Patents

Literature

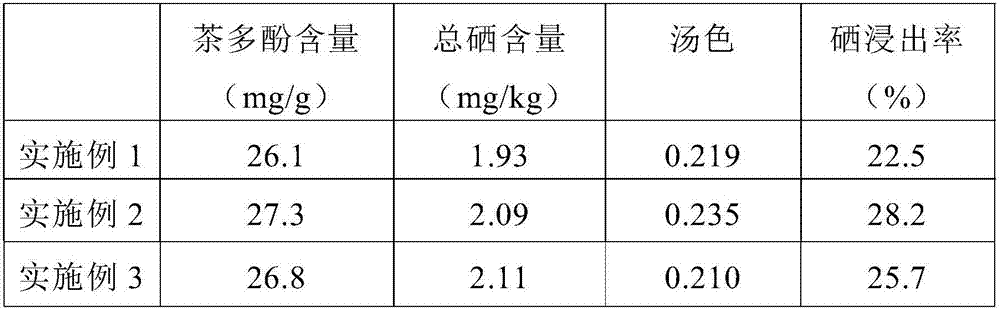

114 results about "Fixation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

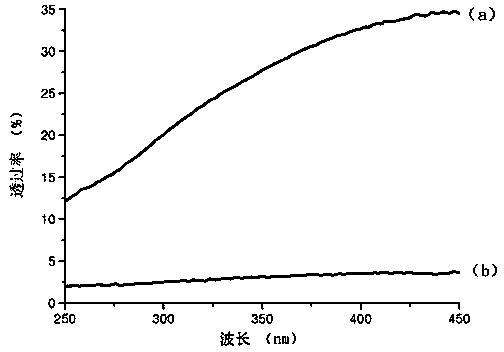

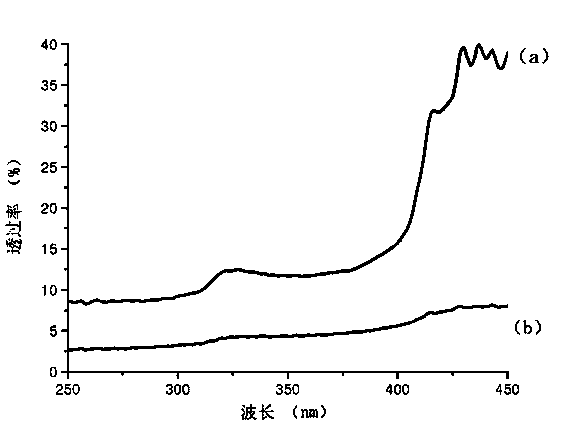

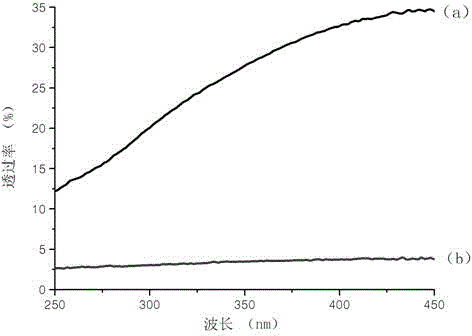

Preparation method of ultraviolet-proof antistatic graphene coating textile fabric

ActiveCN103469555ASimple production processEasy to operateVegetal fibresGraphene coatingFixation time

The invention provides a preparation method of ultraviolet-proof antistatic graphene coating textile fabric. The method is characterized by comprising the following steps: adding a graphene solution to a water-soluble polyurethane solution after shaking and dispersing so as to obtain a mixed solution; fully stirring the mixed solution; putting a graphene screening agent solution into a padder immersion tank; processing textile base fabric under room temperature through implementing a two-dipping and two-rolling procedure; padding the graphene screening agent on a textile, putting kinds of textiles on which the graphene screening agent is padded into a high-temperature oven for drying, wherein the temperature of the high-temperature oven is 75-95 DEG C; the high-temperature fixation time lasts for 5-30 minutes, so as to prepare the ultraviolet-proof antistatic graphene coating textile fabric. The method is simple in process, and easy to operate, and the yield is high; the produced textile fabric has the excellent function of preventing ultraviolet rays and static electricity.

Owner:QINGDAO UNIV

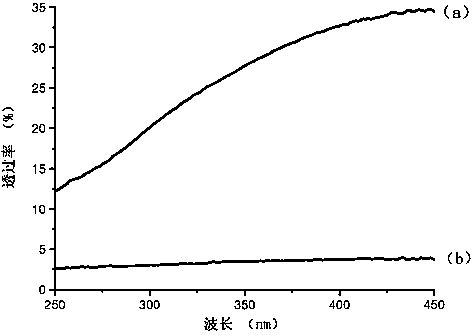

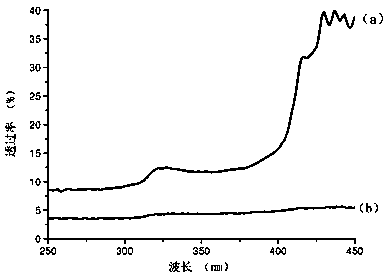

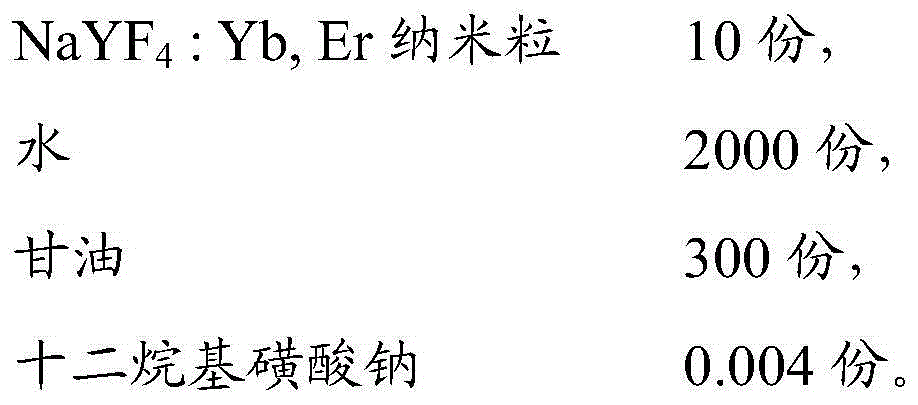

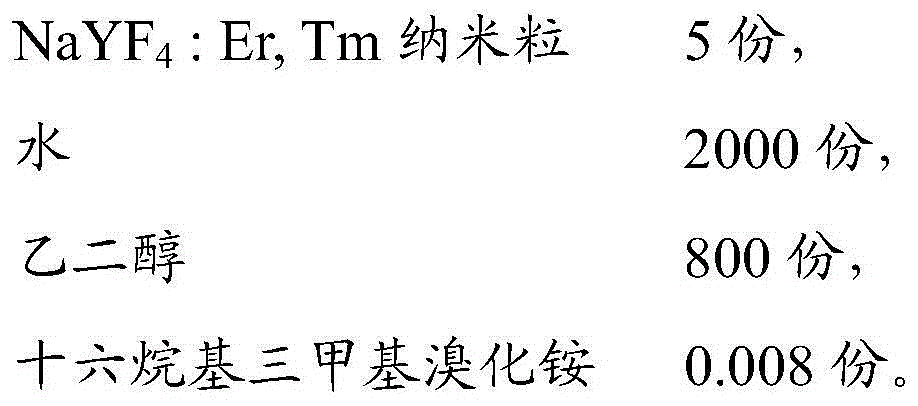

Upconversion fluorescent ink for inkjet printer and preparation method of upconversion fluorescent ink

The invention discloses an upconversion fluorescent ink for an inkjet printer. The upconversion fluorescent ink comprises, by weight, 1-10 parts of rare-earth doped upconversion fluorescent nanoparticles, 1600-2000 parts of ink solvent and 300-800 parts of thickener, the rare-earth doped upconversion fluorescent nanoparticles are sodium yttrium fluoride nanoparticles co-doped by rare-earth activator and rare-earth sensitizer, the rare-earth activator is erbium, thulium or holmium, and the rare-earth sensitizer is ytterbium or erbium. The upconversion fluorescent ink for the inkjet printer has the advantages of good anti-counterfeiting effect and long fixation time and storage life and can realize individualized instant anti-counterfeiting printing.

Owner:XI AN JIAOTONG UNIV

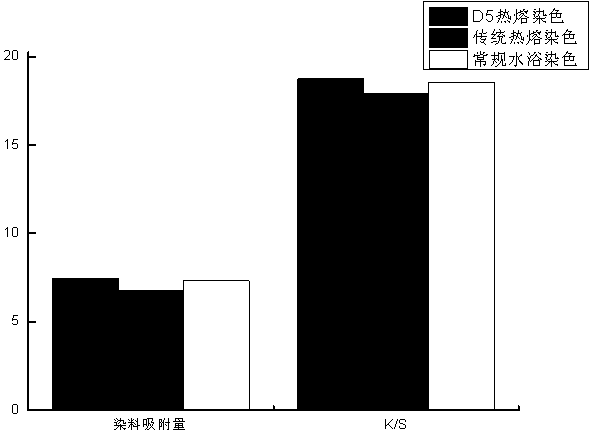

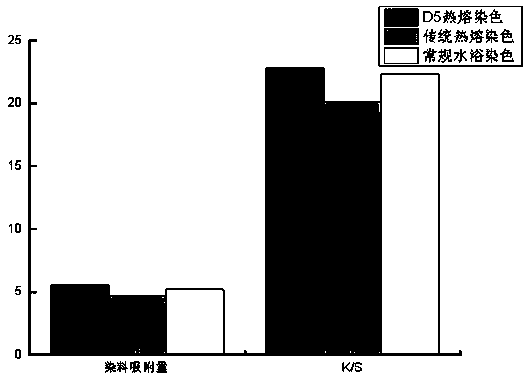

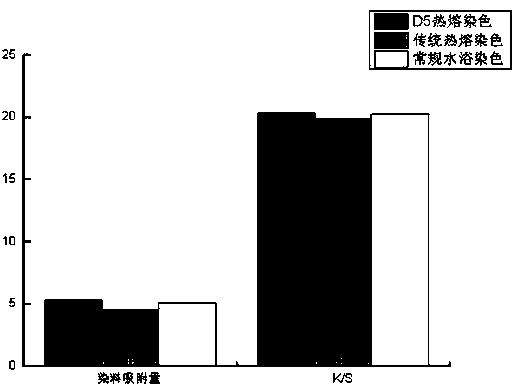

Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

InactiveCN104278576ASave water for dyeingReduce sublimationDyeing processDisperse dyeEcological environment

The invention discloses a disperse dye thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as a medium. The method comprises the following steps: (1) pretreating polyester fabric; (2) adding a certain amount of pure disperse dyes into a dyeing medium D5, controlling the amount of the dyeing medium D5, so that a ratio of the weight of a to-be-dyed fabric to the weight of the medium D5 is 1:10 to 1:30, dyeing in a dyeing machine, heating the system to 90-100 DEG C, preserving the temperature for 5-10 minutes, heating to the temperature of 180-200 DEG C, and performing thermosol fixation, wherein the fixation time is 10-30 minutes; and (3) performing reduction clearing on the dyed fabric according to a GB2394-80 method after dyeing. According to the method, non-aqueous medium dyeing is adopted, lots of water resources are saved, the thermosol temperature can be obtained under normal pressure, the conventional dyeing equipment can be adopted, the operation is simple, pure disperse dyes are adopted for dyeing, lots of dispersing aids are saved, the utilization rate of the dyes is improved, wastewater emission is reduced, and ecological environment protection is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

Nitrogen fertilizer solidifying method by active soil, flocculant, adsorbent composite material and fertilizer

This invention discloses active soil and flocculant, absorbent complex material nitrogen fertilizer fixation method. Sagging bar soil, active chitosan, polyacrylamide and nitrogen fertilizer are used as certain ratio to prepare one kind of new style slow release, low cost and high efficiency solid nitrogen fertilizer. Nitrogen ion is absorbed and fixed through above materials synergistic reaction to prevent fertilizer active ingredient dissipating. Fixation time and crop growing fertilizer phase is same, they are fully absorbed by crops and fertilizer draining or volatilizing is reduced. At the same time, because nitrogen element is efficiently prevented from entering water body, water body nutrition controlling and agricultural ecology environment protection is reached. Traditional fertilizer is placed, and fertilizer using dosage can be reduced, so it has great value for controlling water body nutrition source pollution and protecting ecology environment.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

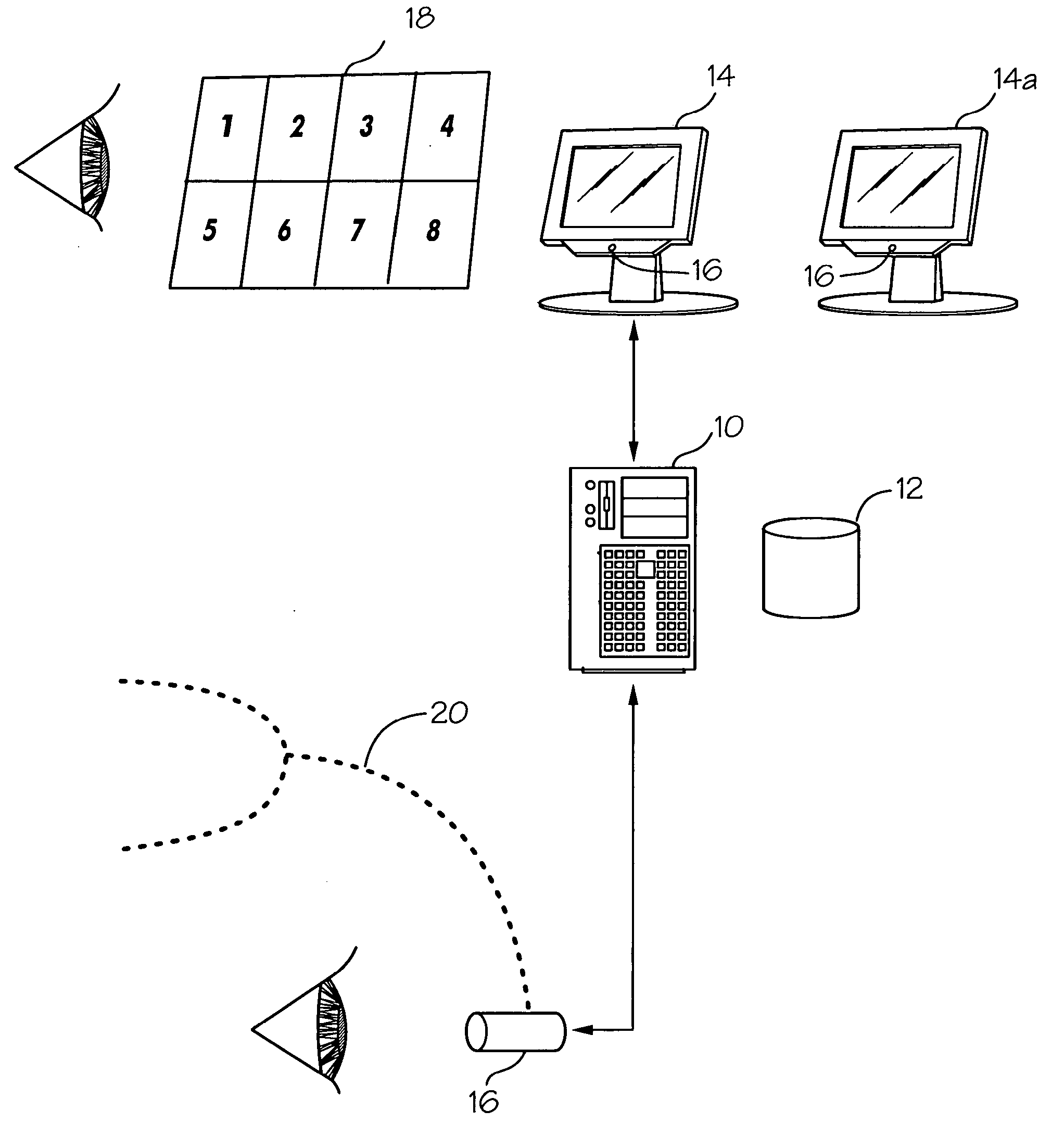

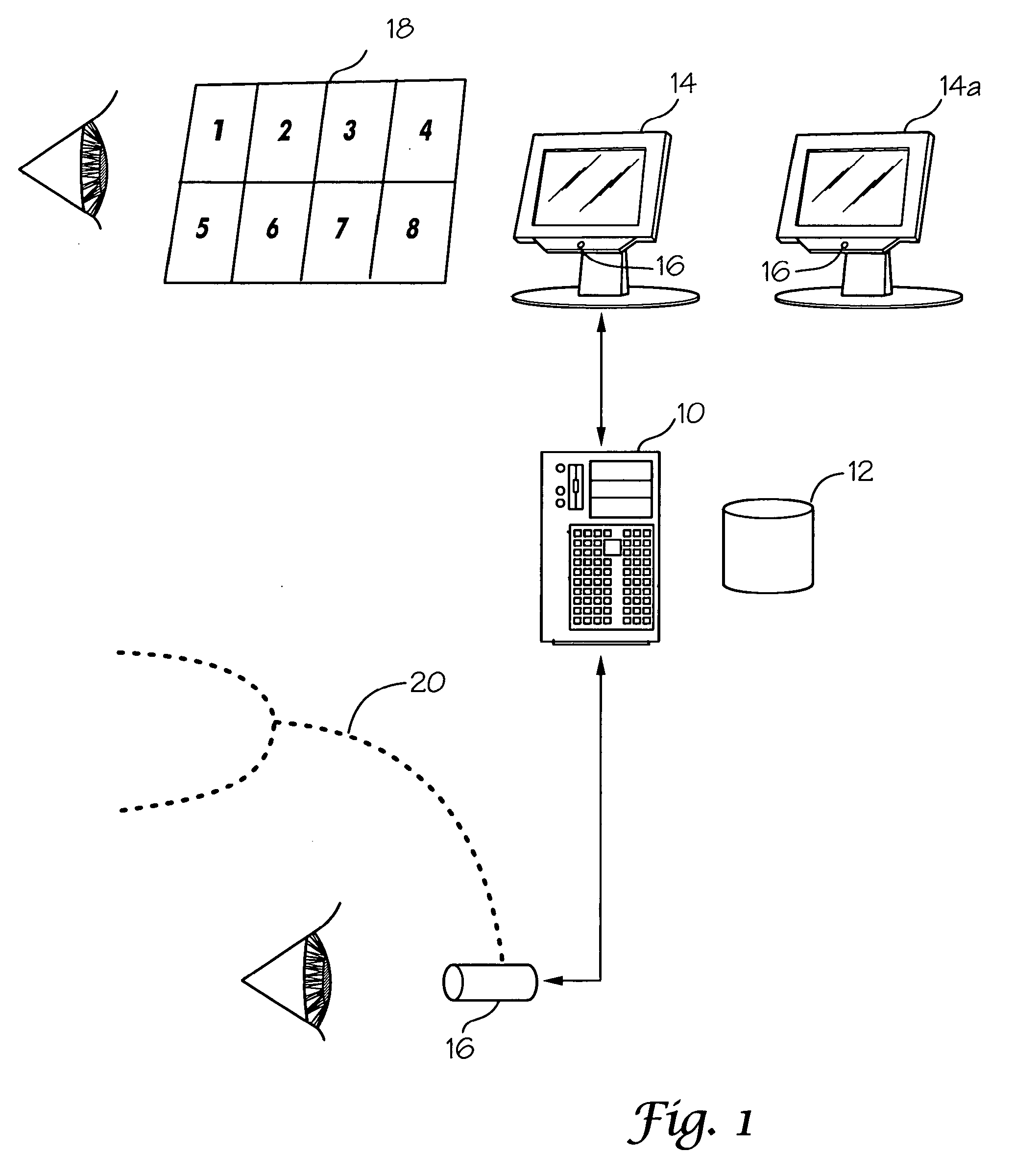

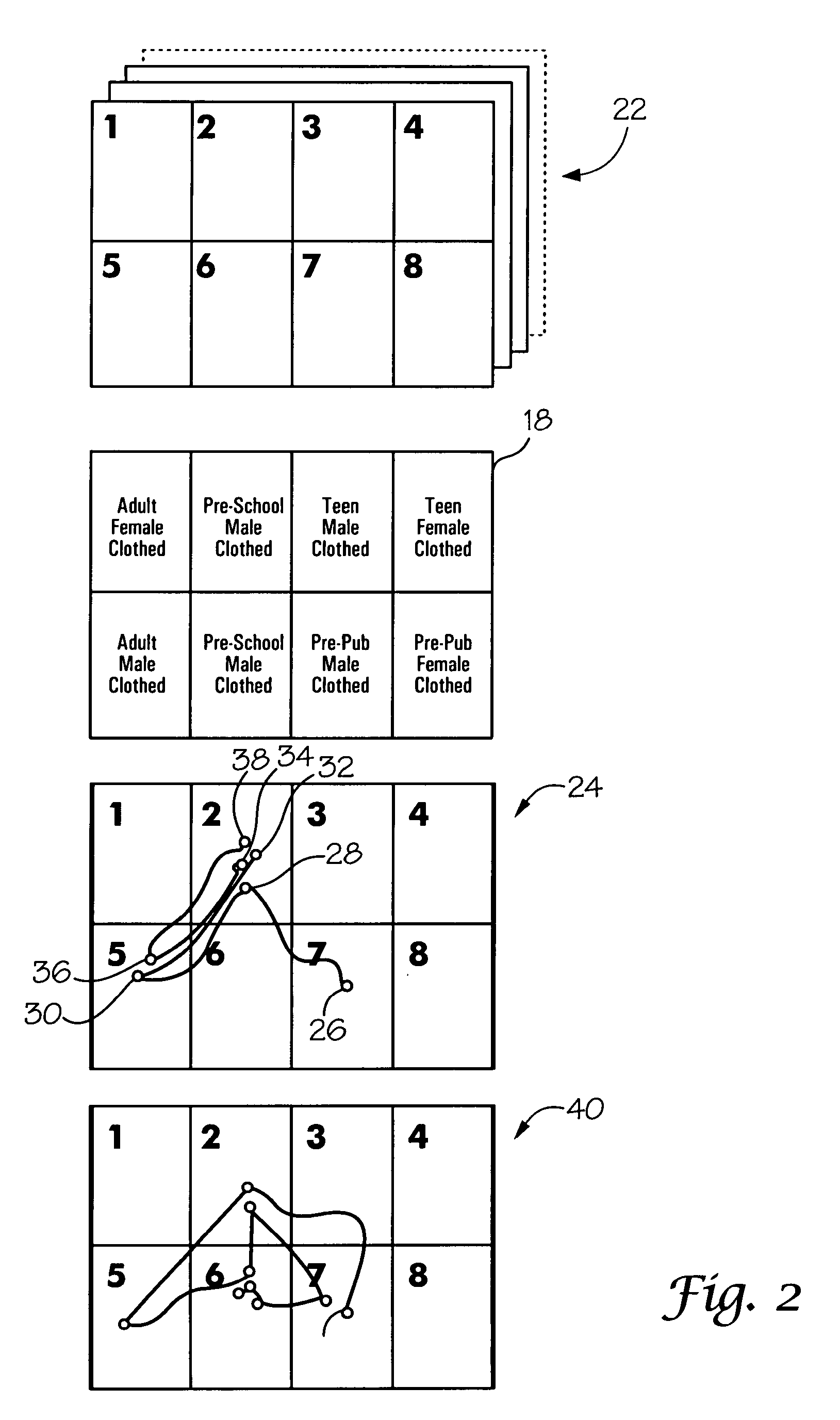

System and method for performing physiological assessments

InactiveUS20090012419A1Person identificationVaccination/ovulation diagnosticsFixation timeDisplay device

A system and method for assessing sexual attention of a test subject comprising: a computer readable medium; a display; an eye-tracking sensor; a set of display sets where each display set has images representing individuals having a plurality of different genders and age groups wherein each display set contains images having a unique combination of gender and age group; and; a set of computer readable instructions embodied in said computer readable medium for display said display sets on said display, determining the test subject's eye fixation time for each image, determining the test subjects saccade time for each displayed image, determining a gaze score according to said fixation time and said saccade time, and determining a gaze score for each combination of gender and age group.

Owner:HEWLETT PACKARD DEV CO LP

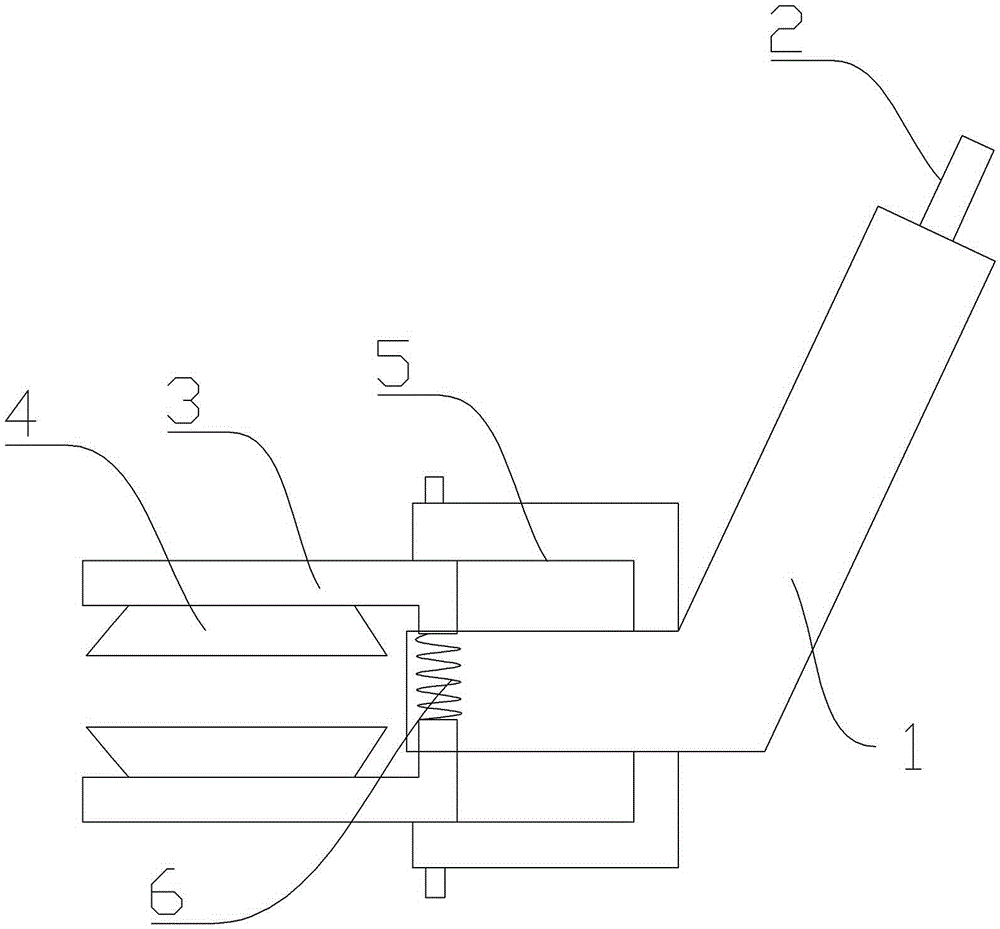

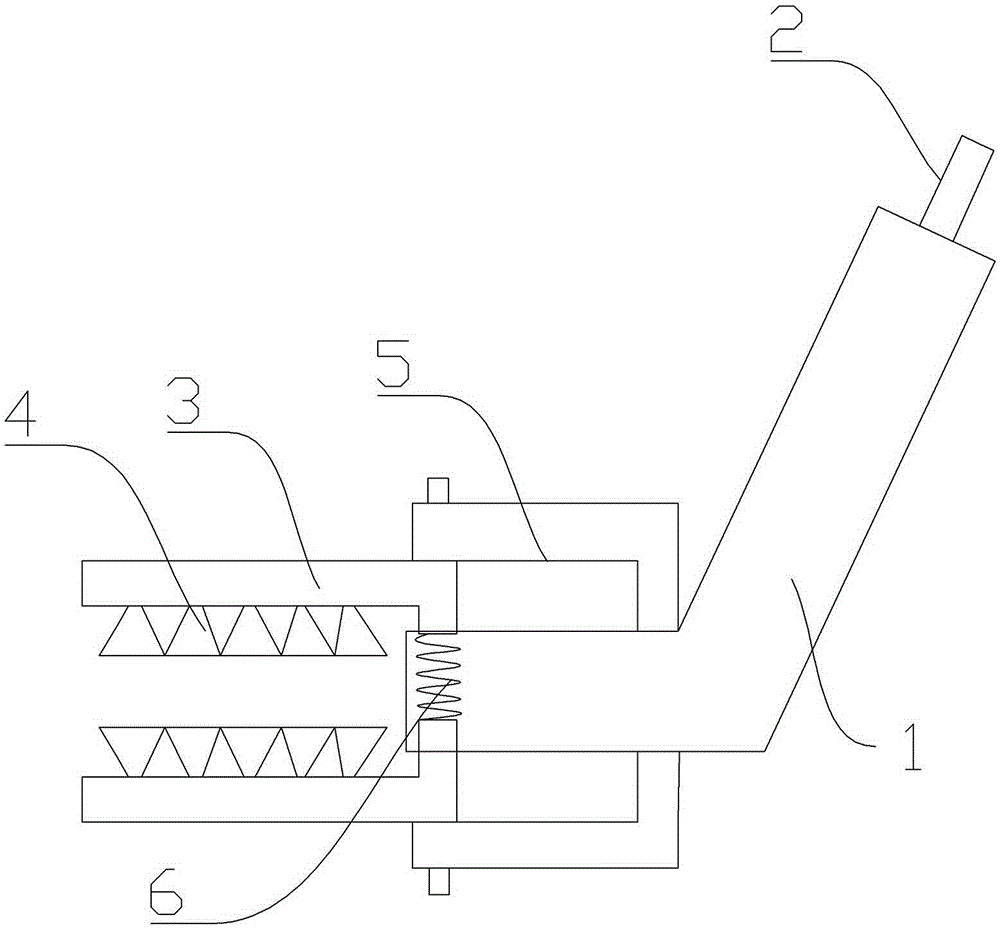

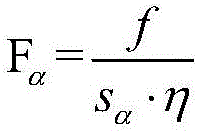

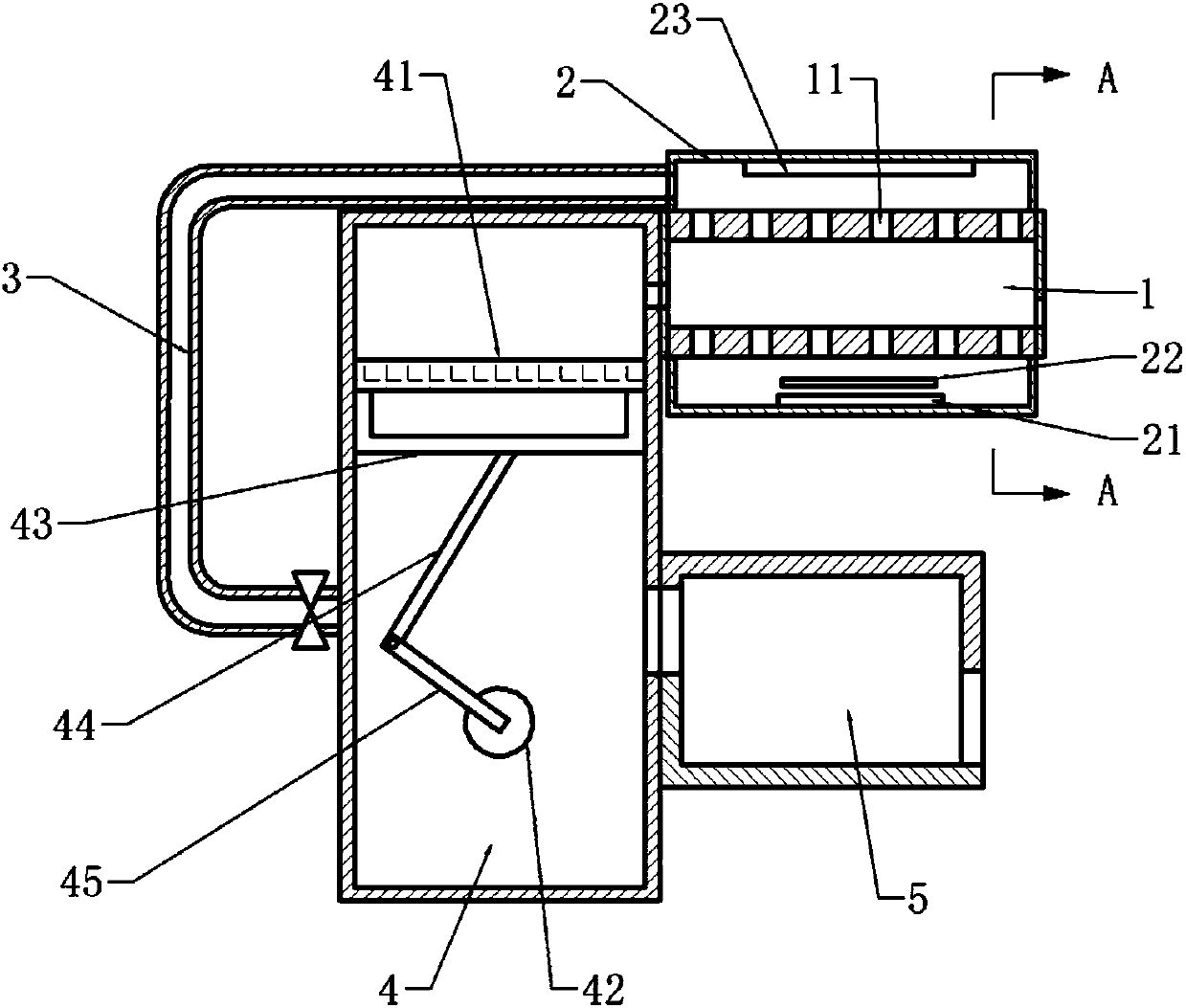

Glass transfer clamping equipment

ActiveCN105417947AImprove fixed timeImprove transmission efficiencyGlass transportation apparatusFixation timeBiochemical engineering

The invention relates to the field of glass processing equipment and in particular relates to glass transfer clamping equipment. The glass transfer clamping equipment comprises a support rod, wherein a connecting rod connected with a transfer mechanism is arranged at one end of the support rod and a clamping mechanism is arranged at the other end of the support rod; the clamping mechanism comprises two parallel clamping plates; suckers are arranged on opposite surfaces of the two clamping plates; the clamping plates are connected with the end of the support rod in a sliding manner; a spring is arranged between the two clamping plates; a compressing plate is also arranged on the support rod; threaded holes are formed in the compressing plate; screws are arranged on the clamping plates and are in threaded connection with the compressing plate by passing through the threaded holes. The glass transfer clamping equipment has the beneficial effects that through relative movement of the screws and the compressing plate, the screws can drive the clamping plates to move to achieve clamping and loosening of glass; the glass transfer clamping equipment is convenient to operate, is fast and firm in clamping and has the effect of greatly increasing the glass fixation time, thus improving the glass transfer efficiency.

Owner:滁州众石玻璃科技有限公司

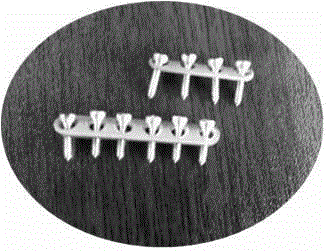

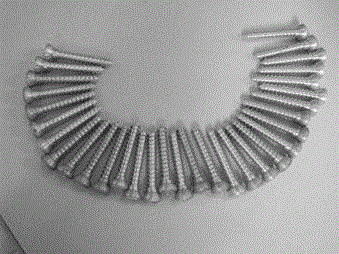

Coated magnesium alloy bone nails, bone plates and cancellous bone screws and preparation method thereof

ActiveCN104623739APromote growthSatisfy the requirement of strong fixed timeSurgeryMetallic material coating processesElemental compositionBiocompatibility Testing

The invention discloses coated magnesium alloy bone nails, bone plates and cancellous bone screws. The magnesium alloy consists of Mg of which the purity is more than 99.99wt%, Zn and adding elements, wherein the adding elements refer to one, two or three in Zr, Sr, Ca and Ag; and the magnesium alloy comprises the following components in percentage by mass: 3 percent of Zn, 0.2-1.0 percent of Zr, 0-1.0 percent of Sr, 0-1.0 percent of Ca, 0.0-1.0 percent of Ag and the balance of Mg. The coated magnesium alloy bone nails, bone plates and cancellous bone screws have the advantages that after being subjected to comprehensive treatment, the magnesium alloy bone nails, bone plates and cancellous bone screws have reasonable degradation rate, capacity of promoting new bone growth in the living body and high biocompatibility; particularly, after the bone nails, bone plates and cancellous bone screws are treated by the mixed aqueous solution of hydrofluoric acid and calcium and phosphorus compounds, the corrosion rate can be regulated by virtue of the thickness of the surface fluorides and fluorapatite layer, and the requirement on rigid fixation time of the bone nails, bone plates and cancellous bone screws before internal fracture fixation within 3 months can be met.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

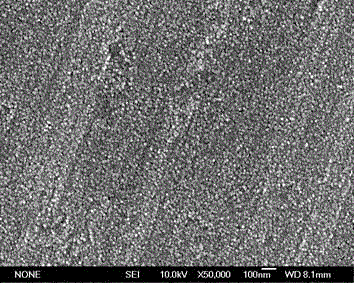

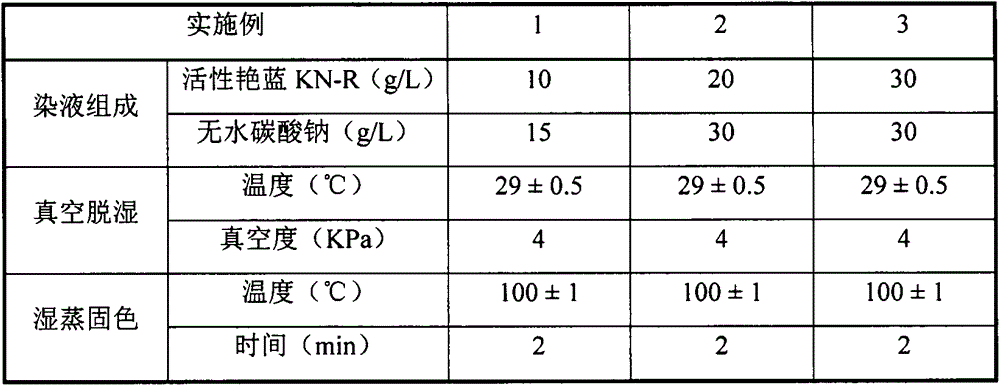

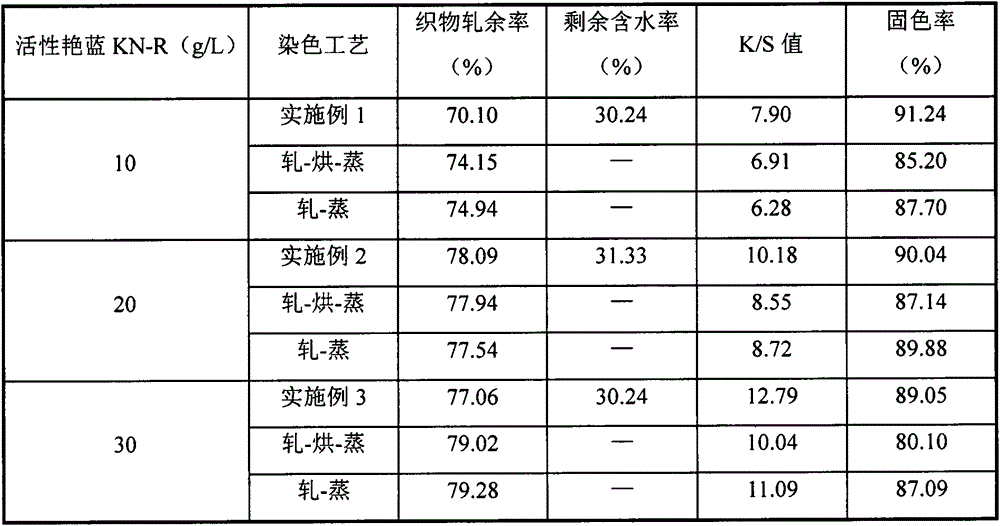

Padding, wet steaming and dyeing method of reactive dye

InactiveCN104532499AFast heating rateRapid dehumidificationLiquid/gas/vapor removalDyeing processFixation timeHigh water content

The invention relates to a padding, wet steaming and dyeing method of a reactive dye, belongs to the technical field of dyeing of textiles, and aims at solving the problems of a traditional padding, wet steaming and dyeing method of the reactive dye, in which cloth is directly steamed after being padded in a dyeing solution, the cloth with high water content is slowly heated, the steaming and fixation time is prolonged, and the reactive dye is highly hydrolyzed. The padding, wet steaming and dyeing method of the reactive dye is characterized in that the cloth is dehumidified in vacuum after being padded in the dyeing solution so as to enable the content of water of the cloth to be quickly lowered down to reach a certain level, then the cloth is steamed and fixed through saturation steam under normal pressure, and finally the cloth is washed with the water to finish the dyeing process. According to the method, the reactive dye is subjected to padding, wet steaming and dyeing, so that the problem that the steaming and fixation conditions fluctuate greatly due to high-water-content cloth in a steaming box can be avoided; the cloth heating rate is increased, the fixation time is reduced, the hydrolyzing of the dye on the cloth in a damp and hot and alkaline environment can be reduced, and therefore, the fixation rate of the reactive dye can be increased.

Owner:TIANJIN POLYTECHNIC UNIV

Method and system for determining student status in remote online teaching

InactiveCN108492648AReal-time monitoring of learning statusLearn about the status of online learningDiagnostic recording/measuringSensorsFixation timeSaccade

The invention discloses a method and a system for determining a student status in remote online teaching. The method comprises steps: eye coordinates of the student acquired by an eye tracker at a preset frequency are acquired; according to the eye coordinates and a corresponding acquisition moment, the fixation time duration and the saccade time duration of the eyes of the student are calculated;and according to the fixation time duration and the saccade time duration, whether the student is in an absent-minded status, an irritable status or a focusing state can be determined. According to the method and the system of the invention, a teacher can be assisted to know the online learning state of the student more comprehensively.

Owner:何戴娆

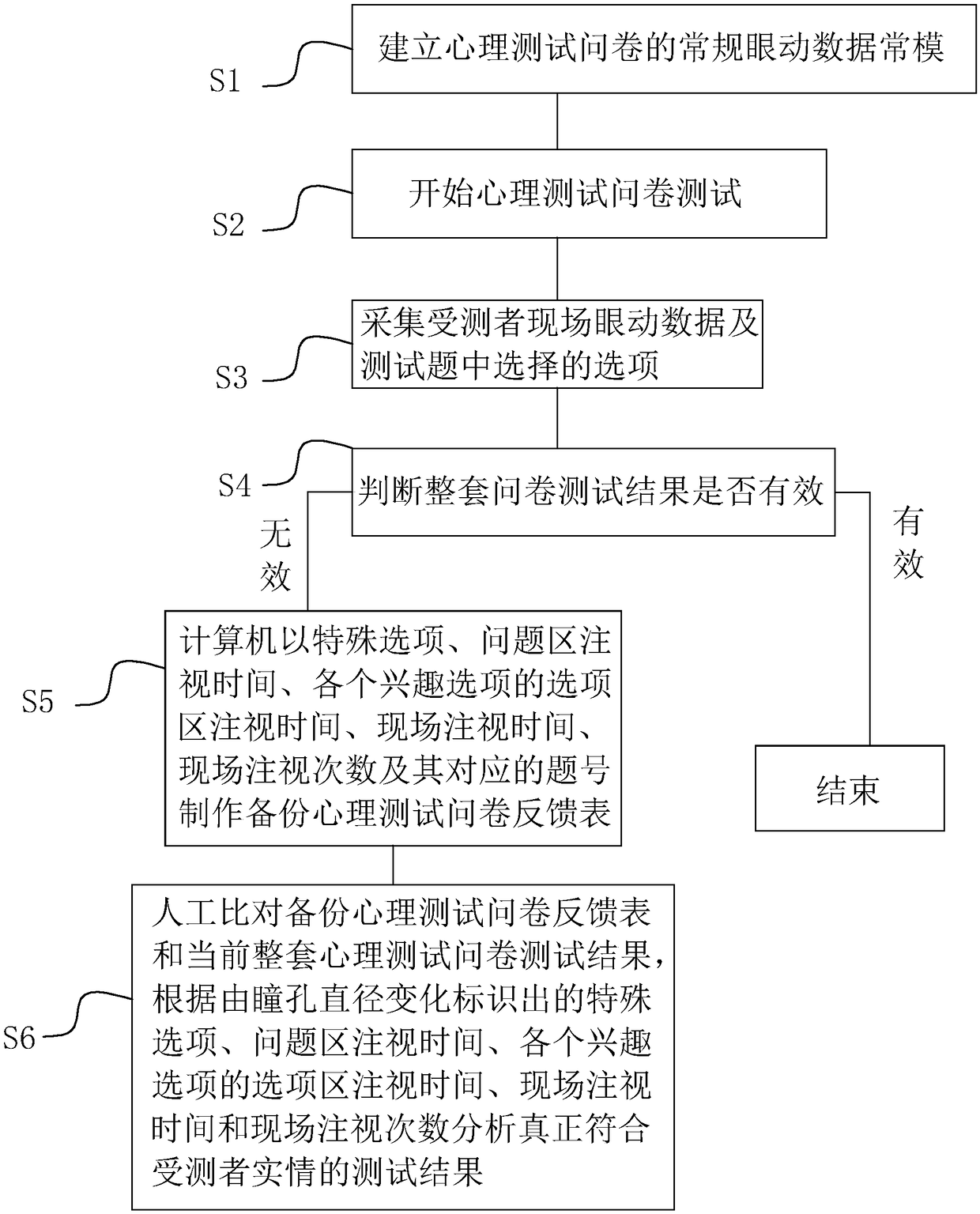

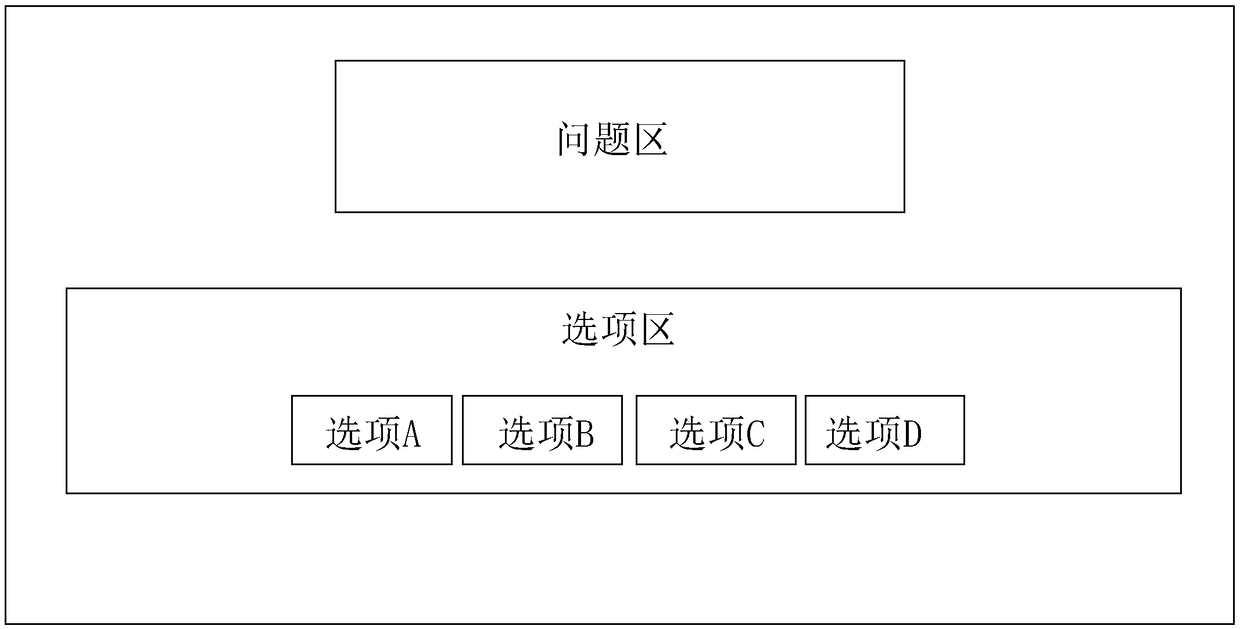

Method for judging reliability of psychological test based on eye movement technology

The invention discloses a method for judging reliability of psychological tests based on an eye movement technology. The method comprises the following steps: step S1, establishing a routine eye movement data norm of a psychological test questionnaire; 2, starting the psychological test questionnaire test; 3, collecting eye movement data of that testee on the spot and options selected from the test questions; 4, judging whether that whole set of questionnaire t result is valid; 5, that compute makes the feedback table of the backup psychological t questionnaire by using the special option, theon-site fixation time, the on-site fixation times and the question number; 6, artificially comparing that feedback table of the backup psychological test questionnaire and the test results of the current whole set of psychological test questionnaires, and analyze the test results which are really in conformity with the actual situation of the testee according to the special options marked by thechange of the pupil diameter, the on-site fixation time and the on-site fixation times. The method can improve the accuracy of the psychological test and avoid the distortion of the test result causedby the reaction deviation and the like of the testee.

Owner:WENZHOU POLYTECHNIC

Preparation method of ultraviolet-proof anti-electromagnetic radiation textile fabric

The invention provides a preparation method of ultraviolet-proof anti-electromagnetic radiation textile fabric. The preparation method is characterized by comprising the following steps: adding PEDOT / PSS (poly(3,4-ethylenedioxythiophene) / polystyrolsulfon acid) aqueous dispersion into a water-soluble polyurethane solution after shaking and dispersing so as to obtain a mixed solution; fully stirring the mixed solution, wherein the PEDOT / PSS aqueous dispersion is 30-60%; the water-soluble polyurethane solution is 40-70%; putting the PEDOT / PSS solution into a padder immersion tank; processing textile base fabric under room temperature through implementing a two-dipping and two-rolling procedure; padding the PEDOT / PSS mixed water solution on a textile, wherein the rolling rate of the textile is 60-80%; putting the padded textile into a high-temperature oven for drying, wherein the temperature of the high-temperature oven is 75-95 DEG C; the high-temperature fixation time lasts for 5-30 minutes, so as to prepare the ultraviolet-proof anti-electromagnetic radiation PEDOT / PS (polystyrene) coated fabric. The method is simple in process, and easy to operate, and the yield is high; the produced textile fabric has the excellent function of preventing ultraviolet rays and radiation.

Owner:QINGDAO UNIV

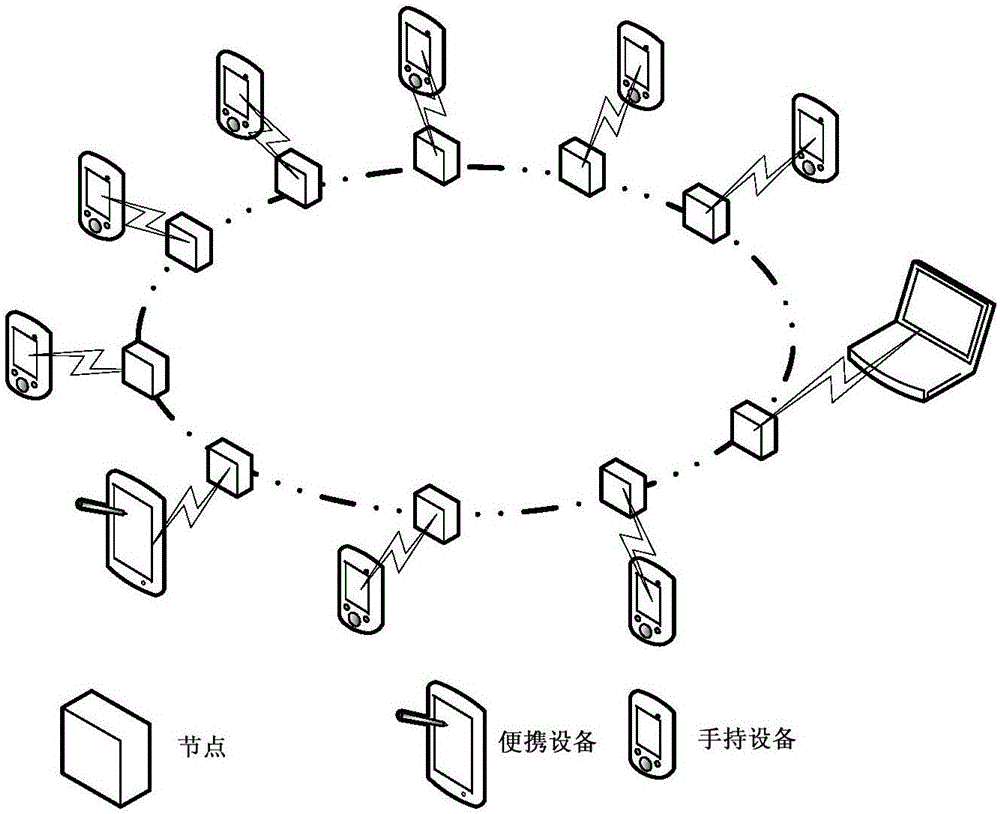

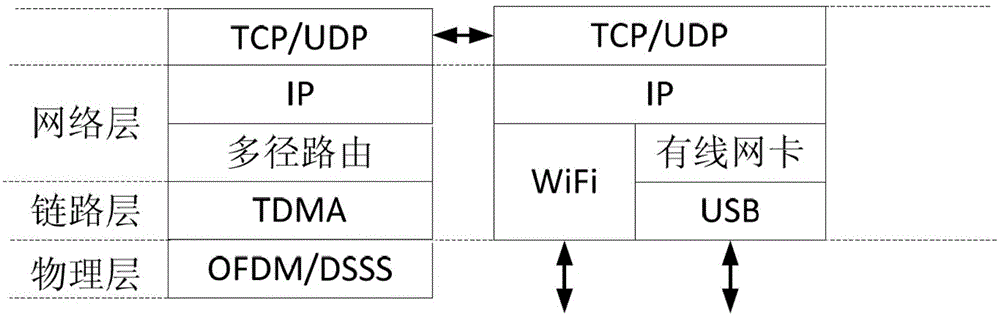

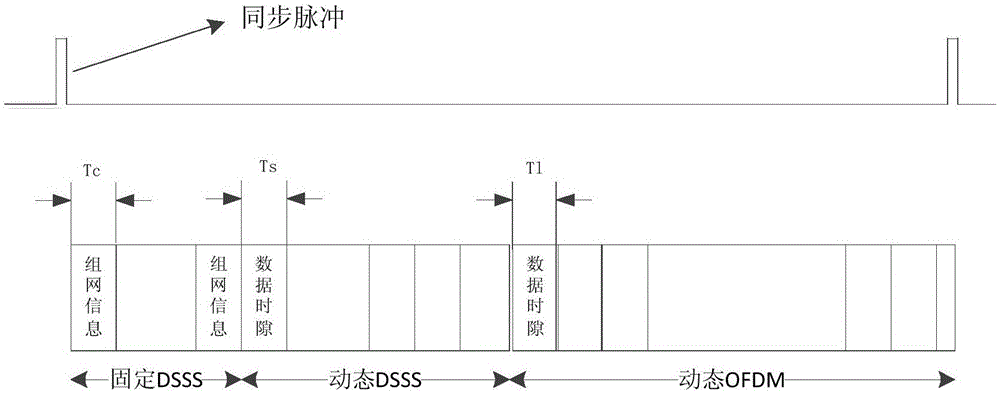

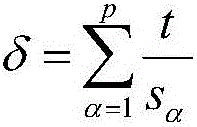

Miniaturized multiservice wireless mobile ad hoc network system

ActiveCN106535207AImprove bandwidth utilizationGuaranteed reliabilityNetwork topologiesNetwork planningHigh rateData information

The invention provides a miniaturized multiservice wireless mobile ad hoc network system. A physical layer comprises a DSSS module and an OFDM module, wherein the OFDM module provides an OFDM protocol for transmitting service data information with a higher rate requirement, the DSSS module provides a DSSS protocol for transmitting network maintenance and control information of each node and service data information with a lower rate requirement. A link layer employs a TDMA mode to segment time into periodic frames and then segments the frames into DSSS fixation time slot portions, DSSS dynamic time slot portions and OFDM dynamic time slot portions. A network layer provides a multipath route protocol for transmitting all information, employs an active route mode to maintain one-hop neighbor nodes and employs an on-demand route mode to maintain neighbor nodes of more than one hop. The wireless mobile ad hoc network system can simultaneously satisfy a miniaturization transmission requirement and a multiservice transmission requirement.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

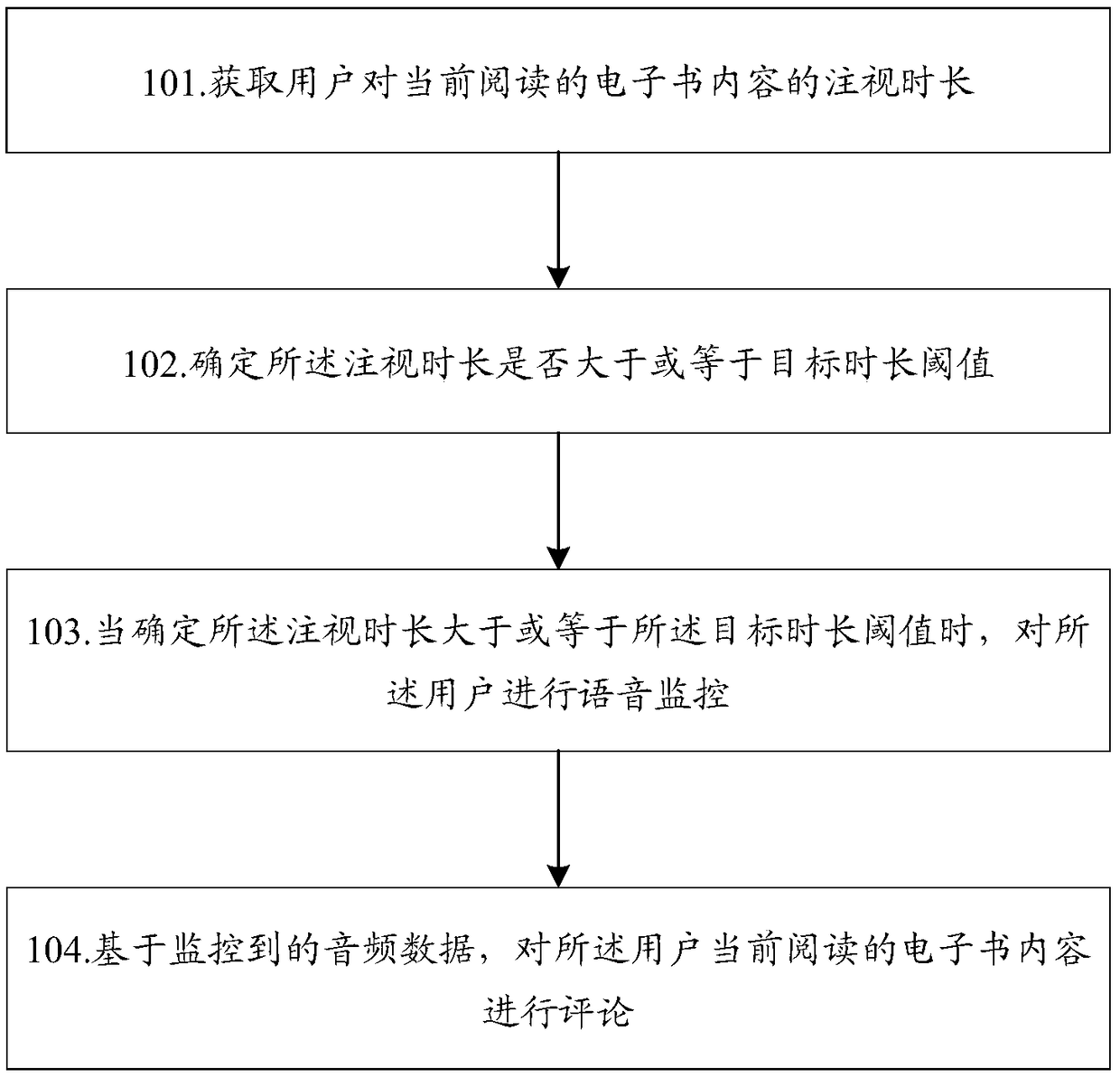

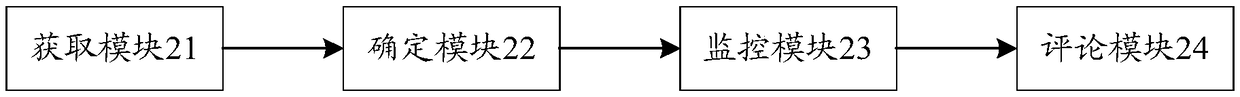

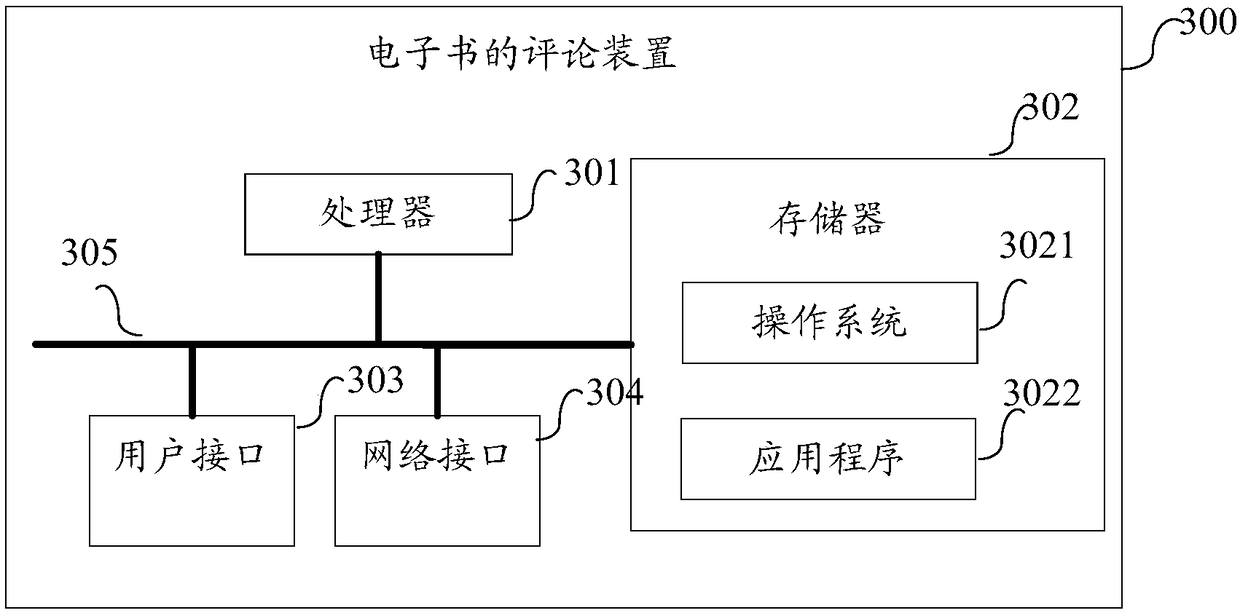

Electronic book comment method and device and computer readable storage medium

ActiveCN109343696AImprove experienceComment quick implementationInput/output for user-computer interactionNatural language data processingFixation timeElectronic book

The invention discloses an electronic book comment method, which comprises the following steps of acquiring the fixation time length of a user to the currently read electronic book content; determining whether the fixation duration is greater than or equal to a target duration threshold; performing voice monitoring on the user when it is determined that the fixation is longer than or equal to thetarget duration threshold; based on the monitored audio data, commenting the content of the e-book currently read by the user. The invention also discloses an electronic book comment device and a computer-readable storage medium.

Owner:MIGU DIGITAL MEDIA CO LTD +2

Process for cotton reactive dye applying in silk broadcloth dying

The invention relates to a technique for dyeing silk fabrics by a cotton reactive dye. The technical problem to be solved is that the technique needs to dye silk fabrics by the cotton reactive dye effectively, has the characteristics that the dye uptake is high, the fixation ratio is high, the color depth of the product is increased greatly, the coloring matter is saved and the dyeing quality is high; moreover, the residual liquid discharge concentration is decreased and the environment is protected. The technical proposal is to adopt the cotton reactive dye for dyeing silk fabrics and has the following steps that: 1) the silk broadcloth after the pre-treatment is placed into a dye vat, a dye solution is prepared and is added into the dye vat to dye, the dye solution has a pH value ranging from 6.5 to 7.5, the dye temperature ranges from 85 to 98 DEG C, the dye time lasts one to two hours; 2) the dye residual solution is discharge partially or completely, clear water is added, the temperature is adjusted to 50 to 60 DEG C; 3) certain amount of ammonium polycarylate is added to fix the color, the pH value is kept to be 9 to 10, the fixation time lasts one to two hours, the temperature of the clear water ranges from 4 to 20 DEG C.

Owner:HIGH FASHION CHINA CO LTD

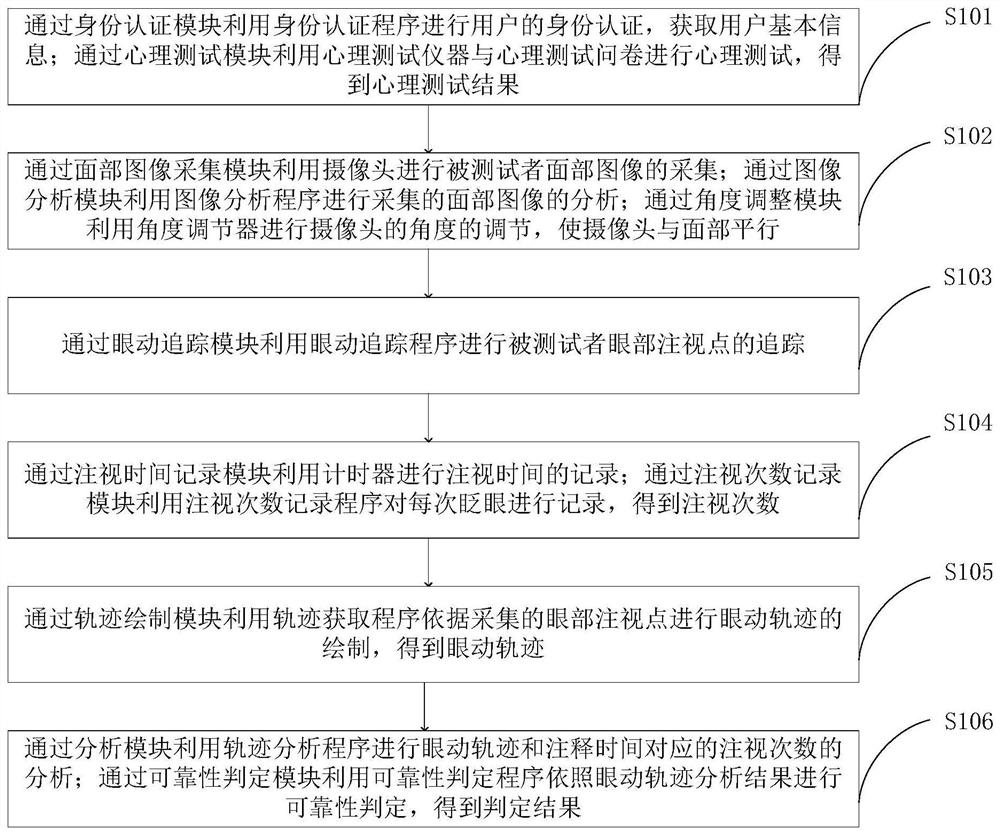

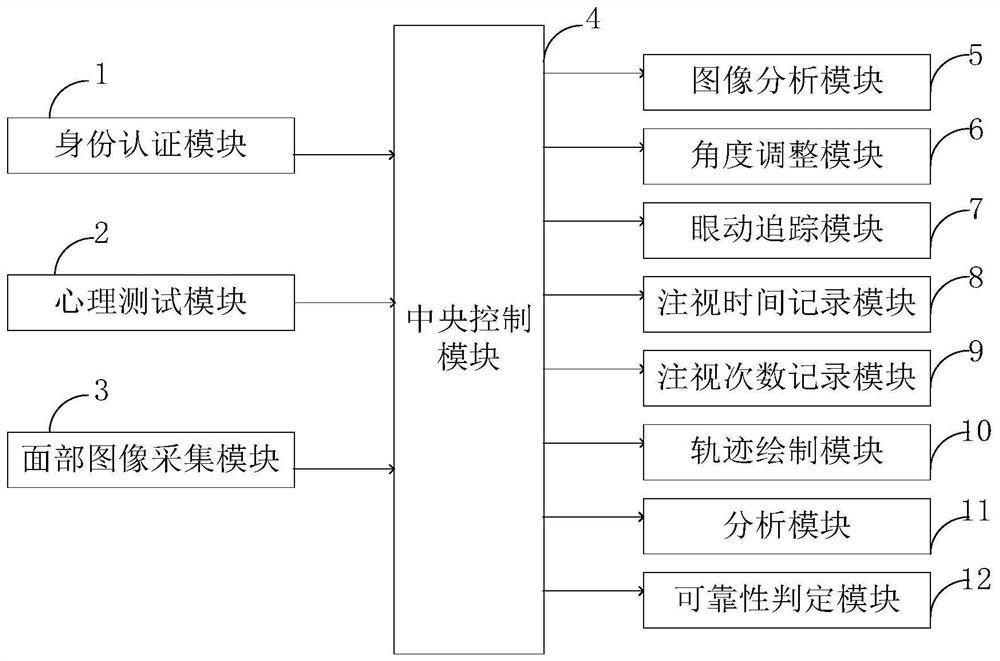

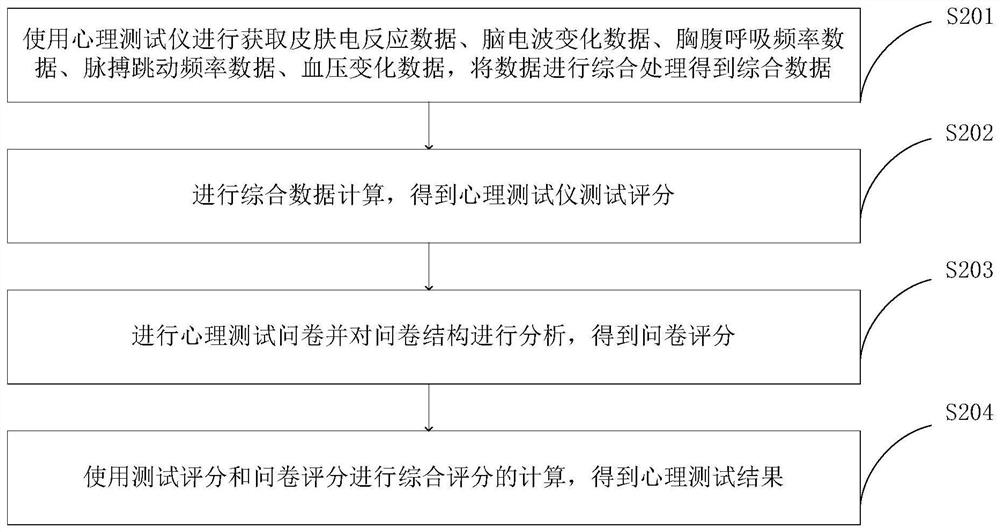

System and method for judging psychological test reliability based on eye movement technology

PendingCN112472089AImprove accuracyDiagnostic signal processingMental therapiesPhysical medicine and rehabilitationImaging analysis

The invention belongs to the technical field of psychological tests, and discloses a system and a method for judging psychological test reliability based on an eye movement technology. The system forjudging the psychological test reliability based on the eye movement technology comprises an identity authentication module, a psychological test module, a facial image acquisition module, a central control module, an image analysis module, an angle adjustment module, an eye movement tracking module, a fixation time recording module, a fixation frequency recording module, a trajectory drawing module, an analysis module and a reliability judgment module. The psychological test instrument and the psychological questionnaire are subjected to dual detection, and the obtained psychological test result is more accurate. After the psychological test results are obtained, the eye movement technology is adopted for reliability evaluation, the accuracy of state monitoring during psychological test of the testee can be improved, whether the psychological test results are effective or not is judged, psychological test response deviation caused by various factors is selected, and the test accuracyis improved.

Owner:HENGYANG NORMAL UNIV

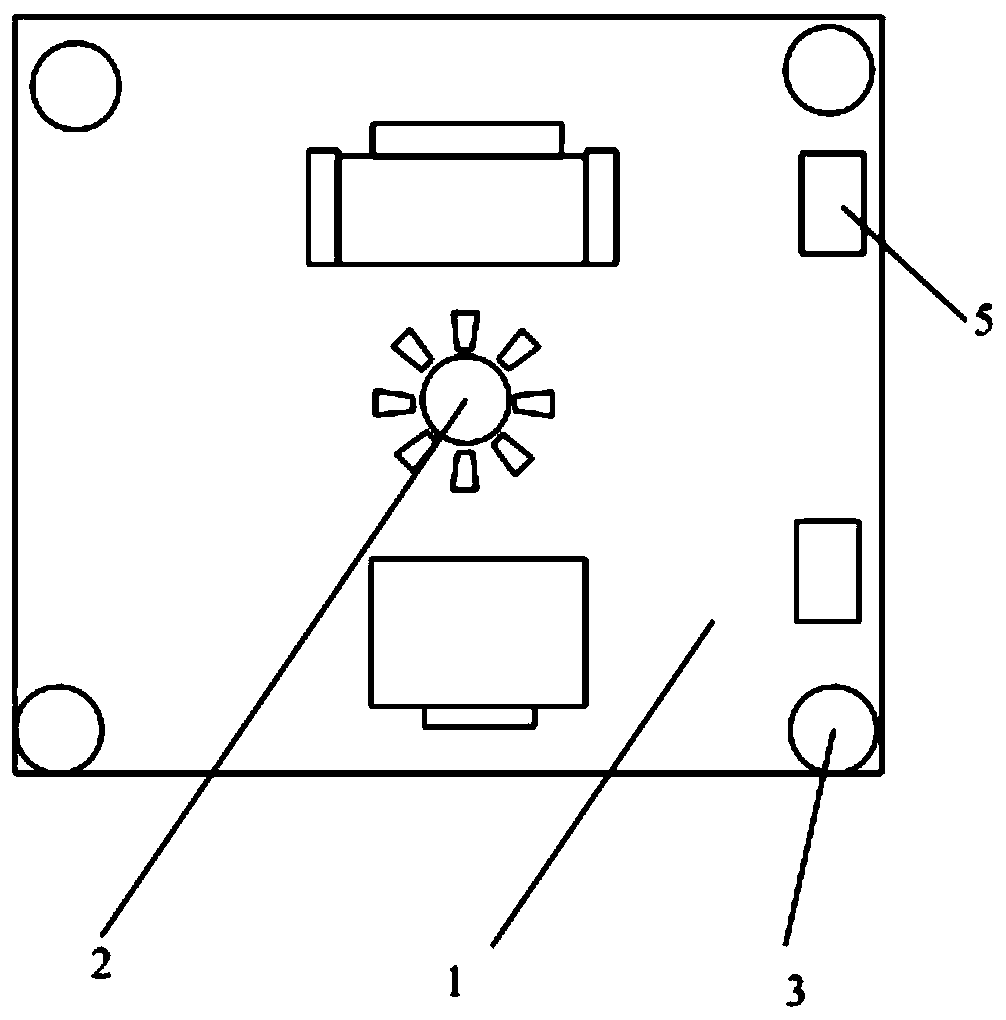

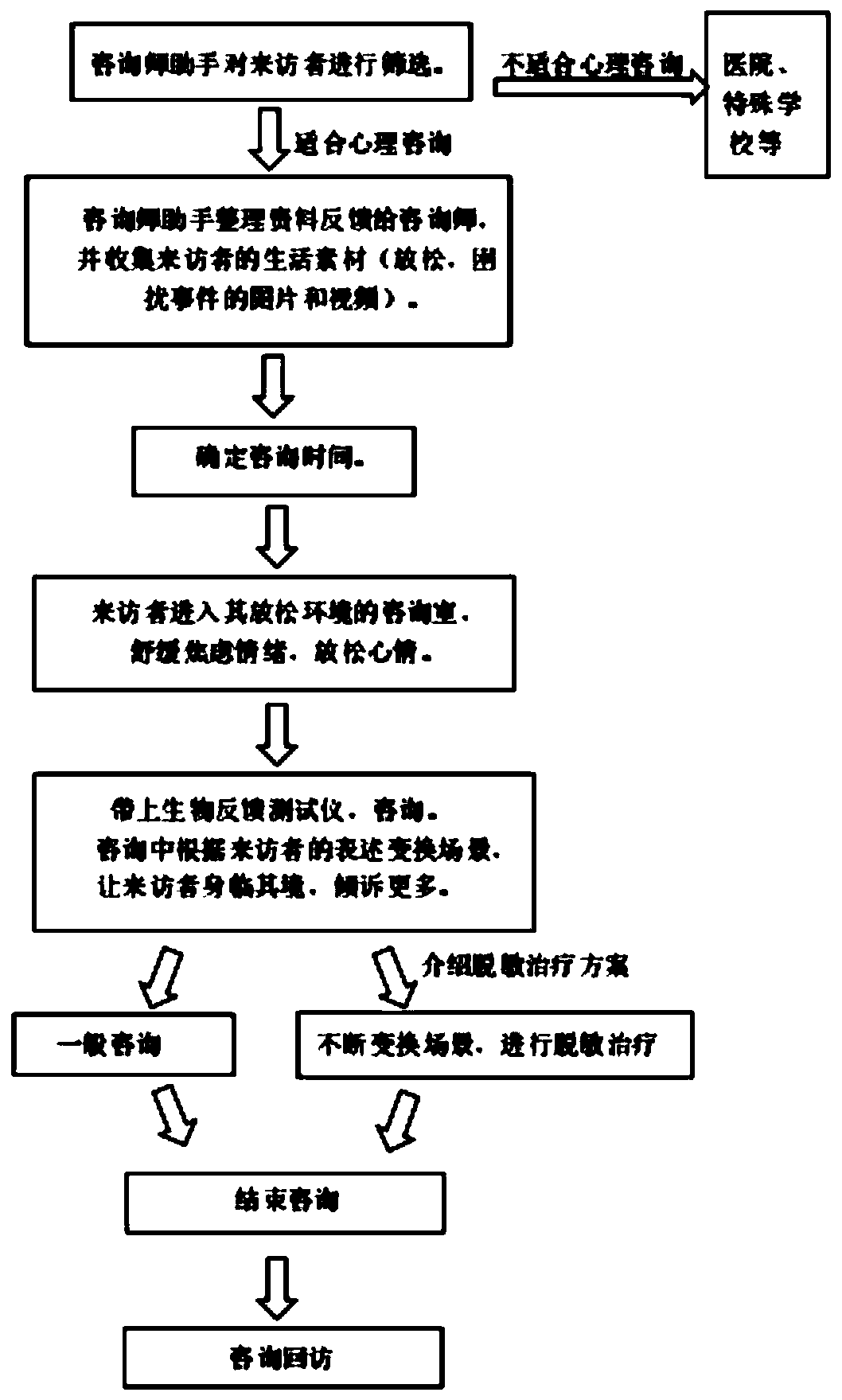

Panoramic psychological counseling room and its counseling system

PendingCN110090346AEffective induction to overcome psychological factorsGood treatment effectElectrocardiographyMedical devicesFixation pointFixation time

The invention provides a panoramic psychological counseling room, which comprises a closed space, and a laser projector disposed above the closed space for playing different panoramic images in the closed space, so that a therapist feels in different environments and the scenes; a LED bottom display screen disposed at the bottom of the closed space to adjust the bottom situation of the closed space; an eye tracker disposed above the closed space, wherein the eye tracker tracks an eye track signal of the therapist, and extracts the data such as the fixation point, the fixation time and the frequency, saccade amplitude, the pupil size and the like; wherein the eye tracker is connected to a following control module; a physiological information collector connected to the controller described below; and the controller acquiring a human physiological signal and an eye movement trajectory signal, and converting the human physiological signal and the eye movement trajectory signal into readable data, and displaying the data to a consultant through a display screen connected to the controller.

Owner:郝东

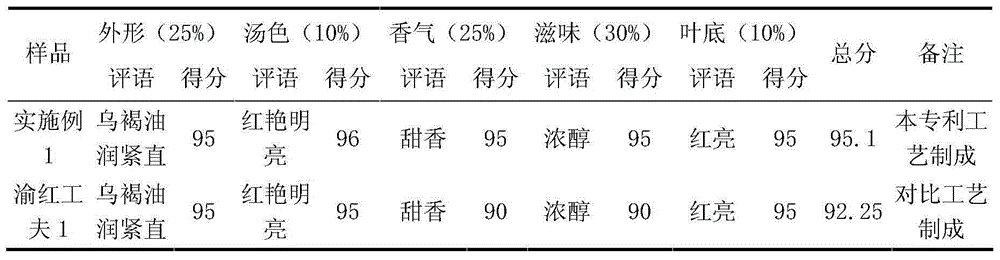

Processing method of high-quality black tea

ActiveCN105028716AConsistent qualityEasy to shapePre-extraction tea treatmentCooking & bakingFixation time

The invention discloses a processing method of a black tea. The processing method sequentially comprises the following steps: selecting raw materials; picking; withering; kneading; fermenting; steaming and dehydrating; re-kneading; shaping; primarily baking; stacking and re-baking, wherein the processing method is characterized in that a steam-heating fixation machine is adopted for steaming and dehydrating; when the steam temperature reaches 150-160 DEG C and the hot air temperature reaches 100-110 DEG C, leaves are evenly fed; the leaf feeding amount is 1Kg / min; the fixation time is controlled within 35-40 seconds; the hot air dehydration time is controlled within 90-120 seconds; and the moisture content of the dehydrated leaves is 55%-65%. The black tea obtained by the processing method of the black tea is tight, fine and straight in appearance, black in color and luster, visible in golden tip, red and bright in soup, sweet, fragrant, high in purity, mellow and brisk in taste, sweet in aftertaste, bright and living in infused leaf, regular and intact; the dry tea is straight and robust in appearance; the tea soup is red and bright in color and luster; the fragrance is strong and sweet; the soup is strong, red and bright; and the taste is fresh and strong.

Owner:CHONGQING YUNLING TEA IND TECH

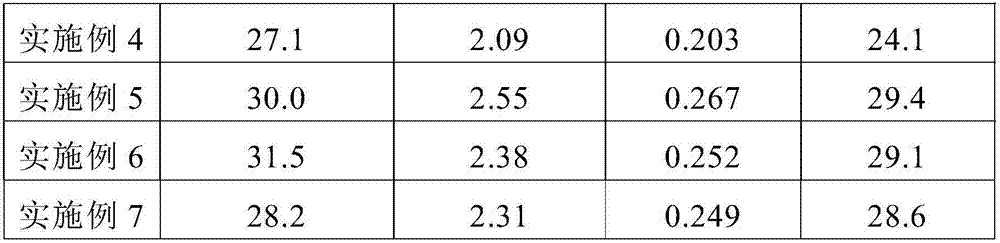

Selenium-rich Ampelopsis grossedentata tea and production method thereof

PendingCN107242072AImprove qualityPromote growth and developmentSuperphosphatesExcrement fertilisersAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses selenium-rich Ampelopsis grossedentata tea and a production method thereof; the production method comprises the steps of (1) producing microbial fermented fertilizer; (2) producing nutrient compound fertilizer; (3) applying the fertilizers; (4) performing field planting; (5) fixing; (6), rolling, and drying. The selenium-rich Ampelopsis grossedentata tea and the production method thereof have the advantages that the influence of fertilizing conditions upon the main quality ingredients and active ingredients of Ampelopsis grossedentata tea are studied to seek high quality and high selenium content fertilizing conditions of Ampelopsis grossedentata; by applying the nutrient compound fertilizer, it is possible to provide corresponding nutrients for Ampelopsis grossedentata, improve physiochemical traits of soil and promote the absorption and utilization of soil nutrients, and accordingly, plant growth and development and quality improvement are promoted; optimal process parameters for fixation of Ampelopsis grossedentata tea are studied, the influences of the different fixation modes such as microwave fixation, bleaching fixation and steam fixation upon the quality of Ampelopsis grossedentata tea are studied in terms of fixation time, leaf addition, fixation mode and the like, and it is ensured that the nutrients of the Ampelopsis grossedentata tea are finally absorbed and utilized by human bodies.

Owner:滁州市恩典硒文化传媒有限公司

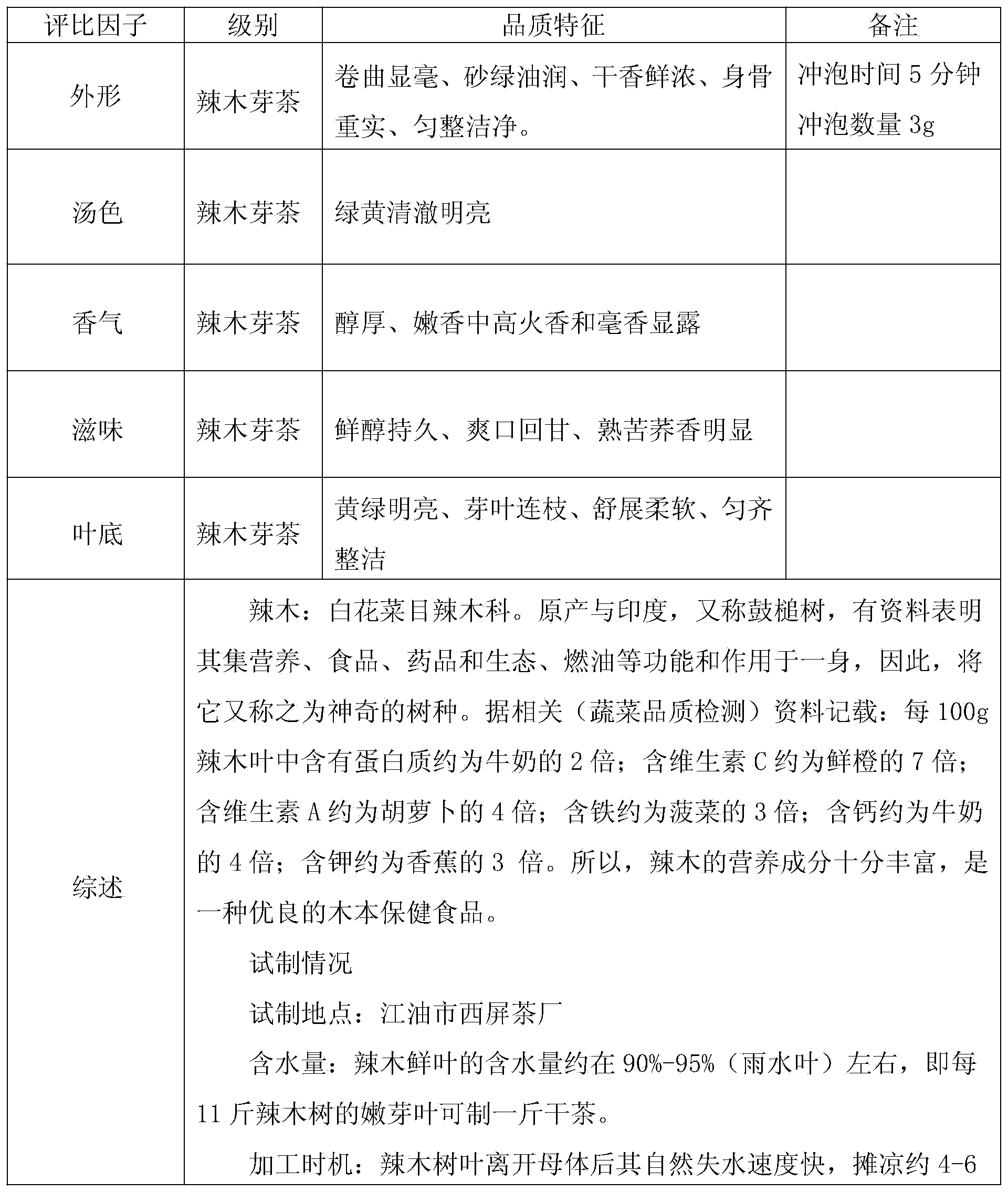

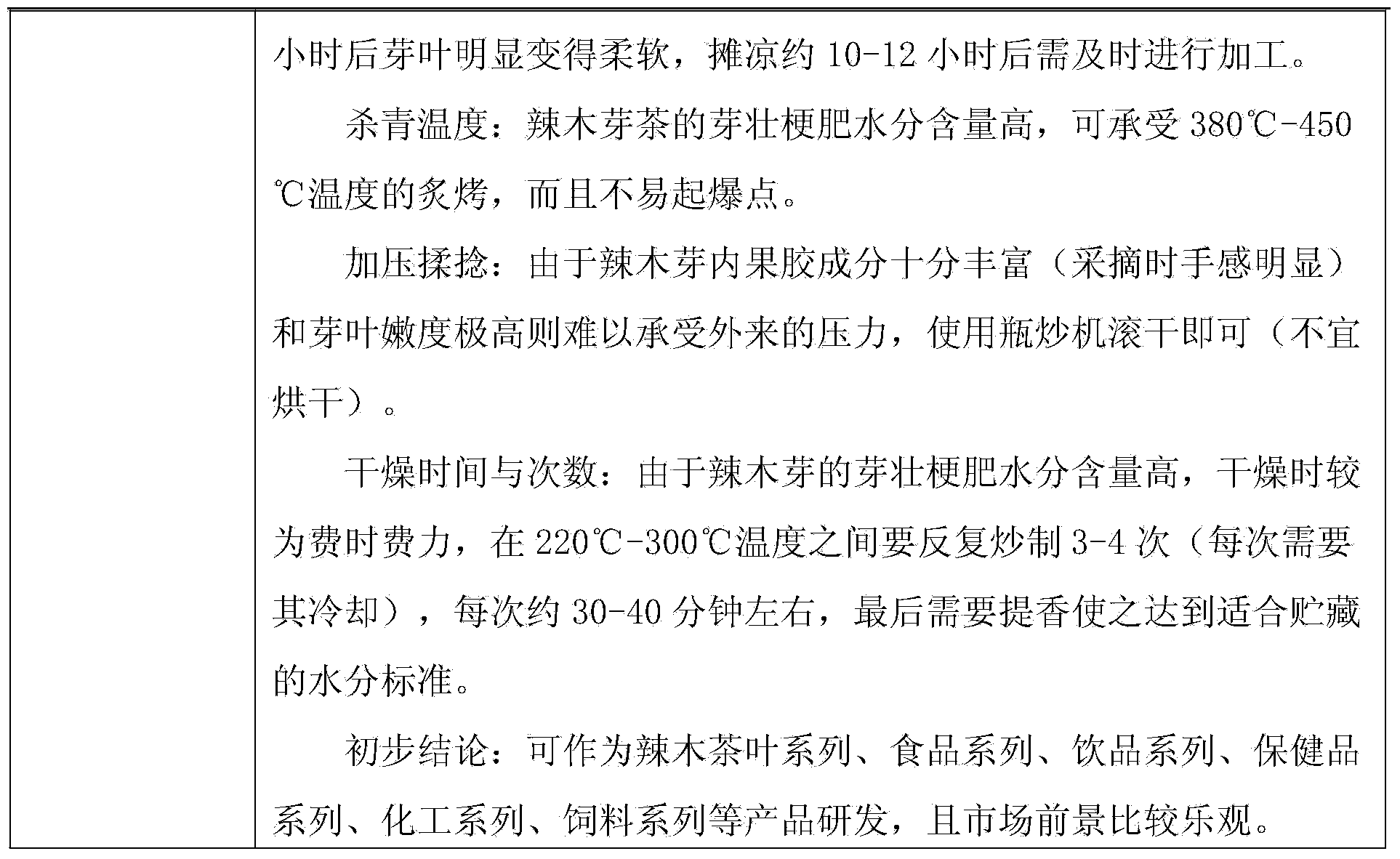

Production method of moringa bud tea

InactiveCN104322723AHigh surface finishPreserve nutrientsPre-extraction tea treatmentMoringaHigh humidity

The invention discloses a production method of moringa bud tea. The production method of moringa bud tea comprises the following steps: picking the raw material, namely picking buds of moringa trees which are moringa buds as the raw material; spreading and airing the raw material for the first time; carrying out fixation, namely firstly carrying out fixation by a continuous roller fixation machine or a bottle type tea frying machine under the conditions as follows: the temperature of the continuous roller fixation machine is 380-400 DEG C, the material feeding capacity is 12-600kg, the rotation rate of the fixation machine is 45-55 revolutions per minute, the fixation time lasts for 40-50 minutes, and the fixation time of the bottle type tea frying machine lasts for 40-50 minutes; then carrying out fixation by a microwave fixation machine under the conditions as follows: the temperature is 140-160 DEG C and the fixation time lasts for 0.5-2 minutes; spreading and airing for the second time; primarily rolling; spreading and airing for a third time; rolling for a second time; spreading and airing for a third time; spreading and airing for a fifth time; drying; and checking, packaging, storing the tea in a storehouse and completing the production of the moringa bud tea. By virtue of the method of firstly carrying out fixation by the roller or bottle type tea frying machine, and then carrying out microwave fixation, most of moringa taste and herbaceous taste are volatilized under the conditions of high temperature and high humidity; meanwhile, the nutritional components are preserved; the quality of the moringa bud tea is improved.

Owner:JIANGYOU AOZHONG AGRI DEV

Preparation method of ultraviolet-proof antistatic graphene coating textile fabric

ActiveCN103469555BSimple production processEasy to operateVegetal fibresGraphene coatingFixation time

Owner:QINGDAO UNIV

Fixation method for folium mori tea

ActiveCN103999961AKeep the fragranceKeep the colorPre-extraction tea treatmentFixation timeFixation method

The invention discloses a fixation method for folium mori tea. The fixation method is characterized by comprising the following steps: putting picked and selected folium mori into boiling water; boiling while agitating to remove dirt on the folium mori and the grass smell; then fishing out the boiled folium mori and putting the folium mori into cold water for fixing the color; and dehydrating the folium mori with the fixed color, kneading, drying and improving the aroma to obtain the folium mori tea. The time spent on boiling and agitating the folium mori is 90-180 seconds. The step of fixing the color in the cold water is carried out at a water temperature of 10-20 DEG C. The fixation method is short in fixation time and the temperature is not very high so as to be good for keeping useful substances in the folium mori; meanwhile, the faint scent and the color of the folium mori are also kept so that the aims are completely reached.

Owner:南充尚好桑茶有限公司 +1

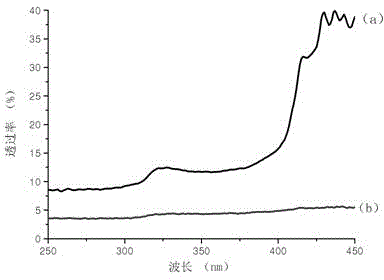

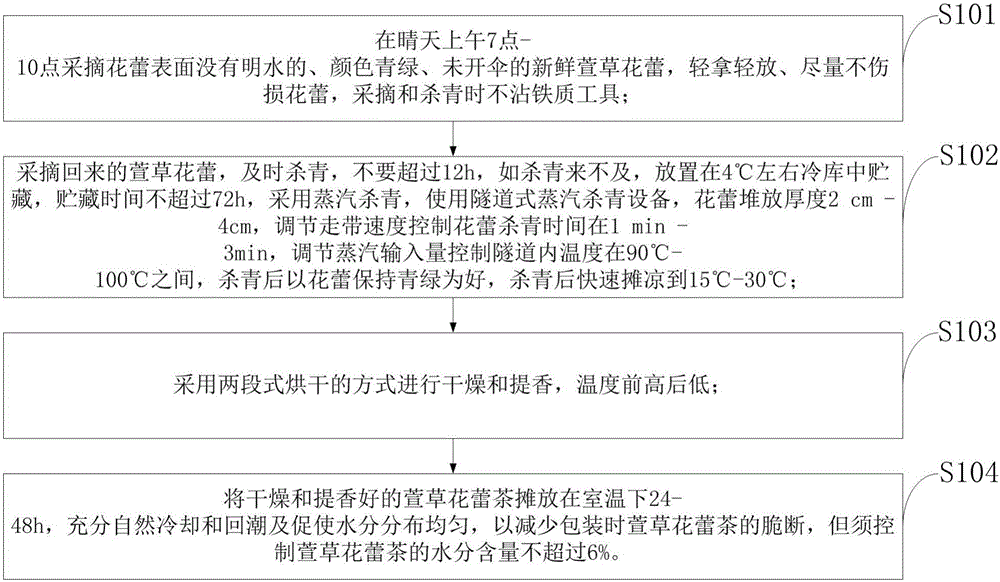

Preparing method of day lily bud tea

The invention discloses a preparing method of day lily bud tea. The preparing method comprises the steps that fresh day lily buds are picked; the picked day lily buds are subjected to fixation with steam, the bud fixation time is 1-3 min, the temperature in a tunnel is 90-100 DEG C, and the buds are rapidly spread and aired to the room temperature after fixation; drying and fragrance extraction are performed with a two-section type drying method, and the temperature is high before and low after; the dried and fragrance-extracted day lily bud tea is spread under the room temperature for 24-48 h, full cooling, moisture regain and moisture uniform distribution are performed, and the moisture content of day lily bud tea is controlled not to be higher than 6%; according to the day lily bud tea prepared with the method, the bar shapes are perfect and regular, the color quality is superior, the fragrance is delicate, and the day lily bud tea can be brewed for drinking and can also be used and eaten like dry day lily; the turquoise of the day lily bud tea can be maintained by steam fixation, and no black spot occurs to bud tips; the two-section tunnel type drying method is adopted, the temperature is high before and low after, the luster is well kept, and the fragrance is the best.

Owner:NANJING LONGZHUANG BIOTECH

Dyeing and finishing technology for silkworm silk fabrics

The invention relates to a dyeing and finishing technology for silkworm silk fabrics. The steps comprises: firstly, a processing solution is prepared, ammonium hydroxide, an acetic acid solution and hydrogen peroxide are mixed fully, the pH value of the processing solution is adjusted to 3, the bath ratio is 1:30, and the temperature is risen to 25 DEG C; silkworm silk fabrics are placed in a water bath with a temperature of 25 DEG C and processed for 3-5min, then the temperature is risen to 60 DEG C, and processing is carried out for 30-40min; the silkworm silk fabrics are subjected to pre-setting and soft processing, then the processed silkworm silk fabrics are subjected to dyeing, namely, anhydrous sodium sulphate, an alkaline agent and dye are added at a room temperature, and fabrics after dyeing are obtained; then the fabrics are subjected to water washing and acid washing at a normal temperature, then are immerged into a soap washing solution, are washed for 10-20min and then are subjected to dye fixation, the dye fixation time is 20-30min, and finally setting is carried out on a setting machine. The dyeing and finishing technology is advantaged by environmentally friendly raw materials, simple operation, easy control and stable dyeing performances.

Owner:JIANGSU XINFANG TEXTILE GROUP

Method for automatically determining layout area of safety sign at construction site

InactiveCN107180310AArrange the area reasonablyImprove scienceCharacter and pattern recognitionEye diagnosticsVisit timeFixation time

The invention discloses a method for automatically determining a layout area of a safety sign at a construction site. In the method, the eye movement indicators such as the visit time, fixation times, pupil diameter, regression times and the like of operating staff to each area at a construction site are captured in real time by an eye tracker, main concerns of the operating staff are automatically found out, and the layout area of the safety sign is determined. According to the invention, the rationality of the layout area of the safety sign at the construction site can be improved, the precaution ability of the operating staff is thus improved, and the occurrence of accidents is reduced or avoided.

Owner:CHINA THREE GORGES UNIV

Tea leaf processing method

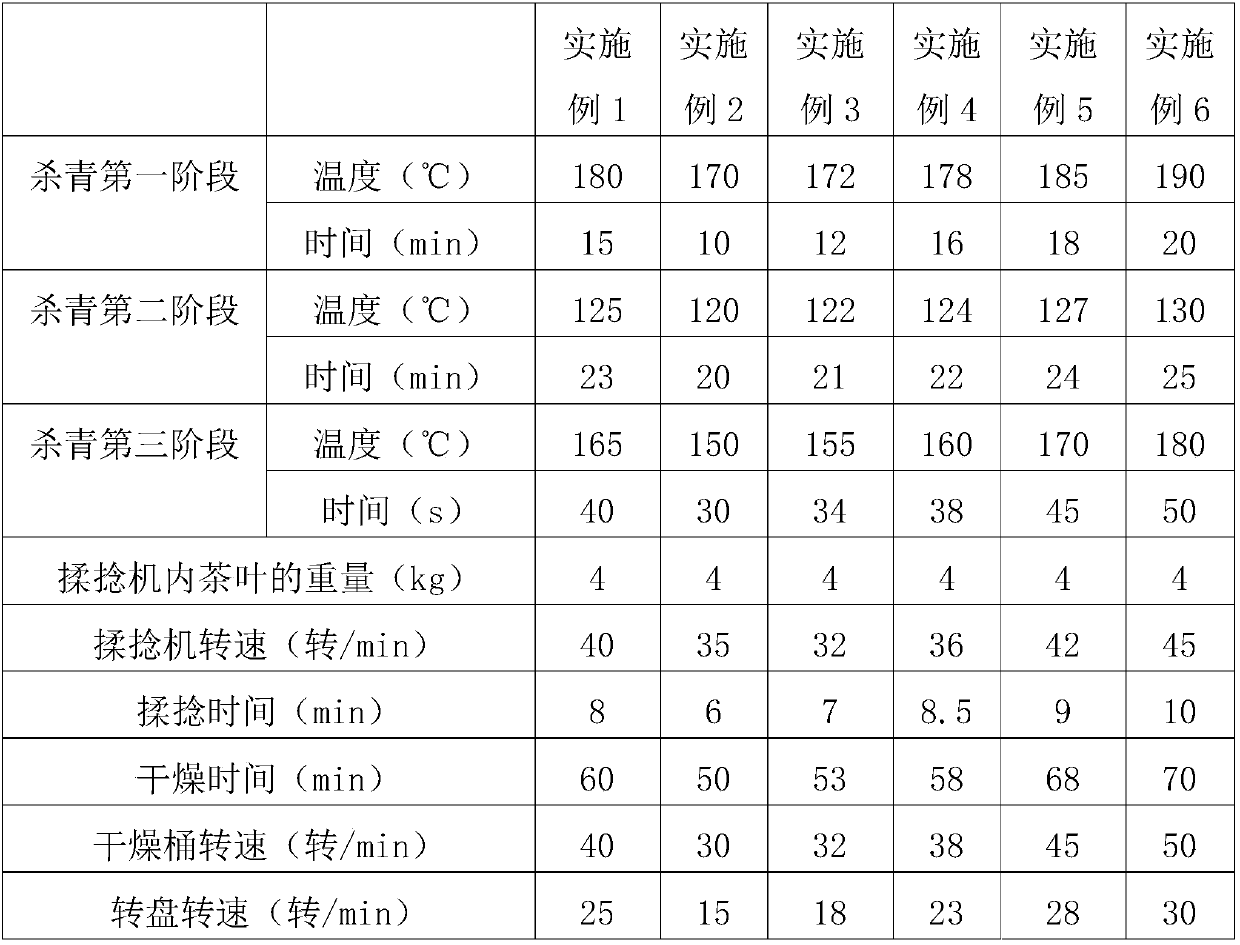

InactiveCN107647002APrevent mildewAvoid dripping condensationPre-extraction tea treatmentDrying gas arrangementsFixation timeThree stage

The invention belongs to the technical field of processing and producing of tea leaves, and discloses a tea leaf processing method. The tea leaf processing method comprises the steps of performing fixation, performing rolling and performing drying. The step of performing fixation comprises three stages, and the fixation temperature and the fixation time of different stages are collocated, so thatthe fixation effect is better; during rolling, the rotational speed and the rolling time of a rolling machine are collocated, so that the rolling degree of tea leaves is basically consistent; and during drying, a drying device is used for drying, when the tea leaves are dried, the tea leaves are sieved, the tea leaves which are not completely dried are sieved out, and drying is performed once again. Through the adoption of the tea leaf processing method disclosed by the invention, the problem that in the prior art, poor ventilation exists in a drying machine, steam generated by the dried tea leaves can be not liable to exhaust, when the drying machine stops heating, the steam in the drying machine condenses to be in contact with the tea leaves, the water content of the tea leaves is too high, and the tea leaves are easy to mildew is solved.

Owner:湄潭县渝乾茶叶有限公司

Processing method for making gunpowder tea from chimonanthus praecox

The invention relates to the field of tea production, in particular to a processing method for making gunpowder tea from chimonanthus praecox. The method comprises the following steps of chimonanthus praecox leaf picking, wherein a bud and a bud and two leaves are picked, the length is controlled to be within 6 cm, buds and leaves are uniform, no old leaf or stalk stem or impurity exists, air-permeable bamboo baskets and baskets are adopted as containing tools, and the leaves are not compressed; spreading, wherein chimonanthus praecox leaves are spread on a bamboo tray thinly, the thickness ranges from 5 cm to 8 cm, the leaves are 4-6 kg per square meter, and the spreading time is 2-3 h; fixation, wherein chimonanthus praecox leaves obtained after spreading are put into a fixation machine, 2-3 kg of leaves are put into each pot, the temperature of each pot is 280 DEG C, the method of covering first and then throwing is adopted, the temperature for fixation is 80-90 DEG C, and the fixation time ranges from 2.5 min to 3 min; rolling, wherein the chimonanthus praecox leaves obtained after fixation are rolled through a rolling machine, the leaves are loaded to the position 4-6 cm away from a barrel opening, the light-heavy-light principle is adopted in the rolling process, and the rolling time ranges from 30 min to 40 min, the rolled twig rate reaches 80%-90%, and the cell broken rate is 45%-60%. The processing method is simple, easy to implement, the product quality can be guaranteed, the high economic benefit is achieved, and popularization is easy.

Owner:SHAANXI QIYUAN TECH DEV

Simple hand-operated puncher

InactiveCN102974863AEasy to punchEasy to reamPortable drilling machinesStone-like material working toolsFixation timeElectric power

The invention discloses a simple hand-operated puncher and relates to the technical field of portable drilling machines. The simple hand-operated puncher comprises a drill rod and a drill bit and is characterized in that the middle of the drill rod is provided with a U-shaped rocking arm; the rocking arm is provided with a sleeve; one end of the drill rod is provided with a chuck, the drill bit is fixedly connected with the drill rod by virtue of the chuck; and the other end of the drill rod is provided with a grab handle. The simple hand-operated puncher is simple in structure, convenient to carry and use, and convenient in bit replacement, especially can be used for conveniently and easily punching and broaching an ammeter box and a wall under the condition of no power supply in the power construction process, is rapid and accurate, and can be used for greatly shortening the installation and fixation time of the ammeter box and improving the overall working efficiency; and the chuck is convenient to use, and the drill bit can be firmly chucked.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

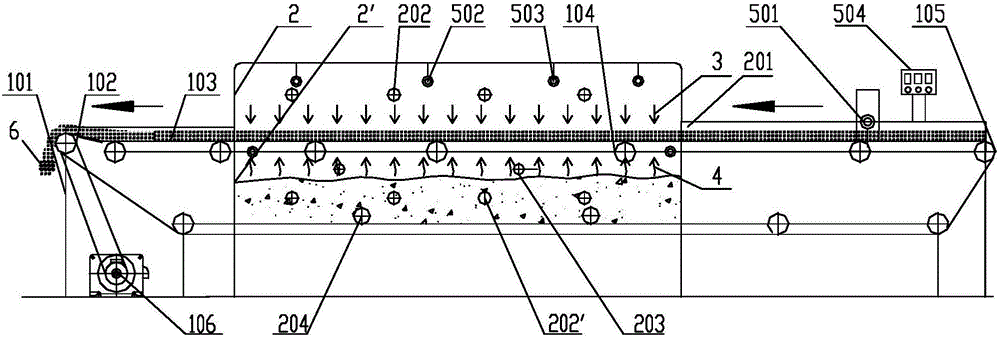

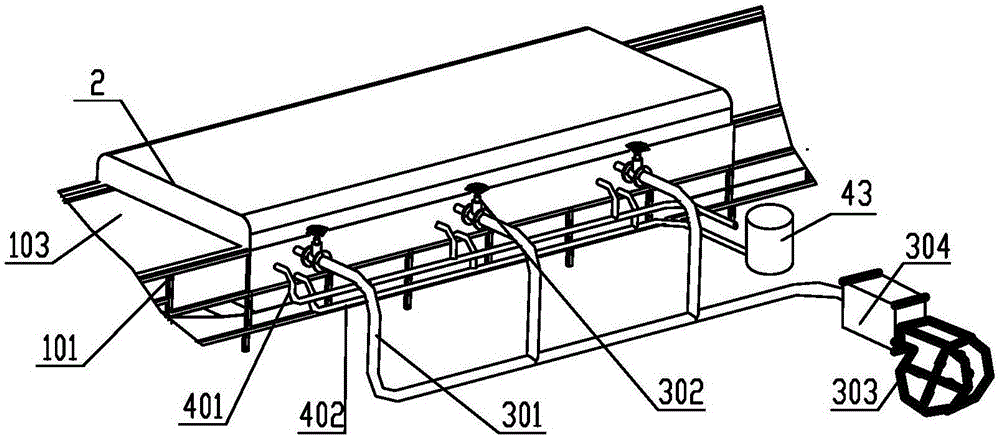

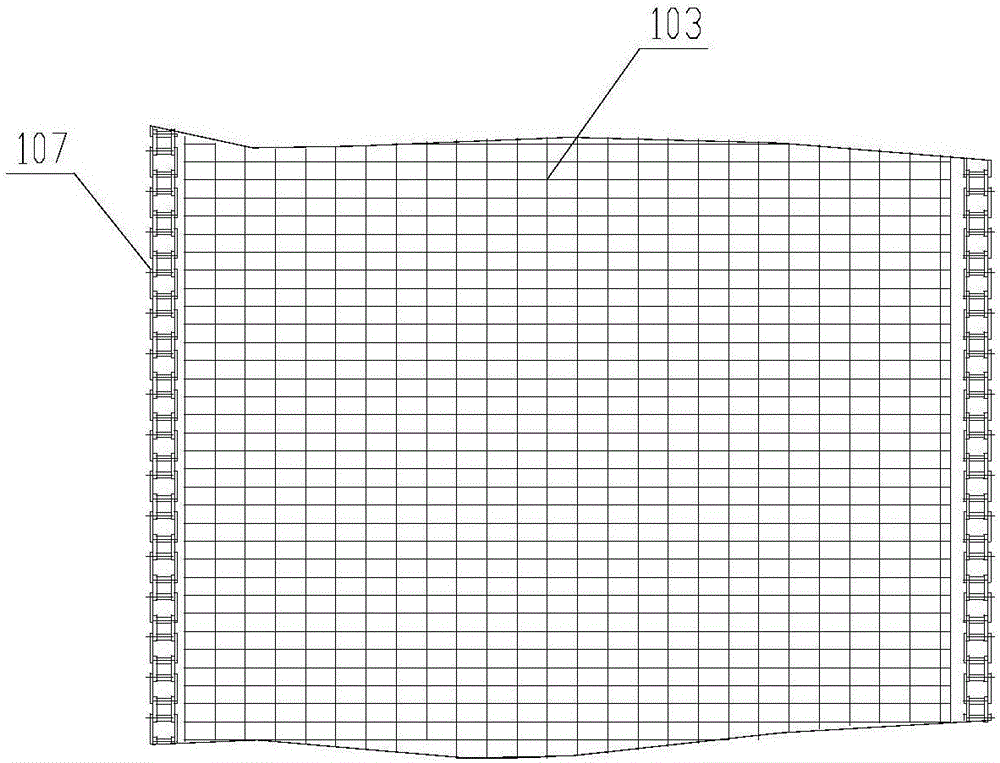

Fixation device suitable for dry vegetable products

ActiveCN106490130AGuaranteed temperatureAvoid lostFruits/vegetable preservation by heatingColor changesSuperheated steam

The invention discloses a fixation device suitable for dry vegetable products. The device comprises a fixation chamber arranged on a material conveying system and is closed, a conveying belt of the material conveying system penetrates through and passes the fixation chamber through channels in the two ends of the fixation chamber and divides the fixation chamber into an upper cavity and a lower cavity, the upper cavity is connected with an overheated steam system, the lower cavity is connected with a steam system, and fresh vegetable materials are laid on the breathable conveying belt. By means of the principle that overheated steam and steam are combined, the materials penetrate through the fixation device along with the conveying belt, the high-temperature overheated steam and steam generated by water in a water tank act on the vegetable materials together, the overheated steam guarantees vegetable fixation time, the steam grantees humidity in the fixation chamber, vegetable nutrient loss and color change caused by excessively high temperature are prevented, and automatic fixation processing is achieved.

Owner:湖南新发食品有限公司

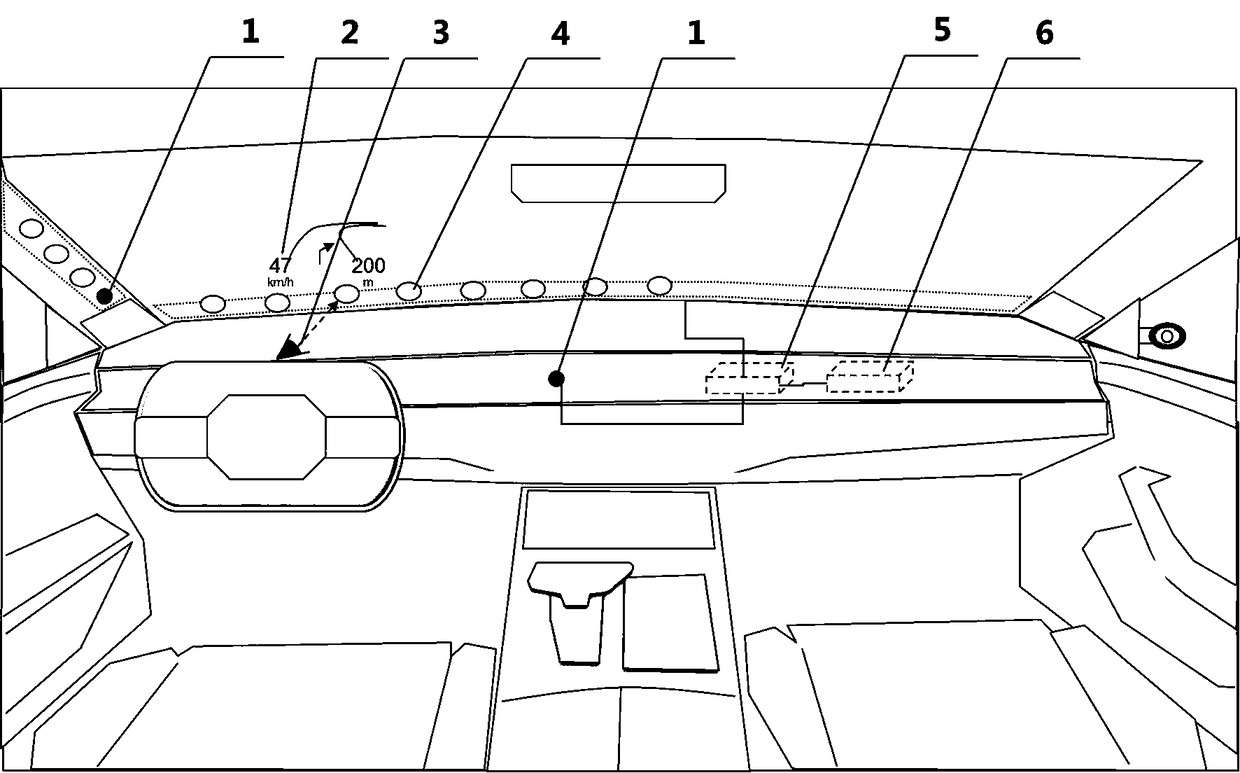

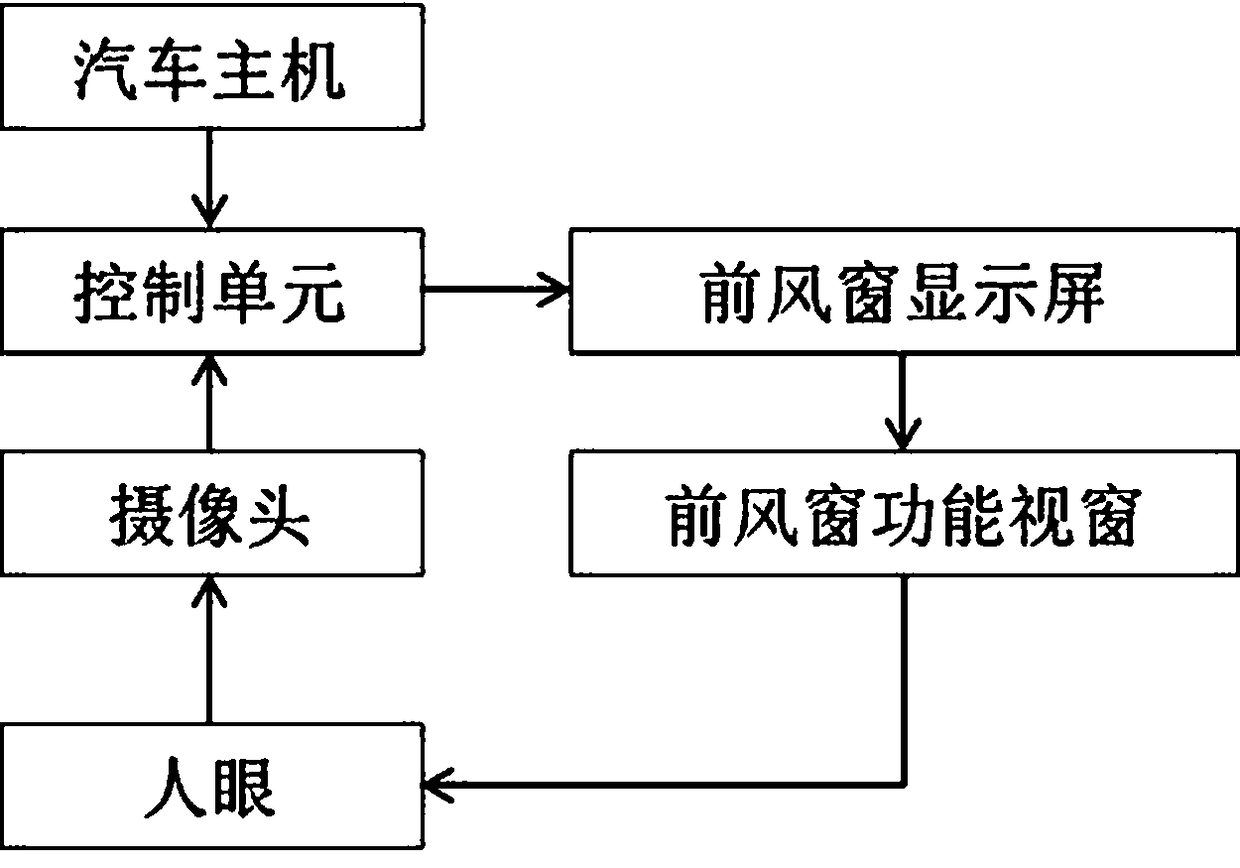

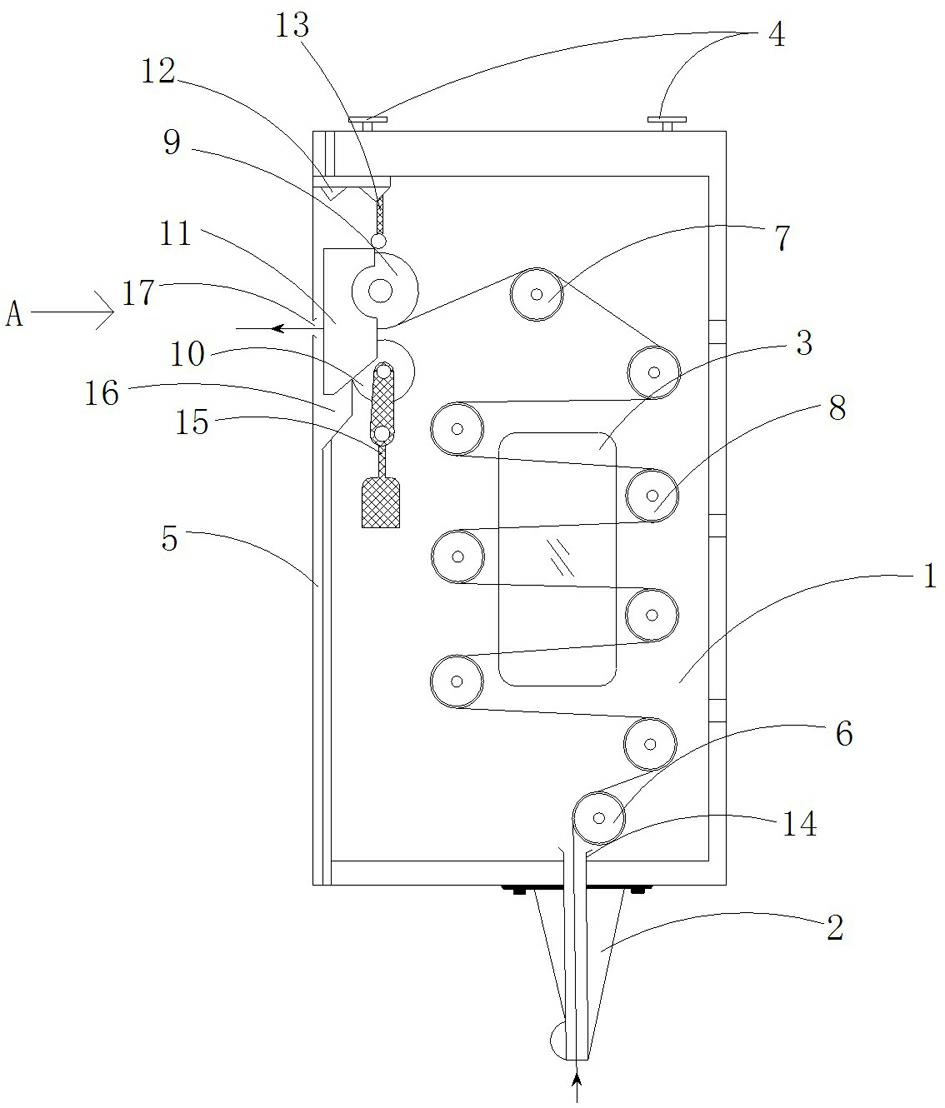

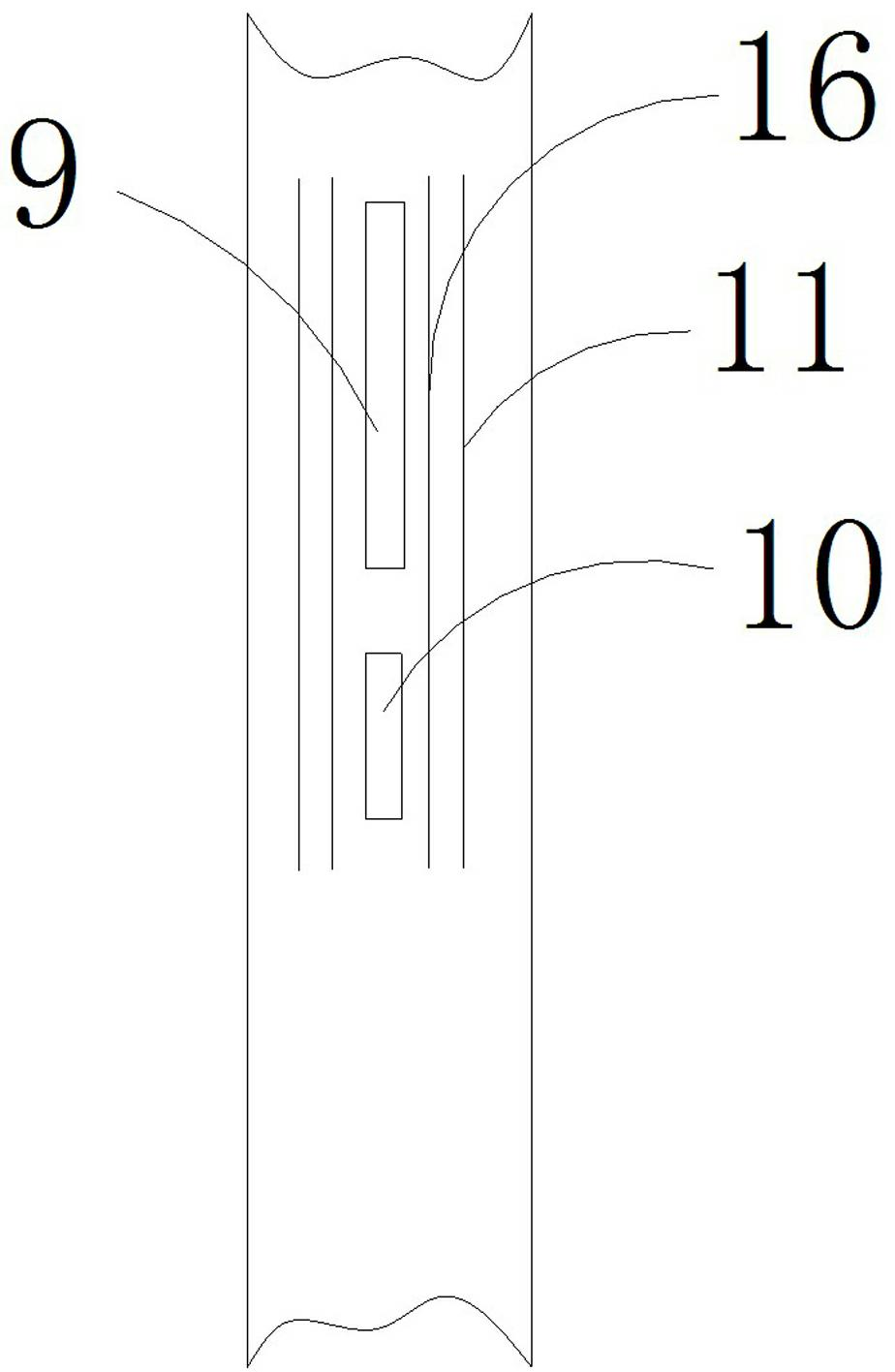

Visual control system for front windshield of automobile

InactiveCN109109666AEnsure driving safetyClear shotVehicle componentsMathematical modelControl system

The invention discloses a visual control system for a front windshield of an automobile, belonging to the field of automobile interactive control technology, and including an automotive main engine, awindshield display, a camera and a control unit, a windshield function window is arranged on the windshield display screen, the control unit is connected to the automotive main engine, an image is processed by a human eye recognition function in the control unit, and then the line of sight is solved by the mathematical model of human eyes, the line of sight of the driver 's eyes is identified andthe spatial position of the visual focus of both eyes is calculated, then, the spatial mathematical model is used to calculate whether the spatial position of the visual focus is in the spatial areaof the windshield function window or not, and to determine whether the driver is looking at a function command icon of the windshield function window according to the residence time of the visual focus, so as to realize the visual control. The invention realizes visual control by combining the blinking or fixation time to realize the visual control, and provides the driver with the demand information.

Owner:王宣武

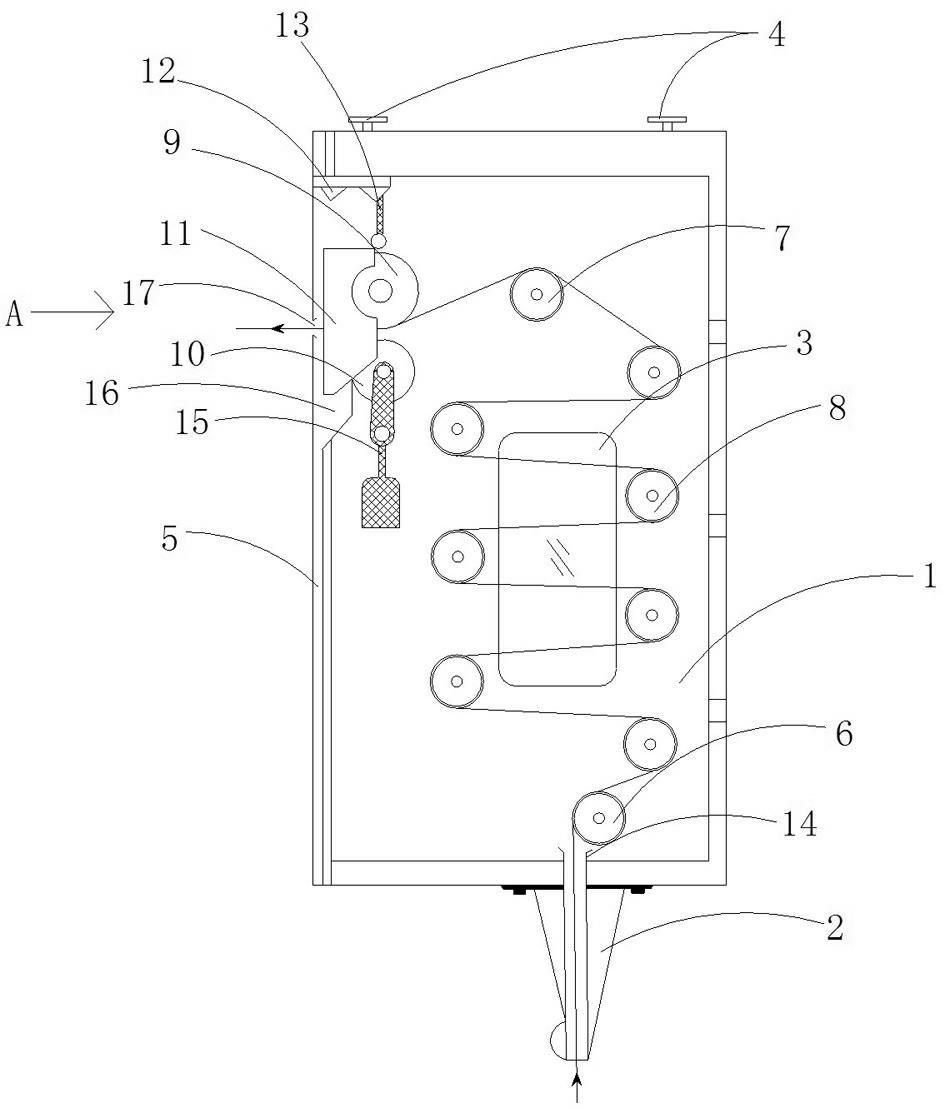

Vapor sealing box for printing and dyeing

ActiveCN102182032ASimple structureIncrease productivityTextile treatment containersFixation timeMechanical engineering

The invention relates to a vapor sealing box, and in particular relates to a vapor sealing box for printing and dyeing. The vapor sealing box is connected with a padding machine reduction box. The vapor sealing box is characterized in that a cloth guide mechanism and a vapor leakage preventing and heat insulating mechanism are arranged in a box body; the cloth guide mechanism comprises a lower cloth guide roller, an upper cloth guide roller and a cloth guide roller group; the lower cloth guide roller corresponds to a cloth inlet; the cloth guide roller group is formed in such a manner that cloth guide rollers are distributed in a staggered manner; the upper cloth guide roller is arranged above the cloth guide roller group; the vapor leakage preventing and heat insulating mechanism comprises an upper regulation roller, a lower regulation roller, sealing side plates, a heat insulating plate and a heating tube; the upper regulation roller and the lower regulation roller are vertically distributed; the sealing side plates are arranged at the two sides of the upper regulation roller and the lower regulation roller; the heat insulating plate is arranged above the upper regulation roller; a cloth outlet is arranged on the side wall of the box body corresponding to the space between the upper regulation roller and the lower regulation roller; and the heating tube is connected with the heat insulating plate. The vapor sealing box has a simple structure and has the following beneficial effects: the production efficiency is improved, the fixation time is sufficient, the product quality is improved and the vapor usage amount is reduced.

Owner:杭州航民美时达印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com