Patents

Literature

1694 results about "Water chiller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water chiller is a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere.

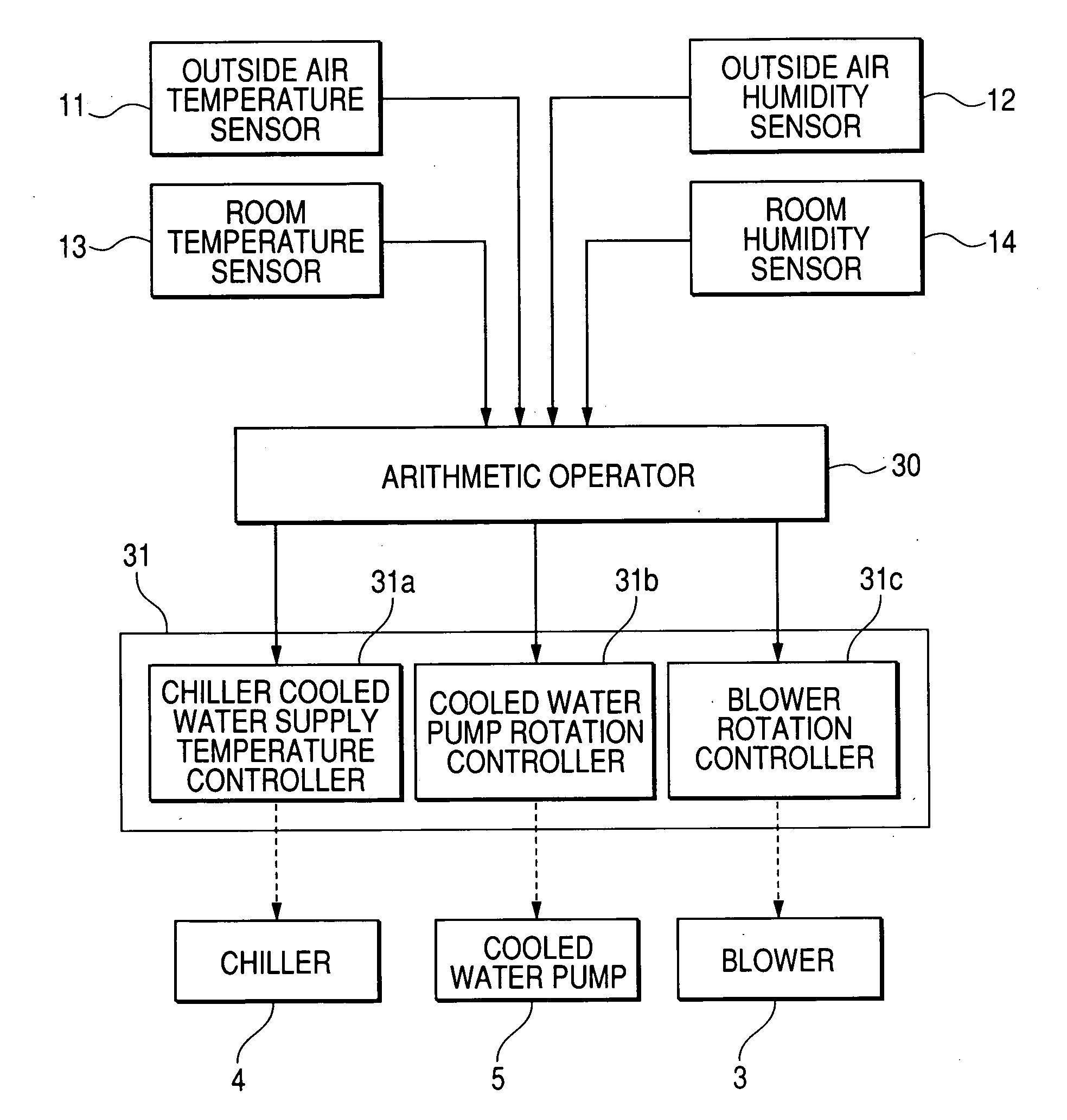

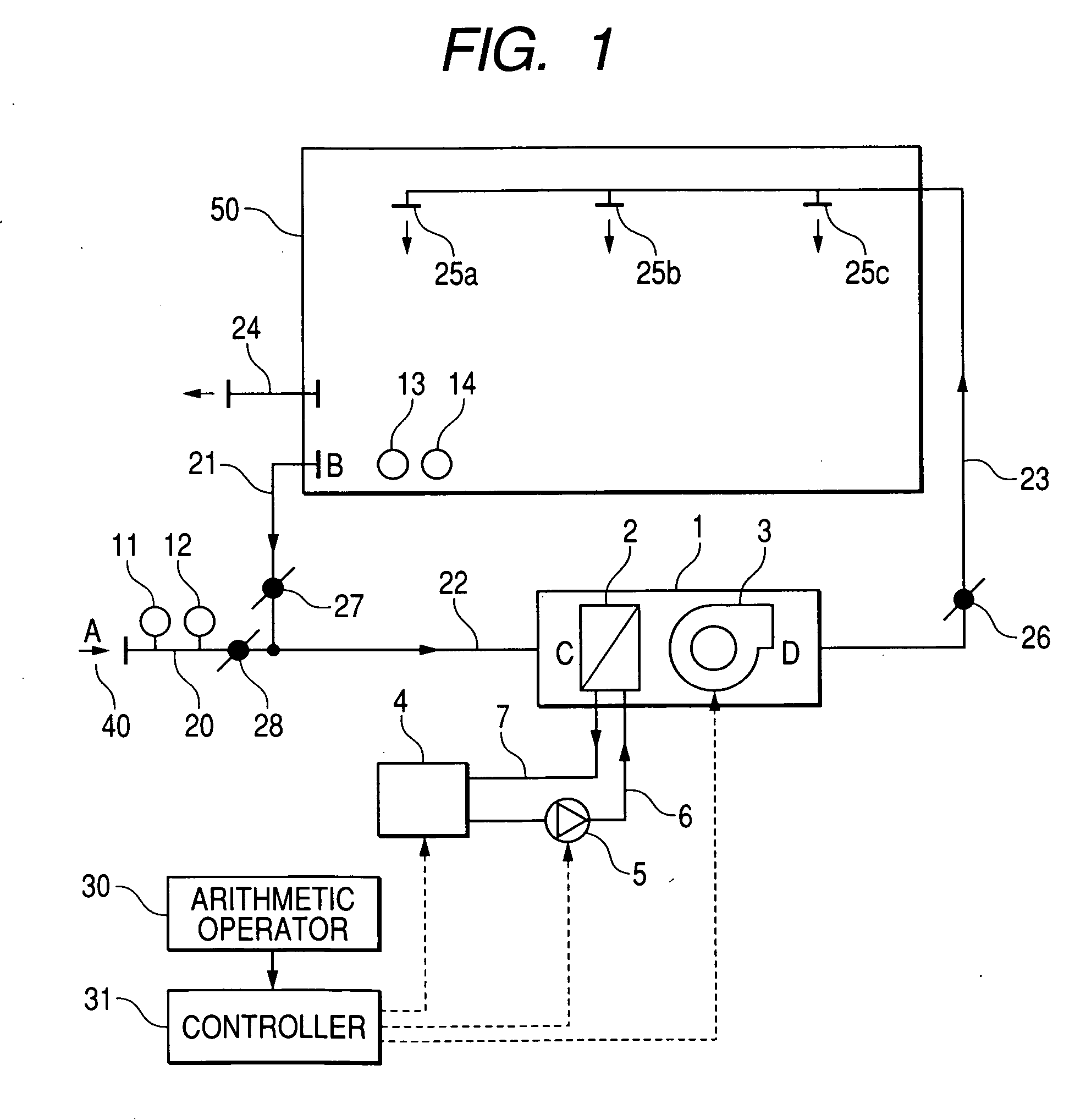

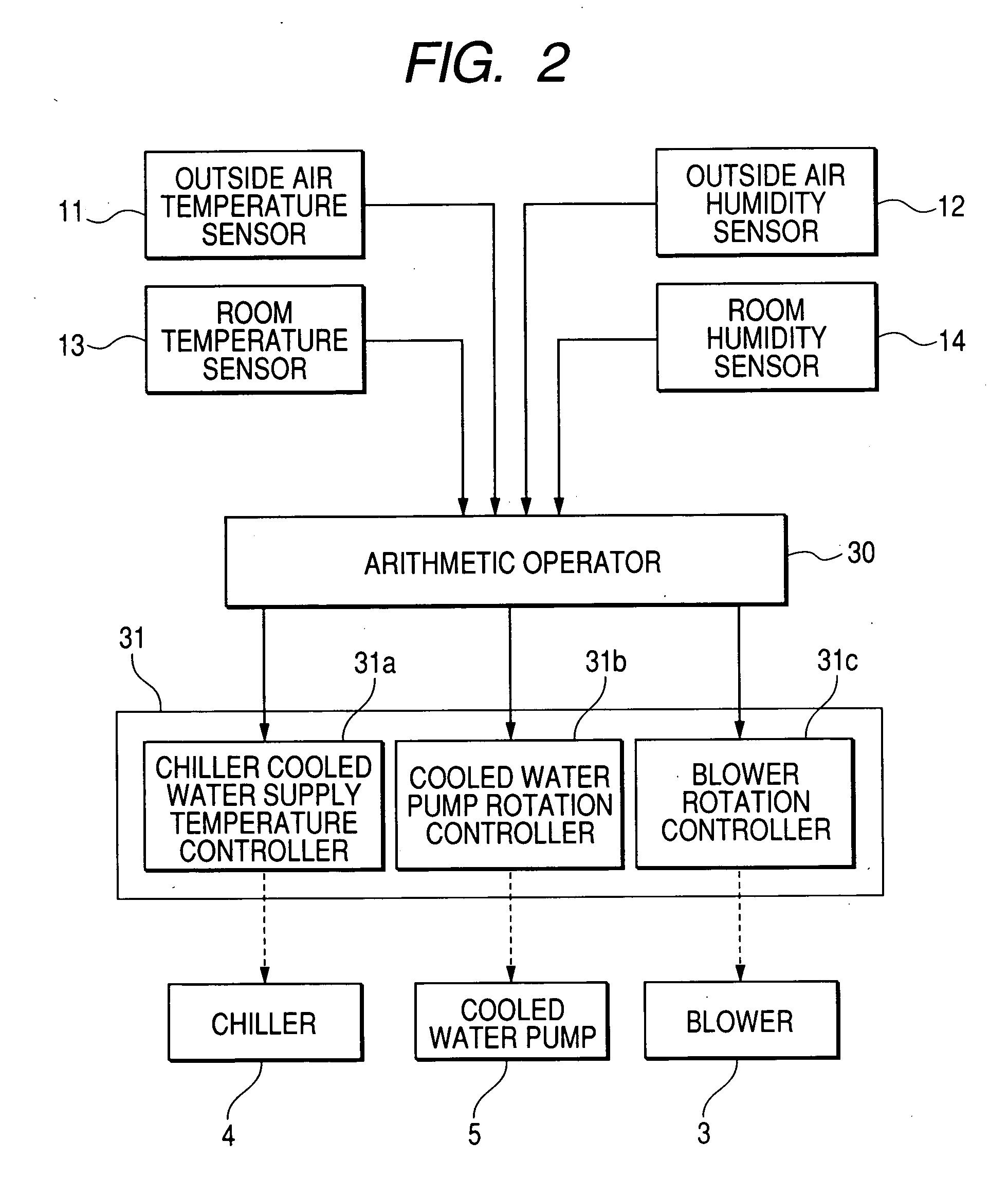

Air conditioning apparatus

InactiveUS20070107450A1Increase in chiller load can be preventedQuantity minimizationMechanical apparatusSpace heating and ventilation safety systemsAir volumeCoolant flow

An air conditioning apparatus comprises an air-conditioning unit including at least a cooling coil as a heat exchanger, a blower, a chiller, and a coolant pump for conducting air-conditioning, wherein the coolant pump pumps the coolant cooled by the chiller to the cooling coil, the cooling coil cools the air through heat exchange of the coolant and the air, the blower supplies the cooled air into a room. Coolant temperature of the chiller, the coolant flow rate of the coolant pump, and the air flow rate of the blower are calculated in accordance with the set points of the indoor temperature and the indoor humidity, and the chiller, coolant pump, and blower are controlled on the basis of the arithmetic calculation results. Thereby, the indoor temperature and indoor humidity are independently controlled in the central air-conditioning system.

Owner:HITACHI LTD

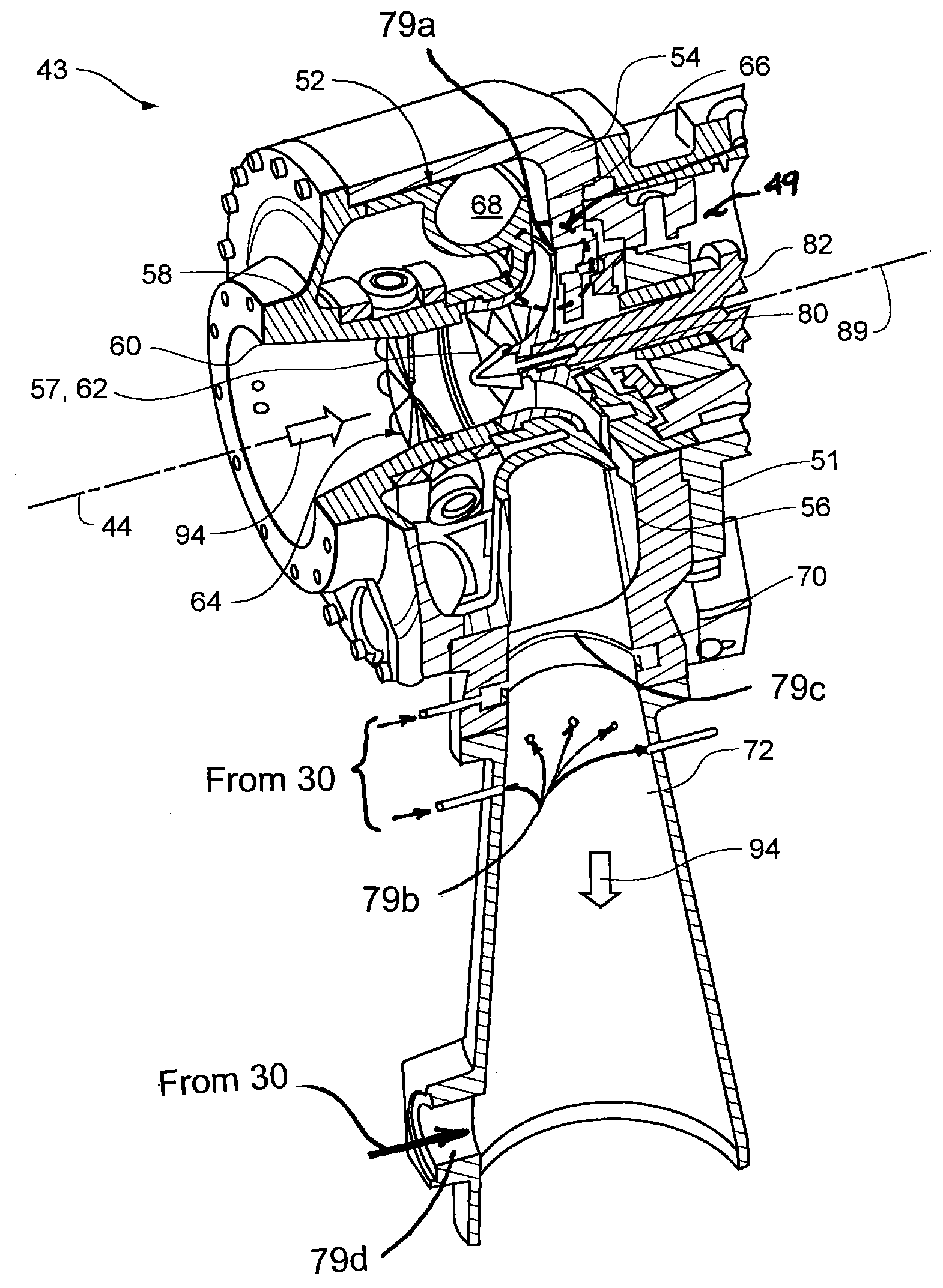

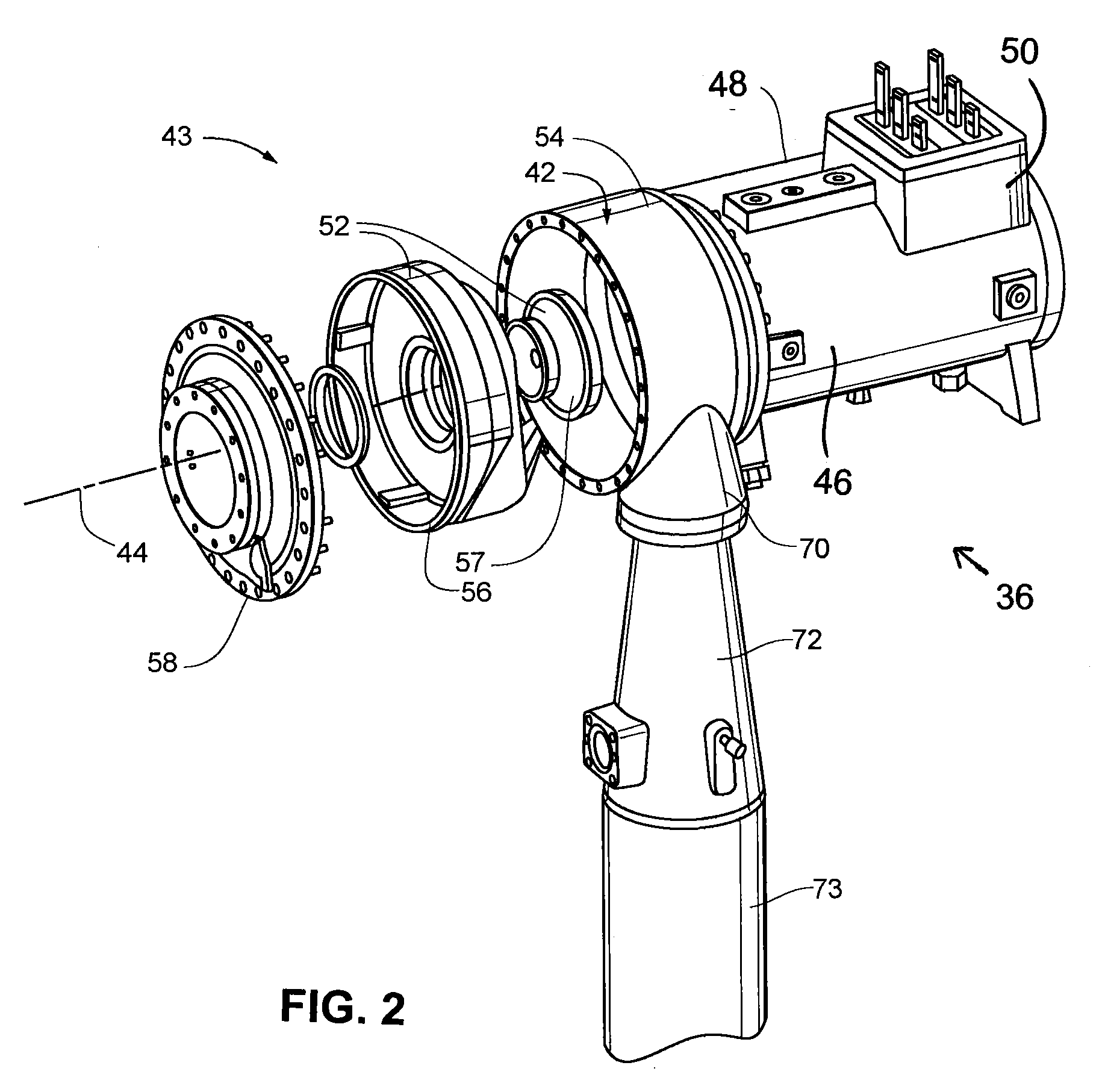

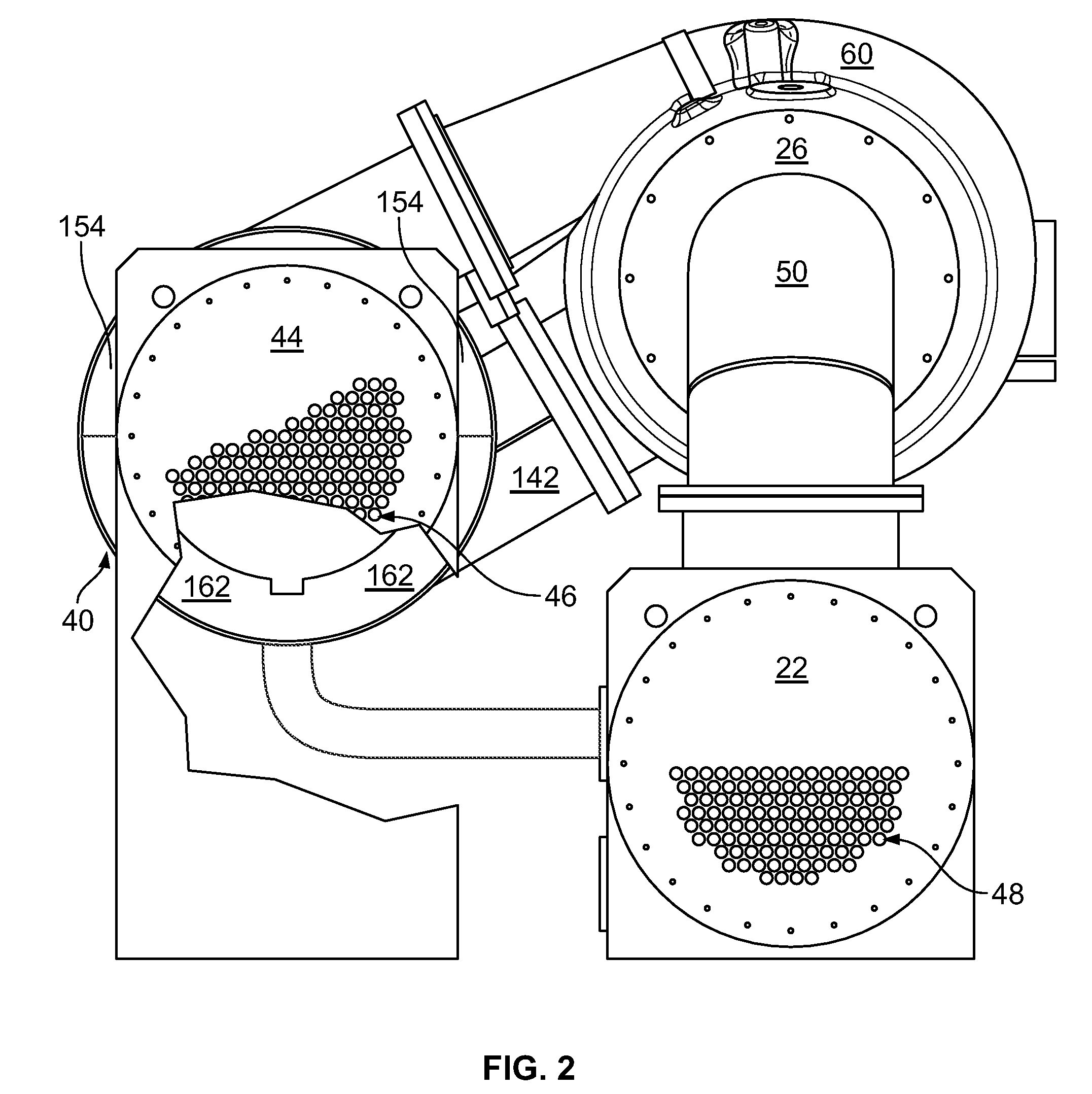

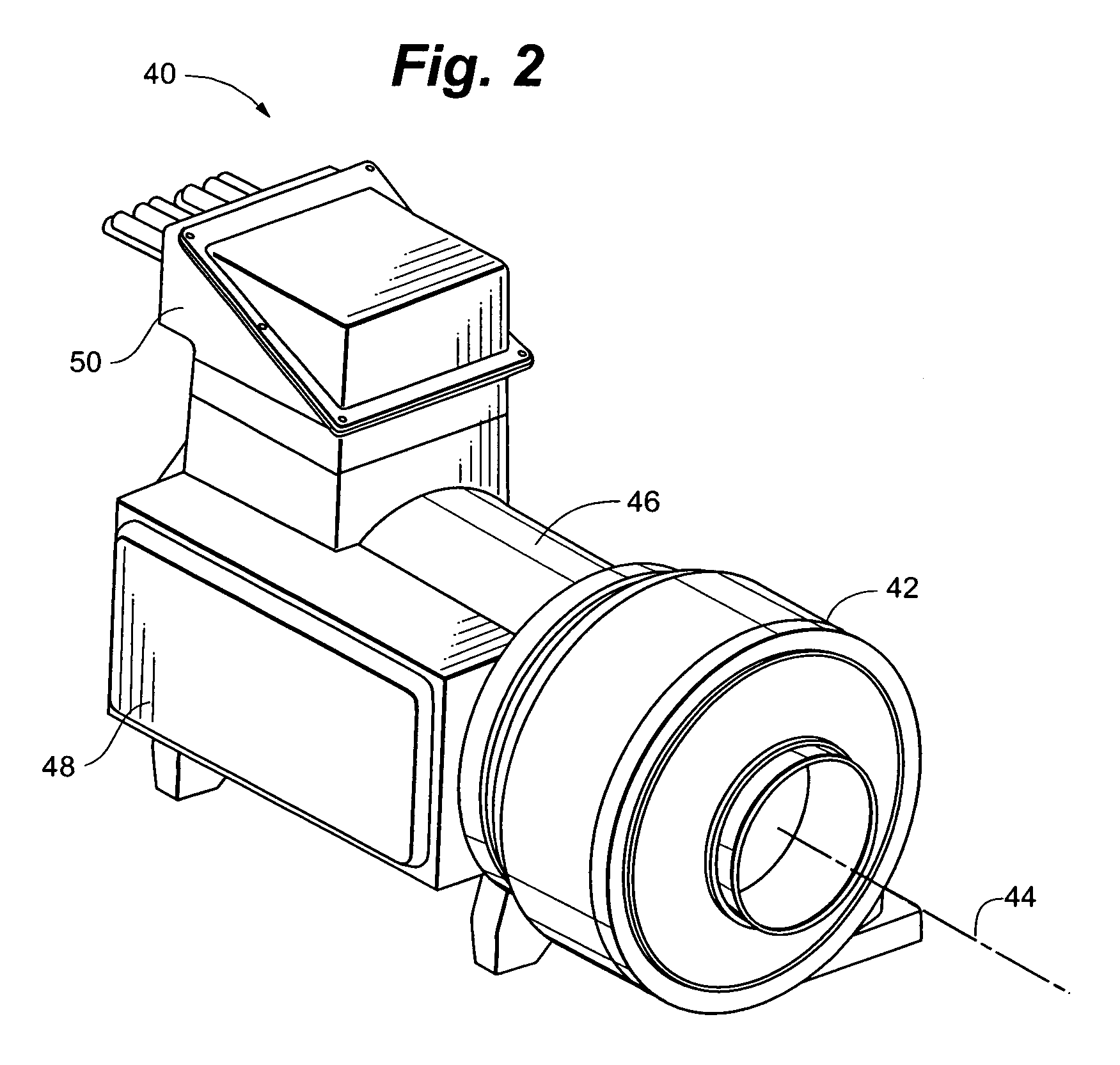

High capacity chiller compressor

ActiveUS20080115527A1Improve efficiencyIncrease power outputWind motor controlEfficient regulation technologiesMagnetic bearingEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

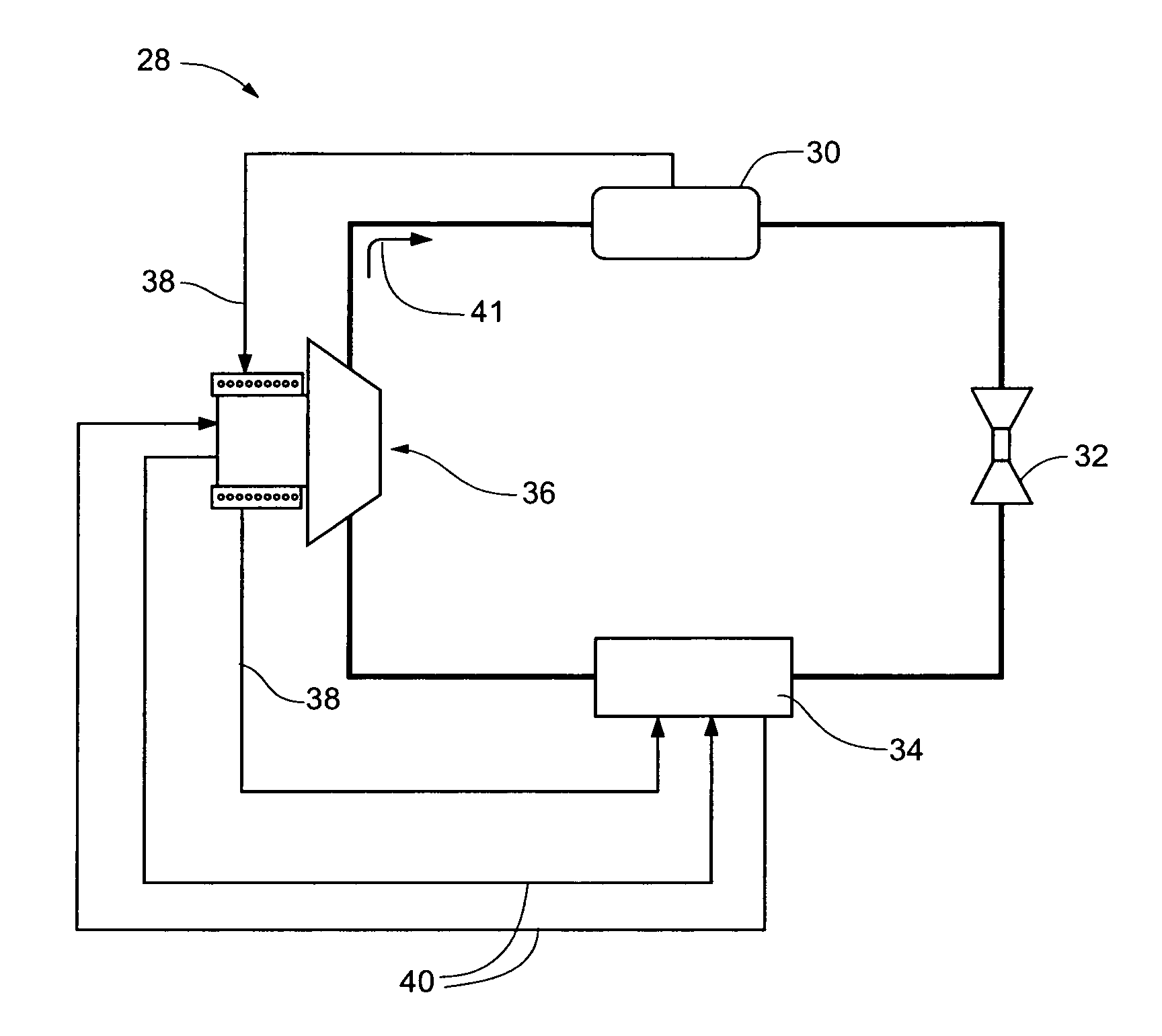

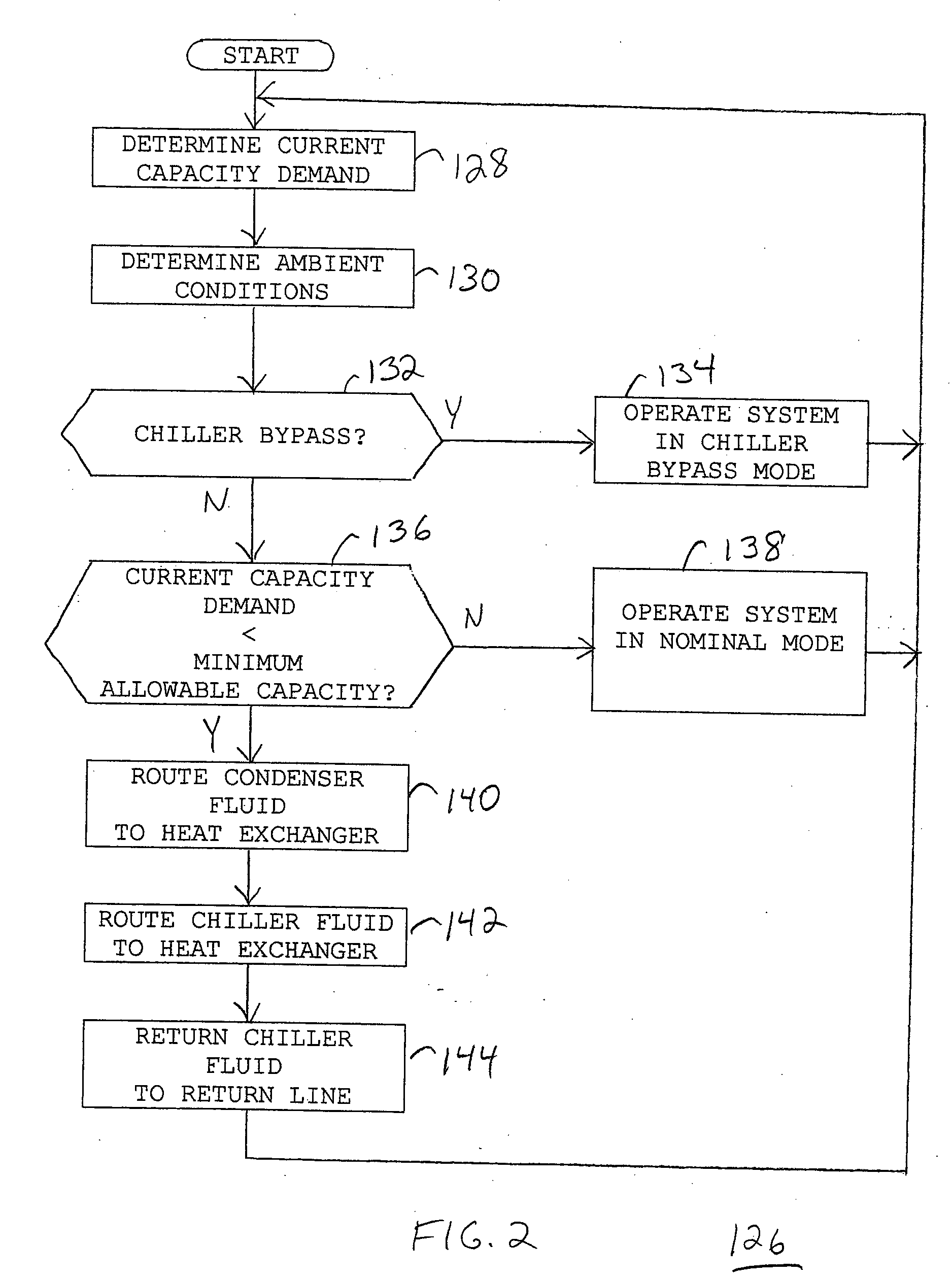

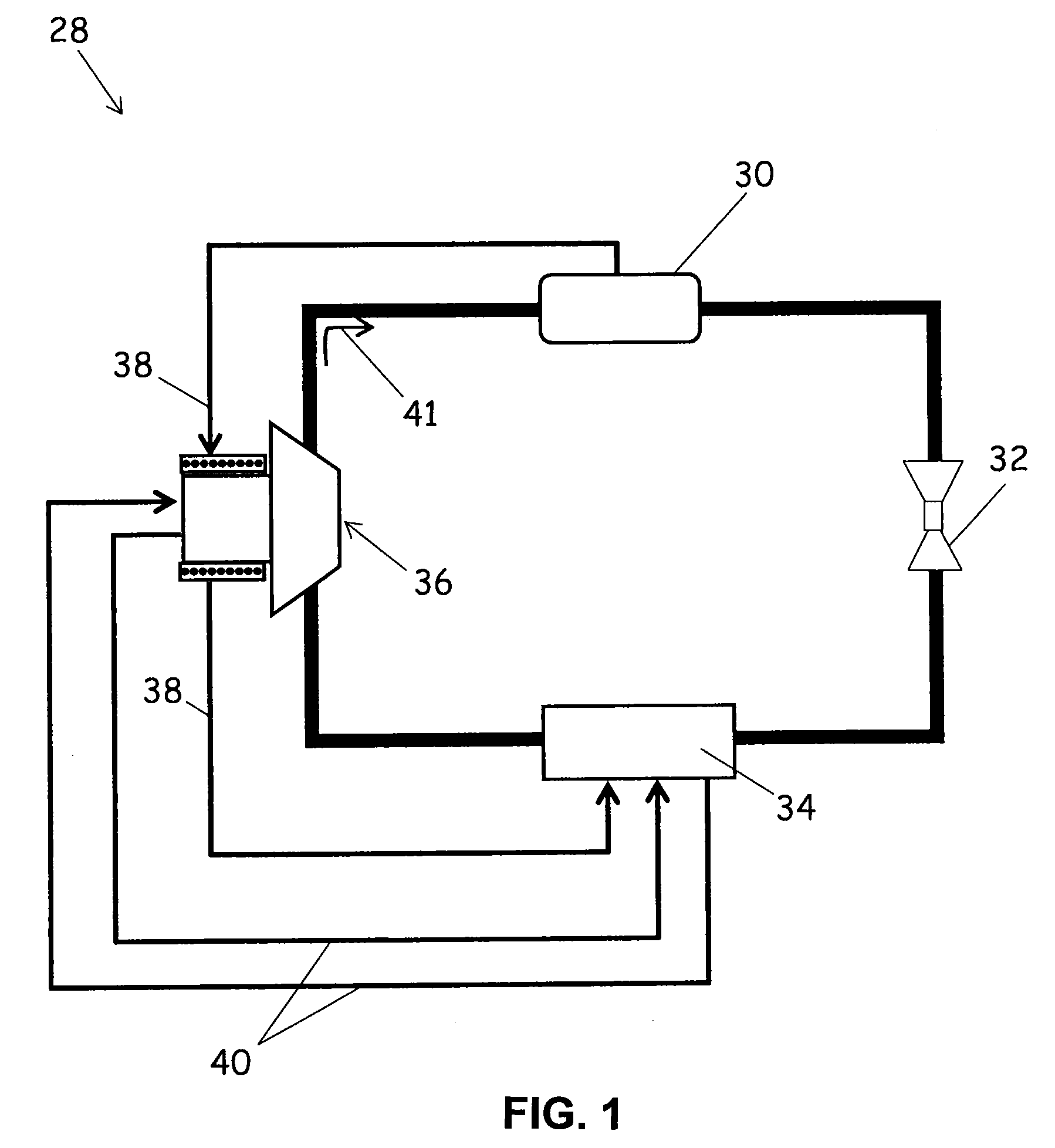

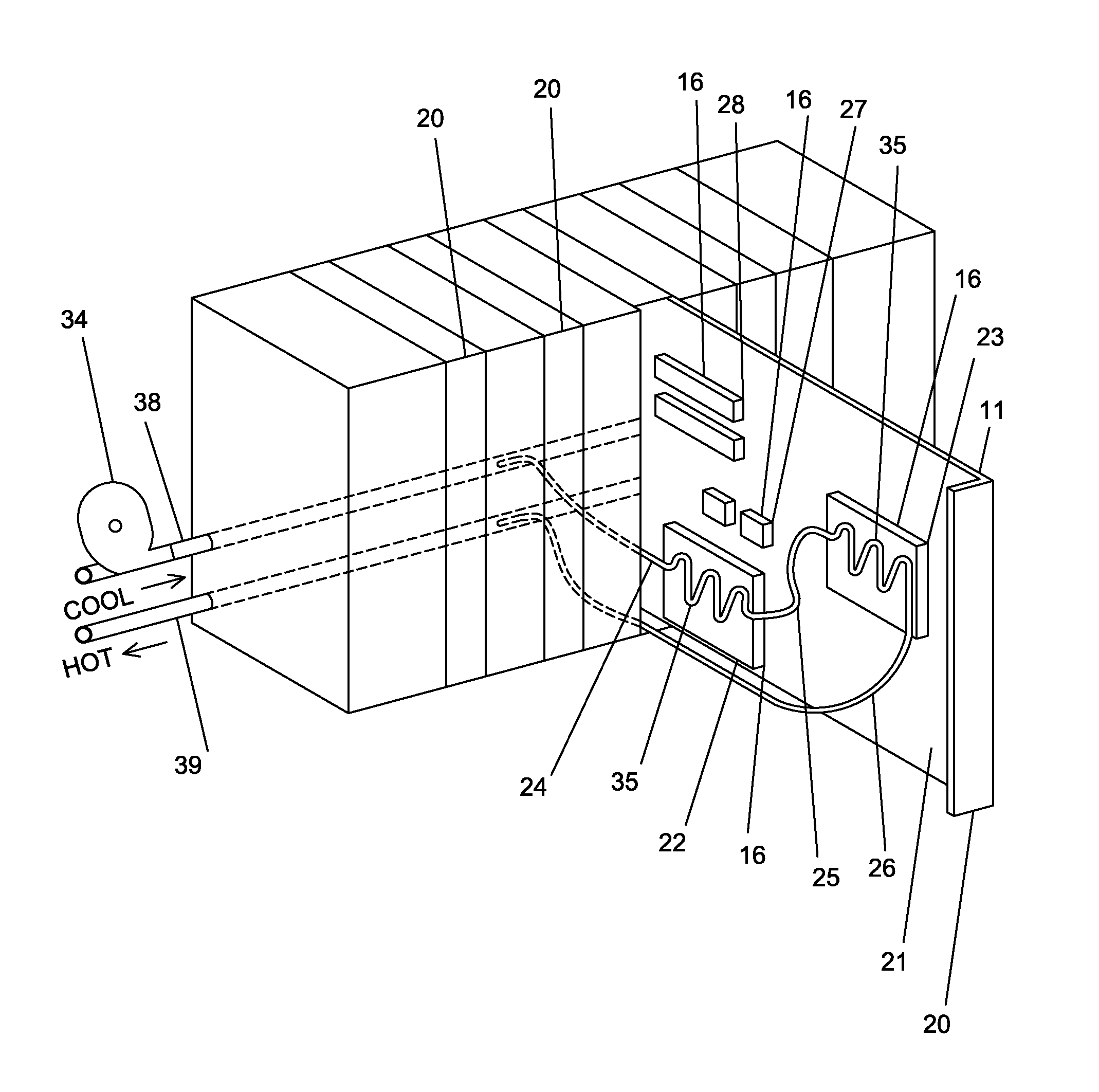

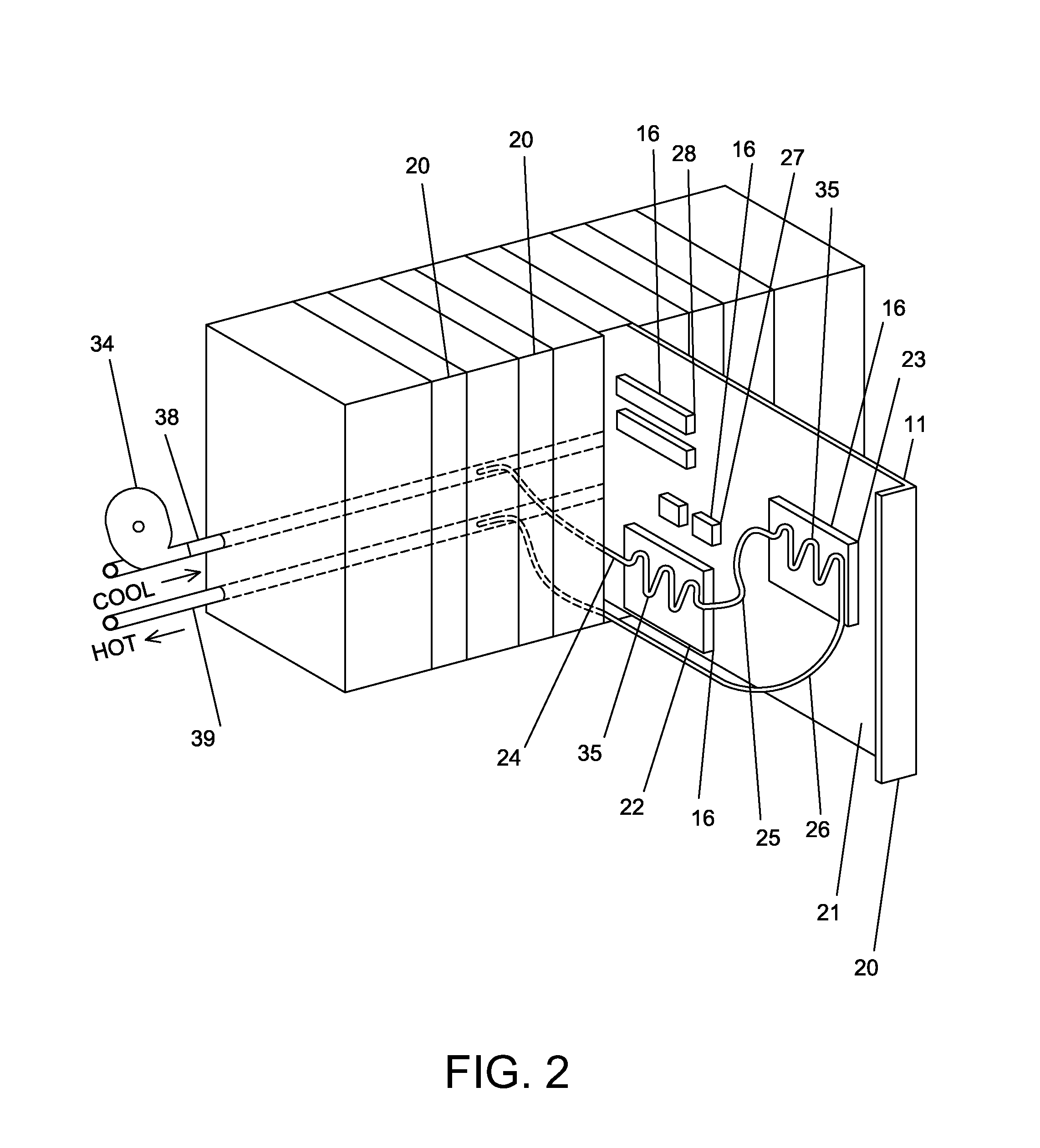

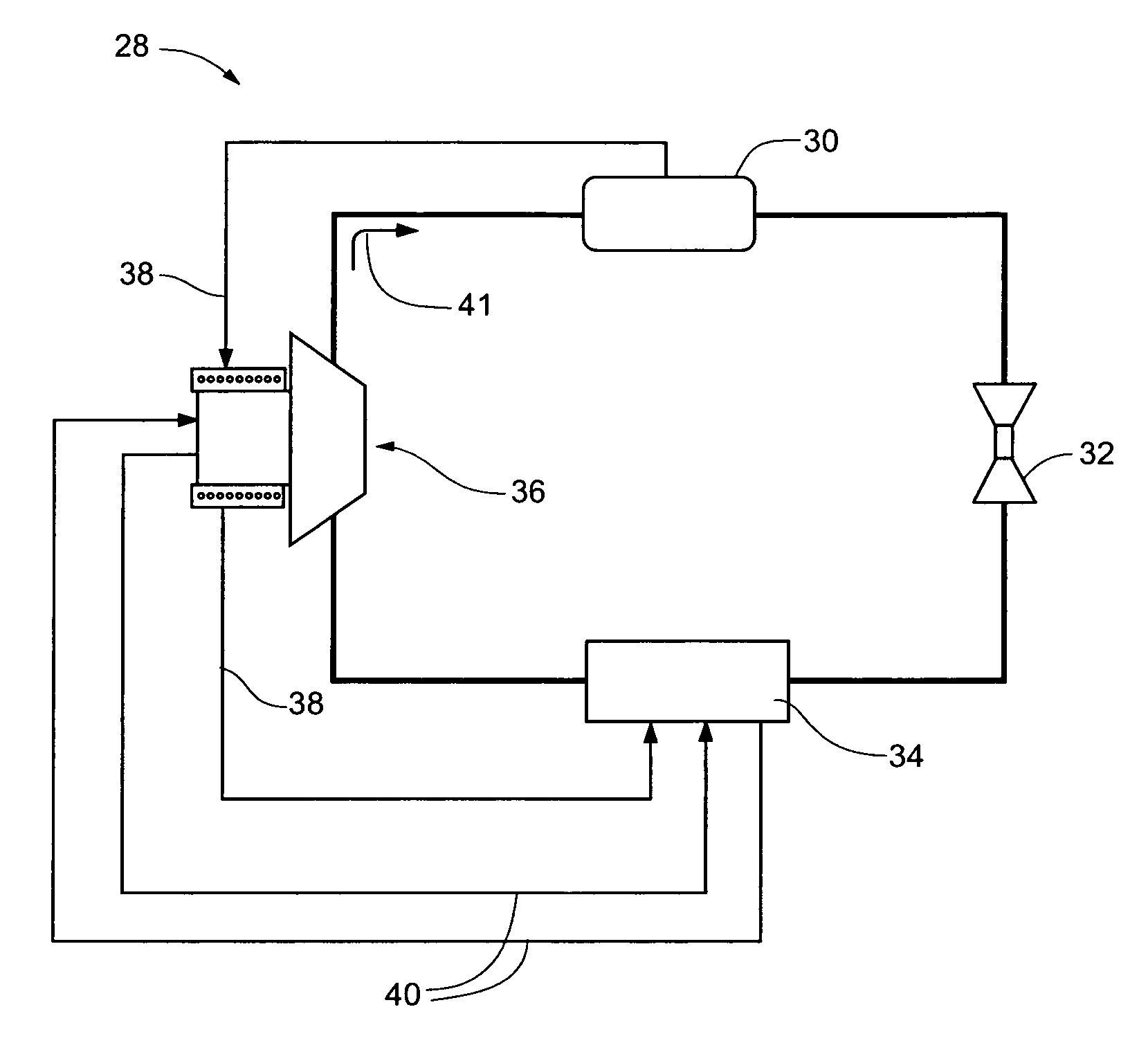

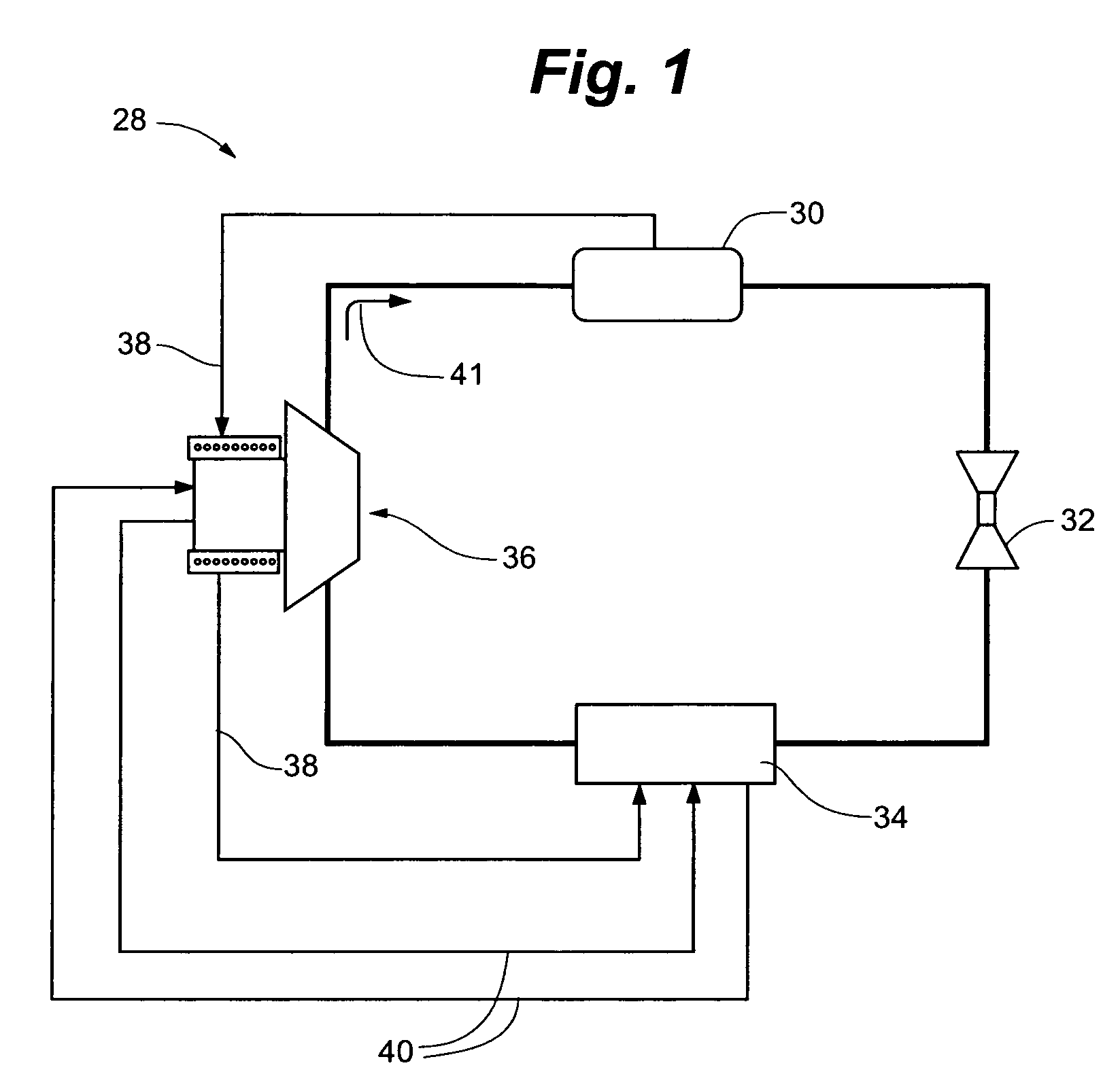

Chiller system with low capacity controller and method of operating same

InactiveUS20060010893A1Reduce capacityReadily and incorporatedMechanical apparatusSpace heating and ventilation safety systemsControl theoryChiller

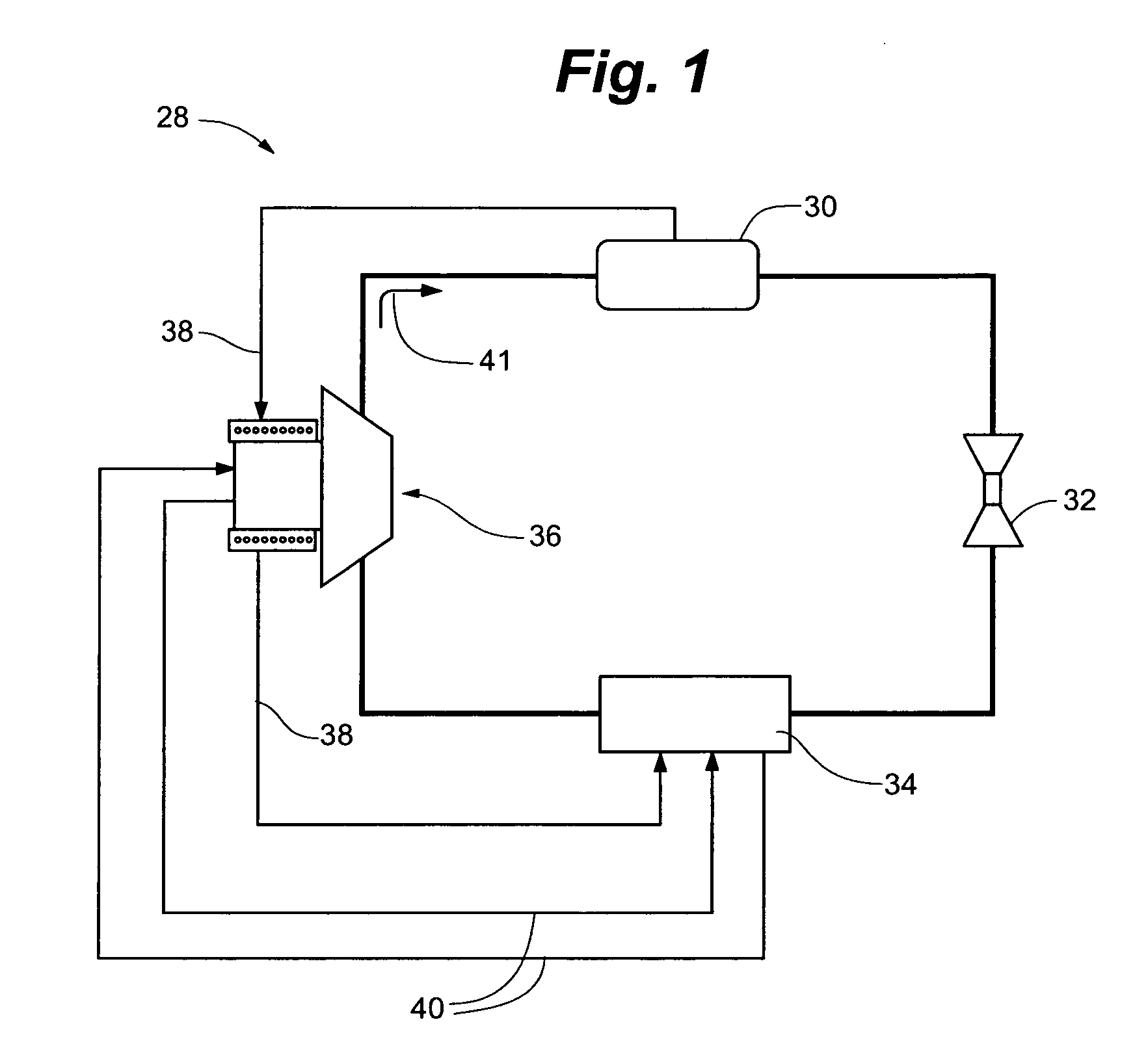

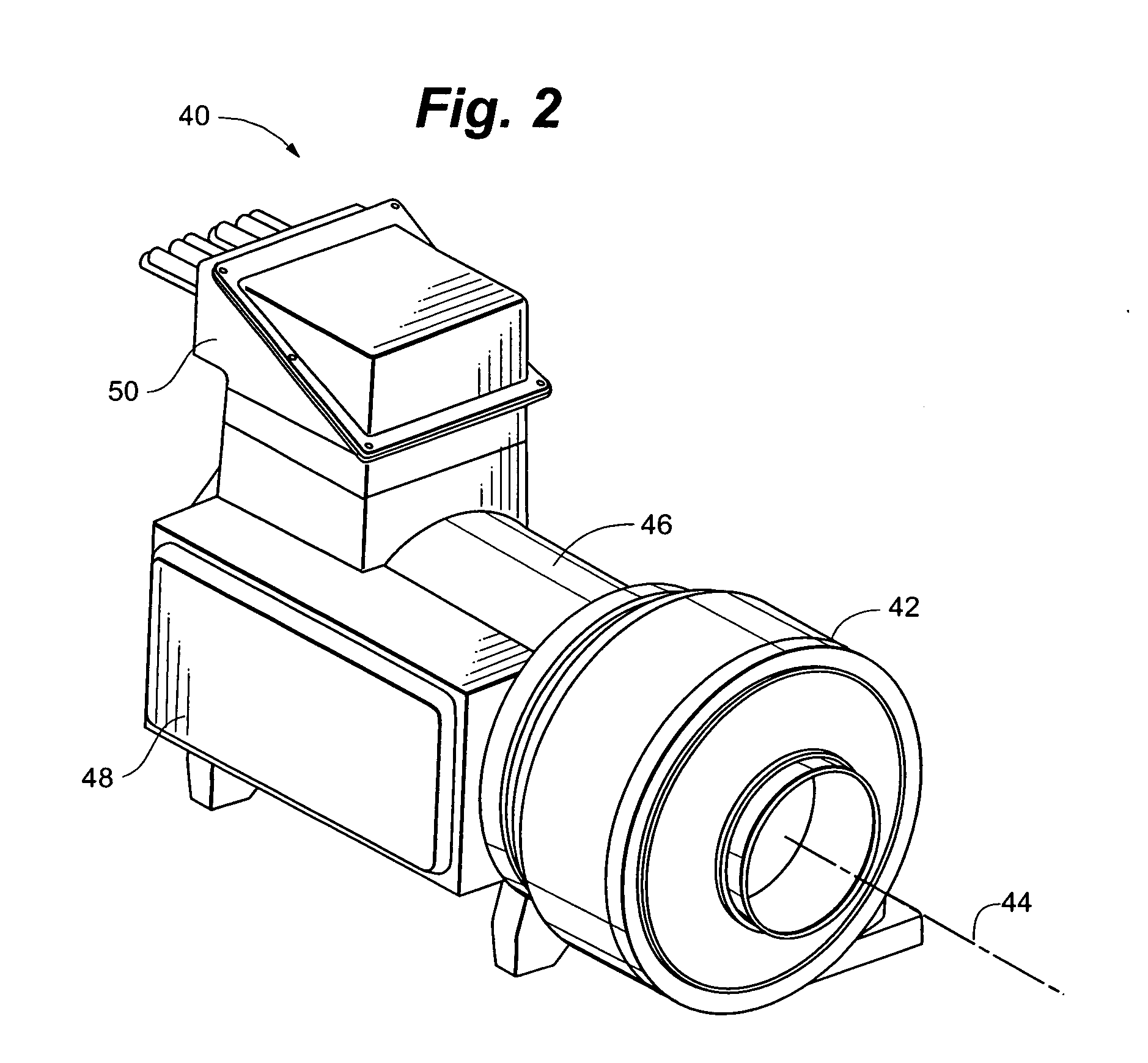

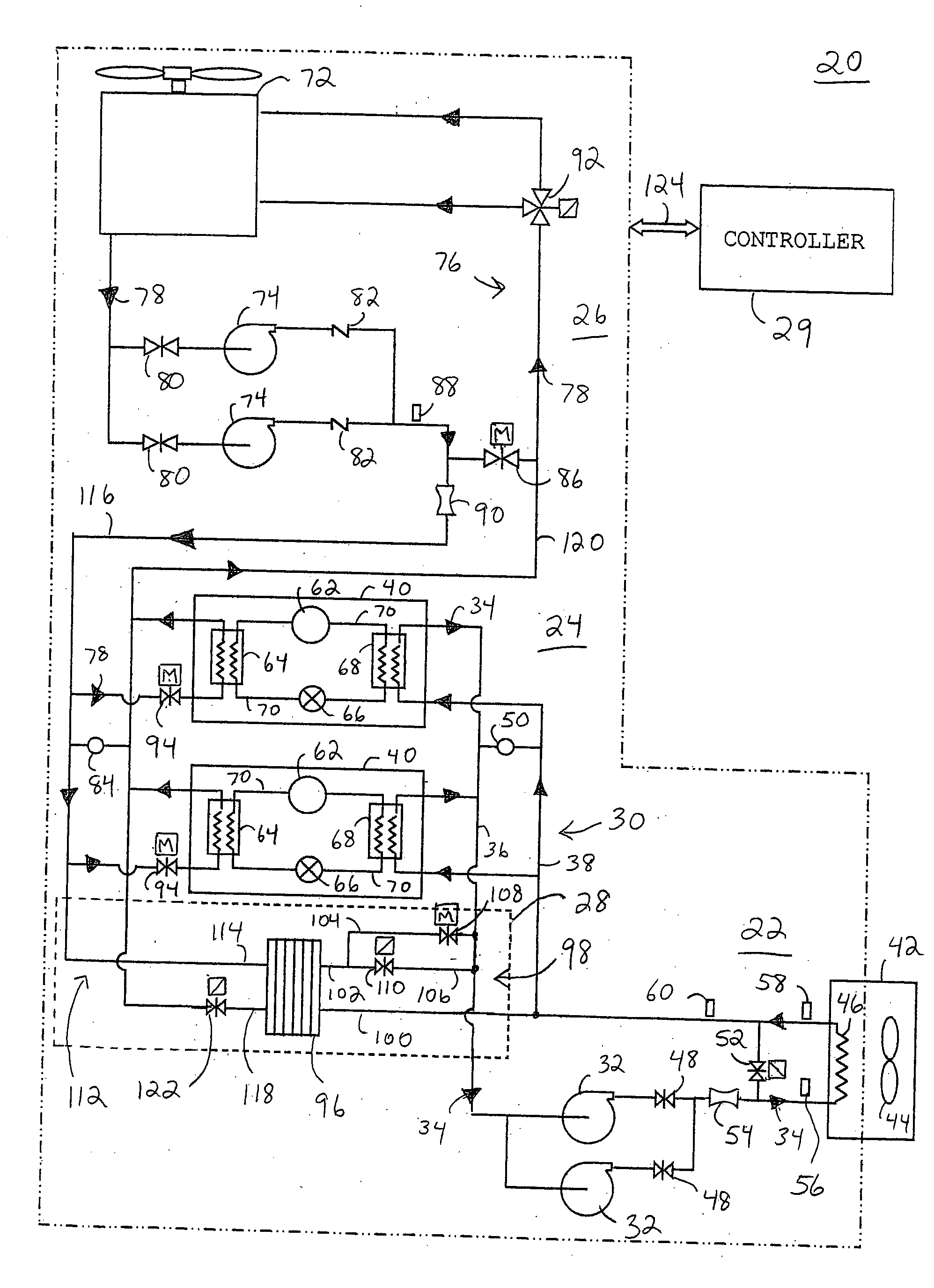

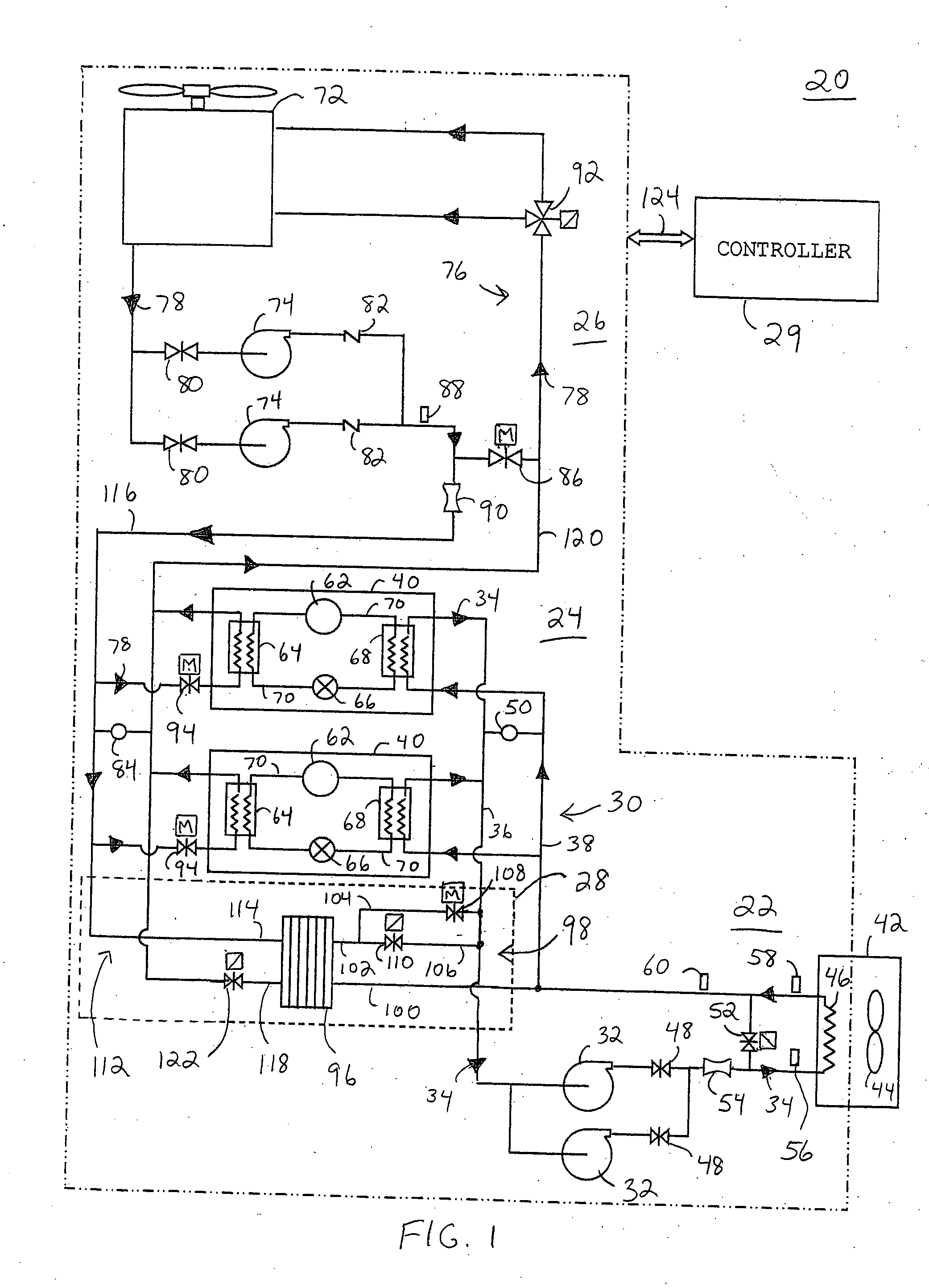

A method (126) and a low capacity controller (28) enable a chiller system (20) to operate below a minimum allowable capacity. The chiller system (20) includes a chiller (40) and a chiller fluid loop (30), having a supply line (36) for conveying a chiller fluid (34) from the chiller (40) and a return line (38) for returning the chiller fluid (34) to the chiller (40). A capacity demand for the chiller (40) is determined. When the capacity demand is less than a minimum allowable capacity of the chiller (40), the chiller fluid (34) is routed from the return line (38) to a heat exchanger (96) of the low capacity controller (28) where the chiller fluid (34) is warmed and returned to the return line (38). The warmed chiller fluid (34) establishes a false capacity demand, detectable at the chiller (40), that is at least the minimum allowable capacity.

Owner:AIR MATRIX MANAGEMENT

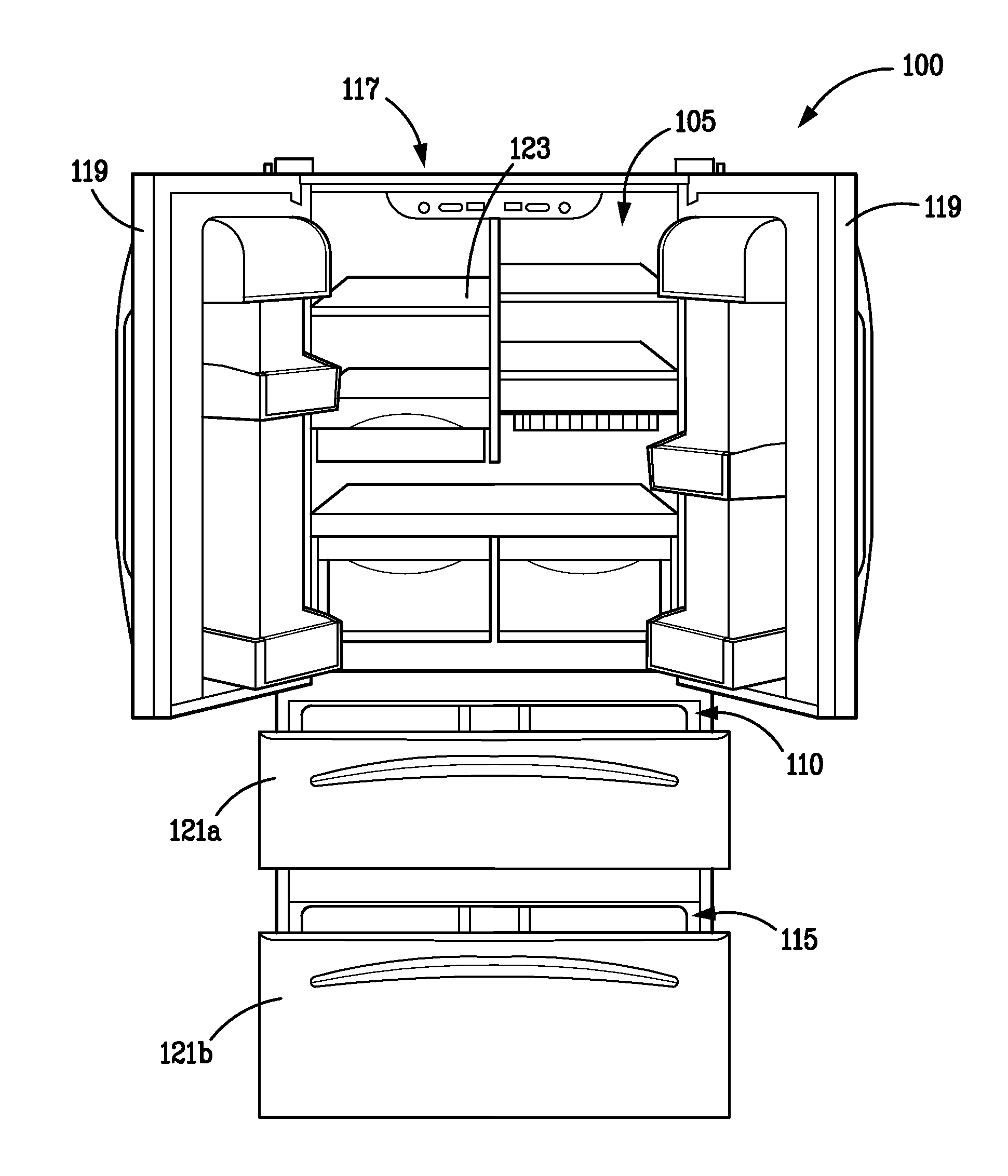

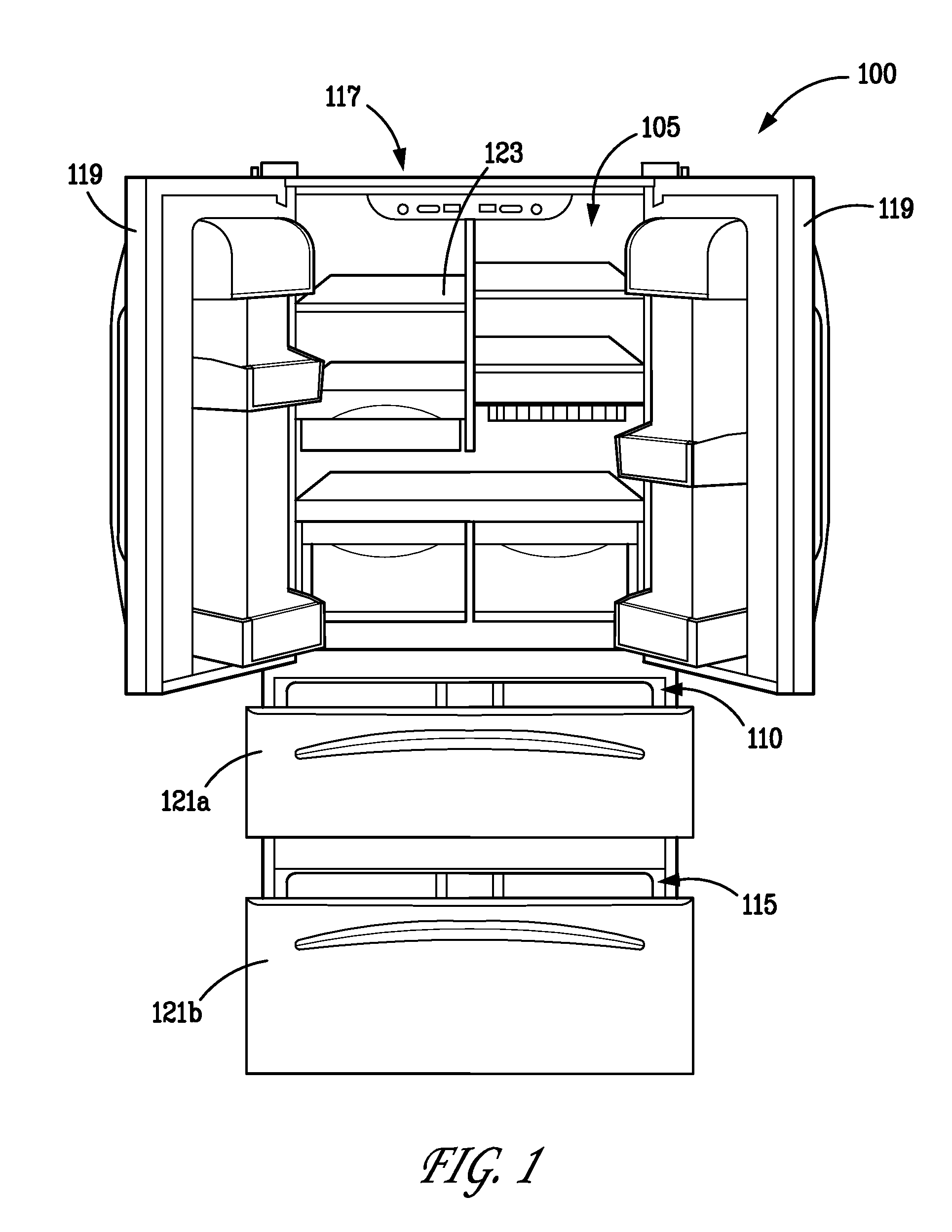

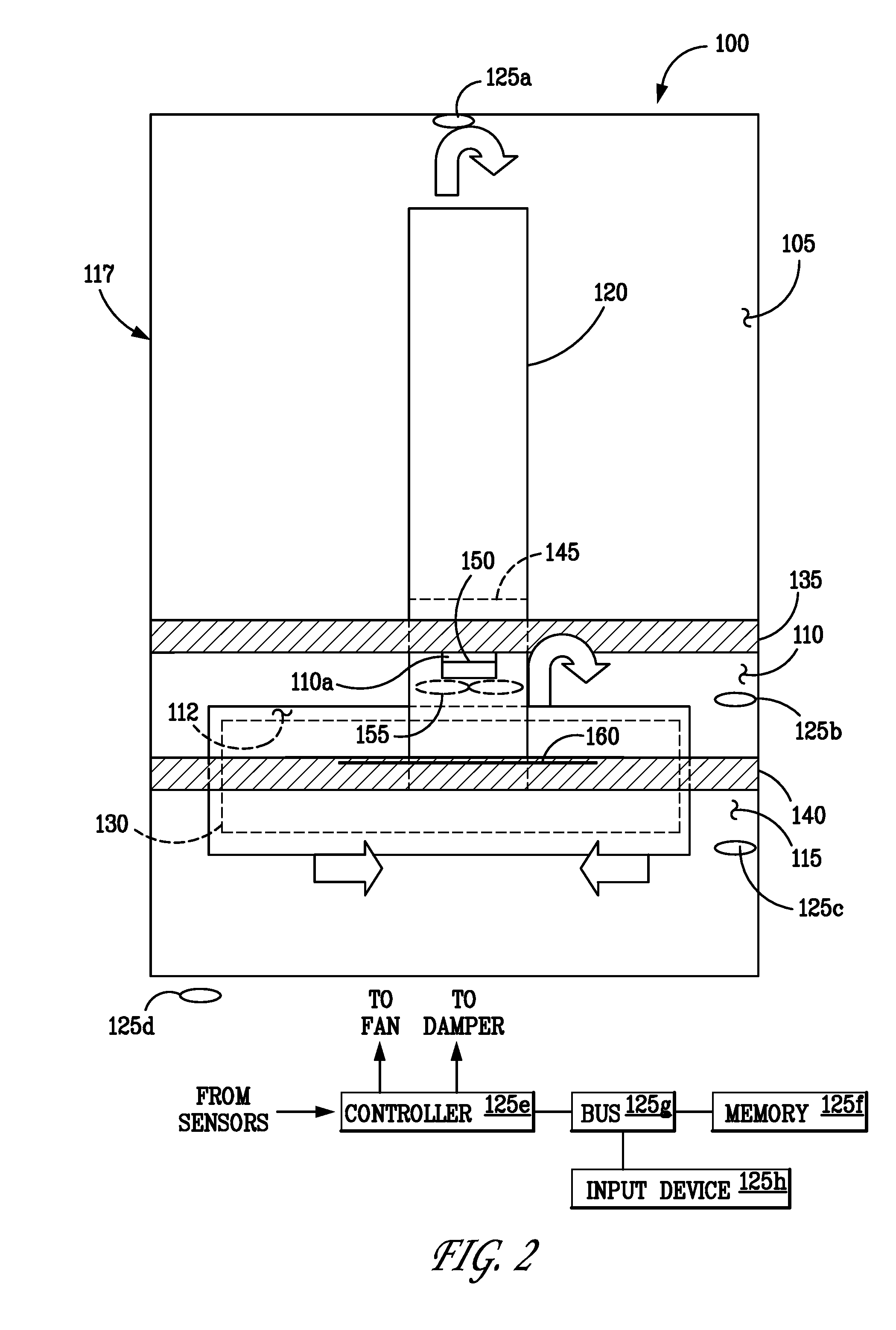

Refrigerator with a convertible compartment

A refrigerator includes a first compartment, a second compartment and a multi-functional compartment that is disposed between the first compartment and the second compartment and is adjustable between temperature modes selected from the group consisting of a fresh food temperature mode, a soft freeze mode, a freezer mode and a chiller temperature mode.

Owner:HAIER US APPLIANCE SOLUTIONS INC

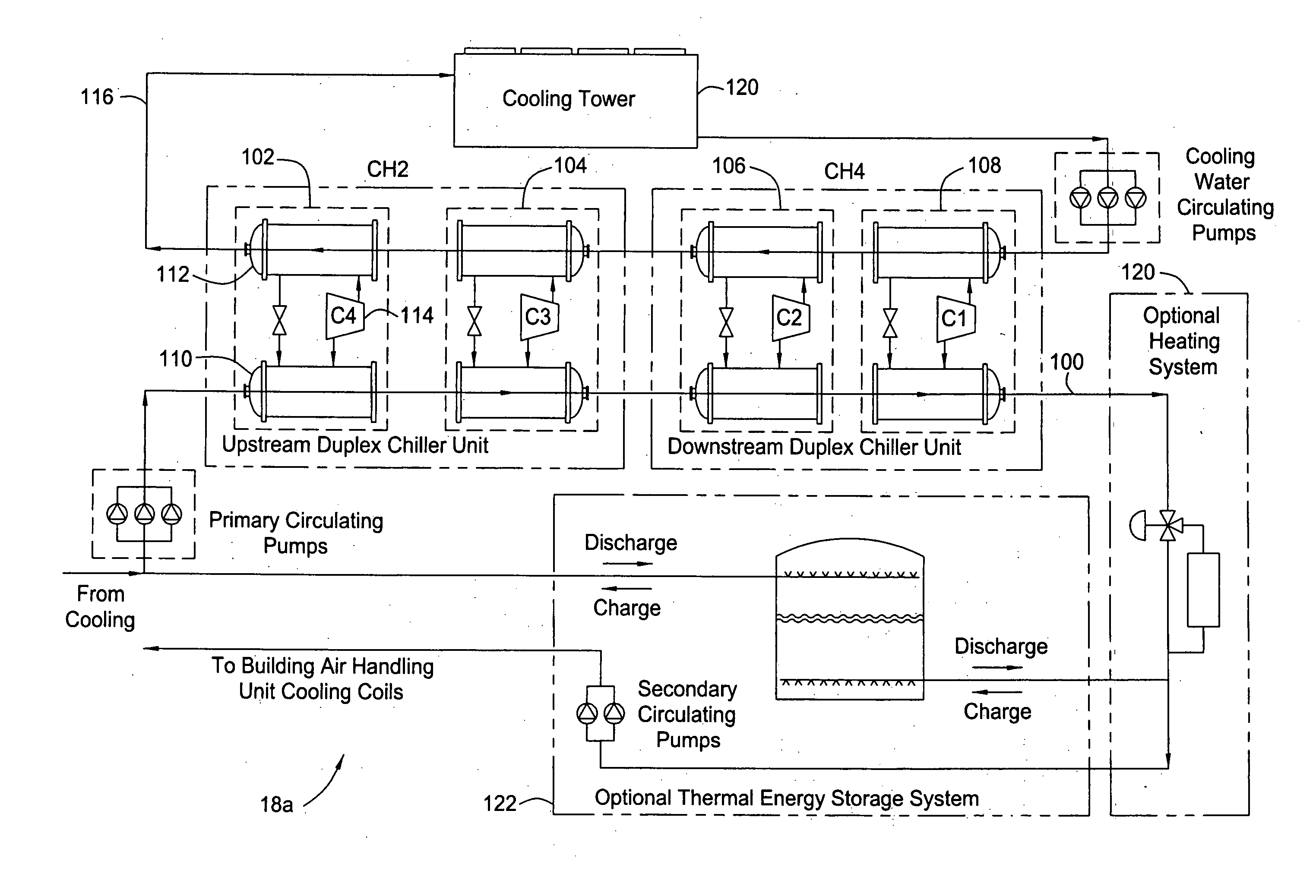

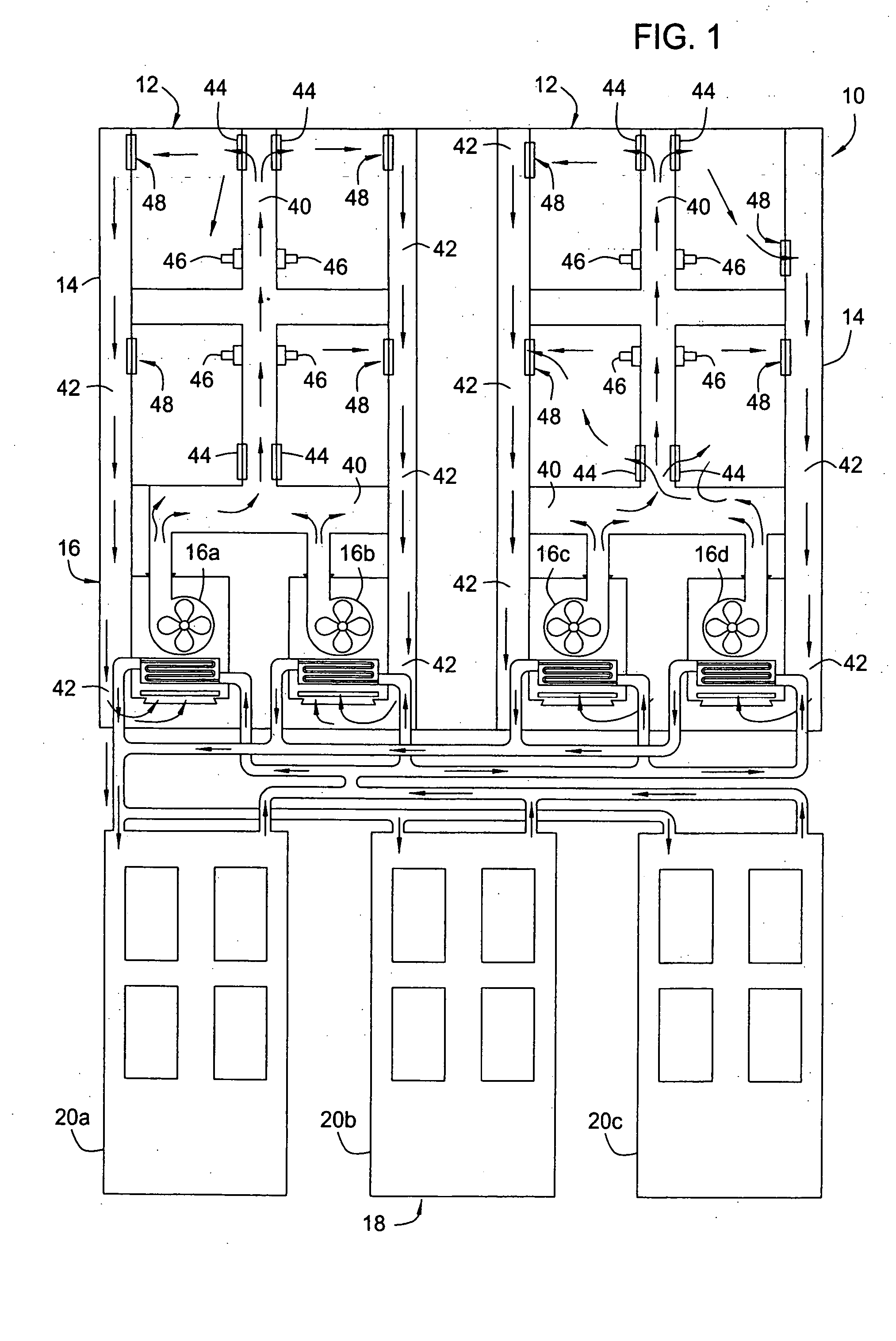

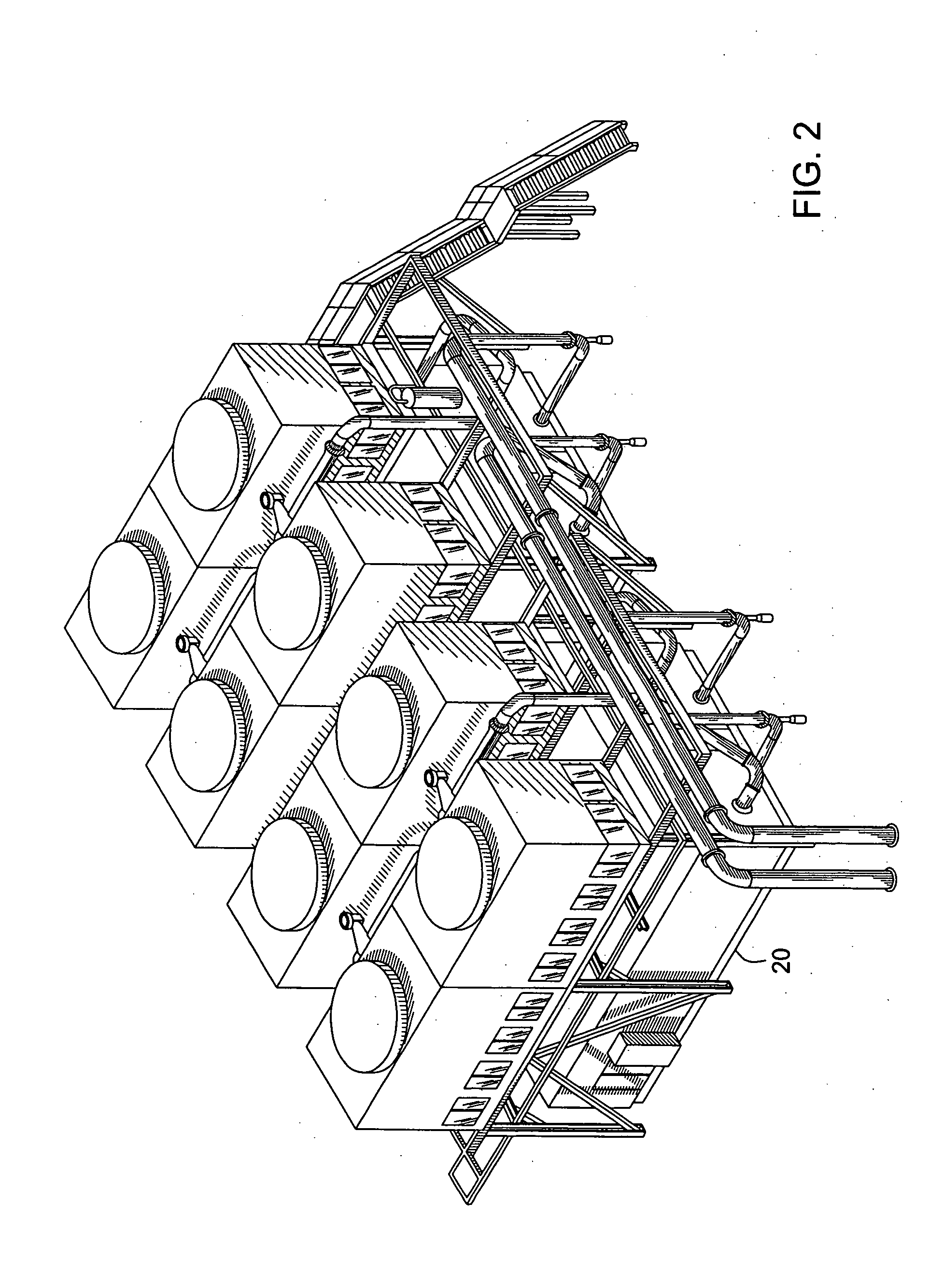

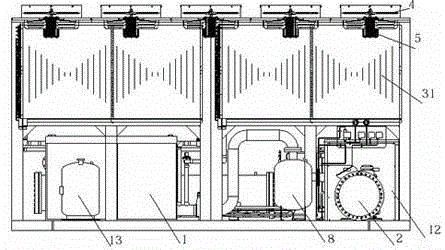

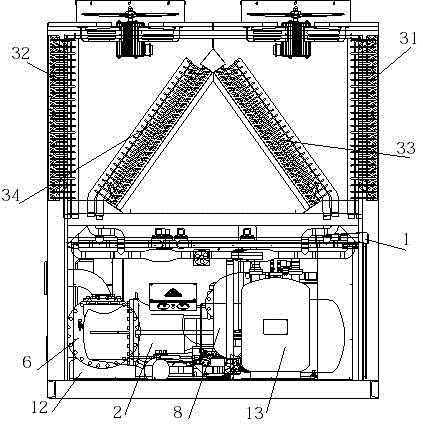

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

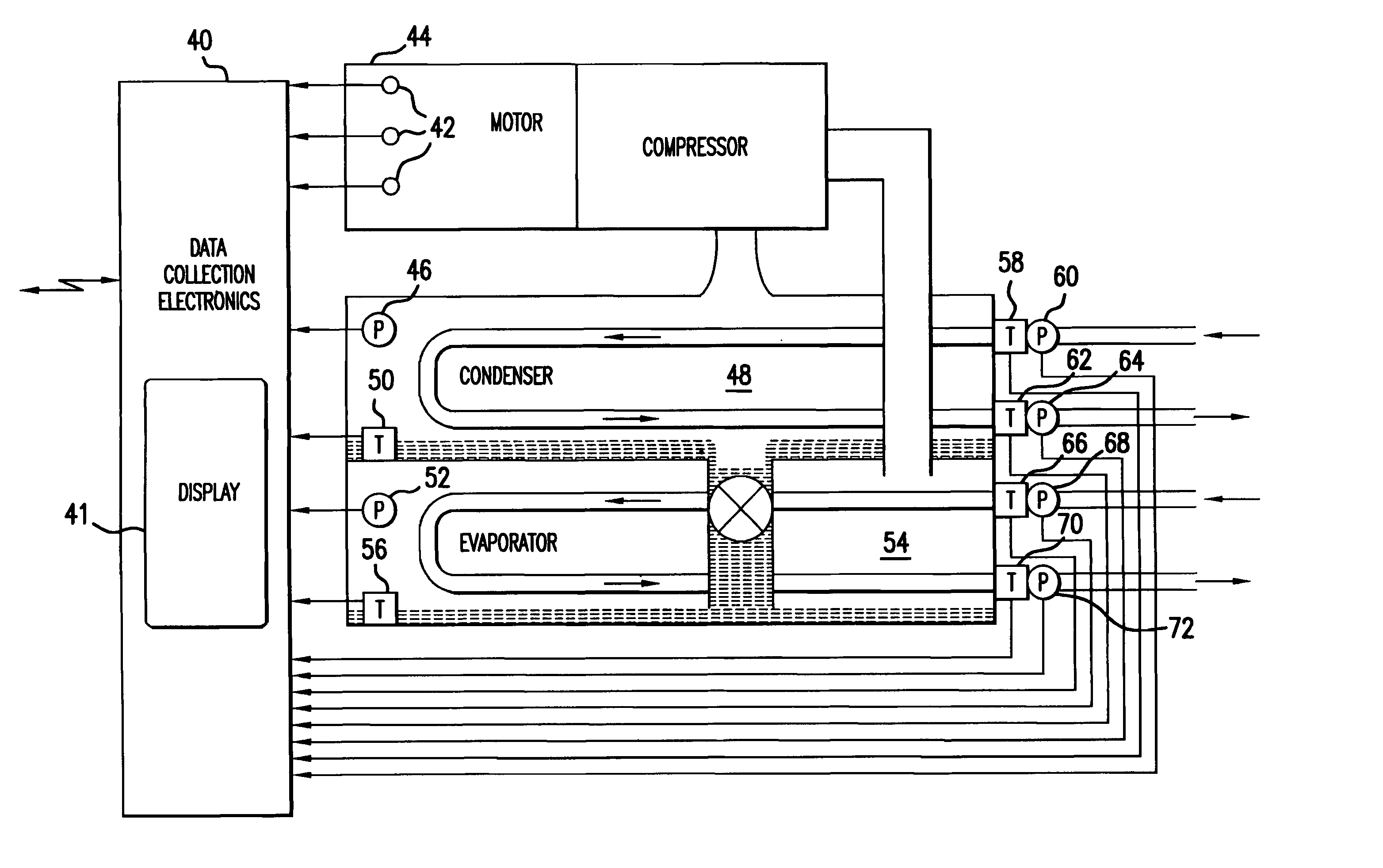

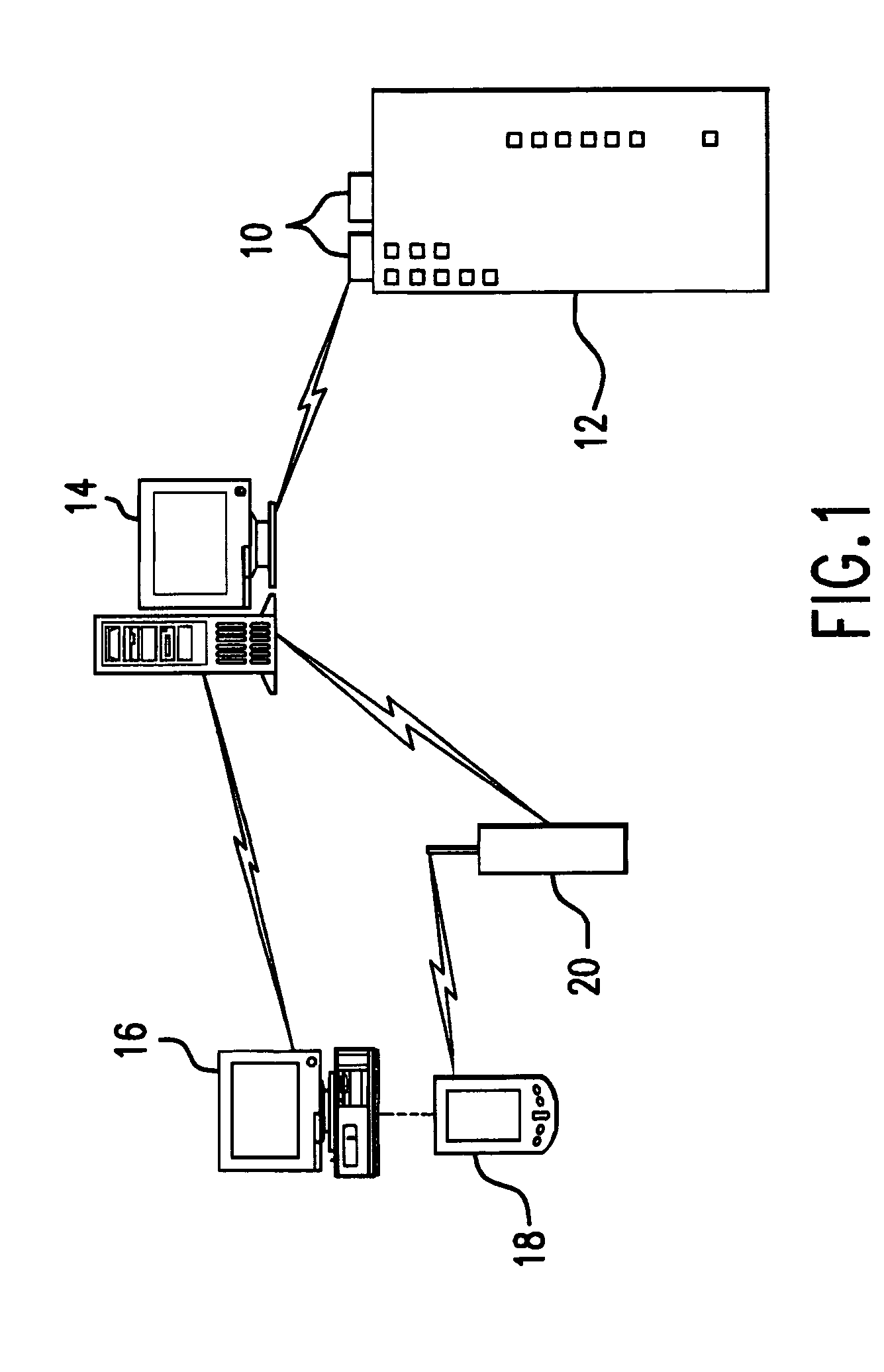

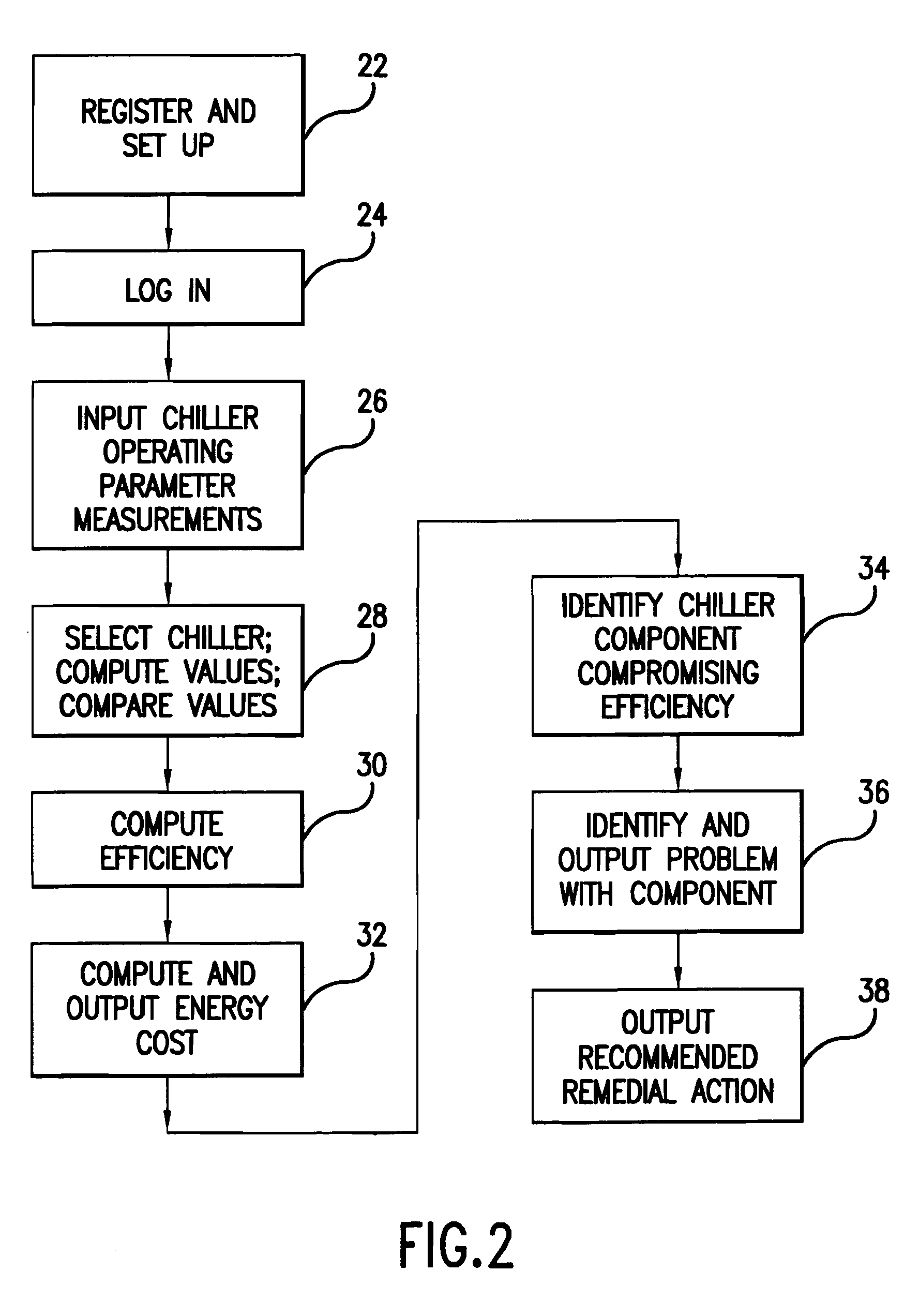

Method and system for evaluating the efficiency of an air conditioning apparatus

InactiveUS20050251293A1Computing chiller efficiencyMechanical apparatusTemperatue controlCurrent loadSimulation

The applicant describes a system and methods of calculating the overall operating efficiency of an air conditioning chiller that evaluates efficiency of the component parts of the chiller and generates an overall efficiency based on these component efficiency values. If the overall chiller efficiency is less than the maximum attainable chiller efficiency, the cost of the inefficiency is calculated and presented to the user. The accuracy of the overall efficiency calculation is improved, insight is obtained regarding the causes of the inefficiency, and recommendations for corrective action to restore maximum chiller efficiency are identified and presented to the user. The system also adjusts the efficiency calculations as appropriate to account for actual compressor current load conditions.

Owner:CHILLERGY SYST

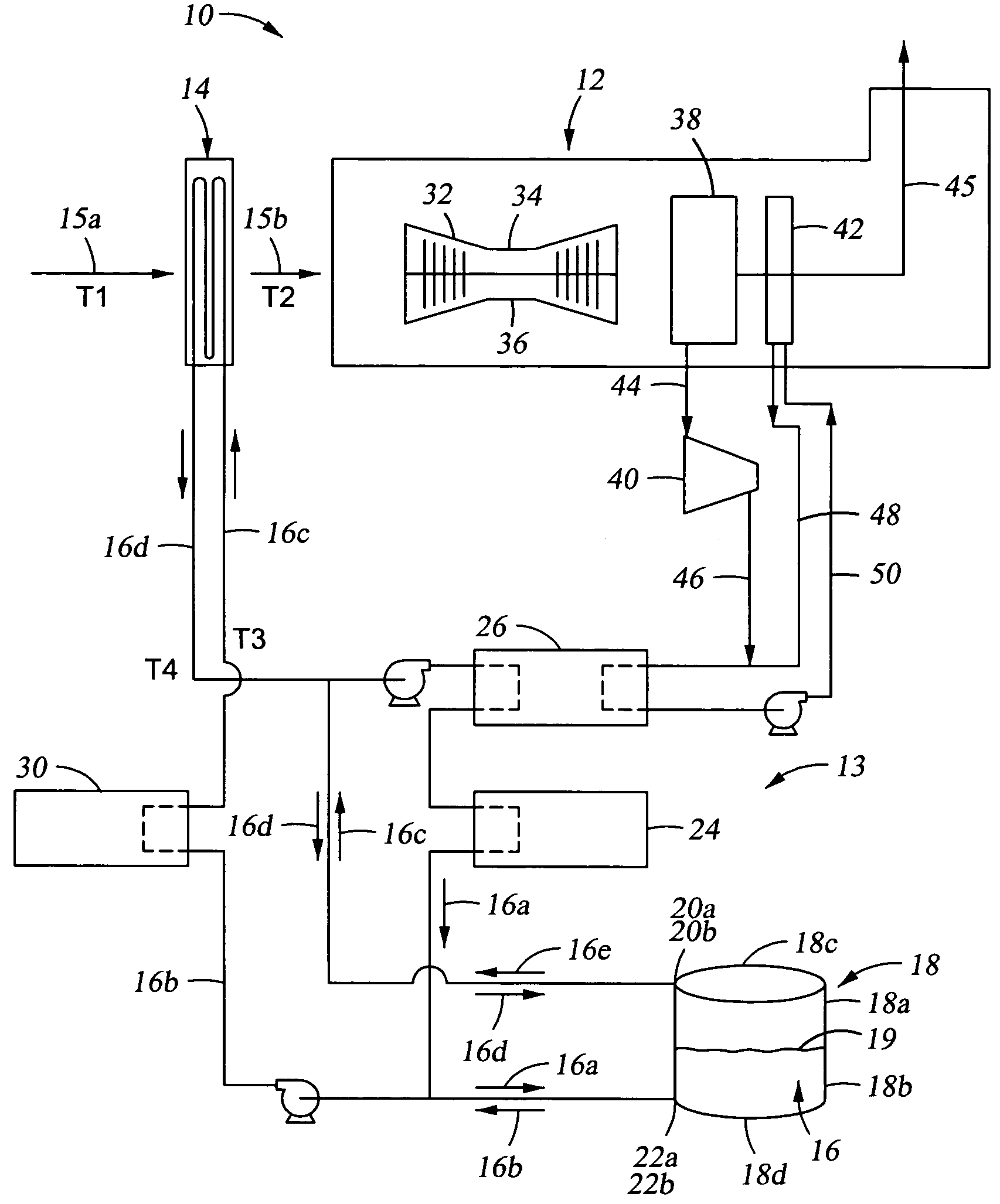

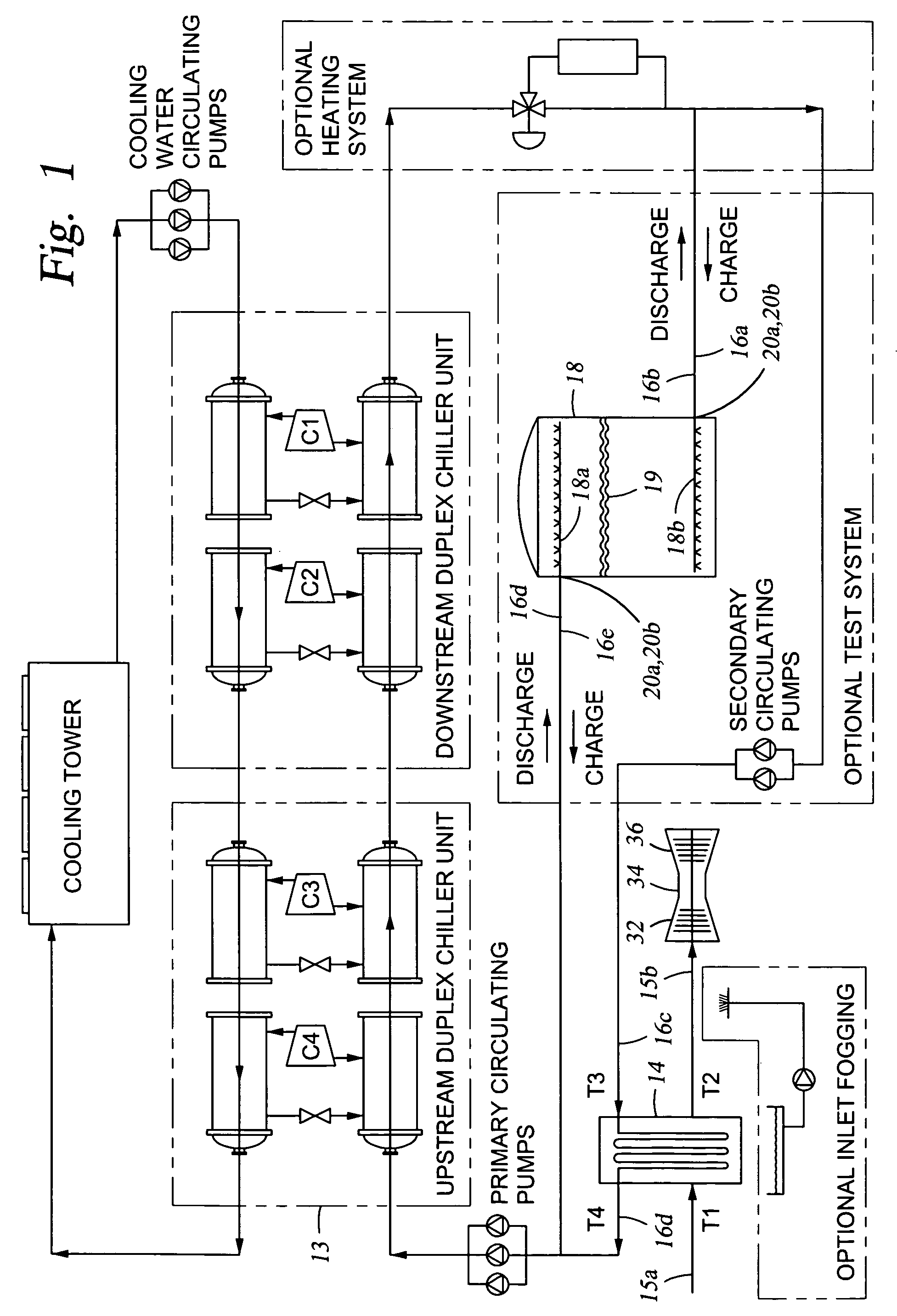

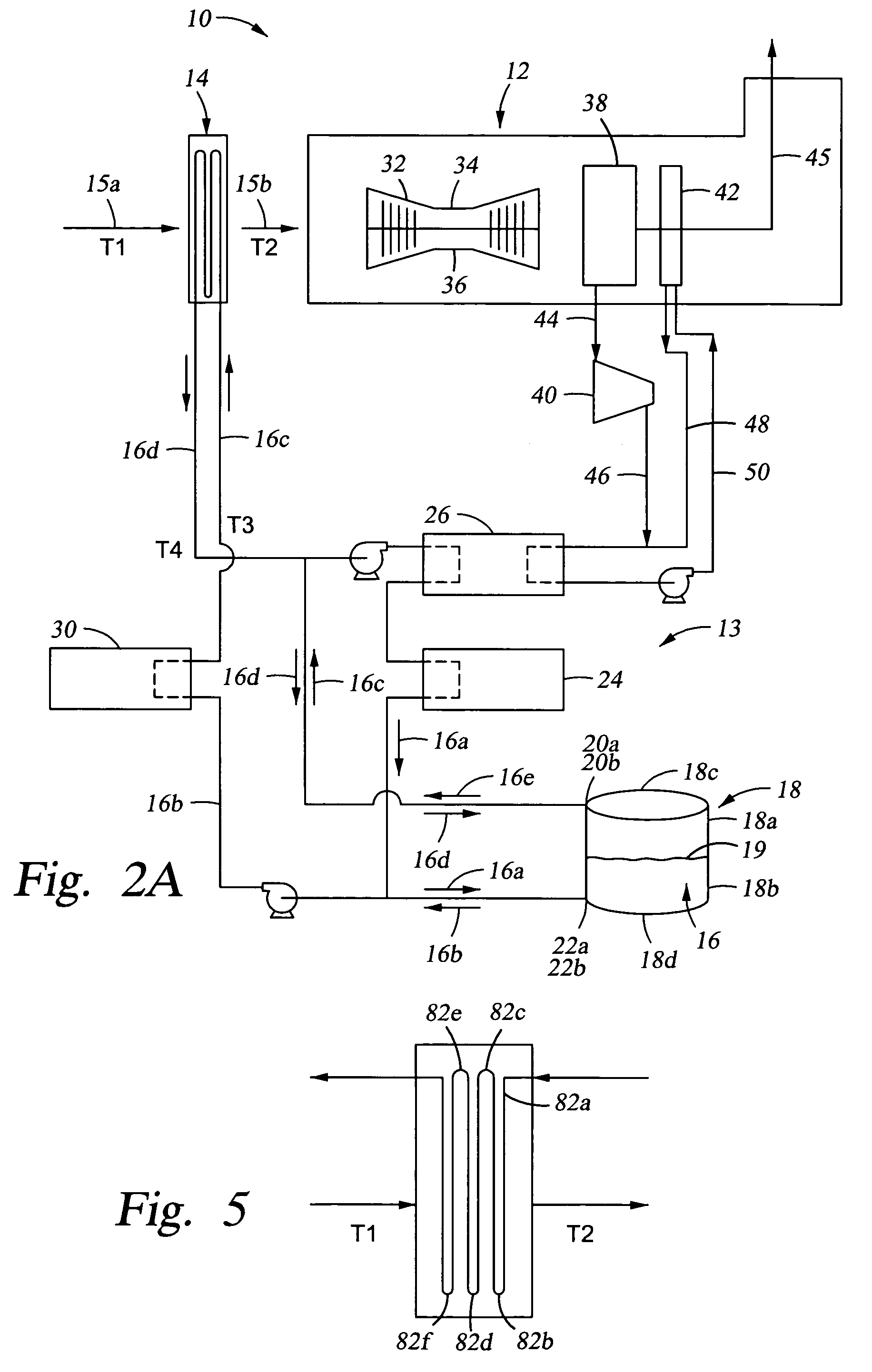

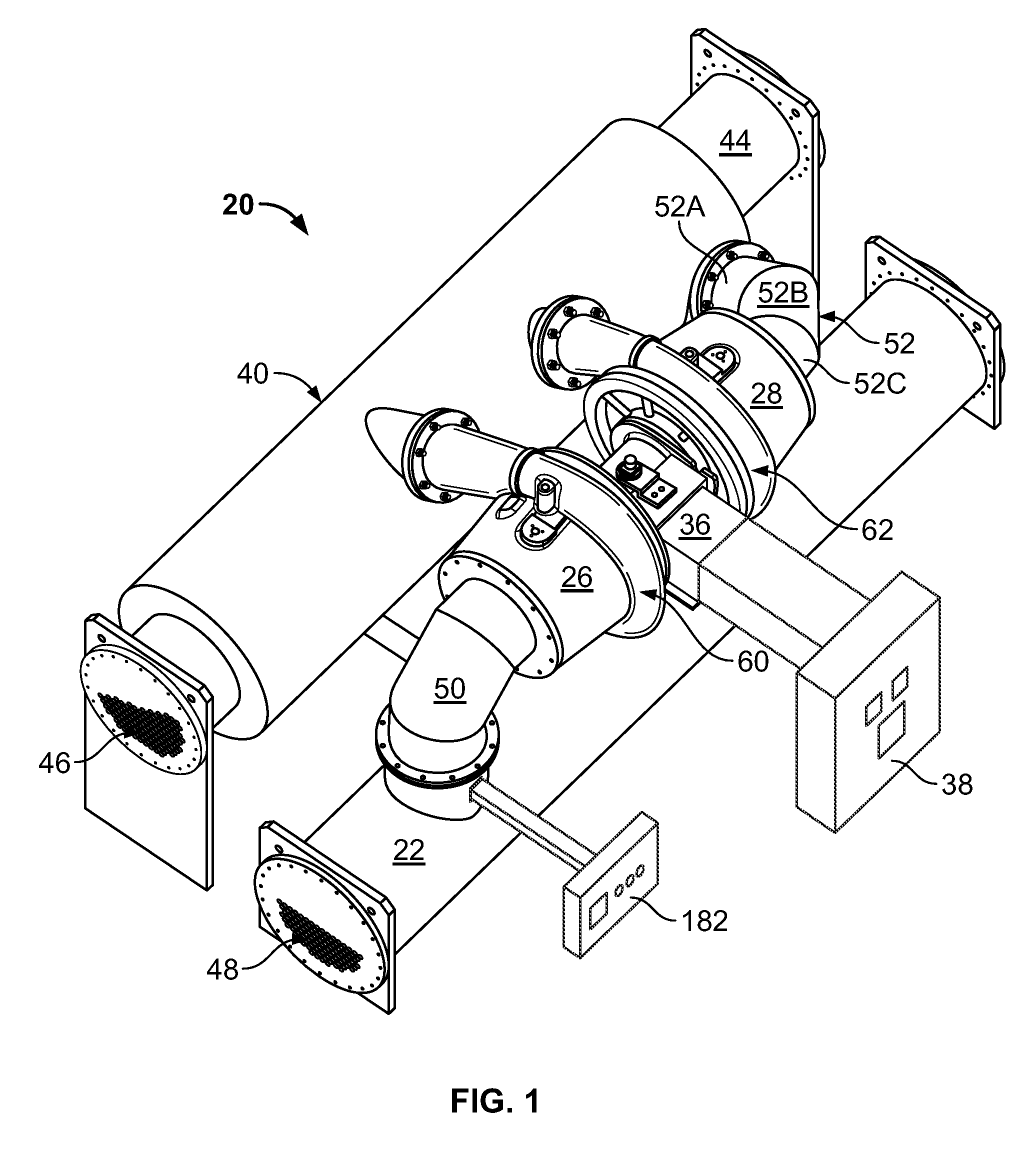

Method of chilling inlet air for gas turbines

InactiveUS7343746B2Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

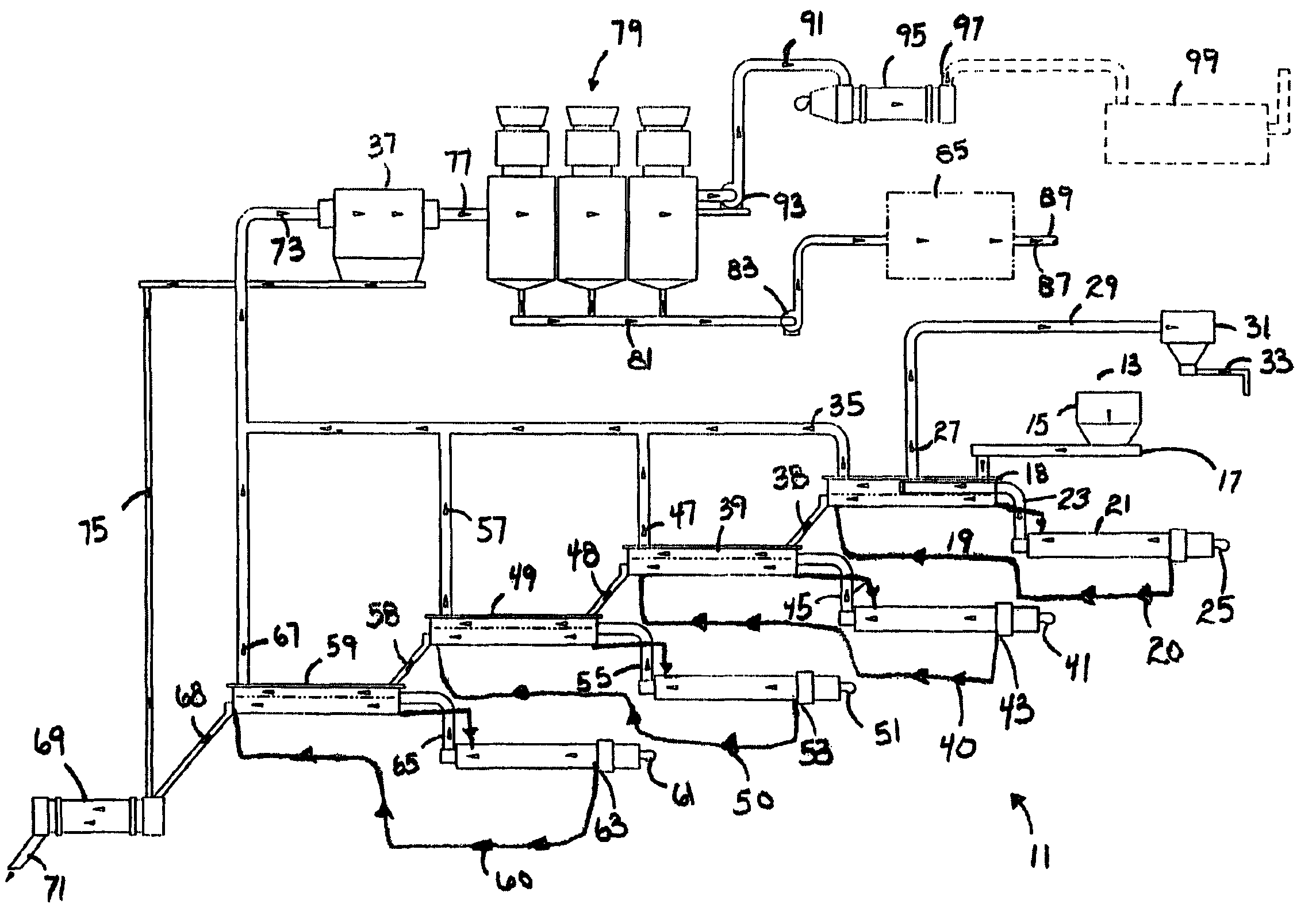

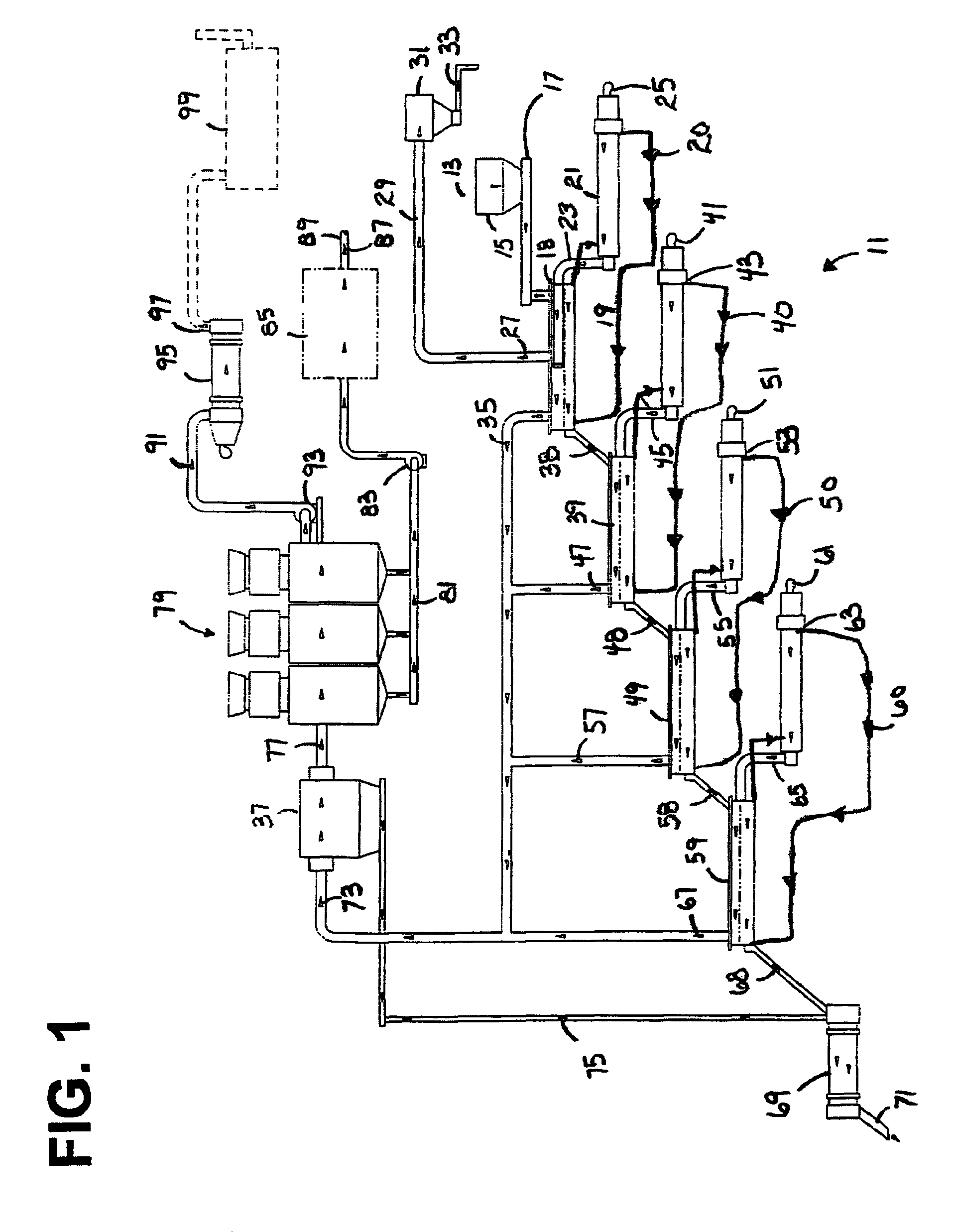

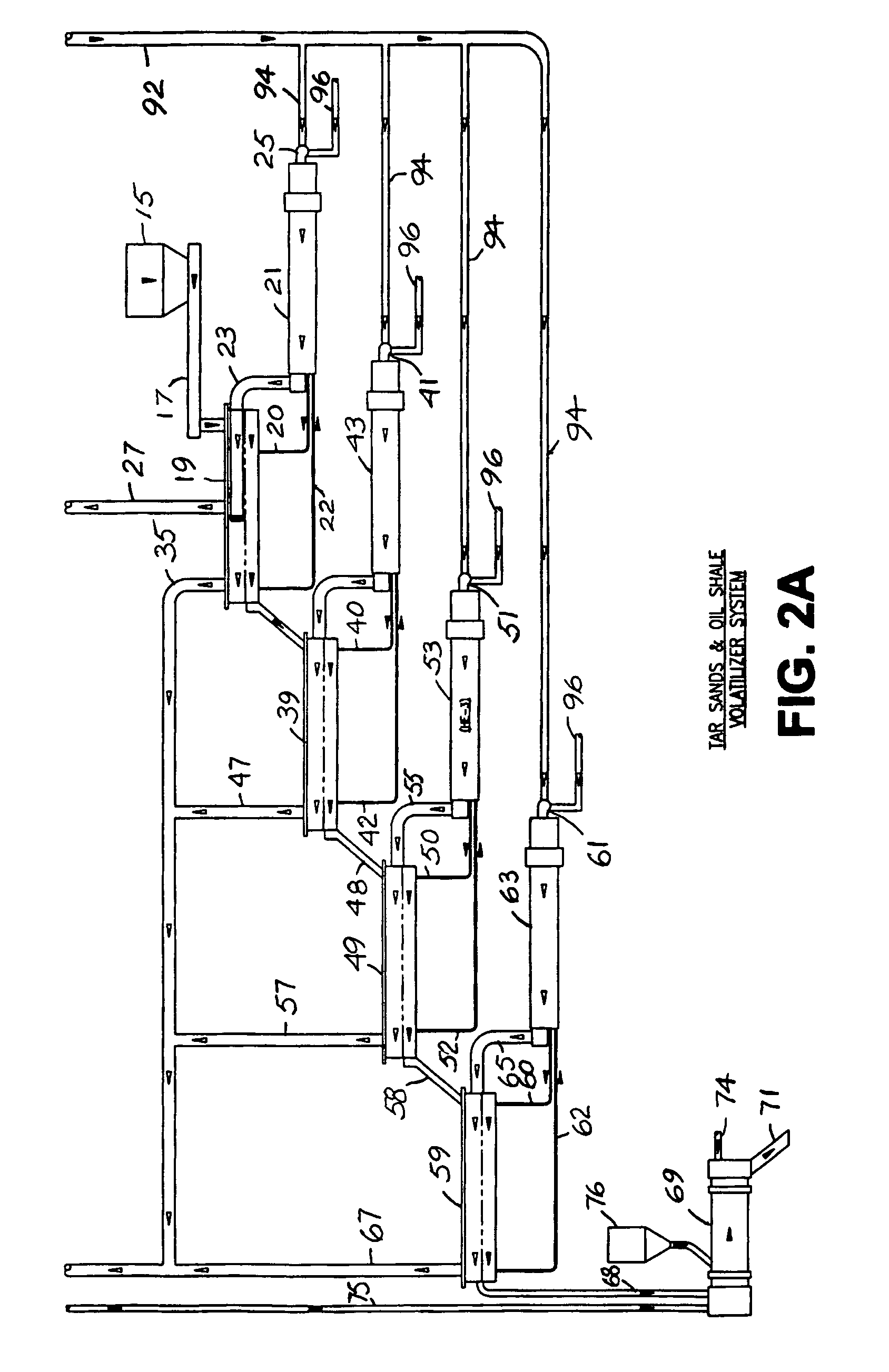

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

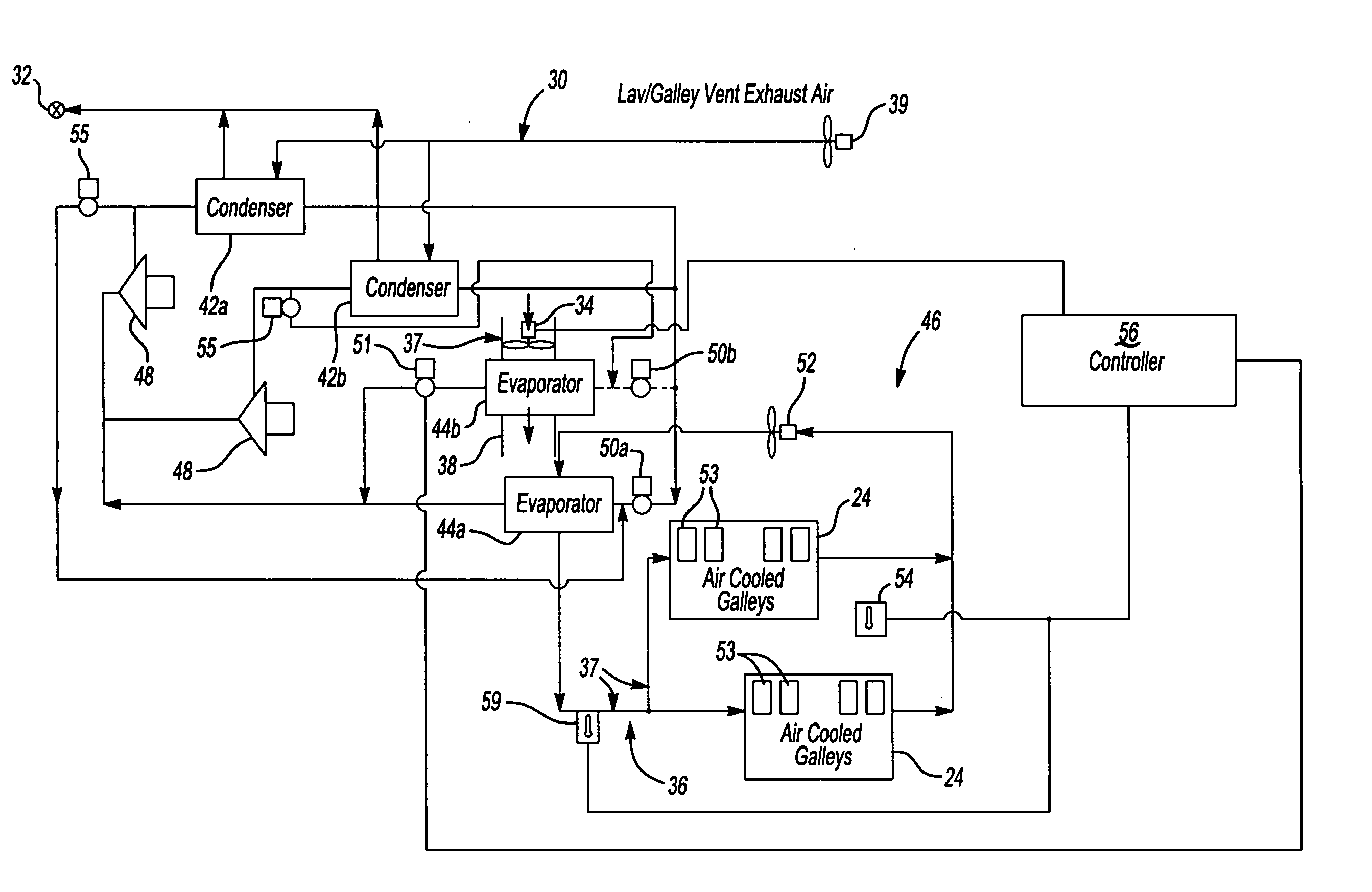

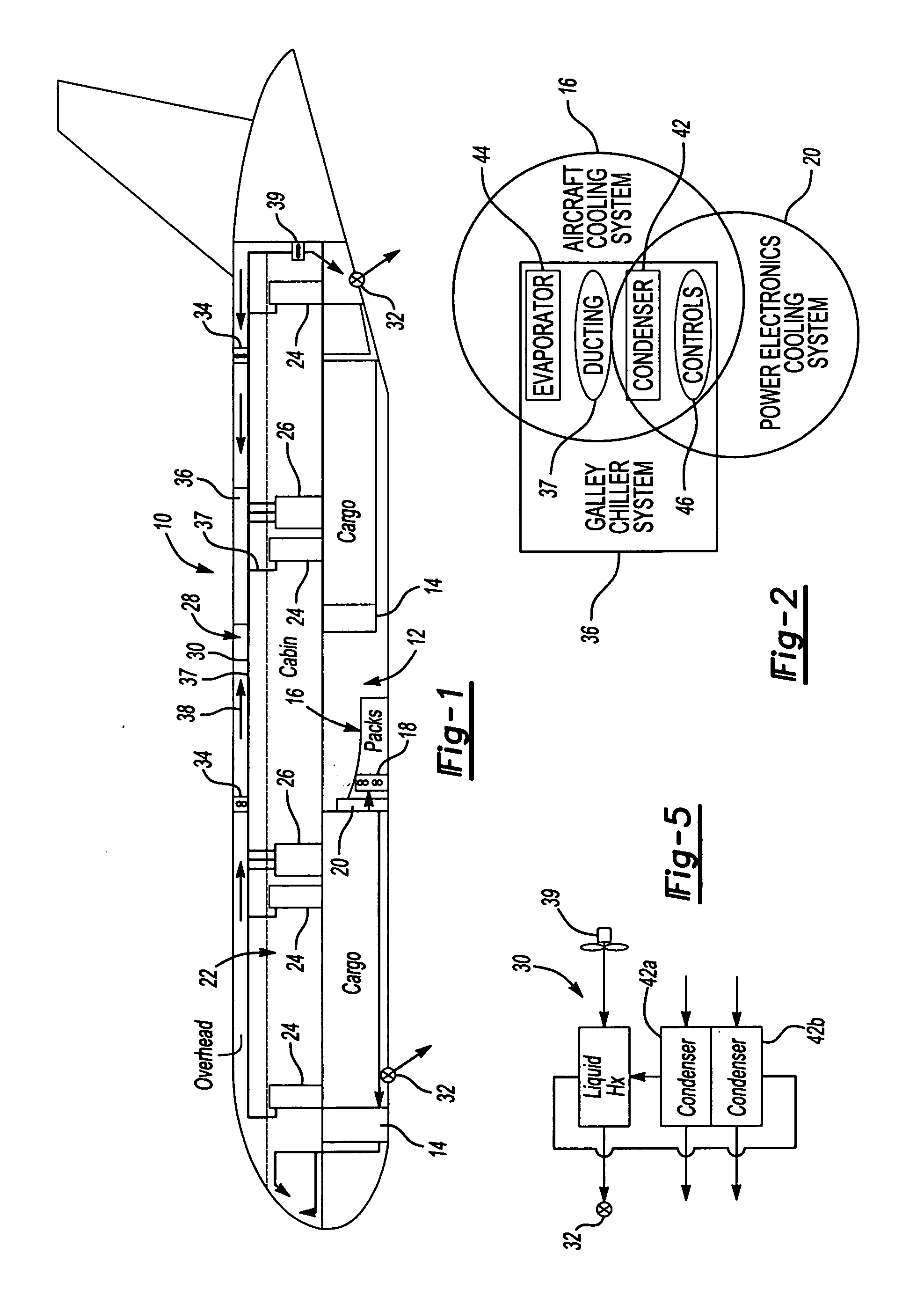

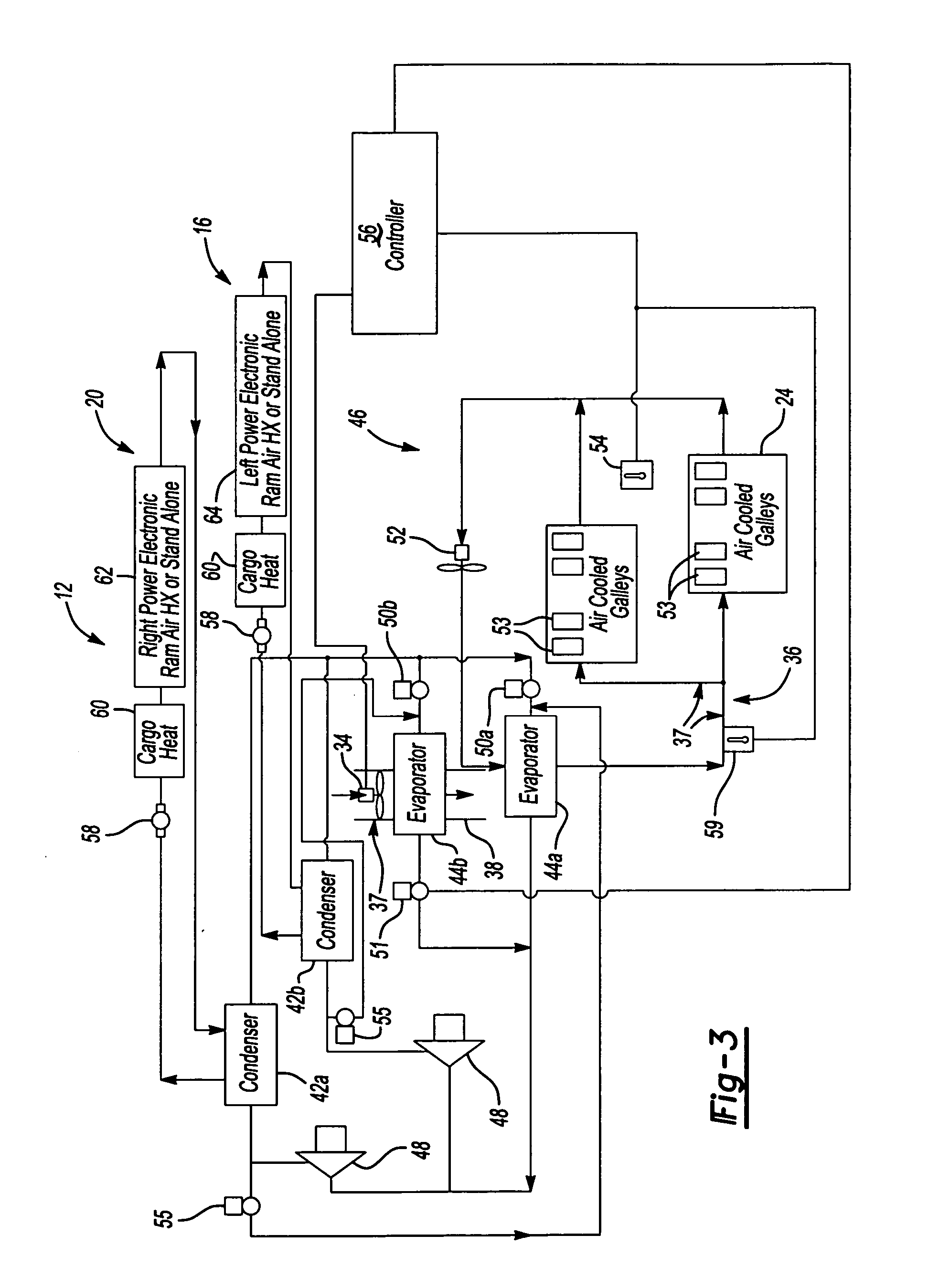

Aircraft galley chiller system

ActiveUS20050061012A1Lower requirementEasy to useMechanical apparatusAir-treating devicesEngineeringChiller

A galley chiller system for an aircraft includes at least one condenser having a refrigerant fluid. The fluid within the condenser rejects heat to a first surrounding environment. To more efficiently use the condenser of the galley chiller system and reduce the requirement on other cooling systems within an aircraft, the condenser may reject its heat to a desired location using a heat exchanger. The galley chiller system includes at least one evaporator that receives fluid from the condenser. A first evaporator absorbs heat from a galley, which may include a bank of carts. The first evaporator is arranged in ducting that carries cooled air to the carts. A second evaporator may absorb heat from a cabin recirculation air duct of the aircraft cooling system. In this manner, the evaporators of the inventive galley chilling system cools not only the galley carts but also provides supplemental cooling to the aircraft cooling system thereby reducing its cooling requirements.

Owner:HAMILTON SUNDSTRAND CORP

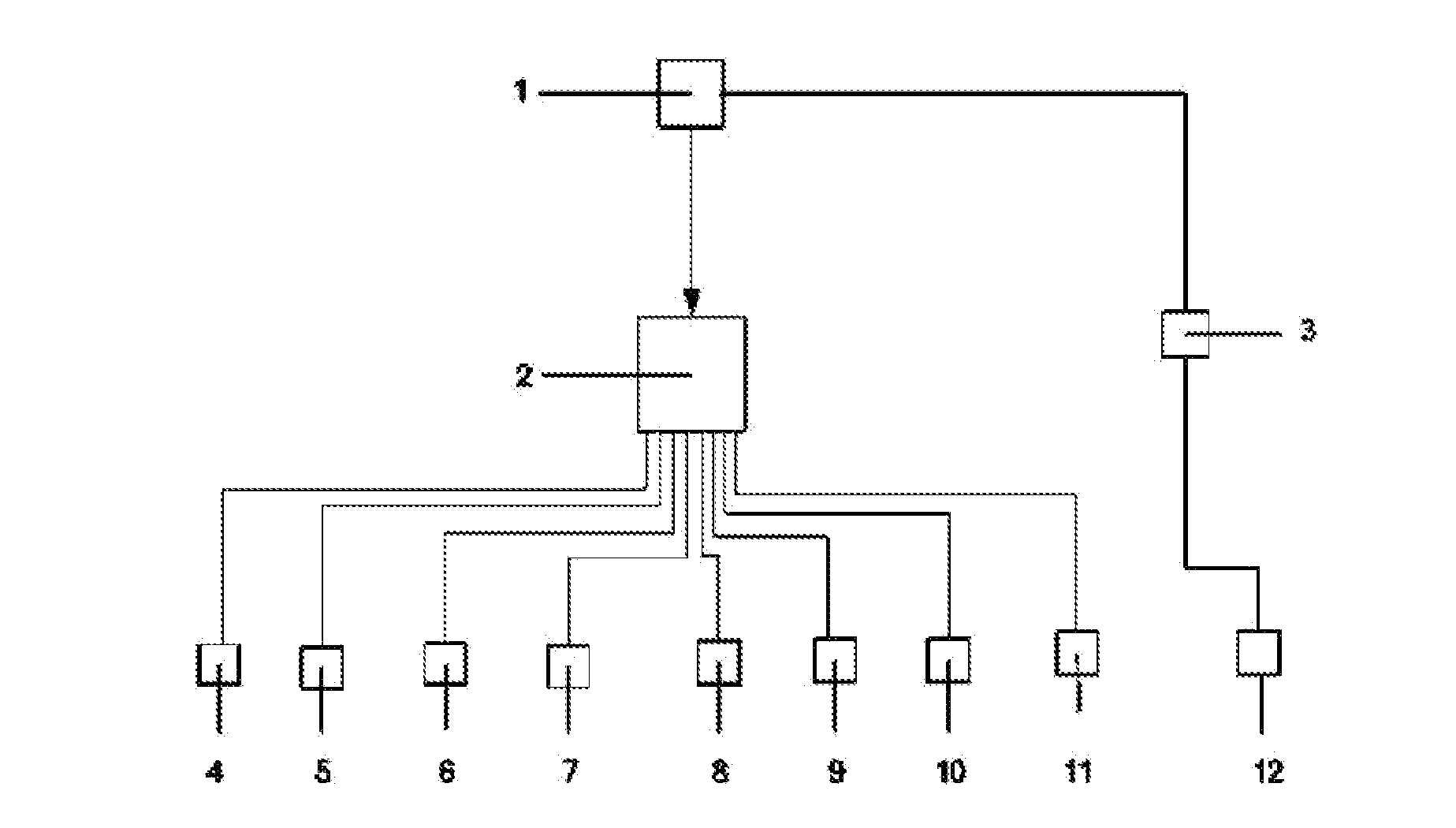

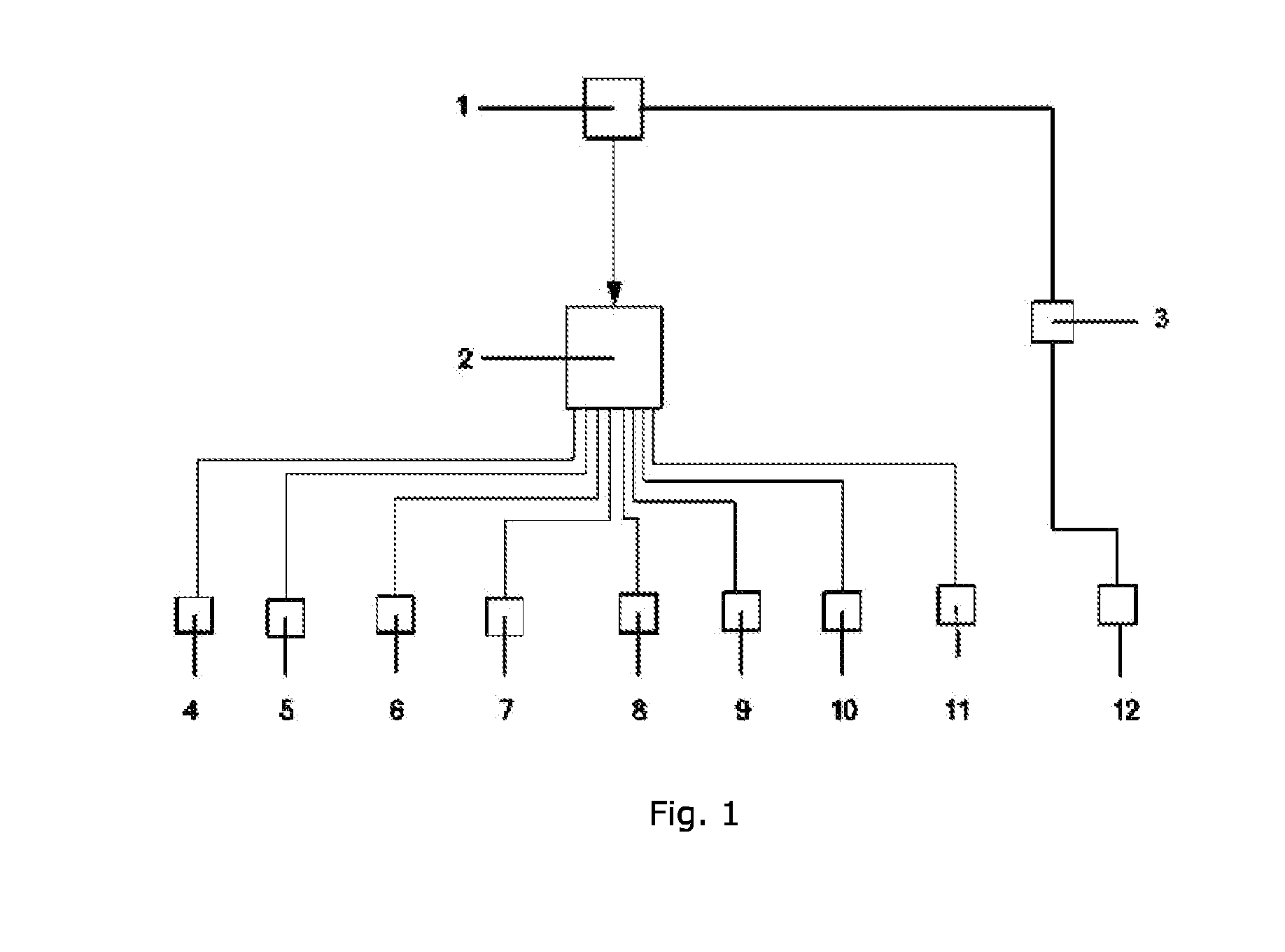

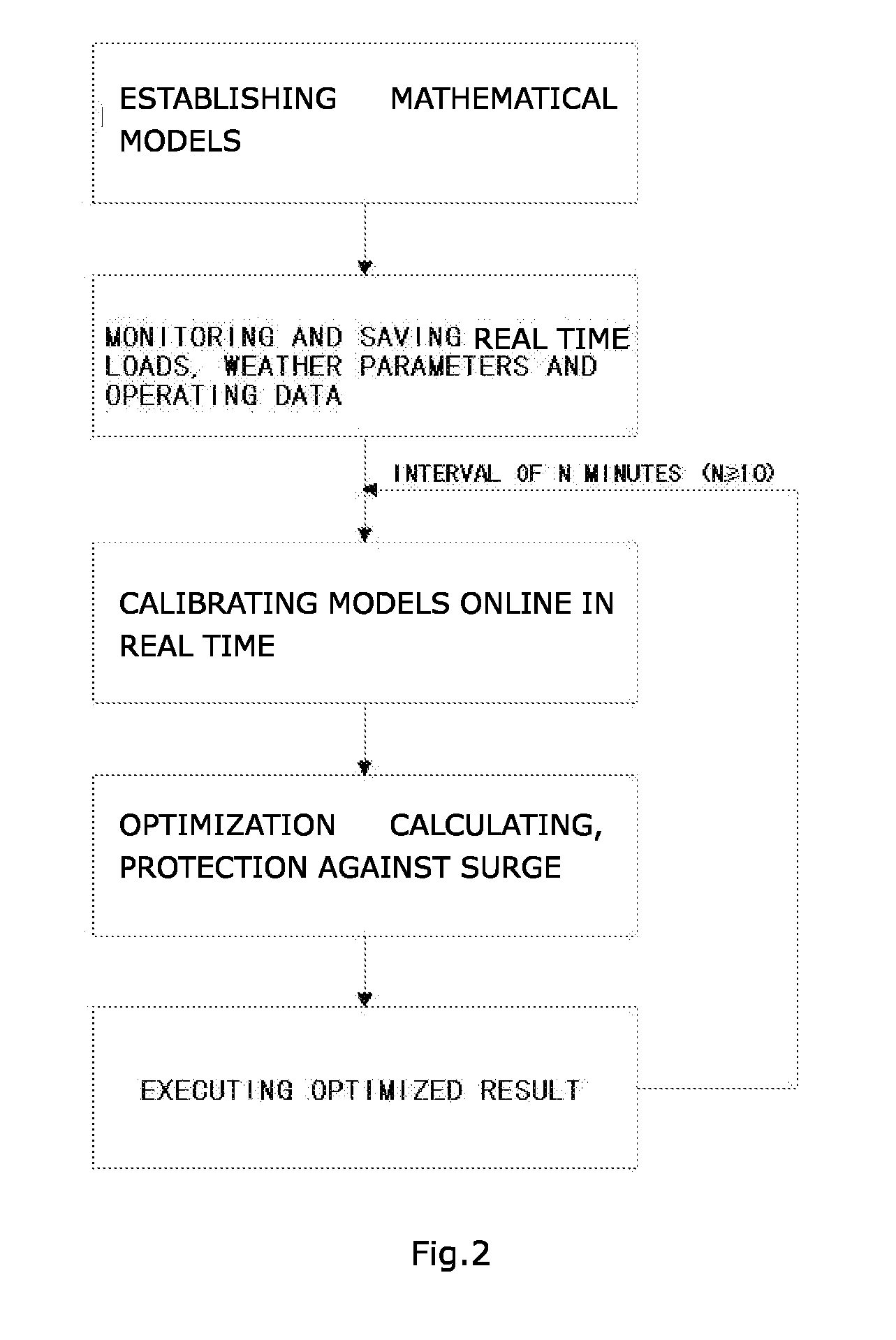

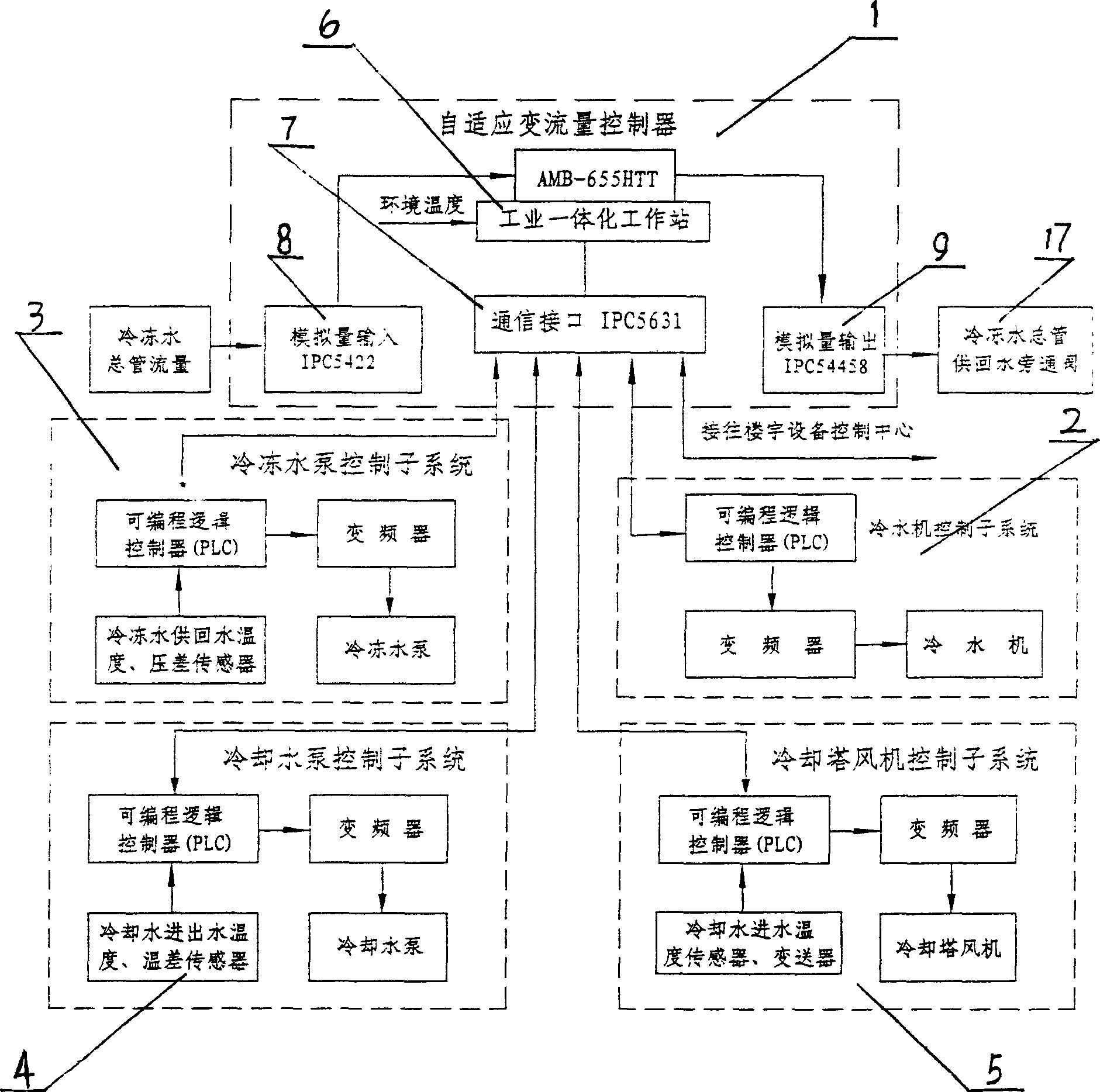

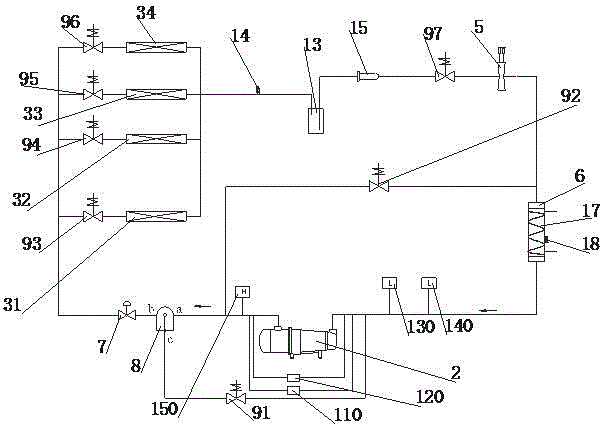

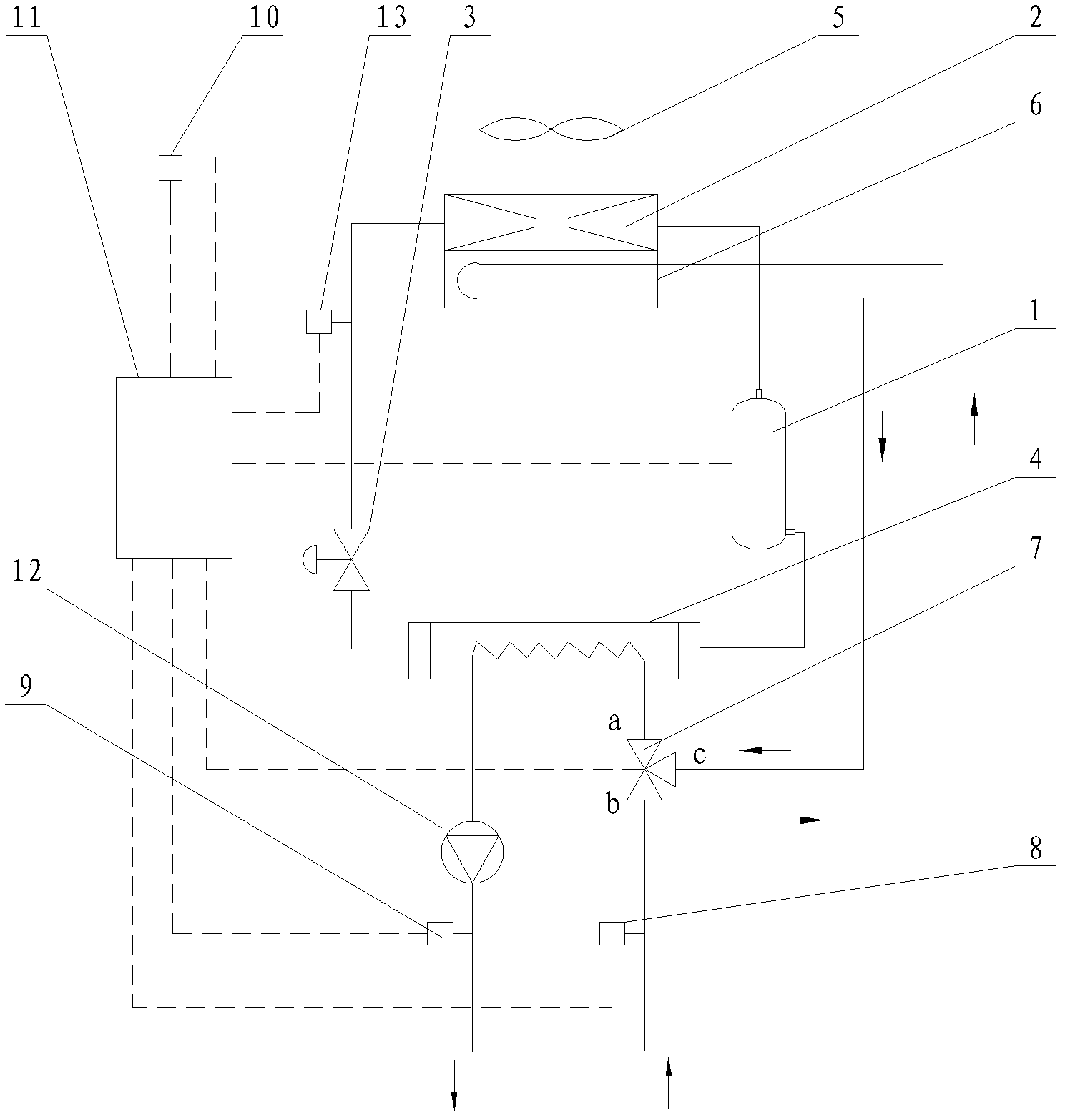

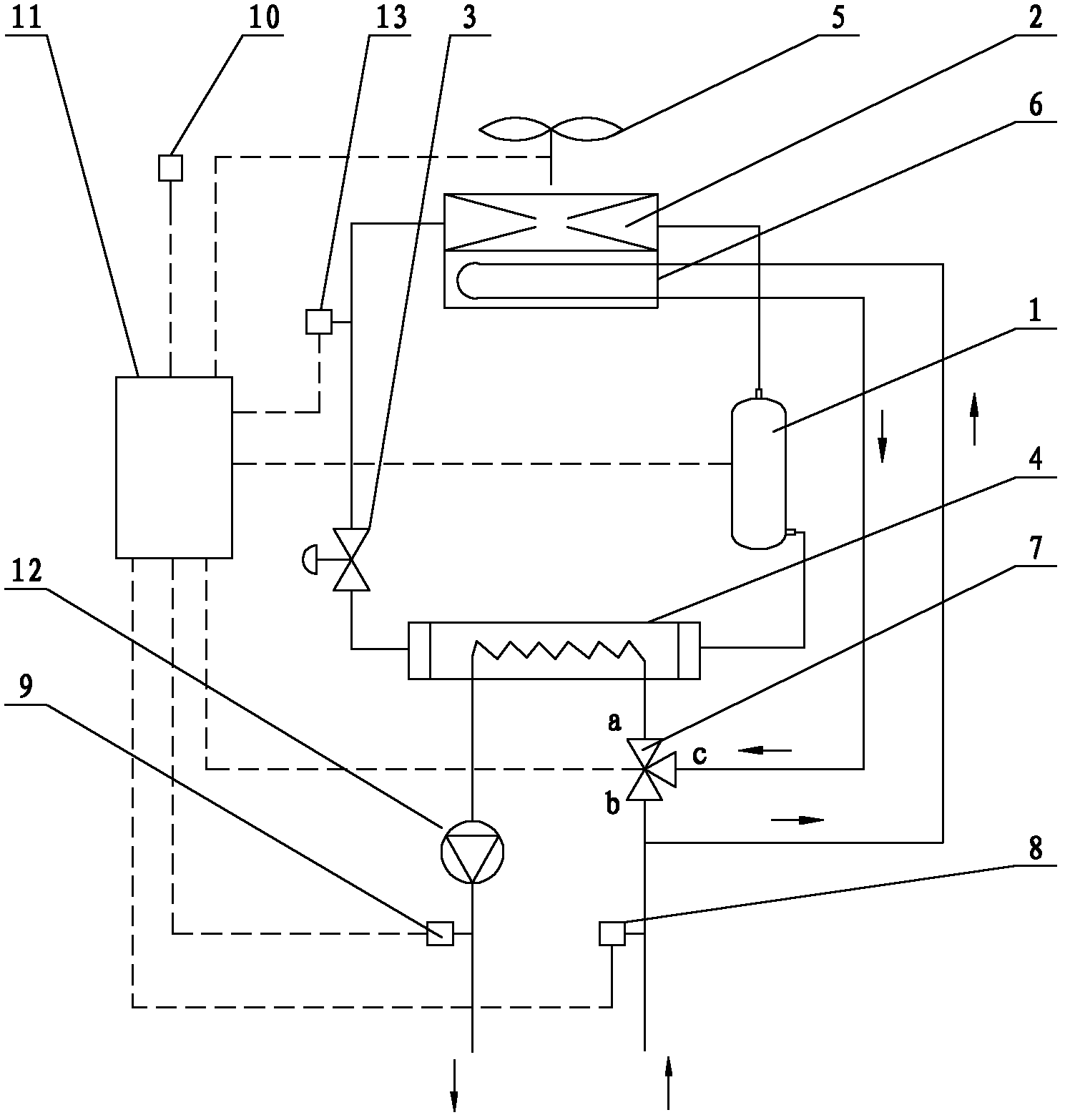

Energy-saving optimized control system and method for refrigeration plant room

ActiveUS20130167560A1Improve energy efficiencySave energy consumptionMechanical apparatusSpace heating and ventilation safety systemsRefrigeration plantOutdoor temperature

An energy-saving optimized control system for a chiller plant room comprises an industry control computer (1), a flow sensor (4), a temperature sensor (5), an outdoor temperature and humidity sensor (6), a three-phase active power transmitter (7), a water pump variable speed driver (9) and a cooling tower fan variable speed driver (10), which are respectively connected with a programmable controller (2), wherein the programmable controller (2) communicates with the industrial control computer (1) through an industrial Ethernet; and an RS485 communication interface module (3) is connected with chillers and communicates with the industrial control computer (1) through a ModBus protocol. An energy-saving optimized control method for a chiller plant room is also provided. By establishing a mathematical model of the relationship between the energy consumption and operation parameters of each equipment in the refrigeration plant room and combining the real-time cooling loads and weather parameters, the operating state of each equipment is adjusted so as to reach the lowest operating energy consumption of the whole chiller plant room under the premise of meeting the cooling loads.

Owner:WELDTECH TECH SHANGHAI

High capacity chiller compressor

ActiveUS20090229280A1Improve efficiencyIncrease power outputCompressorPositive displacement pump componentsSingle stageEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. A cooling system provides direct, two-phase cooling of the rotor by combining gas refrigerant from the evaporator section with liquid refrigerant from the condenser section to affect a liquid / vapor refrigerant mixture. Cooling of the stator with liquid refrigerant may be provided by a similar technique. A noise suppression system is provided by injecting liquid refrigerant spray at points between the impeller and the condenser section. The liquid refrigerant may be sourced from high pressure liquid refrigerant from the condenser section.

Owner:DAIKIN IND LTD

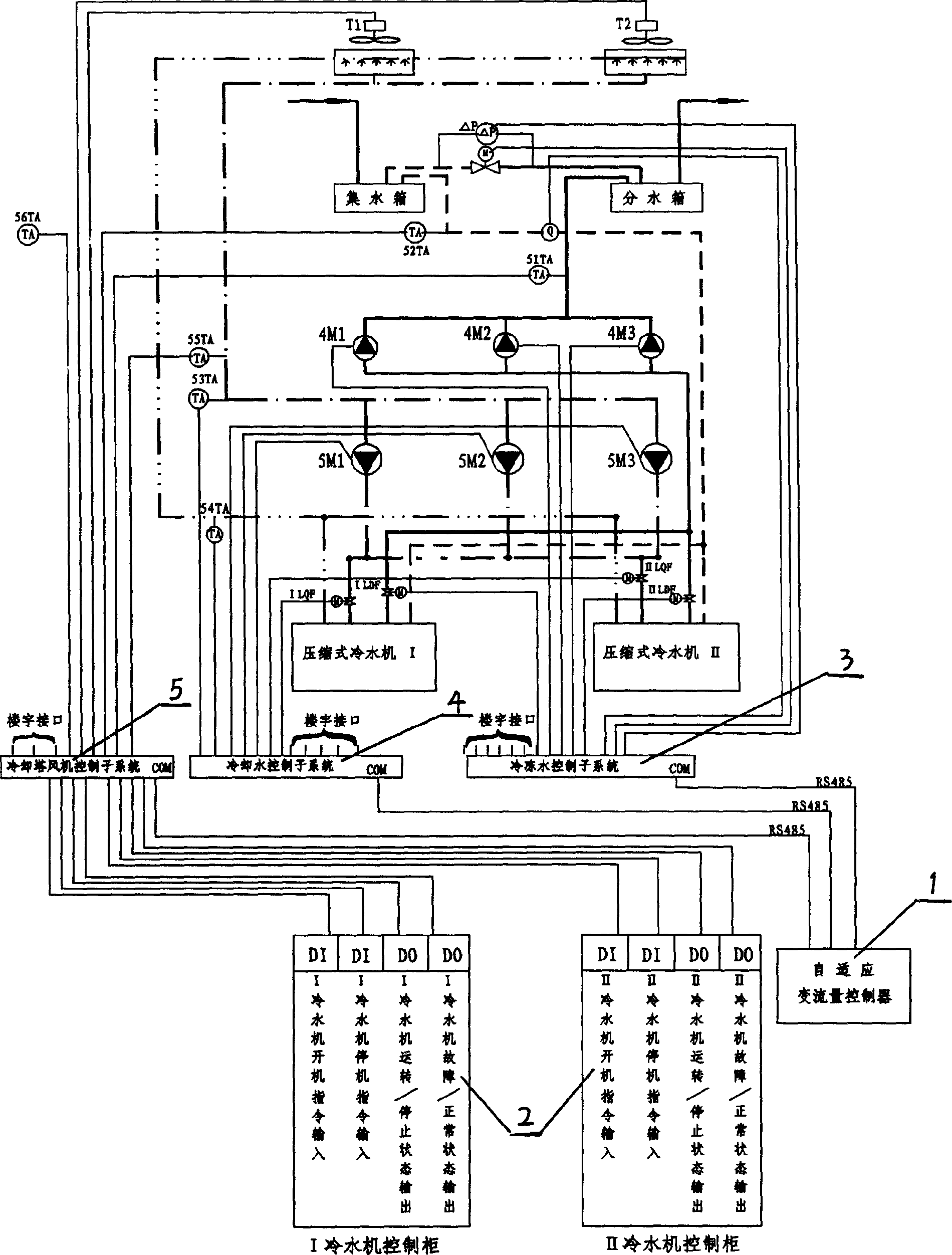

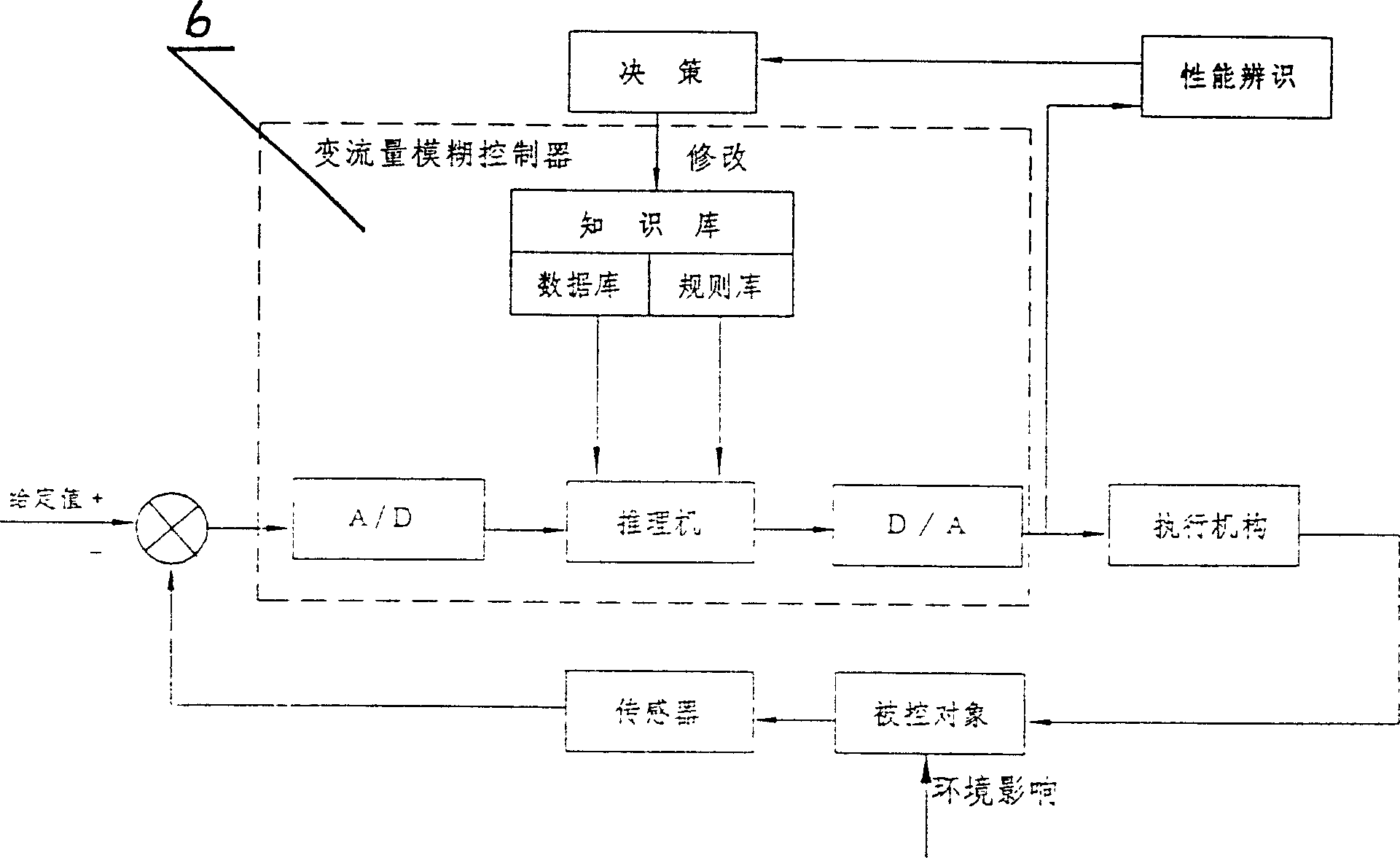

Self-adapting energy saving control device with variable flux for compression type central conditioner

InactiveCN1415915AReduce wearWith the purpose of saving energy and reducing consumptionSpace heating and ventilation safety systemsLighting and heating apparatusIce waterCooling tower

This invention discloses a compressed central air-conditioning adaptive variable flow energy saving control device composed of an adaptive variable flow controller, ice water control subsystem, frozen water control subsystem, cooling water control subsystem, cooling tower blower fan control subsystem, the adaptive variable flow controller connects with control subsystem of ice water device, frozen water pump, cooling water and blower fan of cooling tower capable of making every operational target to reach the most optimized.

Owner:贵州华城楼宇科技有限公司

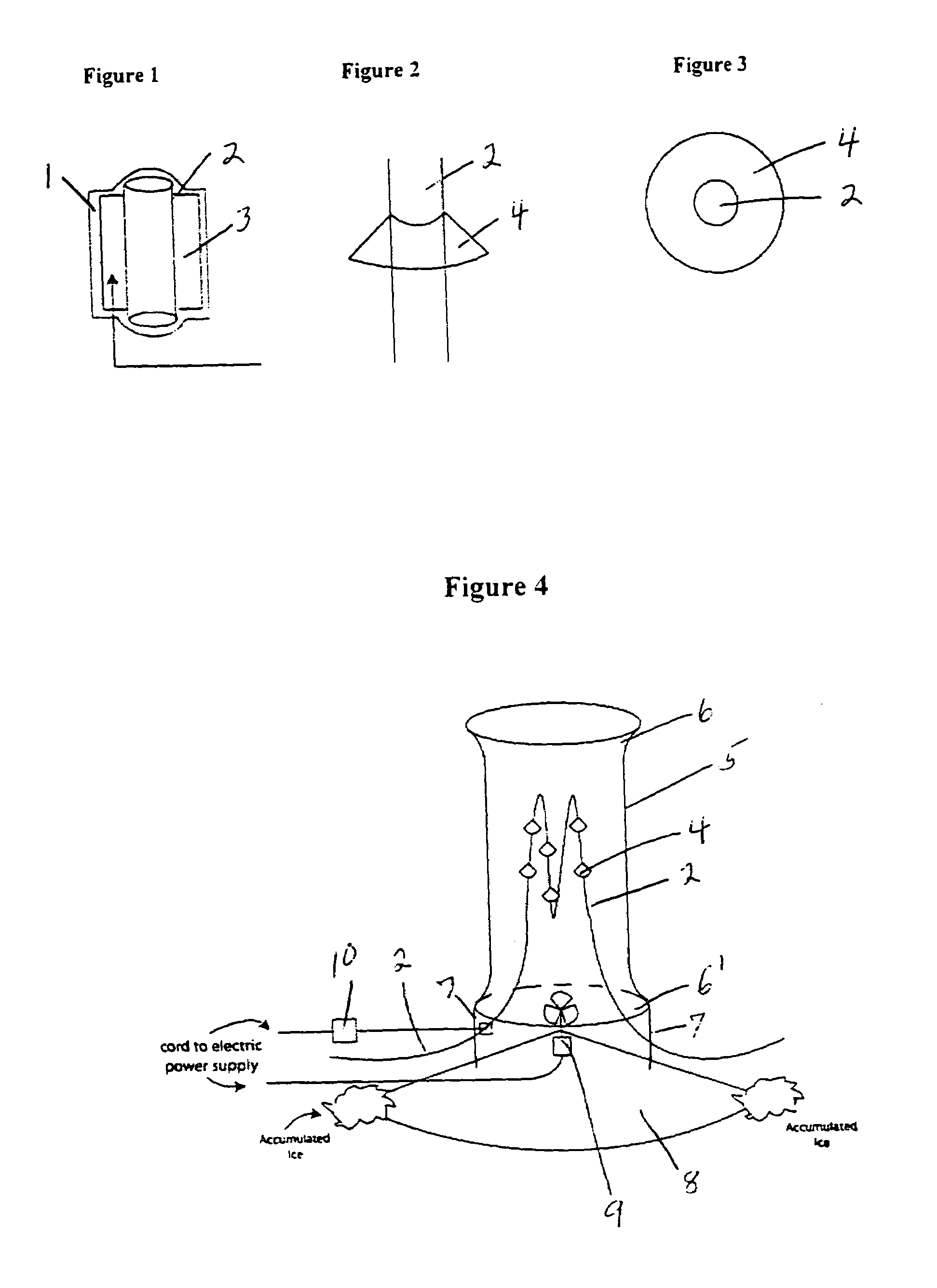

Method and apparatus for inhibiting ice accumulation in HVAC systems

InactiveUS6971248B1Degrades design efficiencyEasy to operateAir heatersCorrosion preventionHeat sinkHeating system

A non-stick coating, which inhibits frozen moisture accumulation, is applied to exterior exposed portions of heating and cooling systems where ice or other frozen moisture can accumulate and impair system design operational efficiencies; where heat exchange tubing and fins are downwardly sloped or angled; with an optional protective shell encasement which can be shaped to provide a vena contracta effect; with an optional electric fan to enhance airflow for heat exchange; with an optional electric vibrator to enhance inhibition of frozen moisture accumulation; with a downwardly sloped base to direct falling frozen moisture away from the heat exchange equipment; for use in conjunction with an air source heat pump system, an evaporative cooling system or a chiller, or as a supplement to a water-source heat pump system or to a direct expansion heat pump system; and for use with any other refrigerant-based heating system or cooling system.

Owner:WIGGS B RYLAND

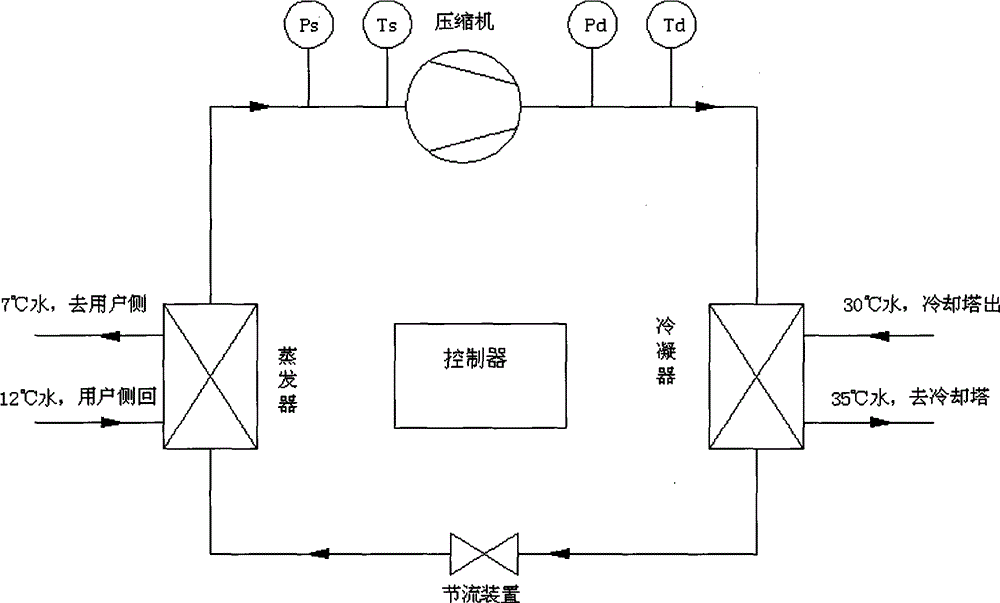

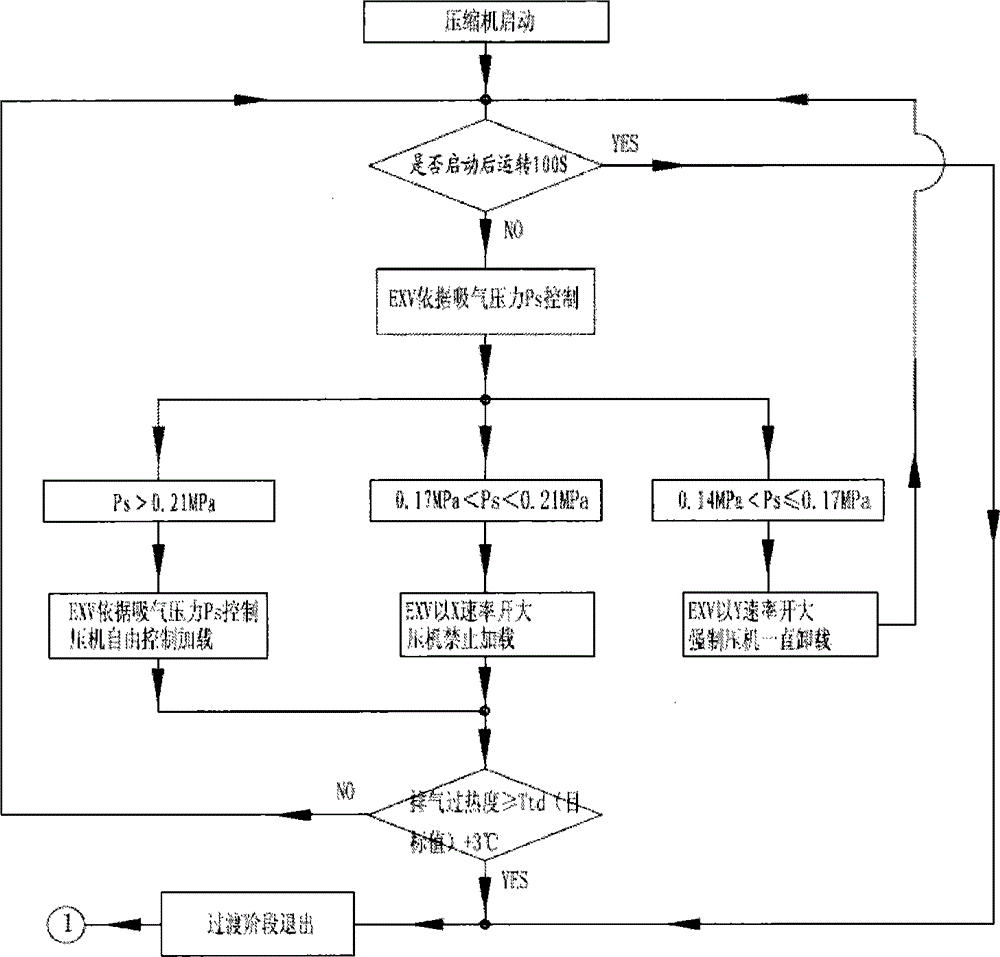

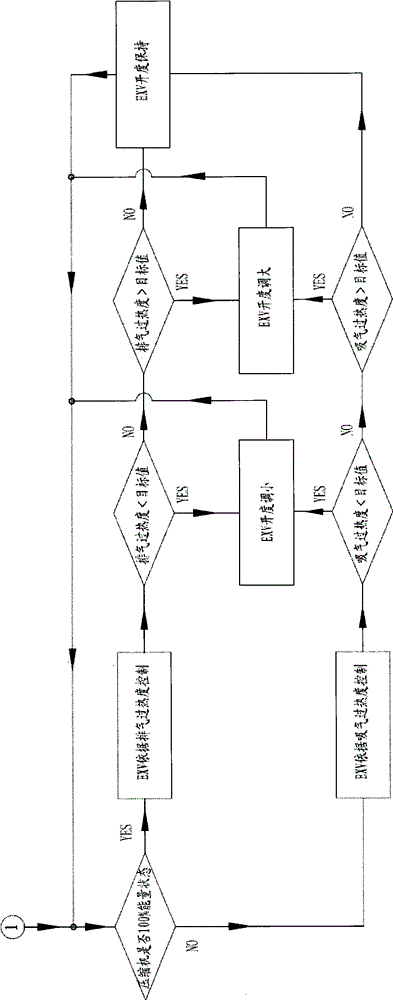

Electronic expansion valve control system and method

InactiveCN104634033AReduced risk of low inspiratory pressureReduce the risk of aspirating fluidRefrigeration safety arrangementDischarge pressureEvaporator

The invention discloses an electronic expansion valve control system which comprises sensors and a controller. A suction pressure sensor which is used for detecting suction pressure Ps and a suction temperature sensor which is used for detecting suction temperature Ts are arranged in a pipeline from an evaporator to a compressor, and an exhaust pressure sensor which is used for detecting exhaust pressure Pd and an exhaust temperature sensor which is used for detecting exhaust temperature Td are arranged in another pipeline from the compressor to a condenser; the controller takes a Ps signal, a Ts signal, a Pd signal and a Td signal collected through the sensors as criterion of control logic of the compressor and an electronic expansion valve. Accordingly, the advantages of controlling the degree of overheat of the suction and controlling the degree of overheat of the exhaust are combined, and at the same time the electronic expansion valve conducts control according to the suction pressure in a certain time after the compressor is stared up. The electronic expansion valve control system and method are used for controlling a water chilling unit, the stability of the electronic expansion valve control of the water chilling unit is guaranteed, the reliability of the water chilling unit is improved, and requirements of users for water chilling unit products are met.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

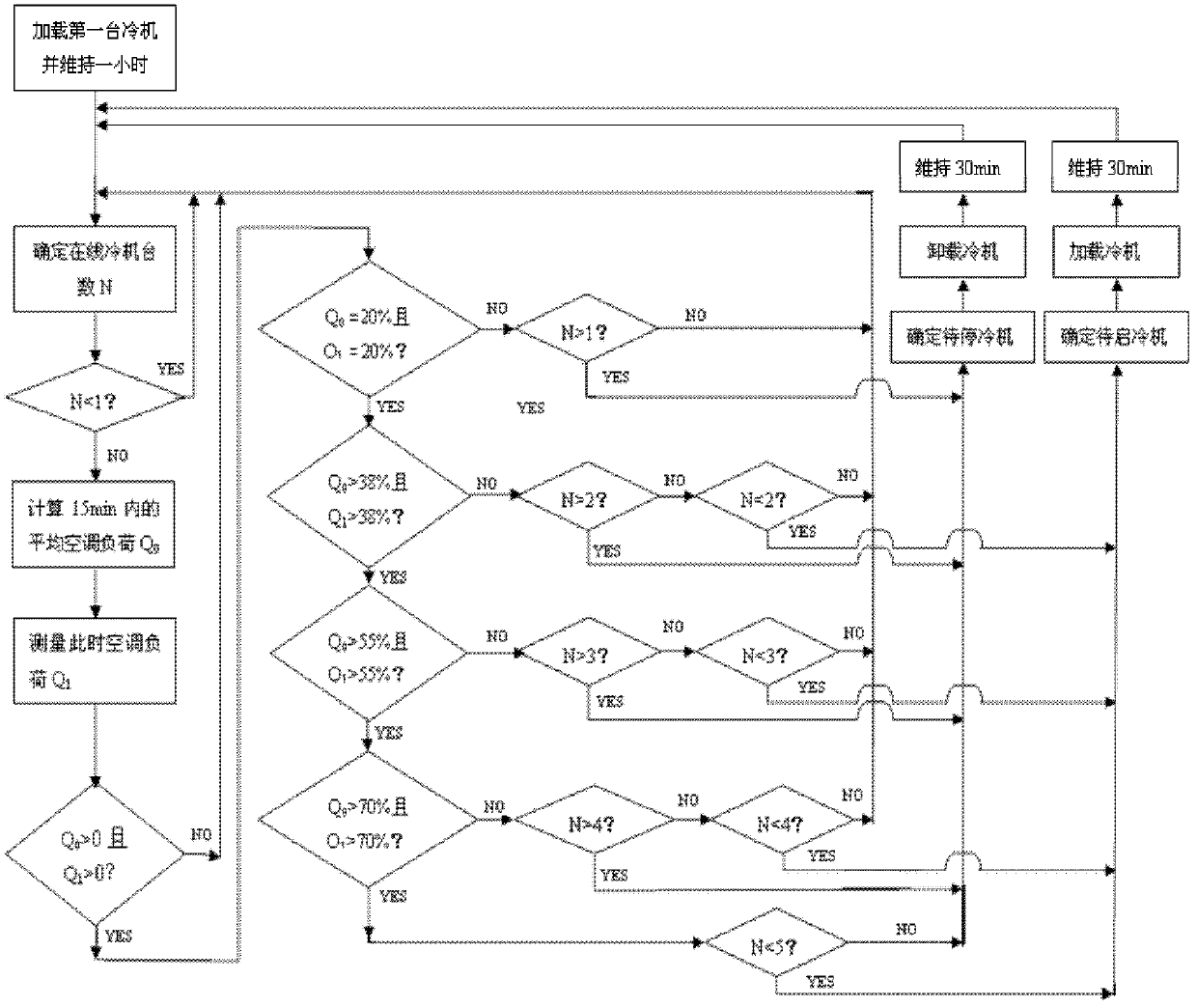

Group control method for central air conditioning refrigerating unit

ActiveCN103375878AEconomical and energy efficient operationExtend your lifeSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlChilled water

The invention provides a group control method for a central air conditioning refrigerating unit. The group control method for the central air conditioning refrigerating unit comprises step A, entering into a step B when the water outlet temperature of a refrigerating unit basically achieves a stable temperature; step B, measuring the temperature and flow amount for water supply and water return of chilled water to obtain temperature difference and the flow amount of the water supply and the water return; step C, computing the load according to the temperature difference and the flow amount of the water supply and the water return; step D, controlling loading and unloading of refrigerating machines of the refrigerating unit. According to the group control method for the central air conditioning refrigerating unit, the group control algorithm for the refrigerating unit is achieved through thermal, the refrigerating unit is operated under an economical and energy saving state and the purposes of prolonging the service life of the device and reducing the energy consumption are achieved. The group control method for the central air conditioning refrigerating unit has a good popularization prospect in the fields of building automatic control and building energy saving.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Air treatment device and air treatment method

InactiveCN102418966ARaise the evaporation temperatureImprove energy efficiencySpace heating and ventilation safety systemsLighting and heating apparatusThermodynamicsAir treatment

The invention discloses an air treatment device and an air treatment method. The air treatment device is characterized by comprising an air treatment part and a control and regulation part, wherein the air treatment part comprises a return air inlet (1) for receiving indoor return air, a return air regulating air valve (2), a fresh air port (3) for receiving indoor fresh air, a fresh air regulating air valve (4), a high-temperature meter cooler (5) communicated with high-temperature chilled water, a low-temperature meter cooler (7) communicated with low-temperature chilled water, a bypass regulating air valve (9), a heater (10), a humidifier (11), a fan (12) for supplying air to an indoor space, and an air outlet (13) for supplying air to the indoor space, wherein the high-temperature meter cooler (5) and the low-temperature meter cooler (7) which are connected in turn are arranged in a flow direction of the air entering the air treatment device and flowing out of the air treatment device. The evaporating temperature of a water chiller is improved, and the energy efficiency of an air-conditioning system is improved.

Owner:SOUTHEAST UNIV

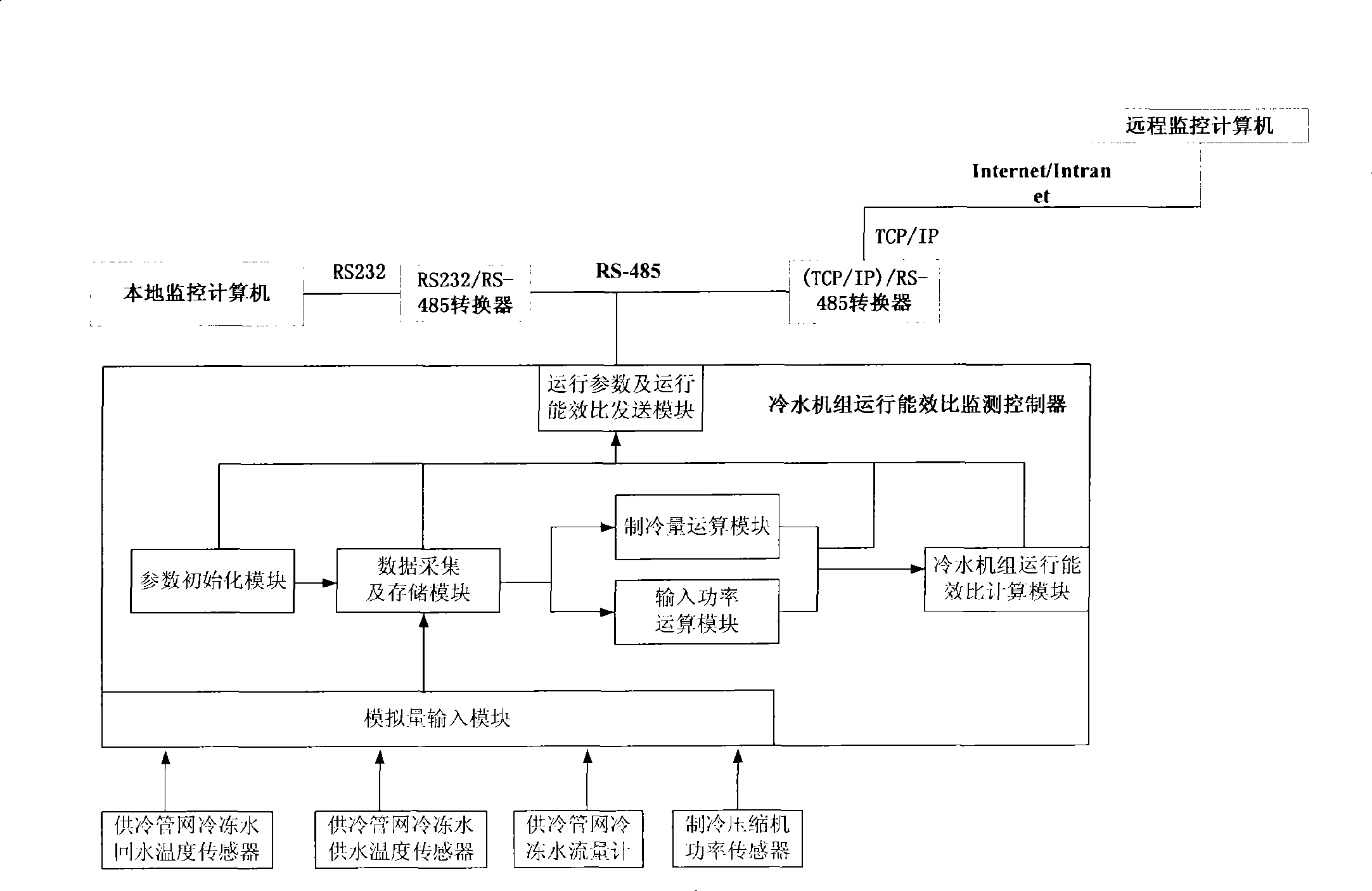

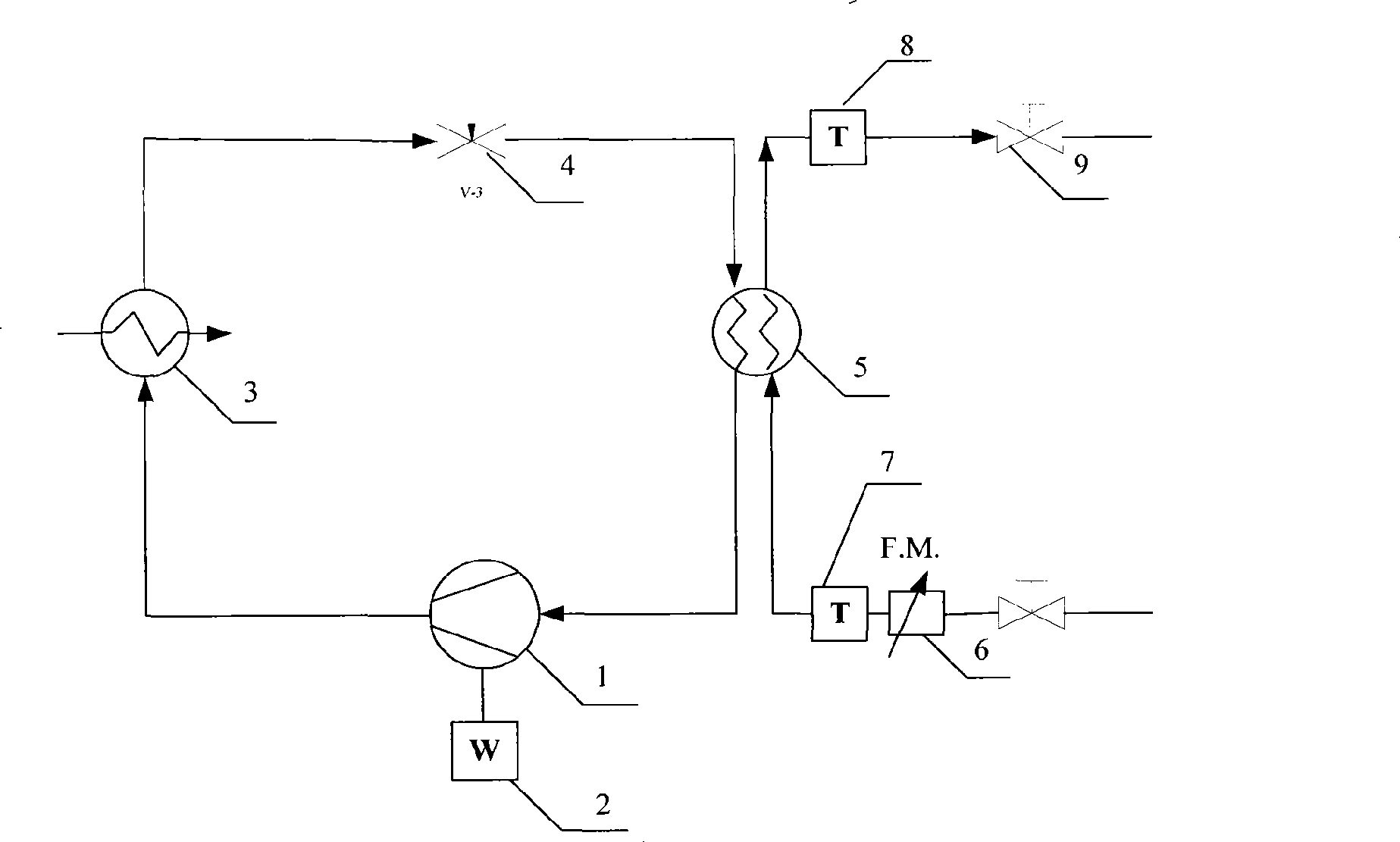

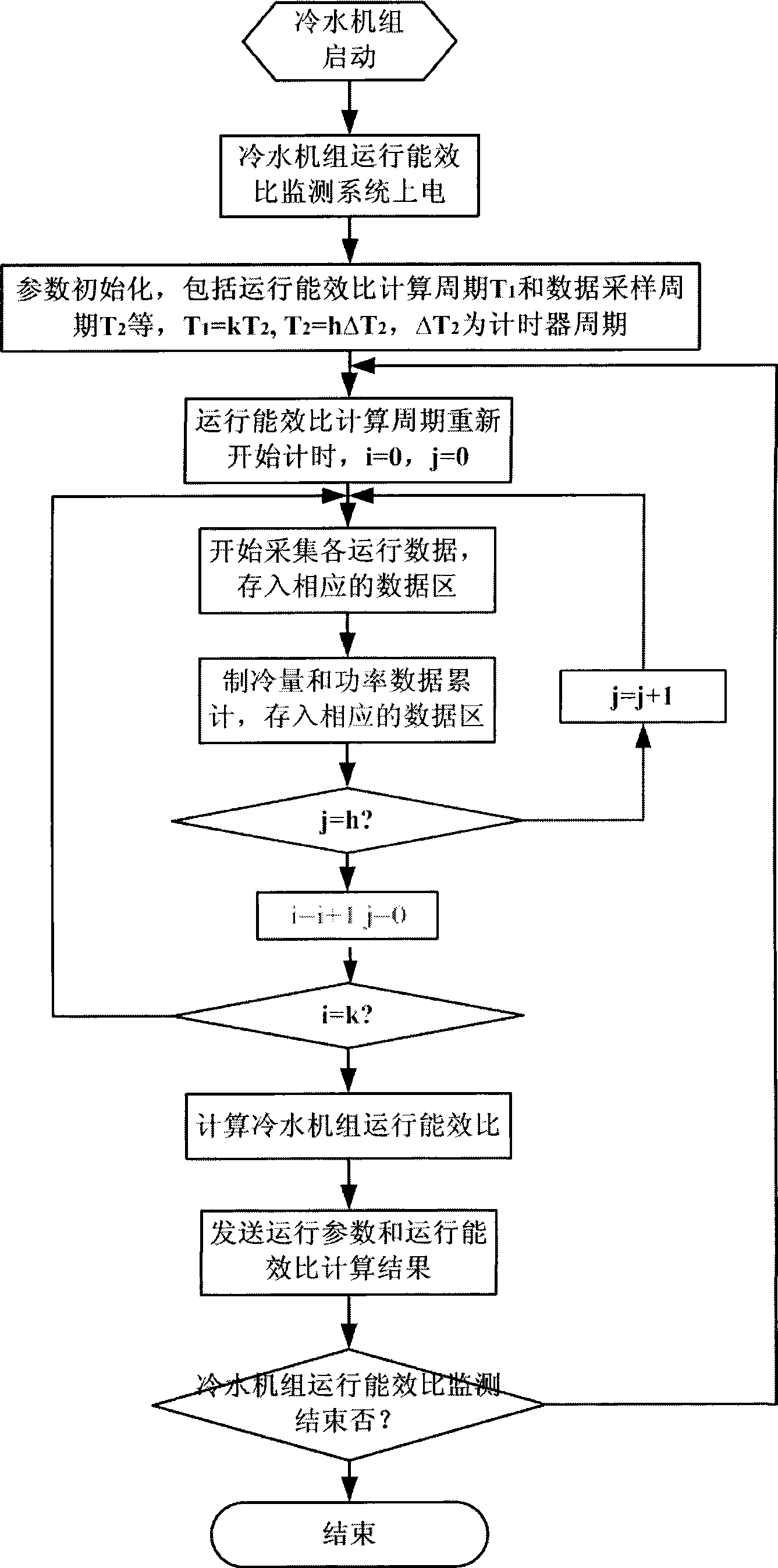

System and method for monitoring operation energy efficiency ratio of water chilling unit

ActiveCN101435643AReal-time maintenanceReduce wasteSpace heating and ventilation safety systemsSpace heating and ventilation control systemsPower sensorRefrigeration compressor

The invention relates to a system for monitoring energy efficiency ratio of operation of a water cooler set and a monitoring method thereof. The system comprises a controller for monitoring the energy efficiency ratio of operation of the water cooler set, a local monitoring computer, a remote monitoring computer and a frozen water supply temperature sensor of a cold supply pipe network, a frozen water return temperature sensor of the cold supply pipe network, a frozen water flowmeter of the cold supply network and a power sensor of a refrigeration compressor which are correspondingly connected with the water cooler set; the frozen water supply temperature sensor of the cold supply pipe network, the frozen water return temperature sensor of the cold supply pipe network, the frozen water flowmeter of the cold supply network and the power sensor of the refrigeration compressor are connected with the controller for monitoring the energy efficiency ratio of operation of the water cooler set respectively; and the local monitoring computer and the remote monitoring computer are connected with a signal of the controller for monitoring the energy efficiency ratio of operation of the water cooler set through a convertor I and a convertor II respectively. The system is suitable for the water cooler set of a central air conditioning system using electric power as primary drive energy; and the measured energy efficiency ratio of operation of the water cooler set is suitable for supervising daily energy-saving operation of the water cooler set.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

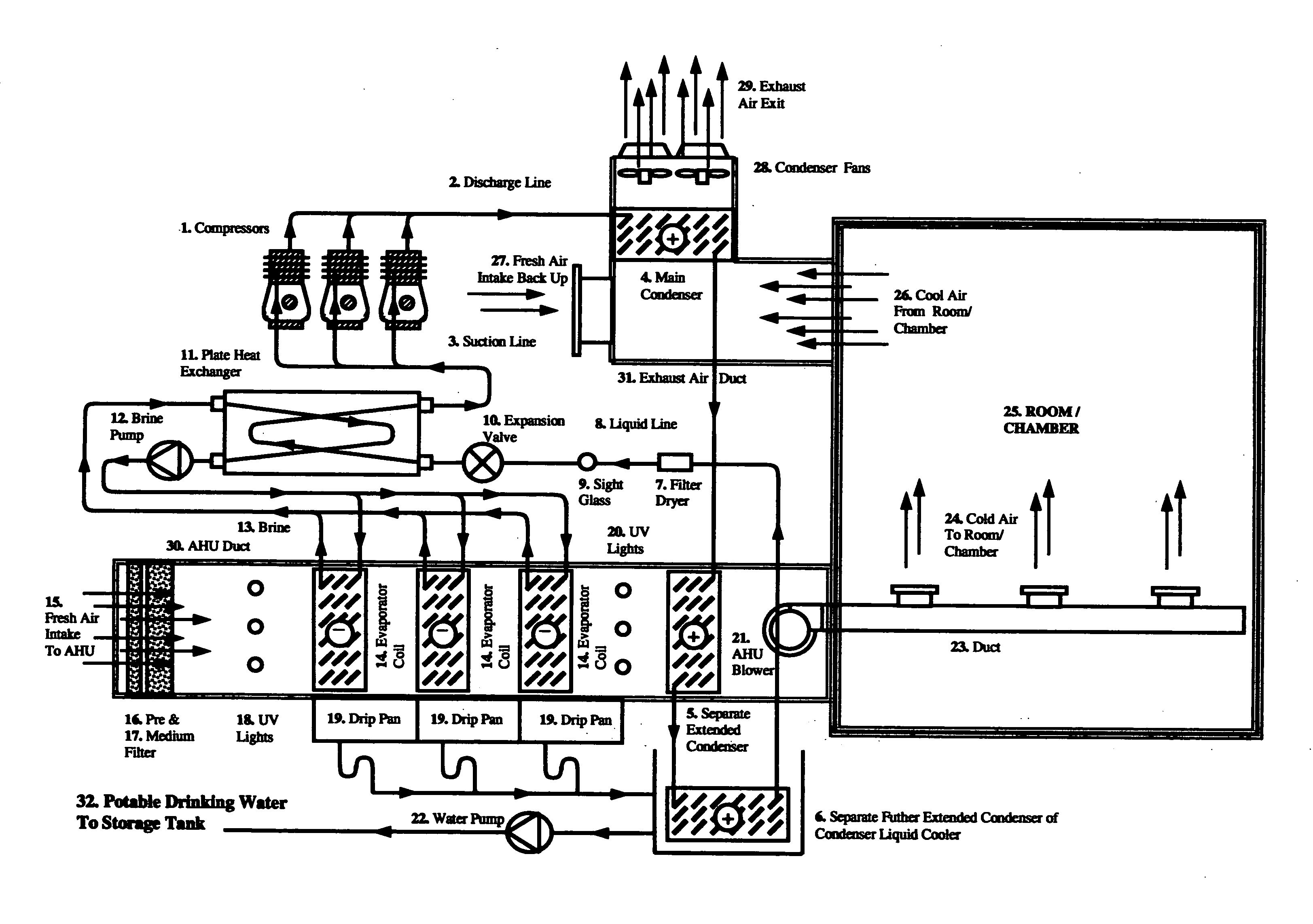

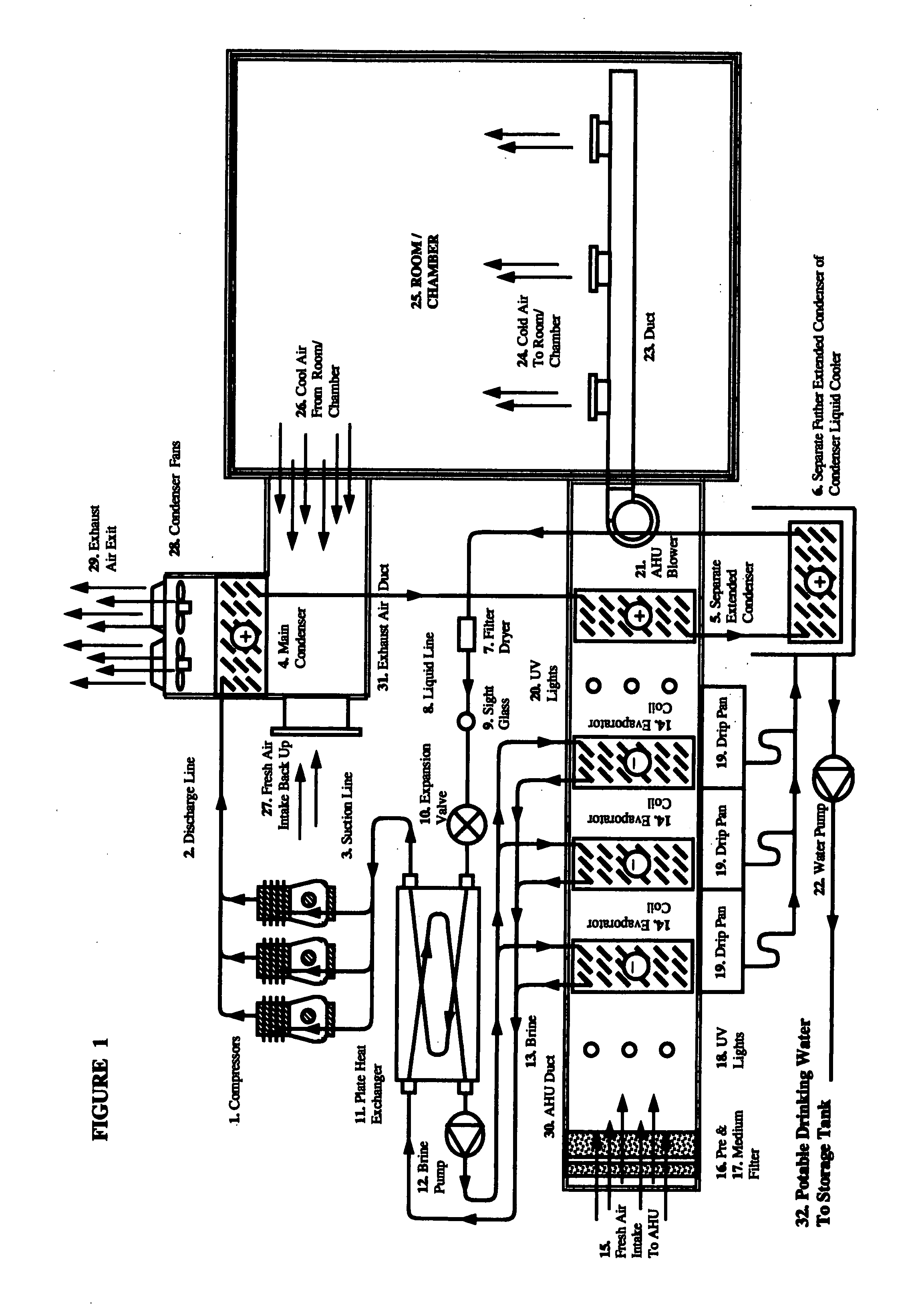

Energy saving and environmentally friendly atmospheric dehumidifier chiller for drinking purposes

InactiveUS20080276630A1Save energyDelay in treatmentGeneral water supply conservationLighting and heating apparatusCold airSaline water

A method and machine to produce drinking water from fresh air using an energy saving and environmentally friendly chiller is comprising the following steps of: Filtering and sterilize fresh air, then passed to several evaporator coils to condensate the moisture and the condensate collected to a pan.Passing secondary condenser by cold air after passing evaporator coil and dipping tertiary condenser to a cold condensate water tank, so the refrigerant after the condenser will be subcooled and after passing through the expansion valve, will heat exchange with the brine as a secondary refrigerant in the heat exchanger.Where brine is passed to several evaporator coils in air handling unit to cool and condensate the moisture passing through the air handling unit, a part of the air will condensate and the other part will passed to a cooled room where the cold air of the room then will exhaust and used to cool the main condenser through the exhaust air duct.

Owner:PT DIVINE ETERNAIR WATER INDONESIA

Natural cold source cooling water chiller

InactiveCN101988722AReduce noiseSolution to short lifeLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerCooling tower

The invention relates to a natural cold source cooling water chiller which comprises an outdoor unit and an indoor unit, wherein the outdoor unit mainly consists of a refrigeration system composed of a totally-enclosed scroll compressor, an evaporator, an evaporative condenser and a natural cold source collection device, and a water channel circulating system with a three-way valve so as to realize the mechanical refrigeration of the evaporative condenser and the evaporative cooling and the air cooling of the natural cold source collection device. The water chiller is characterized in that the evaporative condenser and the high-efficiency natural cold source collection device are arranged simultaneously above a cooling circulating water pool, and an axial-flow fan is installed on upper space. When the outdoor wet-bulb temperature is higher than 6 DEG C to 8 DEG C, the evaporative condenser is mainly used to realize refrigeration, when the outdoor wet-bulb temperature is lower than 6 DEG C to 8 DEG C and higher than 0 DEG C and 2 DEG C, the natural cold source collection device which is in the form of cooling tower spraying is mainly used to realize the evaporative cooling, and when the outdoor wet-bulb temperature is lower than 0 DEG Cto 2 DEG C, the natural cold source collection device which is in the form of air cooling is mainly used to realize cooling.

Owner:郭海新 +1

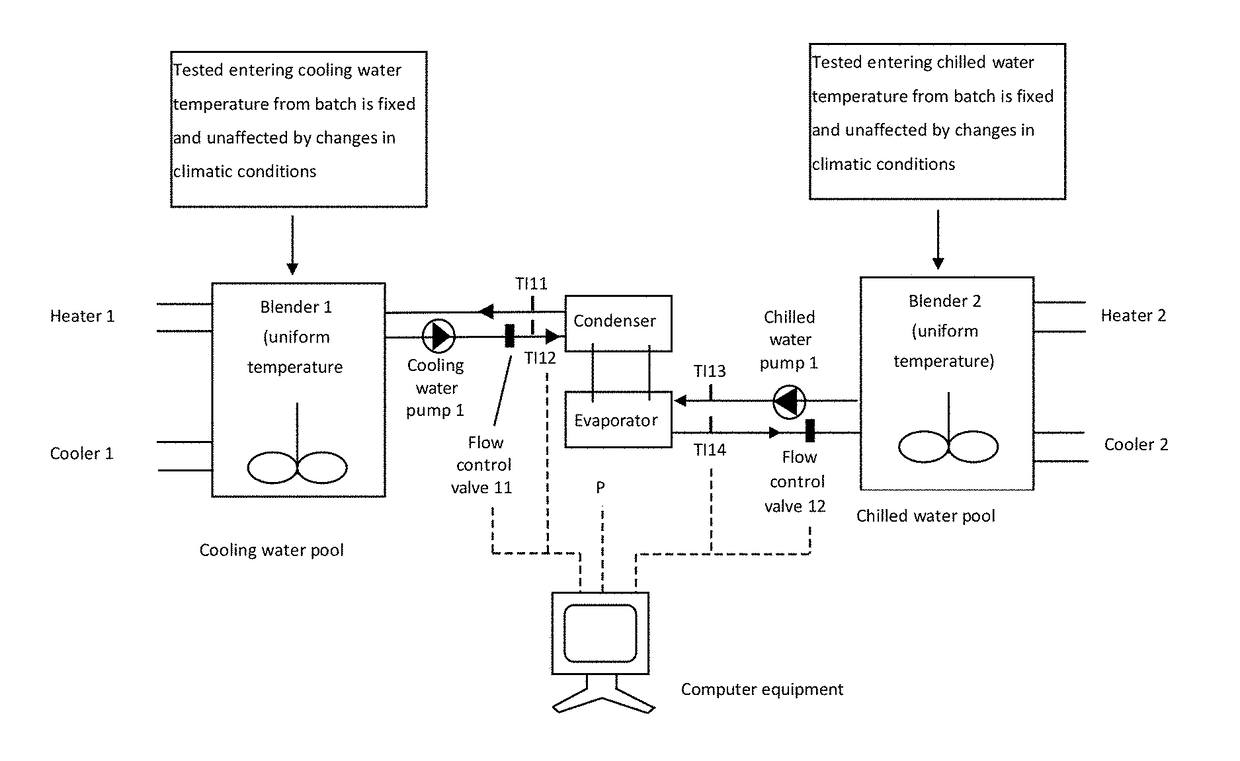

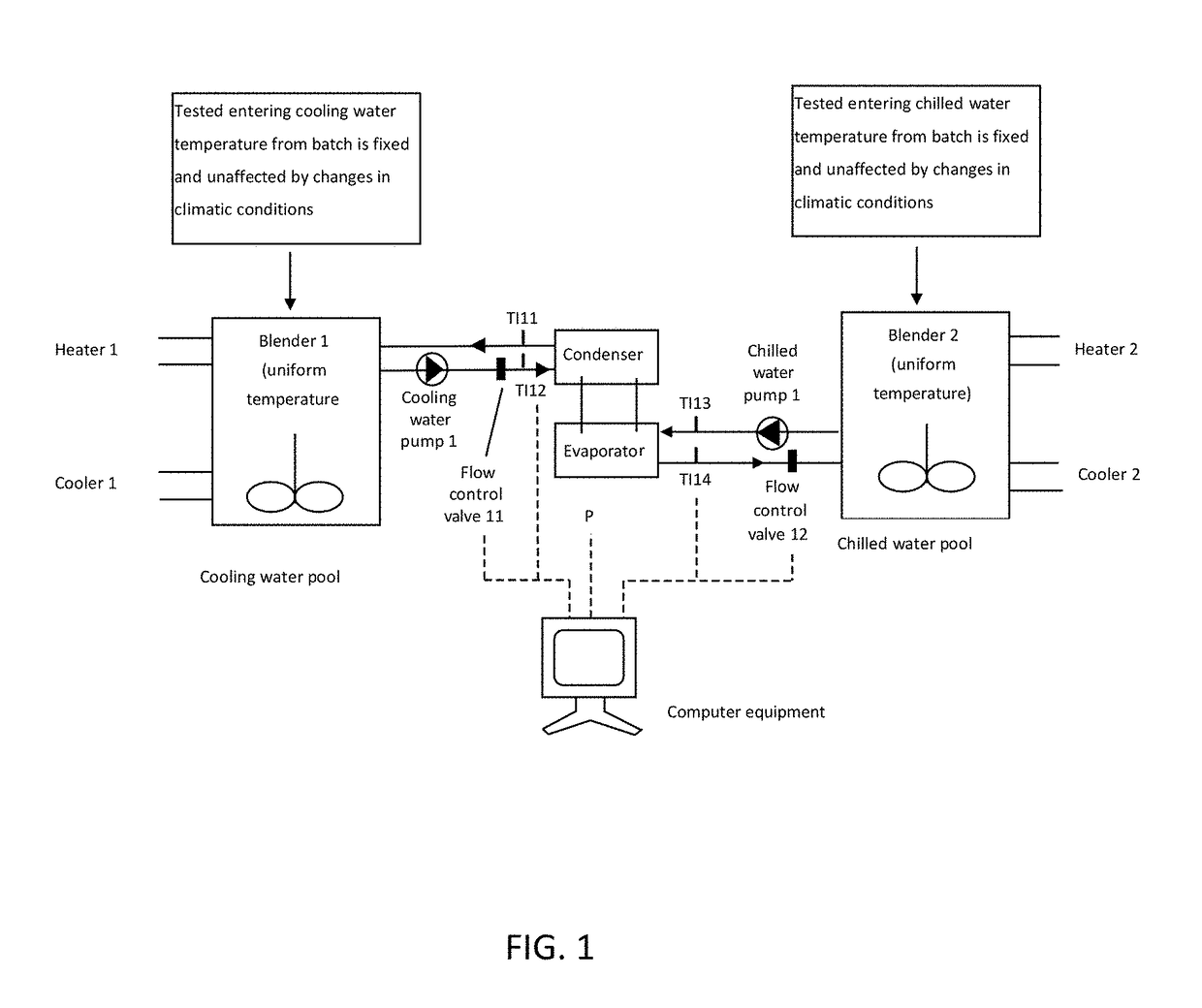

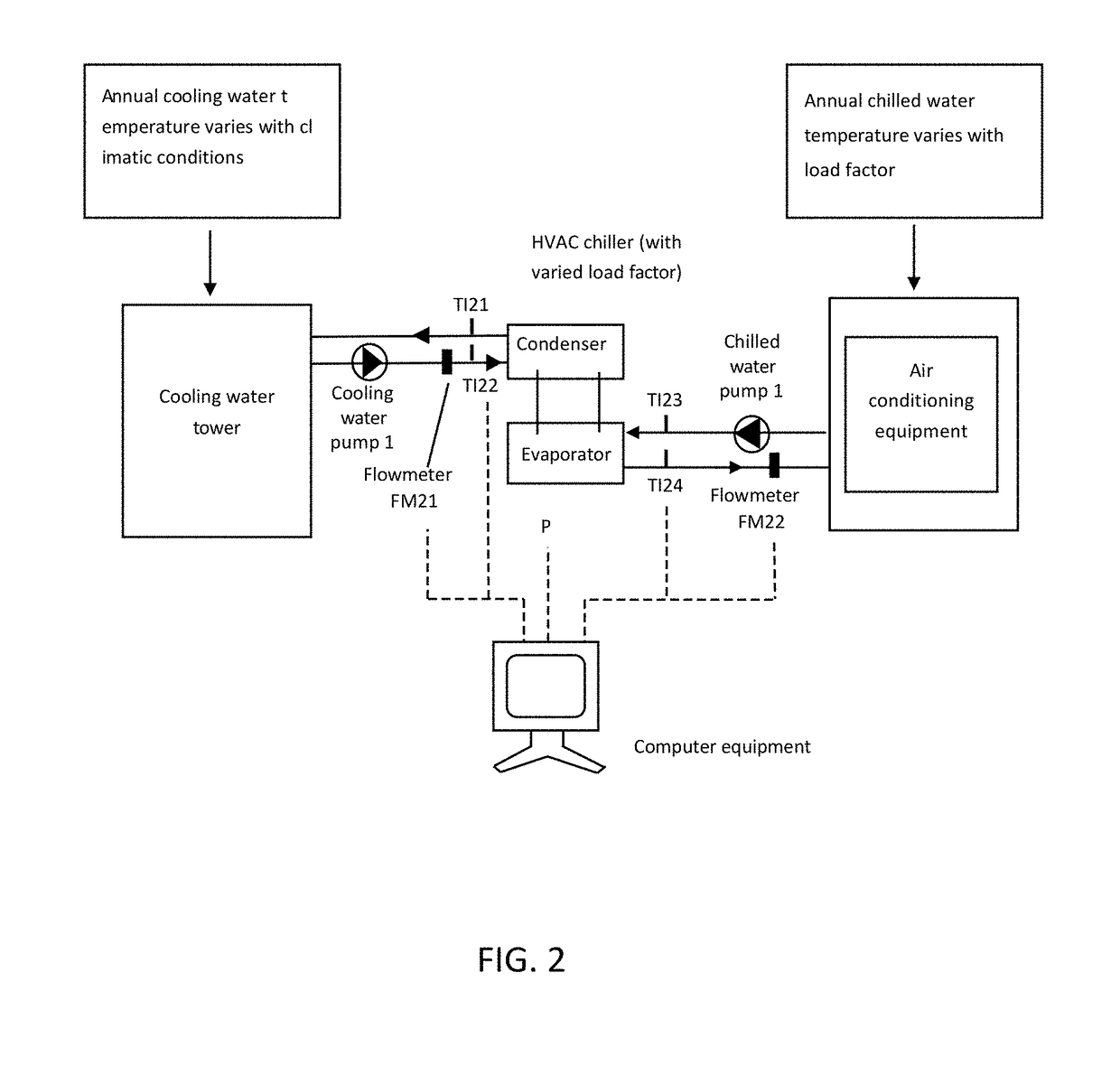

Method of verifying and analyzing energy efficiency ratio EER of a heating ventilation and air conditioning HVAC chiller unit

ActiveUS20170277816A1Avoid wasting electricityLower standardsMechanical apparatusData processing applicationsBusiness efficiencyManagement indicators

A method of verifying and analyzing energy efficiency ratio (EER) of an HVAC chiller unit in accordance with the present invention provides verification and analysis of HVAC chiller units to build daily steady-state data and non-steady state data out of field dynamic EER values and provides analysis of the steady-state data, based on selected integer temperatures and tenfold load factors in the annual scale that are subject to the dynamic changes in temperatures and load factors along with chiller seasonal operation to build monthly or seasonal running EER trend, and to determine-management index values for a period of time and to determine whether energy consumption meets specified criteria, as a basis of comparison of calculations, and resulting amplitude ratios between before and after the energy-saving improvement and of totally saved energy.

Owner:CHEN CHU FU

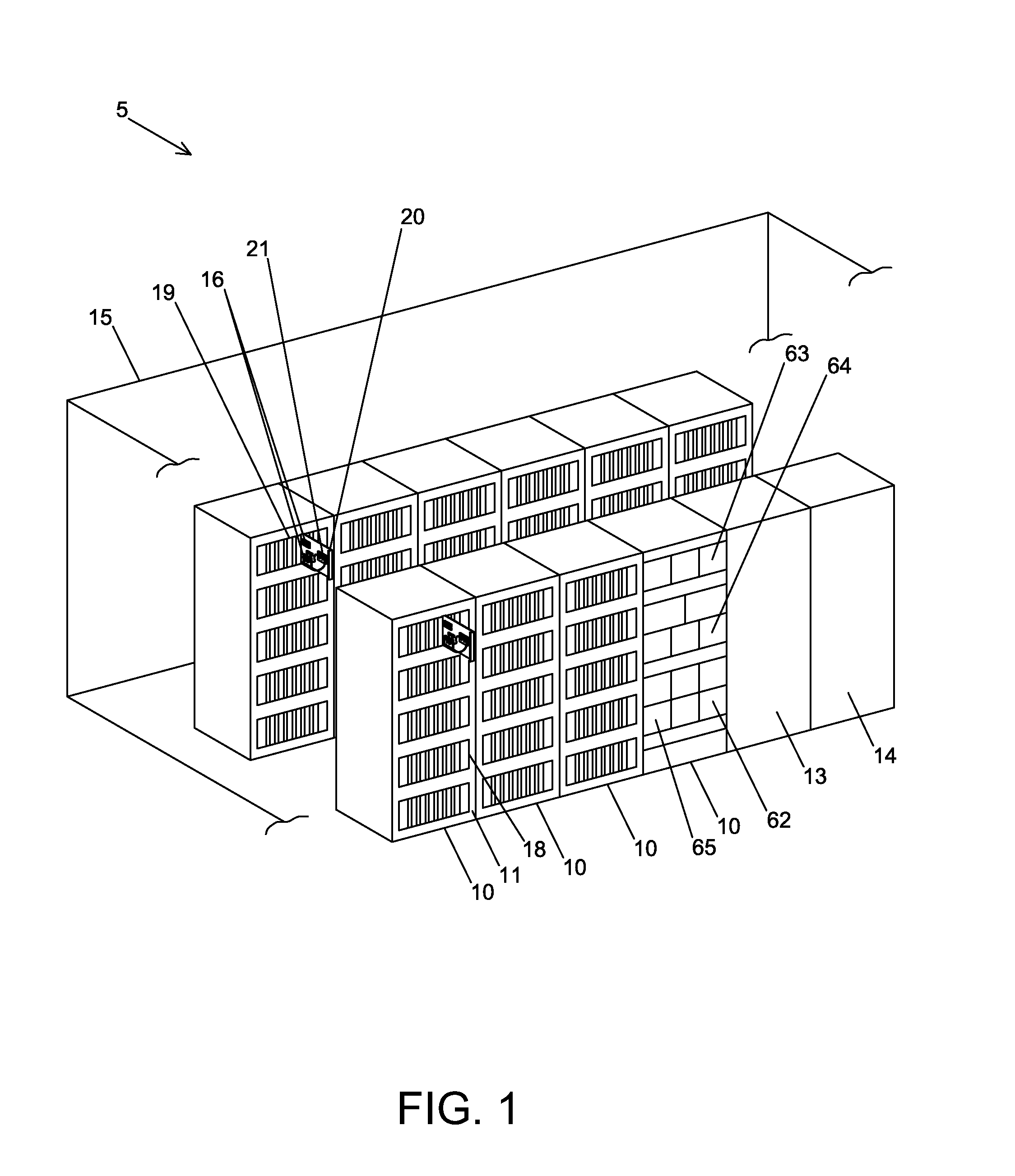

Utilization of data center waste heat for heat driven engine

InactiveUS8522569B2Reduce loadImprove efficiencyClimate change adaptationCompression machines with cascade operationData centerEngineering

A method and system of utilizing waste heat from a plurality of data center equipment comprising the steps of collecting waste heat from a plurality of data center equipment and utilizing said waste heat as the driving heat input for a heat driven engine. Heat recovery means collects waste heat from heat-producing equipment and transfers it in the form of hot water to drive a heat driven engine such as a chiller or heat pump. The output of the heat driven engine may be put to many productive uses, thereby reducing the over all energy load on the data center.

Owner:INDAL IDEA PARTNERS

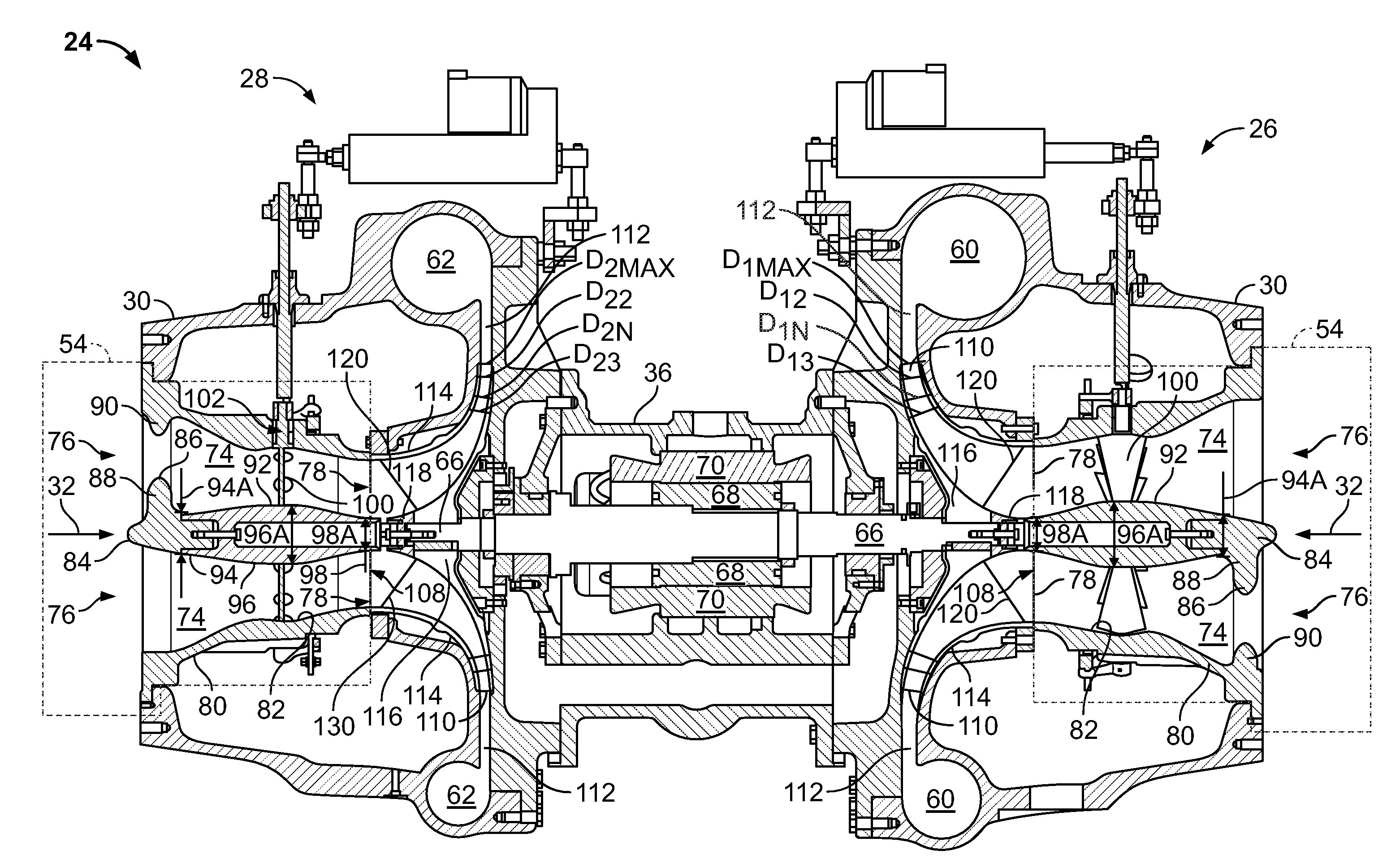

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

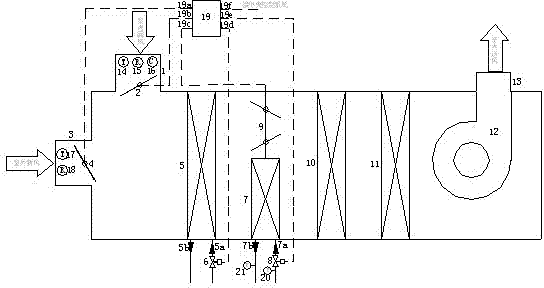

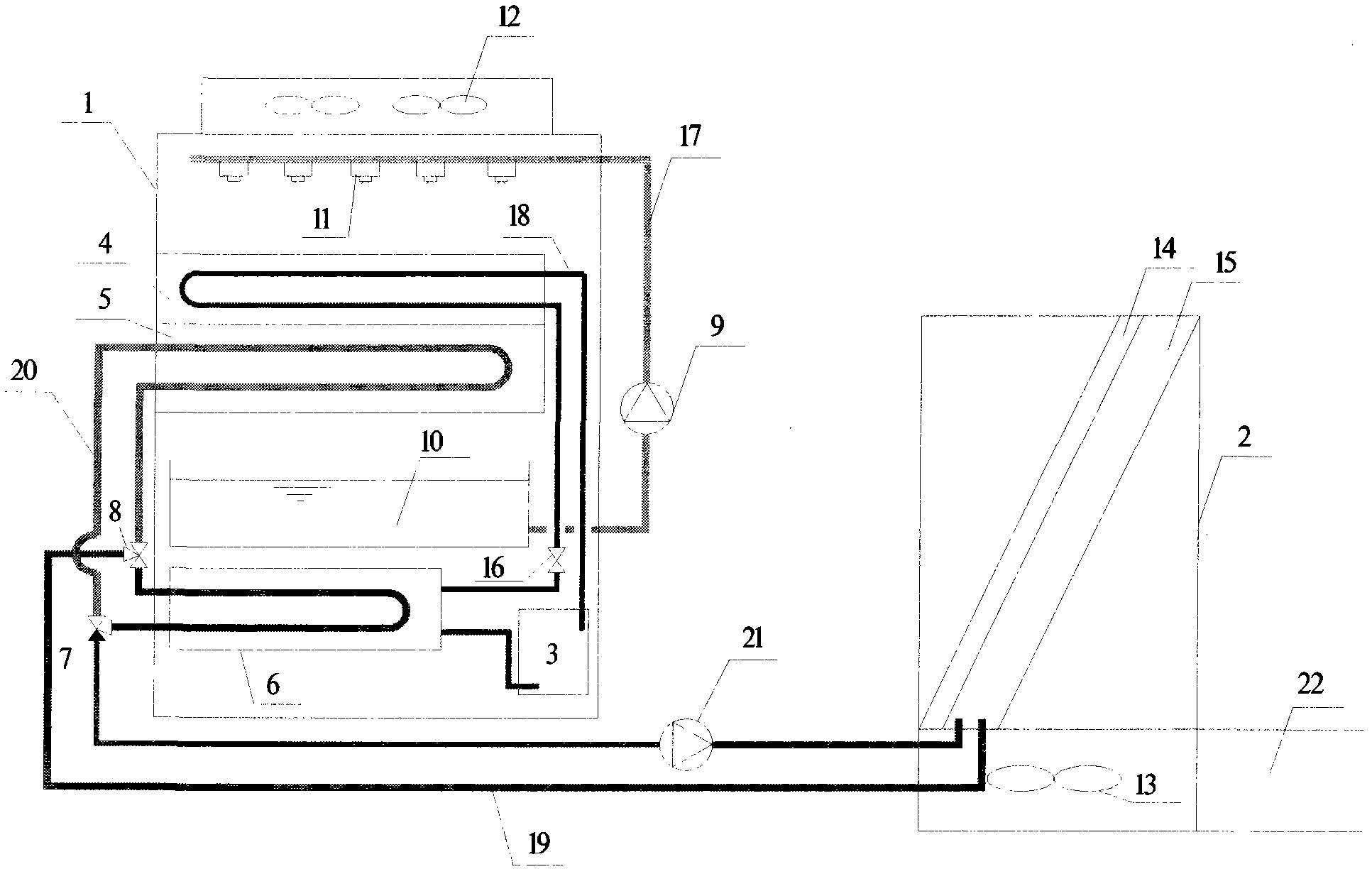

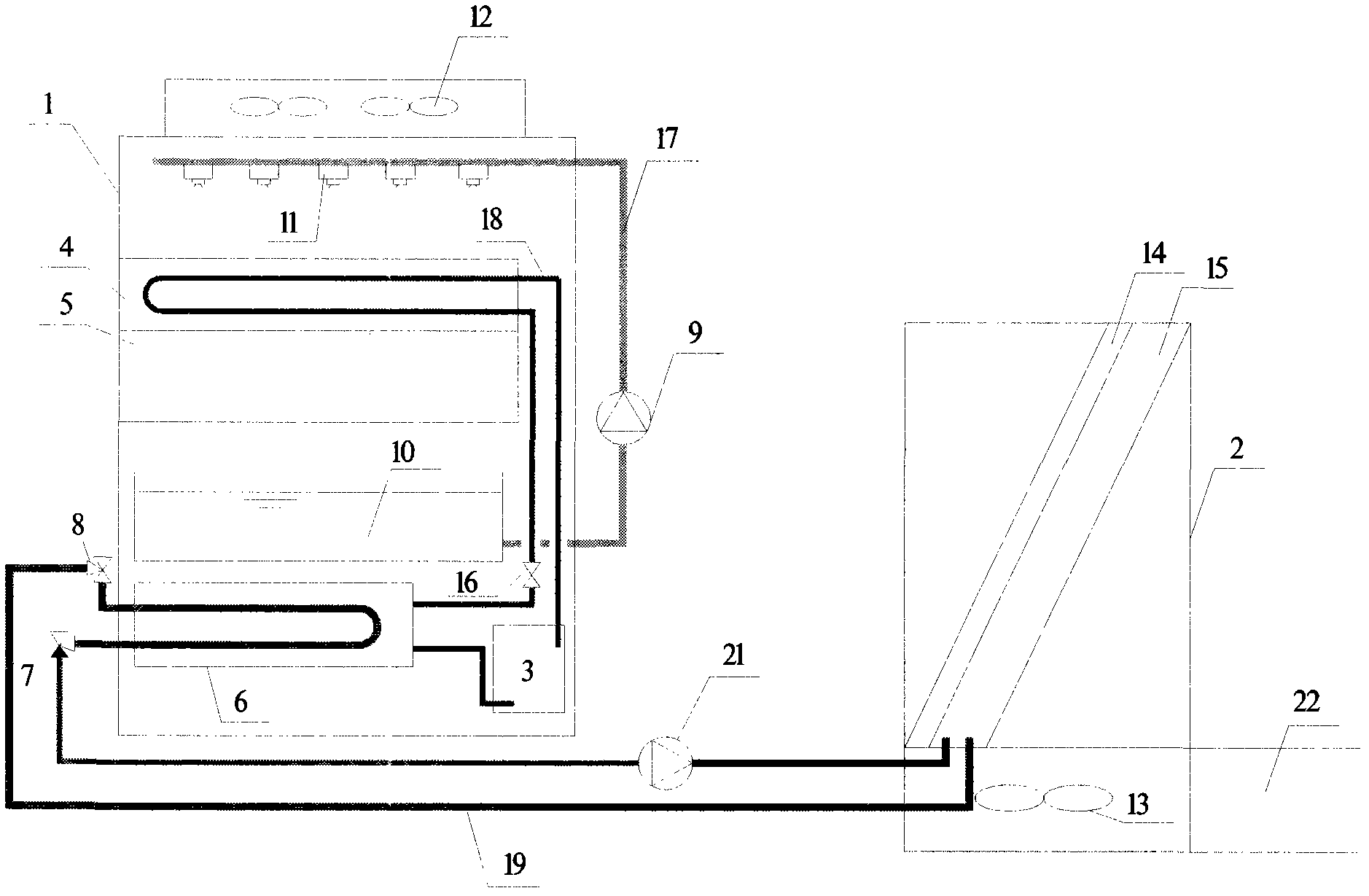

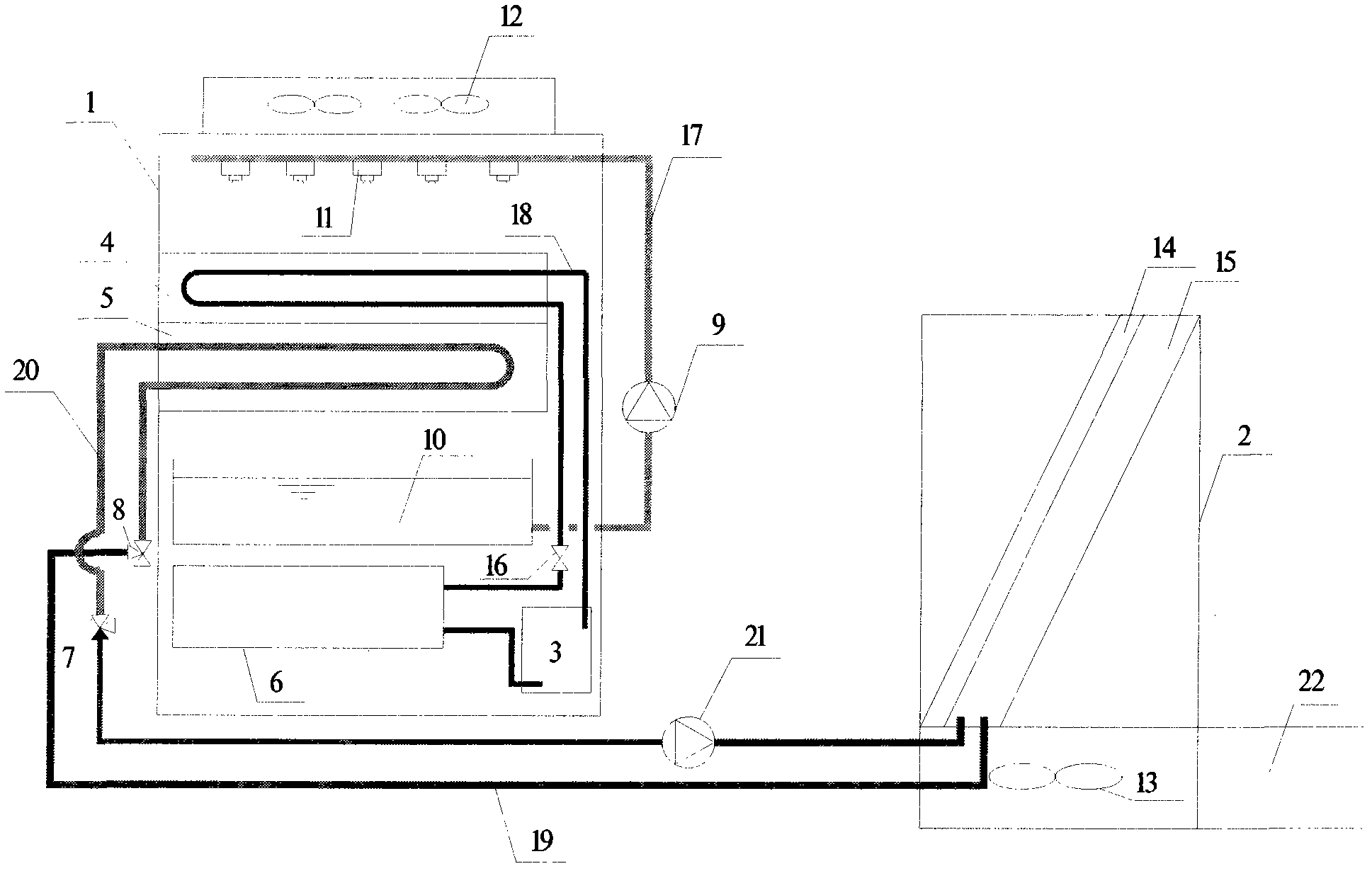

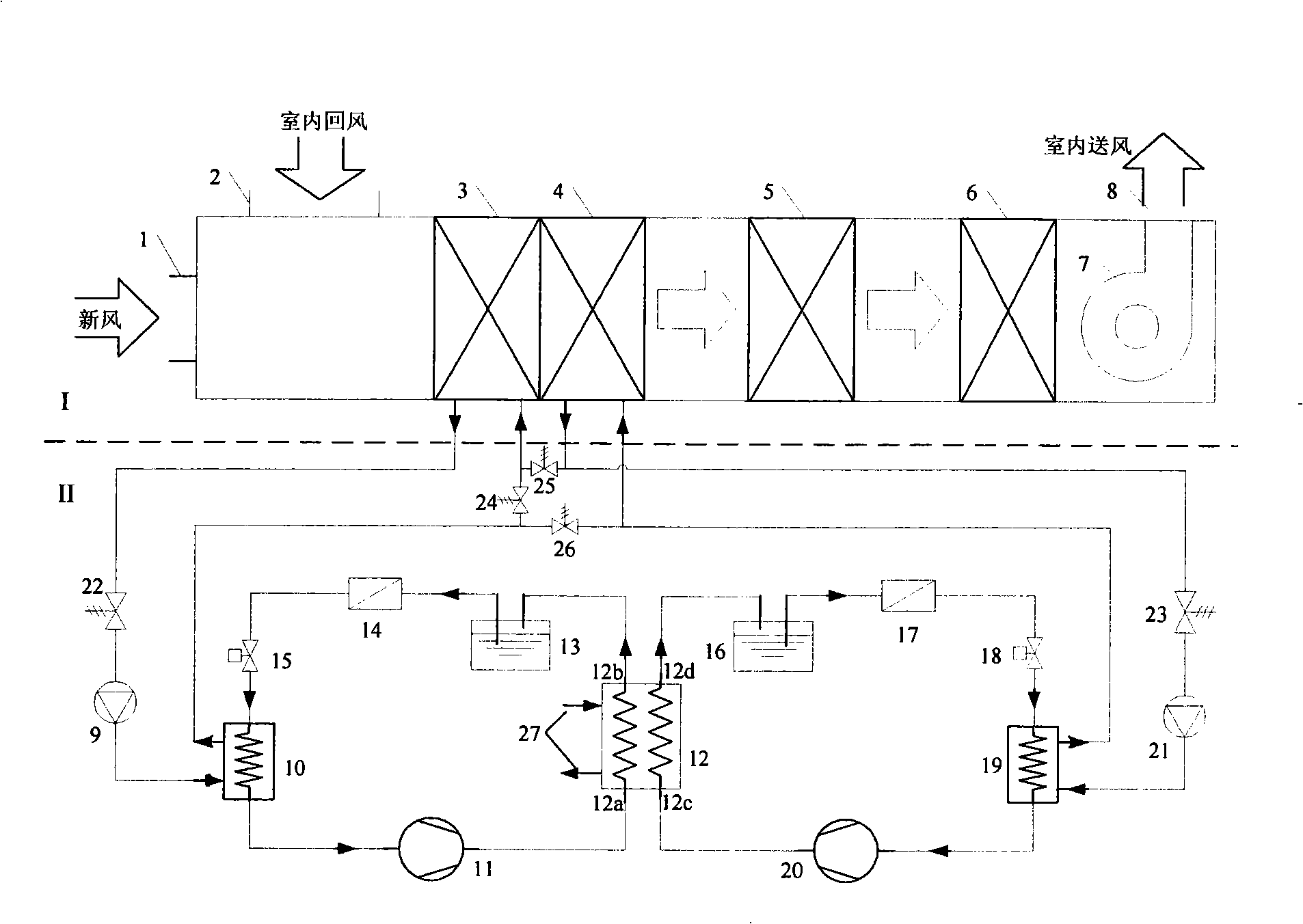

Heat moisture segmental processing air-conditioning unit device and its air-treatment method

InactiveCN101261024AMeet the dehumidification load requirementsRaise the evaporation temperatureLighting and heating apparatusAir conditioning systemsLiquid storage tankEngineering

The invention relates to an air-conditioning unit device by heat-moisture subsection treatment and an air treating method thereof. The air treating method is divided into two parts, wherein, the air treating method of heat-moisture subsection treatment comprises that: indoor return air and fresh air are mixed, exchange heat with high-temperature cooling water through a first surface air cooler (3) first, reduces to the dew-point temperature through constant wetness, removes most of sensible heat load and enters to a second surface air cooler (4); in the second surface air cooler (4), air and low-temperature cooling water further exchange heat, are cooled, generate condensed water and remove the sensible heat load; the air after temperature reduction and dehumidification is treated to an air feeding state point by a heater (5) and a humidifier (6), finally pressurized by a blower (7) and sent to an air-conditioning room; the air-conditioning unit device adopts the following method that: refrigerant in a first water chiller unit is compressed and discharged by a first compressor (11) and enters a condenser (12) for condensation, then passes through a first liquid storage tank (13) and a first filter (14), is throttled and depressurized by a first electronic expansion valve (15) and enters a first evaporator (10) for heat exchange with cooling water.

Owner:SOUTHEAST UNIV

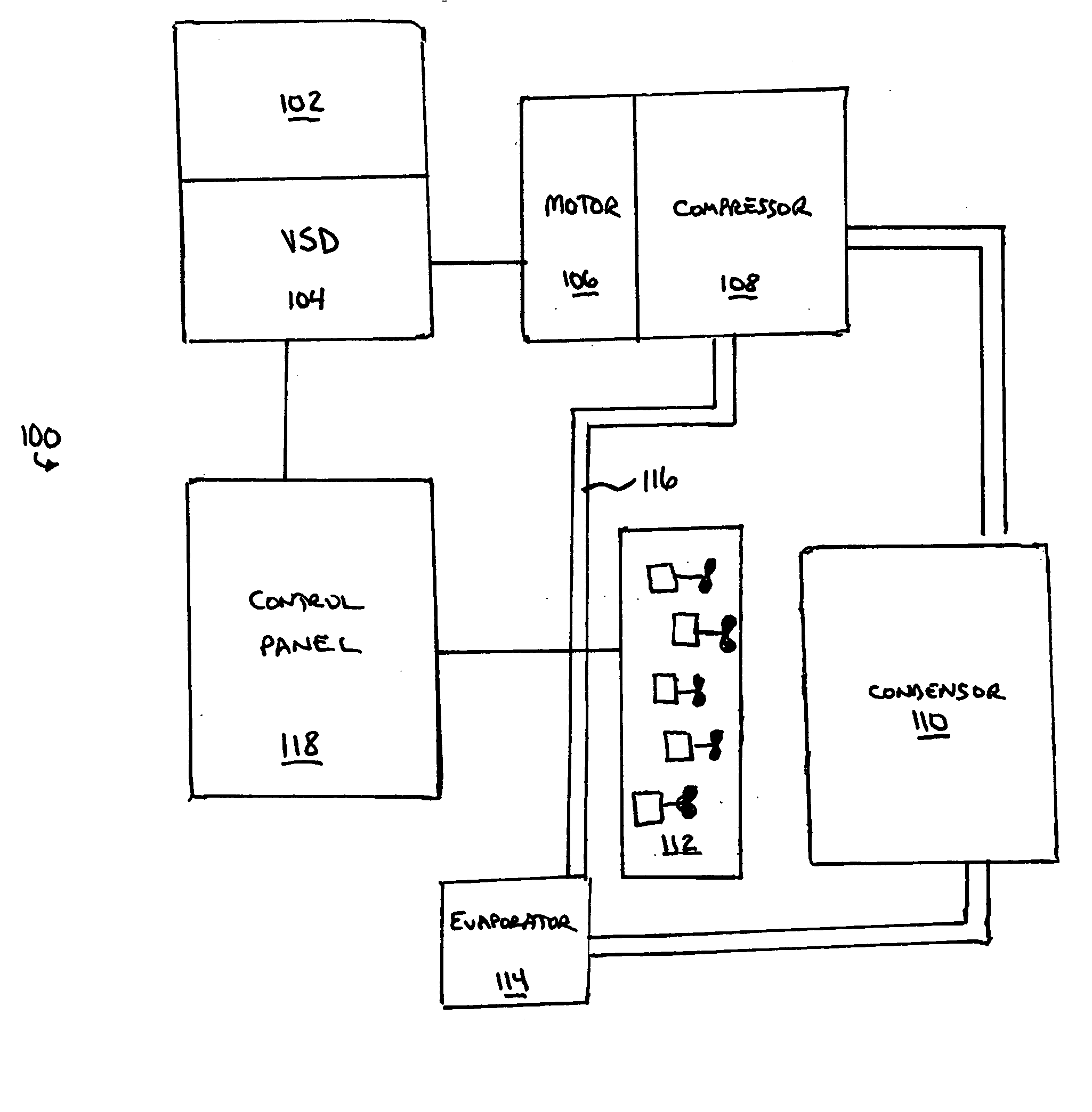

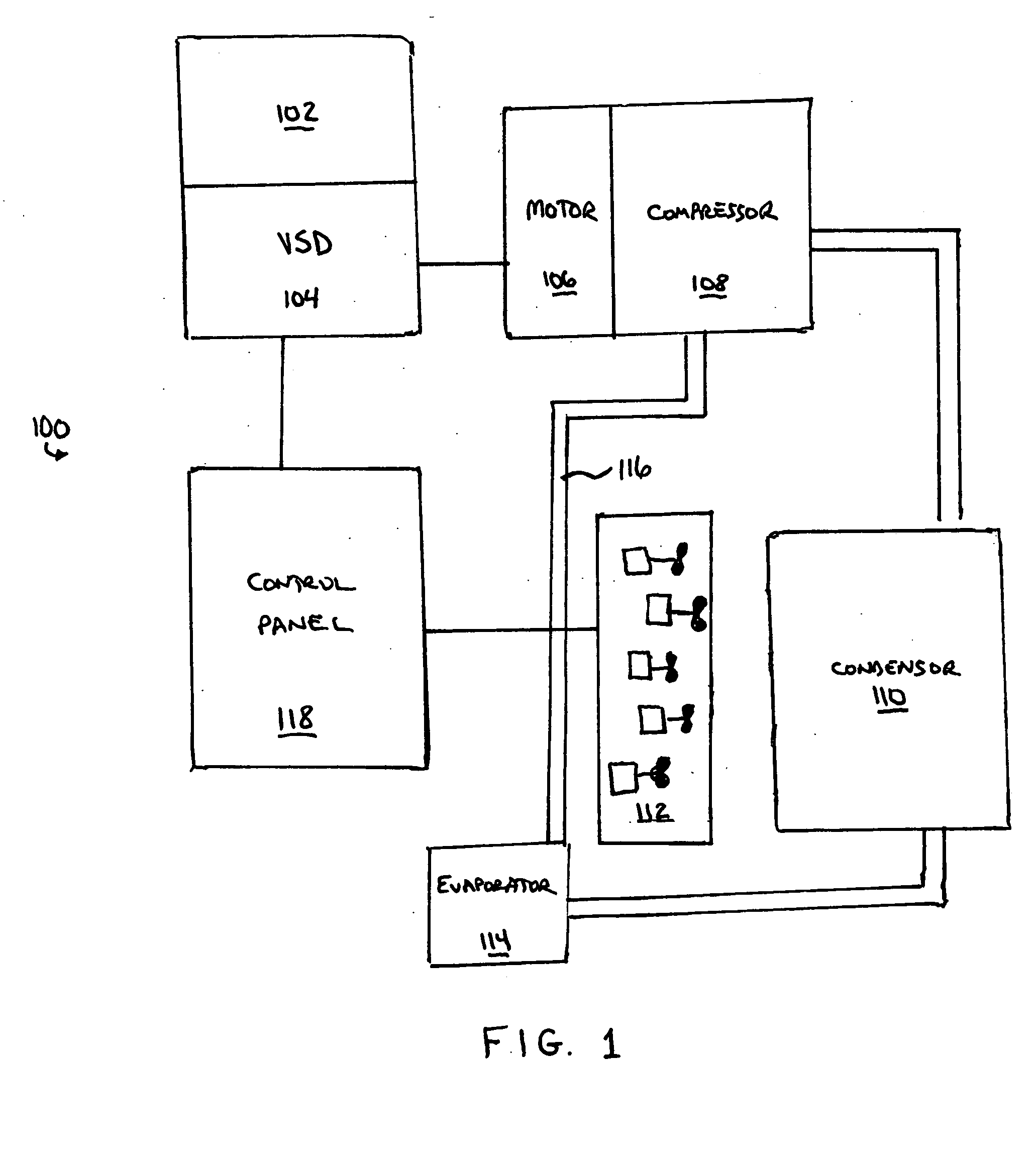

High capacity chiller compressor

ActiveUS8156757B2Improve efficiencyHigh outputWind motor controlEfficient regulation technologiesFriction reductionMagnetic bearing

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

Low-temperature air-cooled water chiller unit and control method thereof

ActiveCN104089347AGuaranteed normal operationReduce startup timeCompressorSpace heating and ventilation safety systemsNuclear powerChilled water

The invention discloses a low-temperature air-cooled water chiller unit and a control method thereof. The low-temperature air-cooled water chiller unit comprises an electric cabinet for control operations of the unit, a compressor for compressing refrigerant, a condenser exchanging heat with the ambient temperature, a fan for accelerating heat dissipation of the condenser, an expansion valve for reducing the pressure of the refrigerant and throttling the refrigerant, and an evaporator for preparing chilled water. A pressure maintaining valve for rapidly establishing pressure difference is arranged between the outlet end of the compressor and the inlet end of the condenser, and a secondary oil separator is arranged between the inlet end of the pressure maintaining valve and the outlet end of the compressor. By means of the technical scheme above, the low-temperature air-cooled water chiller unit overcomes the problems that, at low temperatures, the unit cannot start, the compressor cannot rapidly establish the pressure difference and is difficult to return oil and the like; meanwhile, the low-temperature air-cooled water chiller unit can continuously perform refrigeration at a low temperature of minus 40 DEG C to provide sufficient circulating cooling water for nuclear power equipment and further ensure normal and safe operation of the nuclear power equipment.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

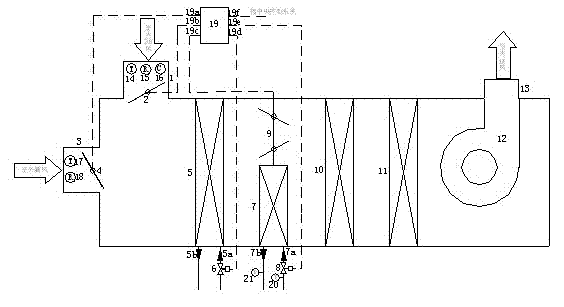

Air-cooled water chiller with natural cooling function and control method for water chiller

InactiveCN102589114AReduce operating energy consumptionAvoid undersupplySpace heating and ventilation safety systemsSpace heating and ventilation control systemsCooling coilFree cooling

Disclosed are an air-cooled water chiller with a natural cooling function and a control method for the water chiller. The air-cooled water chiller with the natural cooling function comprises a compressor, a condenser, a throttler and an evaporator which are sequentially connected, a condensate fan is arranged on the condenser, the air-cooled water chiller further comprises a natural cooling coil, a three-way valve, an inlet chilled water temperature sensor, an outlet chilled water temperature sensor, an outdoor environment temperature sensor and a controller, the natural cooling coil is arranged on an air inlet side of the condenser, the three-way valve comprises a first joint, a second joint and a third joint and is serially connected onto a water inlet pipe of the evaporator through the first joint and the second joint, a water inlet pipe of the natural cooling coil is communicated with the water inlet pipe of the evaporator, and a water outlet pipe of the natural cooling coil is communicated with the third joint of the three-way valve. The air-cooled water chiller has the advantages of remarkable energy-saving effect, high running reliability, simple control method, compact structure, small occupied space and low production cost.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

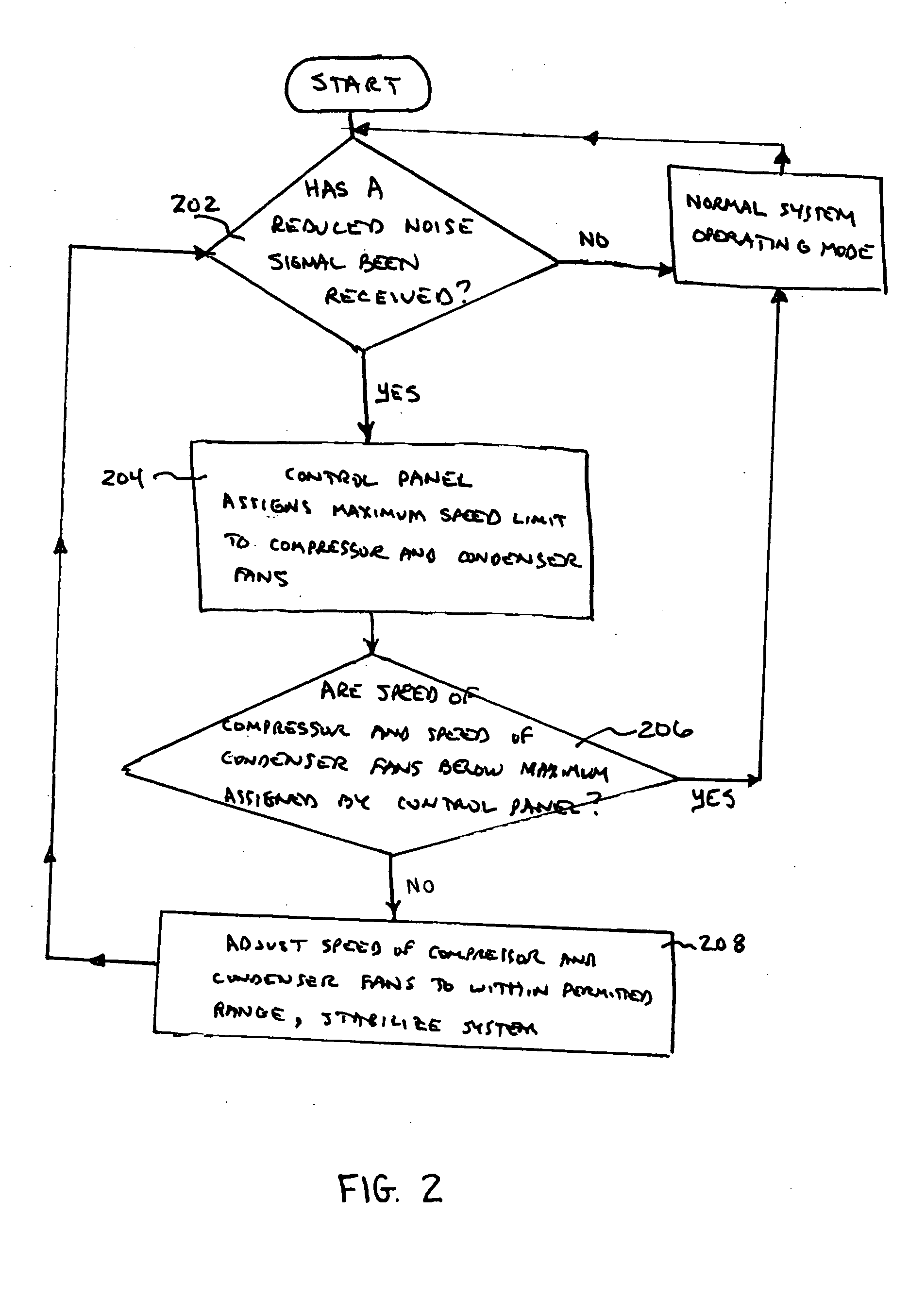

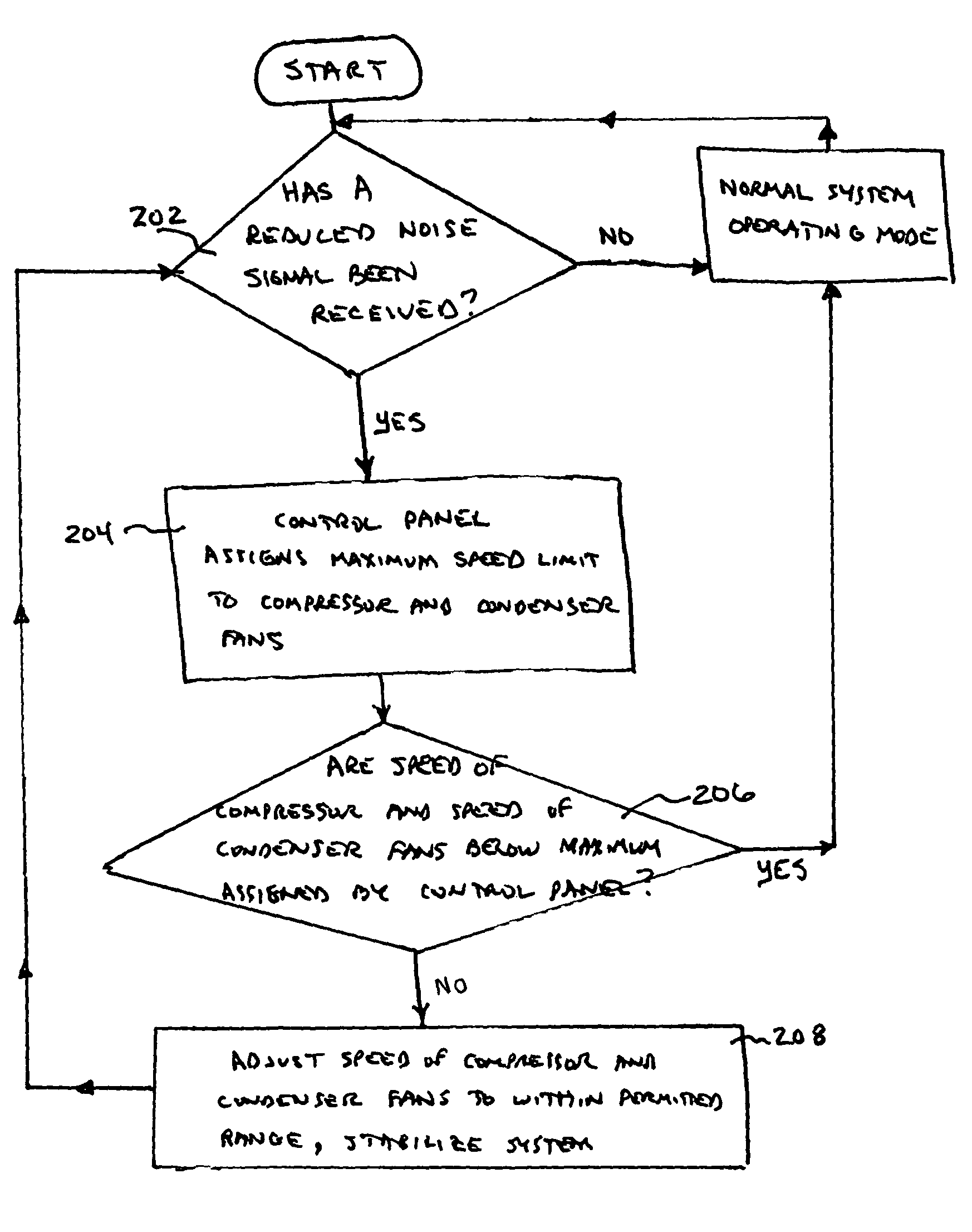

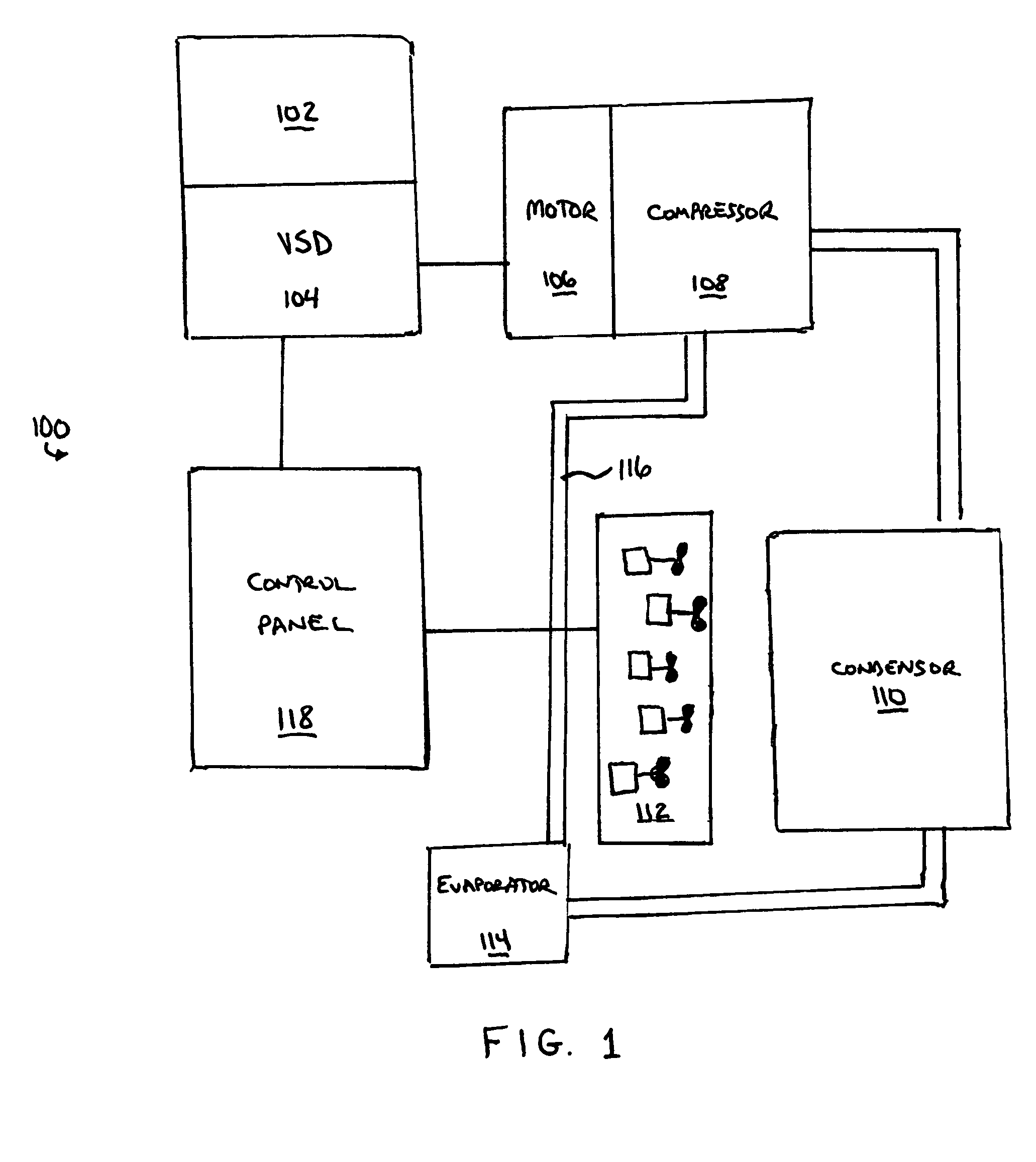

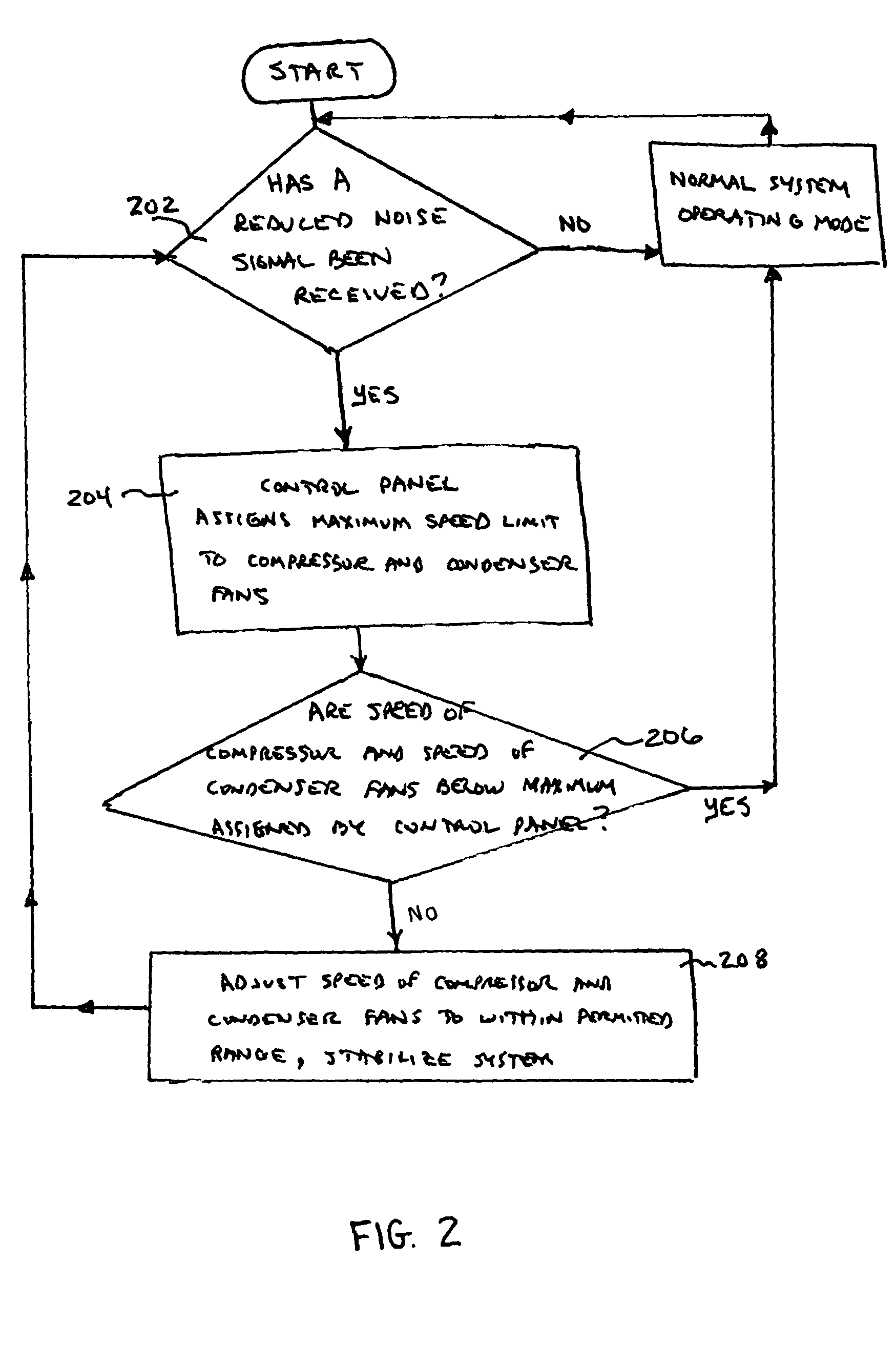

Chiller sound reduction control system and method

ActiveUS20050223725A1Reduce selection requirementsReduce the soundCompression machines with non-reversible cycleEvaporators/condensersNoise generationNoise control

A noise control method is provided for a cooling system having at least one refrigerant circuit. The refrigerant circuit includes a compressor, a condenser, at least one condenser fan, and an evaporator. Noise control is only performed periodically in response to requirements for reduced operation at predetermined times. The request for reduced noise triggers the commencement of the noise control method. The noise control method involves reducing the operating speed of the compressor, as well as reducing the operating speed of at least one condenser fan, to within a predetermined range of allowable reduced operating speeds. The noise control method temporarily overrides the ability of the cooling system to fully respond to increased cooling or heating demands. When the noise control method is terminated, such as by the end of the stated period of time requiring reduced noise generation, the system is restored to normal operation, and remains fully responsive to cooling and heating demand until commencement of the next period of reduced noise requirements.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

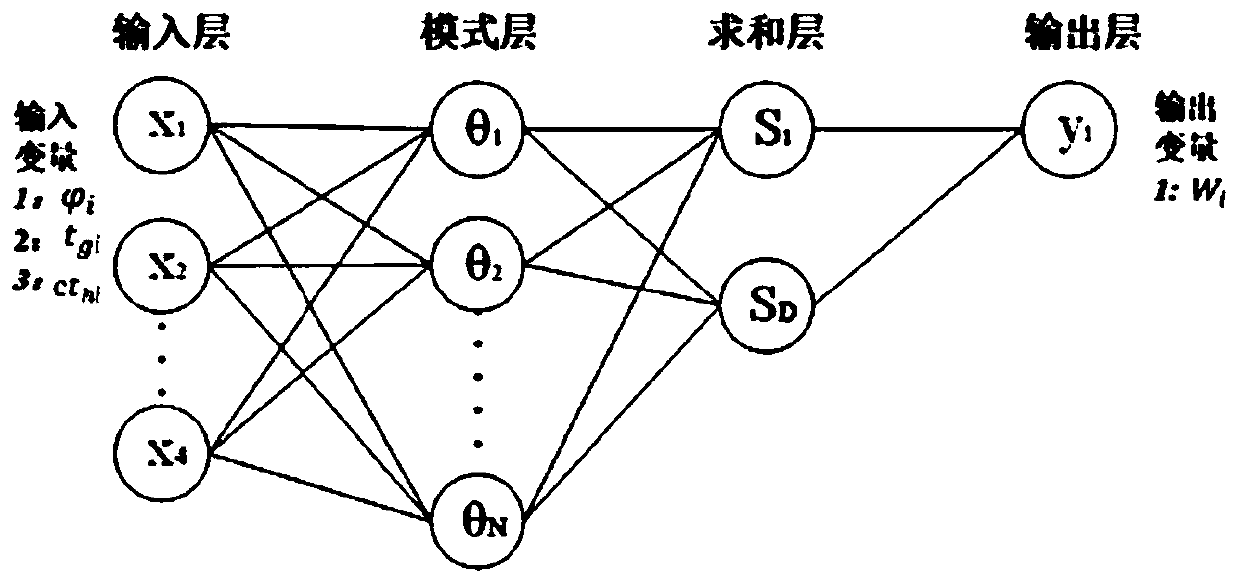

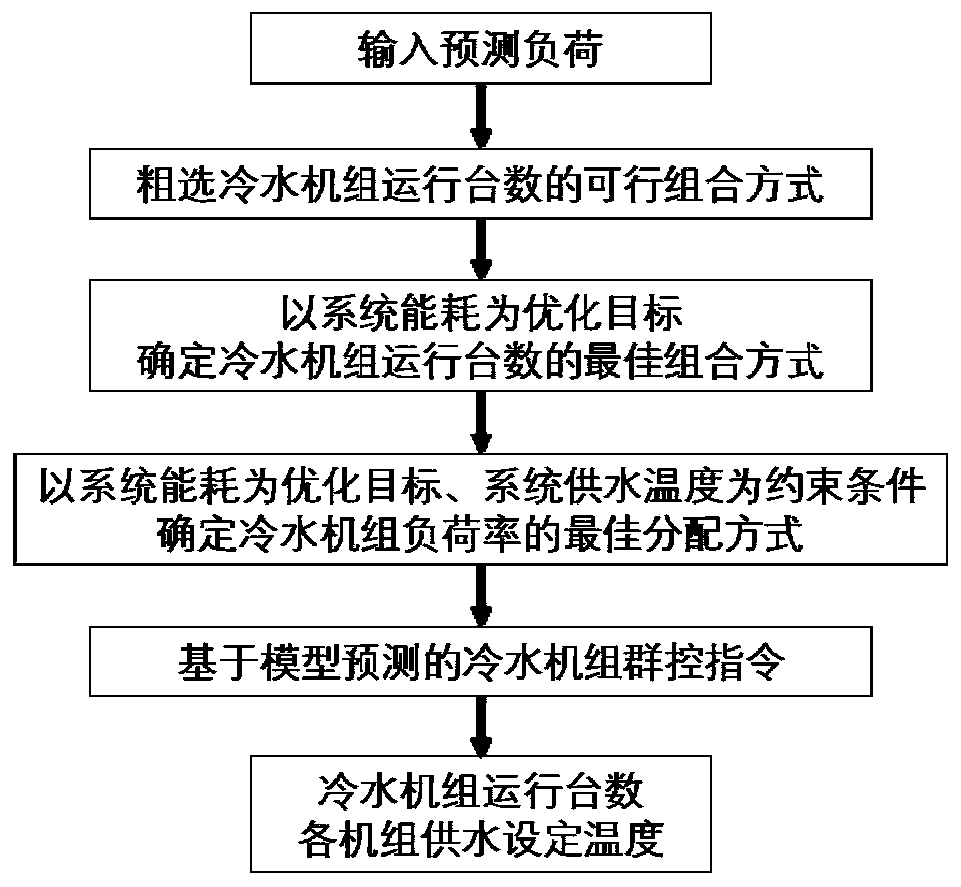

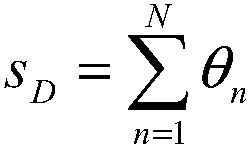

Water chilling unit combined operation optimal control method based on model prediction

ActiveCN111256294ATruly reflect the actual operating performanceSimple modelMechanical apparatusForecastingProcess engineeringEnvironmental engineering

The invention provides a GRNN-based water chilling unit energy efficiency model modeling method and a water chilling unit group-control method based on cold load prediction and a water chilling unit energy efficiency model, and belongs to the field of water chilling unit energy saving. The water chilling unit energy efficiency model is established by using a GRNN technology and actual operating data of a refrigeration system, so that the energy consumption of the water chilling unit under different operating conditions can be predicted quickly and accurately. The operating unit number and theload rate distribution of the water chilling unit are optimized in real time by using the cooling load prediction data and the water chilling unit energy efficiency model with a goal of minimum systemenergy consumption, so that the operation energy efficiency of the refrigeration system is effectively improved.

Owner:深圳市得益节能科技股份有限公司

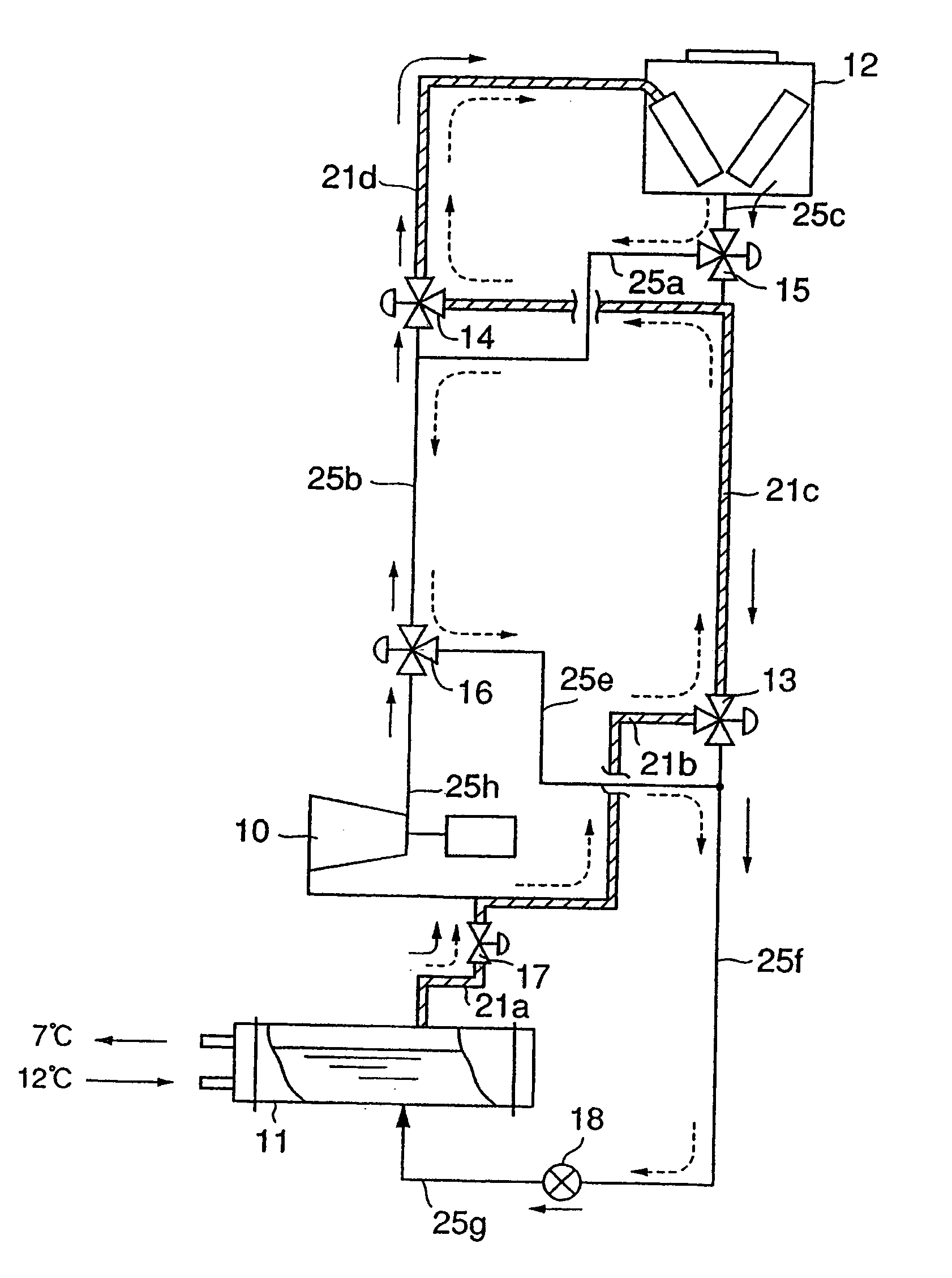

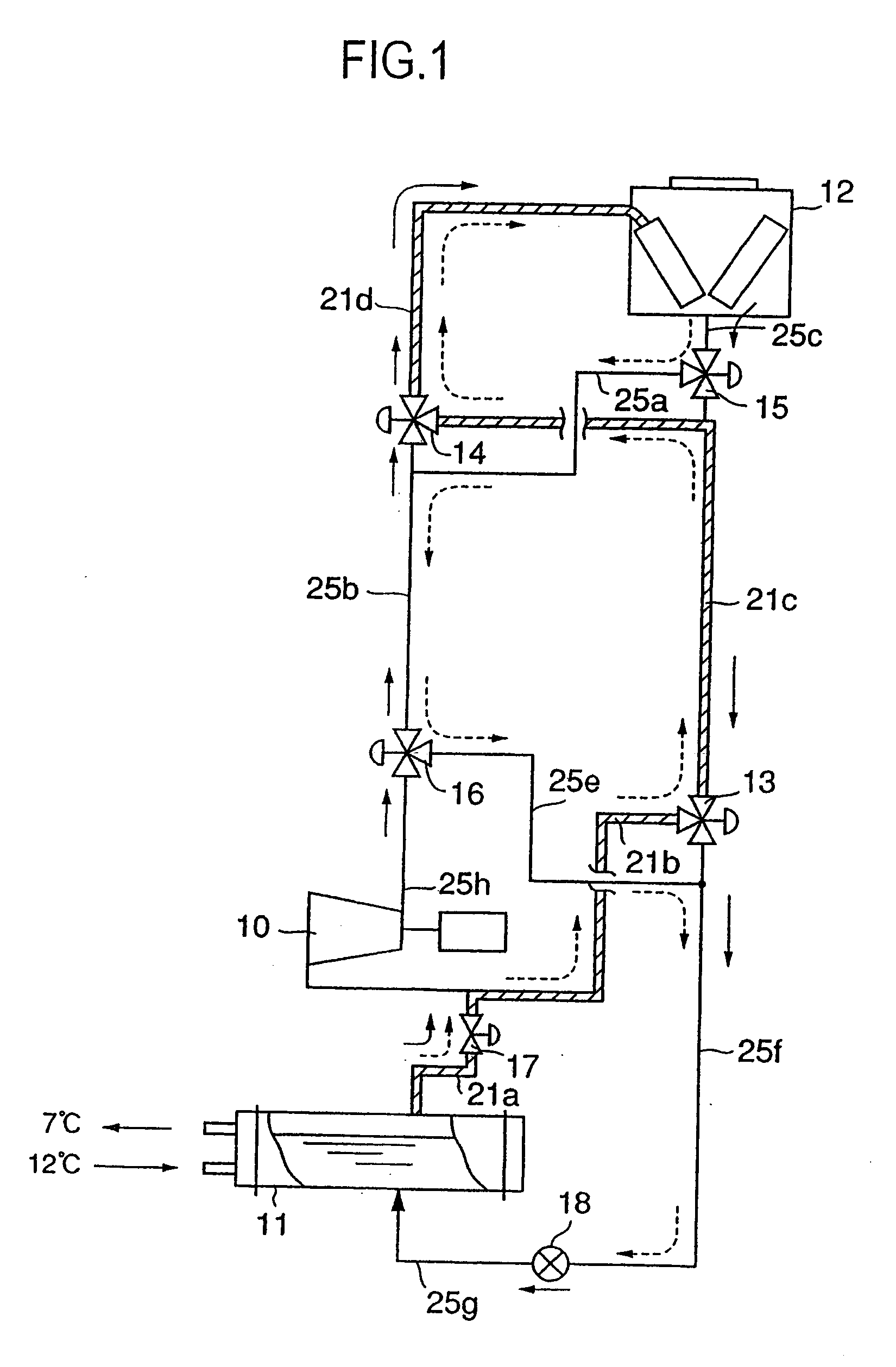

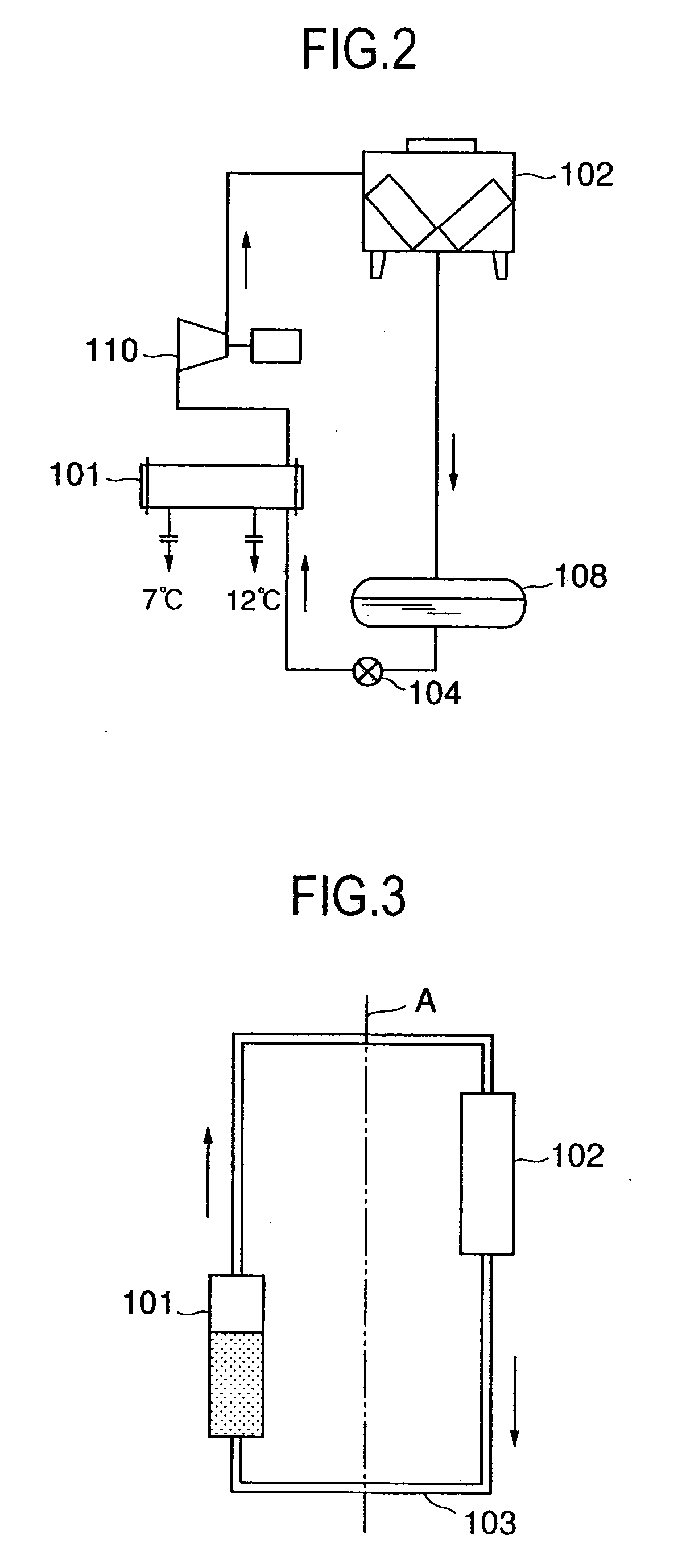

Thermo siphon chiller refrigerator for use in cold district

InactiveUS20050284169A1Mechanical apparatusCompression machines with non-reversible cycleIceboxProcess engineering

In order to provide a thermo-siphon chiller refrigerator for use in cold districts which performs natural refrigerant-circulation refrigerating cycle and also can perform a forced refrigerant-circulation refrigerating cycle when outside air temperature is high by using an indoor heat exchanger, an outdoor heat exchanger, and a compressor, and combining them with refrigerant piping, the thermo-siphon chiller refrigerator for use in cold districts of the invention has a compressor (10) additionally installed to a natural refrigerant-circulation refrigerating system comprising an outdoor heat exchanger (12), an indoor heat exchanger (11) located at a position lower than that of the outer heat exchanger (12), and an expansion valve (18). When the refrigerating capacity of the natural refrigerant circulation refrigerating system is not sufficient, the additional compressor (10) is operated to perform a forced refrigerant-circulation cycle i.e. a vapor compression refrigerating cycle.

Owner:MAYEKAWA MFG CO LTD

Chiller sound reduction control system and method

ActiveUS7743617B2Reduce selection requirementsReduce the soundCompression machines with non-reversible cycleEvaporators/condensersNoise generationNoise control

A noise control method is provided for a cooling system having at least one refrigerant circuit. The refrigerant circuit includes a compressor, a condenser, at least one condenser fan, and an evaporator. Noise control is only performed periodically in response to requirements for reduced operation at predetermined times. The request for reduced noise triggers the commencement of the noise control method. The noise control method involves reducing the operating speed of the compressor, as well as reducing the operating speed of at least one condenser fan, to within a predetermined range of allowable reduced operating speeds. The noise control method temporarily overrides the ability of the cooling system to fully respond to increased cooling or heating demands. When the noise control method is terminated, such as by the end of the stated period of time requiring reduced noise generation, the system is restored to normal operation, and remains fully responsive to cooling and heating demand until commencement of the next period of reduced noise requirements.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com