Patents

Literature

739results about How to "Achieve placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

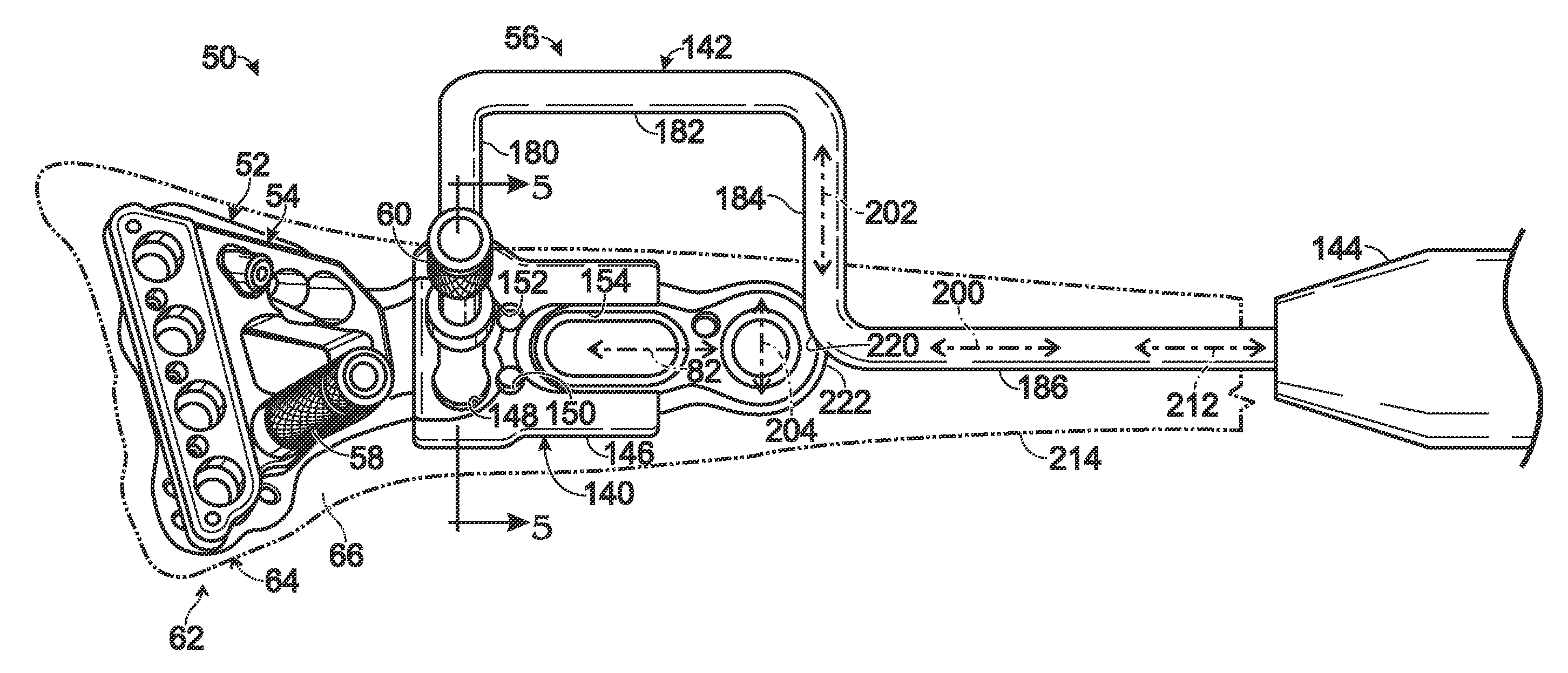

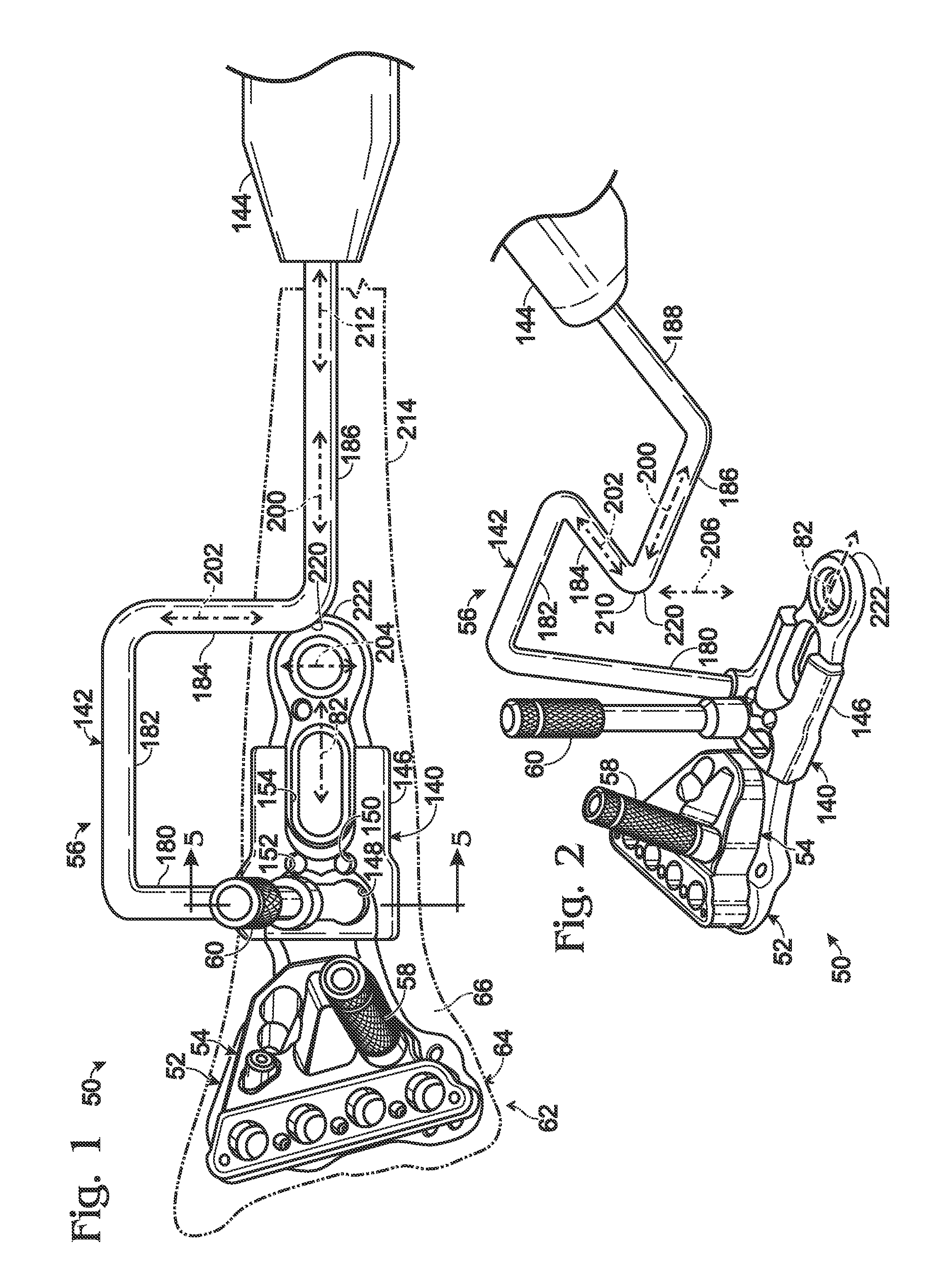

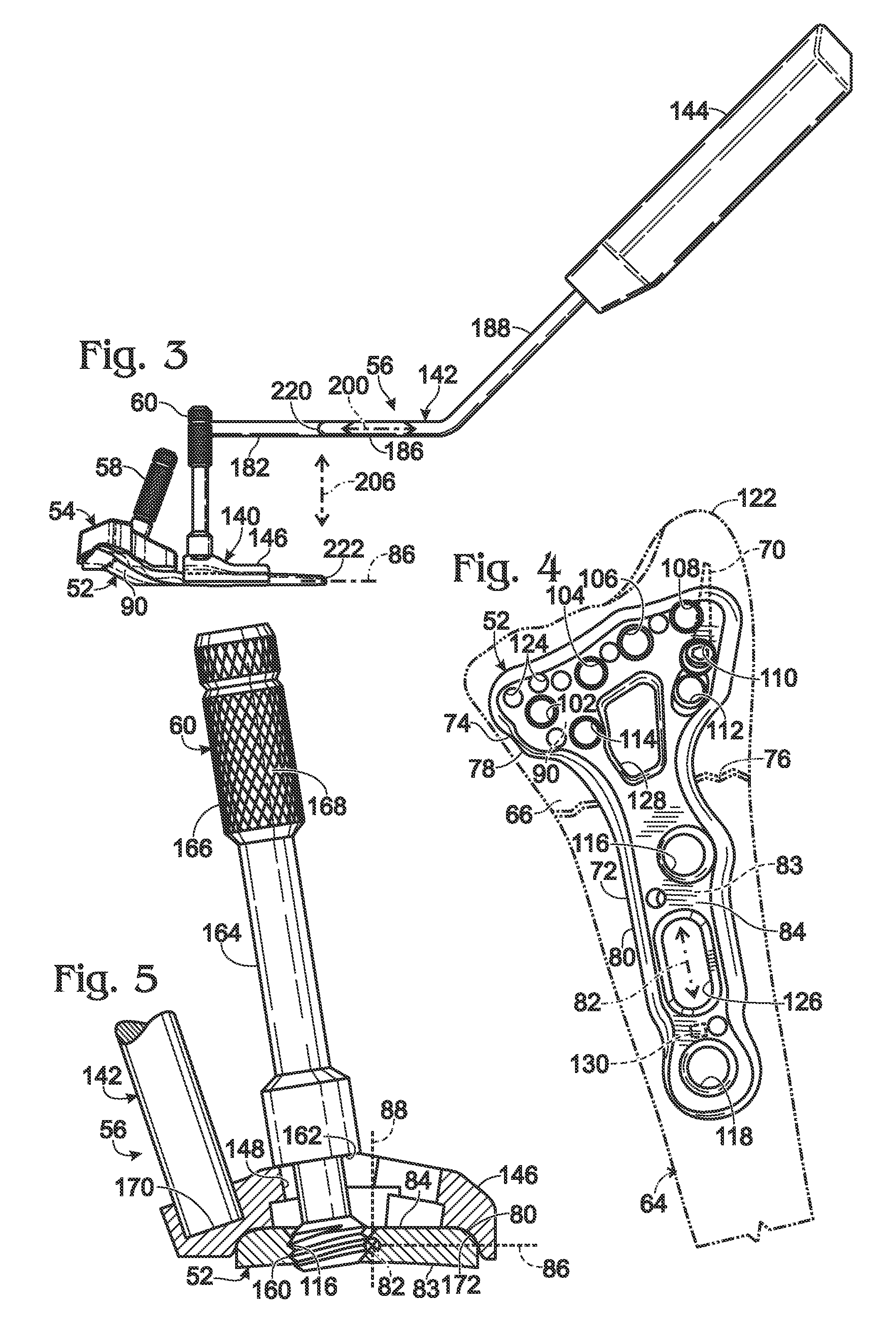

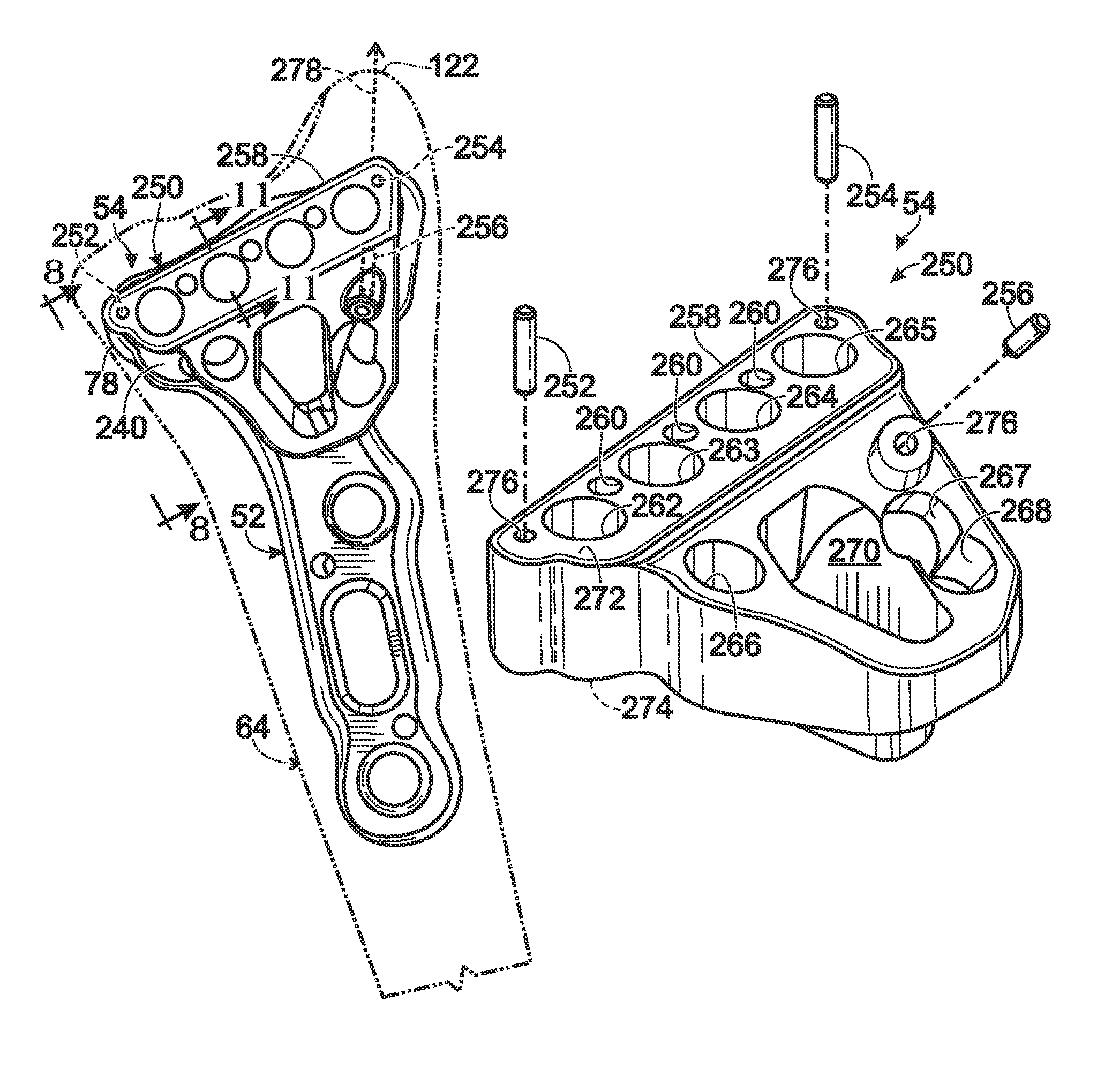

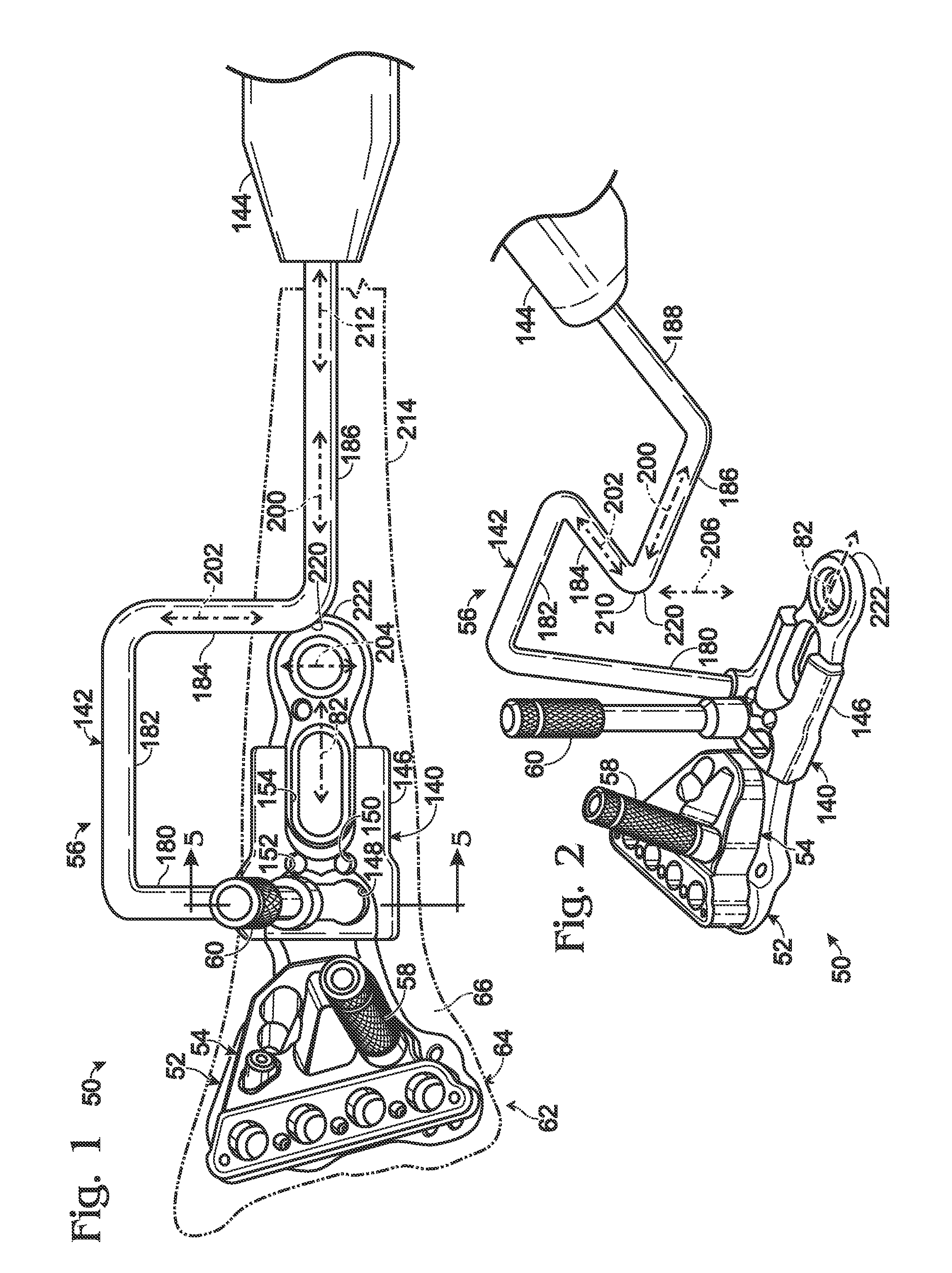

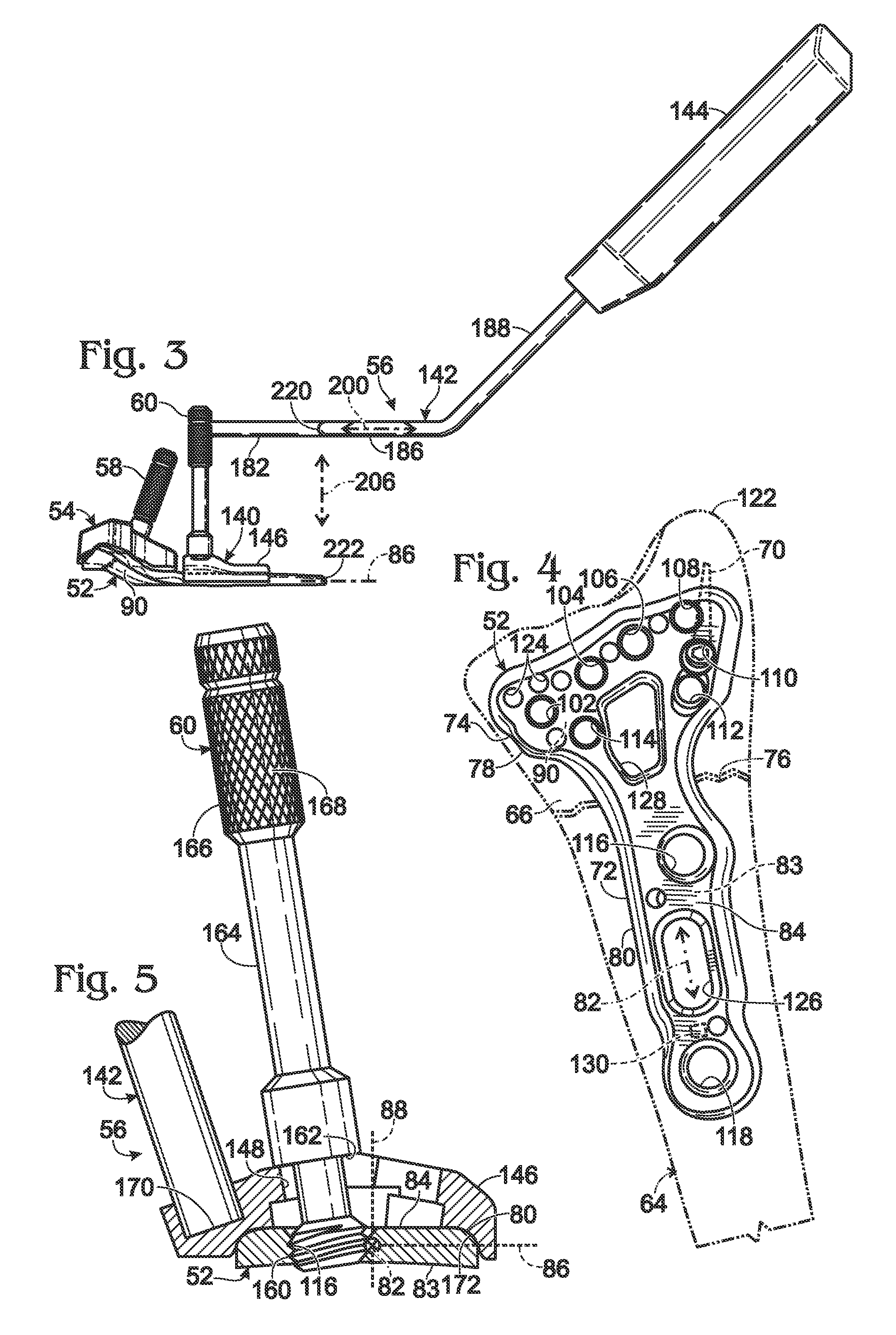

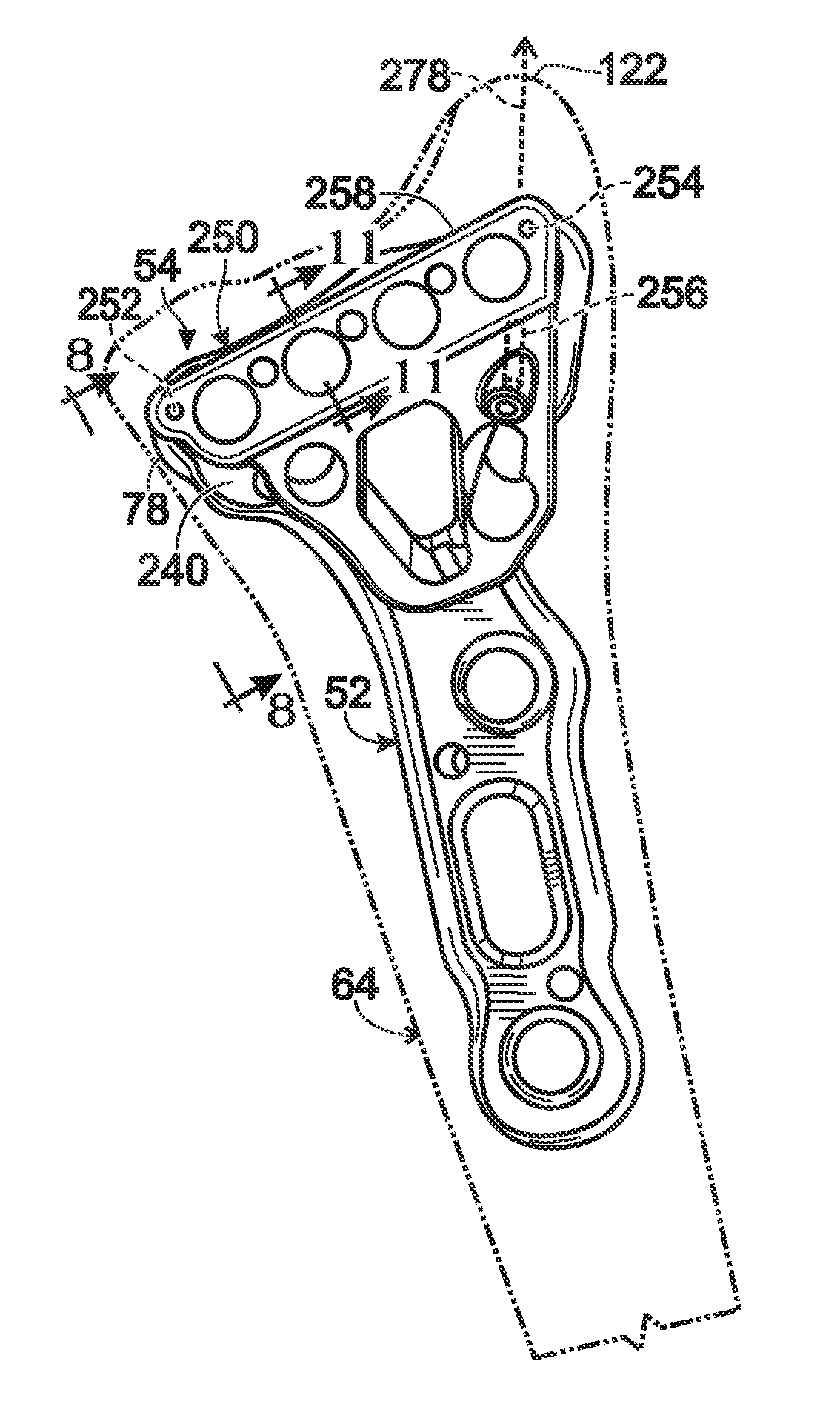

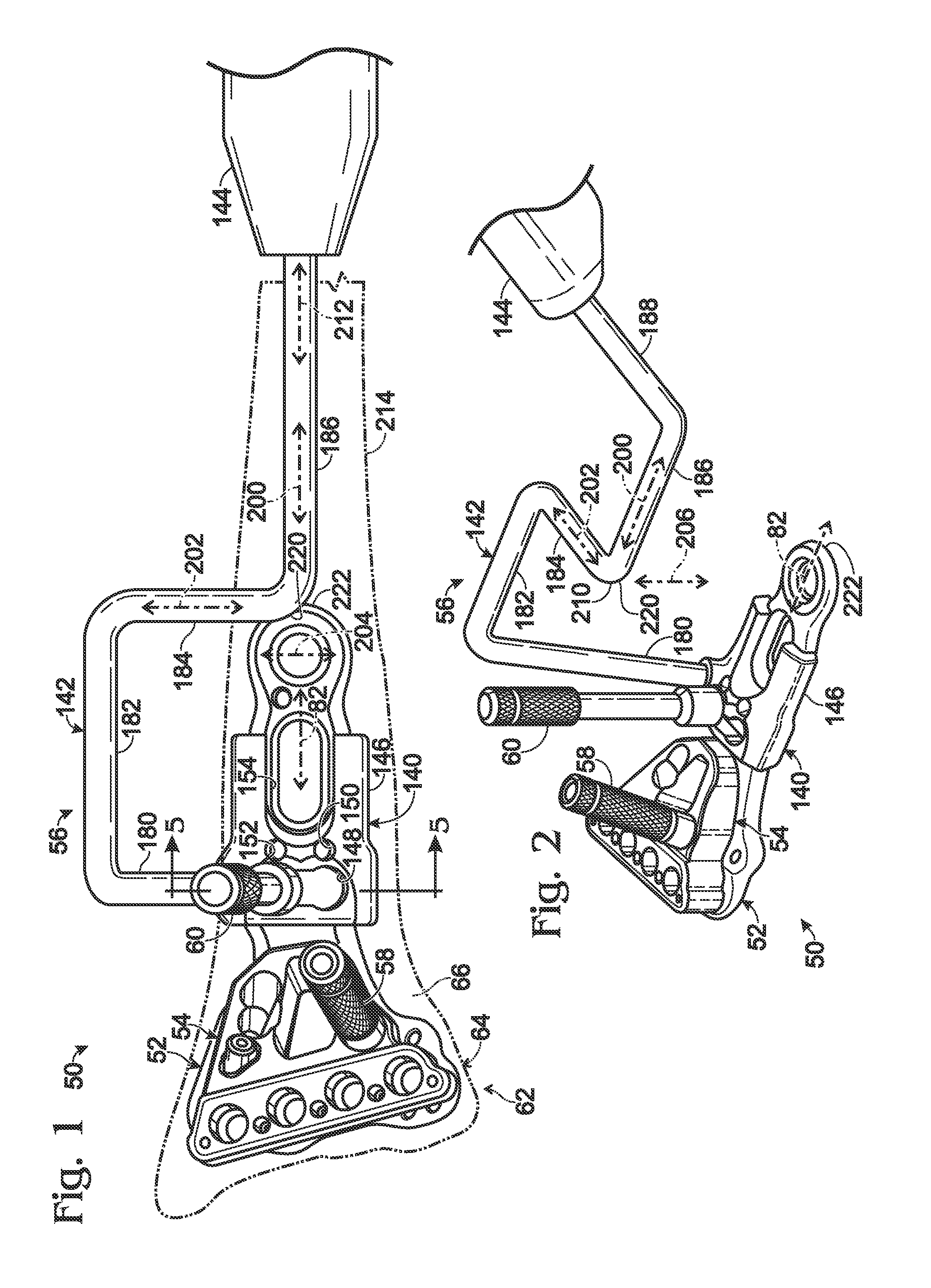

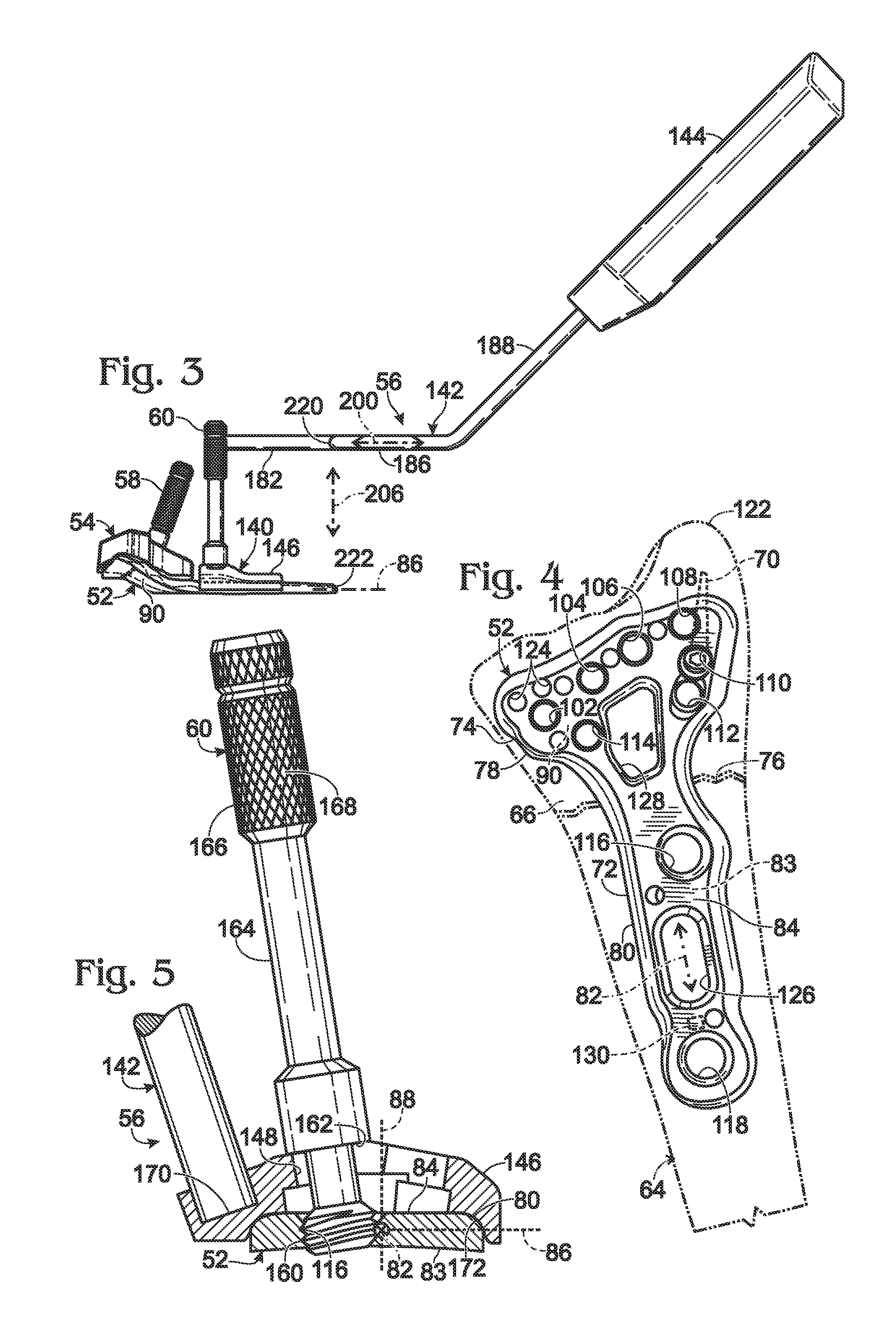

Targeting guide with a radiopaque marker to facilitate positioning a bone plate on bone

Bone fixation system, including methods, apparatus, and kits, and comprising a bone plate and at least one instrument that attaches to the bone plate and provides at least one radiopaque region to facilitate positioning the bone plate on bone visualized by radiographic imaging. The instrument may be a handle assembly and / or a targeting guide.

Owner:ACUMED

Targeting guide with a radiopaque marker to facilitate positioning a bone plate on bone

Bone fixation system, including methods, apparatus, and kits, and comprising a bone plate and at least one instrument that attaches to the bone plate and provides at least one radiopaque region to facilitate positioning the bone plate on bone visualized by radiographic imaging. The instrument may be a handle assembly and / or a targeting guide.

Owner:ACUMED

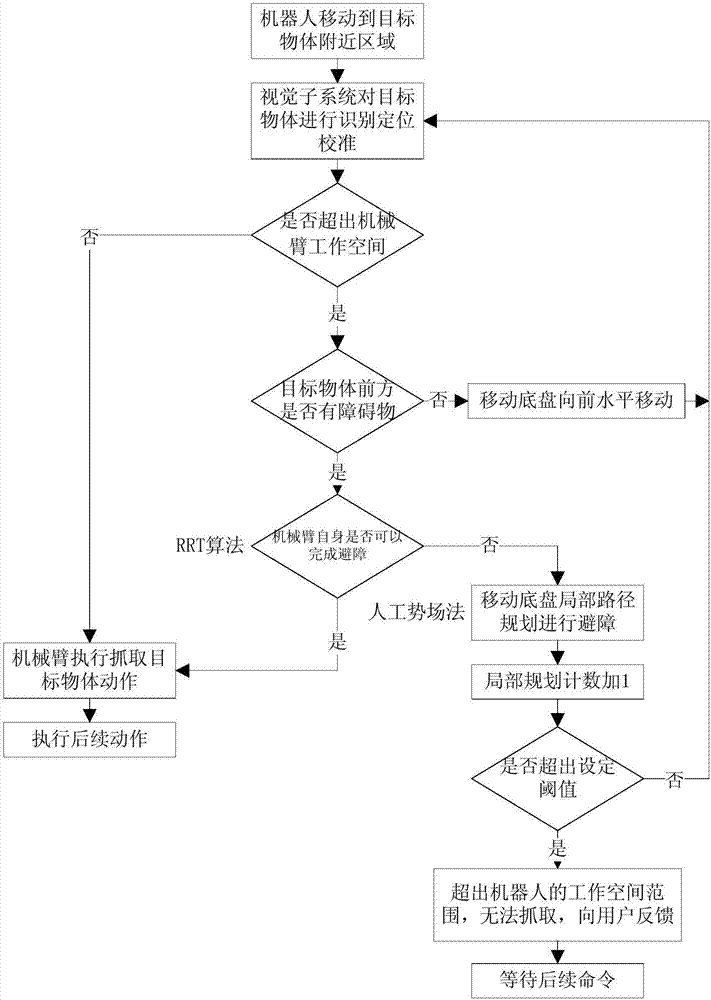

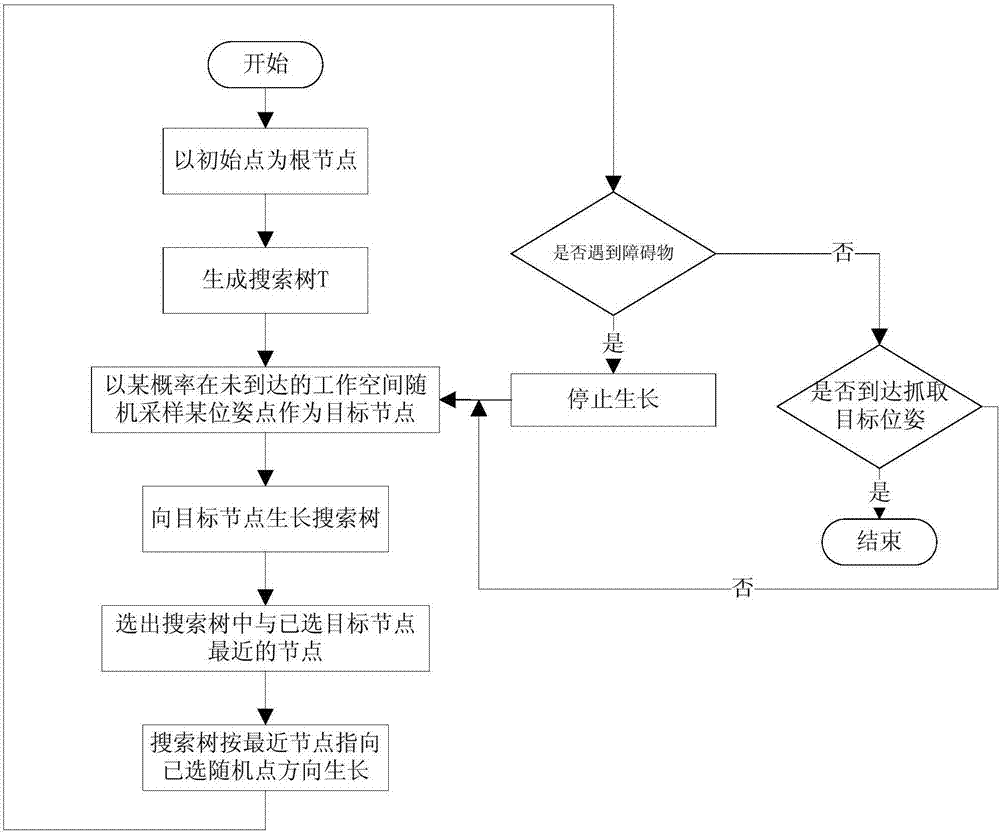

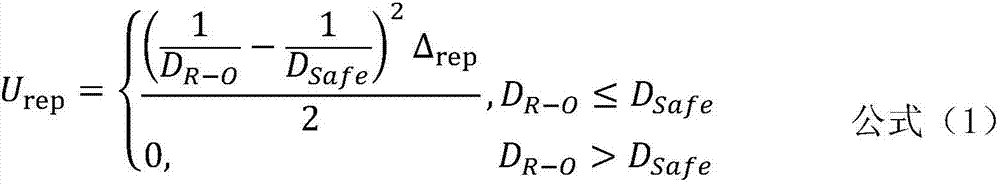

Robot local path planning method

InactiveCN106990777AAchieve crawlingAchieve placementProgramme-controlled manipulatorPosition/course control in two dimensionsPotential fieldSimulation

The invention provides a robot local path planning method which comprises following two parts: (1) a vision sub-system is adopted to perform closed-loop detection: a mechanical arm sub-system is separated from a mobile underpan sub-system, closed-loop detection control is performed through the closed-loop detection, and pick or place from the mechanical arm to a target object on the best substrate position is realized; (2) the local path plan is formed by a combination of the artificial potential field and the RRT algorithm, and mobile underpan and mechanical arm separation plan is realized through the local path plan; when the local path plan is performed, the mobile underpan adopts the artificial potential field to plan, and after every local path planning, the mechanical arm is planned through the RRT algorithm to judge if the movement of avoiding barrier and smoothly pick up a target object can be completed. According to the invention, the different plans for the mobile underpan and the mechanical arm are combined, so that overall coordination operation of the robot is realized.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

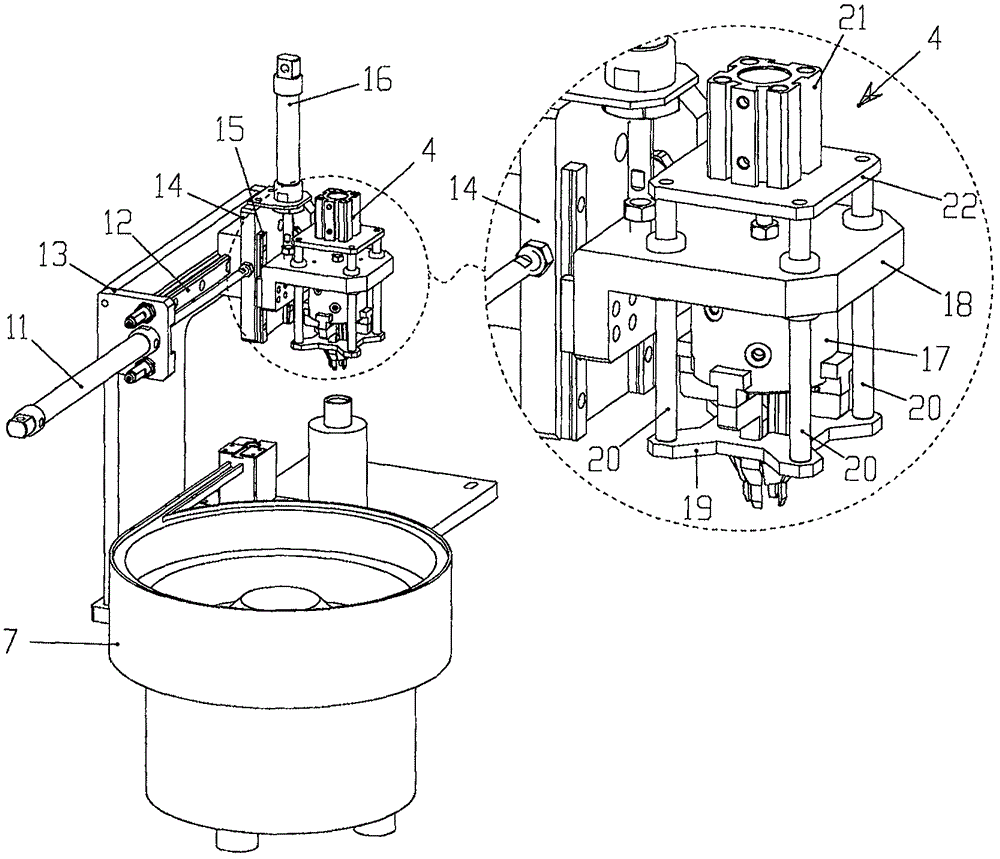

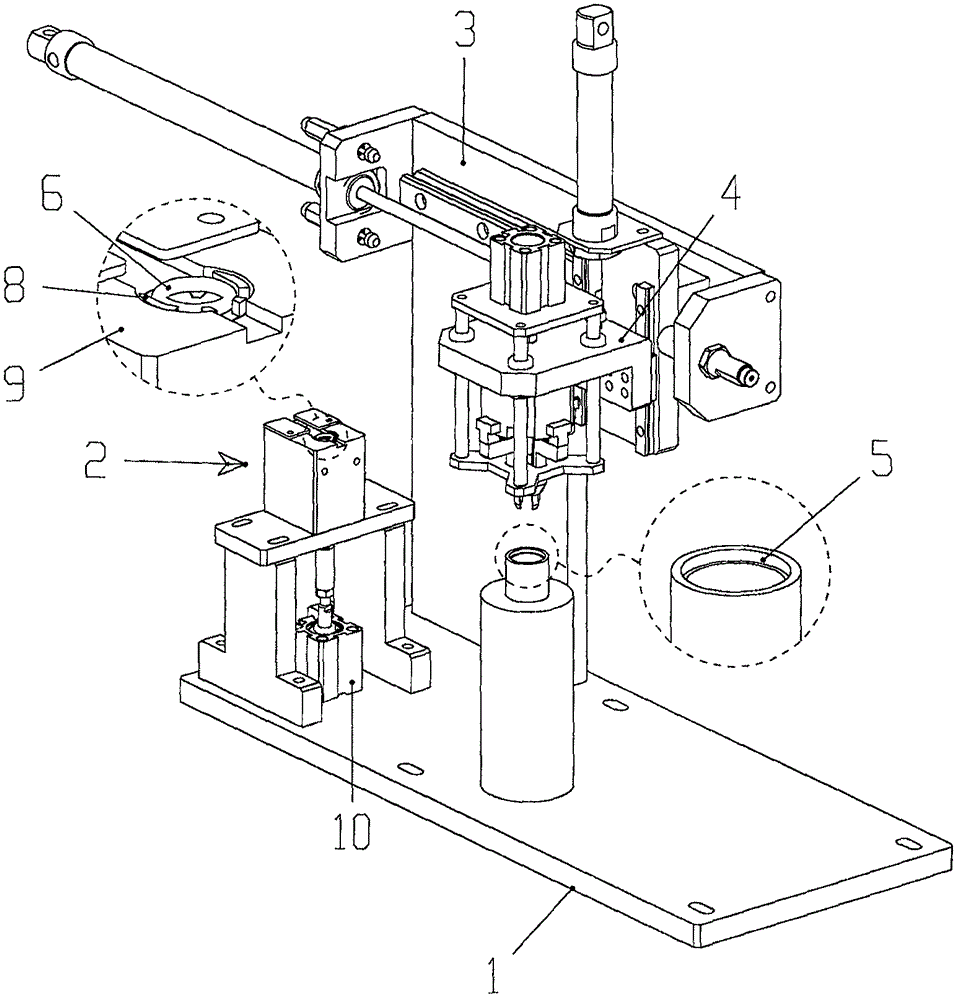

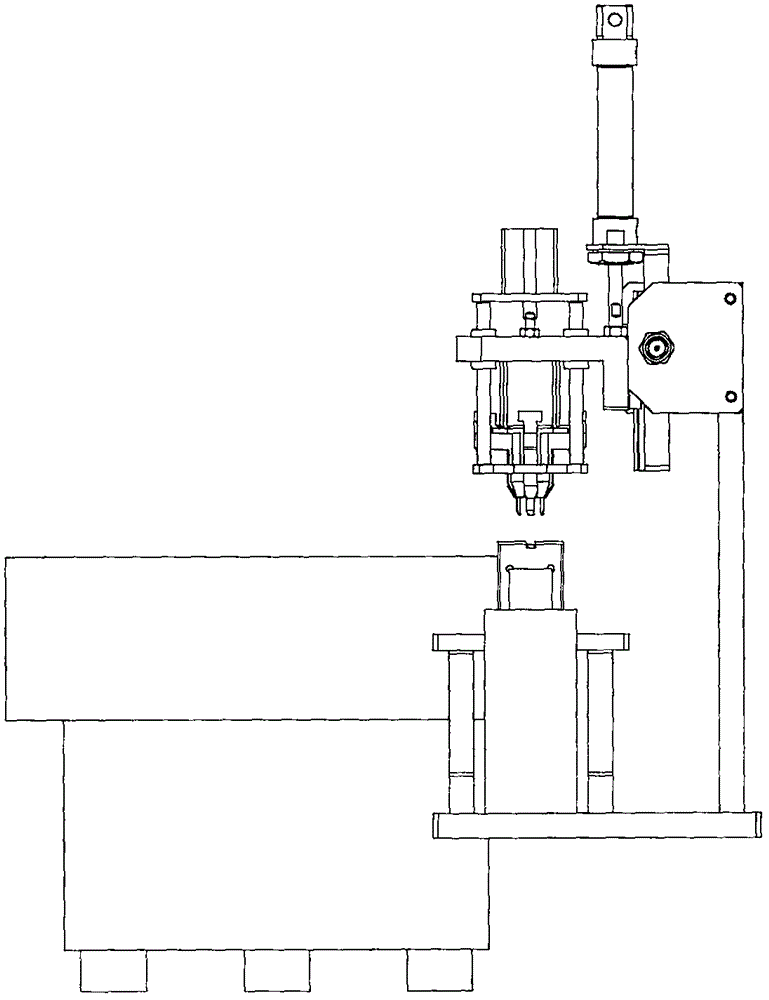

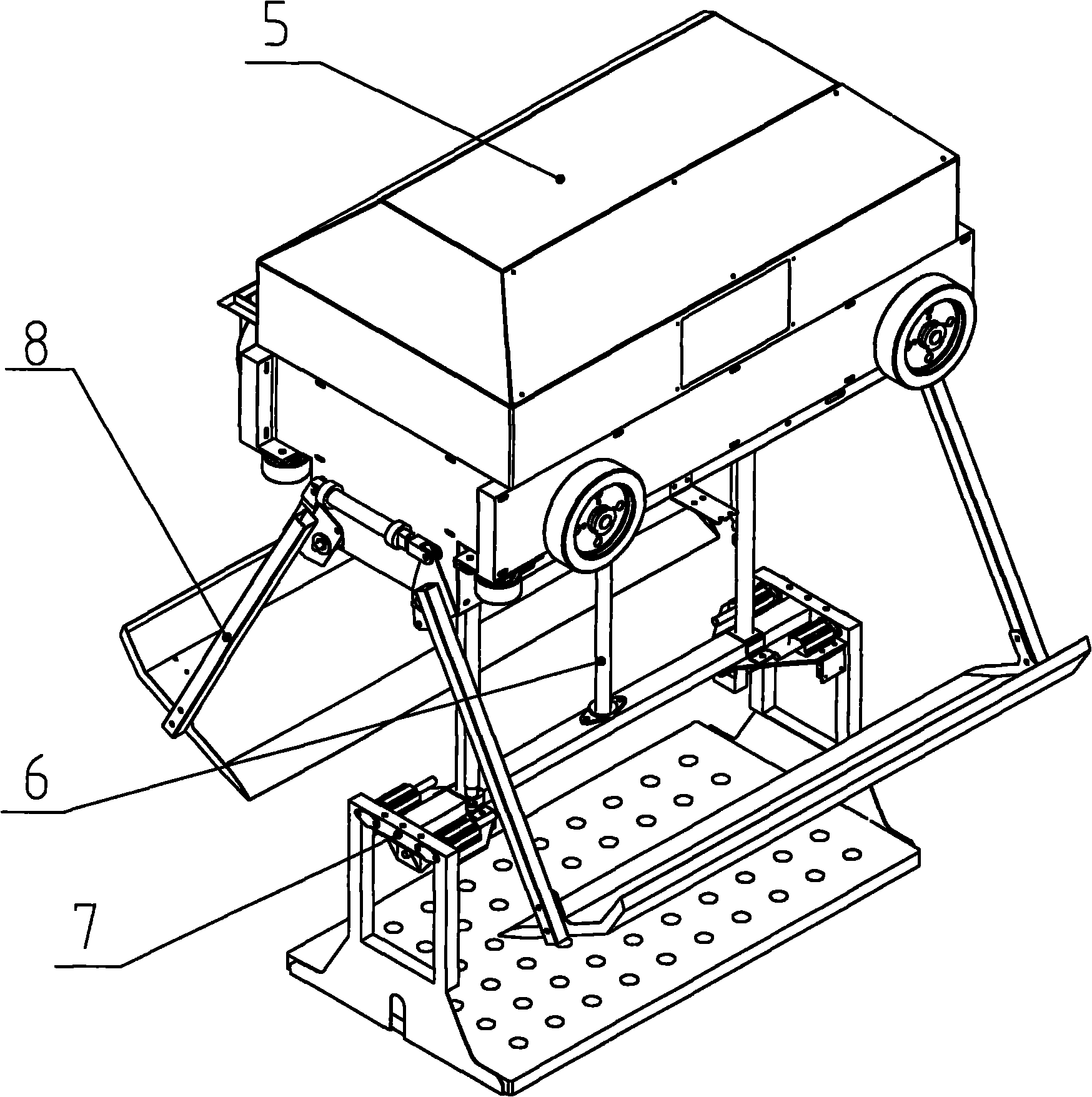

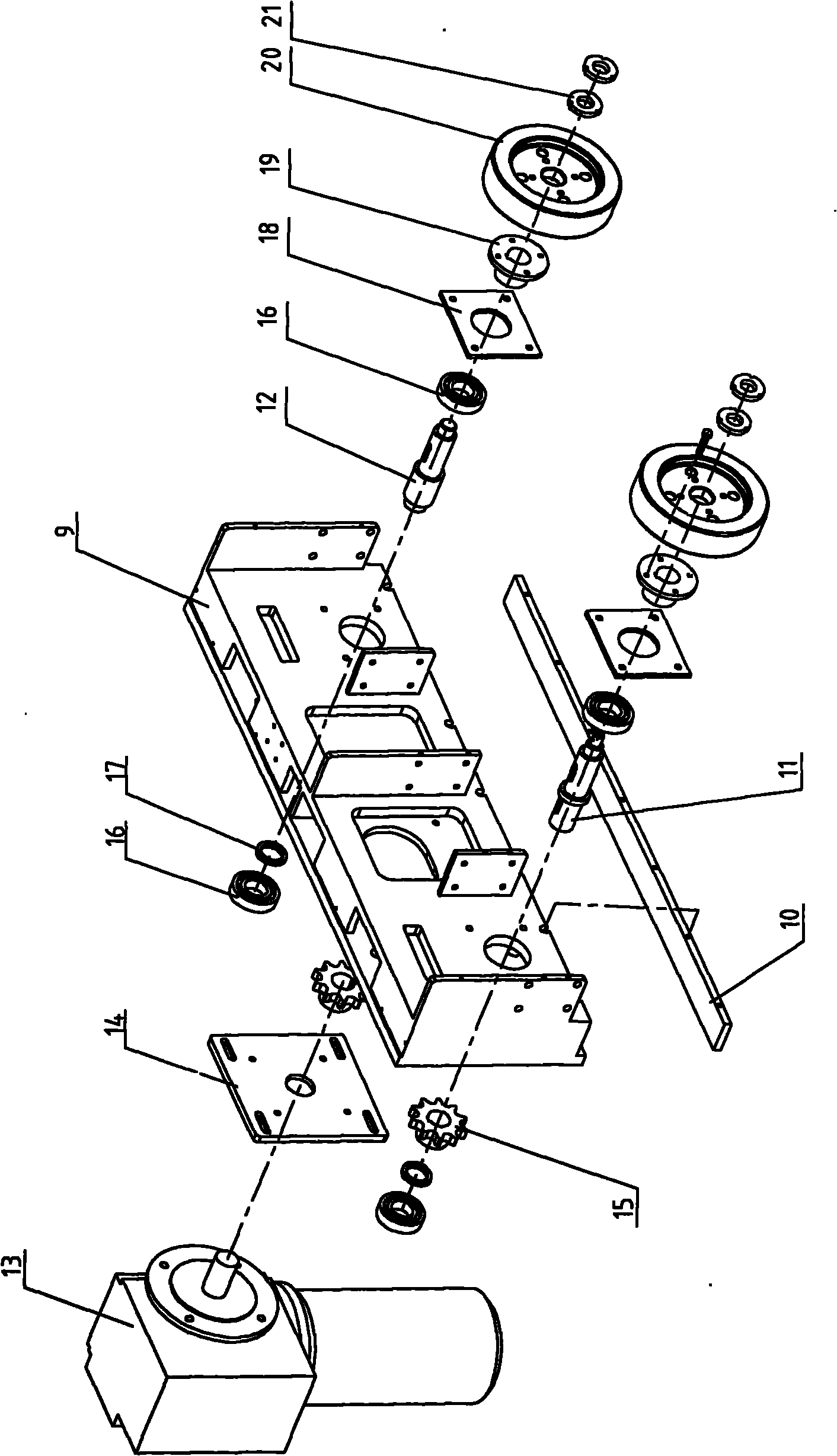

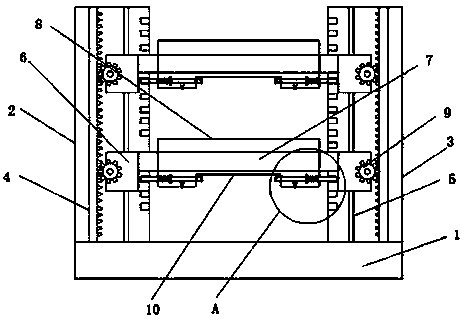

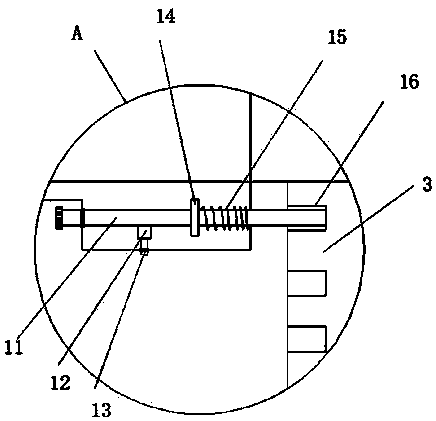

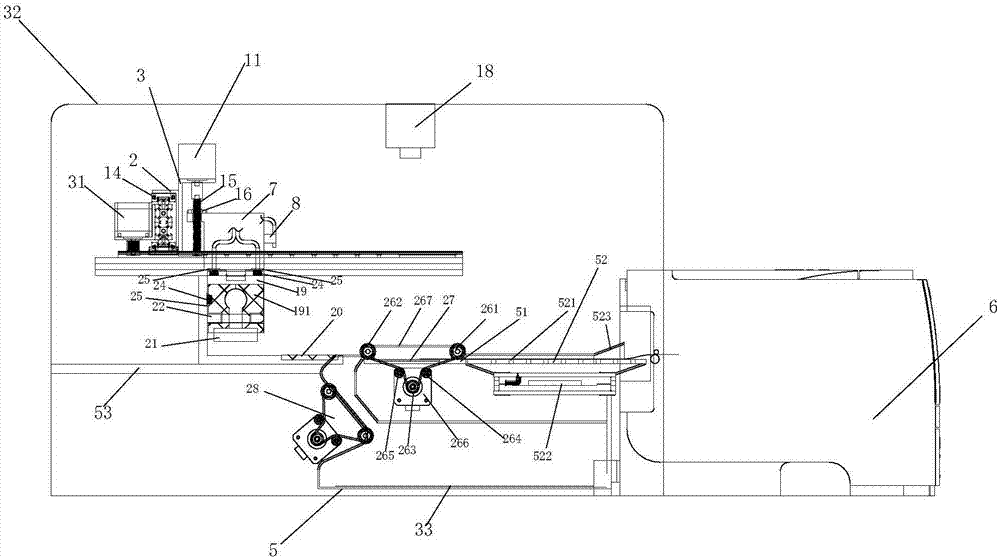

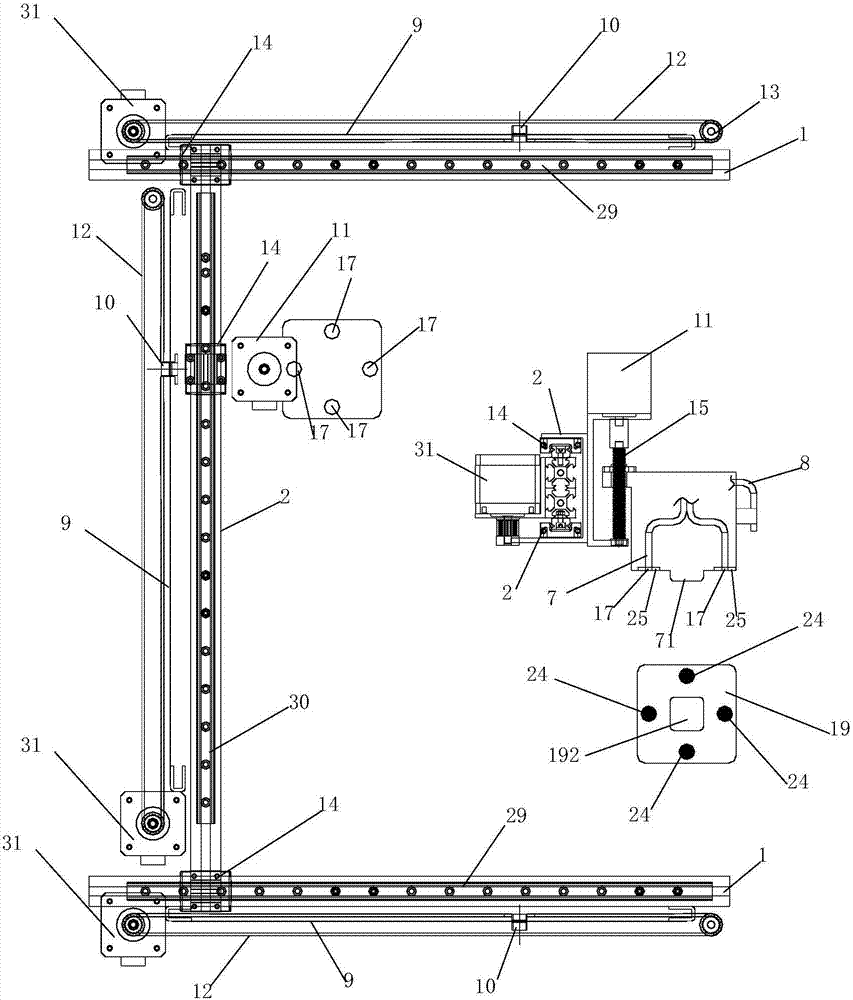

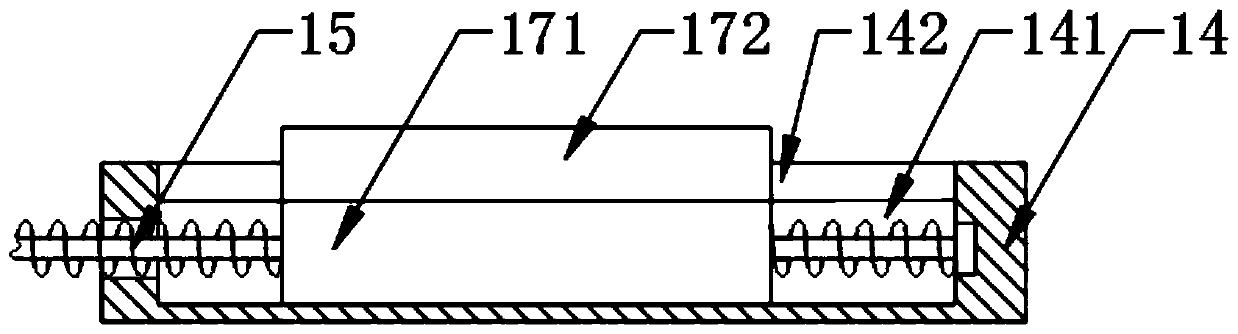

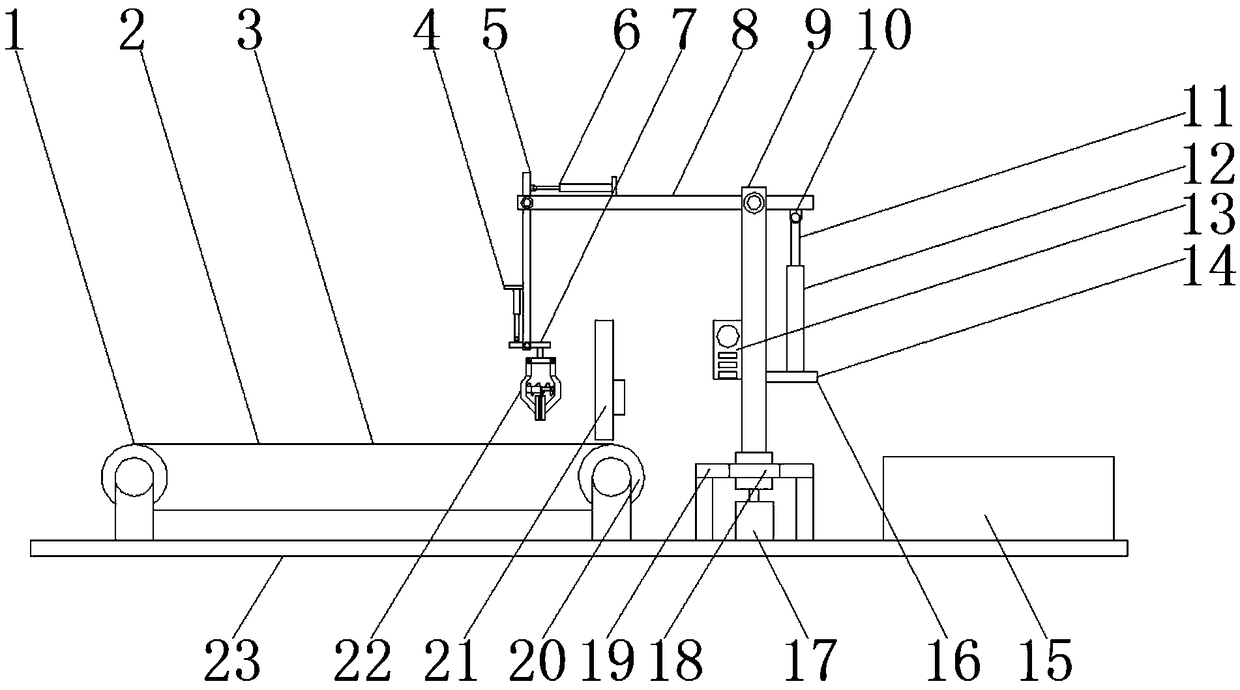

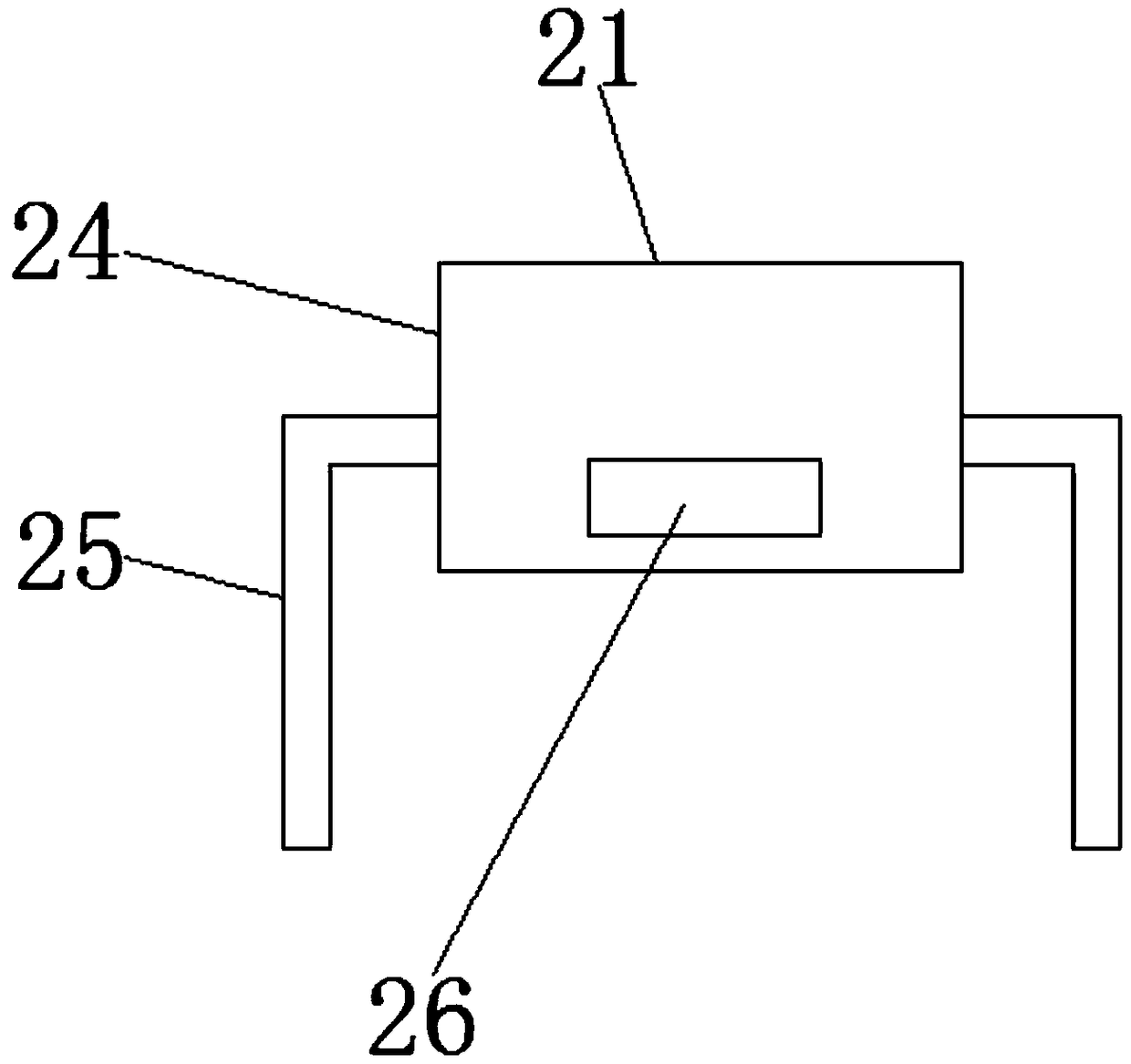

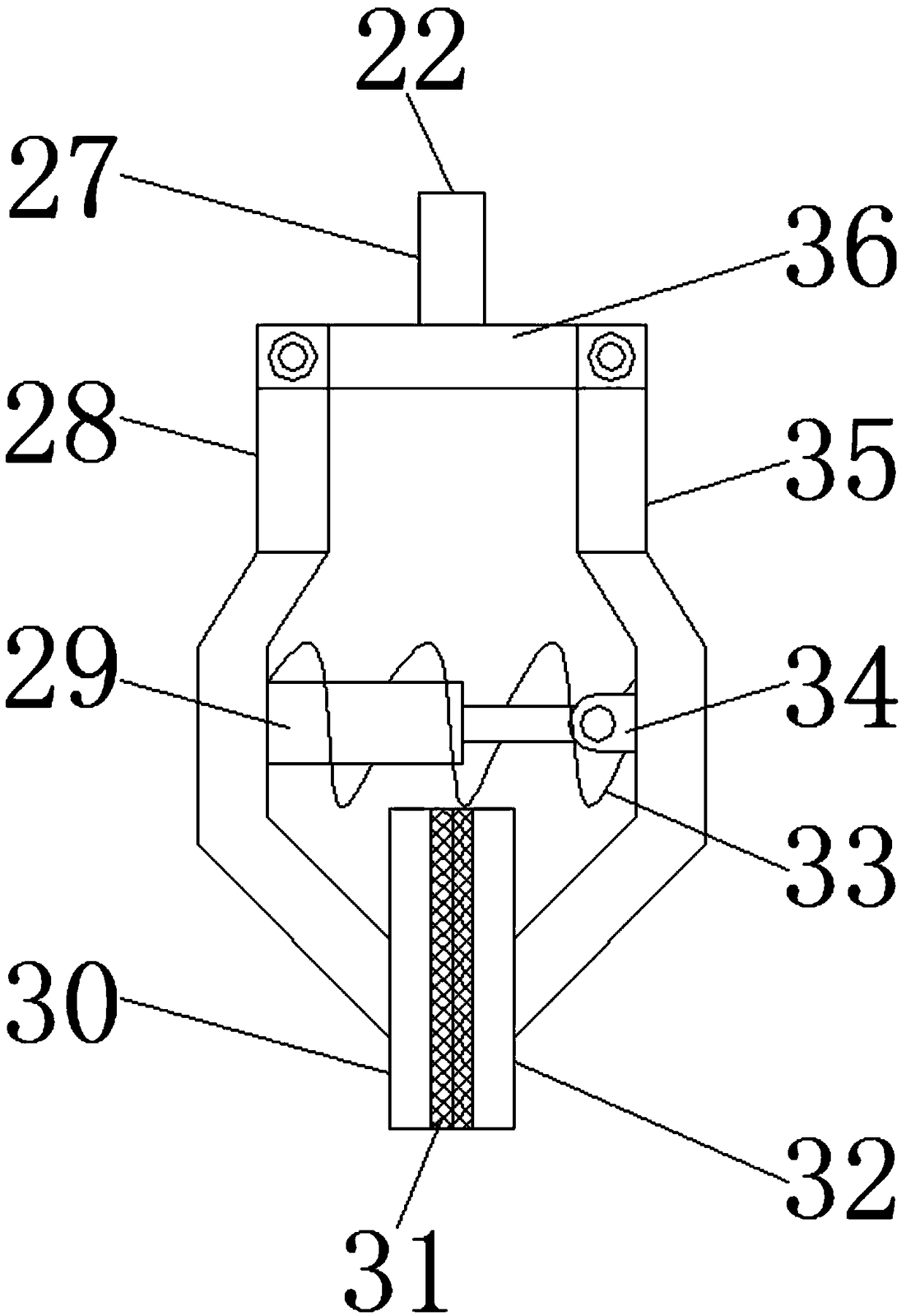

Compliance assembly equipment for O-shaped sealing rings

InactiveCN106363407ATo achieve horizontal movementTo achieve vertical movementMetal working apparatusRobotic armEngineering

The invention relates to industrial manufacturing equipment, in particular to automated assembly equipment for combining sealing rings. The invention provides compliance assembly equipment for O-shaped sealing rings. The compliance assembly equipment for the O-shaped sealing rings comprises a base, a feeding mechanism, a mechanical arm and a gripper mechanism, wherein the feeding mechanism is used for providing the O-shaped sealing rings; the mechanical arm is used for driving the gripper mechanism to move; the gripper mechanism is used for grabbing the O-shaped sealing rings; the feeding mechanism, the mechanical arm and a workpiece are fixedly connected to the base; a feeding track of a vibrating plate is connected to the feeding mechanism; the gripper mechanism is fixedly connected to the mechanical arm; and the feeding mechanism and the workpiece are positioned on the lower part of the gripper mechanism. By the compliance assembly equipment for the O-shaped sealing rings, the O-shaped sealing rings can be assembled and manufactured in an unmanned manner, efficiency is high, and quality is good. According to the compliance assembly equipment for the O-shaped sealing rings, the O-shaped sealing rings are automatically supplied by the vibrating plate, and then the mechanical arm grabs the O-shaped sealing rings to assemble the O-shaped sealing rings into the workpiece.

Owner:WENZHOU POLYTECHNIC

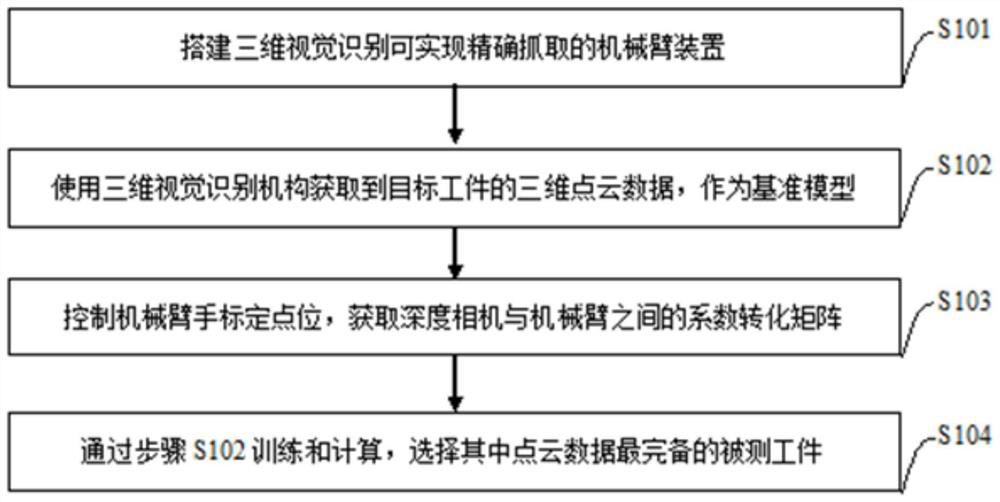

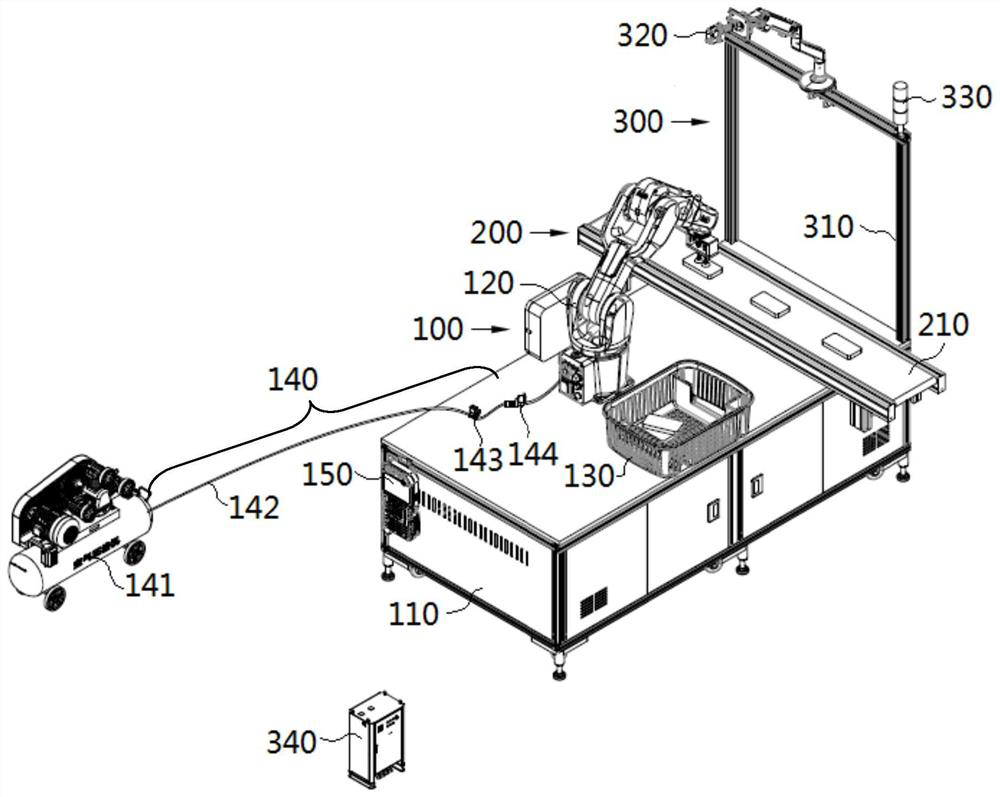

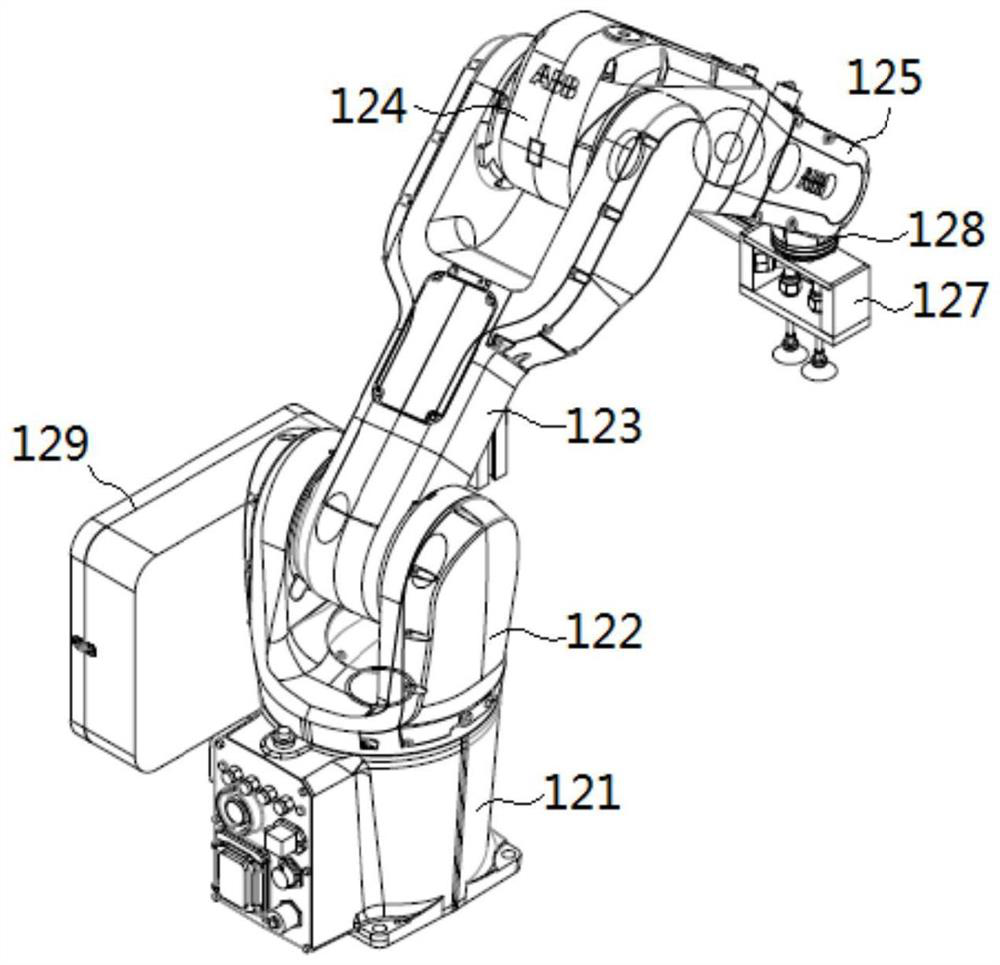

Method for realizing accurate grasping by combining three-dimensional vision recognition

ActiveCN111791239AAchieve crawlingAchieve placementProgramme-controlled manipulatorPoint cloudEngineering

The invention discloses a method for realizing accurate grasping by combining three-dimensional vision recognition, and belongs to the technical field of mechanical arm application. The method comprises the steps of step S101, building a mechanical arm device which can realize accurate grasping by three-dimensional vision recognition; step S102, obtaining three-dimensional point cloud data of a target workpiece by using a three-dimensional vision recognition mechanism, and using the three-dimensional point cloud data as a benchmark model; step S103, controlling the calibration point location of the mechanical arm, and obtaining a coefficient conversion matrix between a depth camera and the mechanical arm; step S104, training and calculation by the step S103: collecting the visual information of the depth camera of the vision recognition mechanism, and conducting three-dimensional visual guidance when the mechanical arm moves; and by system calibration, obtaining the point cloud data and conducting pose estimation for the workpiece, calculating the grasping movement track of the workpiece, and controlling the mechanical arm to grasp and place the workpiece. The method has high flexibility and adaptability.

Owner:苏州国岭技研智能科技有限公司

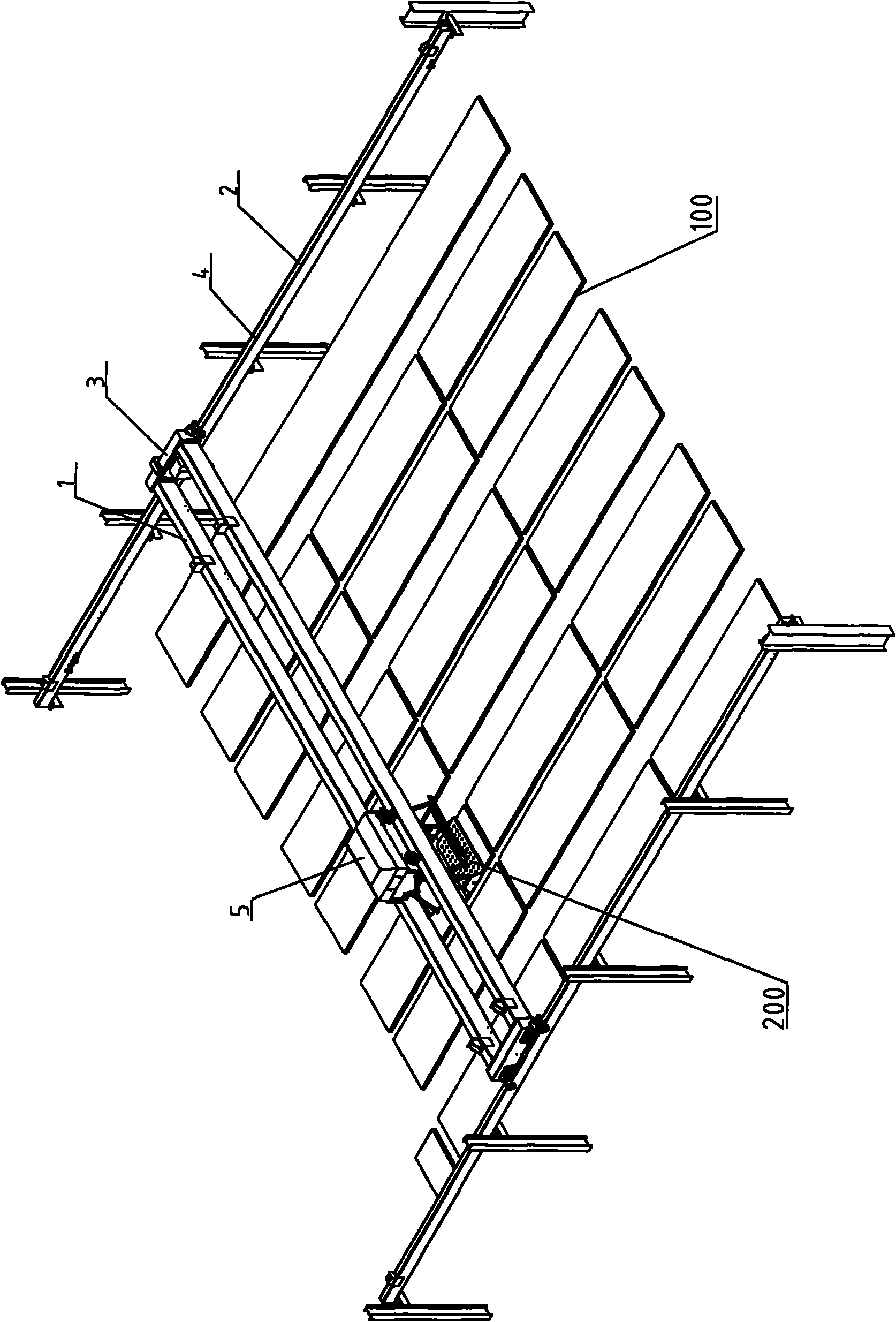

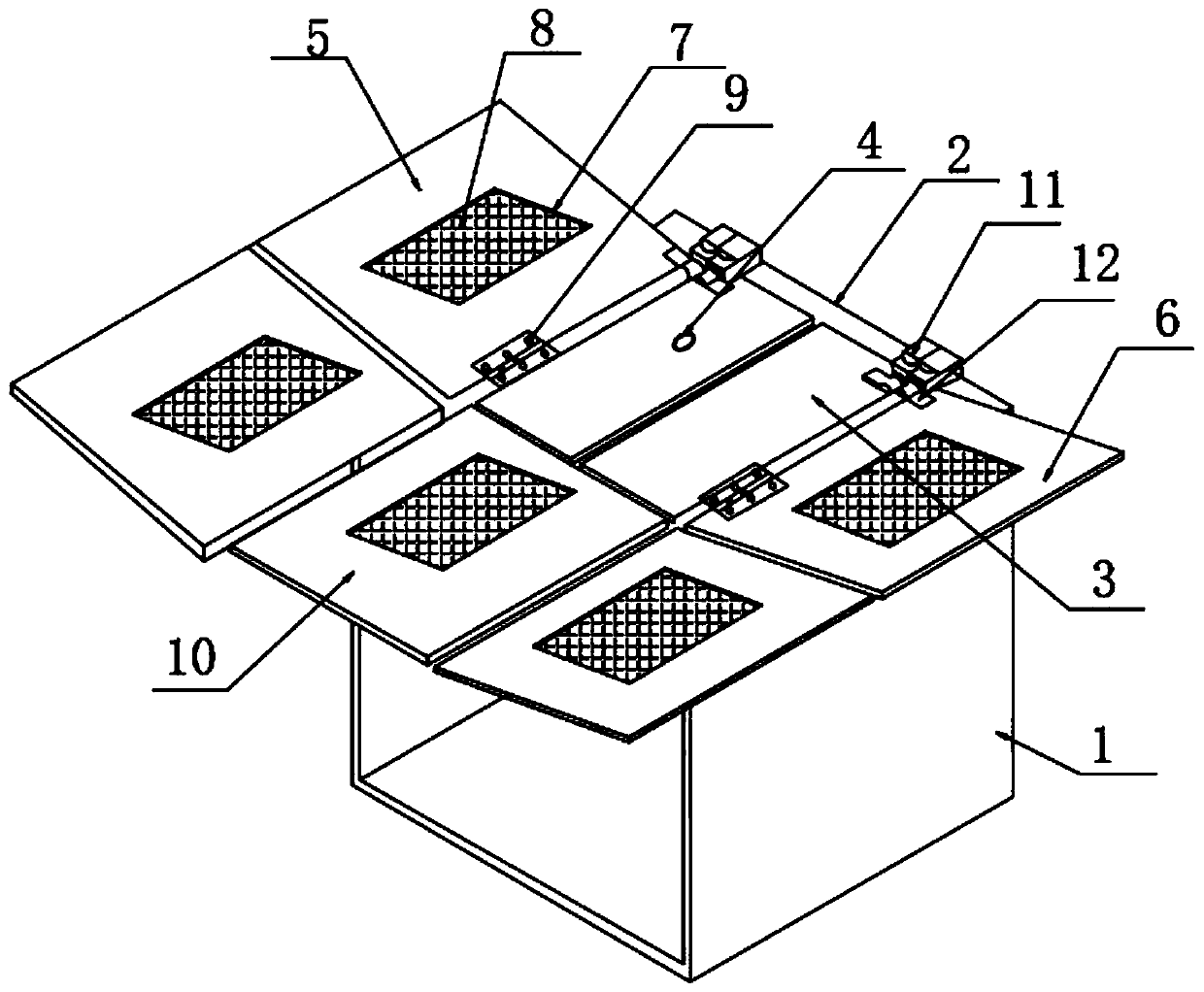

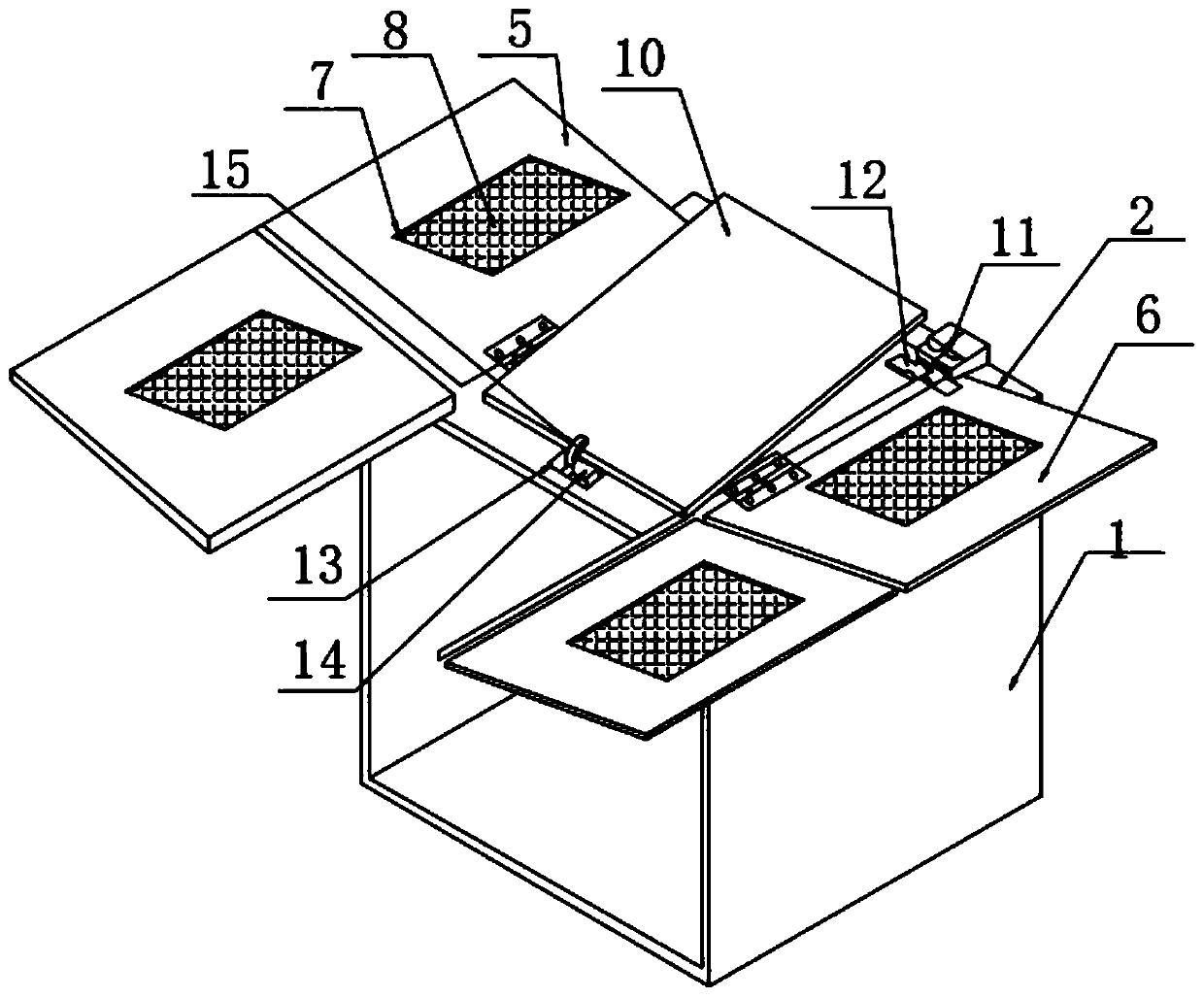

Conveying device for plug transplantation

ActiveCN101792064AIncrease the effective use areaIncrease profitCultivating equipmentsConveyor partsWheel driveSprocket

The invention relates to a conveying device for plug transplantation, which comprises stationary rails, two movable rails and a mobile car device, wherein the stationary rail is respectively erected at the two sides of a whole seedling bed in a greenhouse, and the two movable rails bestride the two stationary rails; the movable rail consists of two sprocket wheel driving devices, and the same sides of the two movable rails are respectively fixed on a pair of movable rail moving devices; the movable rail moving devices are erected on the stationary rails and can move along the stationary rails, and the mobile car device is arranged on sprocket wheels of the two movable rails; the lower part of the mobile car device is connected with a pneumatic lifting device, and the output end of the pneumatic lifting device is connected with a pneumatic gripping device; a pneumatic protecting device is arranged below the mobile car device, and at least one of a movable rail movement detecting deviceand a mobile car detecting device is assembled; and sensors for detecting and positioning are assembled on the pneumatic lifting device, the pneumatic gripping device and the pneumatic protecting device. The invention aims to reduce the labor intensity of workers, reduce the number of the workers, improve the utilization rate of greenhouse space, and increase the number of plugs in the existing greenhouse area to increase yield.

Owner:BEIJING KINGPENG INT HI TECH CORP

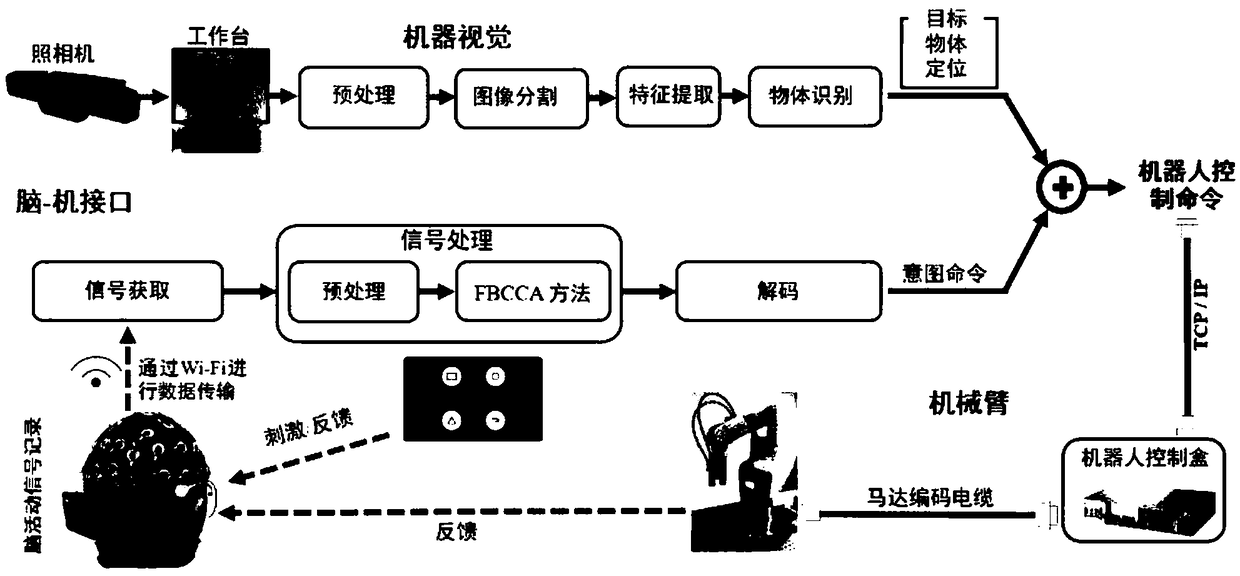

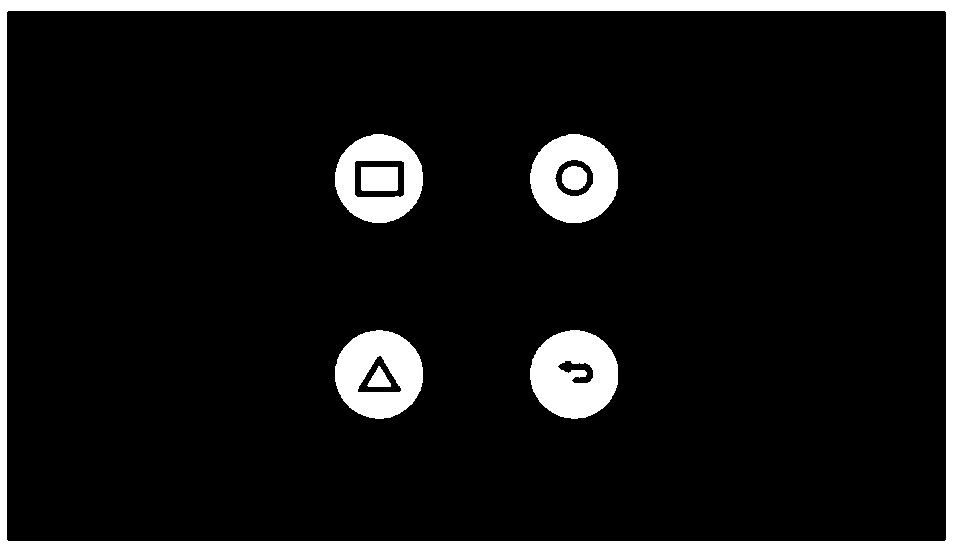

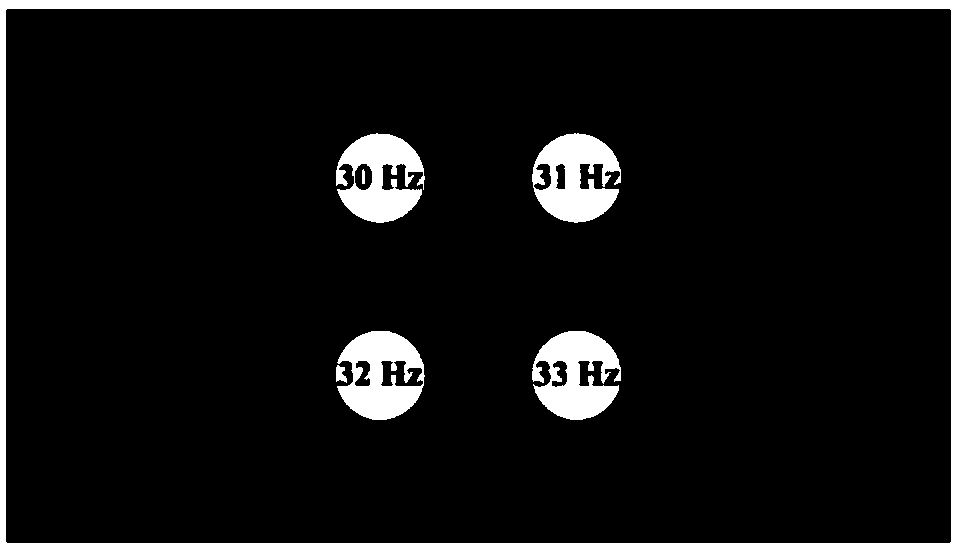

Advanced mechanical arm control system based on BCI and implementation method

InactiveCN109366508APrecise Control FunctionHigh stimulation frequencyInput/output for user-computer interactionProgramme-controlled manipulatorVisual evoked potentialsBrain computer interfacing

The invention relates to an advanced mechanical arm control system based on BCI and an implementation method thereof. The system comprises a machine vision subsystem, a brain-computer interface subsystem and a mechanical arm subsystem; the brain-computer interface subsystem and the machine vision subsystem are connected to the mechanical arm subsystem through a TCP / IP for communication, and the machine vision subsystem recognizes and positions coordinates of a target object in a photographing mode; and the brain-computer interface subsystem is used for acquiring scalp electroencephalogram signals generated by steady-state visual evoked potentials and performing real-time analysis and feature extraction on the scalp electroencephalogram signals, the control intention of a person is online decoded and a computer-recognizable control command is generated, and the machine arm subsystem operates according to the control command. According to the system, the design is reasonable, the controlintention of the person can be decoded online and the computer-recognizable control command is generated to control the mechanical arm to operate, the accurate multi-objective control function is realized, and the system has the characteristics of being safe, efficient and reliable.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

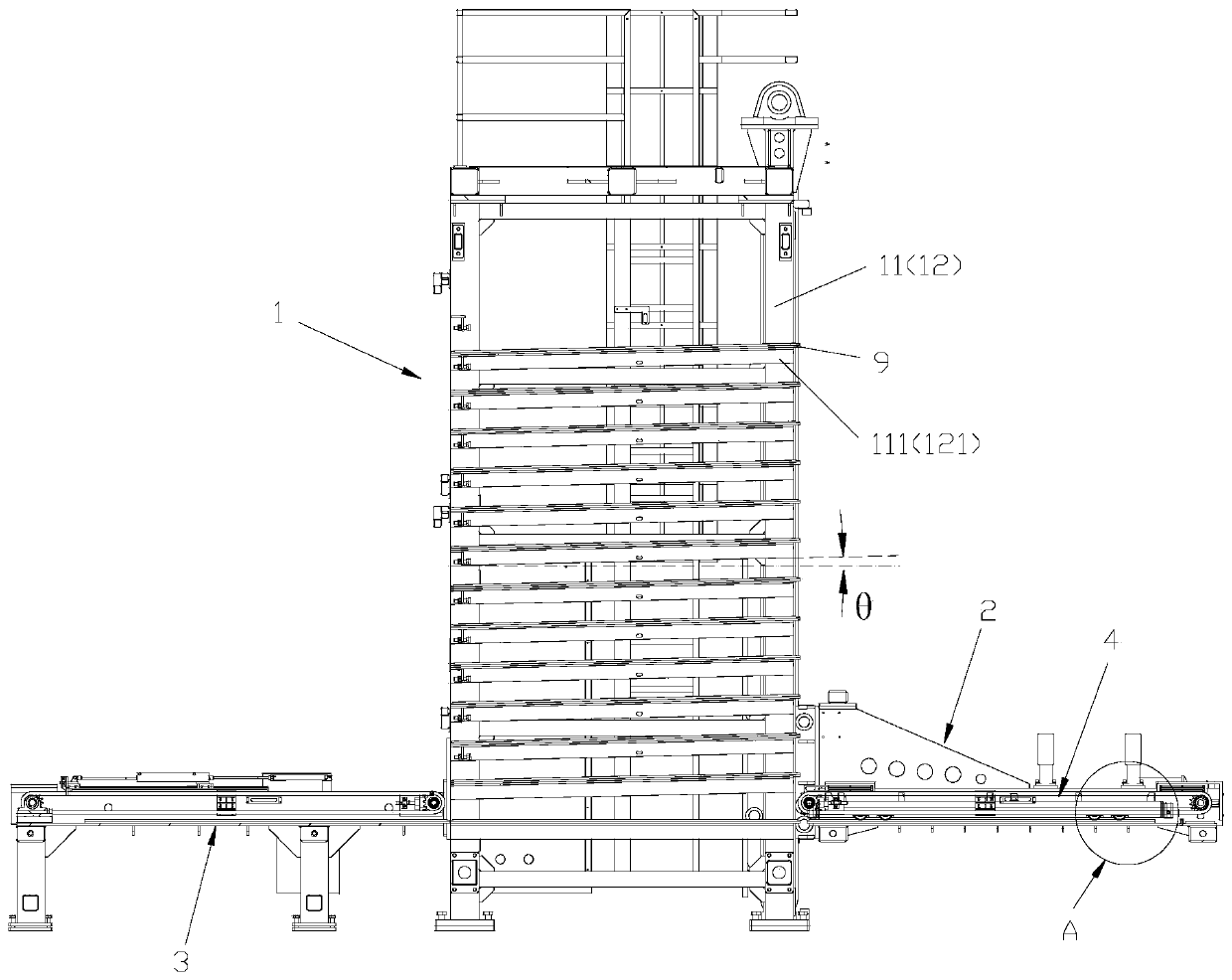

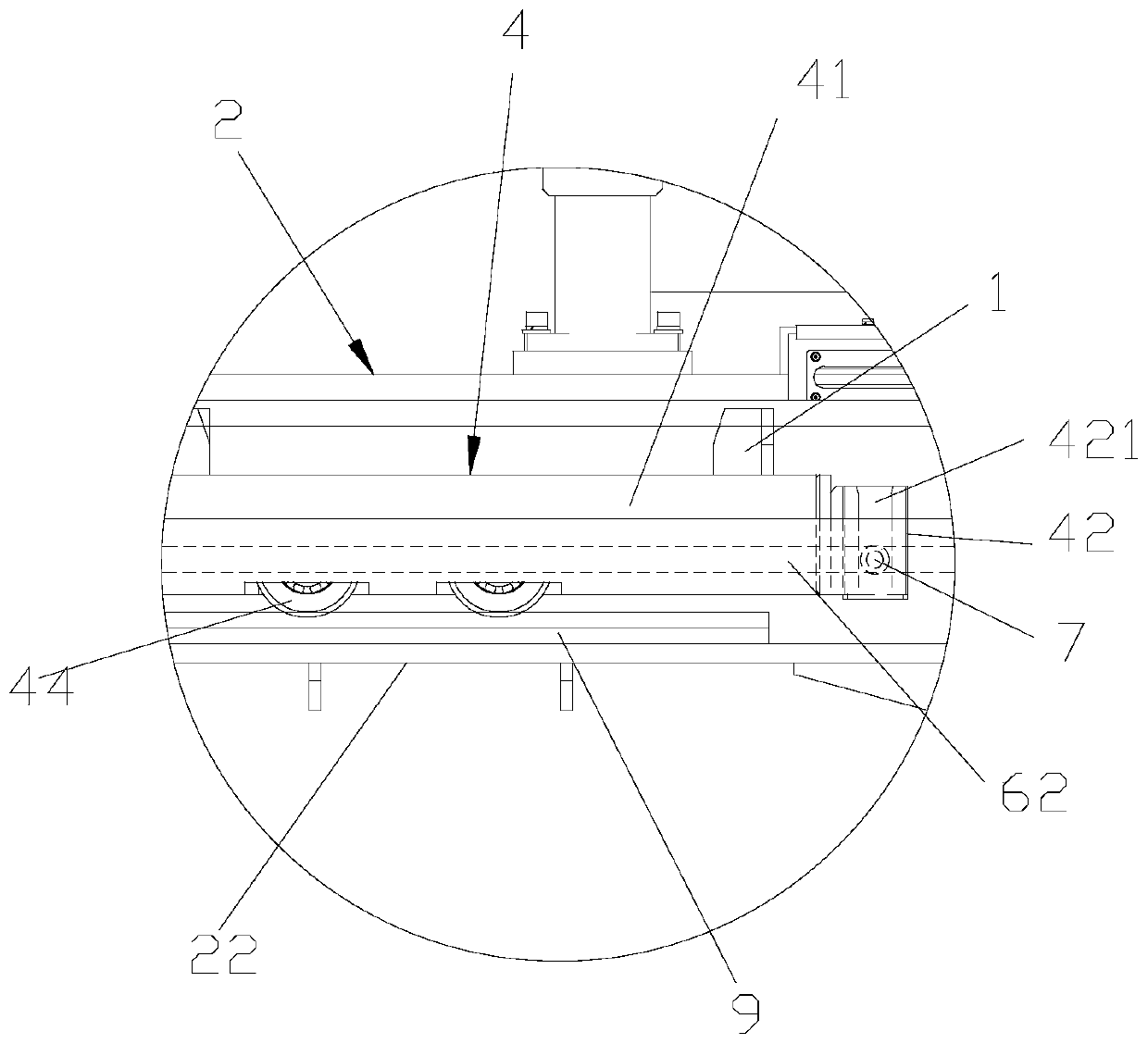

Lifting goods shelf used for logistics warehousing

InactiveCN107720073AAchieve liftingAchieve fixationStorage devicesLogistics managementArchitectural engineering

Owner:NANLING ZHENHUI GREEN AGRI PROD PRODN & MARKETING FARMER PROFESSIONAL COOP

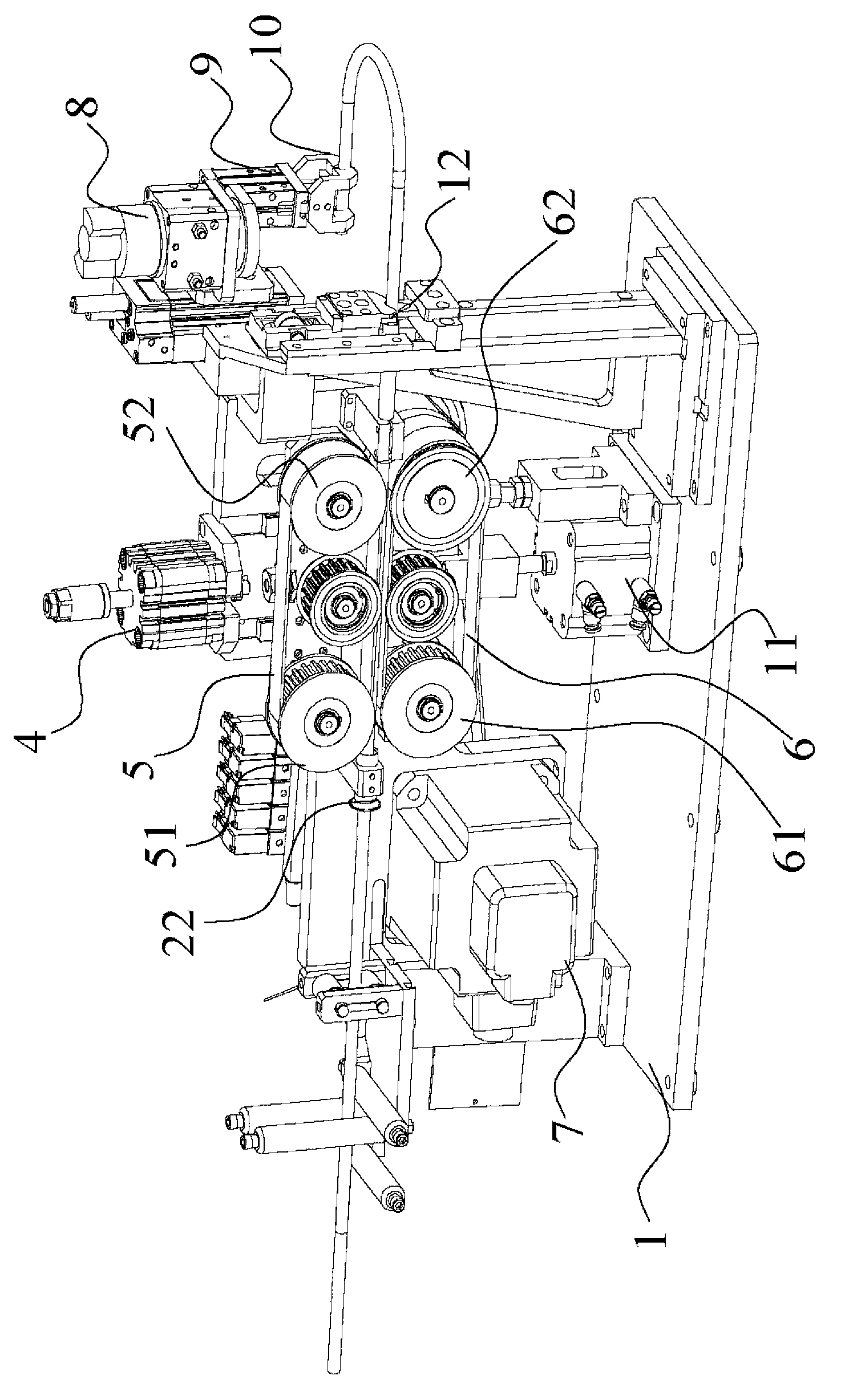

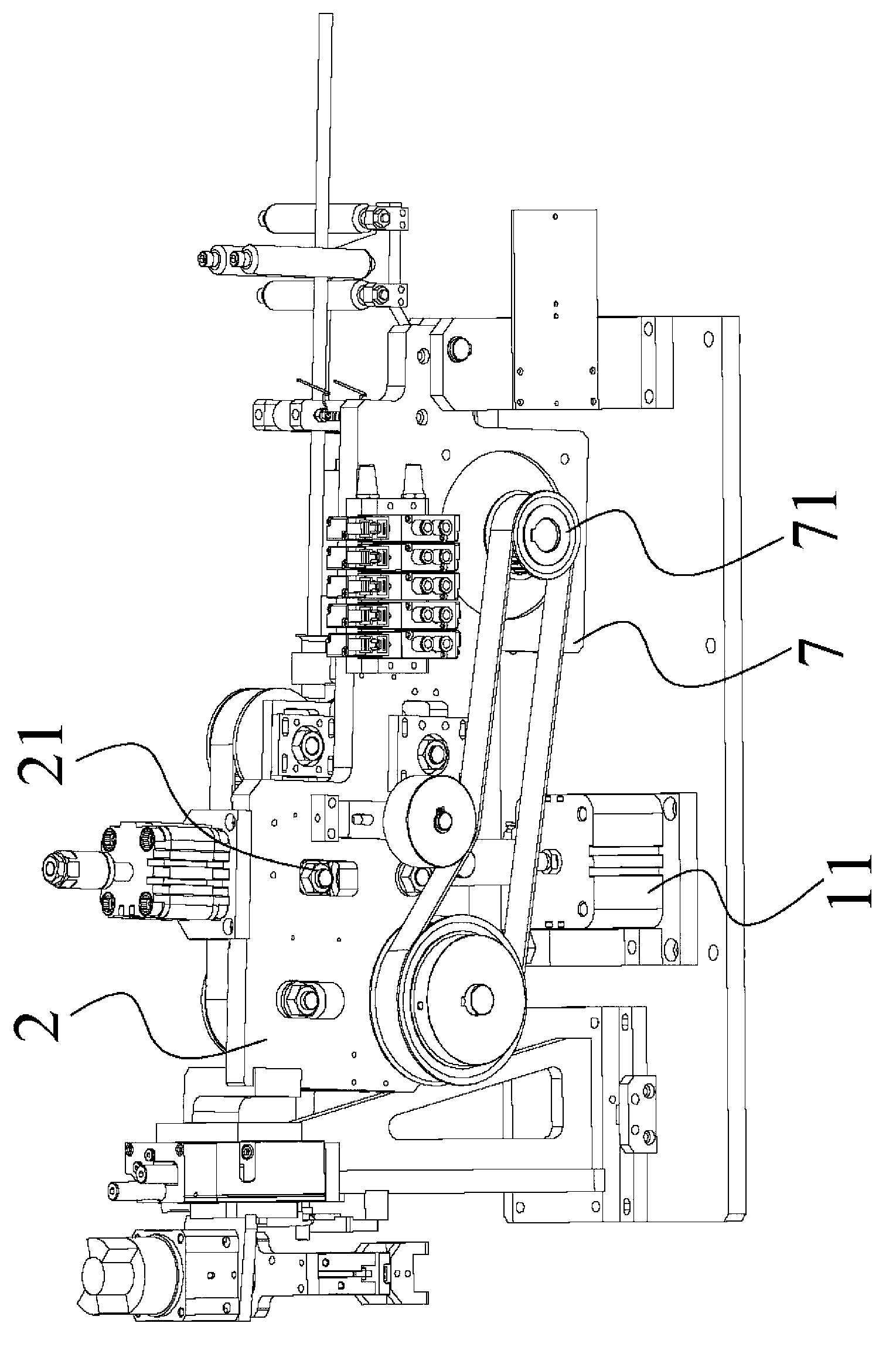

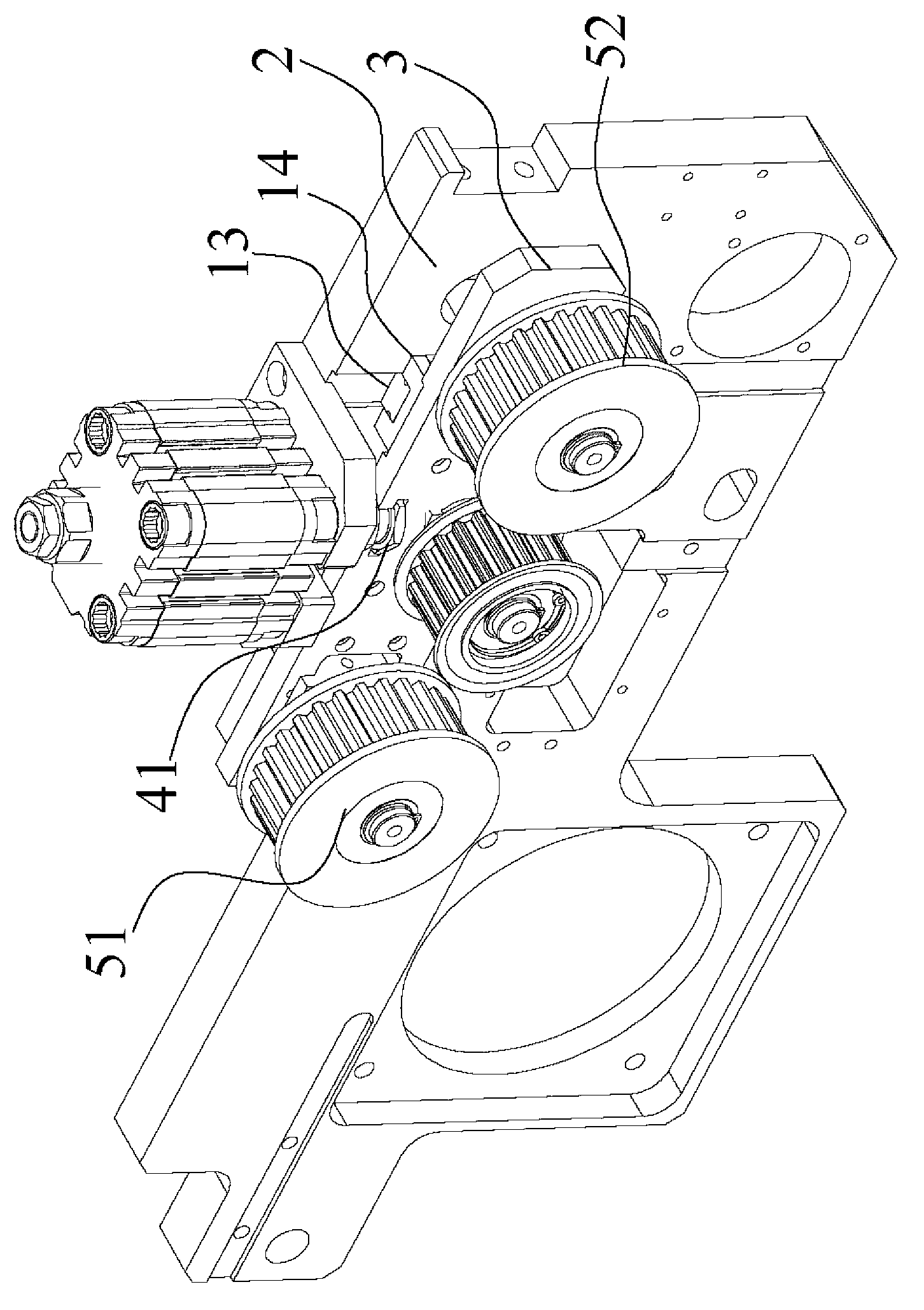

Cable feeding mechanism for three-core cable automatic terminal pressing machine

ActiveCN103078234AAchieve placementFully automatedLine/current collector detailsVertical planeEngineering

The invention discloses a cable feeding mechanism for a three-core cable automatic terminal pressing machine. The cable feeding mechanism is characterized in that a moving plate is positioned on a machine frame, the moving plate can do micro-movement in a vertical plane, the moving plate is provided with a connecting plate, the connecting plate can move opposite to the moving plate, the movement of the connecting plate is controlled by an upper air cylinder, the moving plate is fixedly provided with downward pressing type synchronous pulleys, upward pressing type synchronous pulleys on the connecting plate are driven by the upper air cylinder to move downwards and press the three core cables, the conveying lengths of the three core cables are simultaneously controlled through the driving of a servo motor, a double-end clamping jaw is arranged at the lower end of a rotary air cylinder and is used for grabbing and respectively placing the two ends of the three core cables into two carriers in one procedure, and the three core cables are cut off by a cutter and through the action of a pull-down air cylinder pivoted on the moving plate. The cable feeding mechanism has the advantages that the completion of cable conveying, cable accurate cutting and placing of the cable on one station is ensured; and the cut cables can be placed on the double-end carriers, so the full automation is practically realized, and the equipment of the integral machine of the three-core cable automatic terminal pressing machine is simplified.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

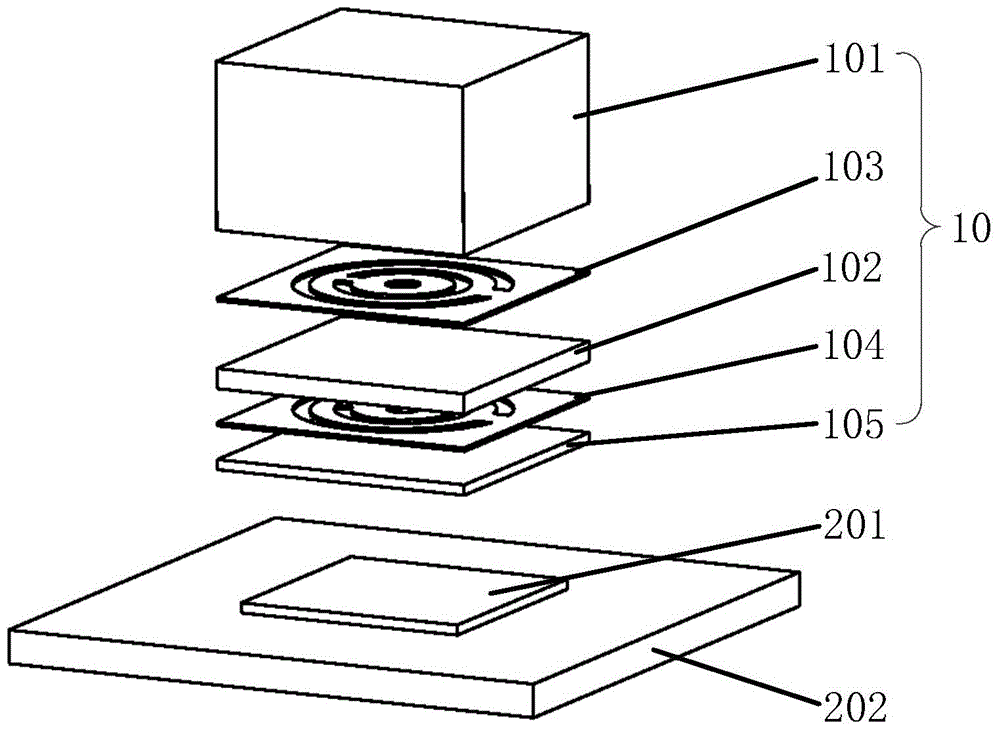

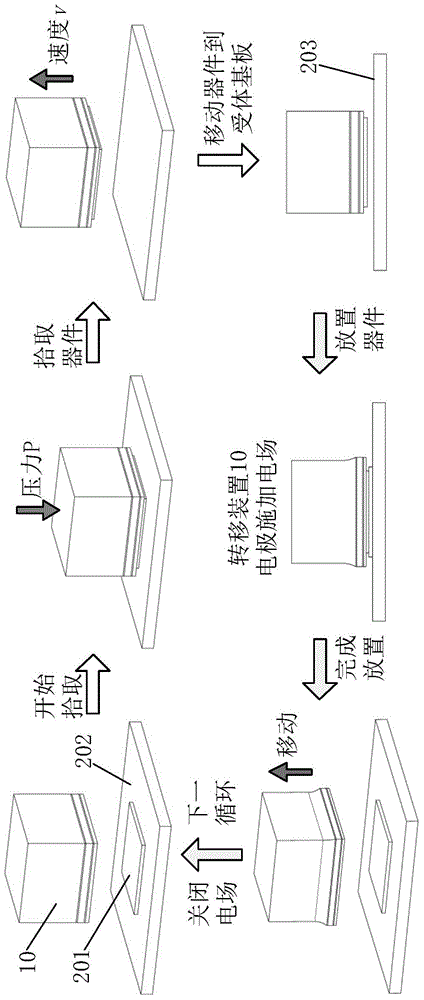

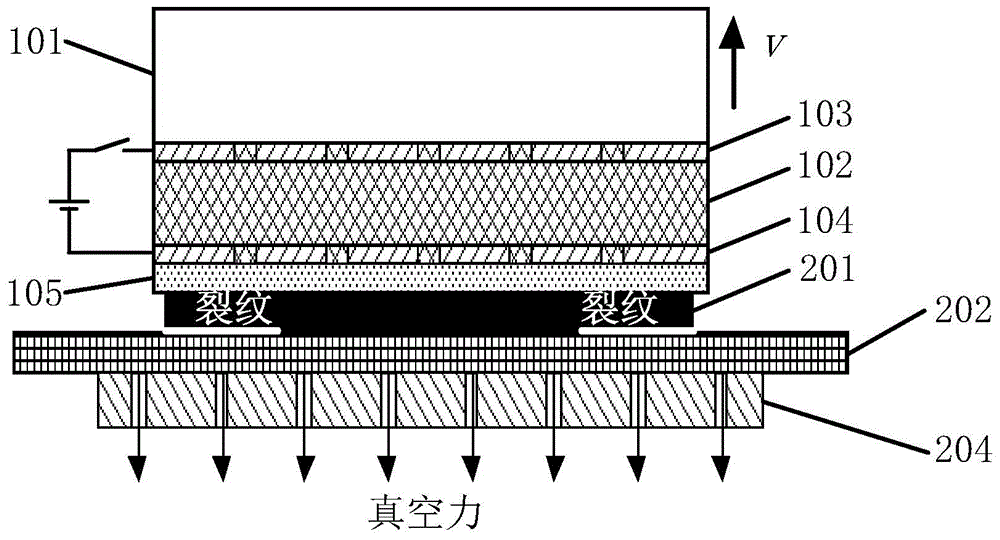

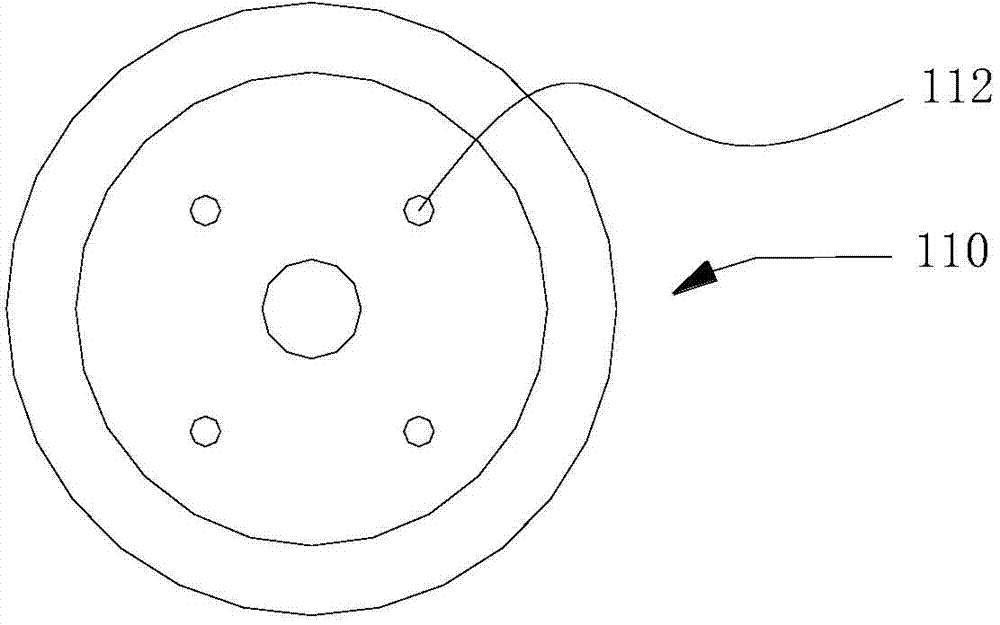

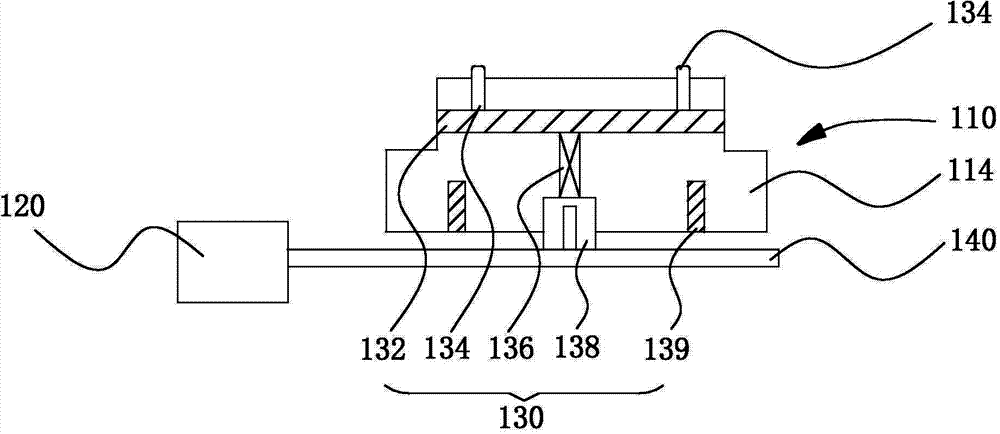

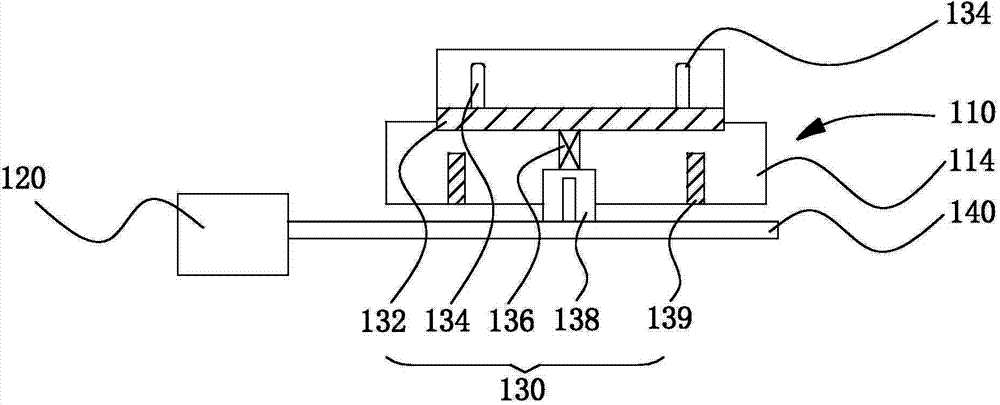

Device and method for ultrathin and flexible electronic device transfer and application of device

ActiveCN104538344APick and placeEasy to useSemiconductor/solid-state device manufacturingConveyor partsFlexible electronicsElectric field

The invention discloses a device for electronic device transfer. The device comprises an upper electrode layer, a lower electrode layer, a viscous layer and an electrical active layer, wherein the upper electrode layer and the lower electrode layer are arranged oppositely in a spaced mode, an electric field can be generated between the upper electrode layer and the lower electrode layer after electrification, the viscous layer is fixedly connected to the lower surface of the lower electrode layer, the electrical active layer is arranged between the upper electrode layer and the lower electrode layer and can be squeezed to deform longitudinally or horizontally under the action of the electric field generated between the two electrode layers after electrification, the deformation of the electrical active layer drives the electrode layers and the viscous layer to deform so that shearing force and / or concave-convex ejecting force can be generated, and then the electrode layers and the viscous layer are debonded to be placed on a receptor substrate. The invention further discloses a method for electronic device transfer by means of the device and the application of the device. The method and device can be used for active placing of electronic devices. The device is simple in structure, quick and reliable in use, easy to control and the like. The method and device can be used for transfer of ordinary ultrathin and flexible electronic devices in various specifications as well as transfer of large-area array micro-electronic devices / structures.

Owner:HUAZHONG UNIV OF SCI & TECH

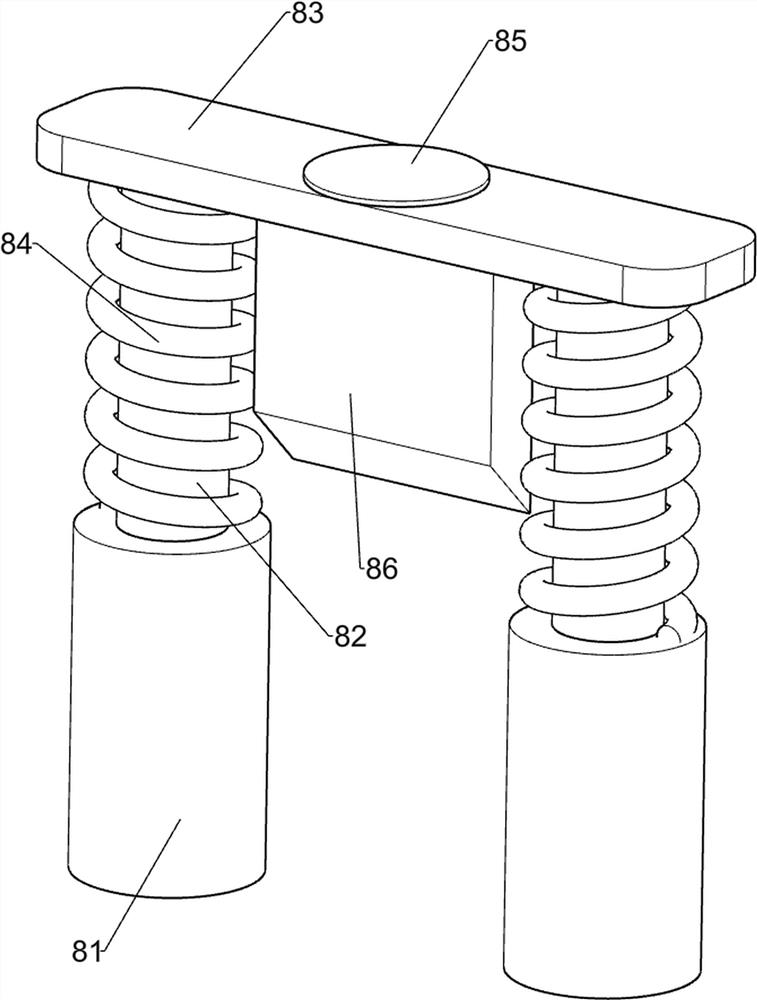

Baseplate conveying device

ActiveCN104743361AAchieve placementTransfer Tick SavingsCharge manipulationConveyor partsOperational costsElectromagnetic devices

The invention discloses a baseplate conveying device. The baseplate conveying device comprises a vacuum sucker, a vacuum device and a vacuum breaker. An accommodating cavity is formed in the vacuum sucker; a through hole is formed in the top of the vacuum sucker; the vacuum device is communicated with the accommodating cavity of the vacuum sucker through a vacuum pipe, and is formed to a vacuum channel with the through hole; the vacuum breaker is accommodated and mounted in the accommodating cavity, and comprises a magnetic moving plate, an elastic device and an electromagnetic device; a thimble fitting the through hole is arranged at one side, aligned to the top of the vacuum sucker, of the magnetic moving plate; the electromagnetic device is mounted at the bottom of the vacuum sucker; and the magnetic moving plate is connected with the electromagnetic device through the elastic device. In the baseplate conveying device, when a baseplate is placed, the conveying beat of a mechanical arm and the vacuum release are synchronously performed without needing communication, so that the time is saved, the conveying beat of the mechanical arm is increased, and the production efficiency is improved. In addition, the vacuum is released without needing air blowing, so that the dry compressed air is saved, and the operational cost is reduced.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

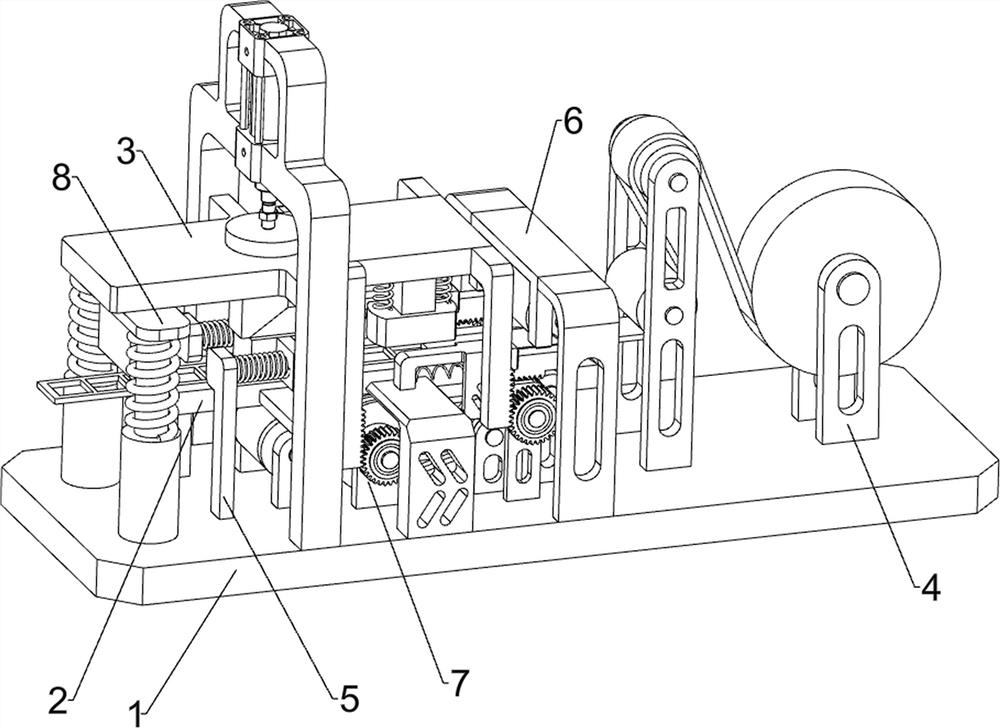

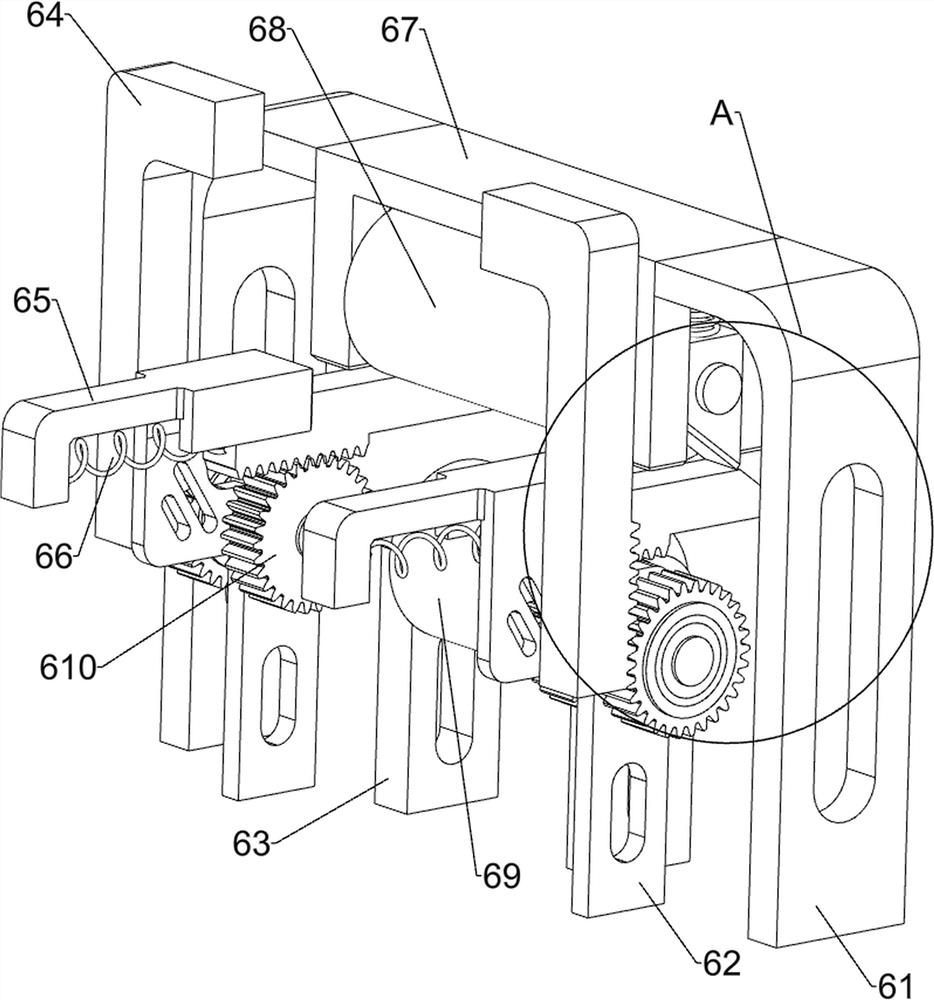

Printing and sealing device

ActiveCN106985549AAchieve grippingAchieve placementTypewritersStampingPulp and paper industryInstrumentation

The invention provides a printing and sealing device. The device comprises a bracket module, a seal frame, a console, a printer and a controller; the seal frame is provided with a seal for sealing; the bracket module is provided with a clamping structure for clamping the seal; the clamping structure can be controlled by the controller to move on the bracket module in any direction; the clamping structure is provided with a paper position detecting instrument; the top of the console is divided into a sealing area and a paper guide area; the paper guide area is positioned in a paper outlet of the printer; the controller and the paper position detecting instrument are connected wirelessly or through a signal wire; position signals of papers acquired by the paper position detecting instrument are input in the controller; the signals are initial data of positions of the papers; and the controller analyzes and compares the data of the appointed seal position and the initial data, and controls the clamping structure to move to the appointed position according to the compared and analyzed results. The printing and sealing device has such advantages as precise positioning and conveying, capability of quickly moving to an appointed area, and convenience to operate.

Owner:胡金钱

Glass transfer clamping equipment

ActiveCN105417947AImprove fixed timeImprove transmission efficiencyGlass transportation apparatusFixation timeBiochemical engineering

The invention relates to the field of glass processing equipment and in particular relates to glass transfer clamping equipment. The glass transfer clamping equipment comprises a support rod, wherein a connecting rod connected with a transfer mechanism is arranged at one end of the support rod and a clamping mechanism is arranged at the other end of the support rod; the clamping mechanism comprises two parallel clamping plates; suckers are arranged on opposite surfaces of the two clamping plates; the clamping plates are connected with the end of the support rod in a sliding manner; a spring is arranged between the two clamping plates; a compressing plate is also arranged on the support rod; threaded holes are formed in the compressing plate; screws are arranged on the clamping plates and are in threaded connection with the compressing plate by passing through the threaded holes. The glass transfer clamping equipment has the beneficial effects that through relative movement of the screws and the compressing plate, the screws can drive the clamping plates to move to achieve clamping and loosening of glass; the glass transfer clamping equipment is convenient to operate, is fast and firm in clamping and has the effect of greatly increasing the glass fixation time, thus improving the glass transfer efficiency.

Owner:滁州众石玻璃科技有限公司

Pipeline embedding device for water conservancy projects

InactiveCN110937518AAchieve placementEasy to placePipe laying and repairBase supporting structuresElectric machineryHydraulic engineering

The invention discloses a pipeline embedding device for water conservancy projects, and relates to the technical field of pipeline embedding devices. A winch is fixedly installed at the bottom of a threaded seat, a support rod is fixedly connected between two groups of connecting steel blocks, the bottom ends of the two groups of connecting steel blocks are fixedly equipped with clamping devices,the left end of a second lead screw penetrates through a fixing seat to be fixedly connected to a second motor, an inner cavity of the fixing seat is provided with a guide seat connected to the outerwall of the second lead screw in a sleeving manner, an object containing plate is fixedly arranged between fixing frames, the top of the object containing plate is evenly and fixedly provided with limiting rings, two groups of guide plates are fixedly arranged on the right side of the top of a base, protection plates are fixedly assembled on the side walls between the two groups of guide plates, and a discharging channel is arranged between the two groups of protection plates. Automatic clamping and laying of pipelines are realized, pipeline protection can be realized, the needs of continuouspipeline placing and laying are met, and the pipeline laying efficiency is improved.

Owner:宁夏中康建设集团有限公司

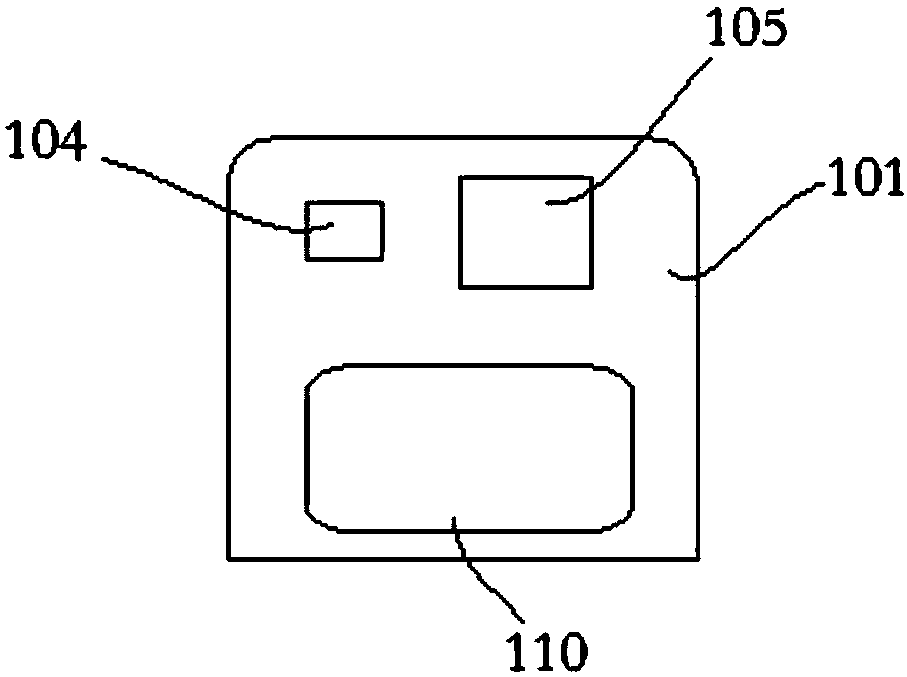

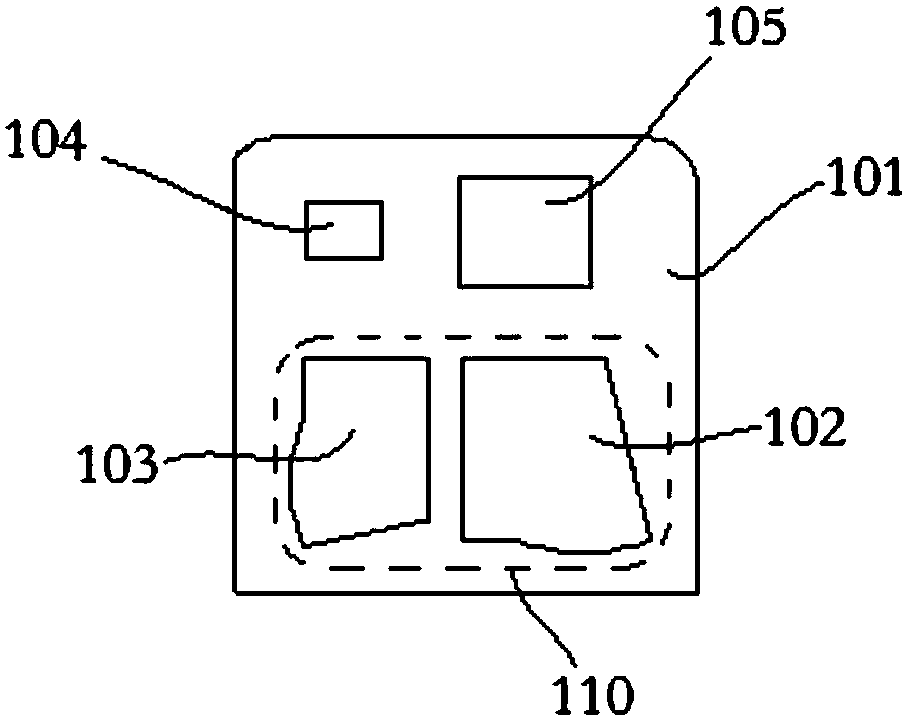

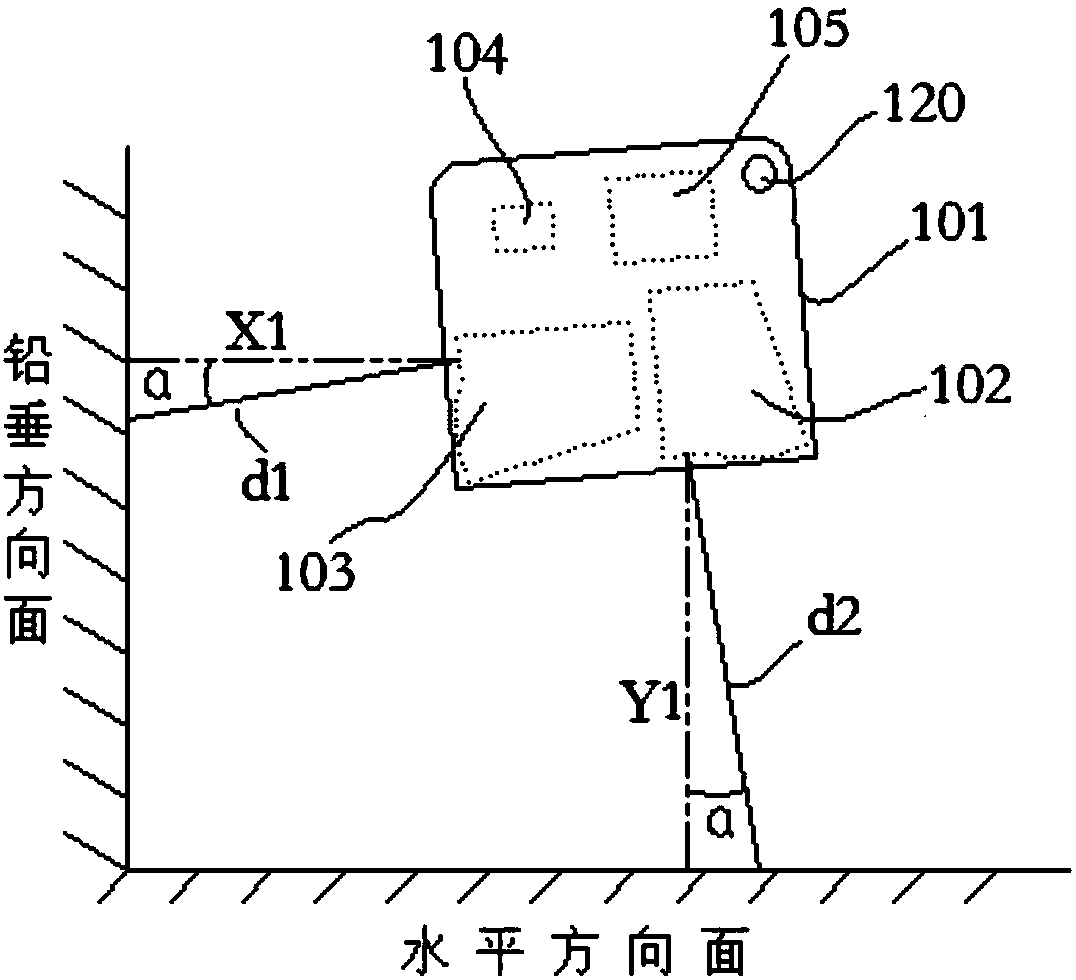

Laser positioning device

PendingCN108196263AAchieve placementImplement the layoutElectromagnetic wave reradiationIrradiationGravitation

The invention discloses a laser positioning device, which comprises a distance measuring unit, an acceleration sensing unit and a control unit. Wherein the distance measuring unit measures the distance between the actual irradiation point of the laser positioning device in the target space to the horizontal direction and the distance to the actual irradiation point on the vertical direction respectively; the acceleration sensing unit measures the current acceleration direction of the laser positioning device; the control unit calculates an angle deviation between the current acceleration direction and the gravity direction of the distance measuring unit in the current direction, and calculates the positioning coordinates of the laser positioning device in the target space by using the measured distance to actual irradiation point on the horizontal direction and the distance to actual irradiation point on the vertical direction. By obtaining the accuracy compensation of the distance from the horizontal direction surface and / or the vertical distance to the vertical direction surface, the invention realizes the quick and accurate positioning of the target object in the target space, and improves the operational reliability and precision of the device.

Owner:NORTHWEST INSTR SHANGHAI +1

Oily sludge gel particle profile control agent and preparation method thereof

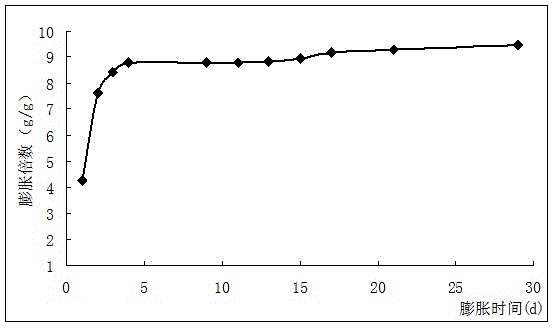

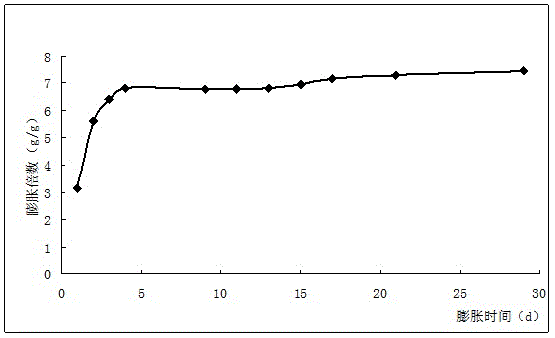

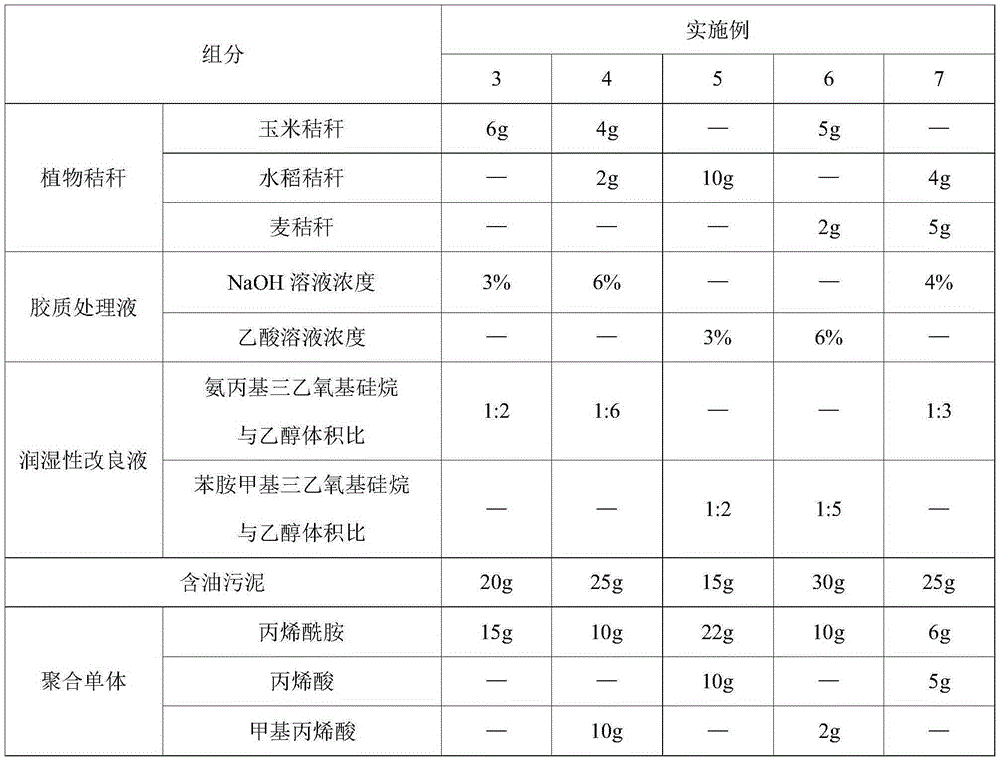

The invention relates to an oily sludge gel particle profile control agent and a preparation method thereof, and belongs to the technical field of profile control water plugging of oil fields. The oily sludge gel particle profile control agent is formed by mixing plant straw, oily sludge slurry, polymeric monomers, an initiating agent, a cross-linking agent and water. Specially treated plant straw is added to the oily sludge slurry to prepare an oily sludge profile control agent inner core wrapped with the plant straw, then chemosynthetic gel is filled with the inner core, and the plant straw strengthened gel particle profile control agent is obtained. The density and strength of the profile control agent are adjusted by adjusting the adding proportion of the plant straw, the density of the particle profile control agent is decreased, and meanwhile higher strength of the profile control agent can be guaranteed; water absorption can reach 4.8-9.5 times, the expanding time is 5-28 days, good expansion capacity and delayed expansion performance are achieved, and deep placement and effective plugging of an oil reservoir can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

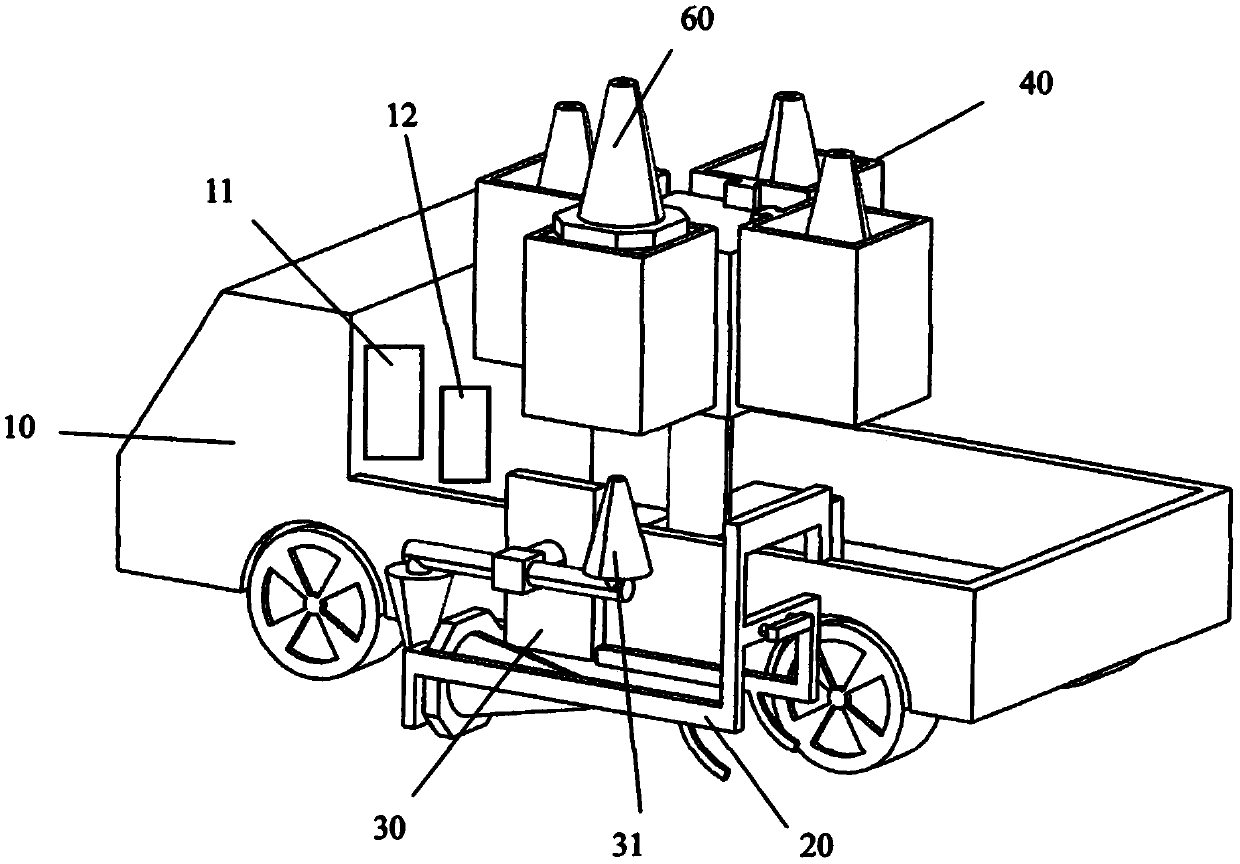

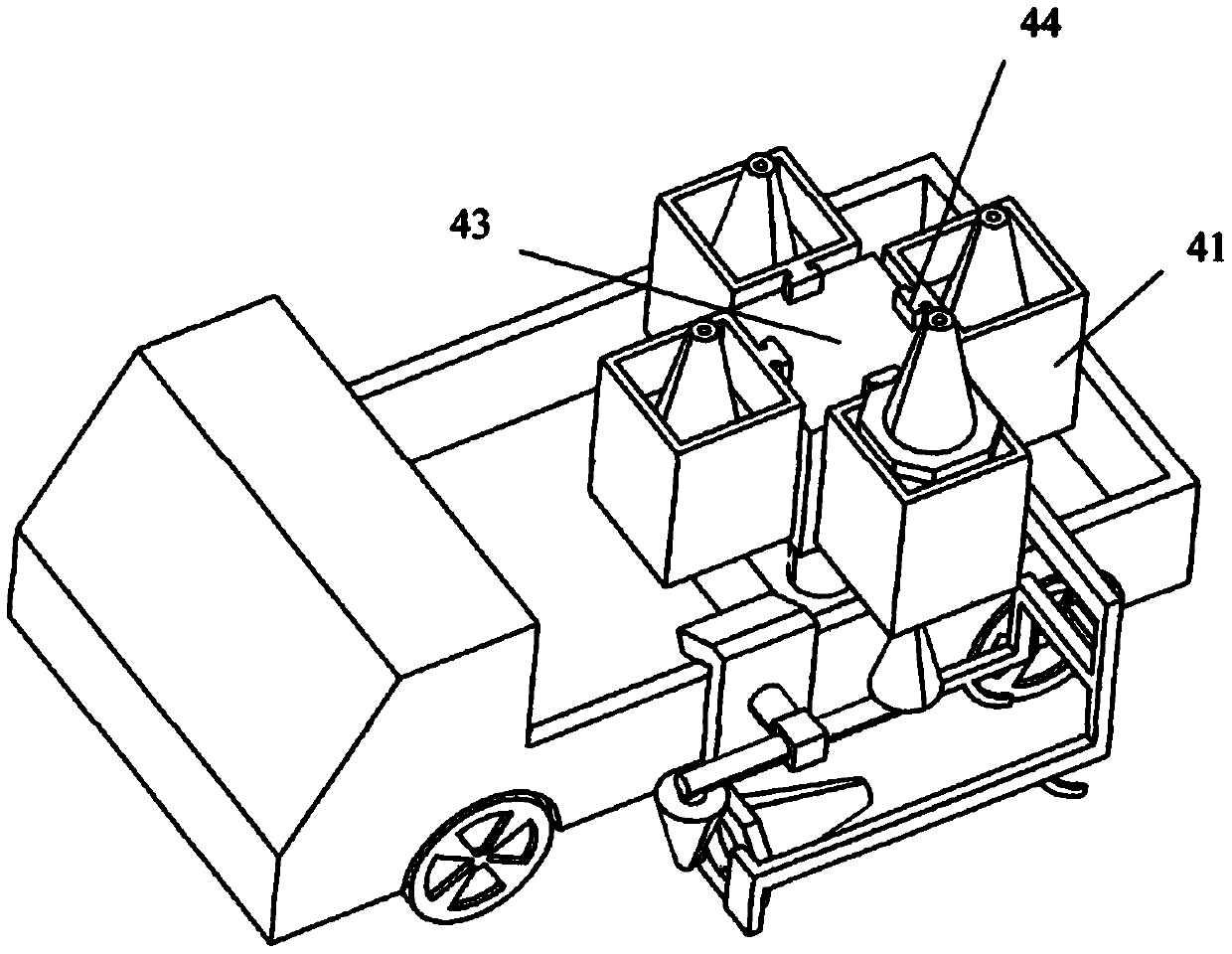

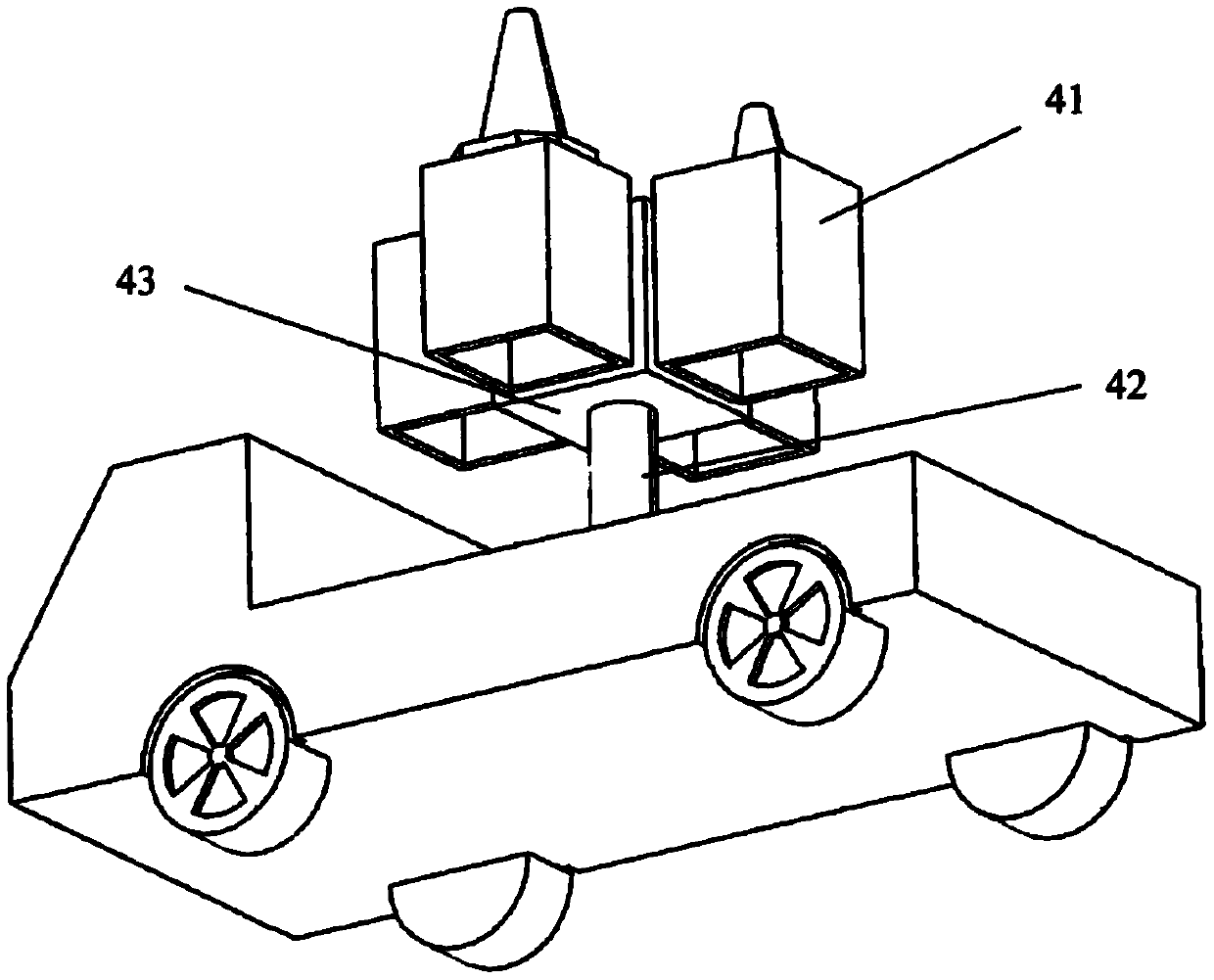

Traffic road cone automatic folding and unfolding vehicle and folding and unfolding method

ActiveCN111501612AAchieve placementAchieve mechanical propertiesTraffic signalsRoad signsStructural engineeringAutomotive engineering

The invention relates to a traffic road cone automatic folding and unfolding vehicle and a folding and unfolding method. The road cone storage device is used for stacking road cones, and the road cones can controllably and orderly fall one by one; the rotary collecting and releasing device is used for receiving the falling road cone at the upper part and transporting the falling road cone to the ground to be in a lying state, or is used for lifting the road cone lying on the ground to the upper part of the device; and the road cone swinging and pushing device is used for righting the road coneor pushing down the road cone. The problem that road cones are manually placed on an existing Chinese road is solved, and mechanical road cone placement is achieved. Mechanization of transportation hub operation is achieved, and convenience is brought to highway maintenance.

Owner:JINHUA VOCATIONAL TECH COLLEGE

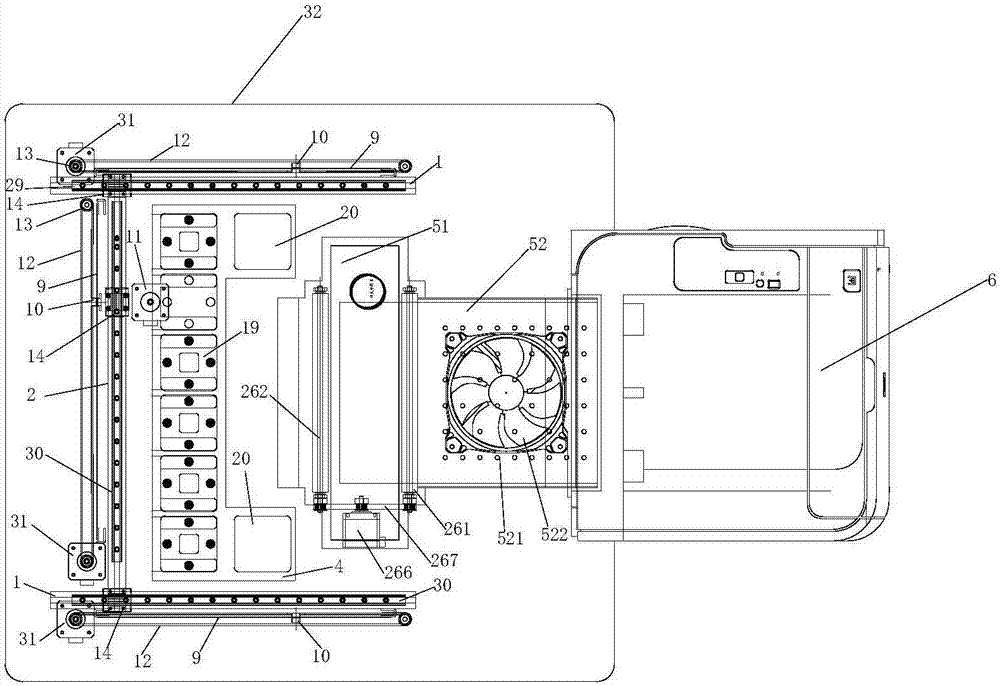

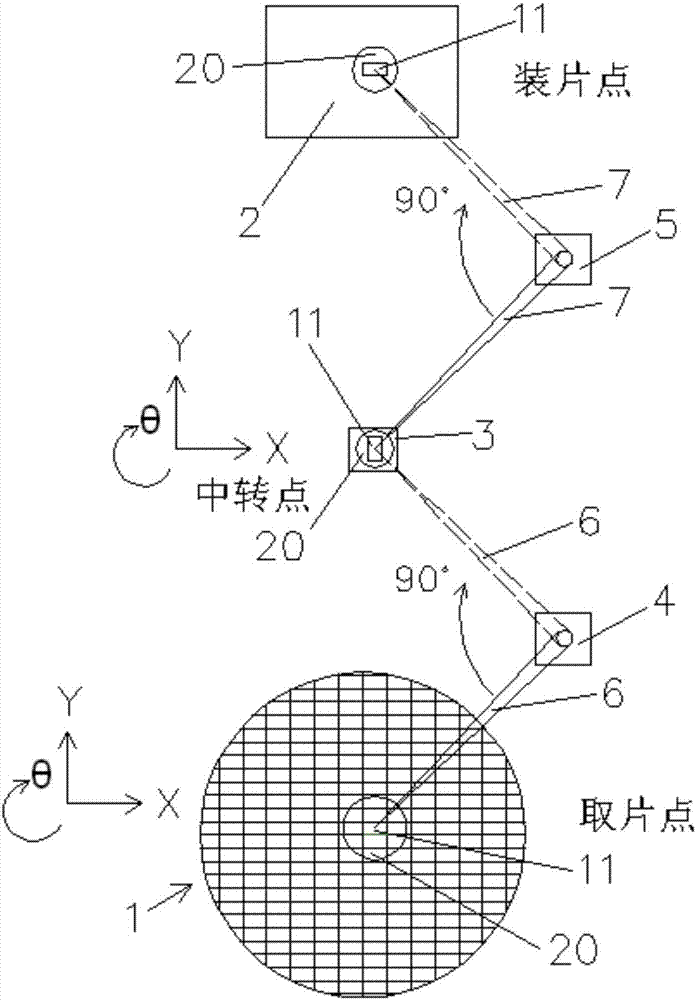

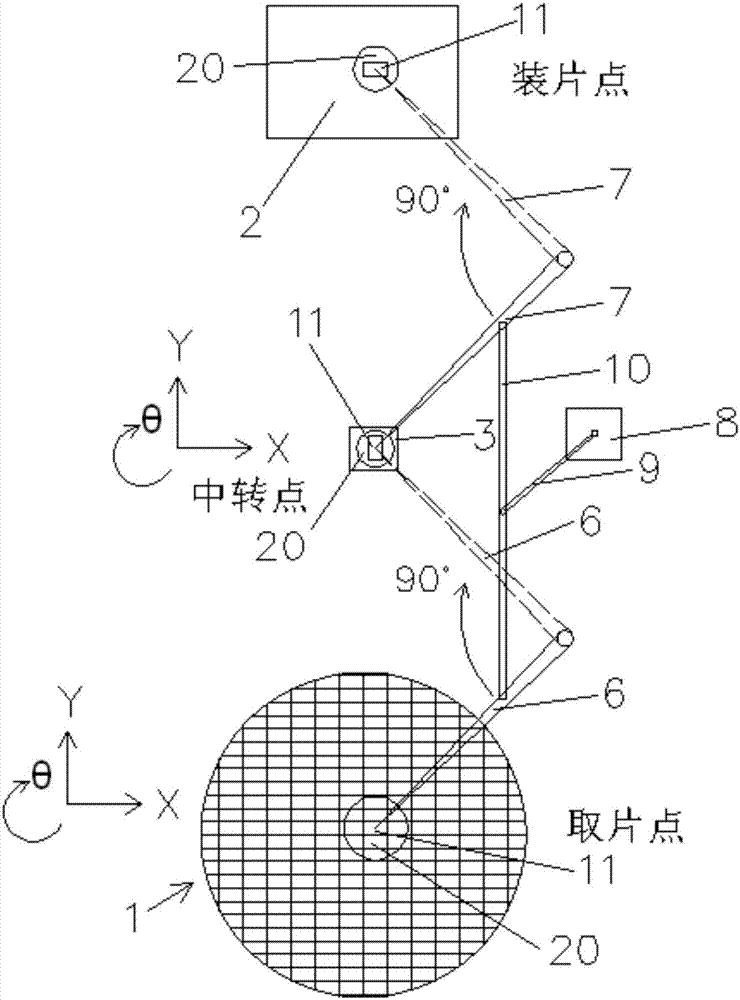

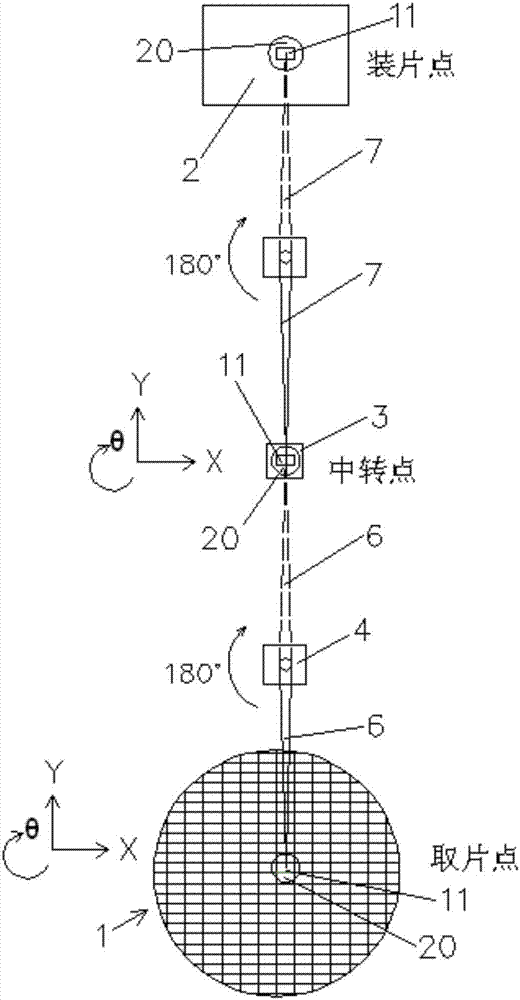

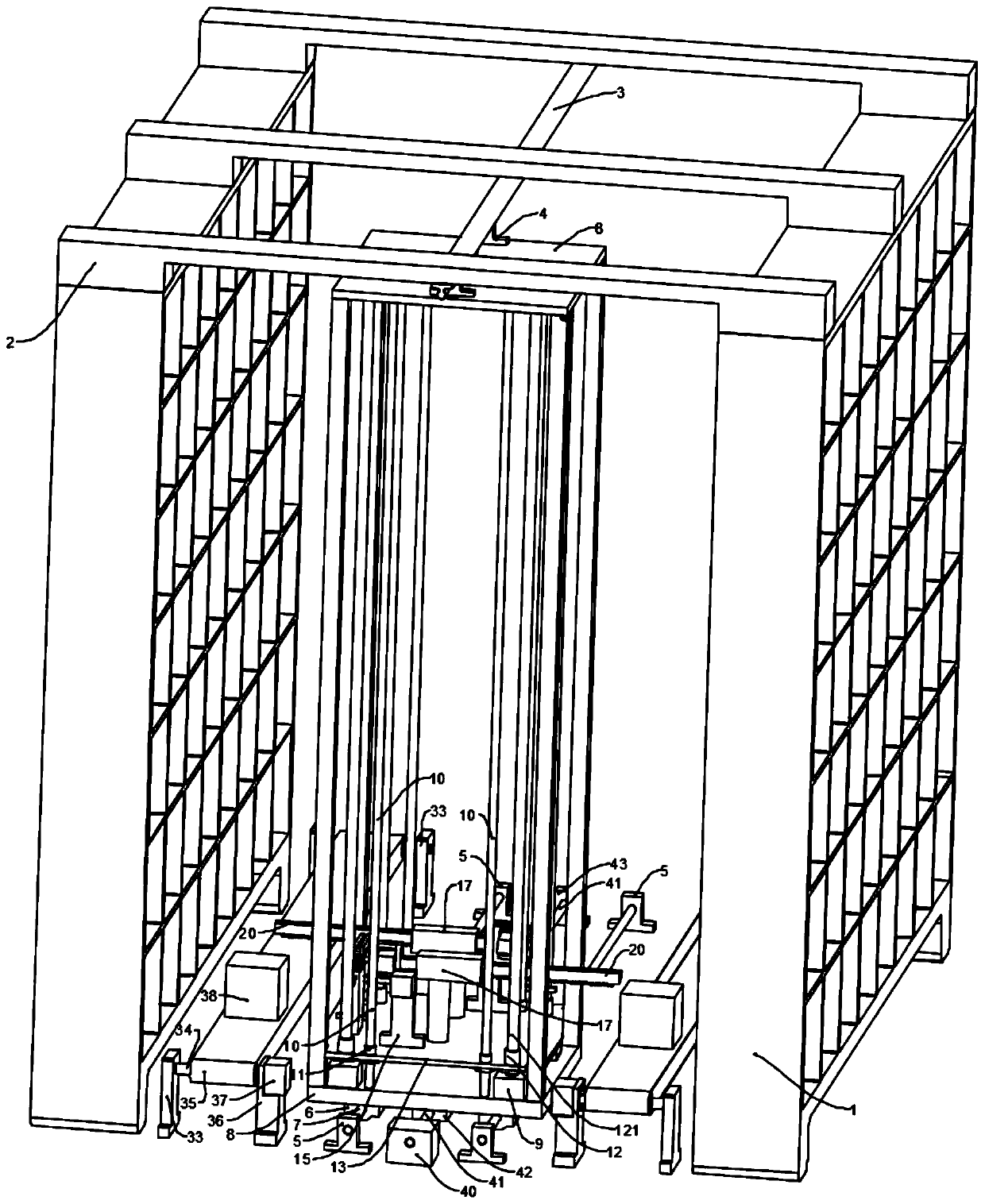

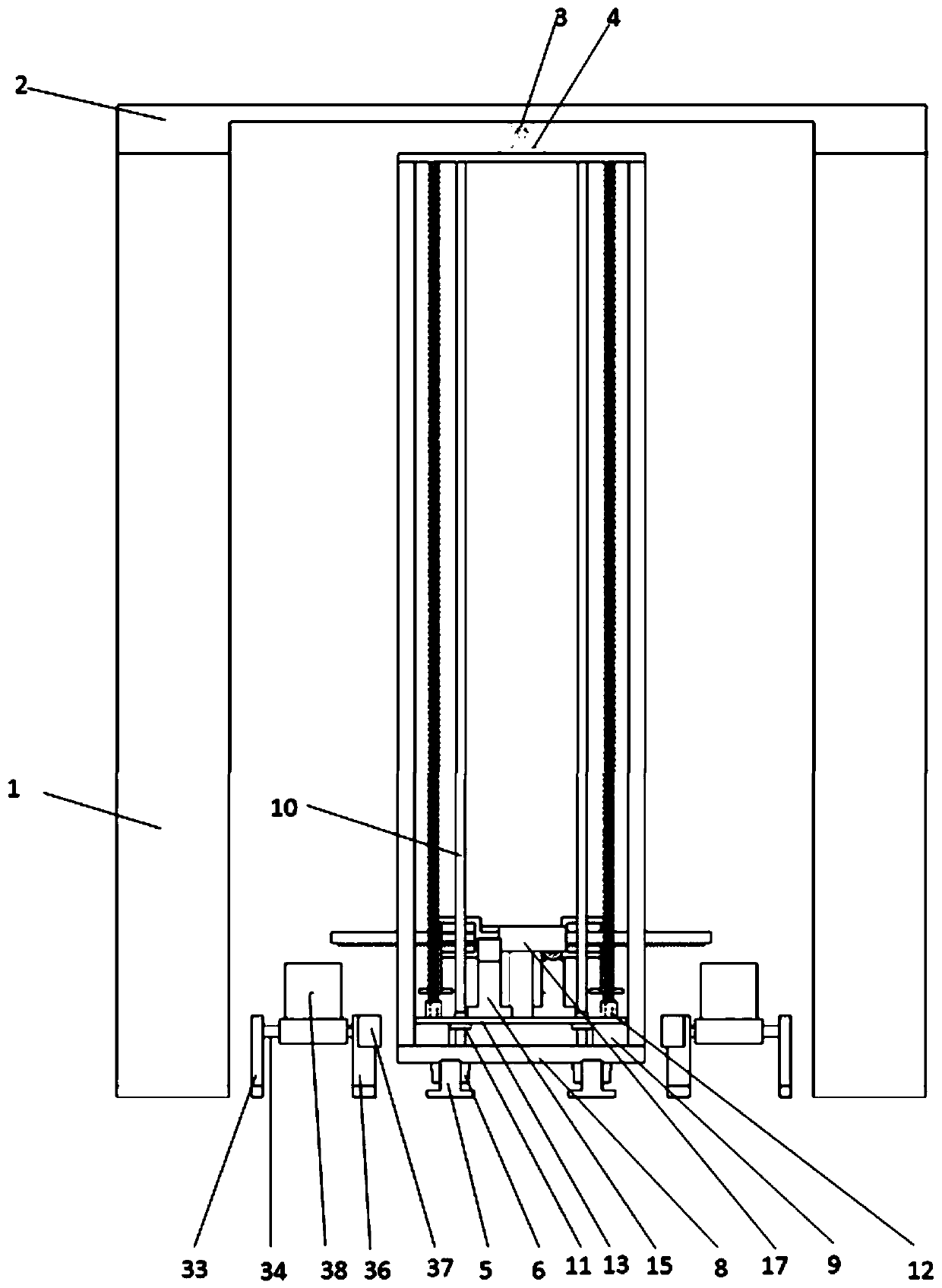

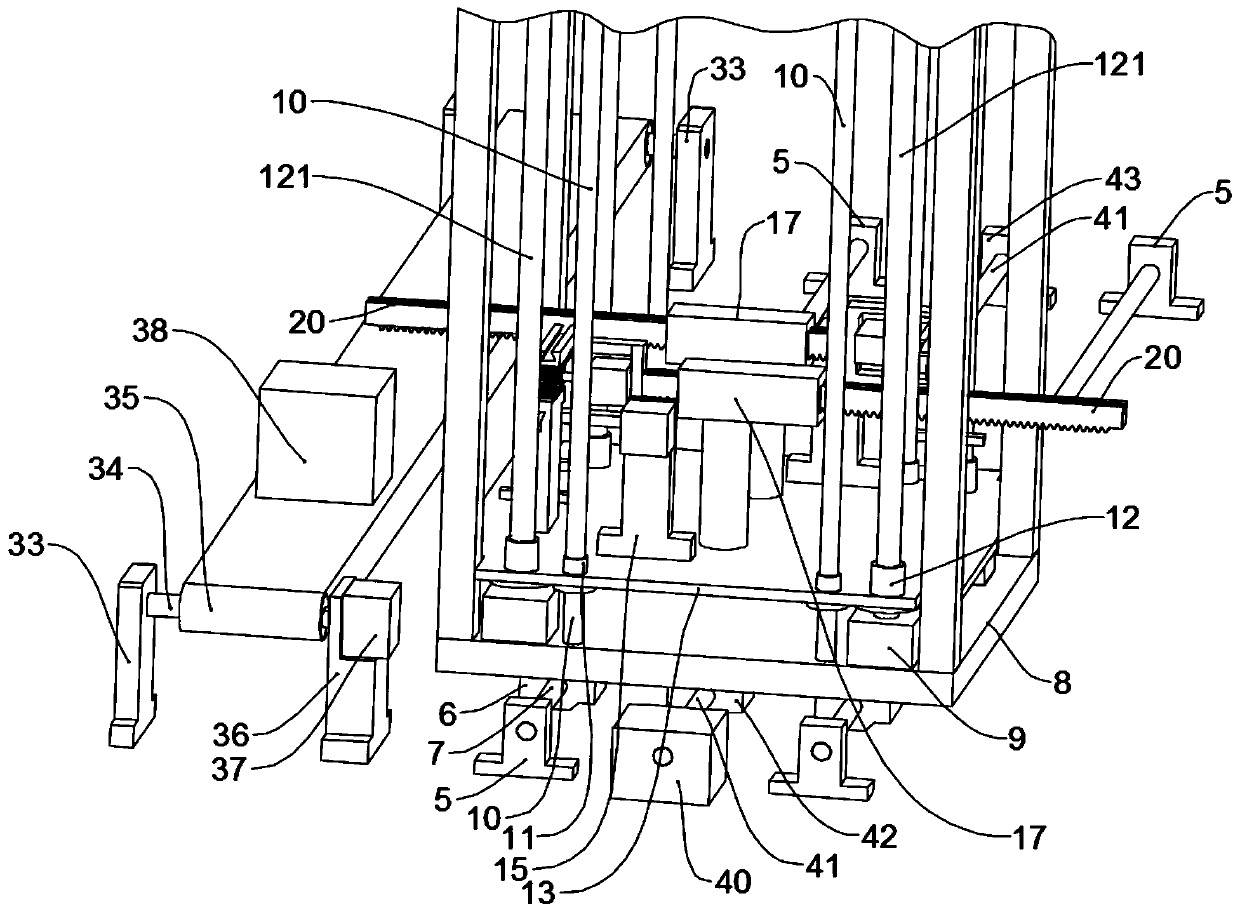

Relay type rapid chip taking and chip assembling device and chip assembling machine employing same

PendingCN107248501AShorten the lengthShort strokeSemiconductor/solid-state device manufacturingConveyor partsComputer hardwareWafer

The invention discloses a relay type rapid chip taking and chip assembling device and a chip assembling machine employing the same. A first rotation arm is used for taking out a chip on a wafer and placing the chip on a transit table after rotation, a second rotation arm is used for taking out the chip on the transit table and placing the chip on a substrate after rotation, a welding head is used for taking out the chip and placing the chip and is arranged at one end of the first rotation arm and one end of the second rotation arm, the welding head moves in a reciprocating way along a direction parallel to a rotation shaft of the first rotation arm or the second rotation arm, and a driving device is used for driving the first rotation arm and / or the second rotation arm to rotate. The relay type rapid chip taking and chip assembling device has the beneficial effects that with the arrangement of the chip transit table, chip taking and chip assembling of the rotation arms can be synchronously performed; and remote chip taking and chip assembly is required, compared with a traditional chip taking and chip assembling mode employing a single rotation arm, the relay type rapid chip taking and chip assembling device has the advantages that the efficiency is improved by 50-70%, and the chip assembling accuracy is higher.

Owner:SUZHOU ACCURACY ASSEMBLY AUTOMATION CO LTD

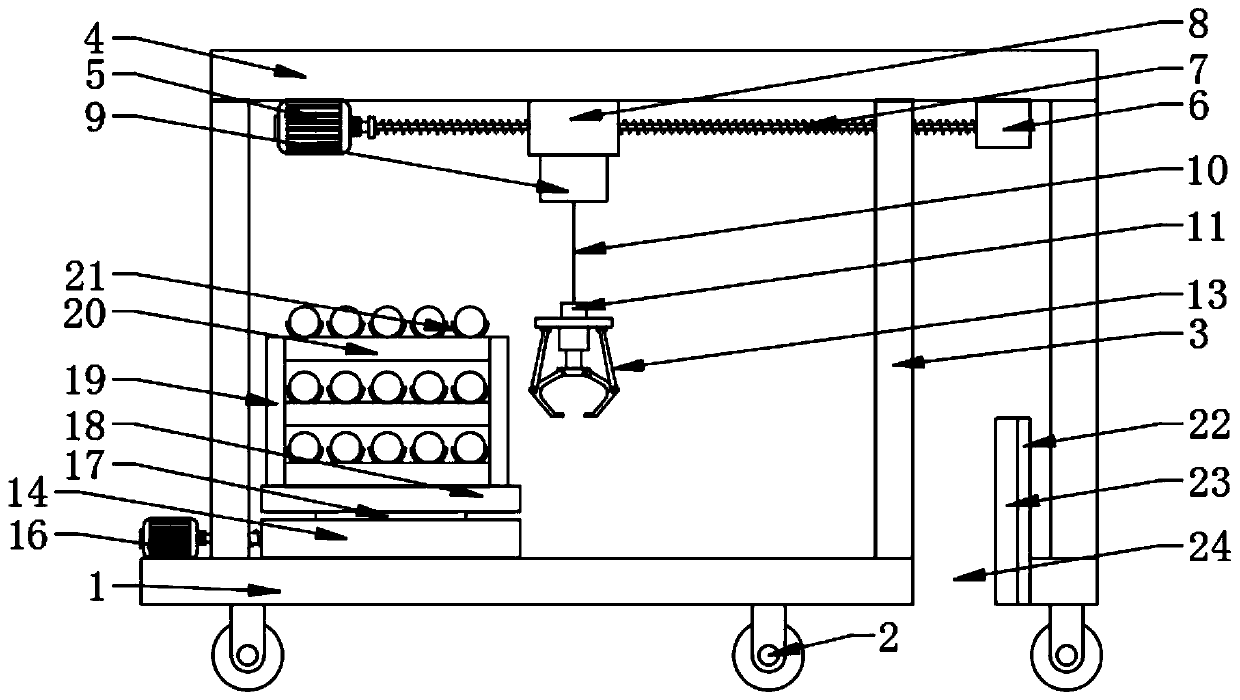

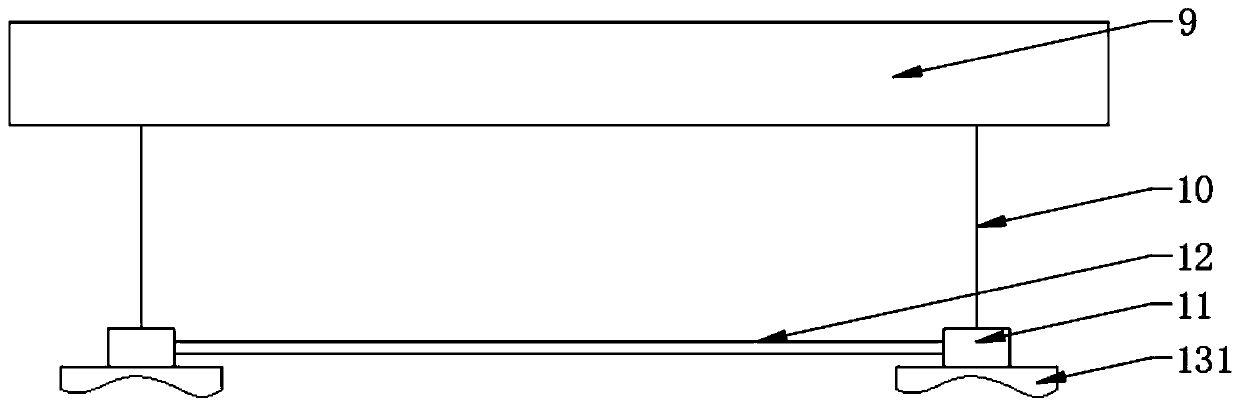

Intelligent-linked stereoscopic warehouse device based on internet of things technology

PendingCN110406873ARealize automatic fixed-point accessImprove utilizationStorage devicesConveyor partsMechanical engineeringInternet of Things

The invention discloses a stereoscopic warehouse device, and particularly relates to an intelligent-linked stereoscopic warehouse device based on an internet of things technology. The device comprisesa goods shelf structure, a roadway type stacking lifting mechanism and a warehousing working table, wherein the roadway type stacking lifting mechanism is arranged beside the goods shelf structure side by side, and the warehousing working table is arranged between the roadway type stacking lifting mechanism and the goods shelf structure; and the device is characterized in that a mechanical grabbing device is arranged on the roadway type stacking lifting mechanism. The device has the advantages of being stable in overall structure operation, firm in grabbing, stable in movement, high in working efficiency and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

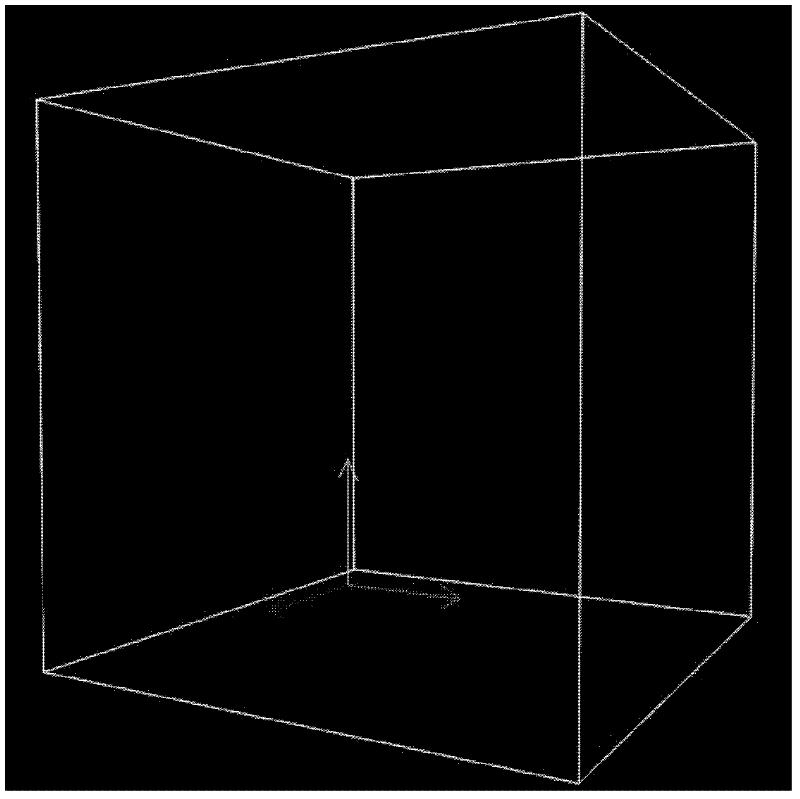

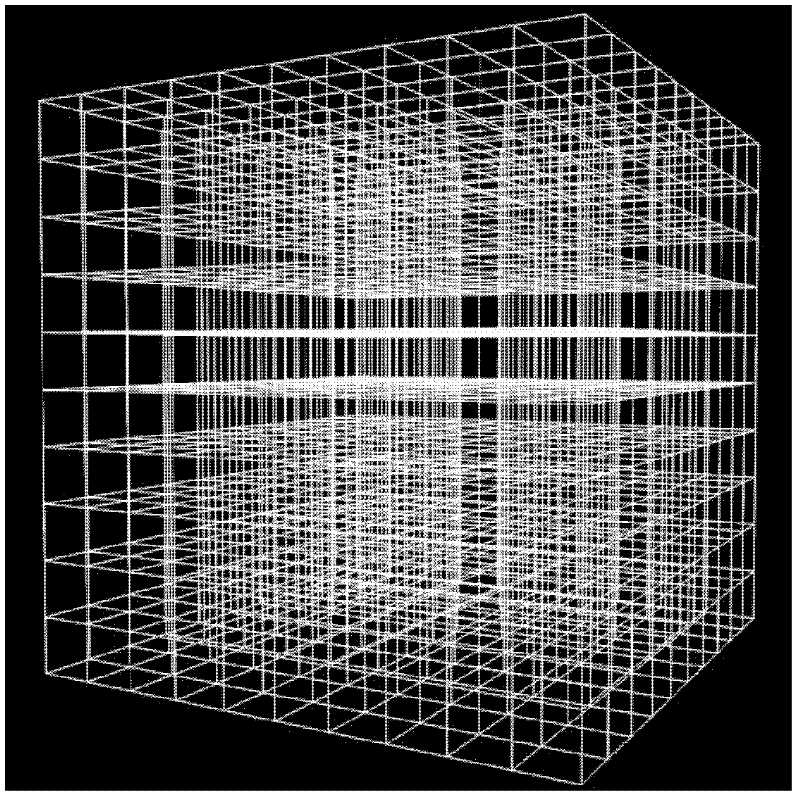

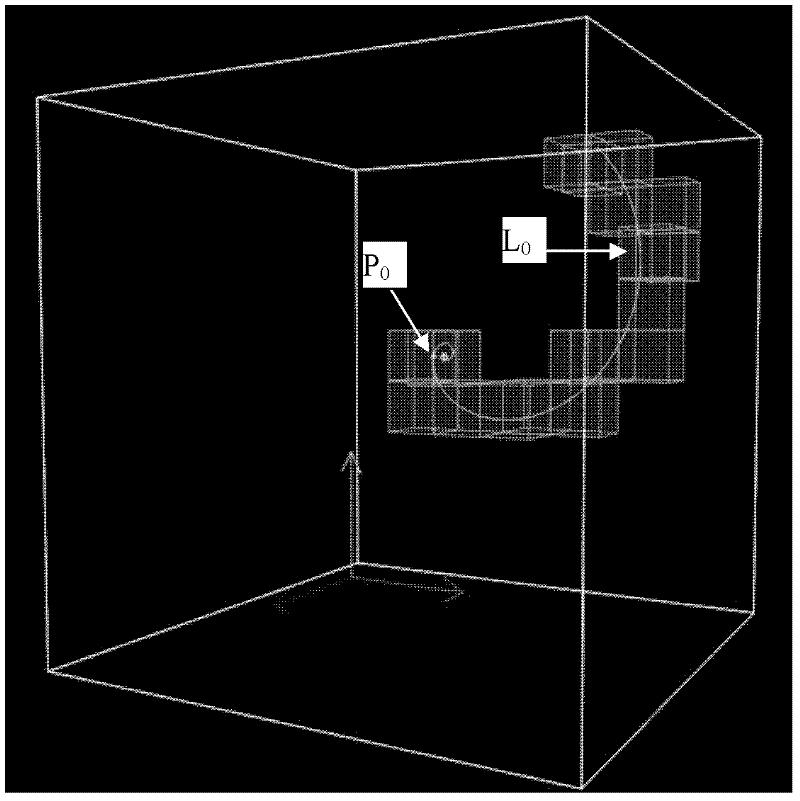

Three-dimension flow line placing method with basically uniform intervals

InactiveCN102646288AEven distribution of streamlinesSmall amount of calculation3D modellingGrid cellComputer science

The invention relates to a three-dimension flow line placing method with basically uniform intervals and belongs to the technical field of scientific calculation visualization. The method comprises the following steps that: 1, for a given three-dimension flow field, a three-dimension orthogonality control lattice with a definition domain corresponding to the given three-dimension flow field is built; 2, any one six-communication blank region is freely found in the three-dimension orthogonality control lattice, and the found six-communication blank region is set to be R; 3, a flow line seed point is selected in the six-communication blank region R obtained in the step 2; 4, the flow lines passing through the points are calculated and obtained according to the flow line seed points obtained in the step 3; 5, the flow lines obtained in the step 4 are used as new flow lines to be placed into the flow field, and the counting values of the control lattice units related by the flow lines are updated, i.e. 1 is added to the counting values of each control lattice unit related by the flow lines; 6, the step 2, the step 3, the step 4 and the step 5 are repeated until any blank six-communication region does not exist in the three-dimension control lattice; and 7, the flow line placing process is completed, and all flow line placing work is completed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

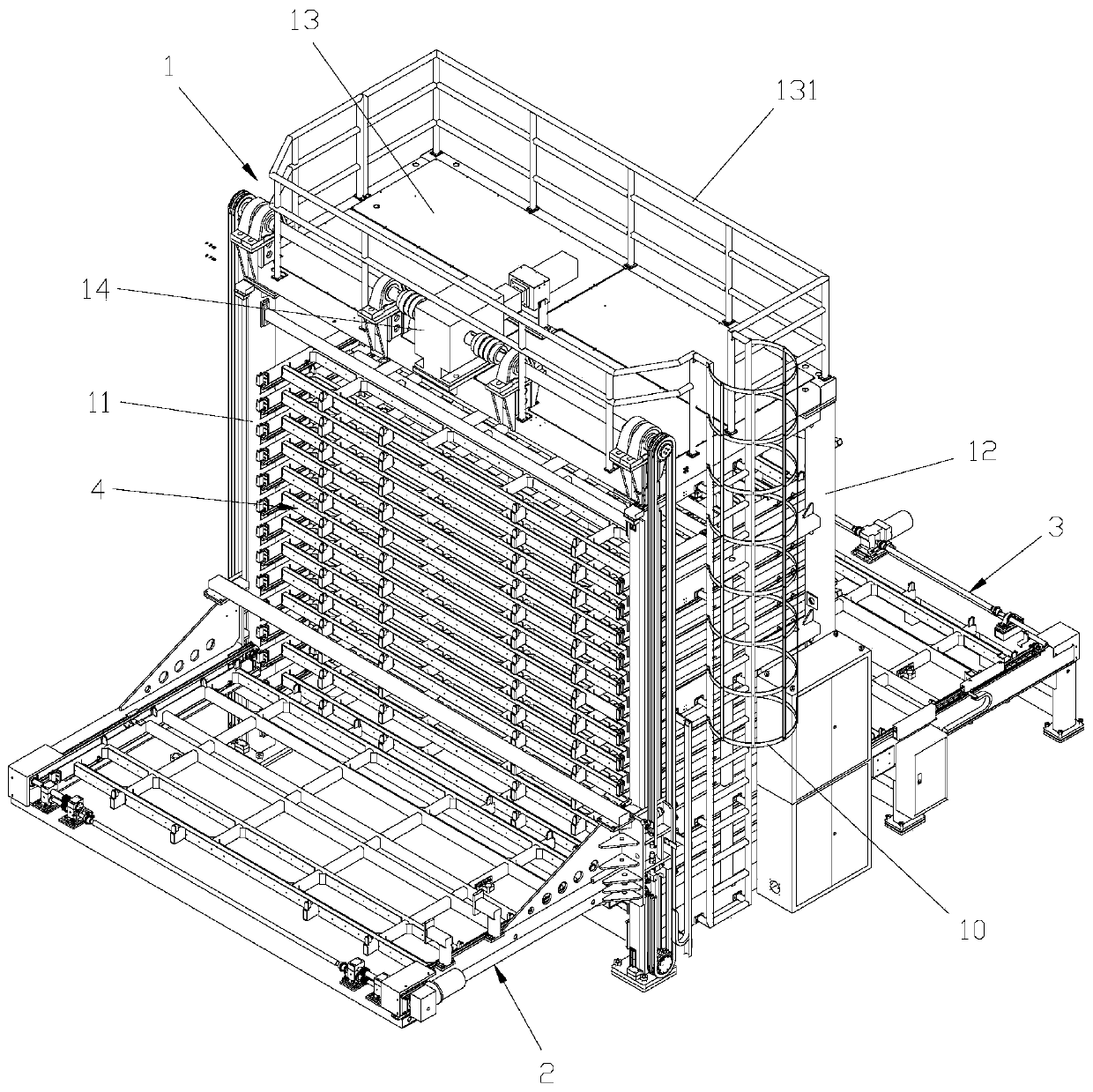

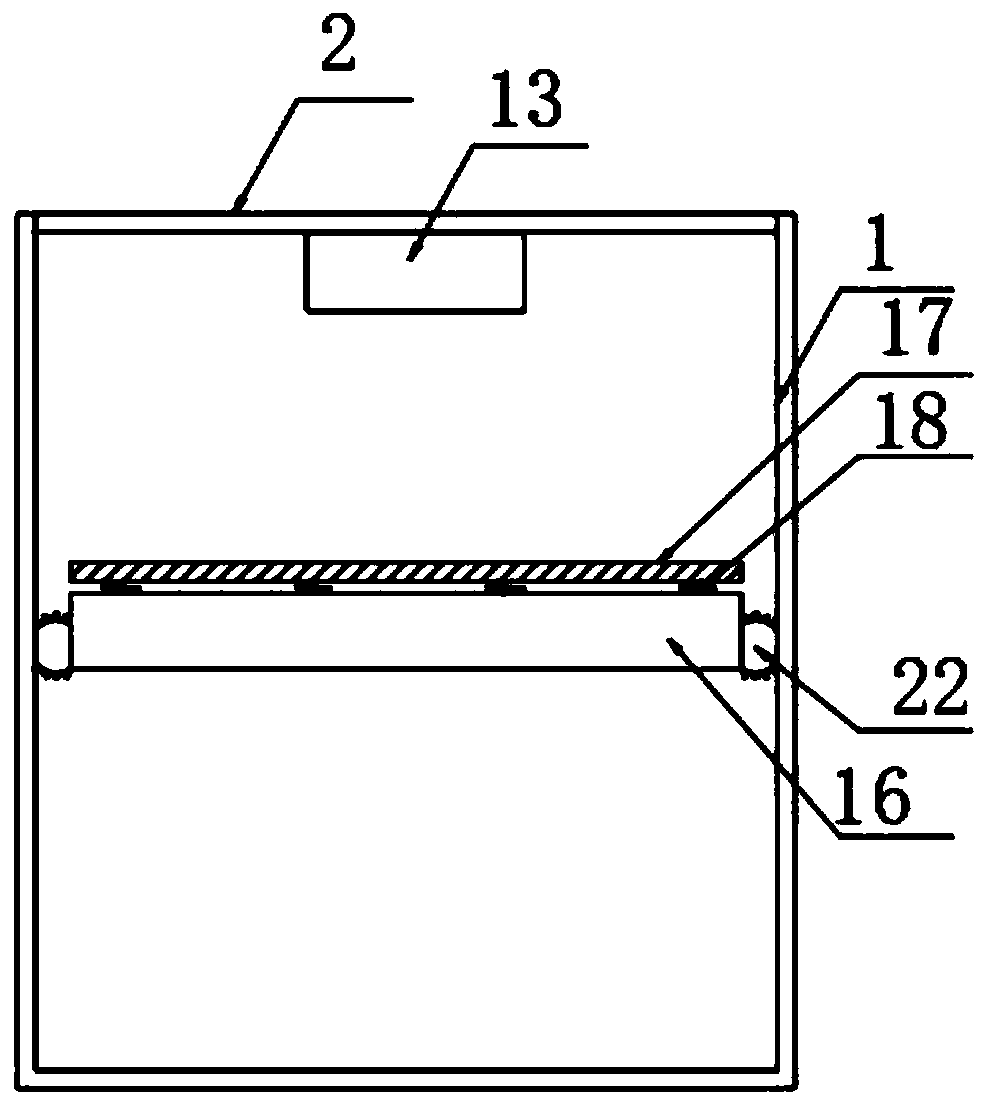

Automatic storage and taking warehouse

The invention provides an automatic storage and taking warehouse. The automatic storage and taking warehouse comprises a warehouse main frame, a lifting platform, a supply platform and a storage car;multiple first support bars and second support bars corresponding one to one and with equal heights are arranged in the warehouse main frame in the height direction; each set of the first support barsand the second support bars form a storage bin position for placing storage cars; the warehouse main frame is provided with a driving device; the driving device drives the lifting platform to move inthe height direction of the warehouse main frame, can be joined with each layer of the storage bin positions, and can drive the storage cars to drive in or out from any one layer of the storage bin positions; and the supply platform is joined with the bottommost layer of the storage bin positions, and can drive the storage cars to drive in or out from the bottommost layer of the storage bin positions. The multiple layers of the storage bin positions are provided for storing multiple different types of materials; and when the materials need to be taken or stored, the lifting platform and the supply platform are cooperated to carry the materials out or into the warehouse main frame, so that the taking and the placement are quick, the continuous machining of automatic production can be met,and the production efficiency is improved.

Owner:HANS LASER TECH IND GRP CO LTD +1

Handle assembly having a radiopaque region to facilitate positioning a bone plate on bone

ActiveUS20120078312A1Help positioningLess obtrusiveDiagnosticsBone drill guidesBONES BONERadiography

Bone fixation system, including methods, apparatus, and kits, and comprising a bone plate and at least one instrument that attaches to the bone plate and provides at least one radiopaque region to facilitate positioning the bone plate on bone visualized by radiographic imaging. The instrument may be a handle assembly and / or a targeting guide.

Owner:ACUMED

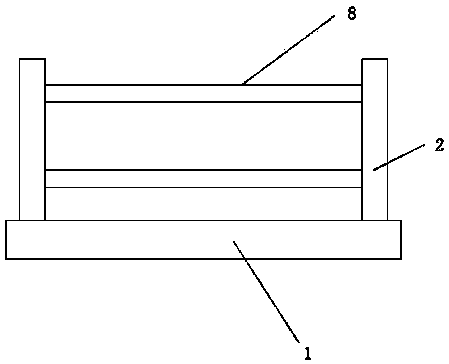

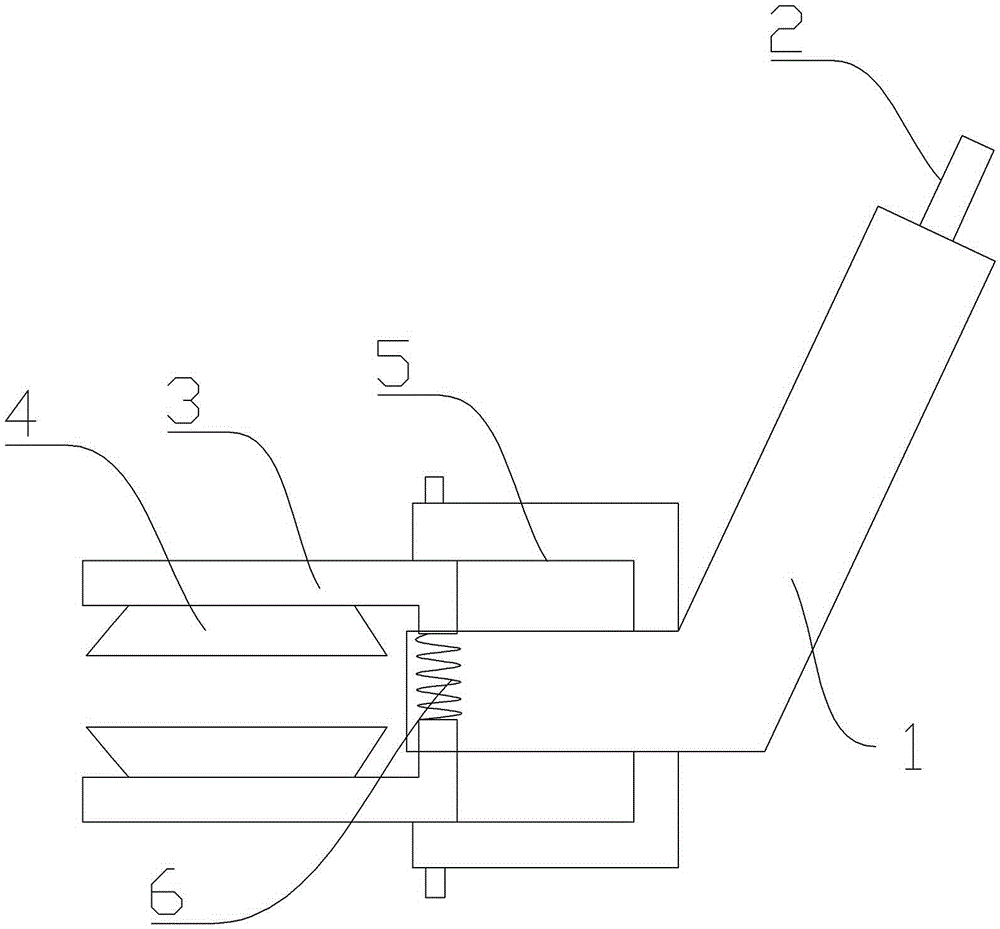

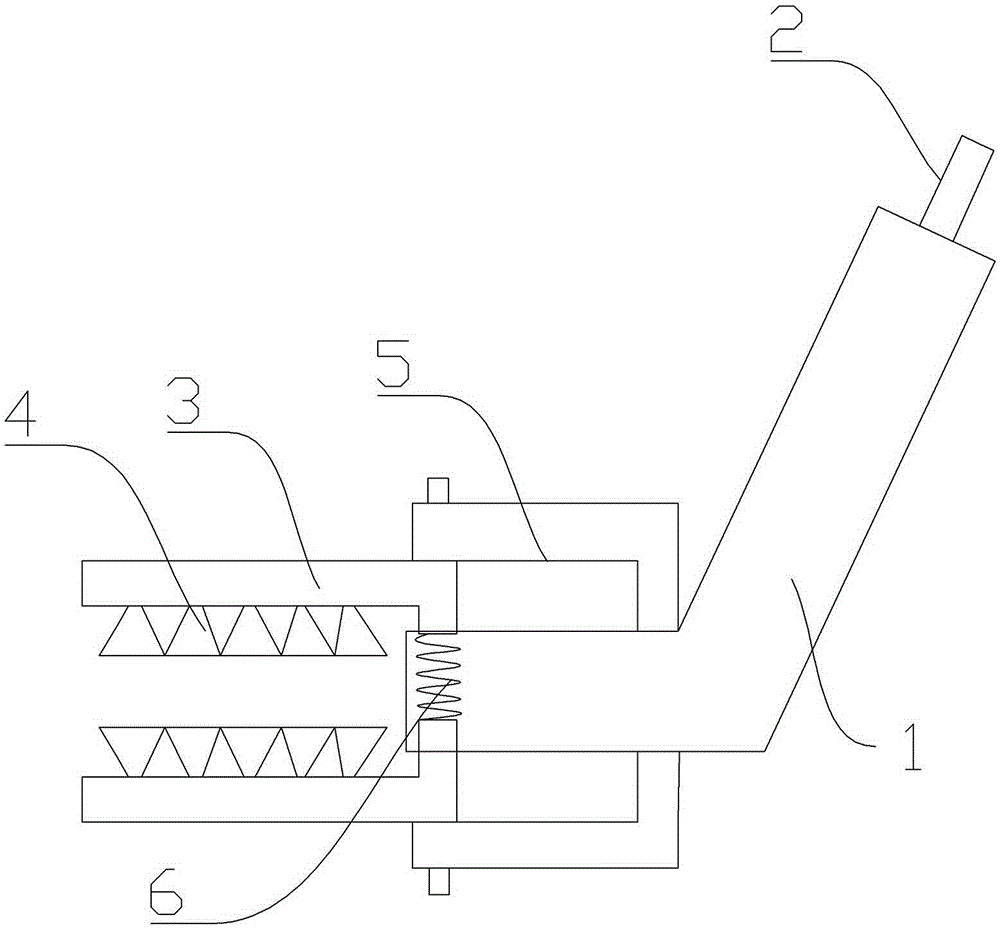

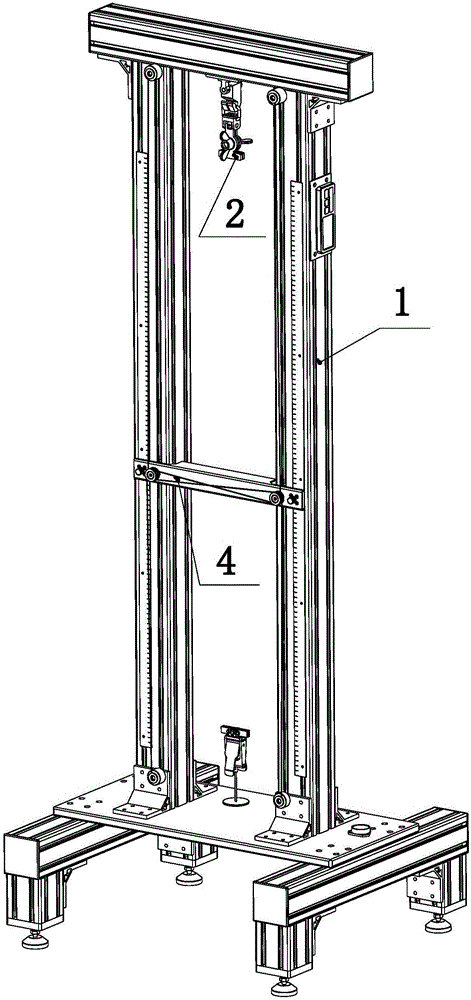

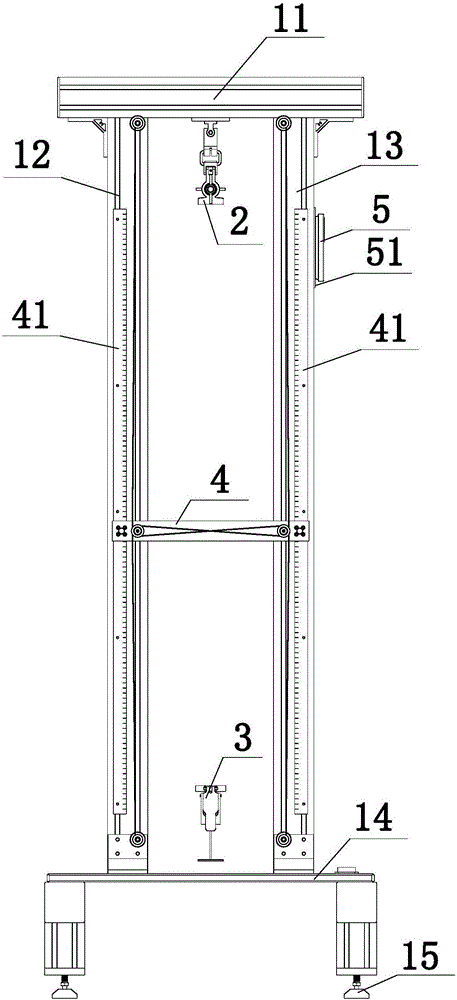

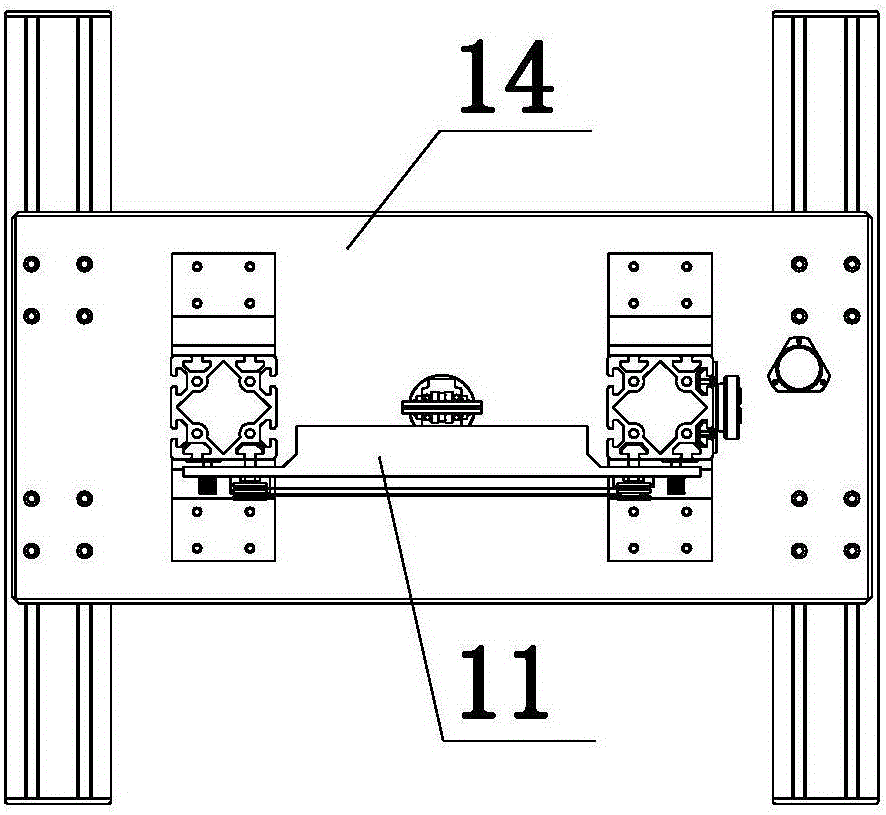

Tester for extension and recoverability of textiles

InactiveCN105928797ASimple test methodEasy to operateMaterial strength using tensile/compressive forcesEngineeringTimer

The invention provides a tester for the extension and the recoverability of textiles. The tester comprises a supporting frame used for providing a mounting space, an upper clamp mounted on the supporting frame and used for clamping the upper parts of the textiles, a lower clamp acting on the lower parts of the textiles and exerting load, a length measuring device mounted on the supporting frame and used for measuring the lengths of the textiles, and a timer mounted on the supporting frame and used for recording time for the extension of the textiles. According to the tester provided by the invention, load is vertically exerted on the textiles through the upper clamp and the lower clamp, then the extension lengths of the textiles can be measured through the length measuring device, and the timer is used for timing; the tester for the extension and the recoverability of the textiles is wide in application scope, the testing method is simple and easy, and the data is stable; moreover, the tester provided by the invention has the characteristics of simple operation, high measuring efficiency and high measuring accuracy, and makes up to the shortage of a conventional method.

Owner:宁波市纤维检验所

Full-automatic book management robot

The invention provides a full-automatic book management robot. The full-automatic book management robot comprises a base, an outer shell, an inner shell, a carrying mechanism, a transferring mechanism, a lifting mechanism, a taking and placing mechanism and a circuit part. An inner book inlet is formed in the inner shell, and an outer book inlet is formed in the outer shell. The full-automatic book management robot is characterized in that the carrying mechanism is composed of a conveying motor, a conveying belt, a driving belt shaft and a driven belt shaft, the transferring mechanism is usedfor pushing books onto the taking and placing mechanism from the conveying belt, the taking and placing mechanism is arranged on the lifting mechanism, and the lifting mechanism is used for driving the taking and placing mechanism to rise and fall; and the taking and placing mechanism is composed of a lifting plate, a taking and placing motor, a second horizontal lead screw, a pushing block, a manipulator and an opening motor. According to the full-automatic book management robot, books in the manipulator can be pushed to accurate positions of a book shelf, books can also be taken down from atfixed positions of the book shelf, automatic taking and placing of books are achieved, and the technical problem that in the prior art, books have to be placed on book shelves and taken down from thebook shelves by workers is solved; and the full-automatic book management robot has remarkable beneficial effects and is suitable for application and popularization.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

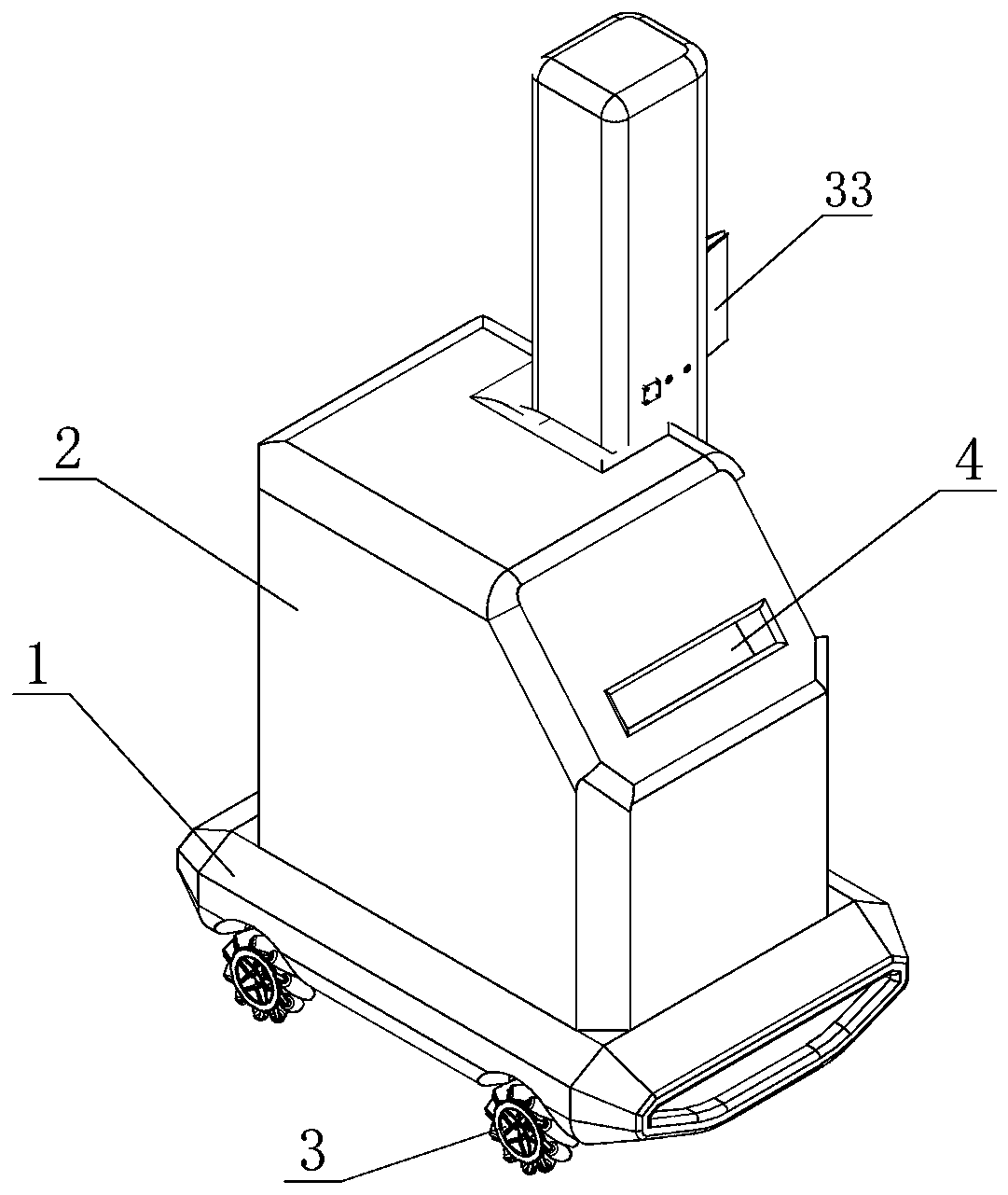

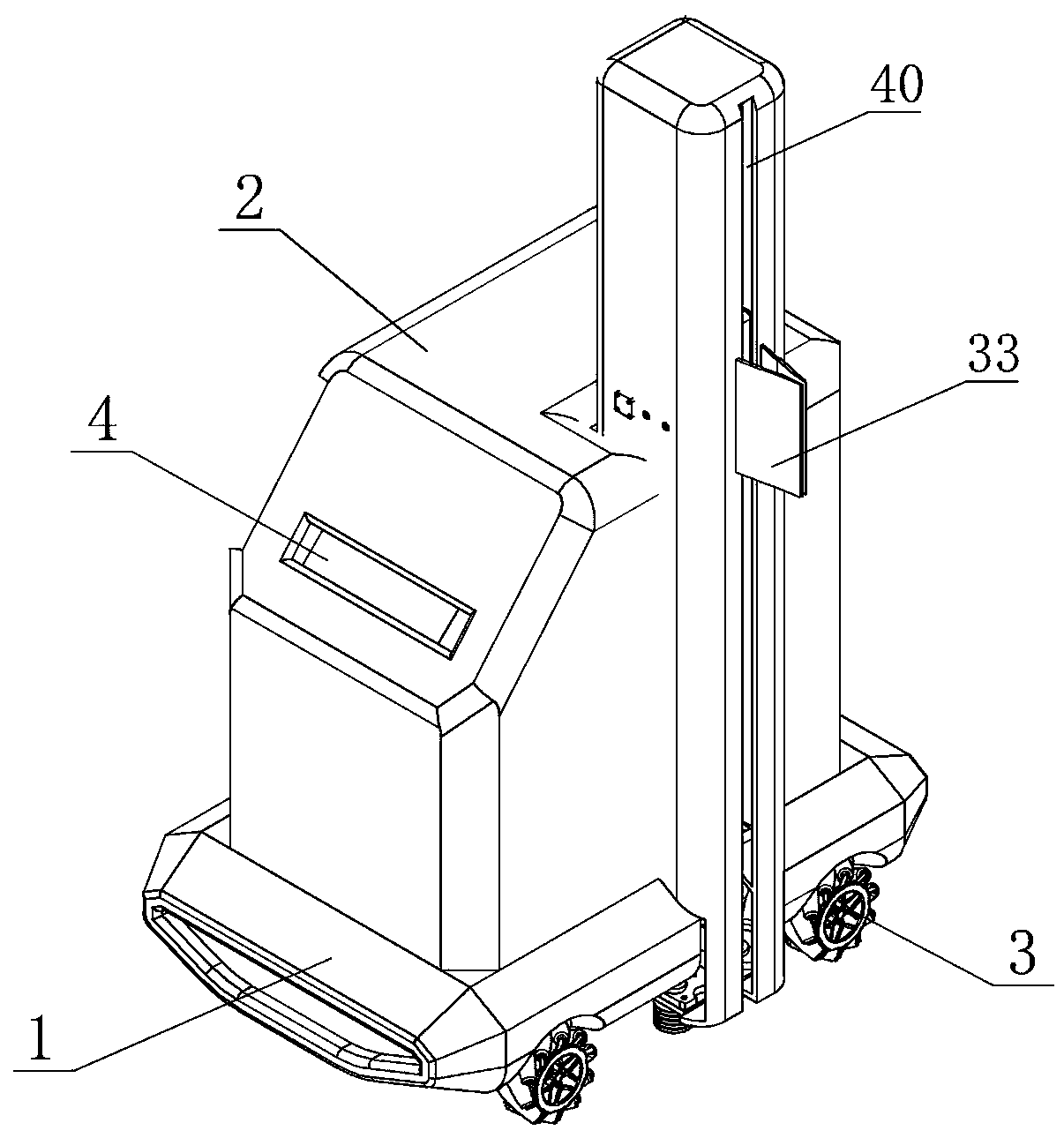

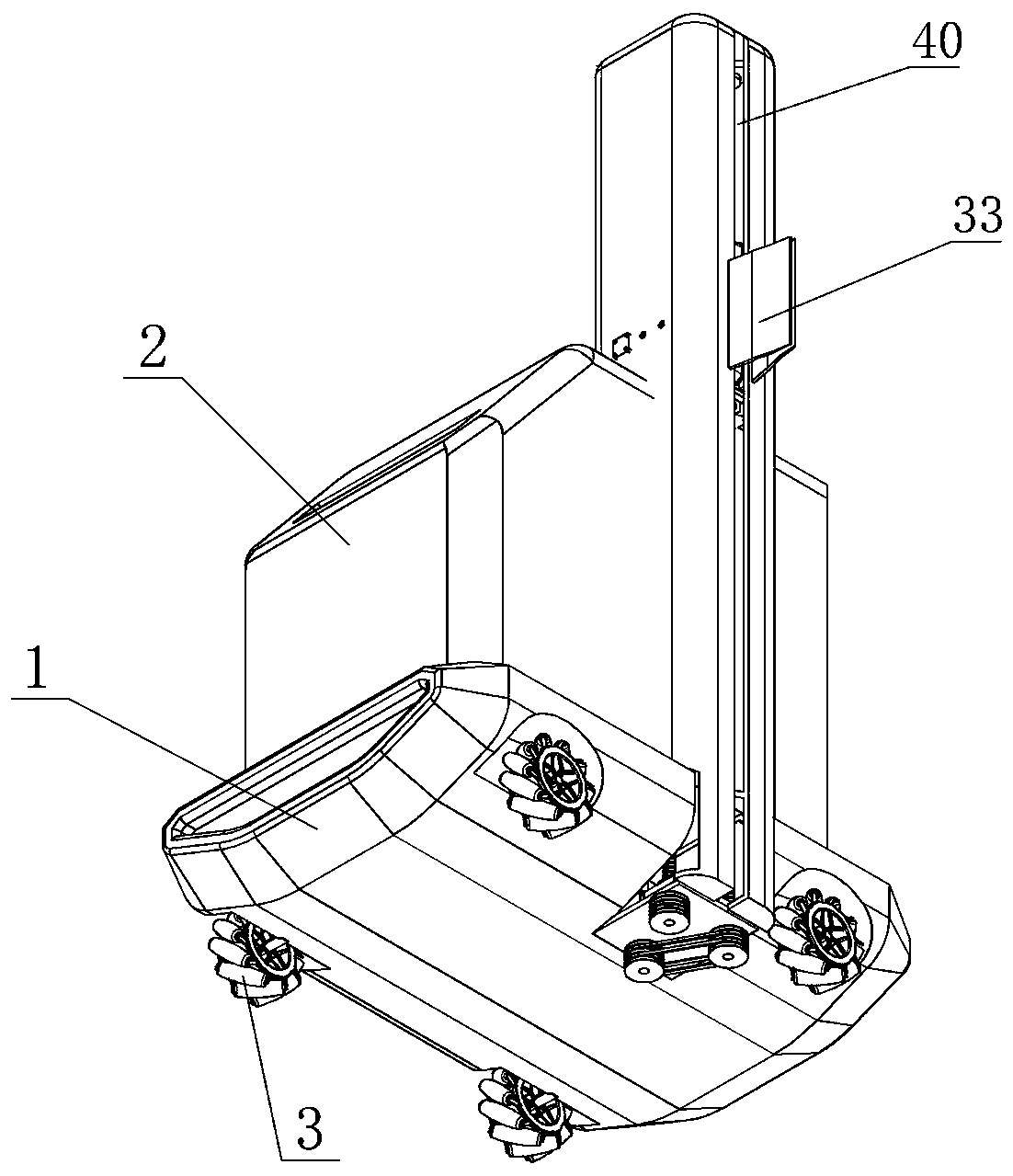

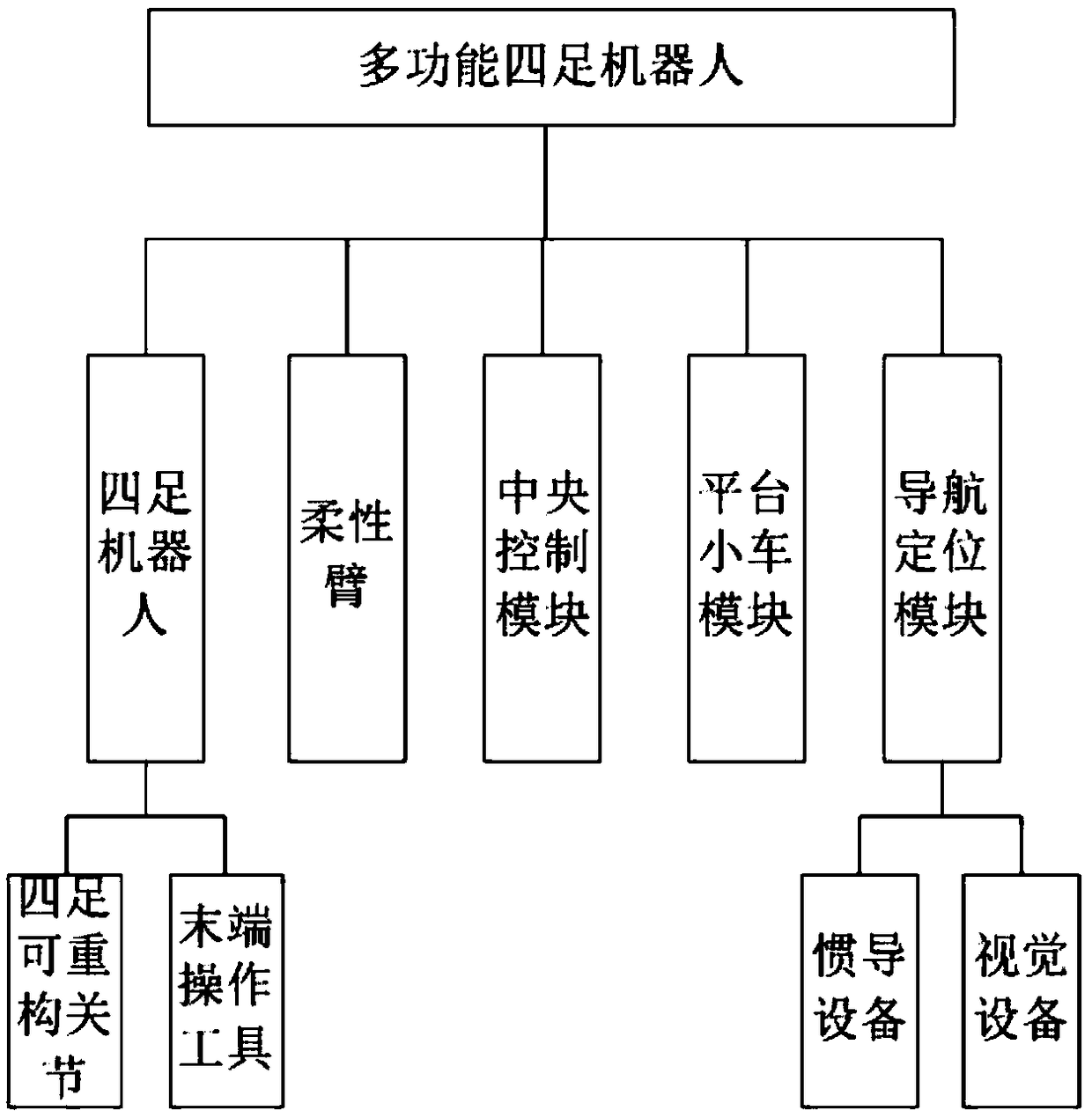

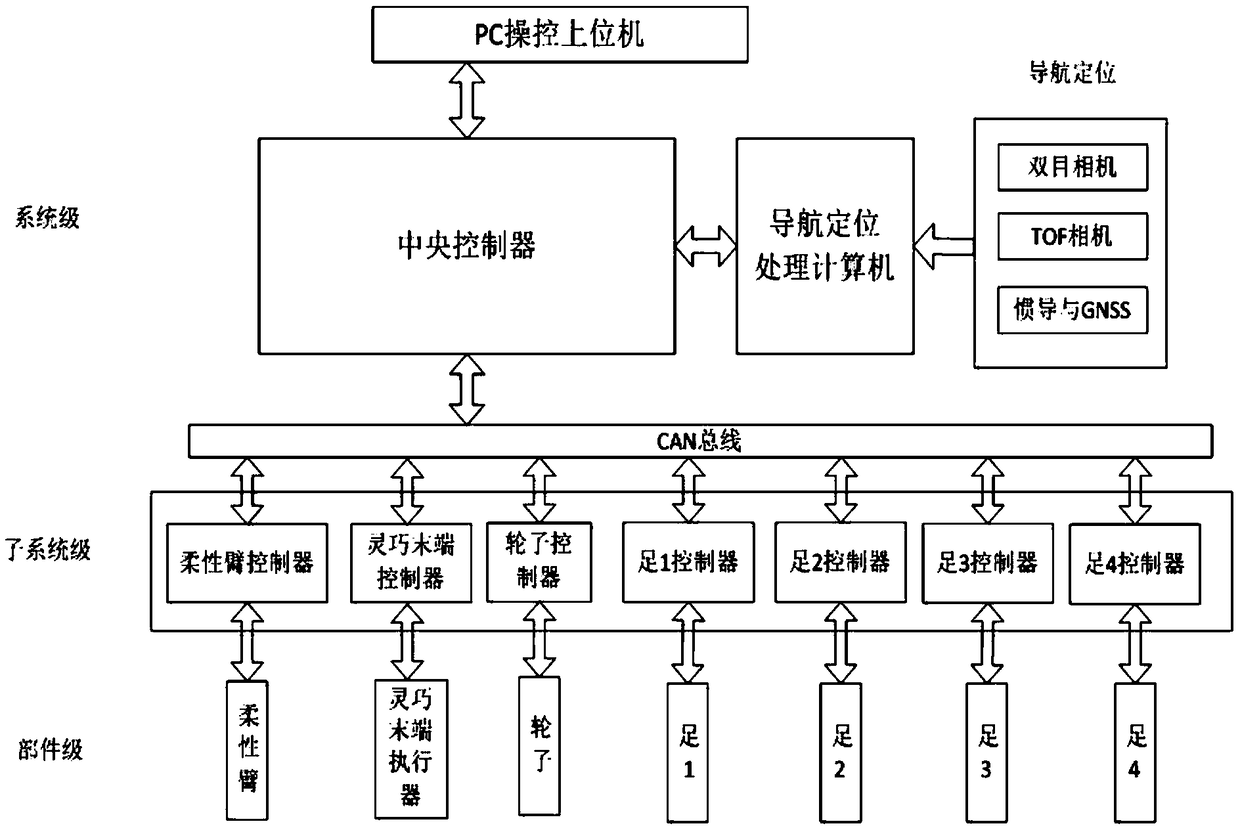

Multifunctional multi-legged robot control system

InactiveCN109249395ASmall amount of calculationAchieving a modular designProgramme-controlled manipulatorControl systemComputer module

A multifunctional multi-legged robot control system is a distributed multi-level control system and comprises a central controller. Multiple levels include a system level, a subsystem level and a component level, the central controller is used for task planning and control of the whole system, receiving task instructions of a PC (personal computer) control upper computer, decomposing the instructions and planning output of control module instructions of the subsystem level, and the subsystem level at least comprises a plurality of single leg controllers for receiving the instructions of the central controller, distributing the instructions to a joint controller of the component level by a preset track planning and control algorithm, controlling all single legs and uploading state information of the component level to the central controller. According to the system, by distributed control of a multifunctional multi-legged robot, improved flexibility, portability, cooperativity and highprecision can be acquired, and the system is strong in applicability to various application scenes.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

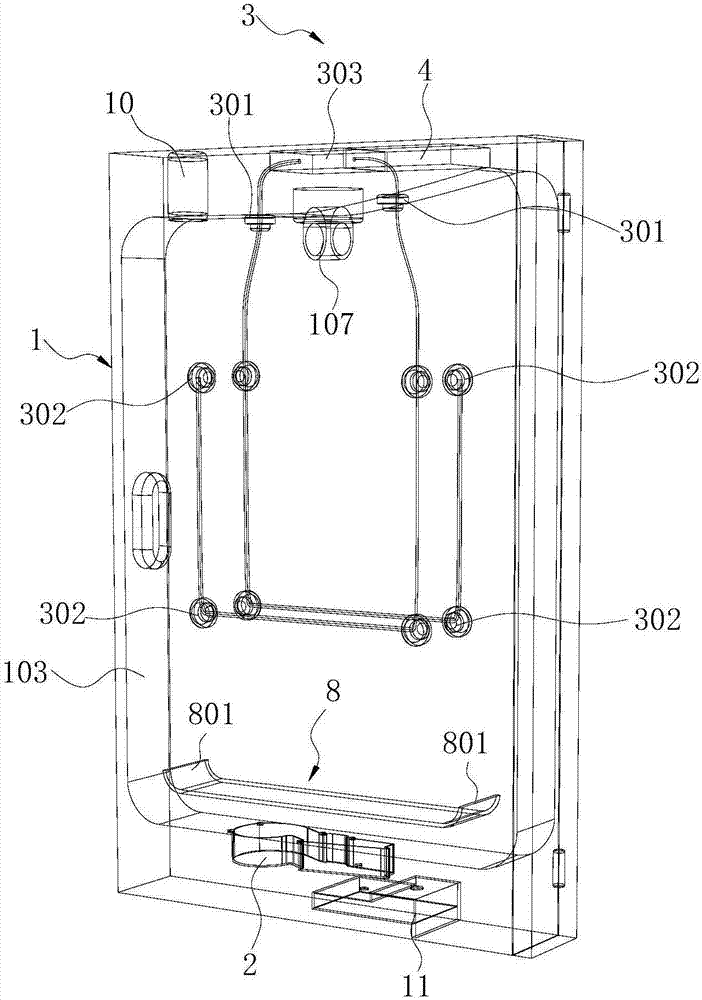

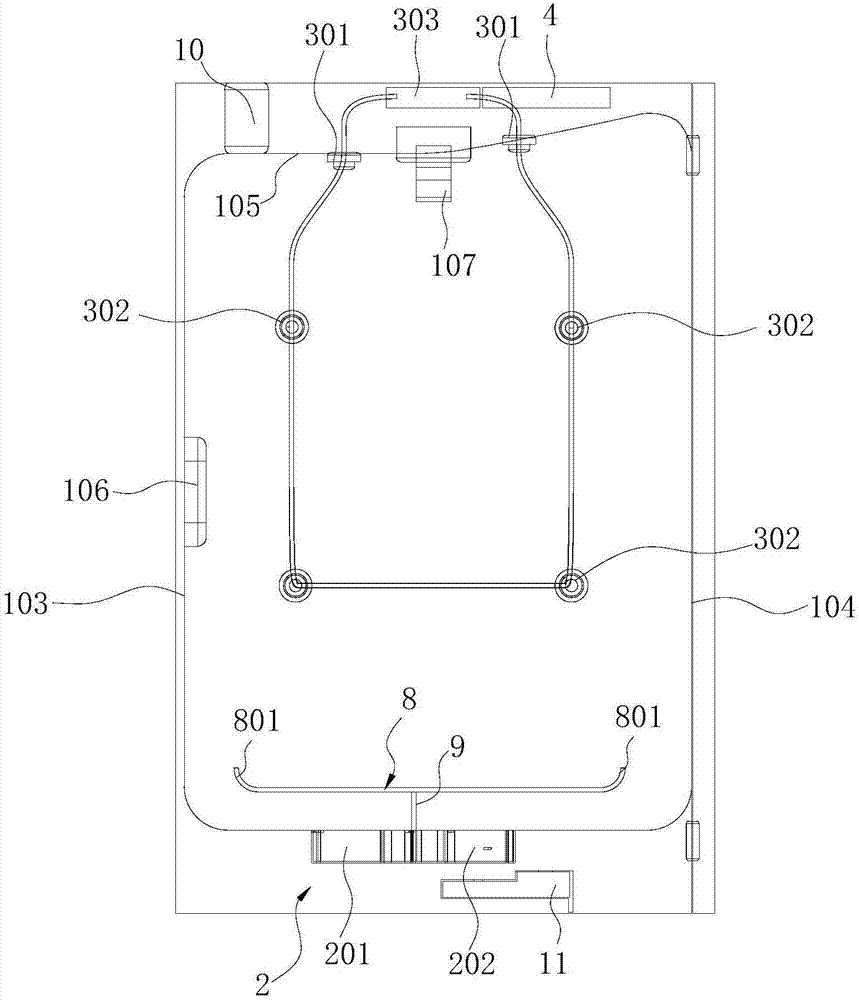

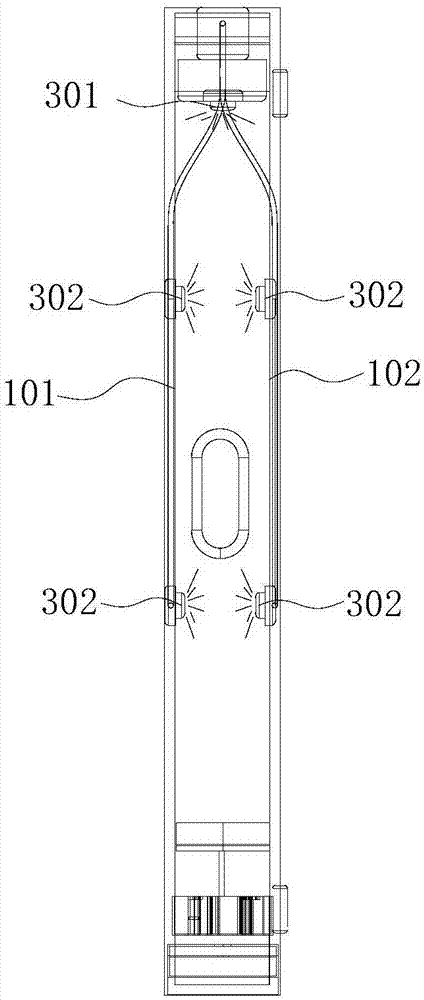

Spraying-type care machine

InactiveCN106948154ADirectionalEven and comprehensiveTextiles and paperConditioning apparatusSprayerEngineering

The invention discloses a spraying-type care machine. The spraying-type care machine comprises a box body used for defining a clothes placement space, a drying device arranged in the bottom of the box body and used for conveying hot air to the box body, a spraying device arranged in the box body, a care liquid container and a piercing device. The spraying device comprises a steam generation mechanism used for generating steam and a spraying mechanism connected with the steam generation mechanism. The spraying mechanism is arranged outside nursed clothes and provided with a sprayer used for applying steam to clothes. The sprayer at least comprises a first group of sprayers and a second group of sprayers. The first group of sprayers is used for applying steam from tops of clothes to clothes. The second group of sprayers is used for applying steam from two opposite sides of clothes. The care liquid container communicates with the spraying device. Liquid in the care liquid container can be extracted through the spraying device. The piercing device corresponds to the care liquid container and is capable of piercing a care liquid capsule in the care liquid container. The spraying-type care machine has the following beneficial effects: the machine is simple in structure; spraying is uniform; there is no dead corners; in addition, operation for inputting care liquid is simplified; efficiency is increased while manpower is saved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Automatic clothes folding machine

An automatic clothes folding machine comprises a lower box. Each of the front and the top end of the lower box is of an opening structure, a supporting frame is fixed at the top of the lower box through screws, falling plates in symmetrical arrangement are hinged on the inner walls of two sides of the supporting frame, a photosensitive sensor is embedded at the top end of one falling plate, a leftclothes folding plate and a right clothes folding plate are arranged on the outer walls of the two sides of the supporting frame respectively, and a hinge is fixed at the edge of one side of the topof each of the left clothes folding plate and the right clothes folding plate through a screw. By arranging a photosensitive sensor, whether there are clothes on the machine can be recognized, and folding and placing functions can be started automatically; a steering engine rotates to drive a slotting connection member so as to drive the folding plates to turn to orderly fold the clothes, so thatthe clothes can be folded to be identical in size specification; the steering engine rotates to drive the slotting connection member so as to drive the falling plates to be opened to enable the clothes after being folded to fall into the lower box to realize placement.

Owner:SHANGHAI MARITIME UNIVERSITY

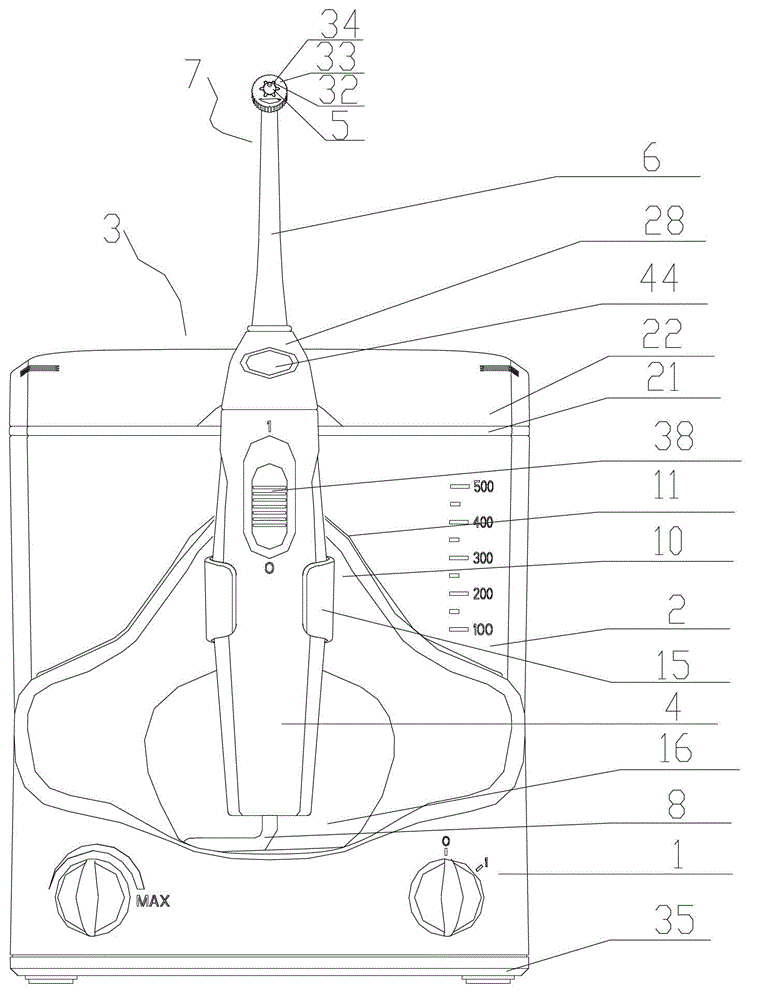

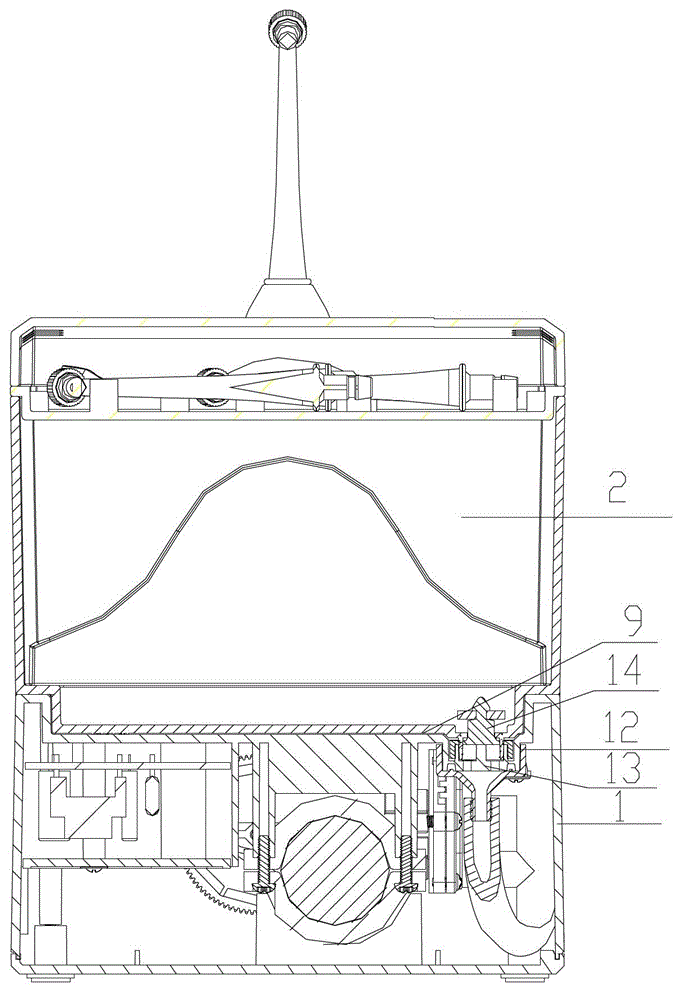

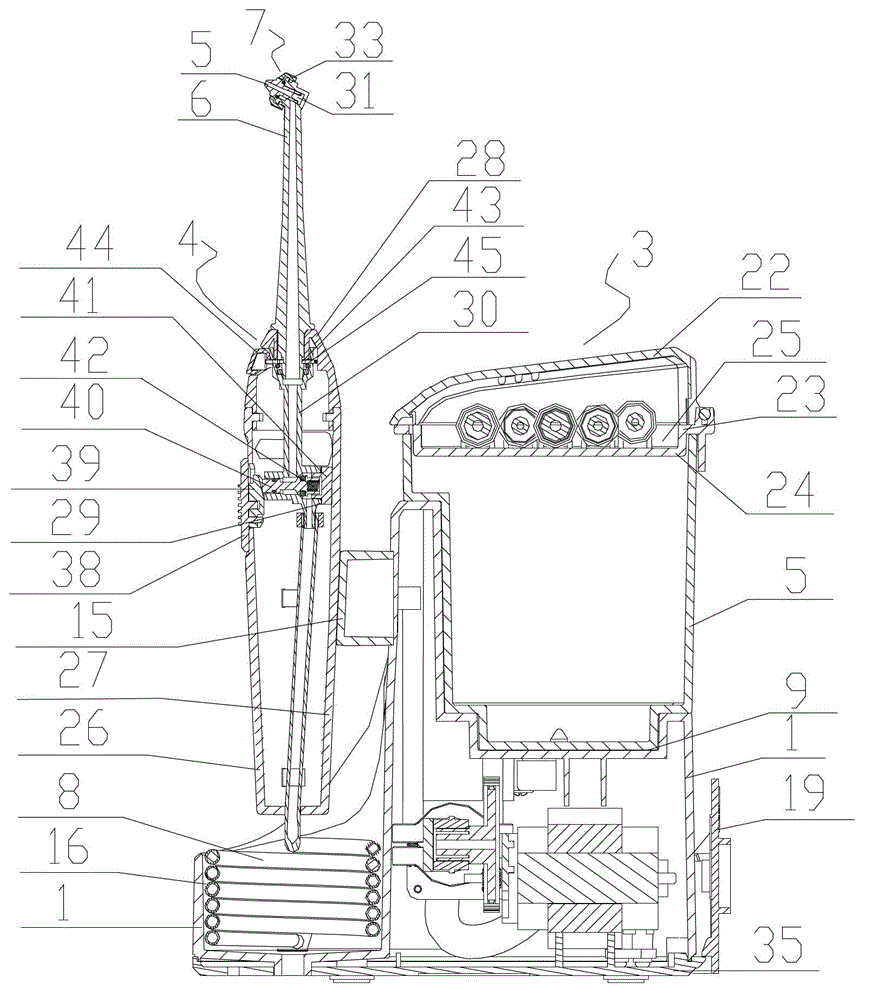

Wall-mounted type multifunctional tooth cleaner

The invention discloses a wall-mounted type multifunctional tooth cleaner. The wall-mounted type multifunctional tooth cleaner comprises a tooth cleaner body, a water tank, a water tank cover, an operating handle, a spray head and a rubber water outlet pipe, wherein the spray head consists of a nozzle and a rod body; the water tank is arranged at a bearing part of the tooth cleaner body; a handle plug base is fixedly connected to the middle part of a positioning plate of the tooth cleaner body; a protruded columned groove for placing the rubber water pipe is formed below the positioning plate of the tooth cleaner body; protruded T-shaped inserting grooves are formed in two rear sides of the tooth cleaner body; hanging plates formed by being integrated with a hanger are inserted into the T-shaped inserting grooves; the water tank cover comprises a cover body, and an upper cover hinged with the cover body; an accessory placing chamber is formed by the edge and the bottom formed on the cover body; the bottom of the cover body is placed at an edge port of the water tank; the operating handle comprises a front cover, a rear cover and an end cover; water inlet valves which are connected with the rubber water outlet pipe are arranged at the parts at which the front cover and the rear cover are arranged; and water outlet pipe sections of the water inlet valves are connected with the rod body in an inserting way, wherein the rod body is arranged in a central hole in the end cover. The wall-mounted type multifunctional tooth cleaner is convenient to clean and use, attractive in appearance, multifunctional, and wall-mounted.

Owner:DONGGUAN INWOOD ELECTRONICS

Manufacturing manipulator with automatic clamping and placing functions

InactiveCN108724167AImprove practicalityEasy to operateProgramme-controlled manipulatorGripping headsManipulatorIndustrial engineering

The invention discloses a manufacturing manipulator with automatic clamping and placing functions. The manufacturing manipulator comprises an air cylinder, a first clamping plate, a second clamping plate, a first clamping arm, a second clamping arm, a base, anti-skidding pads, a reset spring, a motor and a first driving device; a piston rod is driven by the air cylinder to extend so as to push thefirst clamping arm and the second clamping arm to separately rotate around ends which are fixedly connected with a fixed plate, so that the first clamping plate and the second clamping plate are separately located on two sides of an object; the piston rod is further driven to contract by utilizing the air cylinder, so that the first clamping plate and the second clamping plate are pulled to movetoward two sides of the object, and clamping for the object is realized; friction between the first clamping plate as well as the second clamping plate and the object is increased through arrangementof the anti-skidding pads, so that the clamping effect for the object is improved, and practicability of the equipment is improved; and rapid closing of the first clamping plate and the second clamping plate is realized through arrangement of the reset spring, so that practicability of the equipment is improved.

Owner:芜湖盛创新材料科技有限公司

Square sheet stamping equipment for hardware

PendingCN112845773AAchieve placementRealize stampingMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention relates to stamping equipment, in particular to square sheet stamping equipment for hardware. According to the square sheet stamping equipment for the hardware, an iron sheet can be automatically pulled, the cut iron sheet can be automatically wound, and people can conveniently collect the square iron sheet. The square sheet stamping equipment for the hardware comprises a bottom plate, a stamping mechanism and a feeding mechanism, wherein a stamping platform is arranged on the bottom plate, the stamping mechanism is arranged on the bottom plate, and the feeding mechanism is arranged on the bottom plate. According to the equipment, the iron sheet is placed through the feeding mechanism, then the iron sheet is stamped in combination with the stamping mechanism, and therefore the square iron sheet is efficiently manufactured; and through cooperation between a material pulling mechanism and the stamping mechanism, the iron sheet is automatically pulled leftwards, and in this way, the iron sheet does not need to be pulled manually.

Owner:舒李兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com