Patents

Literature

9444 results about "Quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "A part of quality management focused on fulfilling quality requirements".

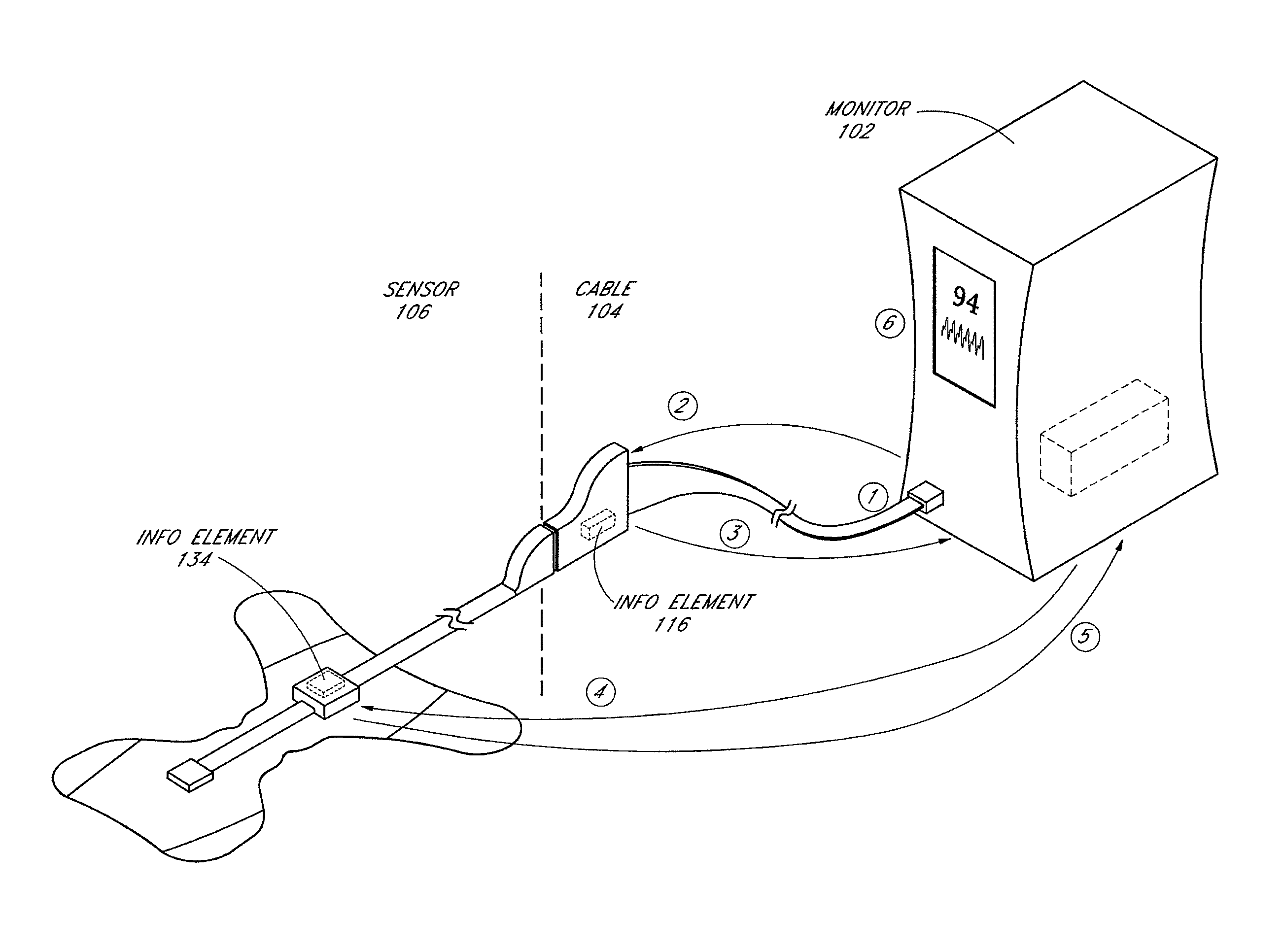

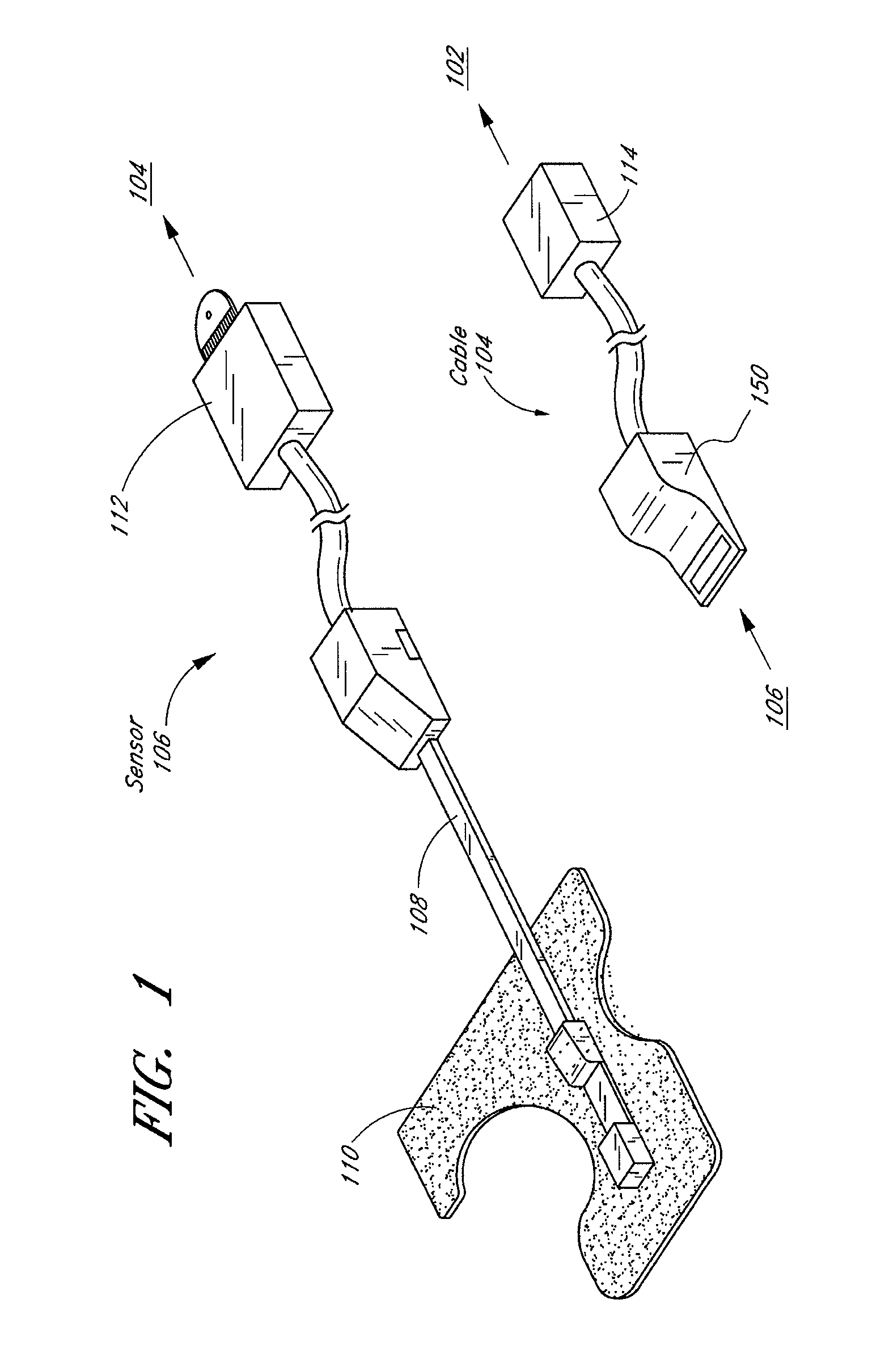

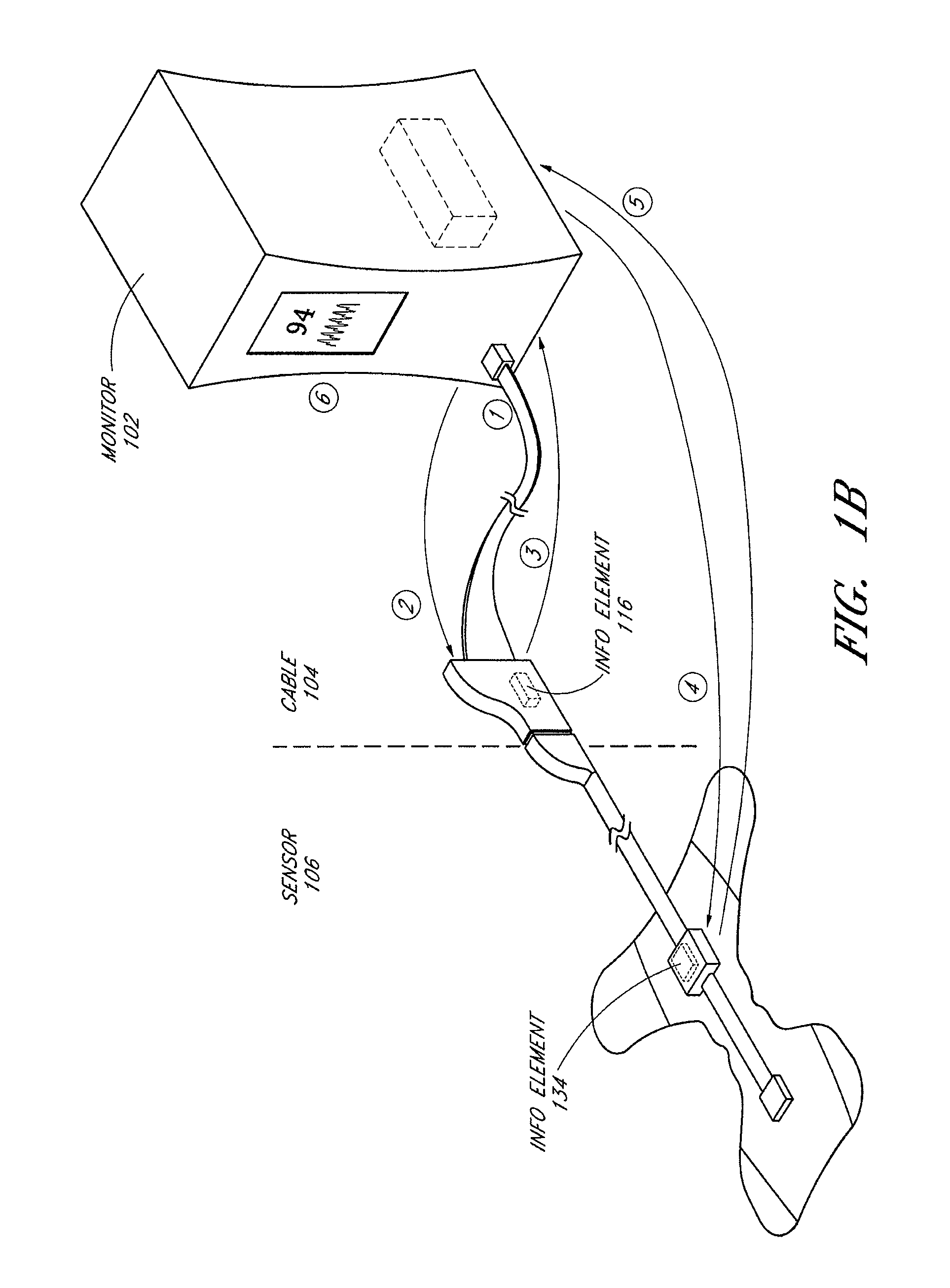

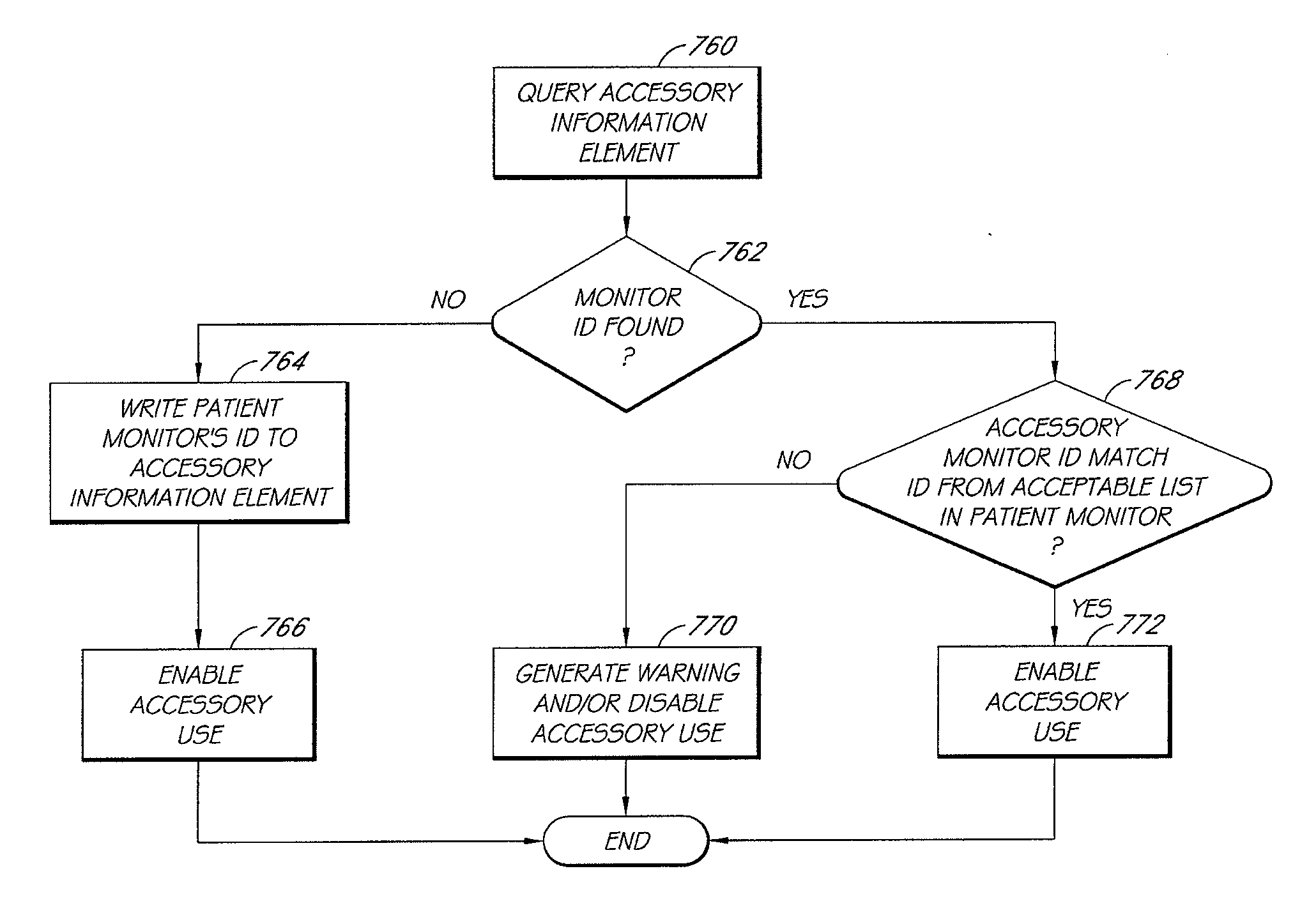

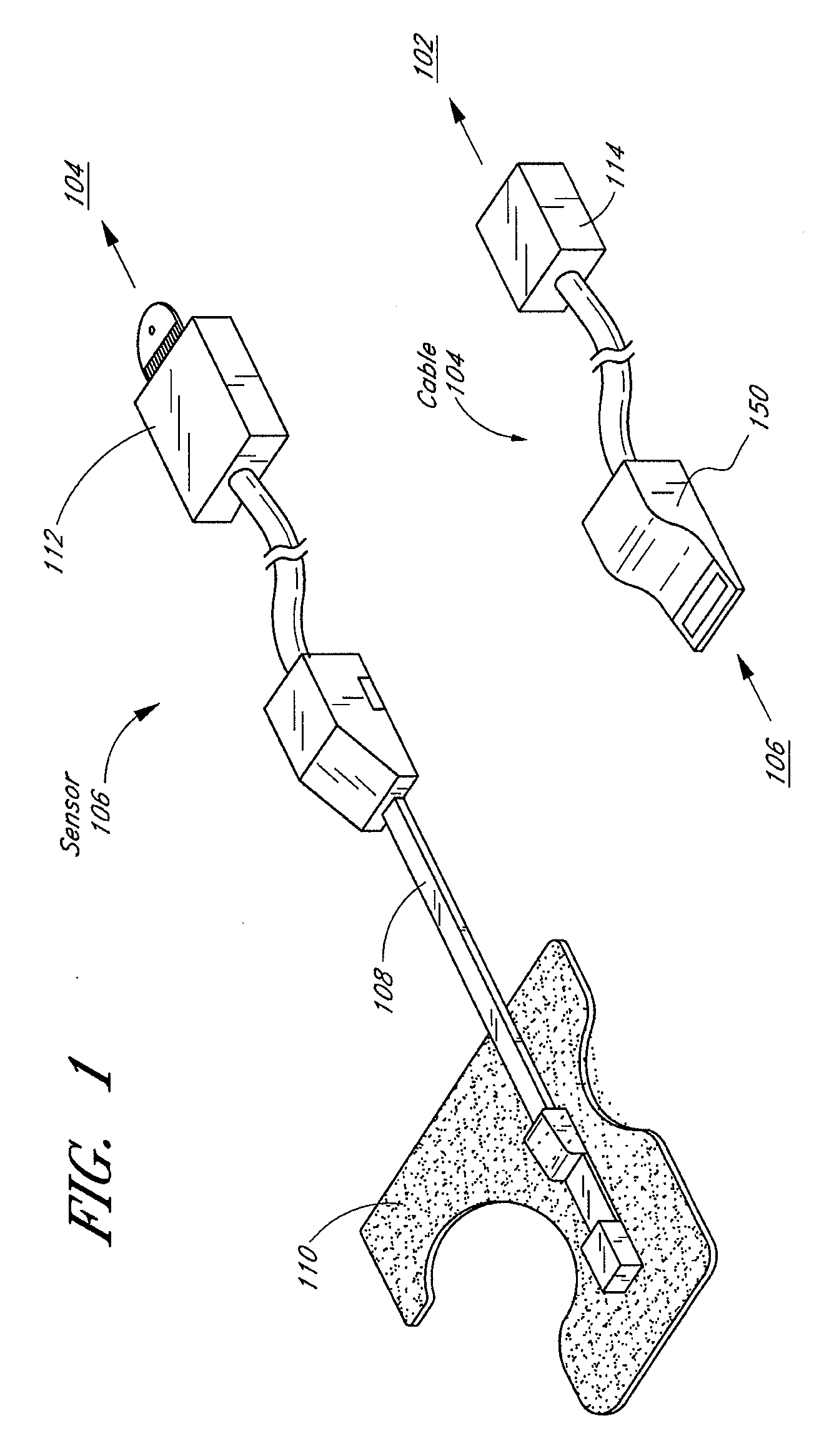

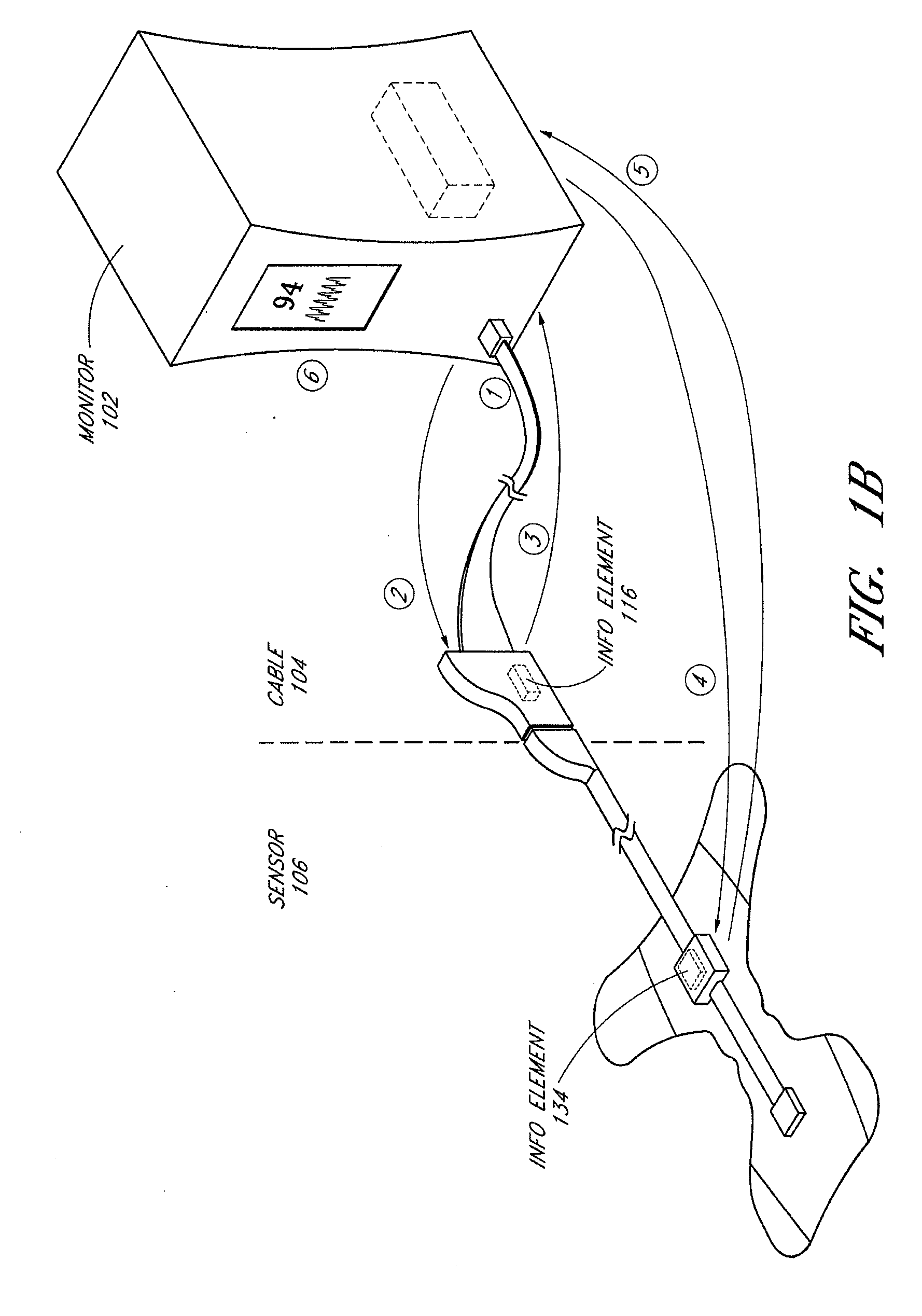

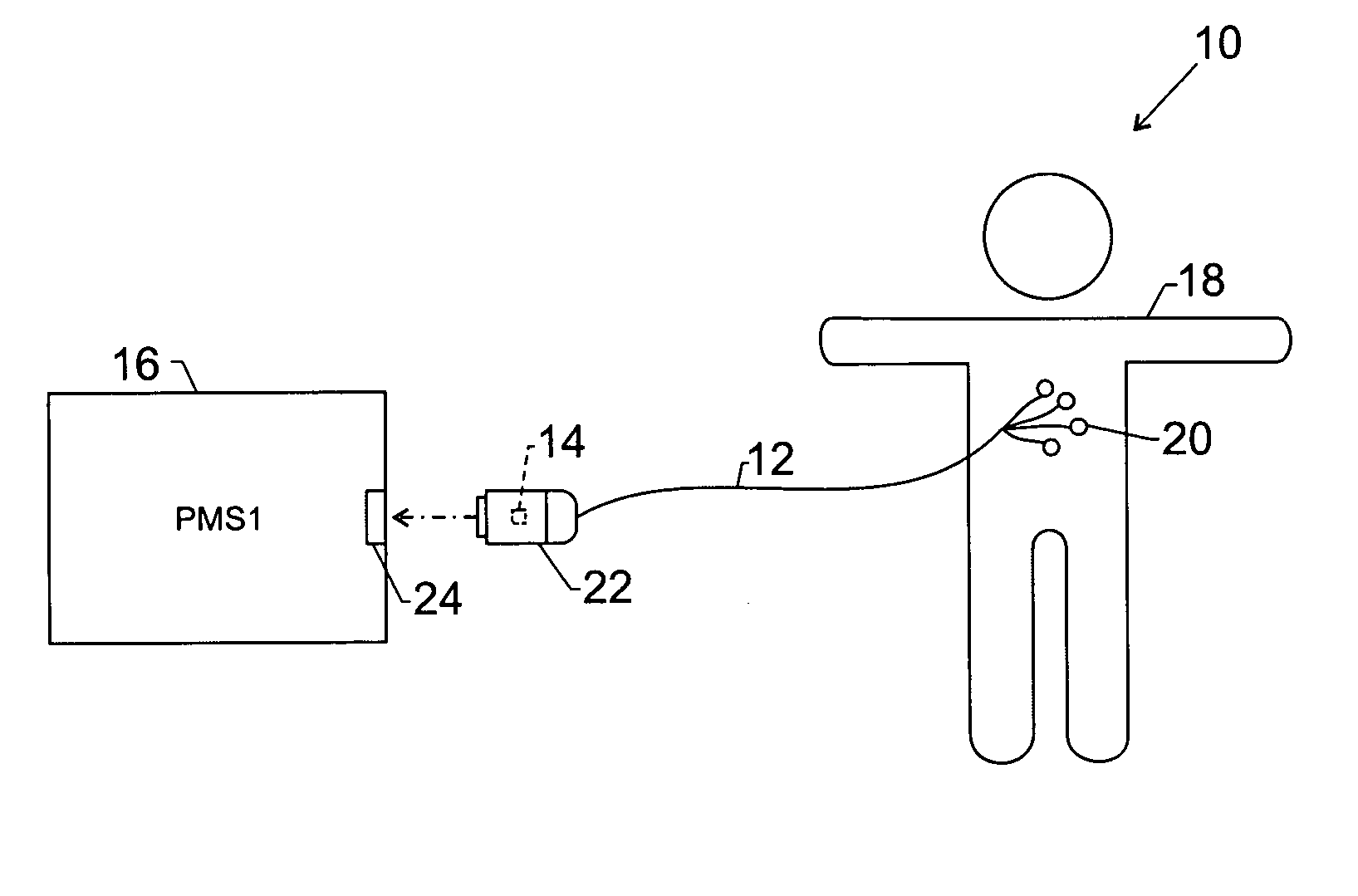

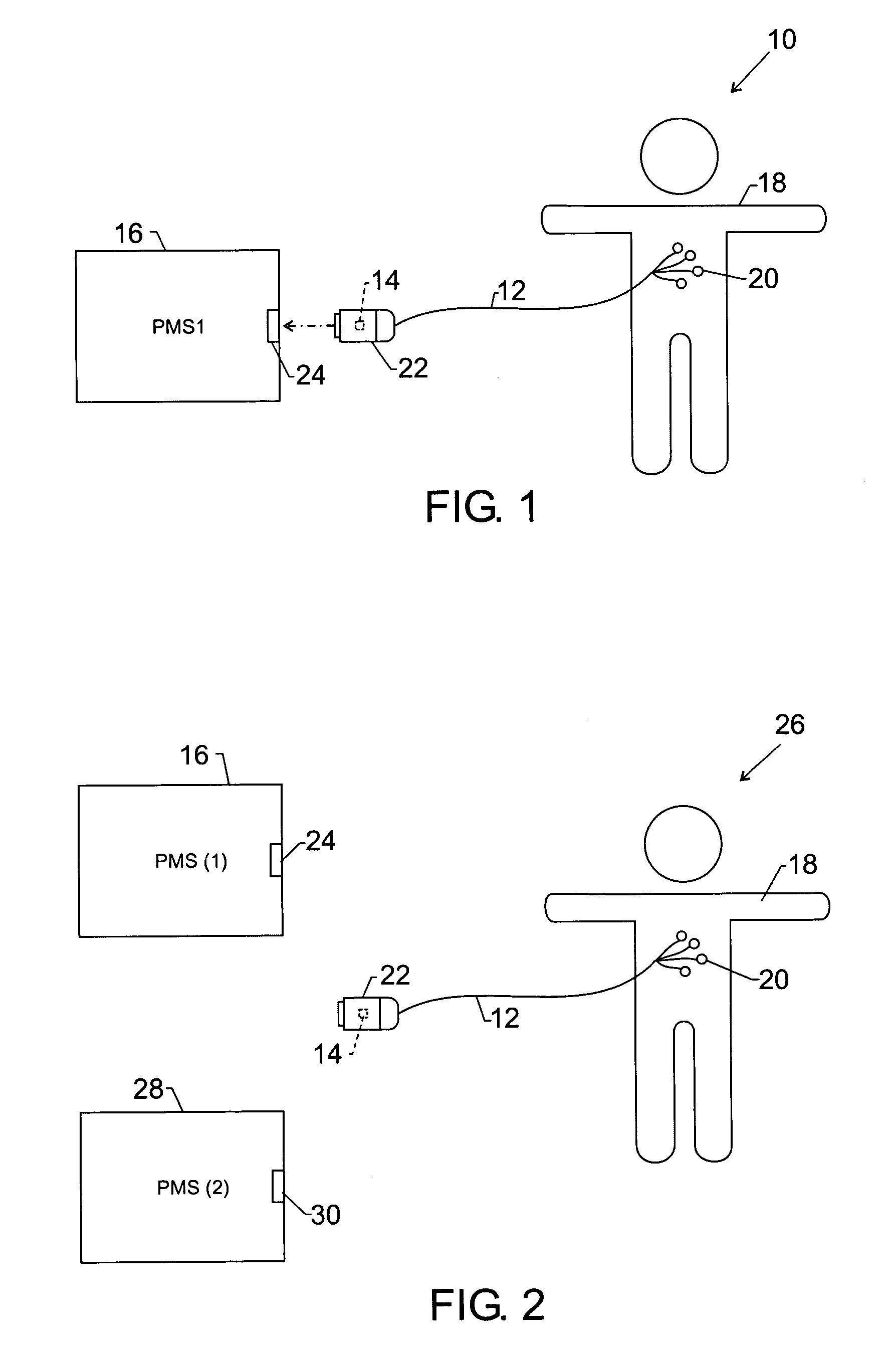

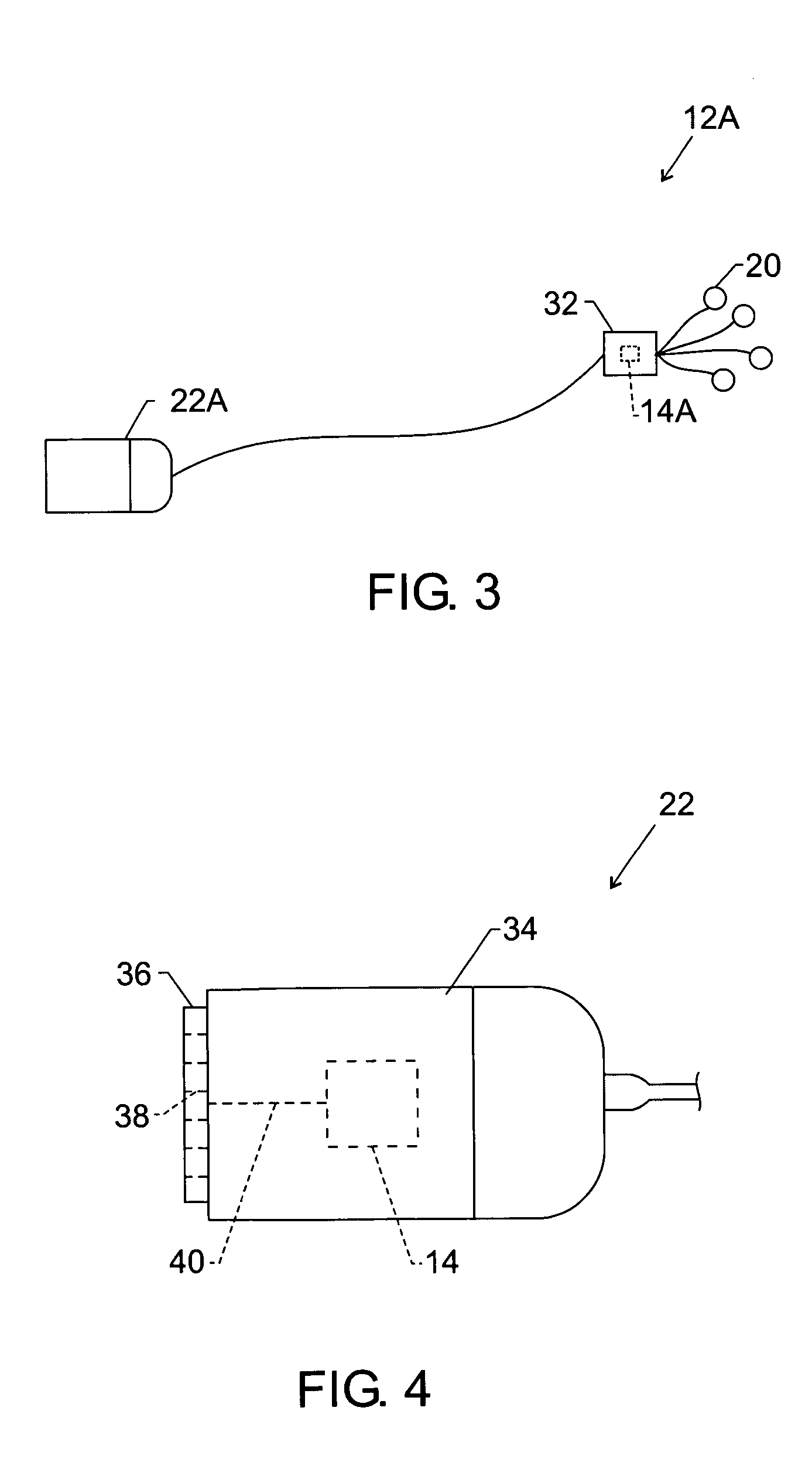

Patient monitor capable of monitoring the quality of attached probes and accessories

ActiveUS8255026B1Reduce capacityReduce the possibilityDiagnostic recording/measuringSensorsQuality controlPulse oximetry

A system and method to help maintain quality control and reduce cannibalization of accessories and attached probes in a highly sensitive patient monitor, such as a pulse oximetry system. One or more attached components may have information elements designed to designate what quality control mechanisms a patient monitor should look to find on that or another component or designate other components with which the one component may properly work. In a further embodiment, such information elements may also include data indicating the appropriate life of the component.

Owner:JPMORGAN CHASE BANK NA

Patient monitor capable of monitoring the quality of attached probes and accessories

ActiveUS20120319816A1Reduce capacityReduce the possibilityProgramme controlElectric signal transmission systemsQuality controlPulse oximetry

A system and method to help maintain quality control and reduce cannibalization of accessories and attached probes in a highly sensitive patient monitor, such as a pulse oximetry system. One or more attached components may have information elements designed to designate what quality control mechanisms a patient monitor should look to find on that or another component or designate other components with which the one component may properly work. In a further embodiment, such information elements may also include data indicating the appropriate life of the component.

Owner:JPMORGAN CHASE BANK NA

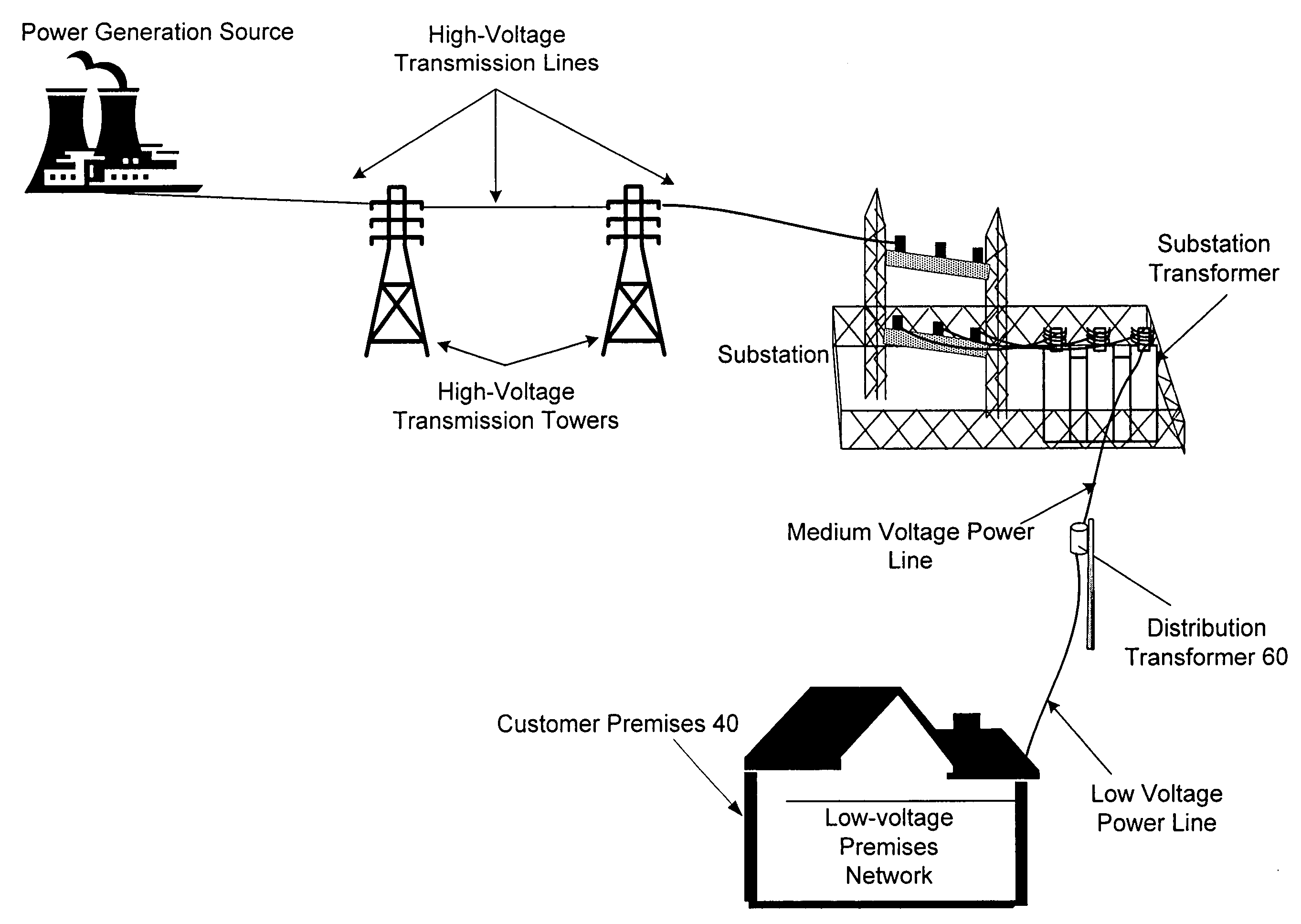

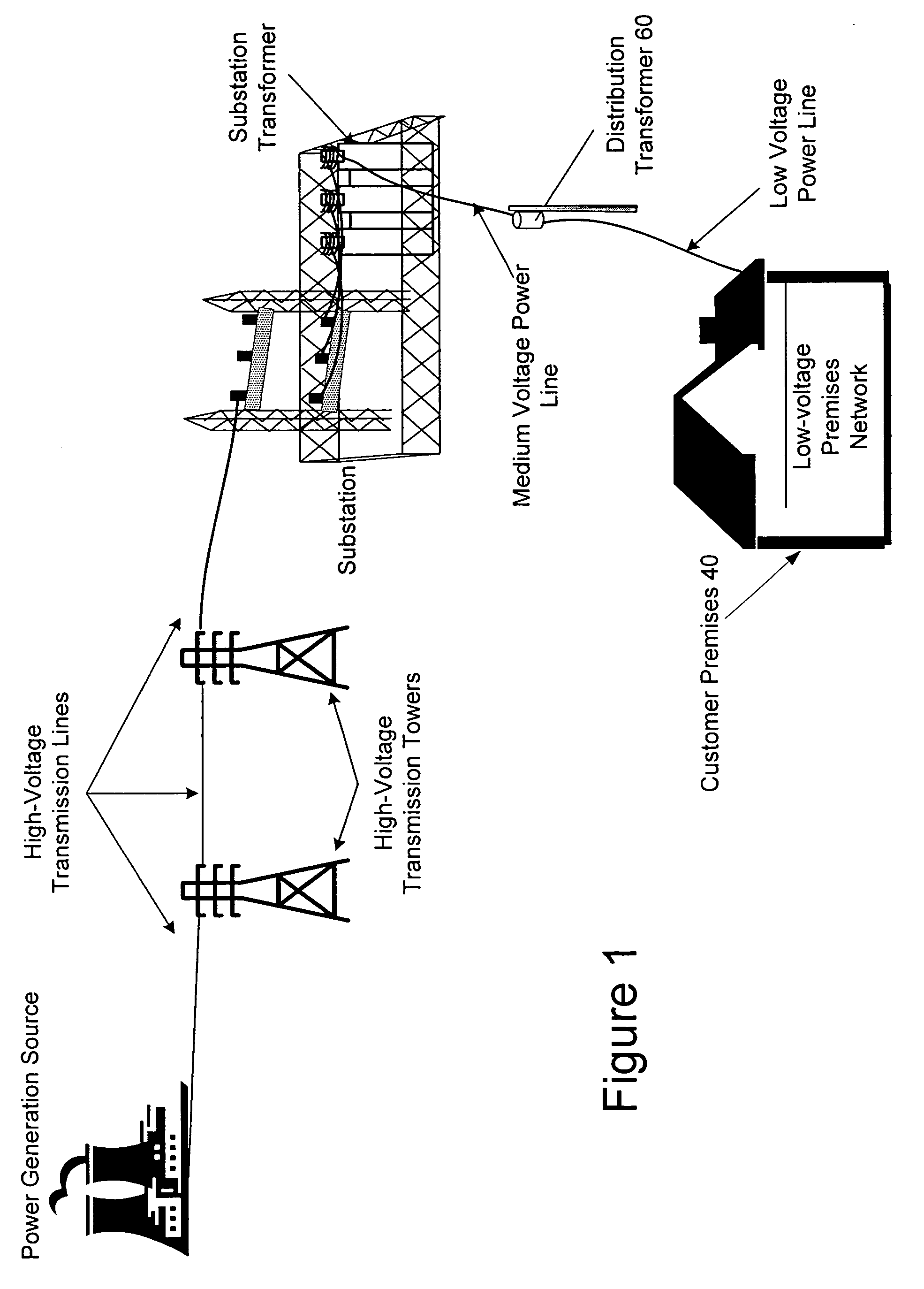

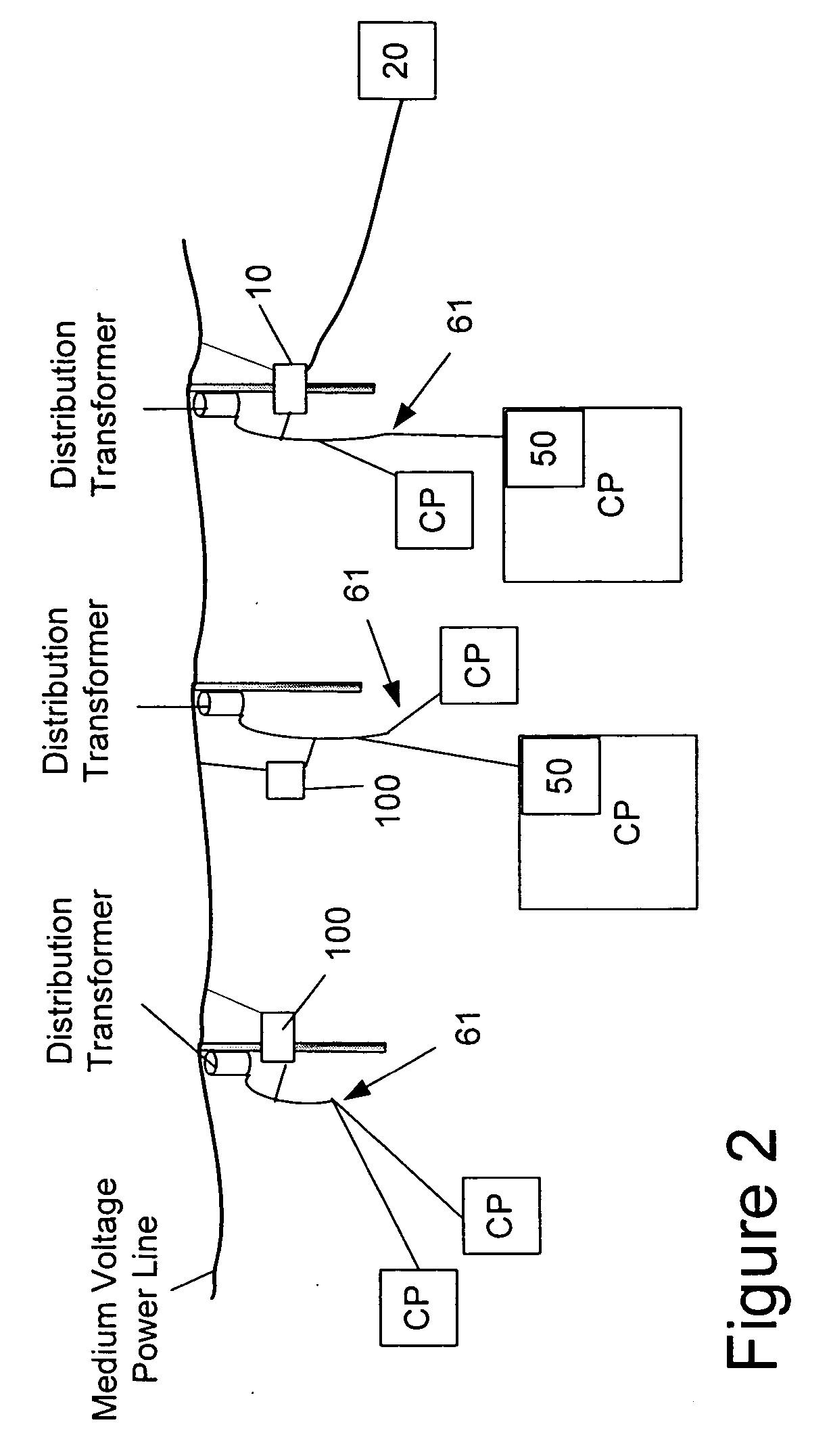

Power line communication rate limiting system and method

InactiveUS20070002771A1Rate limiting quality of service (QoS) controlError preventionTransmission systemsQuality of serviceRate limiting

A power line communications device that may provide rate limiting and quality of service control is provided. The device may include a first modem in communication with one or more user devices via a low voltage power line subnet and a second modem communicatively coupled to a second communications medium. The device also may include a controller in communication with the first and second modems and a computer readable medium encoded with instructions to control the operation of the controller. The controller may rate limit data to and / or from a destination and / or source based one or more parameters such as the destination address, the source address, the type of data, temporal parameters, and other criteria. In addition, the controller may implement QoS for data and transmit QoS parameters to power line modems to allow the power line modems to perform QoS.

Owner:CURRENT TECH

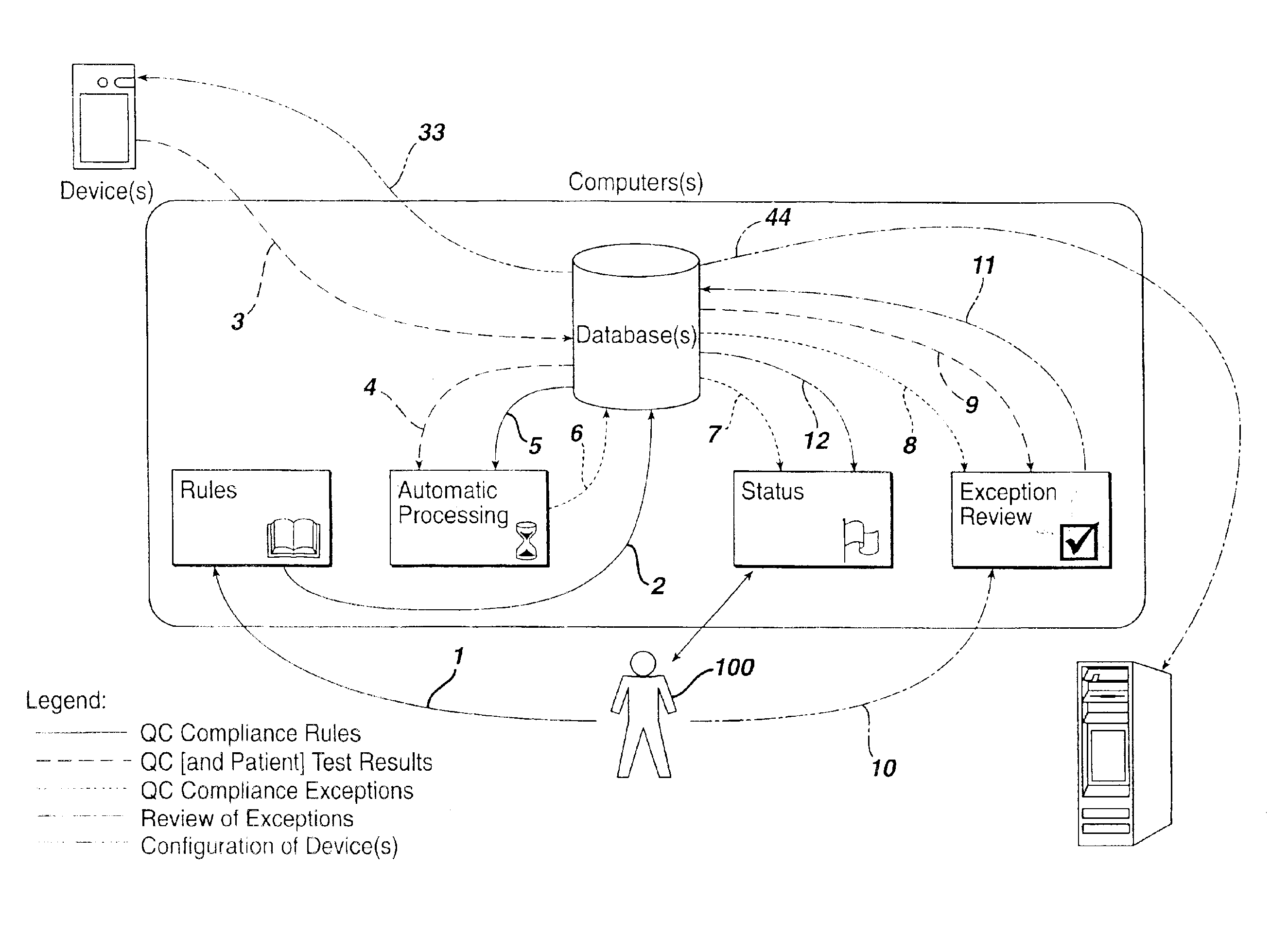

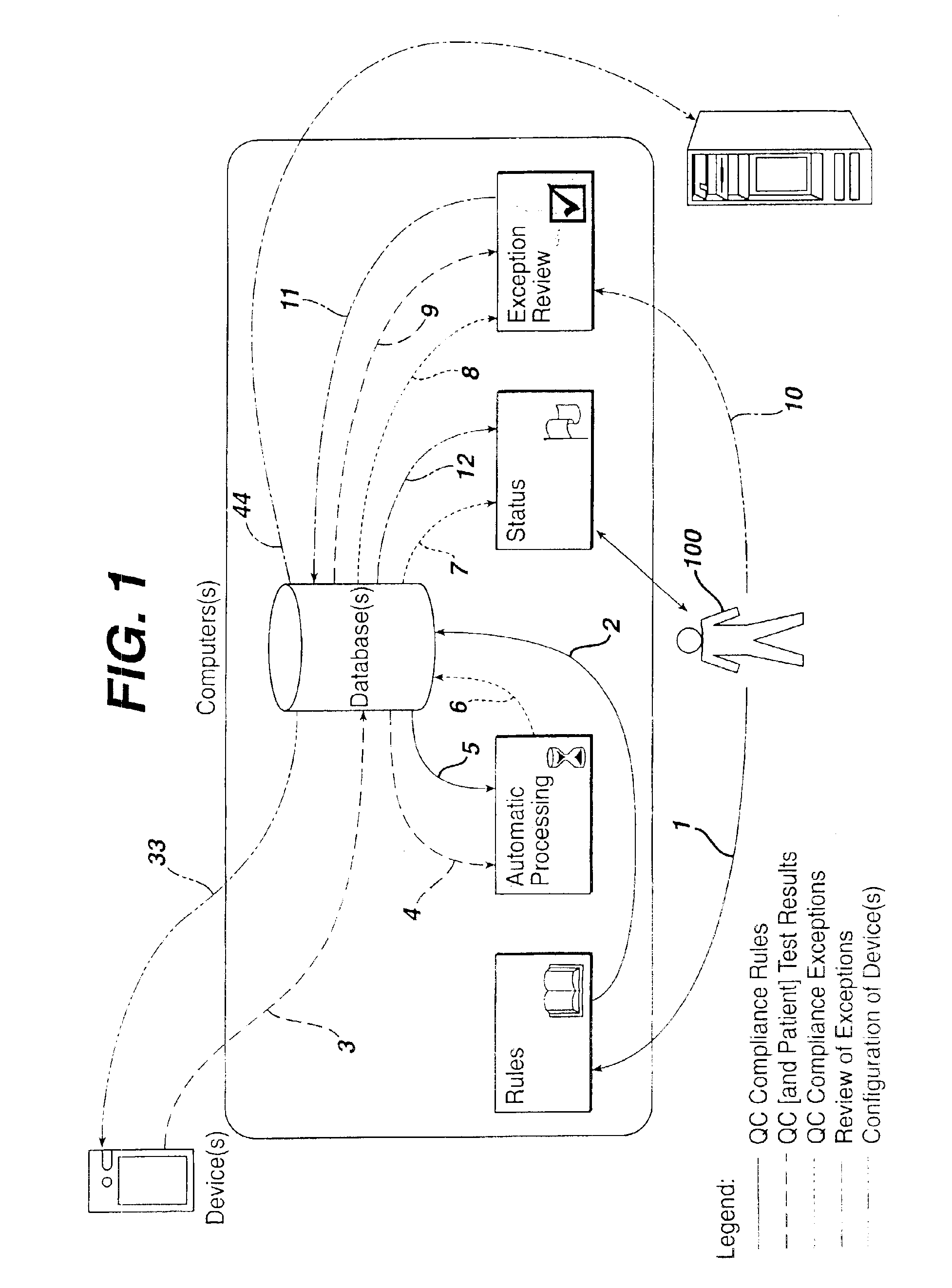

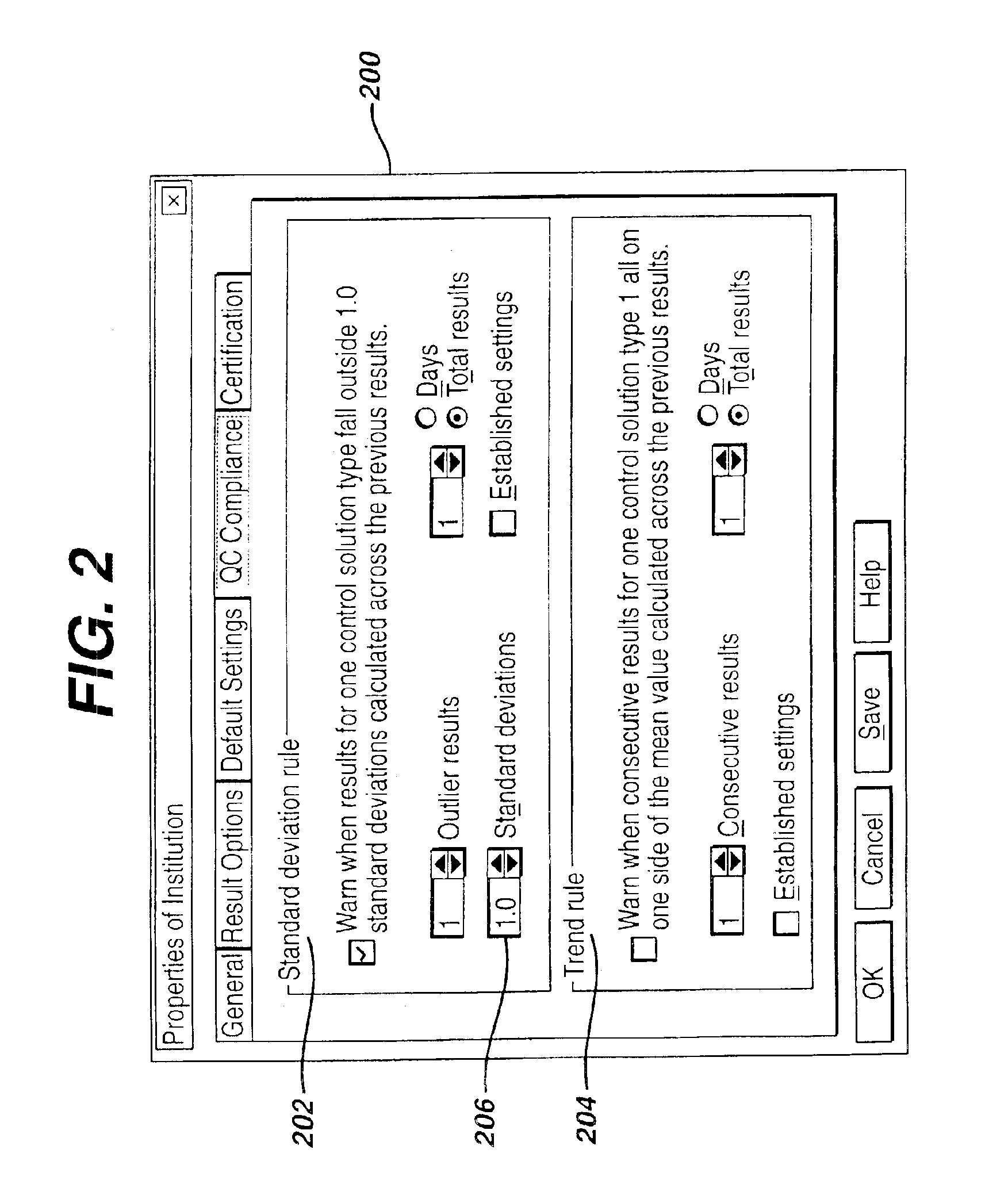

Method for automated exception-based quality control compliance for point-of-care devices

InactiveUS6856928B2Improving patient careQuality improvementDigital computer detailsNuclear monitoringAnalyteQuality control

A computer-implemented method to process POC information for potential QC compliance issues. A system and method for implementation of traditional laboratory analyzer based QC compliance in point-of-care (POC) environments is disclosed. A specific system and method to analyze data from POC testing to identify when the testing exceeds the variation expected under stable operation (i.e., the testing is “out of control”) is disclosed. This system and method is characterized by solving the QC compliance problem for POC devices by individuals not trained in traditional laboratory practices. This also provides the capability in real-time or near real-time to analyze POC testing information regarding the performance of each POC device, reagent kit (i.e., one kit per analyte tested) and / or lot, and operator so one can respond quickly to a particular device, reagent kit and / or lot, or operator that is not performing properly.

Owner:LIFESCAN IP HLDG LLC

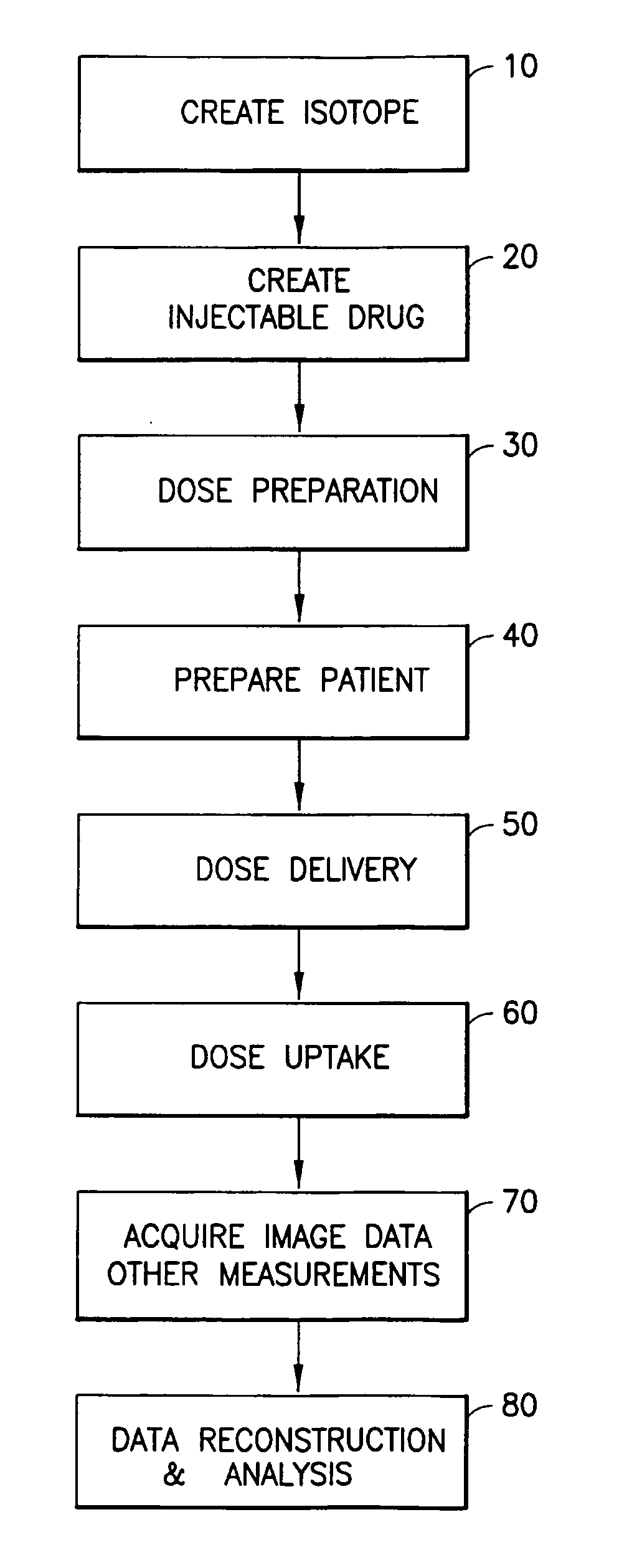

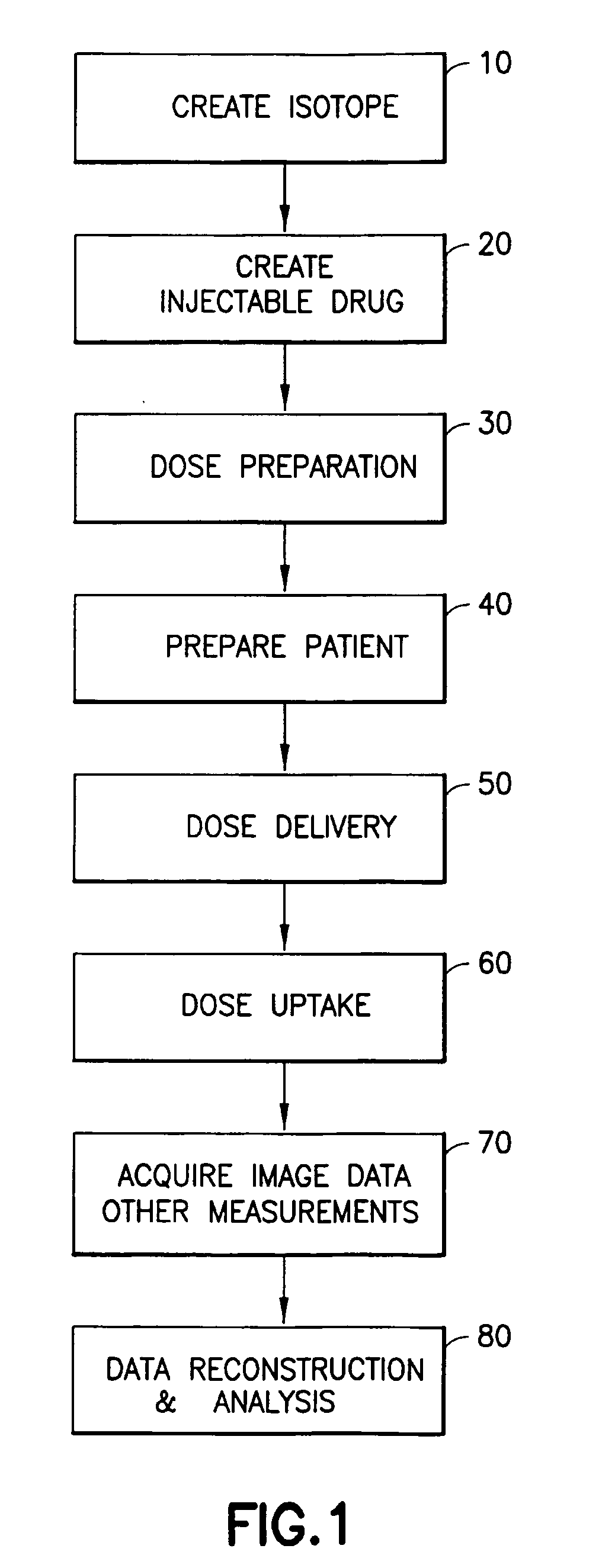

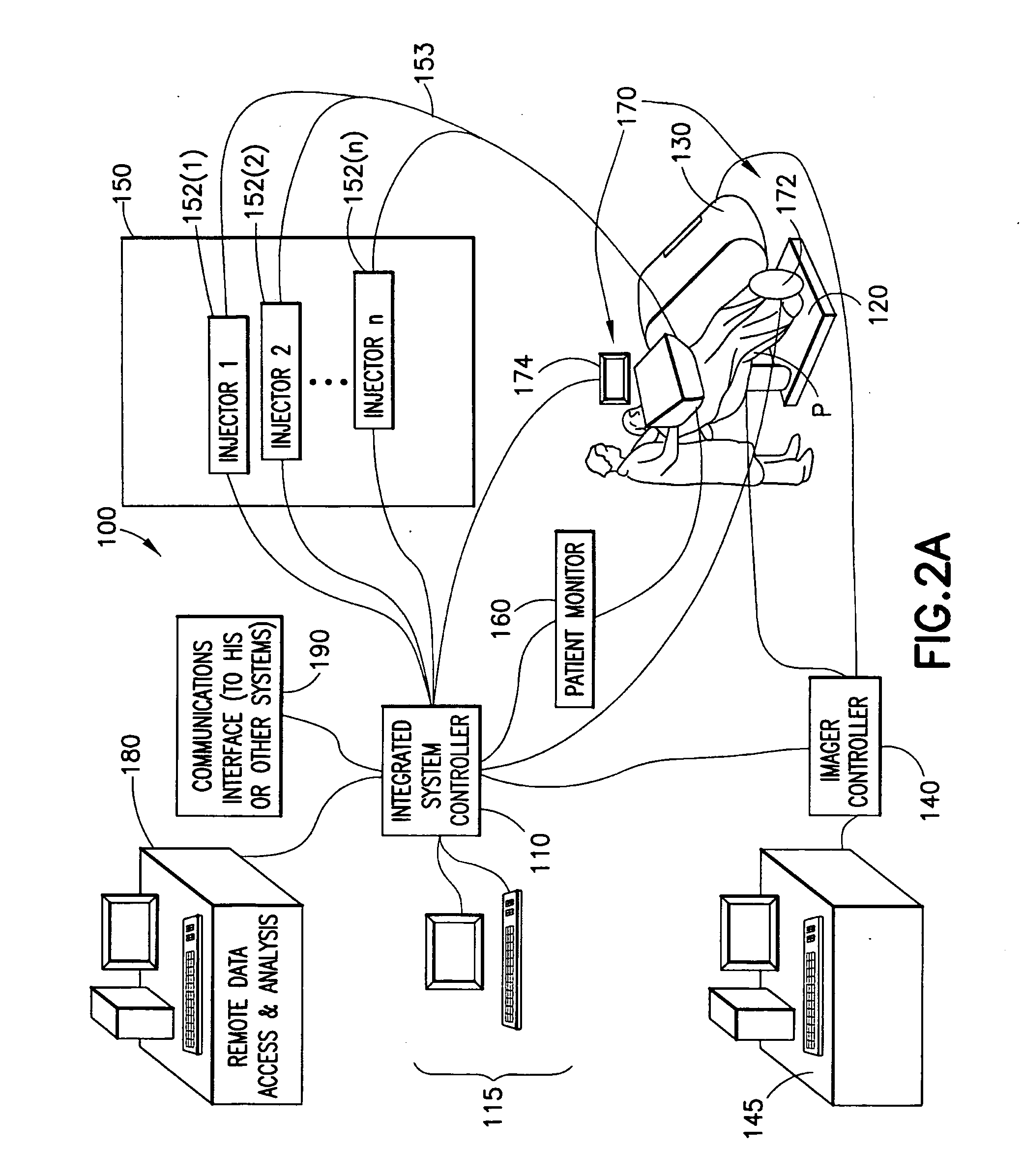

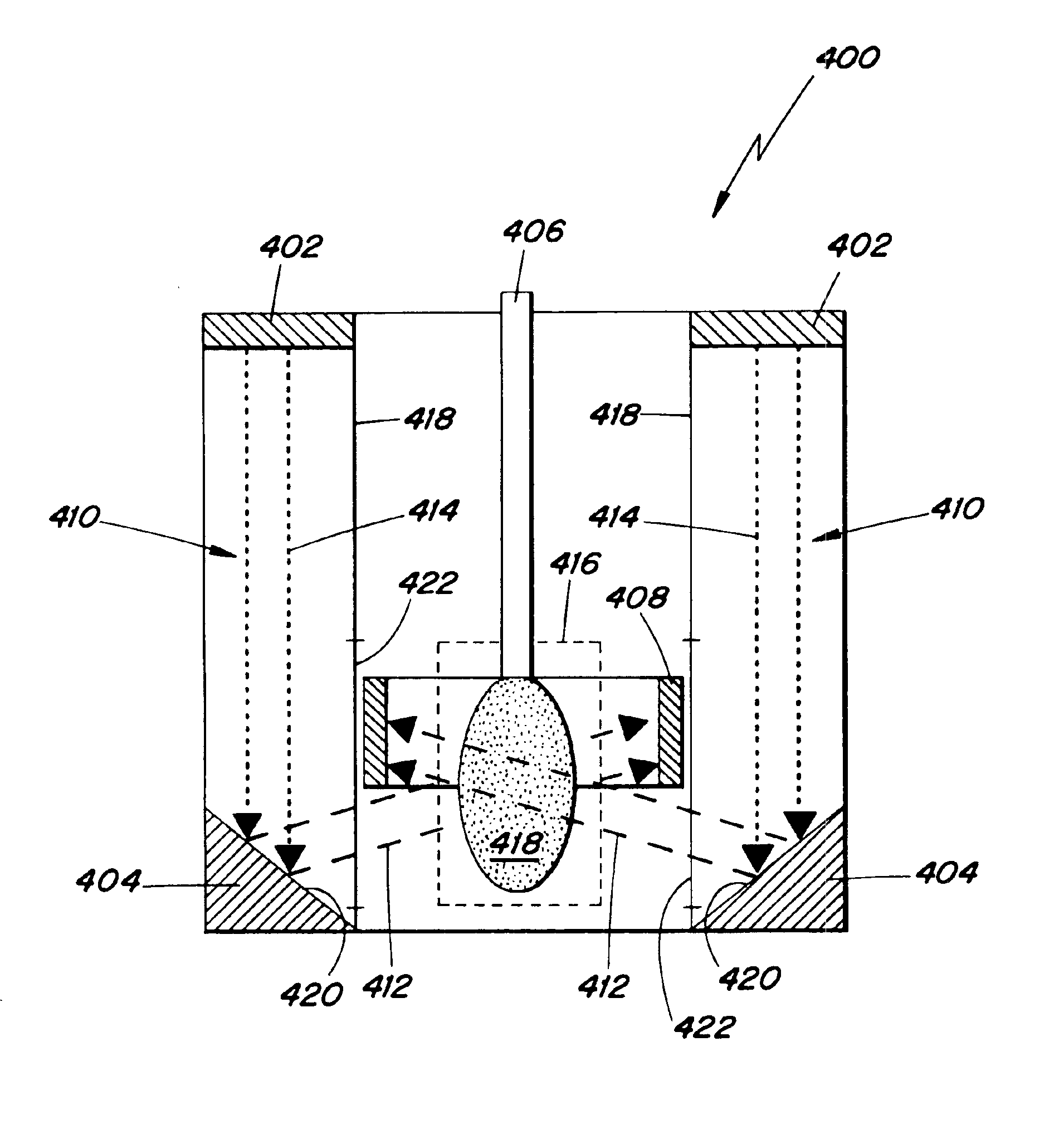

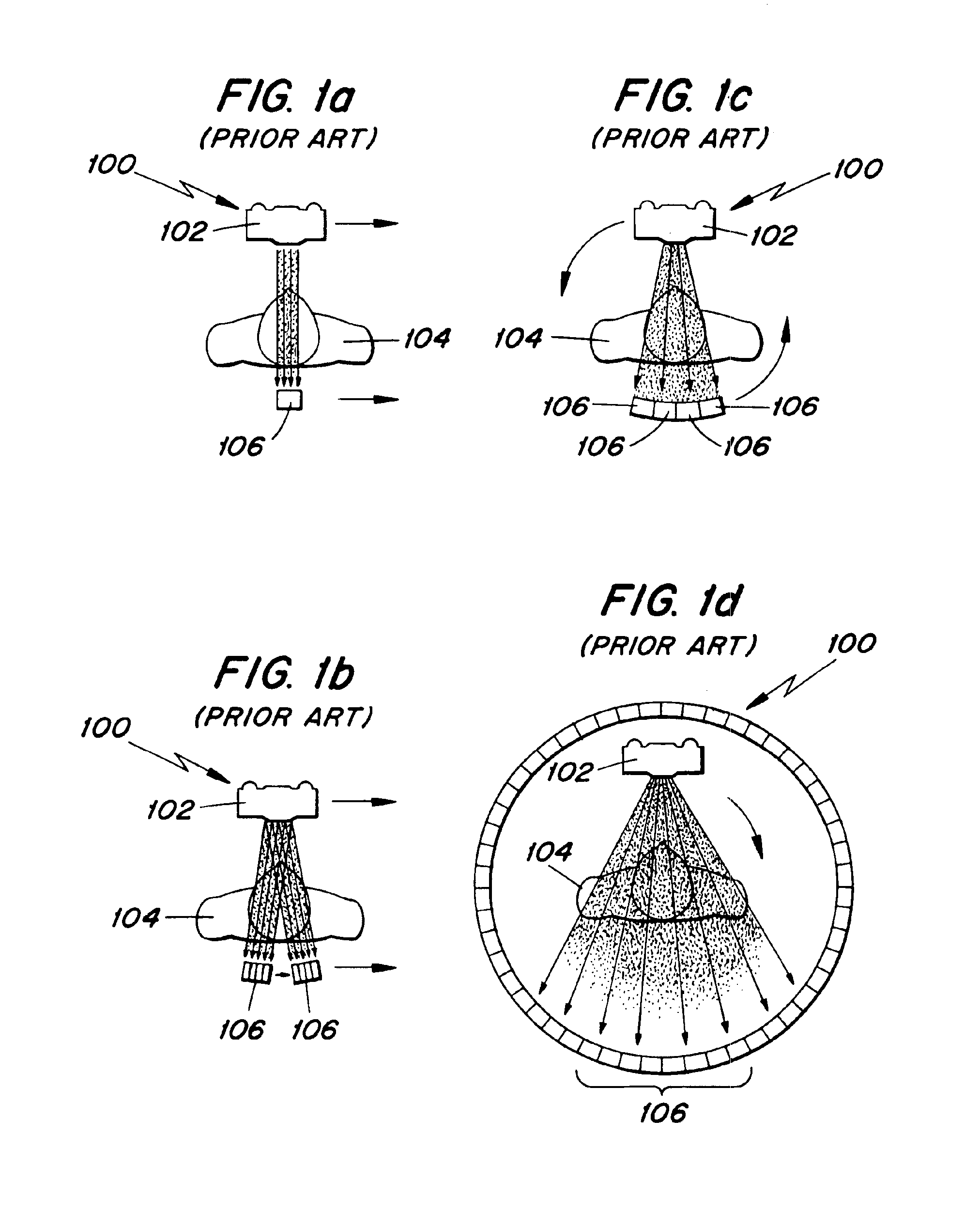

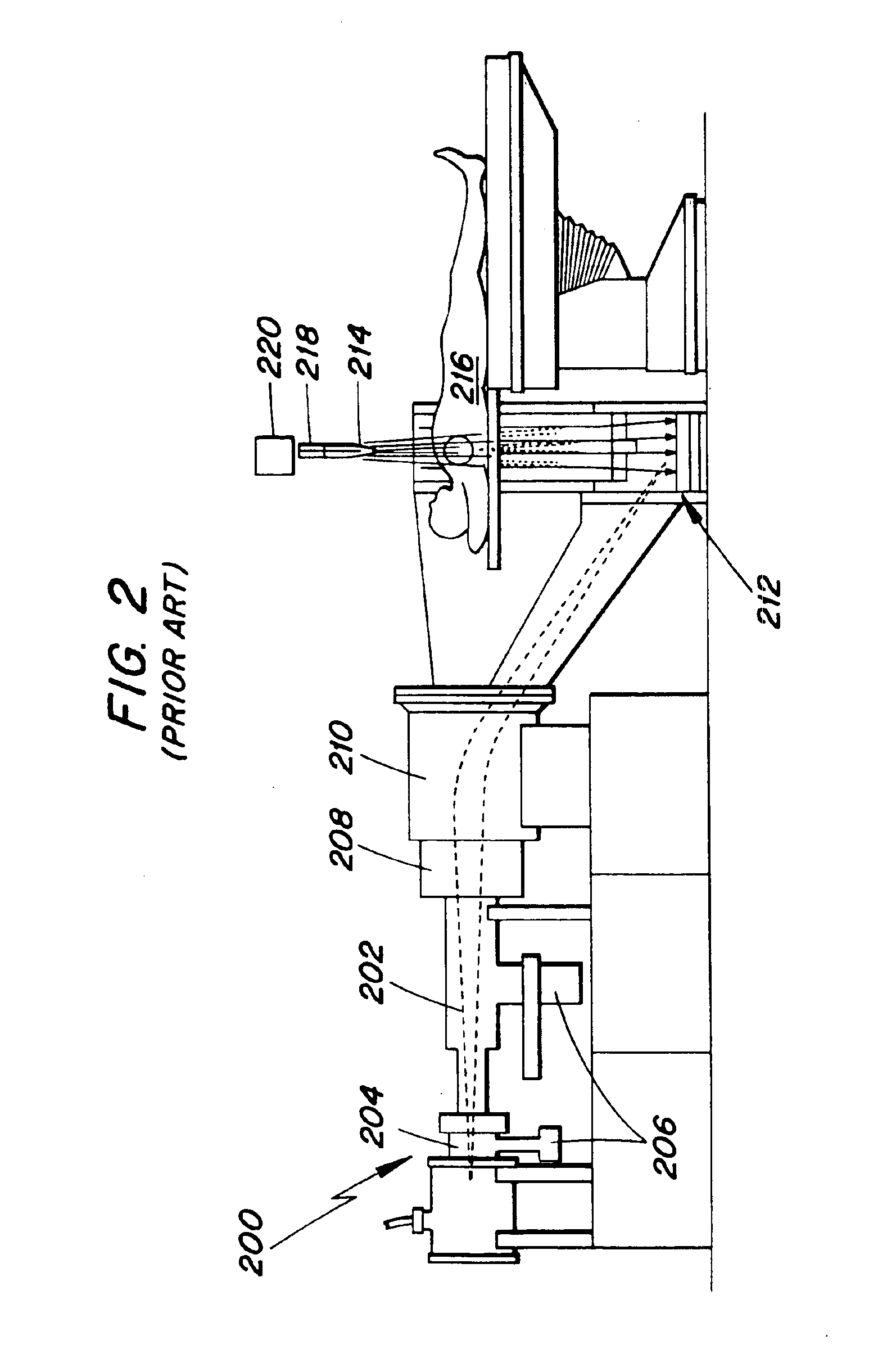

Systems For Integrated Radiopharmaceutical Generation, Preparation, Transportation and Administration

ActiveUS20110178359A1Reduce wasteEliminate needDrug and medicationsMedical devicesDocking stationFluid transport

An integrated radiopharmaceutical patient treatment system is disclosed including a patient support platform with an associated patient stimulus apparatus, an imager proximate the patient support platform, a radiopharmaceutical fluid delivery system for infusing a radiopharmaceutical fluid into a patient, a patient monitor to be associated with a patient, and an integrated system controller operably associated with the patient stimulus apparatus, imager, radiopharmaceutical fluid delivery system, and patient monitor to control and coordinate their operations. Within the patient treatment system the radiopharmaceutical fluid delivery system may be included comprising a radionuclide supply module, a radiopharmaceutical processing module, a quality control module, a patient injection module, and a controller. A hazardous fluid handling system including a docking station and a hazardous fluid transport device adapted to detachably dock with the docking station is further disclosed.

Owner:BAYER HEALTHCARE LLC

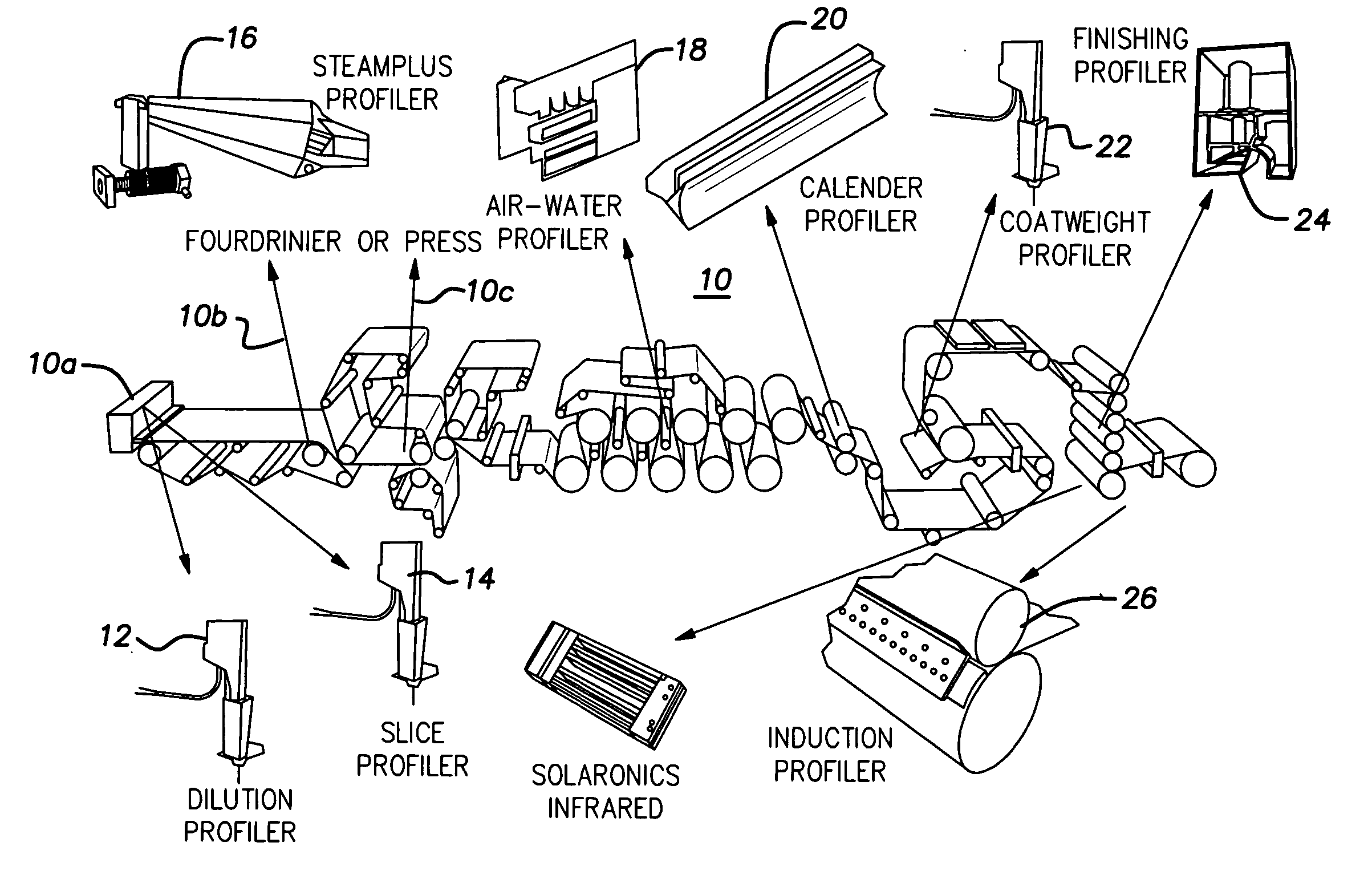

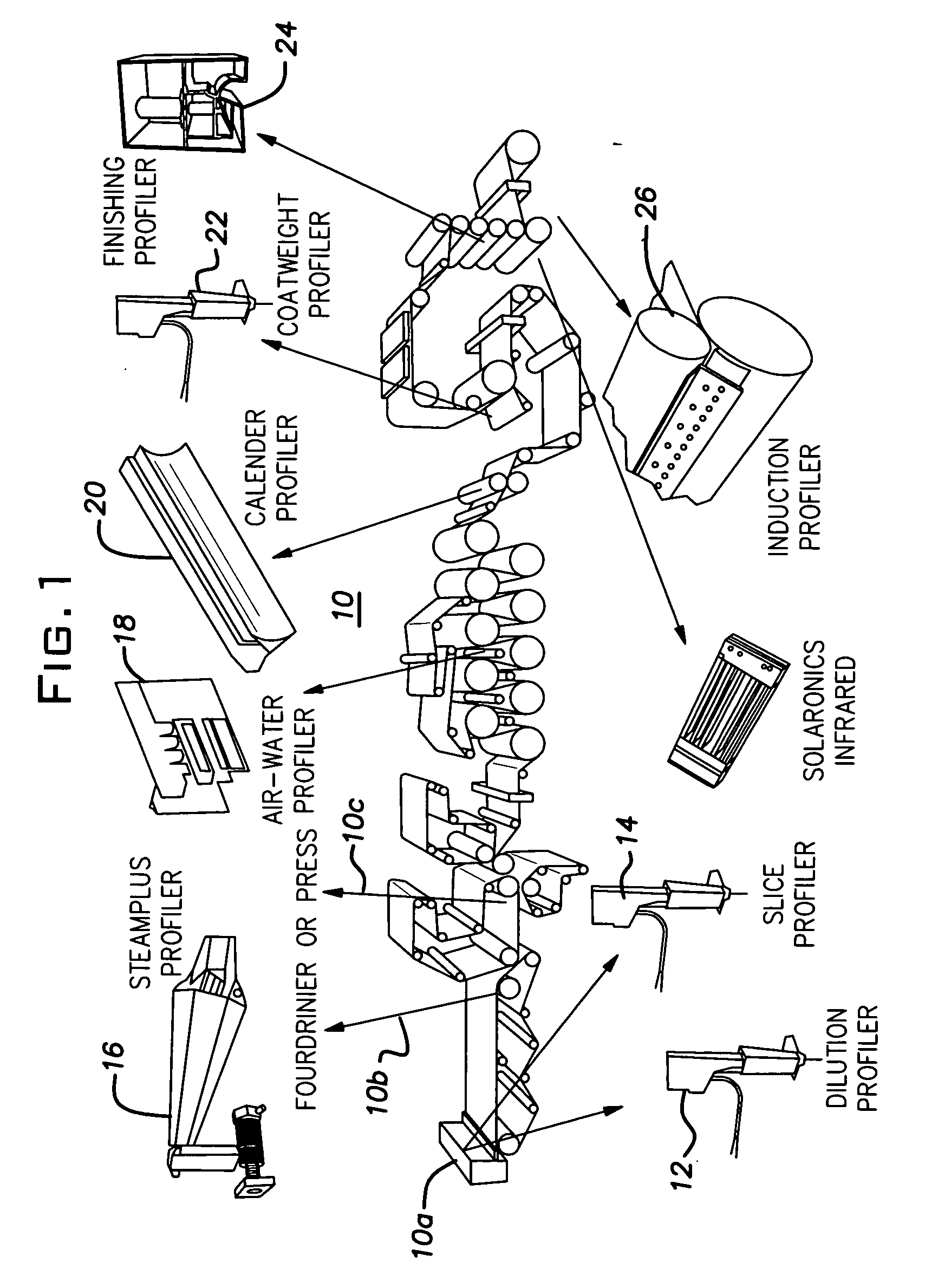

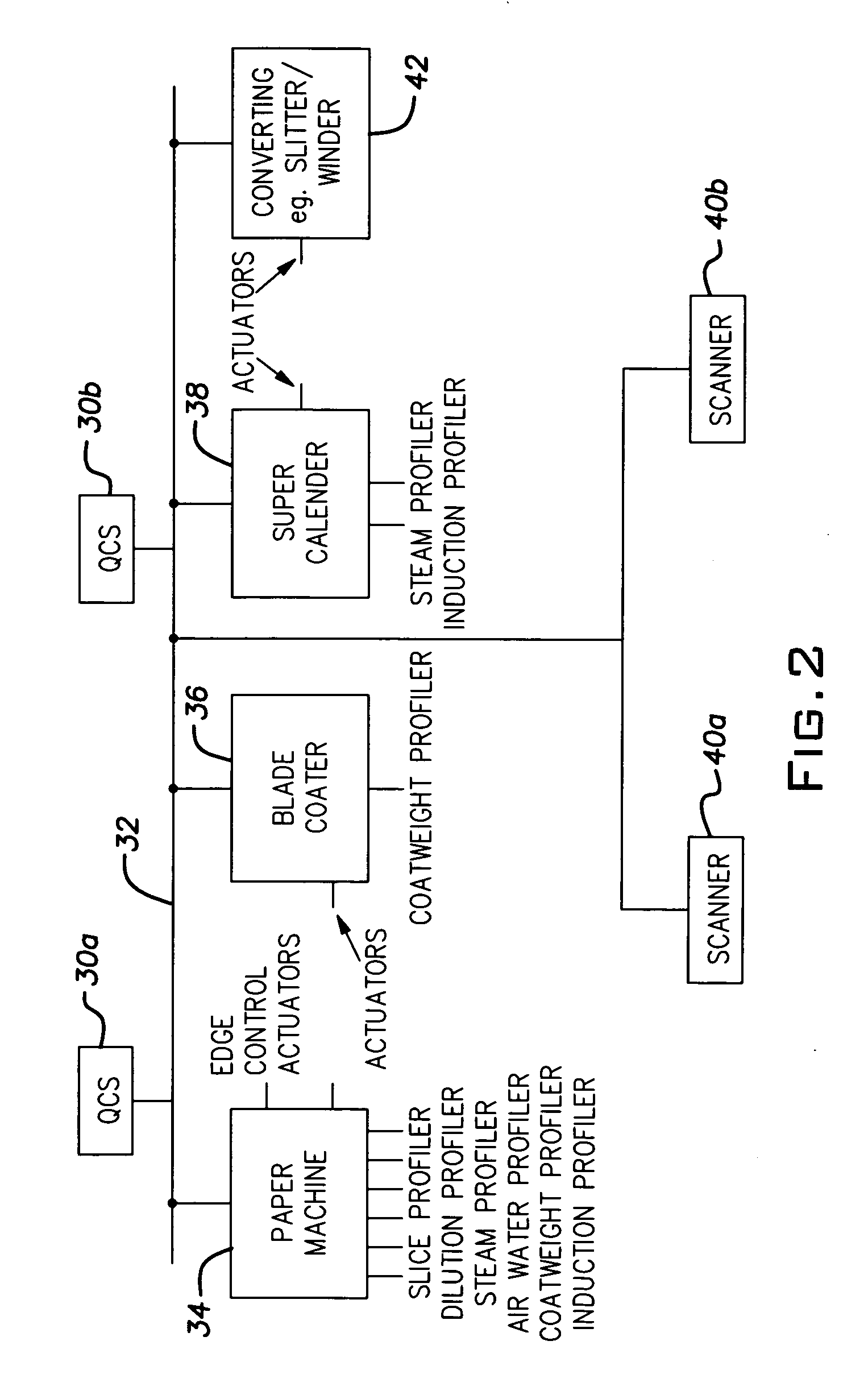

Actuator system for use in control of a sheet or web forming process

InactiveUS20060185809A1Digital differential analysersPaper-making machinesElectric power transmissionPower cable

One or more actuator driven devices on a sheet forming machine receive power and engage in bi-didrectional communications with one or more quality control systems either by having no physically connected cables to transmit the power to the actuators and no physically connected cables used for the bi-directional communications; or contactless power and communication on a power cable; or a cable connected from the power source to the actuators to provide both power and bi-directional communications; or power is provided to the actuators by a cable and the bi-directional communications are wireless.

Owner:ABB RES LTD +1

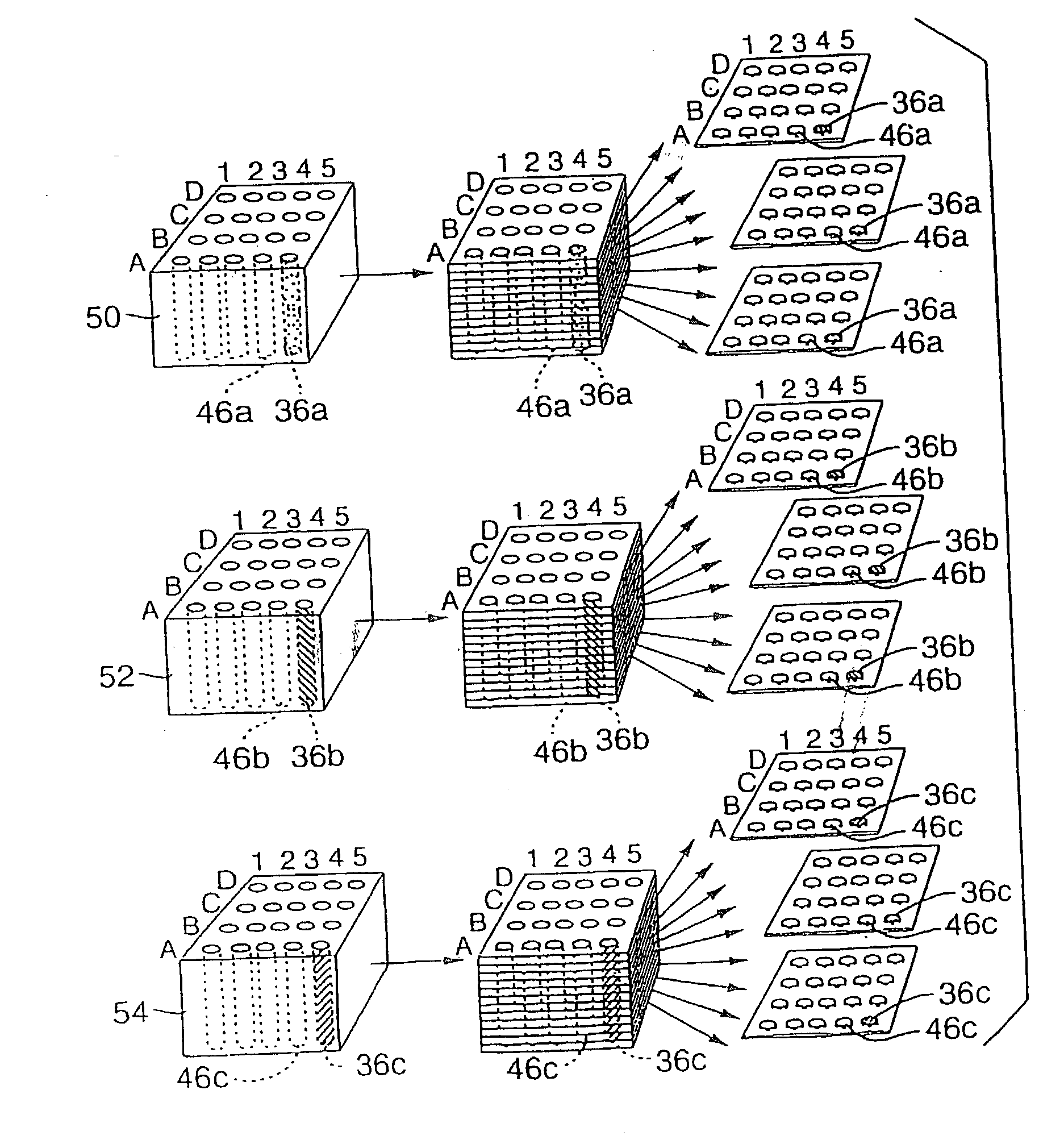

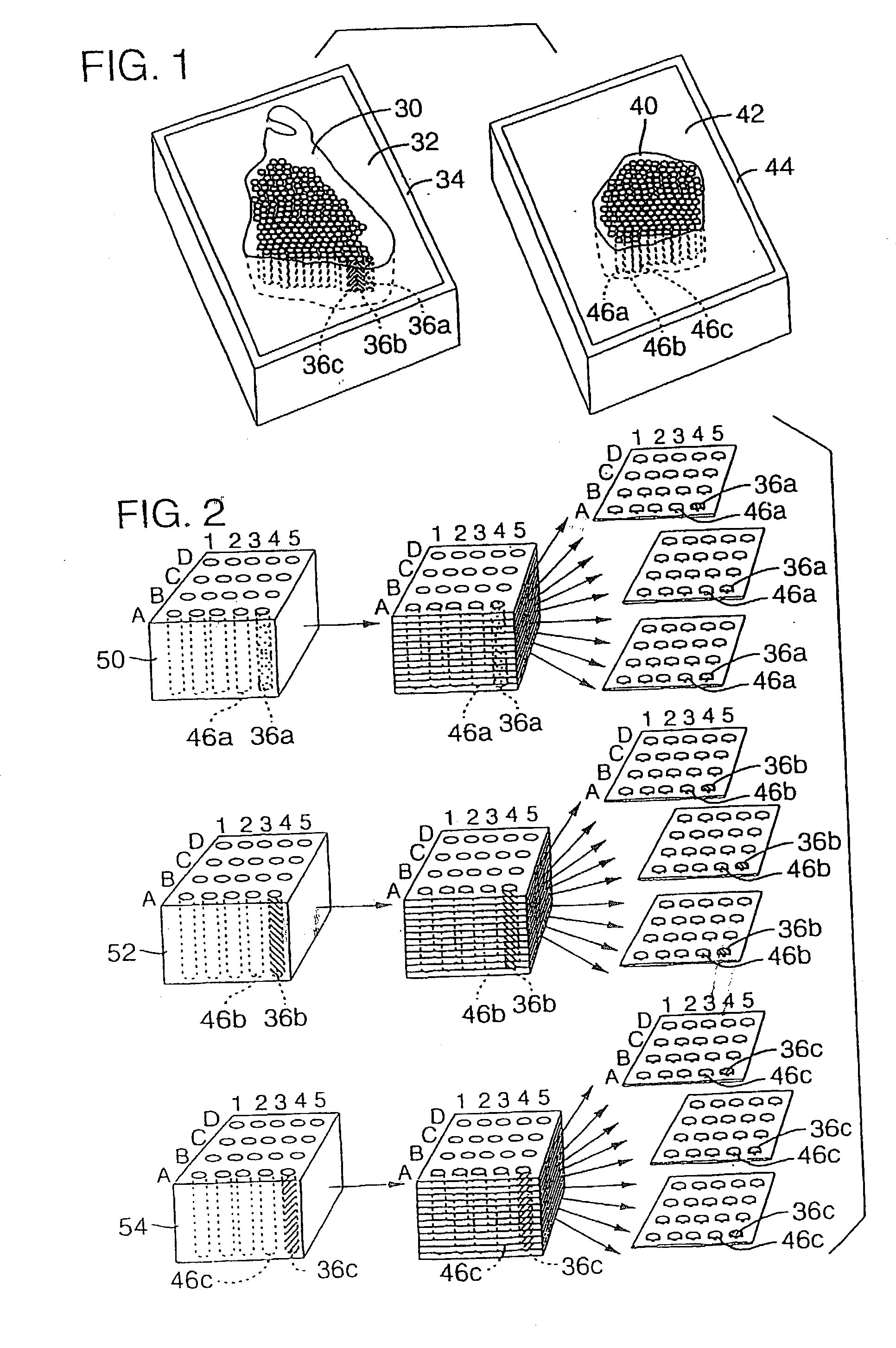

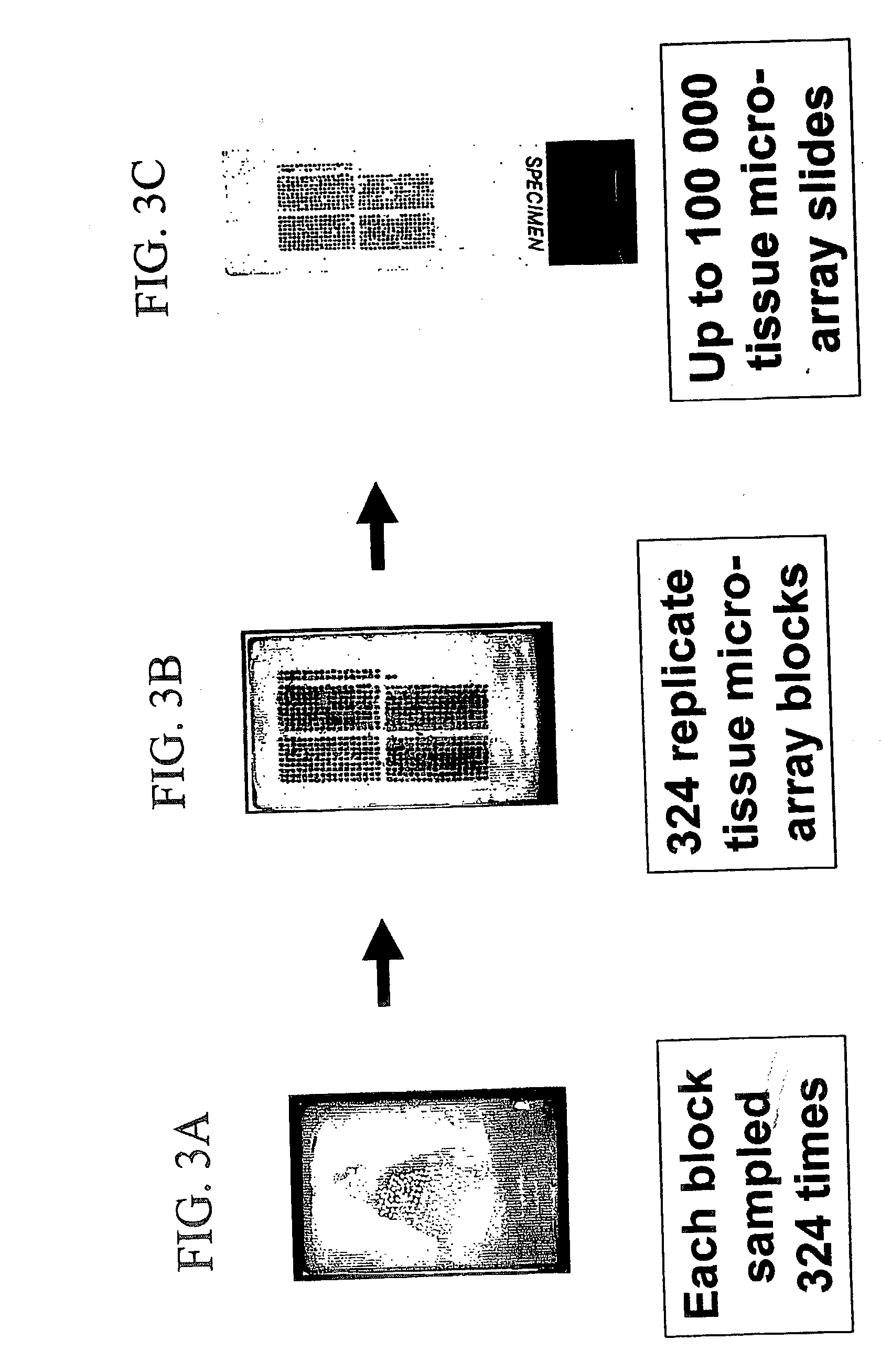

High-throughput tissue microarray technology and applications

InactiveUS20030215936A1Easy to analyzeGood for comparisonBioreactor/fermenter combinationsBiological substance pretreatmentsClinical informationTissue microarray

A method and apparatus are disclosed for a high-throughput, large-scale molecular profiling of tissue specimens by retrieving a donor tissue specimen from an array of donor specimens, placing a sample of the donor specimen in an assigned location in a recipient array, providing substantial copies of the array, performing a different biological analysis of each copy, and storing the results of the analysis. The results may be compared to determine if there are correlations or discrepancies between the results of different biological analyses at each assigned location, and also compared to clinical information about the human patient from which the tissue was obtained. The results of similar analyses on corresponding sections of the array can be used as quality control devices, for example by subjecting the arrays to a single simultaneous investigative procedure. Uniform interpretation of the arrays can be obtained, and compared to interpretations of different observers.

Owner:UNITED STATES OF AMERICA

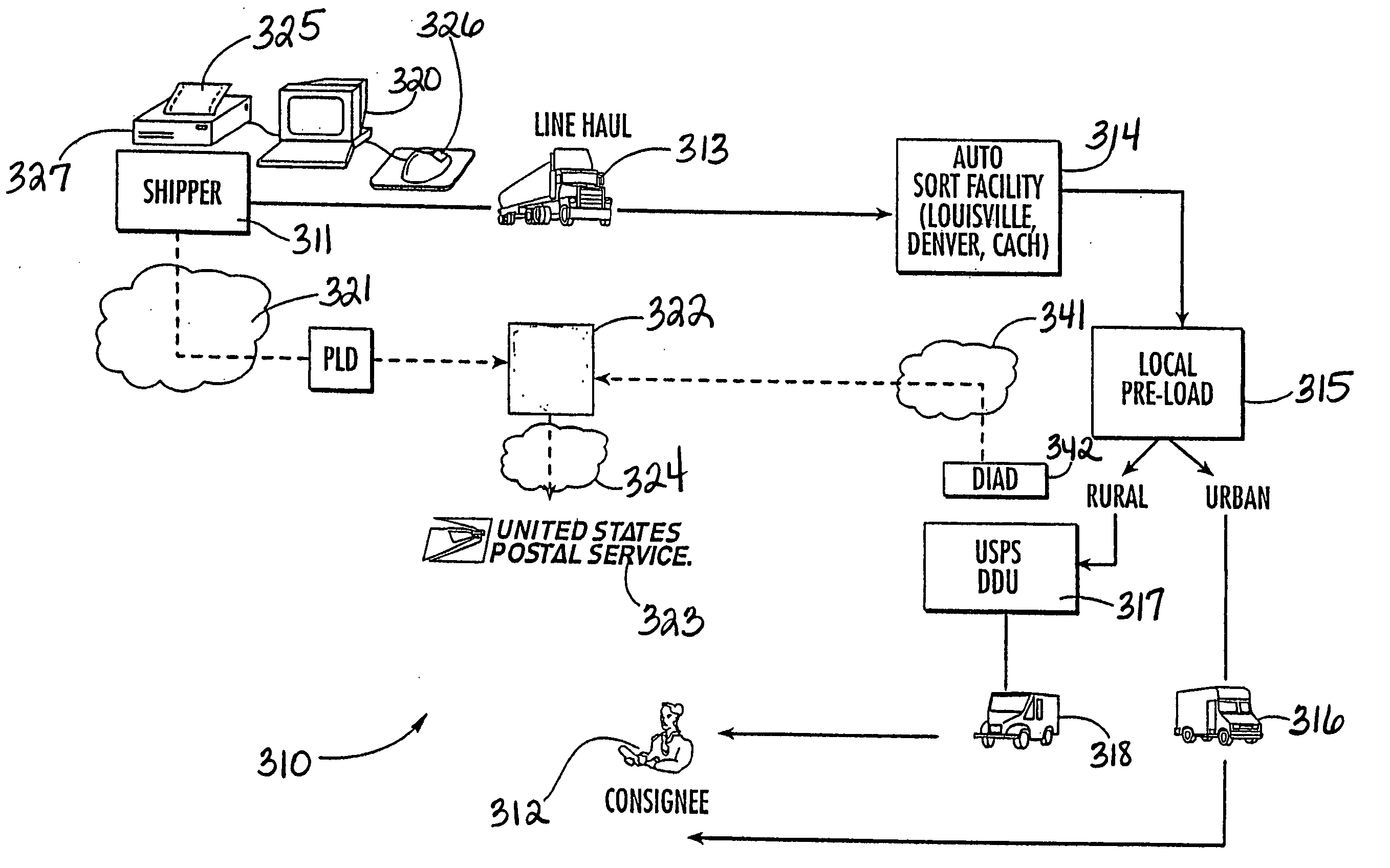

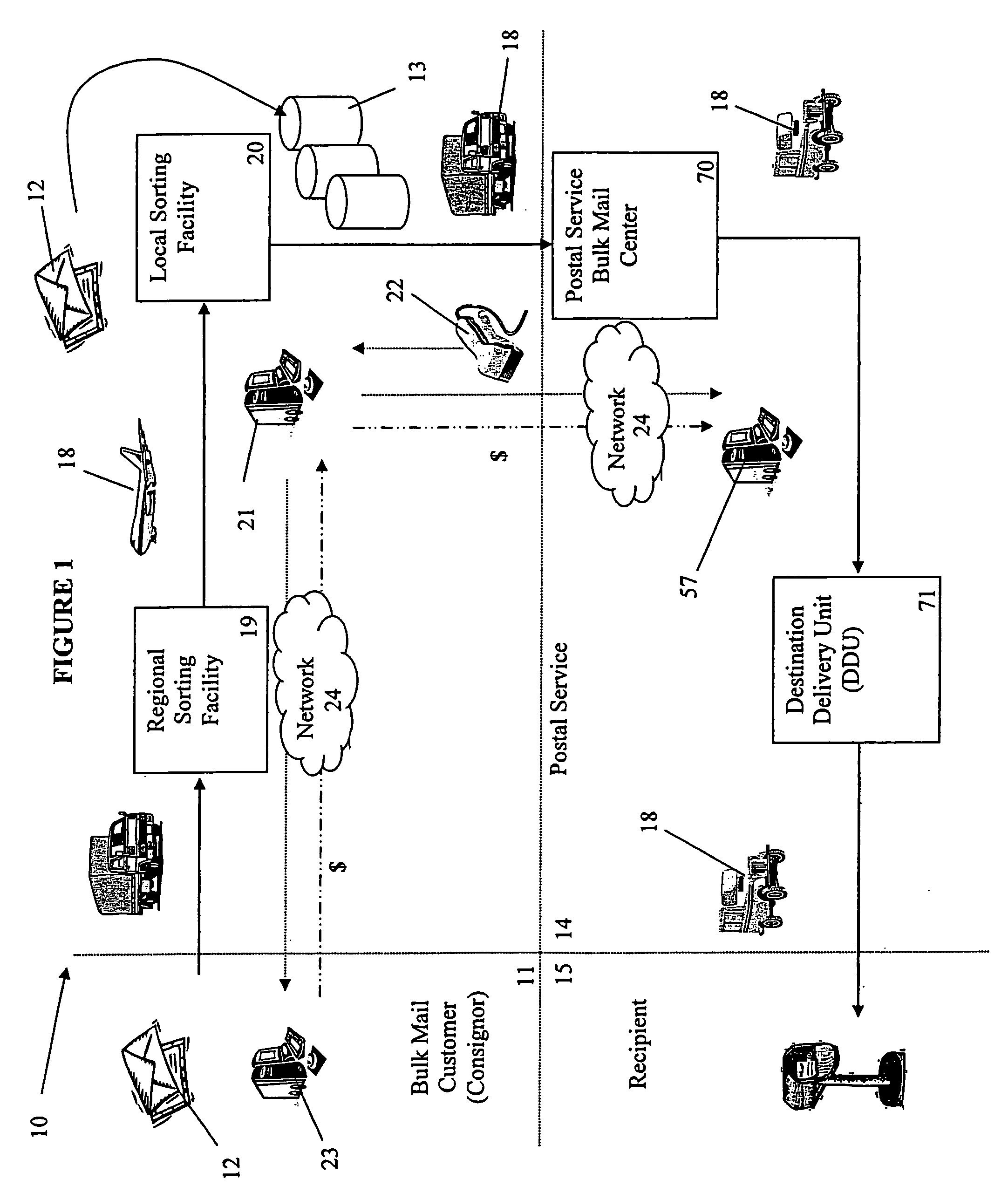

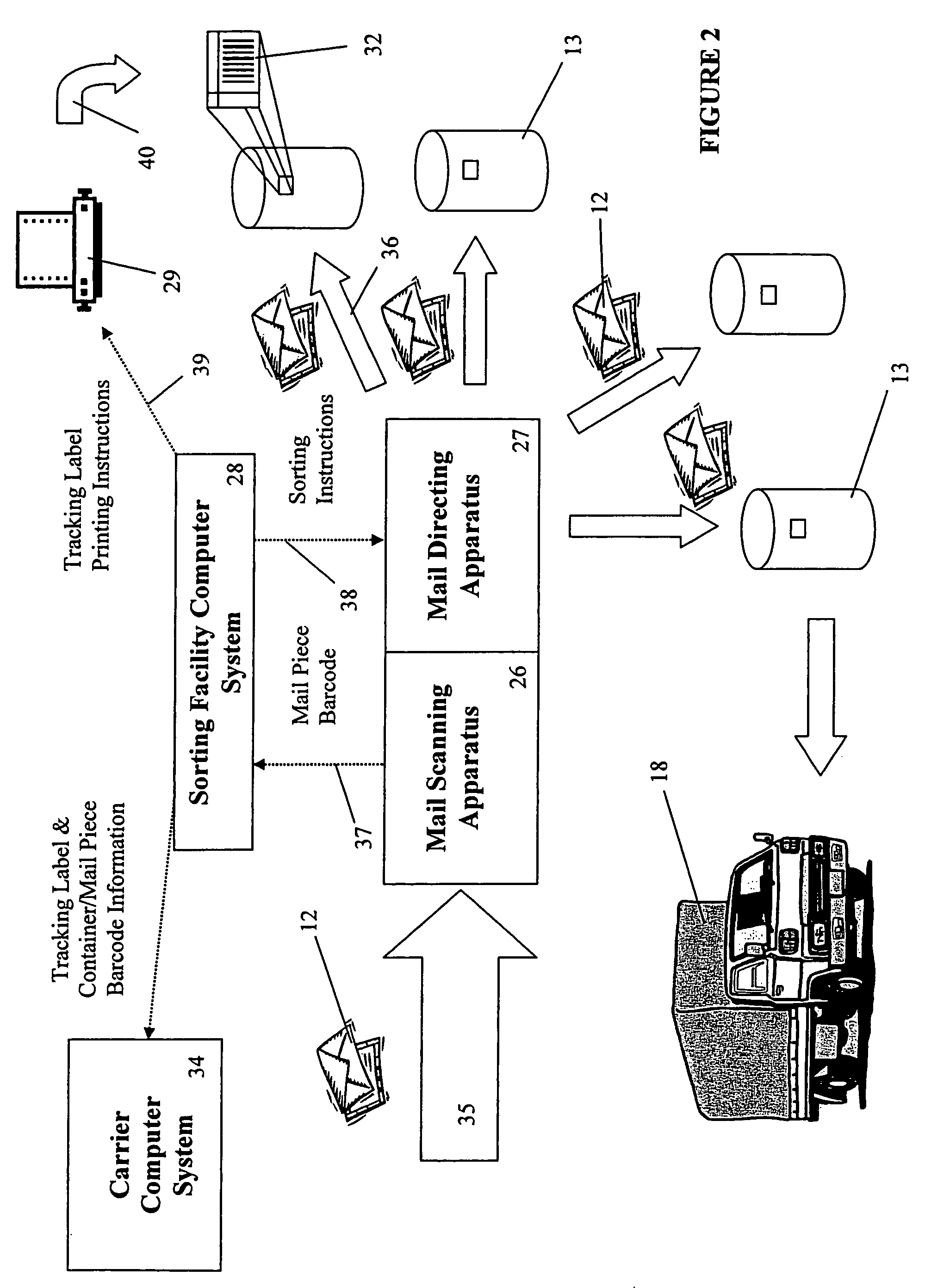

System, method and computer program product for containerized shipping of mail pieces

InactiveUS20050119786A1Accurate and Efficient TrackingFacilitate billing and further deliveryLamination ancillary operationsDigital data processing detailsQuality controlPostal service

A mail delivery system for facilitating delivery of a plurality of mail pieces sorted into a plurality of containers to a postal service. The mail delivery system includes a mail piece information apparatus for determining information about each of the mail pieces, such as by scanning delivery addresses of the mail pieces. A sorting apparatus associates an identifiers of the containers with mail pieces sorted into the containers. A tracking system tracks the containers through delivery using the container identifiers. Paperless manifests describing the mail pieces in the containers and delivery of the containers to a postal service location are generated by the system by correlating tracking information on the containers with contents information for the containers using the identifier. The mail delivery system is also configured to implement quality control processes and billing using the tracking and manifest information, resulting in time savings and increased billing accuracy.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

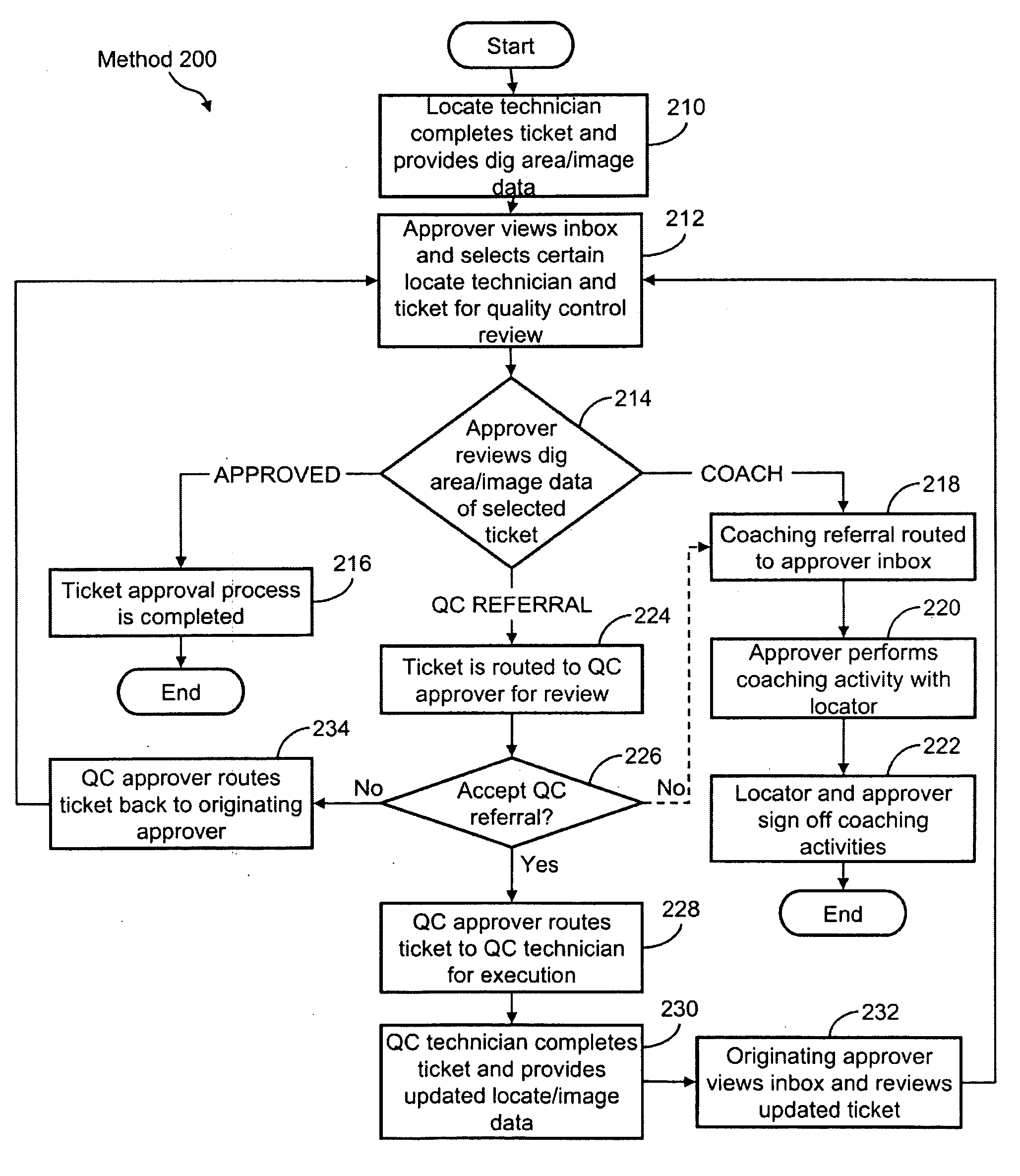

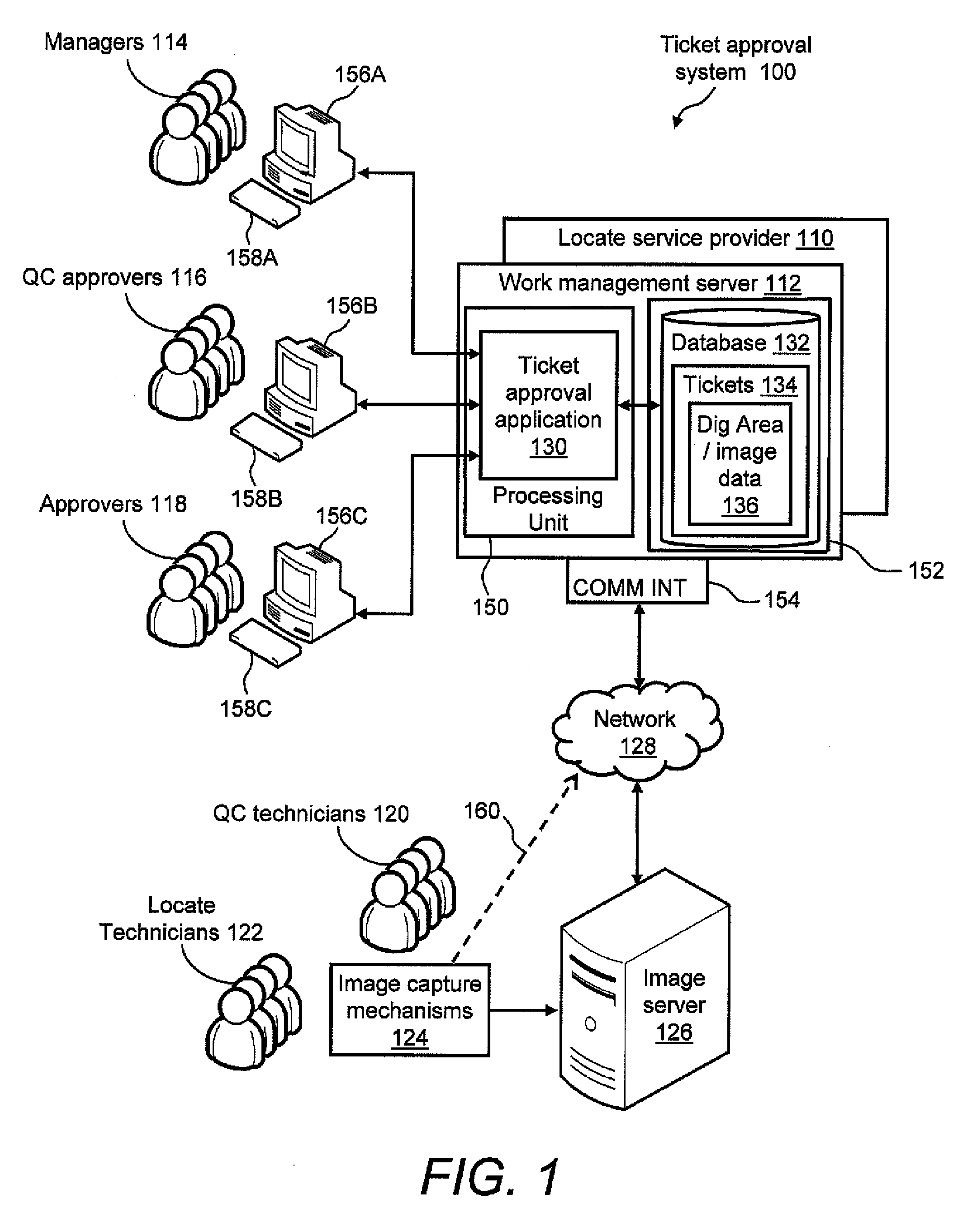

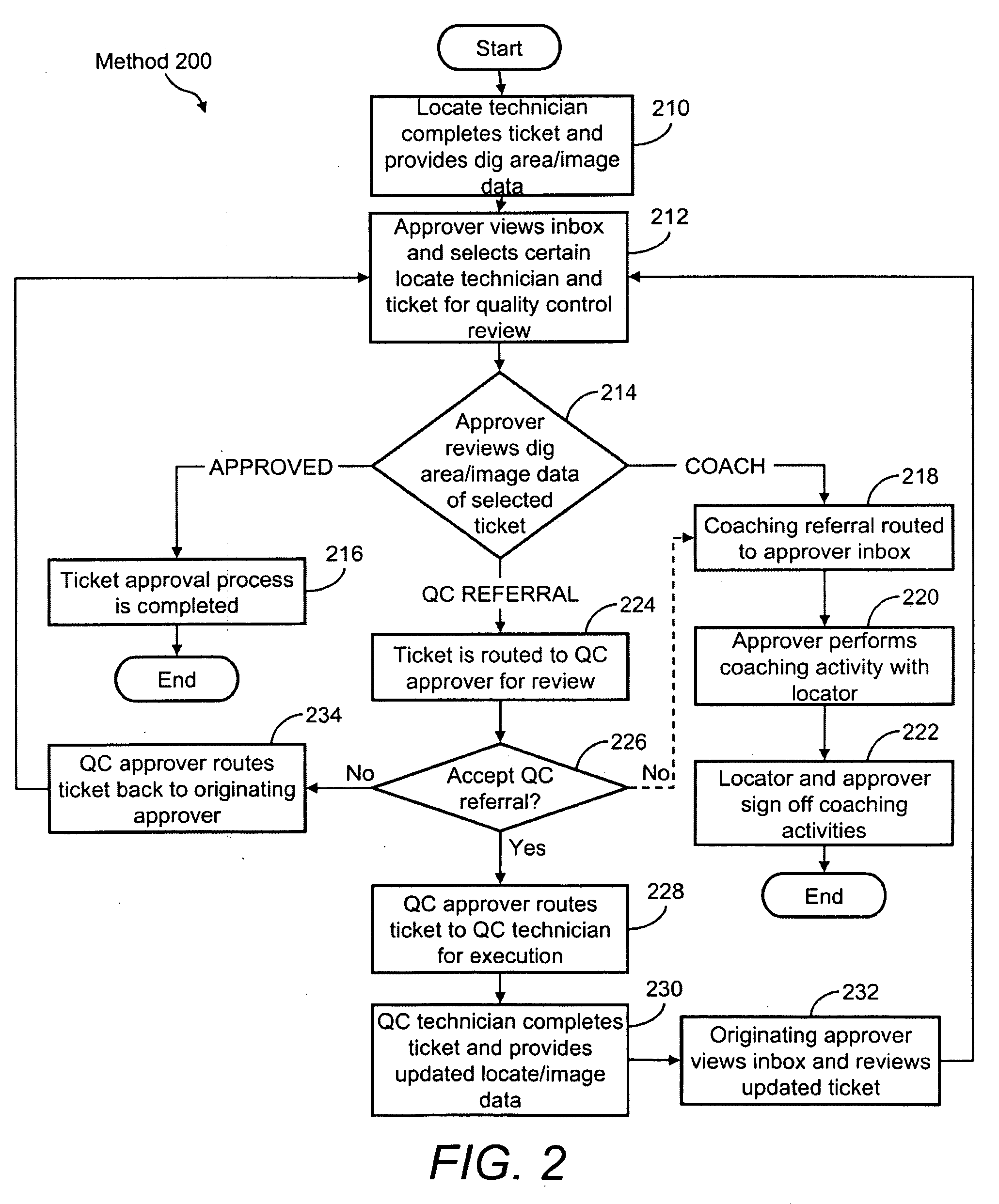

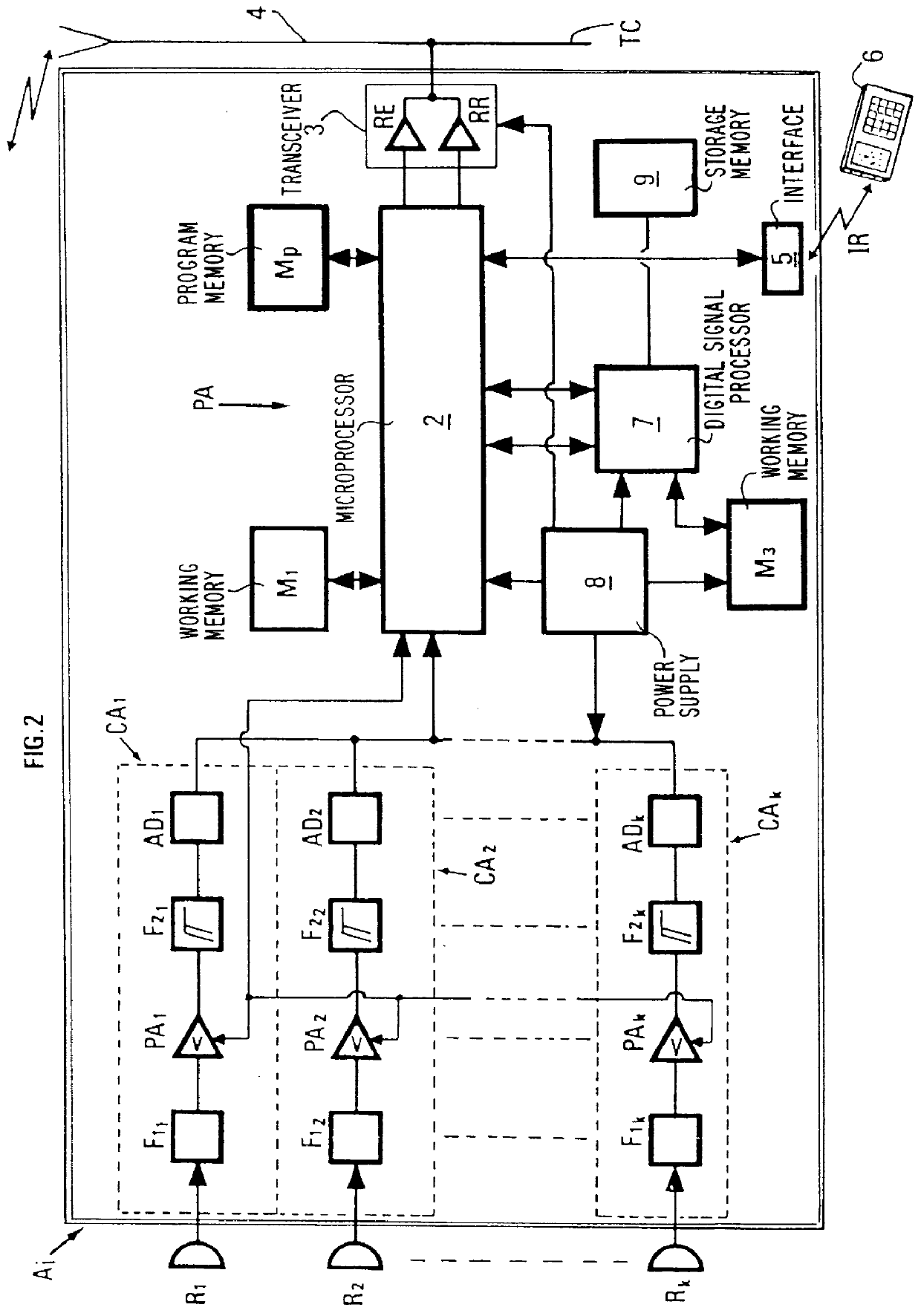

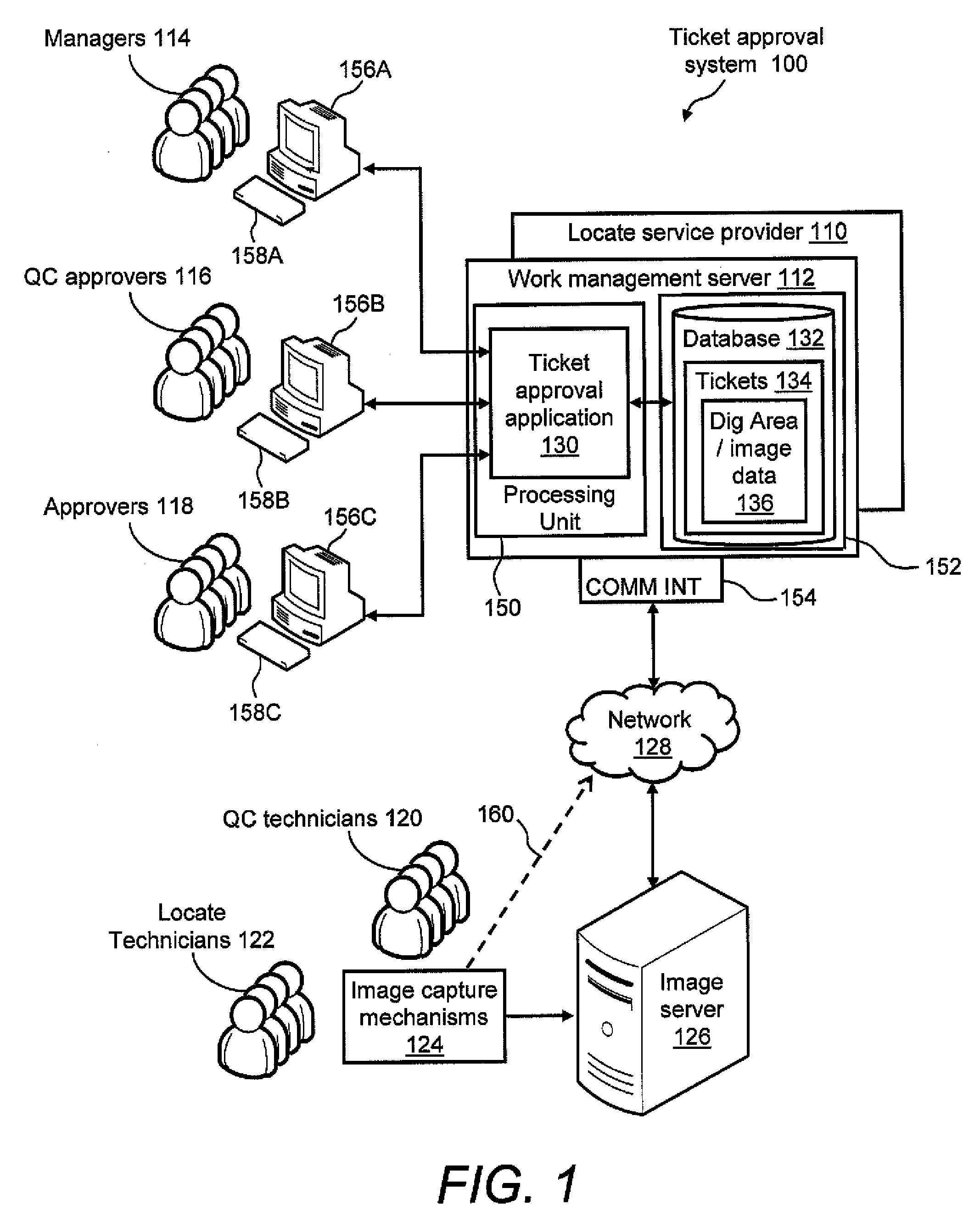

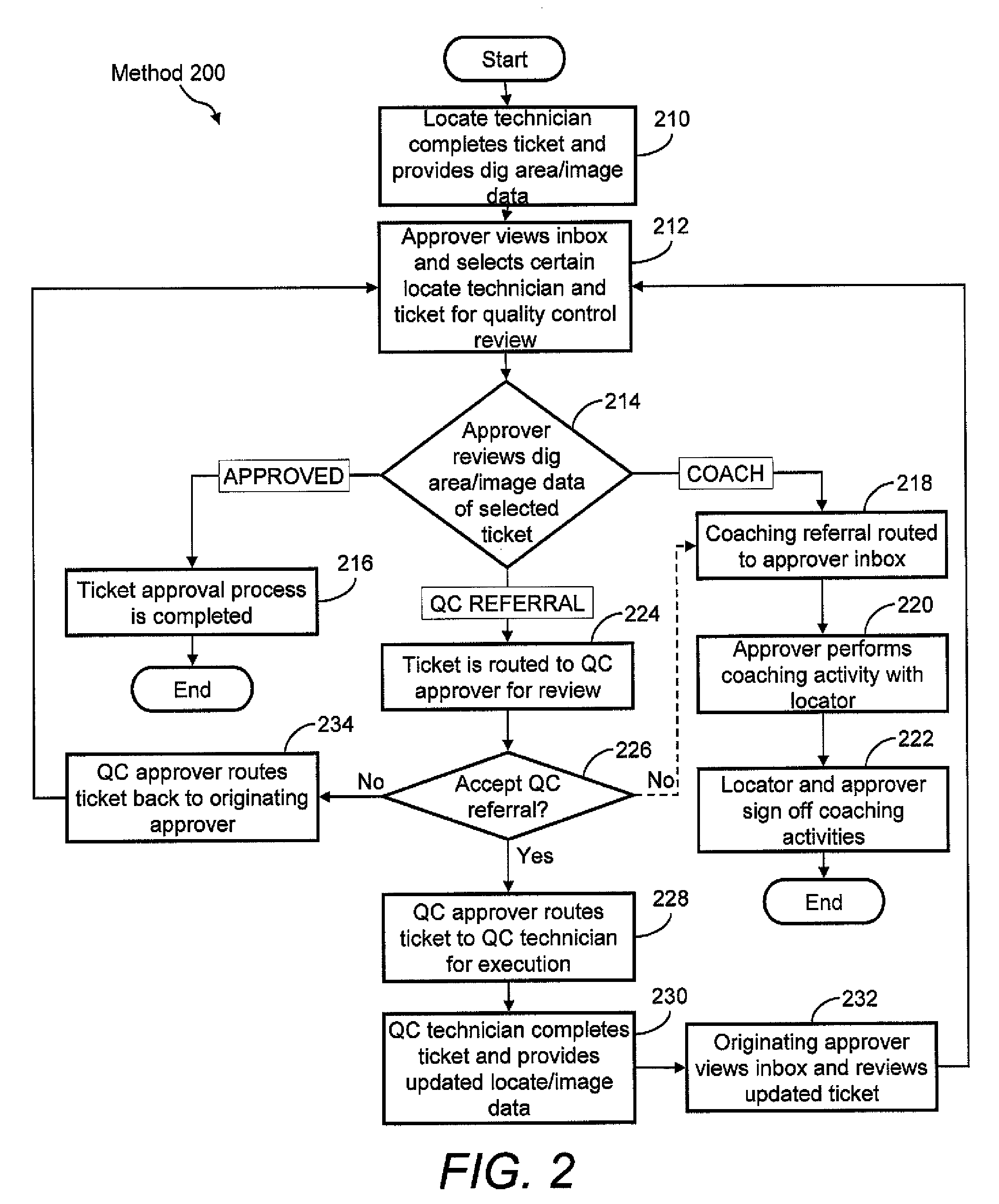

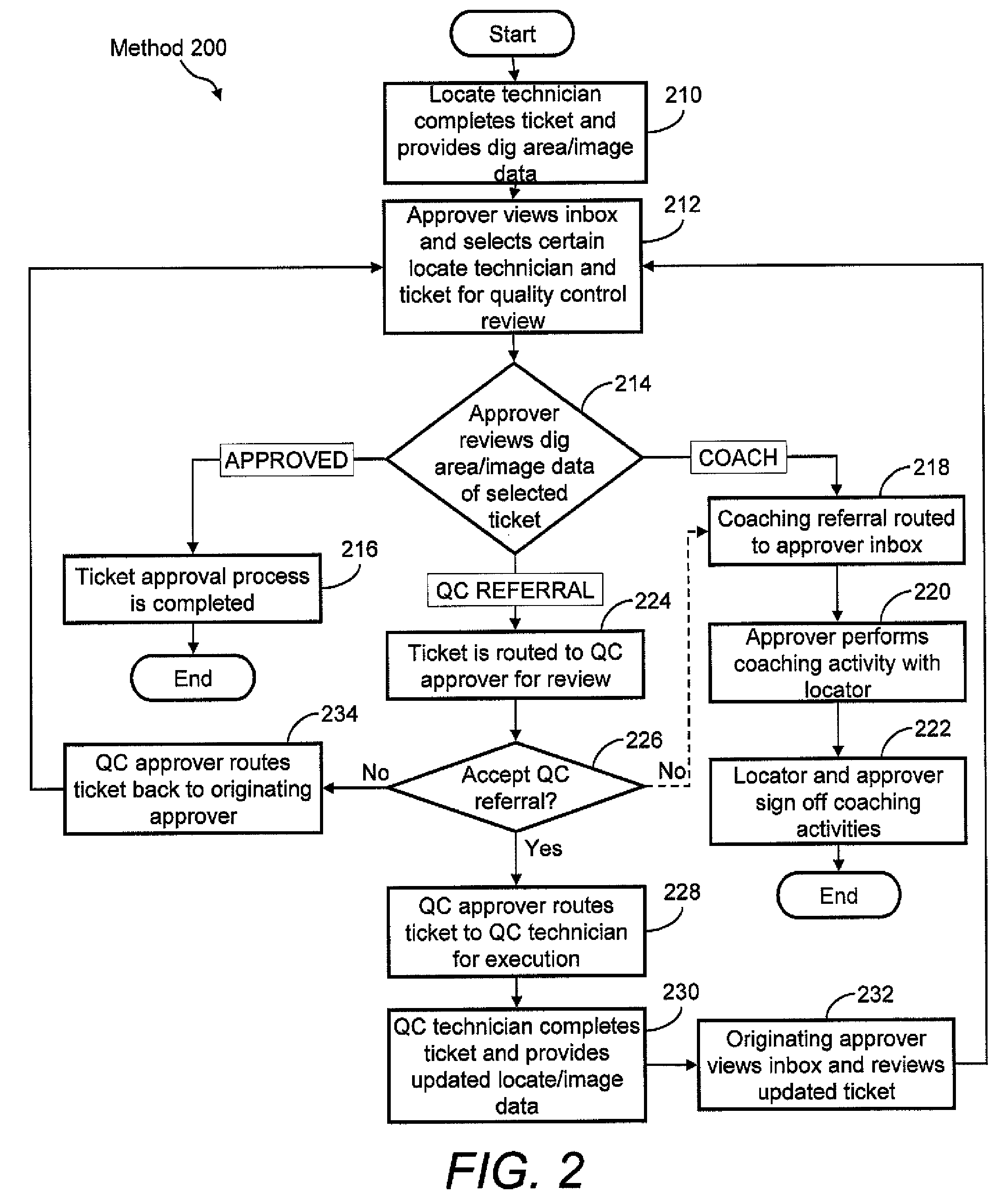

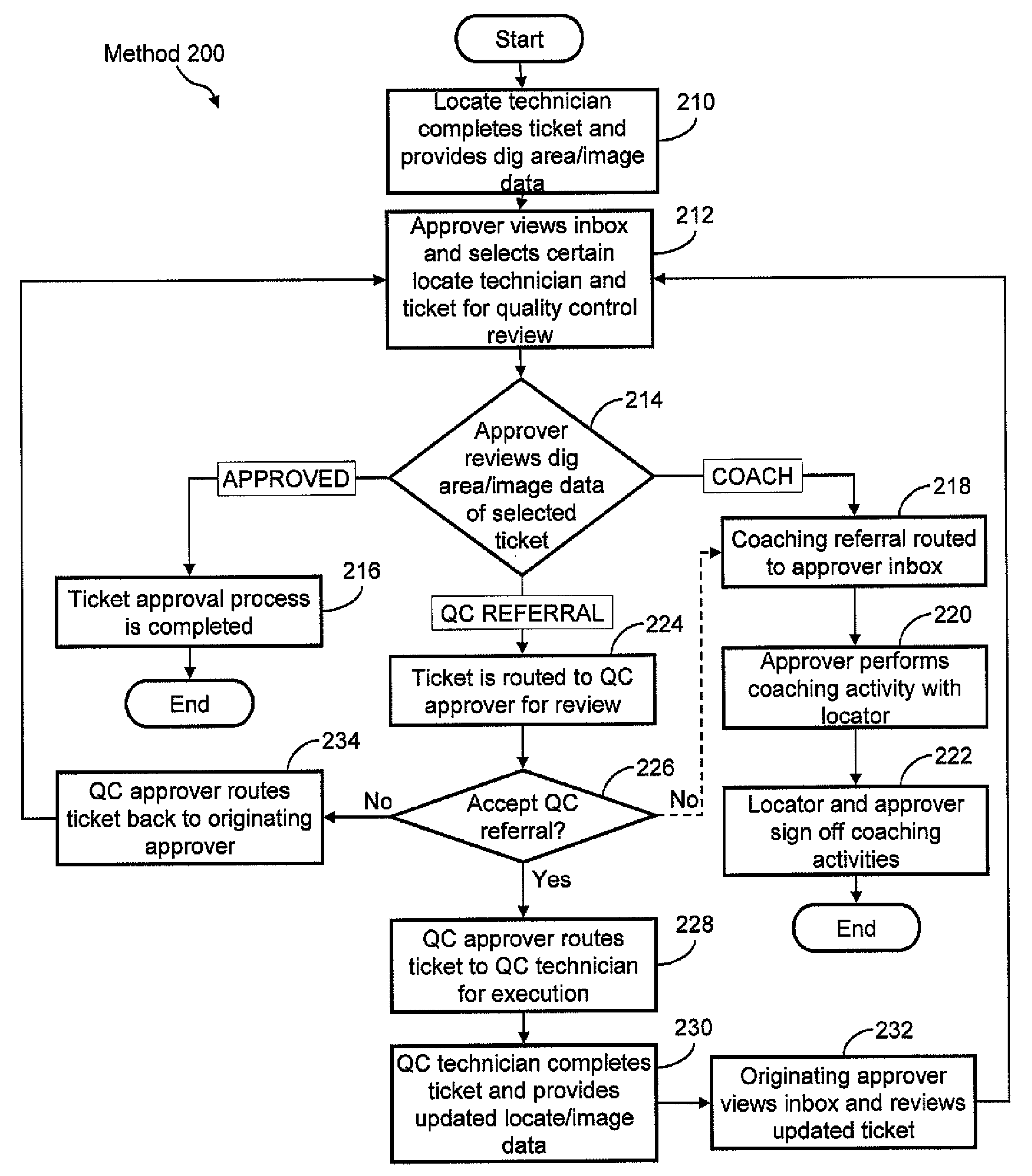

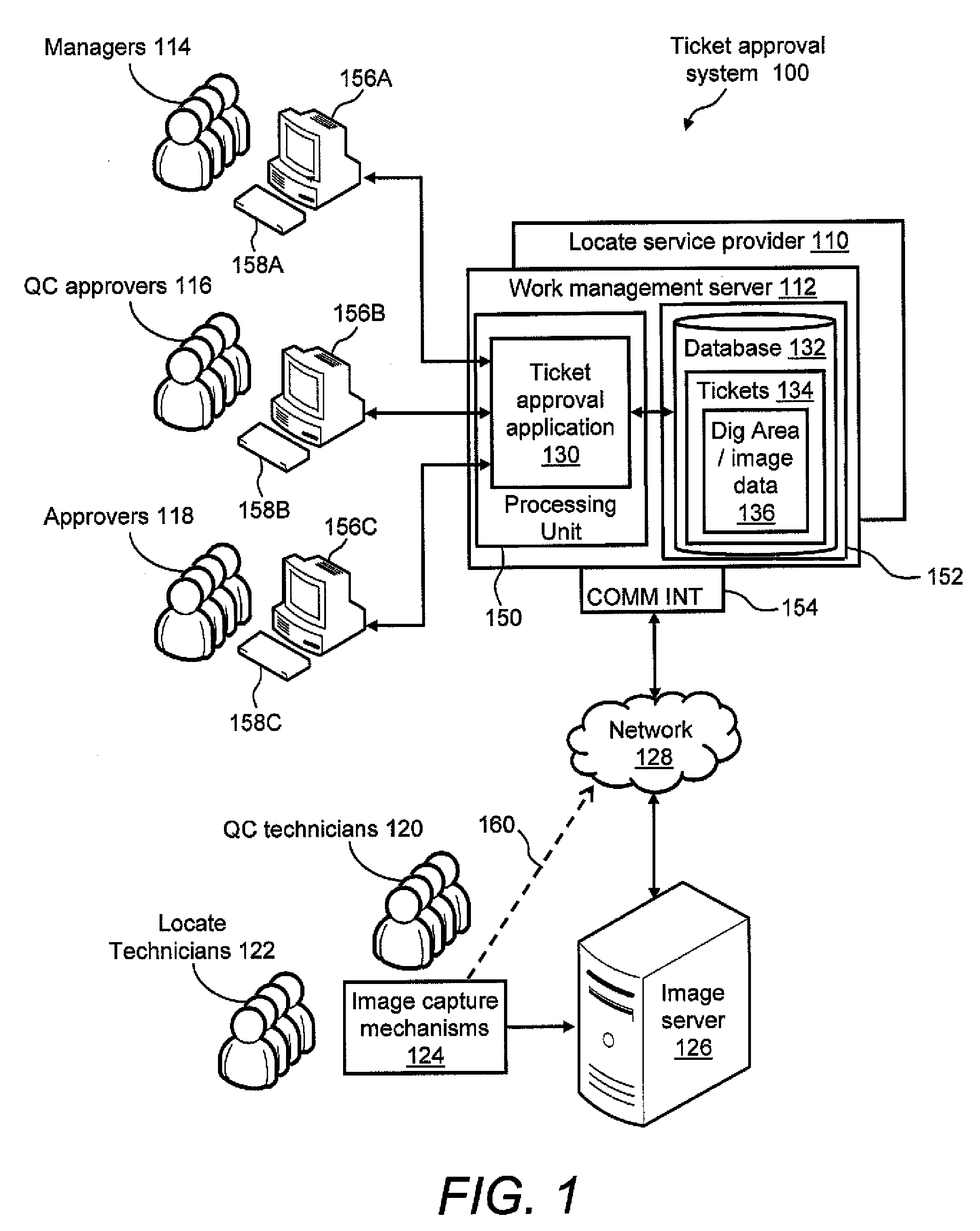

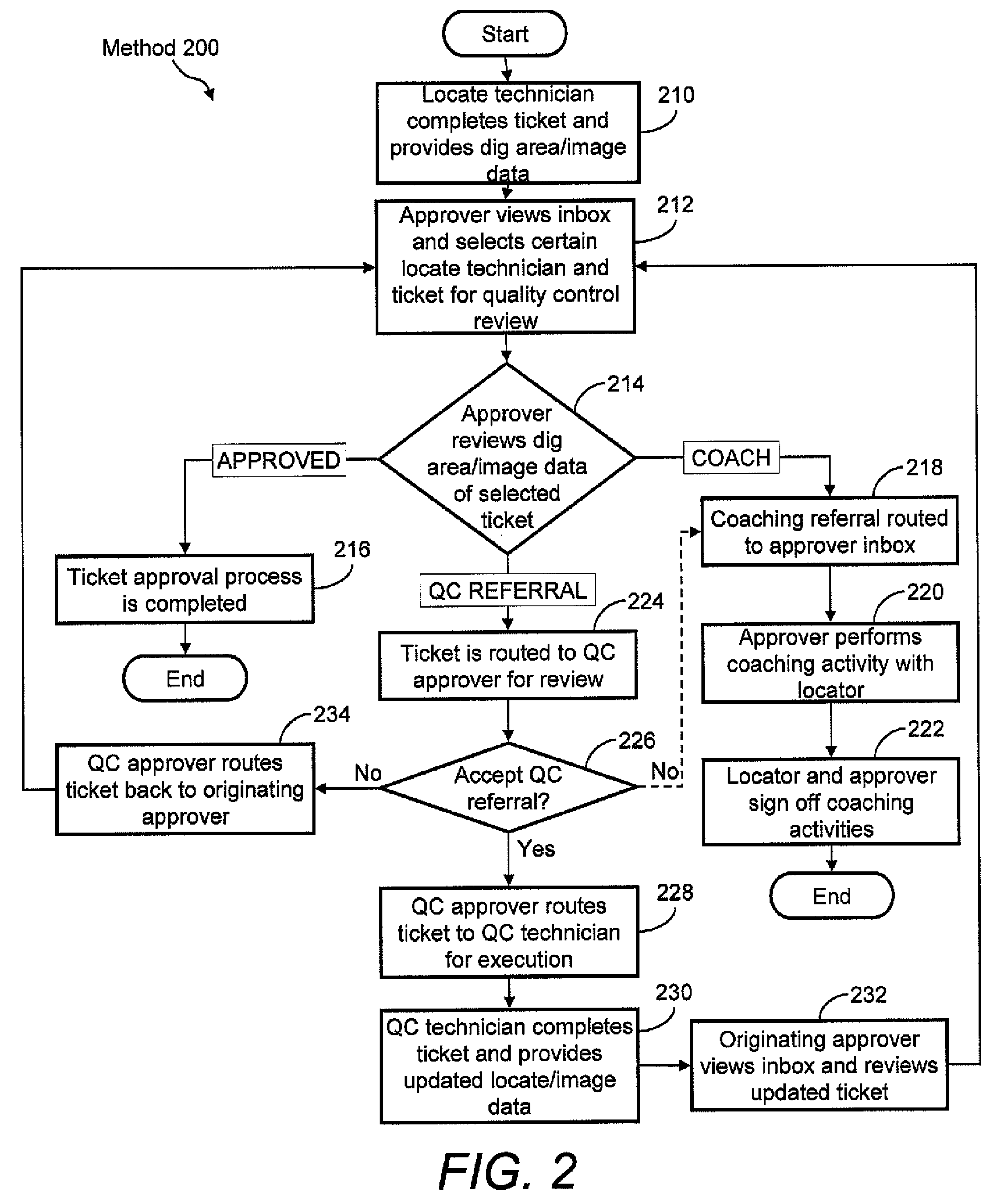

Ticket approval system for and method of performing quality control in field service applications

A ticket approval system and method of performing quality control in a field service application. The method includes obtaining a ticket, performing at least one task associated with the ticket, collecting data associated with at least one task, and transmitting the data to a work management server including database and approval applications. Also provided is a method of reviewing the data received by the approval application for quality control purposes.

Owner:CERTUSVIEW TECH LLC

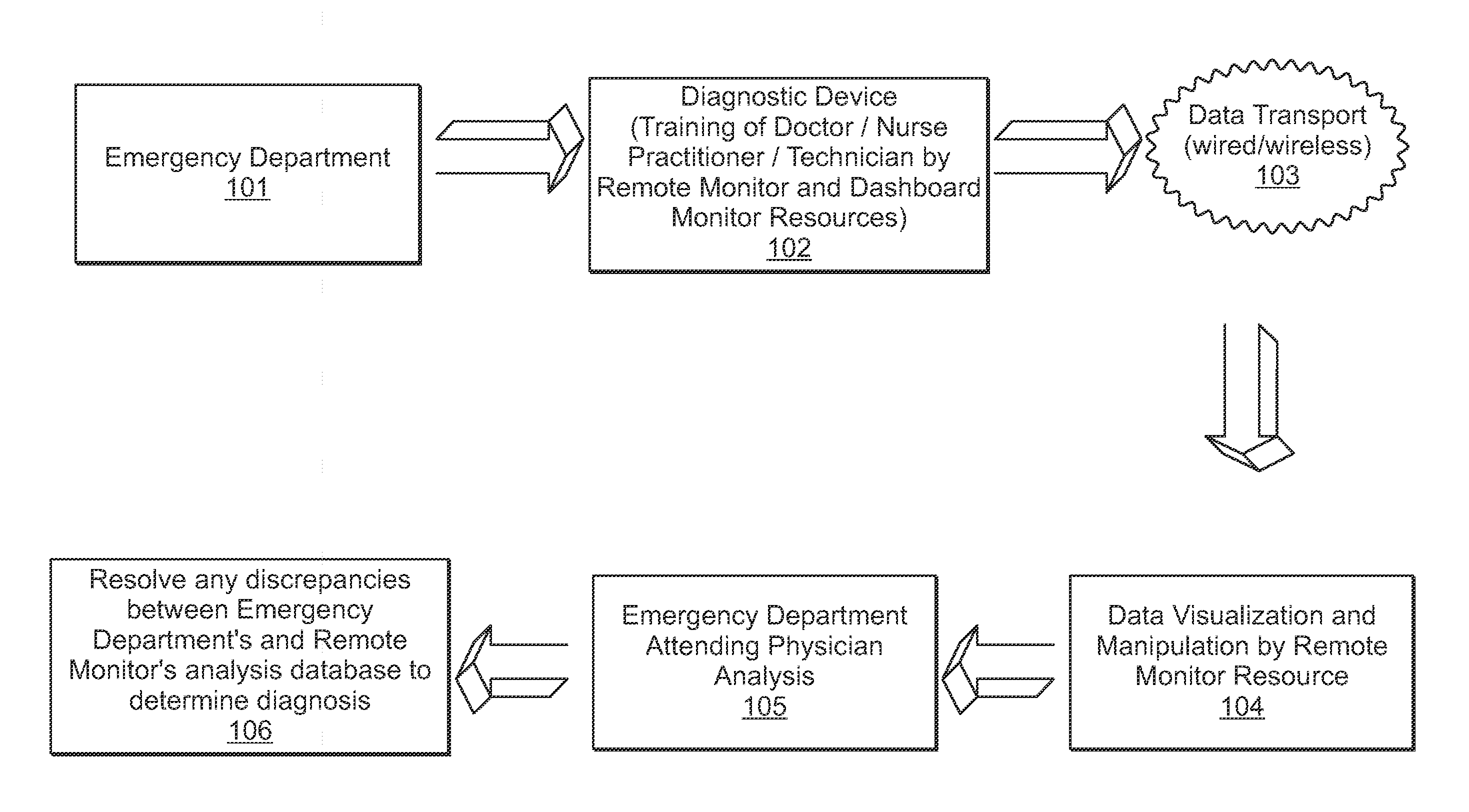

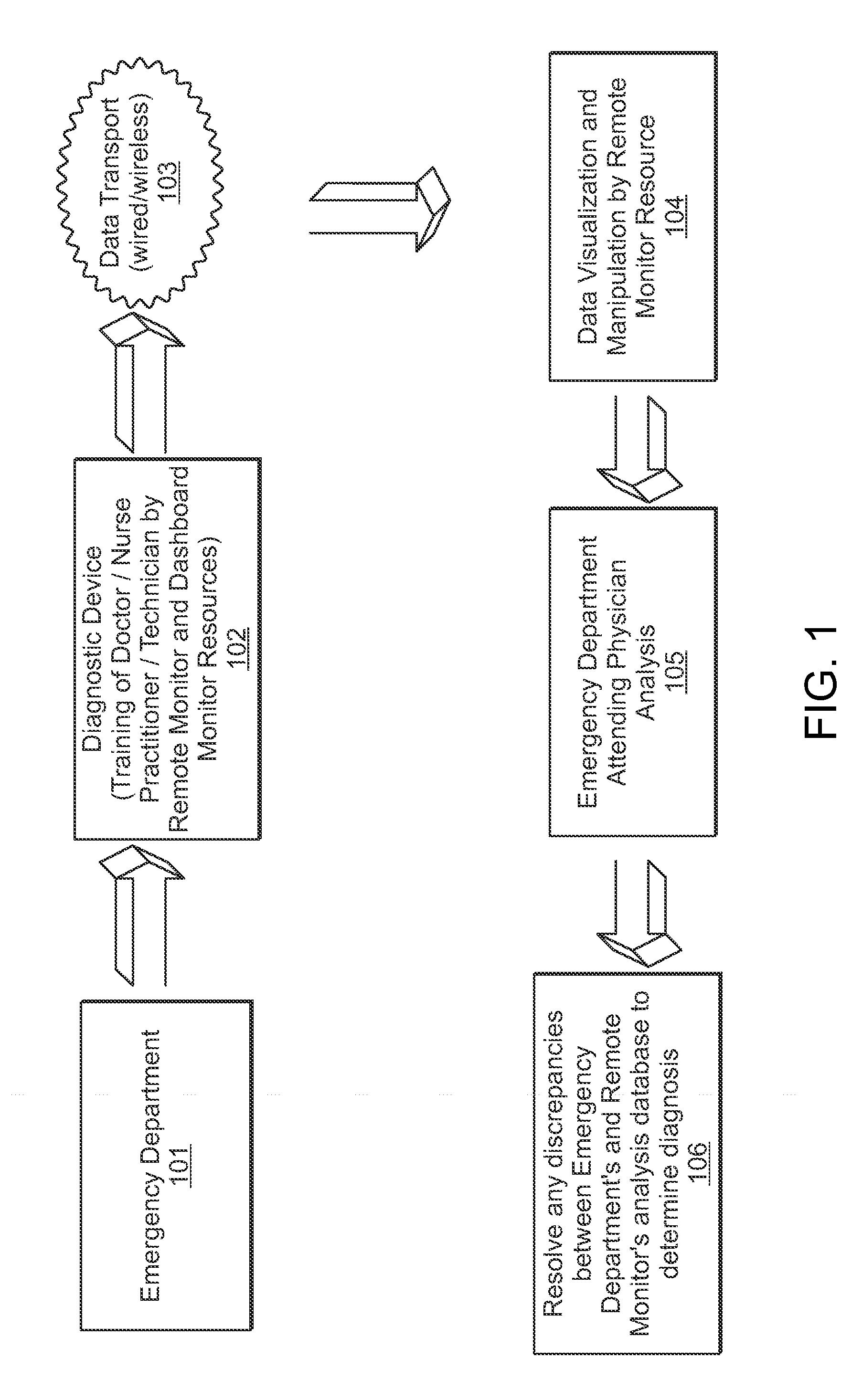

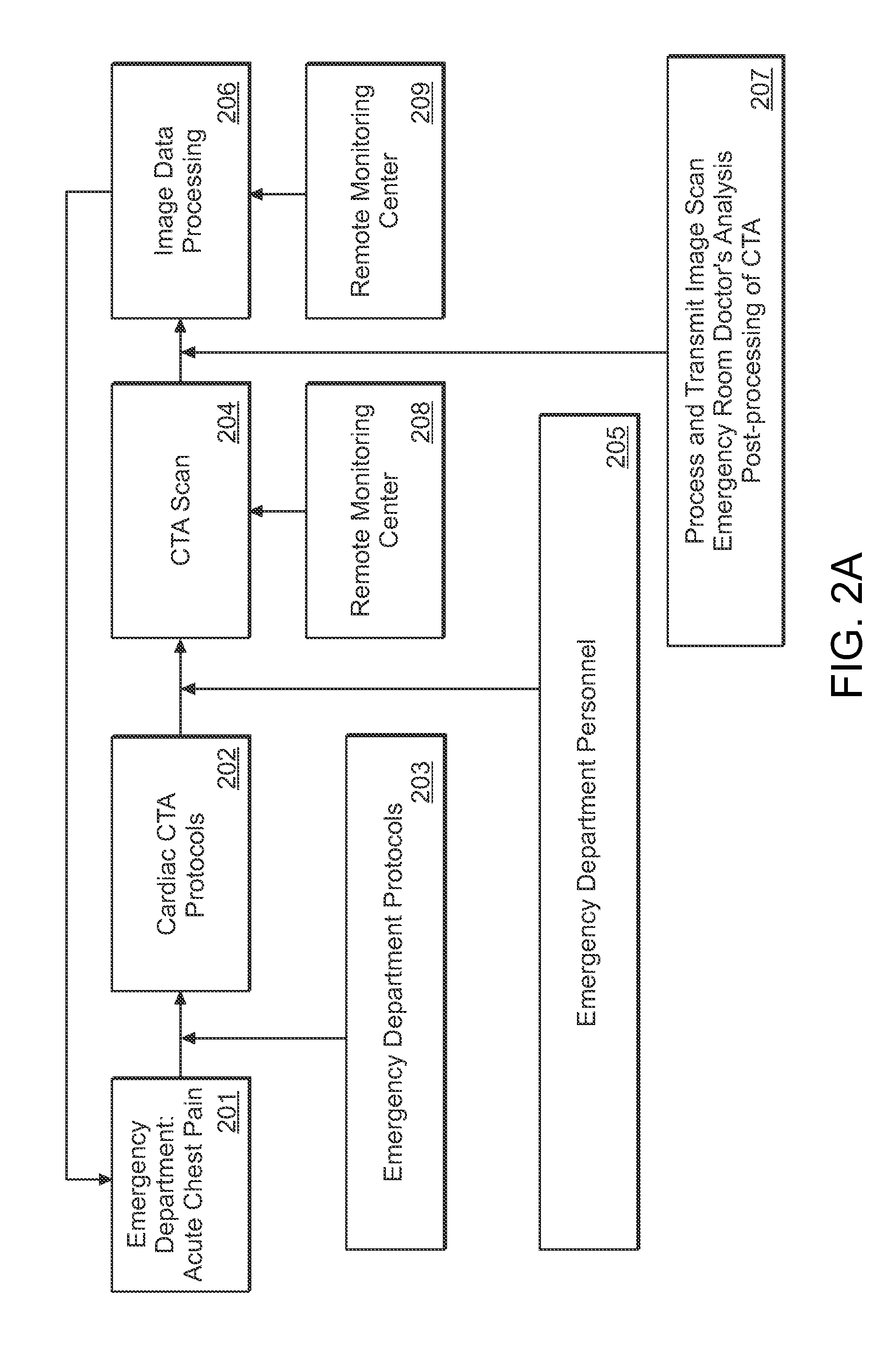

Method and system for guided, efficient treatment

InactiveUS20130024213A1Accurate and efficientAccurate diagnosisRadiation diagnosis data transmissionMedical imagesDashboardMedical record

A system and method is provided in which medical treatment of a patient is effected in a systematic and guided fashion. From a patient's symptoms and electronic medical record, a specific diagnostic test may be recommended. Upon execution of the diagnostic test, the diagnostic scan results may be forwarded to a remote location for assistance in analysis. Once analyzed, the results are transmitted to the attending medical personnel. The results, and information which led to the decision to have a diagnostic test, are also sent to a repository for use in future diagnoses and other determinations. A monitor or dashboard is used to keep track of the various steps of the procedure, to provide on the job guidance in using a diagnostic test device, and the ensure a specific efficiency and protocol are followed. A remote location of experts may also be monitoring the dashboard, as a quality control.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

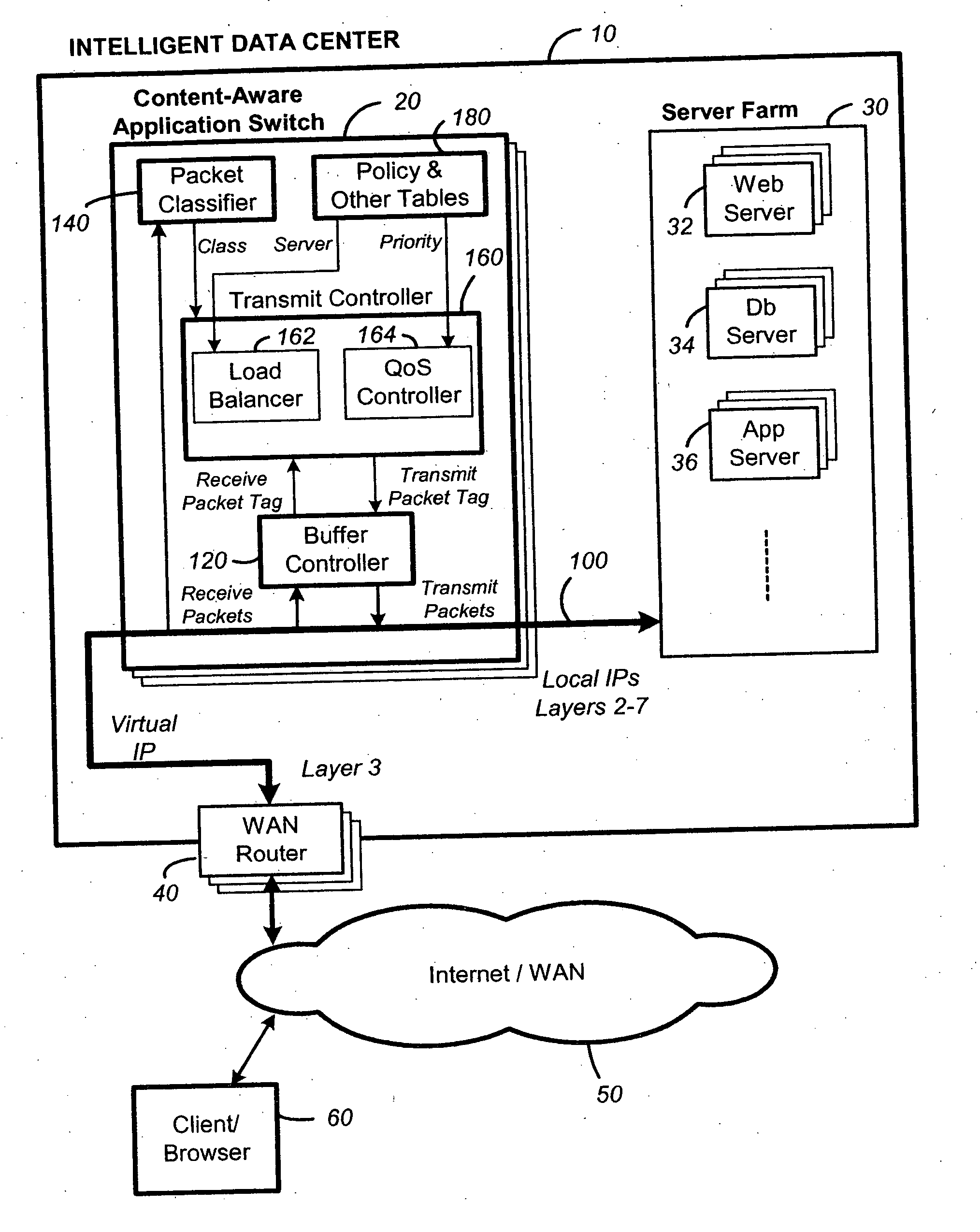

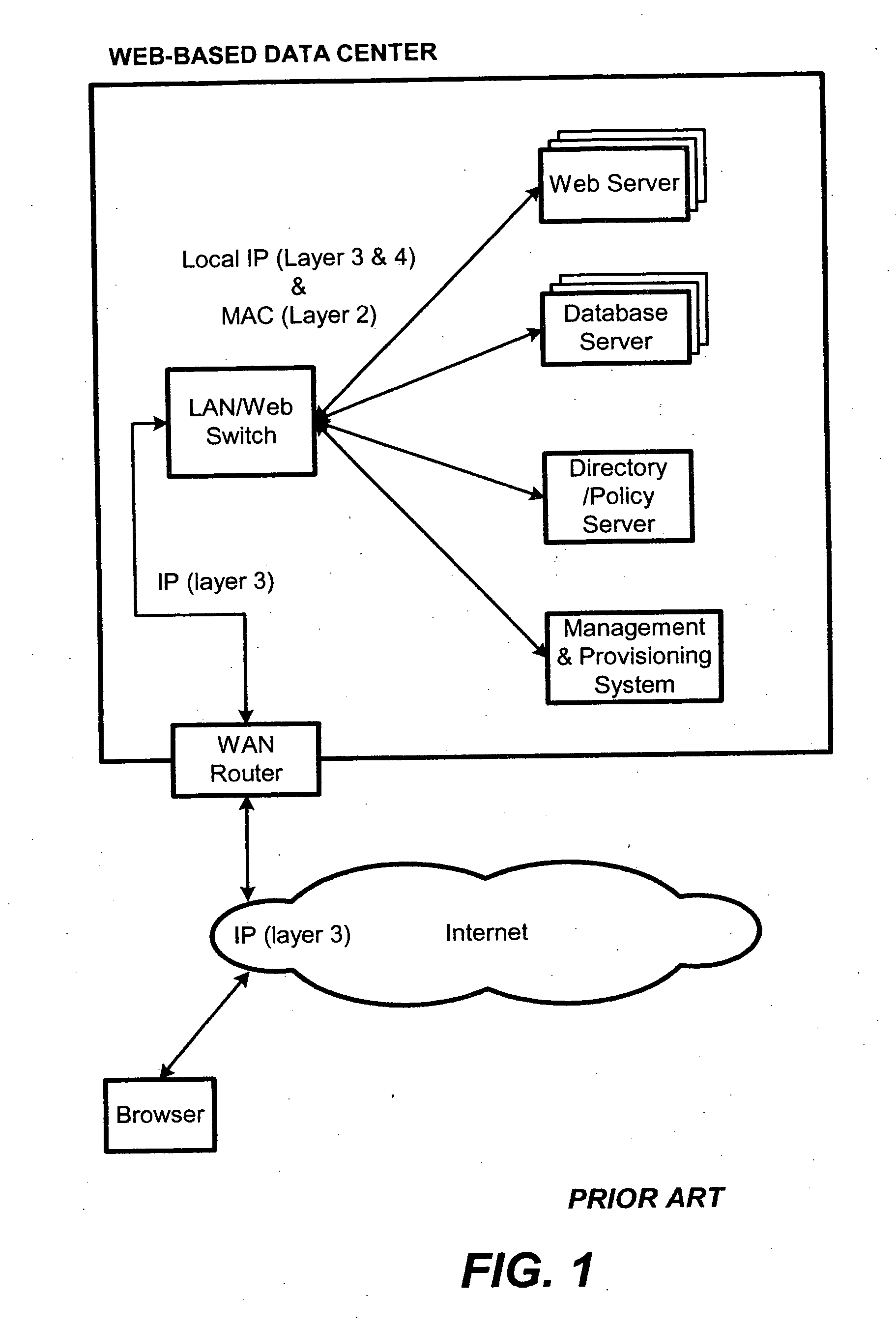

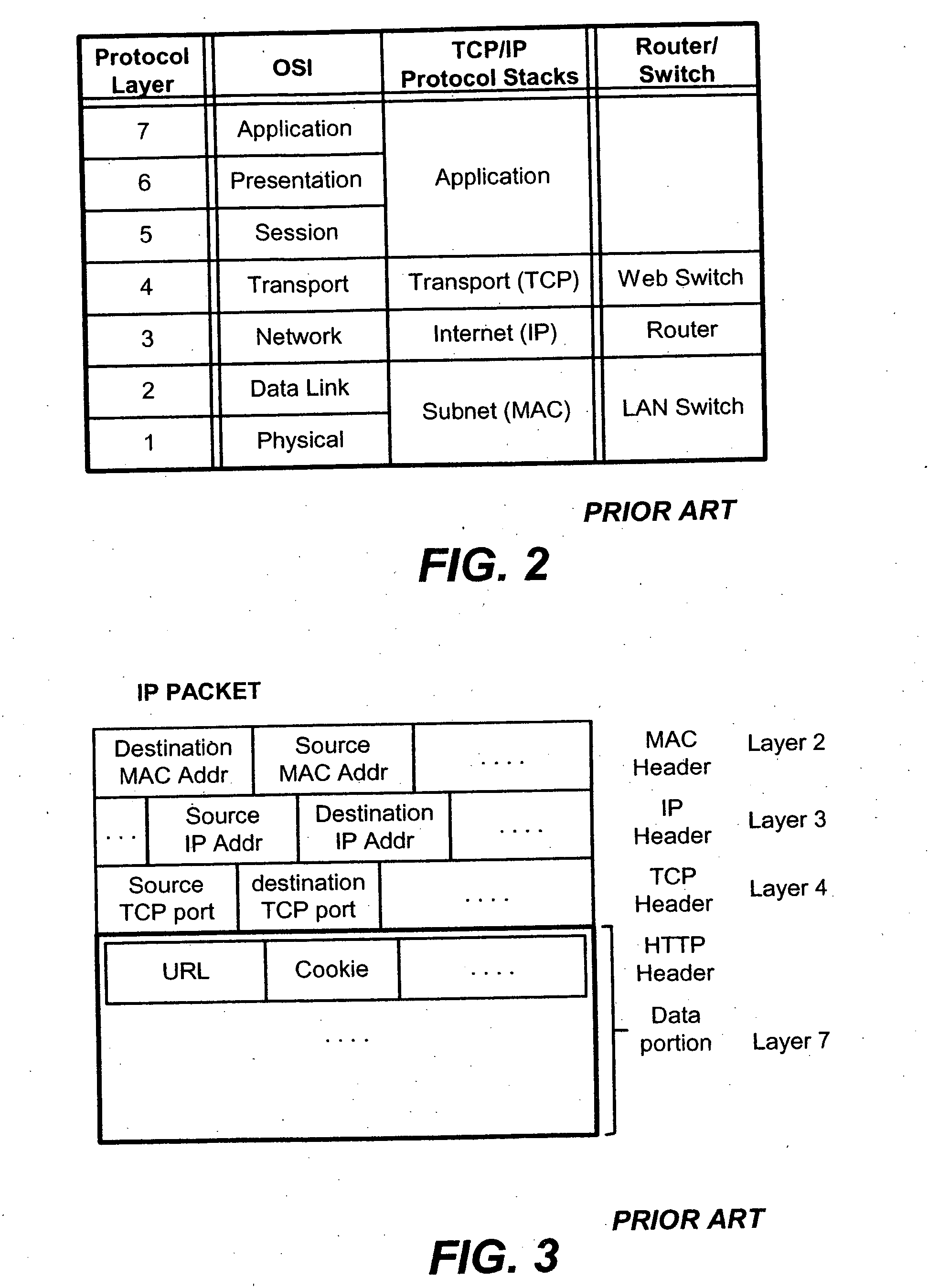

Packet switch and method thereof dependent on application content

InactiveUS20060031374A1Easy to controlControl moreMultiple digital computer combinationsData switching networksData packQuality of service

A content-aware application switch and methods thereof intelligently switch client packets to one server among a group of servers in a server farm. The switch uses Layer 7 or application content parsed from a packet to help select the server and to schedule the transmitting of the packet to the server. This enables refined load-balancing and Quality-of-Service control tailored to the application being switched. In another aspect of the invention, a slow-start server selection method assigned an initially boosted server load metric to a server newly added to the group of servers under load balancing. This alleviates the problem of the new server being swamped initially due to a very low load metric compared to that of others. In yet another aspect of the invention, a switching method dependent on Layer 7 content avoids delayed binding in a new TCP session. Layer 7 content is not available during the initial handshaking phase of a new TCP session. The method uses the Layer 7 content from a previous session as an estimate to help select the server and uses a default priority to scheduling the transmitting of the handshaking packets. Updated Layer 7 content available after the handshaking phase is then used to reset the priority for the transmit schedule and becomes available for use in load balancing of the next TCP session.

Owner:INT BUSINESS MASCH CORP

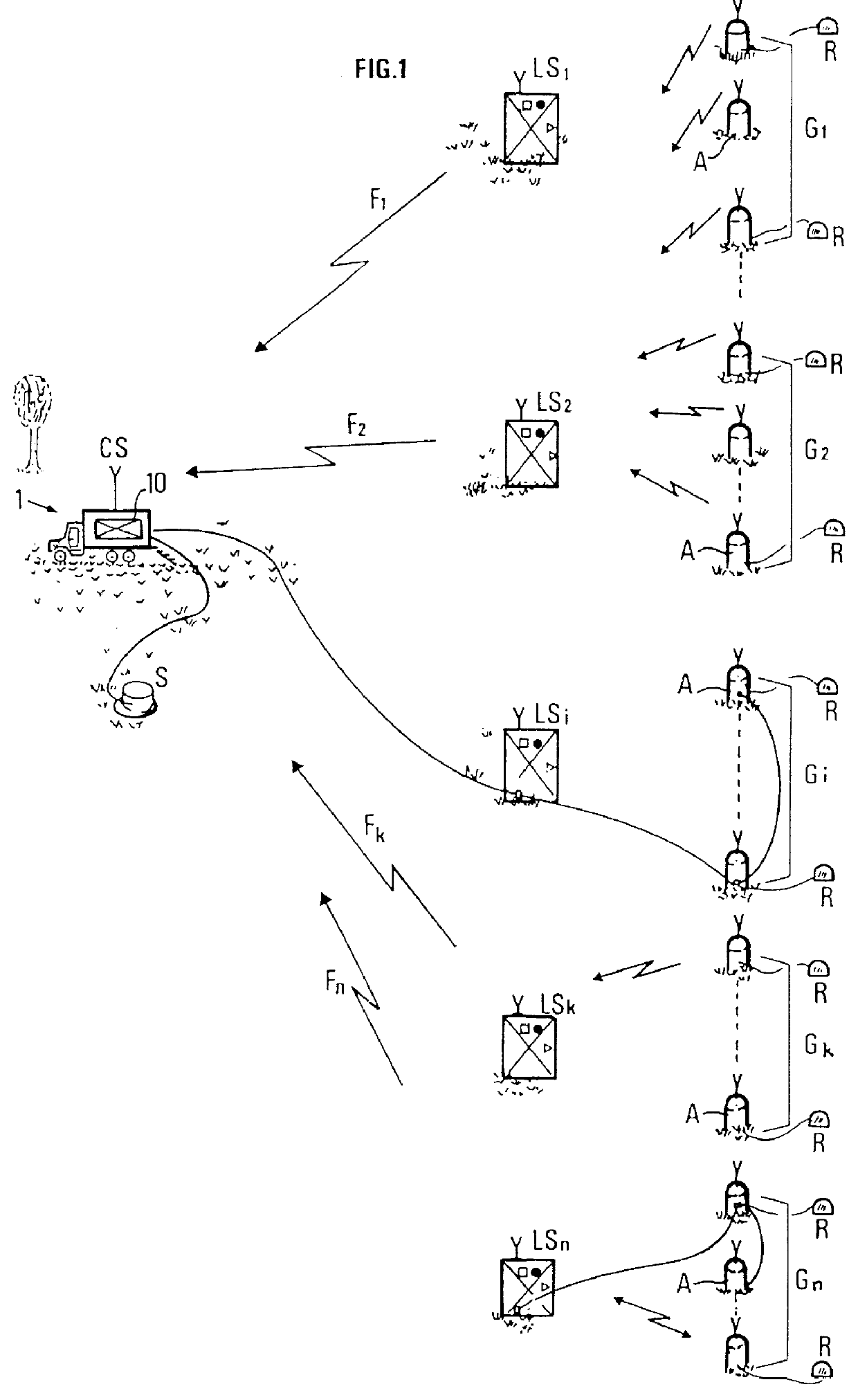

Method and system for transmitting seismic data to a remote collection station

InactiveUS6070129ALarge capacityLarge time lagSeismic signal transmissionSpecial data processing applicationsData streamTime lag

The invention pertains to transmission to a remote station, by means of transmission channels (generally radio transmission channels), of seismic data acquired by a data collection equipment comprising a plurality of acquisition units, each being suited to acquire, to store and preferably to compress the data to be transmitted. The invention comprises ordered storage, in a high-capacity memory (flash type memory for example) of each acquisition unit (Ai), of data obtained during successive emission-reception cycles (acquired and possibly preprocessed seismic data) so as to form a stream of stored data to be transmitted, and progressive transfer of the stored data stream from each acquisition unit to the remote station by means of the transmission channel, by reading each storage memory, with a time lag in relation to the time of their storage depending on the transmission rate of each transmission channel and on the transmission mode selected with preferably, if sending of the data of a cycle is delayed, sending of at least partial data, compressed or not, for quality control purposes. The data transmitted are reconstituted at the remote station. The method can be used for large-scale seismic data transmission.

Owner:INST FR DU PETROLE

Ticket approval system for and method of performing quality control in field service applications

Methods and apparatus for assessing a locate and marking operation. Ticket information is received regarding the locate and marking operation prior to performance. Following performance, a locate manifest is received that includes a digital image associated with a dig area for which the operation was performed. One or more electronic indications are provided, based at least in part on a comparison of the ticket information and the locate manifest, of a quality assessment of the locate and marking operation. The electronic indication(s) indicate one of: 1) a satisfactory operation; 2) an unsatisfactory operation requiring further quality control assessment and / or at least partial re-performance; or 3) a satisfactory operation, but nonetheless requiring technician coaching. An electronic record is generated of the quality assessment of the locate and marking operation based on the electronic indication(s).

Owner:CERTUSVIEW TECH LLC

Ticket approval system for and method of performing quality control in field service applications

Methods and apparatus for facilitating a quality assessment of a locate and marking operation. Ticket information and a locate manifest are received regarding the operation as performed by a technician. One or more electronic indications of the quality assessment are processed based on the locate manifest, the ticket information, and at least one of: a time required to complete the locate and marking operation; a time at which the locate and marking operation was performed; a cost of the locate and marking operation; one or more conditions associated with a dig area in which the operation was performed; a number of facilities to be located as indicated in the ticket information; a discrepancy between the facilities to be located as indicated in the ticket information, but not indicated as marked in the locate manifest; and an efficiency with which the technician performed the locate and marking operation.

Owner:CERTUSVIEW TECH LLC

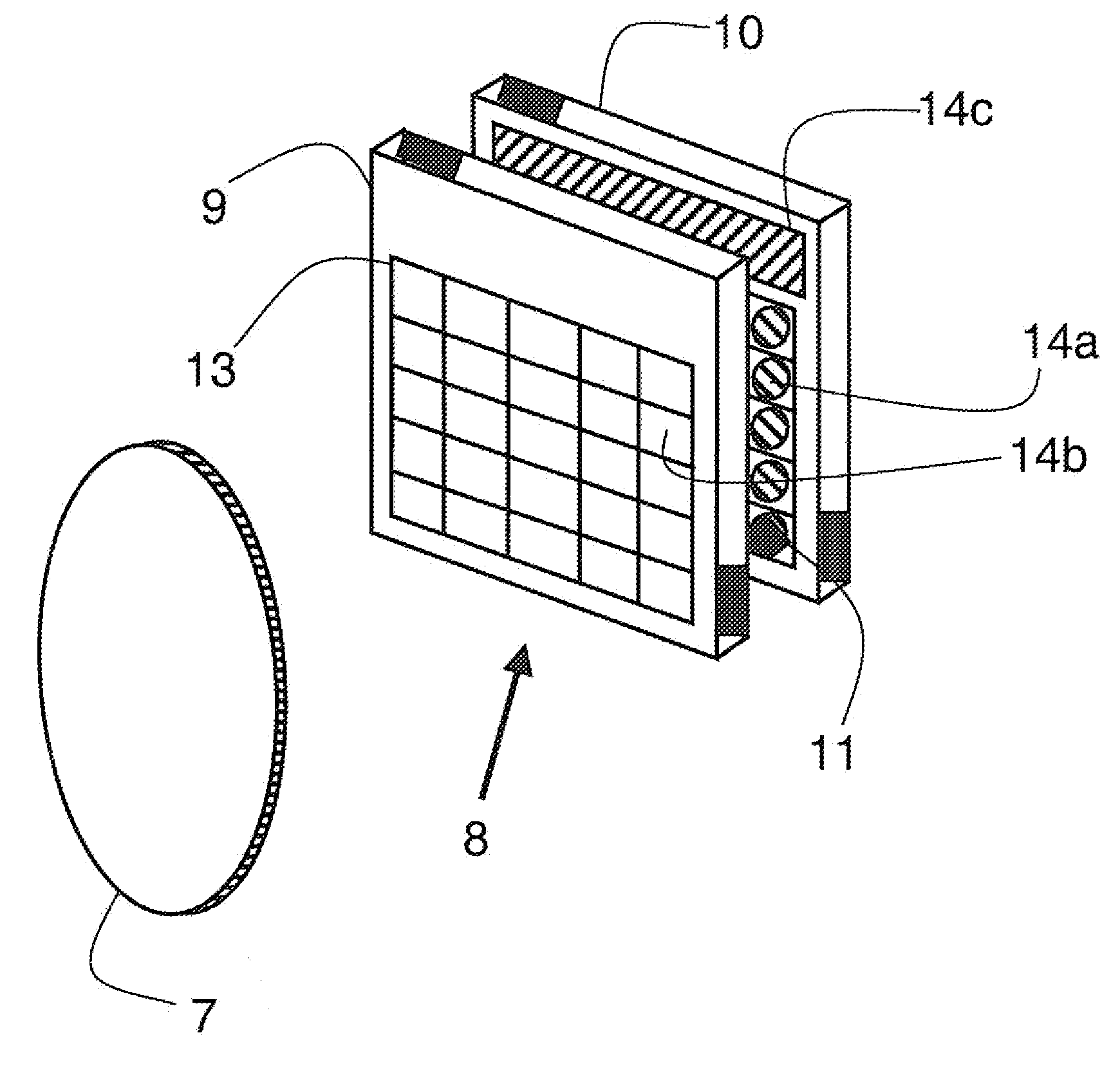

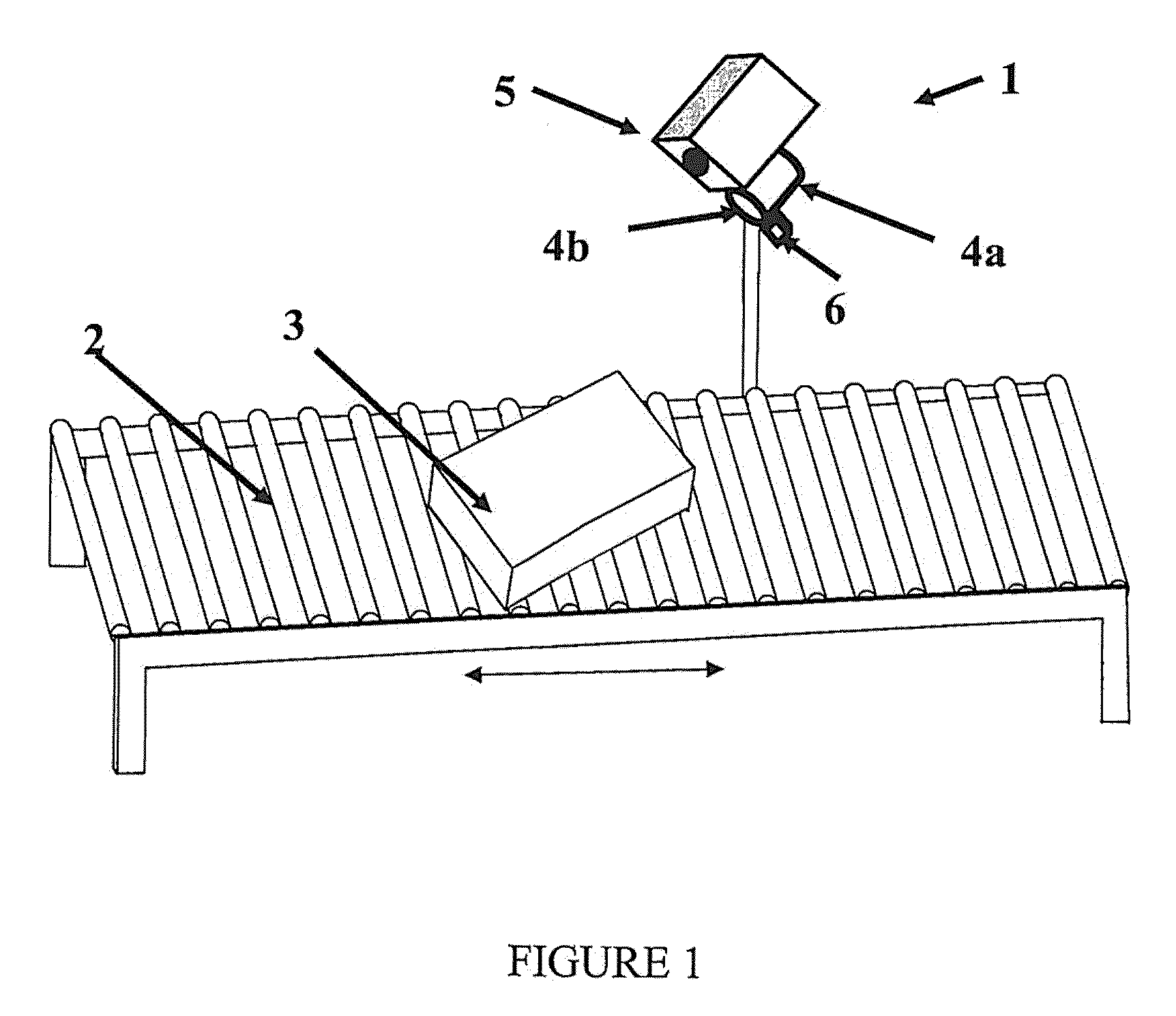

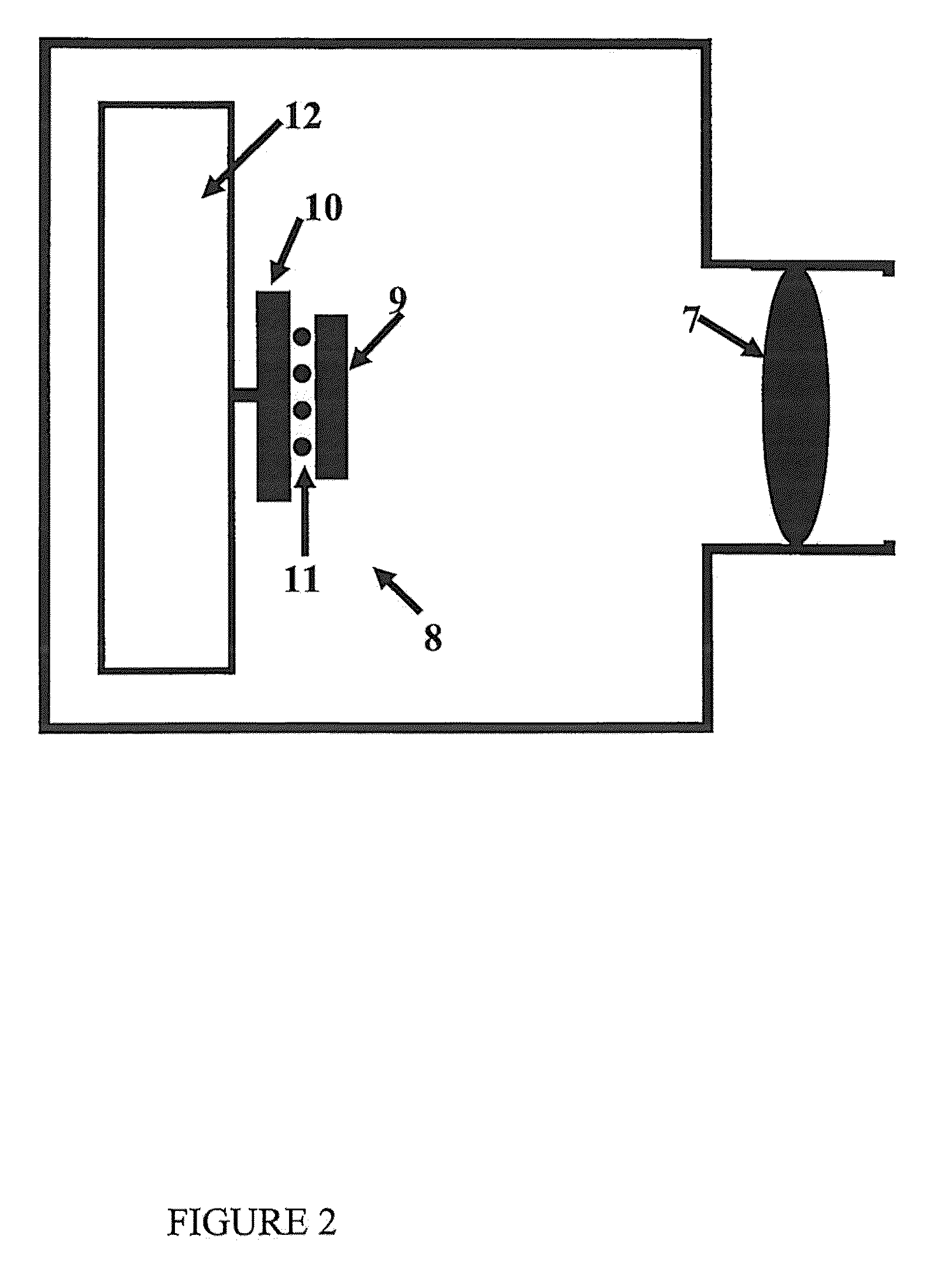

Dimensioning system

ActiveUS20100208039A1Enhanced third dimension accuracyMechanically simpleUsing optical meansRobotQuality controlLaser pulse shaping

The present invention determines the dimensions and volume of an object by using a novel 3-D camera that measures the distance to every reflective point in its field of view with a single pulse of light. The distance is computed by the time of flight of the pulse to each camera pixel. The accuracy of the measurement is augmented by capture of the laser pulse shape in each camera pixel. The camera can be used on an assembly line to develop quality control data for manufactured objects or on a moving or stationary system that weighs as well as dimensions the objects. The device can also ascertain the minimum size of a box required to enclose an object.

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

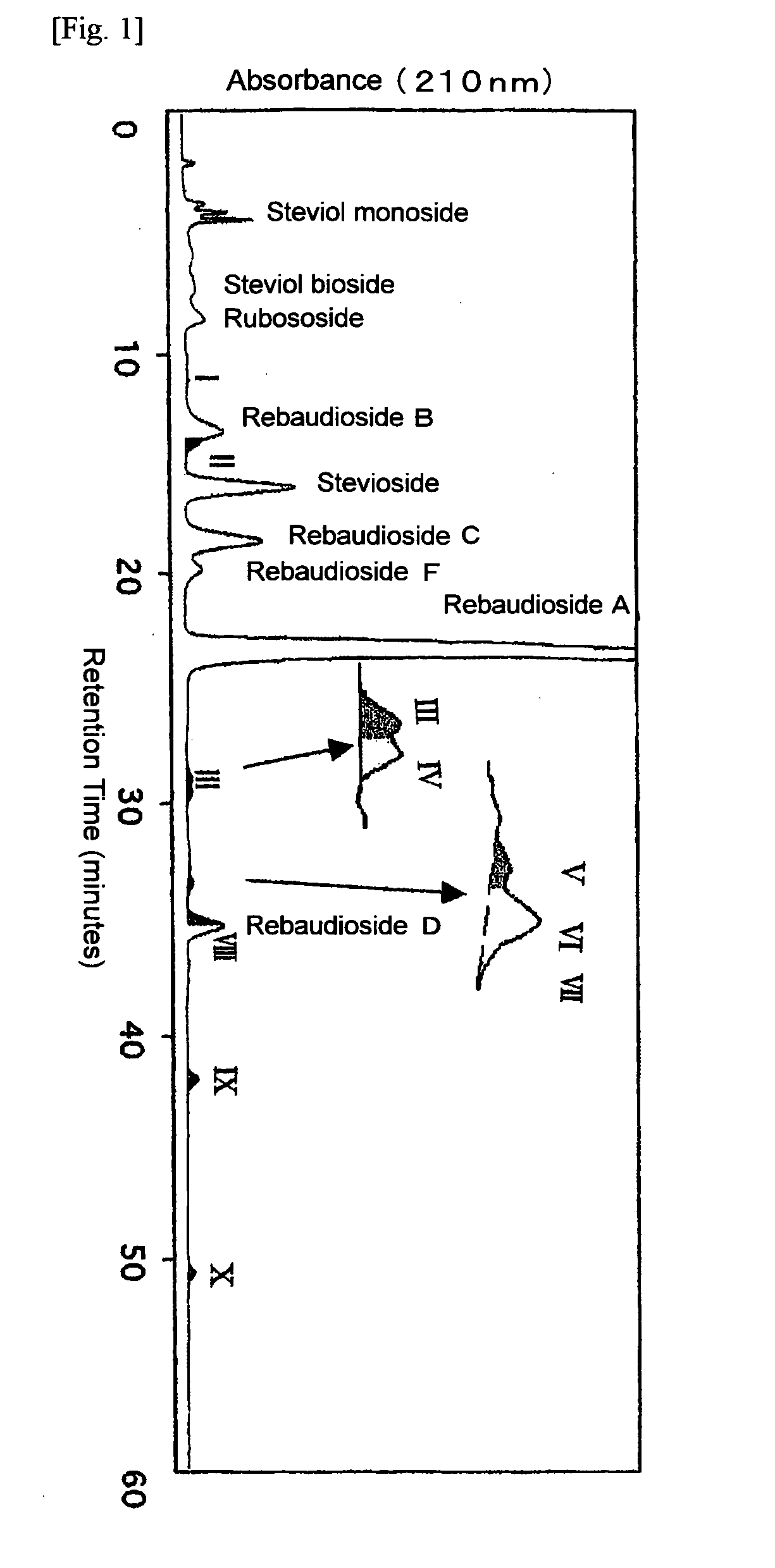

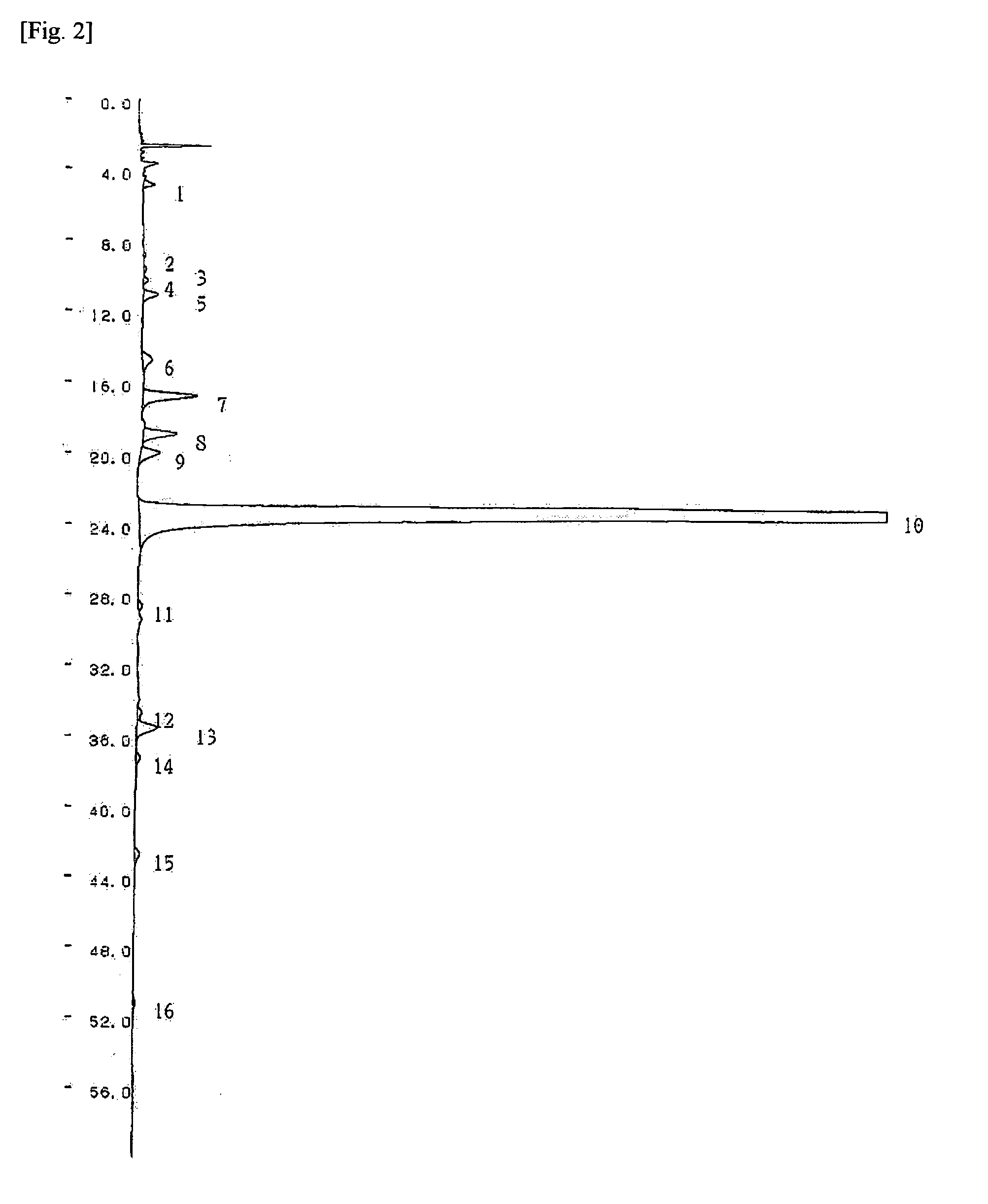

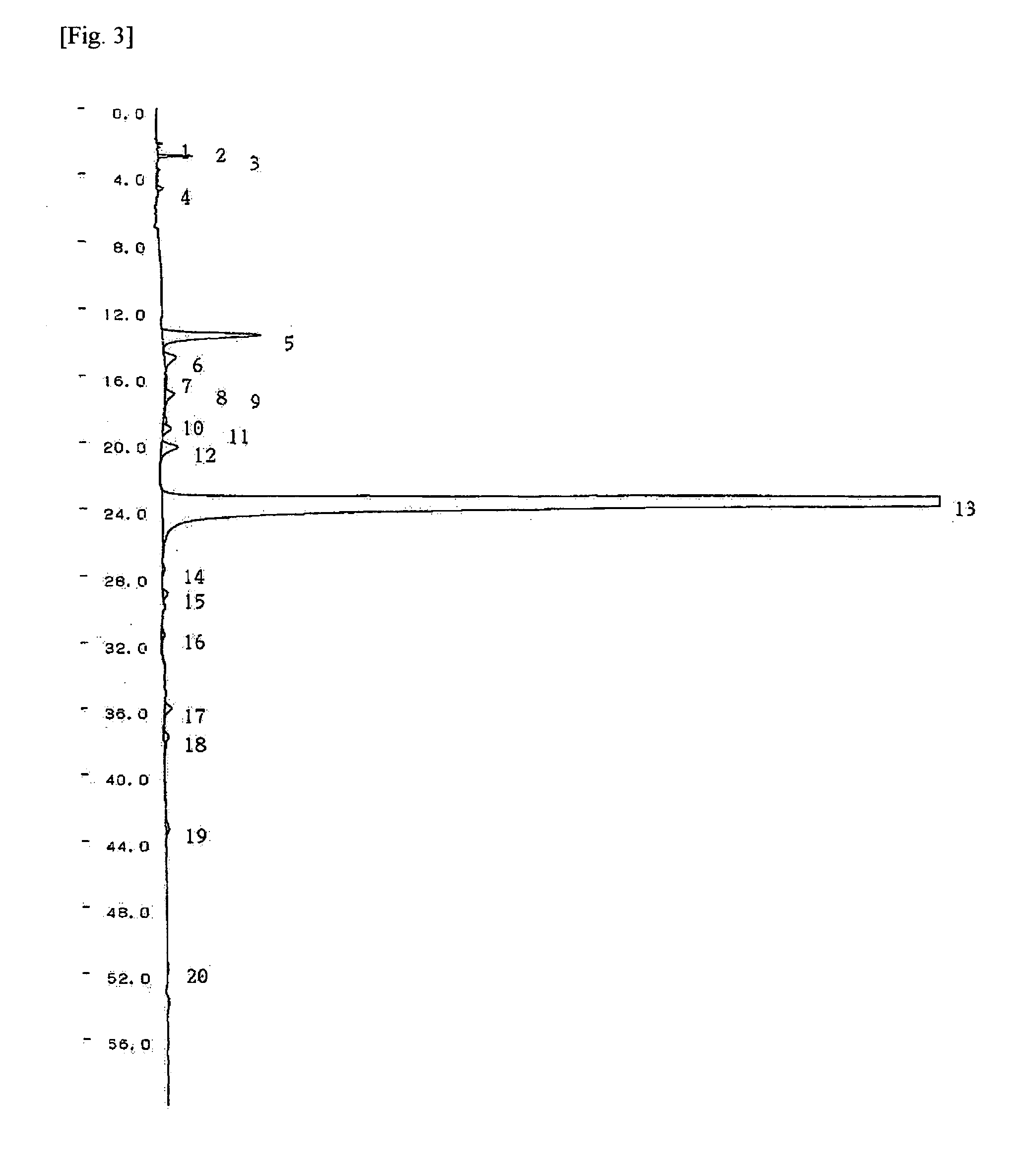

New steviol glycoside

ActiveUS20110183056A1Excellent strong tasteStrong tasteSugar derivativesComponent separationQuality controlSweetness

Nobel Stevia Sweetening components are provided. Through the analysis of the components of the nobel Steviol Glycoside included in the stevia extract and / or crystals, not only the quality control of sweeteners, but judgment on the correctness of indication of origin or infringement of right are facilitated since the raw material of the sweetener can be identified.

Owner:MORITA KAGAKU KOGYO CO LTD

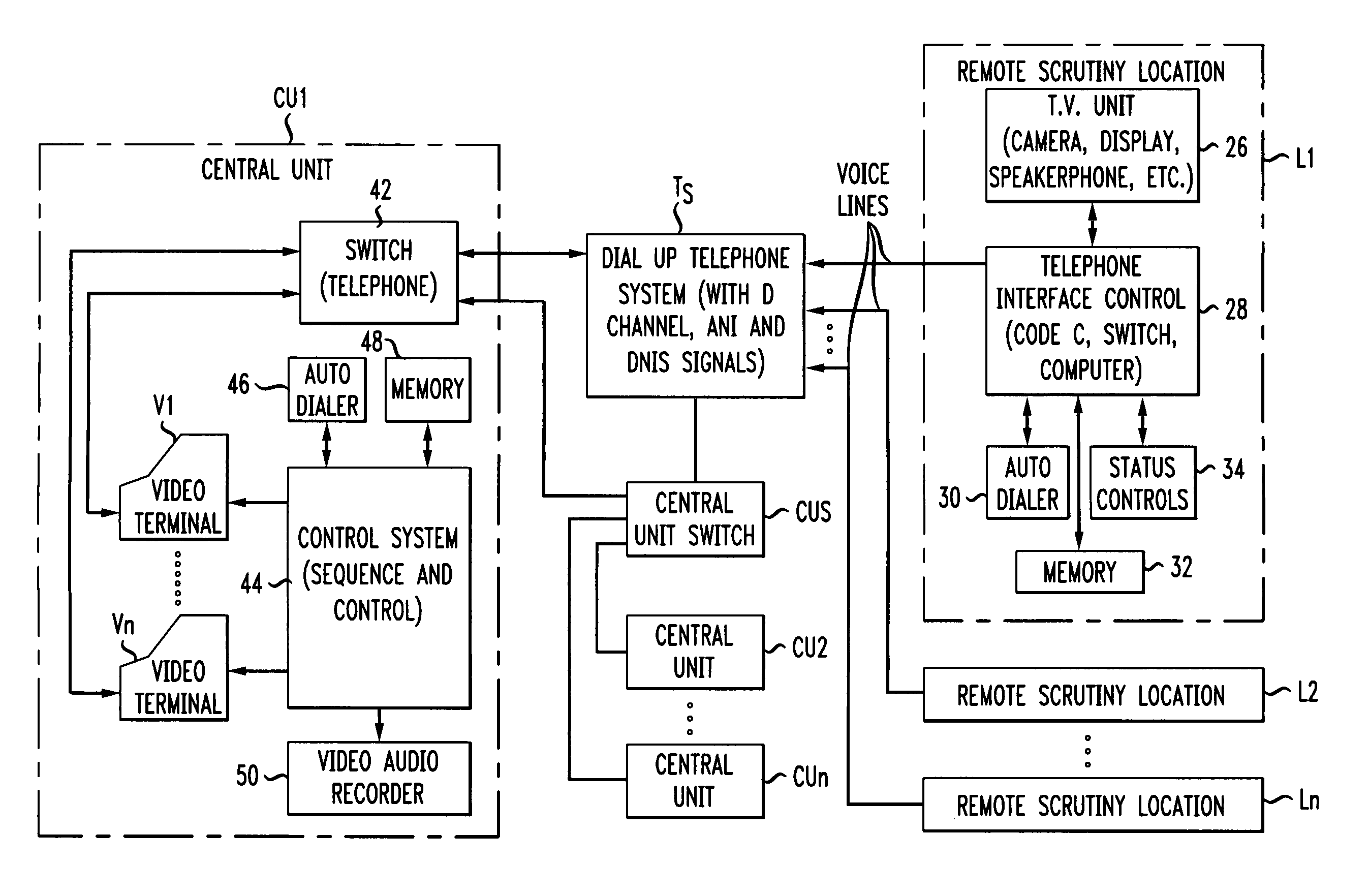

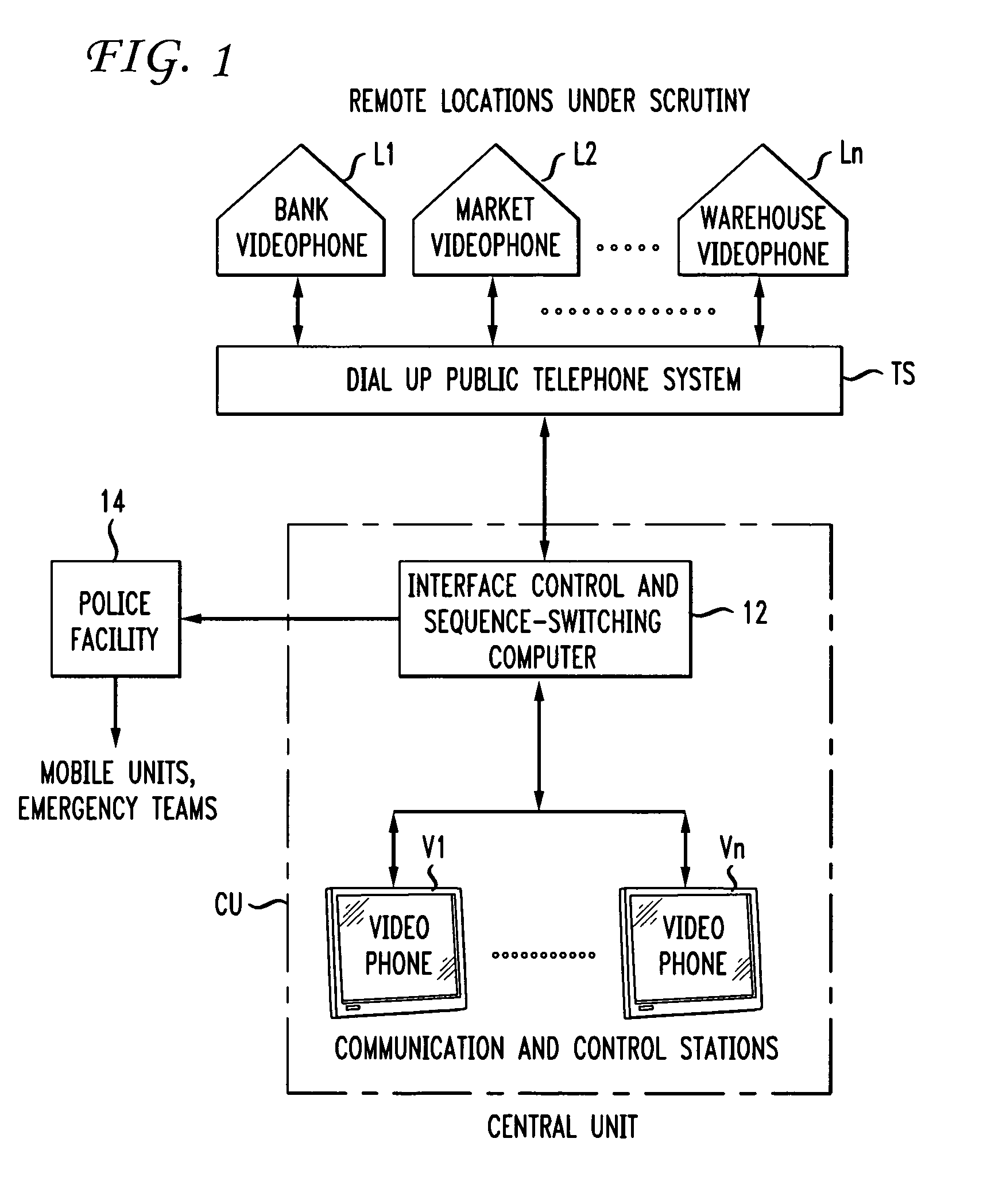

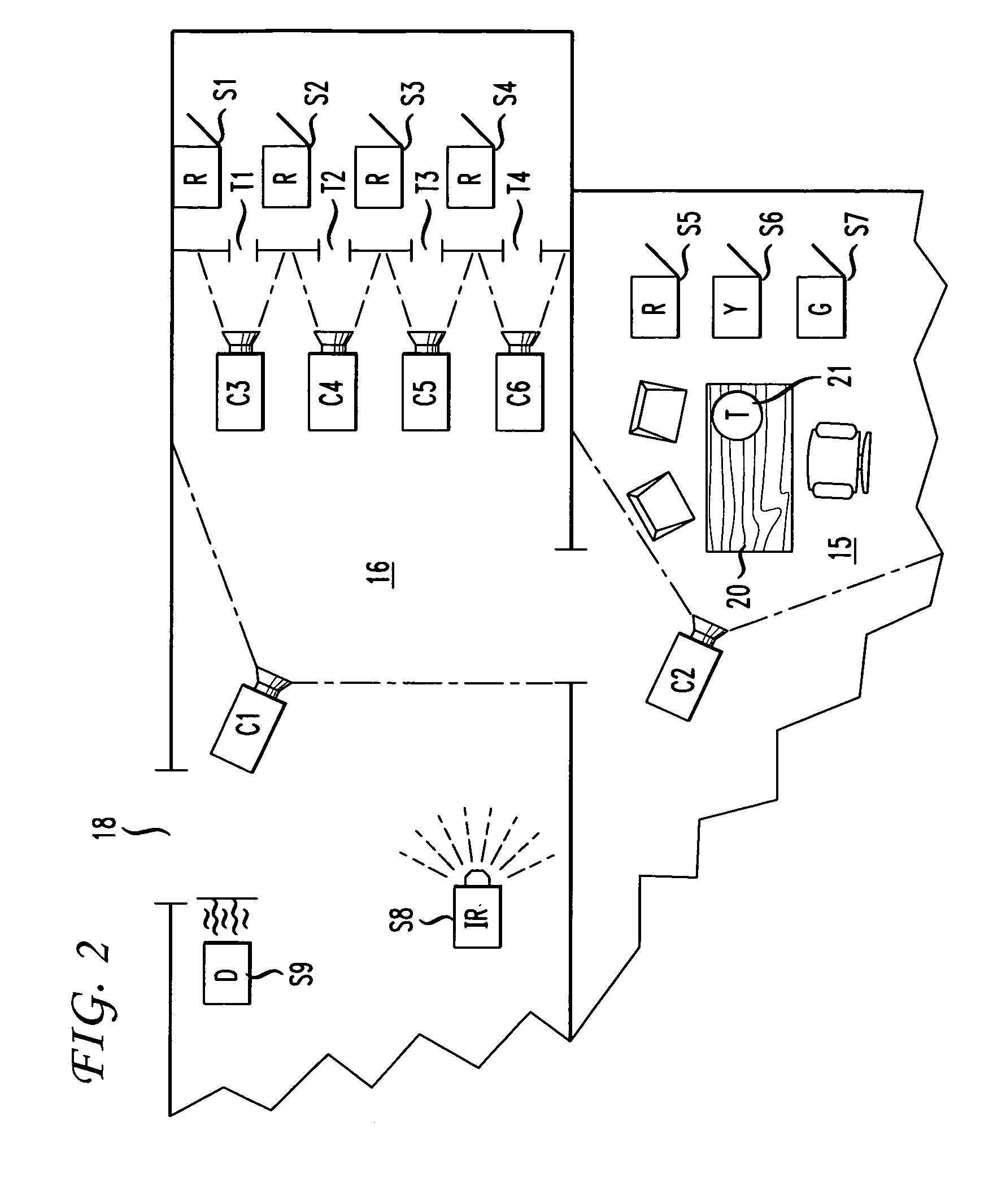

Videophone system for scrutiny monitoring with computer control

InactiveUS7019770B1Television conference systemsSpecial service for subscribersDisplay deviceSTI Outpatient

In conjunction with the dial-up public telephone system, voice quality lines carry videophone signals for monitoring a multitude of locations from at least one central station for use in a variety of applications, such as for security, surveillance, quality control and inspection, regulation of food and / or other standards in food-related and other facilities, market research, remote monitoring of deposit and withdrawal of funds at bank vaults, grocery chains, convenience stores, and the like. At the central station, telephonic interface apparatus is actuated by a control unit to selectively accomplish a telephonic connection with a remote location. Displays include the scene at the remote location and related graphic data. During routine operation, remote locations are displayed in sequence to at least one operator. Such operation may be interrupted either from a remote location or central station in the event of an urgency. In such an event, the concerned scrutiny location is displayed for further communication involving status, camera selection, camera configuration, audio, video and so on. Incoming calls from scrutiny stations imply an urgent situation for immediate display. The called number, by dialed number identification system (DNIS) may indicate the status while the calling number identifies the location by automatic number identification (ANI) signals. Alternative signalling and code techniques afford flexible operation as with respect to various graphic and status indications available for displays.

Owner:TELEBUYER

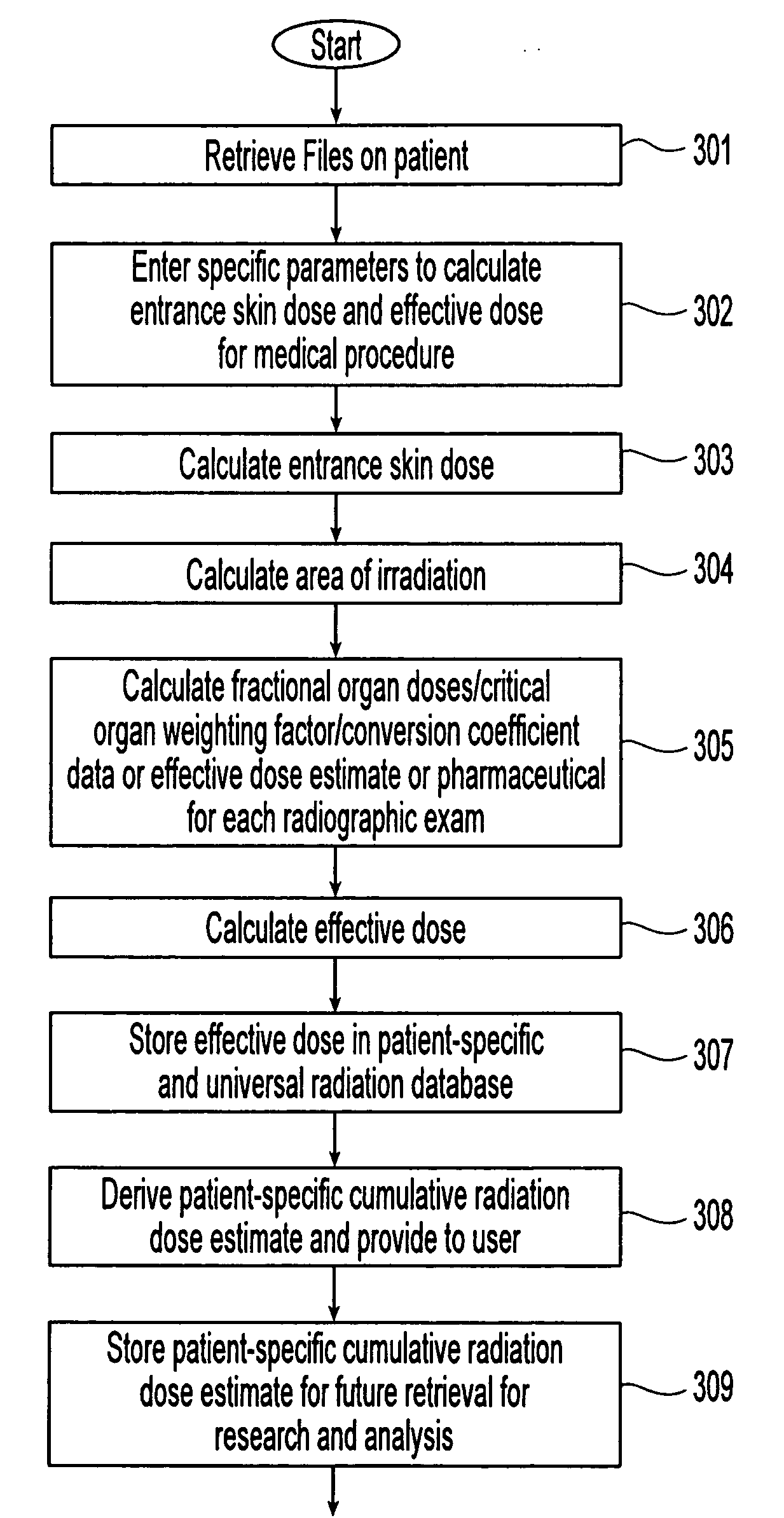

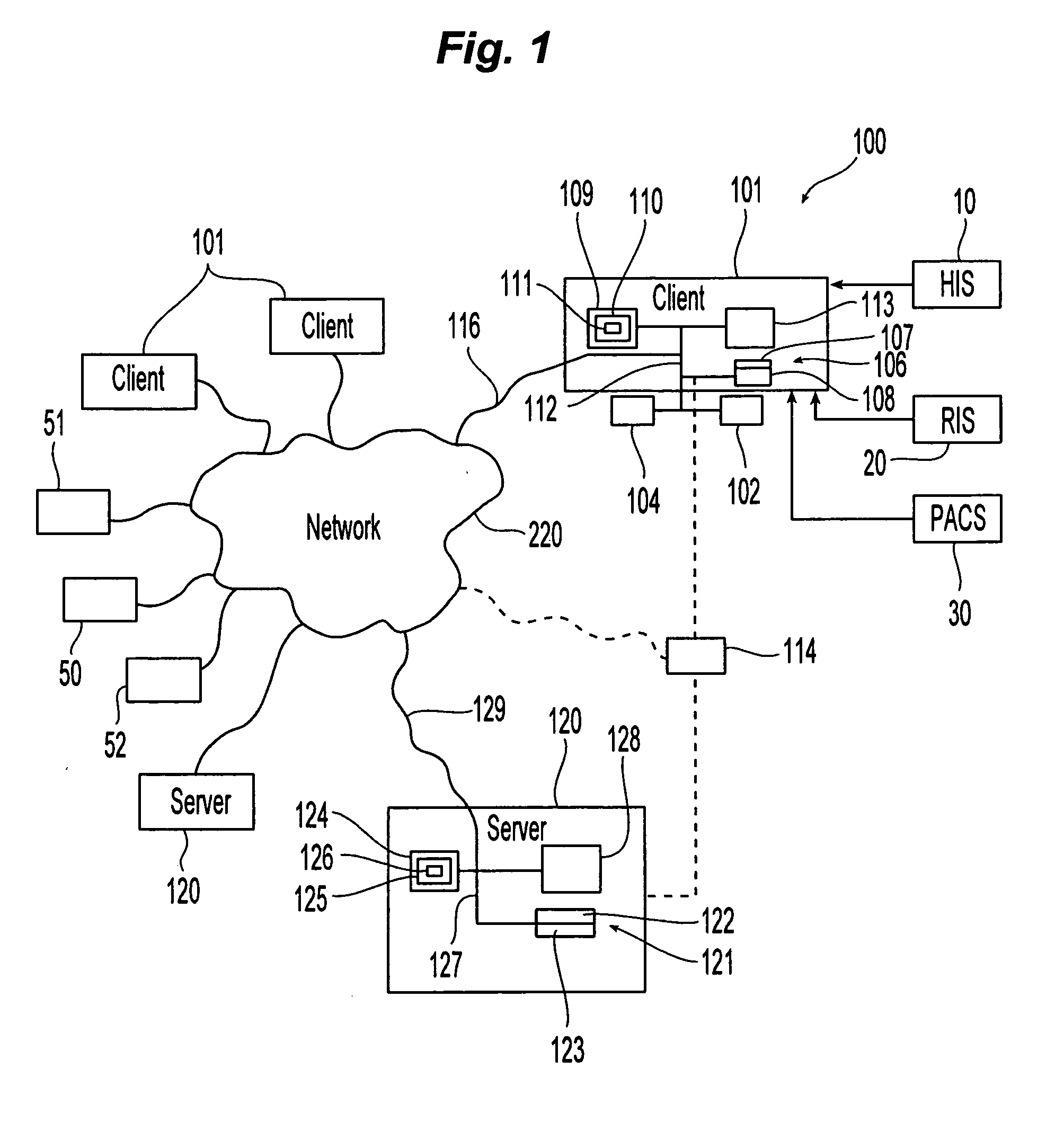

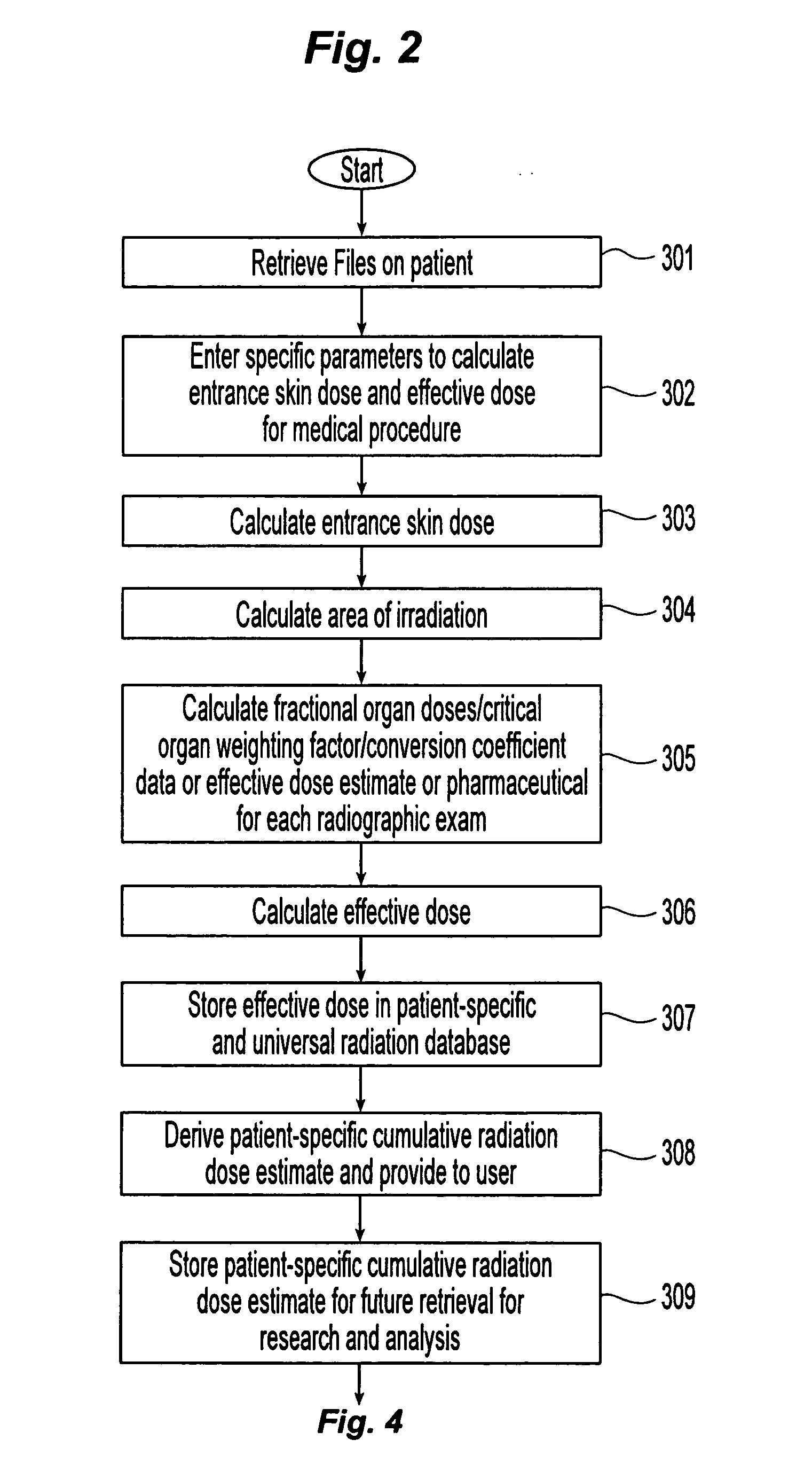

Method and apparatus of providing a radiation scorecard

ActiveUS20080103834A1Improve patient safetyReduce the environmentMechanical/radiation/invasive therapiesColor television detailsRadiation exposureRetrospective analysis

The present invention relates to a method to measure, record, analyze, and report cumulative radiation exposure to the patient population and provide automated feedback and recommendations to ordering clinicians and consultant radiologists. The data provided from this “radiation scorecard” would in turn be automatically recorded into a centralized data repository (radiation database), which would be independent to the acquisition site, technology employed, and individual end-user. Retrospective analysis can also be performed using a set of pre-defined scorecard data points tied to the individual patient's historical medical imaging database, thereby allowing for comprehensive (both retrospective and prospective) medical radiation exposure quantitative analysis. Patient safety can be improved by a combination of radiation dose reduction, exposure optimization, rigorous equipment quality control (QC), education and training of medical imaging professionals, and integration with computerized physician order entry (CPOE).

Owner:REINER BRUCE

Ticket approval system for and method of performing quality control in field service applications

Methods for overseeing and assessing a locate and marking operation. A ticket is received including ticket information regarding the operation, and a first locate technician is dispatched to perform the operation pursuant to the ticket information. A locate manifest is received that includes at least one digital image associated with a dig area in which the locate technician performed the operation. The locate manifest is compared to the ticket information, and a determination is made if the operation is 1) satisfactory, 2) unsatisfactory and requires further quality control assessment and / or at least partial re-performance, or 3) satisfactory but the first locate technician requires coaching. One or more electronic indications of one of 1), 2) and 3) are provided so as to generate an electronic record of a quality assessment of the locate and marking operation.

Owner:CERTUSVIEW TECH LLC

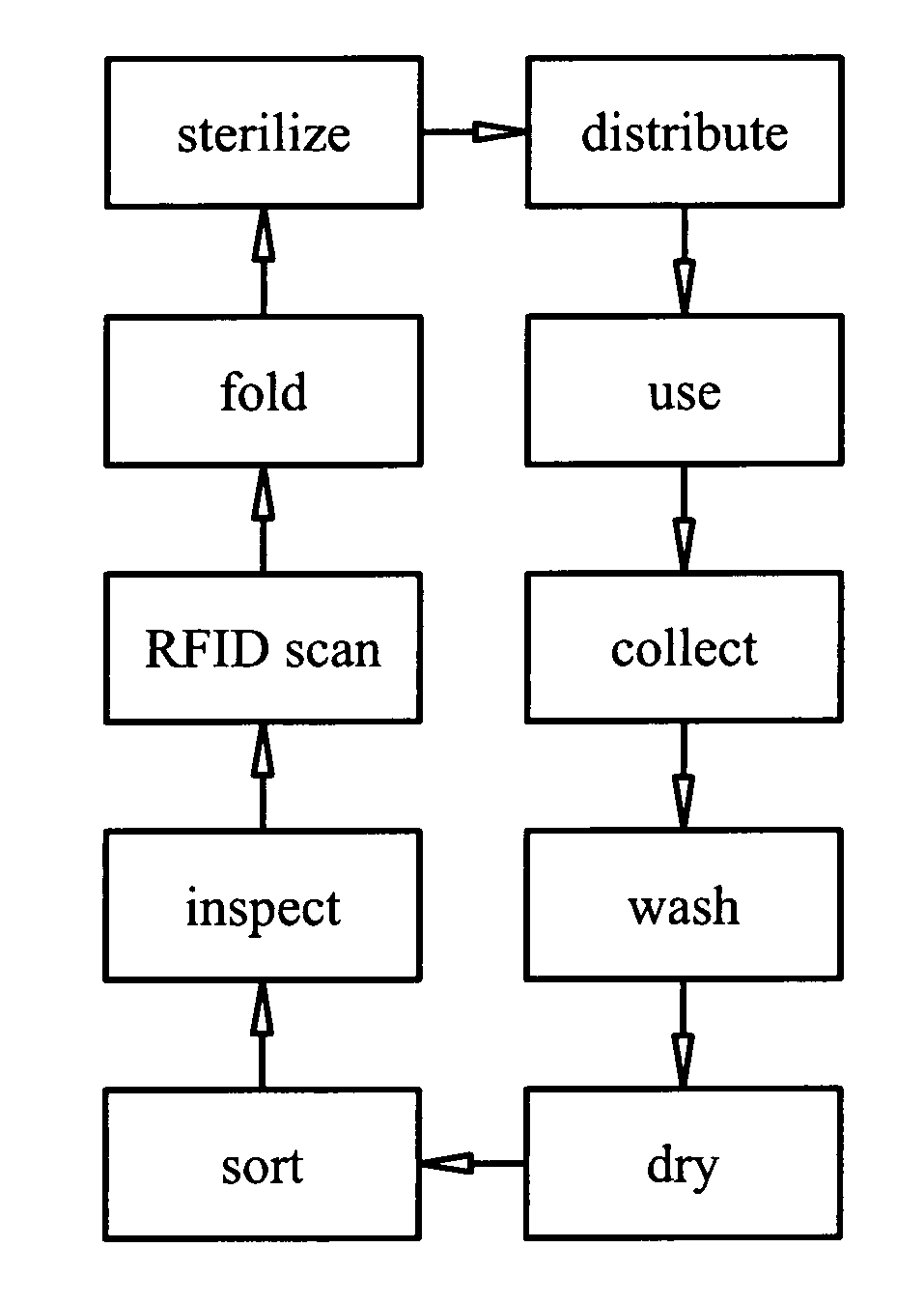

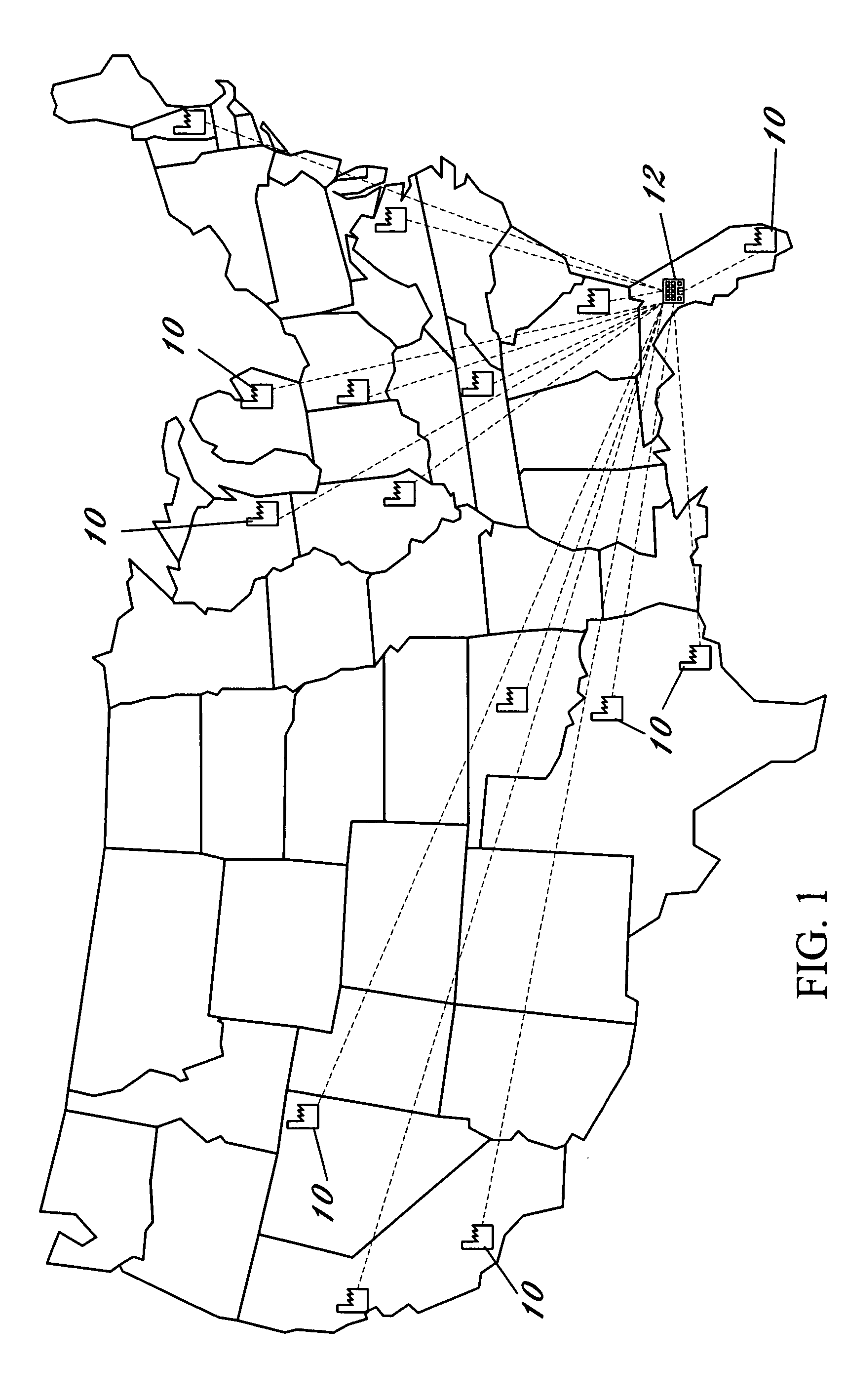

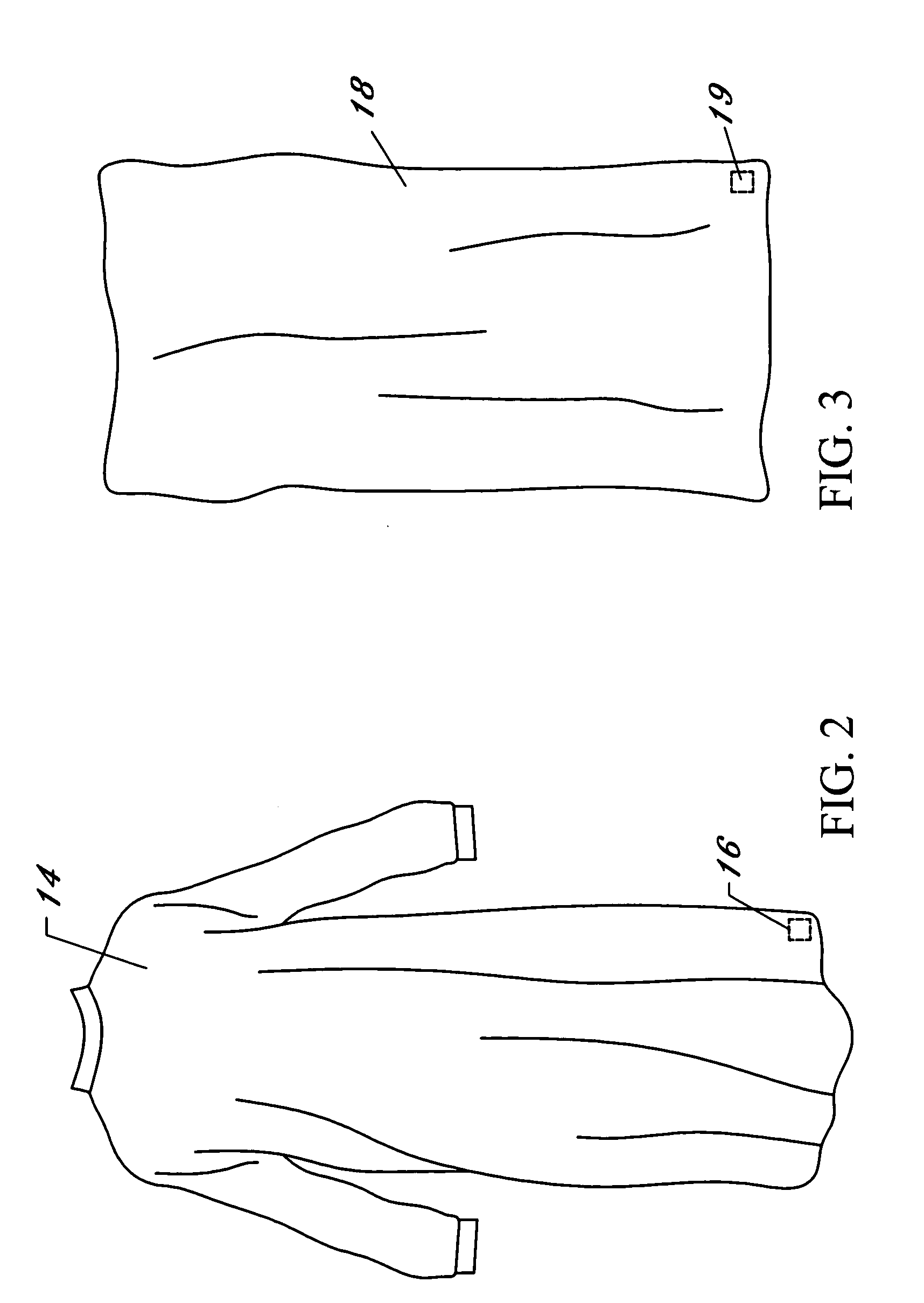

Management and distribution of surgical supplies within an RFID enabled network

InactiveUS7142118B2Efficiency parameters to be monitoredImprove quality controlData processing applicationsDigital data processing detailsWide areaQuality control

The present invention contributes to advancements in the art of inventory management and distribution by providing a system and method for processing, distributing, and tracking reusable inventory items. Reusable articles, such as surgical garments and accessories, are adapted with radio frequency identification (“RFID”) tags having unique identification numbers. A “reader” is used to retrieve stored information from the tags without requiring direct contact or clear line-of-sight. The reusable articles are processed and distributed using an inventory management system wherein lifecycle data is obtained for each reusable article. The reusable articles are distributed to the end users from central processing facilities, used, returned, cleaned, inspected, folded, sterilized, and returned to inventory for re-distribution. Periodic quality control inspections are conducted in response to predetermined usage parameters. The use of RFID tags and a corresponding computer network allows for the acquisition of data corresponding to each reusable article within a distribution system having multiple remote distribution and processing facilities. The acquired data is transmitted to a central computer processing system via a secured wide area computer network for use and analysis. Data processing computer servers at each remote distribution and processing facility electronically linked to a central data processing server provide a fail-safe network for acquired data.

Owner:SRISURGICAL EXPRESS

Large-area individually addressable multi-beam x-ray system and method of forming same

A structure to generate x-rays has a plurality of stationary and individually electrically addressable field emissive electron sources with a substrate composed of a field emissive material, such as carbon nanotubes. Electrically switching the field emissive electron sources at a predetermined frequency field emits electrons in a programmable sequence toward an incidence point on a target. The generated x-rays correspond in frequency and in position to that of the field emissive electron source. The large-area target and array or matrix of emitters can image objects from different positions and / or angles without moving the object or the structure and can produce a three dimensional image. The x-ray system is suitable for a variety of applications including industrial inspection / quality control, analytical instrumentation, security systems such as airport security inspection systems, and medical imaging, such as computed tomography.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

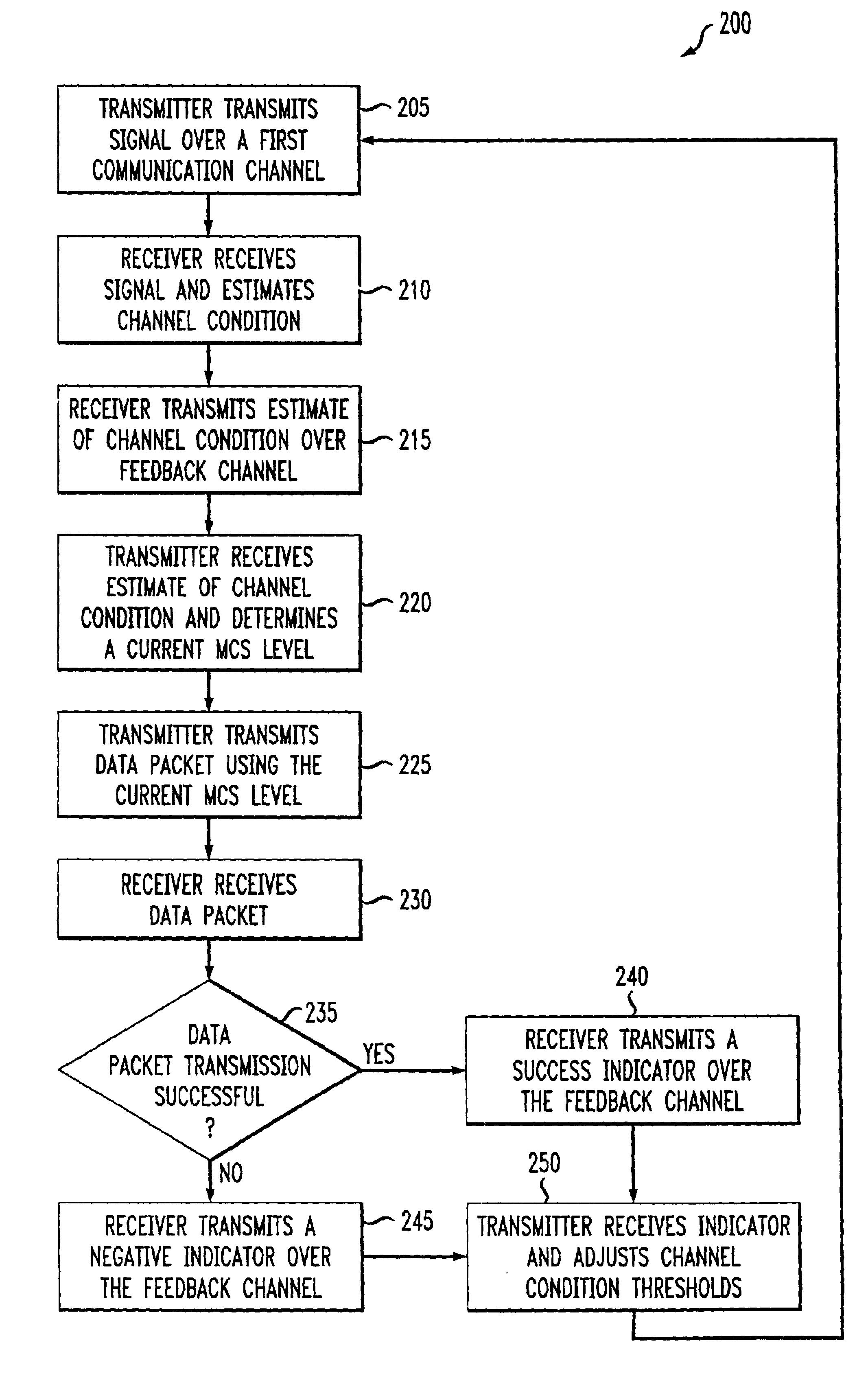

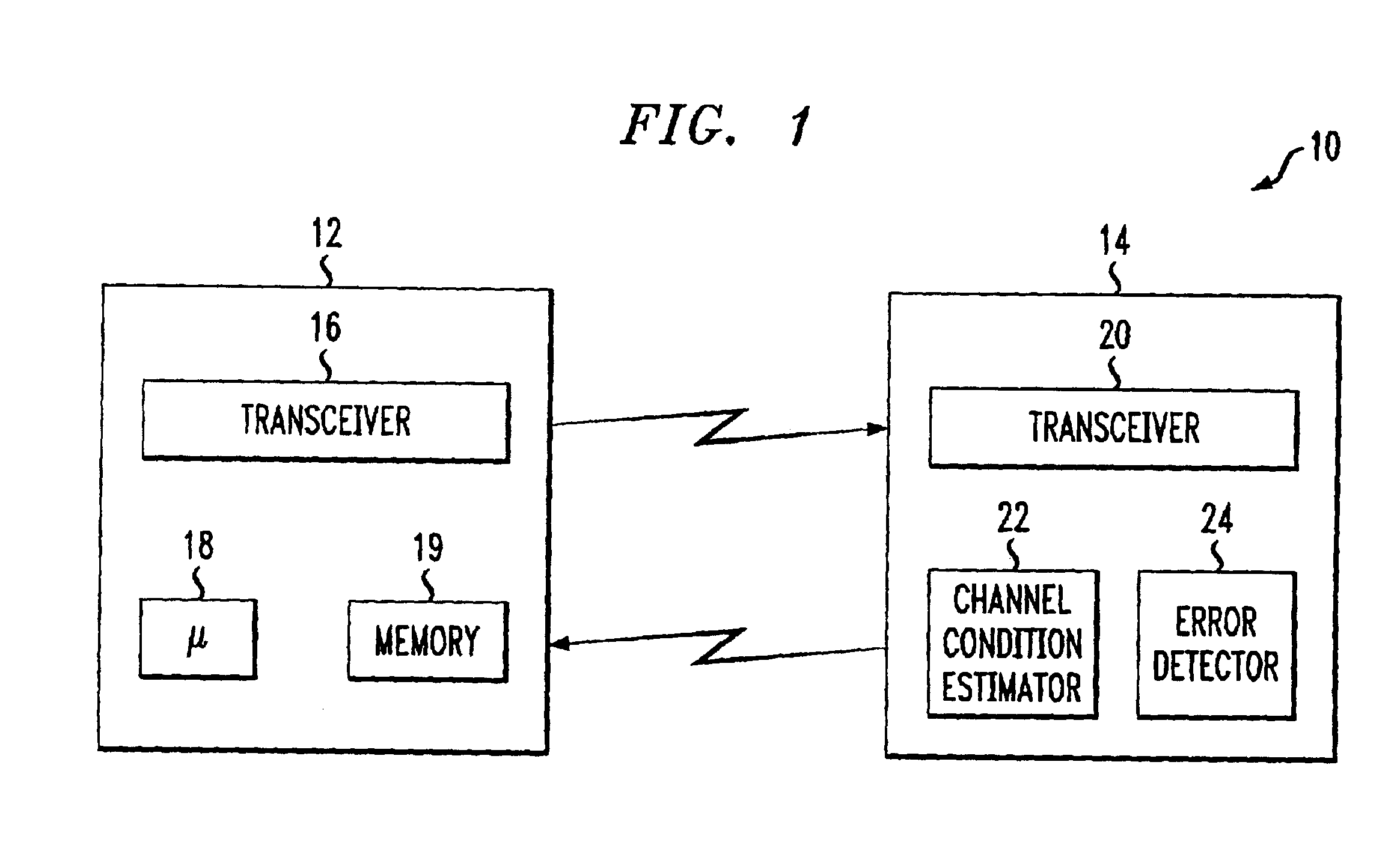

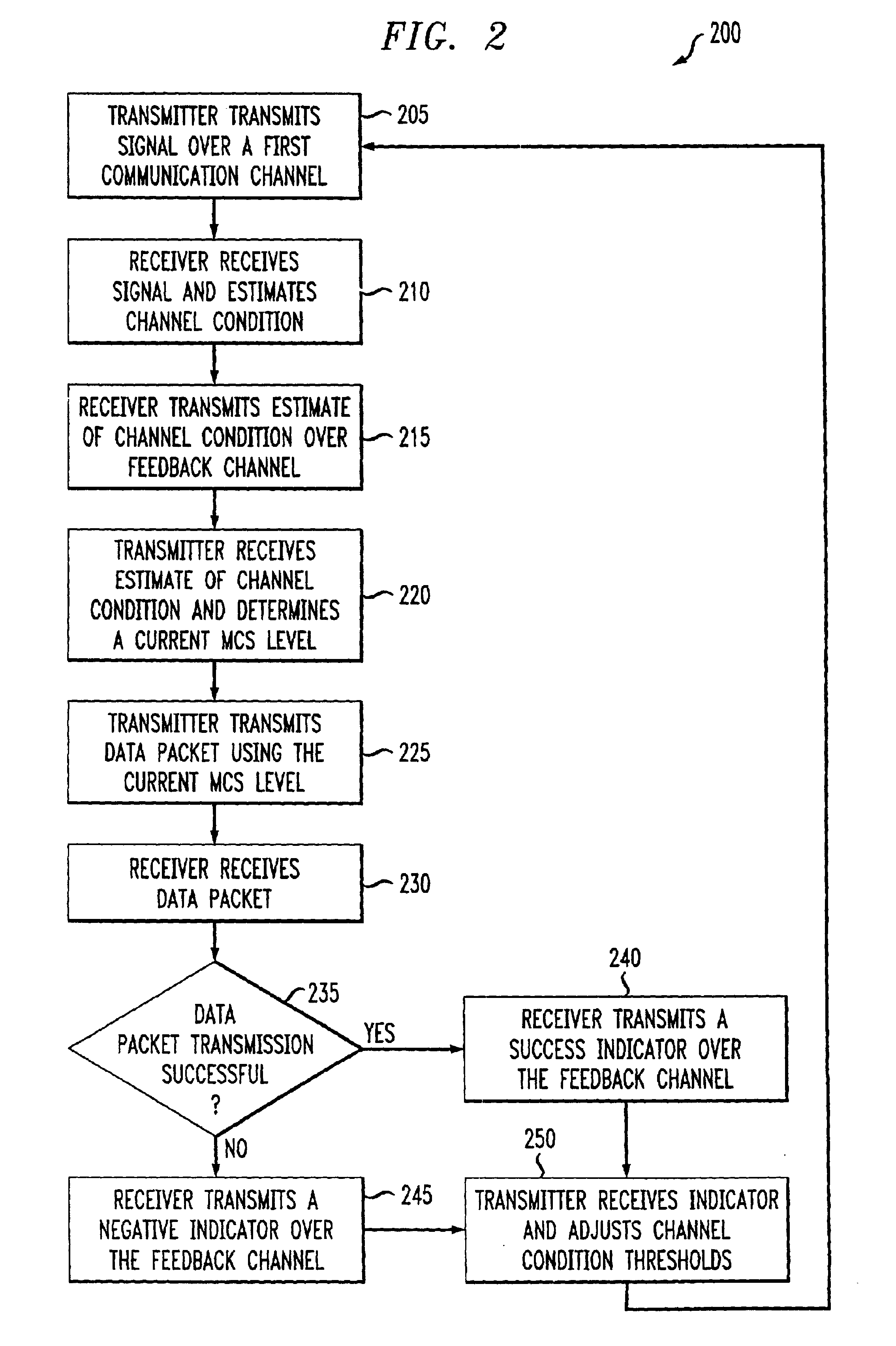

Delay sensitive adaptive quality control loop for rate adaptation

InactiveUS6915477B2Error prevention/detection by using return channelMultiple-port networksCommunications systemRate adaptation

An adaptive quality control loop for link rate adaptation that selectively adjusts channel condition thresholds based on delay sensitivity of data packets being transmitted. For wireless communication systems incorporating an error correction scheme using re-transmissions, the quality control loop adaptively adjusts channel condition thresholds more frequently for delay sensitive data packets, such as video, and less frequently for delay insensitive data packets, such as text messaging. Channel condition thresholds may be adjusted using fixed or variable steps based on error detection results.

Owner:ALCATEL LUCENT SAS

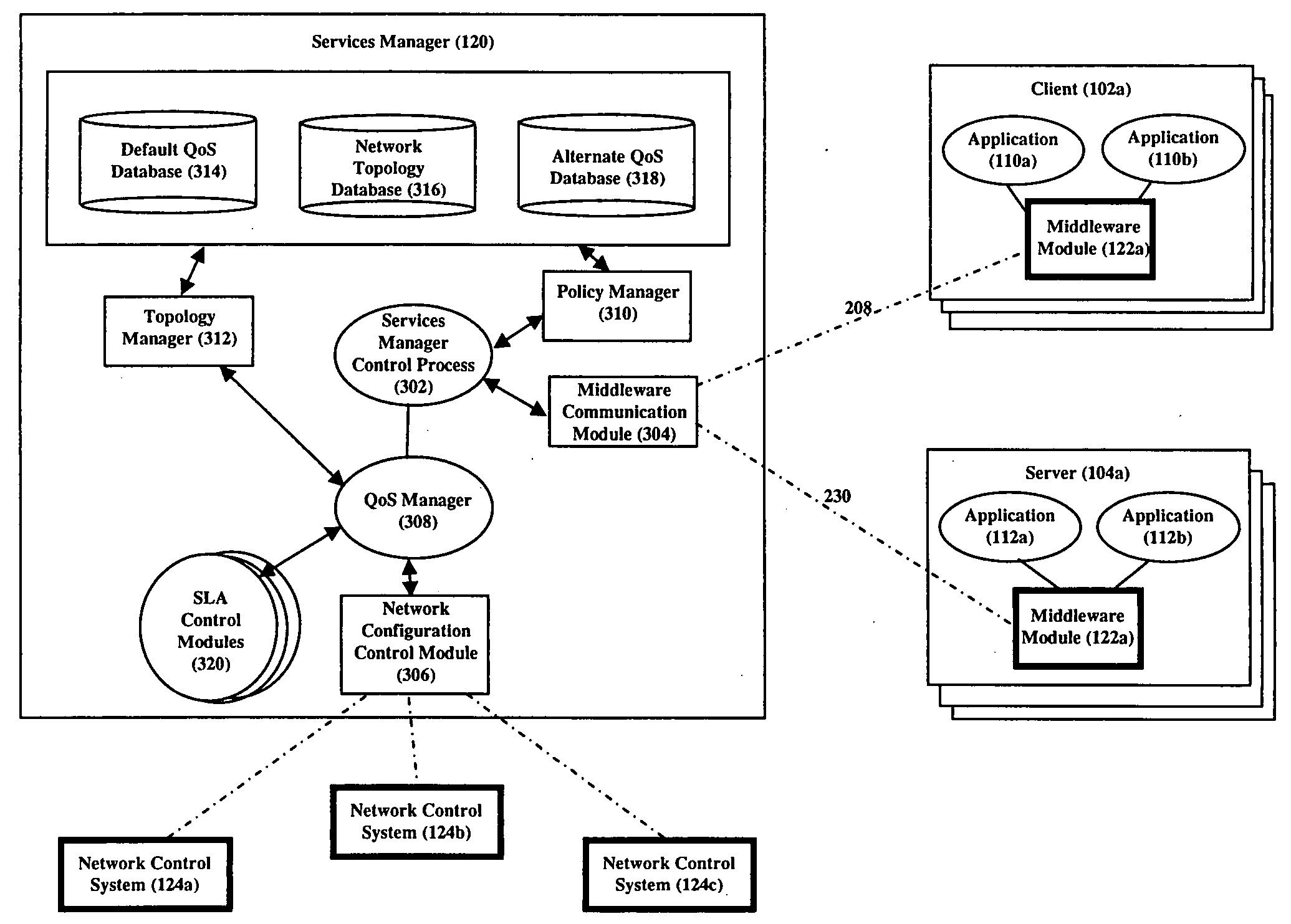

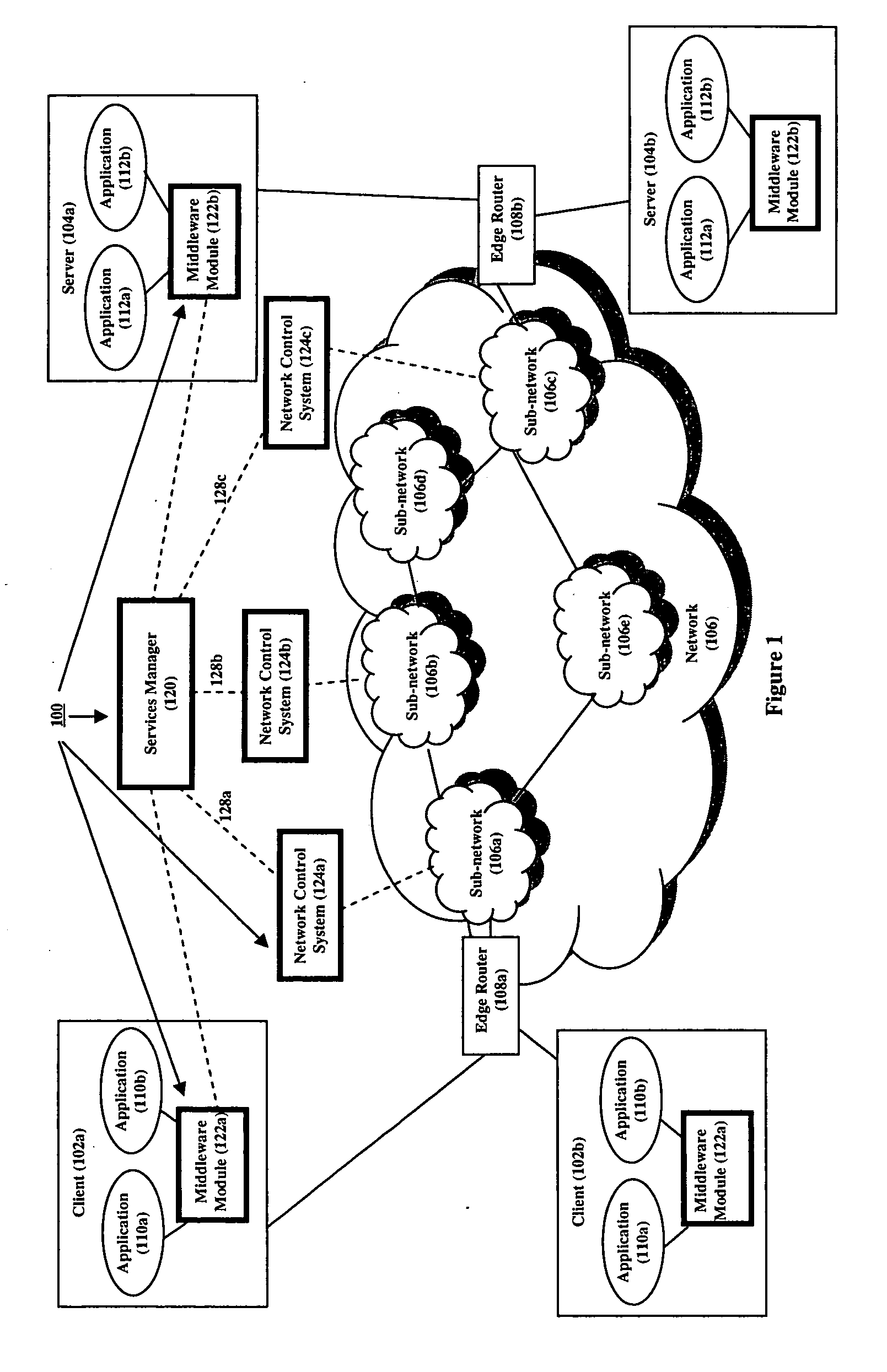

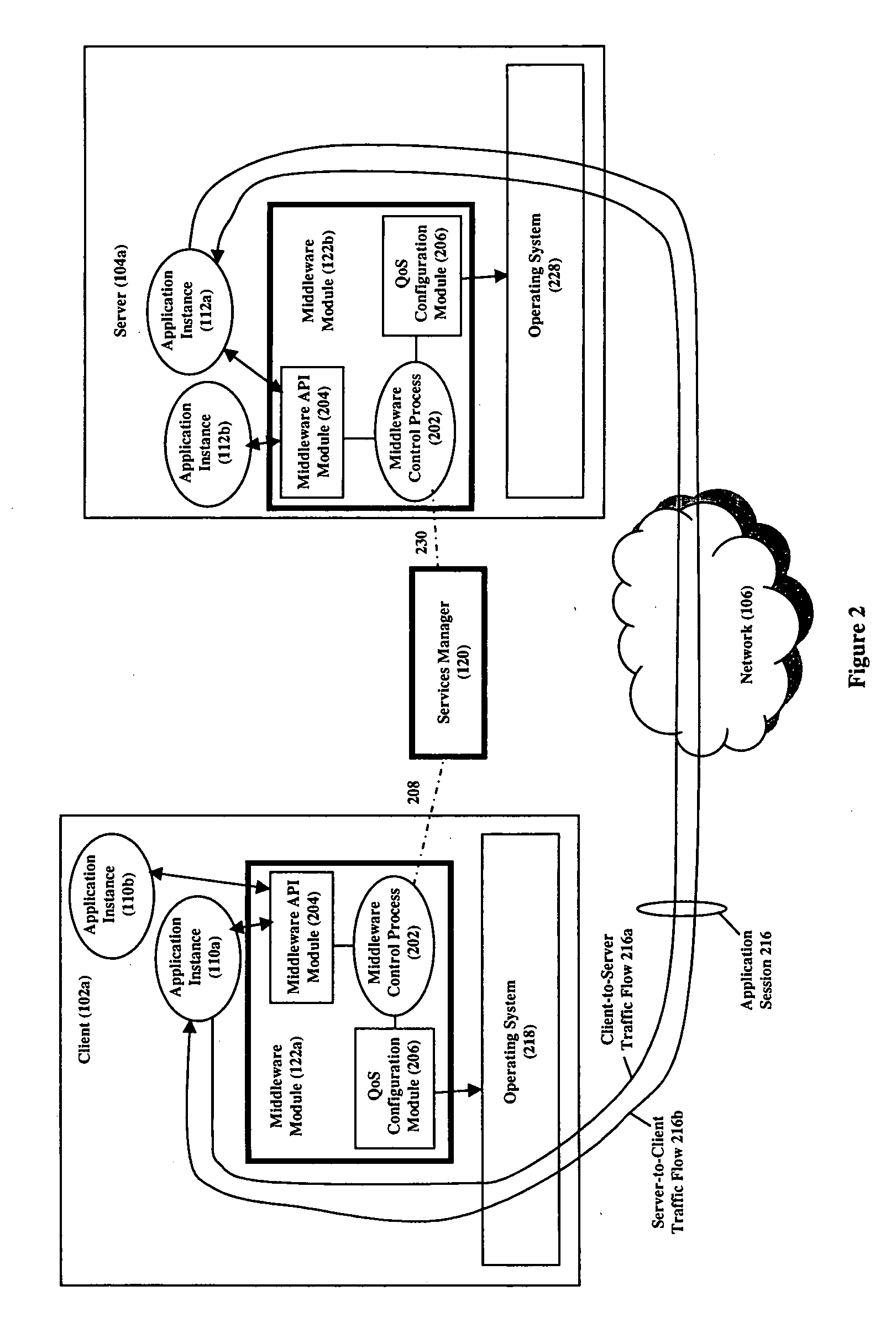

Scalable and dynamic quality of service control

ActiveUS20050114541A1Multiple digital computer combinationsData switching networksData packQuality control

Applications and users dynamically make QoS provisioning requests for individual traffic flows traversing client and server hosts. A traffic flow provisioning request is conveyed to a services manager, which determines a set of traffic attributes for the flow and determines the networks the flow traverses between the client and server hosts. The services manger then oversees the admission of the flow to appropriate traffic classes in each determined network and the obtaining of a DSCP value for each network. Lastly, the services manger conveys the DSCP value of the first network traversed back to the client or server host, depending on the direction of the flow, which host is then configured to appropriately mark the DSCP field of the traffic flow packets. In a further embodiment, the services manager also instructs the client or server host to perform packet policing and shaping for the flow.

Owner:NYTELL SOFTWARE LLC

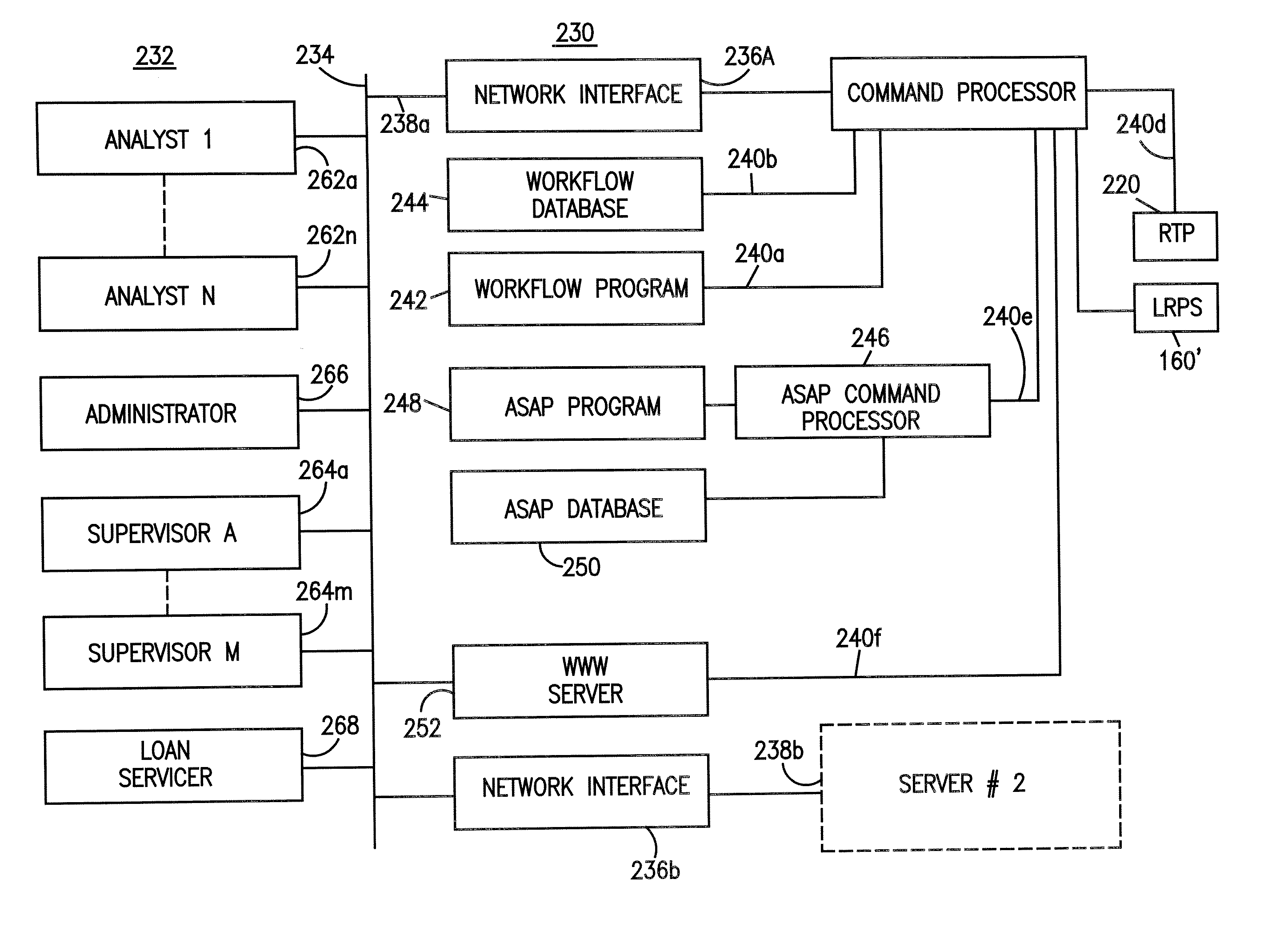

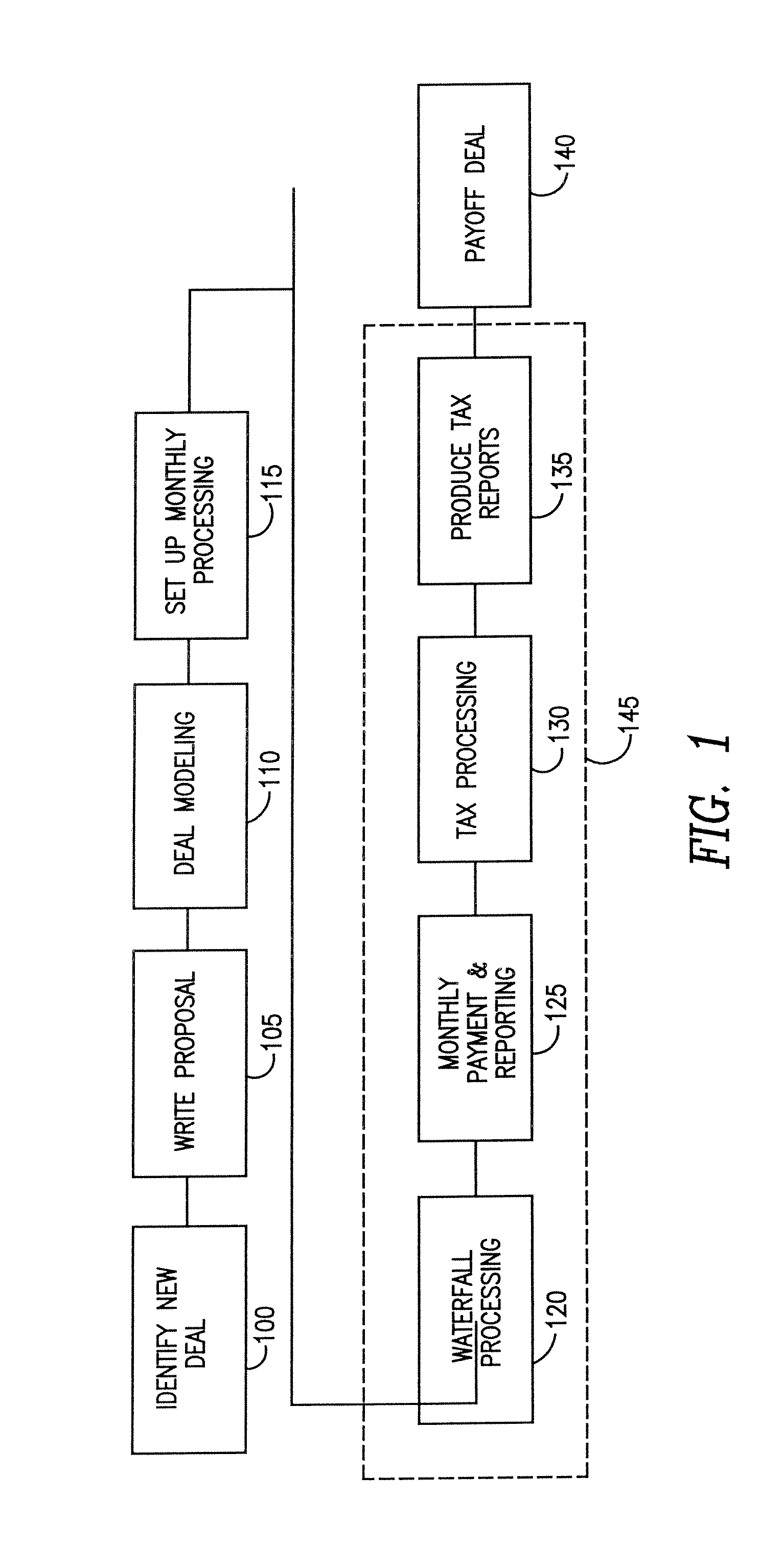

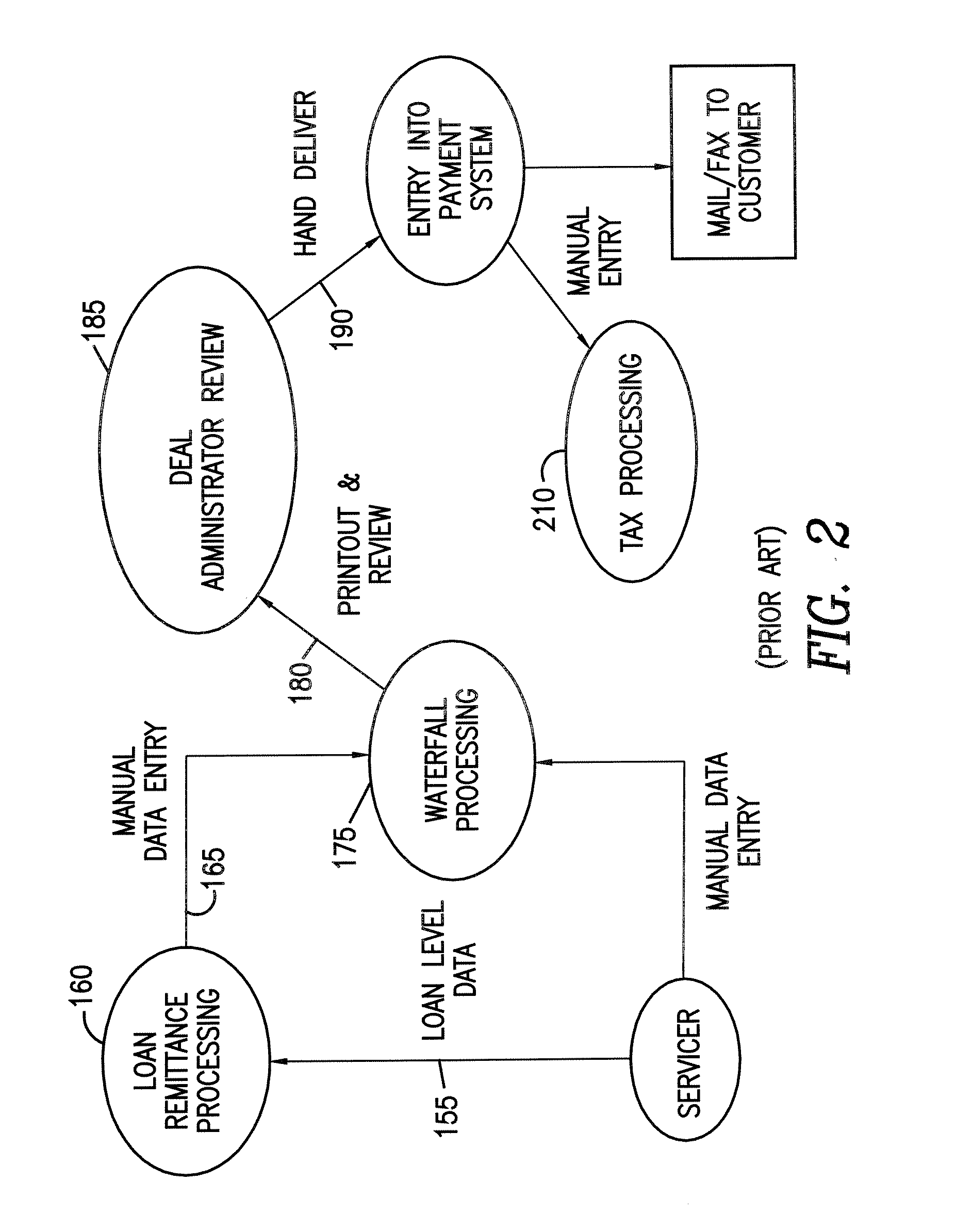

Workflow management system and method

InactiveUS20070208606A1Easy to editFacilitates economy of scale and processing efficiencyFinancePayment architectureStream managementSystems management

A computerized workflow management method and system to provide operational support for complex multi-step processes, having particular utility in supporting operations involving securitizations for which periodic valuation and distribution computations, disbursements and reporting must be set up and executed. The invention permits unification of manual operations and operations performed by legacy software, even if implemented with database structures different from the workflow management system, automated quality control, workflow status display and automatic updating of workflow status records. The method of workflow management involves creating an underlying database structure for recording the processing steps and other information required for each transaction, entering the necessary setup information by selection from lists of pre-stored information about processing functions, associated workflow events and milestones for the queues, mapping the data structures of the subsystem databases and the workflow management database to provide transparent interfacing and convenient manual entry of data were necessary, displaying for the user the workflow status of all transactions for which he or she is responsible, permitting menu driven initiation of required actions and automatically updating the database records for the universe of deals being managed by the system.

Owner:JPMORGAN CHASE BANK NA

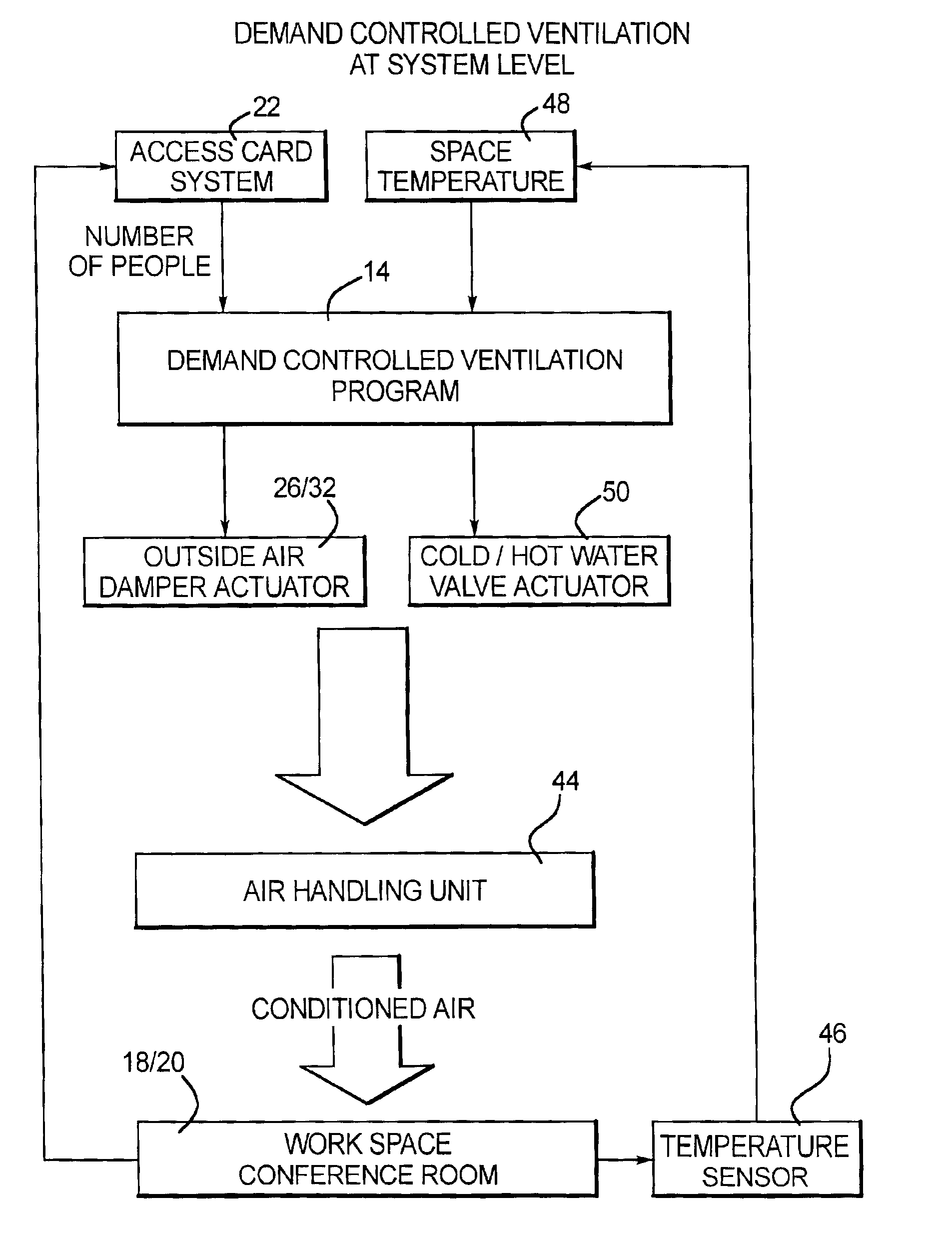

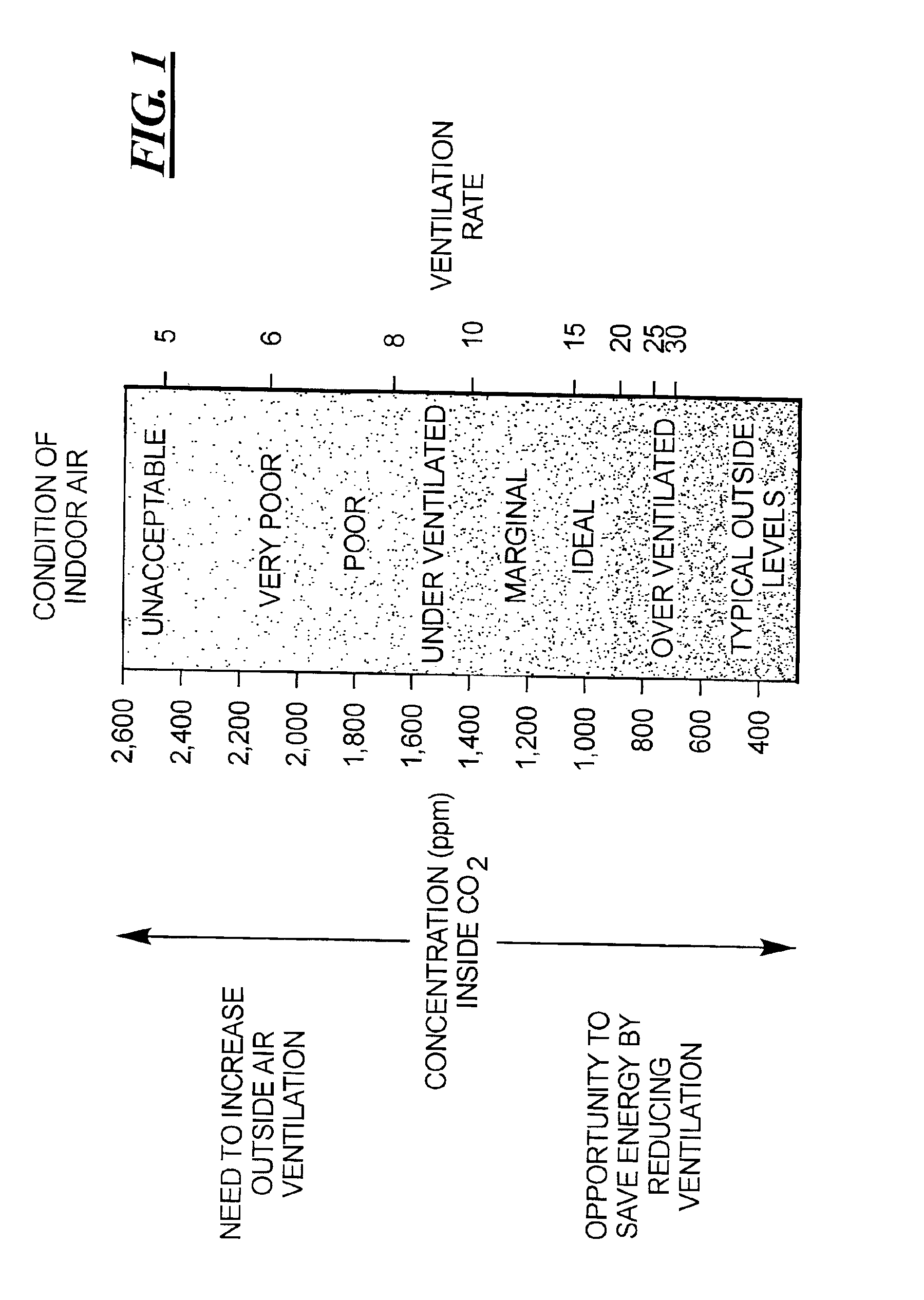

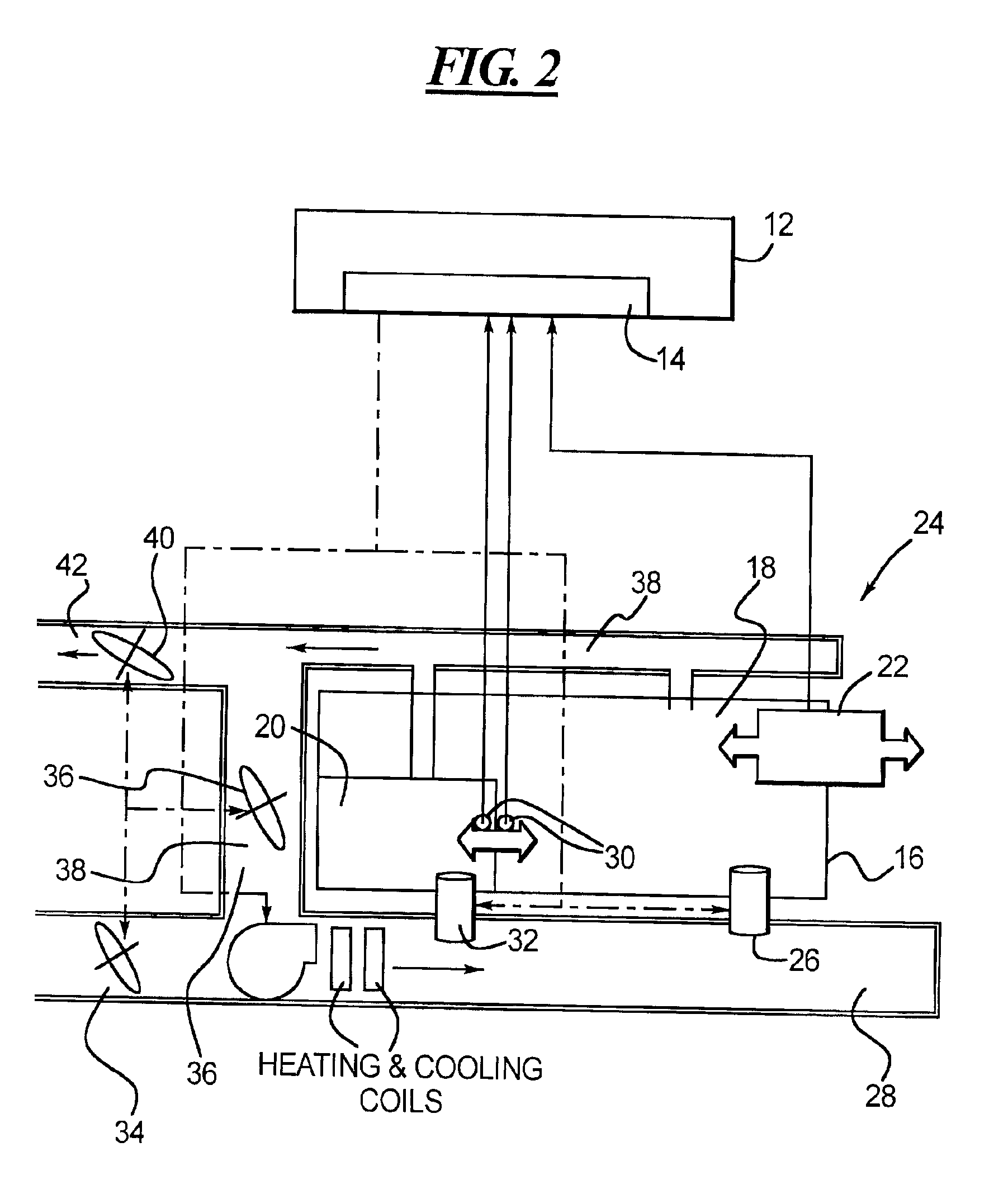

Air quality control system based on occupancy

Air quality within a building is controlled by maintaining a count of people in the building and by ventilating the building with an amount of air dependent on the count. The count may be determined in accordance with an access control system and / or entry and exit sensors, such as infrared sensors.

Owner:HONEYWELL INT INC

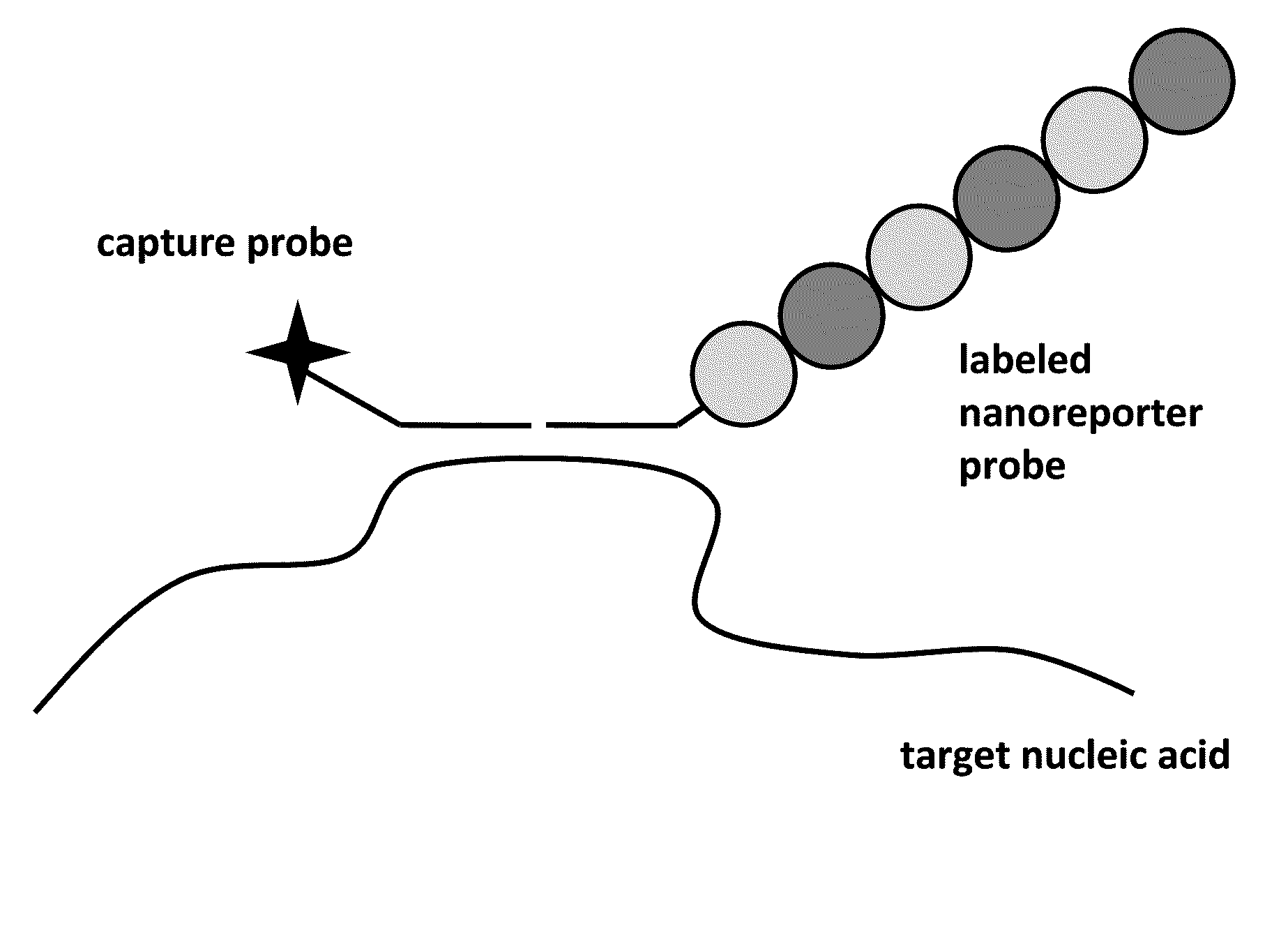

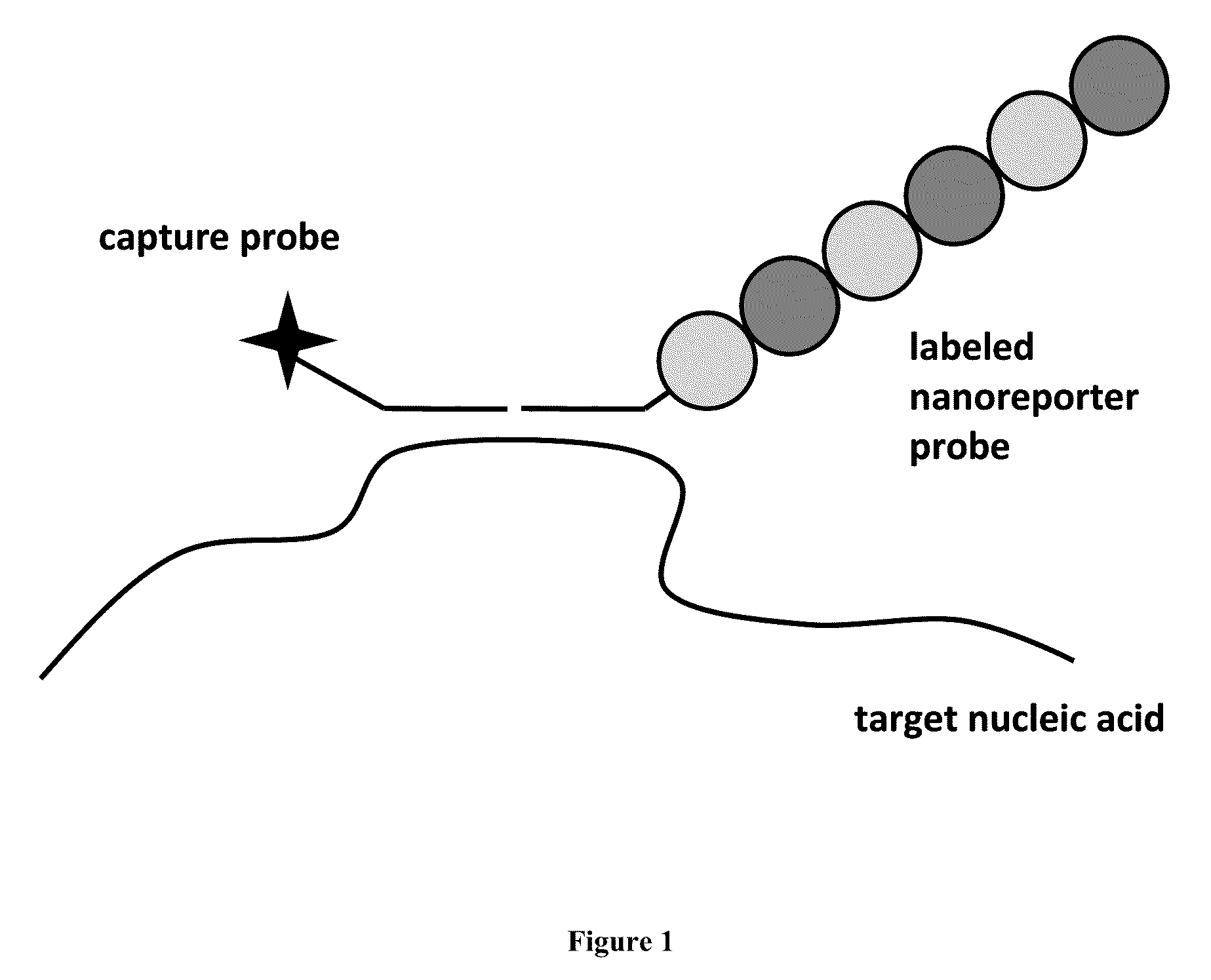

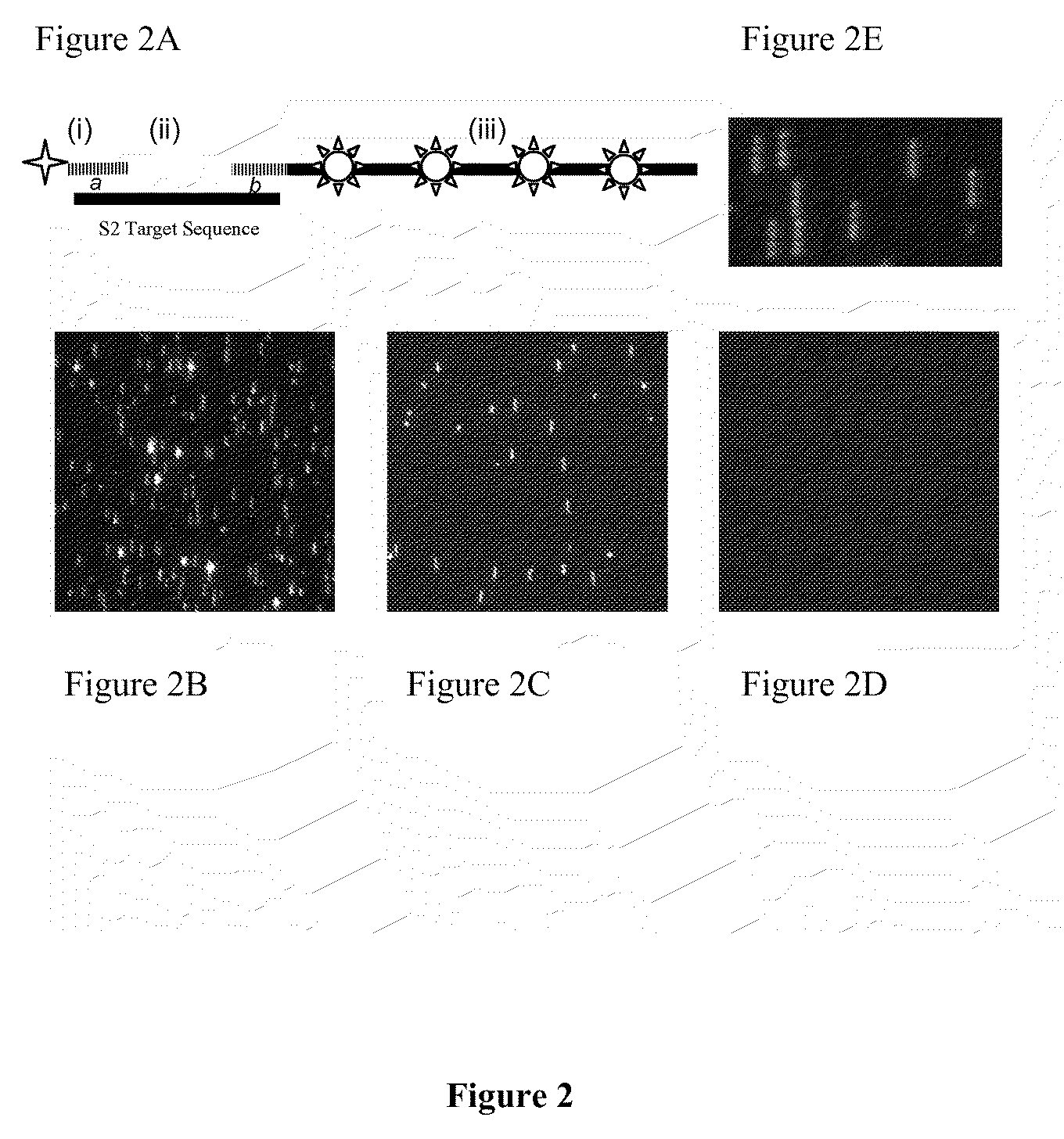

Stable nanoreporters

The present invention relates to compositions and methods for detection and quantification of individual target molecules in biomolecular samples. In particular, the invention relates to improved, stable nanoreporter probes that are capable of binding to and identifying target molecules based on the probes' uniquely detectable signal. Methods for identifying target-specific sequences for inclusion in the probes are also provided, as are methods of making and using such probes. Polynucleotide sequences of certain nanoreporter components are also provided. The probes can be used in diagnostic, prognostic, quality control and screening applications.

Owner:NANOSTRING TECH INC

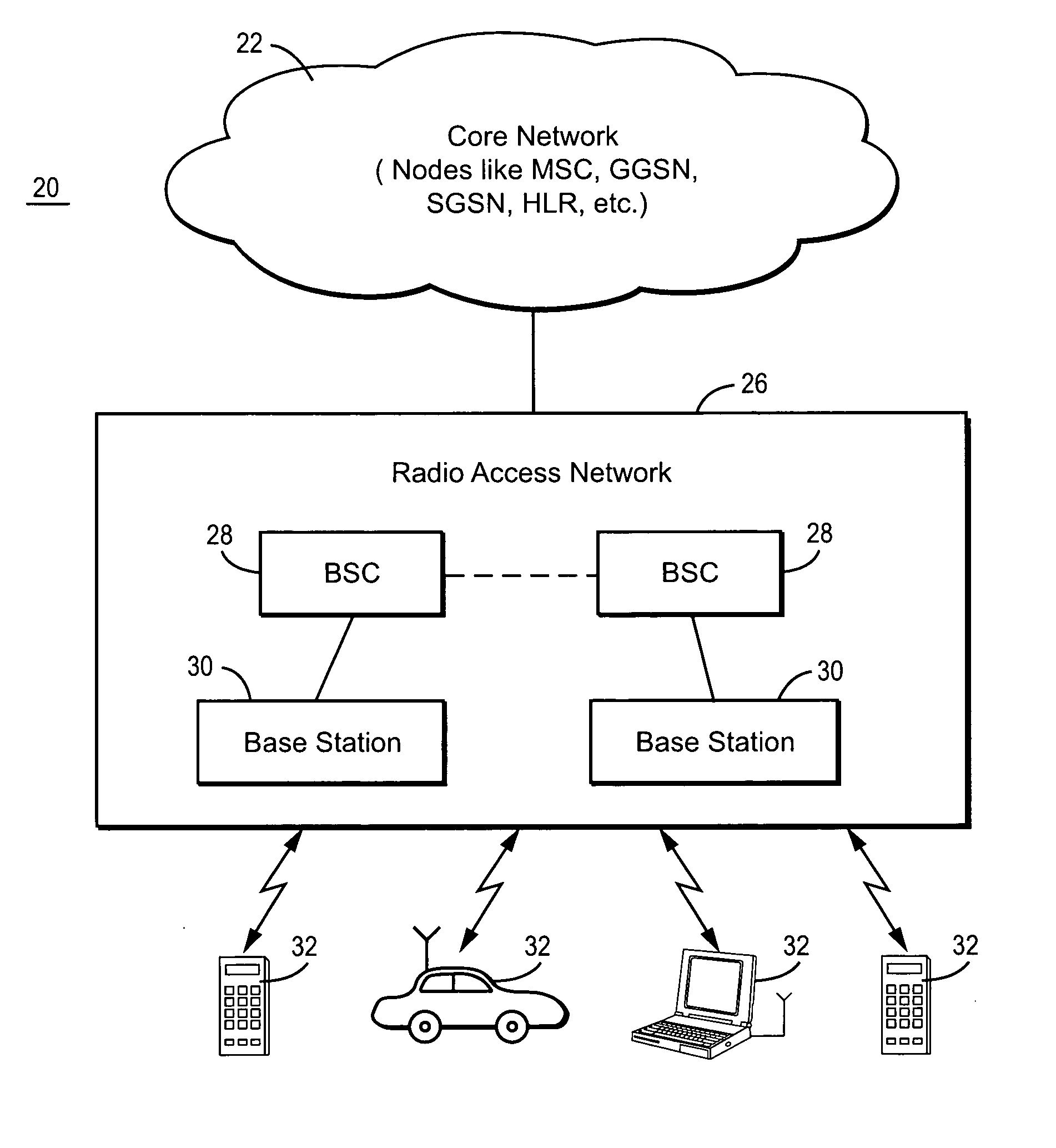

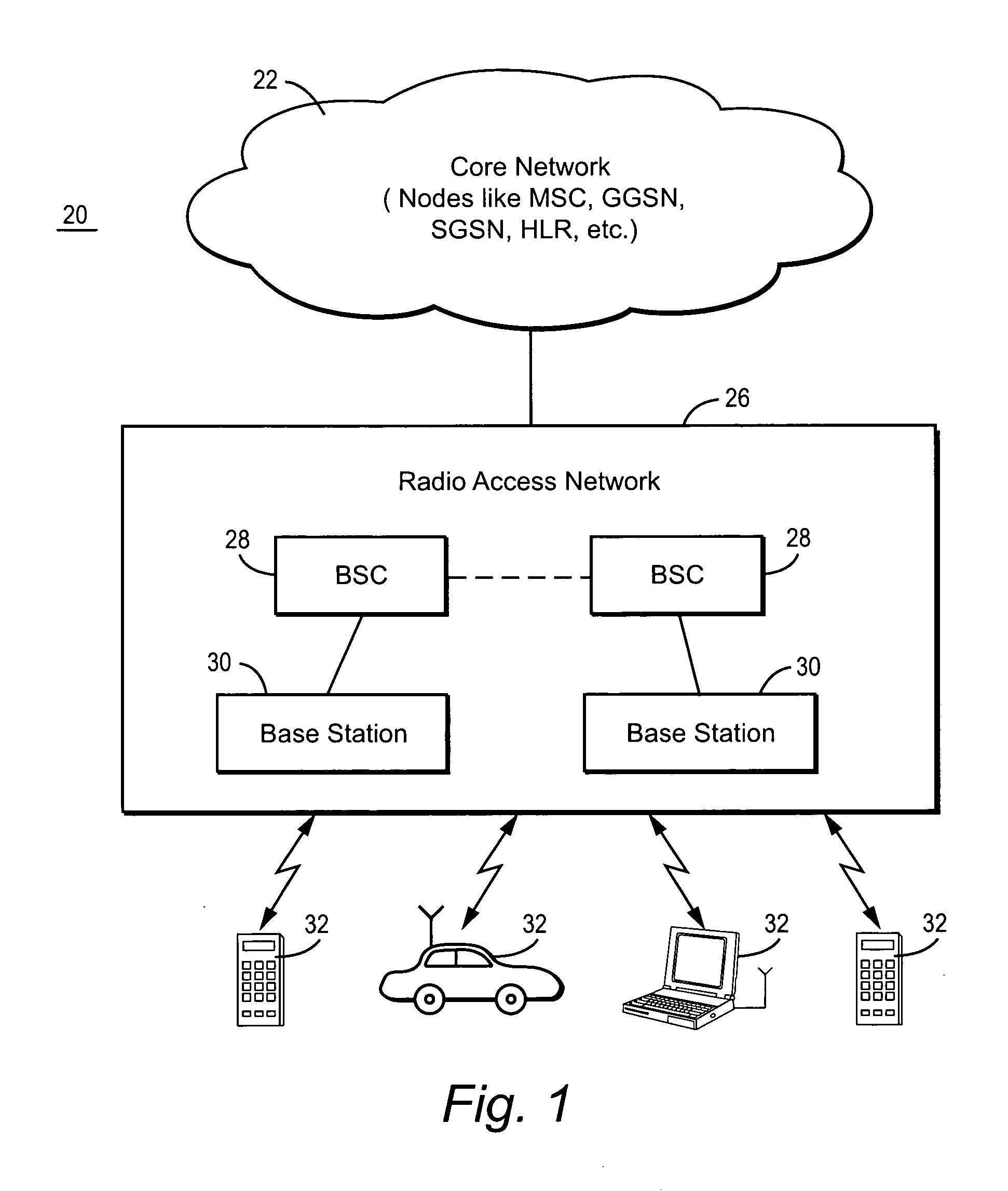

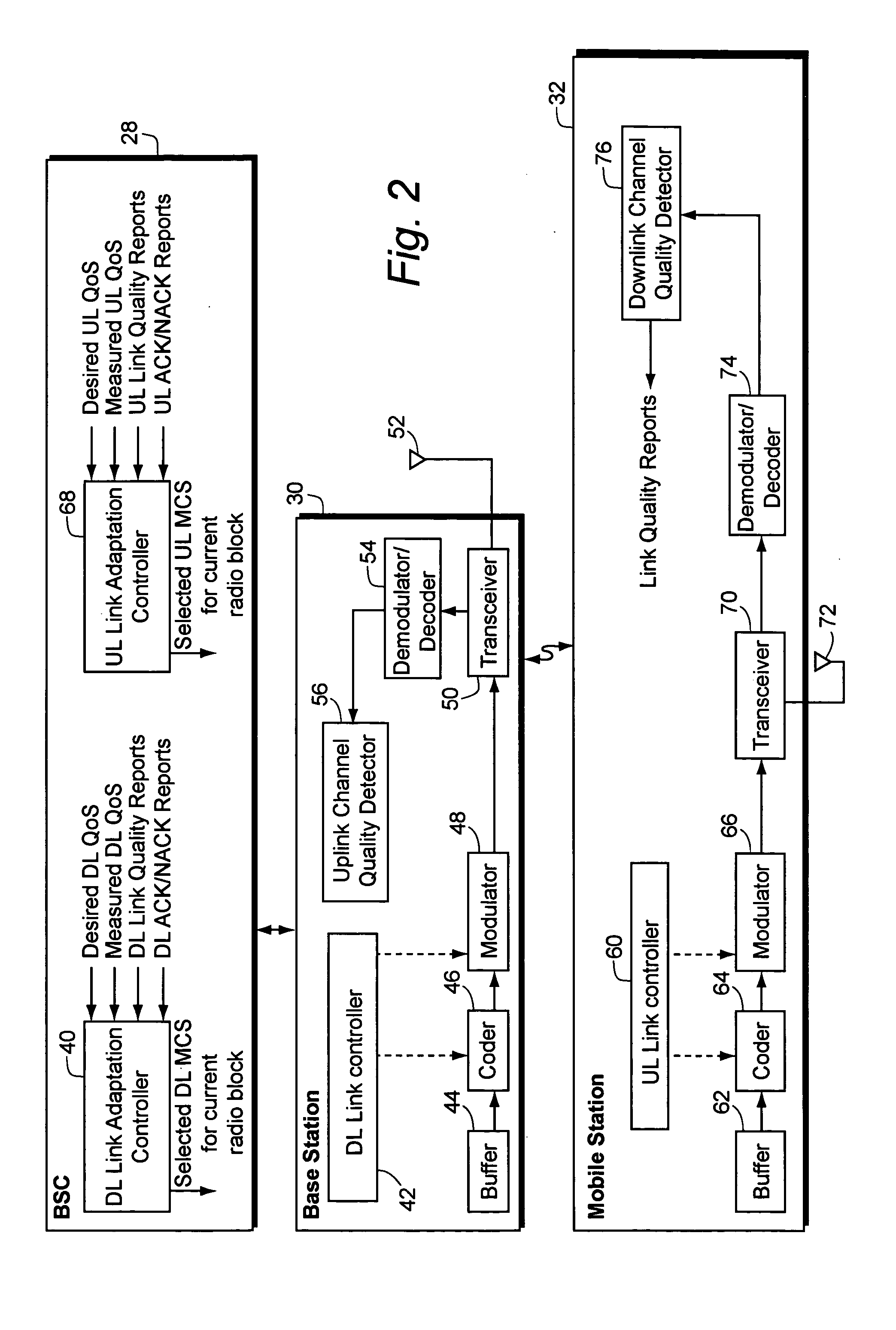

Quality of service controlled link adaptation

InactiveUS20050159166A1Increase data capacityImprove throughputNetwork traffic/resource managementRadio/inductive link selection arrangementsQuality of serviceQuality control

A quality of service profile for a mobile communication subscriber unit is determined and includes one or more mobile-specific desired quality of service parameters. Actual values for the service parameter(s) is(are) determined and fed back to a link quality controller to determine whether they are in an acceptable range or relationship with corresponding actual quality of service parameter values. A modulation and / or coding scheme for transmitting the information over the radio link is selected or adjusted based on whether the desired and actual quality of service parameters are in an acceptable range or acceptable relationship. A combined “desired” quality of service parameter using the first and second quality of service parameters (or more if desired) may be determined. A combined “actual” quality of service parameter using first and second actual quality service parameter values is determined. Those combined desired and actual quality of service parameters are compared to determine whether they are in an acceptable range or relationship. The modulation or coding scheme (or both) is (are) selected or adjusted based thereon.

Owner:TELEFON AB LM ERICSSON (PUBL)

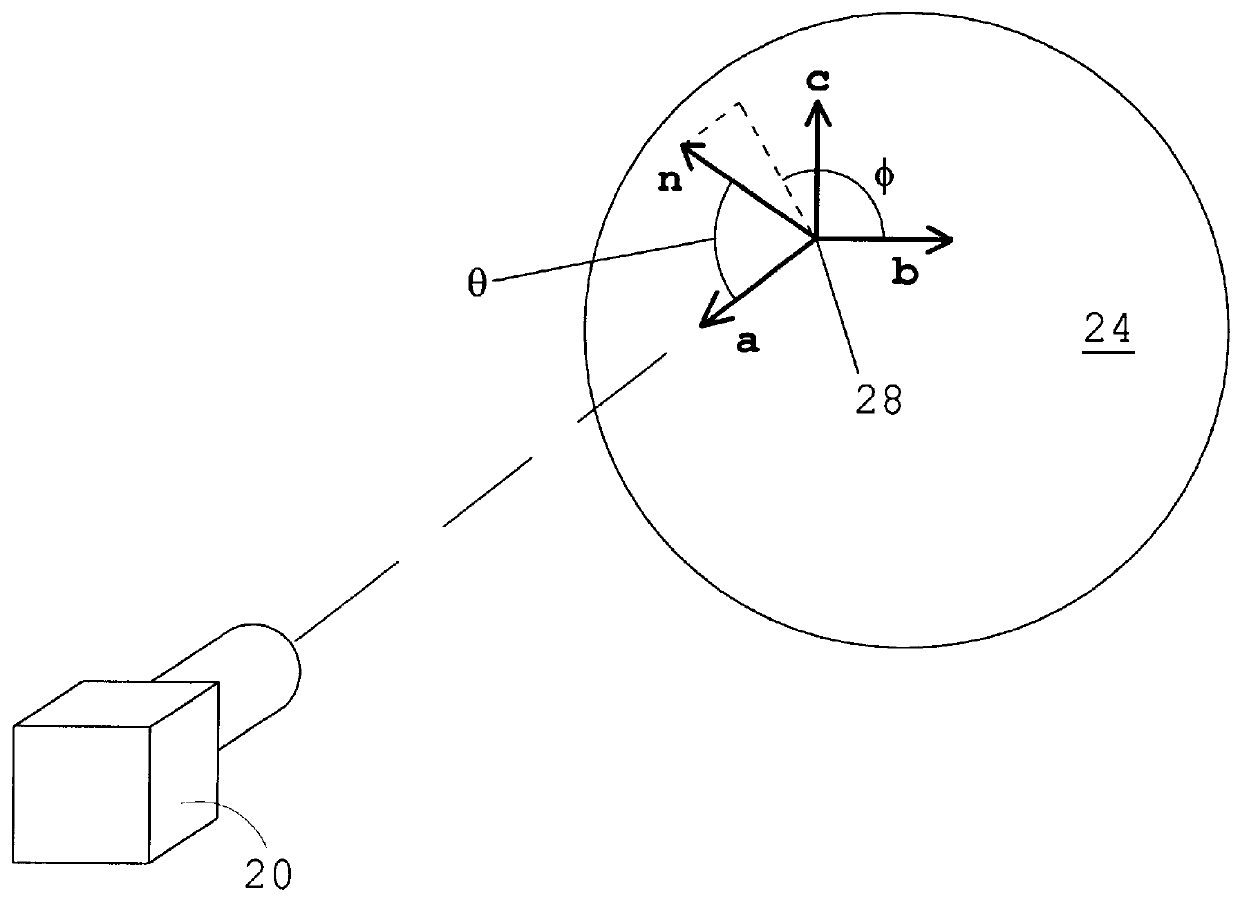

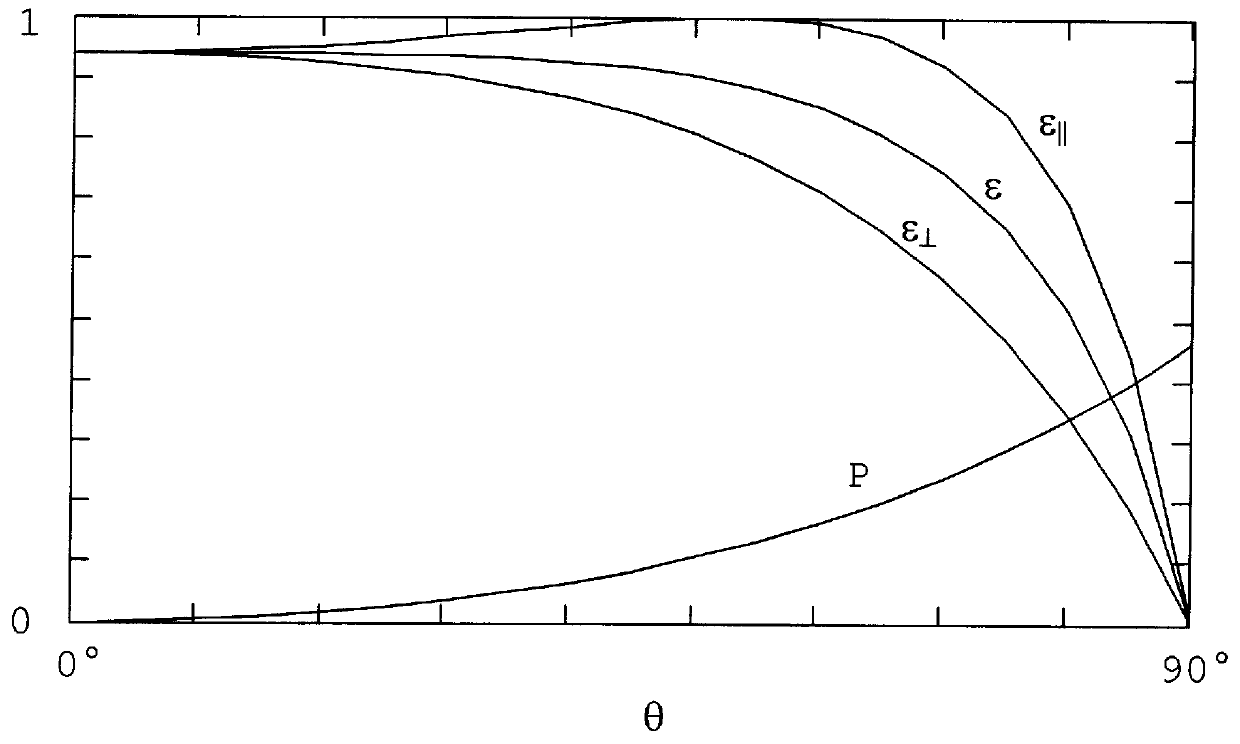

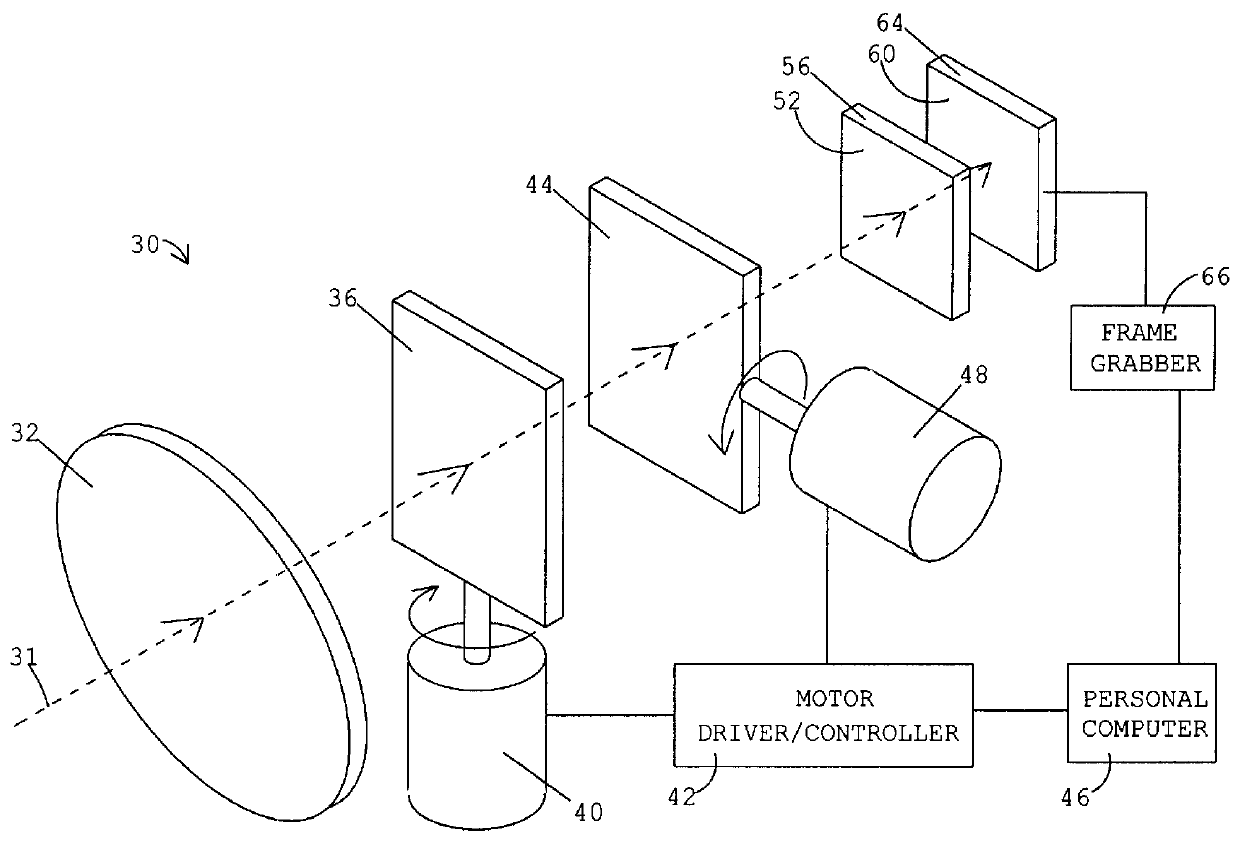

High-resolution polarization-sensitive imaging sensors

An apparatus and method to determine the surface orientation of objects in a field of view is provided by utilizing an array of polarizers and a means for microscanning an image of the objects over the polarizer array. In the preferred embodiment, a sequence of three image frames is captured using a focal plane array of photodetectors. Between frames the image is displaced by a distance equal to a polarizer array element. By combining the signals recorded in the three image frames, the intensity, percent of linear polarization, and angle of the polarization plane can be determined for radiation from each point on the object. The intensity can be used to determine the temperature at a corresponding point on the object. The percent of linear polarization and angle of the polarization plane can be used to determine the surface orientation at a corresponding point on the object. Surface orientation data from different points on the object can be combined to determine the object's shape and pose. Images of the Stokes parameters can be captured and viewed at video frequency. In an alternative embodiment, multi-spectral images can be captured for objects with point source resolution. Potential applications are in robotic vision, machine vision, computer vision, remote sensing, and infrared missile seekers. Other applications are detection and recognition of objects, automatic object recognition, and surveillance. This method of sensing is potentially useful in autonomous navigation and obstacle avoidance systems in automobiles and automated manufacturing and quality control systems.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Patient monitoring system that incorporates memory into patient parameter cables

InactiveUS20050113704A1Simplifies and improves speed of preparationOpportunities decreaseElectrocardiographyCatheterQuality controlMonitoring system

Owner:GE MEDICAL SYST INFORMATION TECH

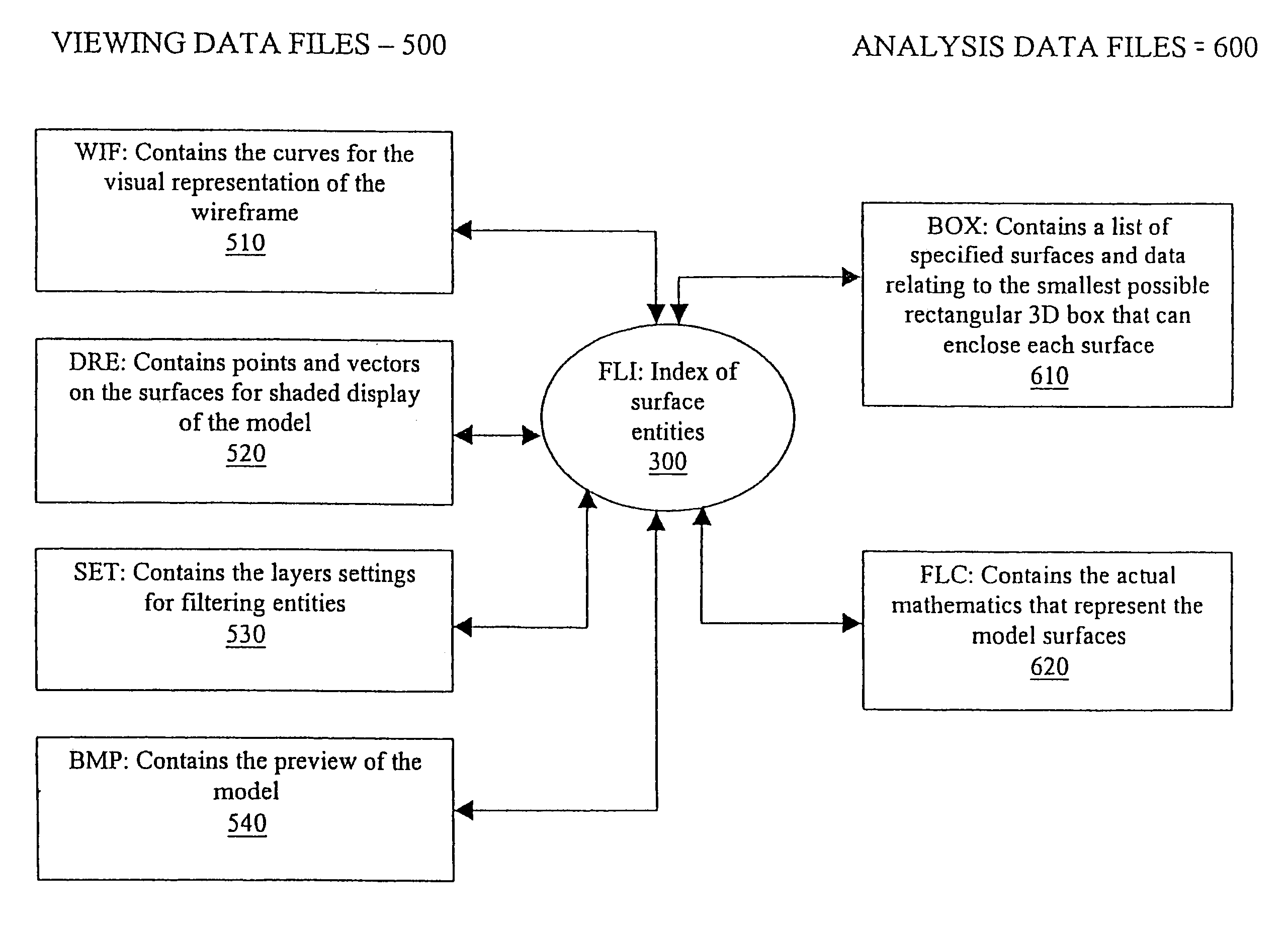

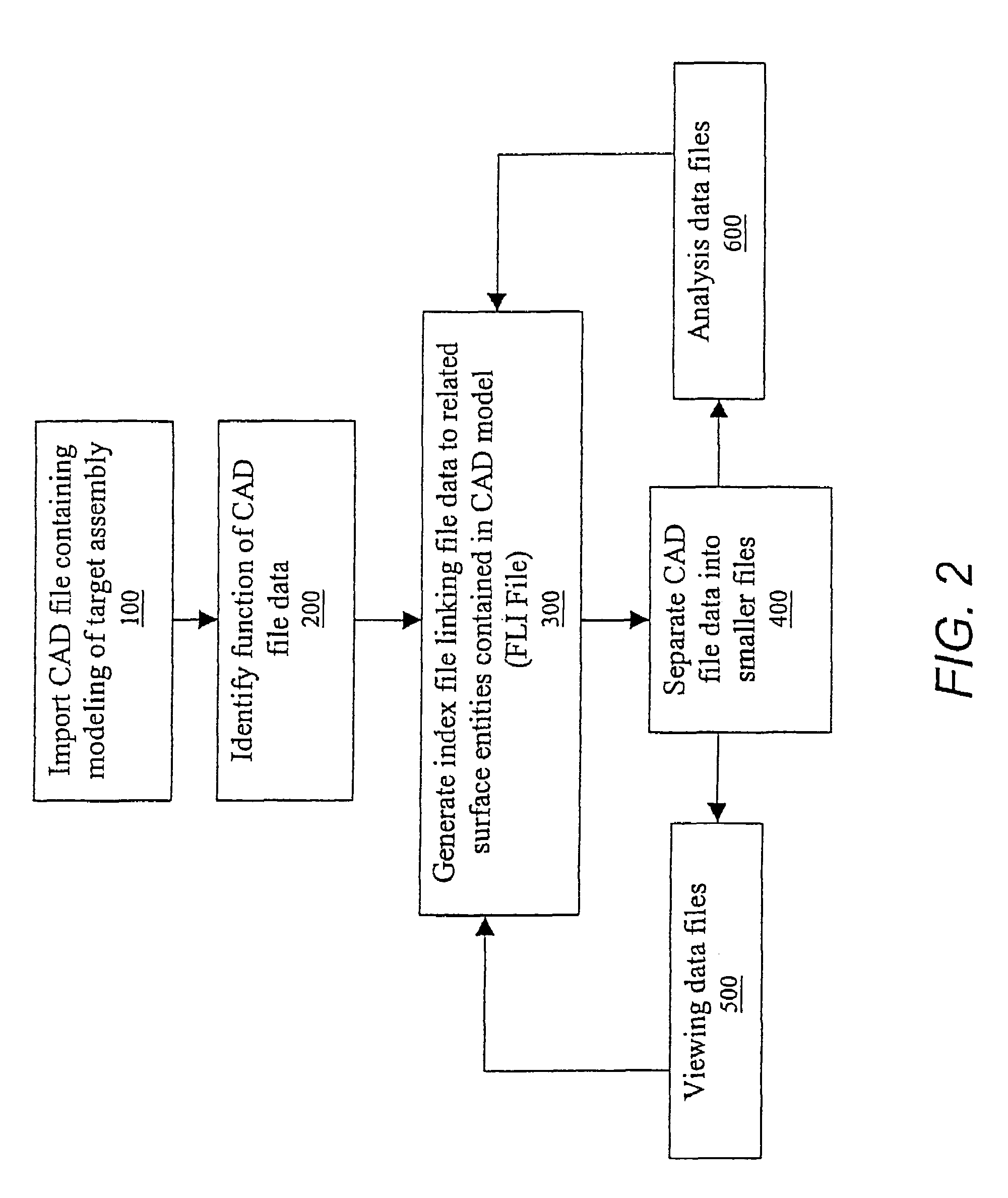

Method and system for computer aided manufacturing measurement analysis

InactiveUS7006084B1Improve quality controlReduce decreaseComputer controlSimulator controlMeasurement pointQuality control

The invention relates to a computer-based method and system to facilitate quality control for manufactured assemblies based on computer aided design (CAD) files. The instant invention mitigates the problems encountered with large CAD files by decomposing each of such files into a multi-file format. A large CAD file is thereby broken-down into smaller files that organize the information contained in the larger file. The organization is performed in such a way that the information pertinent to the measurement process is segregated into a different smaller file than the information not needed to calculate measurements. Thus, the computer running the computation accesses a smaller file containing a higher percentage of required information. Additionally, assisting the user in coordinating a match-up between the physical surfaces being measured and the proper associated CAD model version of that surface further increases the handling speed. In particular, the instant invention uses selection regions for each surface. A selection region consists of the representation of a three-dimensional rectangle region just large enough to enclose each individual surface. A selection region indexes each surface. Thus, when a measurement point is taken, a list of surface regions is automatically scanned in order to determine which region contains that point. The corresponding distance of that measurement point to the surface is then calculated.

Owner:FARO TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com