Method for preparing Si-based binary eutectic in-situ composites

A binary eutectic and composite material technology, which is applied in the directional solidification of eutectic materials, the growth of polycrystalline materials, and the growth of single crystals. The effect of uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

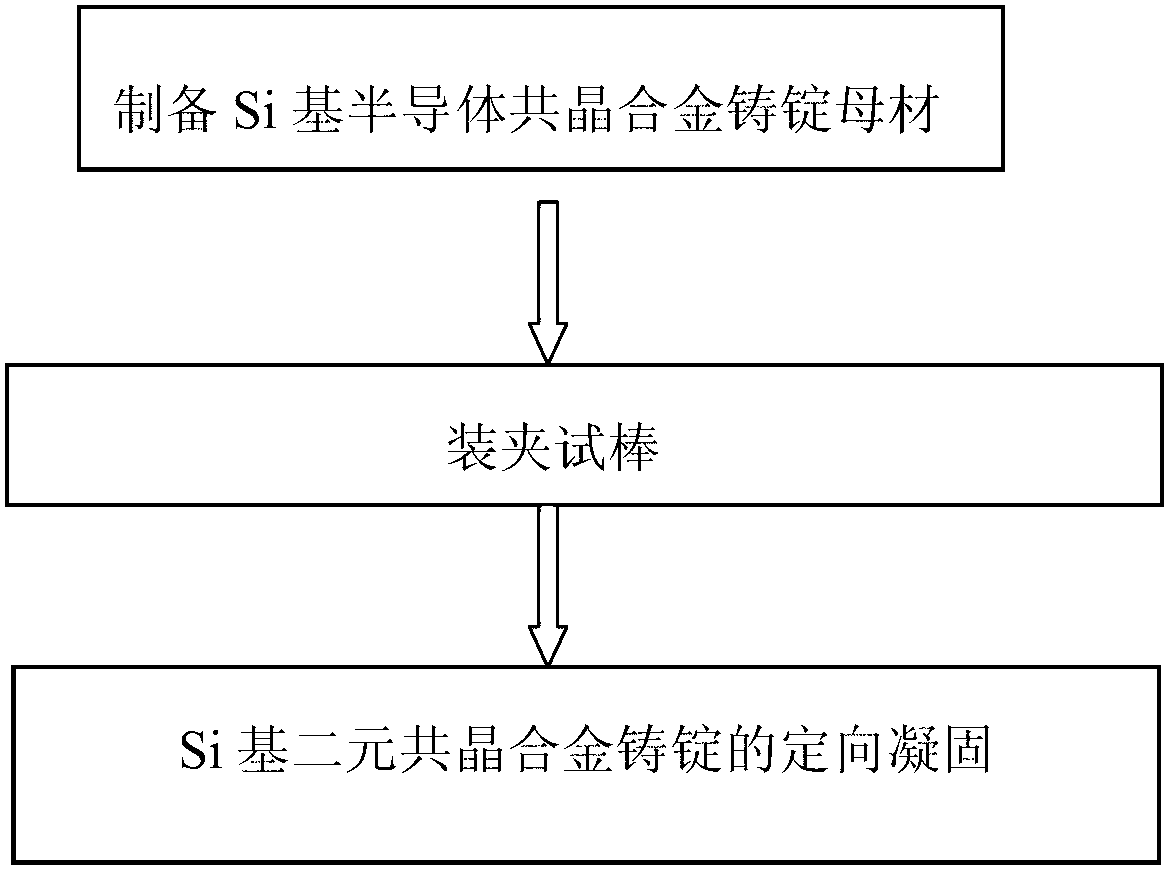

[0034] This embodiment is a method for preparing Si-based semiconductor eutectic autogenous composite material. In this example, Si-CoSi was prepared by high-gradient directional solidification technology in the laser levitation zone. 2 Eutectic self-generated composite materials, the specific process includes the following steps:

[0035] Step 1, preparing Si-based eutectic alloy ingot base material:

[0036] Si with a purity of 99.996% and Co with a purity of 99.999% are used as raw materials, and the eutectic base material is prepared according to the ratio of atomic percentage Si:Co=77.5:22.5; the prepared eutectic base material is loaded into a quartz crucible and placed in the smelting furnace, the smelting furnace is evacuated to less than 2×10 -4 Pa and keep it, gradually heat the melting furnace to 1310°C at a speed of 1kw / 10min to completely melt the raw materials; keep the temperature for 30min; turn off the power and cool with water for 108min to obtain Si-CoSi o...

Embodiment 2

[0042] This embodiment is a method for preparing Si-based semiconductor eutectic autogenous composite material. In this example, Si-TaSi was prepared by high-gradient directional solidification technology in the laser levitation zone. 2 Eutectic self-generated composite materials, the specific process includes the following steps:

[0043] Step 1, preparing Si-based eutectic alloy ingot base material:

[0044] Using Si with a purity of 99.996% and Ta with a purity of 99.999% as raw materials, the eutectic base material raw material is prepared according to the ratio of atomic percentage Si:Co=99.5:1; the prepared eutectic base material raw material is loaded into a quartz crucible and placed in the smelting furnace, the smelting furnace is evacuated to less than 2×10 -4 Pa and keep it, gradually heat the melting furnace to 1450°C at a speed of 1kw / 10min to completely melt the raw materials; keep warm for 30min; turn off the power and cool with water for 138min to obtain Si-T...

Embodiment 3

[0051] This embodiment is a method for preparing Si-based semiconductor eutectic autogenous composite material. In this example, Si-TaSi was prepared by high-gradient directional solidification technology in the laser levitation zone. 2 Eutectic self-generated composite materials, the specific process includes the following steps:

[0052] Step 1, preparing Si-based eutectic alloy ingot base material:

[0053] Si with a purity of 99.996% and Ta with a purity of 99.999% are used as raw materials, and the raw material of the eutectic base material is prepared according to the ratio of Si:Ta=99:1 in atomic percentage; the prepared eutectic base material raw material is packed into quartz Crucible and placed in the melting furnace, the melting furnace is evacuated to less than 2×10 -4 Pa and keep it, gradually heat the melting furnace to 1450°C at a speed of 1kw / 10min to completely melt the raw materials; keep warm for 30min; turn off the power and cool with water for 138min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com