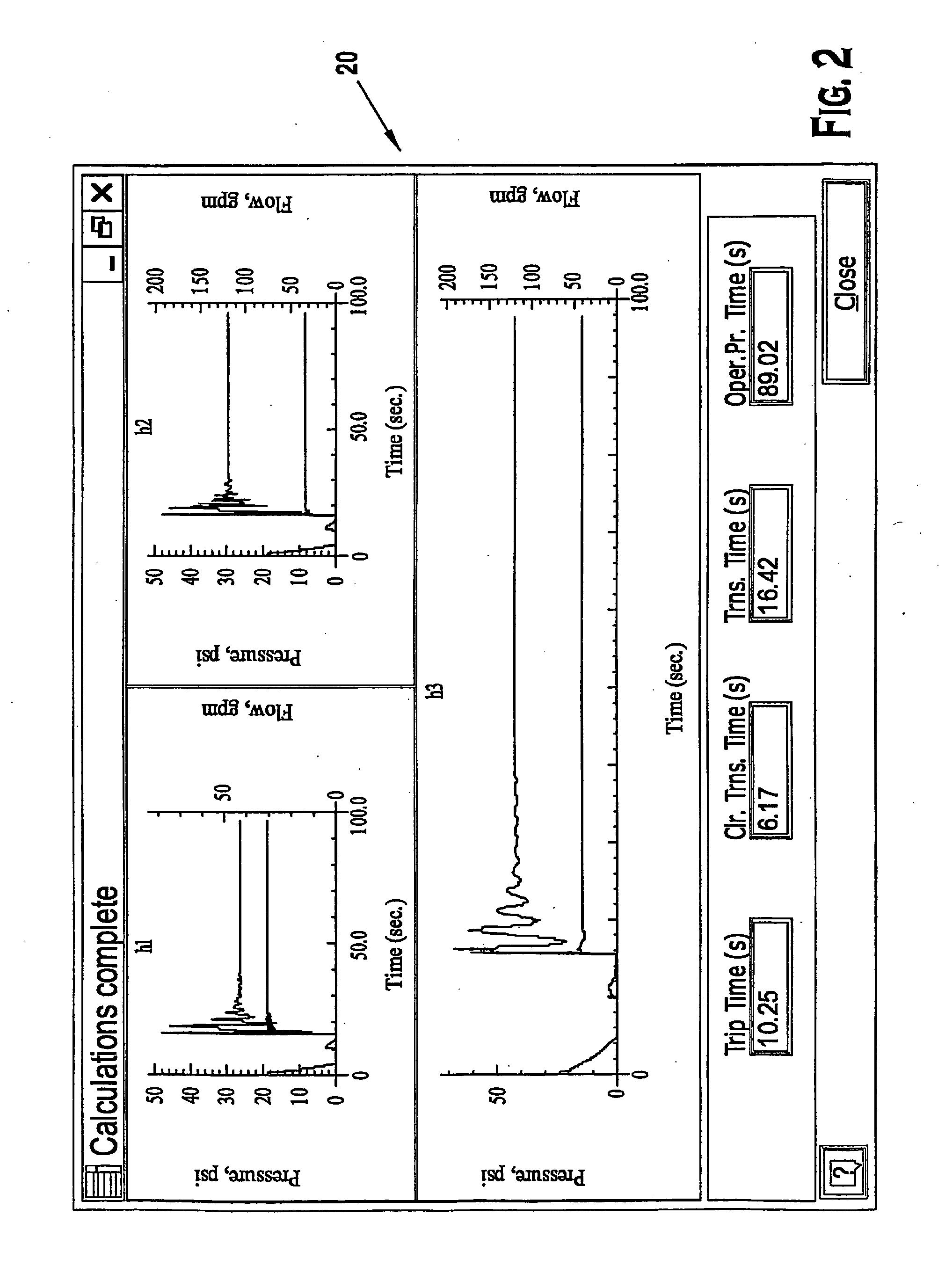

System and method for evaluation of fluid flow in a piping system

A method to model a complex system of pipes. The model takes into account the physical processes in a tree-type piping system and provides for an accurate modeling of a real world tree-type piping system. In a preferred embodiment, a computer program is provided for analyzing models of dry pipe systems. The computer program includes a user interface and a computational engine. The user interface allows a model of a dry pipe system to be defined and the computational engine determines a liquid flow time through the model of the dry pipe system. The computational engine provides a verification of the liquid flow time in a model of a referential dry pipe system within 20% of an actual liquid flow time in the referential dry pipe system.

Owner:TYCO FIRE PRODS LP

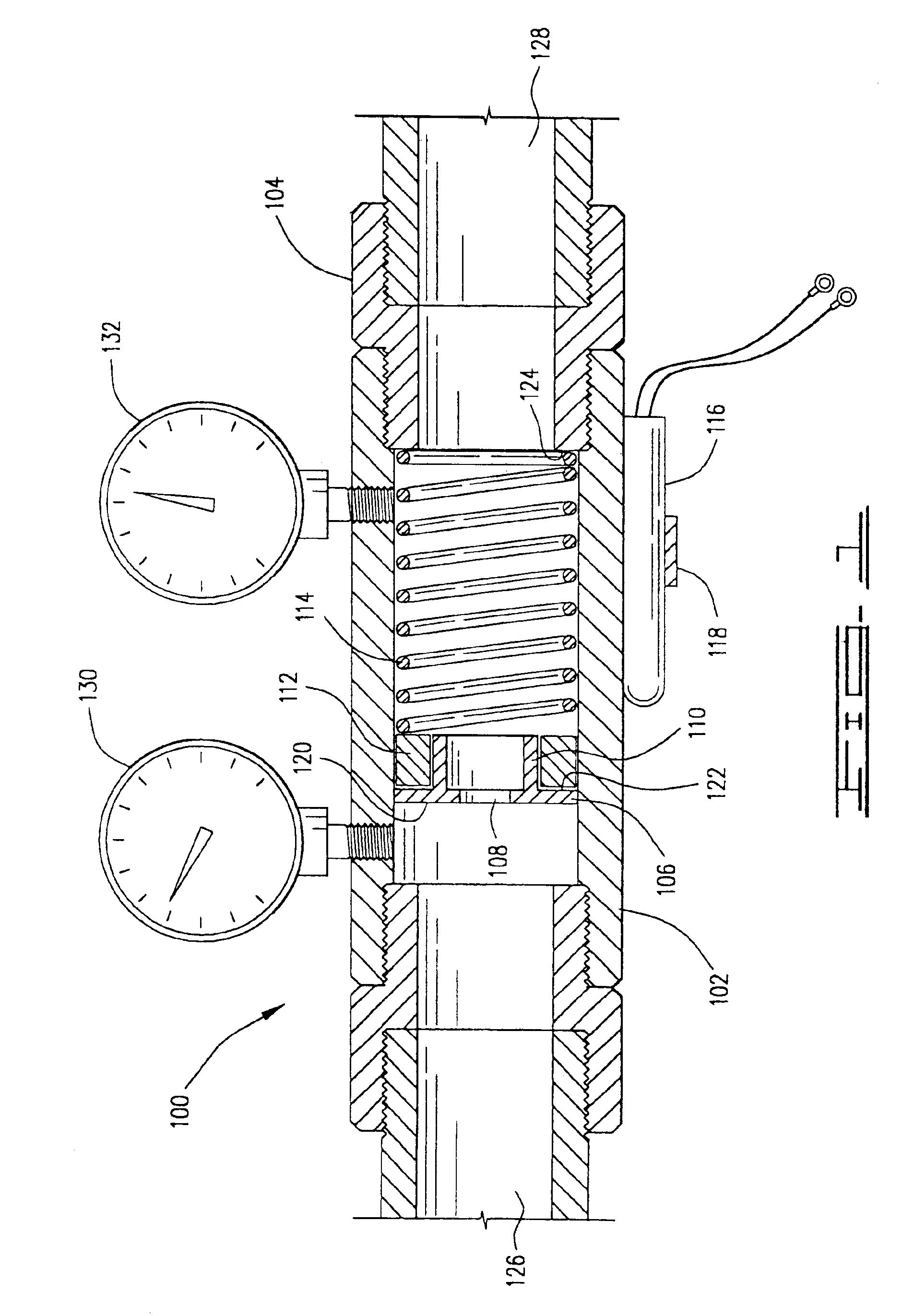

Conduit overheating detection system

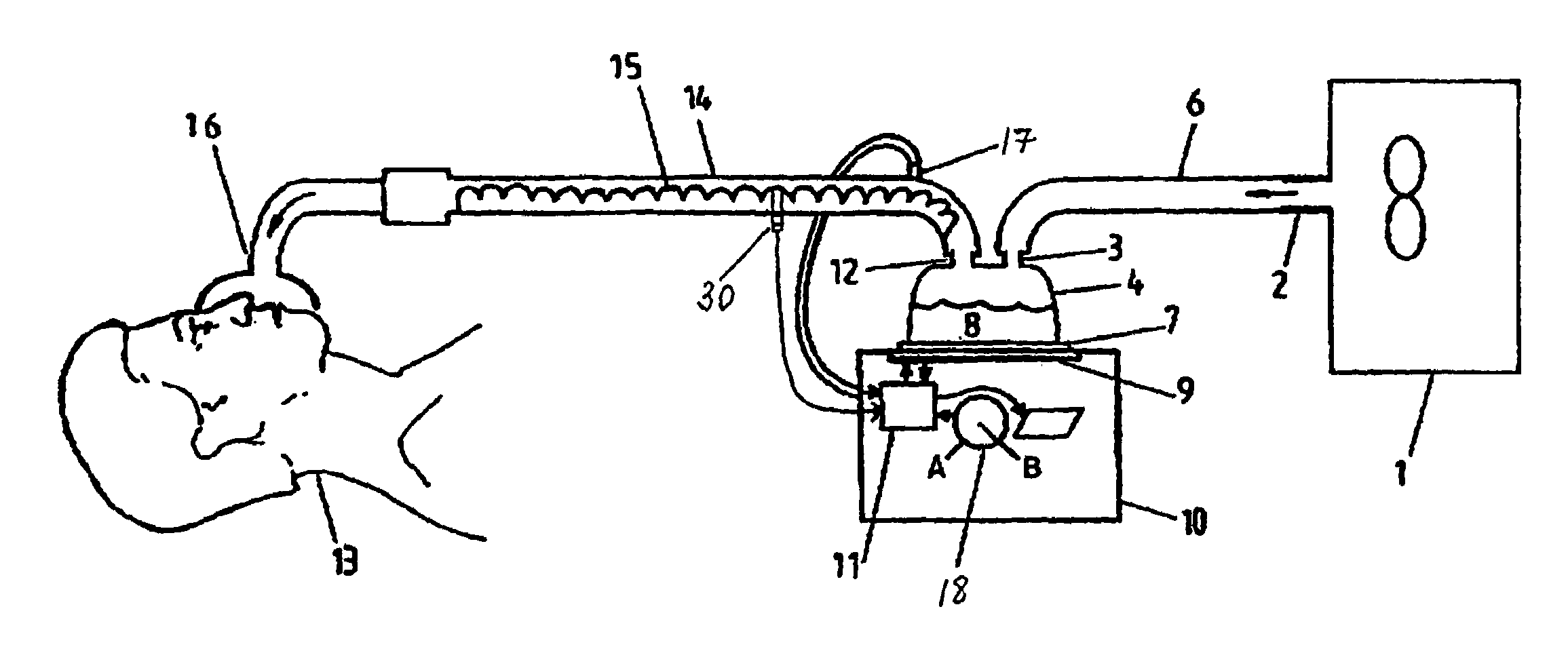

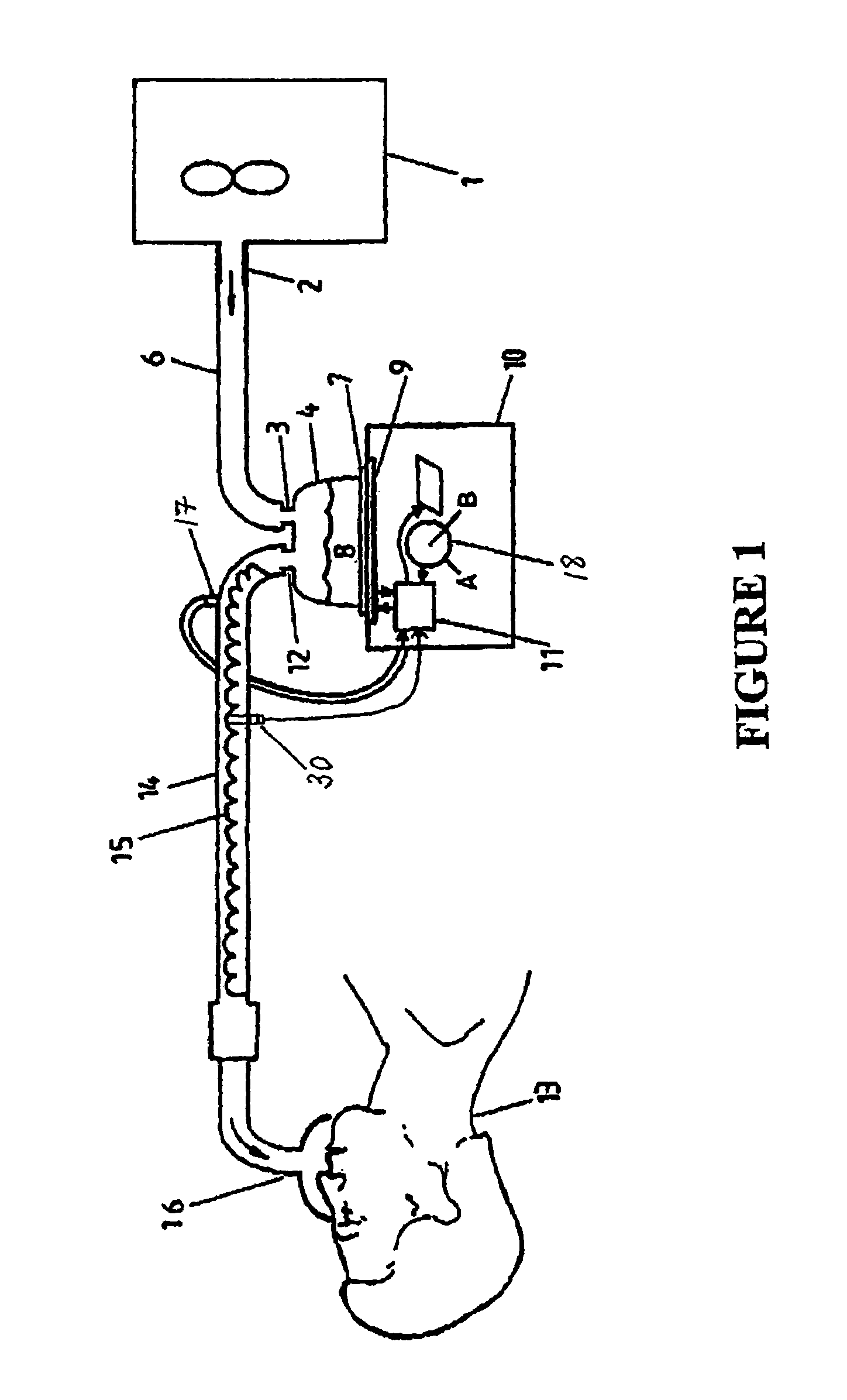

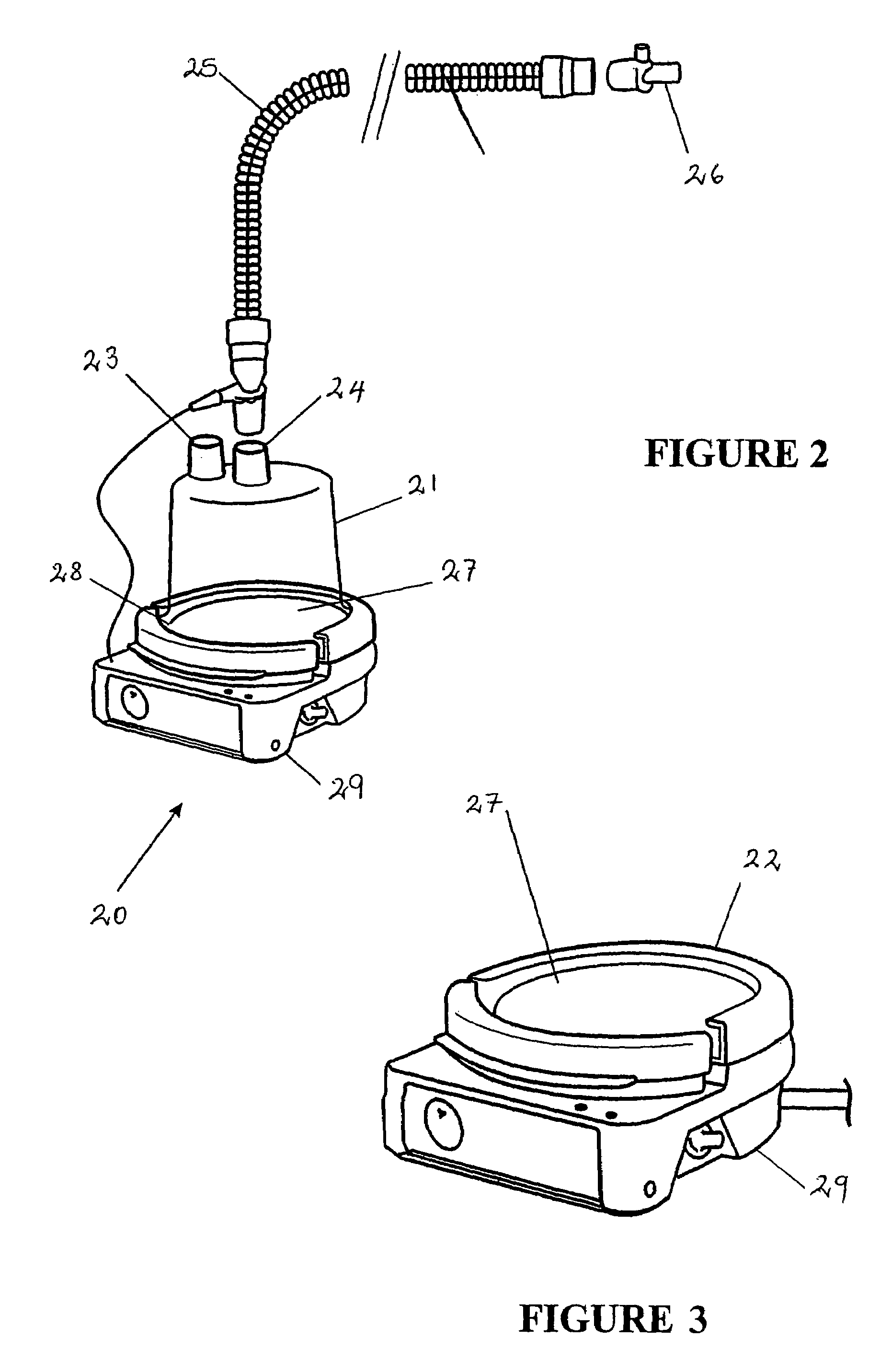

InactiveUS7140367B2Reduce supplyAvoid it happening againRespiratorsOther heat production devicesCatheterEngineering

This invention relates to respiratory humidifiers and heated breathing conduits used to couple a patient to the humidifier. A conduit overheating detection system for a conduit having heating wire or element is disclosed. The overheating detection system may be utilized with a in a single limb conduit system or dual limb system. In each of these systems the conduit overheating detection system monitors the current in the heating element(s) and alters the power to the heating element(s) to prevent the occurrence the heating element(s) and / or conduit from overheating.

Owner:FISHER & PAYKEL HEALTHCARE LTD

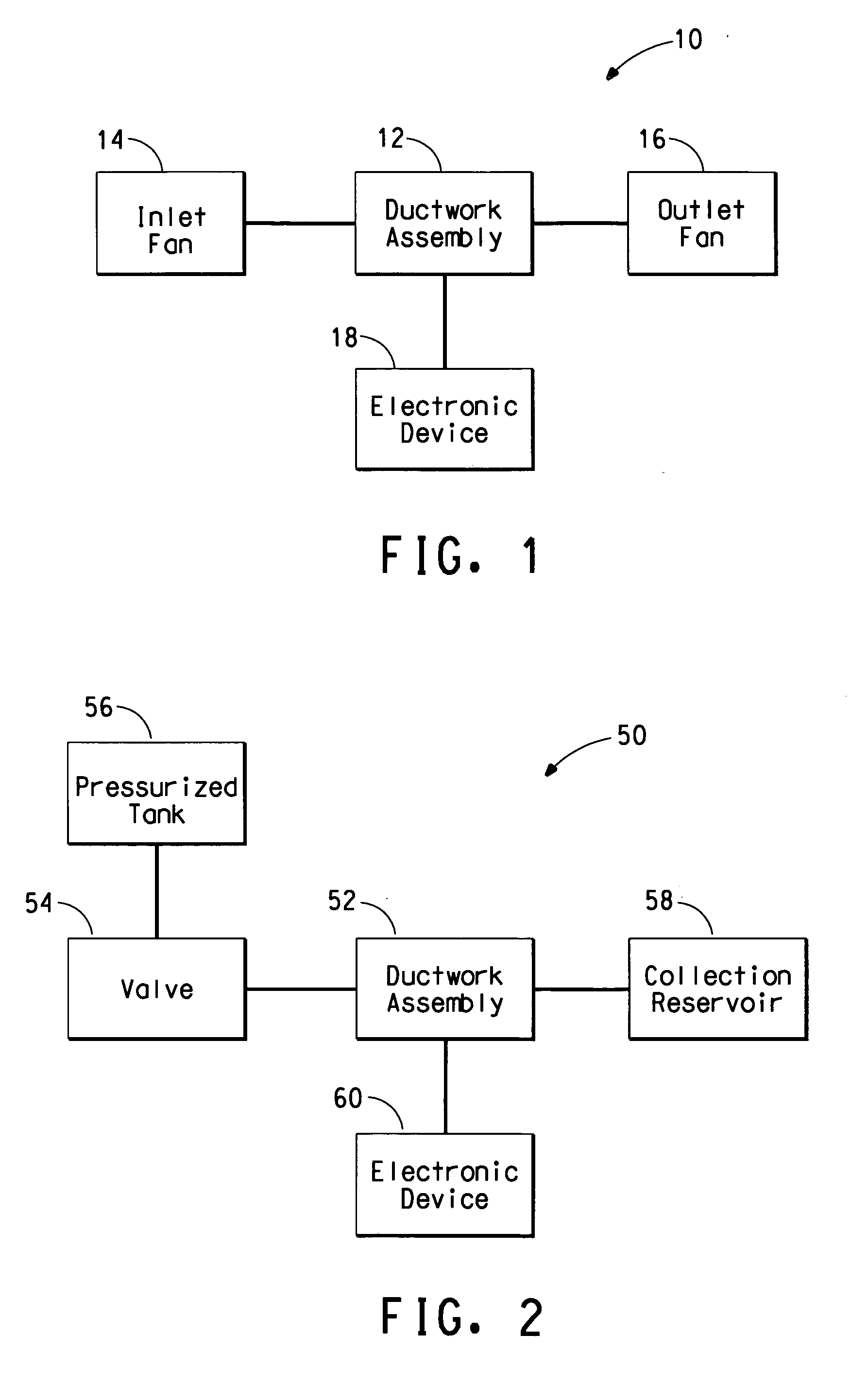

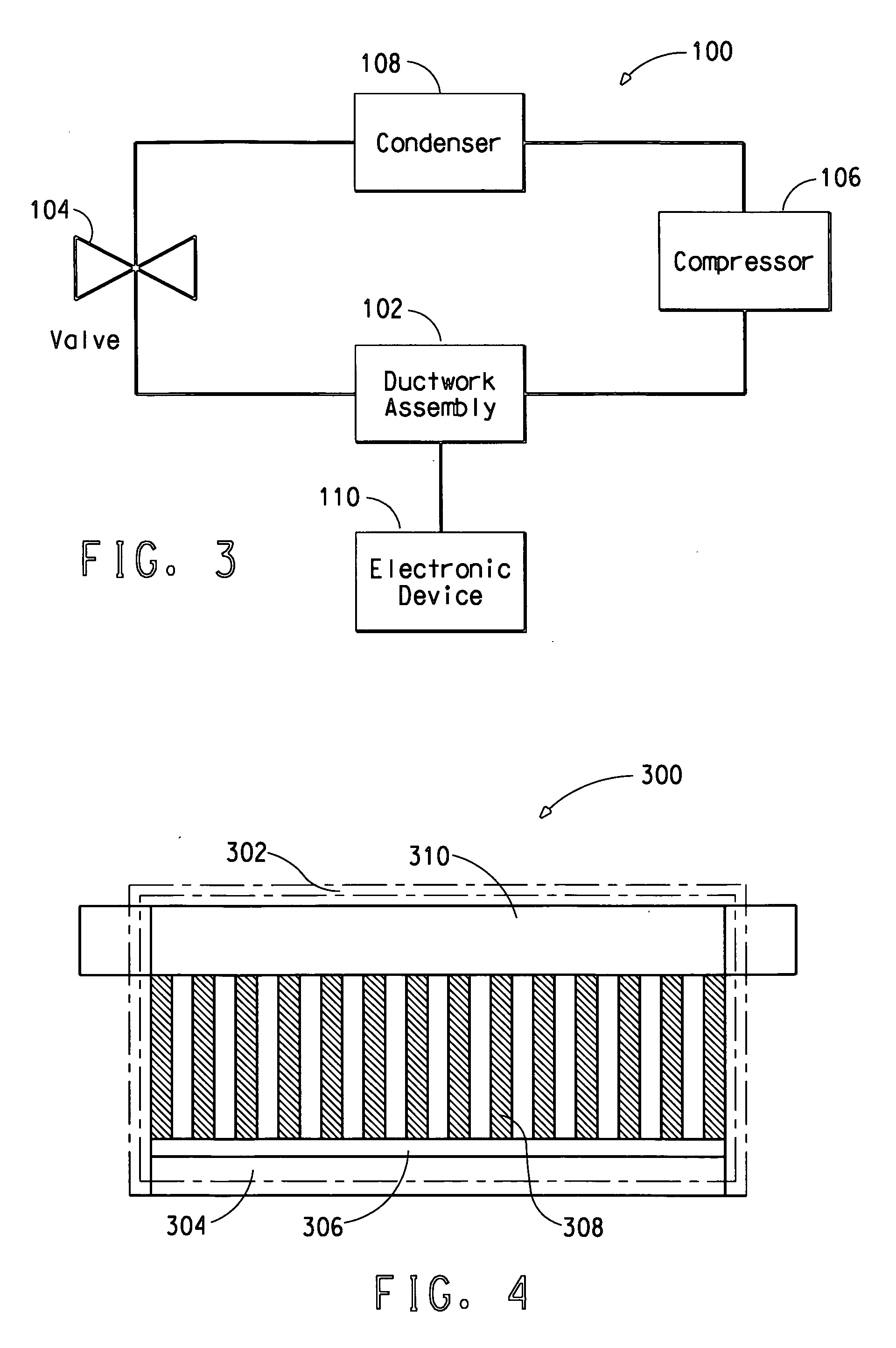

Electronic device having a temperature control system including a ductwork assembly

ActiveUS20060034051A1Television system detailsElectric discharge tubesTemperature controlControl system

A ductwork assembly can be used with an electronic device wherein the electronic device includes a fan and the ductwork assembly is configured to receive a heat transfer fluid from the fan. A disperser lies within the ductwork assembly and is attached thereto in order to affect at least a portion of a flow of the heat transfer fluid. The duckwork assembly may also include a first channel and the first channel is characterized by a first average fluid veloicty that is a hightest average fluid velocity of all channels within the ductwork assembly. The ductwork assembly may include a second channel that is characterized by a second average fluid veloicty that is a lowest average fluid velocity of all channels within the ductwork assembly. The second averaged fluid velocity may be no less than 90% of the first averaged fluid velocity.

Owner:LG CHEM LTD

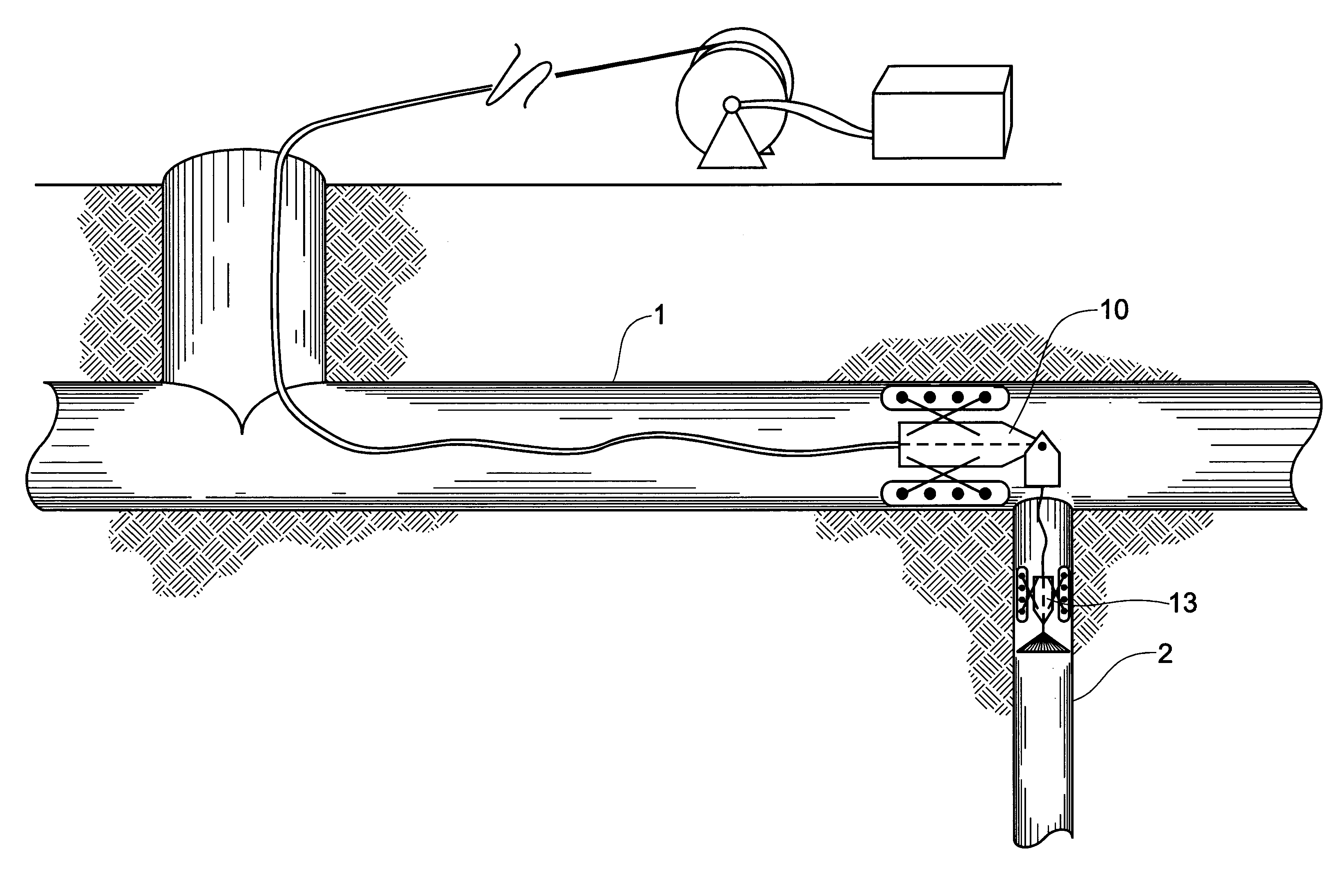

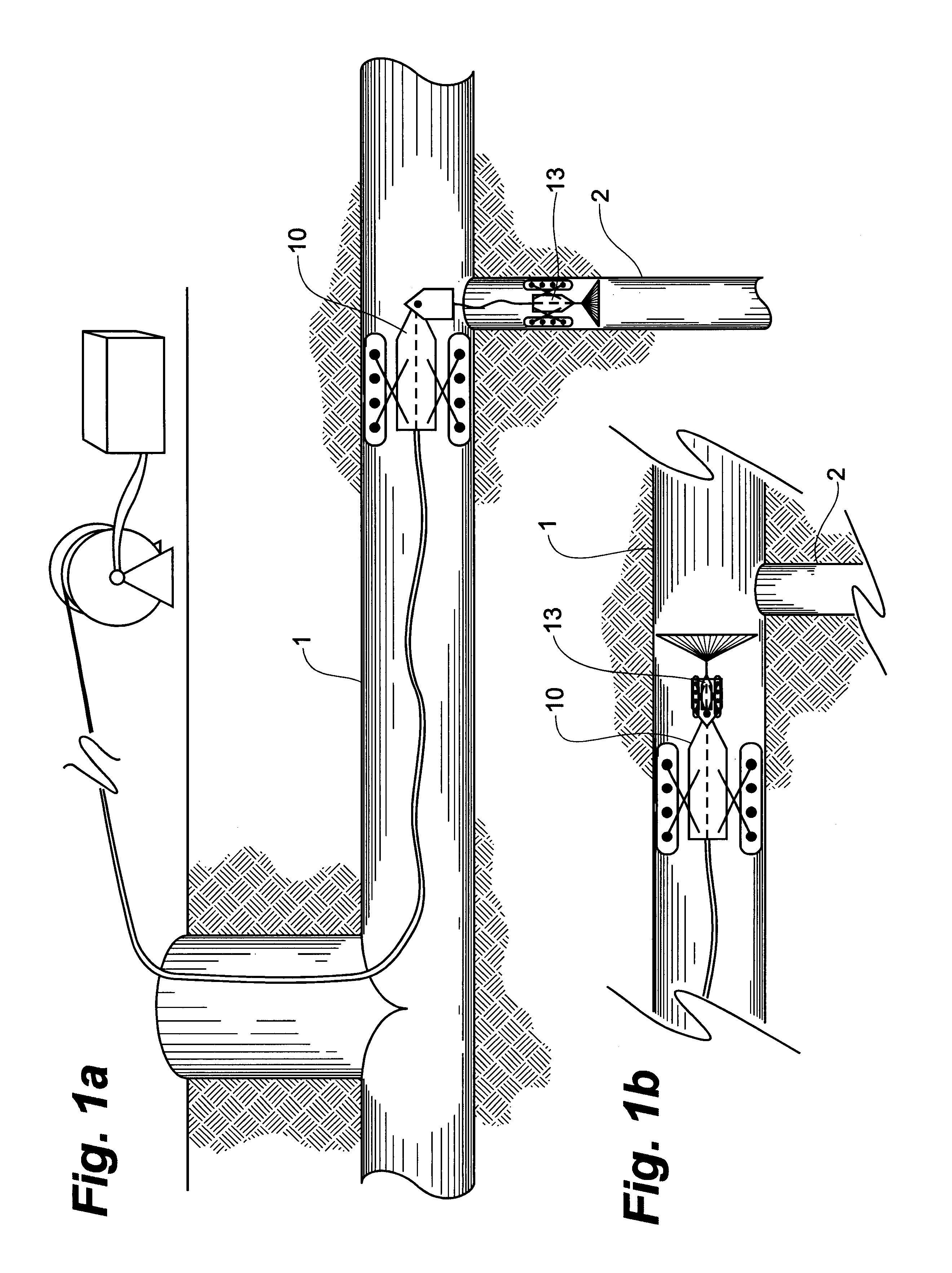

Robotic apparatus and method for treatment of conduits

InactiveUS6887014B2Novel methodMeasurement devicesRailway tunnelsElectrical conductorTeleoperated robot

A robotic apparatus and method for treatment of system of conduits and lateral sub-conduits comprising a remotely controlled robotic vehicle which navigates main conduits which delivers a series of tools to locations within the conduit. The mule's tools comprise a variety of devices including a tape head and a transport housing for a second remotely controlled robotic vehicle, or mouse which can be deployed for traversing and treating sub-conduits. Further, a method to install one or more small diameter flexible elongate members, such as conductors or sheathes to the inside of the system of conduits comprises advancing an elongate member through the conduit system with the mule or mouse, anchoring the elongate member and then taping the elongate member with the taping head while retreating out of the conduit. Preferably the tape is pre-shaped to minimize wrinkling upon application and more preferably, greater security and tape bonding strength is achieved by spraying over the tape and elongate member.

Owner:GEOLYN CONSULTANTS INC

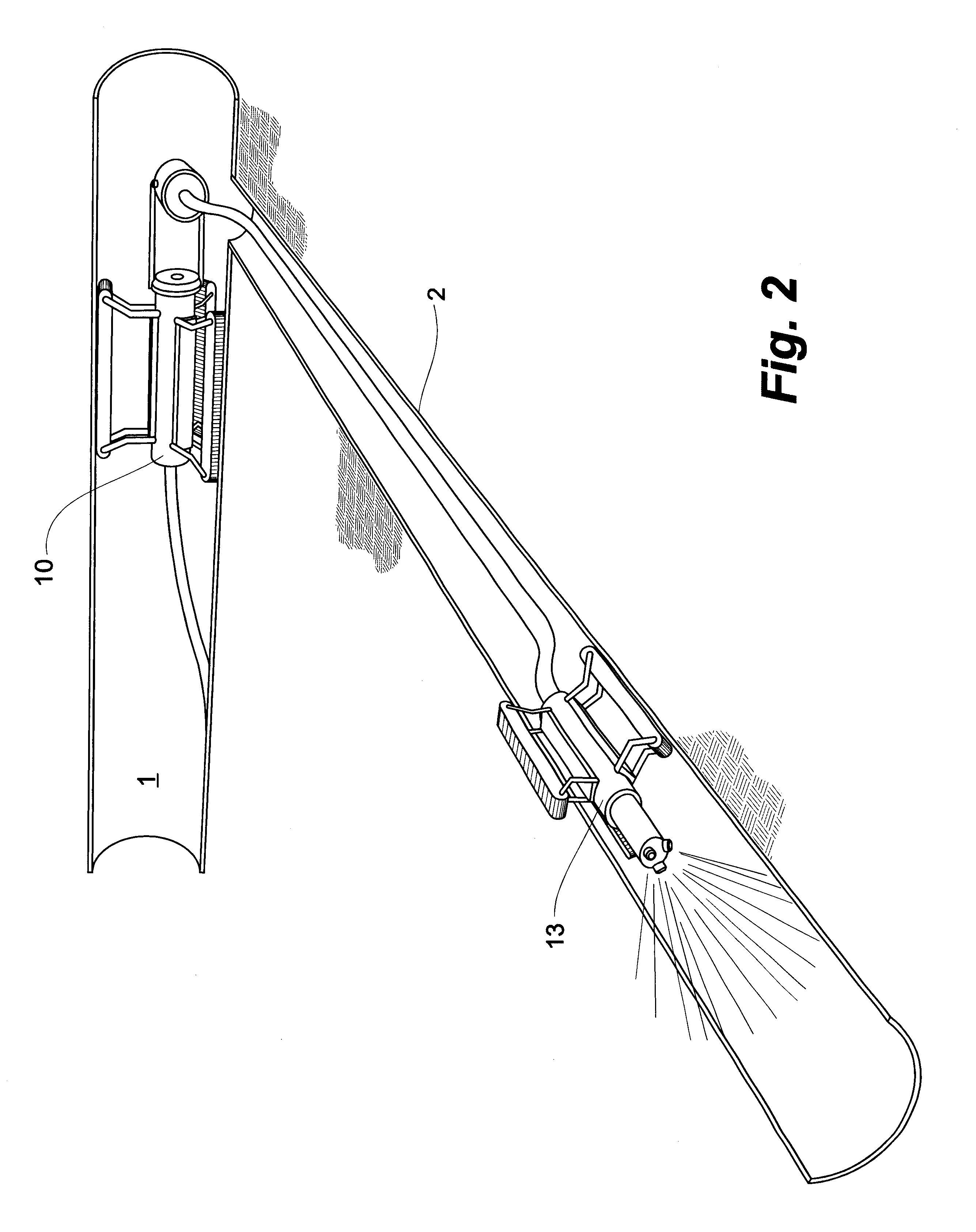

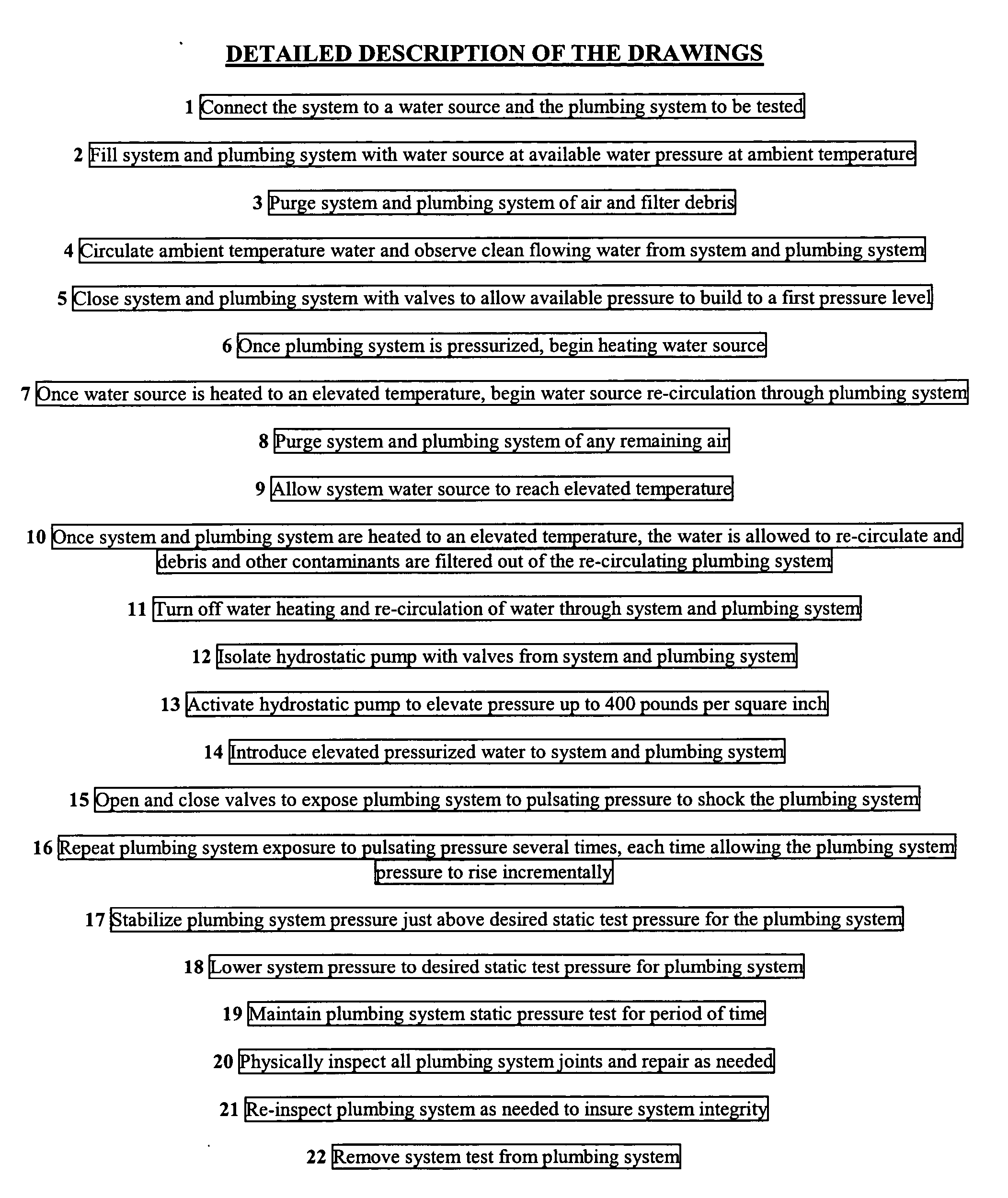

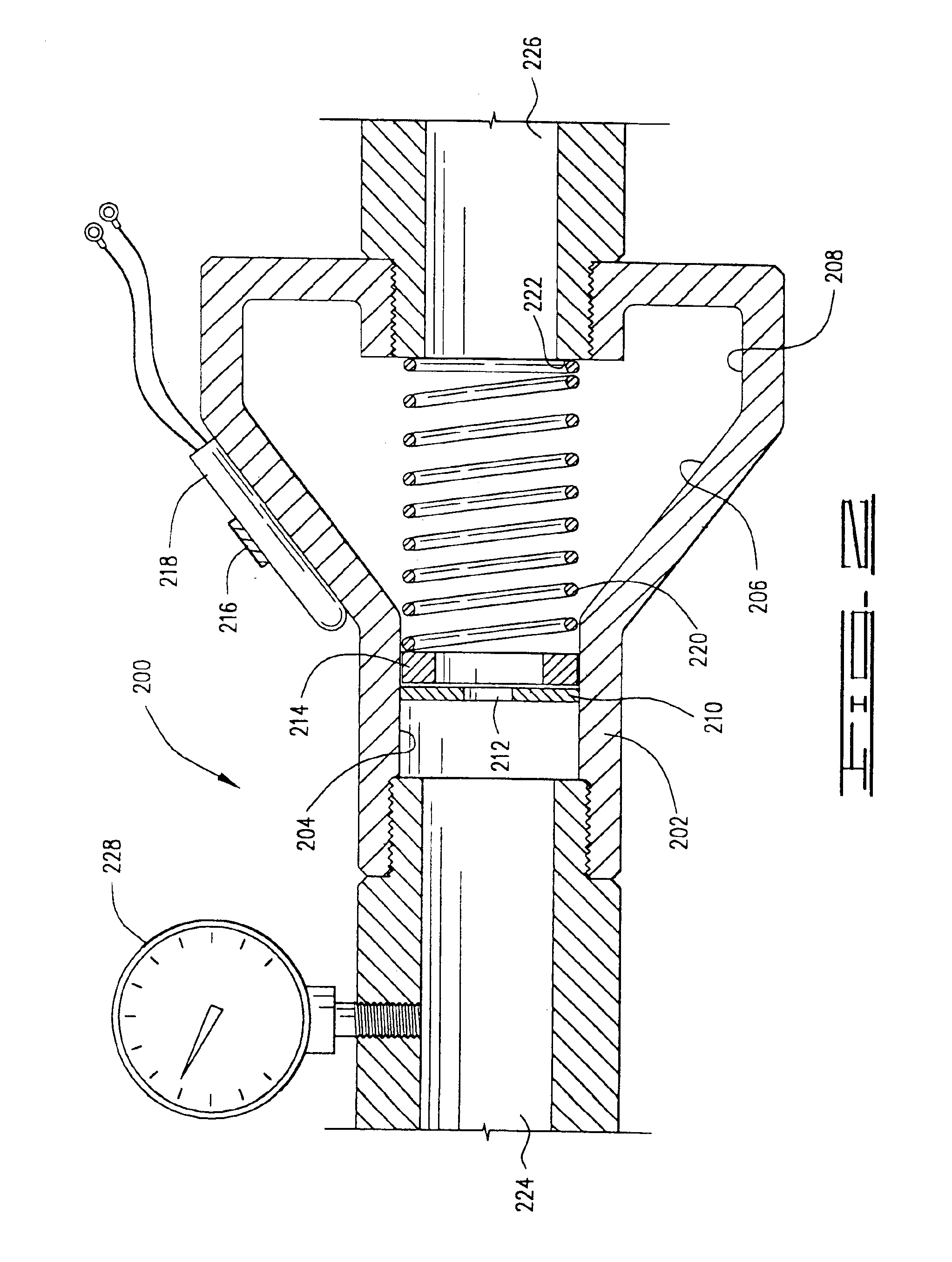

System and method for detecting and preventing leaks in pressurized piping systems

InactiveUS20060196251A1Easy and inexpensive to operateEasy and inexpensive to and maintainDetection of fluid at leakage pointPipe couplingsHydrostatic pressureEngineering

A system and method for testing plumbing systems for leaks by which the original plumbing system is cleaned and flushed using ambient temperature water followed by cleaning and flushing with pressurized recirculating elevated temperature water to filter debris and contaminants, shocking the plumbing system with elevated temperature and high pressure surges followed by a hydrostatic pressure test designed to expose the existence of any leaks in the plumbing system in the rough plumbing stage of construction prior to enclosing the plumbing system in a structure.

Owner:ROBERT C RICHEY TRUSTEE OF THE ROBERT C RICHEY FAMILY TRUST

Message conduit systems with algorithmic data stream control and methods for processing thereof

InactiveUS8239340B2Reduce complexity and costAvoid the needKnowledge representationTransmissionVirtualizationData stream

A method for processing messages is provided where at least one algorithmic conduit is defined, and at least one conduit rule for controlling at least one algorithmic conduit is defined. An algorithmic conduit is a persistent connection, controlled by explicit, independent, dynamic rules, and capable of processing messages among data communicators such as devices, systems, or programs. Messages can be monitored, filtered, transformed, correlated, or processed in other ways without modifying the data communicators. A message conduit hub system allows creation and management of algorithmic conduits to serve as active, virtualized links carrying rules-based data streams among configurable endpoints. These “smart” connections are managed using parameters, logic, and other control interfaces for tailoring behavior to a particular application, site, or user. A message conduit hub system may be implemented as a stand-alone device, as part of a larger system, or as an “encapsulation layer” for an existing application.

Owner:HANSON TREVOR

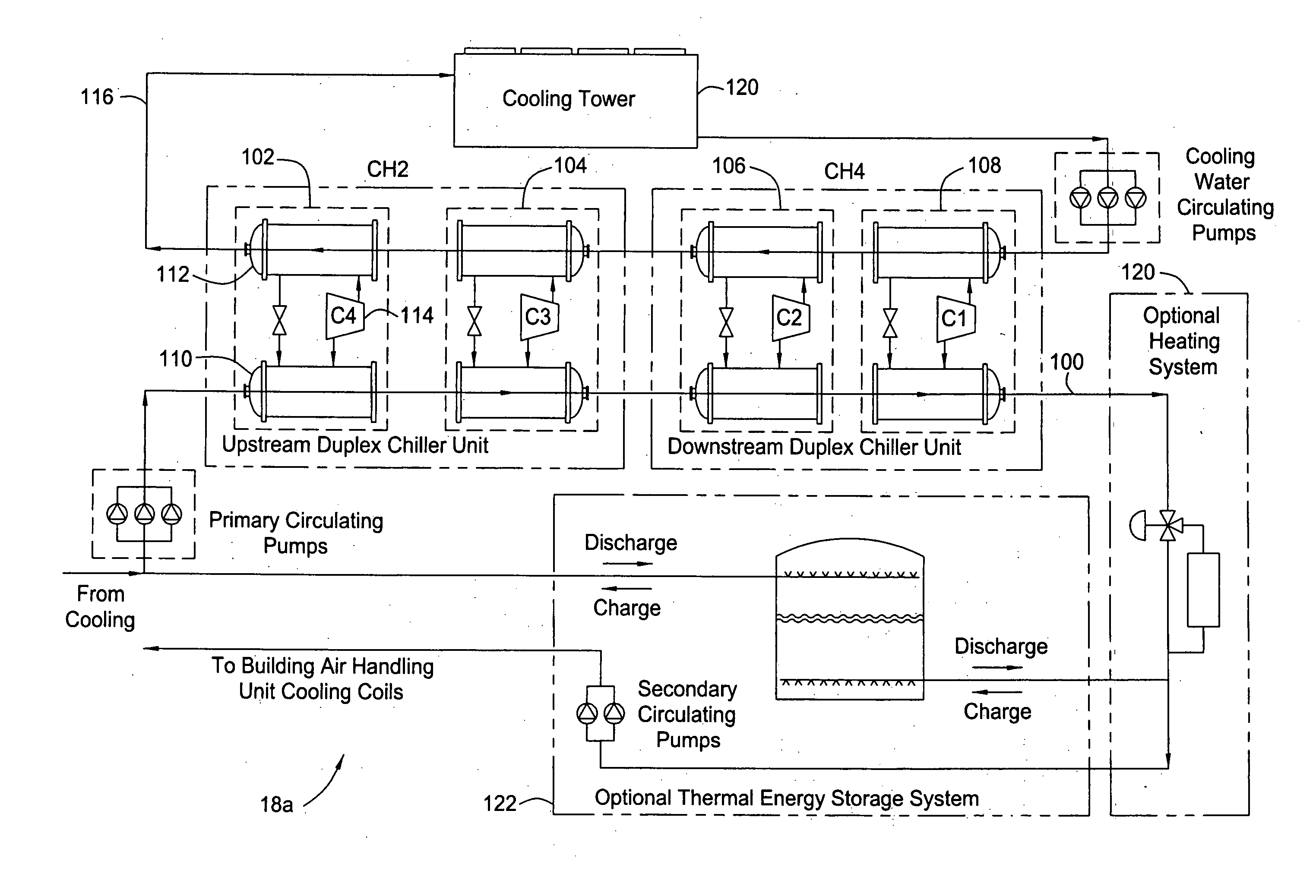

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

High-efficiency air handler

InactiveUS20030000230A1Lighting and heating apparatusCooling fluid circulationCeiling fanPressure rise

A high-efficiency air handler that is suitable for moving large volumes of air. The air handler comprises a coil and a fan. The total air volume moving through the unit is preferably over about 2000 CFM, with a total fan static pressure rise of less than about 0.5 inches and preferably less than 0.2 inches of water. The fan is preferably a modified ceiling fan with a rotational speed of less than about 450 rpm. The air handler is preferably part of a system where dehumidification and sensible cooling functions are separate. The separate dehumidification allows for much higher supply air temperatures, preferably within about 10° F. of the space temperature. Low-velocity air distribution through a ceiling plenum or a vent into the space allows for very low fan static pressures, which greatly reduces fan energy use compared to conventional ducted systems. The low static pressures and high supply-air temperatures allow the use of existing drop ceiling construction with little modification. The system can also include low-cost thermal storage. Latent thermal storage is in the form of a concentrated liquid desiccant solution. Chilled water storage is another option. The result is a major improvement in energy efficiency and comfort while reducing installed cost and peak electrical demand of the system.

Owner:KOPKO WILLIAM L

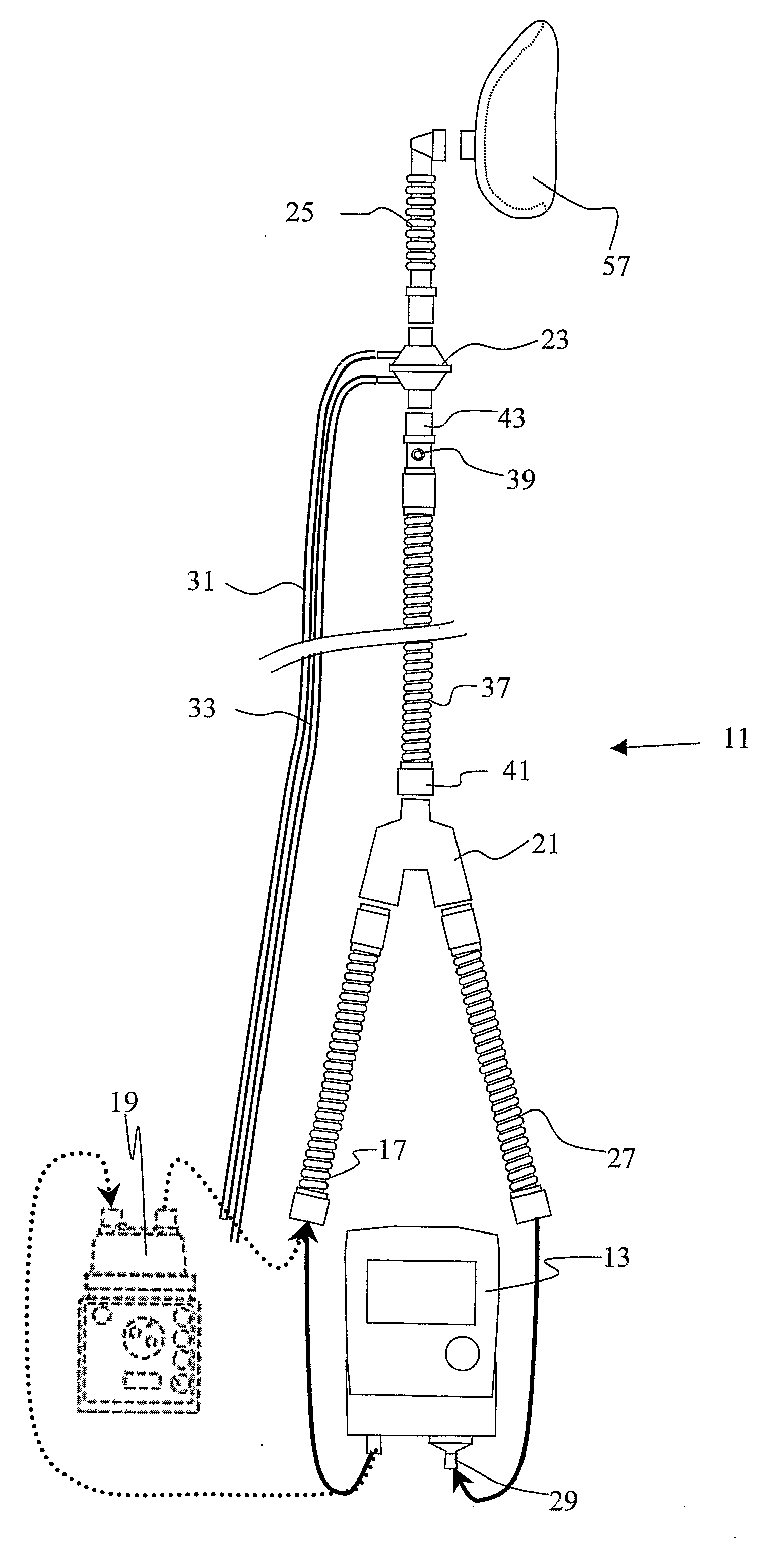

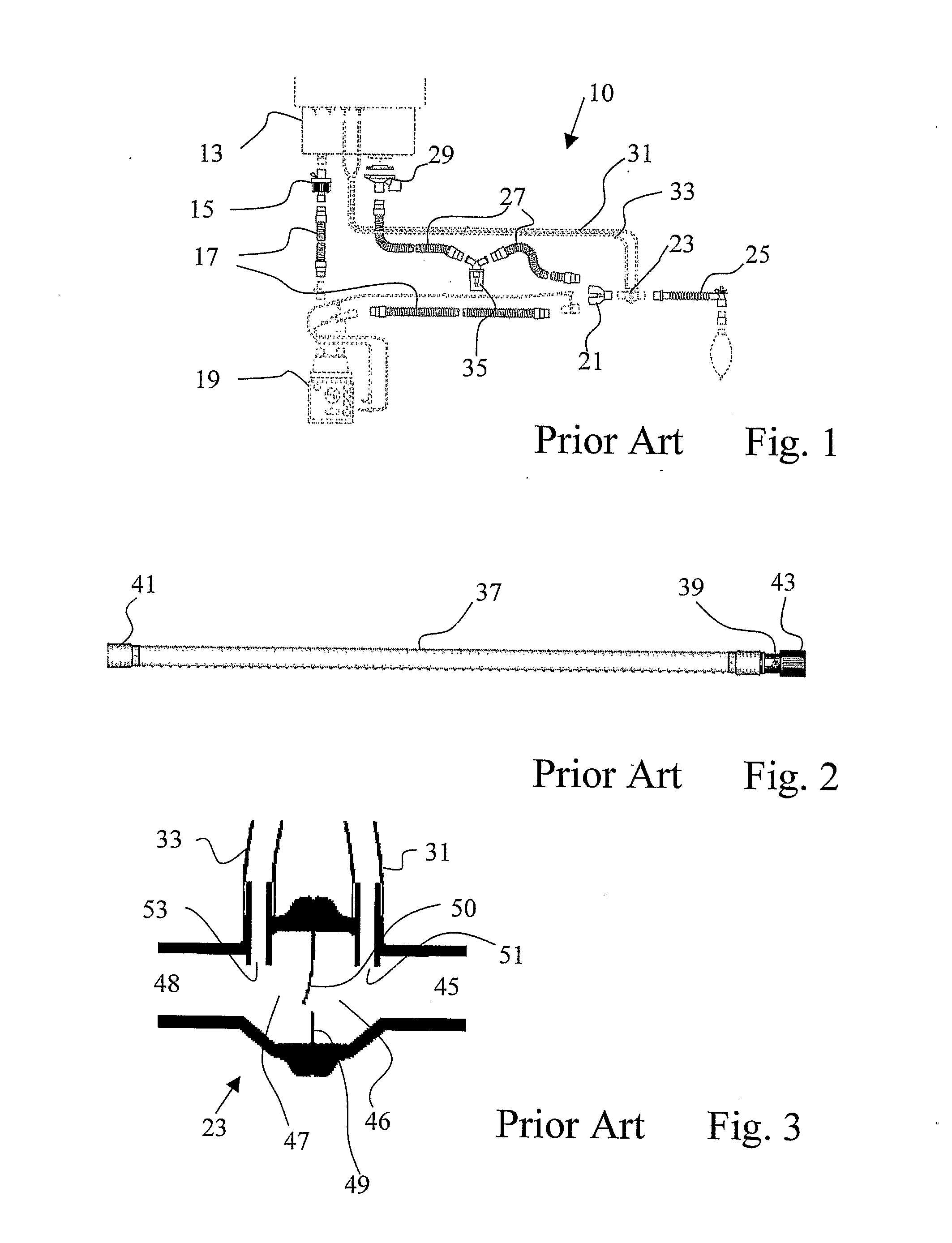

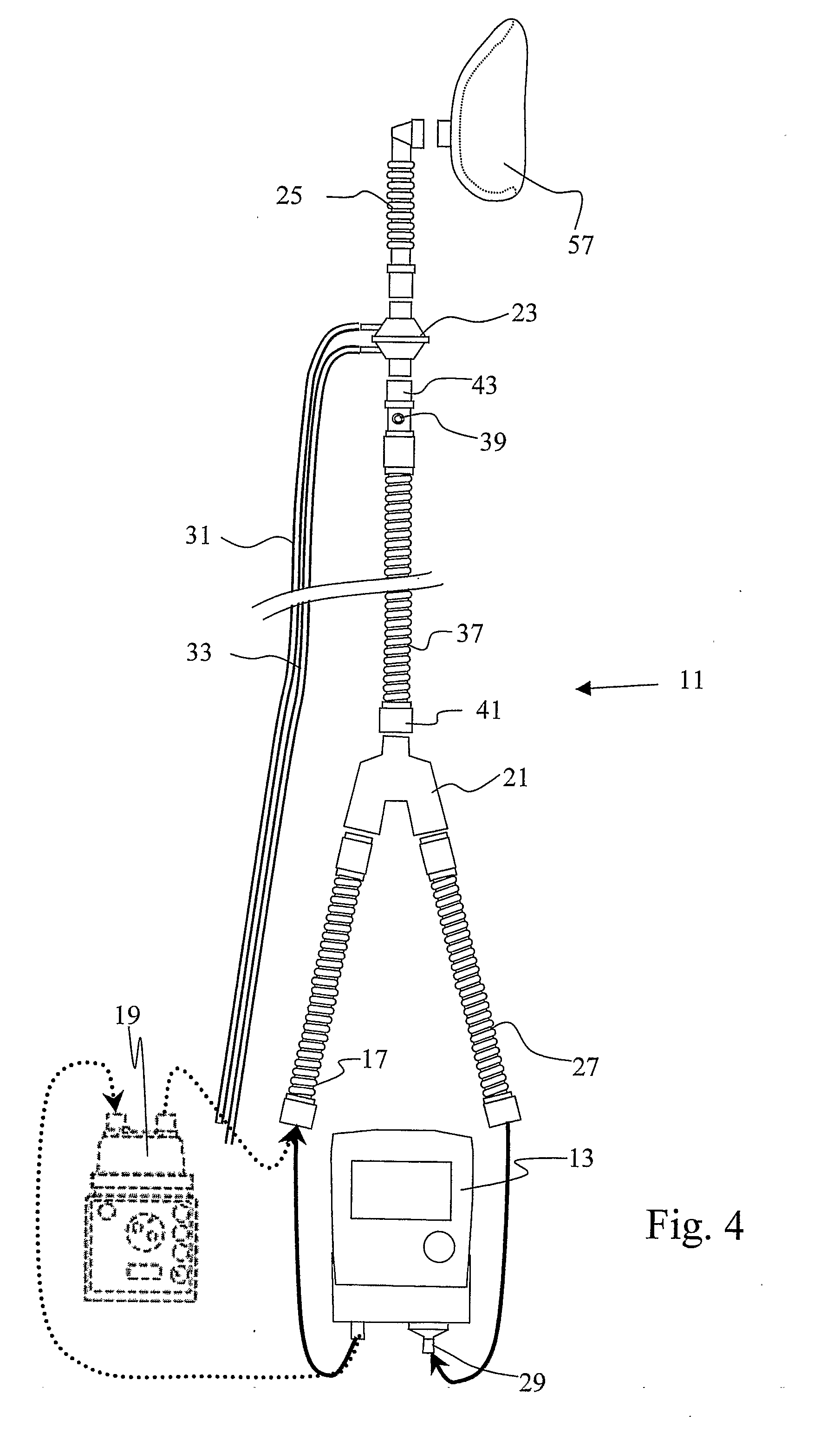

Tube system for ventilation appliances

ActiveUS20090050153A1Reduce restrictionsOperating means/releasing devices for valvesRespiratory masksVentilation tubeIntensive care medicine

The invention relates to a three-arm tube system (11) for a ventilation appliance (13) suitable for invasive ventilation. Such a ventilation appliance comprises an active inhalation valve and an active exhalation valve (29). The tube system (11) comprises an inhalation tube arm (17), an exhalation tube arm (27) and a ventilation tube arm (37) for attachment to a mask (57), and also a flow sensor (23). According to the invention, a defined leakage (39) is established in the ventilation tube (37), and the flow sensor (23) is arranged between leakage (39) and mask (57). The invention further relates to a ventilation appliance having such a tube system, and to a method for operating a ventilation appliance.

Owner:HAMILTON MEDICAL AG

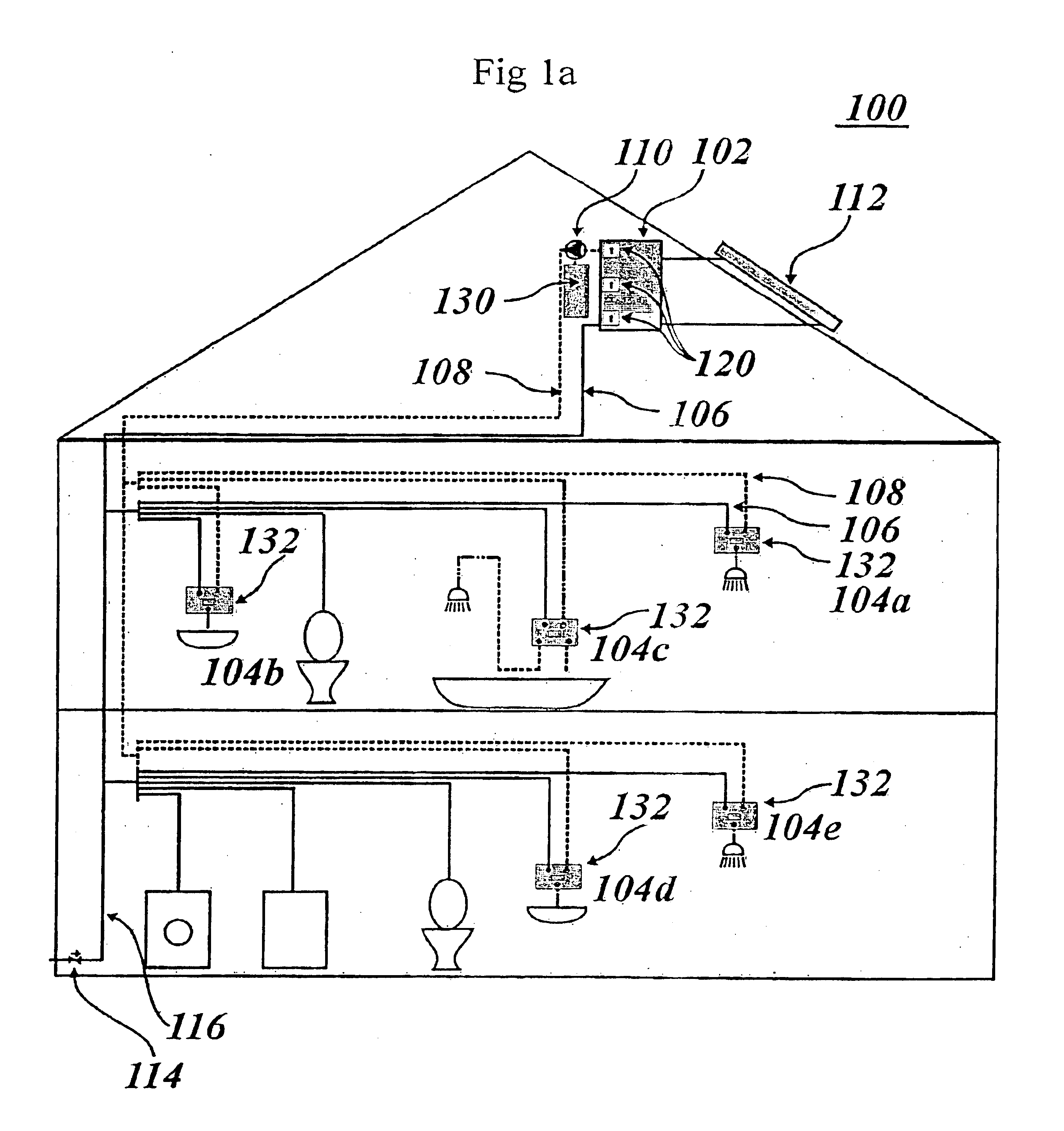

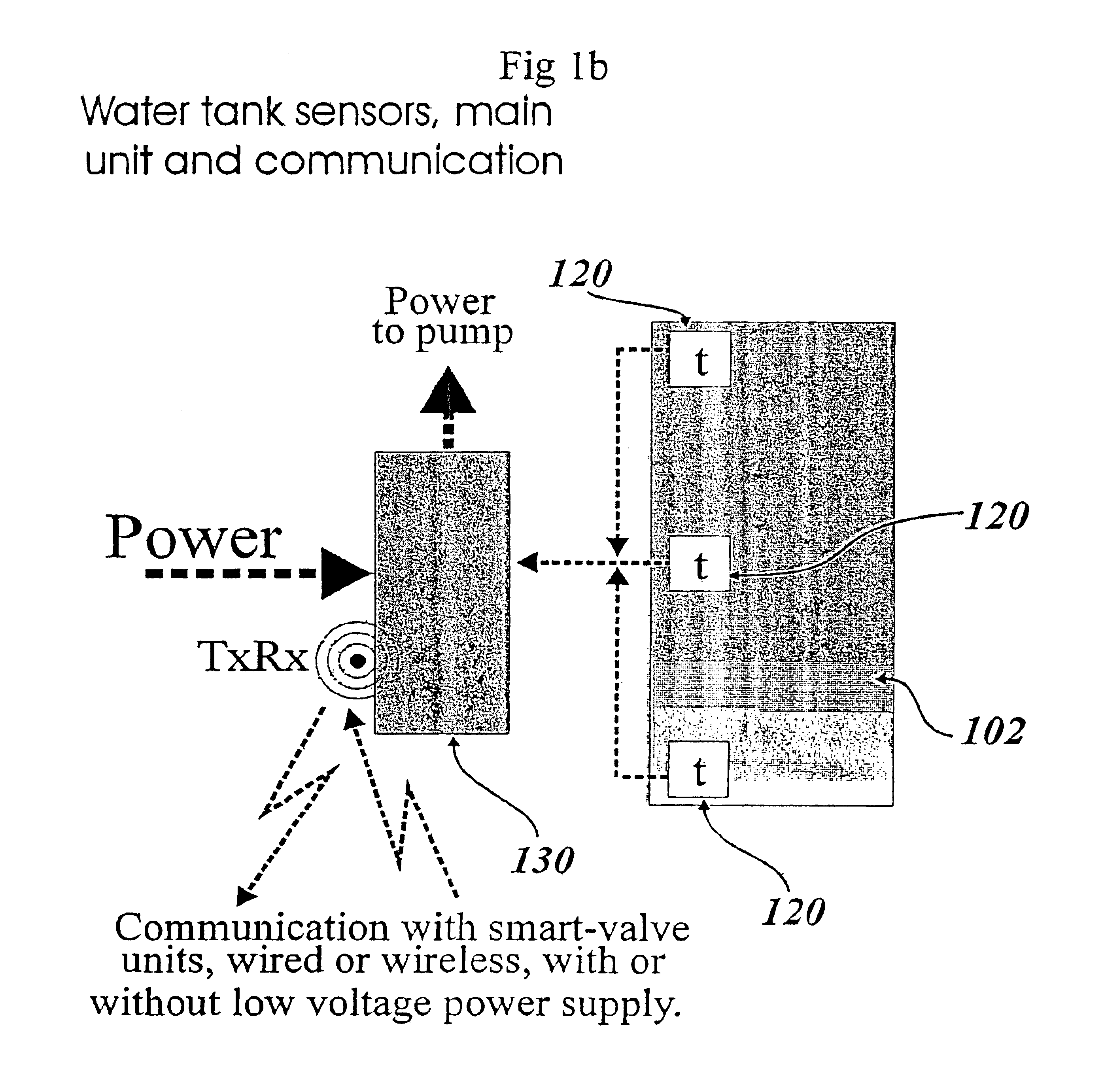

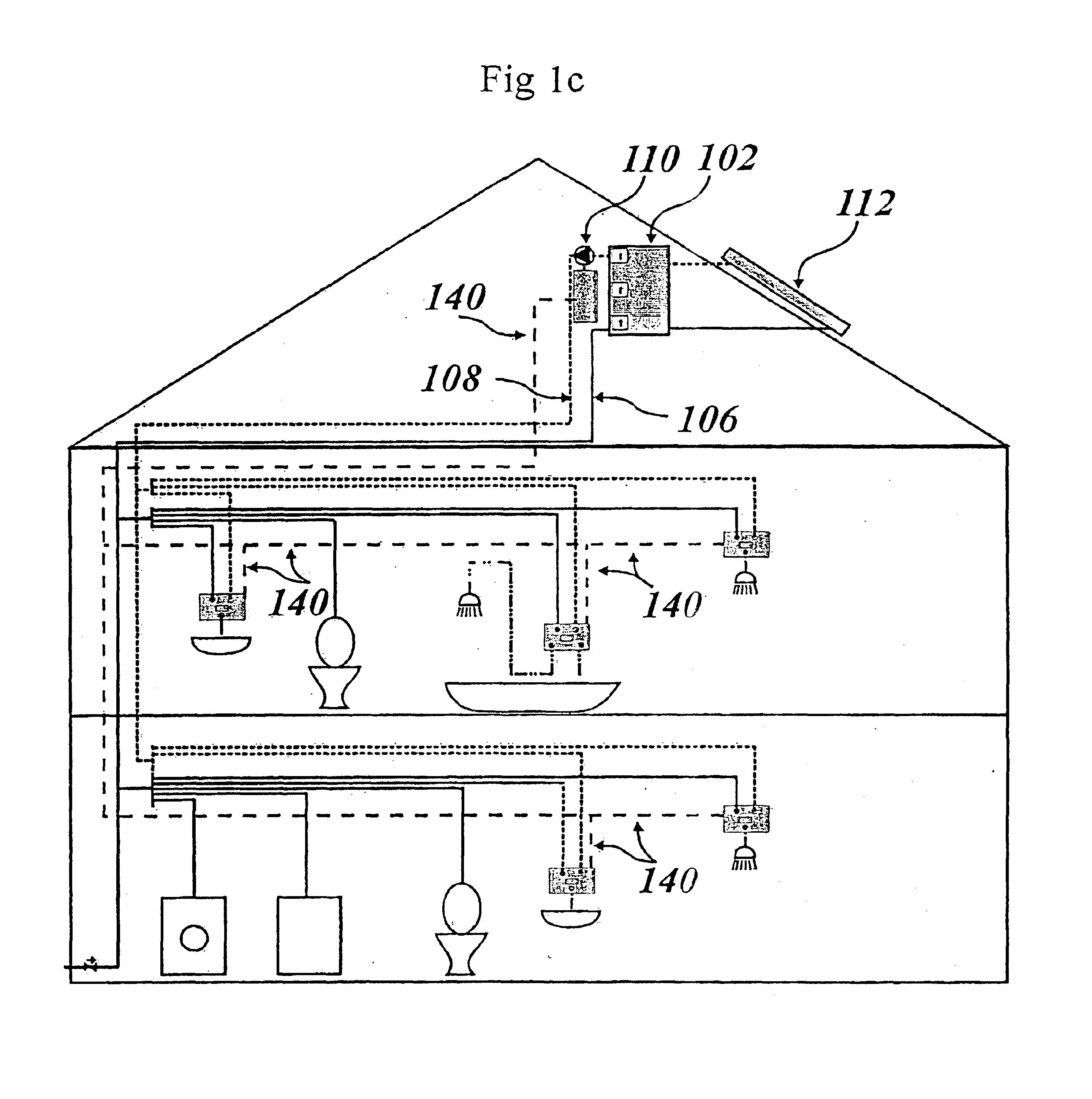

Smart device and system for improved domestic use and saving of water

ActiveUS6895985B2Improved domestic useSavingWater resource protectionLighting and heating apparatusMicrocontrollerWater saving

A system for providing a user with water at a desired temperature comprising a piping system that includes a hot water pipe and a cold water pipe, a pump coupled to the piping system and a smart water delivery device coupled to the piping system and to the pump and operative to allow circulation of water from the hot water pipe to the cold water pipe prior to delivery of water at a desired temperature to the user. The smart water delivery device includes two smart valves coupled to hot and cold water inlets, a smart outlet valve coupled to a device outlet, a microcontroller for controlling the actuation of the pump and of the smart valves, and at least one temperature sensor coupled to the microcontroller and used for sensing the water temperature.

Owner:MADGAL CSF

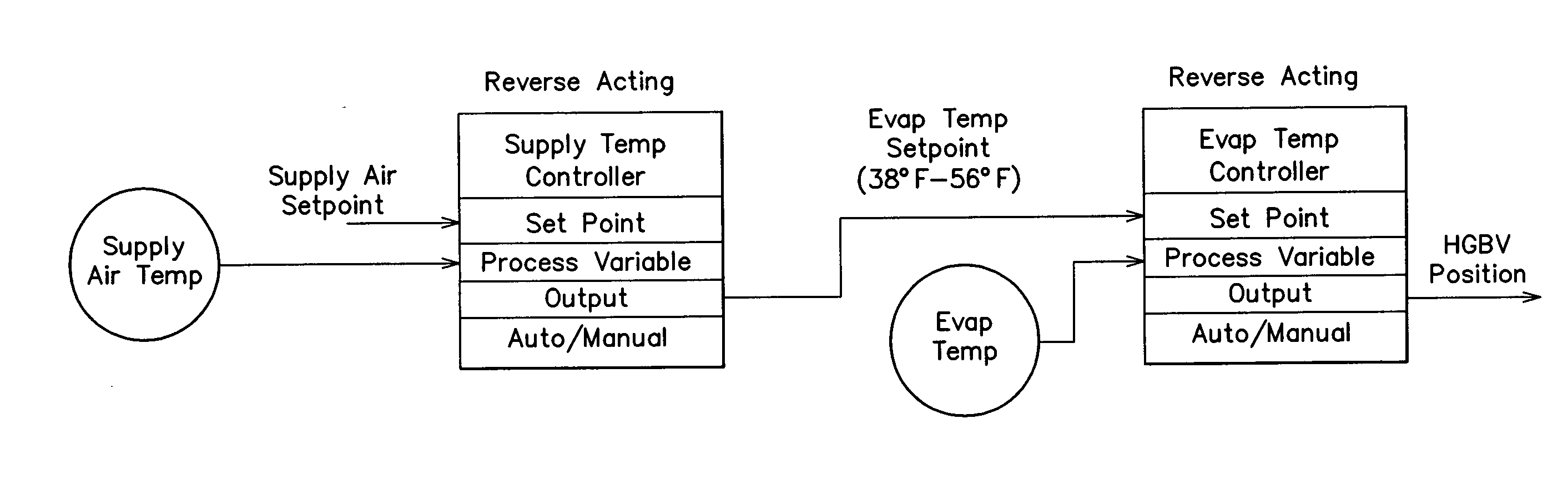

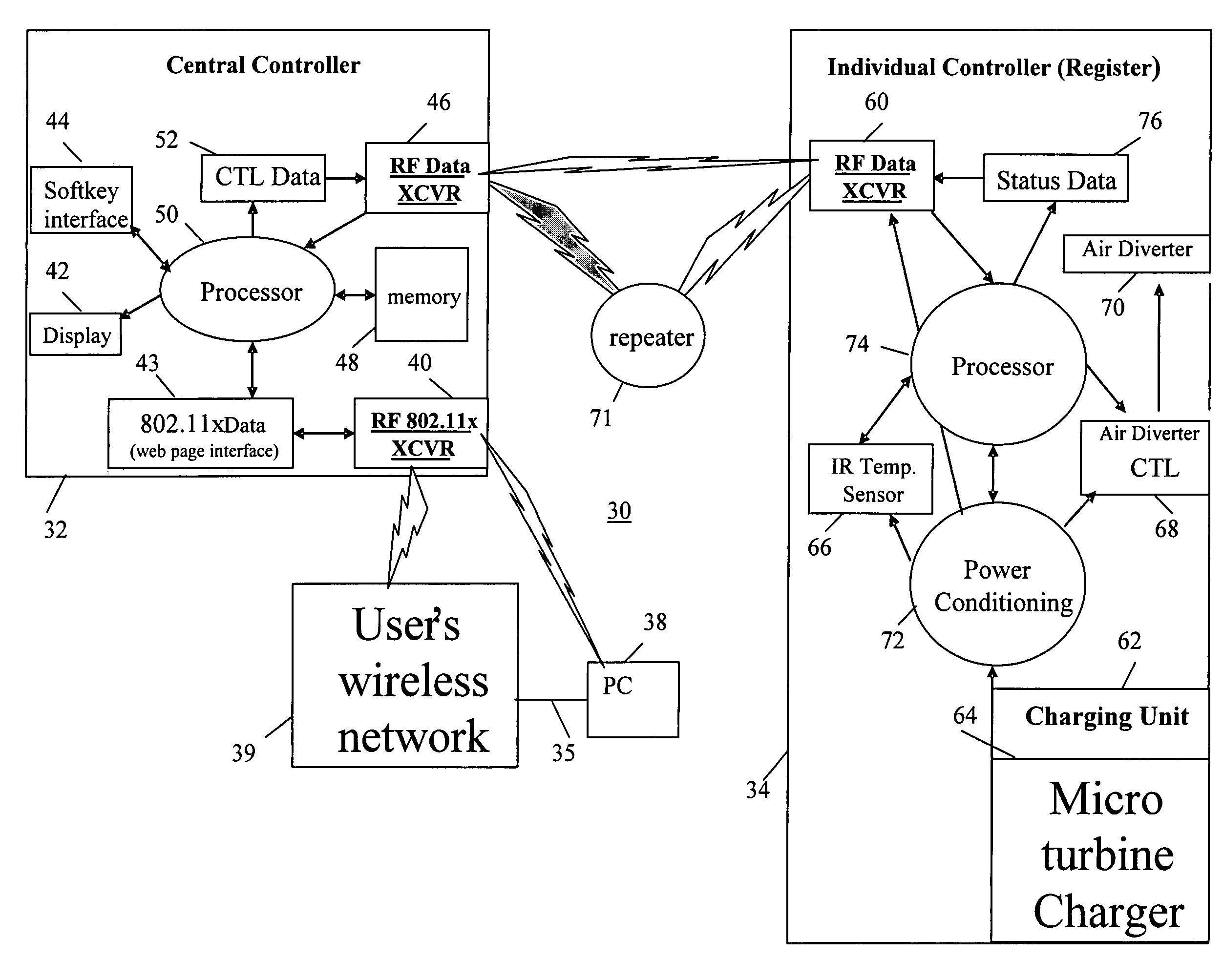

Method and system for controlling heating ventilation and air conditioning (HVAC) units

InactiveUS20080033599A1Reduce needSampled-variable control systemsSpace heating and ventilation safety systemsEngineeringControl theory

An HVAC control system provides a central controller that controls registers / vents which capture energy of air flowing in the duct system and convert it to an electrical current that is stored locally in energy storage units in the register / vent. Further, wireless communication between the central controller and the register / vents alleviates the need for wire runs and maintenance. Use of unique register identifiers allows the central controller to individually control each register based on user settings. As such, the user can install one or more registers and individually control one or more registers for desired temperature control in each zone. A wireless network allows user interaction with the central controller via a Web-page utilizing a Web browser on a PC that wirelessly connects to the central controller (e.g., via a wireless network). The register / vent combination is preferably and all-in-one unit that slides into the air duct opening in each zone.

Owner:INNOVATION BY DESIGN

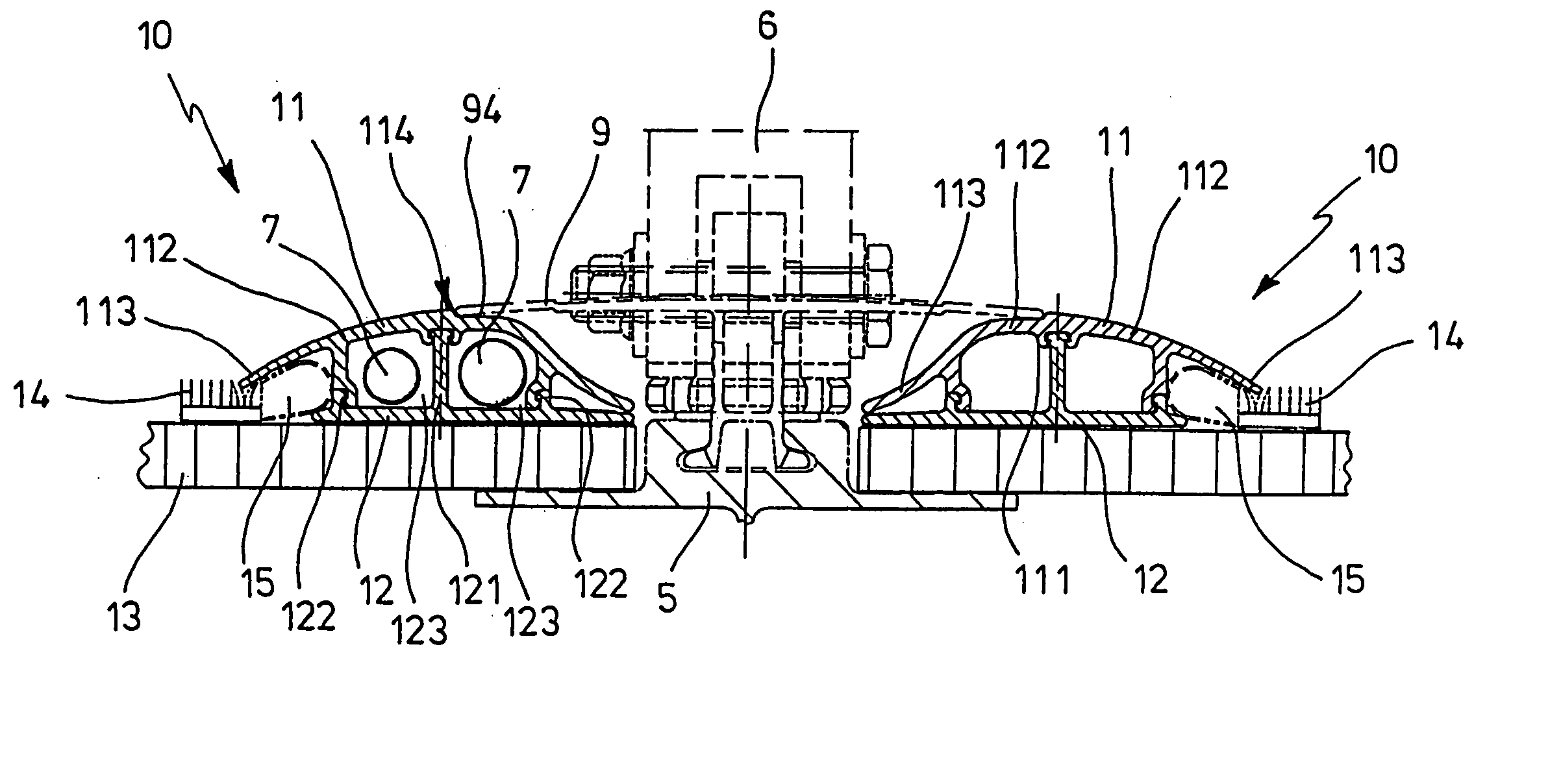

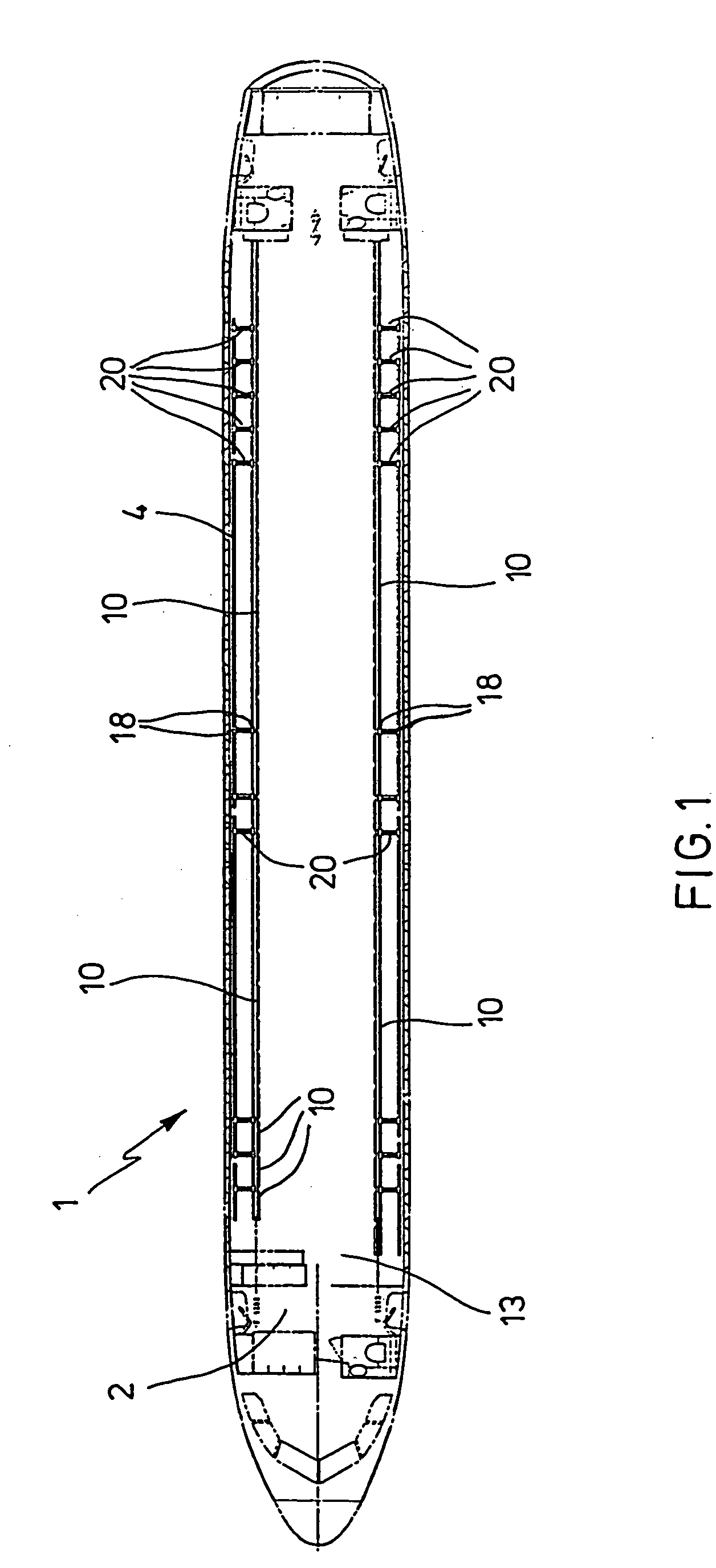

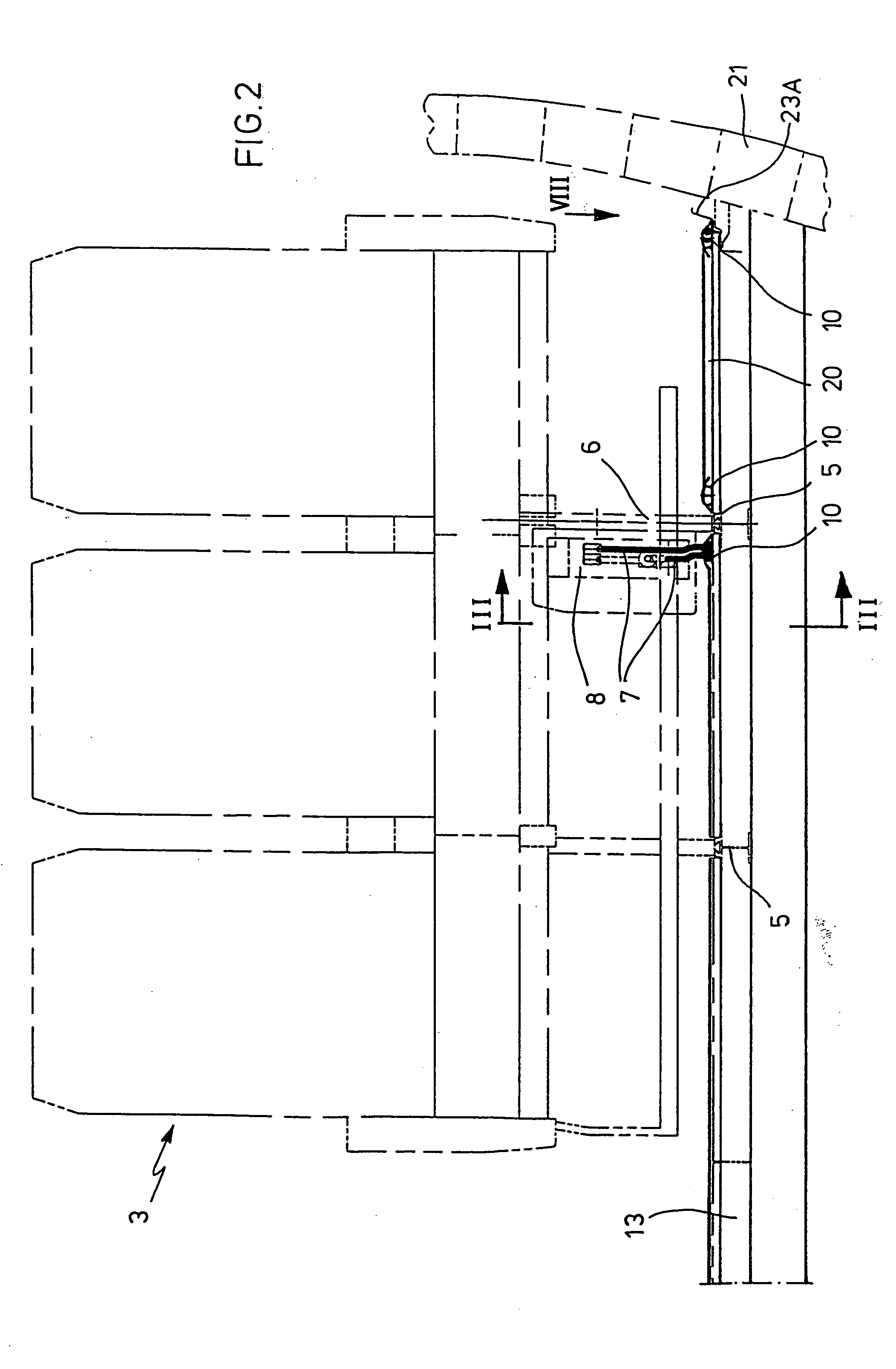

Arrangement for laying cables in the floor area of a passenger transport aircraft

ActiveUS20040129445A1Minimal complexityMinimal effortPipe supportsClosed circuit television systemsNacelleEngineering

A conduit system for laying cables along the floor of a passenger cabin of an aircraft includes longitudinal and transverse cable guide elements respectively forming cable channels, and cable branch junctions at intersections of the longitudinal and transverse guide elements. Each guide element includes a lower part secured to the cabin floor, and an upper part secured (e.g. snap fitted) onto the lower part to cover the cable channel. The cable branch junction includes a lower section secured to the floor and covered by an upper section, and allows the cables to continue straight through the junction or to be deflected by 90° or by 180°. With this arrangement, a greater number and greater diameter of cables can be laid out with a minimal installation effort. The components of the system are easily adaptable to any required installation layout, while providing a continuous covered protected enclosure for the cables.

Owner:AIRBUS OPERATIONS GMBH

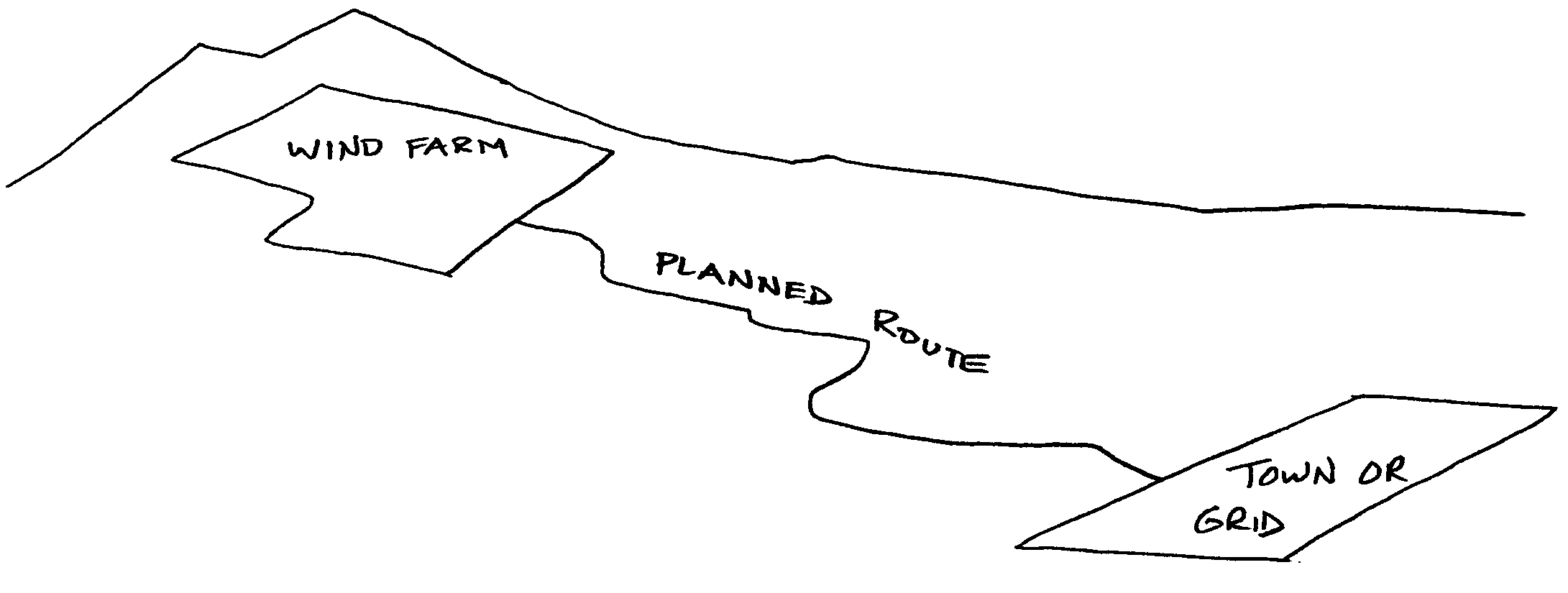

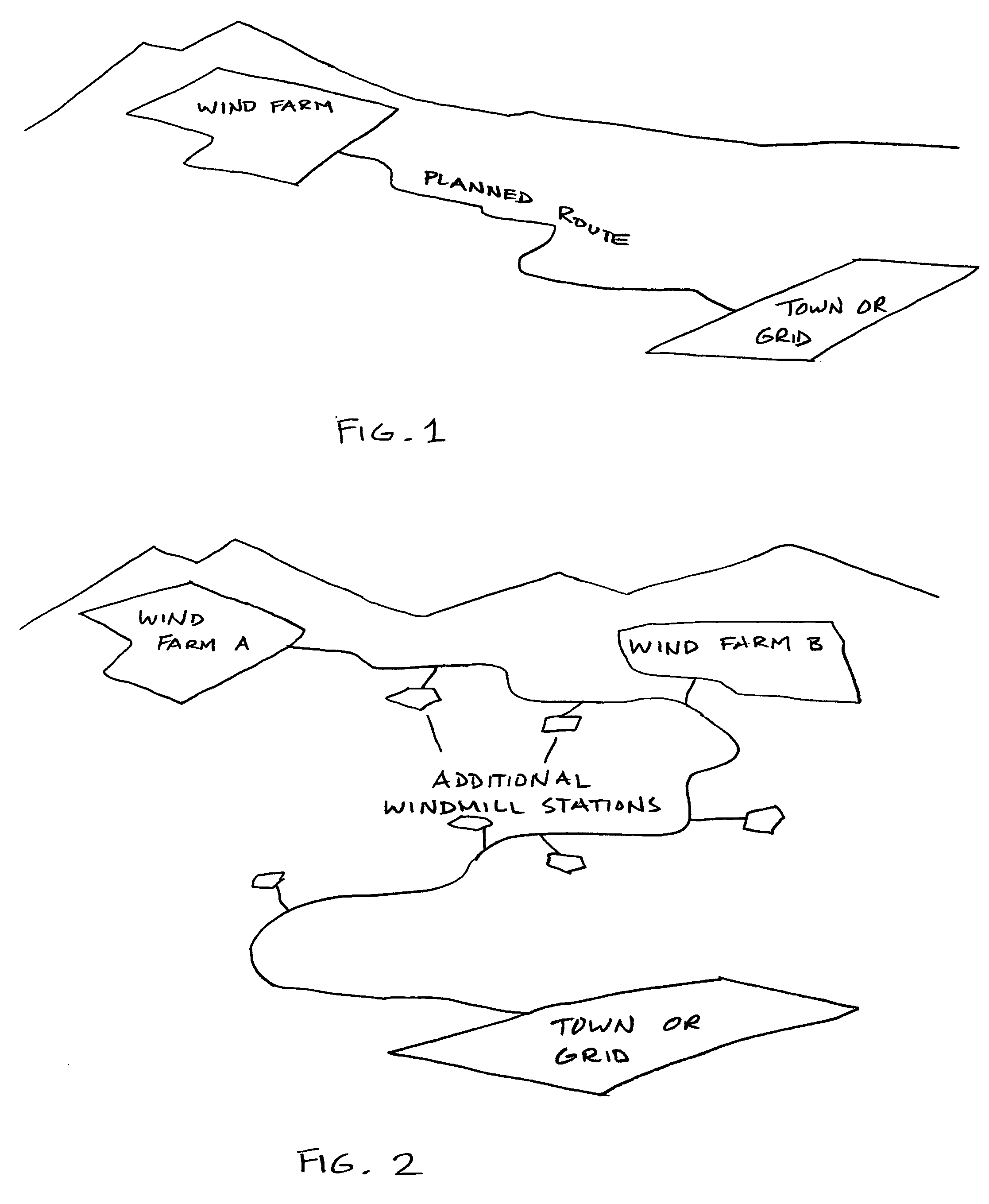

Method of storing and transporting wind generated energy using a pipeline system

InactiveUS20050016165A1Inhibit swellingEfficient designFluid couplingsWind energy with garvitational potential energyElectricityAlternator

The invention relates to a method of using a pipeline system for storing and transporting compressed air energy generated by wind turbines, wherein the pipeline preferably extends along a predetermined route, between a remote location where wind conditions are relatively consistent and predicable, and a power grid or community needing the power located a distance away. The remote location is preferably provided with a large number of windmill stations for generating electrical and mechanical energy, which is used to compress air into the pipeline. The route is preferably extended along an existing road or easement, and can incorporate abandoned existing piping when available. Turbo expanders and alternators are preferably provided at the user end of the pipeline, to release the compressed air and generate electricity for the grid or community.

Owner:ENIS BEN M +1

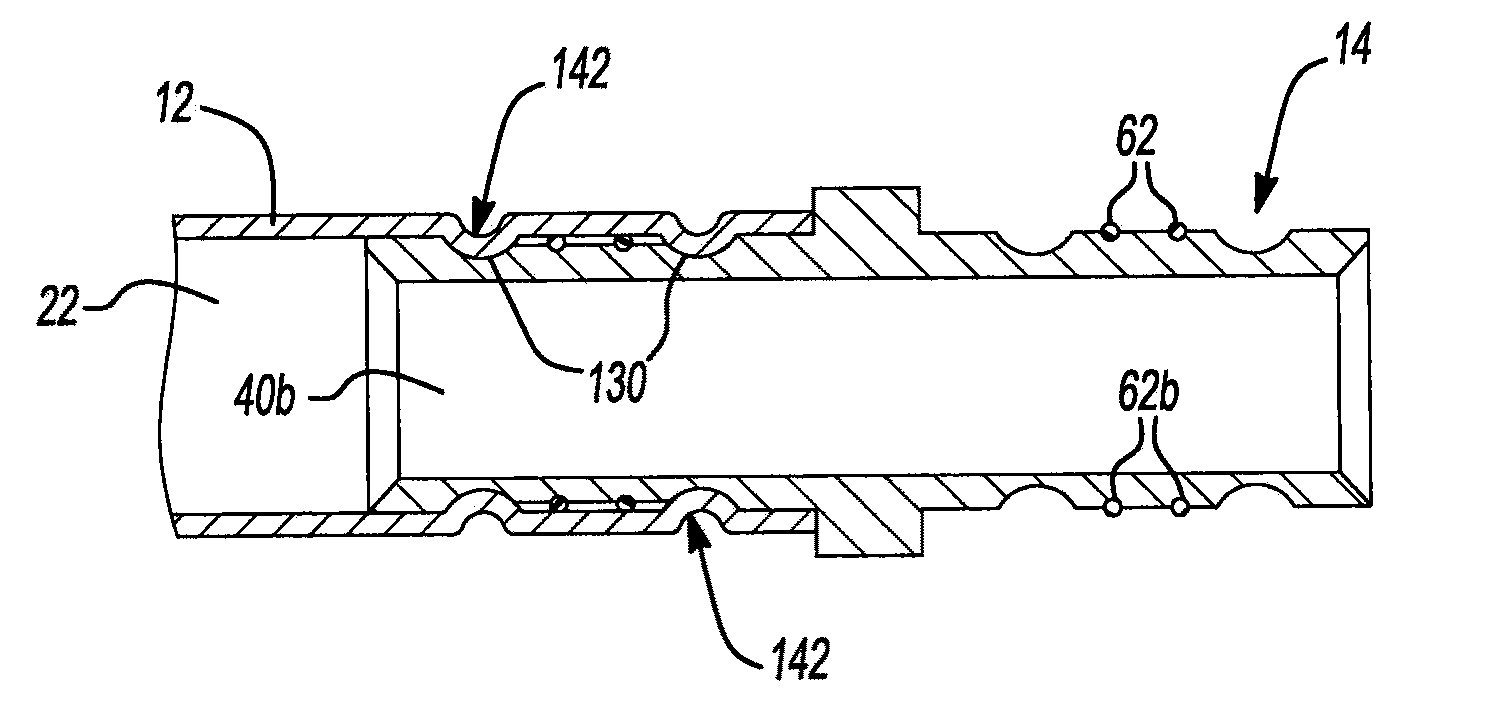

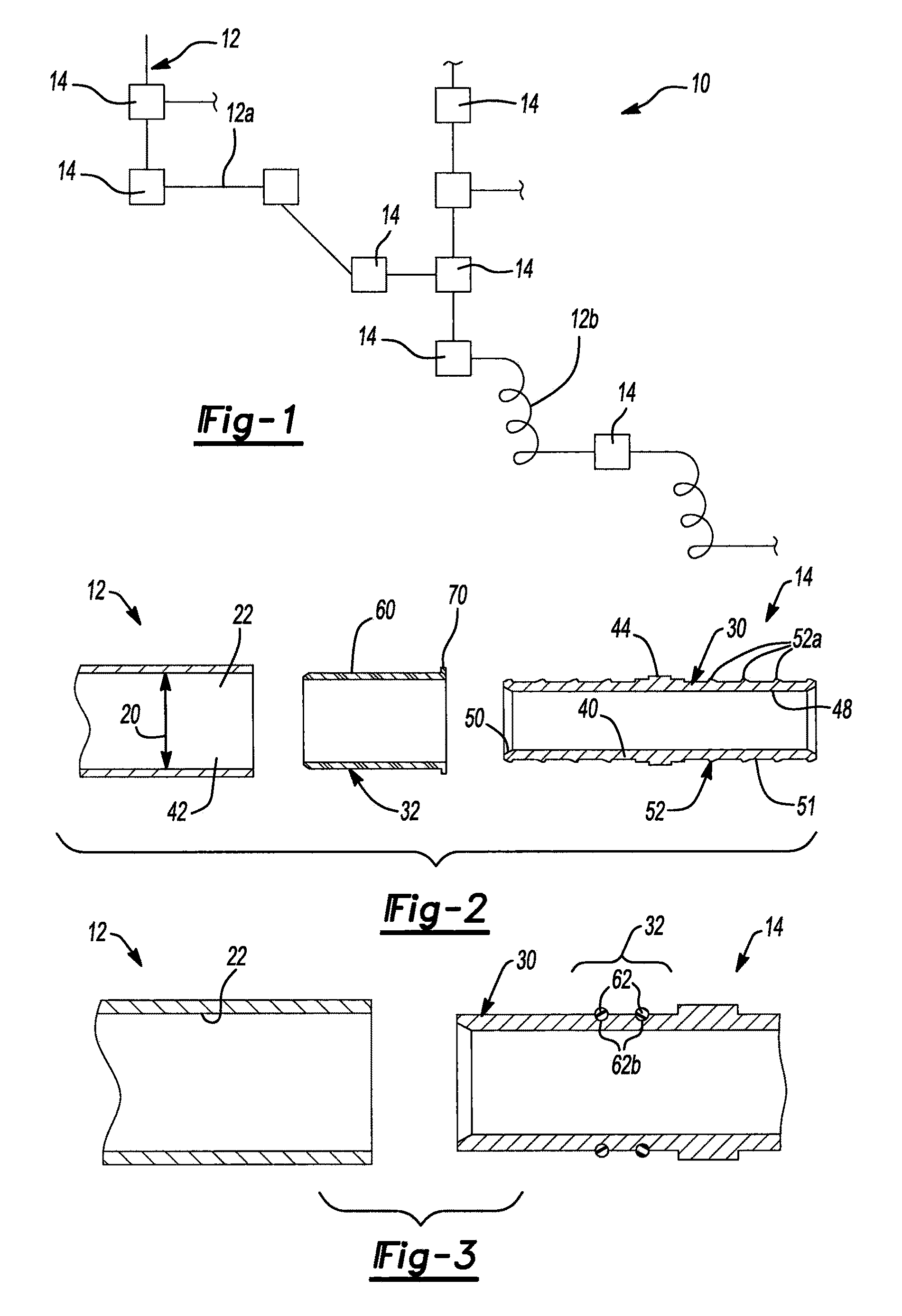

Fluid conduit system and fittings therefor

Owner:MUELLER IND INC

Johnson reversible engine

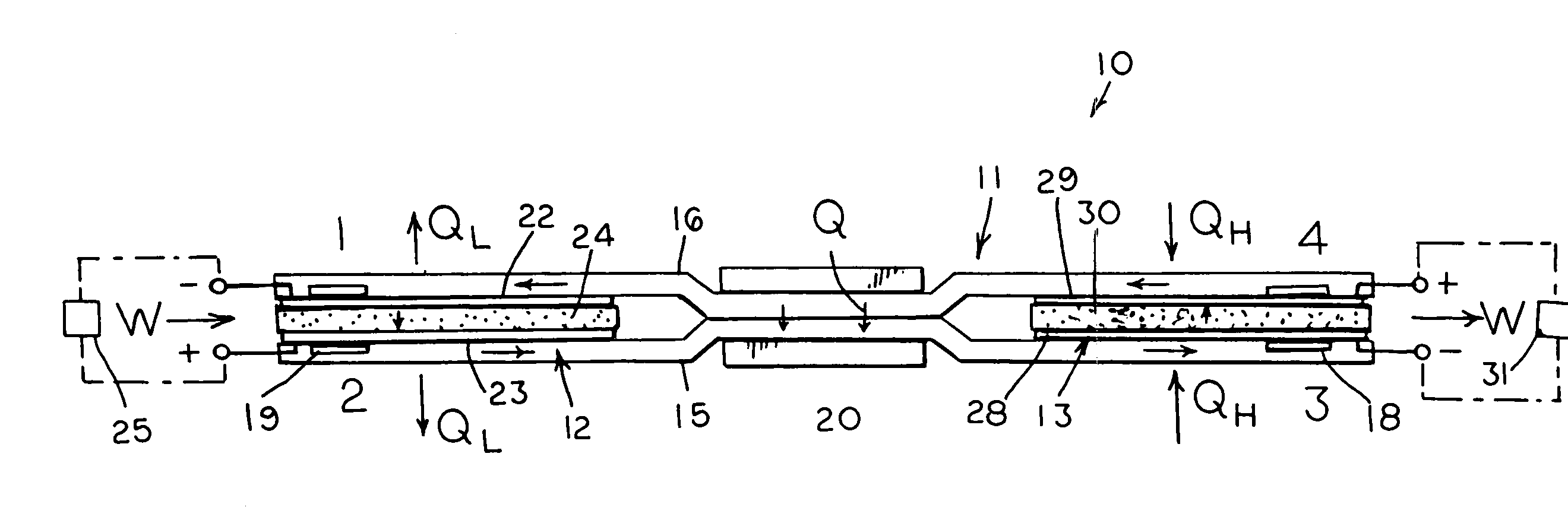

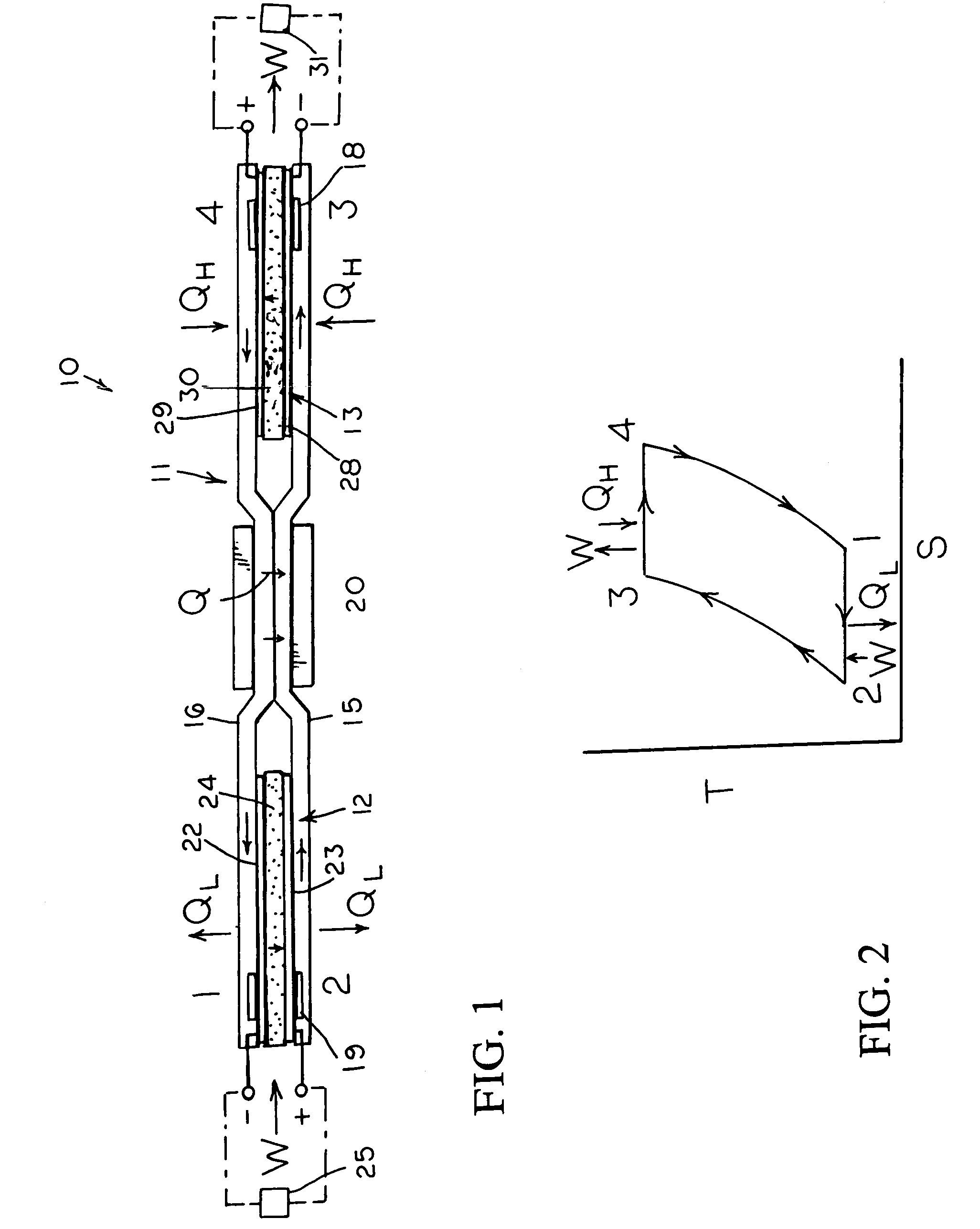

InactiveUS7160639B2Increase pressureReduce pressureHeat pumpsFuel cell heat exchangeEngineeringElectrochemical cell

An reversible engine (10) is disclosed having a conduit system (11), a first electrochemical cells (12), and a second electrochemical cell (13). The conduit system (11) includes a first conduit (15) extending from the first electrochemical cell (12) to the second electrochemical cell (13), and a second conduit (16) extending from the second electrochemical cell (13) to the first electrochemical cell (12). The heat engine (10) also includes a heater (18) mounted in thermal communication with the conduit system (11) adjacent the second electrochemical cell (13), a cooler (19) mounted in thermal communication with the conduit system (11) adjacent the first electrochemical cell (12), and a regenerative heat exchanger (20) thermally coupled to the first and second conduits (15) and (16) for the transfer of heat therebetween.

Owner:JTEC ENERGY INC

Fire extinguishing system

ActiveUS7389824B2Minimize, if not eliminate compressible gas in the systemPrevent costly contaminationSelf-acting watering devicesMovable spraying apparatusEngineeringCheck valve

An early suppression fast response fire protection system includes a sprinkler piping system with at least one sprinkler head assembly, a water supply system, and a check valve in fluid communication with the sprinkler piping system and the water supply system. An antifreeze solution supply system is in fluid communication with the sprinkler piping system, with the check valve isolating the antifreeze solution from the water supply unless a fire condition occurs. A control is provided that is in communication with a flow detector, which detects the pressure of the antifreeze solution in the sprinkler piping system, and a pressure detector, which detects the flow of water through the check valve, and controls the flow of the antifreeze solution to the sprinkler piping system and maintains the pressure of the antifreeze solution in the sprinkler piping system unless the flow detector detects the flow of water through the check valve in which case the control stops the flow of antifreeze solution to the sprinkler piping system to limit the discharge of antifreeze solution from the fire protection system.

Owner:VIKING

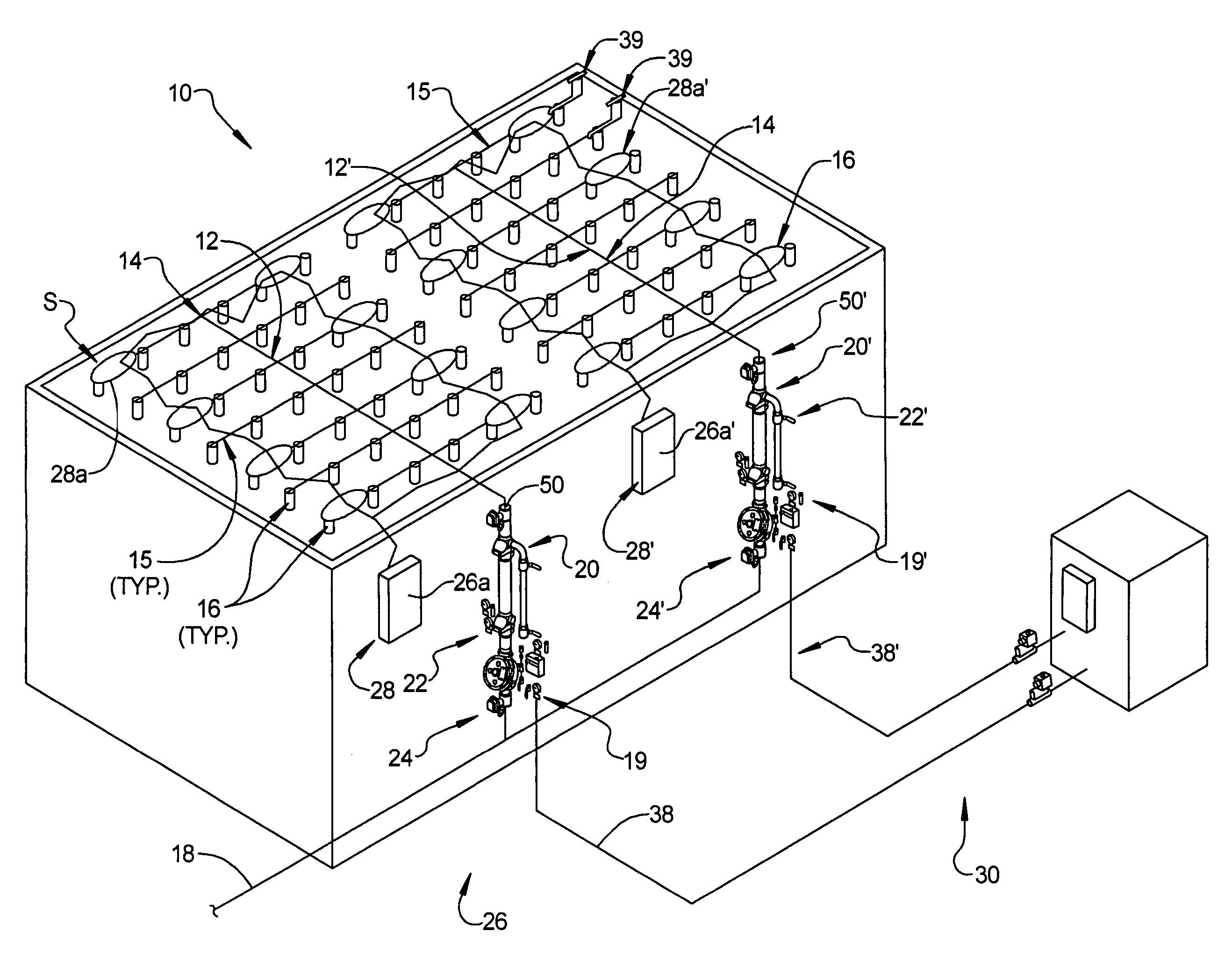

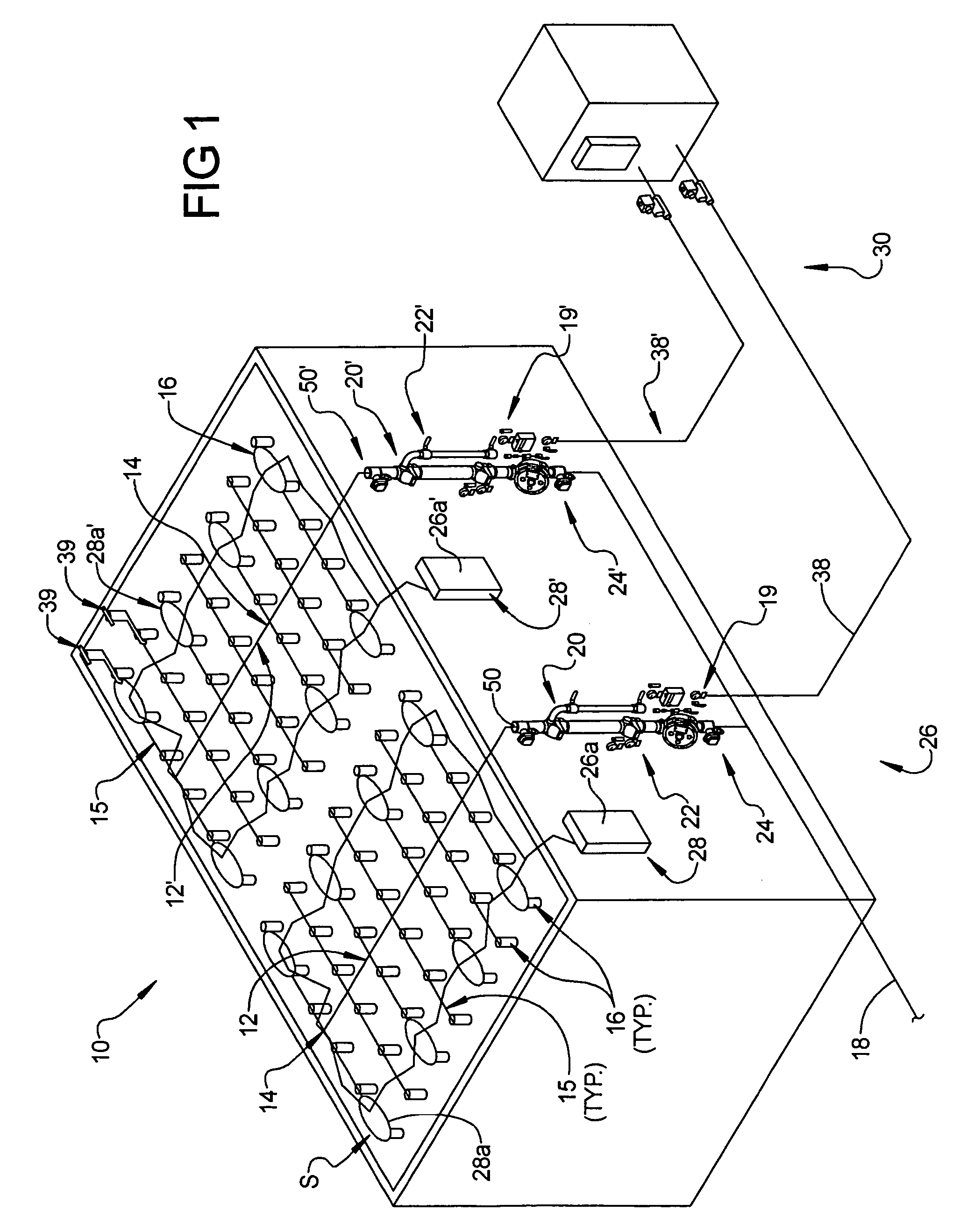

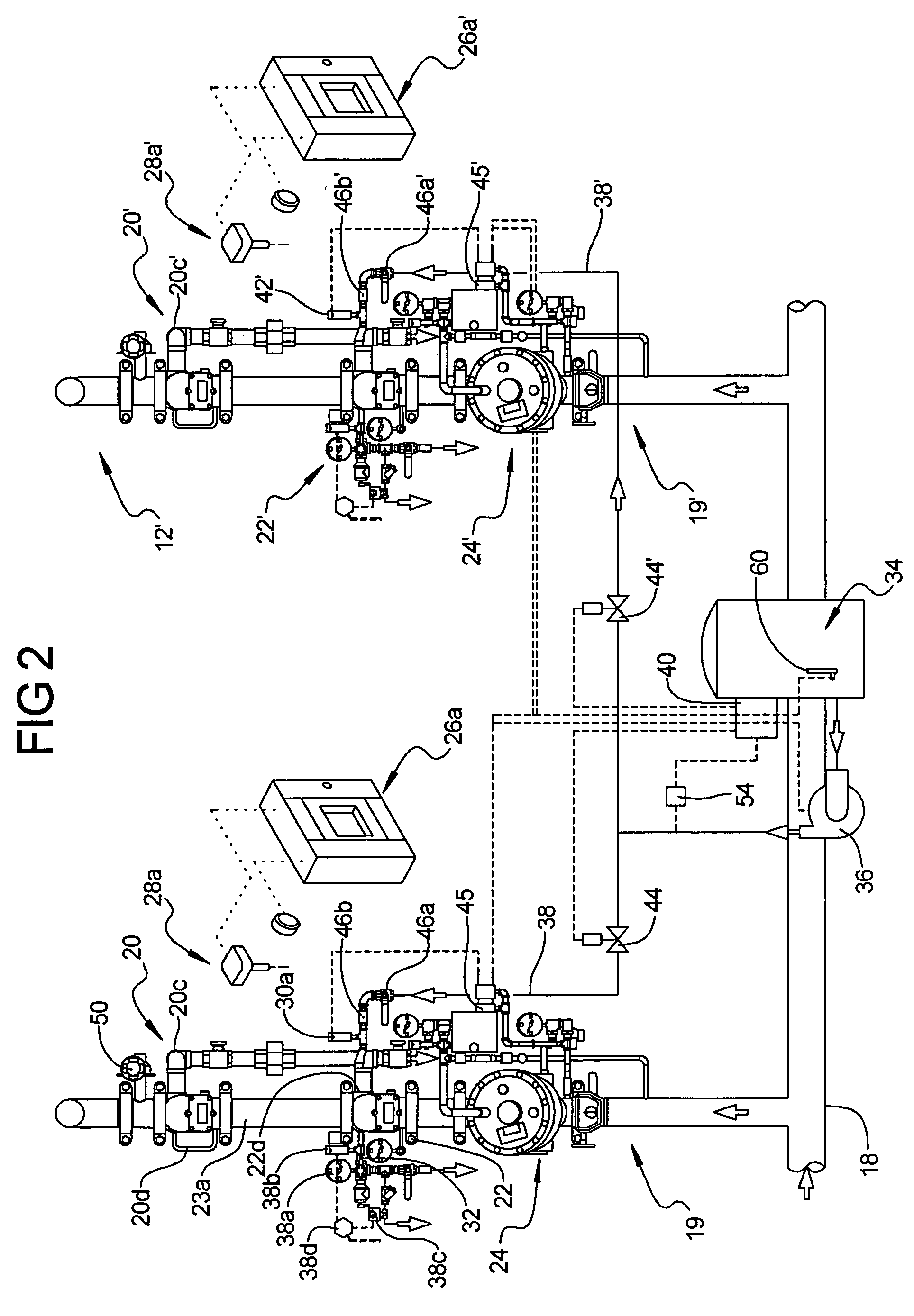

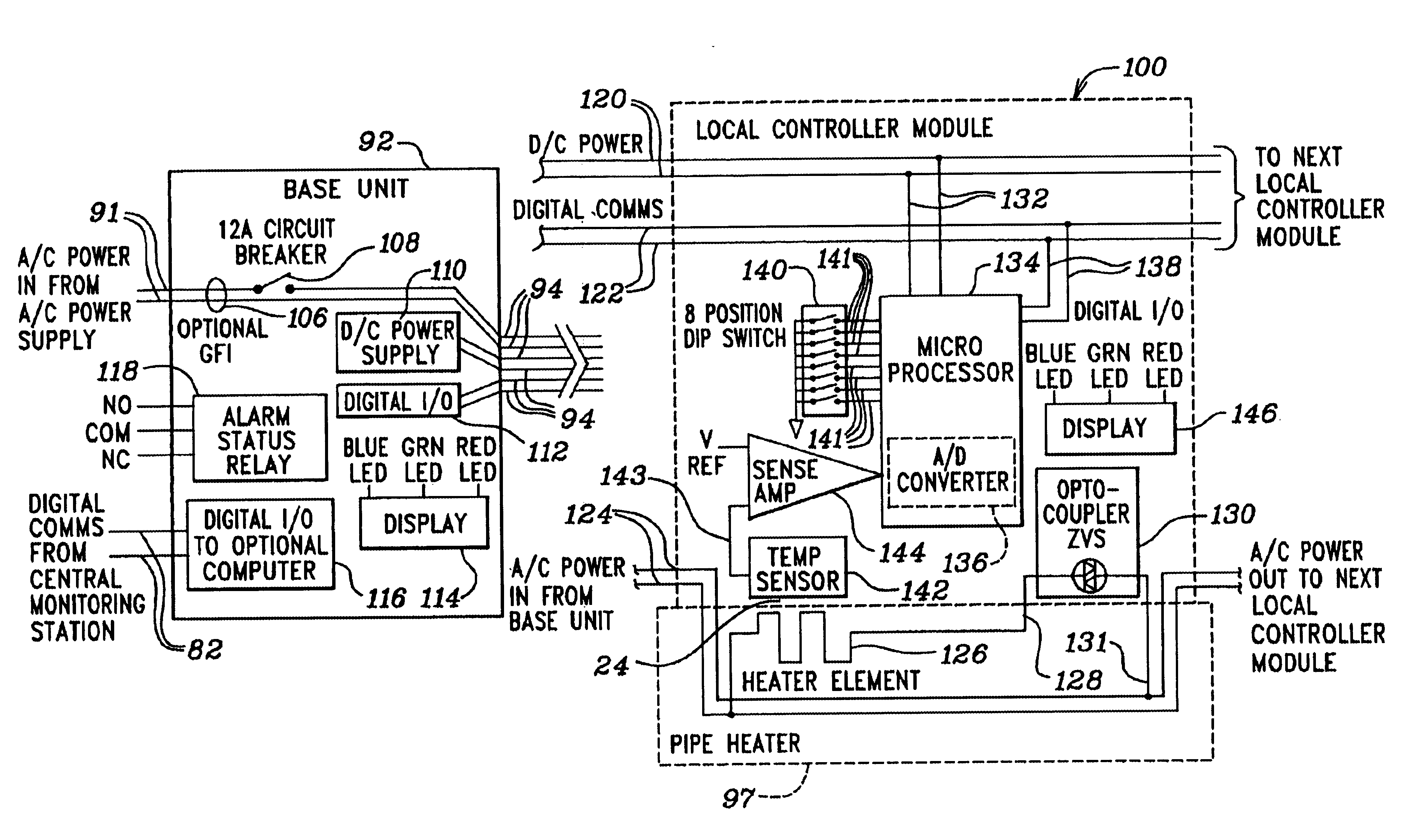

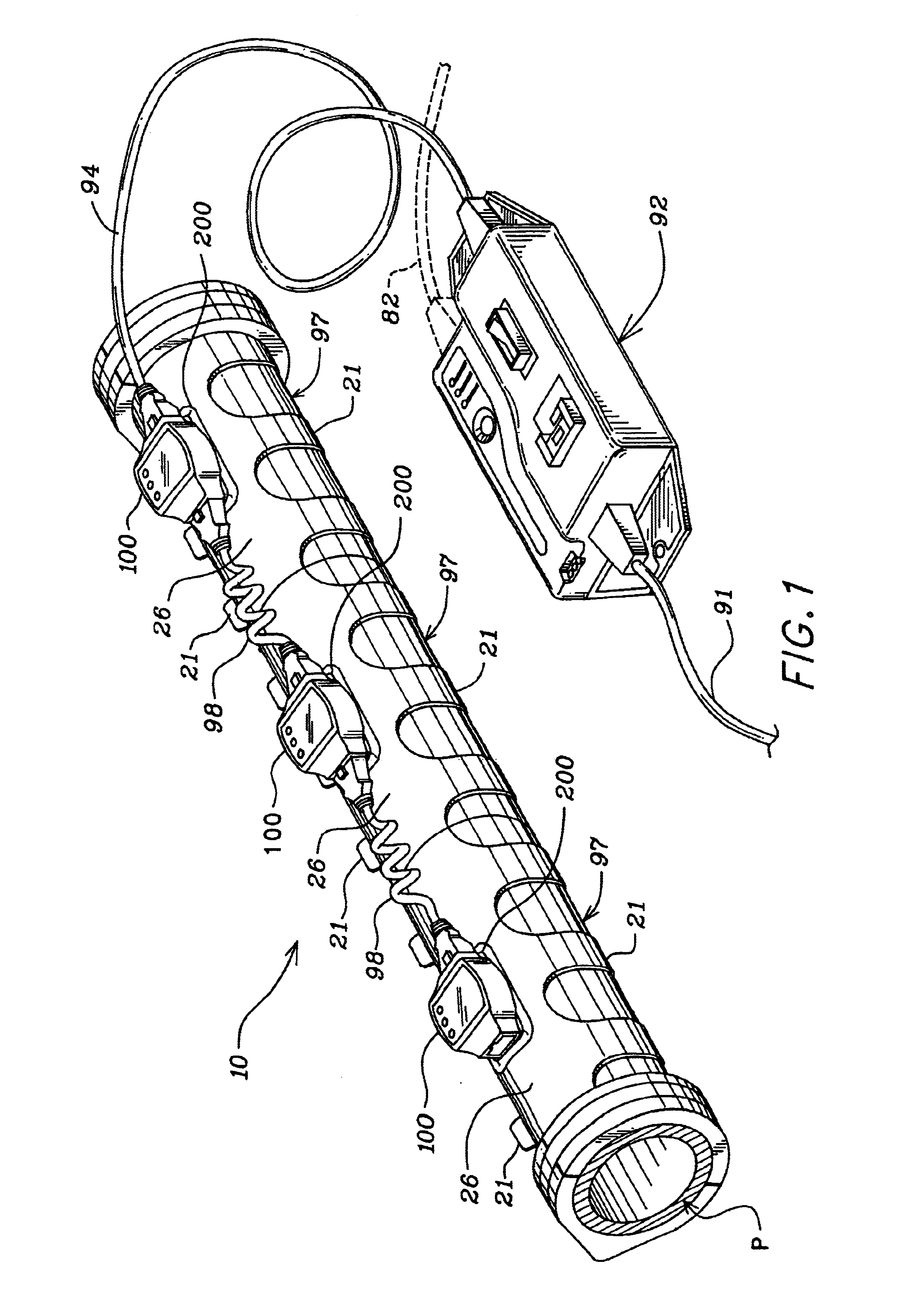

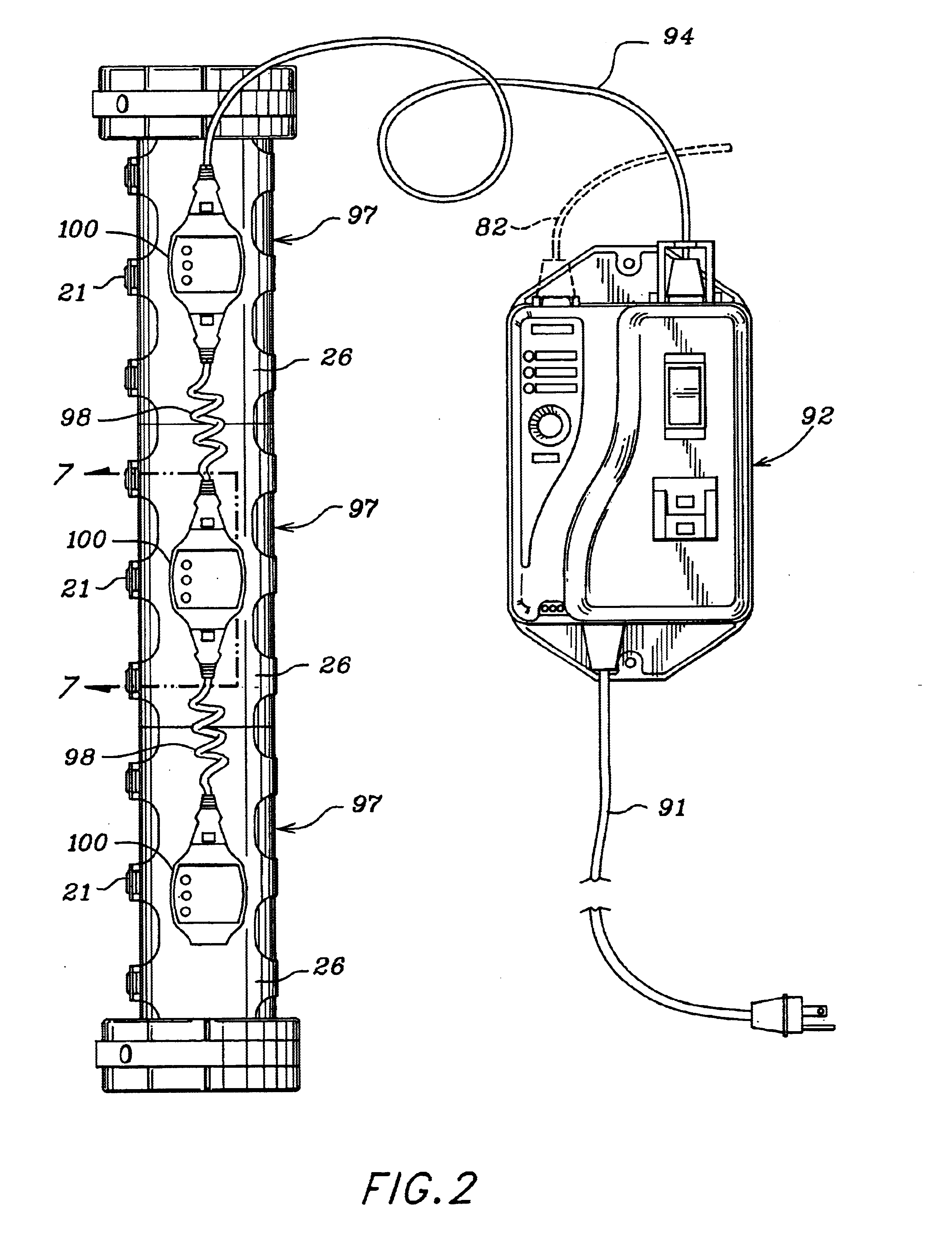

Heater control system with combination modular and daisy chained connectivity and optimum allocation of functions between base unit and local controller modules

InactiveUS6894254B2Increase heightMinimizing physical sizeDc network circuit arrangementsOhmic-resistance heating detailsTemperature controlRemote conditioning

A heater control system that utilizes electronic temperature control at each of a number of interconnected heaters is provided for monitoring and operating heaters within a narrow temperature range. In one embodiment, a heater control system is provided that is adapted for controlling a number of heaters positioned on pipe and components of a piping system from a remote location. The heater control system includes satellite controllers mounted on each heater connected daisy chain fashion and includes a monitoring station with a user interface for allowing a user to monitor and to remotely control the operating status or temperature of each heater in the heater control system. To satisfy the user's space requirements, the size of each controller is maintained at a small form factor and a single cord is used to provide power and communications lines to and between the controllers. Each controller integrates power supply and control with electronic temperature control to minimize the use of mechanical switching and to increase the accuracy of temperature control. The temperature set point is adjustable at each controller and, in one embodiment, the temperature set point is remotely adjustable from a remote monitoring station. The operating status of each controller is displayed on the exterior of the controller's housing and in one embodiment, the operating status, such as temperature, is displayed at a base station for each line of controllers and heaters and on a user interface monitor at a monitoring station.

Owner:MKS INSTR INC

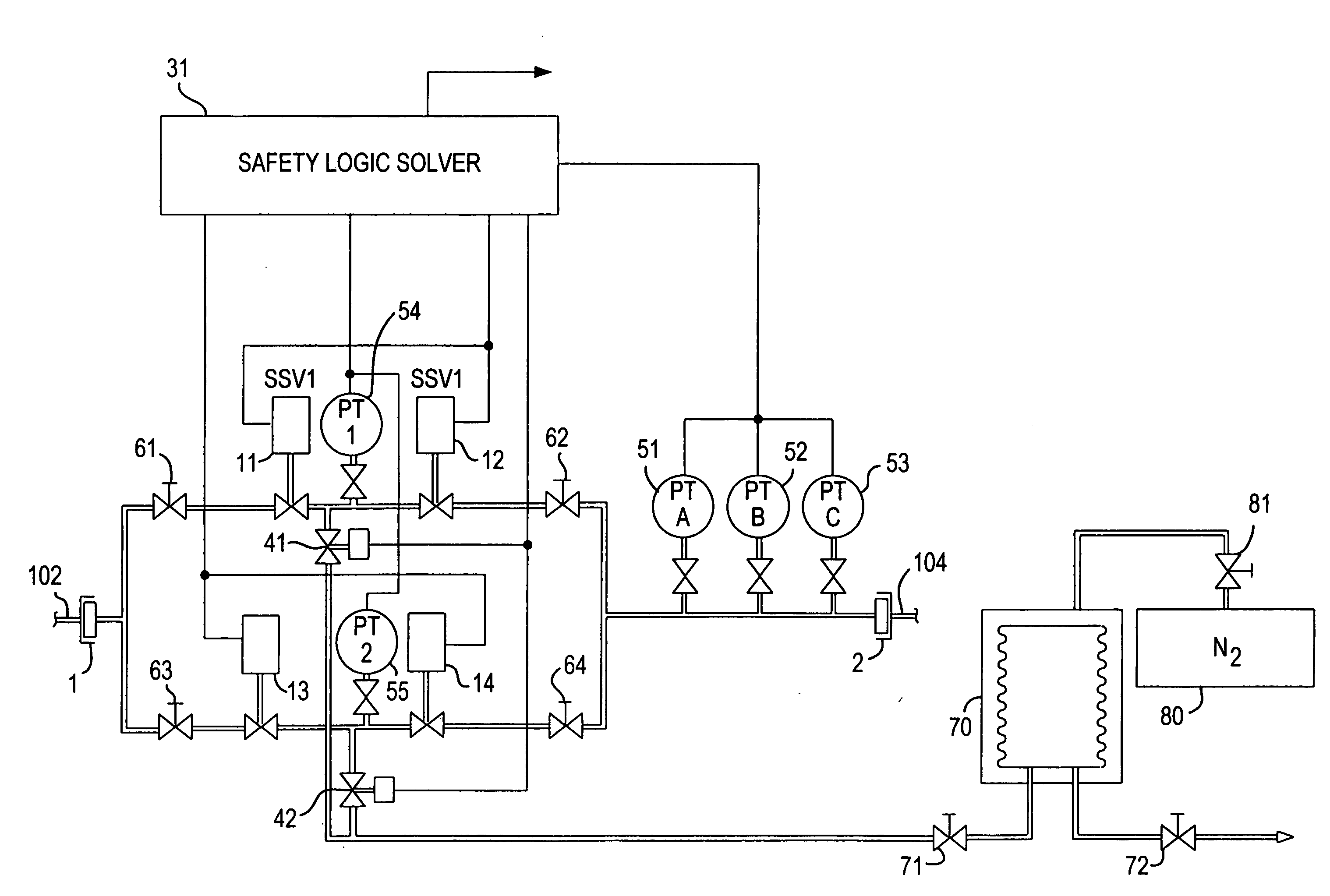

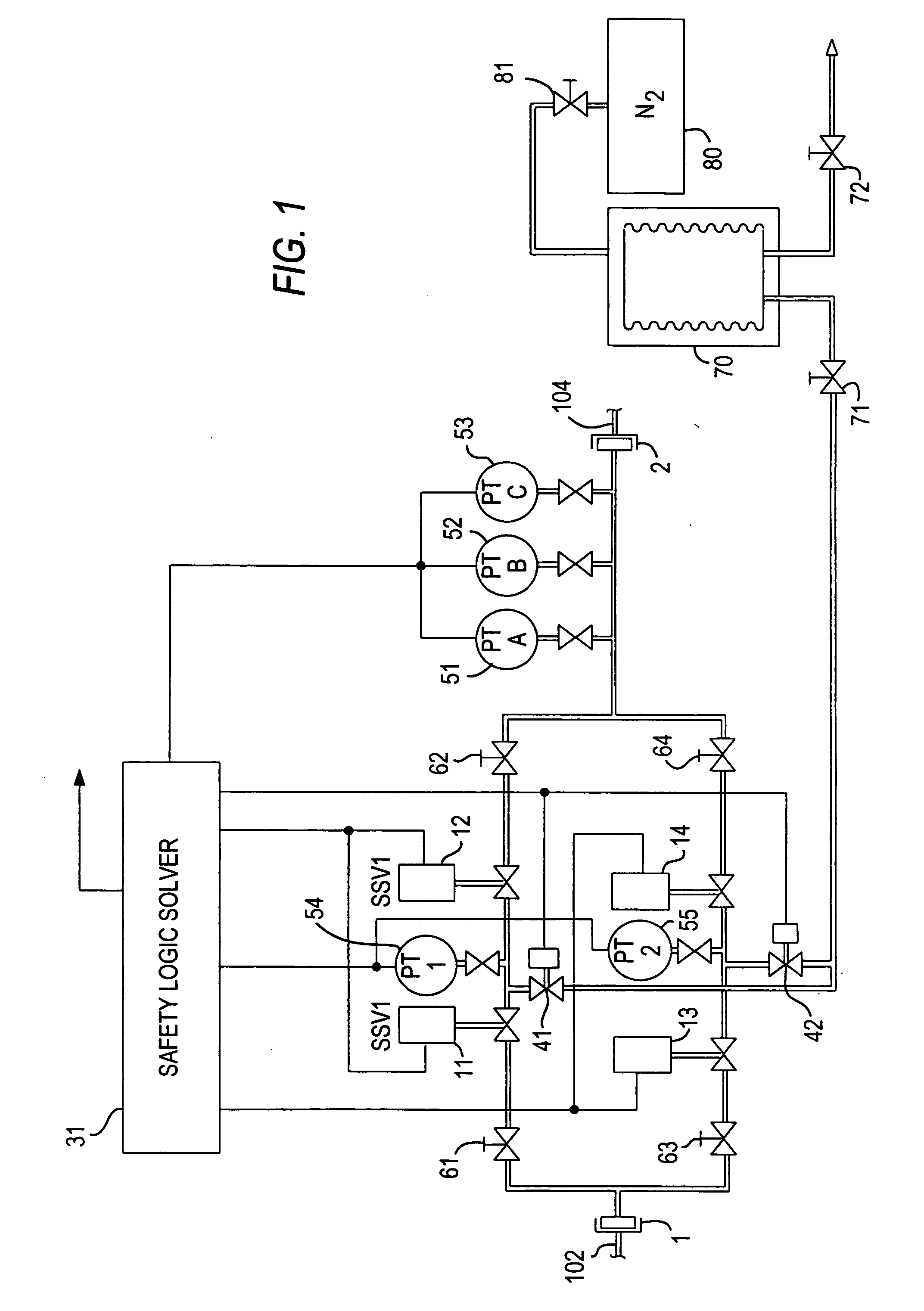

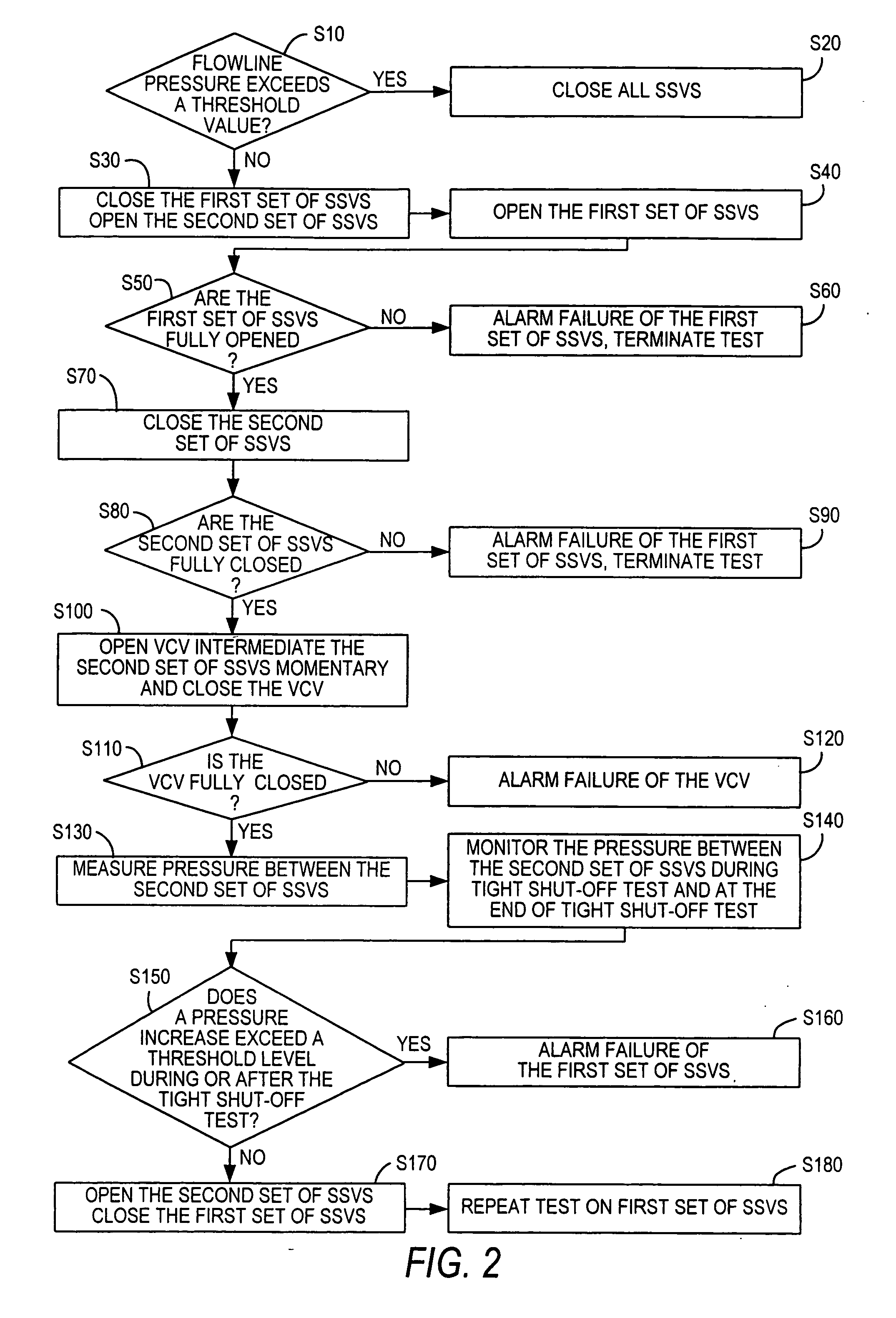

Apparatus and method for wellhead high integrity protection system

InactiveUS20080156077A1Relieve and reduce line pressureDetection of fluid at leakage pointVolume/mass flow measurementPressure senseEngineering

A high integrity protection system (HIPS) for the protection of a piping system downstream of a wellhead has an inlet connected to the wellhead and an outlet connected to the downstream piping system and includes: two sets of series-connected surface safety valves (SSVs) in fluid communication with the inlet, the two sets being in parallel fluid flow relation to each other, each set of SSVs consisting of two SSVs in series, either one or both of the two sets of SSVs operable as a flowpath for fluids entering the inlet and passing through the HIPS outlet to the piping system; two vent control valves (VCVs), each of which is connected to piping intermediate each of the two series-connected SSVs, each of the VCVs being in fluid flow relation to each other, each set of SSVs consisting of SSVs in series, either one or both of the two sets of SSVs operable as a flowpath for fluids entering the inlet and passing through the HIPS outlet to the piping system; two vent control valves (VCVs), each of which is connected to piping intermediate each of the two series connected SSVs, each of the VCVs being in fluid communication with a vent line, whereby, upon opening of a VCV, process pressure between the two SSVs is vented; a signal-generating safety logic solver, in accordance with preprogrammed safety and operational protocols; and pressure sensing transmitters attached to piping upstream of the HIPS outlet. The HIPS performs independent, tight shut-off tests of each of the series-connected SSV sets and all valves are closed in the event of an electrical and / or hydraulic system failure.

Owner:SAUDI ARABIAN OIL CO

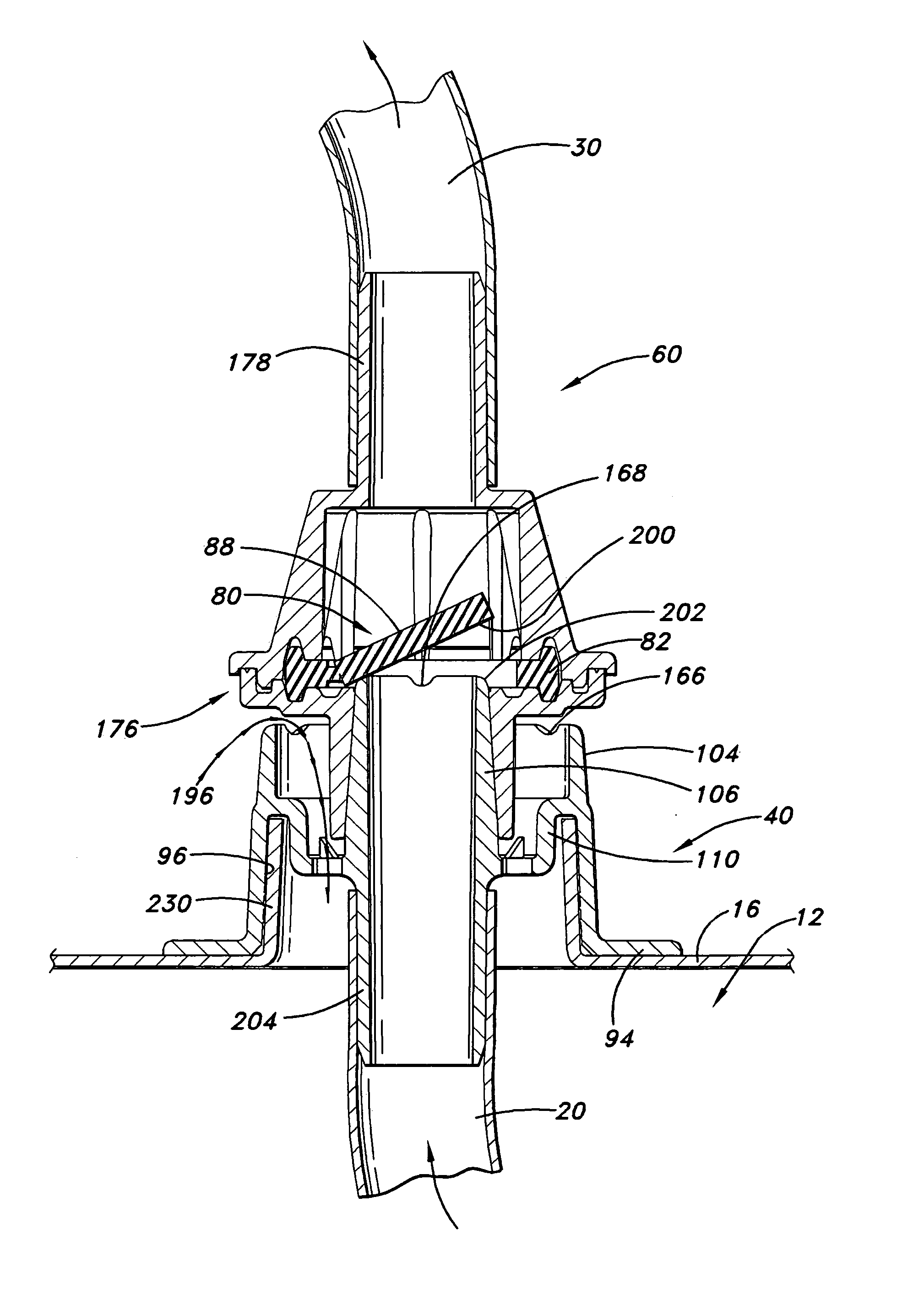

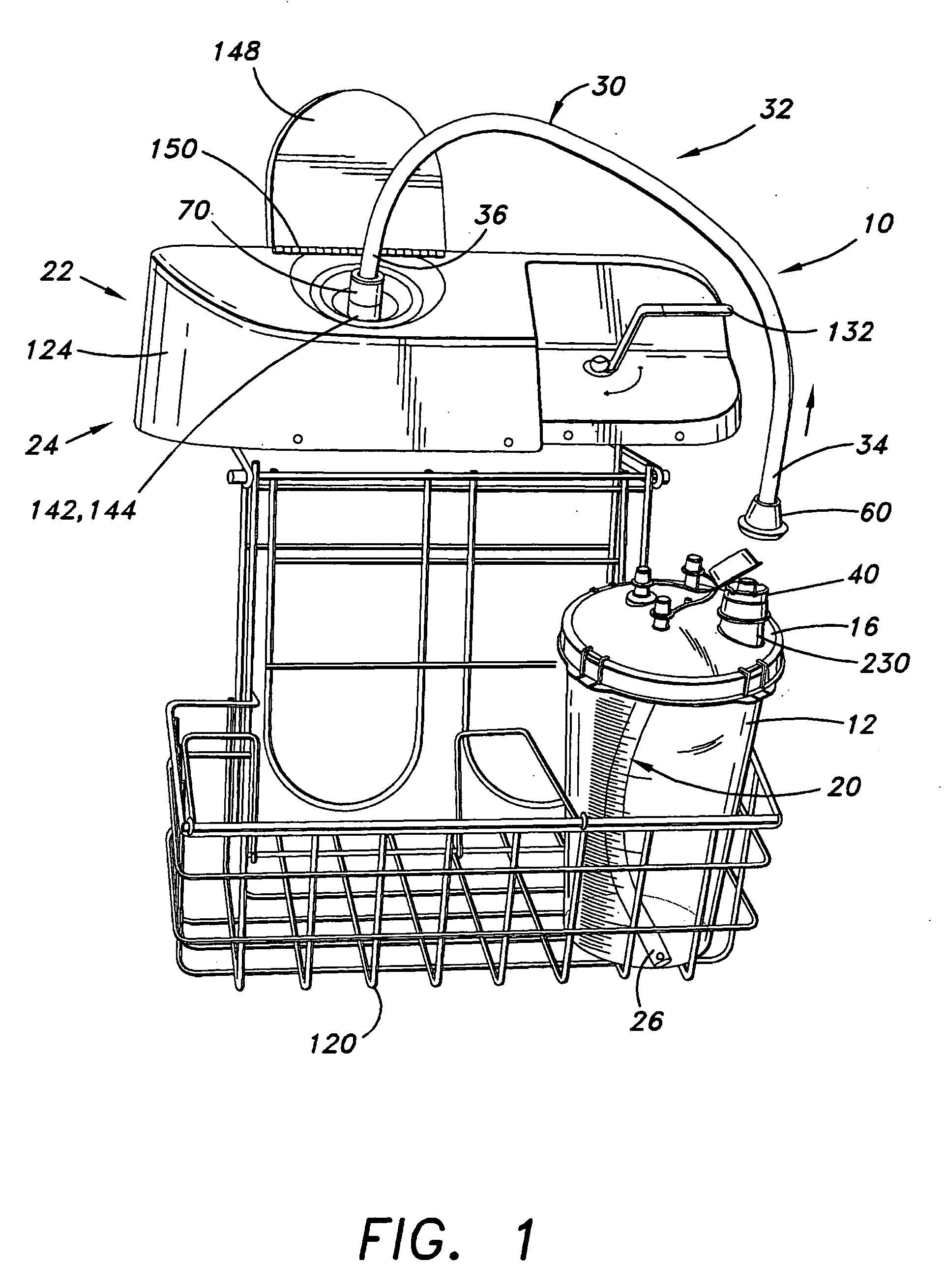

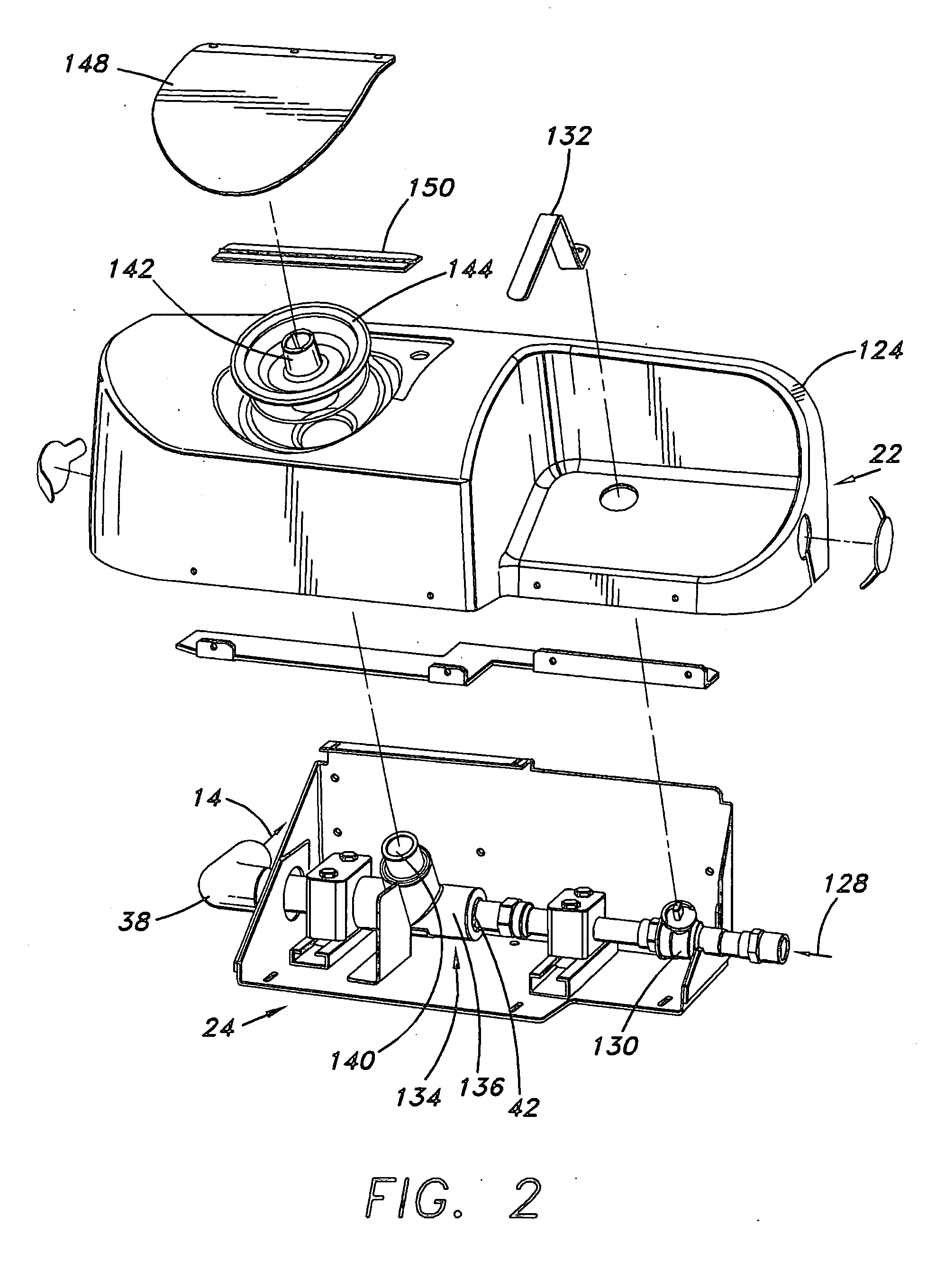

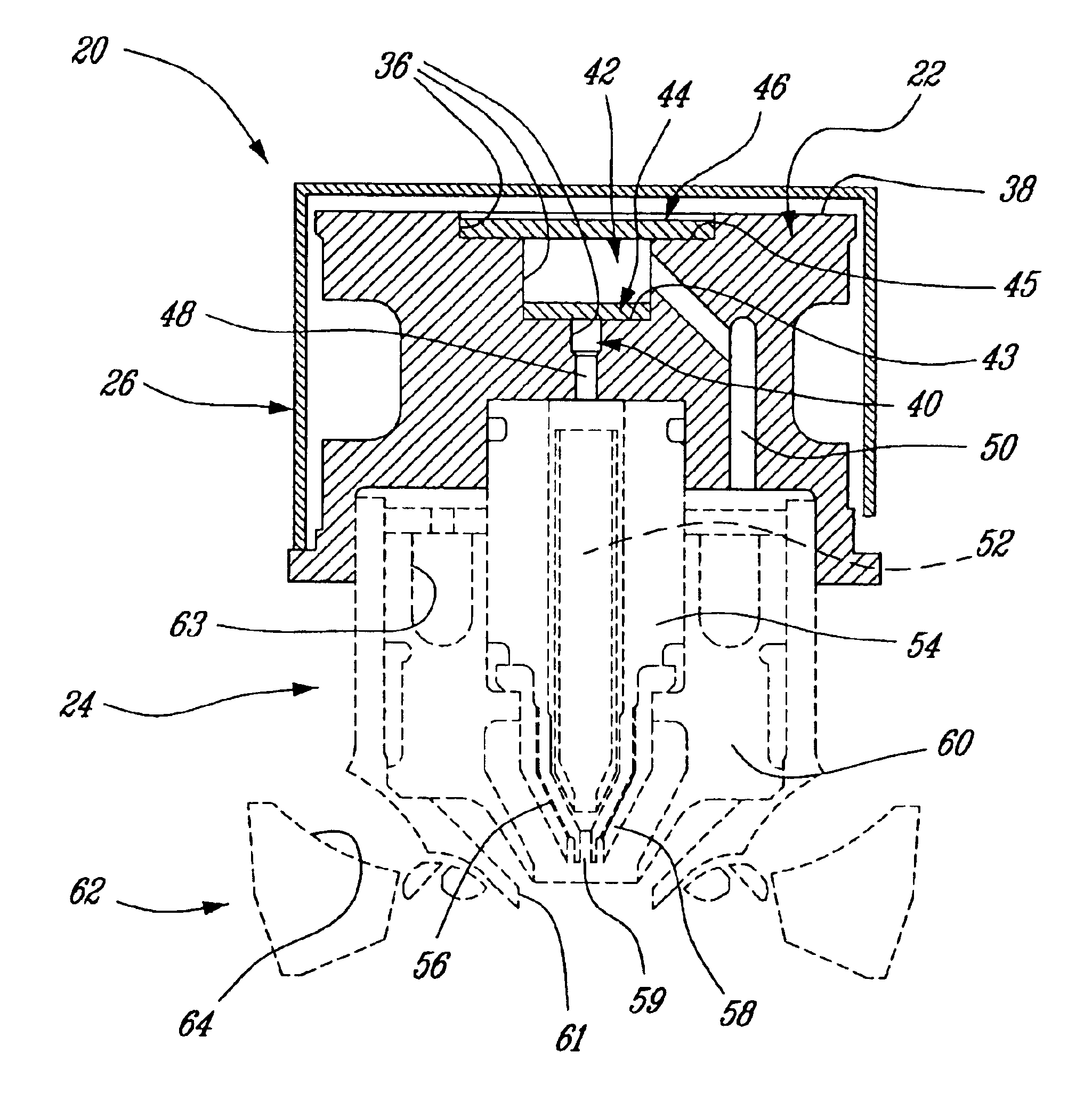

Method and apparatus for the disposal of waste fluids

An innovative method and apparatus for disposing of waste fluids, especially human body fluids such as are generated during surgery, into a hospital's sanitary sewer system is provided. A conduit system is adapted to transport waste fluid from a receptacle to a sanitary sewer using an eductor having a venturi device. The conduit system includes first and second conduits. First and second connectors are used to easily connect the first conduit to the second conduit. The second connector includes a flap that acts as a check valve.

Owner:ALLEGIANCE CORP

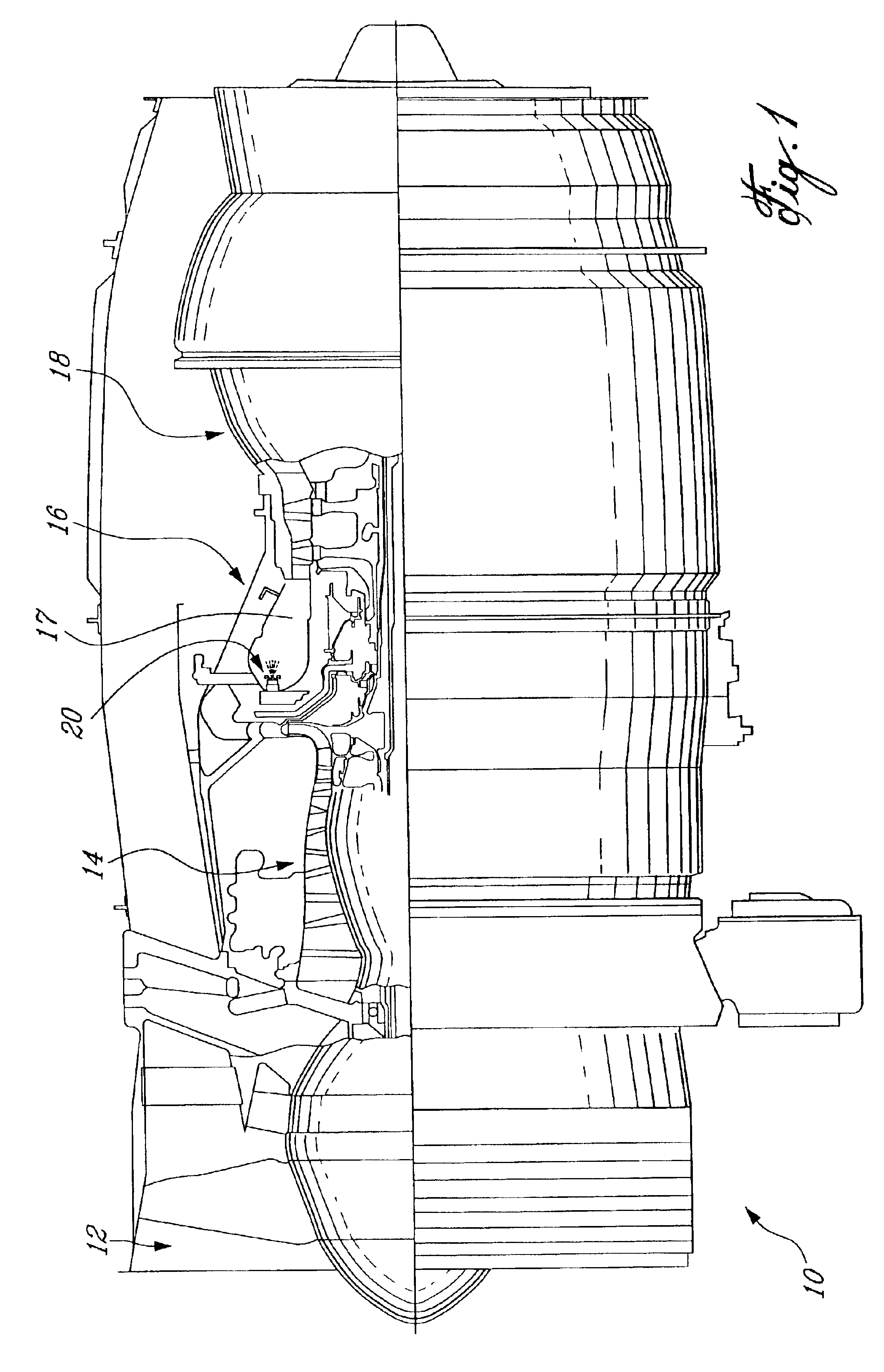

Apparatus for fuel transport and the like

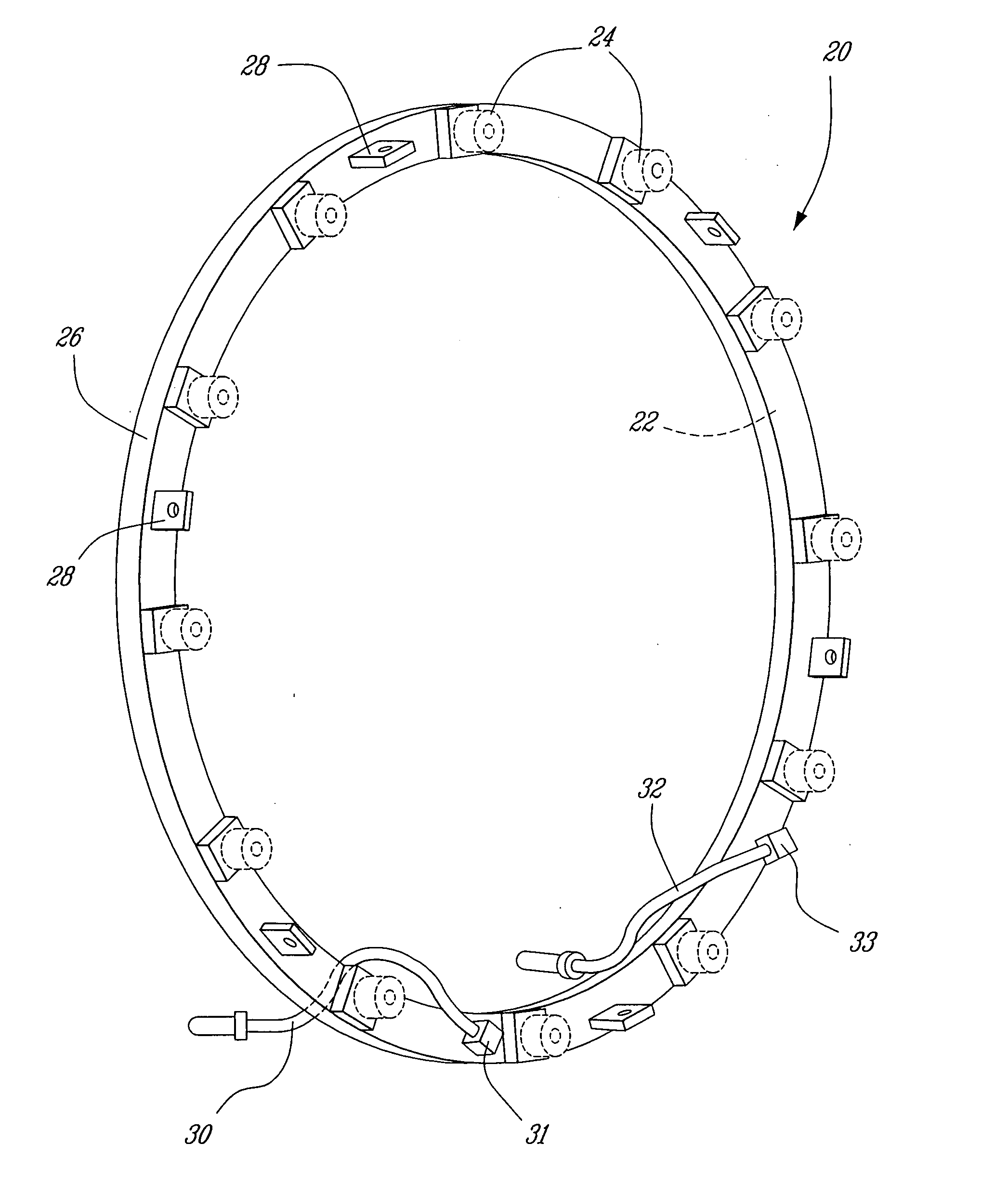

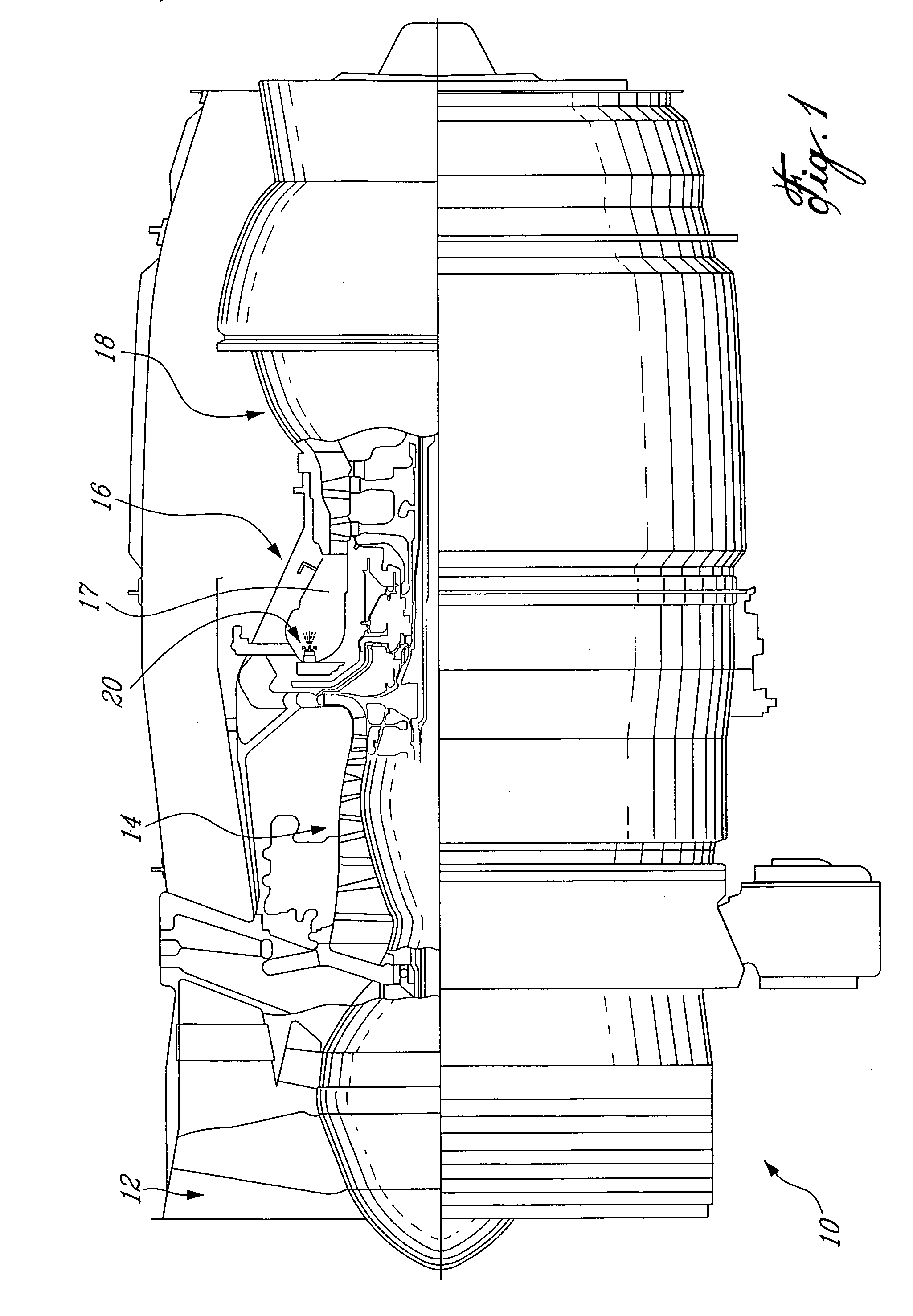

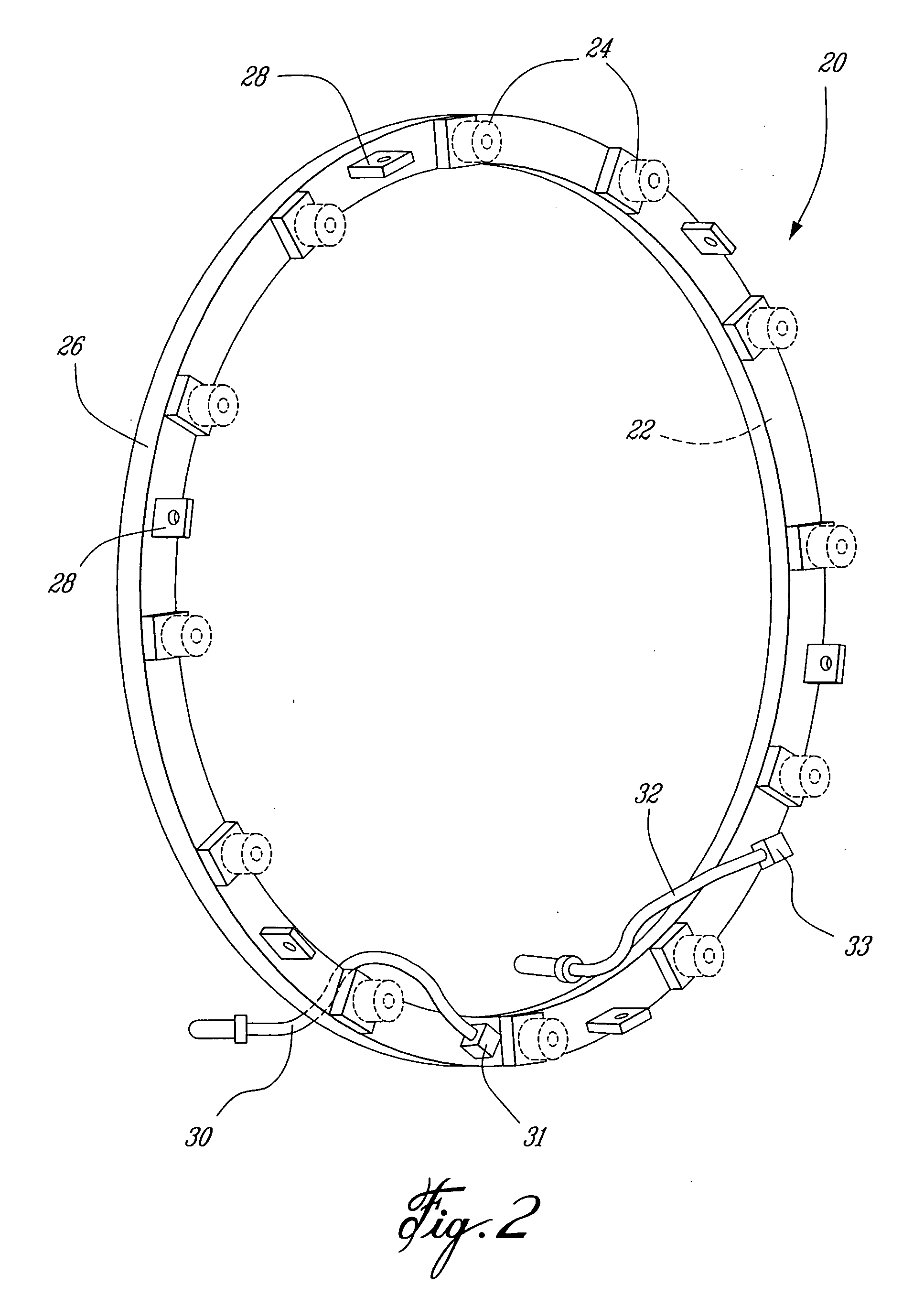

ActiveUS20050188699A1Continuous combustion chamberTurbine/propulsion fuel flow conduitsCooling effectGas turbines

Fuel conduit systems for internal installation in a gas turbine engine are provided which are low cost and easy to manufacture. First and second members co-operate to provide a channel to define a discrete fuel carrying conduit. The direction of fuel flow can be adapted to provide desired cooling effect.

Owner:PRATT & WHITNEY CANADA CORP

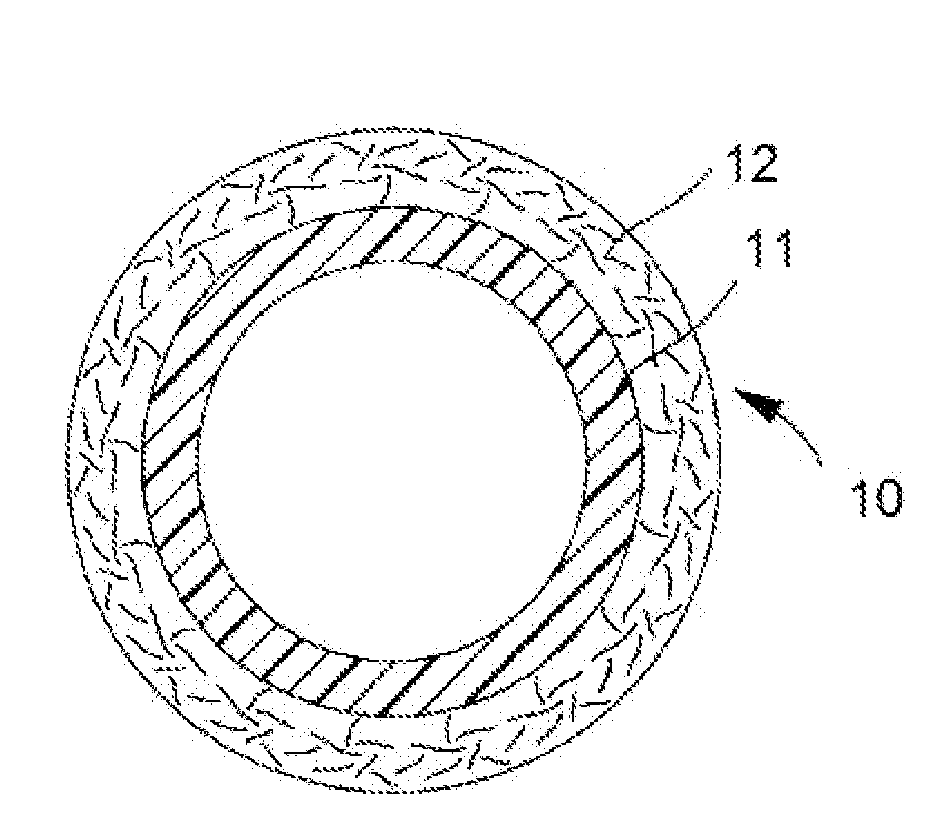

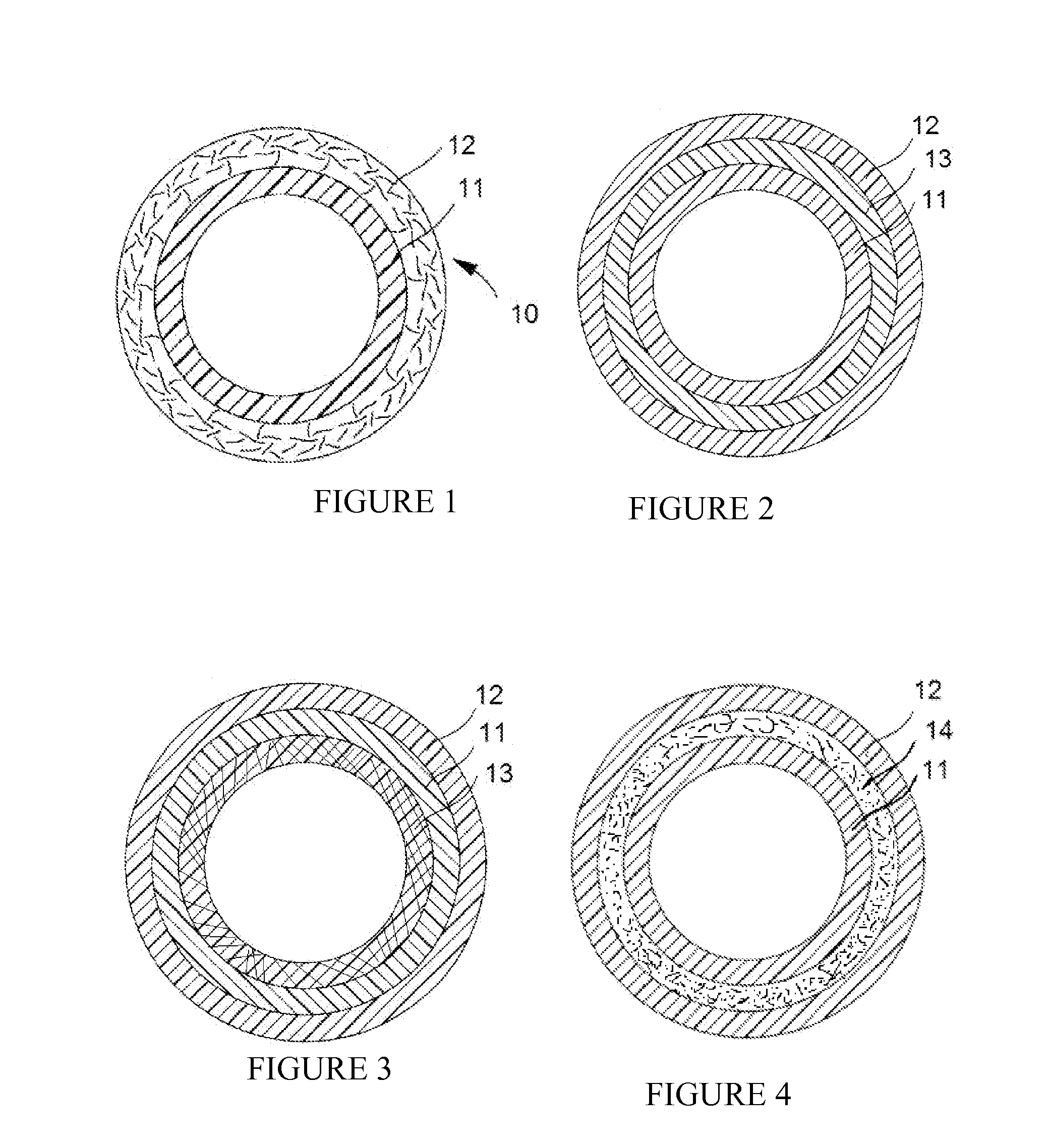

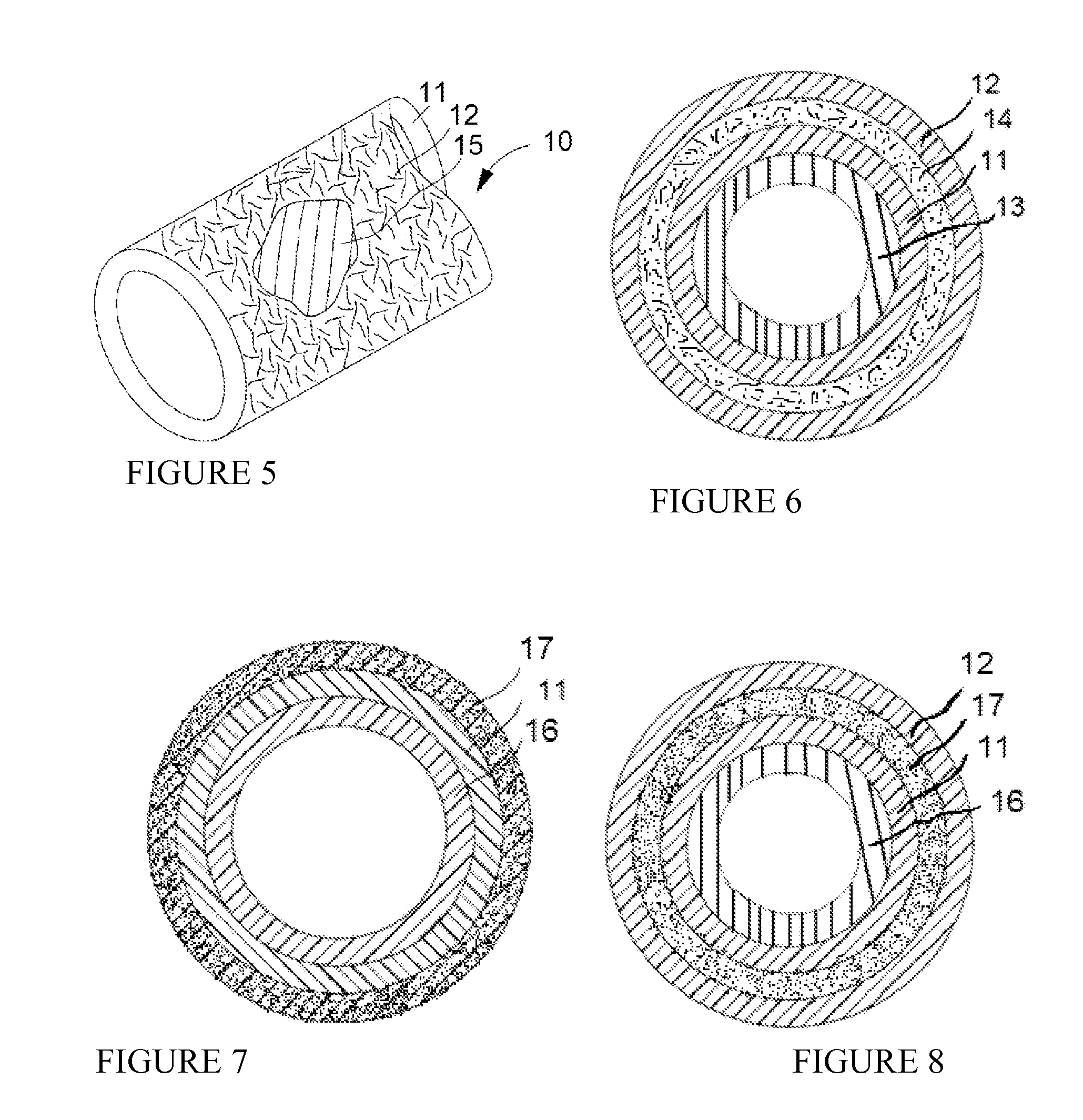

Structural Components for Oil, Gas, Exploration, Refining and Petrochemical Applications

A structural component for use in oil, gas, exploration, refining and petrochemical applications in the form of a pipe system is provided. The pipe system contains at least two pipe sections are that fusion bonded together, each pipe section comprises a plurality of layers, an inner layer in contact with the corrosive petroleum product comprising a thermoplastic material, a structural layer comprising a composite material, and an outer layer comprising a fire resistive material. In one embodiment, the pipe system meets level II fire endurance standard according to IMO A 18 / Res.753 fire testing protocol.

Owner:CHEVROU USA INC

Apparatus for flow detection, measurement and control and method for use of same

InactiveUS6914531B1Easy to operateEasy CalibrationValve arrangementsMeasurement of fluid loss/gain rateFire sprinklerDifferential pressure

A flow sensor having an inlet and an outlet comprising: a plate moving in response to fluid flow therethrough, being displaced further as flow increases; a sensor for determining moving plate's position and creating an electronic signal related thereto; a biasing means for biasing the plate towards the sensor's inlet end. The sensor may include a sealing means for preventing flow therethrough until a specified differential pressure is reached allowing the device to be used as a bypass mechanism. The sealing means may also constitute a check valve means to prevent flow in an undesired direction. The check means comprises: a bullet rod adapted to be received within an orifice defined in a moving plate, such that the bullet rod prevents flow through the orifice until the moving plate is displaced past a terminal end of the bullet rod; and a plate means sealingly and slidingly received within a cylinder, which is closed for a portion of its length and open for another portion of its length, such that flow is prevented until the plate is displaced past the closed portion of the cylinder. The method using the sensor in multipurpose piping systems includes use of the apparatus in a system incorporating at least one fire sprinkler, the piping system also preferably providing at least one other use in the structure. The other use in the structure may be supplying domestic needs, or supplying heating / cooling water for a heating / air conditioning system.

Owner:YOUNG RICHARD

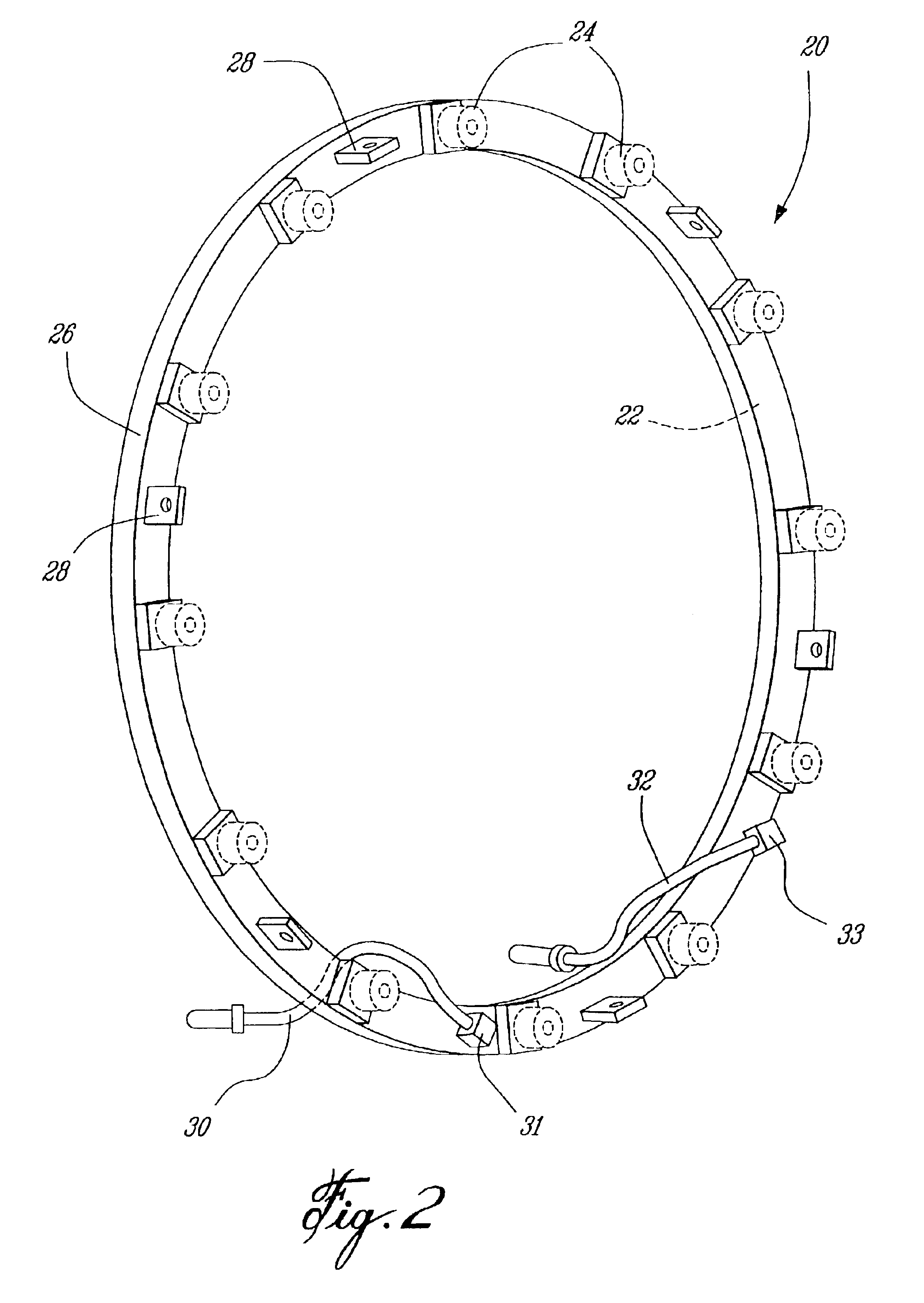

Nested channel ducts for nozzle construction and the like

InactiveUS7028484B2Simpler and economical to manufactureLiquid fuel feeder/distributionContinuous combustion chamberGuide tubeGas turbines

A multiple conduit system for a gas turbine engine, the multiple conduit system extending between a plurality of conduit inlet and outlets. A channel is formed in a surface of a gas turbine engine component, and the channel is adapted for conveying a fluid flow from an inlet to an outlet. At least a first sealing member is disposed within the channel and divides the channel into at least a first discrete conduit and a second discrete conduit. A second sealing member encloses the channel to define the second discrete conduit. The first and second discrete conduits are each adapted to direct an independent fluid flow from respective inlets to respective outlets.

Owner:PRATT & WHITNEY CANADA CORP

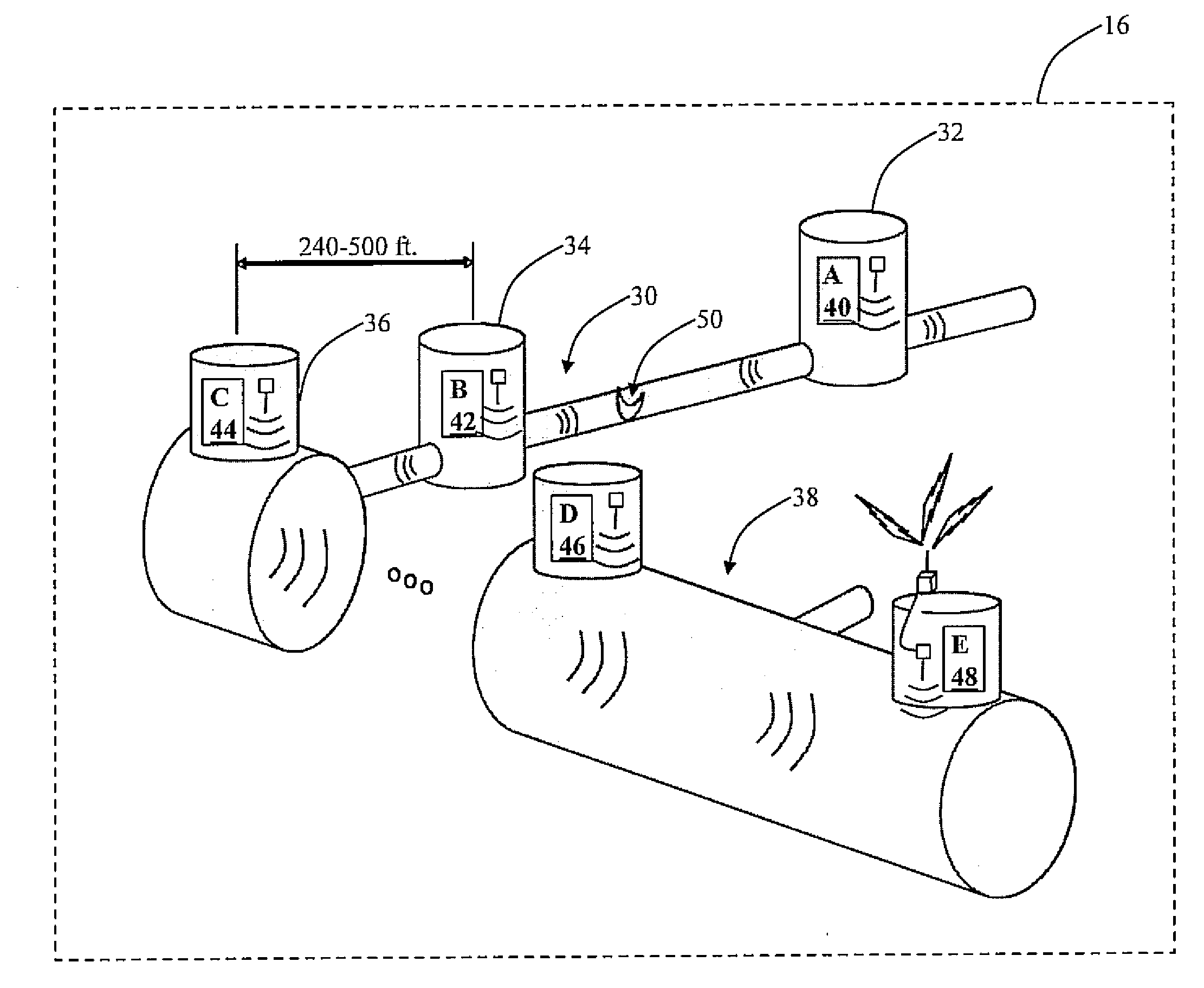

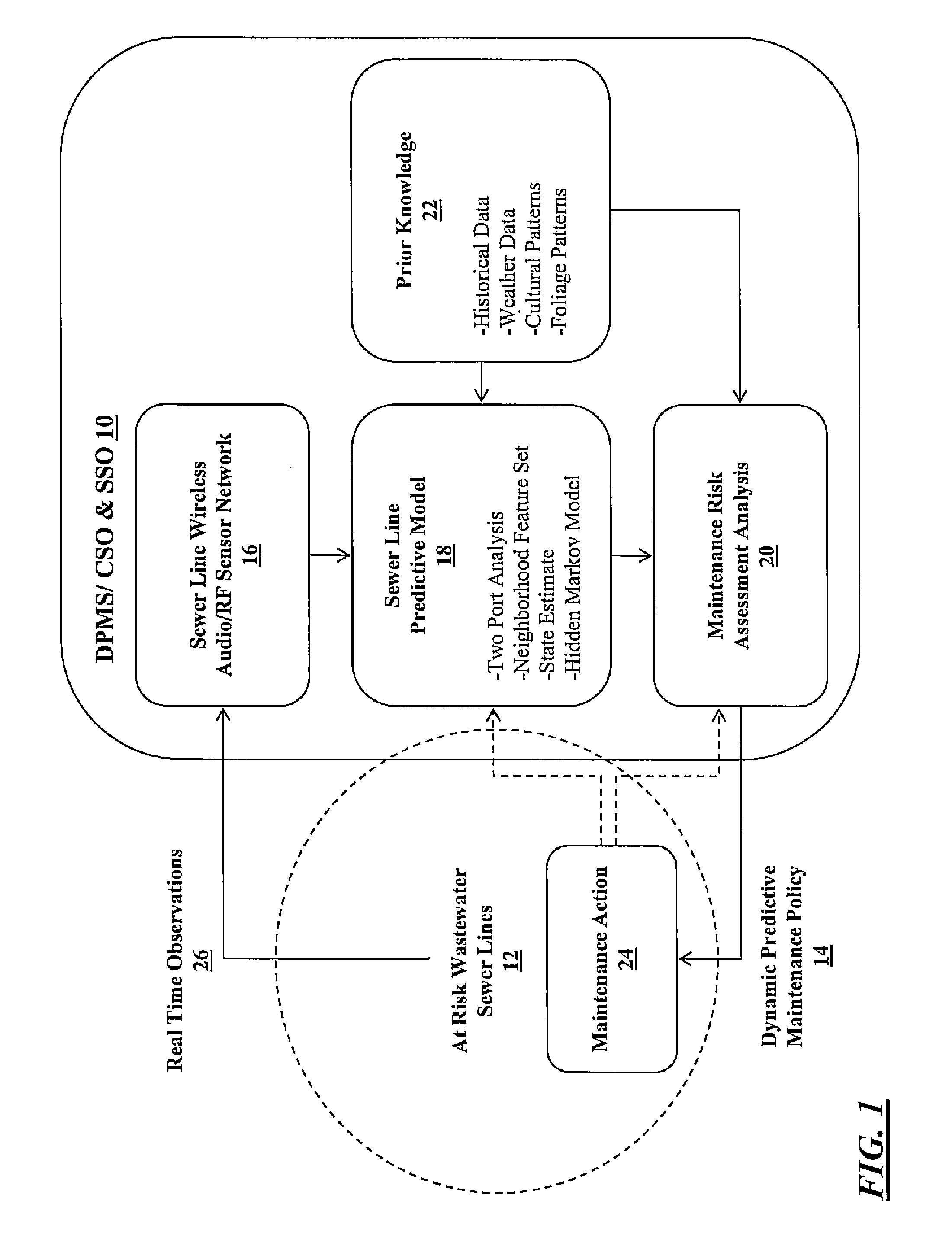

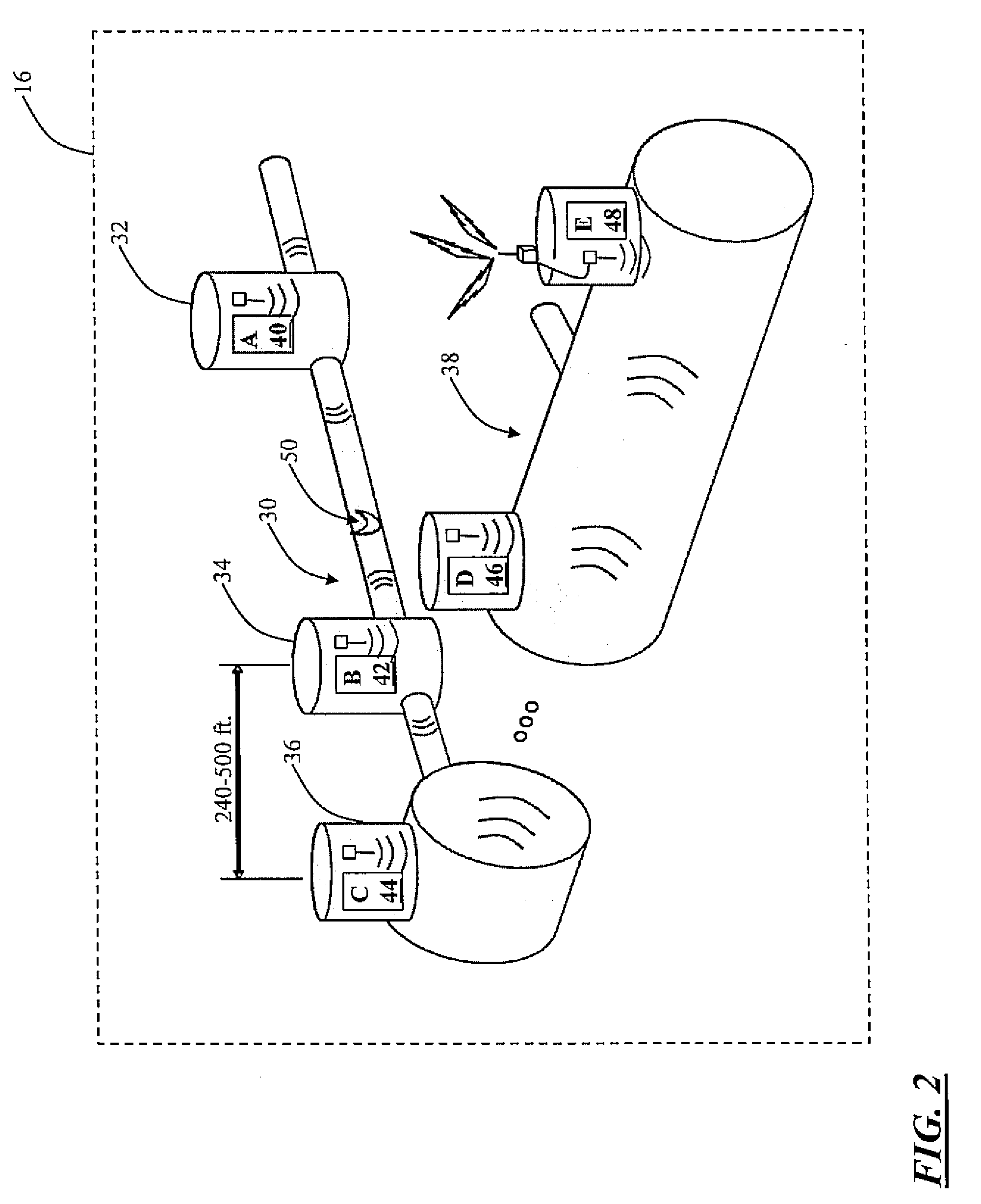

Monitoring systems and methods for sewer and other conduit systems

The present invention provides a monitoring system for a conduit network including one or more conduit sections joined at one or more conduit nodes, including: one or more sensor devices disposed at selected ones of the one or more conduit nodes, wherein each of the one or more sensor devices is operable for sensing a blockage or breakage in an associated conduit section, and wherein each of the one or more sensor devices is operable for communicating blockage or breakage information to a central location. Optionally, each of the sensor devices includes one of an audio sensor device and a radio frequency sensor device. Each of the sensor devices is operable for sensing the blockage or breakage in the associated conduit section by measuring an attribute of a transmitted / received signal, alone or in combination with another sensor device. Each of the sensor devices is operable for communicating the blockage or breakage information to the central location via a wireless link.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com