Patents

Literature

5889 results about "Measurement point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A point is a standard measurement unit for type sizes. One point equals approximately 1/72 of an inch.

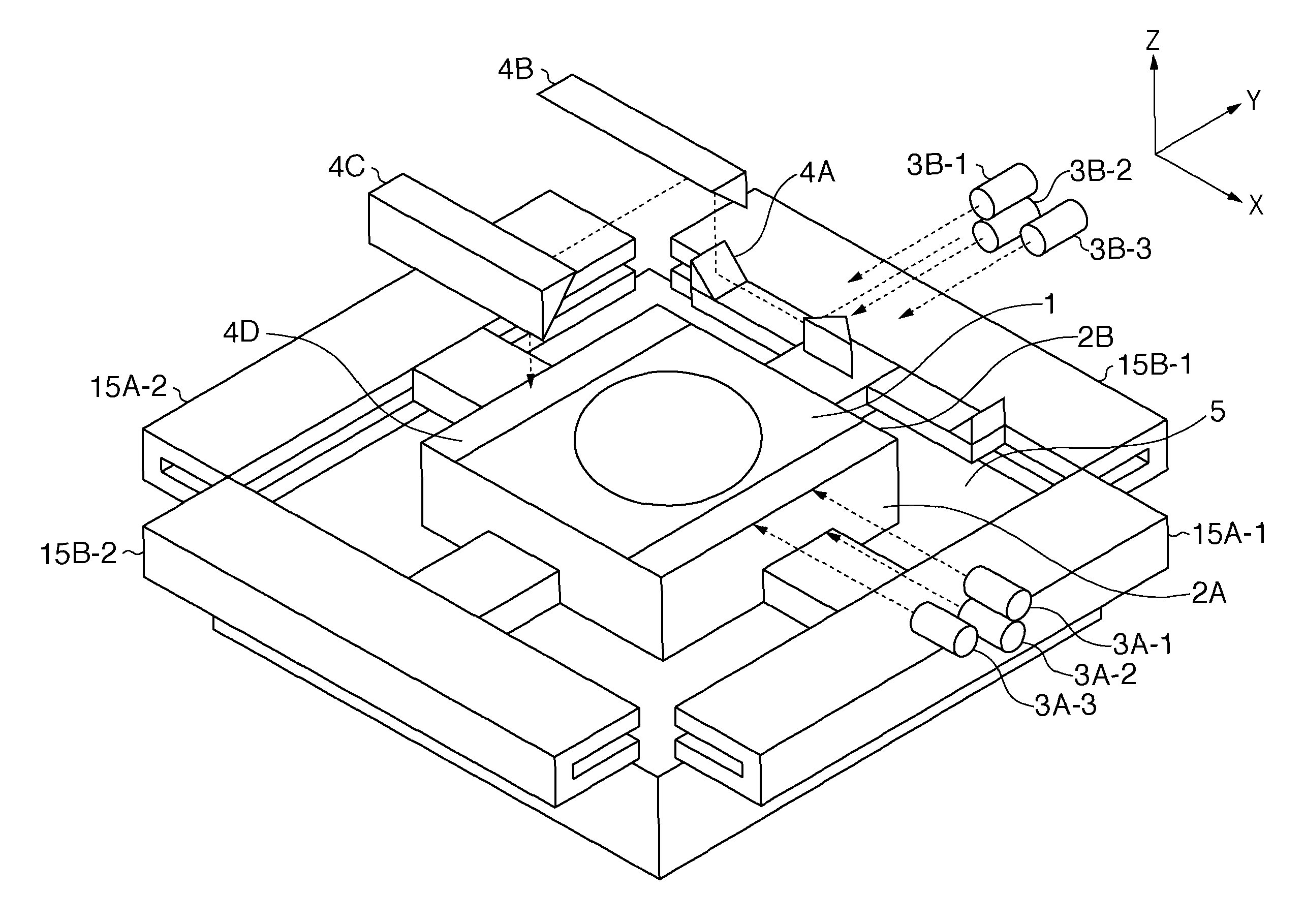

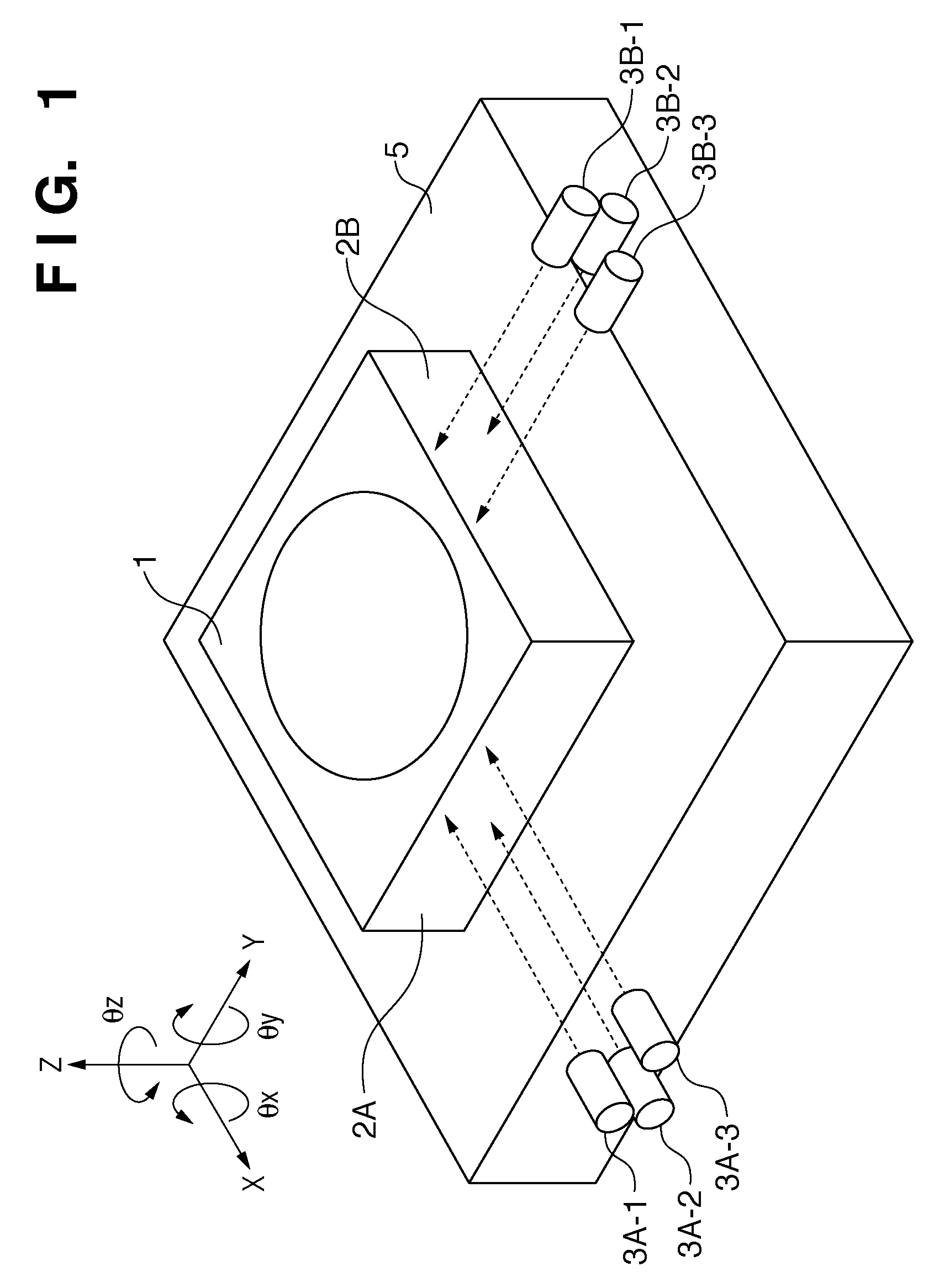

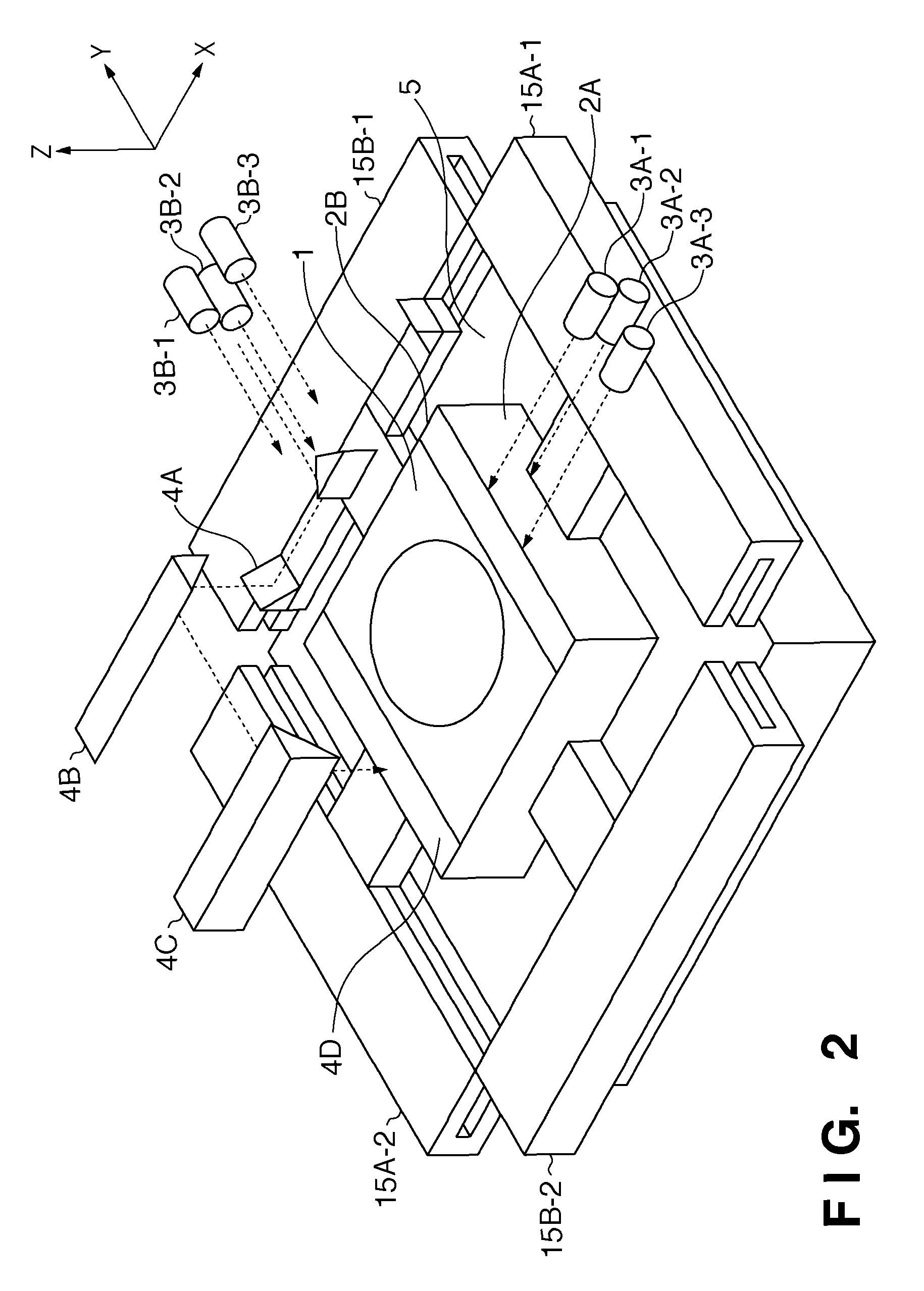

Exposure apparatus and method of manufacturing device

InactiveUS7884918B2Improve accuracyIncrease productivityPhotomechanical apparatusSemiconductor/solid-state device manufacturingObservational errorMeasurement device

Owner:CANON KK

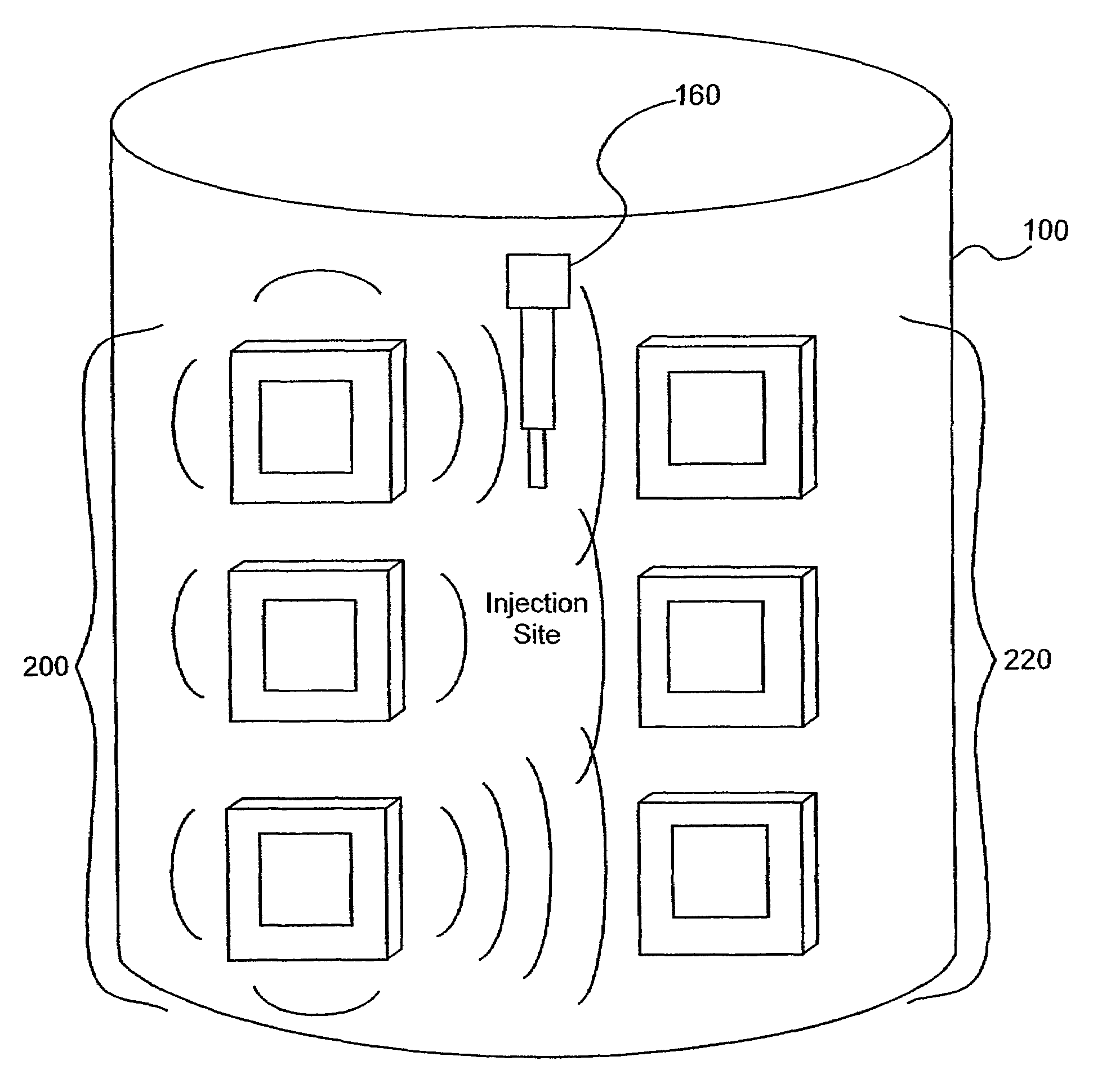

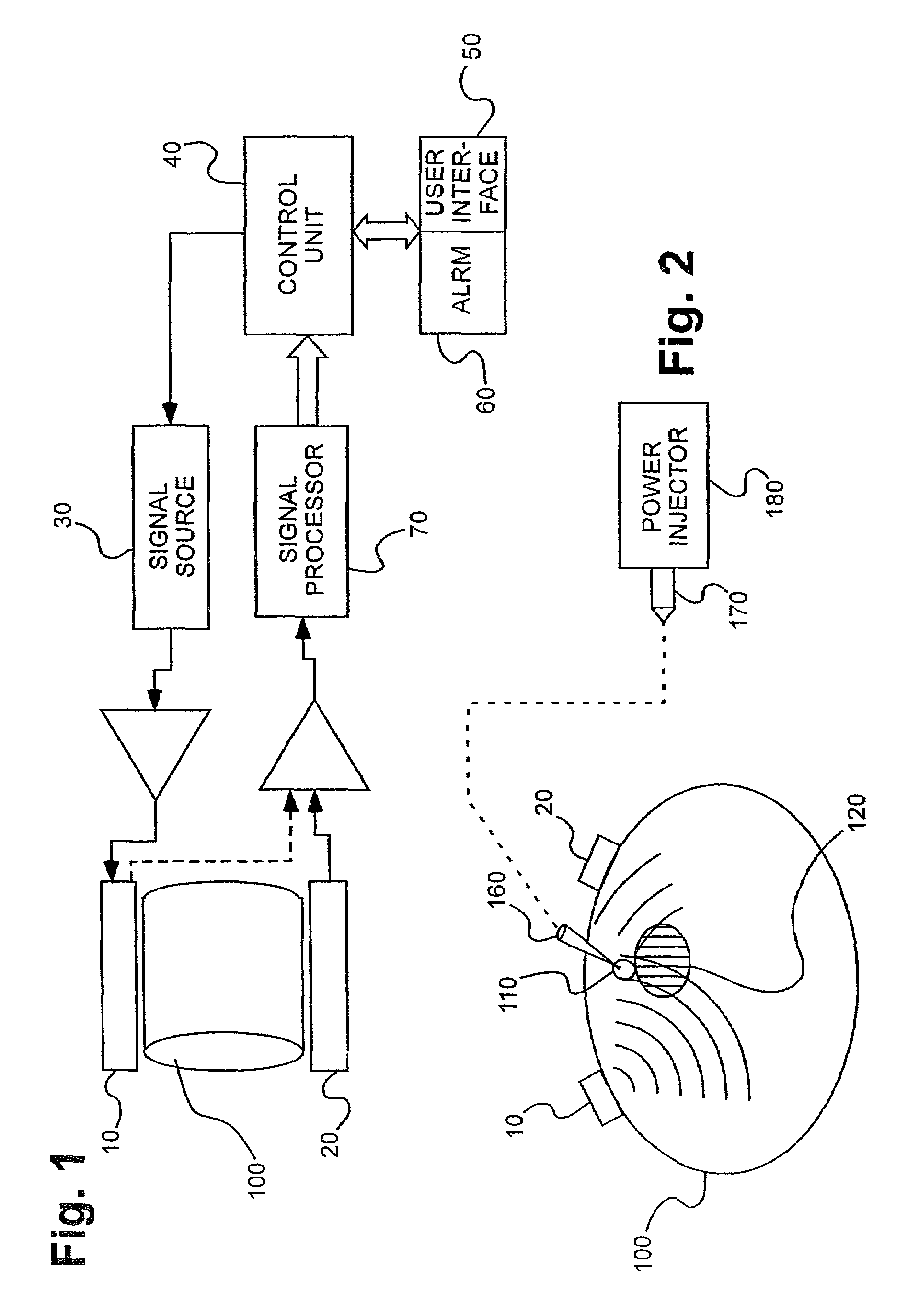

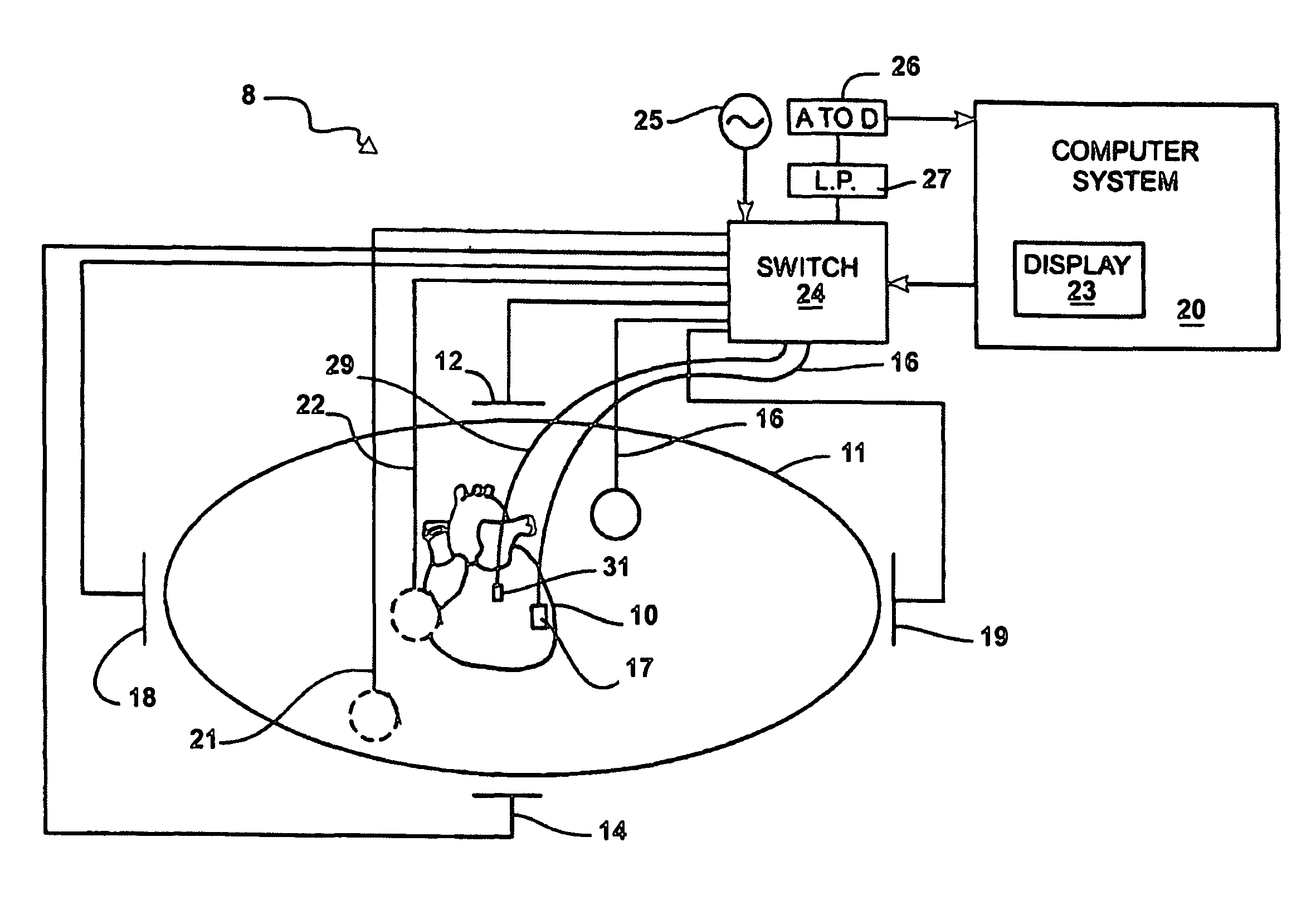

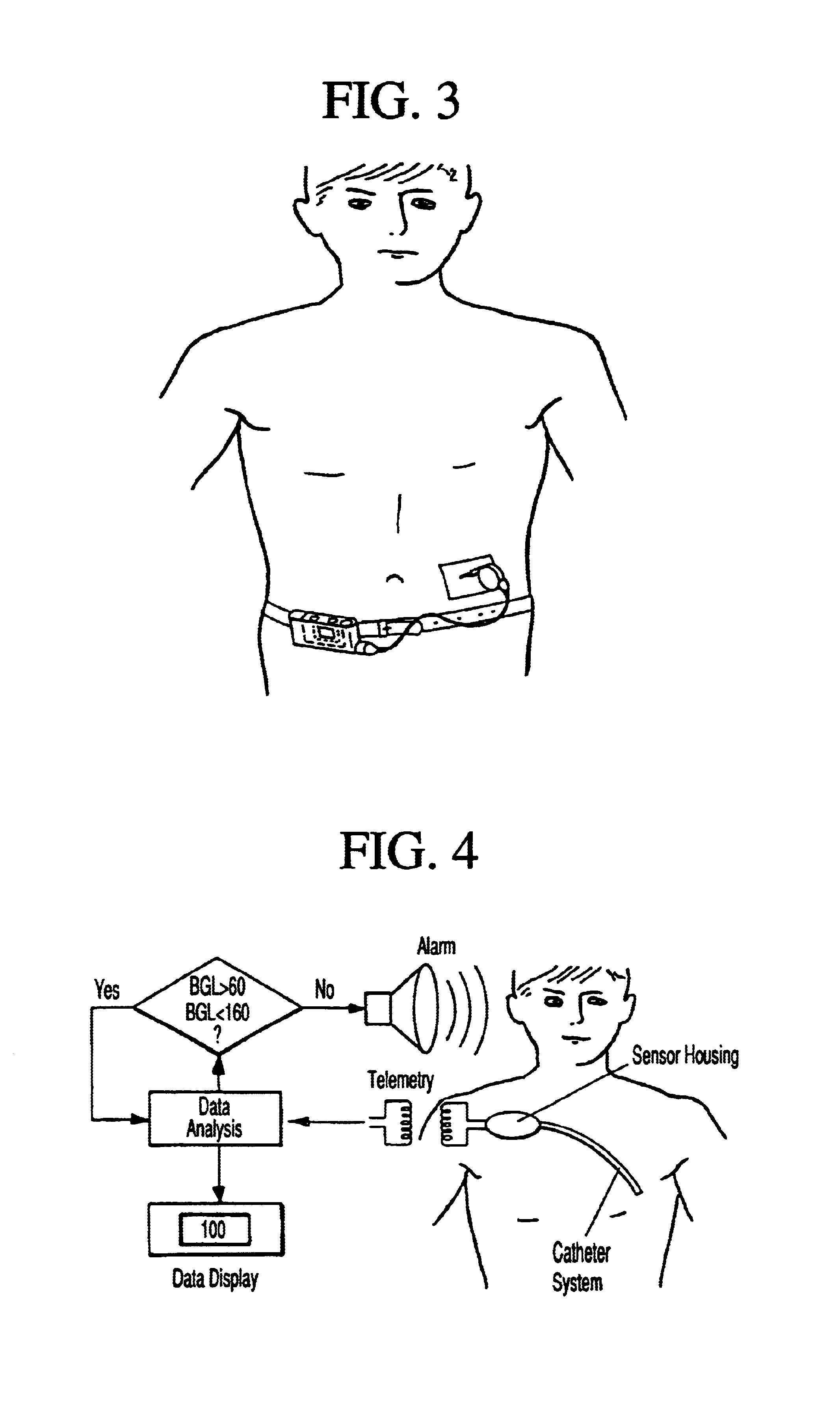

Electromagnetic sensors for biological tissue applications and methods for their use

ActiveUS7591792B2Improves signal couplingImproves resulting measurementElectrotherapyAntenna supports/mountingsMeasurement pointEngineering

Tissue sensors house one or more sensor elements. Each element has a housing mounted substrate and a superstrate with a planar antenna between. A transitional periphery (TP) of a superstrate outer surface interconnects a base to a plateau. At least some of the TP has a generally smooth transition. Plural elements are spaced by the housing. Alternately, the superstrate TP is flat, the housing extends to the outer superstrate surface and a shield surrounds the element. The housing is flush with or recessed below the superstrate and defines a TP between the housing and superstrate. A method converts a reference signal to complex form; plots it in a complex plane as a reference point (RP); converts a measurement signal to complex form; plots it in the complex plane as a measurement point (MP); determine a complex distance between the MP and the RP; and compares complex distance to a threshold.

Owner:BAYER HEALTHCARE LLC

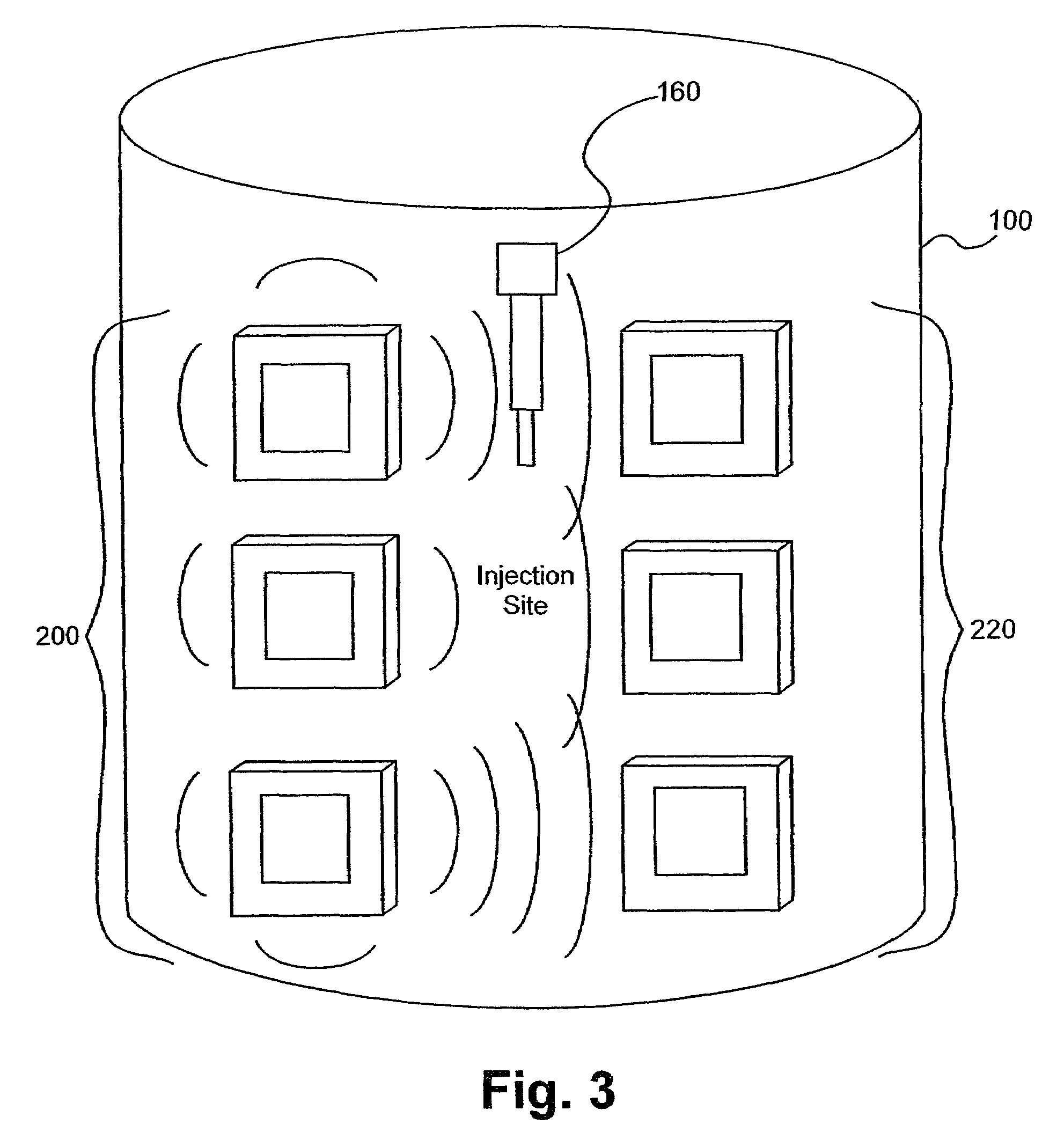

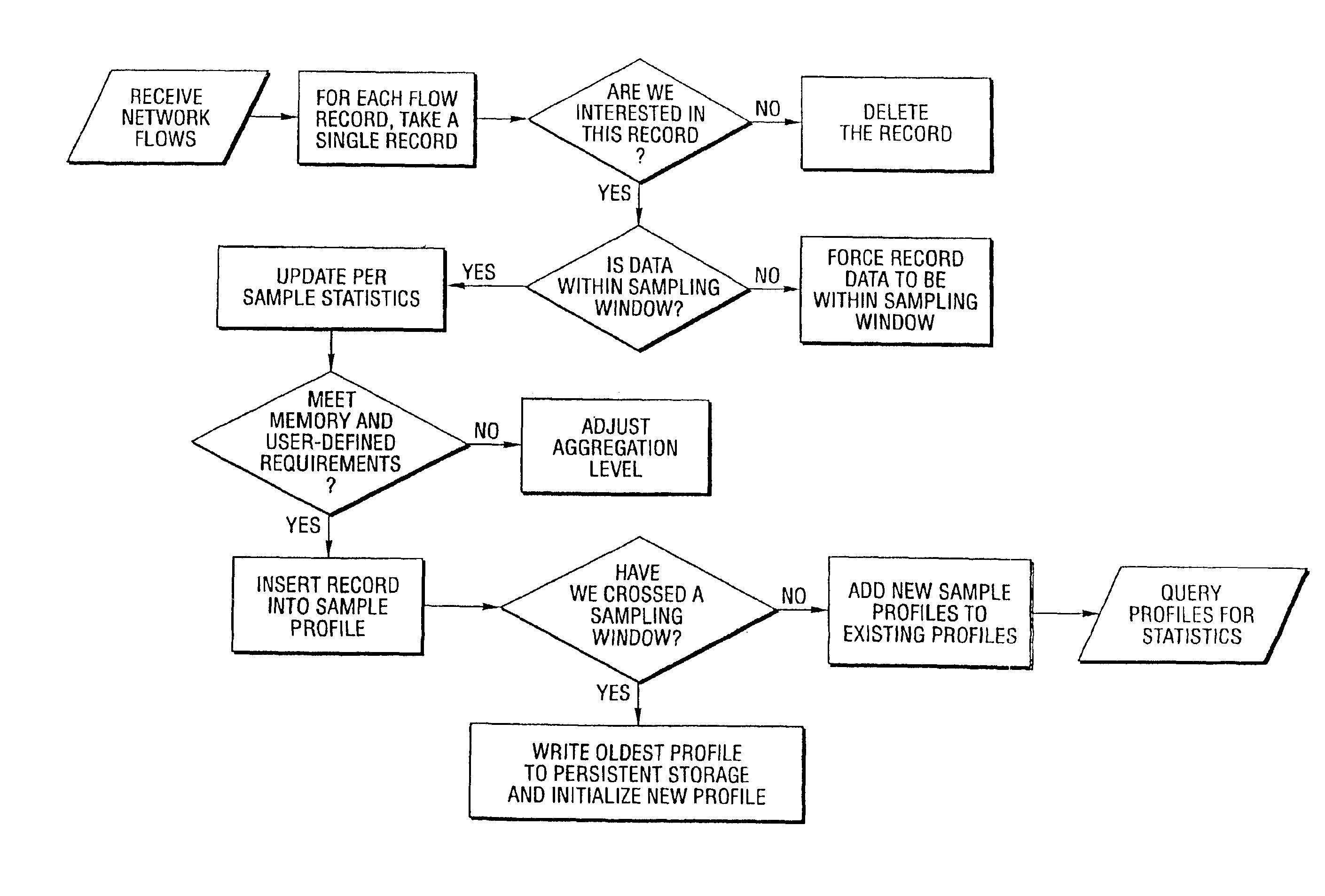

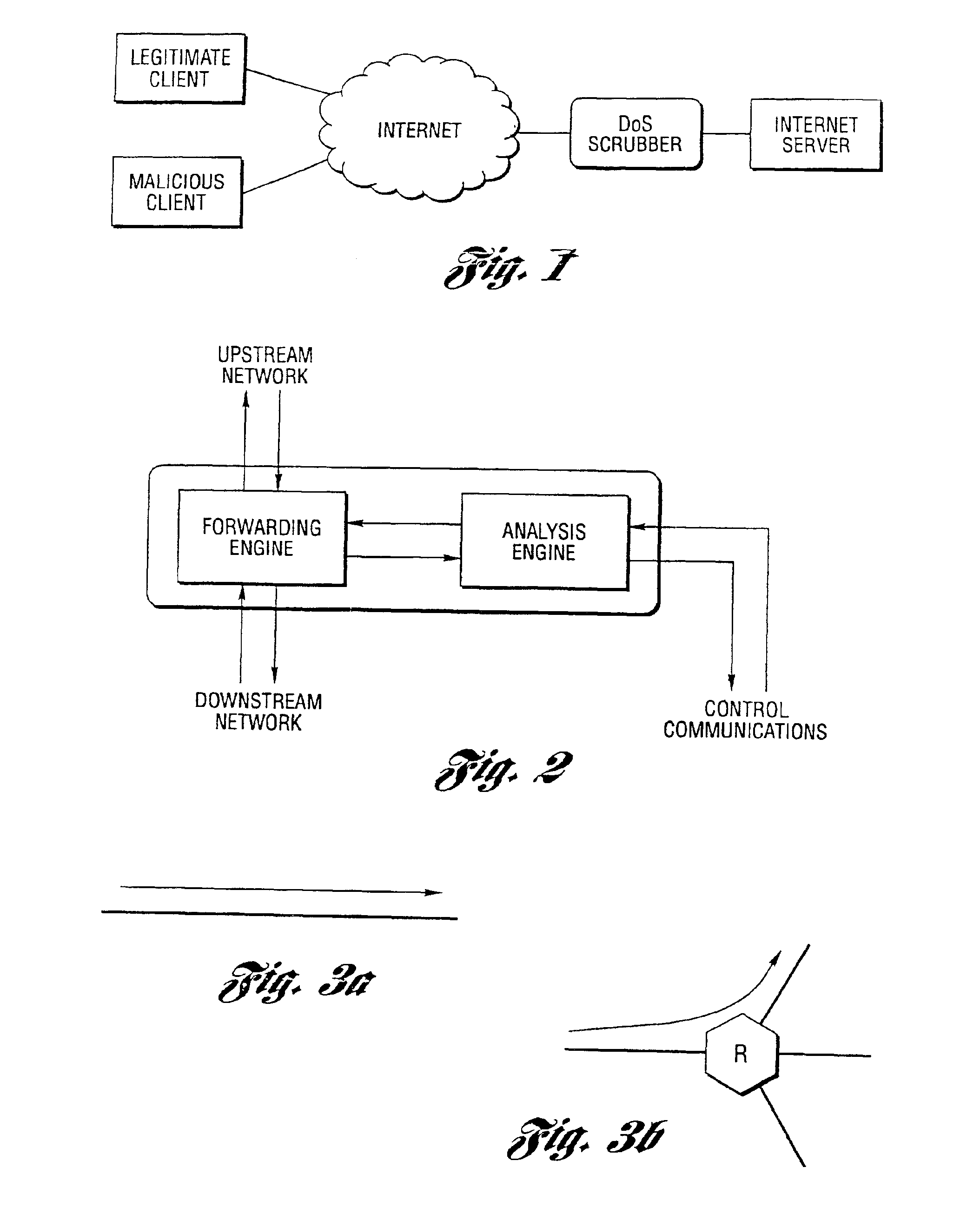

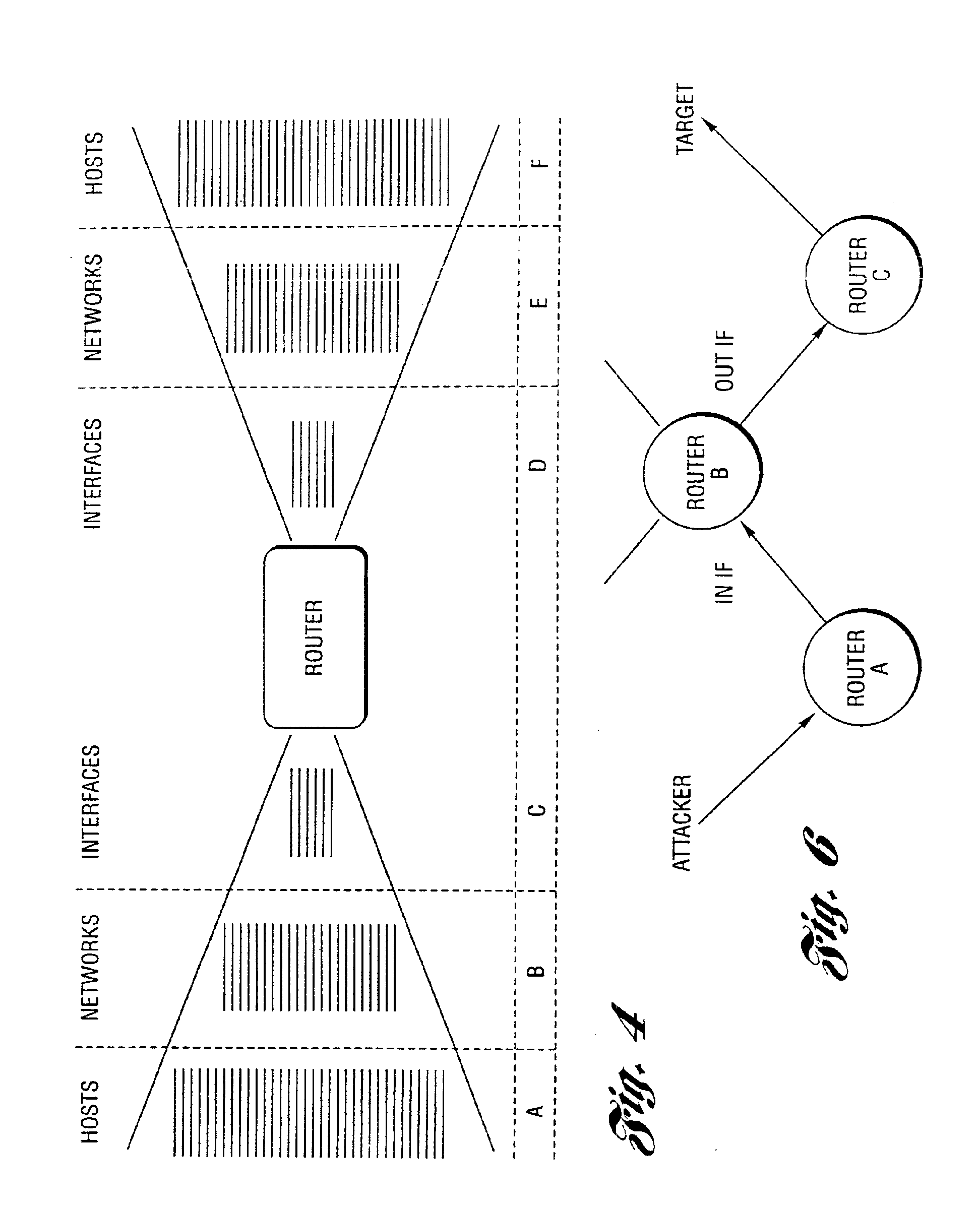

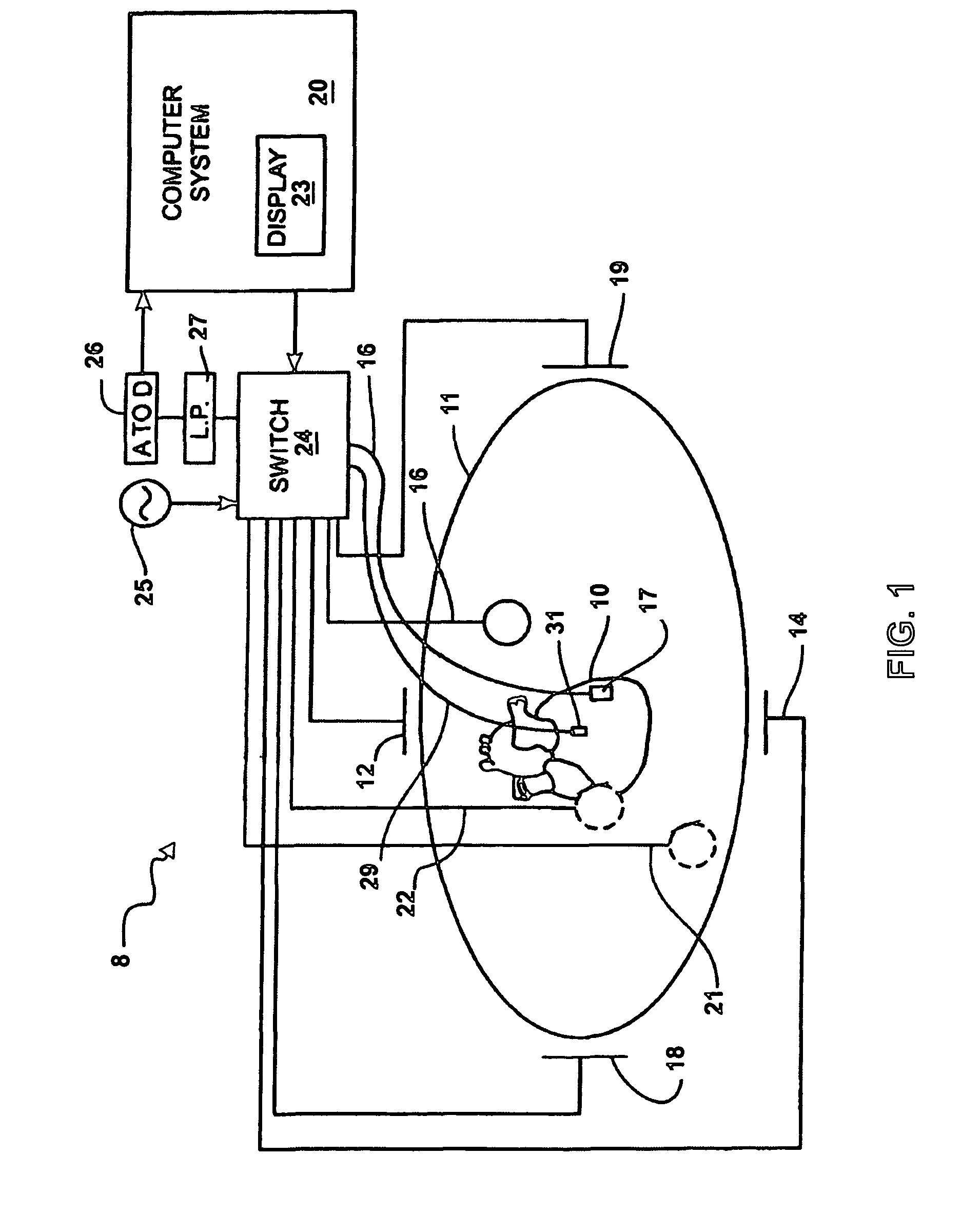

Method and system for profiling network flows at a measurement point within a computer network

InactiveUS6944673B2Multiple digital computer combinationsData switching networksTraffic characteristicMeasurement point

A method and system for profiling network flows at a measurement point within a computer network is provided. The method includes measuring network flows having invariant features at a measurement point located within routing infrastructure of the computer network to obtain flow statistics. The method also includes aggregating the flow statistics to obtain a traffic profile of the network flows at the measurement point. The method and system utilize the natural hierarchy in the Internet addressing scheme to provide a means for making tractable measurements of network traffic in high-speed networks. Moreover, the method and system adapt dynamically to the changing underlying traffic characteristics to maintain a maximum memory footprint for the profiles. The method and system adapt by adjusting the level of aggregation of the traffic endpoints along a scale from Interface to fully specified network address.

Owner:RGT UNIV OF MICHIGAN

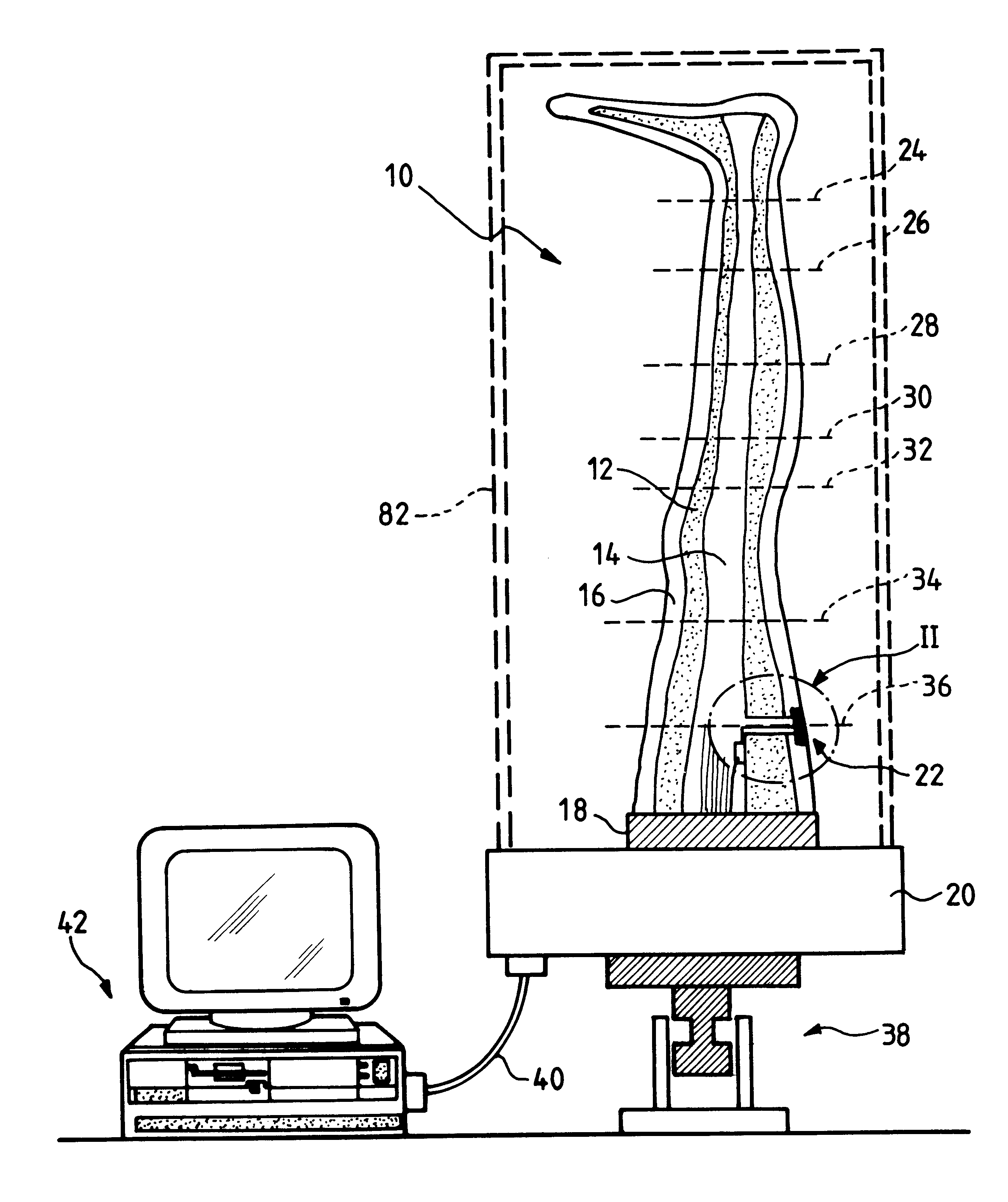

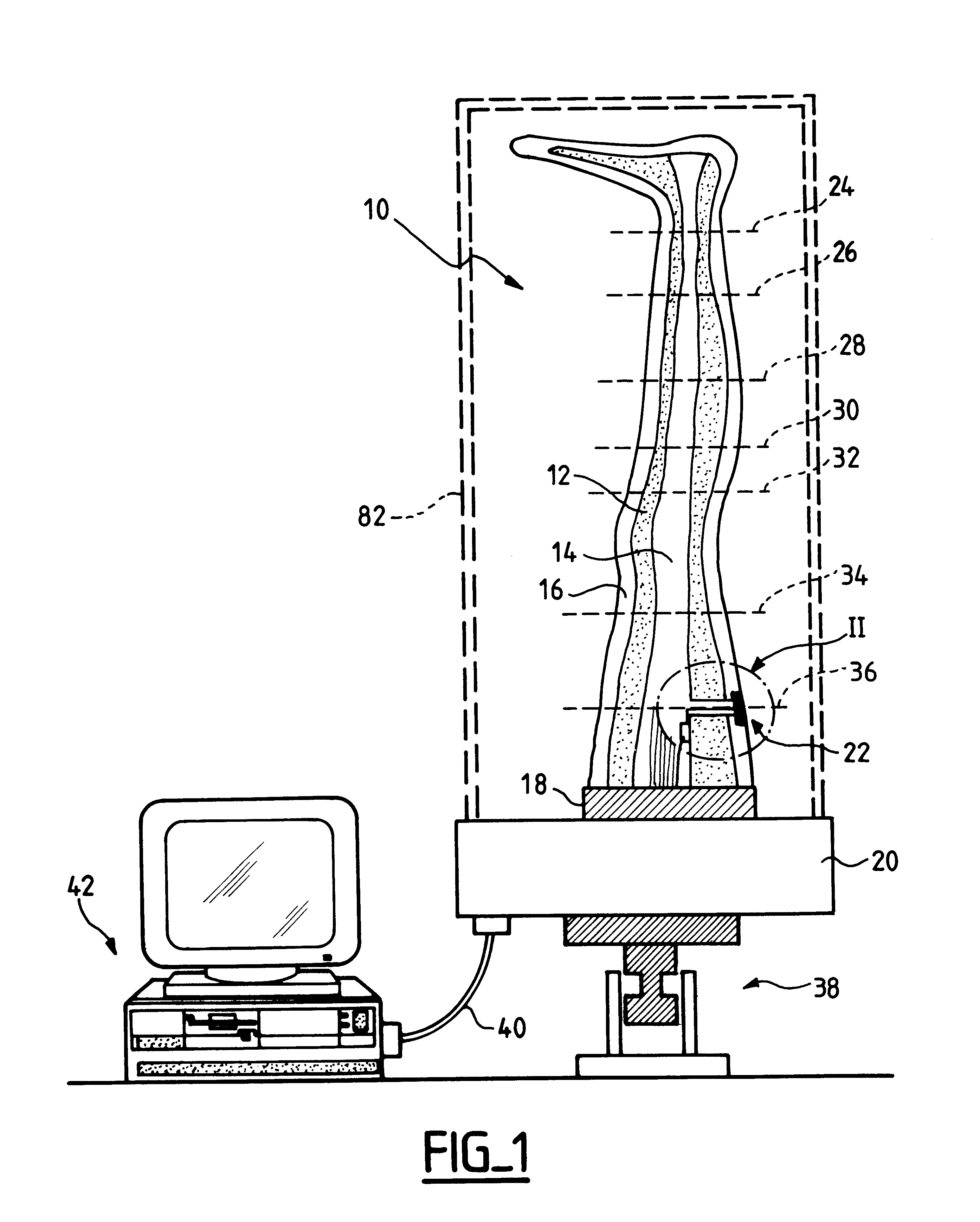

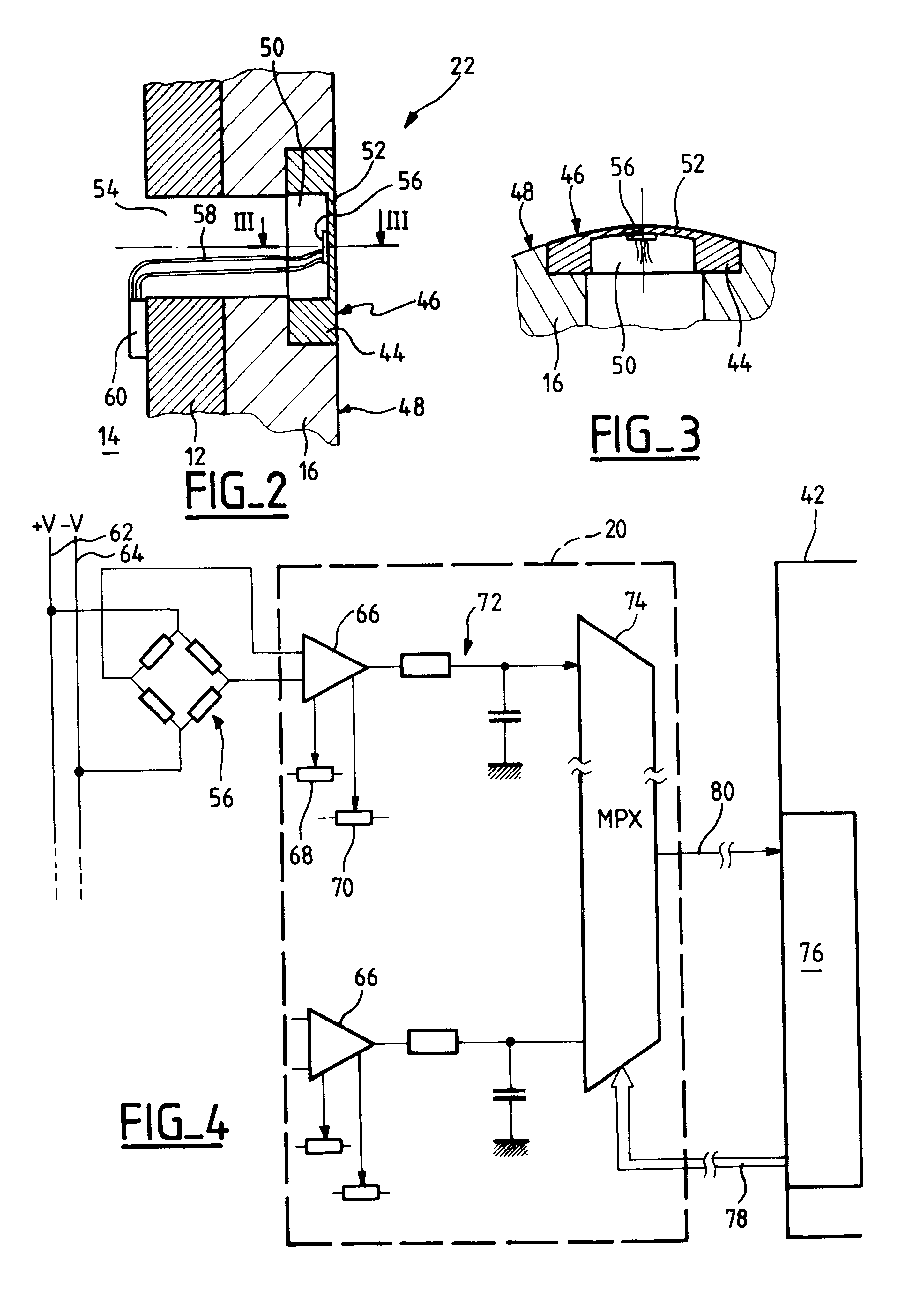

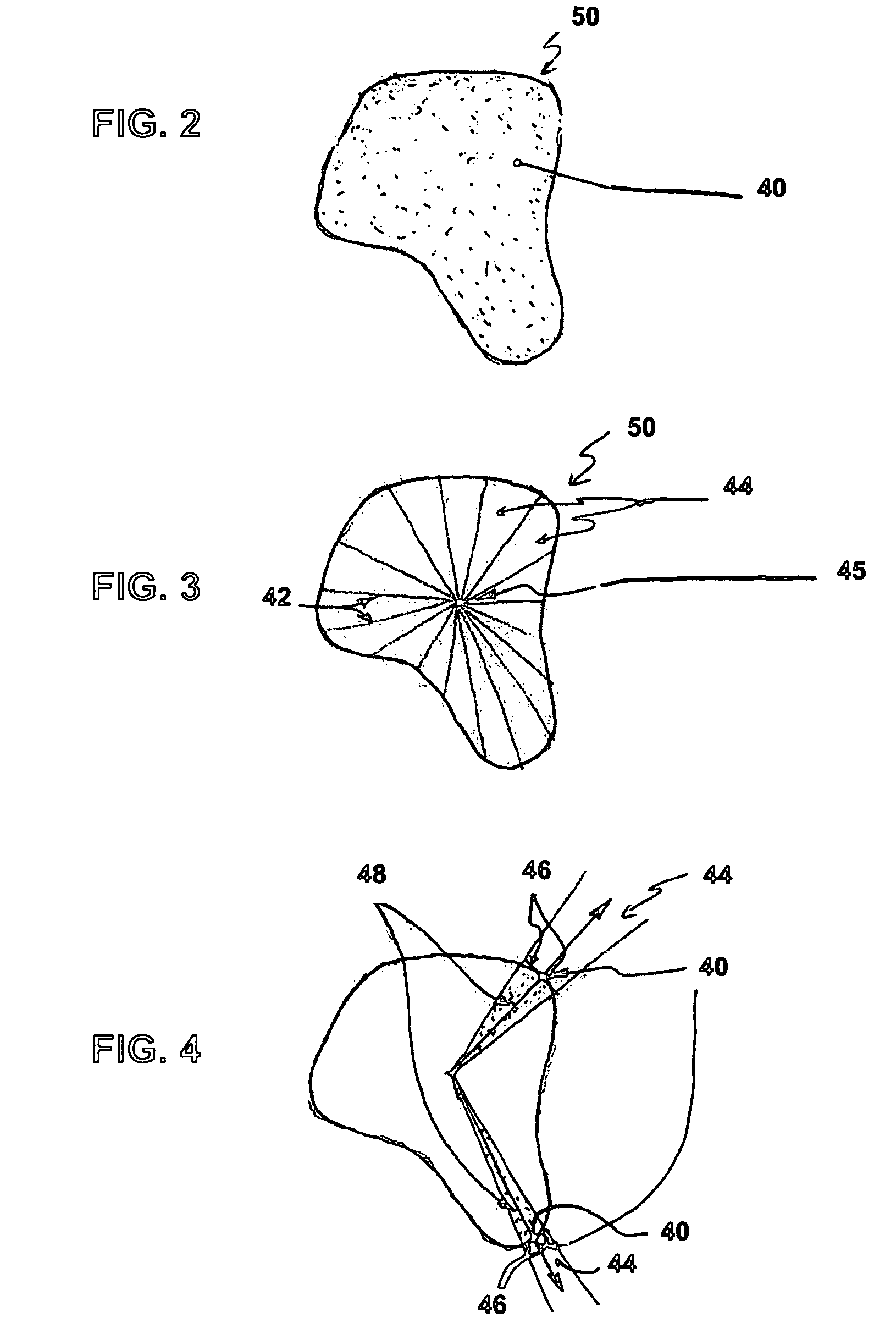

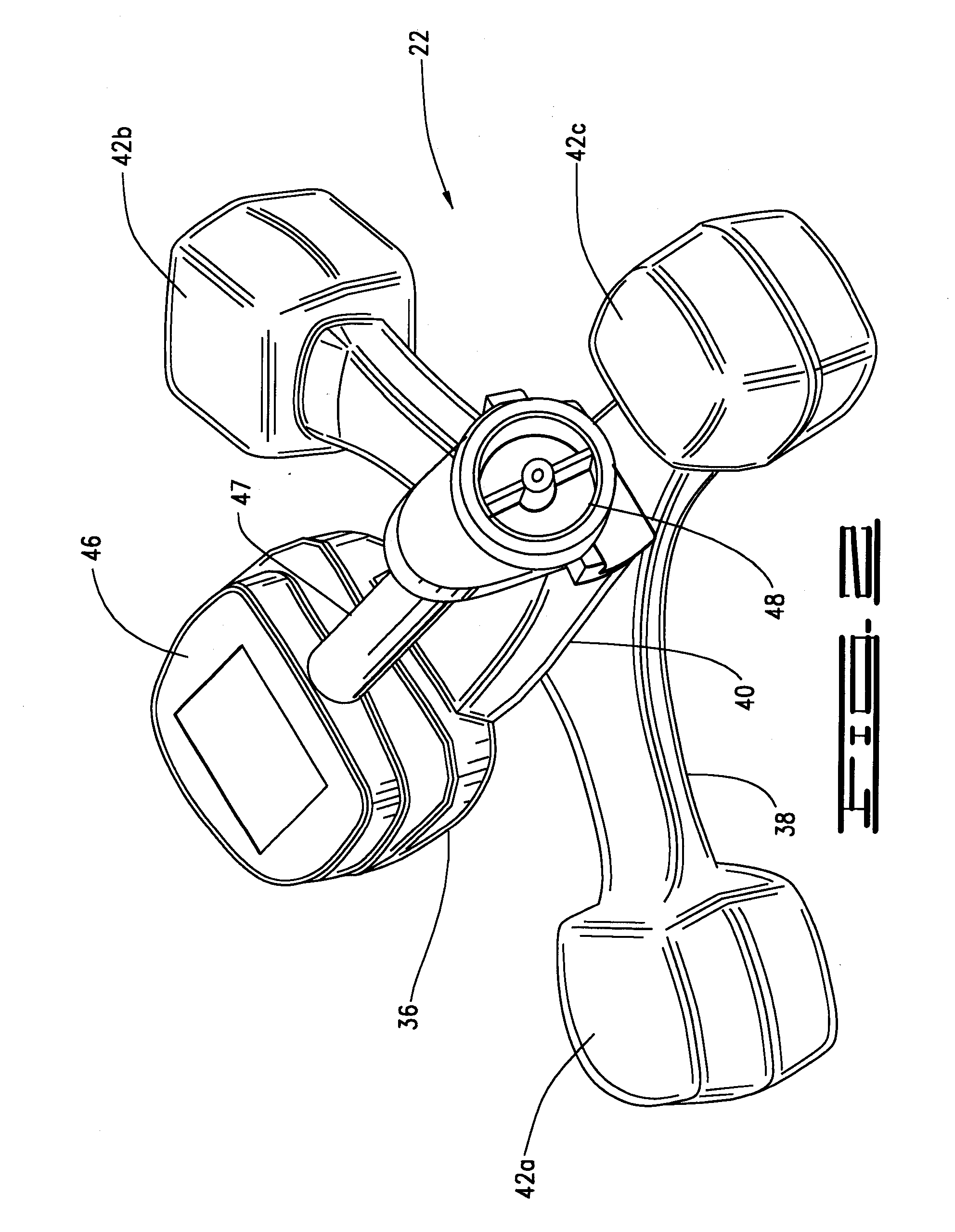

Device for measuring pressure points to be applied by a compressive orthotic device

The device comprises a rigid former reproducing the volume of a portion of the body and suitable for receiving the compressive orthosis. The former (10) incorporates a plurality of sensors (22) distributed over various points of the former and configured in such a manner as to avoid significantly modifying the surface profile of the former, the sensors essentially measuring the pressure applied locally on the former by the orthosis at the location of the sensor and perpendicularly to the surface of the former. Advantageously, at the location of the measurement point, each sensor comprises a thin wall capable of being subjected to microdeformation under the effect of the pressure applied by the orthosis, and means such as a strain gauge bridge, for example. The thin wall can constitute a portion of a support pellet which is fitted to the former in such a manner that its outside surface, which includes the thin wall, is flush with the outside surface of the former.

Owner:INNOTHERA TOPIC INT

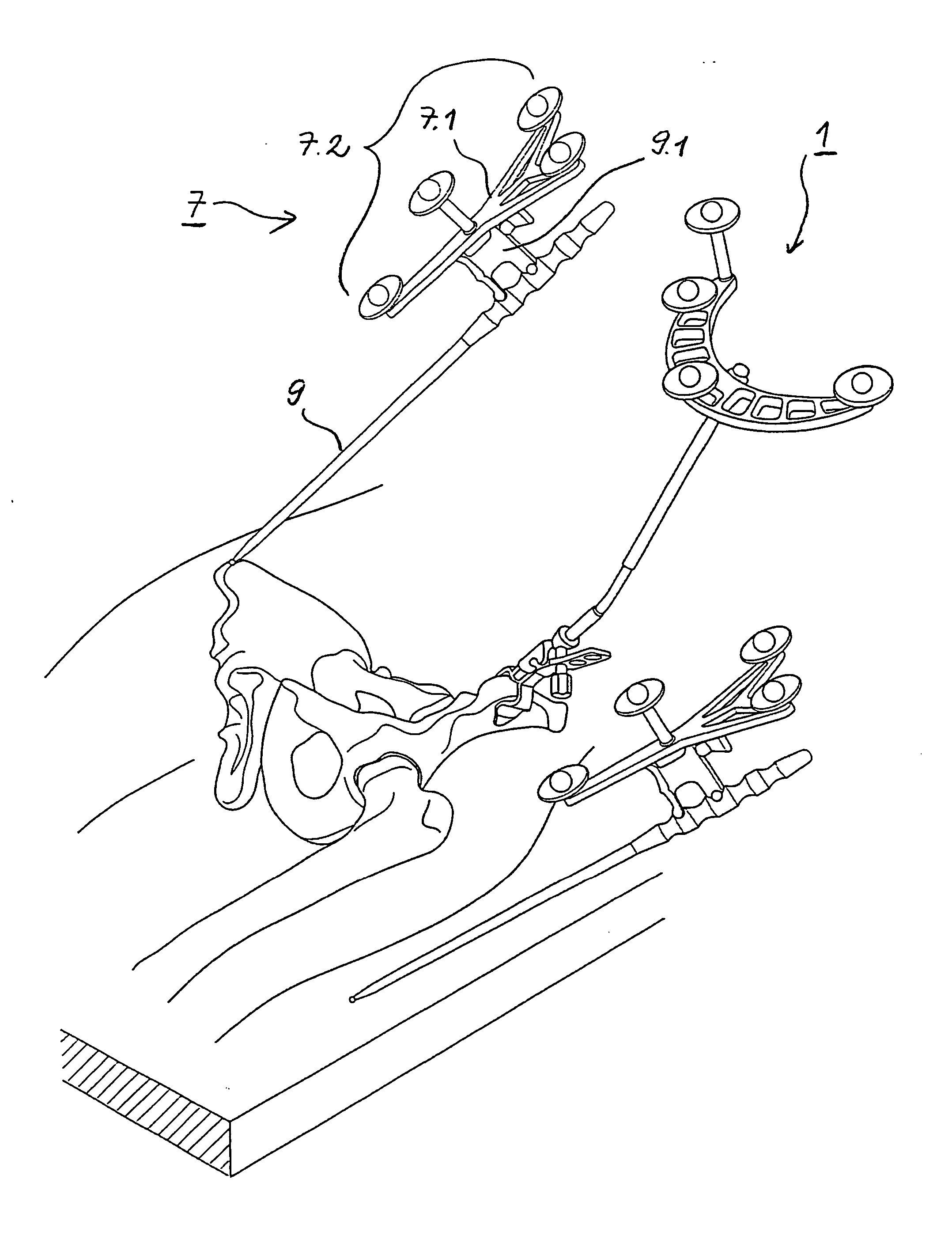

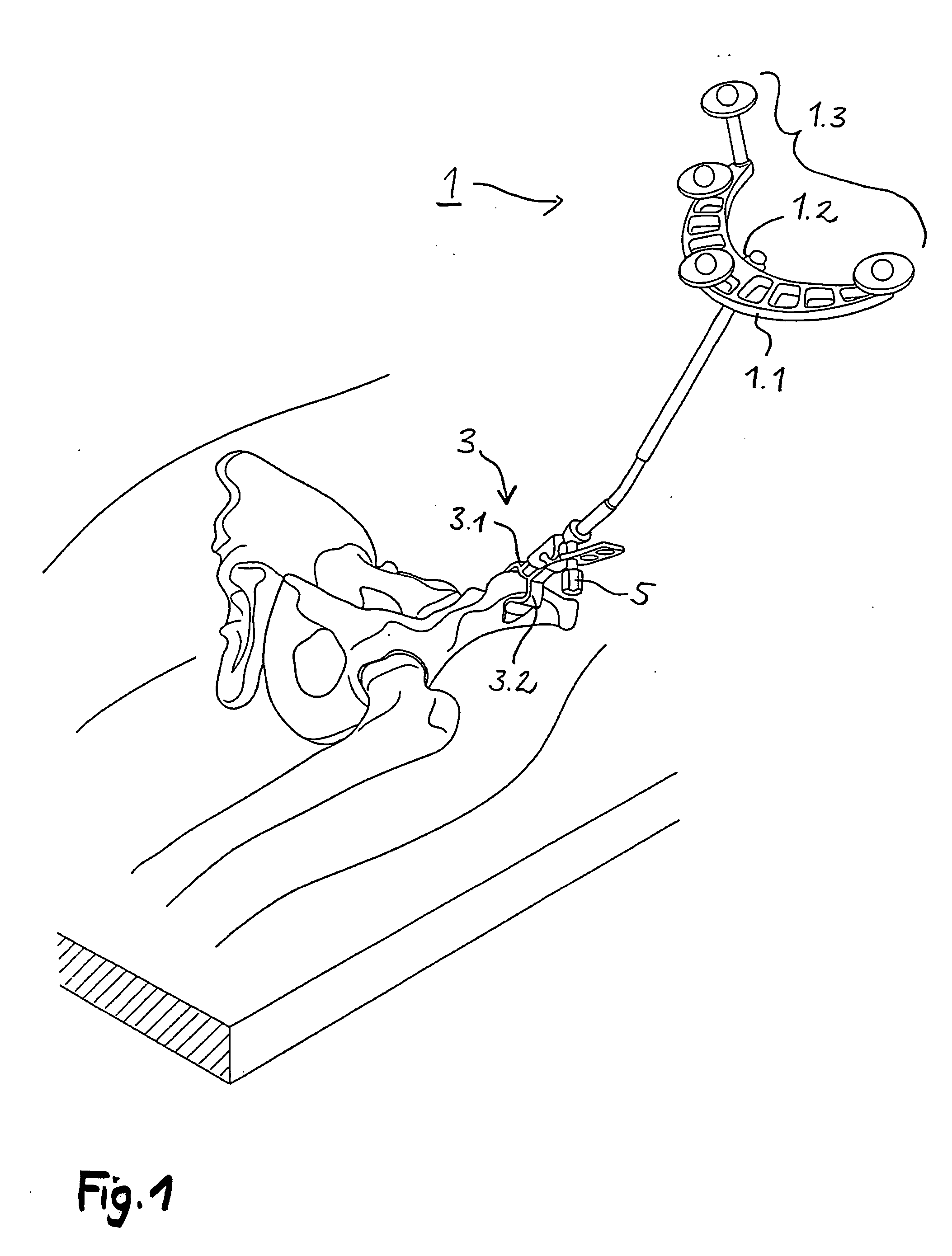

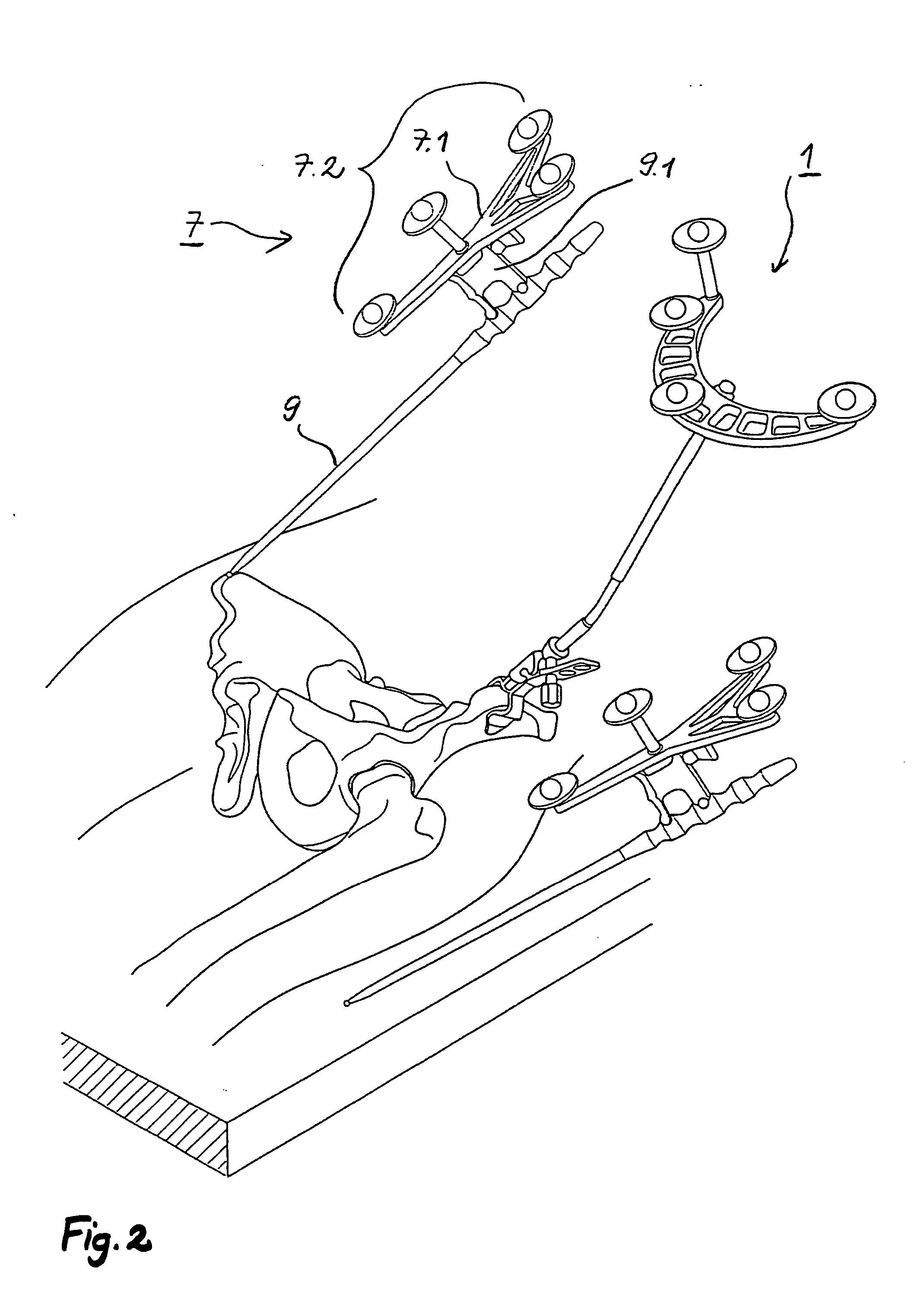

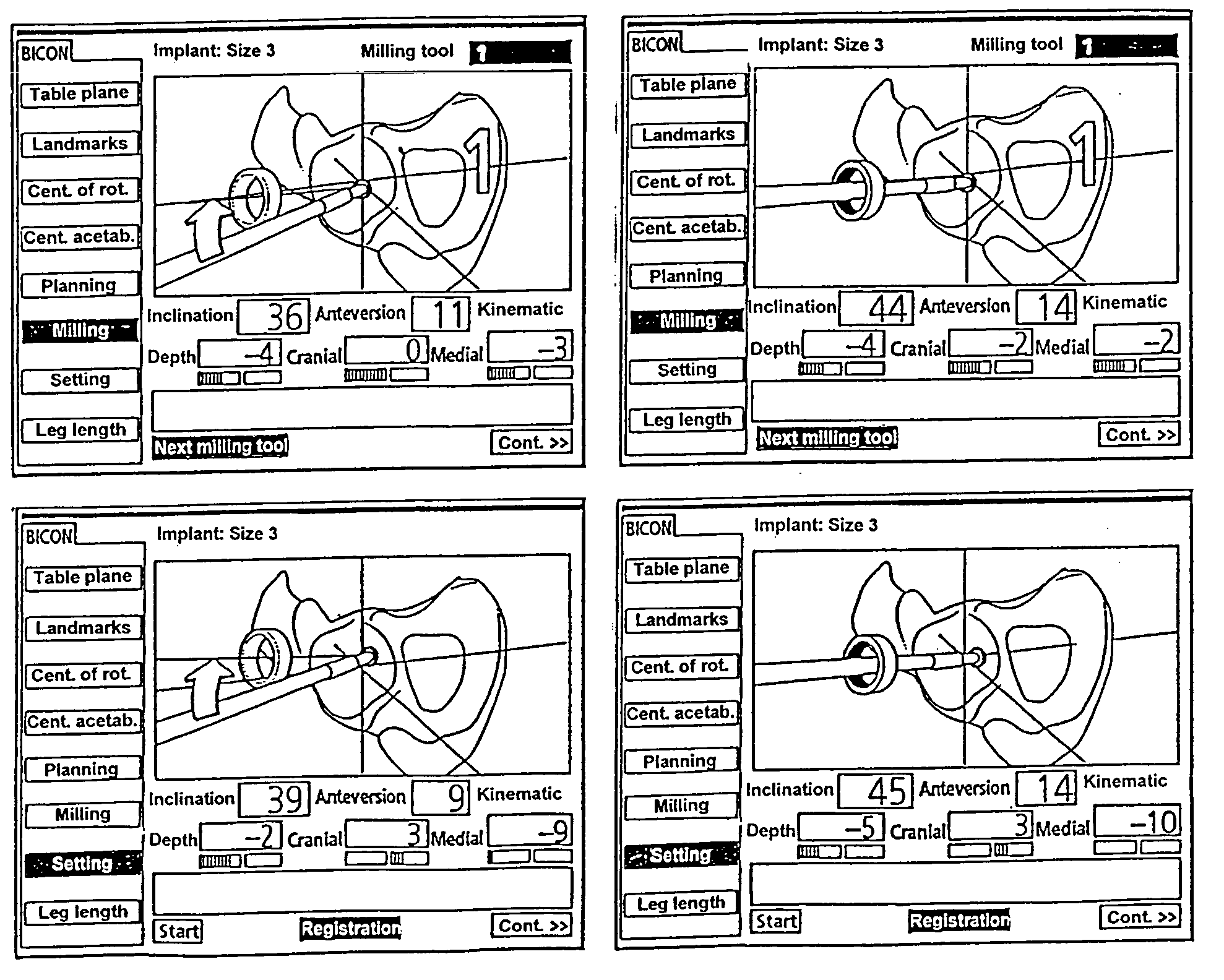

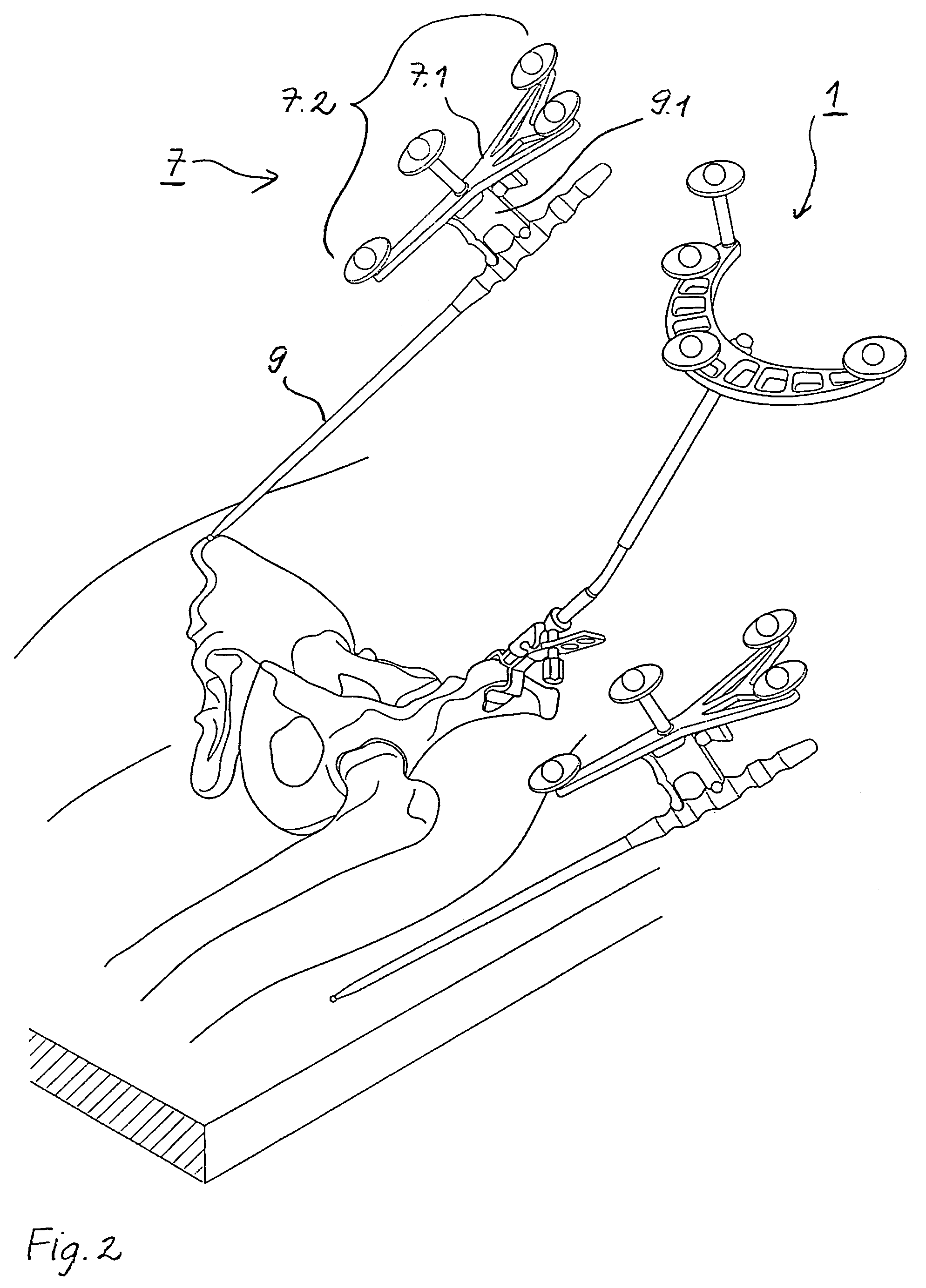

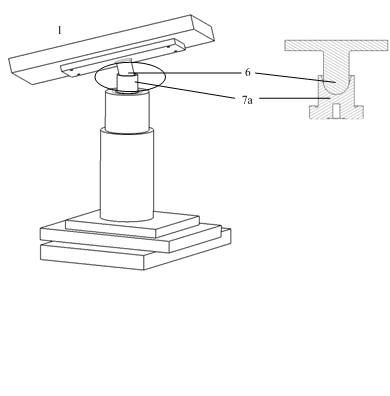

Arrangement and method for the intra-operative determination of the position of a joint replacement implant

InactiveUS20050149050A1Easy to operateLow risk of errorPerson identificationJoint implantsReference vectorMeasurement point

Arrangement for the intra-operative determination of the spatial position and angular position of a joint replacement implant, especially a hip socket or shoulder socket or an associated stem implant, or a vertebral replacement implant, especially a lumbar or cervical vertebral implant, using a computer tomography method, having: a computer tomography modeling device for generating and storing a three-dimensional image of a joint region or vertebral region to be provided with the joint replacement implant, an optical coordinate-measuring arrangement for providing real position coordinates of defined real or virtual points of the joint region or vertebral region and / or position reference vectors between such points within the joint region or vertebral region or from those points to joint-function-relevant points on an extremity outside the joint region or vertebral region, the coordinate-measuring arrangement comprising a stereocamera or stereocamera arrangement for the spatial recording of transducer signals, at least one multipoint transducer, which comprises a group of measurement points rigidly connected to one another, and an evaluation unit for evaluating sets of measurement point coordinates supplied by the multipoint transducer(s) and recorded by the stereocamera, and a matching-processing unit for real position matching of the image to the actual current spatial position of the joint region or vertebral region with reference to the real position coordinates of the defined points, the matching-processing unit being configured for calculating transformation parameters with minimalization of the normal spacings.

Owner:SMITH & NEPHEW ORTHOPAEDICS

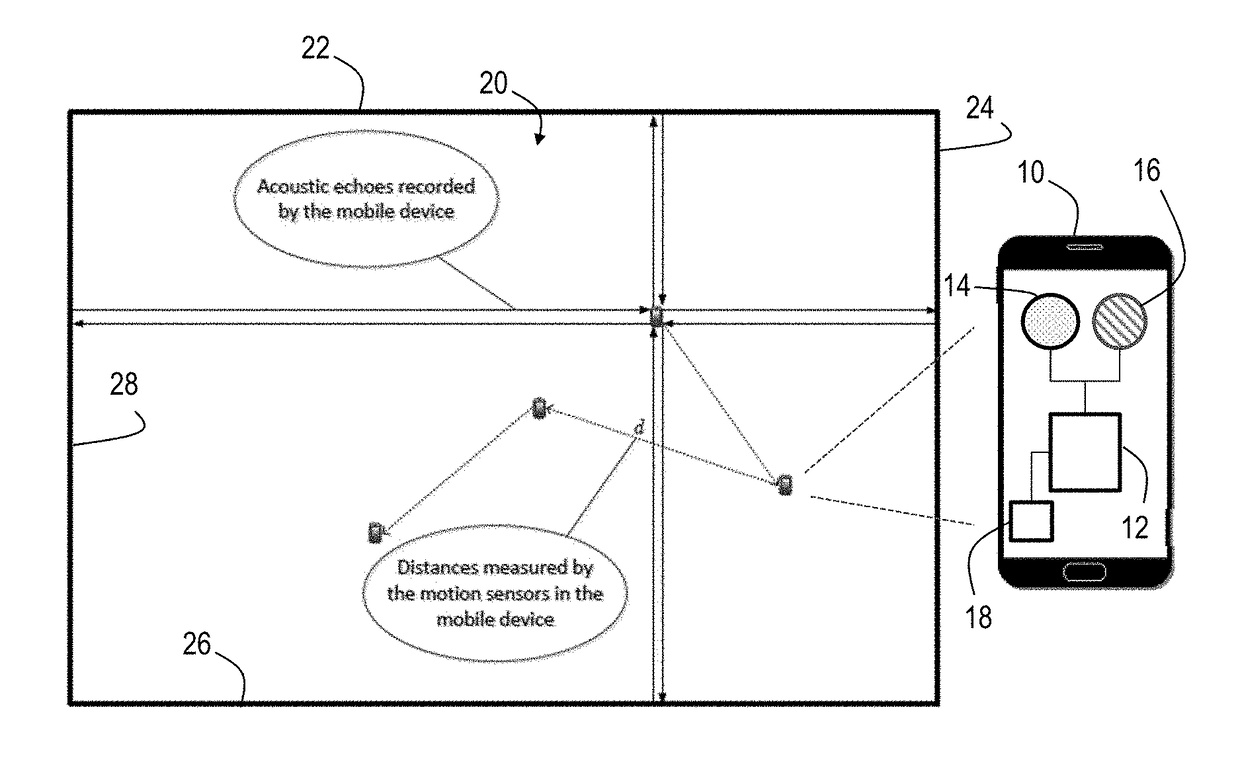

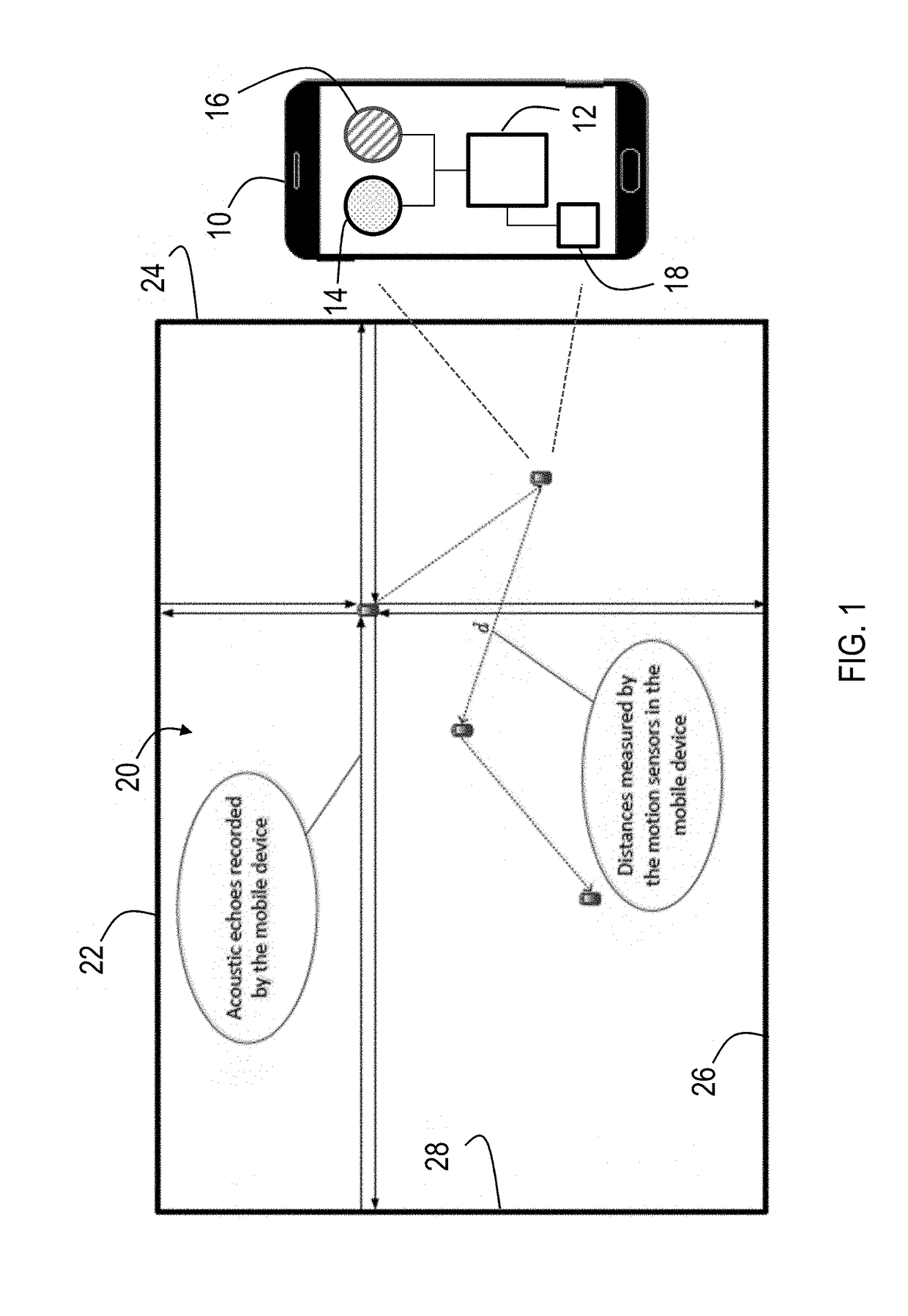

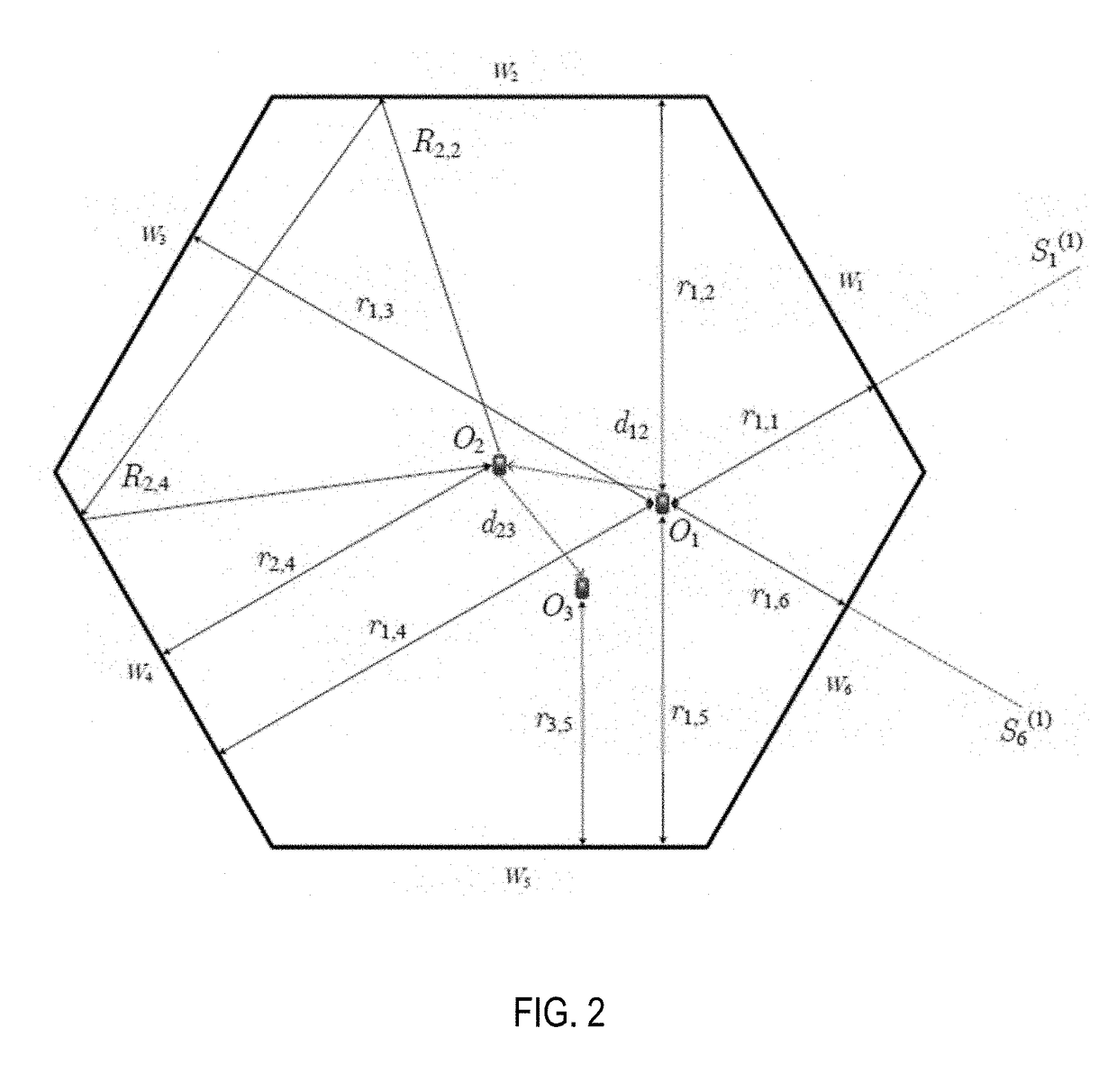

Motion sensor assisted room shape reconstruction and self-localization using first-order acoustic echoes

ActiveUS20170370710A1Improve performanceUsing subsonic/sonic/ultrasonic vibration meansAcoustic wave reradiationPractical algorithmContinuous measurement

Simultaneous 2-D room shape reconstruction and self-localization is accomplished using no pre-established infrastructure. A mobile device with co-located microphone and loudspeaker is used to collect echoes reflected by the walls. The system uniquely recovers arbitrary 2-D convex room shape as well as the position of mobile device 10 by collecting and processing distances between three consecutive measurement points as well as acoustic echoes from the device. A practical algorithm for room shape reconstruction and self-localization in the presence of noise and higher order echoes is proposed. Experimental results are provided to demonstrate the effectiveness of the approach.

Owner:SYRACUSE UNIVERSITY

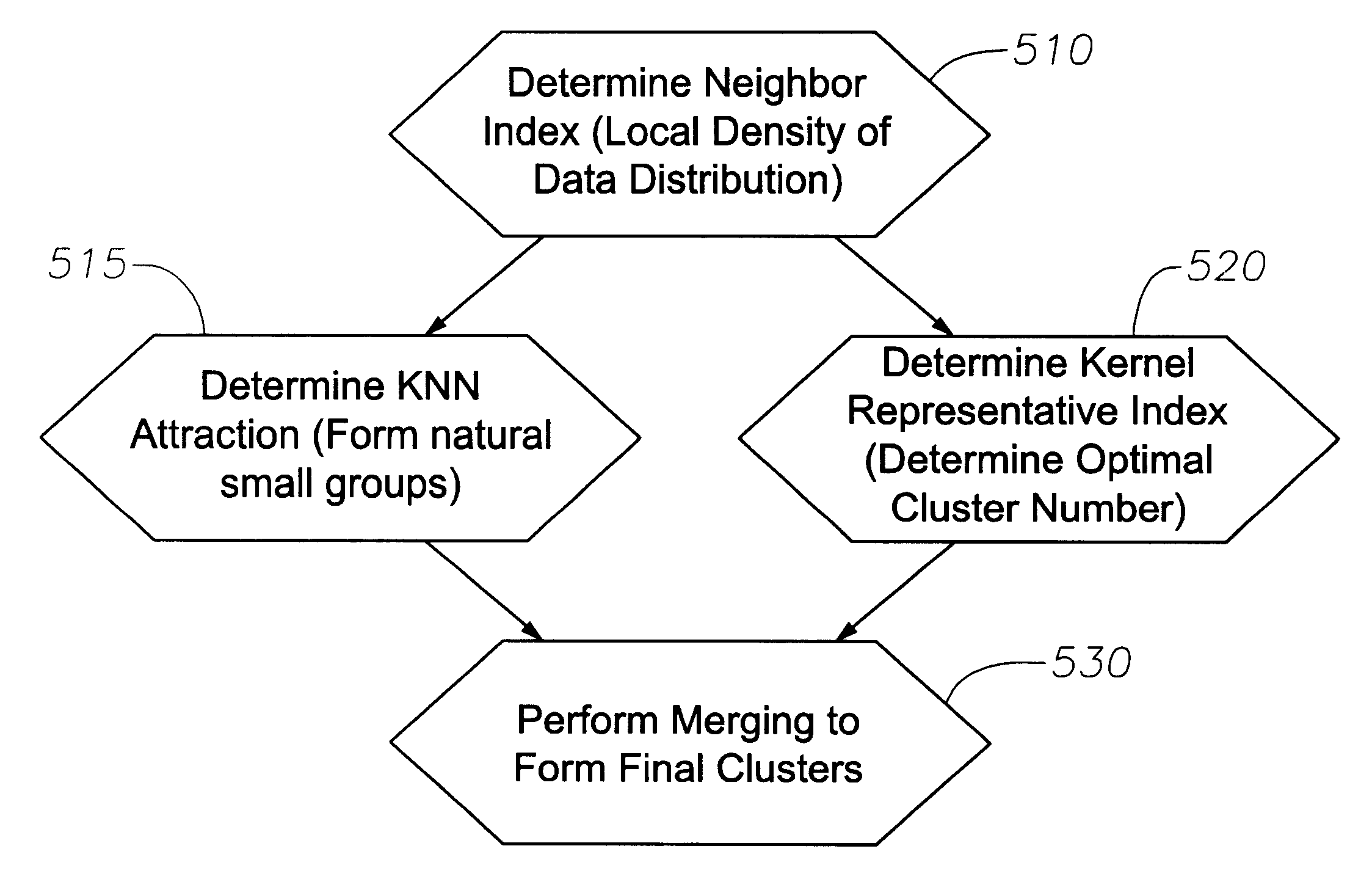

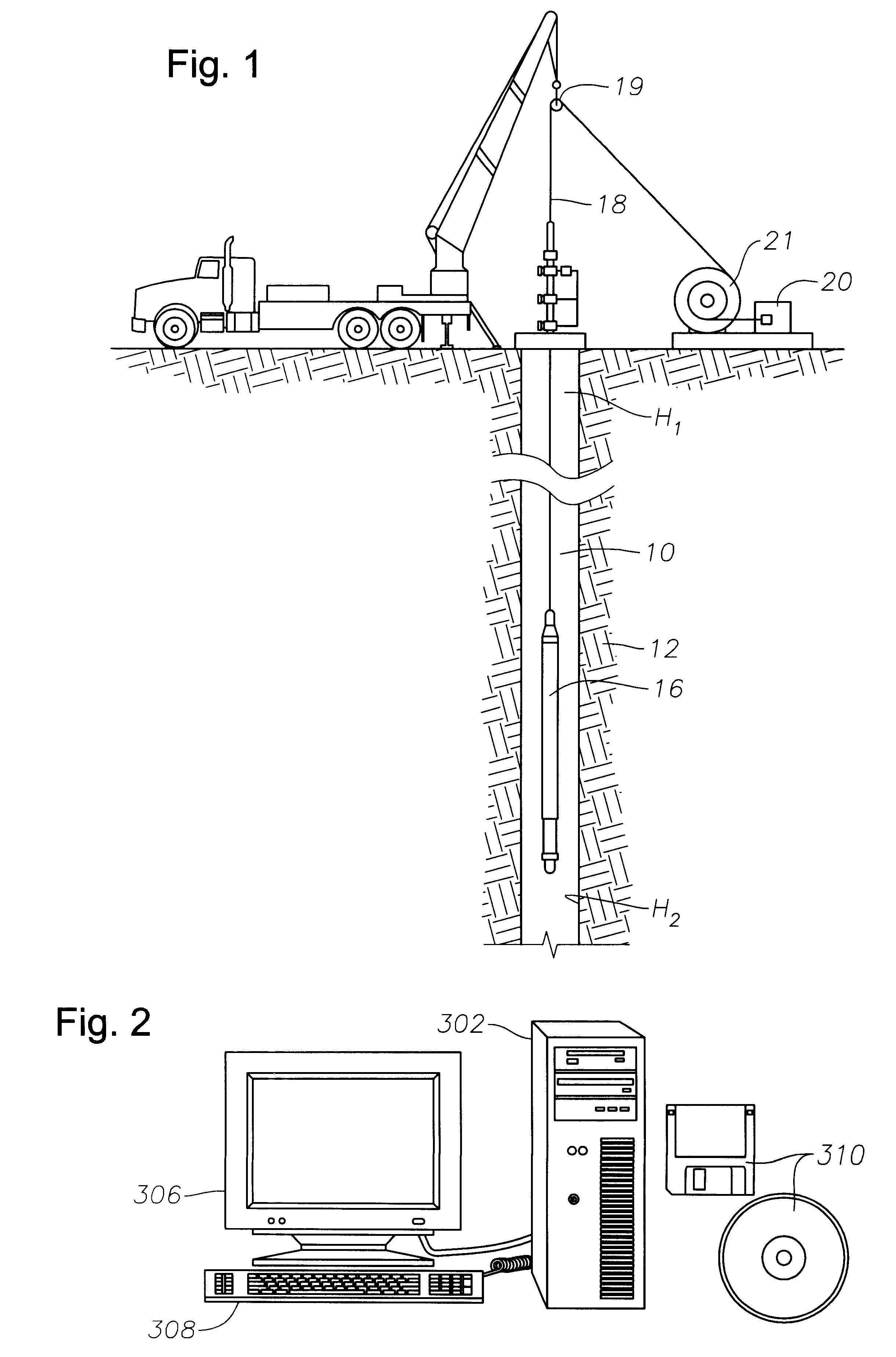

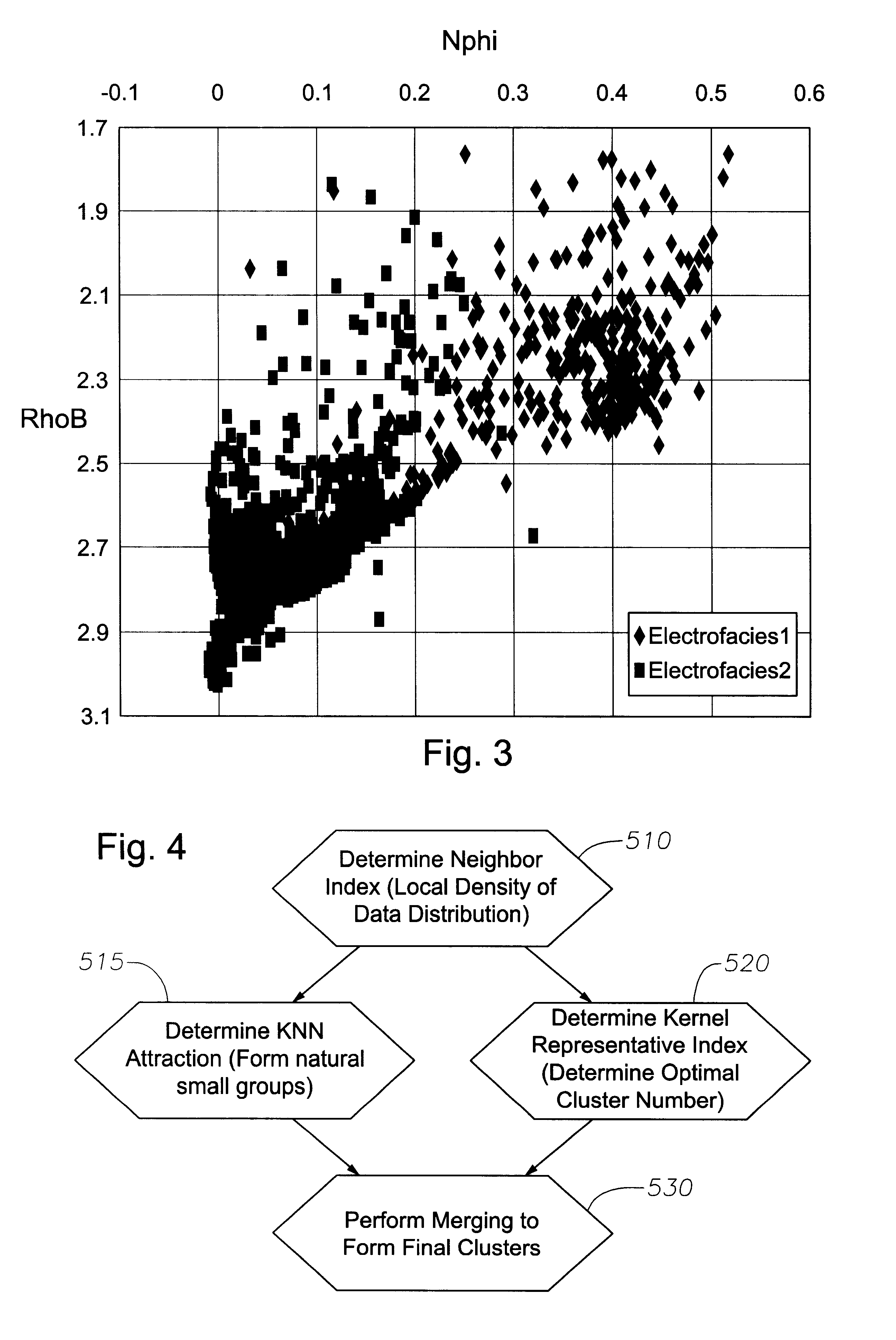

Multi-resolution graph-based clustering

InactiveUS6295504B1Electric/magnetic detection for well-loggingCharacter and pattern recognitionReference sampleData set

An apparatus and method for obtaining facies of geological formations for identifying mineral deposits is disclosed. Logging instruments are moved in a bore hole to produce log measurements at successive levels of the bore hole. The set of measurements at each such level of the bore hole interval is associated with reference sample points within a multidimensional space. The multidimensional scatter of sample points thus obtained is analyzed to determine a set of characteristic modes. The sample points associated with characteristic modes are grouped to identify clusters. A facies is designated for each of the clusters and a graphic representation of the succession of facies as a function of the depth is thus obtained. To identify the clusters, a "neighboring index" of each log measurement point in the data set is calculated. Next, small natural groups of points are formed based on the use of the neighboring index to determine a K-Nearest-Neighbor (KNN) attraction for each point. Independently of the natural group formation, an optimal number of clusters is calculated based on a Kernel Representative Index (KRI) and based on a user-specified resolution. Lastly, based on the data calculated from the prior steps, final clusters are formed by merging the smaller clusters.

Owner:HALLIBURTON ENERGY SERVICES INC

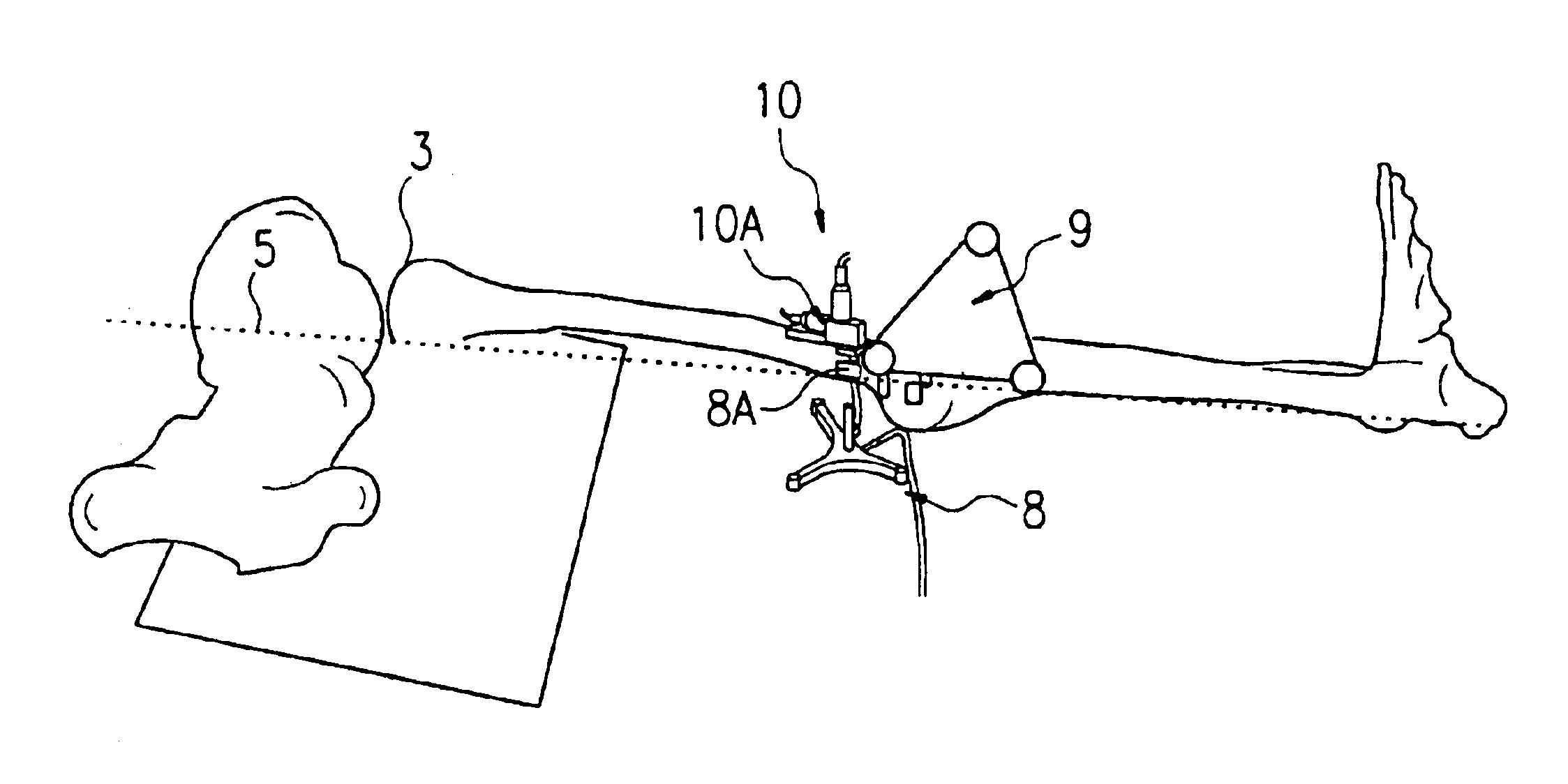

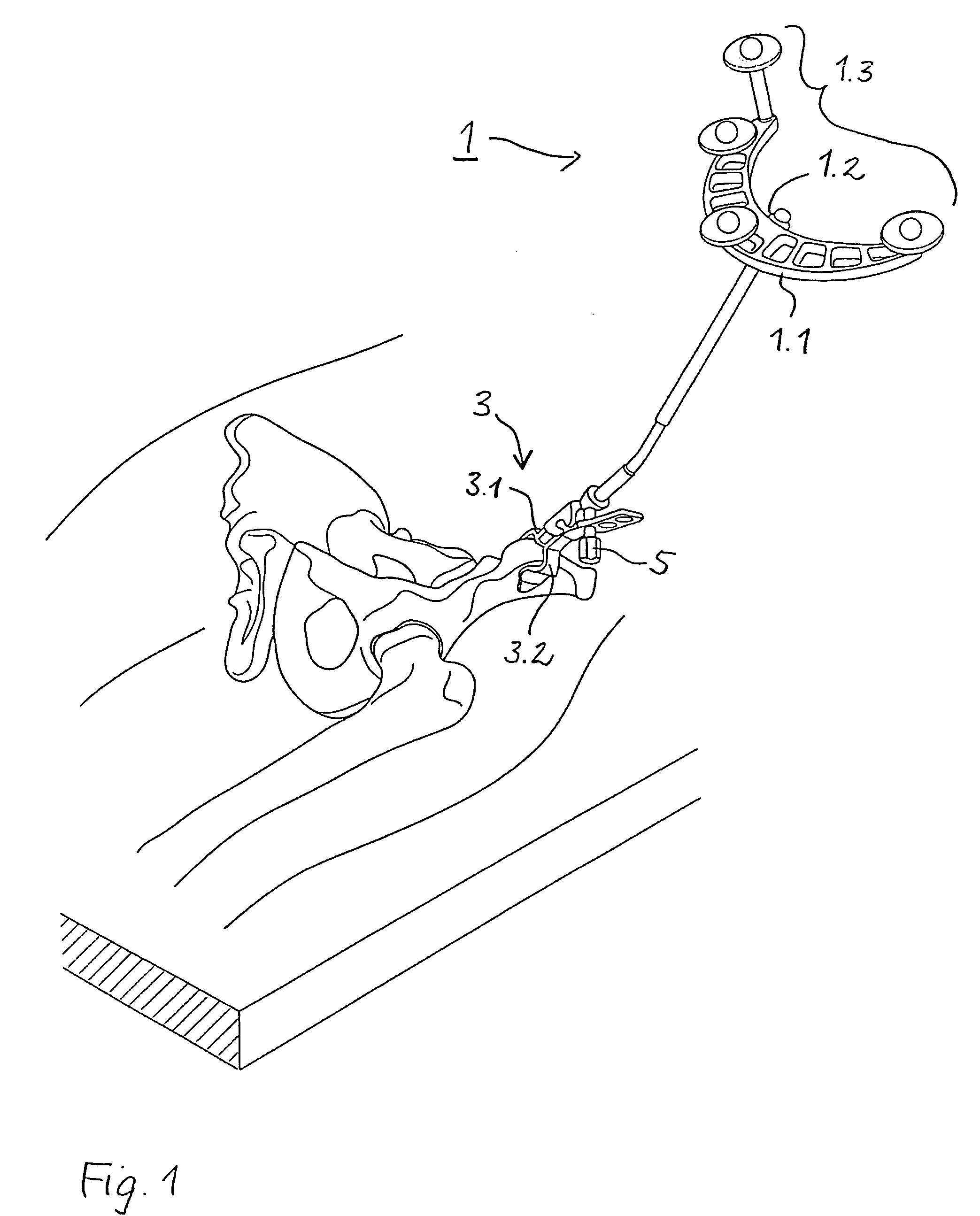

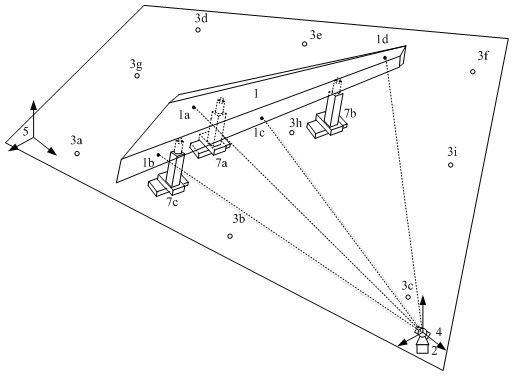

Method and apparatus for finding the position of a mechanical axis of a limb

InactiveUS6928742B2Shorten the timePromote quick completionPerson identificationSurveying instrumentsMeasurement deviceMeasurement point

A method of finding the position of a mechanical axis running in the longitudinal direction through a limb that is rotatably supported by its first end in a center of rotation that is not fixed and is not accessible for the mechanical determination of coordinates, by means of an optical coordinate-measurement device with an indicator to detect measurement-point coordinates in one rotational position of the limb, such that, for each rotational position, a multi-point indicator rigidly attached near the second end of the limb signals several measurement-point coordinates, and, from the sets of measurement-point coordinates detected in a plurality of rotational positions, at least one group is selected that can be assigned to the same site of the center of rotation, and the measurement-point-coordinate sets assigned to this site of the center of rotation are used to calculate the mechanical axis.

Owner:PLUS ENDOPROTHETIK AG

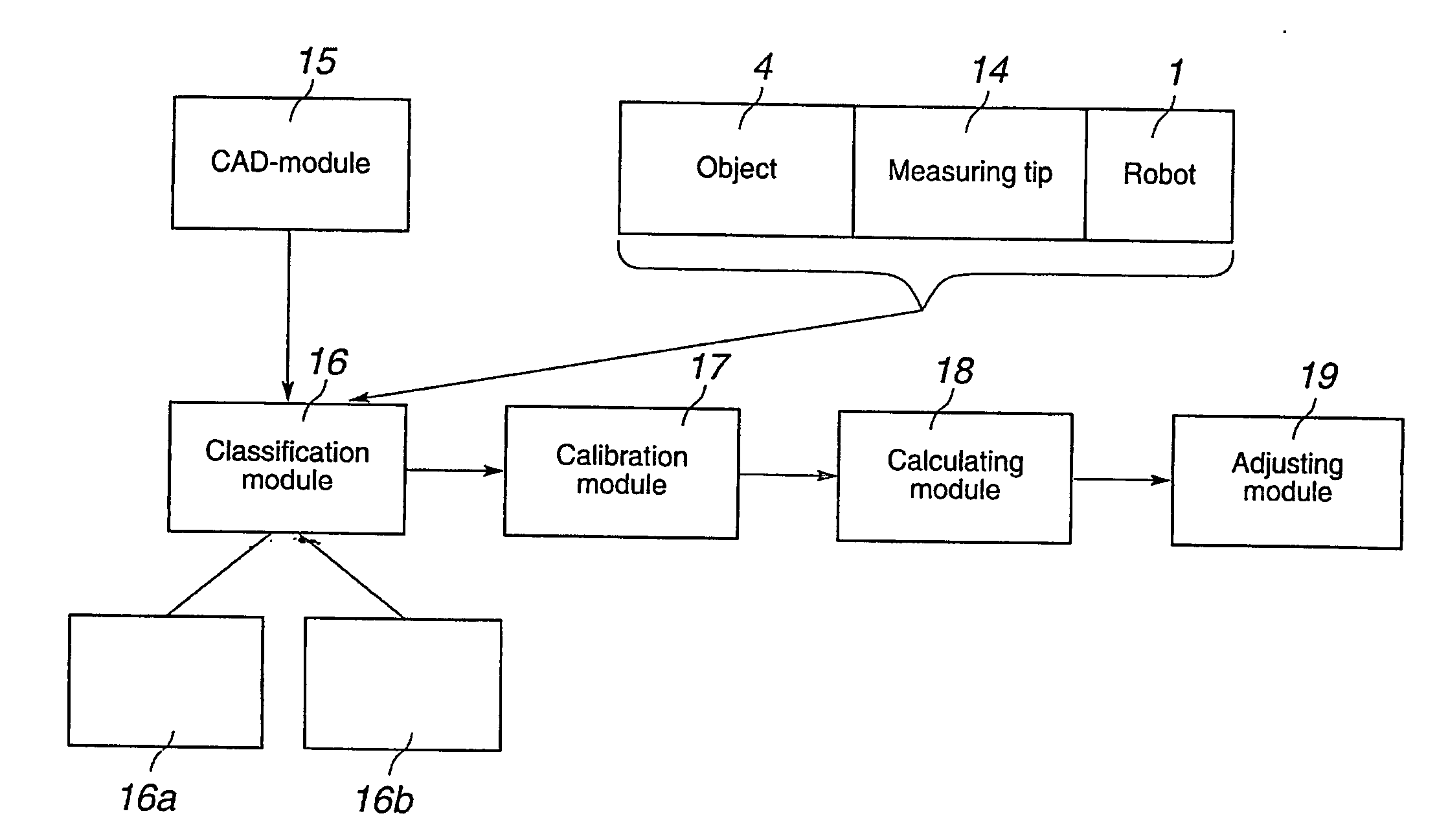

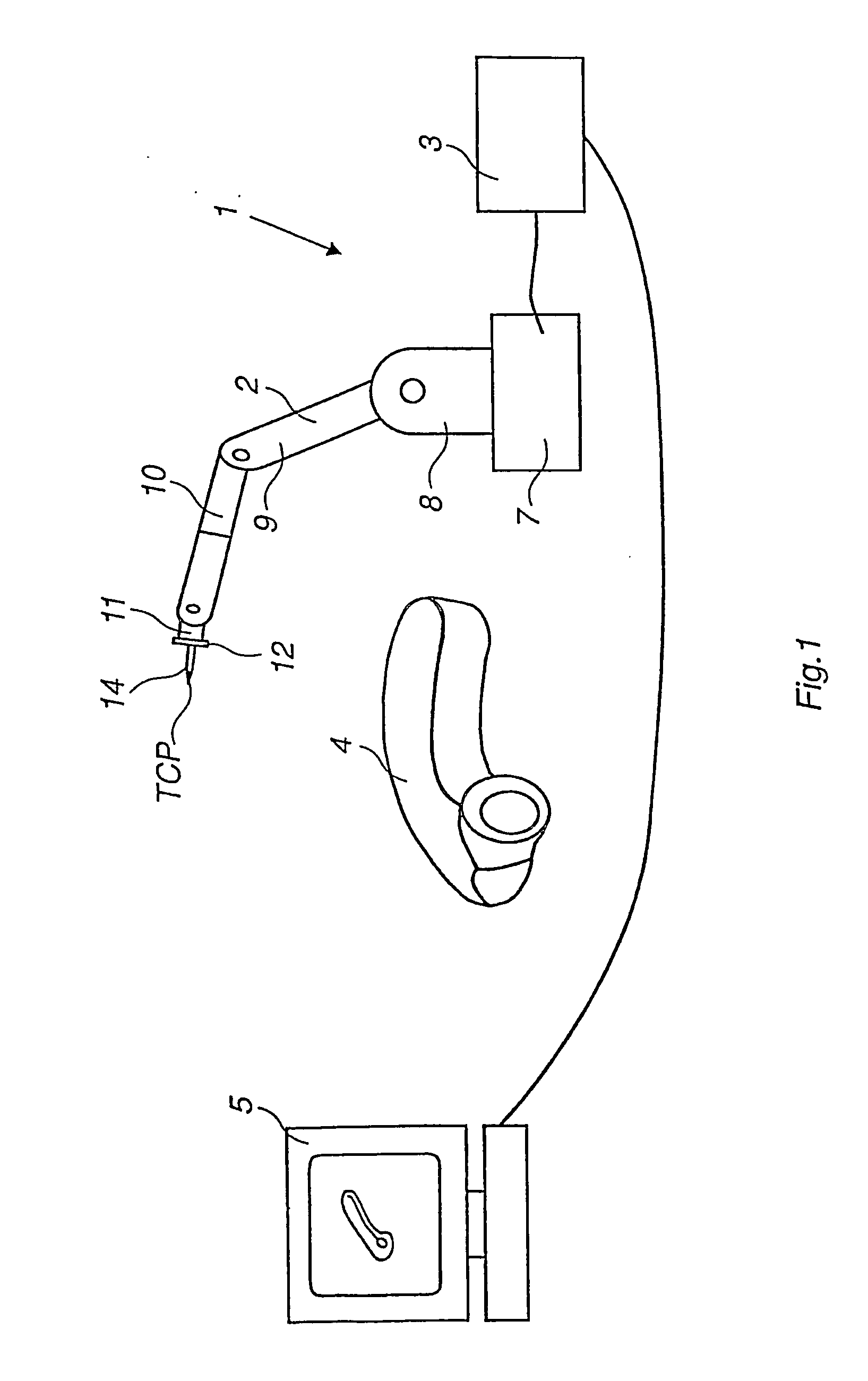

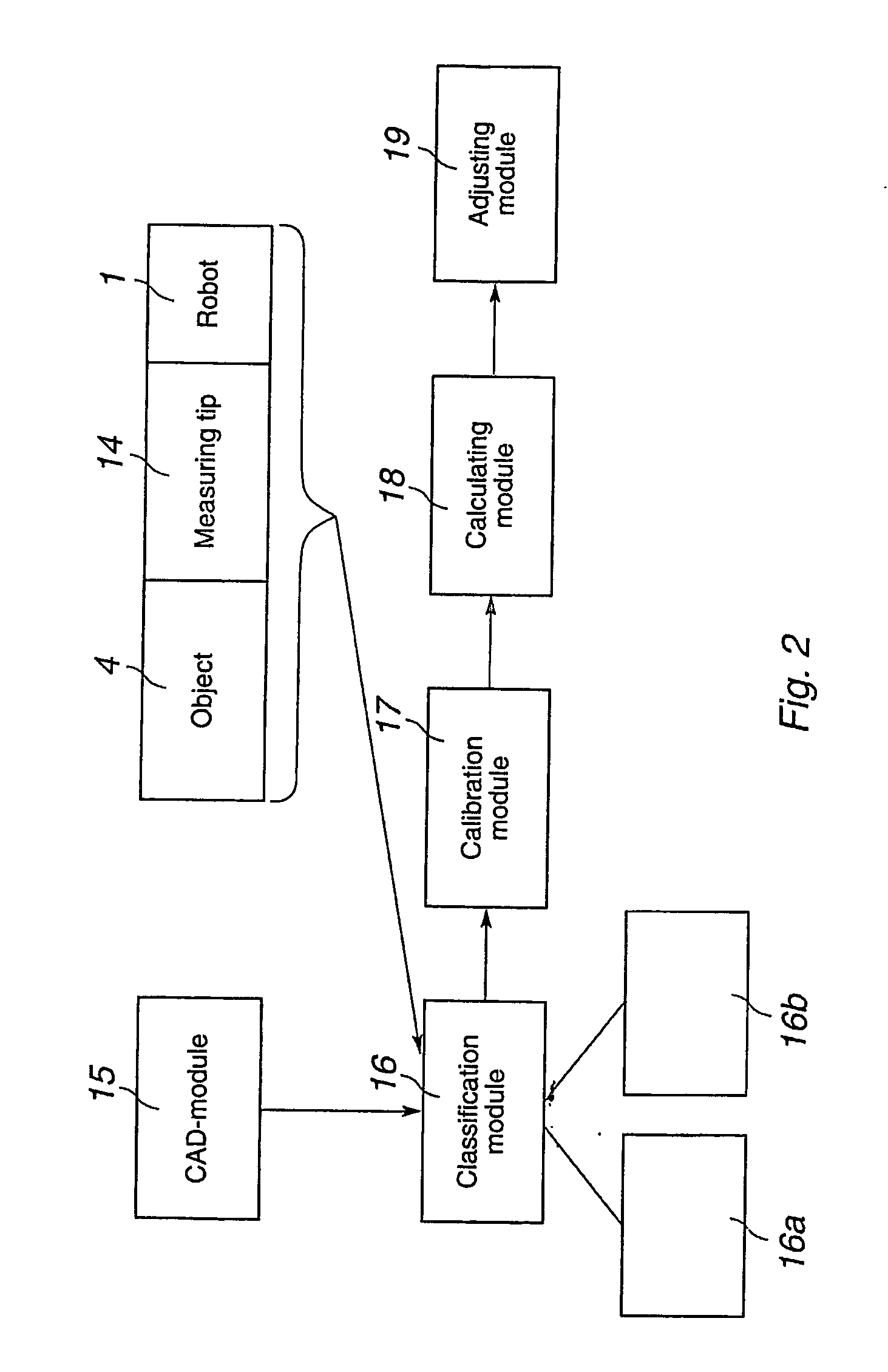

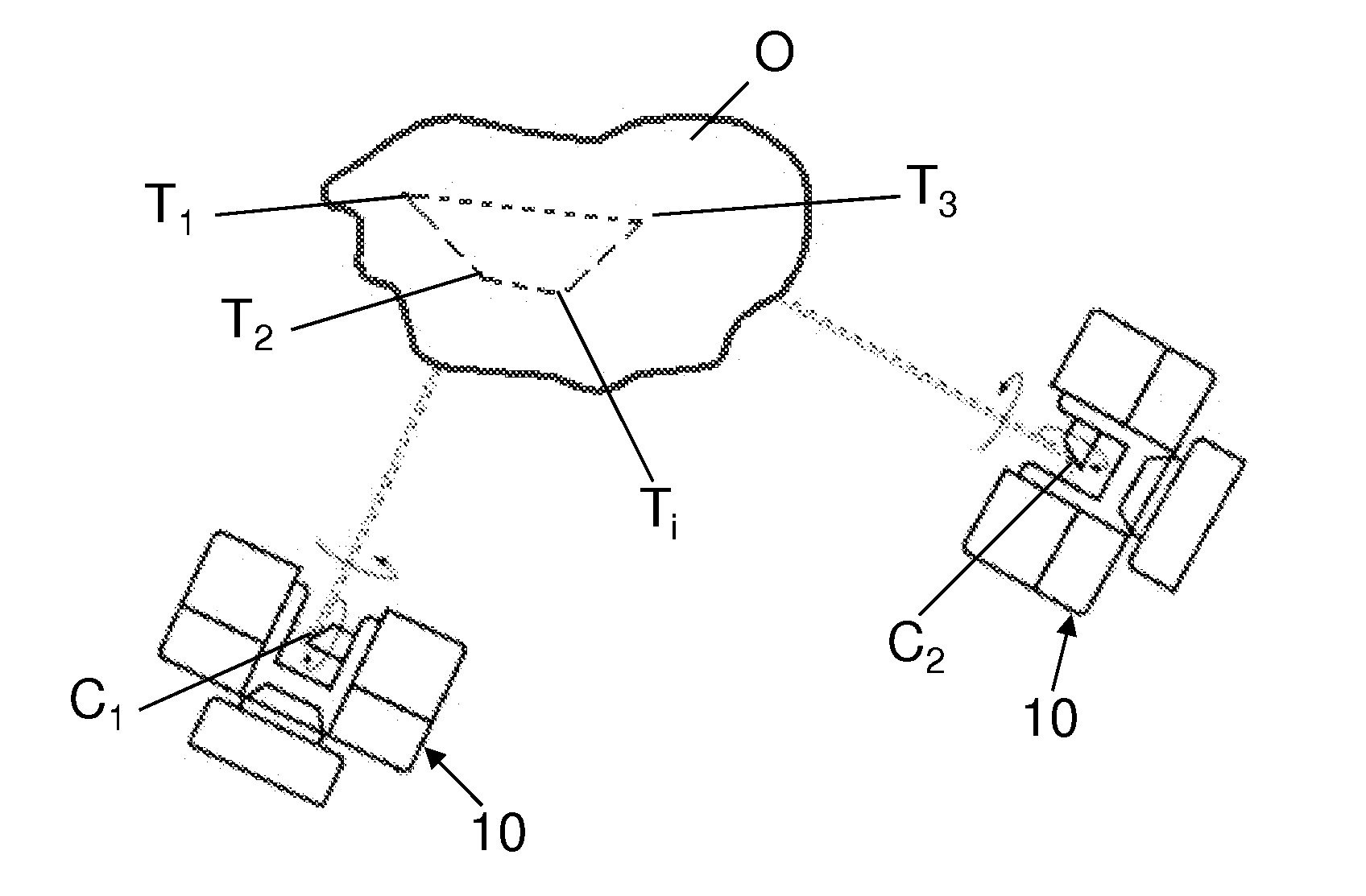

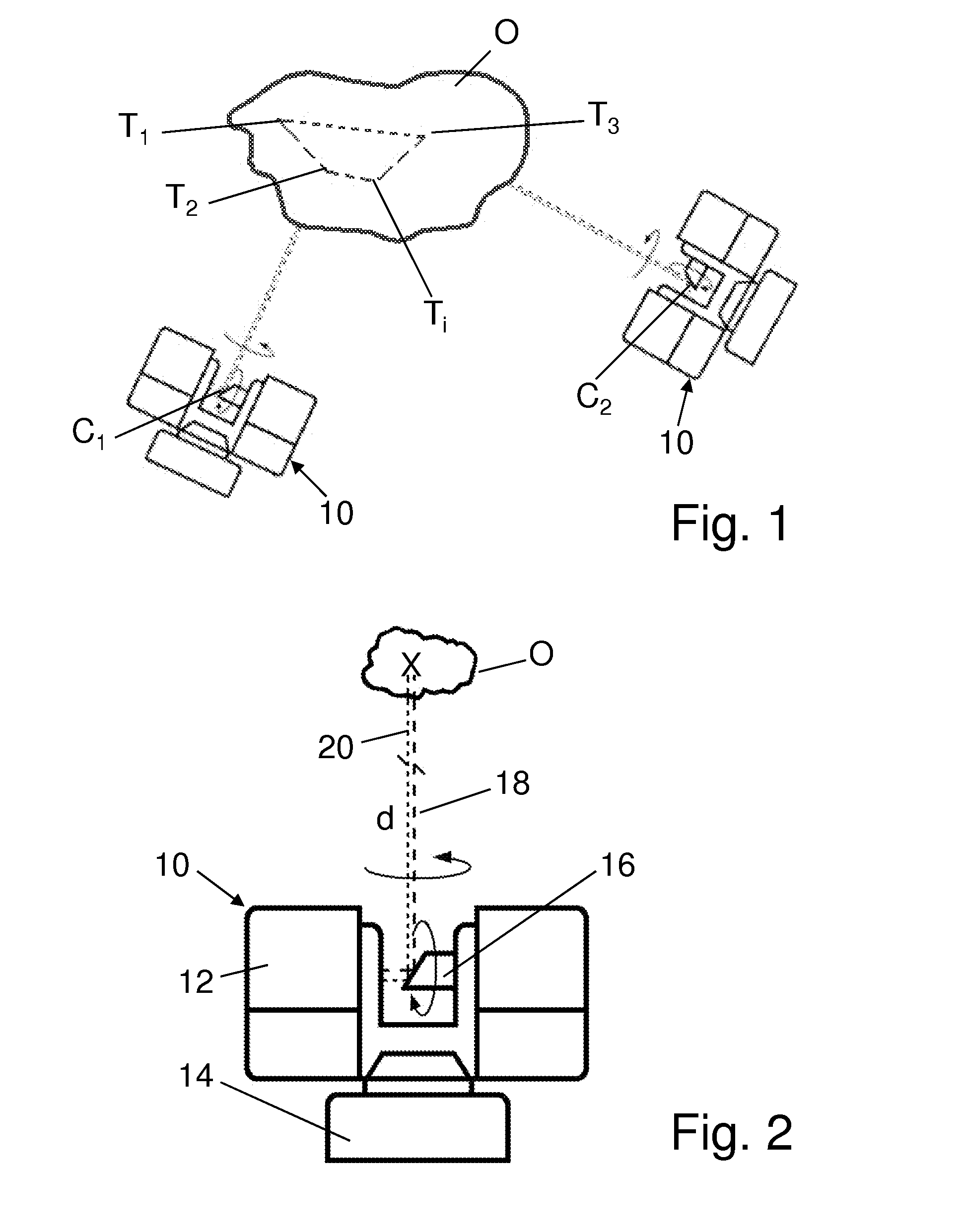

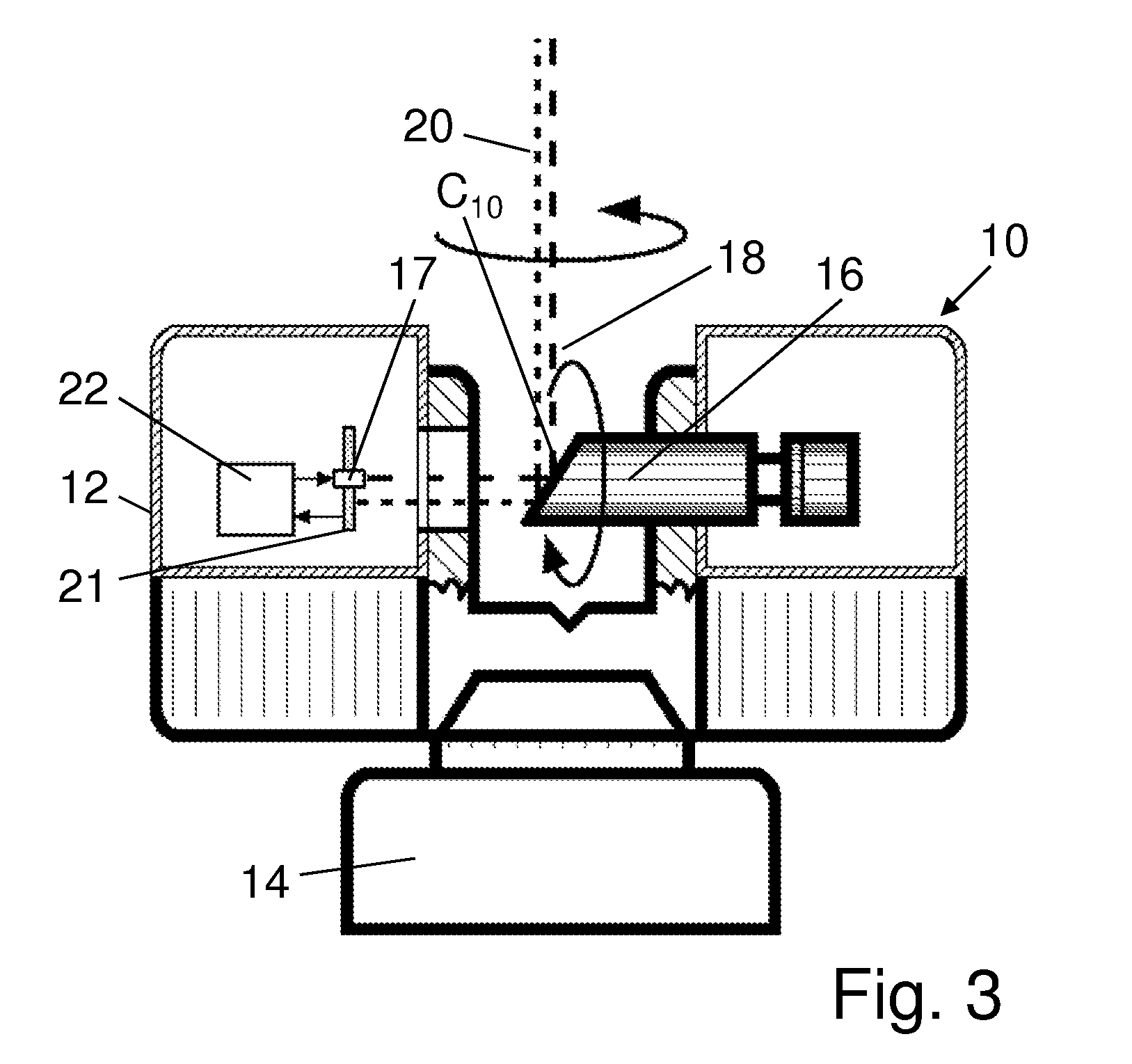

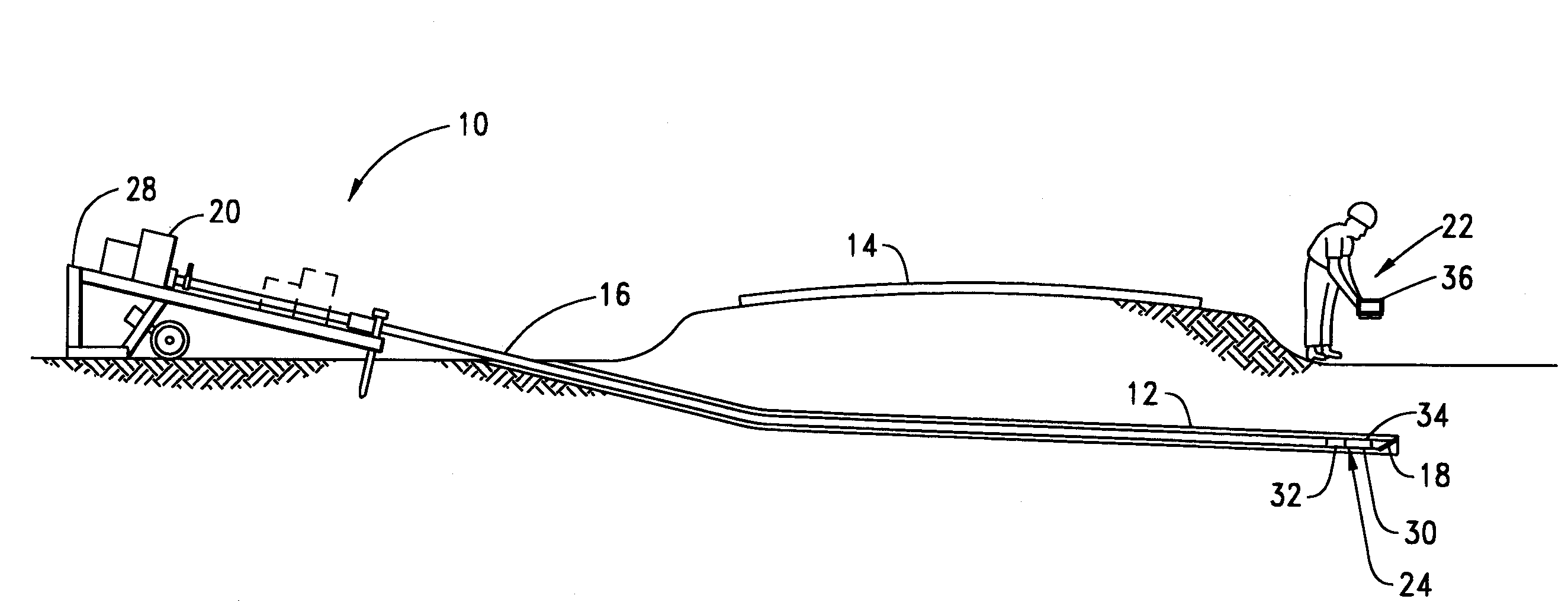

Method and a system for programming an industrial robot to move relative to defined positions on an object, including generation of a surface scanning program

ActiveUS20060181236A1Easy CalibrationSimple programmingProgramme-controlled manipulatorComputer controlMeasurement pointSimulation

A method and a system for programming an industrial robot to move relative to defined positions on an object. The system includes a geometrical model of the object, the real object, and an industrial robot. A plurality of measuring points are generated corresponding to different points on the surface of the real object expressed in a coordinate system associated with the robot. The system further includes a calibration module arranged to determine orientation and position of the geometrical model of the object relative to the coordinate system associated with the robot, a calculating module arranged to calculate the deviation between the measuring points and corresponding points on the geometrical model, and an adjusting module arranged to adjust the defined positions based on the calculated deviations.

Owner:ABB (SCHWEIZ) AG

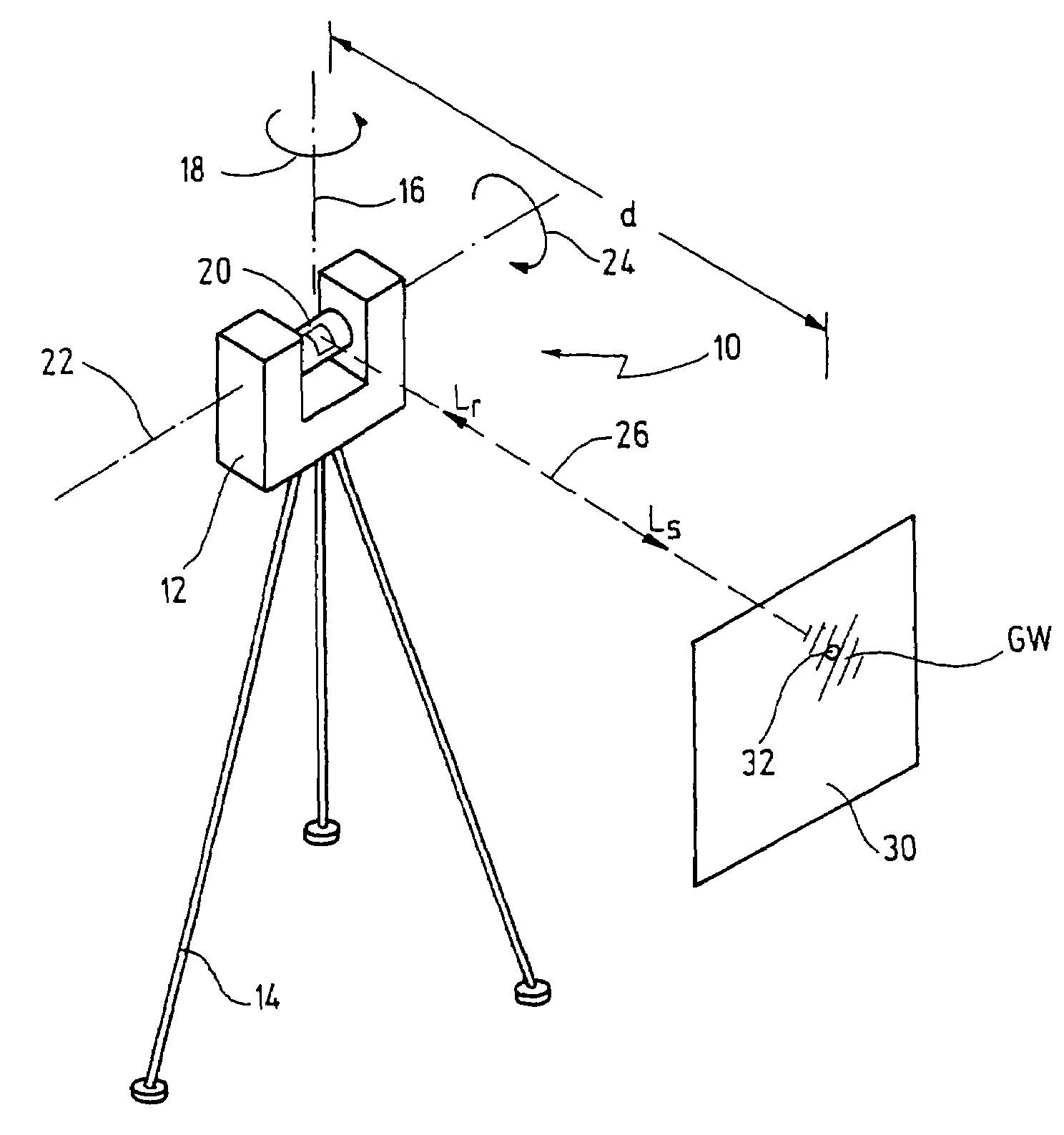

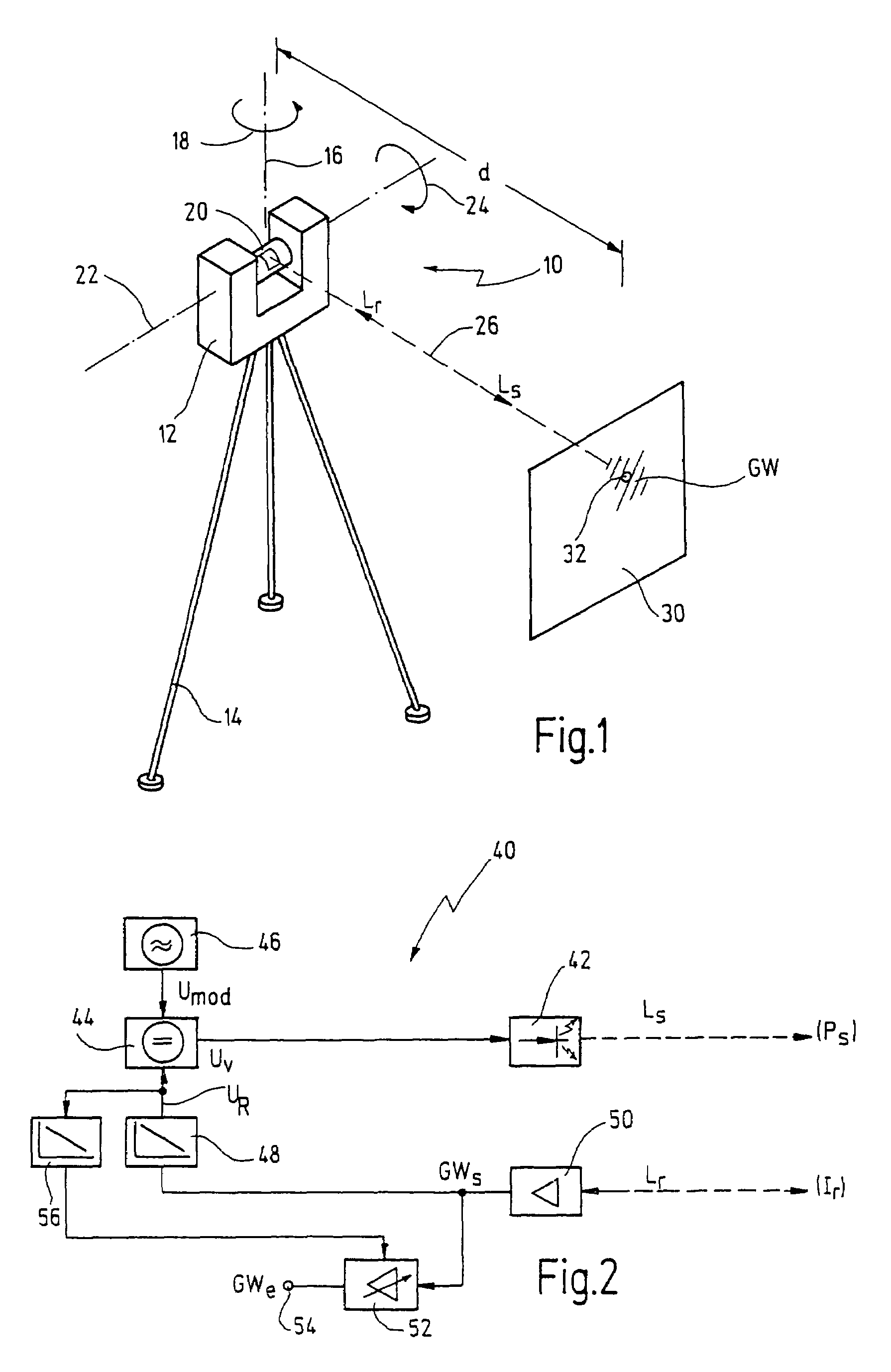

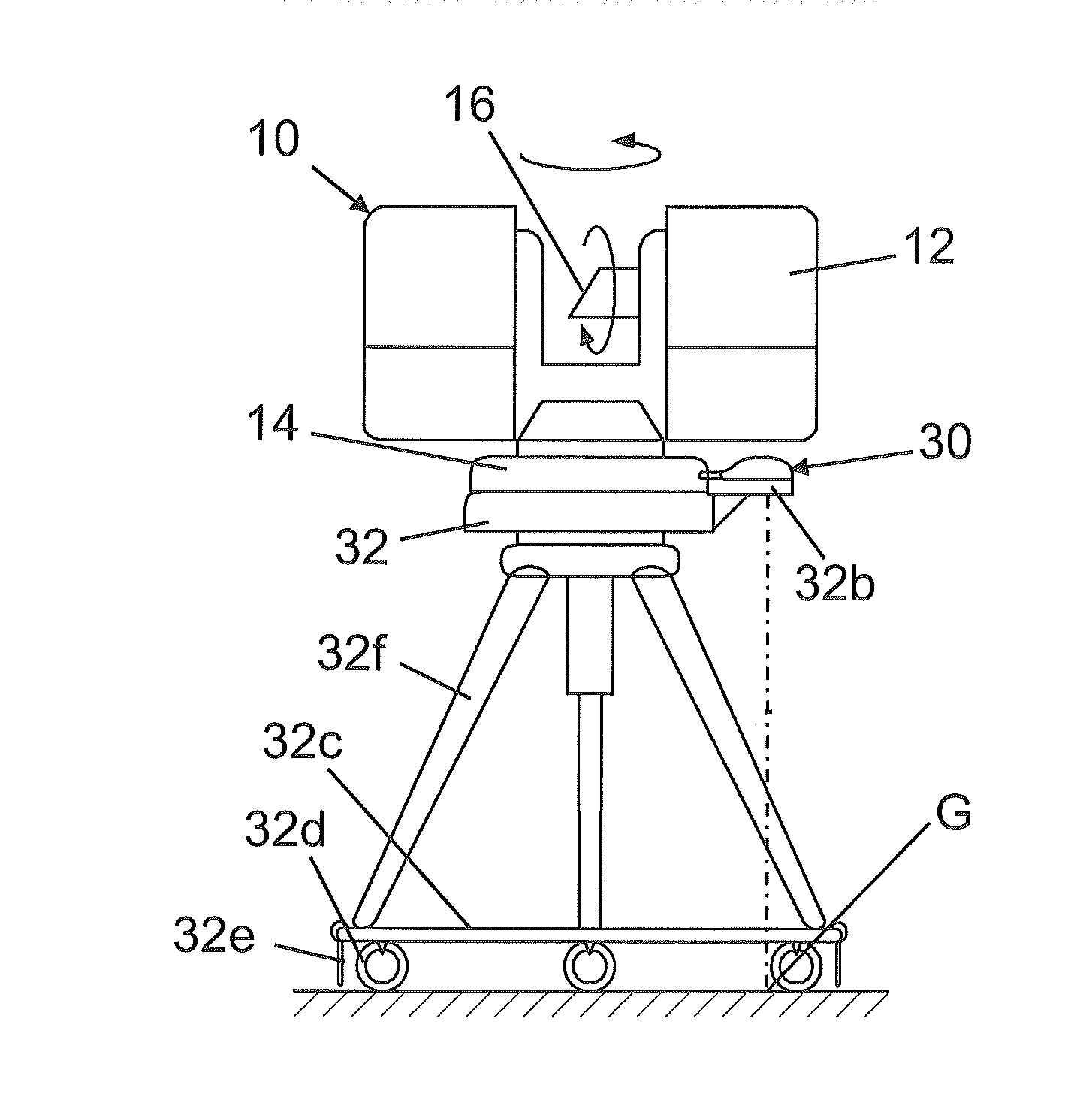

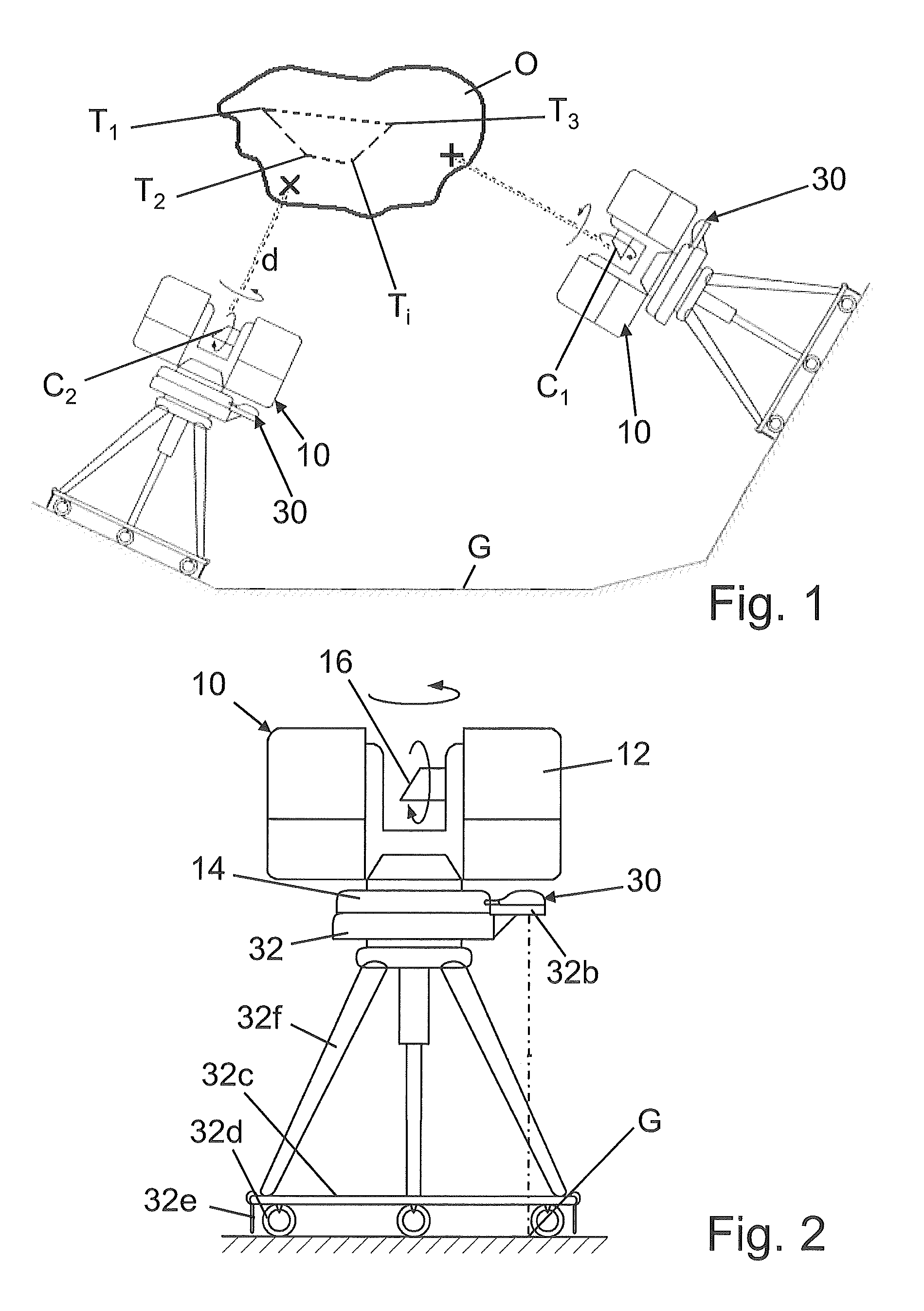

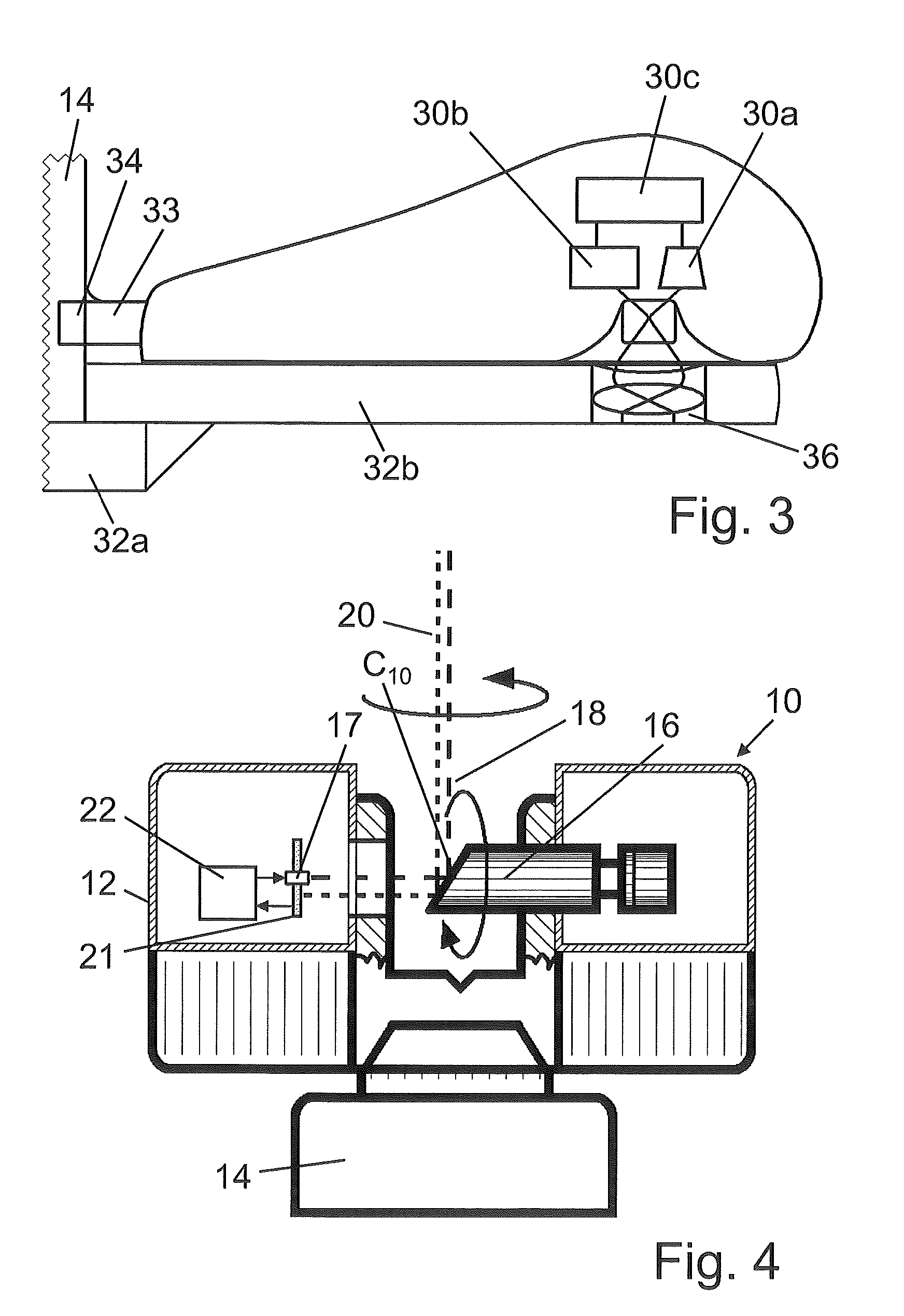

Laser scanner and method for optically scanning an environment

ActiveUS7193690B2Reduce transmit powerAvoid imaging errorsOptical rangefindersActive open surveying meansMeasurement pointLaser scanning

A laser scanner for optically scanning and measuring an environment comprises a light transmitter having a predetermined transmission power for emitting a light beam. The emitted light beam is reflected at a measurement point in the environment. The reflected light beam is received with a certain intensity by a receiver. The transmission power is adjustable as a function of the intensity of the reflected light beam. Furthermore, a gray-scale value of the measurement point is determined as a function of the transmission power adjusted.

Owner:FARO TECH INC

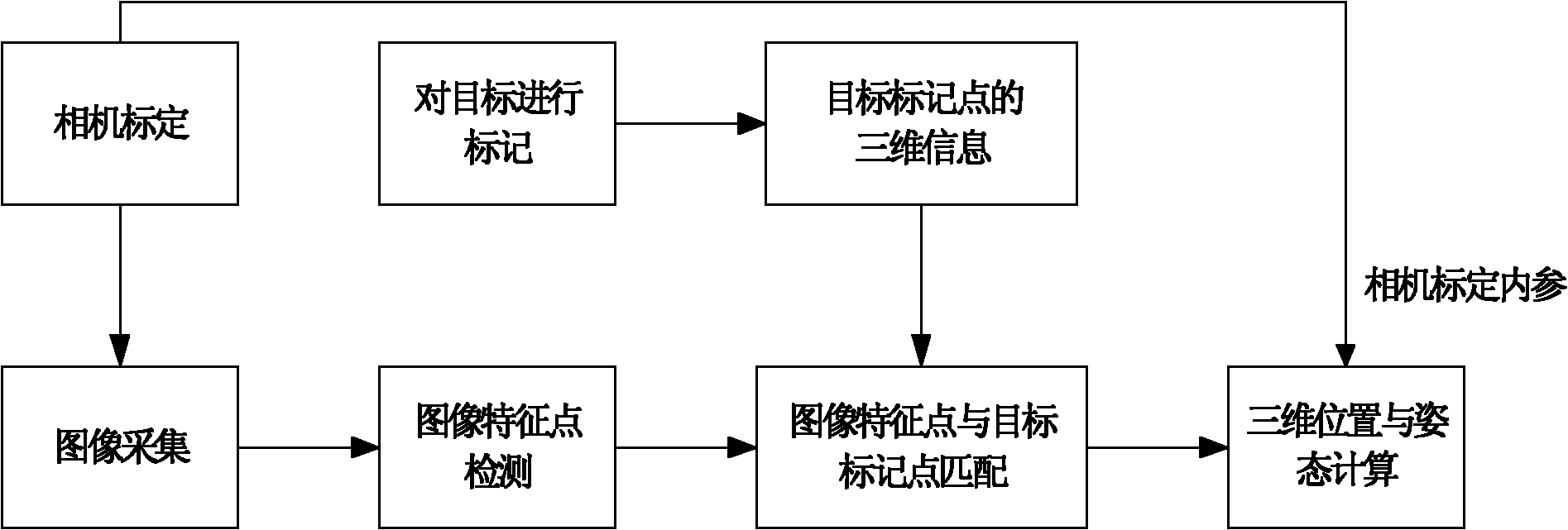

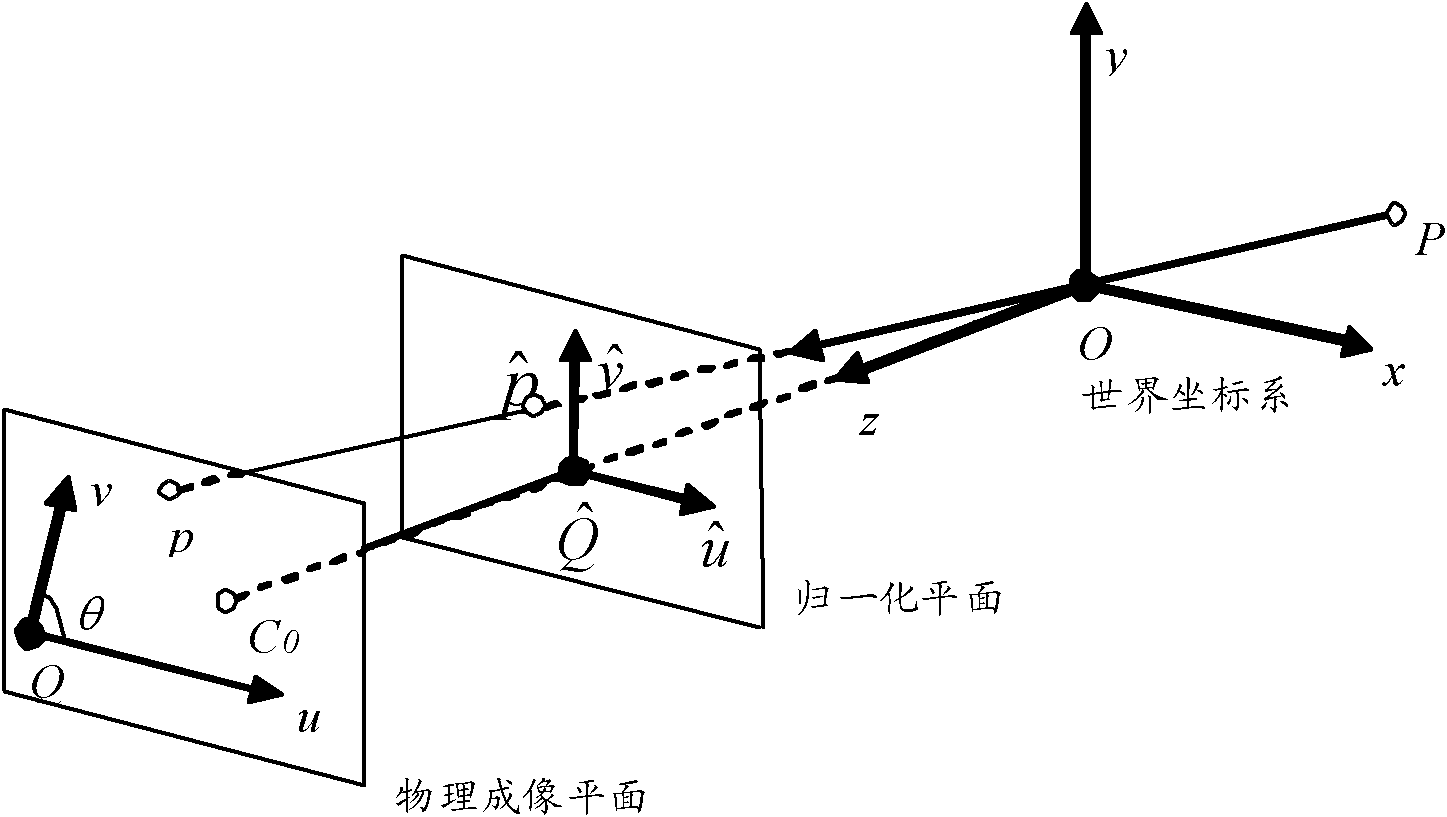

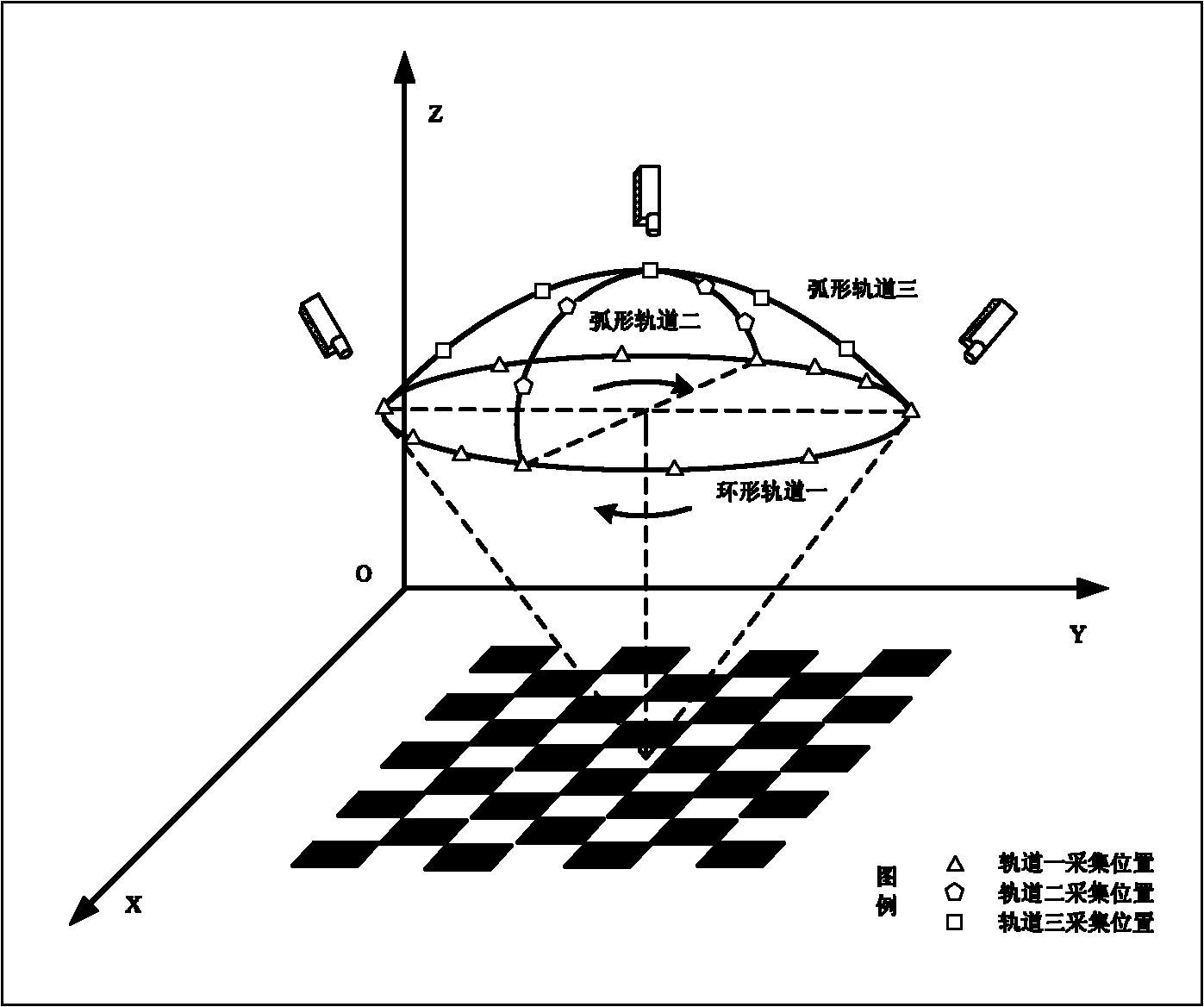

Method for measuring three-dimensional position and stance of object with single camera

InactiveCN101839692AReduce cost of measurementReduce volumeUsing optical meansPicture interpretationThree-dimensional spaceMeasurement point

The invention discloses a method for measuring the three-dimensional position and the stance of an object with a single camera. The method comprises the following steps of: acquiring an image of a target to be measured by utilizing a single camera; confirming the real-time three-dimensional position and stance information of the target to be measured by accurately identifying marking points on the target to be measured; selecting a suitable camera according to a detection scene and a range and calibrating the camera to acquire inner and outer parameters of the camera; designing target marking points according to the target to be measured and reasonably arranging the marking points; then, detecting the target, identifying characteristic points according to the image shot by the camera, and matching the detected characteristic points with the marking points; and finally, solving the three-dimensional position and stance information of the target to be measured according to the corresponding relation between the measuring points and the object marking points. Whether a non-rigid object is deformed or not can also be detected by using the method. In the invention, the single camera is adopted to realize three-dimensional measurement, acquire the information of the target in a three-dimensional space, such as space geometrical parameters, position, stance, and the like, decrease the measuring cost and the size of a measuring system, and facilitate the operation.

Owner:XI AN JIAOTONG UNIV

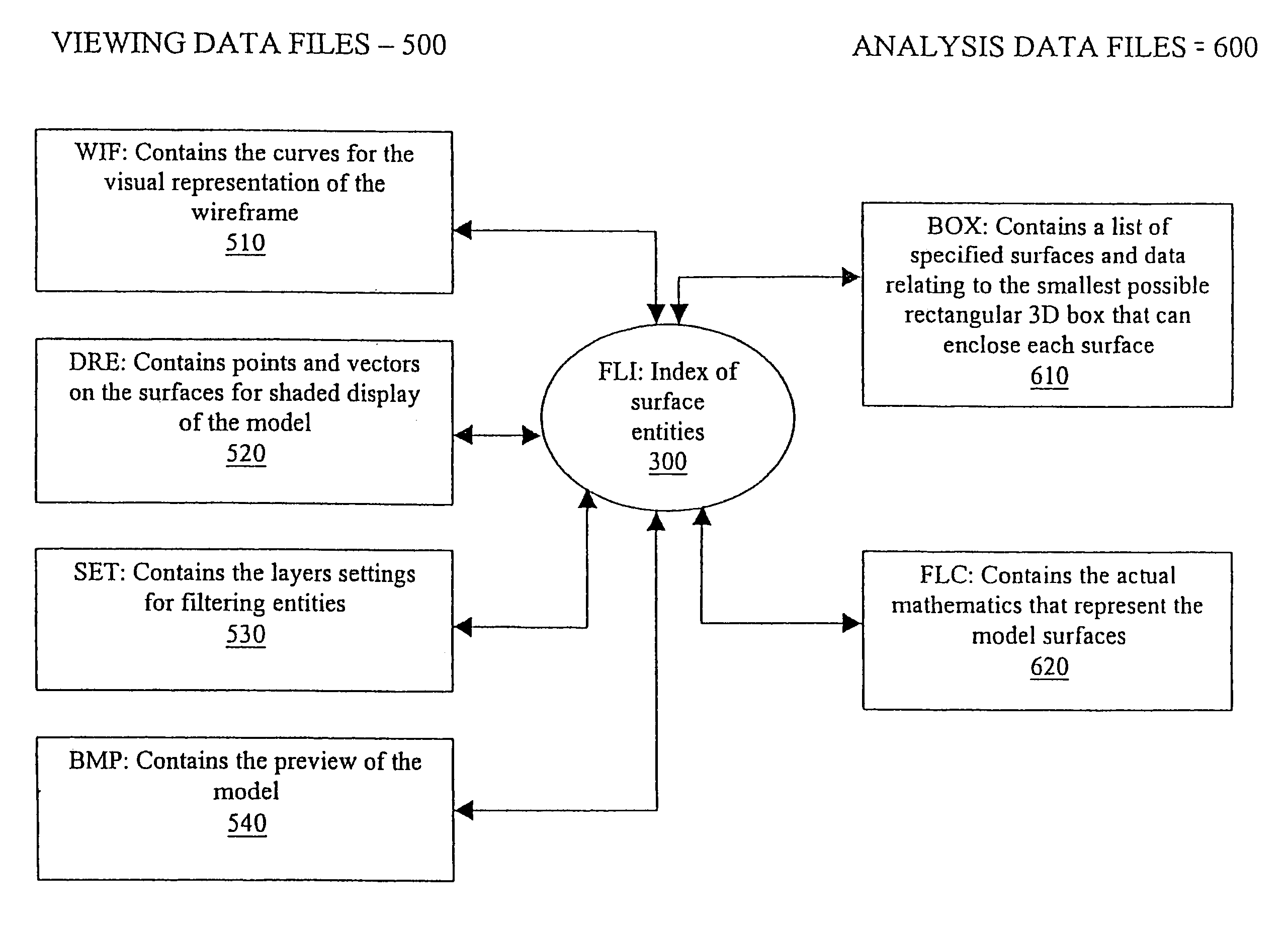

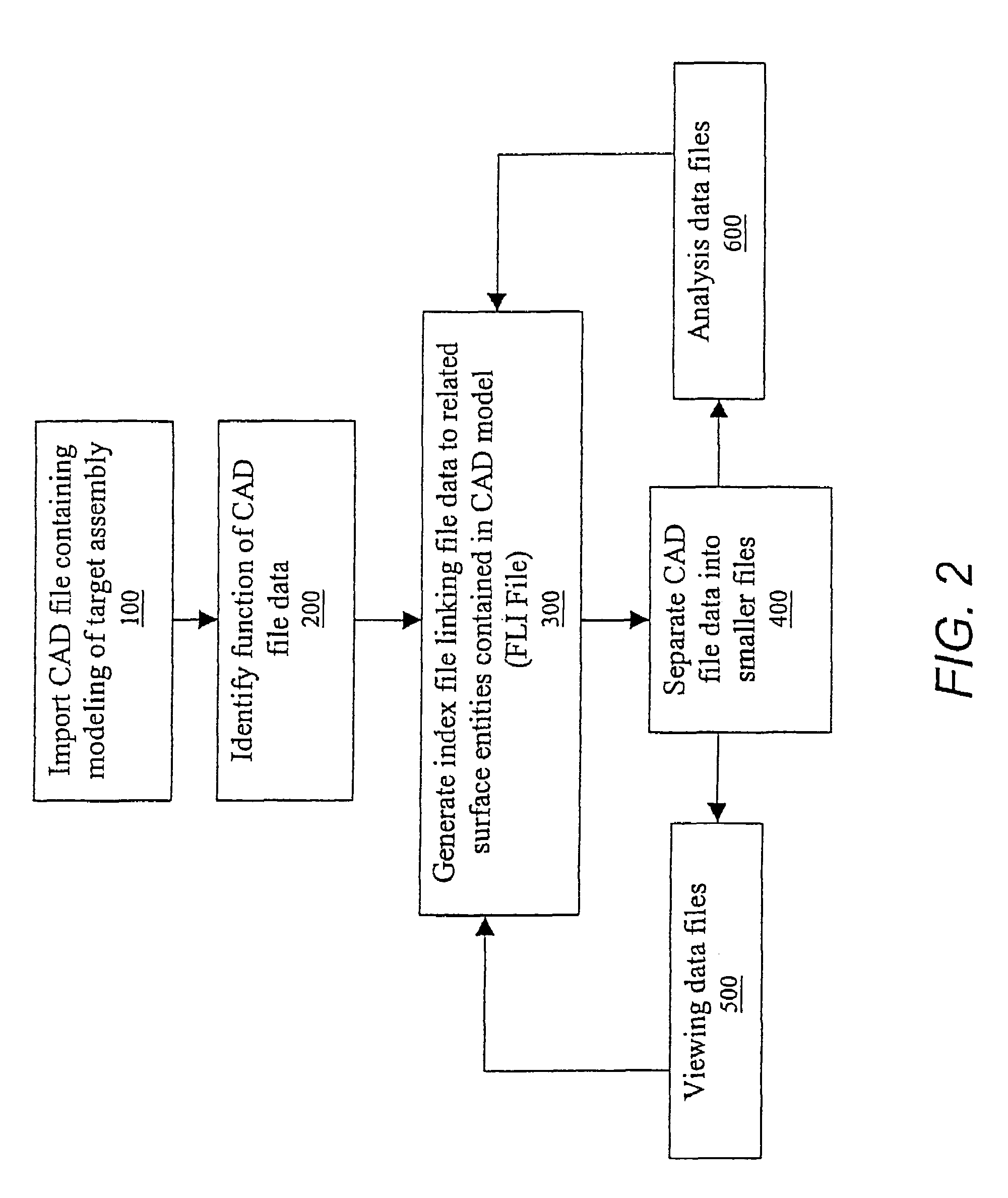

Method and system for computer aided manufacturing measurement analysis

InactiveUS7006084B1Improve quality controlReduce decreaseComputer controlSimulator controlMeasurement pointQuality control

The invention relates to a computer-based method and system to facilitate quality control for manufactured assemblies based on computer aided design (CAD) files. The instant invention mitigates the problems encountered with large CAD files by decomposing each of such files into a multi-file format. A large CAD file is thereby broken-down into smaller files that organize the information contained in the larger file. The organization is performed in such a way that the information pertinent to the measurement process is segregated into a different smaller file than the information not needed to calculate measurements. Thus, the computer running the computation accesses a smaller file containing a higher percentage of required information. Additionally, assisting the user in coordinating a match-up between the physical surfaces being measured and the proper associated CAD model version of that surface further increases the handling speed. In particular, the instant invention uses selection regions for each surface. A selection region consists of the representation of a three-dimensional rectangle region just large enough to enclose each individual surface. A selection region indexes each surface. Thus, when a measurement point is taken, a list of surface regions is automatically scanned in order to determine which region contains that point. The corresponding distance of that measurement point to the surface is then calculated.

Owner:FARO TECH INC

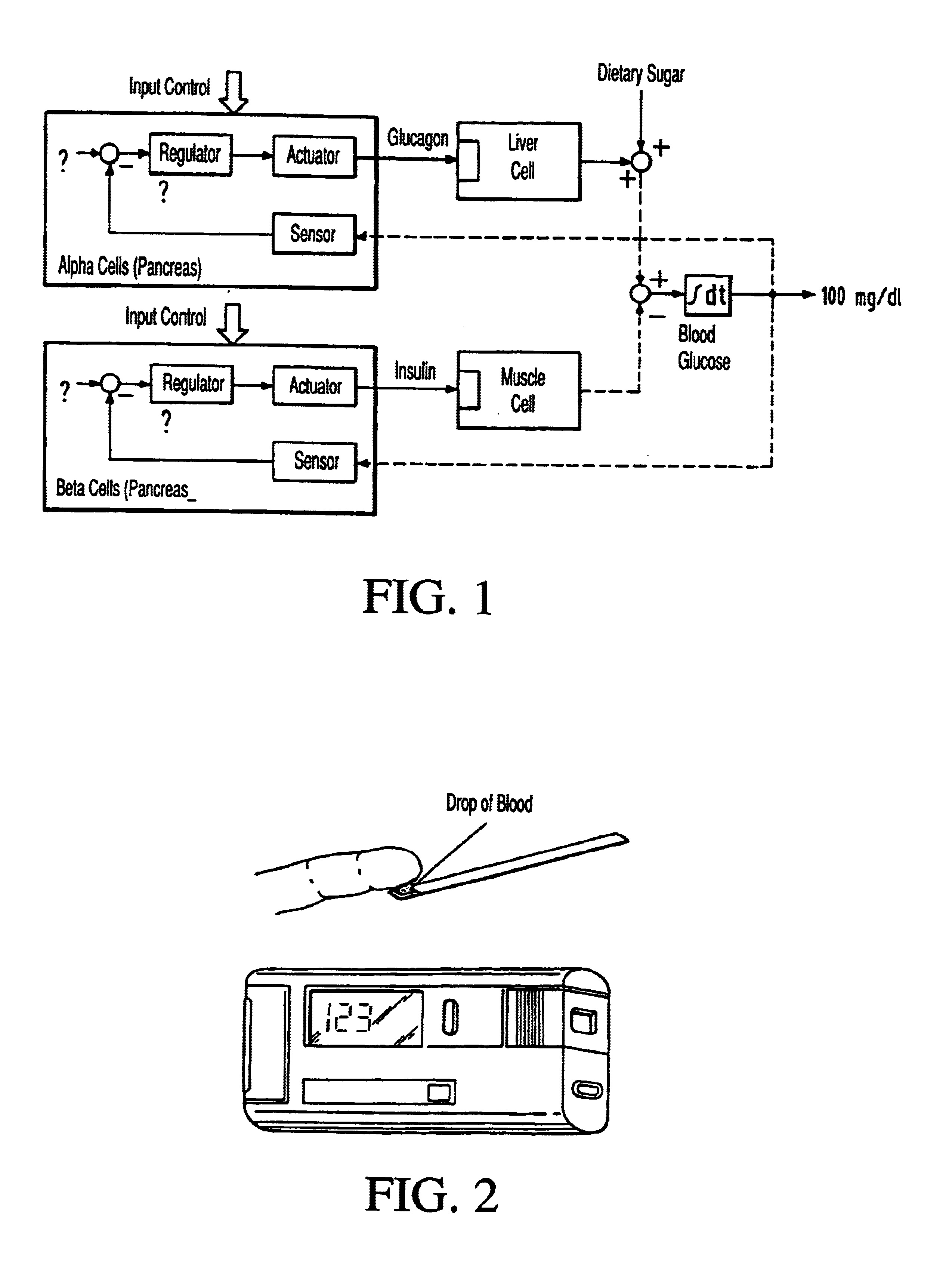

System and method for complex geometry modeling of anatomy using multiple surface models

ActiveUS7988639B2Accurate modelingImprove abilitiesElectrocardiographyCatheterComputational scienceHuman anatomy

Disclosed herein are methods and systems for creating a complex model of the human anatomy. The anatomy may be modeled using multiple geometries. Generally, a plurality of line-of-sight models may be combined into a composite model. Multiple clouds of points may be used to create surface models which may then be merged into a common volume. The resulting composite model may include portions that are not within a line of sight of a mean center point of the composite model. The surface models may be modeled using polygons, including for example, triangles. Disclosed herein are also ways in which electrophysiology data and / or other information may be mapped from a measurement point to a point on the composite model.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

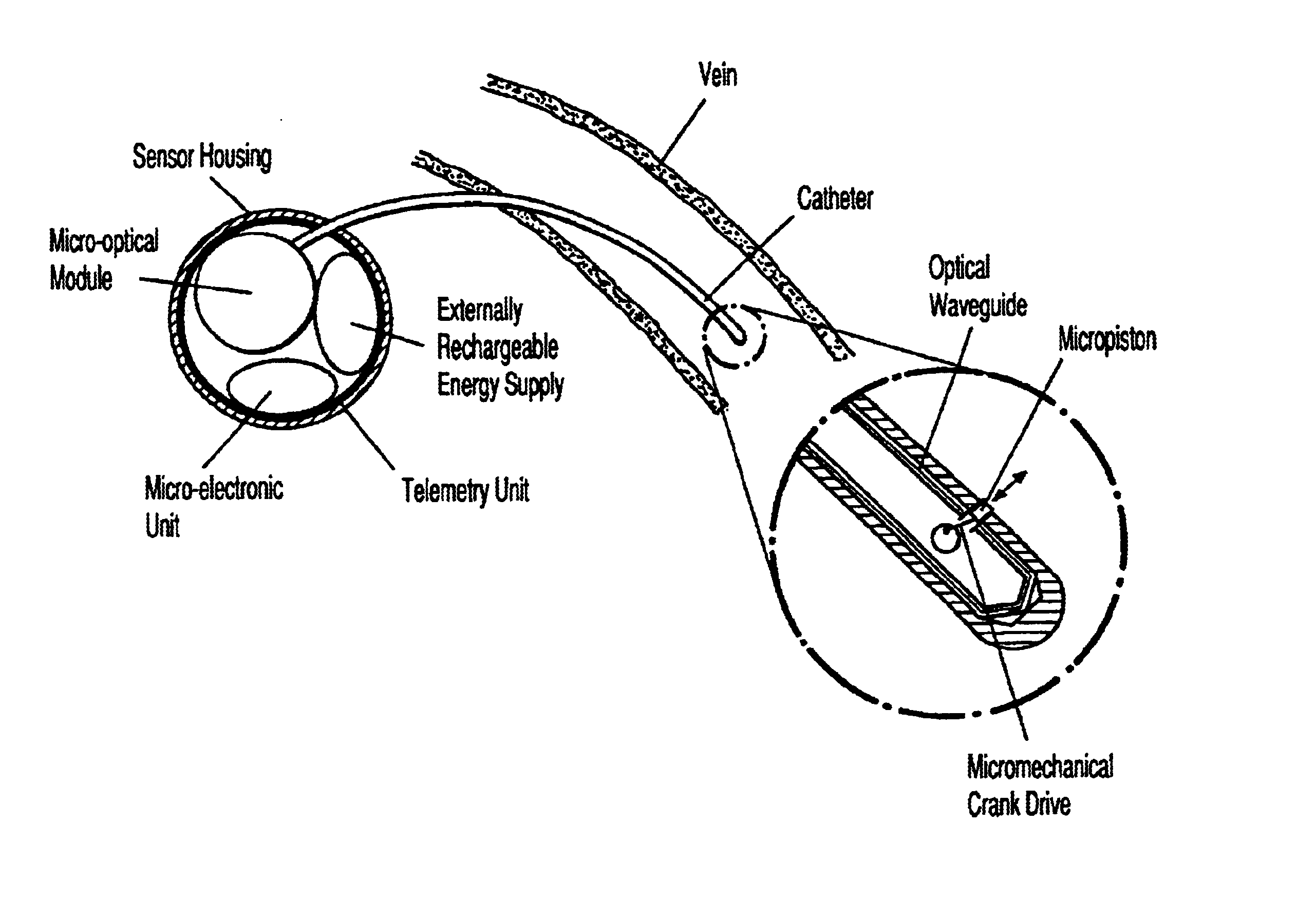

Device for measuring human blood sugar levels

InactiveUS6885881B2Accurate measurementEasy to useCatheterDiagnostic recording/measuringMeasurement pointGlycemic

Device for measuring human blood sugar levels with a catheter, the free end of which is positioned in a blood vessel, wherein the catheter consists of at least one optical waveguide comprising a light source for coupling light into the at least one optical waveguide, a measurement point at the free end of the catheter at which point the light is emitted from the at least one optical waveguide, wherein the light is dispersed by the blood and / or transmitted by the blood and wherein the dispersed and / or transmitted light is coupled again into the minimum of one return optical waveguide, a detector to receive the light which is returned, and a computer unit for analysing the light received by the detector. Provision is made for a cleansing device to be located at the point of measurement for removing the tissue particles deposited from the blood in order to provide a device which is as accurate as possible and which delivers constant measurement values over time for blood sugar levels which can be used as the basis for further data analysis.

Owner:LEONHARDT STEFFEN

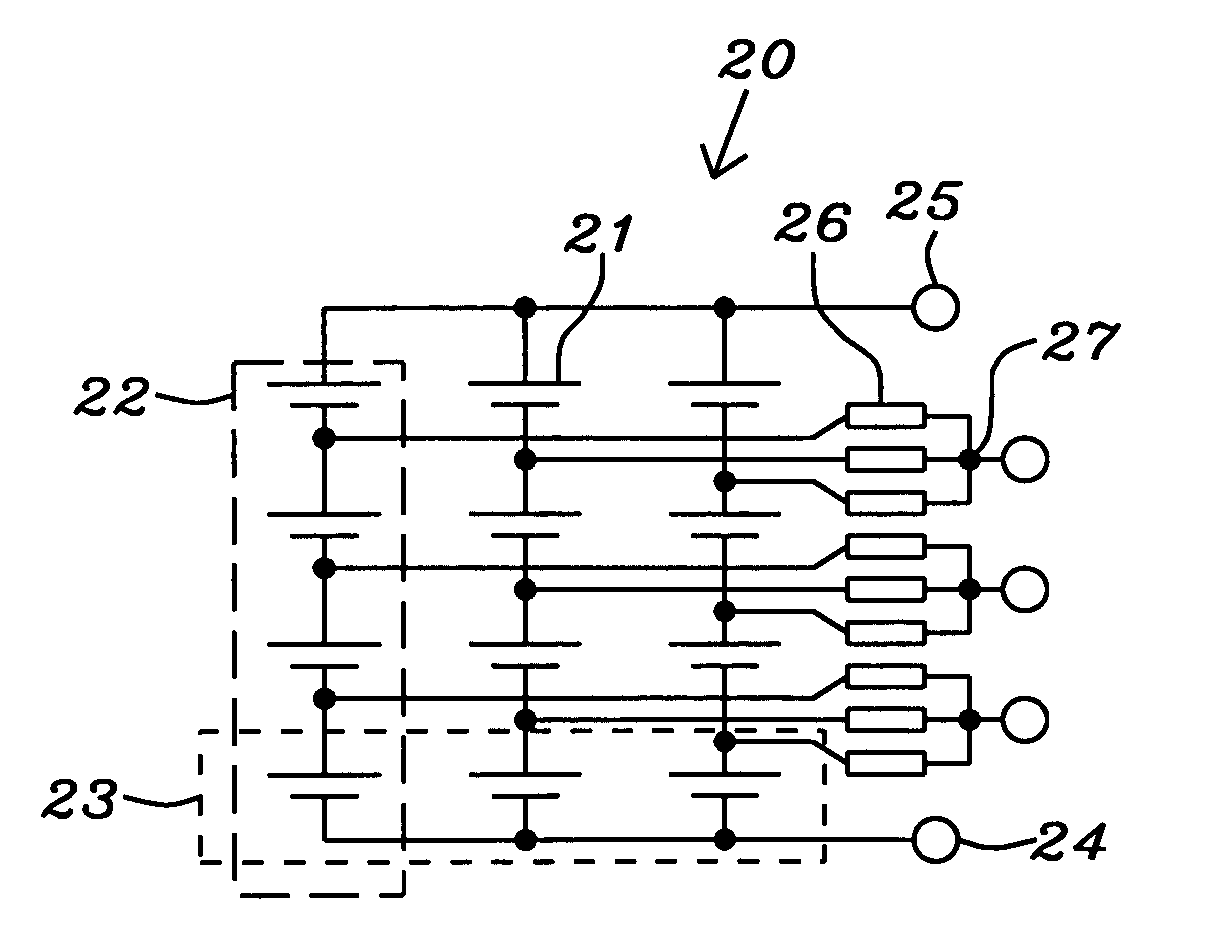

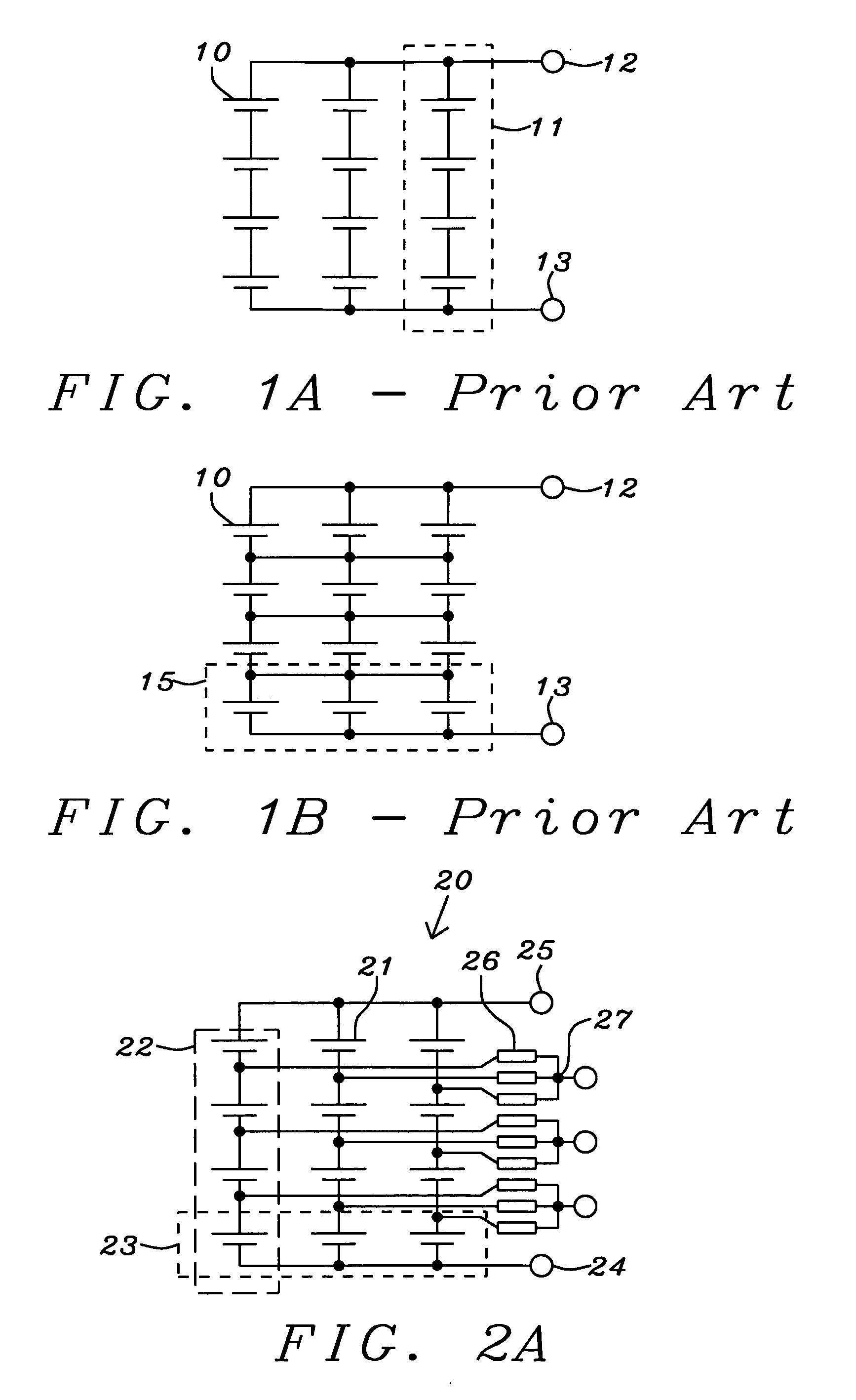

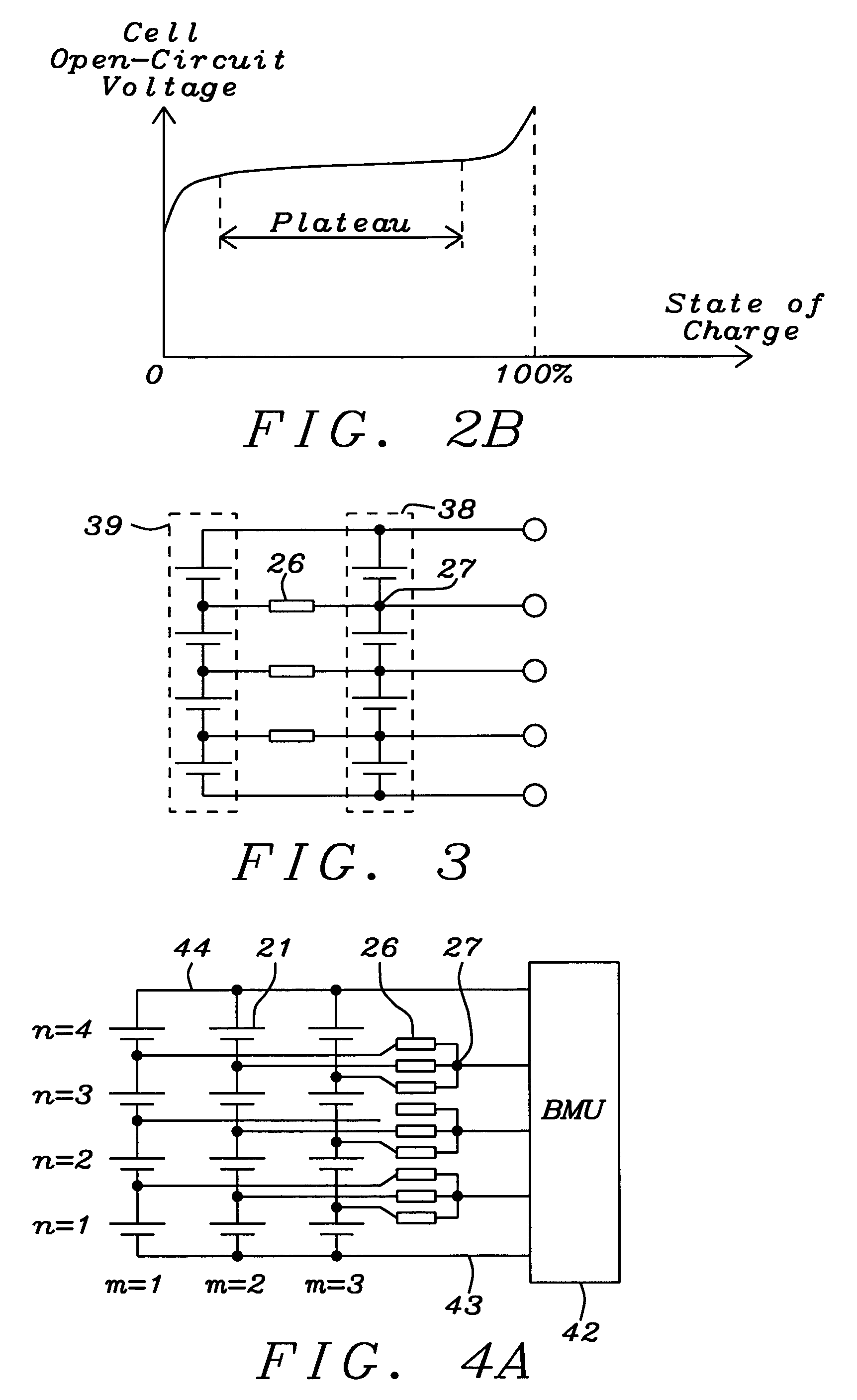

Connection scheme for multiple battery cells

ActiveUS20110003182A1Total current dropEnsure adequate isolationCharge equalisation circuitCircuit monitoring/indicationElectrical resistance and conductanceManagement unit

A series-parallel battery system with a buffer resistor coupled to each junction of batteries or battery cells. Buffer resistors on the same row are coupled to a measurement node. Terminals of the battery system and the measurement nodes are treated as measurement points that are coupled to a conventional battery management unit. The buffer resistors provide a means for limiting in-rush current and a means for maintaining voltage balance across the row of batteries in the parallel columns of batteries. A control unit in series with each series of batteries monitors current in the series and comprises a switch to deactivate the column when the current exceeds a set of predetermined current levels.

Owner:AMPEREX TECH

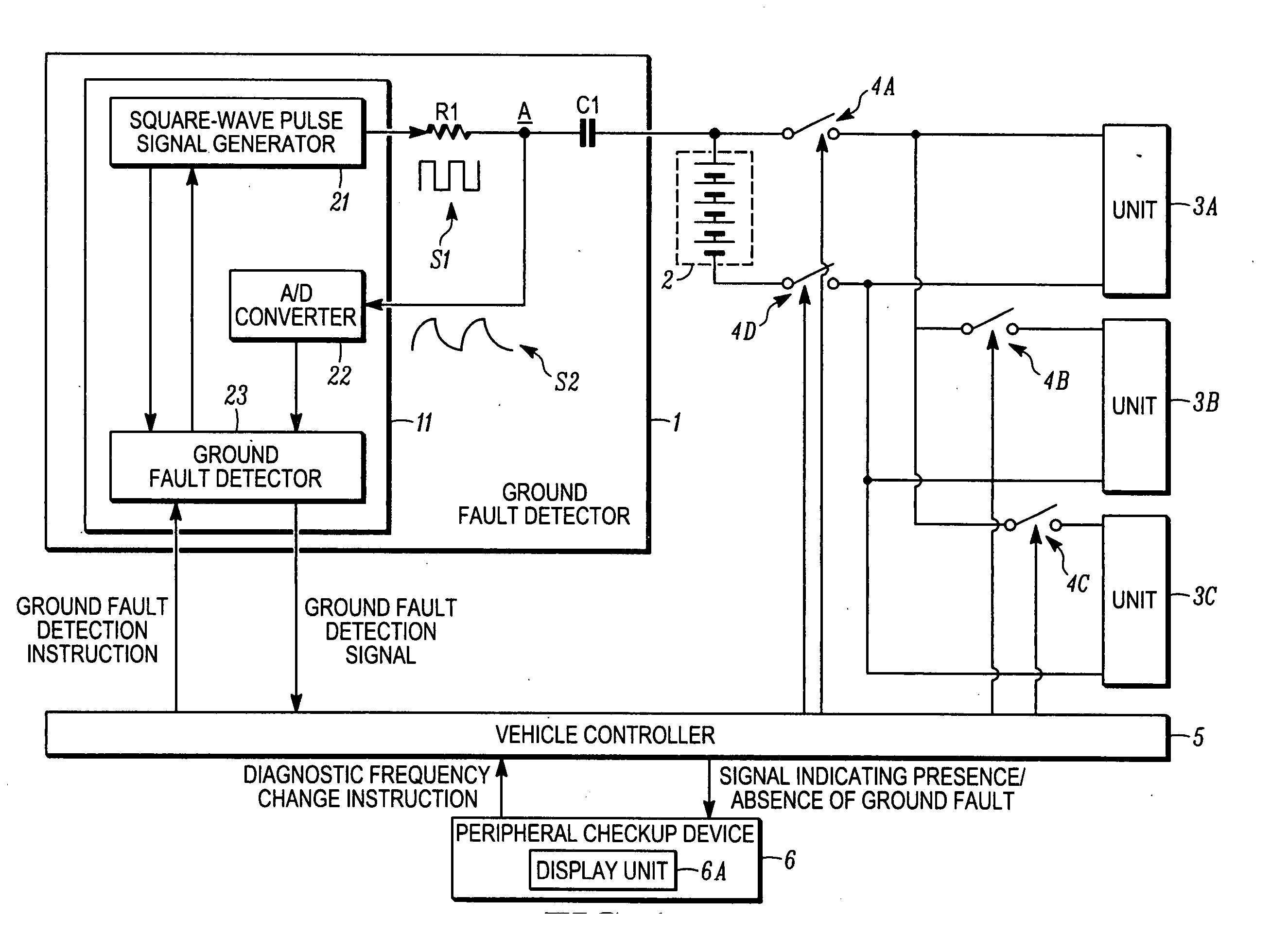

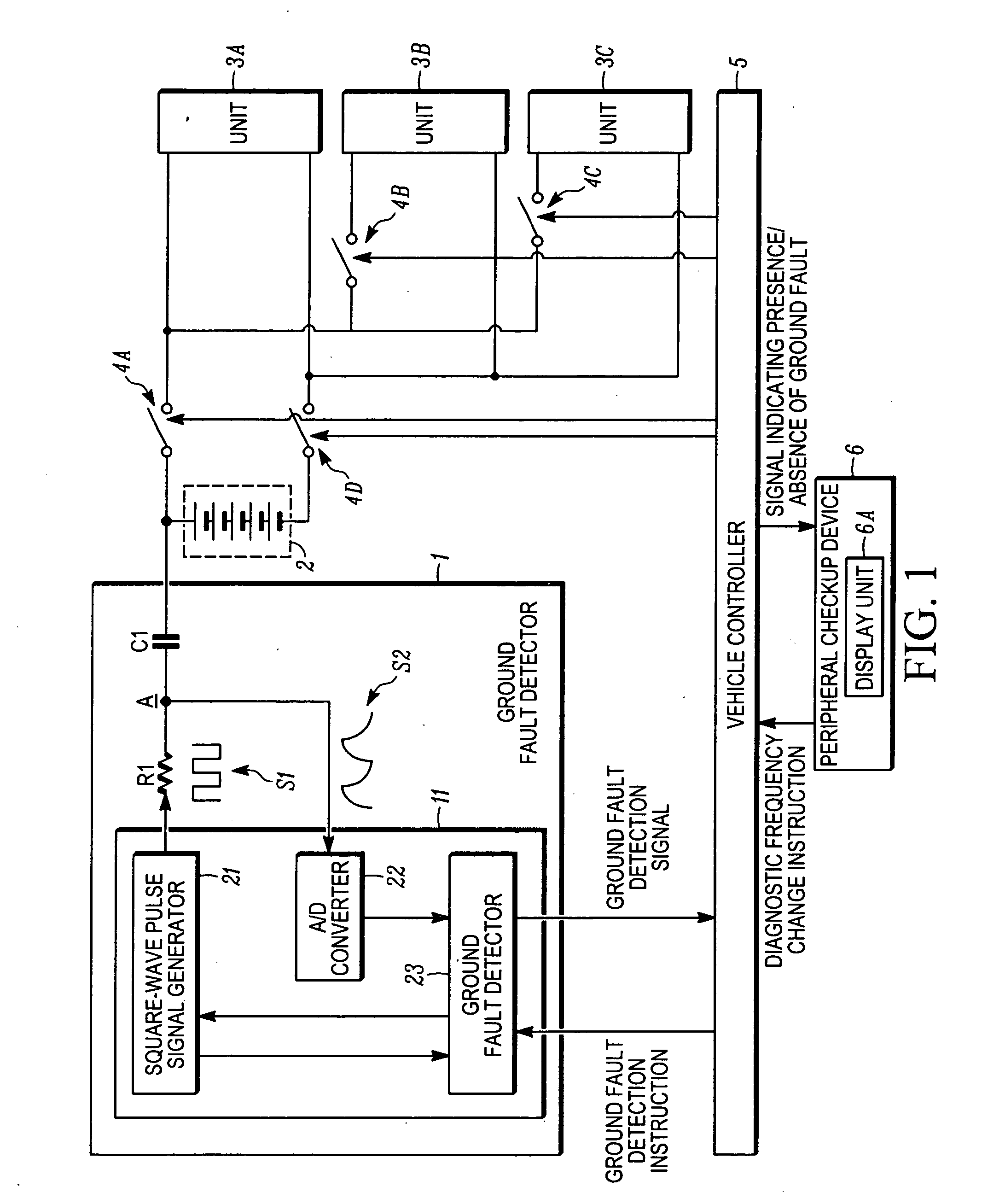

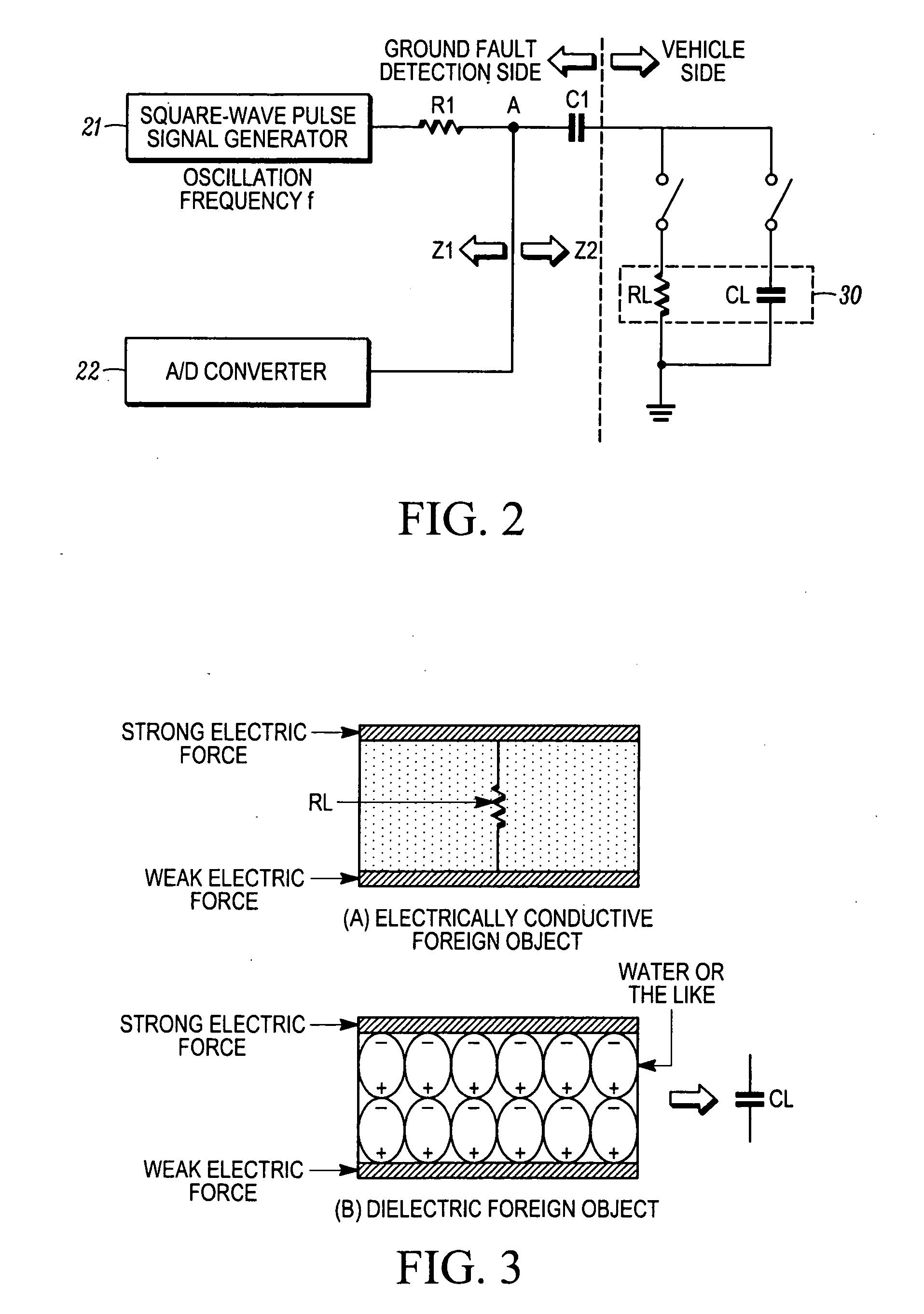

Ground fault detector for vehicle

A ground fault detector and detection method for a vehicle that can determine the cause of the occurrence of a ground fault after detecting the presence of the ground fault. The output terminal of a high-voltage battery is connected to one side of a coupling capacitor. In operation, a pulse signal is applied to a measurement point on the other side of the coupling capacitor, and the voltage generated at that point is detected. Whether the high-voltage battery or the electrical equipment units are grounded is determined. To determine the cause of the ground fault, the oscillation frequency of the square-wave pulse signal is changed and applied to the measurement point. From the change in voltage amplitude detected, it is determined whether the cause of the ground fault is a resistive or a capacitive ground fault, according to the change in the impedance of the battery or the units.

Owner:NISSAN MOTOR CO LTD

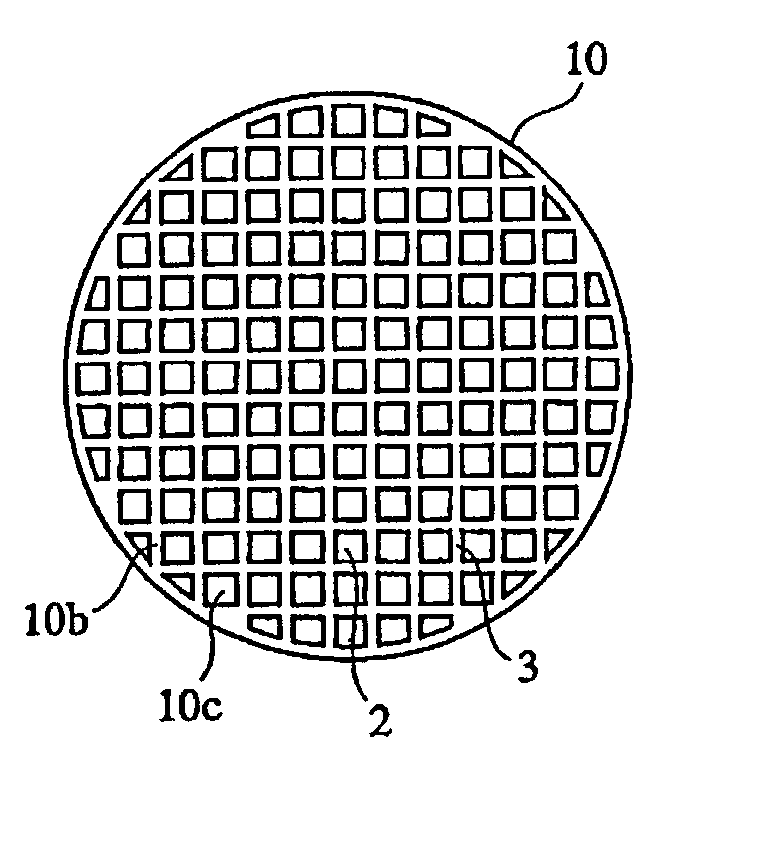

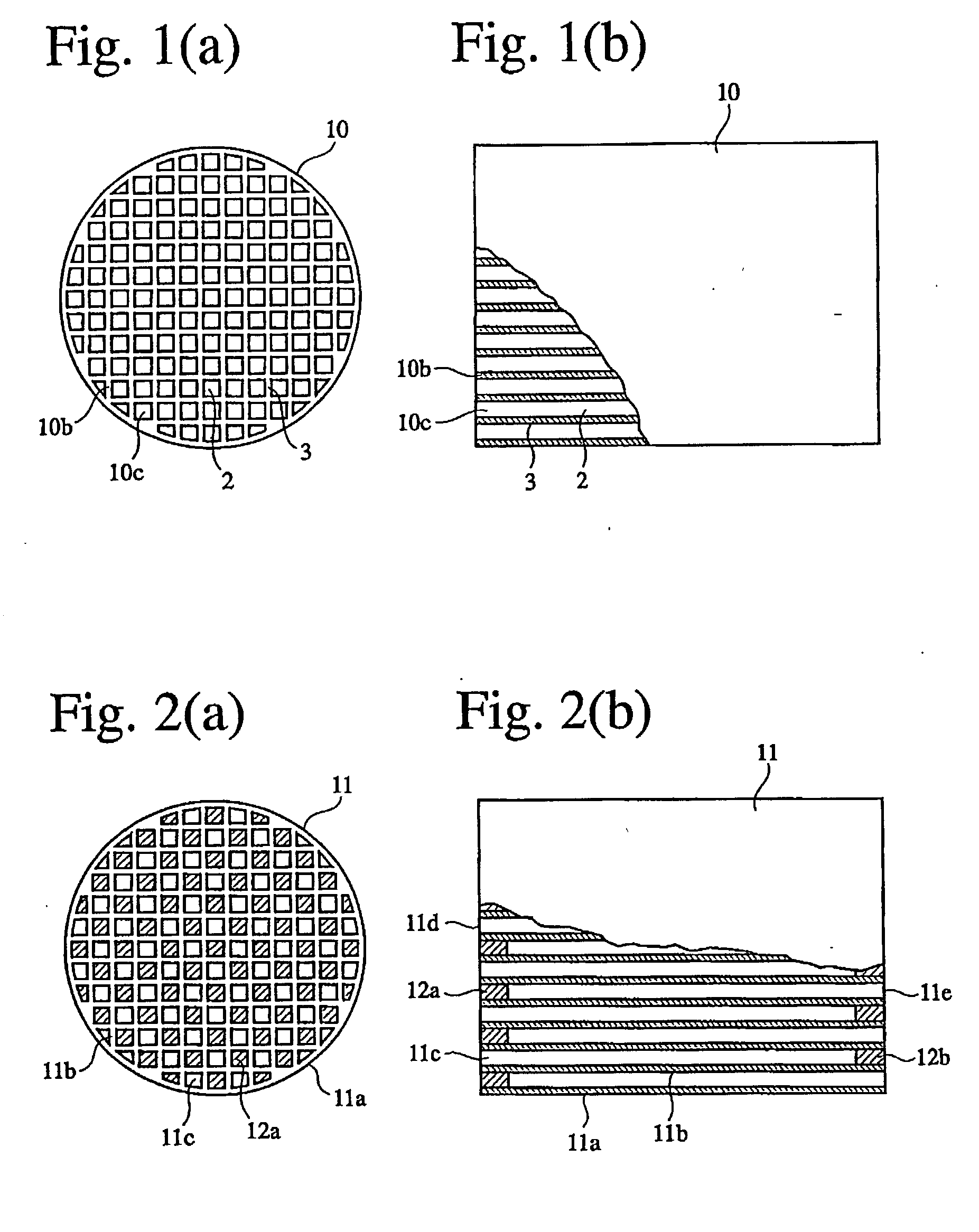

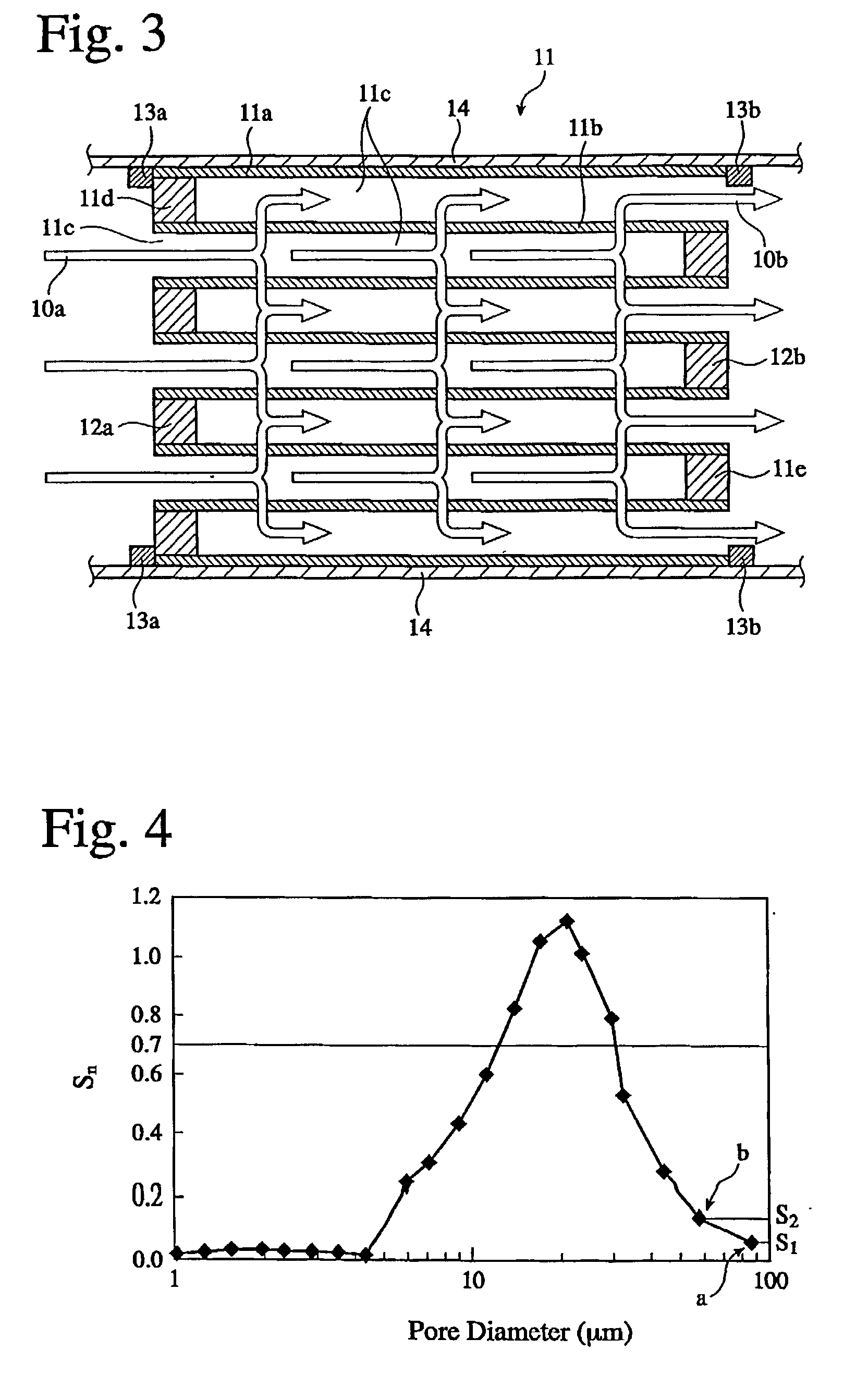

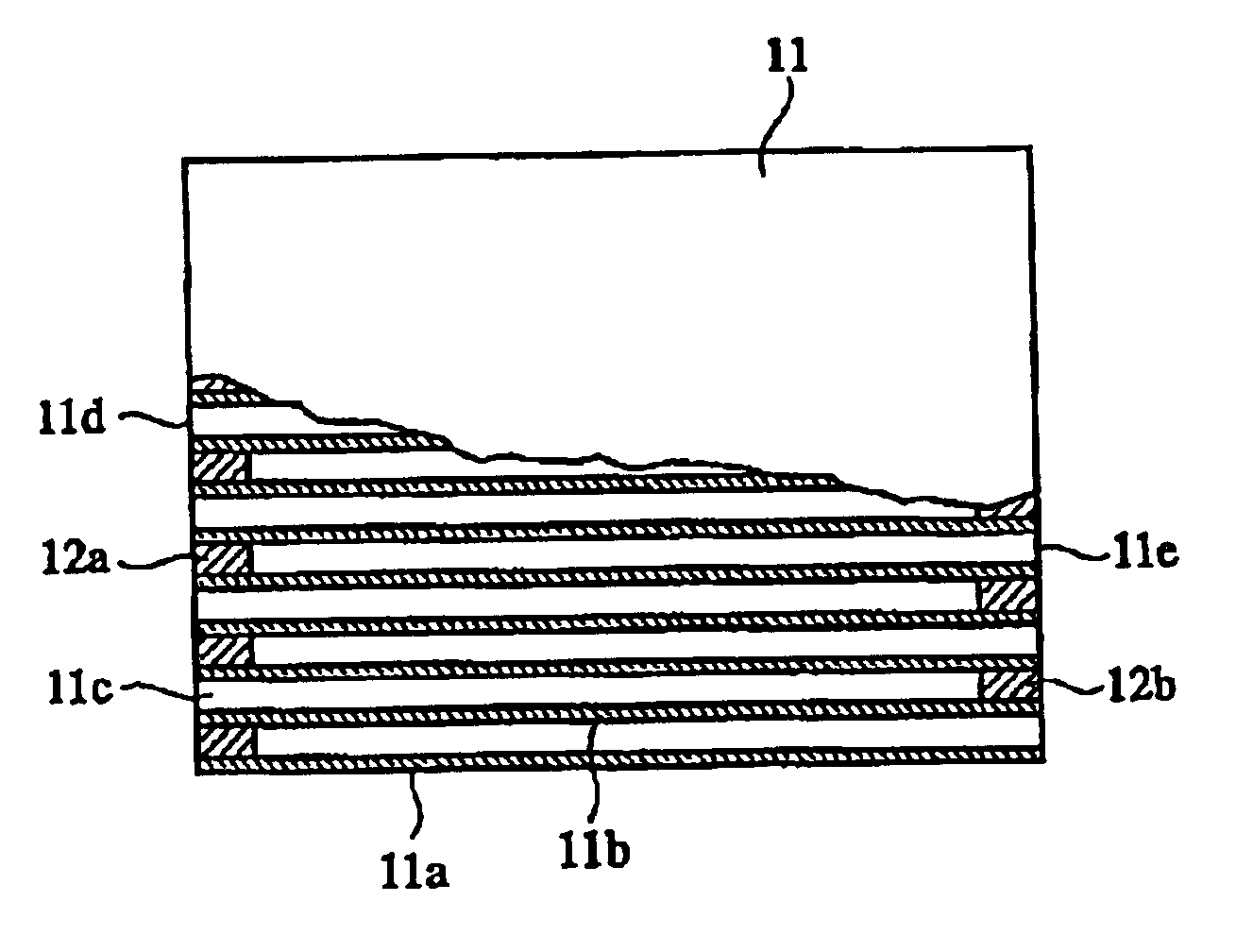

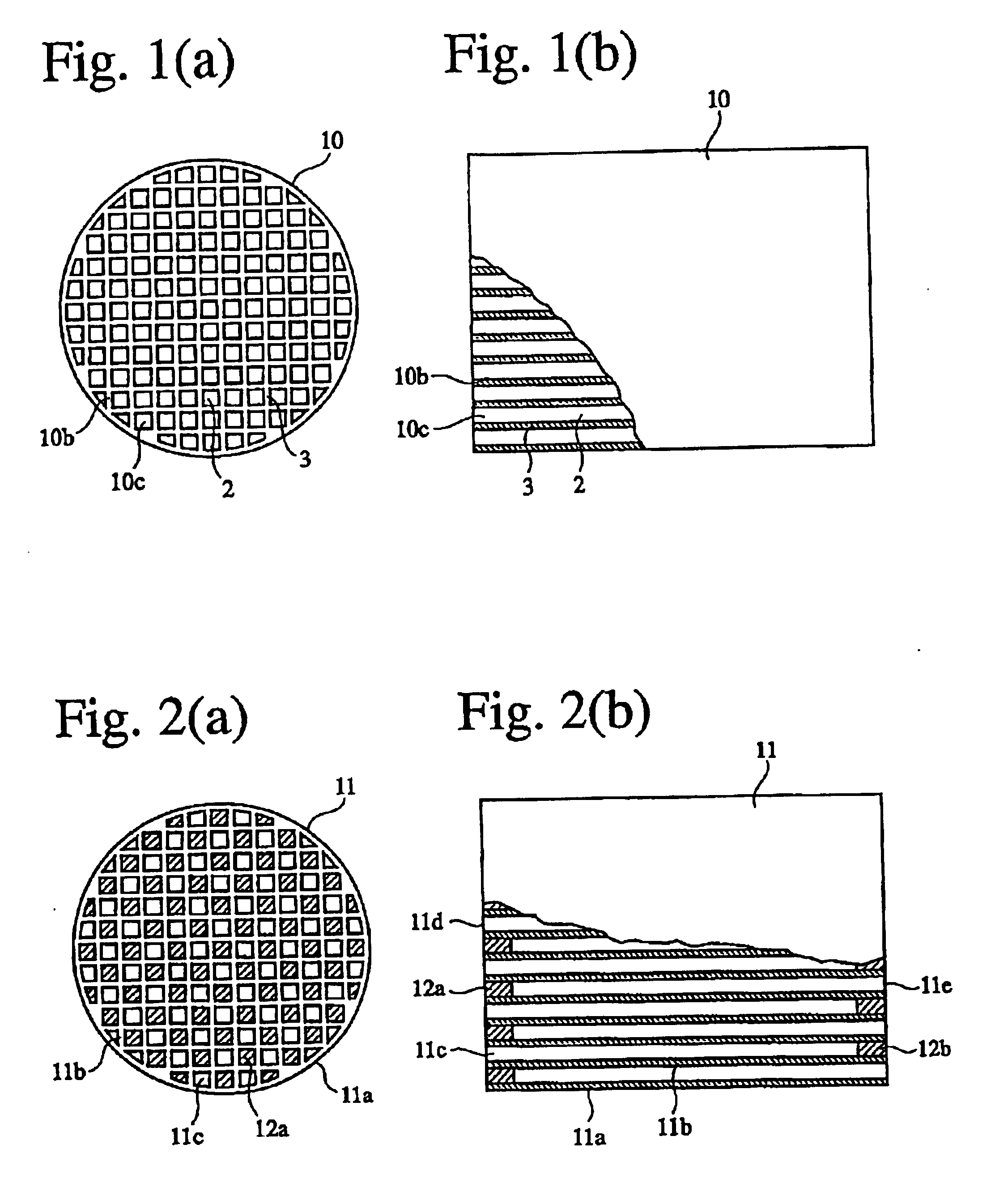

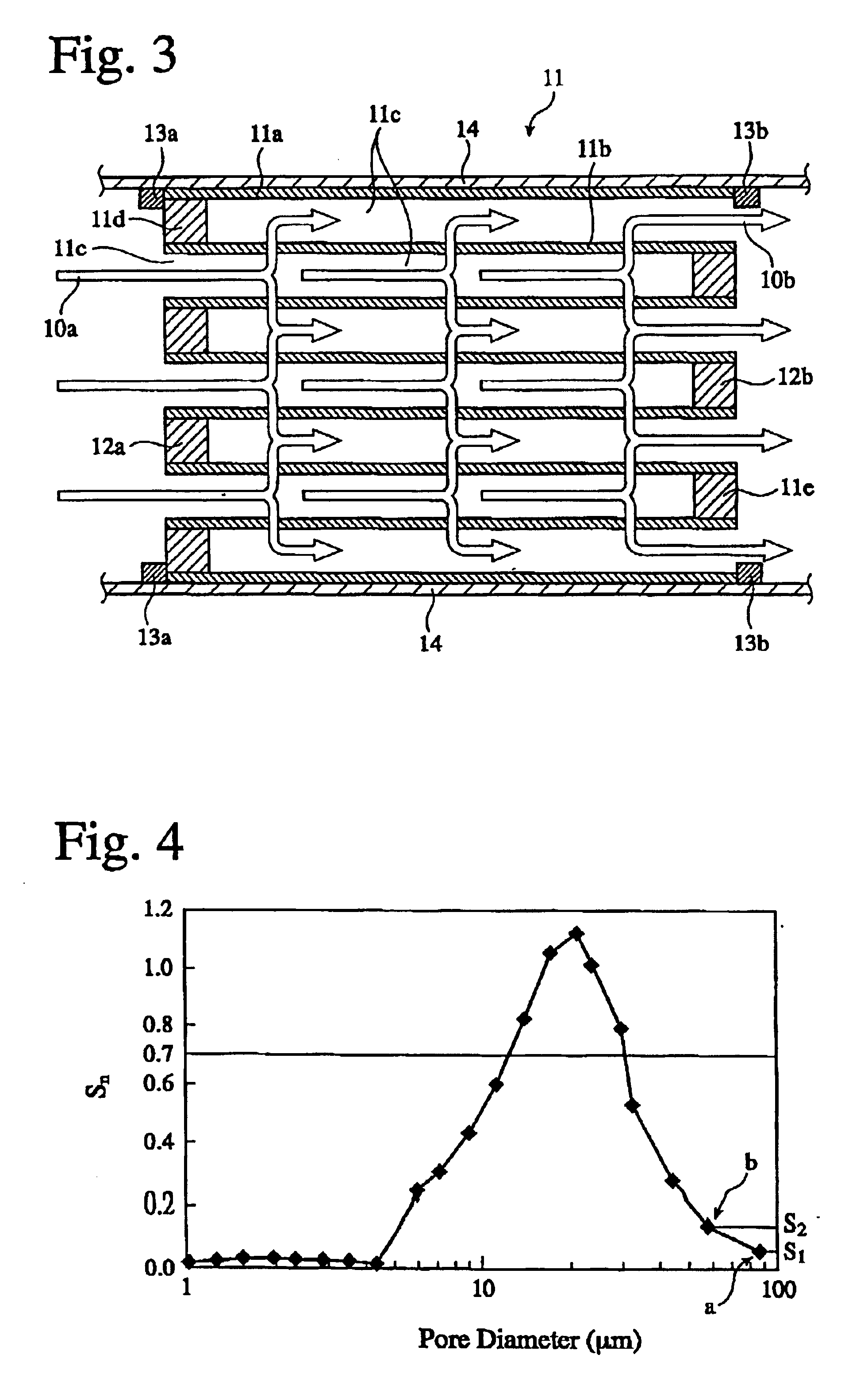

Ceramic honeycomb filter

InactiveUS20030093982A1Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sb being represented by the following formula (1): Sn=-(Vb-Vn-1) / [log Dn-log (Dn-1)] (1), wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm3 / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm3 / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

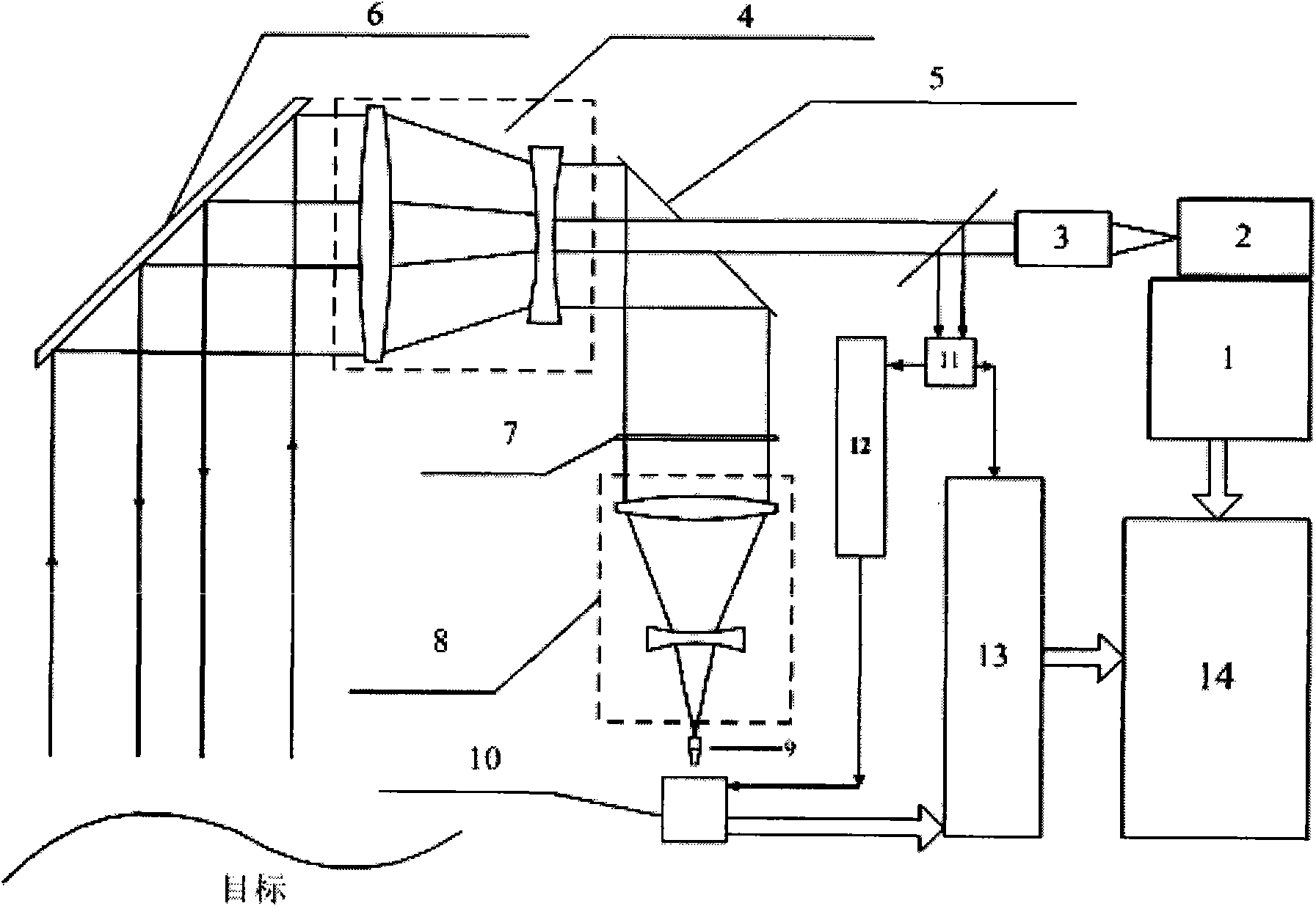

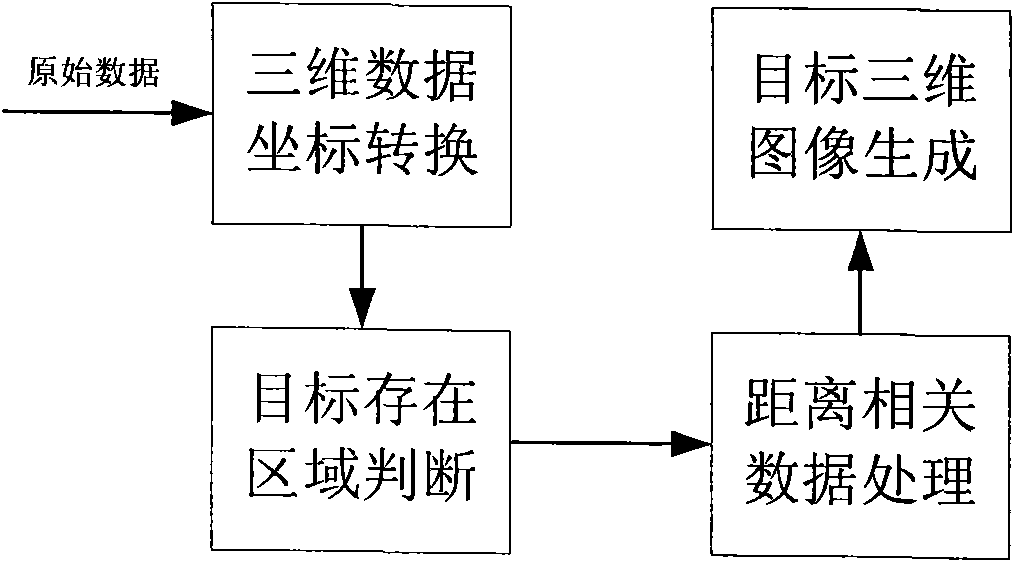

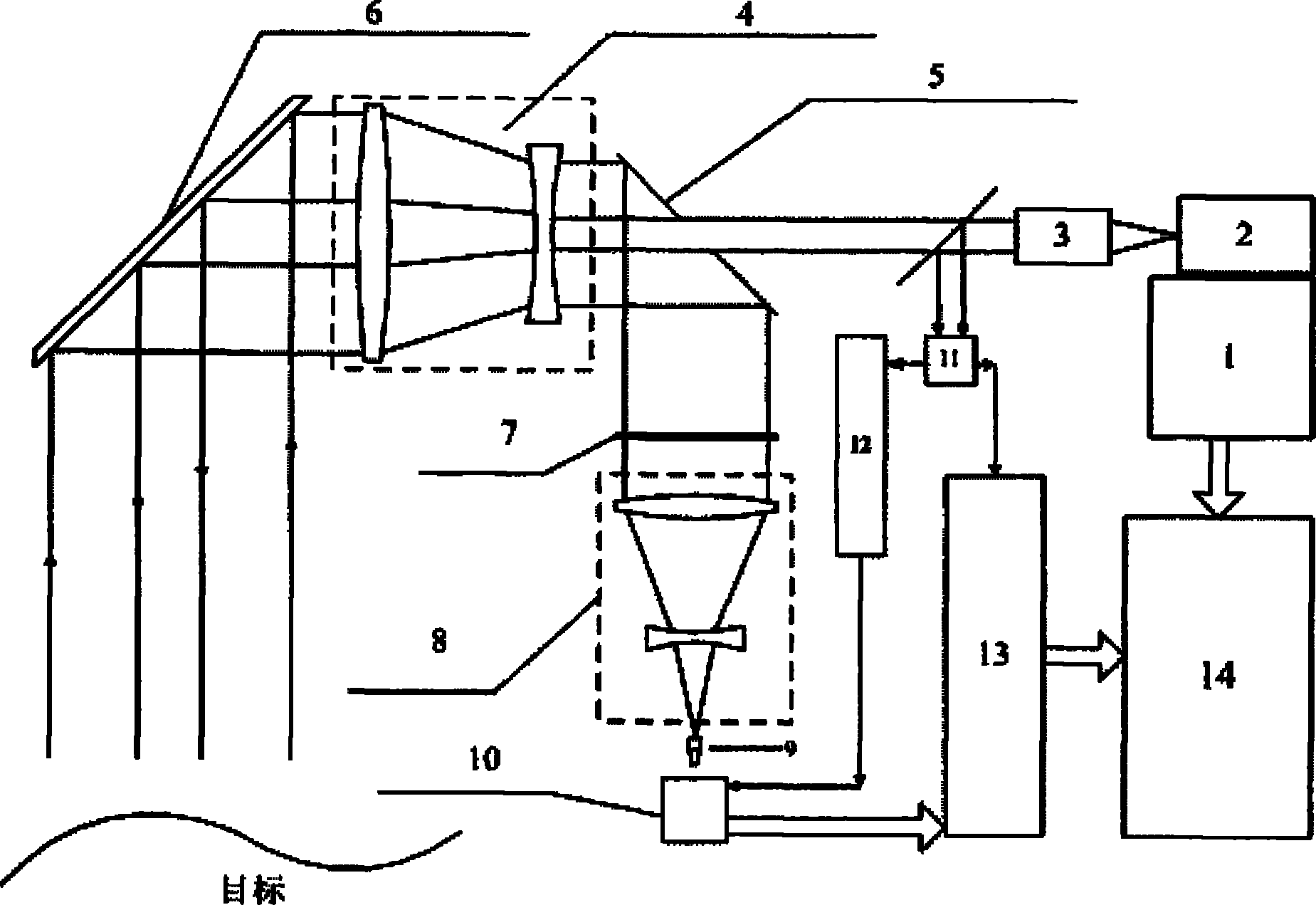

Laser three-dimensional imaging device based on single-photon detector

InactiveCN101776760AHigh sensitivityMiniaturizationElectromagnetic wave reradiationOptical elementsMeasurement pointFlight time

The invention discloses a laser three-dimensional imaging device based on a single-photon detector, belonging to the technical field of photoelectric instruments. A target to be detected is irradiated by the laser pulse emitted by a pulsed laser via a scanning system; the returning photons are received by a receiving / emitting co-axial optical system, i.e., the returning photons are received by a double-gating single-photon detecting module via a spectral filter and a spatial filter and an arriving pulse is outputted, so that the photon flight time of the target measuring point can be measured by combining the laser emission detection and the multi-photon arriving pulse time; and a data processing unit is used for carrying out the coordinate conversion based on the position and attitude data, scanning mirror targeting data, and photon flight time of the three-dimensional imaging device, de-noising and three-dimensional image construction and correction, so as to output the reliable target three-dimensional range image. The invention solves the problems that the existing laser three-dimensional imaging device is incapable of penetrating vegetation and camouflage and being miniaturized when conducting long-distance operations.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

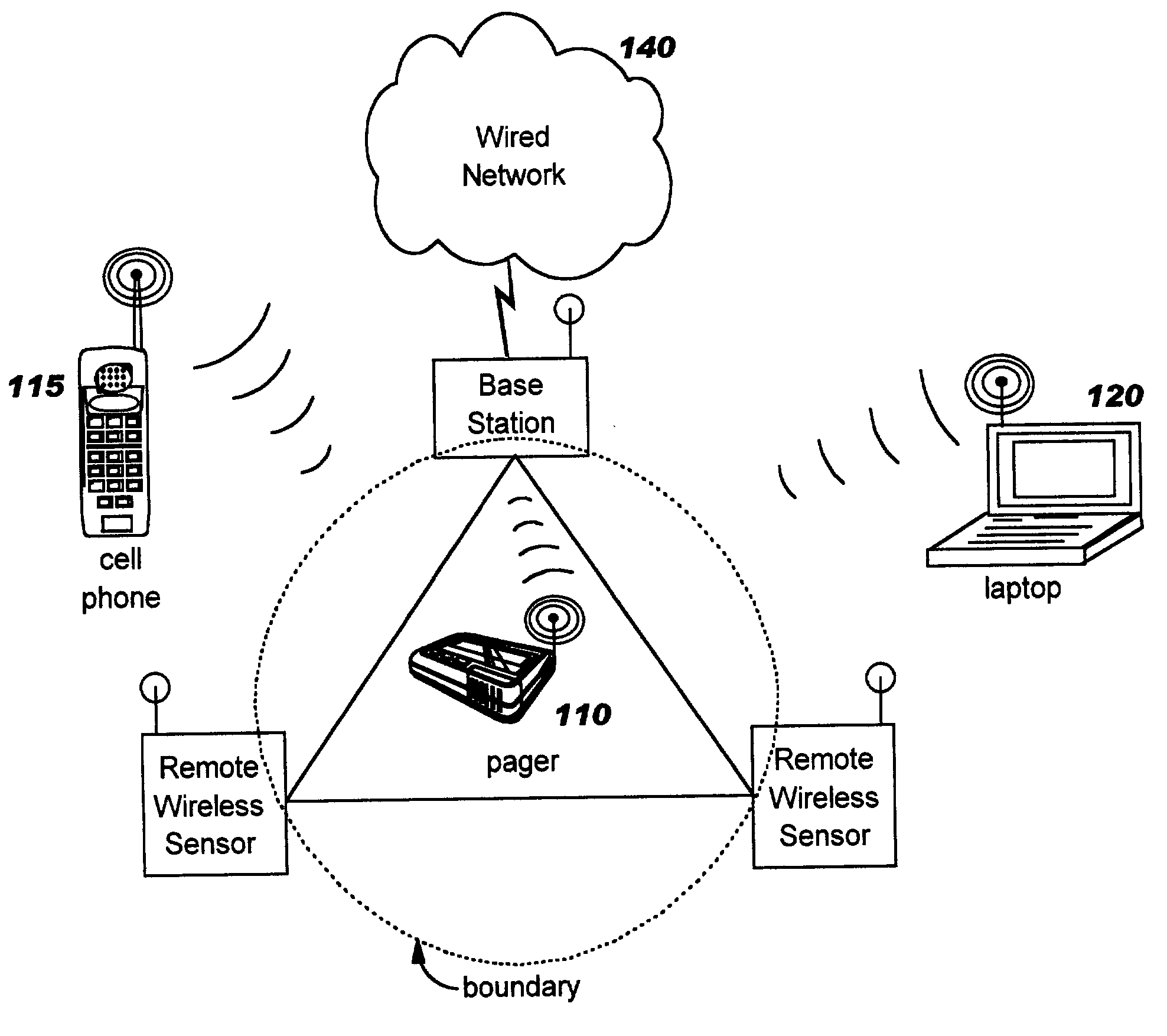

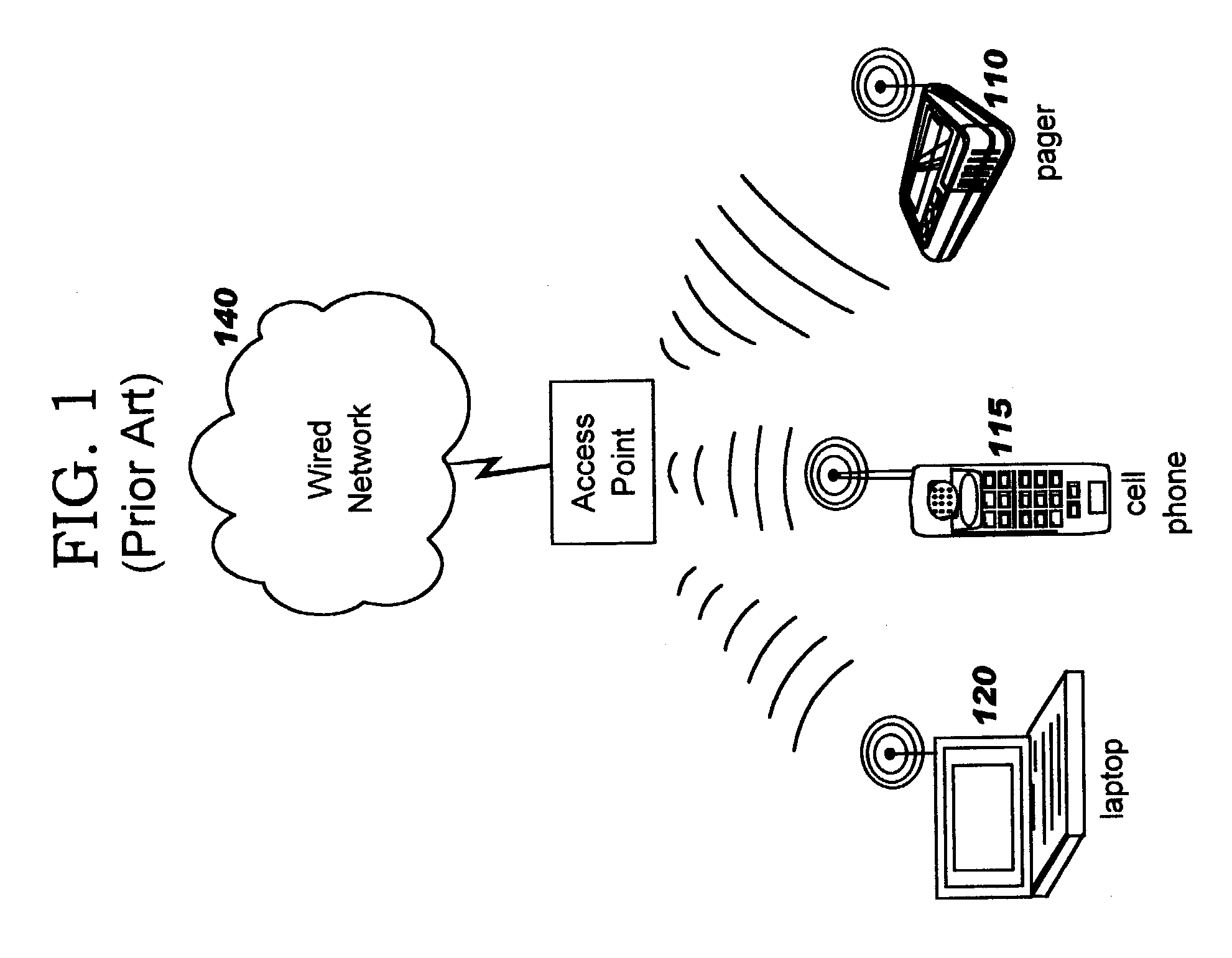

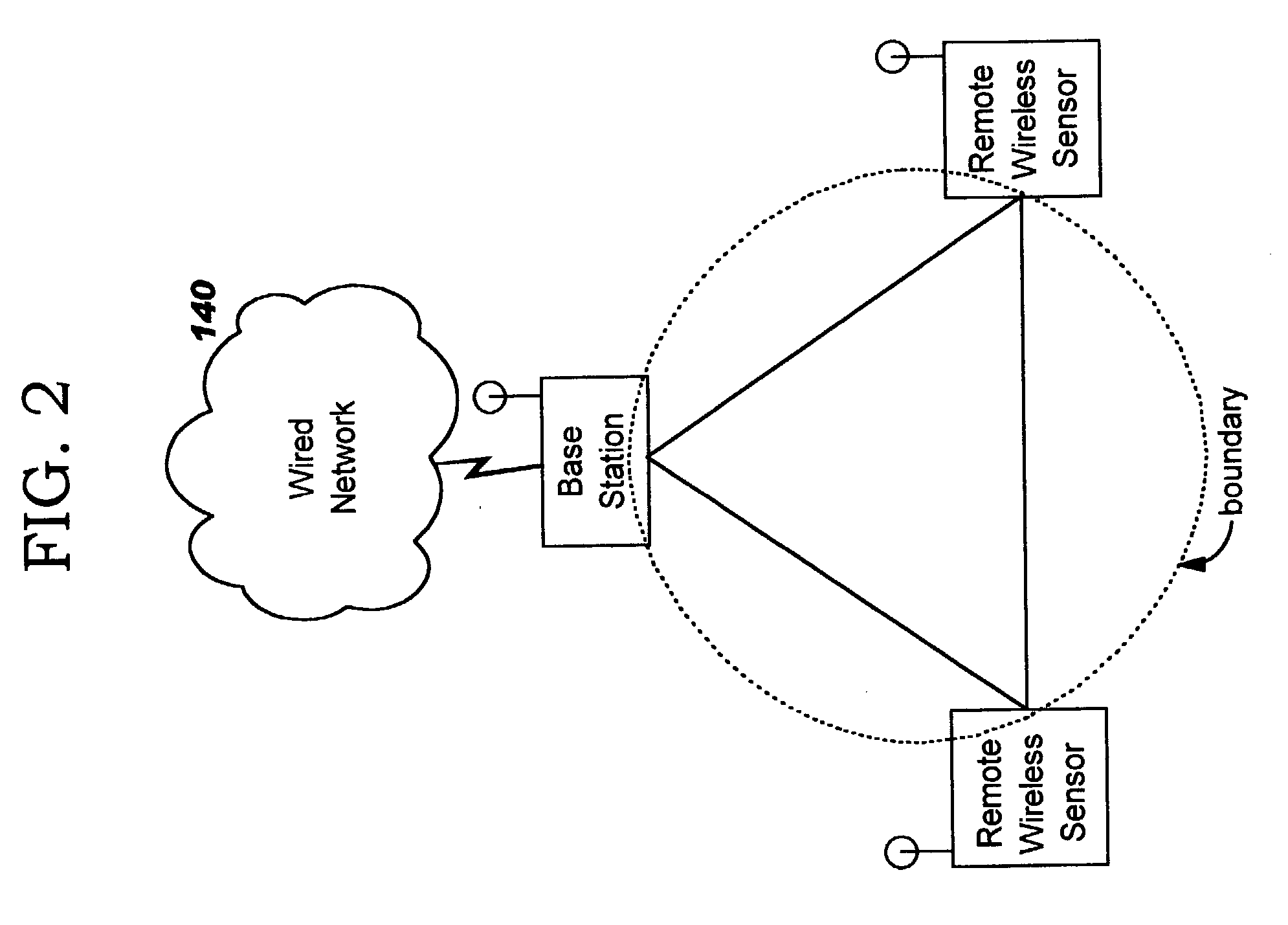

Spatial boundary admission control for wireless networks

InactiveUS20040203910A1Easy to set upDirection finders using radio wavesAssess restrictionTelecommunicationsMeasurement point

Security of wireless networks is improved by rejecting traffic from a wireless device located outside a defined spatial boundary. The device's spatial position with respect to the boundary is determined using directional antenna arrays on a plurality of measurement points, and calculating where the vectors intersect. Having thus determined a device's location, access to a wireless network can be denied if the device is outside a predetermined spatial boundary. Or, the device's location inside or outside of the spatial boundary can be used for other purposes, such as theft detection.

Owner:IBM CORP

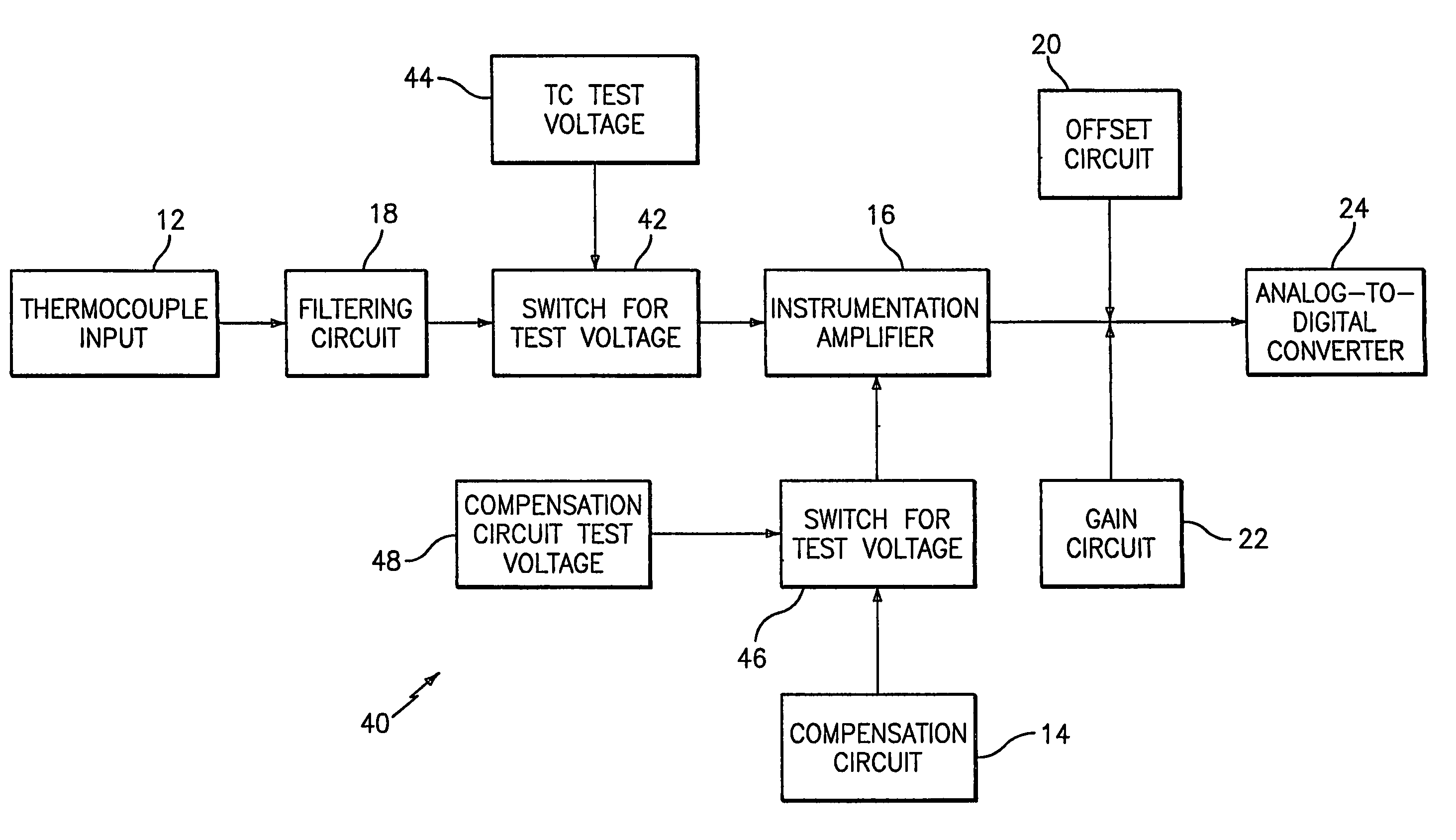

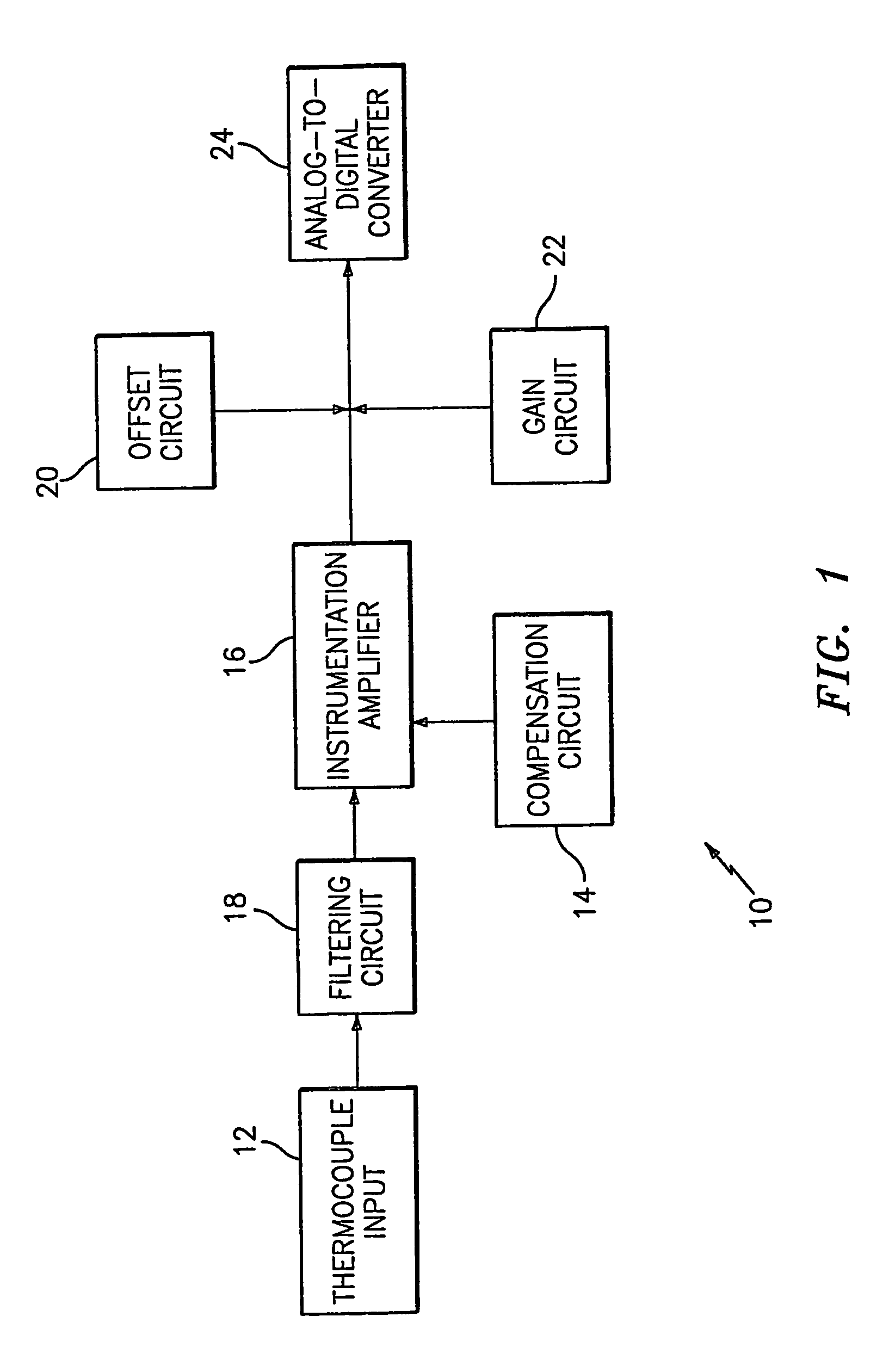

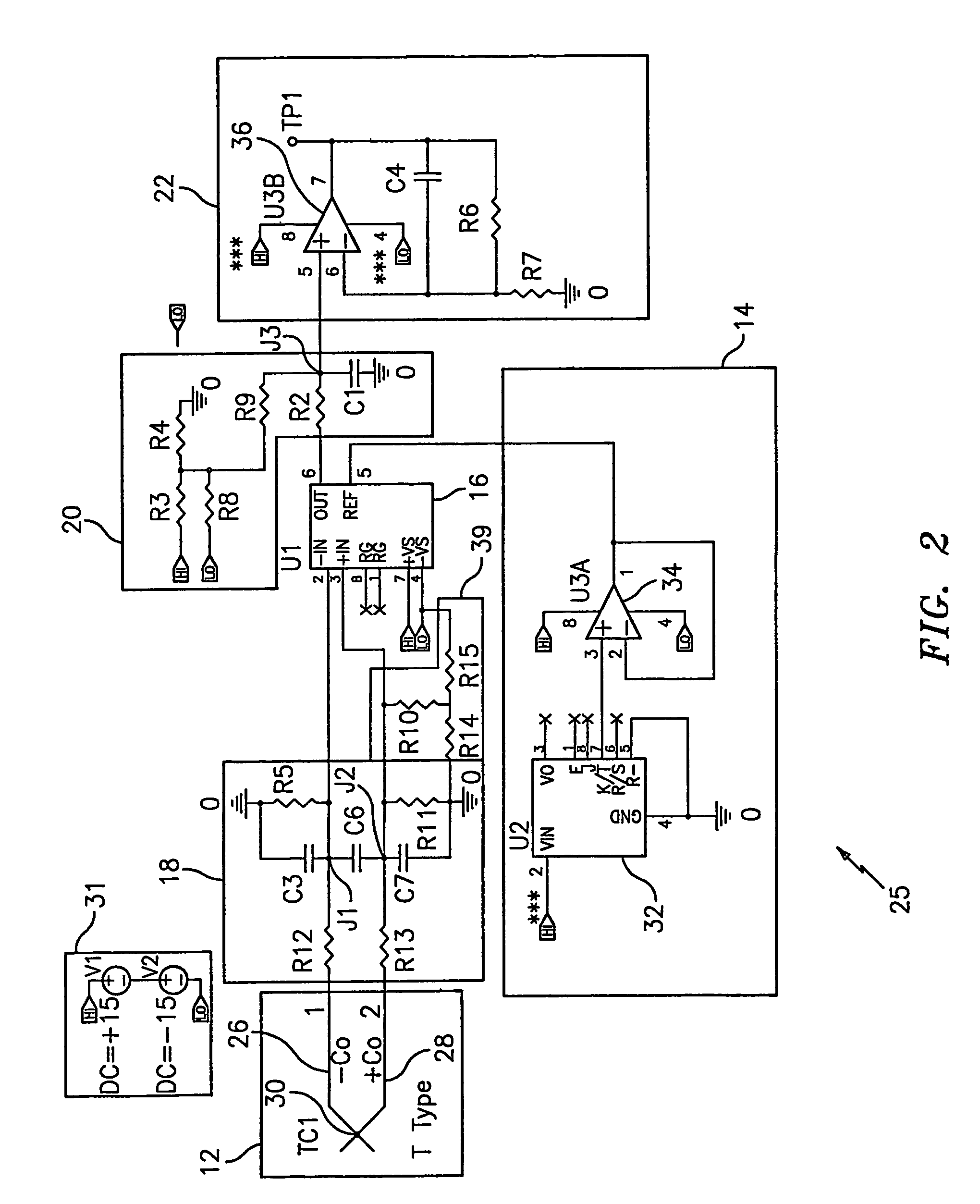

Thermocouple measurement circuit

InactiveUS8104956B2Easy to addThermometers using electric/magnetic elementsUsing electrical meansInstrumentation amplifierAudio power amplifier

A thermocouple measuring circuit for sensing a temperature at a measuring point is provided. The thermocouple measurement circuit (12) includes a thermocouple input for sensing a temperature at a measuring point, a compensation circuit (14) for compensating thermocouple effects of junctions of the thermocouple, and an instrumentation amplifier (16) for summing an output of the thermocouple and an output of the compensation circuit and outputting a voltage indicative of the temperature sensed, wherein the output of the compensation circuit is a reference voltage for the output of the instrumentation amplifier. Various embodiments of the thermocouple measurement circuit may be employed in electrosurgical generators for controlling output power dependent on temperature conditions.

Owner:COVIDIEN AG

Device for optically scanning and measuring an environment

ActiveUS8384914B2Easy to identifyEasy to moveAngle measurementOptical rangefindersMeasurement pointRest frame

In a laser scanner for optically scanning and measuring an environment, the scanner having a center which defines for a scan the stationary reference system of the scanner and the center of the scan, a light emitter which emits an emission light beam, a light receiver which receives a reception light beam reflected by an object in the environment of the scanner, a control and evaluation unit which determines, for a multitude of measuring points of the scan, at least the distance between the center of the scan and the object, the scanner, for registering a scene with several scans having different centers, being movable between the centers of the scans, and a scanner mouse for registering the path followed by the scanner between the different centers of the scans, the scanner mouse optically registering the movement of the laser scanner relative to a reference surface.

Owner:FARO TECH INC

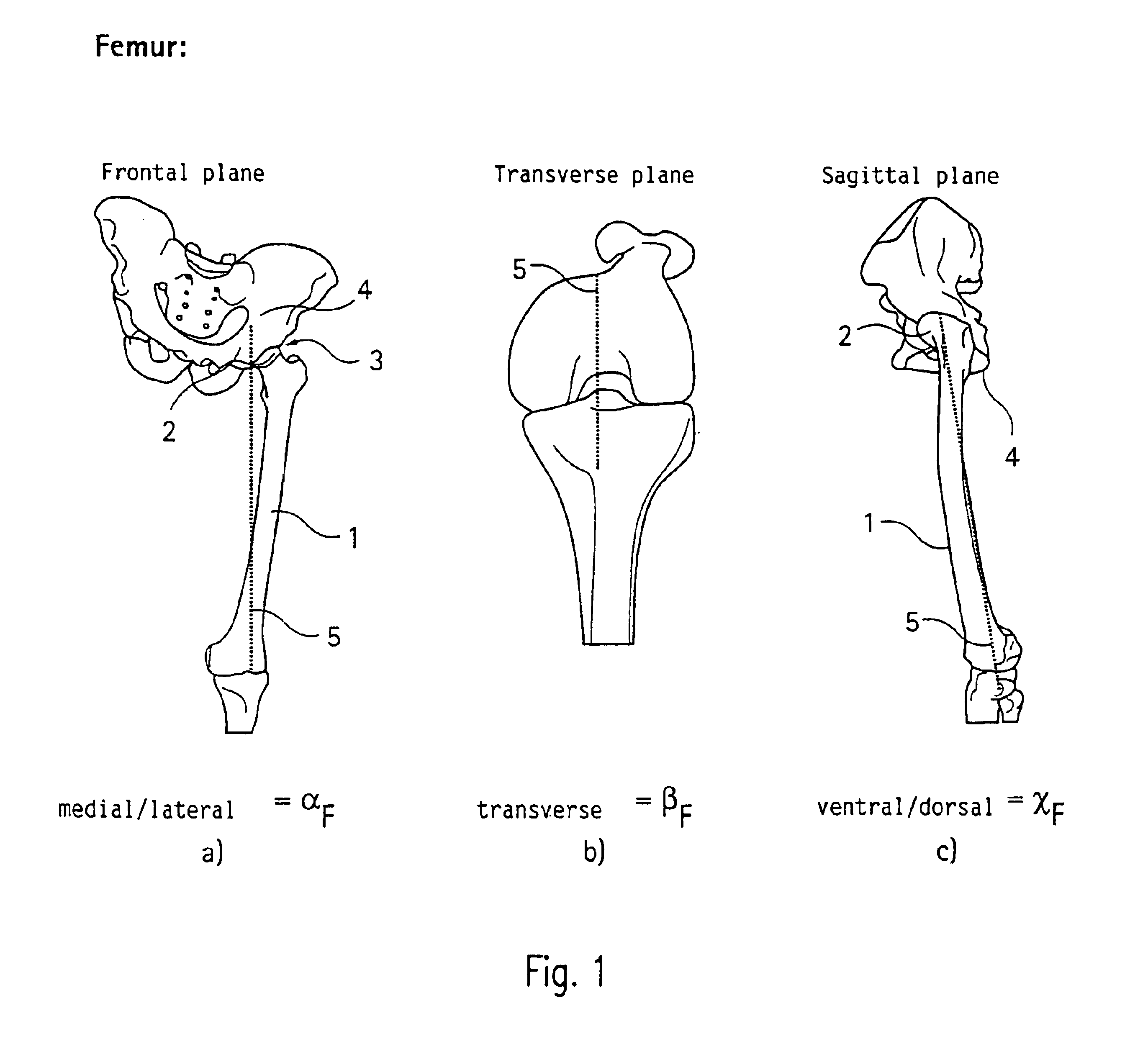

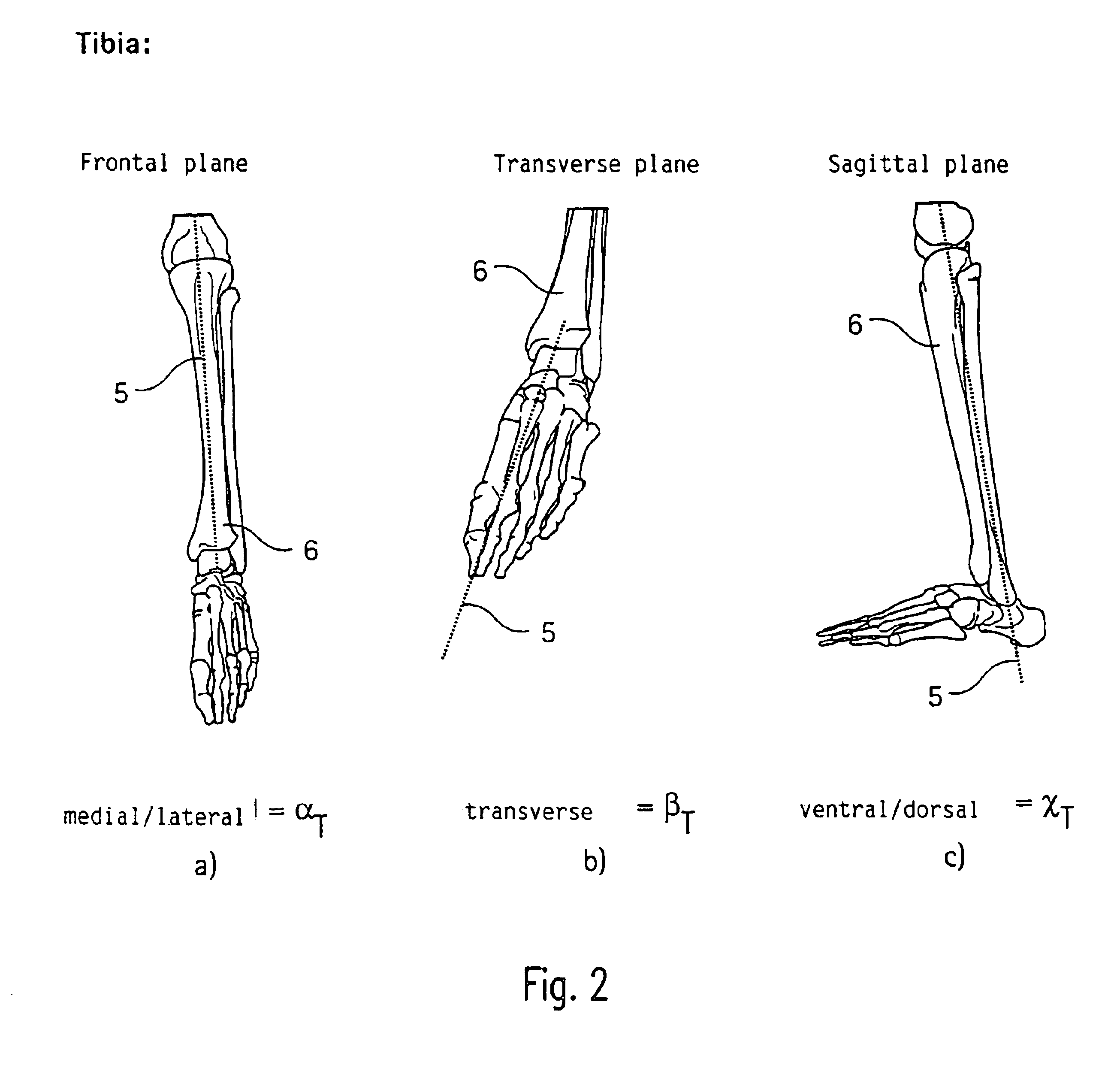

Arrangement for ascertaining function-determining geometric parameters of a joint of a vertebrate

InactiveUS20050182320A1Easy to operateReduce riskSurgical navigation systemsSurgical systems user interfaceStereo cameraMeasurement point

Arrangement for ascertaining function-determining geometric parameters of a joint of a vertebrate, especially a hip or shoulder joint of a human being, in preparation for the installation of a joint replacement implant, especially a hip or shoulder socket or an associated stem implant, by means of an optical coordinate-measuring procedure, having a stereocamera or stereocamera arrangement for the spatial recording of optical transducer signals, a mobile multipoint transducer which is in the form of a movable sensor for sensing bony references in the joint region in order to determine the coordinates thereof, at least one bone-fixed multipoint transducer which is configured for rigid attachment, especially screwed or clamped attachment, (in a region sufficiently distant from the joint) to an extremity originating from the joint, especially close to the proximal end of a femur or a humerus, an interactive sequence controller for controlling the sequential registration and storage of a set of measurement point coordinates supplied by the mobile multipoint transducer and sets of measurement point coordinates recorded in a first plurality of positions of the bone-fixed multipoint transducer in a plurality of rotated positions of the extremity and their subsequent processing in accordance with a previously stored processing sequence, an evaluation unit for evaluating the sets of measurement point coordinates supplied by the multipoint transducers and recorded by the camera arrangement for the purpose of determining the geometric parameters, which comprises means for determining the transversal, vertical and sagittal body axes as well as means for carrying out an iterative procedure, especially an adjustment calculation in accordance with the least squares method, to determine the coordinates of the center of rotation of the joint, and an output unit, which is connected to the sequence controller and to the evaluation unit, for issuing manipulation proposals to an operating surgeon in accordance with the predetermined process sequence and in dependence upon the results of the determination of the geometric parameters, and for displaying the results of the evaluation.

Owner:SMITH & NEPHEW ORTHOPAEDICS

Method for optically scanning and measuring a scene

InactiveUS20120069352A1Promote localizationRegistration result can be improvedImage enhancementImage analysisMeasurement pointLaser scanning

A method for optically scanning and measuring a scene by means of a laser scanner which, for making a scan having a certain center, optically scans and measures its environment provided with targets, whereby two adjacent scans having different centers and scanning the same scene overlap within a range of measuring points so that some targets are scanned by any of the two scans, whereby, for registering the two adjacent scans, the targets are localized in the measuring points during a first step and, during a second step, candidates of correspondence among the localized targets of the two adjacent scans are looked for and, during a third step, a test registration of the two adjacent scans is made which, if there is a sufficient compliance of the measuring points within the overlapping range, is taken over for registration, thus identifying the targets.

Owner:FARO TECH INC

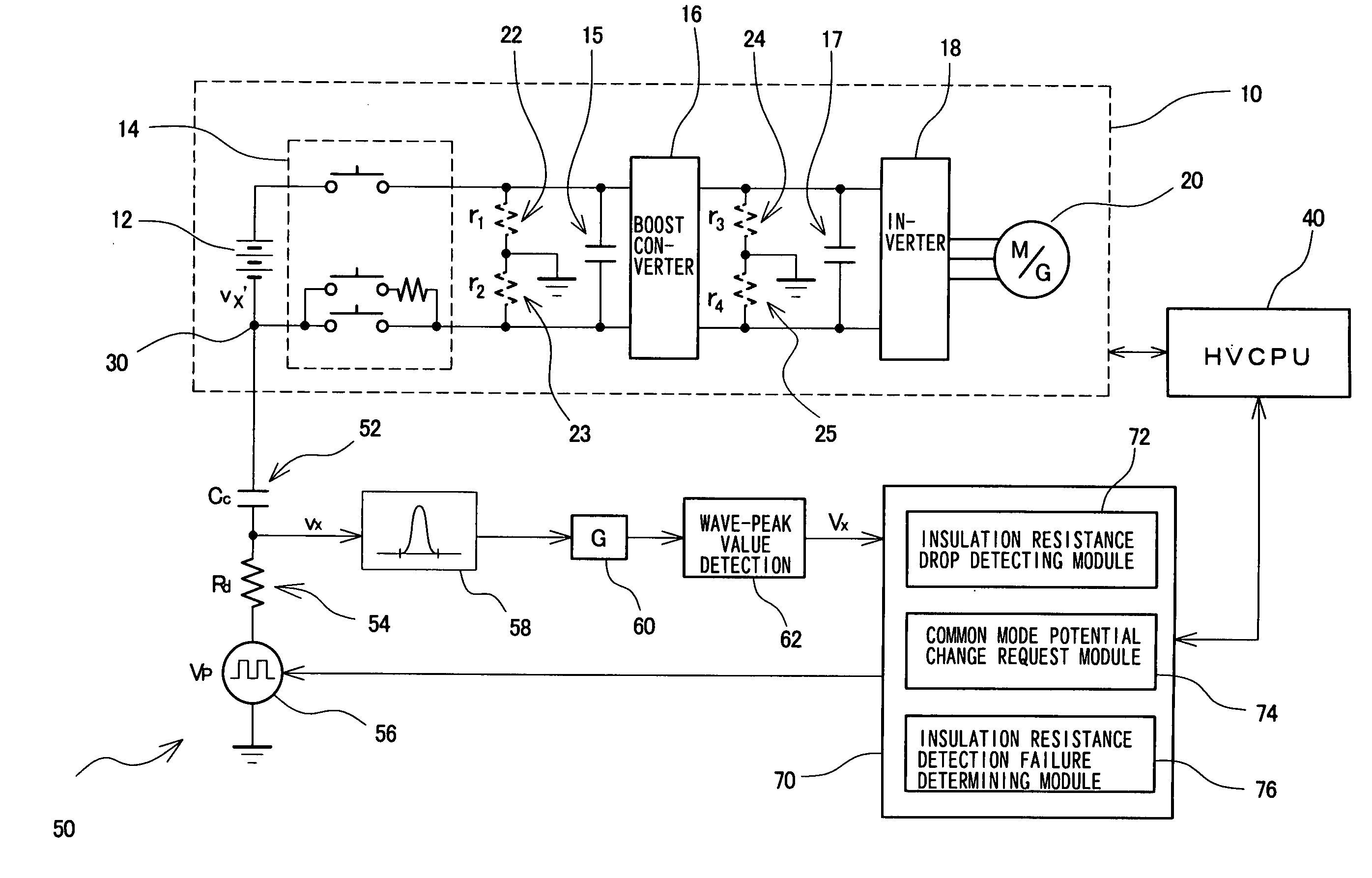

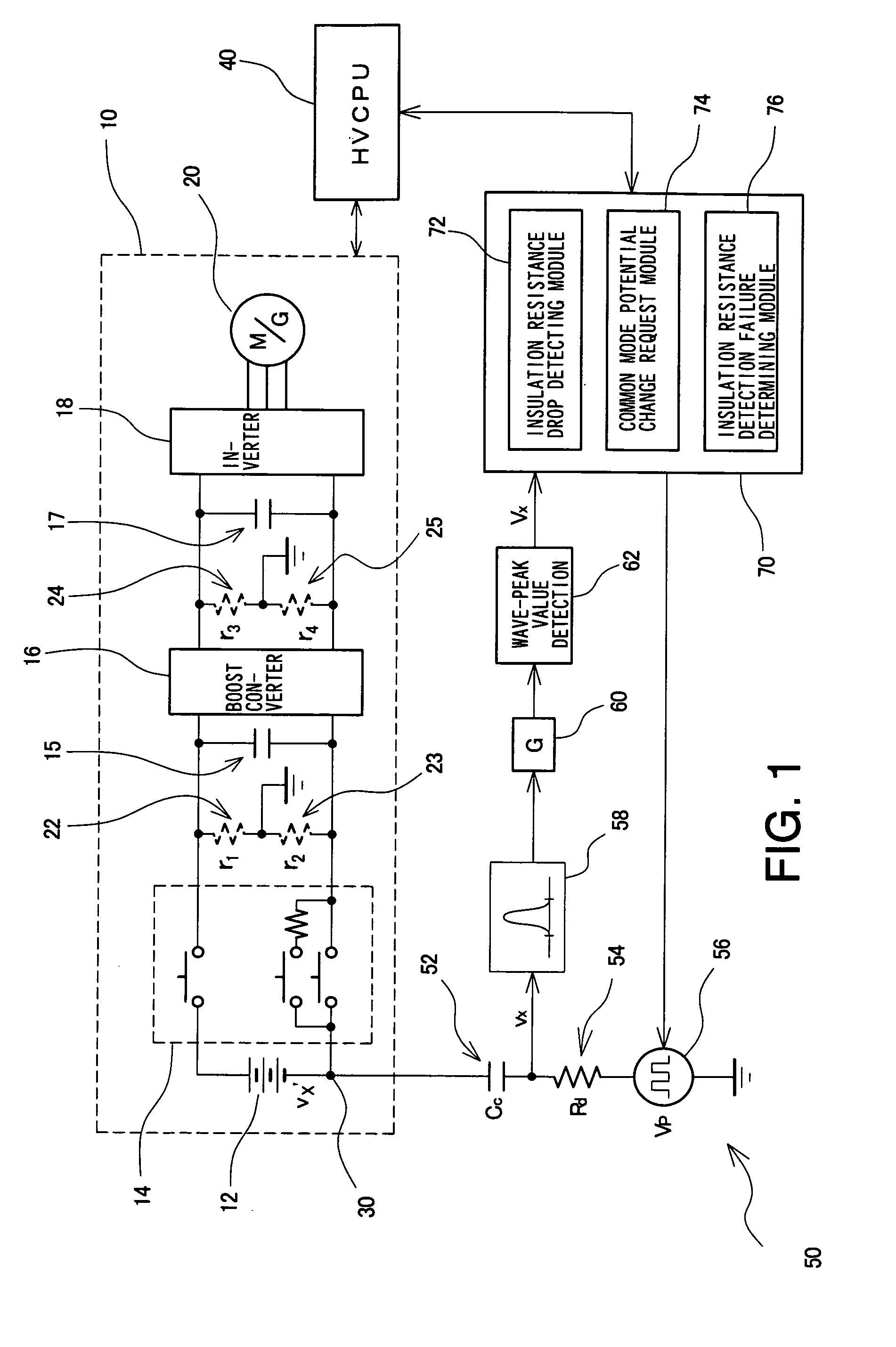

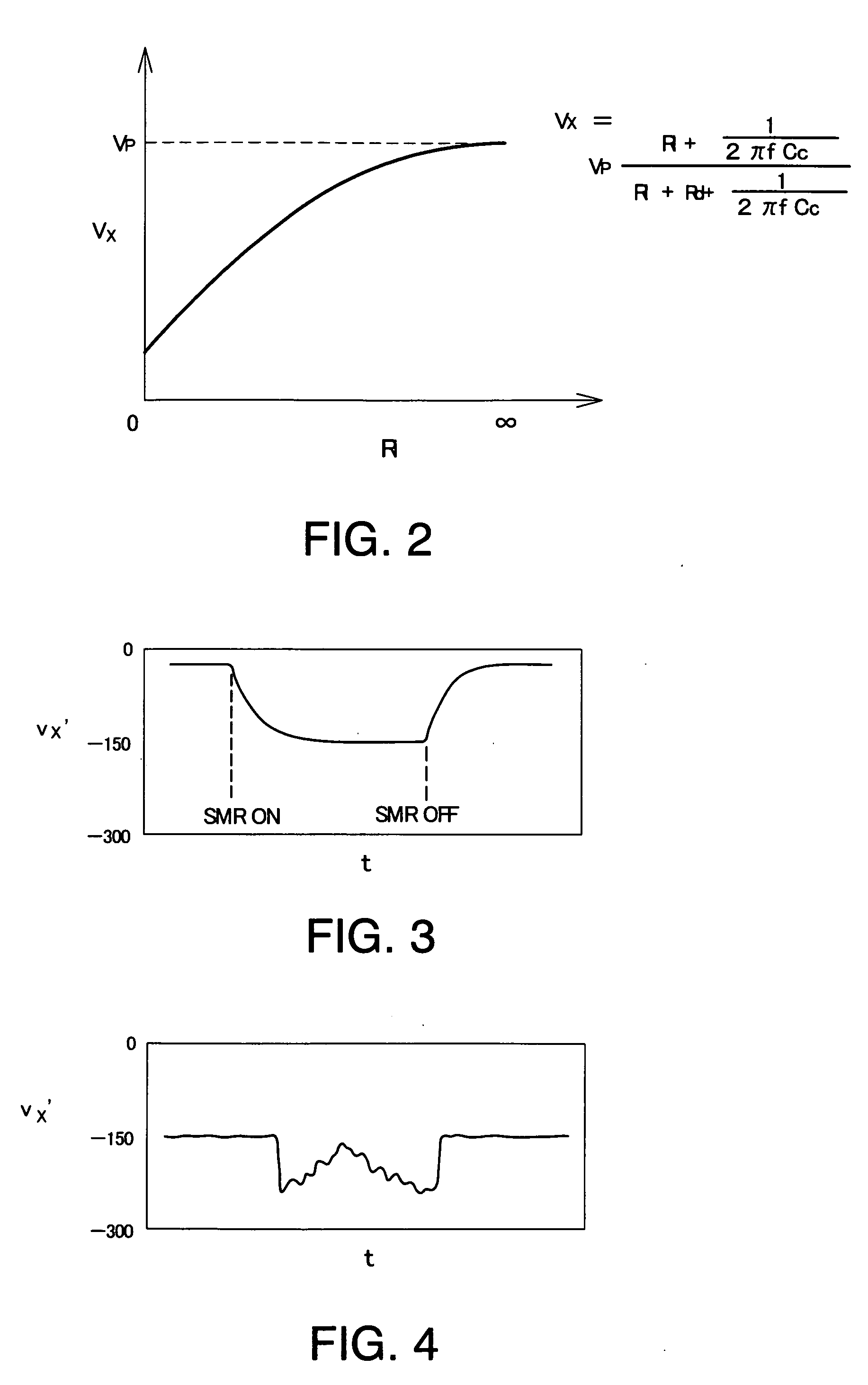

Insulation resistance detection system, insulation resistance detection apparatus and insulation resistance detection method

InactiveUS20090134881A1Accurate fault detectionVery high resistance measurementsElectric devicesPotential measurementPotential change

An insulation resistance determining system (50) comprises an insulation resistance determining portion configured by connecting a coupling capacitor (52), a detection resistor (54), and a pulse oscillating circuit (56) in series with a common mode potential measuring point (30), and an insulation resistance determining portion having a filter (58) which processes an AC signal (vx) at a junction between the coupling capacitor (52) and the detection resistor (54), an amplifier (60), a wave-peak value detection circuit (62), and a controller (70). The controller (70) has functions for detecting a drop in insulation resistance in response to an output of the wave-peak value detection circuit (62); for requesting an HVCPU (40) to change the common mode potential so as to determine a failure of the insulation resistance determining portion; and for determining a failure of the insulation resistance determining portion from an output change of the wave-peak value determining circuit (62) between before and after the common mode potential change.

Owner:TOYOTA JIDOSHA KK

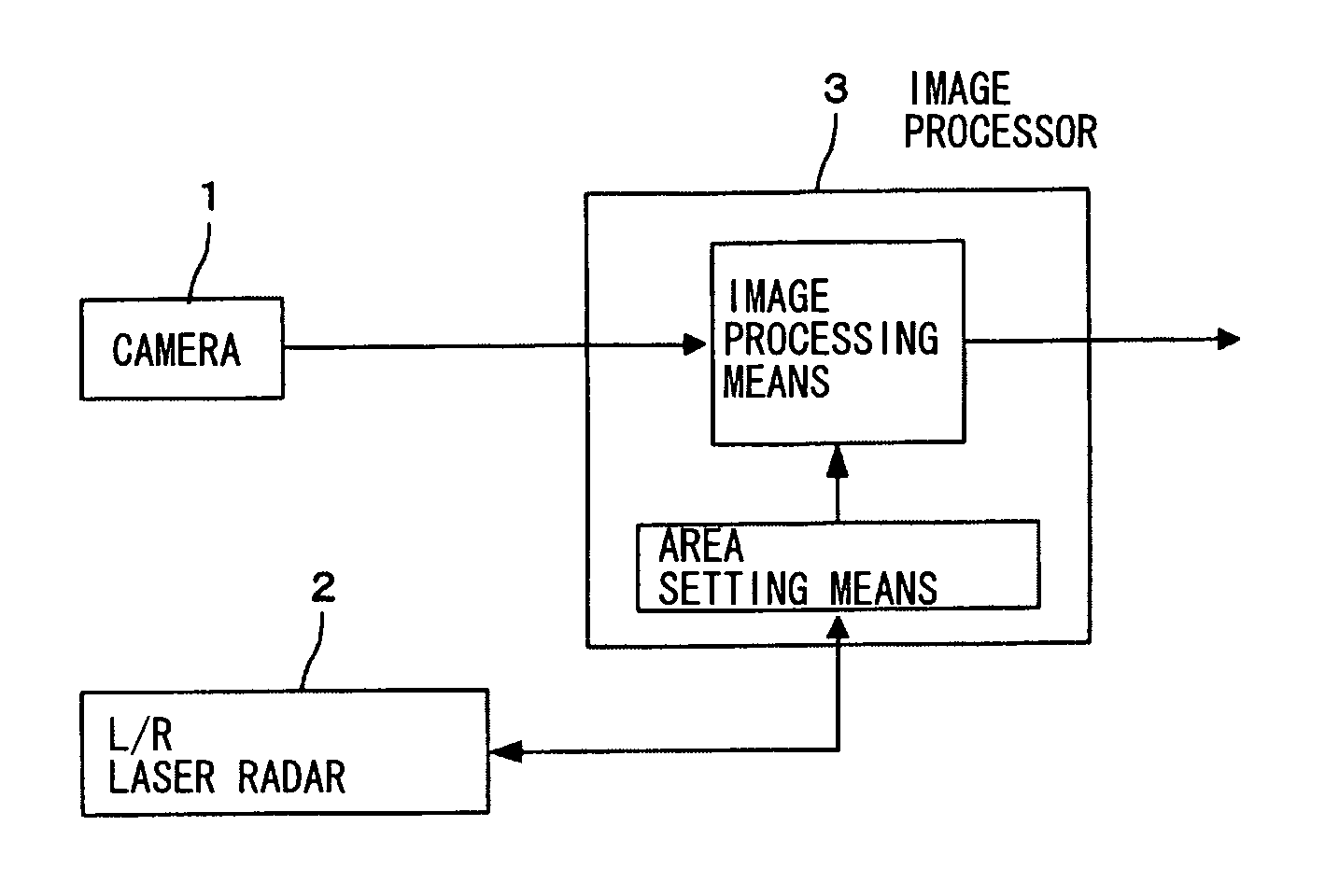

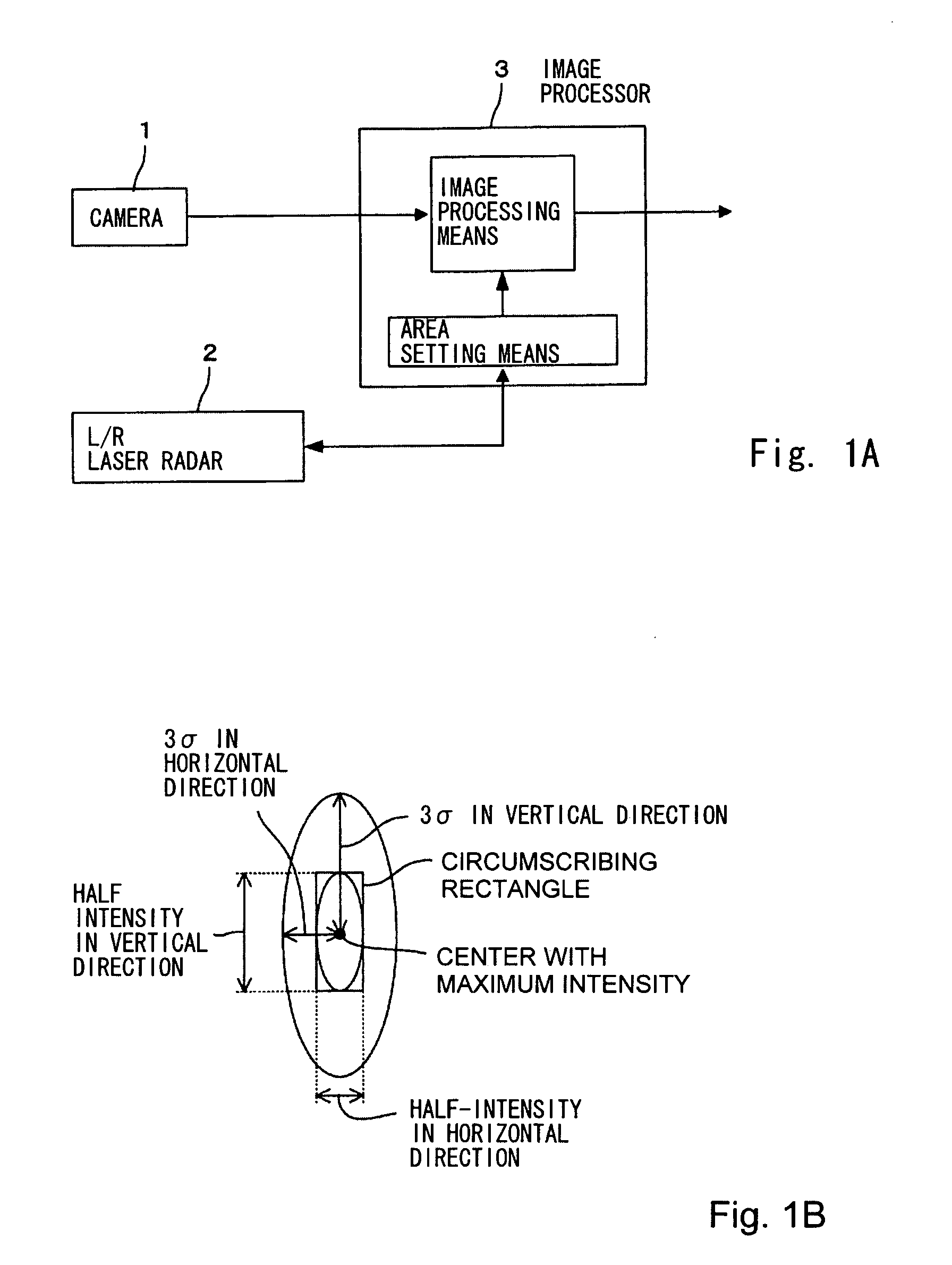

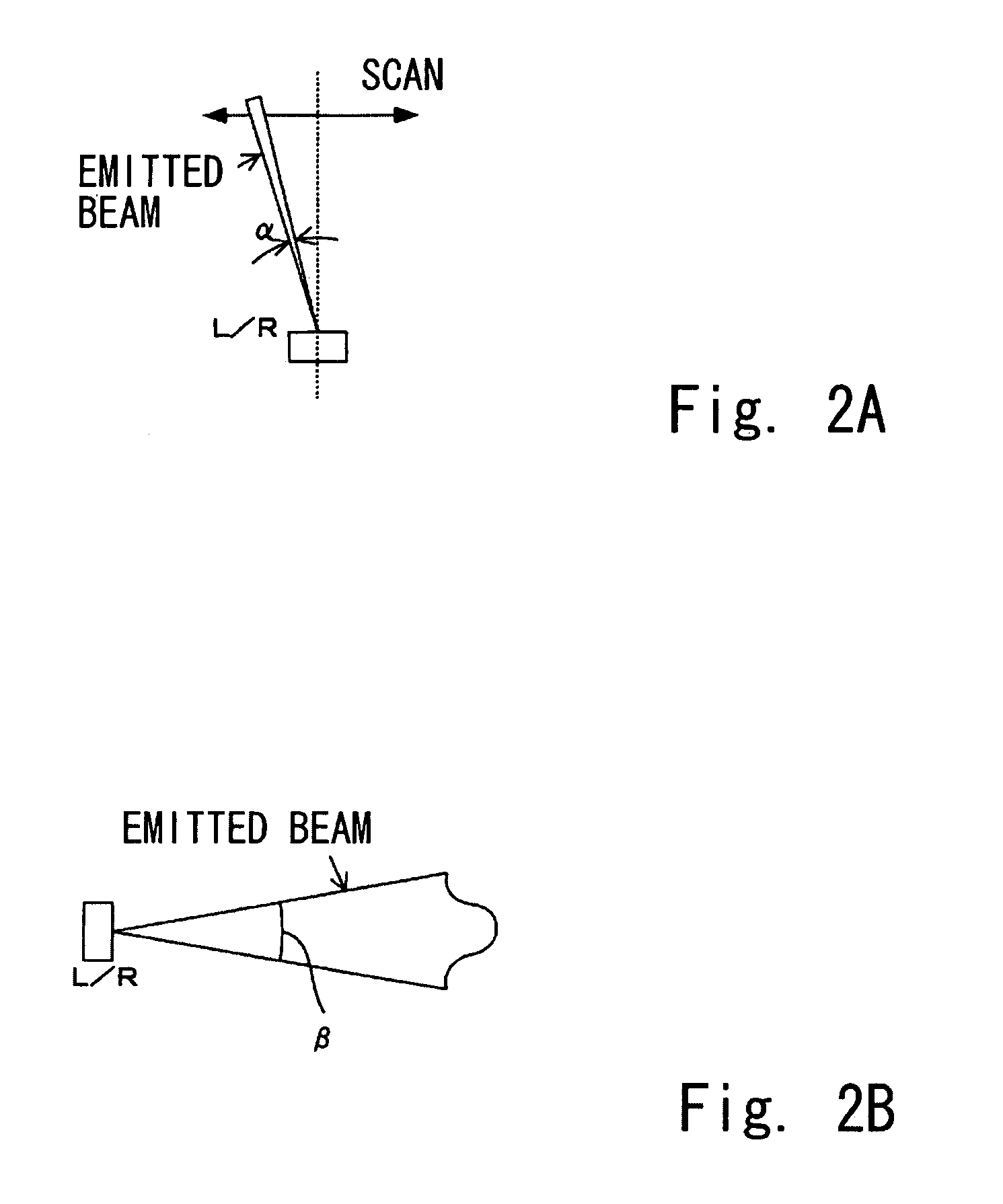

Image processing system for mounting to a vehicle

InactiveUS7176830B2Appropriate settingImage analysisOptical rangefindersImaging processingObject based

An image processing system to be mounted to a vehicle includes a radar adapted to measure distance and direction to an object based on reflected electromagnetic waves which are outputted to scan the exterior of the vehicle, an image-taking device such as a camera for obtaining an image, and an image processor for carrying out image processing on a specified image processing area in an image obtained by the image-taking device. The image processor is adapted to determine a center position of the image processing area according to a measurement point of an object detected by the radar and the size of the image processing area according to a beam profile of electromagnetic waves outputted from the radar.

Owner:ORMON CORP

Ceramic honeycomb filter

InactiveUS6827754B2Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sn being represented by the following formula (1):wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm<3> / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm<3> / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

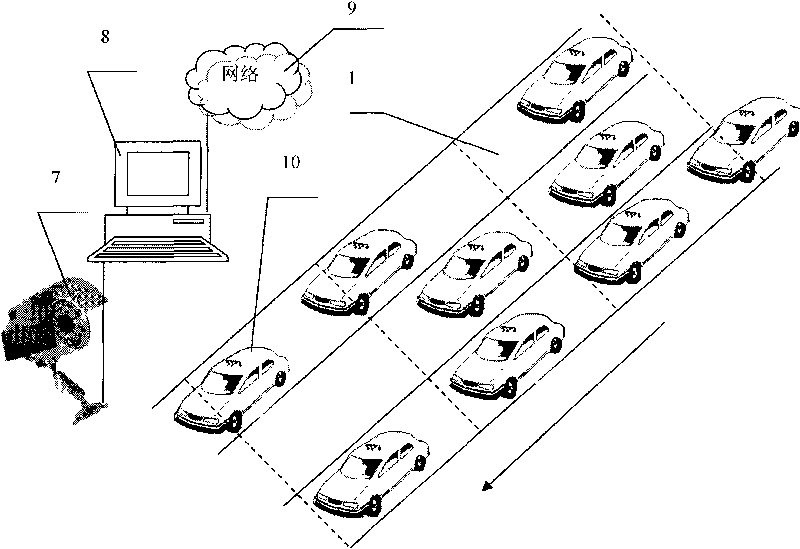

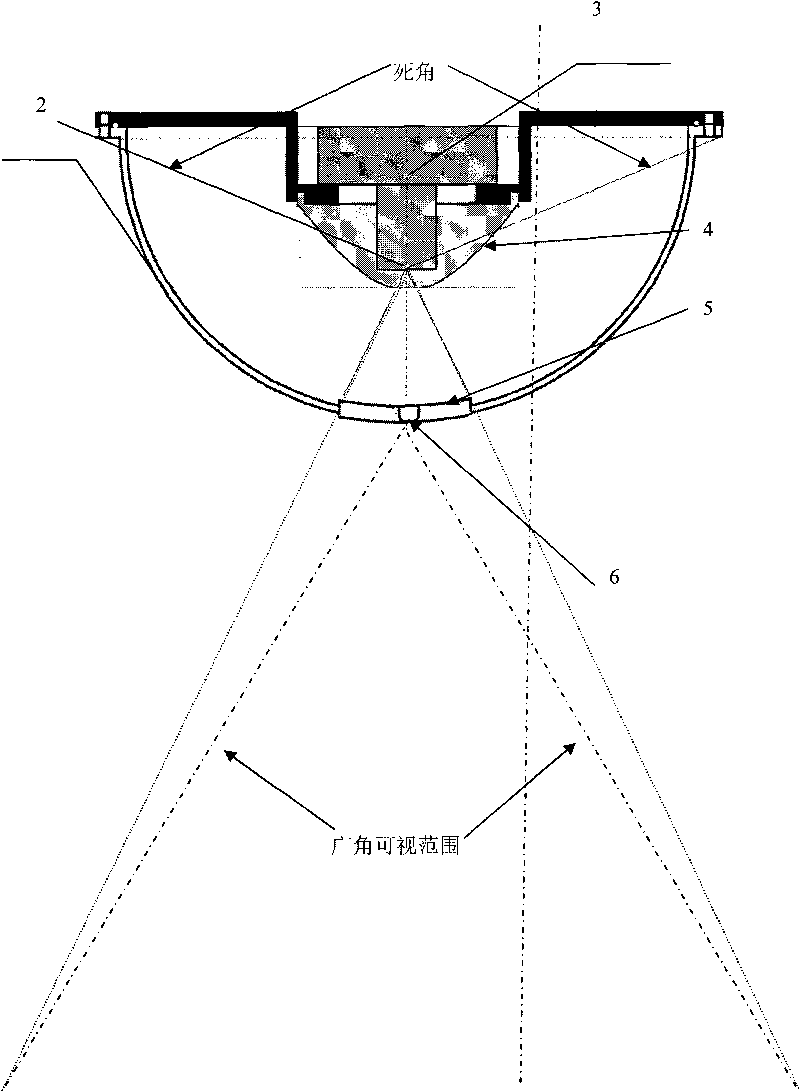

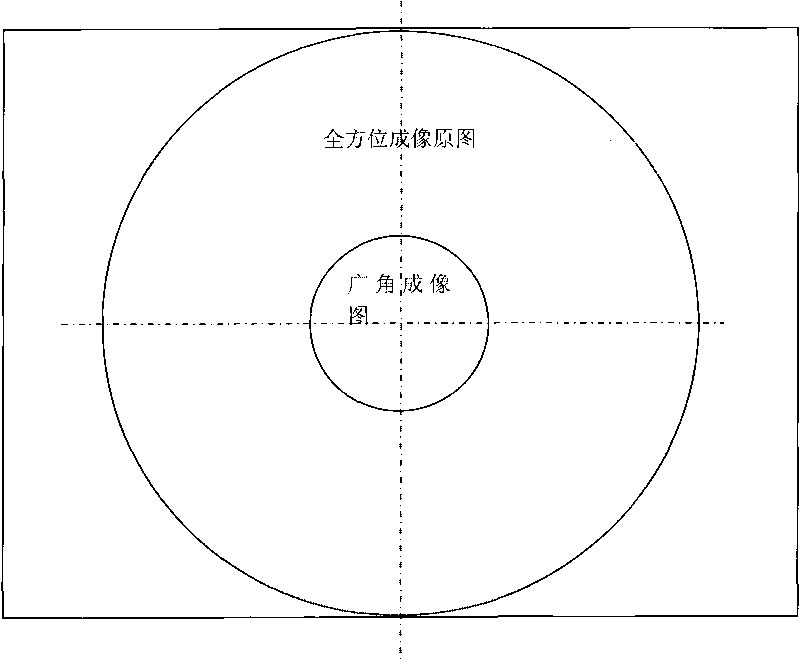

Road traffic state detecting device based on omnibearing computer vision

InactiveCN101710448AWill not affect trafficEasy to implementDetection of traffic movementLearning unitMeasurement point

The invention relates to a road traffic state detecting device based on omnibearing computer vision, comprising shooting devices and a microprocessor, wherein the shooting devices are installed on all measuring points in all roads in a road network; the microprocessor is used for evaluating the road traffic state according to the video data of the shooting devices and comprises a full-view image obtaining unit, a road service capability customizing unit, a road service level self-learning unit, a road service level judging unit, a detecting data processing unit and an artificial checking unit. The road traffic state detecting device based on omnibearing computer vision has wide detecting range, high detecting precision, good detecting instantaneity, convenient application, visual and clear detecting result, subjective sensitivity index data and objective evaluation index data and is convenient for all grades of road networks of a city to carry out comprehensive evaluation on the road traffic state in time and space.

Owner:ZHEJIANG UNIV OF TECH

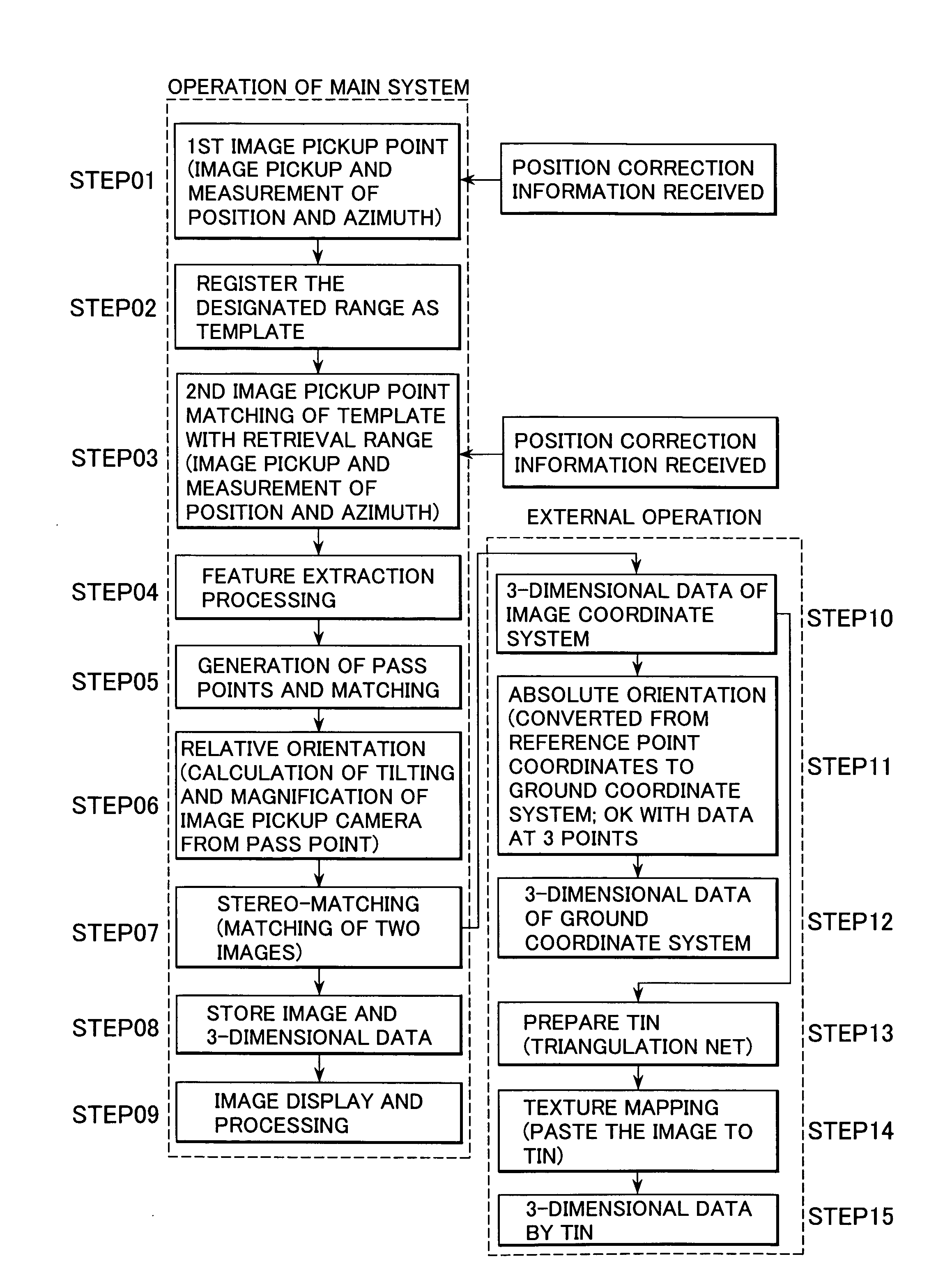

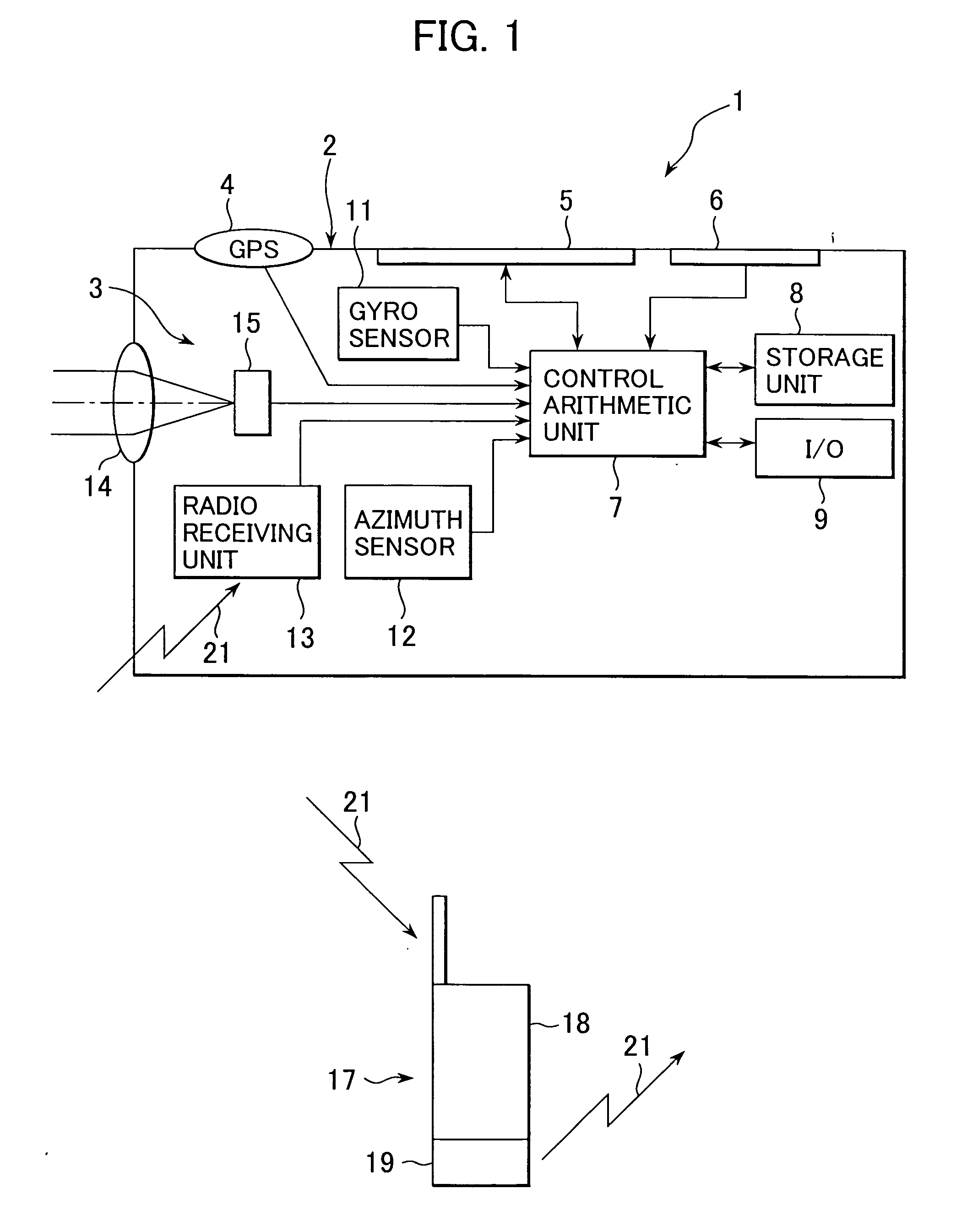

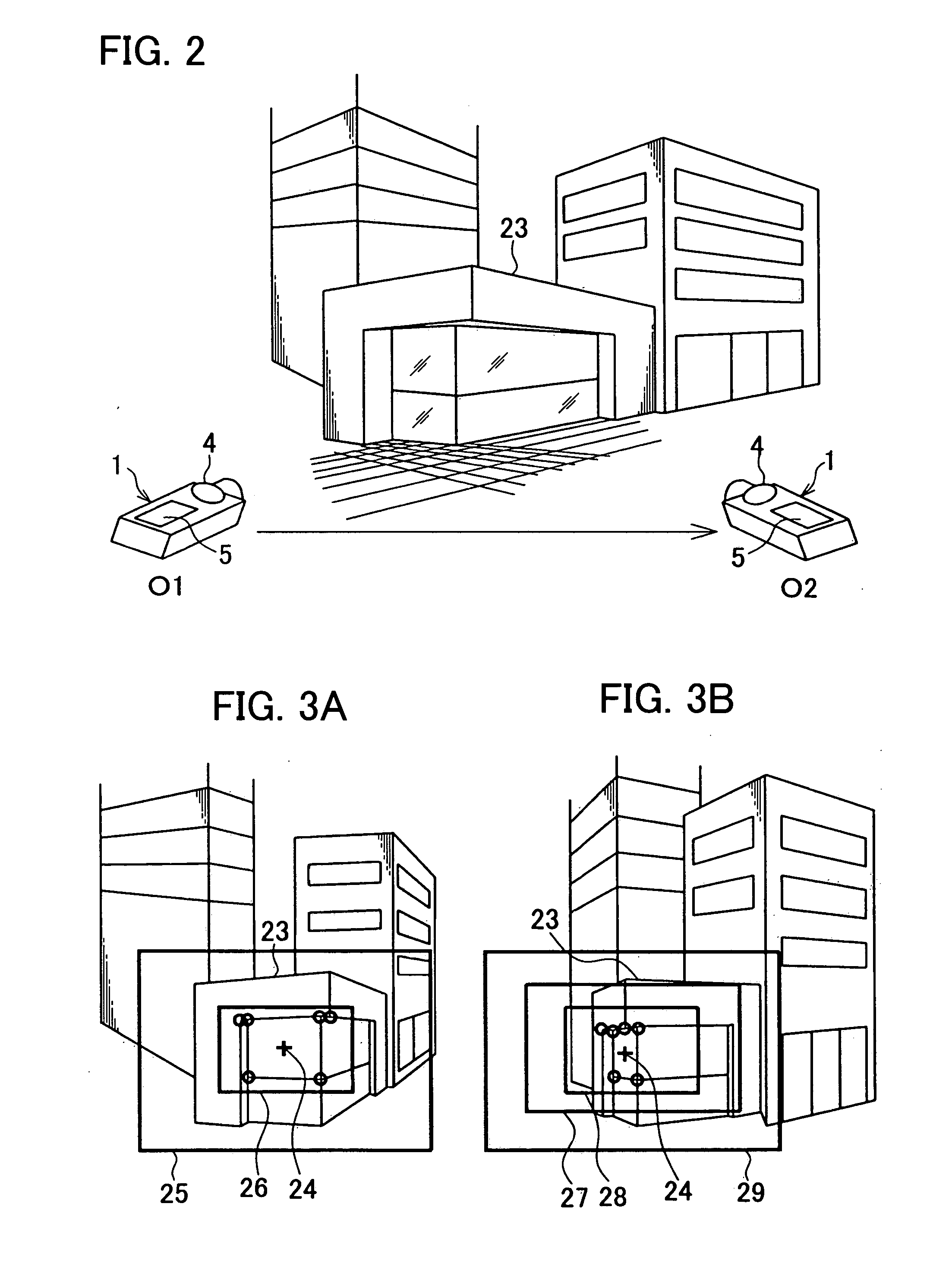

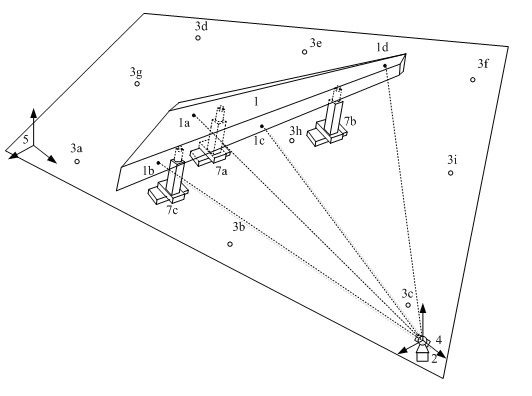

Geographic data collecting system

InactiveUS20070010924A1Improve work efficiencyVehicle testingRegistering/indicating working of vehiclesMeasurement pointDigital image

Owner:KK TOPCON

Method for measuring positioning points based on laser tracker in docking process of airplane parts

InactiveCN102519441AImprove assembly measurement accuracyReduce work intensitySurveying instrumentsUsing optical meansJet aeroplaneObservation point

The invention discloses a method for measuring positioning points based on a laser tracker in a docking process of airplane parts. The method provided by the invention comprises the following steps of 1, establishing a model of transformation between an airplane global coordinate system and a laser tracker measure coordinate system according to common observation points, 2, acquiring current calculating positions of positioning measure points of airplane parts according to a process joint sphere centre position, and 3, controlling and driving a laser tracker to search current accurate positions of the positioning measure points of the airplane parts from the current calculating positions according to a cross helical search method and to carry out automatic measure. The method provided by the invention has the advantages that 1, an advanced laser measure technology is adopted so that the airplane assembling measure precision is improved; and 2, a measure process does not need artificial light introduction and full automatic search measure of a docking assembling process is realized according to an algorithm so that working efficiency and measure precision are greatly improved and working strength of workers is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

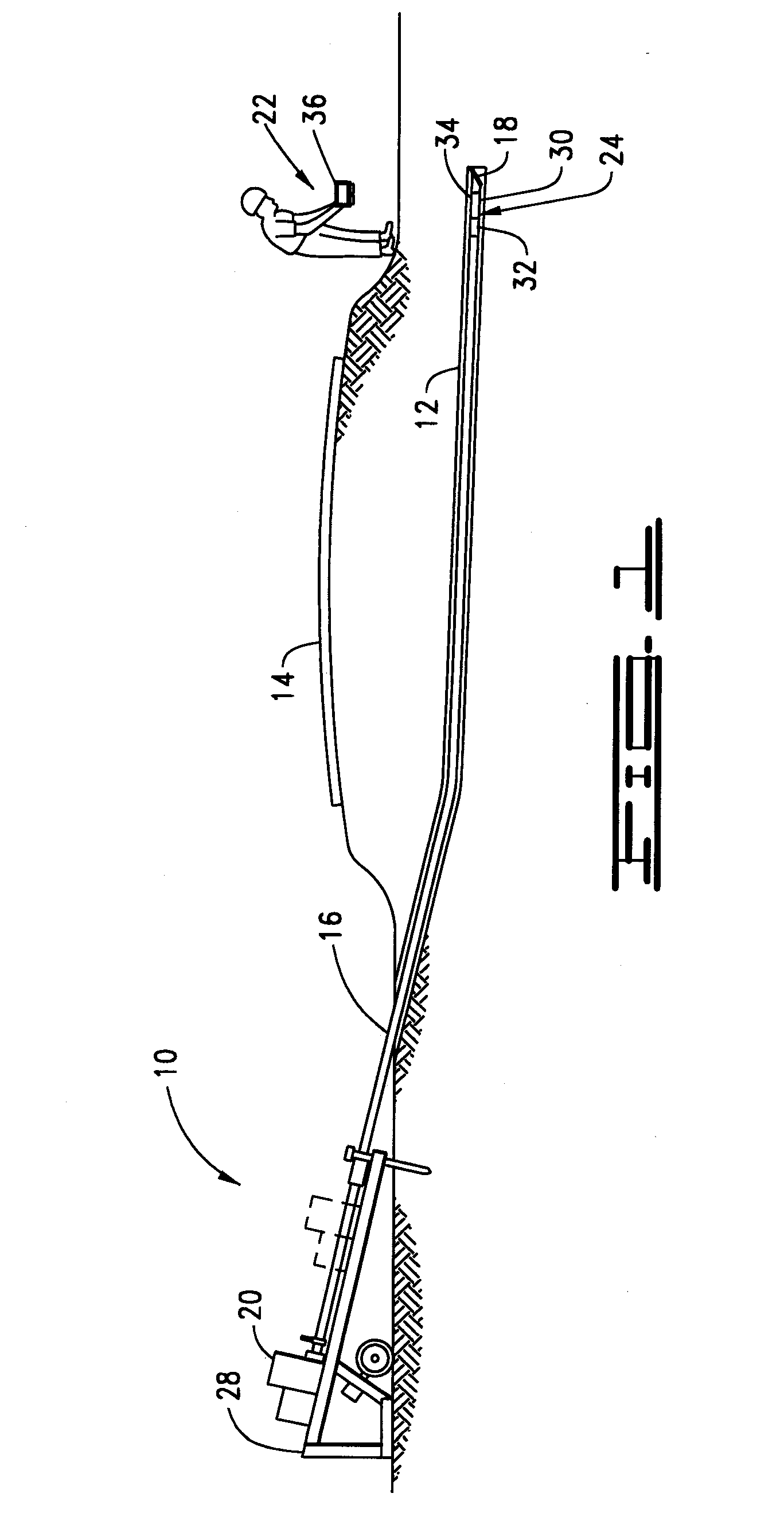

Dipole locator using multiple measurement points

ActiveUS20060254820A1Electric/magnetic detection for well-loggingSurveyMeasurement pointConductor Coil

A receiver and tracking system for identifying a location of a magnetic field source. In a preferred embodiment a plurality of tri-axial antennas are positioned at three distinct points on a receiver frame. Each antenna detects a magnetic field from a source and a processor is used to determine a location of the source relative to the frame using the antenna signals. Each tri-axial antenna comprises three windings in each of three channels defined by a support structure. The windings each define an aperture area. The windings have substantially identical aperture areas and have a common center point. The receiver may to display to the operator the relative location of the field source or may direct the operator to a spot directly above the field source.

Owner:CHARLES MACHINE WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com