Patents

Literature

105 results about "Industrial inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial Inspection & Training Services (IITS) is focusing on customer needs, improving quality, reducing downtime, delivering quality services and saving costs. Industrial Inspection & Training Services (IITS) is an NDT Company based in Bangladesh.

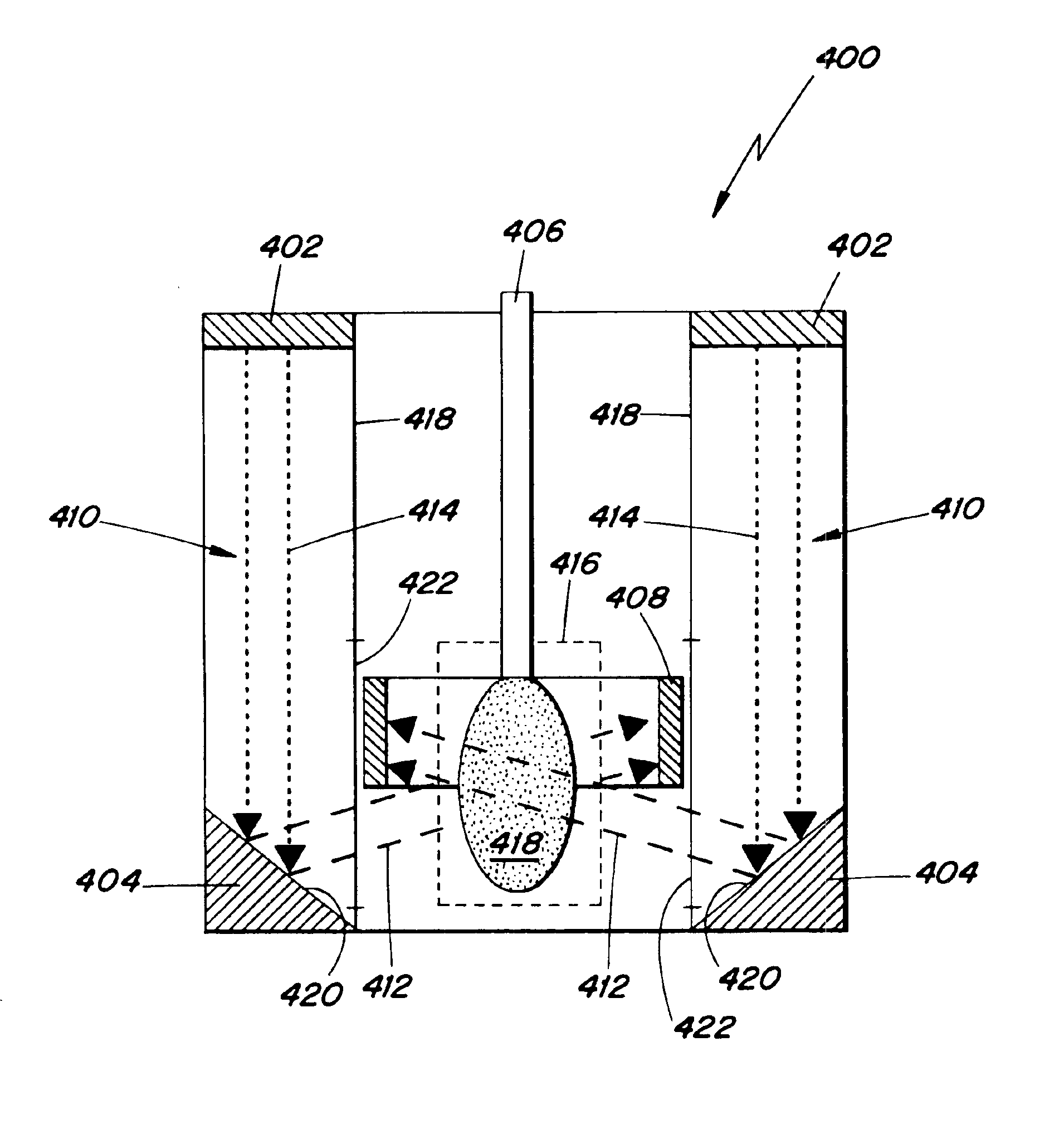

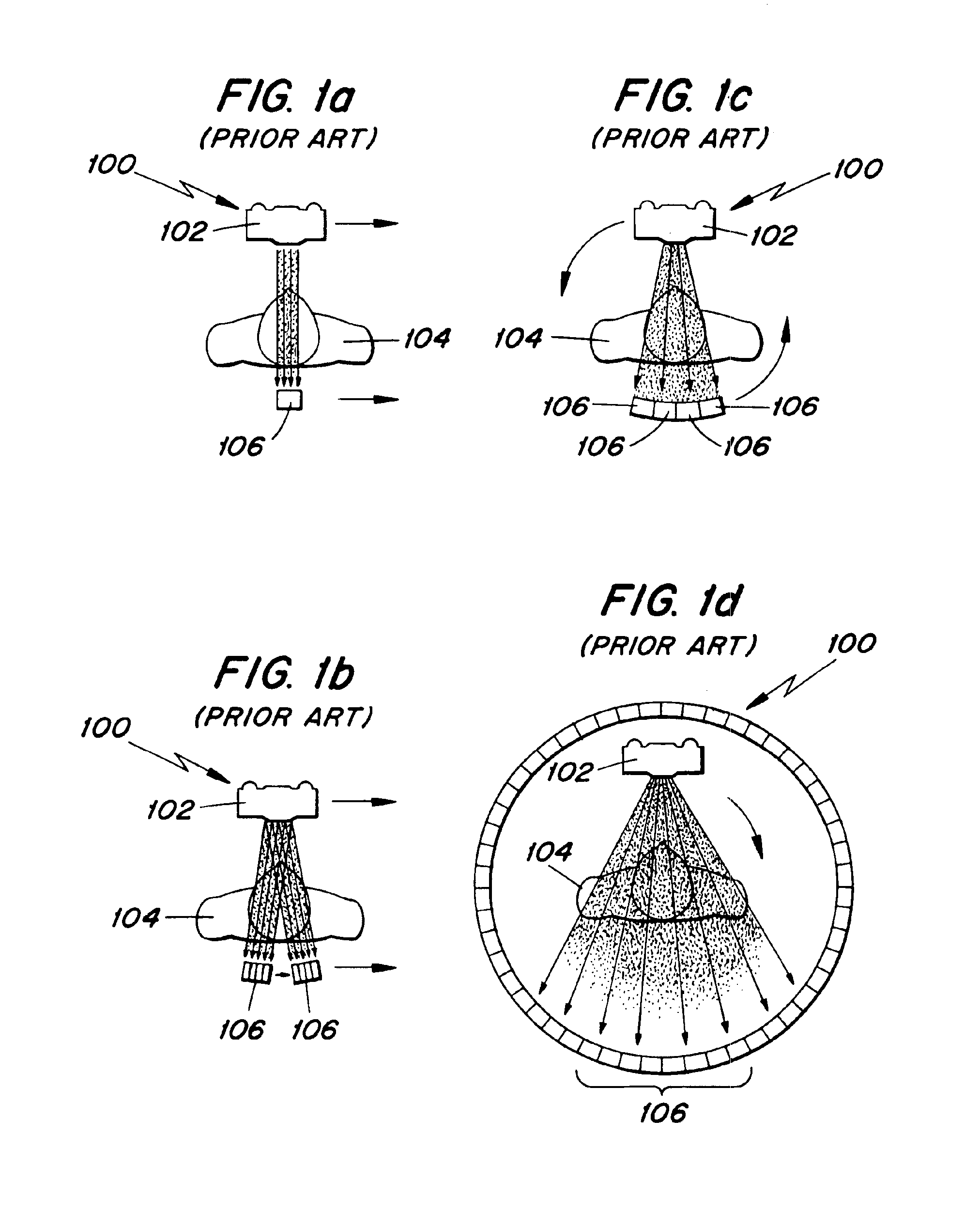

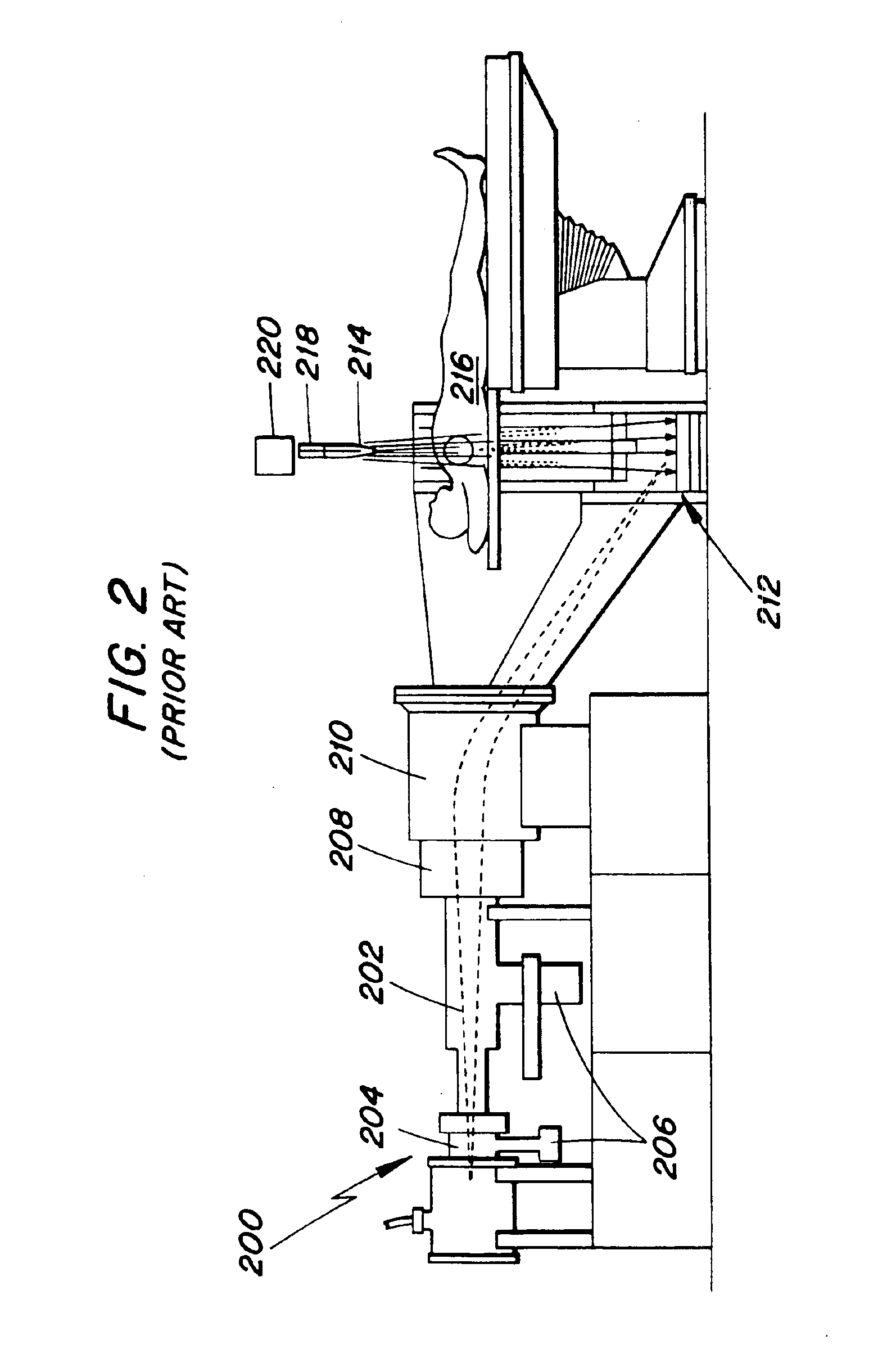

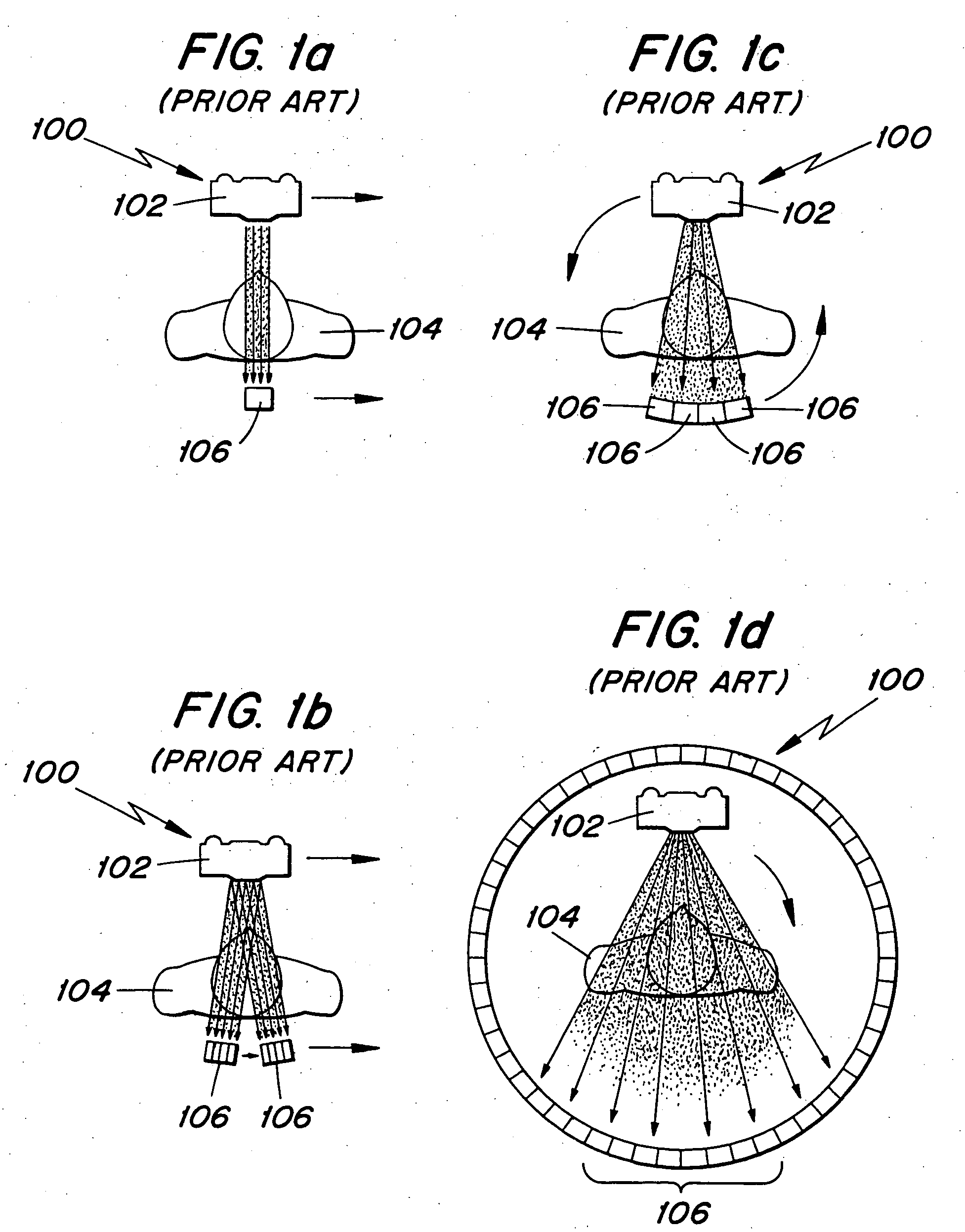

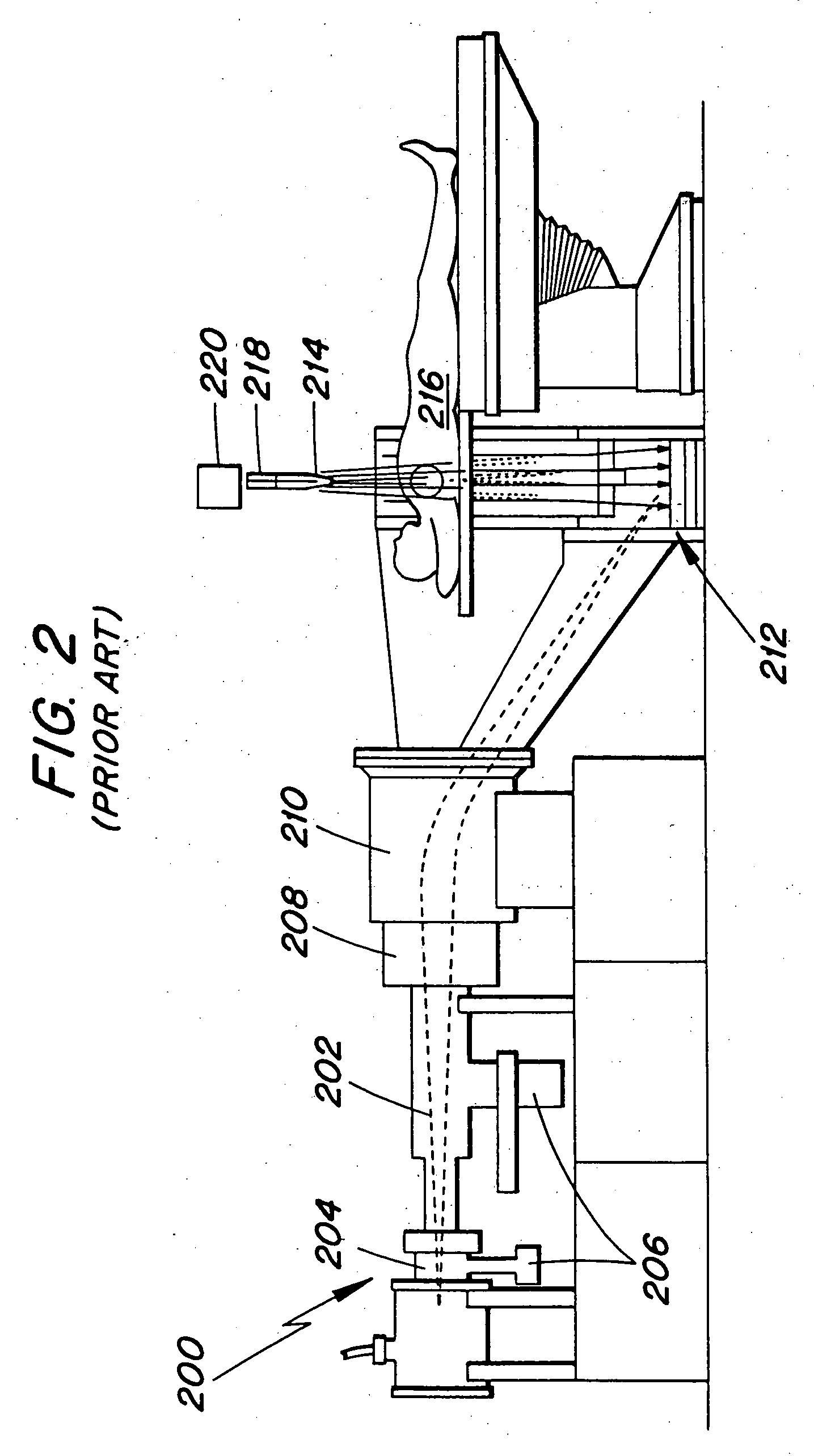

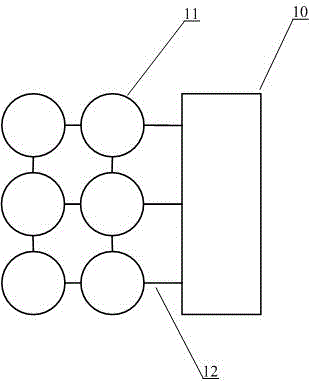

Large-area individually addressable multi-beam x-ray system and method of forming same

A structure to generate x-rays has a plurality of stationary and individually electrically addressable field emissive electron sources with a substrate composed of a field emissive material, such as carbon nanotubes. Electrically switching the field emissive electron sources at a predetermined frequency field emits electrons in a programmable sequence toward an incidence point on a target. The generated x-rays correspond in frequency and in position to that of the field emissive electron source. The large-area target and array or matrix of emitters can image objects from different positions and / or angles without moving the object or the structure and can produce a three dimensional image. The x-ray system is suitable for a variety of applications including industrial inspection / quality control, analytical instrumentation, security systems such as airport security inspection systems, and medical imaging, such as computed tomography.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

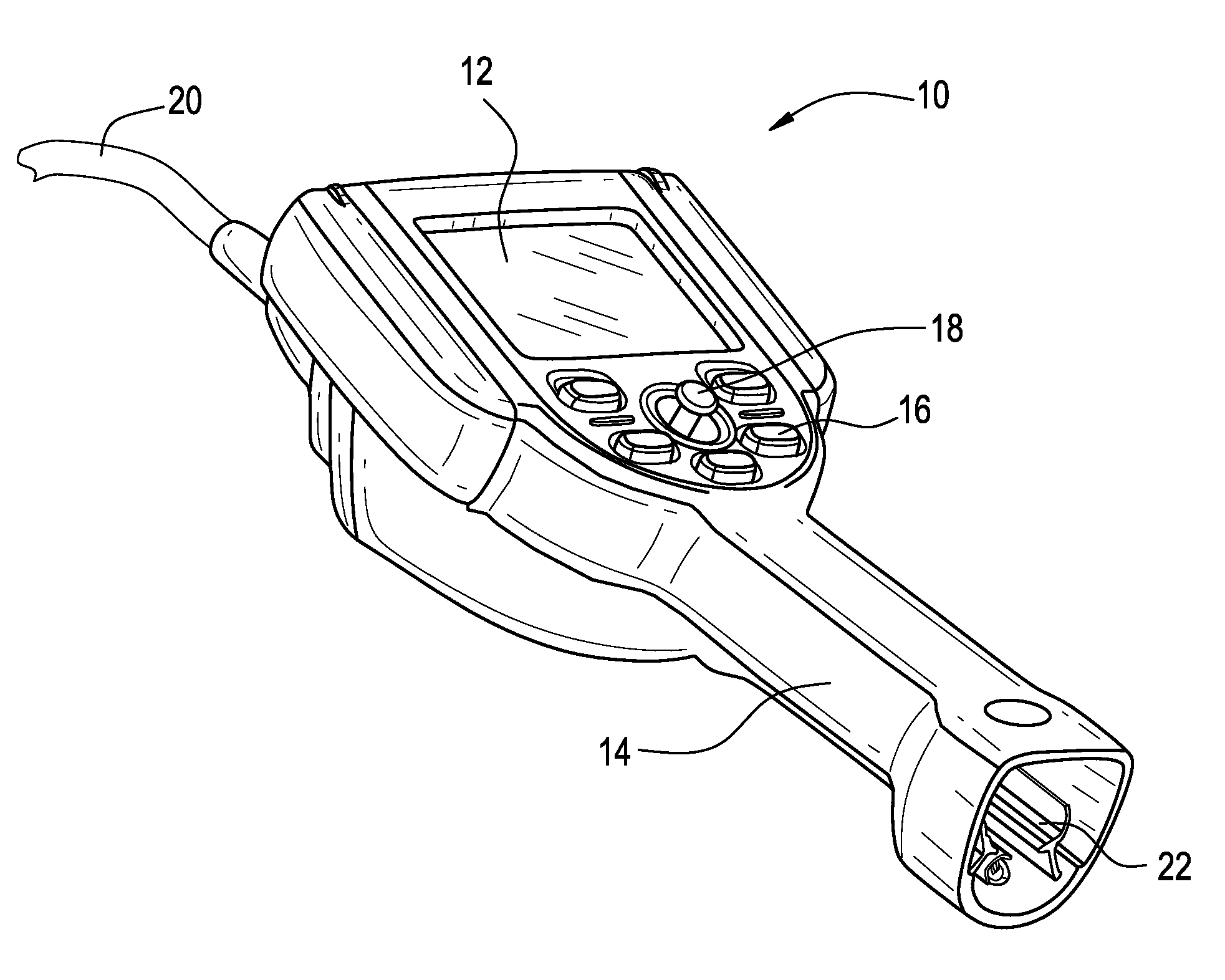

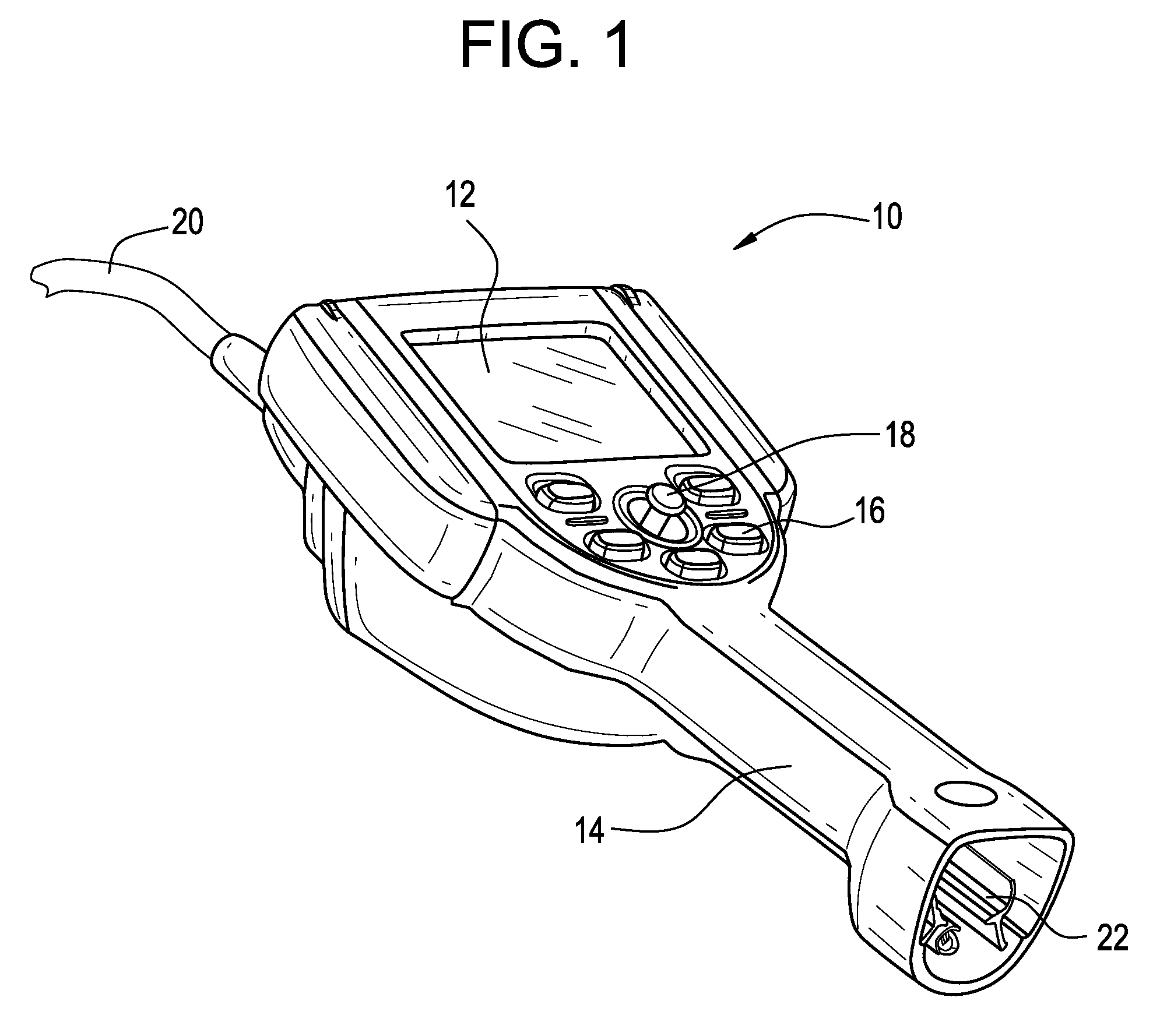

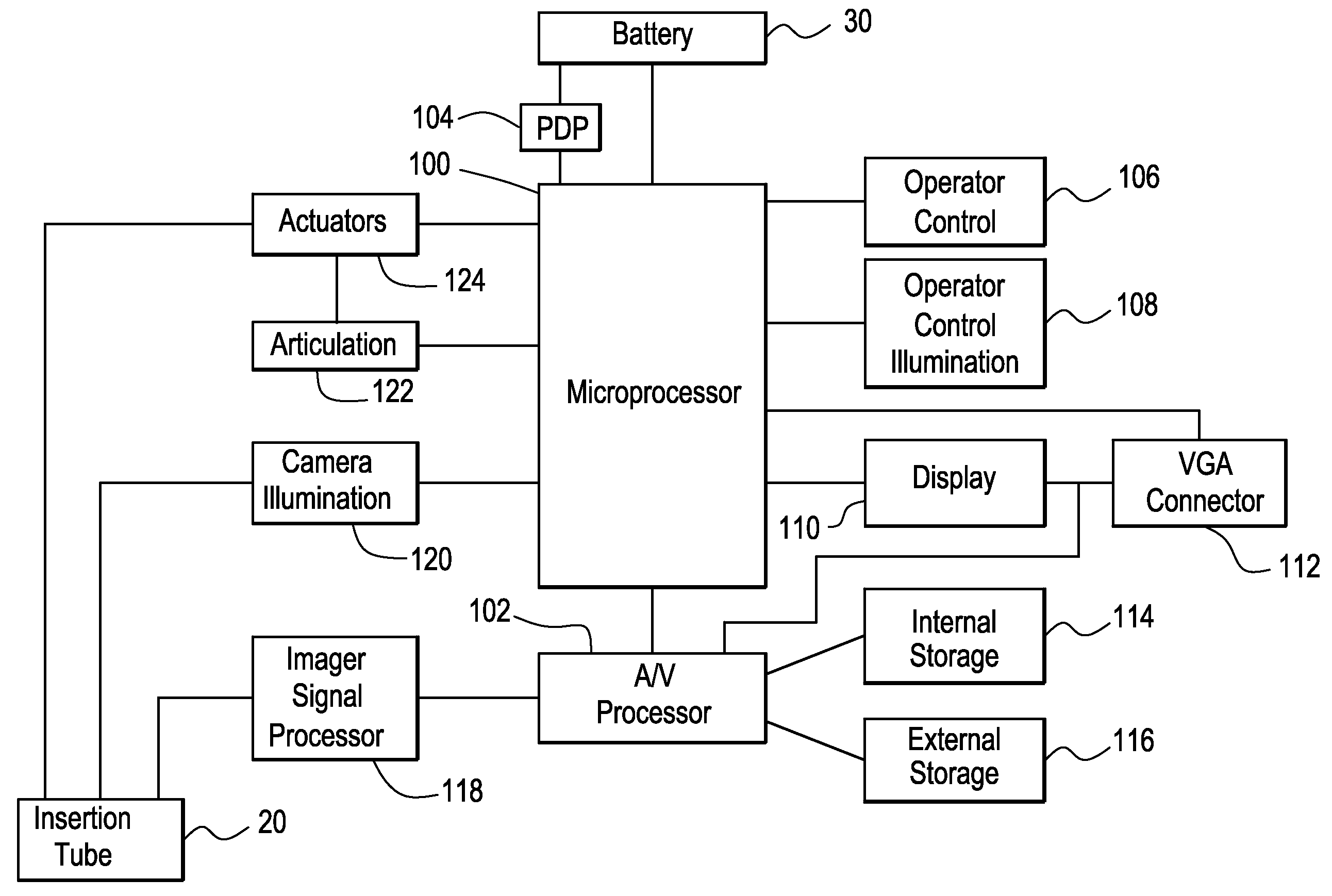

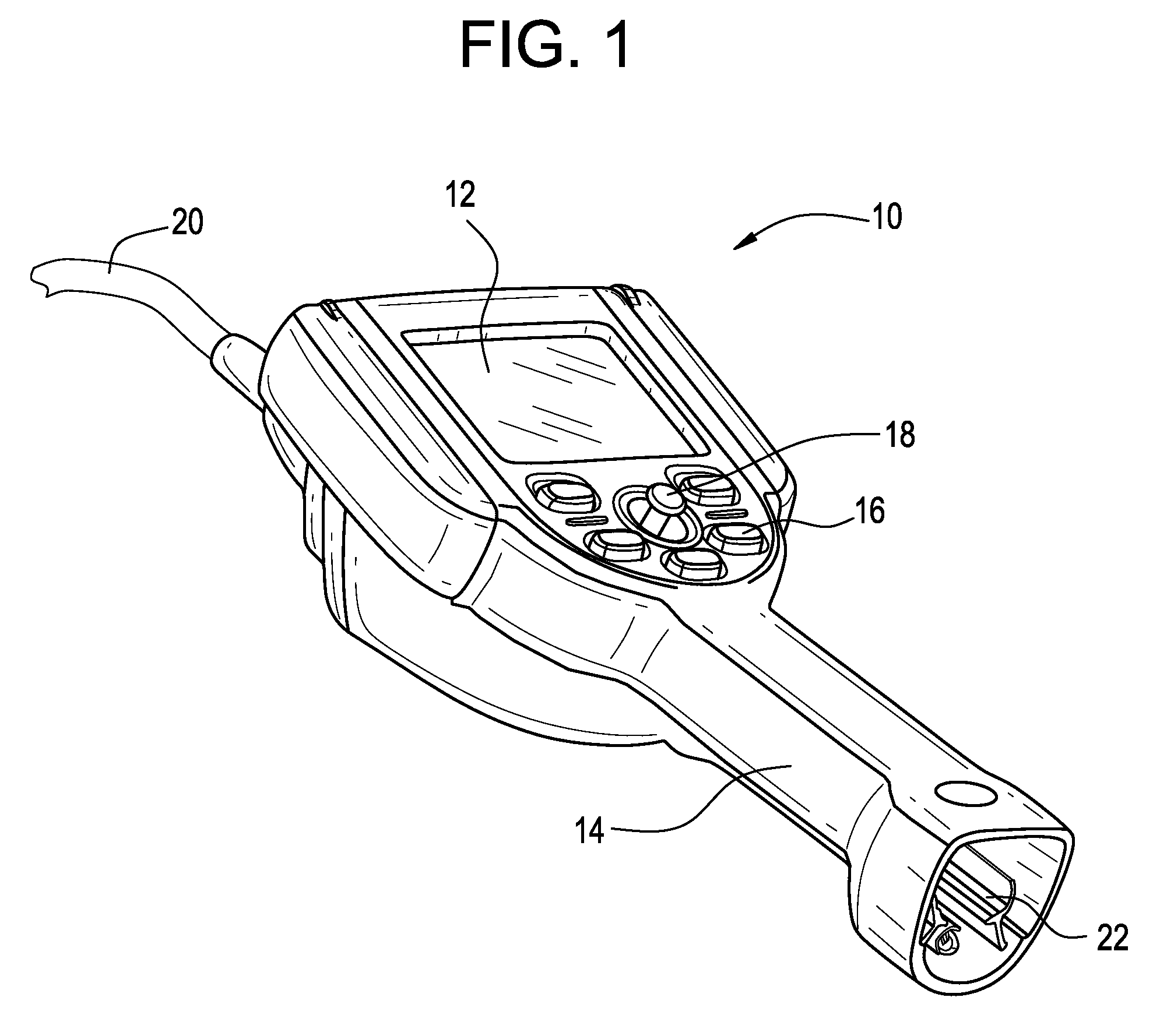

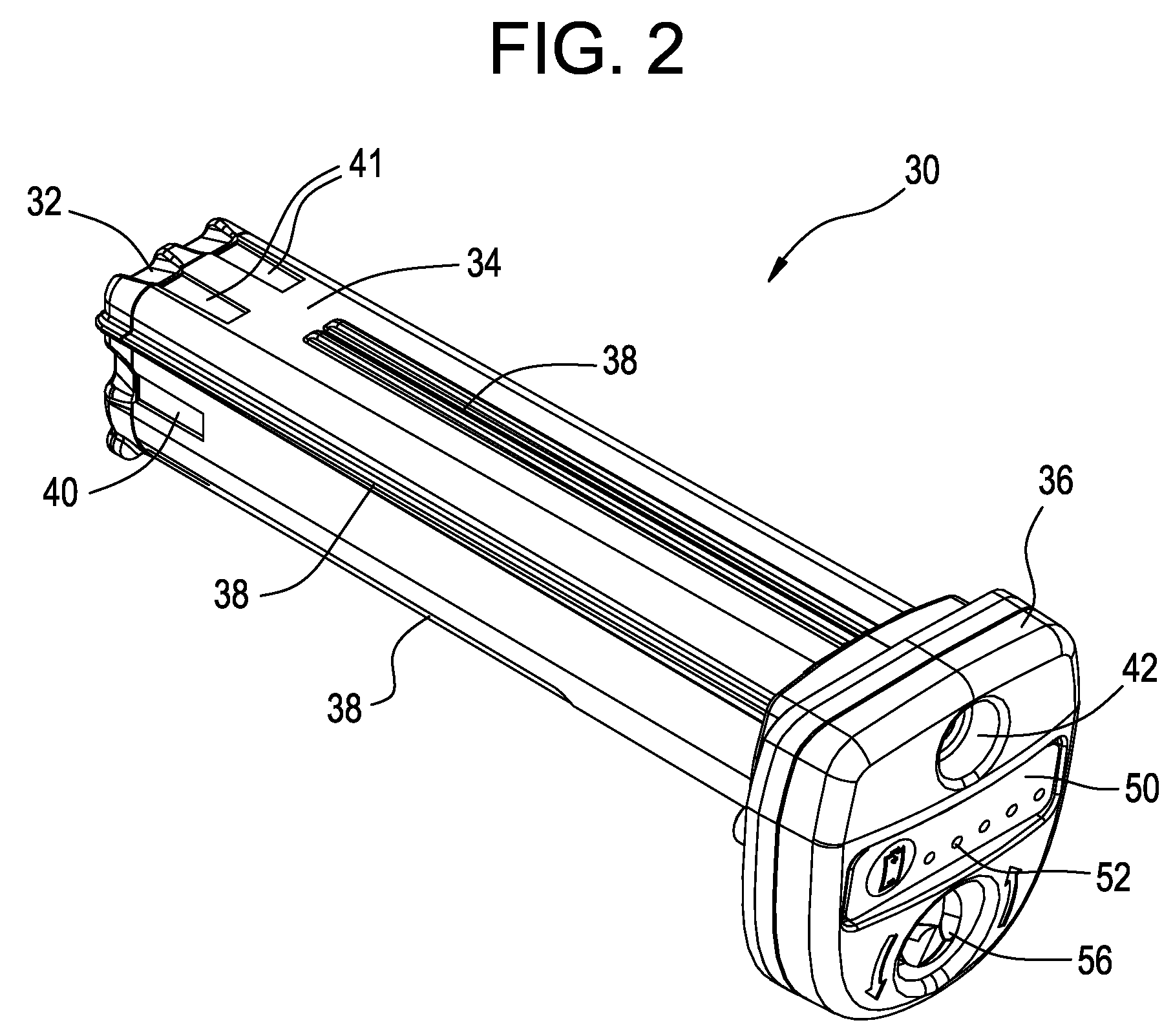

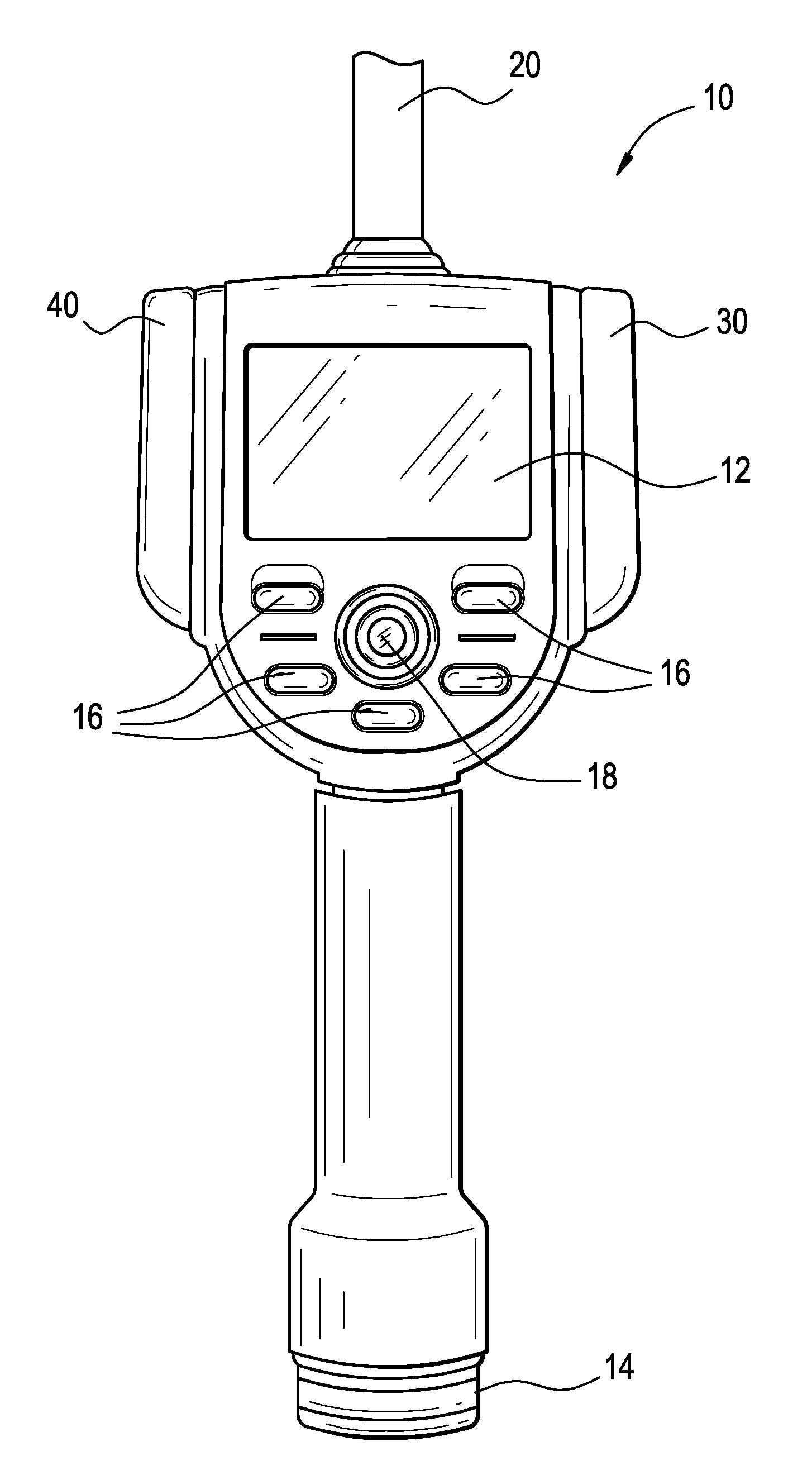

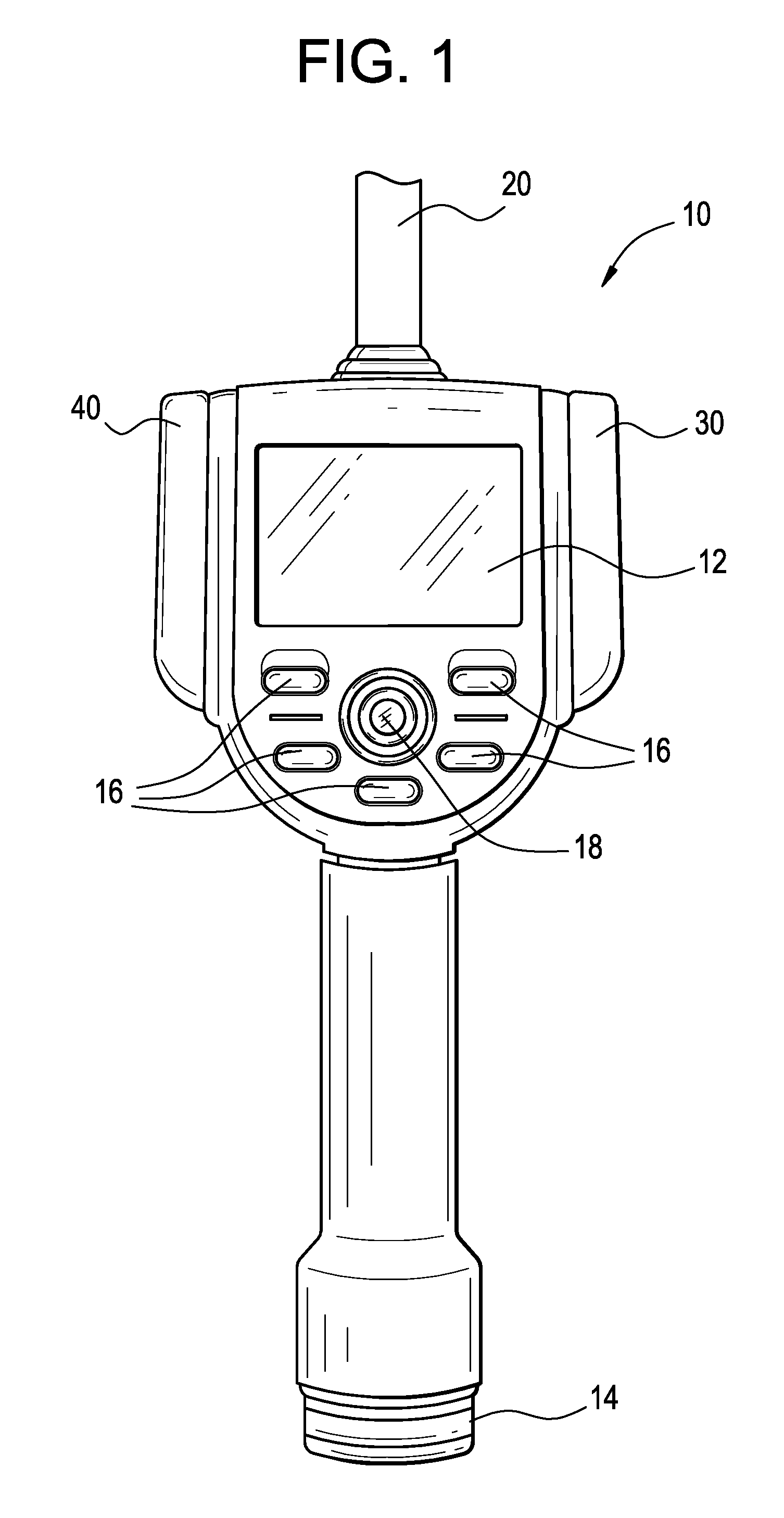

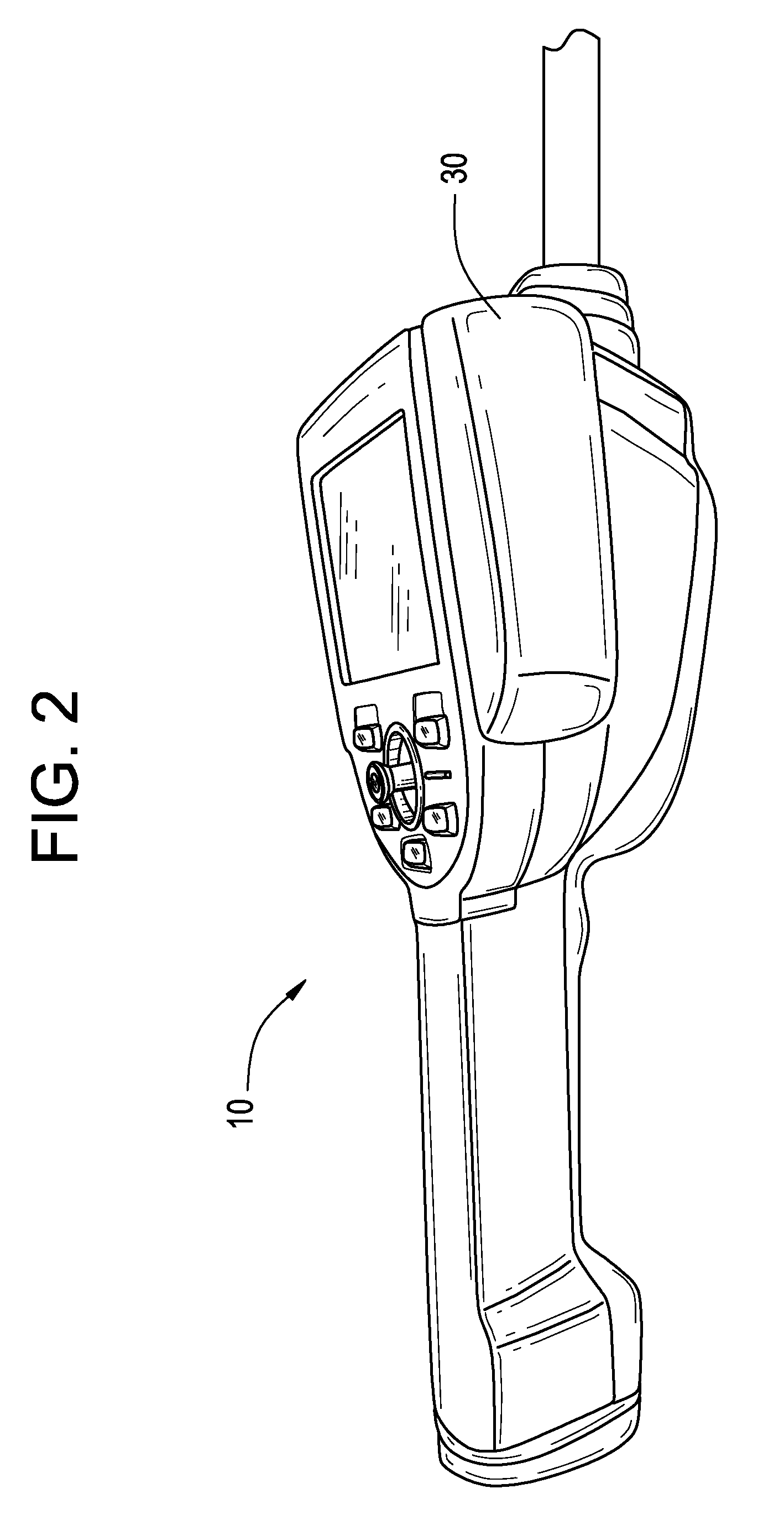

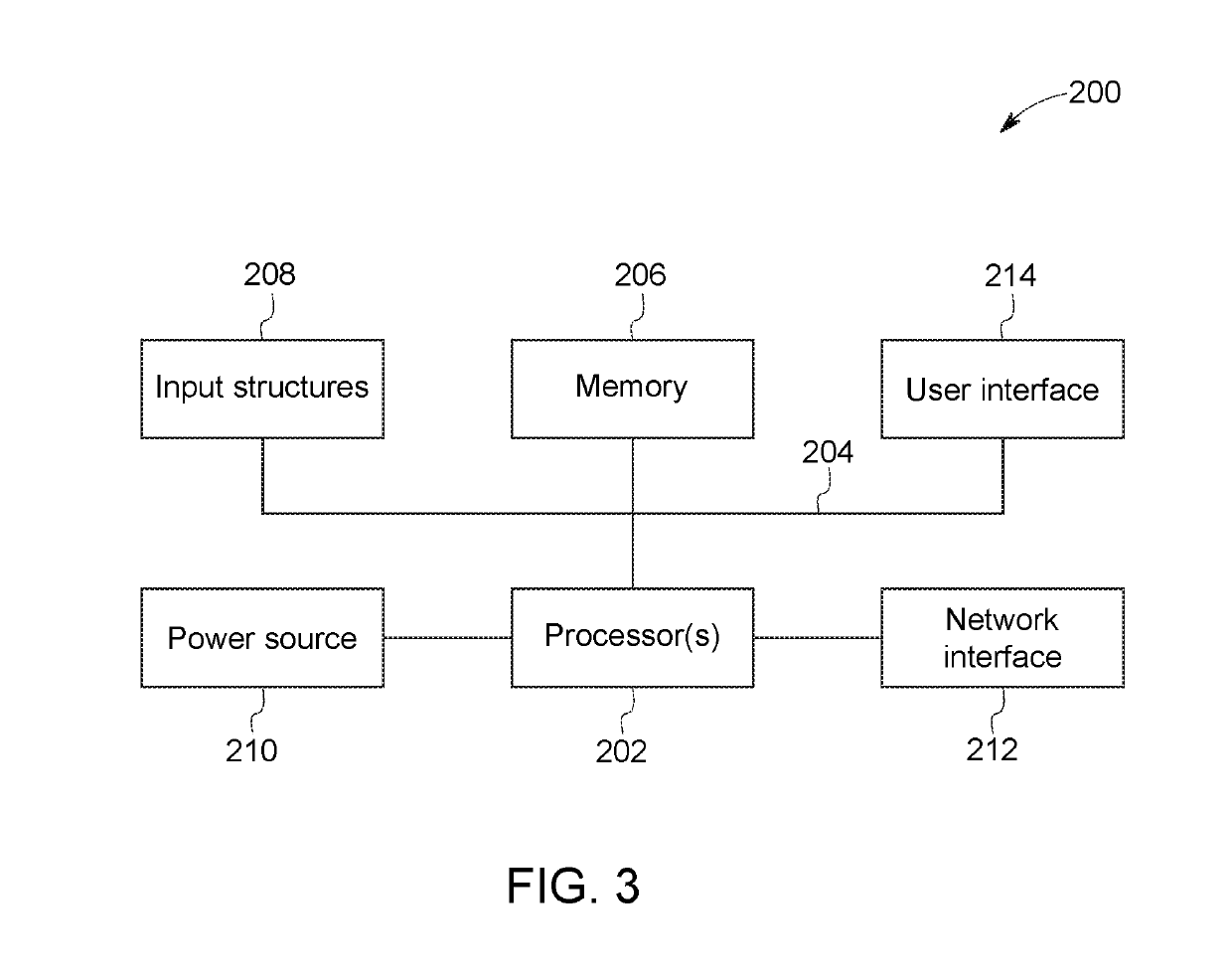

Battery and power management for industrial inspection handset

ActiveUS7902990B2Increase gain valueTelevision system detailsCircuit monitoring/indicationElectrical batteryEngineering

An industrial inspection handset is disclosed, comprising a battery assembly for providing power to the handset, wherein the battery assembly comprises a connector for connecting a battery charger, a battery circuit for communicating with a processor in the handset, and a battery charge indicator on the surface of the battery assembly connected to the battery circuit for providing a visual indication of the charge remaining in the battery assembly. A method of power management for an industrial inspection handset is also disclosed comprising the steps of setting a first maximum power output value for the camera illumination for the insertion, monitoring an imager signal processor, to determine that the gain value of the image signal processor is less than a predetermined gain value, and setting a lower second maximum power output value for the camera illumination in order to increase the gain value. Additional methods of power management for an industrial inspection handset are disclosed, comprising the steps of setting a first maximum power output value for the articulation of the insertion tube attached to the handset, monitoring the operator controls to determine that there has been no articulation for a first predetermined amount of time, monitoring the position of the insertion tube to determine whether the insertion tube position is inside or outside of a predetermined zone of coordinates, and reducing or turning off the articulation power to hold the position of the insertion tube.

Owner:GE INSPECTION TECH LP

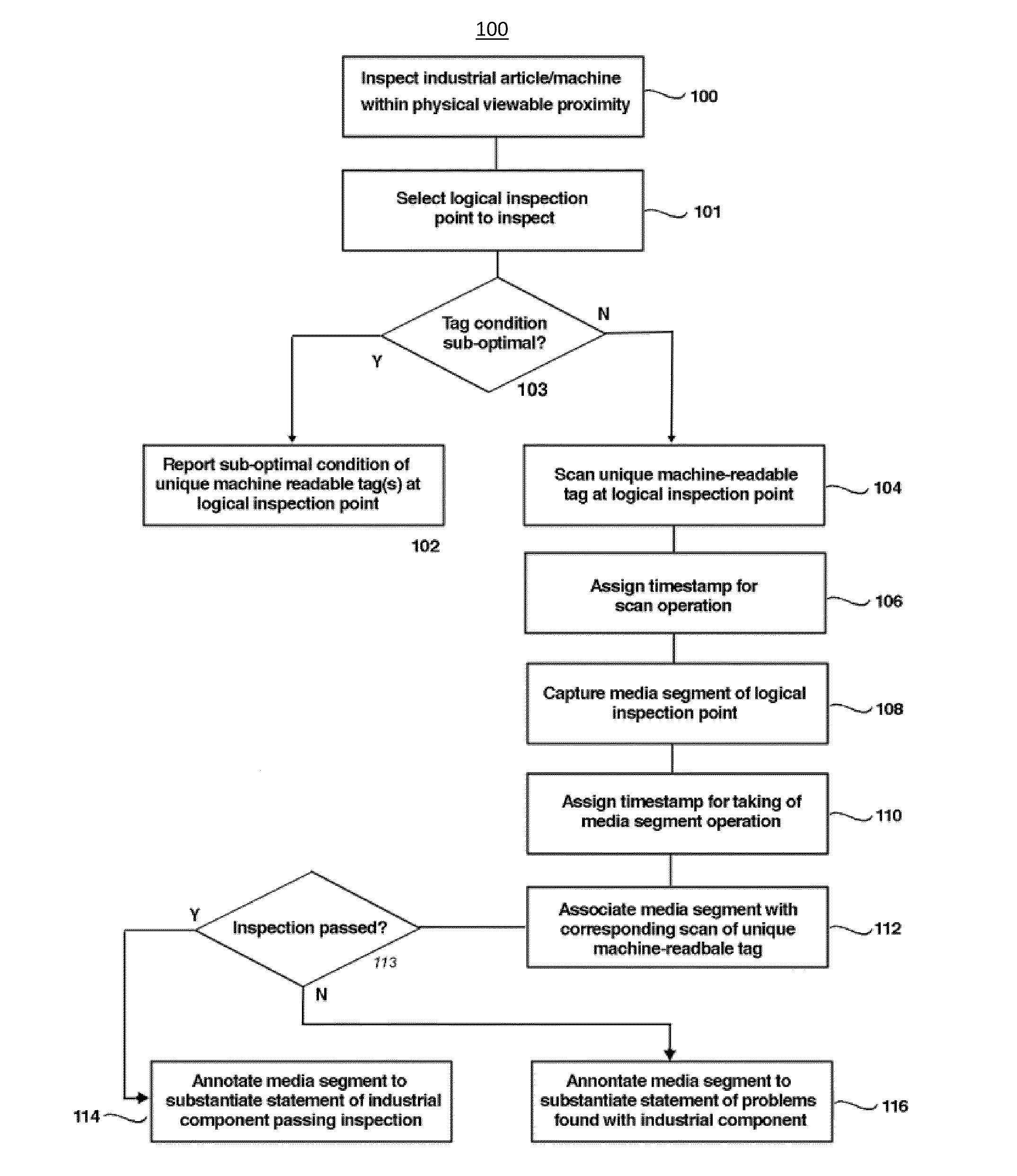

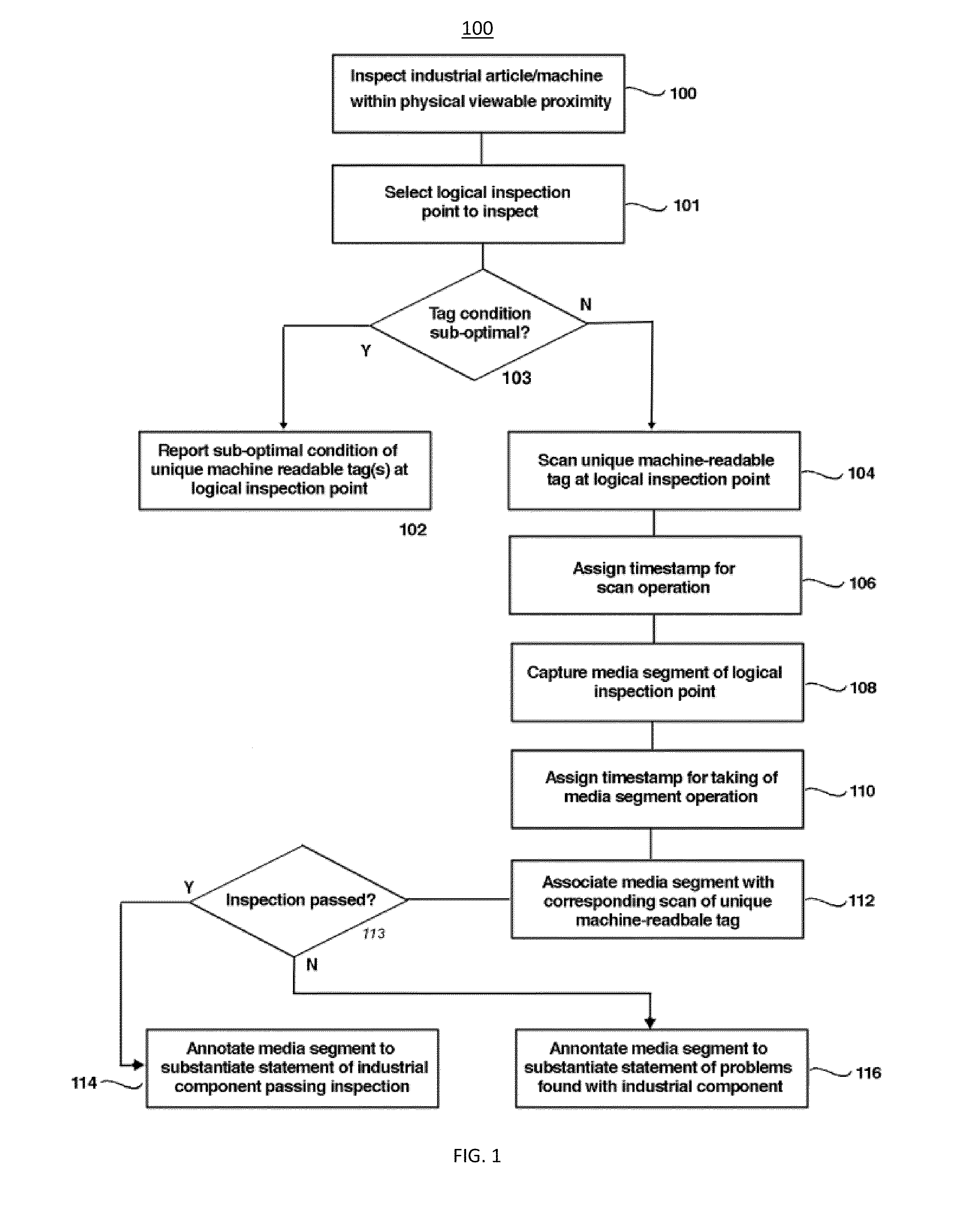

System and method used for configuration of an inspection compliance tool with machine readable tags and their associations to inspected components

The present invention relates to configuration of inspection systems and compliance verification systems using a handheld device and a remote database. Disclosed here is a method for configuring a project having one or more installation of assets for use with an industrial inspection compliance system, including the steps of (a) defining an installation and storage area for the project; (b) assigning the assets uniquely into the one or more installation or storage area; (c) segmenting each asset into components; (d) assigning logical inspection points for the project, installations, and the assets; (e) defining inspection criteria for each logical inspection point; (f) assigning tag locations for a machine-readable tag having a unique serial number at or near each logical inspection point; (g) capturing a media sample of each logical inspection point; (h) capturing location coordinates for each logical inspection point; and (i) requiring the collection of data such as a unique machine-readable tag serial number, media sample, location coordinates, and an encrypted security signature to confirm that the inspection actions actually occurred.

Owner:SECURENET SOLUTIONS GRP

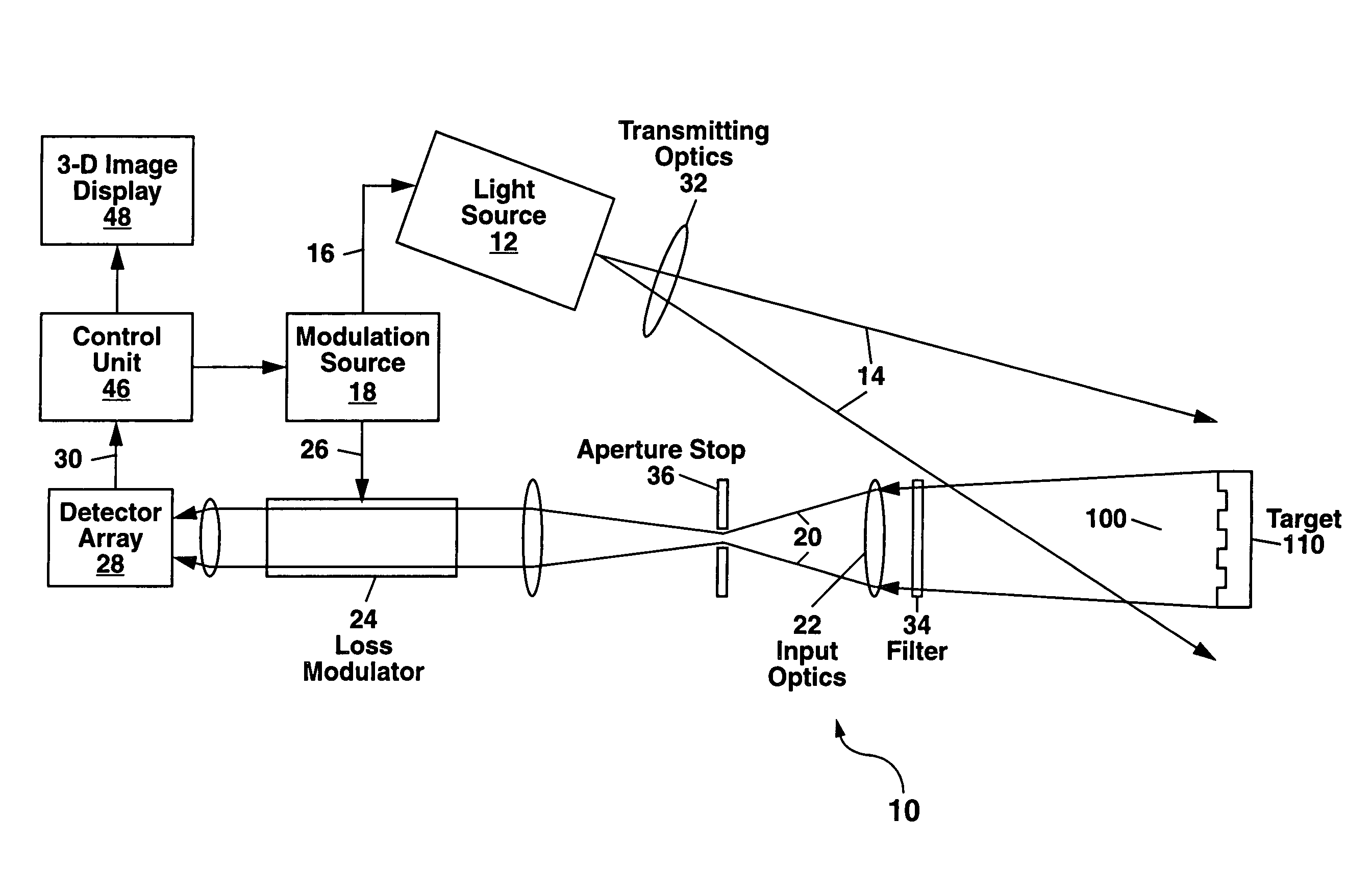

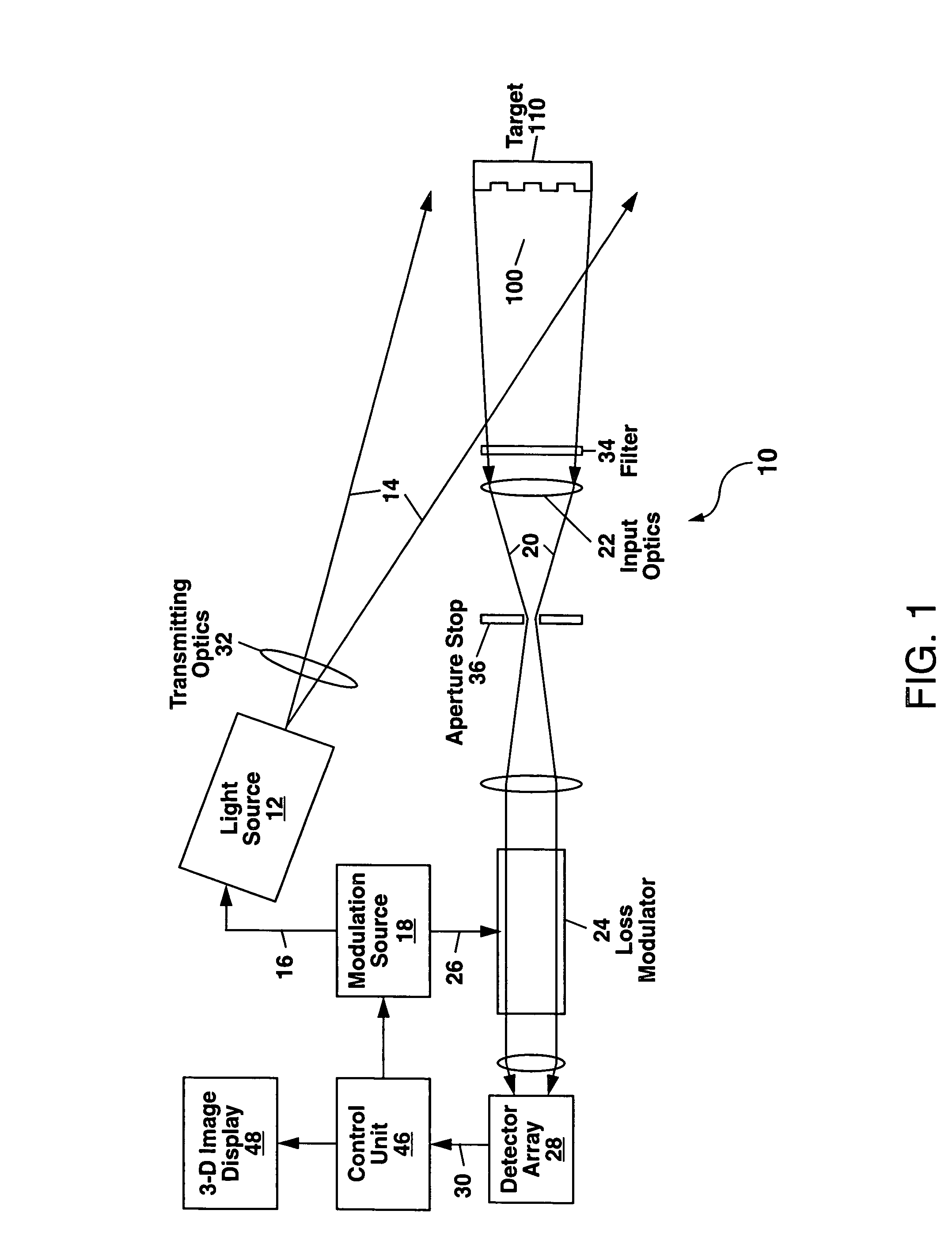

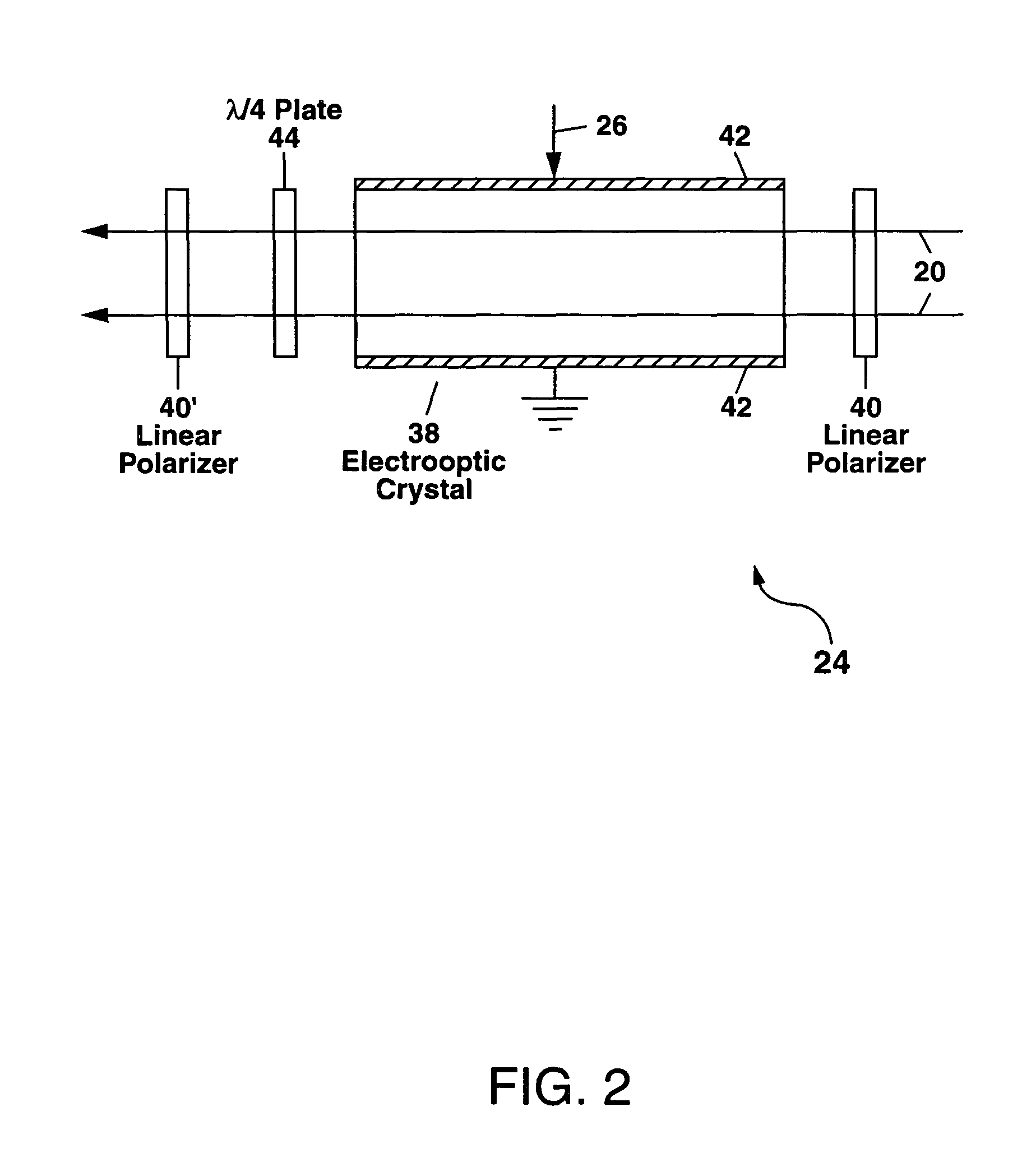

Scannerless laser range imaging using loss modulation

A scannerless 3-D imaging apparatus is disclosed which utilizes an amplitude modulated cw light source to illuminate a field of view containing a target of interest. Backscattered light from the target is passed through one or more loss modulators which are modulated at the same frequency as the light source, but with a phase delay δ which can be fixed or variable. The backscattered light is demodulated by the loss modulator and detected with a CCD, CMOS or focal plane array (FPA) detector to construct a 3-D image of the target. The scannerless 3-D imaging apparatus, which can operate in the eye-safe wavelength region 1.4-1.7 μm and which can be constructed as a flash LADAR, has applications for vehicle collision avoidance, autonomous rendezvous and docking, robotic vision, industrial inspection and measurement, 3-D cameras, and facial recognition.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

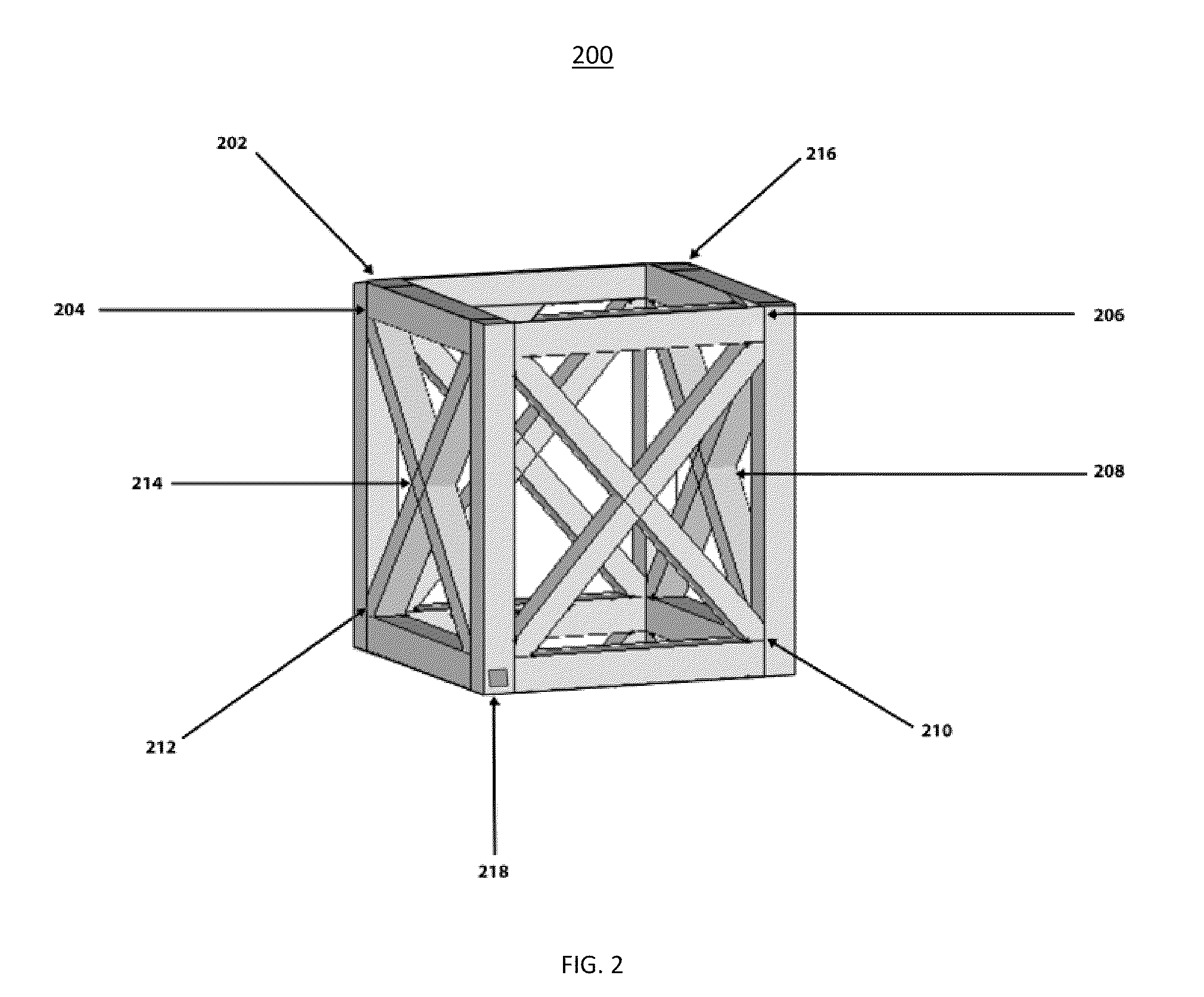

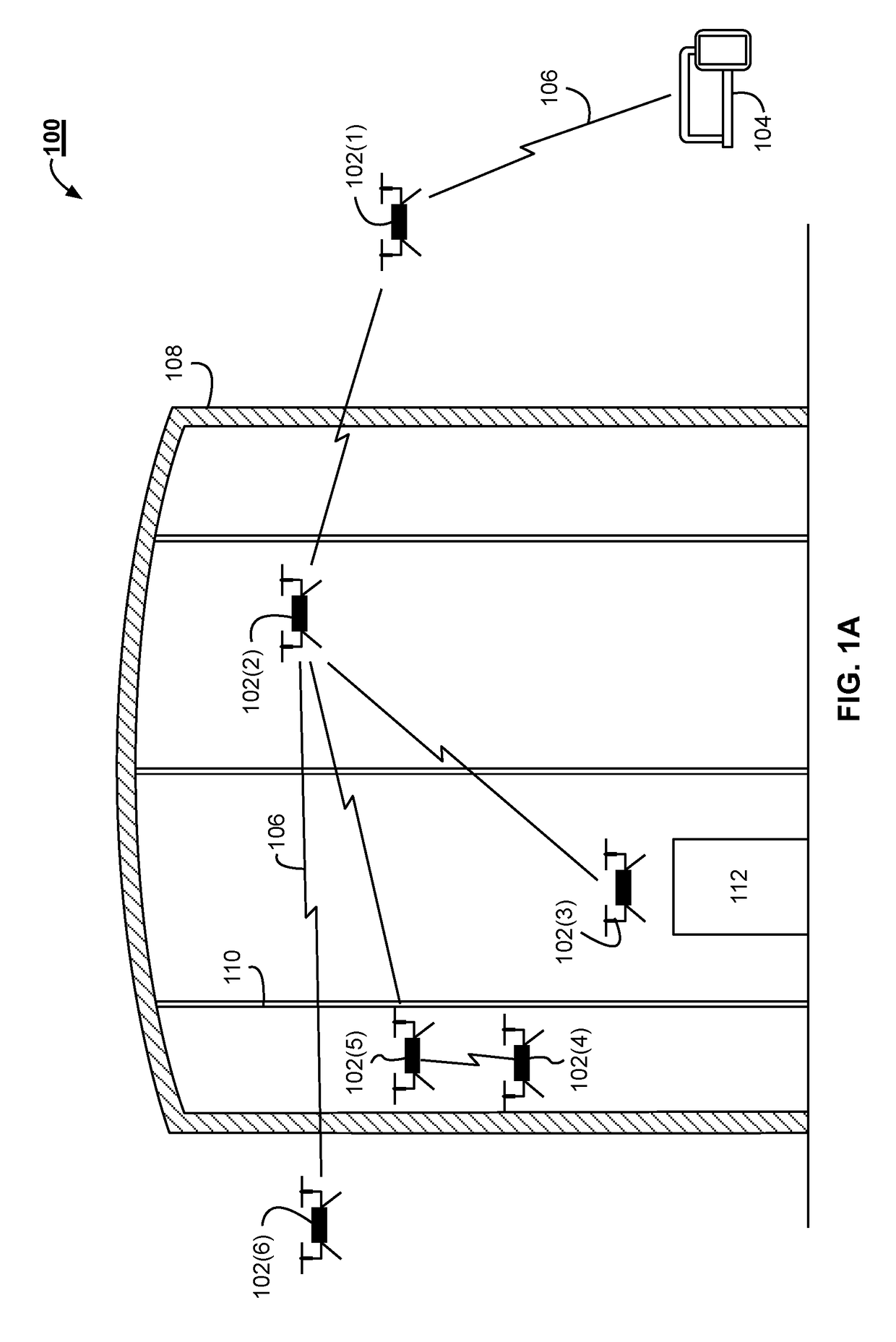

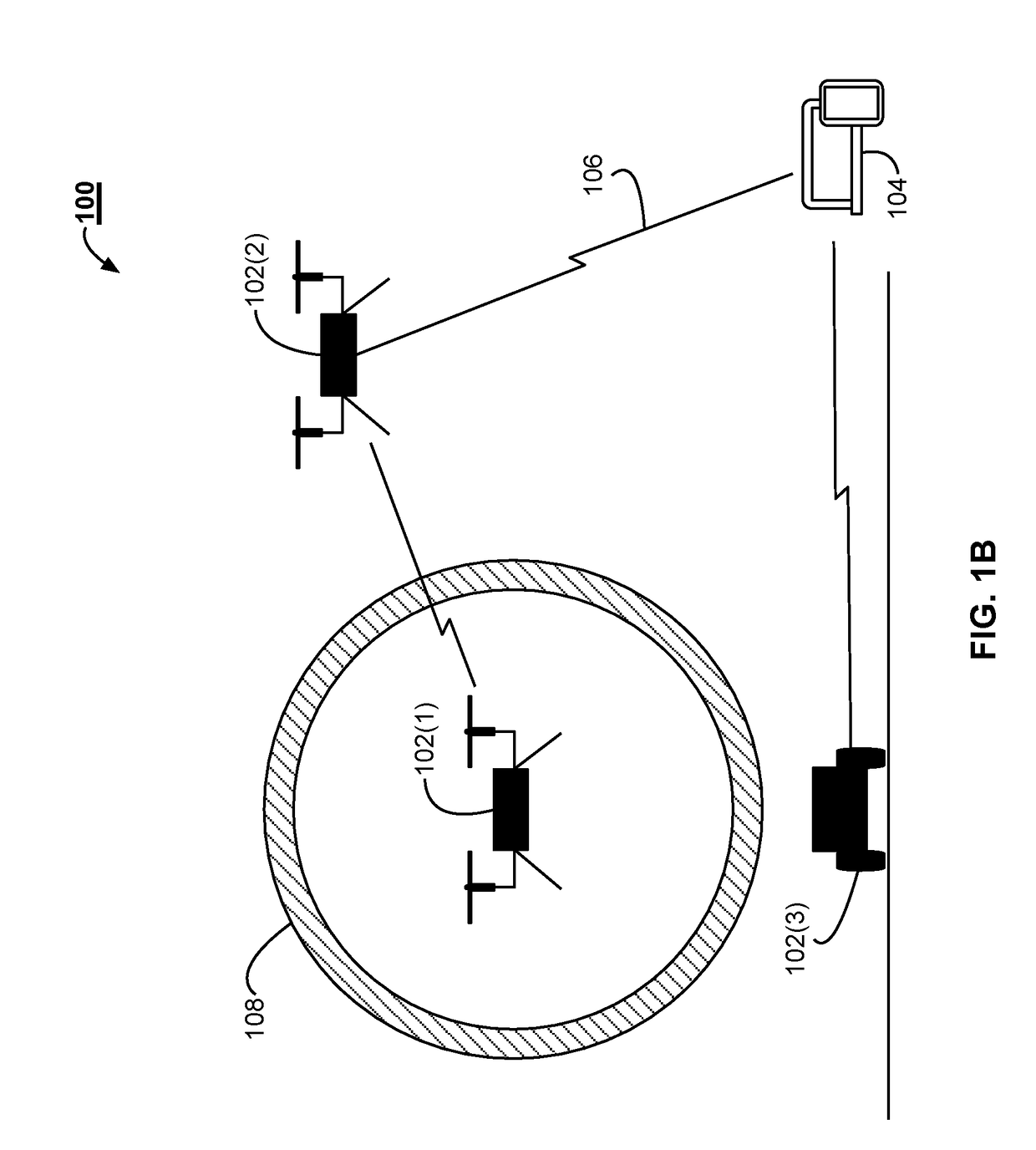

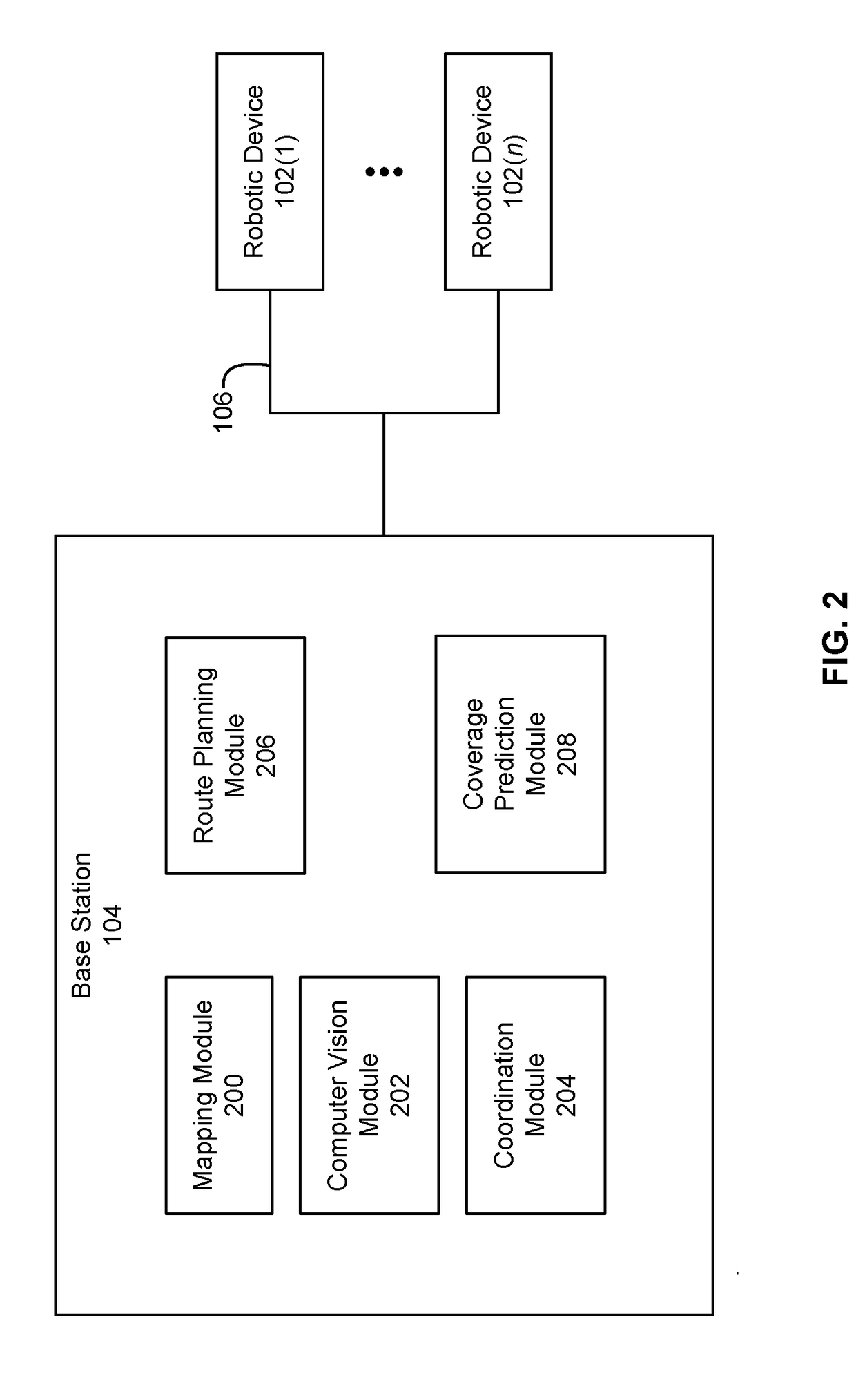

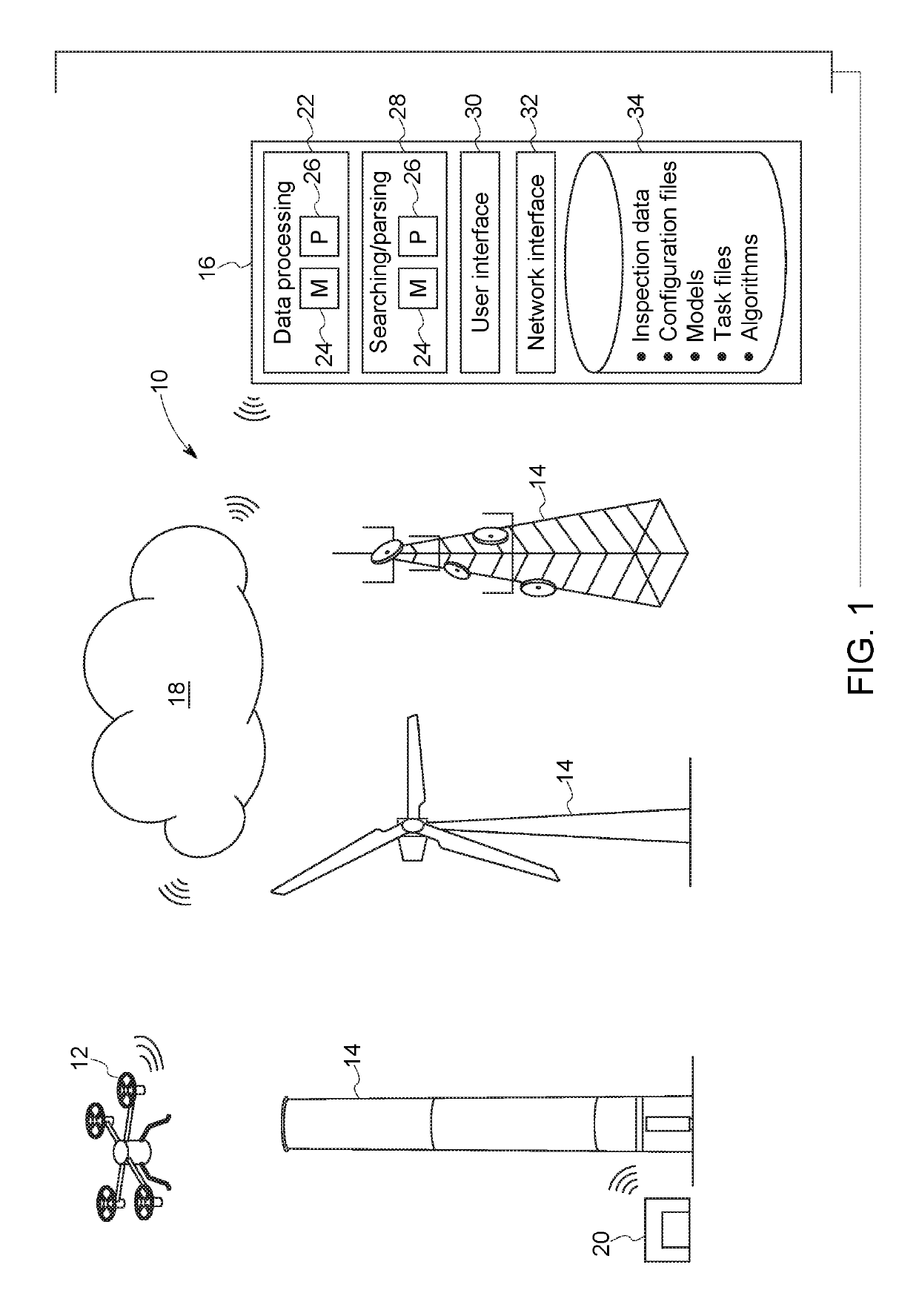

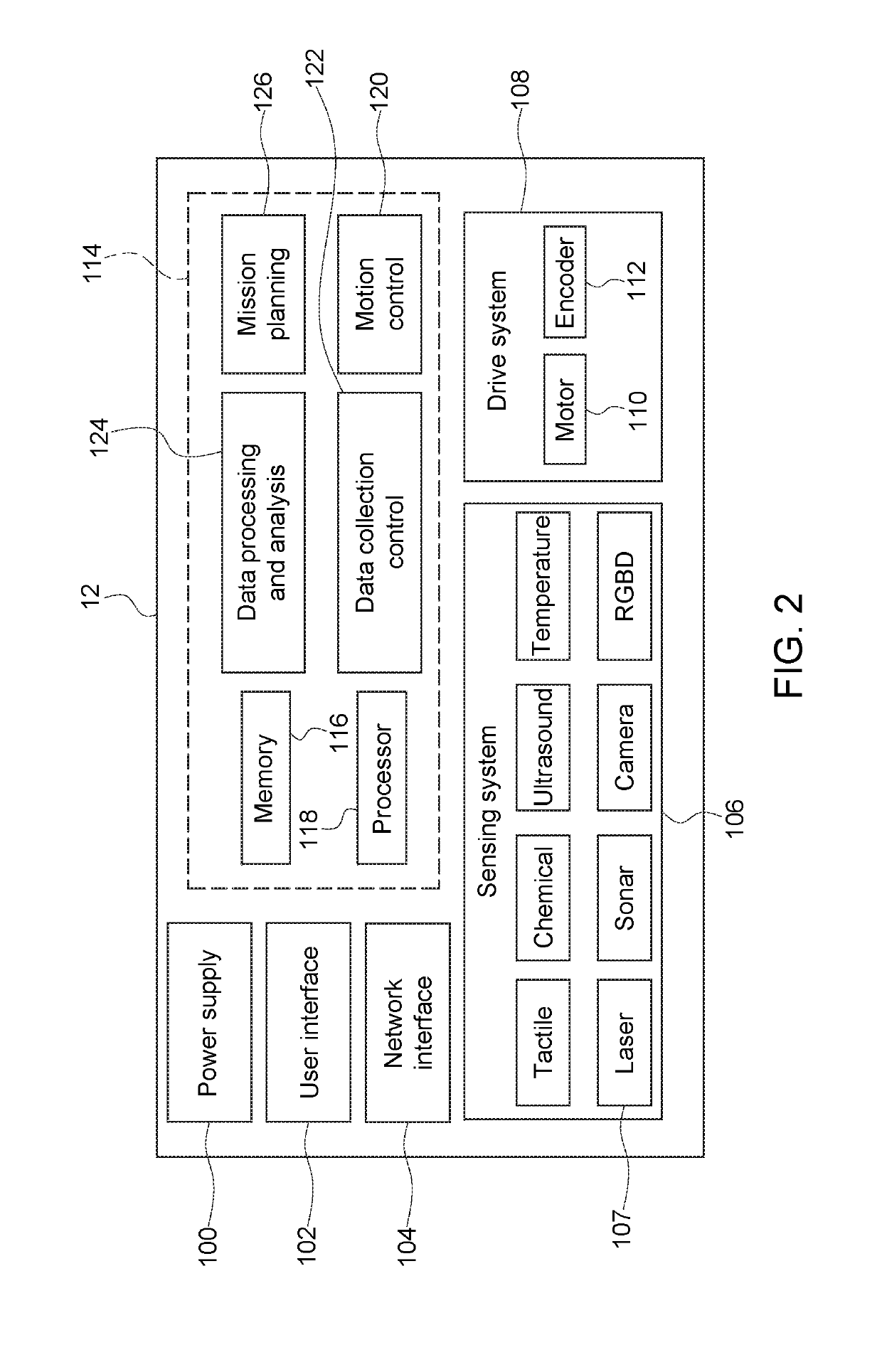

Autonomous robotic technologies for industrial inspection

ActiveUS20190049962A1Reduce riskFlexible scaleImage enhancementImage analysisEngineeringAutonomous robot

The present solution provides autonomous robotic technologies for industrial inspection that can flexibly scale to meet many different types of industrial inspection. By utilizing the autonomous robotic technologies disclosed herein, increasingly large and complex industrial inspections may be completed in a fraction of the time previously required for inspections of smaller scales.

Owner:RAVENOPS INC

Large-area individually addressable multi-beam x-ray system and method of forming same

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

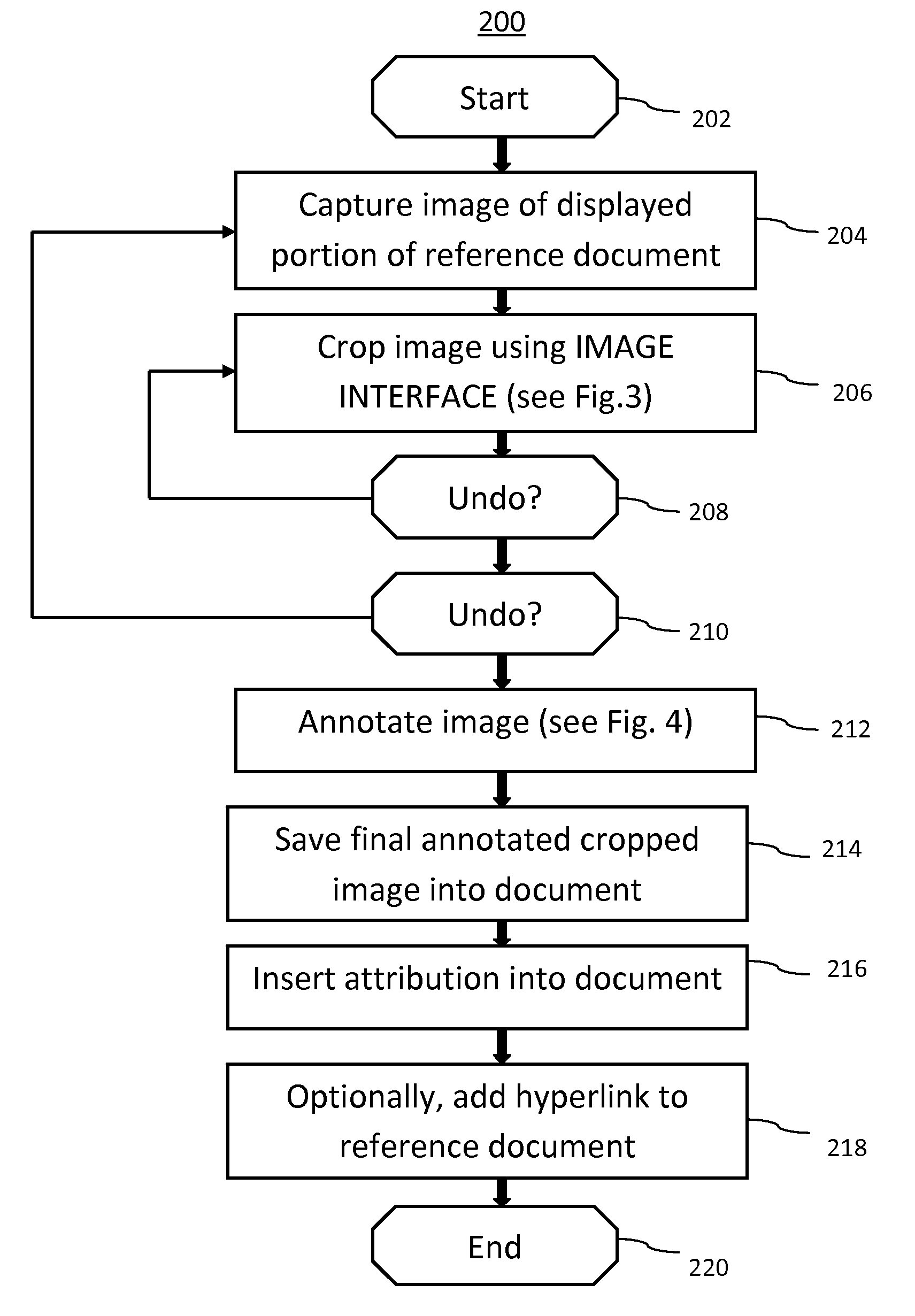

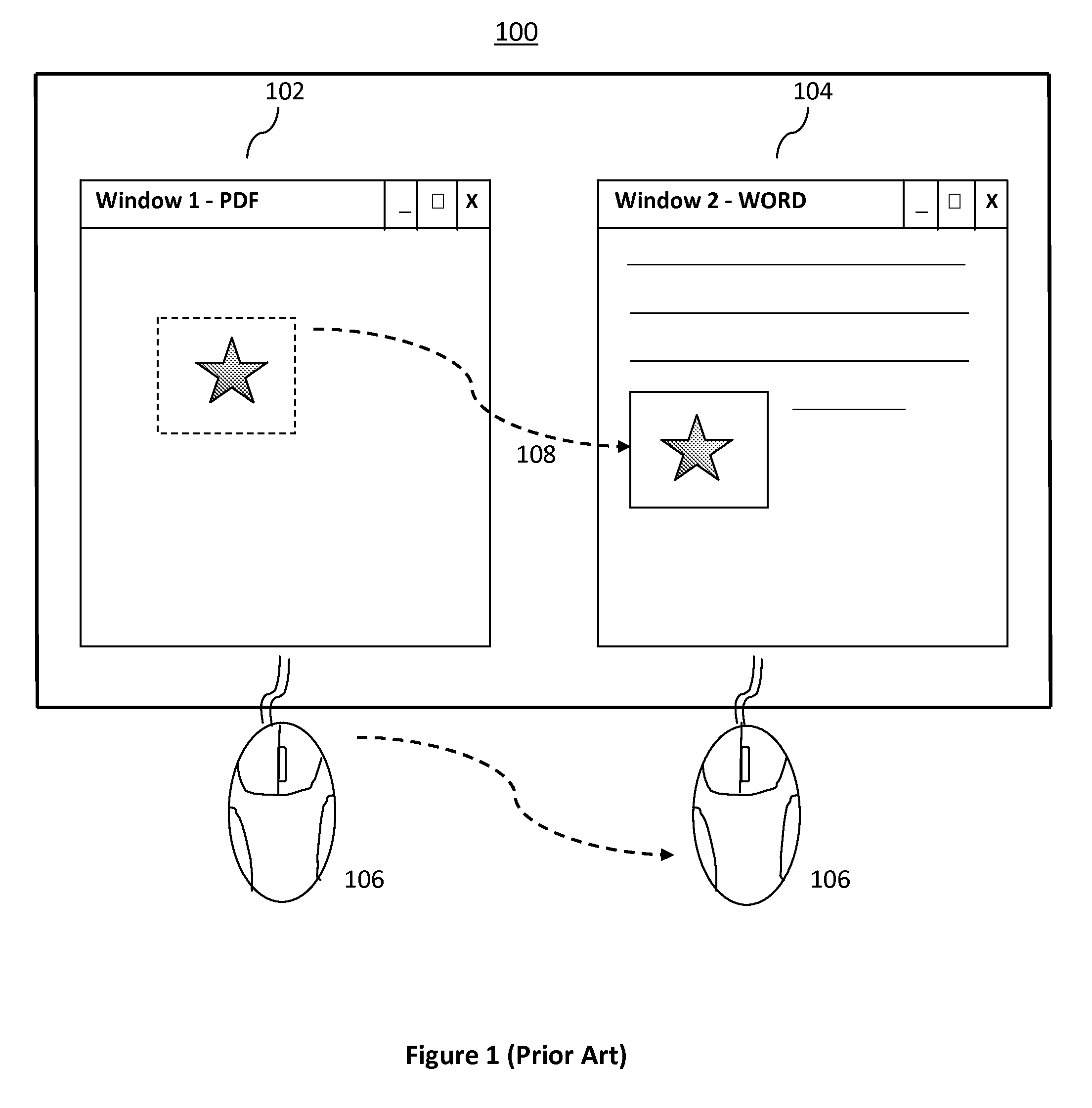

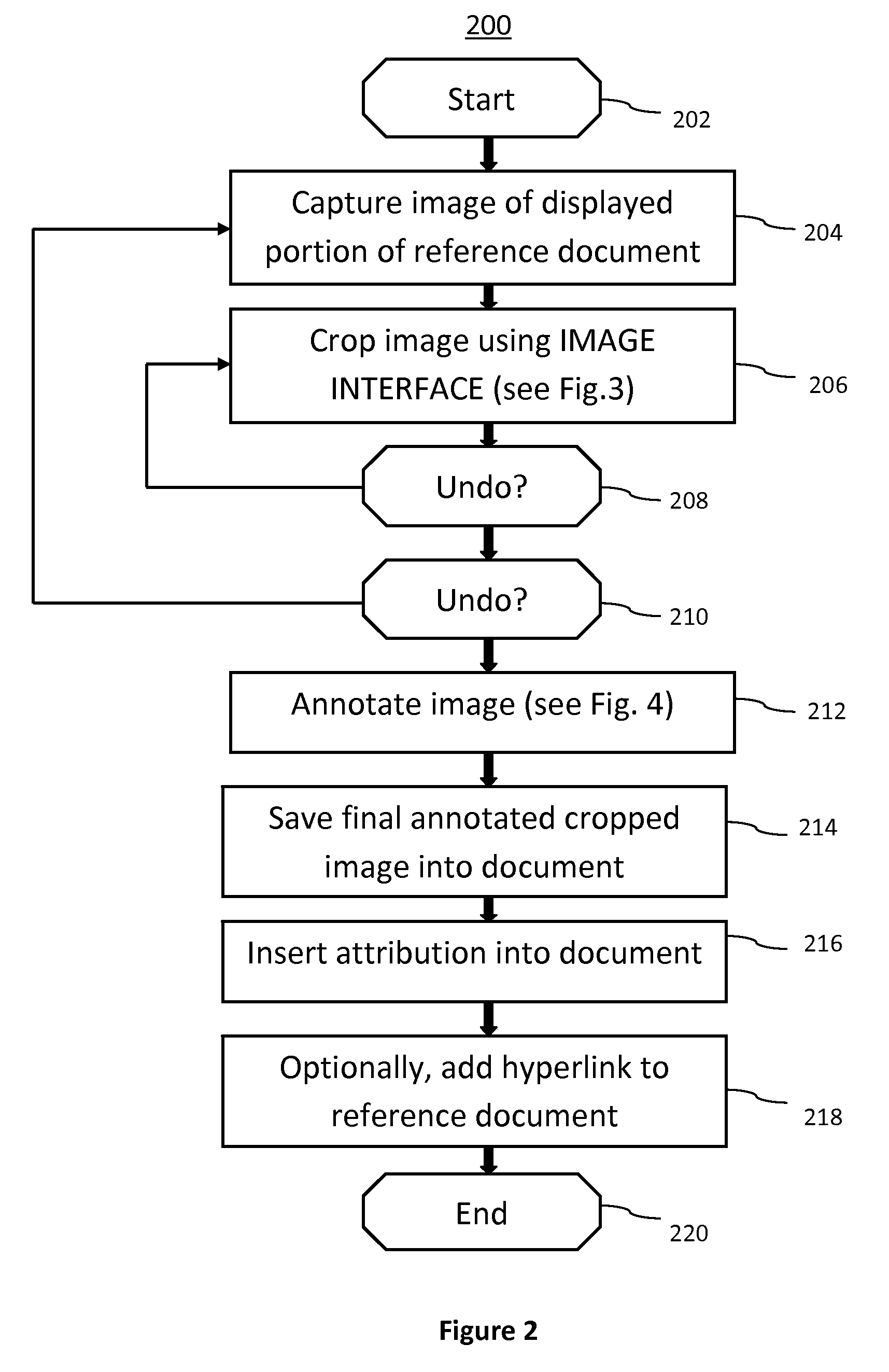

System and method for generating quotations from a reference document on a touch sensitive display device

The present invention is a system and method for generating quotations from a reference document on a touch sensitive display device or other handheld device, including the following steps: (a) providing a reference document; (b) displaying the reference document; (c) capturing an image of a portion of the reference document; (d) editing the captured portion of the reference document; and (e) generating a quotation comprising an image quotation and a bibliographical reference to a referenced portion of the reference document. The present invention may be used in Apple iPhones®, hand-held devices that inspectors may use to quote reference documents to substantiate statements of problems found during industrial inspections, and in other purposes.

Owner:SECURENET SOLUTIONS GRP

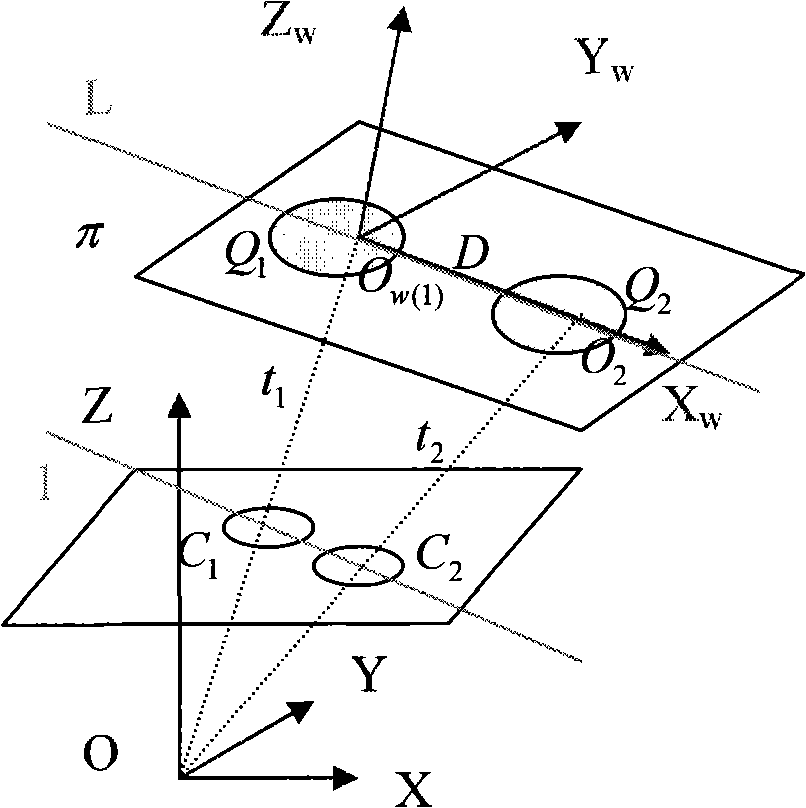

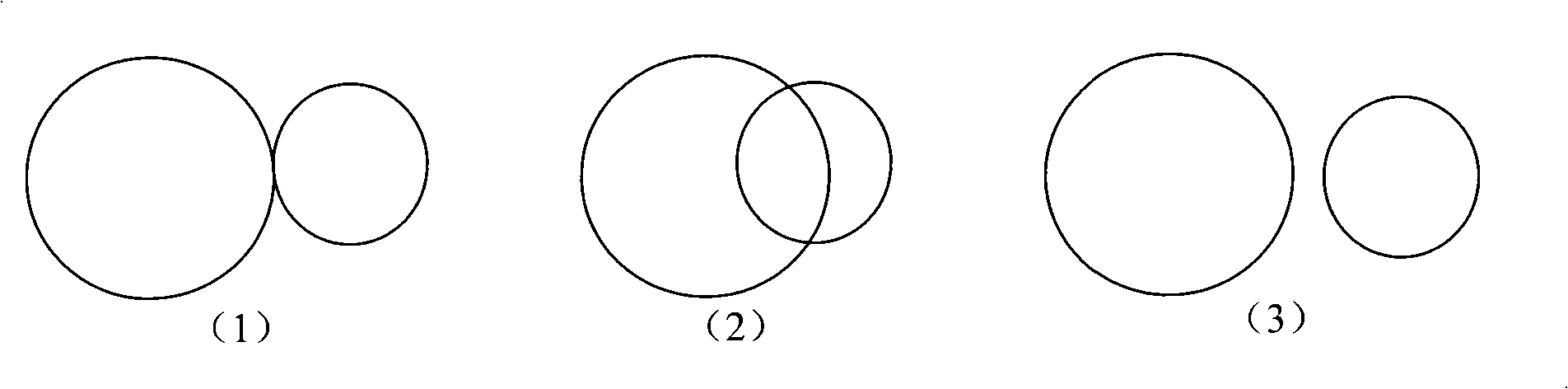

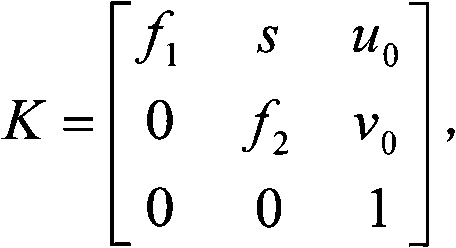

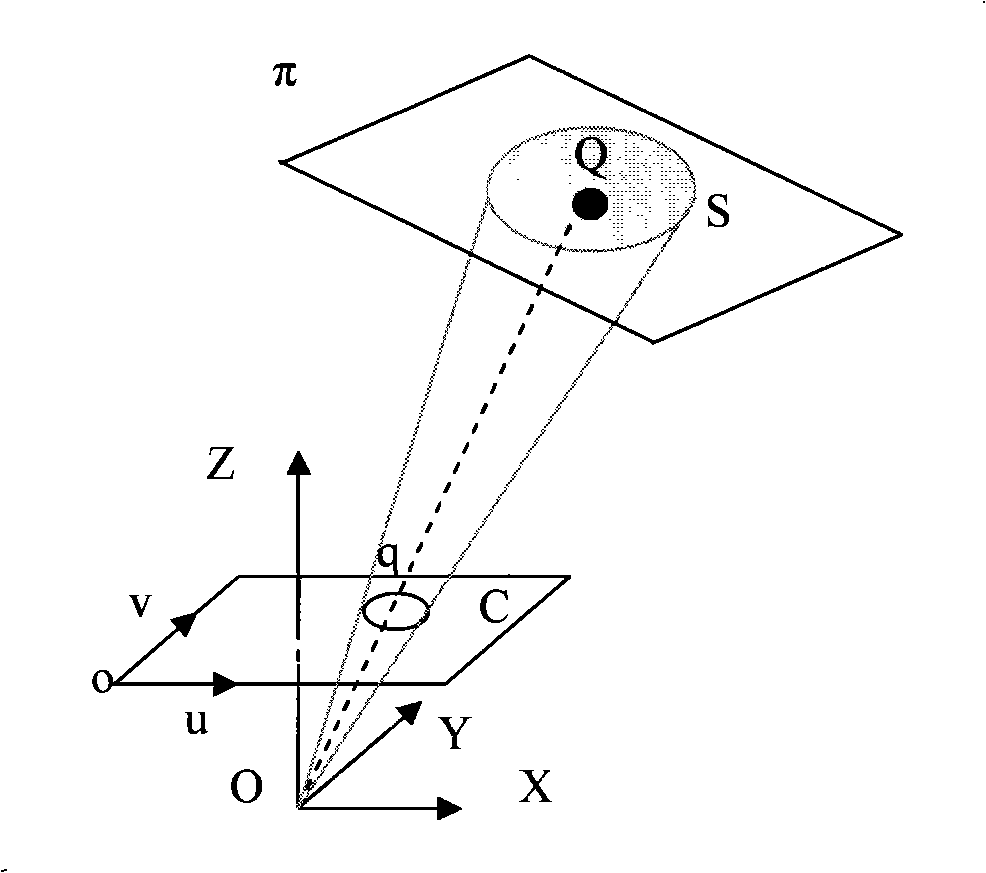

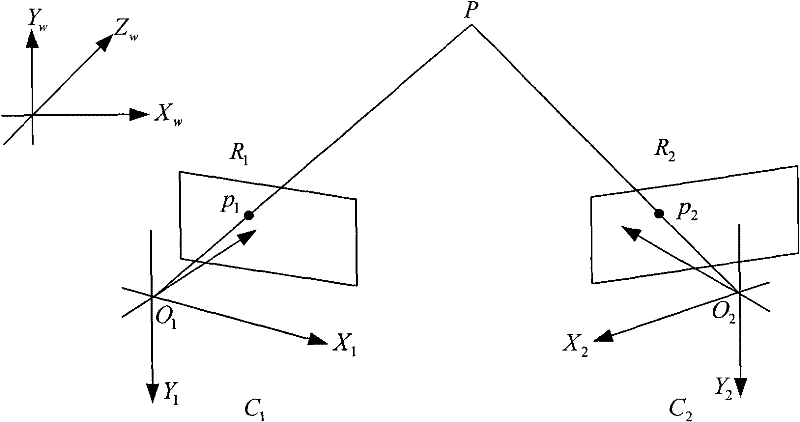

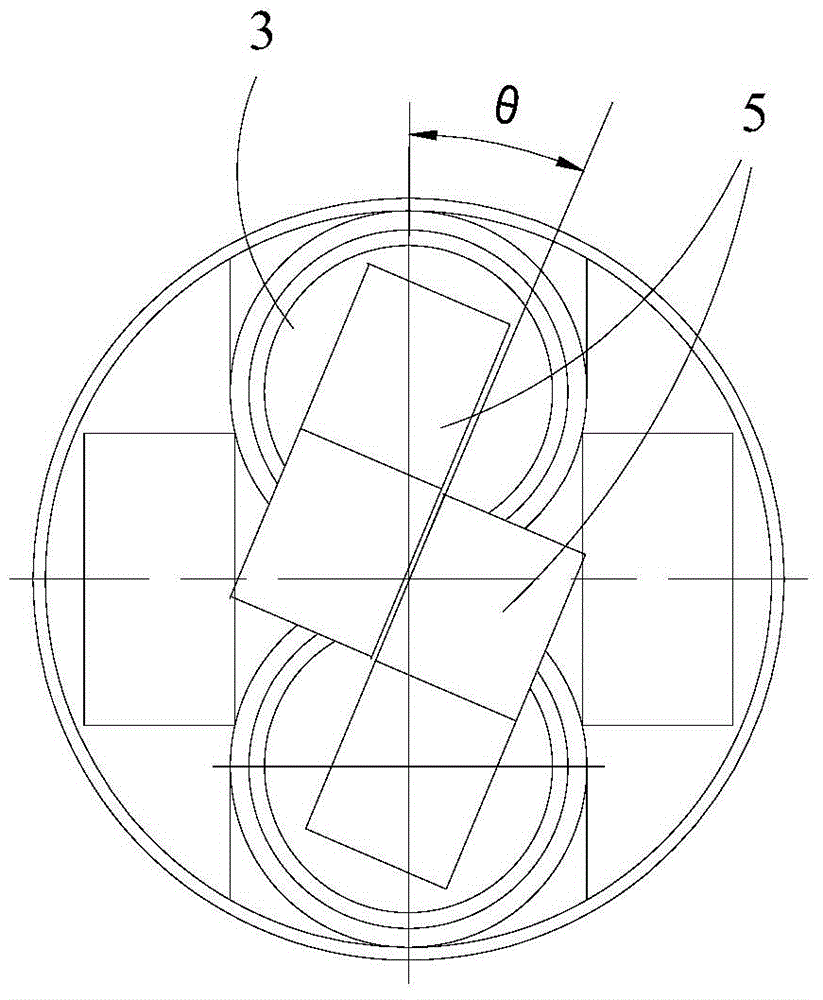

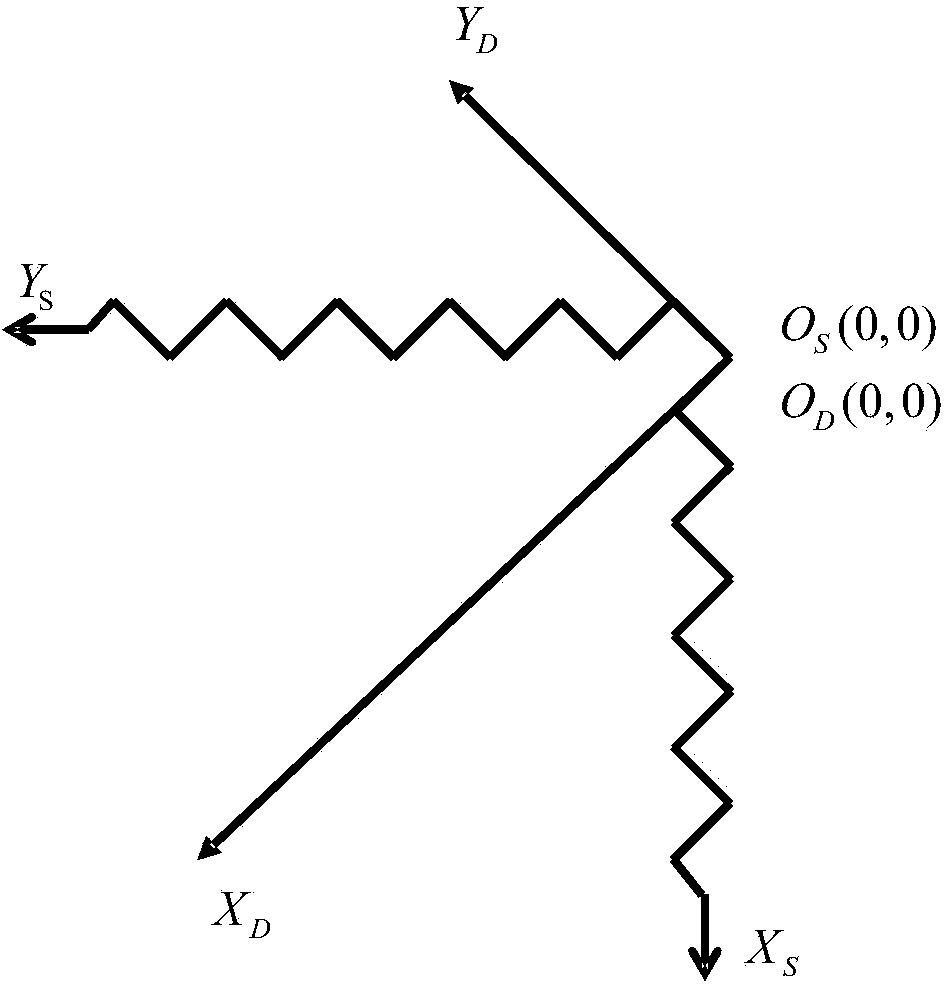

Method for positioning video camera using two arbitrary coplane circles

InactiveCN101329764AEasy CalibrationRealize fully automatic calibrationImage analysisAutonomous Navigation SystemEllipse

The invention relates to a method for calibrating a camera by any two coplanar circles, and two non-concyclic centre coplanar circles are used as the calibration objects. A clear image is taken by the camera for the calibration objects, to define the equations of two elliptical shadows in the images and solve the coordinates of the image points of the focoids. The image point coordinates of the focoids and the shadow equations of absolute secondary curves are utilized to define the focal distance of the camera; a world coordinate system is set up, with the center of any of the two circles as the origin, and Z axis is parallel with the normal direction of the plane of the two circles. A rotation matrix is defined according to the relation between blanking points, blanking lines and the elliptical shadows; the solved position, of the world coordinate system, under the camera coordinate system is the right translation vector. The method of the invention can easily and conveniently define all variable parameters every time when the camera is calibrated, can realize the wholly automatic calibration, reduce calculation errors arisen by human intervention, and is particularly suitable for non-contact industrial inspection and the vision-based independent navigation system.

Owner:SHANGHAI JIAO TONG UNIV

Battery and power management for industrial inspection handset

ActiveUS20090109045A1Increase gain valueTelevision system detailsCircuit monitoring/indicationElectrical batteryEngineering

An industrial inspection handset is disclosed, comprising a battery assembly for providing power to the handset, wherein the battery assembly comprises a connector for connecting a battery charger, a battery circuit for communicating with a processor in the handset, and a battery charge indicator on the surface of the battery assembly connected to the battery circuit for providing a visual indication of the charge remaining in the battery assembly. A method of power management for an industrial inspection handset is also disclosed comprising the steps of setting a first maximum power output value for the camera illumination for the insertion, monitoring an imager signal processor, to determine that the gain value of the image signal processor is less than a predetermined gain value, and setting a lower second maximum power output value for the camera illumination in order to increase the gain value. Additional methods of power management for an industrial inspection handset are disclosed, comprising the steps of setting a first maximum power output value for the articulation of the insertion tube attached to the handset, monitoring the operator controls to determine that there has been no articulation for a first predetermined amount of time, monitoring the position of the insertion tube to determine whether the insertion tube position is inside or outside of a predetermined zone of coordinates, and reducing or turning off the articulation power to hold the position of the insertion tube.

Owner:GE INSPECTION TECH LP

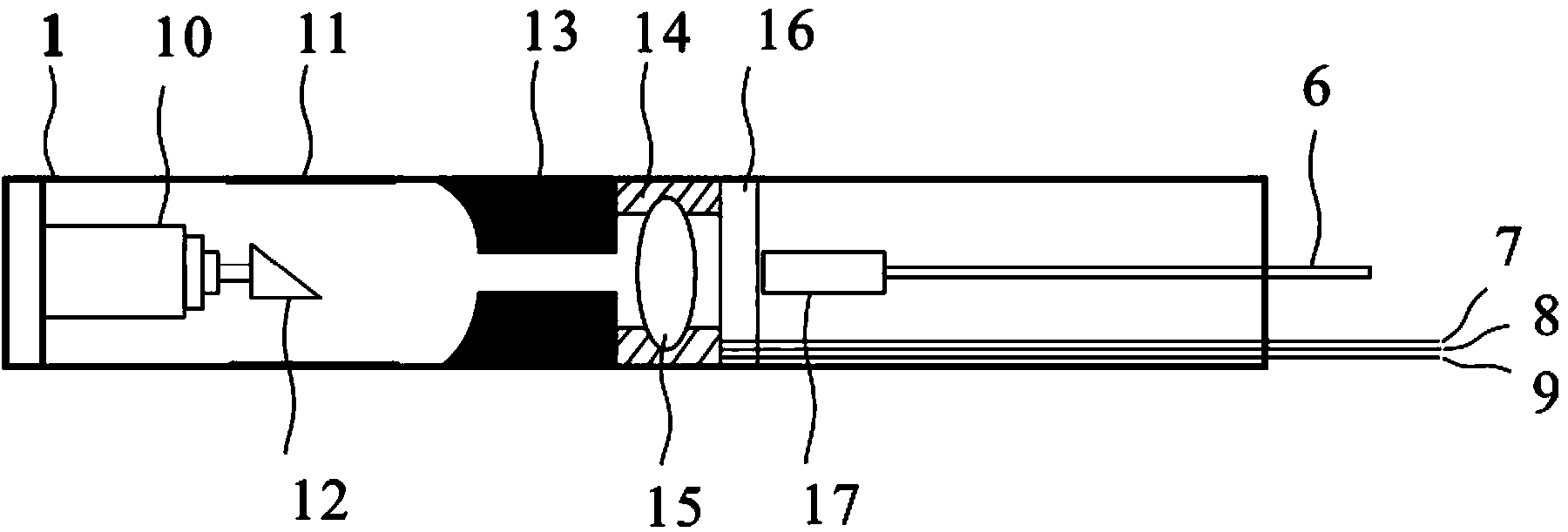

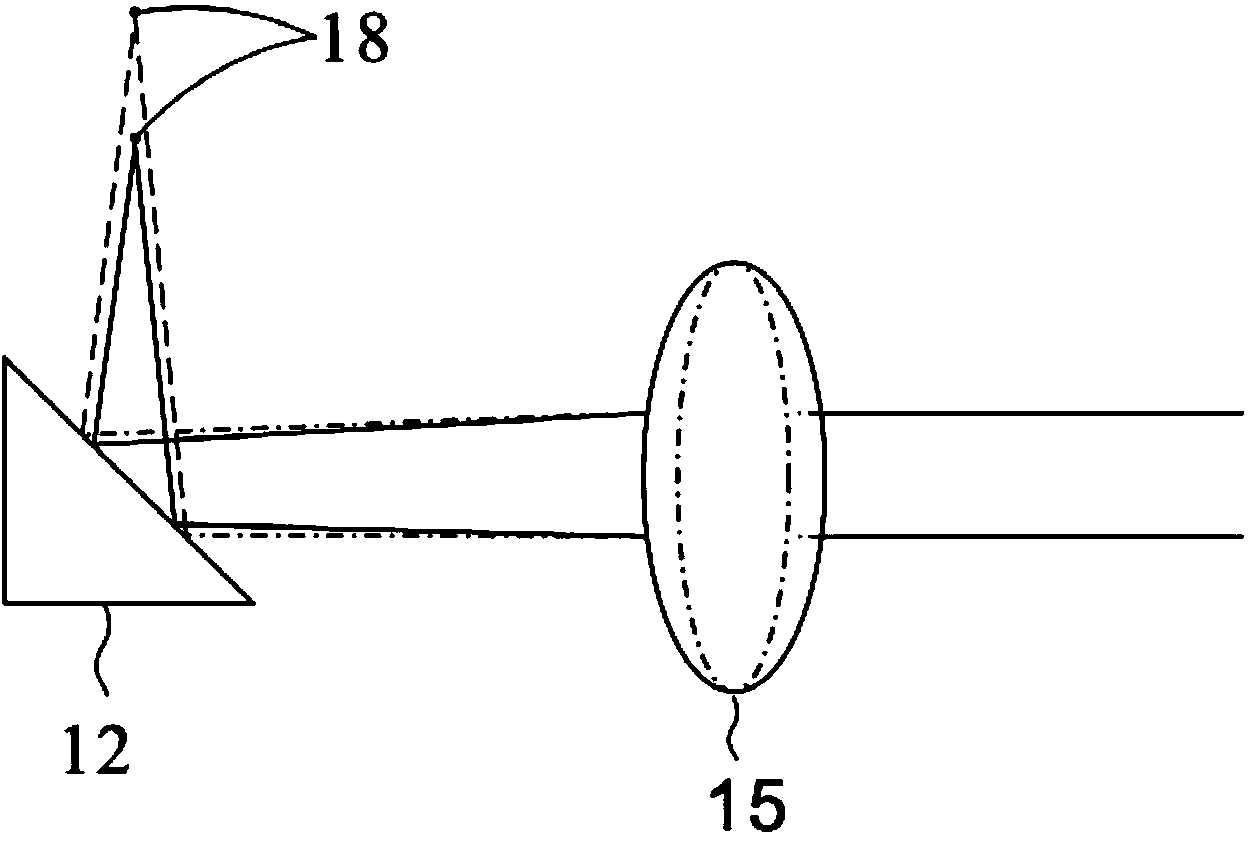

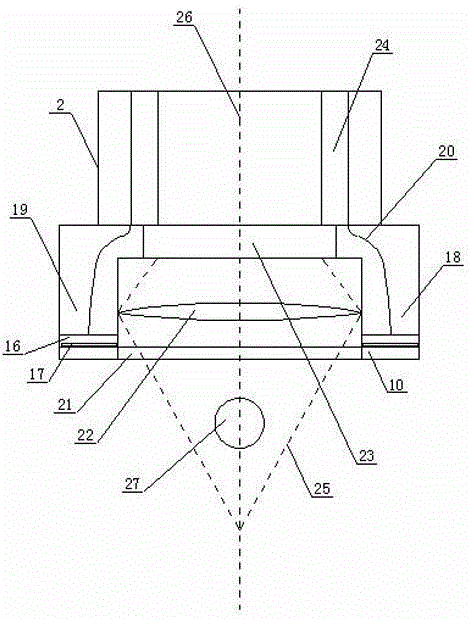

Liquid lens-based dynamic focusing photoacoustic proctoscope imaging device and method

ActiveCN103637766AHigh detection sensitivityCorrect the phenomenon of uneven resolutionEndoscopesRectum colonoscopesImaging ProceduresHigh contrast

The invention discloses a liquid lens-based dynamic focusing photoacoustic proctoscope imaging device. The device comprises a sleeve, a laser annular scanning system, a dynamic focusing system, a laser alignment system and a signal acquisition and image reconstruction system, wherein the laser annular scanning system, the dynamic focusing system and the laser alignment system which are sequentially connected through a light path are arranged in the sleeve; the sleeve is respectively connected with the signal acquisition and image reconstruction system; and high and uniform image resolution and contrast ratio in a certain range are realized, and the detection sensitivity is improved. The invention also discloses an imaging method by using the dynamic focusing photoacoustic proctoscope imaging device. The liquid lens technology is applied to the field of photoacoustic imaging, a focus drift phenomenon during annular scanning of the photoacoustic proctoscope is corrected, dynamic focusing and imaging of the photoacoustic proctoscope is realized, and high image resolution and high contrast ratio are guaranteed. The device can be widely applied to the fields of industrial inspection and medical imaging.

Owner:广州佰奥廷电子科技有限公司

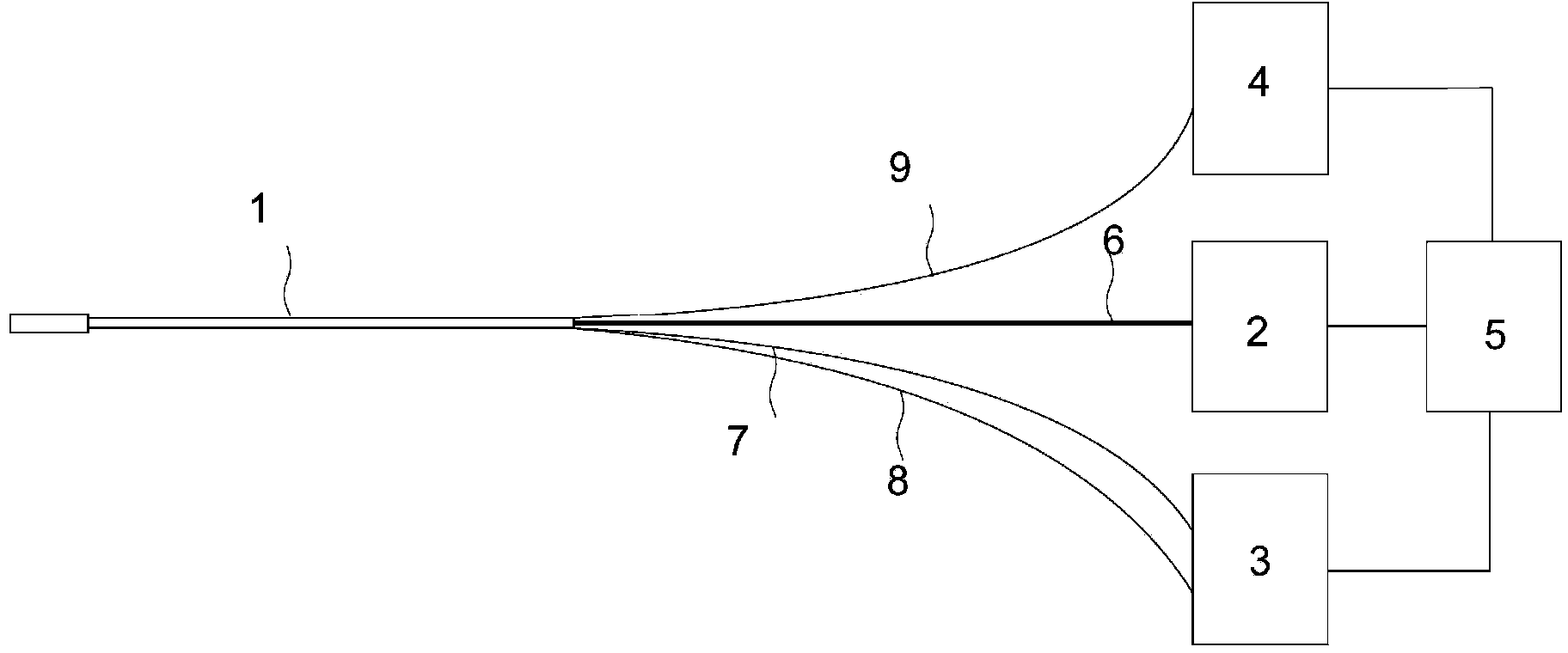

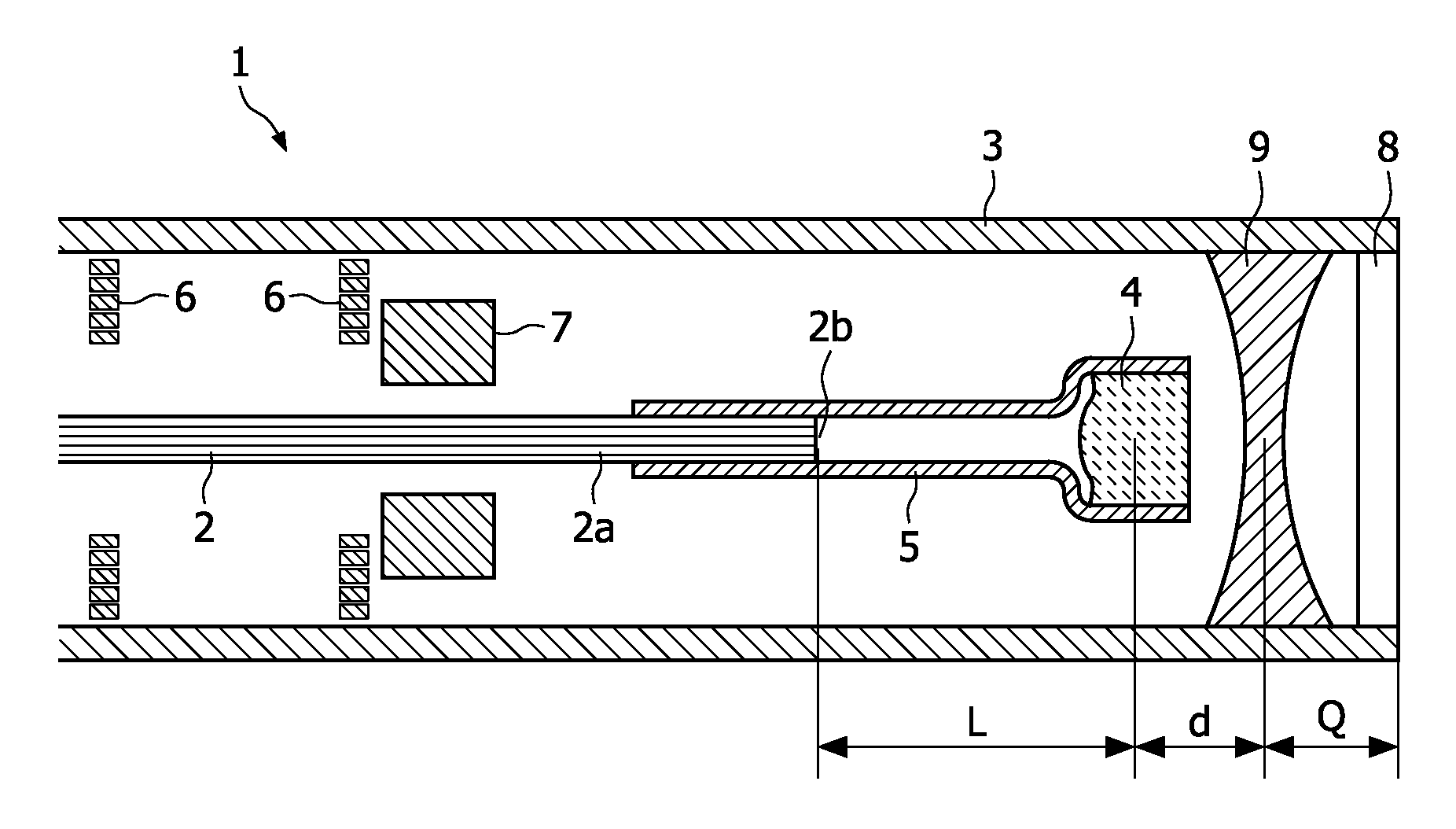

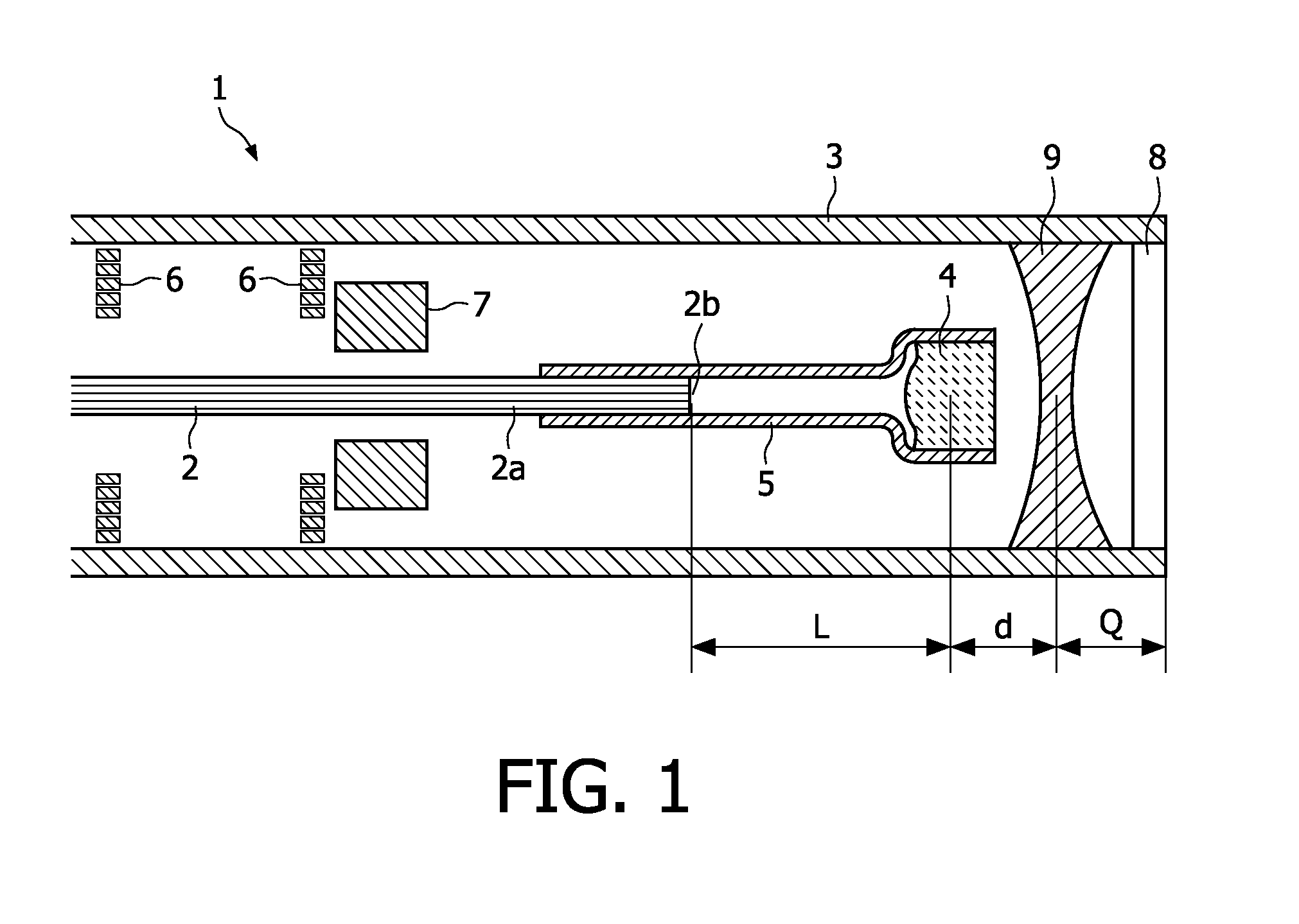

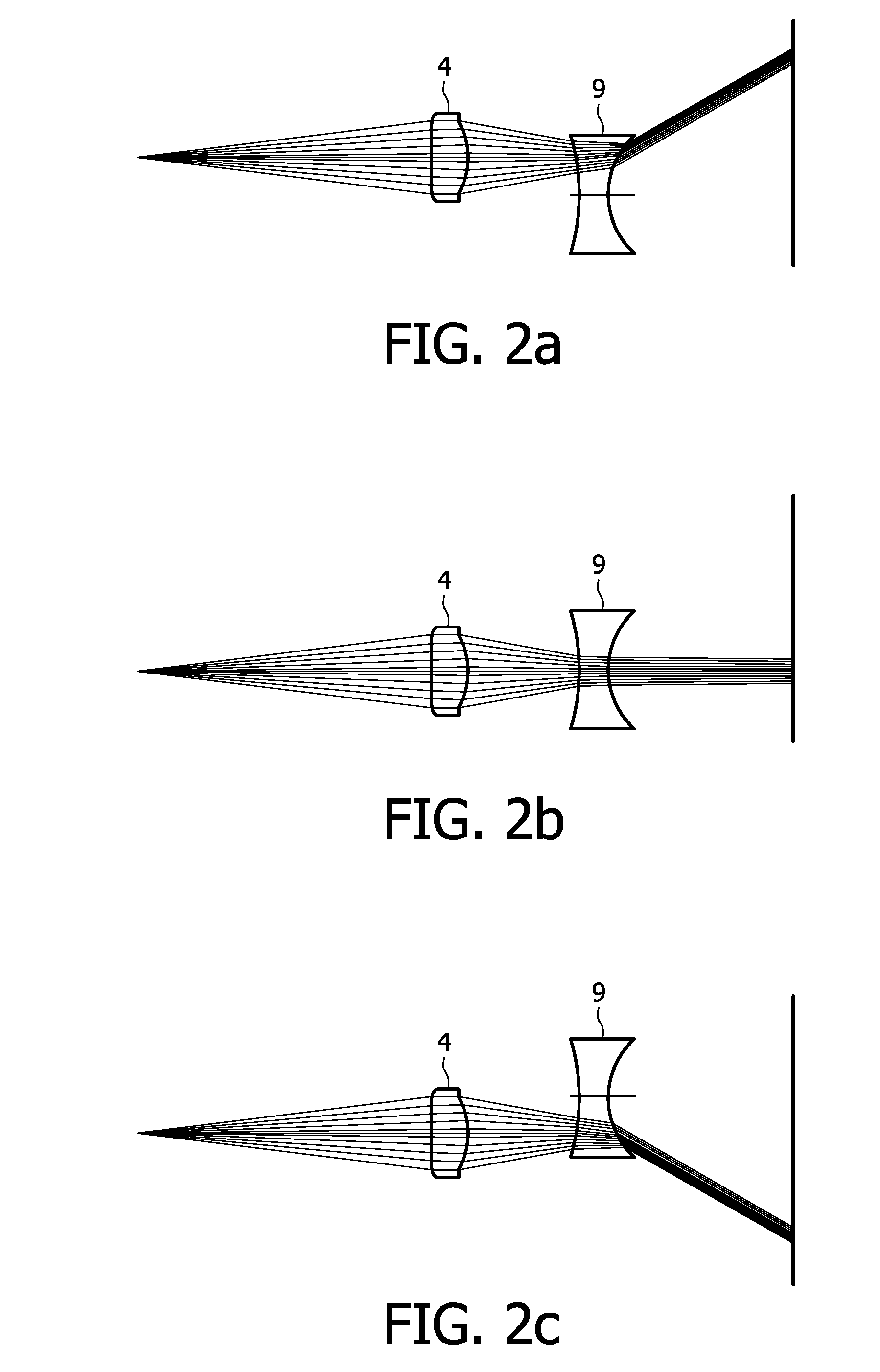

Optical fiber scanning probe

InactiveUS20110211104A1Low costImproved optical probeTelevision system detailsEndoscopesField of viewEndoscope

The invention relates to optical probes for miniature applications, e.g. medical inspections and procedures or in industrial inspections, in particular a probe applying a confocal scanning-scanning endoscope. The probe comprises an optical guide (2), a first lens system mounted (4) on a distal end portion (2A) of the optical guide for focusing light from the optical guide, actuation means (6,7) for displacing the distal end portion and the first lens system to enable optical scanning, and a second lens system (9) fixed inside the probe to receive radiation from the first lens system. The second lens system is selected to enable a deflection of radiation from the first lens system in a direction corresponding to a direction of displacement of the first lens system by the actuation means. The second lens system can be a cheap negative lens, and the invention is thereby particularly useful for increasing the field of view (FOV) cheap, disposable optical probes.

Owner:KONINKLJIJKE PHILIPS NV

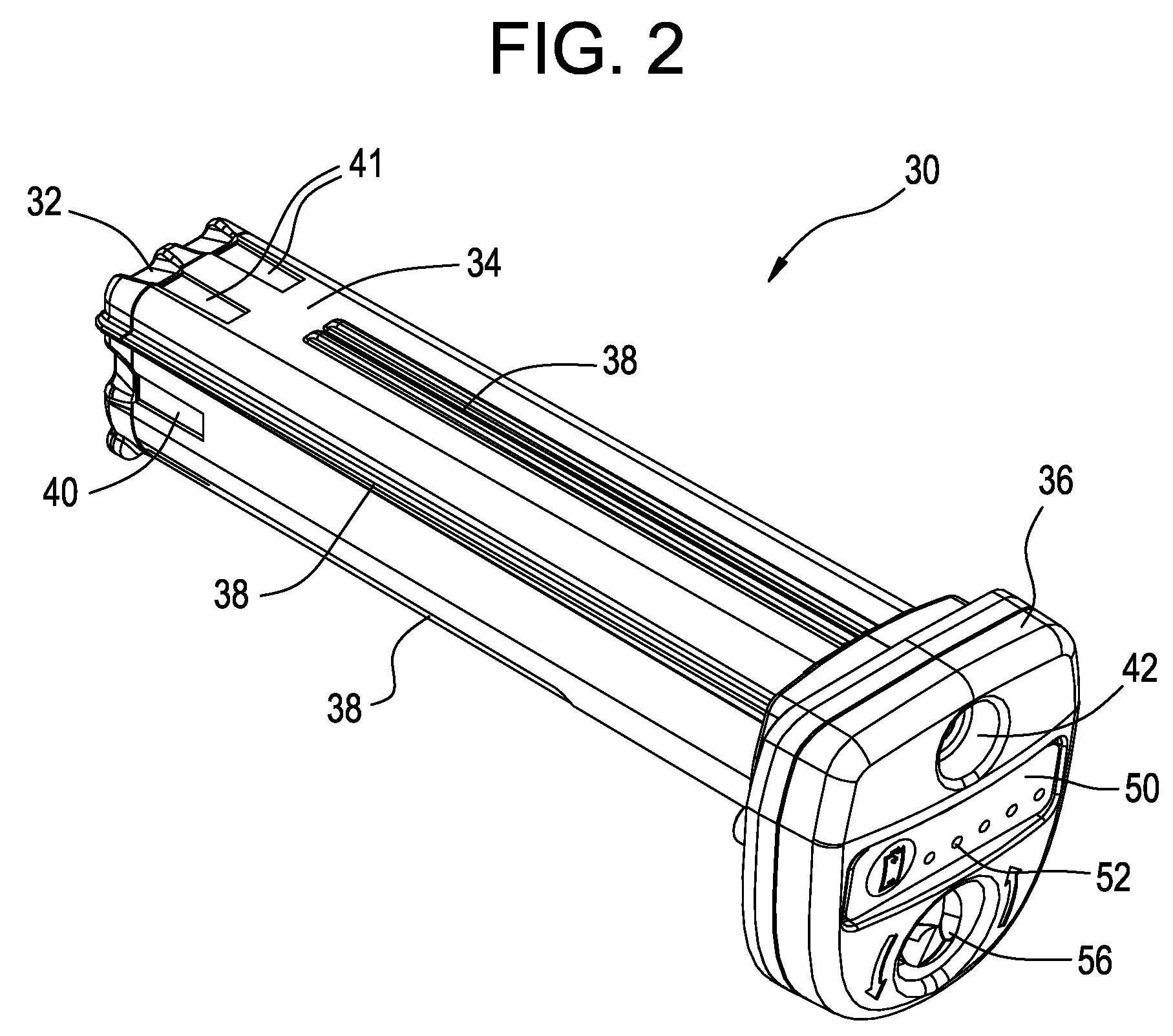

Integrated storage for industrial inspection handset

ActiveUS20090109283A1Digital data processing detailsCasings with display/control unitsIndustrial inspectionHandset

An industrial inspection handset is disclosed, comprising a connector for connecting a peripheral device to the handset, wherein the connector is oriented such that the peripheral device can extend substantially parallel to the housing surface of the handset, and a cover tethered to the handset by a first tab, wherein the cover when mounted on the housing of the handset encloses the connector and the peripheral device. In an alternative embodiment, the handset comprises a connector oriented such that the peripheral device can extend substantially perpendicular to the housing surface of the handset, and a cover tethered to the handset by a first tab and a second tab, wherein the cover when mounted on the mounting member encloses the connector. A method of replacing a cover tethered to an industrial inspection handset is also disclosed, wherein the first cover is tethered to the handset by a first tab, comprising the steps of removing the first cover from the first tab; forcing the first tab through an opening in the handset and into the interior of the handset; and tethering a second cover to the handset by inserting a second tab attached to the second cover through the opening in the handset.

Owner:GE INSPECTION TECH LP

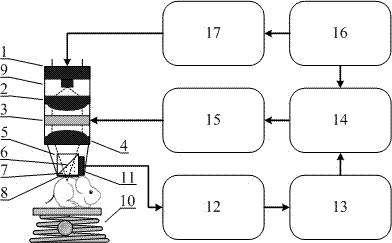

Optoacoustic and ultrasonic bimodal endoscope imaging system and imaging method

ActiveCN103976703AProcessing size is smallImprove excitationSurgeryCatheterSonificationAnnular array

The invention discloses an optoacoustic and ultrasonic bimodal endoscope imaging system. The optoacoustic and ultrasonic bimodal endoscope imaging system is composed of an endoscope lens, a light source, a controlling and processing device, an impulse voltage generator, an interface module, a cable, a display screen, a crystal oscillator circuit and a power circuit. The optoacoustic and ultrasonic bimodal endoscope imaging system can achieve endoscopic type optoacoustic and ultrasonic bimodal imaging. According to the optoacoustic and ultrasonic bimodal endoscope imaging system, a high density CMUT ring array manufactured by using surface micro fabrication technology is used, an excitation unit and a sensing unit are designed into coaxial and homocentric integrative microstructure, and integration, microminiaturization and practical performance of optoacoustic and ultrasonic excitation and sensing are achieved. The optoacoustic and ultrasonic bimodal endoscope imaging system can be widely used in fields of medical endoscopic diagnosis, jewelry identification, industrial inspection and flaw detection and the like.

Owner:JIANGXI SCI & TECH NORMAL UNIV

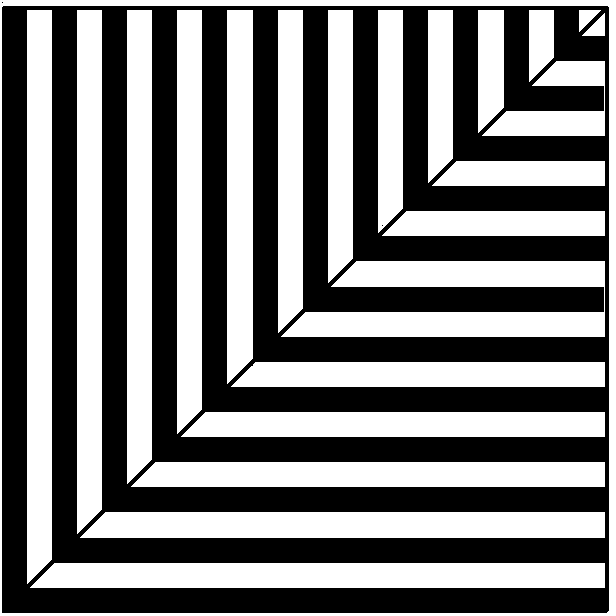

Optical resolution type photoacoustic microscope based on optical beam scanning

InactiveCN102854142AReduce volumeLow priceMaterial analysis by optical meansPhotoacoustic microscopyRapid imaging

The invention provides an optical resolution type photoacoustic microscope based on optical beam scanning. The photoacoustic microscope comprises a laser diode, a collimating lens, a multidimensional laser galvanometer, a focusing lens, a rectangular prism, a coupling liquid box, an ultrasonic coupling liquid, a film, a shell, a lifting platform, an ultrasonic sensor, a signal processing circuit, a data acquisition circuit, a computer, a galvanometer driving circuit, a clock circuit and a driving power circuit. According to the invention, miniature, inexpensive and easily maintained laser diode is applied to the field of optical resolution forward photoacoustic microscopy excitation, and the laser galvanometer is used to realize substitution of mechanical scanning by beam scanning to achieve fast imaging. The photoacoustic microscope has the advantages of portable volume, high resolution and fast imaging, and can be widely applied to photoacoustic microimaging in the fields of material detection, industrial inspection and medical image.

Owner:曾吕明

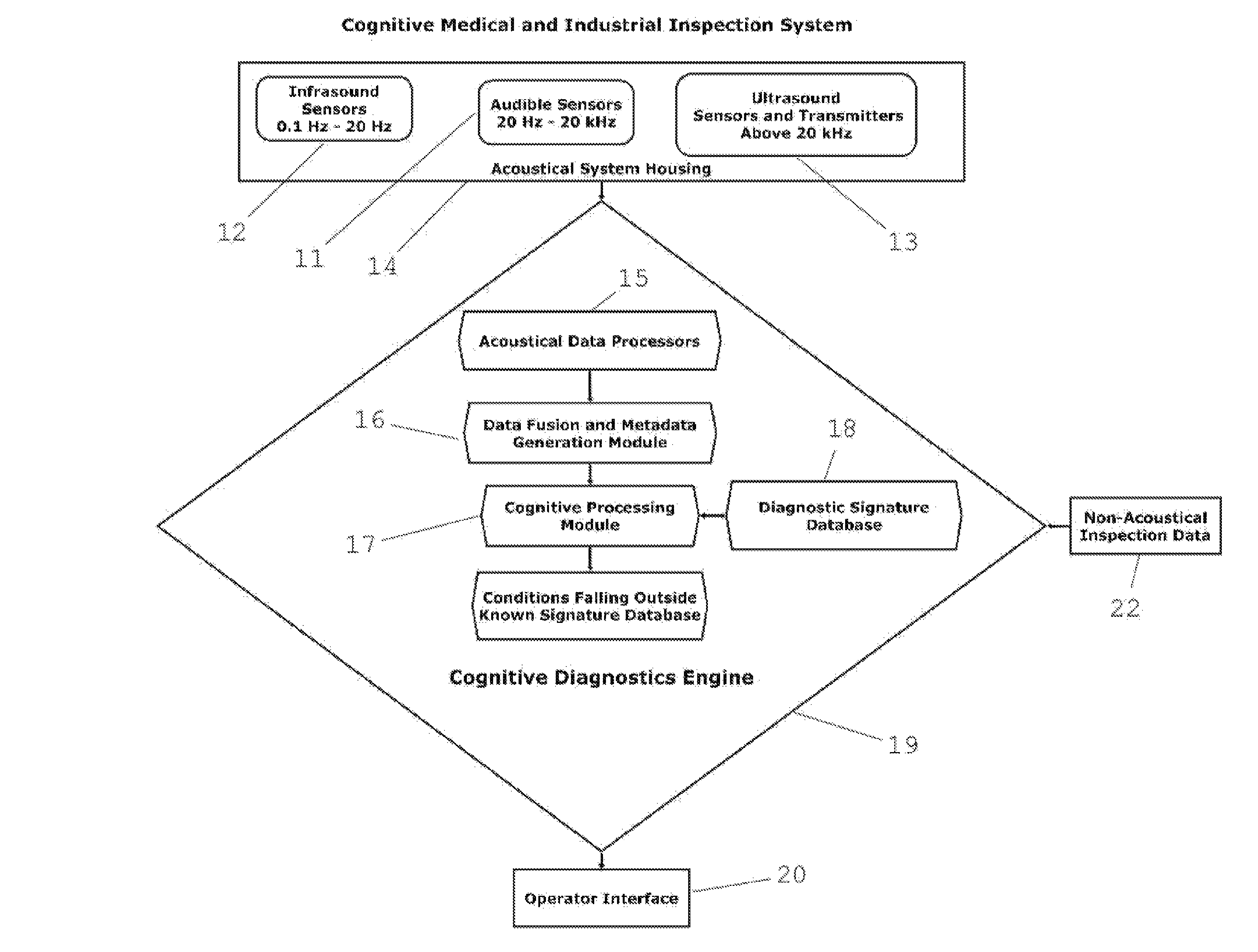

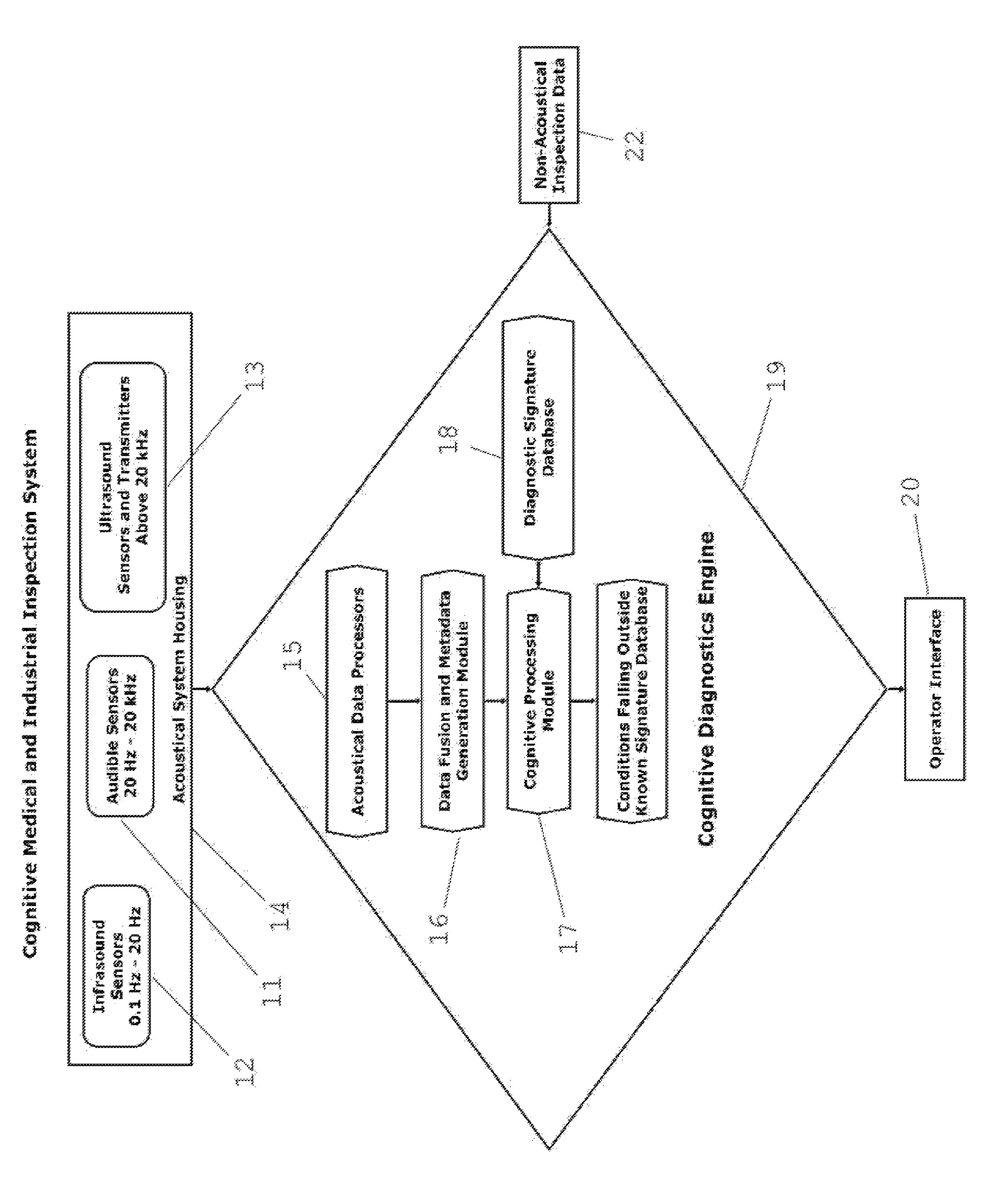

Cognitive medical and industrial inspection system and method

ActiveUS9349098B1Low costSimplifies initial inspectionMedical simulationUltrasonic/sonic/infrasonic diagnosticsGamma rayCompanion animal

The present invention relates to inspection of medical patients including, but not limited to, phonocardiography, auscultation and ultrasound medical imaging and other non-acoustical inspection techniques; and industrial non-destructive testing and evaluation of materials, structural components and machinery; and more particularly to the incorporation of cognitive artificial intelligence into an inspection system and method that utilizes cognitive mathematical techniques which emulate the cognitive processing abilities of the human brain including, but not limited to, symbolic cognitive architectures and inference process algebras, to analyze data collected from infrasound acoustical sensors (0.1 Hz-20 Hz), audible acoustical sensors (20 Hz to 20 kHz), ultrasound acoustical sensors and transmitters above 20 kHz, data collected from other non-acoustical inspection devices and systems including, but not limited to electrocardiography (EKG), computed-tomography (CT), single photon emission computed tomography (SPECT), positron emission tomography (PET), magnetic resonance imaging (MRI), electromagnetic testing (ET), magnetic particle inspection (MT or MPI), magnetic flux leakage testing (MFL), liquid penetrant, radiographic (x-ray and gamma ray), eddy-current testing, low coherence interferometry, and combinations thereof (i.e., multi-modality inspection data); fuse this data resulting in the generation of new metadata; and then utilize cognitive mathematical techniques to interpret this data against inspection signatures that characterize conditions being diagnosed. The present invention has the ability to also identify and anticipate abnormal conditions that fall outside known inspection signature patterns; and communicate the inspection results to an operator thereby simplifying the initial inspection and diagnosis for medical patients and industrial objects; minimizing false negative and false positive initial inspection results and lowering costs.

Owner:1619235 ONTARIO LTD

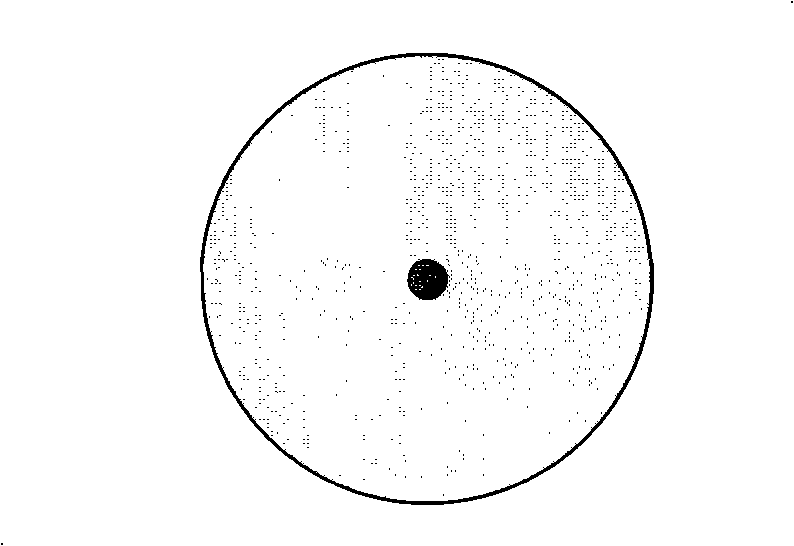

Video camera parameter calibration method by adopting single circle as marker

InactiveCN101334894ASimple and accurate determinationRealize fully automatic calibrationImage analysisUsing optical meansAutonomous Navigation SystemCalculation error

The invention relates to a calibration method for the intrinsic parameters of a camera by adopting a single circle as a calibration object; the method comprises the following steps that: first, three different images of a calibration object are shot by using a camera; then an image point location of a circular point of each image is identified; by utilizing the image point of the three groups of the circular points, projection curve equation of absolute conic is fitted; finally, all intrinsic parameters of the camera are calculated in a way linearly, including a principal point location, aspect ratio and tilt factor. The method of the invention can identify all intrinsic parameter of the camera once, and can realize automatic calibration and reduce calculation error caused by human intervention, and is particularly applicable to a non-contact type industrial inspection and an autonomous navigation system based on vision.

Owner:SHANGHAI JIAO TONG UNIV

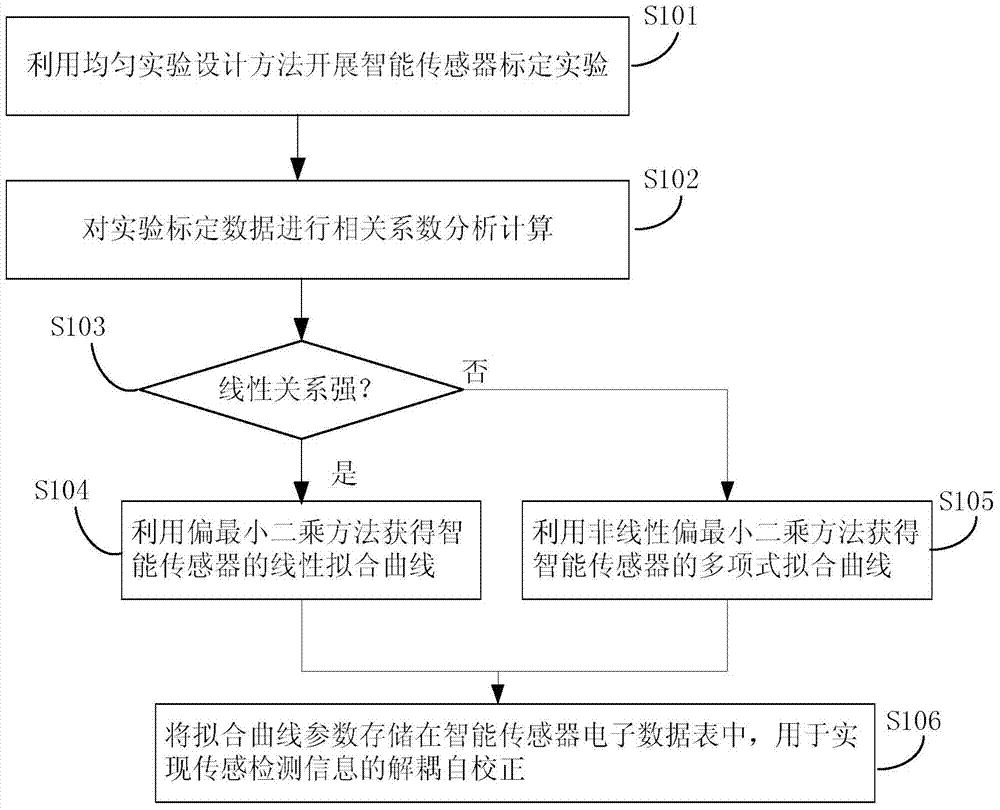

Intelligent sensor self-correcting method

InactiveCN104236615AAchieving decoupled self-calibrationDecoupled self-calibrating high-speedInstrumentsCorrelation coefficientAlgorithm

The invention discloses an intelligent sensor self-correcting method and relates to decoupling self-correcting of multi-message coupling of intelligent sensors in the field of industrial inspection. The intelligent sensor self-correcting method includes steps of carrying out experiment calibration on the intelligent sensors by a uniform experimental design method, calculating correlation coefficient between independent variables and dependent variables according to experiment calibration data; modeling the intelligent sensors according to relevancy of the independent variables and the dependent variables, utilizing the partial least absolute regression method to obtain intelligent sensor polynomial fitting curves if linear relation between the independent variables and the dependent variables is tight, and utilizing the nonlinear partial least absolution regression method to obtain intelligent sensor polynomial fitting curves if linear relation between the independent variables and the dependent variables is weak; storing curve parameters into spreadsheets of the intelligent sensors by means of the obtained fitting curves and decoupling and autocorrecting sensor detecting information by the curve parameters in the spreadsheets when the intelligent sensors work. The intelligent sensor is capable of realizing high-speed decoupling and self-correcting of multi-dimensional sensor information in the field of industrial detection.

Owner:GUANGDONG IND TECHN COLLEGE

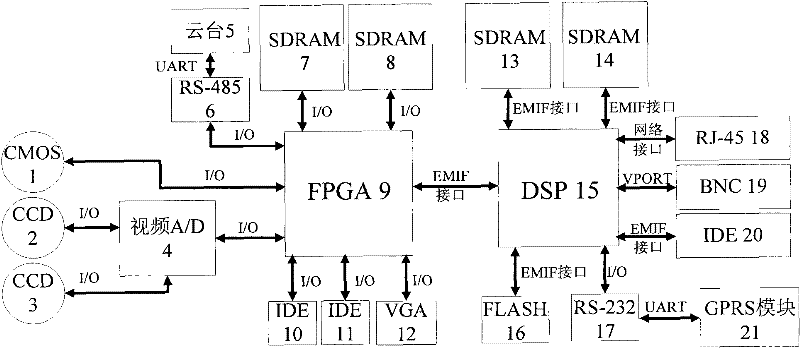

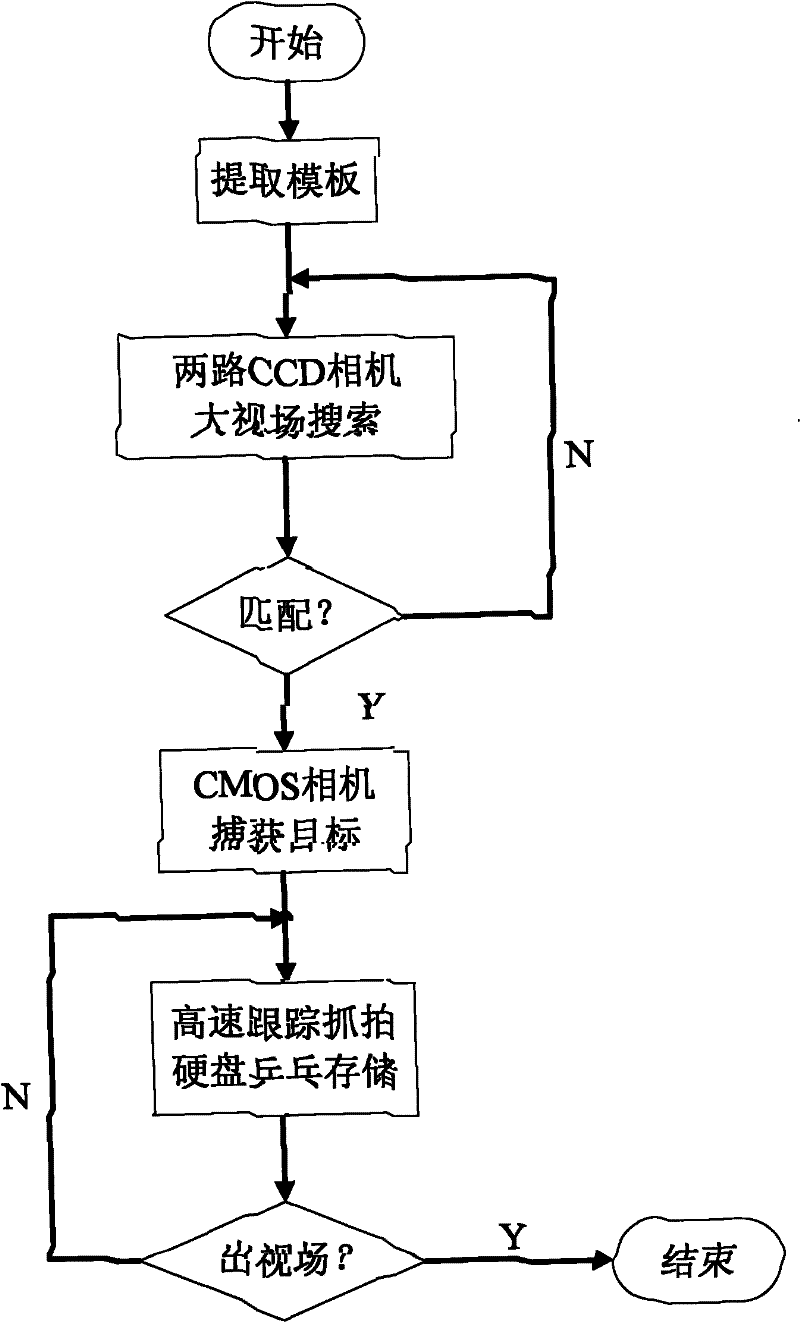

Intelligent multimode multi-view integrated camera

InactiveCN102238368AGet enoughCompact structureTelevision system detailsImage analysisFully developedData information

The invention relates to an intelligent multimode multi-view integrated camera, and provides a novel embedded visual system with multifunction and high resolution, frame frequency and performance. The camera adopts an embedded platform, simultaneously integrates two paths of charge coupled device (CCD) cameras and a path of complementary metal oxide semiconductor (CMOS) camera, and fully develops the advantages of the cameras adopting a CCD mode and a CMOS mode. The system has a compact structure and high hardware integration degree, provides standard interfaces such as an RS-232 interface, an RS-485 serial port, a network port, integrated development environment (IDE) interfaces, a video graphics array (VGA) interface, a bayonet nut connector (BNC) video interface and the like, and can access a network in a wired or general packet radio service (GPRS) / enhanced data rate for global system for mobile communication (GSM) evolution (EDGE) / third-generation (3G) wireless way and transmit video data, control information and the like. The RS-485 serial port controls holder and camera parameters and the like. VGA output and BNC output is used for local display and playback. Besides acquiring videos, the two paths of CCD cameras also can be used for binocular positioning and the acquisition of target three-dimensional depth information. The CMOS camera is used for high-speed target capturing and tracking. The IDE interface mounts a hard disk for the storage of image data information and the like. The camera can be flexibly used in the fields of traffic monitoring, military scouting, machine vision, industrial inspection and the like.

Owner:CHANGCHUN BOHONG ELECTRONICS TECH GENERAL PARTNERSHIP

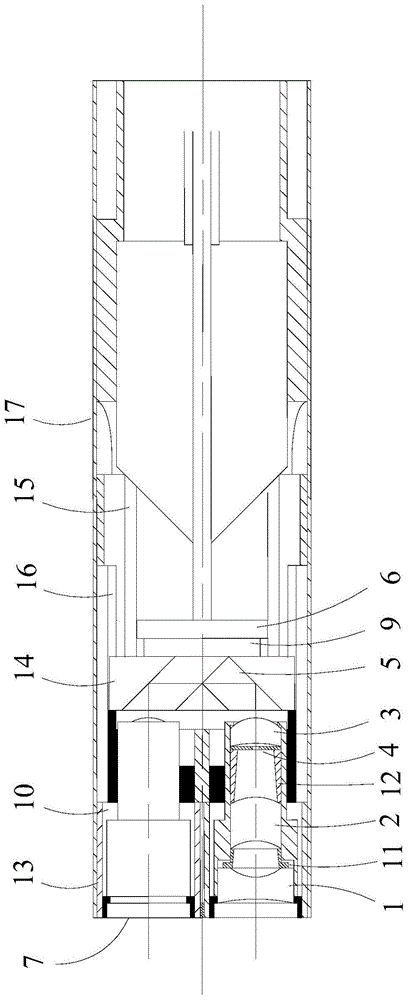

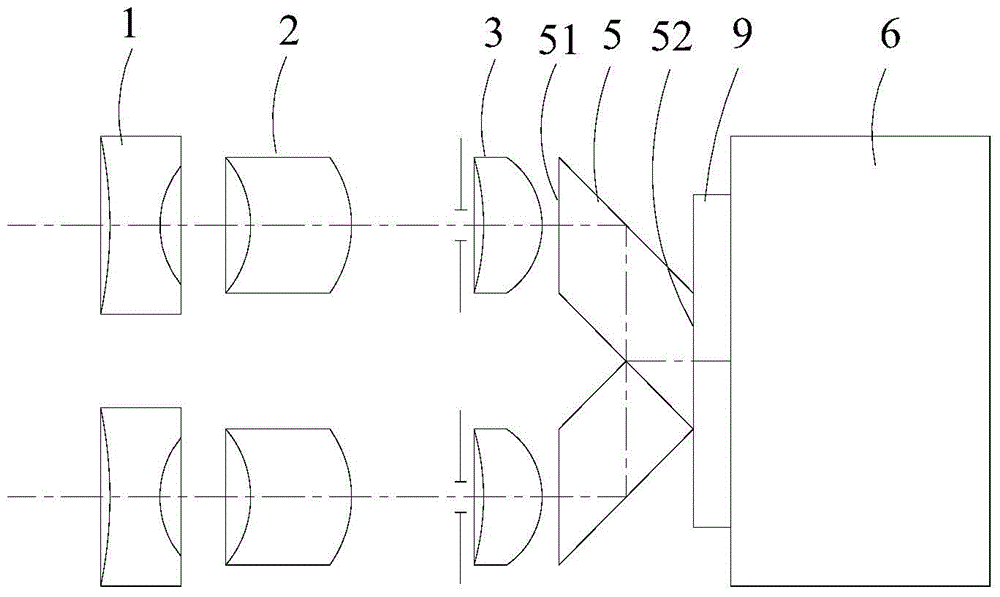

Endoscope binocular optical system with double objective lens and single image sensor

ActiveCN104656242AReduce working diameterMeet the requirements of detection in the cavityEndoscopesTelescopesGrismTarget surface

The invention is applicable to the technical field of endoscopes, and provides an endoscope binocular optical system with double objective lens and a single image sensor. The endoscope binocular optical system comprises a first optical lens set and a second optical lens set which are arranged in parallel, as well as the image sensor, wherein each of the first optical lens set and the second optical lens set comprises a first lens, a second lens, a diaphragm and a third lens which are arranged in sequence in the light incidence direction; a prism is arranged in the emergent direction of each third lens; the incidence surface and emergent surface of each prism are parallel; the image sensor is arranged in the emergent directions of the two prisms; the emergent surfaces of the two prisms are coplanar, and correspond to different areas of target surfaces of the image sensor. The invention provides an image sensor target surface partition technology, only the single image sensor is needed to be adopted, so that the working diameter of an endoscope can be effectively reduced, wider space is provided for the selection of the image sensor, the diameters of the two objective lenses are not needed to be greatly reduced, and further, the cost is greatly reduced; the system is a superfine endoscope optical system with relatively high cost performance, and can be applied to the fields of industrial inspection, medical treatment and the like.

Owner:SHENZHEN INST OF ADVANCED TECH

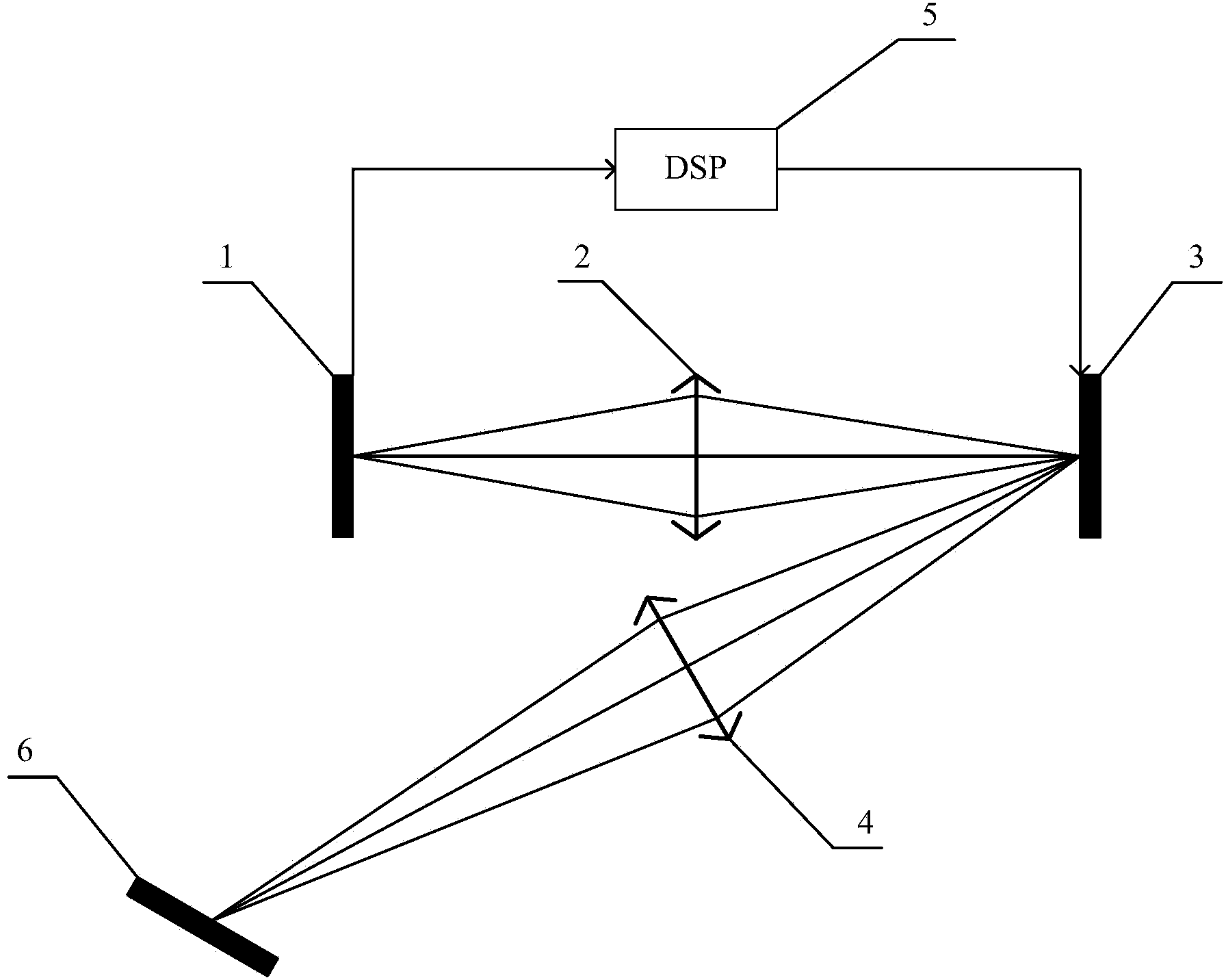

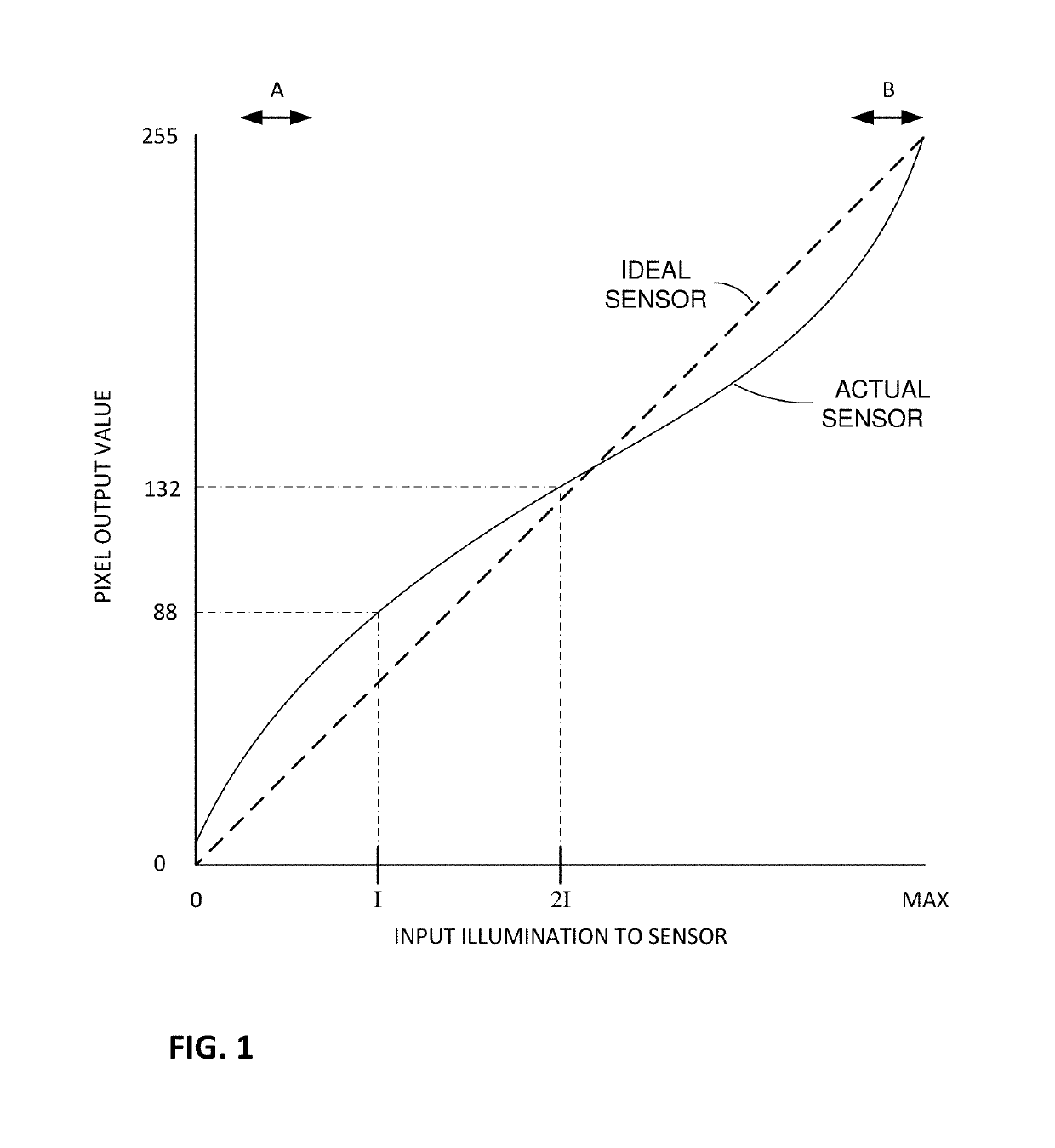

DMD-based imaging pre-processing device and method

InactiveCN103716538AImprove dynamic rangeRealize the processing functionTelevision system detailsColor television detailsImaging qualityVisual perception

The invention discloses a DMD-based imaging pre-processing device and a DMD-based pre-imaging processing method. The DMD-based pre-imaging processing device comprises a CCD, a first lens group, a DMD, a second lens group, a DSP and an object space working surface. Spatial one-to-one correspondence between micro mirror-image elements in the DMD and CCD pixels is realized, and coordinate corresponding relation imaging of the CCD and the DMD and corresponding relation imaging of the DMD and the object space working surface are performed, and therefore, the pre-imaging processing device can process incident light before imaging. According to the DMD-based imaging pre-processing device and method of the invention, the focus of the work of image processing is shifted from post-imaging to an optical path of pre-imaging; and corresponding imaging of the CCD and the DMD is utilized, such that the gray range index of an imaging gray histogram can be increased, and therefore, the dynamic range of an imaging system can be expanded. With the DMD-based imaging pre-processing device and method of invention adopted, defects in environmental lighting and a field of view can be eliminated, and imaging quality and visual expressivity of an object can be improved. The DMD-based imaging pre-processing device and method of the invention can be widely applied in fields such as industrial inspection, medical imaging and astronomical observation.

Owner:TIANJIN UNIV

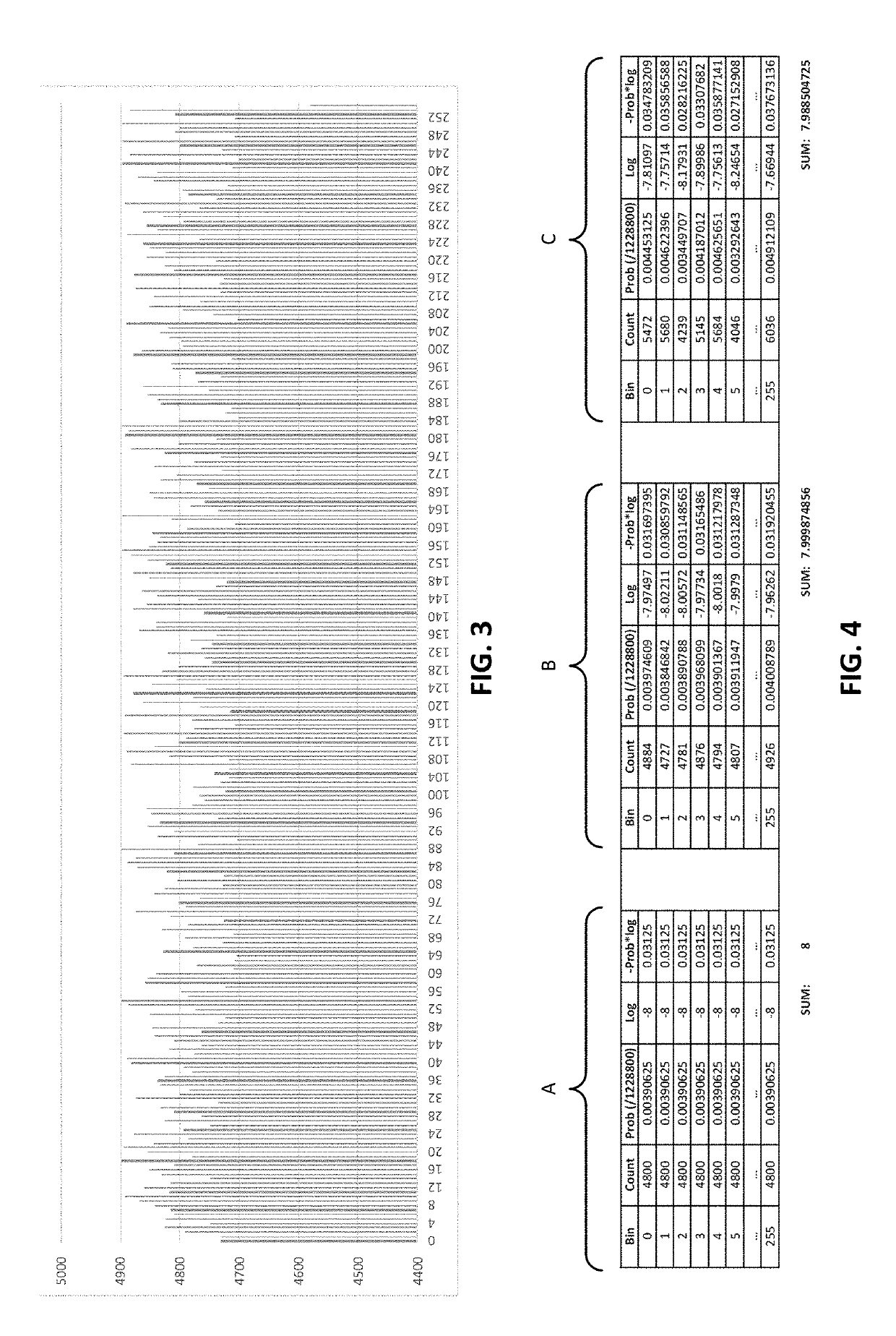

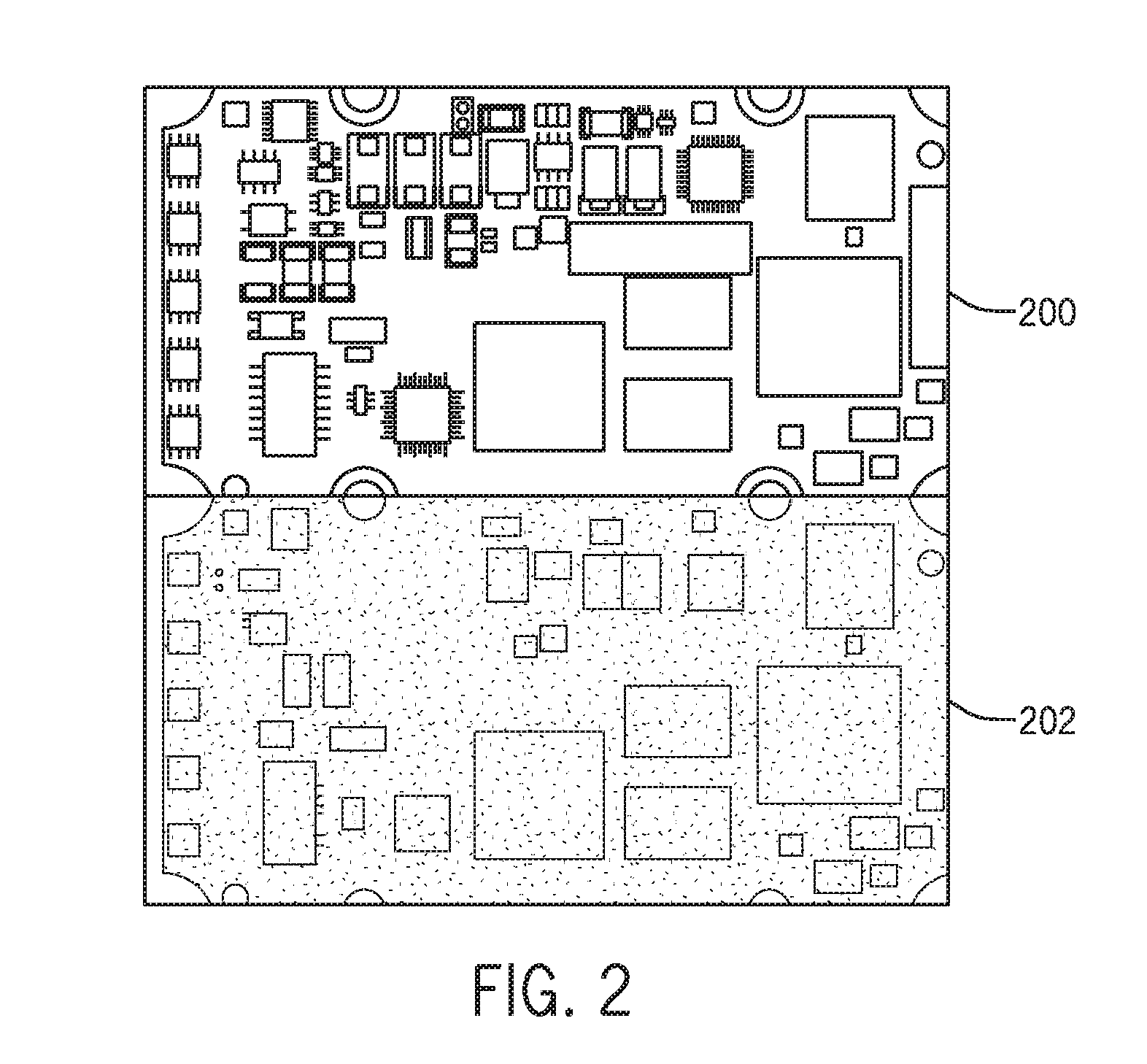

Methods and arrangements for configuring industrial inspection systems

ActiveUS10593007B1Easy to detectImage enhancementMaterial analysis by optical meansComputer graphics (images)Engineering

In computer vision systems that need to decode machine-readable indicia from captured imagery, it is critical to select imaging parameters (e.g., exposure interval, exposure aperture, camera gain, intensity and duration of supplemental illumination) that best allow detection of subtle features from imagery. In illustrative embodiments, a Shannon entropy metric or a KL divergence metric is used to guide selection of an optimal set of imaging parameters. In accordance with other aspects of the technology, different strategies identify which spatial locations within captured imagery should be successively examined for machine readable indicia, in order to have a greatest likelihood of success, within a smallest interval of time. A great variety of other features and arrangements are also detailed.

Owner:DIGIMARC CORP

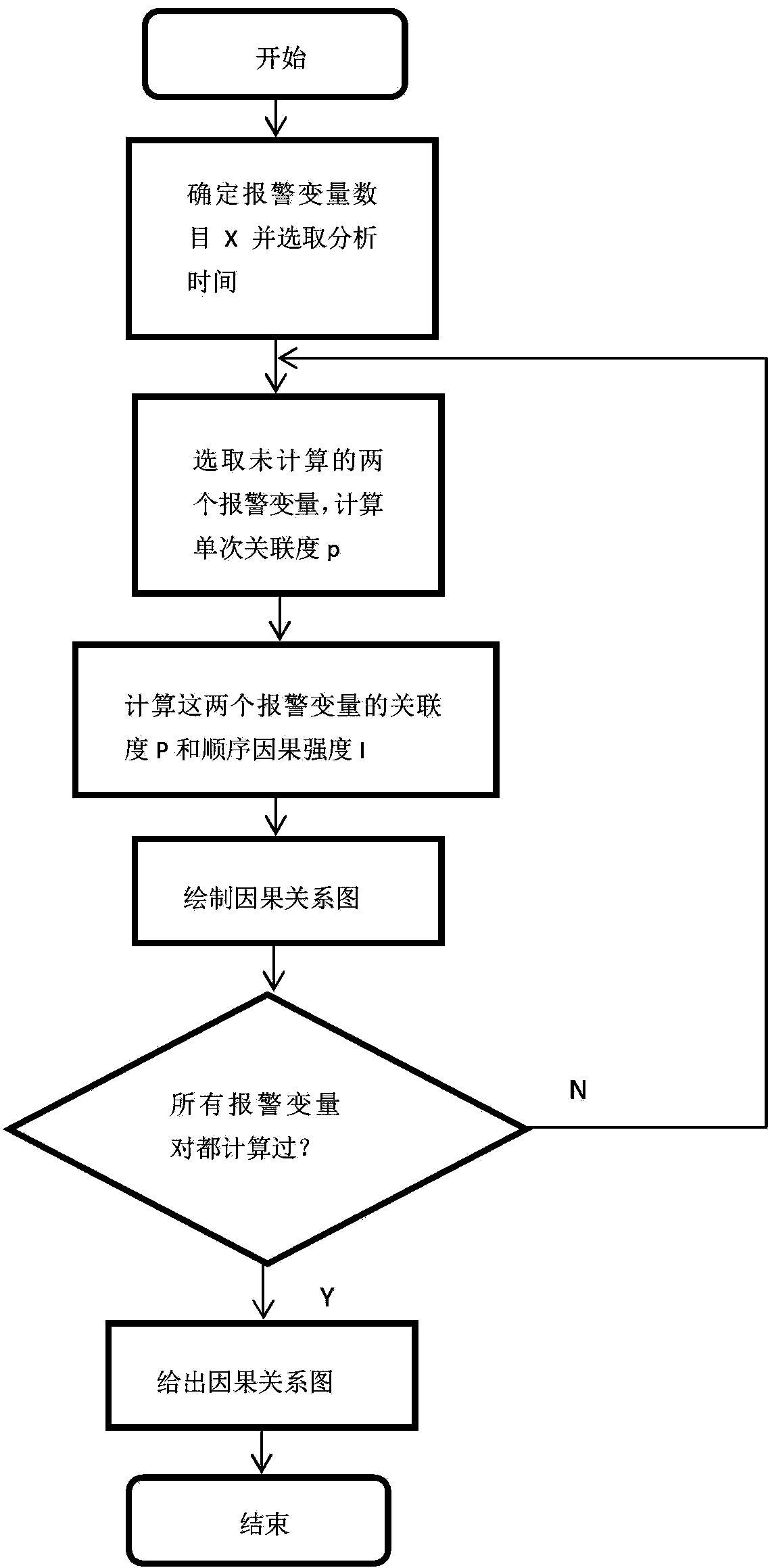

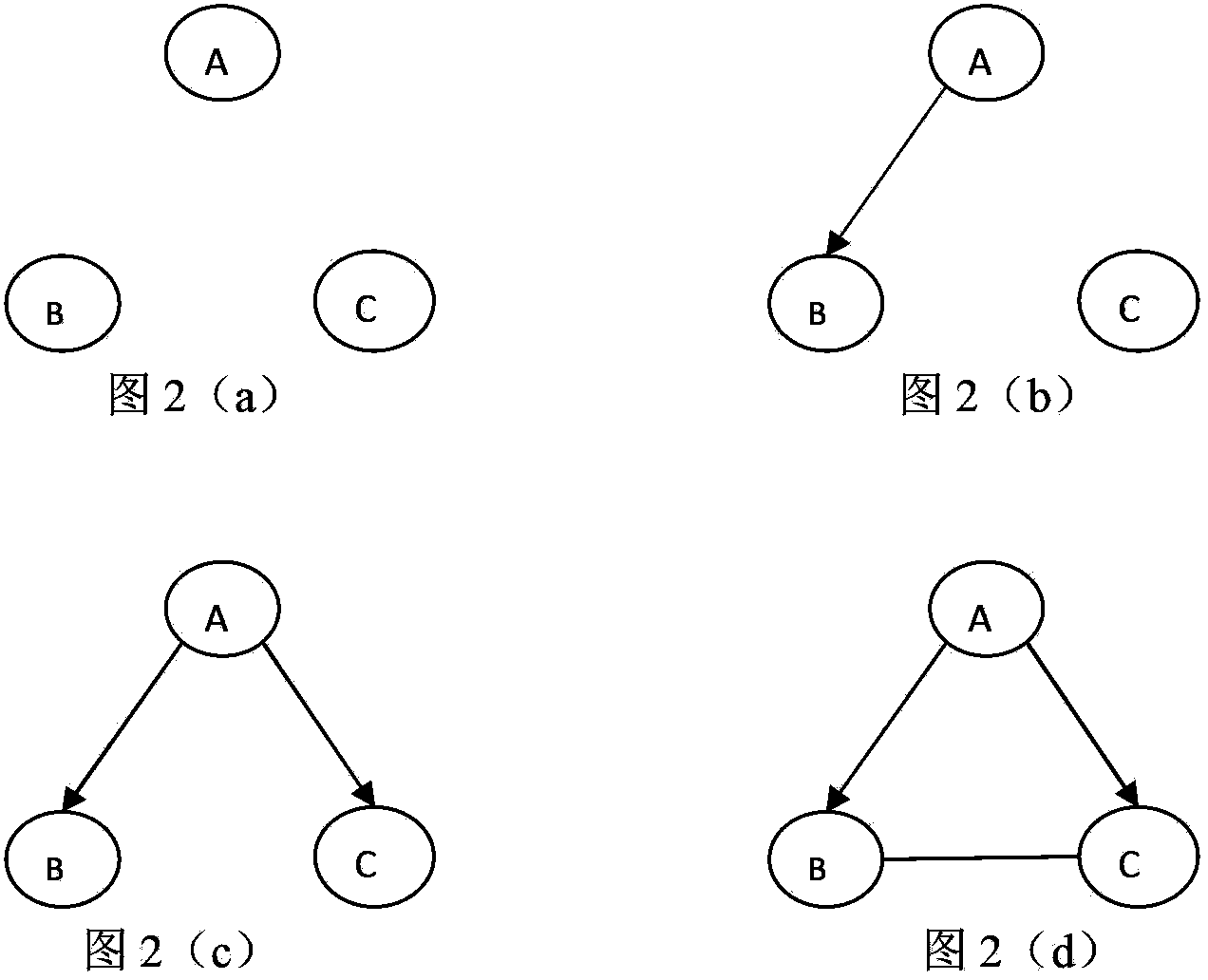

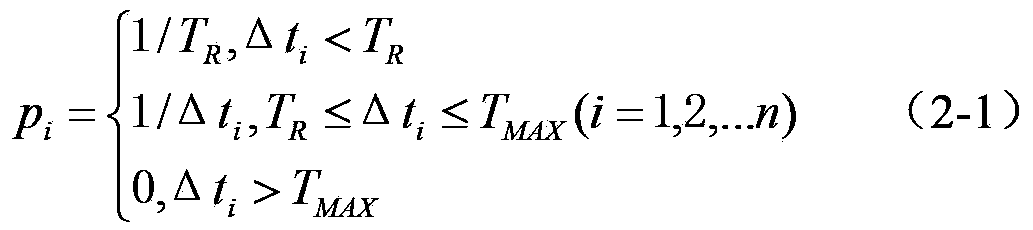

Relevant alarm identification method based on data extraction

The invention relates to a relevant alarm identification method based on data extraction, and belongs to the technical field of industrial inspection and alarm technologies. The method comprises the steps that the number of alarm variables in a detected system is determined, and alarm time of each alarm variable is monitored and recorded; a causal relationship topology graph with an independent alarm variable as the node is drawn, namely, a period of time is firstly selected, whether two alarm variables are mutually related or not is determined according to the alarm time of the two alarm variables; regarding to all alarm variable pairs which are not calculated in the detected system, association degree and causal strength between each alarm variable pair are acquired, and the causal graph is supplemented to be complete according to the calculation result. The alarm causal graph, within a period of time, of a system can be acquired through the causal strength, between every two alarm variables, given by the bidirectional association degree, if the causal strength exceeds a contain threshold value, a user can determine that two alarm signals are related, and therefore operation efficiency is improved.

Owner:TSINGHUA UNIV

Systems and method for robotic industrial inspection system

ActiveUS20190137995A1Web data indexingEncryption apparatus with shift registers/memoriesData transmissionTico Robot

An asset inspection system includes a robot and a server. The server receives a request for data from the robot, wherein the requested data comprises an algorithm, locates the requested data in a database stored on the server, encrypts the requested data, and transmits the requested data to the robot. The robot is configured to collect inspection data corresponding to an asset based at least in part on the requested data and transmit the collected inspection data to the server.

Owner:GENERAL ELECTRIC CO

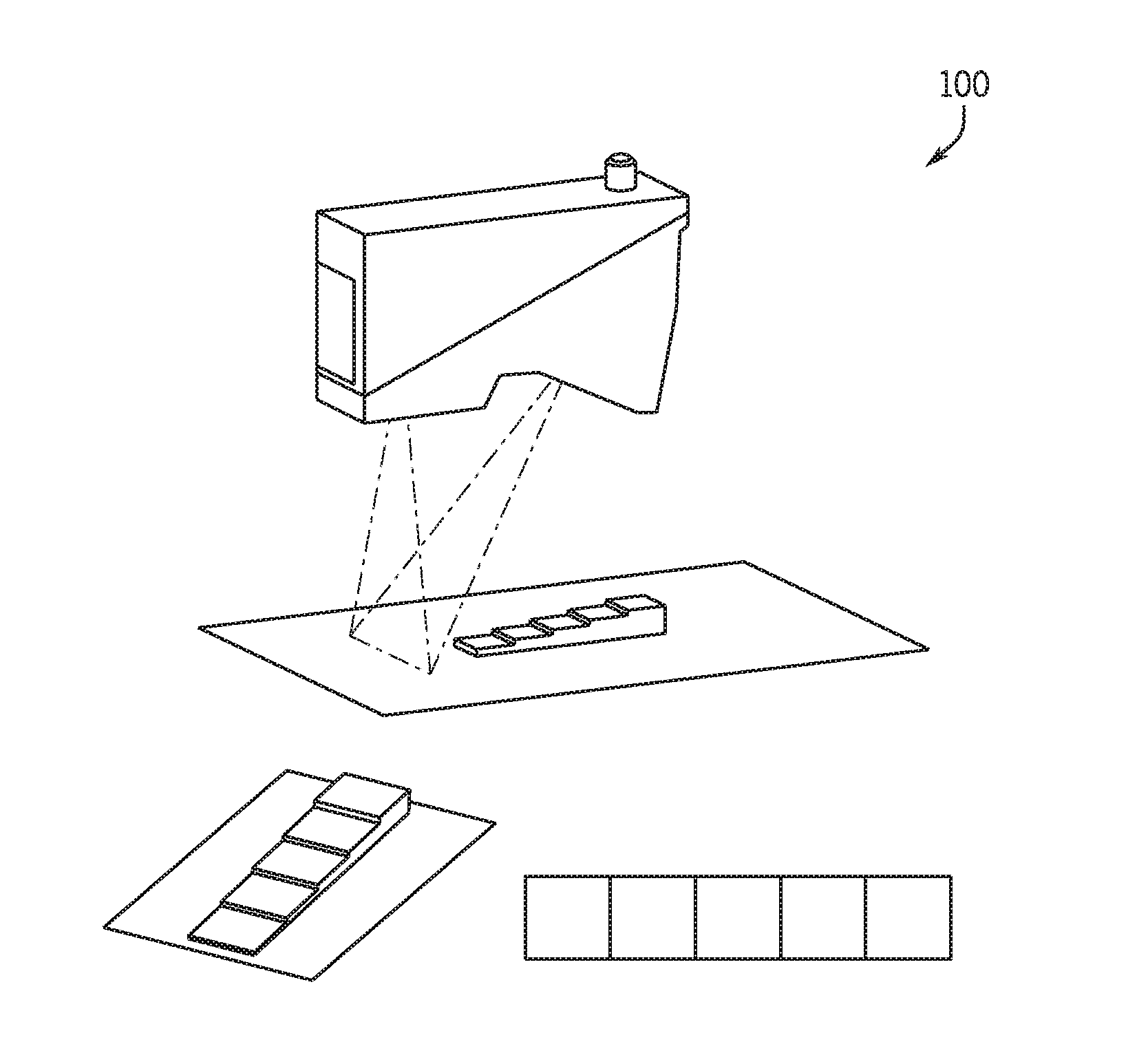

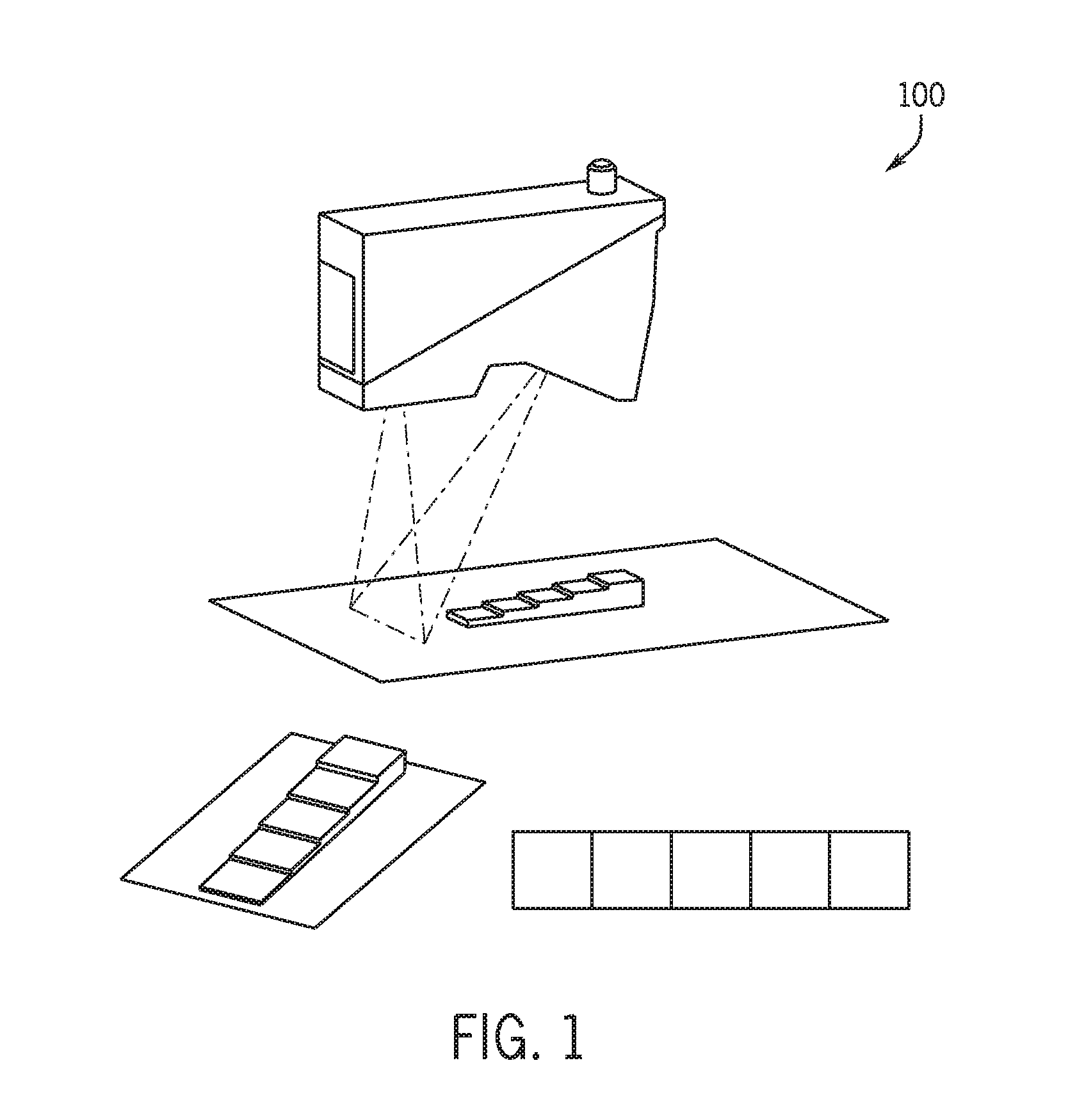

Using 3D vision for automated industrial inspection

ActiveUS20160379351A1Weight moreLose weightImage enhancementImage analysisVision inspectionVisual perception

A system and method for three dimensional (3D) vision inspection using a 3D vision system. The system and method comprising acquiring at least one 3D image of a 3D object using the 3D vision system, using the 3D vision system; extracting a 3D visible runtime mask of the 3D image; using the 3D vision system, comparing the 3D runtime visible mask to a 3D reference visible mask; and, using the 3D vision system, determining if a difference of pixels exists between the 3D runtime visible mask and the 3D reference visible mask.

Owner:COGNEX CORP

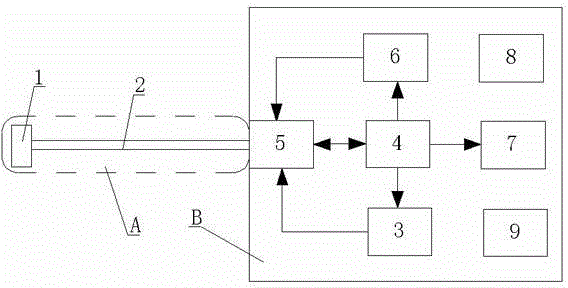

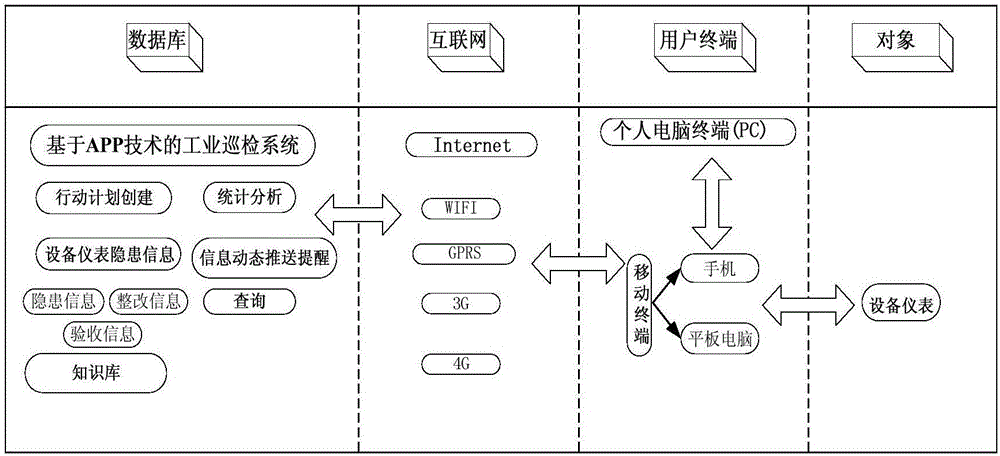

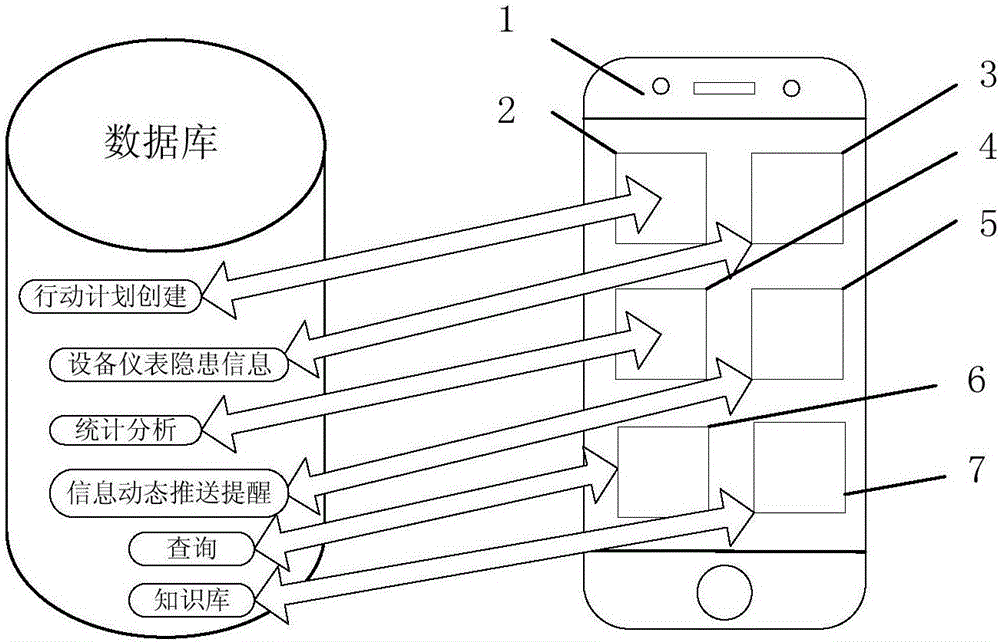

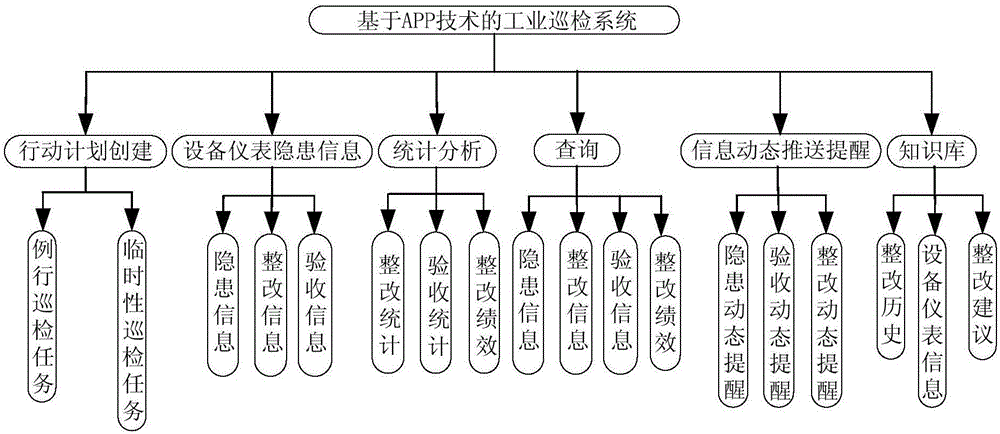

APP technology based industrial inspection system

InactiveCN106408197APerformance appraisal saves time and effortImprove management efficiencyResourcesSpecial data processing applicationsProgram planningAction plan

The invention relates to an APP technology based industrial inspection system which is based on the mobile internet and APP technology to realize the mobile management and control over on-the-spot equipment and instruments. The system comprises the following steps: action plan creating, instrument and equipment hidden hazard recording, hidden hazard modifying process recording, hidden hazard and modification state pushing, modification inquiring, modification statistics, modification evaluation performance statistics, equipment and instrument inquiring, spare component management and knowledge database function realizing. According to the invention, it is possible to rapidly and effectively solve the problems that on-the-spot hidden hazard cannot be instantly reported; that the modification process is hard to trace back; that the equipment and instrument information is incomplete and that the spare components are hard to manage. Therefore, in the end, the hidden hazard in equipment and instrument can be recorded on the spot and reported. The entire modification process can be tracked. The hidden hazard of the equipment and instrument can be predicted so that people can know in advance. The evaluation performance of a person can be done in a more effort saving manner. Therefore, the management efficiency of the factory is obviously increased, the operation cost is reduced and long term safe and stable production can be achieved.

Owner:上海异工同智信息科技有限公司

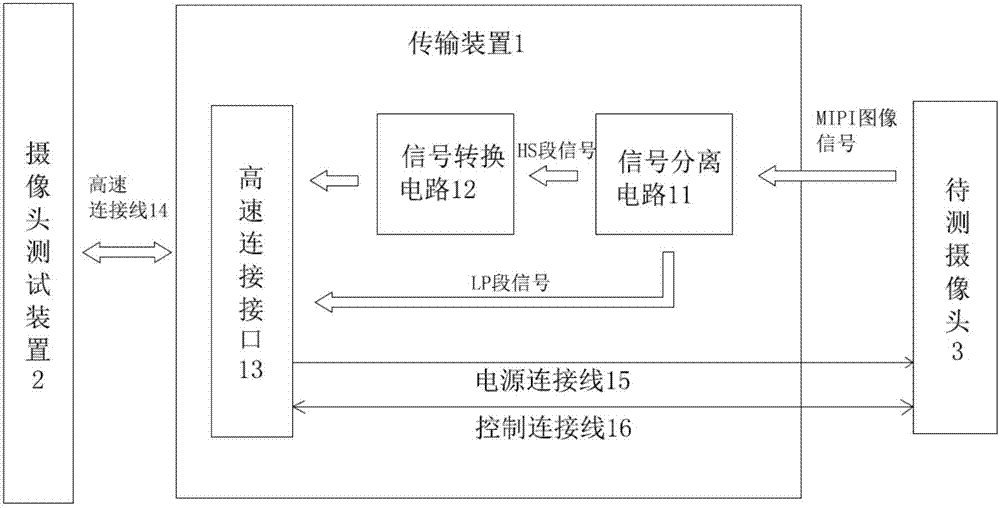

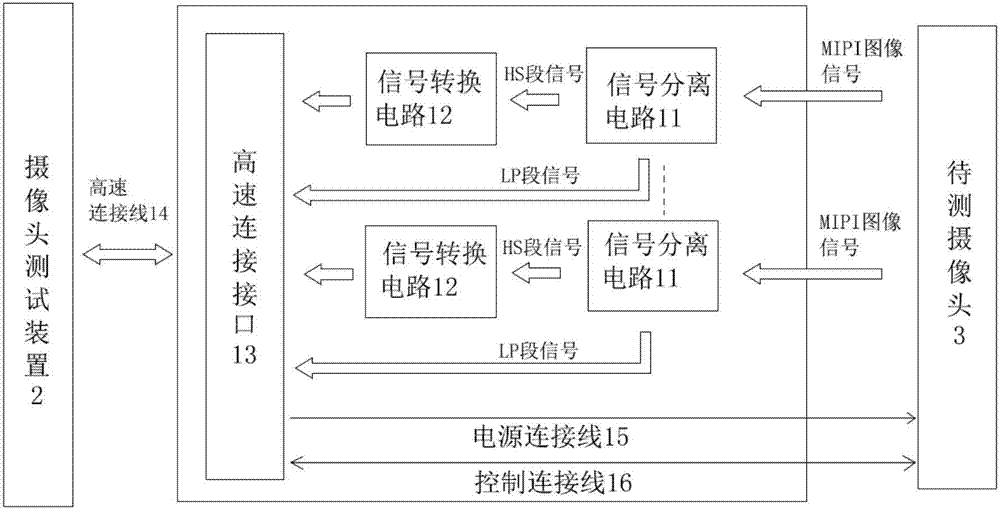

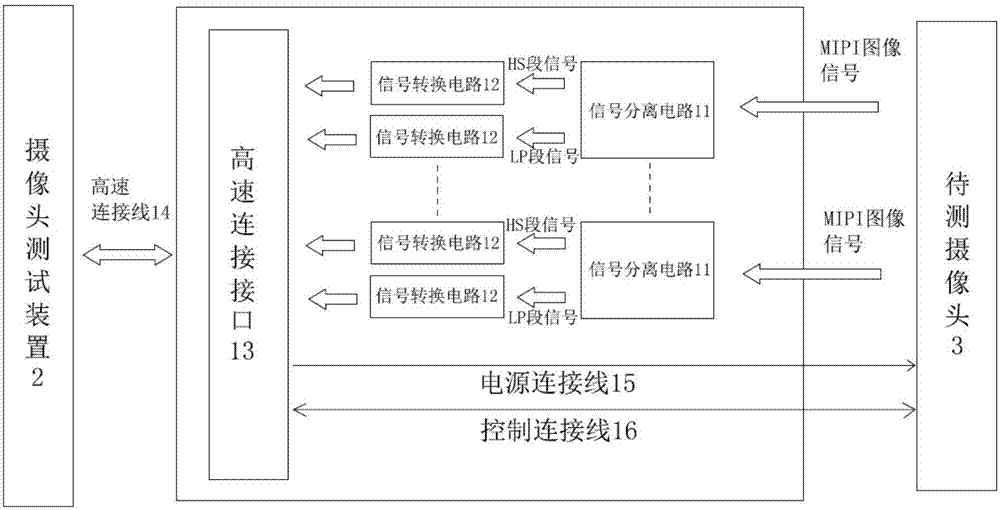

System and method for long-distance transmission of MIPI camera signals

PendingCN107371017AResolve Signal SkewFix jitterTelevision system detailsColor television detailsHigh frame rateControl signal

The invention relates to a system and a method for long-distance transmission of MIPI (Mobile Industry Processor Interface) camera signals. A transmission device is arranged between a camera test device and a camera under test. The camera test device is connected with the transmission device through a high-speed connecting line. The camera under test is connected with a signal separation circuit and a signal conversion circuit in sequence. The camera under test is connected with the power signal of the camera test device through a power connecting line, and transmits the control signal of the camera test device through a control connecting line. The control signal is used to configure the parameters of the camera under test. The signal offset, jitter, attenuation and distortion problem caused by long transmission distance and the weak anti-interference ability of MIPI image signals during signal transmission between the camera under test and the camera test device is solved. The camera test device can detect a high-performance MIPI camera over a long distance under large data volume and high frame rate. Industrial inspection of cameras is facilitated.

Owner:SHENZHEN DOTHINKEY TECH

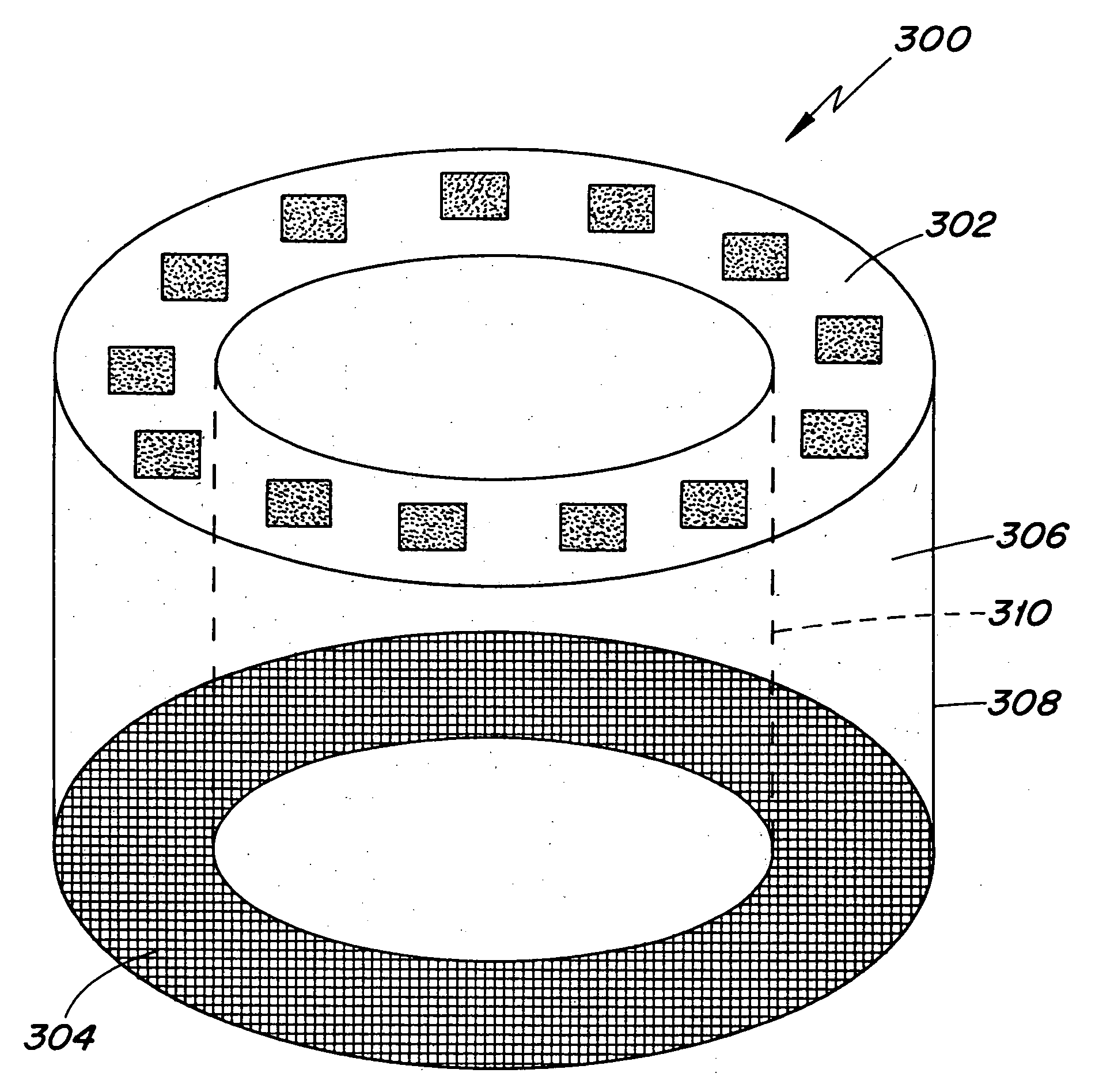

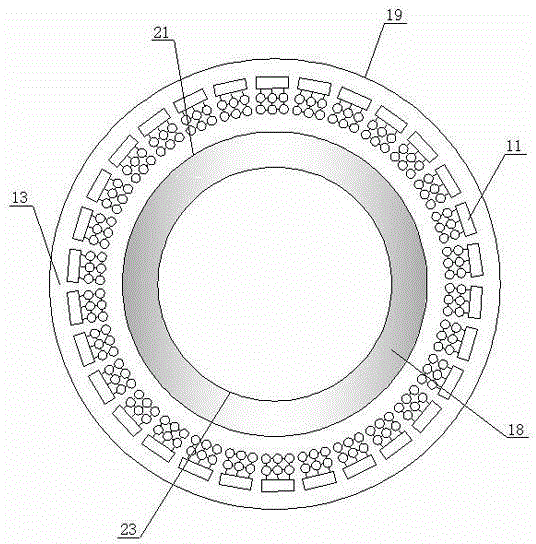

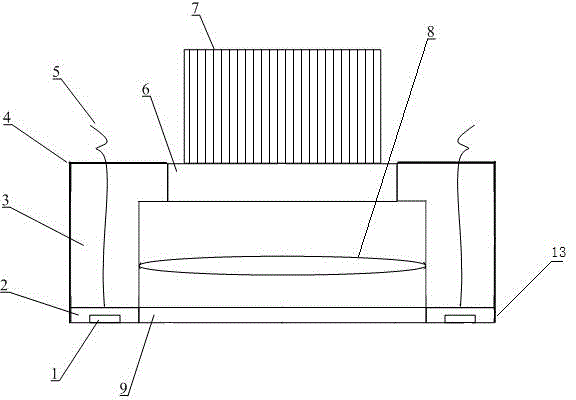

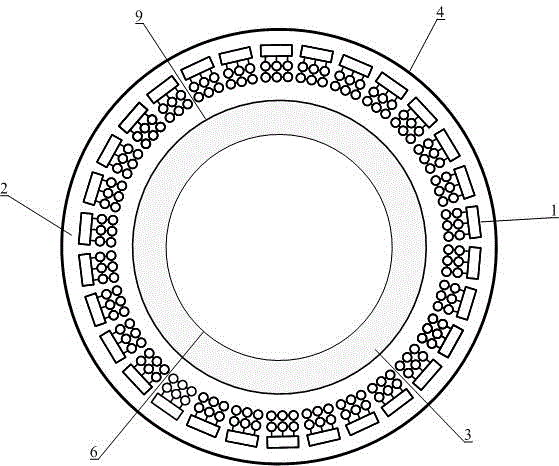

CMUT (Capacitive Micro-machined Ultrasonic Transducer) annular array based micro-photoacoustic transducer

InactiveCN103976743AReduce volumeIncrease array densityOrgan movement/changes detectionSurgeryMicro structureUltrasonic sensor

The invention discloses a CMUT (Capacitive Micro-machined Ultrasonic Transducer) annular array based micro-photoacoustic transducer. The CMUT annular array based micro-photoacoustic transducer comprises an optical fiber head, a lens, a CMUT annular array probe, a CMUT array element and a light transmitting protective film. The nondestructive photoacoustic excitation and transducing integrated micro-structure is achieved and the CMUT annular array based micro-photoacoustic transducer can be widely applied to the fields of blood sugar and blood oxygen detection, brain damage diagnoses, breast cancer censuses, endoscopic type medical imaging, industrial inspection and detection and the like.

Owner:JIANGXI SCI & TECH NORMAL UNIV

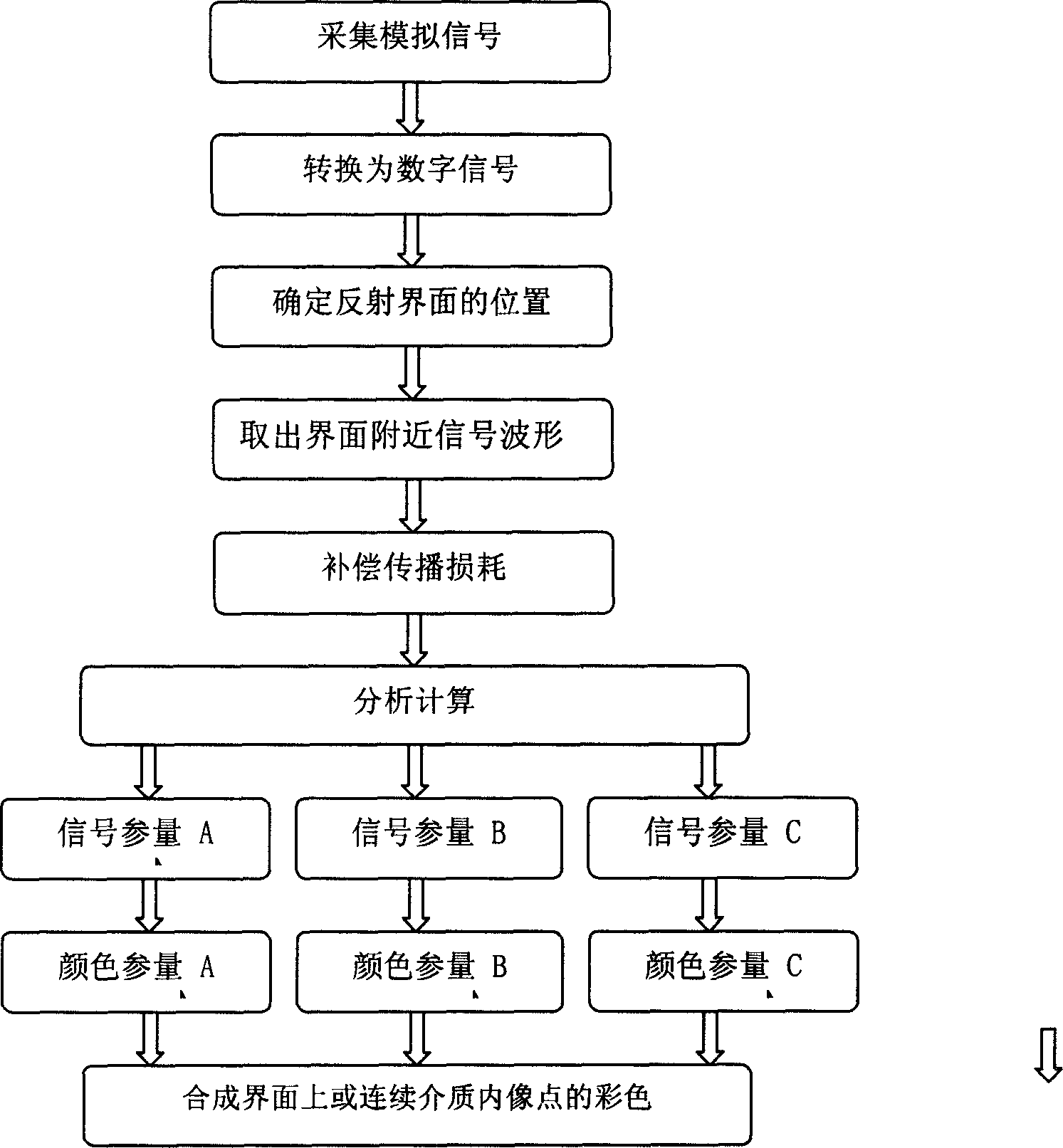

Ultrasonic image color display device and method

InactiveCN1607459AImprove the recognition rateImprove accuracyUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesColor imagePhysical space

The invention discloses an ultrasonic image color display device and method suitable for industrial detection and medical diagnosis. This method extracts multiple physical quantities from the ultrasonic signal corresponding to each image point of the detected target to define the color of the image point. The color image obtained by this method can simultaneously display the spatial distribution of multiple physical quantities on the detected target, which contains far more abundant information about the detected target than any traditional ultrasonic image, making full use of the bandwidth of the human eye for color images, The far richer and easier-to-recognize information is transmitted to the brain of the map reader in the first time, which greatly improves the speed of map reading, and the recognition rate and accuracy of abnormal phenomena. The color ultrasonic image proposed by the present invention, while maintaining the traditional ability to detect the position of the acoustic interface in the measured object, can also provide the effective expression of the continuous medium between the interfaces that the traditional ultrasonic instrument lacks.

Owner:CLEAR SOUNDS TECH SHANGHAI CO LTD

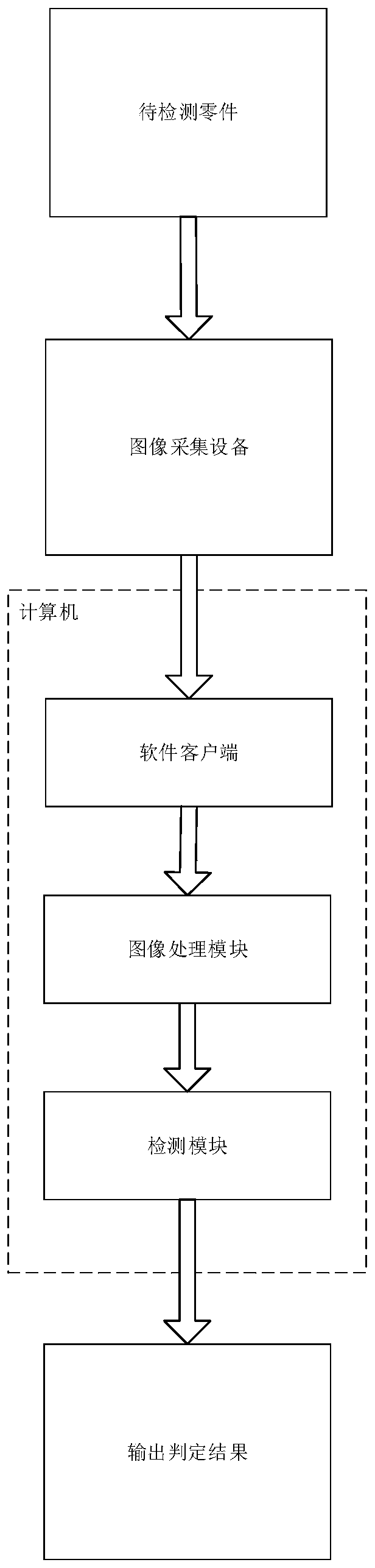

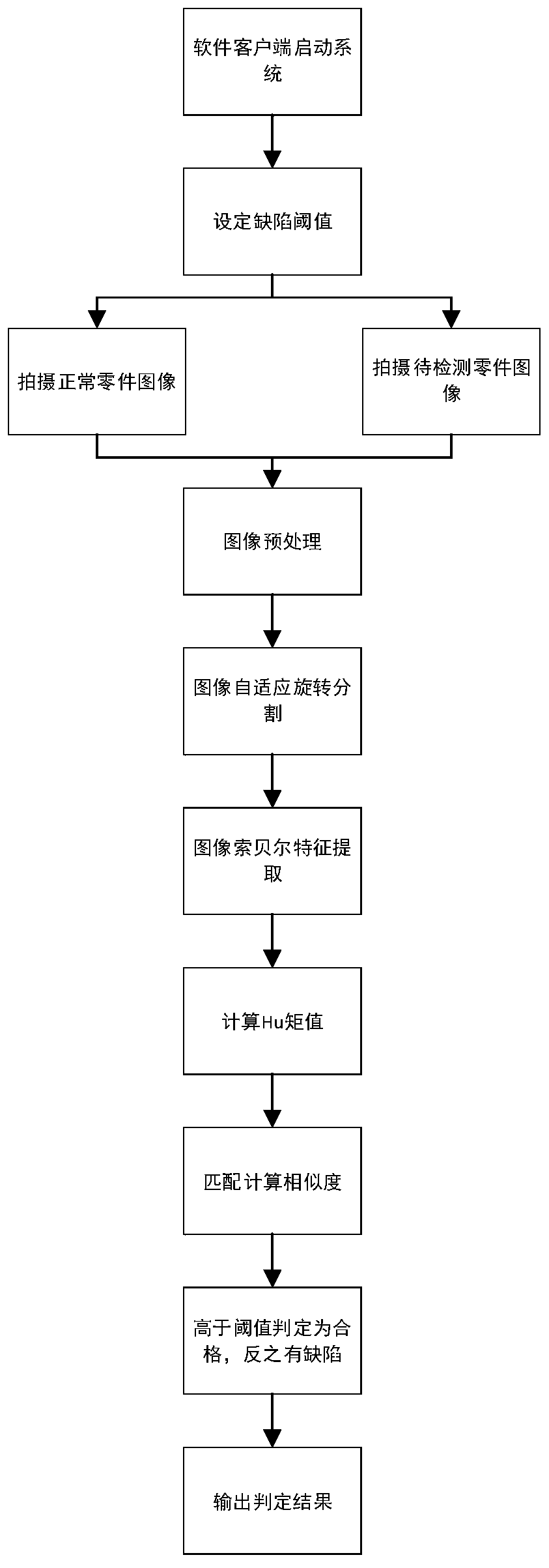

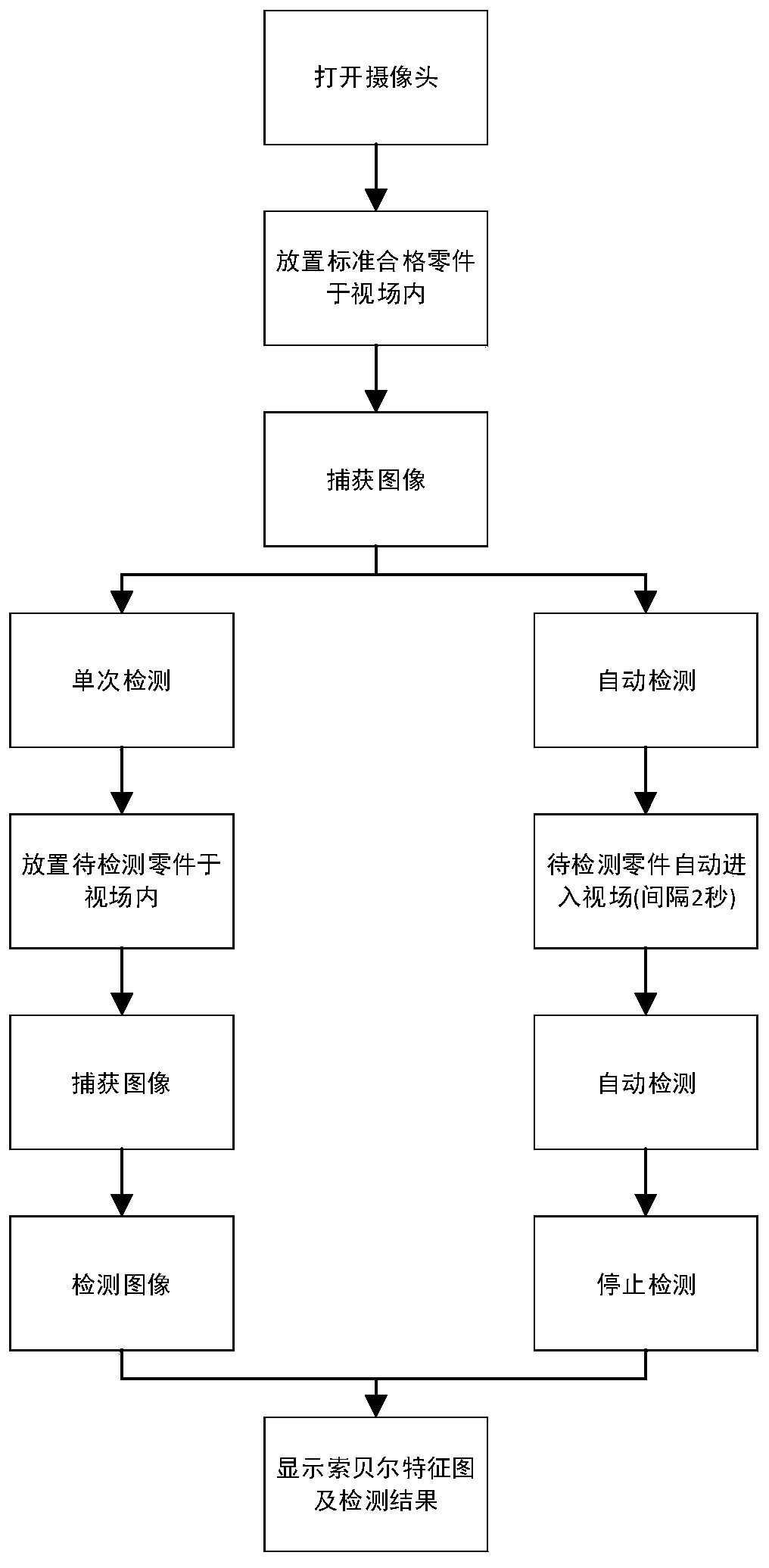

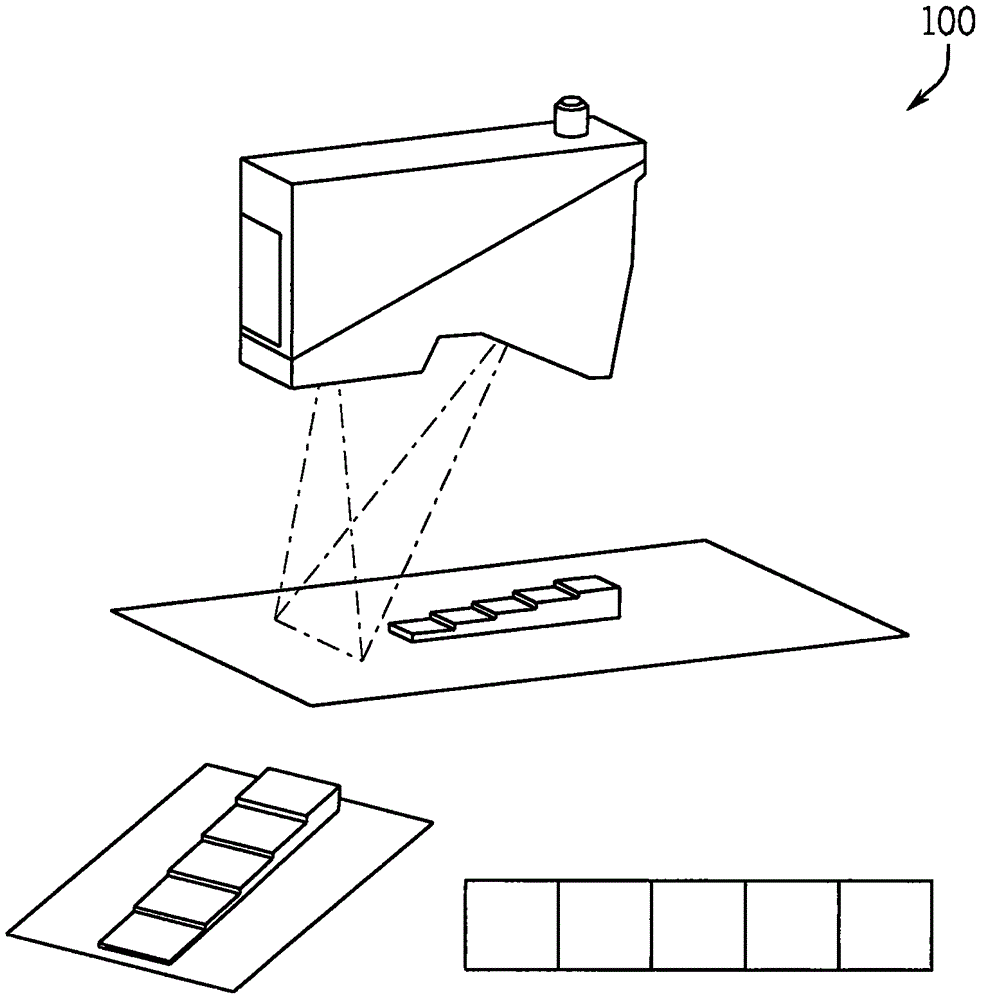

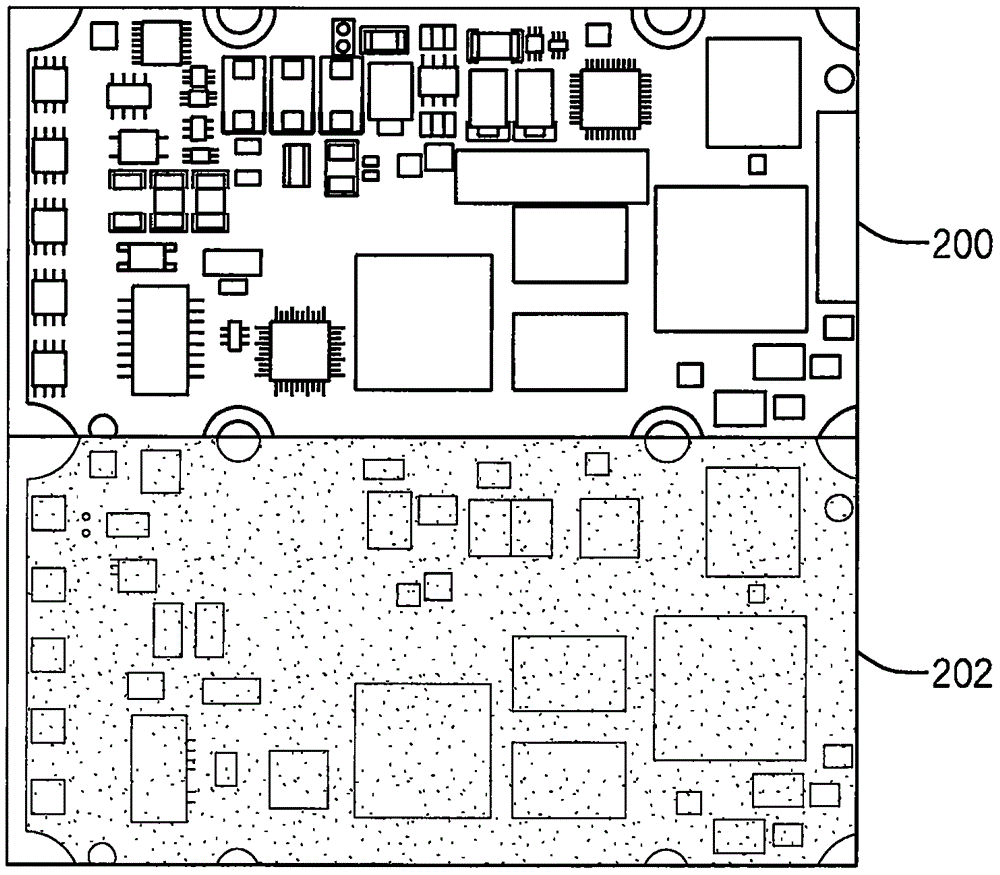

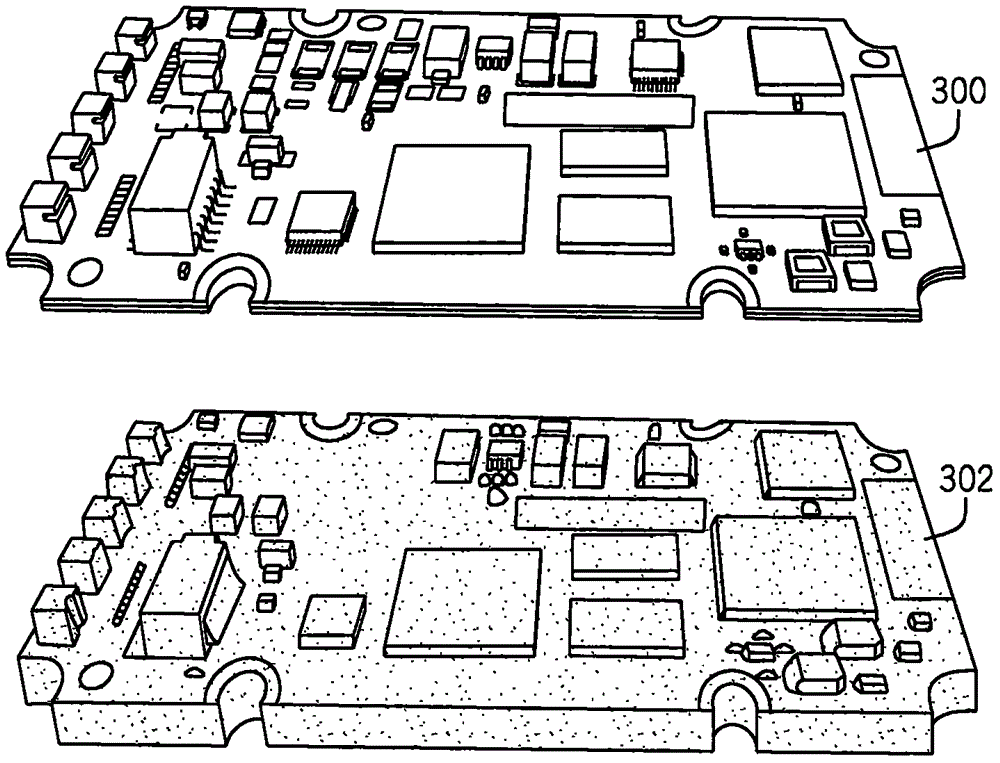

On-line detection system and detection method for surface defects of parts based on feature matching

PendingCN109946304AReduce computational complexityFast recognitionImage analysisCharacter and pattern recognitionImaging processingCcd camera

The invention discloses an on-line detection system and detection method for surface defects of parts based on feature matching. The system includes an image acquisition device and a computer. The image acquisition device includes a CCD camera and a light source connected to the computer. The computer includes a software client, an image processing module, and a detection module. The software client is used for realizing the control, detection and display functions of online detection of the surface defects of parts and is connected to the image processing module. The detection module is connected to the image processing module. According to the system, a Hu moment value is calculated based on the Sobel characteristic map of the part and similarity matching is performed to complete surfacedefect detection of the part. The image acquisition device shoots a part image; the image processing module preprocesses the image, carries out segmentation, and extracts features; the detection module calculates the similarity by the Hu moment value and outputs a determination result. The system has a simple structure and is suitable for the detection scene of part defects in the field of industrial inspection; and real-time online detection of the high-precision part surface defect is realized.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Using 3D vision for automated industrial inspection

A system and method for three dimensional (3D) vision inspection using a 3D vision system. The system and method comprising acquiring at least one 3D image of a 3D object using the 3D vision system, using the 3D vision system; extracting a 3D visible runtime mask of the 3D image; using the 3D vision system, comparing the 3D runtime visible mask to a 3D reference visible mask; and, using the 3D vision system, determining if a difference of pixels exists between the 3D runtime visible mask and the 3D reference visible mask.

Owner:COGNEX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com