Patents

Literature

21759results about How to "Fully automated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Migration of complex applications within a hybrid cloud environment

ActiveUS20150096011A1Increase the number ofFully automatedMultiple digital computer combinationsProgram controlResource poolData center

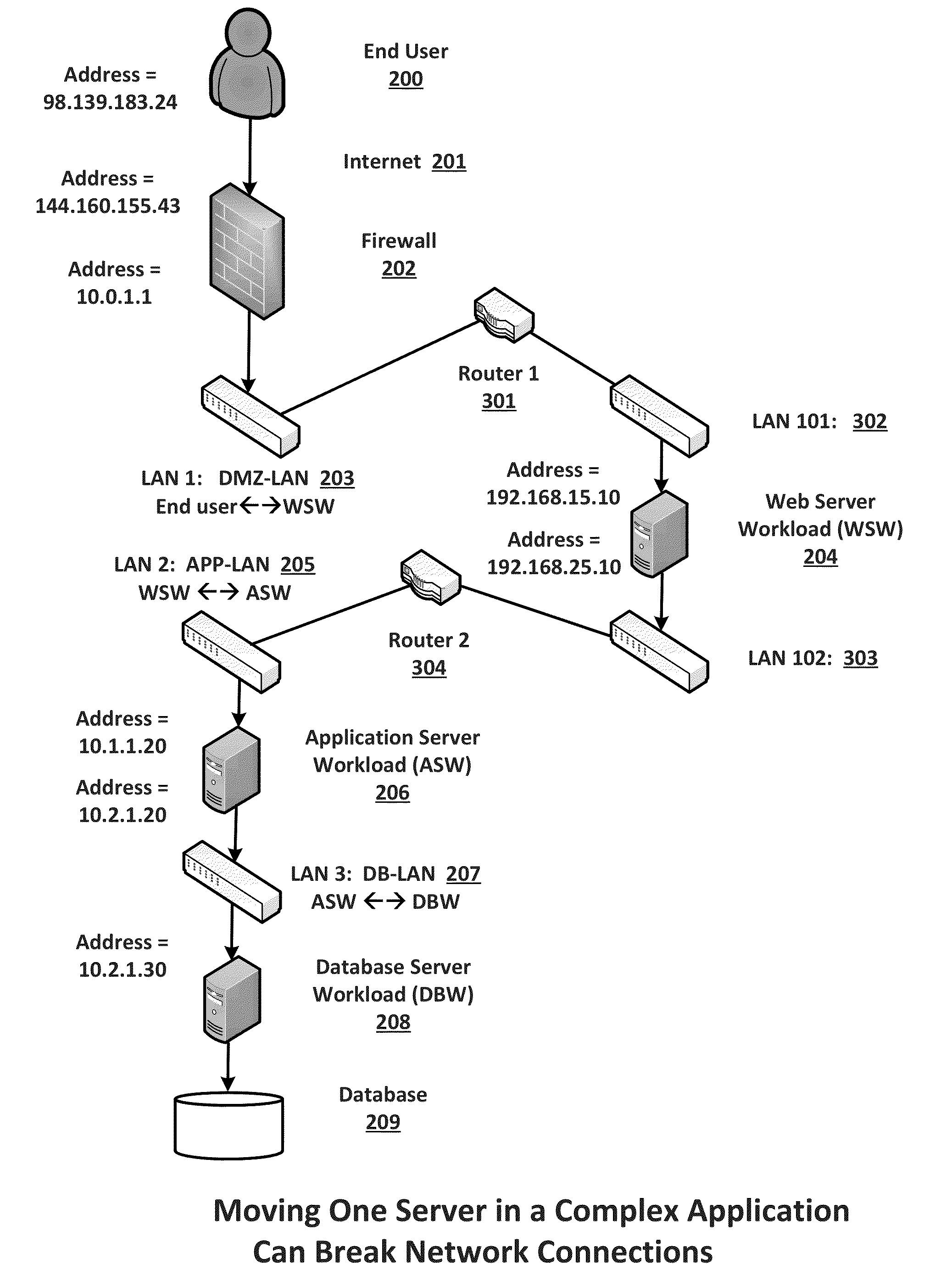

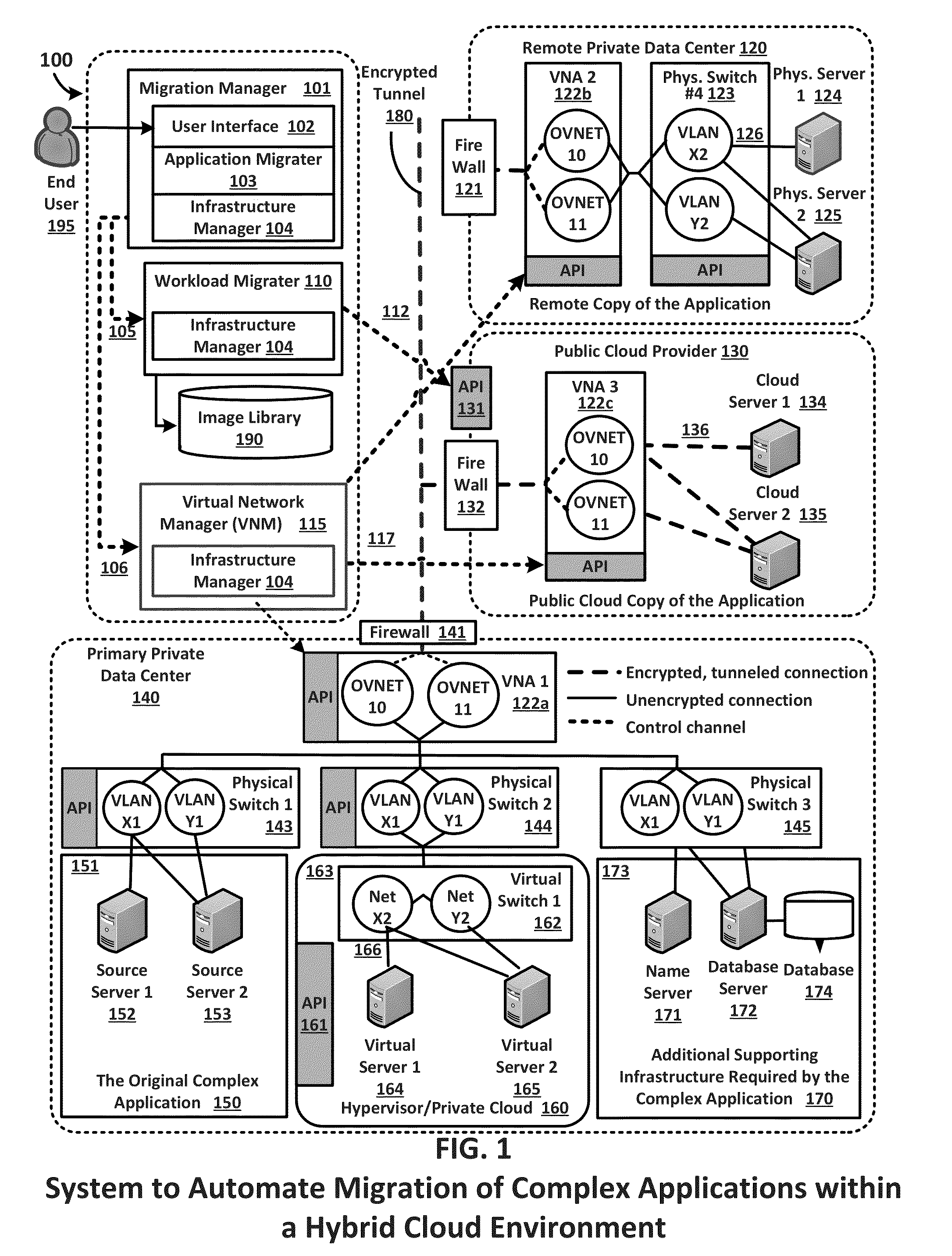

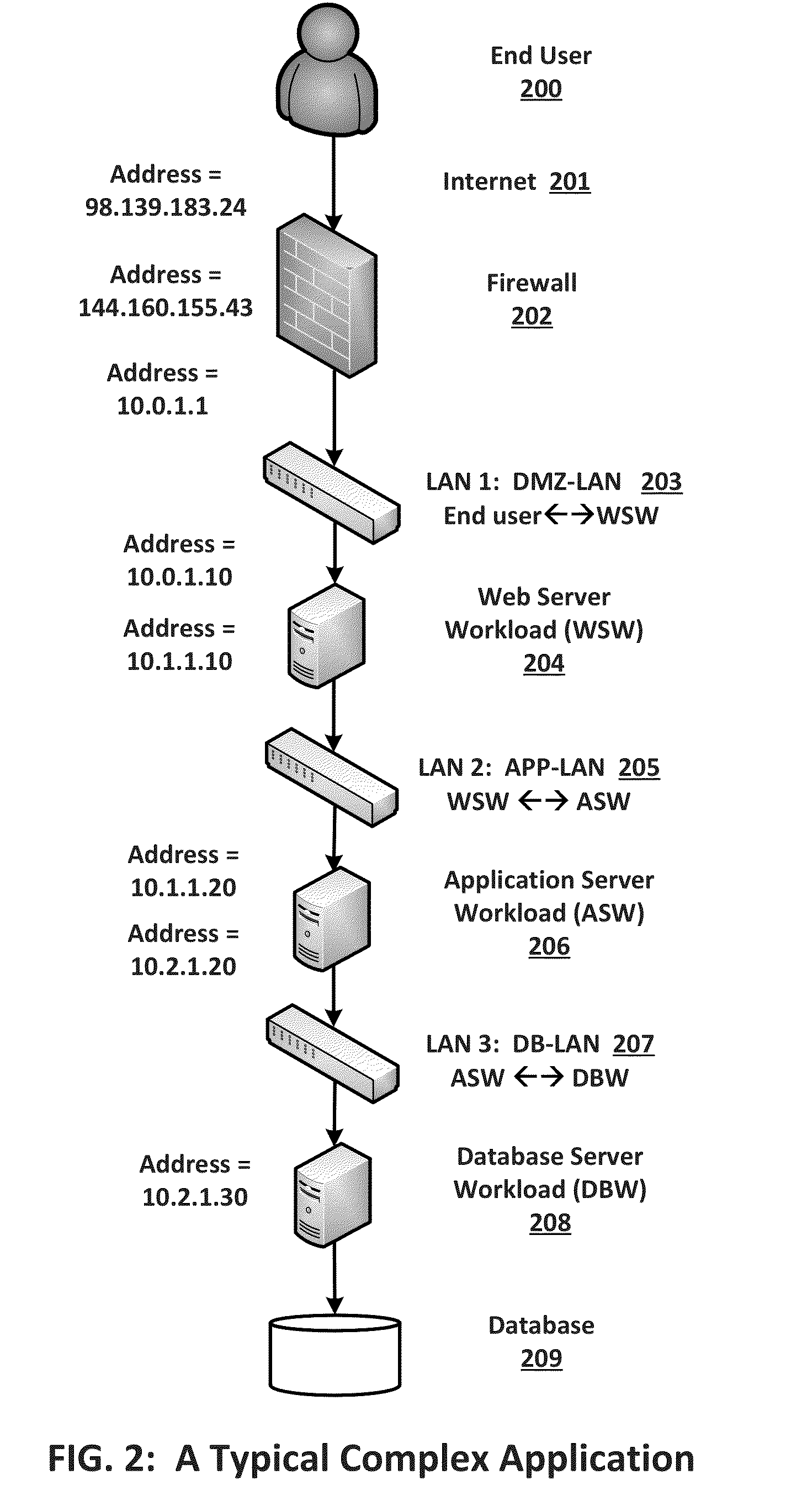

A system and methods for the migration of complex computer applications and the workloads comprising them between physical, virtual, and cloud servers that span a hybrid cloud environment comprising private local and remote customer data centers and public cloud data centers, without modification to the applications, their operational environments, or user access procedures. A virtual network manager securely extends the subnets and VLANS within the customer's various data center across the distributed, hybrid environment using overlay networks implemented with virtual network appliances at nodes of the overlay network. A server migrater migrates individual workloads of servers used by the complex application from one pool of server resources to another. A migration manager application provides a control interface, and also maps and manages the resources of the complex application, the hybrid environment, and the virtual network spanning the hybrid cloud environment.

Owner:RACEMI

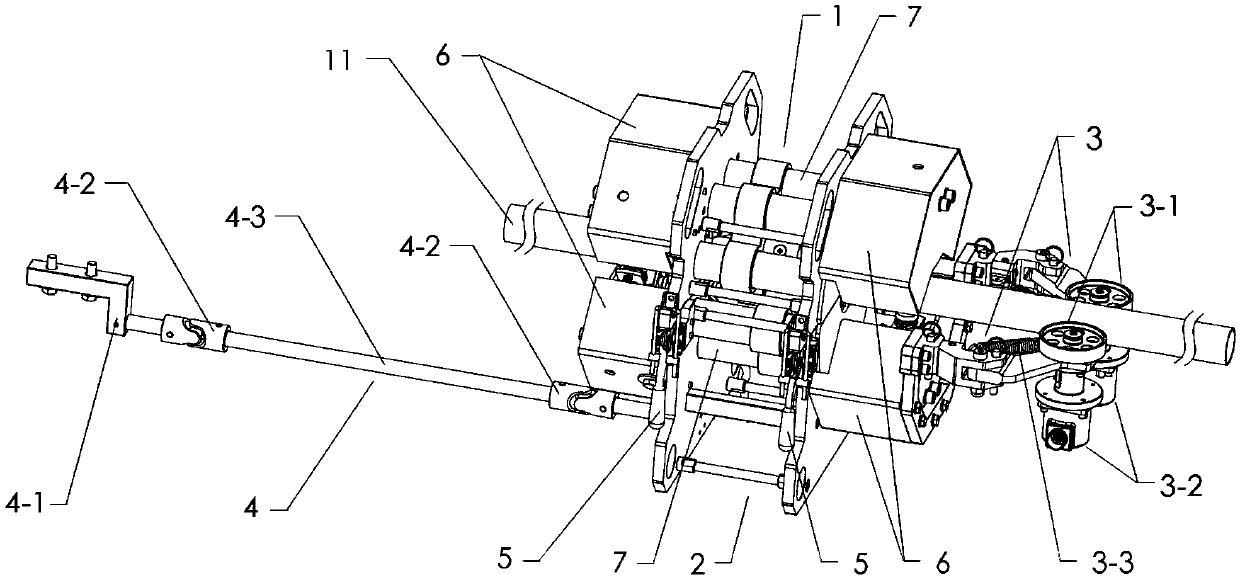

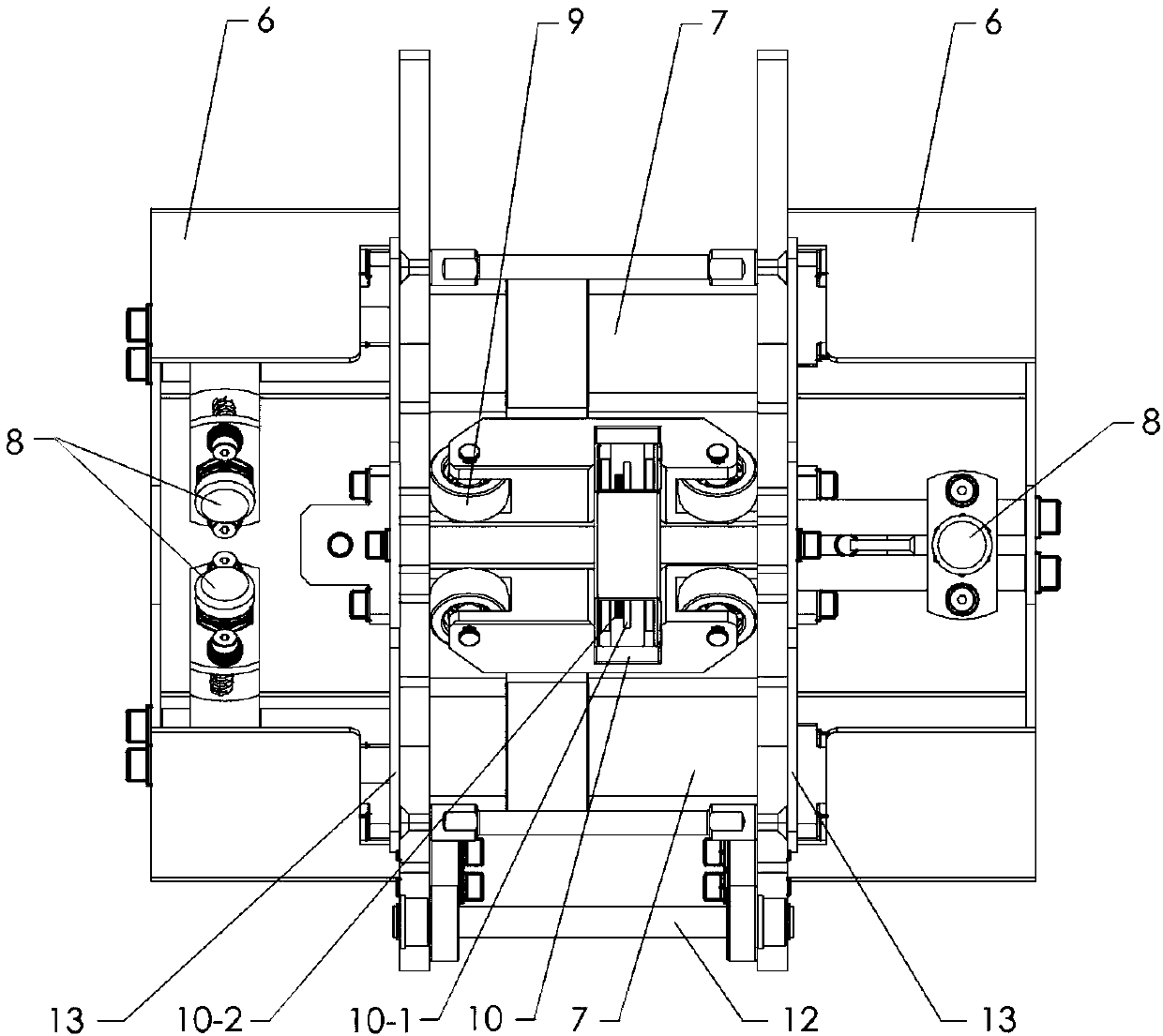

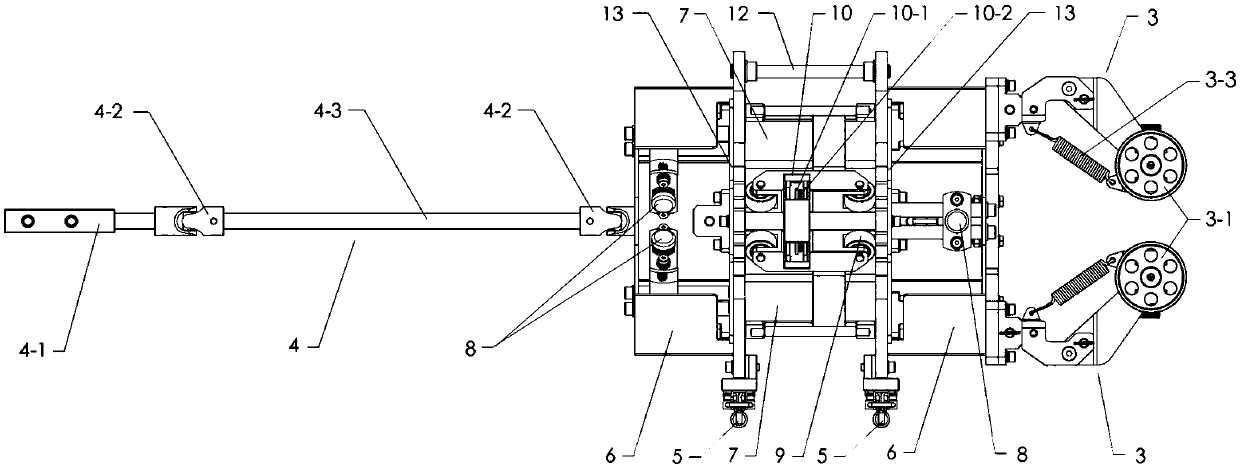

Integrated coiled tubing defect detection device

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

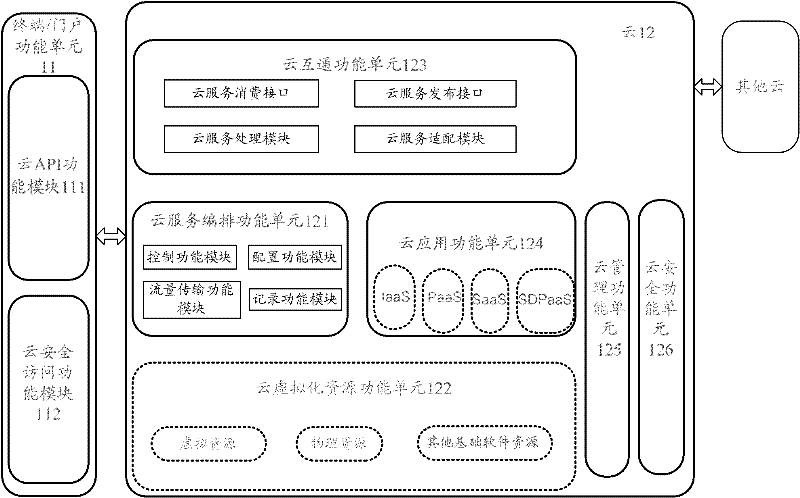

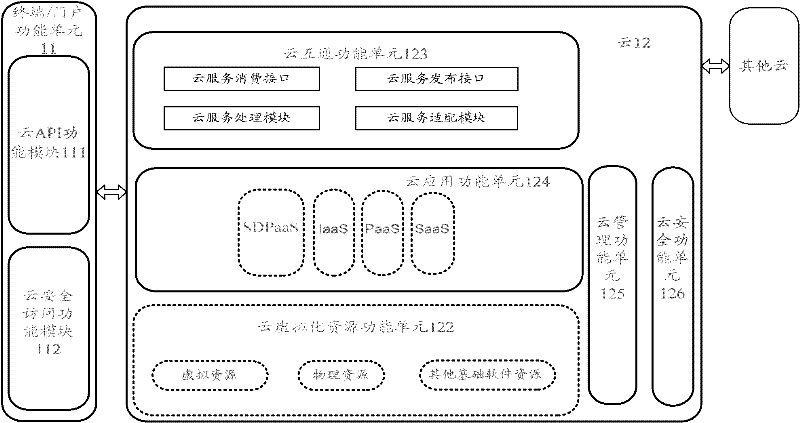

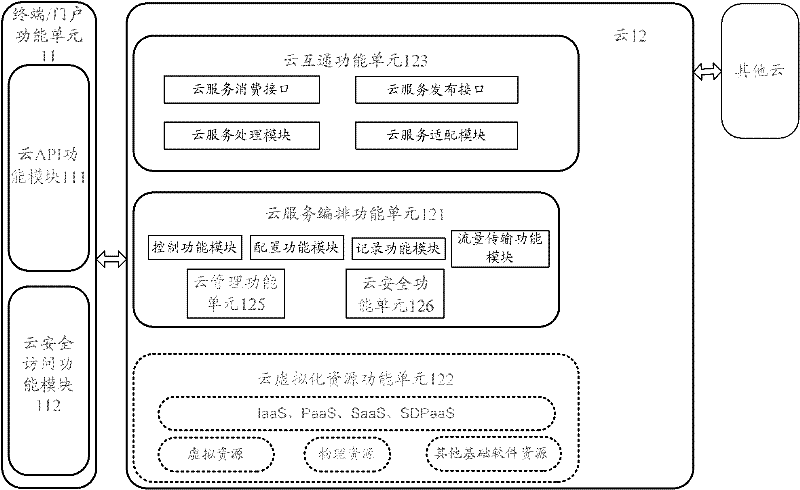

Cloud computing system, cloud computing method and cloud

ActiveCN102546735AAchieve integrationImplement virtualizationTransmissionVirtualizationComputing systems

The invention discloses a cloud computing system. A terminal and / or a door function unit build / builds a safety mechanism with cloud and send / sends cloud service request to the cloud. After the cloud receives the cloud service request, other cloud is accessed by the cloud itself and / or through a cloud interworking function, cloud computing resource is arranged, and cloud service is provided for the terminal and / or the door function unit. The invention further discloses a cloud computing method and the cloud. By means of the technical scheme, integration, virtualization and automation of the cloud computing system can be achieved, the cloud can coordinate uniformly and arrange the cloud computing resource automatically, efficiency is improved, and defect that the existing cloud computing system can not arrange the cloud computing resource automatically is overcome.

Owner:ZTE CORP

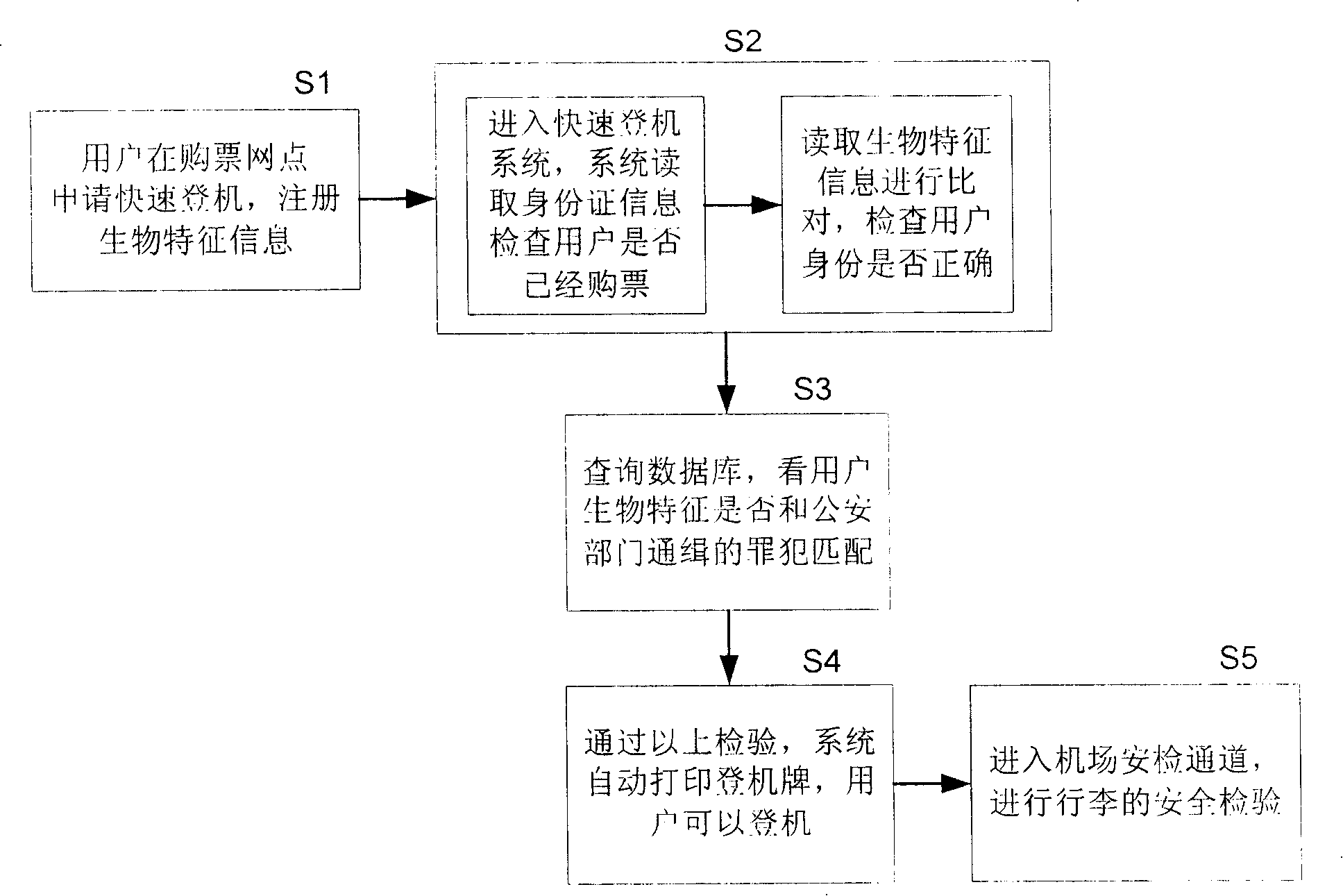

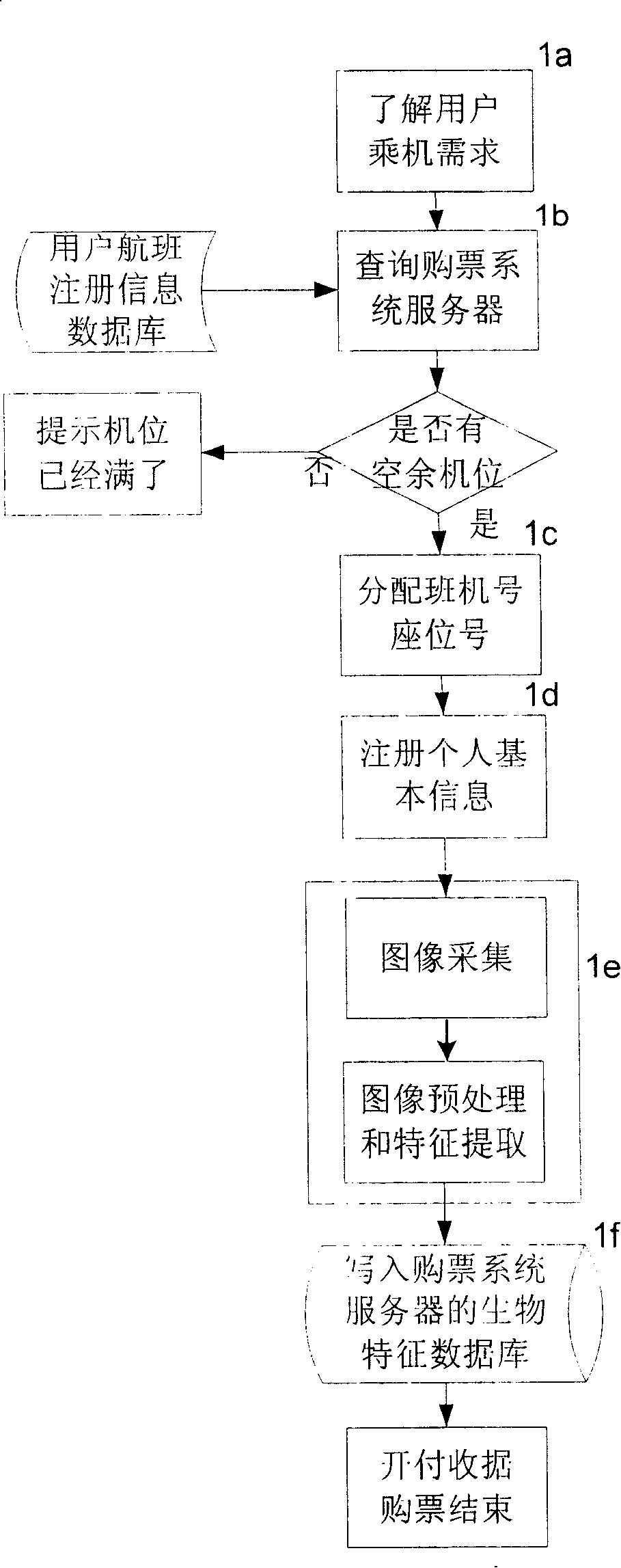

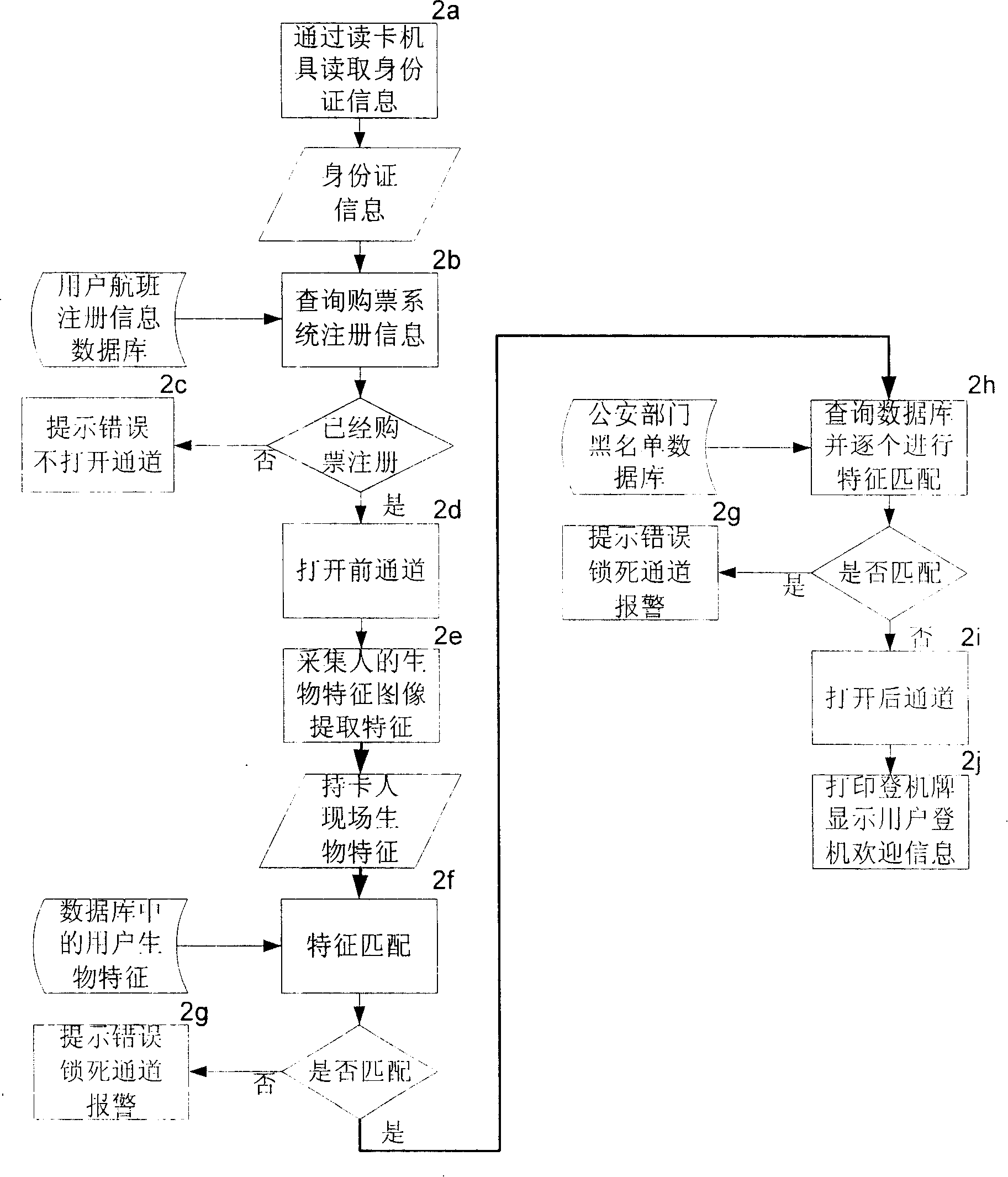

Rapid go-aboard system and method based on id card and biological characteristic recognition technique

InactiveCN101226653ASave human effortImprove efficiencyIndividual entry/exit registersMachines for printing and issuing ticketsPurchasingManagement system

The invention discloses an express boarding system and a method based on identification cards and biometrics identification technology, relating to identification technique. When users boarding, the system automatically reads the information of an identification card to inquire whether the user purchases and registers, and rapidly and accurately inspects whether identity of the user is correct through the biometrics identification technology, and thereby red tape, such as queuing for checking in and the like, is avoided, finally achieving express boarding. The system obtains ticket purchasing information and biometrics of the user by connecting a network, a booking system and public security department systems. A boarding passage is composed of devices of an identification card reader, a biometrics identification device, a computer, a switch passage door and the like. The invention checks identity of people based on the identification card technique and biometrics identification technology, which is accurate and reliable. The invention can realize automatic boarding management, which is speedy, convenient and time-saving. The invention can be used in airport boarding management systems, and also can be applied to occasions which need to rapidly and accurately perform identification.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Welding visual detection method and device based on convolutional neural network

ActiveCN105891215AHigh precisionHigh speedOptically investigating flaws/contaminationTest phaseRegion of interest

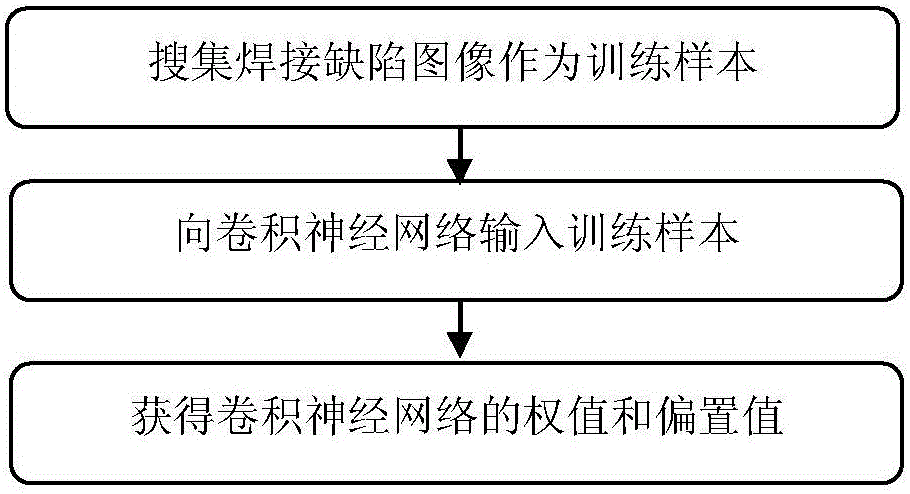

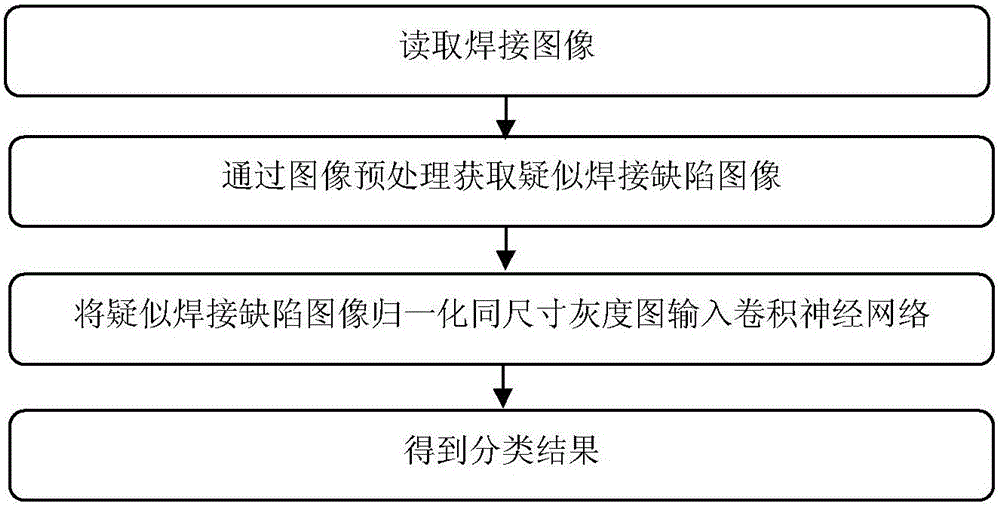

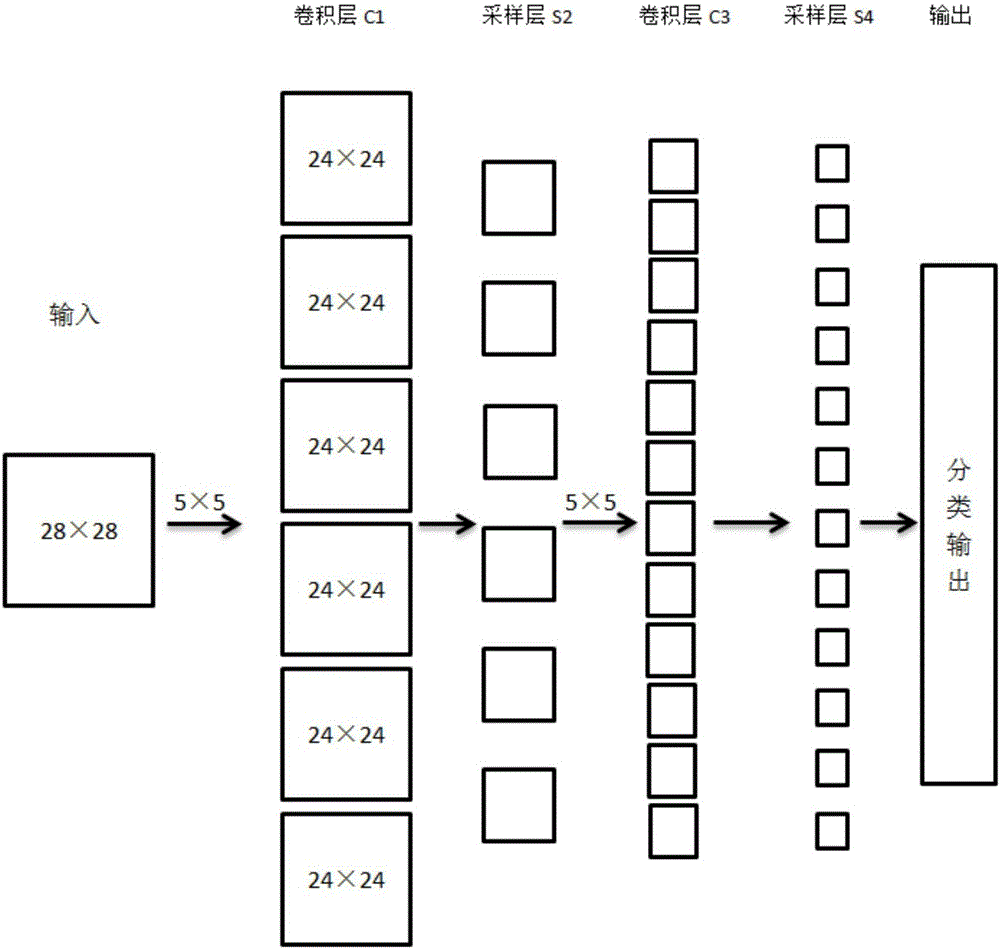

A welding visual detection method based on a convolutional neural network includes the following steps that firstly, at the training stage, a training sample is input into the convolutional neural network, and the connection weight and offset value of the convolutional neural network are obtained; secondly, at the testing state, a welding picture is read in and preprocessed with the digital picture processing technology, and a region of interest is extracted and then subjected to picture size normalization processing to serve as input of the convolutional neural network. The invention further provides a welding visual detection device based on the convolutional neural network. The welding visual detection device based on the convolutional neural network comprises a crawling mechanism, a power transmission mechanism, visual detection equipment and a weld defect detection and analysis system. By means of the welding visual detection method and device based on the convolutional neural network, the automaton and intelligence level is improved, the detection precision is effectively improved, and the detection speed is effectively increased.

Owner:ZHEJIANG UNIV OF TECH

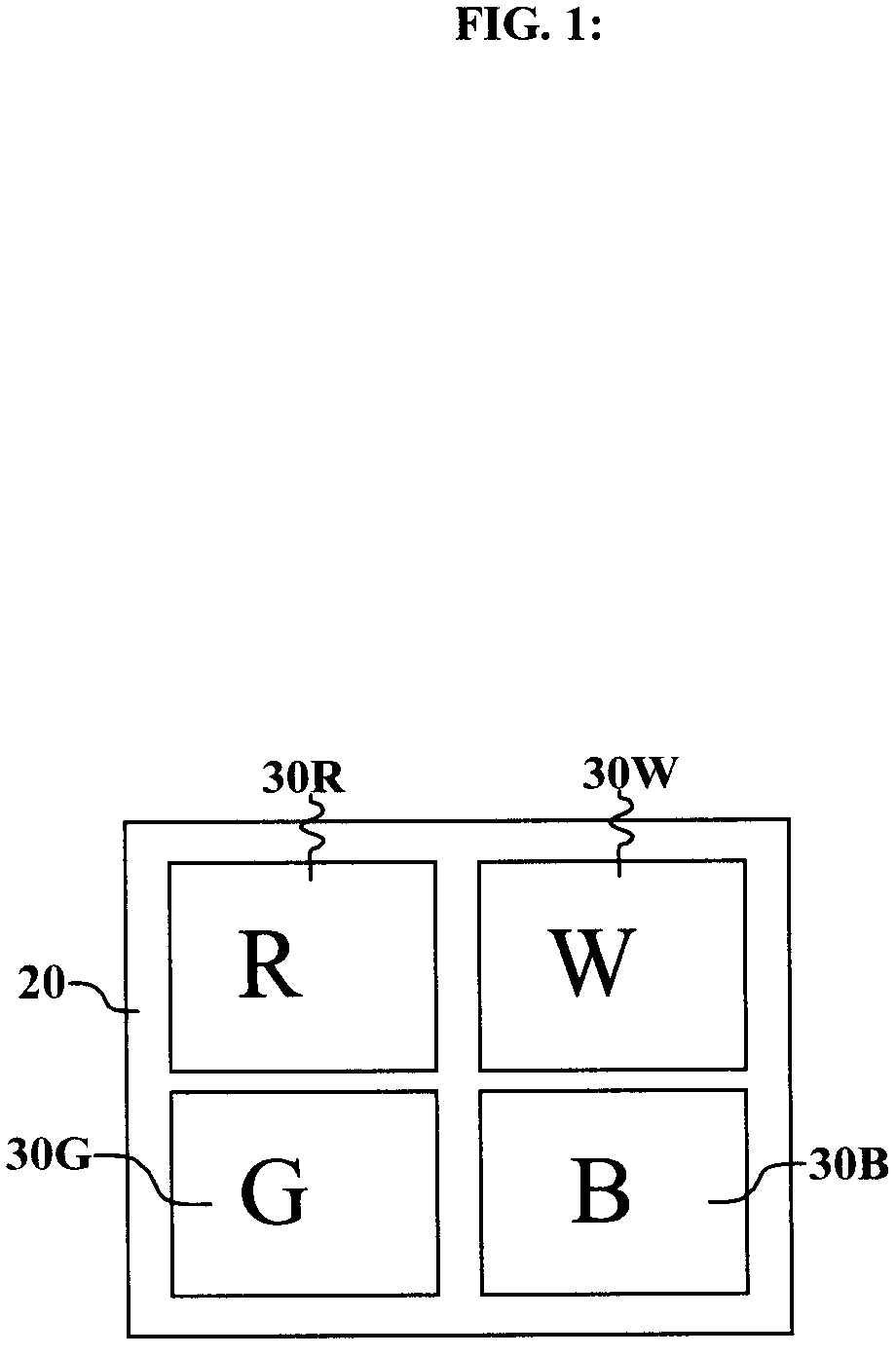

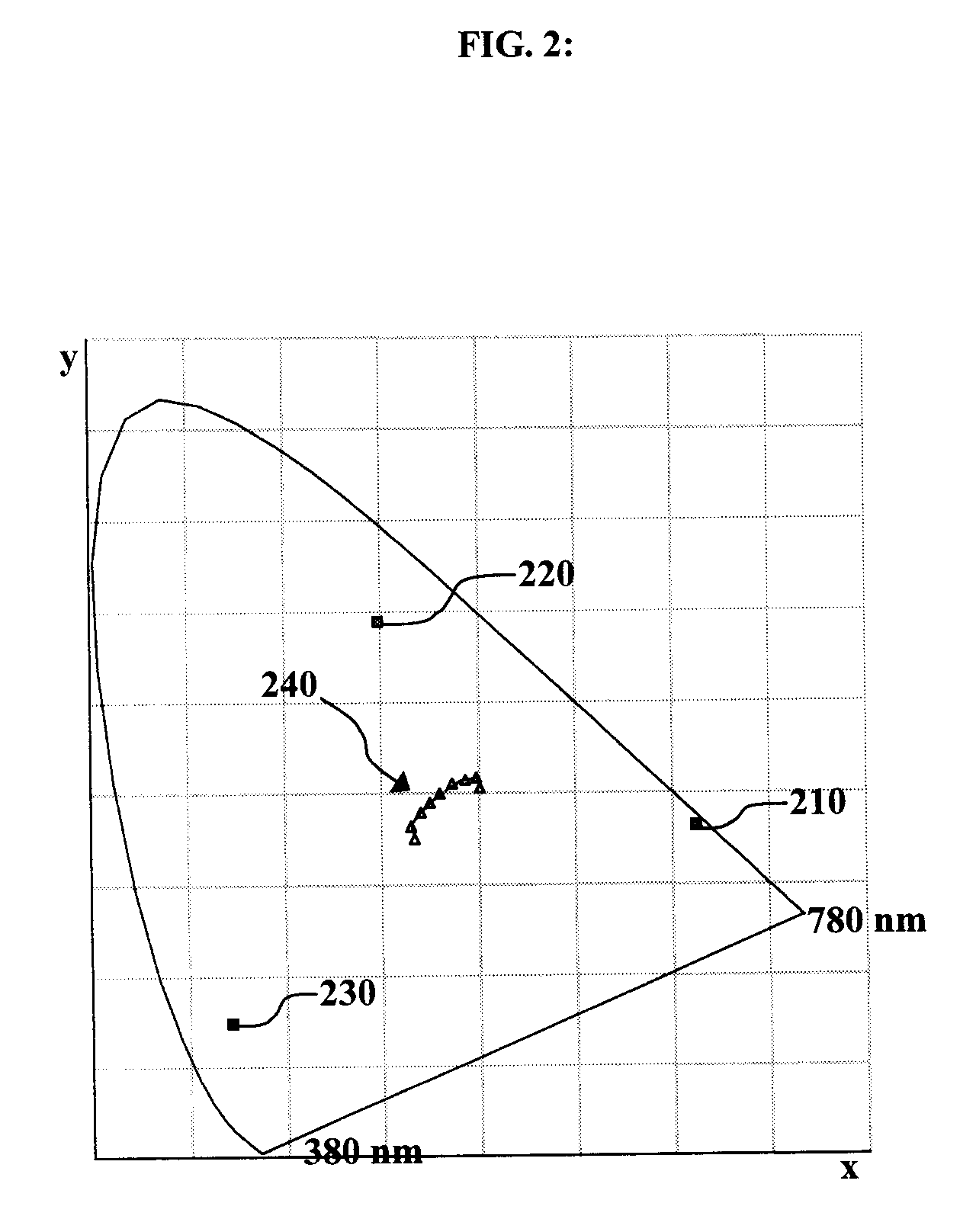

Method for input-signal transformation for rgbw displays with variable w color

InactiveUS20080252797A1Easy to measureSmall memoryColor signal processing circuitsStatic indicating devicesGamutDisplay device

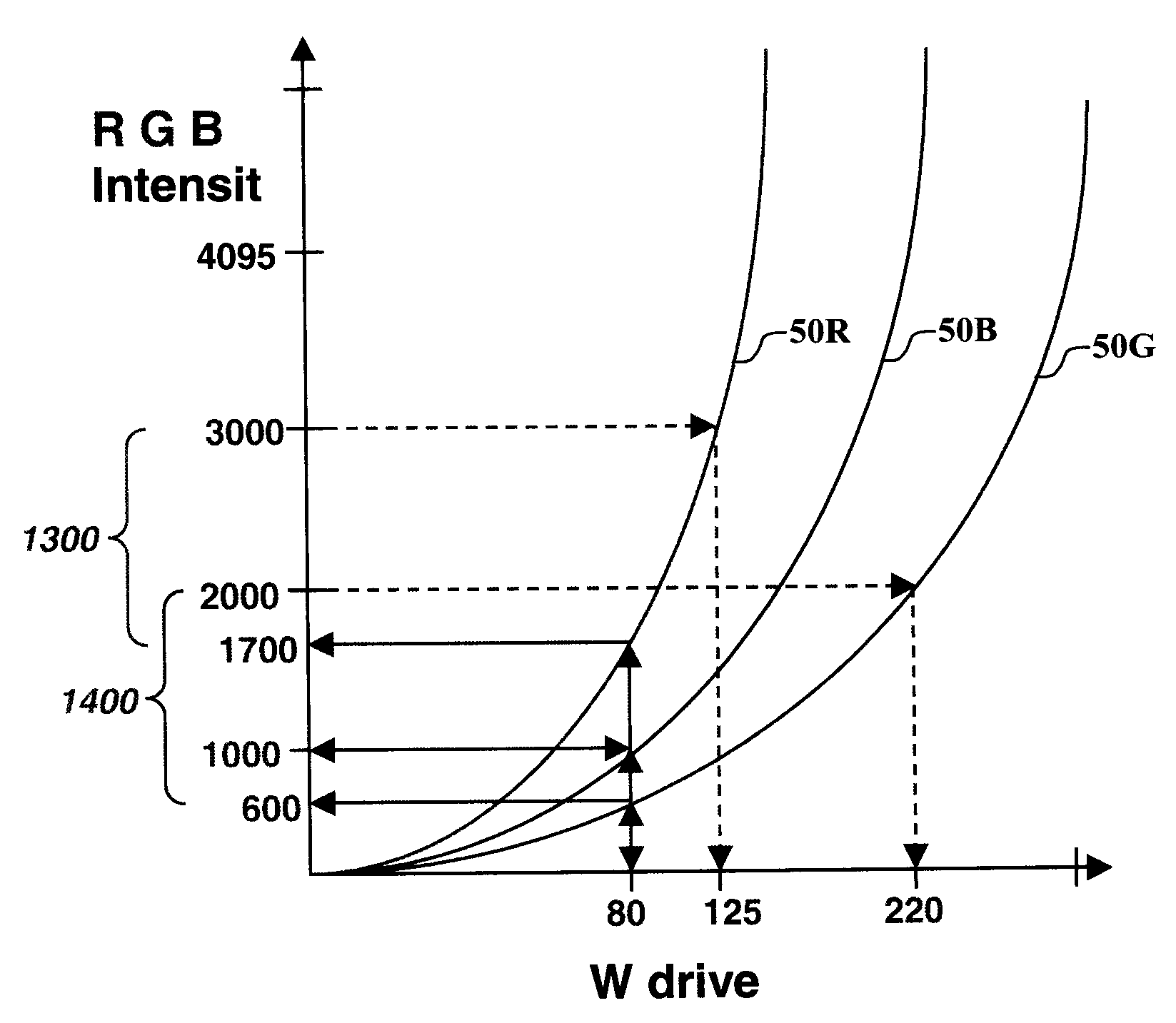

A method for transforming three color-input signals (R, G, B) corresponding to three gamut-defining color primaries of a display to four color-output signals (R′, G′, B′, W) corresponding to the gamut-defining color primaries and one additional primary of the display, where the additional primary has color that varies with drive level, comprising: a) determining a relationship between drive level of the additional primary and intensities of the three gamut-defining primaries which together produce equivalent color over a range of drive levels for the additional primary; and b) employing the three color-input signals R, G, B and the relationship defined in a) to determine a value for W of the four color-output signals, and modification values to be applied to one or more of the R, G, B components of the three color-input signals to form the R′, G′, B′ values of the four color-output signals.

Owner:GLOBAL OLED TECH

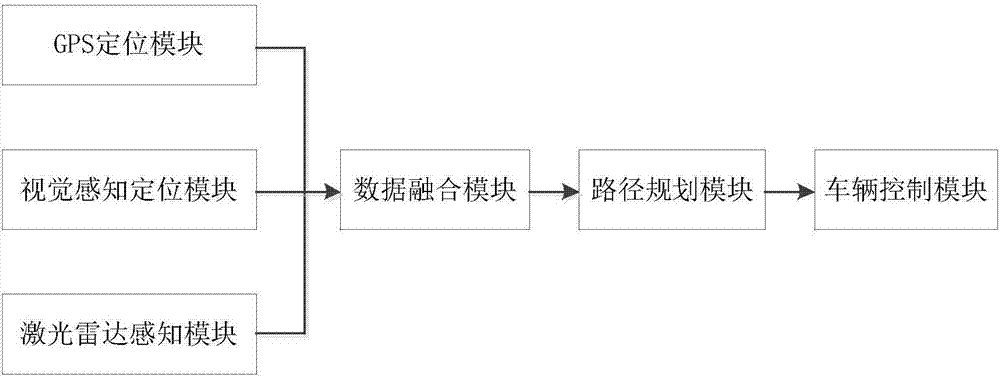

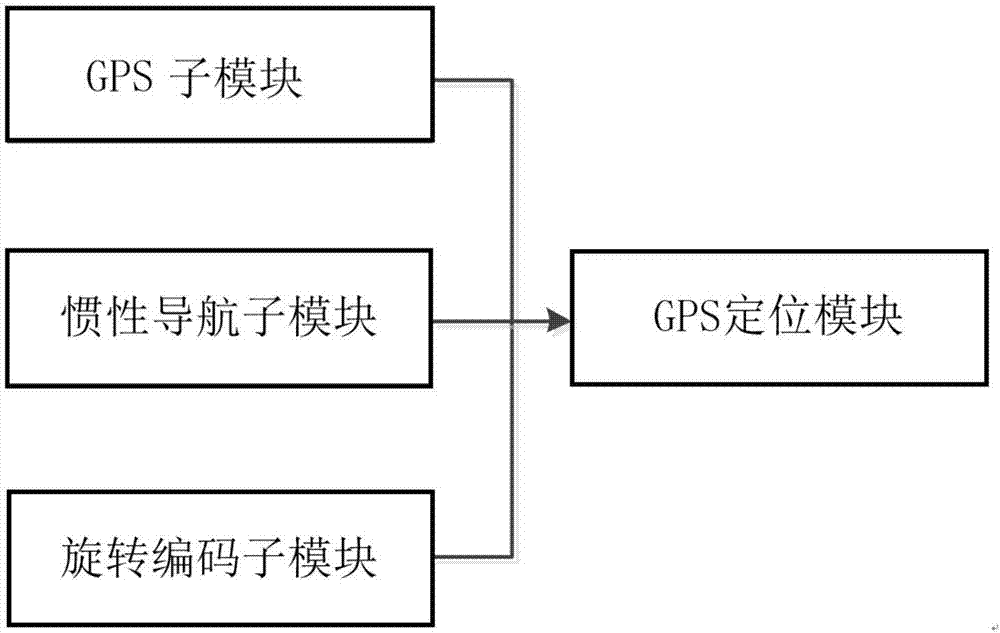

AGV transport system based on vision guidance and driving control method thereof

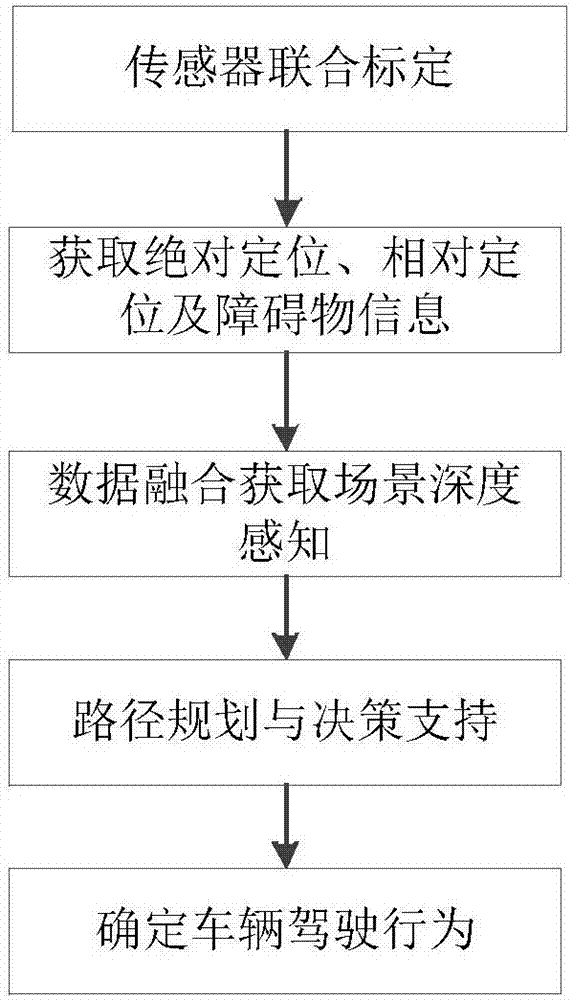

InactiveCN107422730AEasy to install and maintainLow costPosition/course control in two dimensionsVehiclesElectronic mapRoute planning

The invention discloses an AGV transport system based on vision guidance and a driving control method thereof. The AGV transport system comprises a GPS positioning module used for obtaining the absolute position and course information of an AGV; a visual perception positioning module used for recognizing ground lane lines and laid visual markers and obtaining the spatial position relations of the lane lines and the visual markers relative to a visual sensor and high-precision positioning information of the AGV; a laser radar perception module used for recognizing the position, the motion state and shape information of an obstacle in a short distance range in front of the AGV; a data fusion module used for obtaining fusion data; and a route planning module used for performing positioning and route planning on the AGV according to the fusion data and a known navigation electronic map and providing a positioning and route planning result to a vehicle control system. According to the system and the driving control method thereof, the cost is low, the precision is high, stability, safety and reliability are achieved, and the automation of the transport of port containers can be realized.

Owner:武汉市众向科技有限公司

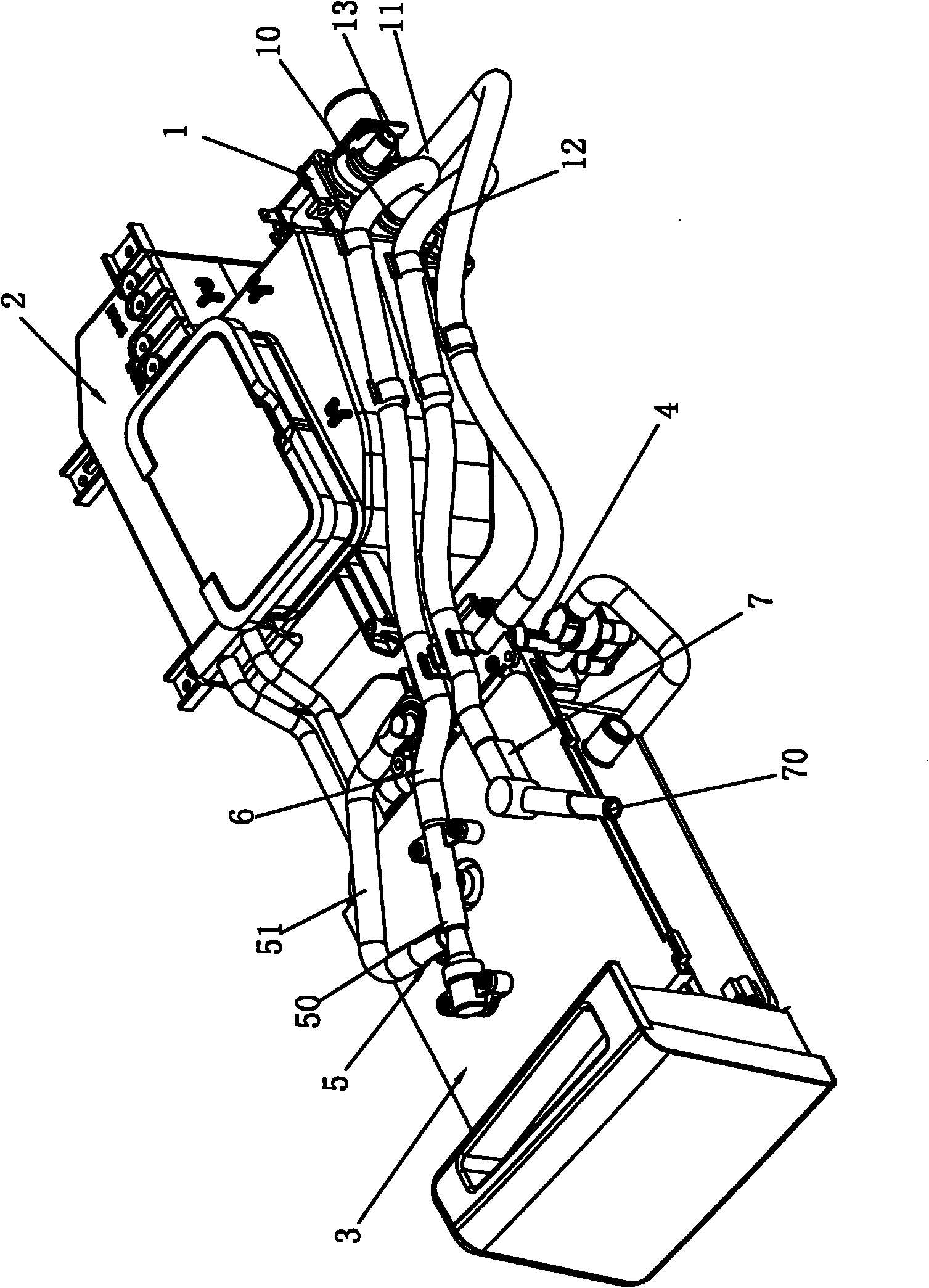

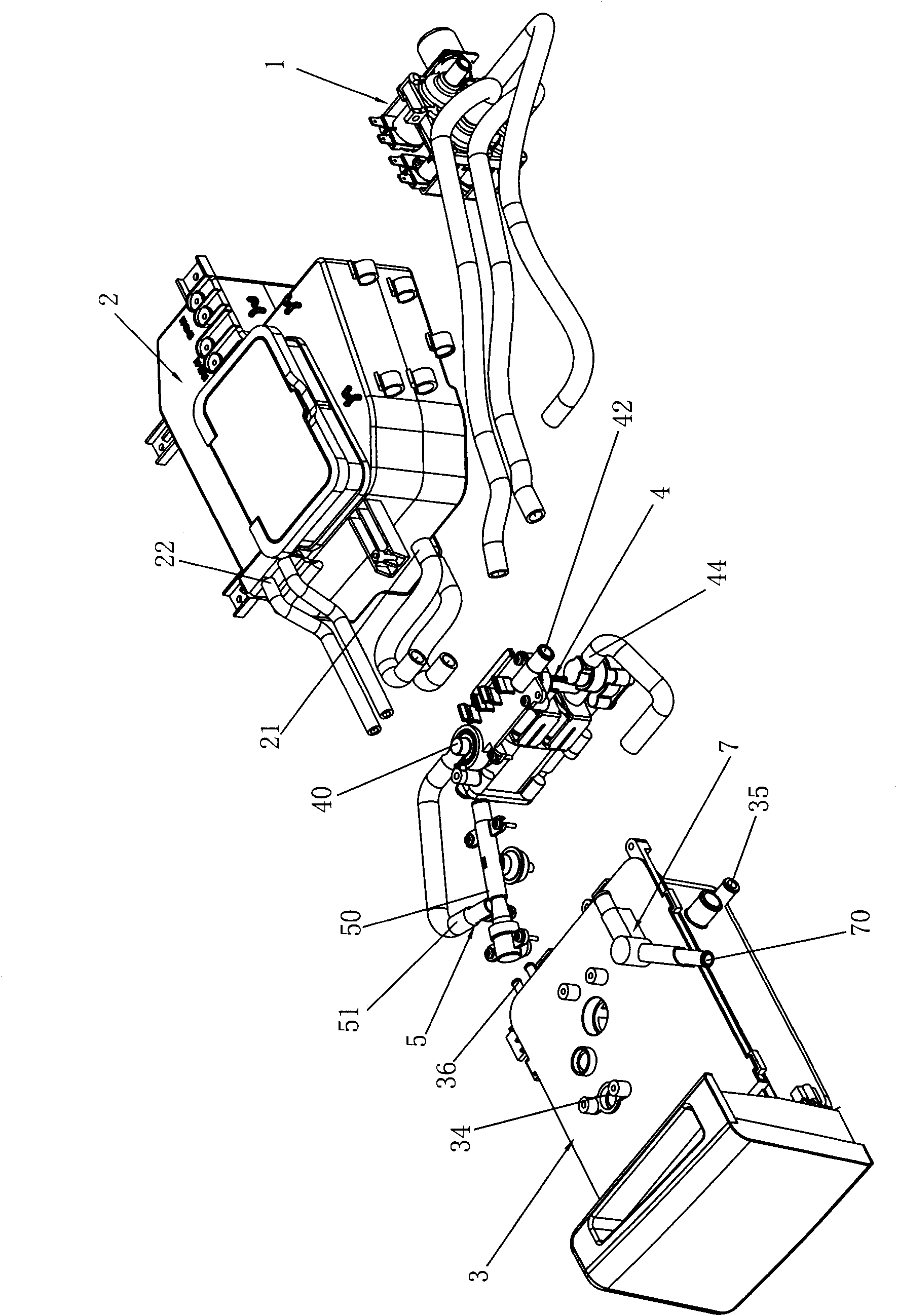

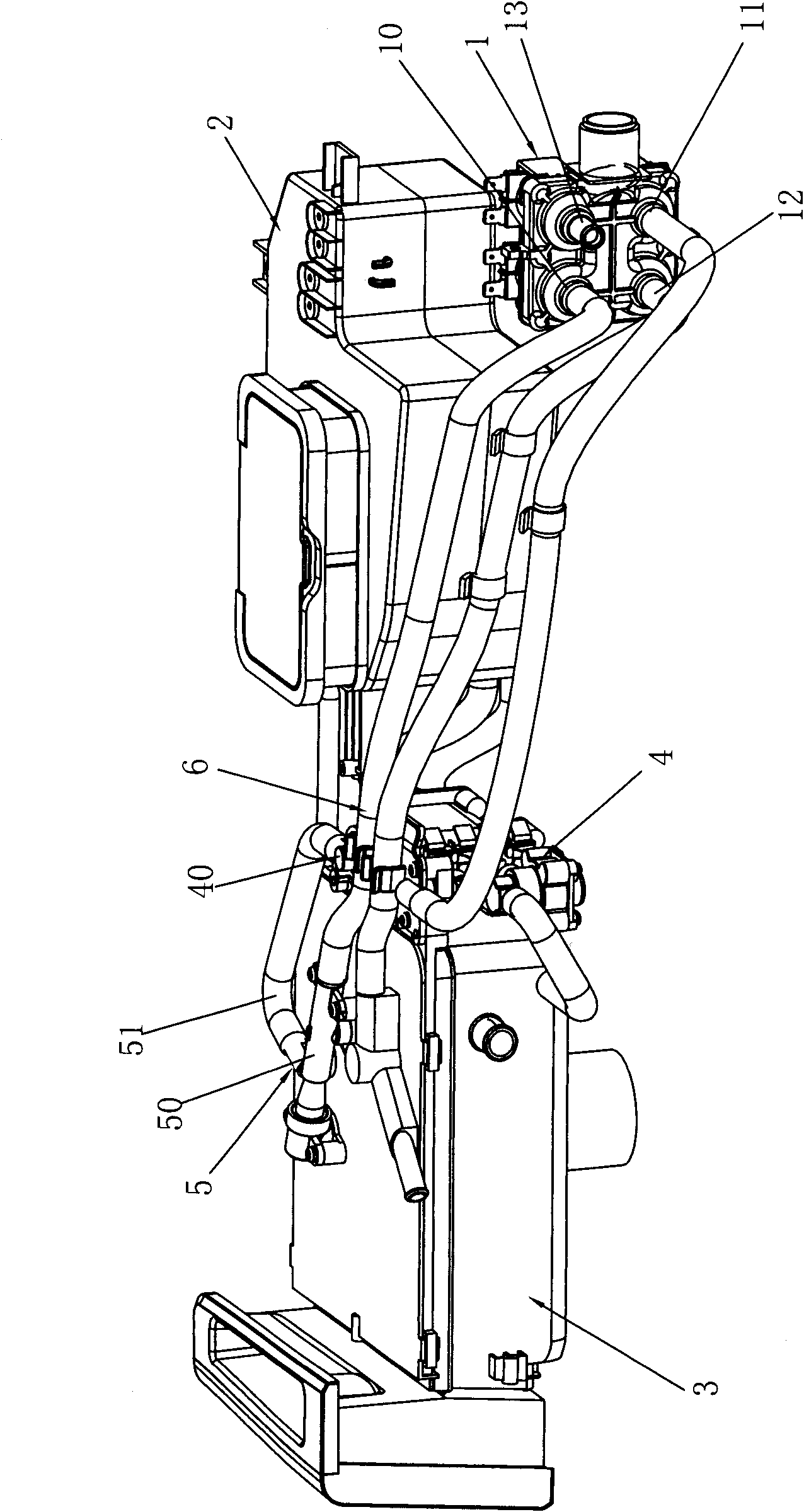

Detergent for washing machine and automatic disinfectant adding device

ActiveCN101956311AReduce pollutionFully automatedOther washing machinesTextiles and paperDisinfectantInlet valve

The invention discloses a detergent for a washing machine and an automatic disinfectant adding device. The automatic adding device comprises a washing machine water inlet valve, a solvent box and a washing machine sink component; the automatic adding device also comprises an automatic adding precise control device which is connected with the washing machine water inlet valve, the solvent box and the washing machine sink component through connecting pipelines respectively; the automatic adding precise control device is provided with a negative pressure suction port and a constant volume container; and a solvent in the solvent box is pumped into the constant volume container by negative pressure generated by inlet water of the washing machine sink component, and the quantitative solvent is flushed into the washing machine sink component by the inlet water of the automatic adding precise control device and further flows to a washing drum. The automatic adding device makes great contribution on the aspect of adding the detergent to the washing machine, can precisely add different detergents, can fully realize automatic addition by using the negative pressure generated by the inlet water, has a simple structure, realizes automation of the washing process, and improves the washing efficiency.

Owner:HAIER GRP CORP +2

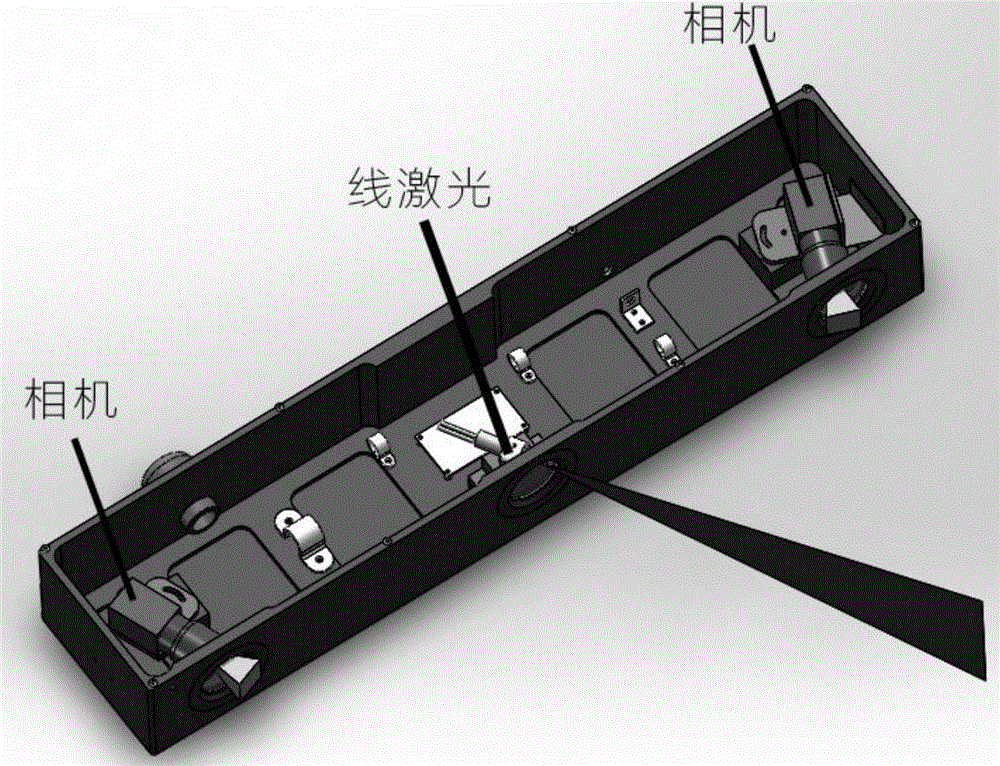

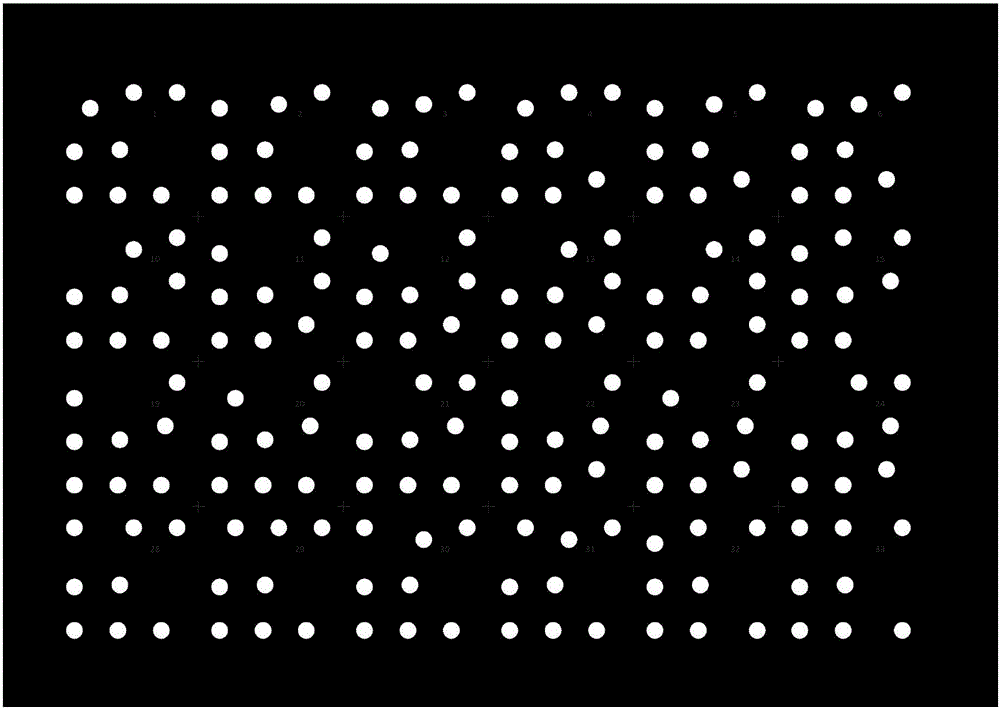

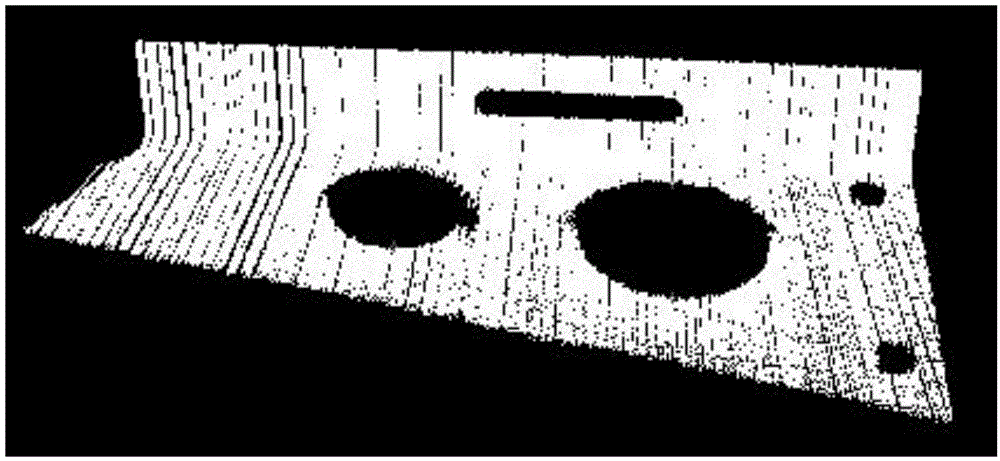

Control method of manipulator grabbing control system based on binocular stereoscopic vision

ActiveCN106041937AAchieve placementRealize the assemblyProgramme-controlled manipulatorPoint cloudTriangulation

The invention discloses a control method of a manipulator grabbing control system based on binocular stereoscopic vision. The control method comprises the following steps: camera parameters are calibrated, and a teaching manipulator is used for realizing conversion of a camera coordinate system and a manipulator coordinate system; line laser performs an arc surface scanning cloud motion, and a camera acquires images; laser lines of the images shot by the camera are respectively extracted; the positions of the laser lines are precisely determined by using a sub pixel algorithm; the homonymy point matching is performed for the laser lines extracted in the images; three-dimensional space coordinates of all points on the laser lines are calculated through a triangular measuring principle to finish scanning of workpieces in a scene so as to obtain point cloud data in the viewing field of the camera; a workpiece point cloud template is built, a manipulator grabbing point position is selected, and the obtained point cloud data is matched with the workpiece point cloud template to calculate a conversion relation of the two; the manipulator grabbing point position in the point cloud template is converted to a present coordinate, is converted to a coordinate under the manipulator coordinate system, and is transferred to the manipulator; and the manipulator finishes actuation actions.

Owner:HENAN ALSONTECH INTELLIGENT TECH CO LTD

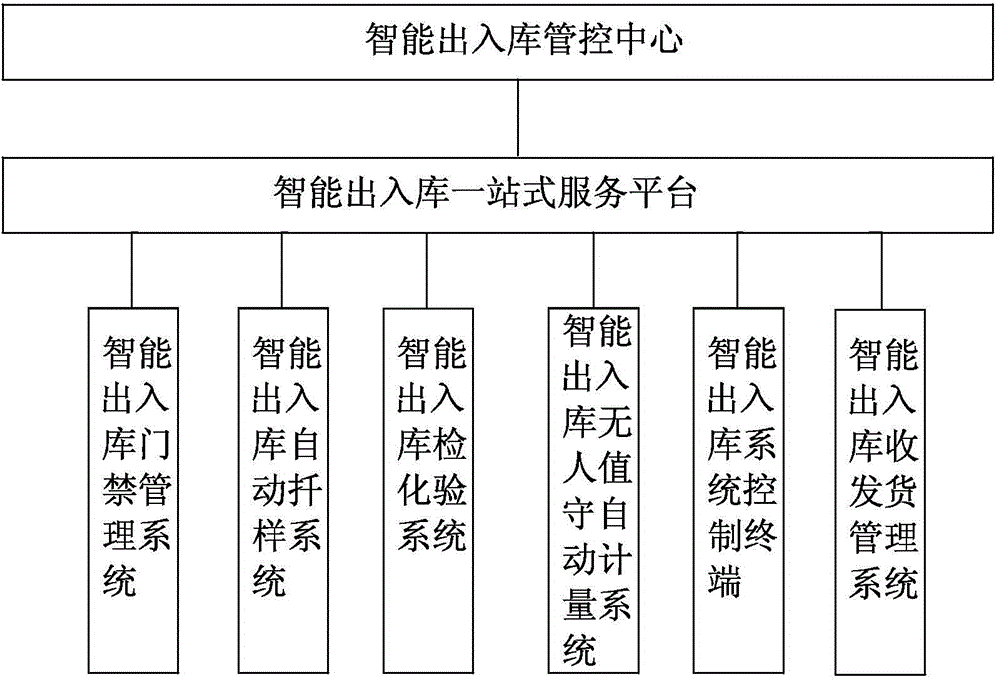

Intelligent depot output-input system of digital grain depot

ActiveCN103559605ASimplify business processesRealize paperless managementIndividual entry/exit registersLogisticsIntelligent managementComputer science

The invention discloses an intelligent depot output-input system of a digital grain depot. The intelligent depot output-input system of the digital gain depot comprises an intelligent depot output-input access control system, an intelligent depot output-input automatic sampling system, an intelligent depot output-input examination assay system, an intelligent depot output-input unattended operation automatic metering system, an intelligent depot output-input system control terminal, an intelligent depot output-input goods receiving-sending management system, an intelligent depot output-input system one-stop service platform and an intelligent depot output-input system control center. The intelligent depot output-input access control system, the intelligent depot output-input automatic sampling system, the intelligent depot output-input examination assay system, the intelligent depot output-input unattended operation automatic metering system, the intelligent depot output-input system control terminal, the intelligent depot output-input goods receiving-sending management system and the intelligent depot output-input system control center are connected with the intelligent depot output-input system one-stop service platform. According to the intelligent depot output-input system of the digital grain depot, a computer, the RFID internet of things technology, the communication technology and the information technology are converged together, networking, automation and intelligent management of the depot output and input are achieved, and labor participation is reduced.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

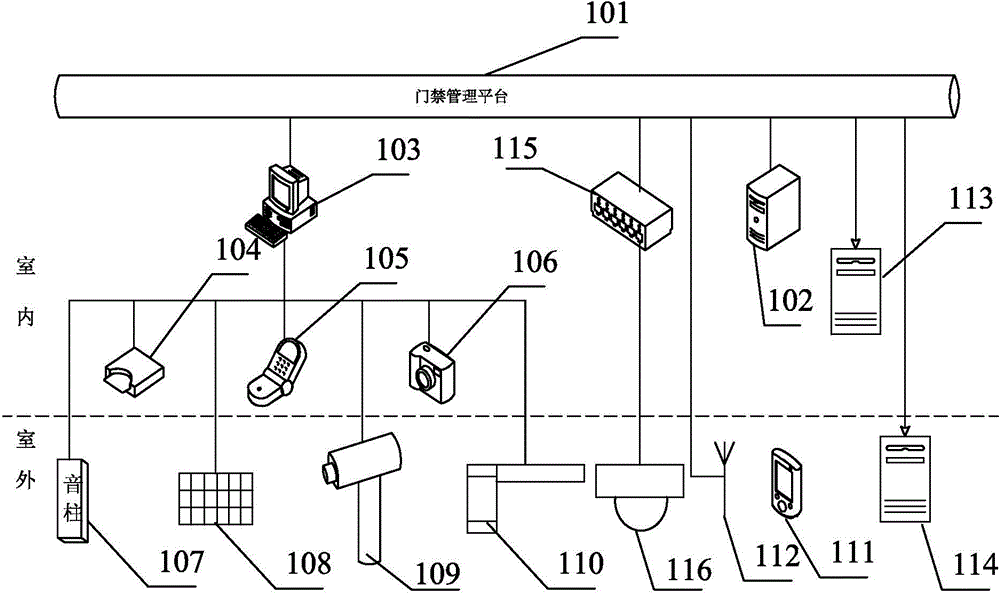

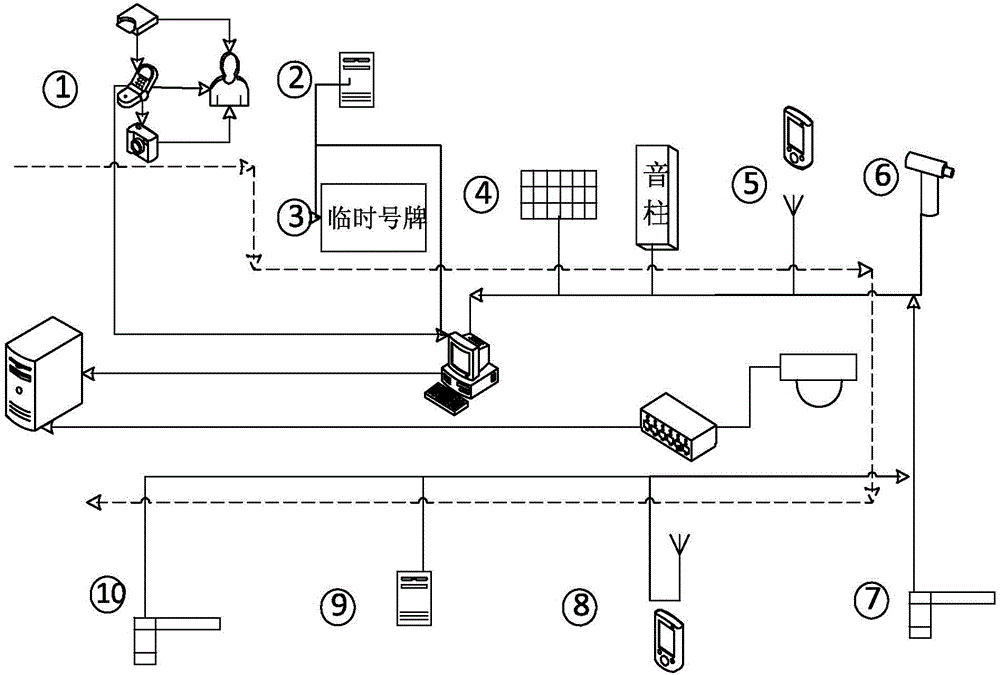

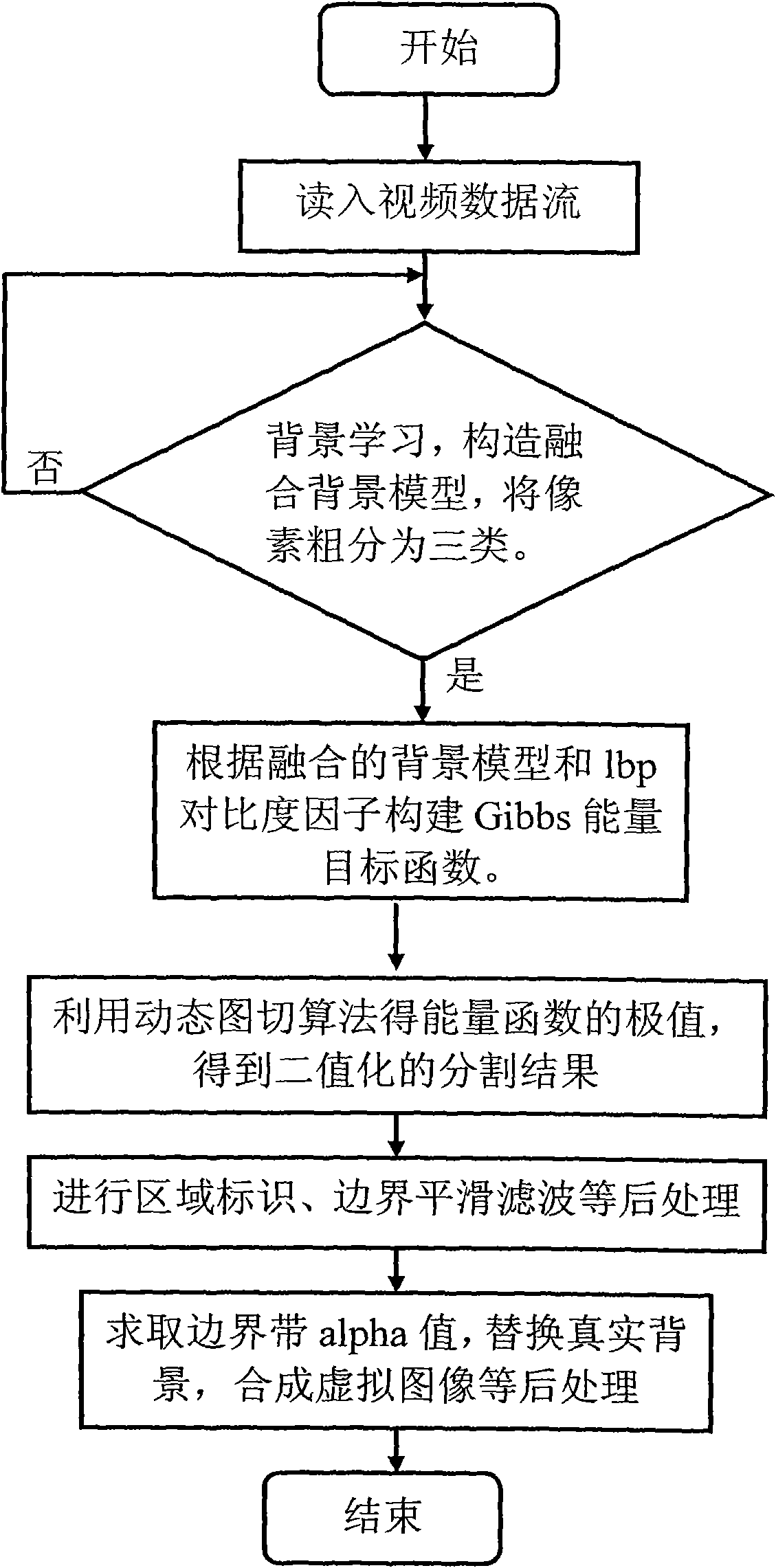

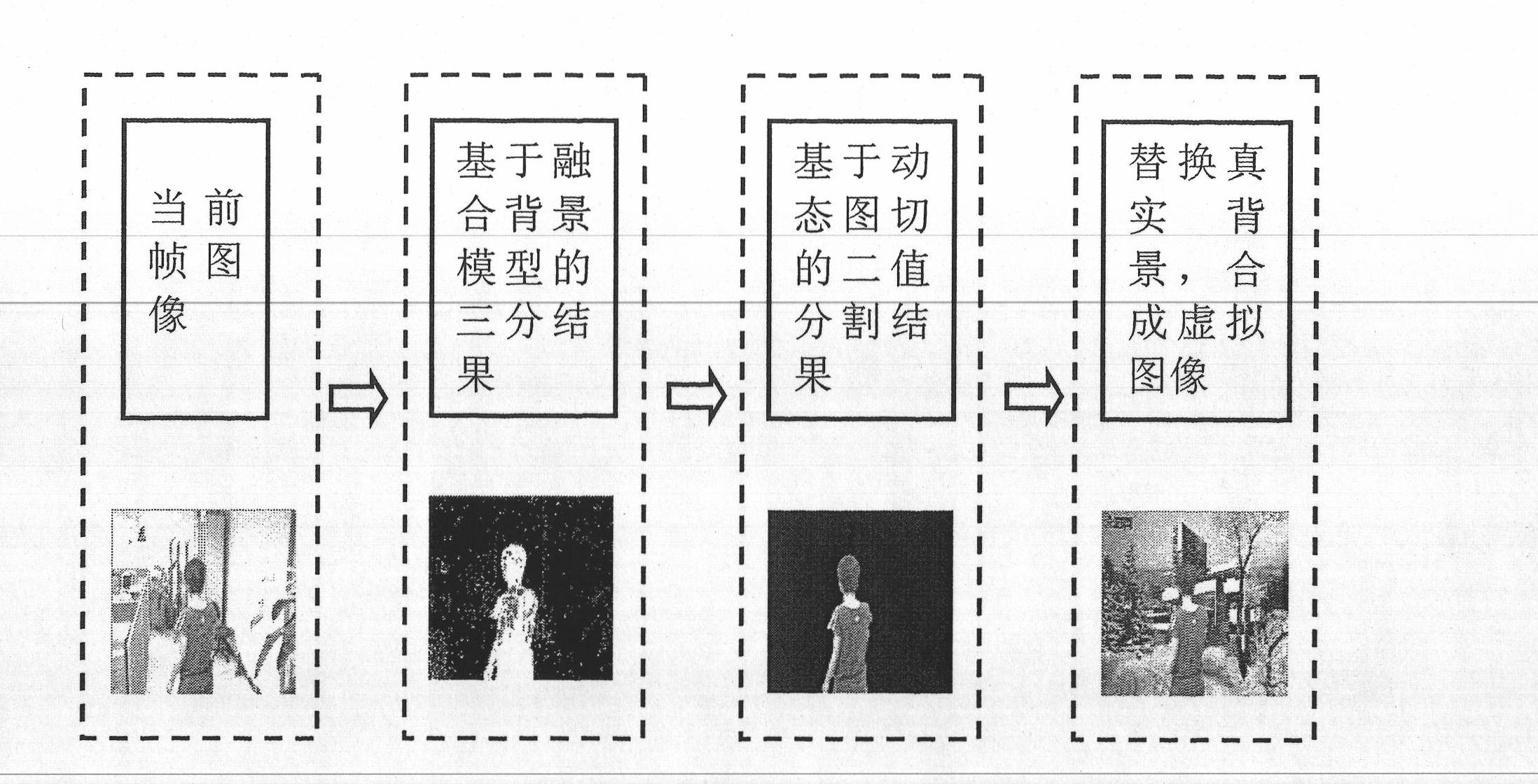

Complex background real-time alternating method based on background modeling and energy minimization

InactiveCN101777180AImprove segmentation efficiencyEasy to buildImage analysisEnergy functionalImage segmentation

The invention provides a complex background real-time alternating method based on background modeling and energy minimization, comprising the steps of: firstly, segmenting a current frame image into a foreground pixel set, a background pixel set and an unknown label pixel set by using a provided fusion background model; secondly, constructing a target energy function according to the color and contrast information under a dynamic diagram cutting frame, designing a data item of the fusion background model based on time continuity information and a contrast smooth item based on a local two-value mode, solving two-value labels of all pixels by using a diagram cutting algorithm minimization energy function; and seamlessly fusing segmented foreground targets into a virtual background by adopting postprocessing methods of boundary smooth, alpha value estimation and the like. Experimental results show that the method can better segment the targets in the complex background in real time and really synthesize the segmented targets into the virtual background. The invention has the characteristics of automatically segmenting the complex background in real time and replacing the segmented complex background into the virtual background to obtain a virtual effect sequence diagram with high quality.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

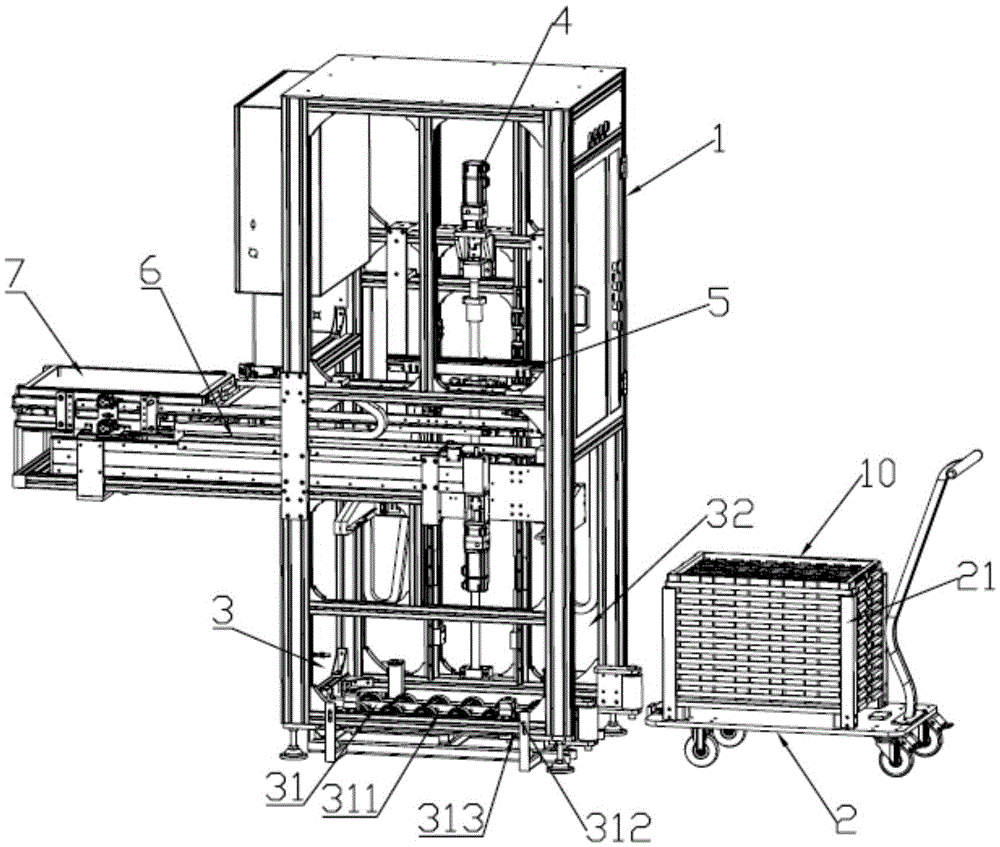

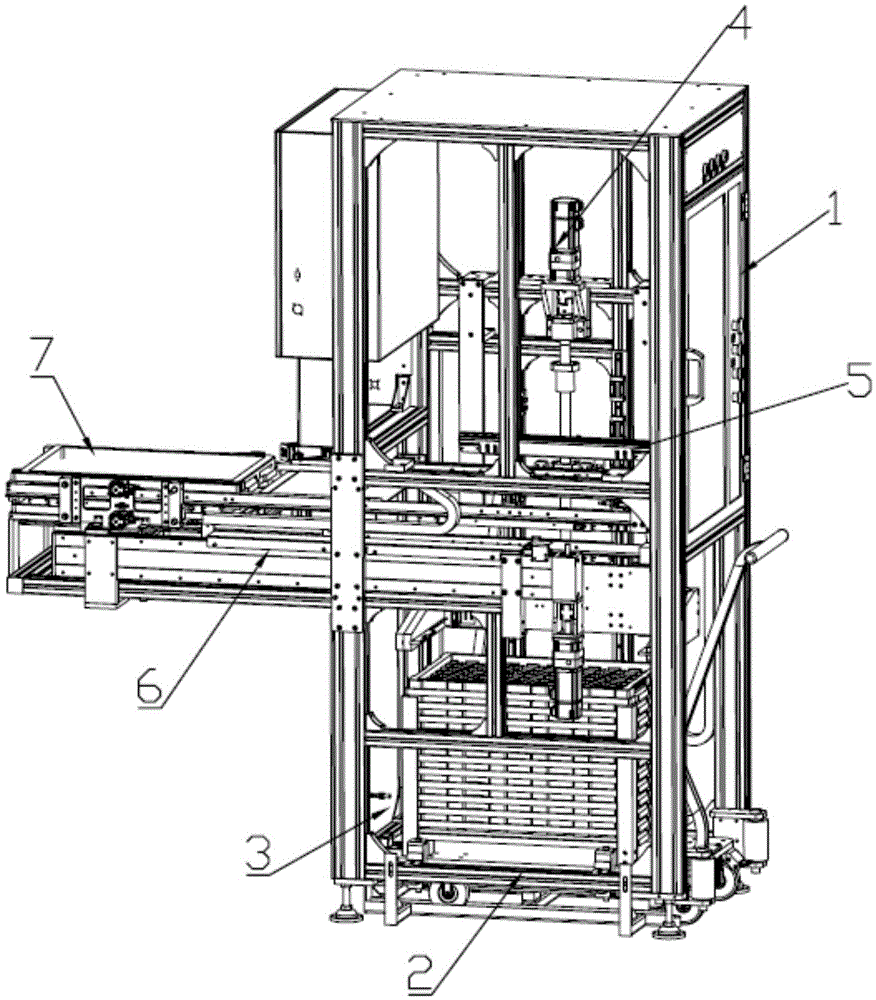

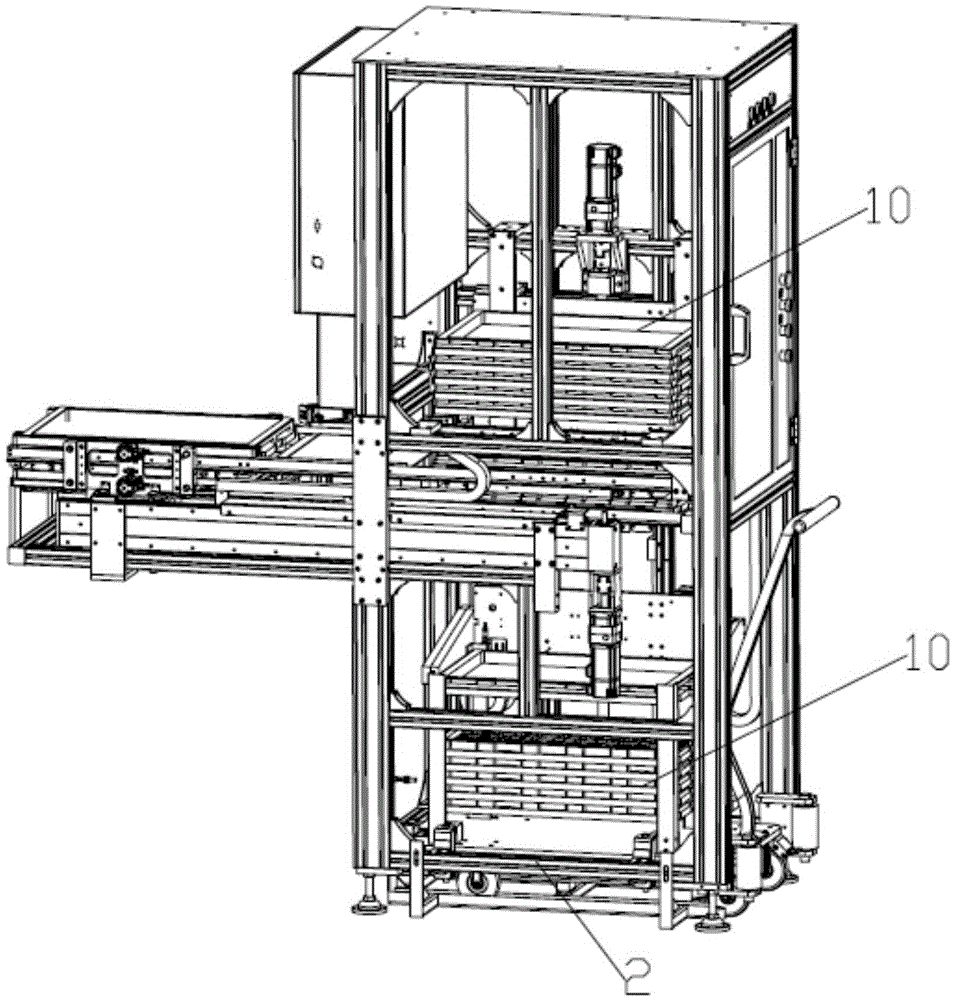

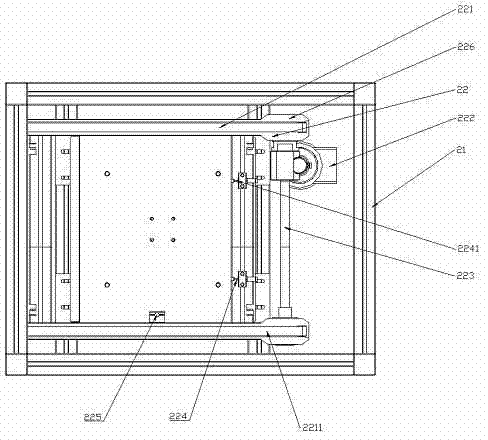

Tray type automatic supply and retraction equipment

InactiveCN105621110AFully automatedRealize intelligenceConveyorsStacking articlesButt jointEngineering

The invention discloses tray type automatic supply and retraction equipment. The equipment comprises a frame and multiple supply cars; a loading area is formed under the frame; a car positioning mechanism is arranged in the loading area; a supply car feed port is formed in one side surface of the loading area in the X direction; and after the support cars enter the loading area from the supply car feed port, the car positioning mechanism locks and positions the supply cars. The frame is provided with a tray hoisting mechanism in the Z direction in an area above the loading area; three layers of tray lifting mechanisms are symmetrically spaced on two sides of the Y direction of the middle part of the frame; a tray carrying mechanism in the X direction is arranged corresponding to two layers of tray lifting mechanisms on the lower side; and a butt joint equipment taking area is formed on the outer side of the tray carrying mechanism. The tray type automatic supply and retraction equipment divides a tray into a mother tray and son trays; for materials with different shapes, only the corresponding son trays need to be replaced, so that the replacement is convenient, and the resource is saved; and a robot is matched to clamp the materials so as to realize the material supply automation and intelligence more efficiently, more accurately and more quickly.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

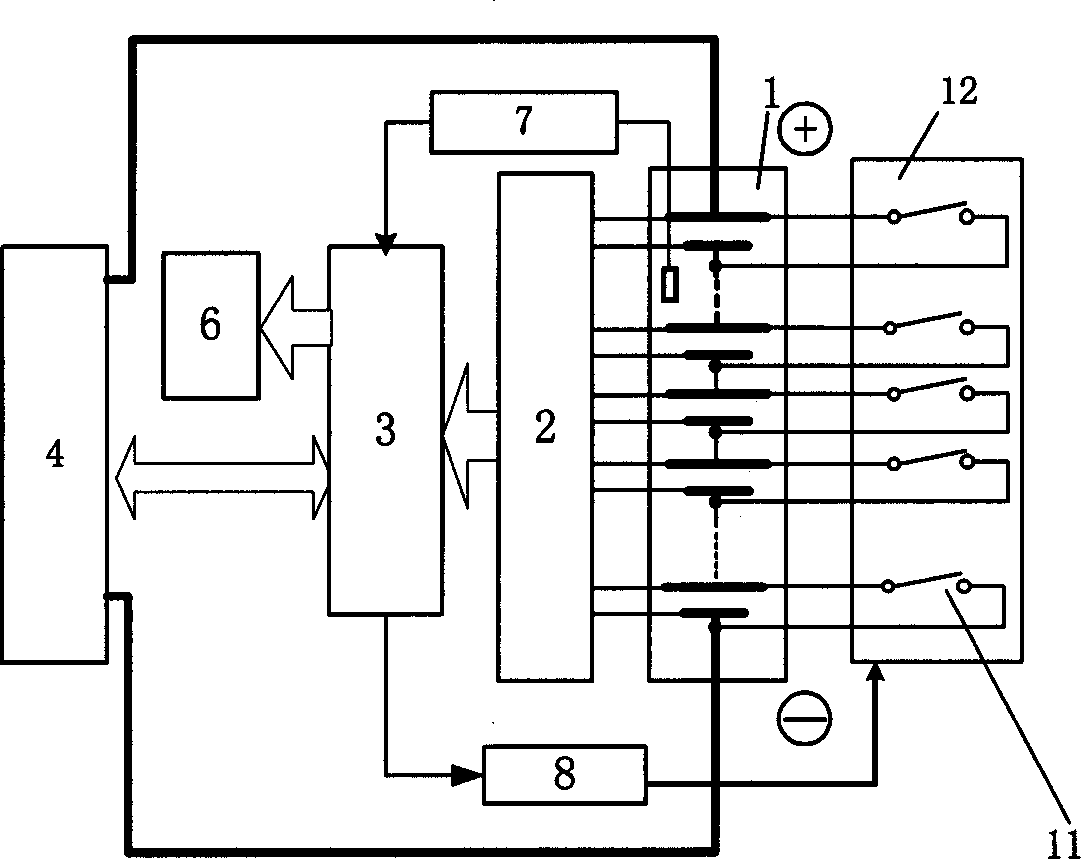

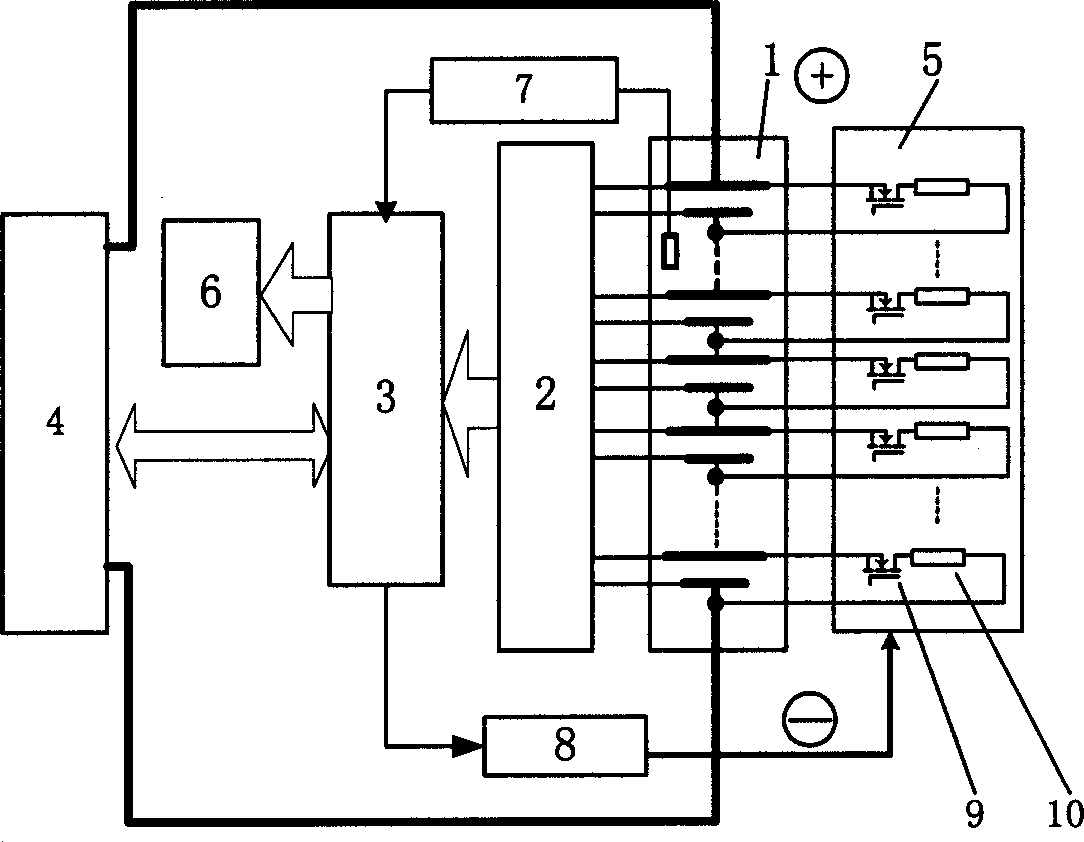

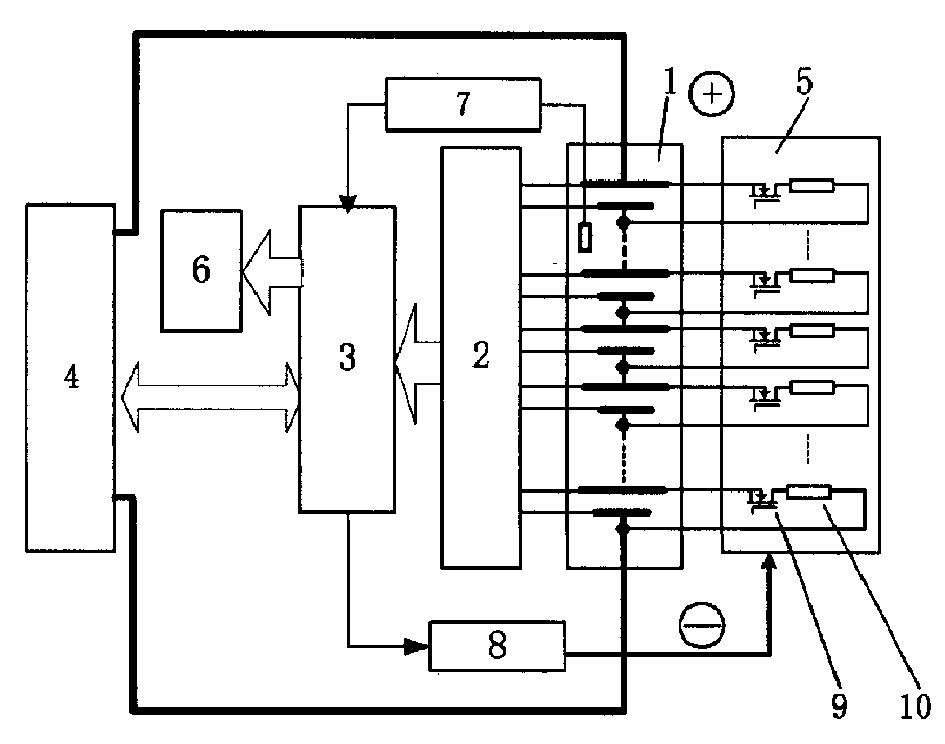

Automatic equalizing charging device for series-connected battery set

InactiveCN1367565AAchieve equalizationHigh voltageBatteries circuit arrangementsElectric powerTransducerEngineering

The present invention is an automatic equalizing charge device which uses discharging network formed by MOS tube connecting with power resistance in series to replace power switch and bypass flow network formed by it to execute the automatic equalizing charge for series battery group in quick and safe way with in existing equalizing charge technique including series battery group waiting for charge, real time collecting and isolation circuit for battery voltage signal, main control circuit board, contravariant charging power source, patrol inspection and indication circuit of battery voltage,temperature transducer, isolation driving circuit, power source and bypass flow network formed by it.

Owner:BEIHANG UNIV

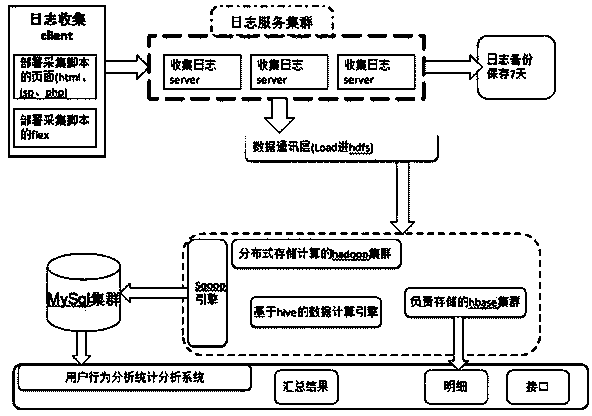

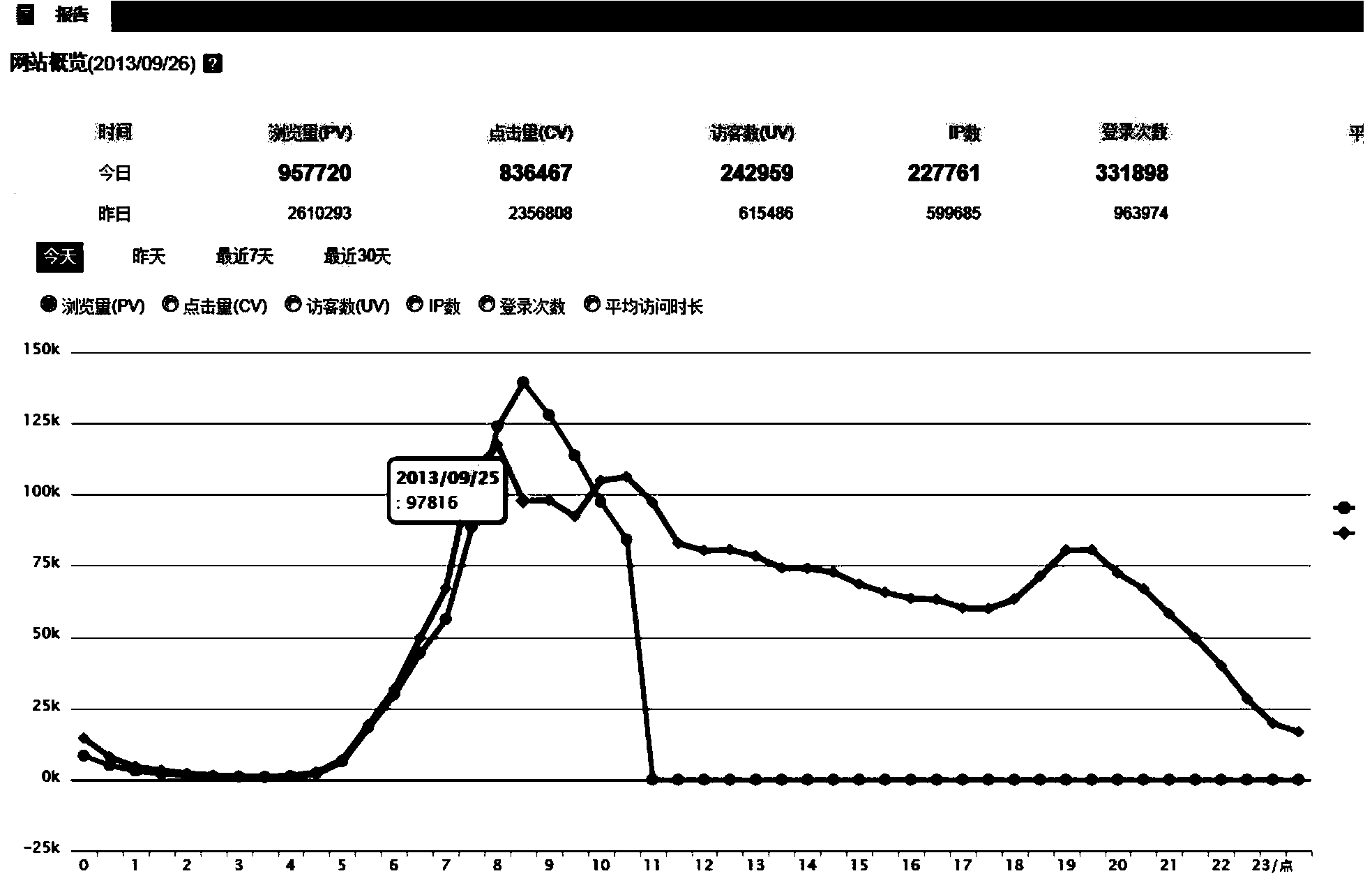

Method for monitoring and analyzing website user behaviors

The invention relates to a method for monitoring and analyzing website user behaviors. The method includes the steps of analysis object determination, page point insertion, log collection, HDFS storage, distributed summary calculation and result display. The method can be applied to websites with large page views (a hundred million page views per day), data such as website page views and click views can be accurately displayed in real time, and millisecond-level search of detail data can be achieved as well. The method is designed completely based on open source software development, a common pcserver and a common sata hard disk are adopted, redundant design is adopted in system architecture, and data will not be lost if any data node or the hard disk is damaged. All links can be automatically carried out, graphic monitoring can be achieved, and the method is easy to implement.

Owner:INSPUR SOFTWARE CO LTD

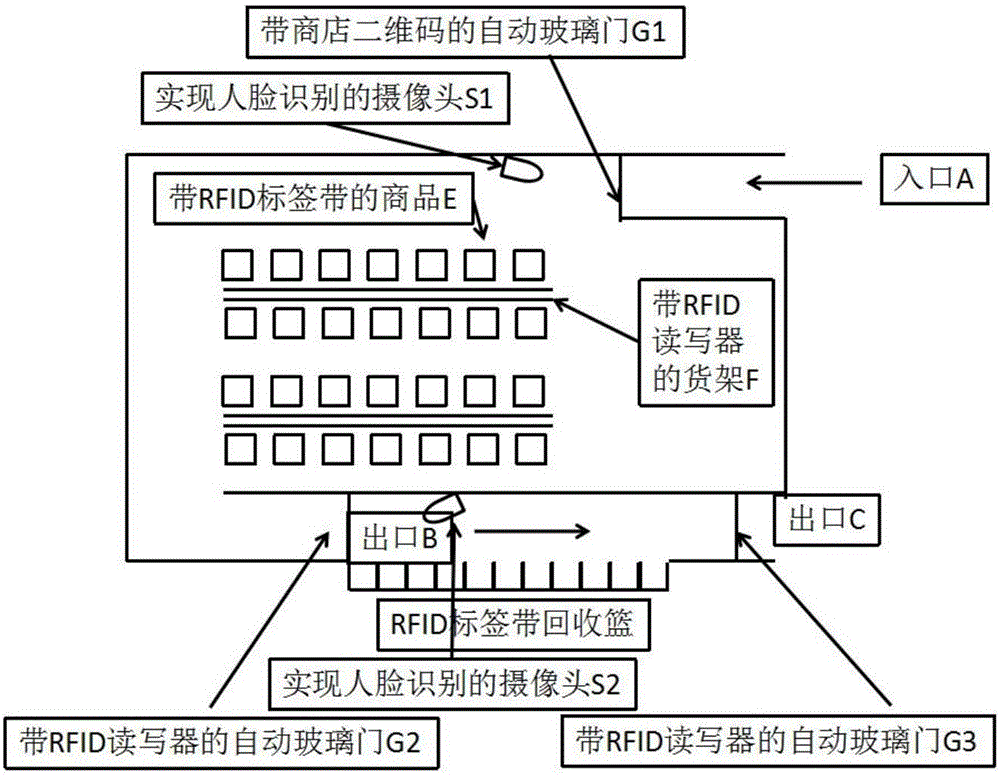

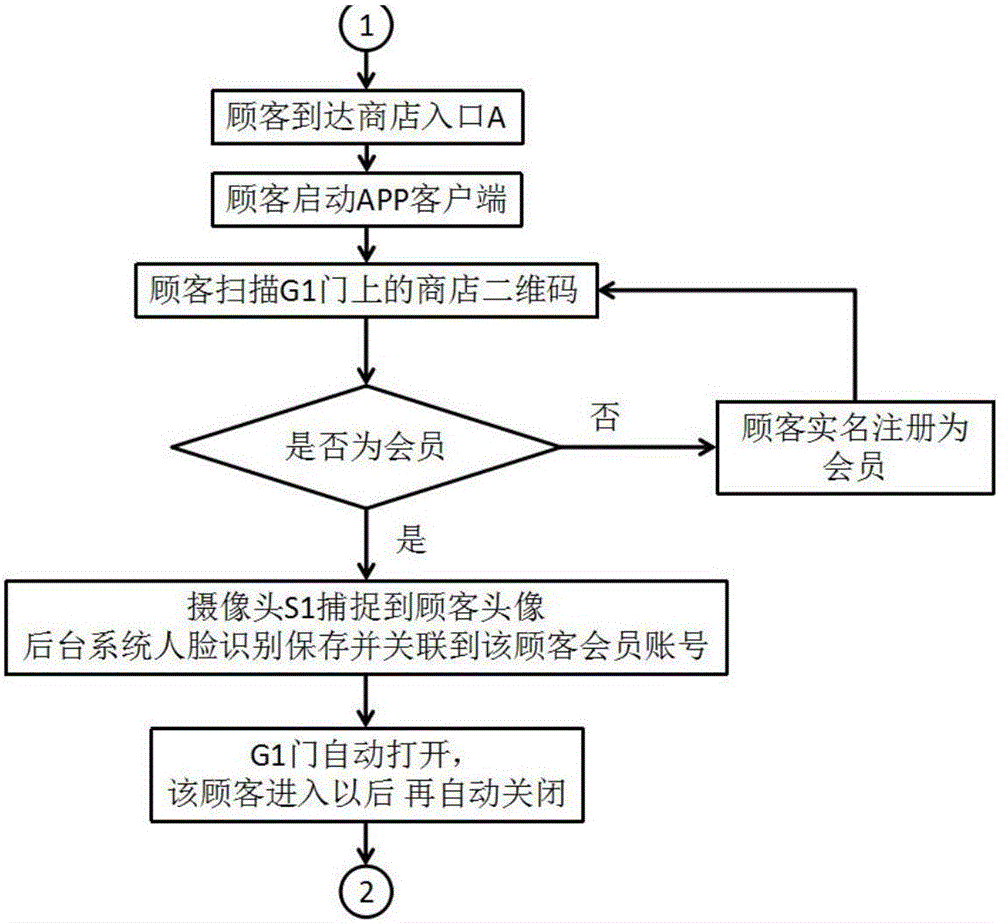

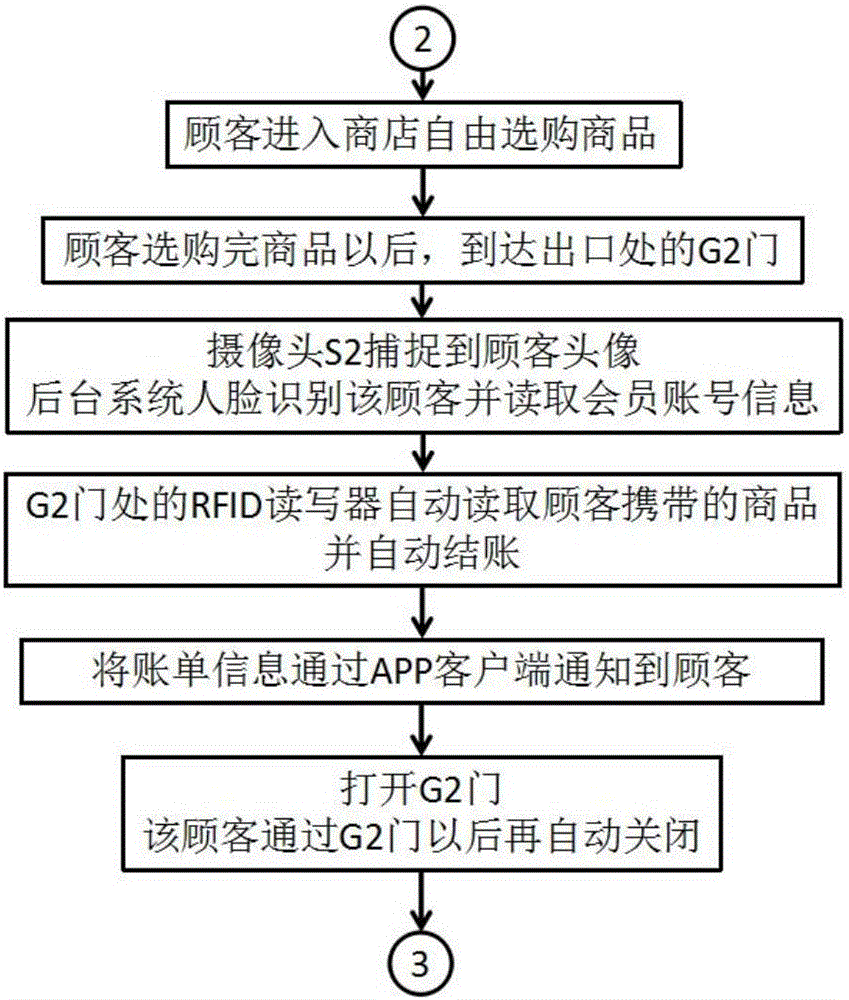

Unattended automatic settlement shop and achieving method thereof

InactiveCN106779690ARealize free choiceFully automatedPoint-of-sale network systemsPaymentComputer terminal

The invention discloses an unattended automatic settlement shop. Automatic doors are arranged on an entrance and exit of the shop, and a two-dimensional code is arranged on the entrance. A mobile intelligent terminal and a server are further included, the mobile intelligent terminal is provided with an APP client side for collecting and verifying personal information and binding an individual payment account, and the APP client side is in communication connection with the server. RFID labels are further included and bound to commodities, RFID read-write equipment is arranged on goods shelves for storing the commodities and the automatic door arranged on the exit of the shop, and the RFID read-write equipment arranged on the two automatic doors is connected with the signal input end of an automatic door controller to serve as door opening signal sources of the automatic doors. Customers can freely pick the commodities, the whole process is automatic (identity verification automation, settlement automation and goods tallying automation), and unattended operation is truly achieved.

Owner:湖南孚利购科技有限公司

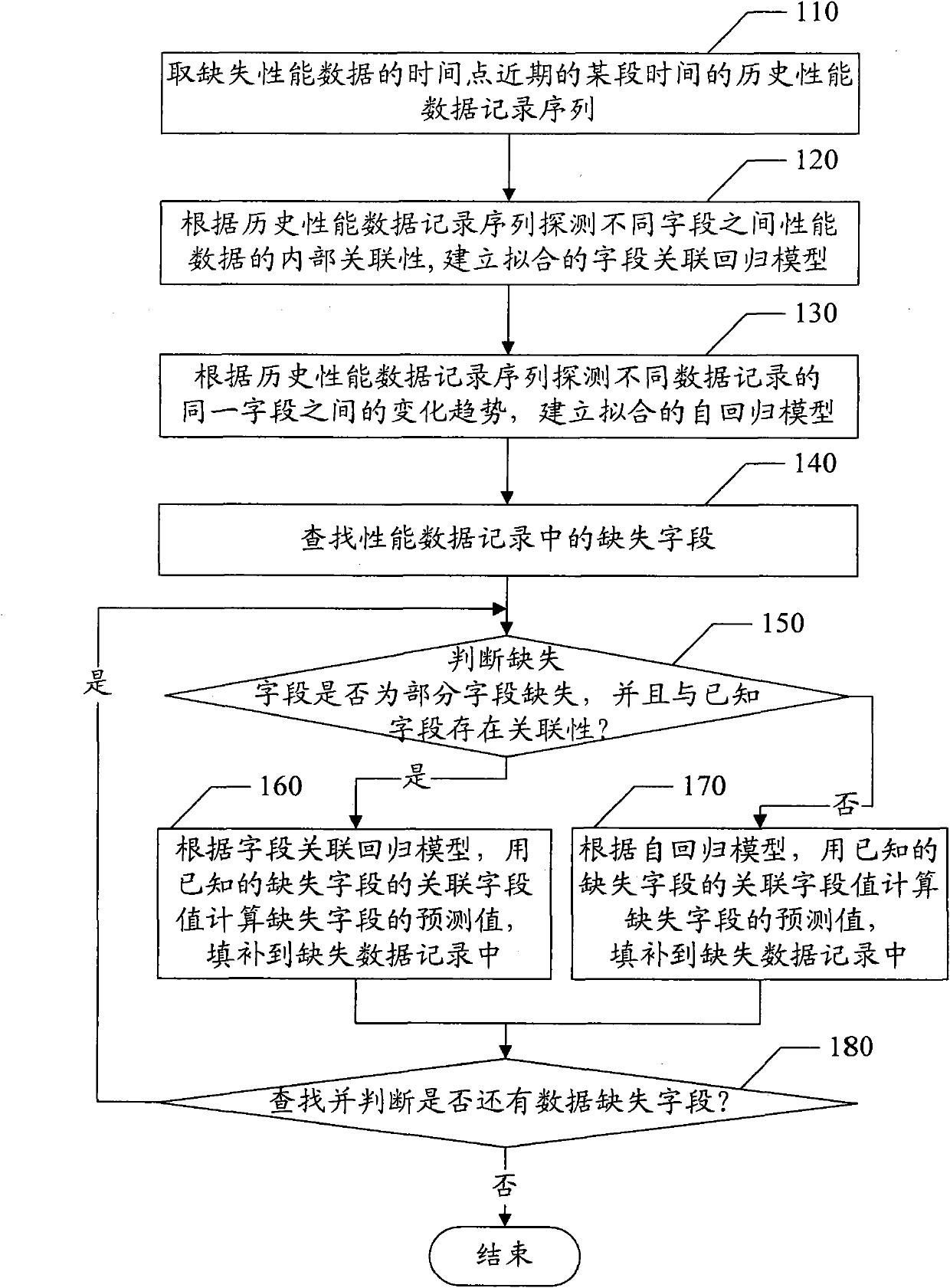

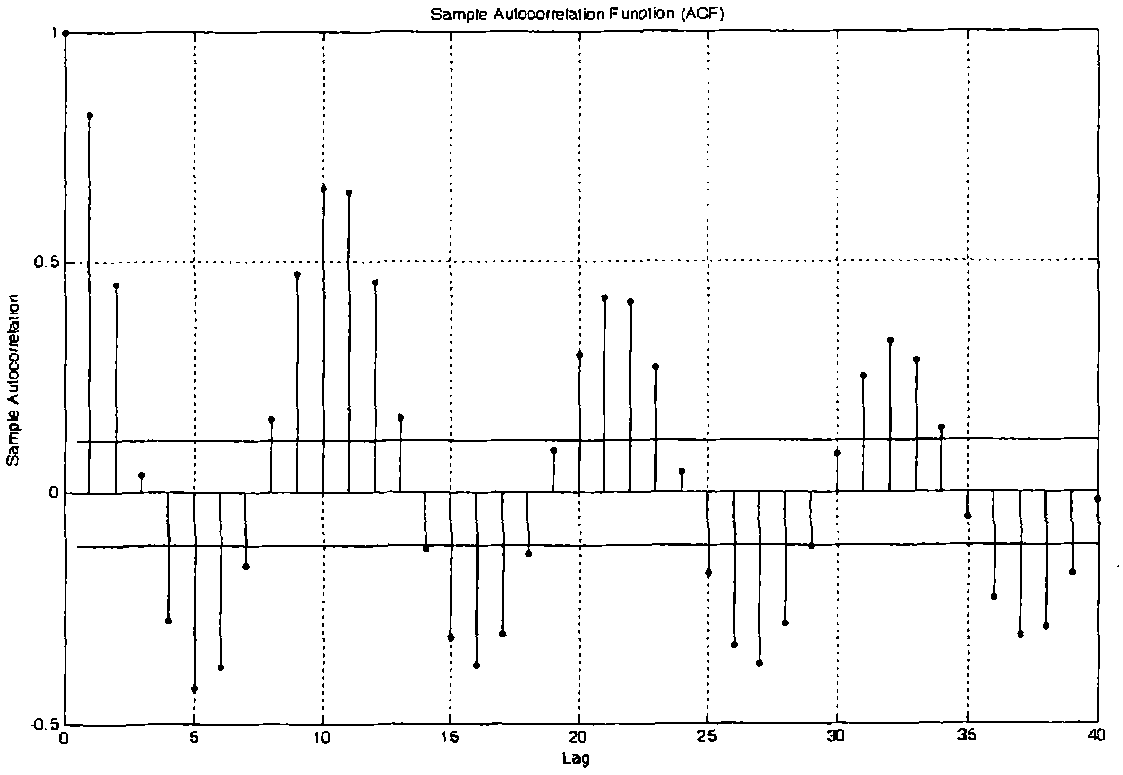

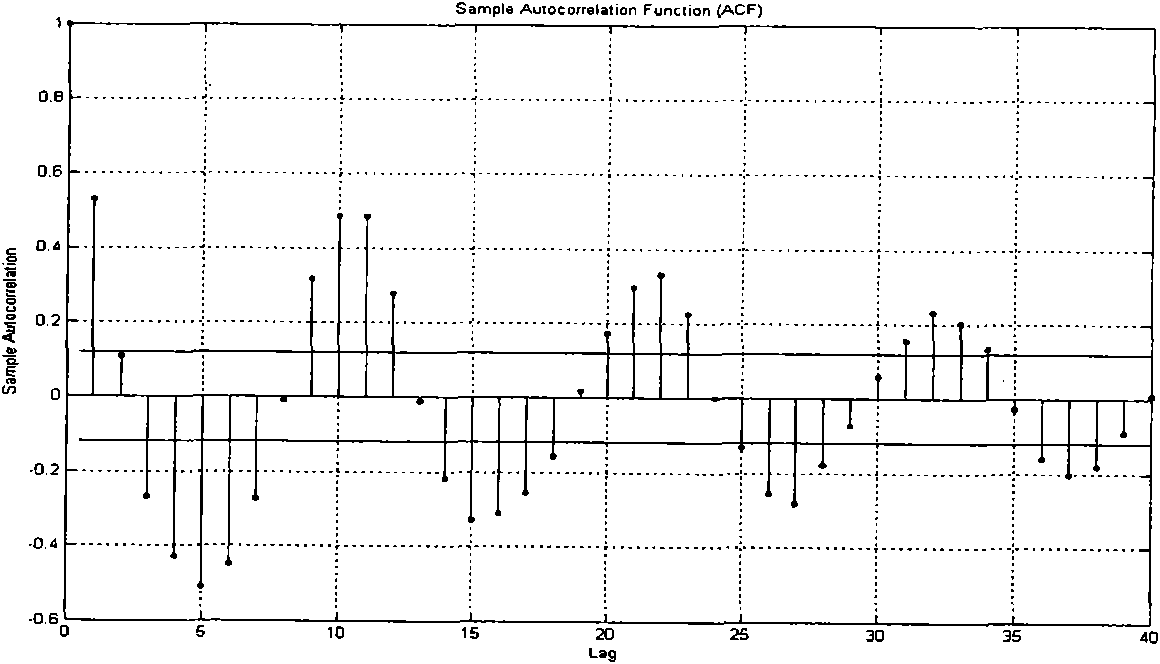

Filling method and device thereof for performance data

ActiveCN102025531AGuaranteed accuracyRealize scientificData switching networksSpecial data processing applicationsMissing dataNetwork management

The invention provides a filing method and a device thereof for performance data, and the method comprises the following steps: getting a sequence of historical performance data records; detecting the internal association among different data items with specific relationship according to the sequence of the historical performance data records; establishing a regression model for mutual fitting for the associated data items with the internal association; and using the corresponding regression model to calculate estimation values of the data items in deletion according to the known values of the associated data items if the deletion of the data items occurs in the performance data records and filling the estimation values to the performance data records in deletion. The modeling method based on mathematical statistics and data mining technology is firstly applied in filling of the performance data in a network management system, thereby realizing scientification, intelligentization and automation of the filling method, not only effectively ensuring the accuracy of data filling, but also greatly improving the filling efficiency of the batch data in deletion.

Owner:BEIJING BOCO COMM TECH +2

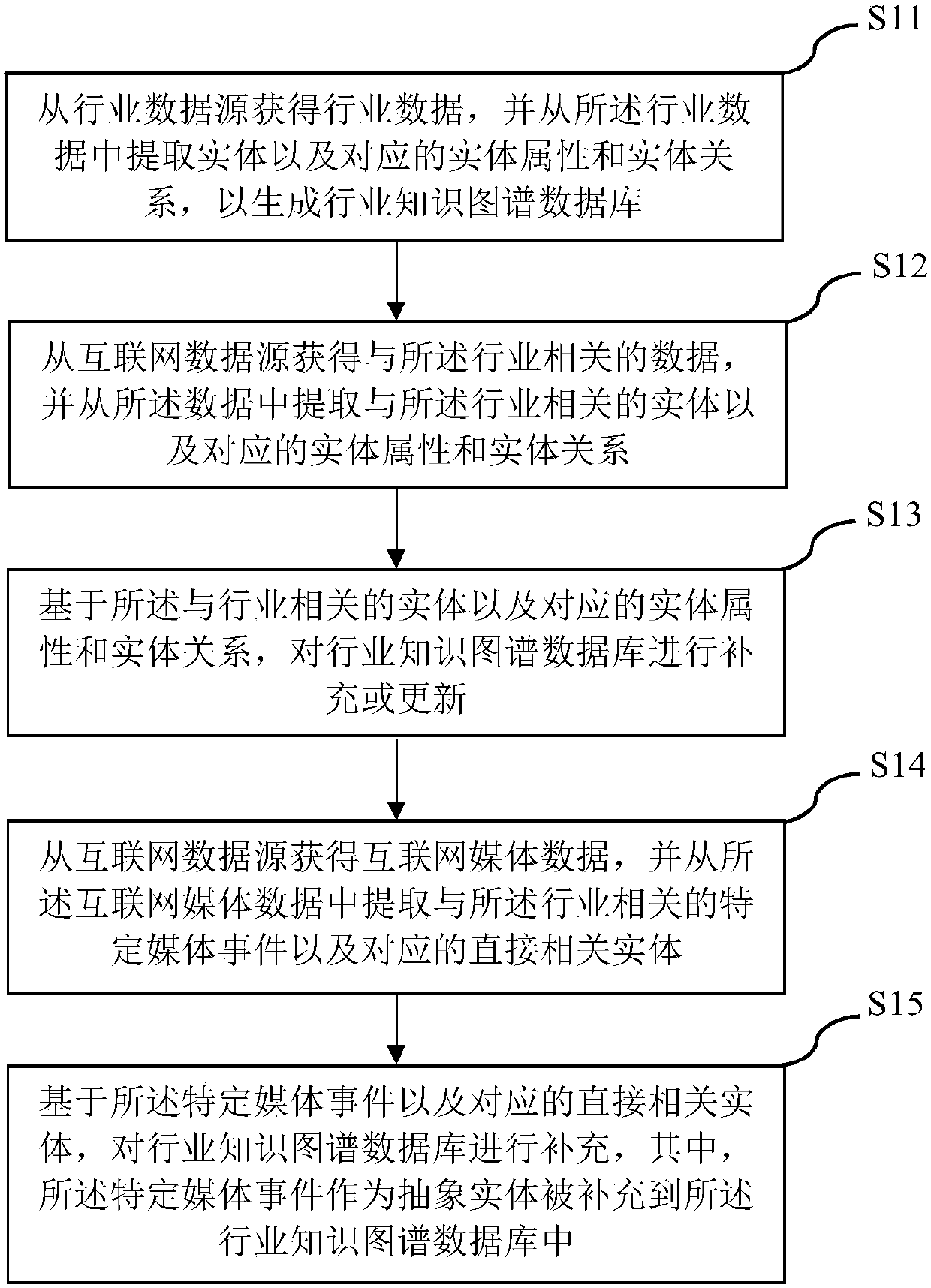

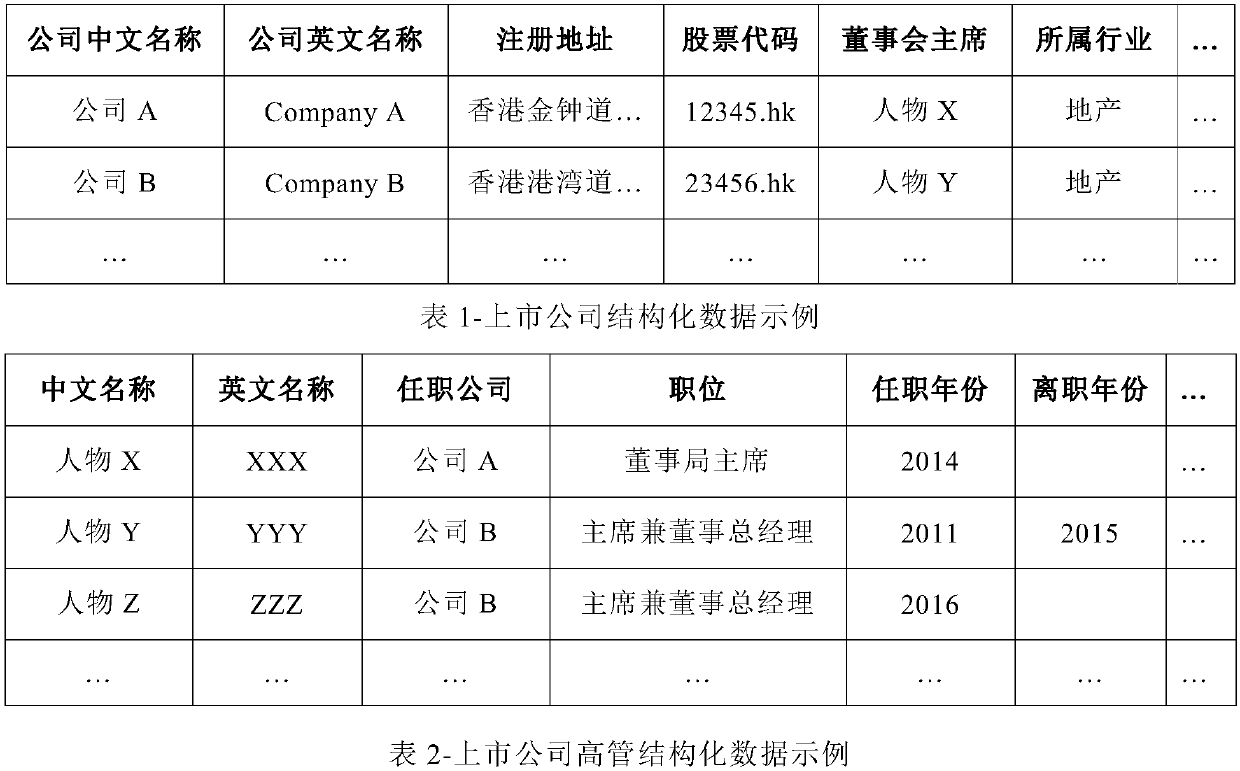

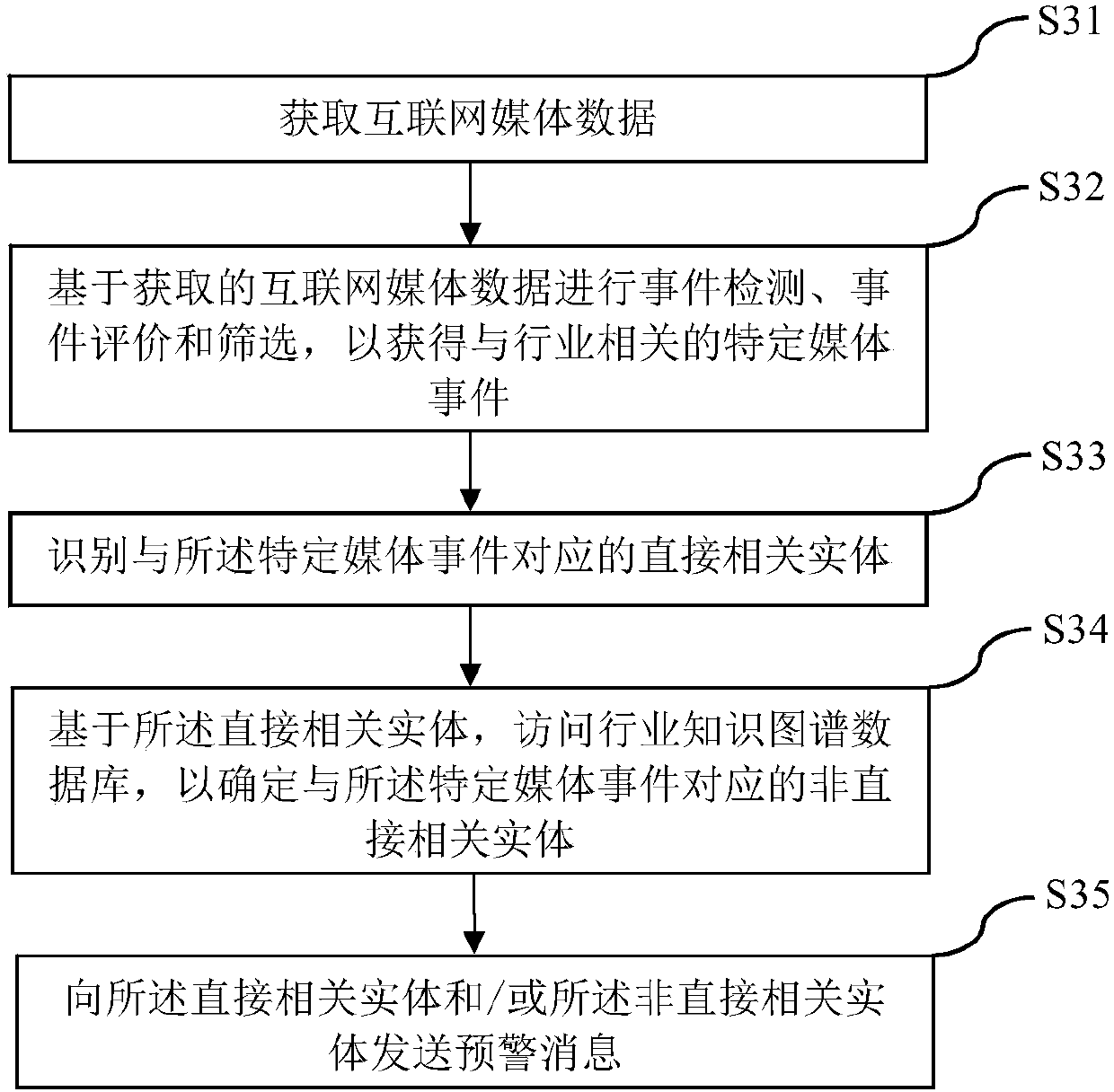

Method, device and system for monitoring internet media events on the basis of industry knowledge mapping database

ActiveCN107783973AFully automatedRealize in-depth monitoringWeb data indexingRelational databasesData sourceInternet media

The invention provides a method for building an industry knowledge mapping database. The method comprises the following steps: obtaining industry data from a data source; processing the industry datain order to extract an entity related to an industry and a corresponding relationship between an entity attribute and / or the entity; and building the industry knowledge mapping database on the basis of the extracted entity, the entity attribute and / or the entity relationship. The invention further provides a method for monitoring specific media events related to an industry on the basis of the industry knowledge mapping database. The method comprises the following steps: obtaining internet media data; detecting events, evaluating events and singling out events on the basis of obtained internetmedia data in order to obtain a specific media event related to the industry; recognizing a direct related entity corresponding to the specific media event; visiting the industry knowledge mapping database on the basis of the direct related entity to determine a non-direct related entity corresponding to the specific media event; and sending pre-warning information to the direct related entity and / or the non-direct related entity.

Owner:WISERS INFORMATION LTD

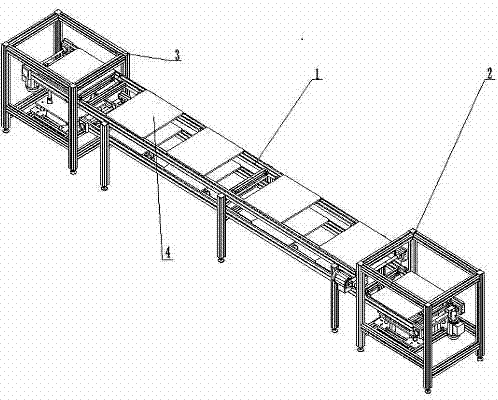

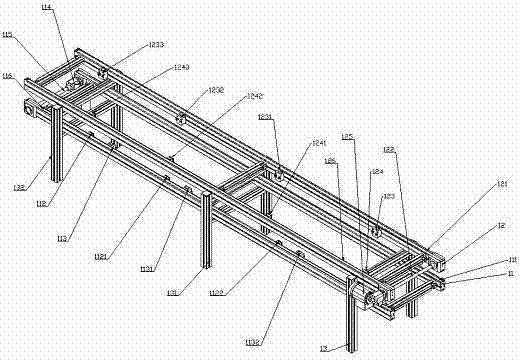

Method and conveying system for intelligently and circularly conveying products in vertical lift manner

InactiveCN104724455ARealize intelligenceFully automatedControl devices for conveyorsMechanical conveyorsProcess engineeringData management

The invention discloses a method and a conveying system for intelligently and circularly conveying products in a vertical lift manner. The method includes: subjecting product trays on a conveying line to reverse circular conveying between an upper tier and a lower tier, allowing vertical lift circular conveying at two ends of the double-tier conveying line, and setting RFID (radio frequency identification) passive reader-writers on the conveying line. The conveying system comprises the double-tier conveying line, lift conveyers mounted at two ends of the double-tier conveying line and a product tray assembly operating on the double-tier conveying line. The method and the conveying system have the advantages that products are under intelligent conveying control during conveying, multi-point operation with different spans is achieved for a production site, less space is used, conveying efficiency is high, input cost is low, the products can be subjected to data management during line production, the produced products are traceable, and automatic productivity of the whole process can be comprehensively improved.

Owner:KEN DAYSTAR SHANGHAI AUTOMATION SYST

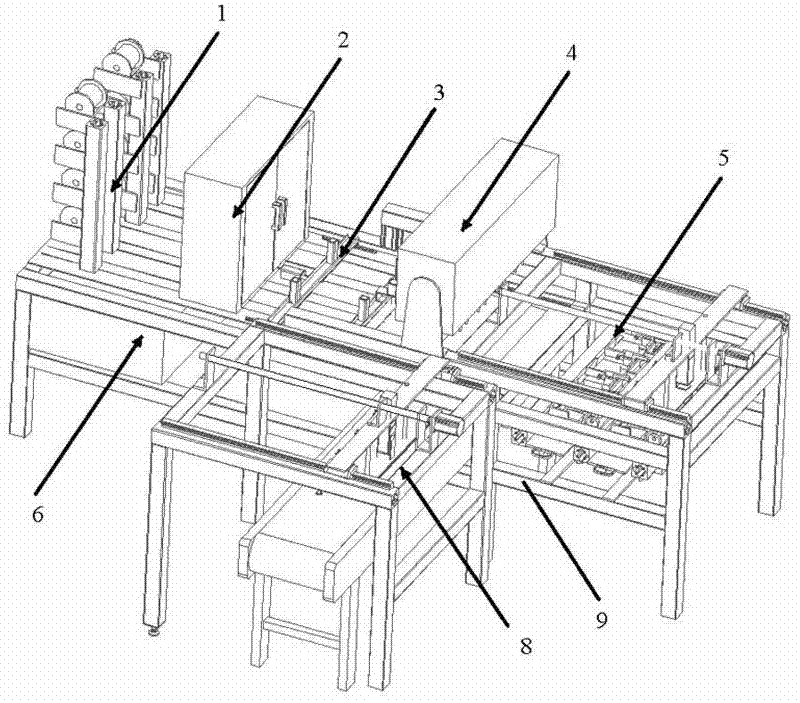

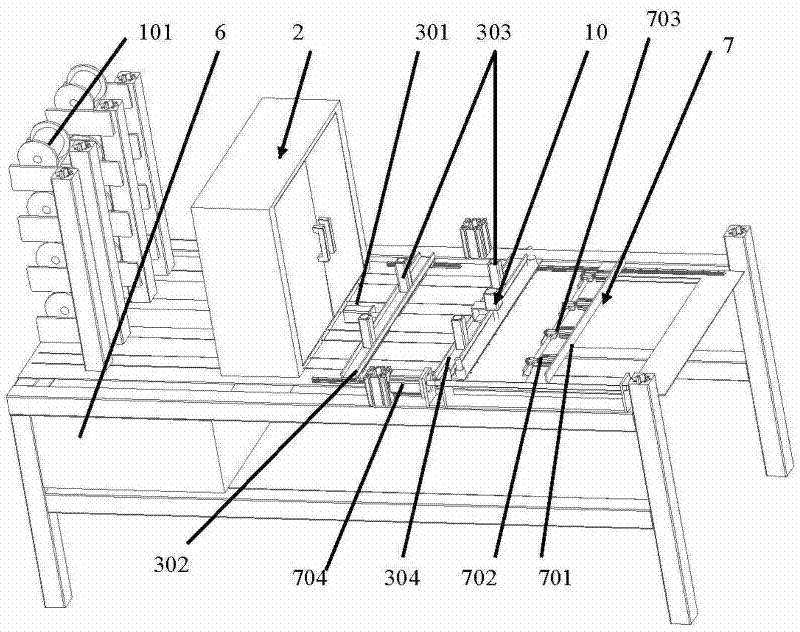

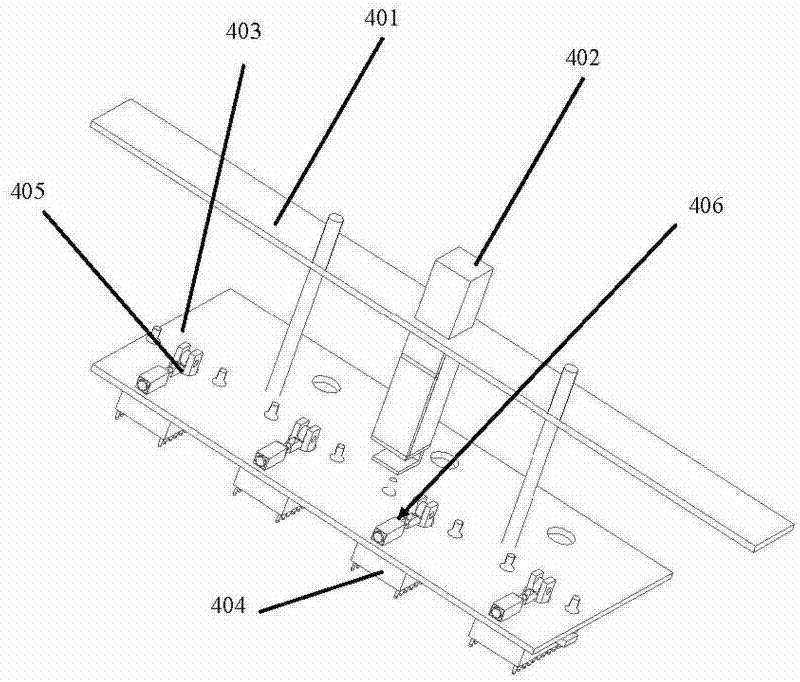

Fully automatic solar cell single welding machine

InactiveCN102294550AAchieve mechanical propertiesFully automatedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSolar battery

The invention discloses a full-automatic solar cell single-welding machine, which comprises a rack, a welding strip material arranging device, a flux coating and drying device, a welding strip straightening device, a welding strip cut-off device, a welding strip dragging and positioning device, a welding device, a solar cell feeding device, and a product conveying device. The single-welding machine is mainly used for solving the problem of single-side welding of a cathode of a solar cell, and has simple process, high automation degree and relatively low cost, the labor intensity is reduced, and the quality of single-side welding is improved.

Owner:江苏爱动力自动化设备有限公司

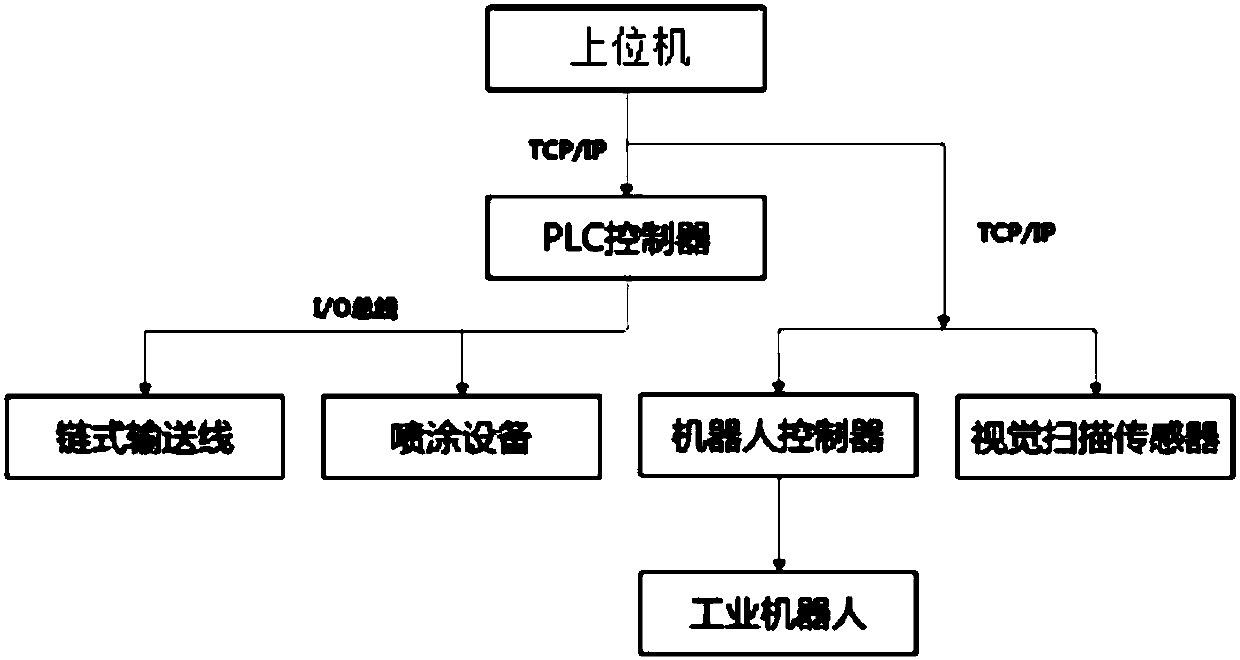

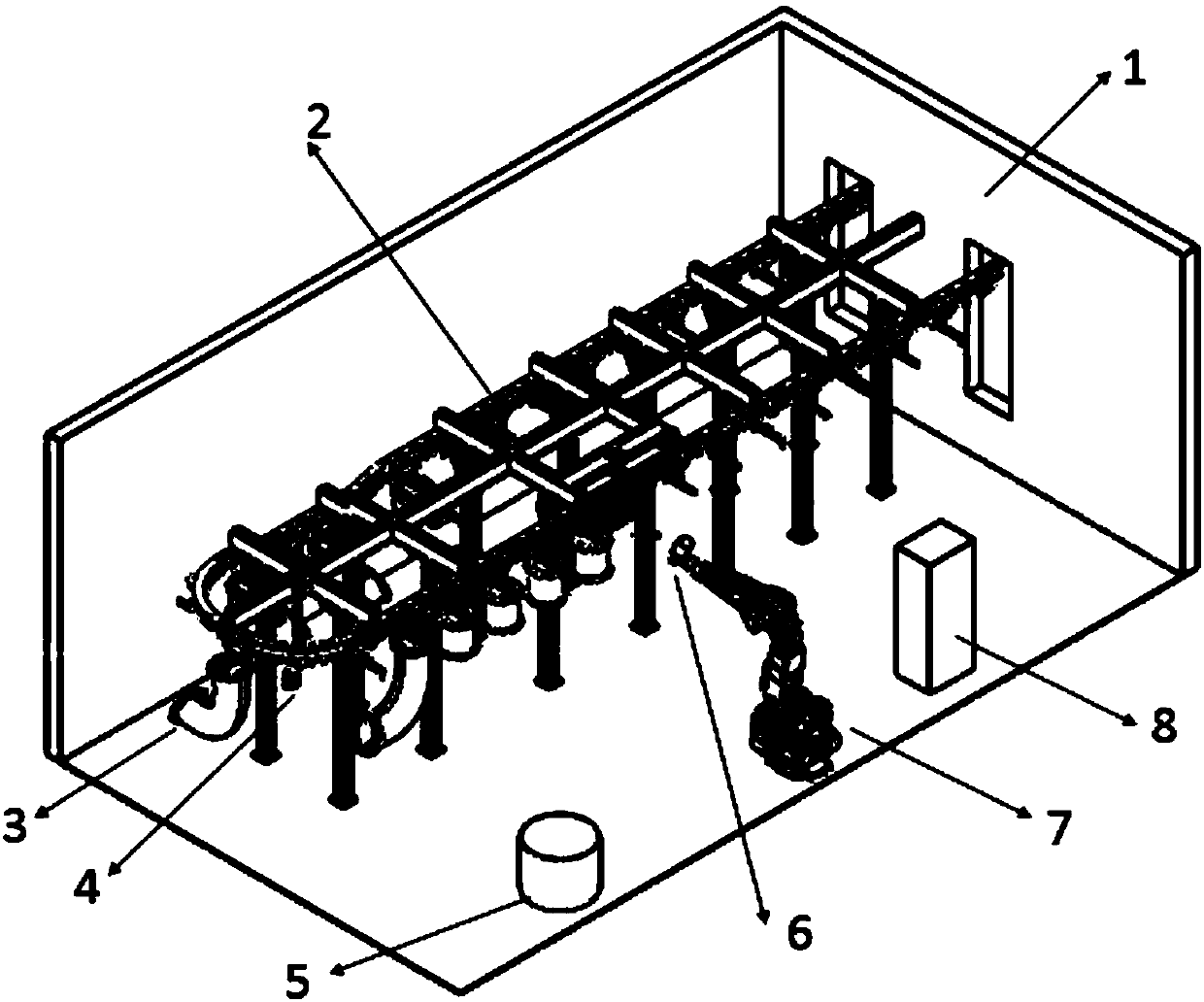

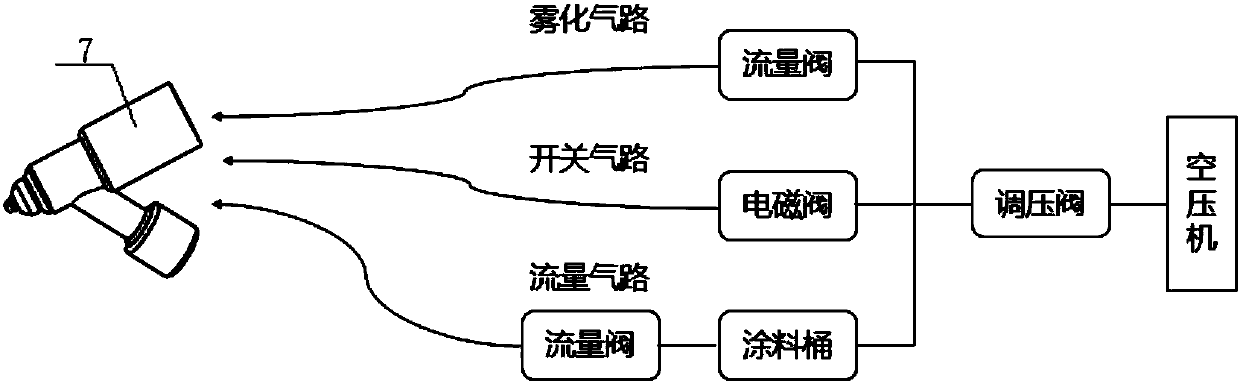

Robot spraying system and control method thereof

InactiveCN107899814AImprove spraying accuracyReduce teaching workloadSpraying apparatusChain typeEngineering

The invention discloses a robot spraying system. The system is provided with a chain type conveying line for conveying a to-be-sprayed workpiece. The chain type conveying line conveys the workpiece tosequentially pass through a vision scanning area and a spraying area. The vision scanning area is provided with a vision sensor used for conducting three-dimensional scanning on the workpiece. The spraying area is provided with an industrial robot. A spray gun is fixed to the end portion of the industrial robot and connected with spraying equipment. The vision sensor outputs signals to an upper computer. The upper computer outputs spraying track signals to a robot controller. The robot controller drives the industrial robot to execute the spraying track. The upper computer outputs the controlsignals to a PLC. The PLC drives the chain type conveying line and the spraying equipment to work. The robot spraying system has the beneficial effects that automatic complex hook face spraying trackplanning can be achieved, and the spraying precision is improved; and the offline programming technology is utilized, the demonstration workload of the robot is reduced to the maximum degree, and productivity can be rapidly achieved.

Owner:WUHU HIT ROBOT TECH RES INST

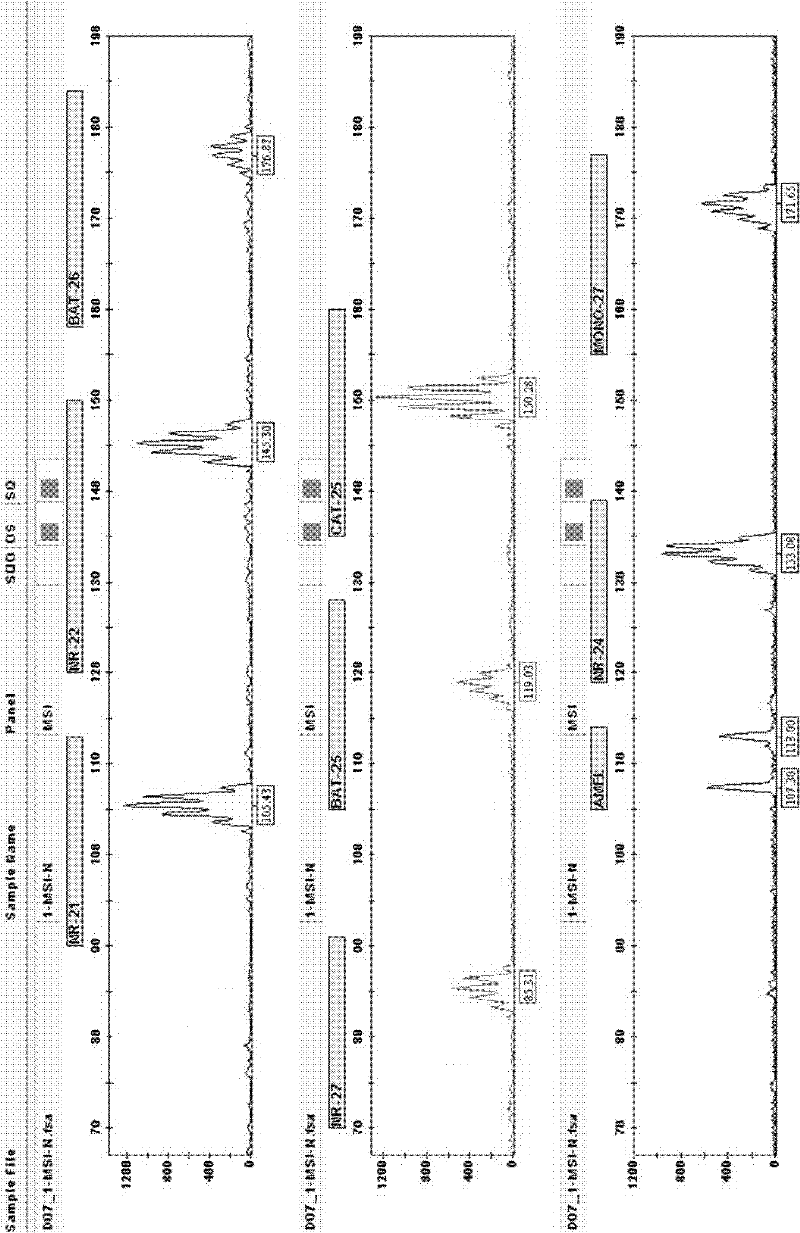

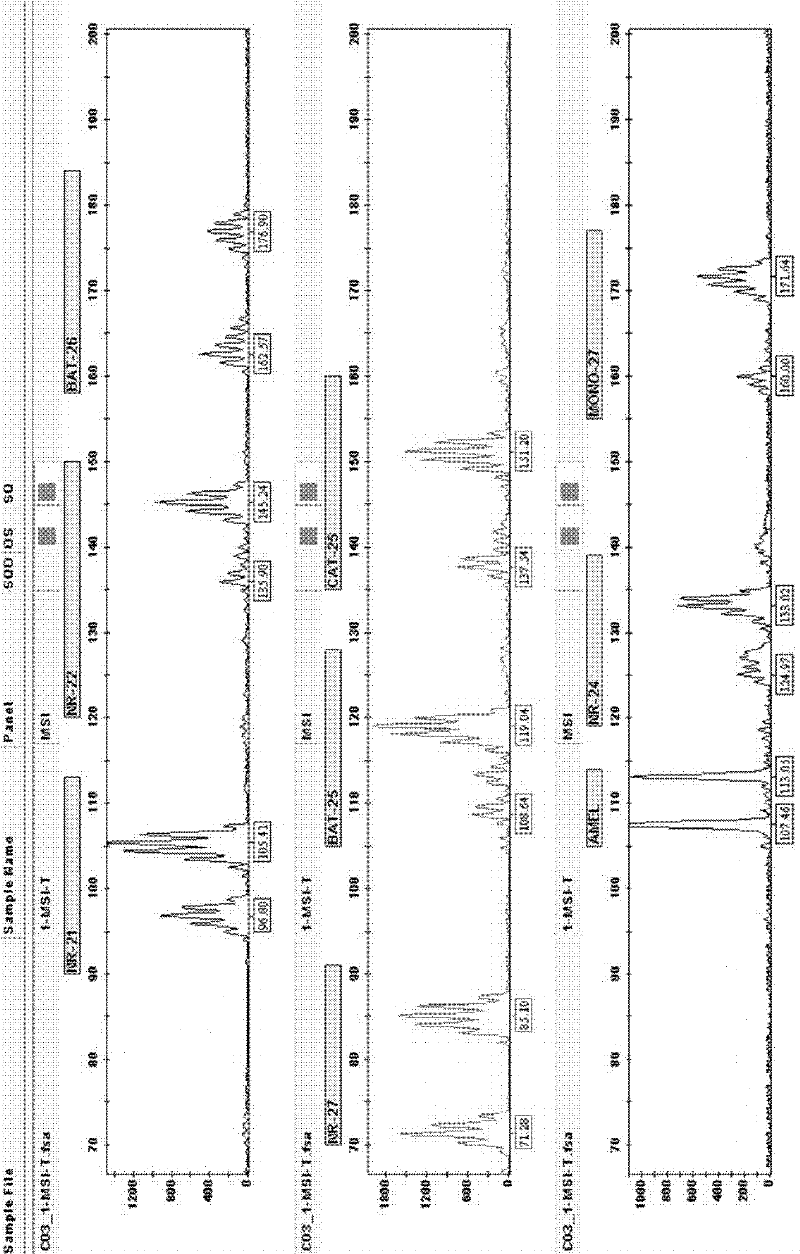

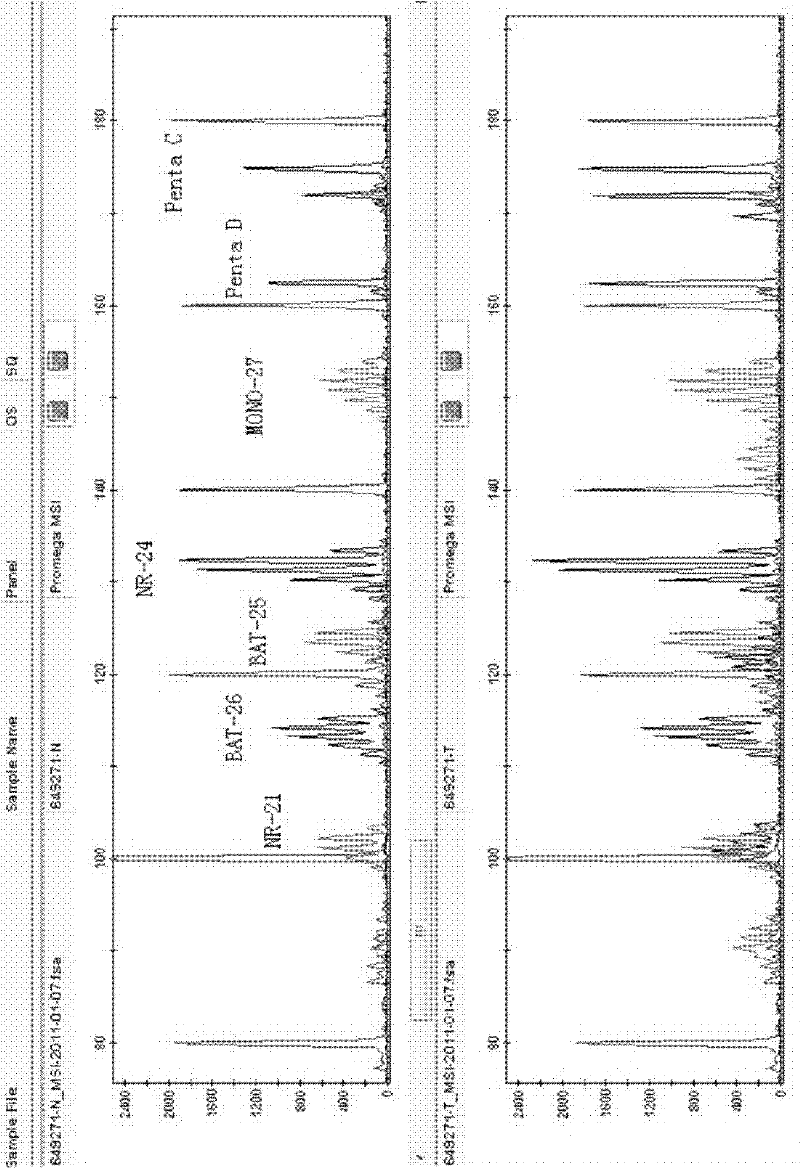

Tumor cell microsatellite instable state complex amplification system and detection kit

ActiveCN102230004AHigh sensitivityImprove accuracyMicrobiological testing/measurementTrue positive rateWilms' tumor

The invention relates to a tumor cell microsatellite instable state complex amplification system and a detection kit and belongs to the field of biotechnology. In the invention, 8 quasi-monomorphic nucleotide repeated loci with high sensitivity and specificity (including NR-21, NR-22, NR-24, NR-27, BAT-25, BAT-26, MONO-27 and CAT-25) are selected to detect microsatellite instability (MSI). Meanwhile, an amelo (AMEL) is added and a 9-loci multiplex amplification system is constructed, so the result is more accurate. The addition of the gender determining locus can prevent an experiment operator from mixing up samples and delivering wrong results to a certain extent. In the invention, the operation is simple, and large-scale promotion is convenient. With the success of the development of the kit, the method can be used for batch production; the use conditions of the method can be modularized; automatic equipment is applied in the whole process, so the whole process is independent of theoperational experiment of people; and the total detection time is about 6 hours.

Owner:BEIJING MICROREAD GENE TECH

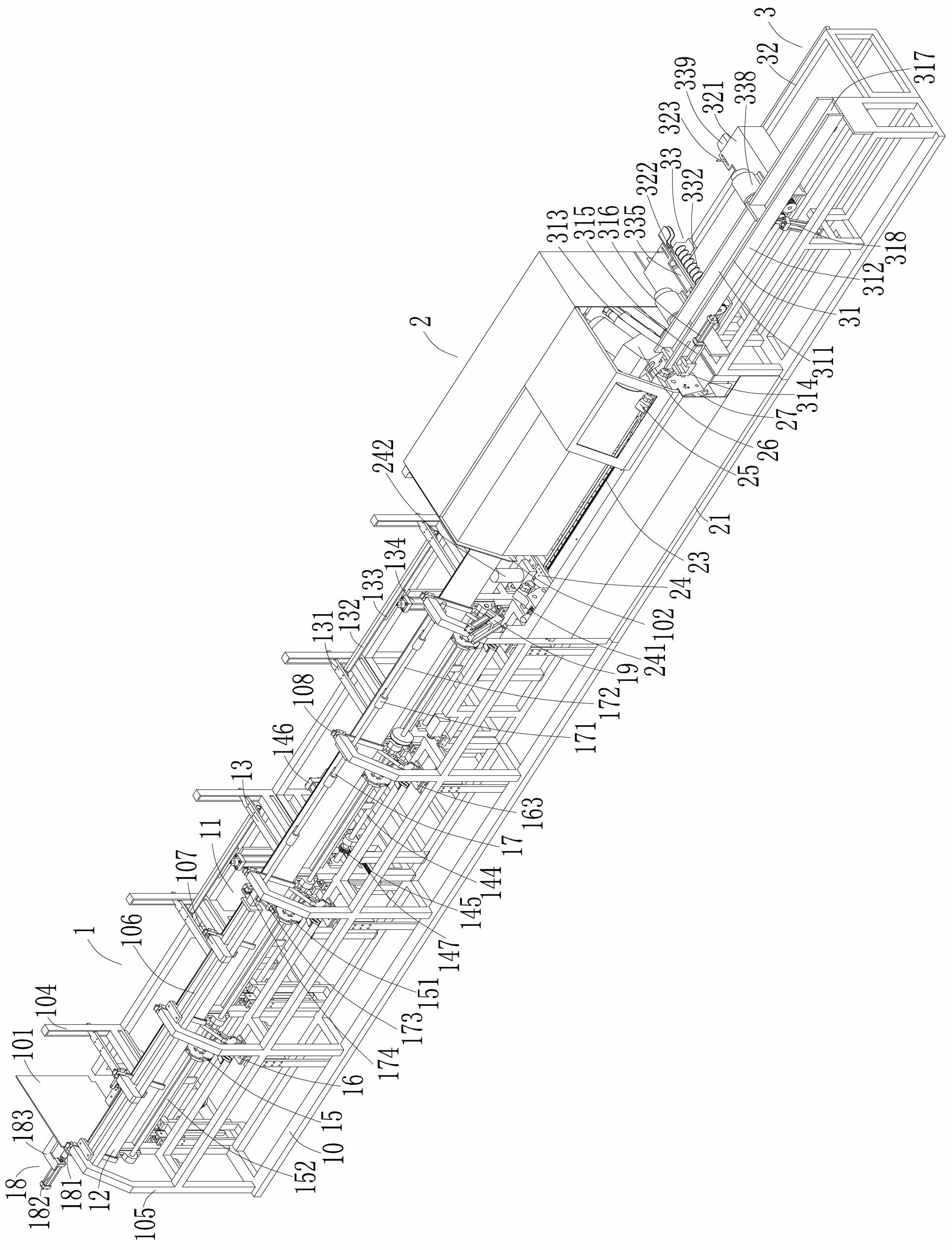

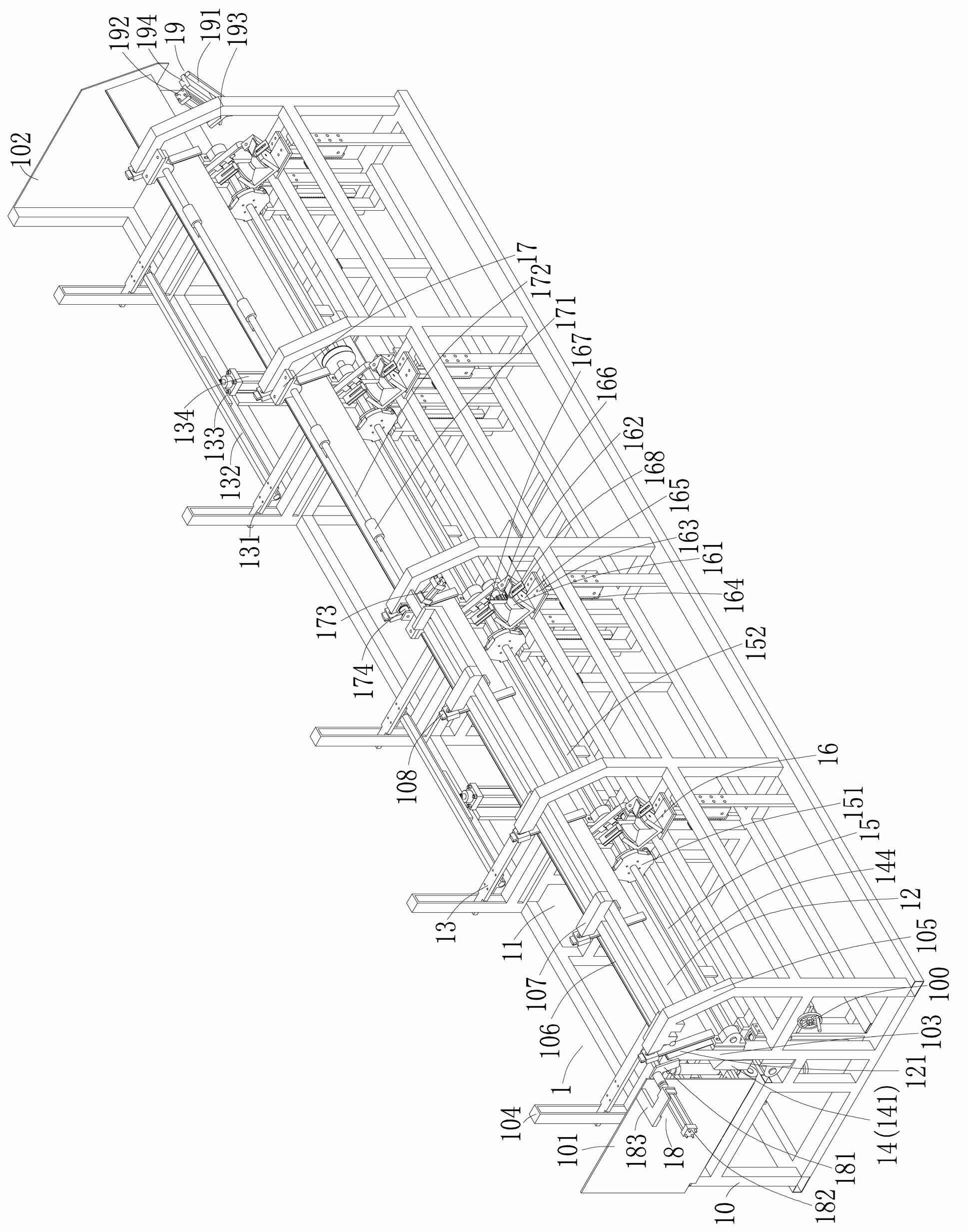

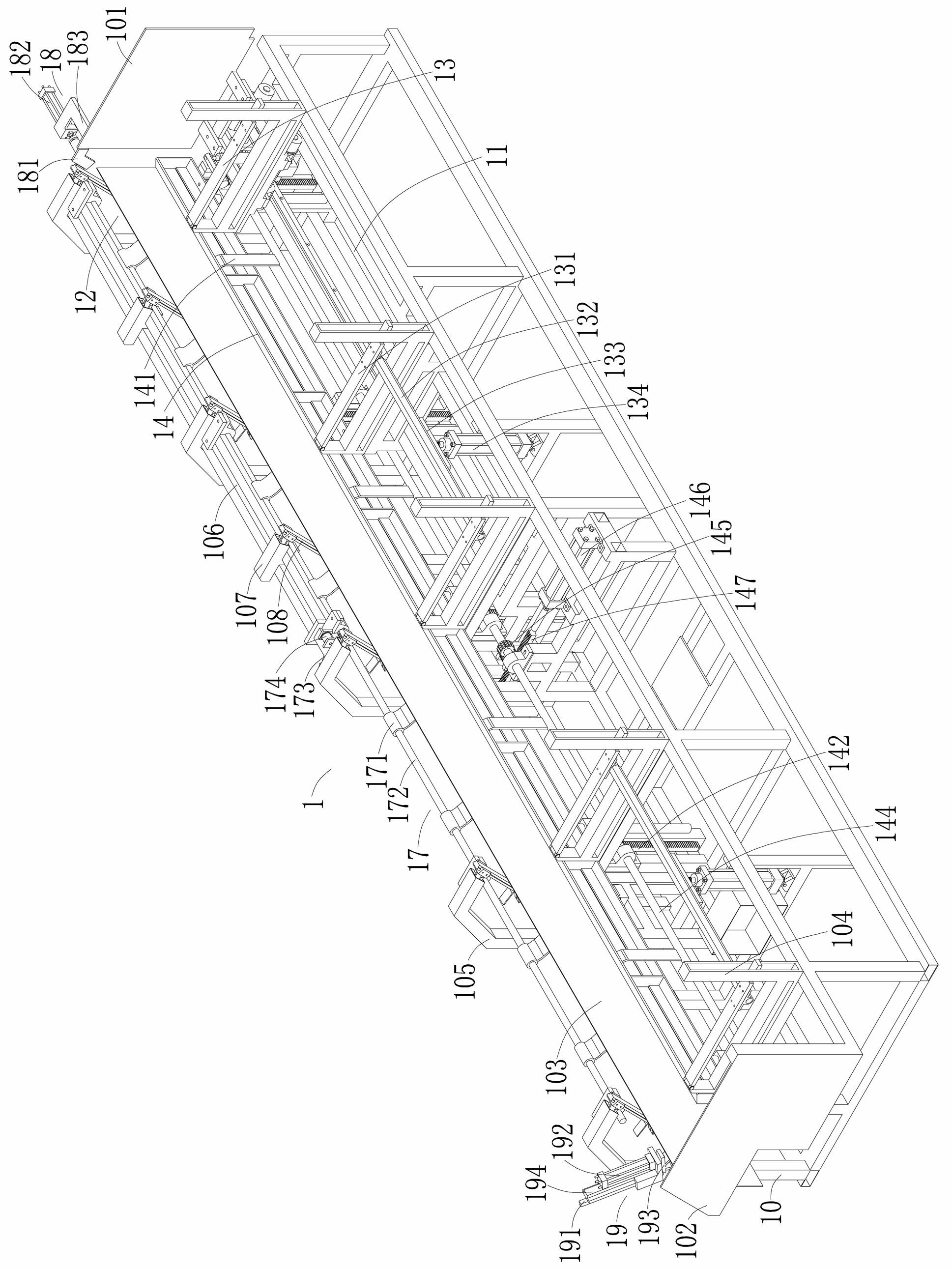

Full-automatic feeding, cutting and receiving equipment and processing method thereof

ActiveCN102145453AAffect normal workIncrease stiffnessOther manufacturing equipments/toolsPositioning apparatusLeveling mechanismMechanical equipment

The invention relates to the field of production machining mechanical equipment and discloses full-automatic feeding, cutting and receiving equipment. A material slot of a feeding device of the full-automatic feeding, cutting and receiving equipment is provided with a shifting mechanism consisting of a shifting fork and a shifting rod. The end of the shifting mechanism, which corresponds to a rear baffle plate of the feeding device, is provided with a leveling mechanism. A feeding bracket at the side of an unloading mechanism, which is correspondingly connected with a tube cutting device, is provided with a clamping mechanism. A lower roller and a side roller which are connected are arranged in the unloading mechanism. A split clamp of the tube cutting device is arranged on a tube cutting bracket through a trapezoid block. A recovery device consists of a recovery mechanism and a return mechanism, wherein the recovery mechanism is arranged at one side of the split clamp in a leveling mode; and the return mechanism is arranged on a recovery bracket at the rear end of the recovery mechanism. A brush wheel is arranged in the return mechanism. A machining method of the equipment comprises the steps of adding, aligning, feeding, cutting and receiving. The full-automatic feeding, cutting and receiving equipment is smooth to feed materials and is clear to separate the materials, so that resource waste is avoided, the machining procedures of the engineering are reduced, the cutting quality is improved, both manpower and material resources are saved and the production efficiency is improved.

Owner:东莞市机信机械有限公司

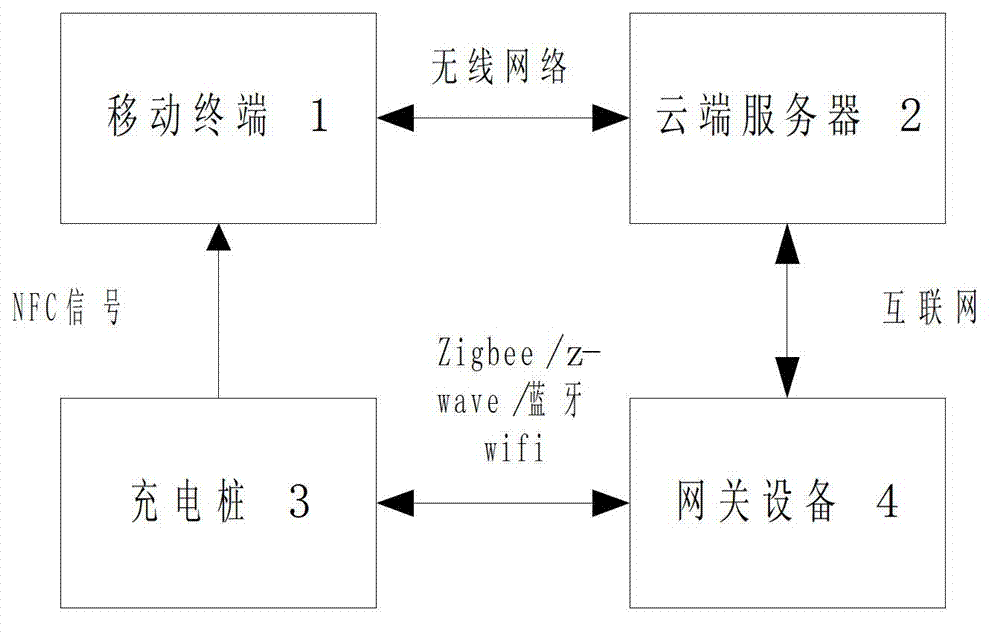

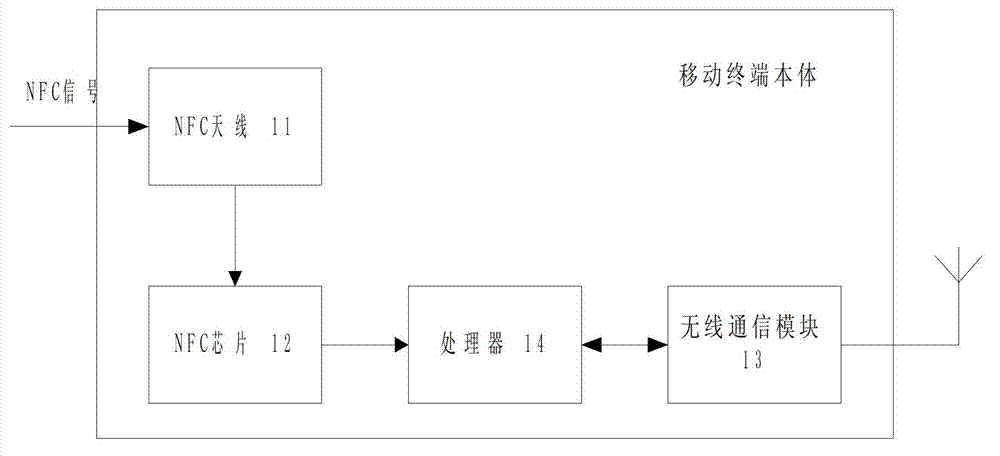

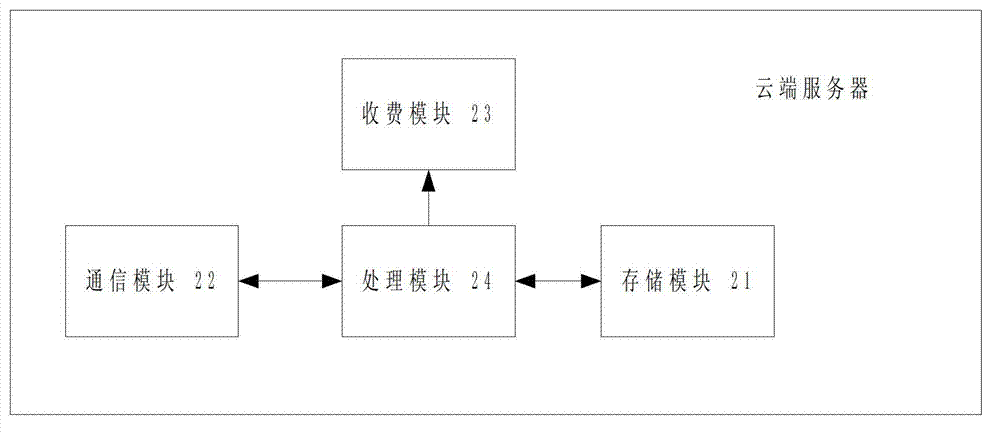

Automobile charging system

ActiveCN102832670AEasy to chargeFast chargingBatteries circuit arrangementsElectric powerCharging stationServer

The invention discloses an automobile charging system which is applied to a charging station of an electromobile. The automobile charging system comprises a mobile terminal, a charging pole and a cloud server, wherein the mobile terminal is used for receiving an NFC (noise feedback coding) instruction signal and transmitting an instruction signal to the cloud server after analysis treatment; the cloud server analyzes and processes the received instruction signal and generates control instruction information to the charging pole, and the charging pole carries out control instruction operation after receiving the control instruction information, starts charging or closes charging, and feeds back the charging cost information to the cloud server. According to the automobile charging system, the automation and intelligence of automobile charging are achieved, and manpower cost of the charging station is greatly reduced.

Owner:NANJING IOT SENSOR TECH

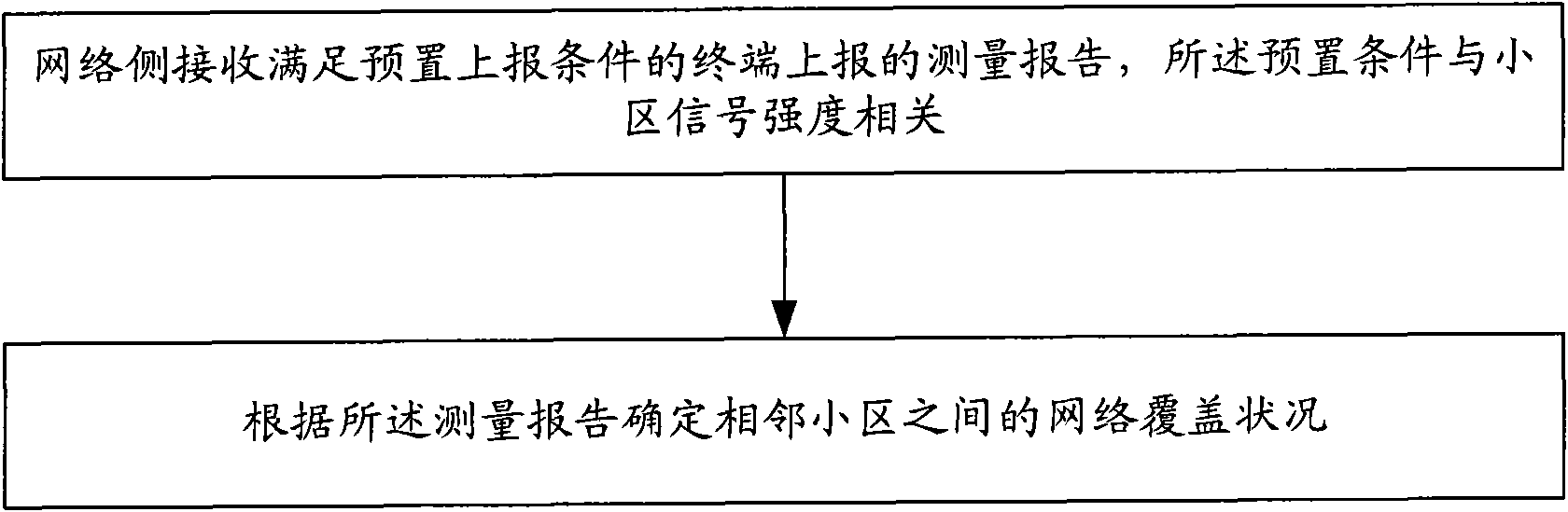

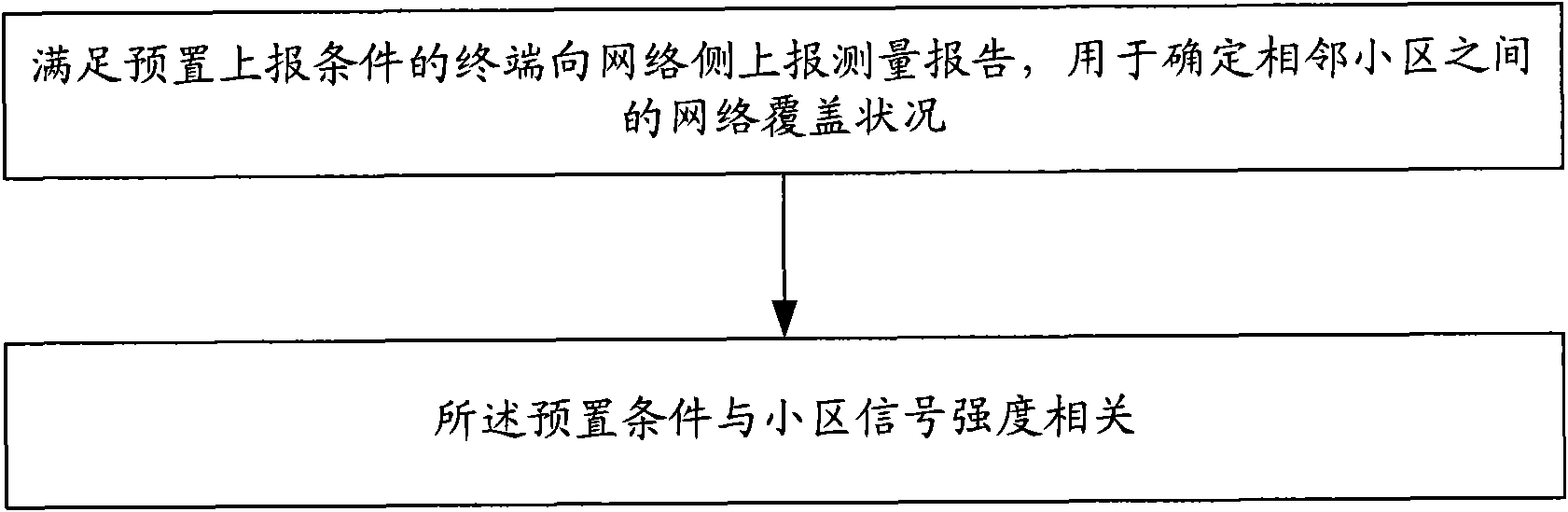

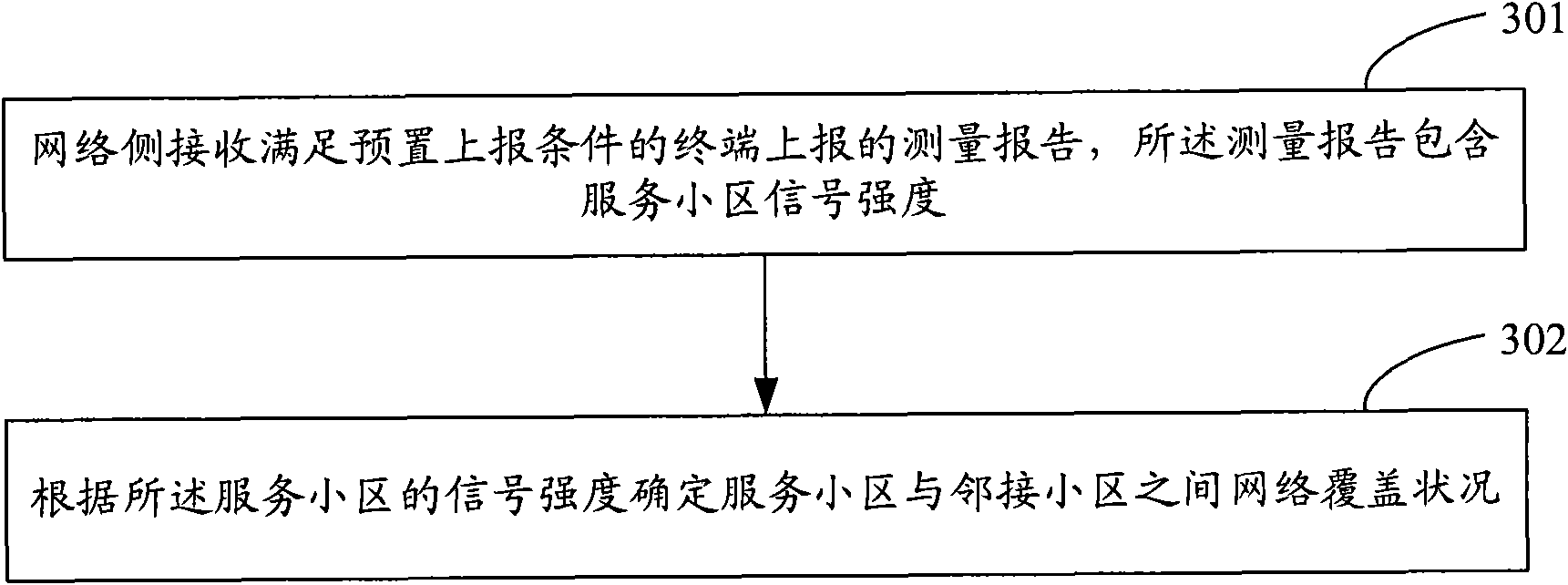

Network coverage detection method and system

InactiveCN101790173ASave drive test stepsReduce the interference of human factorsNetwork planningComputer scienceCells signal

The embodiment of the invention discloses a network coverage detection method, which comprises the following steps of: receiving a measurement report, which is reported by a terminal which meets preset reporting conditions, by a network side, wherein the preset conditions are associated with cell signal strength; and determining the network coverage condition among neighboring cells according to the measurement report. When the network coverage detection method of the embodiment of the invention is used, a road test step can be saved and the network optimization cost is reduced. The embodiment of the invention further comprises a network coverage detection system and a base station and a terminal used for the network coverage detection system.

Owner:HUAWEI TECH CO LTD

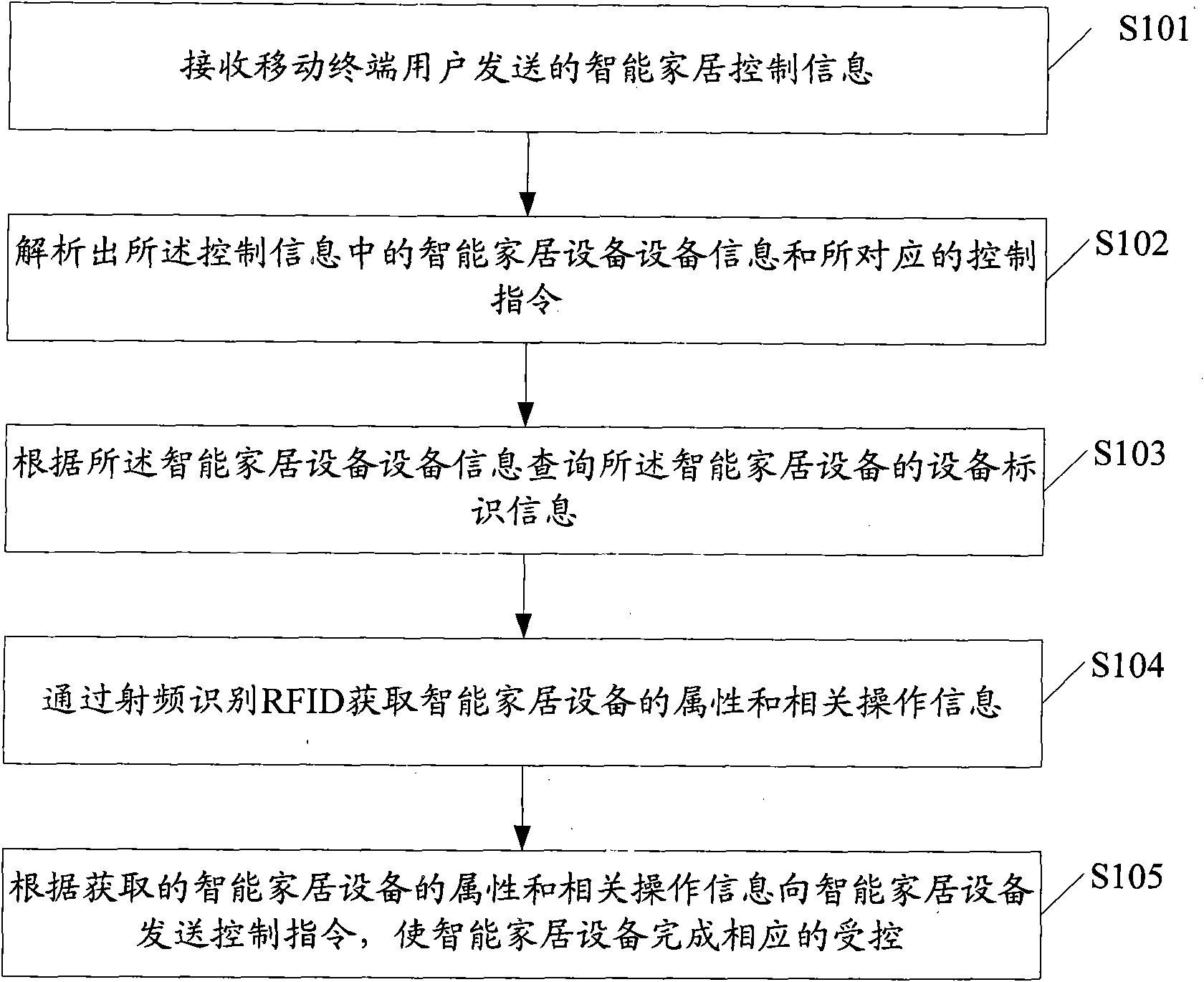

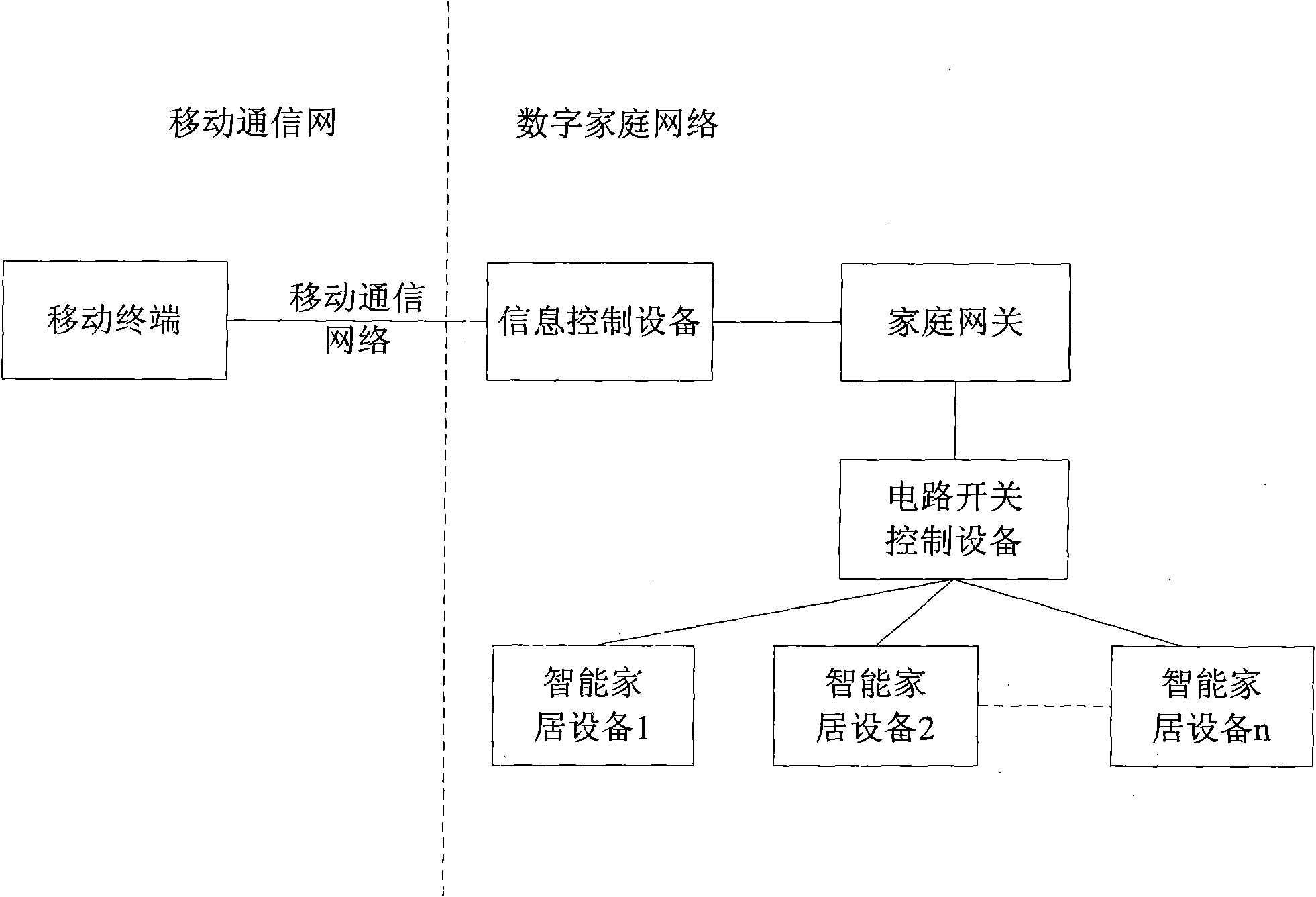

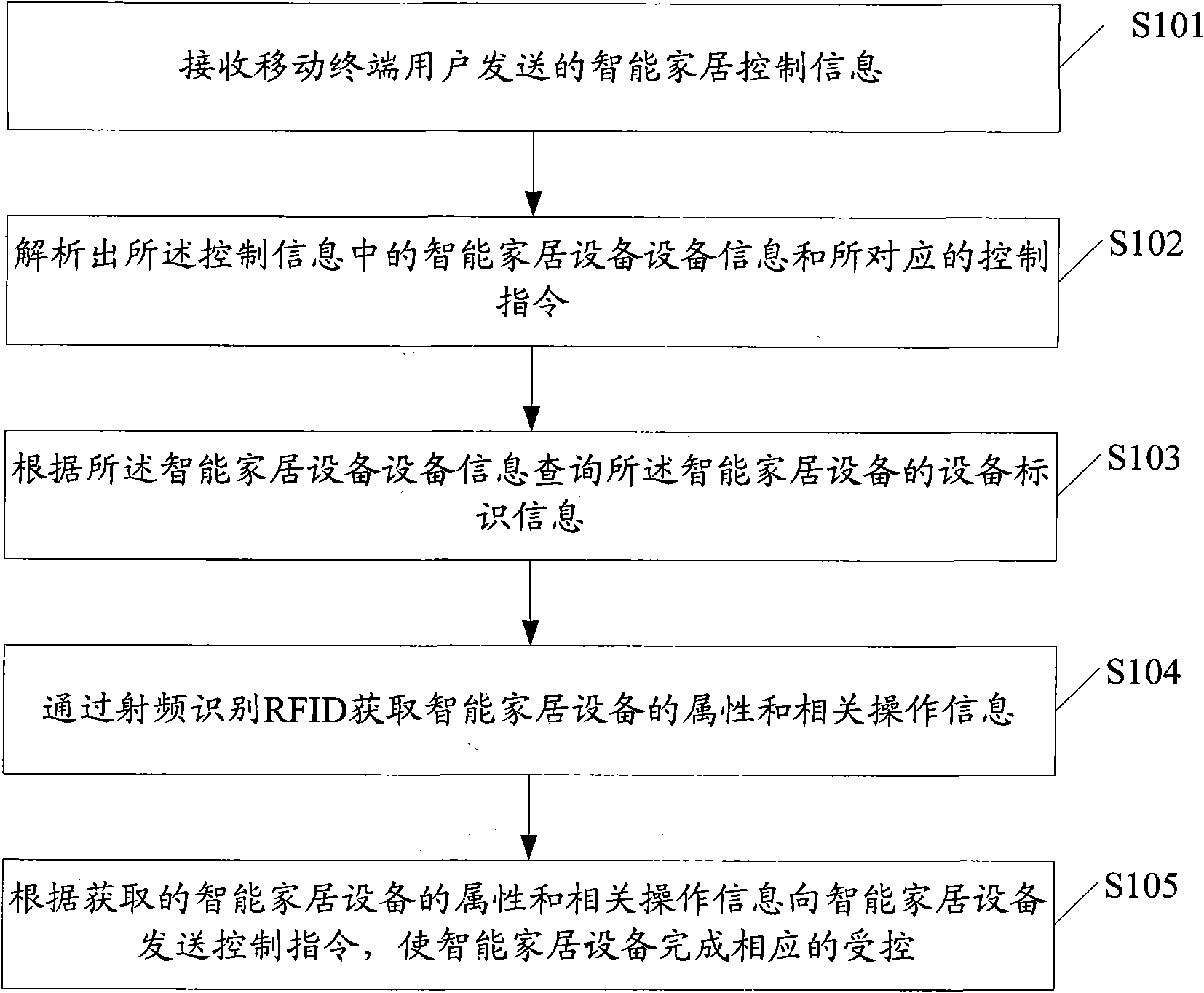

Mobile communication network-based intelligent home control method and system

ActiveCN101894452AEasy to useFully automatedTransmission systemsData switching by path configurationComputer terminalHome appliance

The embodiment of the invention discloses a mobile communication network-based intelligent home control method. The method comprises the following steps of: receiving intelligent home control information transmitted by a mobile terminal user; analyzing equipment information of the intelligent home equipment and the corresponding control commands in the control information; inquiring equipment identifier information of the intelligent home equipment according to the equipment information of the intelligent home equipment, and acquiring the attributes and the related operation information of the intelligent home equipment through radio frequency identification (RFID); and according to the acquired attributes and the related operation information of the intelligent home equipment, and transmitting control commands to the intelligent home equipment to correspondingly control the intelligent home equipment. The embodiment of the invention also discloses a system. Due to the embodiment of the invention, a user can conveniently use various home appliances and the home appliances can be controlled by using a mobile terminal on one hand of the user without needing touching, so that automation of various appliances can be realized at higher level.

Owner:SUN YAT SEN UNIV

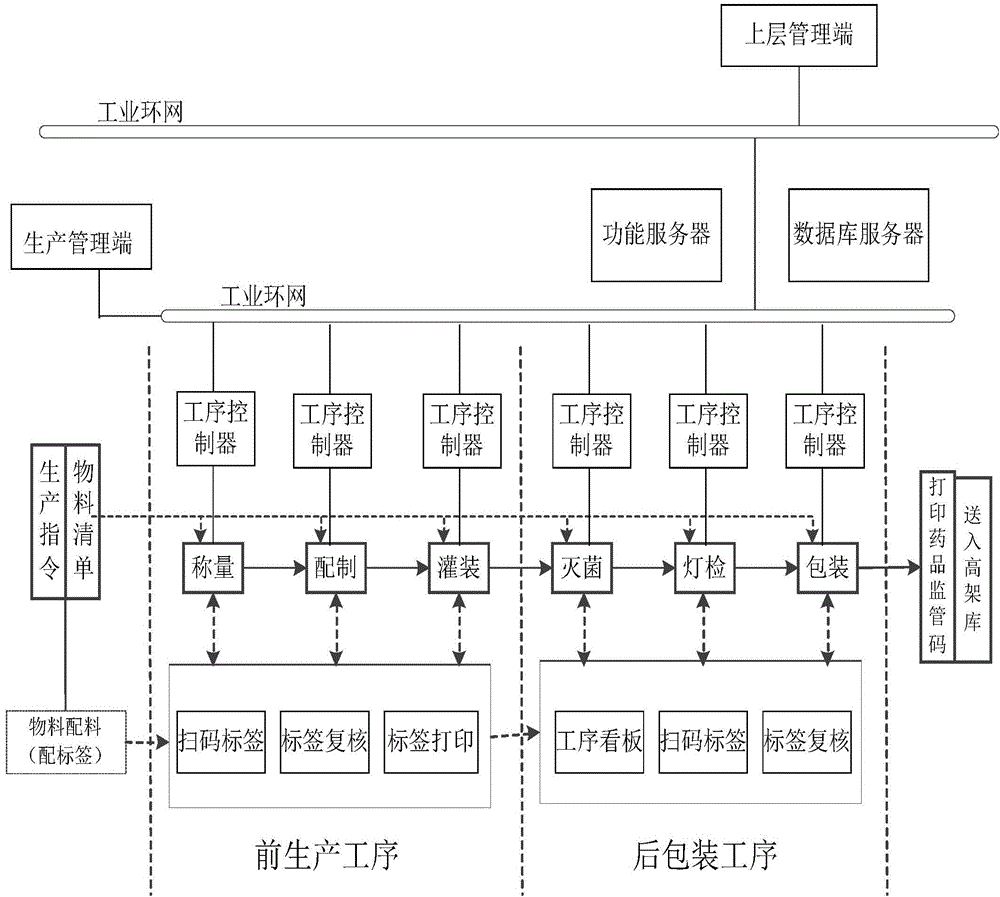

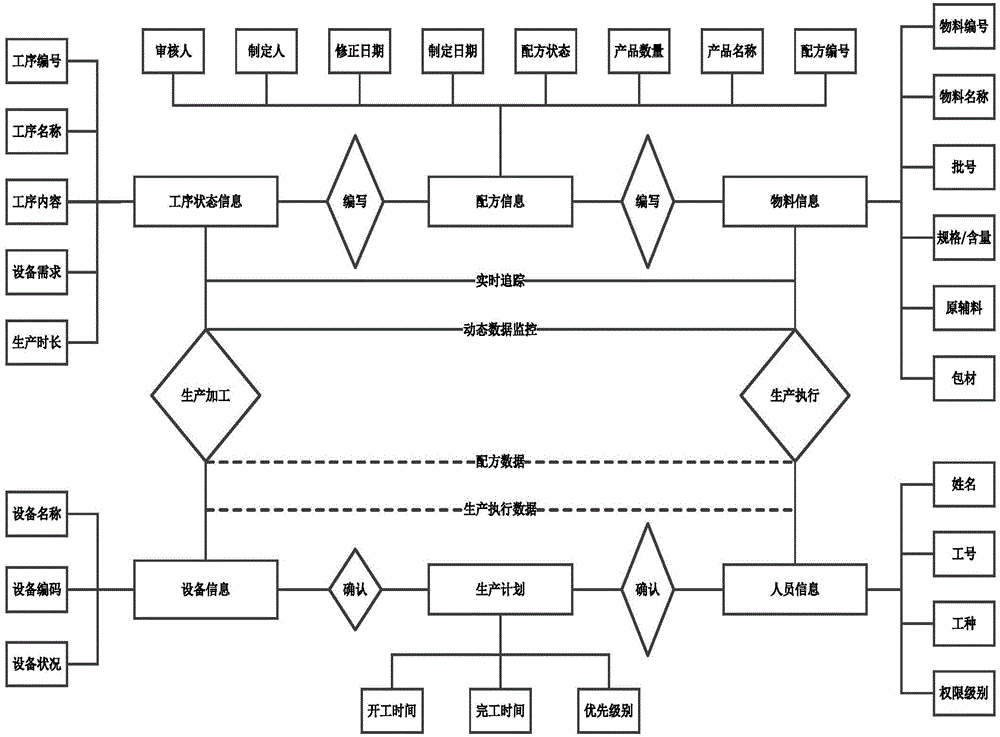

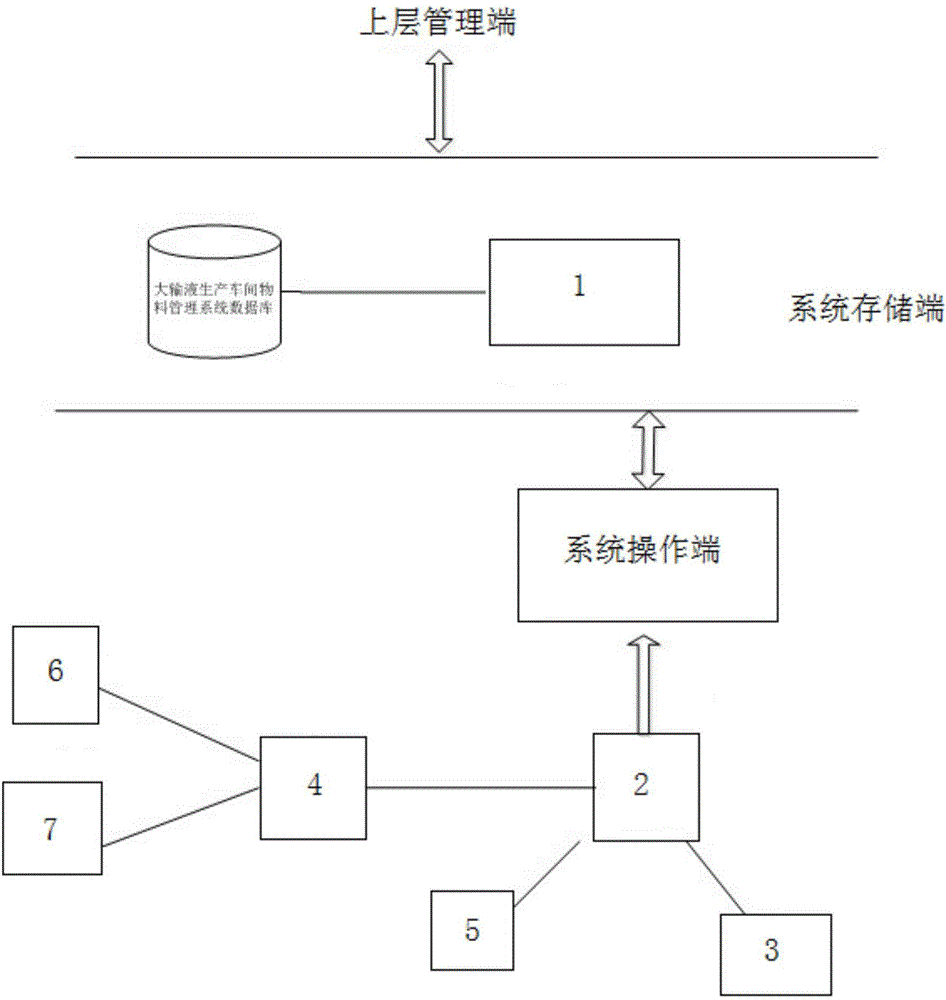

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

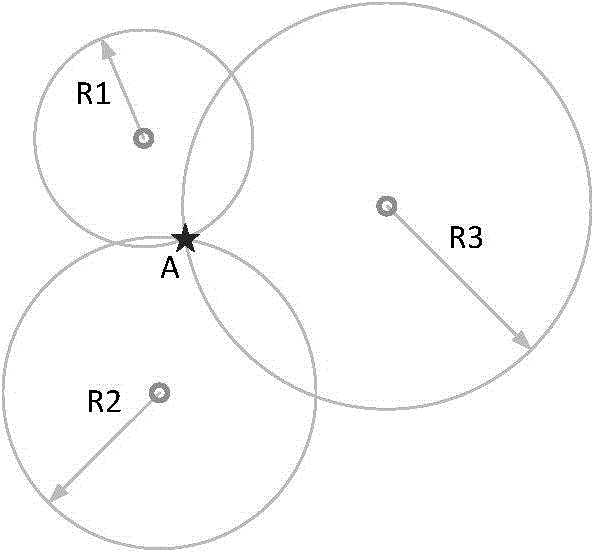

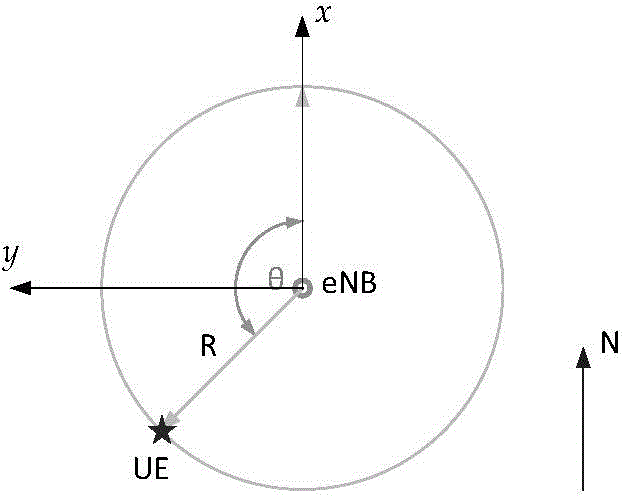

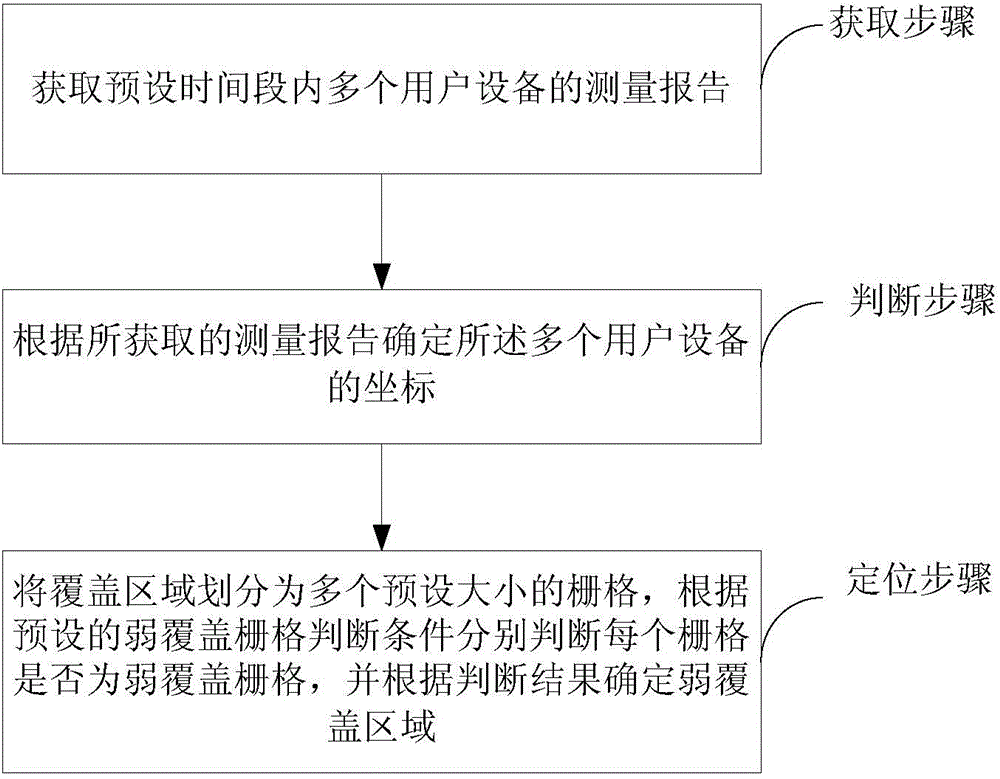

Positioning method and positioning device for weak coverage area

ActiveCN105228242AFully automatedAchieve accuracyWireless communicationCommunications systemThird generation

The invention provides a positioning method and a positioning device for the weak coverage area and belongs to a wireless communication system. The positioning method for the weak coverage area comprises an acquiring step for acquiring a measurement report for a plurality of user equipment within a preset period of time, wherein the measurement report is a report for measuring the user equipment in a 4G and / or 2G and / or 3G system; a positioning step for determining the coordinates of the plurality of user equipment according to the acquired measurement report; a judging step for dividing the coverage area into a plurality of grids of a preset size, respectively judging whether each of the plurality of grids is a weak coverage grid or not according to a preset weak coverage grid judgment condition, and determining the weak coverage area according to judgment results. According to the weak coverage grid judgment condition, for all user equipment within a grid, the ratio of the user equipment with the RSRP thereof smaller than a preset threshold to all the user equipment in the grid is greater than or equal to a preset proportion. According to the technical scheme of the invention, the weak coverage area in the 4G system can be found out.

Owner:CHINA MOBILE COMM GRP CO LTD

Method for manufacturing high-strength X80 steel spiral welded pipe

InactiveCN101205587AReduced dimensional accuracyImprove docking efficiencyArc welding apparatusWelding/cutting media/materialsUltrasound testSteel plates

The invention discloses a method for manufacturing a high-strength (X 80) steel spiral weld pipe. The weld pipe adopts a parent metal of X 80 rolled steel plate, and the chemical compositions of weld pipe are: 0.02 to 0.09 percent of C, 0.10 to 0.42 percent of Si, 1.50 to 1.85 percent of Mn, less than or equal to 0.022 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.45 percent of Cr, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cu, less than or equal to 0.35 percent of Mo, less than or equal to 0.025 percent of Ti, less than or equal to 0.11 percent of Nb, less than or equal to 0.06 percent of V, less than or equal to 0.06 percent of Al, less than or equal to 0.008 percent of N, less than or equal to 0.0005 percent of B, and less than or equal to 0.23 percent of Pcm. The manufacturing procedures includes: decoiling, leveling, edge milling, prebending, molding, internal welding, external welding, pipe end expending, hierarchical ultrasonic examination of parent metal, X-ray examination of welded seam, hydraulic pressure test, ultrasonic examination of welded seam, pipe end chamfering, finished product examination, etc. The (X 80) steel spiral weld pipe( ID: 1219mm, thickness:18.4mm) manufactured by the invention successfully solves the problem of poor stability and unsatisfactory welded seam performance, etc. in the manufacturing process of the high-strength (X 80) steel spiral weld pipe, thereby greatly improving the pass-rate and working efficiency.

Owner:CNPC BOHAI EQUIP MFG +1

A cross-chain method between blockchains and a main blockchain

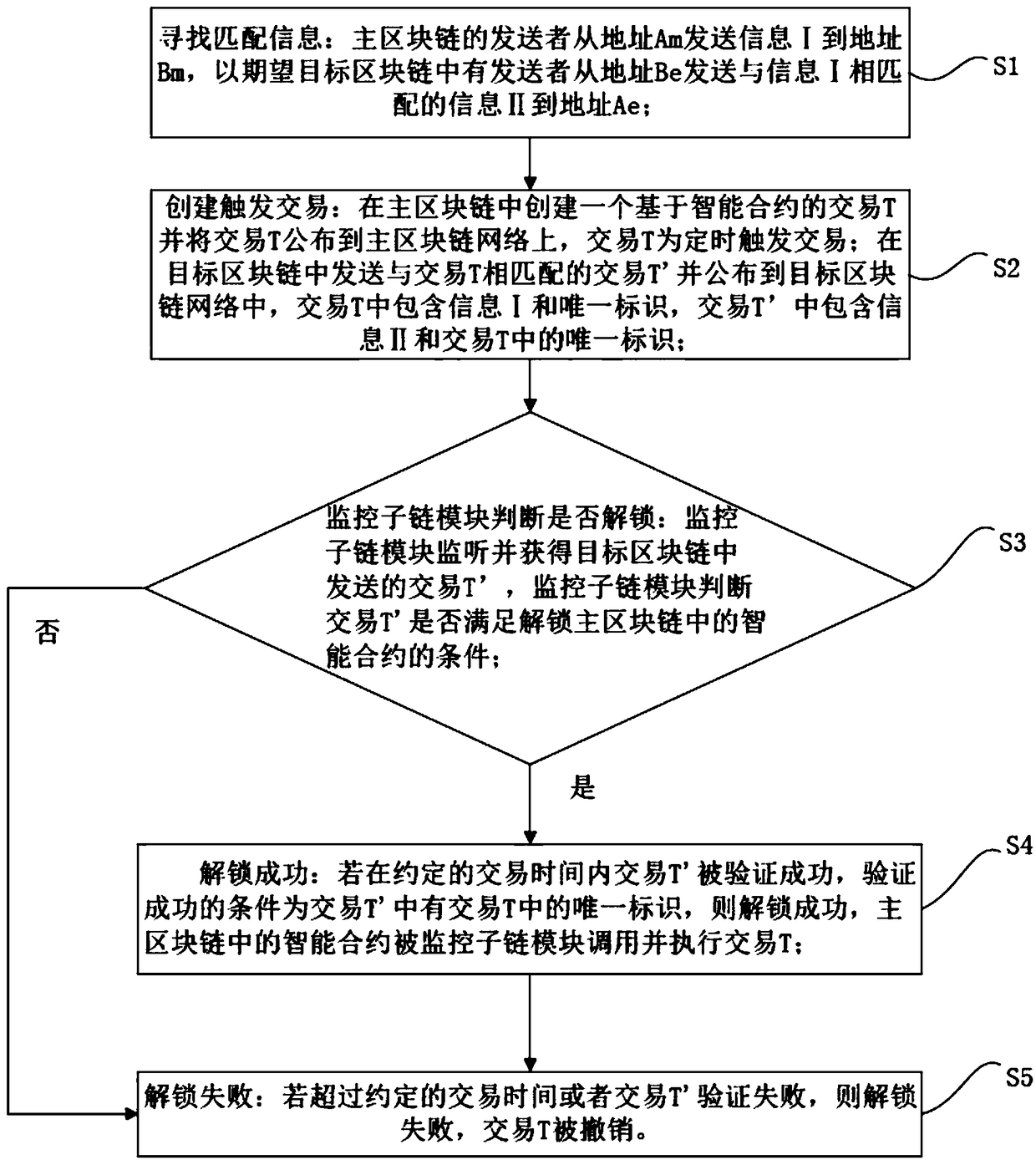

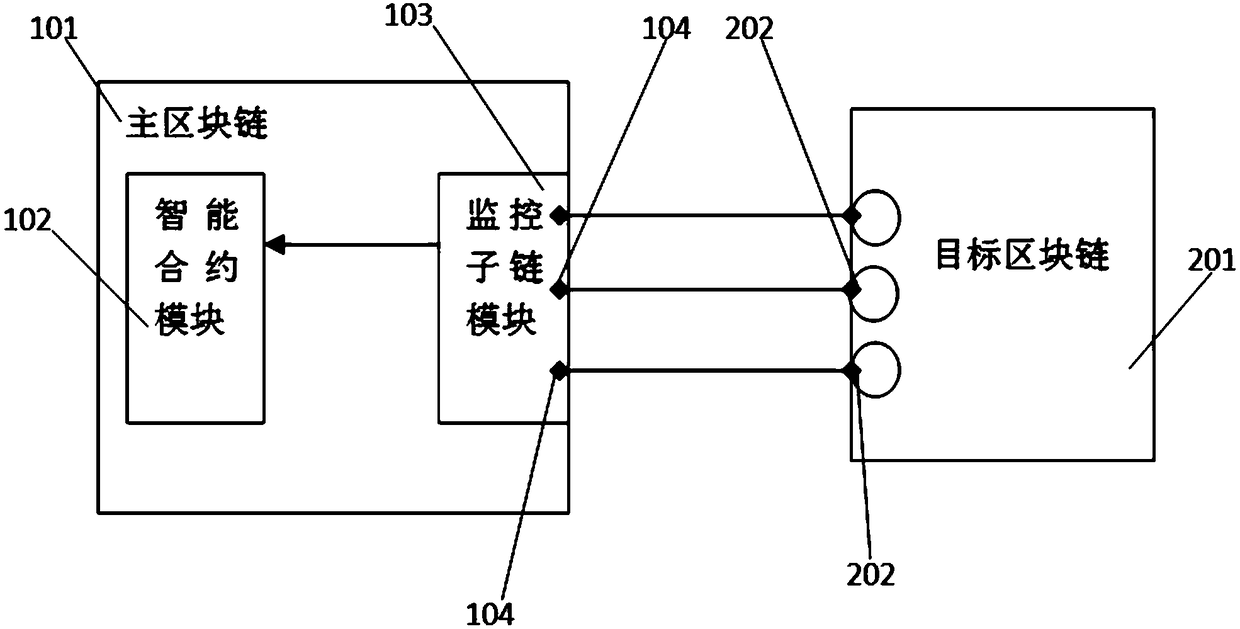

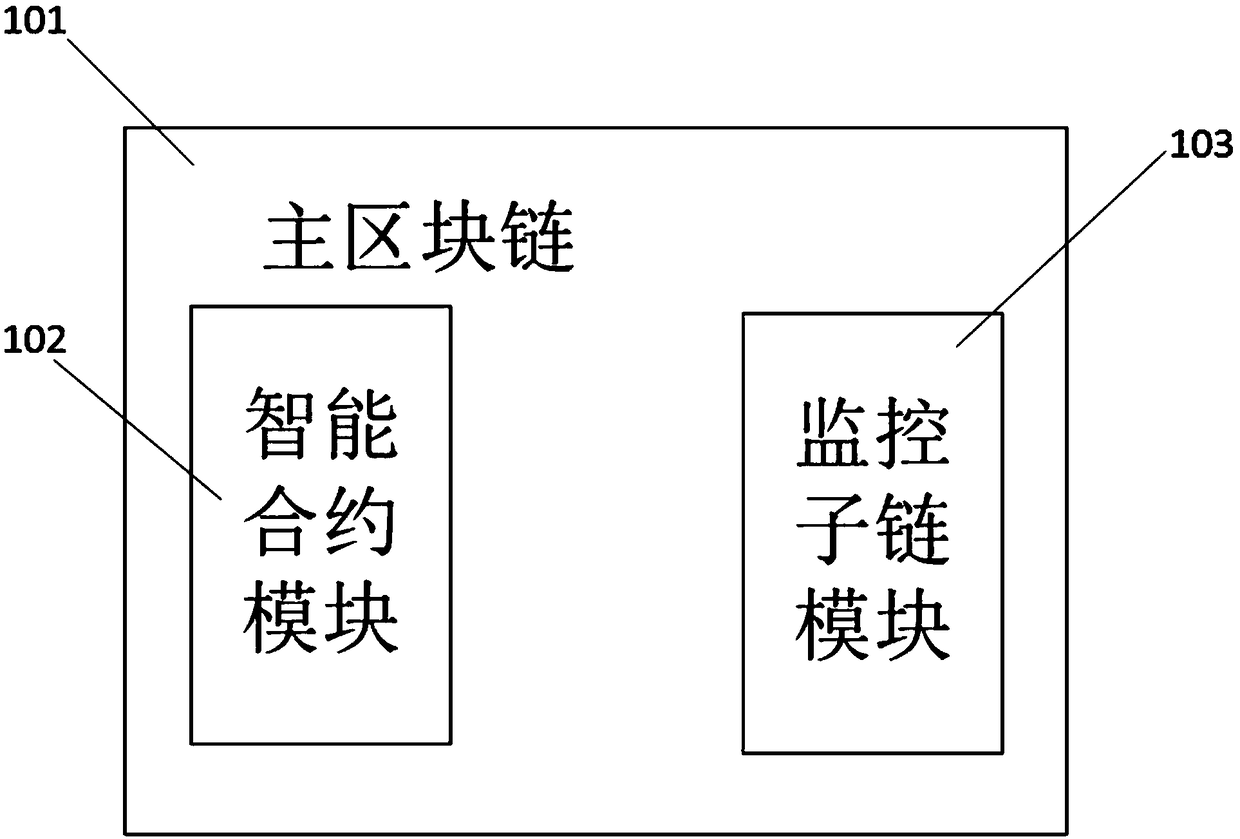

ActiveCN108600301ARealize cross-chain operationFully automatedFinanceTransmissionSmart contractComputer science

The invention relates to the technical field of blockchains, in particular to a cross-chain method between blockchains and a main blockchain. According to the cross-chain method between blockchains, amain blockchain and a target blockchain exist in a cross-chain operation, and at least one sender exists in each of the main blockchain and the target blockchain. The method includes the following steps: searching of match information; establishment of a trigger transaction; monitoring of sub-chains to judge whether unlocking occurs; unlocking success; and unlocking failure. The invention also discloses the main blockchain, which includes an intelligent contract module and a monitoring sub-chain module. The cross-chain method has no special requirements for the target blockchain and can realize the cross-chain operation between the main blockchain and all other blockchains. An effect that a transaction T in the main blockchain and a transaction T' in the target blockchain are carried outsimultaneously or not is realized. Moreover, the monitoring sub-chain module of the main blockchain can automatically trigger an unlocking process of the transaction T in the main blockchain, thus realizing automation of the cross-chain operation.

Owner:青岛墨一客区块链有限公司

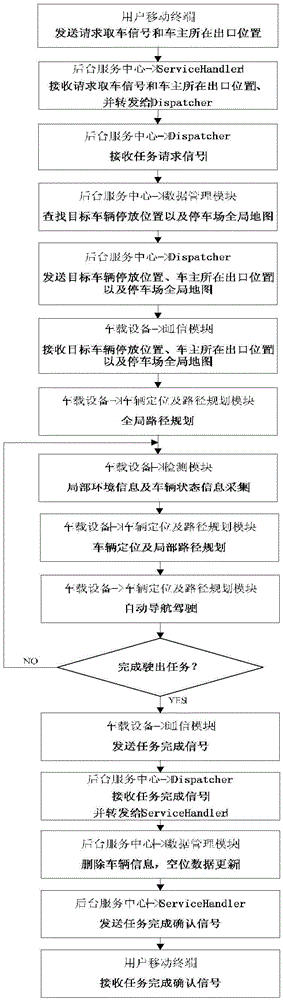

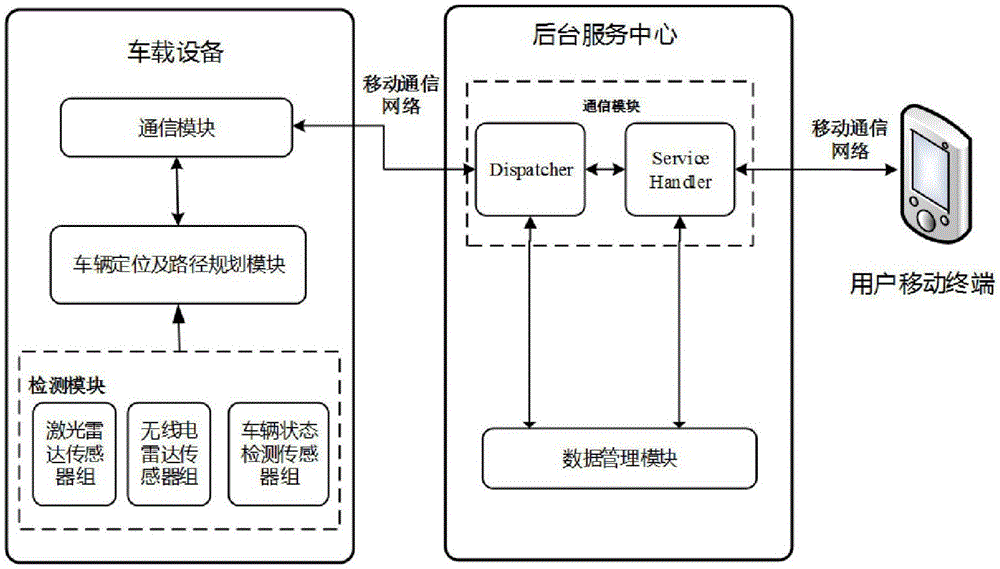

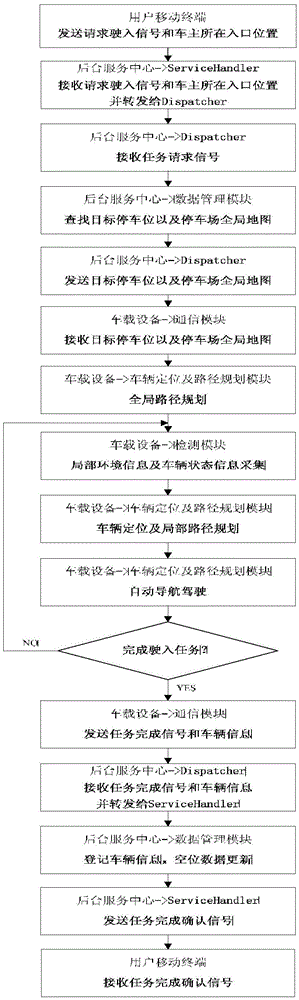

Intelligent vehicle automatic driving system and method in cooperation with intelligent parking lot

ActiveCN105679068AFully automatedRealize intelligenceIndication of parksing free spacesParking areaComputer terminal

The invention makes a request of protecting an intelligent vehicle automatic driving system and method in cooperation with an intelligent parking lot. Intelligent vehicle-mounted equipment comprises a communication module, a vehicle positioning and path planning module, and a detection module. A background service center consists of a communication module and a data management module. The communication module includes a dispatcher part and a service Handler part. A user mobile terminal sends request information of driving into or driving out of a parking lot to the background service center; the background service center sends a parking lot map and a designated terminal position to the vehicle-mounted equipment; the vehicle-mounted equipment carries out global path planning, collects vehicle station and environment information for positioning, plans a local path to control an intelligent vehicle to drive to a terminal point automatically, and sends terminal point arrival information to the background service center; and the background service center sends the terminal point arrival information to the user mobile terminal.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com