Patents

Literature

1351 results about "Hydraulic turbines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic turbine. A machine which converts the energy of an elevated water supply into mechanical energy of a rotating shaft. Hydraulic turbine. A machine which converts the energy of an elevated water supply into mechanical energy of a rotating shaft.

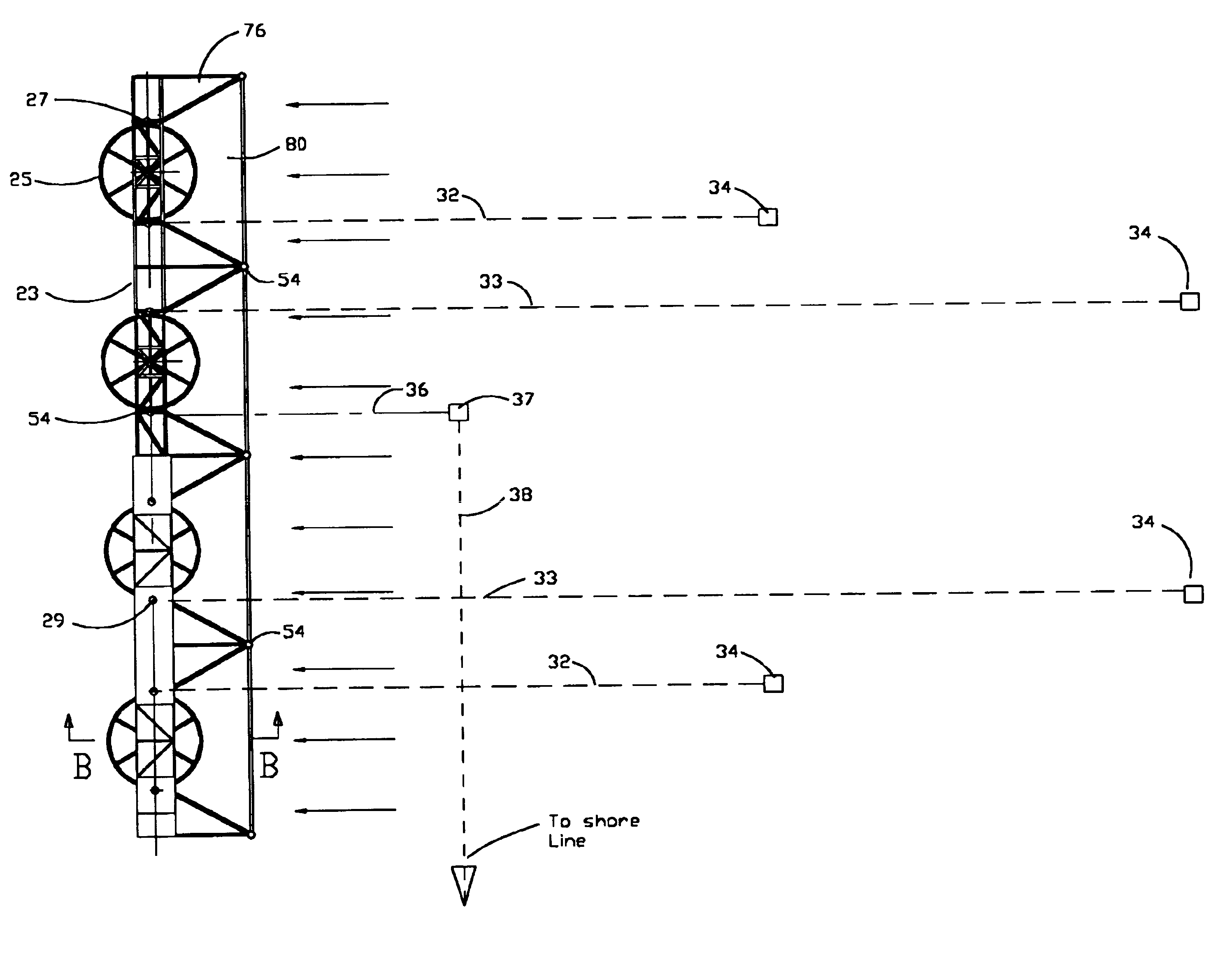

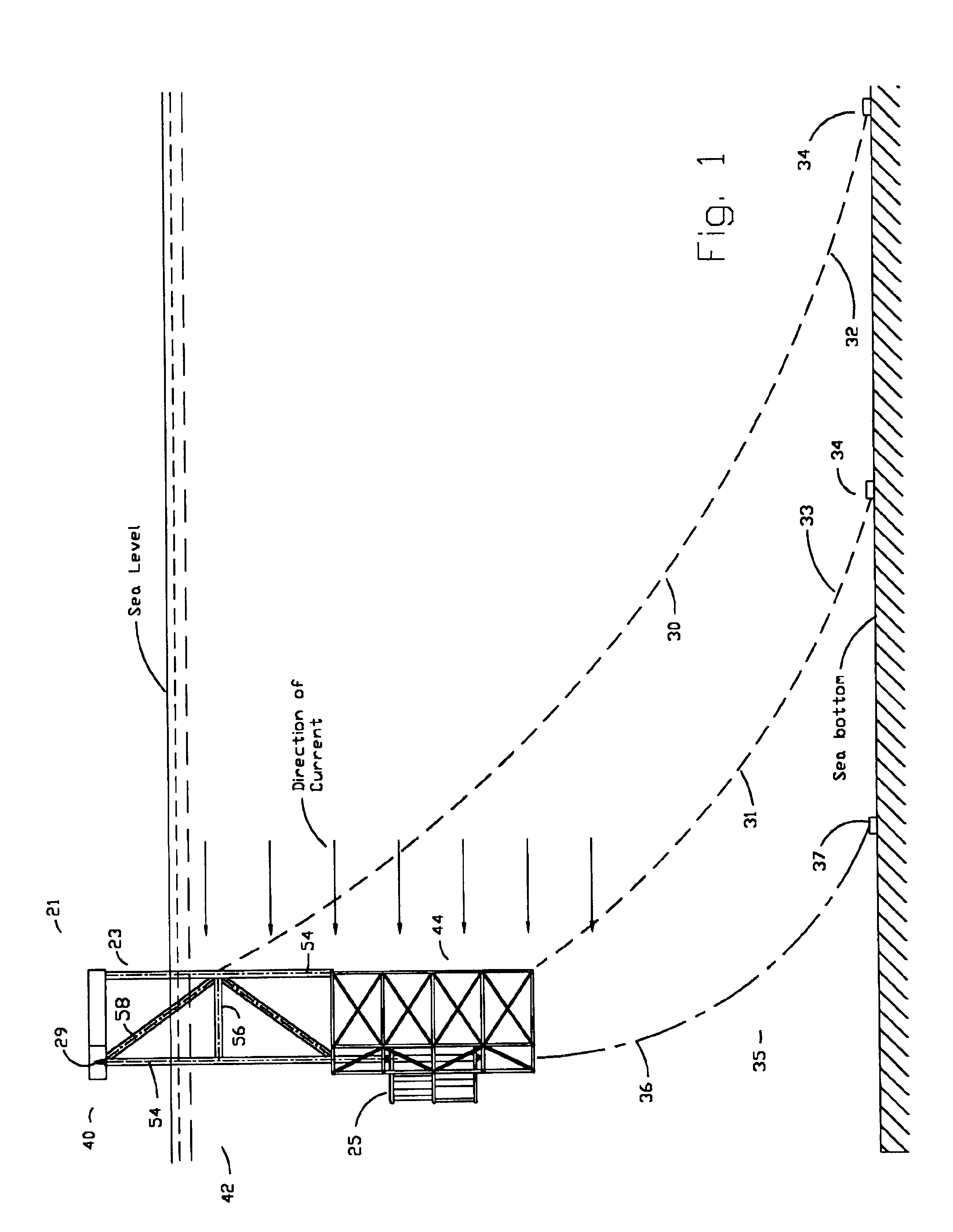

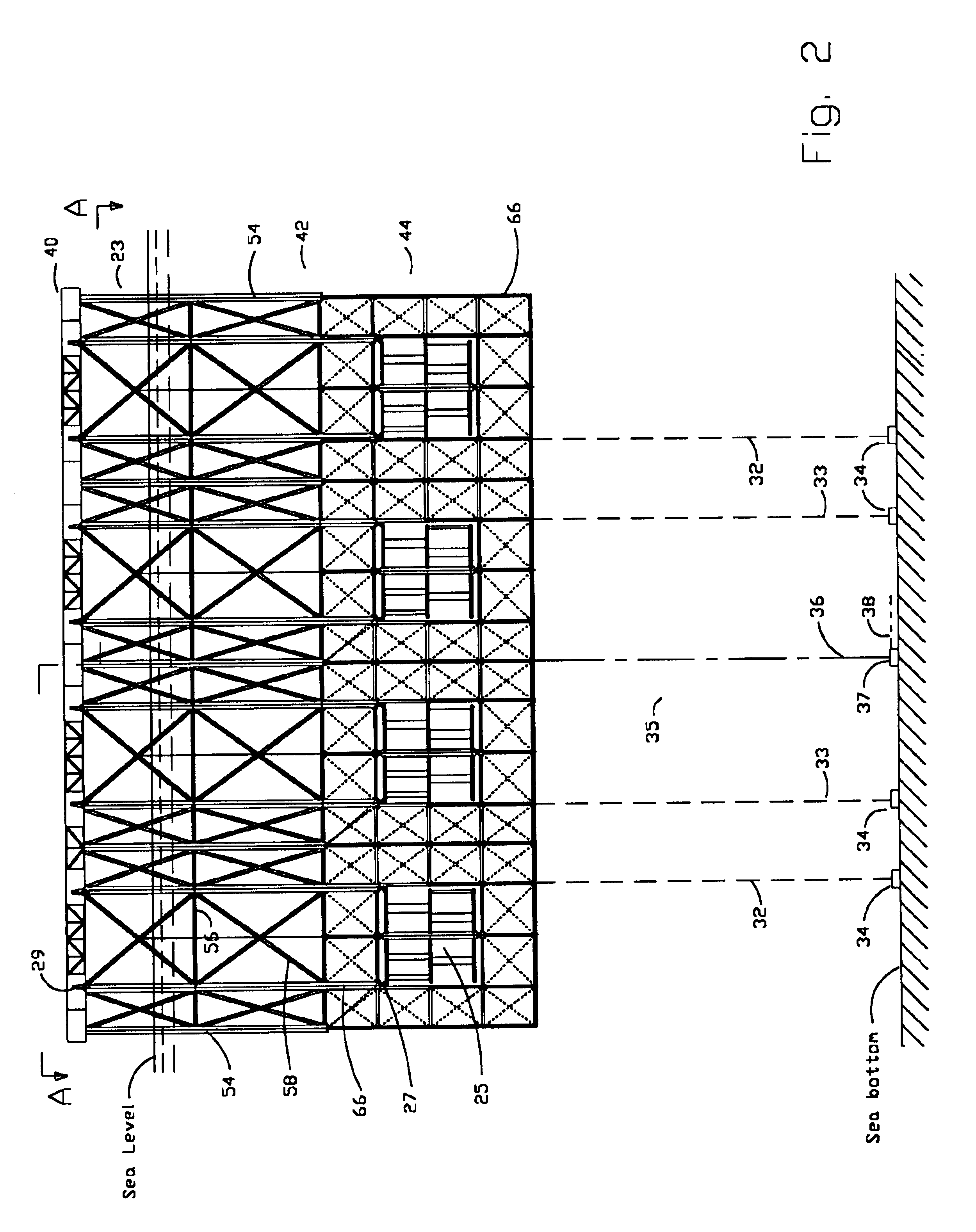

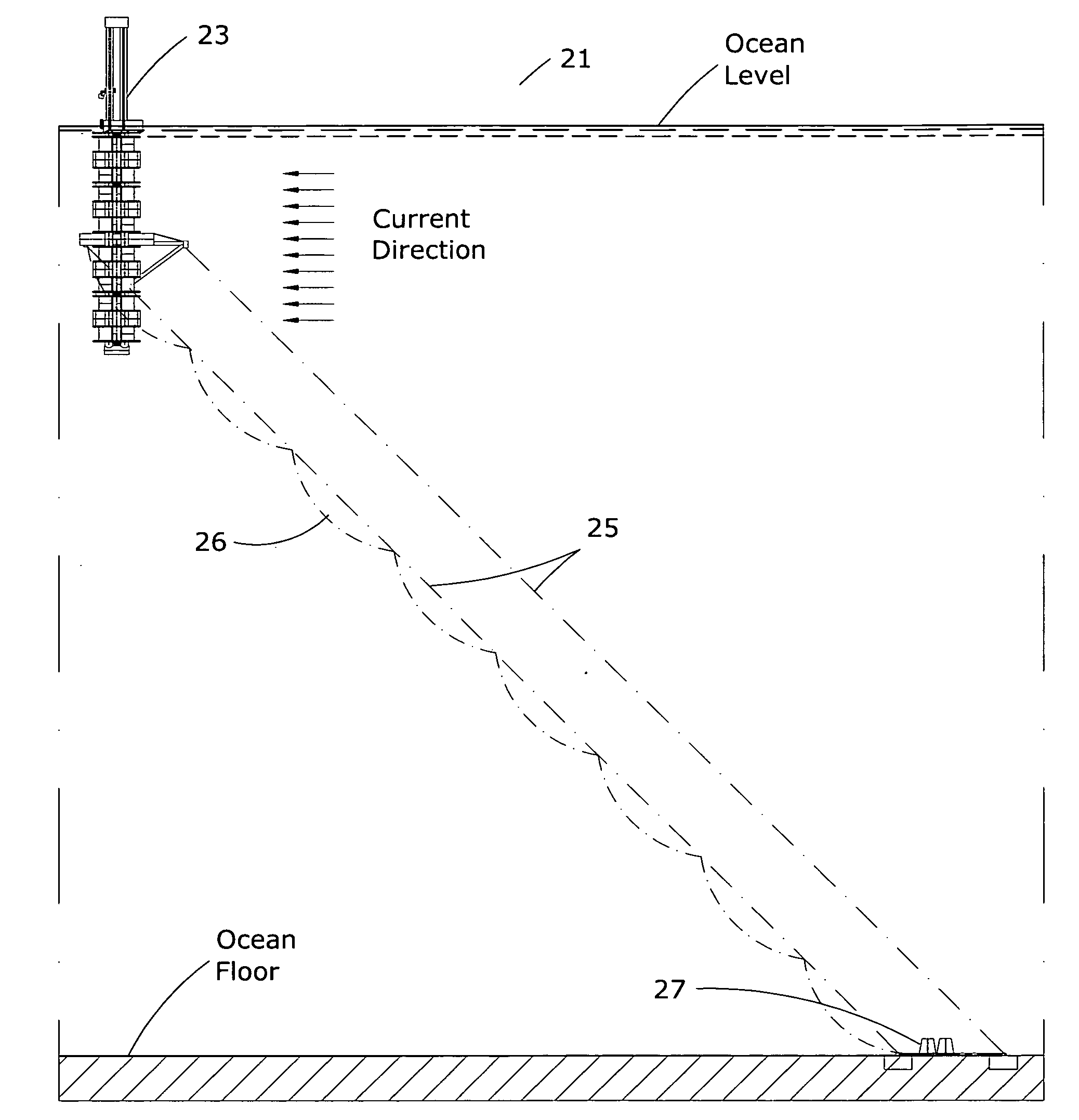

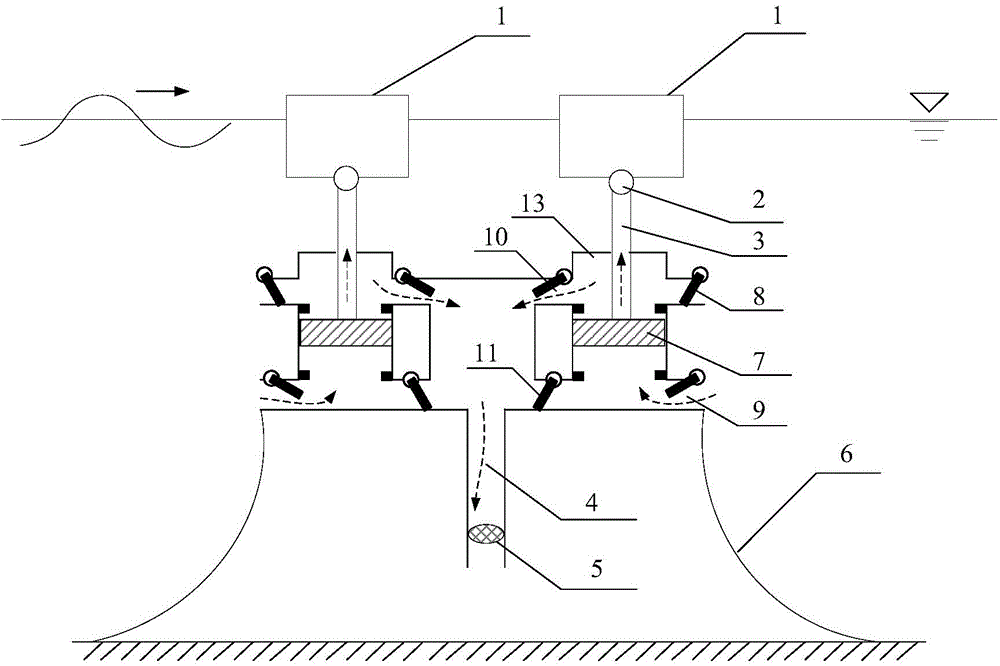

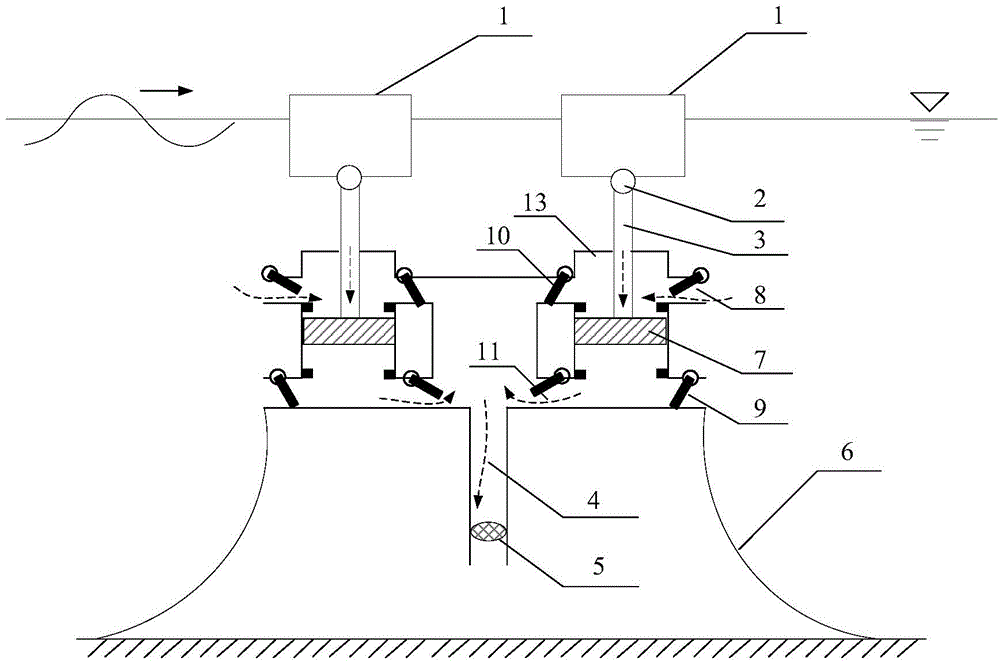

Installation for harvesting ocean currents (IHOC)

Installation for harvesting kinetic energy of ocean currents in deepwaters is based on utilization of a semisubmersible platform and the multiple of vertically oriented Darrieus type hydraulic turbines with funnels. The turbines are located bellow sea level on distance sufficient to exclude them from being affected by wave actions. The electric power generators are located on a structure above water and transmit electric power to the shore utilizing flexible cable from semisubmersible to the sea bottom and underwater cable going to the shore, where it connected to the power distributing network. One of the Embodiments of this invention is designed to harvest energy of tides in deepwaters.

Owner:BELINSKY SIDNEY IRVING

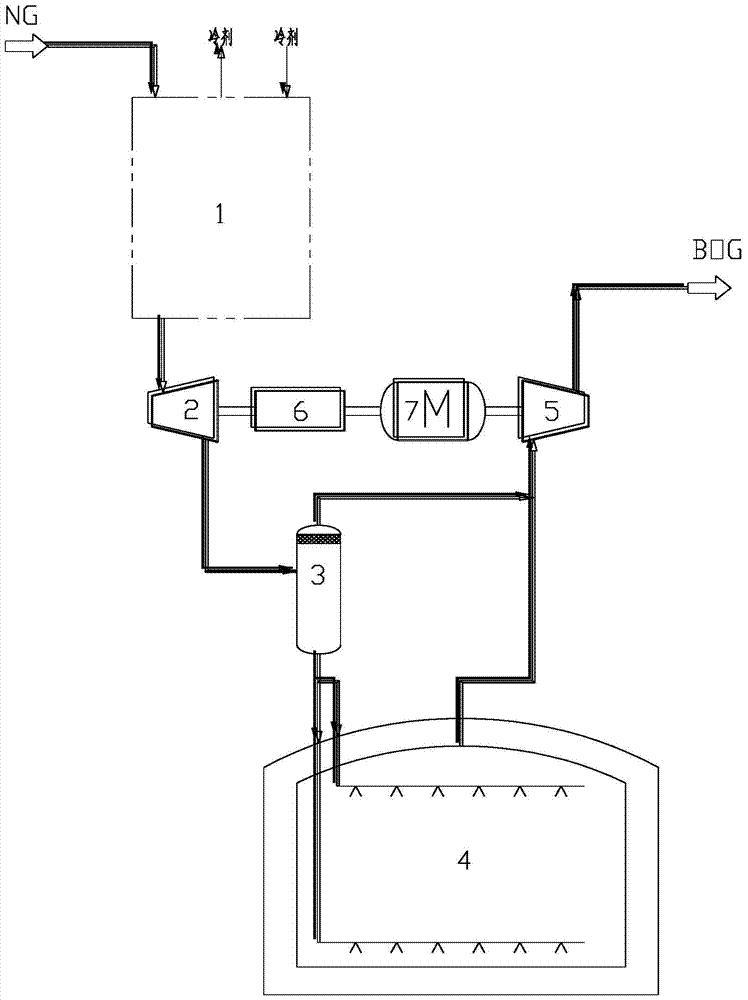

A kind of lng energy recovery process

ActiveCN105240064BReduce the temperatureIncrease productionSteam engine plantsGas phaseMechanical energy

The invention relates to the technical field of natural gas low temperature equipment, in particular to an LNG energy recovery process. By an LNG hydraulic turbine device (or expanding machinery in other forms), high pressure and low temperature LNG converts pressure energy to mechanical energy which is output by a supercharging end of the LNG hydraulic turbine device. Depressurized LNG is further cooled, a gas phase and a liquid phase generated in a depressurizing process are separated by a gas-liquid separation tank, the liquid LNG is charged to an LNG storage tank, and the gas phase BOG and BOG of the LNG storage tank are supercharged together by the supercharging end, namely, a BOG supercharger, of the LNG hydraulic turbine device. The LNG hydraulic turbine device replaces a J-T valve of the LNG product for expanding throttling, as the LNG is lower in temperature, output of the BOG is reduced, LNG yield is improved, and mechanical energy can be recovered by BOG supercharging of the BOG supercharging end.

Owner:SICHUAN HENGRI GAS ENG CO LTD

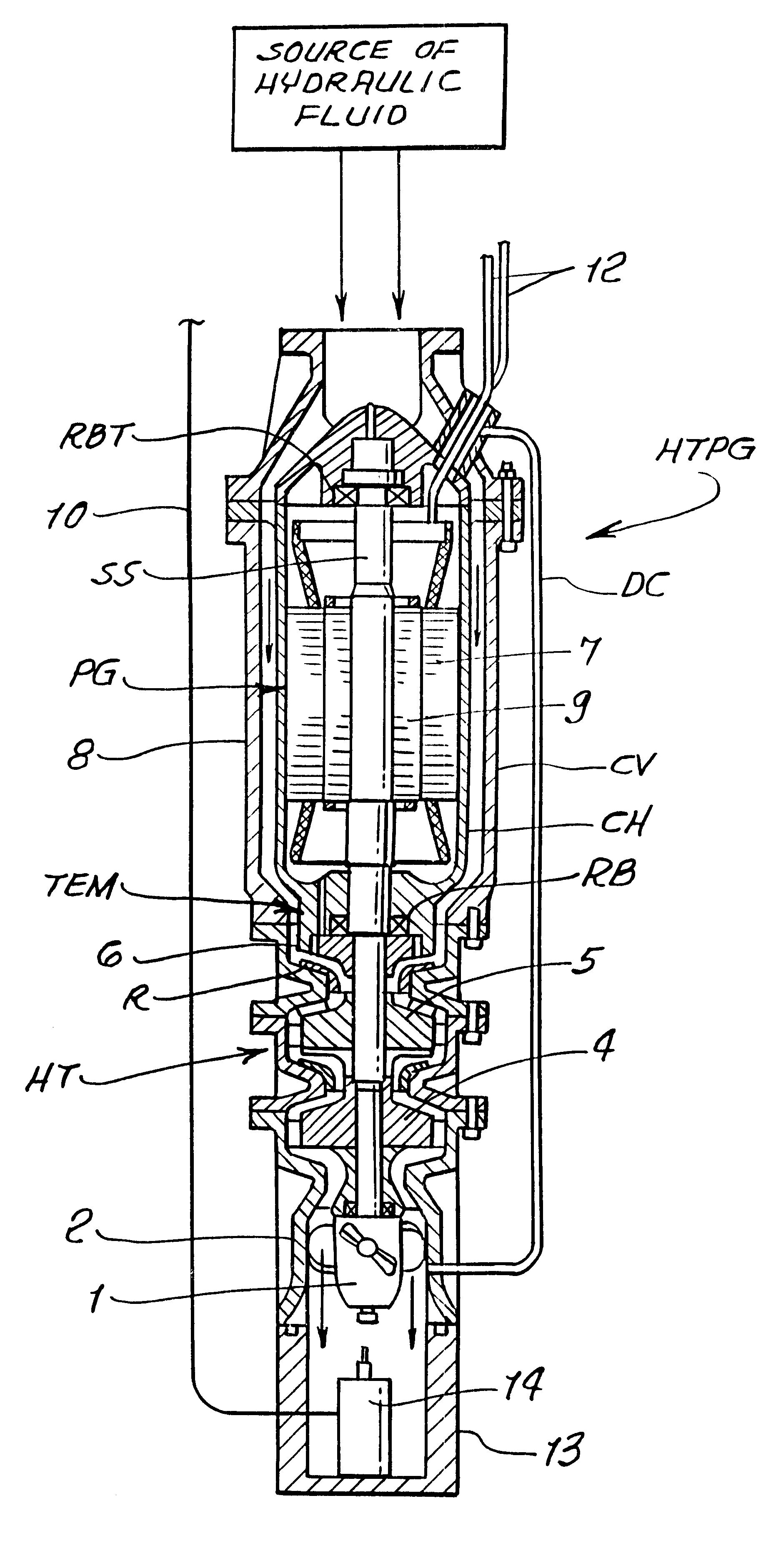

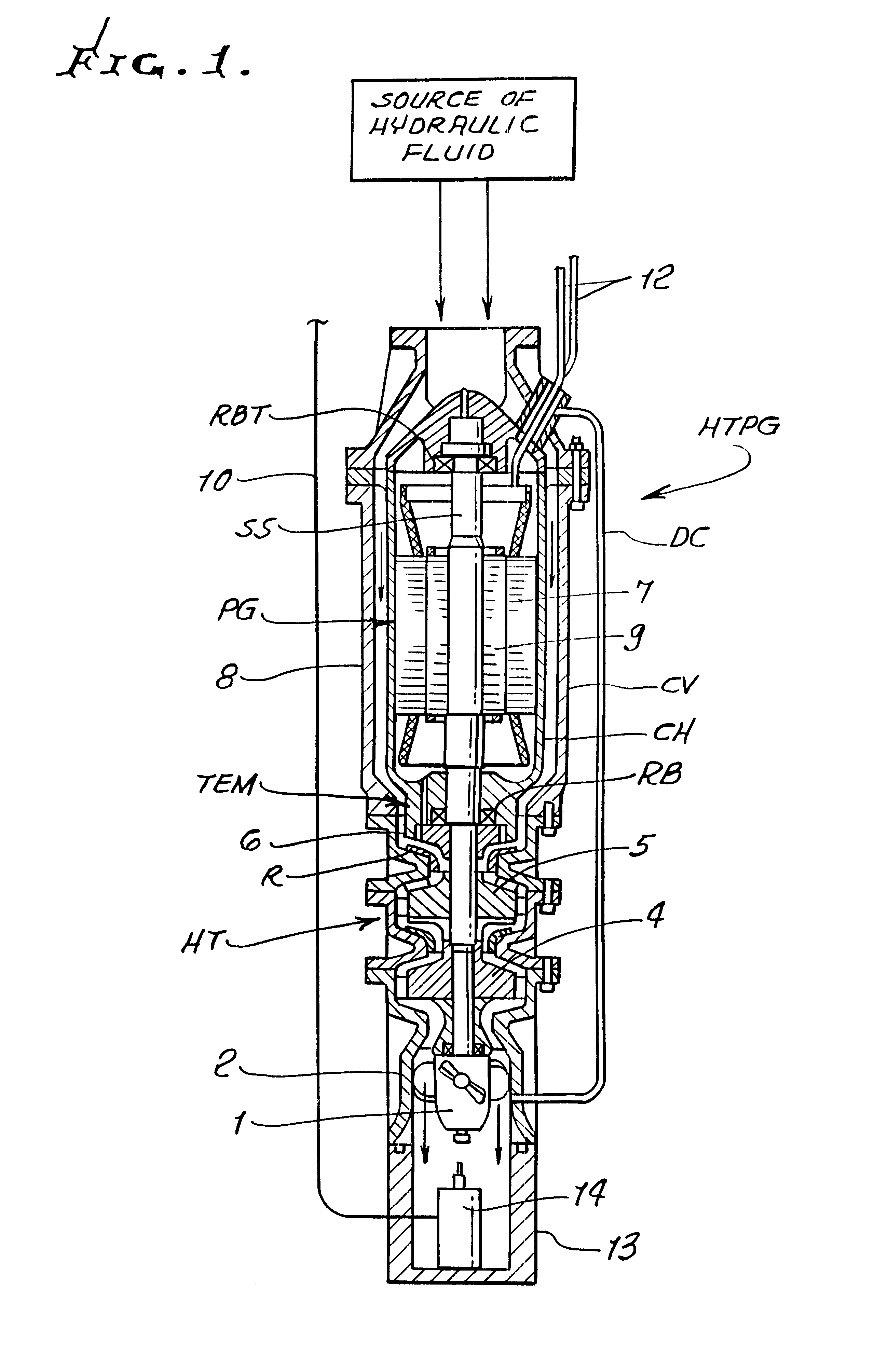

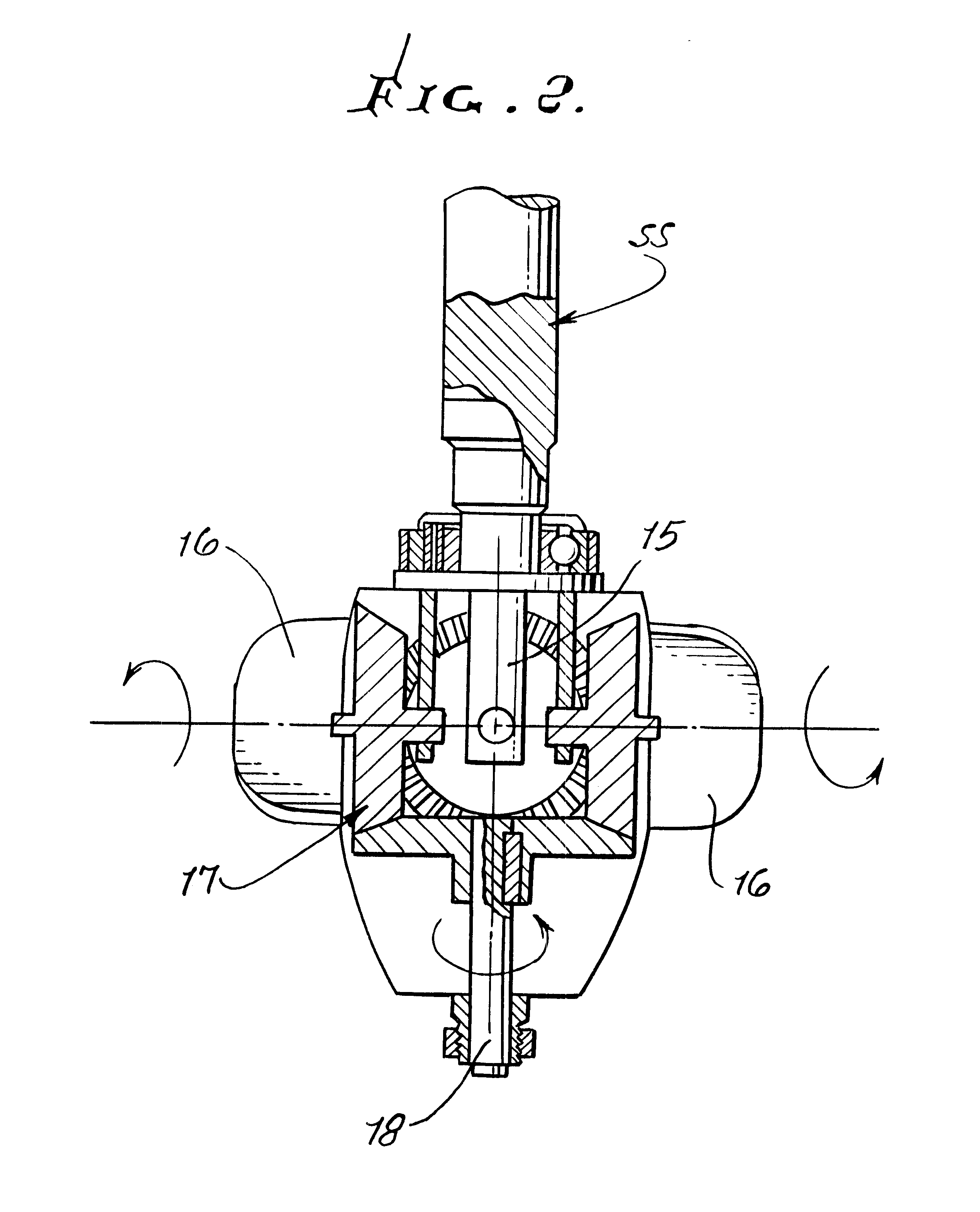

Dual type multiple stage, hydraulic turbine power generator including reaction type turbine with adjustable blades

InactiveUS6441508B1Maximize efficiencyConstant speedGas turbine plantsReaction enginesEngineeringHydraulic fluid

A hydraulic turbine power generator mounted on a single shaft wherein the hydraulic turbine means includes a plurality of reaction type turbine stages arranged to be in combination, rotatably responsive to the hydraulic fluid coupled to the turbines. One of the turbine stages having axial turbine runner means mounted to the single shaft and having a plurality of adjustable blades for permitting the pitch of the blades to be adjusted for controlling the effective operative fluid head to cause the shaft to rotate at a preselected speed and including means for adjusting the pitch of the adjustable blades. The turbine stages can be a Francis type turbine and a Kaplan type turbine. The hydraulic turbine power generator can be oriented in an upward direction to cause the fluid flow to travel upwardly through the turbine stages and function as a two phase turbine expander resulting in the separation of the liquid phase from the gas / vapor stage.

Owner:ELLIOTT CO

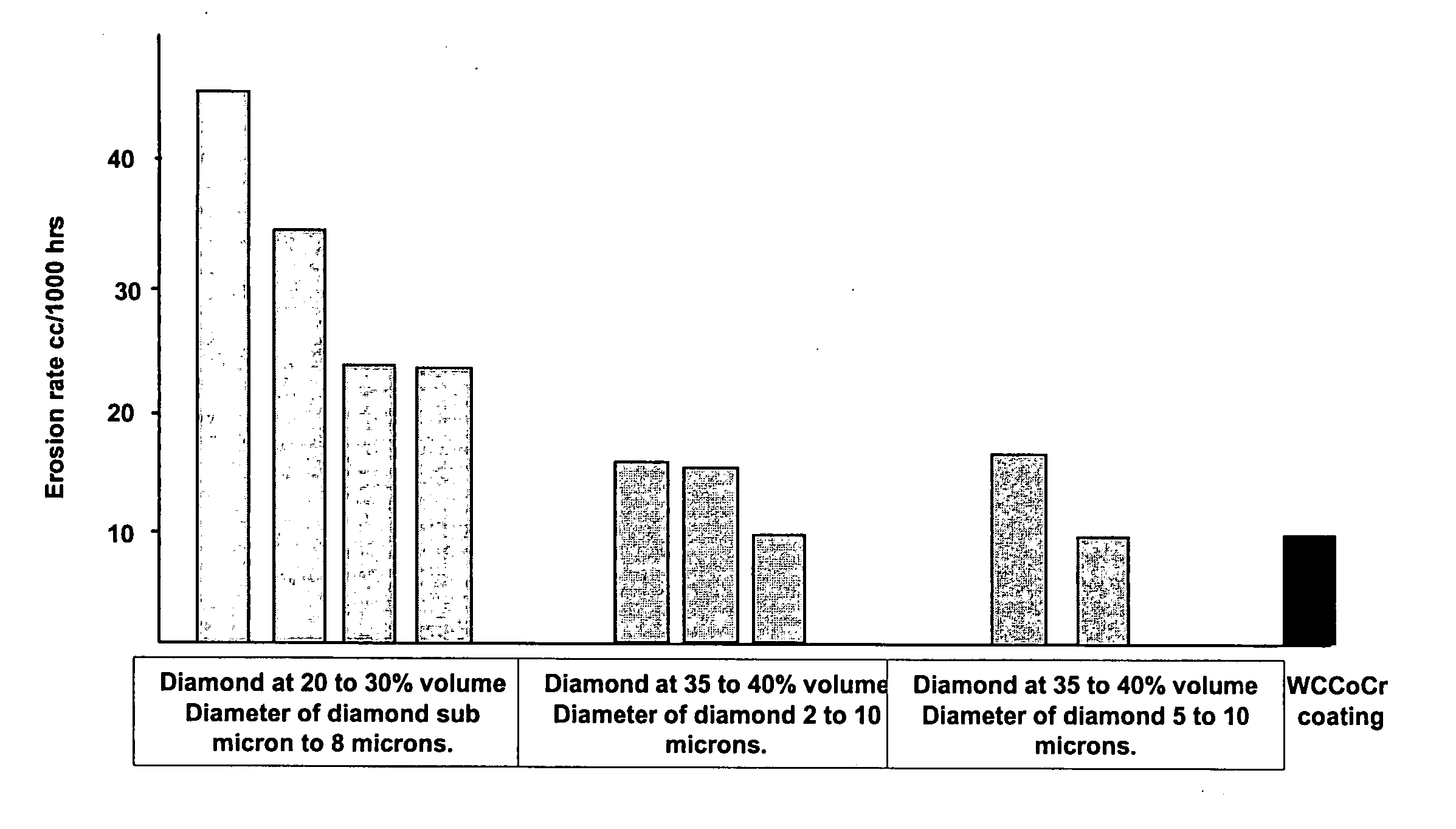

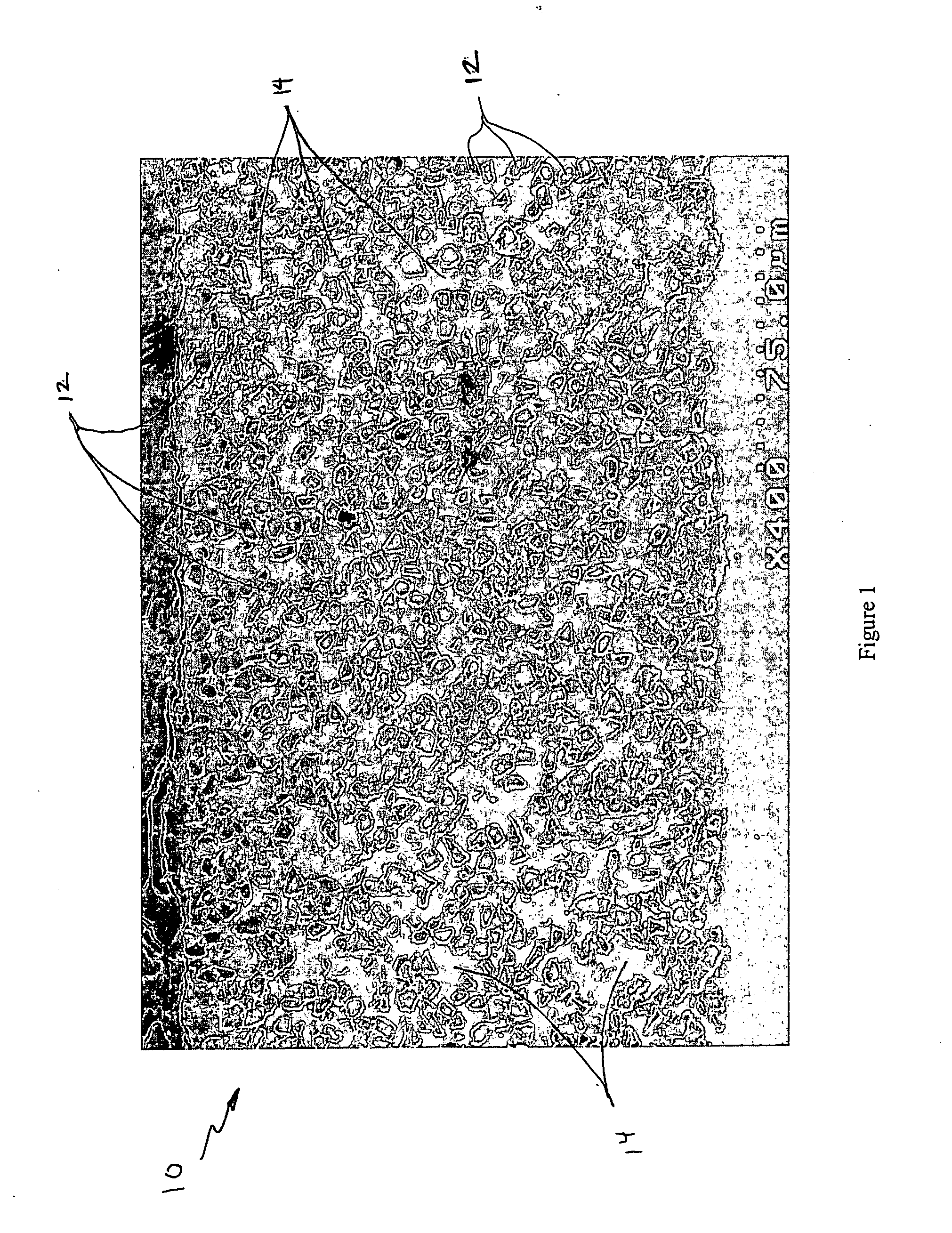

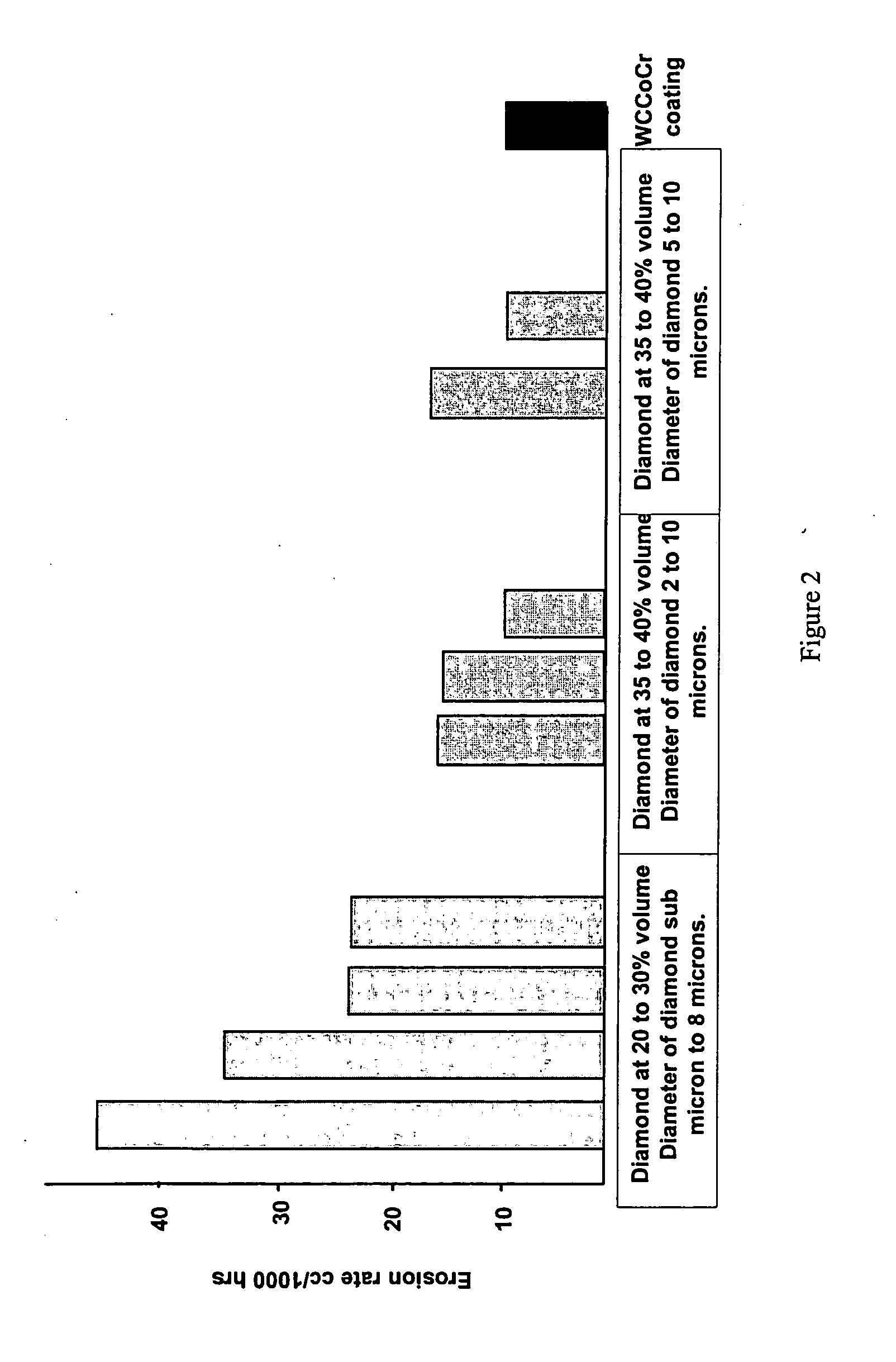

Erosion resistant coatings and methods thereof

Erosion resistant coating compositions include hard particles in a metal matrix such as nickel-based, cobalt-based and iron-based matrices applied by a plating process for complex geometry or hard to access component surfaces or by thermal spray processes for line of sight applications. These materials and processes are especially suited for providing erosion resistance to hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

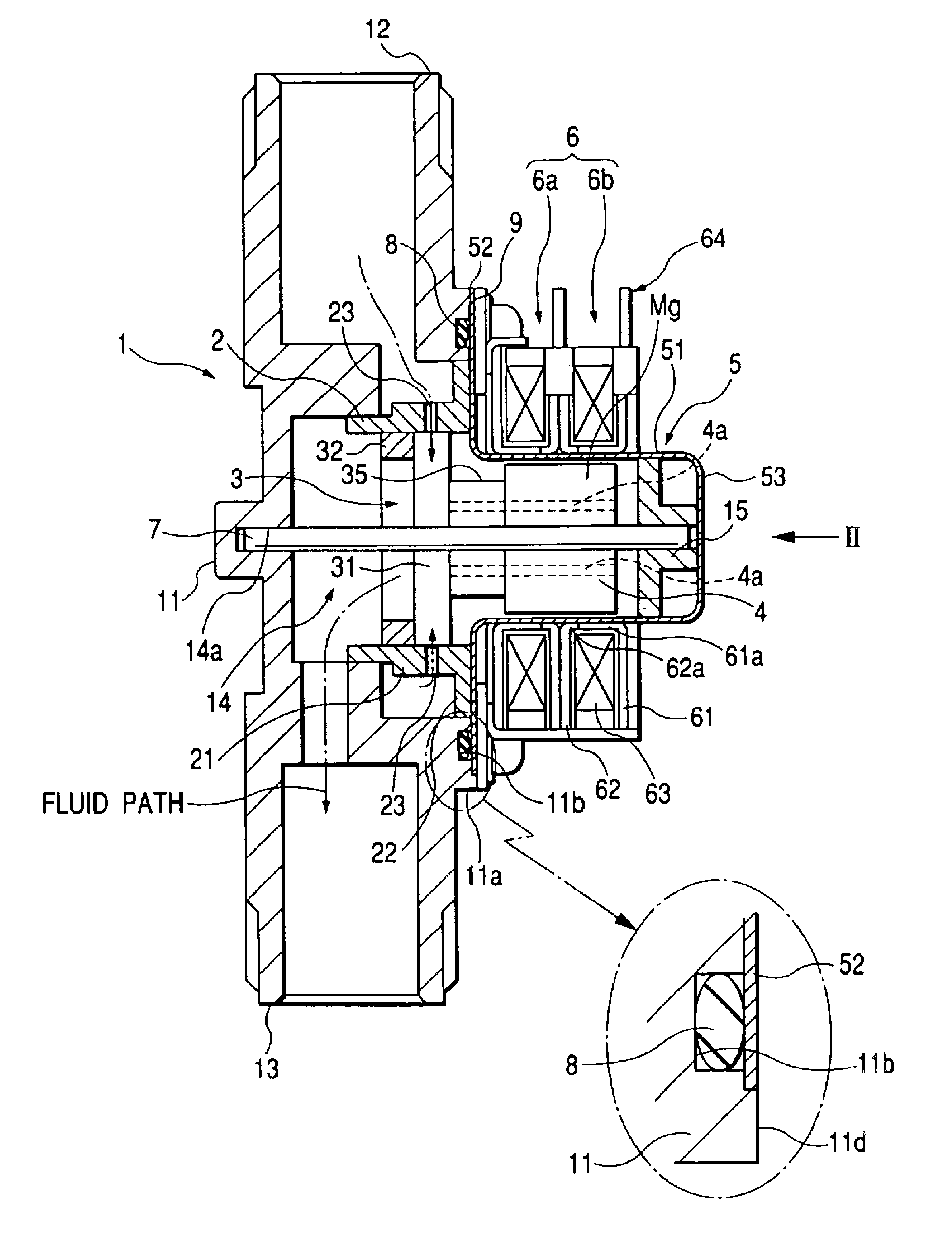

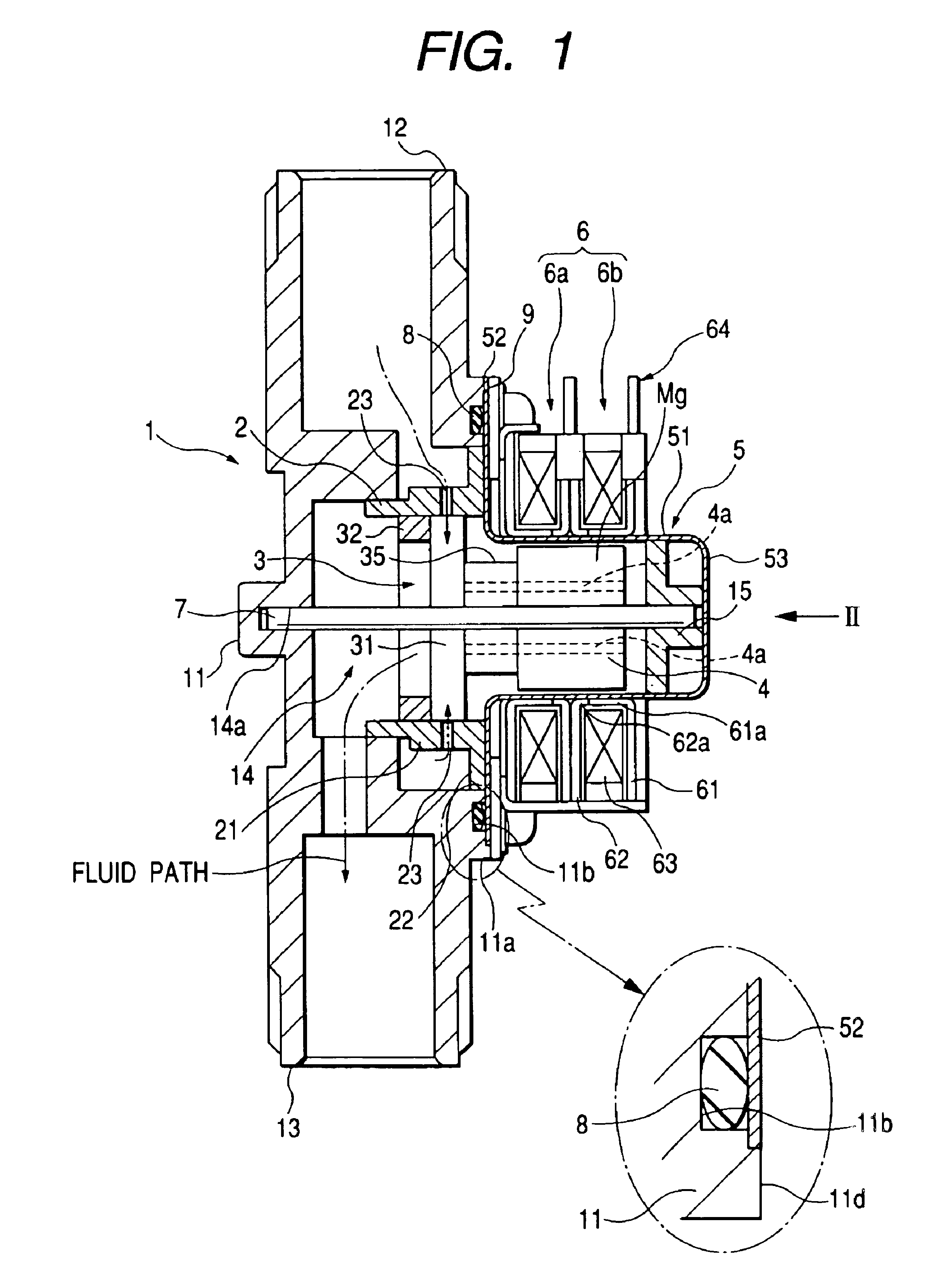

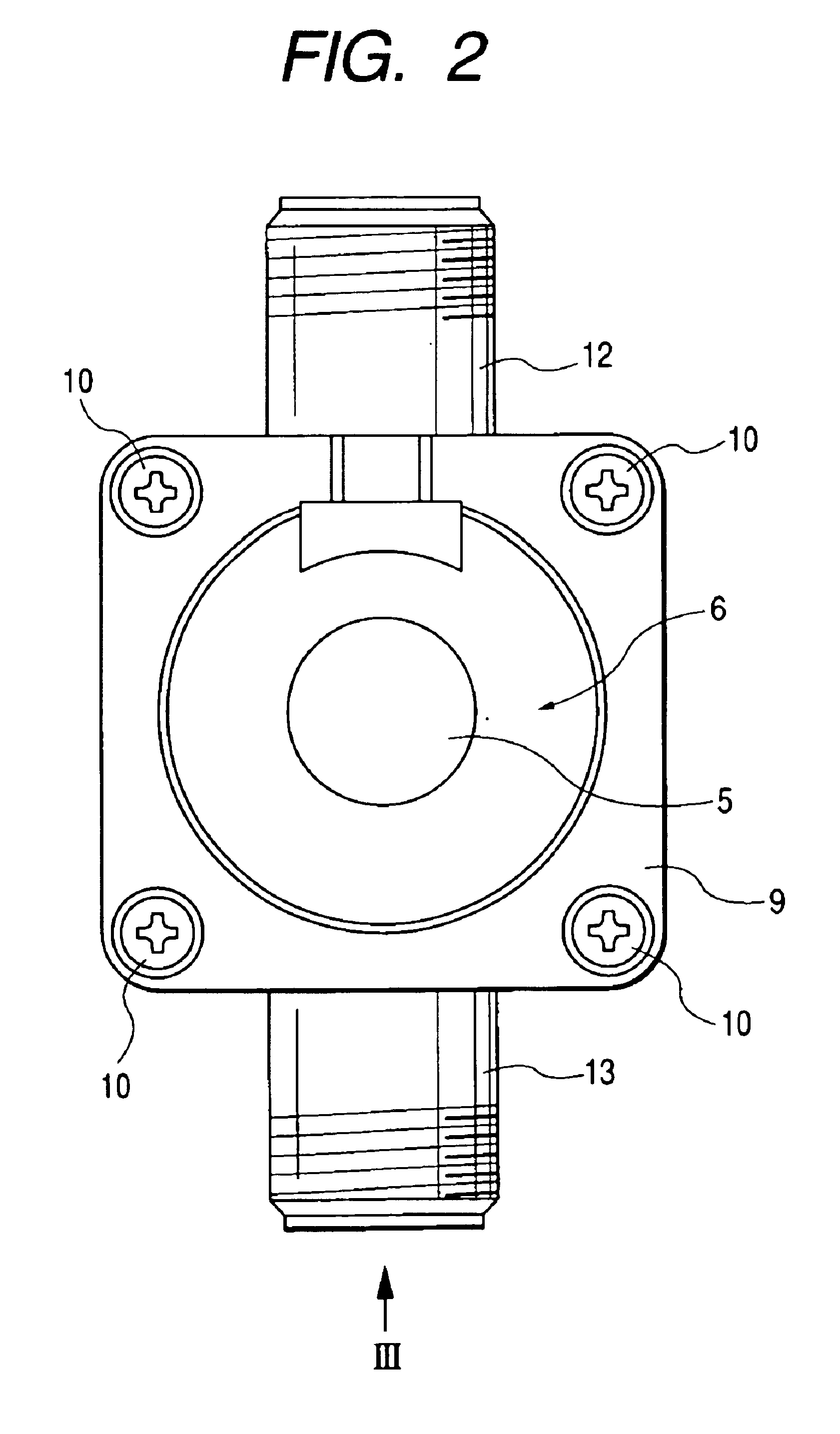

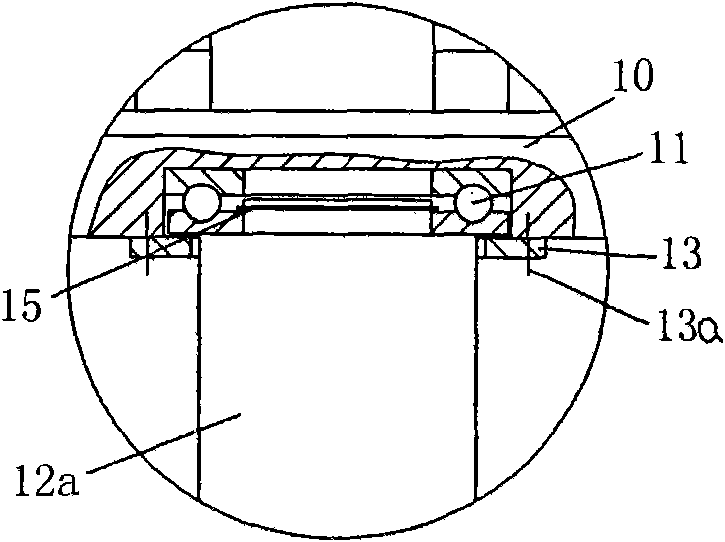

Small power generating device and water faucet device

InactiveUS6876100B2Reduce settingsEfficiently obtainedGas turbine plantsEngine componentsElectric machineWater turbine

A small generator includes a hydraulic turbine provided in a fluid path rotating with a passage of a fluid in a predetermined flow and a rotator coupled to the hydraulic turbine rotating together with the hydraulic turbine which acts as a rotor portion opposed to a stator portion having multiple layers in a stepping motor including the stator portion, wherein the rotor portion relatively rotates with respect to the stator portion with the passage of the fluid, thereby generating a power.

Owner:SANKYO SEIKI MFG CO LTD +1

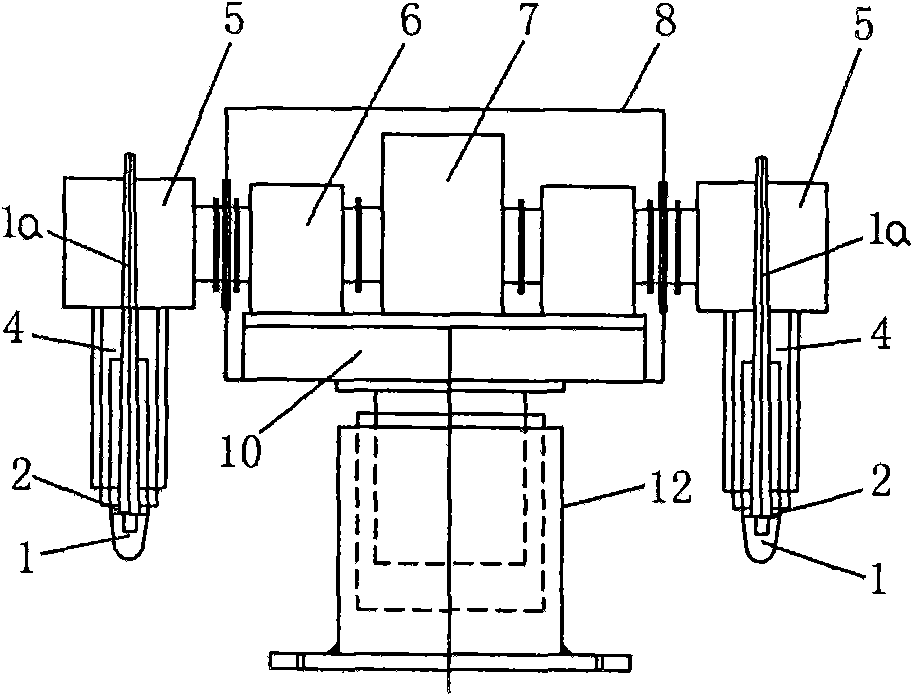

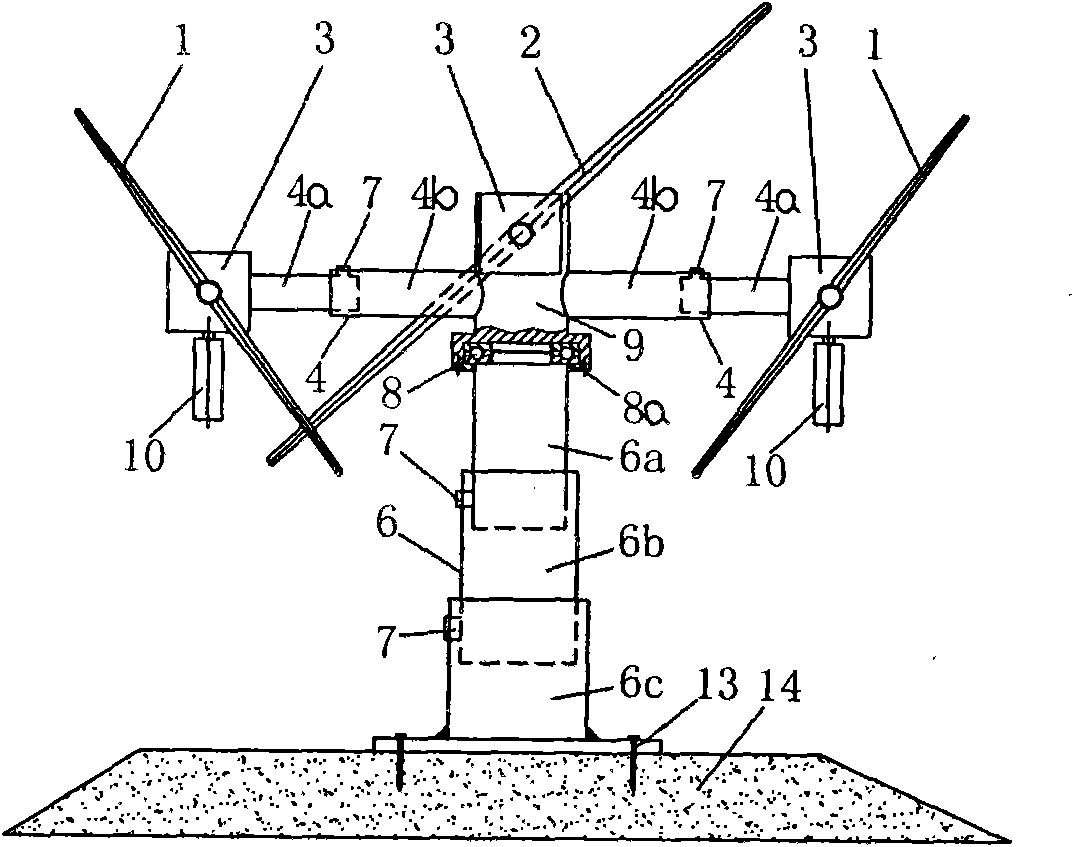

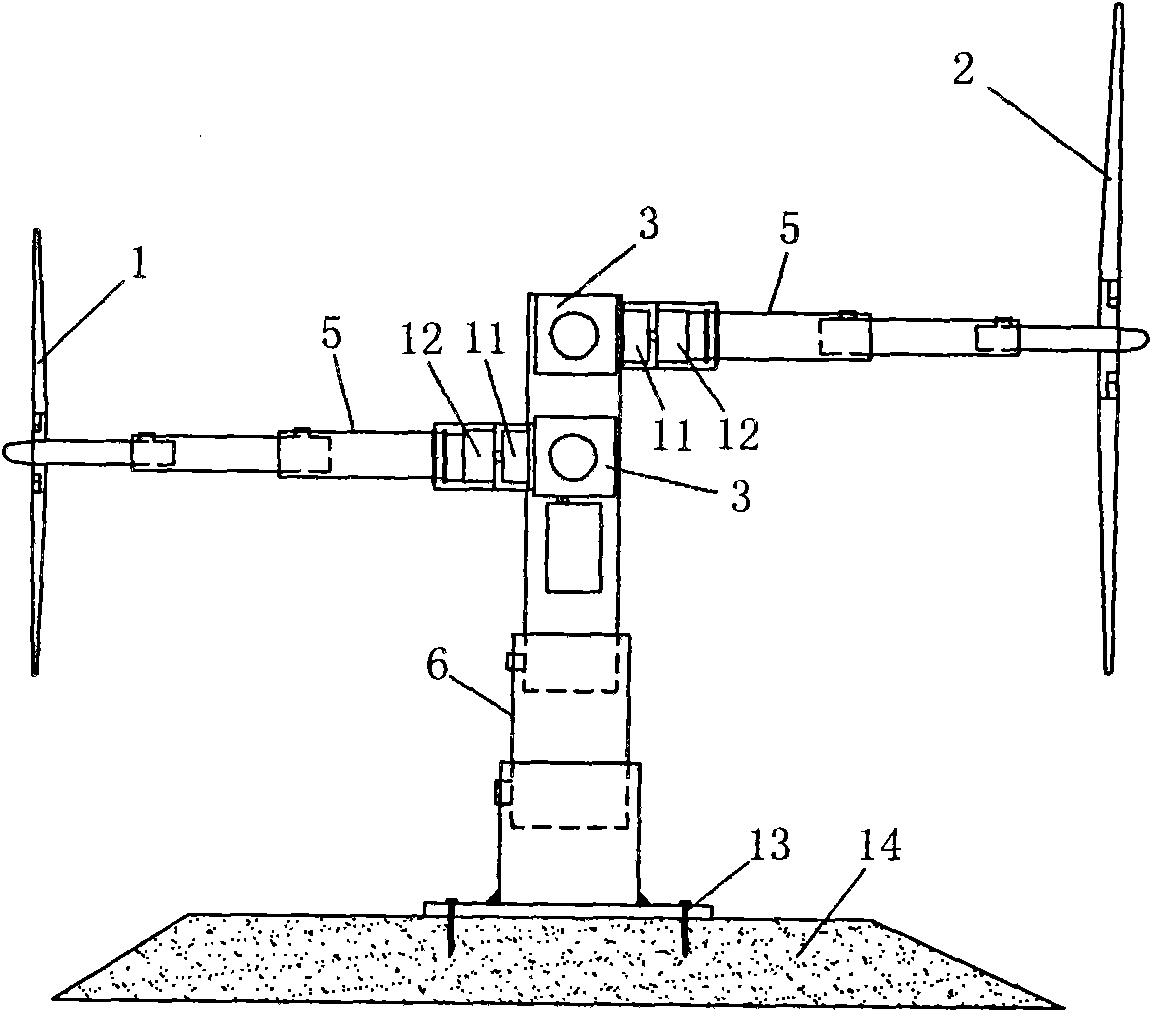

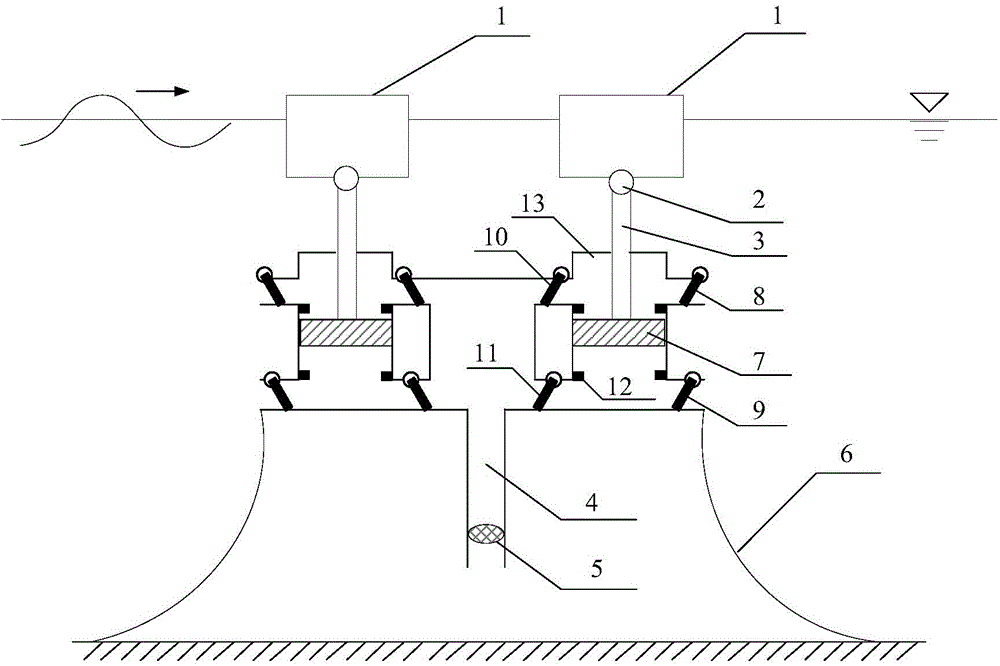

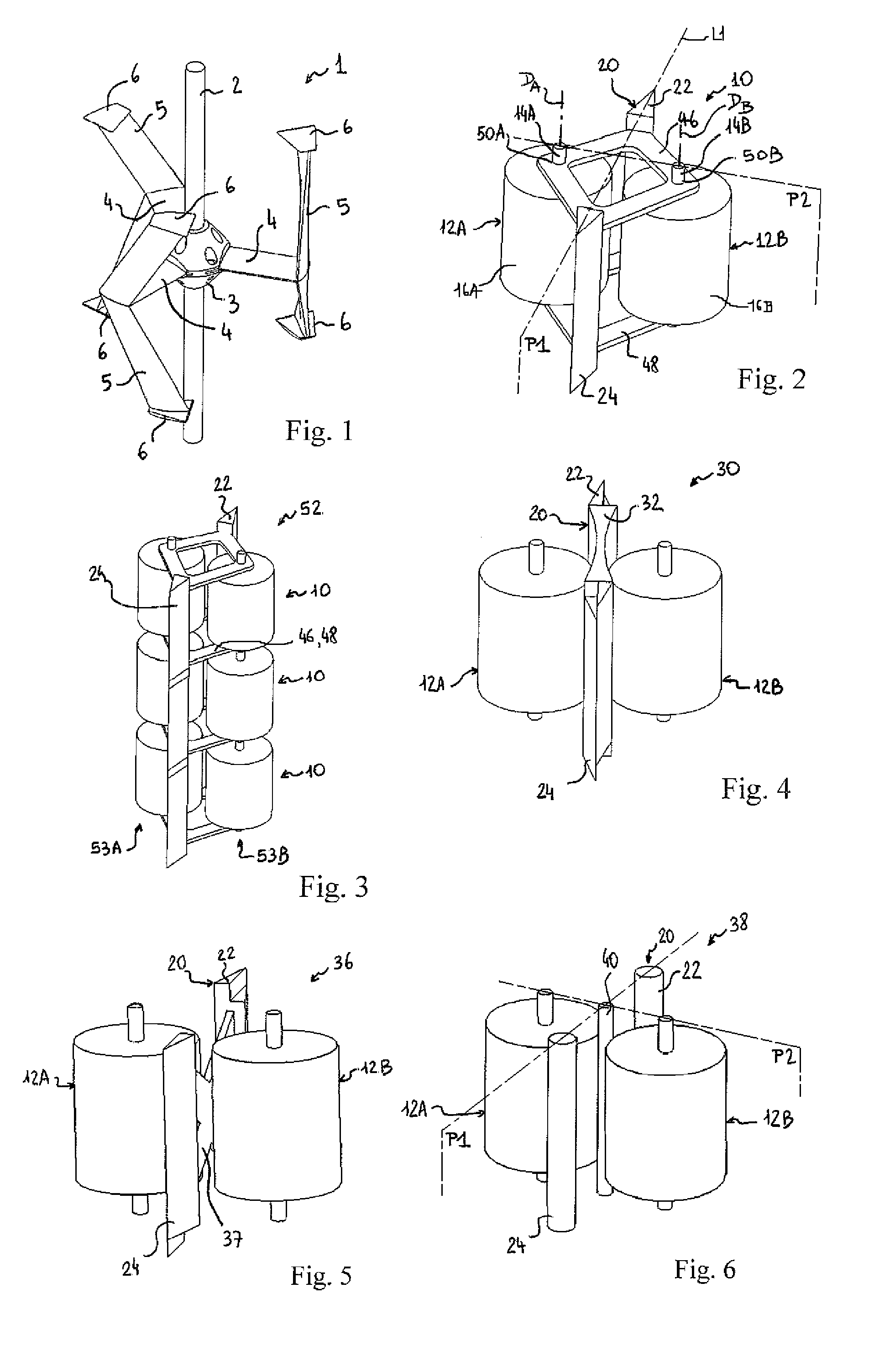

Bi-reverse folding-type cross shaft tidal stream energy hydroturbine

InactiveCN101907054AExtend your lifeAvoid disassemblyWorking fluid for enginesReaction enginesOcean bottomThrust bearing

The invention relates to a bi-reverse folding-type cross shaft tidal stream energy hydroturbine belonging to the technical field of electricity generation by utilizing tidal stream energy. In the bi-reverse folding-type cross shaft tidal stream energy hydroturbine, either end of a generator is provided with an impeller, a connecting rod, a steering joint and speed-increasing gearboxes, wherein the generator and the speed-increasing gearboxes at both ends are fixe on a common base which is mounted on a supporting column by the aid of a thrust gearing in a rotating mode, the supporting column is fixed on the cement basis of a seabed, and the blades of the impeller, the connecting rod and the supporting column adopt folding structures. The tidal stream energy hydroturbine reduces the size of the whole device and is convenient to transport by effective folding, avoids dismounting among all parts, decreases the mounting cost of the seabed by more than 50 percent than the traditional cost and prolongs the service life of the hydroturbine by longer than 5 years.

Owner:DALIAN UNIV OF TECH

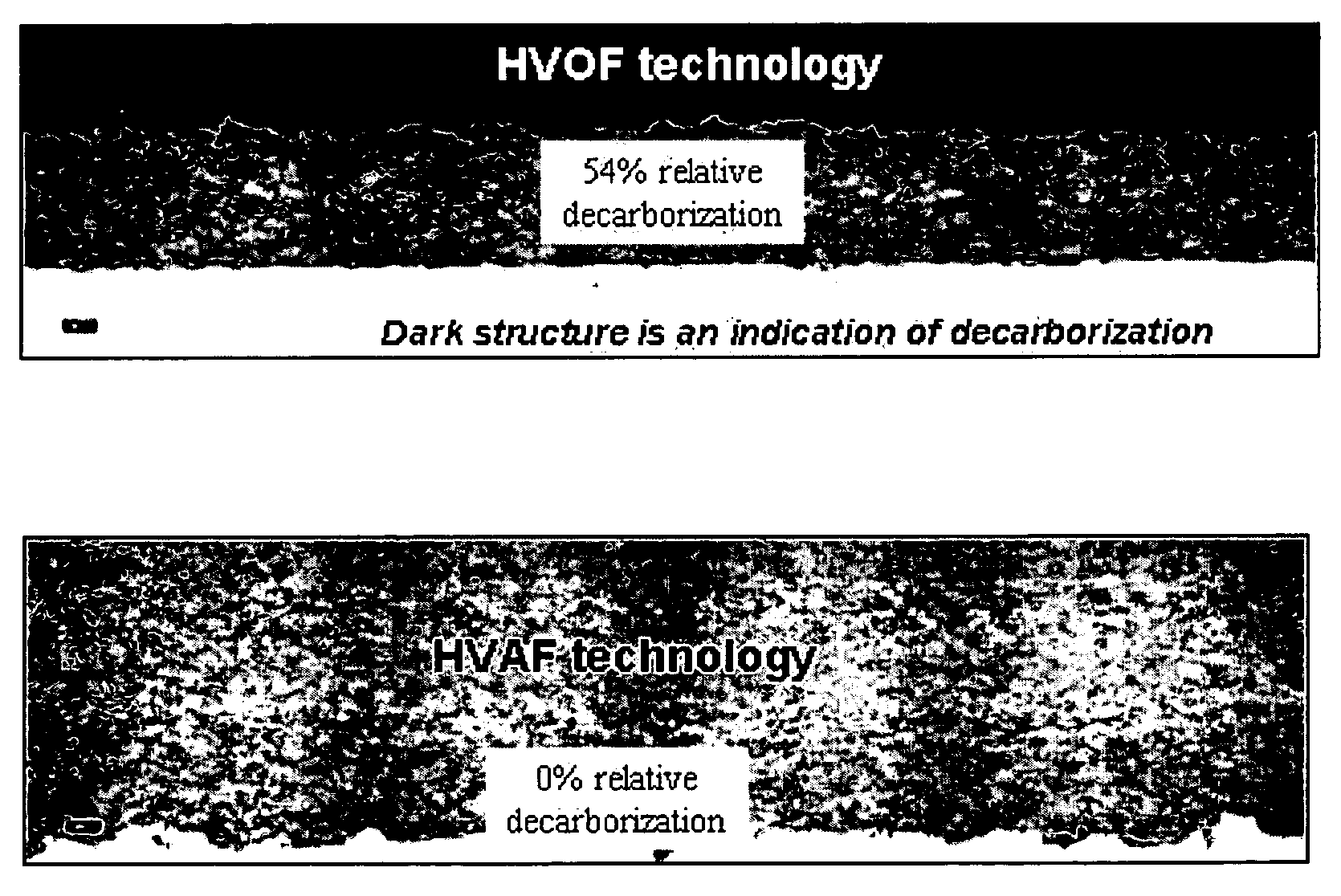

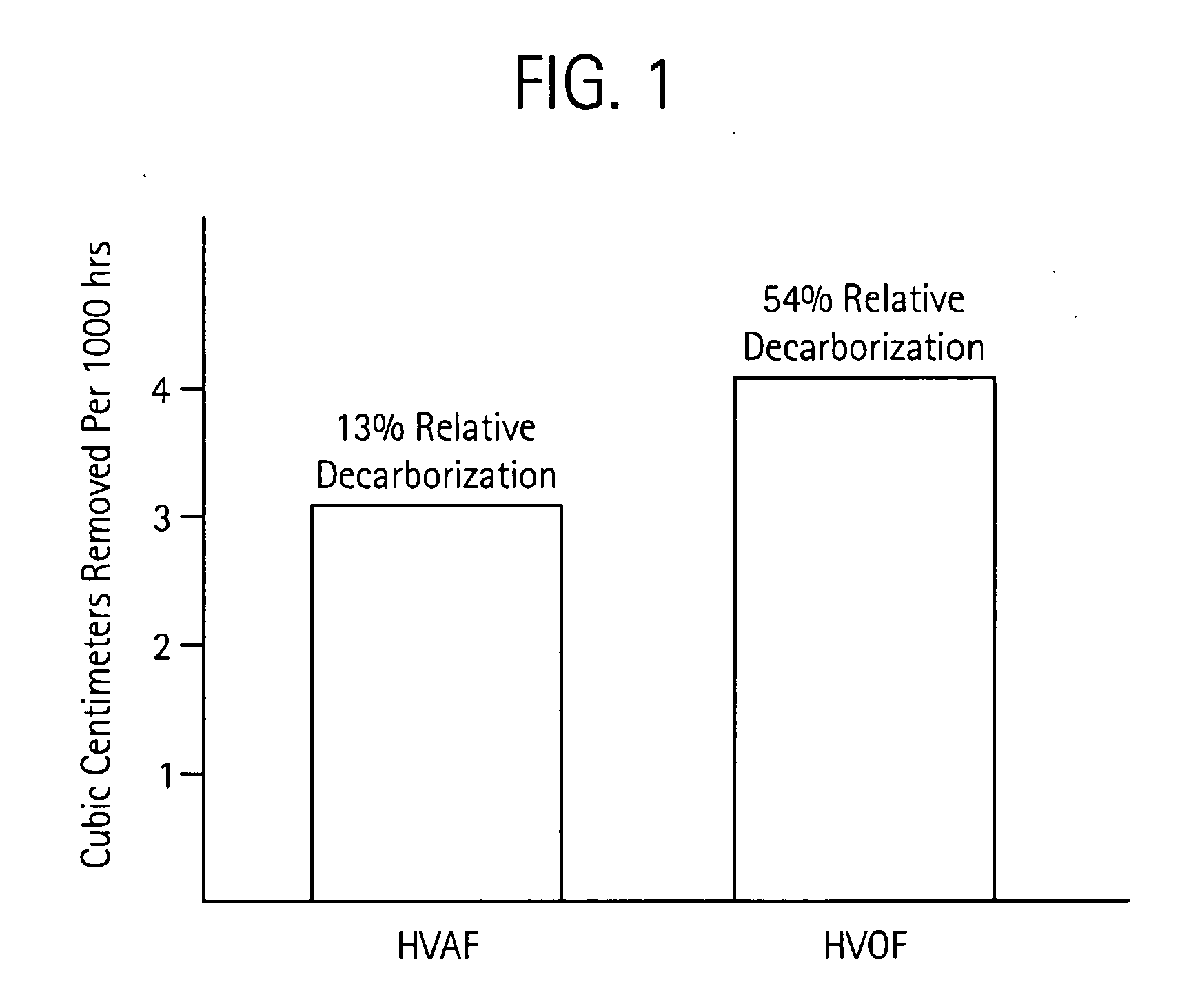

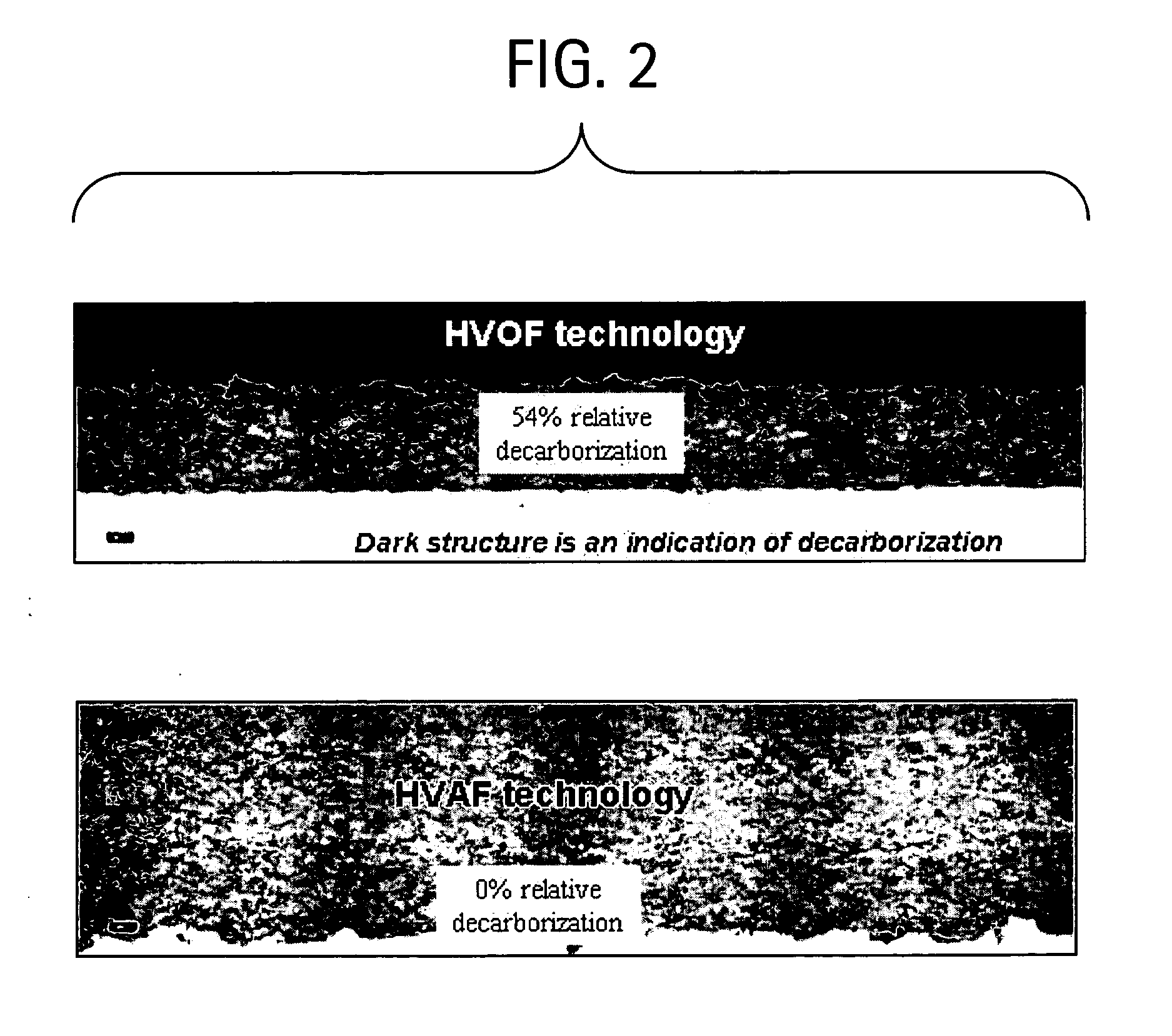

Erosion resistant coatings and methods thereof

Erosion resistant coating processes and material improvements for line-of-sight applications. The erosion resistant coating composition includes nanostructured grains of tungsten carbide (WC) and / or submicron sized grains of WC embedded into a cobalt chromium (CoCr) binder matrix. A high velocity air fuel thermal spray process (HVAF) is used to create thick coatings in excess of about 500 microns with high percentages of primary carbide for longer life better erosion resistant coatings. These materials and processes are especially suited for hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

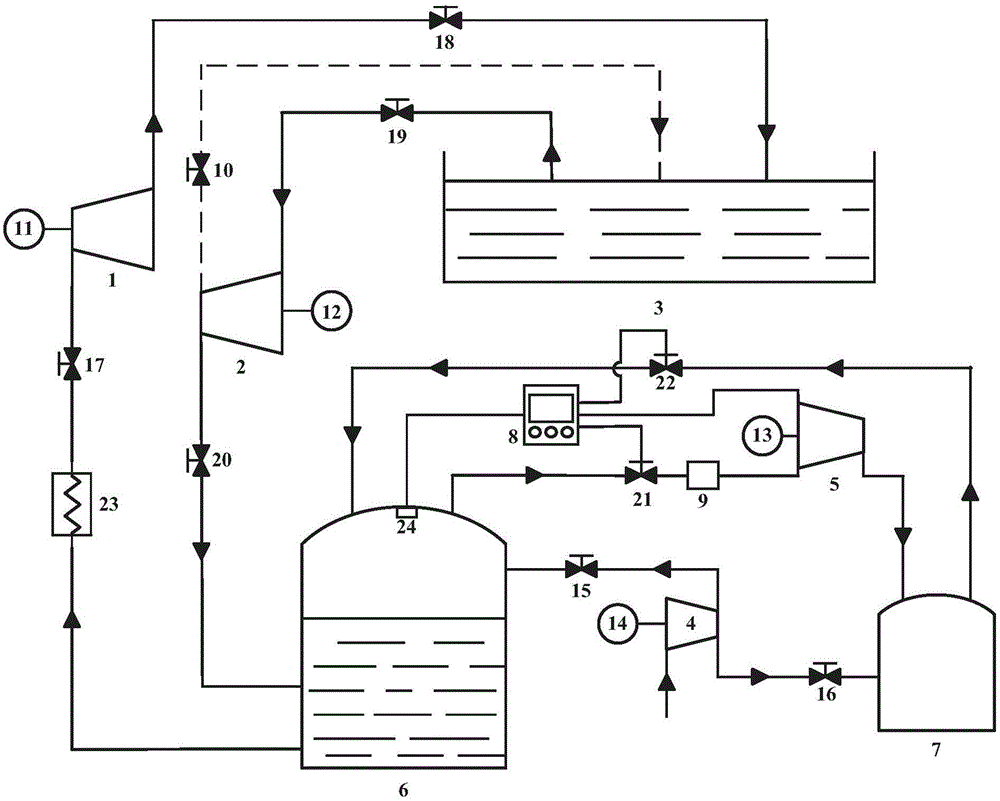

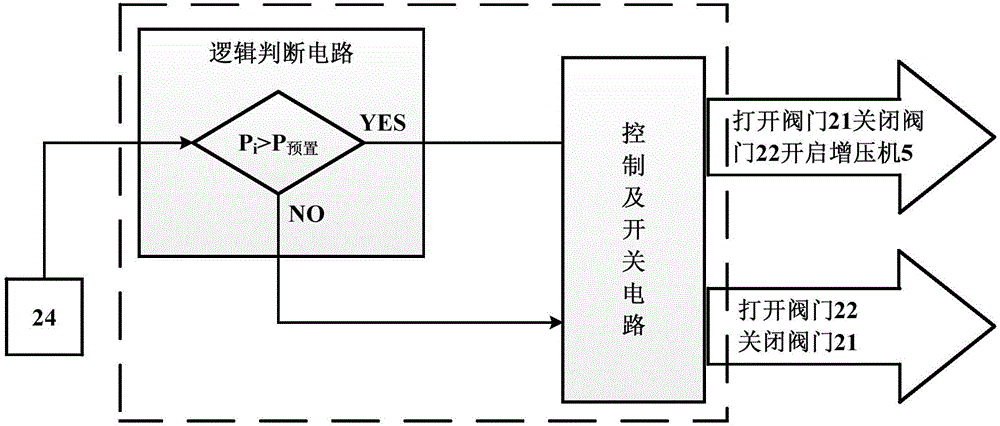

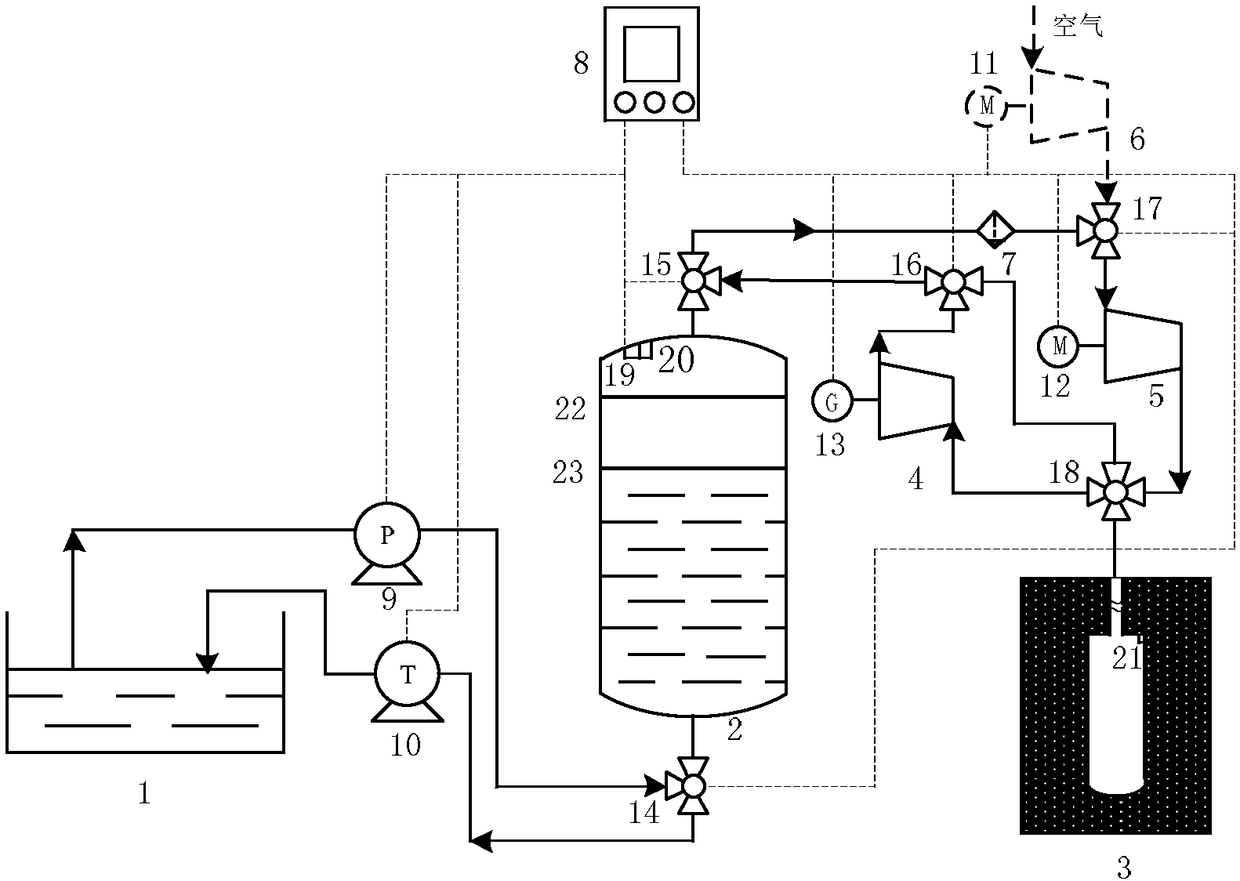

Water-gas common-cabin electric power energy storage system utilizing high pressure gasholder to maintain constant pressure

ActiveCN104100441ASolve the problem of water pressure stabilityHigh energy storage densityPump controlEngine componentsGas compressorHigh pressure

The invention discloses a water-gas common-cabin electric power energy storage system utilizing a high pressure gasholder to maintain constant pressure. The water-gas common-cabin electric power energy storage system comprises a water-gas common-cabin, a compressor unit, a water pump unit, a water storage pool and a water turbine, wherein a water exhaust port of the water turbine supplies inlet water to the water storage pool through a pipeline, the water pump unit pumps water from the water storage pool through a pipeline, a gas exhaust port of the gas compressor unit is communicated with the water-gas common-cabin, a water outlet of the water-gas common-cabin is communicated with the water turbine, and a generator is driven by the water turbine to generate electricity for outputting electric energy. The water-gas common-cabin electric power energy storage system is characterized by also comprising a supercharger and the high pressure gasholder, wherein the high pressure gasholder is connected with two pipelines, one pipeline is communicated with an outlet at the upper part of the water-gas common-cabin through the supercharger, a water and gas separator and a first electric control valve, and the other pipeline is communicated with an inlet at the upper part of the water-gas common-cabin through a second electric control valve.

Owner:XI AN JIAOTONG UNIV

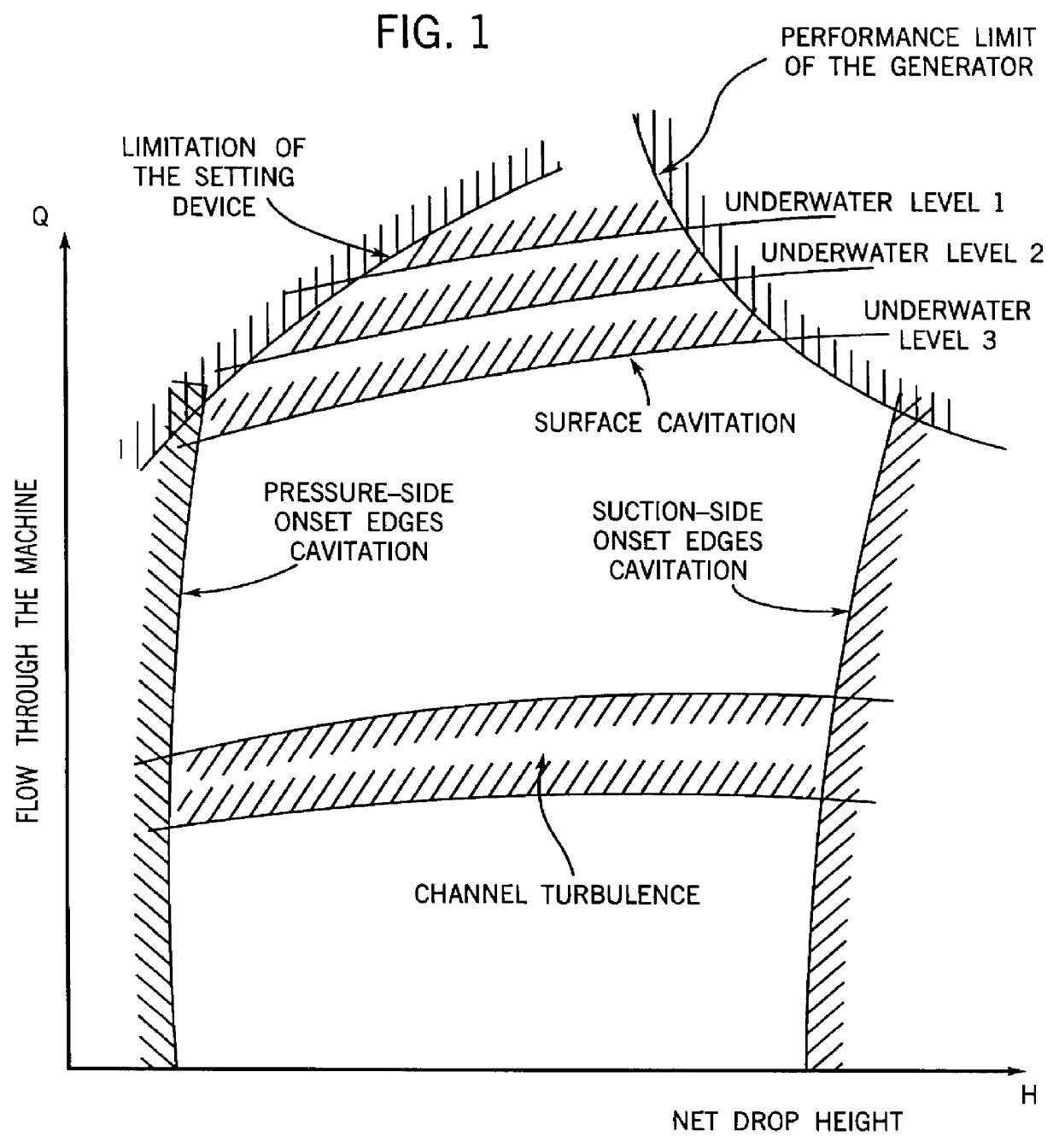

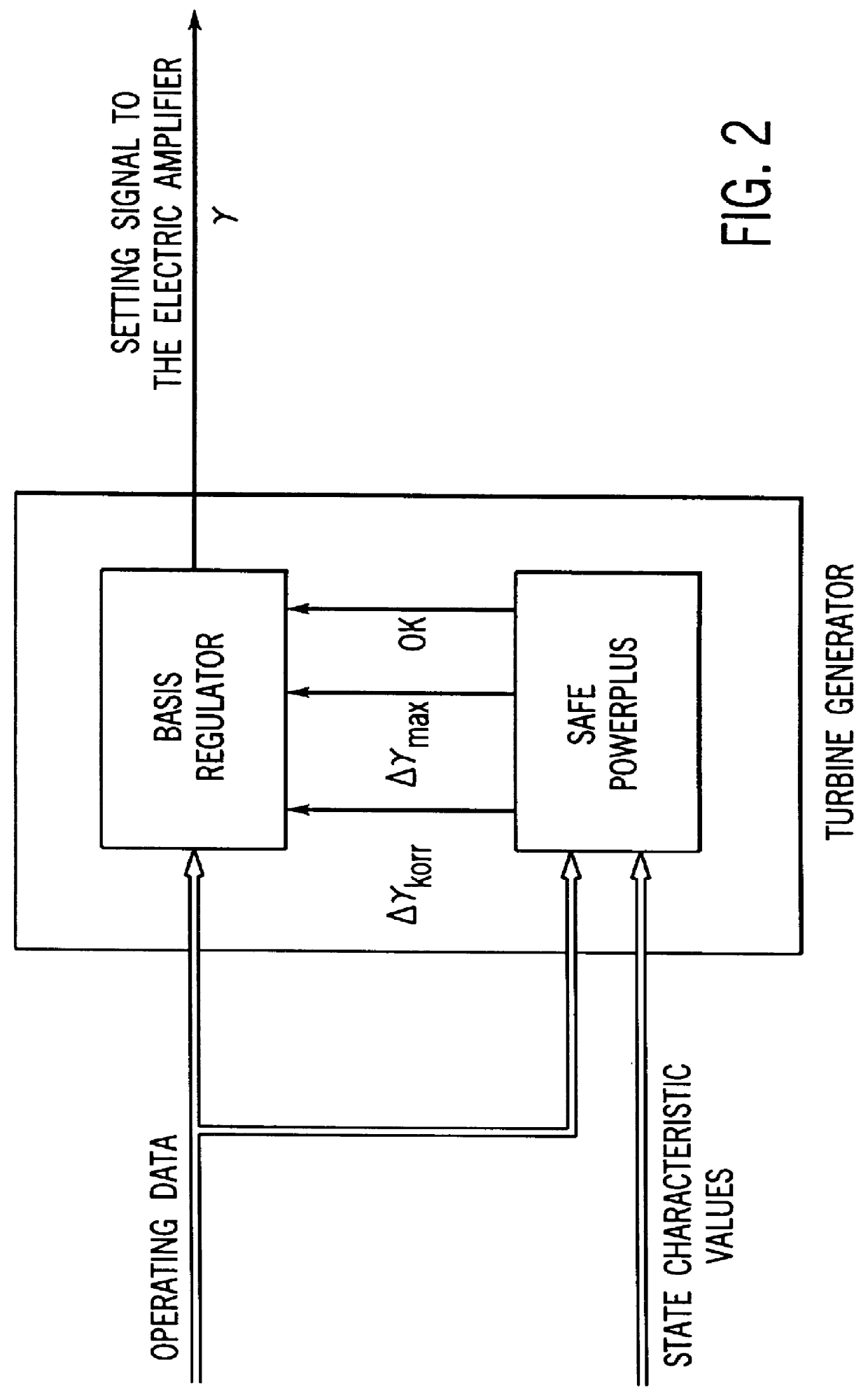

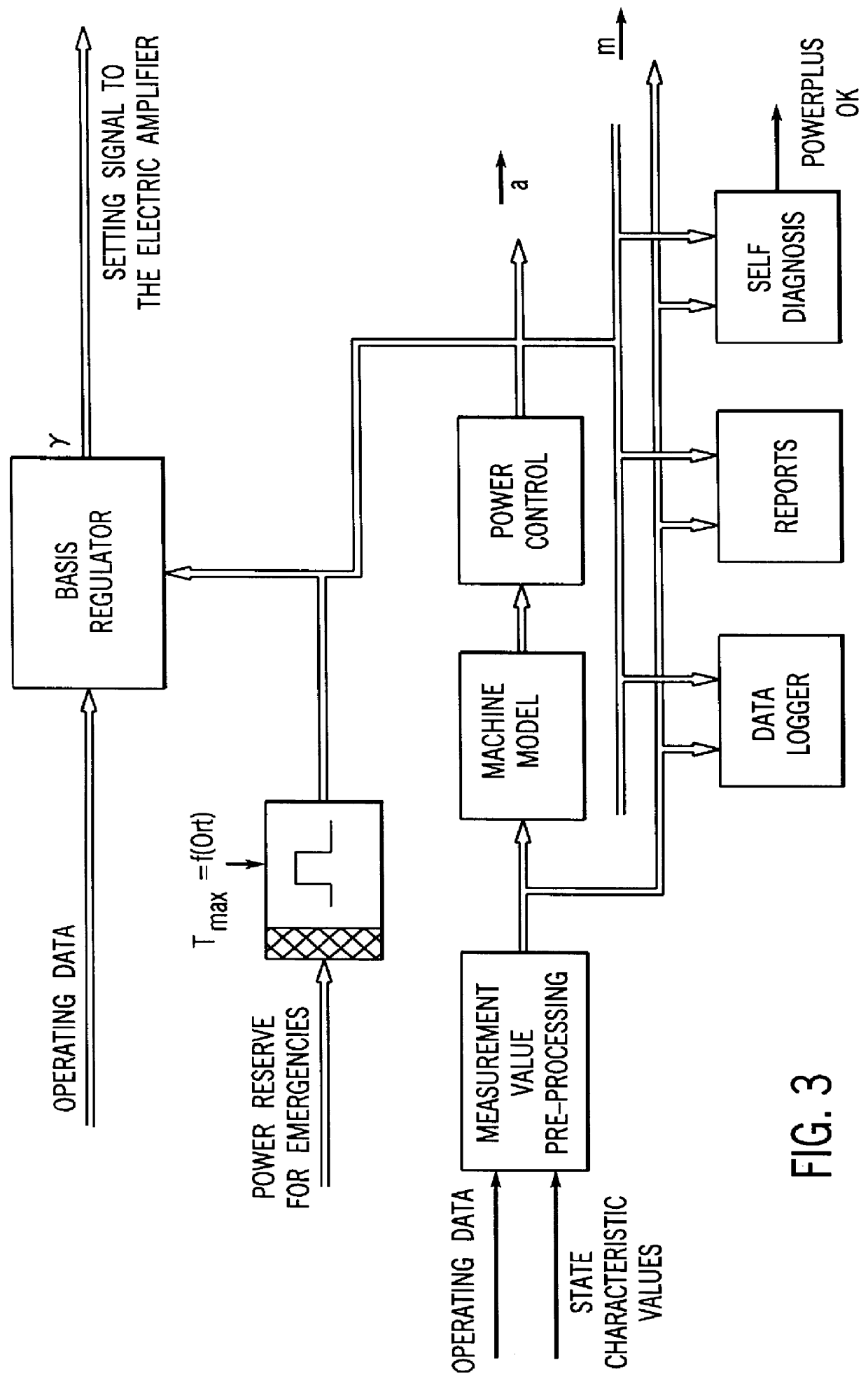

Method for operation of hydraulic turbine

InactiveUS6152684ASignificant utilityCavitation safety is givenWind motor controlHydro energy generationOperating pointCavitation

A process for operating a hydraulic machine, especially a hydro-turbine, includes the step of detecting an actual machine state during operation of the machine by ascertaining operating data. The ascertained operating data includes flow through the turbine (if present), effective and reactive power fed into the electric mains, guide vane opening, pressure before the machine and at the suction pipe exit, headwater level, and tailwater level. The method further includes the step of processing at least one state characteristic values of a first cavitation characteristic value (indicative of cavitation intensity), a second cavitation characteristic value (indicative of an abrupt rise in cavitation manifestations), vibration characteristic values, suction pipe pressure, sand concentration, air pressure, water temperature, and generator temperature (for example winding temperature). The method also includes the step of altering an operating point of the machine based on the at least one processed characteristic value to reduce cavitation and / or quiet running.

Owner:VOITH HYDRO

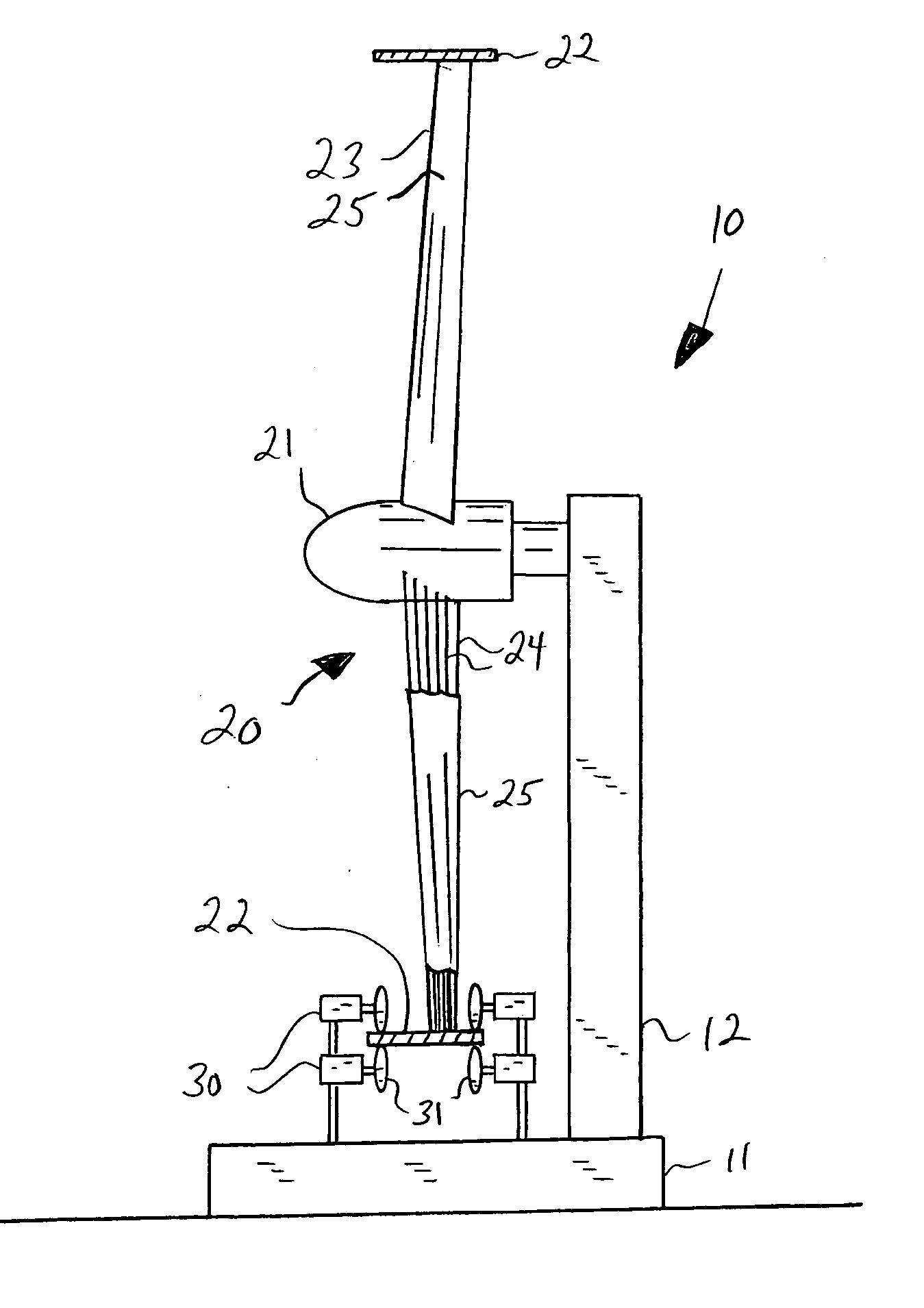

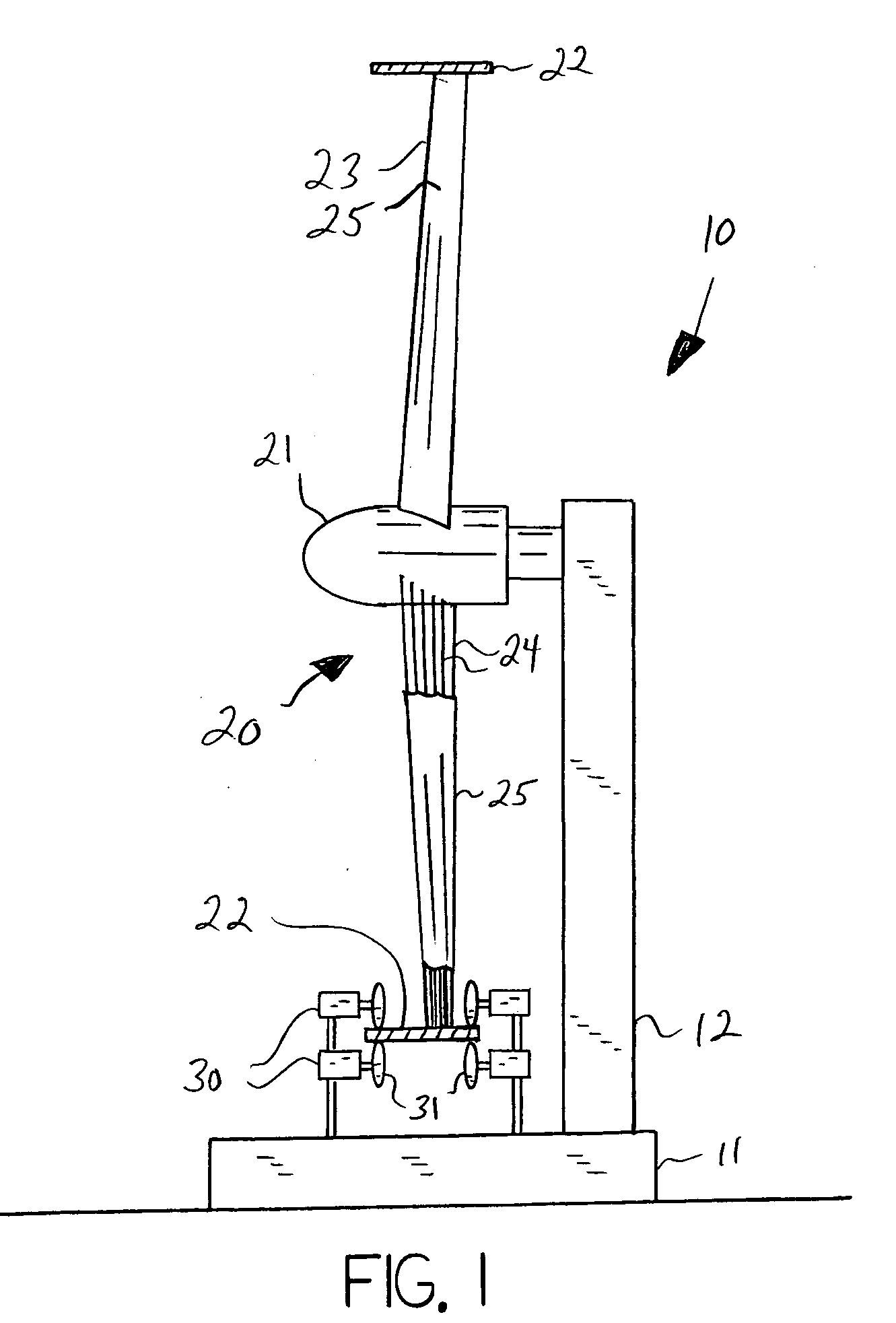

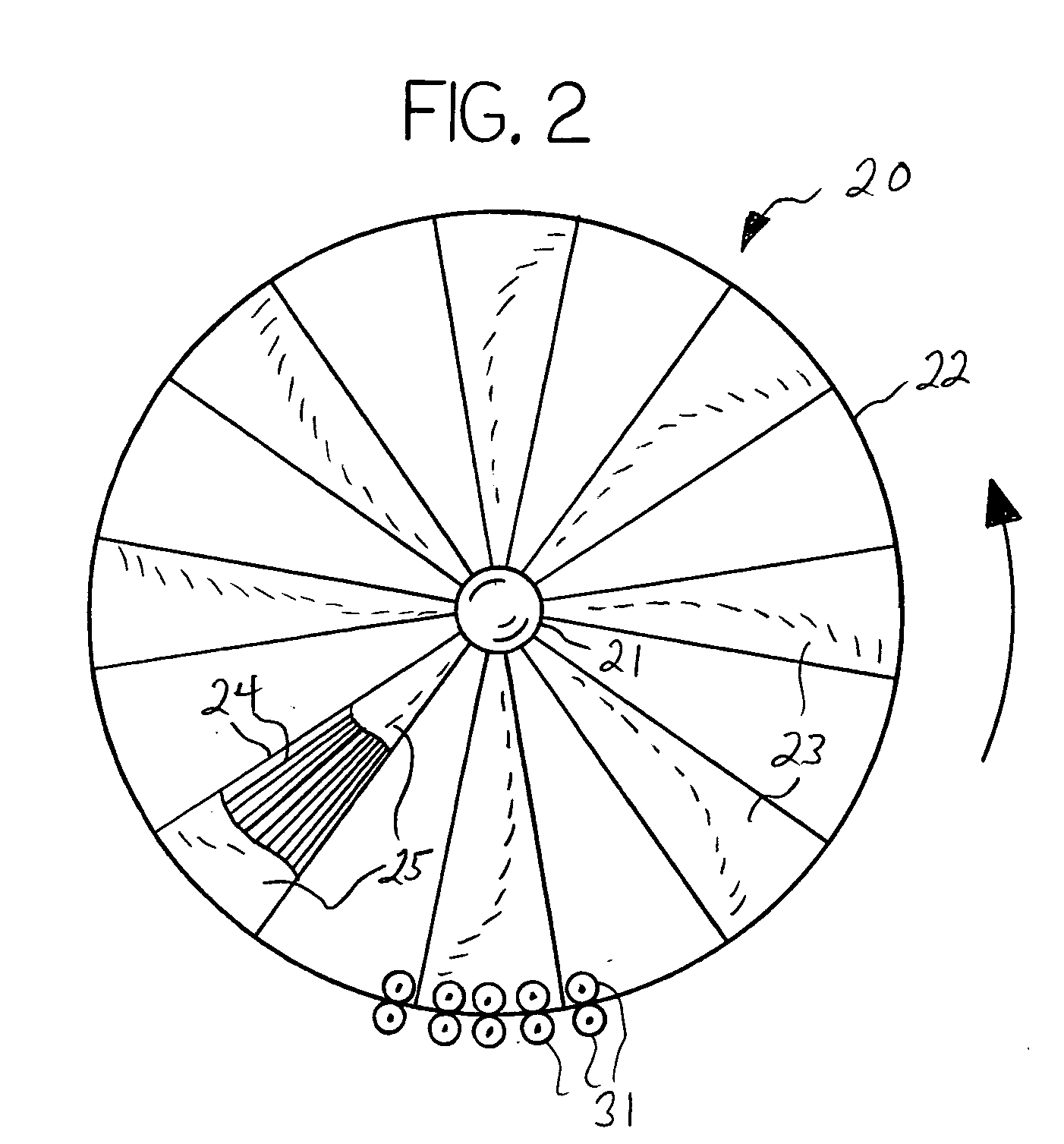

Wind turbine

A fluid turbine, such as a wind or hydro turbine, for generating electrical power, the turbine having a rotor assembly comprising a hub, a rim and a plurality of tensioned cable members joining them together, the cable members being grouped into sets to define a plurality of supports for individual skin members to create a plurality of lightweight blade members.

Owner:WILLIAMS HERBERT L

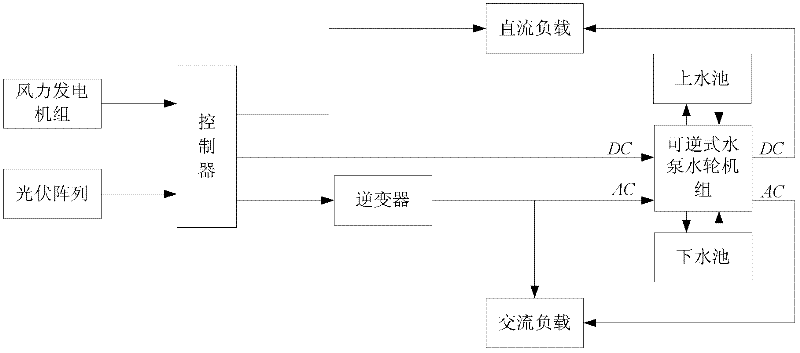

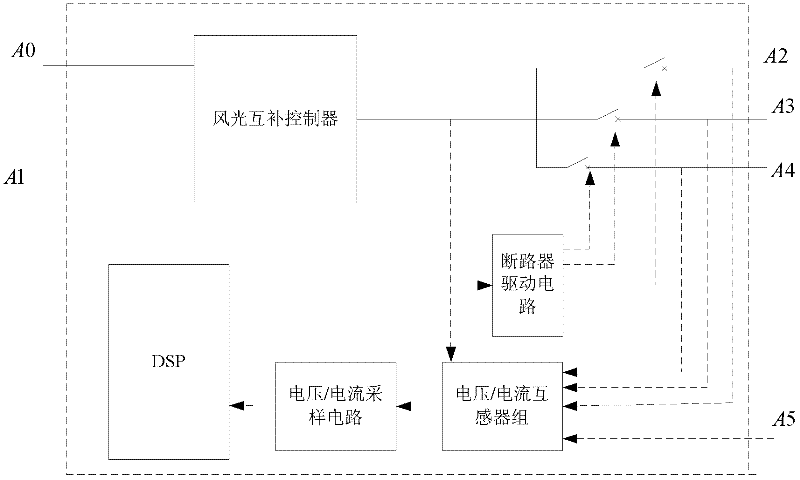

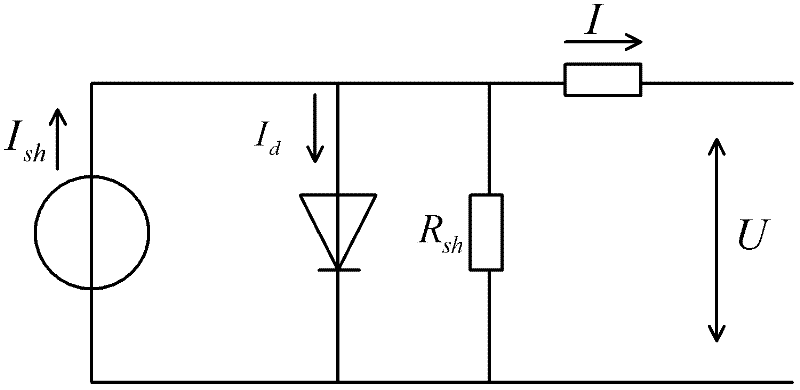

Mixed wind-light compensation water pumping and energy storing system and control method thereof

InactiveCN102384039AImprove stabilityImprove power supply reliabilityBatteries circuit arrangementsPV power plantsOperational costsAlternating current

The utility model provides a mixed wind-light compensation water pumping and energy storing system comprising a wind-light compensation unit, a controller, a direct current load, an alternating current load, an inverter and a water pumping and energy storing unit. The wind-light compensation unit comprises a wind generating set and a photovoltaic array; the water pumping and energy storing unit comprises reversible water pump-water wheel unit, an upper water pond and a lower water pond; and the controller comprises a wind-light compensation controller, a digital signal processor chip, a voltage / current sampling circuit, a voltage / current transformer set, a breaker driving circuit and three breakers. In the invention, a traditional wind-light compensation system, namely an energy storing device-storage battery set, is replaced by a pumped storage and power generation system, on the water pumping and energy storing unit, the reversible water pump-water wheel unit is used for pumping water or generating electricity, and by applying a segmented integration method, the energy of the upper water pond of the water pumping and energy storing unit is monitored and controlled. With the mixed wind-light compensation water pumping and energy storing system, the defects of expensiveness, short service life, environmental pollution and the like of a storage battery set can be solved, the system stability and power supply reliability can be improved, and the system building and running cost can be lowered.

Owner:NORTHEASTERN UNIV

Moving body electric generating apparatus

The invention discloses a motion object generation device, belonging to generation device technical field. The motion object generation device comprises a surface layer deformed when subjecting to force, a plurality of hydraulic cylinders arranged below the surface layer, a hydraulic turbine, and a generator connected with the hydraulic turbine; the hydraulic cylinder is internally provided with a hydraulic piston which can move up and down; the hydraulic piston is contacted with the surface layer; the hydraulic cylinder is internally provided with liquid; the hydraulic cylinder is provided with a liquid outlet and a liquid inlet; the liquid outlet and the liquid inlet are respectively connected with a check valve; the liquid outlet of each hydraulic cylinder is communicated with an inlet of the hydraulic turbine by a liquid outlet pipe; the outlet of the hydraulic turbine is communicated with a liquid inlet of each hydraulic cylinder by a liquid inlet pipe. The invention can convert the mechanical energy of vibration on the road surface caused by gravity of vehicle into the electric energy; with simple structure, the invention is a generation device without pollution or consuming the natural resources.

Owner:张晓东

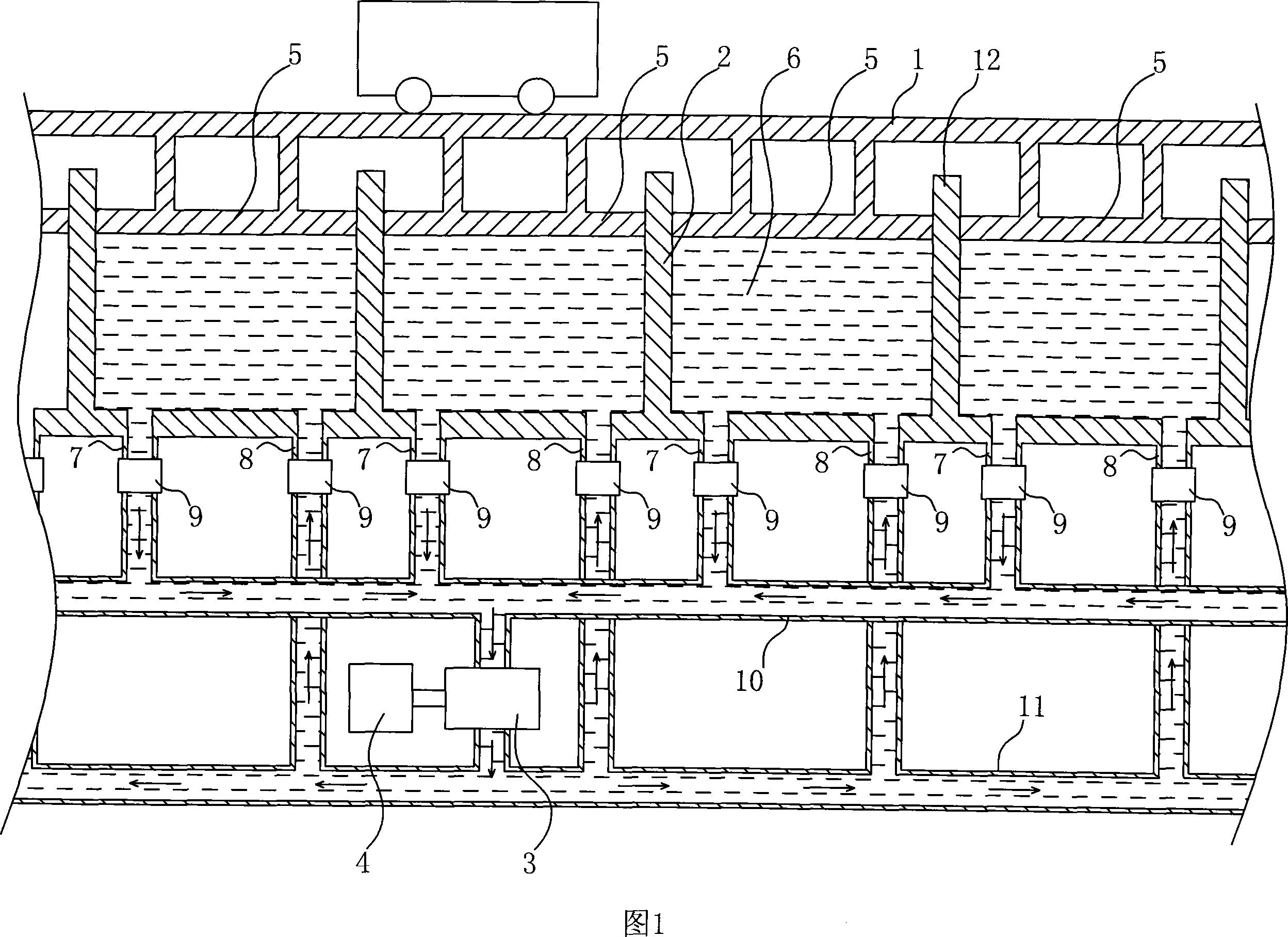

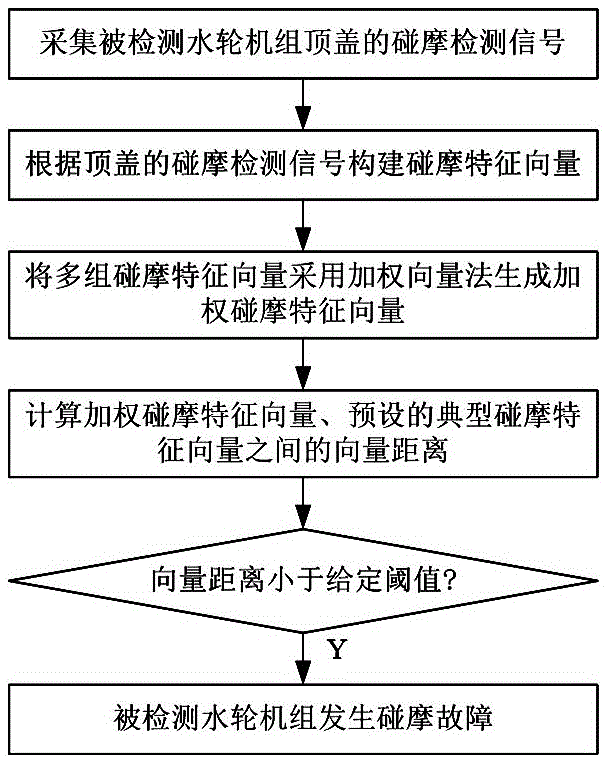

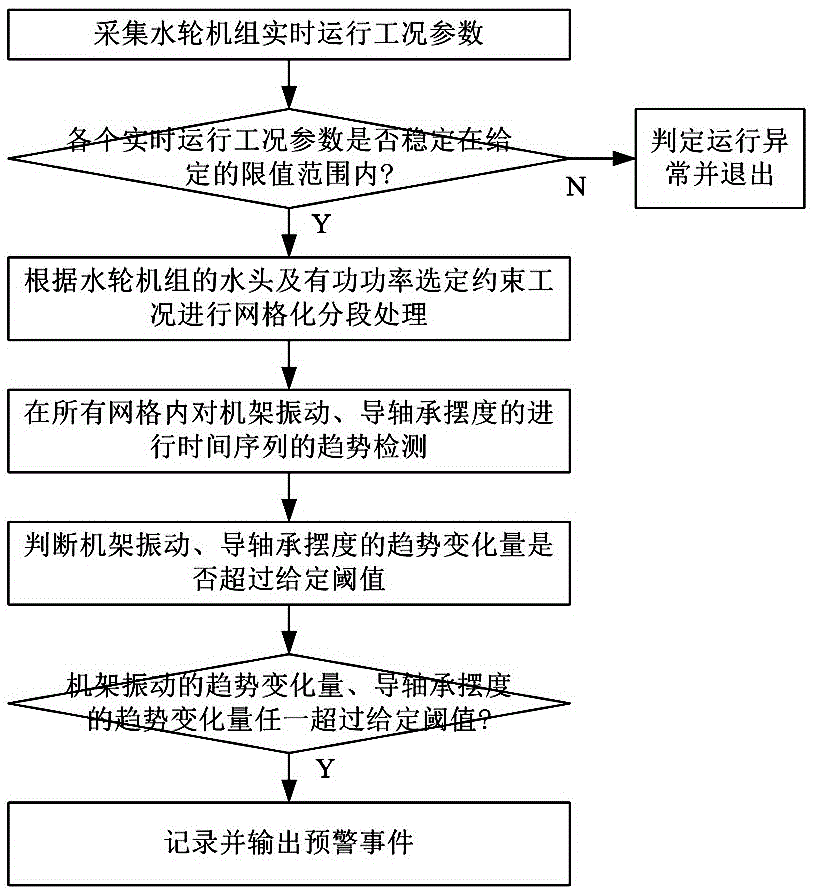

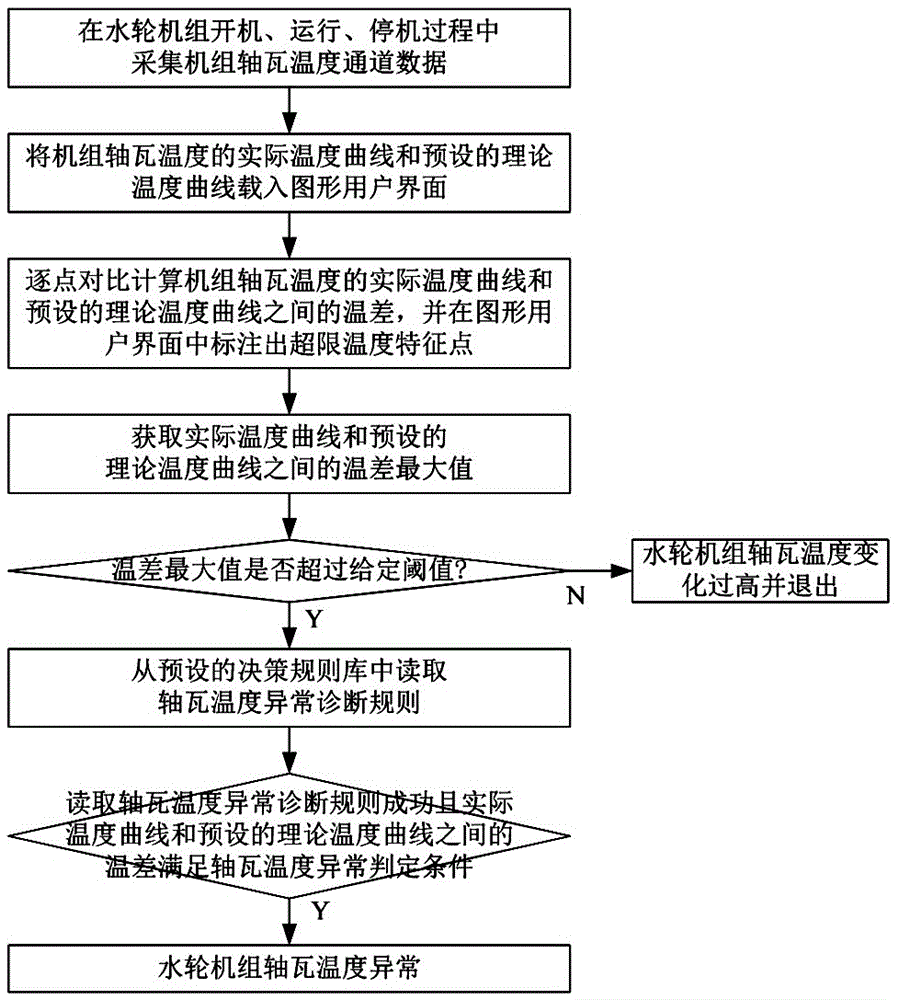

Running state monitoring and diagnosing method of hydraulic turbine set

InactiveCN106017936AVersatileAccurate detection and diagnosis of rubbing faultsEngine testingFeature vectorVertical vibration

The invention discloses a running state monitoring and diagnosing method of a hydraulic turbine set. The method comprises friction fault monitoring steps that 1) friction detection signals, including a horizontal vibration signal, a vertical vibration signal and a water leading throw signal, of a top cover of the detected hydraulic turbine set are collected; 2) a friction characteristic vector is constructed according to the friction detection signals of the top cover; 3) a weighted vector method is carried out on different friction characteristic vectors to generate a weighed friction characteristic vector; and 4) vector distance between the weighted friction characteristic vector and a preset typical friction characteristic vector is calculated, and if the vector distance is lower than a given threshold, it is determined that a friction fault occurs in the detected hydraulic turbine set. The method can be used to detect and diagnose the friction fault occurred in the detected hydraulic turbine set accurately, functions of a state monitoring system of a hydraulic power plant are completed, more useful information is provided for remote analysis and diagnosis of experts, and occurred faults can be handled in a targeted manner.

Owner:STATE GRID CORP OF CHINA +2

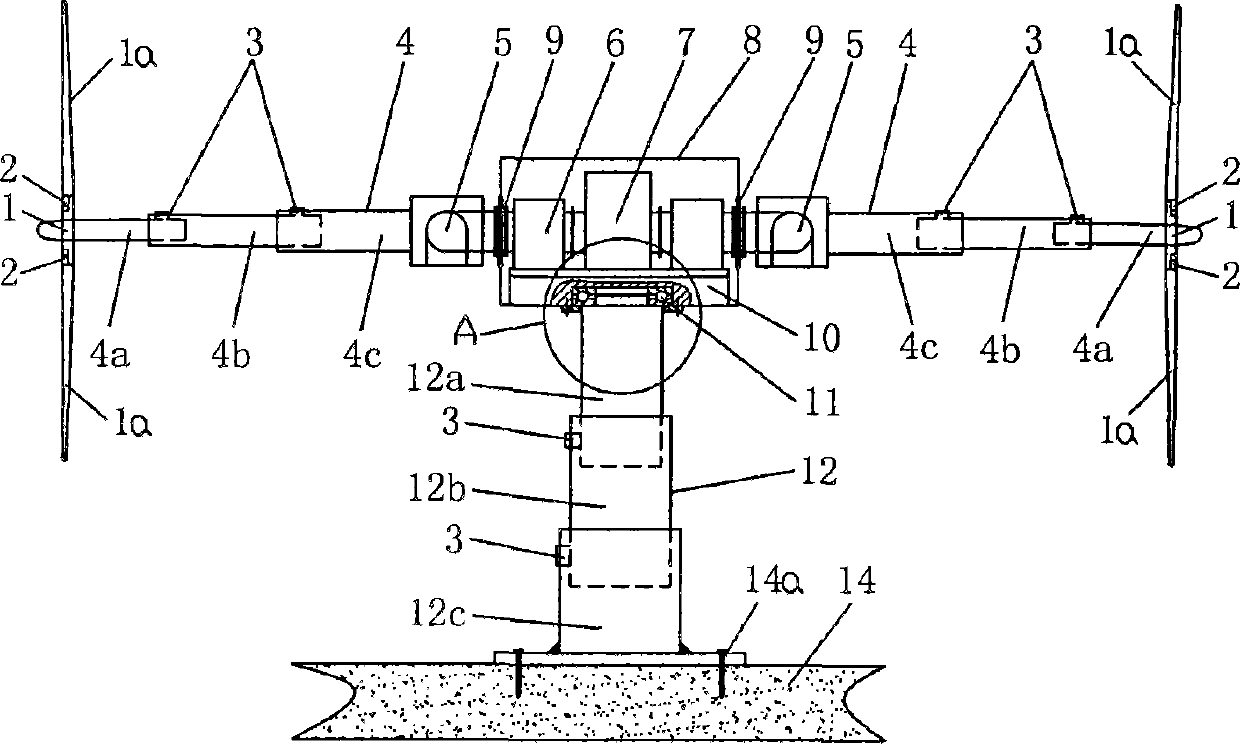

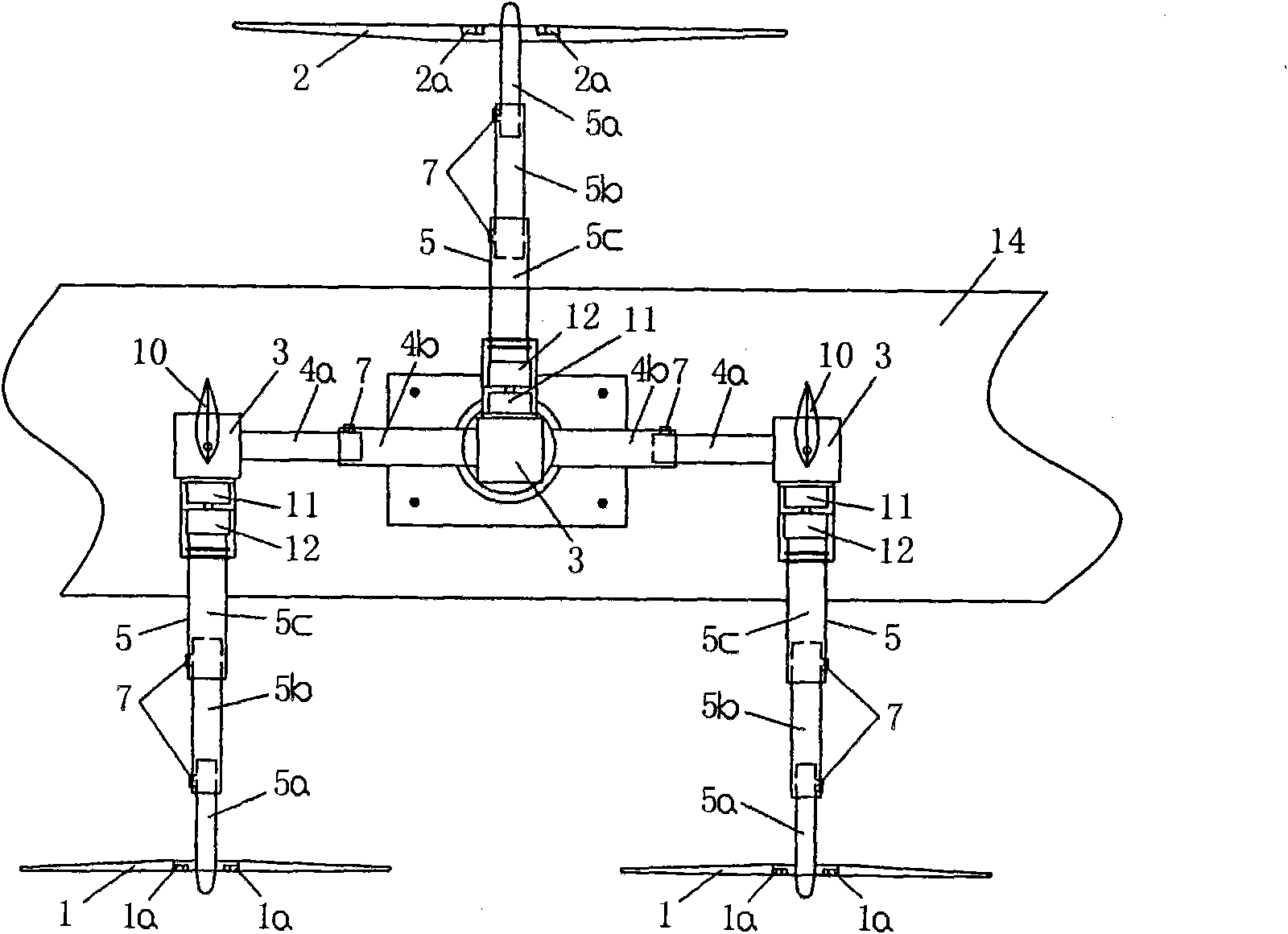

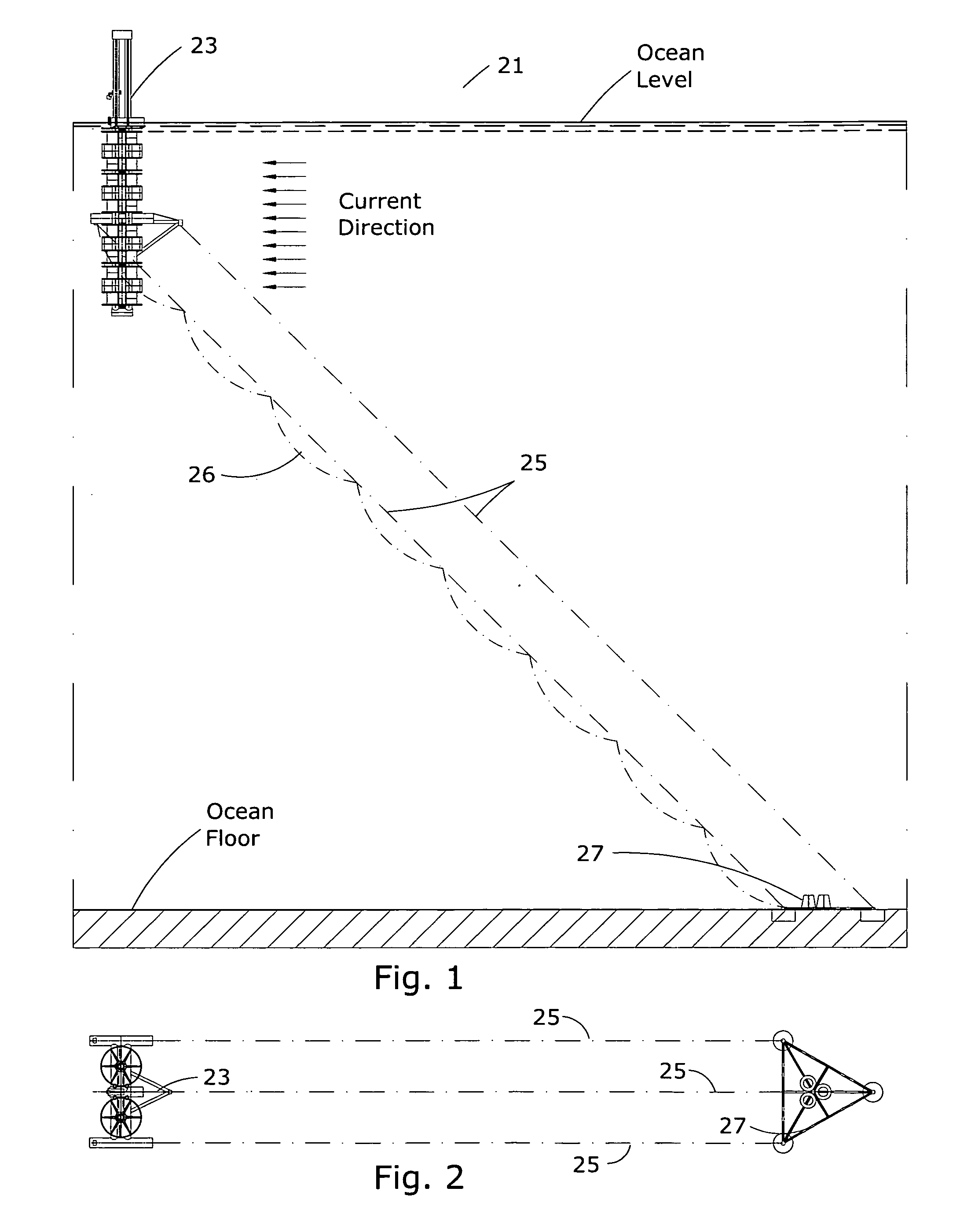

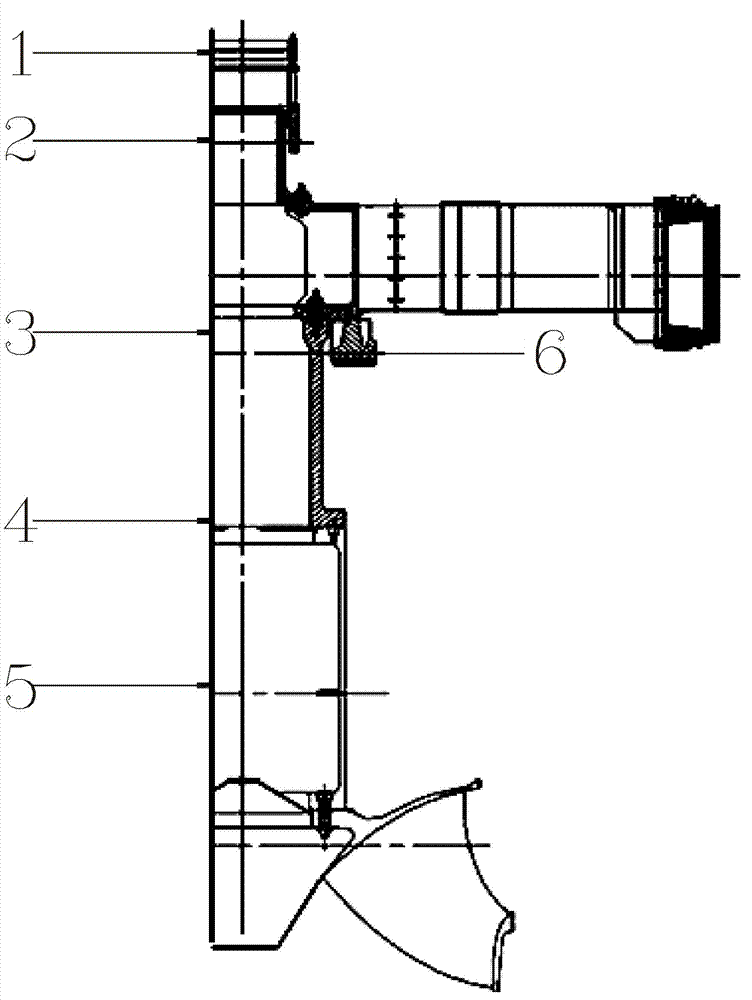

Efficient three-wheeled telescopic folding horizontal-shaft tidal current energy generating equipment

InactiveCN101915199AImprove power generation efficiencyAvoid disassemblyReaction enginesEngine componentsImpellerOcean bottom

The invention discloses efficient three-wheeled telescopic folding horizontal-shaft tidal current energy generating equipment, belonging to the technical field of tidal current energy generation. The generating equipment is respectively connected with steering knuckles at two sides of a connection body through a telescopic folding cross arm; a generator and a speed-increasing gearbox are respectively fixed at one side of one steering knuckle; a small impeller is connected with the speed-increasing gearbox through a telescopic folding connection rod; the lower side of the steering knuckle is equipped with a rudder which can ensure the tidal current direction is directly opposite to the impeller; the top of the connection body is equipped with the other steering knuckle, and the generator and the speed-increasing gearbox are fixed at one side of the steering knuckle; and a large impeller is connected with the speed-increasing gearbox through the telescopic folding connection rod. The generating equipment is simultaneously provided with three hydro-turbine units for power generation, thus improving generating efficiency of single generating equipment; and main components adopt telescopic folding structures to achieve effective telescoping and folding, thus reducing volume of the whole equipment, facilitating transportation, avoiding disassembly and assembly among the components, reducing submarine installation cost by over 50%, and prolonging service life of a hydro-turbine by over 5 years.

Owner:DALIAN UNIV OF TECH

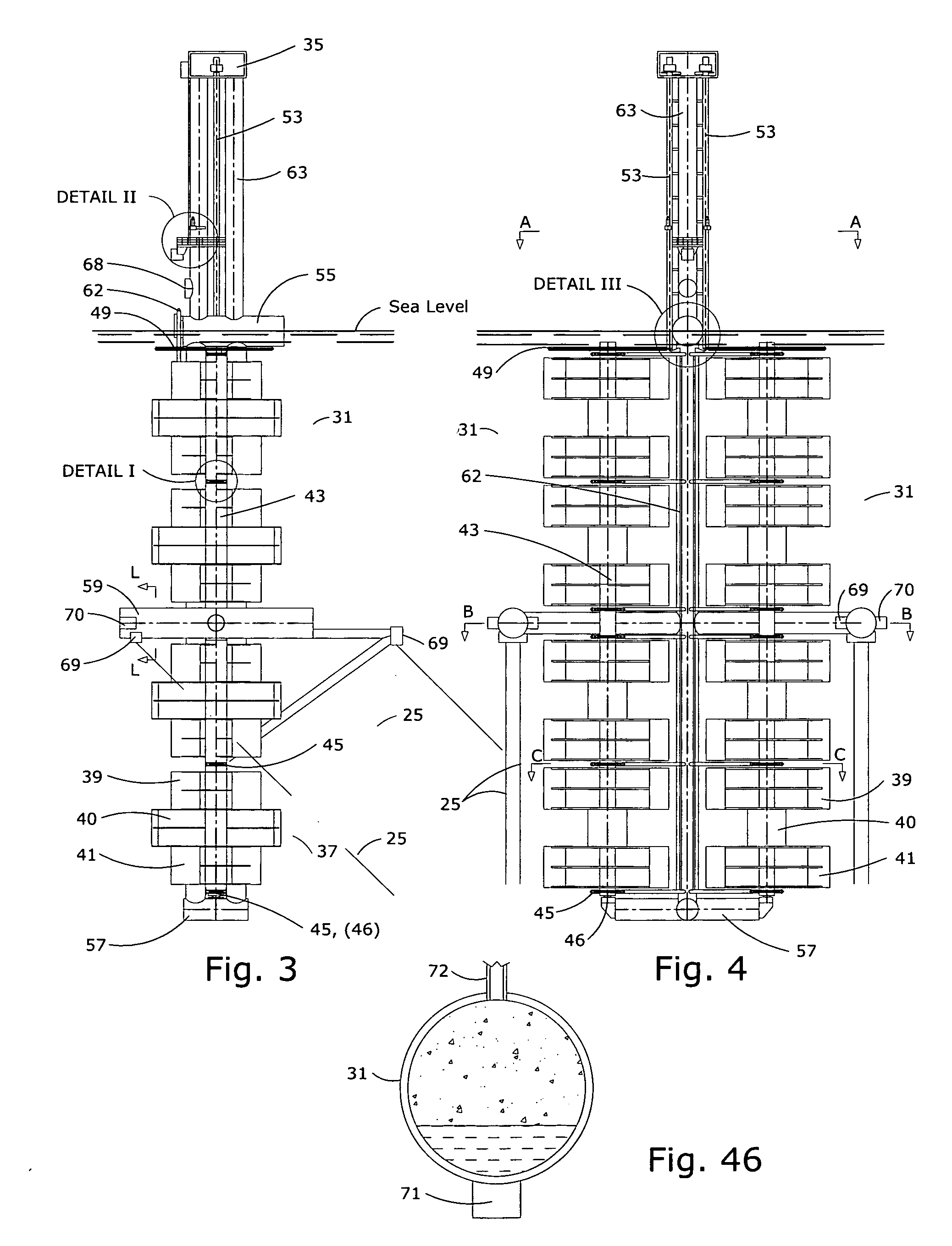

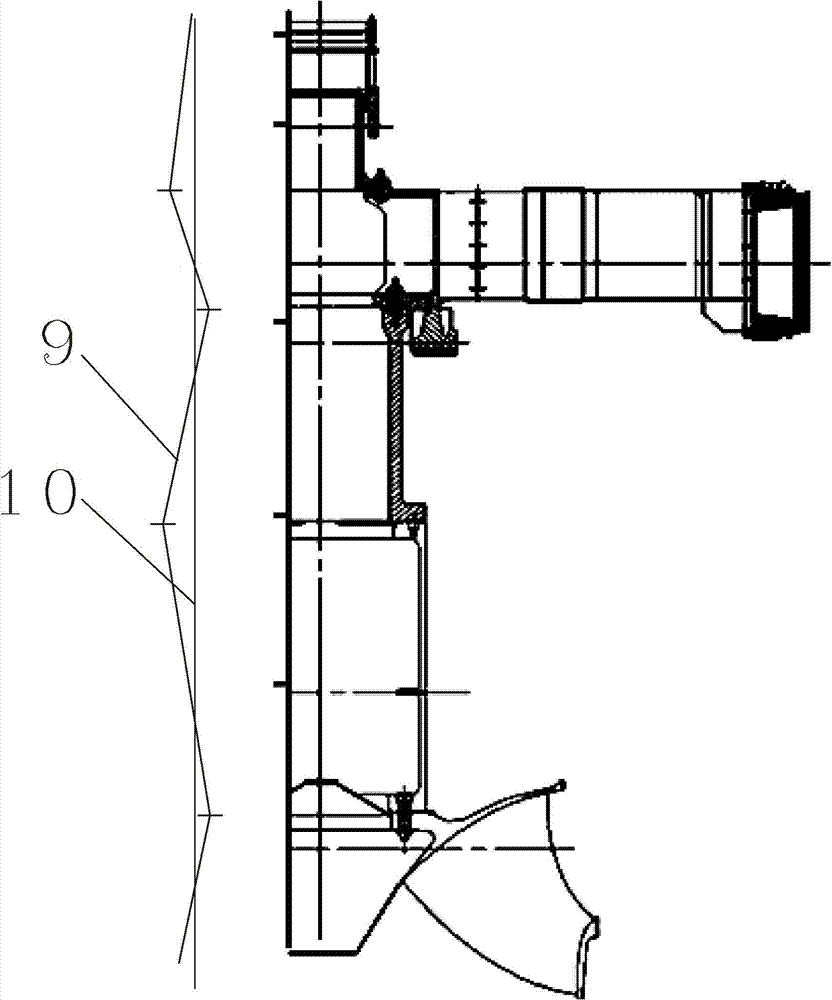

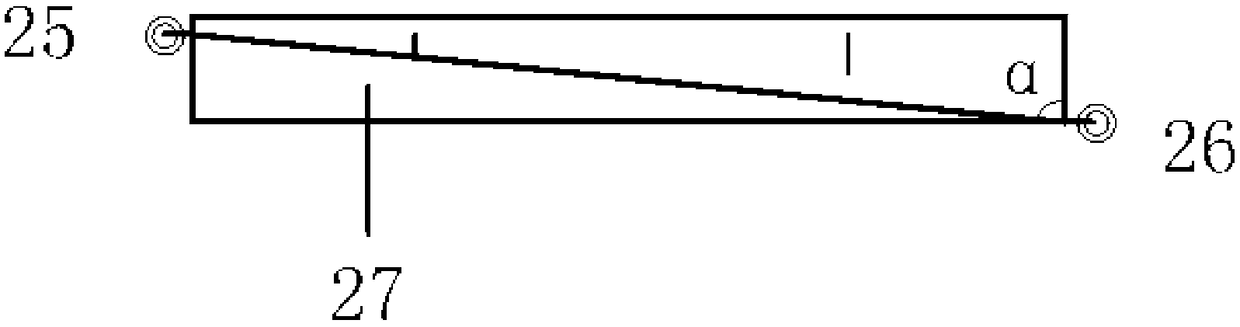

Installation for harvesting ocean currents (IHOC) and methods and means for its delivery, installation and servicing

InactiveUS20100164230A1Increasing and lowering pressureLittle strengthEngine fuctionsMachines/enginesElectric power transmissionEngineering

Installation for harvesting energy of ocean currents (IHOC) in deepwaters is based on utilization of a semisubmersible platform and the multiple of vertically oriented Darrieus type hydraulic turbines. The turbines are located as close as possible to ocean surface, where speed of current is usually at its maximum. Since speed of current fluctuate during the seasons a system controlling buoyancy force of that keeps IHOC floating near surface is employed. The mooring system consists of three tethers, which prevent transferring of overturning moment applied to IHOC to anchoring base. The electric power generators are located in a machinery room on a structure well above sea level and would transmit electric power to the shore utilizing flexible cable. During hurricane it will be lowered to the depth preventing turbines from being affected by wave actions, at the same time it would keep machinery room above wave action. For the purpose of delivery assembled on shore Turbine Housing to destination site and installing it there a special convoy is formed consisting of Catamaran Delivery Barge and Stabilizing Platform.The second Embodiment of this invention is designed to harvest energy of tides in deepwaters.

Owner:BELINSKY SIDNEY IRVING +1

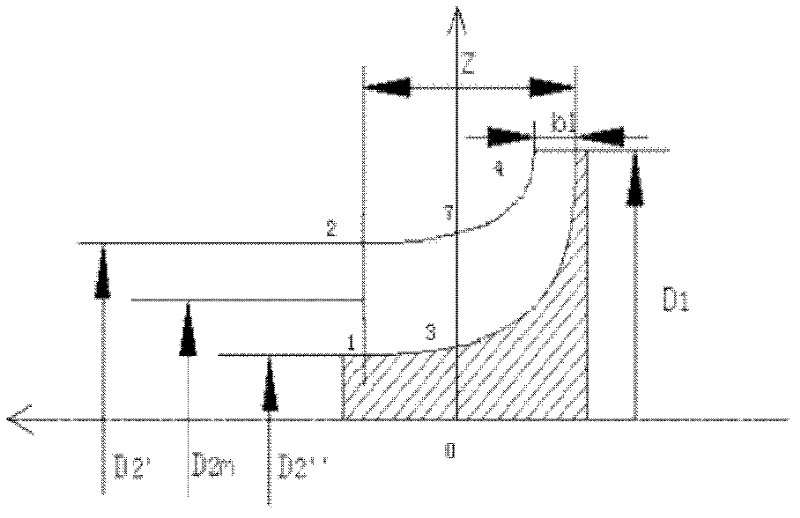

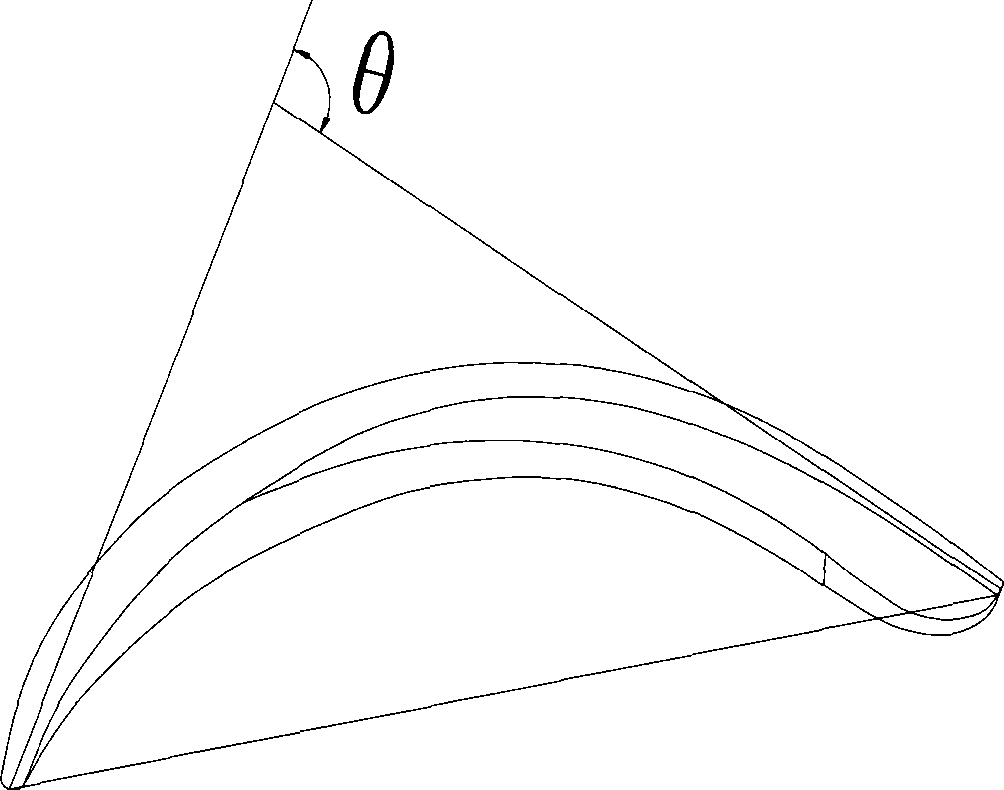

Optimization design method of radial-flow-type hydraulic turbine

ActiveCN102608914ASmall amount of calculationHigh precisionAdaptive controlImpellerMultivariable optimization

Owner:开山(西安)透平机械有限公司

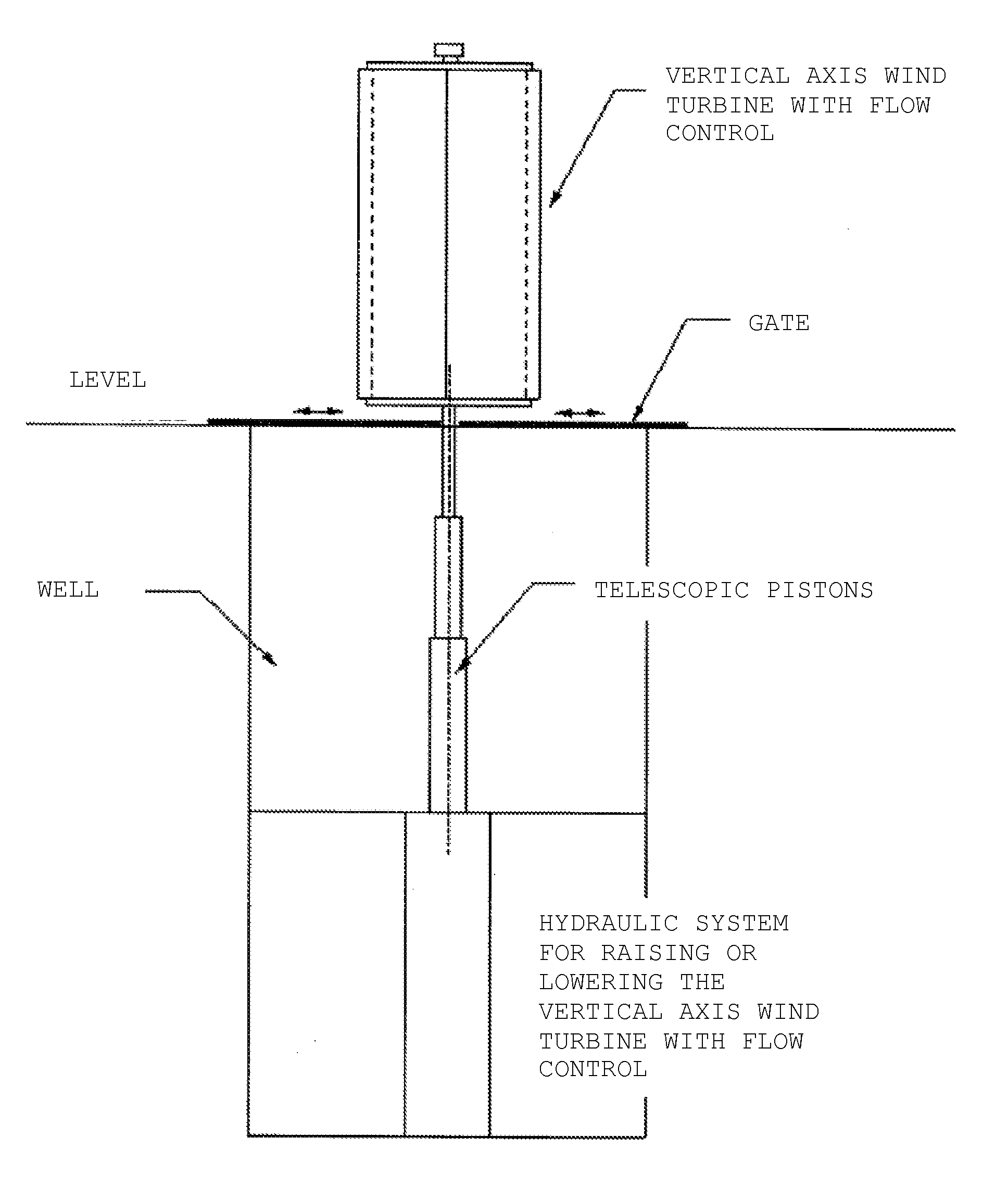

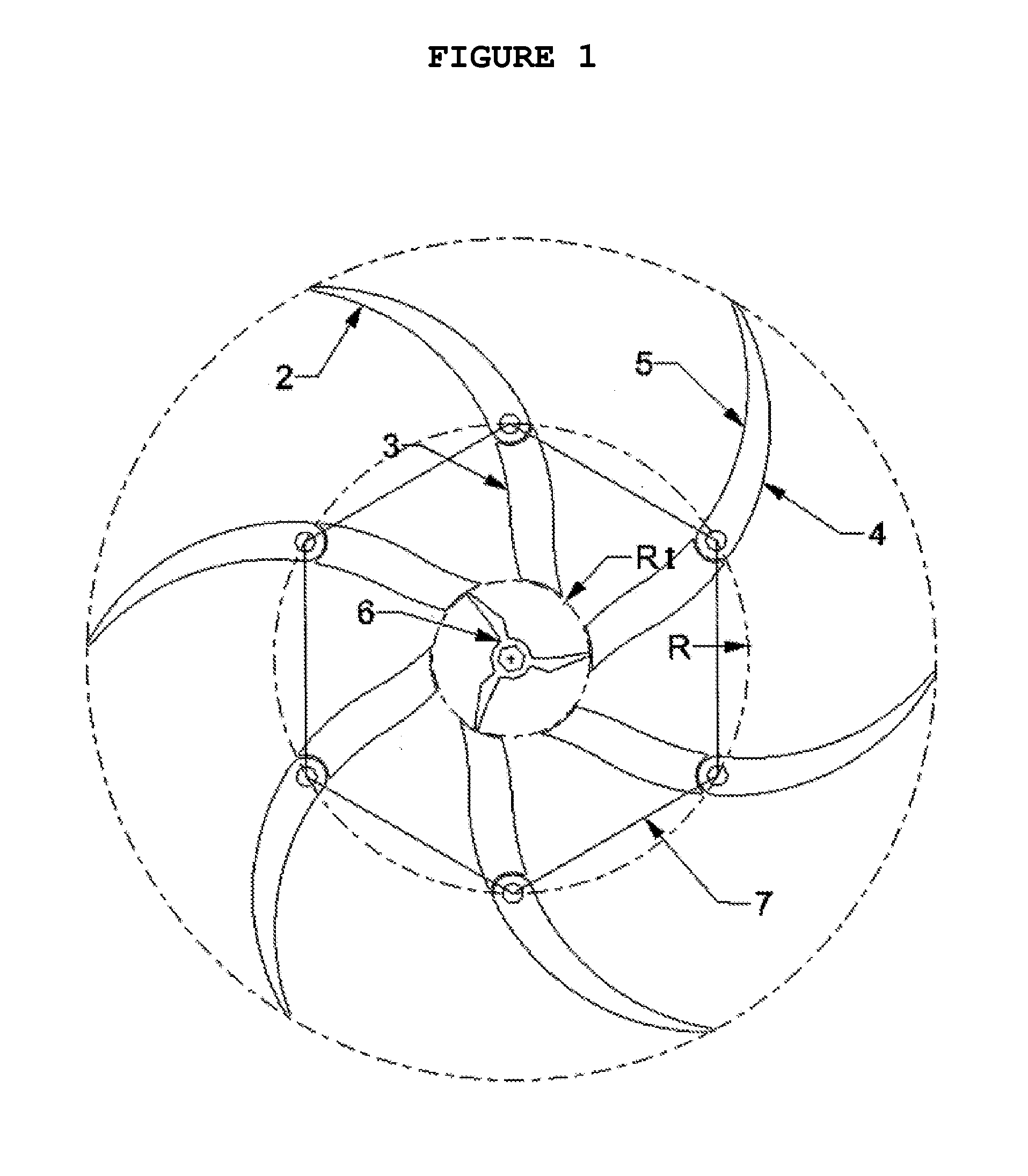

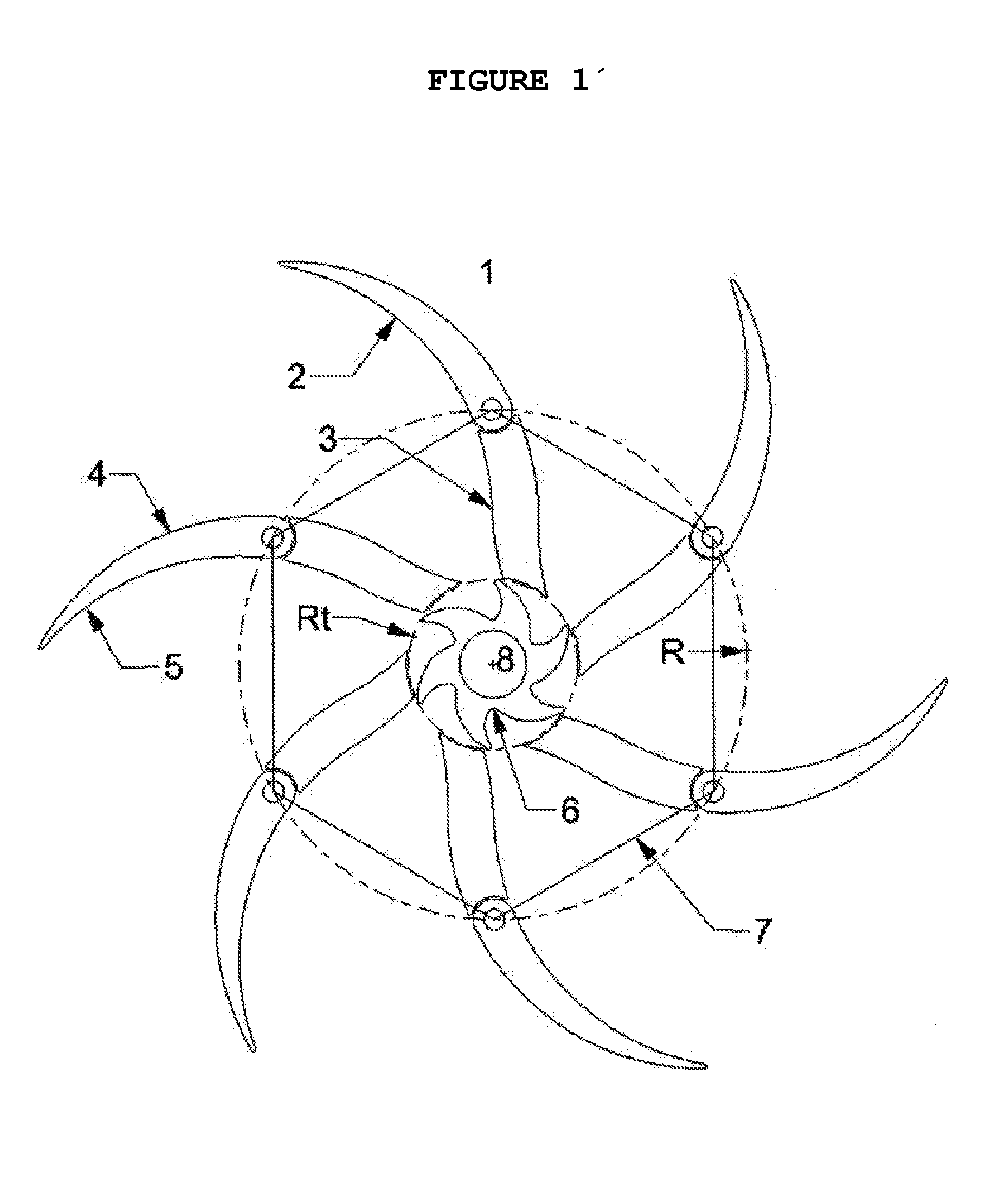

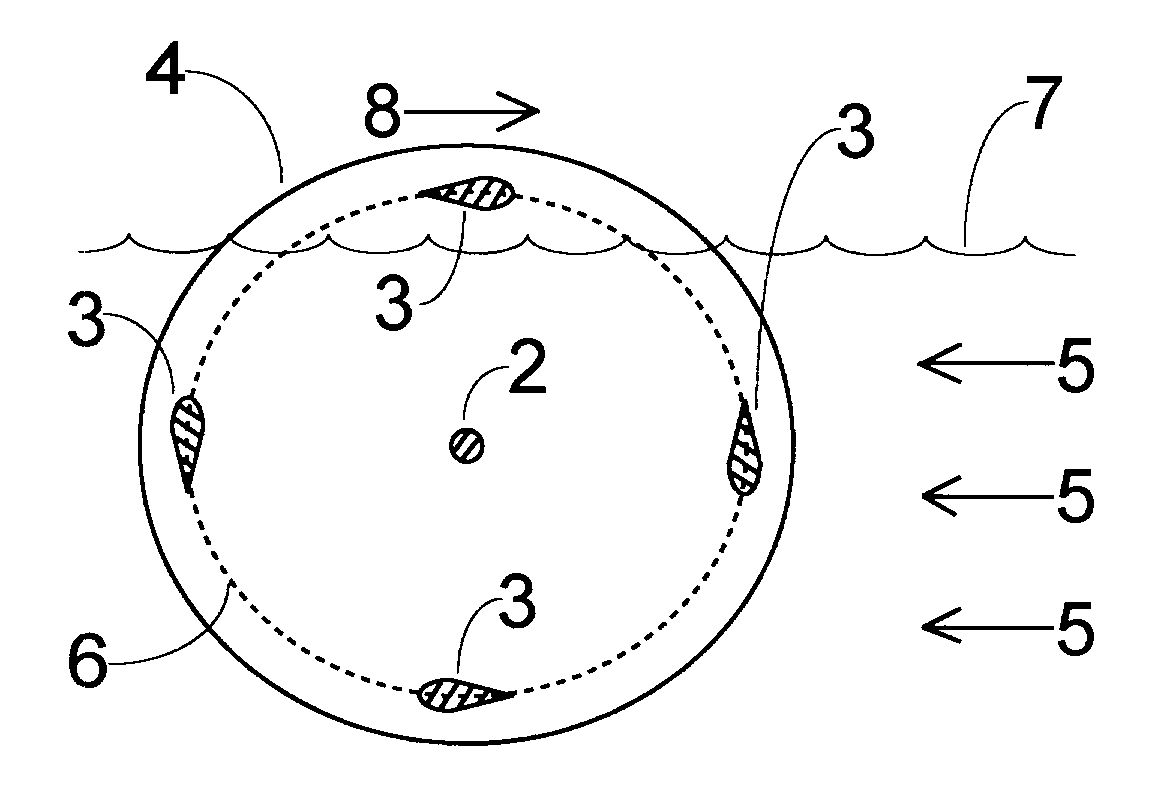

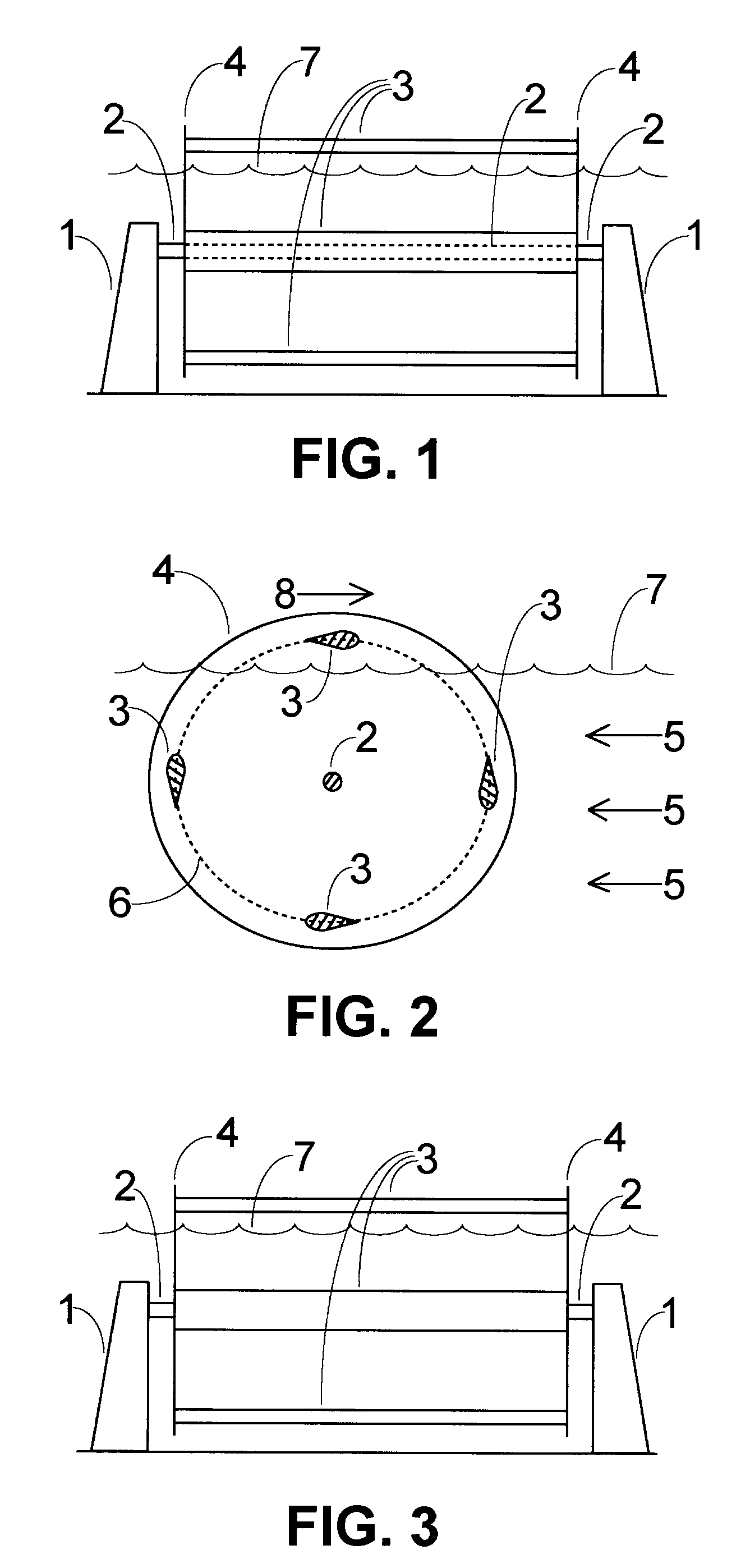

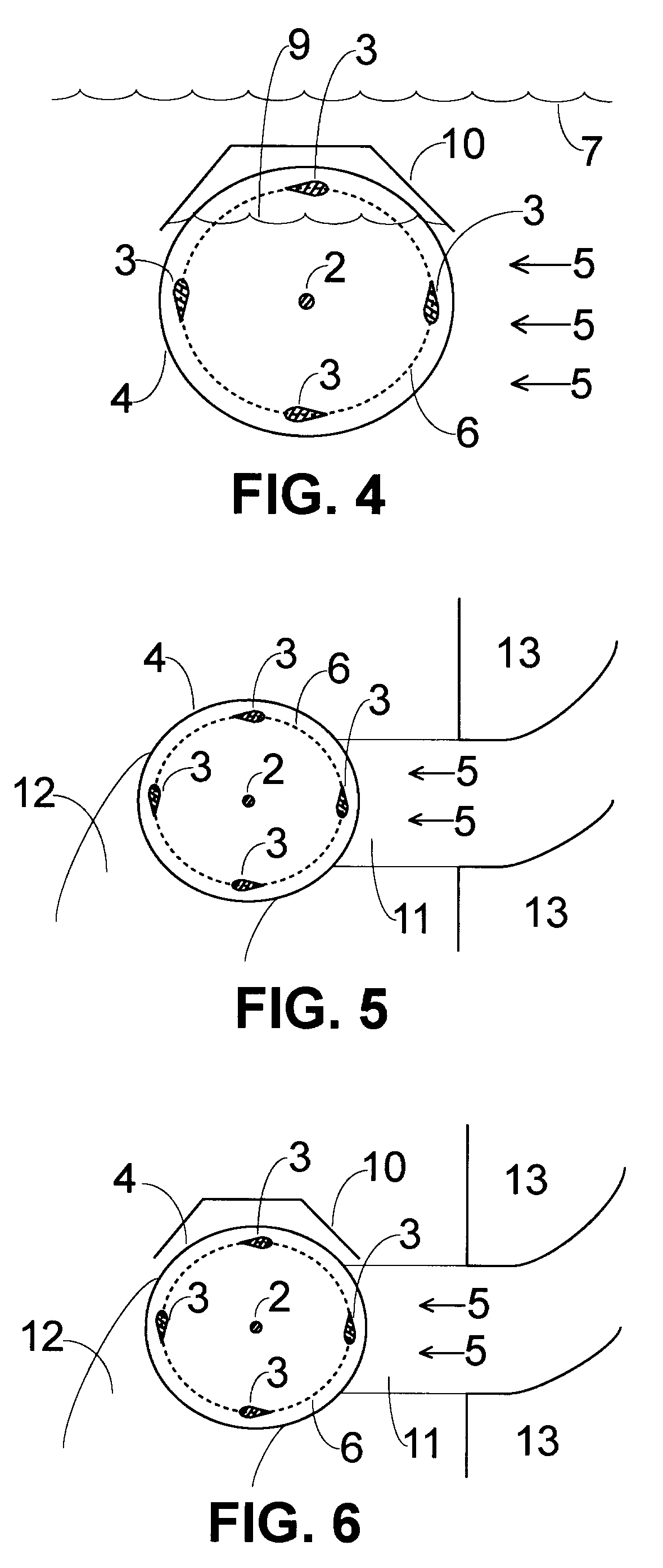

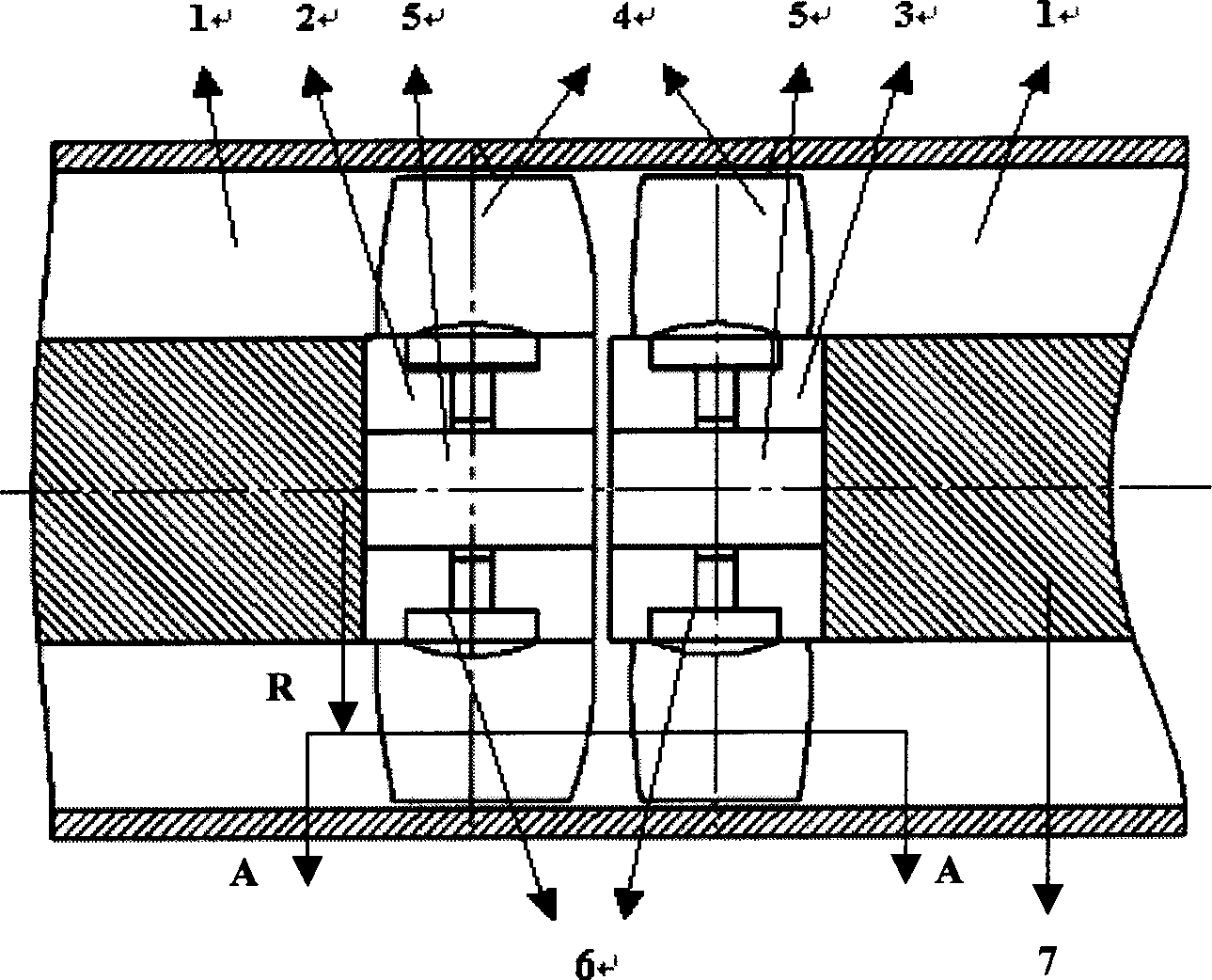

Vertical axis wind and hydraulic turbine with flow control

InactiveUS20140023500A1Increase water flowIncrease speedPropellersPump componentsVertical axis wind turbineVertical axis

A vertical axis wind and hydraulic turbine with flow control including a regular hexagonal structure of radius R, parallelepiped-shaped, inside which a rotor rotates with three or more vanes on a vertical axis which is located in the center of the hexagon as seen from above, wherein the vanes when rotating generate a circle of radius Rt, further including six articulated deflector vanes that grab and concentrate the flow of air or liquid entering the rotor vanes, from the wind or liquid current entry side to the turbine and diffuse the flow of air or liquid exiting from the rotor vanes, from the side opposite to the wind or liquid entry side to the turbine.

Owner:RUBIO

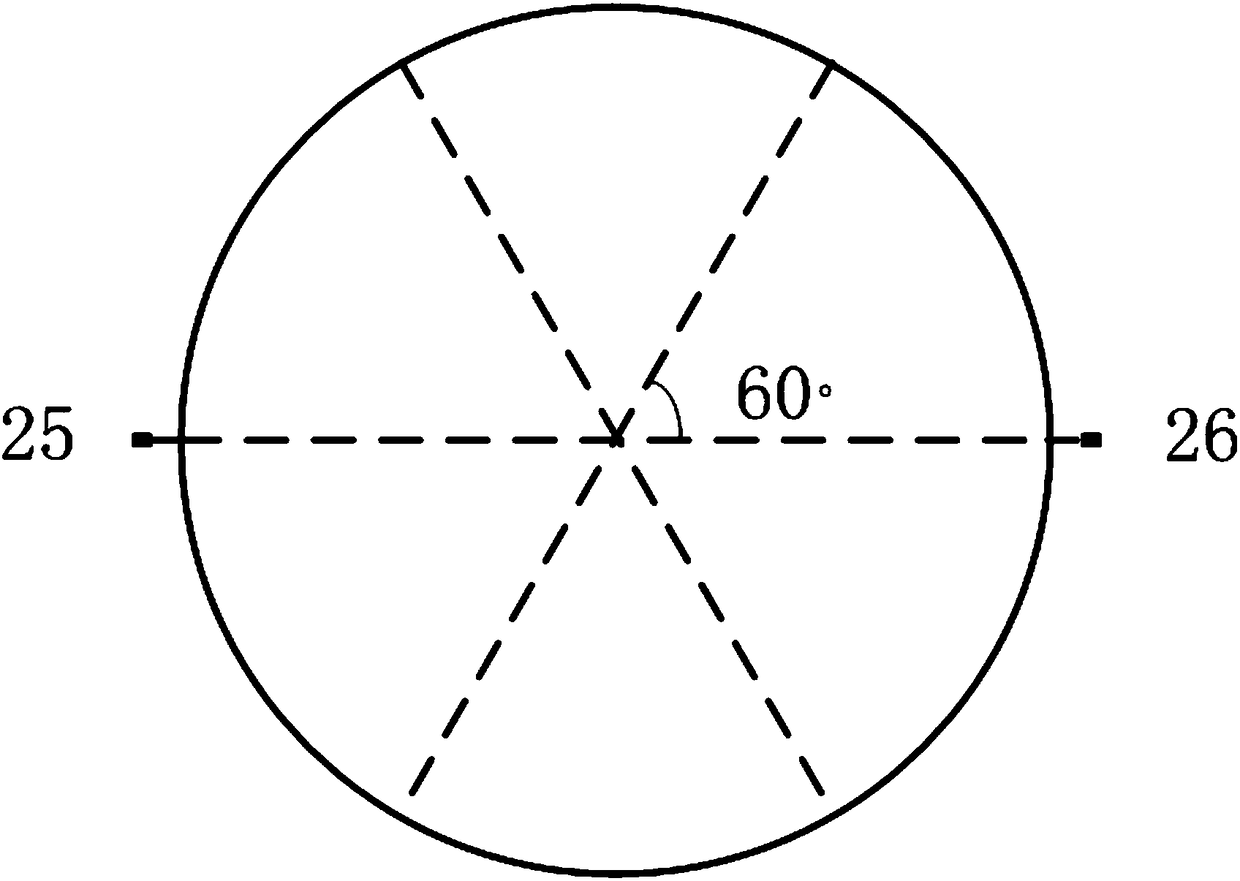

Method for accurately and continuously measuring and processing axis throw of hydraulic turbine set

InactiveCN103245283AUnderstanding Overall Offset StatusAccurate acquisitionUsing electrical meansUsing optical meansContinuous measurementMeasurement point

A method for accurately and continuously measuring and processing an axis throw of a hydraulic turbine set comprises the steps as follows: 1) according to a shafting composition of the set, a displacement sensor used for measuring outer wall displacement is arranged on each composition shaft and taken as a measuring point; 2) corresponding displacement values epsilon i are obtained according to rotation angles theta i; 3) according to multiple displacement values epsilon i, a fitting axis throw sine curve is obtained, and components of the maximum throw values on an X axis and on a Y axis are obtained through the throw sine curve; 4) the maximum throw eccentric distance and eccentric angle of each measuring section are obtained through calculation; and 5) a guide bearing measurement section is taken as a standard, and correction values of axis sections are obtained through calculation of coordinate points of the maximum throw eccentric distances. According to the method, an actual operation condition of the set can be more truly simulated, measured data are more accurate, the set is more accurately and faster adjusted, the installation rate of the set is accelerated, the installation quality of the set is guaranteed, and conditions are provided for safe operation of the set.

Owner:CHINA GEZHOUBA GROUP CO LTD

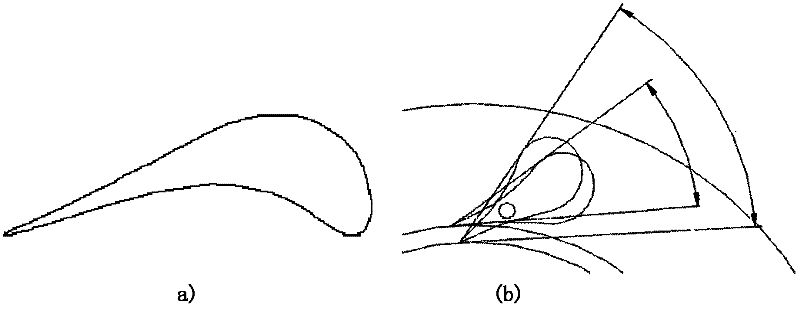

Darrieus water wheel turbine

ActiveUS20090194997A1Simple and reliable processEliminate the effects ofWind motor controlHydro energy generationWater wheelWater flow

A reaction turbine system for the generation of hydroelectricity is disclosed. It consists of a Darrieus type turbine with a horizontal axis of rotation. The blades may be straight or helical, and are held equidistant from the central rotating shaft by blade support members. The blades are oriented so that a blade at its rotational apex moves directly opposite to the direction of water flow. The turbine is elevated such that the top portion, where blades travel directly against the direction of water flow, is in the air and above the water level. This design greatly reduces stresses on the system and increases energy output relative to a Darrieus turbine fully immersed in water flow. This design also enables the turbine to self-start.

Owner:STABINS PETER ANDREW

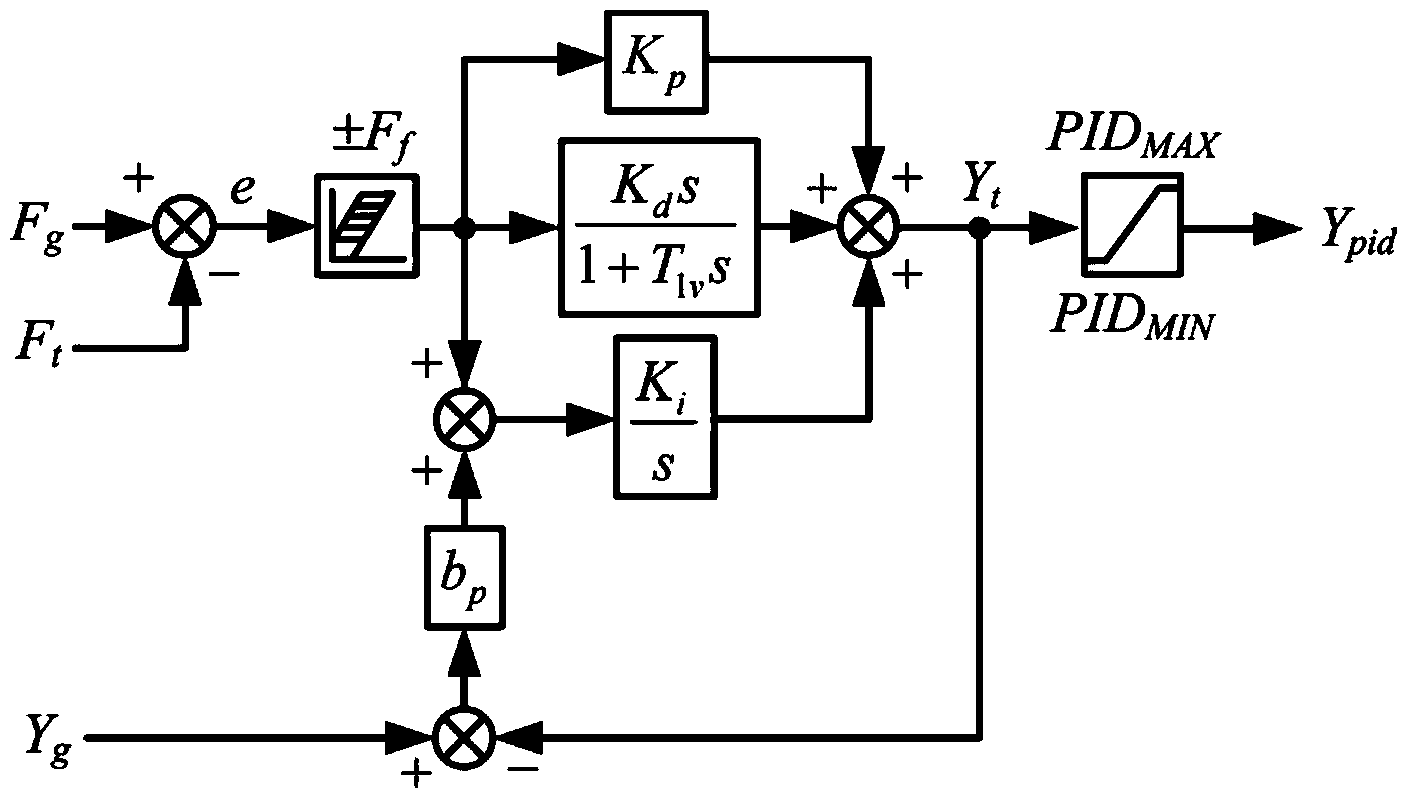

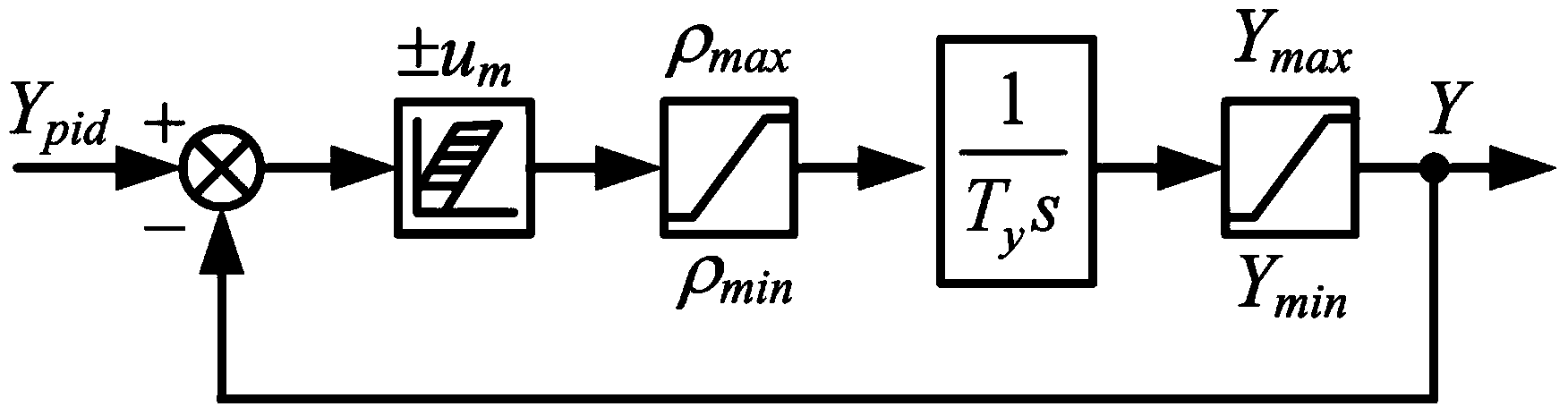

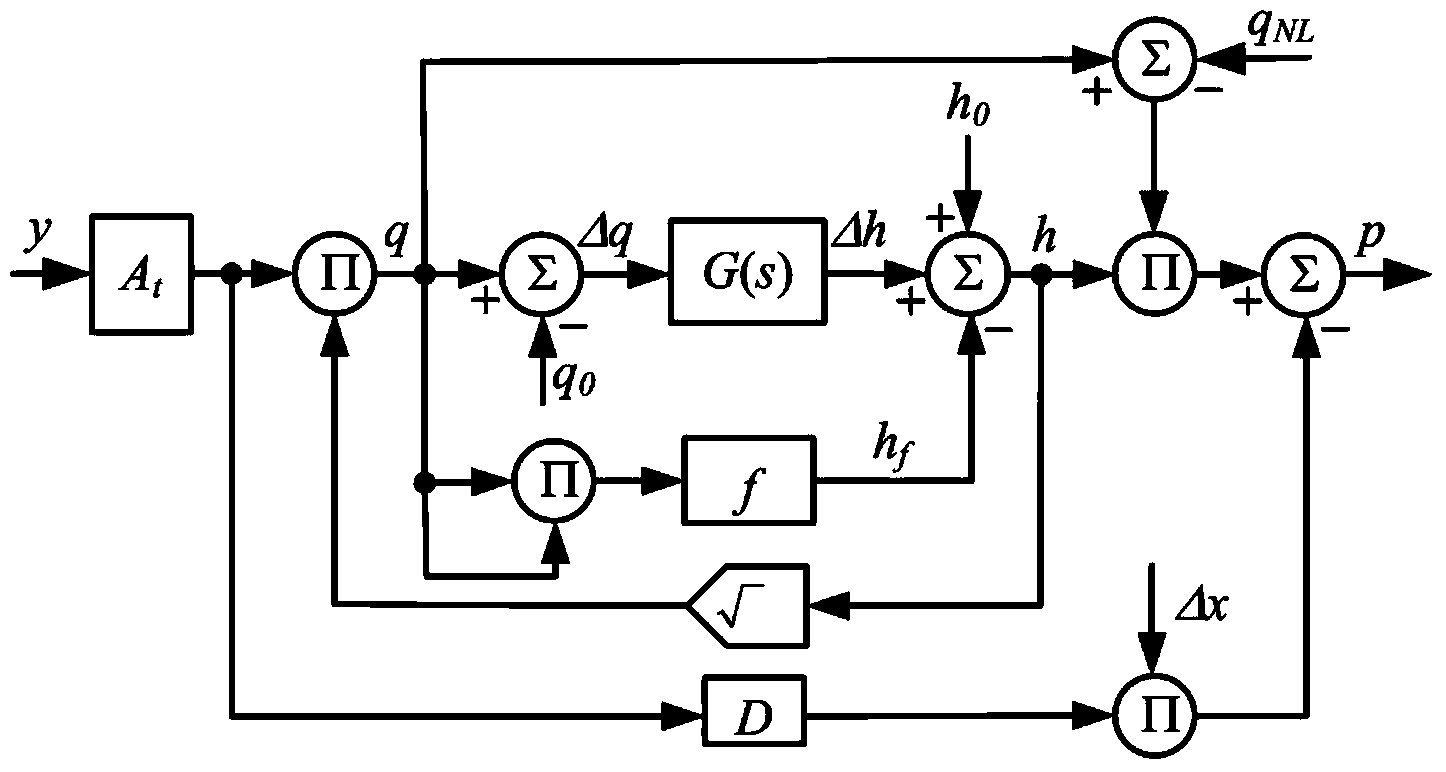

PID hydraulic turbine governor parameter optimization method based on multi-working-condition time domain response

InactiveCN103590969ASatisfied with dynamic characteristicsImprove robustnessHydro energy generationMachines/enginesOptimal controlField tests

The invention discloses a PID hydraulic turbine governor parameter optimization method based on multi-working-condition time domain response. The method includes the following steps that (1) a hydraulic turbine regulating system model is built, wherein the hydraulic turbine regulating system model particularly comprises a PID hydraulic turbine governor model, a hydraulic turbine-water diversion pipeline model and a generator model; (2) parameters of the hydraulic turbine regulating system model are obtained in a field test and parameter recognition mode; (3) a comprehensive fitness function based on multi-working-condition time domain response is designed, and the optimization objectives of finding out an optimum PID control parameter and enabling a comprehensive fitness function value to be minimum are determined; (4) the optimal PIC control parameter is obtained through an intelligent optimization algorithm. The control parameters obtained through the method enable a system to keep satisfying dynamic characteristics under different working conditions, and robustness of the system is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

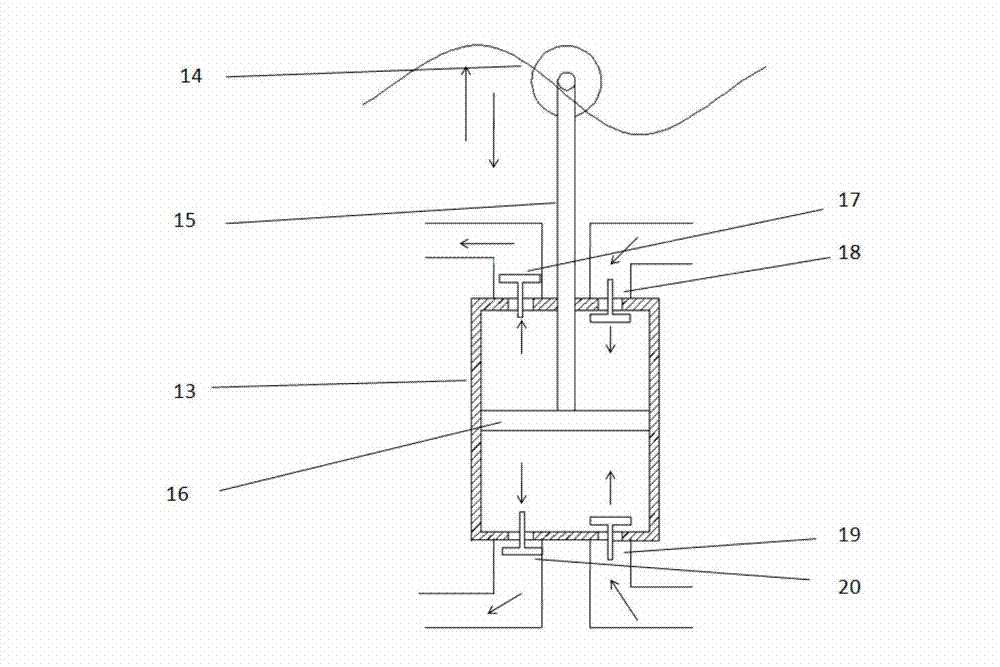

Double-floating-body type wave energy power generation device utilizing water turbine

InactiveCN104314741ASimple designImprove adaptabilityMachines/enginesEngine componentsElectric power systemEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Runner of opposite-rotating through flow turbine capable of bidirectionally generating electricity

InactiveCN1828042ATake advantage ofSimple structureHydro energy generationReaction enginesElectricityWater flow

The invention relates to a disrotation through flow hydraulic turbine wheel with bidirectional generation. It is characterized in that: it comprises two groups of wheels that reversely mounted along the middle axle of hydraulic turbine, which are mounted with S-shape blades in same number and in reverse rotational directions. The invention can realize bidirectional generation, without guide blade. It has simple structure, while the back wheel uses the circular amount at the outlet of front wheel; the water flows out axially. And the positive and passive directions have same efficiency, to fully utilize the tide energy.

Owner:TSINGHUA UNIV

High pressure heat insulation gas storage pumping compressed air energy storage system

ActiveCN108571415AShorten the payback periodConstant flowHydro energy generationEngine componentsThermal energyThermal energy storage

The invention discloses a high pressure heat insulation gas storage pumping compressed air energy storage system. Air in a water-gas common-cabin passes a supercharger and then directly enters a gas storage vertical shaft, and pressure of gas in the water-gas common-cabin passes is kept stable and unchanged. Potential energy and heat of compressed air are stored at the same time because of the thermal storage effect of the gas storage vertical shaft. At the stage of energy releasing, output electric energy of the system comprises the following two parts: for one part, high pressure air with certain temperature in the vertical shaft enters a turbine to do work through expansion; for the other part, water in the water-gas common-cabin pushes the turbine to generate electric energy, and the energy density and operating efficiency of the system are improved. As a heat insulating layer is arranged outside the gas storage vertical shaft, the air is high in temperature and flows through the turbine and is expanded, then the temperature is reduced, the fact that the temperature in the water-gas common-cabin is low is guaranteed, and damage to the turbine caused by temperature rise of wateris avoided. The system stores high pressure air through the gas storage vertical shaft, greatly reduces the investment cost of a high pressure container, shortens the payback time, and improves the operating economy.

Owner:XI AN JIAOTONG UNIV

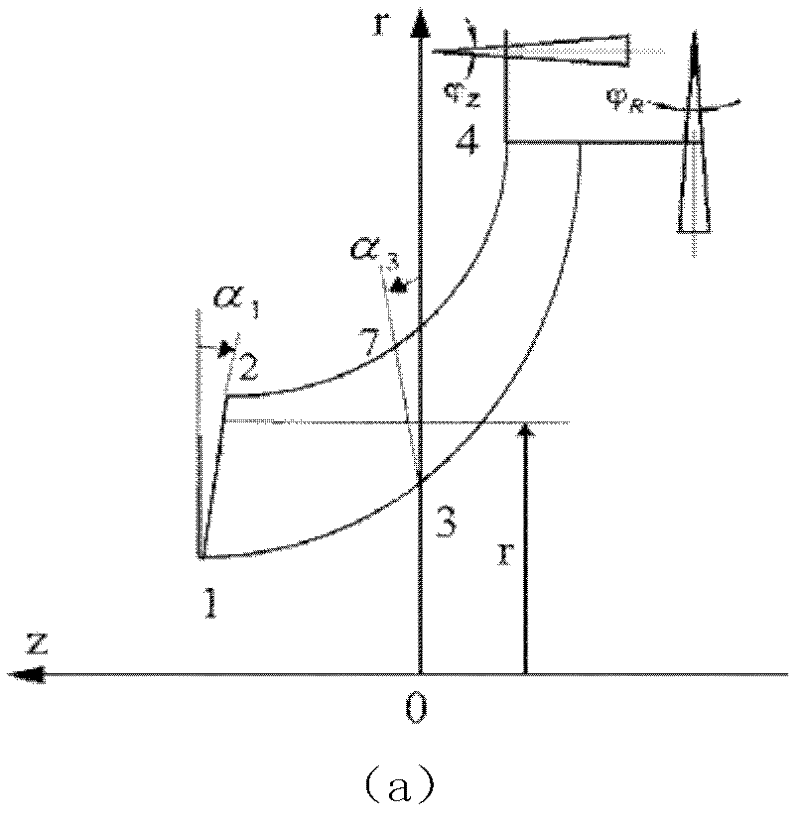

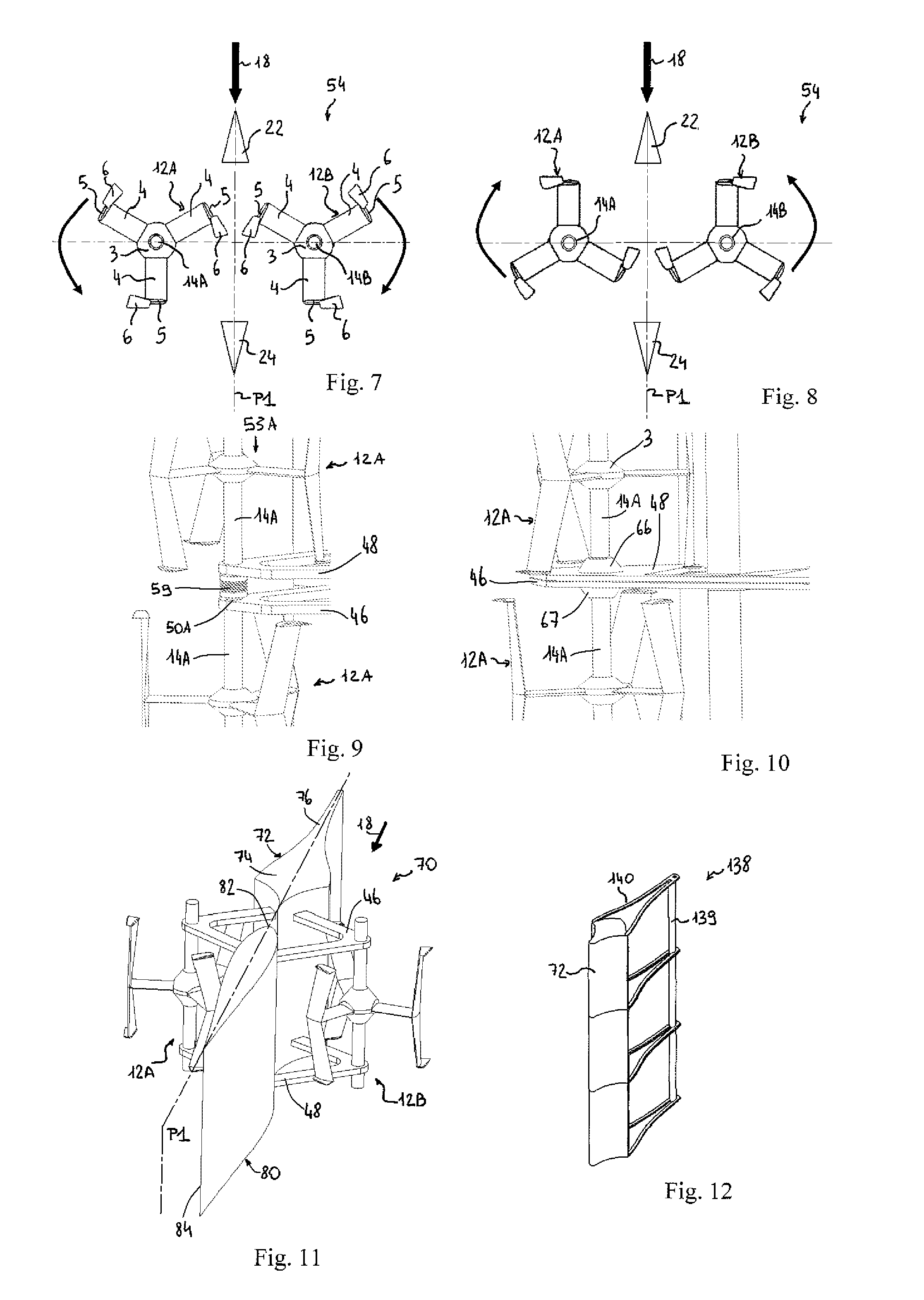

Turbine engine with transverse-flow hydraulic turbine having reduced total lift force

ActiveUS20110006534A1Maintain speedReciprocating combination enginesCombination enginesCouplingCross-flow turbine

The invention relates to a turbine engine that includes at least first and second lift turbine stacks with transverse flow. The shafts of adjacent turbines in the first stack are connected by a first coupling device adapted for compensating space misalignments, and the shafts of adjacent turbines in the first stack are connected by a second coupling device adapted for compensating for space misalignments. The turbine engine includes a device for supporting the first and second turbine stacks, which is symmetrical to said plane, and a control device adapted for permanently maintaining the symmetry between the first and second turbine stacks relative to the plane, and for maintaining the rotation speeds of the first and second turbine stacks at equal values in opposite rotation directions.

Owner:INSTITUT NAT POLYTECHN DE GRENOBLE +1

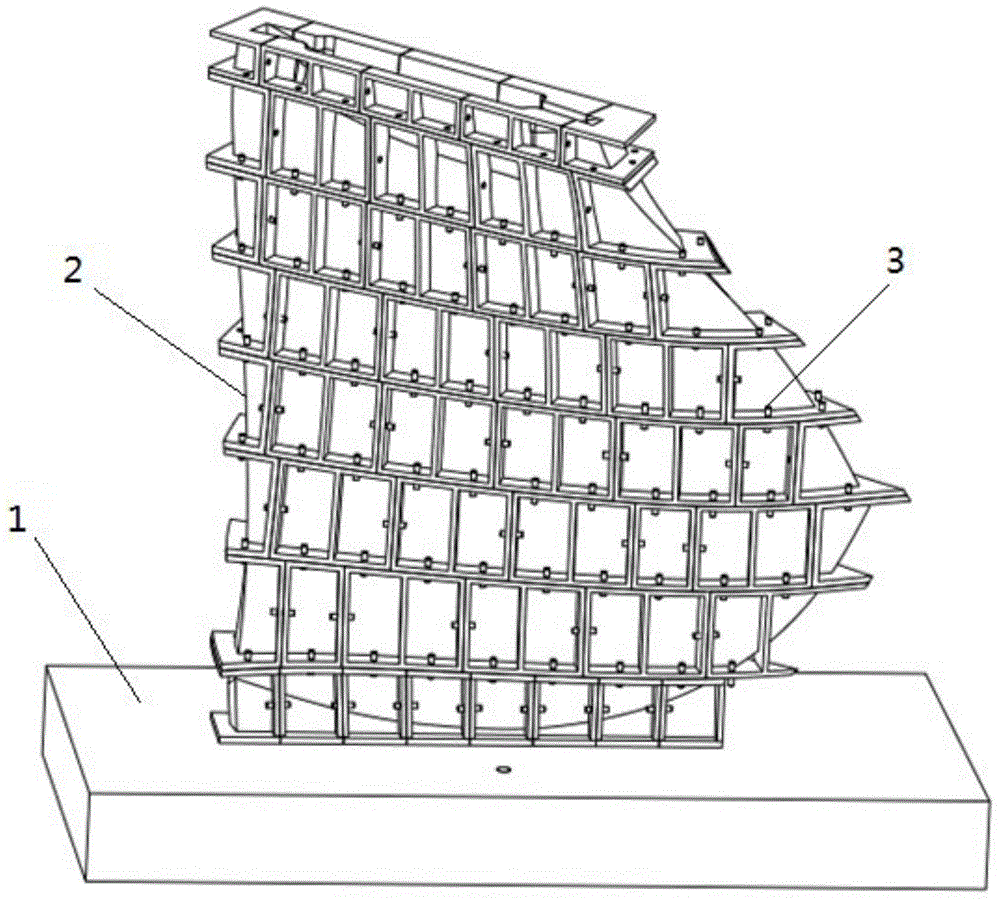

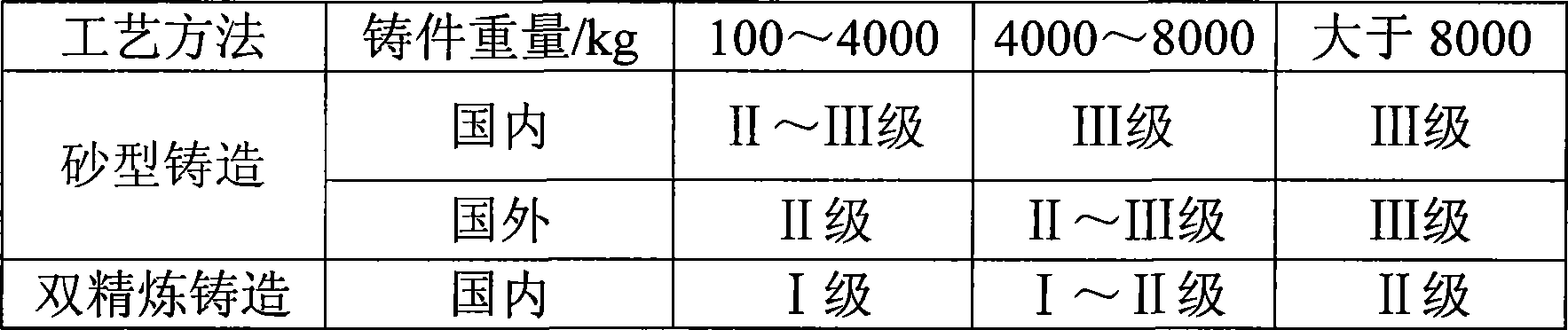

3D-printing sand core moulding method of large-scale hydraulic turbine blade

InactiveCN104416120AImprove product qualityReduce labor intensityFoundry mouldsFoundry coresConventional castingUltimate tensile strength

The invention relates to a 3D-printing sand core moulding method of a large-scale hydraulic turbine blade. In the method, a wood mould manufacturing process in a conventional casting production process is free while a plurality of moulds of sand cores are designed in 3D-cartographic software. The sand cores are directly printed and moulded by a 3D printer and finally the sand cores are assembled layer-by-layer to complete the moulding process. In the method, the conventional mould manufacturing process is omitted so that the 3D-printing sand core moulding method is significantly reduced in production period, is reduced in production cost, is high in moulding accuracy, is low in labor intensity, is low in environmental pollution and is especially suitable for large-scale hydraulic turbine blade production in various models and in large production scale.

Owner:北京瑞泓翔宏大科技发展有限公司

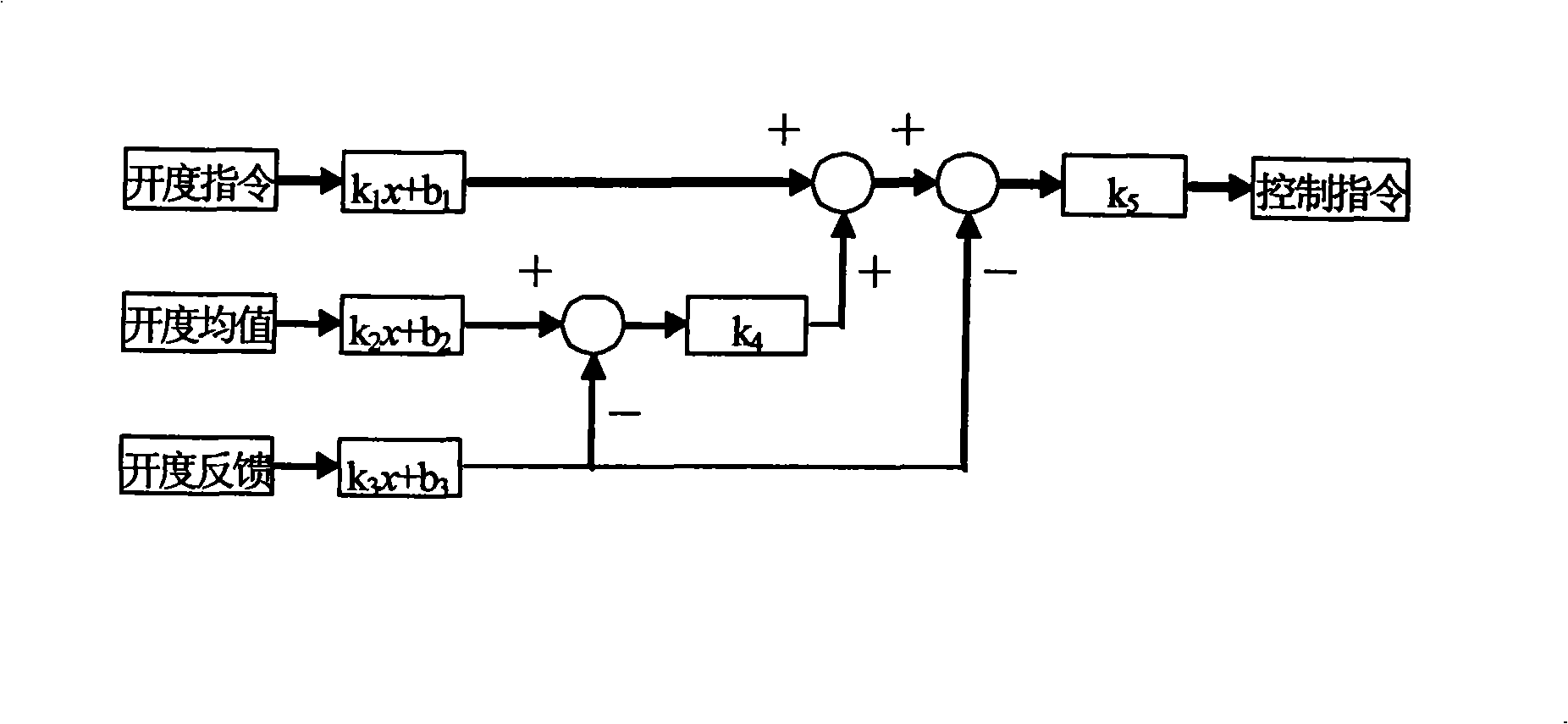

Large hydraulic turbines stationary guide blade synchronous regulation and control method

ActiveCN101260858AHigh control precisionSmall opening commandHydro energy generationMachines/enginesStart timeFull scale

The invention discloses an adjustment and control method for the synchronism of guide vanes of a large-scale water turbine, comprising the following steps: the resistance value of a drive coil of a servomotor is measured and then accurately defined in a single guide vane controller; the zero position and the full scale of a single guide vane instruction of the single guide vane controller are adjusted; a guide vane in the single guide vane controller synchronously controls adjustment of the zero position and the full scale of the instruction; the zero position and the full scale of a guide vane opening displacement sensor are adjusted; the vane mechanical bias voltage is measured and adjusted; the control parameter of the single guide vane is set; the synchronous control parameter of the guide vane is set; the starting time and the closing time of the guide vane are measured and adjusted; a single guide vane displacement transmitter gives a failure alarm; a single guide vane control loop gives an alarm; and an overall guide vane control loop gives an alarm. The adjustment and control method improves the control precision of guide vanes of a hydropower generating unit; the deviation of the opening instruction and the feedback is small; the action synchronism of the guide vane is good; both the starting time and the closing time of the guide vane meet the design requirements; the maximum deviation of the switching time is better than that of the standard requirement.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

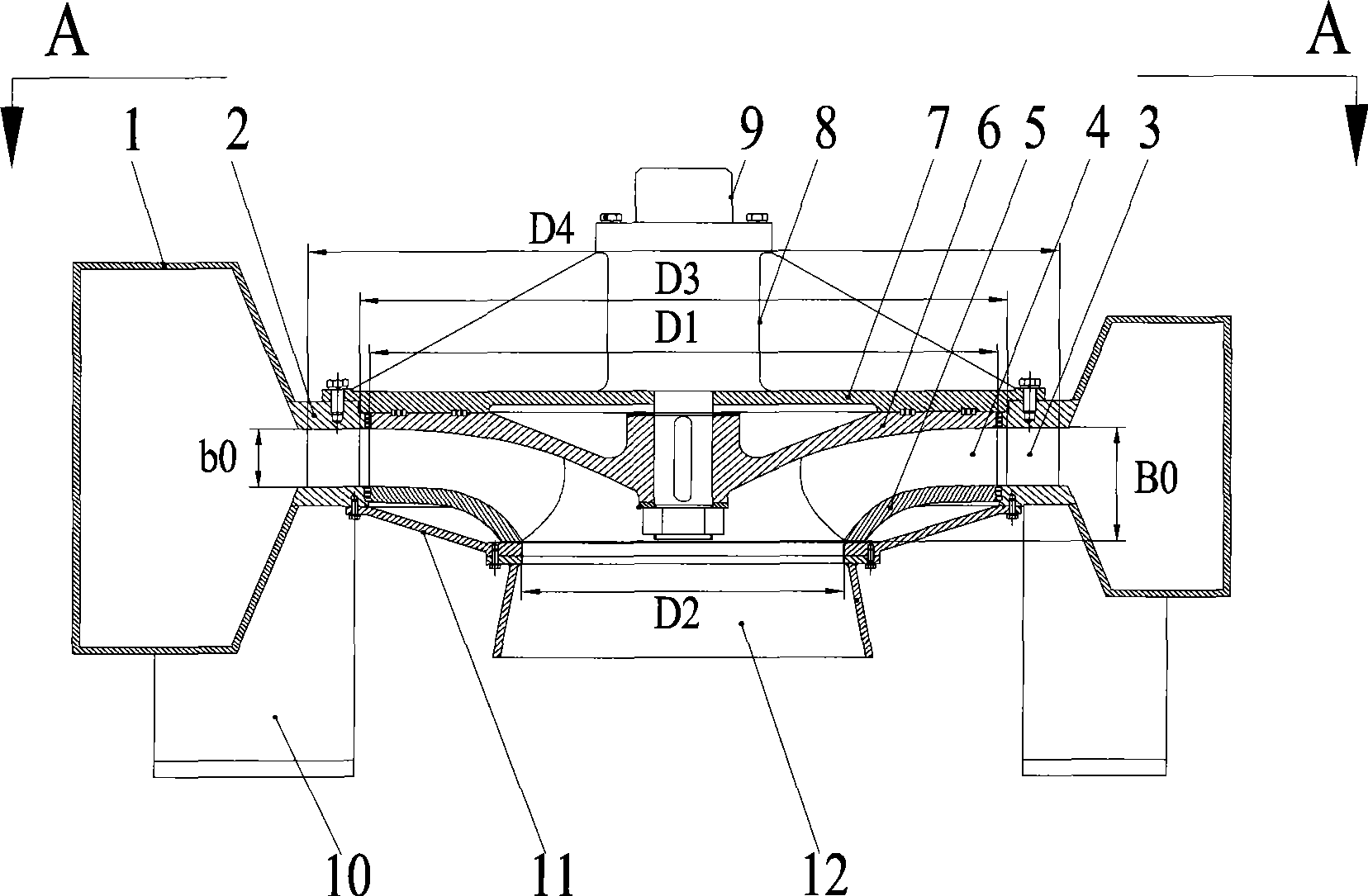

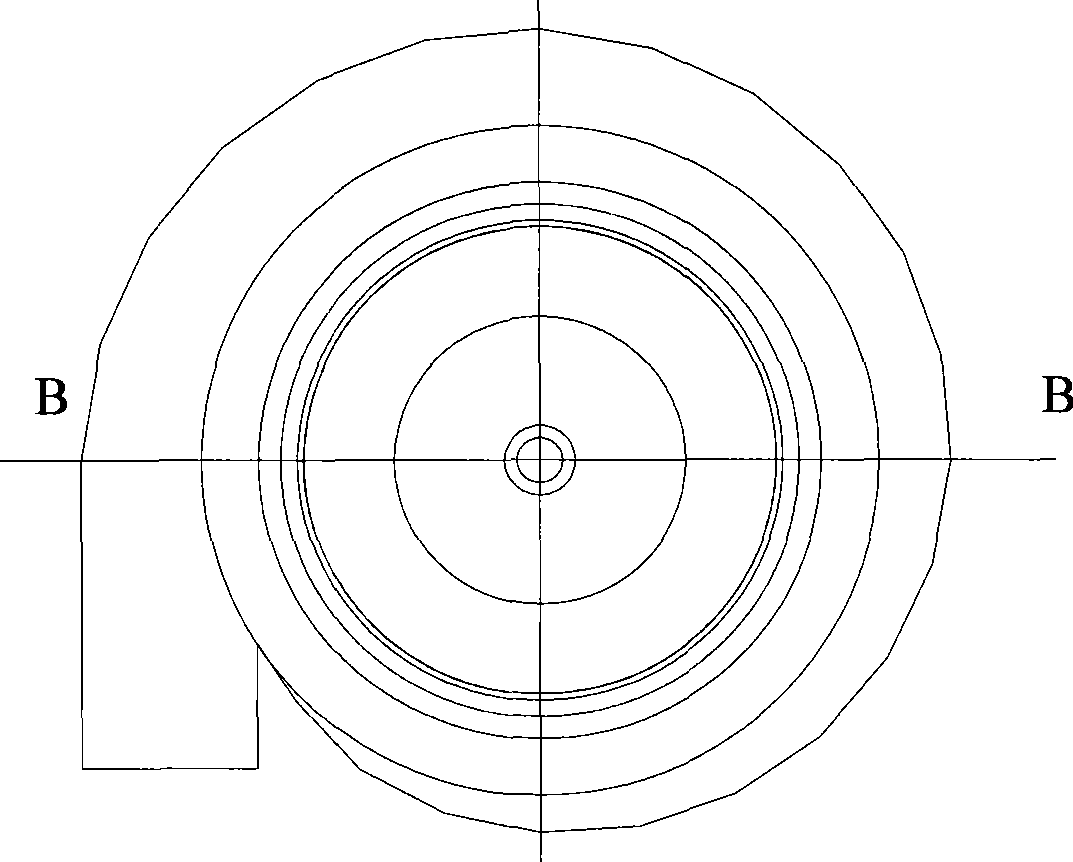

Ultra-low specific speed mixed-flow type turbine

InactiveCN101482083ASolve technical problems with low efficiency and complex structureHydro energy generationReaction enginesMixed flowHydraulic turbines

An ultra-low specific speed mixed-flow turbine relates to a mixed-flow turbine and belongs to the technical field of energy and power. A main shaft in the invention is arranged on a bearing support, and the bearing support is arranged in the middle of the upper side of a cover plate; the lower side of the cover plate is provided with the runner crown of a low specific speed turbine; the end of the cover plate is fixedly connected with a seating ring; the runner band of the low specific speed turbine is relatively arranged below the runner crown of the low specific speed turbine; one end of the runner band of the low specific speed turbine is connected with the seating ring, and the other end is connected with a conical draft tube; a metal scroll casing is connected outside the seating ring and is arranged on a rest pier; 16 to 18 single-row annular negative camber guide vanes are arranged on the seating ring, and the runner blades of the low specific speed turbine are arranged inside the inner cavity between the runner crown of the low specific speed turbine and the runner band of the low specific speed turbine. The invention solves the technical problem that low specific speed mixed-flow turbine has low efficiency and complicated structure in the prior art.

Owner:NANJING XINGFEI COOLING EQUIP

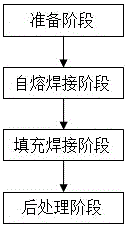

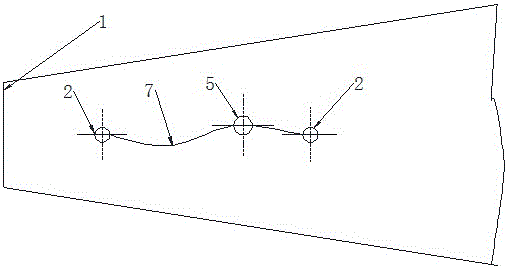

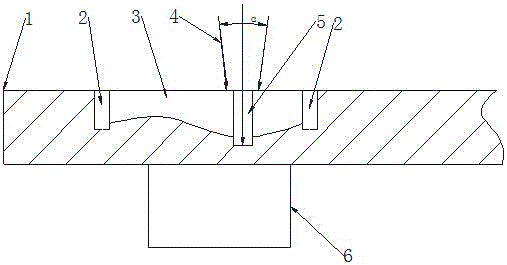

Method for restoring crack of blade of hydraulic turbine

InactiveCN105108337AExtended service lifeImprove bindingLaser beam welding apparatusPorosityEngineering

The invention discloses a method for restoring a crack of a blade of a hydraulic turbine. The method mainly comprises a preparation stage, a self-melting welding stage, a filling welding stage and an aftertreatment stage. At the preparation stage, the blade to be restored is cleaned and detected; at the self-melting welding stage, an inclined convergent laser beam with a negative defocusing amount is adopted for carrying out scanning in the extending direction of the crack, a V-shaped melting pool is formed, and molten metal liquid sinks to the bottom of the melting pool under the action of gravity, and is solidified to form a self-melting weld joint; at the filling welding stage, a material identical to a body of the blade is adopted as a welding wire for surface layer bead welding; at the aftertreatment stage, distressing tempering and blade surface finishing machining are carried out after welding is completed. In the restoring process, based on self-melting of the material of the body of the blade, the blade is filled with a few materials identical to the body of the blade, the material of the weld joint is identical to that of the blade, the material and the blade are combined well, a weld joint defect is not likely to be generated, and the combining strength of the weld joint is improved. In the self-welding welding and filling welding processes, molten metal in the melting pool is vibrated through ultrasonic waves generated by an ultrasonic generator on the back face of the blade to remove gas, and the defects of weld porosity and the like are reduced.

Owner:GUANGDONG UNIV OF TECH

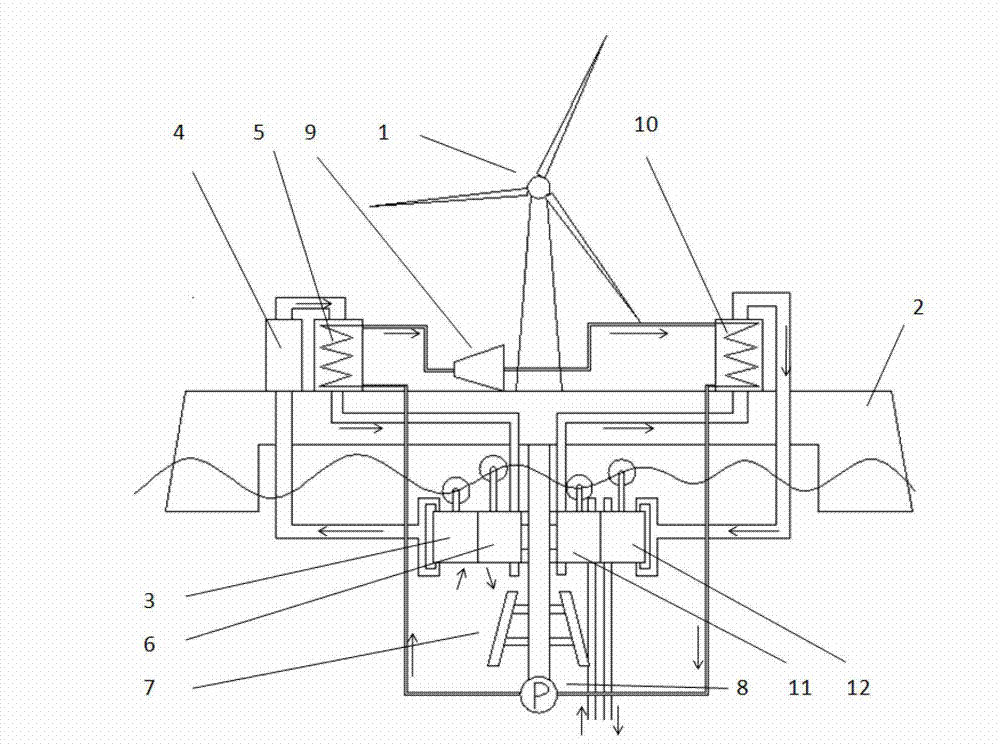

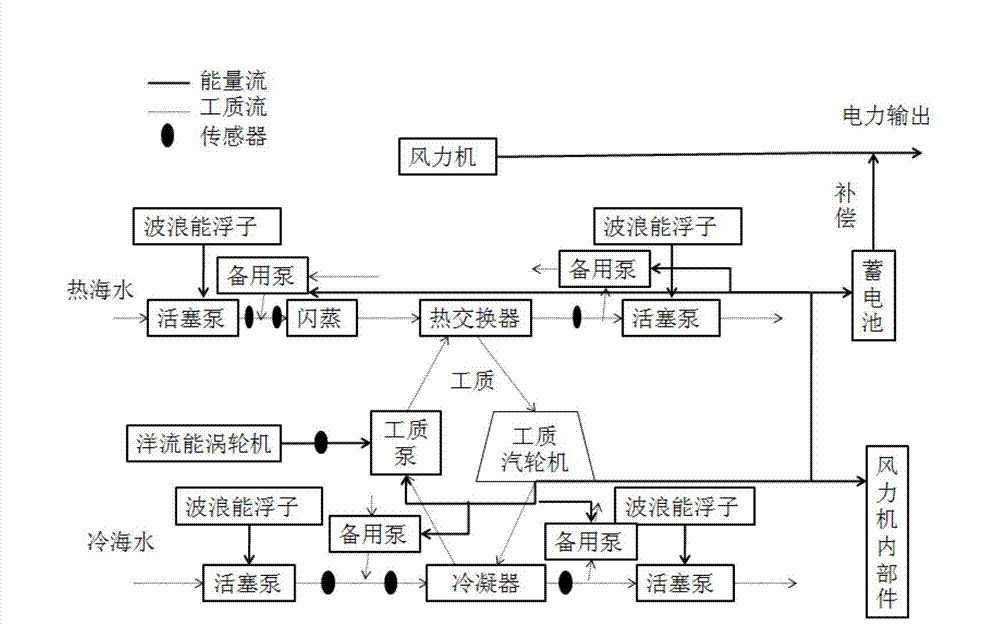

Comprehensive deep sea energy utilizing system

ActiveCN103047085ALow costStable output powerWind motor combinationsMachines/enginesEngineeringTemperature difference

The invention discloses a comprehensive deep sea energy utilizing system. The comprehensive deep sea energy utilizing system comprises a wind turbine, a temperature difference energy generating device, a wave energy utilizing device and an ocean current energy utilizing device. The temperature difference energy generating device comprises a flash evaporator, a working medium circulating unit and a generator, liquid working medium in the working medium circulating unit is delivered to an evaporating heat exchanger via a working medium pump, is changed into unsaturated air by absorbing heat in the evaporating heat exchanger to push a steam turbine to act, and then enters a condensing heat exchanger to be condensed into liquid to flow back to the working medium pump. In the ocean current energy utilizing device, the upper end of a tower column is fixed connected at the bottom of a floating platform, a hydraulic turbine for driving the working medium pump is arranged on the tower column and close to the lower end. The wave energy utilizing device comprises a plurality of floater power units which are arranged below the floating platform and close to the sea surface, a water inlet of at least one floater power unit I is communicated with the surface seawater, a water outlet of the one floater power unit I is communicated with the flash evaporator, a water inlet of at least one floater power unit II is communicated with the deep seawater, and a water outlet of the one floater power unit II is communicated with the condensing heat exchanger.

Owner:中科国风科技有限公司

Turbine wicket gate double-refining casting technique

ActiveCN101450376AQuality improvementReduce gas contentFurnace typesHeat treatment furnacesMaterials scienceHydraulic turbines

The invention provides a hydraulic turbine guiding blade double refining casting process, which adopts an AOD or VOD refining method to prepare a raw material consumable electrode, and the weight percentages of chemical compositions of the prepared raw material consumable electrode are : C is less than or equal to 0.05 percent, Si is less than or equal to 0.6 percent, Mn is less than or equal to 0.58 percent, P is less than or equal to 0.03 percent, S is less than or equal to 0.03 percent, Cr is between 11.5 and 13.5 percent, Ni is between 3.5 and 5.0 percent, Mo is between 0.4 and 1.0 percent, W is less than or equal to 0.5 percent, O is less than or equal to 0.008 percent, H is less than or equal to 0.00035 percent and the balance is Fe. Then a prepared consumable plate is made into a hydraulic turbine stainless guiding blade component by an electroslag smelting casting method; and the double refining casting process can refine and purify steel liquid completely and effectively so as to remove the gas and non-metallic inclusions in steel greatly. The crystal structure of the casting is uniform and compact, and has low sulfur and phosphorus content, less non-metallic inclusions, higher toughness, anti-fatigue performance and good welding performance.

Owner:SHENYANG RES INST OF FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com