Patents

Literature

1002 results about "Amylose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

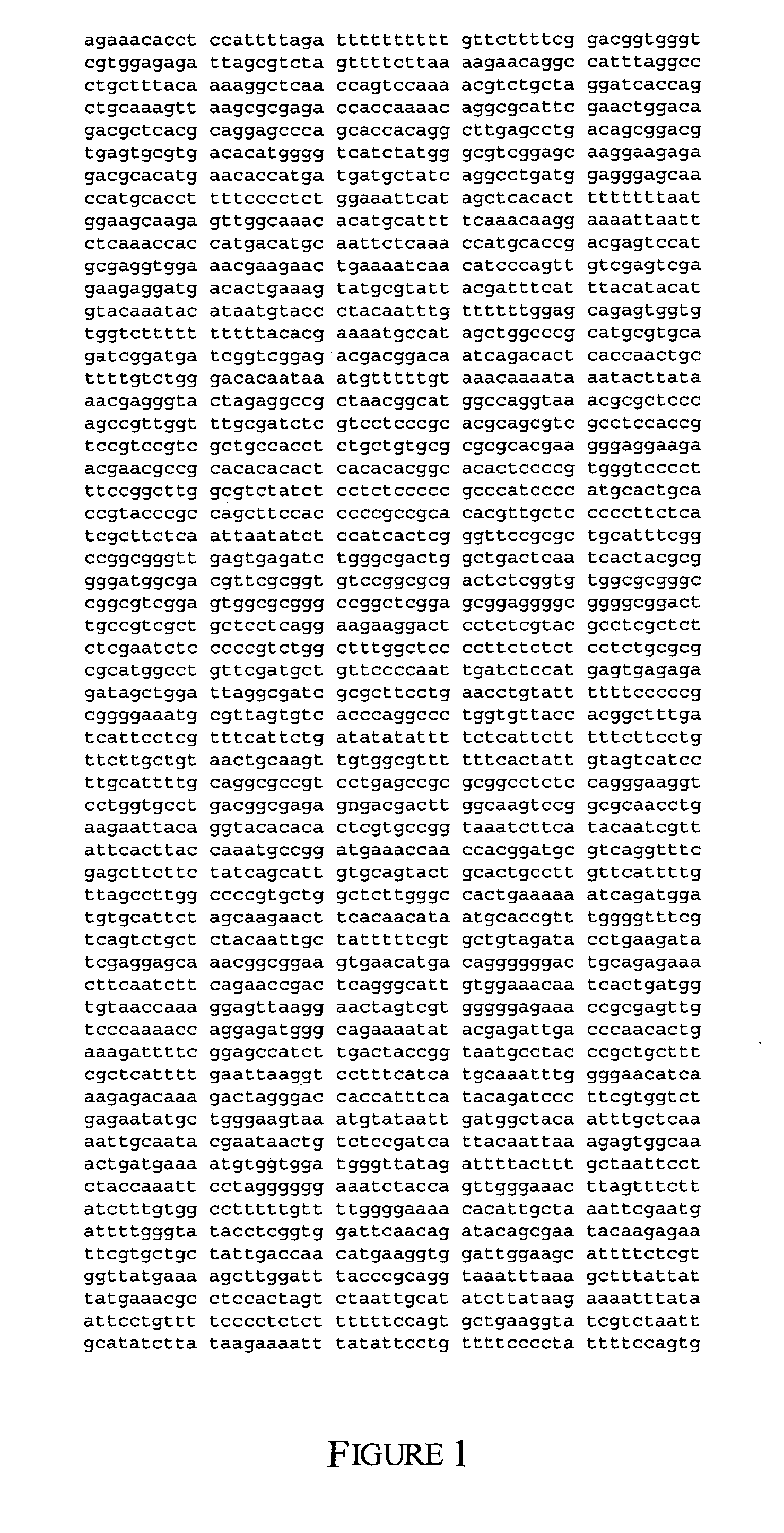

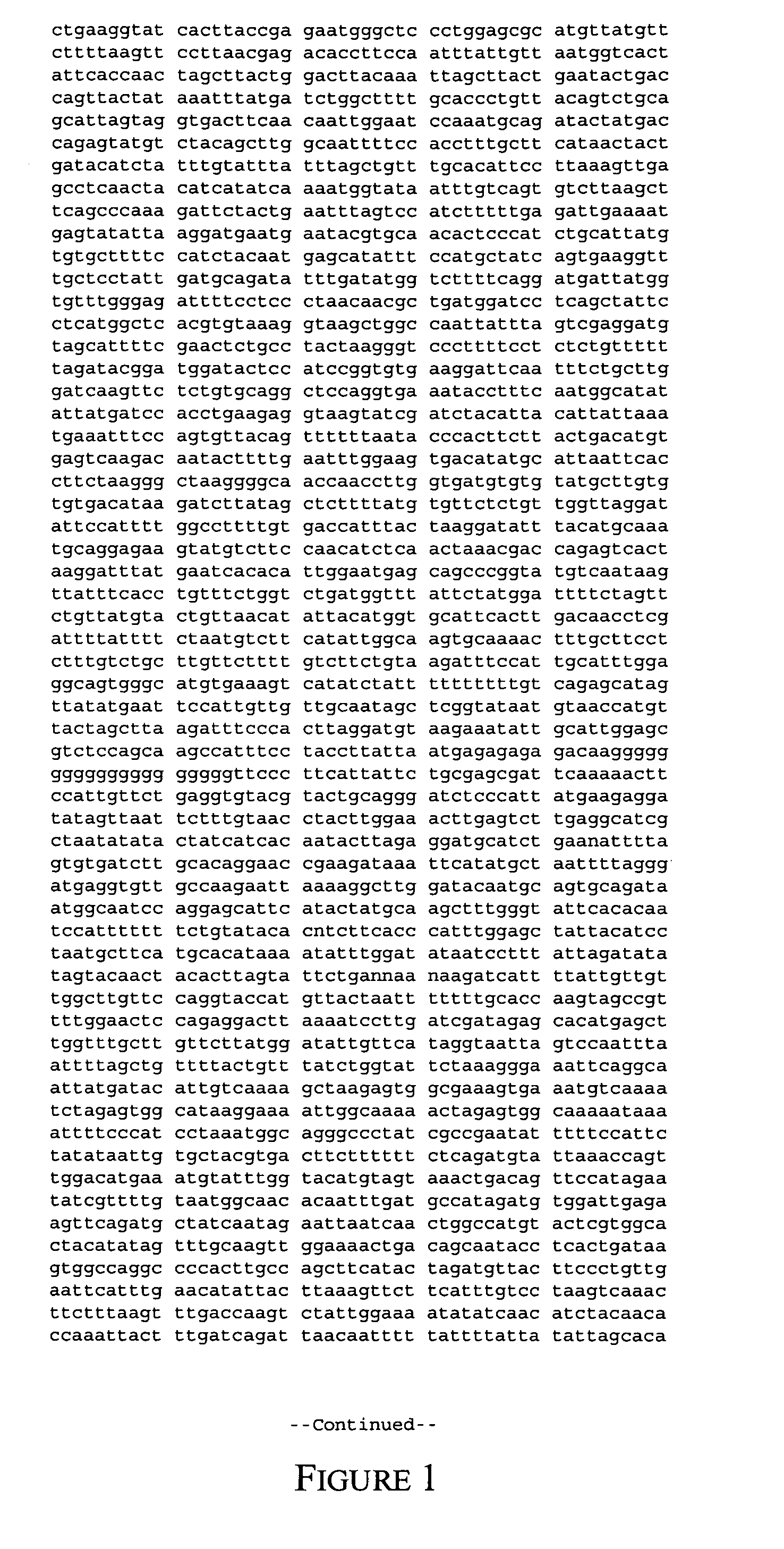

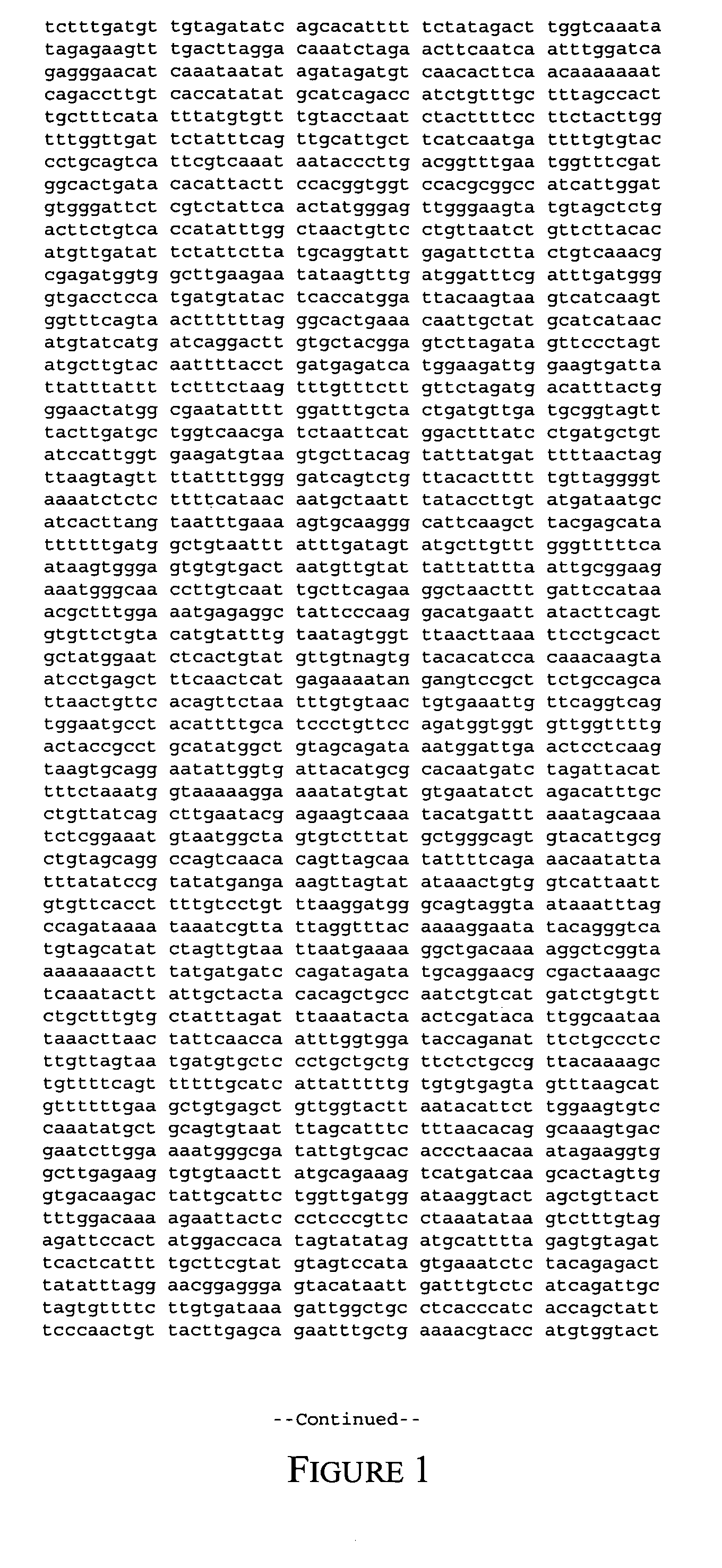

Amylose is a polysaccharide made of α-D-glucose units, bonded to each other through α(1→4) glycosidic bonds. It is one of the two components of starch, making up approximately 20-30%. Because of its tightly packed helical structure, amylose is more resistant to digestion than other starch molecules and is therefore an important form of resistant starch.

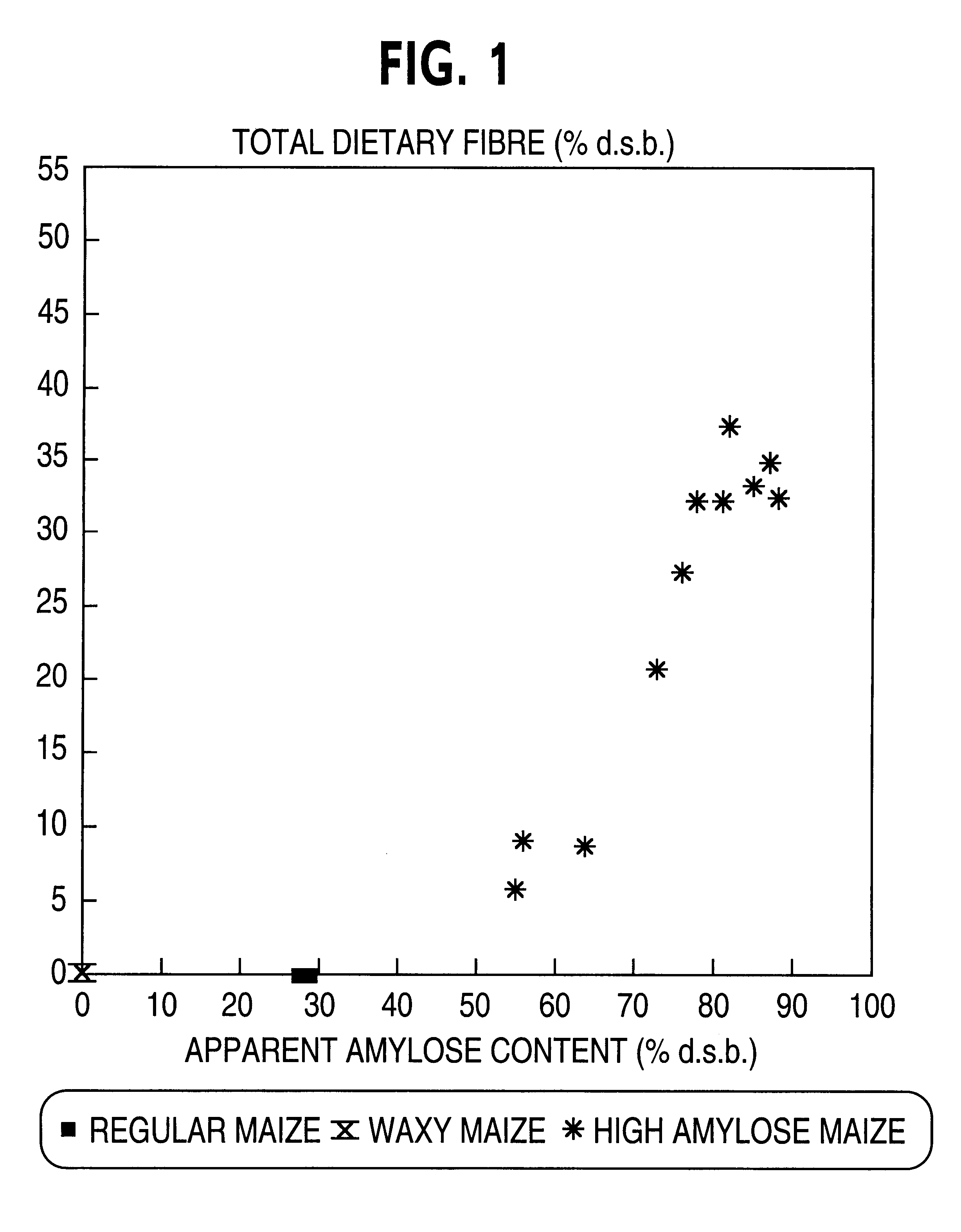

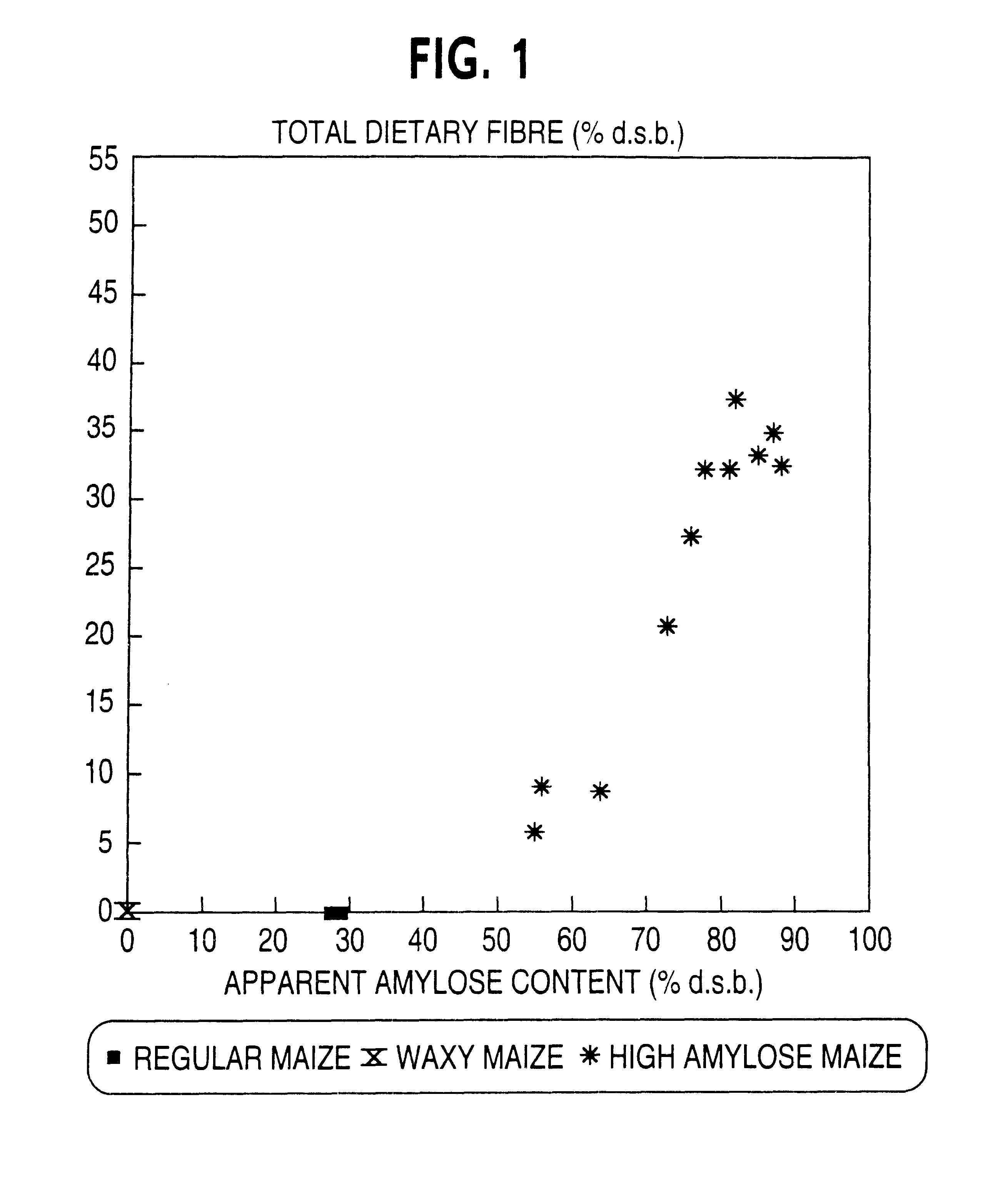

Food compositions including resistant starch

The invention described in this application relates to food compositions such as breakfast cereals, bread and the like which have an enhanced dietary fibre content. In each case the source of dietary fibre is a starch, preferably a maize starch, having an amylose content of 50% or more, the starch being incorporated into a food composition as appropriate. Alternatively, grains or legumes or parts thereof which include starch of this amylose content may be used.

Owner:CORN PROD DEV INC

Dressing material containing medicine chitoholosida and its preparation method

InactiveCN1579559AHas therapeutic effectSustained releaseAbsorbent padsBandagesSolid componentPhosphate

The invention produces polyethylene alcohol hydrogel dressing containing medicine and chitosan with 60Co gamma-radial or high energy electron beam radial cross linking. Additional, adds in some humectant, plasticizer, medicine, the solvent is the secondary distilled water, physiological saline or phosphate neutral buffer liquid. The product can release medicine slowly and has natural amylose chitosan with biology sterilization activity, it has active sterilization function, at the same time, it has high water quantity, and good water reserving performance, the mechanical intensity is moderate, and the light penetration and air penetration are excellent. It can accord the demands for curing each kind of wound. It can used as the permanent dressing for light skin injuries, and it also can be applied to the temporally close of severe skin organization wound or burn wound.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method and means for improving bowel health

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30% and / or the grain comprises a reduced level of SBEIIa enzyme activity and / or protein relative to wild-type grain.

Owner:ARISTA CEREAL TECH

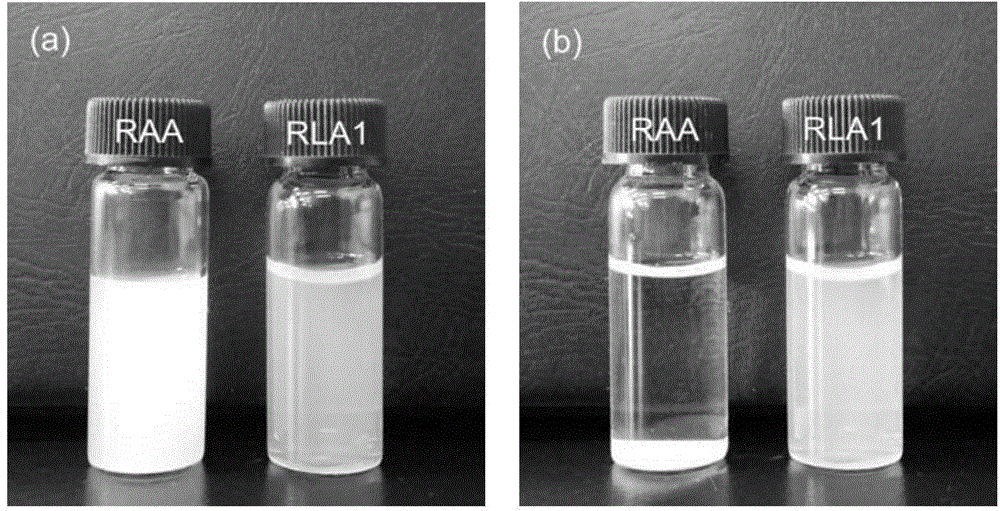

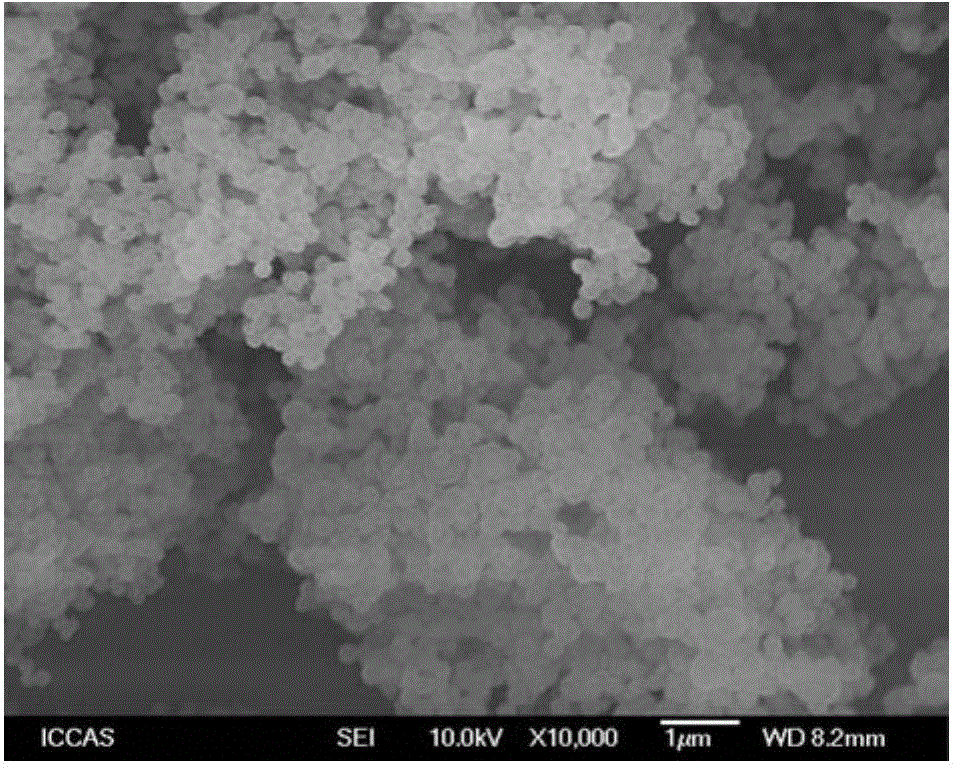

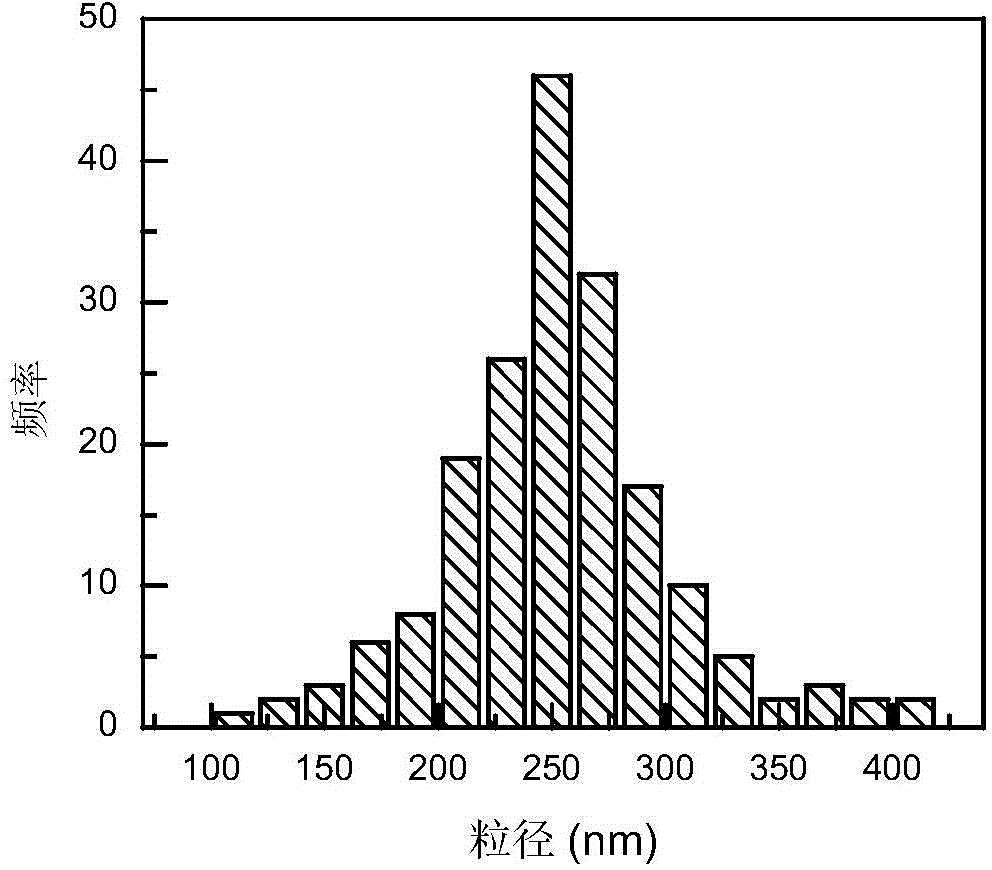

Preparation method for starch nanospheres

InactiveCN104785179AEasy to operateEasy to controlMicroballoon preparationMicrocapsule preparationFood additiveMicrosphere

The invention discloses a preparation method for starch nanospheres. The method comprises the following steps: (1) dissolving amylase in an alkaline solution, and stirring to obtain suspension; (2) completely freezing the suspension obtained in the step (1); (3) thawing a product obtained in the step (2), and obtaining a starch solution; (4) dialyzing the starch solution obtained in the step (3), and obtaining starch dispersion liquid; (5) filtering the starch dispersion liquid obtained in the step (4), and drying to obtain the starch nanospheres. The preparation method is energy-saving, environment-friendly and simple to operate, and a process is easy to control; the preparation method only adopts a general chemical reagent and simple experimental equipment, can realize large-scale production and is easy for industrialized promotion; the starch nanospheres prepared with the method are high in purity, and the starch structure is not changed; the starch nanospheres prepared with the method are controllable in particle size and uniform in particle size distribution, can be stably dispersed in water, and can be used for biomedical carriers and food additives.

Owner:INST OF CHEM CHINESE ACAD OF SCI

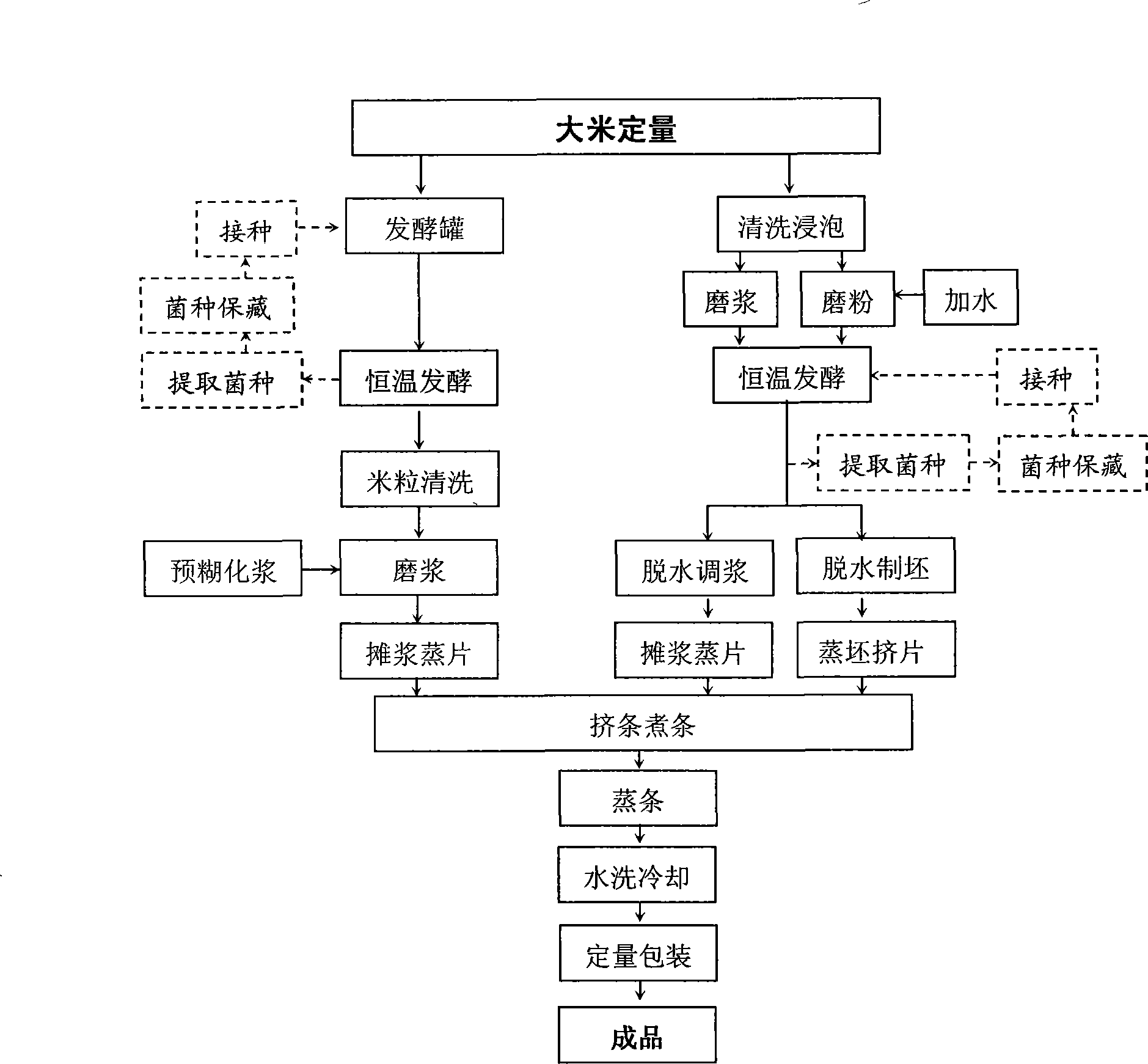

Method for processing lactic acid bacteria fermentation rice-flour noodles

InactiveCN101248852AShorten the production cycleReduce manufacturing costFood preparationBiotechnologyBroken rice

The invention discloses a processing method for fermenting rice flour by lactobacillus, namely using the lactobacillus to ferment and produce rice flour food with high quality, belonging to the technology field of food process. The technical proposal comprises the following steps of grinding the rice flour to thick liquid, spreading the thick liquid to steam a sheet, extruding and cooking rice bars, steaming the rice bars, and washing and cooling the rice bars. The processing method is characterized in that the selected material is rice or broken rice with amylose starch content more than 20%, the lactobacillus is added into the rice flour for fermentation at a constant temperature before or after grinding the rice flour to thick liquid, the number of the lactobacillus is 10<6> - 10<11>cfu / ml, the fermentation temperature is 30-50 DEG C, and the fermentation time is 8-18 hours. The processing method avoids the danger of latent miscellaneous bacteria by adopting pure strain enrichment fermentation, improves the flexibility and ensures the cleanness and the quality of the rice flour by utilizing pre-pasting rice milk instead of reserved rice sheet and fermented glutinous rice, and saves production cost due to the short production period.

Owner:CHINA AGRI UNIV

Method and means for improving bowel health

ActiveUS7993686B2Improve blood sugar controlLow in carbsBiocideOrganic active ingredientsAnimal scienceMetabolic health

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30%.

Owner:ARISTA CEREAL TECH

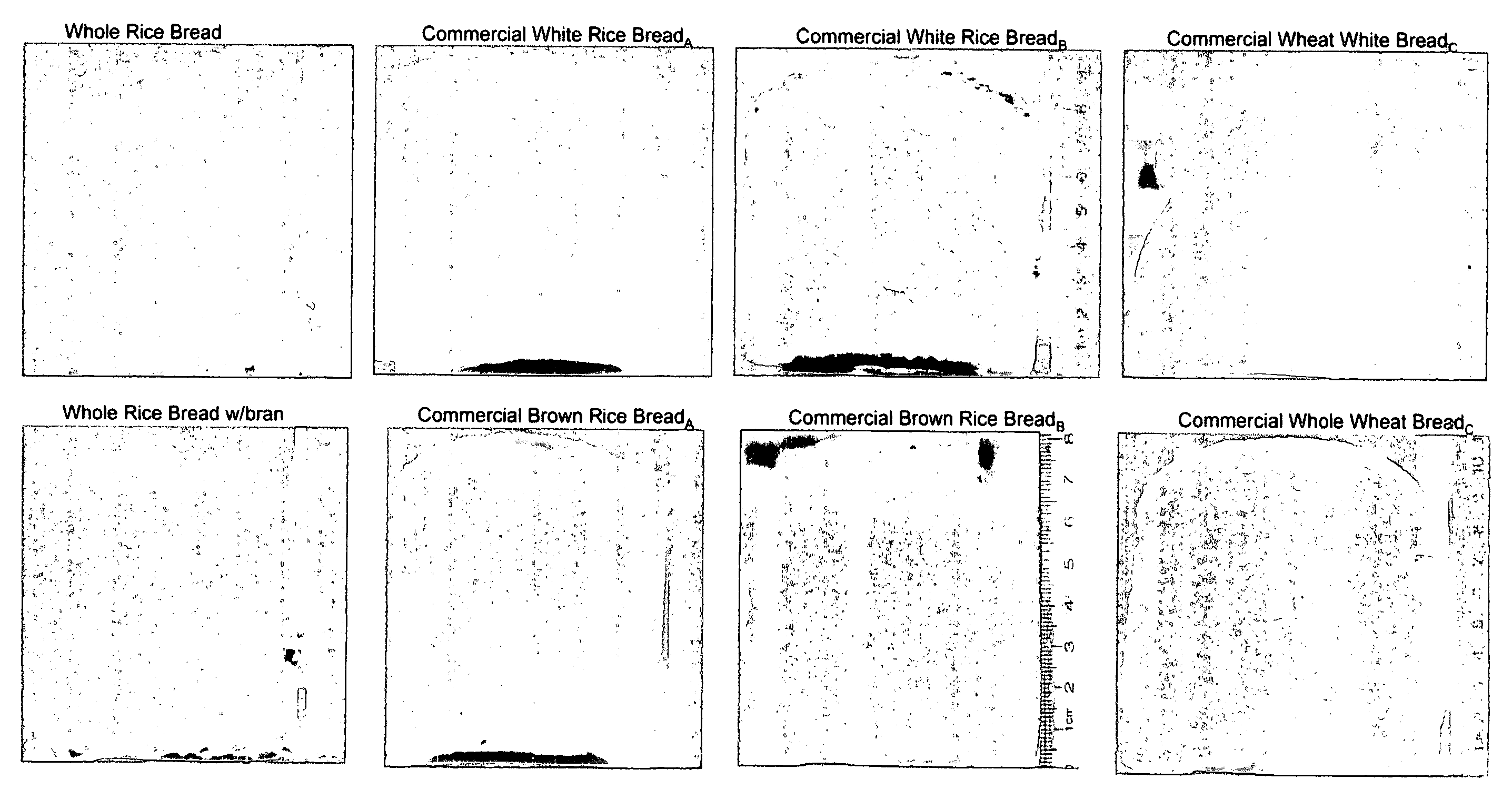

Baked products containing rice flour

A mix for the preparation of rice-containing baked products, containing 100% rice flour (containing about 15 to about 26% amylose), about 0 to about 20% waxy rice flour, about 1 to about 4% hydroxypropyl methylcellulose food gum, about 1 to about 5% yeast, about 0 to about 10% rice bran, about 4 to about 20% sugar, and about 1 to about 4% salt. A method for preparing a rice-containing baked product, involving mixing 100% rice flour (containing about 15 to about 26% amylose), about 0 to about 20% waxy rice flour, about 1 to about 4% hydroxypropyl methylcellulose food gum, about 1 to about 5% yeast, about 0 to about 10% rice bran, about 4 to about 20% sugar, and about 1 to about 4% salt with an amount of water and oil and for a time sufficient to wet all the particles, and baking.

Owner:US SEC AGRI

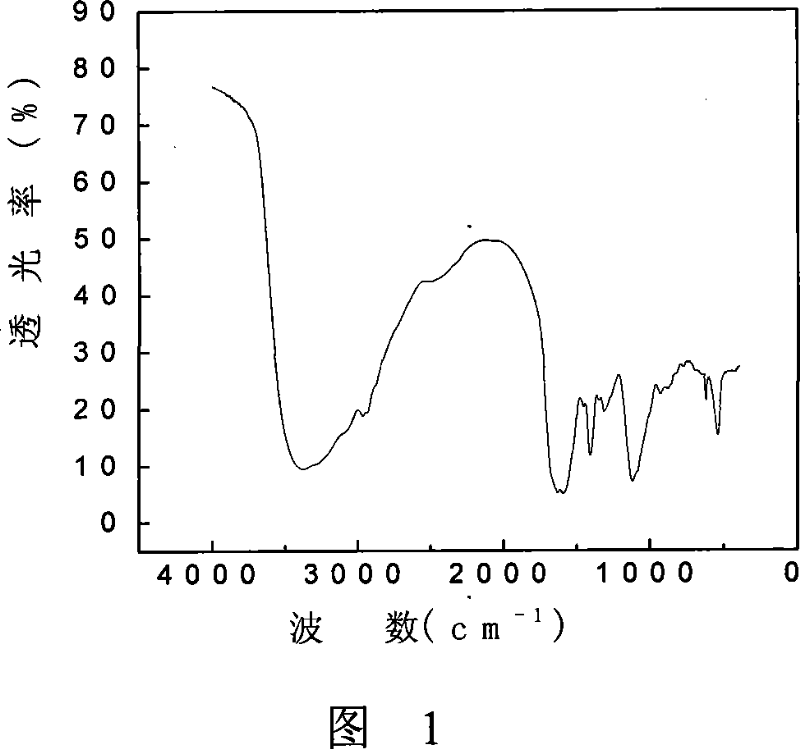

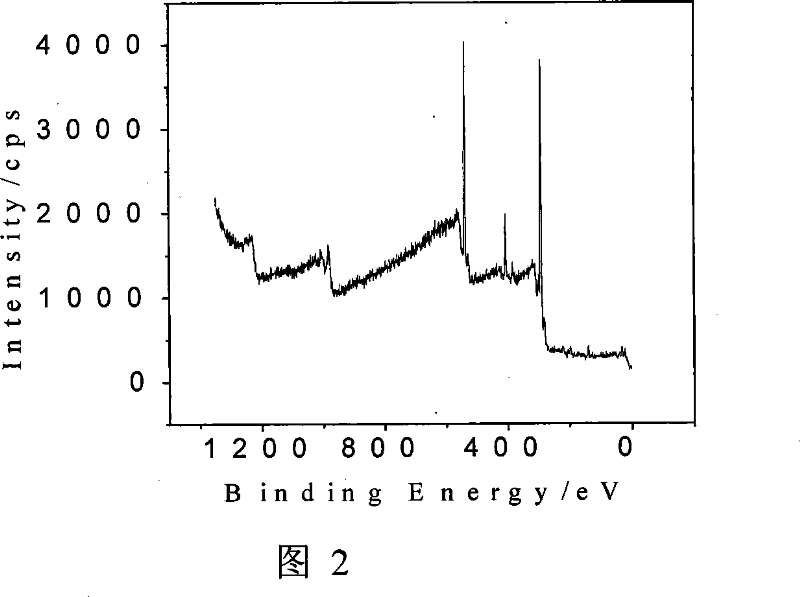

Method for preparing anti-pollution chitosan-nonwoven cloth composite porous filter membrane

InactiveCN101497002AImprove mechanical stabilityGood chemical stabilitySemi-permeable membranesWater bathsNonwoven fabric

The invention discloses a method for preparing an antipollution chitosan-nonwoven fabric composite porous filter membrane and belongs to the technical field of microfilter and ultrafilter composite membranes. The method is characterized in that the method adopts nonwoven fabric with nominal aperture of between 0.1 and 10 microns as a base membrane; a crosslinking agent is adopted to carry out pretreatment on the base membrane; 0.1 to 10 mass percent amylose is dissolved in an acetic acid solution; the crosslinking agent and a hole formation agent are added into the acetic acid solution; after the crosslinking reaction, a casting film liquid is obtained; at negative pressure, the casting film liquid is evenly coated on the surface and pores of the porous base membrane; and after treatment by a sodium hydroxide solution and a hot water bath, the antipollution chitosan-nonwoven fabric composite porous filter membrane is formed. The method has the advantages that the prepared composite membrane has good mechanical performance and chemical stability; and the surface of the membrane is levelled and smooth. The composite membrane has dual functions of hydrophile and antibiosis, can lighten adsorption of pollutants on the surface of the membrane, inhibit the growth and reproduction of thalli on the surface of the membrane, and keep the penetrating performance of the membrane and is widely applied to the water treatment process of various fields.

Owner:DALIAN UNIV OF TECH

Rice flour compositions

ActiveUS20060286271A1Less expensiveAbsorbs less fatDough treatmentLeguminous plant bakery productsCross-linkSnack food

A rice flour composition having: from about 20% to about 95%, by weight, of a rice flour that has a WAI of from about 2.6 to about 9; and a Peak Viscosity from about 4 RVU to about 130 RVU; and from about 5% to about 80%, by weight, of rice starch materials that have a WAI of below about 2.2; a Peak Viscosity from about 100 RVU to about 900 RVU, and a soluble amylose content of less than 10%, by weight. The rice starch materials can be selected from the group consisting of waxy rice starch, acetylated rice starch, cross linked rice starch and mixtures thereof. The compositions can be used to produce food products such as fabricated sheeted snacks, extruded products, sauces, coatings for fried foods, dog foods, dog biscuits, baby foods and breads. The preferred dough formed from the inventive rice flour composition is sheetable and forms a cohesive dough. Fabricated snacks made from this dough has the desired taste and texture characteristics. A dry blend for a preferred fabricated snack comprises from about 2% to about 100%, preferably from about 20% to about 85%, most preferably from about 40% to about 75%, of the rice flour composition.

Owner:KELLOGG NORTH AMERICA

Food compositions including resistant starch

The invention described in this application relates to food compositions such as breakfast cereals, bread and the like which have an enhanced dietary fiber content. In each case the source of dietary fiber is a starch, preferably a maize starch, having an amylose content of 50% or more, the starch being incorporated into a food composition as appropriate. Alternatively, grains or legumes or parts thereof which include starch of this amylose content may be used.

Owner:CORN PROD DEV INC

Method and means for improving bowel health

ActiveUS20060204597A1Reduces excessive insulin responseReduce probabilityBiocideAntipyreticAnimal scienceWild type

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30% and / or the grain comprises a reduced level of SBEIIa enzyme activity and / or protein relative to wild-type grain.

Owner:ARISTA CEREAL TECH

Method and means for improving bowel health

ActiveUS20060286186A1Improve blood sugar controlLow in carbsOrganic active ingredientsBiocideMetabolic healthWheat starch

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30%.

Owner:ARISTA CEREAL TECH

Method for preparing boil proof vermicelli without alum

A process for preparing the high-toughness alum-free long-thread vermicelli includes such steps as proportionally mixing starch, konjak starch, Arabic gum, straight-chain starch, modified soybean phosphoride, sodium dihydrogen phosphate, sodium carbonate and water, stirring, gelatinizing, cooling, ageing, cutting to become long-thread vermicelli, drying, moistening, drying again and cutting short.

Owner:SHENYANG POLYTECHNIC UNIV

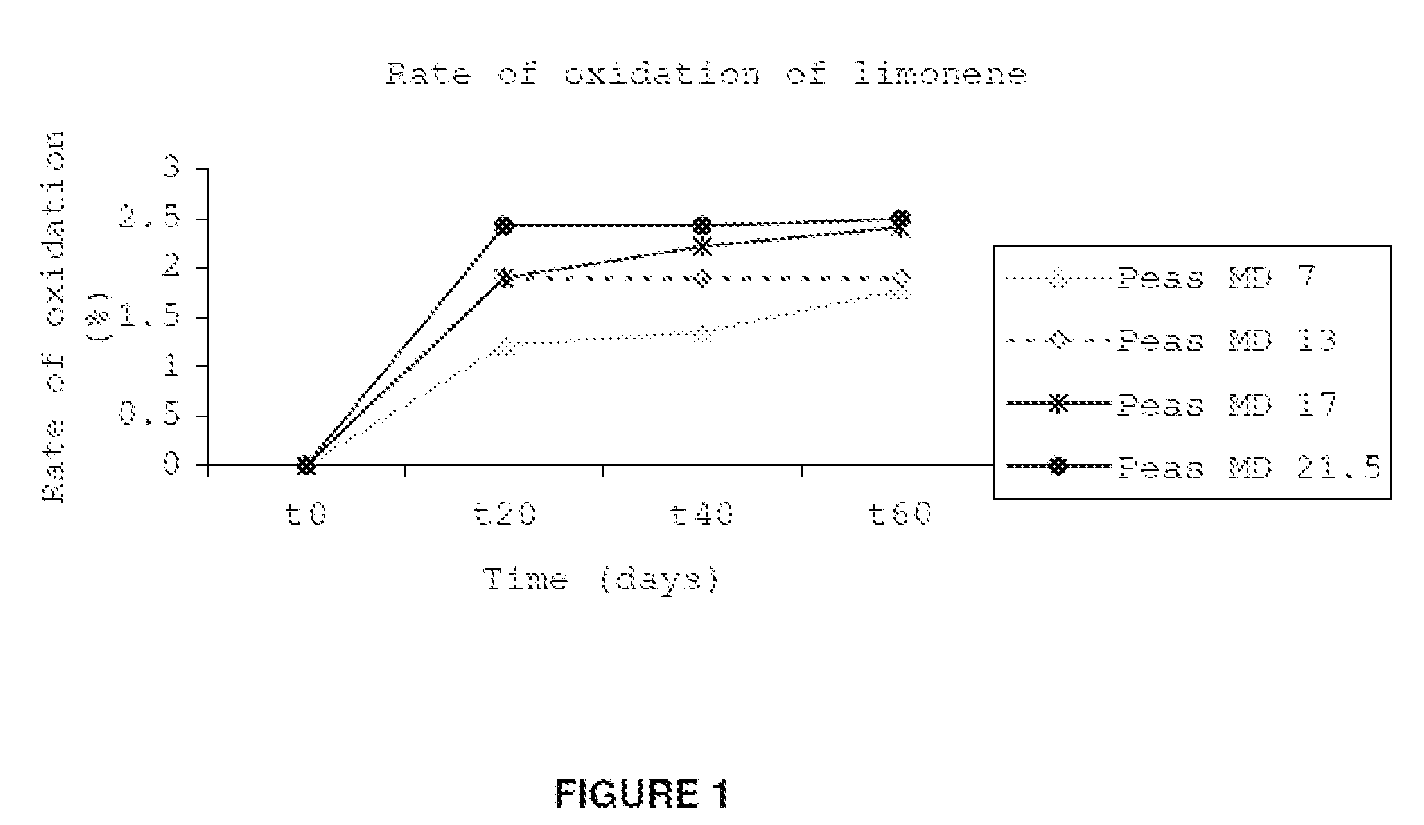

Encapsulation agent comprising a pea maltodextrin and/or a pea glucose syrup, compositions containing it and its preparation method

Owner:ROQUETTE FRERES SA

Agent for phytoremediation of soil polluted by heavy metals using the waste active Sludge as the original material and the method of the phytoremediation of soil polluted by heavy metals

InactiveCN101036917AThe enrichment effect is obviousRealize ecological restorationContaminated soil reclamationActivated sludgePhosphoric acid

Provided is a heavy metal pollution soil repairing agent using excess activated sludge as the rawmaterial, a method of extraction and a method for repairing the heavy metal pollution soil, which relates to a heavy metal pollution soil repairing agent and a method thereof and a method for repairing the heavy metal pollution soil, and solves the problems of high cost, easily secondary pollution and complex operation existing in the repair of the heavy metal pollution soil. The heavy metal pollution soil repairing agent is composed of amylose, protein, nucleic acid, phosphoric acid, amino acid, humic acid compound, uronic acid and the organic substance required for cell lifecycle. The method for distilling the heavy metal pollution soil repairing agent is as follows: the wastewater treatment excess activated sludge reacts under the condition of 80-120 KPa and 60-100 DEG for 8-20 minutes; then centrifuges for 8-20 min at the rotating speed of 5000-7000r / min. The invention adopts the home position repairing or the heterotopia repairing to repair the heavy metal pollution. The invention has low cost and no secondary pollution, simple operation, short repairing period, strong activity and wide range of application.

Owner:HARBIN INST OF TECH

Special formulation fertilizer for rice

ActiveCN101054326APromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersFiberProcess quality

The invention belongs to fertilizer technical field, more particularly relates to a rice special formula fertilizer, which is characterized in that effective elements of the fertilizer are calculated by weight percent of pure nutrient are nitrogen 25-15, phosphorus pentoxide 15-9, potassium oxide 20-12, silicon dioxide 5-0, calcium 8-0, sulphur 5-1 and zinc 2-1. Compared with the present technique, the rice special formula fertilizer of the invention has reasonable match, accords with the nutrient absorption law of rice, can promote rice growth obviously and raise rough rice output, increase economic benefits and improve rice nutriment quality. In application test, the rice special formula fertilizer of the invention increases the rice yield by 660-820 kg per hectare, increases income 756-146 RMB, increases crude protein, raw fat, crude fiber, nitrogenfree extract and crude ash by 4.1-8.6, 0.14-0.80, 0.4-0.8, 0.1-3.0, 0.4-1.0 percentage points respectively, increases brown rice rate, integral white rice rate, white rice rate of rice processed quality by 1.4%, 1.7% and 1.8% respectively, reduces chalkiness granule rate, chalkiness by 3.2% and 1.9% respectively, reduces content of amylose by 1.0%. In the meanwhile, the fertilizer utilization efficiency is raised by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

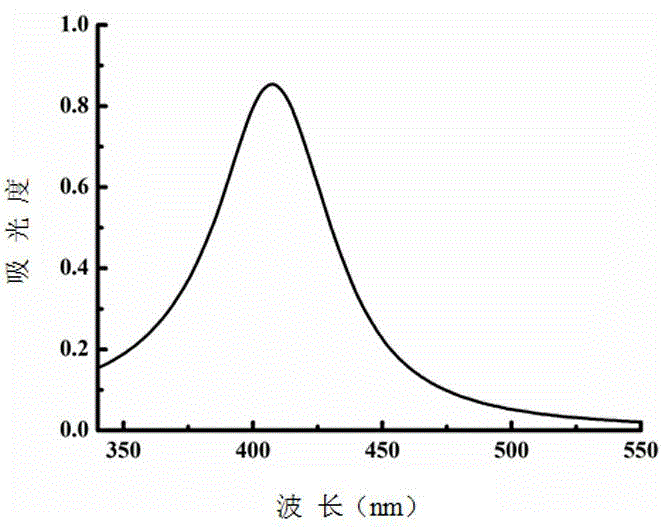

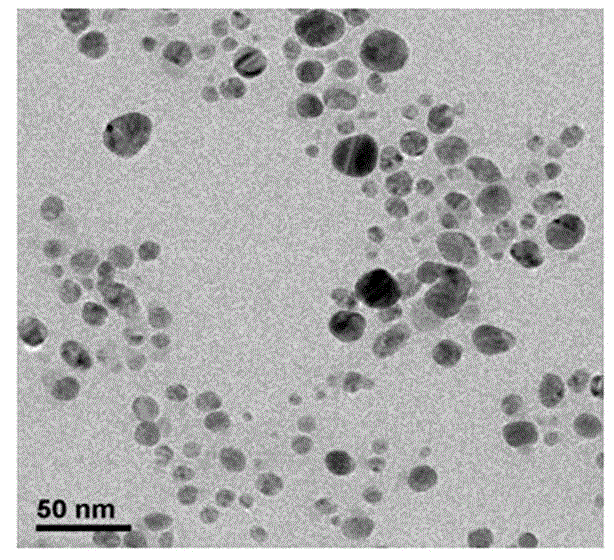

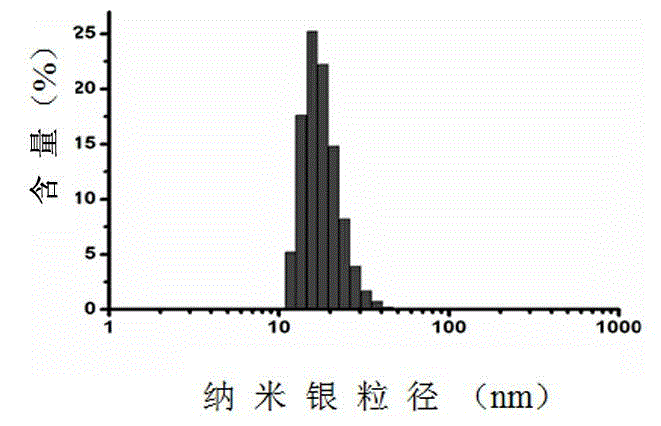

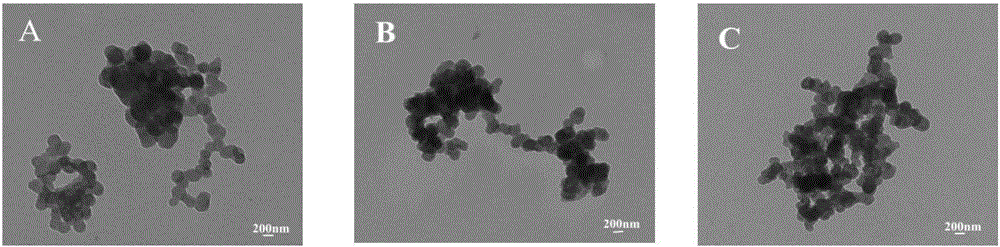

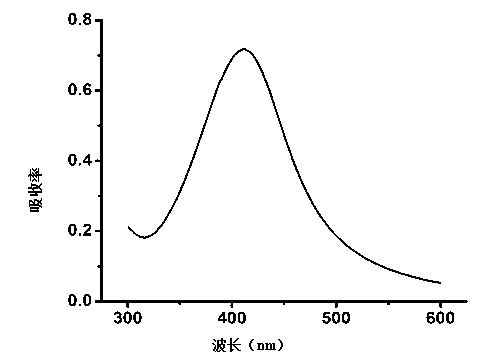

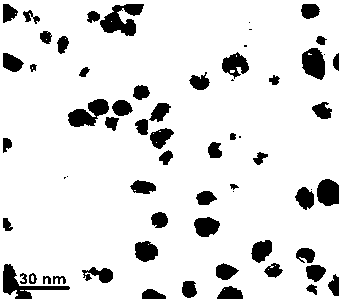

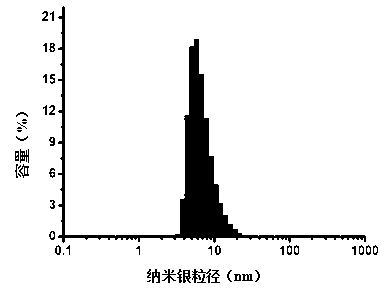

Method for preparing nano-silver hydrosol by using plant extract

The invention discloses a method for preparing nano-silver hydrosol by using a plant extract. The method comprises the following steps of: dissolving or dispersing soluble amylose into deionized water, stirring until the soluble amylase is completely gelatinized; adding a Tollens solution and mixing to obtain a starch-Tollens compound solution; freezing the compound solution into ice blocks and smashing the ice blocks into colloidal particle ice powder; and adding the colloidal particle ice powder into an alkaline plant blade extract and fully mixing to obtain the nano-silver hydrosol with the particle size of 1 to 100 nm. By the method, a silver ion and protecting agent compound solution is frozen and smashed; the obtained ice powder carried with silver ions is activated and reduced to obtain nano silver; the method is simple, convenient and high in controllability; and the prepared nano-silver hydrosol is high in stability and has the advantages of small nano-silver particle size, uniform distribution, high antibacterial efficiency and the like and can be widely applied to the field of electrons, textile, catalysis, medical materials, medical treatment and public health and the like.

Owner:SUZHOU UNIV

Method and means for improving bowel health

ActiveUS20110212916A1Improve blood sugar controlLow in carbsOrganic active ingredientsBiocideAnimal scienceWild type

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30% and / or the grain comprises a reduced level of SBEIIa enzyme activity and / or protein relative to wild-type grain.

Owner:ARISTA CEREAL TECH

Aqueous biopolymer-containing labeling adhesive

InactiveUS20070240823A1Improve biodegradabilityImprove suitabilityLayered productsStarch adhesivesBiopolymerBottle

Adhesives particularly useful for industrial bottle labeling are provided. The adhesives comprise at least one starch component and at least one protein component (which is not gelatin or casein). The adhesive is also free of synthetic polymer. The label, along with the adhesive, can be easily removed from the bottle during the recycling process. In one embodiment, the starch component does not contain leguminous starch having an amylose content of 25% or more. In another embodiment, the adhesive comprises a crosslinking agent.

Owner:HENKEL KGAA

A method for preparing natural fruit vegetables antistaling agent using capsule technique

InactiveCN101161082ASolve the preservation problemSolve storage problemsFruits/vegetable preservation by coatingCitric acidHeating temperature

The present invention belongs to a method for preparing nature fruit vegetable antistaling agent using capsule technology. The mixing ratio as well as method is: getting 0.01 to 2 percent of foliage oil, 0.1 to 5 percent of microcapsule wall material, adding water of one kilogram and mixing them fully to obtain fruit vegetable antistaling agent; the fruit vegetable antistaling agent is coated fruit exterior, forming a translucence film composed of foliage oil and microcapsule after drying, so as to reach antistaling; the chitose and the konjak amylose etc. dissolve slowly in water, it is need to heat or add auxilytic agent into the water, the auxilytic agent includes: citric acid and vinegar acid, the ratio is 0.5 percent to 2 percent, the heating temperature is 20 DEG C to 90 DEG C. The method is that the fruit vegetable antistaling agent is nature safe and high effect, which not only solve the problem of antistaling as well as storing effectively, but also the leftover on the fruit has no toxicity, and reaching edible standard, which solves the problem that the medical antistaling agent has remnant poison and can improve the economy efficiency of fruit vegetable.

Owner:陈绳良

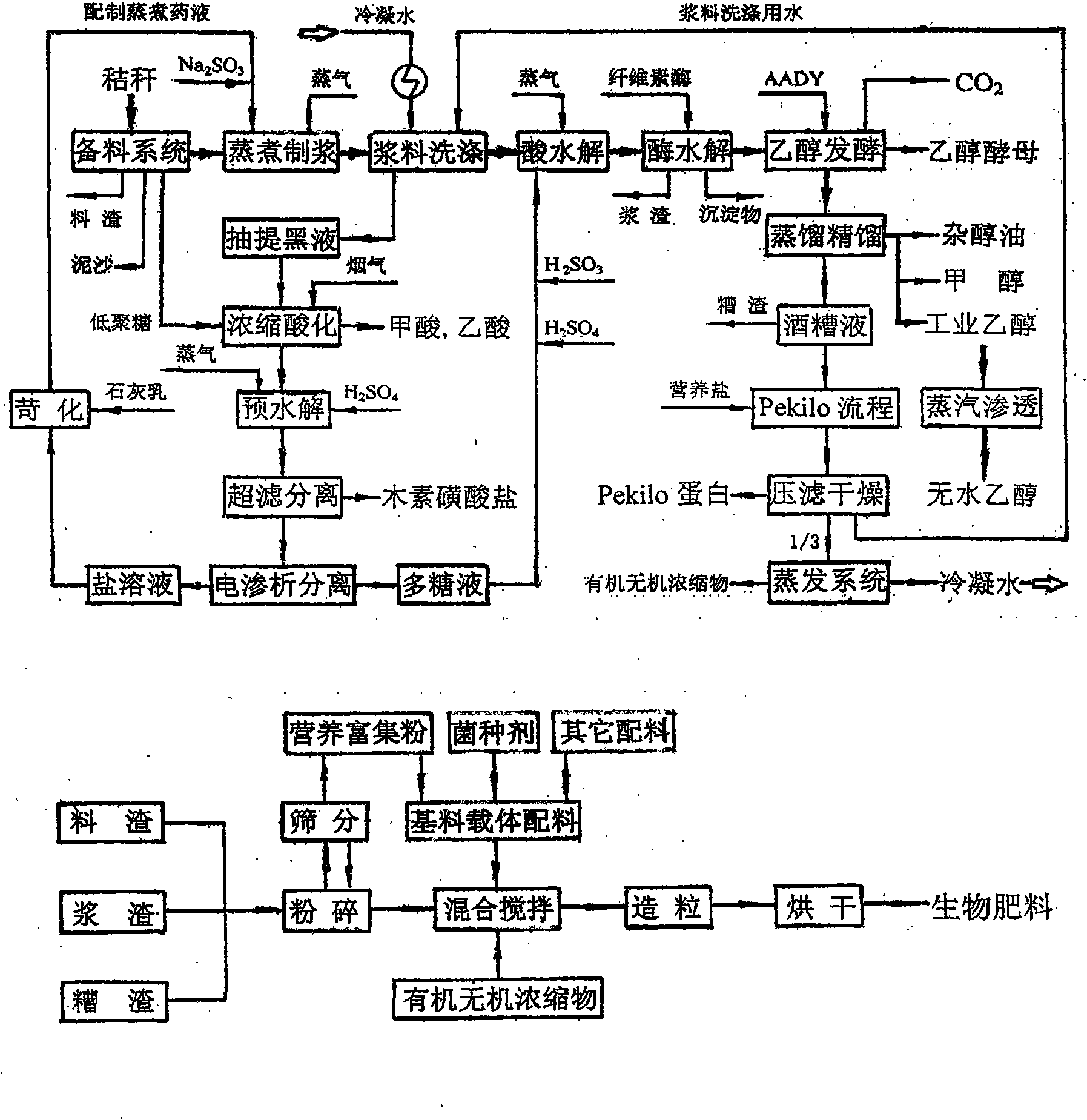

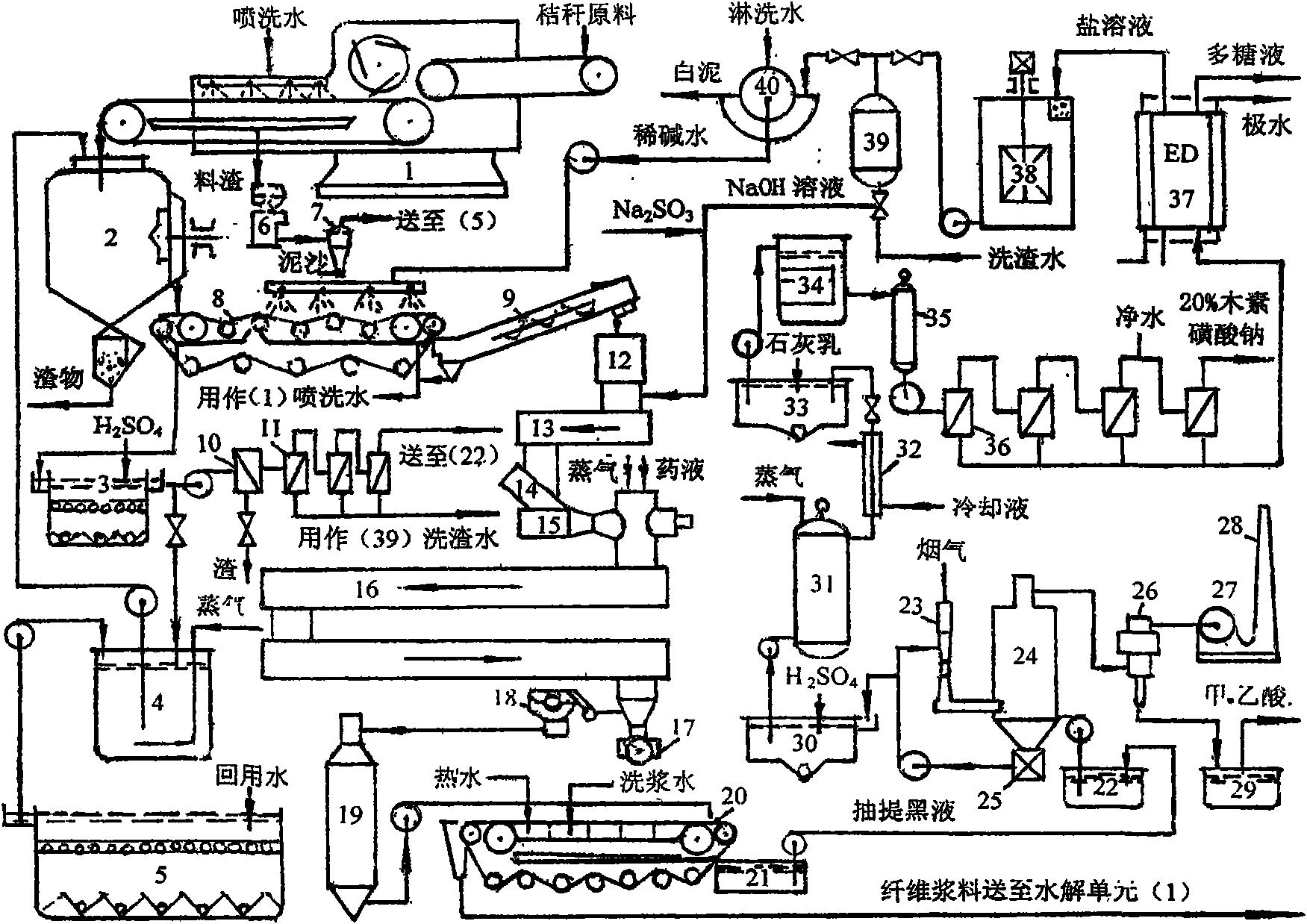

Ethanol-guiding straw bio-refining full-sealing integration system

InactiveCN101555495AImprove productivityStrong profitabilityBy-product recoveryFungiFiberLiquid waste

The invention relates to a fiber biomass refining technology, in particular to an ethanol-guiding straw bio-refining full-sealing integration system. Based on the clean pulping of the straw, a chemical and biological combined method is used for totally hydrolyzing amylose separated from a cellulose and a hemicellulose separated into pulps and braised waste liquid to prepare a hexose and a pentose;and the hexose and the pentose are converted into series of chemical and biological products which taking ethanol as dominant product. As a firstly separated and subsequently disposed straw bio-refin ing integration system, the cellulose and the hemicellulose in the straw raw material are utilized effectively; furthermore, 20-25% of the lignin in the raw material and the material slag, slurry slag, trough slag and ashes (mineral matter) produced in the production process are totally converted into the product with high additional values, thus realizing the environment objects of full sealing and zero draining and controlling the production cost (apportionment cost after the straw biomass is totally utilized) of the fuel ethanol within 1800-2000RMB / t.

Owner:徐守才

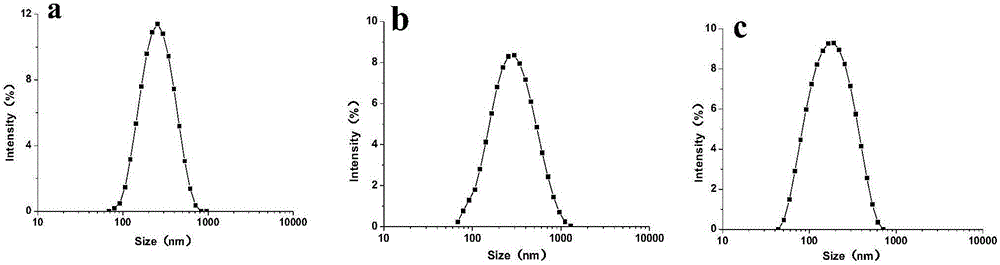

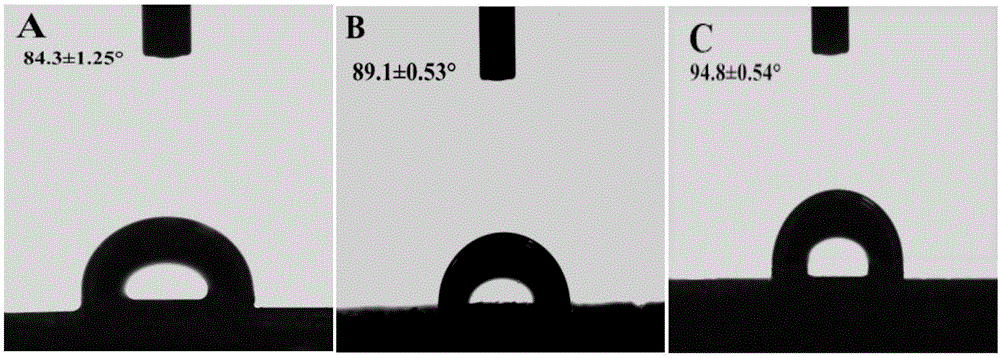

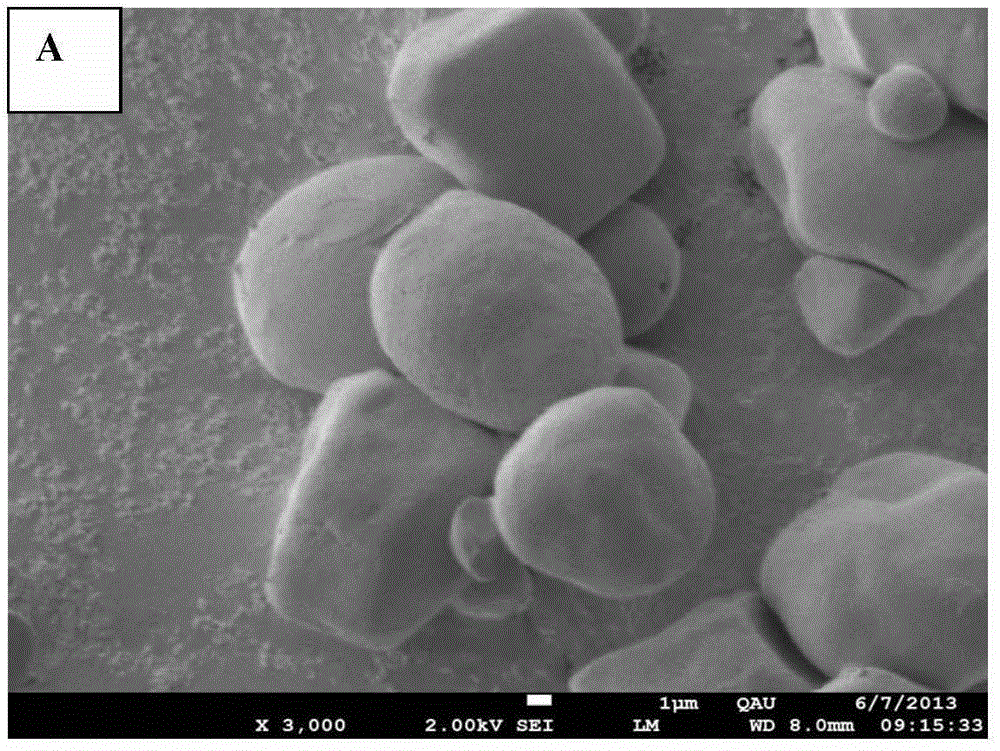

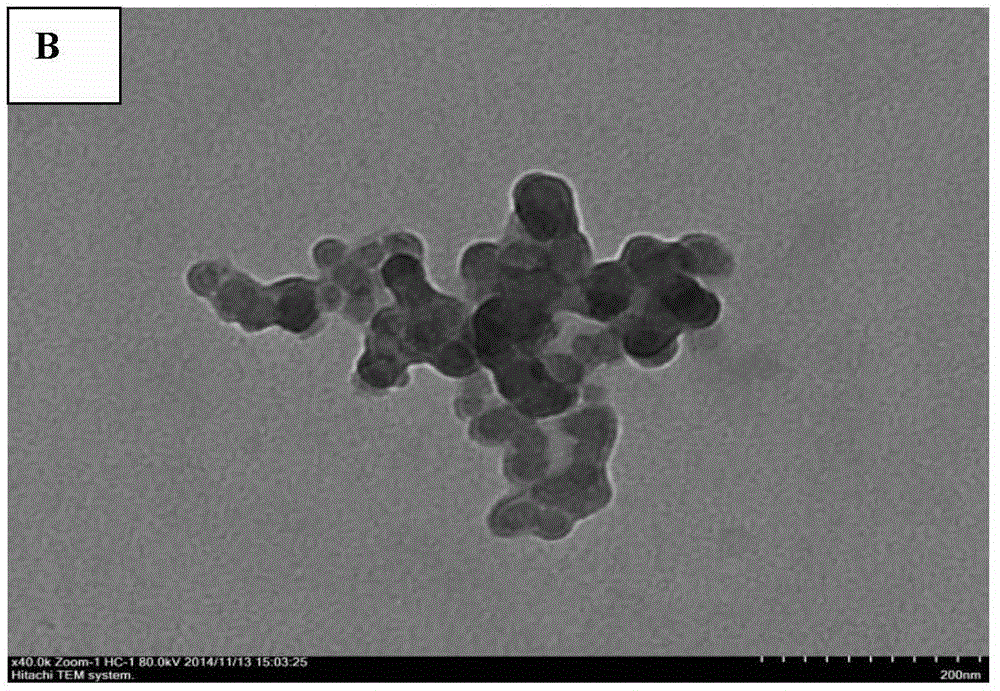

Preparation method of Pickering emulsion with stable starch nanoparticles

The invention relates to a preparation method of Pickering emulsion and particularly relates to a preparation method of Pickering emulsion with a stable starch nanoparticle emulsifier. The preparation method comprises the following steps: selecting starch with the amylose content of 20%-40%; after gelatinizing, titrating with absolute ethyl alcohol; centrifuging, and freeze-drying sediment to obtain starch nanoparticles; and adding the starch nanoparticles into an oil-water mixed solution to prepare the Pickering emulsion. According to the preparation method of the Pickering emulsion with the stable starch nanoparticle emulsifier, raw materials are natural and preparation conditions are moderate; strong-corrosion reagents including sulfuric acid and the like are not used, so that a preparation process is green and environment-friendly and has no toxin and no emission of harmful substances; the prepared Pickering emulsion has good stability and good sensitive environment stability, and has relatively good heat resistance and salt resistance; and the invention provides an efficient, green and environment-friendly preparation method of starch nanoparticles and the starch nanoparticles can be widely applied the fields of foods and cosmetics, and medicines.

Owner:QINGDAO AGRI UNIV

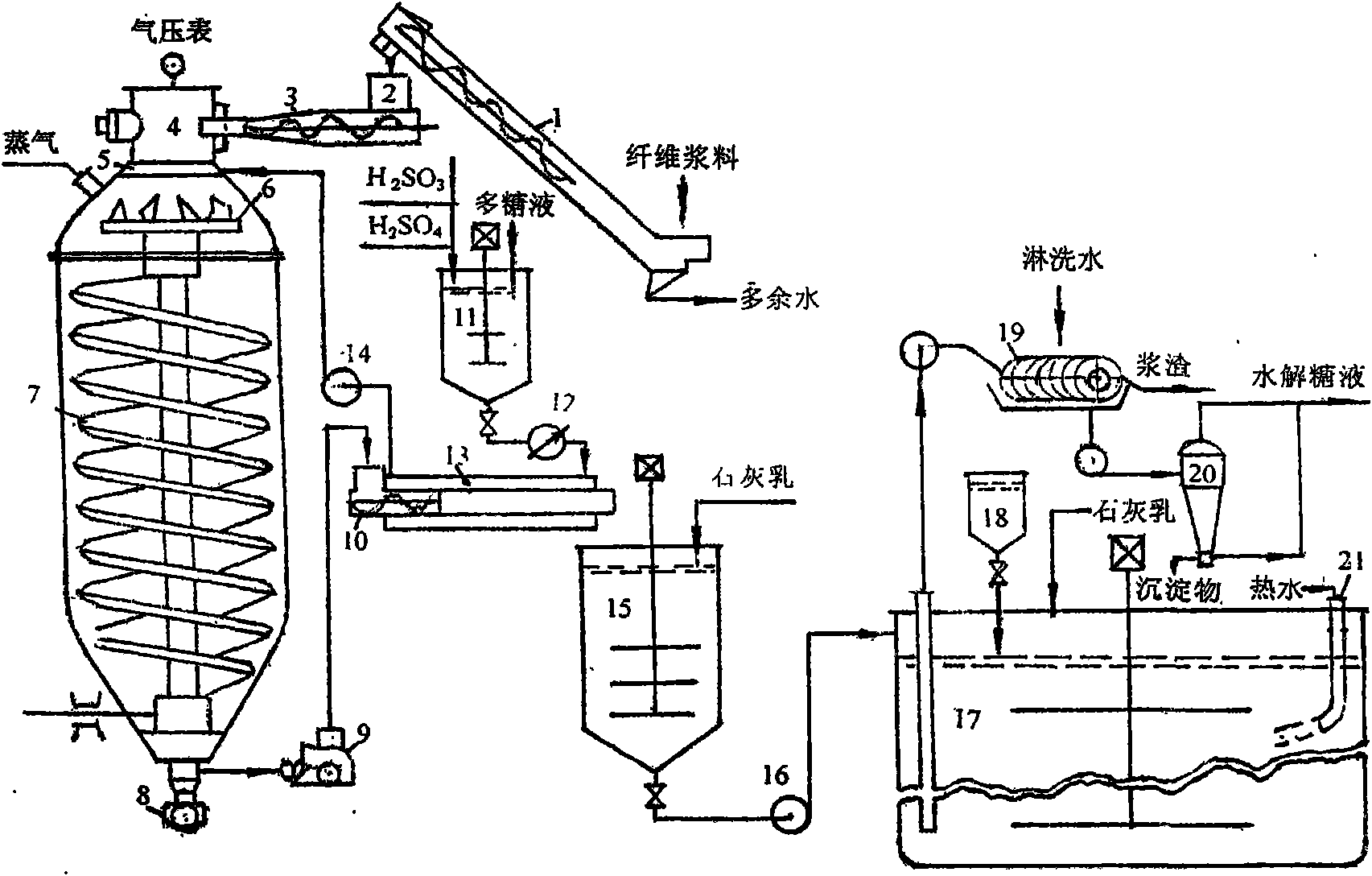

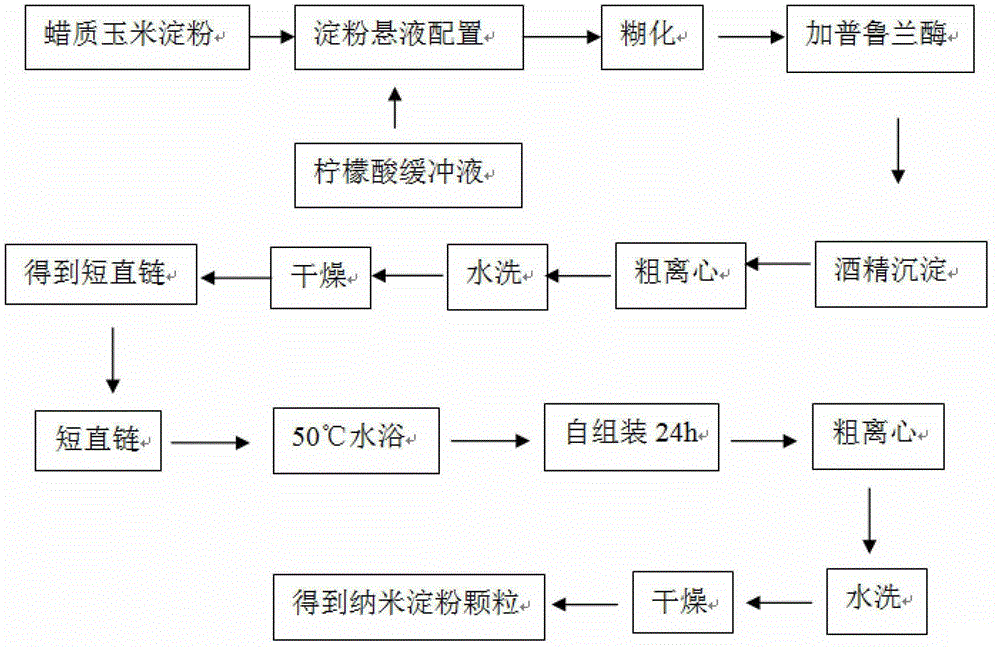

Process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose

The invention discloses a process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose. The process particularly comprises the following steps: (1) preparing a buffer solution; (2) preparing a starch water solution; (3) past-forming; (4) enzymolyzing, and then using anhydrous ethanol to precipitate the degreased starch solution; (5) preparing short amylose; (6) preparing nano starch. According to the process, enzyme hydrolysis starch is adopted to prepare nano starch at 30-70 DEG C in an anabiosis manner, the nano starch prepared by the method is high in productivity, low in cost, safer and more environment-friendly, and can serve as embedding materials of medicines, active ingredients and the like, and the application field of the process in the food industry is widened.

Owner:QINGDAO AGRI UNIV

Method for preparing fibroin nano-silver hydrosol

InactiveCN102935521ANon-toxic and environmentally friendlyWide range of raw materialsHYDROSOLReducing agent

The invention discloses a method for preparing fibroin nano-silver hydrosol. The method comprises the following steps of: dissolving or dispersing soluble amylose in deionized water, stirring the mixture until the amylose is completely gelatinized to obtain a starch solution, adding a silver nitrate solution, and then mixing the mixture with a fibroin solution to obtain a fibroin-starch-silver nitrate ternary complex solution; adjusting the pH value of the ternary complex solution to be at 8-10 by ammonia water, and fully mixing at the temperature condition of 20-80 DEG C to obtain the fibroin nano-silver hydrosol with the silver particle size being 1-100nm. According to the method, micromolecule fibroin peptide is used as a capturing agent and a reducing agent, the soluble starch is used as a dispersing agent and a protective agent, and the micromolecule fibroin peptide and the soluble starch are used for reducing and preparing nano-silver. The prepared nano-silver hydrosol is small in silver particle size, uniform in distribution and good in stability, in the prepared process, the reaction is mild, the operation is convenient, the green and environment-friendly aim is realized, and the fibroin nano-silver hydrosol can be widely used as a functional nano-material.

Owner:SUZHOU UNIV

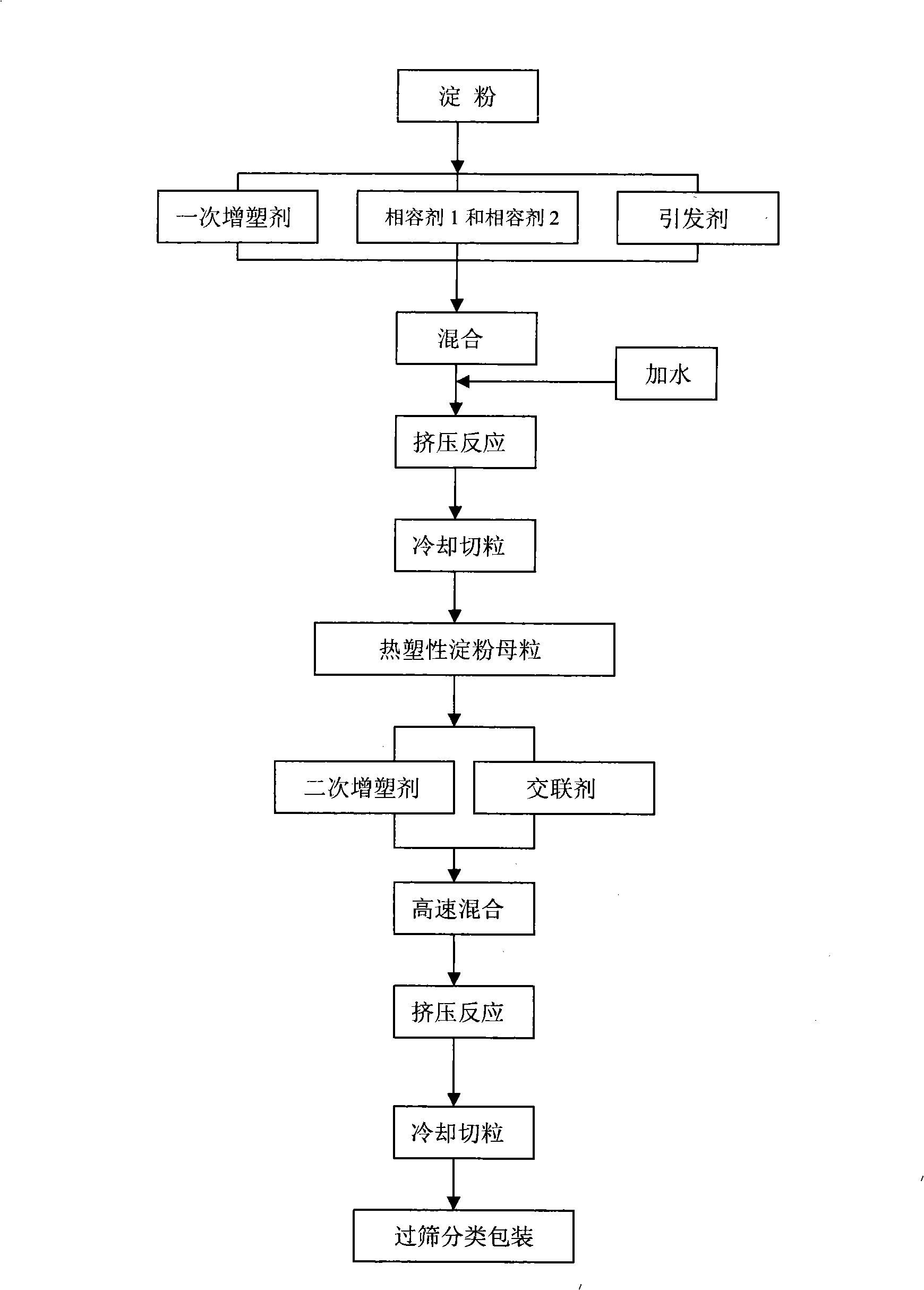

Thermoplastic starch plastic

The invention relates to thermoplastic starch plastics. The preparation compositions, the weight portions and the manufacturing technique are as follows: firstly, 100 kilograms of starch, 17.5 kilograms of primary plasticizer, 3 kilograms of maleic anhydrides, 0.035 kilograms of overoxidized tertiary butyl and 3 kilograms of Di-2-ethylhexyl maleate are taken and mixed; secondly, extrusion reaction is performed on water and mixture together at a temperature of between 140 and 160 DEG C; thirdly, agglomerates are obtained after cooling of the mixture; fourthly, all the agglomerates are mixed with 16.5 kilograms of secondary plasticizer and 0.75 kilograms of glutaric dialdehyde which are taken by weight portion through a high-speed mixing machine, and extrusion reaction is performed subsequently; fifthly, the thermoplastic starch plastics are obtained after cooling and granulation of extruded materials. Compared with the products of the same kind, the thermoplastic starch plastics have low cost and simple manufacturing technique and do not need special amylase extract from starch; the degradation speed is lower than the accumulation speed; the heat resistance, the water resistance and the physical characteristics are obviously improved; the comprehensive cost is close to the common plastic cost; and the condition is created for popularizing completely degraded plastics.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

Preparing method of perilla oil powder and perilla oil powder

InactiveCN101224002AEasy to receiveExtensive additiveFood shapingFood preparationEmulsionPerilla oil

The invention relates to a method for preparing perilla herb oil powder, which comprises the following steps: one part of wall-material aqueous solution combined by protein and amylose is added into the perilla herb oil to form W / O type emulsion which is phase converted into O / W type emulsion; the O / W type emulsion and the remaining two parts of the wall-material aqueous solution form an emulsion, the pH value of which is adjusted to lead the protein in the wall materials after being condensed to be treated with spay drying so as to prepare the perilla herb oil powder. The perilla herb oil powder obtained by the method has low surface oil rate and high encapsulation efficiency. The product is mainly used in infant formula milk power, middle and old-aged people formula milk powder, formula food, pregnant women foods and other functional foods.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

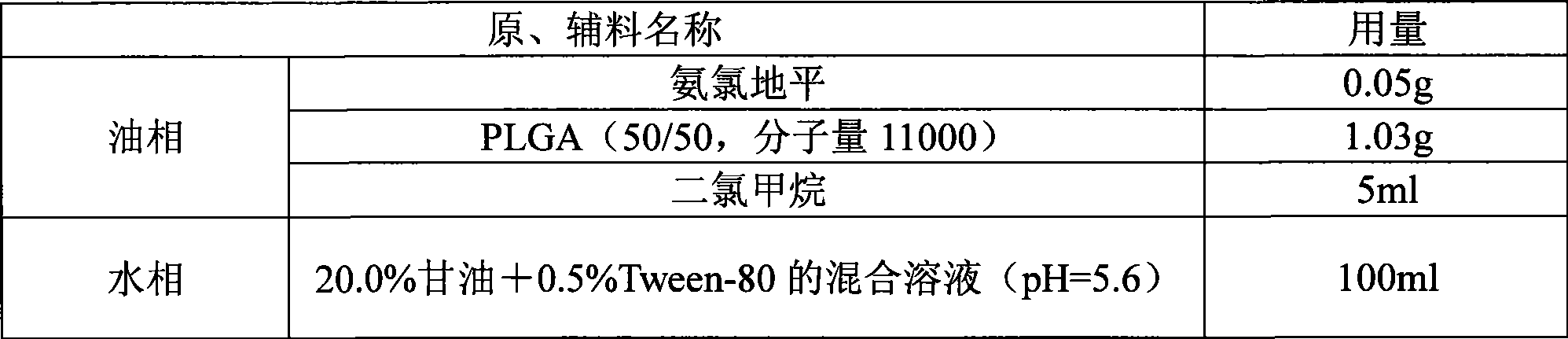

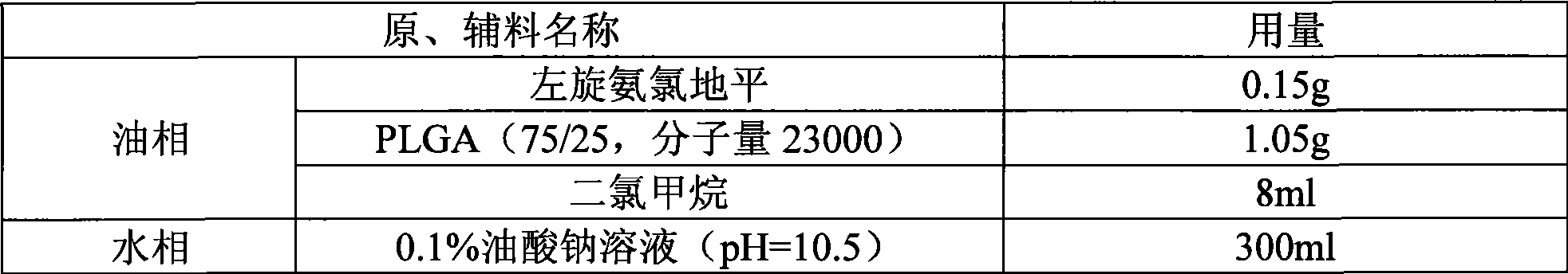

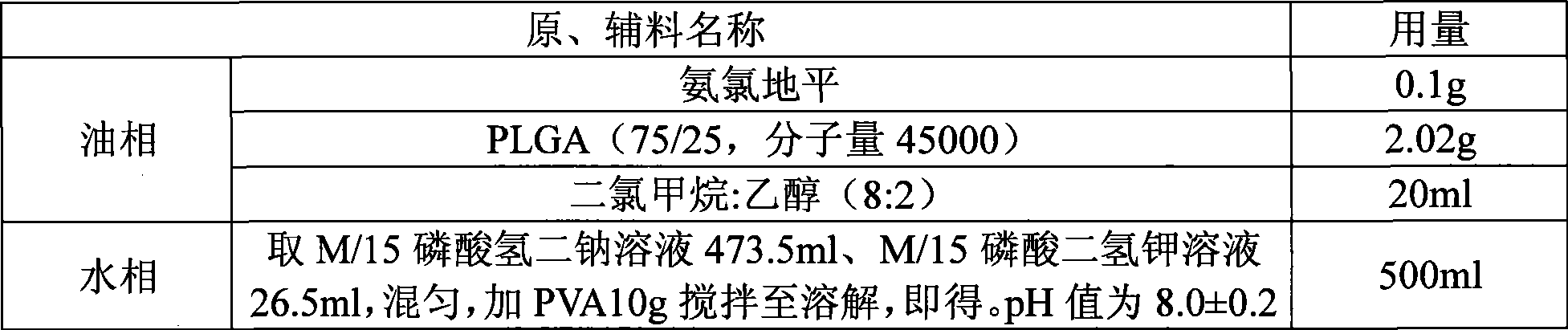

Method for preparing an amlodipine microsphere

InactiveCN101530396ARound shapeUniform particle size distributionOrganic active ingredientsPharmaceutical non-active ingredientsCelluloseMicrosphere

The method discloses a method for preparing an amlodipine microsphere. Medicament wrapped by the prepared amlodipine microsphere is amlodipine and organic acid salts of the amlodipine; a carrier material of the microsphere is polylactic acid (PLA), a polylactic acid-glycolic acid copolymer (PLGA), a polylactic acid-glycol block copolymer (PLA-mPEG) or other biodegradable materials; a surfactant solution, a monosaccharide or amylose solution, a polyalcohol solution, a cellulose solution and a colloid solution are used as a dispersion medium; and through an emulsion solvent evaporation method, the amlodipine microsphere is prepared under the mechanical stirring or high-speed shearing action. The microsphere has a round shape and even distribution of grain diameter; the grain diameter is within the range between 1 and 125 mu m; the medicine loading capacity can reach more than 1.5 percent; and the encapsulating rate is more than 70 percent.

Owner:XIAN LIBANG PHARMA TECH

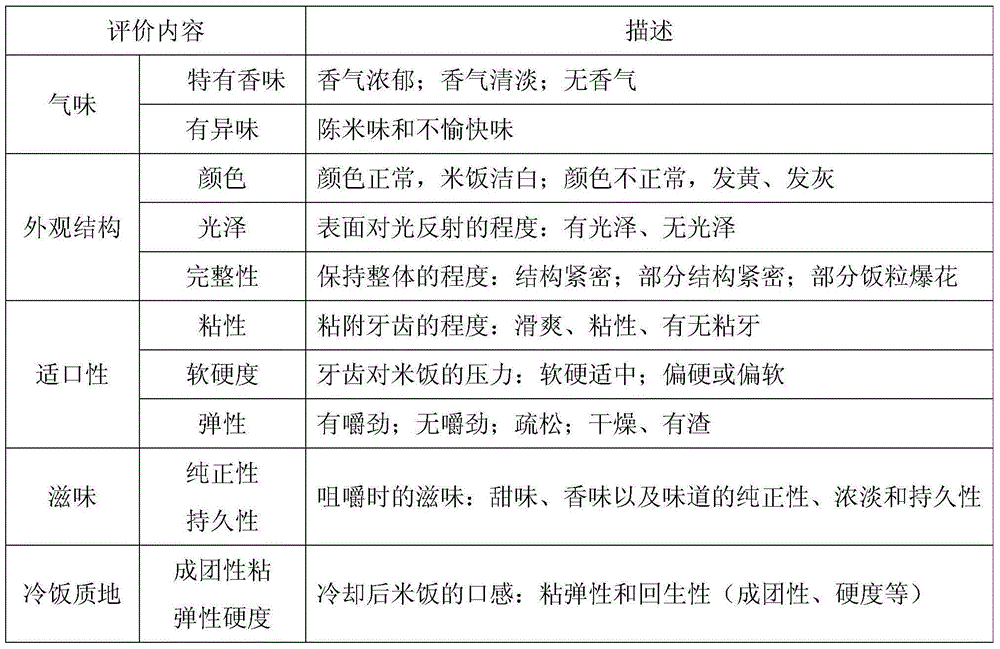

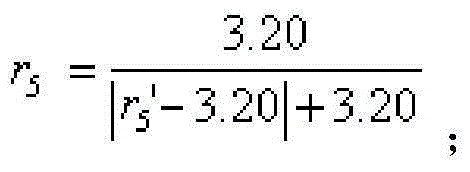

Method for determiningtaste quality of rice by using physical and chemical property indexes of rice quality

ActiveCN105067784AMake up for the shortcomings of the cumbersome sensory evaluation process for eating qualityFast processTesting starch susbtancesMaterial analysis by optical meansEvaluation resultFeature vector

The invention discloses a method for determining taste quality of rice by using physical and chemical property indexes of rice quality. The method comprises the following steps: respectively obtaining measured values of five physical and chemical indexes of rice to be determined: amylose, gel consistence, alkali spreading value, protein and grain shape; carrying out conversionof characteristic vectors forthe measured values of thefive physical and chemical indexes of rice; obtaining angles ofthefive physical and chemical indexes of rice; carrying out characteristic vector analyses of each index by means of radar map; carrying out a comprehensive evaluation analysis by means of radar map; carrying out a conversion of thecomprehensive evaluation result, and obtaining a rice taste value. The method provided by the invention can be used for rapidly determining taste quality of rice.

Owner:CHINA NAT RICE RES INST

Improved noodle food

InactiveCN101467532AGuaranteed intakeAvoid it happening againDough treatmentBlood sugarHealthful food

The invention provides an improved flour food. The improved flour comprises dietary fiber, whole wheat flour dietary fiber and amylose extracted from corn, potato, sweet potato and rice; the flour can be made into fine dried noodles, dumplings, gruel, bread, pastry, cake, steamed bread and so on. The food has low glycemic index, can satisfy health and nutrition of human body, delay the sugar absorption, effectively control blood sugar in diabetes patients, make the glycolated hemoglobin restore to normal value; the food with low glycemic index can reduce load of pancreatic islet, recover pancreatic islet function, secrete insulin resistance and protect B cell; the food with low glycemic index supplies high-nutrition content natural food to diabetes patients with nutrition utilization obstacle and nutrition deficiency caused by metabolic disorder; the invention is a kind of convenient health food.

Owner:TIANJIN ZHONGYING HEALTH FOOD

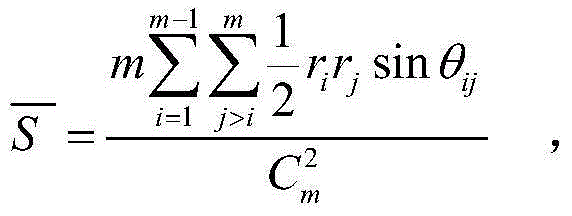

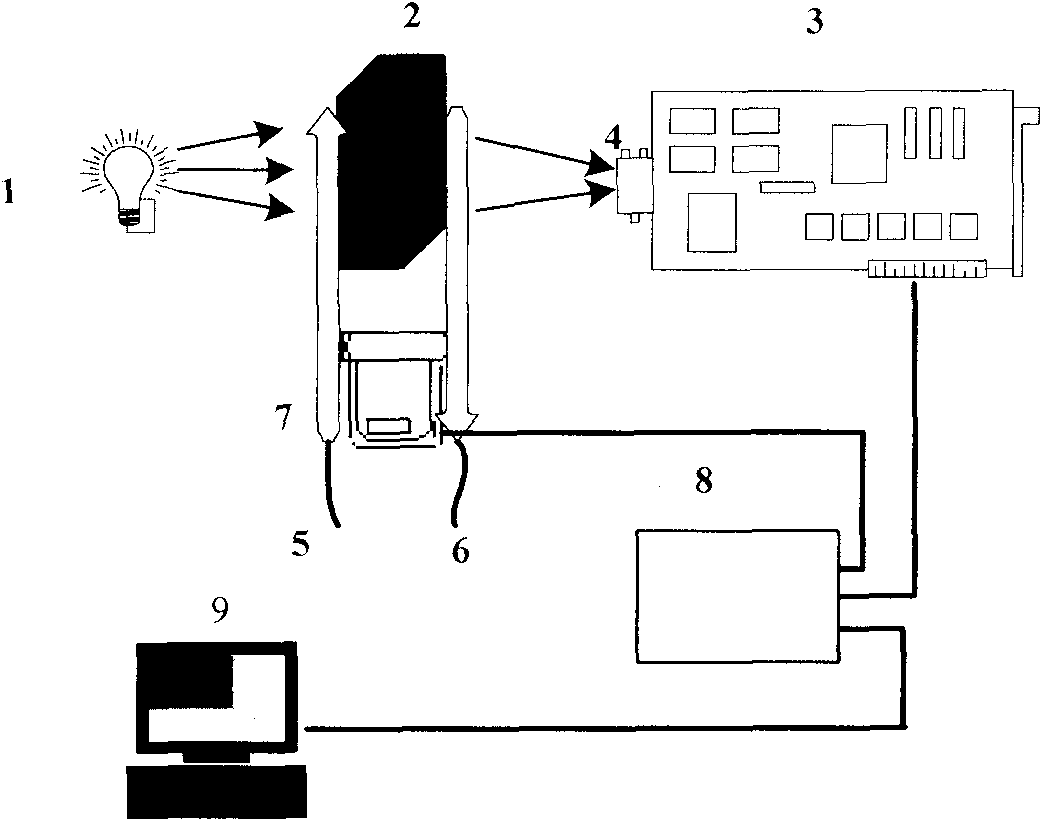

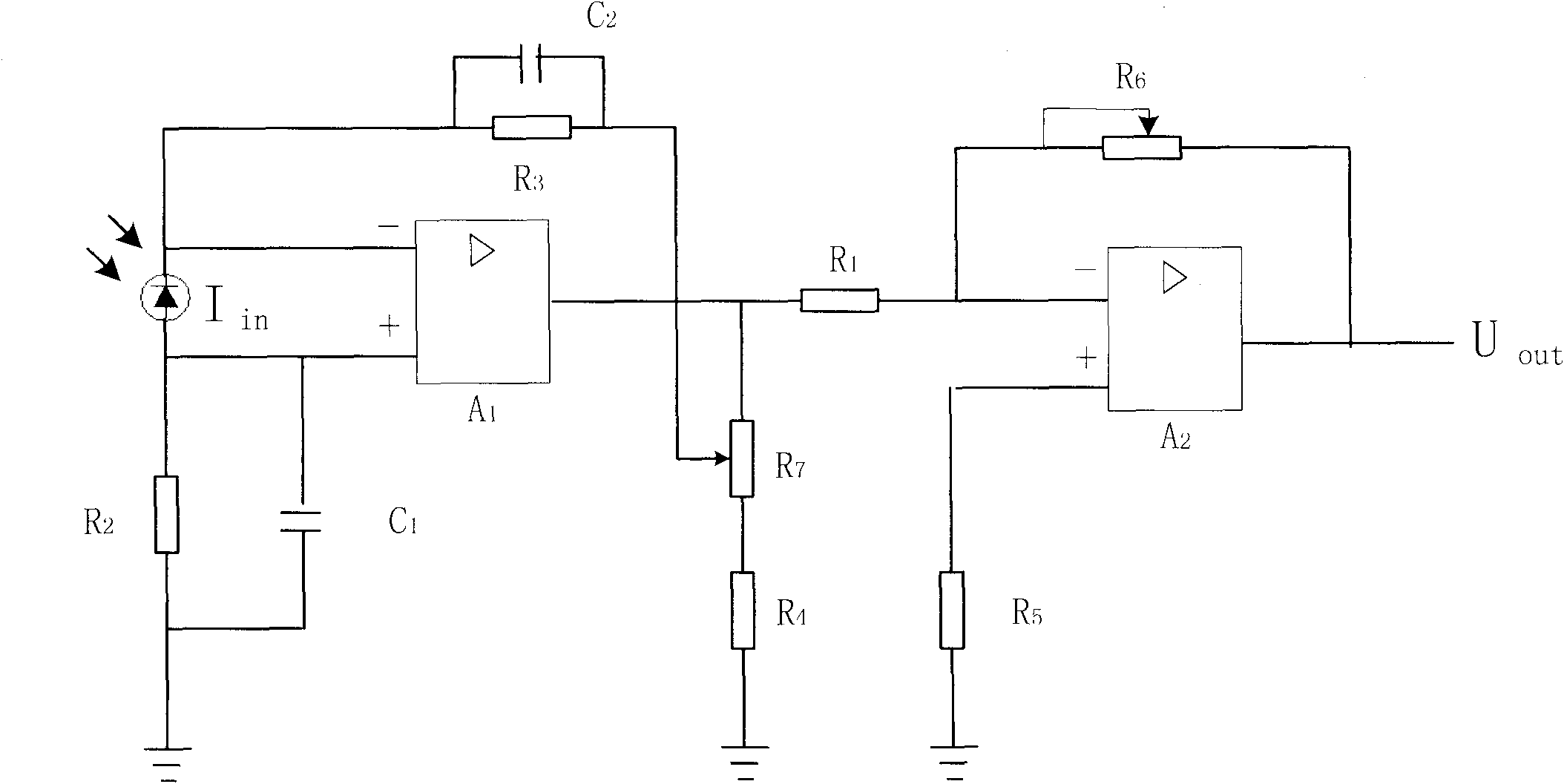

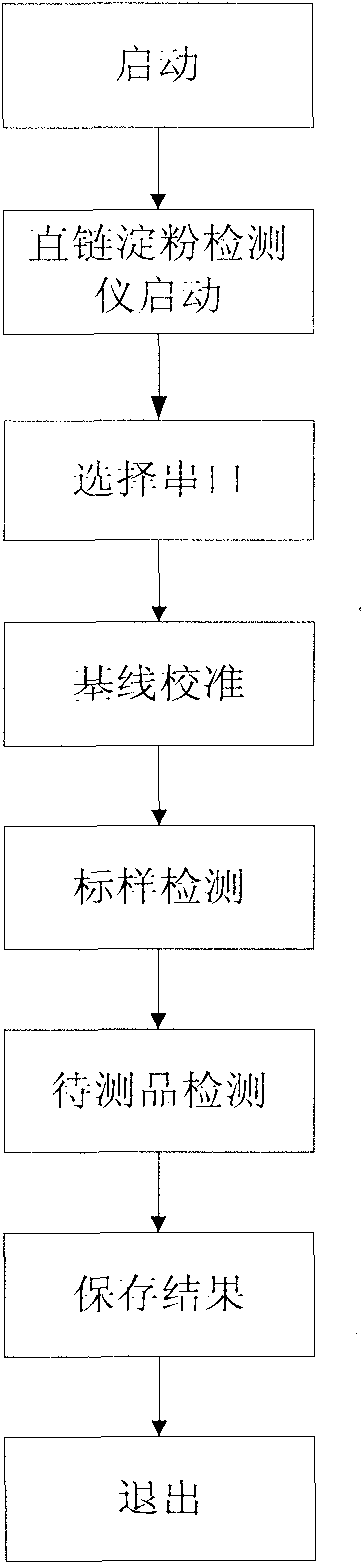

Amylose detector and method for detecting amylose

The invention provides an amylose detector, which comprises a laser emitter, a photoelectric detecting unit, a sample injector, an analog input module and a control unit, wherein detection solution after pretreatment is filled in the sample injector; the sample injector converts laser light emitted by the laser emitter into light signals, and transmits the light signals to the photoelectric detecting unit; the photoelectric detecting unit converts the light signals into electric signals and supplies the electric signals to the analog input module which converts the electric signals into digital signals and transmits the digital signals to the control unit; and the control unit calculates the amylose content according to a relation between the absorbance and a detection voltage. The amylose detector provided by the invention uses laser detection, so the accuracy is high, the stability is high, the volume is small and the composition is simple. The invention also provides a method for detecting amylose, which has the advantages of simple steps, short detection time and high accuracy for a detection result.

Owner:王一鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com