Patents

Literature

10916results about "Bakery products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical and cosmetic carrier or composition for topical application

A pharmaceutical or cosmetic carrier or composition for topical application characterized by rheological properties which render the carrier or composition semi-solid at rest and a liquid upon application of shear forces thereto. The composition or carrier are prepared by mixing 1-25 percent of a solidifying agent and 75-99 percent of a hydrophobic solvent, by weight, wherein at least one of them has therapeutic or cosmetic benefits, in the presence or absence of a biologically active substance.

Owner:VYNE PHARMA LTD

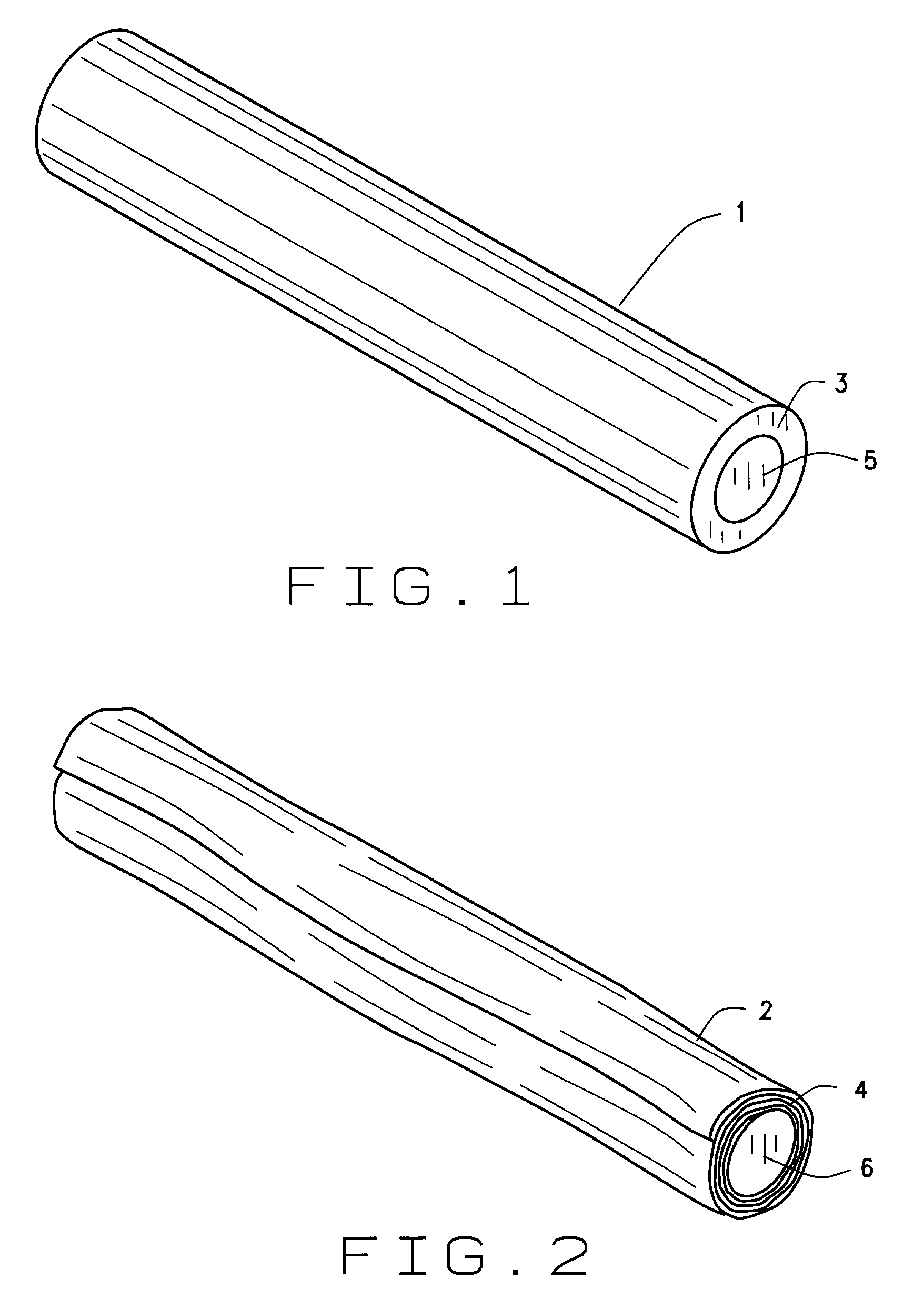

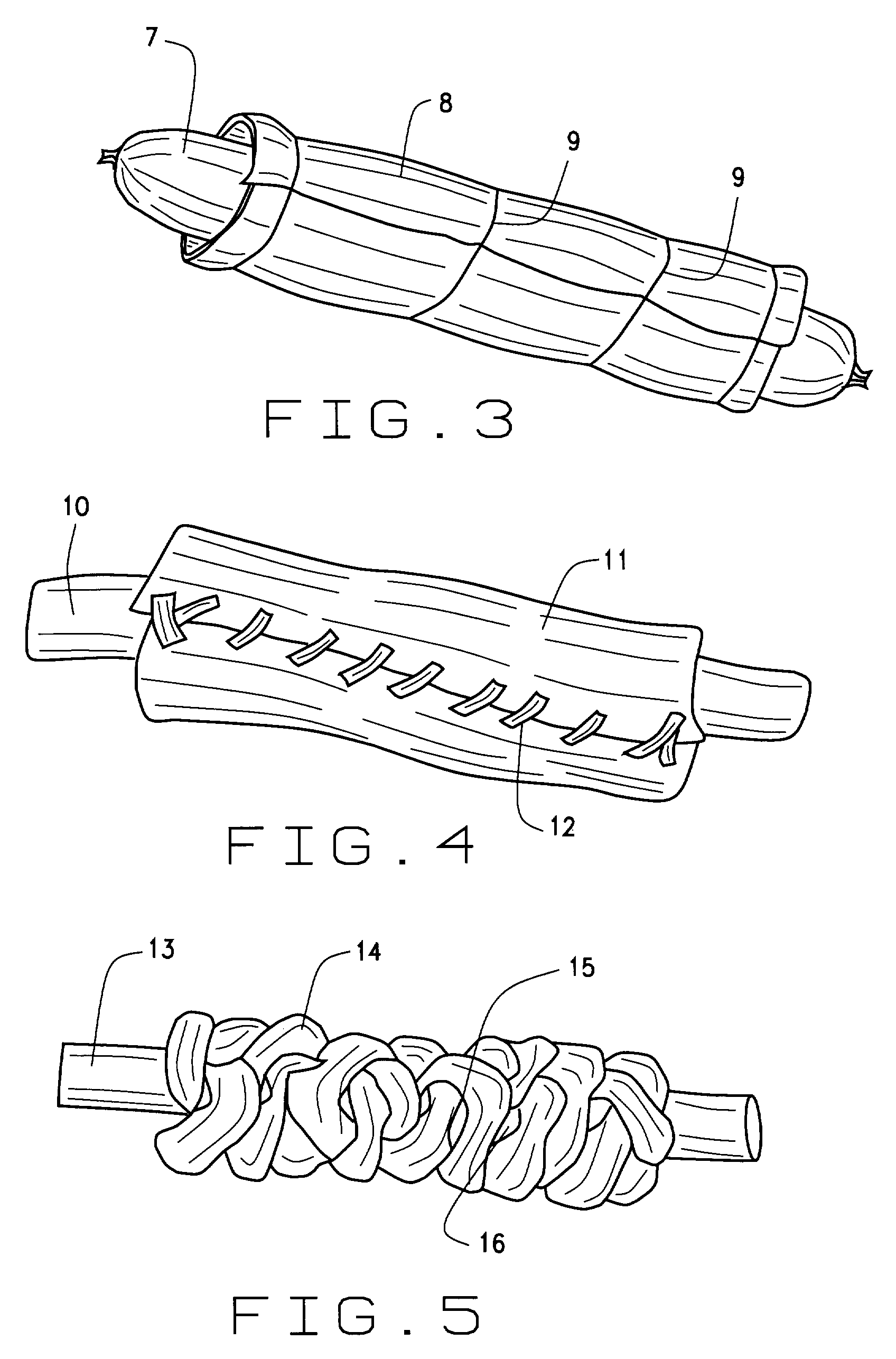

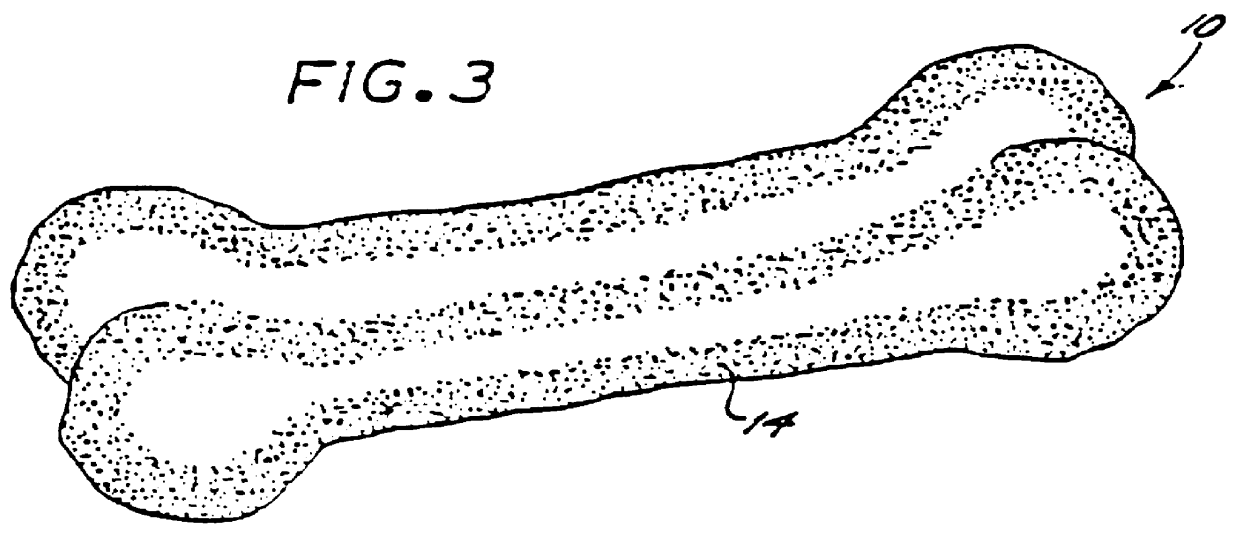

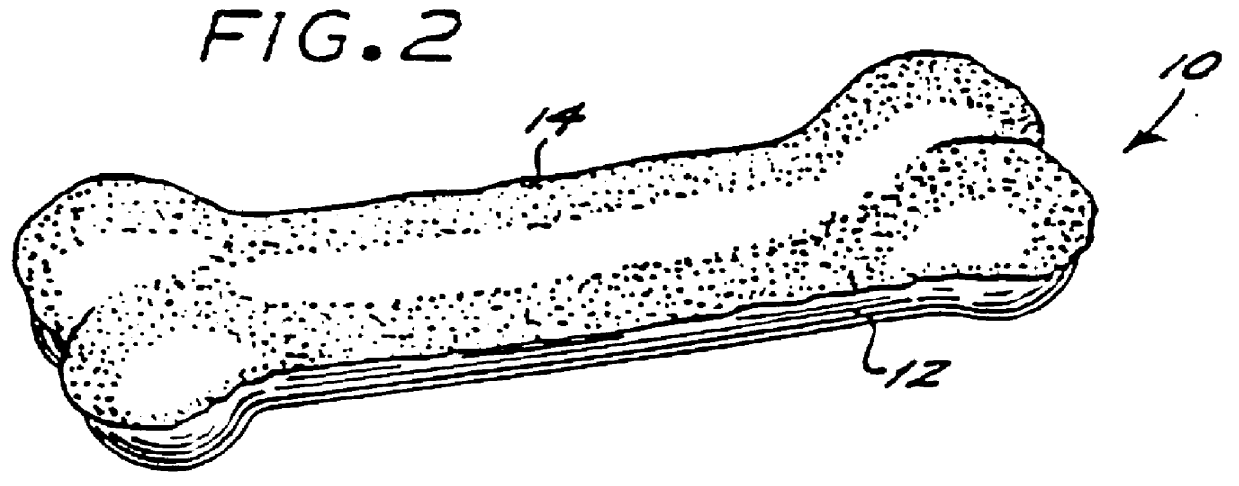

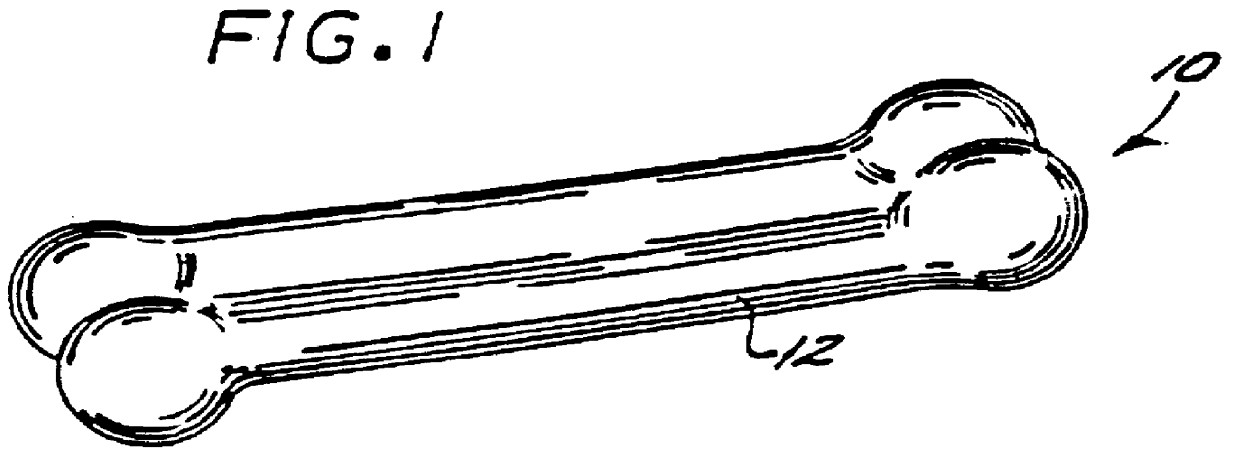

Combination rawhide and formulated food pet chew

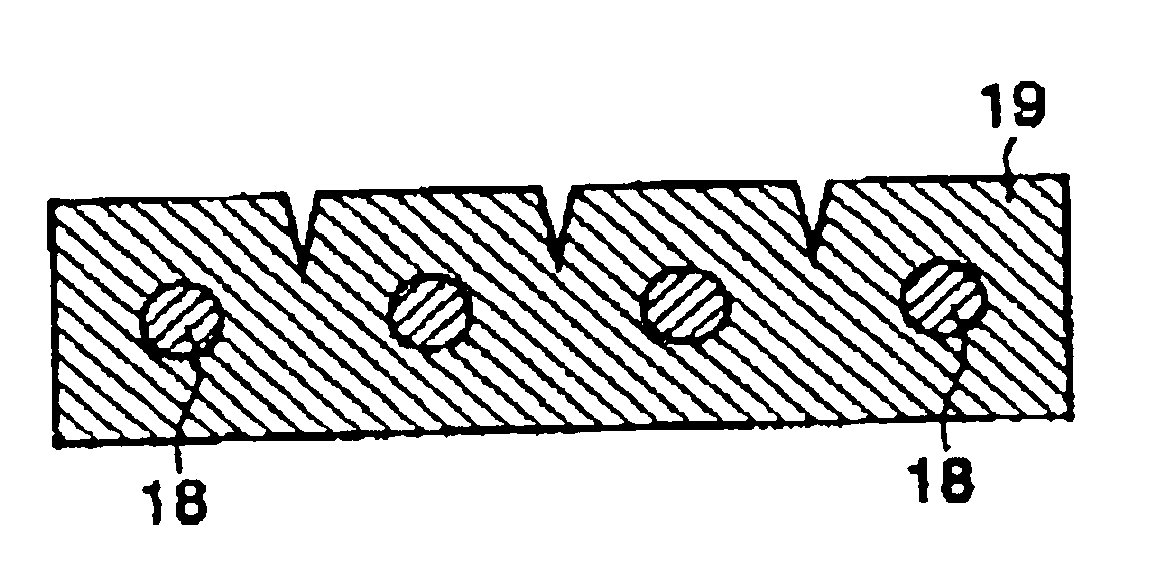

InactiveUS6277420B1Limited toughnessChew life increaseProtein composition from fishMeat/fish preservationWater activityCapillary action

A highly palatable and long lasting dog chew for pets has been developed by combining a formulation and processing sequence which results in a highly palatable meat based filling being incorporated into the center of a preformed rawhide stick or rawhide roll. Such outside rawhide fraction is extremely tough and chewy which results in a dog chew which takes a long period of time for the dog to consume. The inside meat filling is highly palatable which results in the animal maintaining interest in the treat until nearly the entire chew has been consumed. The interior meat filling is preserved by reduced water activity to below 0.85 as a result of incorporating of salt, sugars and natural humectants. Said filling is formulated and processed in such a manner that the water phase is bound within the filling and does not pass by capillary action to the outside rawhide fraction. This results in the outer rawhide shell maintaining a tough and chewable texture until such point as the dog is offered the finished chew.

Owner:ANDERSEN DAVID B +1

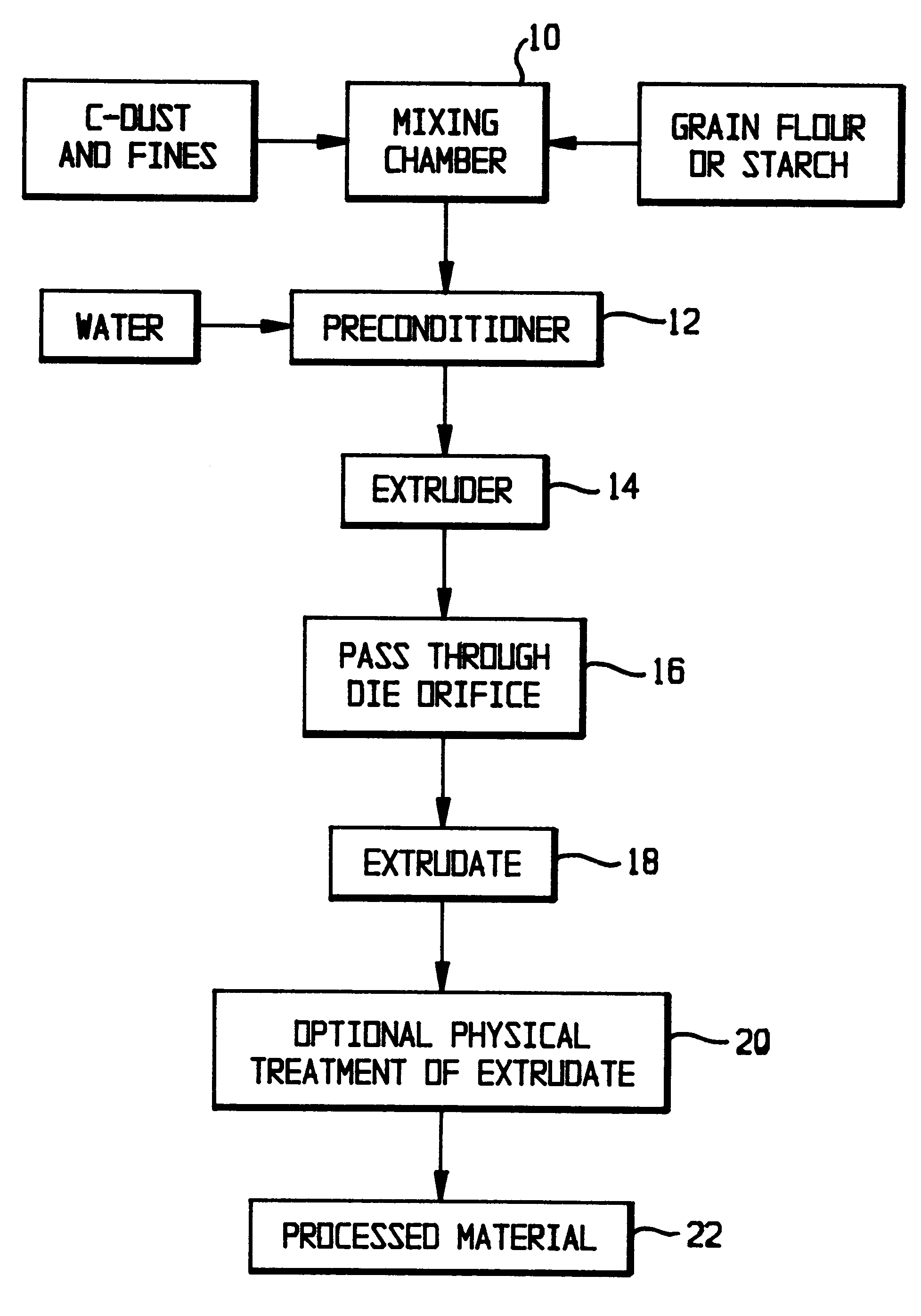

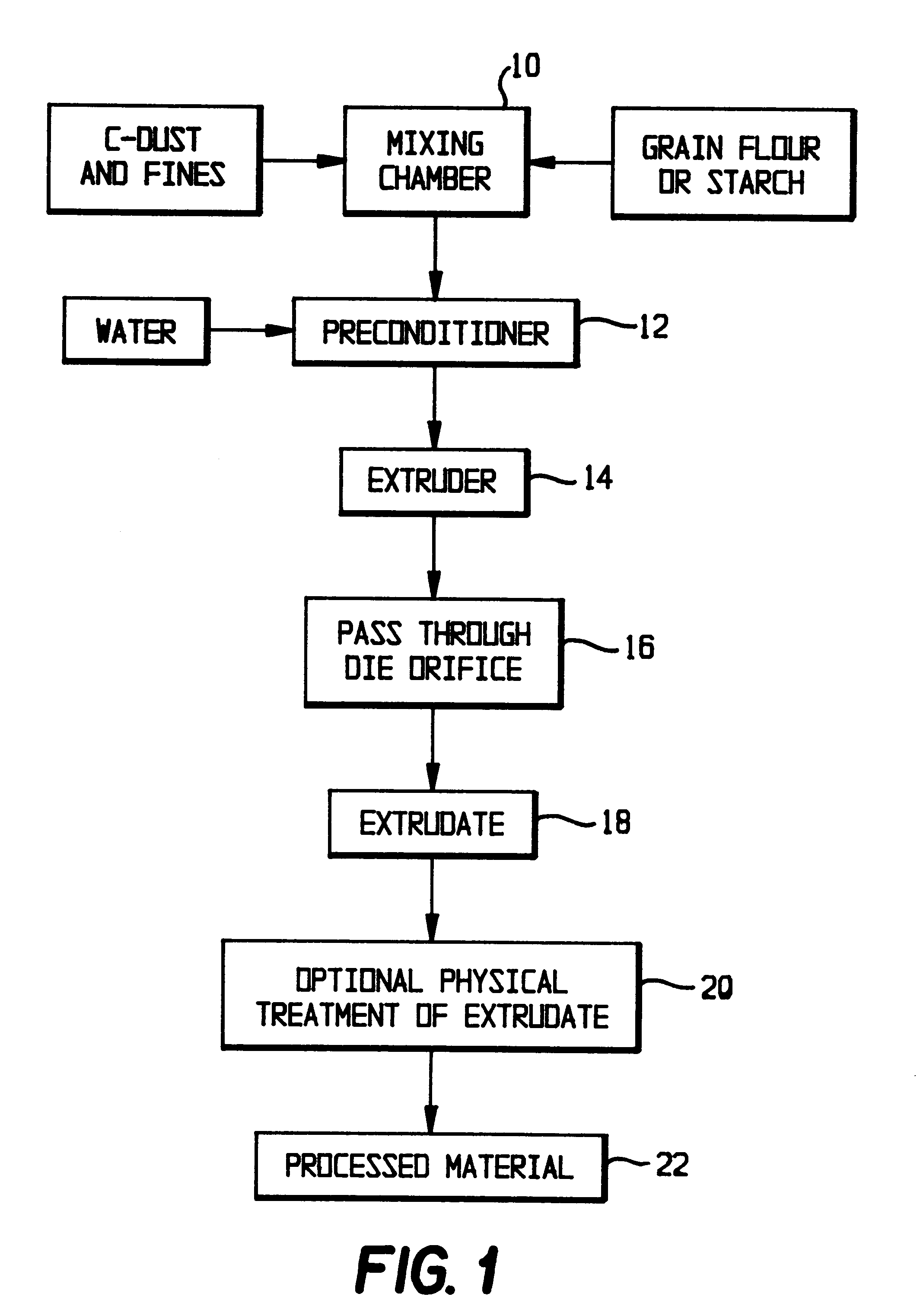

Low-density tobacco filler and a method of making low-density tobacco filler and smoking articles therefrom

InactiveUS6182670B1Pleasing tobacco odorImprove the smoke effectTobacco preparationDough treatmentSolventLow density

A low-density filler material for cigarettes from either a low-density tobacco composition or an extruded grain or starch composition. The low-density tobacco composition and a method of making the low-density tobacco composition by extruding a mixture of tobacco and flour or tobacco and starch under conditions whereby the solvent in the extruded mixture flashes into vapor upon release from the extrusion head. The low-density tobacco composition is formed without the aid of an added binder. The low-density flour or starch material and a method of making it by extruding flour or starch with a filler material such as calcium carbonate under conditions whereby the solvent in the extruded mixture flashes into vapor upon extrusion through the orifice die. The extruded composition can then be cut and used in place of cut tobacco filler.

Owner:R J REYNOLDS TOBACCO COMPANY

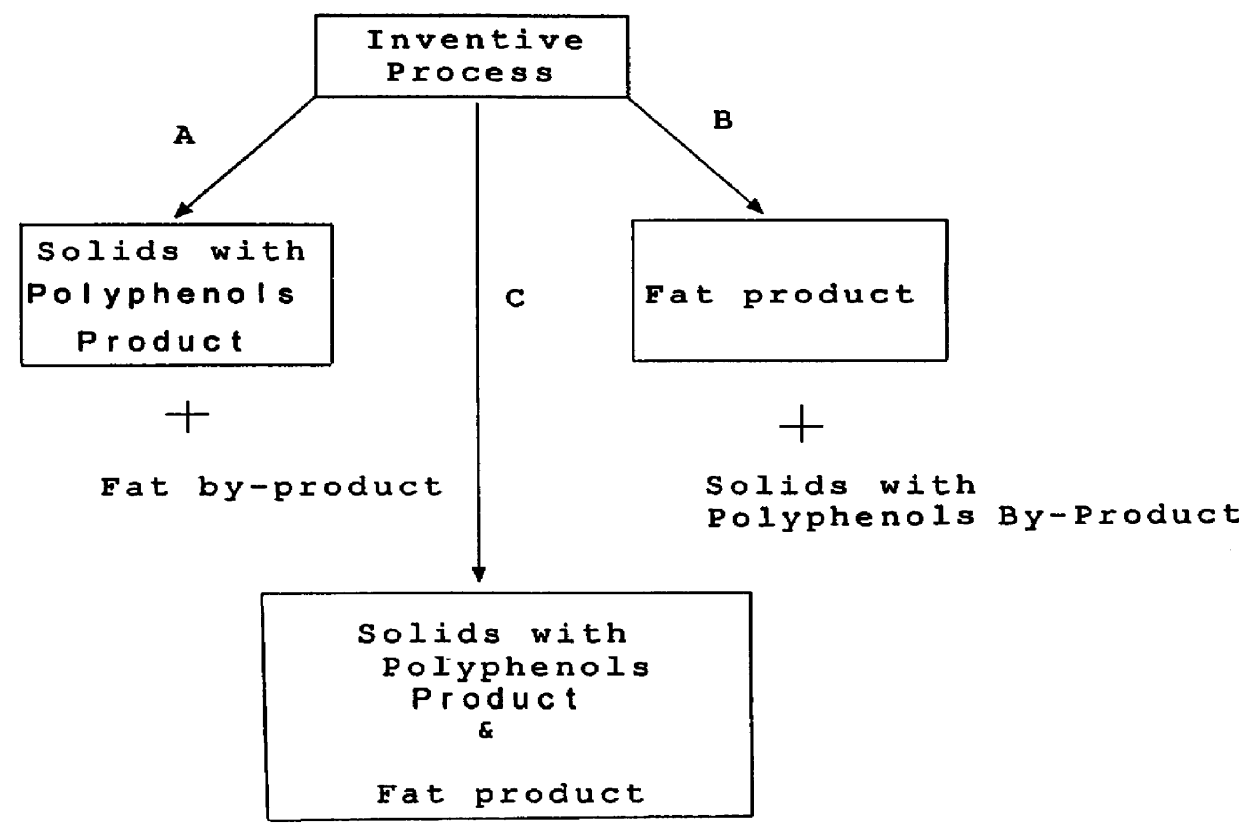

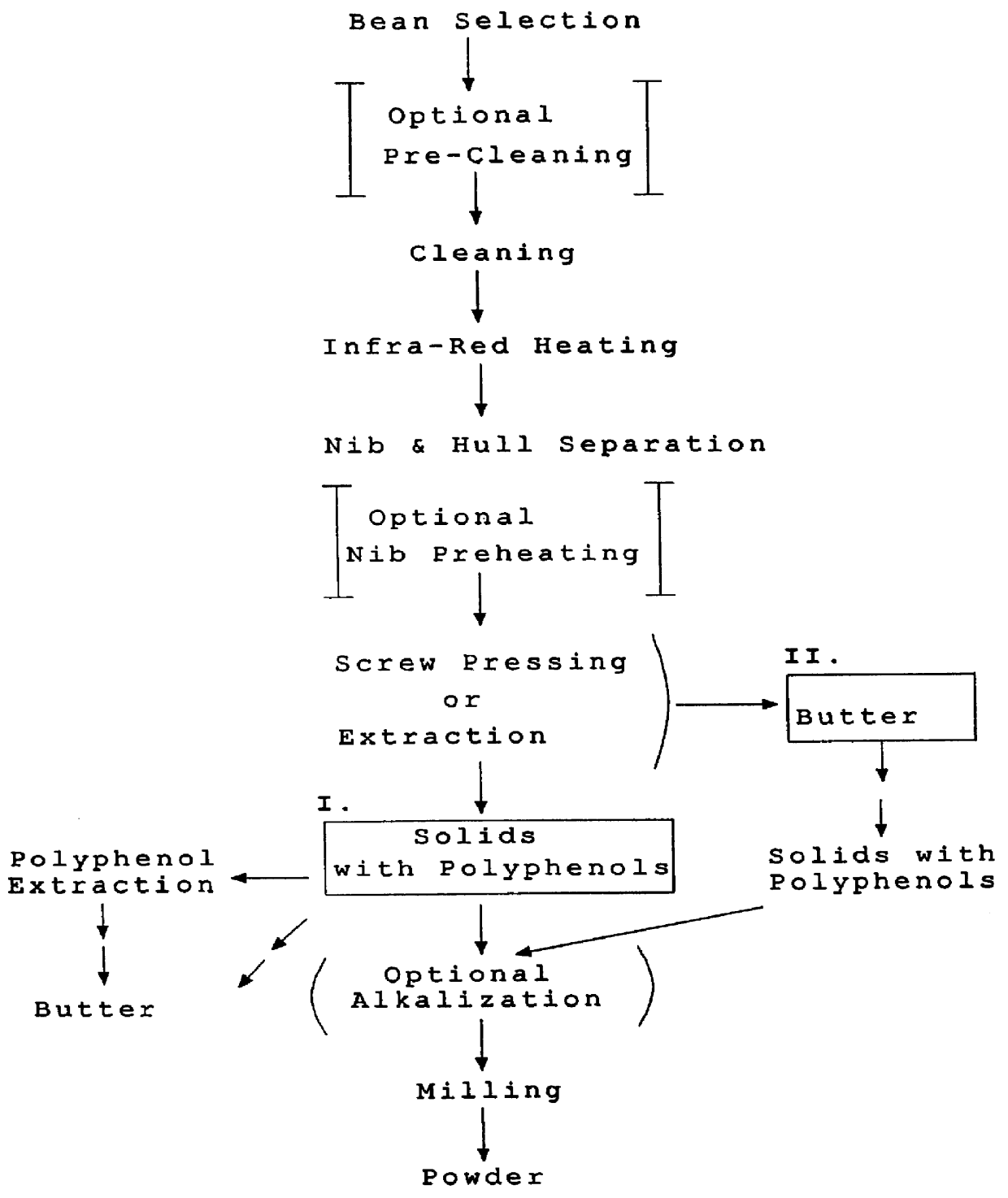

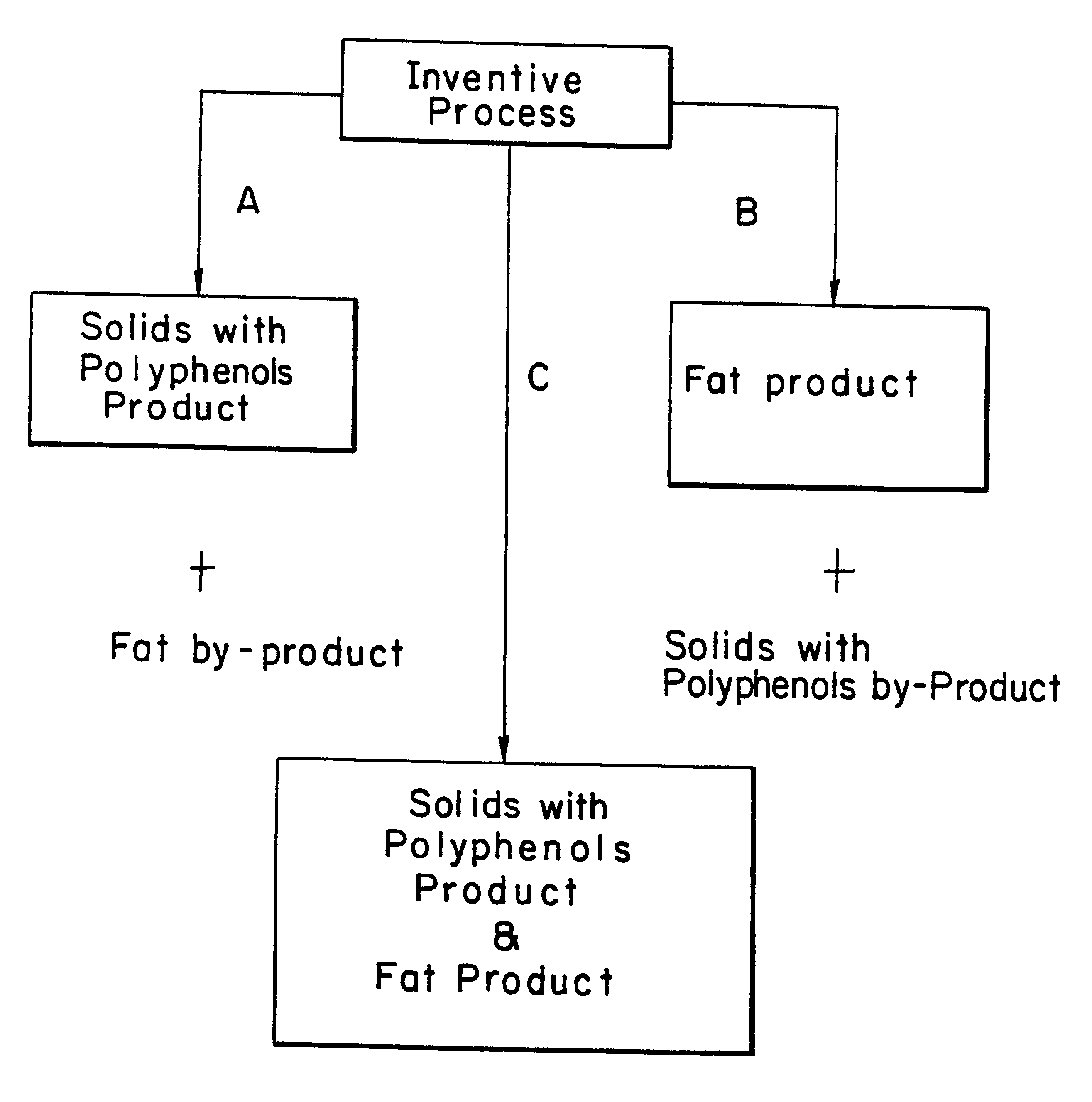

Method for producing fat and/or solids from cocoa beans

InactiveUS6015913AHighly conserved levelReduce moisture contentBiocideDough treatmentPolyphenolCOCOA BEAN

The present invention is directed to a method of processing a fat-containing bean, e.g., cocoa beans, for producing solids comprising active polyphenols and / or fat-containing products, comprising extracting the fat to produce solids and fat-containing products. Additionally, the inventive method also provides cocoa compositions comprising at least one active polyphenol, wherein the concentration of the polyphenol(s) with respect to the nonfat solids is conserved with respect to the concentration of the active polyphenol(s) in the bean from which the compositions are derived.

Owner:MARS INC +1

Wheat and casein dog chew with modifiable texture

InactiveUS6110521ANutritional diversityEasily digested by dogsDough treatmentBaking mixturesHardnessDog owners

A completely digestible highly nutritious dog chew formulated primarily of wheat flour, casein and starch carbohydrate, the texture of hardness of which is easily modified to suit a particular dog by the dog owner. By irradiating the chew in a microwave oven, the chew is caused to expand and is thereby rendered more easily chewable.

Owner:T F H PUBLICATIONS

Diet for dietotherapy and health preservation

ActiveCN102423073AReduce adverse reactionsReduce dosageConfectionerySweetmeatsPumpkin seedDry weight

The invention relates to a diet for dietotherapy and health preservation which is prepared by medicine-food materials, and belongs to the field of nutrition and health preservation; the basic formula comprises the following raw materials on a dry weight basis: 30-60 parts of black sesame, 4-6 parts of poria cocos, 2-8 parts of hawthorn, 2-8 parts of medlar, 2-5 parts of coix seeds, 1-5 parts of spine date seeds, 2-5 parts of lotus seeds, 2-5 parts of Chinese yam, 1-5 parts of lily, 5-10 parts of jujube, 1-5 parts of donkey-hide gelatin, 1-4 parts of roses, 2-8 parts of carrots, 2-5 parts of walnut kernels, 2-5 parts of pumpkin seeds, 2-5 parts of black soybeans, 2-5 parts of black fungus, 1-3 parts of honeysuckles, 1-3 parts of sea-tangle, and 1-3 parts of mulberry. The invention can alsobe combined with other materials to form a secondary formula by using the basic formula as a main component. The formula of the invention is not excessively cold or hot, has a moderate character and taste, is convenient for using, has a less using amount, can be eaten frequently for a long term, has a lot of efficacy and effect and definite effect, and the efficacy is confirmed to reach the expectation and to be satisfied through long-term eating by a lot of people.

Owner:李超建

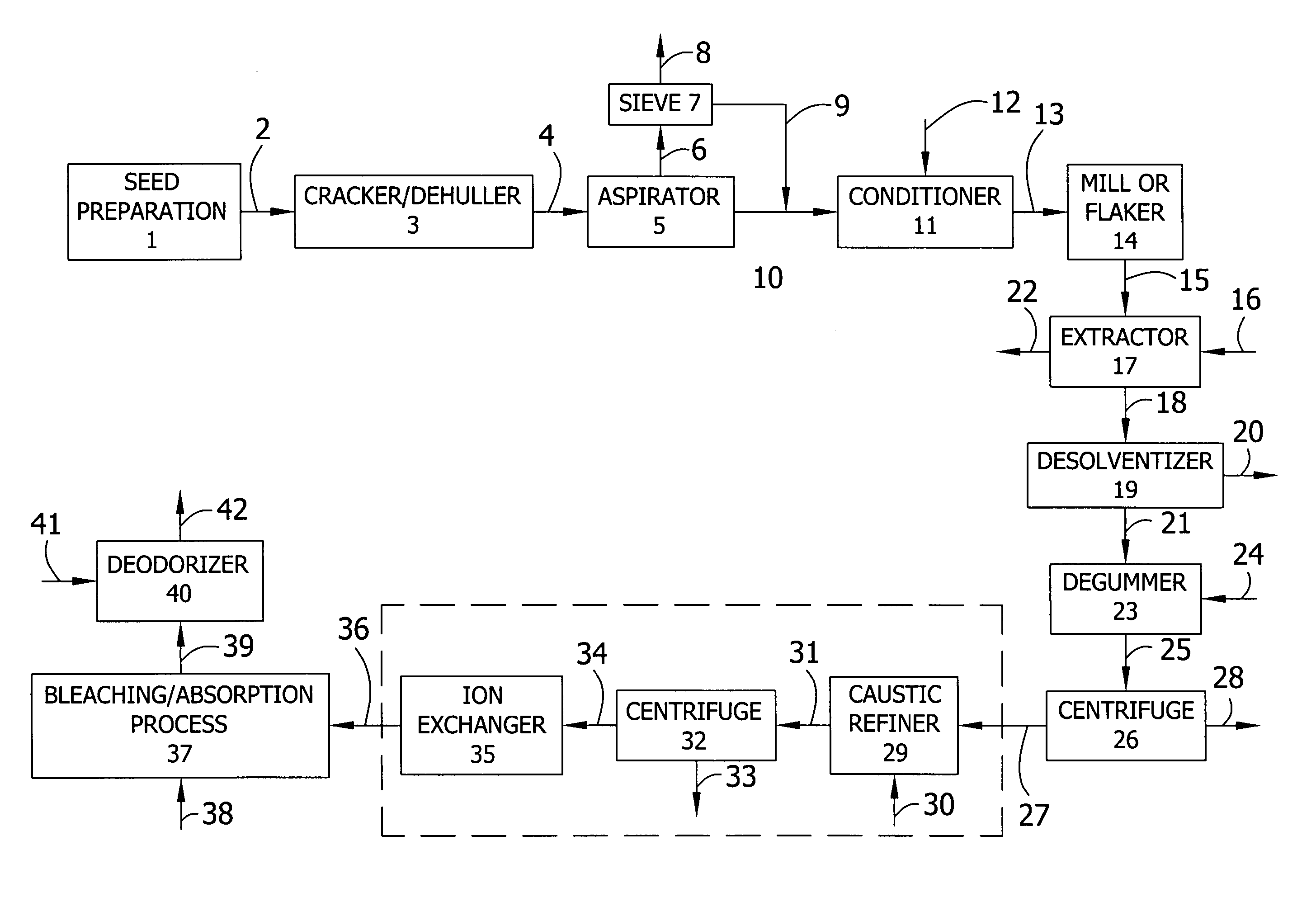

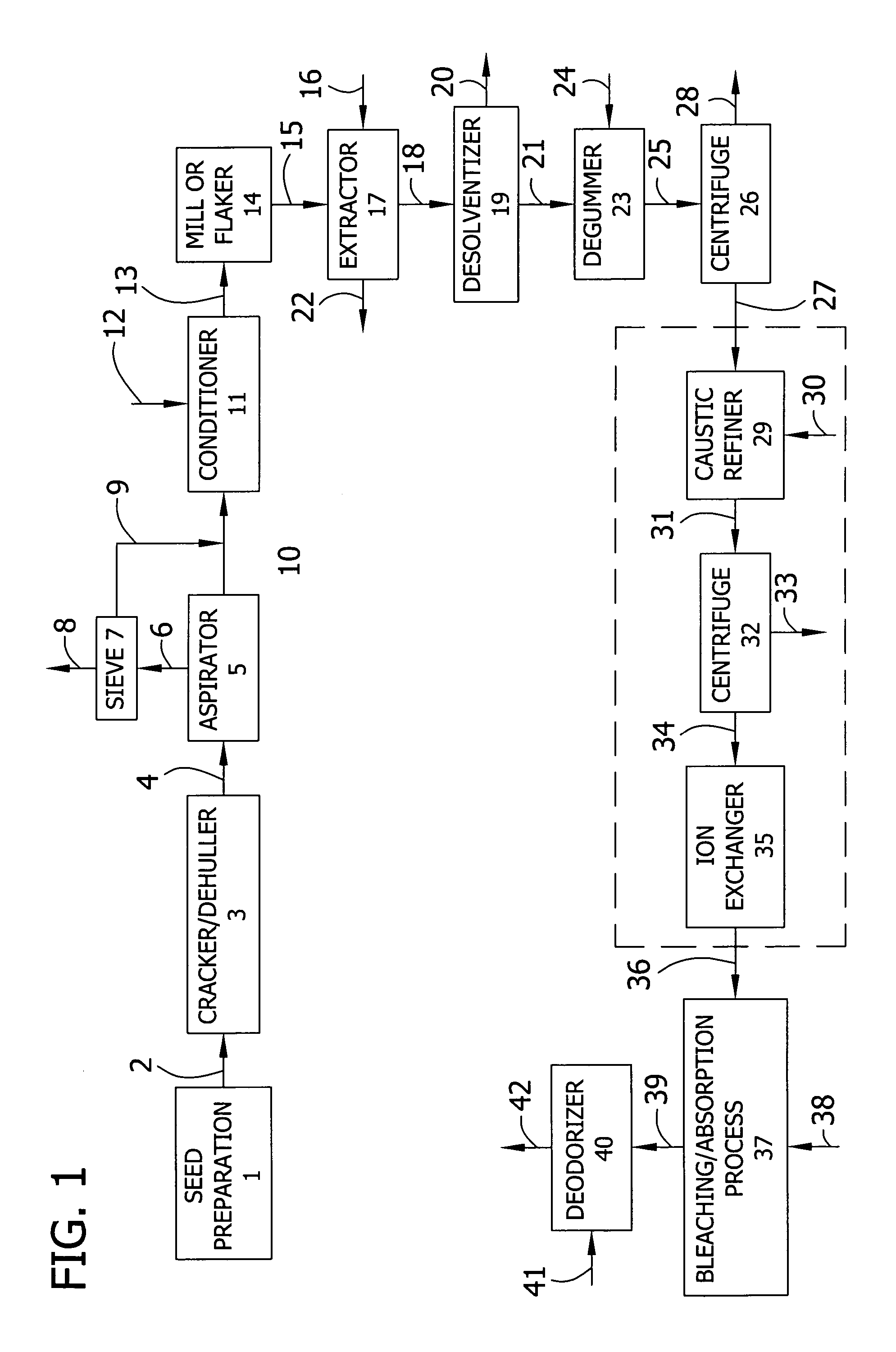

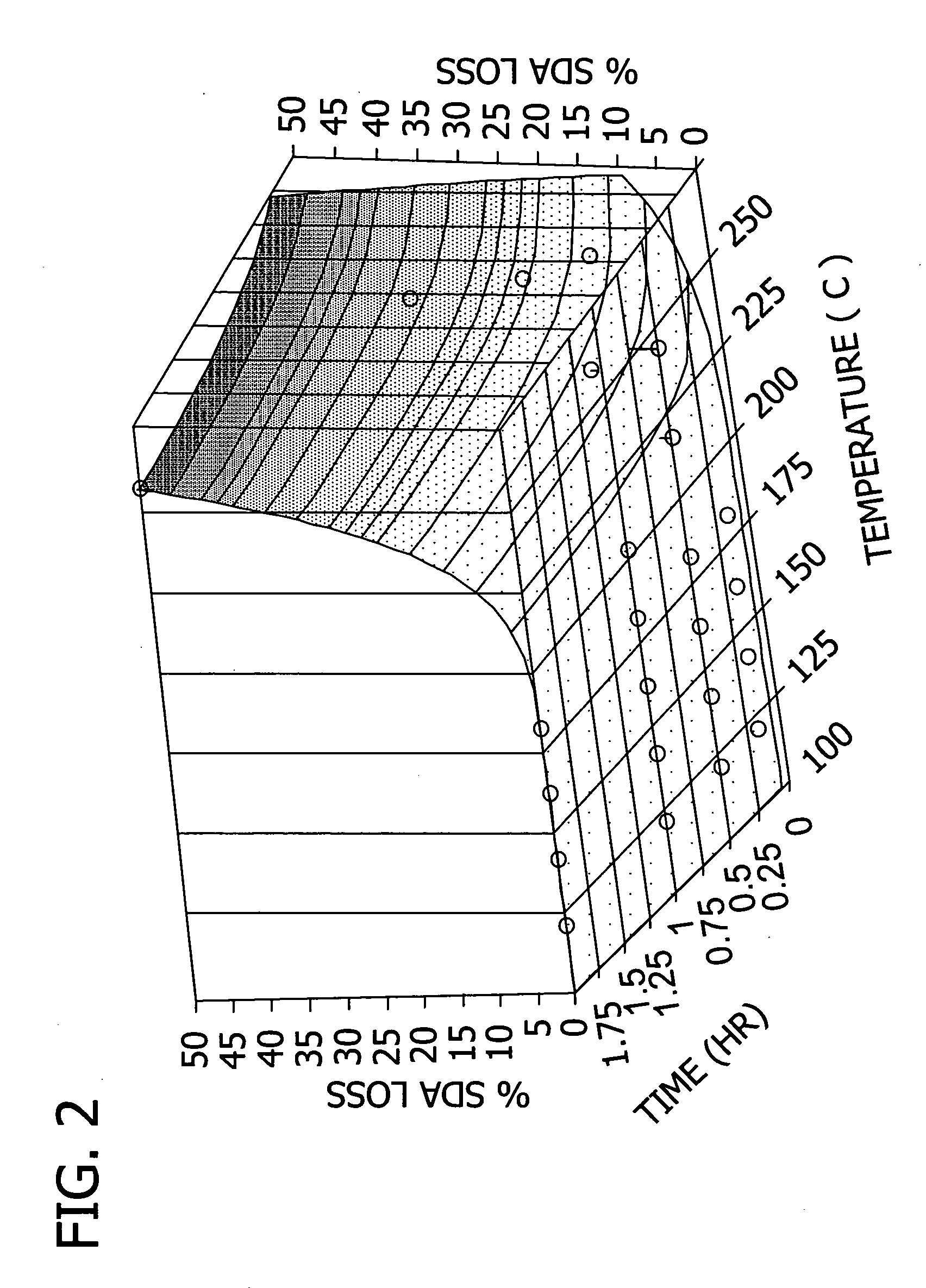

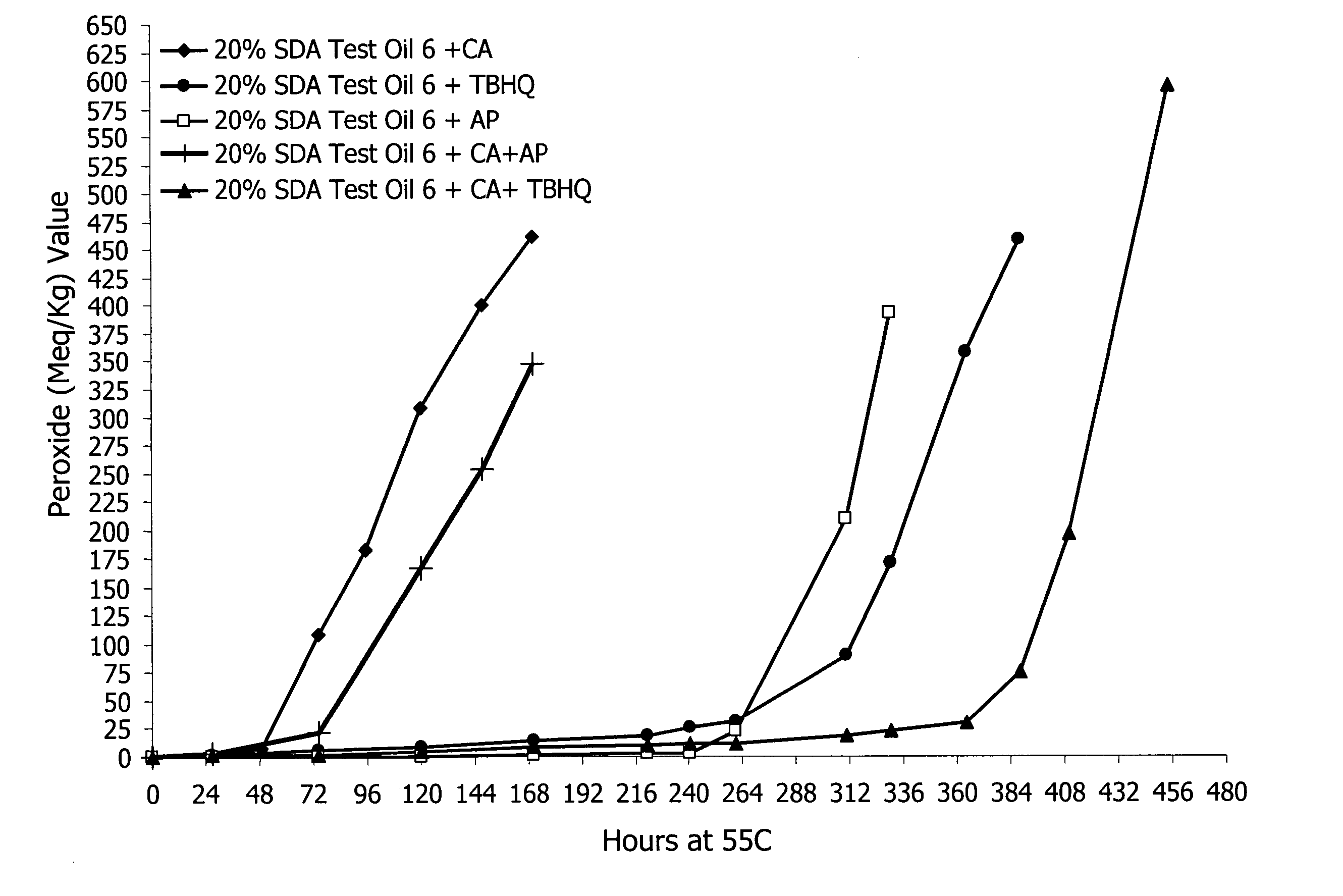

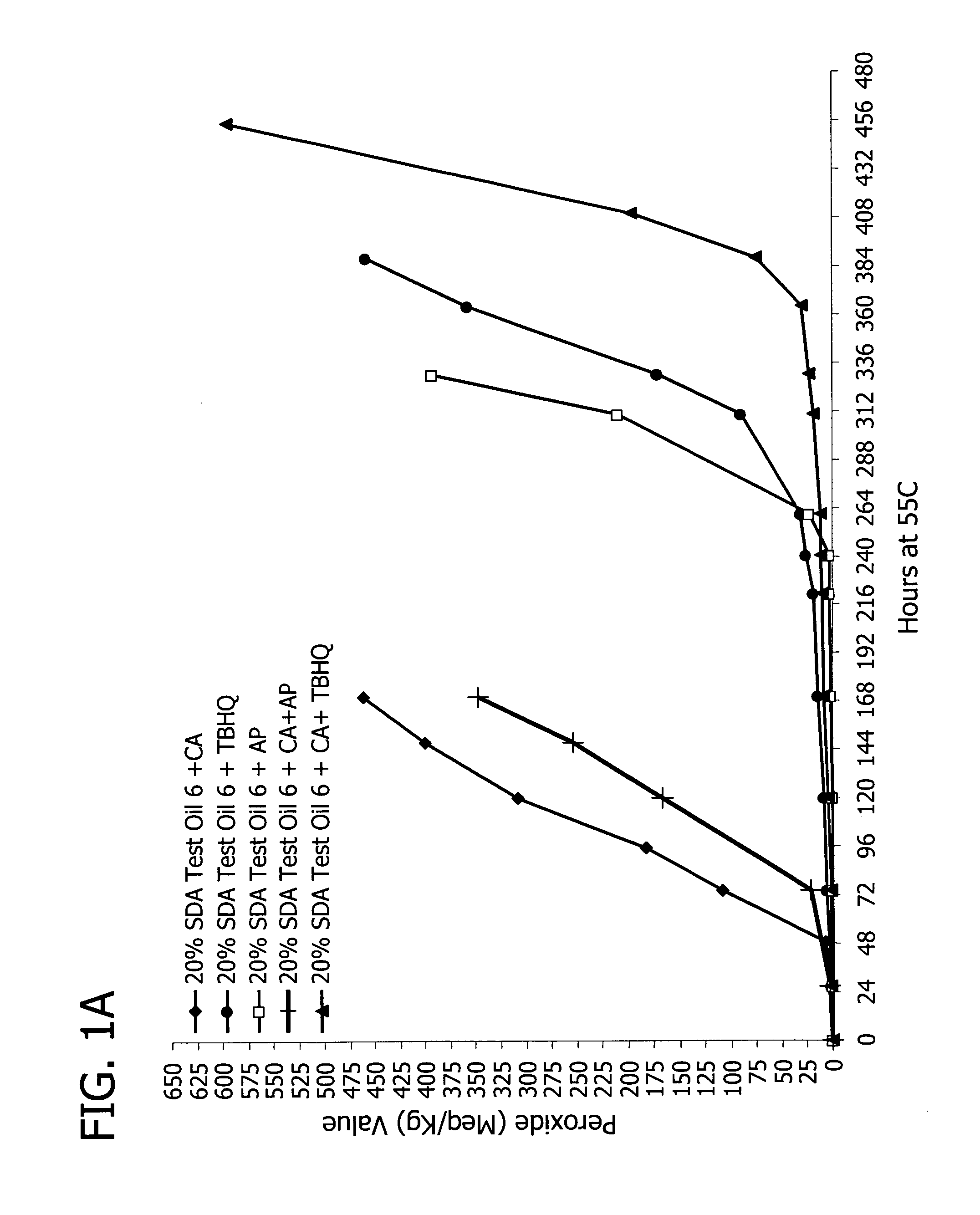

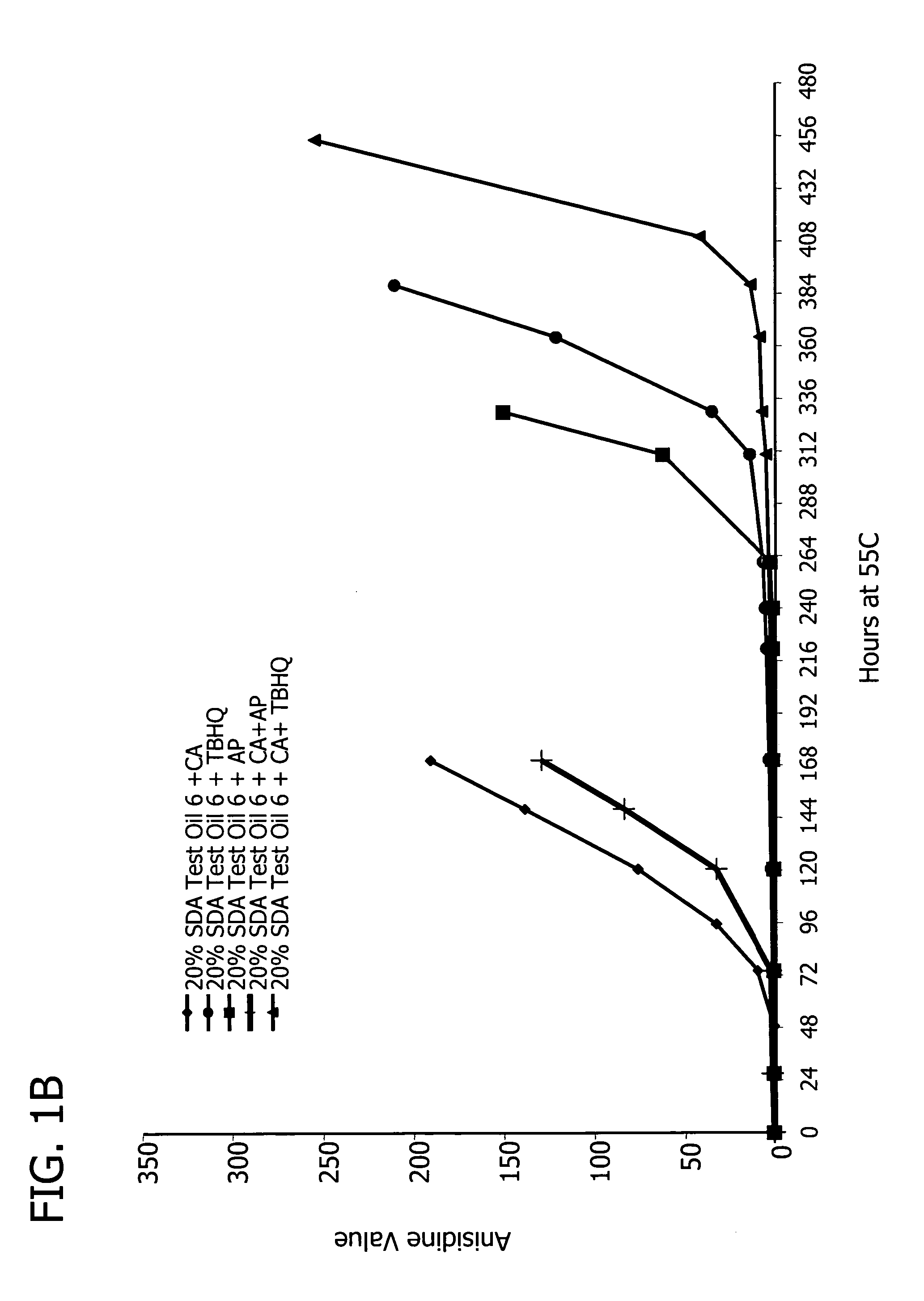

Processes for preparation of oil compositions

ActiveUS20060111578A1Reduce oxidationMinimizes isomerizationFatty substance preservation using additivesEdible seed preservationHigh concentrationΑ-linolenic acid

The present invention is directed to processes for preparing oil compositions having a high concentration of poly-unsaturated fatty acids and oil compositions having a low concentration of α-linolenic acid. In addition, the present invention is directed to processes for preparing oil compositions having advantageous stability characteristics.

Owner:MONSANTO TECH LLC

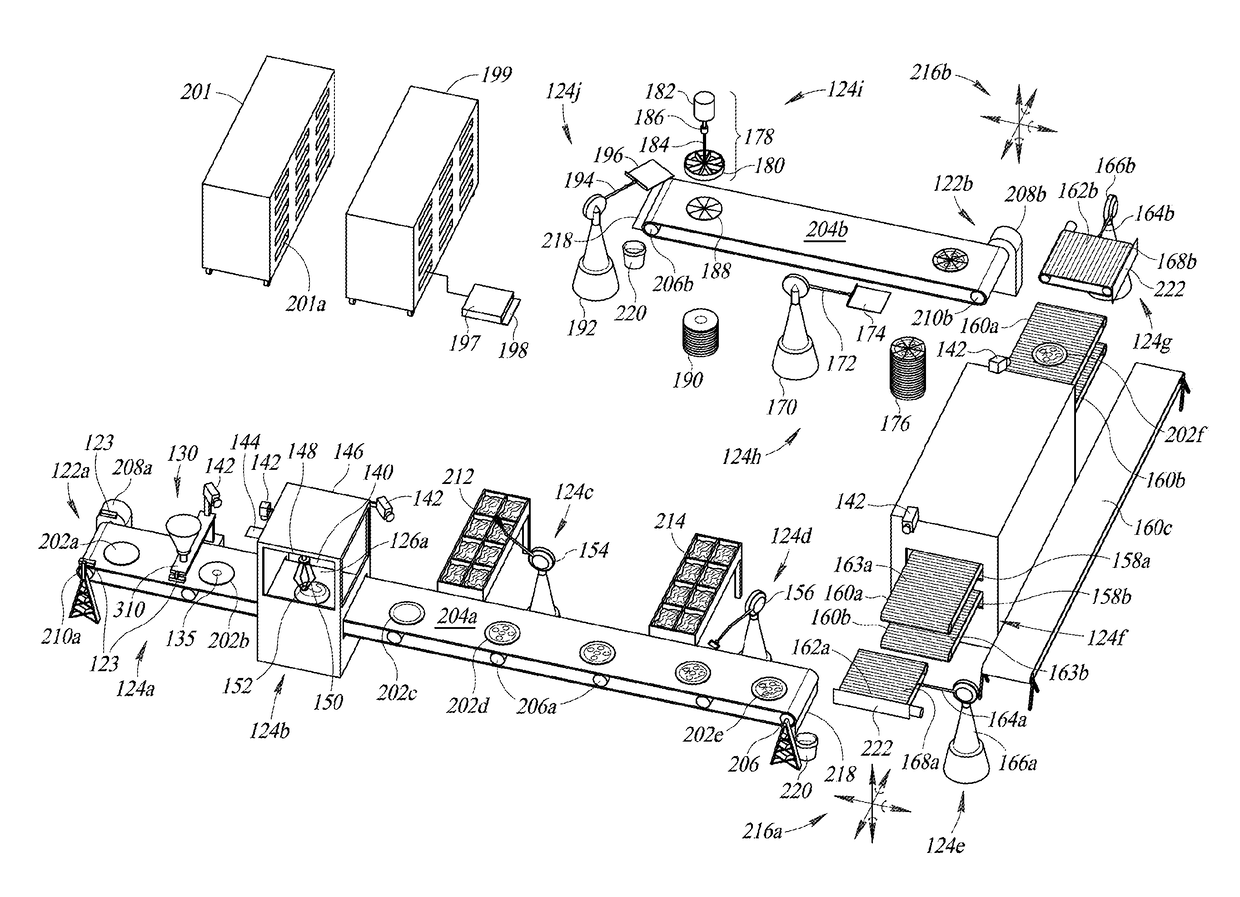

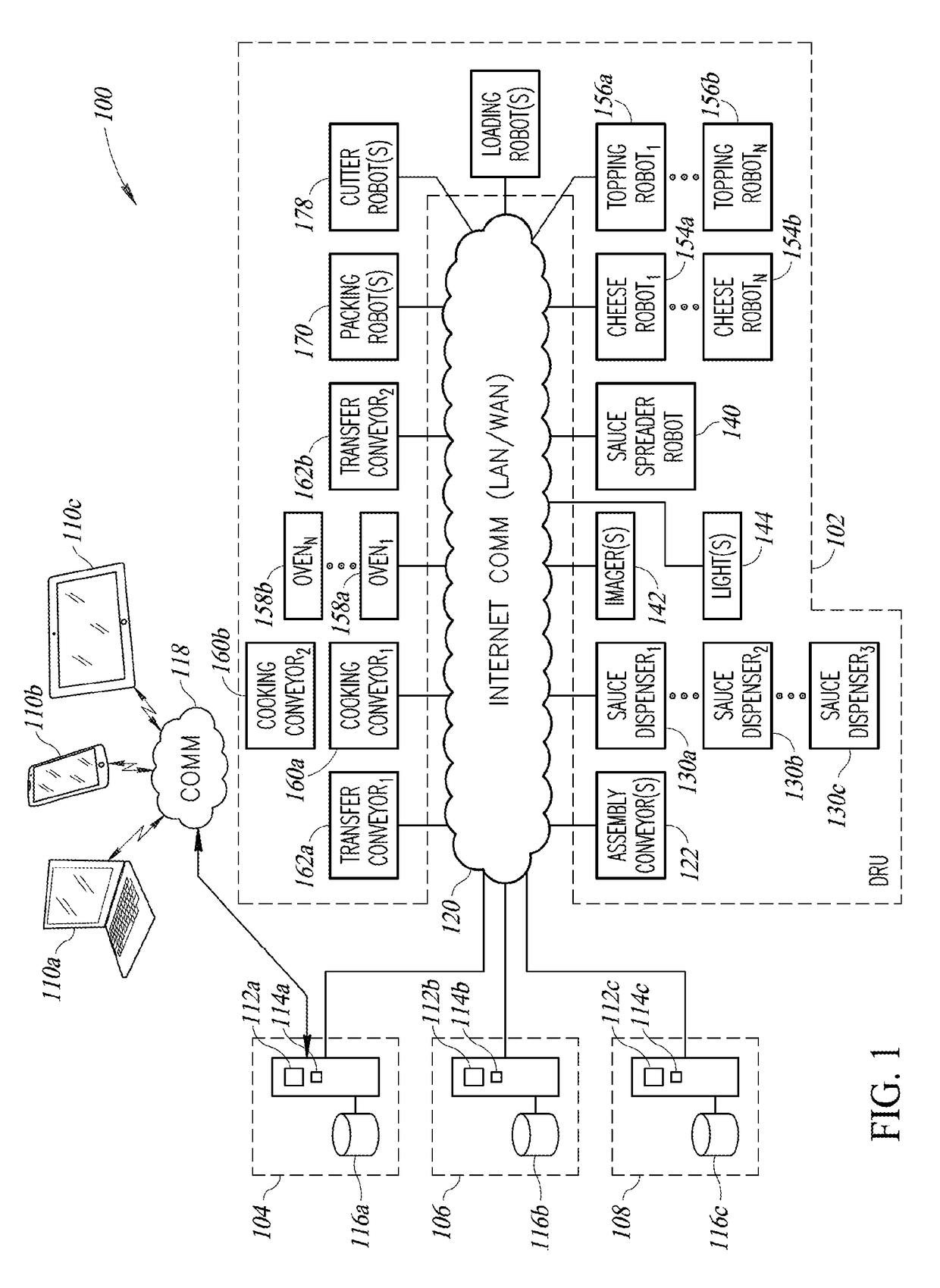

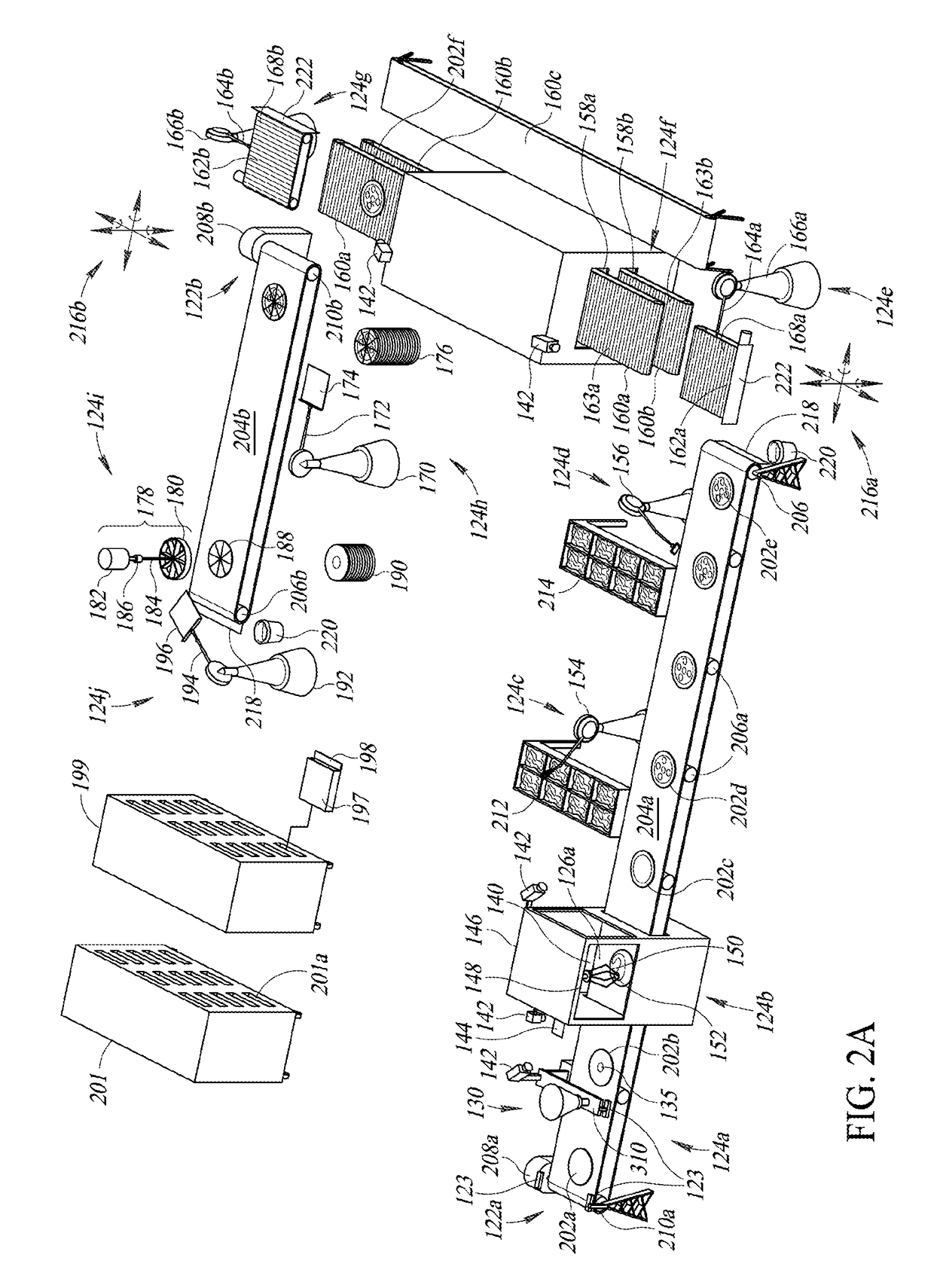

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

High-Potency Sweetener Composition With Preservative and Compositions Sweetened Therewith

ActiveUS20080108710A1Improve flavor profileImproving temporal profile profileBiocideDough treatmentPreservativeSweetness

The present invention relates generally to sweetener compositions comprising non-caloric or low-caloric high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high-potency sweetener, at least one sweet taste improving composition, and at least one preservative. The present invention also relates to sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Meat Analog Compositions and Process

Analog meat compositions produced from vegetable protein and processes for producing the analog meat compositions are described. The compositions are produced with high moisture content, low vegetable protein content, carbohydrate, and, optionally, an edible lipid material and provides a product that simulates the fibrous structure of animal meat and has a desirable meat-like moisture, texture, mouthfeel, flavor and color.

Owner:UNIVERSITY OF MISSOURI

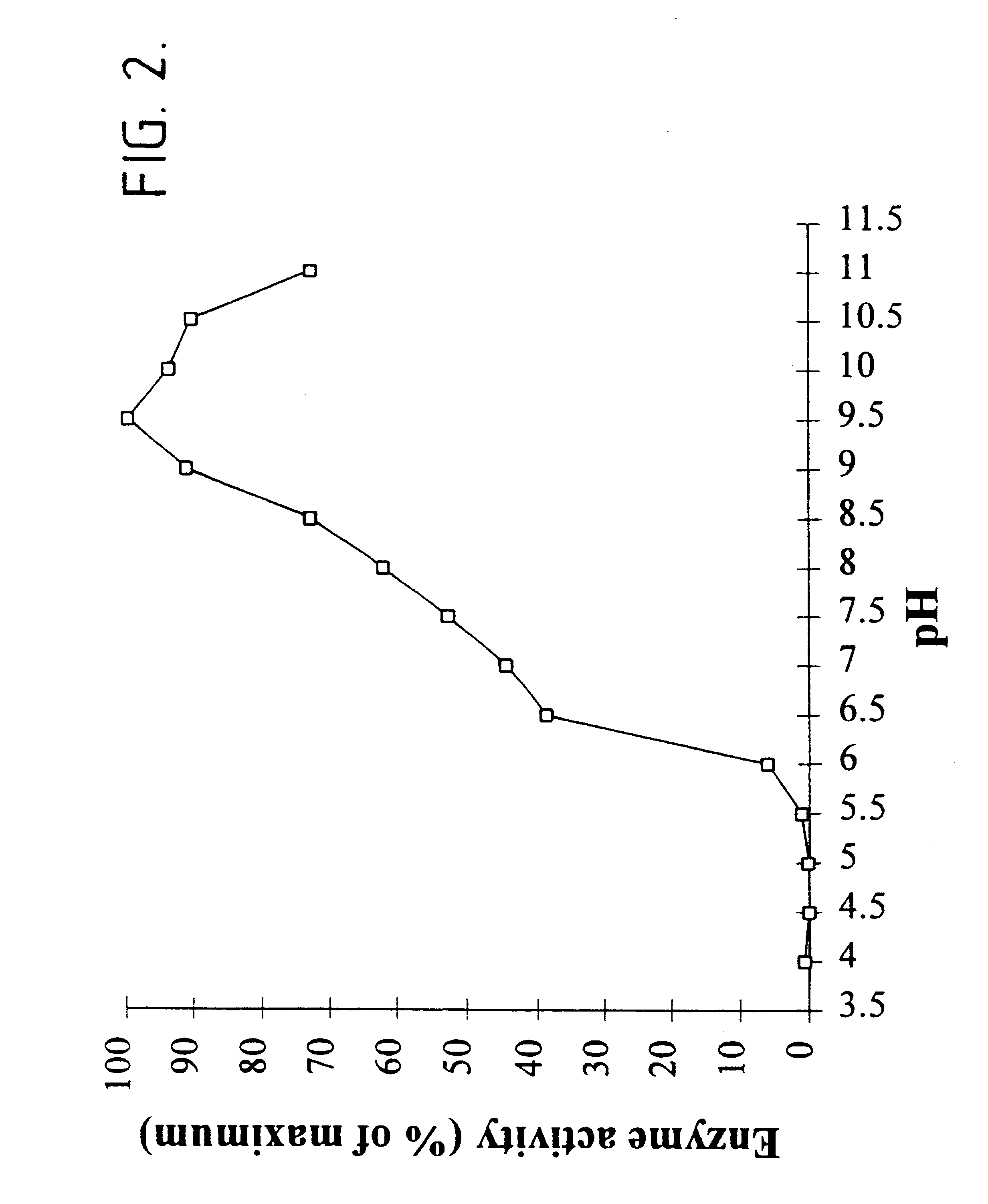

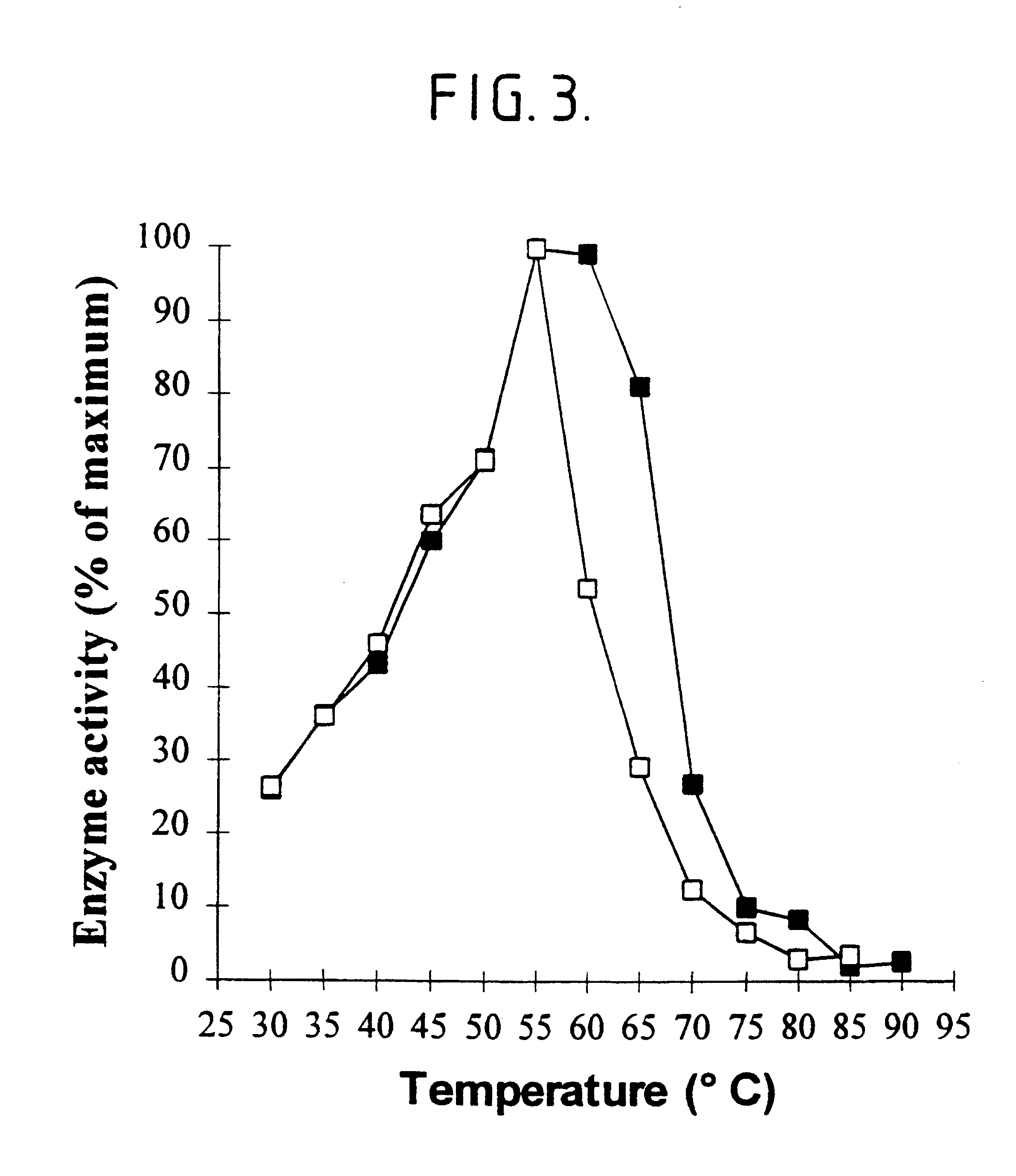

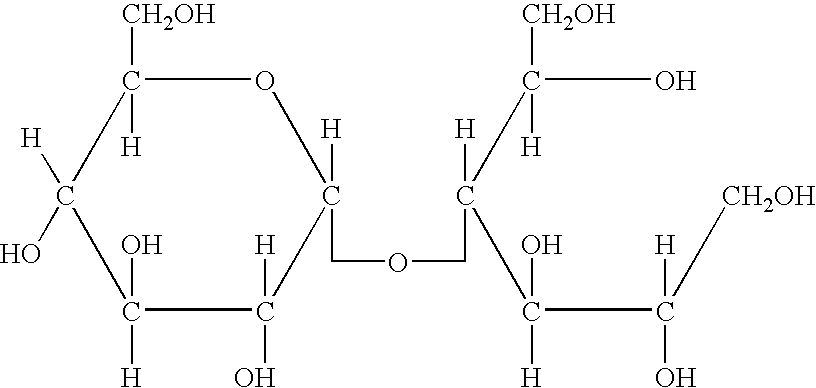

Non-maltogenic exoamylases and their use in retarding retrogradation of starch

InactiveUS6667065B1Highly effective in retarding or reducing detrimental retrogradationImprove propertiesDough treatmentHydrolasesAmylosucrase activitySide chain

The present invention relates to a process for making a bread product. The process includes the addition of a non-maltogenic exoamylase that hydrolyses starch to a starch medium, and the application of heat to the starch medium. The non-maltogenic exomylase cleaves one or more linear malto-oligosaccharides, predominantly consisting of from four to eight D-glucopyranosyl units, from non-reducing ends of amylopectin side chains. The non-maltogenic exoamylase has an endoamylase activity of less than 0.5 endoamylase units (EAU) per unit of exoamylase activity.

Owner:DUPONT NUTRITION BIOSCIENCES APS

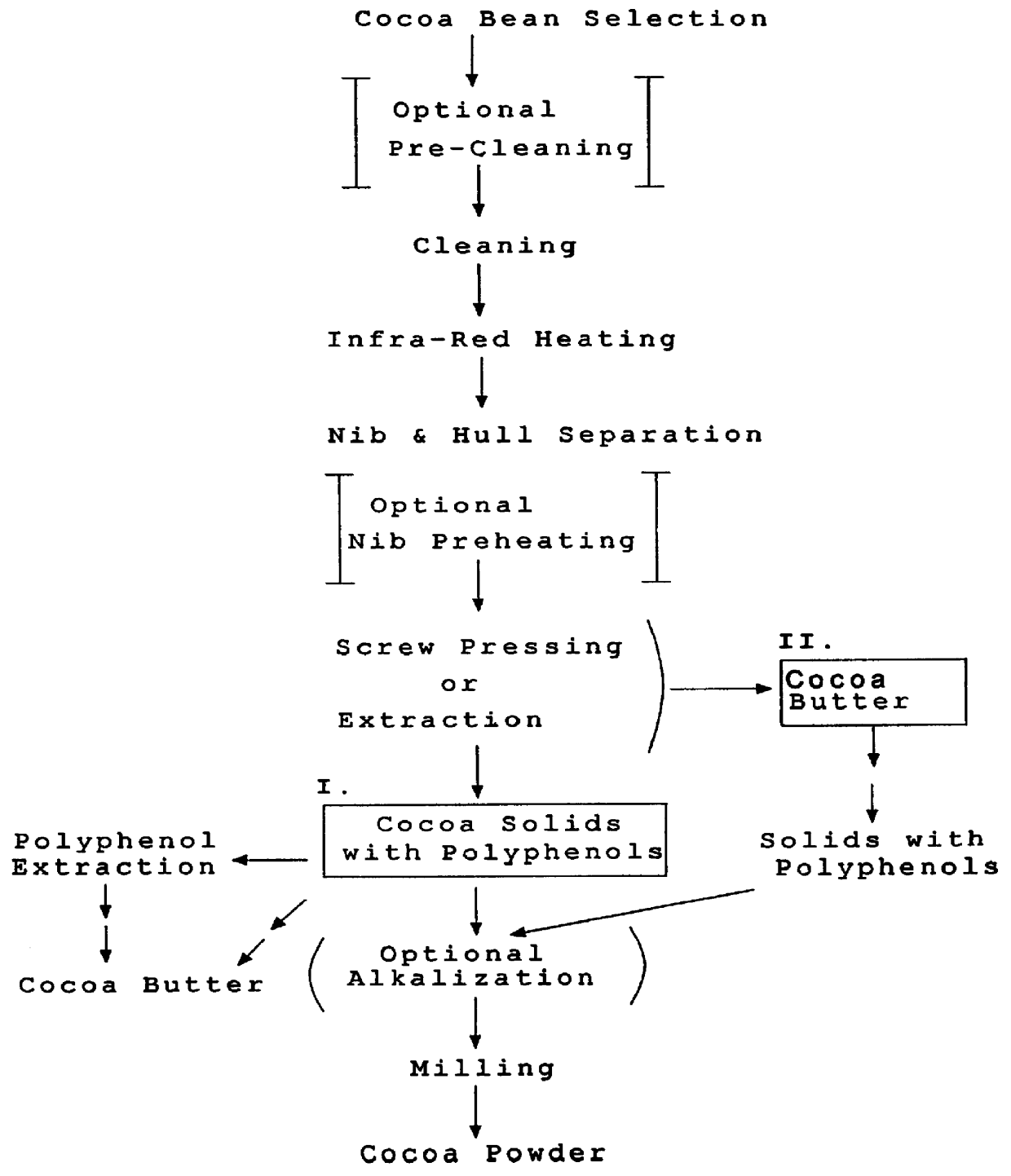

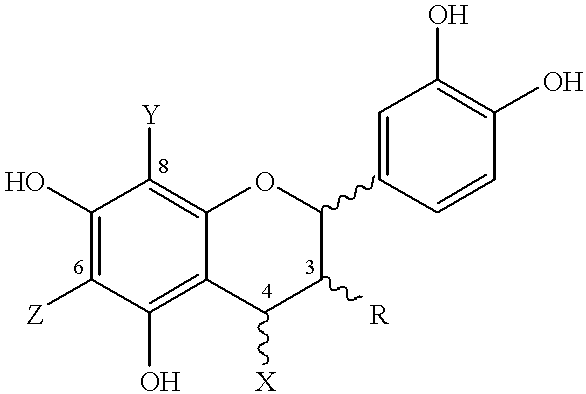

Cocoa components, edible products having enriched polyphenol content, methods of making same and medical uses

InactiveUS6312753B1Enhanced levelGood for healthAntibacterial agentsOrganic active ingredientsButter cocoaMammal

Cocoa components having enhanced levels of cocoa polyphenols, processes for producing the cocoa components while conserving a significant amount of the cocoa polyphenols, compositions containing the cocoa components or the cocoa polyphenols, and methods of using the cocoa components or the cocoa polyphenols for improving the health of a mammal are described. The cocoa components include partially and fully defatted cocoa solids, cocoa nibs and fractions derived therefrom, cocoa polyphenol extracts, cocoa butter, chocolate liquors, and mixtures thereof. The invention provides processes for extracting fat from cocoa beans and for otherwise processing cocoa beans to yield a cocoa component having conserved concentrations of polyphenols relative to the starting materials.

Owner:MARS INC

Gluten-free Foods Containing Microalgae

InactiveUS20100297323A1Improve health benefitsDesirable sensory propertySpread compositionsDough treatmentAdditive ingredientCholesterol

Disclosed herein are microalgae-containing gluten-reduced and gluten-free finished food compositions, as well as microalgae-containing food ingredients for the large-scale manufacture of gluten-reduced and gluten-free foods. Foods and ingredients of the invention, while reducing or eliminating gluten, also have increased health benefits through reduction or elimination of less healthy oils and fats via replacement of primarily monounsaturated algal oils. The novel food compositions also possess more desirable sensory properties and shelf life than previously existing gluten free foods. Foods and ingredients disclosed herein, whoch containing reduced or no gluten, also containing high dietary fiber levels, reduced or eliminated cholesterol, and healthier oil content than existing gluten free foods. Also disclosed are methods of reducing food allergies and symptoms of diseases such as Celiac-Sprue to address increasing rates of sensitivity to gluten-containing products. Also disclosed are methods of formulating and manufacturing microalgae-containing gluten-free foods and ingredients for the formulation of such foods.

Owner:CORBION BIOTECH INC

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

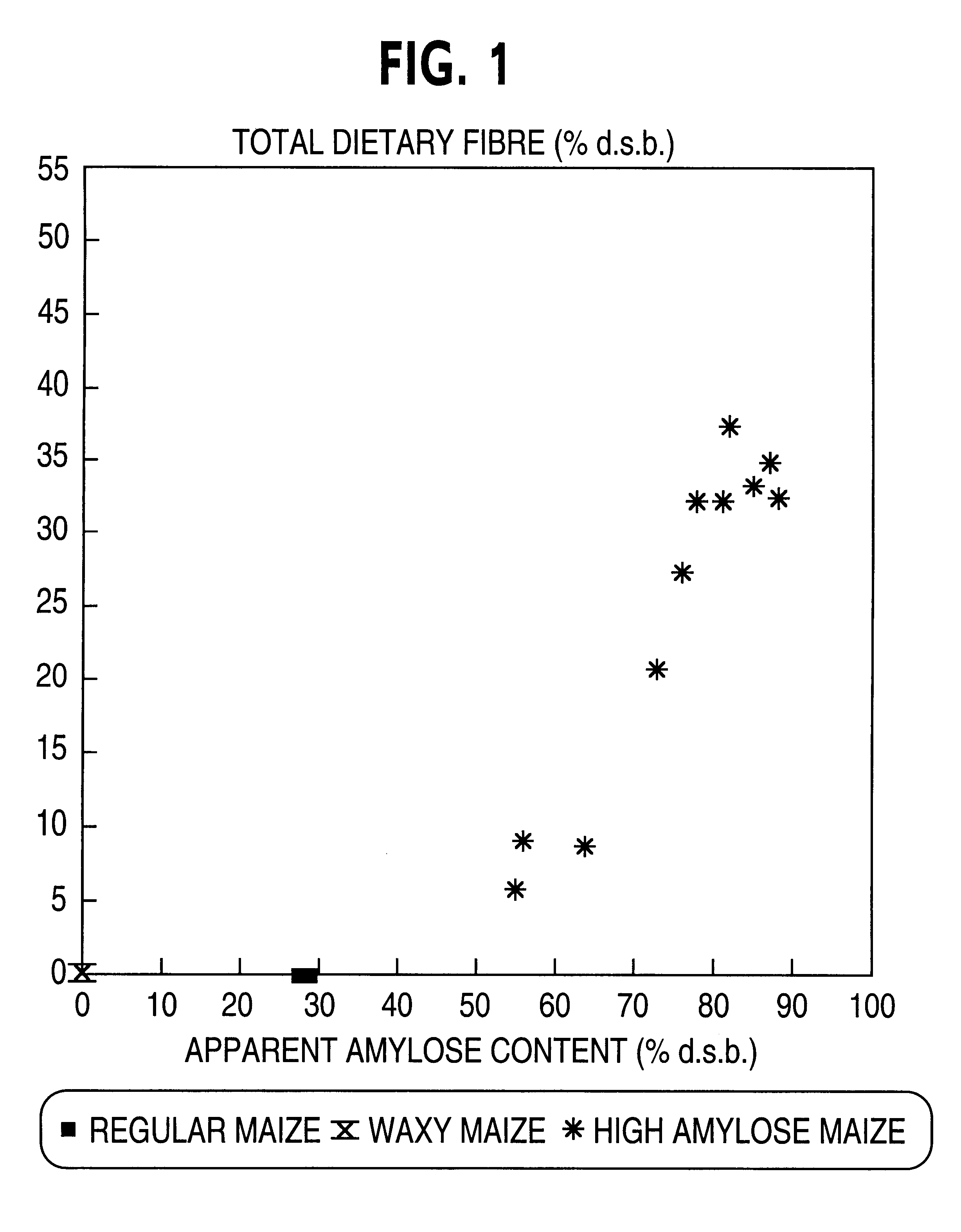

Food compositions including resistant starch

The invention described in this application relates to food compositions such as breakfast cereals, bread and the like which have an enhanced dietary fibre content. In each case the source of dietary fibre is a starch, preferably a maize starch, having an amylose content of 50% or more, the starch being incorporated into a food composition as appropriate. Alternatively, grains or legumes or parts thereof which include starch of this amylose content may be used.

Owner:CORN PROD DEV INC

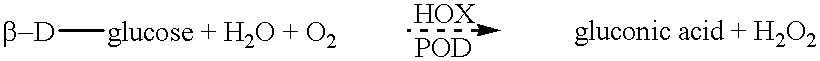

Method of improving the properties of a flour dough, a flour dough improving composition and improved food products

InactiveUS6358543B1Reduce disadvantagesReduce stickinessDough treatmentHydrolasesIridophycus flaccidumEuthora cristata

A method of improving the rheological properties of a flour dough and the quality of the finished product made from such a dough, including adding an effective amount of an oxido-reductase capable of oxidizing maltose, in particular a hexose oxidase, e.g. isolated from an algal species such as Iridophycus flaccidum, Chondrus crispus or Euthora cristata and a dough improving composition containing the oxidore-ductase.

Owner:DUPONT NUTRITION BIOSCIENCES APS

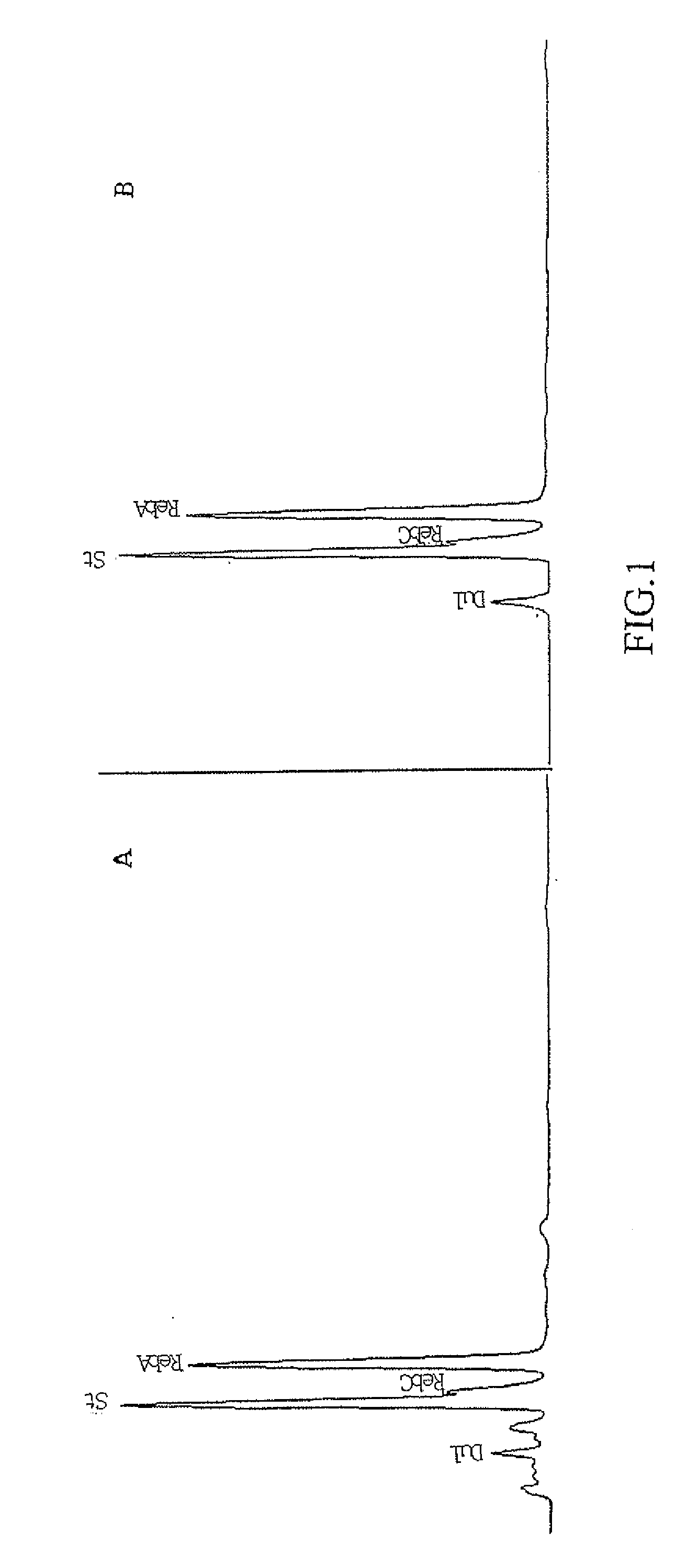

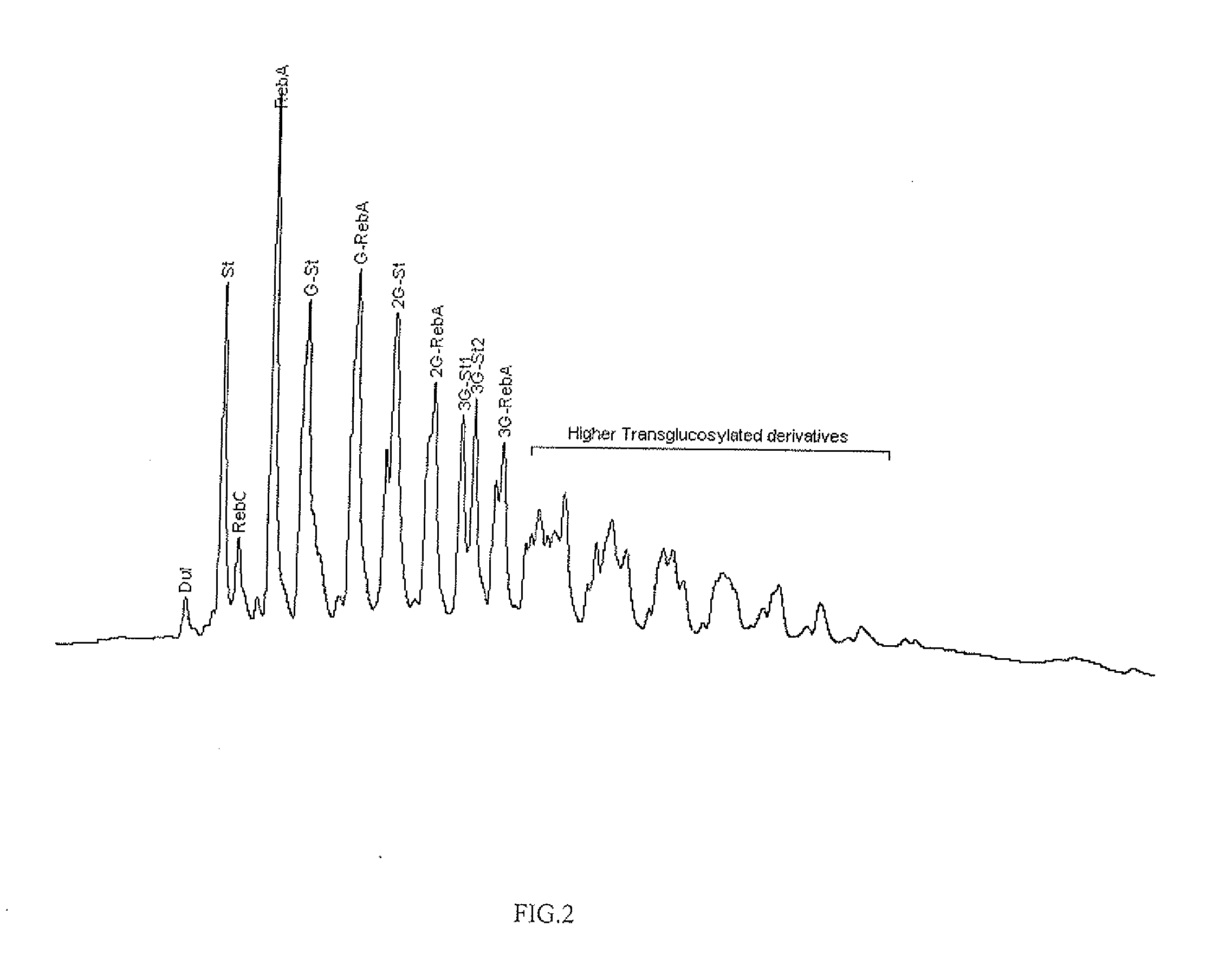

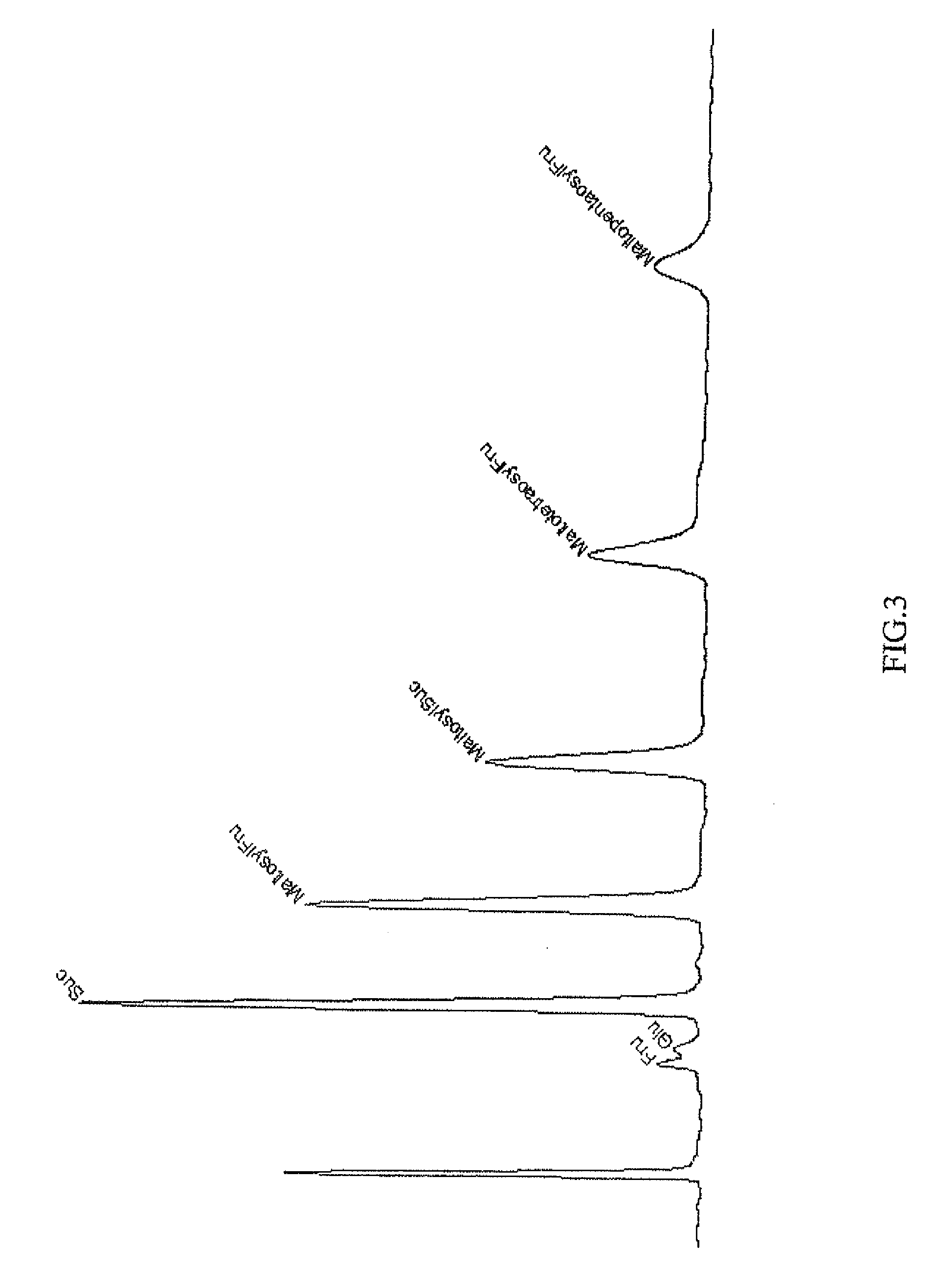

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglucosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transformed to the fructose-terminated oligosaccharides by the addition of sucrose. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

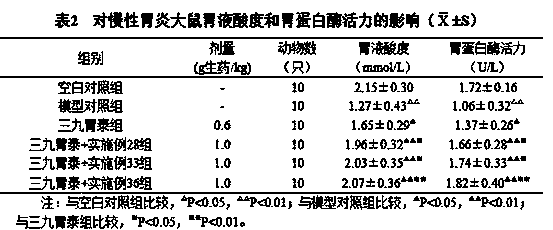

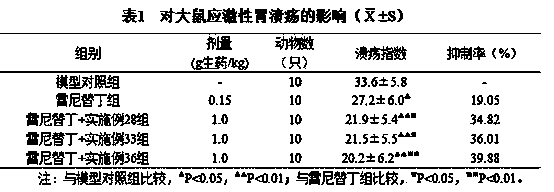

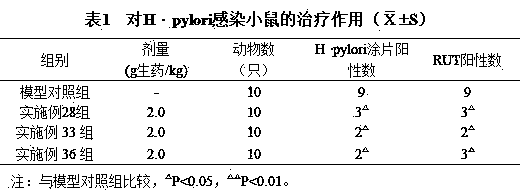

Health-care flour composition and food

ActiveCN103651657AImprove gastritisSymptoms improvedDough treatmentBakery productsNutritionDuodenal ulcer

The invention provides a health-care flour composition and food and a preparing method thereof. According to the preparing method, hericium erinaceus and flour are used as main raw materials, swelling agents, sweetening agents, oil, salt and the like are added and mixed with water, and then rolling, forming, baking, oil injection and cooling are carried out to obtain various foods made of flour or pastries such as cookies, cakes and noodles. The health-care flour composition and food are even in texture, capable of being stored for a long time easily, good in mouthfeel and rich in nutrient, and market vacancy is filled. The health-care flour composition and food have definite effects in repairing gastric mucosal damage caused by chronic gastritis, or gastric ulcers or duodenal ulcers, relieving abdominal pains caused by chronic gastritis, or gastric ulcers or duodenal ulcers, inhibiting helicobacter pylori, and assisting the treatment of chronic gastritis, gastric ulcers and duodenal ulcers.

Owner:江中食疗科技有限公司

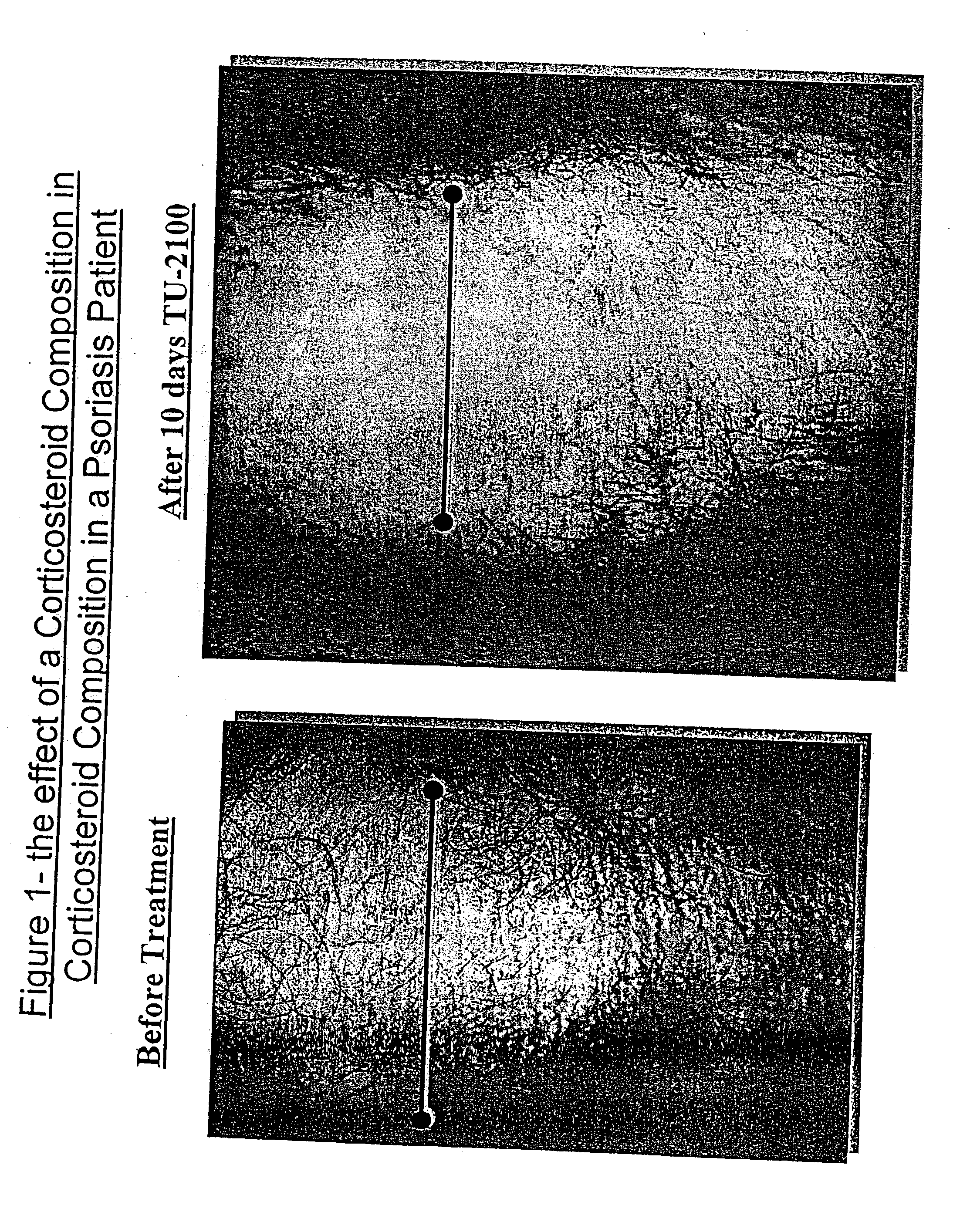

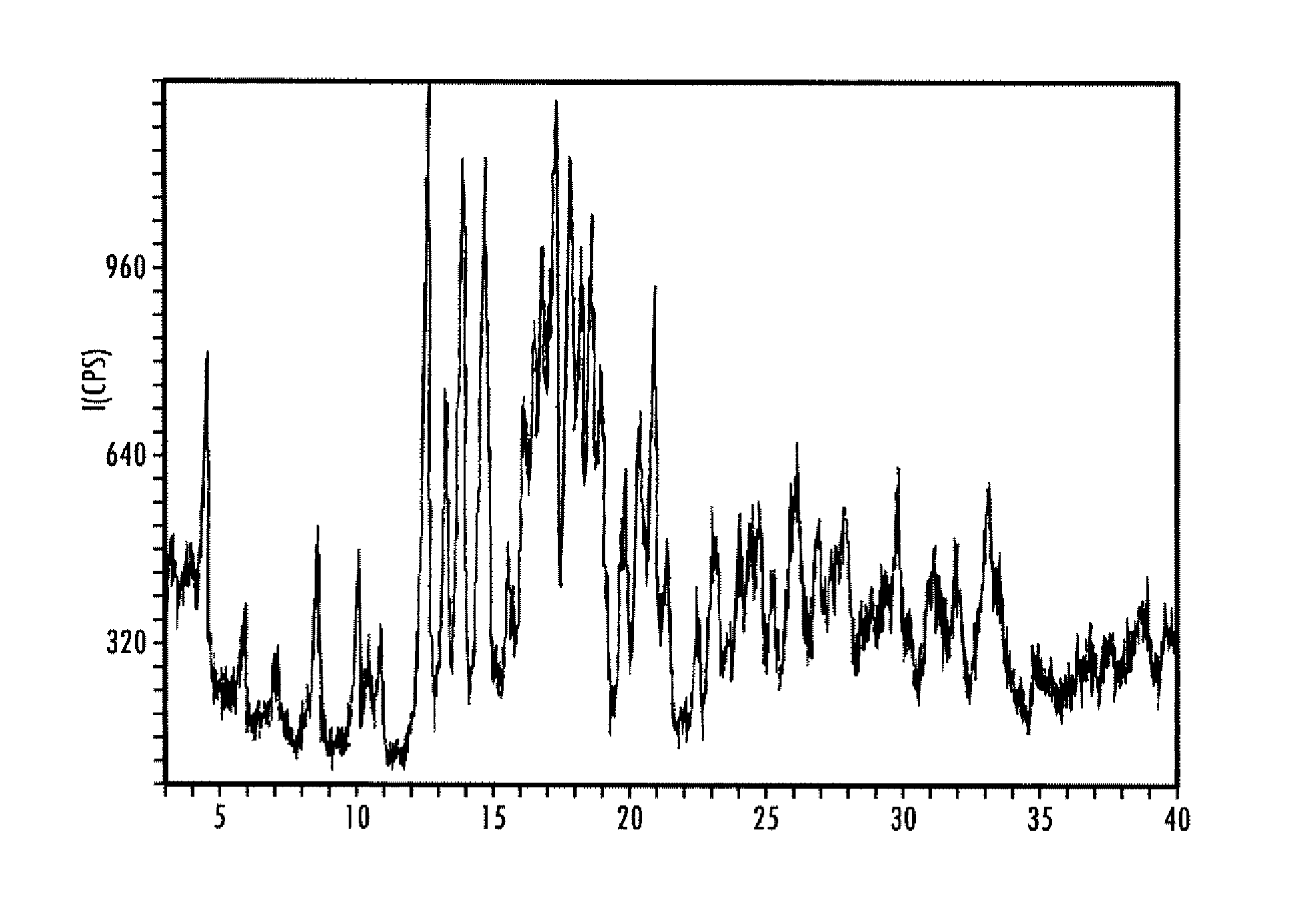

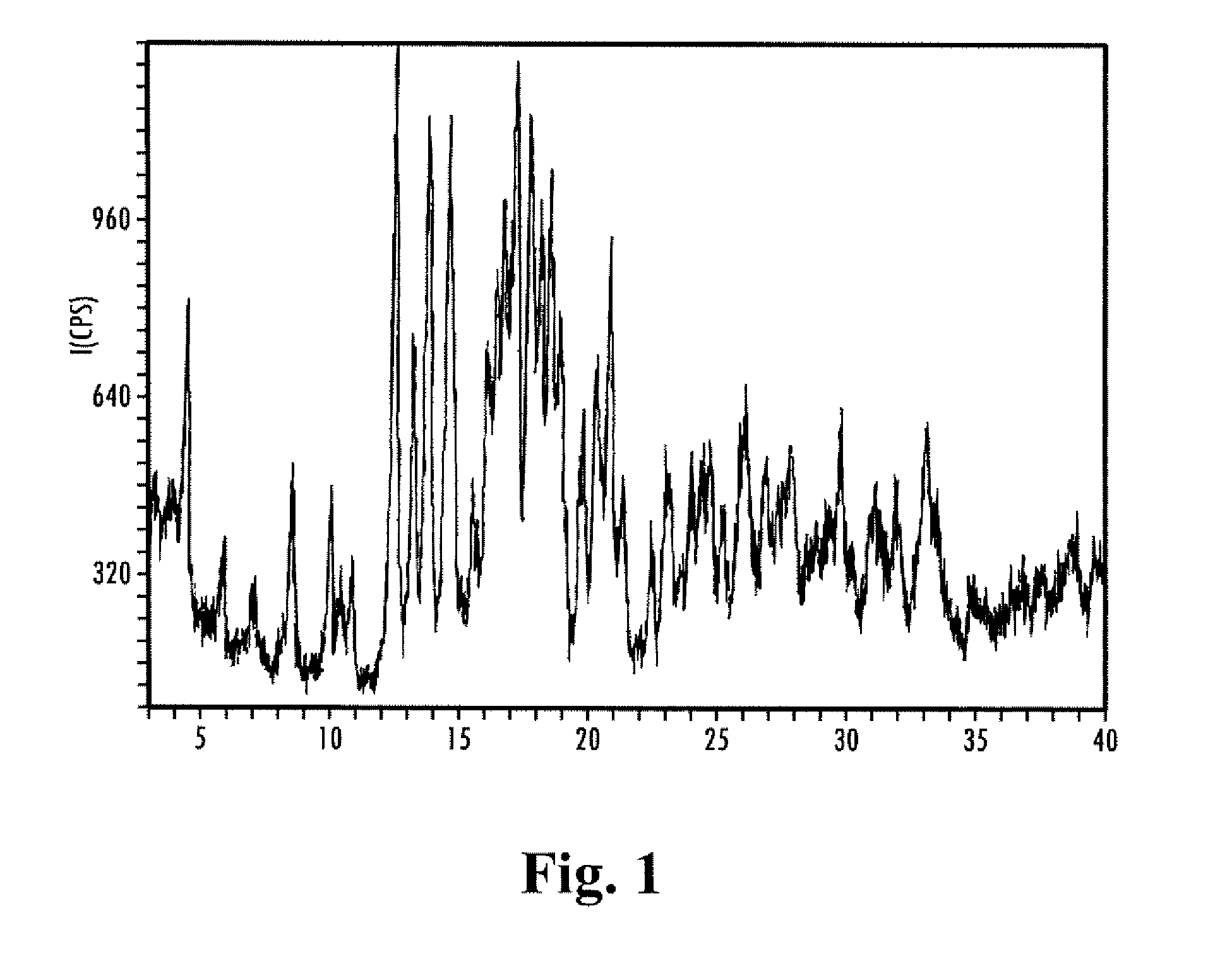

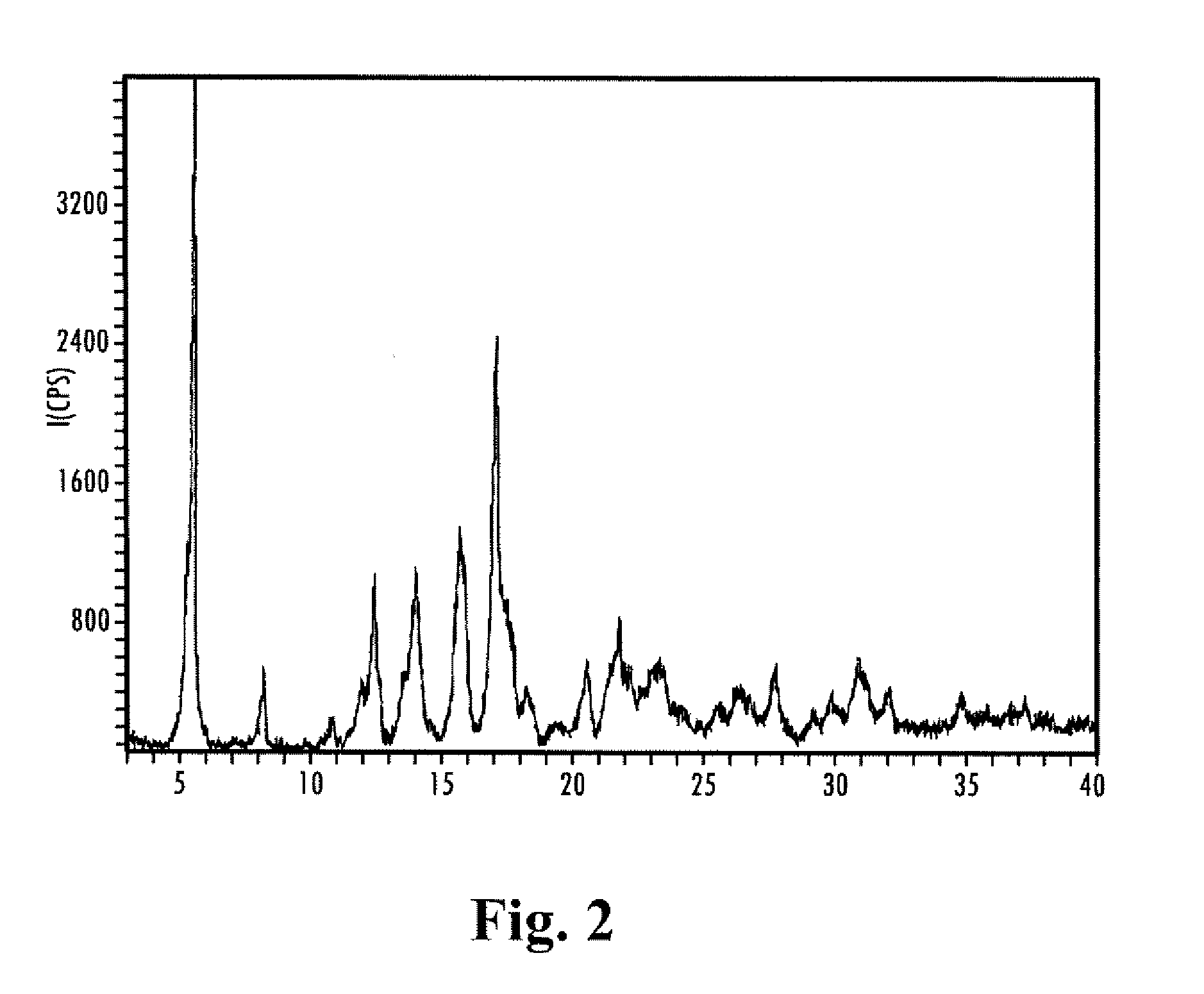

Pharmaceutical and cosmetic carrier or composition for topical application

InactiveUS20040253275A1Antibacterial agentsOrganic active ingredientsPharmaceutical SubstancesHydrophobe

A pharmaceutical or cosmetic carrier or composition for topical application characterized by rheological properties which render the carrier or composition semi-solid at rest and a liquid upon application of shear forces thereto. The composition or carrier are prepared by mixing 1-25 percent of a solidifying agent and 75-99 percent of a hydrophobic solvent, by weight, wherein at least one of them has therapeutic or cosmetic benefits, in the presence or absence of a biologically active substance.

Owner:VYNE PHARMA LTD

Compound mixed grain nourishing food and producing method thereof

InactiveCN101223900AFull of nutritionRich foodDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention relates to a compound coarse cereal nutrition food and a production method thereof. The compound coarse cereal nutrition food can overcome the problems of single variety, insufficient nutrition and poor eating effect of the current coarse cereal food so as to meet different demands of people on coarse cereal foods. The technical proposal to solve the problems is that the food is produced by 4-6 portions of wheat flour, 4-6 portions of purple rice flour, 8-12 portions of rye flour, 7-11 portions of barley flour, 7-11 portions of oat flour, 7-11 portions of buckwheat flour, 8-12 portions of corn flour, 8-12 portions of millet flour, 4-6 portions of sorghum powder, 4-6 portions of pearl barley powder, 2.5-3.5 portions of soybean flour, 1.5-2.5 portions of black soybean powder, 1.5-2.5 portions of pea meal, 0.8-1.2 portions of black sesame seed powder, 1.5-2.5 portions of black rice flour, 7-11 portions of rice flour, 3-5 portions of sweet potato dry powder and water by weight. 3-5 portions of mung bean powder can be added if the food is eaten in spring, summer and autumn. The food has scientific composing prescription, rich nutrition and good taste and is convenient for eating, conducive to the health of people and a great creation of food deep processing, thus having great economic and social benefits.

Owner:单良才

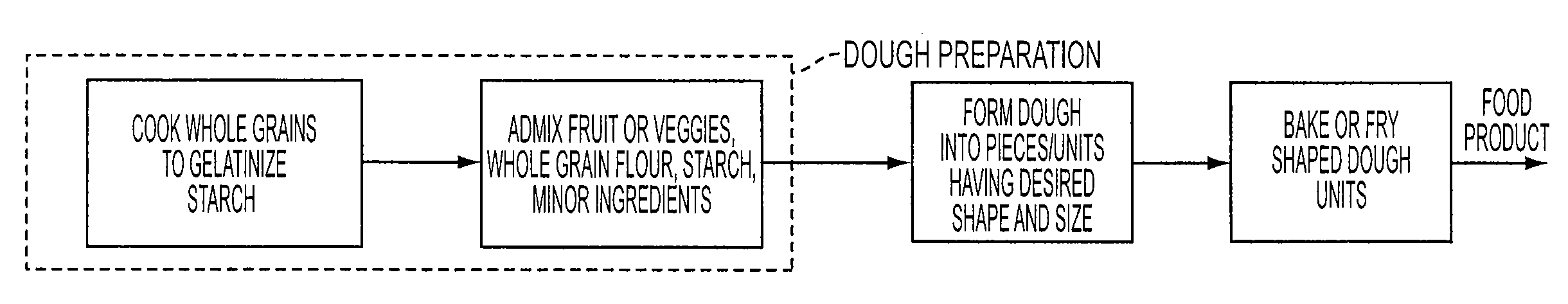

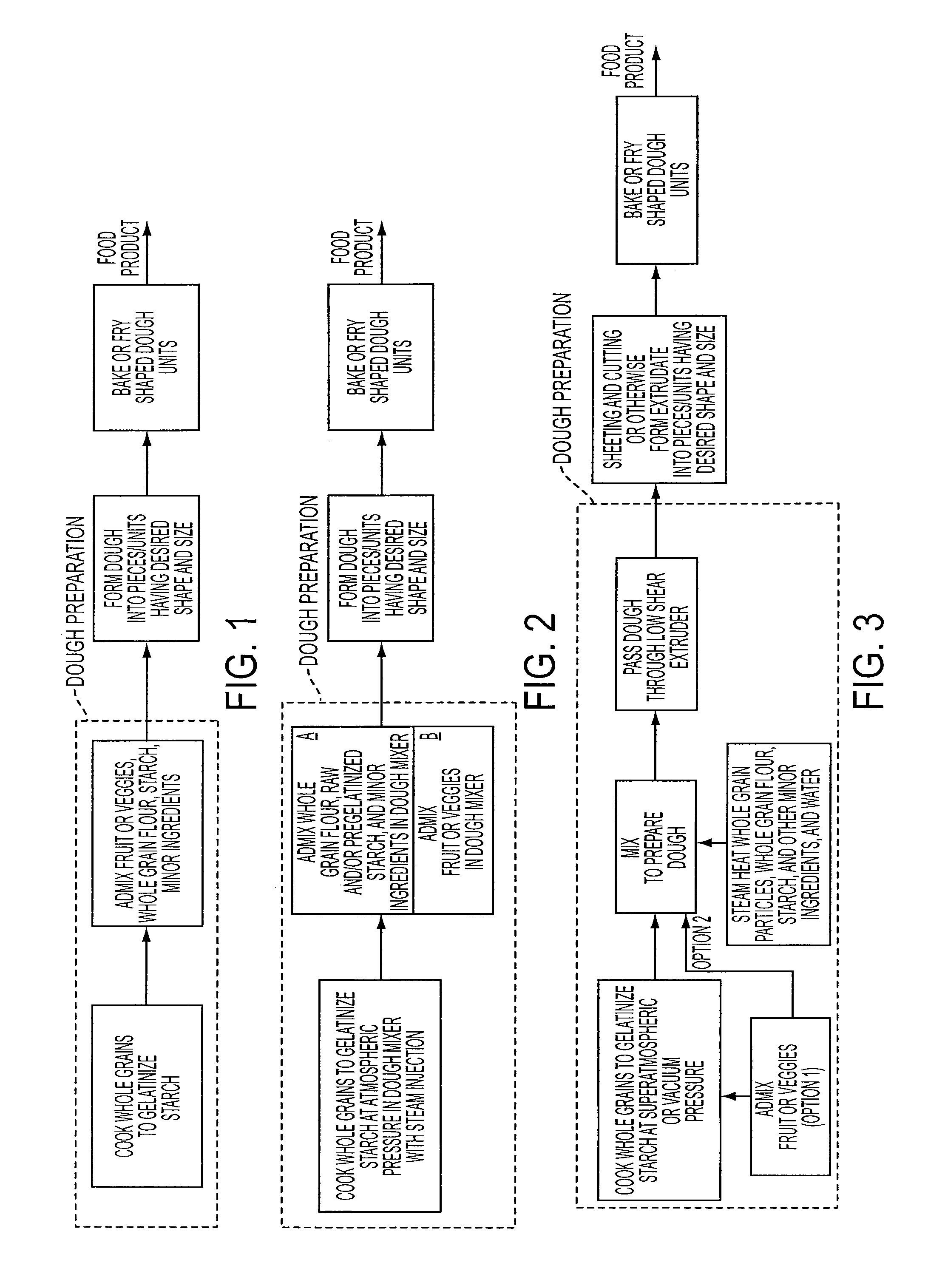

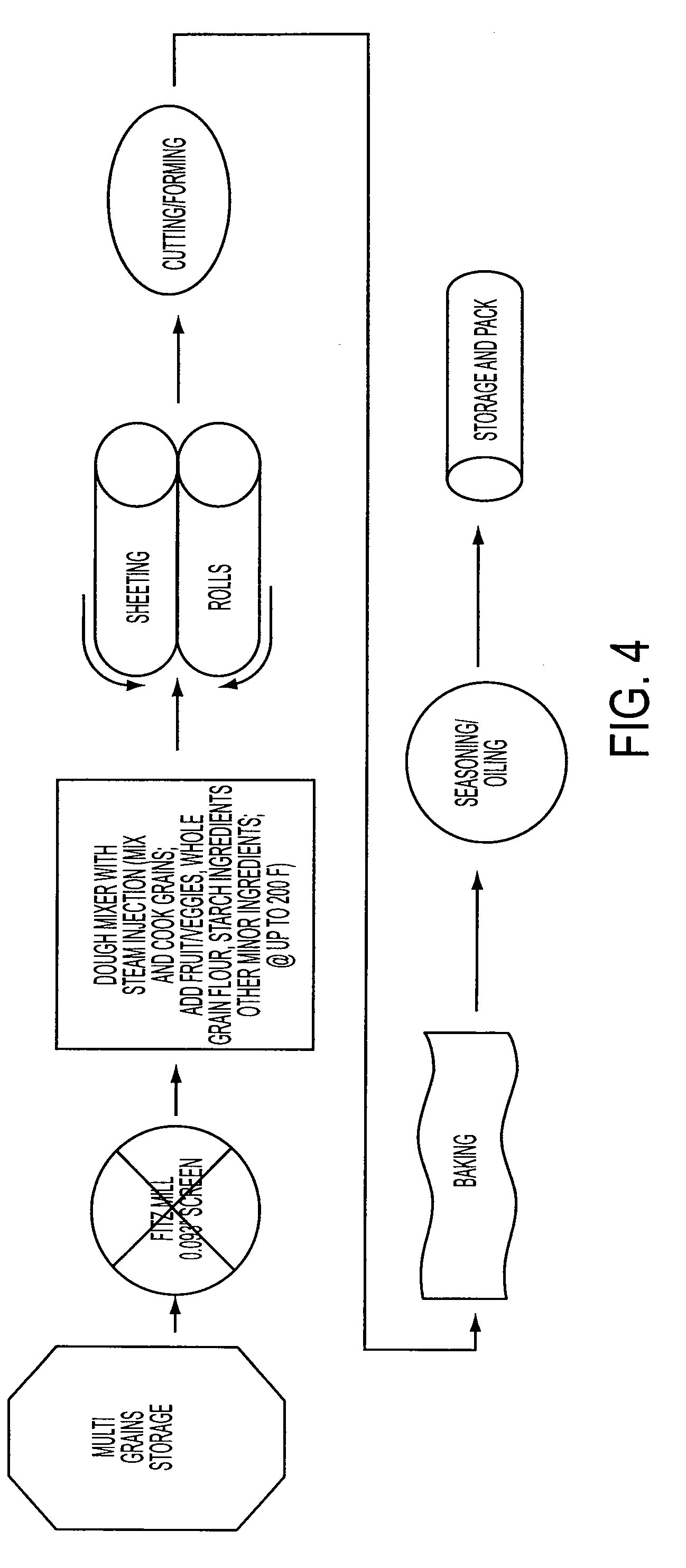

Production of whole grain-containing composite food products

ActiveUS20080003340A1Acceptable machinabilityFood safetyBaking mixturesConfectioneryDietary fiberAdditive ingredient

Shelf-stable whole grain-containing composite food products, such as savory and sweet snacks and cereals, are continuously produced by preparing a dough comprising cooking whole grain cereal grain particles in the presence of water effective to gelatinize starch content of the whole grain cereal particles to provide gelatinized whole grain cereal grain particles, and mixing the gelatinized whole grain cereal grain particles with starch, whole grain flour, optional minor dough ingredients such as leavening agent, and a food component selected from the group consisting of vegetables and fruits, effective to prepare dough. The dough is formed into discrete dough units, which are baked or fried to provide a whole-grain containing composite food product that is nutritious, low fat, multi-flavored, and a good source of dietary fiber.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method of preparing an improved low-calorie, low-fat food foodstuff

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Edible inks for ink-jet printing on edible substrates

InactiveUS20040086603A1Difficult to printImprove adhesionMeasurement apparatus componentsFrozen sweetsWaxImage resolution

High resolution ink-jet printing on edible substrates is disclosed in which fat or wax-based edible inks, which contain a colorant, a fat or wax dispersible carrier, and a fat or wax base, are used to produce high resolution images on edibles. The methods utilize a piezoelectric printhead; and the edible products include confectionery pieces having non-planar, hydrophobic surfaces, such as wax-polished sugar shell surfaces, with a printed image thereon having a resolution greater than 100 dpi, preferably greater than 300 dpi.

Owner:MARS INC

High PUFA oil compositions

ActiveUS20060110521A1Organic chemistryFatty substance preservation using additivesHigh concentrationFatty acids.polyunsaturated

The present invention is directed to oil compositions having a high concentration of poly-unsaturated fatty acids. In addition, the oils of the present invention have advantageous stability characteristics and minimal trans-fatty acids.

Owner:MONSANTO TECH LLC

Dermatological application with solidified fat compositions

InactiveUS20030157138A1Antibacterial agentsEdible oils/fats ingredientsFirming agentCosmetic vehicle

A pharmaceutical or cosmetic carrier or composition for topical application characterized by rheological properties which render the carrier or composition semi-solid at rest and a liquid upon application of shear forces thereto. The composition or carrier are prepared by mixing 1-25 percent of a solidifying agent and 75-99 percent of a hydrophobic solvent, by weight, wherein at least one of them has therapeutic or cosmetic benefits, in the presence or absence of a biologically active substance.

Owner:VYNE PHARMA LTD

Baked Goods Comprising High-Potency Sweetener

ActiveUS20070224321A1Improve flavor profileImproving temporal profile profileDough treatmentBakery productsBaked goodsSweetness

The present invention relates generally to baked goods comprising non-caloric or low-caloric high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different baked goods comprising at least one non-caloric or low-caloric natural and / or synthetic high potency sweetener and at least one sweet taste improving composition. The present invention also relates to baked goods and methods that can improve the tastes of non-caloric or low-caloric natural and / or synthetic high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the baked goods and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Browning agent

A browning agent for foodstuffs having at least two carbonyl groups is disclosed. A method for using the browning agent in or on a substrate is also disclosed. The browning agent may be coated onto foodstuffs such as biscuits, pizza, pie coverings or hash brown potatoes and heated by microwave or convection oven to induce browning.

Owner:GENENCOR INT INC

Scored savory dough with toppings or fillings

InactiveUS6942885B2Minimizes and eliminatesEasily preformedReady-for-oven doughsDough treatmentSugar substituteChemistry

A ready-for-use refrigerated or frozen dough that is prepared from flour, a leavening agent, fat; has no greater than 0.5 weight percent sugar or sugar substitute; and preferably includes one or more toppings, fillings, or both. The dough has a surface that includes grooves, score lines, or combinations thereof which define pieces of the dough to be separated into individual bakery products. The grooves, score lines, or combinations thereof each have a depth of about 3% to about 95% of the thickness of the dough. The dough is in the form of a sheet or a parallelepipedal, cylinder, prismatic block or polygon having a thickness of from about 0.5 to 5 cm.

Owner:SOC DES PROD NESTLE SA

Method for preparing flour doughs and products made from such doughs using lipase

InactiveUS6852346B2Improve the immunityLess-prone to mechanical deformationFungiDough treatmentPore diameterSpecific volume

Owner:DUPONT NUTRITION BIOSCIENCES APS

Lacteal coated pizzas

From dietary health to product diversity, Lacteal Coated Pizzas outperform the venerable four-hundred year old ethnic (Italian) pizzas. Lacteal Coated Pizzas are comprised of soft leaven dough / sourdough that is topped with a delicious, nutritious Lacteal Batter, and a conventional topping. The present invention's Lacteal Batters are innovative, heat-stable, hydrocolloidal-proteineous mixtures that possess unique performance-enhancing, rheological properties.

Owner:BODY STRUCTURES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com