Patents

Literature

864results about How to "Fast heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Test device for simulating and testing thermal fatigue failure of high-temperature part in real time

ActiveCN101762452AFast heating and cooling ratesWide temperature rangeWeather/light/corrosion resistanceHeating systemInterfacial oxide

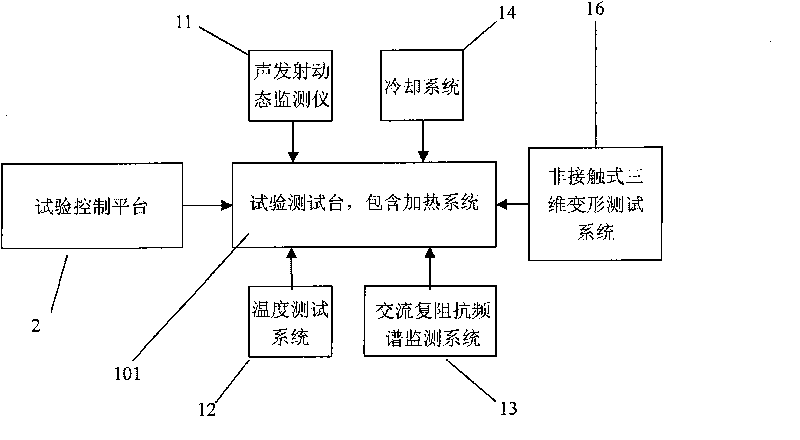

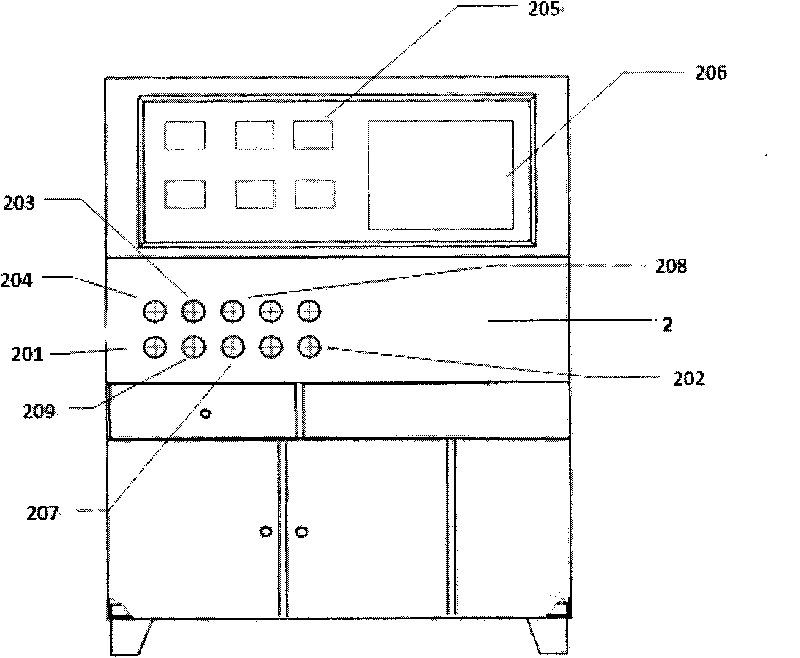

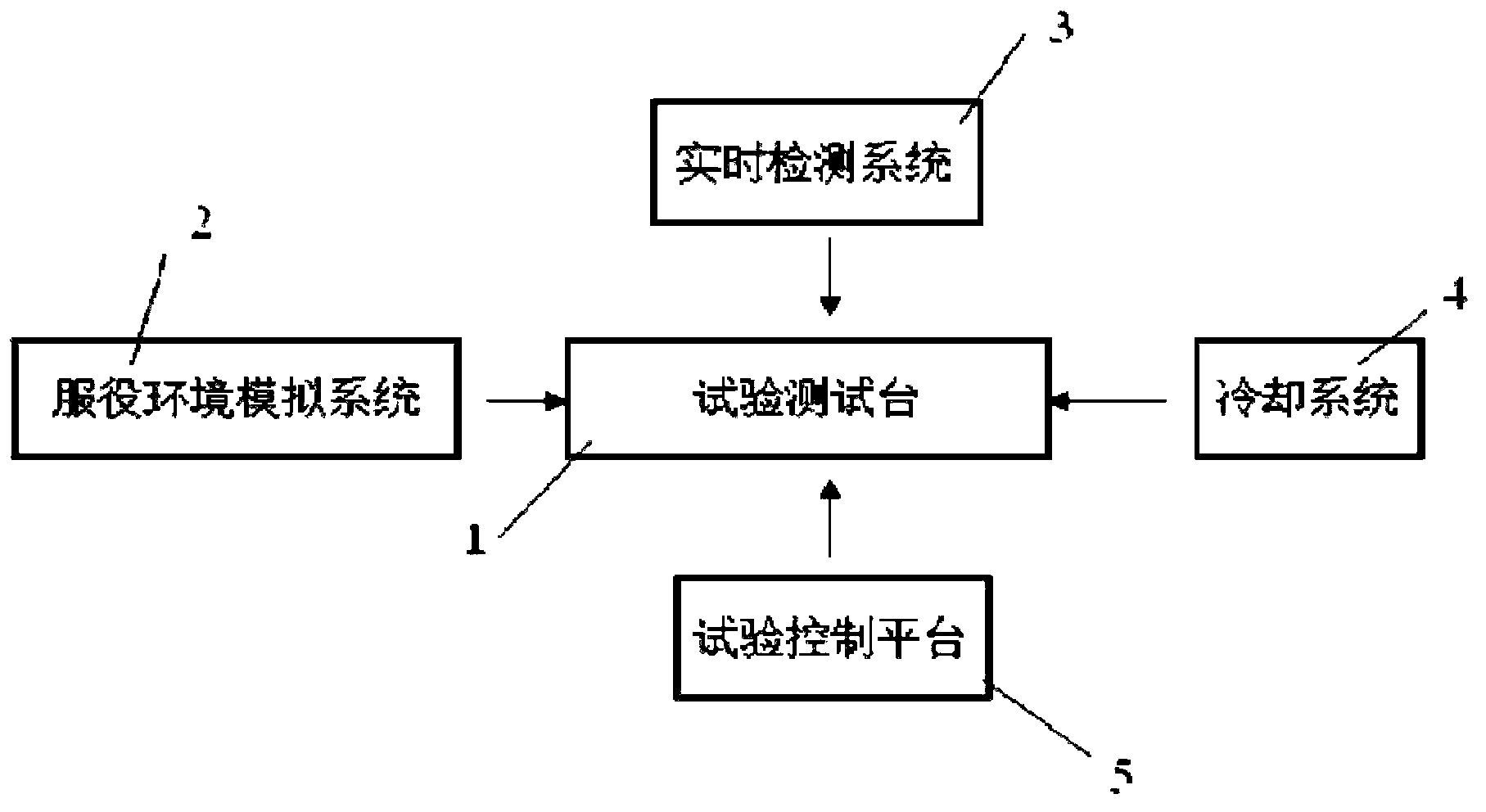

The invention belongs to the field of high-temperature part detecting equipment, in particular to a test device for simulating and testing the thermal fatigue failure of a high-temperature part in real time. The device mainly comprises a high-temperature gas two-way heating system, a real-time temperature testing and collecting system, a cooling system, an ARAMIS non-contact three-dimensional deformation test system, a PCI-2 AE non-destructive detection system, a 1260+1296-type material electric property AC impedance spectroscopy test system, a test control platform and the like. The device can simulate the thermal fatigue work environment of alternating temperature cycle in a high-performance aircraft engine, and synchronously realize the real-time testing and the analysis to the sample temperature, temperature gradient, surface morphology image evolution, three-dimensional deformation field, three-dimensional displacement field, interfacial oxide layer and thickening law, thermal fatigue crack initiation and propagation, cooling gas flow and other data. The device can provide an important experimental platform for effectively evaluating the fatigue failure process and the failure mechanism of the high-temperature part in the high-temperature thermal cycle environment.

Owner:XIANGTAN UNIV

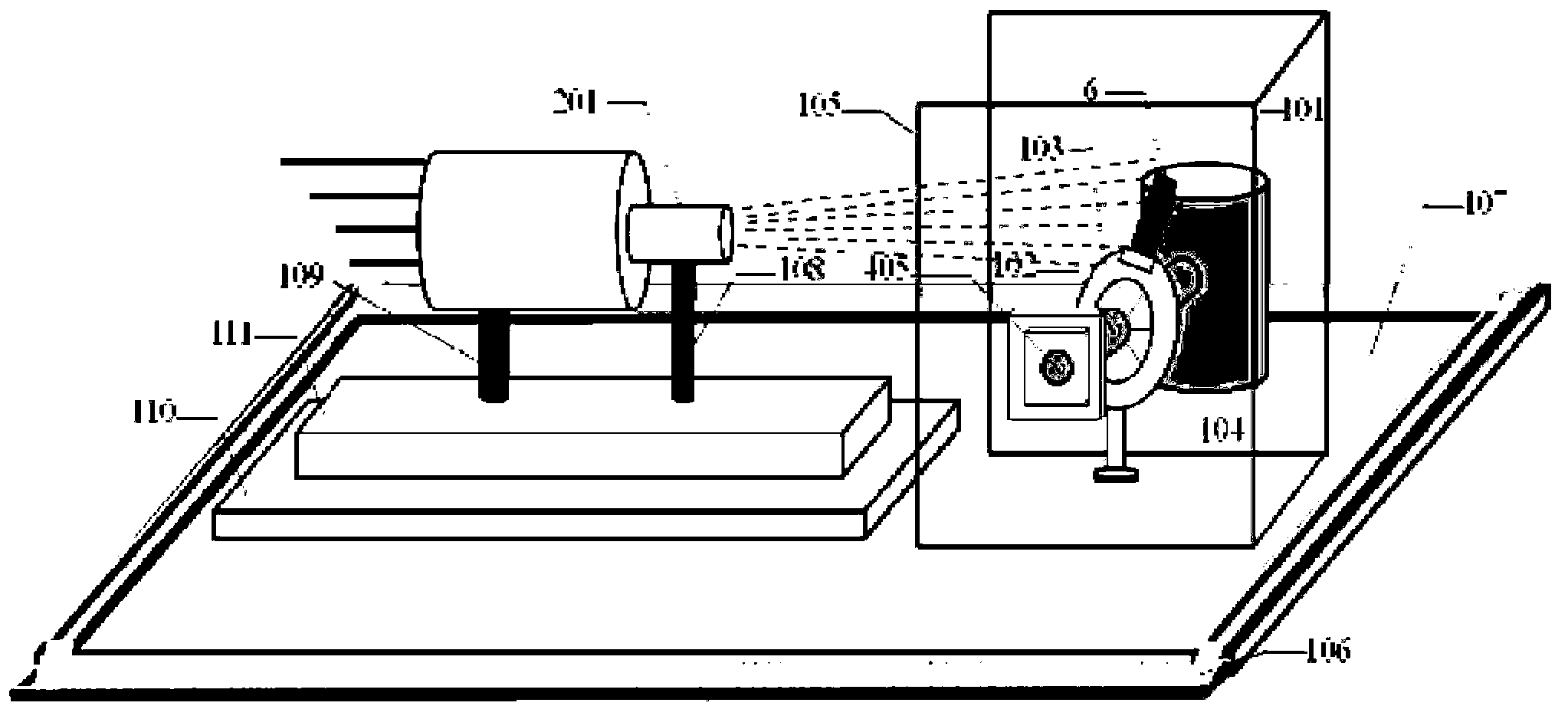

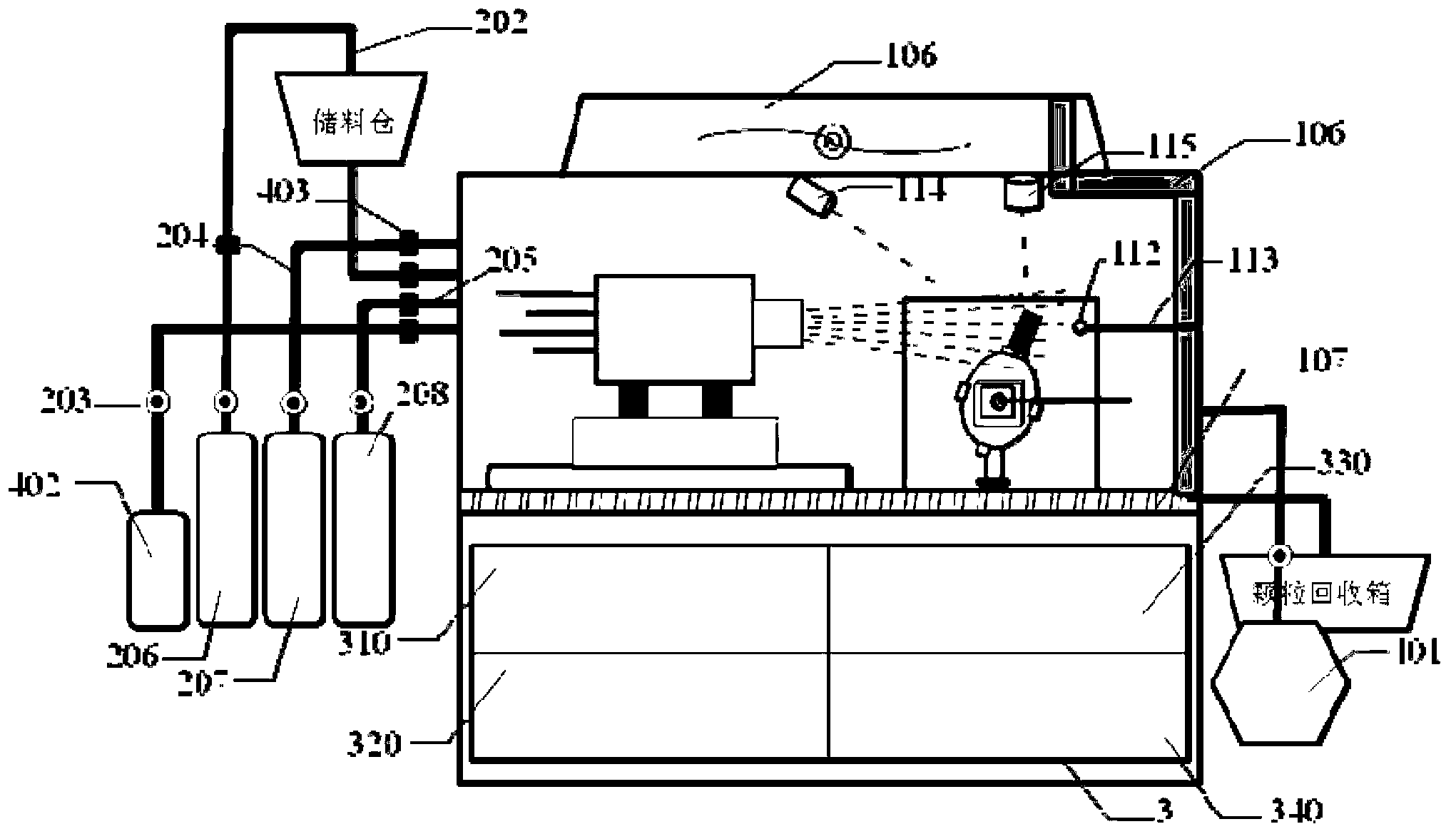

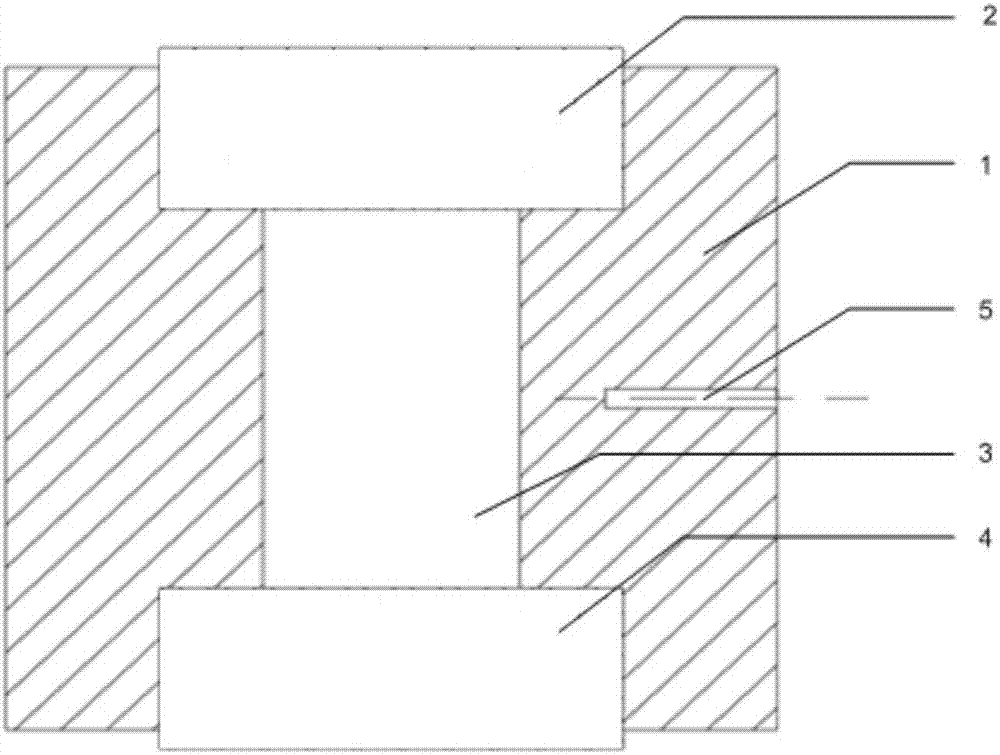

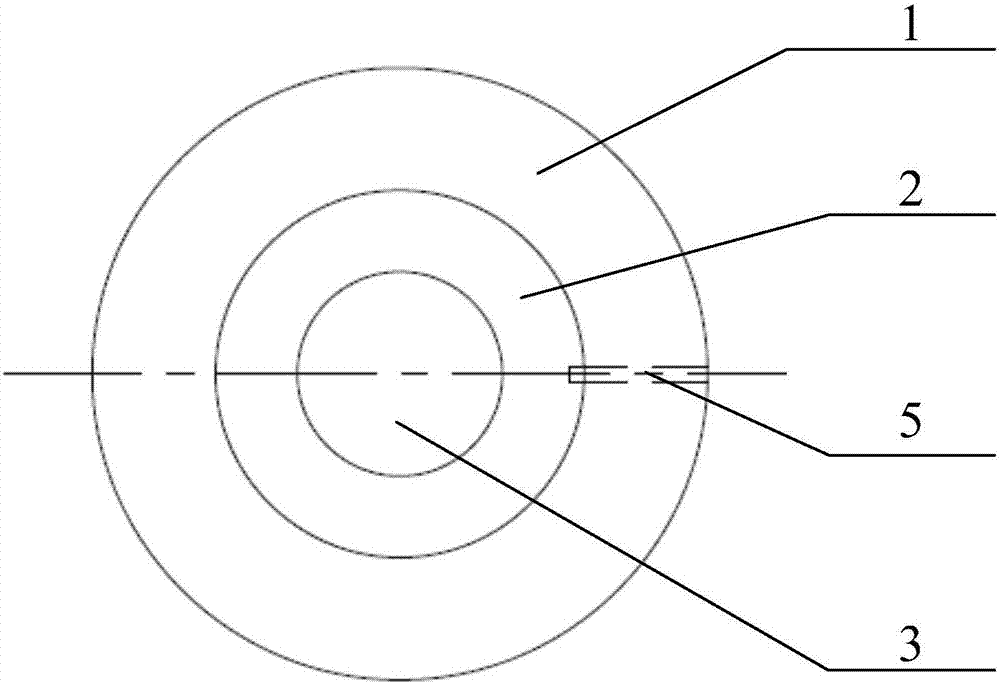

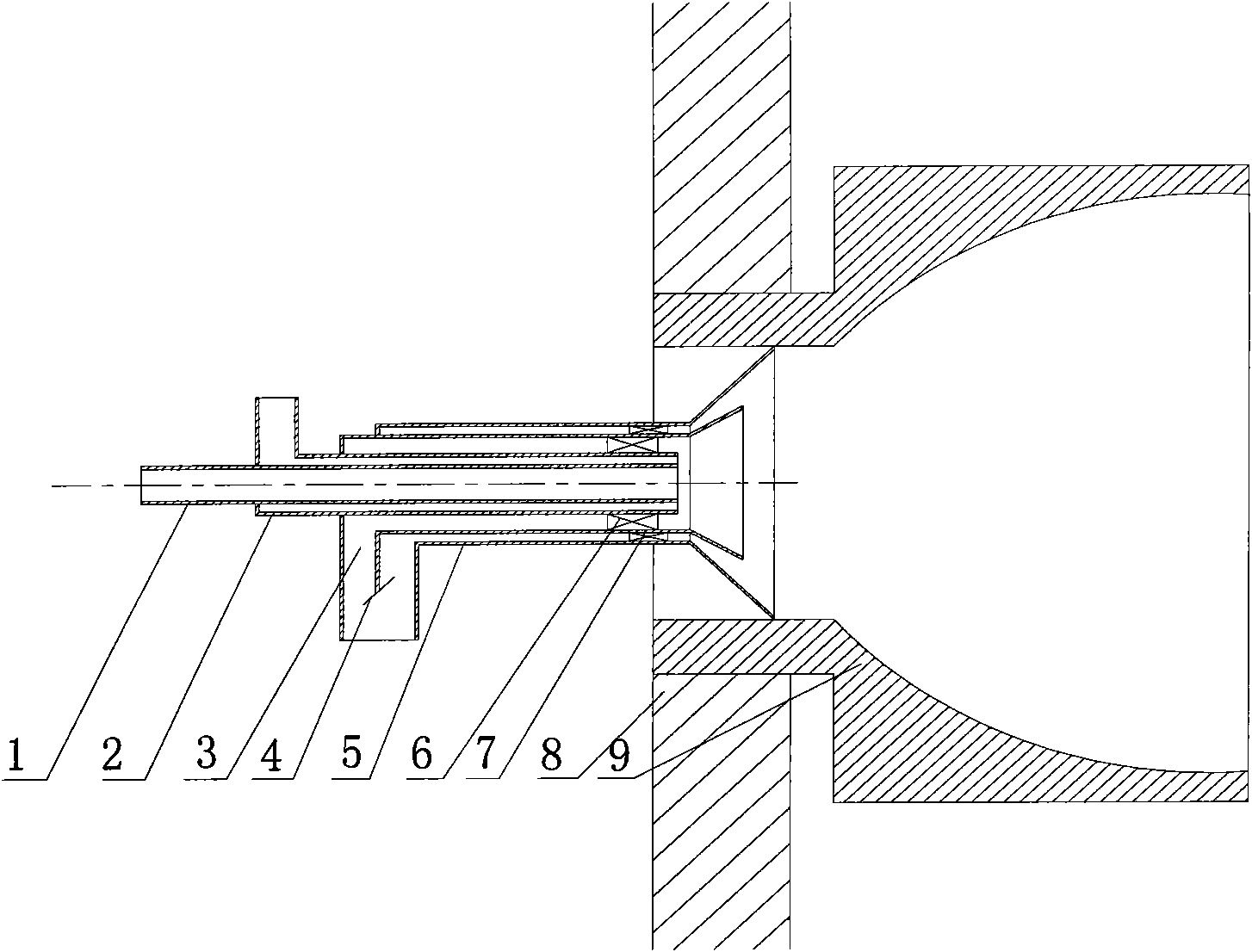

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

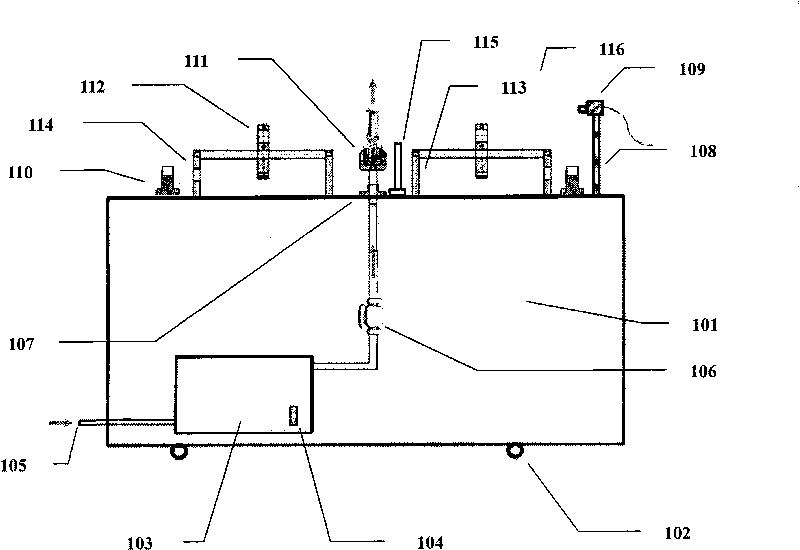

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

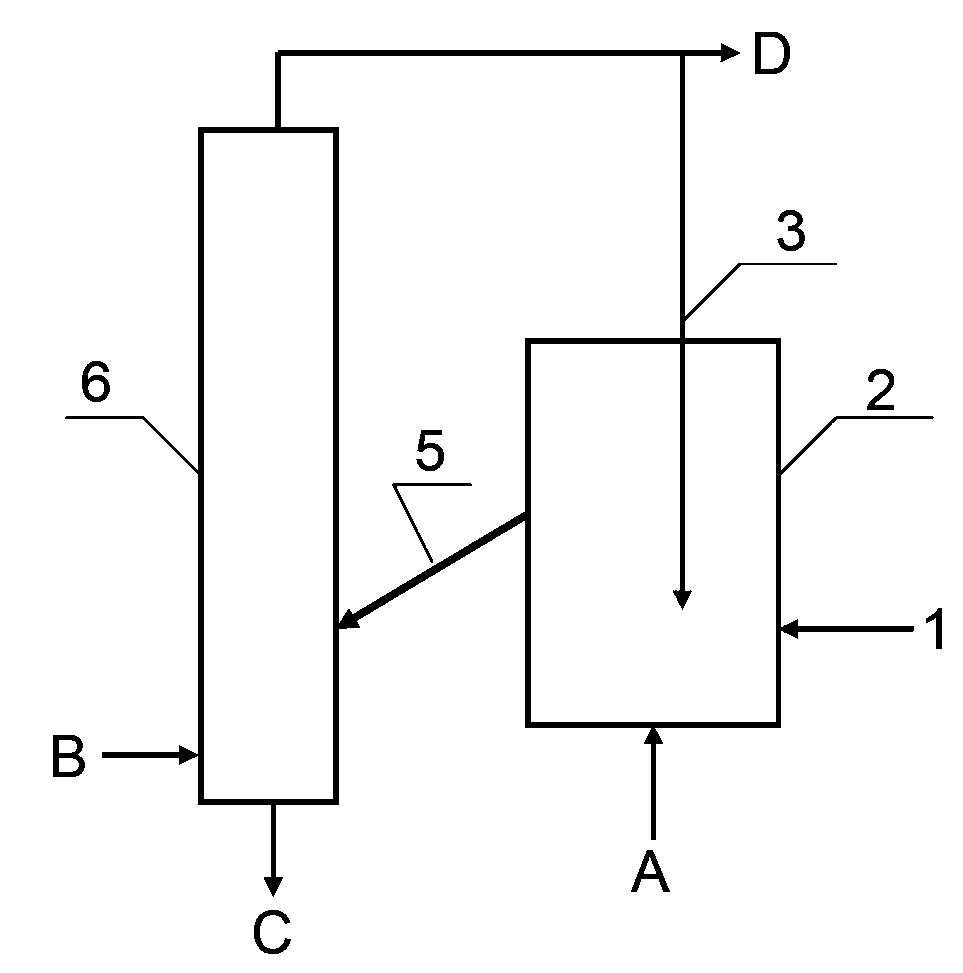

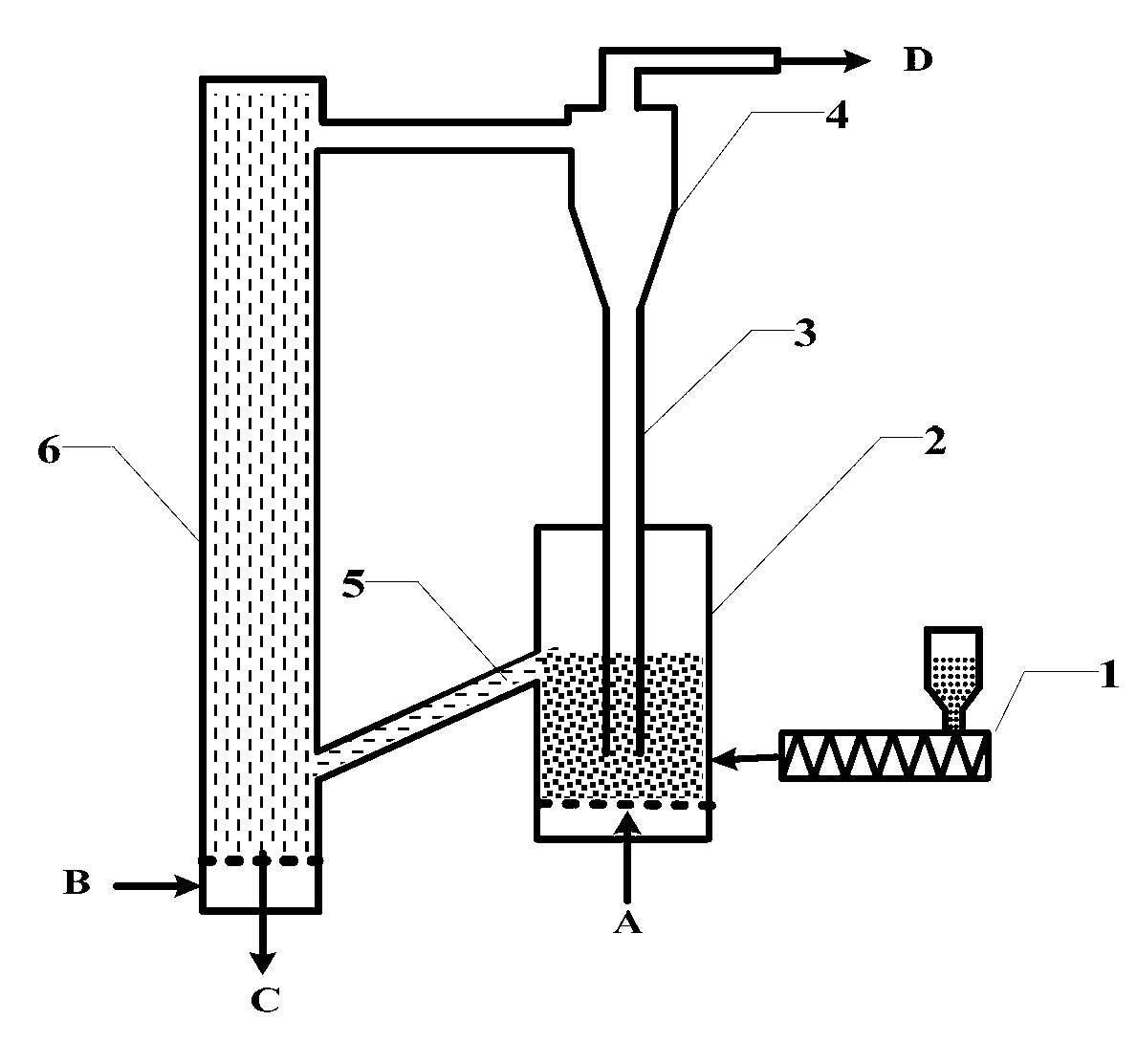

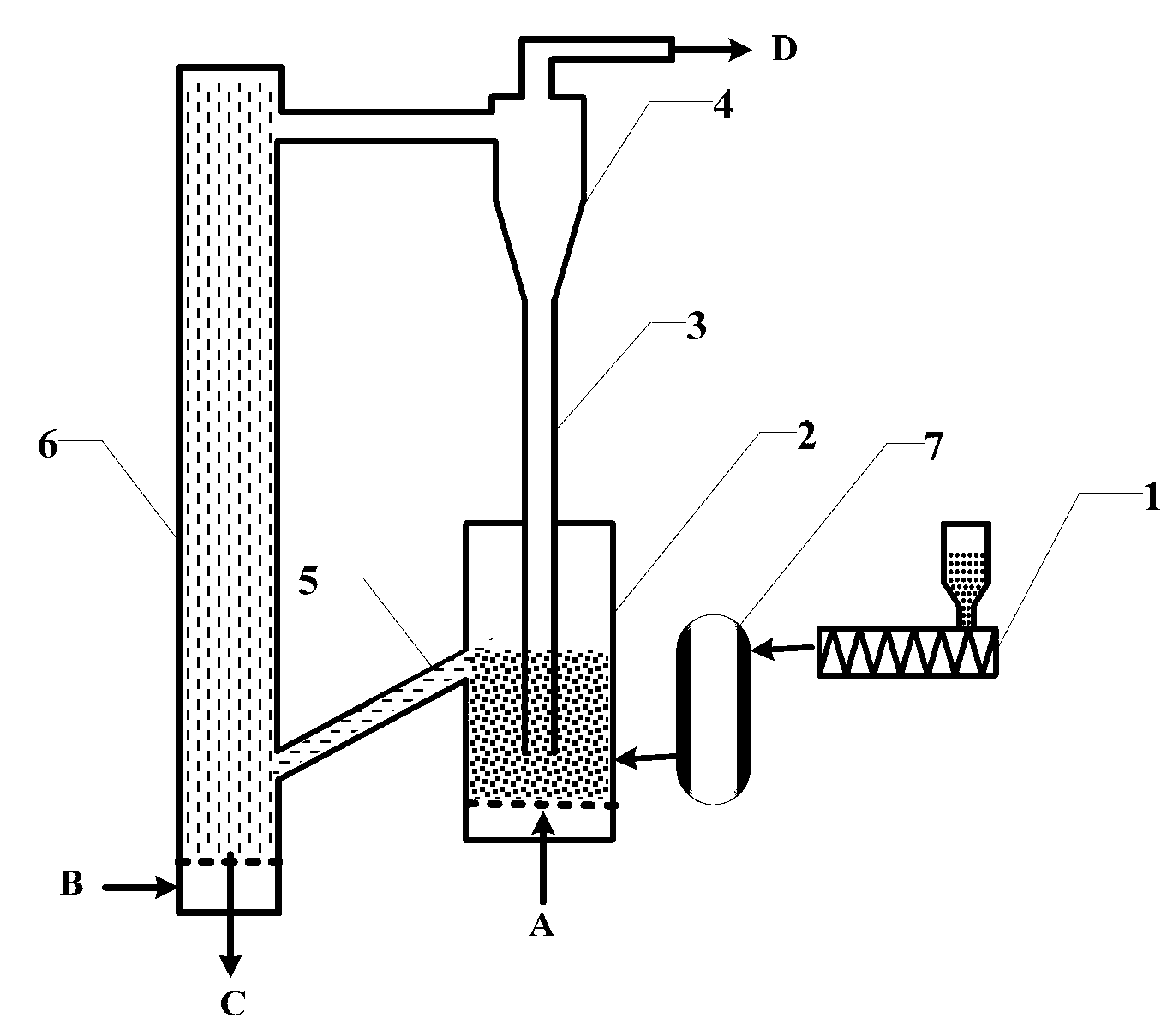

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

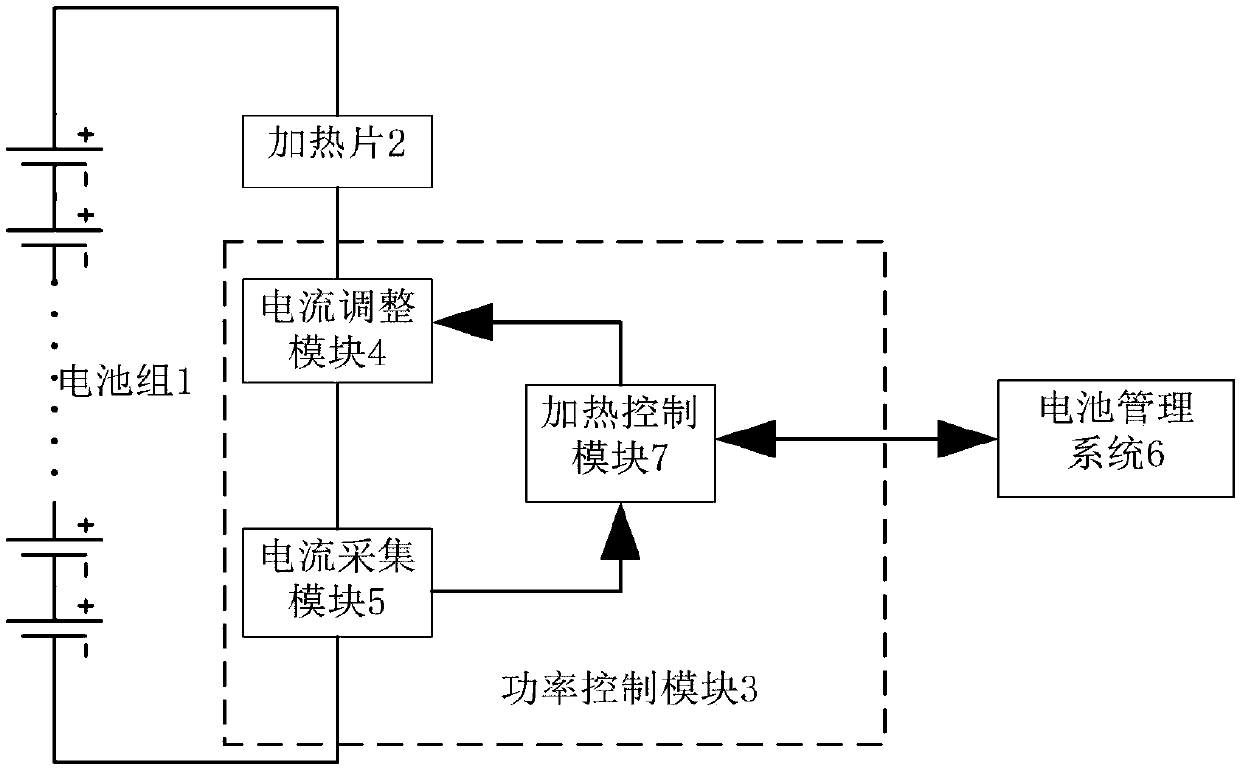

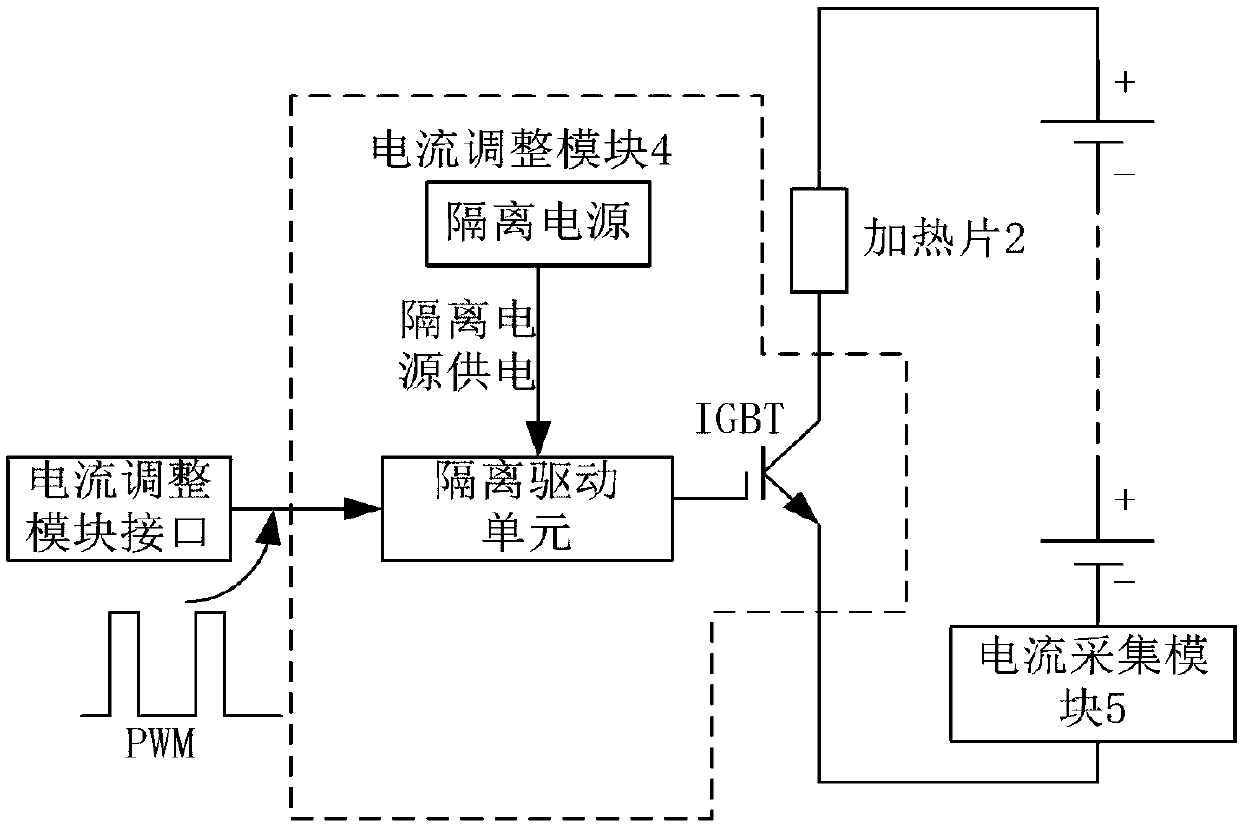

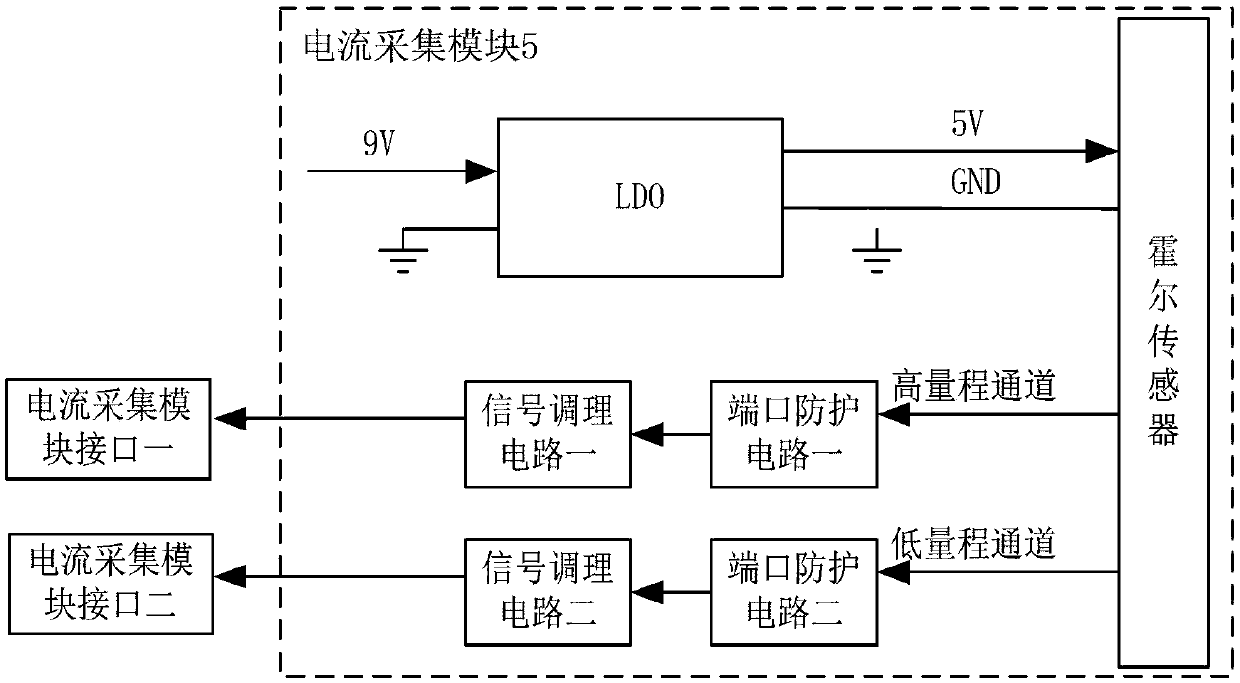

Battery system with adjustable heating speed and control method thereof

PendingCN111216600AFast chargingFast heating rateSilver accumulatorsVehicle sub-unit featuresFast chargingSwitching frequency

The invention relates to a battery system with an adjustable heating speed and a control method thereof. The battery system comprises a battery pack, a heating sheet, a power control module and a battery management system. When the temperature of the battery pack is lower than a preset self-heating starting temperature, the power control module is started, the battery management system transmits collected battery pack state information to the power control module, the power control module adjusts the current on-off time and the switching frequency of the heating sheet through PWM signals to adjust the heating power and the heating speed, therefore battery self-heating is achieved. When the temperature of the battery pack reaches a preset self-heating closing temperature, the power controlmodule is turned off, and heating is stopped; wherein the power control module further comprises a current adjustment module, a current acquisition module and a heating control module. The power battery system has the beneficial effects of high heating rate at low temperature, long driving range, and quick charging at low temperature.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

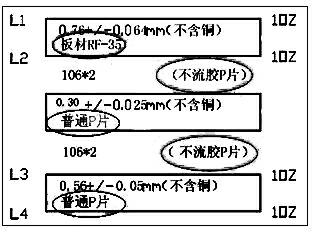

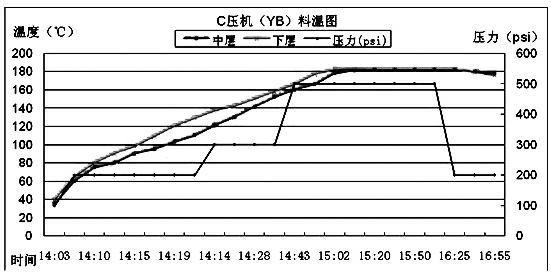

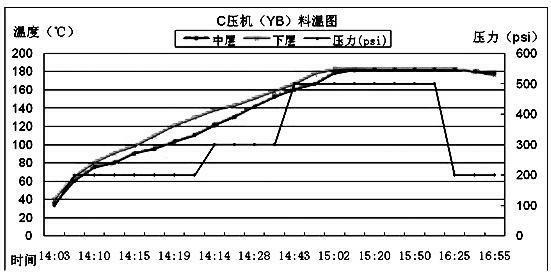

Process for manufacturing printed circuit boards having high-frequency and low-frequency mixed board structures

InactiveCN102523693AIncrease cooling areaImprove securityHigh frequency circuit adaptationsLaminationEpoxySolder mask

The invention discloses a process for manufacturing printed circuit boards having high-frequency and low-frequency mixed board structures, which includes steps of A) cutting high-frequency boards and low-frequency boards, manufacturing inner patterns, performing brownification, pressing, removing liquid adhesives and drilling holes; B) removing adhesives by plasmas, plating copper outside the high-frequency and low-frequency pressed board with drilled holes and electroplating the integral pressed board; C) forming outer patterns; D) printing solder mask and texts after solder mask of plug holes in a screen manner; E) printing characters after plating the integral board with nickel and gold and forming a circuit board in a screen manner; and F) testing and detecting electric performance and appearance of a finished board and manufacturing the finished product. By the design of the high-frequency and low-frequency mixed press structure, a necessary layer can be made of high-frequency boards with PTFE (poly tetra fluoro ethylene) structures so as to guarantee high speed and undistorted transmission of signals and the requirement of impedance matching, and other signal layers can be made of common boards with epoxy resin substrates on the condition of meeting the requirements of the integral performance, and cost is saved for clients by optimized combination.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

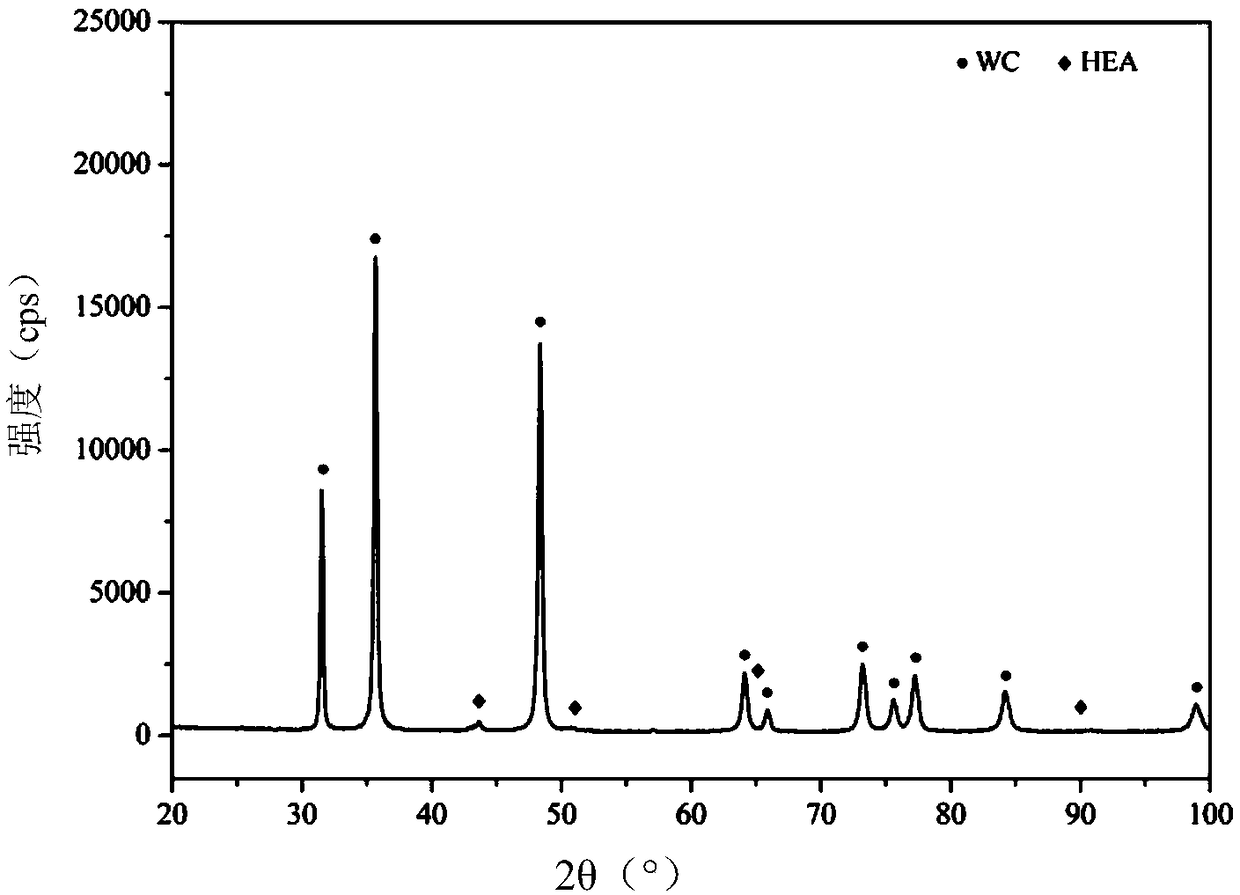

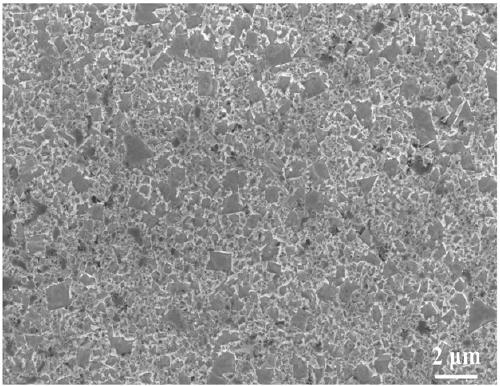

High-entropy alloy binding phase ultrafine tungsten carbide hard alloy and preparation method thereof

The invention belongs to the technical field of hard alloy, and discloses high-entropy alloy binding phase ultrafine tungsten carbide hard alloy and a preparation method thereof. According to the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy, high-entropy alloy is used as a binding phase, and tungsten carbide is used as a hard phase; the high-entropy alloy is prepared fromthe components of five or more of Al, Co, Cr, Cu, Fe and Ni, and an atomic percentage of each element is 5-35%. The method comprises the steps that after high-entropy alloy powder and WC powder are mixed, spark plasma sintering forming is conducted to obtain the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy. The tungsten carbide hard alloy is fine and small in crystal grain, and is good in comprehensive mechanical performance; adding a crystal growth inhibitor is not needed; consumption of the Co is significantly reduced, so that the raw material cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

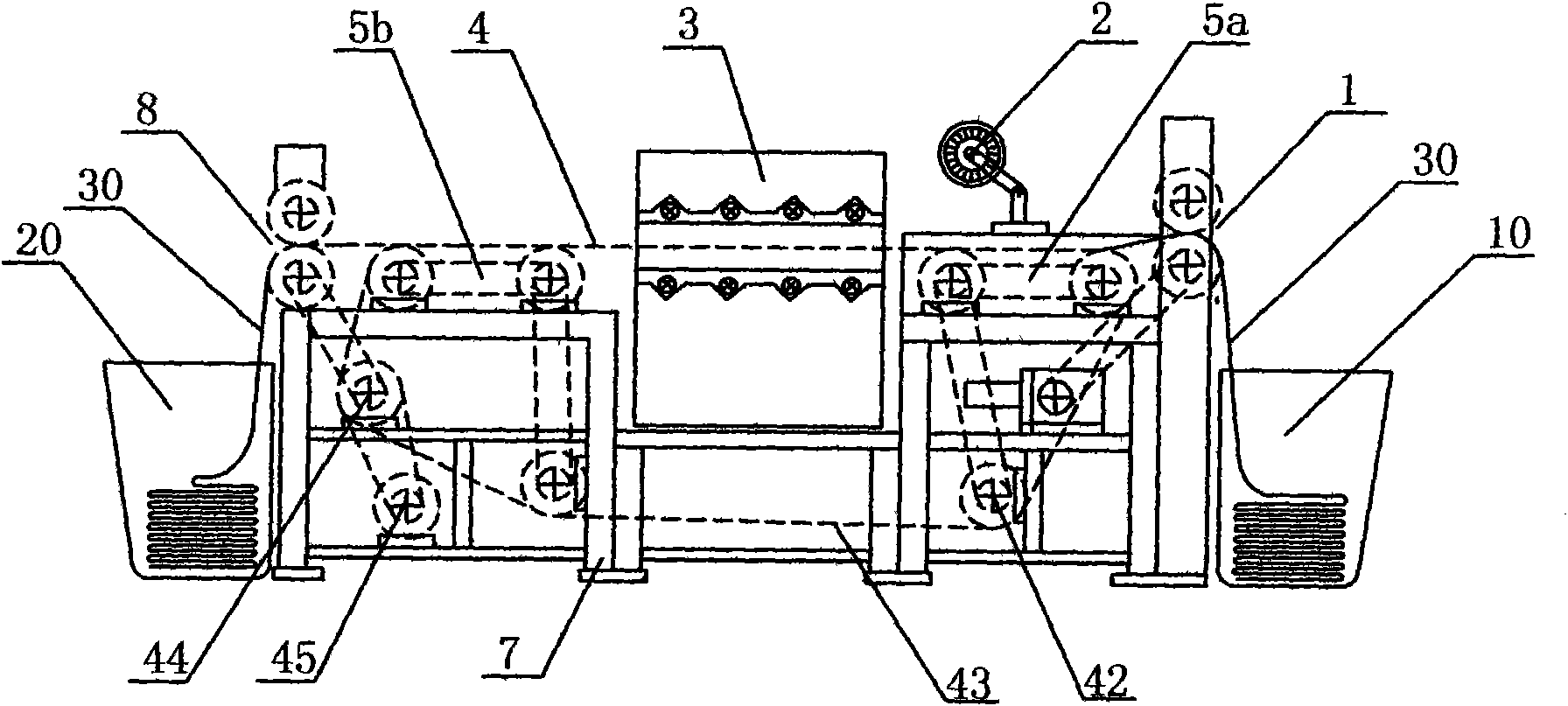

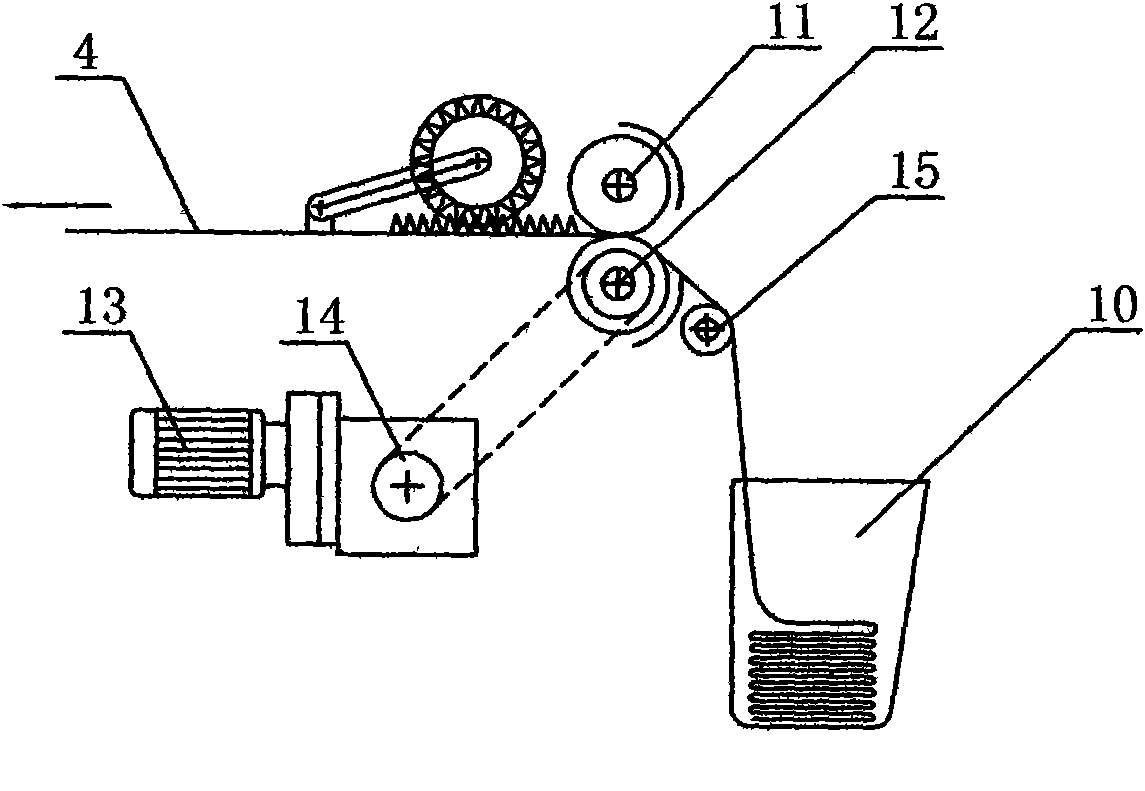

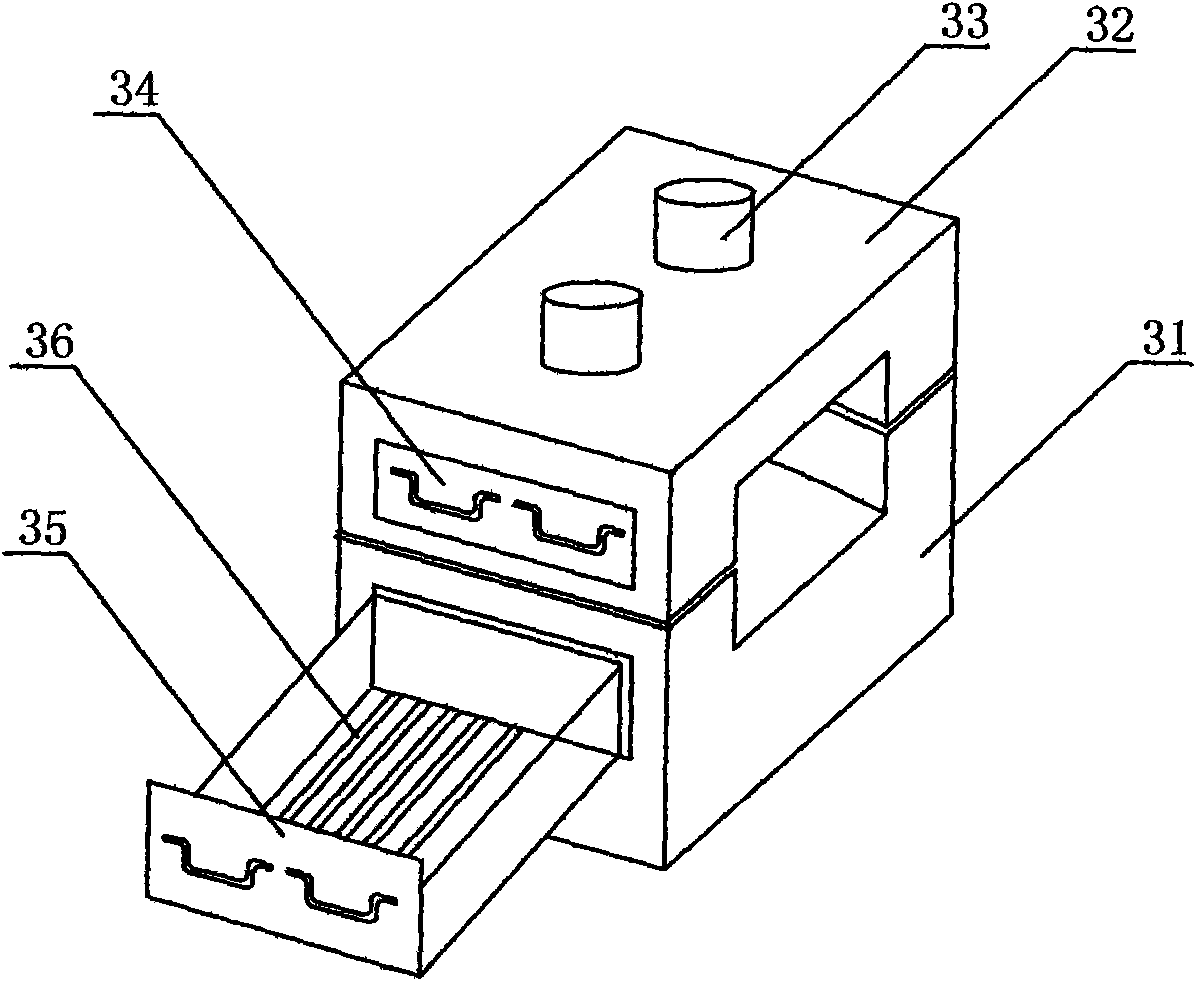

Novel pilot test setter

InactiveCN101660253AReach the gram weight requirementRequirements for Achieving Buffer ExpansionHeating/cooling textile fabricsStretchingEngineeringFar infrared

The invention discloses a novel pilot test setter which belongs to the technical field of pilot test dyeing equipment and is characterized by comprising a rack, cloth over-feeding actuating devices, sectional type stretch expanders, an infrared oven and a cloth discharge cooling device, wherein a cloth feeding barrel and a cloth discharging barrel are installed at two ends of the rack so as to beused for arranging cloth samples, an actuating device is installed on the rack and used for connecting a cloth feeding end with a cloth discharging end so as to complete the delivery of the cloth samples; the cloth over-feeding actuating devices are sequentially installed along the actuating device from the cloth feeding end to the cloth discharging end, and installed at the cloth feeding end, adjust the linear velocity when the cloth samples enter and realize over-feeding function; the sectional type stretch expanders are installed at two sides of the infrared oven and realize buffering expansion; and the infrared oven is arranged in way of double layer (an upper layer and a lower layer), and conducts infrared drying and setting. The novel pilot test setter integrates the technologies ofheating by far infrared radiation, overfeeding and sectional expansion into a whole, and has the advantages of quick heating rate, short processing time, low energy consumption, high processing efficiency and good finishing effect.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH +1

Method for regenerating and recovering cathode material of waste lithium ion battery

ActiveCN107978816ALess prone to secondary pollutionUniform temperatureWaste accumulators reclaimingBattery recyclingSlagStrong acids

The invention discloses a method for regenerating and recovering a cathode material of a waste lithium battery. The method comprises the steps of firstly performing graded treatment on cathode materials of waste lithium ion batteries with organic substances on the surfaces thereof disassembled and removed, and removing powdered small particles from the waste lithium ion battery material; then grinding and mixing the waste materials obtained after grading with lithium salt balls in a suitable proportion or immerging the waste materials into a lithium salt solution to obtain a uniformly lithium-mixed waste material; and finally performing heat treatment on the lithium-mixed waste material in an atmosphere of air or oxygen by adopting a microwave sintering method, and regenerating and preparing a lithium ion battery material. As microwave sintering is adopted in the method, the material temperature rise speed is fast and the efficiency is high; furthermore, strong acid and strong alkalineare not required in the whole recovery process, so that no waste slag, no acid wastewater and no alkaline wastewater is generated, and secondary pollution is hard to occur. Meanwhile, the method is simple in process; and the temperature inside the material is more uniform, the quality of the regenerated product is stable and the performances are good during the microwave heating process.

Owner:广西埃索凯循环科技有限公司

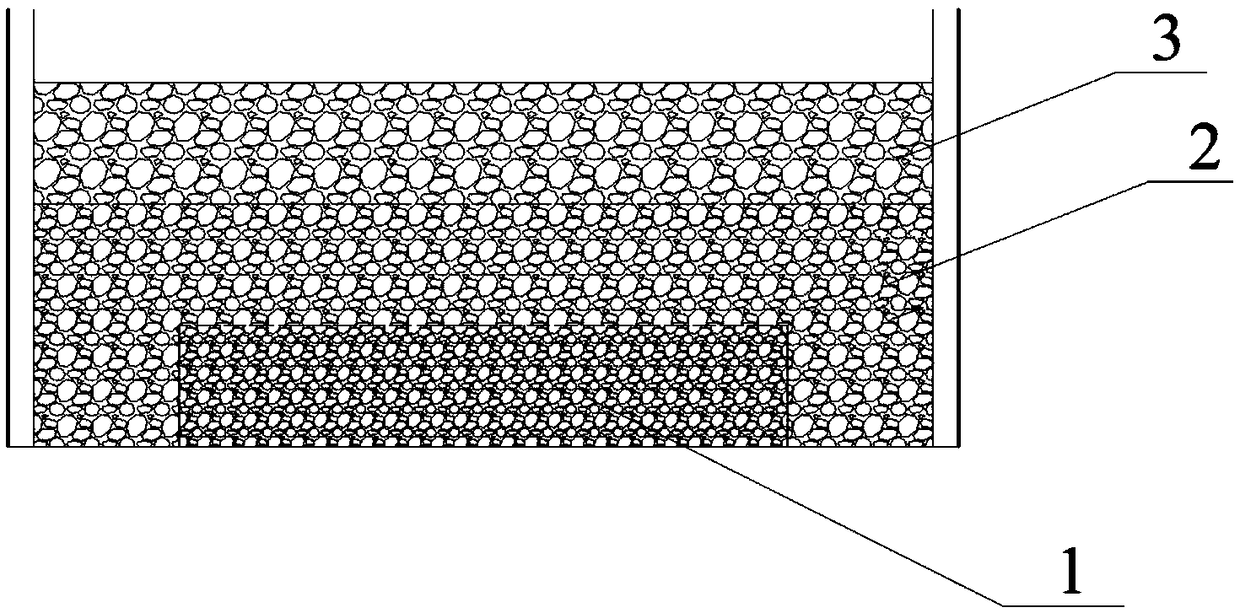

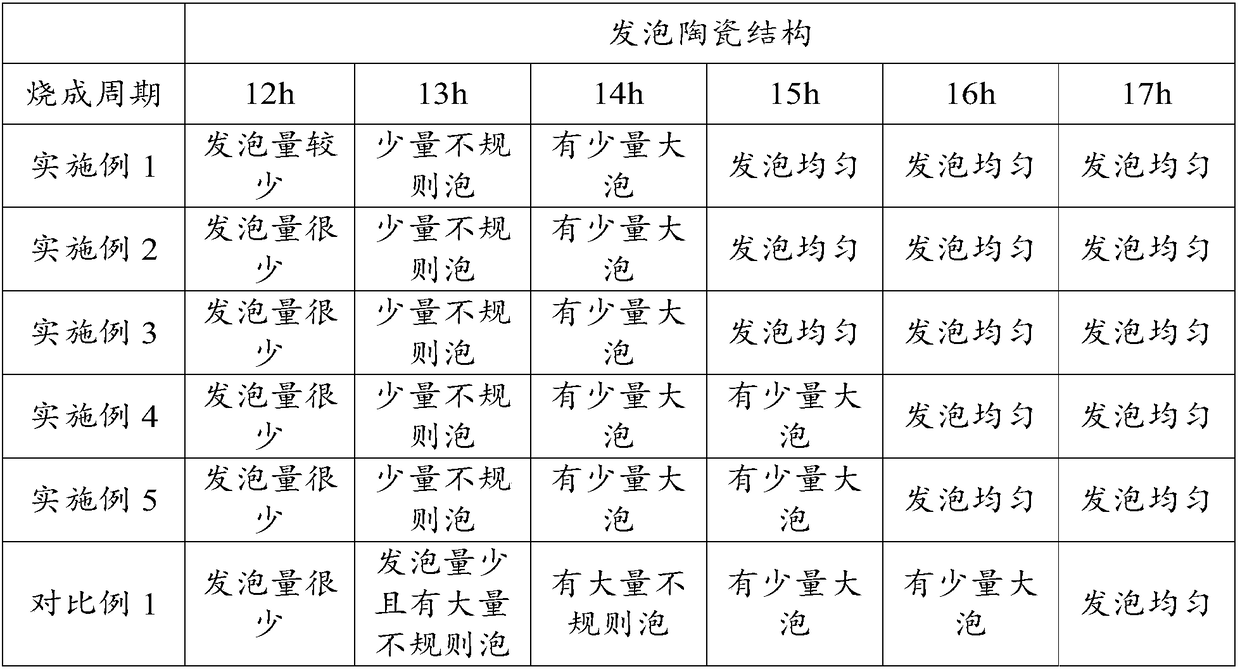

Process for producing foamed ceramic through layered material preparation and allocation and foamed ceramic material

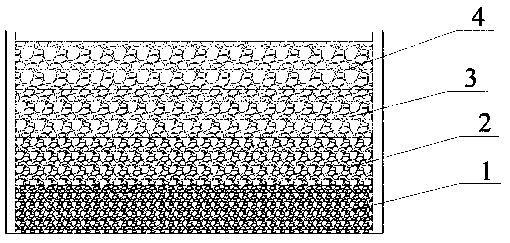

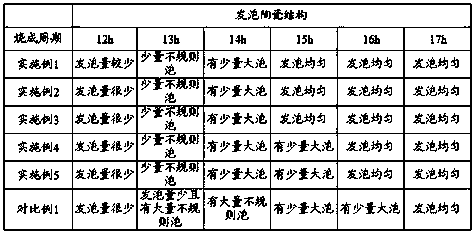

ActiveCN109053214AShorten the production cycleEasy to passFeeding arrangmentsCeramic materials productionMaterials preparationFoaming agent

The invention discloses a process for producing foamed ceramic through layered material preparation and allocation and belongs to the field of materials. According to the process, multiple foamed ceramic granule materials of different oxidant contents and granularities are adopted to produce a foamed ceramic material through layered material preparation and allocation. Due to the adoption of oxidants, a foaming agent in a ceramic raw material can be promoted to be oxidized to generate gases; due to the adoption of a setup mode of small lower-layer granule particle sizes, high oxidant contents,large upper-layer granule particle sizes and low oxidant contents, channels are provided for low-temperature gas exhaust, and the low-temperature gas exhaust time can be shortened; moreover, the setup mode is beneficial to heat conduction, uneven foams caused by temperature gradients can be made up, the heating velocity in a foaming combustion period can be increased, the foaming temperature keeping time is shortened, and furthermore the production period of the whole foamed ceramic material can be shortened; the foamed ceramic material is prepared from the foamed ceramic produced through layered material preparation and allocation, and is high in quality, small in defect, short in production period and applicable to on-scale production.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

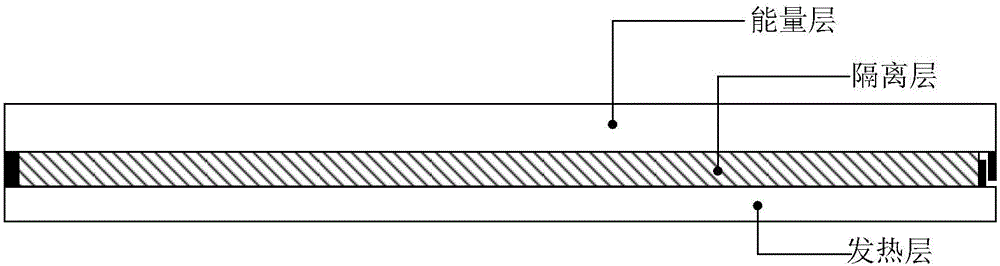

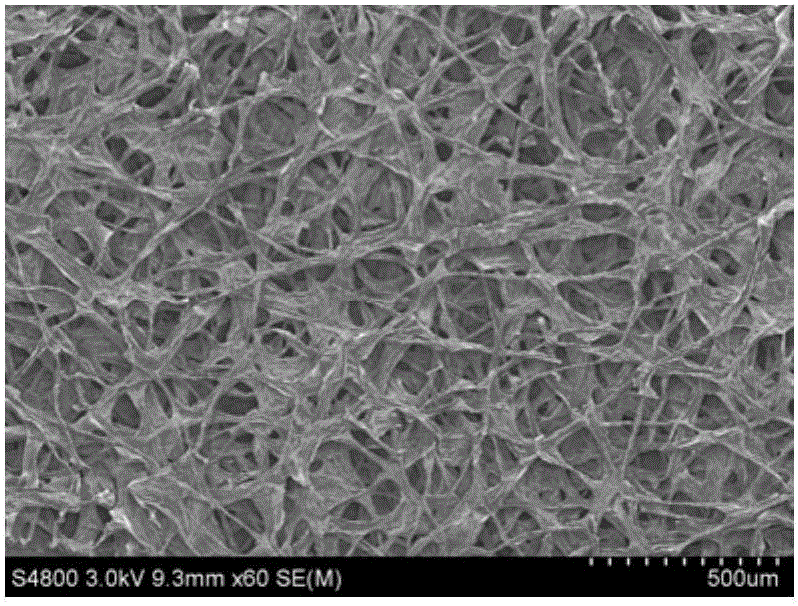

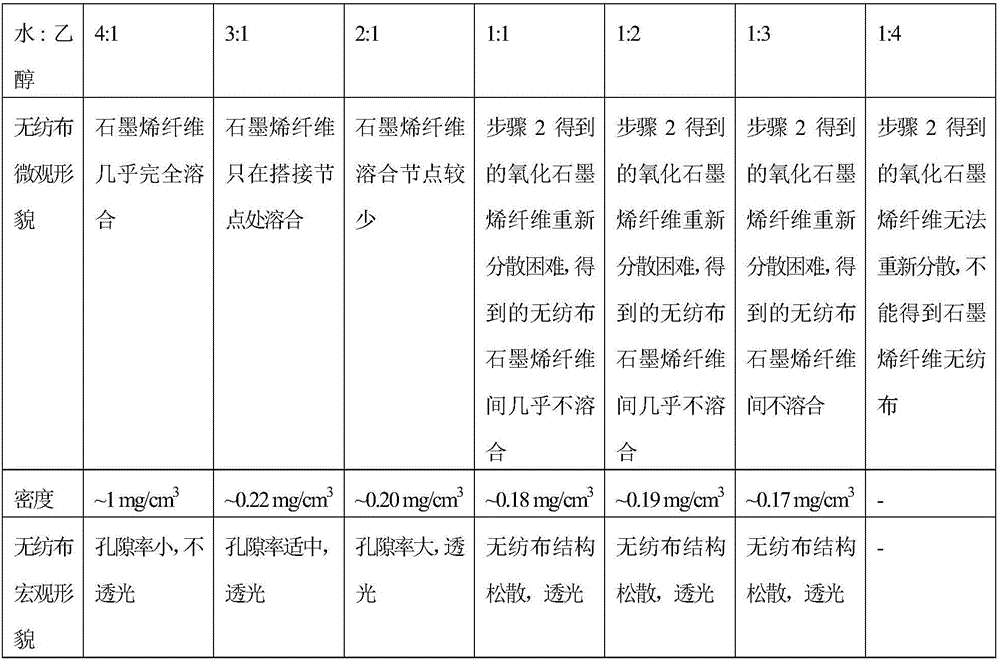

Self-heating film based on graphene fiber nonwovens

ActiveCN106183142AImprove conductivityLow densityLayered productsWet spinning methodsThermal insulationFilm base

The invention discloses a self-heating film based on graphene fiber nonwovens and a preparation method thereof. The self-heating film is provided with voltage and current by a photovoltaic film as an energy layer, and a heating layer is formed by using the electric-induced-heating effect of the graphene fiber nonwovens. The energy layer is separated from the heating layer by a thermal insulation material. As the graphene fiber nonwovens have a high electrical conductivity and a relatively low density, larger heating temperature and higher heating and cooling rates at a relatively low operating voltage can be obtained. Meanwhile, the graphene fiber nonwovens have high flexibility and structural stability, and the self-heating film is still able to show a stable heating behavior at bending state, so the self-heating film based on graphene fiber nonwovens can be used for novel wearable heating device using clean energy.

Owner:杭州德烯科技集团有限公司

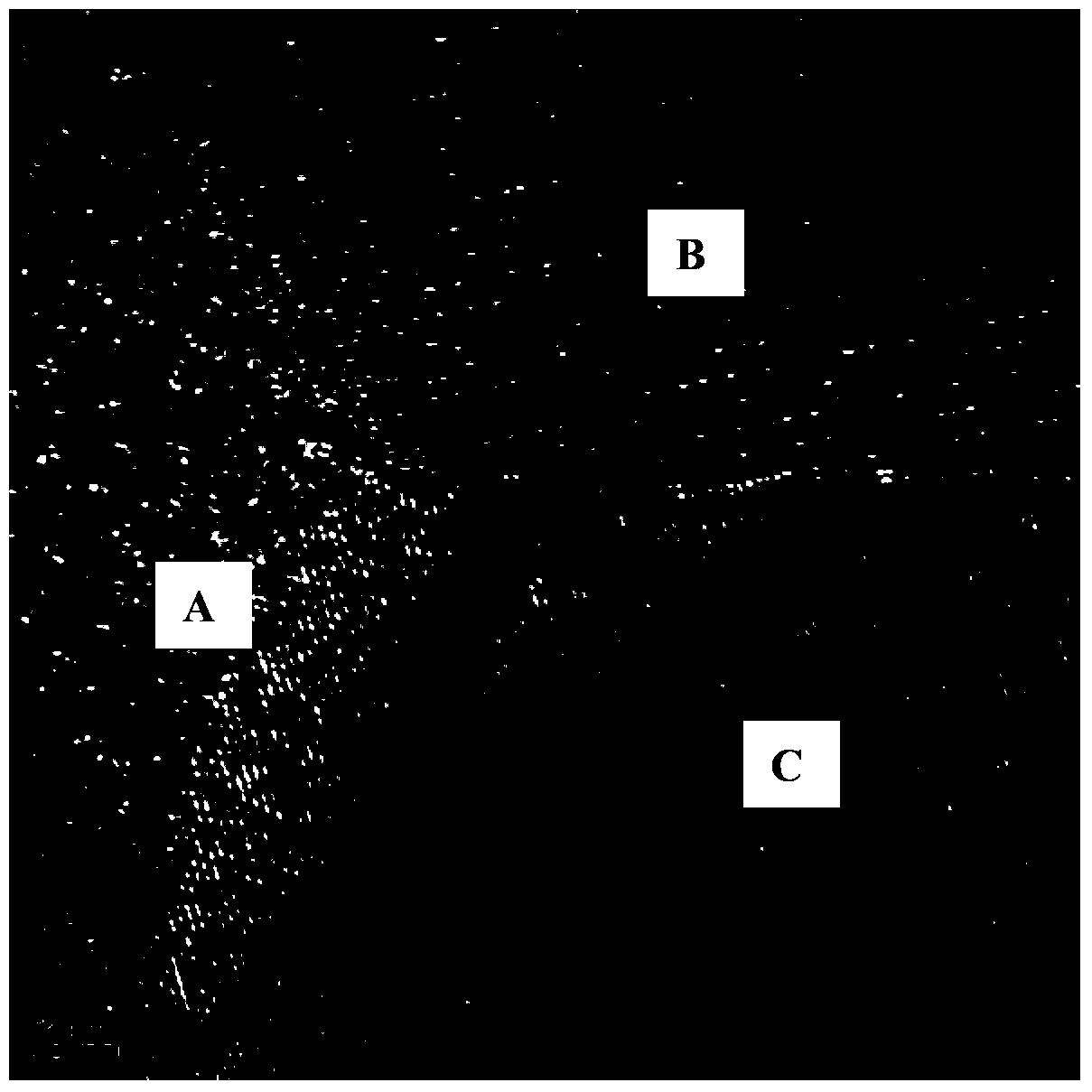

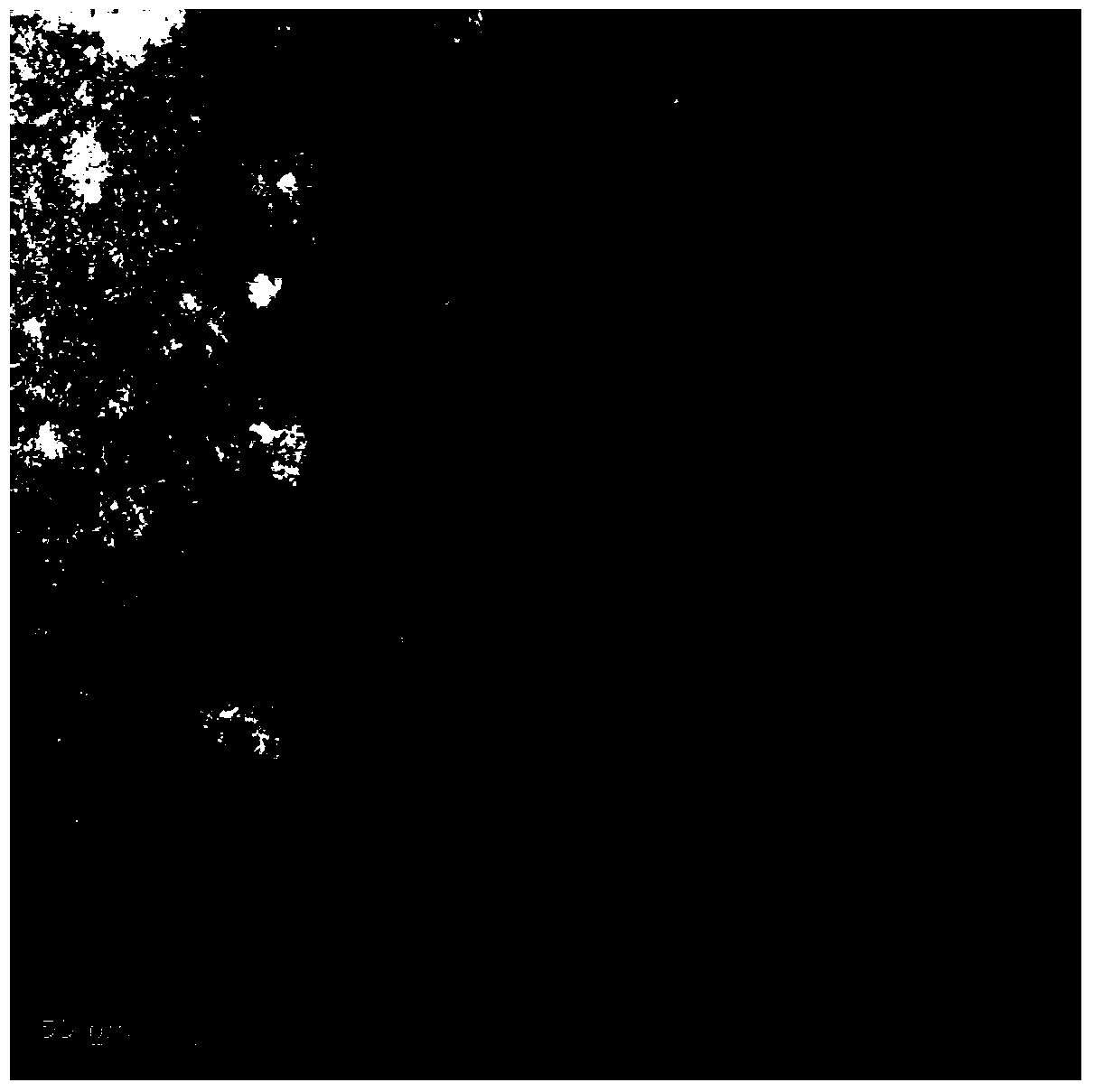

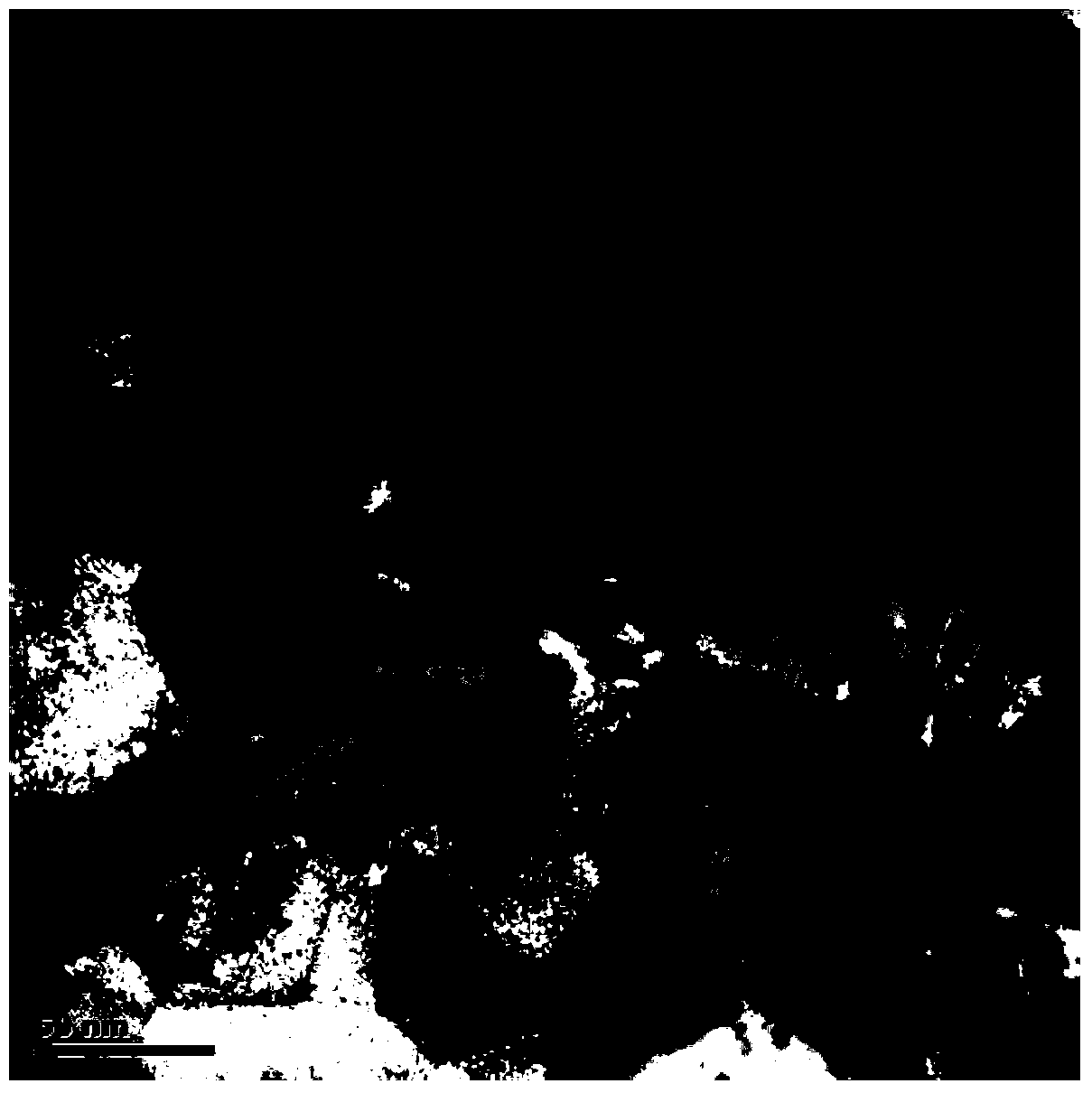

Superfine multi-component composite ceramic powder and preparation method thereof

The invention provides a preparation method of superfine multi-component composite ceramic powder. The preparation method comprises the following steps: (A) mixing a Ti source, an M source and a carbon source, and carrying out high-energy ball milling to obtain activated nano-crystalline raw material powder; and (B) subjecting the prepared activated nano-crystalline raw material powder to a carbothermal reduction reaction, so as to obtain the superfine multi-component composite ceramic powder. According to the preparation method provided by the invention, raw materials are pretreated by utilizing the ball milling operation, thereby obtaining the uniformly-mixed activated nano-crystalline raw material powder; meanwhile, the technical characteristics of spark plasma sintering are sufficiently utilized; compared with a conventional carbothermal reduction reaction, the carbothermal reduction reaction involved in the invention has the advantages that the temperature rise rate is very high, the synthesis temperature is relatively low, the heat preservation period is very short, and a powder product of which the particle size is relatively small can be easier to obtain; and the ball milling operation and the spark plasma sintering operation are ingeniously combined, thereby improving the raw material reaction driving force and diffusivity, enhancing the component reactivity, greatly lowering the synthesis temperature, and shortening the reaction period.

Owner:HAINAN UNIVERSITY

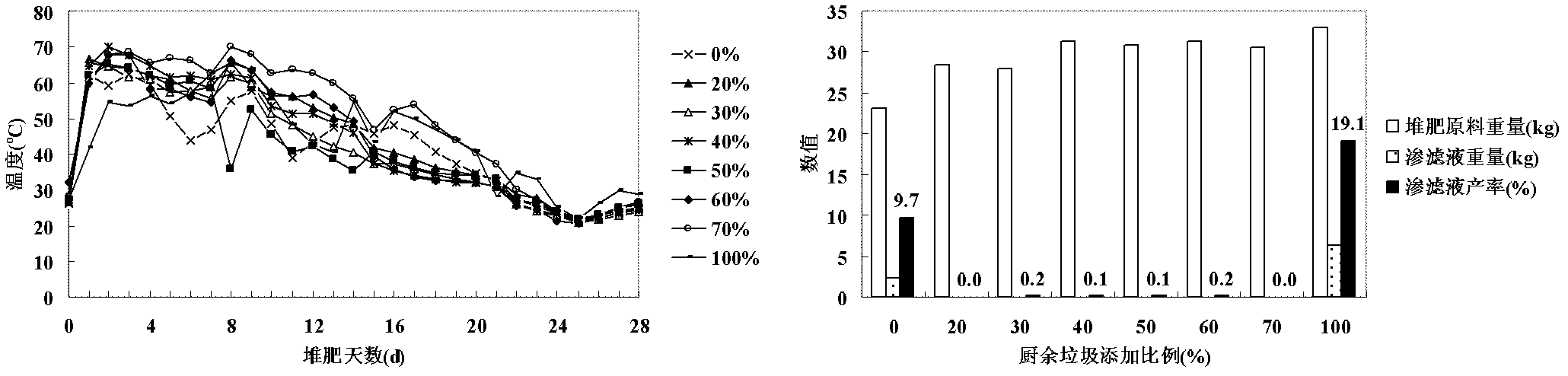

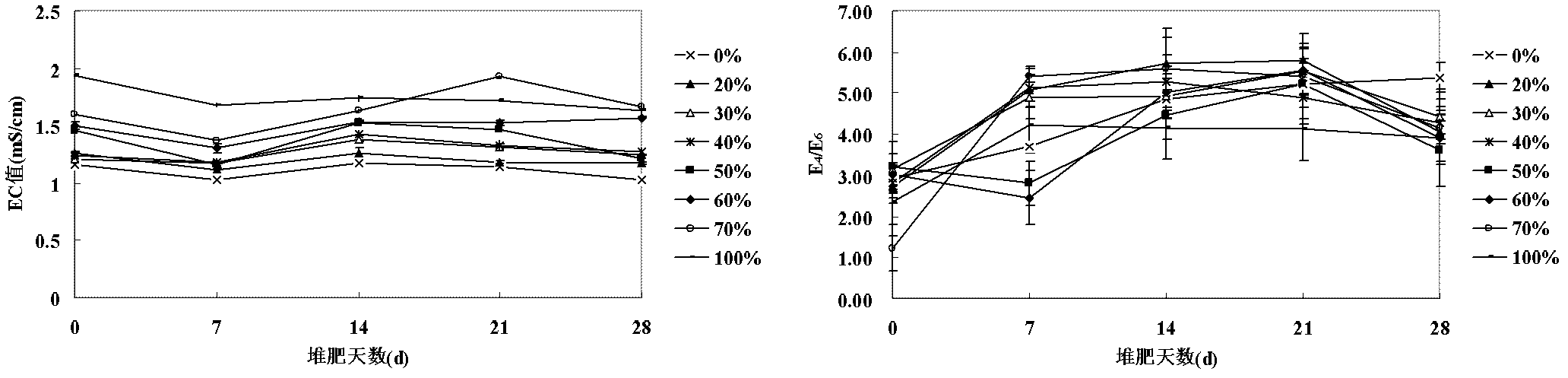

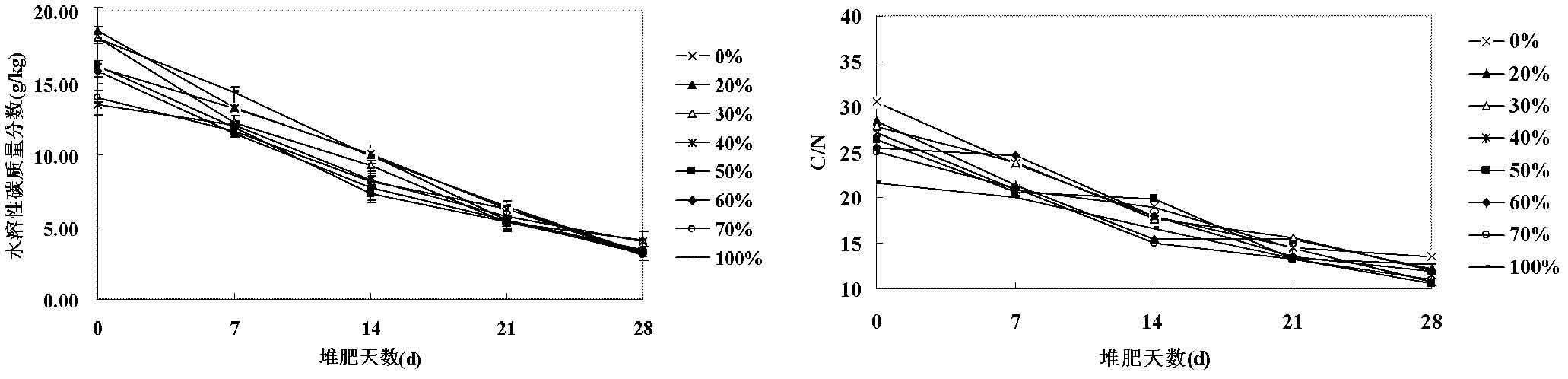

Method for changing kitchen garbage into fertilizer

ActiveCN102826878AFast heating rateReduce generationBio-organic fraction processingOrganic fertiliser preparationFecesLivestock manure

The invention discloses a method for changing kitchen garbage into a fertilizer. The method provided by the invention comprises the following steps of: mixing livestock manure, crop straw and kitchen garbage to obtain a mixture; and fermenting the mixture to obtain the fertilizer. An appropriate proportion of kitchen garbage is added into pig manure and straw which are used as main materials of compost, thus solving problems of unventilated defect, slow heating and generation of a lot of leachate and the like by individually composting. It shows through a fermenter composting test that heating speed of compost can be accelerated by the addition of residual kitchen garbage into straw and pig compost and simultaneously the generation of leachate can be greatly minimized. Germination rate indexes of residual kitchen garbage compost products added in any proportion are all greater than 80%, and the compost products all reach the putrescibility standard. Considering temperature, leachate, putrescibility and odor discharge together as a whole, the percentage of the added residual kitchen garbage is supposed to be controlled within 30% to 60%. In addition, by the adoption of the method, delivering quantity of house refuse can be effectively minimized, resources are saved, generation of malodorous gases is controlled, and the goal of energy saving and emission reduction is realized.

Owner:CHINA AGRI UNIV

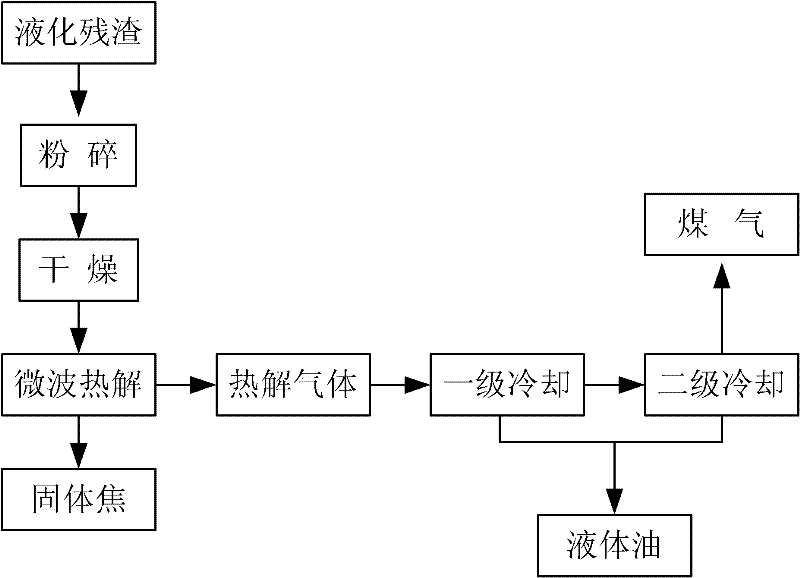

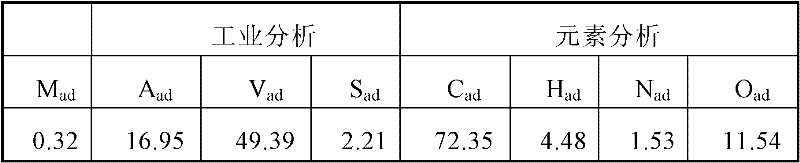

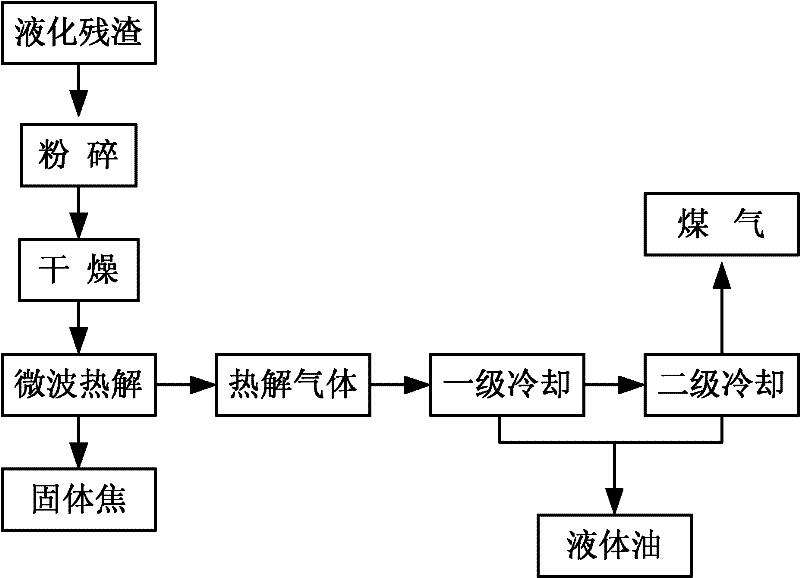

Method for quick pyrolysis of coal direct liquefaction residues by utilizing microwaves

InactiveCN102199434AFast heating rateGood choiceLiquid hydrocarbon mixture productionSpecial form destructive distillationProcess engineeringCoal liquefaction

The invention relates to a method for the quick pyrolysis of coal direct liquefaction residues by utilizing microwaves, which comprises the following steps of: heating the coal direct liquefaction residues to the temperature of between 500 and 900 DEG C by utilizing the microwaves as a heating heat source; crushing the coal direct liquefaction residues to less than 30 millimeters, and putting into drying equipment for drying; and putting the dried coal direct liquefaction residues into a microwave pyrolysis reactor, heating to the temperature of between 500 and 900 DEG C to obtain solid coke and pyrolysis gas, and cooling to separate liquid oil from gas. The method is mainly used for recycling the coal direct liquefaction residues comprehensively, and hydrogen-rich gas is obtained while the liquid oil is separated quickly and efficiently, so the method has characteristics of high pyrolysis speed, production efficiency, yield of the liquid oil and hydrogen content in the gas.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

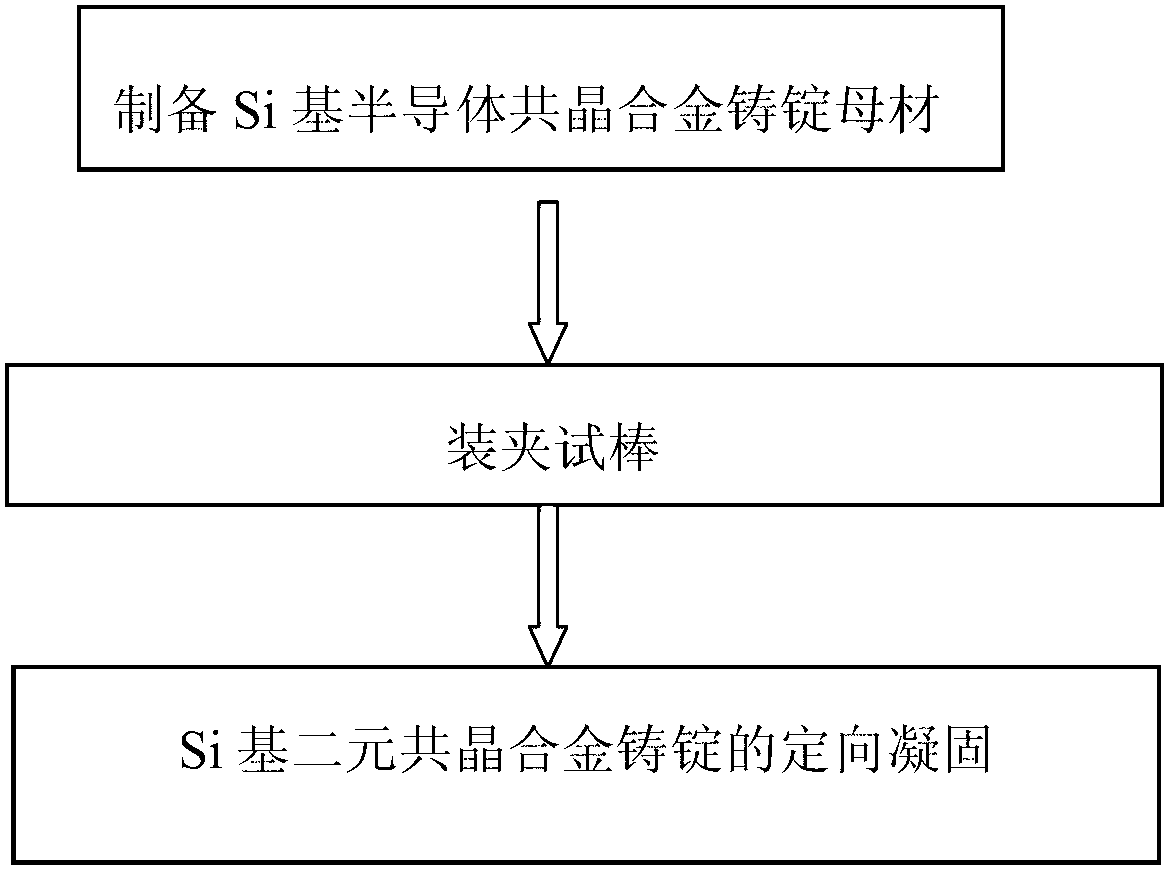

Method for preparing Si-based binary eutectic in-situ composites

ActiveCN102703971ANo crackLow costPolycrystalline material growthEutectic material solidificationFiberCrucible

A method for preparing Si-based binary eutectic in-situ composites is realized through the following steps: a test rod cut form eutectic alloy base metal is placed in a laser suspension zone melt directional solidification furnace and is kept coaxially with a pull mechanism; a laser suspension directional solidification device is used to symmetrically zone melt the test rod by two beams of symmetrical laser with equal quality; and after stable melt zones are obtained, continuous directional solidification of the composites can be realized through pulling. During the process of laser suspension zone melt directional solidification, the laser power is 400 to 1200 W, the pulling speed is 1 to 500 micrometers per second, the lengths of the melt zones are 5 to 9 mm, and the laser spots are 2 to 4mm. Through the method, the crucible-free rapid directional solidification of Si-based binary eutectic alloy at the temperature gradient of 5000 to 7000 K / cm and the pulling speed of 1 to 500 micrometers per second, pollution and cracks caused by the conventional directional solidification crucible are completely eliminated, and the Si-based binary eutectic in-situ composites with an ultra fined structure and uniform fiber distribution are obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing chromium salt

The invention discloses a method for preparing chromium salt. The method is characterized by comprising the following steps: sufficiently and uniformly mixing a raw material containing chromium oxide (chrome ore or chromium slag) with sodium carbonate, carrying out oxidizing roasting at the roasting temperature of 900-1100 DEG C for 0.5-2.5 hours in an atmosphere with the oxygen content of higher than 20% by using microwaves as a heat source, leaching the roasted product with water, and preparing chromium salt from the leach solution. The chemical analysis on the clinker and leaching slag indicates that the insoluble waste slag contains less than 5% of chromium (on the basis of chromic oxide). The method reduces the chromium content in the discharged chromium slag, enhances the chromium utilization ratio in the chromium salt production process, effectively saves the chrome ore resources, and has obvious advantages of resource saving and environmental protection by using the microwaves as the heat source instead of the traditional coal and natural gas heating.

Owner:LIAONING SING HORN GROUP CO LTD

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

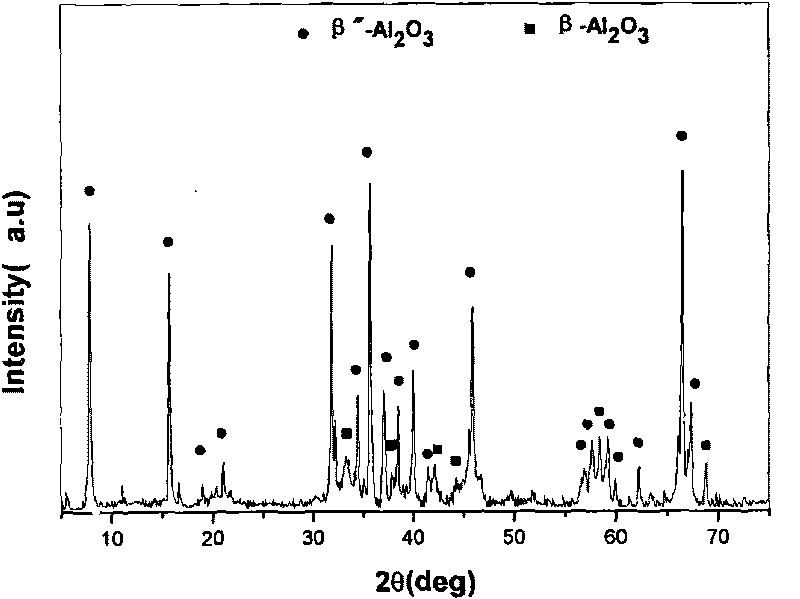

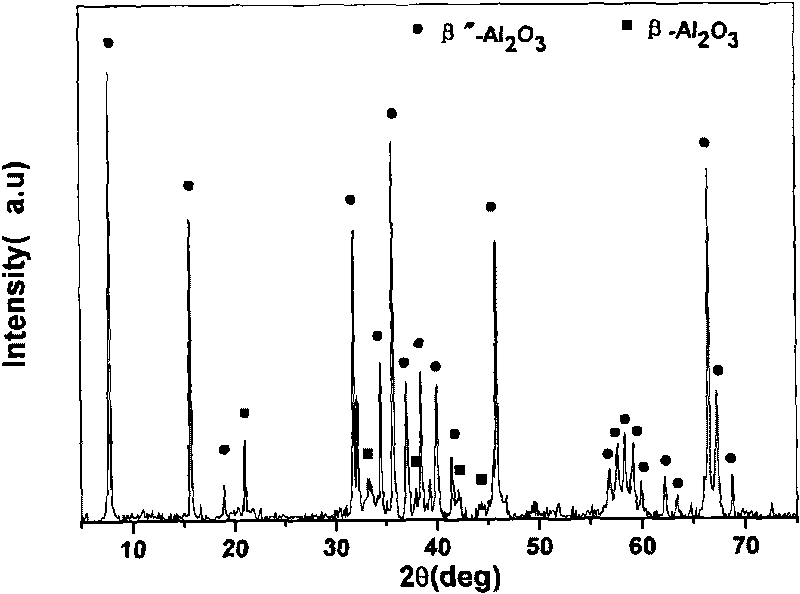

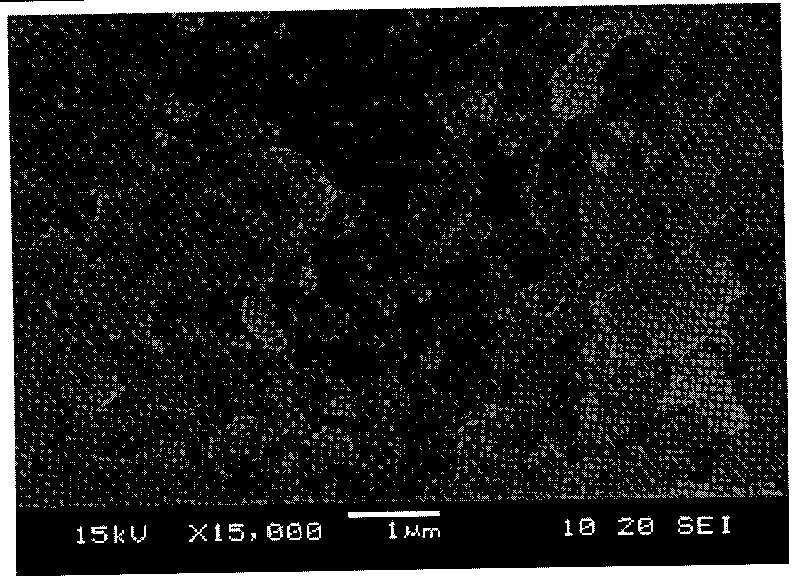

Preparation method of Na-beta''-Al2O3 solid electrolyte

InactiveCN101734911AAvoid churnReduce consumptionCell seperators/membranes/diaphragms/spacersLithiumMicrowave oven

The invention relates to a preparation method of a Na-beta''-Al2O3 solid electrolyte, comprising the following steps of: adding a stabilizer in a compound containing sodium, aluminium and magnesium or lithium as a raw material; preparing precursor powder; placing the prepared precursor powder into a microwave oven after being subjected to prilling and molding; and fast sintering to obtain the Na-beta''-Al2O3 electrolyte. The method not only has short reaction time and can furthest reduce the loss of Na2O and ensure the conductivity of the material, but also has low energy consumption and hightemperature rate and can obtain a sample with higher compactness; and in addition, the Na-beta''-Al2O3 solid electrolyte prepared by the method shows excellent property and is suitable for being usedas the solid electrolyte of a sodium-sulphur battery and a sodium-nickel chloride battery.

Owner:NANJING UNIV OF TECH

Mobile low-temperature adsorption concentration-thermal desorption device and application method thereof

InactiveCN103852370AEffective isolationSolve the fragilePreparing sample for investigationControl systemComputer module

The invention discloses a mobile adsorption concentration-thermal desorption device and an application method thereof. The device comprises a control system, a gas circuit part and a mobile cold trap consisting of a heating module, a refrigerating module and a mobile mechanism. The method comprises the steps of control system starting, operation of the refrigerating module, sample collection, operation of the heating module, sample desorption, pipeline cleaning, and the like. The device has the advantages that a refrigerating fin is easy to damage after long-time overheating, and the gas adsorption and gas enrichment efficiency is effectively improved. In comparison with the prior art, the device shortens the adsorption and analysis time, reduces the time consumption, lowers the cost and improves the concentration efficiency.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

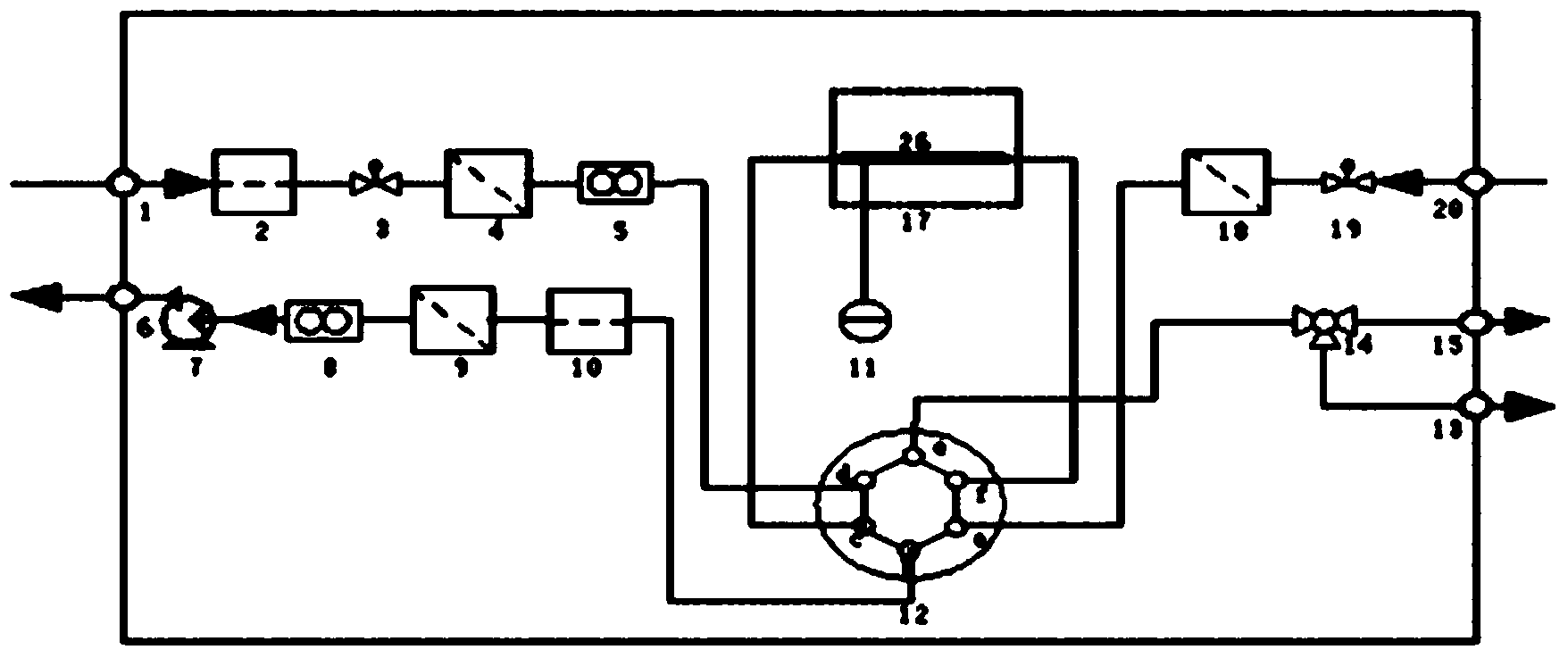

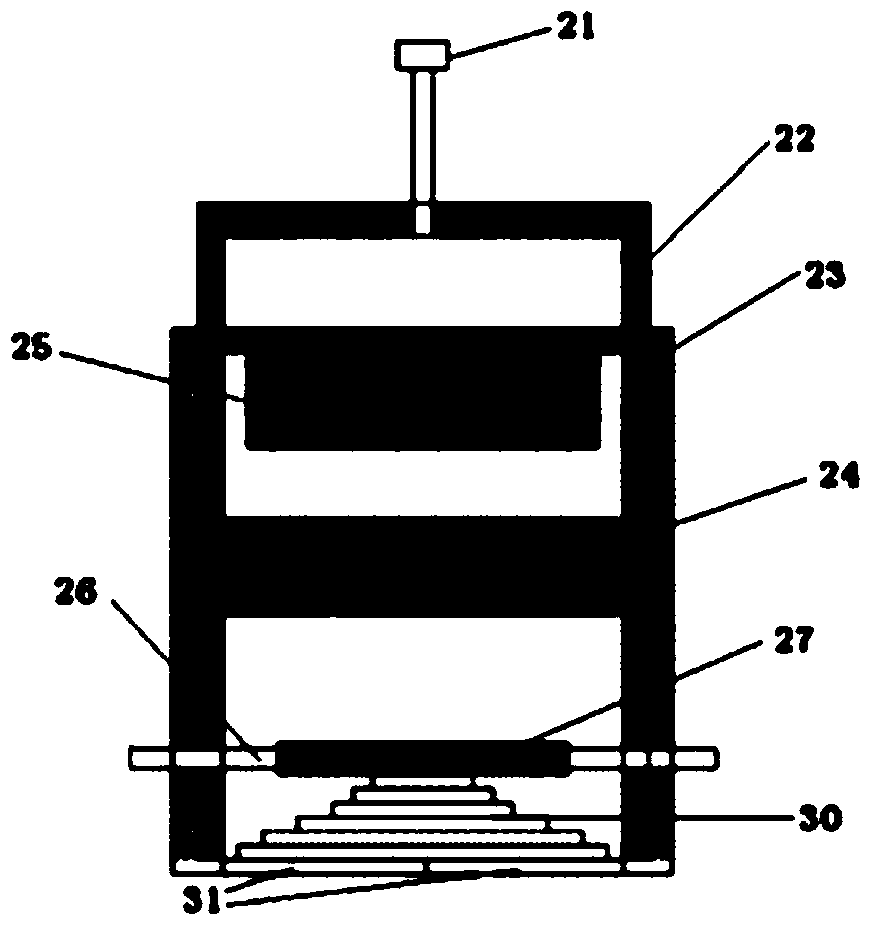

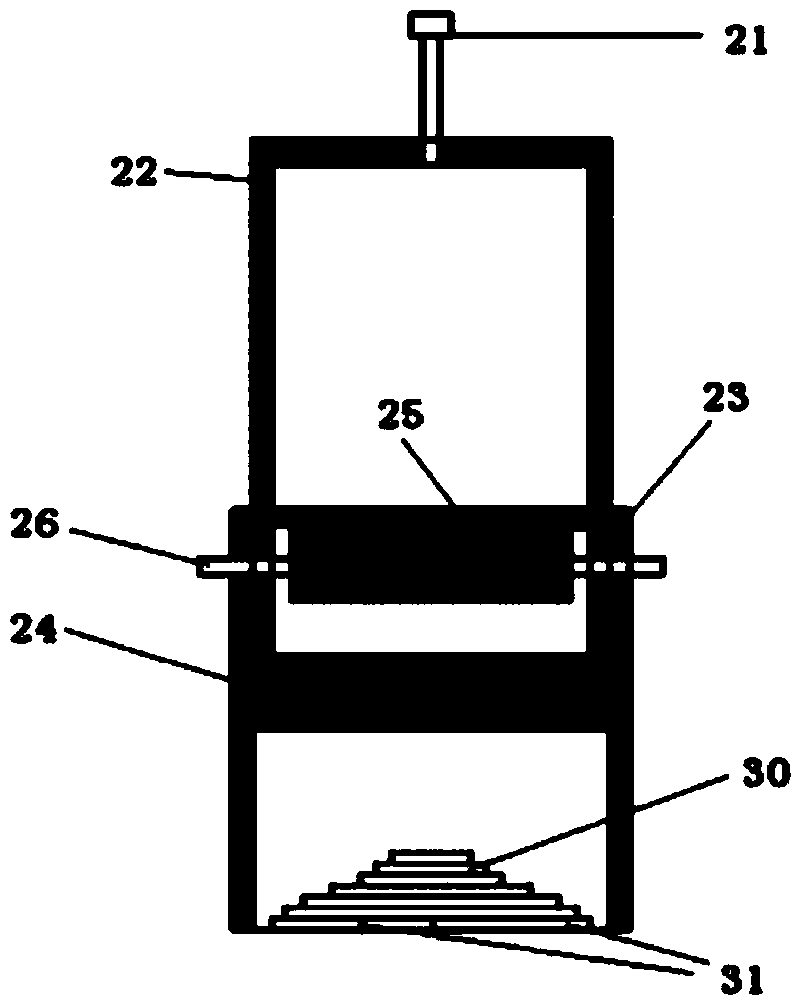

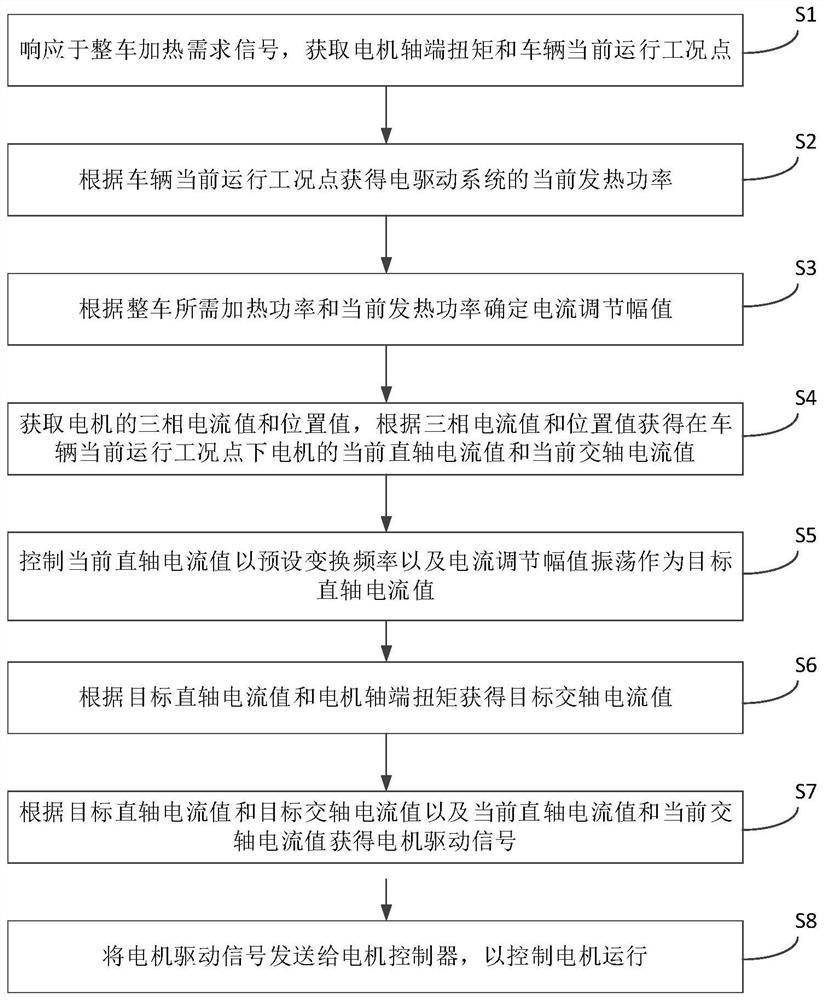

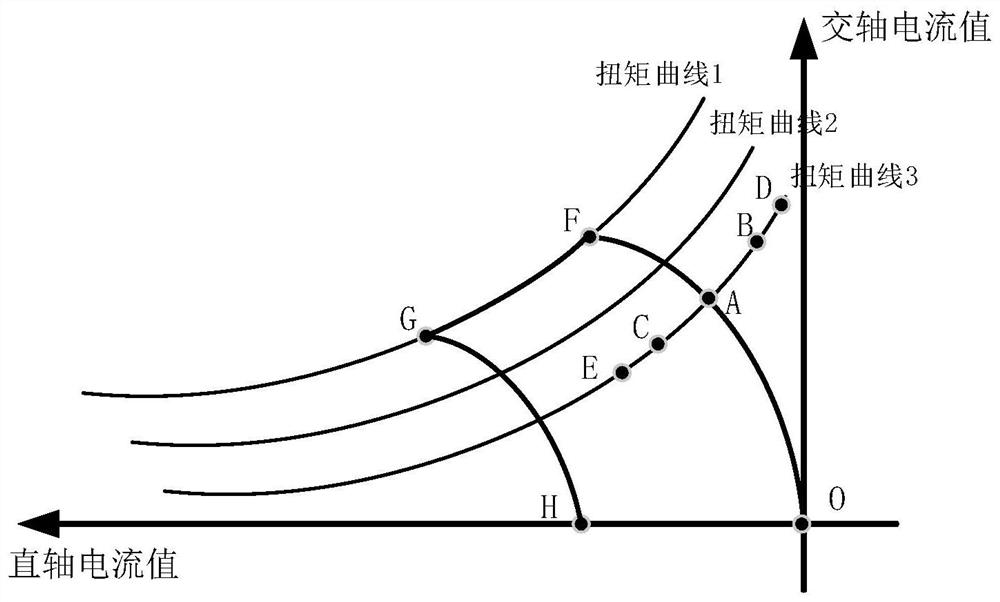

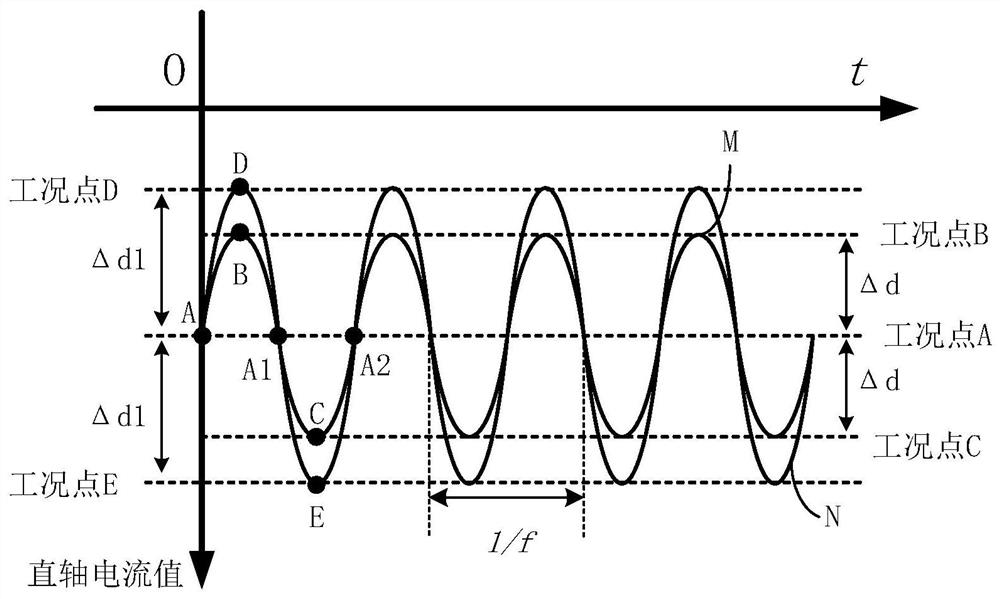

Vehicle electric driving system control method, electric driving system and vehicle

ActiveCN113022326AFast heating rateLow costVector control systemsVehicle sub-unit featuresPower batteryElectric machinery

The invention discloses a vehicle electric driving system control method, an electric driving system and a vehicle. The method comprises the steps of obtaining the current heating power of the electric driving system according to the current operation condition point of the vehicle; determining a current adjusting amplitude according to the heating power required by the whole vehicle and the current heating power; obtaining a current direct-axis current value and a current quadrature-axis current value of the motor under the current operating condition point of the vehicle according to the three-phase current value and the position value of the motor; and controlling the current direct-axis current value to serve as the target direct-axis current value with the preset conversion frequency and the current adjusting amplitude oscillation, then making the electric driving system to heat, the heating rate of the power battery can be increased through oscillation of the current flowing through the power battery, and therefore the vehicle electric driving system can be suitable for cold regions.

Owner:BYD CO LTD

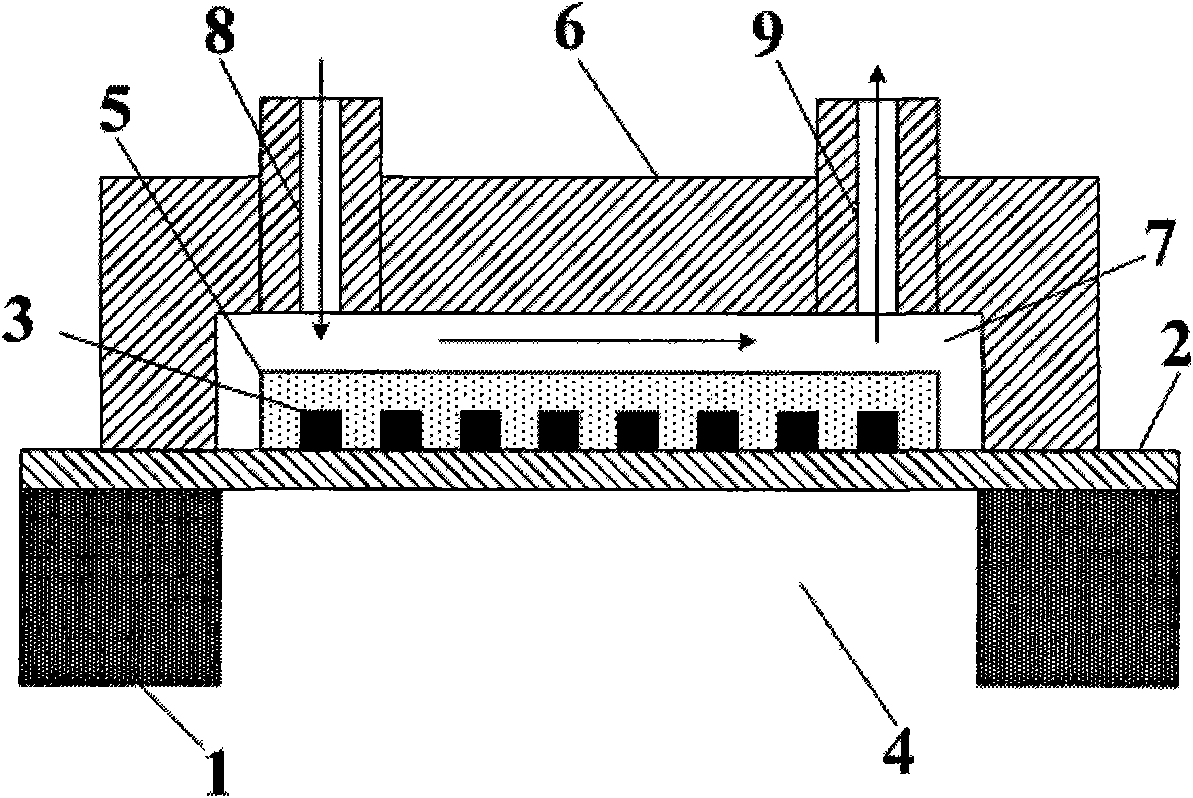

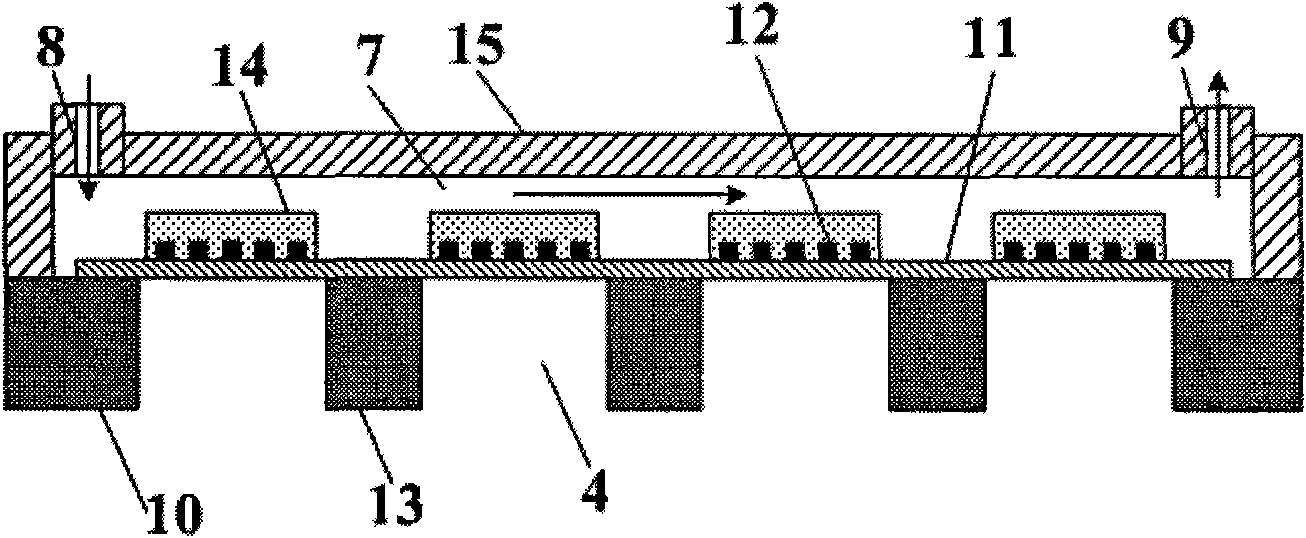

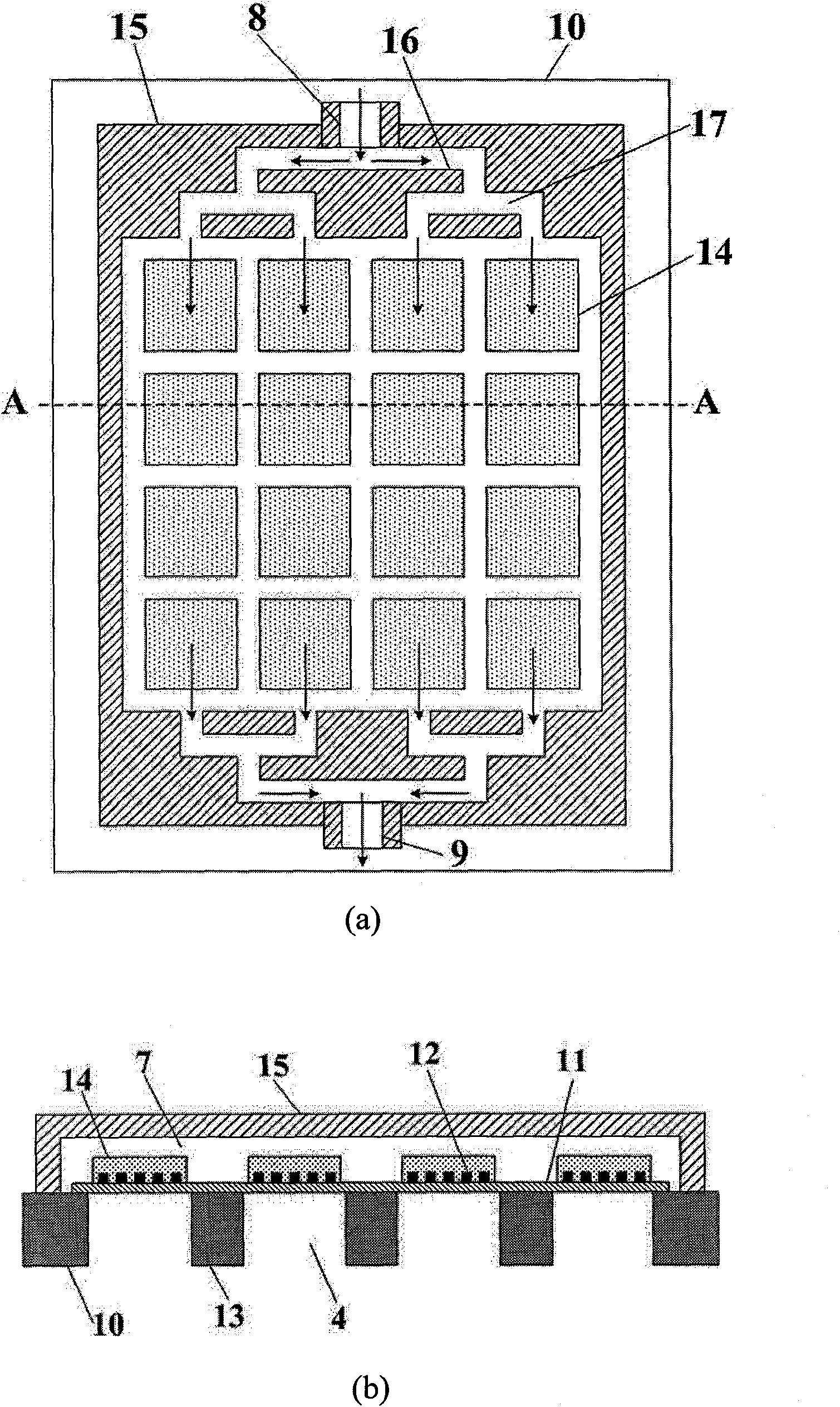

Large area MEMS membrane type gas enricher

InactiveCN101625345AImprove enrichment capacityStrong enrichment abilityTelevision system detailsImpedence networksMembrane configurationEngineering

The invention discloses a large area MEMS membrane type gas enricher, comprising a silicon substrate, a top cap and an enriching region arranged between the silicon substrate and the top cap; wherein the top cap is provided with an air inlet and an air outlet, the enriching region is composed of a plurality of enriching units, each enriching unit is provided with a hanging membrane which are provided with a film heater and an adsorption film, and a silicon frame which are arranged all around the hanging membrane. The invention not only has the advantages of small heat capacity and fast heating rate but also effectively increases absorption area and absorption gross and improves enriching rate by combining a plurality of enriching units.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

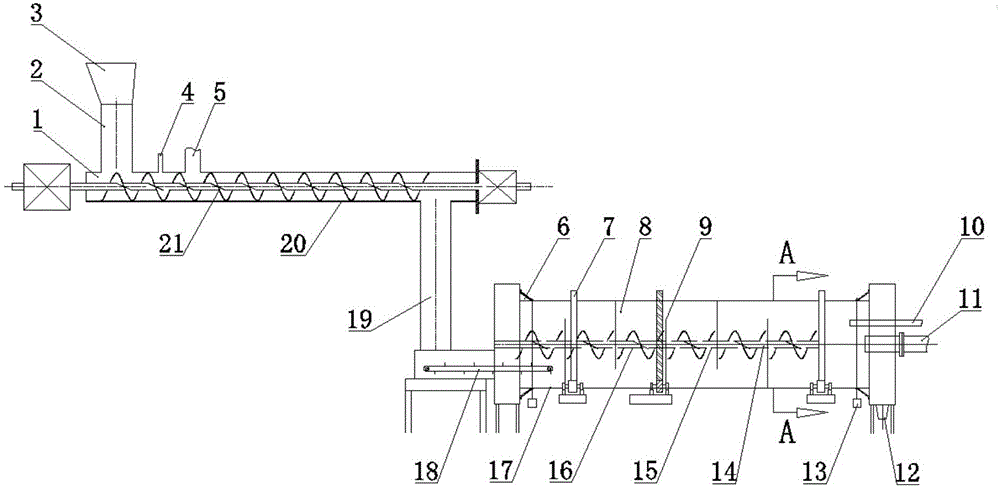

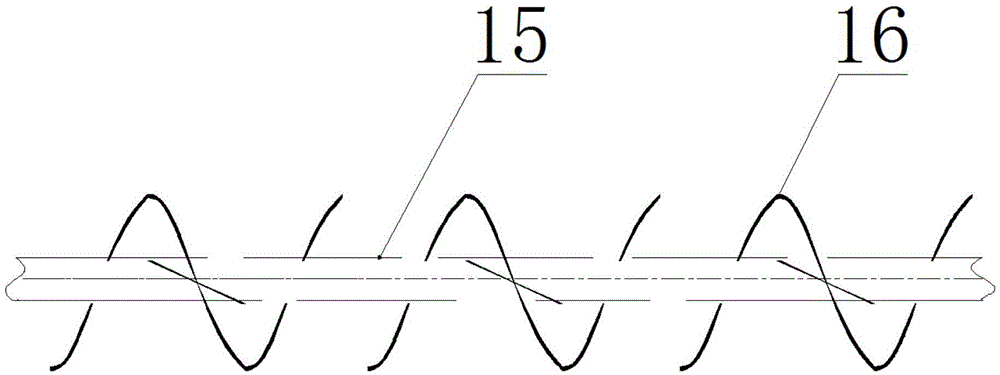

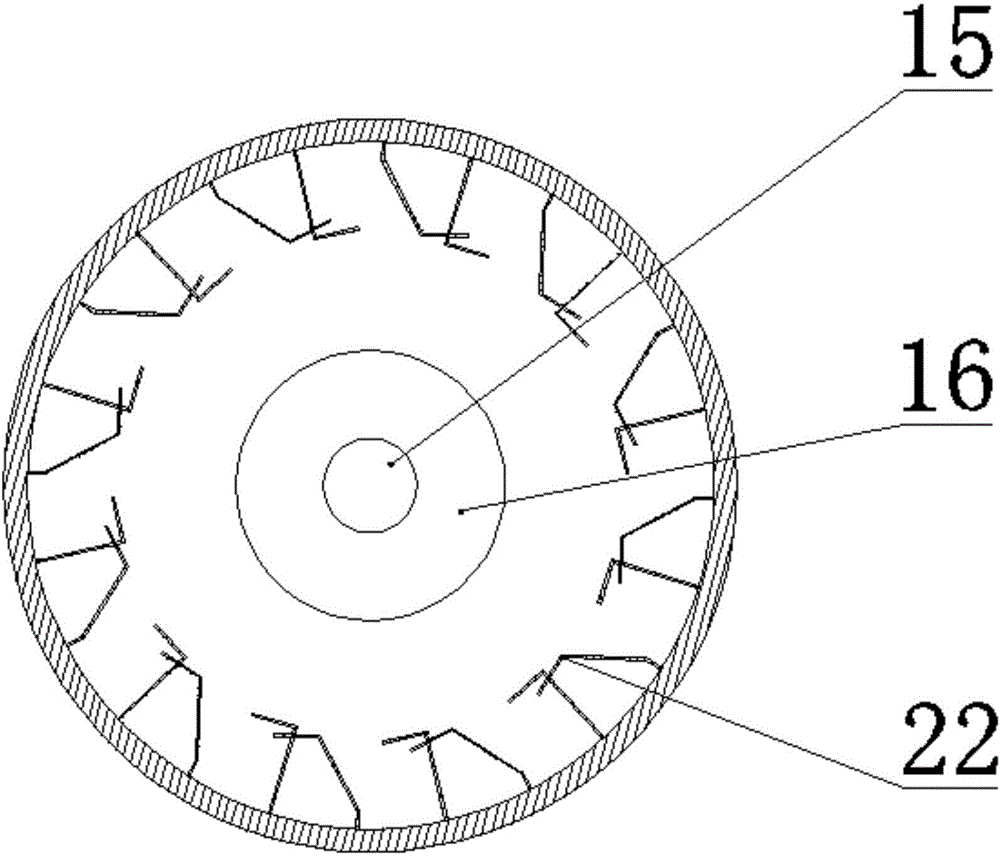

Continuous two-stage biomass nitrogen-rich pyrolytic reaction device

ActiveCN104099118ARealize continuous nitrogen-enriched pyrolysisReasonable control of pyrolysis reaction parametersProductsReagentsSupercapacitorNitrogen

The invention discloses a continuous two-stage biomass nitrogen-rich pyrolytic reaction device. The continuous two-stage biomass nitrogen-rich pyrolytic reaction device comprises an auger pre-pyrolysis reactor and a rotary type turbulence pyrolytic reactor, wherein the auger pre-pyrolysis reactor comprises a pre-pyrolysis reaction cylinder, an auger and a feed pipe, and biomass enters the pre-pyrolysis reaction cylinder through a feed pipe, utilizes the pumped-in powdery exogenous nitrogen to achieve pre-pyrolysis under the pushing action of the auger and can be output through a discharge opening at the other end of the pre-pyrolysis reaction cylinder; the rotary type turbulence pyrolytic reactor comprises a pyrolytic reaction cylinder and a turbulence rotor capable of rotating relative to the pyrolytic reaction cylinder, as well as a gaseous exogenous nitrogen lead-in pipe and a high-temperature oxygen-free heat-carrying gas lead-in pipe, and under the atmosphere of the gaseous exogenous nitrogen and the high-temperature oxygen-free heat-carrying gas, counterrotation of the turbulence rotor and the pyrolytic reaction cylinder is utilized to enable full pyrolytic reaction between pre-pyrolysis biomass raw materials and nitrogenous gas so as to realize two-stage pyrolysis to produce multi-phase products. According to the invention, two-stage introduction of the exogenous nitrogen is utilized to manufacture nitrogen-rich oil and nitrogen-rich coke which can be respectively used for synthesizing high-quality chemicals and preparing high-performance super capacitors.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Combustion device of petroleum coke slurry

InactiveCN101666489ALarge specific surface areaFast heating rateCombustion using gaseous and pulverulent fuelBurnersMature technologyPetroleum

The invention relates to a combustion device of petroleum coke slurry, comprising a heat accumulation cavity, a fuel oil / gas duty nozzle, a petroleum coke slurry atomizing nozzle, an inner combustionair nozzle and an outer combustion air nozzle. The heat accumulation cavity is arranged in a hearth; the fuel oil / gas duty nozzle is arranged on a furnace wall and communicated with the heat accumulation cavity; the petroleum coke slurry atomizing nozzle, the inner combustion air nozzle and the outer combustion air nozzle which are communicated with the heat accumulation cavity are sequentially sleeved at the outer side of the fuel oil / gas duty nozzle from interior to exterior; and an inner combustion air swirl generator and an outer combustion air swirl generator are respectively arranged inthe inner combustion air nozzle and the outer combustion air nozzle. Aiming at the characteristics of combustion difficulty and high combusting NOx contents of the petroleum coke slurry, the inventionadopts an atomizing mode to improve the temperature increase rate of petroleum coke particles; an ignition heat lowering technology realizes the stable ignition and the low-pollution combustion of the petroleum coke slurry; and the invention has the advantages of strong pertinence, convenience, adjustment, mature technology, high combustion efficiency and convenient processing and manufacture.

Owner:XI AN JIAOTONG UNIV

Amorphous composite materials, and preparation method and applications thereof

The invention belongs to the field of metal amorphous composite materials, and discloses amorphous composite materials, and a preparation method and applications thereof. The amorphous composite materials comprise nickel, zirconium, titanium, niobium, aluminum and copper with a nickel-based amorphous phase as a matrix phase and beta-Ti and (Cu,Ni) Ti2 as reinforcing phases, and comprise the specific components according to the atomic percentage: 30-59 at.% of Ni, 10-24 at.% of Zr, 10-35 at.% of Ti, 7-10 at.% of Nb, 3-7 at.% of Al, 1-3 at.% of Cu, and the balance being inevitable trace impurities. The amorphous composite materials are prepared by rapidly sintering a nickel-based amorphous powder and a titanium-based amorphous powder. With control of the addition amount of the nickel-based amorphous powder, the amorphous composite materials with different amorphous phase content can be obtained. The amorphous composite materials are nearly fully dense, and can be applied in the fields of aeronautics and astronautics, military industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

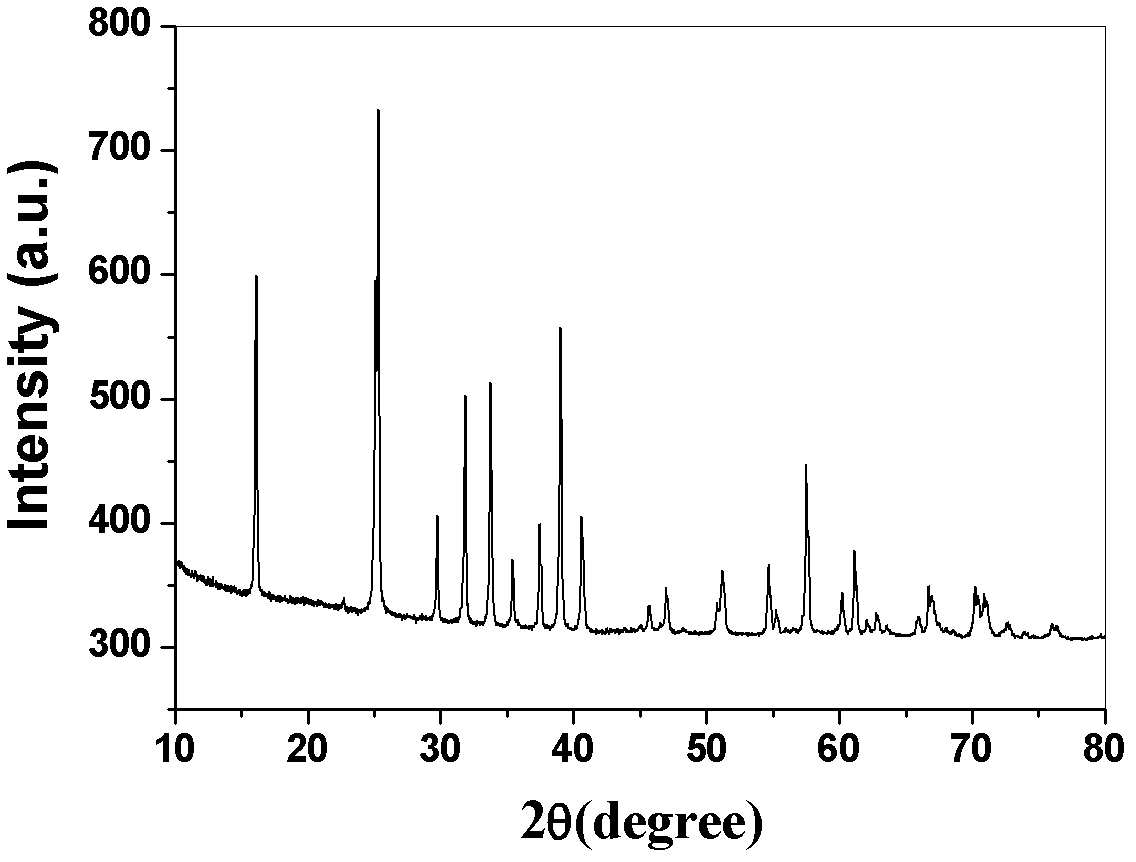

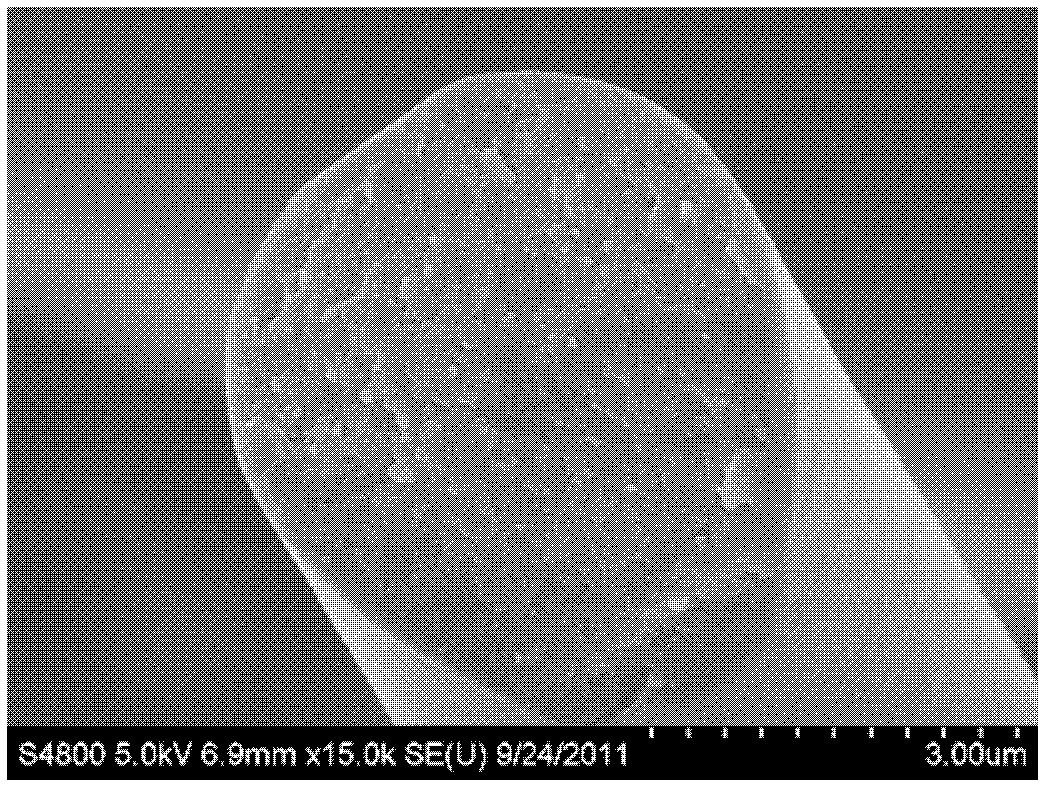

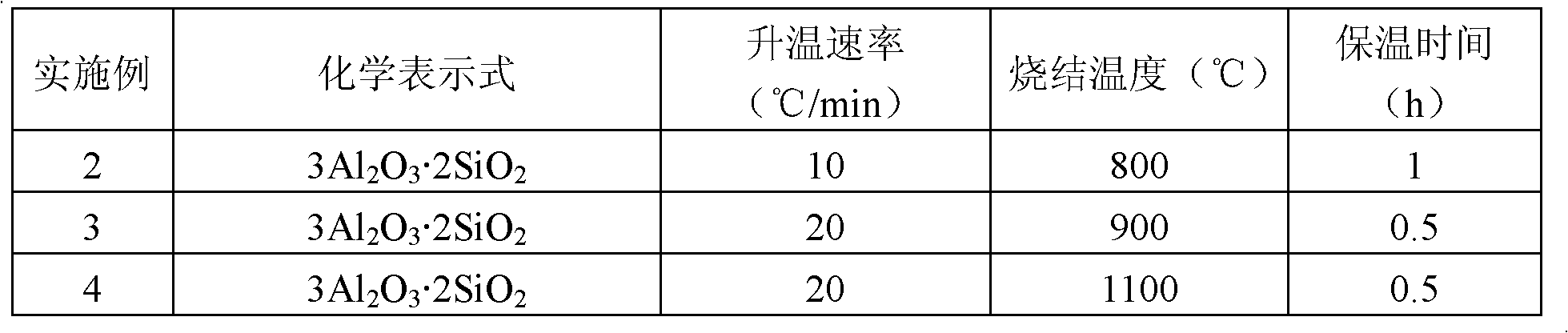

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Foamed ceramic material and process for producing foamed ceramic based on layered and sectionalized material preparation and distribution

ActiveCN109320206AShorten the production cycleEasy to passCeramic materials productionCeramicwareMaterials preparationFoaming agent

The invention discloses a process for producing foamed ceramic based on layered and sectionalized material preparation and distribution, and relates to the field of materials. According to the process, a plurality of foamed ceramic particles different in foaming agent content and particle size are used, and a foamed ceramic material is produced through layered and sectionalized material distribution. The process is characterized in that the particles on the lower layer have small particle sizes and high foaming agent content, while the particles on the upper layer have large particle sizes andlow foaming agent content, so that a channel is provided for low temperature exhaust, and the time for low temperature exhaust is shortened; the arrangement mode is also beneficial to heat transfer;the uneven foaming caused by the temperature gradient is compensated; the temperature rise rate in the foaming and firing stage is increased; the preserving time at the foaming temperature is shortened, and accordingly, the entire production cycle of the foamed ceramic material is shortened. The foamed ceramic material prepared by the process has high quality, few defects and a short production cycle, thereby being suitable for mass production.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

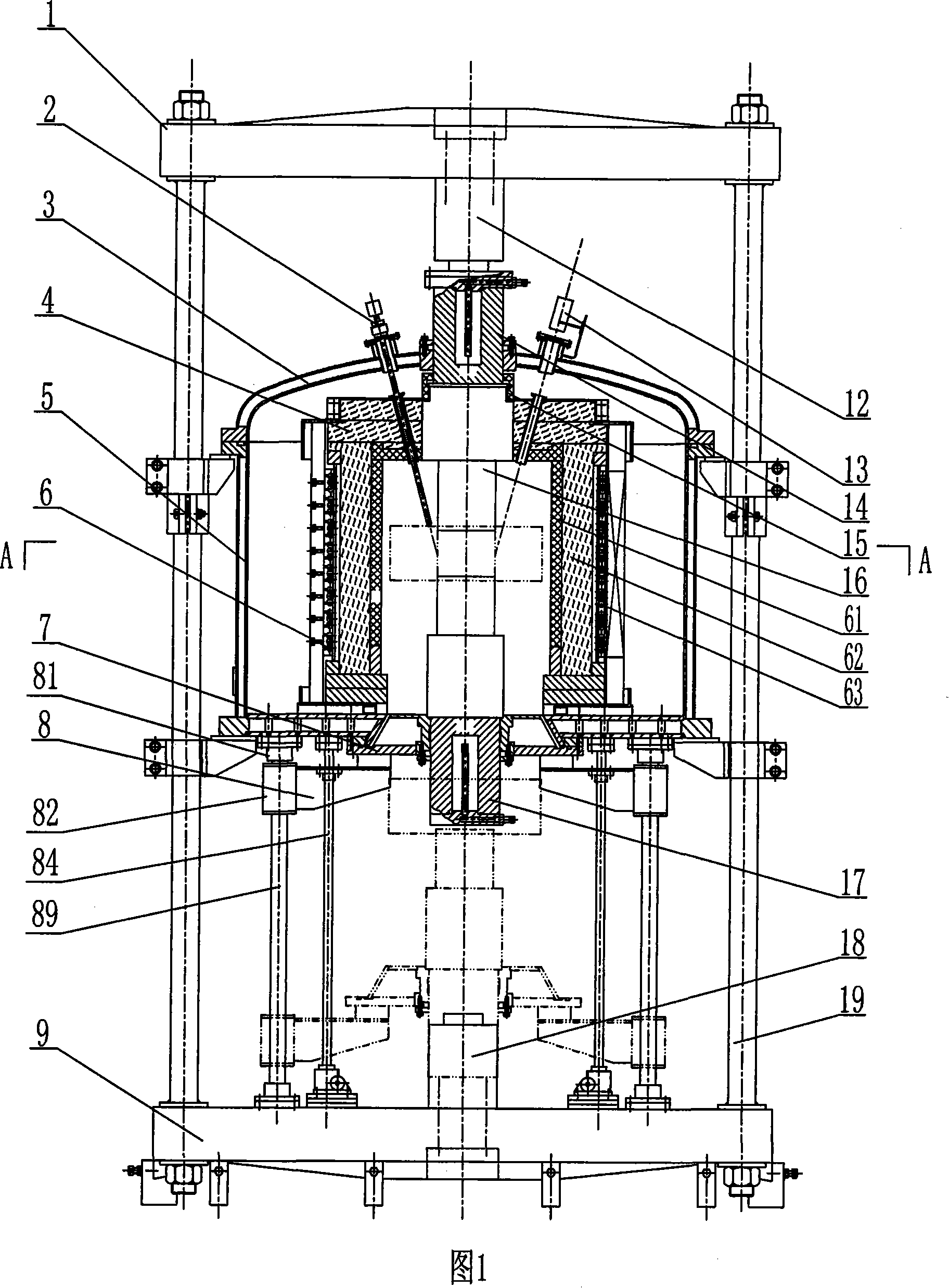

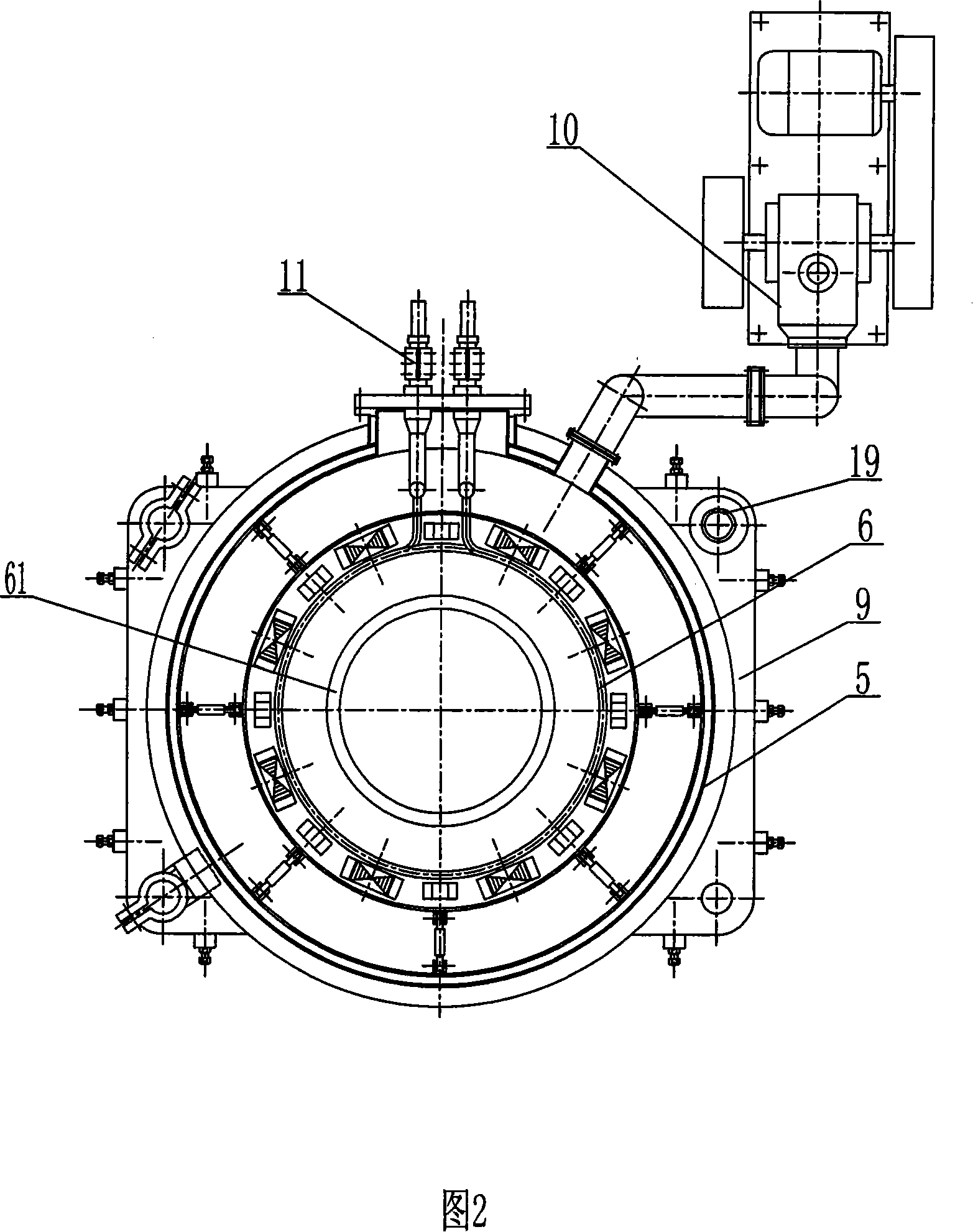

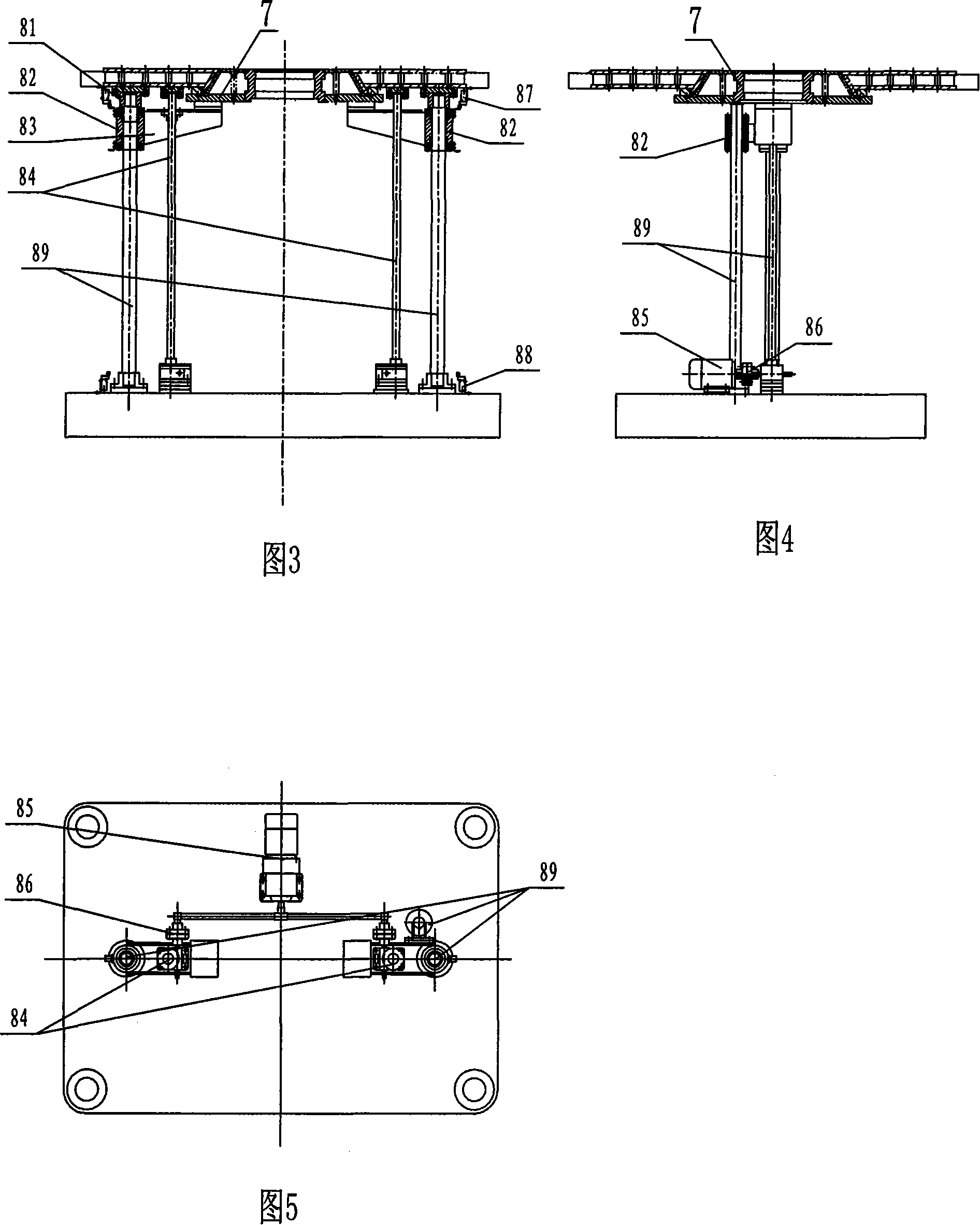

Large-sized vacuum hotpressing stove

InactiveCN101118112AGuaranteed synchronicityLifting height can be adjusted at willMuffle furnacesInduction heatingSusceptorGraphite

The present invention relates to a large vacuum hot pressing furnace, which comprises an electric furnace main body. The electric furnace main body comprises a furnace casing, a furnace casing bottom elevating device and an induced heating device; the furnace casing bottom elevating device comprises a material loading elevating platform, an electrical motor, three plane guideposts supported on the bottom part of the material loading elevating platform, and two adjusting screw rods driven by the same electrical motor; the induced heating device comprises an inductor and a furnace lining; a fire-resisting heat-insulating layer and an electric insulation later are arranged around the furnace lining structure arranged between the induction coil and the graphite heating cylinder of the inductor. The vacuum hot pressing furnace can make the material feeding and discharging process more safe and reliable, and meets requirements of the vacuum sealing performance and improves the planeness of the material loading elevating platform evidently. The adaptation of the induction heating method can make the temperature-rising speed improved significantly, and because the heating element is a graphite susceptor cylinder, which has strong intensity under high temperature, even if the graphite mold breaks under the pressing condition, the heating element can not be damaged.

Owner:SHANGHAI ZHONGJIA ELECTRIC FURNACE

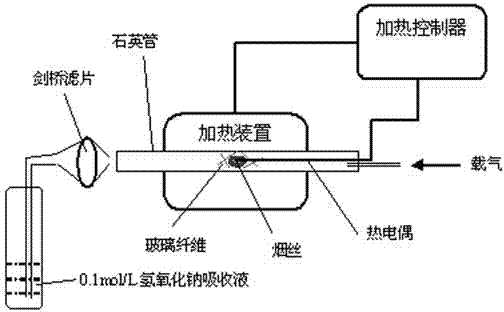

Determination method for experiment of simulating cigarette burning for generating hydrogen cyanide

The invention discloses a determination method for an experiment of simulating cigarette burning for generating hydrogen cyanide. The determination method is characterized by comprising the steps of trapping hydrogen cyanide in pyrolysis products by using a Cambridge filter and absorption liquid by adopting a rapid heating control device and taking a nitrogen-oxygen mixed gas or nitrogen as a carrier gas, and then determining the HCN (hydrogen cyanide) content in the Cambridge filter and the absorption liquid by using an ion chromatography so as to realize the simulation of the cigarette burning for generating the HCN and quantitative analysis. Compared with previous methods of simulating the cigarette burning for generating the HCN, the determination method has the advantages of being large in sample loading capacity, capable of using the oxygen-nitrogen mixed gas with different ratios, high in heating rate, good in experimental repeatability and the like, without preparing experimental cigarettes, and can be applicable to the research on the rapid determination of HCN precursors in smoke.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

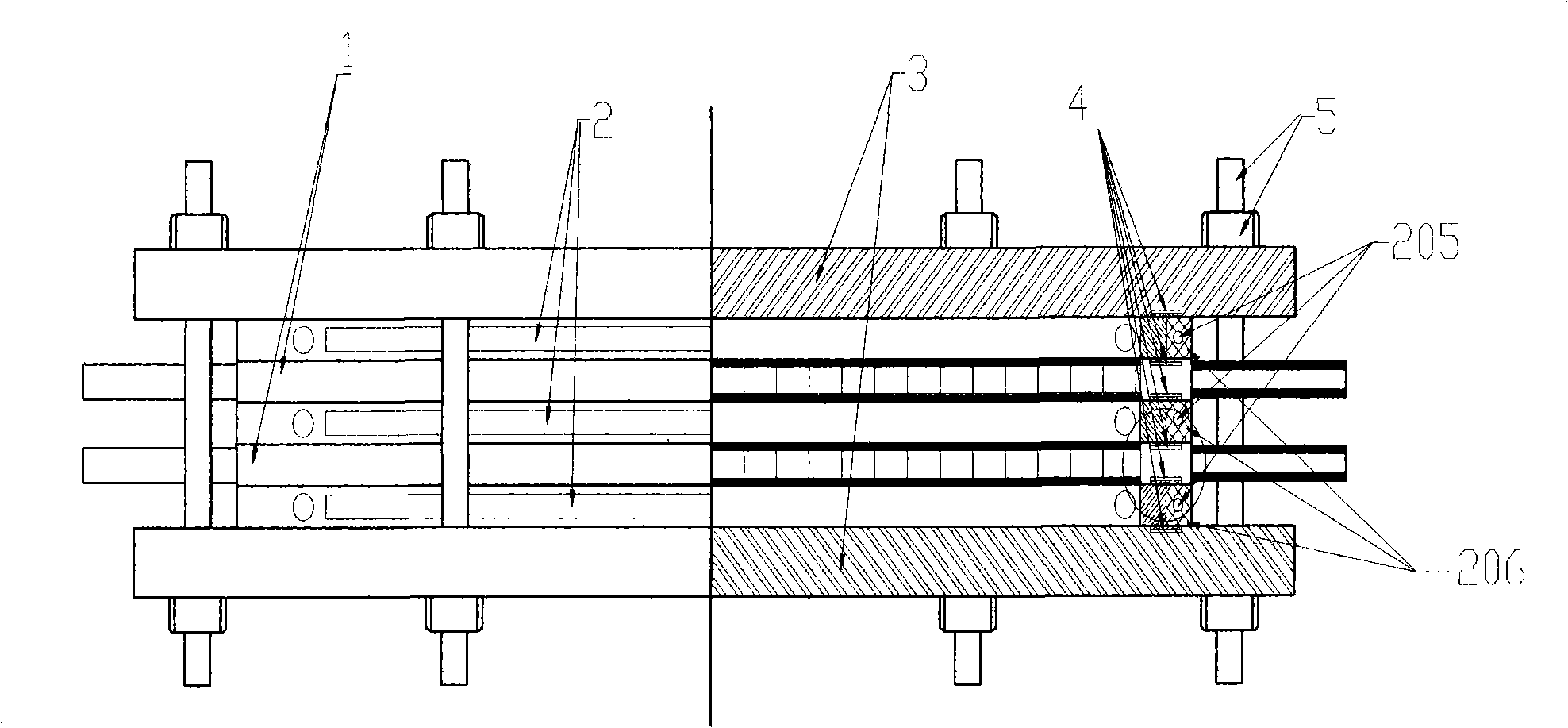

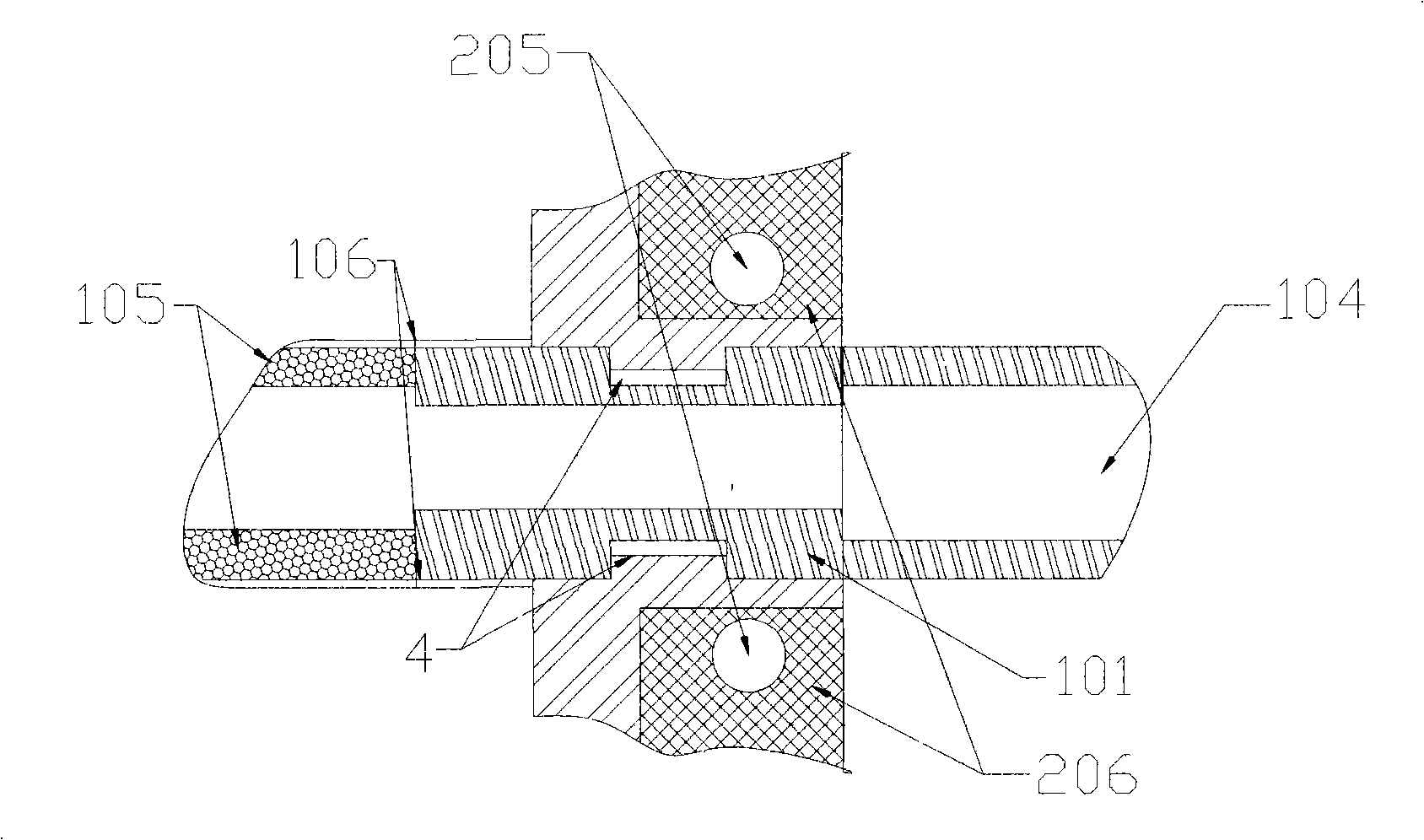

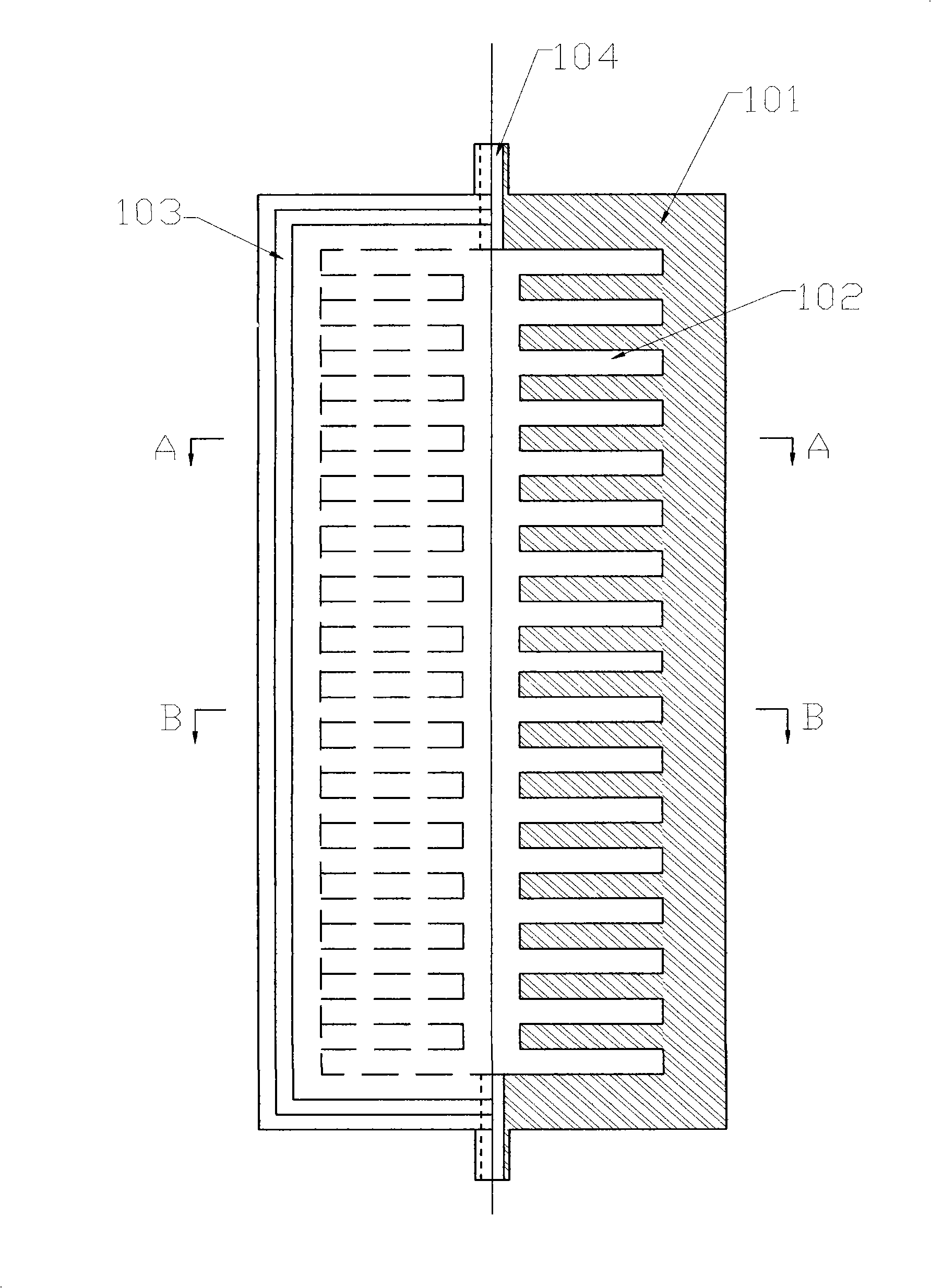

Electric preheating and constant temperature membrane separation device for producing high-purity hydrogen

InactiveCN101406791AEasy to implementFast heating rateHydrogen separationDispersed particle separationTemperature controlElectricity

The invention discloses a film separating device for producing high-purity hydrogen by electric heating. A plurality of palladium film components are arranged between two blank flanges of the device; synthesis gas circulating frames are arranged among the blank flanges and the palladium film components, and among palladium film components; graphite gaskets are arranged between the blank flange and the synthesis gas circulating frame, and between the synthesis gas circulating frame and the blank flange; the synthesis gas circulating frame is a quadrate frame with a cavity in the centre; the quadrate frame forms a closed space with the blank flange or the palladium film component; a hydrogenous synthesis gas lead-in pipe and a hydrogenous synthesis gas lead-out pipe are arranged on the synthesis gas circulating frame; lug bosses are arranged around the synthesis gas circulating frame; grooves are arranged on the four walls of the synthesis gas circulating frame; electric heater strips are arranged in the grooves; and the external surfaces of the electric heater strips are provided with insulating heat preservation materials. The film separating device directly introduces the hydrogenous synthesis gas into both sides of the palladium film component, has the advantages of compact design, small volume, convenient disassembly, quick heating speed, and good temperature control effect, and can continuously produce high-purity hydrogen with high hydrogen transmission rate.

Owner:SOUTH CHINA UNIV OF TECH

Improved type conductive marmite and manufacturing method thereof

InactiveCN103193463AFast heating rateGuaranteed bondingCooking-vessel materialsWarming devicesZincTalc

The invention relates to an improved type conductive marmite and a manufacturing method thereof. The improved type conductive marmite is characterized by sequentially comprising a marmite body ceramic, a glaze and a conductive metal aluminum layer, wherein the conductive metal aluminum layer is positioned at an outer bottom; the marmite body ceramic (1) comprises the following components in percentage by weight: 20%-27% of Suzhou No.1 clay, 12%-17% of camwood knots, 3%-8% of Zhangzhou clay, 35%-43% of spodumene and the balance of Gangxi talcum; the glaze (2) comprises the following components in percentage by weight: 25%-35% of the spodumene, 30%-45% of magnesium oxide, 6%-12% of zinc oxide, 3%-7% of Suzhou No.1 clay, 5%-8% of tin oxide,, 8%-15% of silicon micropowder and the balance of self-made fusion cakes; and the conductive metal aluminum layer (4) is completely covered at the bottom of a marmite body. The manufacturing method comprises the following steps of: weighing materials according to the formula of the marmite body ceramic; and stirring, mixing, adding water, vacuumizing, forming, drying, glazing, and finally burning. The improved type conductive marmite disclosed by the invention is possible to be hopeful in large-scale application on an electromagnetic cooker and has a good market prospect.

Owner:刘俊杰

Preparing method of pitch-based spherical activated carbon with high heat conductivity

ActiveCN106348290ADoes not affect the preparation processDoes not affect ball formationCarbon compoundsActivated carbonPolyvinyl alcohol

The invention discloses a preparing method of pitch-based spherical activated carbon with high heat conductivity. The preparing method comprises the steps of: uniformly mixing high soften point asphalt, naphthalene with a heat conduction agent, and reacting the mixture to prepare modified asphalt; adding modified asphalt into aqueous polyvinyl alcohol, and stirring for 0.5-3 h at 85-150 degrees centigrade to prepare pitch-based spheres; oxidizing and activating pitch-based spheres without dissolving to prepare pitch-based activated carbon spheres; placing pitch-based activated carbon spheres and a nitrogen-containing compound into a high-pressure kettle according to the mass ratio of 1: (0.1-0.3), sealing the kettle, heating the kettle to 150-300 degrees centigrade with the rate of 3-10 degrees centigrade / min, keeping the kettle for 0.5-3h at constant temperature and then cooling the kettle to prepare pitch-based spherical activated carbon. The pitch-based spherical activated carbon has the advantage of excellent heat conductivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com