Patents

Literature

340 results about "Vision inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

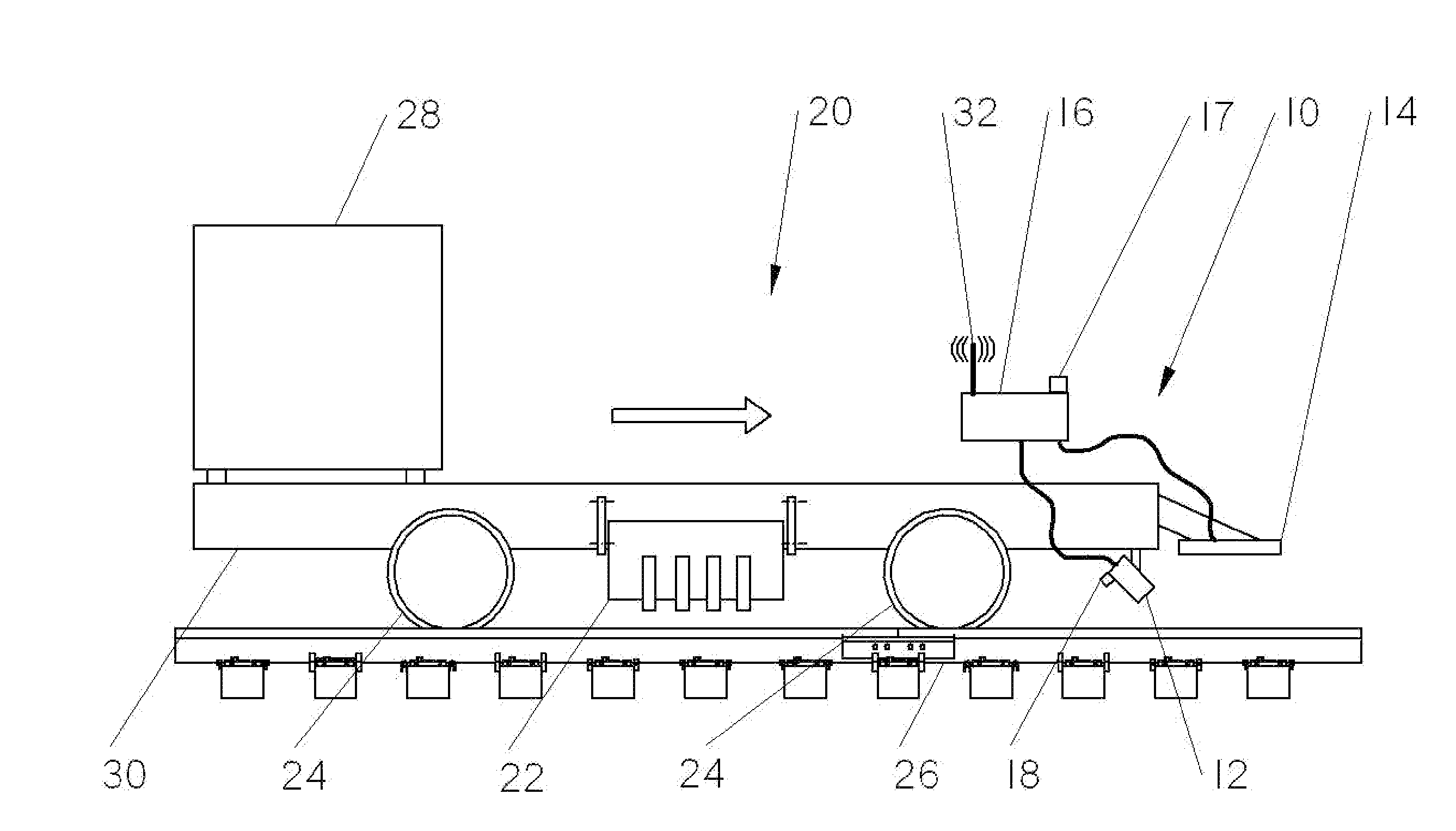

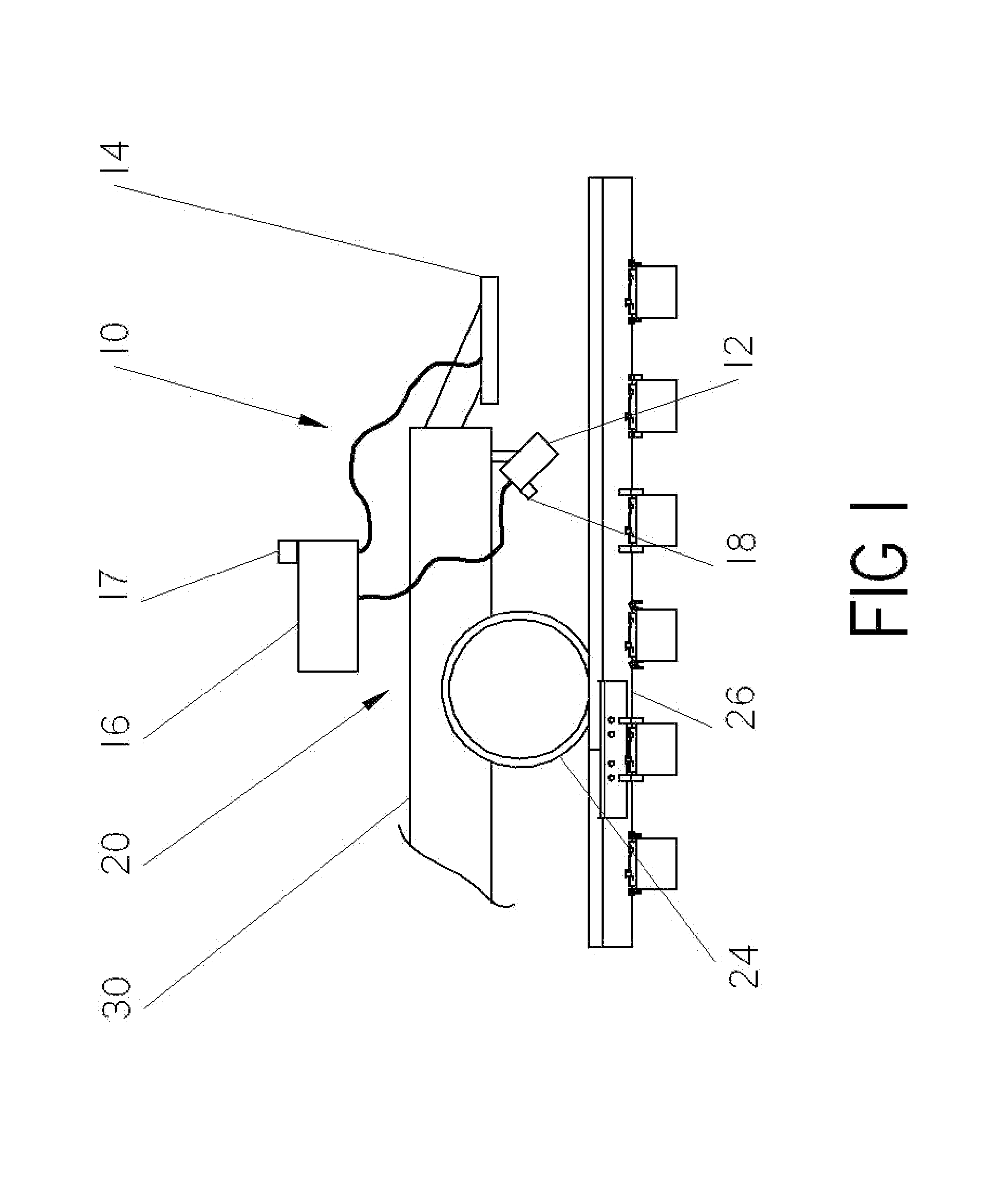

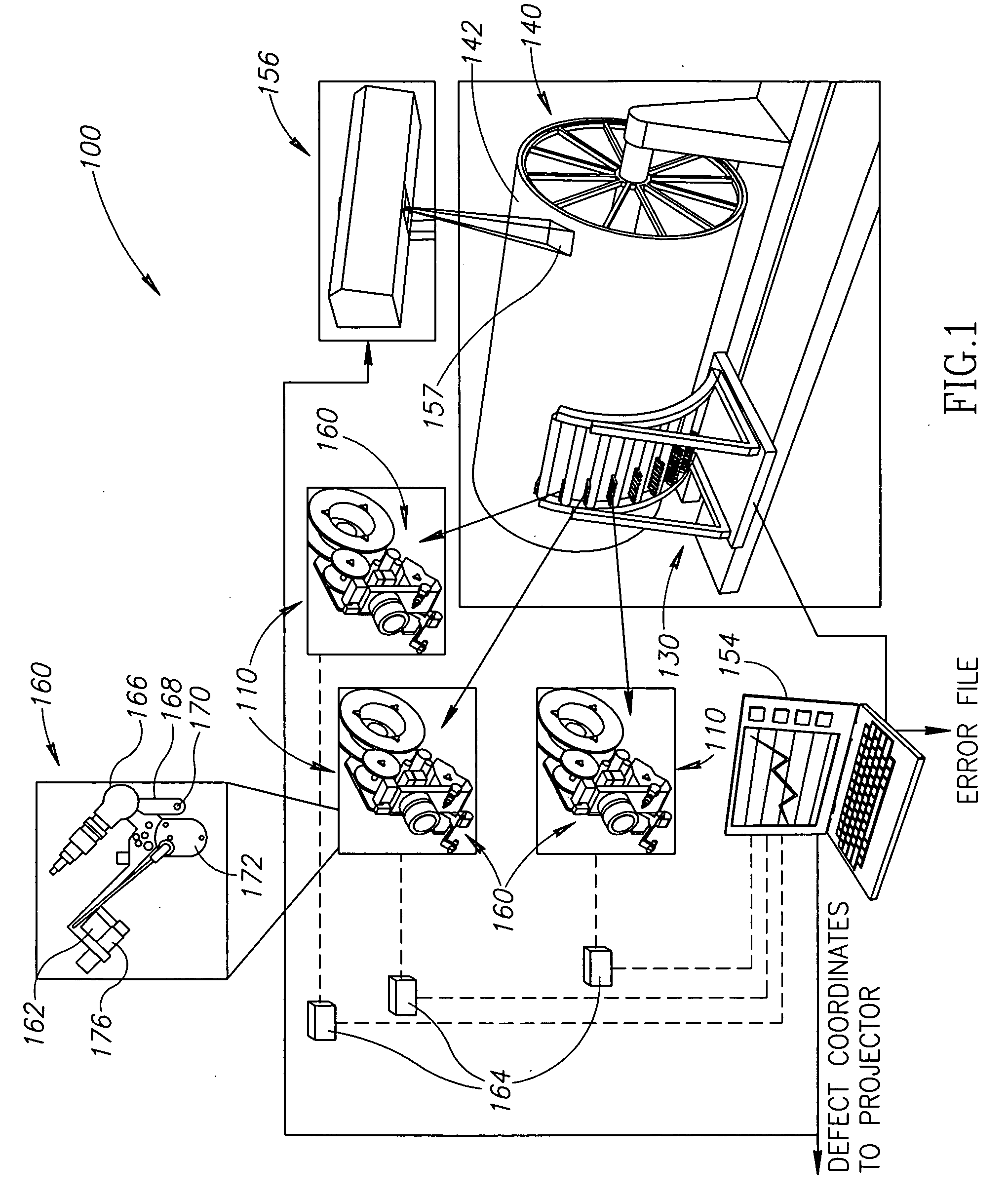

Rail vision system

InactiveUS20120192756A1Digital data processing detailsCharacter and pattern recognitionVision inspectionControl system

A vision inspection system and method for use with a railcar includes a vision device adapted to provide an image of each rail component. An image recognition component analyzes the images taken by the vision device to determine the type and condition of each rail component as the vehicle is traveling on the railroad track. A control system communicates with the vision device and the image recognition component. The control system causes workheads of the vehicle to engage respective rail components based on the input received from the vision inspection system. A method for determining the relative distance between the rail components includes comparing the position of the respective rail components of a first image to the position of the respective rail components of a second image to determine the distance between the respective components and distance the railcar has moved.

Owner:HARSCO CORP

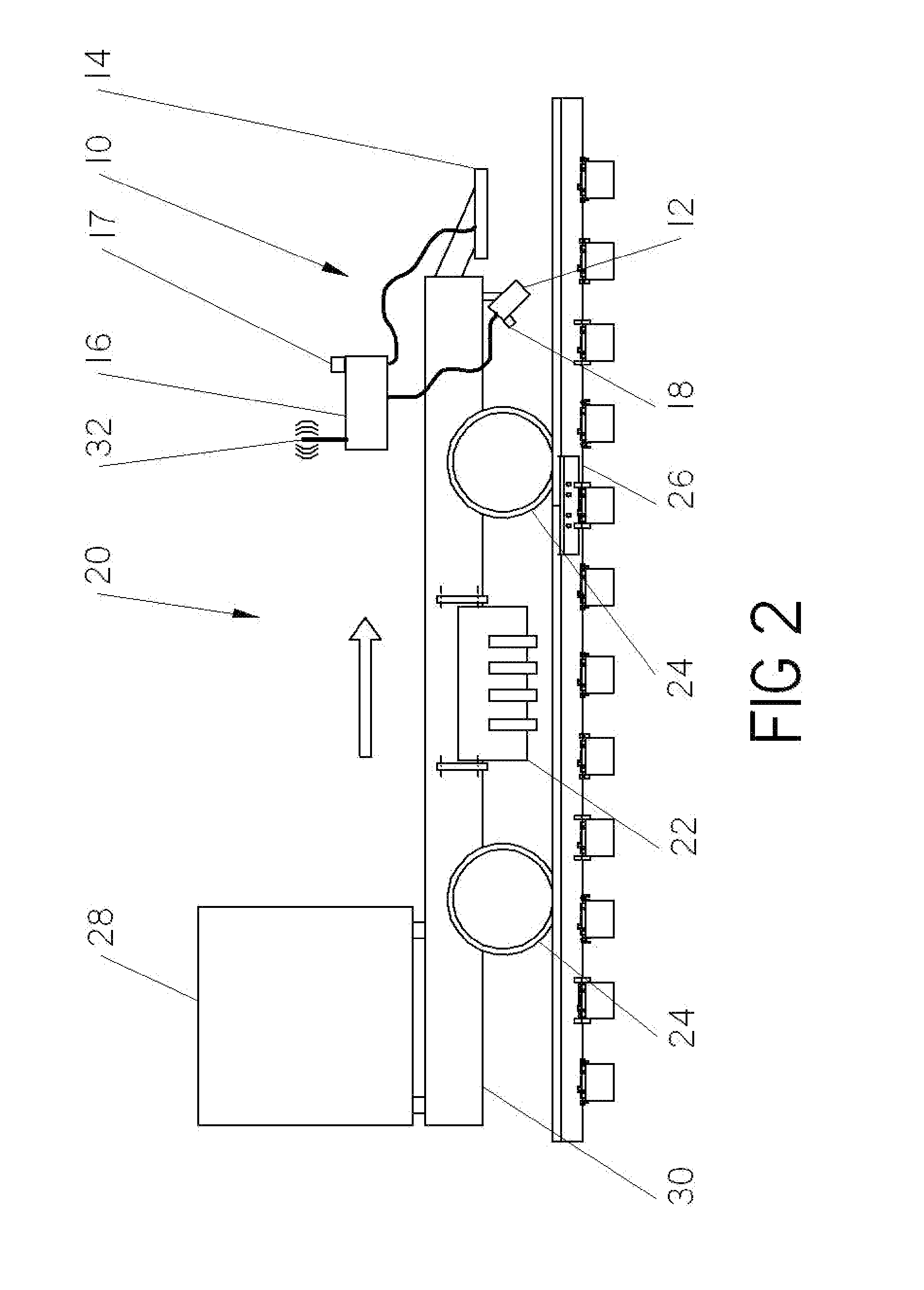

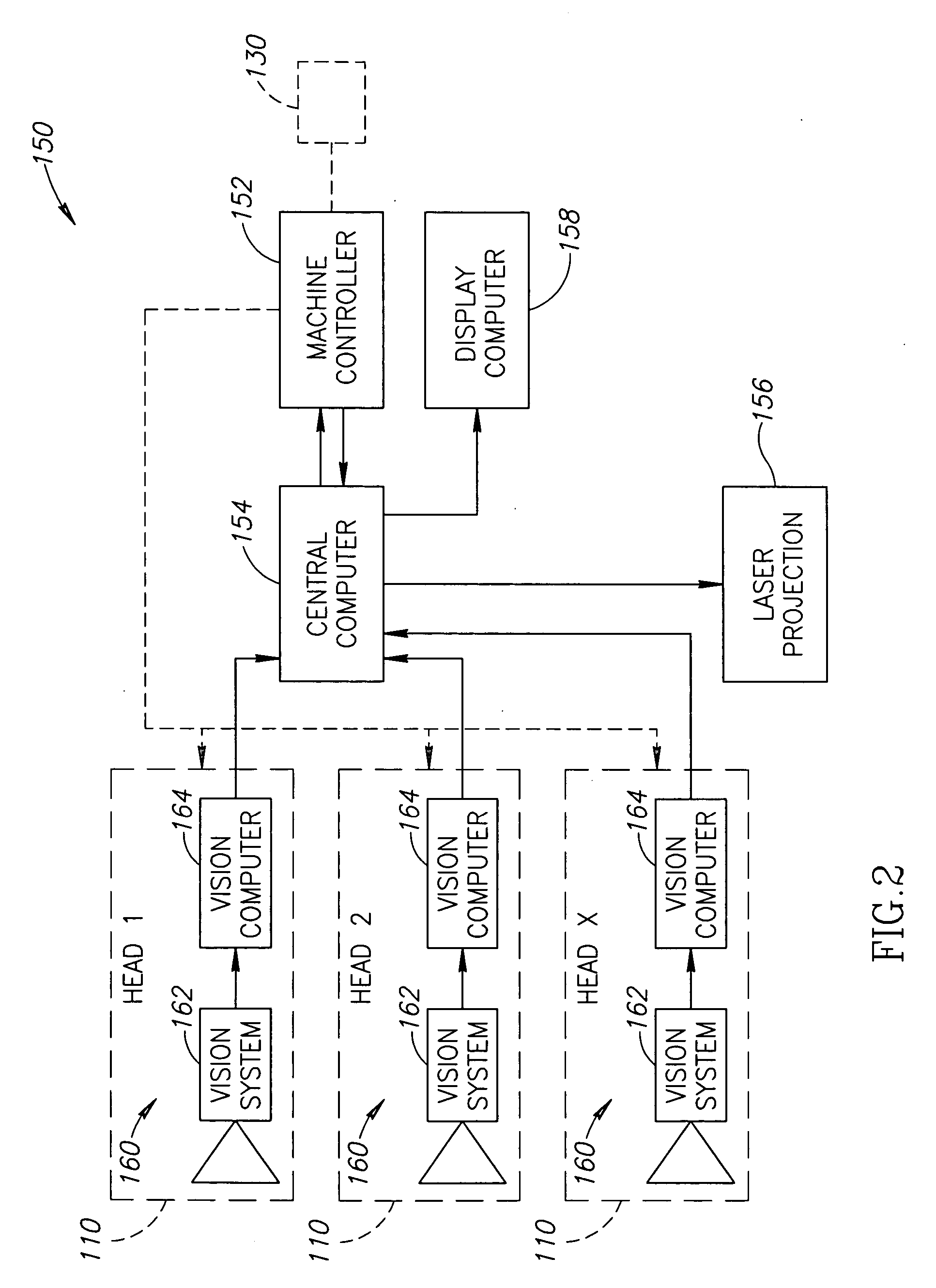

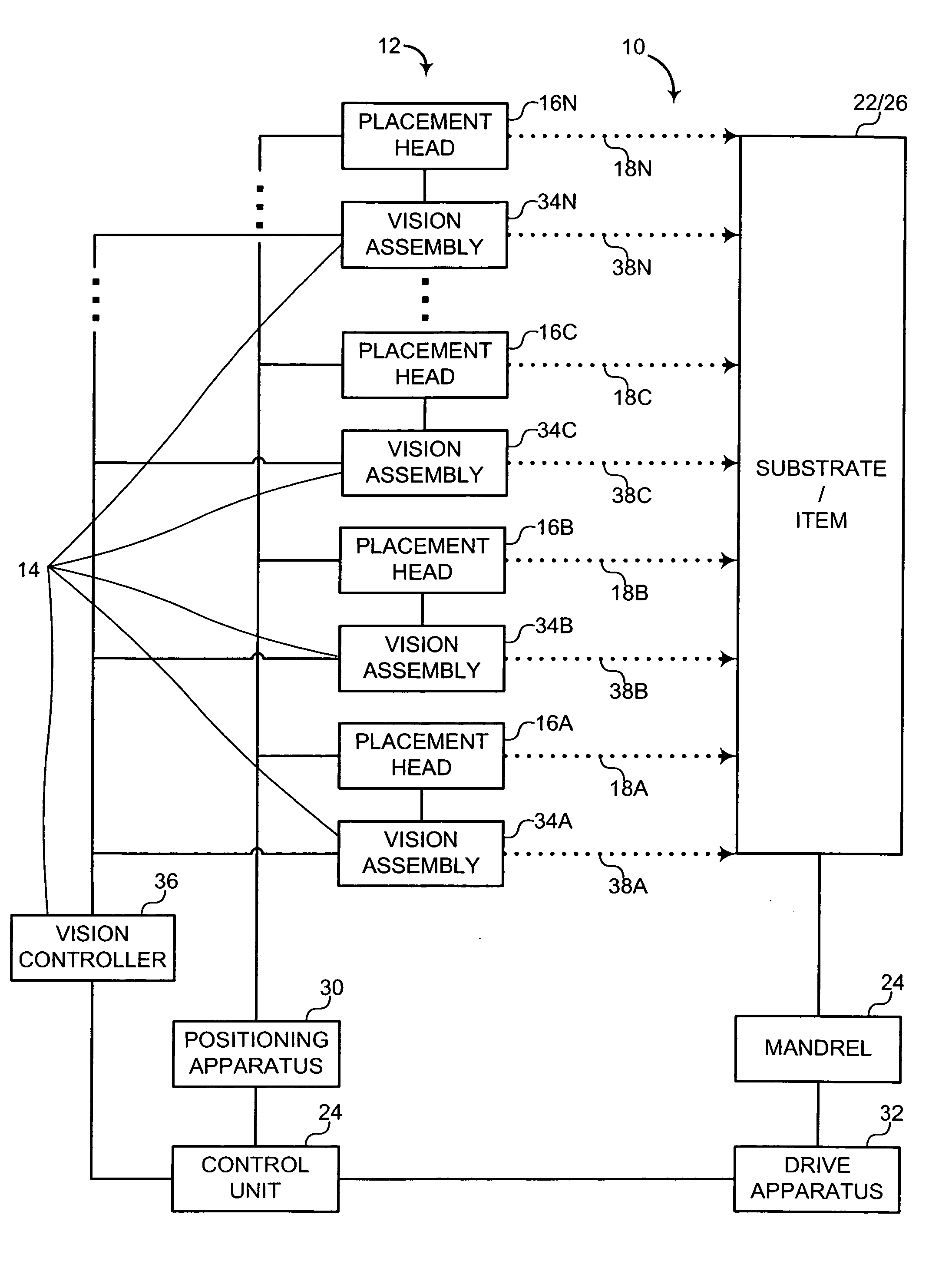

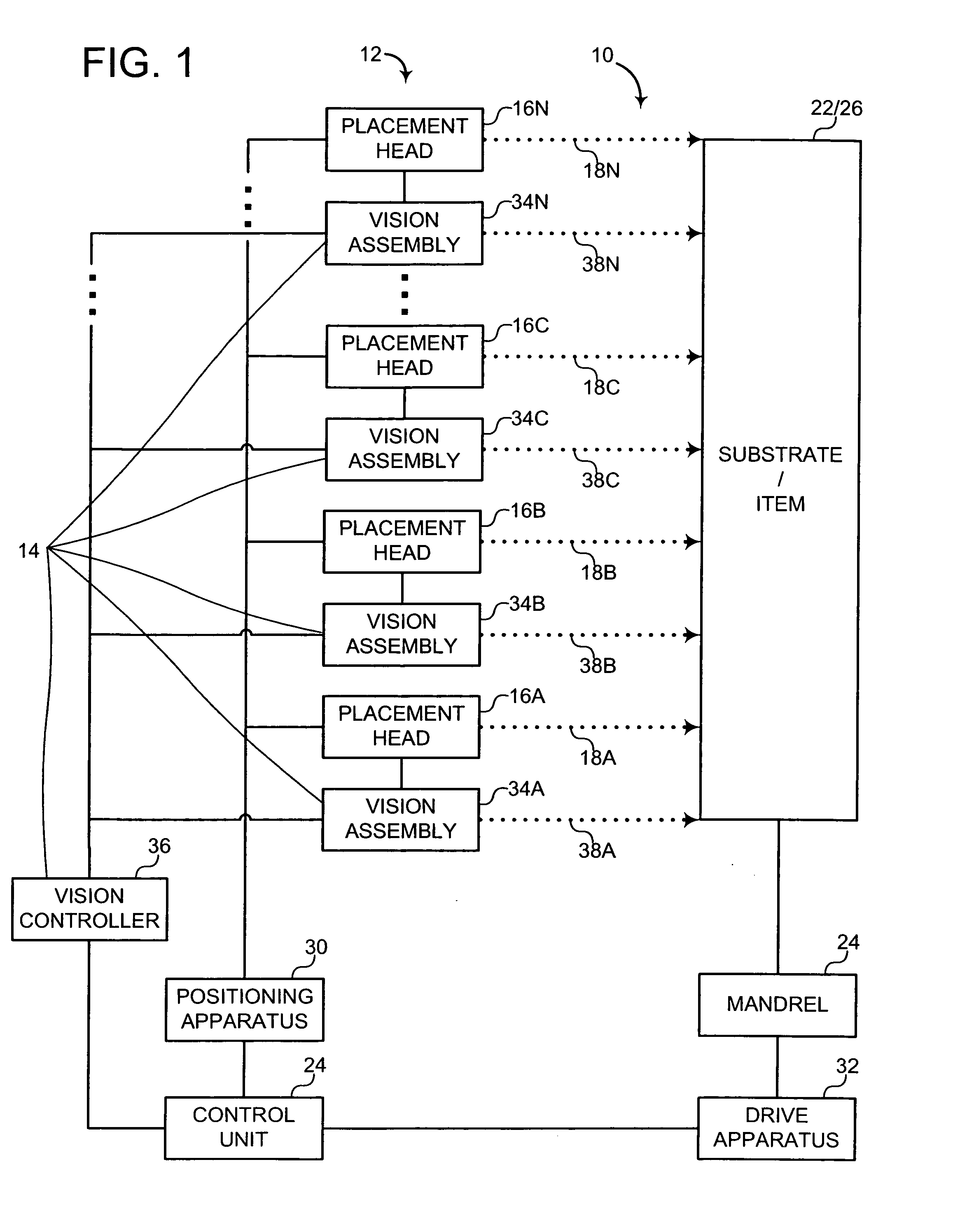

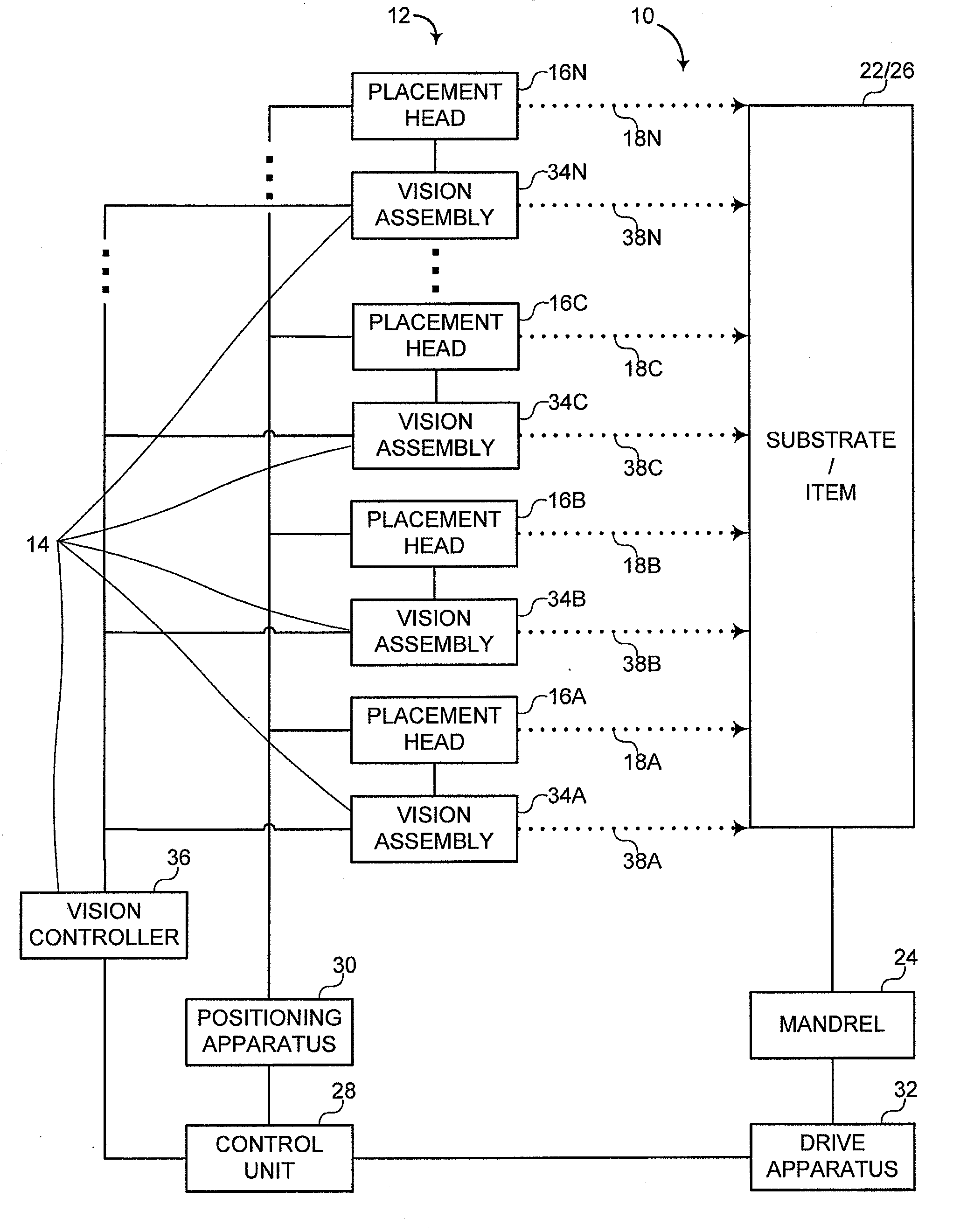

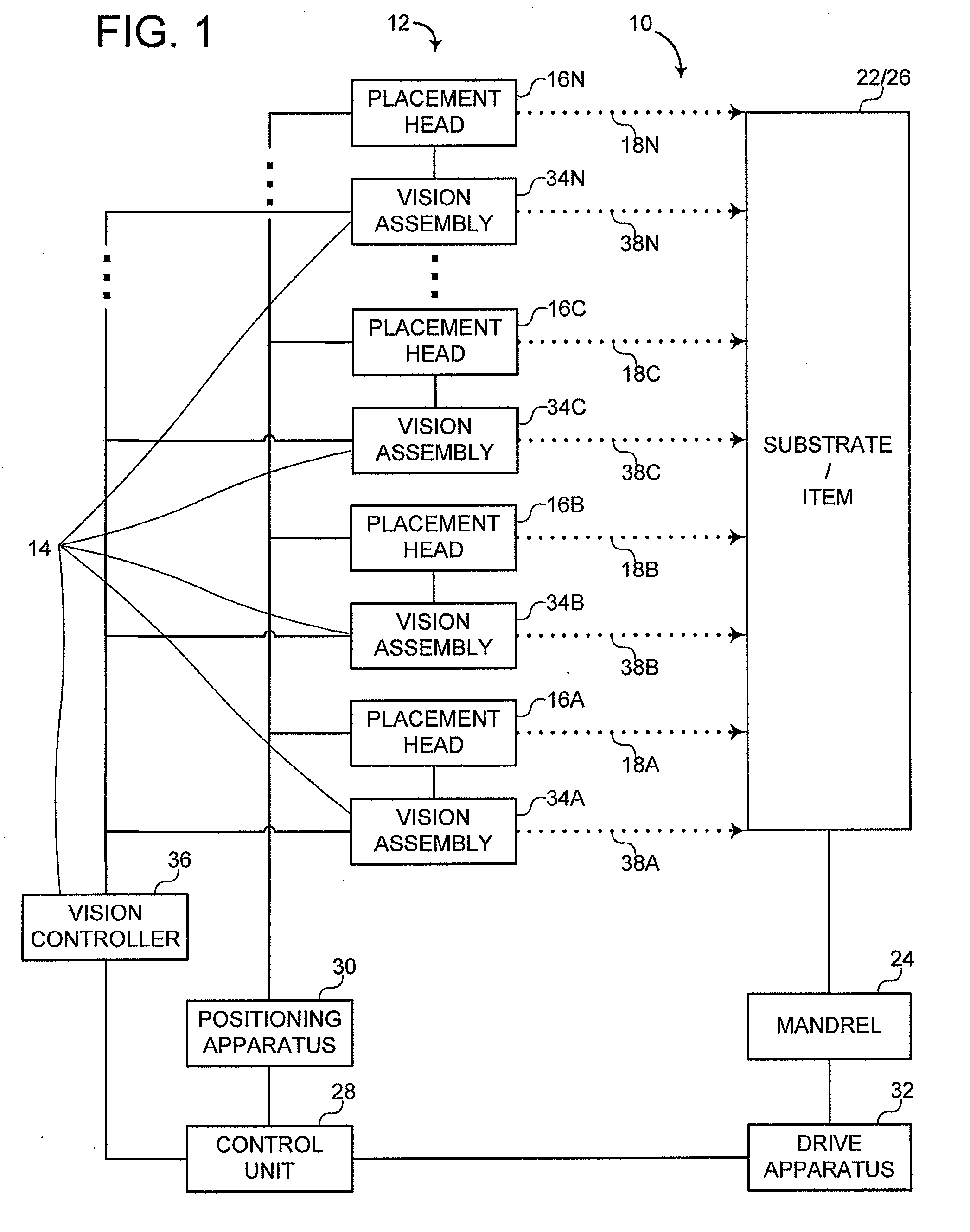

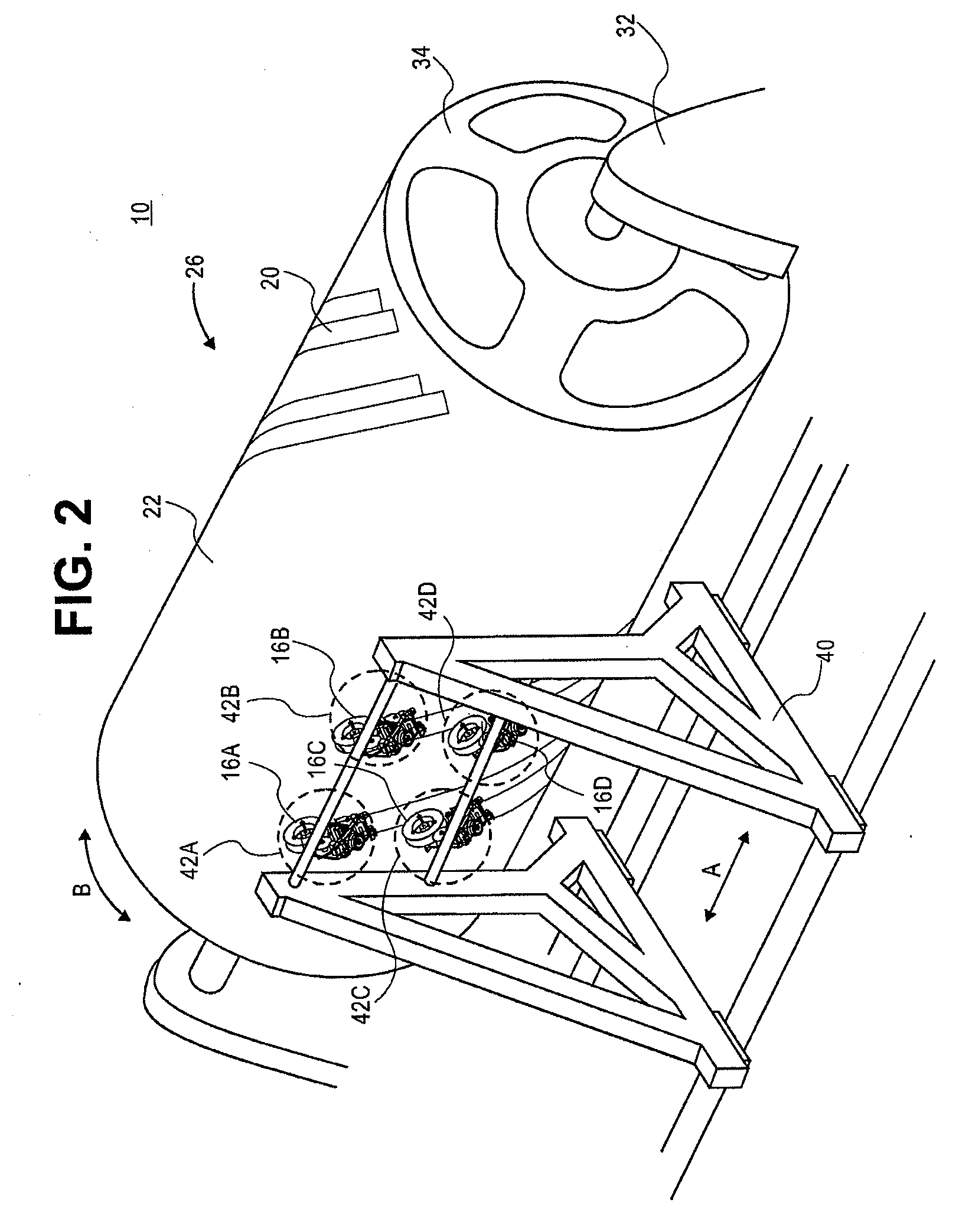

Systems and methods for in-process vision inspection for automated machines

ActiveUS20070034313A1Reduce downtimeAvoid associated costsLamination ancillary operationsInvestigating composite materialsVision inspectionEngineering

Systems and methods for in-process vision inspection for automated machines are disclosed. In one embodiment, a head assembly includes a tool moveable over a workpiece and adapted to perform a manufacturing operation on the workpiece, and an inspection unit operatively positioned proximate the tool and moveable with the tool relative to the workpiece. The inspection unit is adapted to perform a vision inspection of a portion of the workpiece simultaneously with the performance of the manufacturing operation on the workpiece. In a particular embodiment, the inspection unit includes a camera adapted to monitor an area including the portion of the workpiece upon which the tool has performed the manufacturing operation, and a processor operatively coupled to the camera and adapted to receive an image from the camera and to analyze the image to determine a presence of a defect within the portion of the workpiece.

Owner:THE BOEING CO

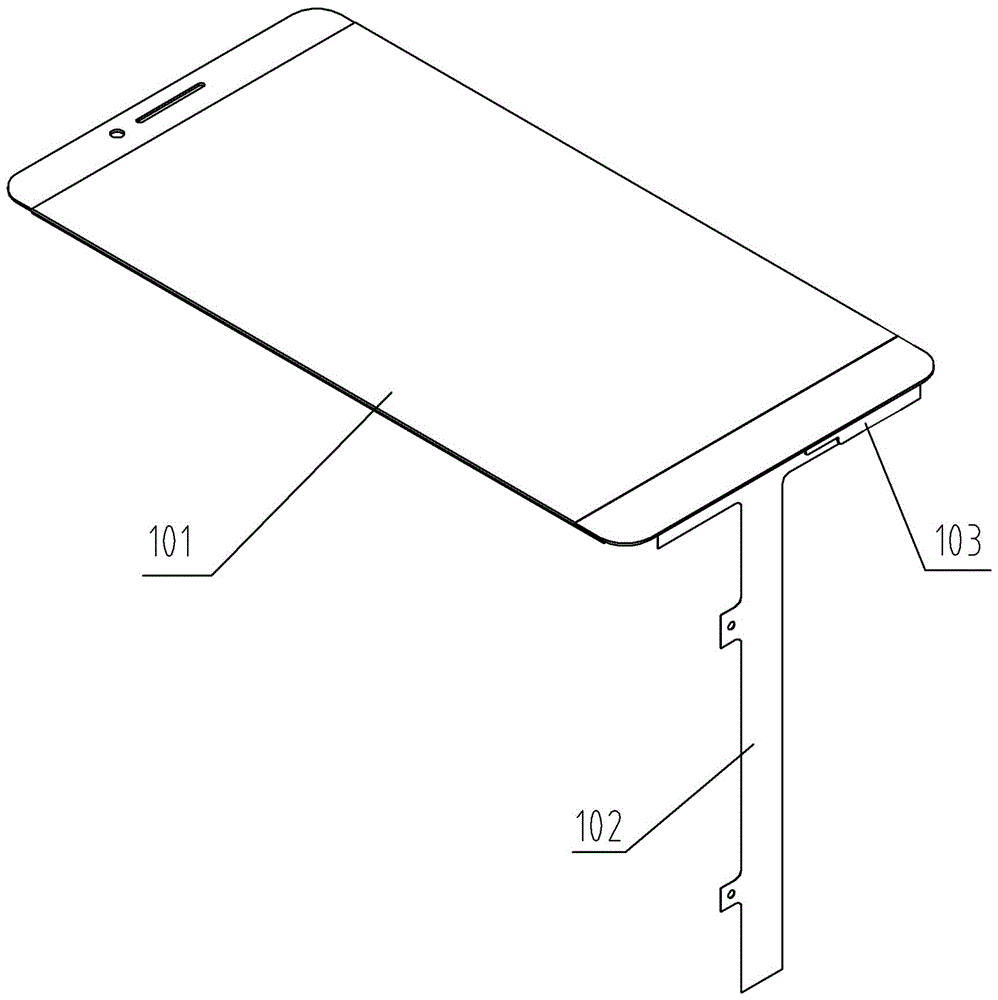

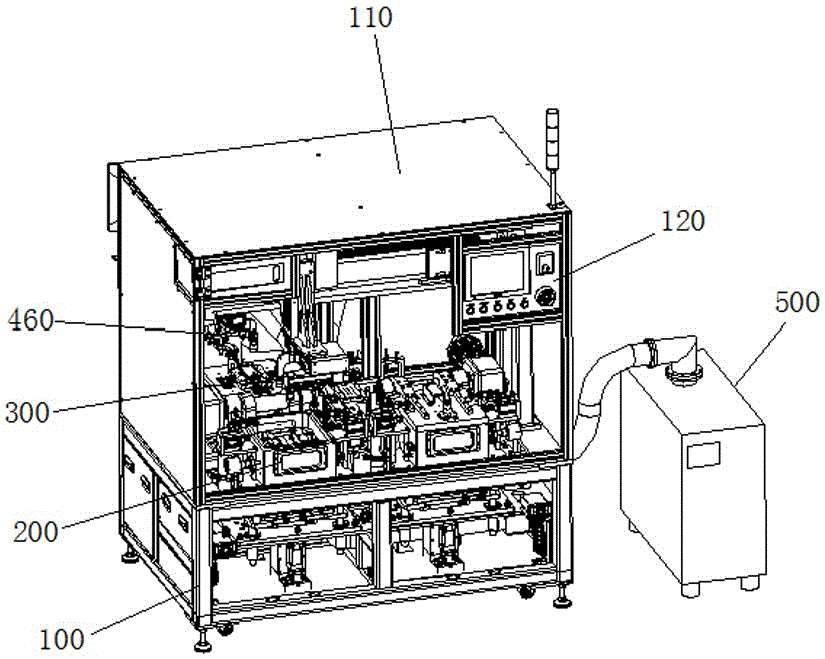

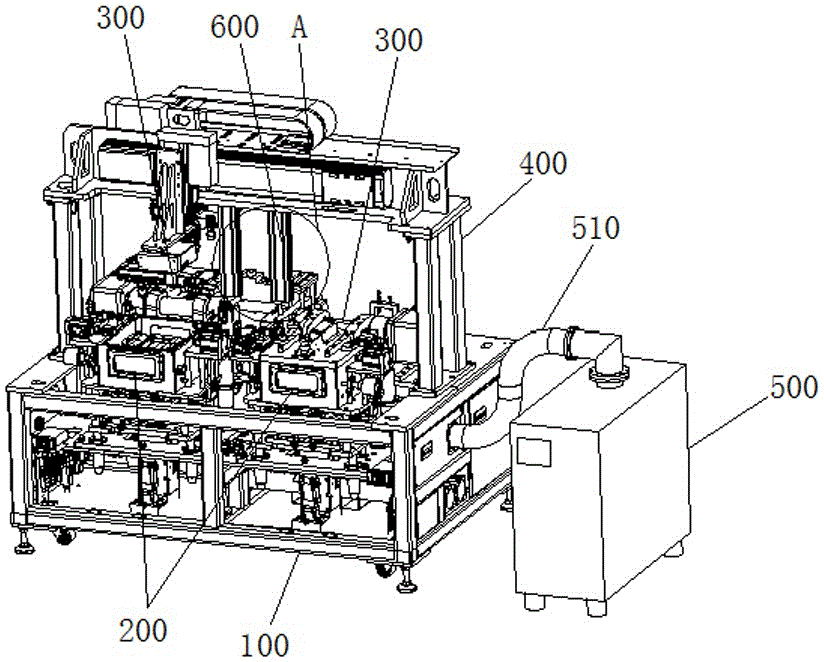

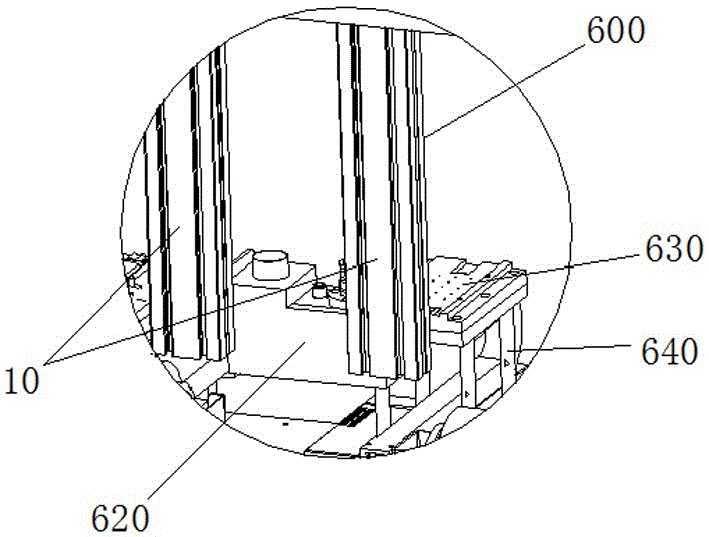

Mobile phone assembling machine

ActiveCN105817881ASimple structureHigh degree of automationAssembly machinesVision inspectionMobile phone

The invention relates to a mobile phone assembling machine. A mobile phone support is respectively provided with a loading and unloading component, a feeding component, a FPC component, an assembling component, a vision inspection device, a film drawing component and a pressure maintaining component. The loading and unloading component respectively grabs a mobile phone screen and a mobile phone shell and then puts the mobile phone screen and the mobile phone shell into a positioning jig of the feeding component for positioning and fixing, the FPC component bends a mobile phone screen circuit board small film and then sends the small film to an assembling position, the mobile phone screen is assembled and clung to the mobile phone shell under the combined action of the assembling component, the vision inspection device and the film drawing component and then enter the pressure maintaining component for pressure maintaining and stabilizing, and then the loading and unloading component realizes unloading. The assembling machine is simple in main structure and high in automation degree, and not only can complete the operation of assembling of the mobile phone screen and the mobile phone shell, but also can greatly improve the working efficiency.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

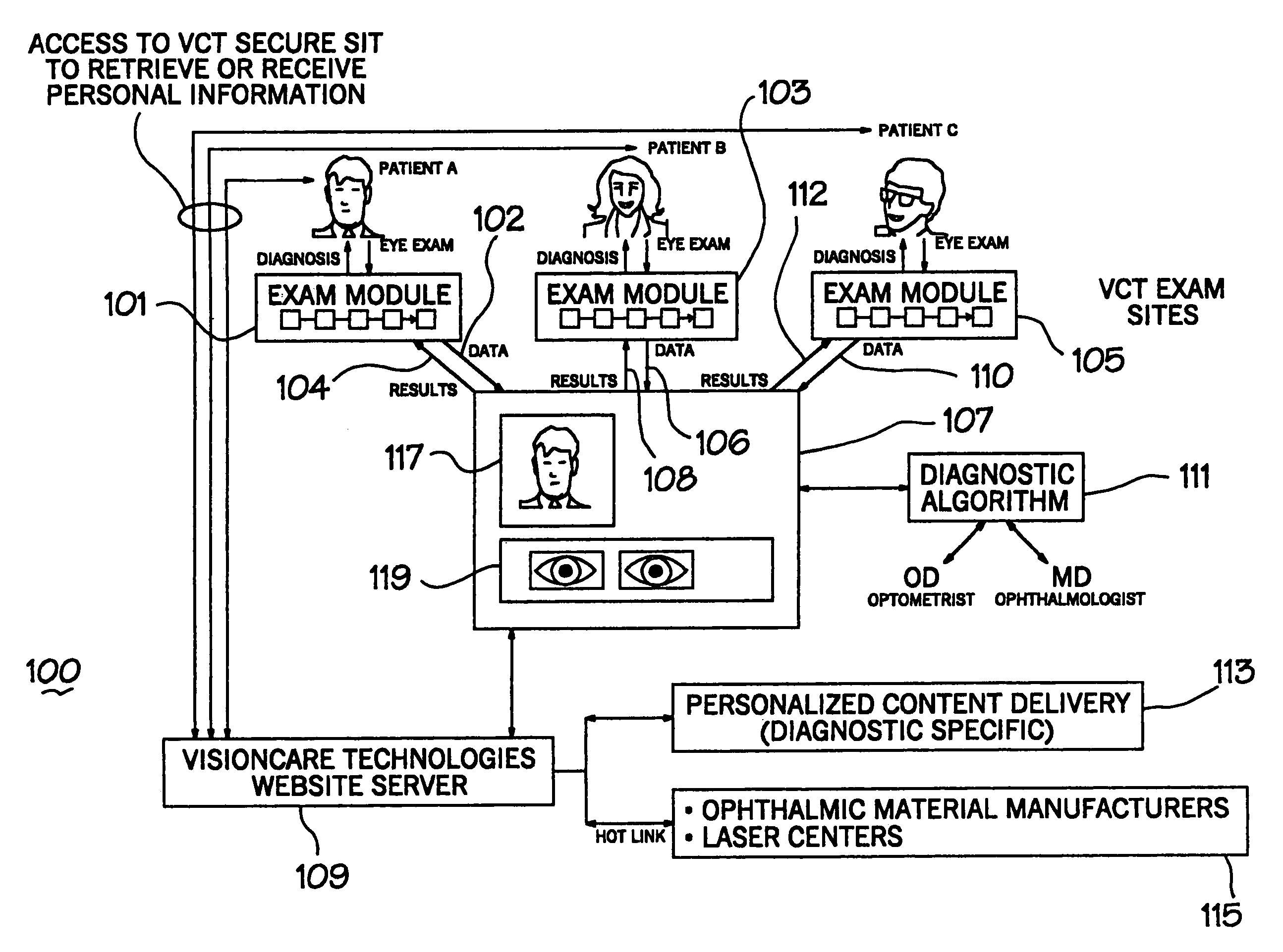

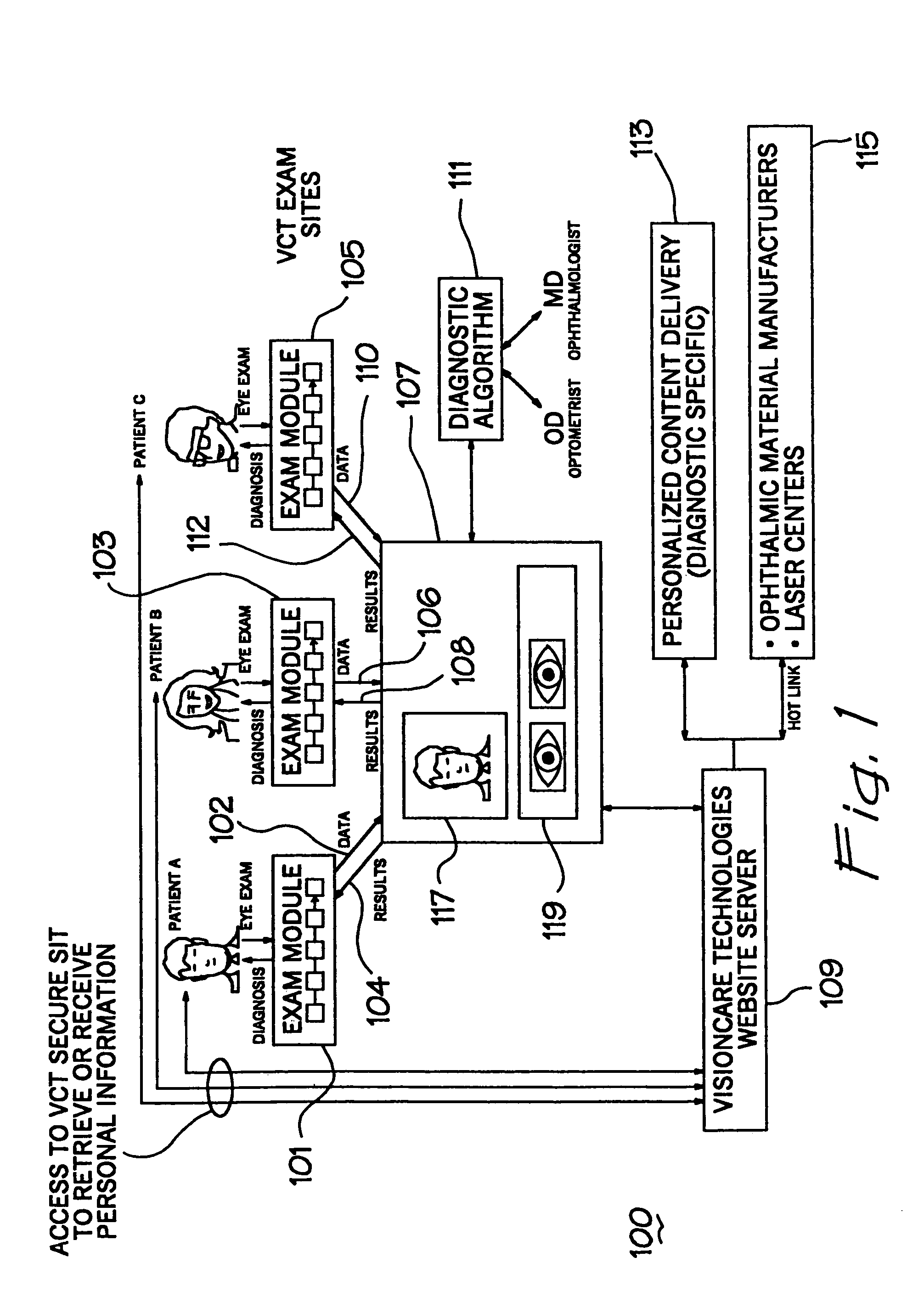

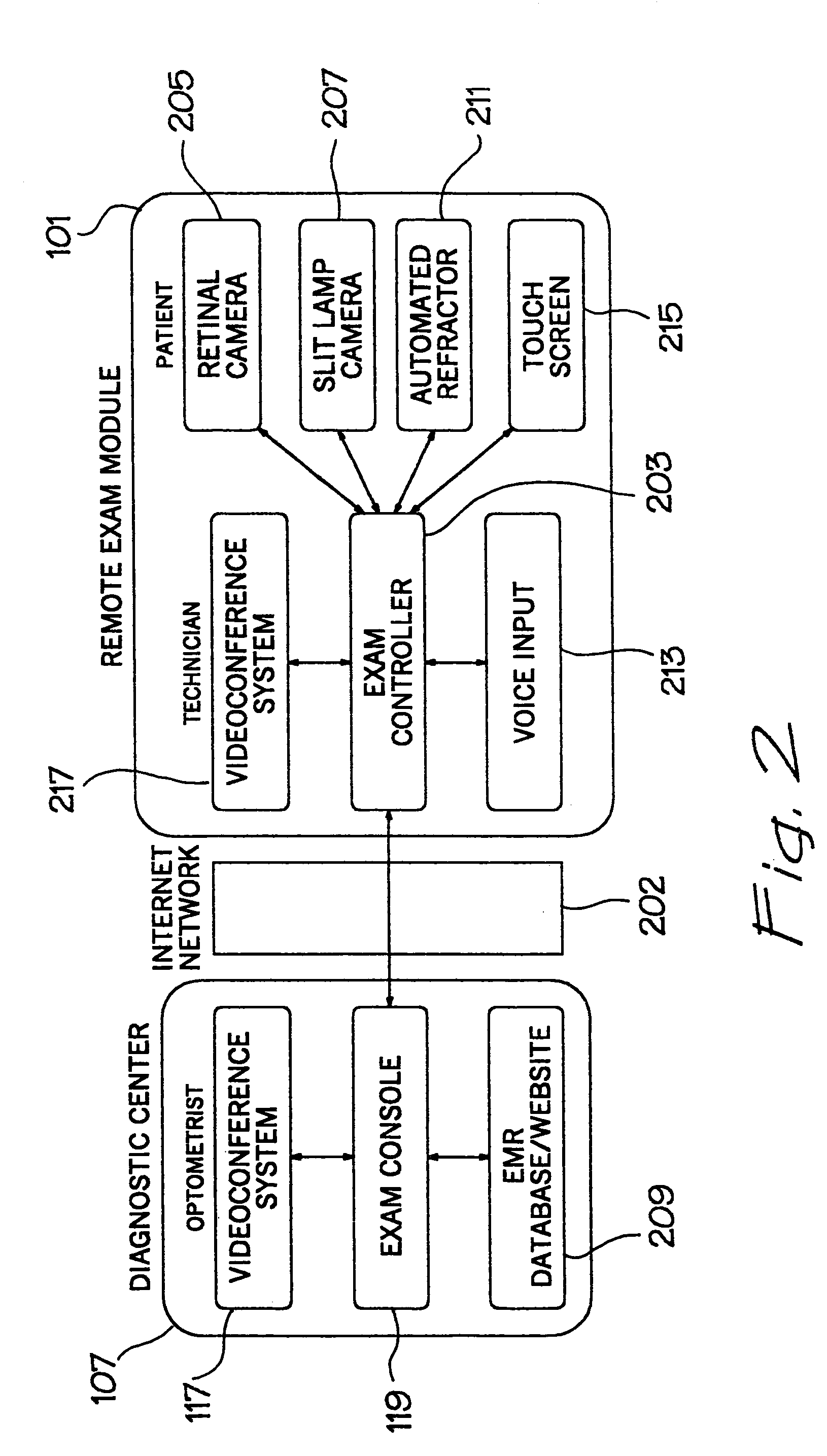

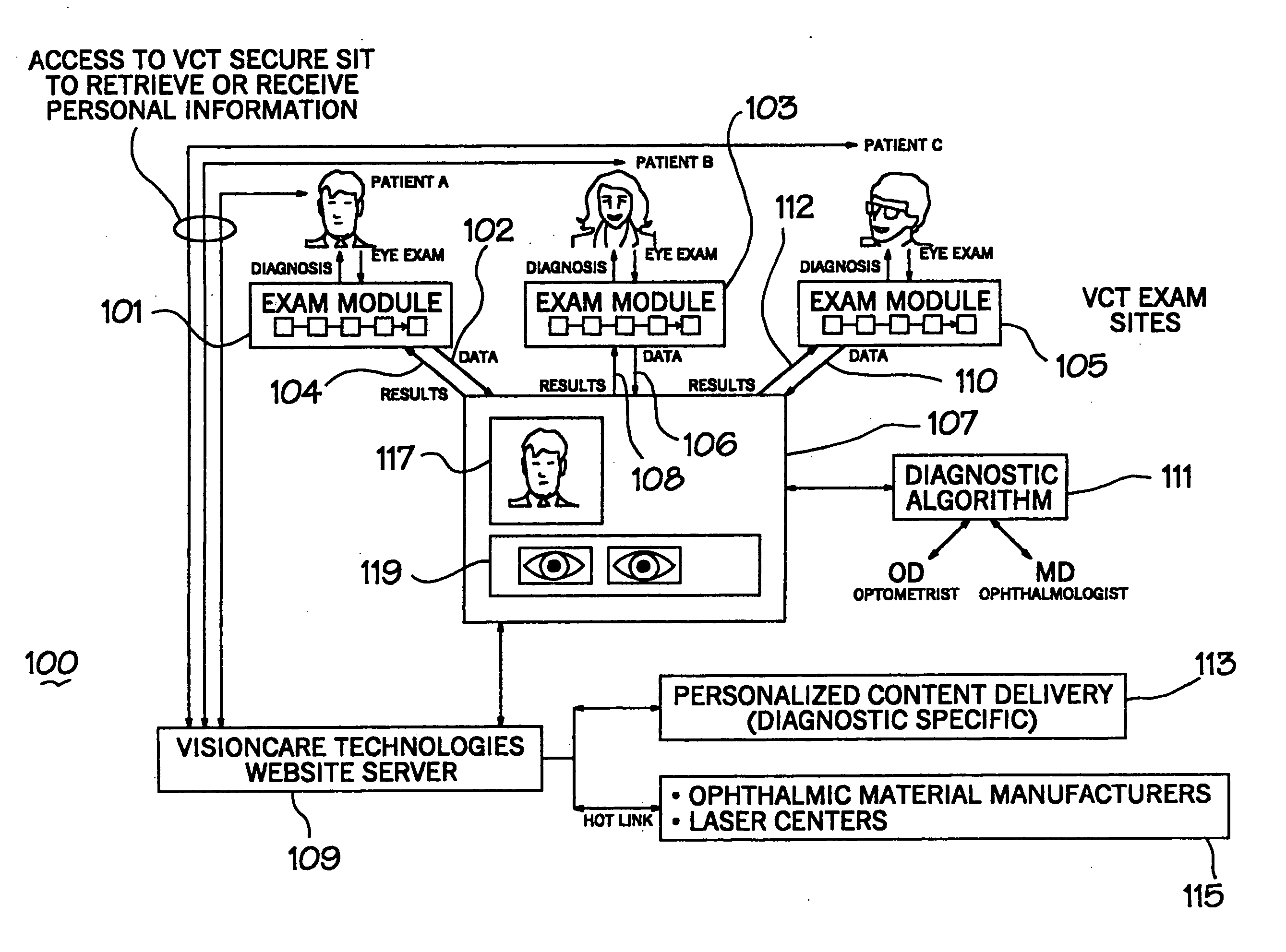

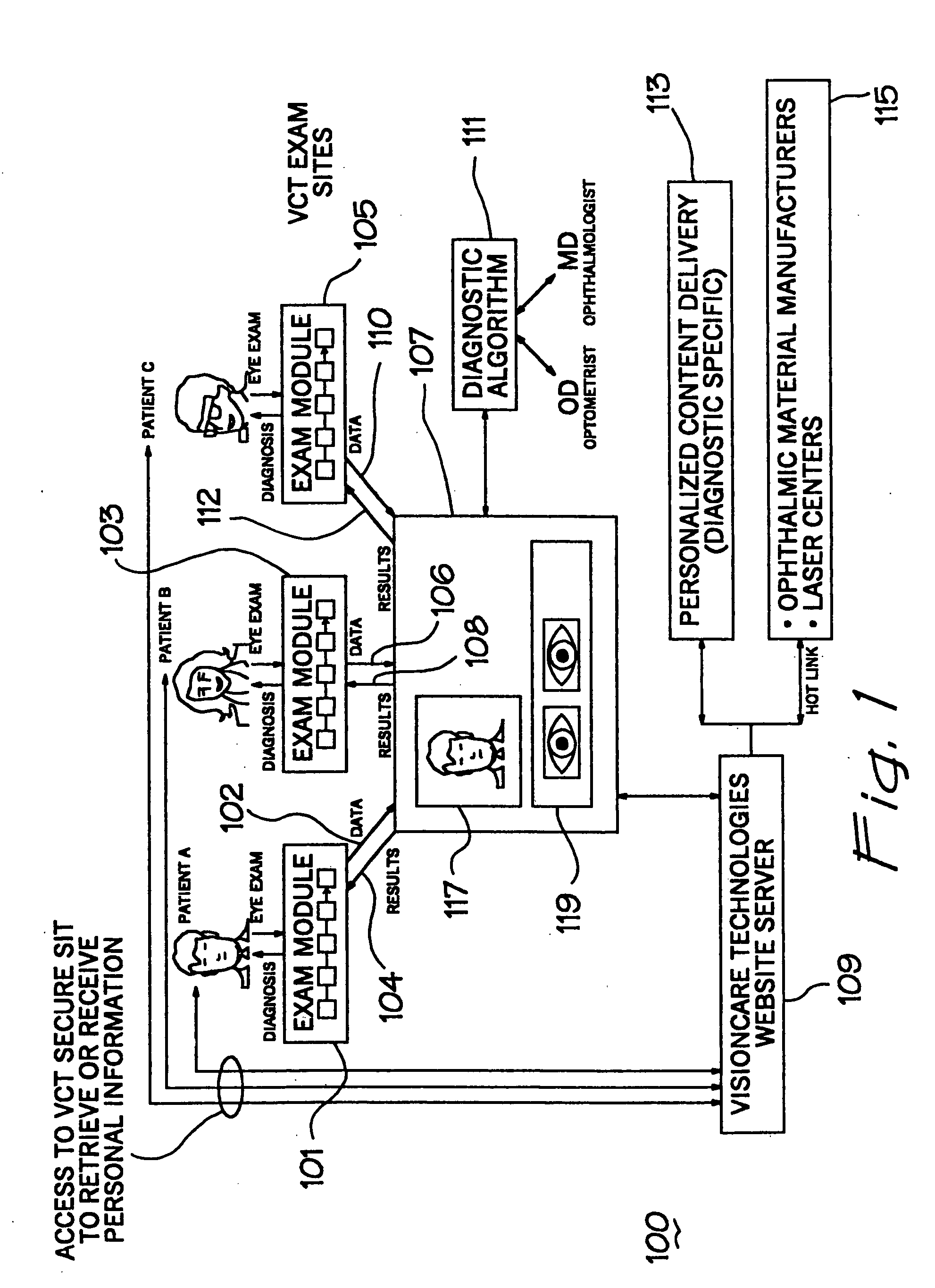

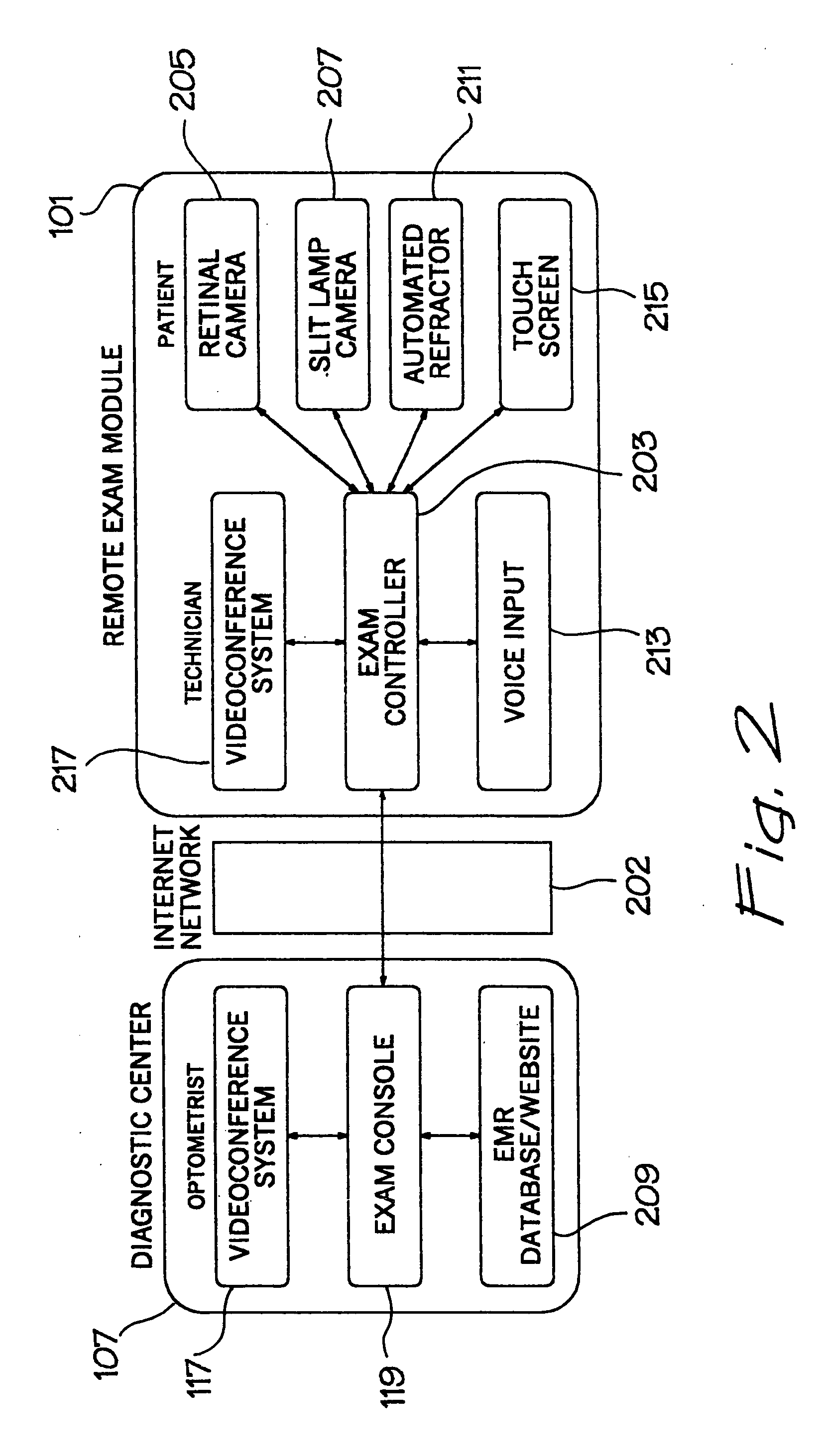

System for vision examination utilizing telemedicine

InactiveUS7232220B2Facilitate communicationData processing applicationsTelemedicineVision inspectionTelecommunications link

The telemedicine method and system disclosed includes at least one remote exam module which in turn includes a plurality of optical devices configured to examine a patient's eye, and a controller for collecting and transmitting the examination data of the patient's eye. The information collected is transmitted via a communications link to a diagnostic center for analyzing the information collected at the remote exam module. The diagnostic center further maintains a database of patient records corresponding to the remotely collected examination information and an exam console for enabling a diagnosis based on the collected information.

Owner:FRANZ RICHARD +1

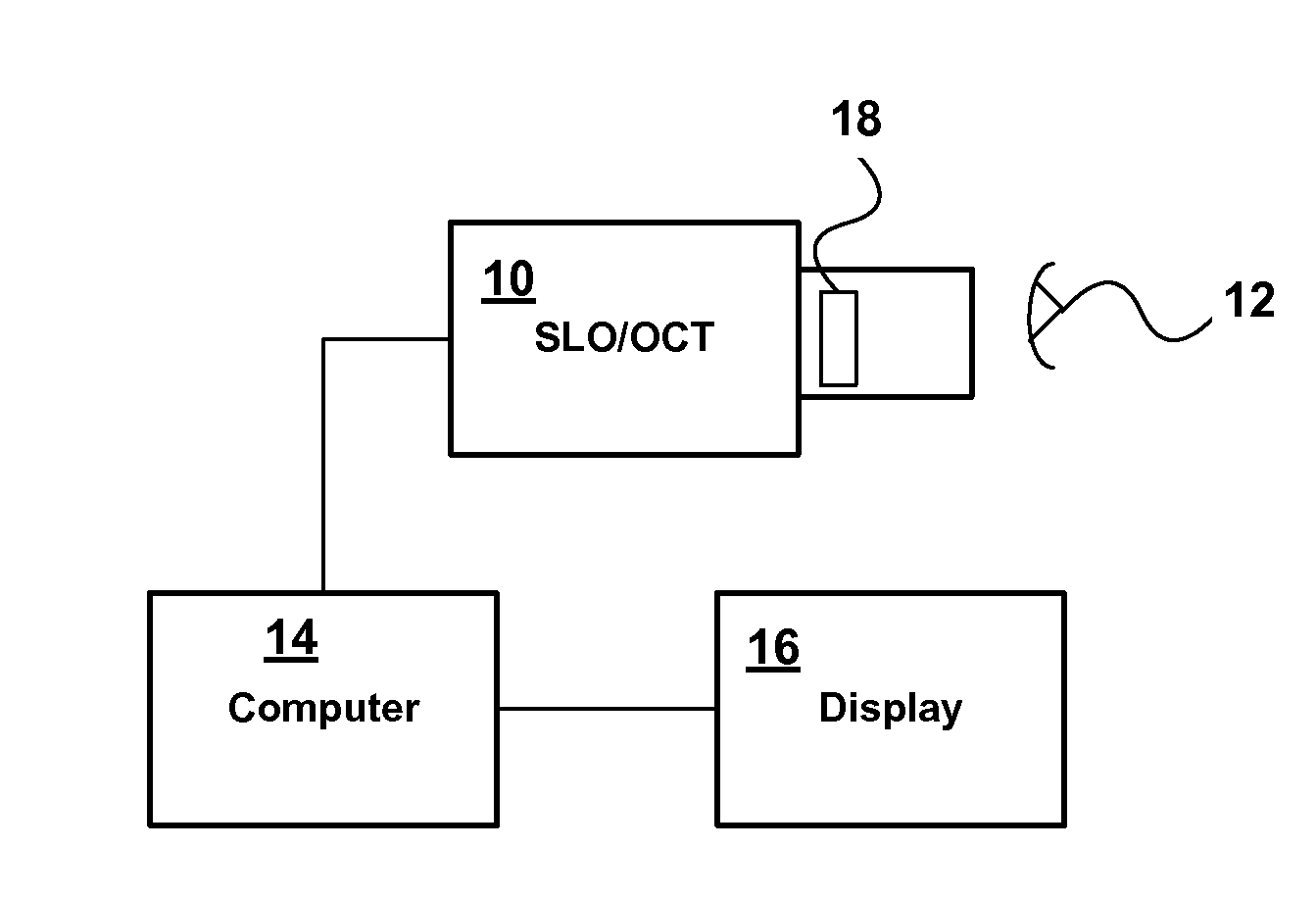

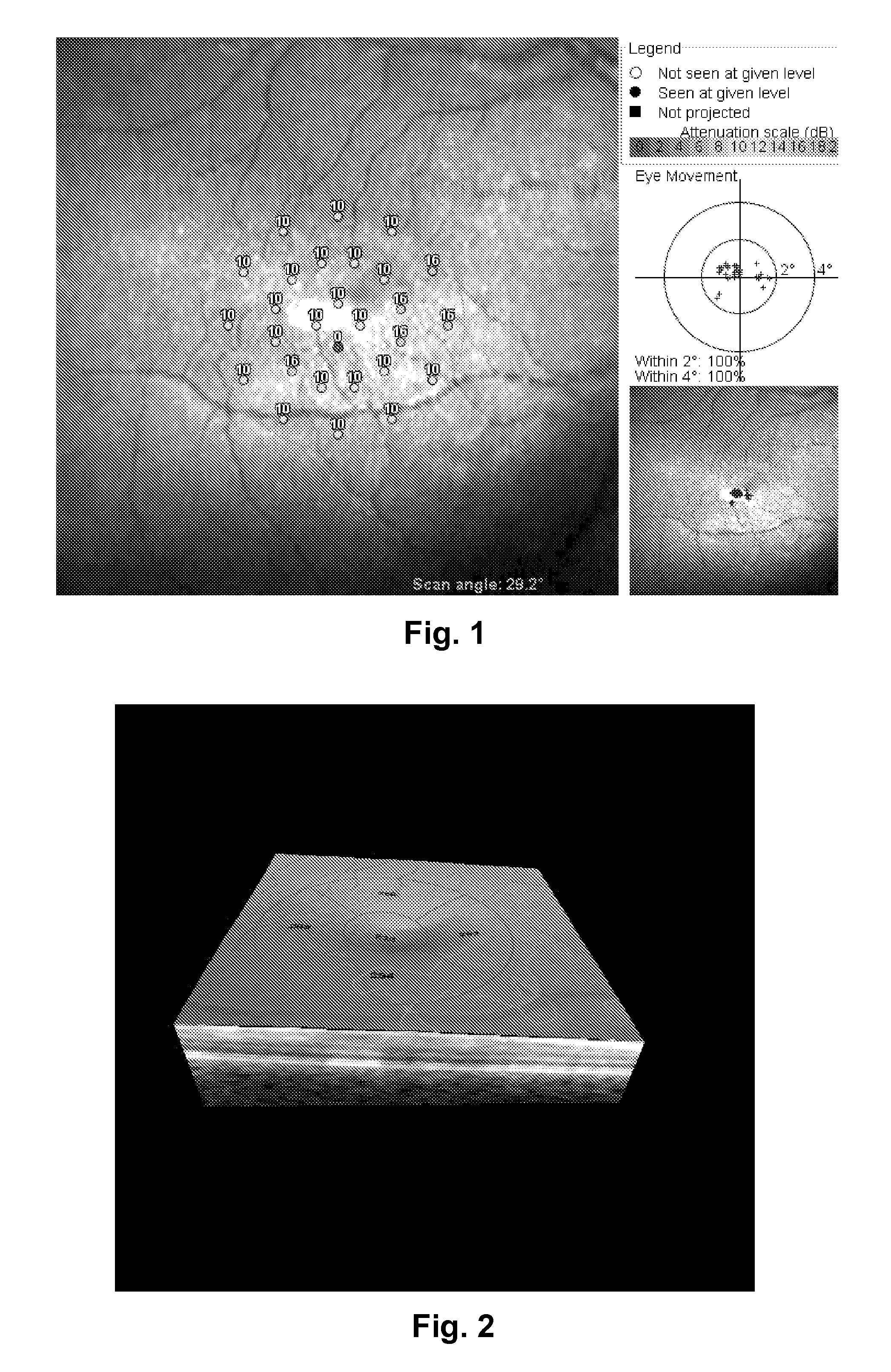

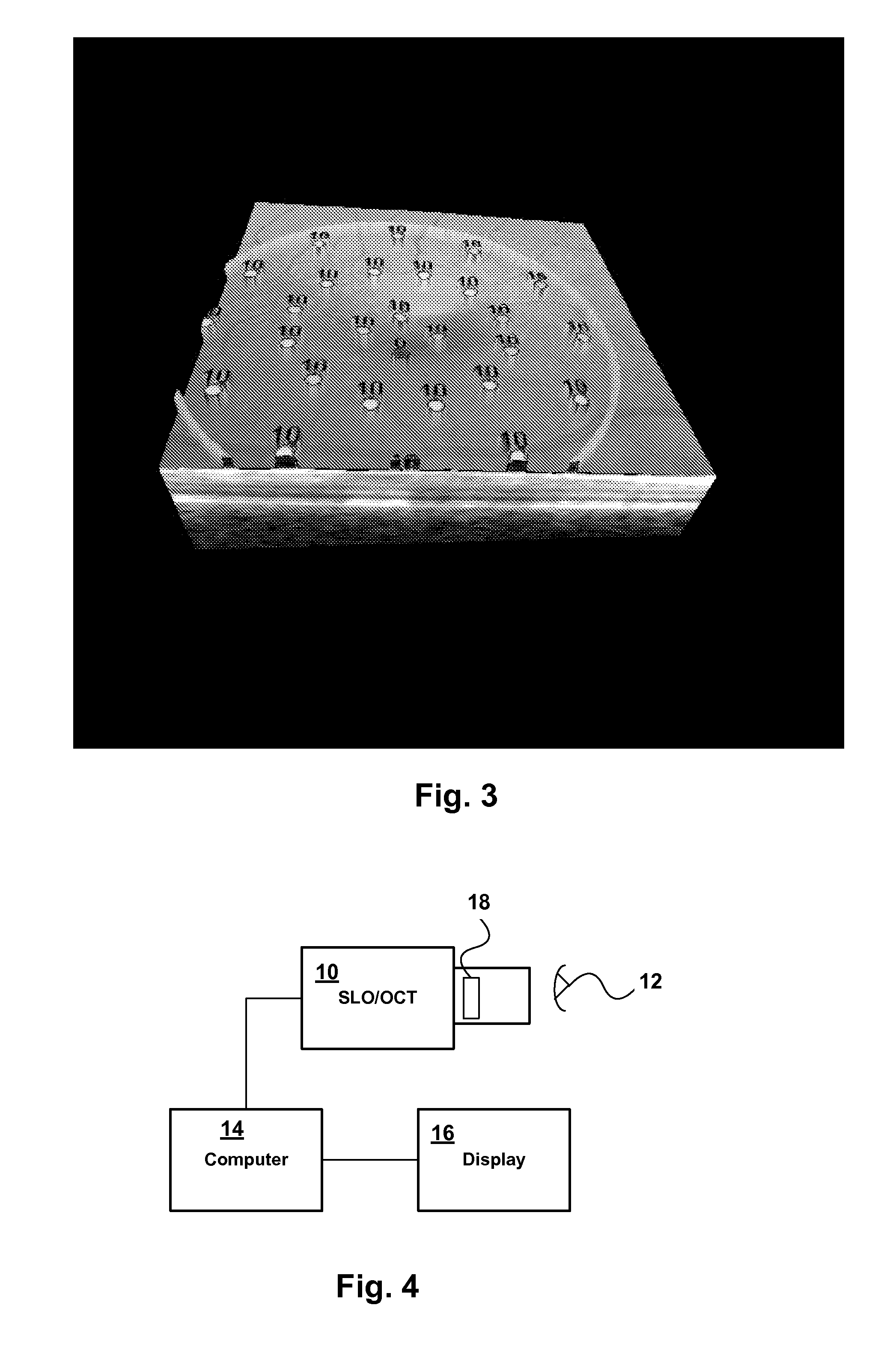

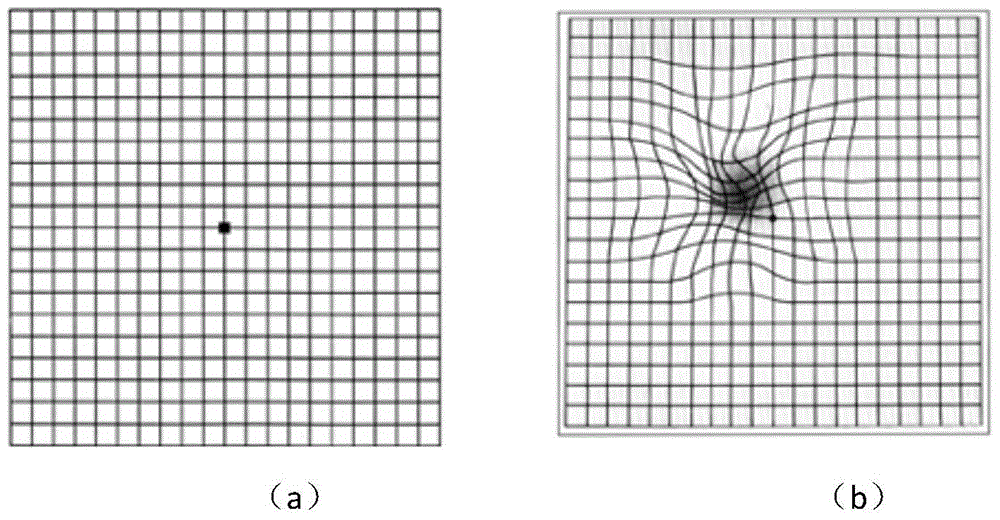

Method for Performing Micro-Perimetry and Visual Acuity Testing

ActiveUS20090141240A1Less examination timePrecise processDiagnostic recording/measuringUsing optical meansVision inspectionRetina

A visual acuity examination is performed on a patient by bringing a confocal imaging apparatus up to a patient's eye. Stimuli at various points in the patient's field of view are generated while the patient fixates on a point. The patient's responses to the stimuli are recorded with the movement of the eye with is tracked with the aid of the confocal imaging apparatus. The position of said stimuli on the retina is corrected to take into account any movement of the eye between stimuli.

Owner:OPTOS PLC

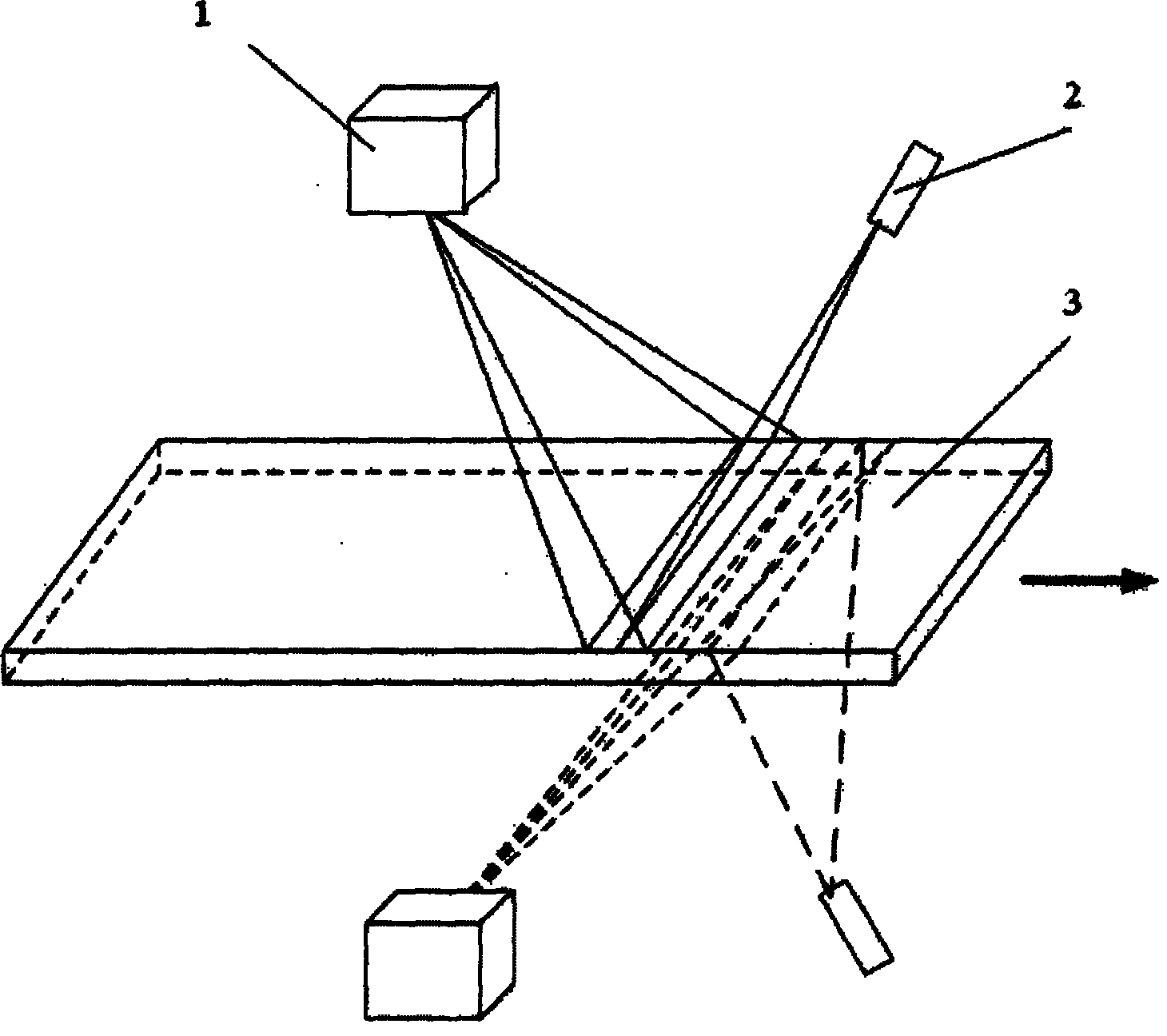

Aluminum flatness visual inspection system

InactiveCN102278958AThe effect is positive and obviousUsing optical meansCamera lensVision inspection

A visual inspection system for flatness of an aluminum plate, comprising a camera and a laser light source, the optical axis of the camera lens forms an angle with the movement plane of the aluminum plate transmission line, the laser light source and the camera are arranged on the same side of the movement plane of the aluminum plate transmission line, and the projection direction of the laser light source is in line with the movement plane of the aluminum plate transmission line The movement plane of the aluminum plate transmission line is at an included angle. The laser light source projects a straight line laser to the aluminum plate on the aluminum plate transmission line. The camera captures the laser projection line on the aluminum plate. According to the bending degree of the laser projection line in the camera, the height change of the aluminum plate plane is judged. The laser projects a straight line from an oblique angle on the plane of the aluminum plate, and detects the degree of curvature of each point of the line in the captured image to obtain the change in height at that point. When the entire aluminum plate is scanned once, the height fluctuation of the entire plane can be obtained. . Compared with the plane of the standard aluminum plate, the area of height change can be obtained to determine whether the flatness of the aluminum plate meets the requirements of process production. According to the inspection results, a qualified or unqualified signal is given.

Owner:SHANGHAI RO INTELLIGENT SYST

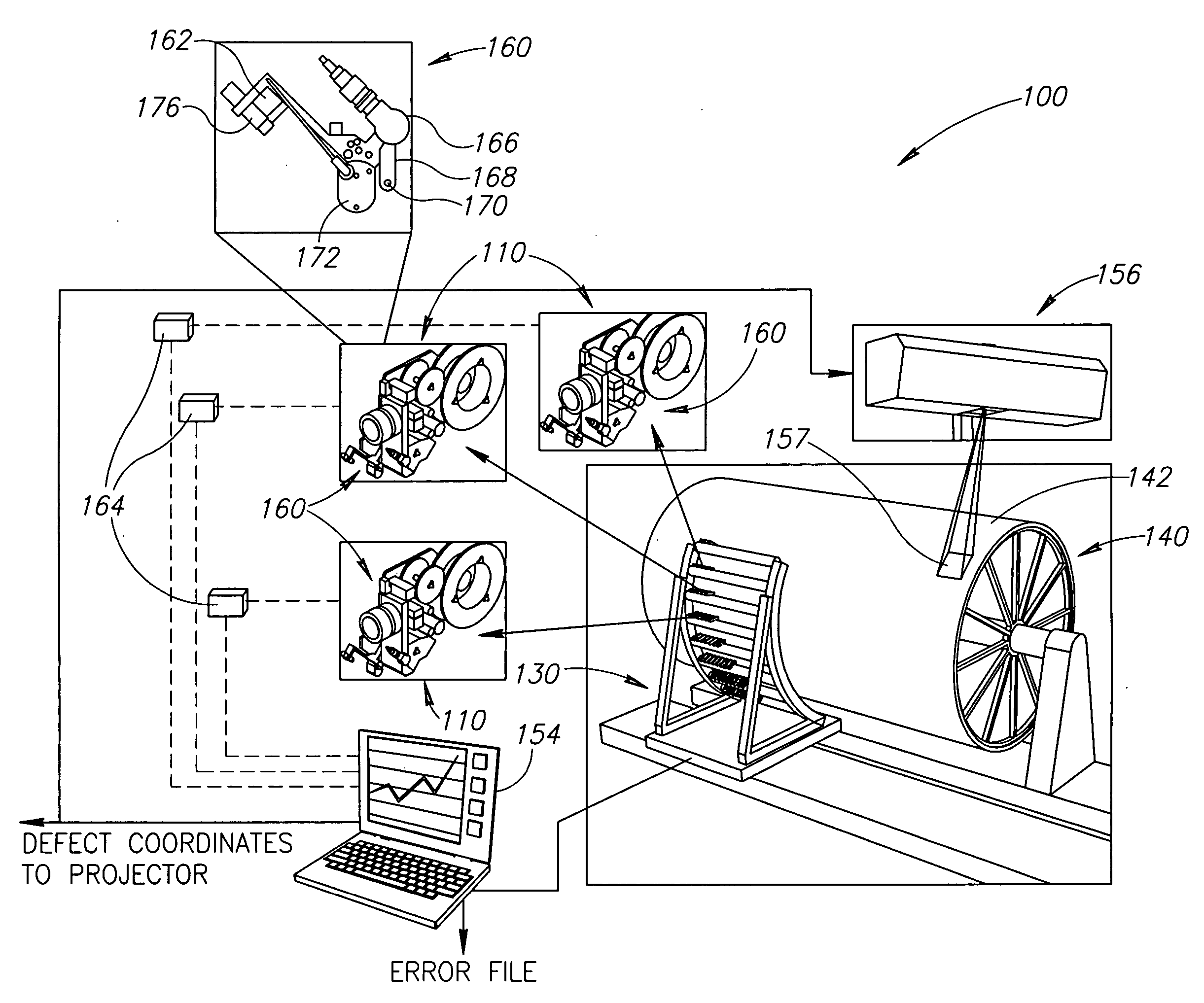

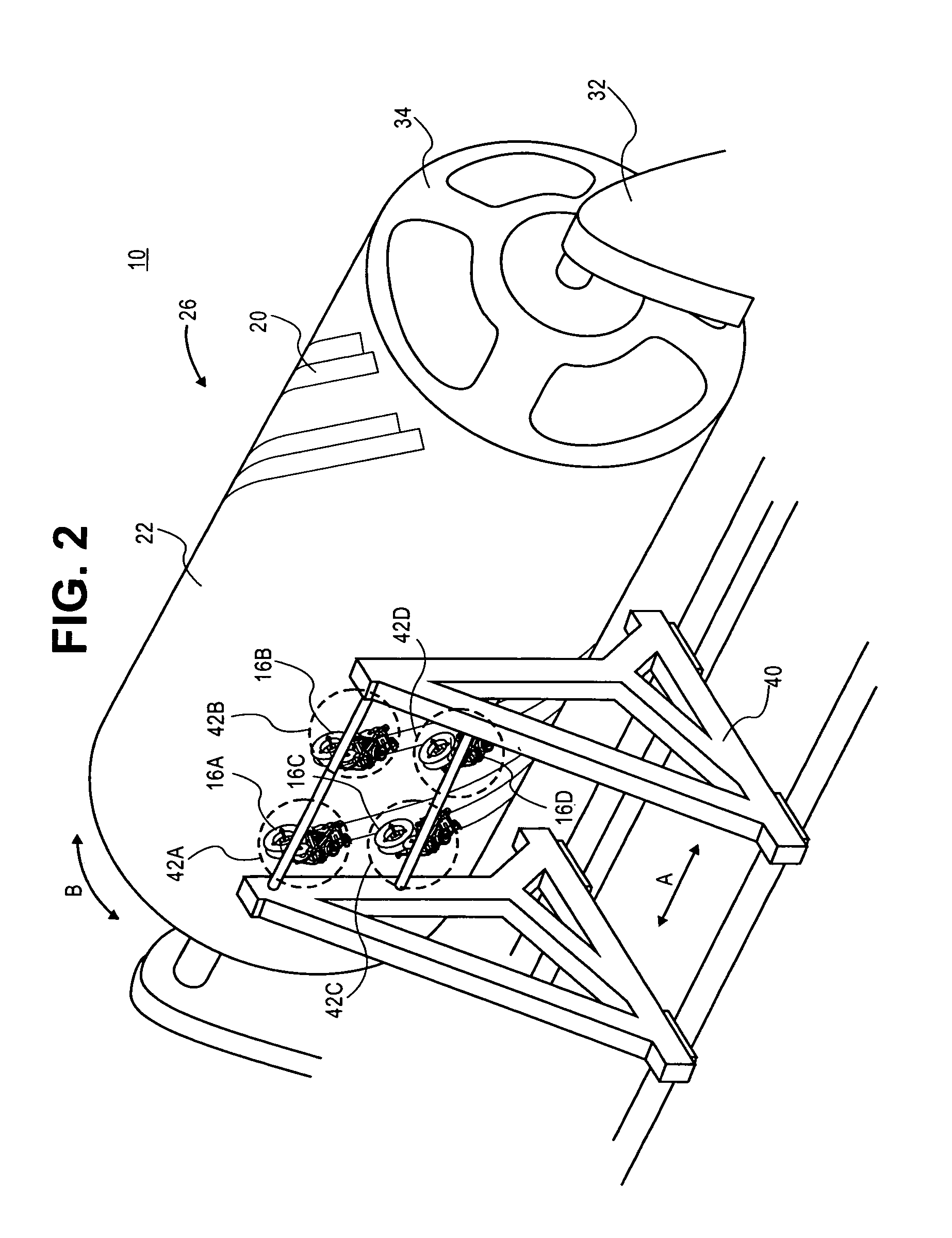

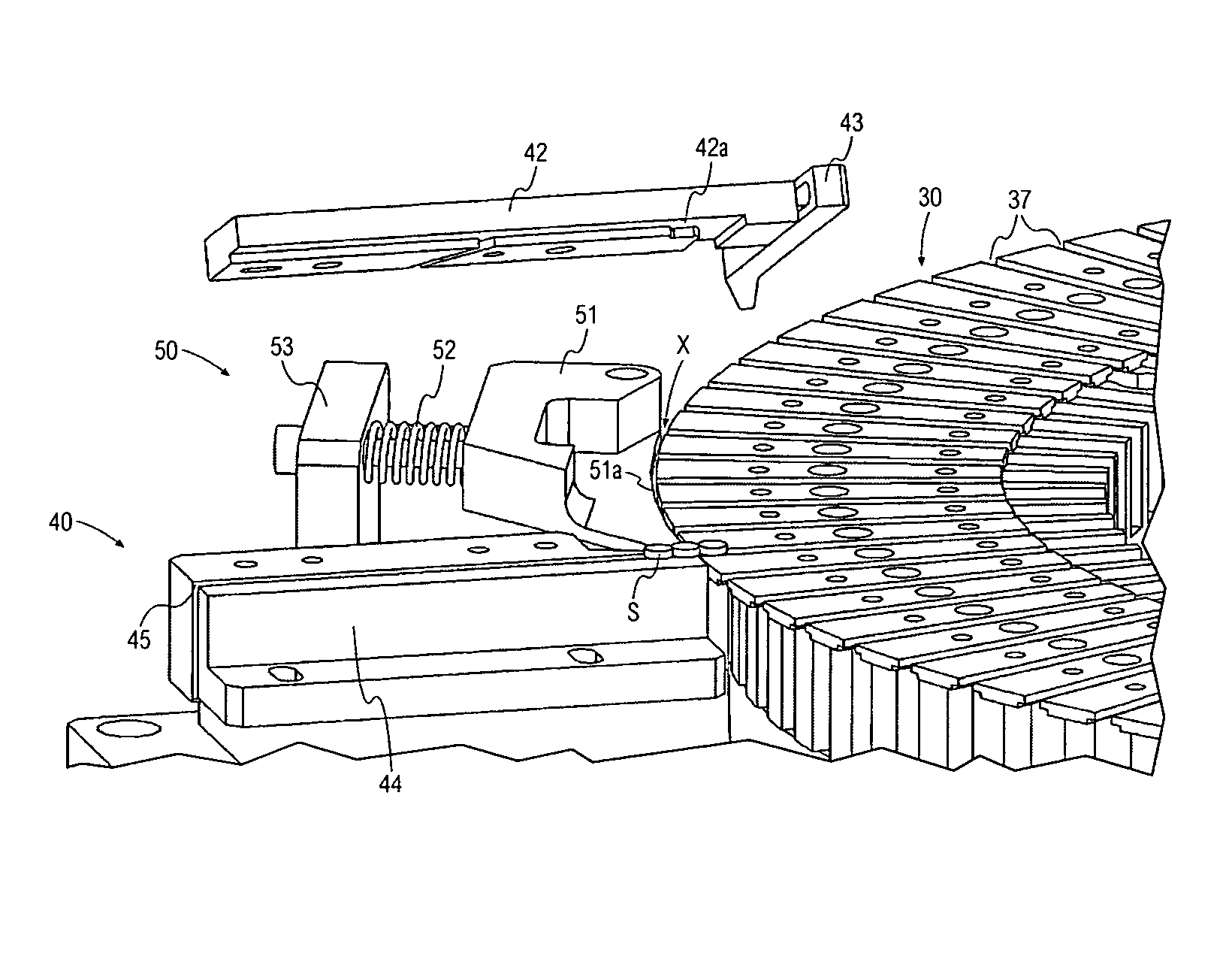

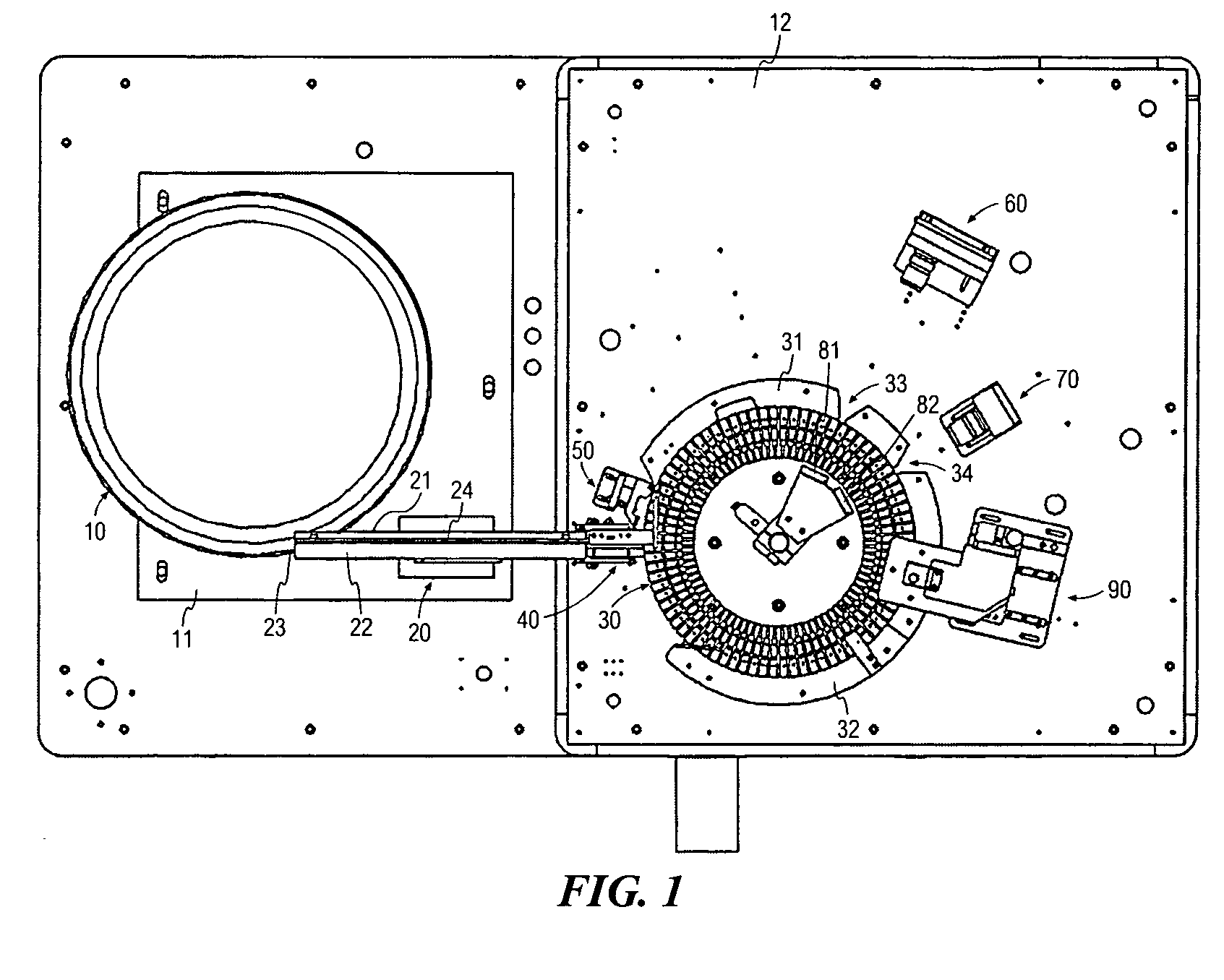

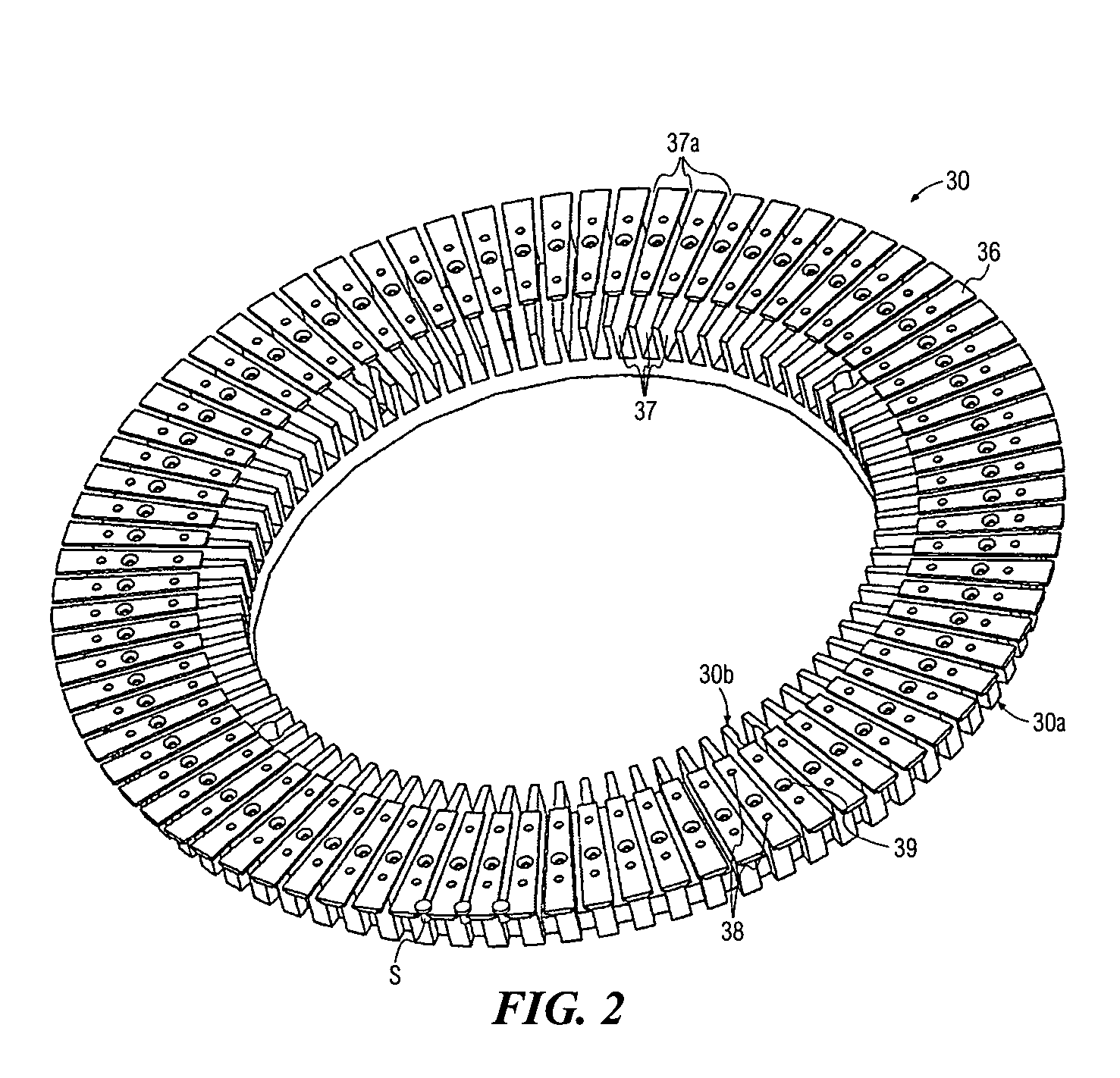

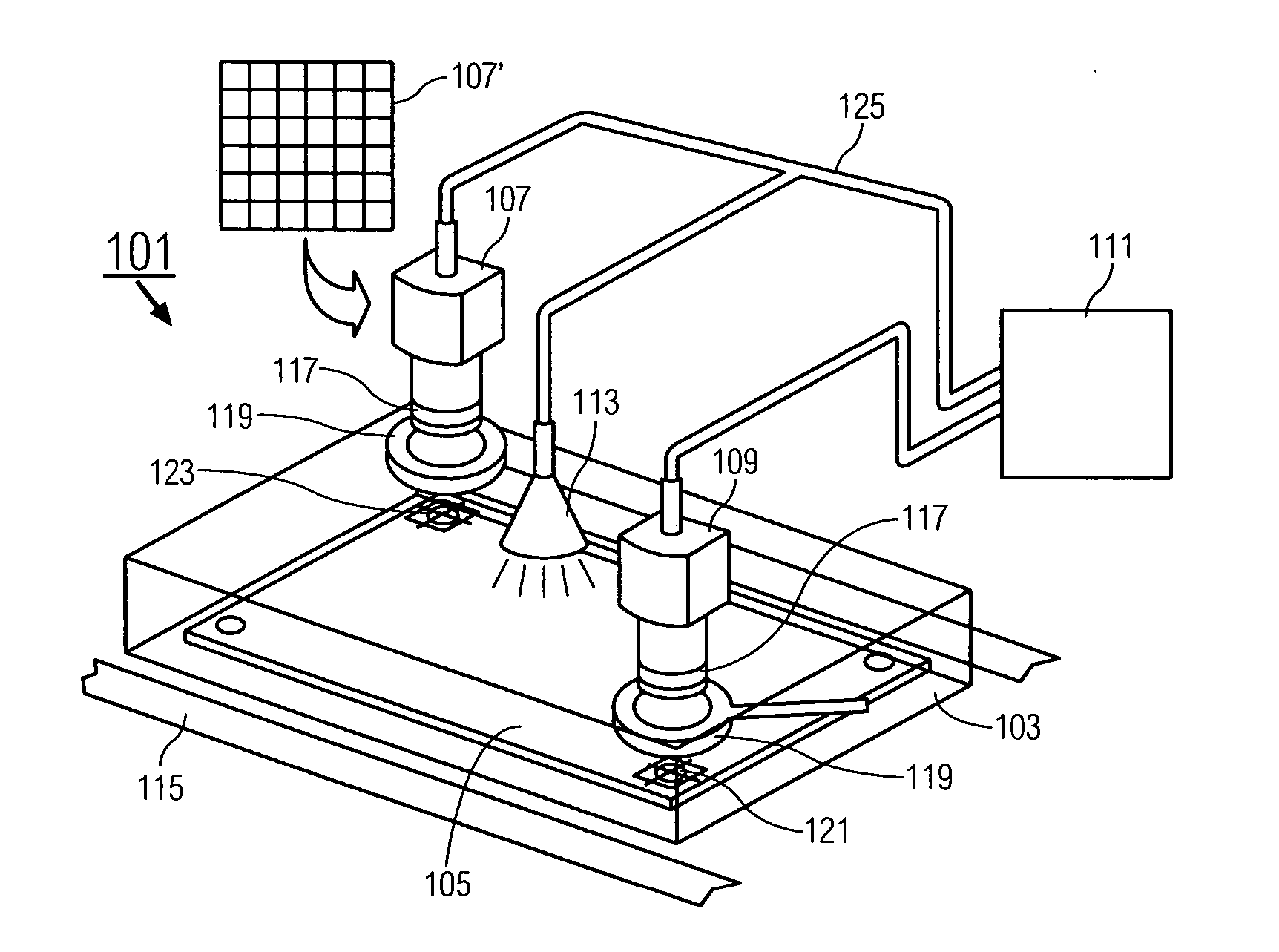

Vision inspection system device and method

ActiveUS20070229805A1Investigating composite materialsOptically investigating flaws/contaminationVision inspectionVisual perception

A course material that is applied to a substrate during fabrication of a composite item is inspected by a system that includes a vision assembly. The vision assembly includes an area light, a line generator, a sensor, and an image processor. The area light illuminates an area of the course material. The line generator generates a line of illumination across the area. The sensor captures an image of the area. The image processor analyzes the image. The image processor is configured to identify debris on the course material in response to the area light being activated and the image processor is configured to identify placement aberrations in response to the line generator being activated.

Owner:THE BOEING CO

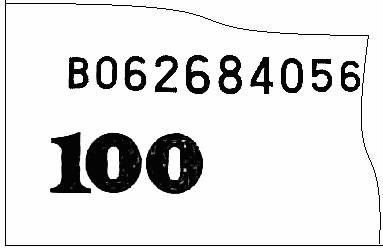

Paper currency number identification method based on currency detector

InactiveCN101923741ASimple recognition calculation methodEfficient identification calculation methodPaper-money testing devicesCharacter and pattern recognitionTemplate matchingVision inspection

The invention discloses a paper currency number identification method based on a currency detector. A COMS (Complementary Metal Oxide Semiconductor) sensor is firstly installed on the currency detector and connected with a control system. The identification method comprises the following steps of: firstly, preliminarily locating a number region on paper currency; secondly, dividing the paper currency numbers which comprises the steps of: preliminarily dividing ten characters, precisely dividing the ten characters and scaling the characters; and thirdly, character identification which comprises the steps of calculating a gridding feature matrix of the divided characters, making a template matrix and identifying the characters by utilizing a matrix template matching identification method. The method mainly aims to Renminbi of 2005 version, adopts vision inspection of a computer as important technical means, utilizes a digital image processing technology, integrates image acquistion, number locating, number dividing and character identification into a whole, finally identifies 26 letters from A to Z and ten numbers from 0 to 9 and realizes the online automatic identification of the paper currency numbers.

Owner:SHAOXING COUNTY RUIQUN TEXTILE MACHINERY TECH

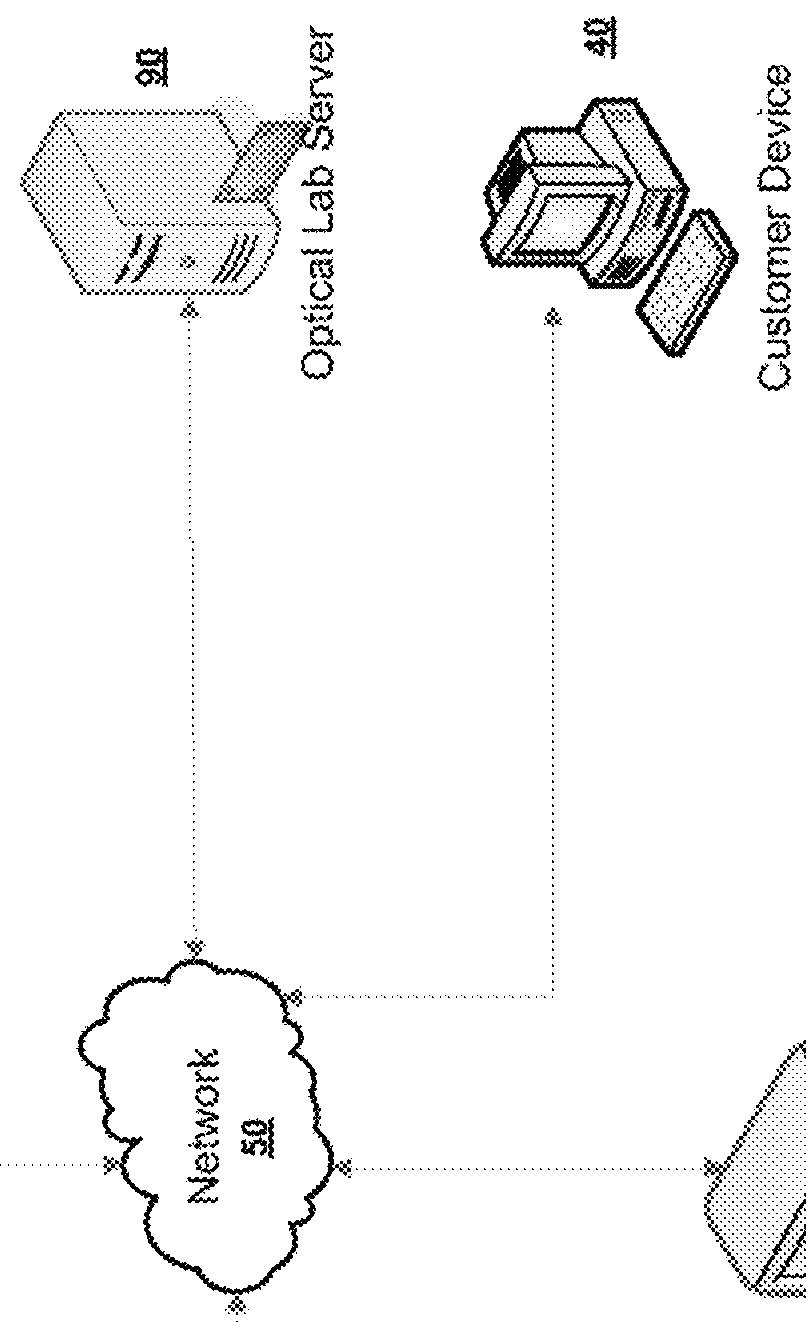

Systems and methods for enabling customers to obtain vision and eye health examinations

Systems and methods are provided for eye health and vision examinations. A customer diagnostic center is configured to generate customer examination data pertaining to an examination of a customer's eye. The customer diagnostic center provides a user interface for communicating with a customer and ophthalmic equipment for administering tests to the customer. A diagnostic center server is configured to receive the customer examination data from the customer diagnostic center over a network and allow the customer examination data to be accessed by an eye-care practitioner. A practitioner device associated with the eye-care practitioner is configured to receive the customer examination data from the diagnostic center server and display at least a portion of the customer examination data to the eye-care practitioner. Customer evaluation data is generated pertaining to the eye-care practitioner's evaluation of the customer examination data. An eye health report is provided to the customer via the network.

Owner:20 20 VISION CENT

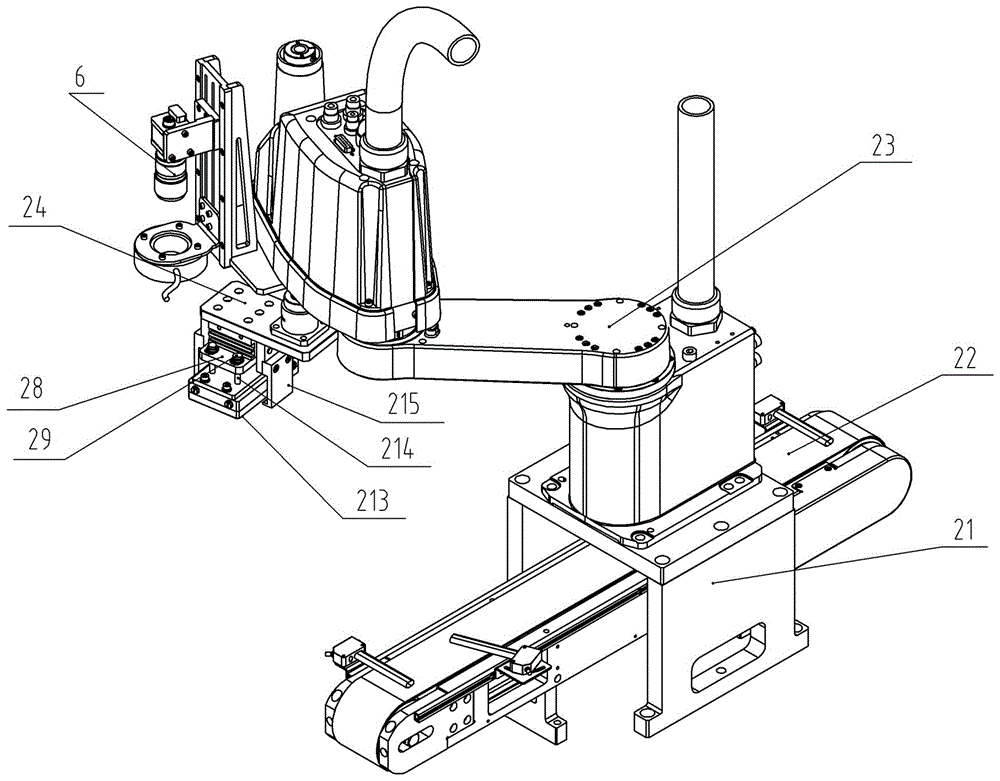

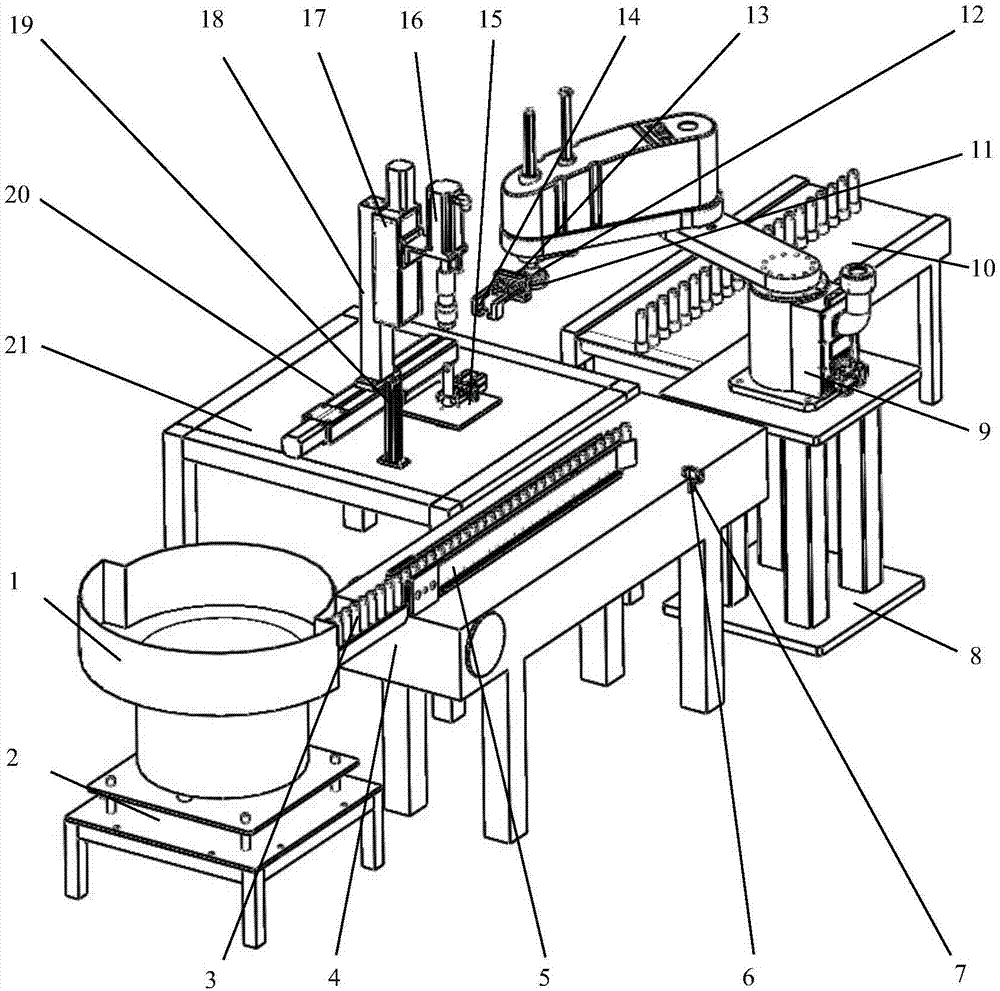

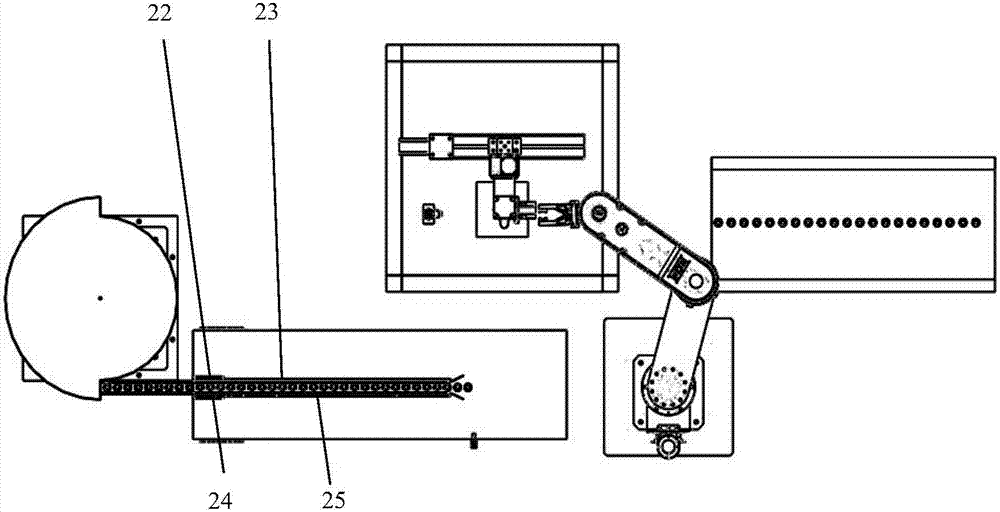

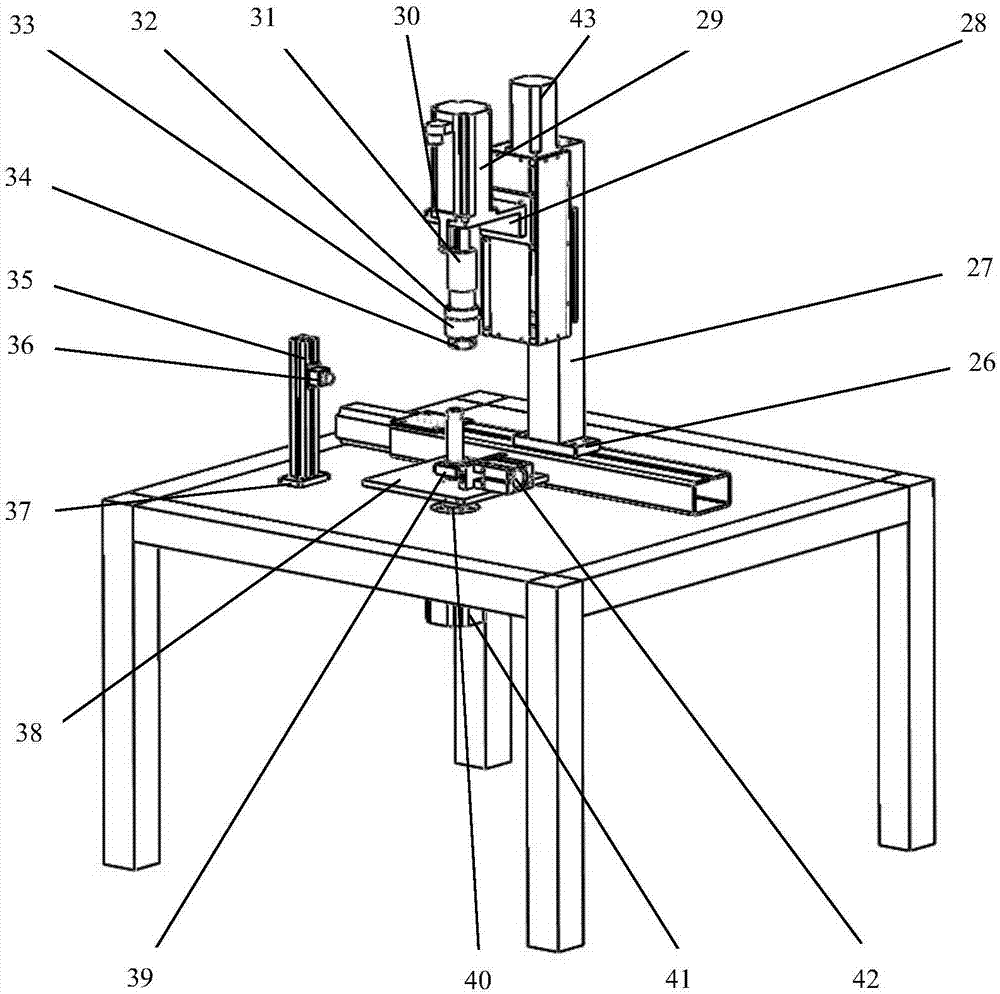

Visual automatic thread inspection device and using method

InactiveCN107289847ALow costReduce labor intensityMechanical clearance measurementsOptically investigating flaws/contaminationVision inspectionEngineering

The invention discloses a visual automatic thread inspection device and a using method. The visual automatic thread inspection device comprises a vibrating disk device, a first conveying line device, a robot device, an integrated inspection platform and a second conveying line; the vibrating disk device comprises a vibrating disk and a vibrating disk bottom plate; the first conveying line device comprises a first conveying line, a limiting device, a thread workpiece, a photoelectric sensor and a photoelectric sensor mounting plate; the robot device comprises a four-degree-of-freedom robot, a first clamping cylinder and a first clamping gripper; the integrated inspection platform comprises a first linear slide rail, a second linear slide rail, a thread go / no go gauge inspection device, a thread vision inspection device and a workpiece fixing device; and the vibrating disk device is located at the input end of the first conveying device, the robot device is located between the output end of the first conveying line device and the input end of the second conveying line, and the integrated inspection platform is arranged on one side of the output end of the first conveying line device. The device can accurately detect the thread size and the appearance defect, and is high in automation degree.

Owner:ANHUI HISEED ROBOT CO LTD

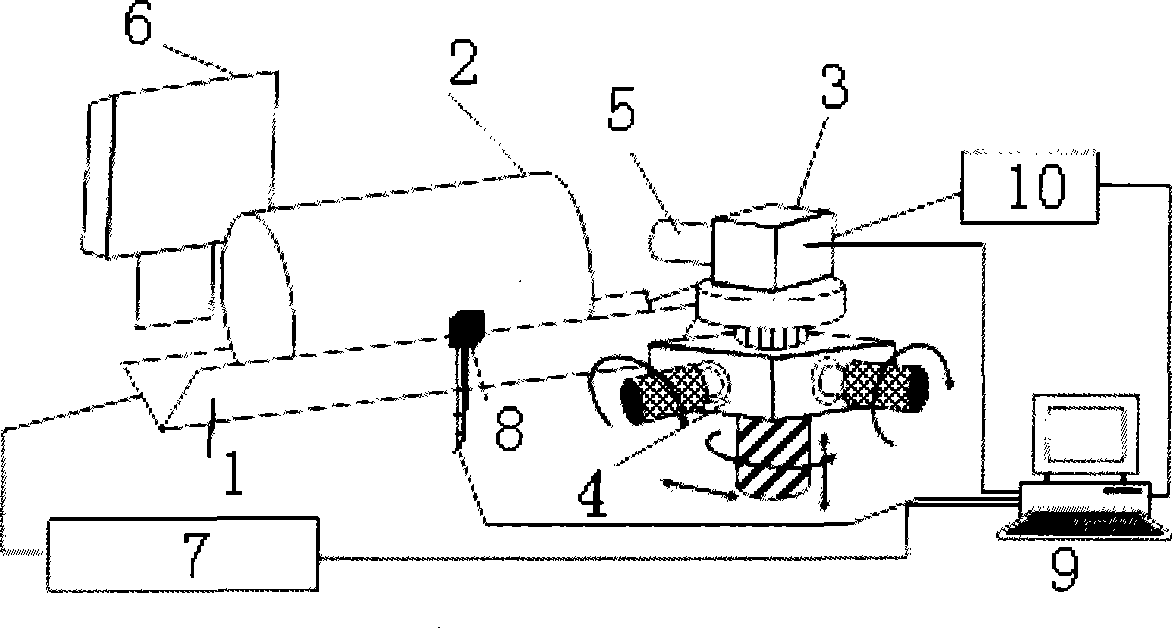

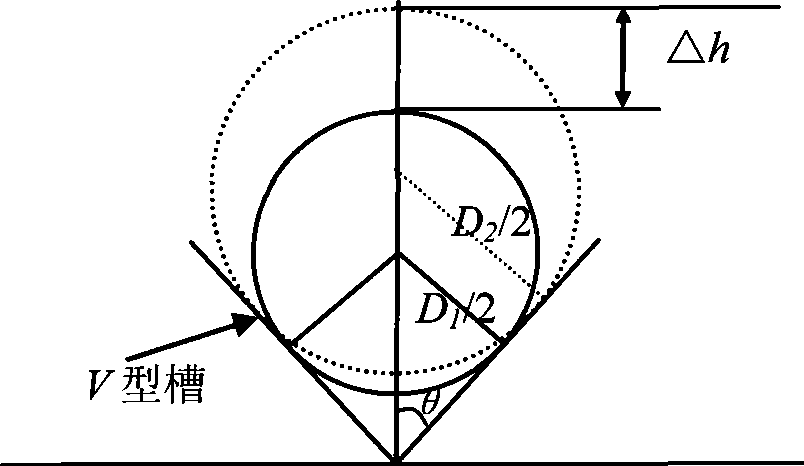

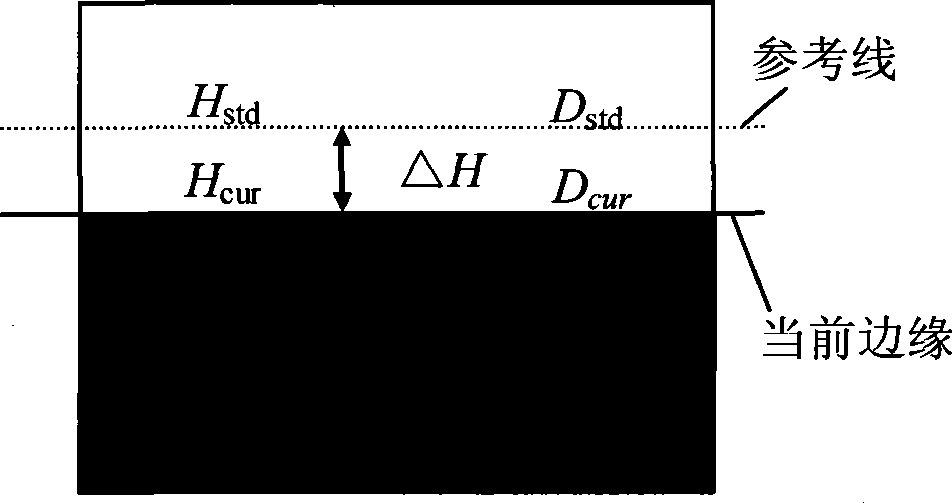

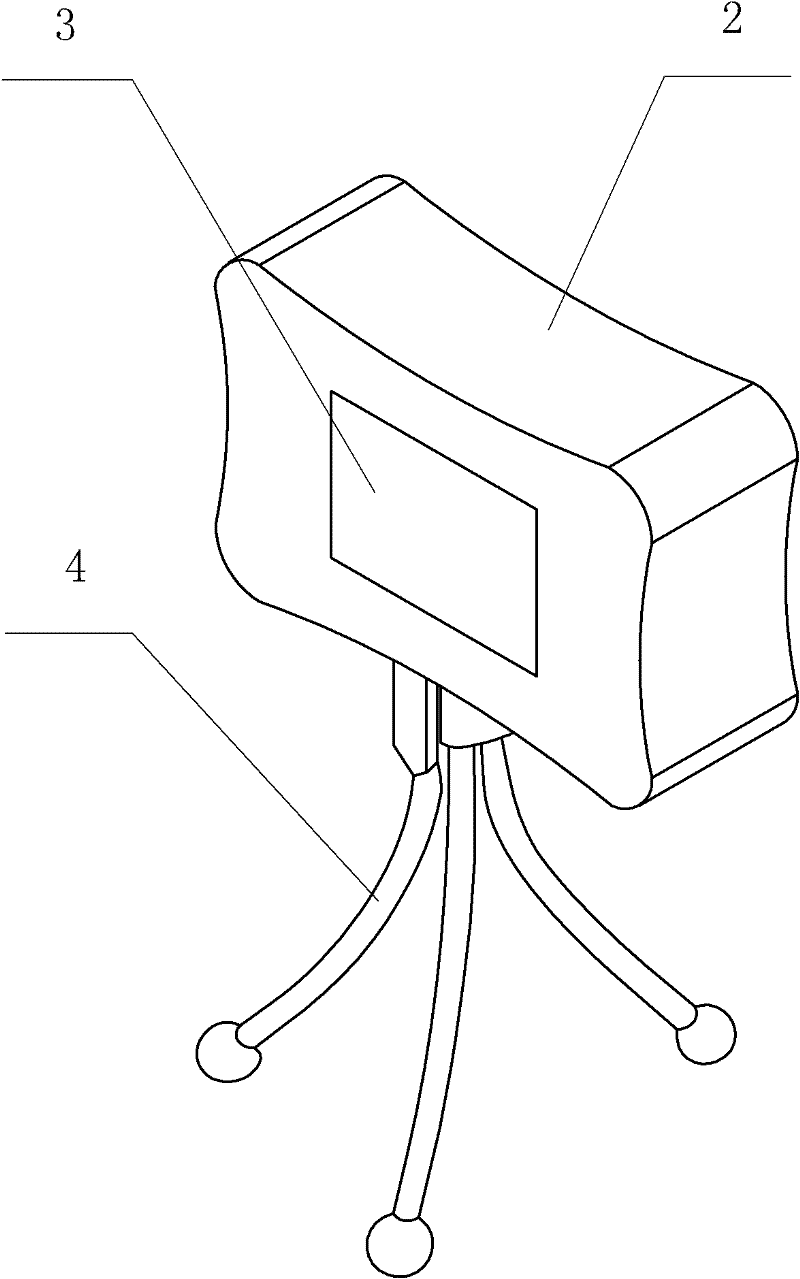

Cylinder on-line diameter measurement apparatus and measurement method thereof

InactiveCN101387499AAchieve precise positioningImprove diameter measurement accuracyUsing optical meansVision inspectionMeasurement device

The invention belongs to the technical field of computer vision inspection and image test, and relates to a device for measuring the diameter of a column on line. The device comprises a V-shaped groove conveyor belt for placing the column to be tested, an electric motor and an electric motor driver for driving the V-shaped groove conveyor belt to move uniformly in a straight line, and a video camera for acquiring images of the column to be tested. The video camera has a micro camera positioned on a tripod head, and the images acquired by the video camera are transmitted to a computer. Meanwhile, the invention provides a measuring method adopted by the device. The device and the method can carry out quick high-precision online measurement for the column. The device has a simple structure, can be regulated conveniently, and is suitable for the measurement of the columns with various diameters.

Owner:TIANJIN UNIV

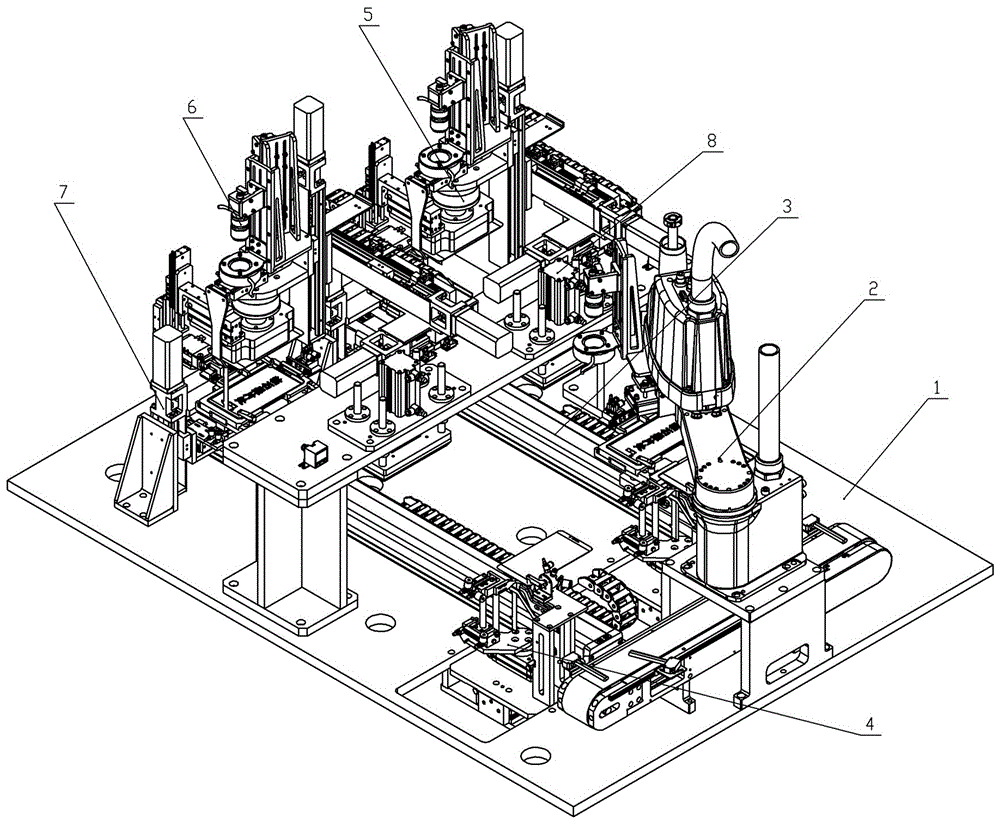

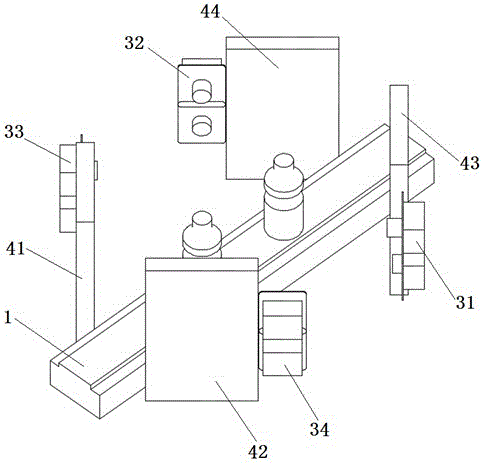

Vision inspection device for appearance defects of rollers

ActiveCN104889075ARealize visual inspectionHigh precisionOptically investigating flaws/contaminationSortingProduct inspectionVision inspection

The invention discloses a vision inspection device for appearance defects of rollers, and relates to the technical field of vision inspection devices. The device comprises a first conveying belt, a second conveying belt, a first image device, a first image processing system and a first inferior-quality product removing device and further comprises a rotating disc, a rotating disc driving device, roller sucking devices, a second image capturing device and a second image processing system. The first conveying belt conveys rollers to be inspected, the second conveying belt conveys qualified rollers, and the first image capturing device, the first image processing system and the first inferior-quality product removing device inspect the appearance defects of the upper sides of the rollers and remove unqualified inferior-quality products; and the rotating disc, the rotating disc driving device, the roller sucking devices, the second image capturing device and the second image processing system are used for inspecting the appearance defects of the lower sides of the rollers and remove the unqualified inferior-quality products. Vision inspection can be comprehensively carried out on the rollers in a no-dead-corner manner, and meanwhile, the unqualified inferior-quality products are removed; and automation and intelligence of the whole process are achieved, and precision and efficiency of roller inferior-quality product inspection can be improved.

Owner:临清市万达轴承有限公司

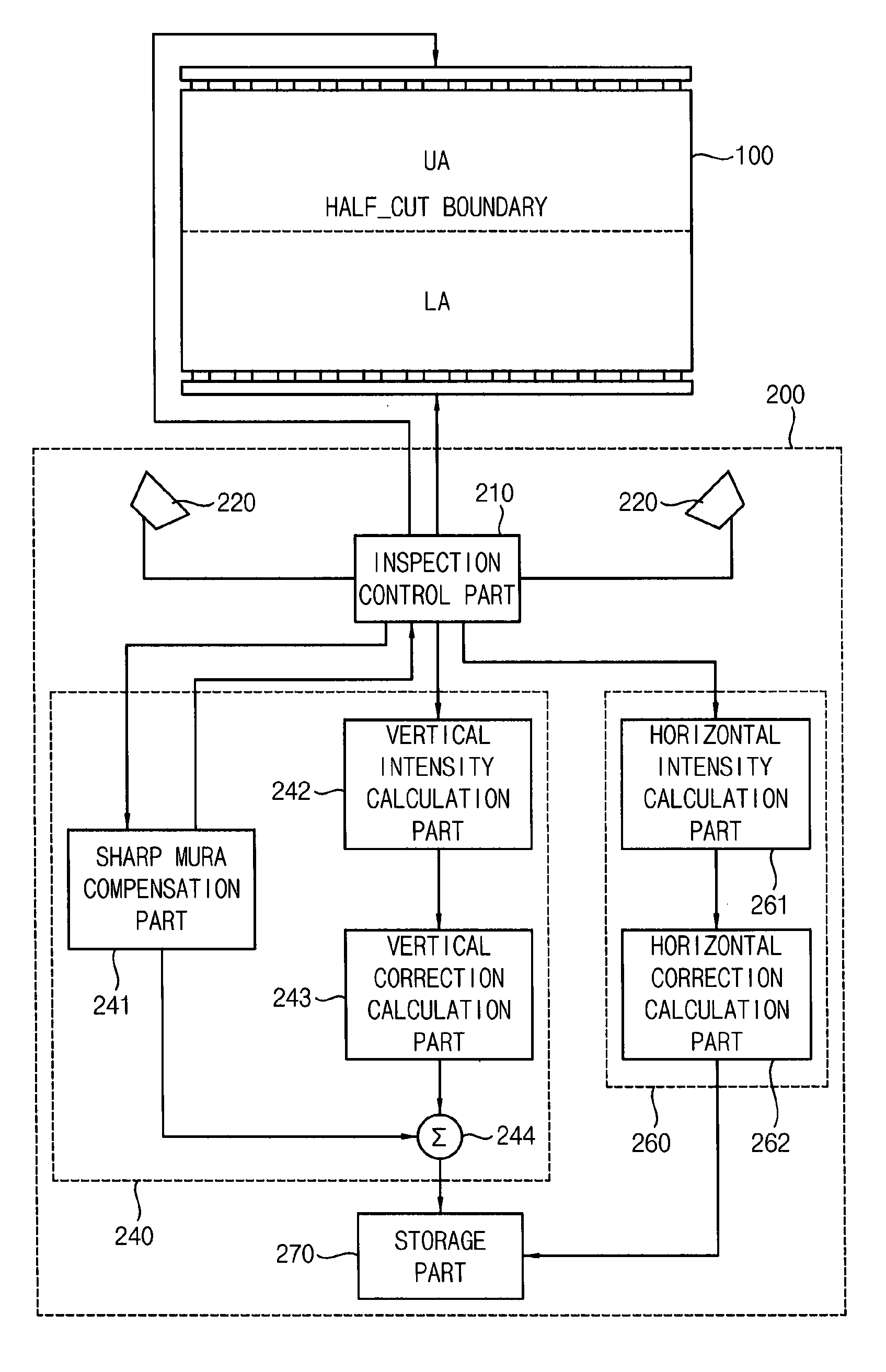

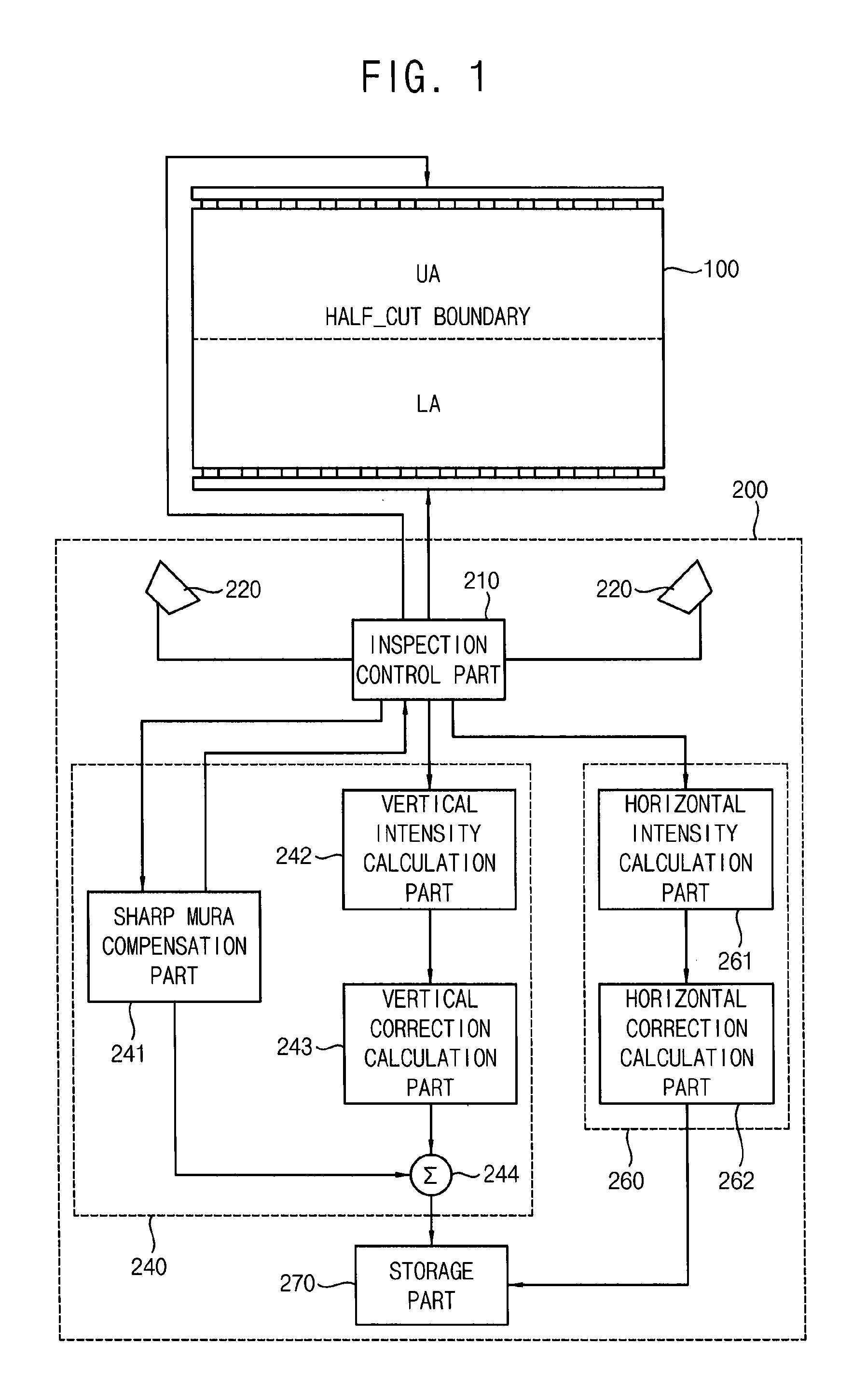

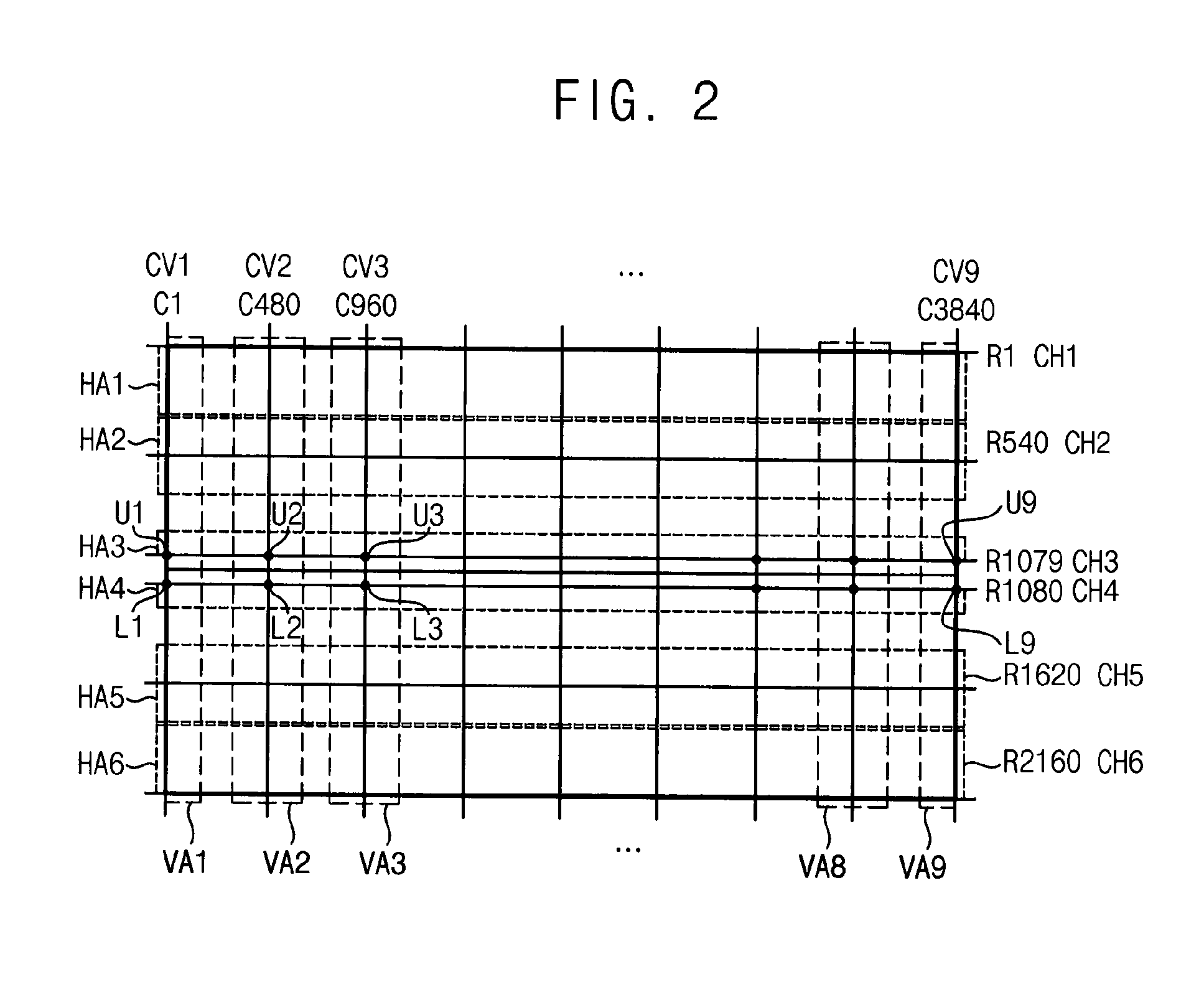

Method of compensating mura of display apparatus and vision inspection apparatus performing the method

ActiveUS20150187289A1Increase the differenceStatic indicating devicesTesting optical propertiesVision inspectionVisual perception

A method of compensating a Mura defect of a display apparatus, which includes a display area divided into an upper area and a lower area, includes calculating a sharp grayscale correction value of a predetermined sample grayscale displayed on the display apparatus, where the sharp grayscale correction value is configured to compensate a sharp horizontal Mura between the upper and lower areas, displaying a corrected sample grayscale on the display apparatus based on the predetermined sample grayscale and the sharp grayscale correction value, sensing the corrected sample grayscale displayed on each of a plurality of sample areas defined on the display area based on a Mura type, calculating an intensity profile of the sample grayscale and a target intensity profile configured to compensate the intensity profile of the sample grayscale, calculating a grayscale correction value of the sample area using the intensity profile and the target intensity profile.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

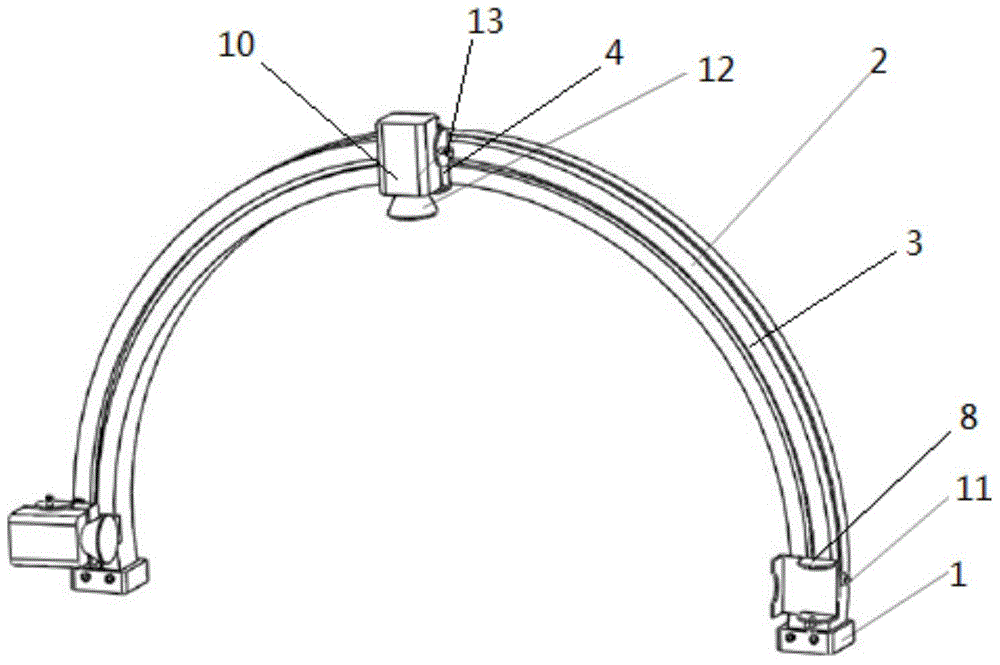

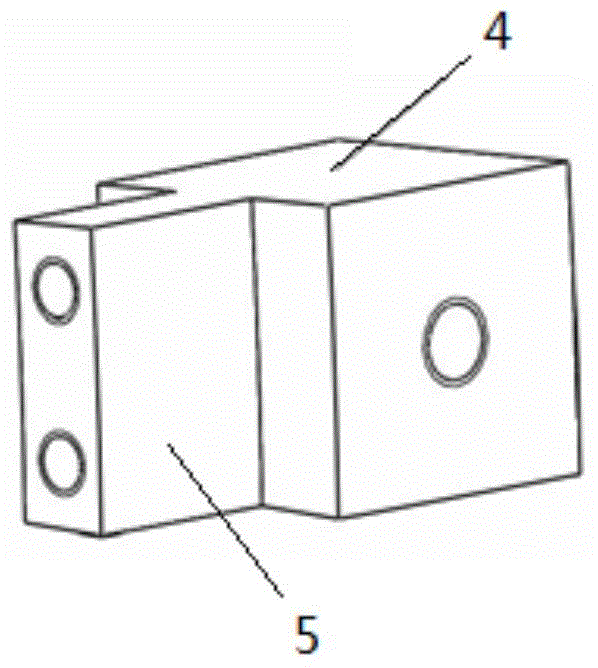

Polar coordinate composite camera rack for vision inspection

InactiveCN104880211AIncrease or decrease the quantity at willEasy to measureMeasurement apparatus componentsVision inspectionVisual inspection

The invention discloses a polar coordinate composite camera rack for vision inspection. The polar coordinate composite camera rack includes end covers and an arc-shaped rack. The two end covers are mounted on two ends of the arc-shaped rack. The end covers are fixed on a working table. The arc-shaped rack is provided with a guide rail. A slide block is mounted in the guide rail. The slide block can slide on the arc-shaped rack along the guide rail. A support fine adjustment device is connected with the slide block fixedly. The support fine adjustable device is connected with the camera fixing support. The support fine adjustment device is used for position adjustment of the camera fixing support which is used for fixing cameras. The camera rack provided by the invention has beneficial effects that the cameras are arranged in the normal direction of the arc-shaped rack and the camera quantity can be changed and the camera positions can be adjusted freely according to detection requirements and lighting modes. The rack can be mounted and dismounted conveniently and the angle parameters facilitate measurement.

Owner:HUBEI UNIV OF TECH

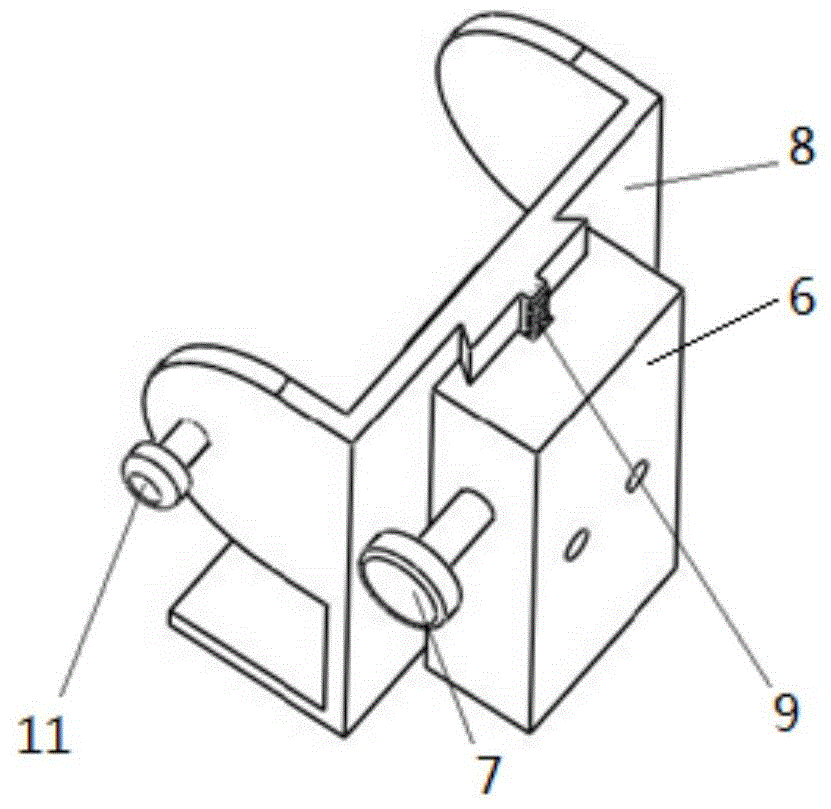

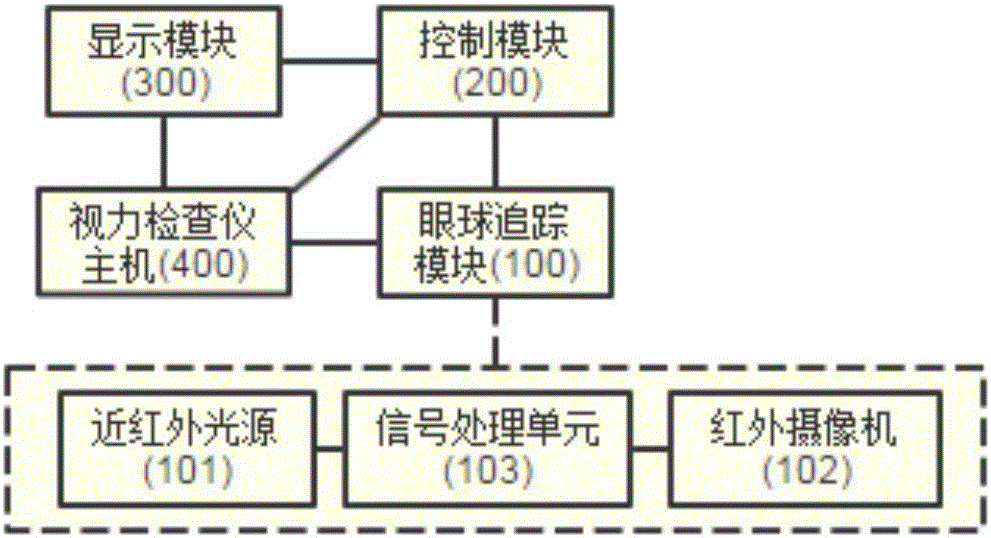

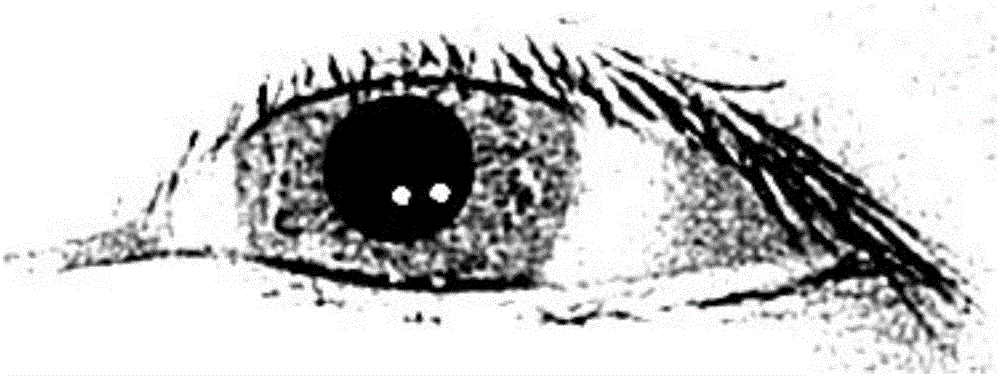

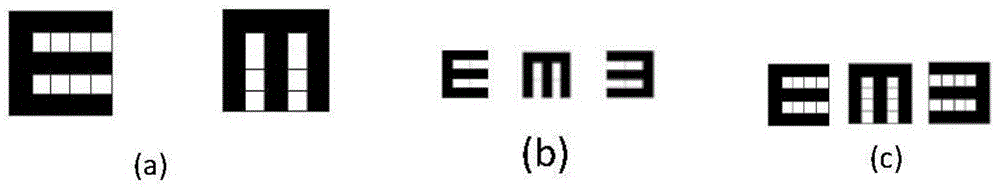

Full-automatic visual acuity examination method and device for infants

ActiveCN106037627ATime-consuming and laborious to solveSolve the resultPhoroptersVision inspectionComputer science

The invention provides a full-automatic visual acuity examination method and an examination device for infants; a stimulus graph can be automatically displayed, and the seeing position, direction and time of eyes of the infant can be automatically recorded and calculated; and meanwhile, a test result can be obtained upon automatic analysis. The full-automatic visual acuity examination device for the infants comprises an eyeball tracking module, a control module, a display module and a visual acuity examination instrument host, wherein the eyeball tracking module and the display module are connected to the visual acuity examination instrument host; the eyeball tracking module is used for locating the seeing position of the human eyes; the display module is used for displaying a pattern for examination; and by virtue of the control module, data communication among the visual acuity examination host, the display module and the eyeball tracking module is achieved.

Owner:上海青研科技有限公司

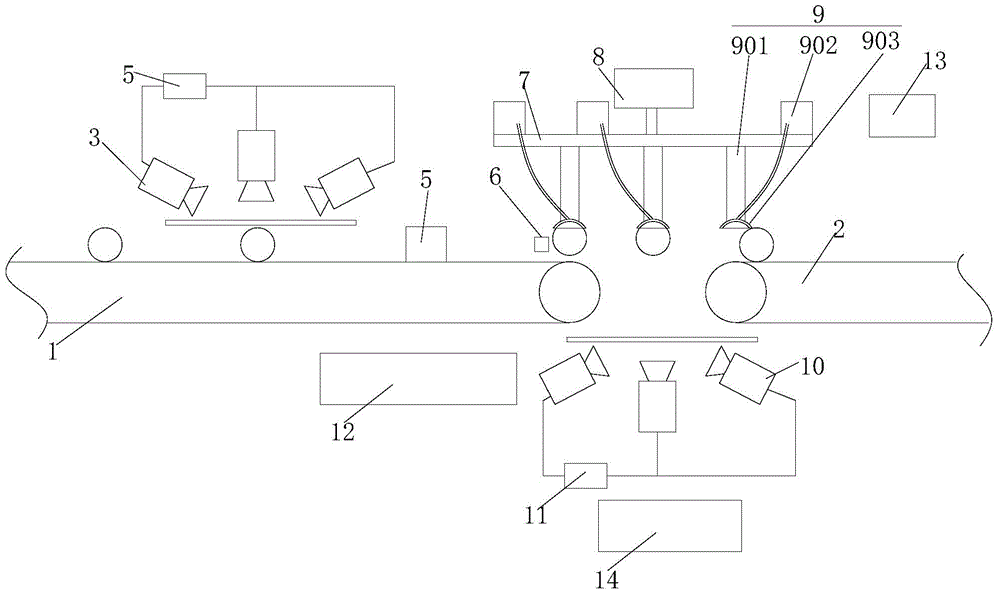

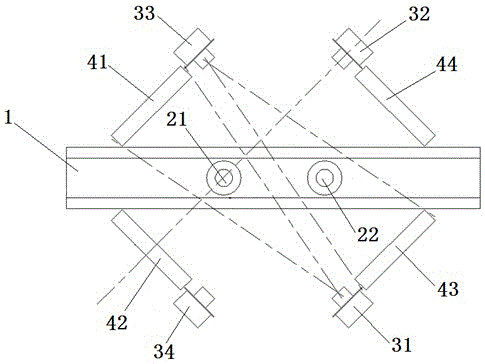

Device and method for 360-degree bottle body production line backlight vision inspection

InactiveCN105158267ASolve the problem of detecting multi-angle efficient photosHighlight blemishesOptically investigating flaws/contaminationProduction lineMachine vision

The invention provides a device and method for 360-degree bottle body production line backlight vision inspection. The device comprises a front inspection station and a back inspection station which are arranged on a conveyor belt of a production line, a first set of cameras, a third set of light sources, a fourth set of cameras and a second set of light sources which are arranged on one side of the conveyor belt of the production line and a second set of cameras, a fourth set of light sources, a third set of cameras and a first set of light sources which are arranged on the other side of the conveyor belt of the production line. According to the device and method, efficient multi-angle photographing of bottle body inspection is achieved, the high-speed exposure characteristics of the industrial cameras and the plane light sources are utilized, vision imaging covering the side face of a bottle body is achieved, industrial defects, such as dirty spots, loss, flashing, deformations and uneven thickness, of the bottle body are highlighted, the two inspection stations are adopted, the space utilization rate is improved, and the structure is compact and reasonable; in addition, through the set photographing order, camera imaging is non-interfering, the device and the method are very suitable for a high-speed integrated machine vision inspection system, and therefore the purpose of efficient inspecting and selecting of the bottle body production line is achieved.

Owner:安徽省科亿信息科技有限公司

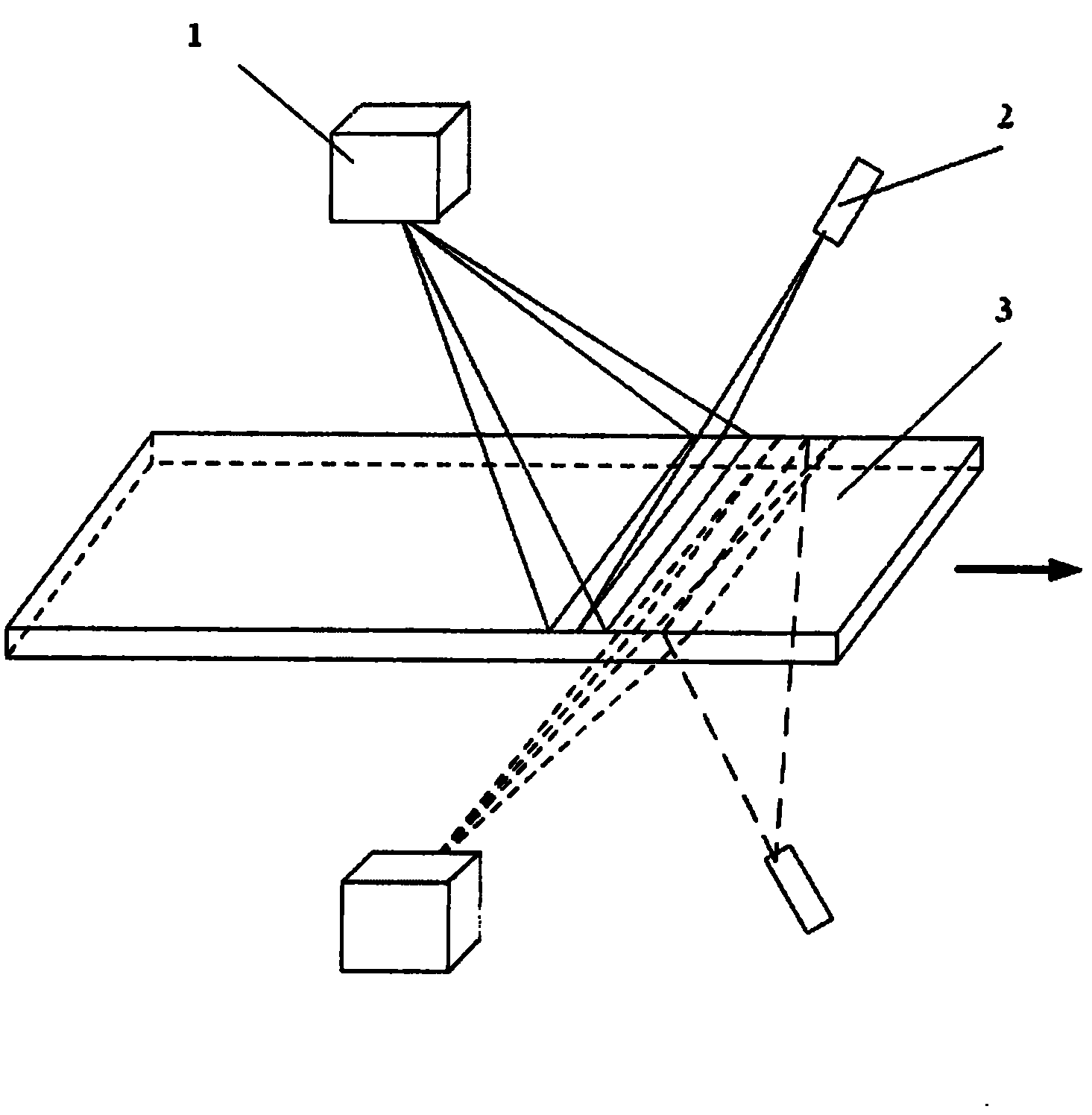

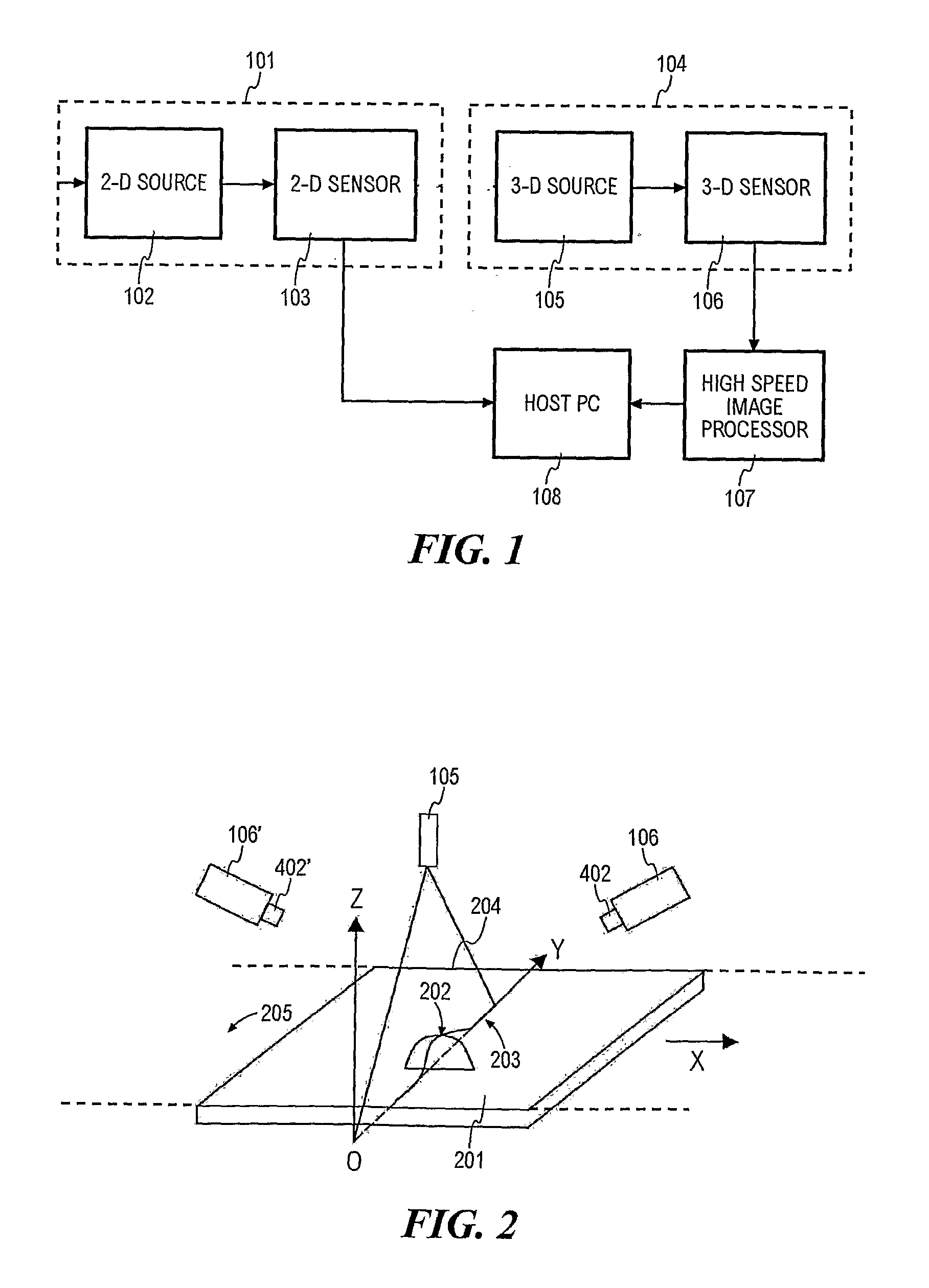

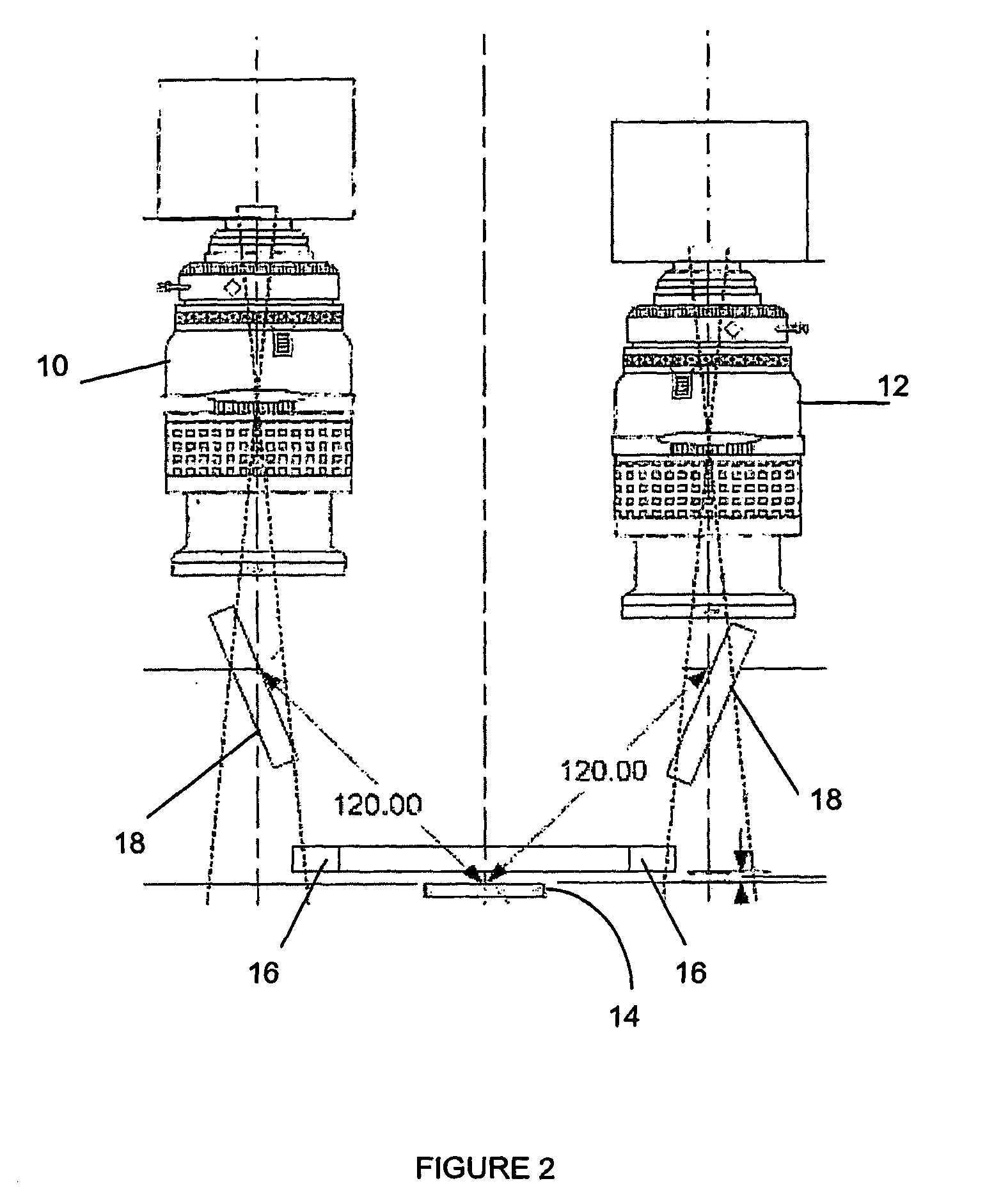

System for 2-D and 3-D Vision Inspection

There is disclosed an inspection system that combines 2-D inspection and 3-D inspection of the components of an electronic device into one compact module. The inspection system of the present invention comprises a 2-D image acquisition assembly for inspecting 2-D criteria of the components, a 3-D image acquisition assembly for inspecting 3-D criteria of the components, and a computer for control and data analyzing. The 3-D image acquisition assembly comprises a 3-D image sensor and a 3-D light source. The 3-D light source is preferably a laser capable of generating a planar sheet of light that is substantially perpendicular to the inspection plane of the electronic device. The 2-D image acquisition assembly comprises a 2-D sensor and a 2-D light source positioned above the holder. The 2D and 3D image acquisition assemblies are arranged so that the 2D inspection and 3D inspection can be done while the electronic device is being held in one location.

Owner:MIT SEMICON (TIAN JIN) CO LTD

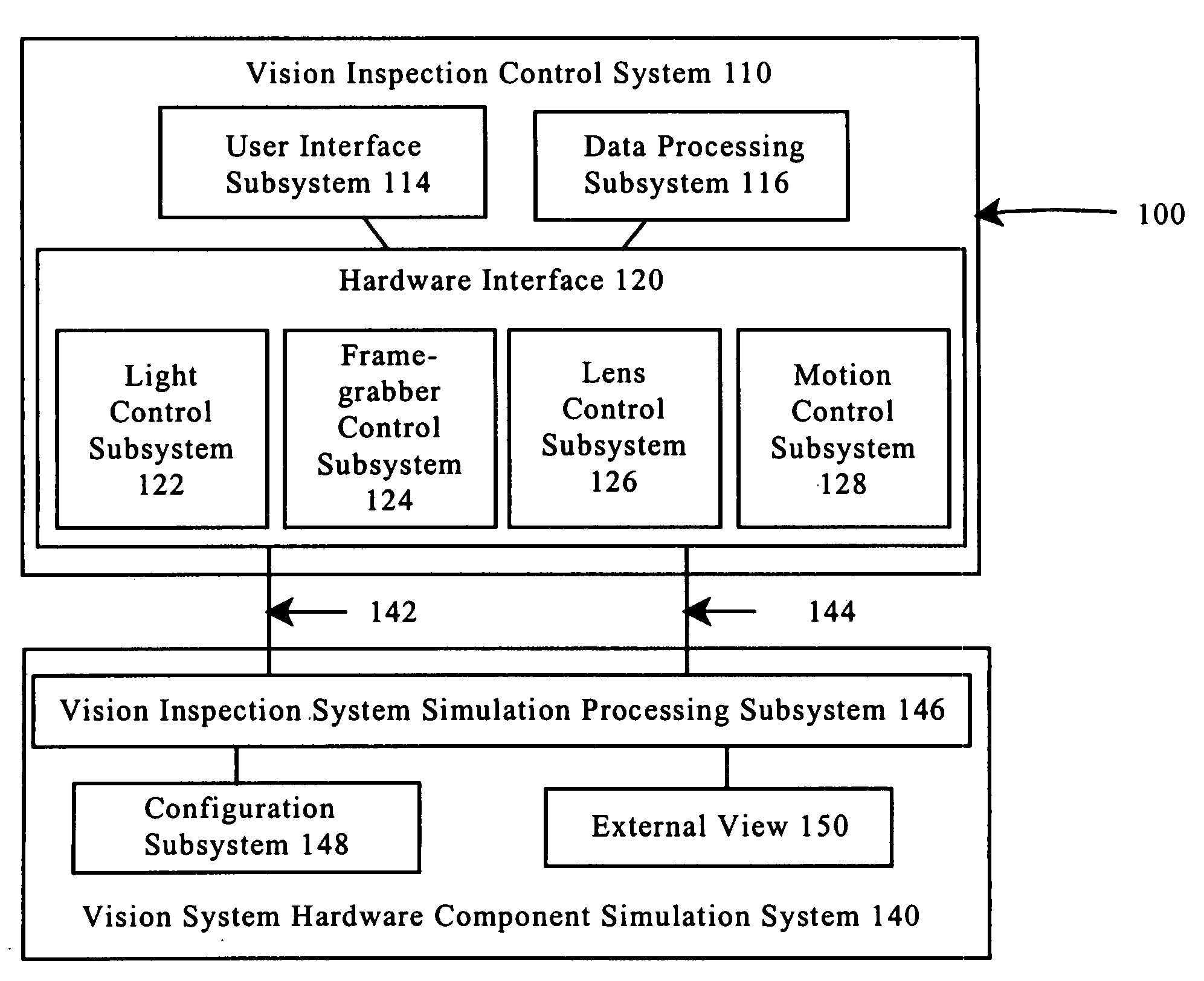

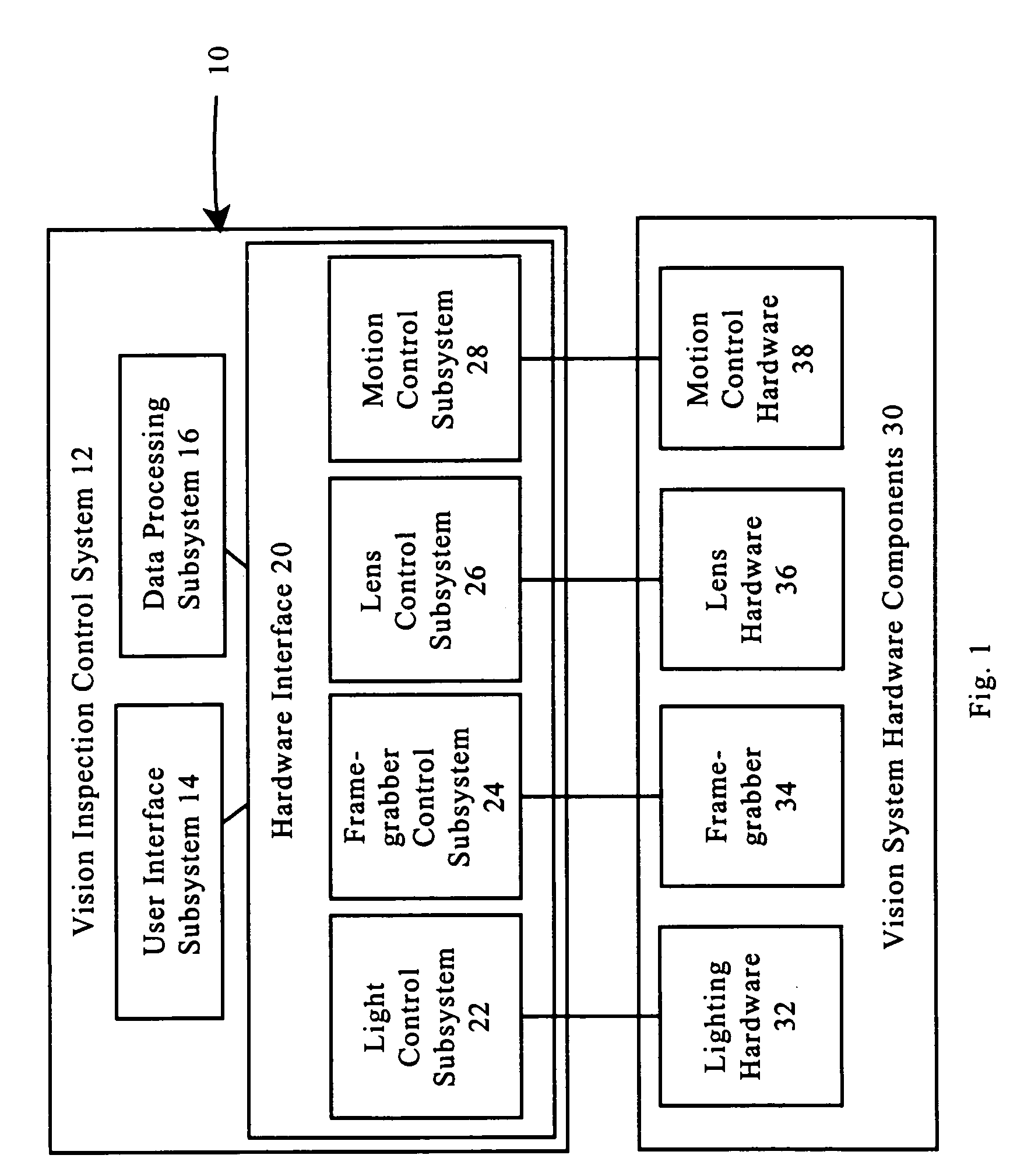

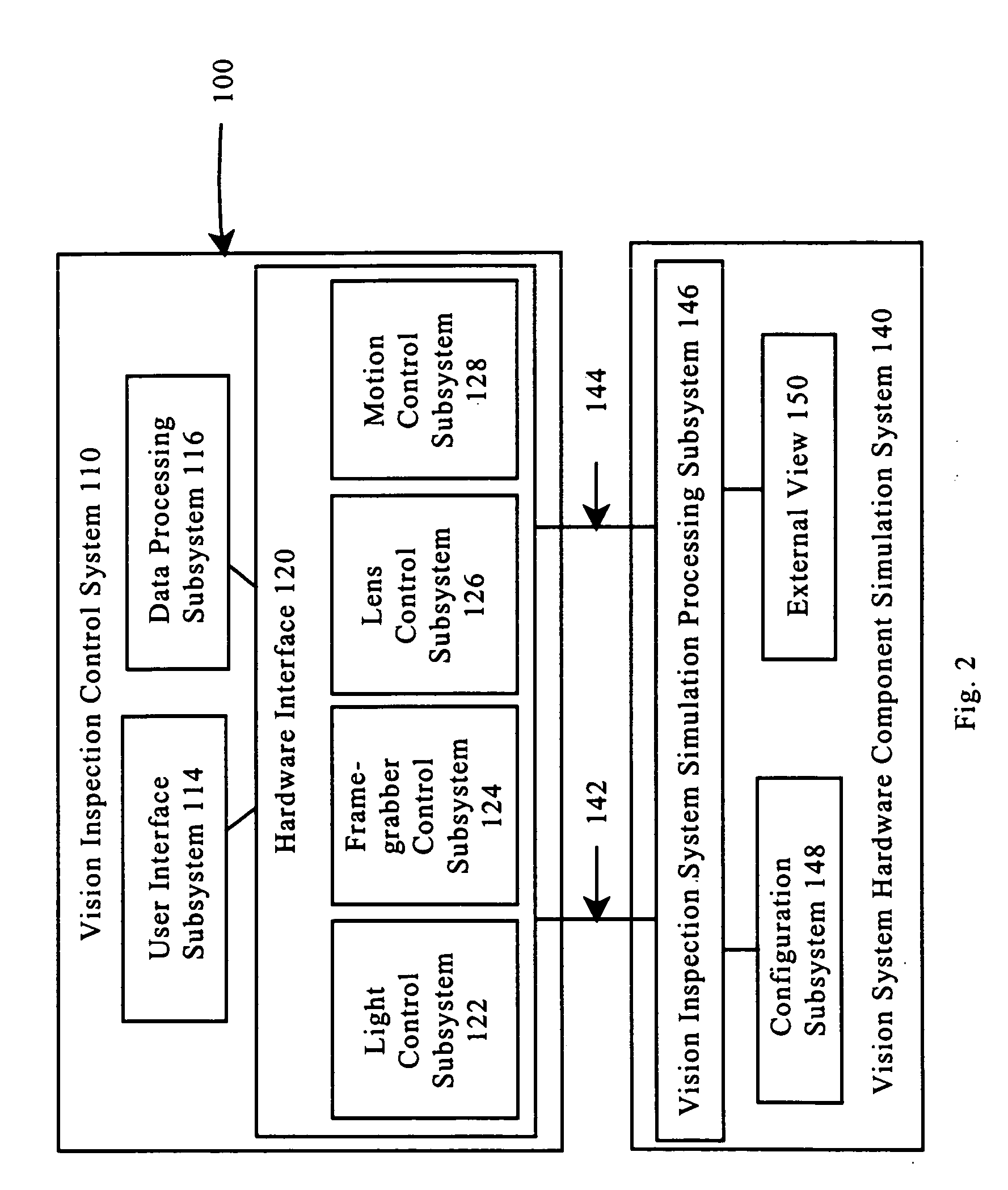

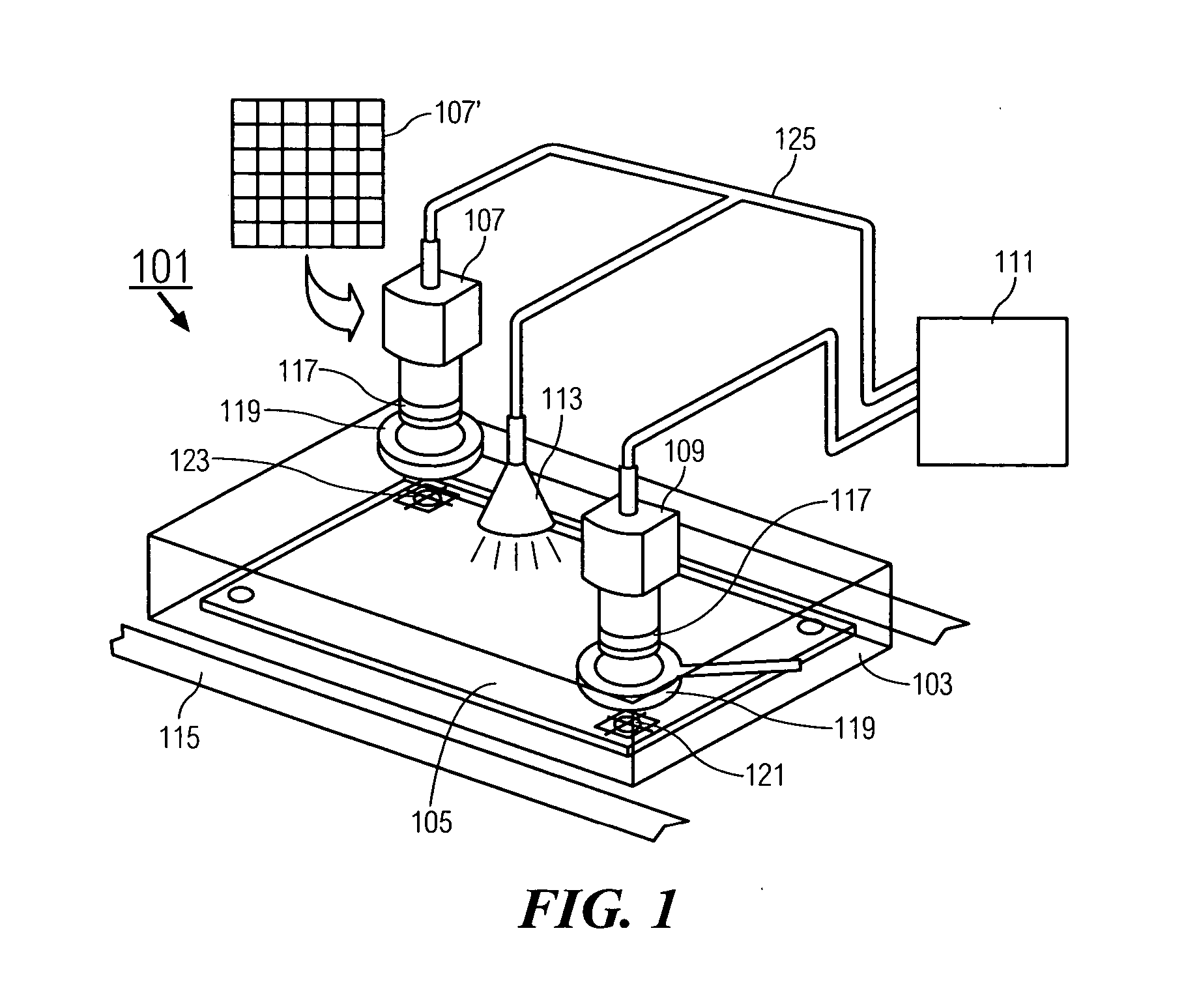

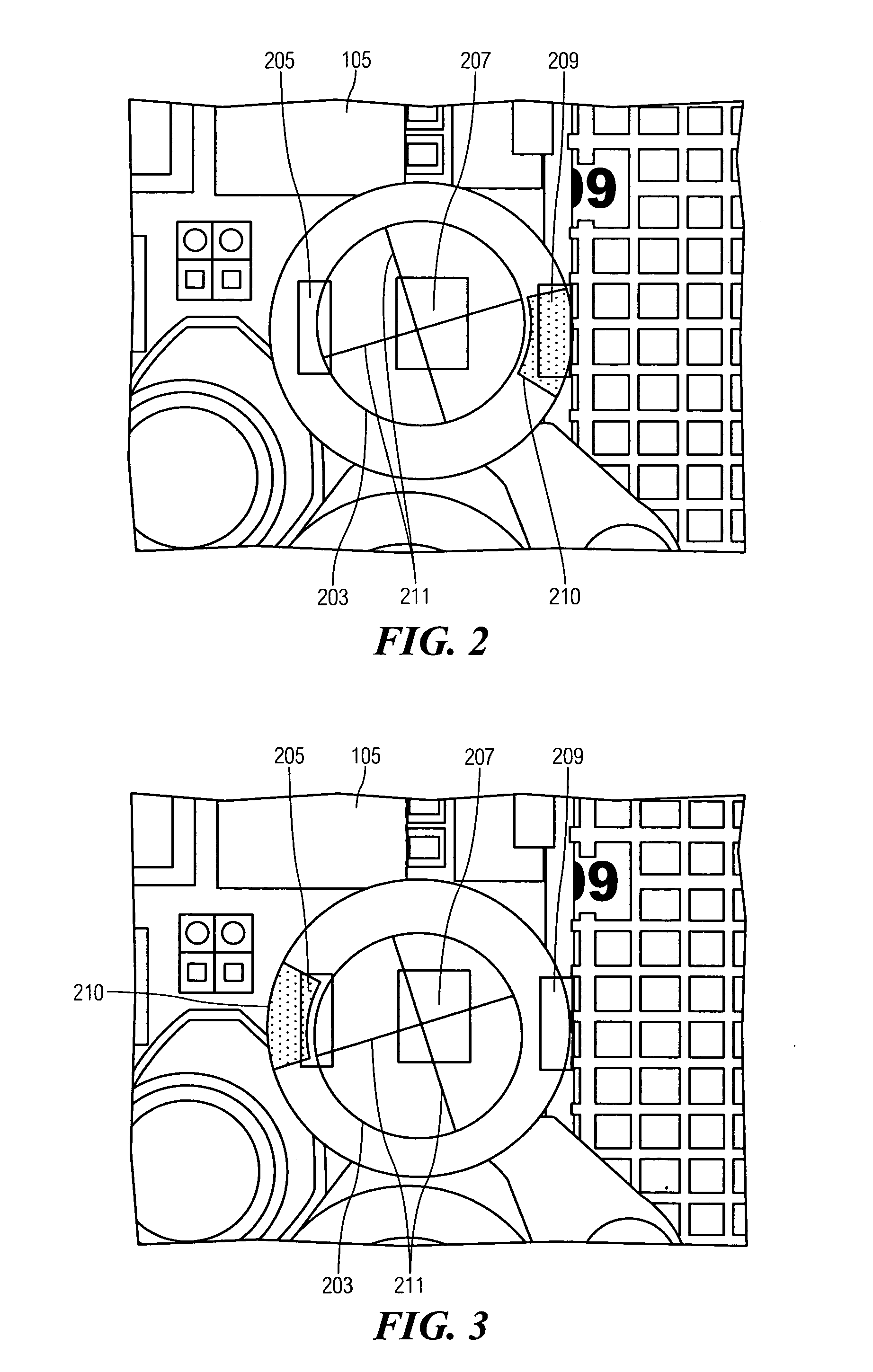

Hardware simulation systems and methods for vision inspection systems

InactiveUS7092860B1Reduce system downtimeAccelerated trainingCosmonautic condition simulationsComputer controlGraphicsCamera lens

The systems and methods of this invention provide simulated images to vision inspection systems. The simulated images emulate the vision of a vision inspection system. Graphical models of objects in a virtual world and lens effects models are used to provide the simulated images.

Owner:MITUTOYO CORP

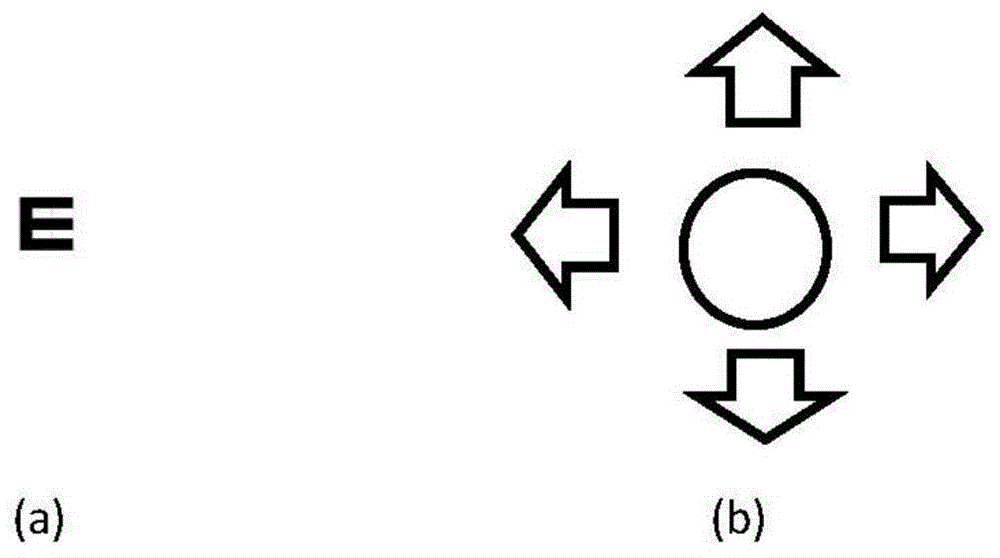

Comprehensive vision self-service detection method based on Internet video terminal

InactiveCN104639643AAchieve masteryMonitor vision changesEye diagnosticsTransmissionInformation processingVision inspection

The invention relates to a comprehensive vision self-service detection system based on an Internet video terminal, which belongs to the technical field of mobile health care. The system comprises a user information registration module, a screen resolution correction module, a vision icon display module, a vision detection information processing module, a vision information calling module and a user vision health archival repository. The method comprises the steps of self-evidence type near vision screening, other-evidence type near vision and distant vision detection and functional check of macula retinae, and each judgment result which is sent by users is received by an Internet cloud vision detection system. According to the comprehensive vision self-service detection system, self-service inspection based on the Internet system and intelligent determination of inspection results can be realized, so that comprehensive vision inspection is standardized, convenient and intelligent, and experience of professional medical personnel is not needed.

Owner:BEIJING INST OF OPHTHALMOLOGY

Multipurpose attaching machine for 3D glass curved screens

The invention discloses a multipurpose attaching machine for 3D glass curved screens. The multipurpose attaching machine comprises a rack, and two vacuum cavities, a vacuumizing mechanism, a glass conveying mechanism and two turning mechanisms are arranged in the rack; the vacuum cavities are used for containing Film protection films, and each vacuum cavity comprises a Film protection film positioning mechanism and a Film protection film fine tuning mechanism; the vacuumizing mechanism is used for vacuumizing the vacuum cavities; the glass conveying mechanism is used for automatically conveying 3D glass, and CCD vision inspection units matched with the Film protection film fine tuning mechanisms are arranged at the bottom of the glass conveying mechanism; the turning mechanisms are used for positioning and turning the glass, and each turning mechanism comprises a cavity cover plate, a glass positioning fixture, a pneumatic clamping mechanism and a rotating shaft; after the 3D glass is manually placed in the glass positioning fixtures in parallel to be clamped, driving mechanisms drive the 3D glass to turn along with the cavity cover plates to the position over the Film protection films to complete attaching of the glass and the Film protection films. The multipurpose attaching machine for the 3D glass curved screens has the advantages of being in precise in glass positioning and Film protection film positioning, good in cavity sealing and vacuumizing effect, high in attaching efficiency, good in attaching effect and the like.

Owner:HUIZHOU LONGHAI TECH

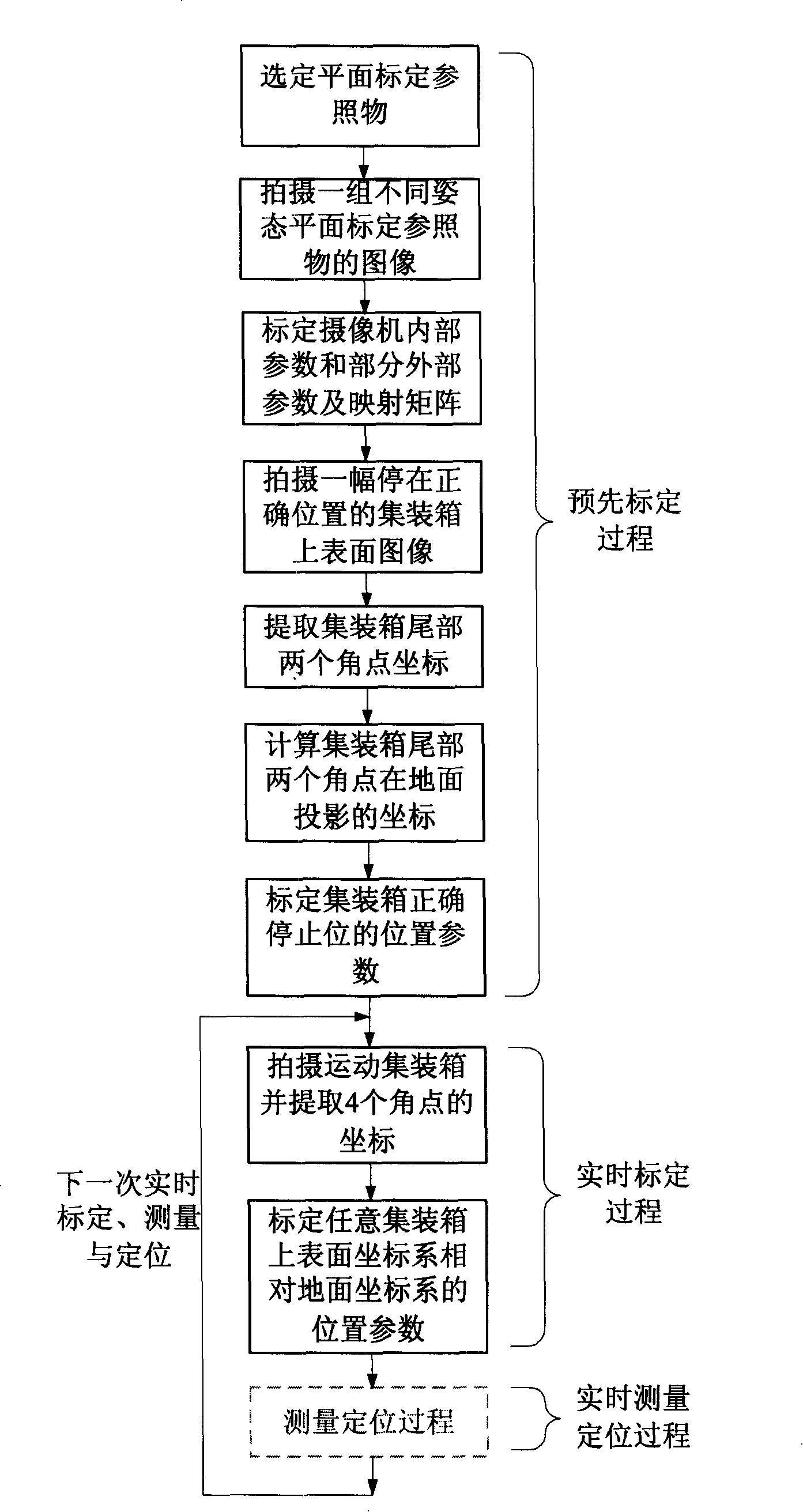

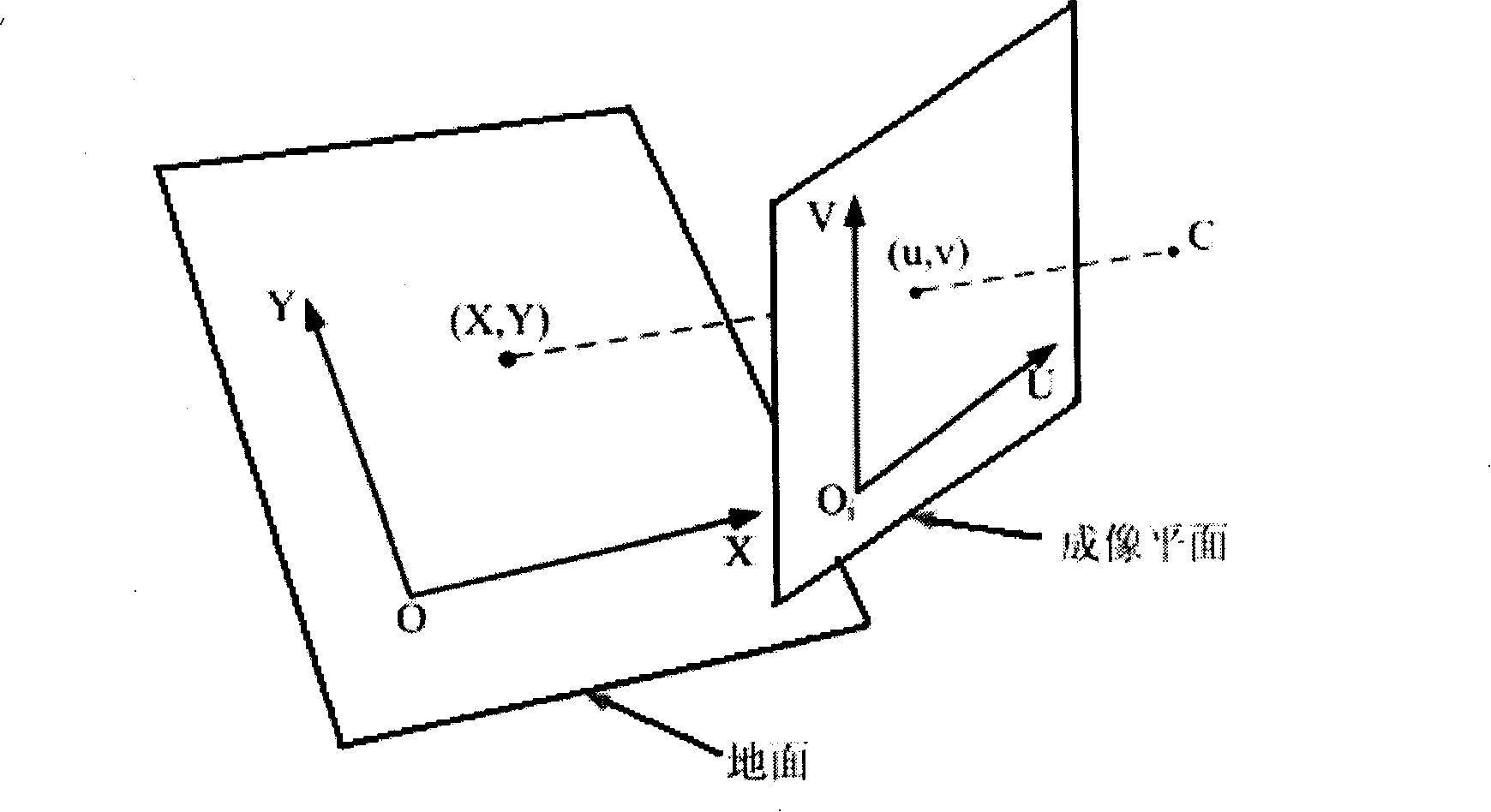

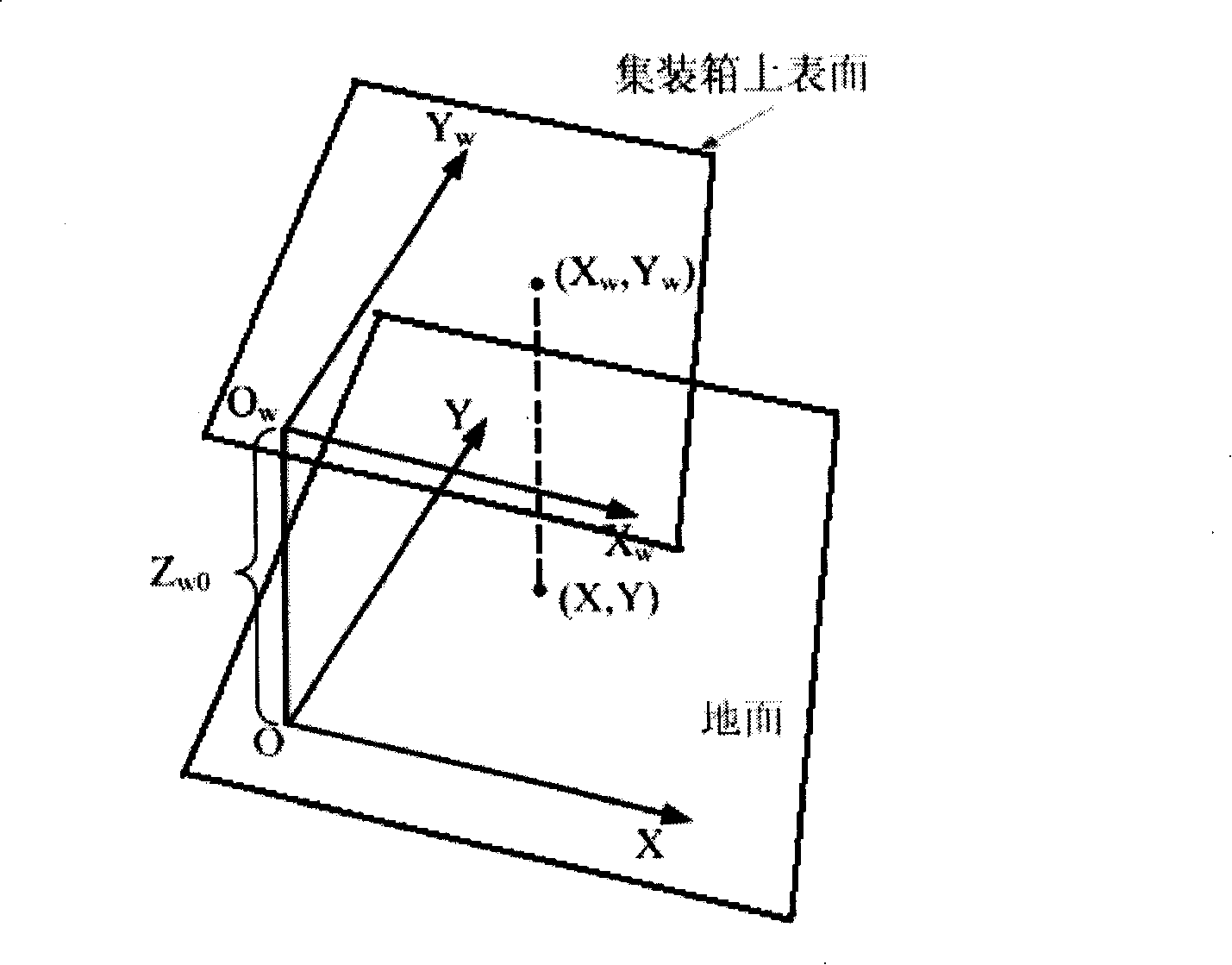

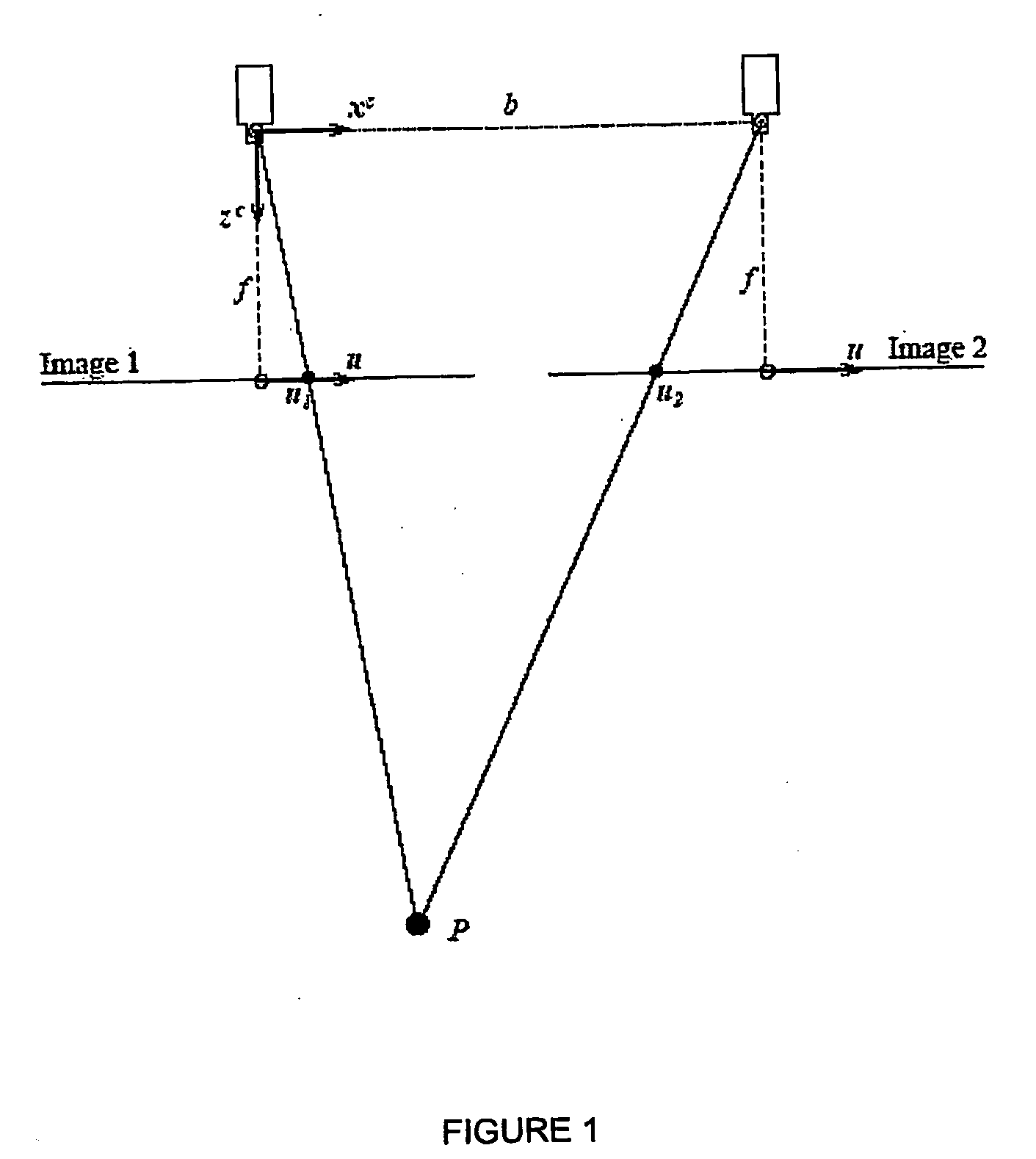

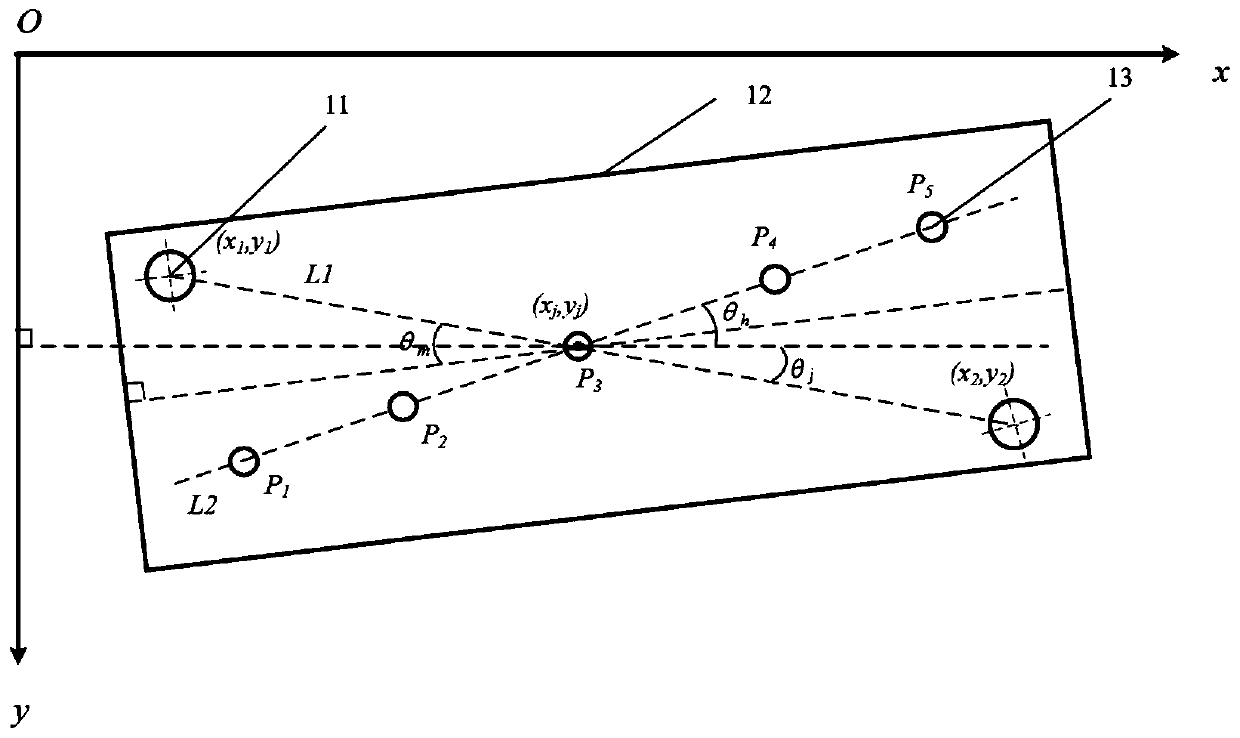

Parameter calibration method for moving containers on ports

InactiveCN101216937AEasy to implementFlexible computingImage analysisUsing optical meansVision inspectionParking space

The invention discloses a parameter calibration method of a port mobile container position system, comprising the following steps of detecting and positioning container trucks on the move at a container terminal; realizing the 3D information perception to an object via a monocular vision system by using the containers' width and length as the known gauge information and demarcating all the unknown parameters expediently, rapidly and accurately; being divided into a pre-demarcated step to perform once before the real time survey after the completion of installation of the position system and a real time demarcated step to perform once before each survey in the real time survey; starting the next survey from the real time demarcation. The invention has the advantages of convenient application without any additional requirements for container and the movement of the containers, flexible and accurate calculation of the distance from the container on the move at any height to the right parking space, being applicable to the similar vision inspection tasks, etc.

Owner:SHANGHAI MARITIME UNIVERSITY

Fastener inspection system

InactiveUS7364043B2Increase speedSeparation devicesOptically investigating flaws/contaminationRotary stageVision inspection

Owner:ZEN VOCE MFG PTE

Vision inspection system device and method

A course material that is applied to a substrate during fabrication of a composite item is inspected by a system that includes a vision assembly. The vision assembly includes an area light, a line generator, a sensor, and an image processor. The area light illuminates an area of the course material. The line generator generates a line of illumination across the area. The sensor captures an image of the area. The image processor analyzes the image. The image processor is configured to identify debris on the course material in response to the area light being activated and the image processor is configured to identify placement aberrations in response to the line generator being activated.

Owner:THE BOEING CO

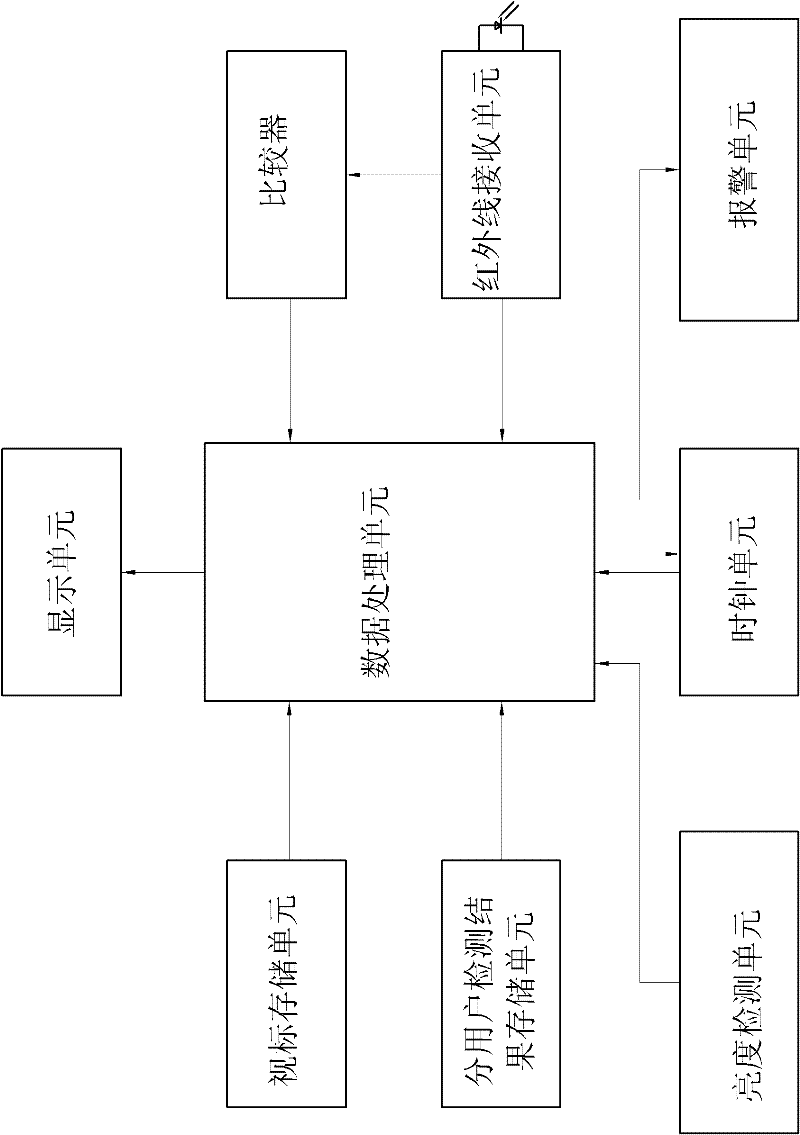

Intelligent vision inspection instrument

InactiveCN102334975ARealize long-term detection and trackingEasy to analyzeEye diagnosticsInfraredVision inspection

The invention discloses an intelligent vision inspection instrument, which is provided with a handheld remote control and a host part, wherein the host part displays a visual target randomly; a tester detects at the standard distance and transmits an infrared signal to the host by pressing a direction key corresponding to a self-considered visual target direction on the handheld remote control; an infrared data receiving unit in the host part receives the infrared signal transmitted from the handheld remote control and sends the infrared signal into a comparator so as to judge whether the judgment of the tester is correct or not; a data processing unit sends a comparison result into a sub-user detection result storage unit and a tester storage unit corresponding to the tester; and after multi-time testing, the tester not only can know the current own vision but also can master the vision change tendency within a certain time, thereby providing a reliable basis for preventing myopia for youngsters and monitoring the vision change of patients with eye diseases. The intelligent vision inspection instrument can be used without help of other people, and therefore the intelligent vision inspection instrument is convenient to use.

Owner:杜学静

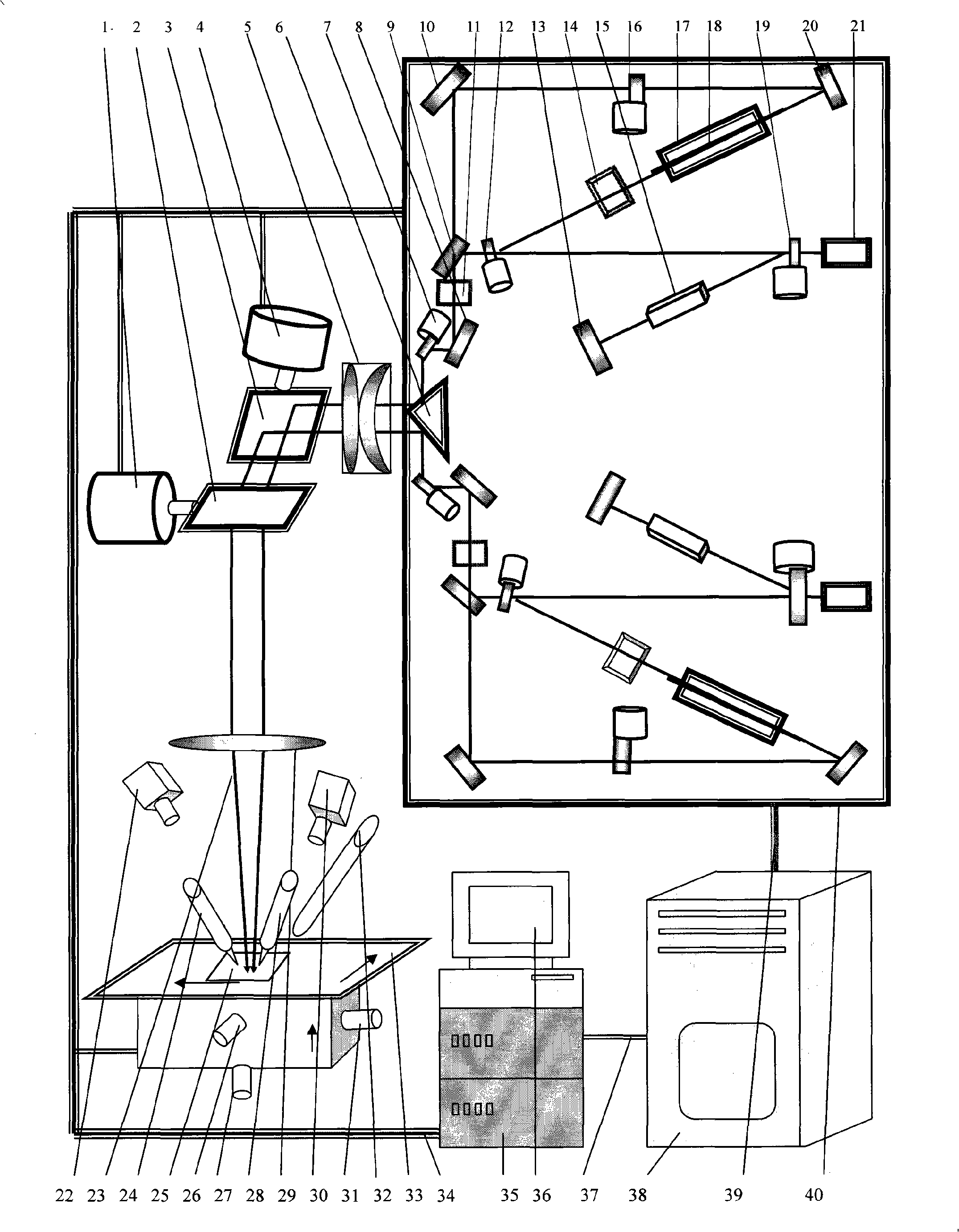

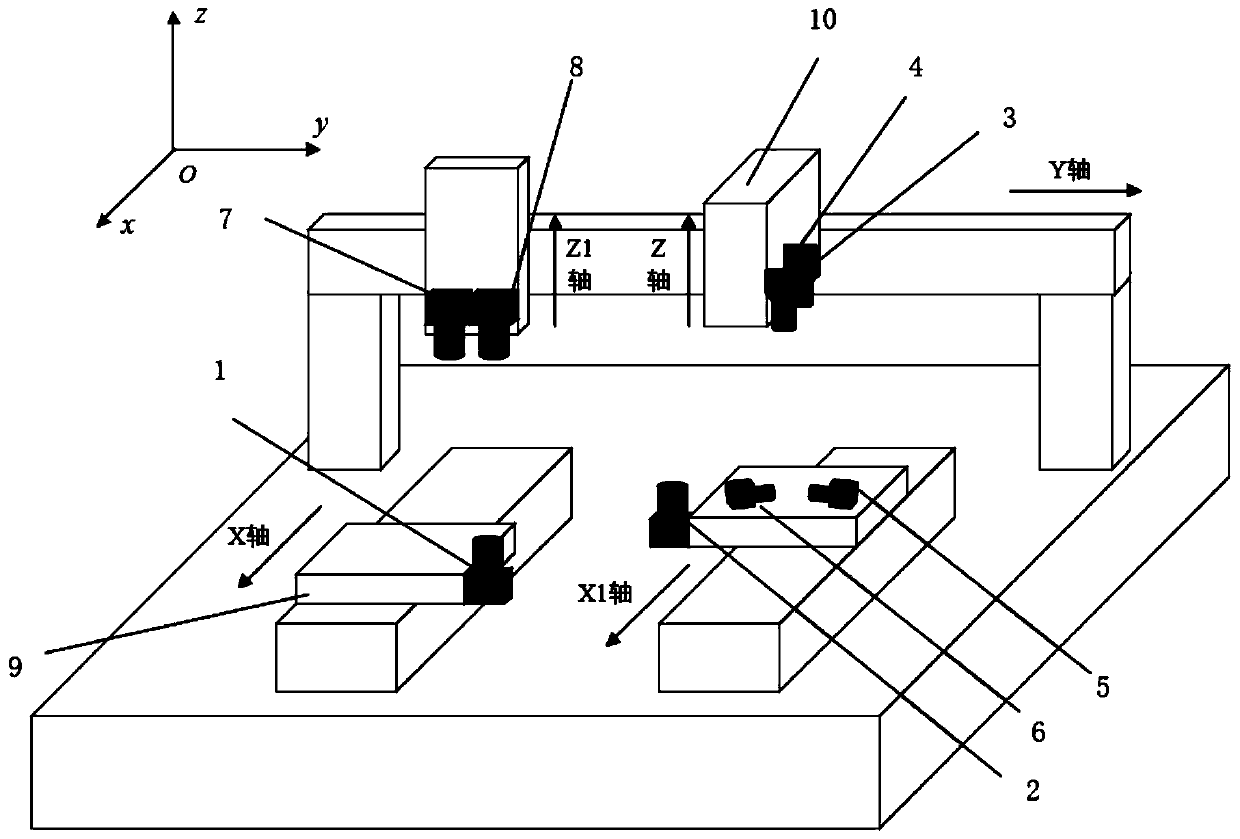

Apparatus for manufacturing hybrid integrated circuit by double-beam double-wavelength laser three-dimensional micro-cladding

InactiveCN101407912AMetallic material coating processesLaser beam welding apparatusElectricityResonant cavity

The invention relates to a device for manufacturing base plates of hybrid integrated circuits by making use of three-dimensional micro-cladding of laser with dual beam and wavelength, which belongs to the technical field of manufacturing hybrid integrated circuits in electricity industries. The device uses an Nd: YAG laser of a symmetrical dual-Z type resonant cavity to transmit laser with dual beam and wavelength through a right angle prism, configures multi-channel intelligent micro-jet powder feeding, controls the moving of an oscillating mirror and a workbench by adopting a five-axle linkage technology and feeds back through a three-dimensional intelligent vision inspection and recognition device, a central control module of the system controls the running of the integral machine, and therefore realizes the laser three-dimensional micro-cladding manufacturing of base plates of hybrid integrated circuits, multilayer and three-dimensional circuit boards.

Owner:无锡浩波光电子有限公司

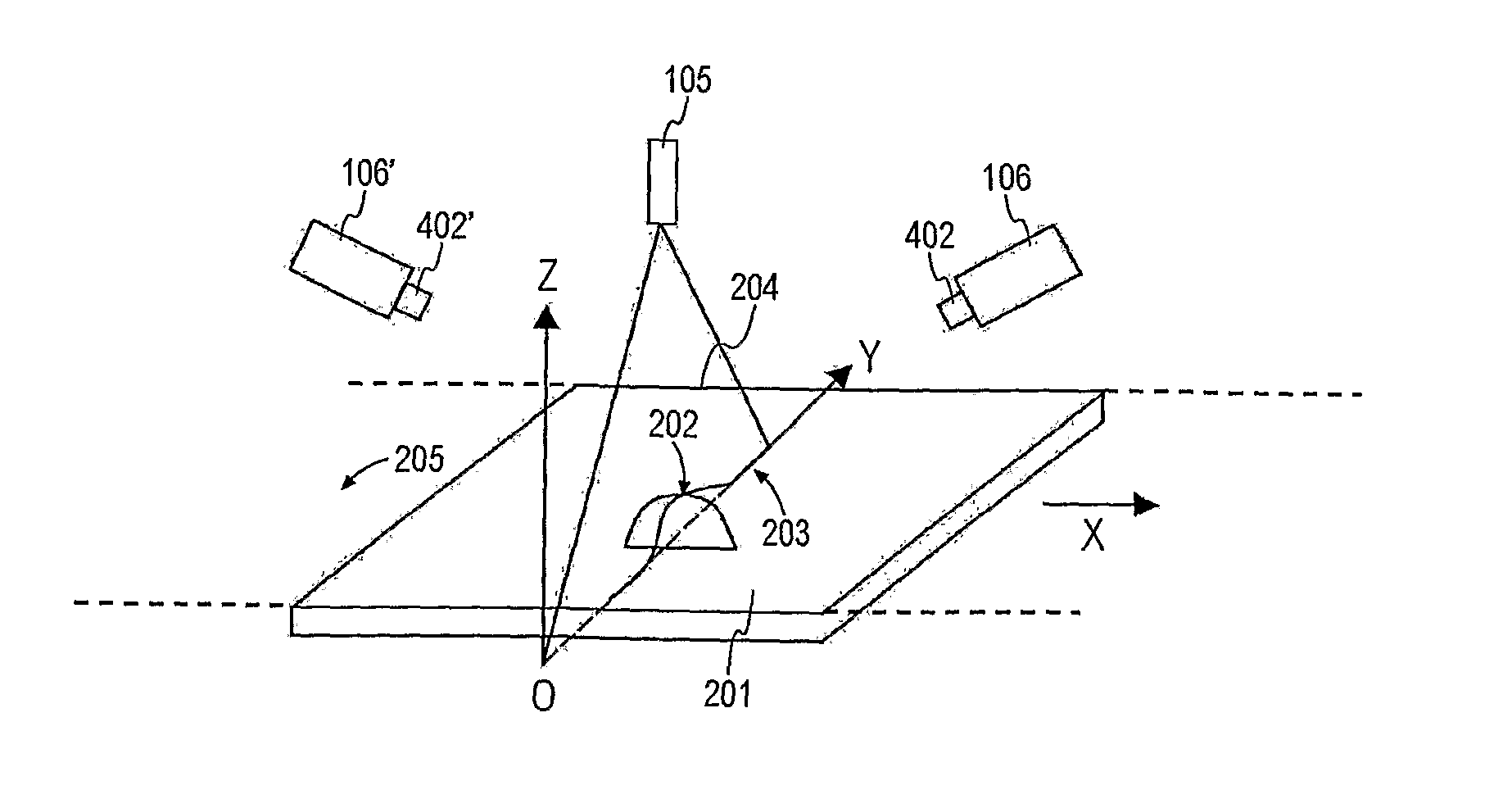

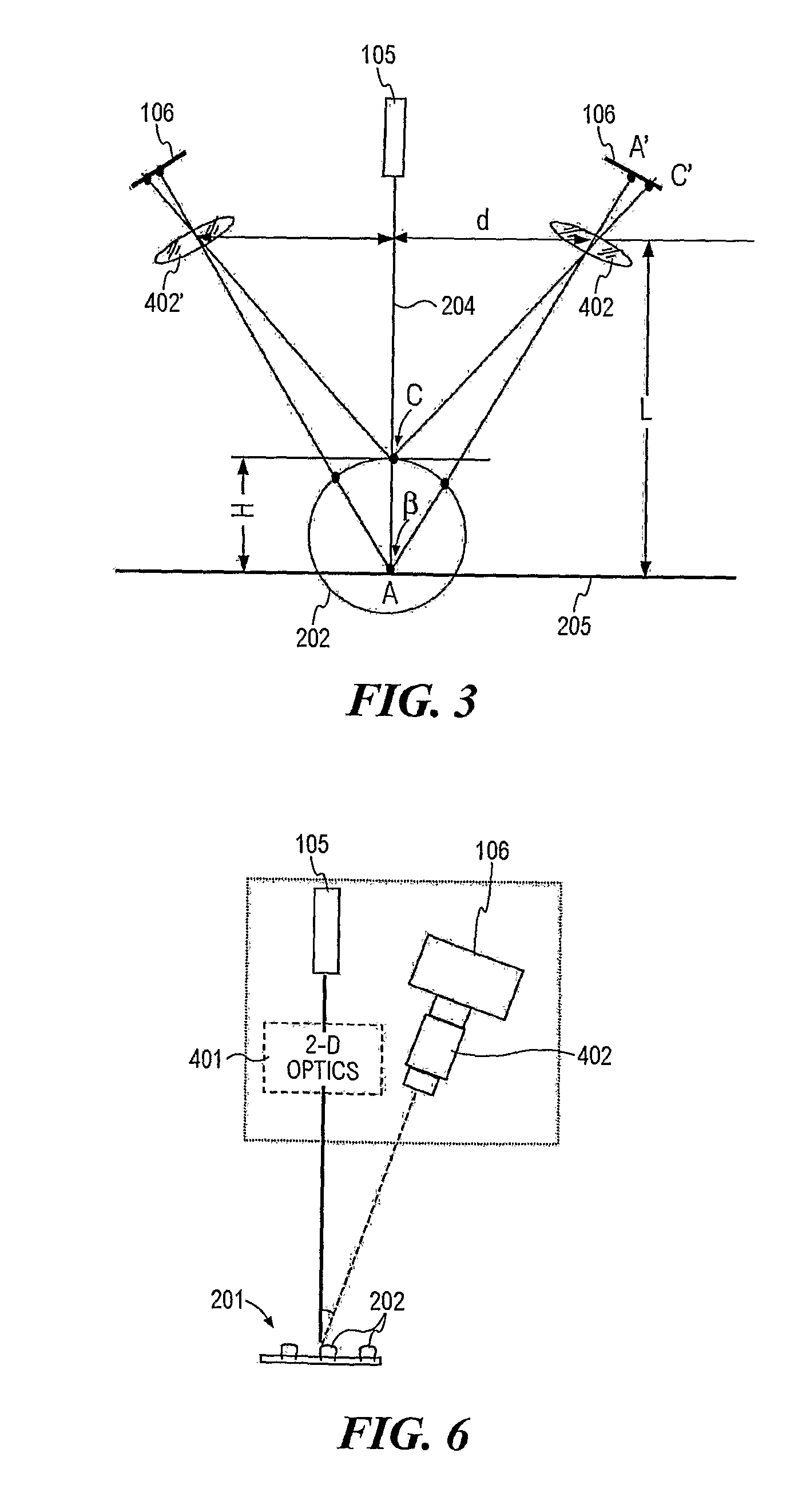

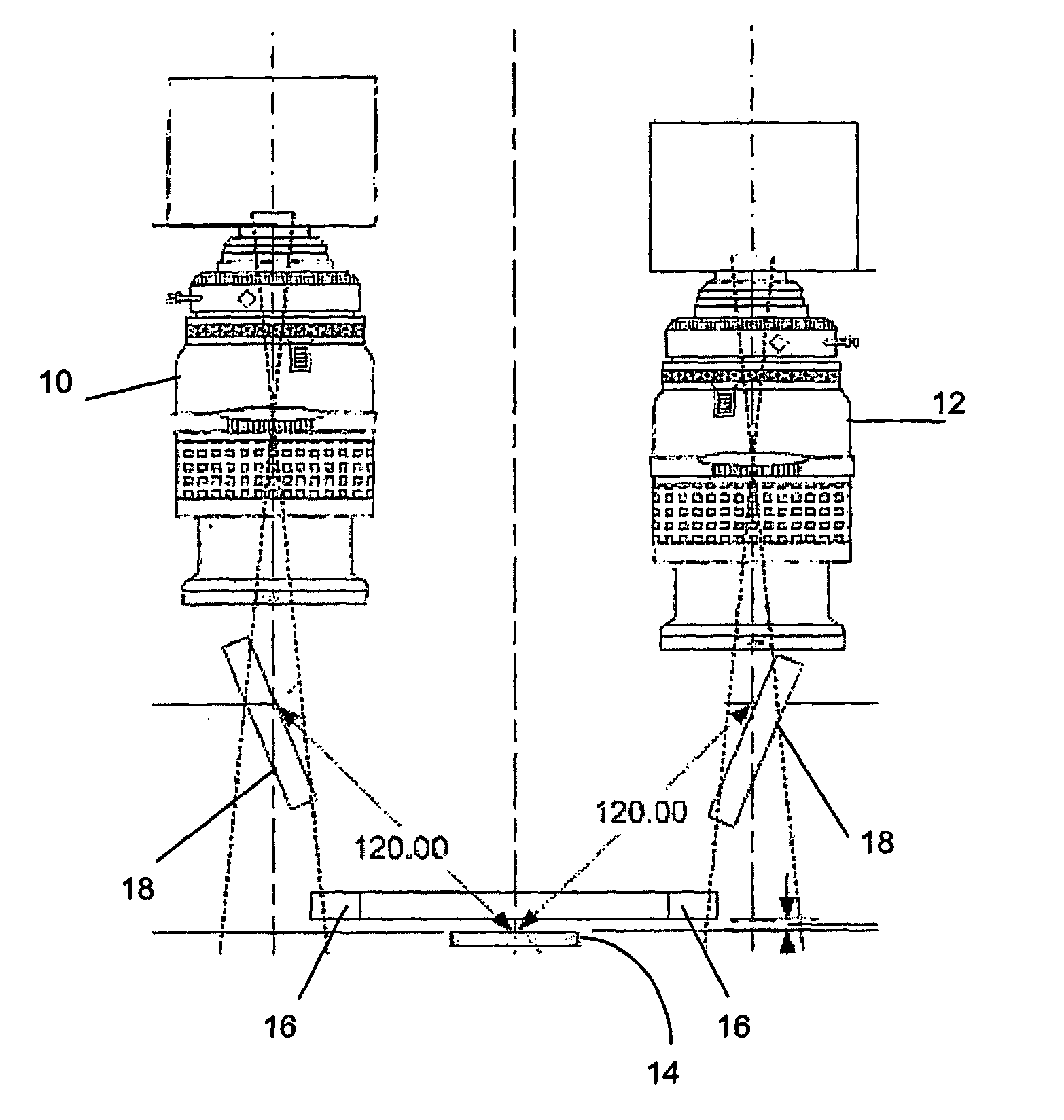

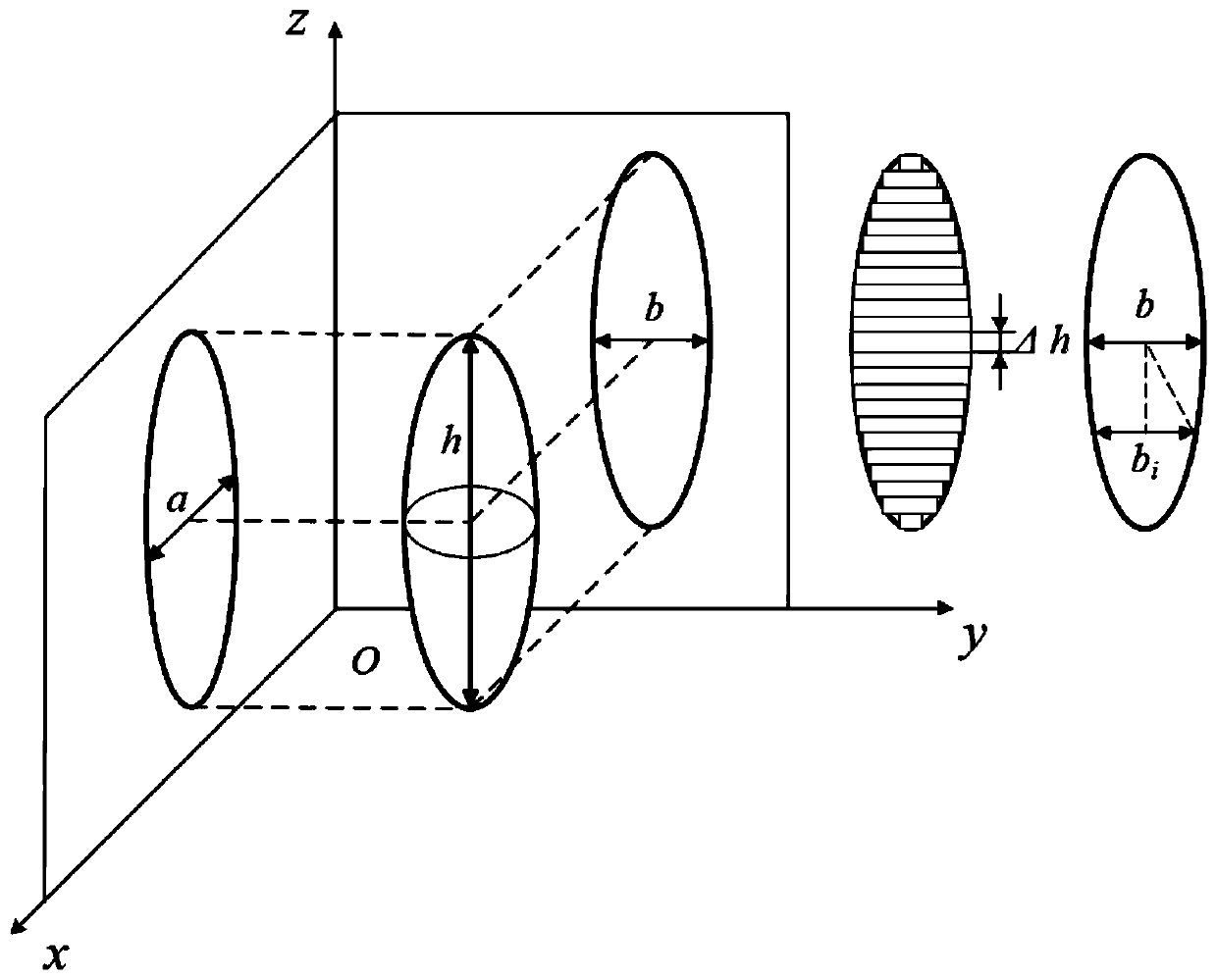

Method and apparatus for 3-dimensional vision and inspection of ball and like protrusions of electronic components

ActiveUS20100328435A1Easy to understandImage enhancementImage analysisVision inspectionElectronic component

A method for 3-dimensional vision inspection of objects, such as microelectronic components, which have protrusions as features to be inspected, such as input / output contact balls, is disclosed. The method comprising the steps of determining interior and exterior parameters of a pair of cameras, forming a rectified coordinate system from the parameters of both cameras determined above with a relative pose of second image capturing means with respect to the first image capturing means. A pair of images of the object having a plurality of co-planar protrusions on one surface are captured by the cameras system wherein image coordinates of the images are transformed into coordinates of the rectified coordinate system. Conjugate points of each protrusion are then determined for the measurement of its co-planarity and height. Various configurations of the apparatus for capturing the images and processing the image data are also disclosed.

Owner:MIT SEMICON (TIAN JIN) CO LTD

System for vision examination utilizing telemedicine

InactiveUS20070195267A1Data processing applicationsTelemedicineVision inspectionTelecommunications link

The telemedicine method and system disclosed includes at least one remote exam module which in turn includes a plurality of optical devices configured to examine a patient's eye, and a controller for collecting and transmitting the examination data of the patient's eye. The information collected is transmitted via a communications link to a diagnostic center for analyzing the information collected at the remote exam module. The diagnostic center further maintains a database of patient records corresponding to the remotely collected examination information and an exam console for enabling a diagnosis based on the collected information.

Owner:FRANZ RICHARD +1

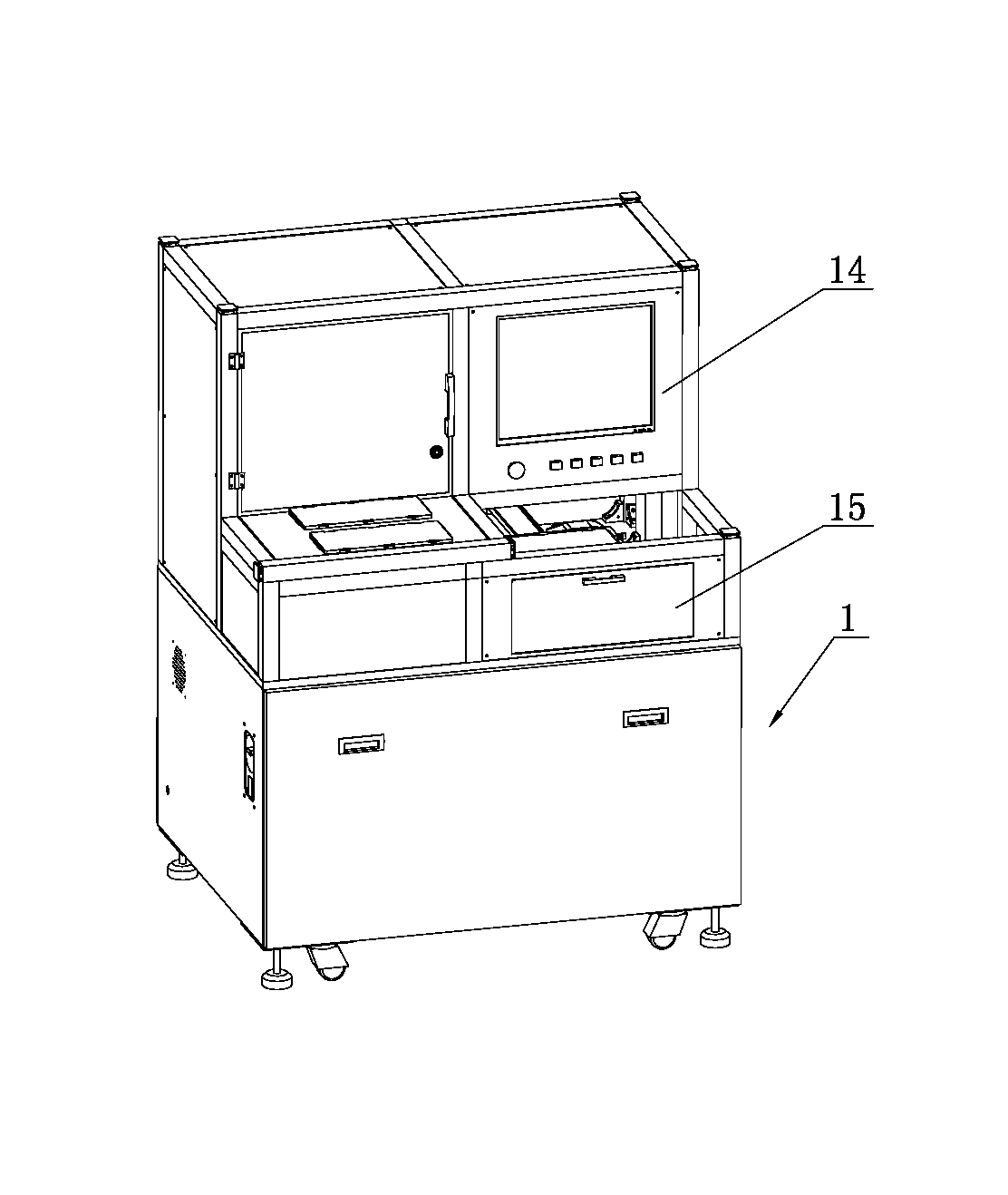

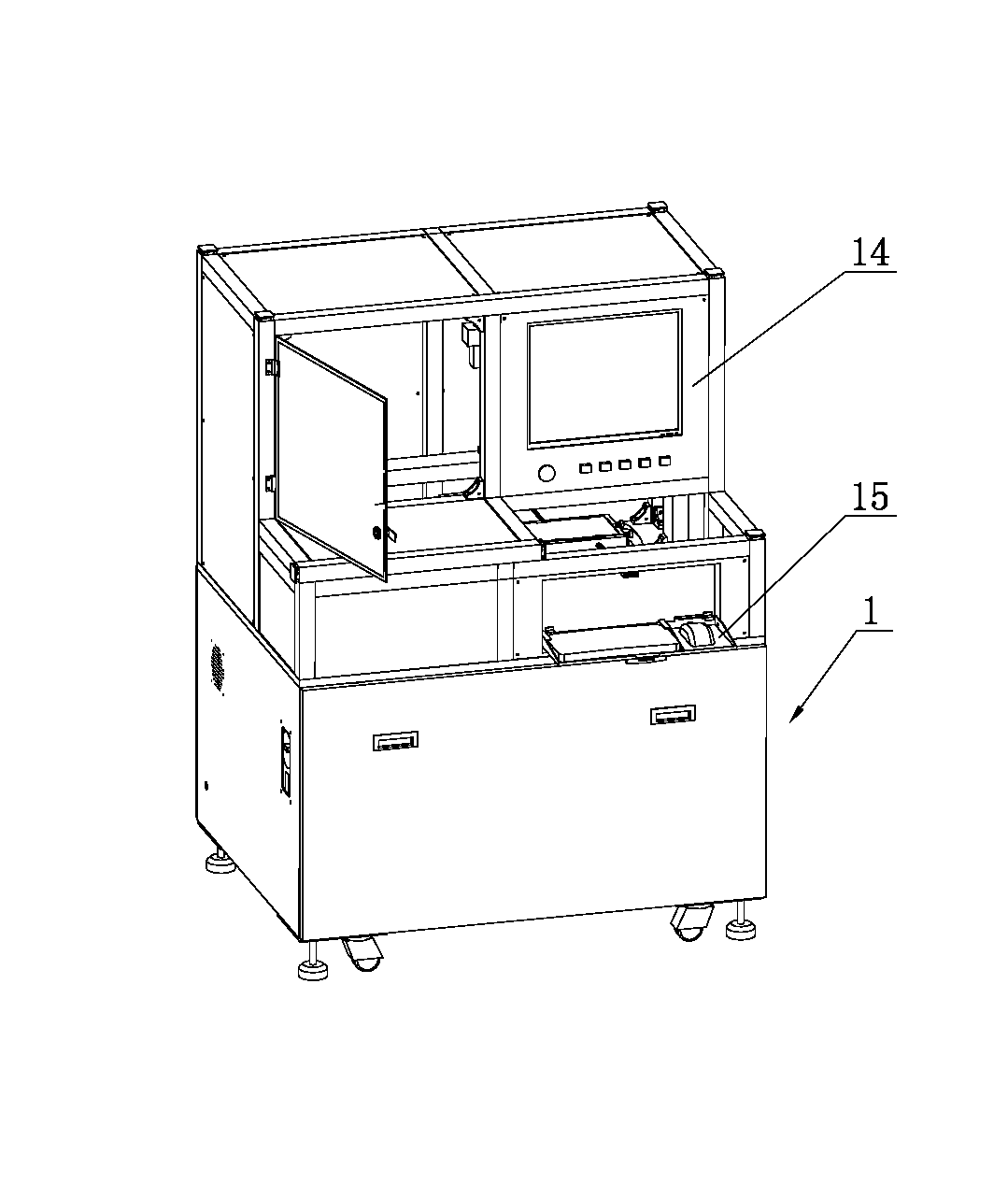

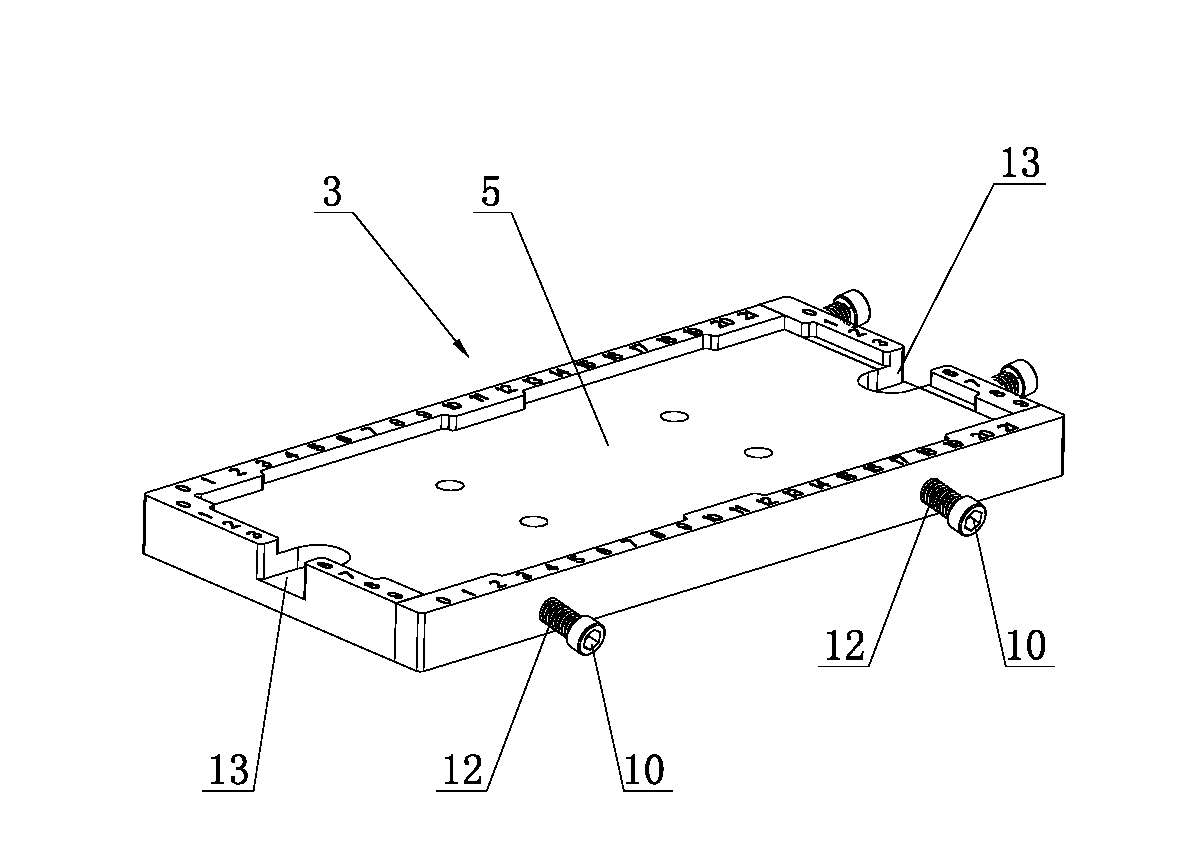

Vision inspection device for convenient assembly and disassembly of tray

InactiveCN102706889AEasy loading and unloadingAchieve loadingOptically investigating flaws/contaminationVision inspectionMechanical engineering

The invention relates to the technical field of vision inspection devices and particularly relates to a vision inspection device convenient assembly and disassembly of a tray. The vision inspection device comprises a rack, a Z-axis mechanism and a horizontal movement mechanism, wherein the Z-axis mechanism is provided with a camera; the horizontal movement mechanism is provided with a tray clamp; the tray clamp comprises a clamp body arranged on the horizontal movement mechanism; the clamp body is provided with a containing cavity; the front side edge and an adjacent edge of the front side edge of the containing cavity are respectively provided with a front pressing strip and a side pressing strip which are detachable; one side edge of the clamp body is provided with a screw hole in which a screw is installed; both the front pressing strip and the side pressing strip are provided with a through hole; the screw is in threaded connection with the screw hole after penetrating through the through hole; the screw is sleeved with a spring; one end of the spring pushes against the end part of the through hole; and the other end of the spring pushes against the head part of the screw. The vision inspection device can be used for not only assembling and disassembling an IC (integrated circuit) tray rapidly, but also calibrating the position of the IC tray conveniently, and the vision inspection device is simple in structure and strong in practicability.

Owner:DONGGUAN SCIENCGO MACHINERY MFG

Multi-view vision inspection system and method for ink-jet printing

ActiveCN111397539AImprove detection accuracyImprove printing efficiencyUsing optical meansOther printing apparatusVision inspectionVisual inspection

The invention belongs to the technical field related to ink-jet printing visual inspection, and discloses a multi-view visual inspection system and method for ink-jet printing, and the method mainly comprises the following steps: (1) firstly, detecting and determining the installation angle of a nozzle; then, performing trial printing to detect and determine the volume, speed and angle of flying ink drops; and finally, detecting and determining the deflection angle of the spray orifice array, the position and angle of the substrate and the offset distance of ink dripping points; and (2) carrying out ink-jet printing according to the obtained parameters, and carrying out liquid film detection on the printed substrate by adopting a predefined defect type after the substrate is printed. Various control parameters required by the whole ink-jet printing process can be detected, the defect that only a single module can be detected in an existing ink-jet printing detection method can be effectively overcome, and higher-precision and higher-efficiency detection of the whole ink-jet printing process is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

In-circuit test fixture with integral vision inspection system

InactiveUS20070013772A1Material analysis by optical meansSemiconductor/solid-state device manufacturingVision inspectionImaging analysis

An in-circuit test fixture performs both electrical tests on a Printed Circuit Assembly (“PCA”) and reads distinguishing features of a feature of interest of the PCA. The in-circuit test fixture physically supports an image sensor array. A light focusing means has a position relative to the distinguishing features and the image sensor such that a focused real image of the distinguishing features is imaged onto the image sensor. The image sensor outputs image information of the distinguishing features. A processor performs image analysis based on the image information of the distinguishing features to determine if defects exist.

Owner:AGILENT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com