Vision inspection device for appearance defects of rollers

A visual inspection device and a technology for appearance defects, applied in the field of visual inspection, can solve problems such as inability to detect bearing rollers, achieve automation and intelligence, and improve accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

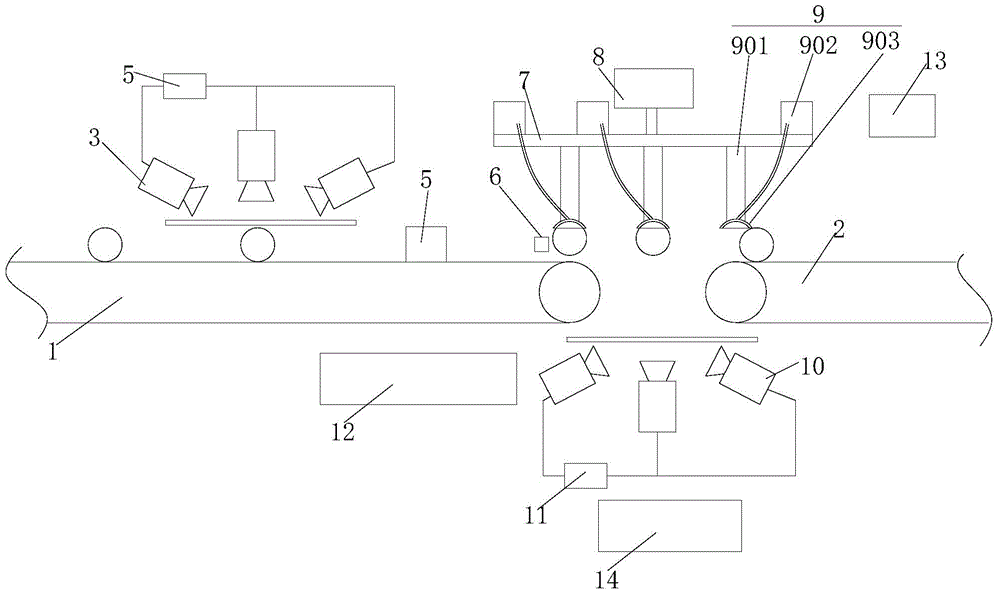

[0031] refer to figure 1 , a visual detection device for roller appearance defects proposed by the present invention, comprising a first conveyor belt 1, a second conveyor belt 2, a first image taking device 3, a first image processing system 4, a first product rejecting device 5, an optical sensor 6. Turntable 7, turntable driving device 8, three roller suction devices 9, second imaging device 10, second image processing system 11 and control device 13;

[0032] The first imaging device 4 and the first product rejecting device 5 are arranged above the first conveyor belt 1 and arranged in sequence along the conveying direction of the first conveyor belt 1, and the first imaging device 4 is connected to the first image processing system 4;

[0033] The turntable 7 and three sets of roller suction devices 9 are arranged between the first conveyor belt 1 and the second conveyor belt 2, and above the first conveyor belt 1 and the second conveyor belt 2, the turntable 7 is driven ...

specific Embodiment 2

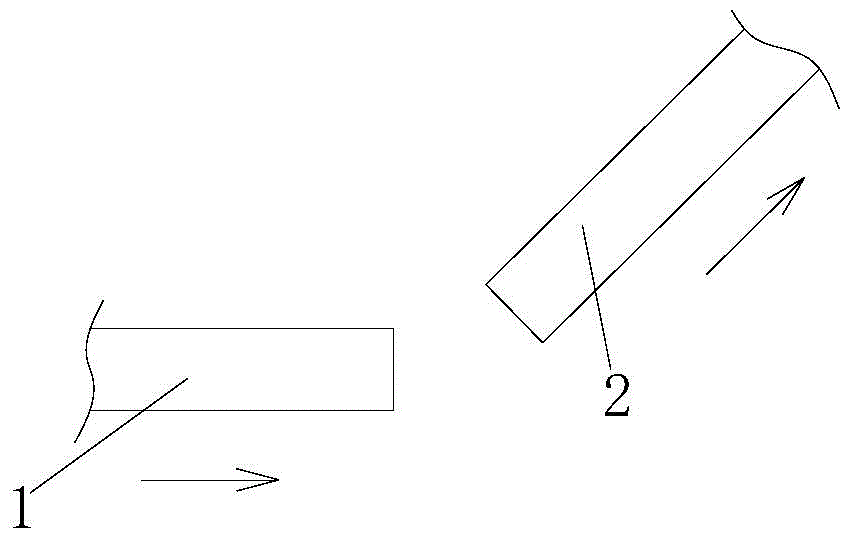

[0051] The main technical solution of this embodiment is the same as that of Embodiment 1, and will not be repeated here. The difference is that, refer to figure 2 , the first conveyor belt 1 and the second conveyor belt 2 are arranged crosswise to make reasonable use of the occupied space.

specific Embodiment 3

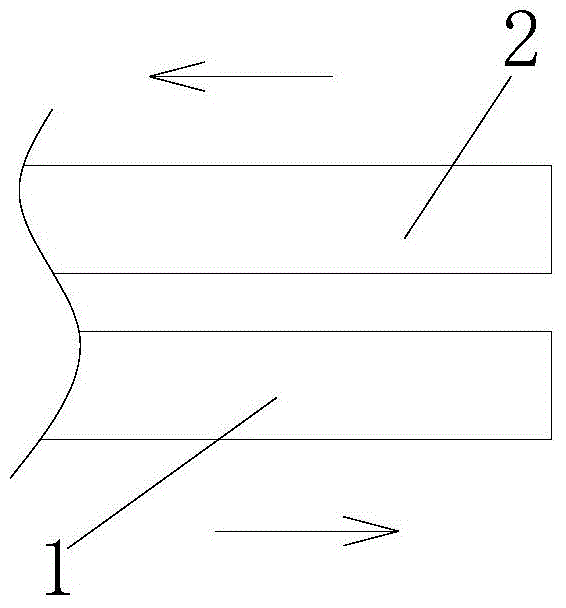

[0052] The main technical solution of this embodiment is the same as that of Embodiment 1, and will not be repeated here. The difference is that, refer to image 3 , the first conveyor belt 1 and the second conveyor belt 2 are arranged oppositely and side by side, so that the space occupied by the visual inspection device in the length direction can be reduced, which is beneficial to the rational use of space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com