Patents

Literature

416 results about "Specific speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific speed Nₛ, is used to characterize turbomachinery speed. Common commercial and industrial practices use dimensioned versions which are of equal utility. Specific speed is most commonly used in pump applications to define the suction specific speed —a quasi non-dimensional number that categorizes pump impellers as to their type and proportions. In Imperial units it is defined as the speed in revolutions per minute at which a geometrically similar impeller would operate if it were of such a size as to deliver one gallon per minute against one foot of hydraulic head. In metric units flow may be in l/s or m³/s and head in m, and care must be taken to state the units used.

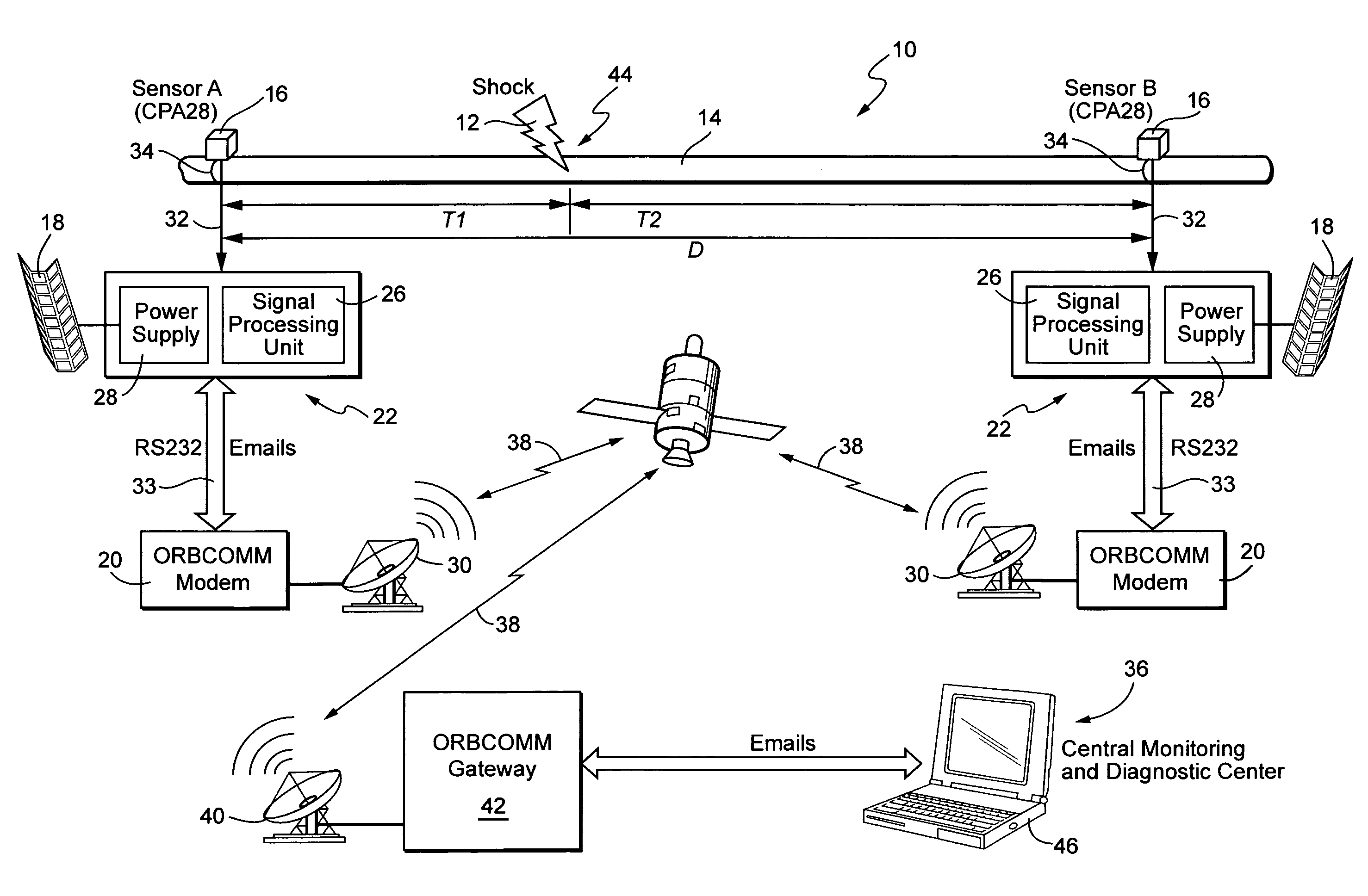

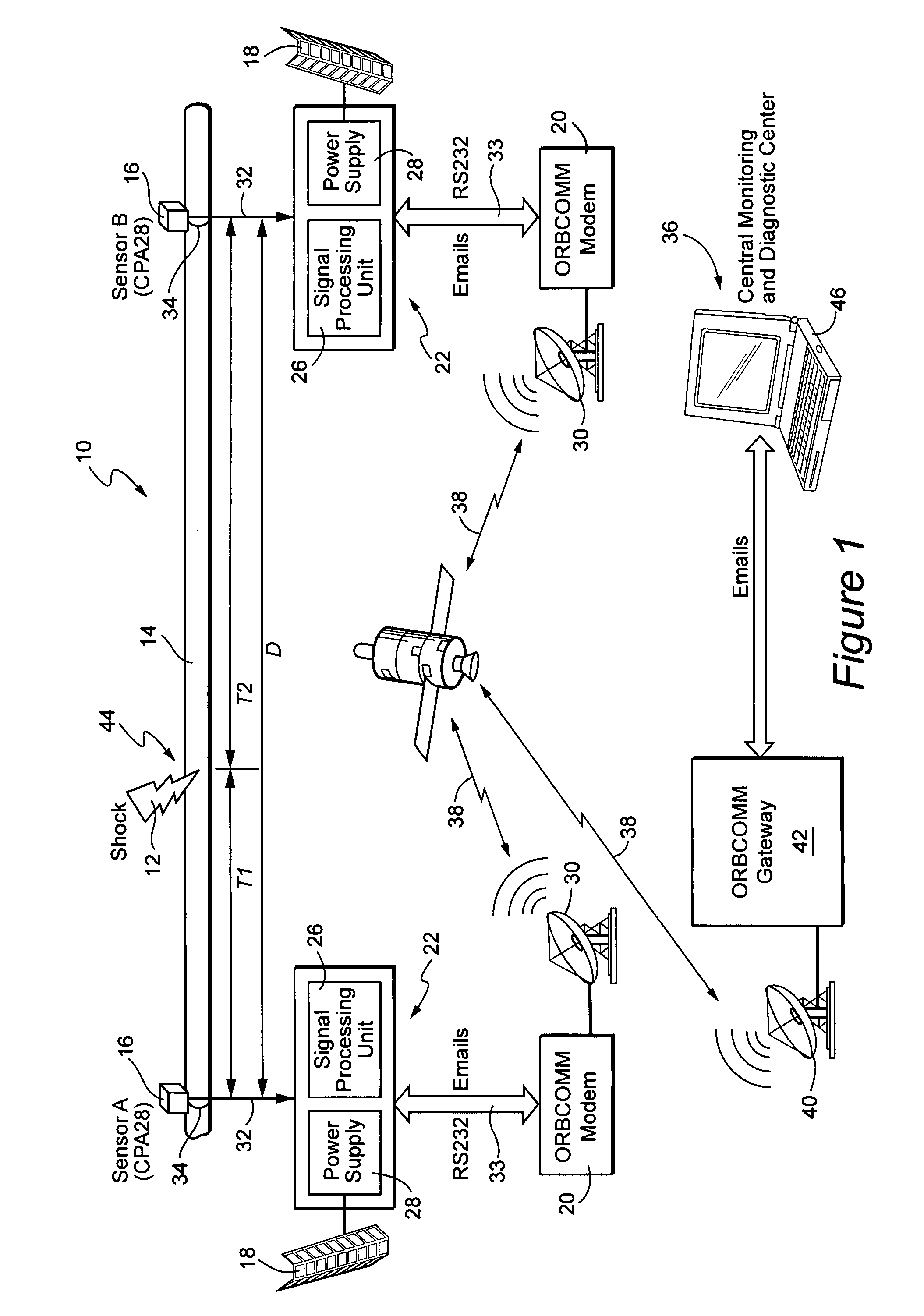

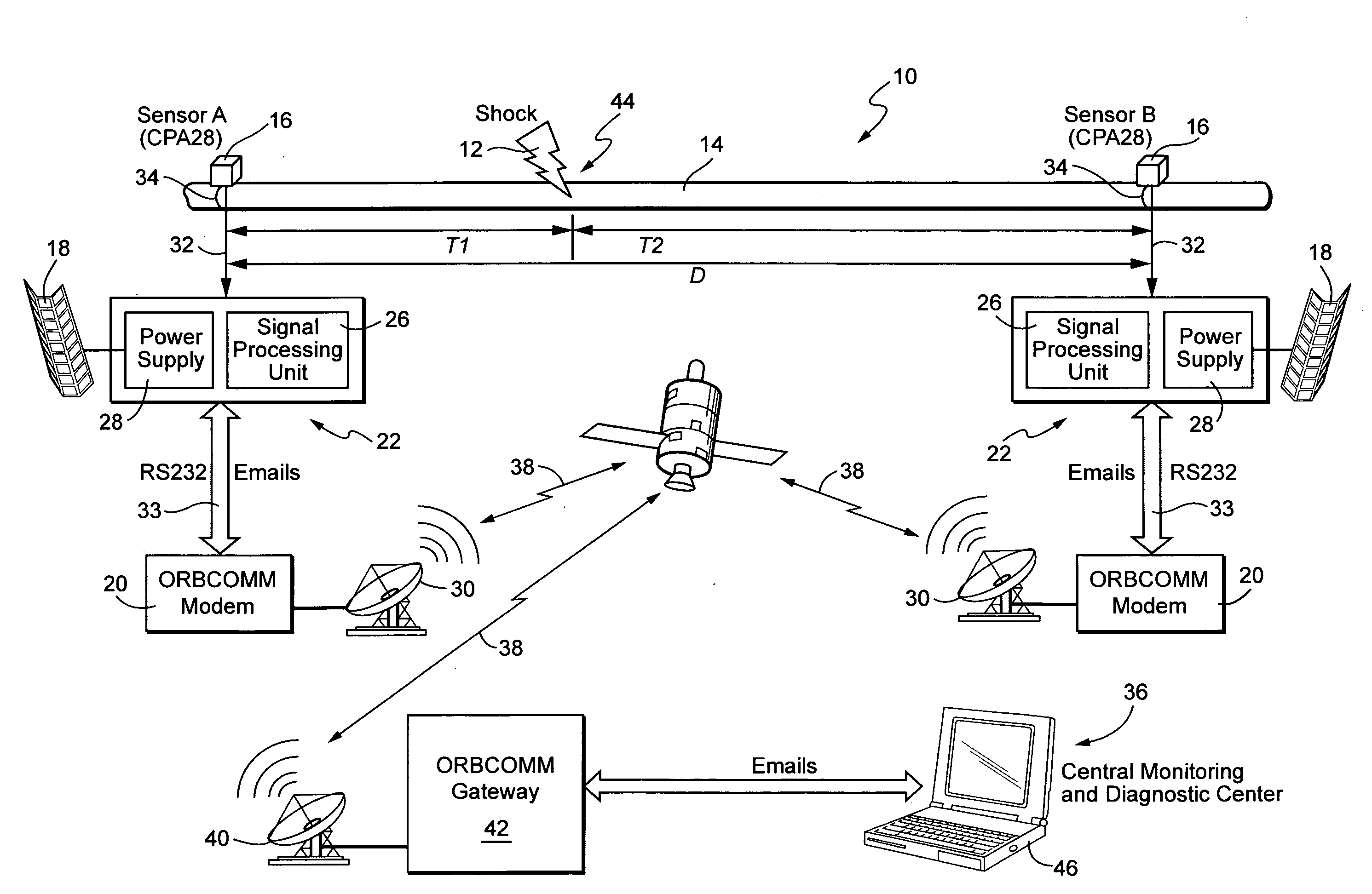

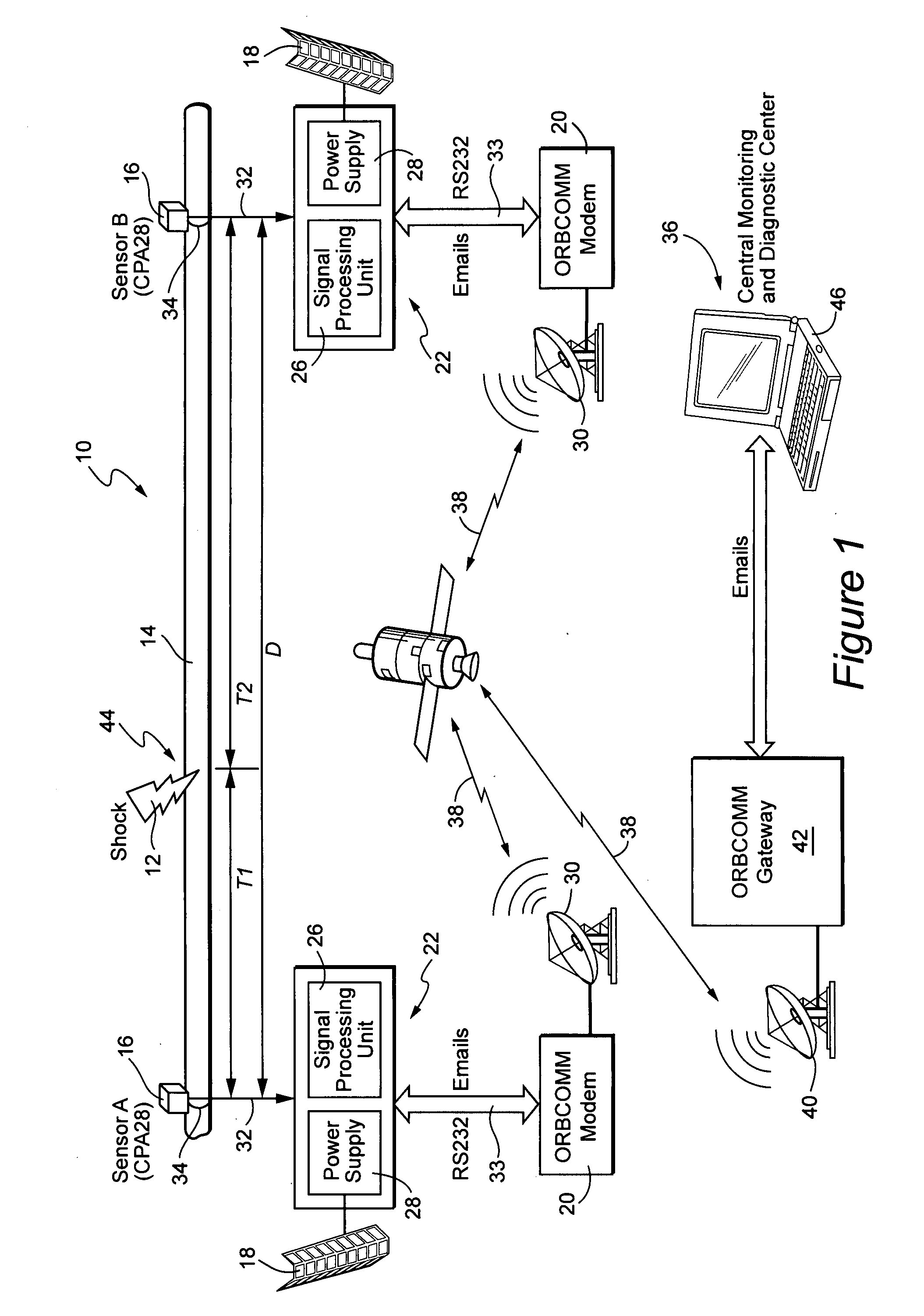

Acoustic impact detection and monitoring system

ActiveUS7607351B2Cost effectiveQuick checkMultiple-port networksVibration measurement in fluidHydrophoneTelecommunications link

A system is disclosed for detecting and locating harmful impacts to pipelines using sensors placed along the pipeline. The exact spacing of sensors is site specific and is set with the goal of maximizing sensor spacing without reducing system performance and reliability. At each sensor location, preferably there are four basic components, i.e., a hydrophone, solar power components, and data processing and communications equipment. Each hydrophone directly measures the acoustic noise fluctuation in a pipe section, which propagates at long distances in the pipeline at the specific speed of sound for the particular type of pipe. If specific signal parameters exceed a programmed threshold, a detection message is generated and transmitted via a communications link to a central monitoring and diagnostic center.

Owner:GENERAL ELECTRIC CO

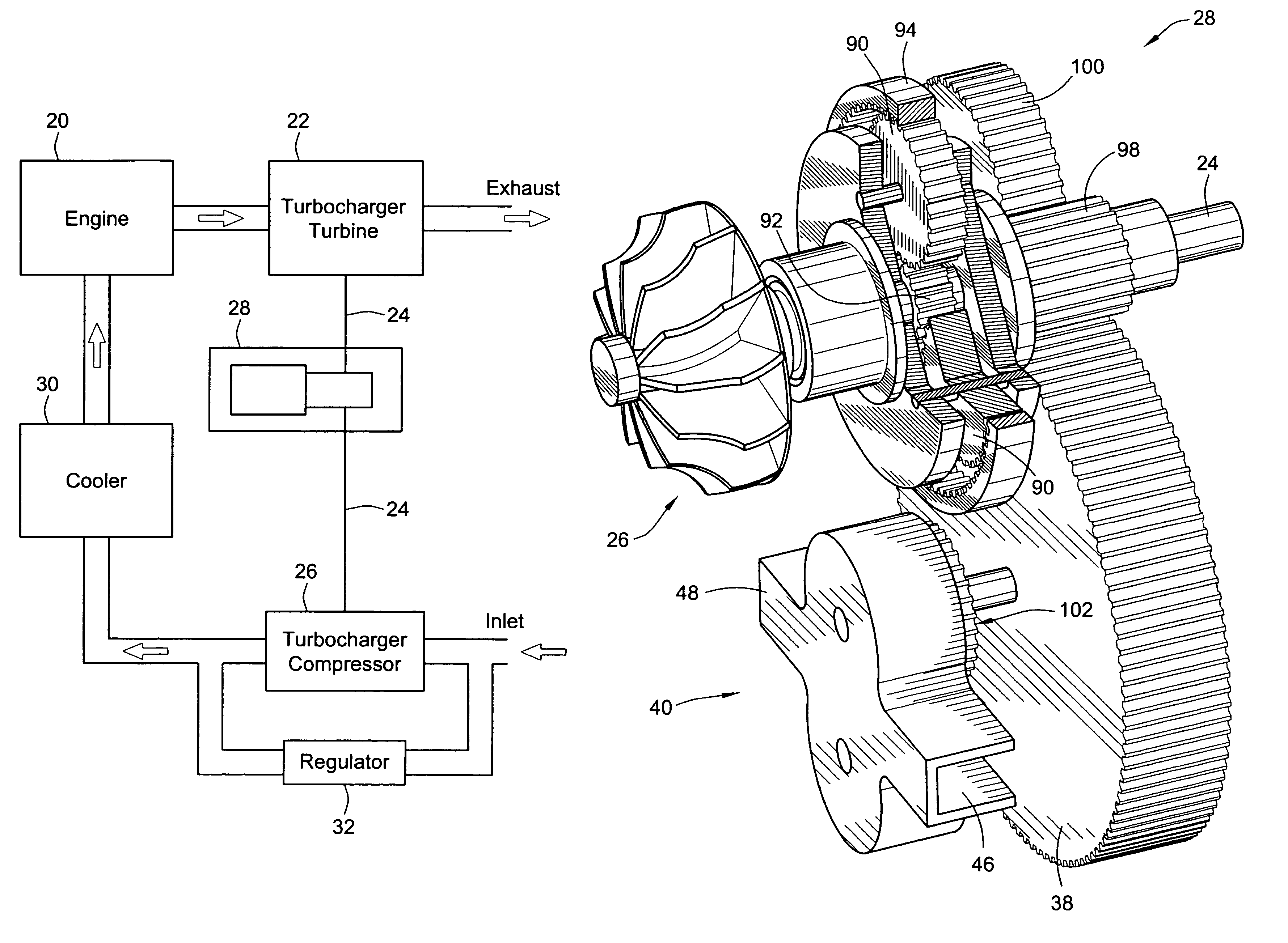

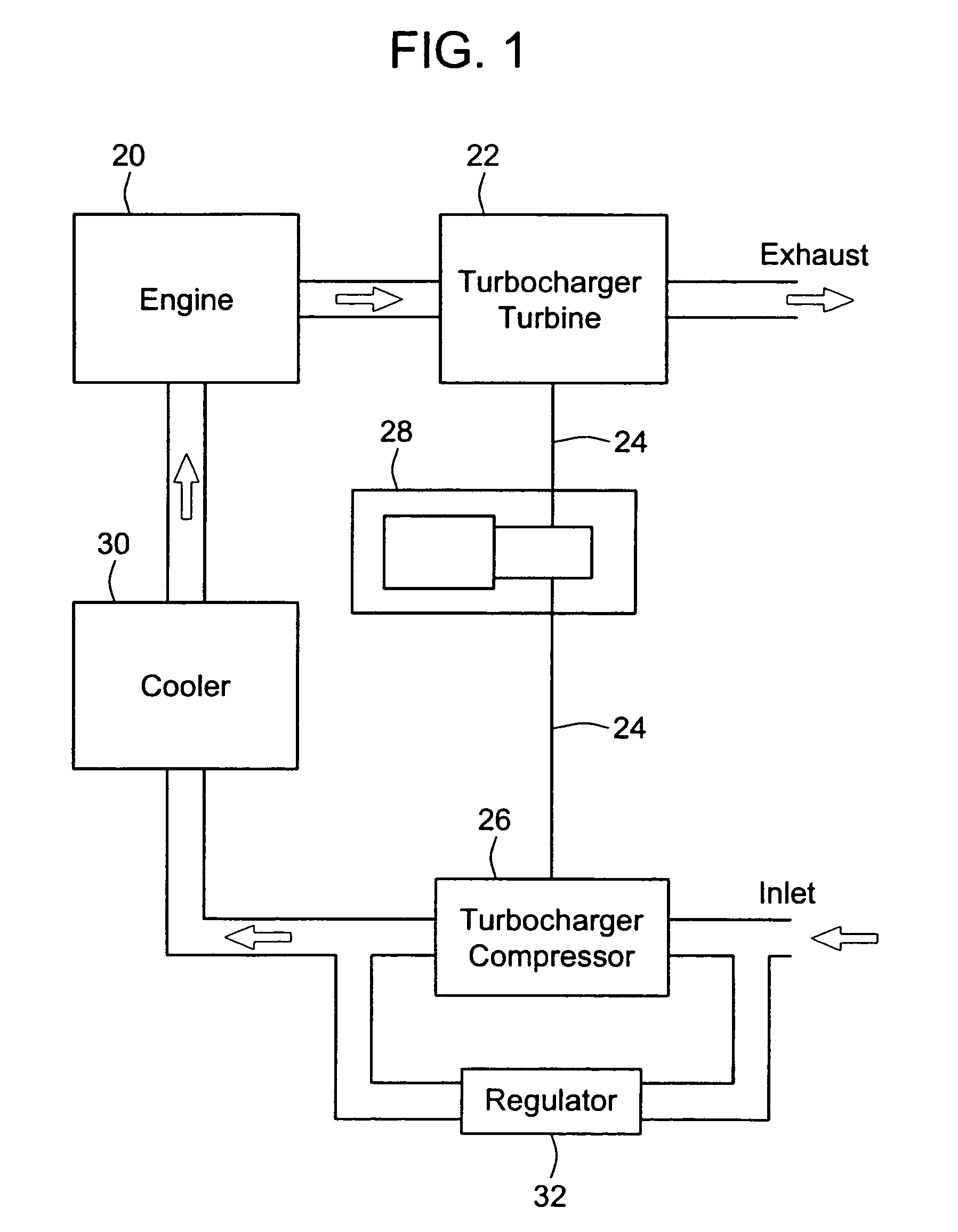

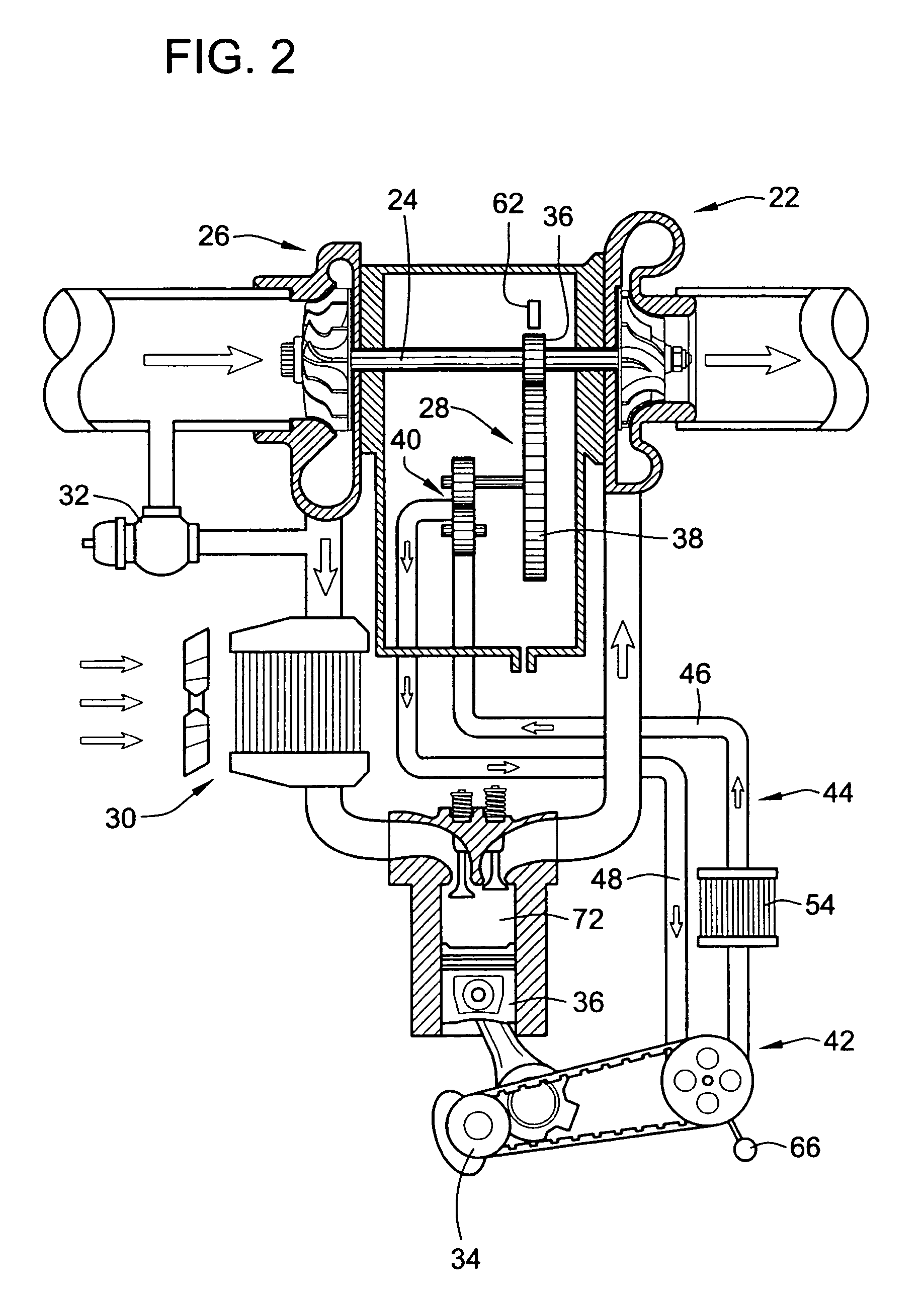

Super-turbocharger

InactiveUS7490594B2Small sizeGood for high torqueInternal combustion piston enginesToothed gearingsLow speedTurbocharger

The invention combines the features of a supercharger, a turbocharger and turbo-compounding into one system, utilizing a hydraulic or mechanical continuously variable transmission to drive the turbocharger up to a specific speed or intake manifold pressure and then holding the ideal speed to keep it at the right boost pressure for the engine condition. The benefits of a supercharger, which is primarily good for high torque at low speed, and a turbocharger, which is usually only good for high horsepower at high speeds are merged. Once the exhaust energy begins to provide more work than it takes to drive the intake compressor, the invention recovers that excess energy and uses it to add torque to the crankshaft. As a result, the invention provides the benefits of low speed with high torque and the added value of high speed with higher horsepower or better fuel economy all from one system.

Owner:VANDYNE SUPERTURBO

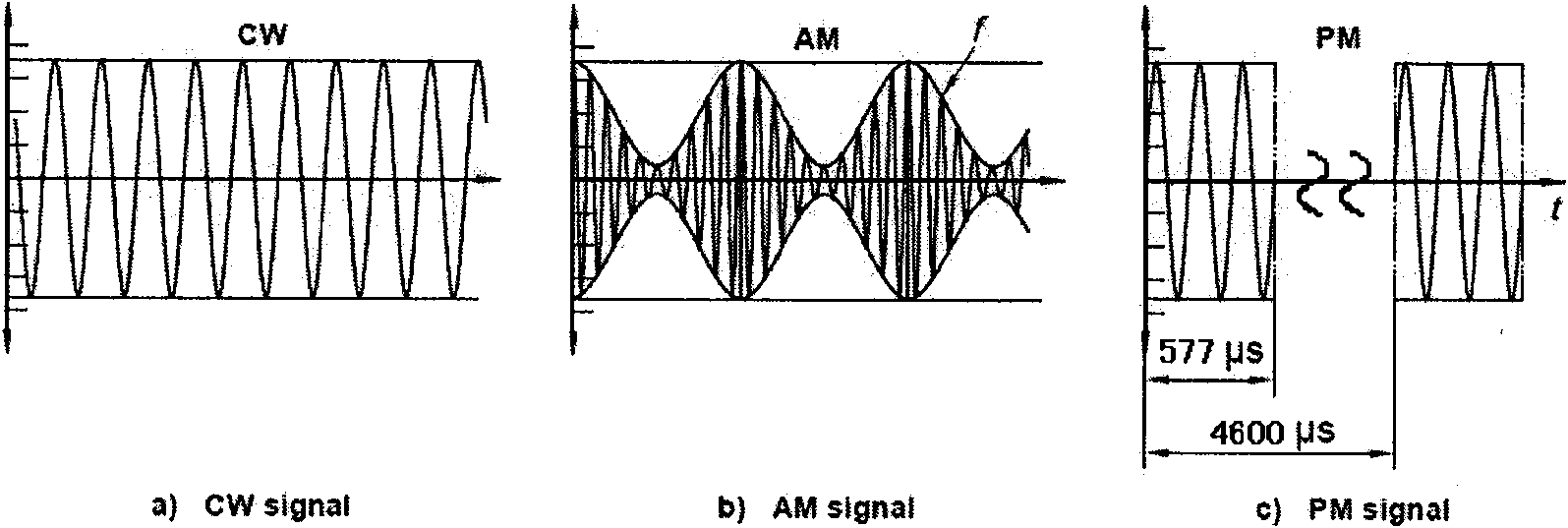

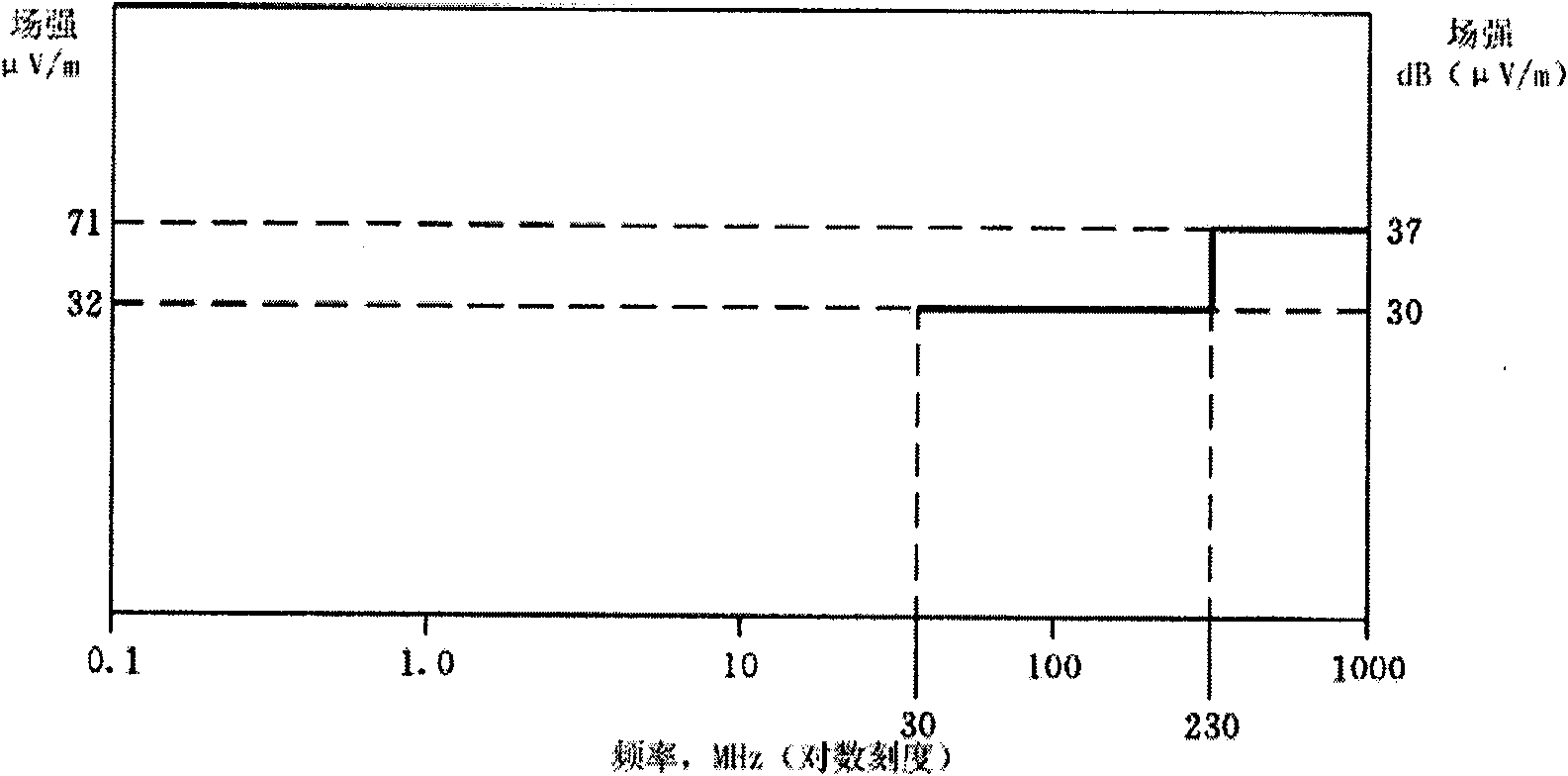

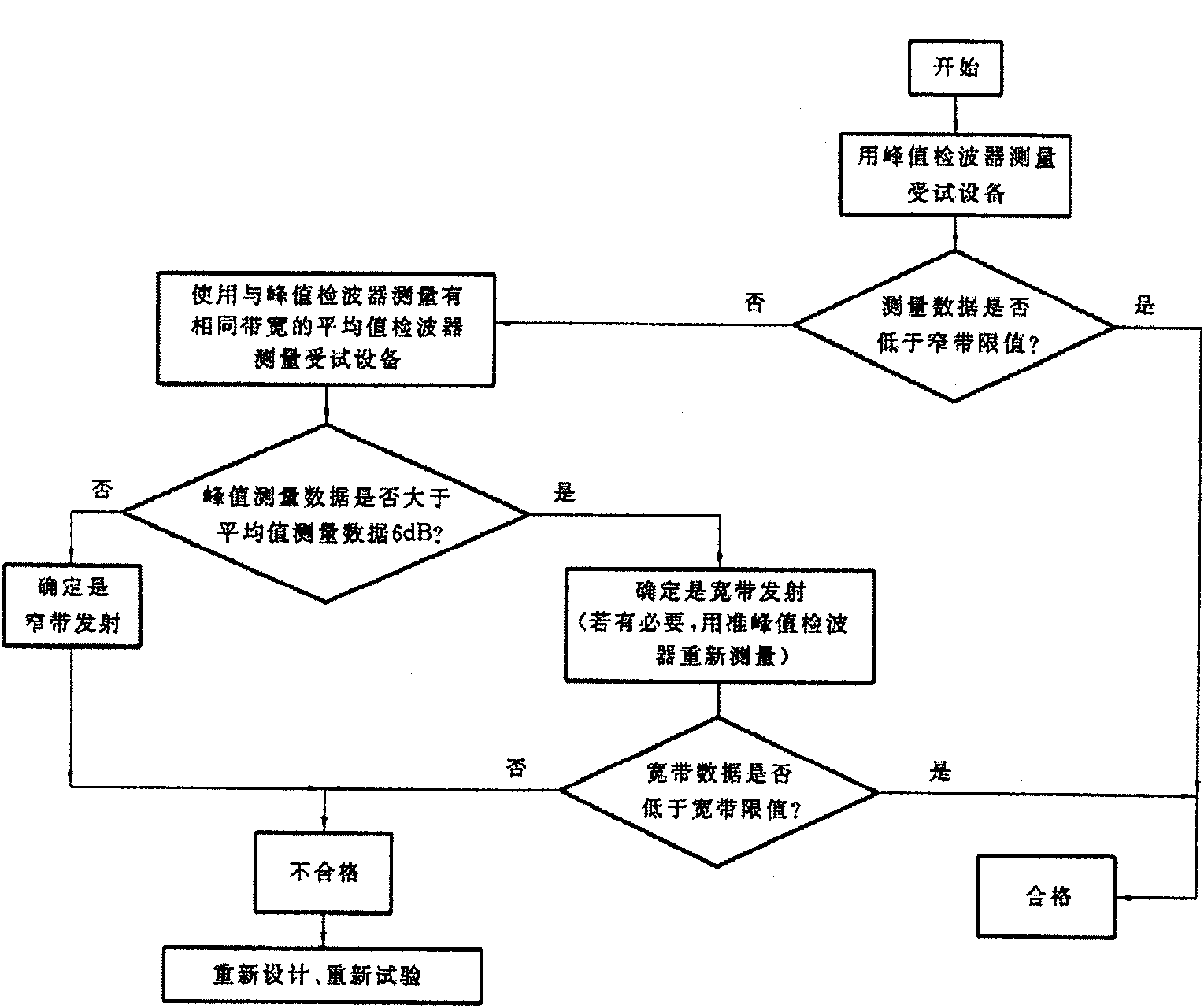

Method for testing electromagnetic compatibility (EMC) of electrically-driven automobile

InactiveCN102043101AShorten the development cycleReduce development costsTesting dielectric strengthElectricityElectronic systems

The invention provides a method for testing the electromagnetic compatibility (EMC) of an electrically-driven automobile. The electromagnetic interference of the electrically-driven automobile is different from that of the common internal combustion engine automobile, as far as the work principle of the electrically-driven automobile is concerned, the electrically-driven automobile has stronger electromagnetic disturbance property and higher anti-electromagnetic interference due to the application of a large-scale electronic system, the electrically-driven automobile is arranged on a loaded chassis dynamometer and runs on the chassis dynamometer at specific speed, the chassis dynamometer realizes energy absorption, and the electromagnetic compatibility of an automobile in a running state is evaluated from two angles of automobile electromagnetic interference (EMI) and automobile electromagnetic susceptibility (EMS), thereby when the automobile normally runs, the electromagnetic interference of the automobile can be accurately measured.

Owner:SHANGHAI MOTOR VEHICLE INSPECTION CERTIFICATION & TECH INNOVATION CENT CO LTD

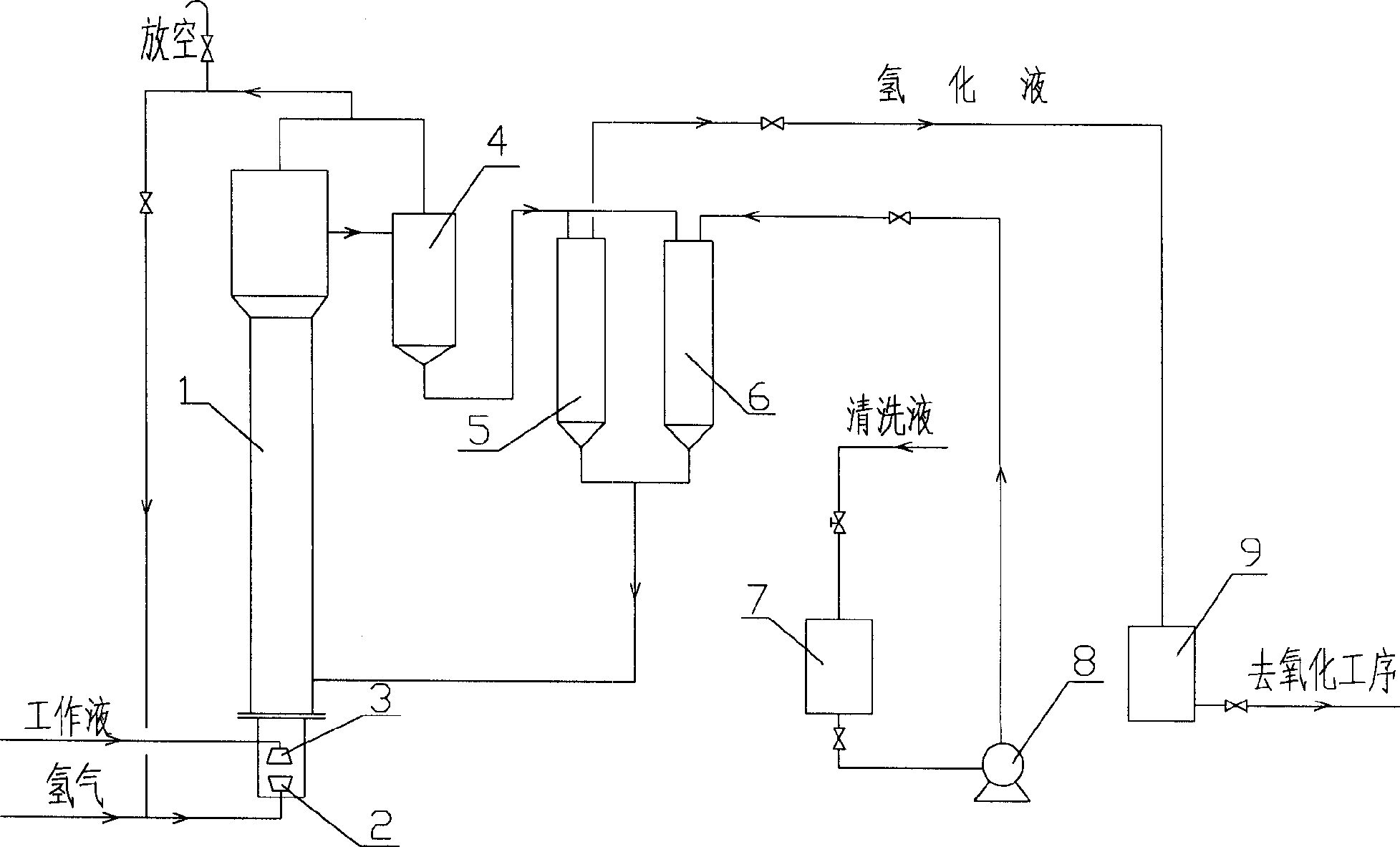

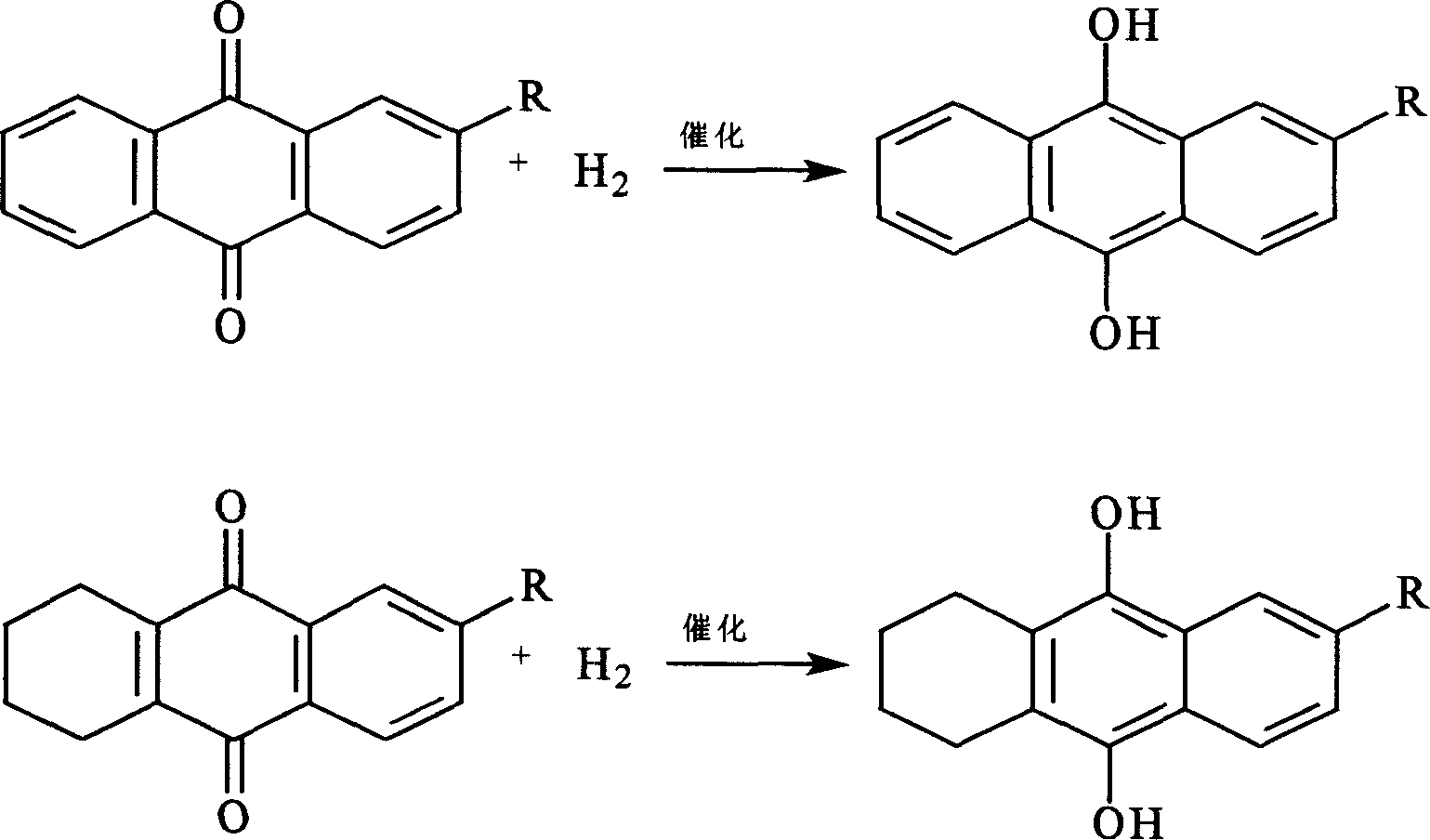

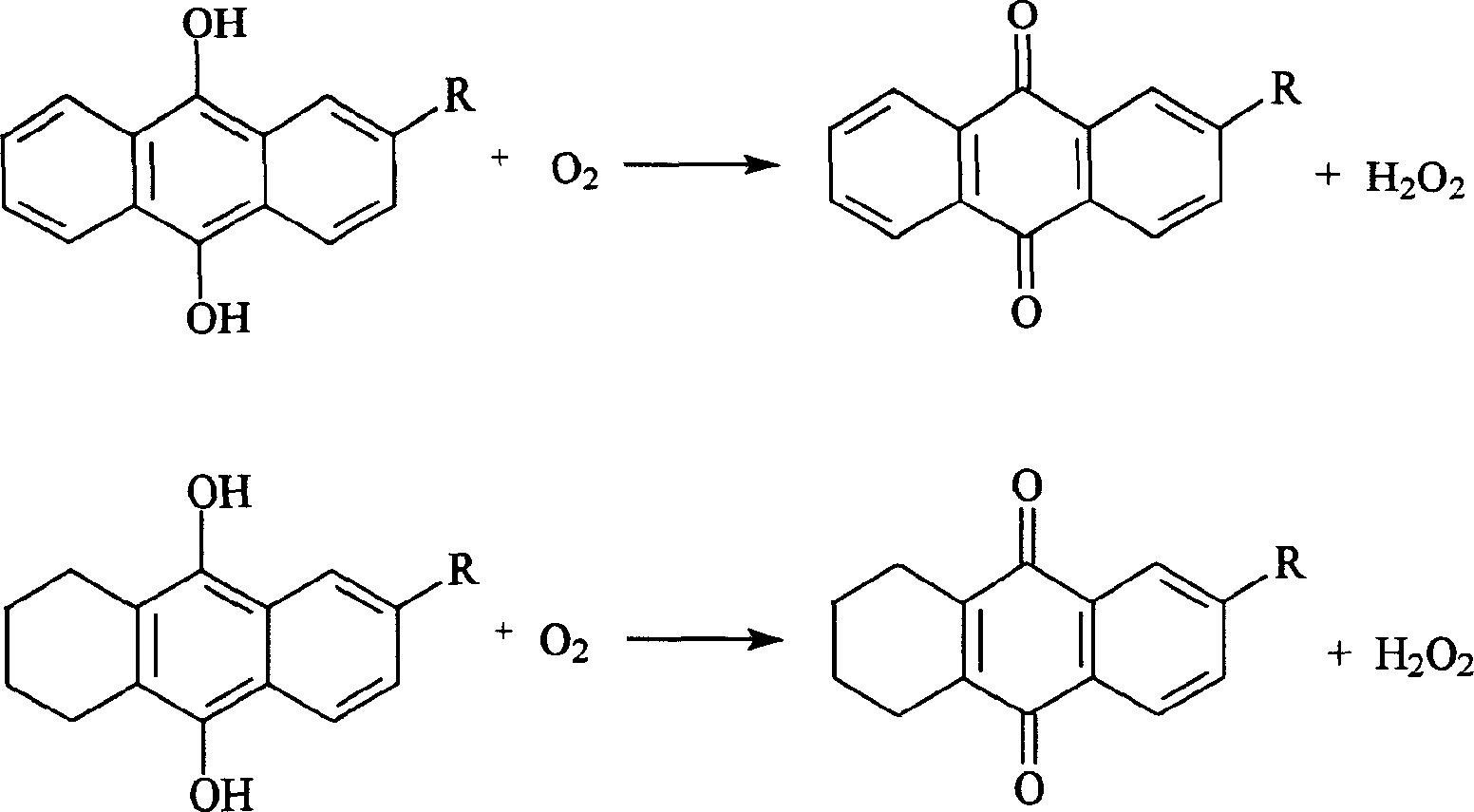

Hydrogenation process of hydrogen peroxide fluidized bed by anthraquinone

InactiveCN1817838AIncrease production capacityReduce differential pressureOrganic chemistryOrganic compound preparationFluidized bedHydrogenation process

A hydrogenation process for producing fluidized bed with hydrogen peroxide by anthraquinone method is carried out by taking empty tower hydrogenation reactor with amplification section on top, moving operating liquid and hydrogen upward at specific speed, floating powdery catalyst in tower body, hydrogenation reacting by free contacting, separating hydrogenated liquid by gas-liquid separating system, filtering by filter system and oxidizing. It has fast hydrogenation speed, low resistance, homogenous distribution and higher utilization rate.

Owner:LIMING RES INST OF CHEM IND

Acoustic impact detection and monitoring system

ActiveUS20090000381A1Limit likelihoodCost effectiveMultiple-port networksVibration measurement in fluidHydrophoneTelecommunications link

A system is disclosed for detecting and locating harmful impacts to pipelines using sensors placed along the pipeline. The exact spacing of sensors is site specific and is set with the goal of maximizing sensor spacing without reducing system performance and reliability. At each sensor location, preferably there are four basic components, i.e., a hydrophone, solar power components, and data processing and communications equipment. Each hydrophone directly measures the acoustic noise fluctuation in a pipe section, which propagates at long distances in the pipeline at the specific speed of sound for the particular type of pipe. If specific signal parameters exceed a programmed threshold, a detection message is generated and transmitted via a communications link to a central monitoring and diagnostic center.

Owner:GENERAL ELECTRIC CO

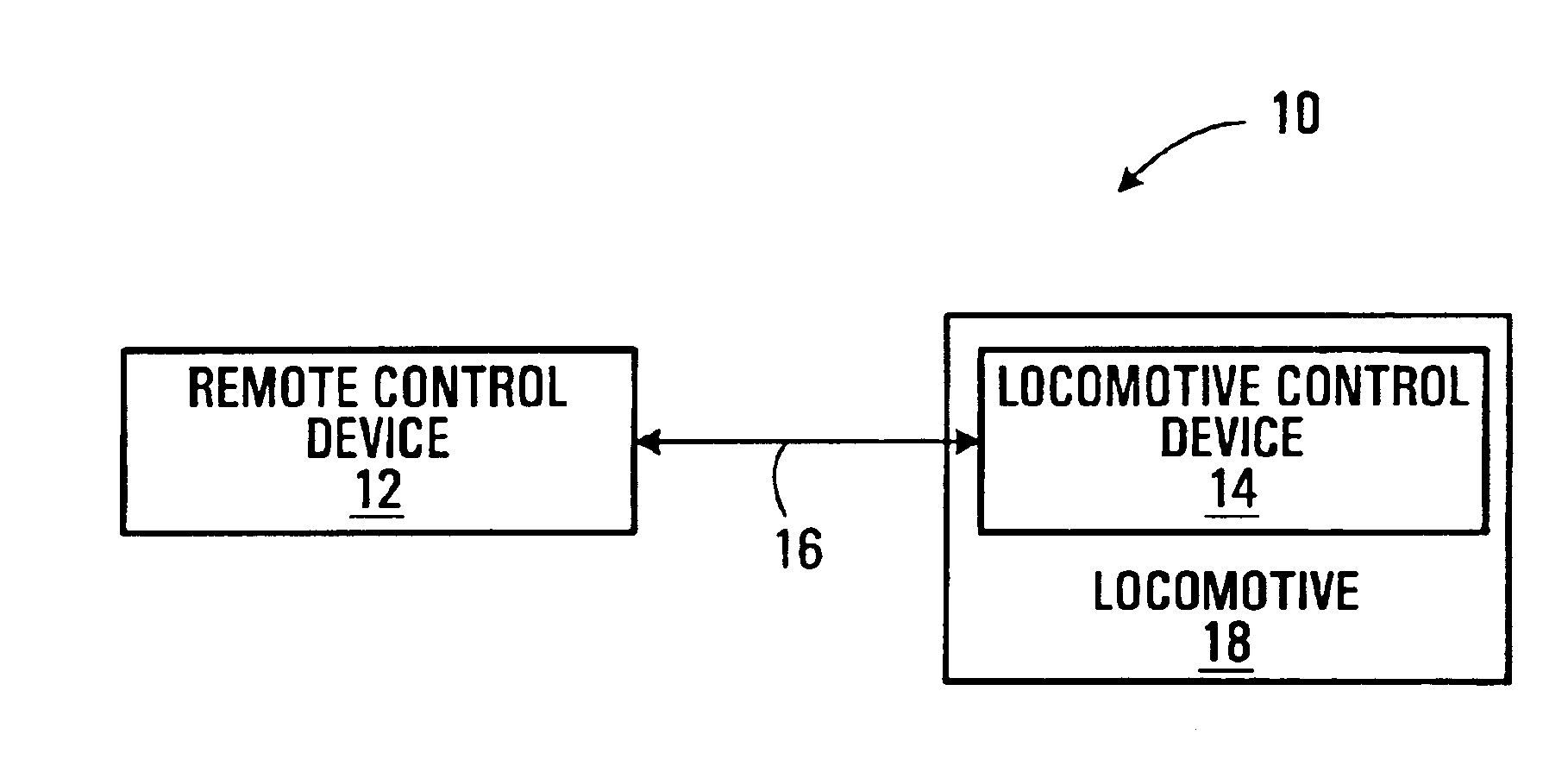

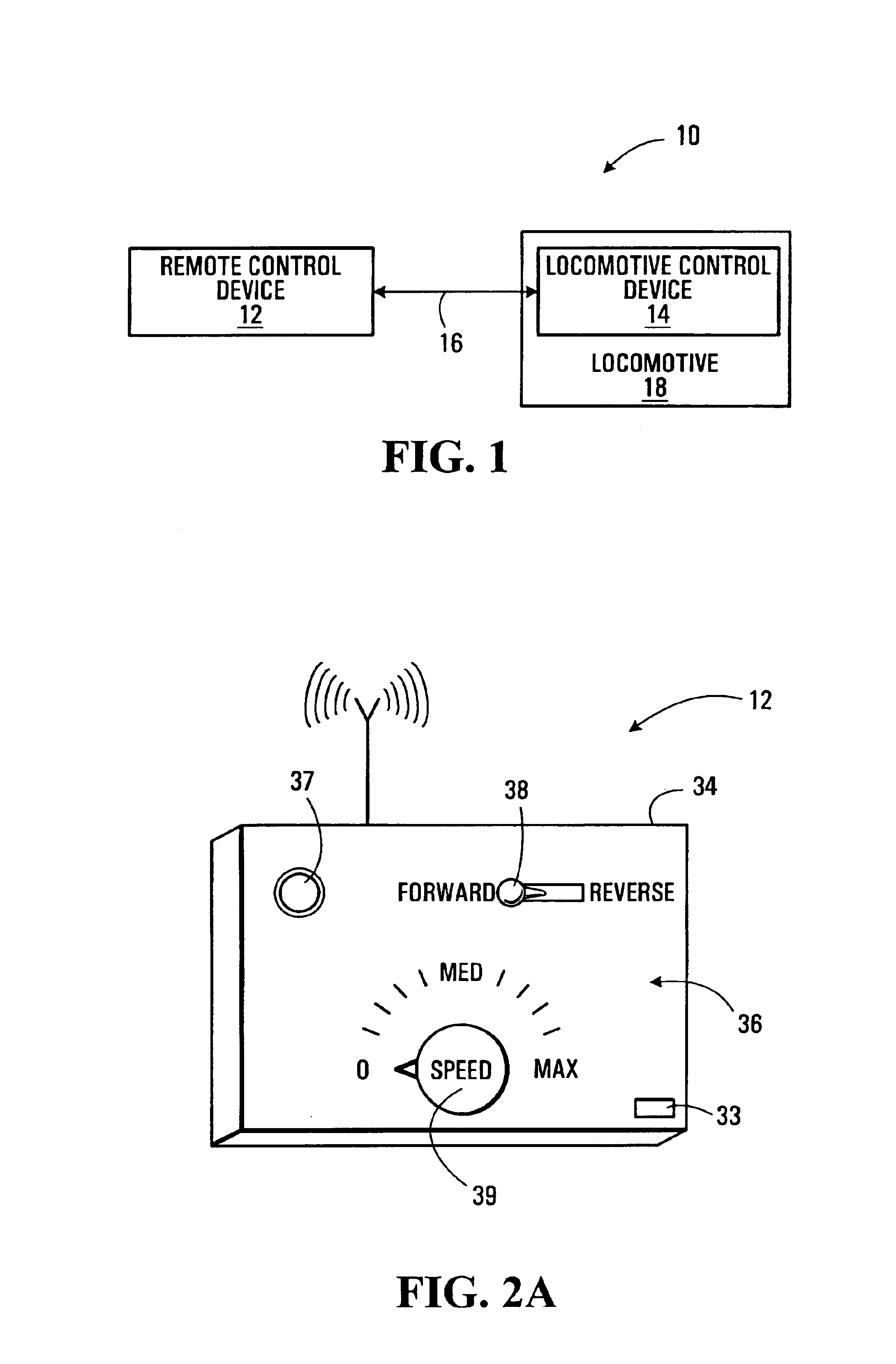

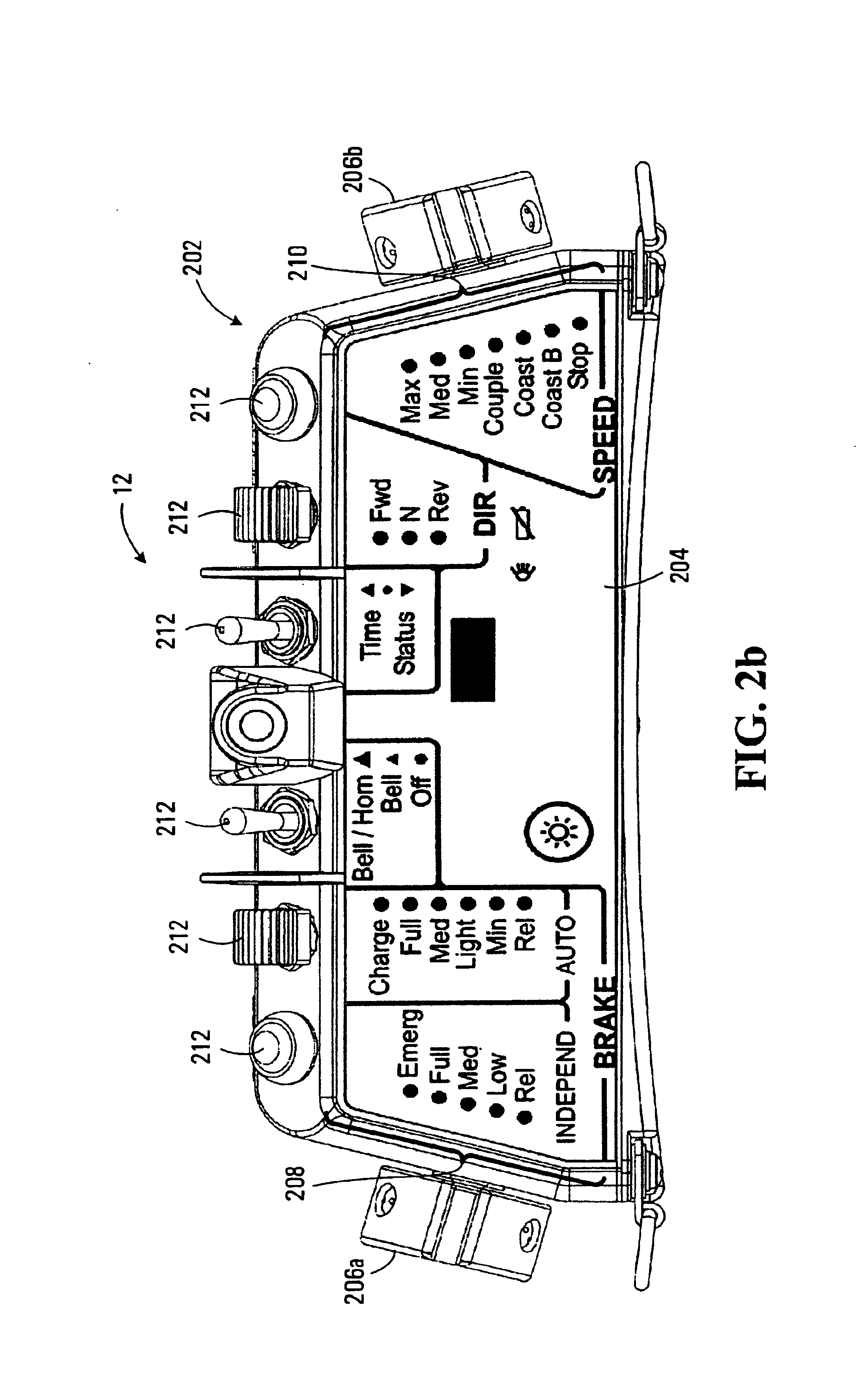

Programmable remote control system and apparatus for a locomotive

The present invention relates to a remote control system for a locomotive having a control interface. The remote control system comprises a portable remote control device and a locomotive control device. The portable remote control device receives command data indicative of speed information, and generates digital command signals for transmission to the locomotive control device for conveying the command data. The locomotive control device is adapted to be mounted on board a locomotive, and is operative for receiving the command signals conveyed by the portable remote control device. The locomotive control device includes a control entity that is responsive to the signal conveyed by the remote control device for deriving a specific speed associated to the command data, wherein the specific speed is a configurable parameter. Finally the control entity is operative for issuing local control signals to the locomotive control interface for causing the locomotive to implement the specific speed.

Owner:CATTRON NORTH AMERICA INC

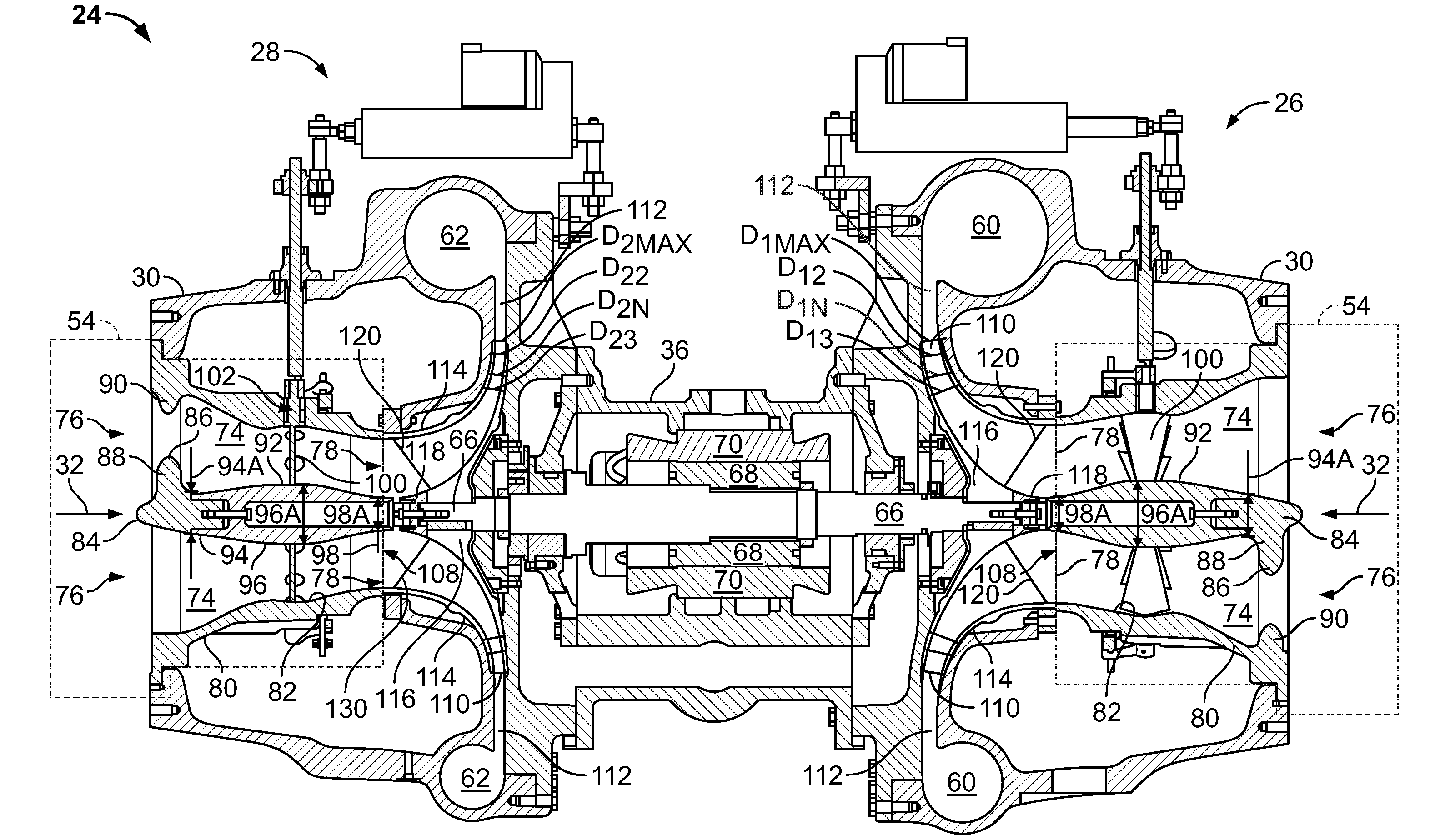

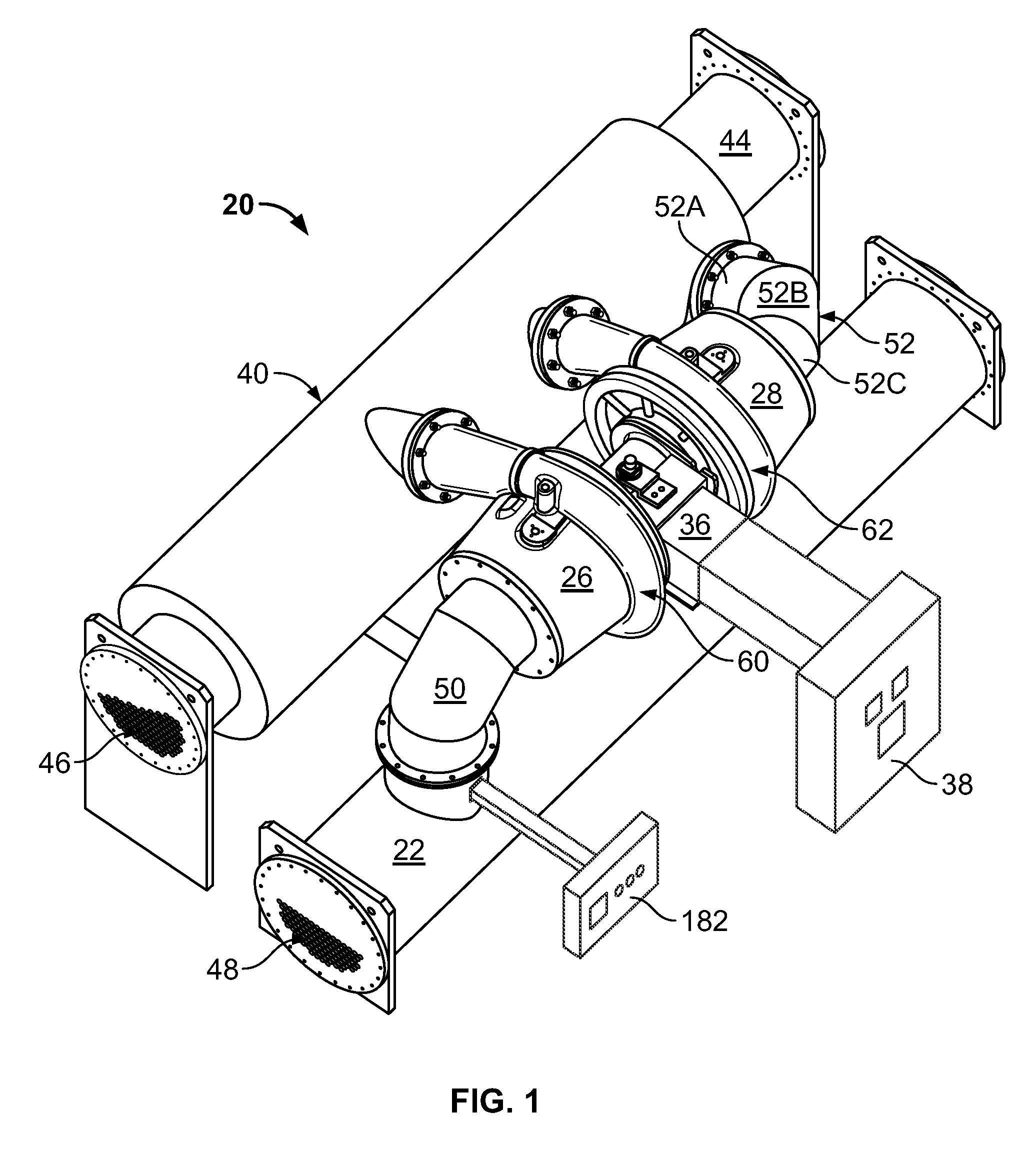

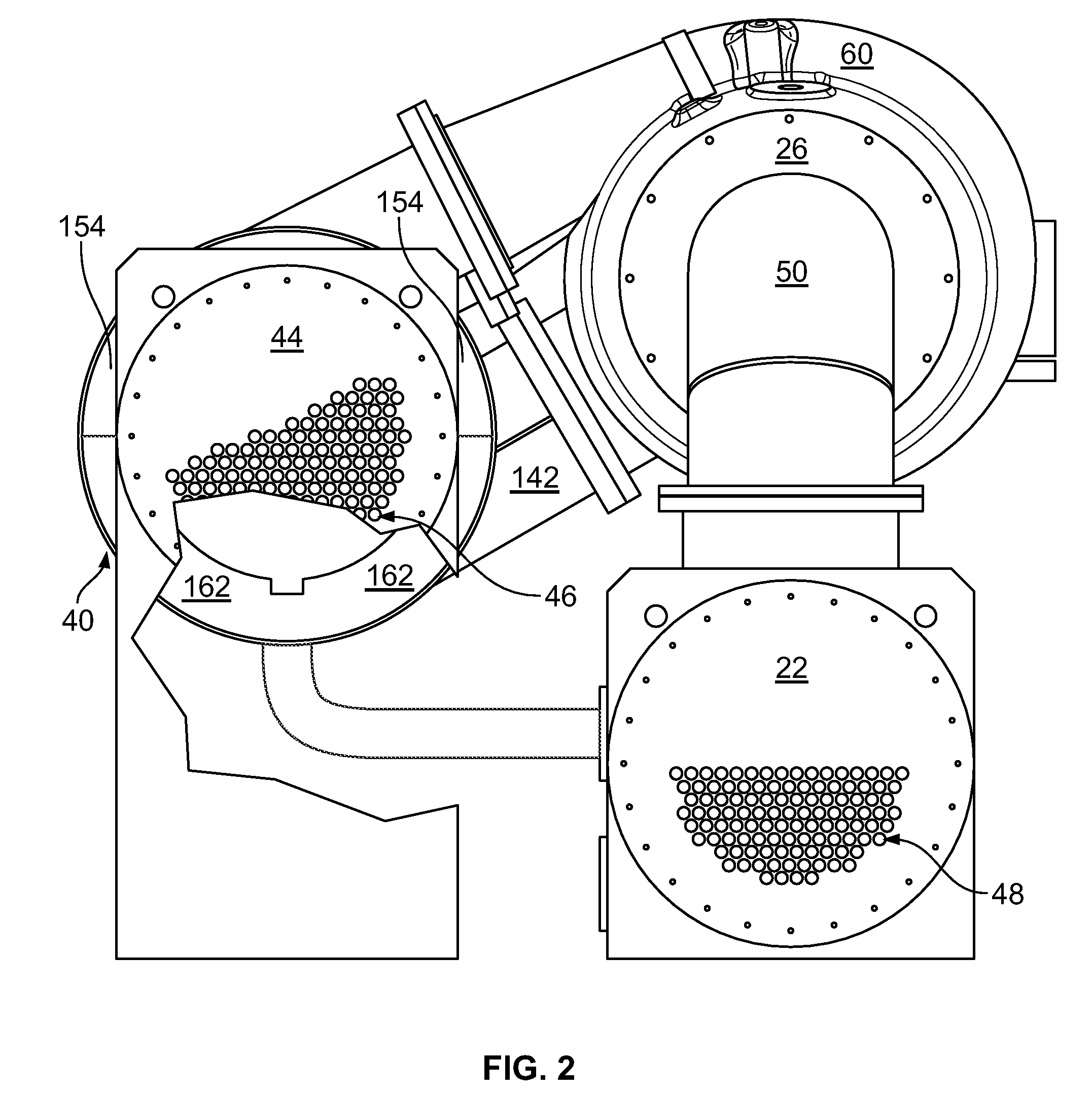

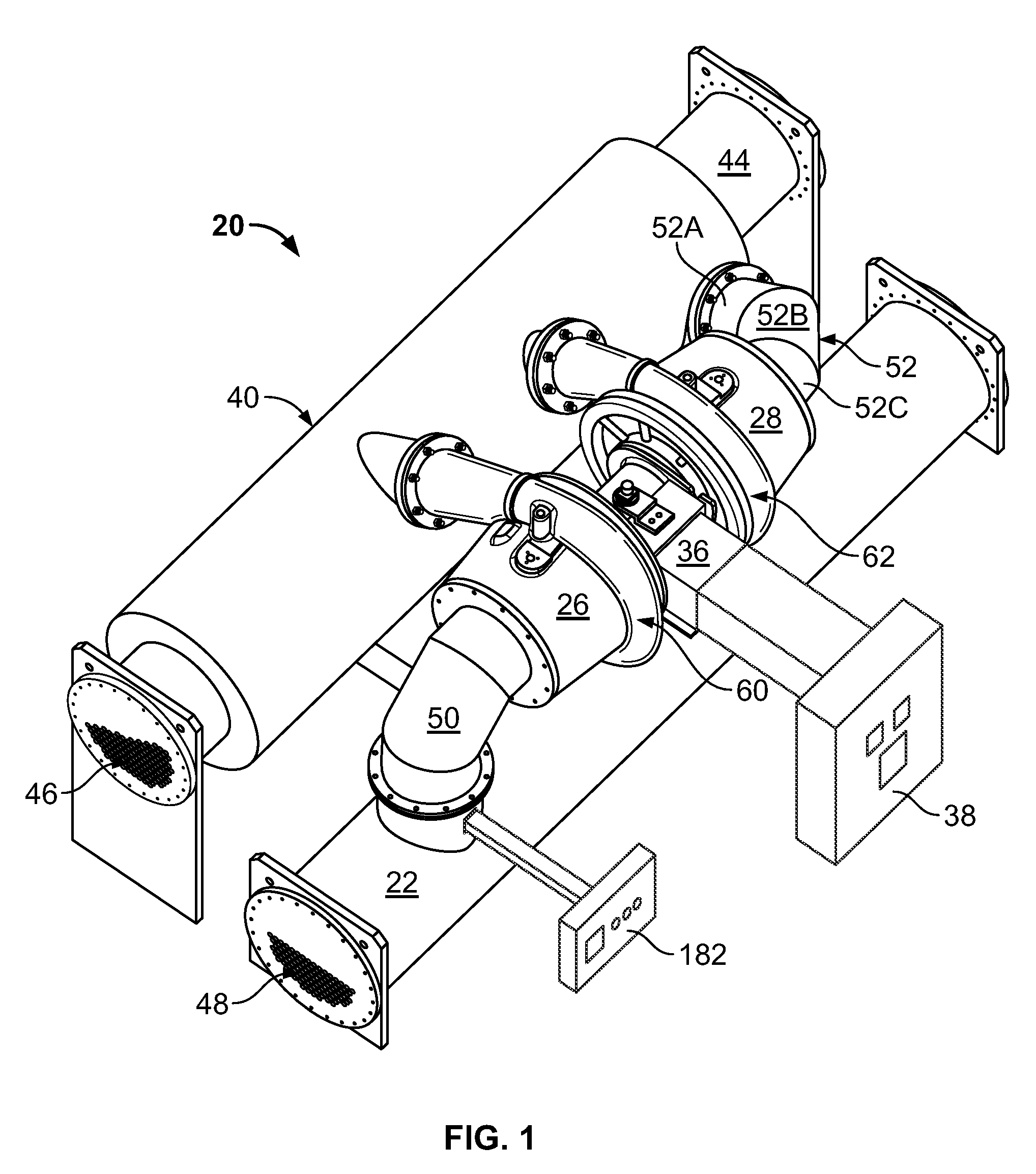

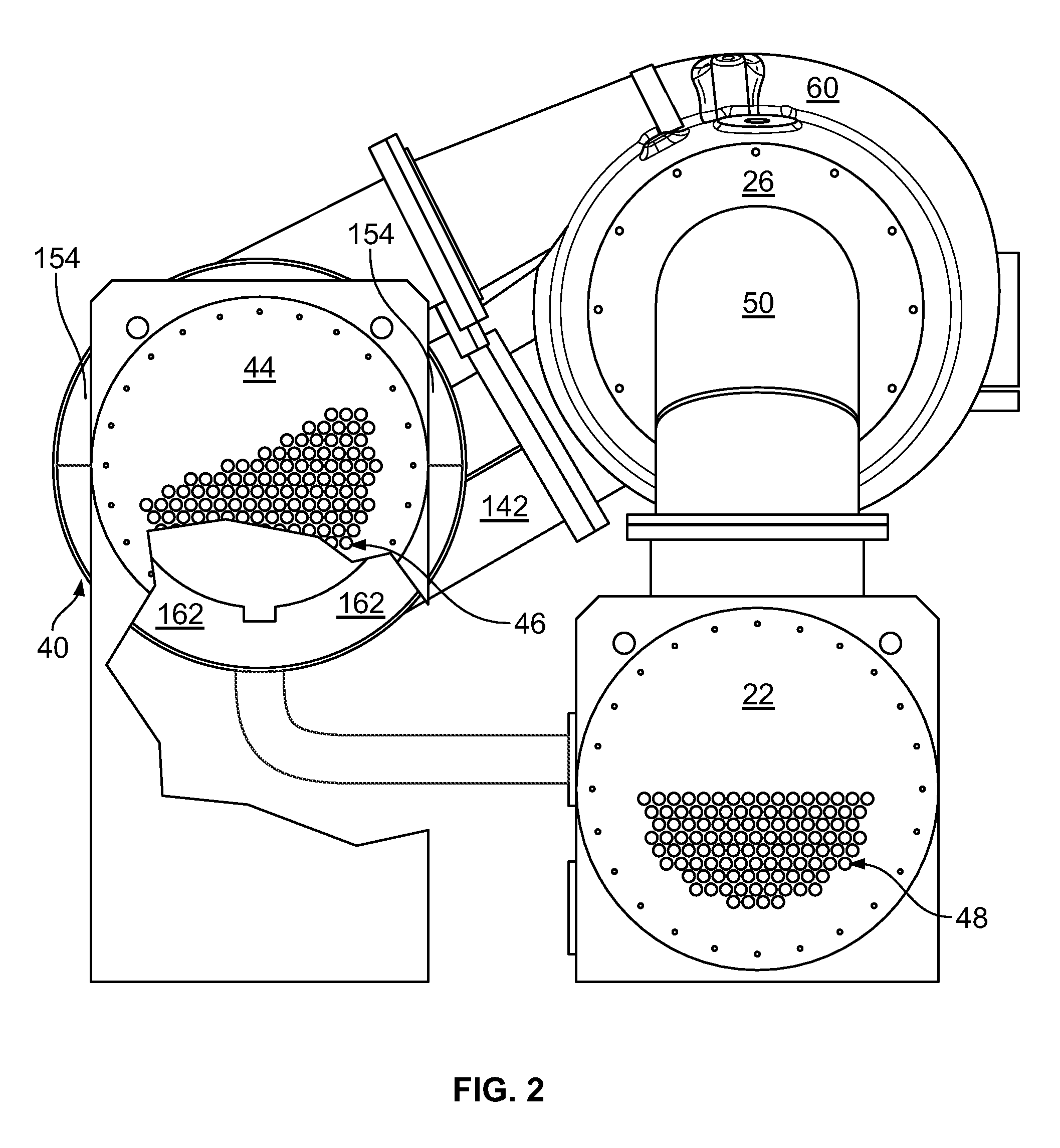

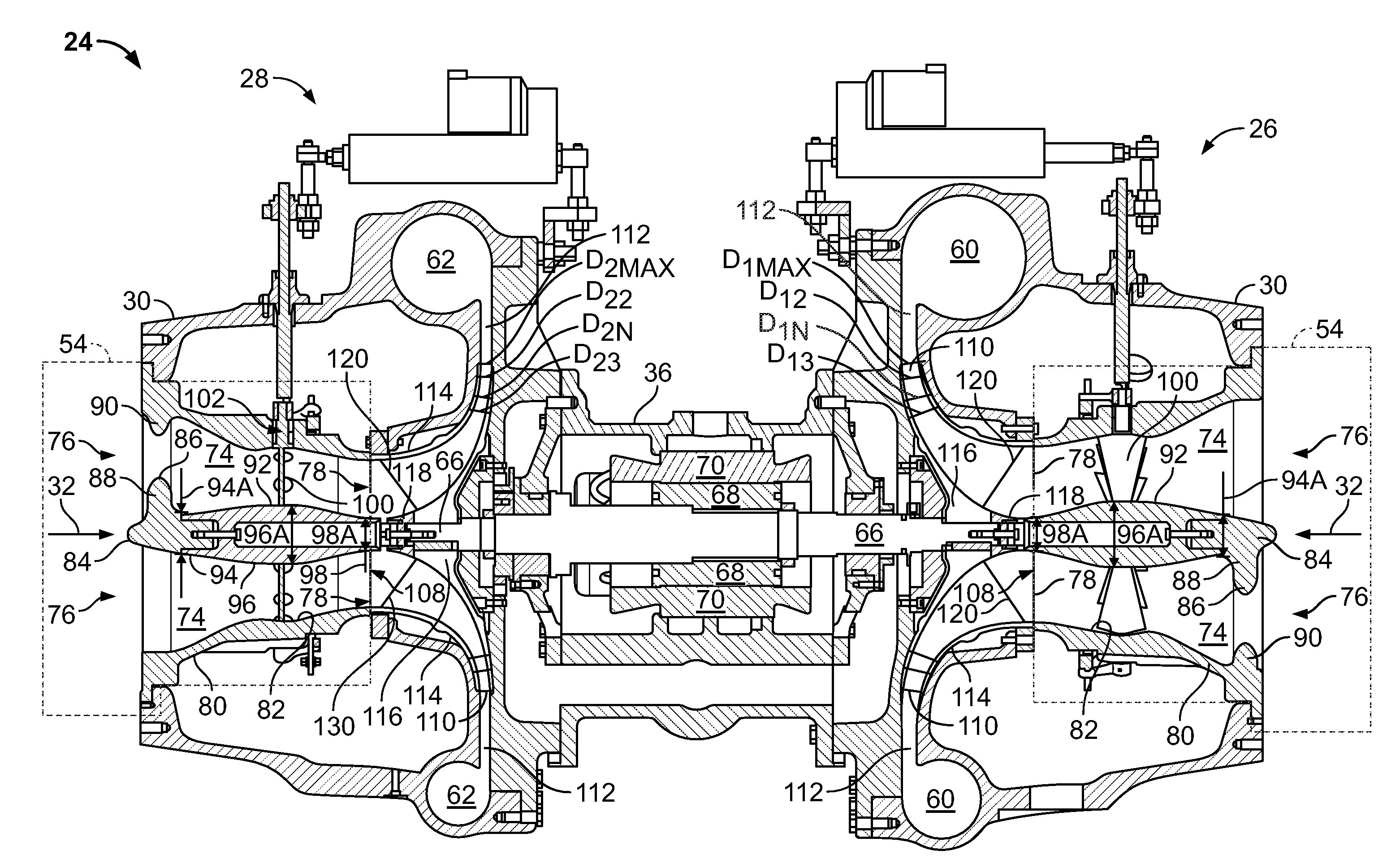

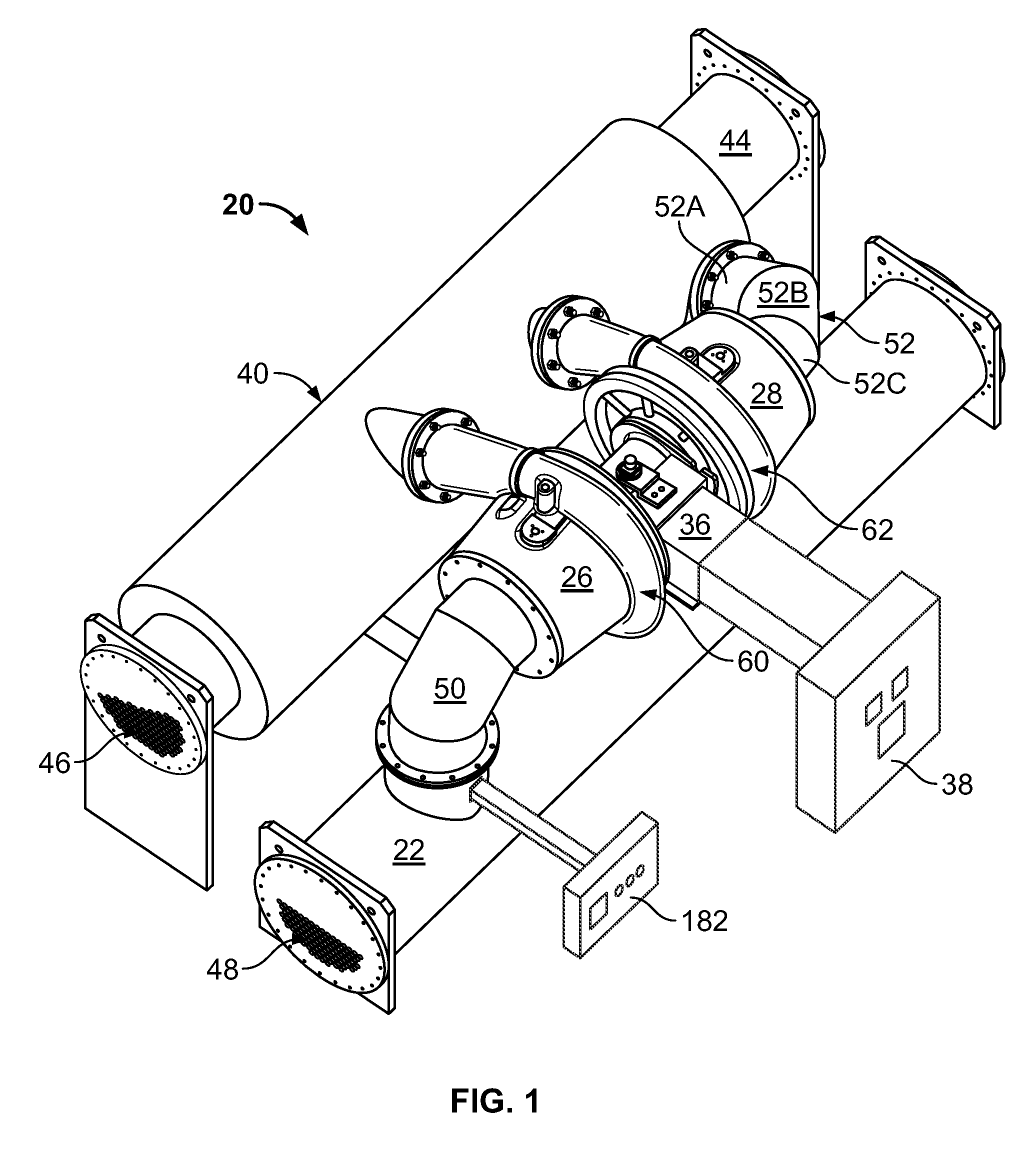

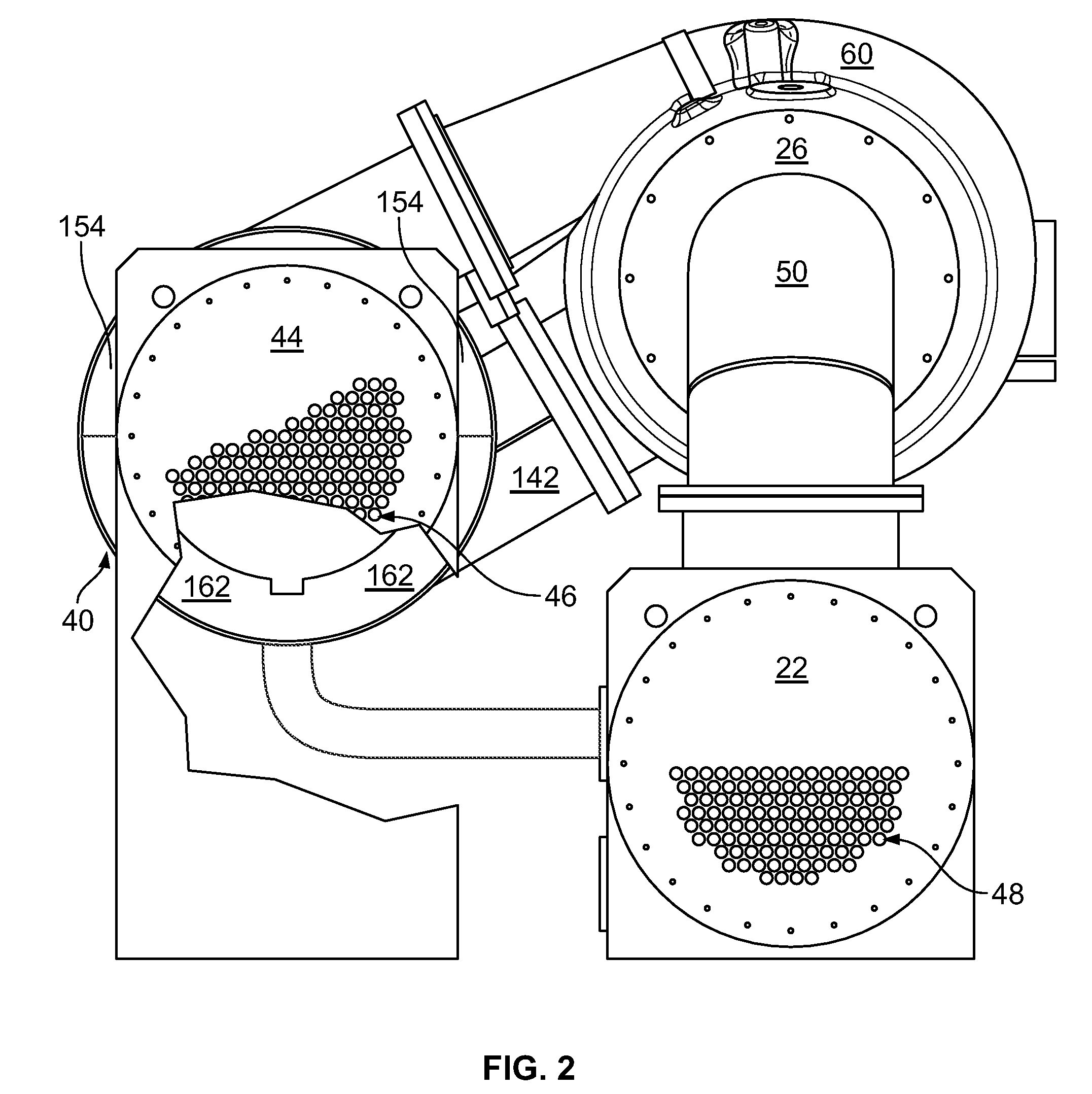

Centrifugal compressor assembly and method

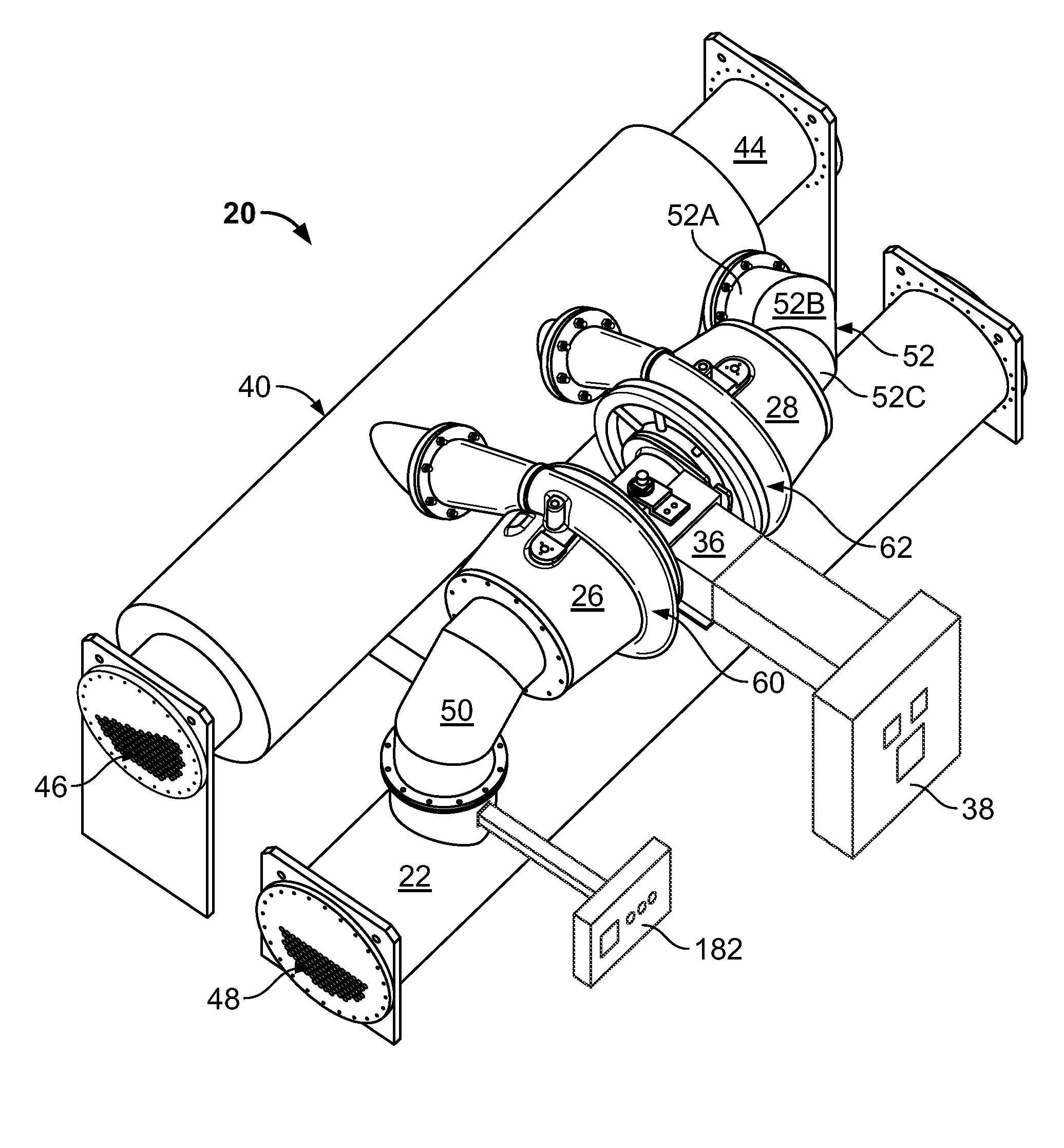

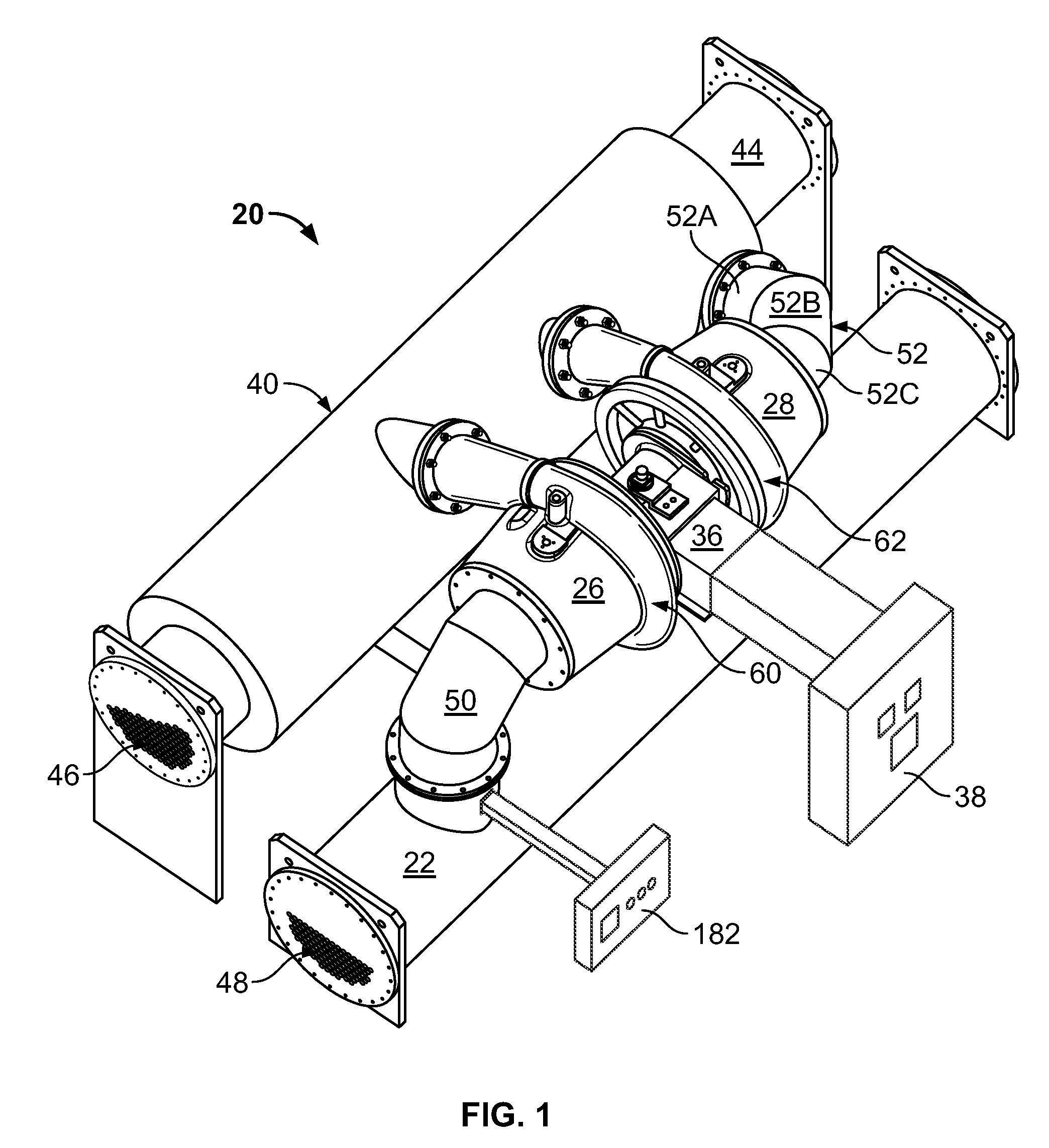

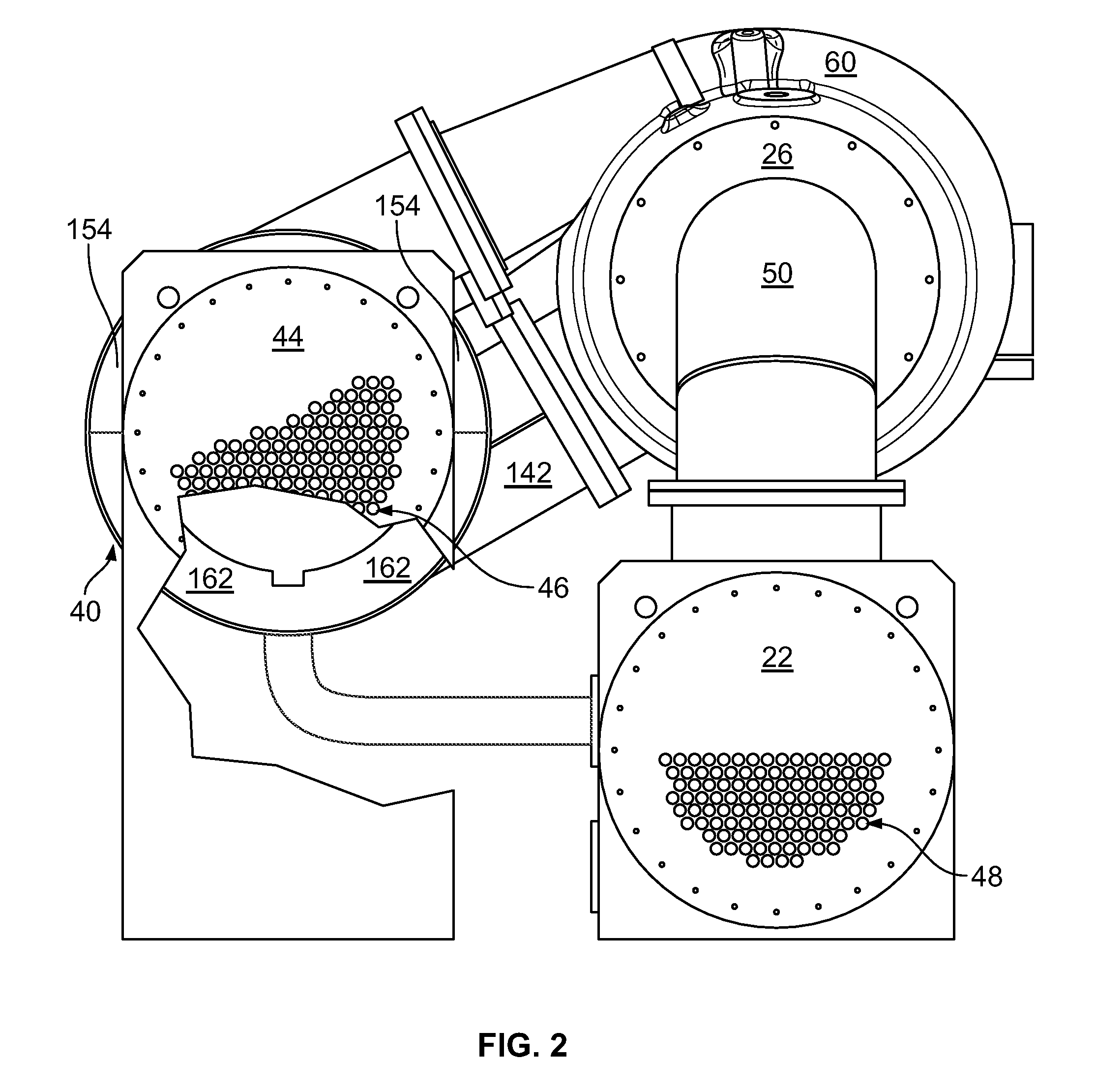

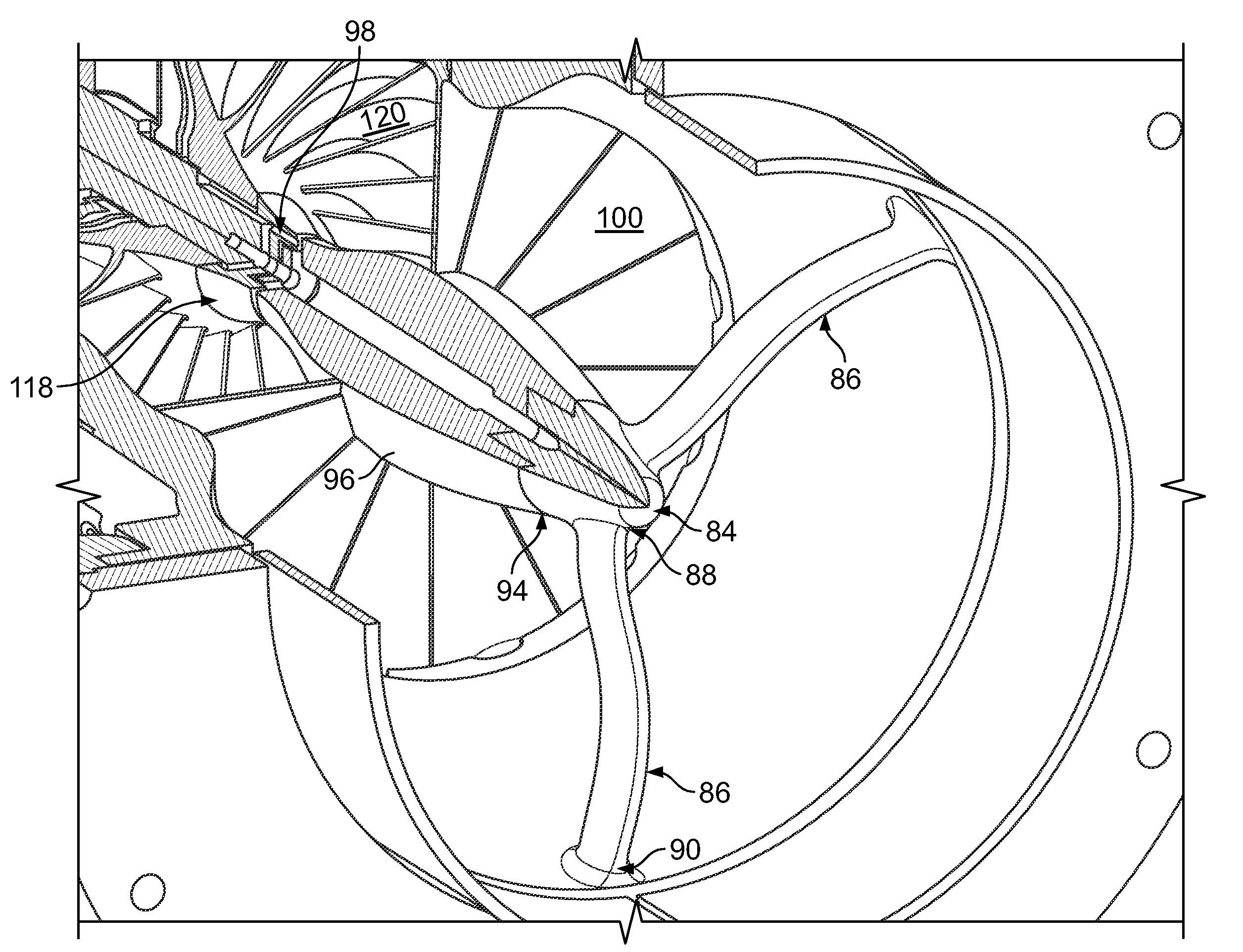

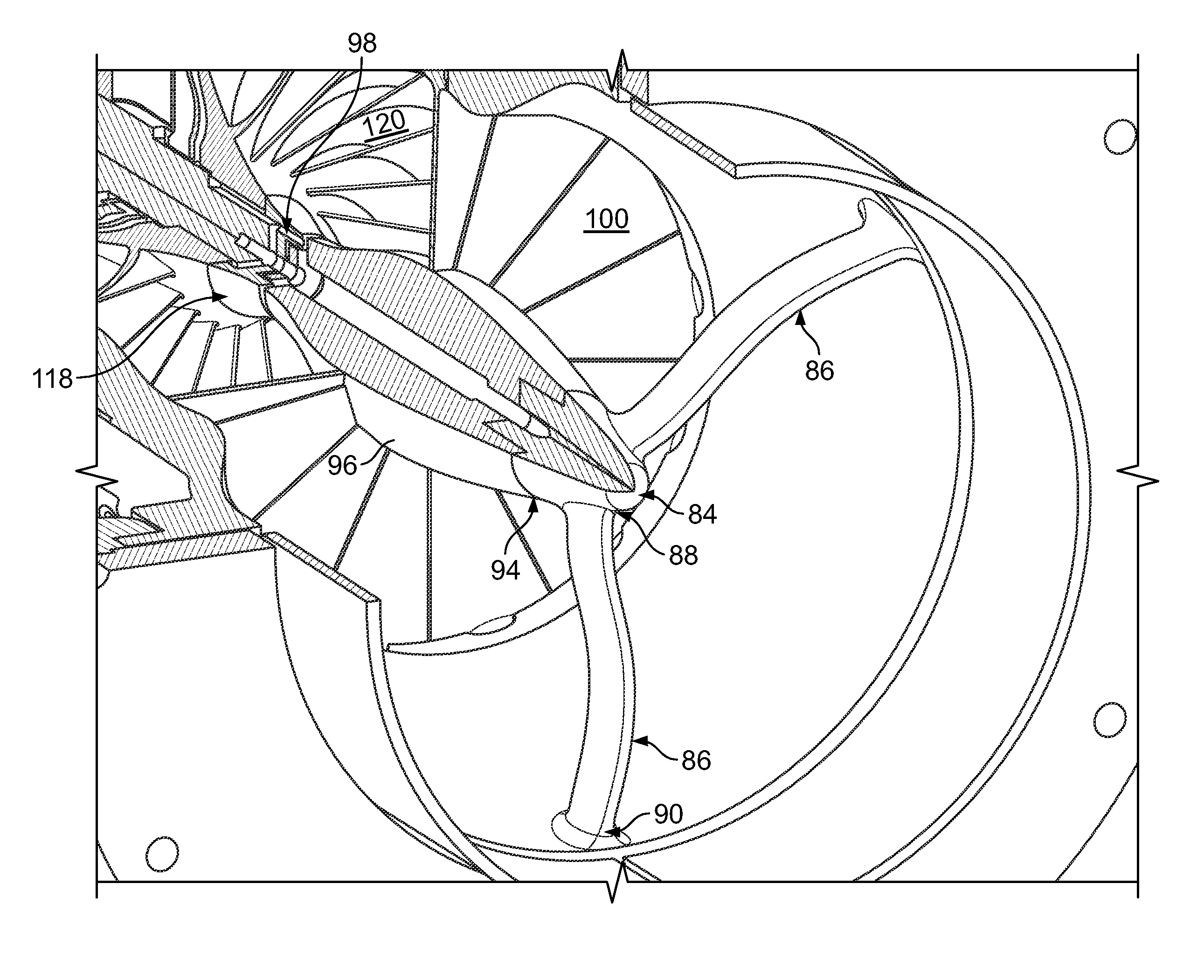

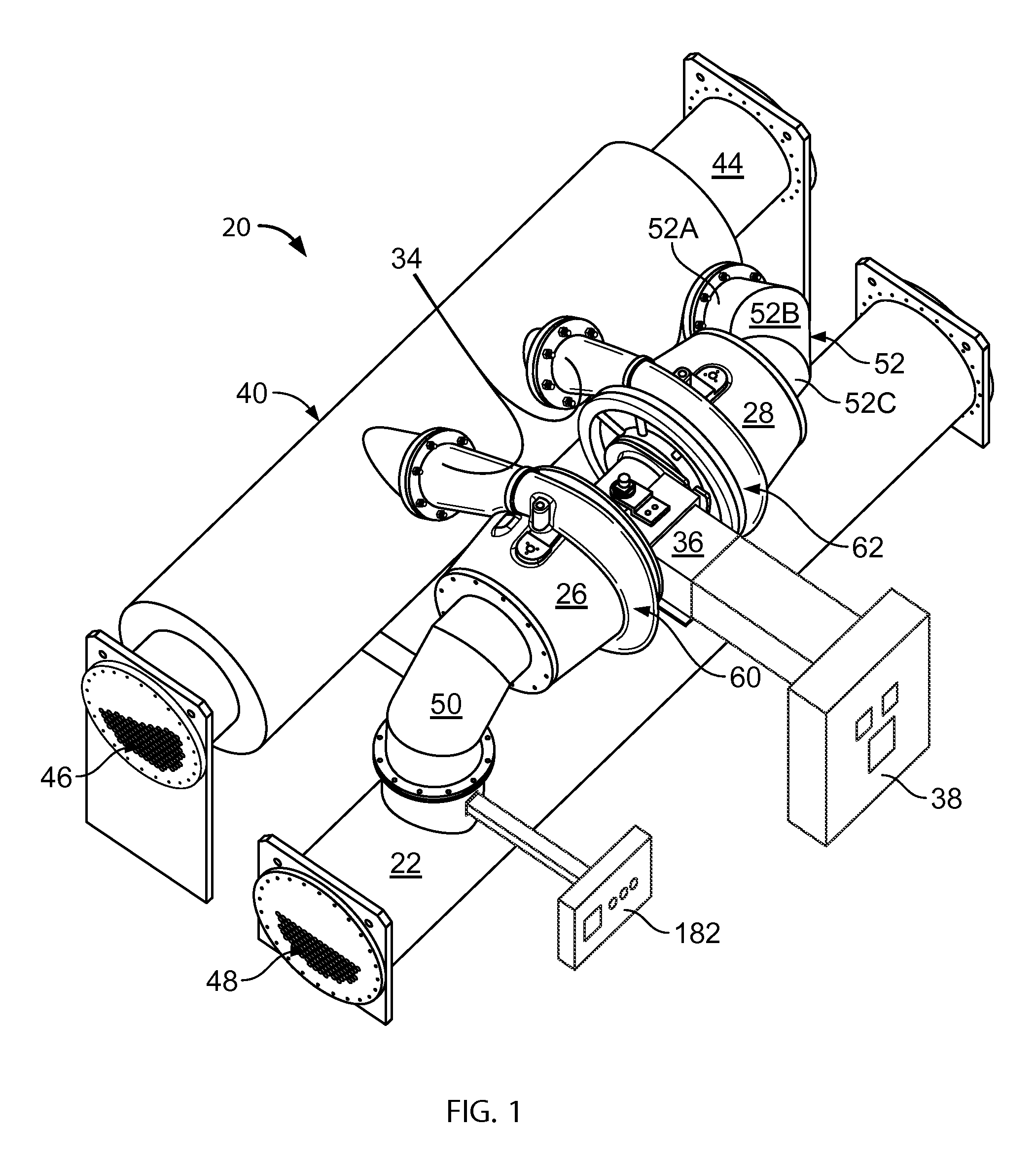

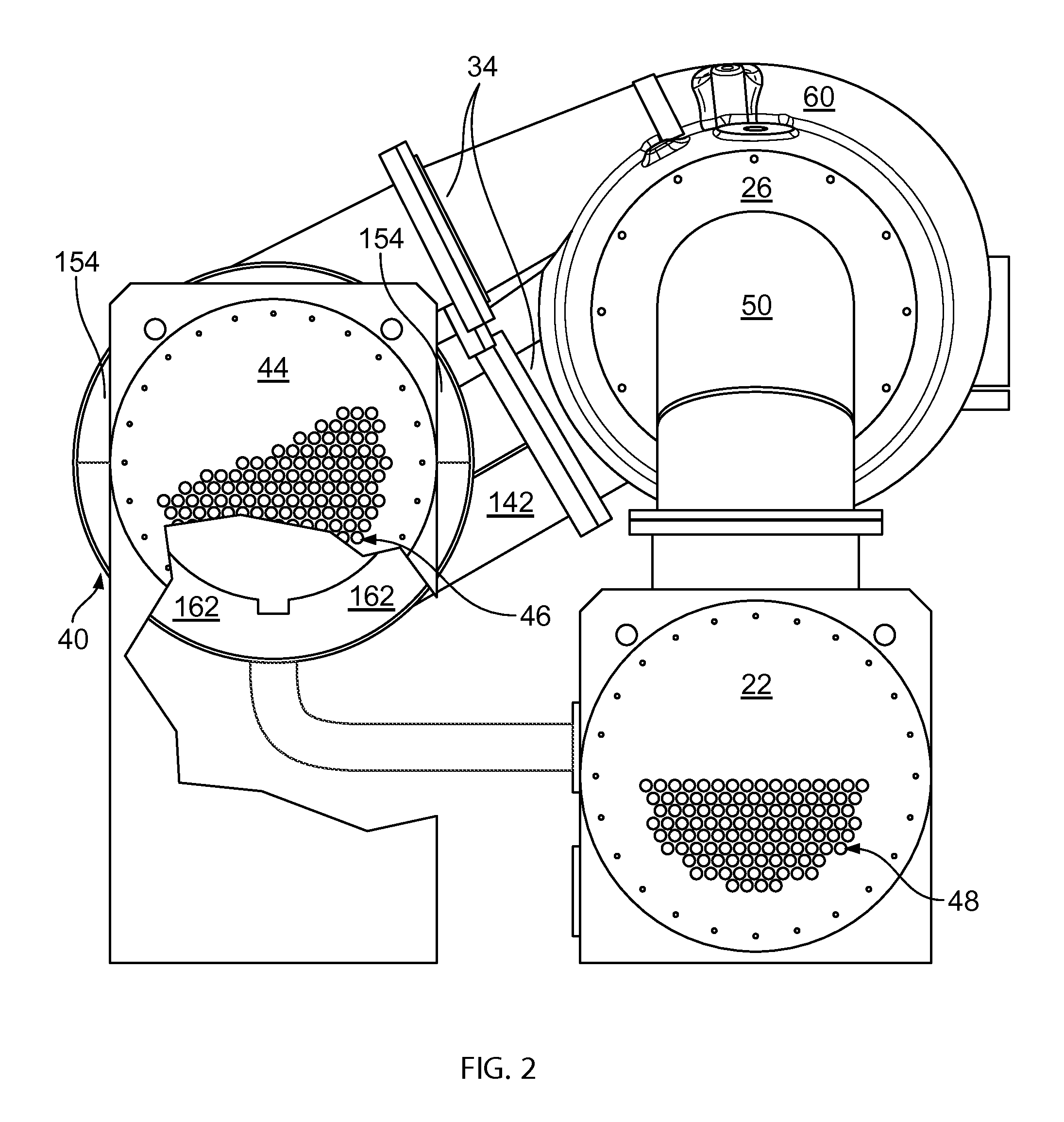

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

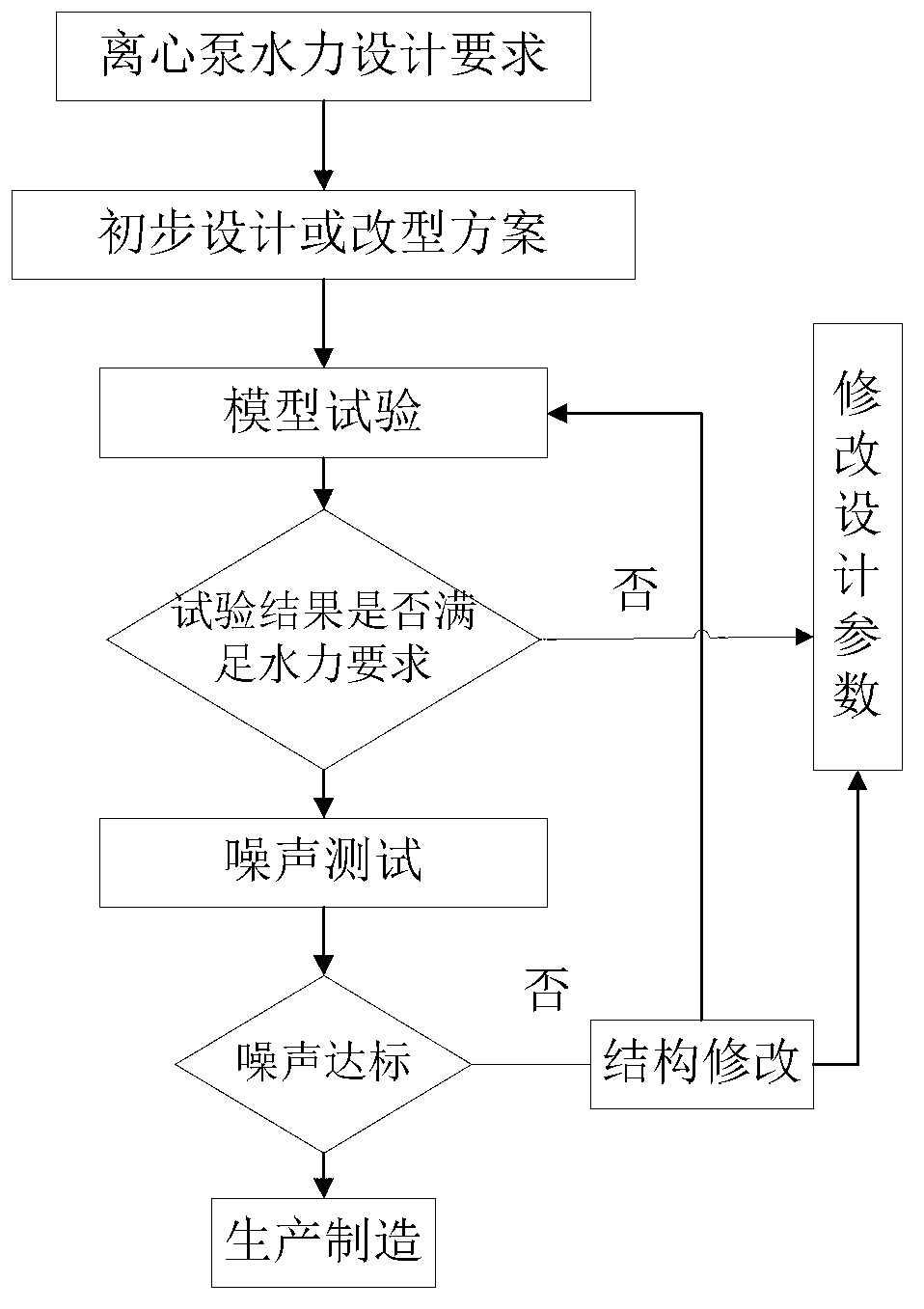

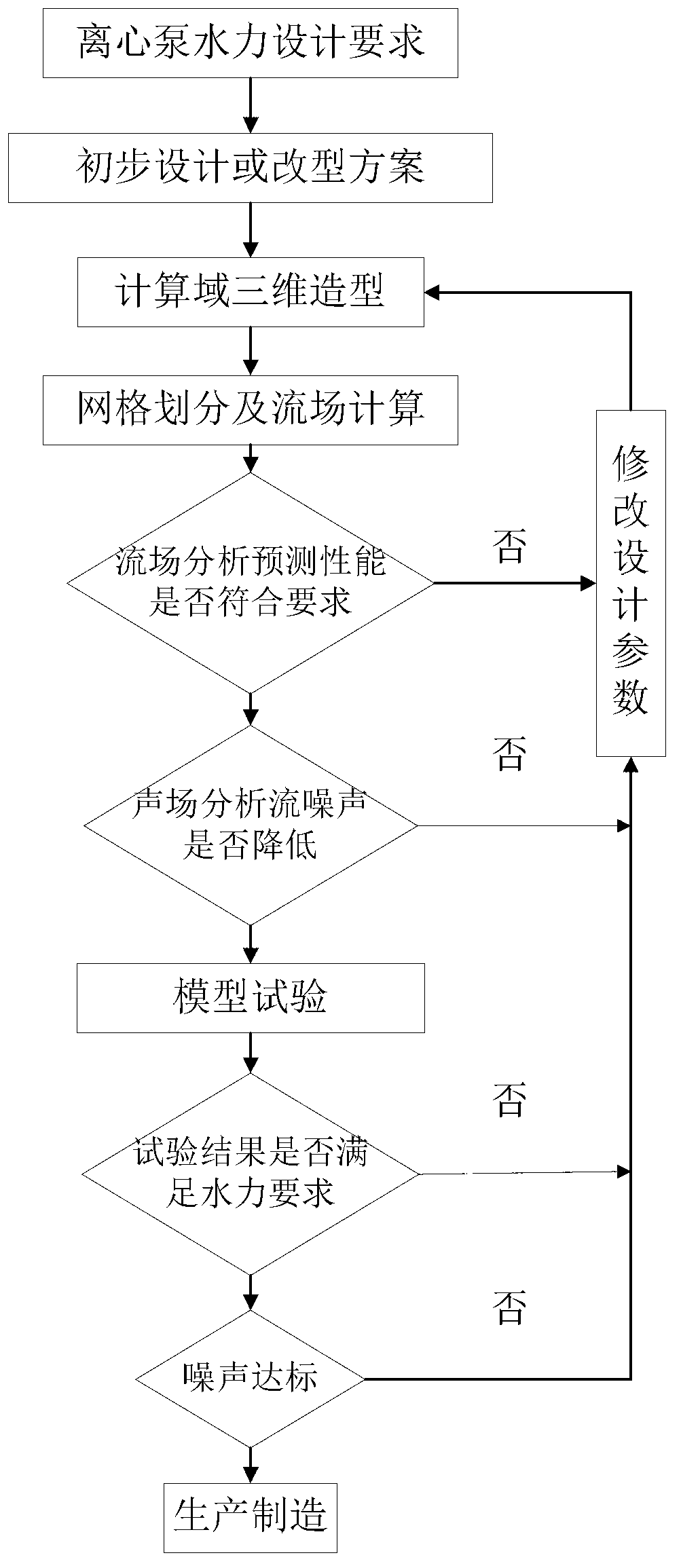

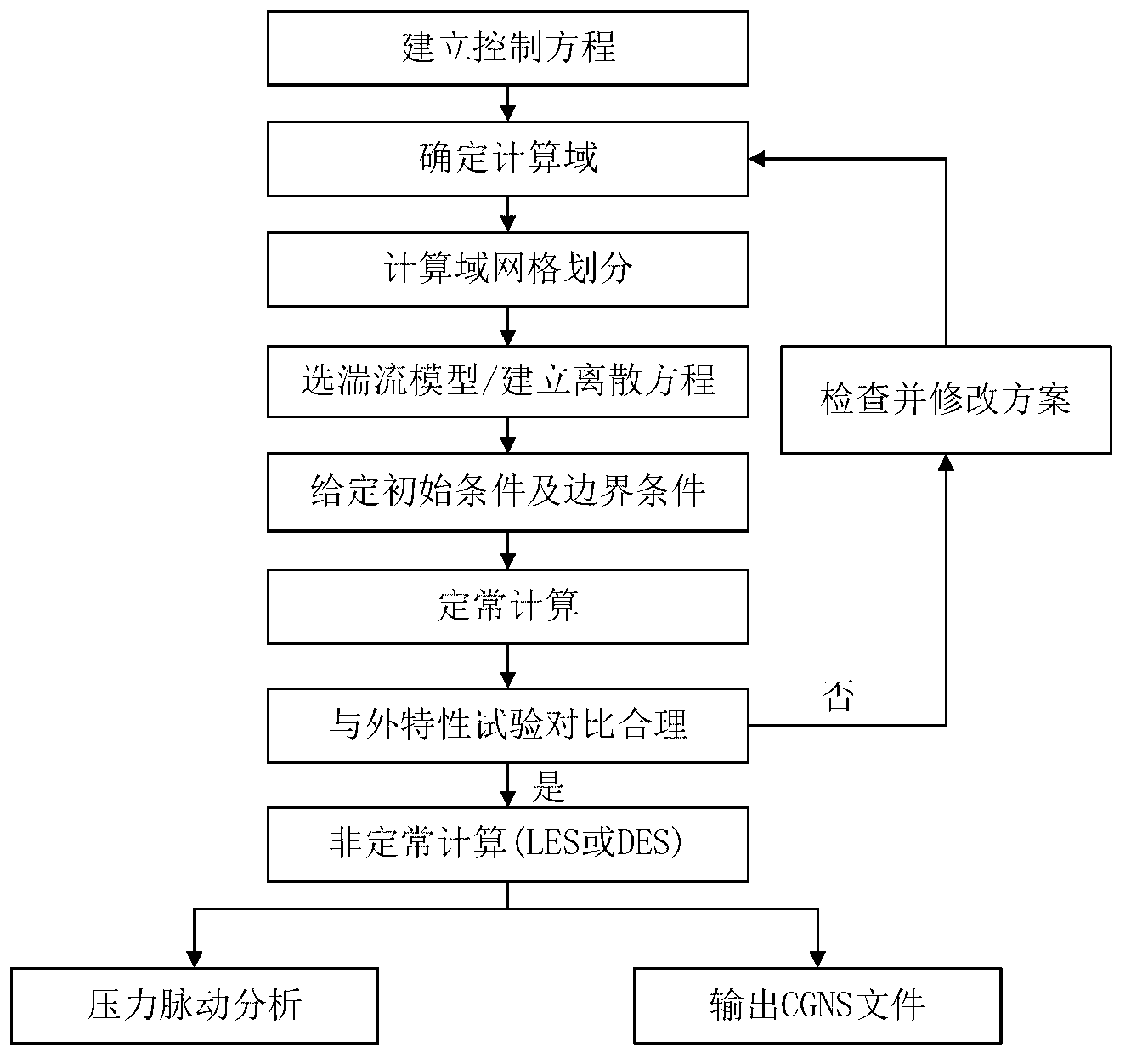

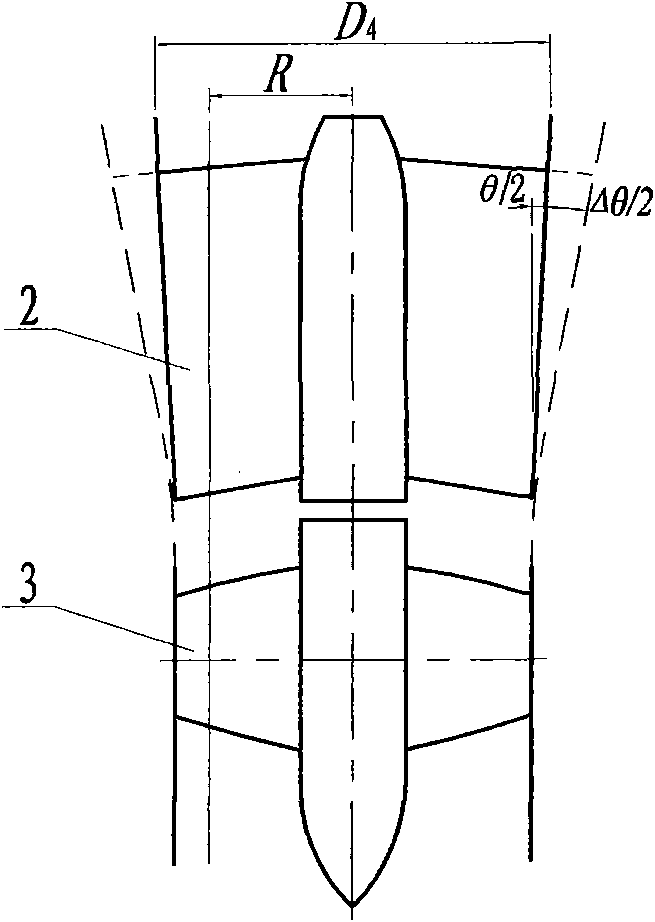

Low-noise hydraulic design method of centrifugal pump with low specific speed

ActiveCN103306985AImprove design qualityImprove machine performancePump componentsSpecial data processing applicationsLow noiseComputational acoustics

The invention discloses a low-noise design method of a centrifugal pump with low specific speed, and relates to an active control method of flow noise of turbomachinery. The design method comprises the steps that firstly, main structural dimensions of a centrifugal pump impeller and a helical pumping chamber (volute) are obtained by the traditional low-specific-speed pump design method; secondly, an internal flow field of the pump is computed by a computational fluid mechanics method; the performance of the pump is predicted whether to meet a design requirement; an optimum design improvement is performed by analyzing a stationary flow field; thirdly, flow induction noise of the pump with low specific speed is predicted by a computational acoustics method; if a flow noise index is qualified, the design is accomplished; if the flow noise index is disqualified, subsequent steps are performed; fourthly, the diameter of the impeller basically meeting a performance requirement in the design is adjusted to allow a gap between the impeller and a volute tongue to be increased continuously to 20%; splitter blades are added in the middles of blades to increase the lift, control the flow situation, and ensure the efficiency; and finally, the pump subjected to the impeller improvement design is subjected to noise prediction; if the flow noise index is qualified, the design is accomplished; and if the flow noise index is disqualified, the beginning step is repeated. The design method shortens the research and development period, saves the development cost, effectively improves the design quality of the centrifugal pump, can simultaneously meet low-noise requirements of the lift and the efficiency, and realizes optimization of the performance of the complete centrifugal pump with low specific speed.

Owner:JIANGSU UNIV

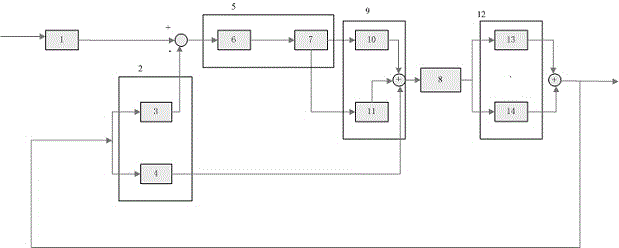

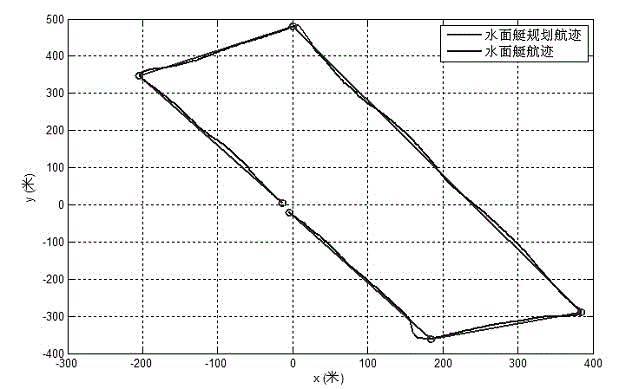

Unmanned surface vehicle trajectory tracking control device and method based on nonlinear control theory

ActiveCN103955218AGuaranteed uptimeReduce consumption costPosition/course control in two dimensionsState variablePath generation

The invention provides an under-actuated unmanned surface vehicle self-adaptive trajectory tracking control device and method. The device comprises a reference path generator, a state sensor, a differential converter, a parameter estimator, a virtual controller and a longitudinal thrust and bow steering torque controller. According to the unmanned surface vehicle actual position and course angle collected by the state sensor (2) and the reference position and reference course angle information generated by the reference path generator (1), the new state variable is obtained through the differential converter (5), the new state variable and the speed and angle speed information collected by a sensor (4) are transmitted to the parameter estimator (8) and the longitudinal thrust and bow steering torque controller (12), a control instruction is obtained through calculation to drive an execution mechanism, and the longitudinal thrust and bow steering torque of an unmanned surface vehicle are adjusted. According to the device and method, the unmanned surface vehicle can reach the specific position within specific time at specific speed. Due to the under-actuated unmanned surface vehicle, energy consumption and manufacturing cost of a system can be lowered, and the weight of the system is reduced.

Owner:精海智能装备有限公司

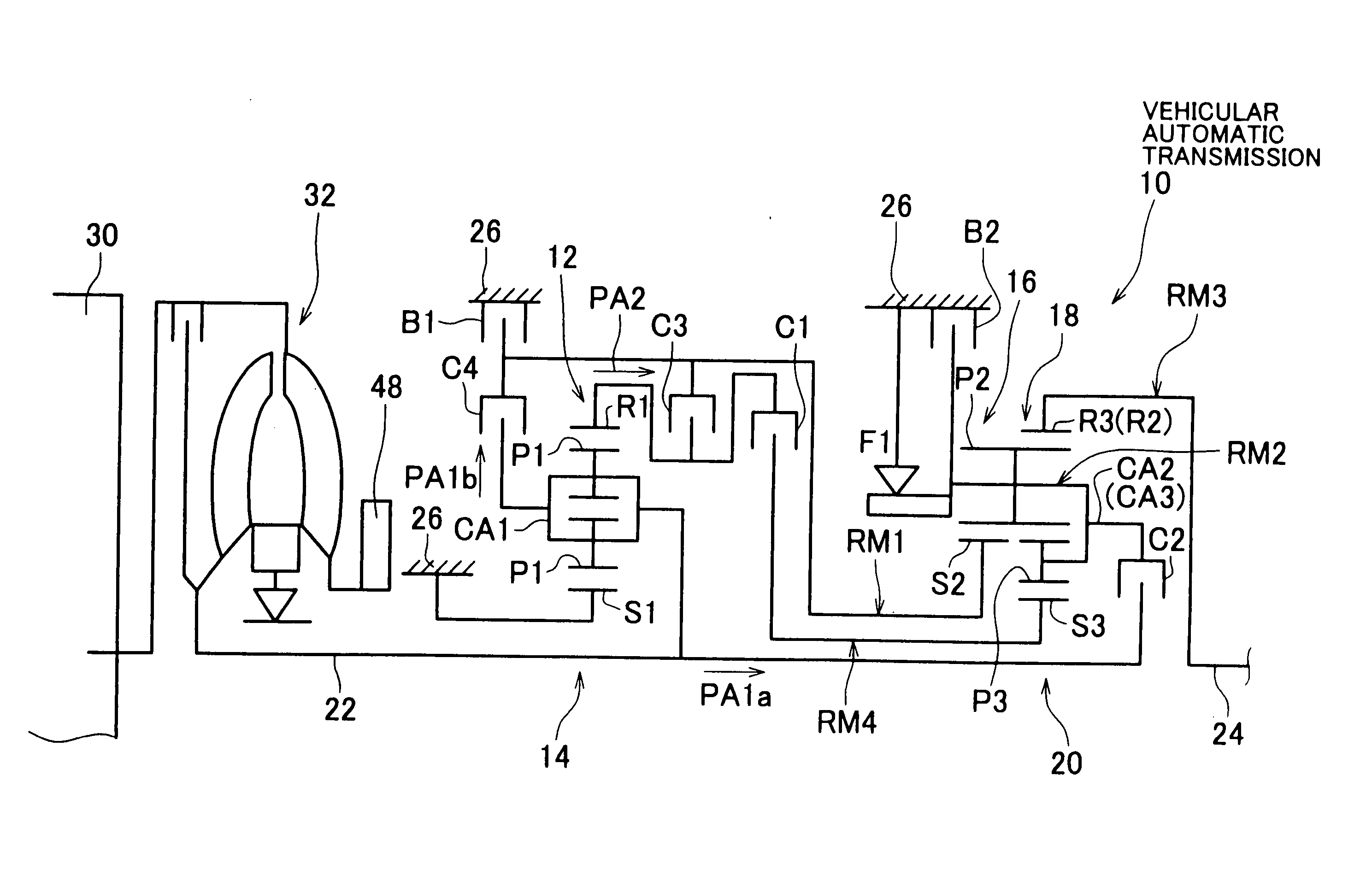

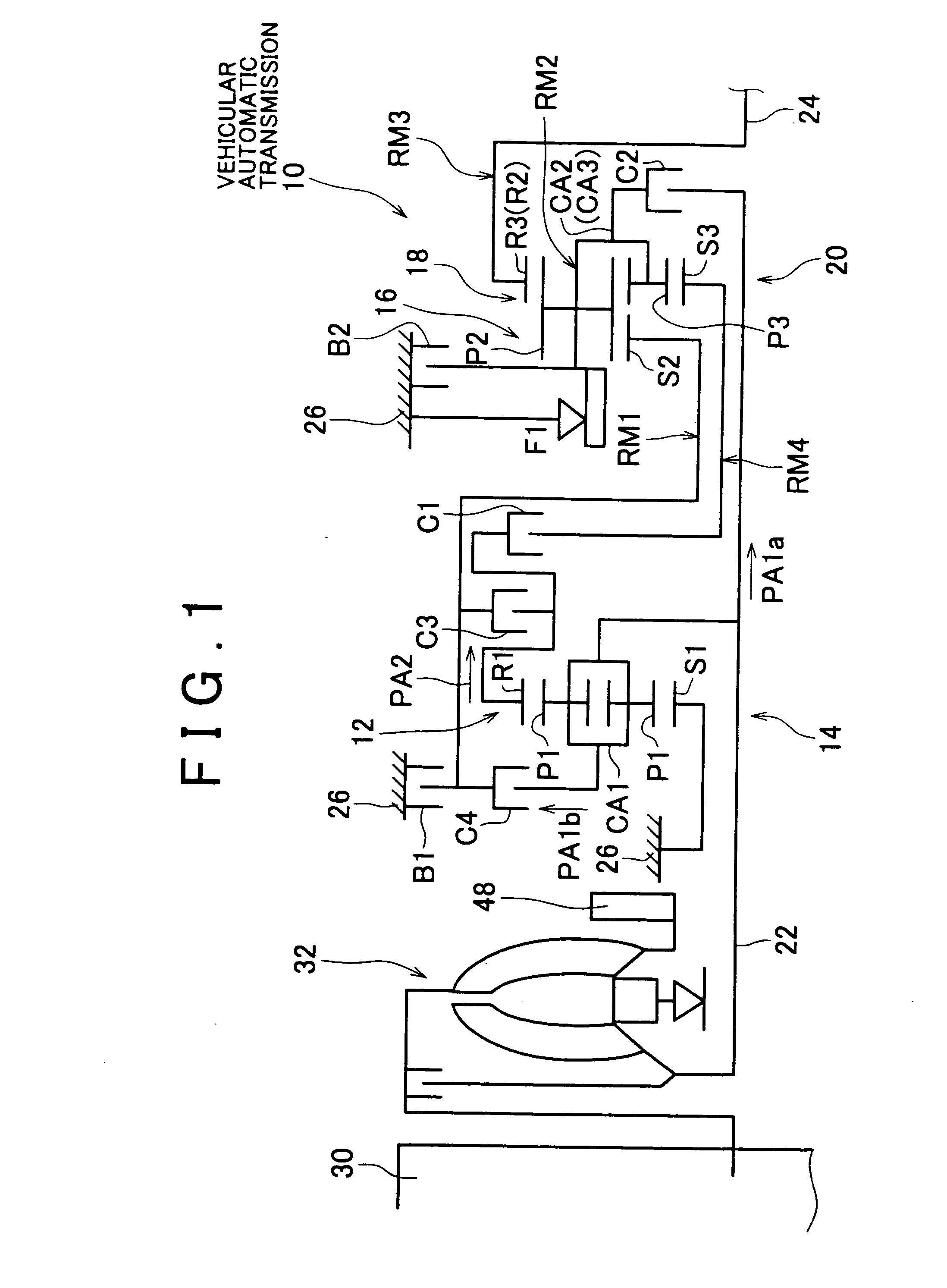

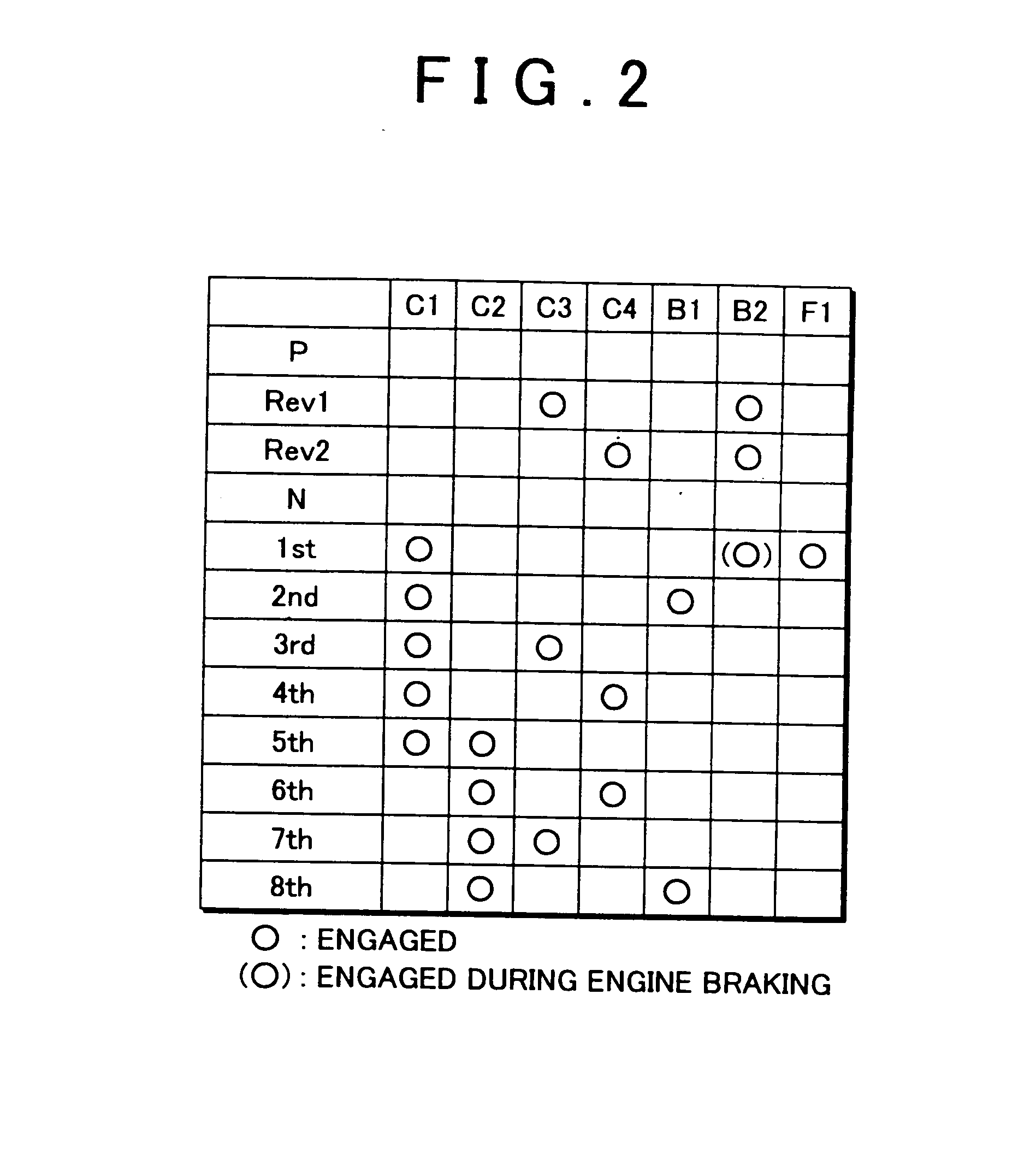

Control apparatus and control method of an automatic transmission

InactiveUS20070015624A1Blocking may occurGearing controlEngine controllersAutomatic transmissionControl theory

A control apparatus and control method of an automatic transmission that establishes a plurality of speeds of different speed ratios by selectively engaging and / or releasing a plurality of engagement devices, detects abnormal engagement of at least one of the engagement devices which causes tie-up to occur in the automatic transmission; establishes a predetermined specific speed set in advance in order to prevent tie-up from occurring in the automatic transmission, when abnormal engagement of the at least one of the engagement devices is detected; and places the automatic transmission in a neutral state when an engine speed will exceed a predetermined allowable speed if the predetermined specific speed is established.

Owner:TOYOTA JIDOSHA KK

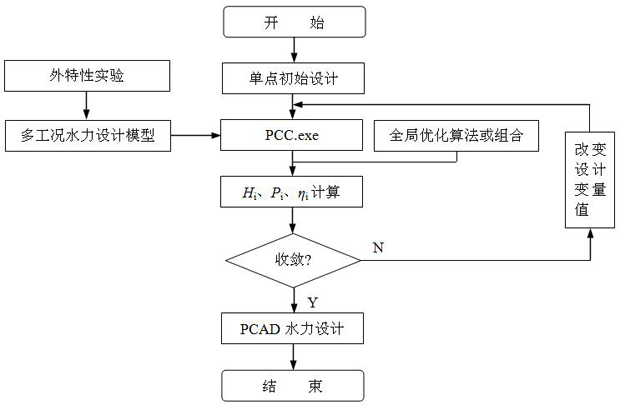

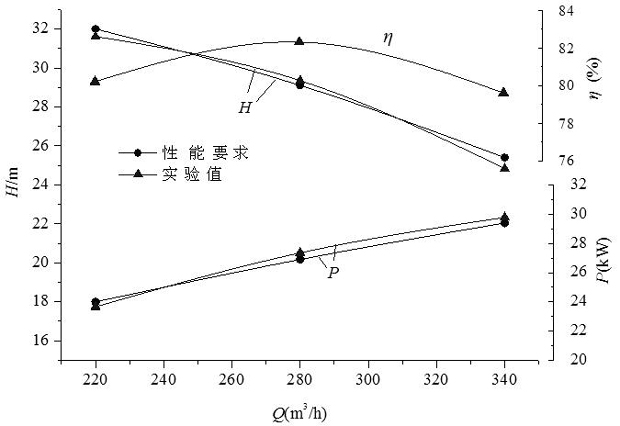

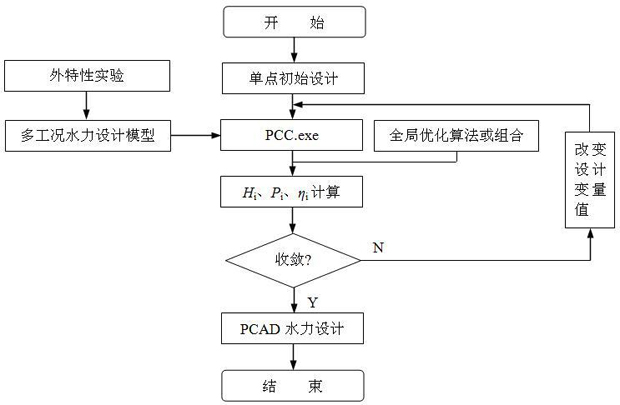

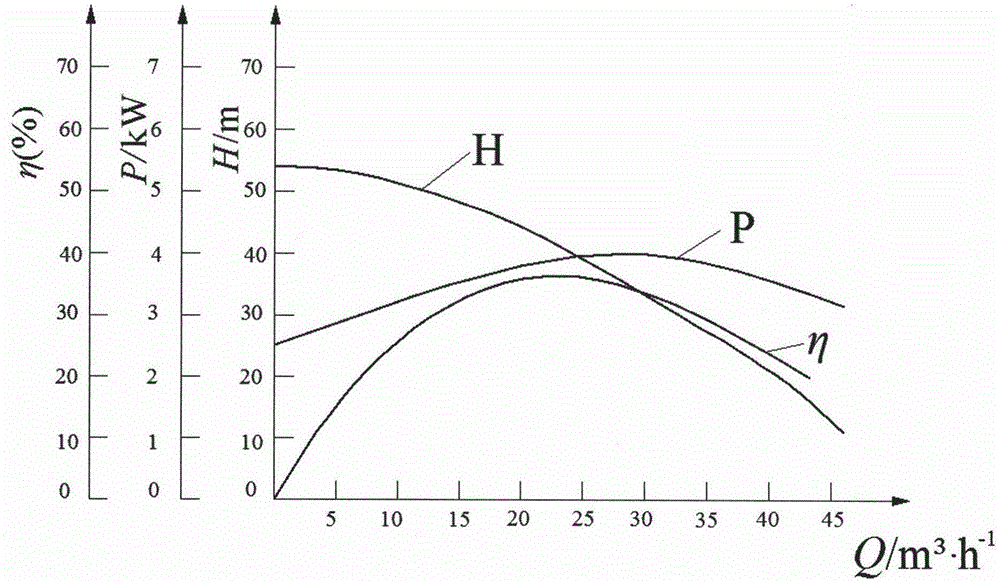

Method for hydraulically optimizing centrifugal pump under working conditions based on loss

ActiveCN101956710AMeet engineering applicationsShorten the design cycleRadial flow pumpsNon-positive displacement fluid enginesProcess engineeringMaximum efficiency

The invention discloses a method for hydraulically optimizing a centrifugal pump under a plurality of working conditions based on loss, which comprises the following steps of: establishing a multi-working condition hydraulic optimization model of the centrifugal pump based on various loss formulae; establishing relationships among various loss coefficients, specific speeds and flows of the centrifugal pump at different specific speeds under the different working conditions by external characteristic experiments; compiling multi-working condition hydraulic optimization programs PCC.exe of the centrifugal pump by adopting Visual C++; integrating the PCC.exe by adopting iSIGHT, taking parameter values of single-point design as initial values, taking heads and power under the plurality of working conditions as constraint conditions, taking maximum efficiency under the plurality of working conditions as a target, and optimizing the centrifugal pump by adopting a global optimization algorithm or combination; and designing a multi-working condition hydraulic model by adopting PCAD according to an optimal solution set obtained in the optimization. The method has the advantages of not only performing multi-working condition hydraulic design on the centrifugal pump according to performance requirements under the plurality of working conditions, but also performing energy-saving alternation on the conventional centrifugal pump.

Owner:JIANGSU UNIV

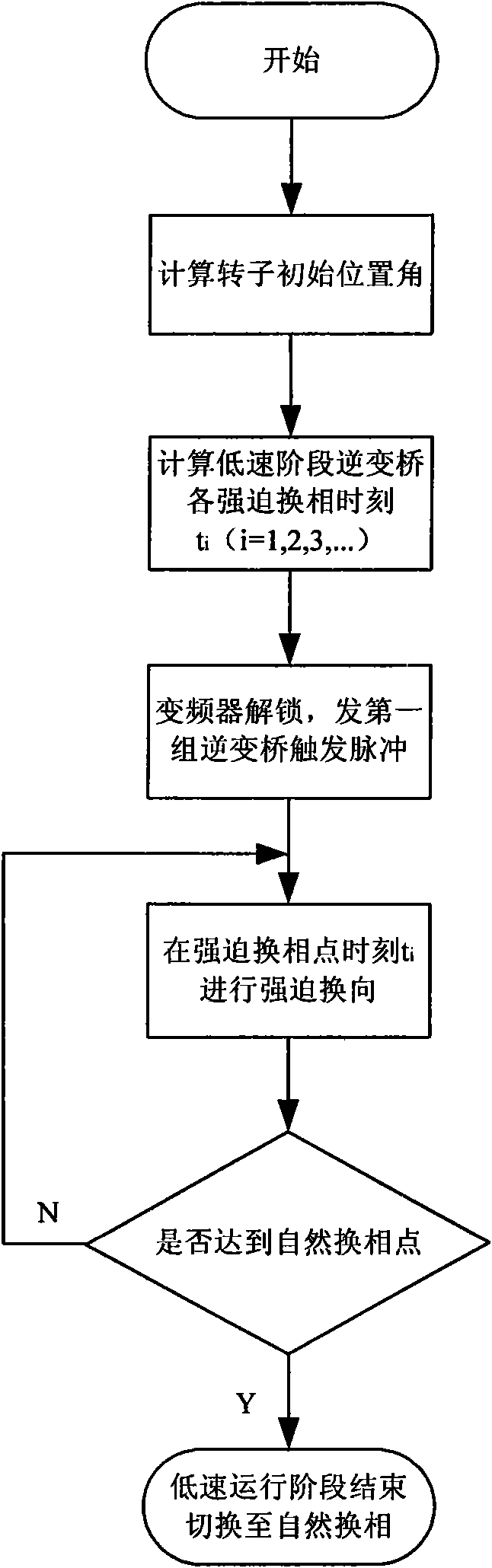

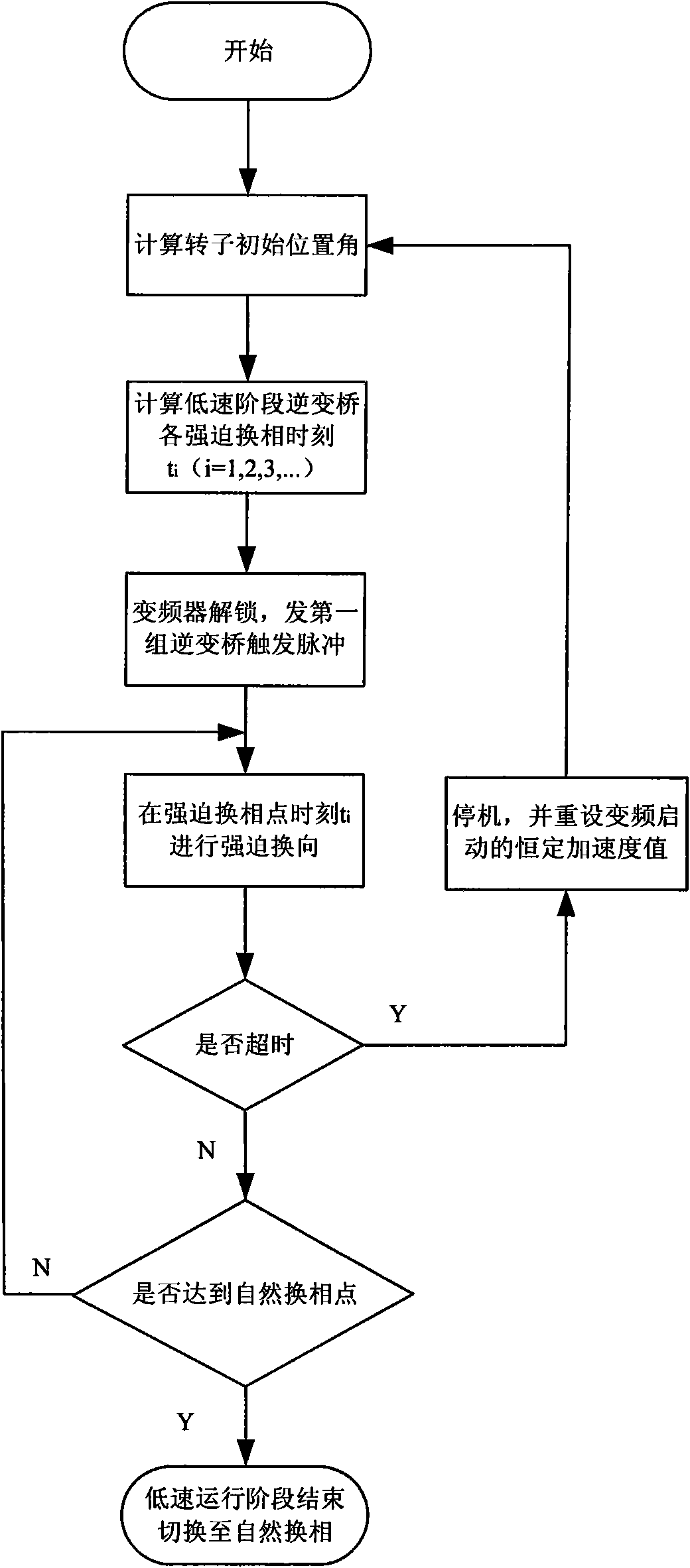

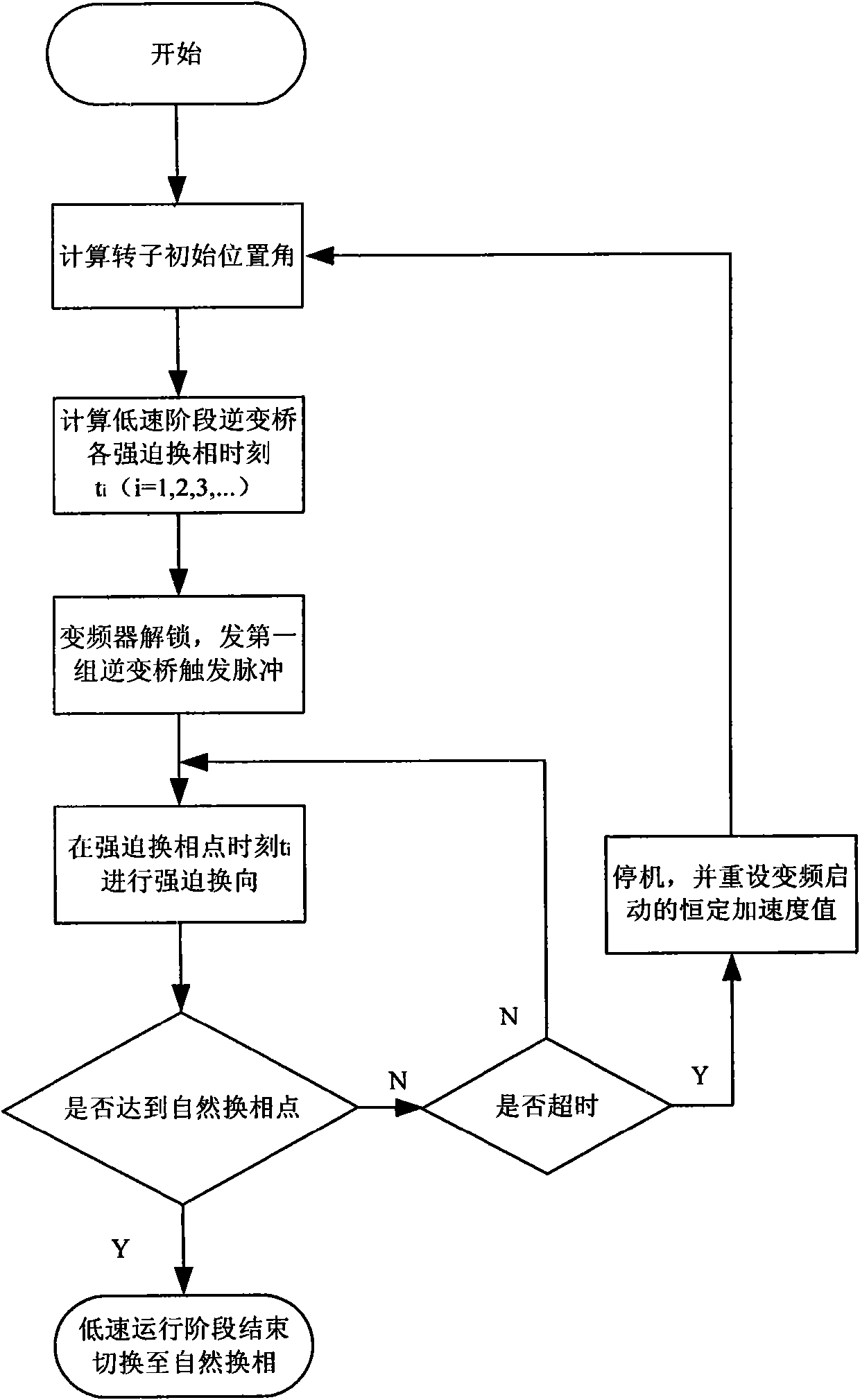

Control method of low-speed stage starting of static frequency conversion starting of pumped storage power station

ActiveCN101621271ARealize frequency conversion startEasy to debugPolyphase induction motor starterFrequency changerLow speed

The invention relates to a control method of low-speed stage starting of static frequency conversion starting of a pumped storage power station, comprising the following steps: calculating the initial position of a rotor; estimating each force commutation moment of a low-speed stage inverting bridge according to a preset constant acceleration value; electrifying an appointed two-phase winding at the unlocking moment of a frequency converter according to an interval to which the initial position of the rotor belongs; switching a rectifier bridge to an inversion run mode at the forced commutation moment, sending a trigger pulse to a thyristor bridge arm corresponding to the appointed two-phase winding according to an interval to which a rotor position angle belongs at the moment after a loop of a frequency converter is cut out and each bridge arm of the inverting bridge is reliably shut off, and simultaneously switching the rectifier bridge to a rectifying run mode, and ending single forced commutation; ending the low-speed run stage if the rotor speed is higher than or equal to 5 percent of specific speed of a machine set, and then switching to a natural commutation stage based on machine terminal voltage, or carrying out the forced commutation again; and if starting exceeds time, regulating the preset constant acceleration value, and then restarting until successful starting. The invention can realize rapid and reliable frequency conversion starting at the low-speed stage of the machine set of the pumped storage power station as long as a set value of the constant acceleration of machine set starting is regulated.

Owner:STATE GRID ELECTRIC POWER RES INST +2

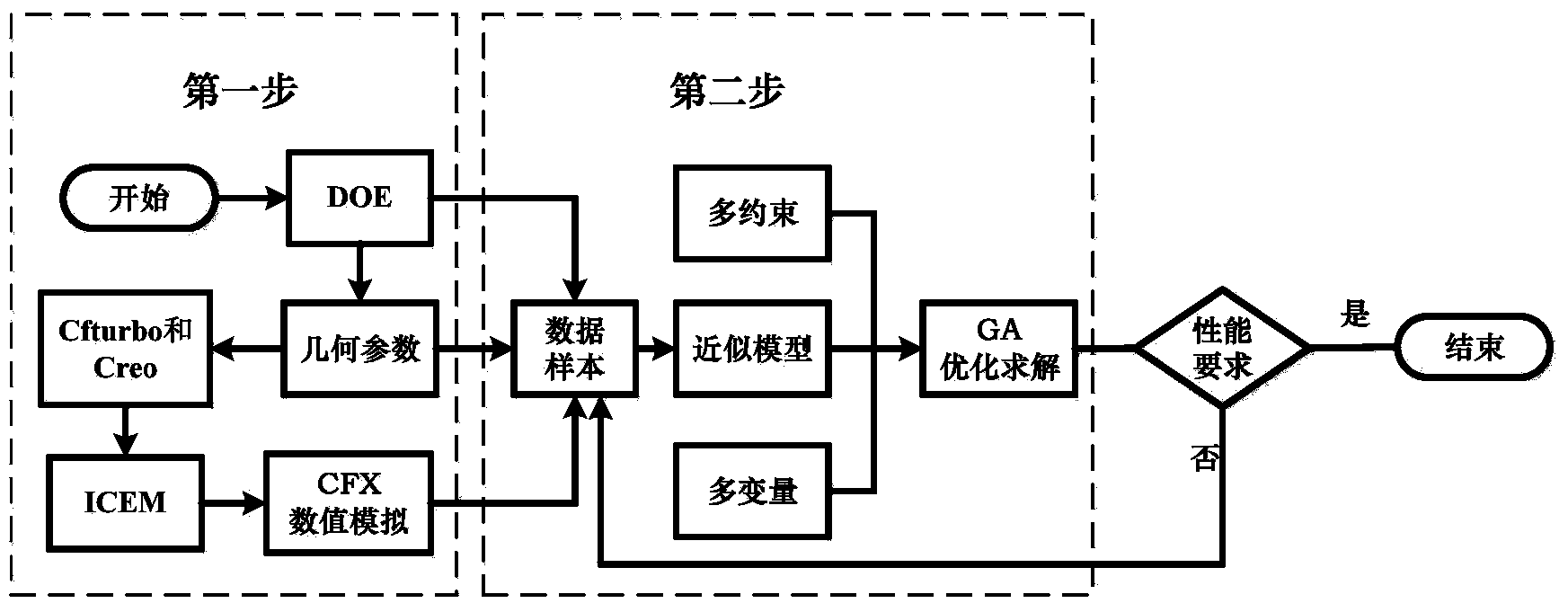

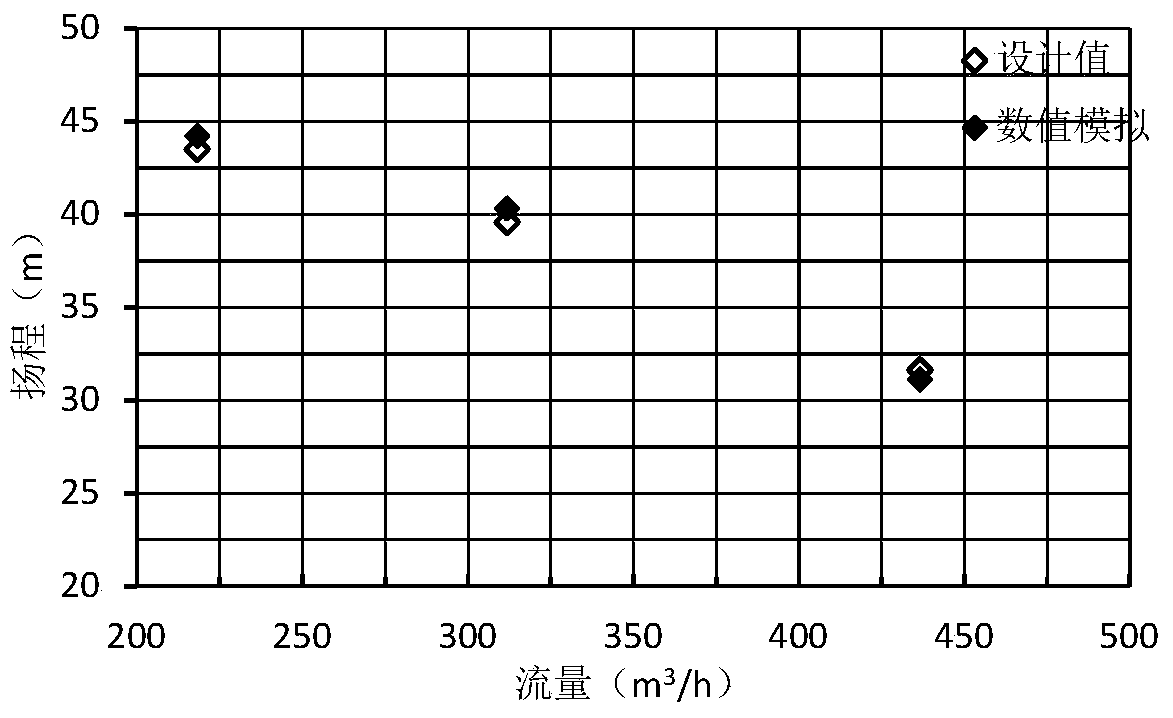

Multiple-working-condition hydraulic design method for guide vane type centrifugal pump

ActiveCN103939389AShorten the hydraulic design cycleMeet the design requirementsPump componentsPumpsGenetic algorithmEngineering

The invention discloses a multiple-working-condition hydraulic design method for a guide vane type centrifugal pump. The multiple-working-condition hydraulic design method for the guide vane type centrifugal pump mainly comprises the following steps that specific speed solution is conducted on the design working conditions of the guide vane type centrifugal pump, and the design working condition with the specific speed as an intermediate specific speed is selected and designed; multiple-scheme design is conducted on an impeller and guide vanes through an experiment design method, and the CFturbo style is adopted; mesh generation is conducted on a model, numerical simulation is conducted on a scheme through CFX, the lift and the efficiency value are read, and function fitting is conducted between the lift and a flow; function fitting is conducted between the lift and the flow of a design parameter point, the coefficient of a fitting function is used as a design goal, input main geometrical parameters are used as input values, an approximate response model is established through the Kriging model, rapid computation is conducted on the approximate response model through a multiple-target genetic algorithm, and then the optimal value is obtained. By the adoption of the multiple-working-condition hydraulic design method for the guide vane type centrifugal pump, the requirement for multiple-working-condition hydraulic design of the guide vane type centrifugal pump can be met; the multiple-working-condition hydraulic design method for the guide vane type centrifugal pump can also be used for multiple-working-condition hydraulic design of other guide vane type centrifugal pumps.

Owner:云南流体规划研究院有限公司

Centrifugal compressor assembly and method

ActiveUS8037713B2Improve performanceReduce physical sizePump componentsRotary non-positive displacement pumpsMixed flowHigh energy

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090208331A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

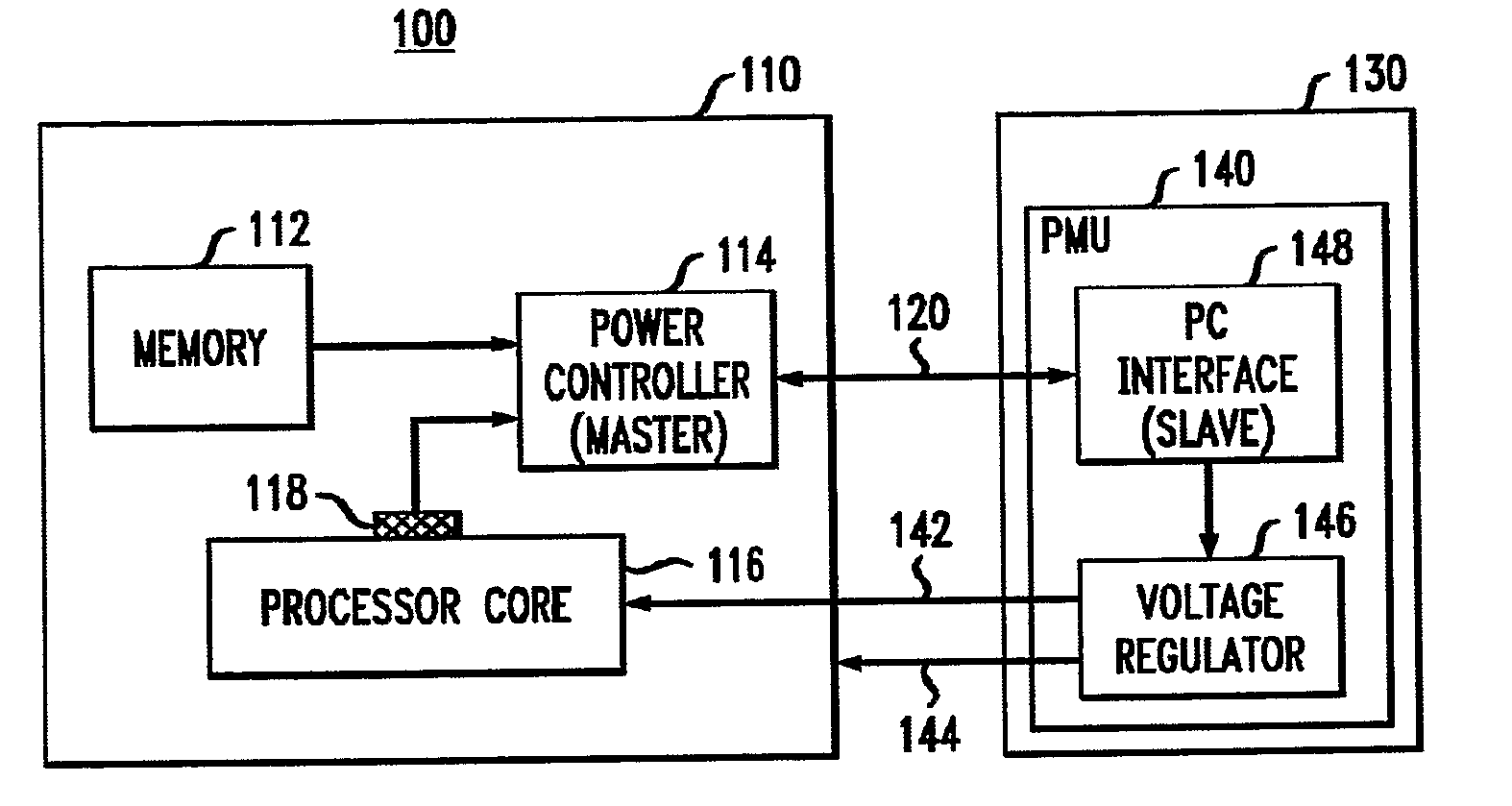

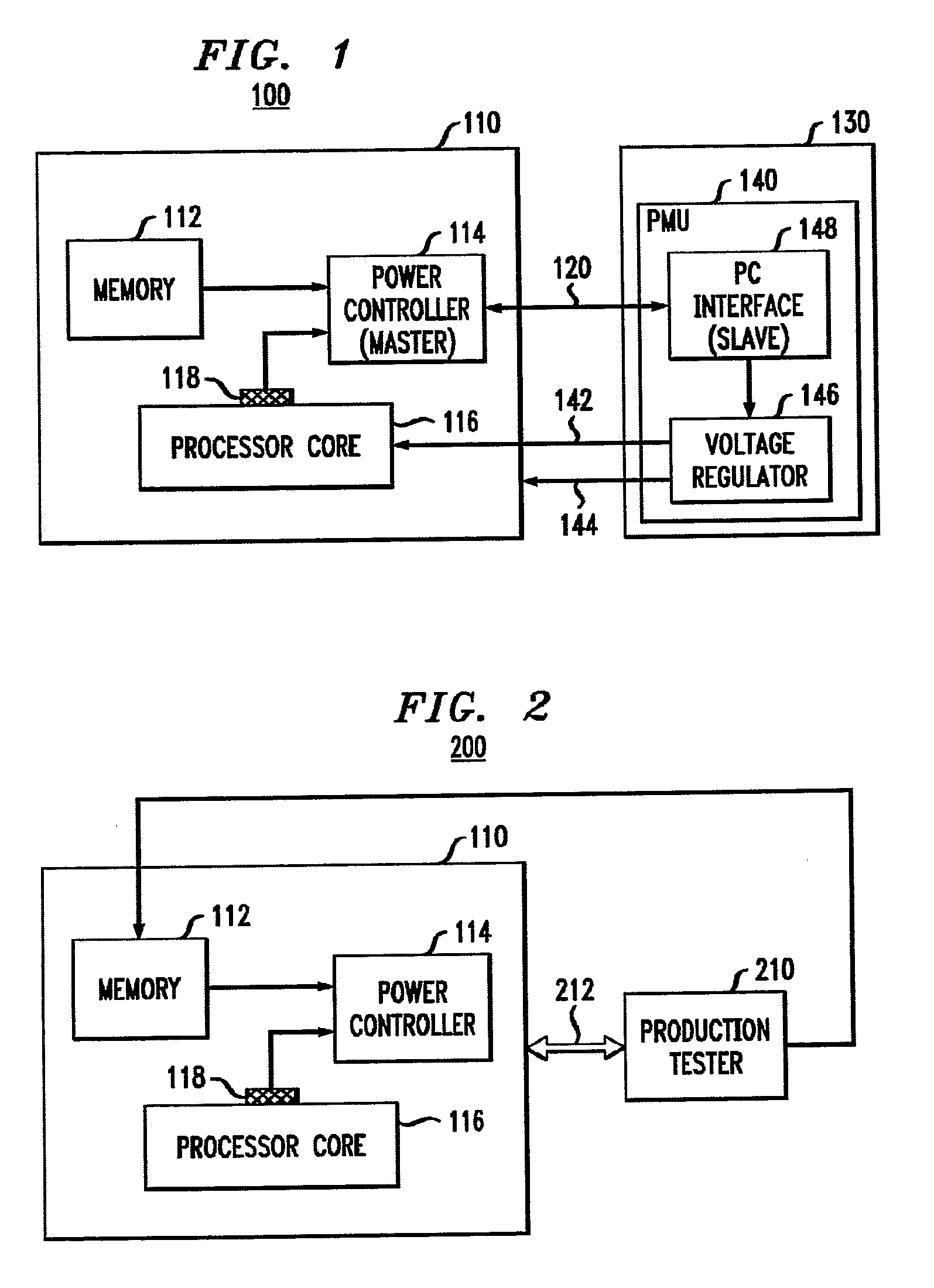

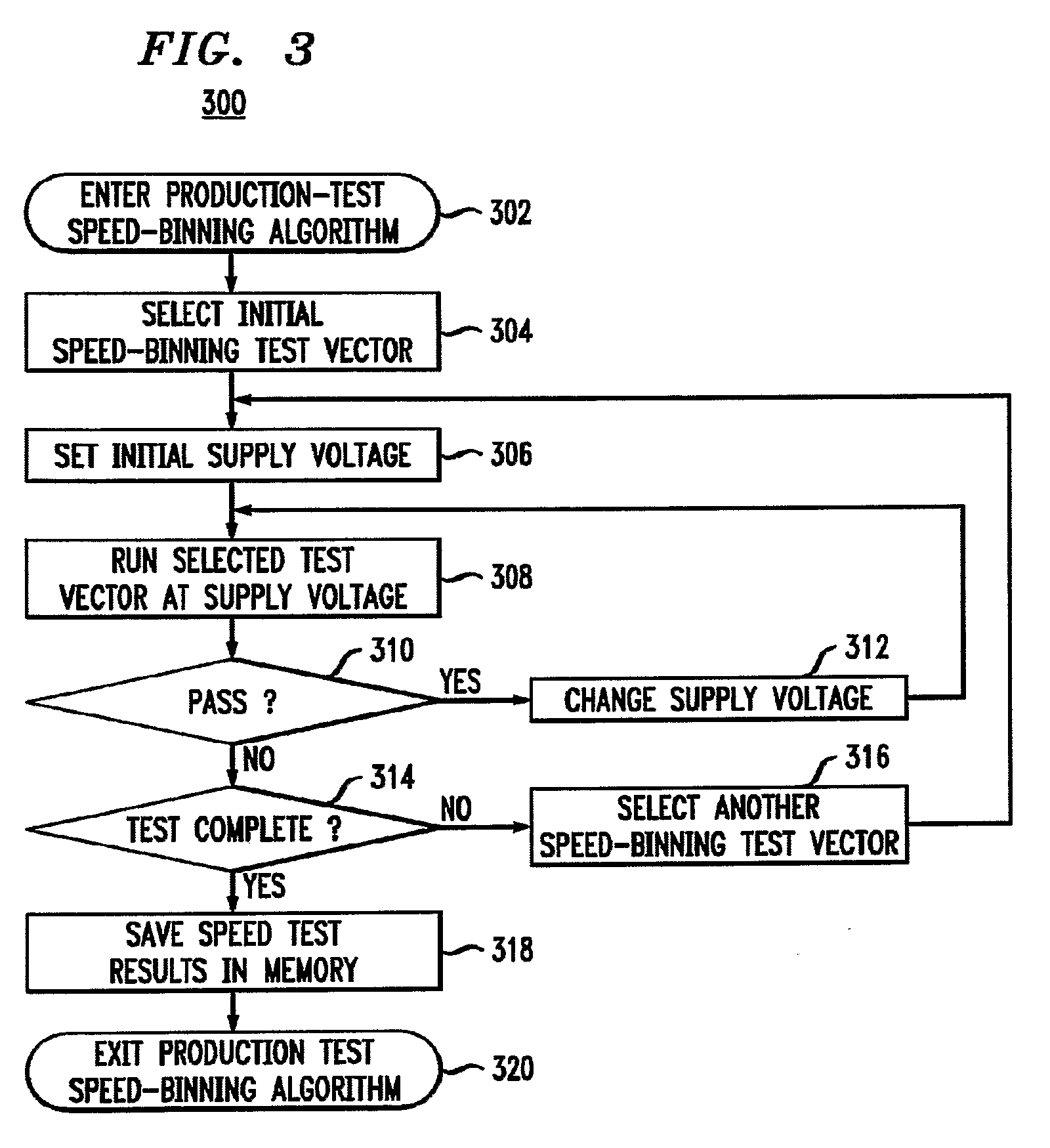

Speed binning for dynamic and adaptive power control

ActiveUS20100017042A1Increase power consumptionGreat customizationMechanical power/torque controlLevel controlPower controllerEngineering

A representative digital circuit of the invention has an on-chip, non-volatile memory, to which chip-specific speed-binning data that characterize performance of the digital circuit are written during production testing. During normal operation, the power controller that controls power-supply signals applied to the digital circuit reads the speed-binning data from the on-chip memory for use as input parameters for dynamic supply-voltage scaling, dynamic clock scaling, and / or adaptive power control that optimize (e.g., minimize) power consumption in the digital circuit. Advantageously over the prior art, the accuracy and efficiency of dynamic and / or adaptive power control arc improved because the chip-specific speed-binning data enable the power controller to better customize the power-management algorithm for the given digital circuit.

Owner:AVAGO TECH INT SALES PTE LTD

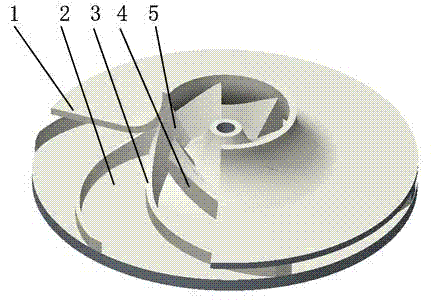

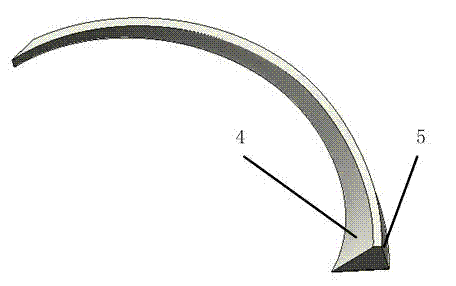

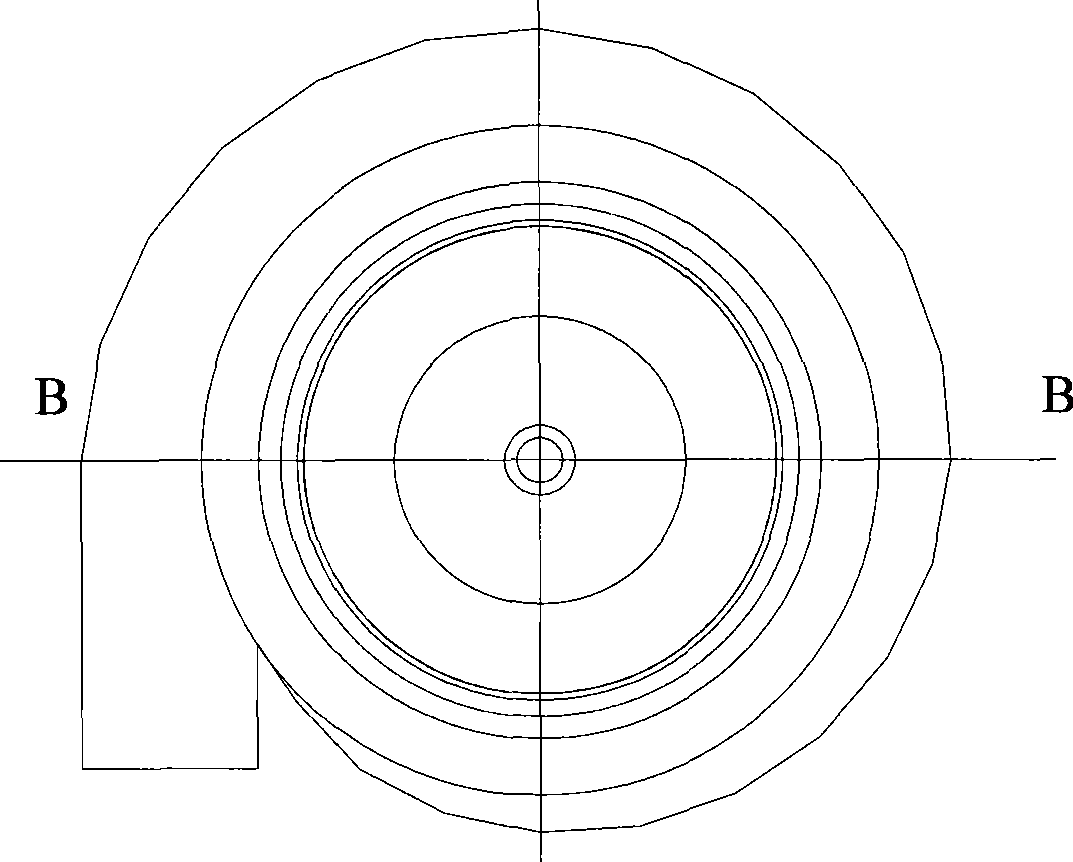

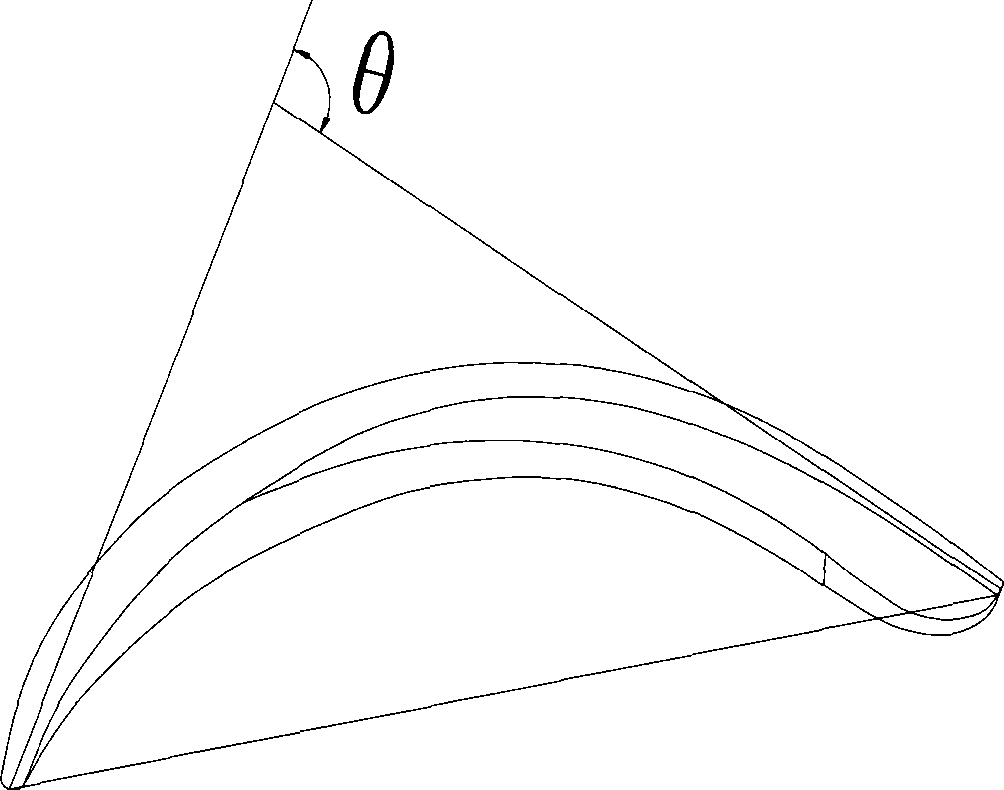

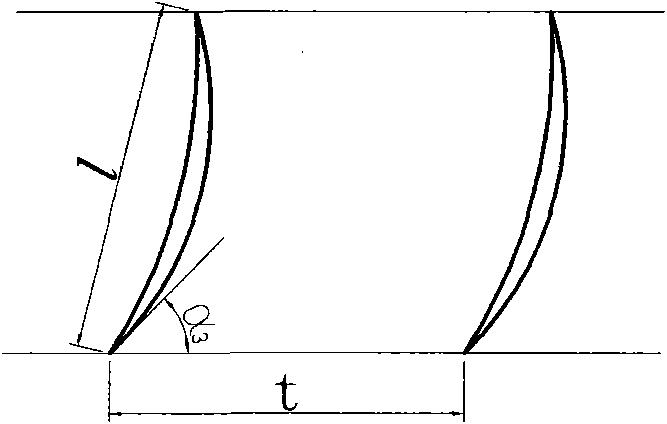

Low-specific-speed impeller and design method for blade thereof

InactiveCN103291653AReduce the cross-sectional areaSatisfy the no-overload characteristicPump componentsPumpsImpellerBackward bending

The invention discloses a low-specific-speed impeller and a design method for a blade of the low-specific-speed impeller. Both a front cover plate and a rear cover plate are of disc structures. The blade is designed according to the method that a column and twisting are combined, namely, a working face (4) or a back face (5) adopts a form of a backward bending column blade and the other side adopts a backward bending blade twisting mode, and therefore the blade accords with the law of fluid motion, reduces hydraulic loss, and improves efficiency of a low-specific-speed centrifuging pump. The thickness of the inlet edge, close to the front cover plate, of the blade is 2-3mm, the thickness of the inlet edge, close to the rear cover plate, of the blade is 5-7mm, and therefore sand mould casting lifting precision is improved, inlet flow passages can be partially blocked, and therefore blade inlet excluding coefficient is reduced, and the non-overload characteristic of the low-specific-speed centrifuging pump is improved. The low-specific-speed impeller and the design method for the blade of the low-specific-speed impeller can be applied to the field of efficient non-overload low-specific-speed impeller designing.

Owner:JIANGSU UNIV

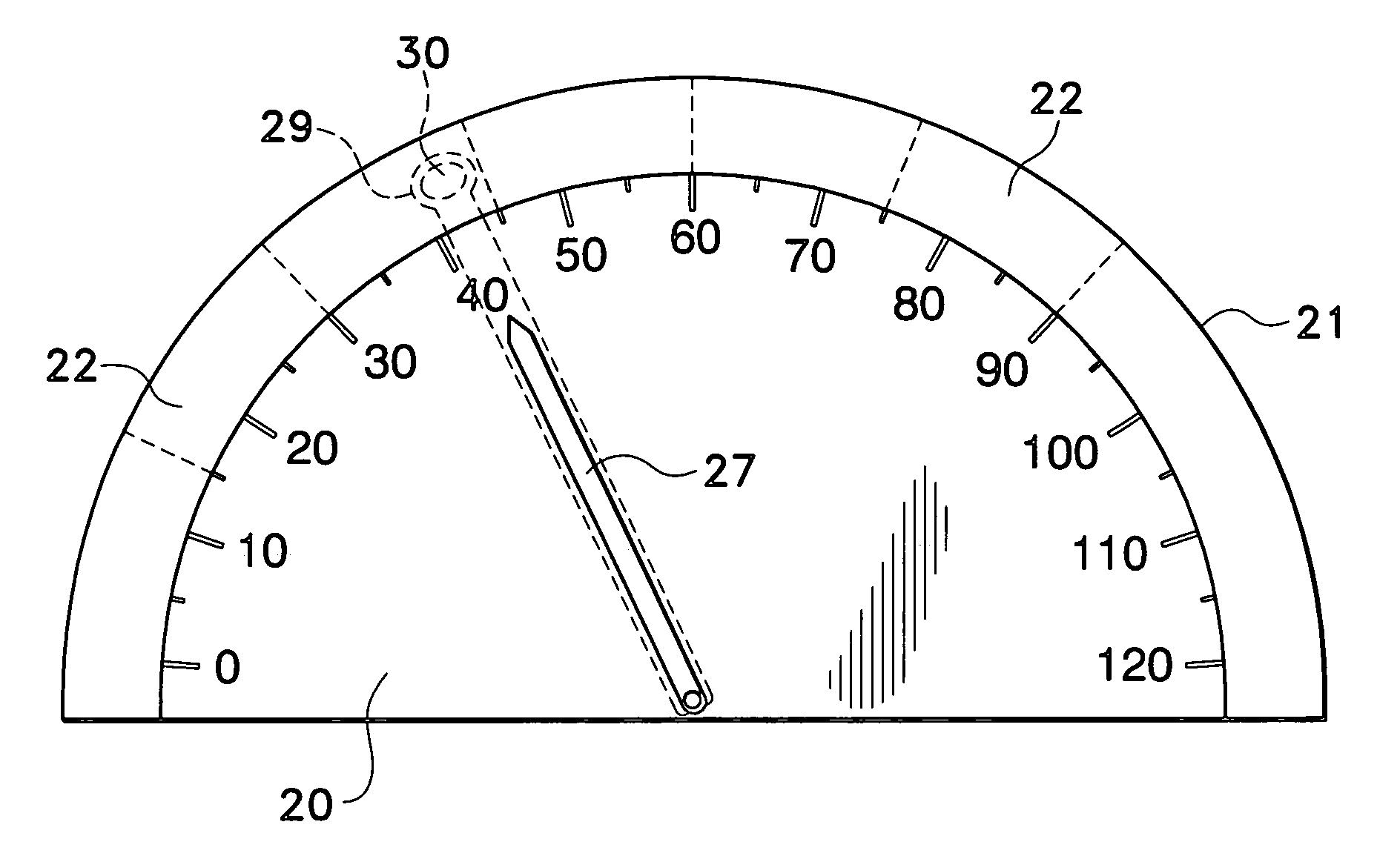

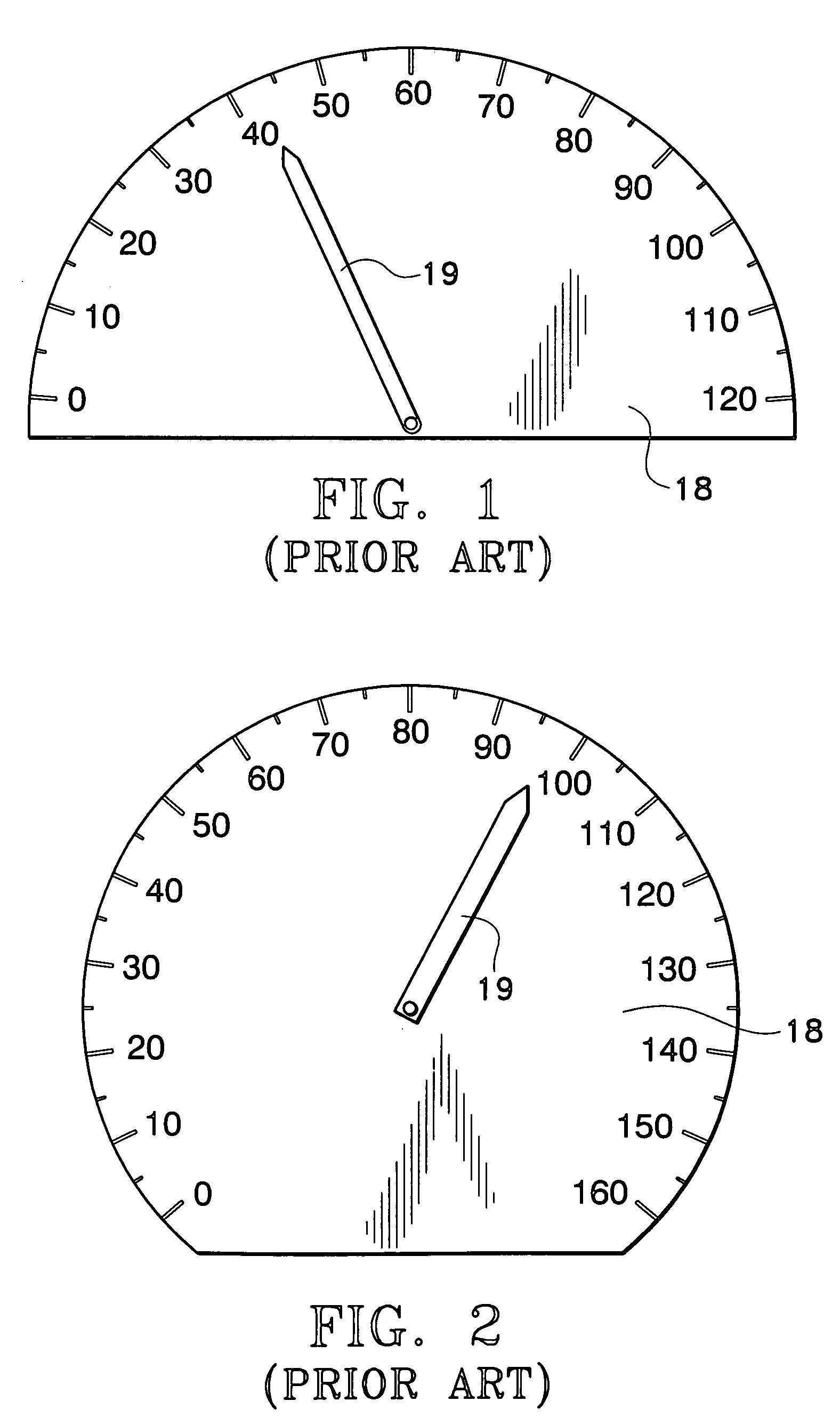

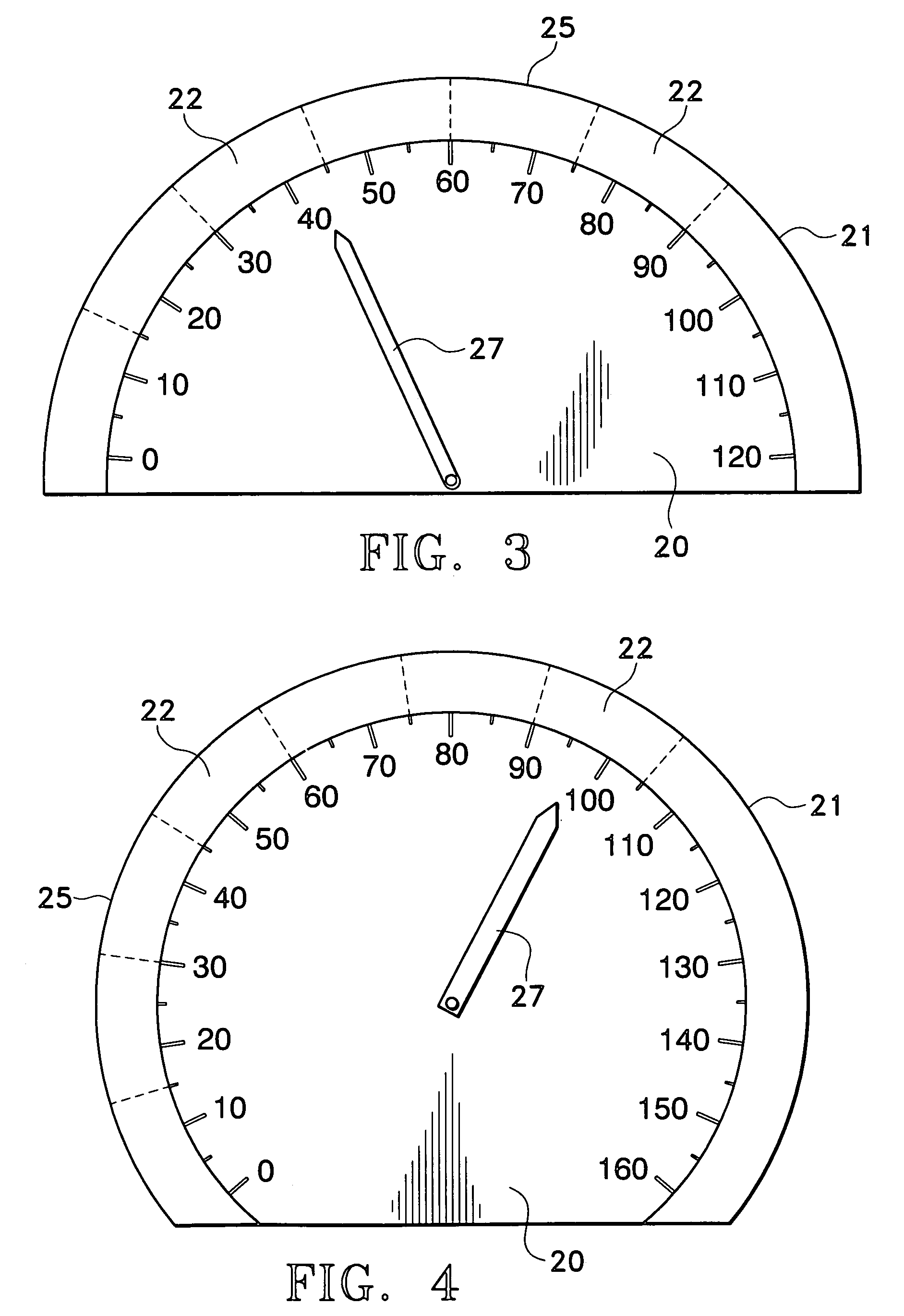

Peripheral view speedometer

InactiveUS7178479B1Smooth transitionThermometer detailsMeasured value indication by color changeDriver/operatorEngineering

A speedometer face plate assembly that incorporates a border of light transmitting segments above the speed indicating numerals is disclosed. Each of the segments is a different color. The colored segments are lighted from behind as the speed changes so that colored light is visible both peripherally and directly to the driver. Each color is associated with a specific speed increment so that once the driver becomes familiar with this speedometer face plate assembly, he or she will be aware of the speed traveled according to the color of the light and will not have to look directly at the speedometer as frequently as is currently necessary. In addition to the colored light transmitting border, there may also be a colored light transmitting section under the numerals or at another area on the speedometer face to further enhance the colored light effect. This speedometer face plate assembly contributes to increasing driving safety.

Owner:RICHTER MILTON

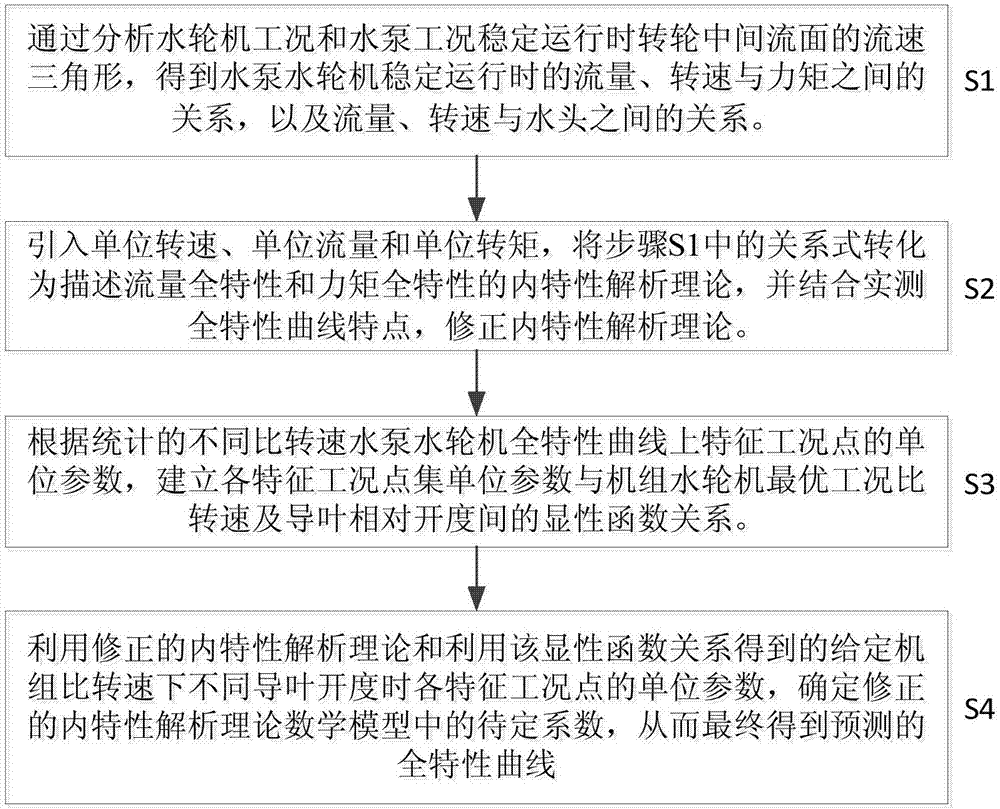

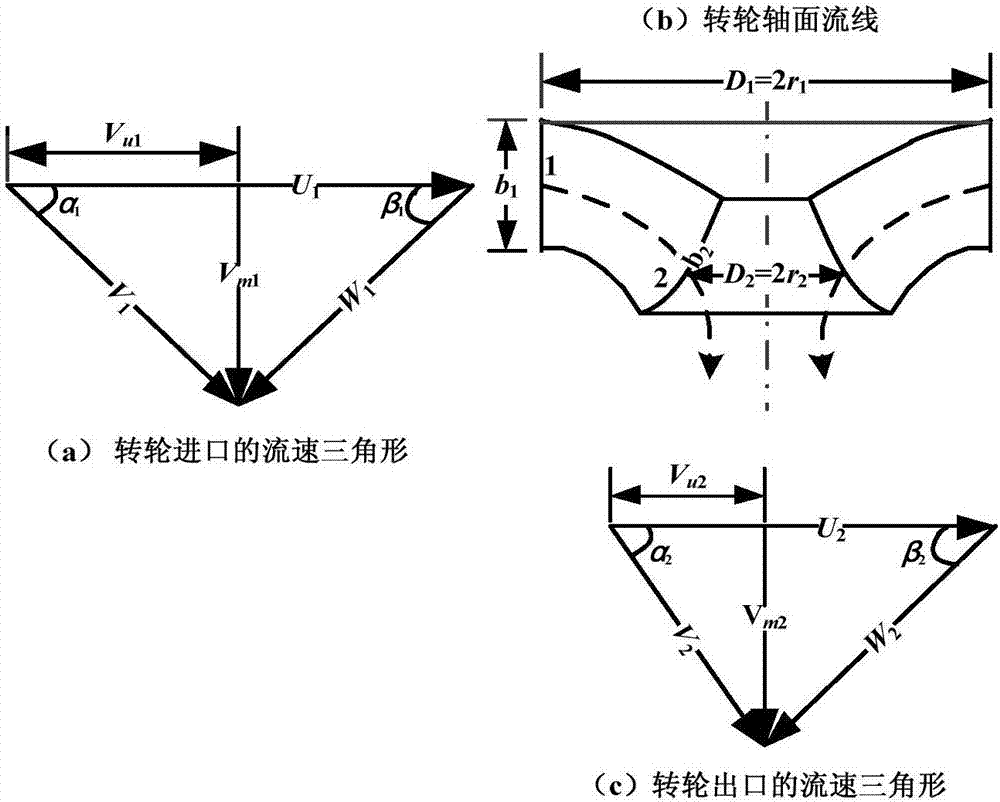

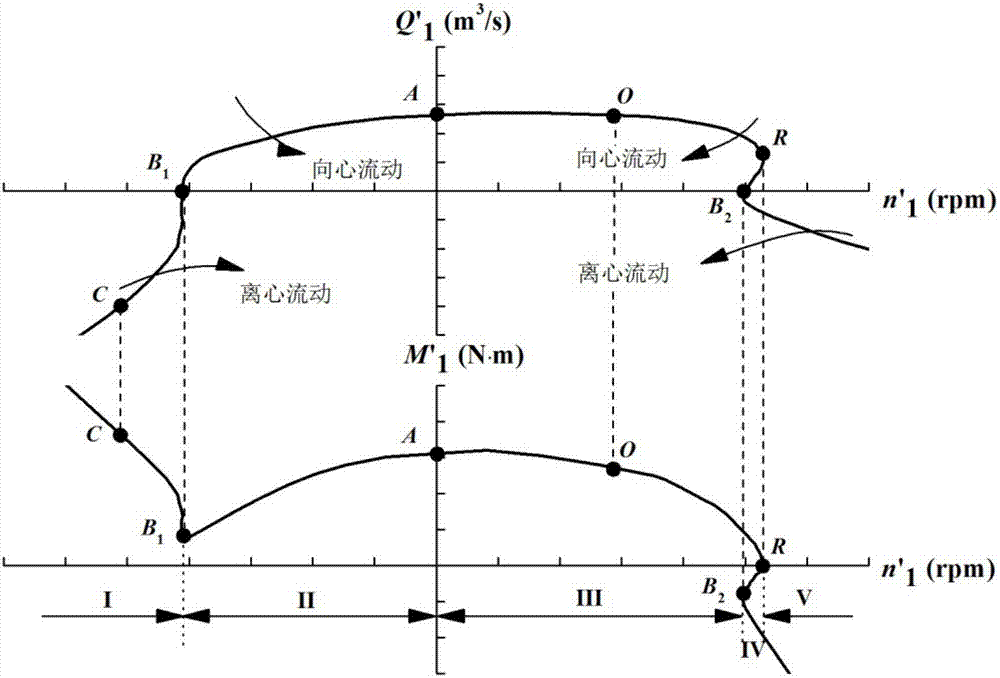

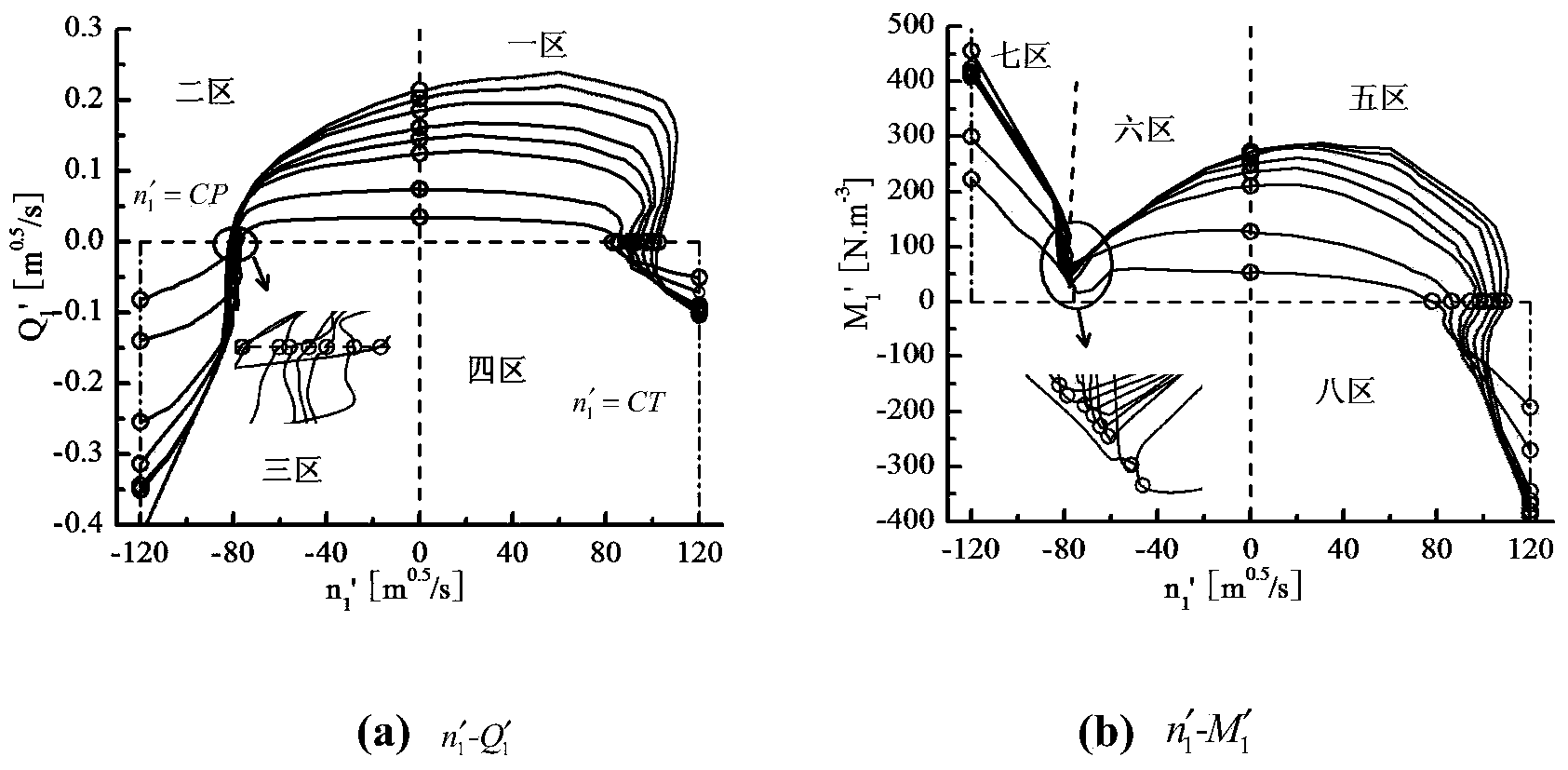

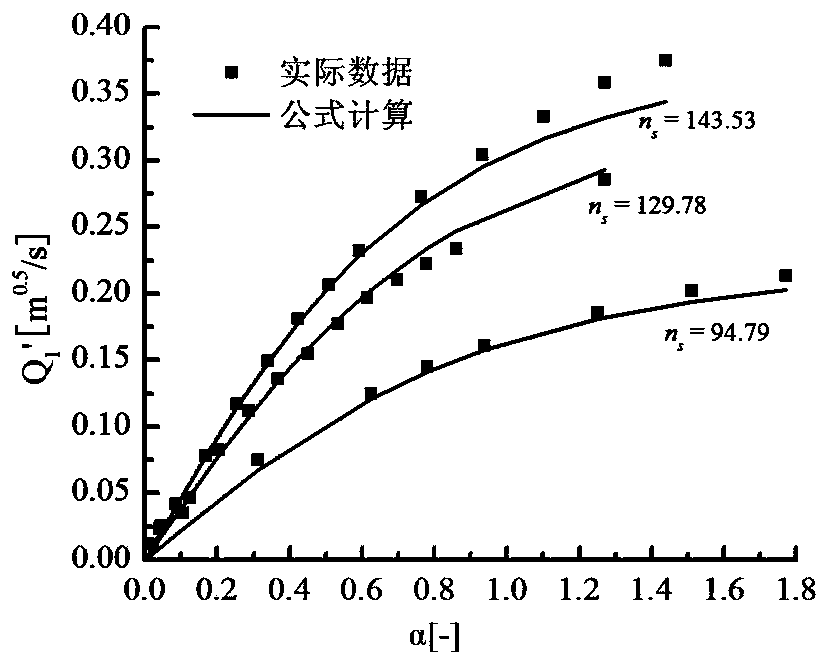

Predication method of complete characteristic curve of mixed-flow pump turbine

InactiveCN107191308AFull Characteristic Curve PredictionAccurate predictionHydro energy generationMachines/enginesOperating pointMixed flow

The invention discloses a predication method of the complete characteristic curve of a mixed-flow pump turbine. The predication method of the complete characteristic curve of the mixed-flow pump turbine comprises the steps that an internal characteristic analysis theory describing the flow complete characteristics and the moment complete characteristics are corrected through the feature of the actually measured pump turbine complete characteristic curve; statistics of unit parameters of feature operating points of the pump turbine complete characteristic curves of different specific speeds is conducted, the dominant function relationships between the unit parameter of each feature operating point and the optimal operating condition specific speed of the pump turbine and between the unit parameter of each feature operating point and the guide vane relative opening degree are established; and according to the dominant function relationships, the unit parameters of each feature operating point at different guide vane opening degrees are obtained, so that the undermined coefficient of the corrected internal characteristic analysis theory is determined, and a predicted complete characteristic curve of the pump turbine at any specific speed is obtained. The complete characteristic curve predicted by the adoption of the predication method is small in error, in this way, in a runner model simulation test, only a small number of feature working conditioner need to be tested, and the model test process is guided and accelerated.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

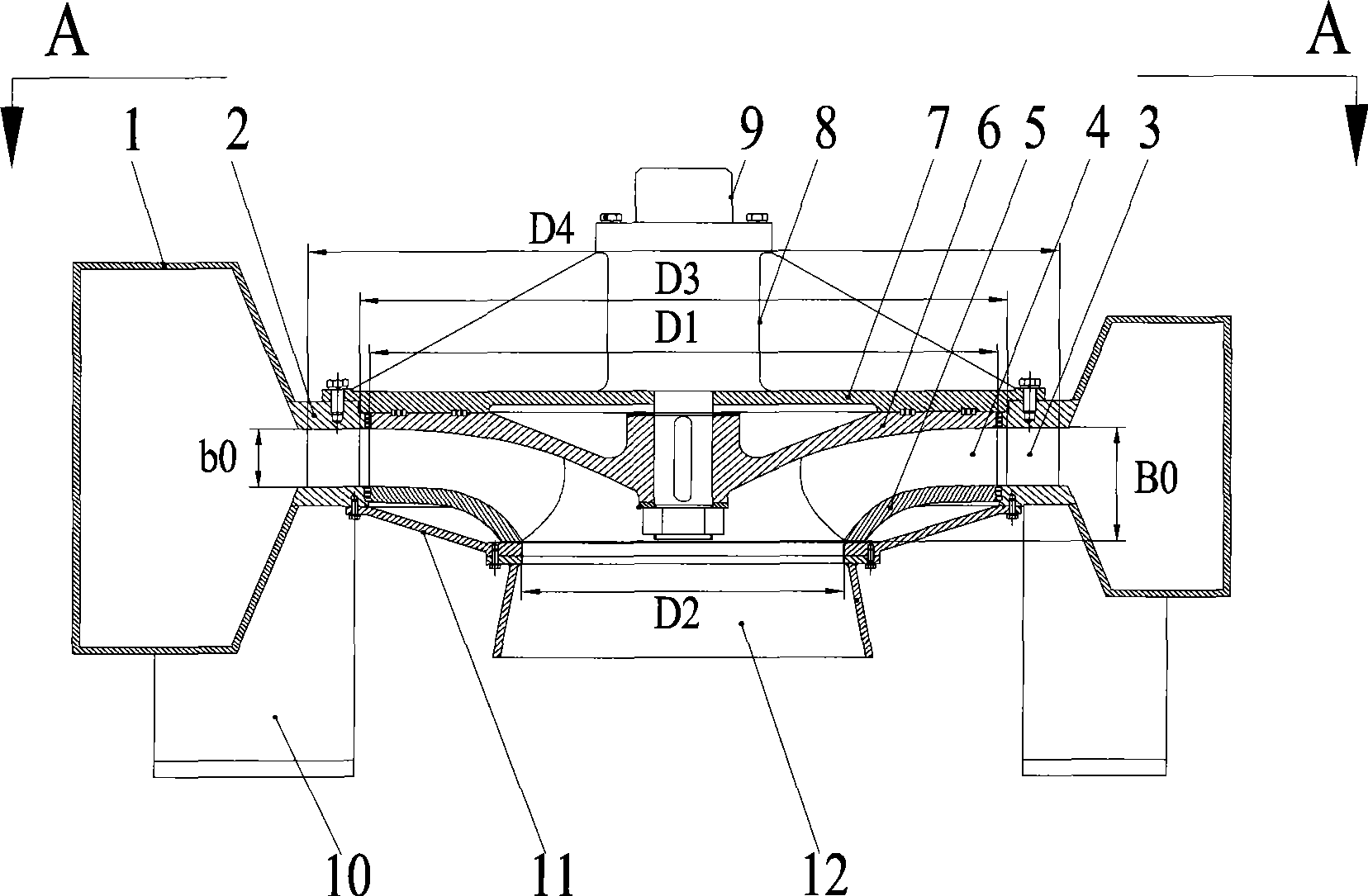

Ultra-low specific speed mixed-flow type turbine

InactiveCN101482083ASolve technical problems with low efficiency and complex structureHydro energy generationReaction enginesMixed flowHydraulic turbines

An ultra-low specific speed mixed-flow turbine relates to a mixed-flow turbine and belongs to the technical field of energy and power. A main shaft in the invention is arranged on a bearing support, and the bearing support is arranged in the middle of the upper side of a cover plate; the lower side of the cover plate is provided with the runner crown of a low specific speed turbine; the end of the cover plate is fixedly connected with a seating ring; the runner band of the low specific speed turbine is relatively arranged below the runner crown of the low specific speed turbine; one end of the runner band of the low specific speed turbine is connected with the seating ring, and the other end is connected with a conical draft tube; a metal scroll casing is connected outside the seating ring and is arranged on a rest pier; 16 to 18 single-row annular negative camber guide vanes are arranged on the seating ring, and the runner blades of the low specific speed turbine are arranged inside the inner cavity between the runner crown of the low specific speed turbine and the runner band of the low specific speed turbine. The invention solves the technical problem that low specific speed mixed-flow turbine has low efficiency and complicated structure in the prior art.

Owner:NANJING XINGFEI COOLING EQUIP

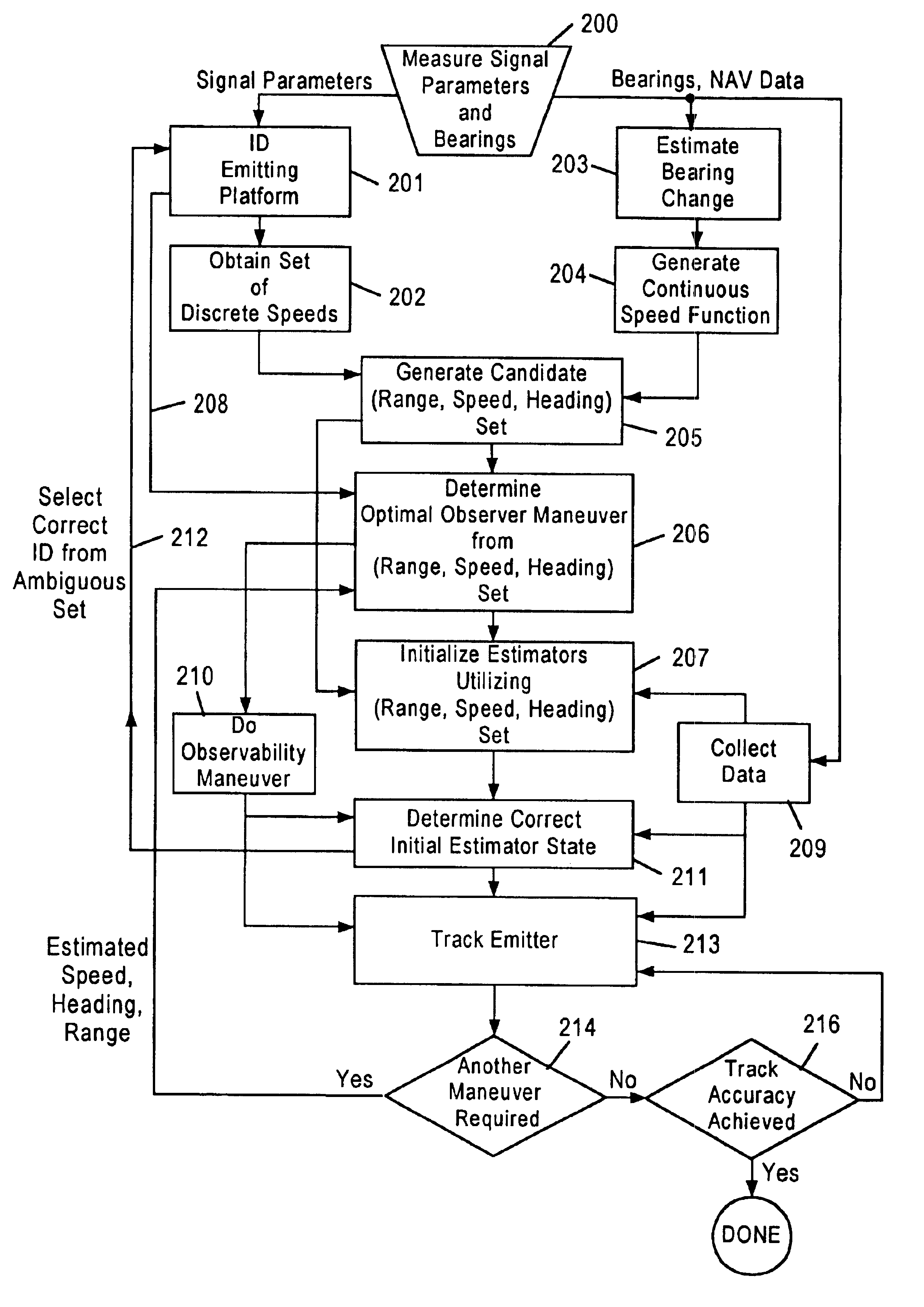

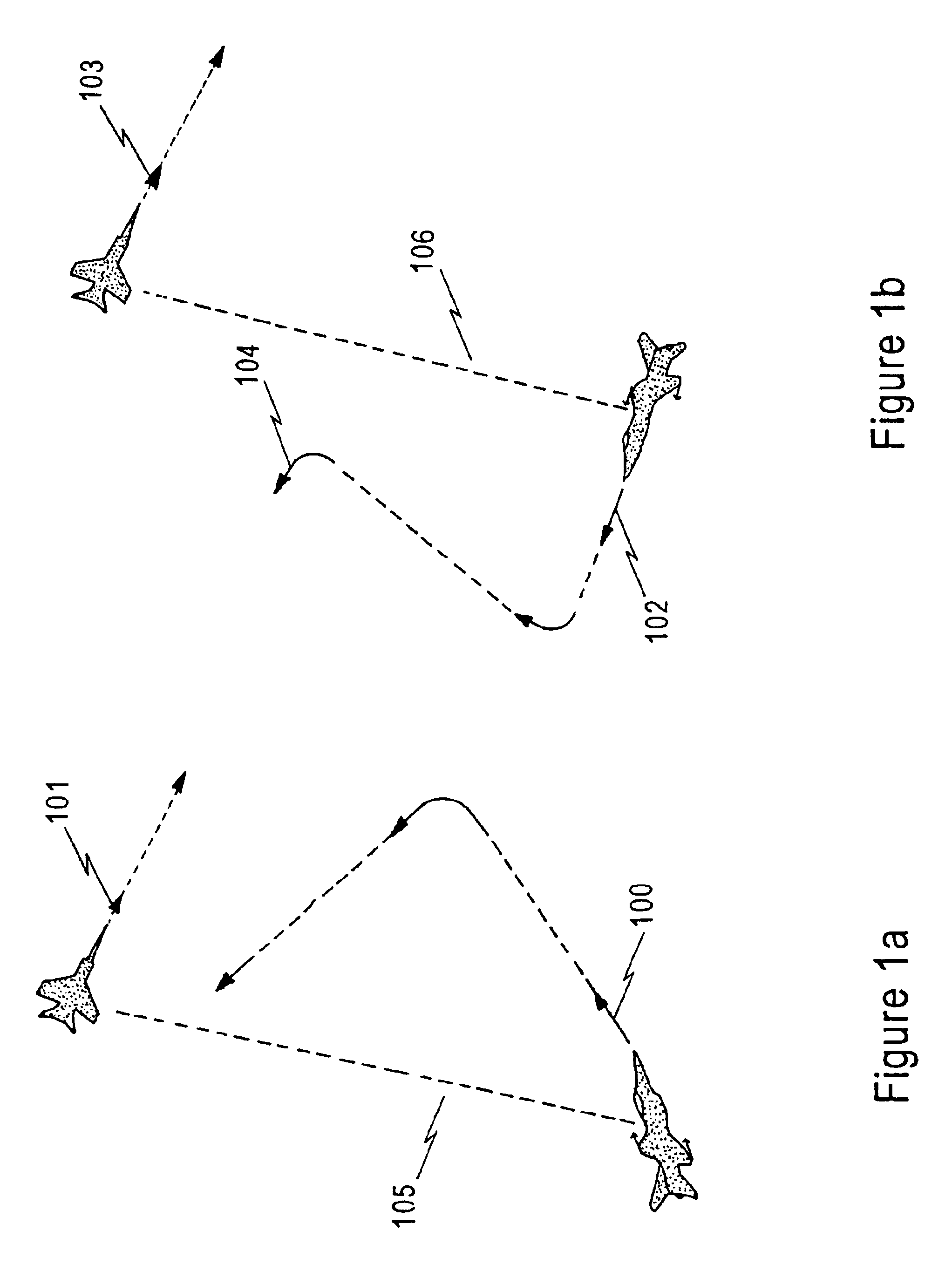

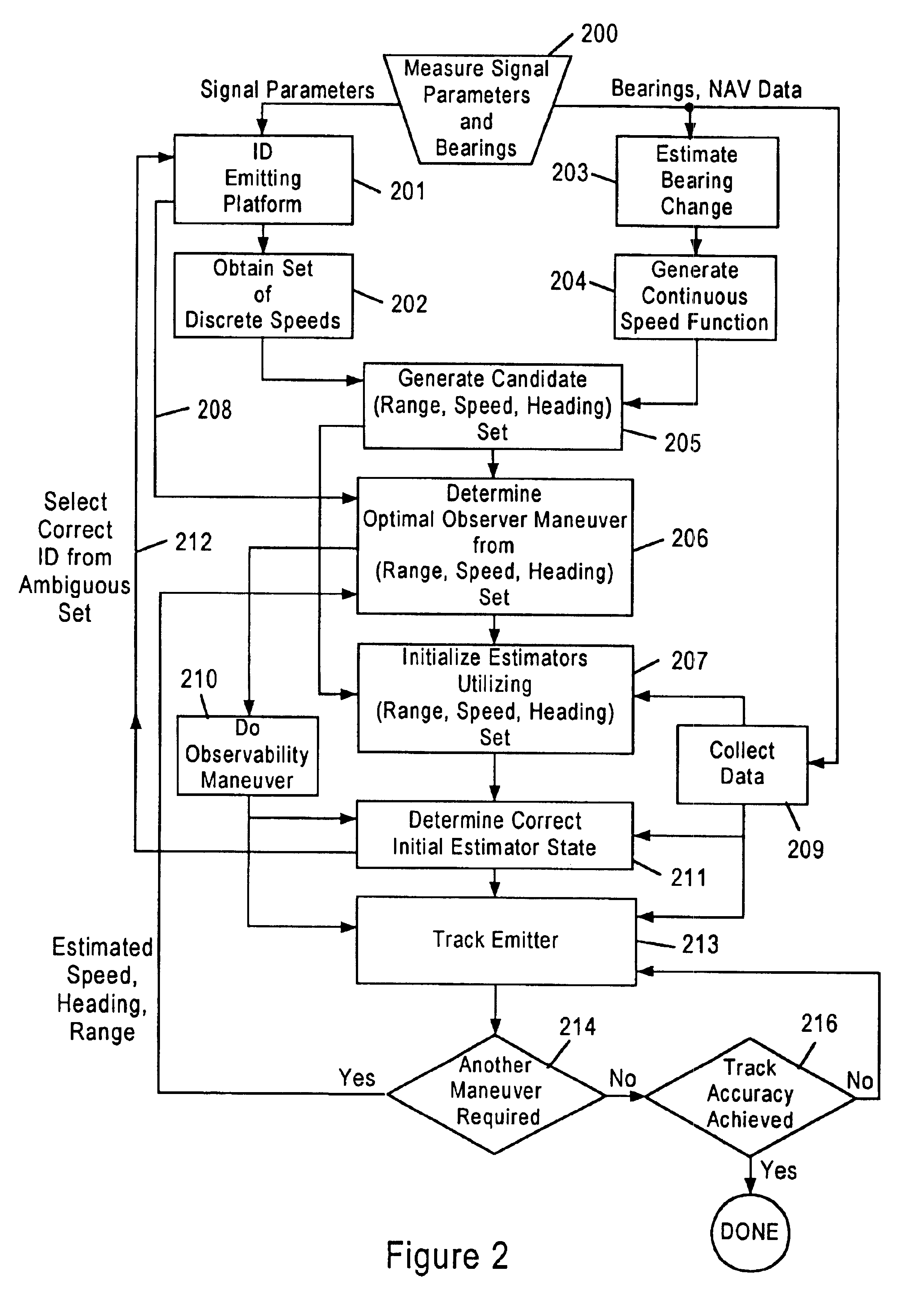

Method for determining the optimum observer heading change in bearings-only passive emitter tracking

InactiveUS6801152B1Improve performanceRemoving the potential vulnerability of the observability maneuverDirection finders using radio wavesPosition fixationTarget Motion AnalysisEngineering

Emitter target range and heading are estimated from bearing measurements enhancing bearings-only estimator convergence to a target track, and permitting optimization of an observer position relative to the target at the end of the total bearing measurement period. One or more estimates of the target range, speed and heading made from bearing measurements before an observer maneuver are used to determine the most appropriate observer maneuver giving complete bearings-only target-motion-analysis observability. A set of parameters characterizing a set of potential emitter signal sources is generated based on measured emitter characteristics. A most probable set of emitter platforms is identified and the emitter operating mode and corresponding platform set are associated with a kinematic regime set. A specific speed or discrete set of speeds best adapted to a set of all possible platform missions, emitter speed as a continuous function of emitter range, and emitter range are all determined.

Owner:NORTHROP GRUMMAN SYST CORP

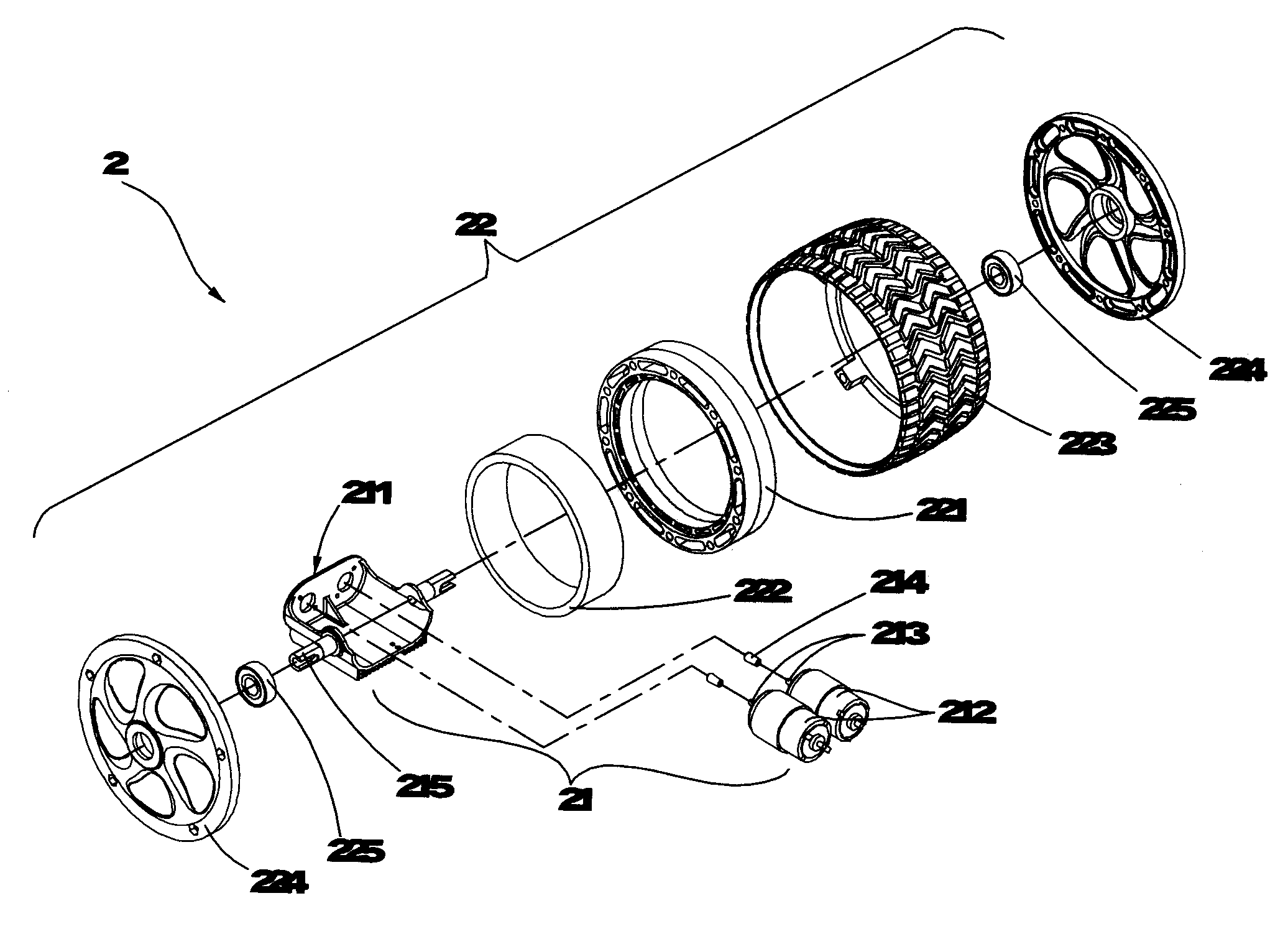

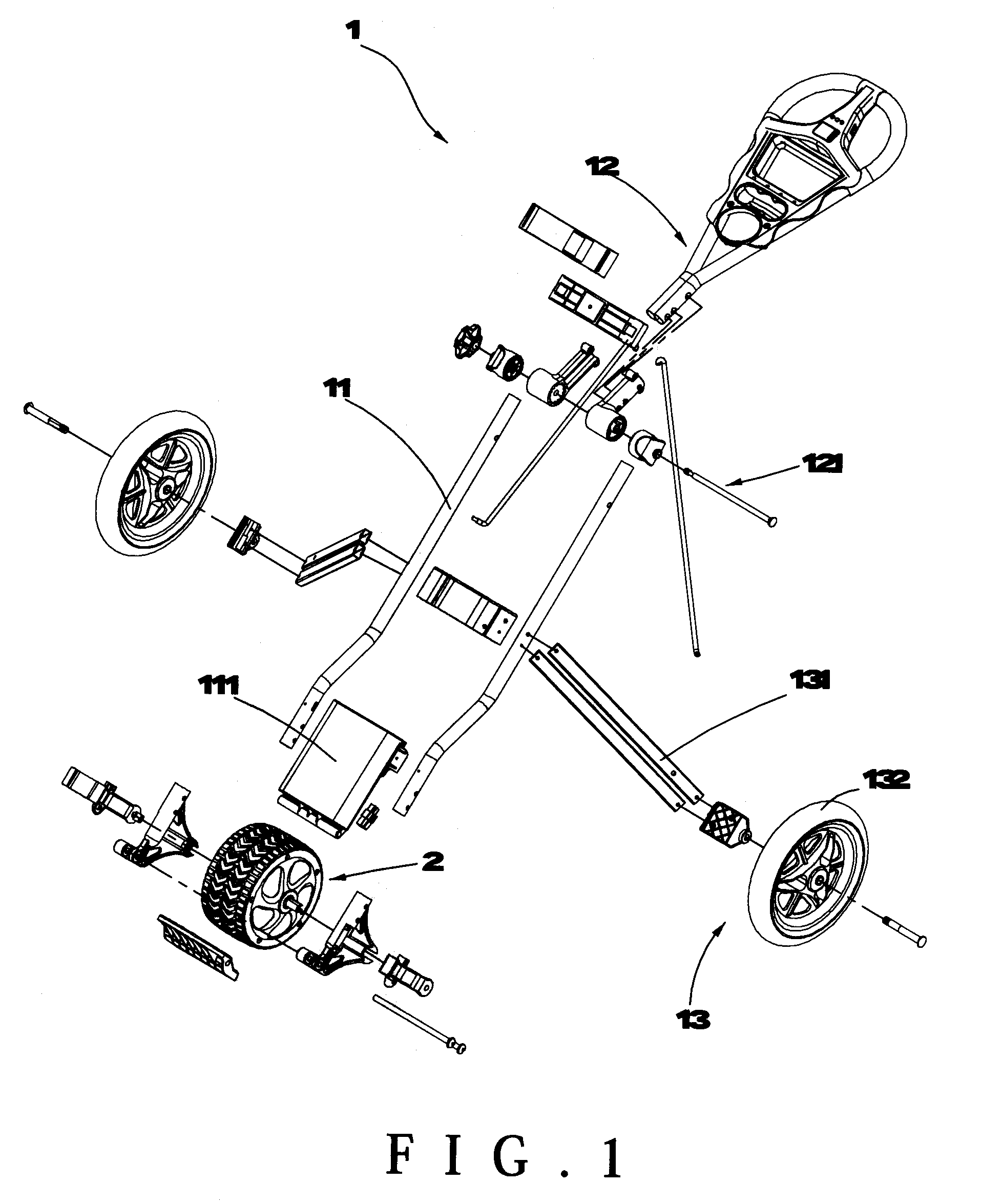

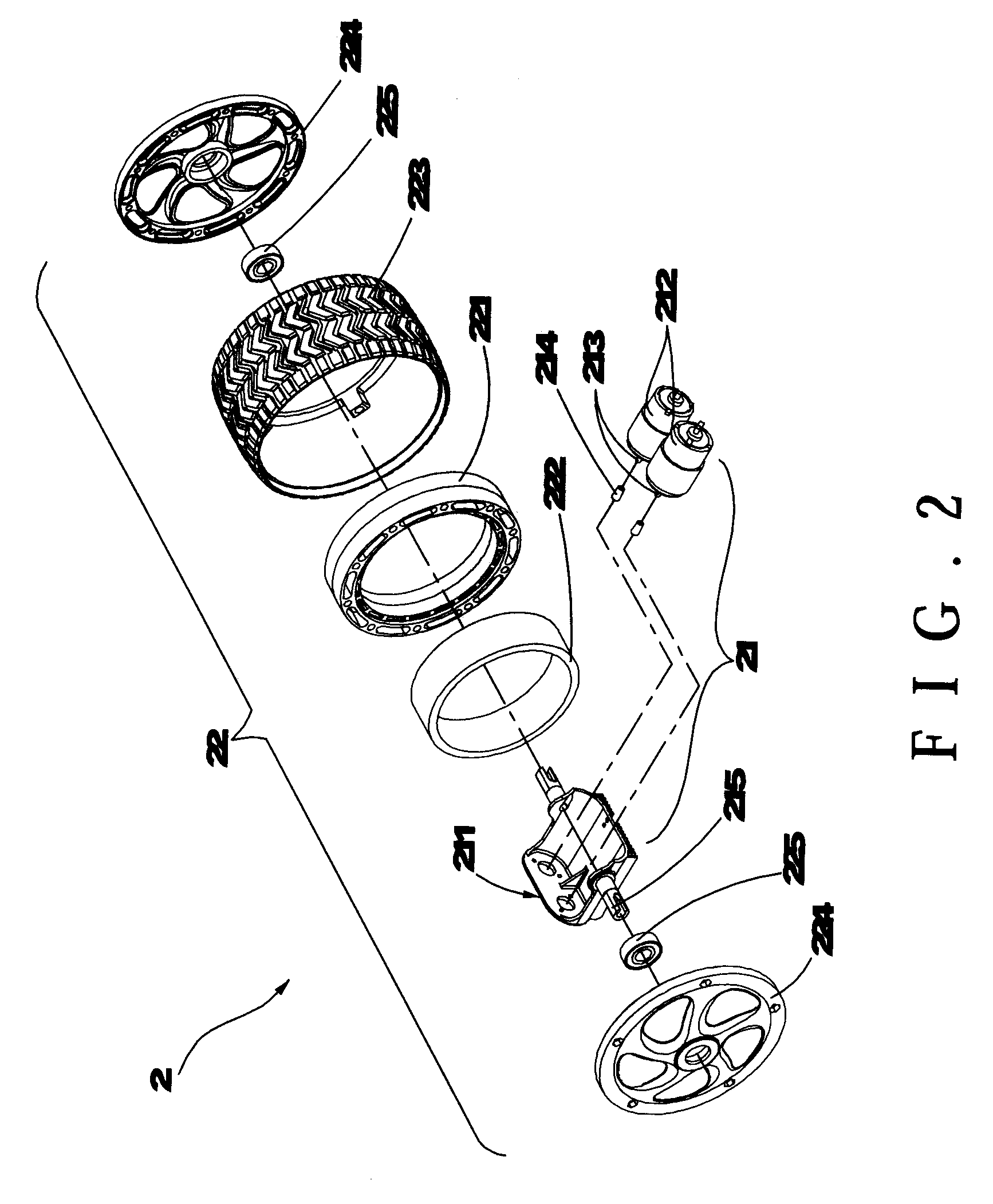

Power assisted vehicle

InactiveUS7392872B2Reduce power consumptionImprove transmission efficiencyElectric devicesElectric propulsion mountingVehicle frameEngineering

A power assisted vehicle includes an auxiliary propelling device disposed to the frame body. The auxiliary propelling device has an auxiliary wheel and at least one transmission portion disposed in the auxiliary wheel. When two friction wheels of the transmission portion fasten to two sides of a friction ring of the auxiliary wheel, and the two power sources is in reverse to drive the two friction wheels for rotating, a wheel rim and a tire are further driven to produce rotations. The power assisted vehicle is therefore capable of self-propelled going forward without any external force. A processing device is further disposed in the power assisted vehicle. The auxiliary propelling device is then activated when the power assisted vehicle is at a specific speed. The energy consumption for the power sources is then reduced and the service life is extended. The transmission force distribution generated from the power sources is further adjustable. The usage of the power assisted vehicle is more efficient.

Owner:CHIU PO LIN +2

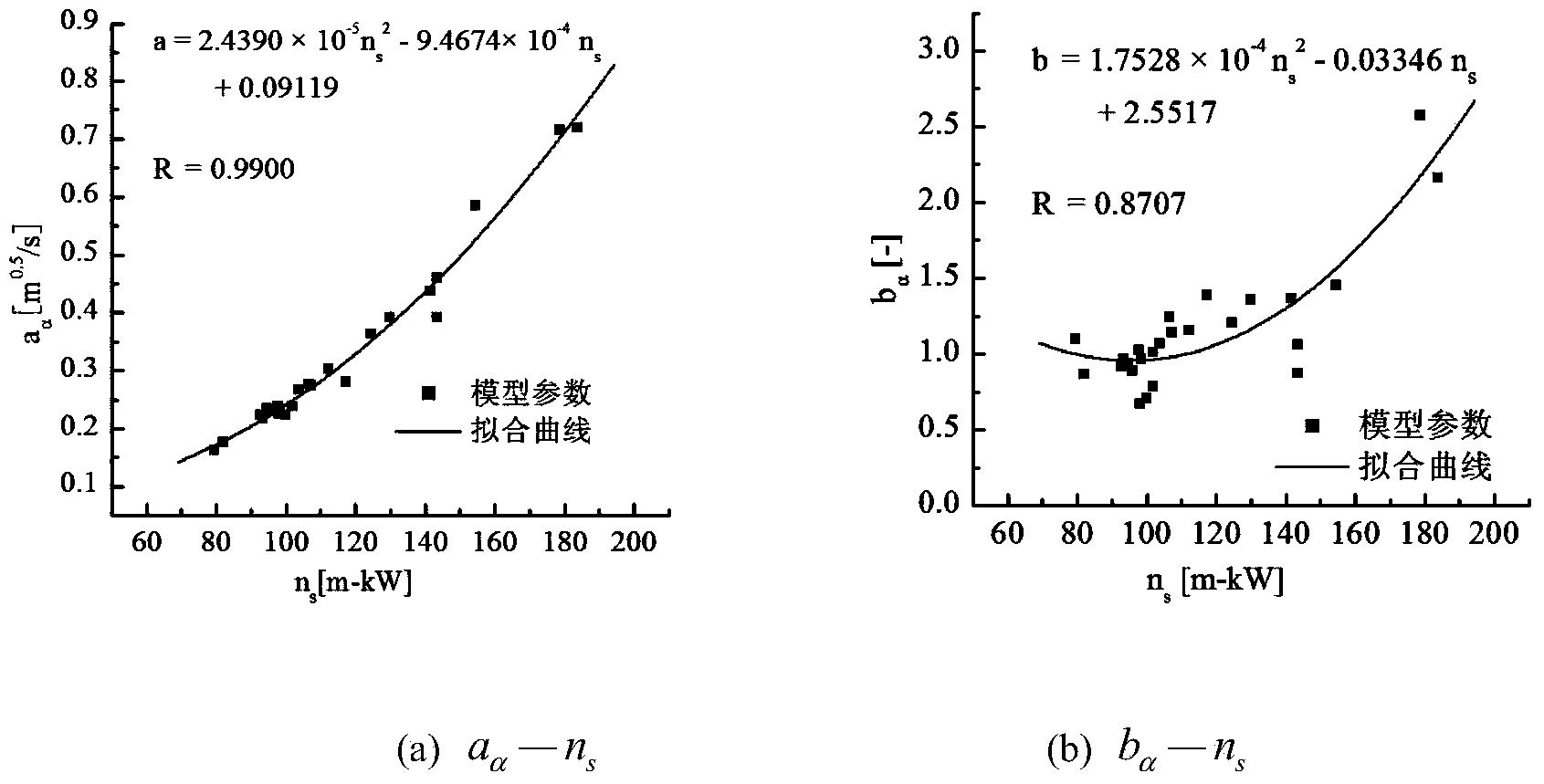

Method for constructing total characteristic curve of pump turbine

The invention provides a method for constructing a total characteristic curve of a pump turbine. By the adoption of a mathematical manipulation method and with the combination of mathematical statistic knowledge, the total characteristic curve at any specific speed is obtained according to existing total characteristic data with the specific speed which is the characteristic parameter of the pump turbine as a standard interpolation. The premise of construction of the total characteristic curve includes the steps of collecting a set of data containing total characteristic curves at different specific speeds, and finally achieving construction of the total characteristic curve at any specific speed according to rule research, mathematical manipulation and mathematical statistic analysis of the collected data and by means of a four-dimensional interpolation method. The method is suitable for early-stage design of a pumped storage station and particularly suitable for early-stage adjustment assurance design of the pumped storage station when total characteristic data of the pump turbine are lacked.

Owner:WUHAN UNIV

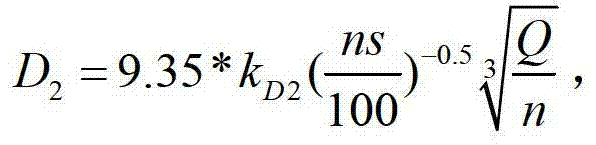

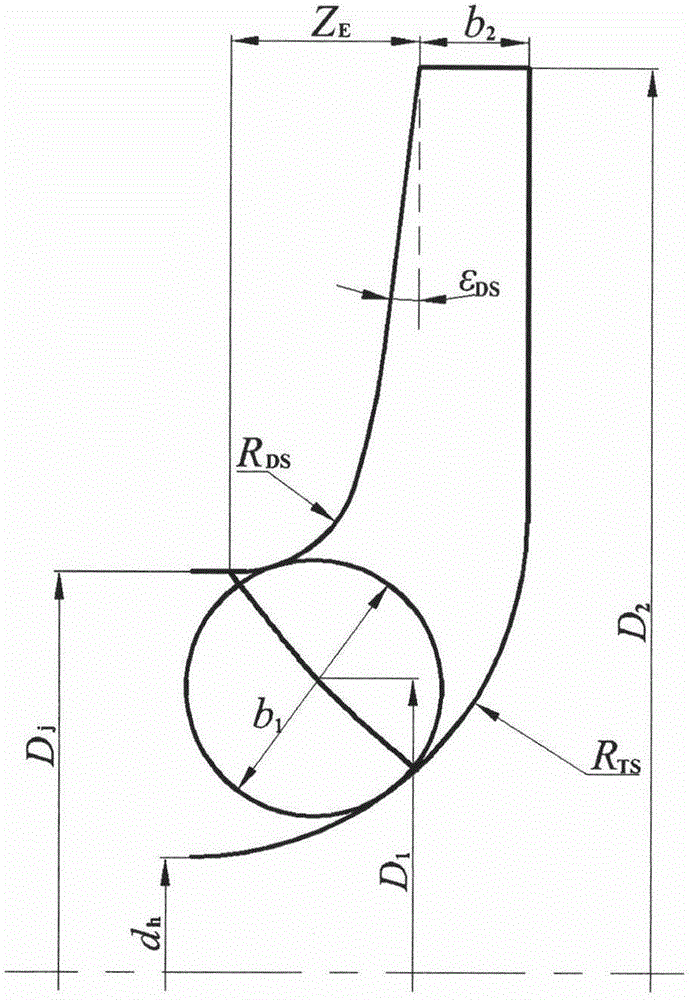

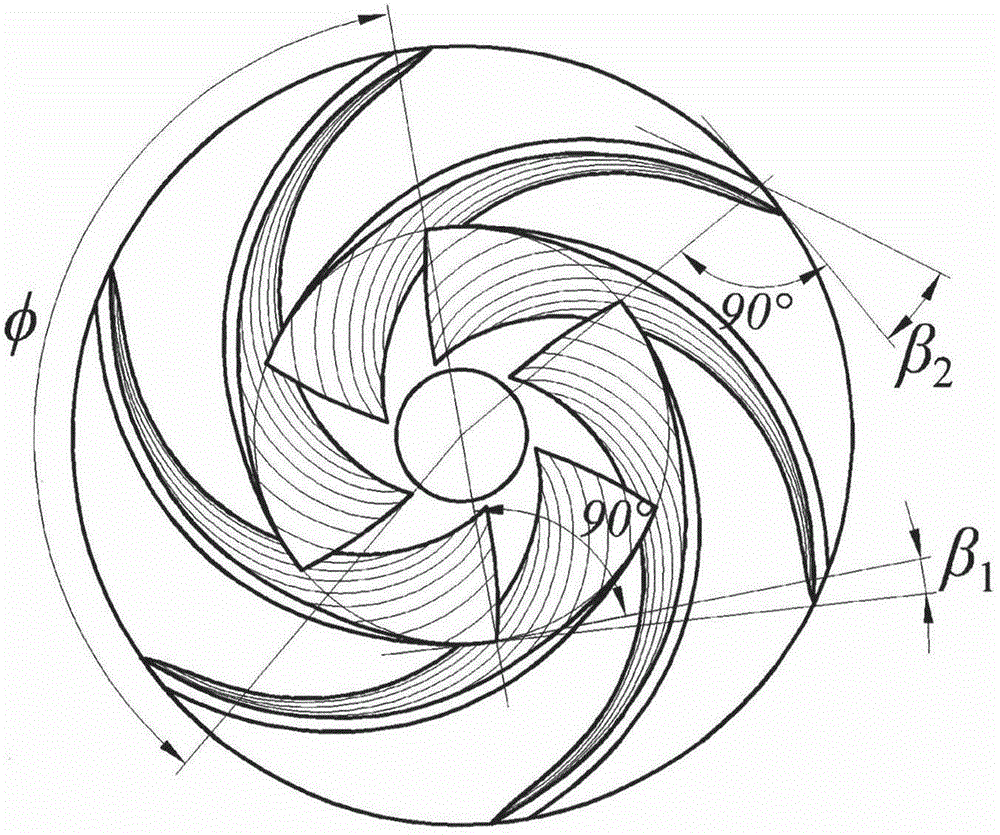

Hydraulic design method for low-specific-speed overload-free centrifugal pump impeller

The invention relates to a hydraulic design method for a low-specific-speed overload-free centrifugal pump impeller. Geometrical parameters of the low-specific-speed centrifugal pump impeller and performance parameters of a design condition point are related together through the method of setting up an equation, the optimal hydraulic performance and the good shaft power characteristic are obtained by adjusting values of the different geometrical parameters, and therefore the designed low-specific-speed centrifugal pump impeller can be free of humps and high in efficiency and can meet the overload-free requirement. A design formula of the main geometrical parameters of the impeller is given and includes the inlet diameter Dj of the impeller, the inlet diameter D1 of blades, the outlet diameter D2 of the impeller, the outlet width b2 of the blades, the number z of the blades, the inlet placing angle beta 1 of the blades, the outlet placing angle beta 2 of the blades, the wrap angle phi of the blades and the real thickness delta of the blades. By the adoption of the low-specific-speed centrifugal pump impeller, it can be ensured that a centrifugal pump can be used reliably under the high-lift and small-flow working conditions and used safely in an overload-free mode under the low-lift and large-flow working conditions.

Owner:南京通莱环保科技有限公司

Centrifugal compressor assembly and method

ActiveUS9353765B2Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

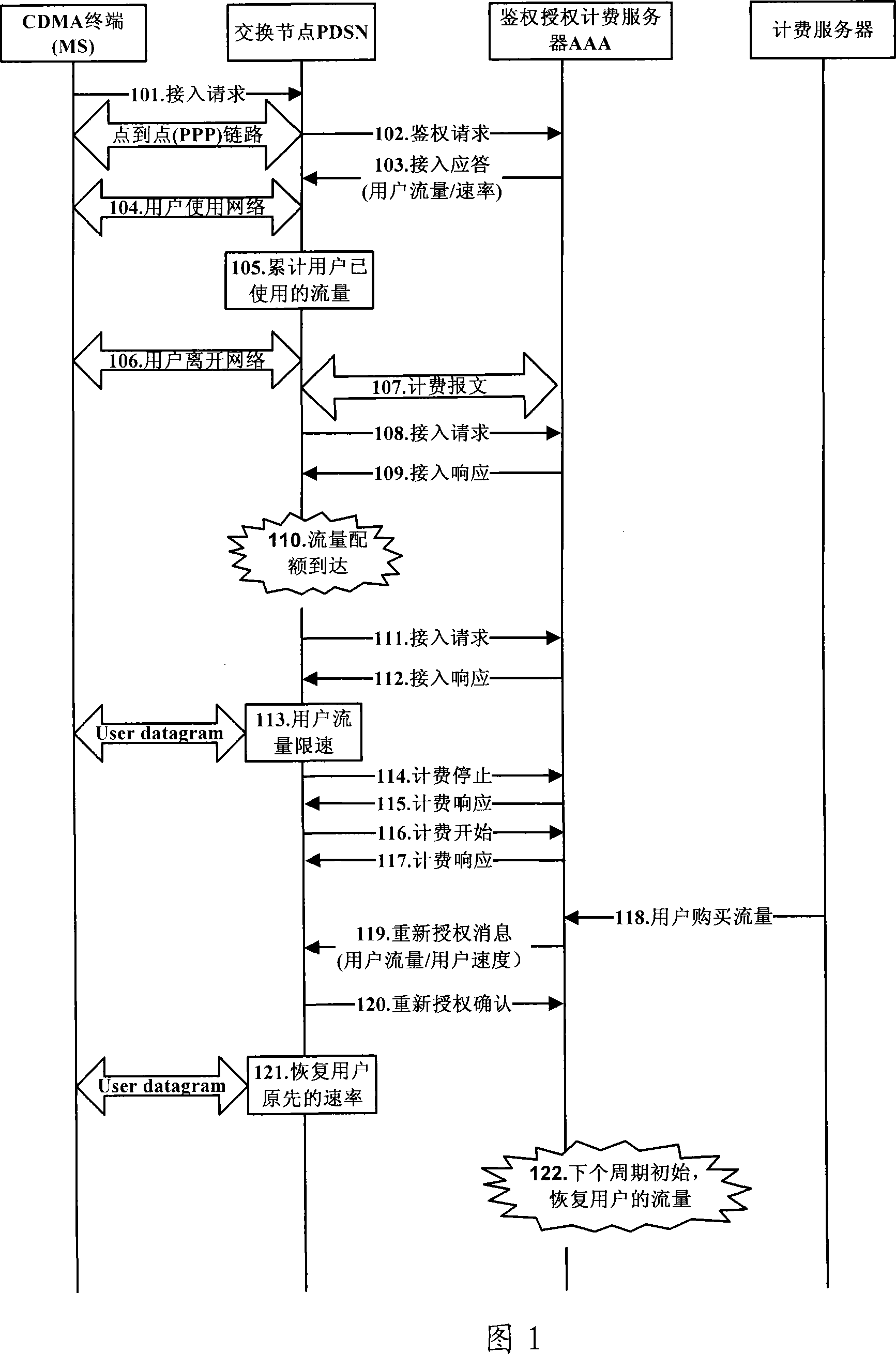

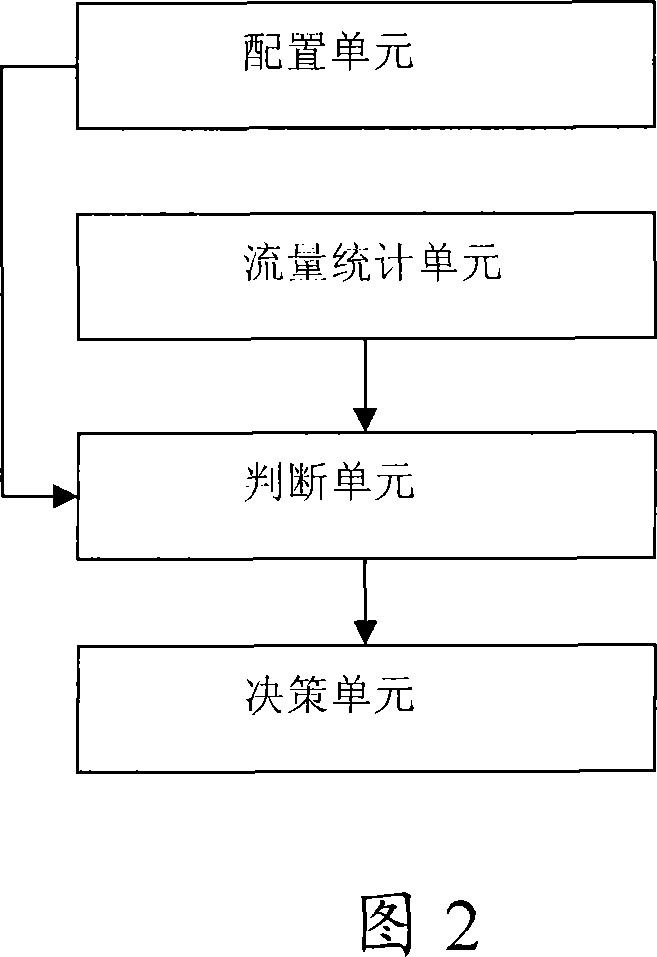

Method and system for controlling velocity based on flux

InactiveCN101110777AFlexible Business ModelMetering/charging/biilling arrangementsTraffic volumeSpecific speed

The present invention discloses a speed controlling method based on the flow rate, which presets the flow rate quota of the network usage of the user and the speed of the network usage according to the attribute of the user. The method comprises: the flow rate of the network usage of the user is calculated; the flow rate of the network usage of the user is compared with the preset the flow rate quota, when the flow rate of the network usage of the user reaches the preset the flow rate quota, the user is refused to go on used the network or the speed of the network usage of the user is decreased. The implementation of the present invention adopts that in each fixed period, the user is allocated with a fixed available flow rate and specific speed index aiming at all kinds of services according to the belonged group, in the period, if the used flow rate surpasses the allocated available flow rate, the user will not be allowed to use the network or the network speed is decreased to a smaller value, in the condition, the user can buy the flow rate through additional cost, and the present invention realizes the purpose of adopting more flexible service model by the operator.

Owner:ZTE CORP

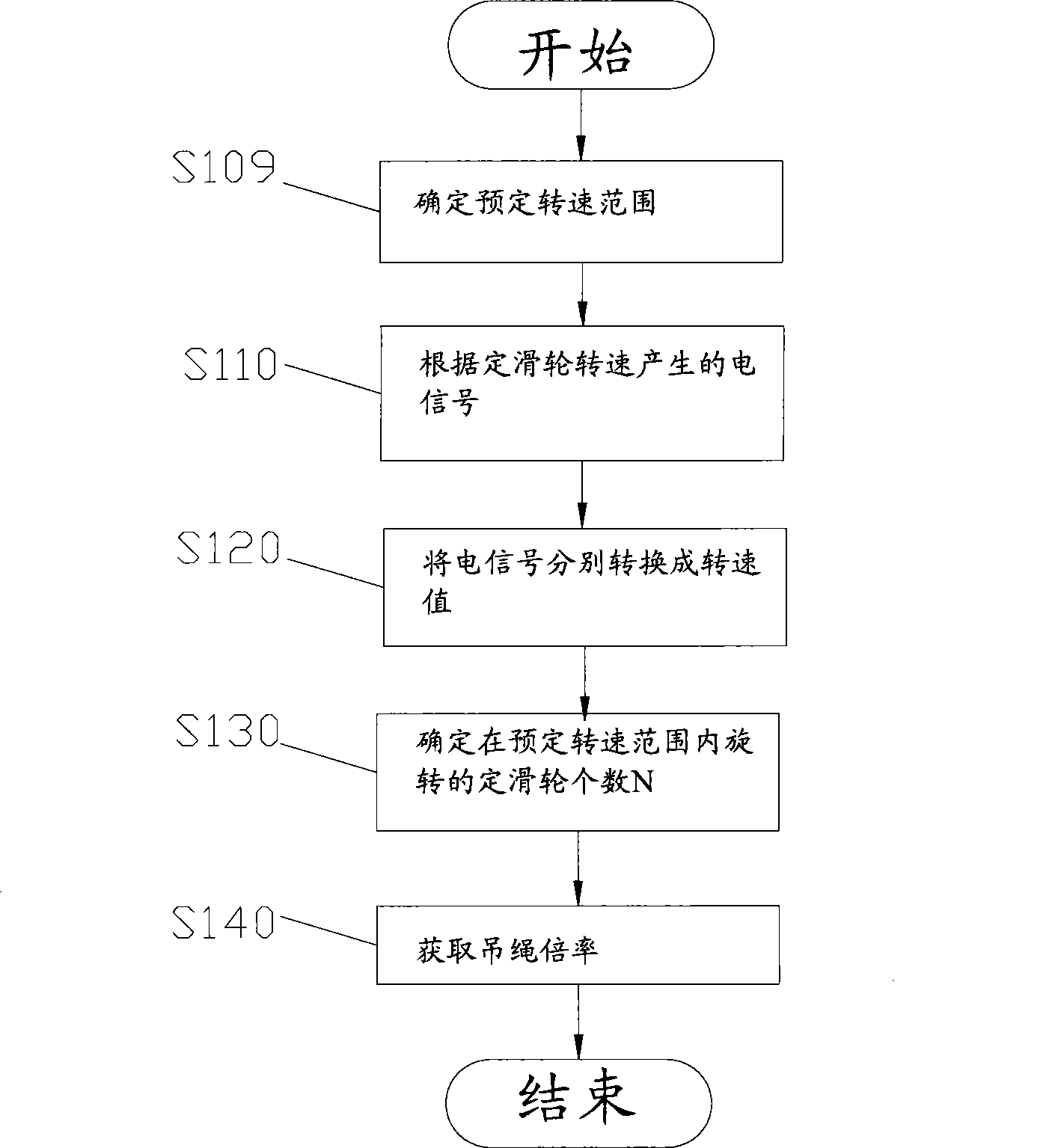

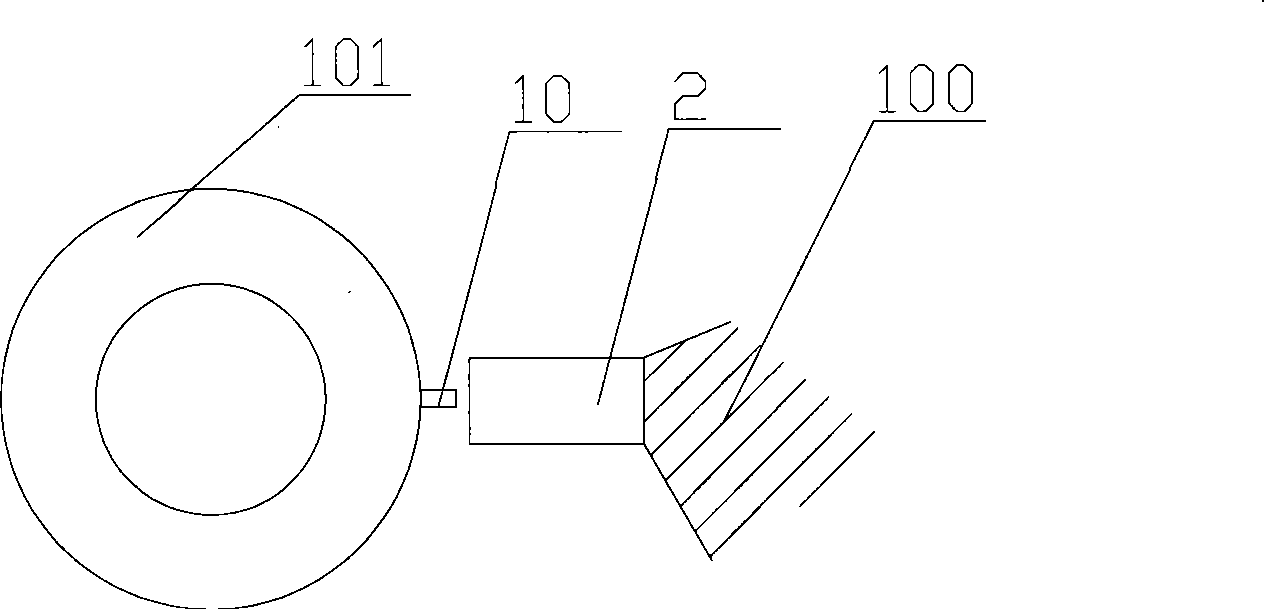

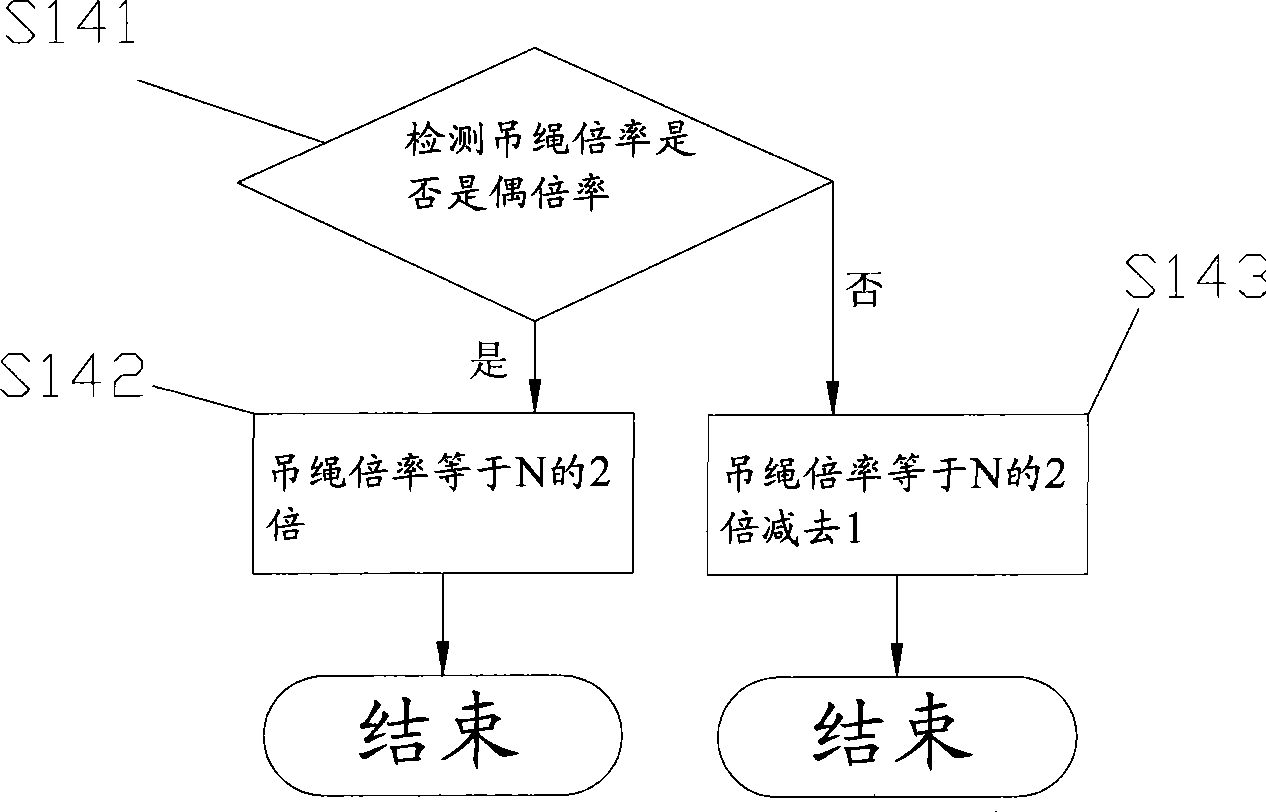

Crane stringer rate acquisition method, system and crane

The invention discloses a method and a system for acquiring multiplying power of a sling of a crane. The method for acquiring the multiplying power of the sling of the crane comprises: utilizing the principle that a fixed pulley of the crane rotates at specific speed under the action of friction force of the sling, generating corresponding electrical signals according to revolution speed of the fixed pulley, and converting the electrical signals into a revolution speed value; and determining the number of the fixed pulleys rotated by the friction force of the sling by judging whether the revolution speed value is within a specific speed range, and acquiring the multiplying power of the sling according to relation between the number of the rotating fixed pulleys and the multiplying power of the sling to reduce influence of human factors on the multiplying power of the sling, so as to ensure reliability for acquiring the multiplying power of the sling. The system for acquiring the multiplying power of the sling of the crane is used for achieving the method, and has the same technical effect. The method and the system for acquiring the multiplying power of the sling of the crane are suitable for the control on the crane, in particular for safety control on the crane.

Owner:SANY AUTOMOBILE MFG CO LTD

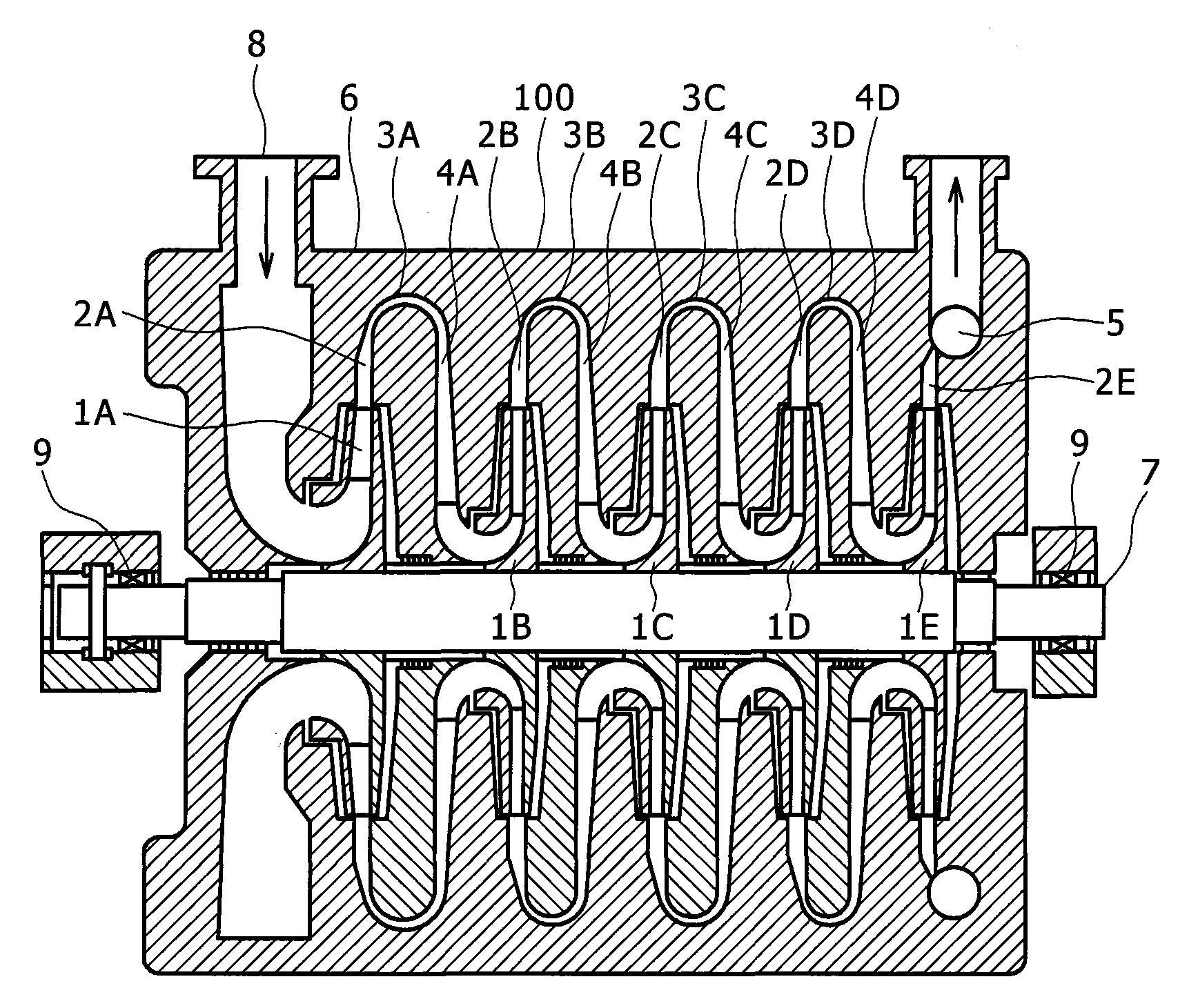

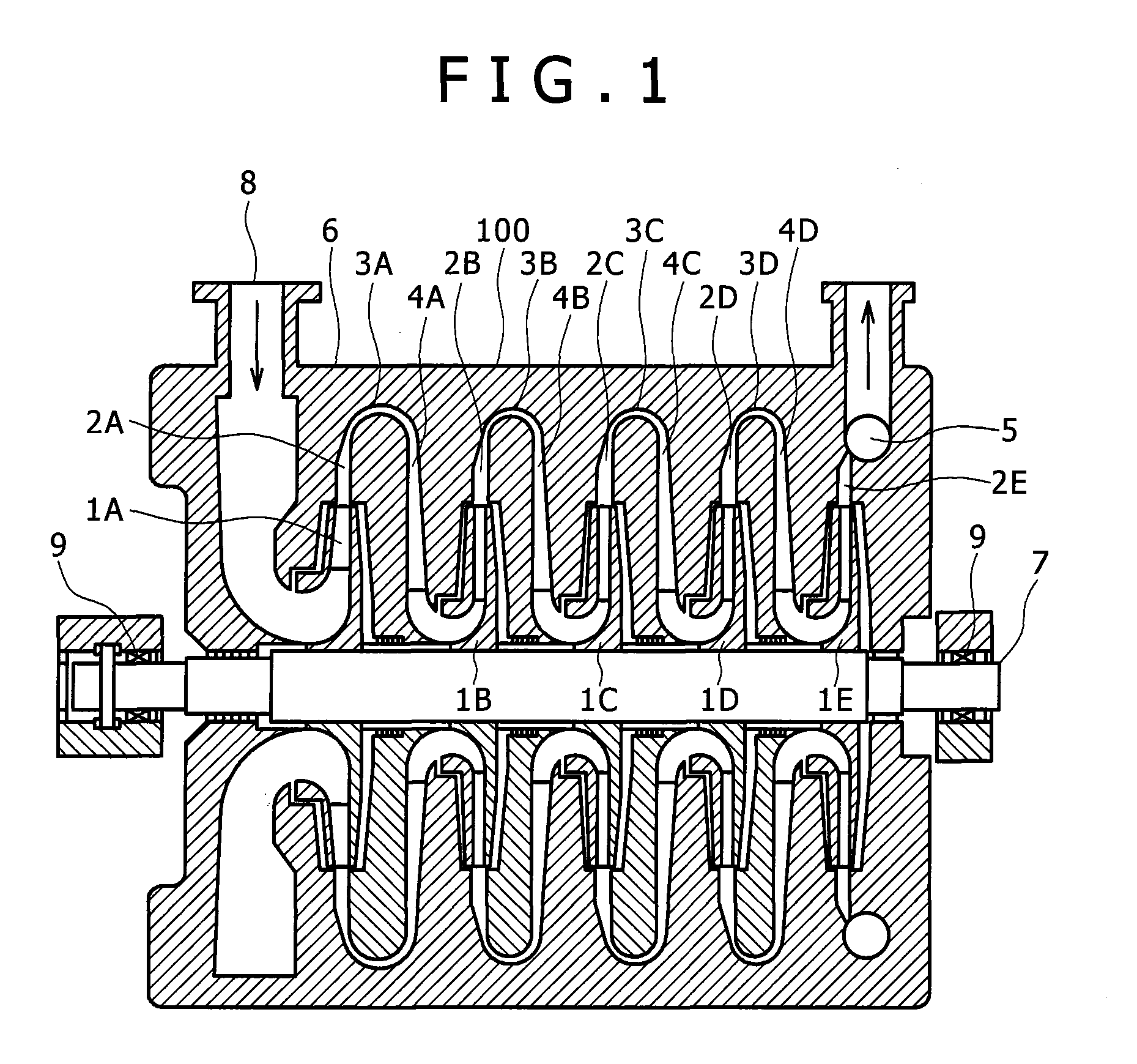

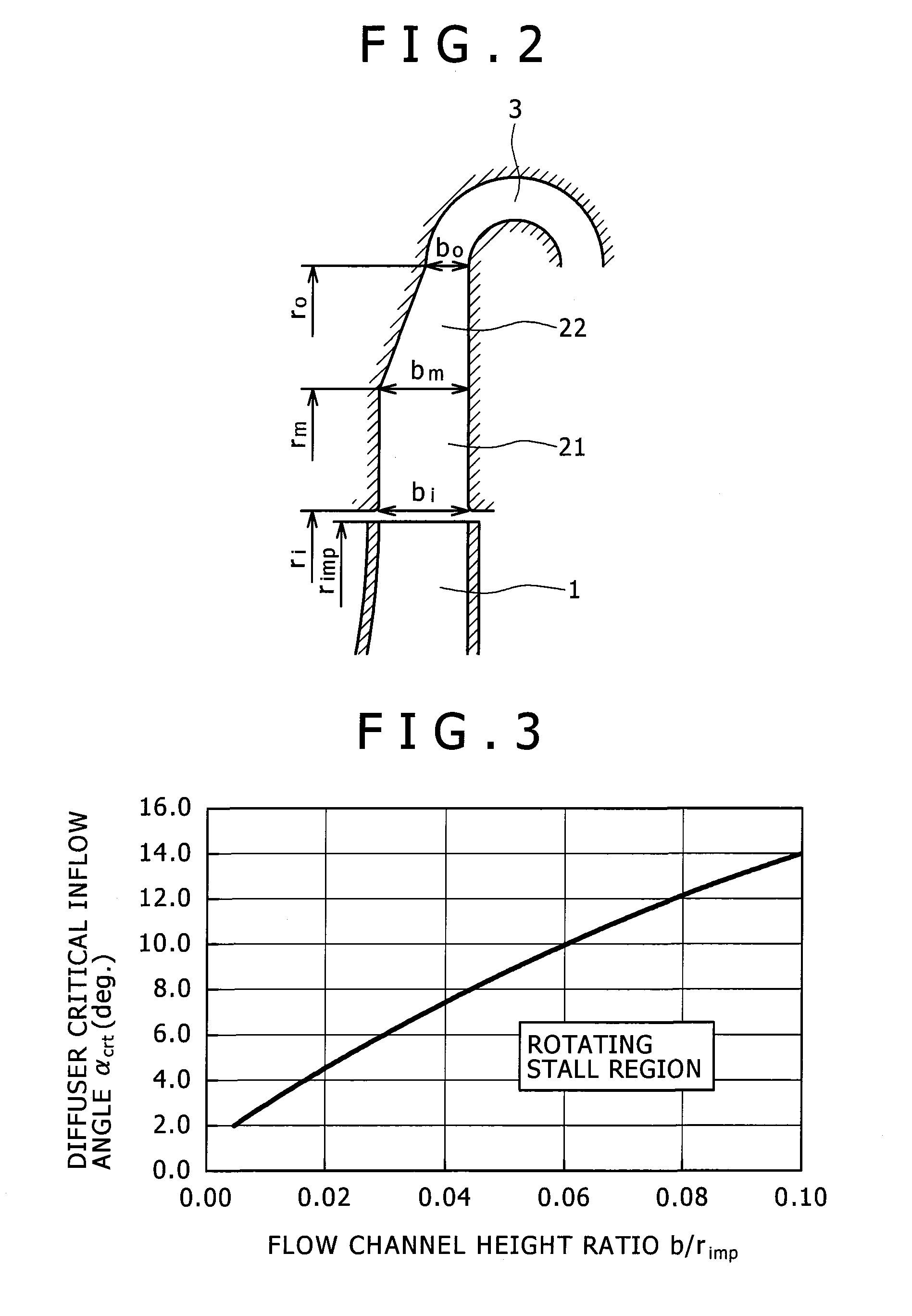

Centrifugal compressor having vaneless diffuser and vaneless diffuser thereof

ActiveUS20090317248A1Improve efficiencyAvoid it happening againPump componentsStatorsHeight decreaseHigh pressure

In a high pressure centrifugal compressor, the occurrence of rotating stall noticeable in a comparatively-low specific speed wheel stage is prevented, thereby high efficient fluid performance is obtained and reliability is improved. The centrifugal compressor has a first vaneless diffuser with a constant flow channel height on the downstream side of an impeller, and a second vaneless diffuser in which the flow channel height decreases in a flow direction from an inlet to an outlet on the downstream side of the first vaneless diffuser. These diffusers are combined with an impeller using thick blades.

Owner:HITACHI IND PROD LTD

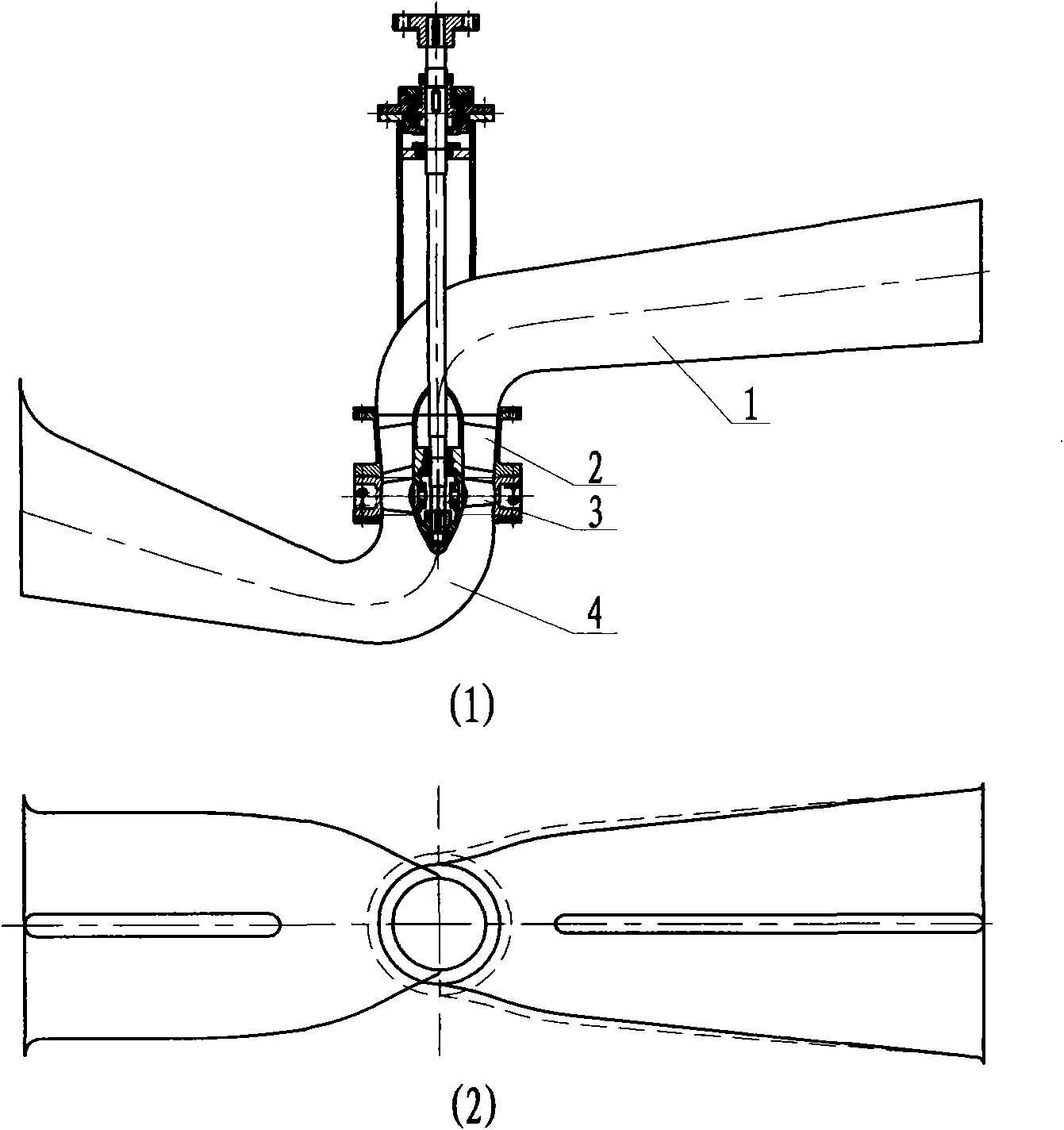

Axial flow pump guide vane body with high specific speed

InactiveCN101881284AIncreased hydraulic lossReduce hydraulic lossPump componentsPumpsAxial-flow pumpConical tube

The invention discloses an axial flow pump guide vane body with high specific speed, overcoming the deficiencies that the traditional axial flow pump guide vane body with high specific speed has larger hydraulic loss, resulting in lower efficiency of a water pump. In the invention, a diffusion angle of a conical tube of the guide vane body is enlarged to enable a single-edge diffusion angle thereof to be ranged from 6 degrees to 10 degrees; because the diffusion degree of the guide vane body is increased, the flow rate is lowered on the basis of ensuring not to cause side wall flow separation, thereby efficiently lowering the hydraulic loss of the guide vane body and enhancing the efficiency of the pump; and also because the diffusion angle of the guide vane body is enlarged and the outlet diameter is increased, a flowing space of a latter water outlet channel is also increased, the hydraulic loss of the water outlet channel is lowered, and the pump device efficiency is further improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com