Spraying-type care machine

A nursing machine and spray technology, applied in the field of clothing care equipment, can solve the problems of using large force or tools, difficulty in opening the package, uneven spraying, etc., achieving uniform and comprehensive position, saving physical strength, reducing The effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

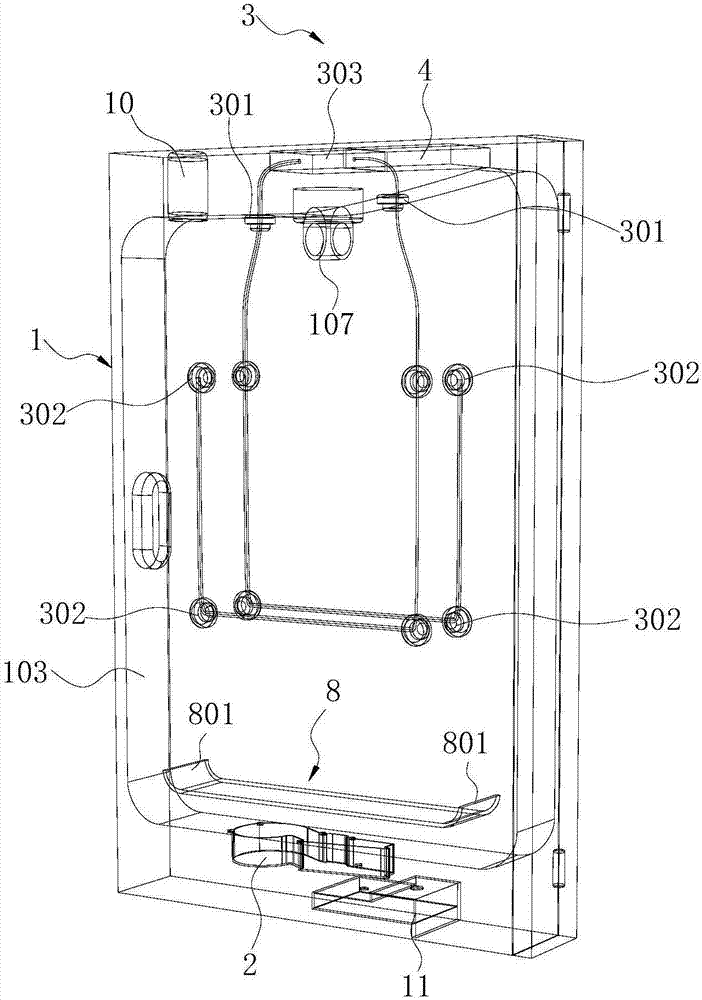

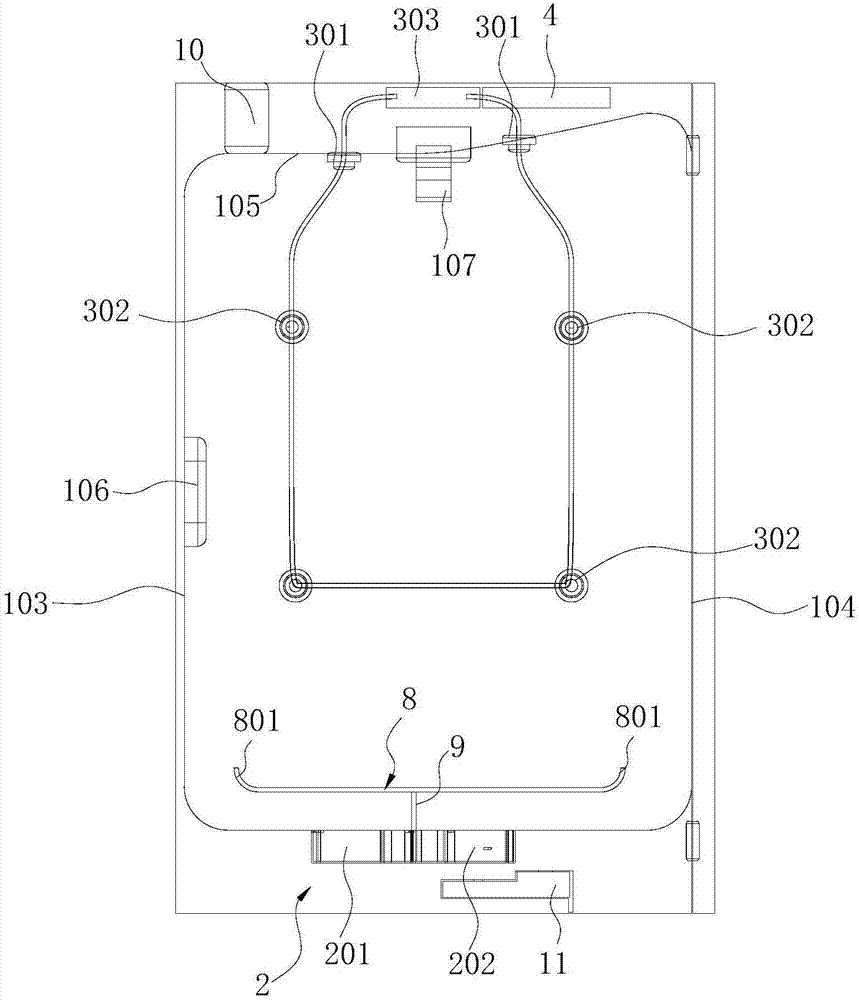

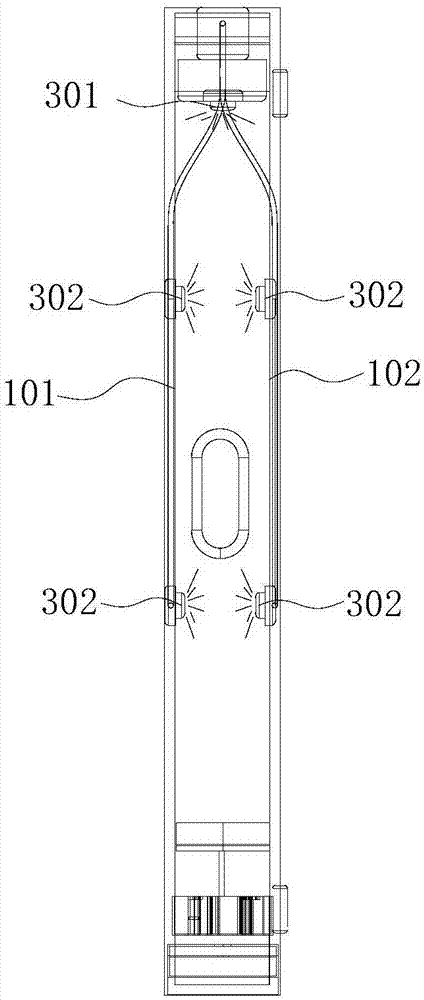

[0041] Such as Figure 1-3 As shown, in an embodiment of the present invention, the spray care machine includes a casing 1, a drying device 2, a spray device 3, a care solution container 4 and a piercing device ( Figure 1-3 not shown in ), wherein the box body 1 is used to limit the space for placing clothes, the drying device 2 is arranged at the bottom of the box body 1, and is used to deliver hot air into the box body 1, and the spray device 3 is arranged on The box body 1 includes a steam generating mechanism for generating steam and a spraying mechanism connected with the steam generating mechanism. The spraying mechanism is arranged on the outside of the clothes to be cared for, and has nozzles for spraying the clothes. Applying steam, the nozzles at least include a first group of nozzles 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com