Method for accurately and continuously measuring and processing axis throw of hydraulic turbine set

An axis and unit technology, which is applied in the field of accurate and continuous measurement and processing of the axis swing of a hydraulic turbine unit, can solve the problems of fast operation speed, high accuracy, and short construction period, and achieves improved measurement accuracy, accurate and fast adjustment, and accurate measurement and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for accurate and continuous measurement and processing of the axis swing of a water turbine unit, comprising the following steps:

[0038] 1. Combined with the actual project situation and the axis structure of the unit, based on the sinusoidal curve equation of the axis swing of the unit and the calculation formula of the maximum swing value eccentricity, eccentricity angle and correction value, the system program is written in combination with the swing value measurement data acquisition method .

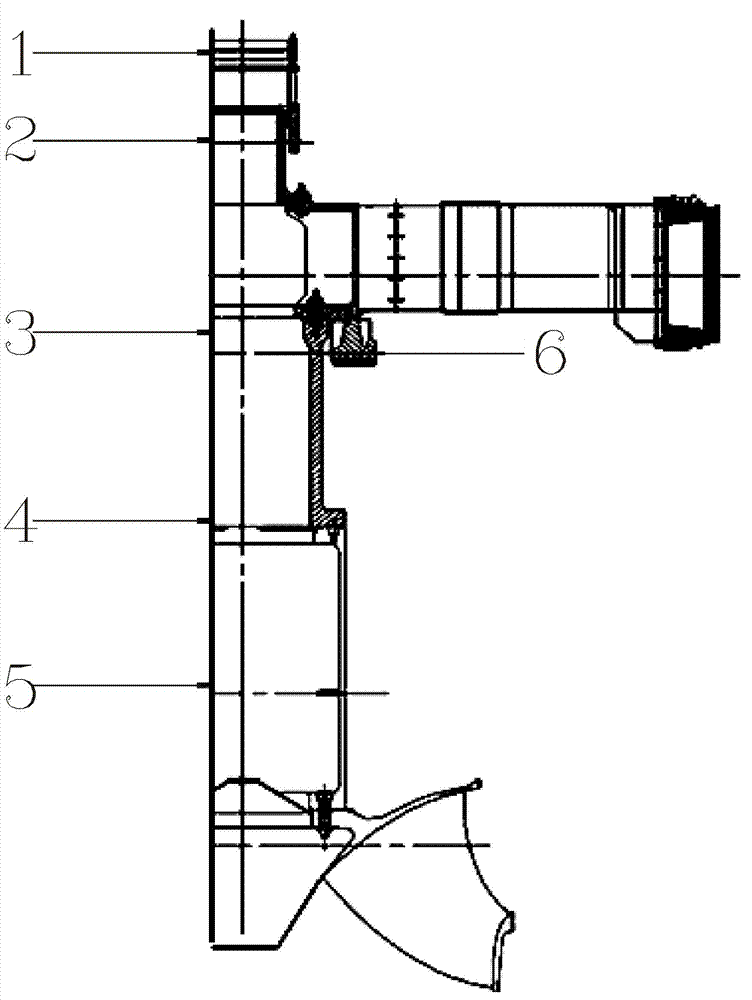

[0039] According to the shaft system composition of the unit, a displacement sensor for measuring the displacement of the outer wall is set on each component shaft as a measuring point. In this example such as figure 1 As shown in , the measuring section 1 of the collector ring, the measuring section 2 of the upper end shaft, the measuring section 3 of the rotor center body, the measuring section 4 of the lower end shaft, the measuring section 5 of the turbine sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com